Patents

Literature

798results about How to "Less waste water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

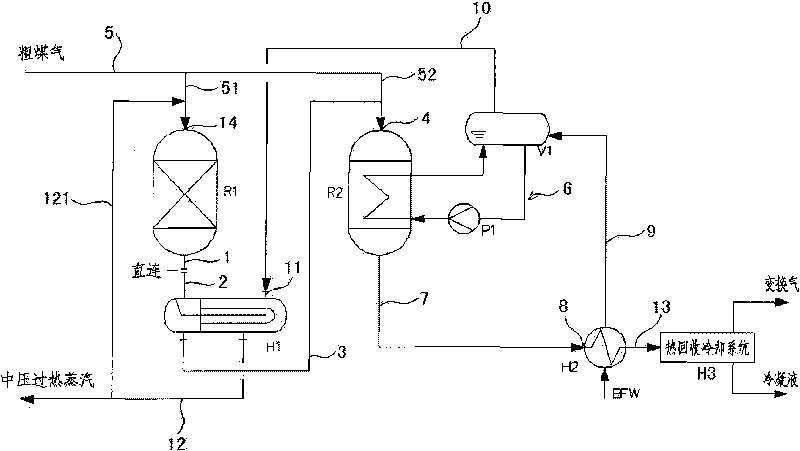

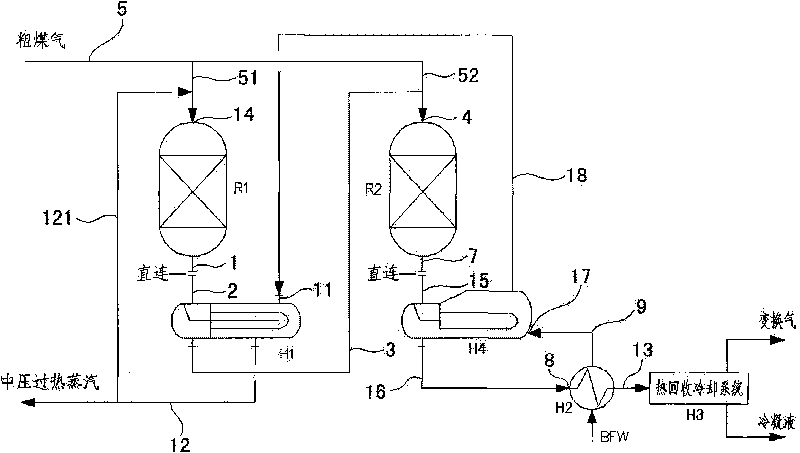

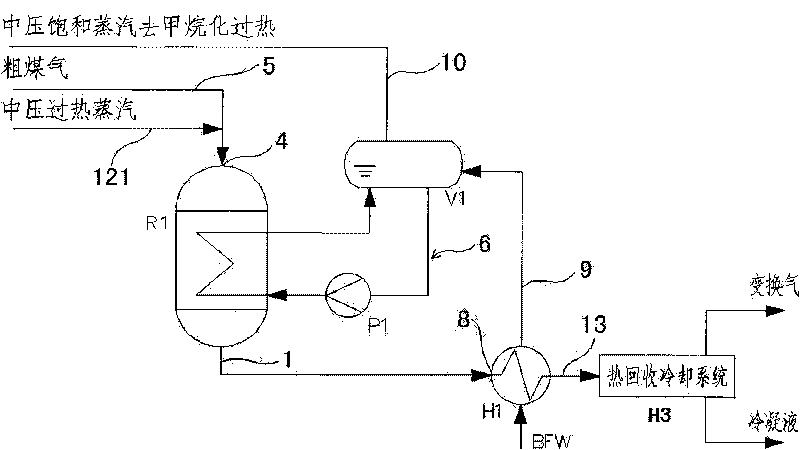

Shunting-type isothermal sulfur-tolerant conversion process and equipment thereof

ActiveCN101704513ASatisfy conversion rate requirementsMeet the requirements of adiabatic conversion control temperature riseHydrogenChemical industryShunt typesSulfur

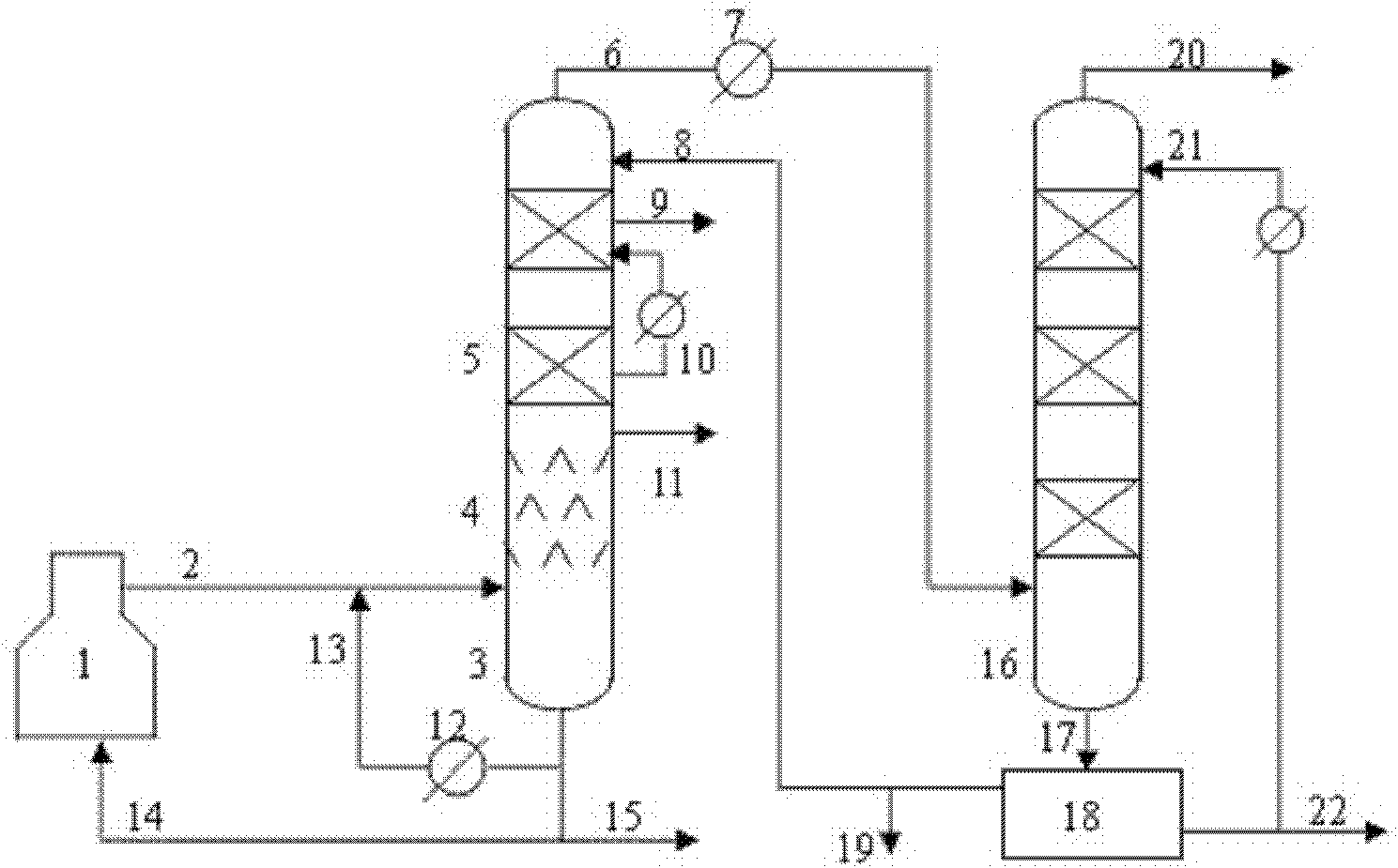

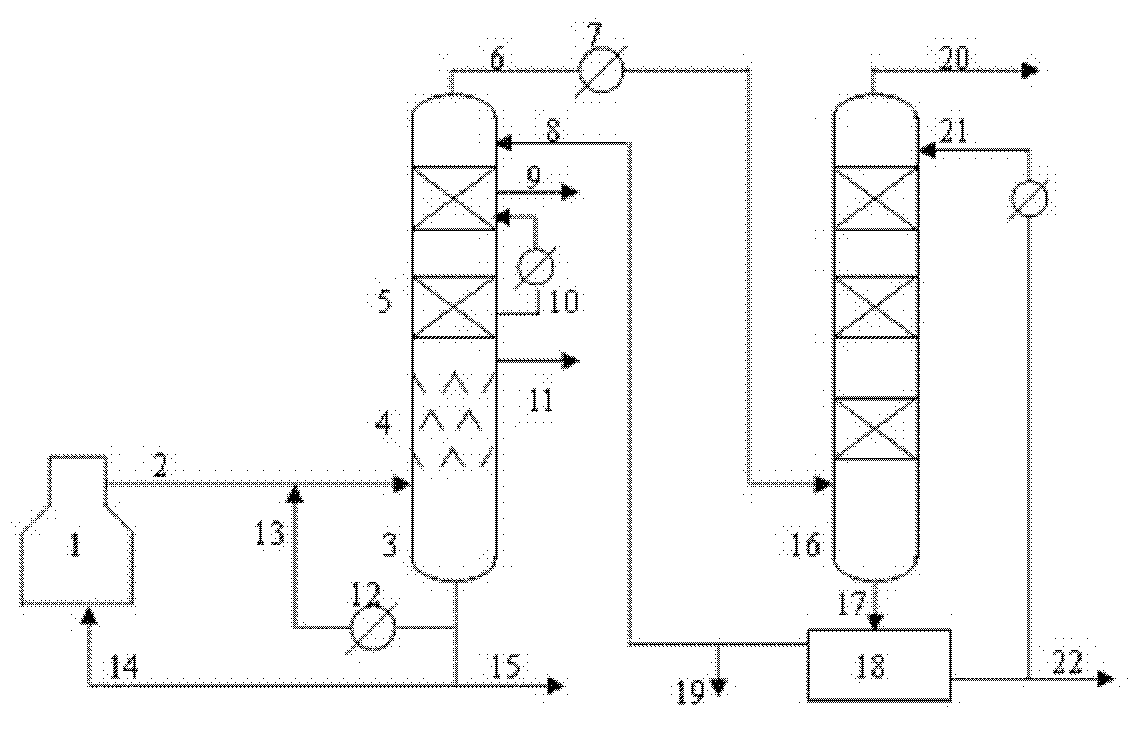

The invention discloses a shunting-type isothermal sulfur-tolerant conversion process. The process comprises the following steps: shunting raw coal gas from exterior into at least two parts; leading overheat stream in the first part of the raw coal gas to increase the temperature to 200-300 DEG C; and then entering a first-stage conversion reaction step to carry out a conversion reaction and generate first conversion gas; and conveying the other part of the raw coal gas to next-stage conversion reaction step to carry out a conversion reaction. The catalyst bed of a shift converter has the advantages of stable temperature, simple control, convenient operation and low output CO content. The invention has the advantages of short conversion flows, few equipment, reduced resistance, great byproduct stream amount, high overheat temperature, stream pressure and heat recovery rate, and the like, thereby achieving the aims of reducing conversion stages, equipment number and resistance fall, decreasing investment, having great byproduct stream amount and high overheat temperature, stream pressure and heat recovery rate, reducing conversion stream consumption and outward wastewater discharge, protecting the environment and easily maximizing the device equipment. The invention also discloses shunting-type isothermal sulfur-tolerant conversion equipment used by the process.

Owner:SHANGHAI INT ENG CONSULTING

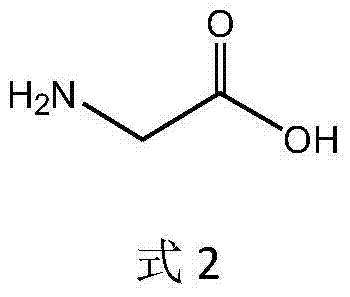

Novel production method for glutamic acid

ActiveCN102703537AReduce lossesLess waste waterOrganic compound preparationMicroorganism based processesHigh concentrationFluidized bed drying

The invention discloses a novel production method for glutamic acid, belonging to the technical field of the production of amino acid. The novel production method for the glutamic acid comprises the following steps of: removing thalli and insolubles by means of high-speed disc separation; evaporating and concentrating separated glutamic acid material liquid through a multi-effect plate type evaporator at low temperature, wherein the generated secondary steam condensed water is used for fermentation ingredients of the glutamic acid; performing continuous isoelectric extraction on the glutamic acid in the evaporated glutamic acid concentrated solution; absorbing the glutamic acid by making supernatant fluid pass through ion exchange columns; performing isoelectric reextraction on the analyzed glutamic acid; inputting high-concentration wastewater into a fertilizer workshop for producing fertilizer; squeezing heavy phase (mycoprotein) through a plate frame, and granulating; and drying through a fluid bed, and thus producing high-protein feed. The novel production method for the glutamic acid has the advantages of low unit consumption of liquid ammonia and sulfuric acid, high extraction yield of the glutamic acid, less ion exchange investment and the like; and meanwhile, the purity of the extracted glutamic acid is high, sodium glutamate can be produced without crystalloblast, resources are fully used in the whole process, the aims of energy conservation and consumption reduction are achieved, and the novel production method for the glutamic acid has a wide application prospect.

