Patents

Literature

35results about How to "Low operating temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

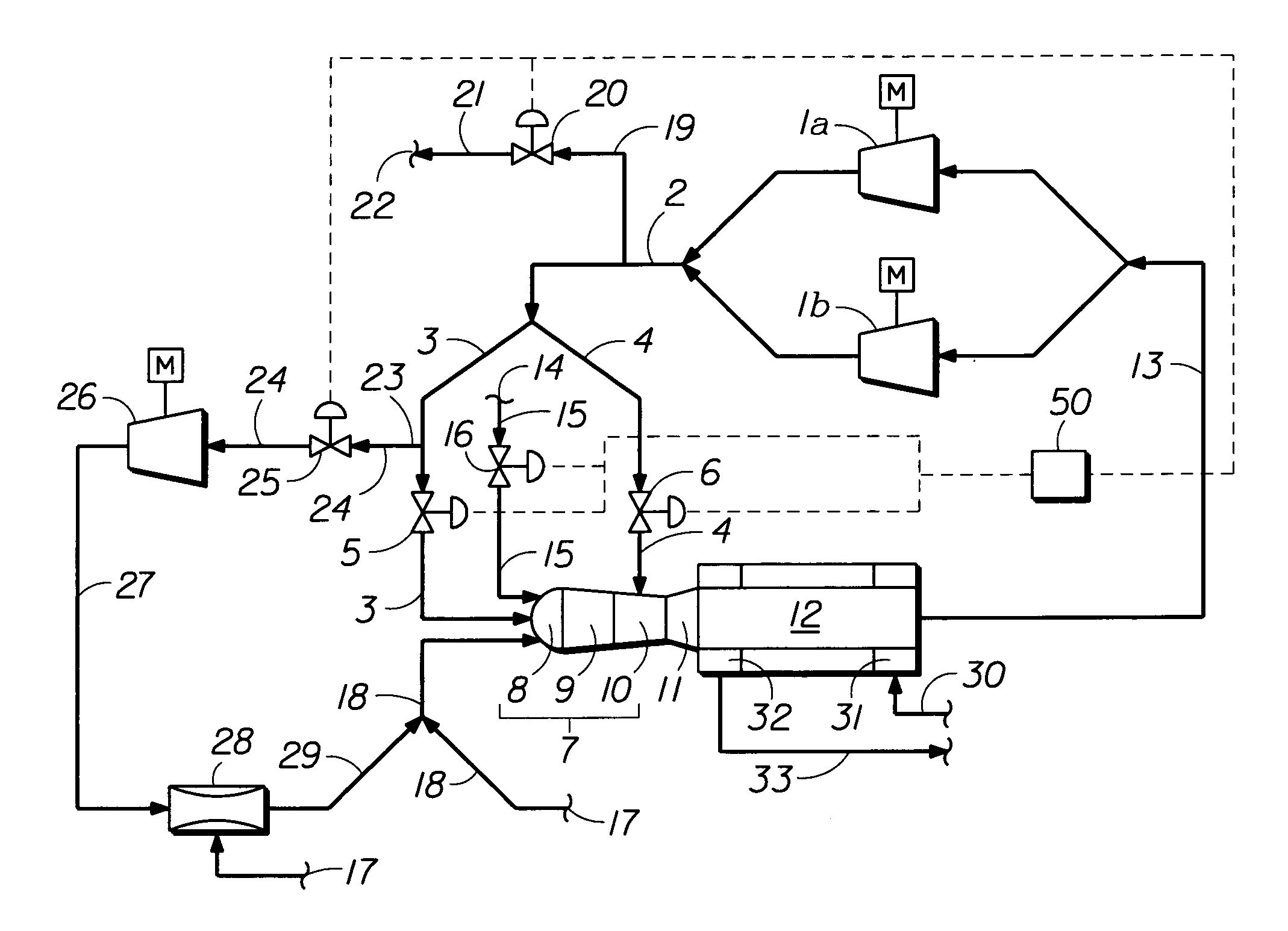

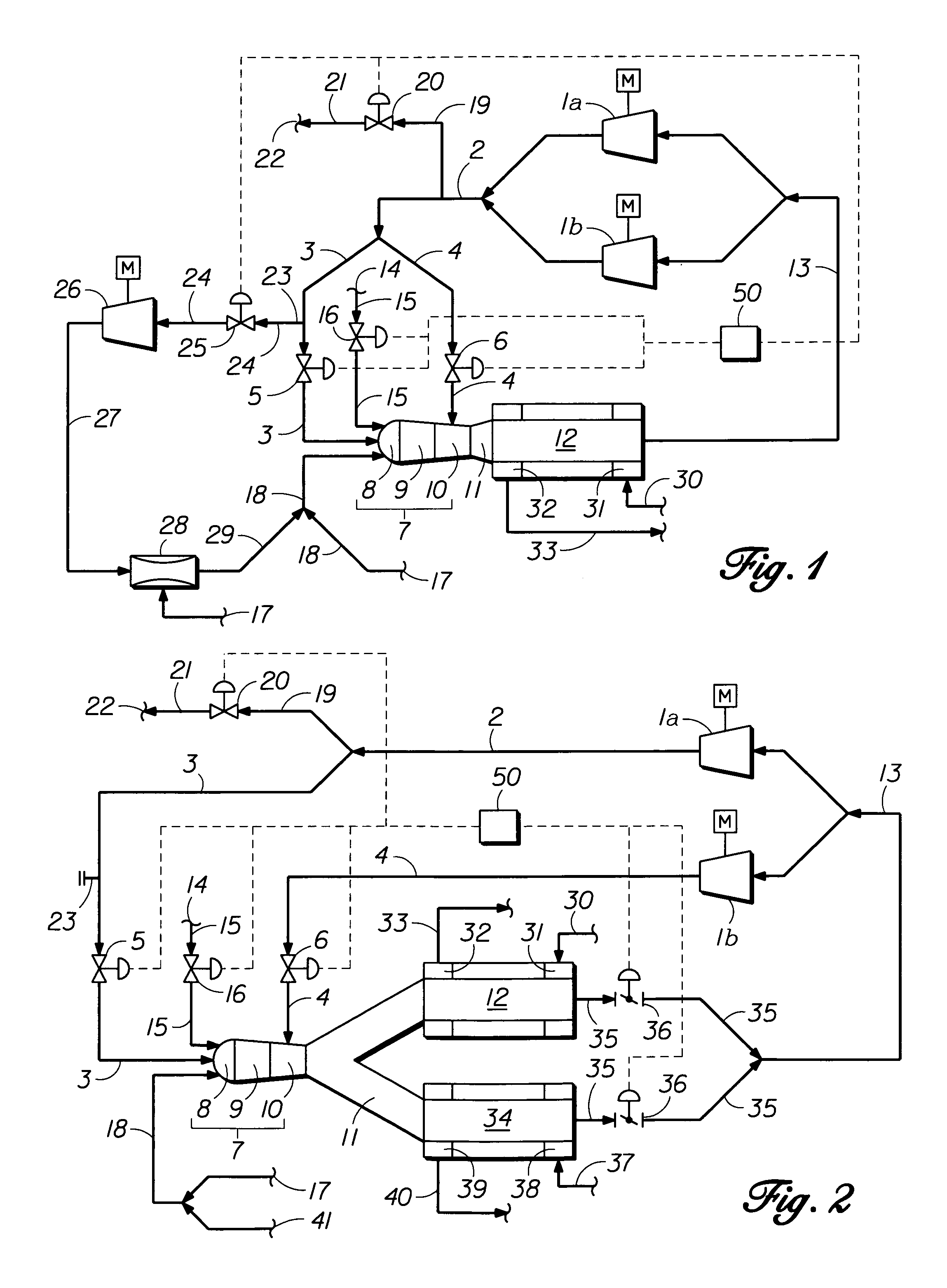

Partially-open fired heater cycle providing high thermal efficiencies and ultra-low emissions

InactiveUS7074033B2Long operate lifeLow operating temperatureFuel supply regulationGas turbine plantsNitrogen oxidesHeat transfer fluid

A partially open fired heater regenerative cycle wherein the fired industrial type heater cycle's heat transfer fluid replaces the air predominant nitrogen heat transfer fluid employed in a conventional air / fuel combustion heater. The heater cycle's method and apparatus means is susceptible to providing a 95 to 98 percent mass flow reduction of fugitive nitrogen oxide and carbon monoxide mass flow emissions as emitted by current art Low-NO.sub.x art heaters on a rated per million Btu per hour basis, and is further susceptible to developing steady-state heat transfer thermal efficiencies exceeding 124 percent.

Owner:AES DEV CO

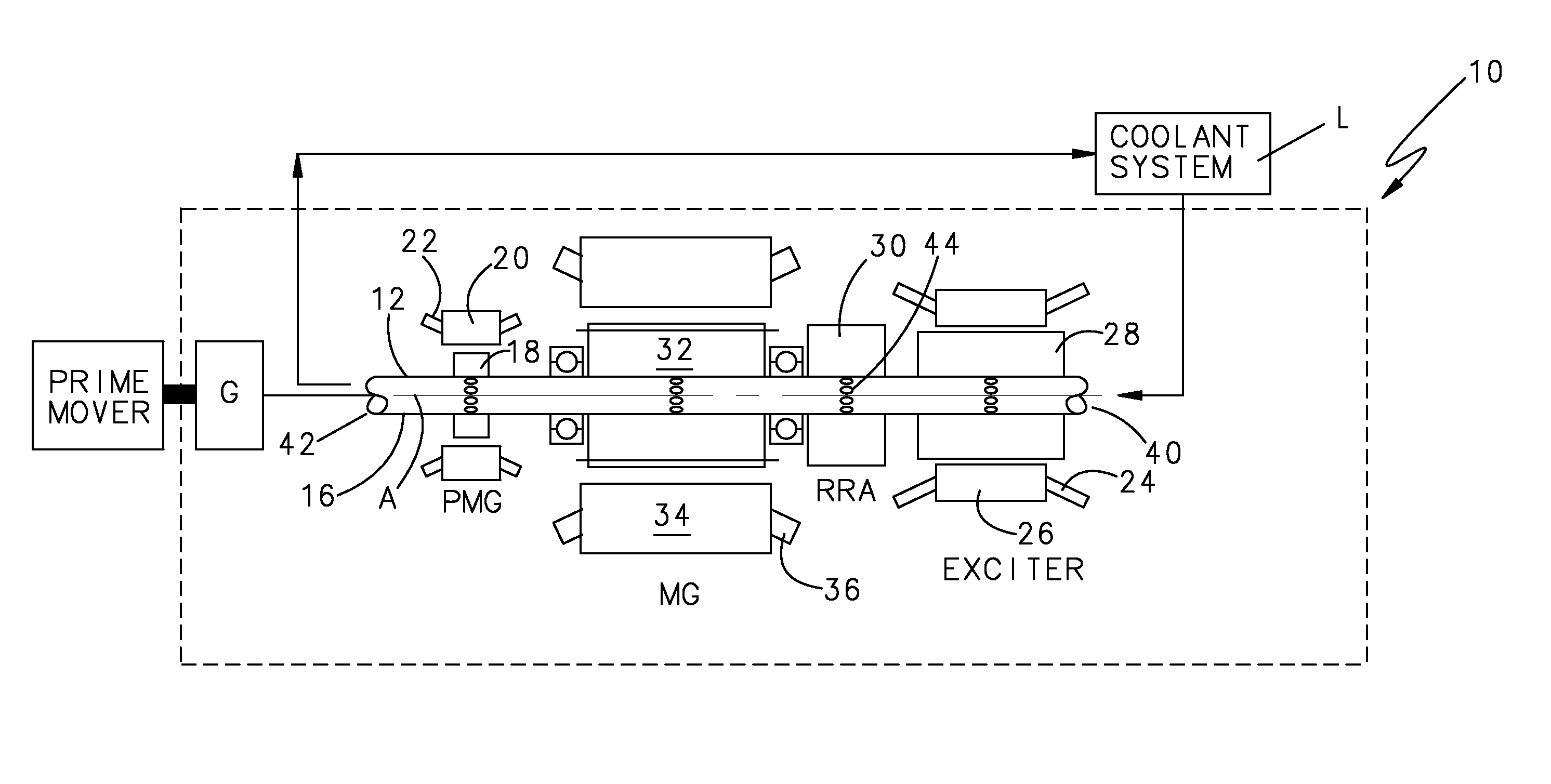

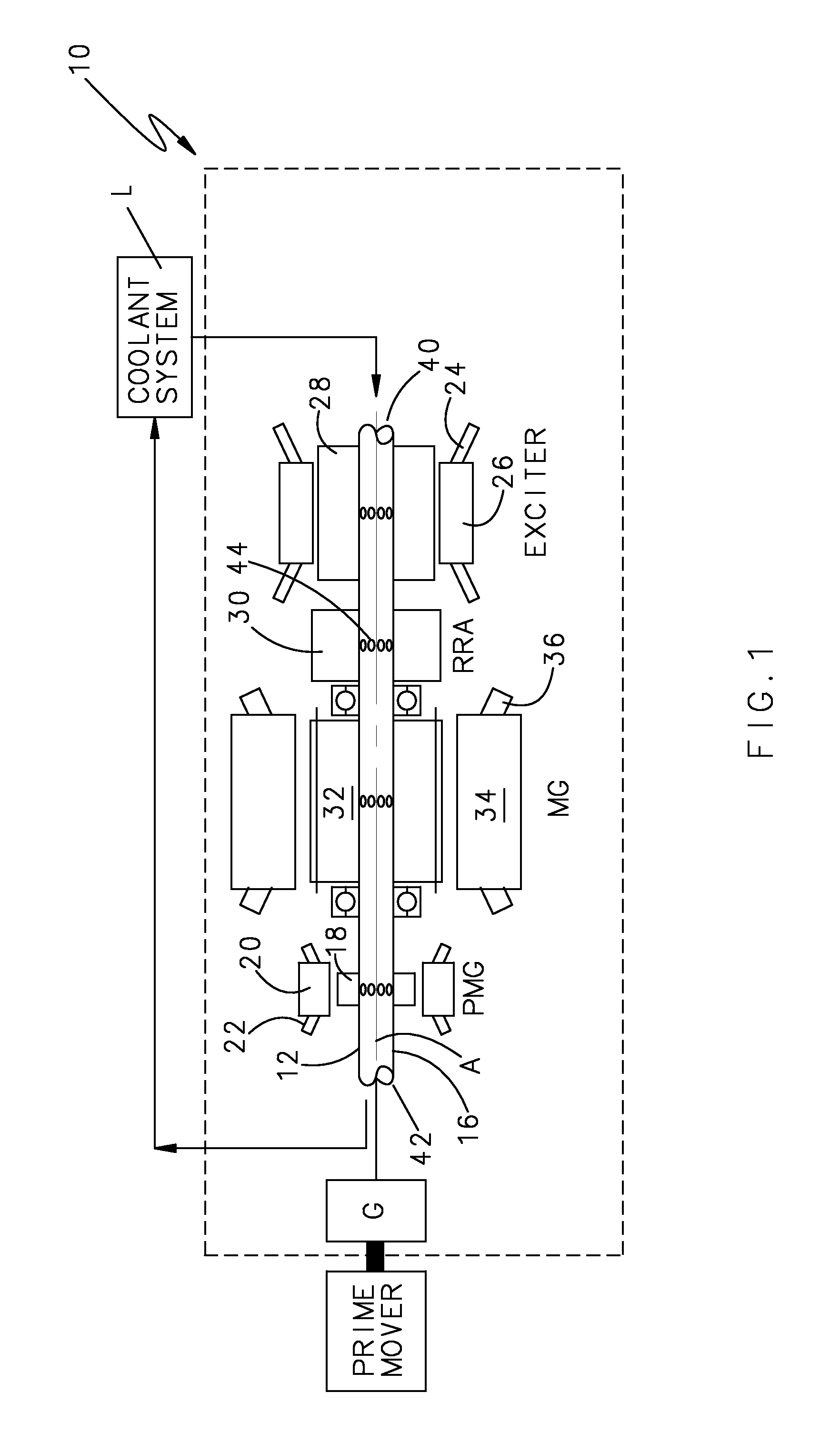

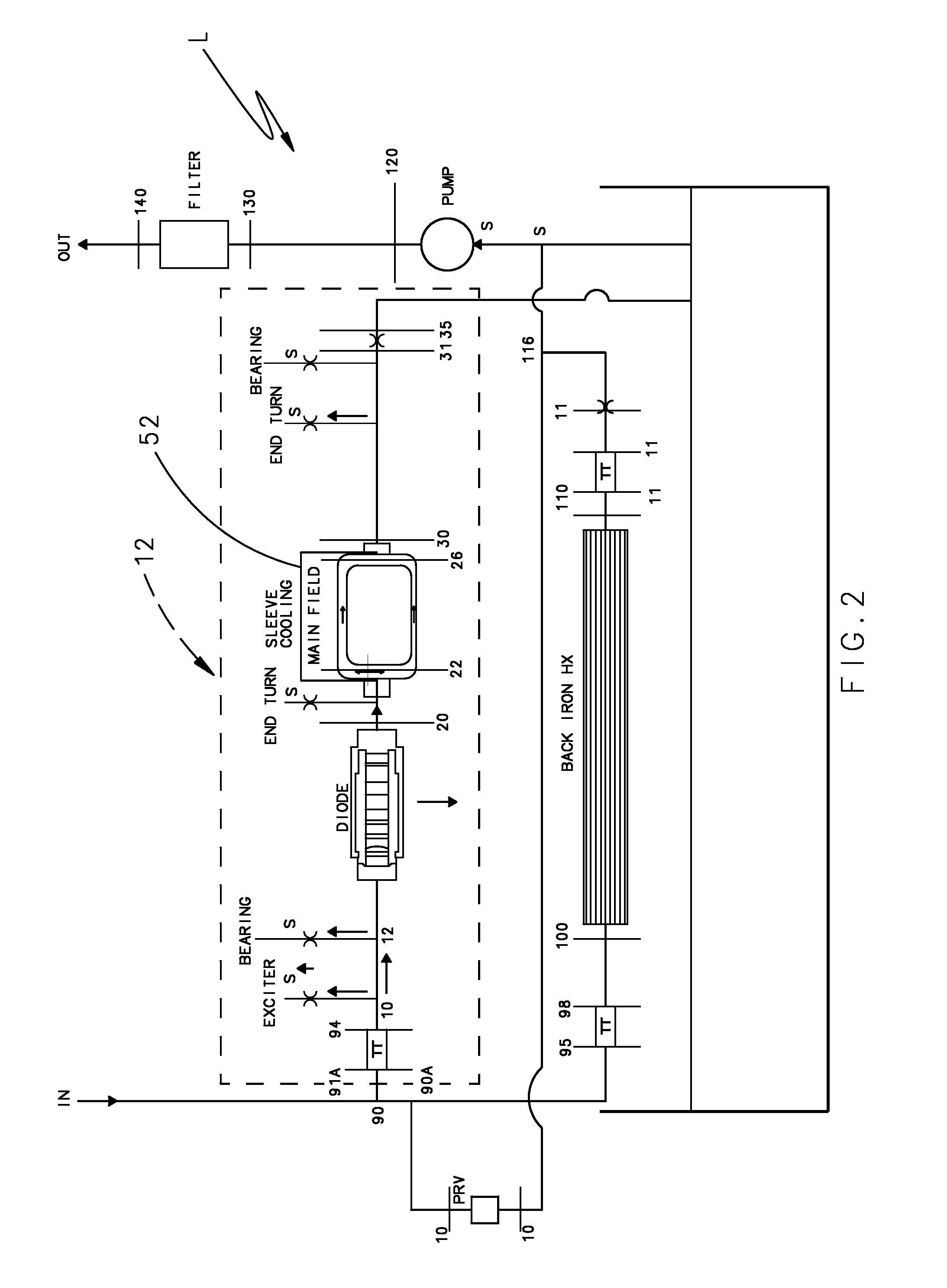

Rotor cooling system for synchronous machines with conductive sleeve

ActiveUS7208854B1Low operating temperatureThin constructionMagnetic circuit rotating partsCooling/ventillation arrangementEngineeringElectrical and Electronics engineering

A wound field synchronous machine includes direct oil cooling along a conductive sleeve with elongated semi-arcuate shaped channels which alternate with damper bar channels containing tie-rod supports structures. With a reduction in sleeve thickness permitted by the direct cooling, the overall weight of the machine is reduced.

