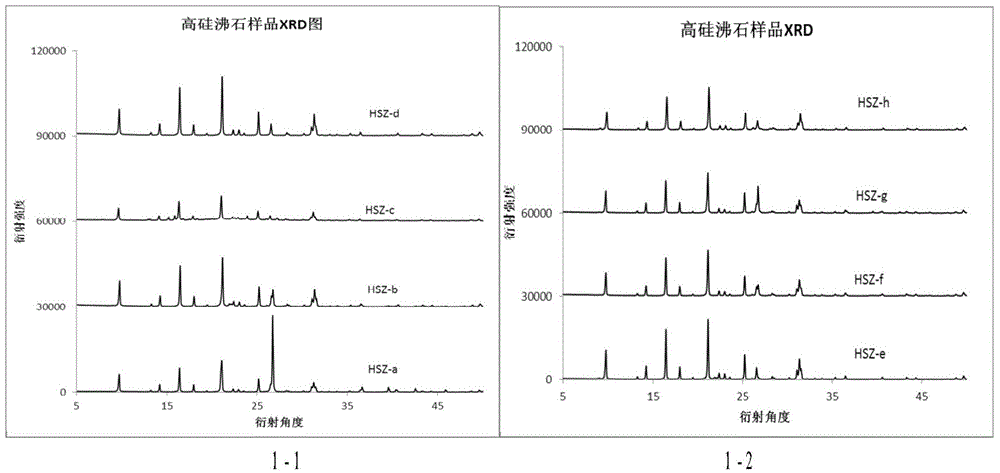

Composite inorganic base method synthesizing chabazite-type molecular sieve with high silica-alumina ratio and application thereof

A technology of high silicon-aluminum ratio and chabazite, which is applied in the field of preparation of zeolite molecular sieves, can solve the problems of low crystallinity and low specific surface area of products, and achieve low acid center density, improved specific surface area, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