Owner:HULUNBEIER NORTHEAST FUFENG BIOTECHNOLOGIES CO LTD

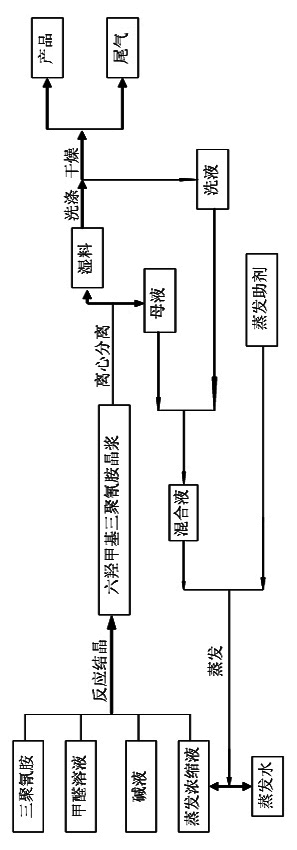

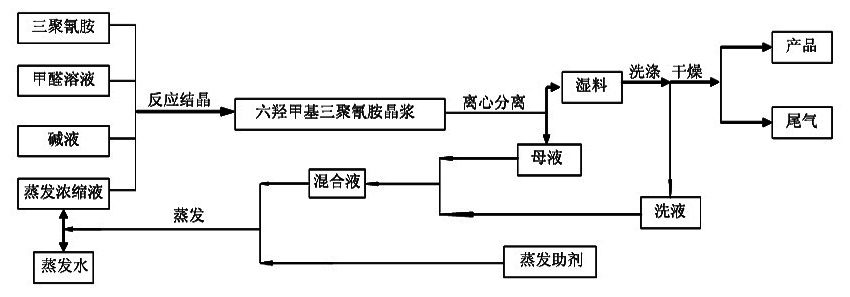

Process for producing hexamethylol melamine

ActiveCN102010380AReduce processingReduce processing difficultyOrganic chemistryWater/sewage treatment by heatingFormateEvaporation

The invention discloses a process for producing hexamethylol melamine, belonging to the field of production and preparation of hexamethylol melamine. The process comprises the steps such as mixing, reaction and crystallization, centrifugalization, evaporation and the like, wherein evaporation auxiliary formate is added when in evaporation so as to change the relative volatility of formaldehyde and water. Furthermore, the process for producing the hexamethylol melamine together with a formaldehyde device can also be used for co-production, so that the concentration of the produced formaldehyde solution is improved to 45wt%-55wt%. The produced hexamethylol melamine provided by the invention has the advantages of small amount of waste water and low formaldehyde content, namely, if 1 ton of hexamethylol melamine is produced, 1 ton of waste water containing 0.84wt% of formaldehyde is discharged. After the process provided by the invention and the formaldehyde device are used for co-production, the formaldehyde production cost and transportation cost are reduced, and the comprehensive cost is 10% less than that of other processes.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

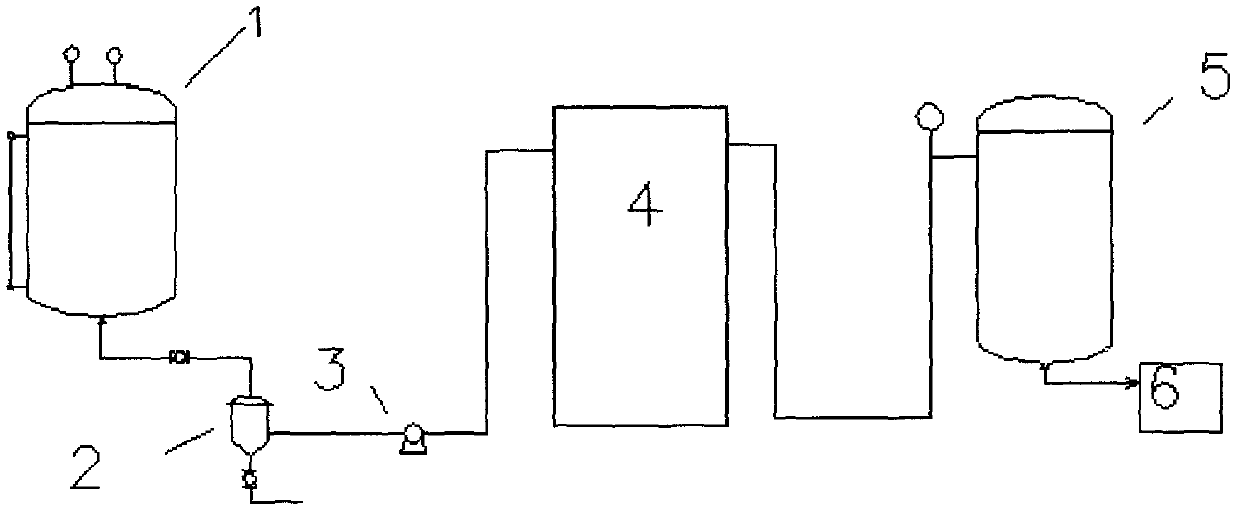

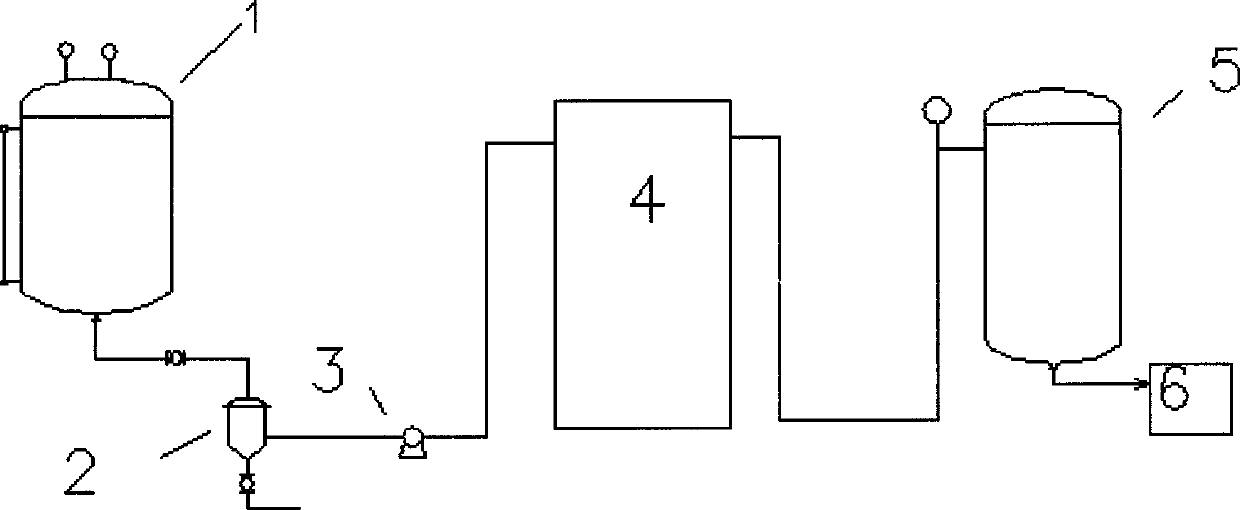

Device and method for continuously producing sodium methyl taurate in pipeline mode

InactiveCN102675160ALess energy consumptionStable concentrationSulfonic acids salts preparationHeat conductingDistillation

The invention relates to a device and a method for producing sodium methyl taurate, in particular to a device and a method for continuously producing sodium methyl taurate in a pipeline mode. The method comprises the following steps of: adding sodium hydroxyethyl sulfonate, water, methylamine and catalyst into a storage tank, pumping the materials into a continuous pipeline reactor through a boosting pipeline pump under the high pressure of 10 to 25MPa, heating to the temperature of between 150 and 300 DEG C through heat conducting oil, and reacting for 10 to 60 minutes in the pipeline reactor; and feeding the materials into an evaporator after reaction, performing multistage distillation, decolorizing, moisturizing, refining, and thus obtaining the qualified sodium methyl taurate. The device is simple and high in process safety, the reaction conditions are easy to control, continuous production is realized, the yield reaches over 90 percent, the sodium methyl taurate is stable in quality, and large-scale production can be realized with low investment in the industry.

Owner:HUANGGANG YONG AN PHARMA

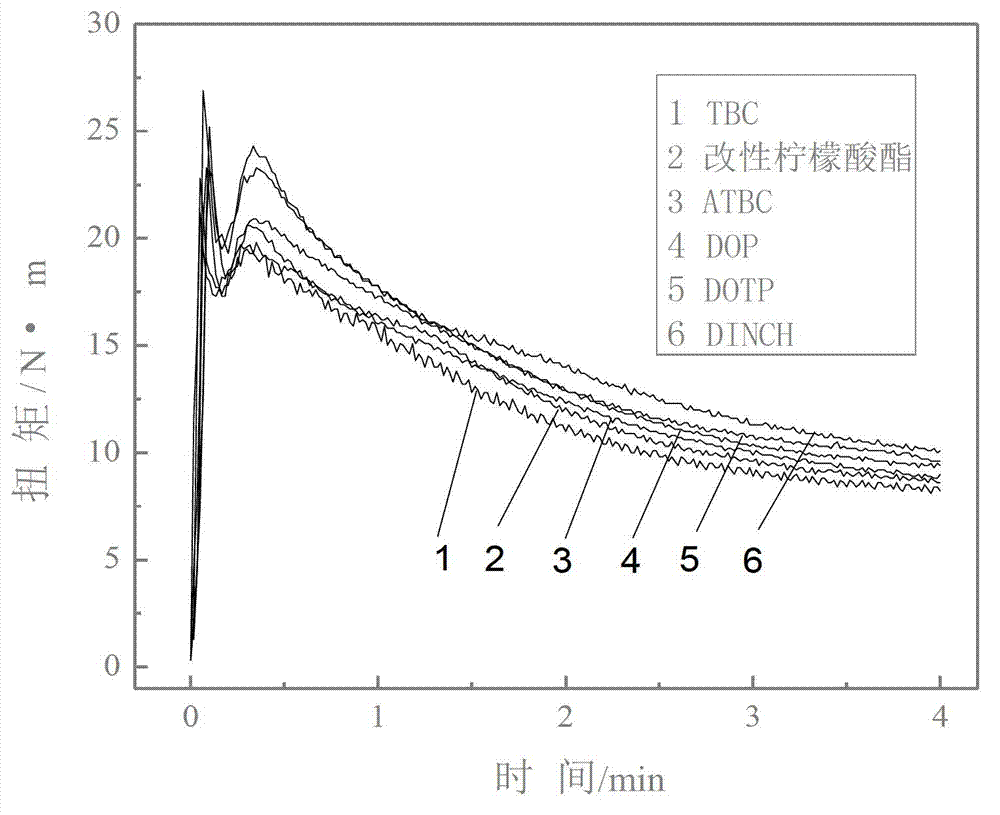

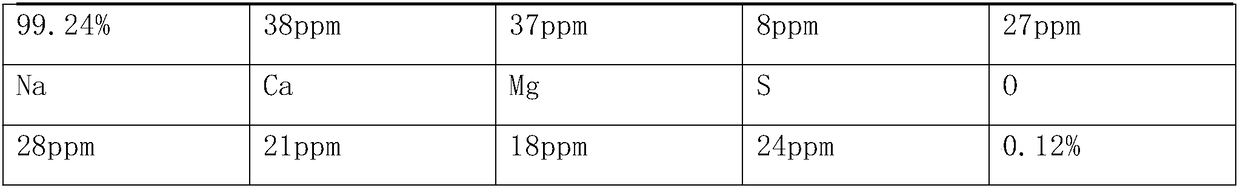

Novel plasticizer and preparation method thereof

ActiveCN103113617AReduce volatilityHigh plasticizing efficiencyOrganic compound preparationCarboxylic acid esters preparationAlcoholCITRATE ESTER

The invention relates to a novel plasticizer and a preparation method thereof, which overcome the defects that the existing low-carbon alcohol citrate plasticizers are non-transference-resistant, high in volatility and high in economic costs and high-carbon alcohol citrate plasticizers are low in efficiency. The novel plasticizer contains at least two types of citrate compounds. The novel plasticizer disclosed by the invention can be used as a plasticizer, and widely applied to the fields of plastic compositions and adhesives and the like.