Owner:HAMILTON SUNDSTRAND CORP

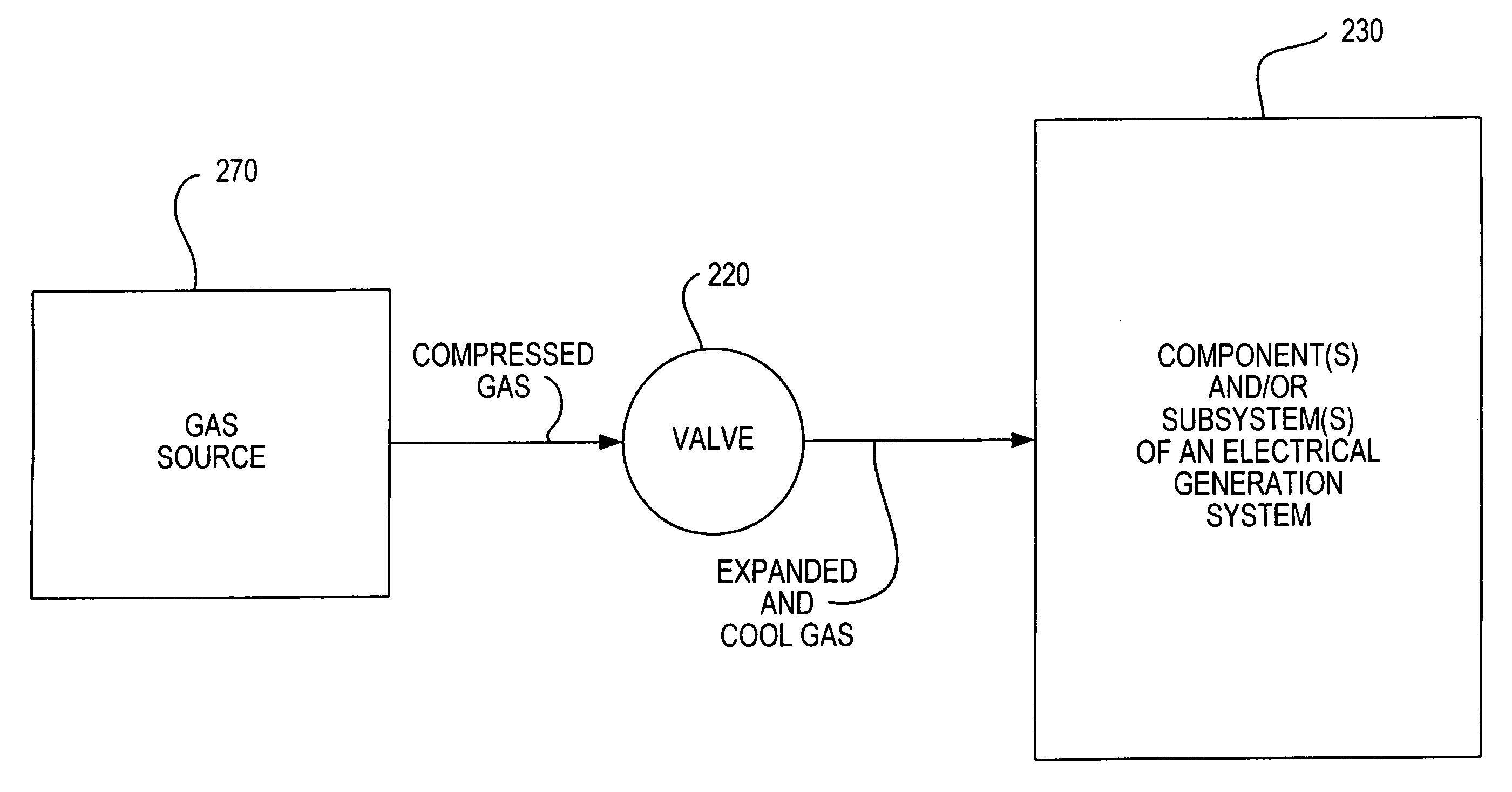

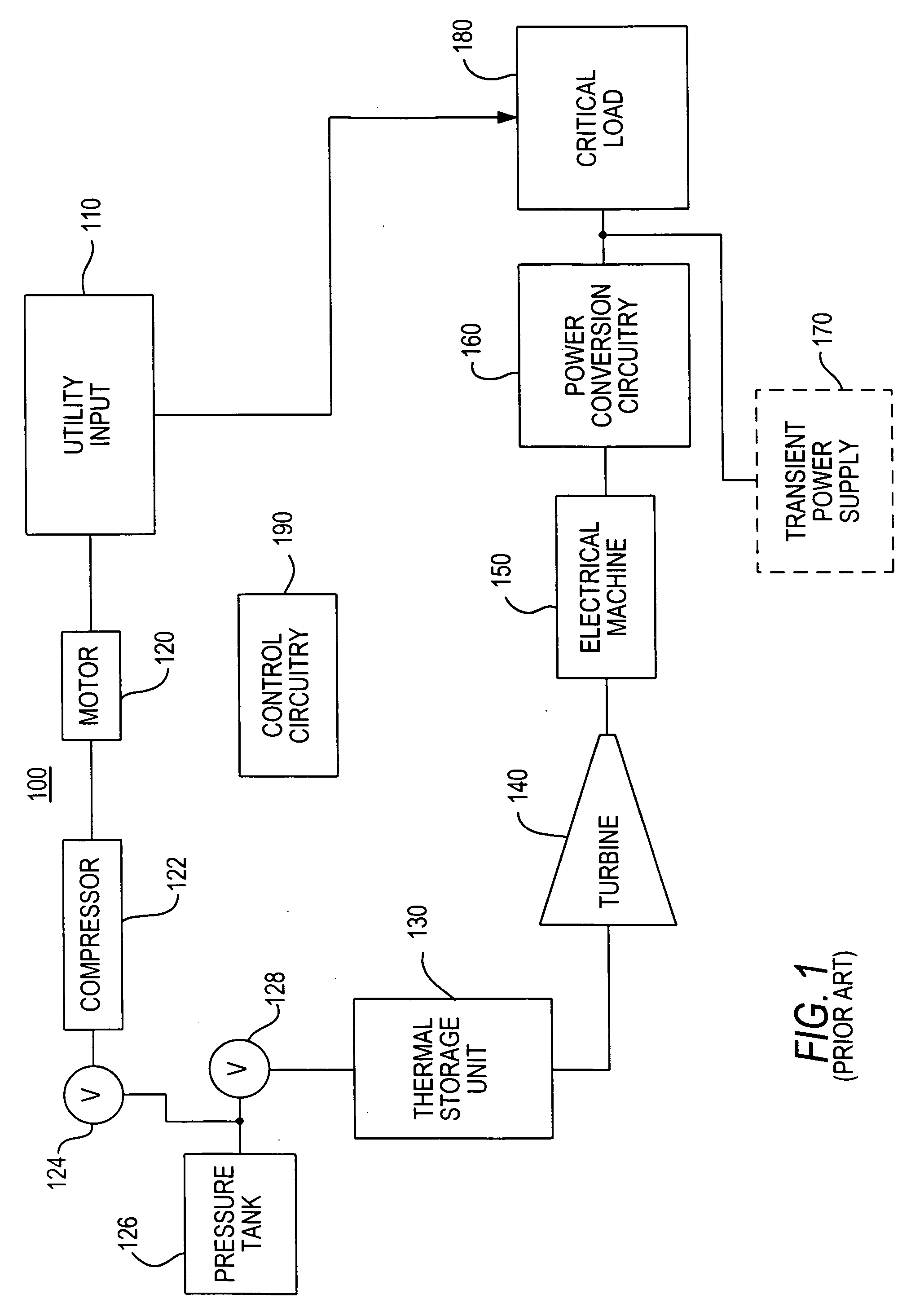

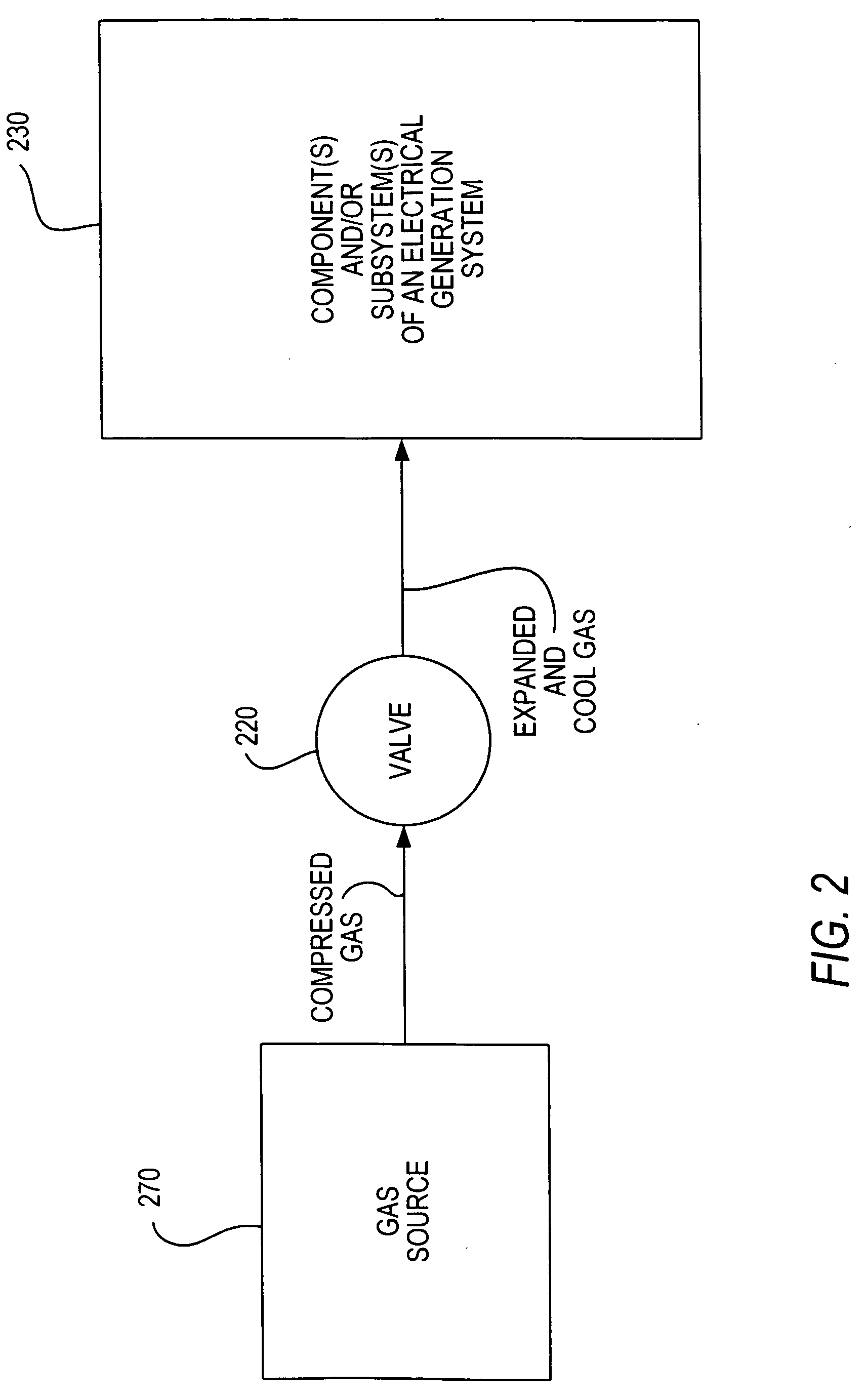

Systems and methods for providing cooling in compressed air storage power supply systems

InactiveUS20060059937A1Low operating temperatureLess costElectrical storage systemDomestic cooling apparatusElectric generatorEngineering

A system and method for cooling electrical machines (e.g., generators), sub-systems (e.g., power electronics), and components (e.g., bearings) in an electrical generation system such as a compressed air storage (CAS) energy system or a thermal and compressed air storage (TACAS) energy system is provided. Cooling is derived from the thermal expansion of a compressed gas, which may be the same gas used to drive a turbine-generator of CAS or TACAS energy system.

