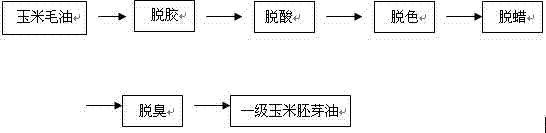

Method for preparing maize germ oil through enzymatic degumming

A corn germ oil and enzymatic technology, which is applied in the direction of edible oil/fat, fat oil/fat refining, and fat production, can solve the problems of difficult oil extraction, difficult to grasp the refining stability, etc., and achieves consumption saving and low phospholipid content. , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

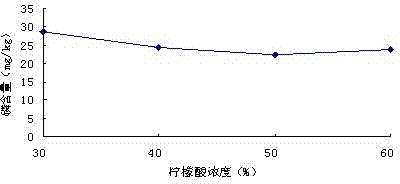

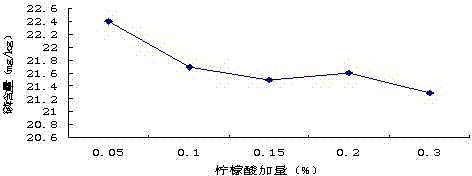

[0049] Optimal experiment of enzymatic degumming process data in corn germ oil refining process

[0050] Experimental plan: through single factor experiments on the type of acid, the amount of acid added, the amount of enzyme added, etc., to explore the best reaction conditions.

[0051]Materials and methods 1.1 Raw materials and reagents Crude corn oil: self-produced, initial phosphorus content 439 mg / kg, free fatty acid content 3.67%; Lecitase® Ultra (E.C.3.1.1.3): A1-position phospholipase, produced by microbial fermentation, Novozyme Company Gift; Other reagents: analytically pure. 1.2 Main instruments FJ-200 high-speed homogenizer, 752 spectrophotometer, electric heating constant temperature water bath, JB90-D powerful electric mixer, etc. 1.3 Phosphorus content analysis Take about 10mL oil sample, in order to facilitate the separation of oil and colloid, first heat to 80°C in water bath, keep warm for 10 minutes, then centrifuge at 5000 rpm for 10 minutes, take 5g of up...

Embodiment 2

[0076] Optimal test parameters for industrial operation

[0077] ⑴ acid reaction.

[0078] Crude oil (flow rate: 8.3 cubic meters / hour) is heated to 55°C through a heat exchanger,

[0079] Citric acid (50% solution) pump flow rate is 13.55 liters / hour;

[0080] Preparation of citric acid solution: 50 kg of citric acid is added to 50 kg of hot soft water at 55°C to fully dissolve;

[0081] Maintain 55°C in the acid reaction tank for more than 30 minutes.

[0082] (2) Alkali addition: 16% NaOH solution, control pH 5-5.3; flow rate of alkali solution is about 12.5 liters / hour;

[0083] (3) Adding enzyme: the flow rate of enzyme solution is 20.472 liters / hour; the amount of enzyme added is 75PPM;

[0084] Enzyme solution preparation: add 5.66 kg of enzyme to 200 kg of cold soft water.

[0085] ⑷ Add water: flow rate 105 liters / hour;

[0086] ⑸ High-speed mixing. After adding the enzyme preparation, the oil enters the enzyme reaction tank through a high-speed shear mixer. H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com