Owner:山东万图高分子材料股份有限公司

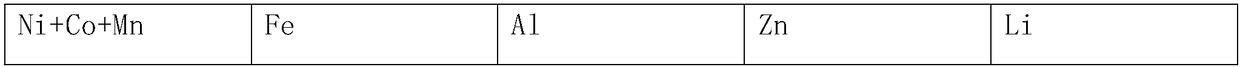

Waste Ni-Co-Mn lithium manganate positive electrode material recycling method

ActiveCN108539309APrevent oxidationHigh recovery rateCell electrodesWaste accumulators reclaimingAluminium hydroxideManganese

The invention discloses a waste Ni-Co-Mn lithium manganate positive electrode material recycling method. The waste Ni-Co-Mn lithium manganate positive electrode material recycling method comprises dismantling waste Ni-Co-Mn lithium manganate batteries, crushing positive electrode sheets, sieving and reducing crushed materials through hydrogen in a reducing furnace; washing reduced materials in hotpurified water to obtain washing solution and washed residues, inletting carbon dioxide into the washing solution to obtain lithium hydrogen carbonate solution and aluminum hydroxide precipitates, calcining the aluminum hydroxide precipitates to obtain ultrafine aluminum oxide, and pyrolyzing the lithium hydrogen carbonate solution to obtain battery-level lithium carbonate; adding the washed residues into hydrazine hydrate solution, then adding and stirring in sodium hydroxide for reaction, filtering the mixture to obtain a second filter liquor and second filtered residues, vacuum-drying thesecond filtered residues inside a vacuum drying oven, screening and magnetically-separating dried materials to obtain Ni-Co-Mn ternary alloy powder, or directly dissolving the dried materials in acidto obtain Ni-Co-Mn ternary mixed solution. The waste Ni-Co-Mn lithium manganate positive electrode material recycling method is low in cost, capable of achieving separation and recycling of all components, and high in recycling rate and value added of products.

Owner:中锂能新能源科技(烟台)有限公司

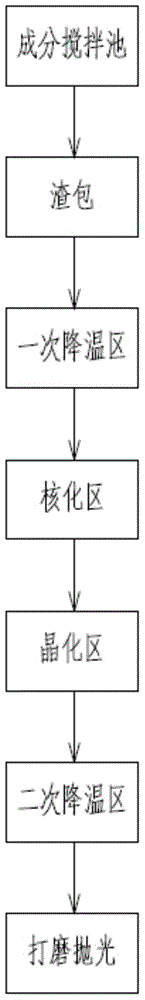

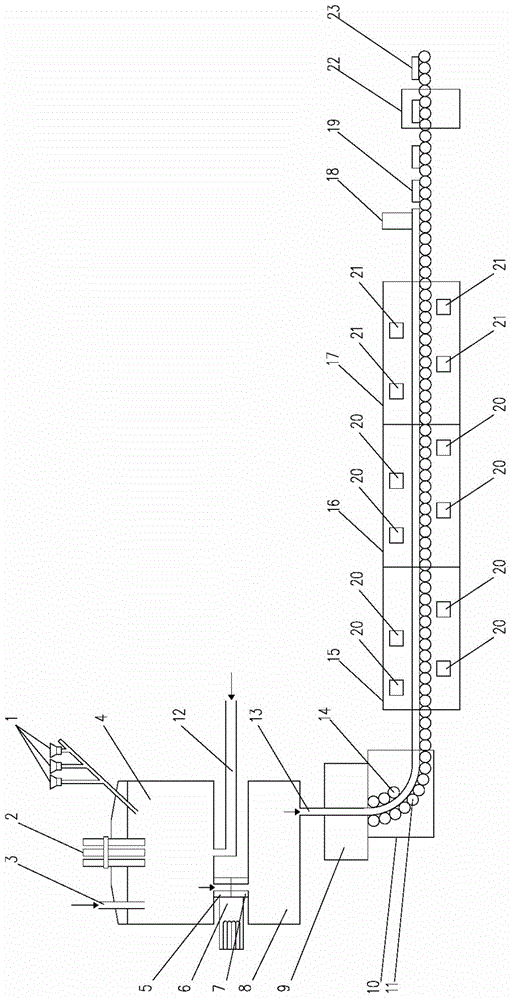

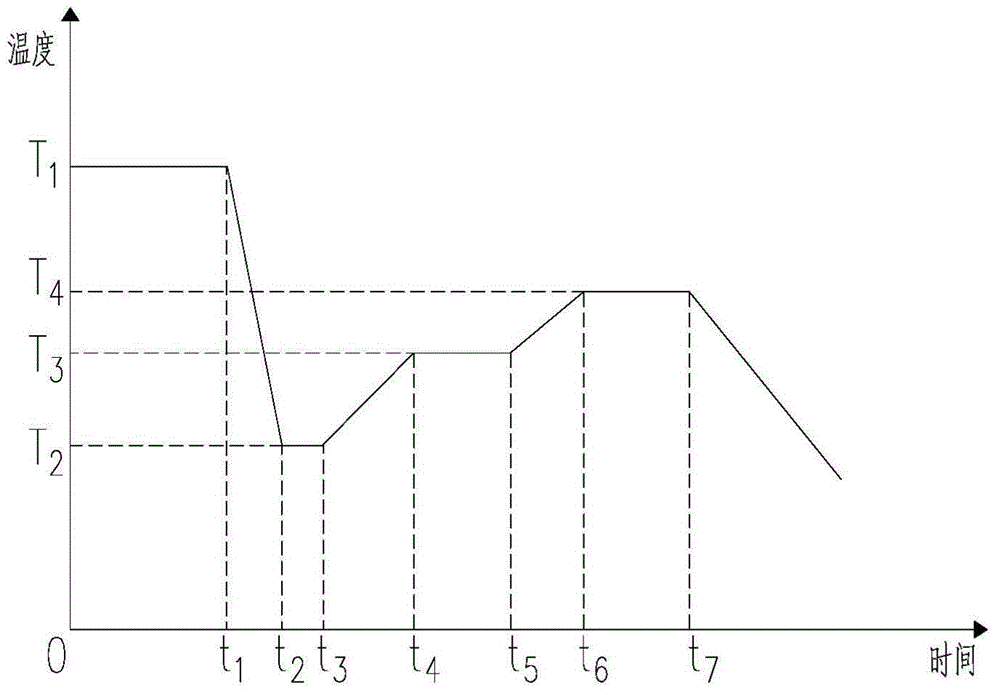

Continuous casting and rolling method and device for producing glass ceramics by utilizing blast-furnace slag

The invention belongs to the fields of metallurgy and inorganic nonmetal materials, and provides a continuous casting and rolling method and device for producing glass ceramics by utilizing blast-furnace molten slag. The method comprises the following steps of (1) transferring a temperature interval when the blast-furnace molten slag is maintained in a blast-furnace tapping hole to a component tempering mixing pool, adding and uniformly stirring corresponding modifiers, coloring agents and nucleating agents, and ensuring that the molten slag stays in a high-temperature interval; (2) driving the molten slag to enter a rolling forming area through a slag port and then enter a primary cooling area, and ensuring that the molten slag enters a nucleating area before the temperature of the surface of a shell is not lower than 500DEG C; (3) continuously heating to a crystallization area; (4) entering a cooling area, and cooling the molten slag to obtain a formed product; (5) cutting the formed product in a fixed size and polishing the surface of the formed product to obtain finished product glass ceramics. By adopting the continuous casting and rolling method and the device, the blast-furnace slag and solid waste resource are utilized, the produced glass ceramics have the advantages of high strength and acid and alkali corrosion resistance, and the economic benefit and the environment-friendly benefit are obvious.

Owner:UNIV OF SCI & TECH BEIJING

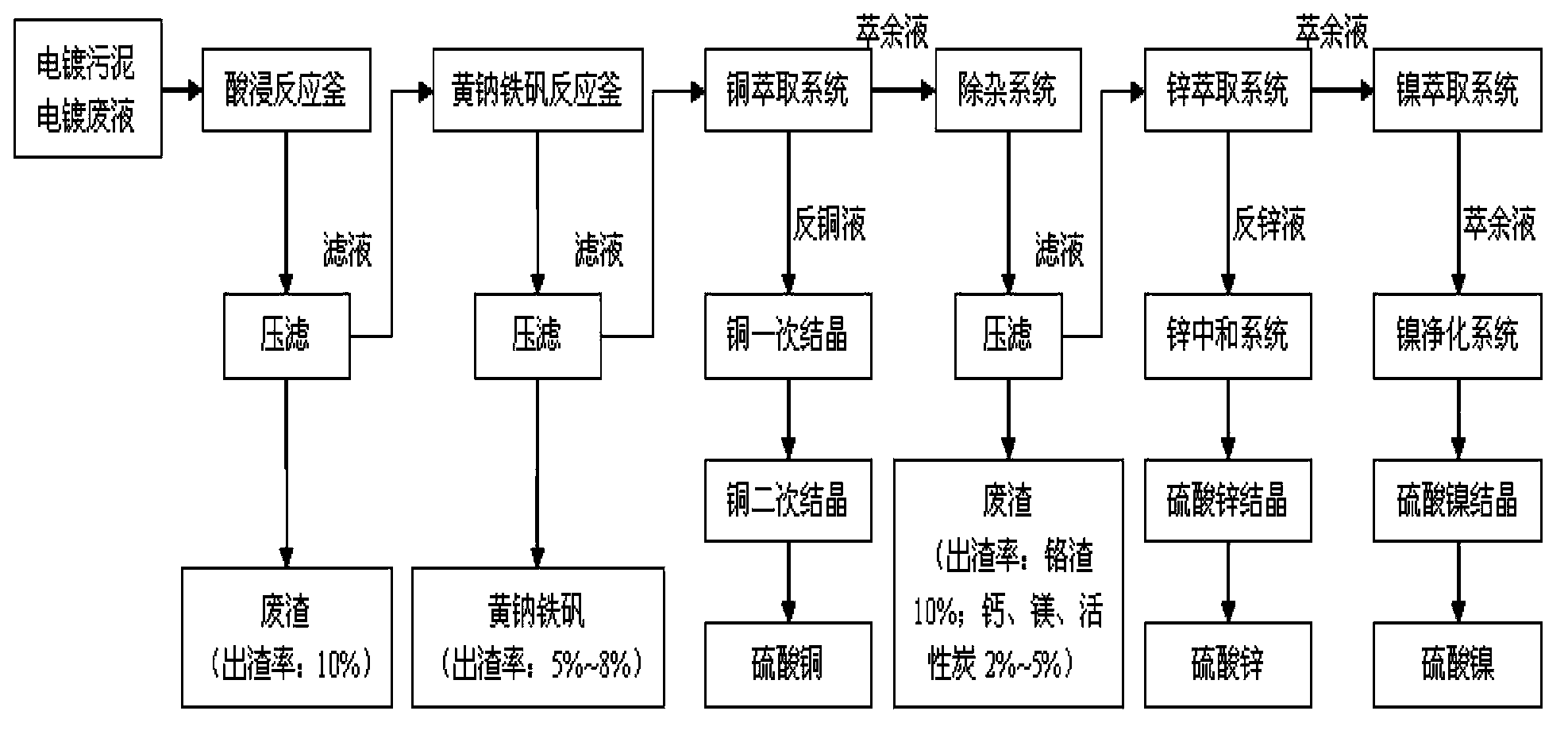

Electroplating sludge recycling technology

InactiveCN104099474AReduce dosageGuaranteed leaching rateZinc sulatesSludge treatmentLiquid wasteSludge

The invention discloses an electroplating sludge recycling technology. The technology comprises the steps of acid dipping, iron removal, copper extraction, impurity removal, zinc extraction, nickel extraction, low acid leaching and high acid leaching, tailings are washed with water, the iron removal step is carried out through a sodium jarosite process, copper extraction adopts two stage extraction, two stage water washing, four stage back extraction, and second stage extraction is carried out after first stage extraction, precipitation, washing and acid dissolution. The technology has the advantages of technological period shortening, guarantee of the product purity through multiple stage extraction, effective use of the waste resource, and reduction of the emission of a waste liquid.