Owner:ACTIVE POWER INC

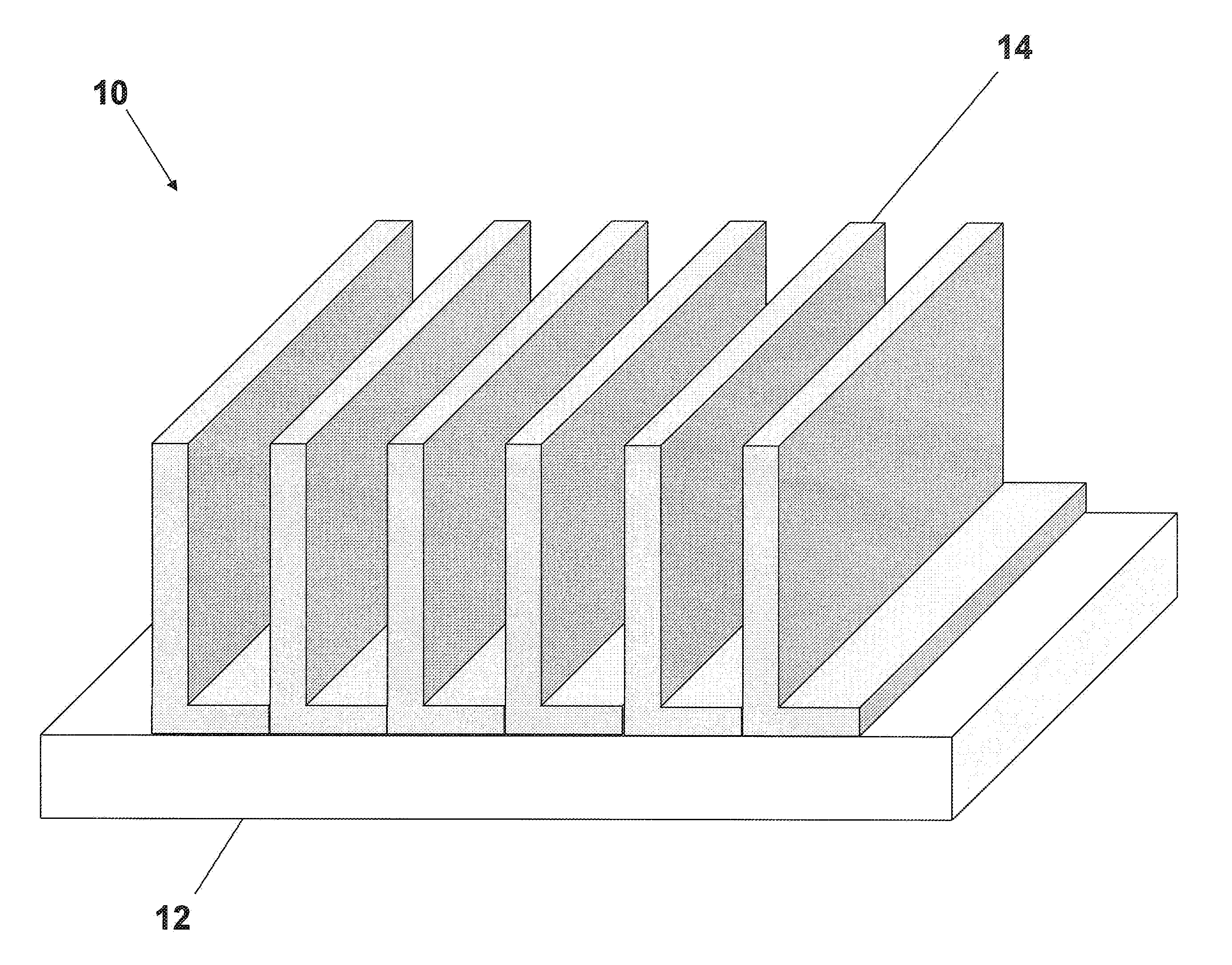

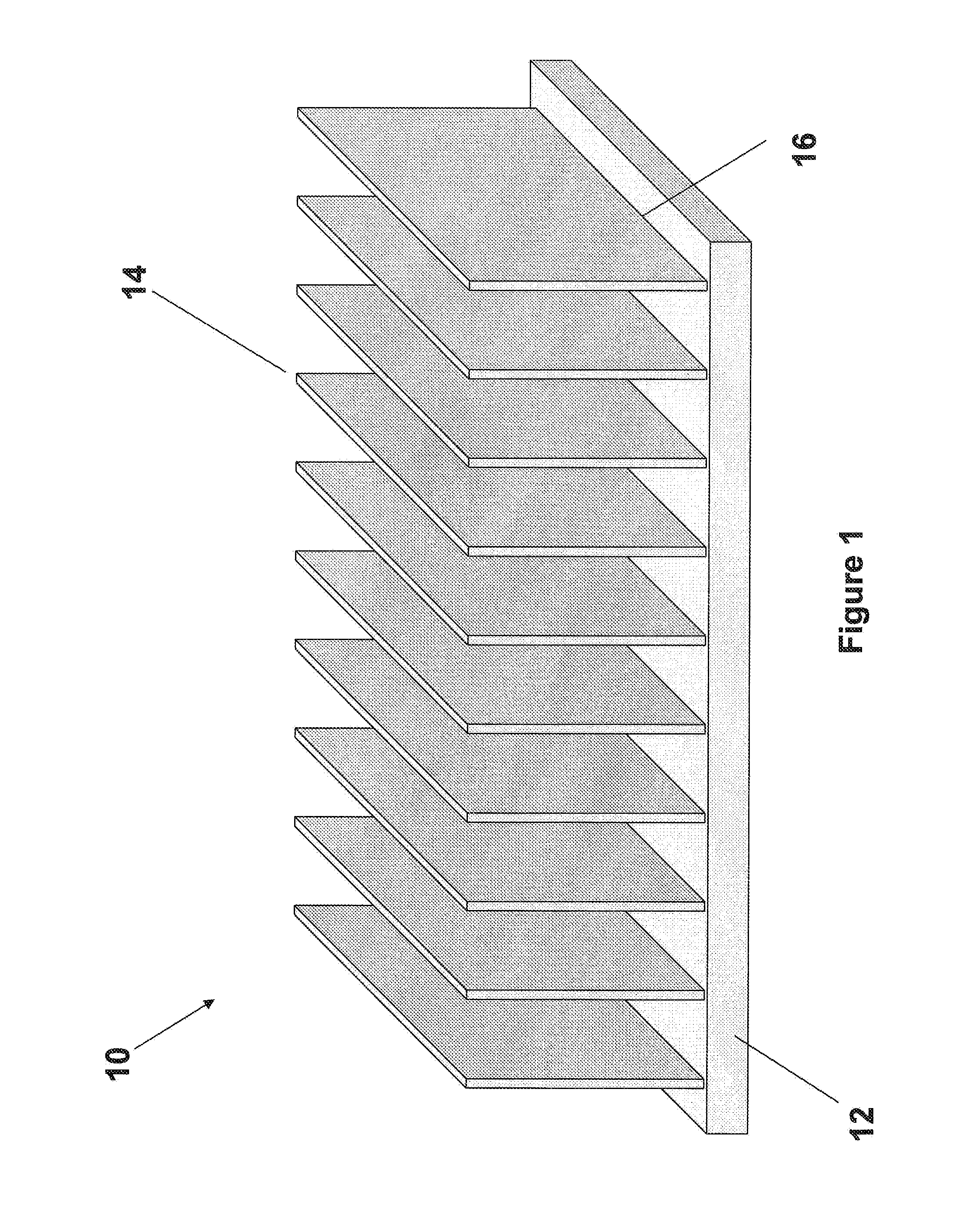

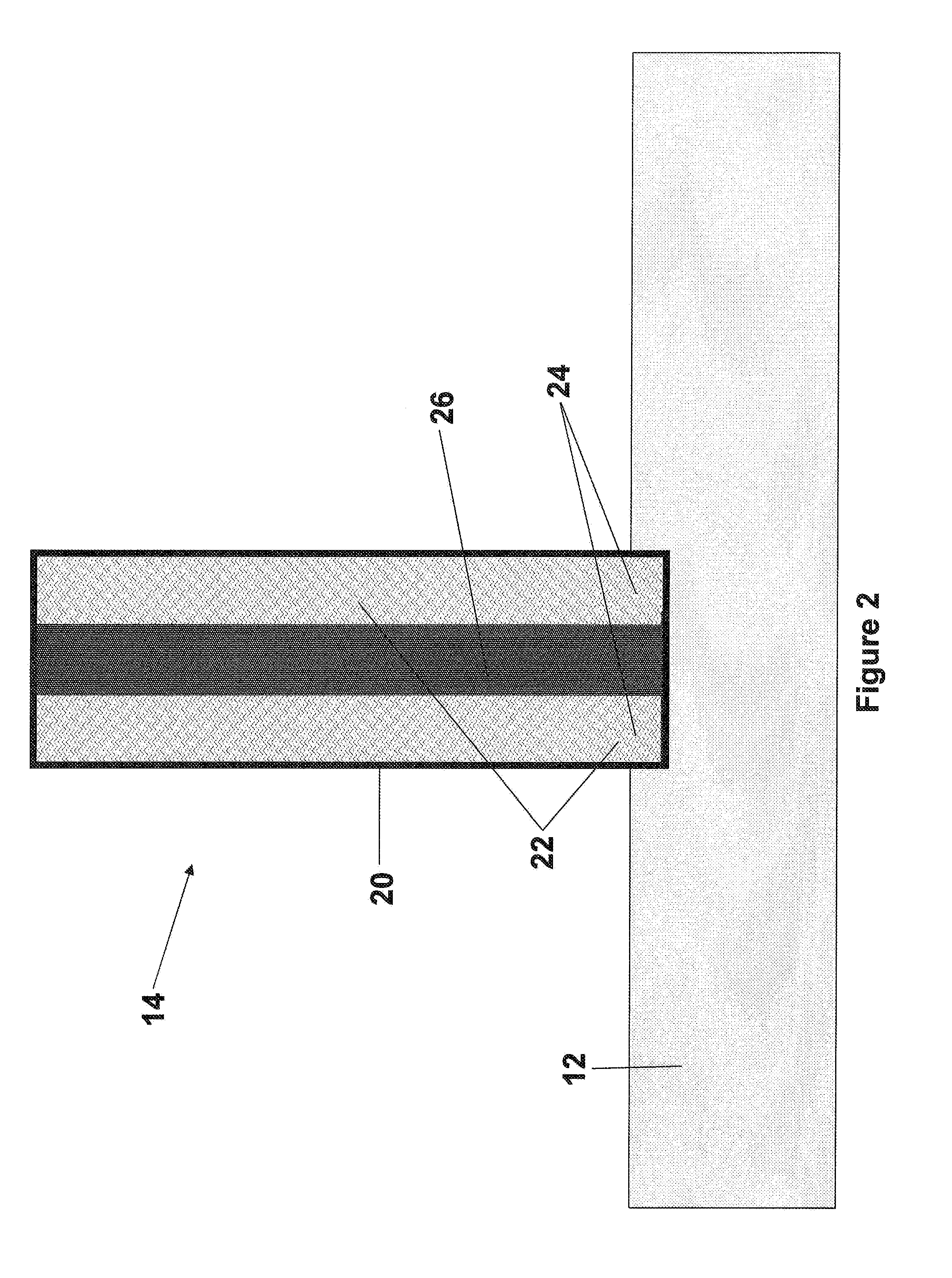

Base Heat Spreader With Fins

InactiveUS20080062651A1Good wettability characteristicLow operating temperatureSemiconductor/solid-state device detailsSolid-state devicesEngineeringThermal energy

A thermal management device for the removal of thermal energy useful for, inter alia, electronic devices or other components.

Owner:NEOGRAF SOLUTIONS LLC

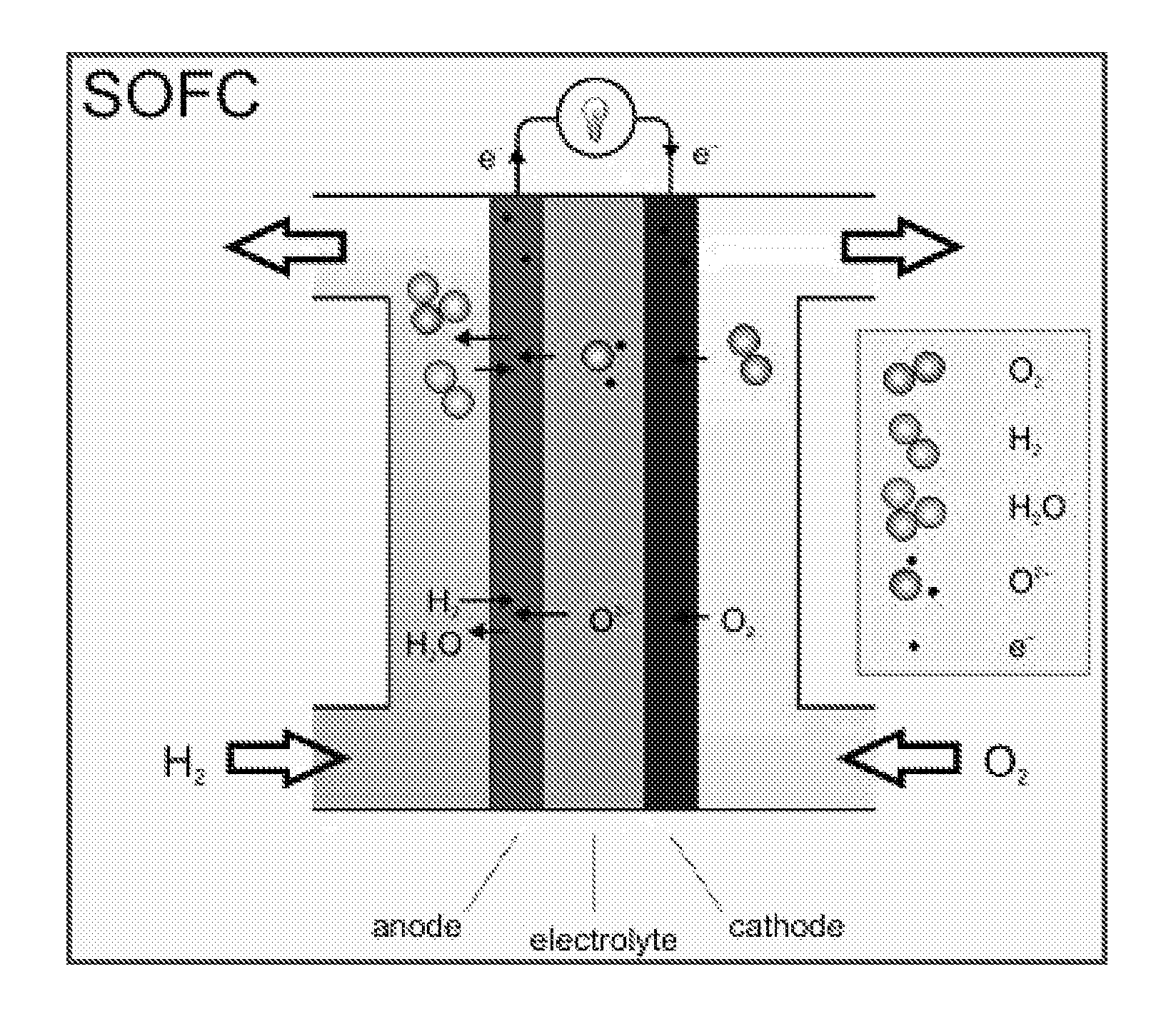

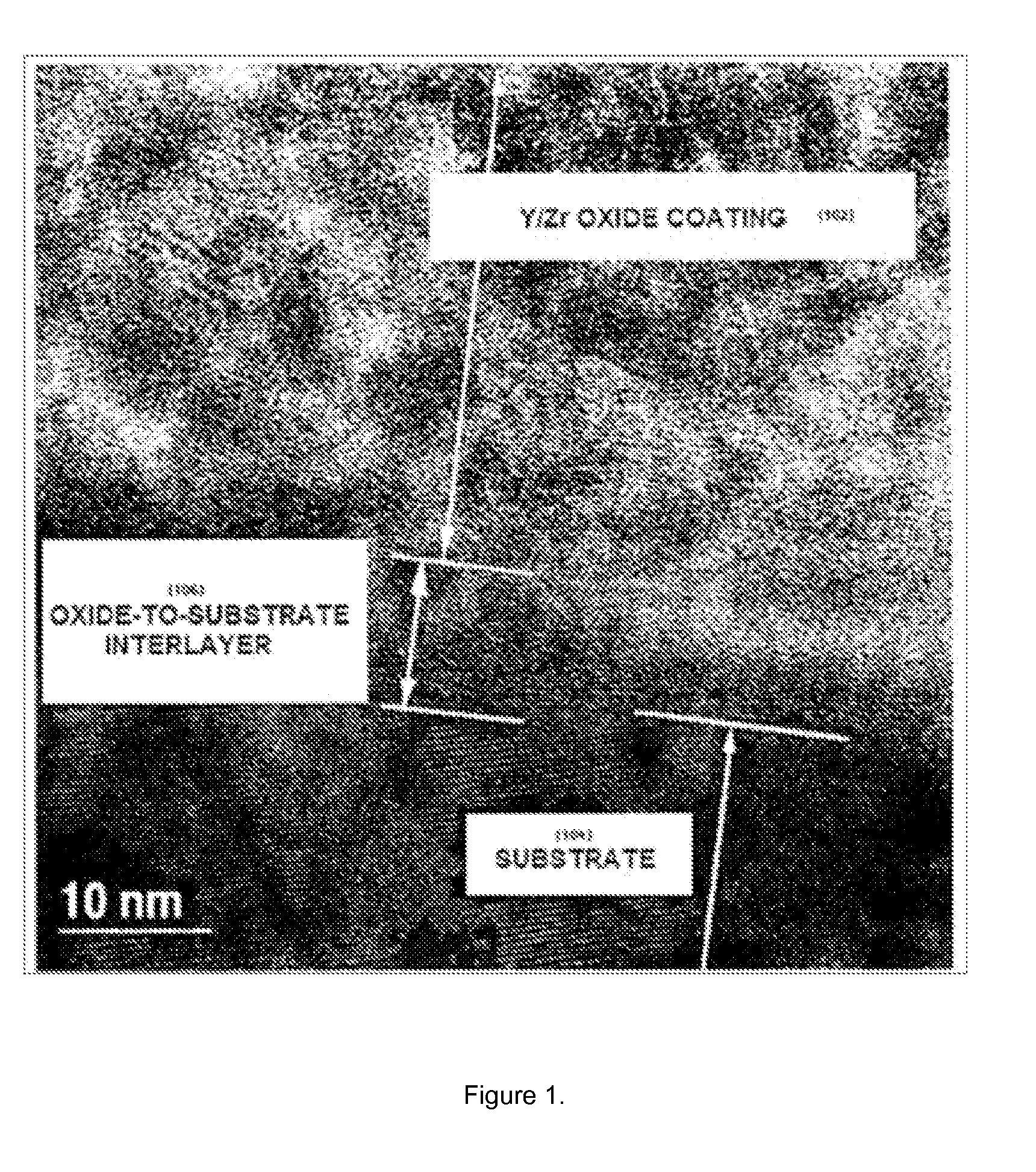

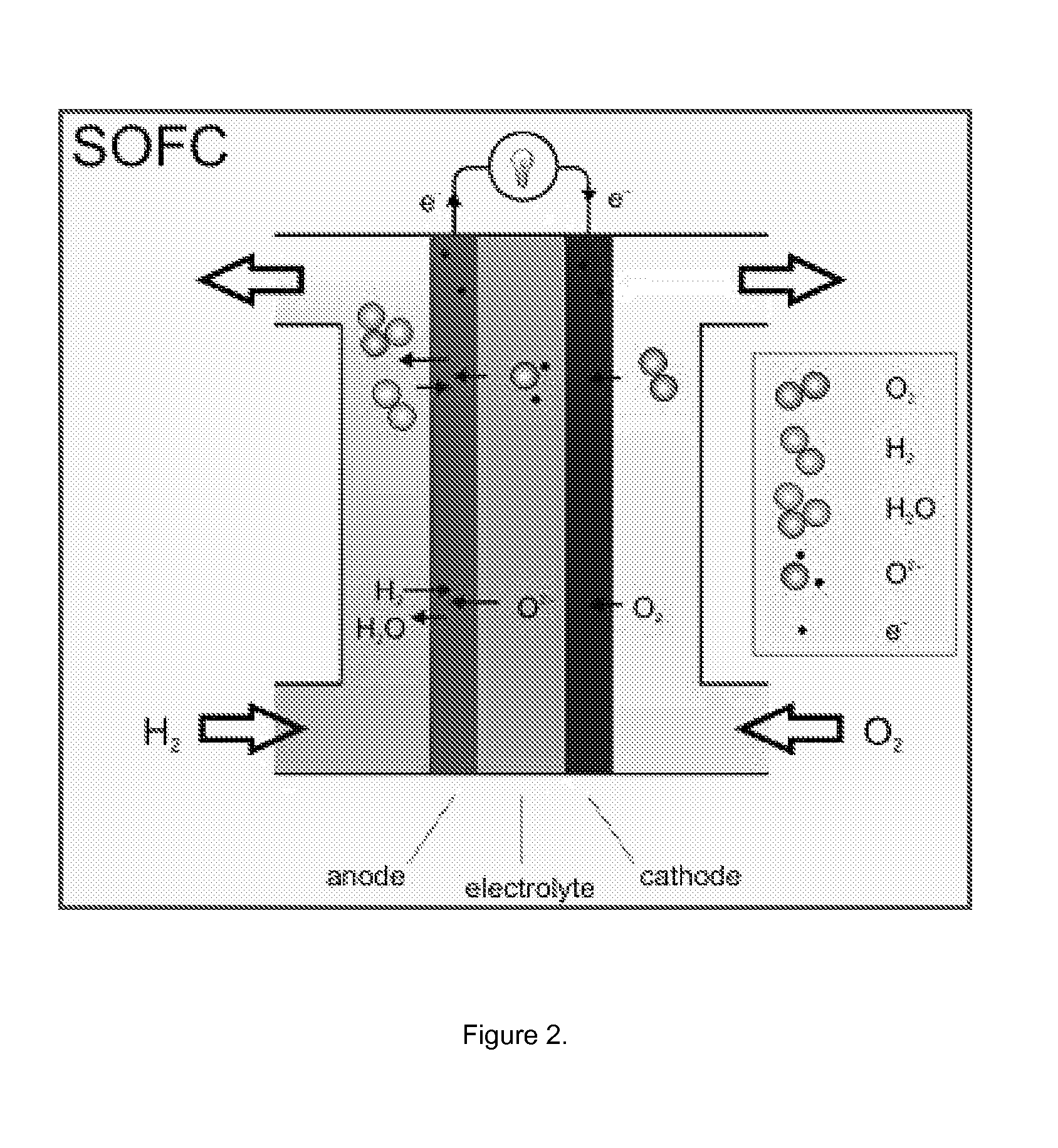

Low Temperature Electrolytes for Solid Oxide Cells Having High Ionic Conductivity

InactiveUS20130146469A1Low operating temperatureLow production costPhotography auxillary processesWeather/light/corrosion resistanceIonOxide

Some embodiments of the present invention provide solid oxide cells and components thereof having a metal oxide electrolyte that exhibits enhanced ionic conductivity. Certain of those embodiments have two materials, at least one of which is a metal oxide, disposed so that at least some interfaces between the domains of the materials orient in a direction substantially parallel to the desired ionic conductivity.

Owner:FCET

Method for preparing elemental silicon

The invention discloses a method for preparing elemental silicon. The method comprises the following steps of: dissolving SiO2 in an alkali metal or alkaline earth metal oxide-containing chloride molten salt, or dissolving alkali metal or alkaline earth metal silicate in the chloride molten salt, wherein the temperature of the chloride molten salt is 600 to 1,000 DEG C, electrolyzing by using graphite or silicon or a metal as a cathode and using graphite or an inert material as an anode to electrically deposit siliconic acid radicals at the cathode, and separating the electrodeposition to obtain the elemental silicon. In the method, the operation temperature is low; raw materials are cheap and available; the molten salt is stable; and the purity of the product is high. The process can be controlled through consistent current; continuous production is easy to be realized; the current efficiency is high; and the production energy consumption and cost of silicon can be obviously reduced.

Owner:WUHAN UNIV

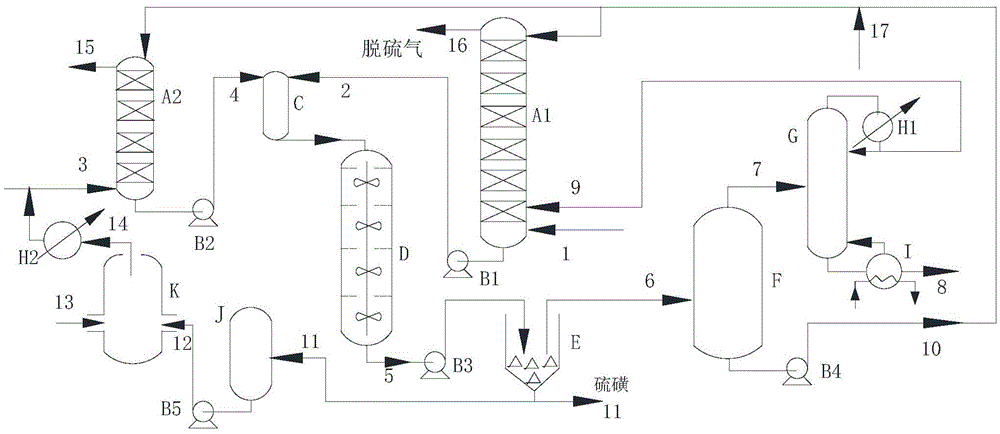

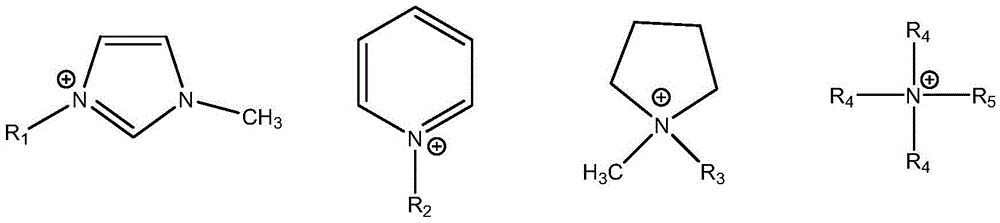

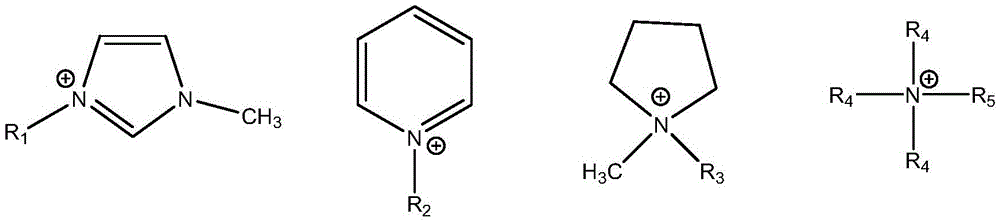

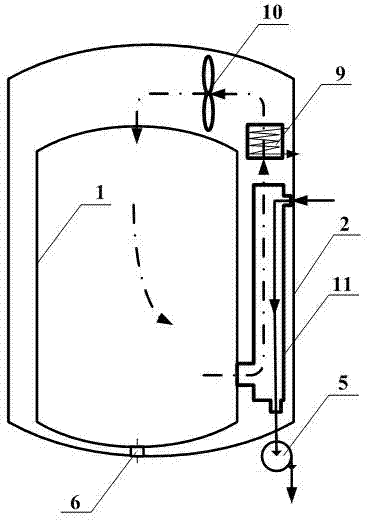

Room-temperature liquid-phase Claus process taking ionic liquid as media

ActiveCN105521696ALow operating temperatureReduce energy consumptionGas treatmentDispersed particle separationInnovation processIon

The invention discloses a room-temperature liquid-phase Claus process taking ionic liquid as media. The room-temperature liquid-phase Claus process includes pumping ionic liquid absorbing H2S and another ionic liquid absorbing SO2 into a reaction tower with baffles and stirring blades inside for action, pumping out the reacted ionic liquid containing solid sulphur via a pump, enabling the ionic liquid containing the solid sulphur to sequentially pass a filtering, washing and drying all-in-one machine and a flash tank, dividing the ionic liquid into two streams to enter two absorption towers for respectively absorbing H2S and SO2, and enabling the ionic liquid after absorbing the H2S and SO2 to return to the reaction tower so as to form circulation. The H2S is sourced from to-be-treated gas, and the SO2 is obtained from part of sulphur by burning. The filtered ionic liquid has good H2S and SO2 dissolution characteristics, and can be recycled for a long time; the developed room-temperature liquid-phase Claus process is low in operating temperature, small in energy consumption, free of VOCs (volatile organic compounds) emission and needless of subsequent tail gas treatment, can be used for producing high-purity sulphur, and is a green and environment-friendly liquid-phase Claus reaction innovation process.

