Solid phase reaction preparation method for iron-molybdenum process catalyst used for methanol oxidation to formaldehyde

A solid-phase reaction and catalyst technology, applied in the direction of catalyst activation/preparation, organic compound preparation, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problems of large waste water, difficult recycling and treatment, etc., and achieve simplified treatment Good process, selectivity and strength, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

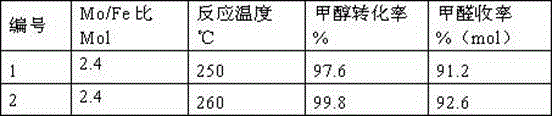

Examples

Embodiment 1

[0017] Add 40 grams of ammonium heptamolybdate to the mortar, weigh 38.16 grams of ferric nitrate 9 water and divide it into 3 parts, first add one-third and mix and grind with ammonium heptamolybdate for 2 minutes, then add one-third and mix and grind for 2 minutes minutes, add the final third and continue grinding. As the grinding continues, the ground material turns bright yellow, the color gradually deepens, the viscosity increases, and it becomes hard after grinding for about 25 minutes, so stop grinding. The ground product was placed in an oven at 70°C and heated for 6 hours to complete the reaction. The reaction product was taken out, ground into powder, washed with deionized water to remove the generated ammonium salt, and heated in an oven at 120°C for 4 hours. The dried material was placed in an electric furnace and roasted at 480° C. for 4 hours to obtain 38.3 grams of an iron molybdate catalyst for the oxidation of methanol to formaldehyde.

[0018] The evaluatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com