Owner:ZHENJIANG HUAKE ENVIRONMENTAL PROTECTION TECH

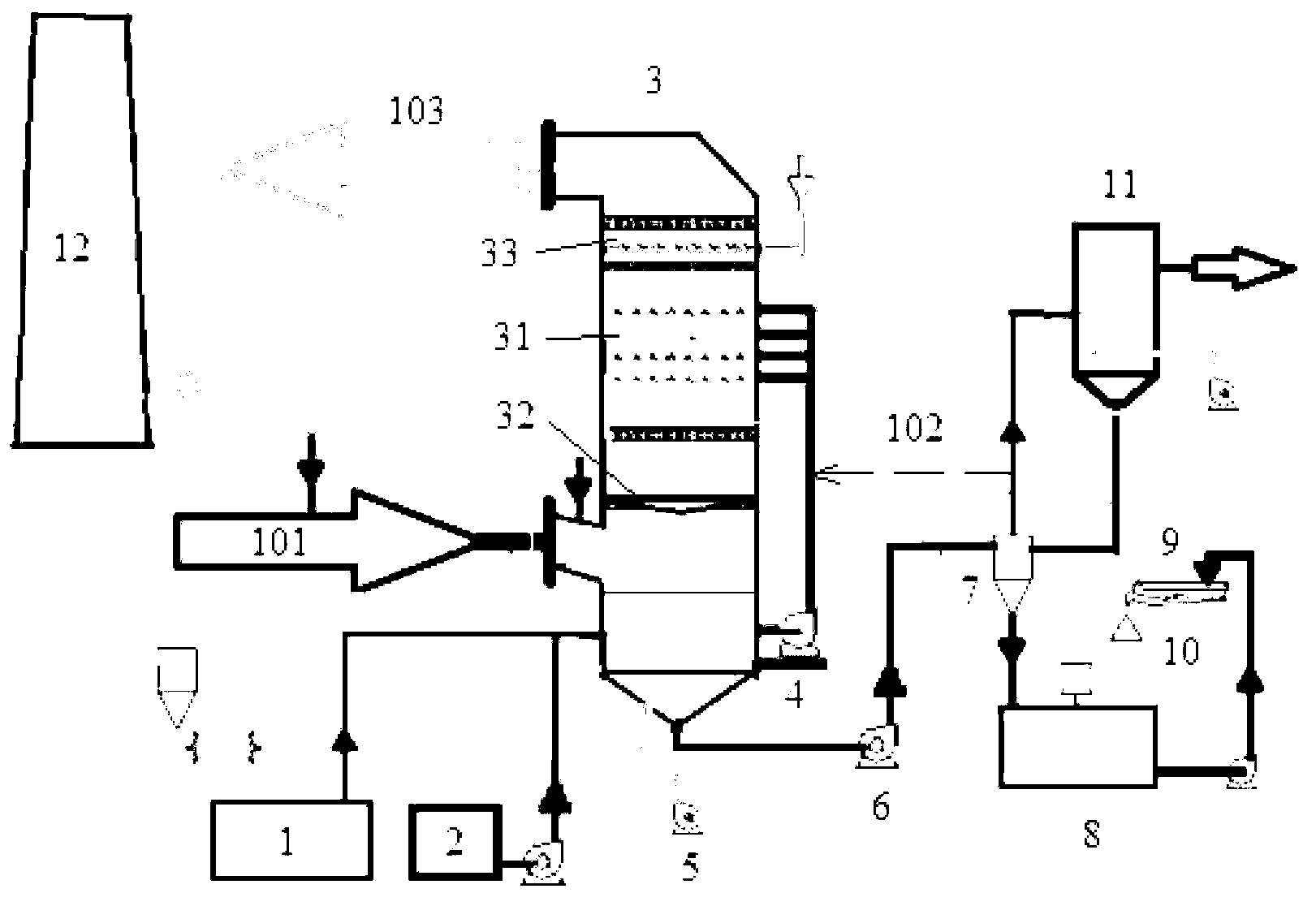

Energy-saving off-gas self-lazy circular sludge drying system and application method thereof

ActiveCN103408213AReduce displacementIncrease profitCombination devicesSludge treatment by de-watering/drying/thickeningSludgeSewage

The invention relates to an energy-saving off-gas self-lazy circular sludge drying system. The system comprises a material cabin, a buffering cabin and a heat exchanger. The material cabin comprises a material inlet I and a screw pump, wherein the screw pump is connected with a buffering cabin material inlet II; the buffering cabin is connected with a disc drier; a heating medium input pipe, a dry sludge discharge port and a condensate discharge port are arranged at the bottom of the disc drier, and an off-gas discharge port I is formed in the top of the disc drier; the dry sludge discharge port is connected with a rotary unloading device I; the condensate discharge port is connected with a condensate tank connected with the heat exchanger; the off-gas discharge port I is connected with a separator connected with a rotary unloading device II and a Venturi dust collector; the rotary unloading device II is connected with the disc drier; the Venturi dust collector is connected with a cooler and a washing tank; the top of the washing tank is connected with a pipe VI, and the bottom of the washing tank is respectively connected with an effluent drainage pipe and a pipe VIII; the pipe VIII is connected with the cooler. Moreover, the invention discloses an application method of the system. According to the invention, investment is less, implementation is easy, and comprehensive utilization ratio is high.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

Method for manufacturing nitrobenzole

ActiveCN101012169AReduce consumptionHigh purityOrganic compound preparationNitro compound preparationBenzeneElectrophoresis

Owner:COVESTRO DEUTSCHLAND AG

Synthetic method of etherified amino resin

ActiveCN103709111BImprove performanceLong shelf lifeOrganic chemistryChemical industryVacuum pumpingViscous liquid

The invention relates to a synthetic method of etherified amino resin. The synthetic method comprises the following steps: putting hexamethylol melamine and ethyl alcohol in a reaction kettle in a certain proportion, adding acid so as to adjust the pH value to 3.0-4.0, heating to 40-55 DEG C, and performing heat-preservation reaction for 30-60 minutes; adding alkali to neutralize the acidity in the system so as to adjust the pH value to 8.0-10.0; starting a vacuum pump and performing dealcoholization and dehydration under a vacuum condition for 1-3 hours; stopping vacuum pumping, adding 2%-5% of diatomaceous earth, and stirring for 20-60 minutes; filtering to obtain a colorless viscous liquid, and packaging. According to the synthetic method of ether amino resin disclosed by the invention, the etherification degree of the obtained product is 10%-20% higher than that in a traditional synthetic method; the obtained etherified amino resin is stable in product performance and long in storage time; moreover, the synthetic method disclosed by the invention is short in technological process, few in produced waste water, energy-saving and environment-friendly.

Owner:CHONGQING JIANFENG HAOKANG CHEM

Method for preparing pentaerythritol triacrylate

InactiveCN101462953AReduce pollutionReduce by-productsOrganic compound preparationCarboxylic acid esters preparationPentaerythritolColor intensity

The invention belongs to a method for preparing pentaerythritol trimethylacrylate, comprising the steps as follows: (1) pentaerythritol, acrylic acid, catalyst, solvent and polymerization inhibitor are put into a reaction kettle to be fully mixed and stirred so as to form a miscible liquid; (2) a steam valve of the reaction kettle is opened to slowly heat the miscible liquid, and the temperature is controlled and maintained at 70-90 DEG C for a 20-40min reaction; (3) the mixture is continued to be heated, when the temperature is increased to 80-115 DEG C, reflow is carried out for 3-5h and then the reaction is finished; (4) soda water solution and sodium chloride water solution are added into the mixture and after washing the upper organic phase is extracted; (5) the upper organic phase is separated from the solvent; (6) and filter pressing is carried out to obtain the end product. The method has simple process, good quality, activity and flexibility, low shrinking percentage and color intensity and high yield coefficient, and produces few by-products or little waste water.

Owner:TIANJIN CHEM REAGENT RES INST

Method for synthesizing ethyl chloride by using gas phase hydrogen chloride and ethanol

InactiveCN102850178AReduce processingLess waste waterChemical industryHalogenated hydrocarbon preparationSteam pressureDistillation

The invention discloses a method for synthesizing ethyl chloride by using gas phase hydrogen chloride and ethanol. The synthesis method is as below: adding anhydrous zinc chloride to a reaction kettle; slowly heating to 85 DEG C by steam; passing the hydrogen chloride gas through a flowmeter, and introducing hydrogen chloride gas to the reaction kettle through an inserting tube in a buffer tank; and at the same time, continuously adding ethanol into the reaction kettle by a pump, respectively controlling a molar ratio of hydrogen chloride to ethanol at 1.02-1.03:1 by the flowmeter; regulating the temperature of the reaction kettle by jacket steam, and controlling the reaction kettle jacket steam pressure at 5-5.5 KG / cm<2>, and the temperature of the reaction kettle at 120-135 DEG C; condensing ethyl chloride gas and water generated by the reaction and unreacted ethanol by a condenser; recovering water and alcohol to a liquid receiving tank, and pumping the water and alcohol to a material groove of an alcohol distillation column for indiscriminate application; successively subjecting the ethyl chloride gas to water washing, alkaline washing and concentrated sulfuric acid drying; and finally condensing by frozen brine to obtain a liquid ethyl chloride product. The invention has advantages of simple process, easy operation, reduced treatment amount of waste water, energy saving and improved efficiency.

Owner:JIANGSU ZHENFANG BIO CHEM CO LTD

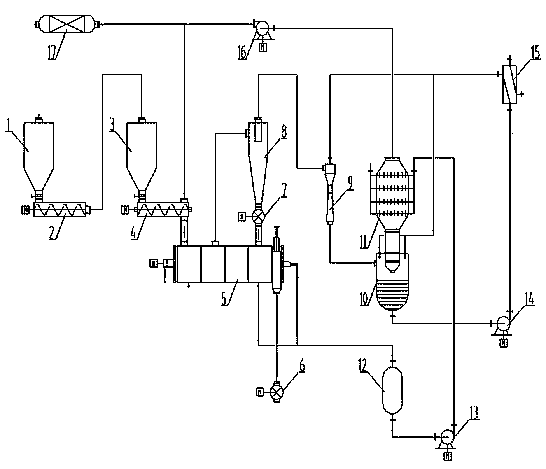

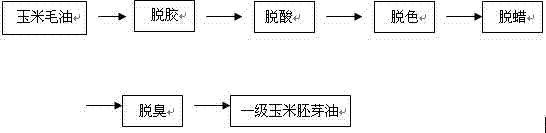

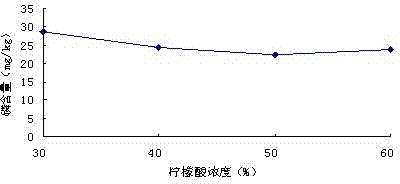

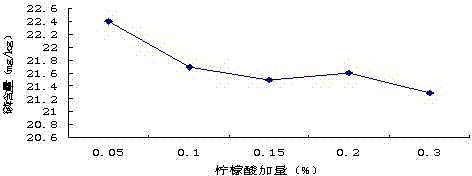

Method for preparing maize germ oil through enzymatic degumming

ActiveCN102206542AObvious advantagesLow operating temperatureFatty-oils/fats refiningEdible oils/fatsEnzymeChemistry

The invention relates to a method for preparing maize germ oil through enzymatic degumming. Specifically, phosphatidase is employed for a degumming treatment of maize crude oil during the refining process. Then after deacidification, decoloration, dewaxing and deodorization, refined maize germ oil can be obtained. Wherein, the degumming treatment comprises acid reaction, alkali neutralization, enzyme reaction, and separation, dehydration and drying; the acid in the acid reaction is citric acid, and the enzyme in the enzyme reaction is phosphatidase. In the invention, the key technology for maize germ oil refining is overcome, and the optimum technological conditions for the enzymatic degumming of maize germ oil are optimized. The maize germ oil prepared through enzymatic degumming has the obvious advantages of: low operation temperature and low energy consumption; obviously superior quality of the obtained oil to the quality of oil prepared by traditional methods, and increased product oil yield by over 1%; reduced consumption of acid and alkali chemicals, and reduced waste water generation by 70%-90%, substantially reduced environmental protection cost and markedly improved economic benefit.

Owner:SHANDONG XIWANG FOOD

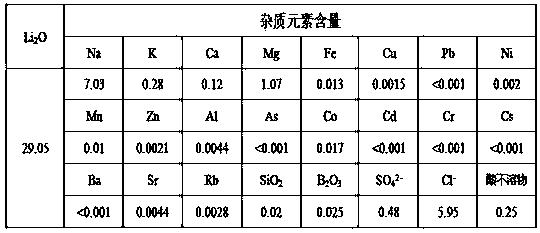

Method for preparing low-magnetism high-purity lithium carbonate by using saline lithium salt

ActiveCN104386715ASimple processEmission reductionLithium carbonates/bicarbonatesImpurityCrystallization

The invention belongs to the technical field of lithium carbonate preparation, and discloses a method for preparing low-magnetism high-purity lithium carbonate by using saline lithium salt. The method using the saline lithium salt as a raw material mainly comprises the following steps: pulping the saline lithium salt, carrying out countercurrent washing, hydrogenating carbonic acid, removing magnetic substances, carrying out resin purification to remove impurities, carrying out evaporative crystallization, refining, calcining, and crushing to prepare the low-magnetism high-purity lithium carbonate product. The purity of the lithium carbonate product prepared through the method is 99.95-99.98%, and the contents of magnetic Fe, magnetic Cr and magnetic Zn in the product are not greater than 0.081g / t, not greater than 0.002g / t and not greater than 0.002g / t respectively. The method has the advantages of simplicity, stable operation process, short production period and small device investment, the prepared lithium carbonate is highly pure, contains a small amount of magnetic substances, has a comprehensive recovery rate of lithium of 98.65%, has a low production cost, and is suitable for industrial production.