Owner:NANJING UNIV

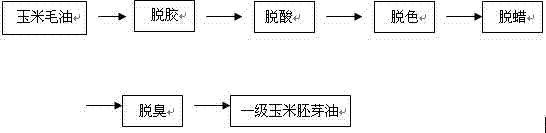

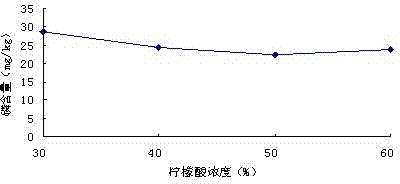

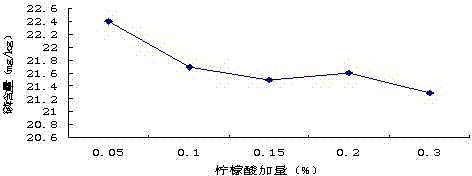

Method for preparing maize germ oil through enzymatic degumming

ActiveCN102206542AObvious advantagesLow operating temperatureFatty-oils/fats refiningEdible oils/fatsEnzymeChemistry

The invention relates to a method for preparing maize germ oil through enzymatic degumming. Specifically, phosphatidase is employed for a degumming treatment of maize crude oil during the refining process. Then after deacidification, decoloration, dewaxing and deodorization, refined maize germ oil can be obtained. Wherein, the degumming treatment comprises acid reaction, alkali neutralization, enzyme reaction, and separation, dehydration and drying; the acid in the acid reaction is citric acid, and the enzyme in the enzyme reaction is phosphatidase. In the invention, the key technology for maize germ oil refining is overcome, and the optimum technological conditions for the enzymatic degumming of maize germ oil are optimized. The maize germ oil prepared through enzymatic degumming has the obvious advantages of: low operation temperature and low energy consumption; obviously superior quality of the obtained oil to the quality of oil prepared by traditional methods, and increased product oil yield by over 1%; reduced consumption of acid and alkali chemicals, and reduced waste water generation by 70%-90%, substantially reduced environmental protection cost and markedly improved economic benefit.

Owner:SHANDONG XIWANG FOOD

Low-temperature selective catalytic reduction (SCR) for flue gas denitrification and preparation method for low-temperature SCR catalyst

InactiveCN102527406ALow operating temperatureLarge specific surface areaDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsChemistryNitrogen atmosphere

The invention discloses a low-temperature selective catalytic reduction (SCR) catalyst for flue gas denitrification. Modified waste tyre pyrolysis slag is used as a carrier, and MnOx-FeOx is used as a main catalyst. The catalyst is prepared by adopting an impregnation method and prepared by the following steps of: 1) crushing the pyrolysis slag; 2) impregnating the waste tyre pyrolysis slag into an aqueous solution of phosphoric acid for phosphoric acid activation, and performing water vapor activation in a sealed furnace body in a nitrogen atmosphere by using high-temperature water vapor; and 3) soaking in an aqueous solution of ferromanganese salt, drying in a water bath to finish main catalyst loading, calcining under the protection of nitrogen or argon atmosphere after drying, and thus obtaining the low-temperature SCR catalyst. The invention has the advantages that: the operating temperature of SCR is reduced, and the catalyst can reach high NO removal rate at the temperature of below 200 DEG C in an SCR technology when NH3 is used as a reducing agent; and by using the modified pyrolysis slag as the carrier, the catalyst is large in specific surface area, strong in adsorption capacity and low in price, and waste can be changed into valuable.

Owner:NANKAI UNIV

Method for producing ultra-low sulfur diesel

ActiveCN101280216AImprove hydrogenation performanceLow operating temperatureTreatment with hydrotreatment processesRefining to eliminate hetero atomsUltra-low-sulfur dieselComposite oxide

The invention relates to a method of producing ultra-low sulfur diesel. The diesel distillate is used as raw oil; the single stage or a stage of series process flow is adopted; the feed stock is mixed with hydrogen to pass the hydrogenation reaction area; under the operating condition of hydrorefining, the quality of diesel is improved greatly; wherein, at least one of the catalysts in the hydrogenation reaction area is bulk phase catalyst; the bulk phase catalyst is composed of composite oxide NixWyO z and oxide MoO3 with the weight ratio of 1:10-10:1; the composite oxide NixWyO z and oxide MoO3 account for 40%-100% of the total weight of the catalyst combination. Compared with the prior art, the method of producing ultra-low sulfur diesel in the invention can reduce the operation severity of the hydrorefining reaction area effectively, improve the processing load of the device, prolong the service life of the catalyst or produce the ultra-low sulfur diesel directly.

Owner:CHINA PETROLEUM & CHEM CORP +1

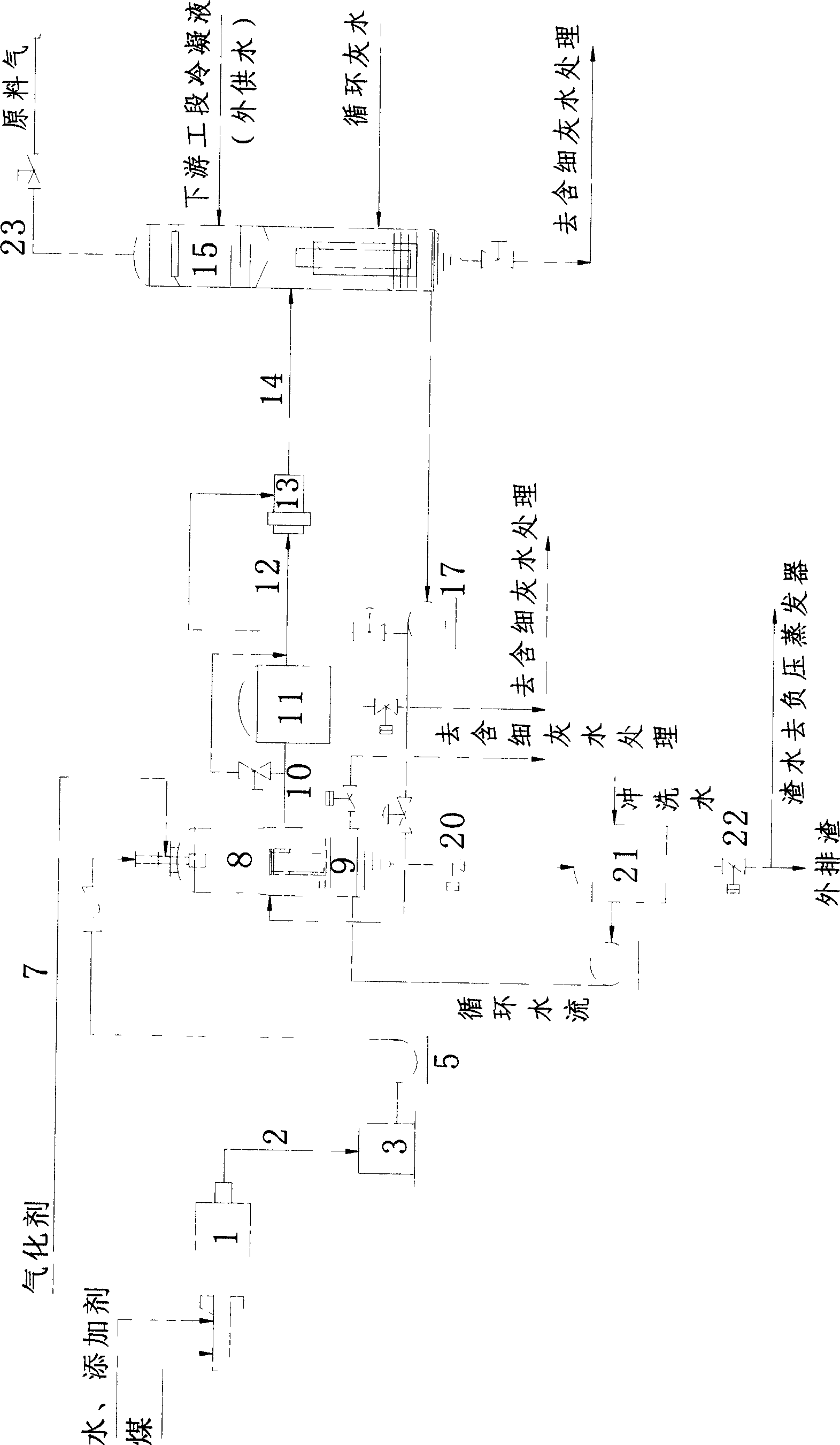

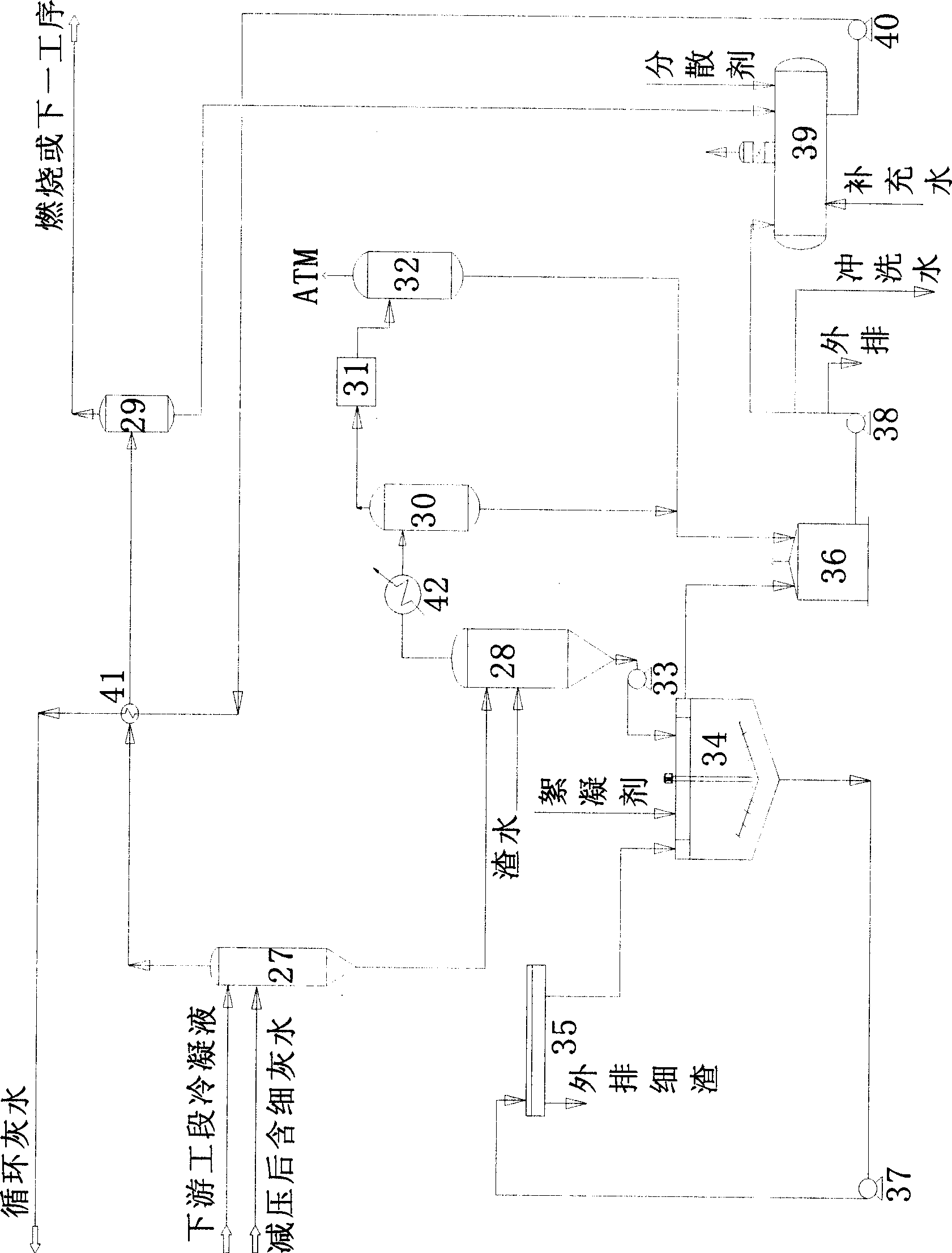

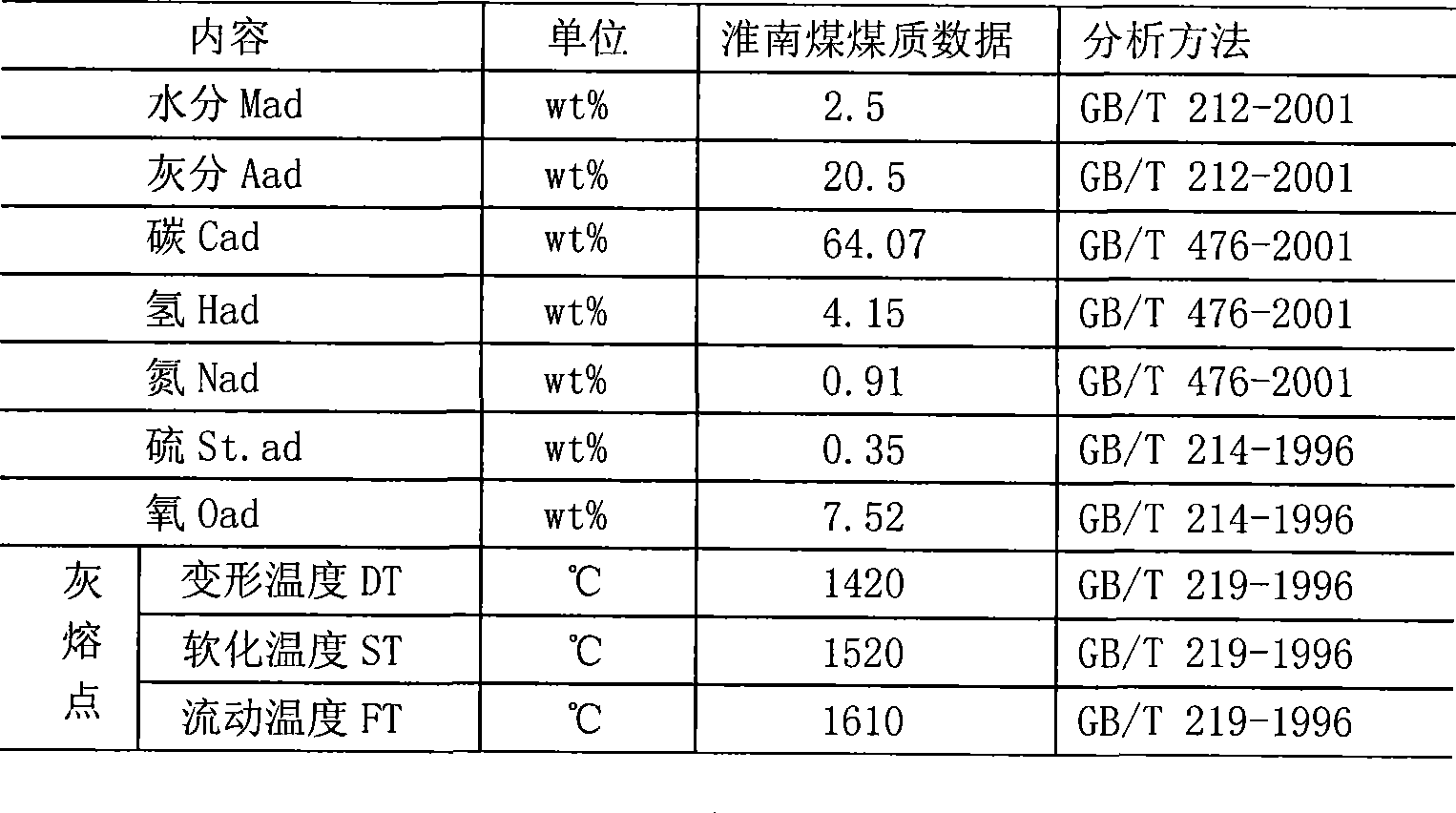

Entrained flow coal gasification method employing solid state slag-tap suitable for high ash content and high ash melting point coal

ActiveCN101457160ALow operating temperatureExtended service lifeCombined combustion mitigationGranular/pulverulent flues gasificationSlagLow demand

The invention provides a coal gasification method employing solid state slag-tap suitable for high ash content and high ash melting point Huainan coal. According to the invention, the gasification reactor temperature is controlled higher than 1100 DEG C and lower than the softening temperature of the high ash melting point coal. Through adjusting the ratio of gasification reactor height and diameter, the included angle of gasification reactor cone part and gasification reactor vertical housing part, the ratio of gasification reactor interior diameter and slagoff port diameter, the ash slag is discharged as solid state without fluxing medium. The method greatly reduces the operation temperature of the gasification reactor, prolongs the service life of fittings in the gasification reactor with little heat dissipation and low demand of refractory materials grade in the gasification reactor, simultaneously reduces the specific oxygen consumption and specific coal consumption, thereby not only saving cost but also saving resource.

Owner:安徽淮化集团有限公司 +2

Rosa banksiae general lactone extract and its preparing process and application

InactiveCN1569849ALow operating temperatureIncreased content and stabilityOrganic active ingredientsOrganic chemistryGallstonesSolvent

The invention discloses a sosa banksiae general lactone extract and its preparing process and use in preparing pharmaceutical composition using the costuslactone as active composition for treating cholecystitis and gallstone diseases, the preparation process comprises, comminuting the banksia rose, extracting by adding right amount of alcohol solvent, condensing, charging water, esters, hydrocarbons or ethers organic solvent for extraction, separating the organic solvent layer, and removing the organic solvent through decompression and concentration.