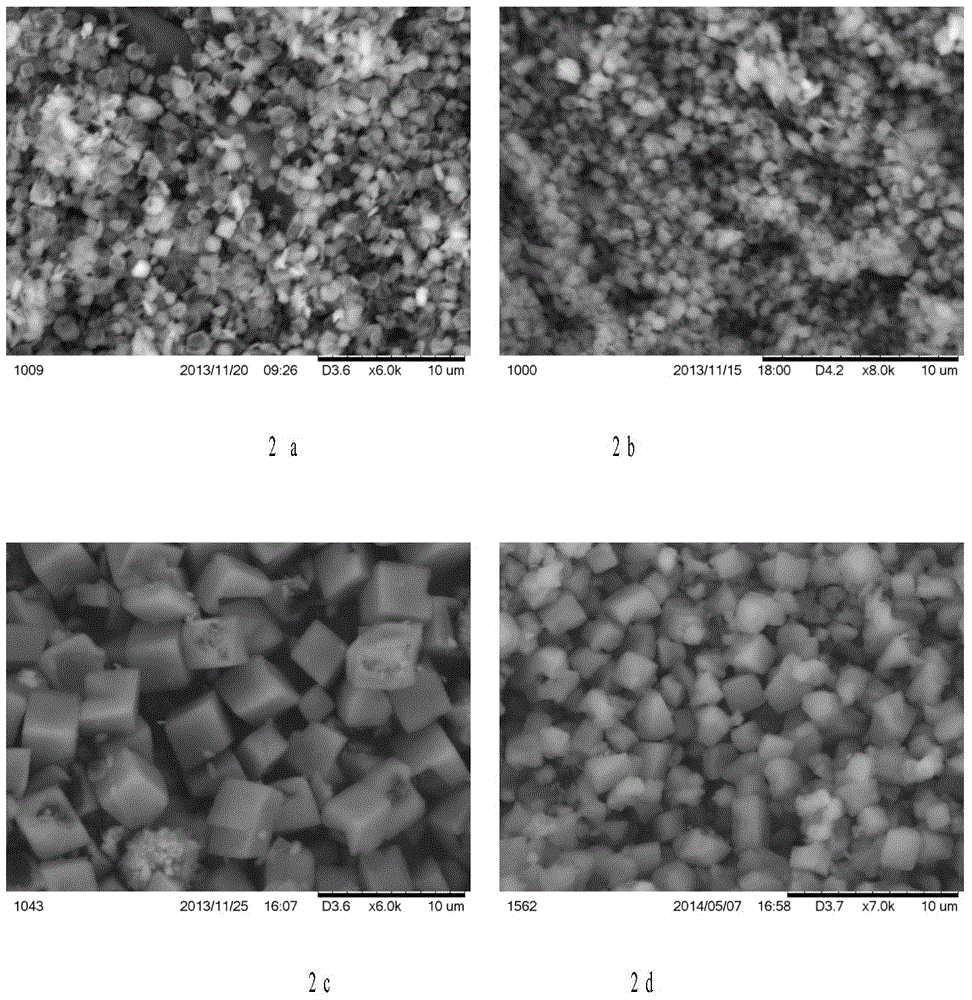

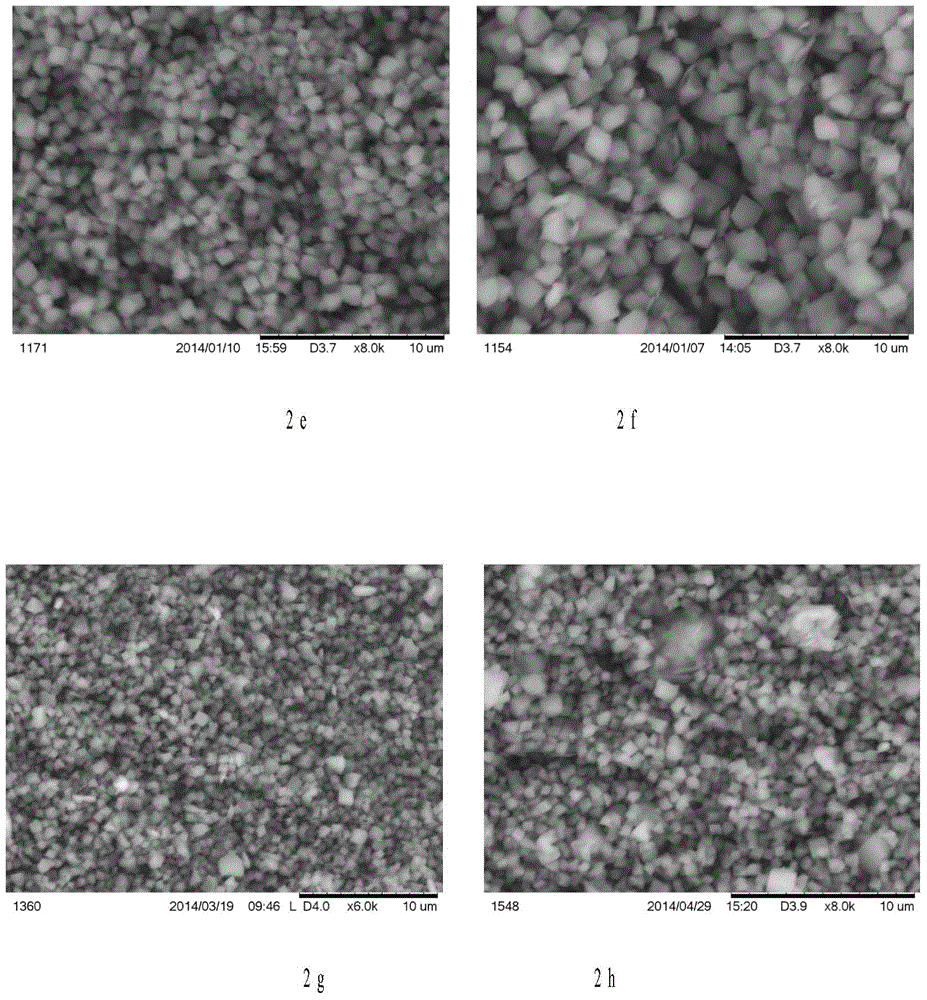

Embodiment 1

[0058] Embodiment 1: adopt composite inorganic base to synthesize high silicon aluminum zeolite (ratio of material is SiO 2 :0.005Al 2 o 3 : 0.05K 2 O: 0.02Na 2 O:0.1 Templating agent: 5H 2 O (water in the system after stopping the distillation))

[0059] Gel preparation: 36g silica mass concentration is 50% alkaline silica sol (silicon dioxide mass concentration is 50%, Na 2 (2 mass content 0.4%) join in the polytetrafluoroethylene reactor, 50 ℃ of water baths are stirred, then add the aqueous solution of the templating agent hydroxide-N, N, N-trimethyladamantane ammonium that 15.825g mass concentration is 40% , stir evenly, slowly add 1.68g potassium hydroxide, then add 0.48g sodium hydroxide, stir evenly, then slowly add an aqueous solution made of 0.9996g aluminum sulfate octadecahydrate and 5.8g deionized water, stir and distill at 50°C, 1 After one hour, about 6.637g of water evaporated, the distillation was stopped, and the mixture was sealed and kept stirring at ...

Embodiment 2

[0064] Embodiment 2: adopt composite inorganic base to synthesize high silicon aluminum ratio chabazite (ratio of material is SiO 2 :0.001Al 2 o 3 : 0.12K 2 O: 0.30Na 2 O: 0.08 Templating agent: 8H 2 O (water in the system after adding aluminum sulfate))

[0065] Gel preparation: 36g silica mass concentration is 40% alkaline silica sol (silicon dioxide mass concentration is 40%, Na 2 (2 mass content 0.3%) join in the polytetrafluoroethylene reactor, 20 ℃ of water baths are stirred, then add the aqueous solution of the templating agent hydroxide-N, N, N-trimethyladamantane ammonium that 16.88g mass concentration is 30% , stir evenly, slowly add 4.032g potassium hydroxide, then add 7.2g sodium hydroxide, stir evenly, then slowly add an aqueous solution made of 0.2g aluminum sulfate octadecahydrate and 9.794g deionized water, seal and keep stirring at 20°C for 6 Hour. Then the gel was stirred on a homogenizer at 20,000 rpm for 10 minutes to obtain a uniform gel.

[0066] ...

Embodiment 3

[0070] Embodiment 3: adopt composite inorganic base to synthesize high silicon aluminum zeolite (ratio of material is SiO 2 :0.008Al 2 o 3 : 0.15K 2 O: 0.15Na 2 O:0.06 Templating agent: 6H 2 O (water in the system after stopping the distillation))

[0071] Gel preparation: 60g silica mass concentration is 30% alkaline silica sol (silicon dioxide mass concentration is 30%, Na 2 (0.2% by mass content) joins in the polytetrafluoroethylene reactor, stirs in 60 ℃ of water baths, then adds 10.38g mass concentration and is the templating agent hydroxide-N, N-dimethyl-N-ethylcyclohexane of 30% Alkane ammonium aqueous solution, stir well, slowly add 5.04g potassium hydroxide, then add 3.6g sodium hydroxide, stir well, then slowly add 1.8g aluminum nitrate nonahydrate and 5.4g deionized water solution, distill at 60°C After 2.5 hours, 22.924 g of water evaporated, the distillation was stopped, and the mixture was stirred at 60° C. for 2 hours. Then the gel was stirred on a homoge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com