Owner:JINCHUAN GROUP LIMITED

Separation and recovery process after imidacloprid synthesis

The invention relates to the field of pesticide production process, in particular to a separation and recovery process after imidacloprid synthesis. The separation and recovery process of the invention comprises the following steps of: primarily distilling DMF (Dimethyl Formamide) from a reaction solution after a condensation reaction of 2-nitroaminoimidazoline, NaOH and 2-chloro-5 chloromethylpyridine; and adding an extractant to extract, wherein the lower substance is 2-nitroaminoimidazoline. The separation and recovery process of the invention also comprises the following steps of: evaporating the extracted supernatant; adding an eluent to crystallize and filtrate; washing the precipitate with the eluent; carrying out the mixed washing on the filtrate; distilling the solution until thevolume is 1 / 10 to 1 / 5; crystallizing; and filtrating under positive pressure to obtain the precipitate again. The separation and recovery process of the invention ensures that the recovery rate of the raw material of the 2-nitroaminoimidazoline is improved and the recovered 2-nitroaminoimidazoline can be directly used as a reaction raw material for realizing continuous reaction, shortens the production cycle, separates residential DMF, improves the imidacloprid purity and decreases the wastewater amount of a refining section.

Owner:SHANGDONG HAILIER CHEM

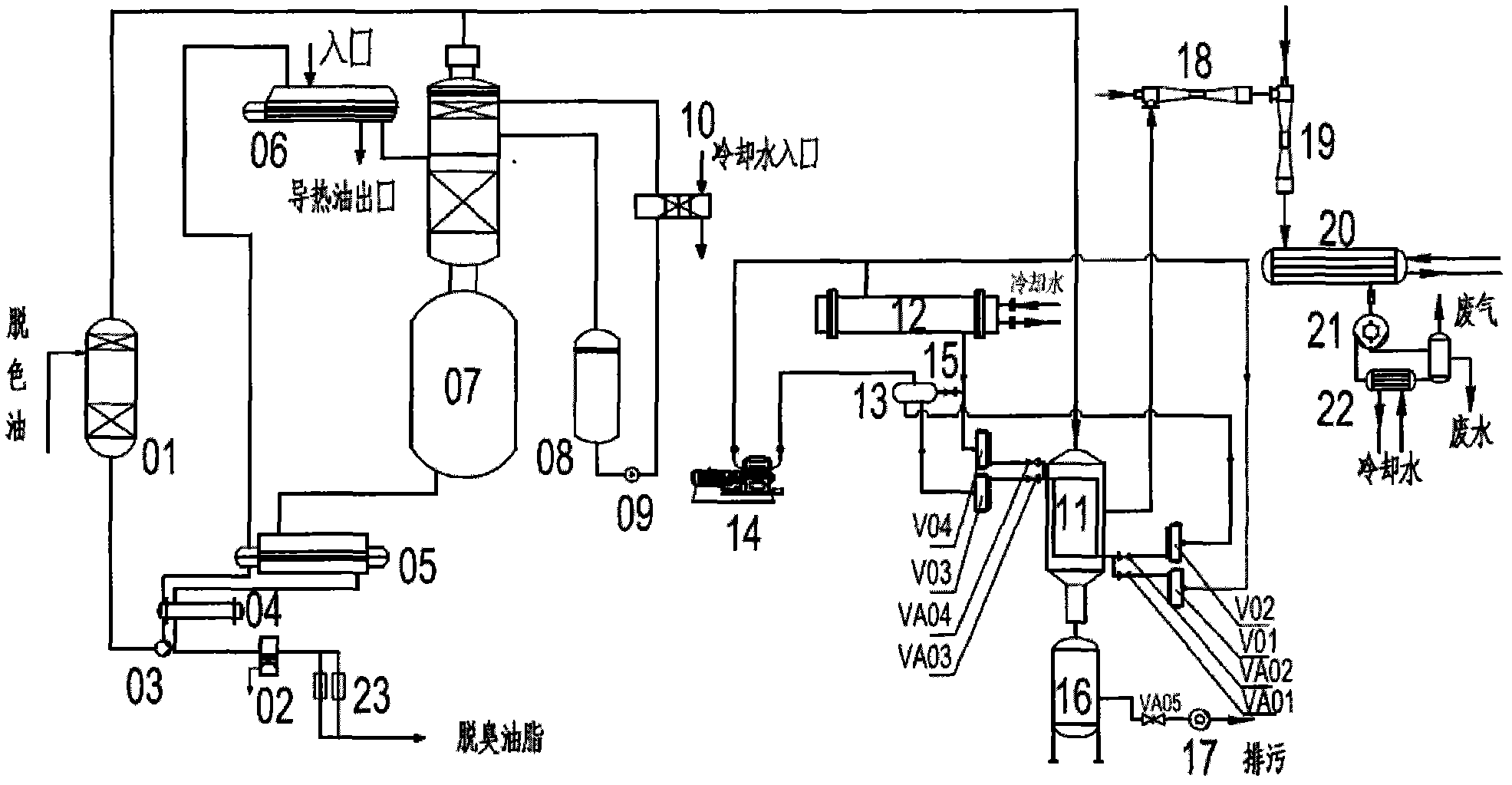

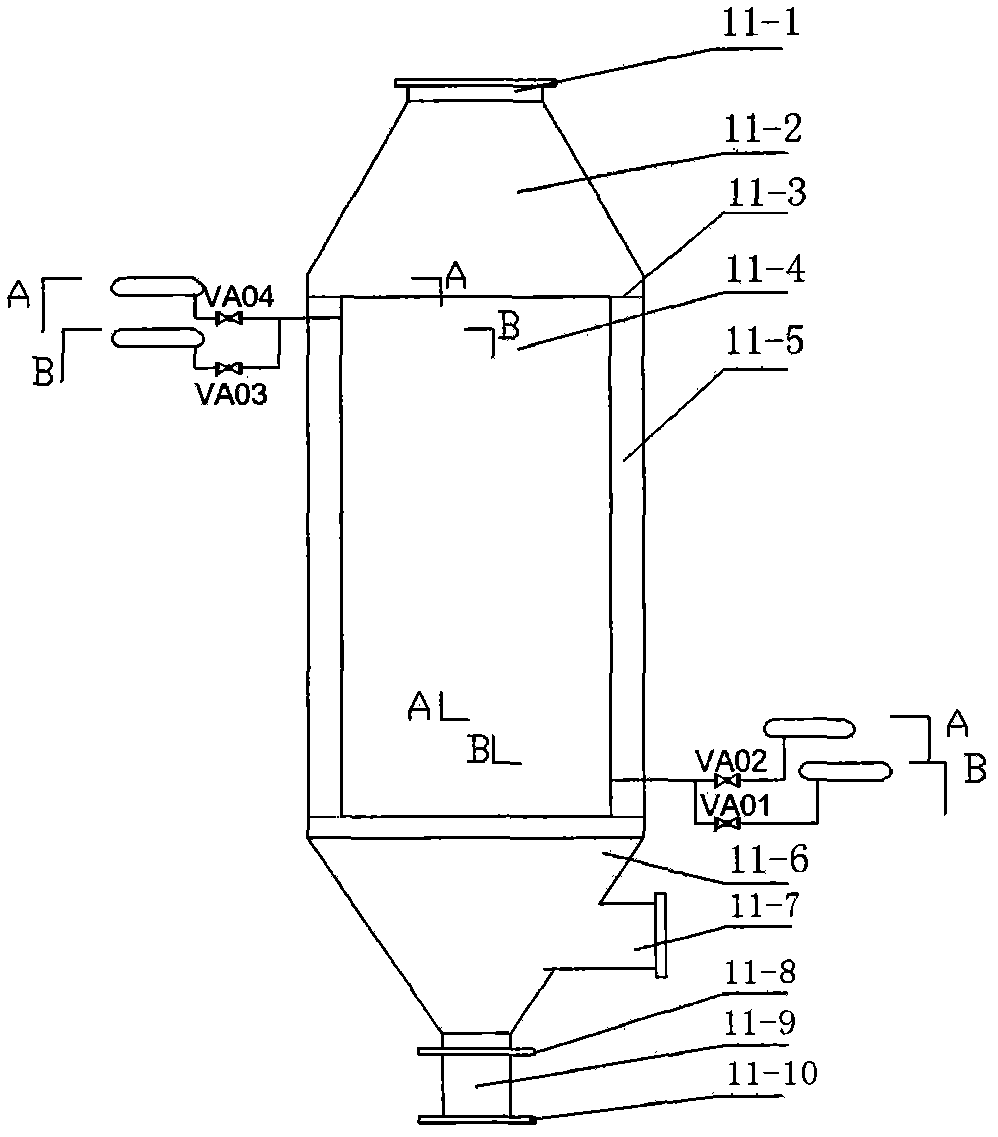

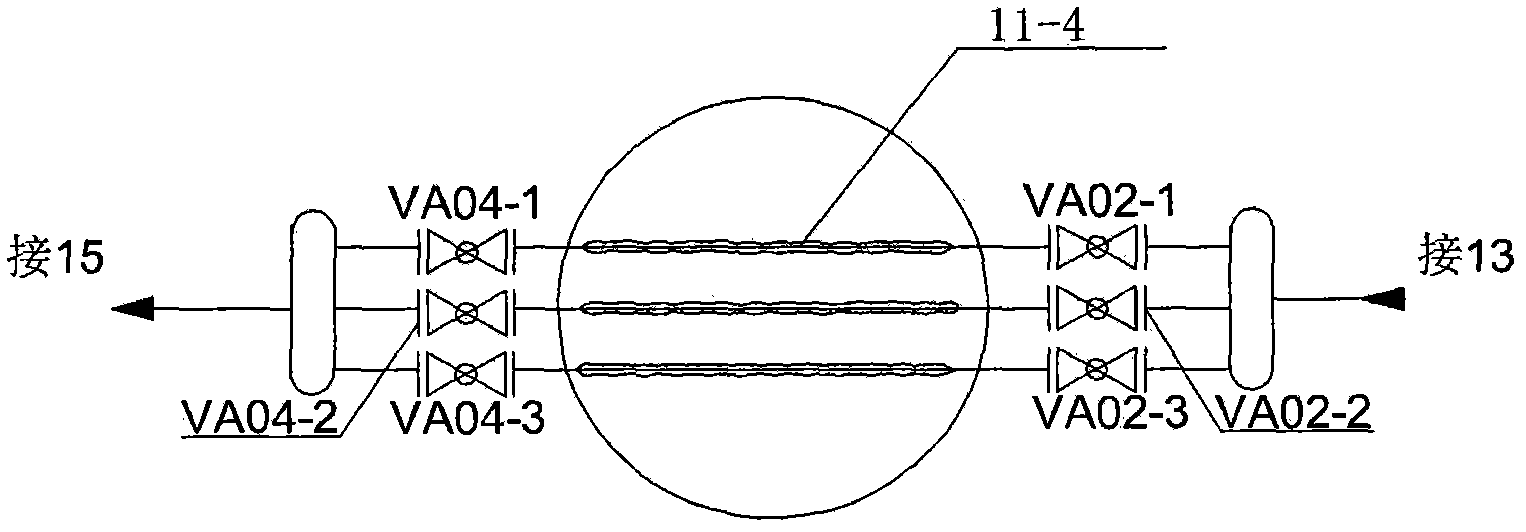

Freeze-condensing vacuum deodorizing method and equipment for fat and oil

The invention relates to a freeze-condensing vacuum deodorizing method for fat and oil. The method is characterized by comprising the following steps of: 1) preparing; 2) performing gassing to remove oxygen; 3) heating; 4) deodorizing; 5) cooling; and 6) freezing, trapping and melting. Equipment using the method is characterized by comprising the following units of: (1) a gassing unit; (2) a heating unit; (3) a deodorizing unit; (4) a fatty acid trapping unit; (5) a vacuum refrigeration unit; (6) a rear vacuum pump unit; and (7) a defrosting unit. When the method and the equipment are used for performing fat and oil deodorizing production, the method and the equipment have the advantages of greatly reducing heating energy, greatly reducing the using amount of injecting steam and the using amount of cooling water and improving production efficiency. Moreover, sealing treatment is performed on a system and no waste gas is discharged, so the method and the equipment also have the advantages of energy conservation, emission reduction, sanitation and environmental protection.

Owner:中机康元粮油装备(北京)有限公司

Production process of hesperidin

InactiveCN103467546AReduce dosageReduce energy consumptionSugar derivativesSugar derivatives preparationAlcoholFiltration

The invention discloses a production process of hesperidin, and in particular discloses a process for extracting the hesperidin from an immature bitter orange. The production process comprises the steps of (1) grinding the immature bitter orange, and adding a mixed solvent of methyl alcohol and alkali for cyclic soaking, extraction and filtration to obtain immature bitter orange residues; (2) washing the immature bitter orange residues with the mixed solvent of the methyl alcohol and the alkali, performing filtration to obtain filter liquid (A), and performing refined filtration on the obtained filter liquid (A) to obtain filter liquid (B); (3) adding acid into the filter liquid (B) to adjust the pH value to 5-6, and performing standing and crystallization; (4) collecting crystals, and performing washing and drying to obtain the hesperidin. The production process is simple, the extracted hesperidin is high in purity, other effective components can be also extracted, the emission of waste water is low, and the cost is low.