Owner:CHINA PHARM UNIV +1

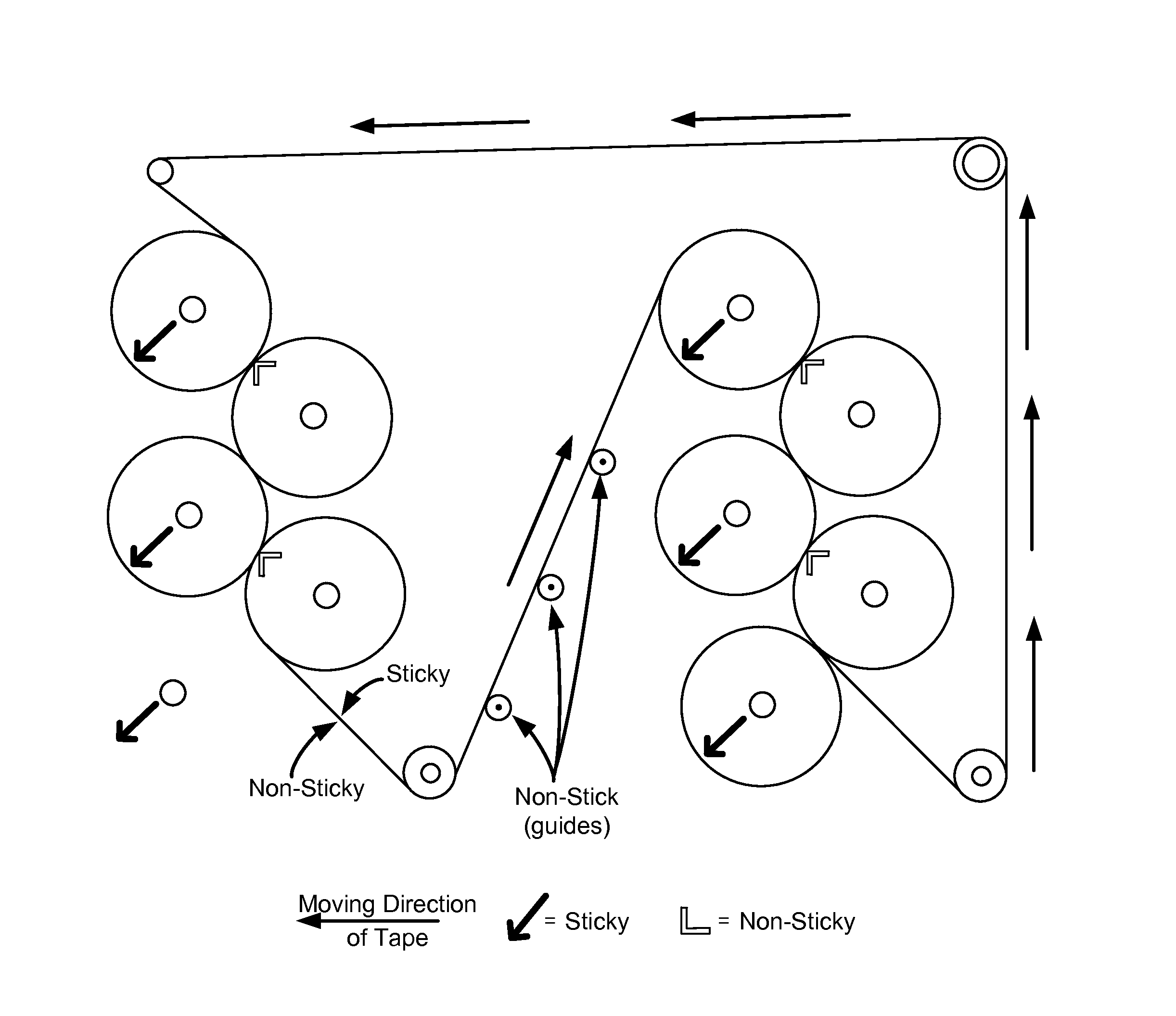

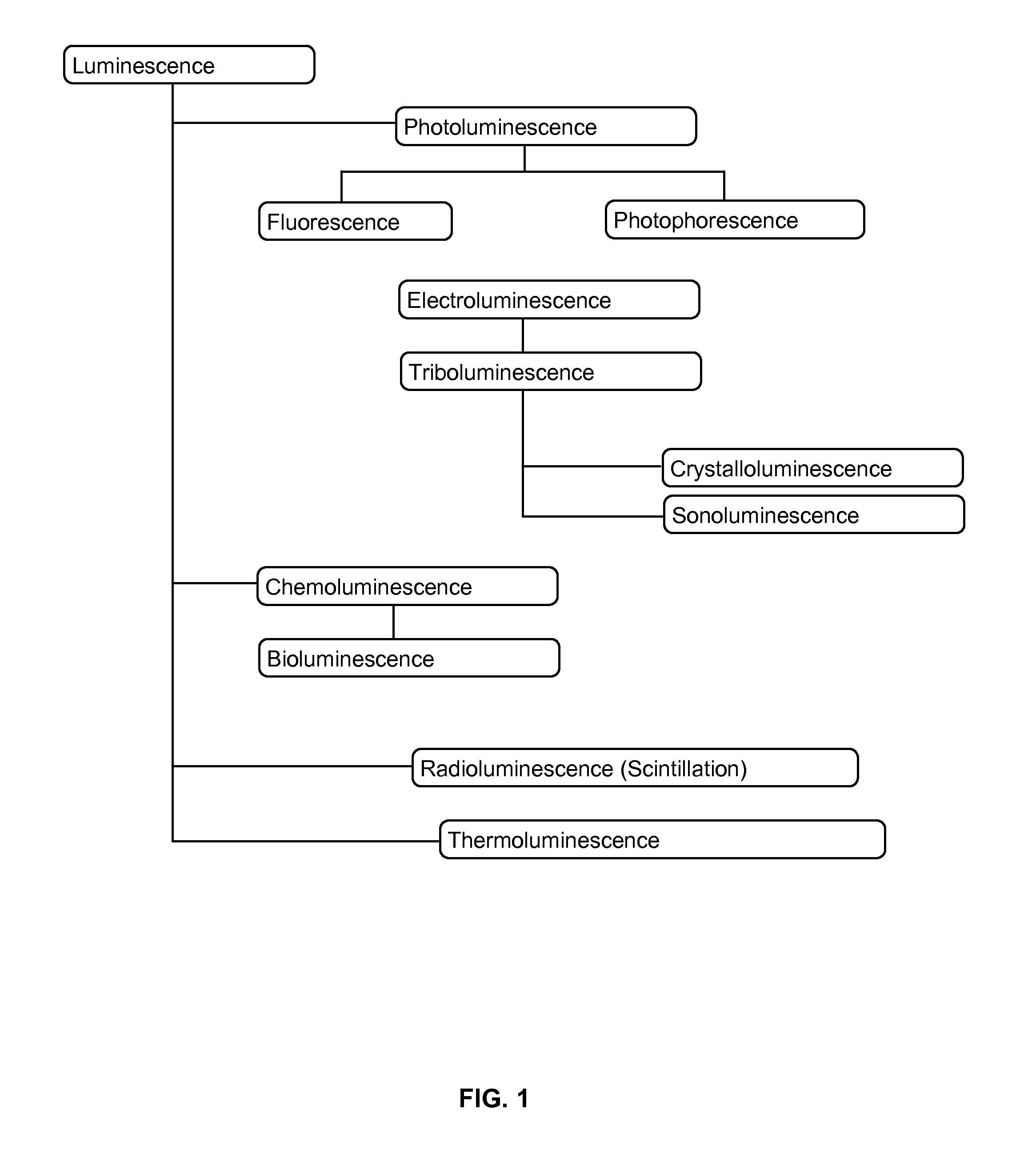

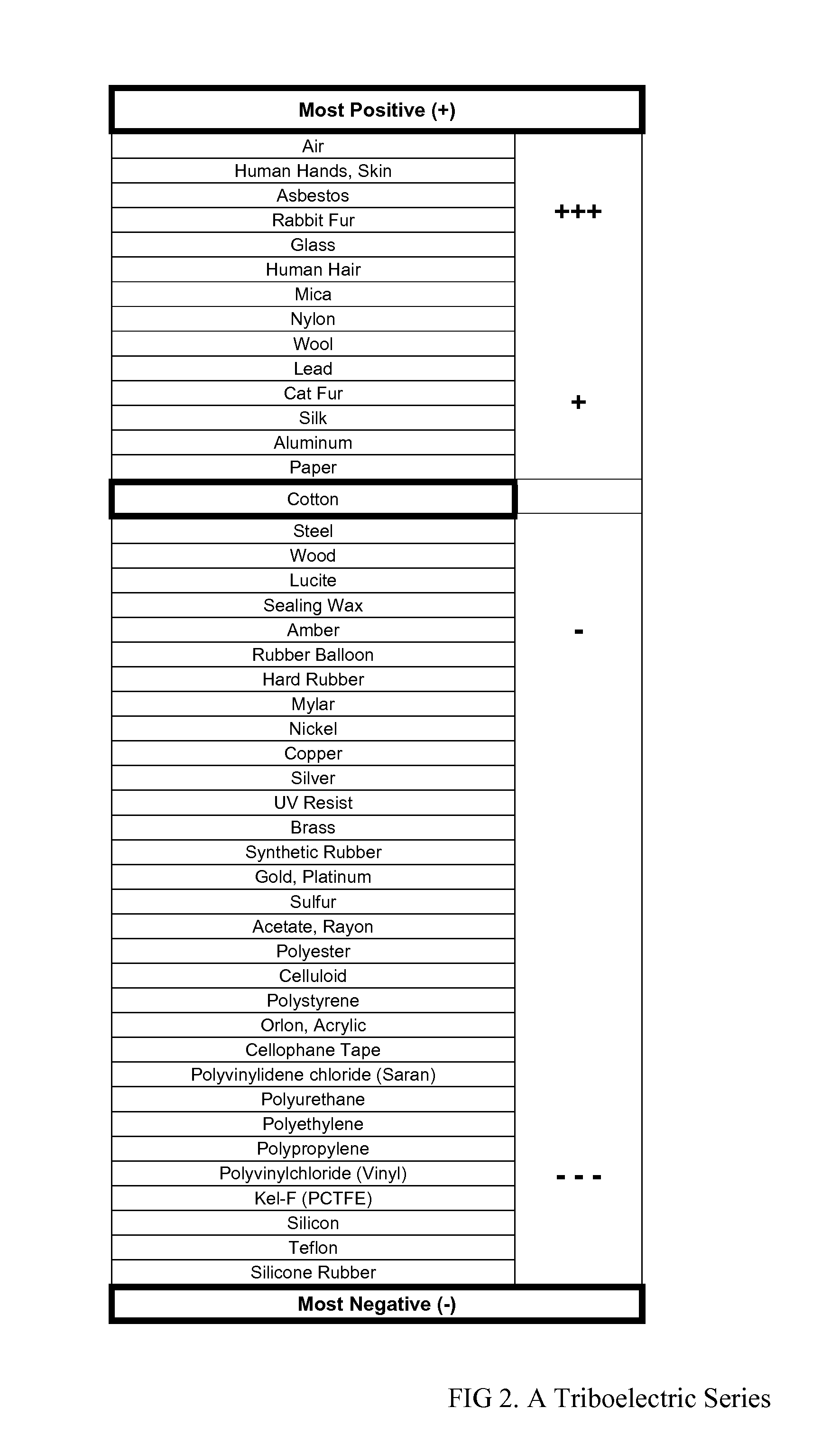

X-ray generation devices and methods

InactiveUS20140369474A1Low operating temperatureEliminate needX-ray tube with very high currentX-ray apparatusRadiationMaterial selection

The present disclosure describes an x-ray generating device comprising at least one pair of rotating objects kept in constant frictional contact. In various embodiments, a first rotating object comprises an outer surface material with RDP of ∈1, a second rotating object comprises a second outer surface material with RDP of ∈2, ∈1 does not equal ∈2 and Δ∈ may be maximized by material selection, wherein the rotating objects are positioned in close proximity such that their first and second outer surface materials are kept in constant frictional contact, and wherein x-ray radiation is generated during rotation of the objects.

Owner:CHIRAL RES

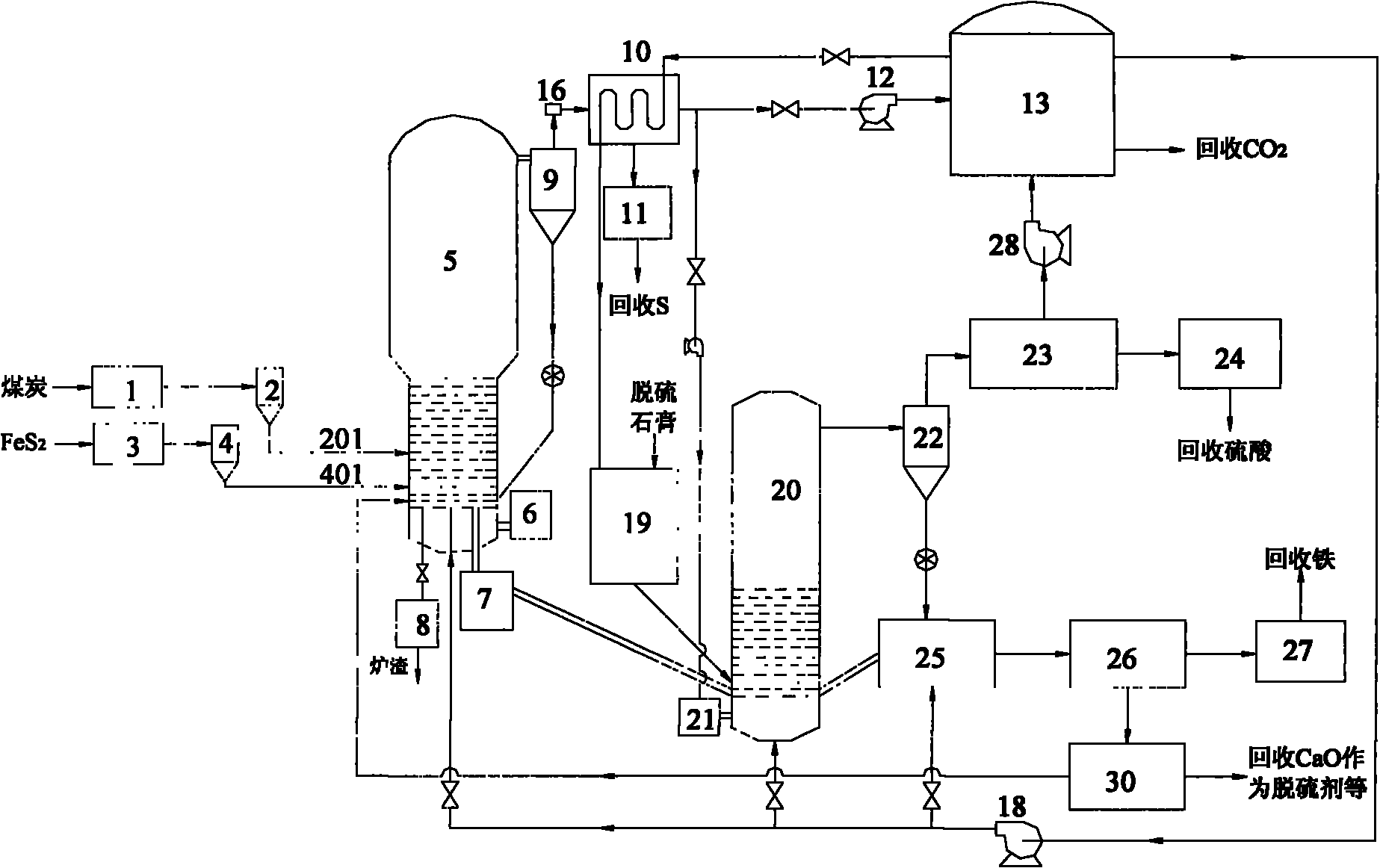

Method for comprehensively treatment of pyrite and desulphurized gypsum by utilizing coal and system thereof

InactiveCN101870493ASimple structureLow operating temperatureCarbon compoundsSulfur compoundsCombustion chamberPyrite

The invention discloses a method for comprehensively treatment of pyrite and desulphurized gypsum by utilizing coal and a system thereof. Coal and CO produced by the same are taken as reducing agents, the pyrite is directly reduced into reduced ferrum Fe and simple substance sulphur S, the desulphurized gypsum is reduced and decomposed into lime CaO and SO2, SO2 is used for preparing sulphuric acid or simple substance sulphur, and the lime CaO can be returned to a desulphurization system to be used as desulphurizing agent or ferrous metallurgy auxiliary material, thus sulphur and ferrum resources are recycled. The system is composed of a fluidized bed pyrite decomposing device, a fluidized bed desulphurized gypsum reaction device, a pyrite feeding device, a coal feeding device, a CO rapid cooling device, a high temperature non-mechanical valve, a desulphurized gypsum drying and feeding device, an ash cooling device, a Fe / CaO collecting and sorting device, a CaO returning device, a combustion starting chamber, a CO combustion device, a CO2 / SO2 cooling and sulphuric acid producing device, a CO2 storage tank, a fan and pipelines.

Owner:NANJING NORMAL UNIVERSITY

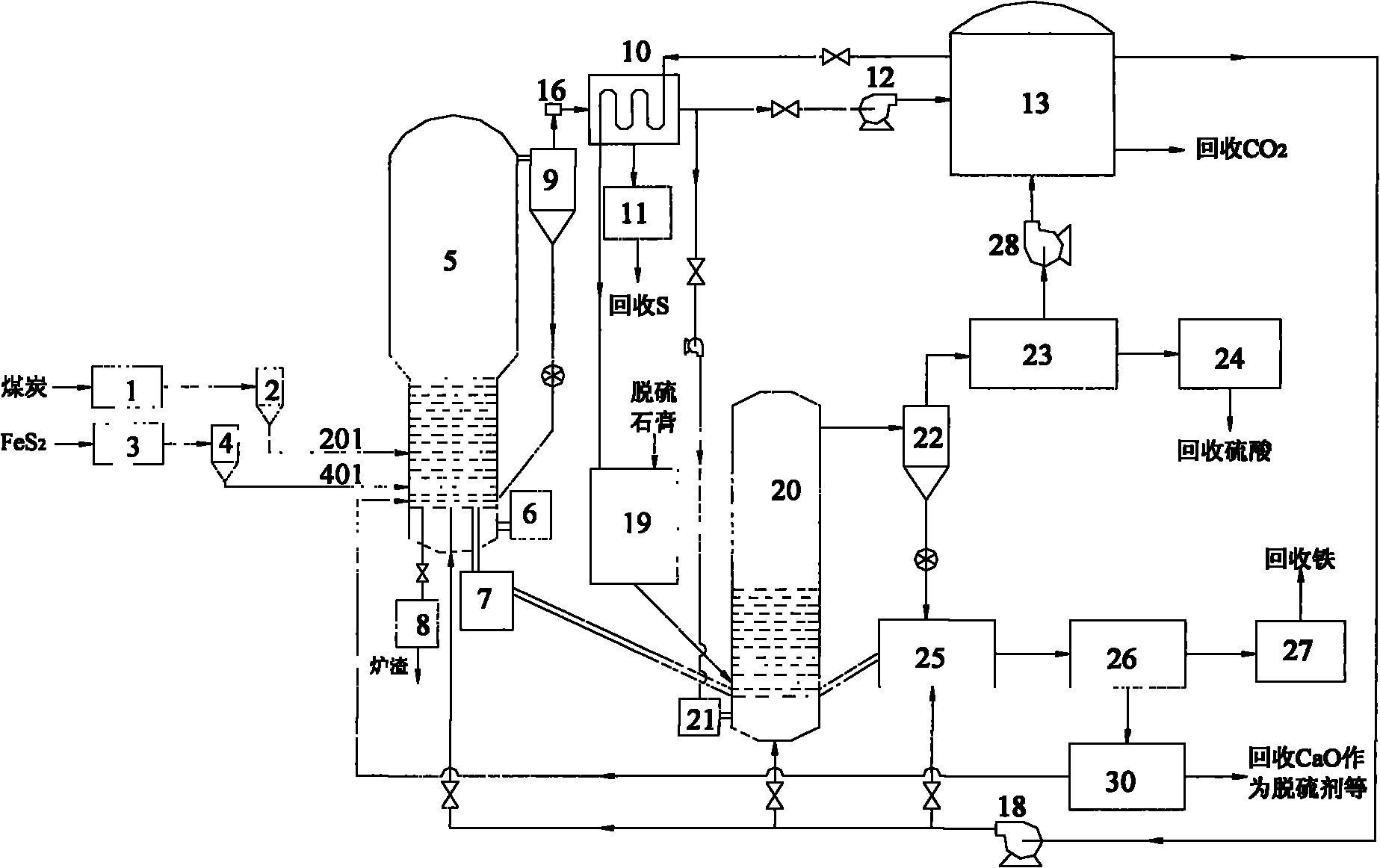

Method for separating and purifying nonane diacid

InactiveCN1970524ALow operating temperatureReduce environmental pollutionCarboxylic preparation by ozone oxidationChemical recyclingSolventChemistry

The invention discloses a separating purifying method of nonadioic acid, which comprises the following steps: oxidizing oleic acid through ozone; cracking; evaporating solvent; recycling; extracting substrate through hot water; crystallizing water phase after extracting; drying to obtain rough product of nonadioic acid; adding rough product of nonadioic acid into organic solvent; stirring; sucking; drying; obtaining the pure product of nonadioic acid. The invention removes monacid and insoluble impurity with purity of nonadioic acid over 98%, which provides clean manufacturing method.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

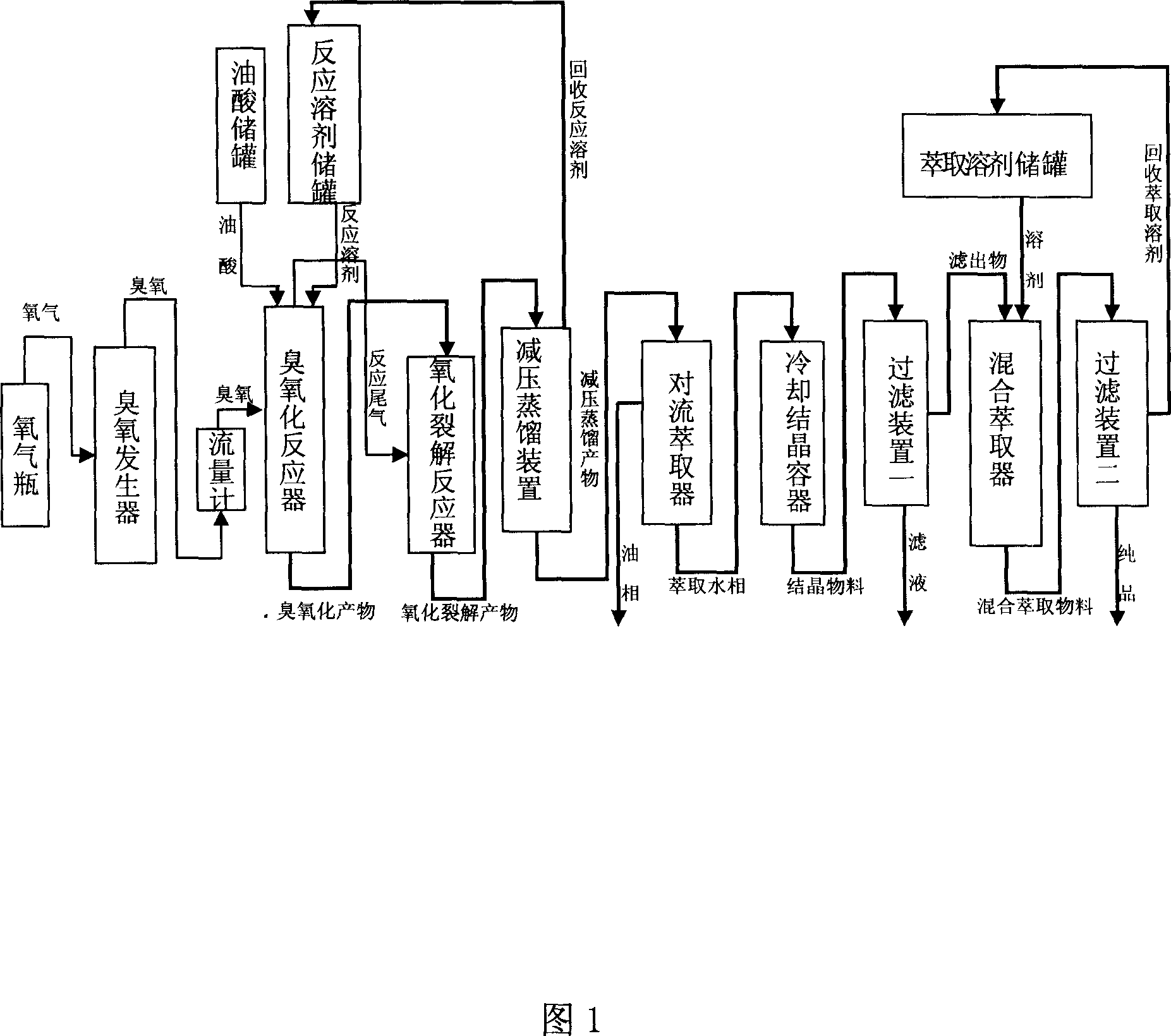

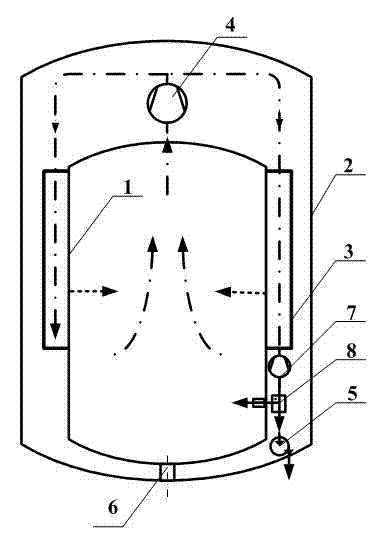

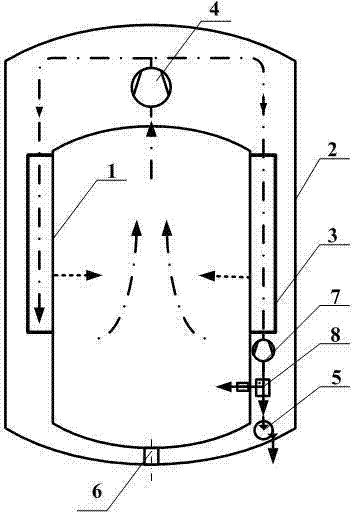

Device and method for drying clothes at low temperature through mechanical vapor recompression (MVR)

ActiveCN102505435ALow operating temperatureSimple processTextiles and paperLaundry driersProcess engineeringLiquid phase

The invention relates to a device and a method for drying clothes at low temperature through mechanical vapor recompression (MVR), and belongs to the field of energy conservation. The device comprises a shell (2), a roller (1) arranged in the shell (2) through a rolling bearing (6), and a sealing jacket (3), a compressor (4), a water discharge pump (5), an expander (7) and a gas-liquid separator (8) which are arranged on the heat-conducting wall surface of the roller (1), wherein the outlet of the roller (1) is connected with the compressor (4), the sealing jacket (3), the expander (7) and the gas-liquid separator (8) in turn; the gas-liquid separator (8) is provided with a gas phase outlet and a liquid phase outlet; the gas phase outlet of the gas-liquid separator (8) is connected with the inlet of the roller (1); the liquid phase outlet of the gas-liquid separator (8) is connected with the inlet of the water discharge pump (5); and the outlet of the water discharge pump (5) is connected with an external environment. The invention has the characteristics of low energy and water consumption, simple and compact process and wide applicable clothes range, and is particularly suitablefor the energy conservation and emission reduction transformation of the conventional clothes drying process.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Single-stage hydrocracking process

ActiveCN101089138AImprove hydrogenation performanceLow operating temperatureHydrocarbon oil crackingChemistrySingle stage

The single-stage hydrocracking process has the VGO and / or other heavy fraction oil as the material oil hydrocracked under certain condition to obtain various kinds of products. The catalyst in the upper region includes at least one kind of bulk phase catalyst comprising complex oxide NixWyOz and oxide MoO3 in the weight ratio 0.1-10 and accounting for 40-100 wt% of total catalyst. The present invention has the advantages of simple technological process, high volume space velocity, low apparatus cost, high material oil adaptability, flexible production scheme and high product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

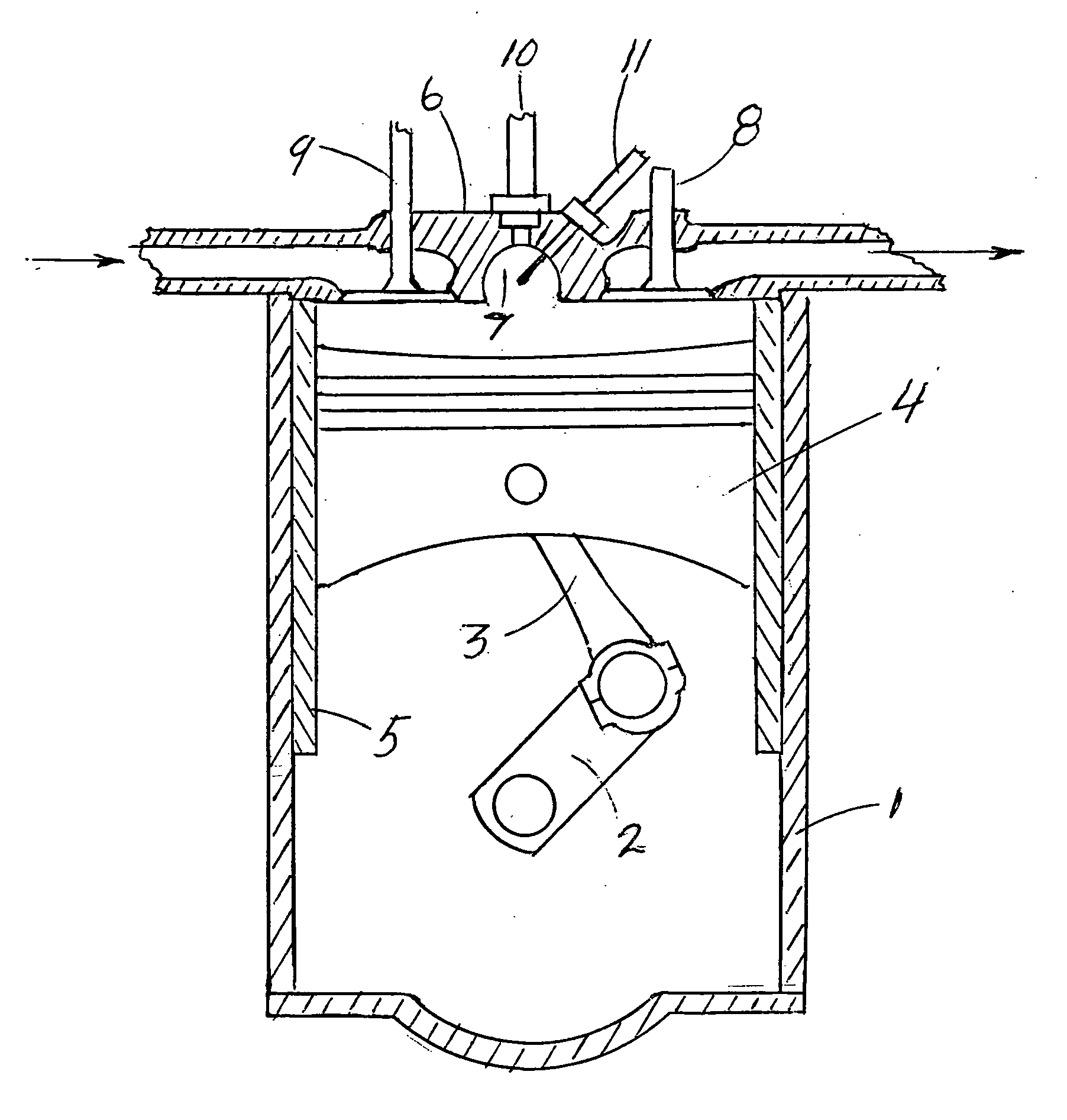

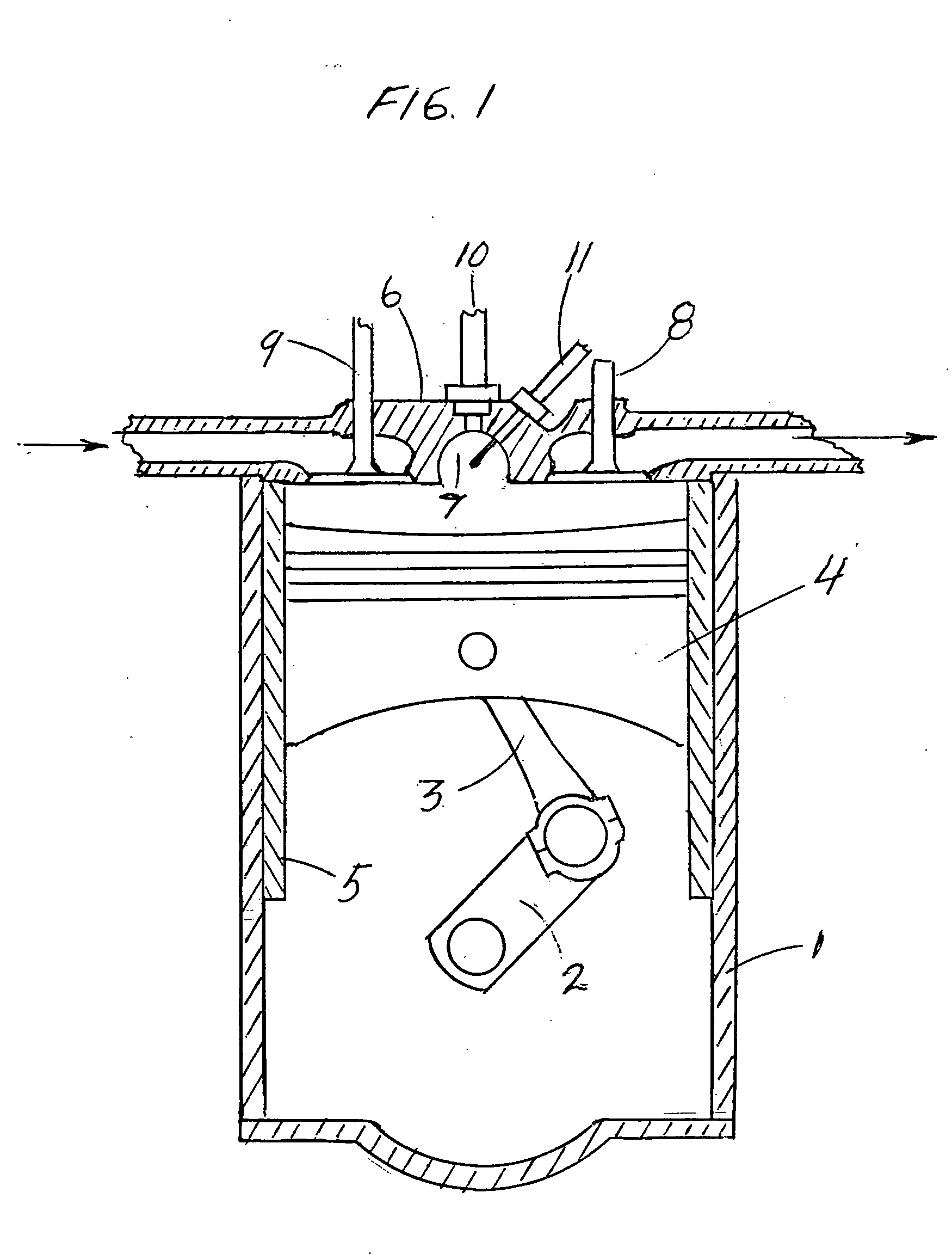

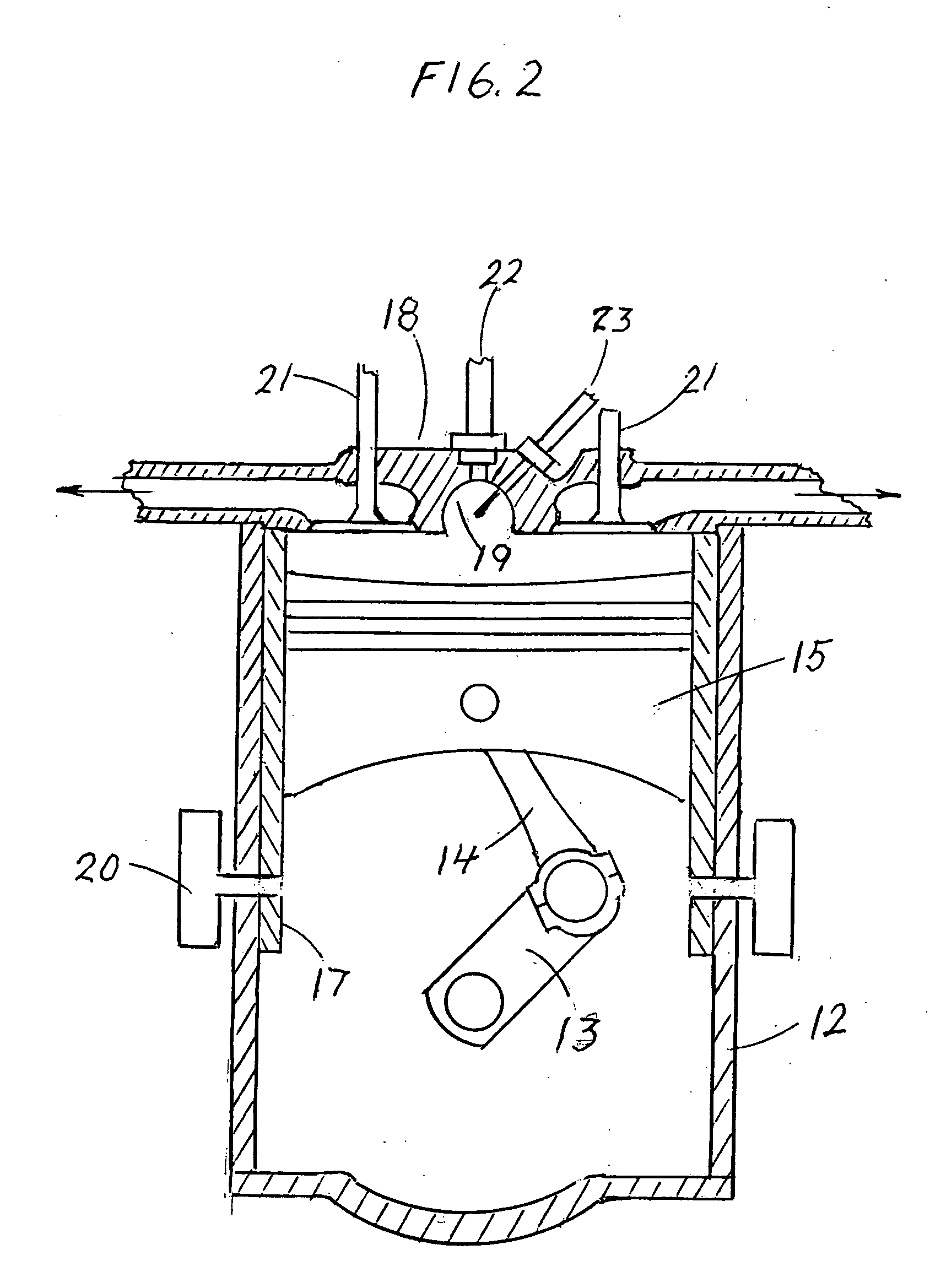

Internal steam engine

InactiveUS20070245734A1Low operating temperatureSteam accumulatorsSteam engine plantsInjectorTop dead center

An internal steam engine comprising one or more cylinders containing pistons, injectors and heating means. Air is drawn into said cavities and compressed as the piston reaches top dead center. The injector means spray the charge of heated compressed air with a non-combustible liquid which is vaporized under constant pressure followed by expansion and power stroke by the piston. The exhaust of the air mixture from the piston cavity is released through the liquid supply tank where the vapor is condensed and recycled to complete a closed operating cycle. A new charge is taken in at the end of the exhaust following either a four- or two-stroke engine process. The heating means are controlled by the cylinder temperature and activated to provide heat to the compression as required. In difference to a conventional steam engine, which generates steam from water in a boiler outside the working cylinder, the internal steam engine vaporizes water intermittently inside the working cylinder and exclusively in each compressed air charge to initiate a power stroke by the piston.

Owner:FLATER ANDERS HARALD

Composite three-dimensional porous bone tissue engineering scaffold material and its preparation method

InactiveCN1799648ALow operating temperatureFast mass transferBone implantBone tissue engineeringChemistry

The invention discloses a composite three-dimensional porous bone tissue engineering cradle material and the preparing method, for the purpose of providing a composite three-dimensional porous bone tissue engineering cradle material with good mechanical property and a preparing method under low temperature and without using organic solvent. The material is prepared by employing polylactic acid (PLA), human bone matrix, animal bone matrix, bone matrix gelatin and fully decalcified bone as raw material, and the preparing method comprises loading the raw material into vessel for hypercritical treatment, pressurizing and heating, and pressure releasing. The material prepared in this invention can be widely used in bone tissue engineering field.