Owner:CHENGDU OKAY PHARMA

Oil washing and energy saving technology and device for condensing and recycling destructive distillation oil and gas of oil shale

InactiveCN101831312AHigh recovery rateQuality improvementChemical industrySpecial form destructive distillationNaphthaFractionation

The invention discloses an oil washing and energy saving technology and a device for condensing and recycling destructive distillation oil and gas of oil shale. The technology is characterized in that high-temperature raw coal gas from a destructive distillation workshop directly enters an oil washing fractionation tower without cooling to separate and recycle heavy oil, shale oil and naphtha; the coal gas and light oil go out of a tower top and then enter a water washing tower; middle section circulation is set at the upper part of the tower for recycling heat; the light oil is cooled with recycled water in the water washing tower; and a part of the light oil circularly enters the oil washing fractionation tower to be used as cooling washing oil. By using the destructive distillation oil and gas of the condensed oil shale, the yield and the quality of shale oil are enhanced; and meanwhile, most of high-temperature heat is recycled and the wastewater quantity is reduced.

Owner:DAQING OILFIELD CO LTD +1

Graphene preparation method

InactiveCN104894594AReduce pollutionLow impurity contentElectrolysis componentsGrapheneEngineeringAuxiliary electrode

The invention belongs to the technical field of preparation of graphene, and in particular, relates to a graphene preparation method. A working layer containing a carbon material is attached on a working current collector to obtain a working electrode; an auxiliary layer containing a power source substance is attached on an auxiliary current collector to obtain an auxiliary electrode; the working electrode and the auxiliary electrode are directly assembled to obtain a pre-reaction body, so that the working layer and the auxiliary layer make direct contact (capable of being electronically conducted); and finally, electrolyte is injected between the working layer and the auxiliary layer, so that the working layer and the auxiliary layer are in ion conduction. Under the condition of synchronous conduction of an ion channel and an electronic channel, a graphite stripping reaction is spontaneously performed to prepare the graphene; and meanwhile, the graphene with a small lamella number can be industrially prepared in large batches with low cost.

Owner:GUANGDONG ZHUGUANG NEW ENERGY TECH

Method for preparing cyclic sulfate by directly oxidizing hydrogen peroxide

PendingCN111909129ALess impuritiesHigh purityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCatalytic oxidation

The method comprises the following steps: dropwise adding hydrogen peroxide into a mixture of cyclic sulfite, an organic solvent and a solid catalyst to carry out catalytic oxidation reaction, filtering out the solid catalyst after the reaction is finished, standing filtrate for layering, taking an organic layer, and performing distilling and concentrating to obtain a cyclic sulfate product. Cheaphydrogen peroxide is used for directly catalyzing and oxidizing cyclic sulfite to prepare cyclic sulfate, so that on one hand, the reaction is mild and easy to control, and the reaction conversion rate is high; on the other hand, no waste salt is generated, the evaporation capacity of water is small, energy consumption is low, generated waste water is little, and the production process is more environmentally friendly; the used solid catalyst contains an active component, an active auxiliary agent and an oxide carrier, and can be recycled, so that the consumption of noble metals is reduced, and the production cost is greatly reduced; the cyclic sulfate prepared by the method is few in impurities, high in purity and wide in market prospect.

Owner:CHANGSHU CHANGJI CHEM +1

Method of selectively synthesizing triethylene diamine

A process for selectively synthesizing trivinyldiamine features the reaction of monoethanol amine and small-grain zeolite catalyst in fixed-bed reactor under feeding ammonia and water. The said small-grain zeolite may be ZSM-5, ZSM-8, ZSM-11, ZSM-5 / ZSM0-11, ZSM-23 and MCM-22. Its advantages are high output rate and selectivity, and less by-product and pollution.

Owner:DALIAN UNIV OF TECH

Water repellent finishing agent and method for manufacturing moisture absorbing and sweat releasing jean fabric by using same

The invention relates to a water repellent finishing agent, which comprises the following components in percentage by mass: 50 to 80 percent of fluorine-containing emulsion, 10 to 30 percent of resin finishing agent, 5 to 20 percent of softening agent and 0.3 to 2 percent of thickening agent; and pH value buffer solution is added to adjust the pH value of the water repellent finishing agent to between 4 and 7. The invention also relates to a method for manufacturing moisture absorbing and sweat releasing jean fabric by using the water repellent finishing agent, which comprises the following steps: performing water repellent coating finishment on the inner side of the jean fabric by using the water repellent finishing agent; and not treating the outer side of the jean fabric to keep the hydrophilicity of cotton, wherein the water repellent coating finishment process comprises the steps of coating the inner side of the jean fabric, pre-drying, baking, and cooling and cloth falling; the pre-drying temperature is between 80 and 135DEG C, and the time is 1 to 150 minutes; and the baking temperature is between 110 and 170DEG C and the time is 2 to 10 minutes. By adopting the water repellent finishing agent and the method for manufacturing the moisture absorbing and sweat releasing jean fabric, common jean fibers can be manufactured into the moisture absorbing and sweat releasing jean fabric with good washing fastness and strong processability.

Owner:GUANGDONG JUNAN JEANS RES INST

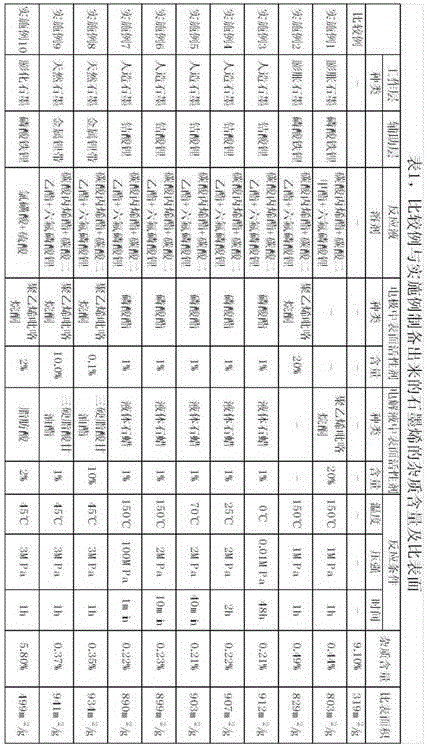

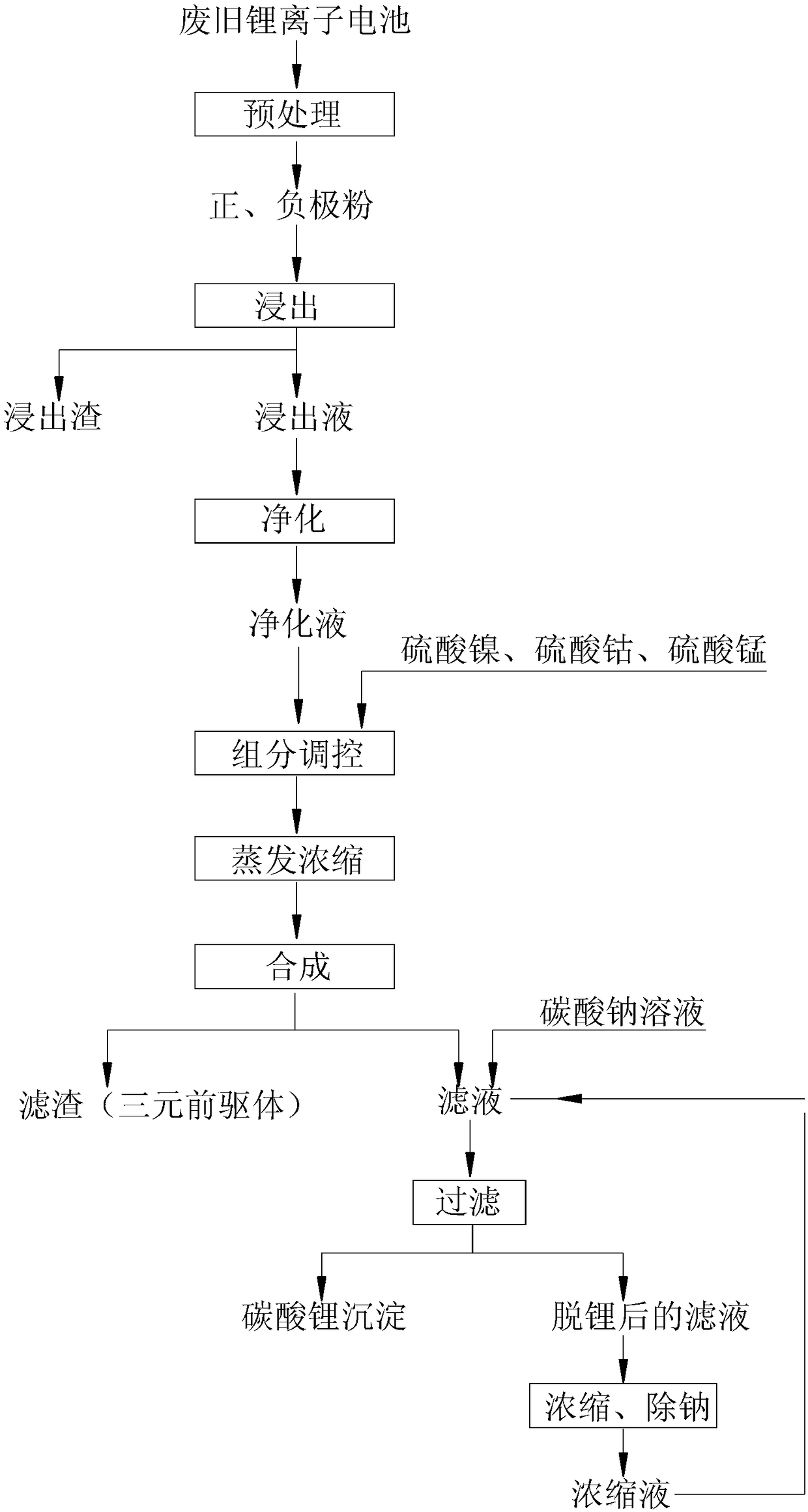

A method for recovering valuable metals from waste lithium ion batteries

ActiveCN108963371AReduce consumptionShort processWaste accumulators reclaimingProcess efficiency improvementPregnant leach solutionManganese

The invention discloses a method for recovering valuable metals from waste lithium ion battery, which comprises the following steps: (1) pretreatment: separating positive and negative electrode powderfrom waste lithium ion battery; 2, leaching, and taking leach solution; 3) purification: adding alkali to that leach solution to adjust the pH value, and removing iron, aluminum and copper to obtainpurified solution; (4) Component control and evaporation concentration: adjusting the proportion of nickel, cobalt and manganese in the purified solution; then evaporating and concentrating, enrichingnickel, cobalt and manganese to set concentration to form precursor preparation liquid; 5) synthesis: passing the precursor preparation liquid, NaOH solution and ammonia water into a reaction kettle,controlling the pH value of the solution in the reaction kettle, carrying out reaction, and filtering after the reaction, wherein the filtered residue is the a ternary precursor. The leaching solution of the invention is purified, nickel cobalt manganese salt is supplemented, evaporated and concentrated, and the precipitant is added to directly synthesize the ternary precursor. The utility modelhas the advantages of short process flow, low consumption of raw materials, high recovery rate and high added value of products.

Owner:赣州寒锐新能源科技有限公司

Method for dedusting and desulfurizing catalytic-cracking oil refining regenerated flue gas

The invention relates to a method for dedusting and desulfurizing catalytic-cracking oil refining regenerated flue gas. The method which utilizes a sodium alkali and magnesia combined sodium-magnesium method comprises the following steps: magnesium hydroxide slurry is prepared from magnesia firstly and is mixed with a sodium alkali solution according to a certain ratio so as to prepare a desulfurization solution, and the desulfurization solution is conveyed to each spraying layer from the bottom of a tower by a desulfurization circulating pump; the flue gas is subjected to spraying, humidifying and cooling at an entrance of a desulfurization tower, then rises from the bottom of the desulfurization tower and is subjected to enhanced dedusting, desulfurizing and acid mist trapping by a combination unit, and the flue gas flowing out of the combination unit is then subjected to deep desulfurizing and dedusting by an upper spraying zone; sulfur dioxide in the flue gas is converted into magnesium sulfite and sodium sulfite; desulfurizing waste liquid is subjected to adequate aeration and oxidation, and then, produced magnesium sulfate and waste residues are discharged by a residue slurry pump and enter a subsequent filtration and dewatering system; and slurry concentrated by a cyclone is subjected to dewatering by a filtering machine so as to obtain disposable solid wastes. Compared with the prior art, the method has the advantages that the cost of the desulfurizing liquid can be remarkably reduced, the wastewater output is reduced, and meanwhile, the dedusting and desulfurization of FCC (Fluidized catalytic cracking) regenerated flue gas can be realized efficiently.