Owner:JINAN UNIVERSITY

Grease rich in unsaturated fattyacid and preparation method thereof

ActiveCN103409224AThe method is simpleLow operating temperatureFatty-oils/fats separationFatty-oils/fats productionUnsaturated fatty acidPalmitoleic acid

The invention relates to the technical field of unsaturated fattyacid extraction and provides grease rich in unsaturated fattyacid and a preparation method thereof. The grease rich in unsaturated fattyacid is prepared through the following steps: first step: grinding horse fat, heating the grinded horse fat, so that liquid grease namely horse oil is obtained; second step: after the horse oil and saponifier by mass ratio of (1 to 2) to (1 to 5) are mixed together, performing saponification for 0.5 h to 3 h at the temperature of 50 DEG C to 90 DEG C, so that saponification liquid is obtained. In the invention, according to different crystallization temperature of components in the horse oil, solvent crystallization is performed, the unsaturated fattyacid is obtained after further separation, the unsaturated fattyacid in the horse oil comprises oleic acid, linoleic acid, linolenic acid and palmitoleic acid. The method can be used for richly extracting monounsaturated fatty acid (oleic acid and palmitoleic acid) and polyunsaturated fatty acid (linoleic acid and linolenic acid), the method is simple and convenient, the operating temperature is low, and the yield is higher.

Owner:新疆西部加斯特药业有限公司 +1

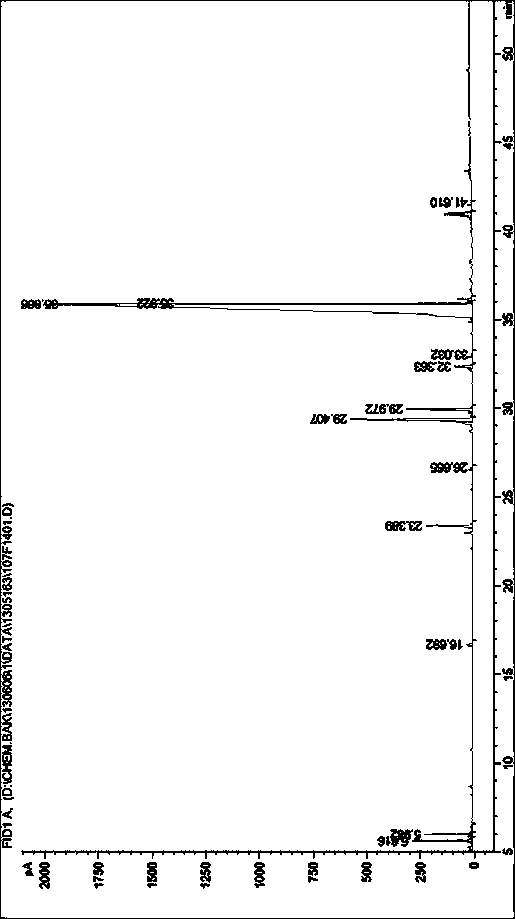

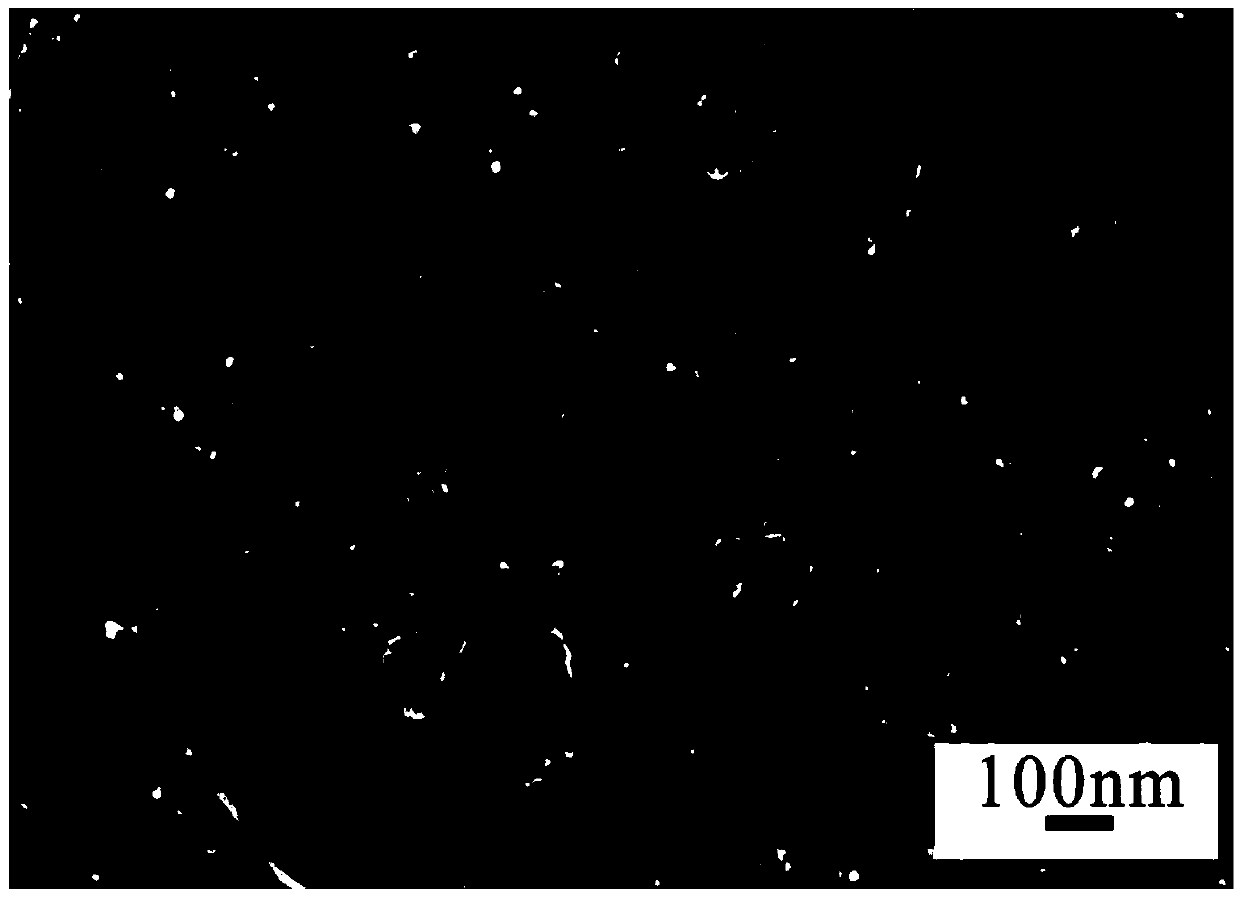

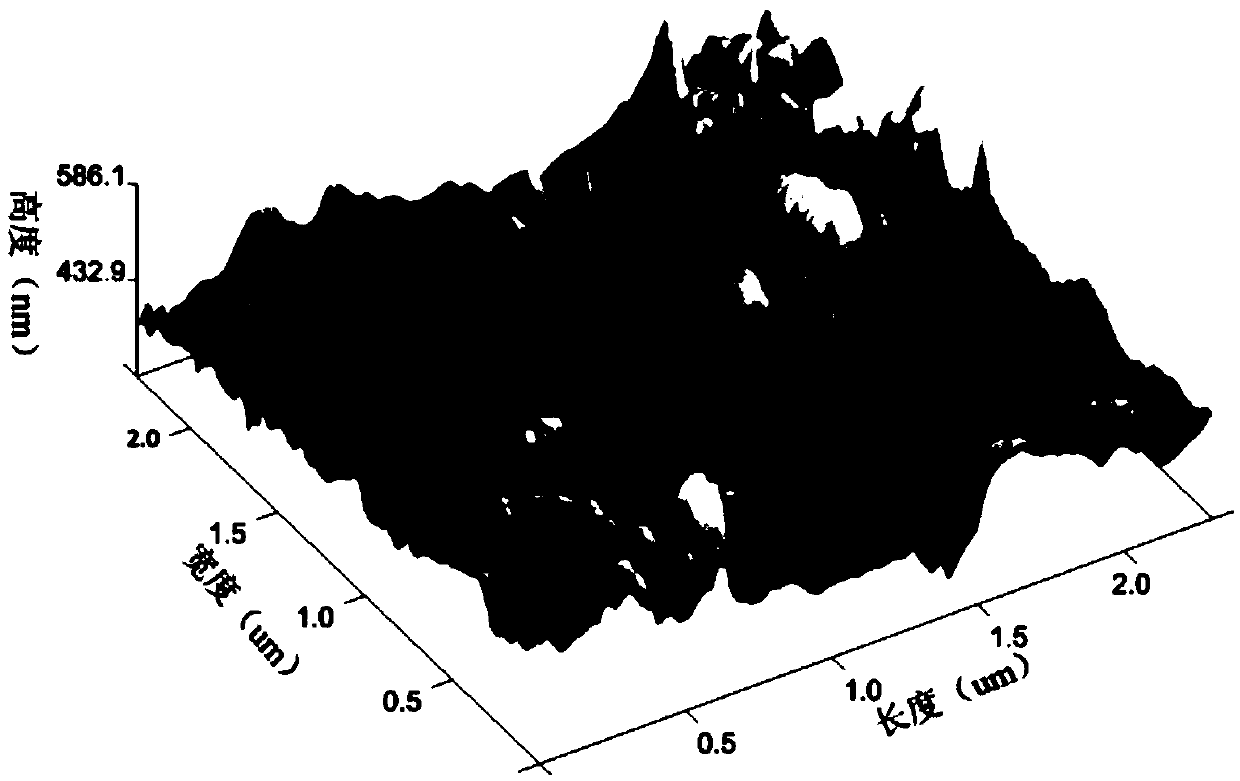

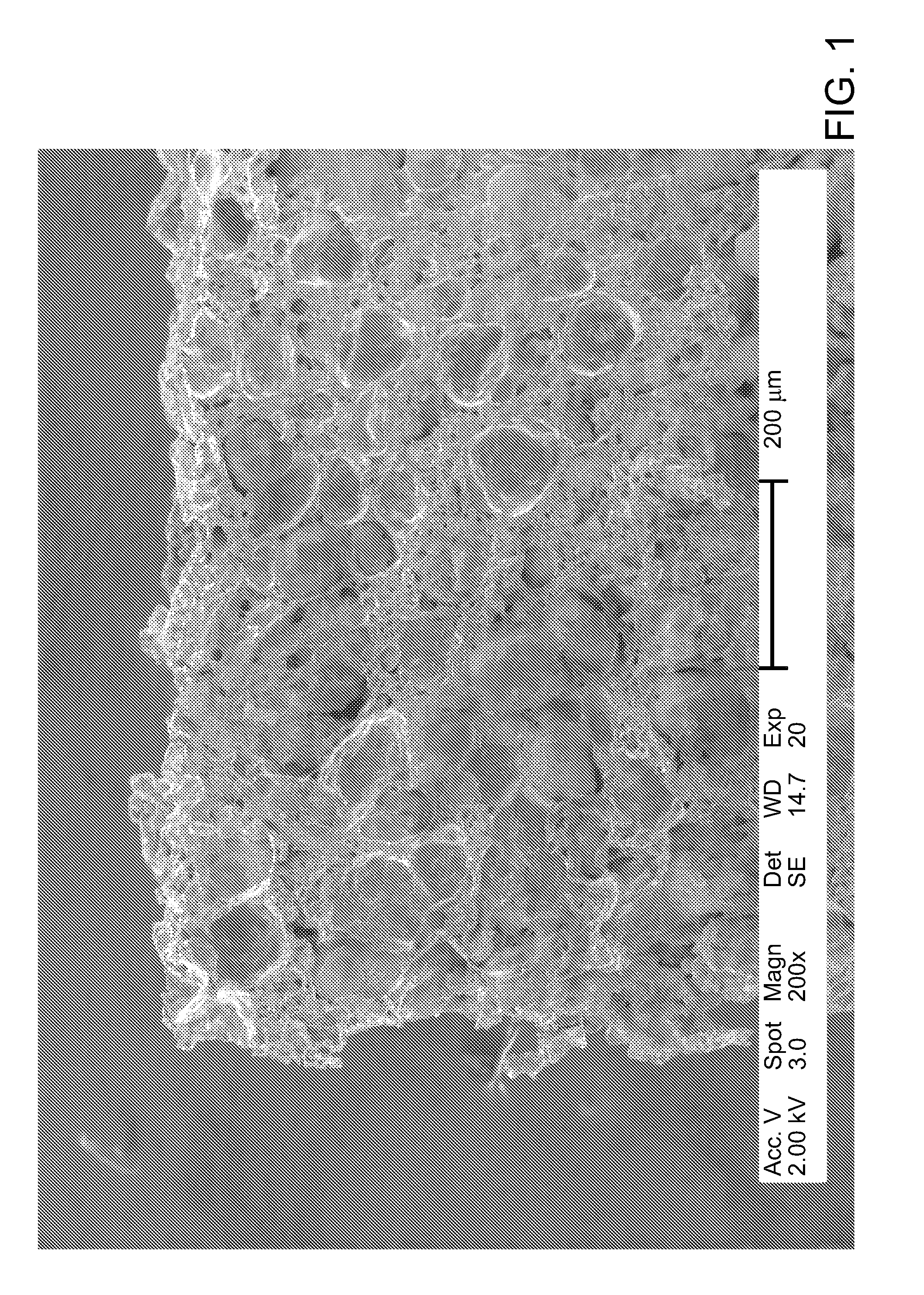

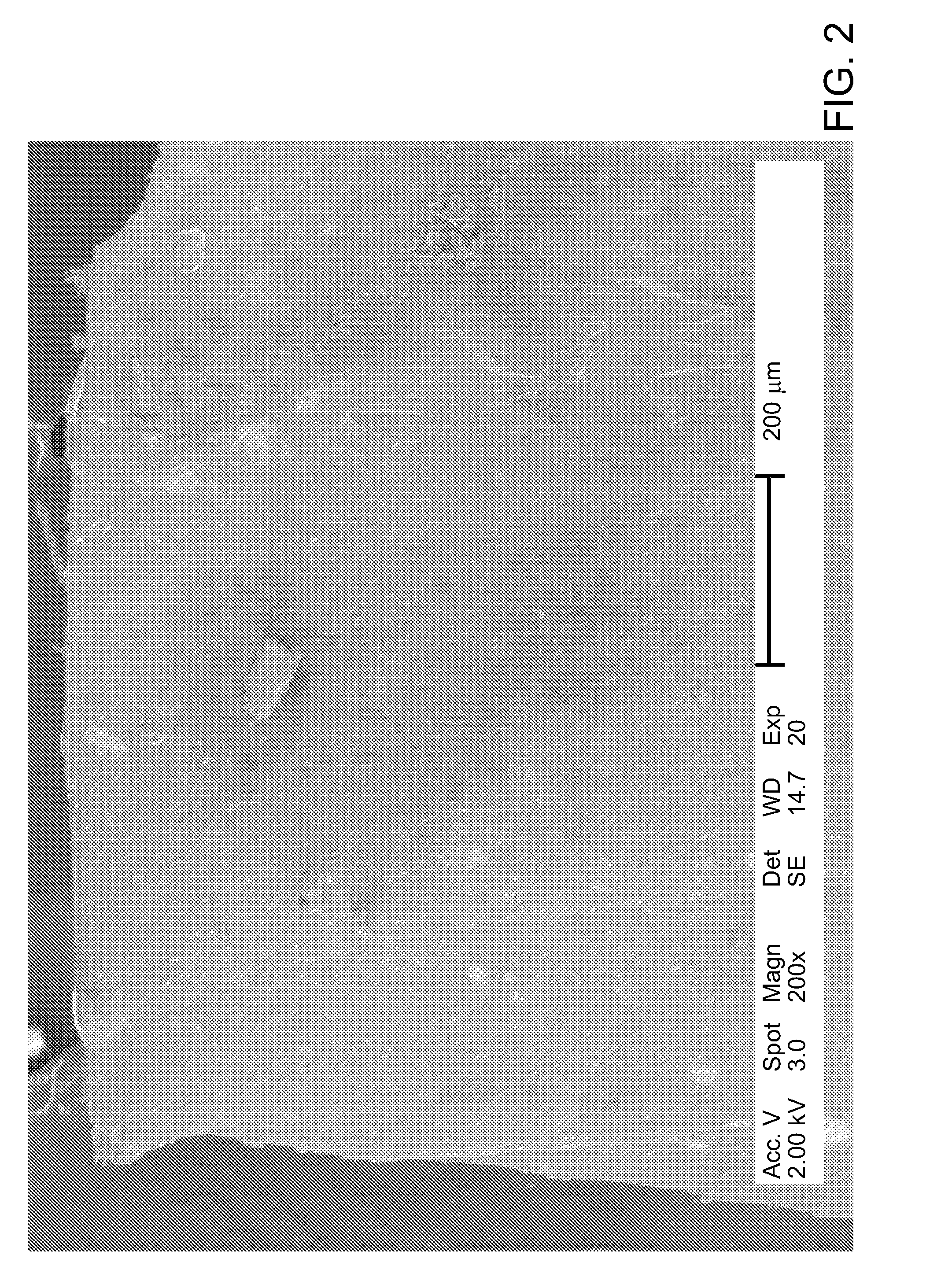

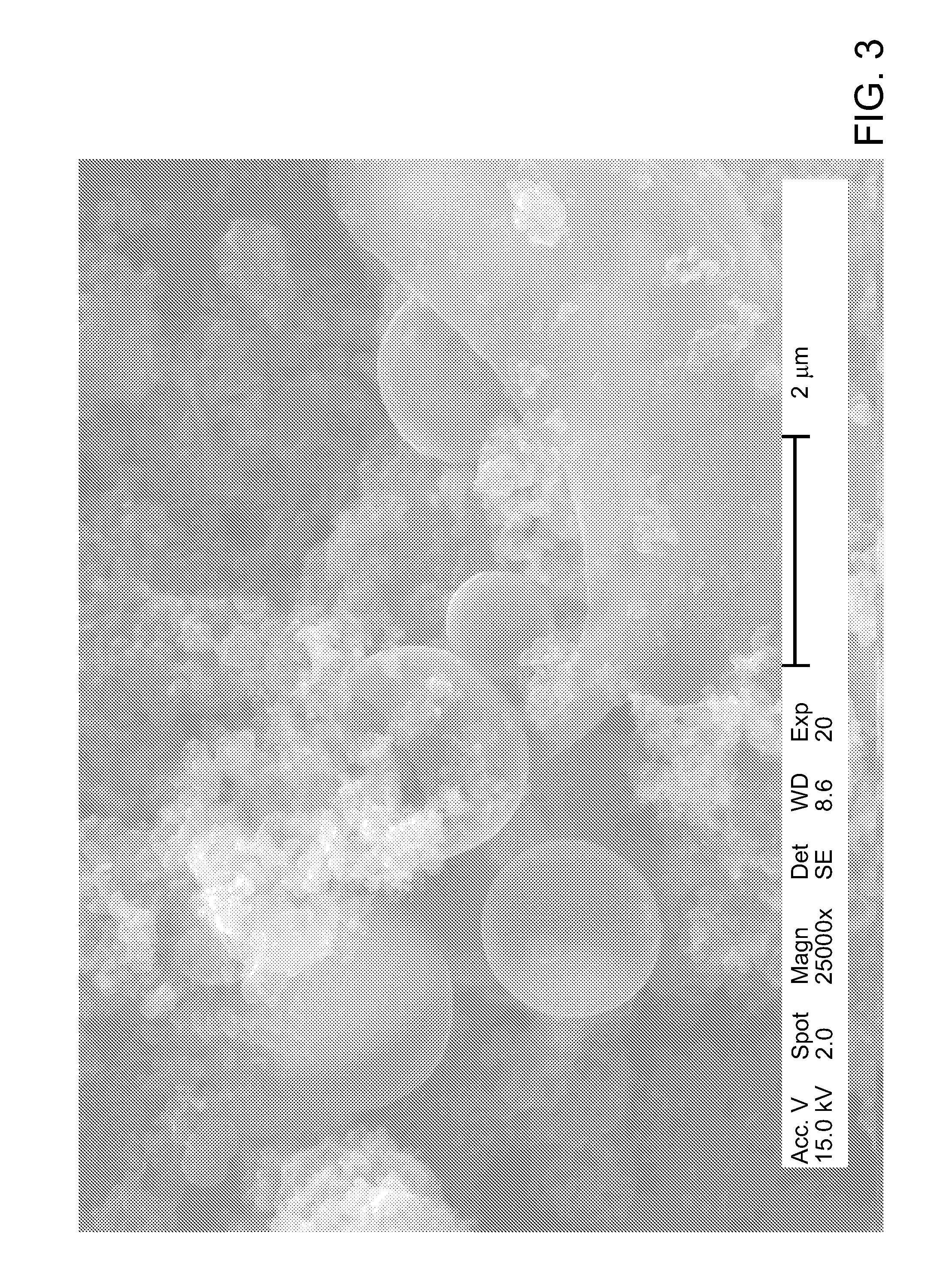

Method for preparing superhydrophobic CNTs/TiO2 hybrid film on base plate

ActiveCN103757611ALow operating temperatureSimple equipmentLiquid/solution decomposition chemical coatingPhotocatalysisFilm material

The invention discloses a method for preparing a superhydrophobic CNTs / TiO2 hybrid film on a substrate, and relates to CNTs / TiO2 hybrid films. The method aims at preparing the superhydrophobic CNTs / TiO2 hybrid film of a high-dispersion and uniform size TiO2 nanoparticle loaded carbon nanotube on the substrate through a low temperature liquid phase sedimentation method; a mixed solution of ammonium hexafluorotitanate and boric acid is used as a raw material, meanwhile, the carbon nanotube is added, and the CNTs / TiO2 hybrid film is prepared on the substrate through the low temperature liquid phase sedimentation method. The method comprises the steps as follows: 1) surface polishing of the substrate; 2) surface sedimentation of the substrate; 3) surface ornament and solidification of the substrate. The CNTs / TiO2 hybrid film of the high-dispersion and uniform size TiO2 nanoparticle loaded carbon nanotube can be obtained without complex treatment. Before and after coated with fluorosilane on the surface, the CNTs / TiO2 hybrid film always has the photocatalysis effect. Therefore, the superhydrophobic CNTs / TiO2 hybrid film is a film material with better performance and self-cleaning function.