Owner:SHANGHAI JIAO TONG UNIV

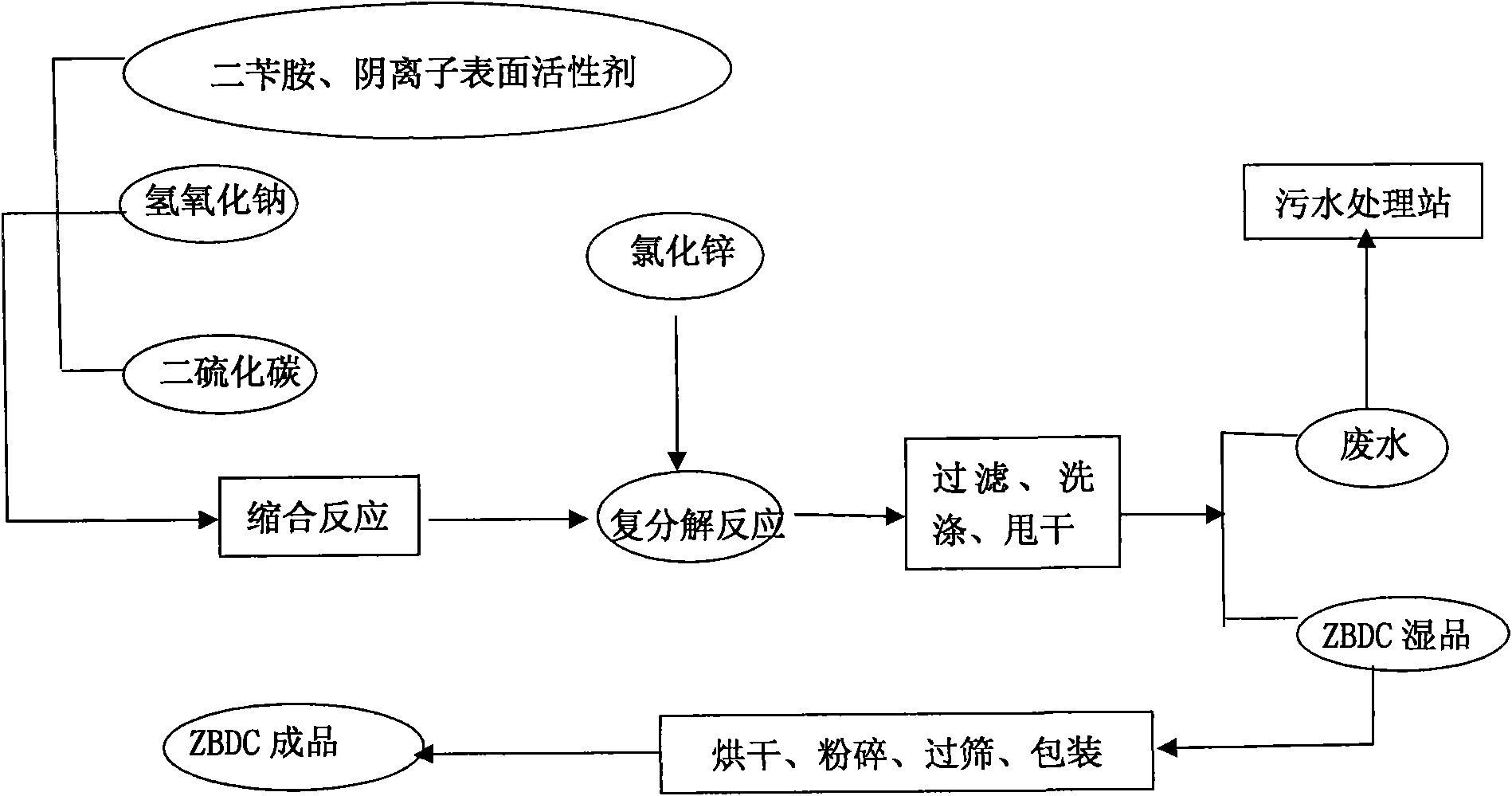

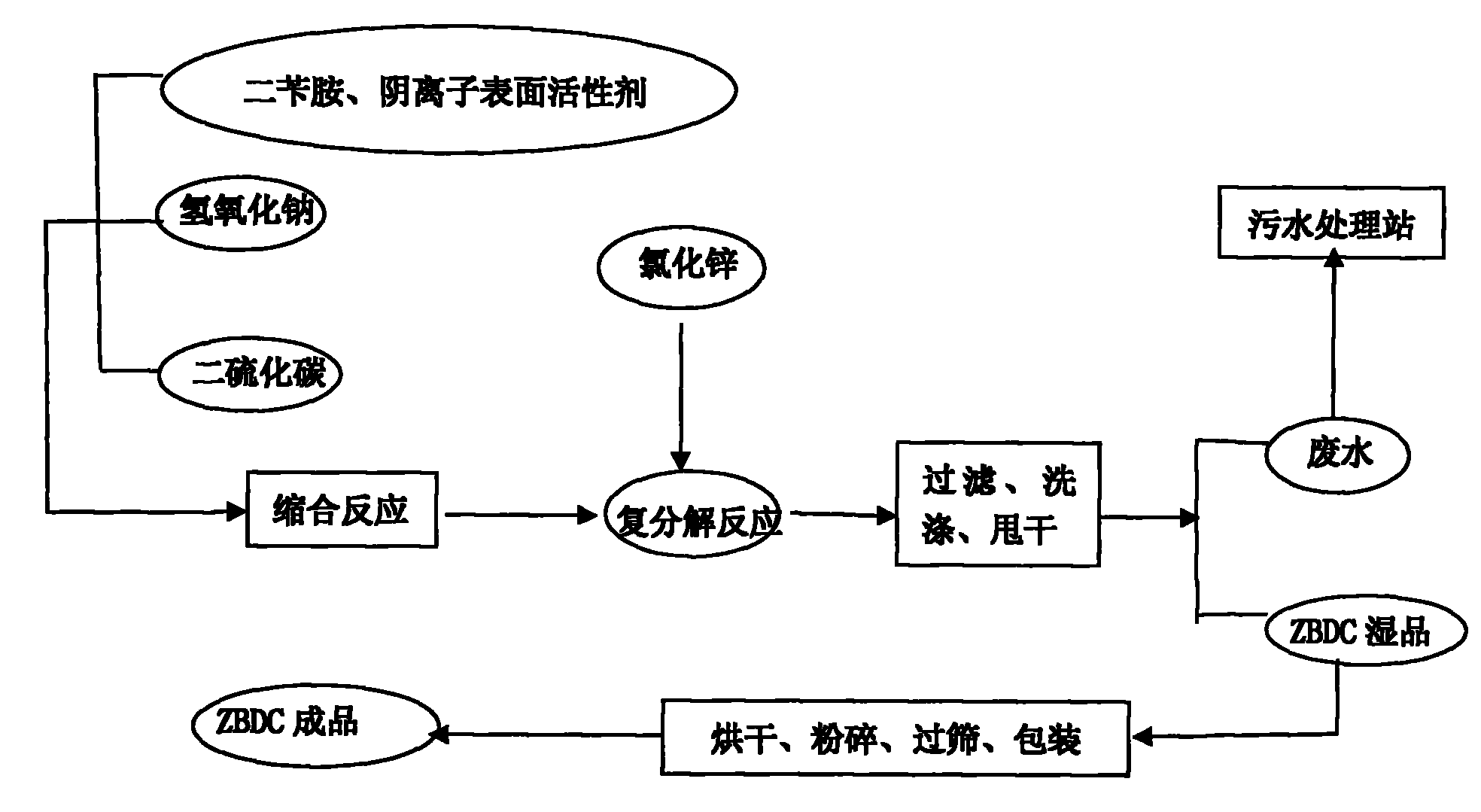

Method for preparing zinc dibenzyl dithiocarbamate (ZBDC) thiofide

ActiveCN101955452AReduce pollutionLess waste waterOrganic chemistryZinc dibenzyldithiocarbamateDodecylsulfonic acid

The invention provides a method for preparing zinc dibenzyl dithiocarbamate (ZBDC) thiofide, which comprises that: the raw materials used are dibenzylamine, carbon disulfide, sodium hydroxide and anionic surfactant, wherein the stoichiometric molar ratio of dibenzylamine to carbon disulfide to sodium hydroxide and anionic surfactant to zinc chloride to sulfuric acid is 1:1.05-1.2:1.05-1.2:0.020-0.025:0.53-0.58:0.005-0.015; and the process comprises: adding dibenzylamine, carbon disulfide, sodium hydroxide and anionic surfactant in a given amount into a reaction kettle holding purified water with stirring in turn, lower the temperature by 10 to 20 DEG C totally, dripping carbon disulfide liquid in a given amount within 6 to 7 hours, stirring for 0.5 to 1 hours after the dripping is finished, keeping the temperature at 30 to 38 DEG C constantly, dripping solution of zinc chloride, performing replacement reaction, regulating the pH value of the reaction liquid to 7 to 9 with sulfuric acid after the replacement reaction is finished, finishing the reaction, stirring for 1 to 2 hours, performing solid-liquid separation, discarding liquid and drying, crushing, sieving and packaging the solid. The anionic surfactant is sodium dodecyl sulfate.

Owner:WILLING NEW MATERIALS TECH CO LTD

Catalyst for producing crotonaldehyde

InactiveCN101462044ANo corrosionShort processMolecular sieve catalystsOrganic compound preparationCrotonaldehydeAlkali metal oxide

The invention provides a catalyst for producing crotonaldehyde, which takes a complex consisting of alkaline earth metal oxide and a molecular sieve or alumina as a carrier, and is prepared by supporting alkaline metal oxide by adopting an impregnation method. Alkaline earth metal is magnesium, calcium or barium, the molecular sieve is an HZSM-5, Hbeta, HY, USY or rare earth Y(ReY) molecular sieve, the alumina is gamma-Al2O3, and alkaline metal is lithium, sodium, potassium or cesium. The mass ratio of the alkaline earth metal oxide and the molecular sieve or the alumina which are taken as the carrier of the catalyst is 1: 20-20: 1, and the mass of the alkaline metal oxide is 1 to 30 percent of the total mass of the complex consisting of the alkaline earth metal oxide and the molecular sieve or the alumina. Compared with a solid catalyst reported by literature, the catalyst has better low-temperature activity, namely the reaction temperature is lower than that of the catalyst reported by literature when the conversion rate of acetaldehyde is equivalent to the selectivity of the crotonaldehyde. The method also additionally produces tolyl aldehyde with higher added value when synthesizing a main product, namely the crotonaldehyde, and further promotes the economic benefit of the catalyst.

Owner:SINOPEC YANGZI PETROCHEM

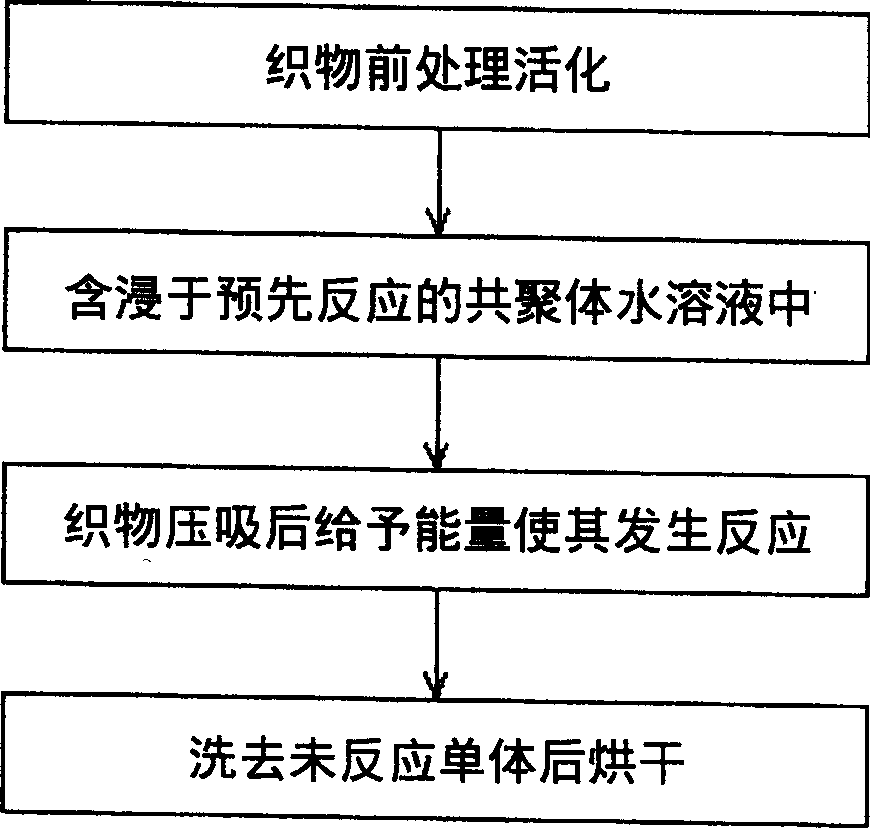

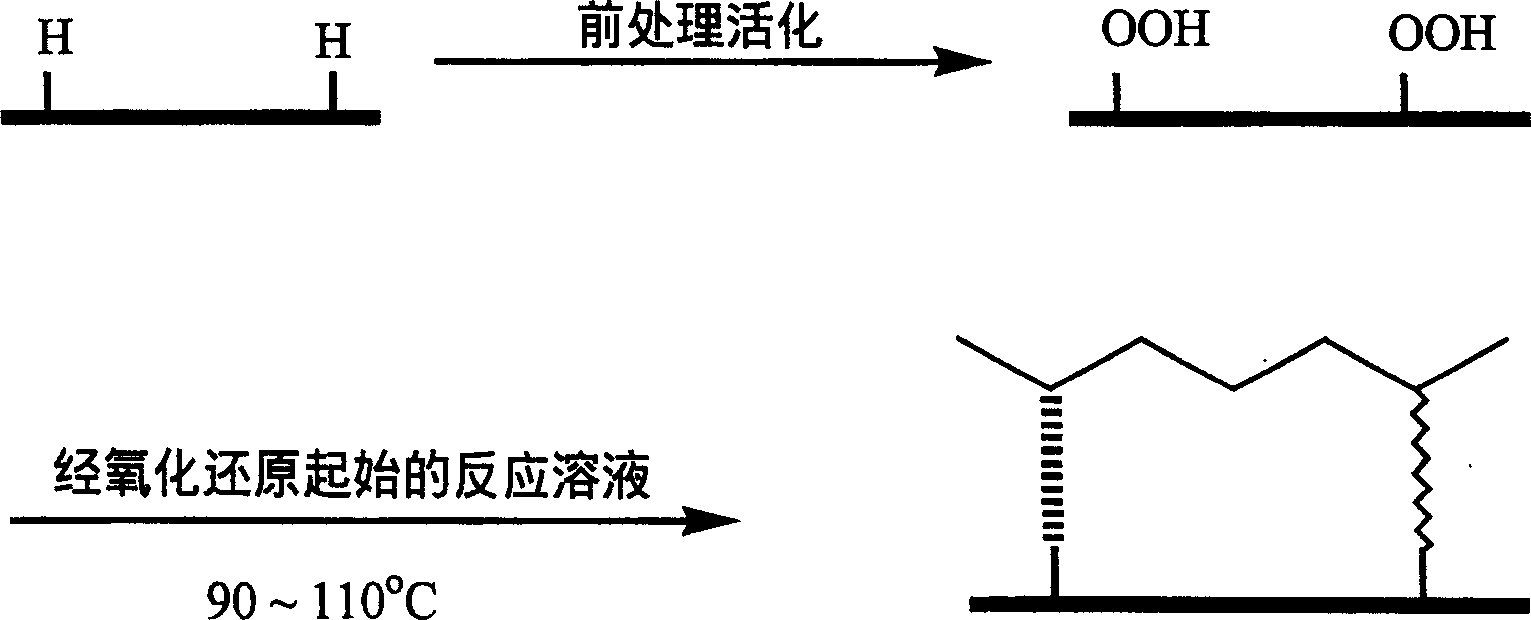

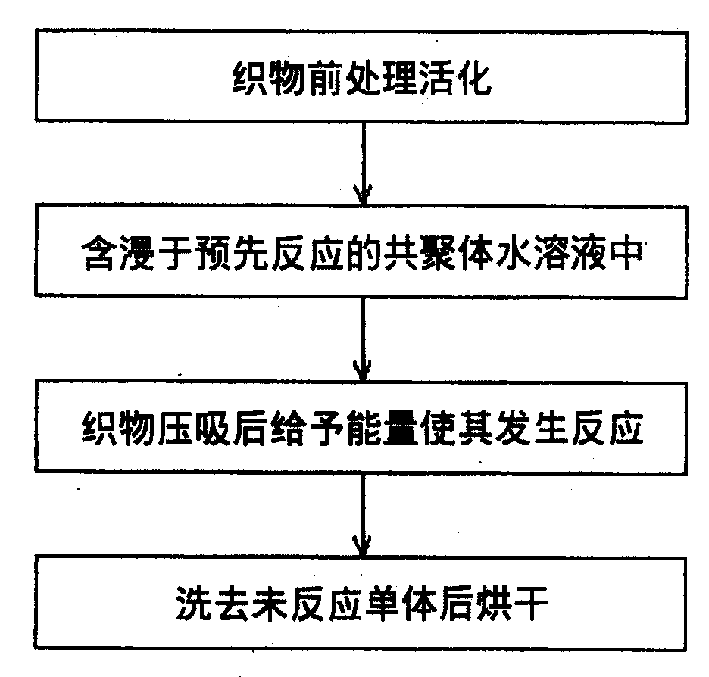

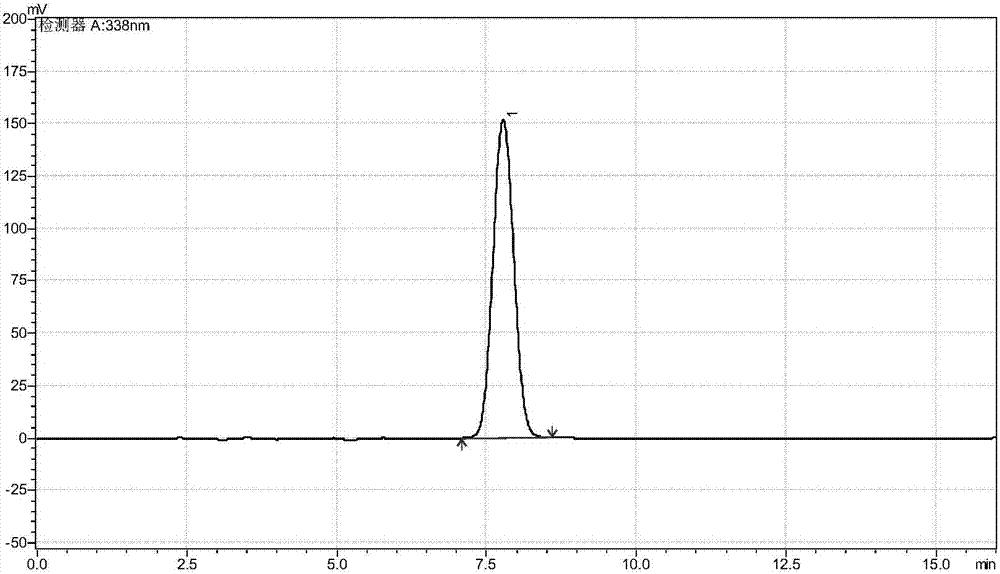

Method for manufacturing fabric with moisture absorption and sweat discharge performance

The invention relates to a method for making fabric having moisture absorbing and sweating property, which includes: pre-activating on the surface of the hydrophobic fabric; then taking grafting reactions with polyalcohol, natural polysaccharide and copolymer formed by unsaturated carboxylic acid with double bond and a covalent bond is formed.

Owner:IND TECH RES INST

Method for producing L-2-aminobutyric acid by virtue of biological catalysis

ActiveCN104774881AImprove protectionHigh yieldFermentationL-2-Aminobutyric AcidL-alpha-Aminobutyric Acid

The invention discloses a new method for synthesising L-alpha-aminobutyric acid with a high optical activity. The new method comprehensively applies alcohol dehydrogenase, threonine aldolase, threonine deaminase and L-amino acid dehydrogenase, and ethanol and glycine raw material are directly synthesised into L-alpha-aminobutyric acid by a 'one-pot' method. According to the method disclosed by the invention, L-alpha-aminobutyric acid is synthesised in one pot by virtue of the simple and easily available raw materials; the method has the advantages of being few in operation steps, environment-friendly, good in bio-safety and simple in equipment, and is beneficial to industrial large-scale production for L-alpha-aminobutyric acid with a high optical activity and L-alpha-aminobutyric acid series products.

Owner:HUNAN FLAG BIOTECHNOLOGY CO LTD

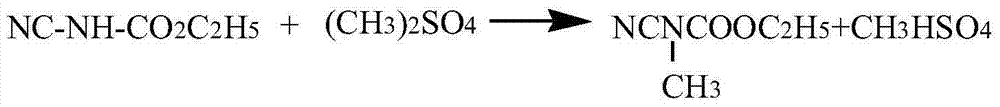

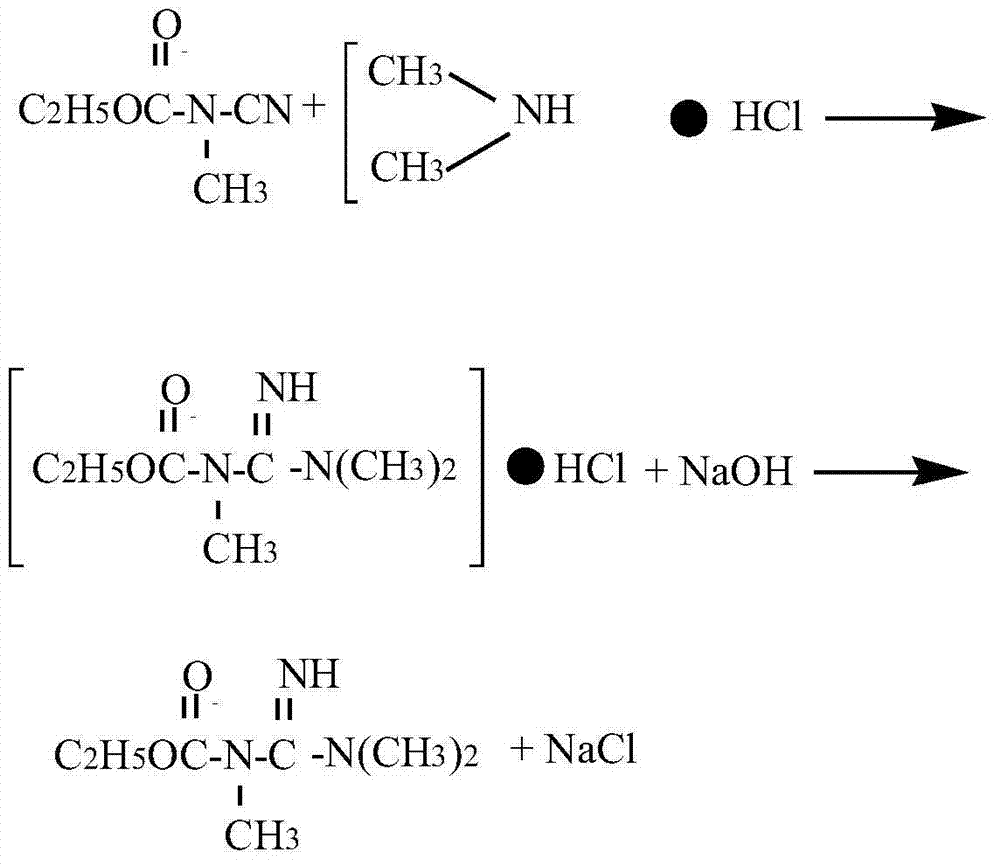

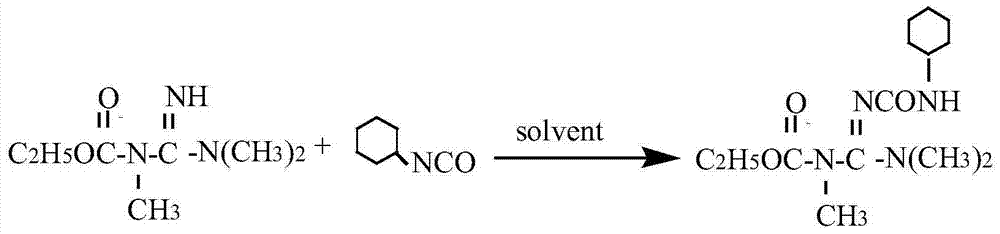

Synthetic process of hexazinone

ActiveCN103755654AOmit extractionReduce extractionOrganic chemistrySodium methoxideChemical reaction

The invention provides a synthetic process of hexazinone. The synthetic process comprises the steps of: by taking ethanol, lime nitrogen, cyclohexylamine, dimethylamine, dimethyl sulfate, sodium methoxide and phosgene as main active ingredients, generating a series of chemical reactions in solvent, and carrying out desolventizing and concentration, crystallizing and separating and drying to obtain a finished hexazinone product. According to the synthetic process, the solvent extraction can be omitted, the reaction procedures can be reduced, the efficiency can be improved, the energy consumption can be saved by 10%, and the conversion rate can also be improved by 5%; while the amount of waste water can be greatly decreased, dimethylamine can be recycled, and the quality of solvent can be guaranteed; a great amount of water can be saved, therefore, the production cost can be greatly lowered.

Owner:ANHUI GUANGXIN AGROCHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com