Owner:XIAMEN UNIV

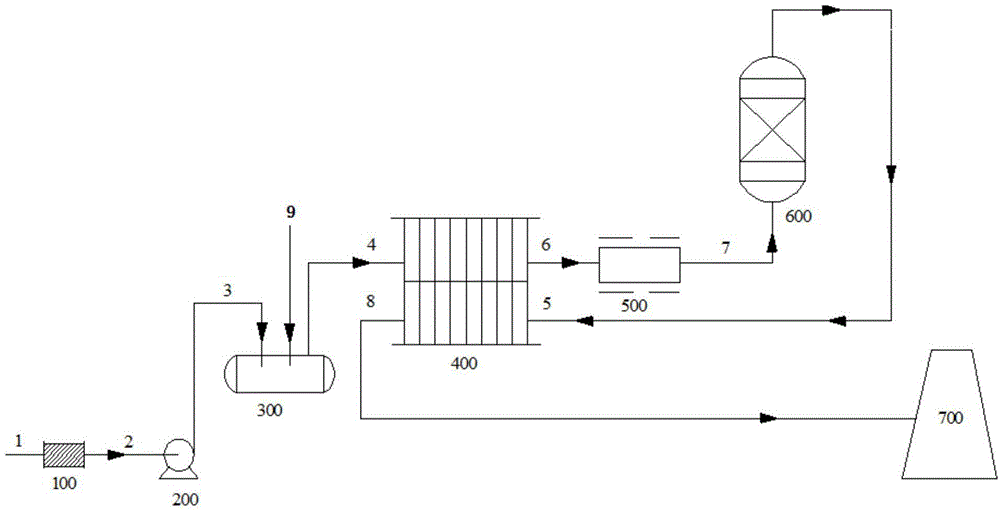

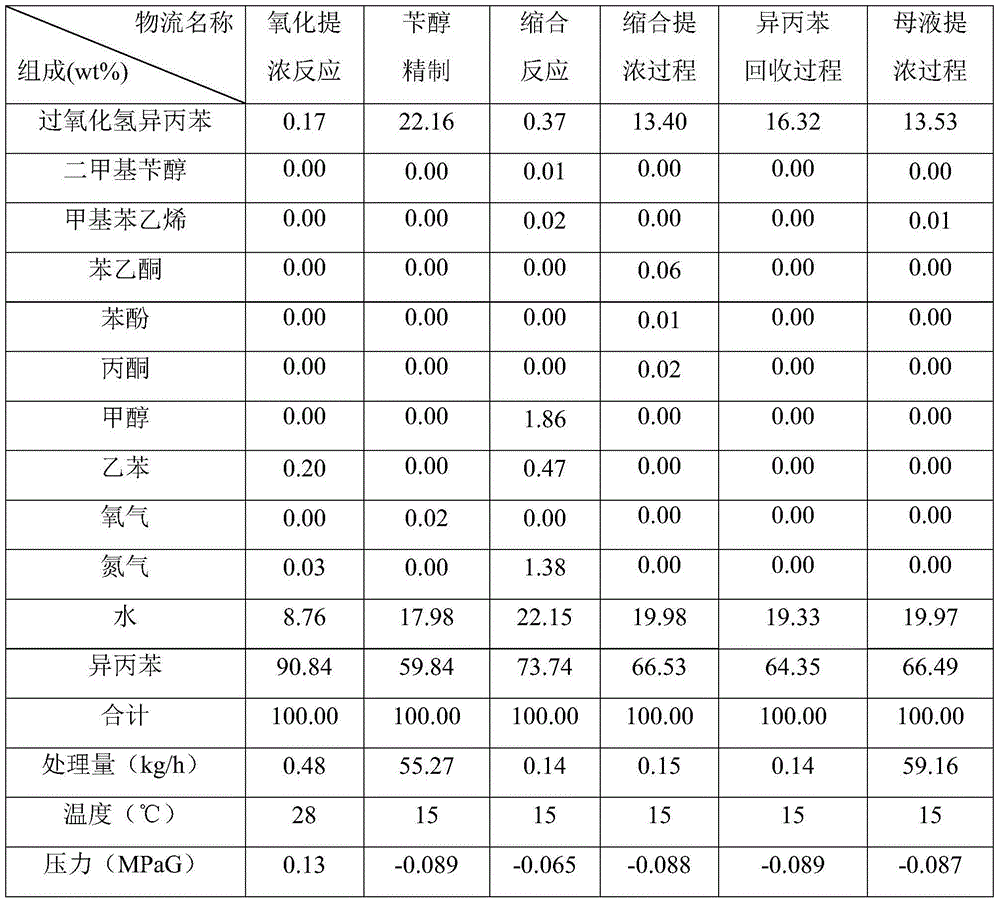

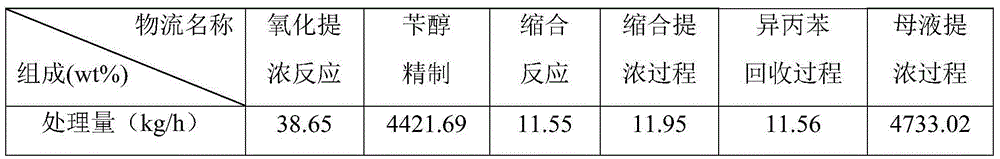

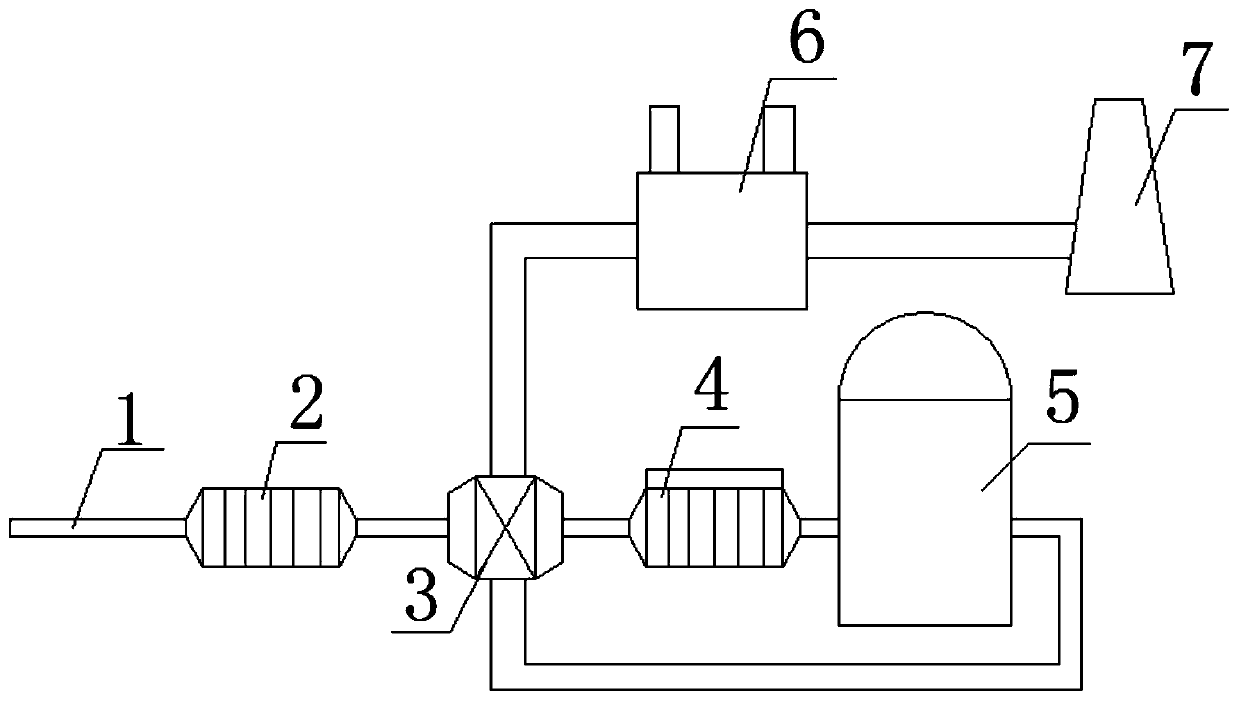

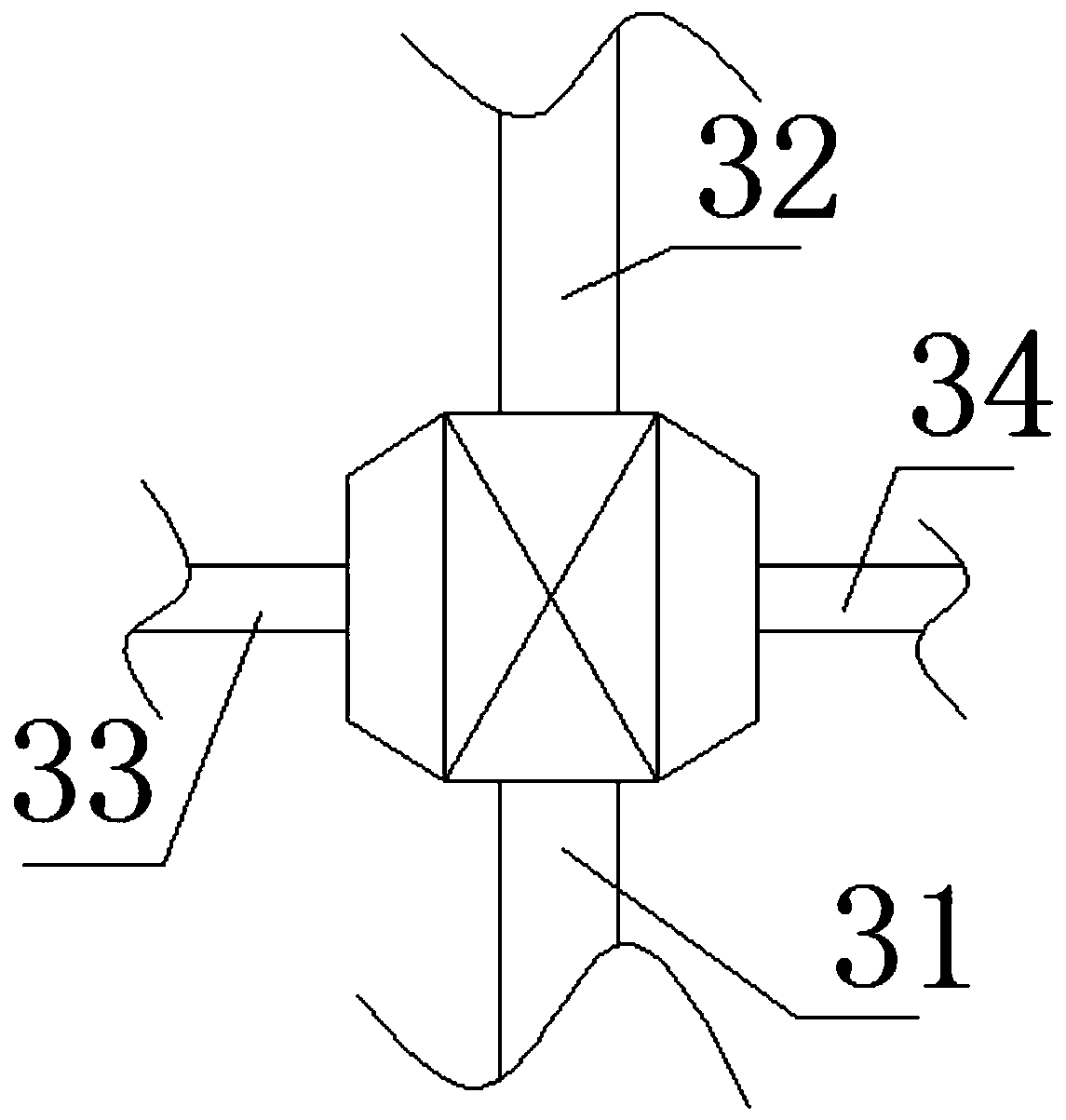

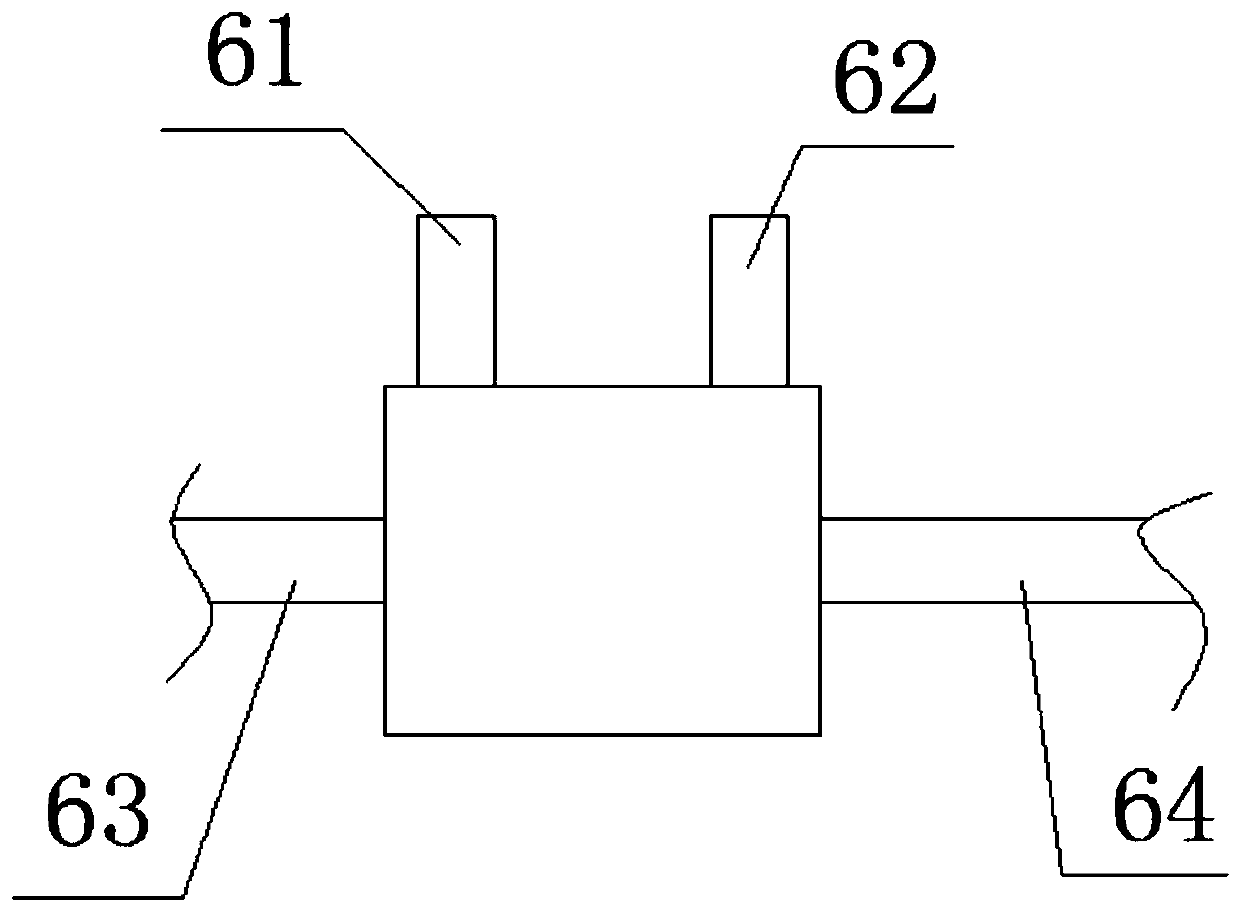

Treatment method for exhaust gas from dicumyl peroxide DCP devices

InactiveCN104785100ASimple processLow operating temperatureDispersed particle separationExhaust gasPollutant

The invention discloses a treatment method for exhaust gas from dicumyl peroxide DCP devices, and mainly solves the problems that the process is long, energy consumption is large, the efficiency is low, the cost is high, the technology is complex and the secondary pollution exists in the prior art. The treatment method of the exhaust gas from the dicumyl peroxide DCP devices disclosed by the invention comprises the following steps: mixed and pressurized vacuum exhaust gases pass through a fire arrester, and then enter a buffer tank to be mixed with oxidized tail gas; the mixed tail gases enter a hot-tube gas-to-gas heat exchanger; preheated mixed tail gases pass through an electric heater and are sent into a catalytic oxidation reactor, and under the effect of a honeycomb catalyst of precious metal, the organic pollutants in the mixed tail gases generate an oxidizing reaction with oxygen; the high-temperature purified tail gases discharged from the catalytic oxidation reactor heat the mixed tail gases through the hot-tube gas-to-gas heat exchanger so as to recycle heat; the purified tail gases after exchanging heat are discharged through an exhaust funnel. The treatment method disclosed by the invention can be used for treating the exhaust gas from the dicumyl peroxide DCP devices.

Owner:SINOPEC SHANGHAI ENG +1

Efficient catalytic treatment device for phthalic anhydride tail gas

PendingCN110523273AReasonable structureLow operating temperatureGas treatmentDispersed particle separationChemistryCarbon dioxide

The invention discloses an efficient catalytic treatment device for phthalic anhydride tail gas. The device comprises a pipeline, a preheater, a heat exchanger, a heater, a reaction furnace, a waste heat recovery furnace and a chimney. The device is reasonable in structure, volatile hazardous substances in the tail gas are converted into water and carbon dioxide through a series of catalytic reactions, due to presence of a purified gas inlet of the heat exchanger, the preheater and the heater can be closed after the reactions are performed a period of time, the reactions are promoted by heat produced by the reactions, any extra energy is not required, soft water is converted into water steam by use of hot gas in the waste heat recovery furnace, heat is further utilized, high-temperature water steam can be used for treating secondary heating of the treatment device and can also be used for heat supply to other production lines, no open fire is produced in the reaction process, safe distance requirements are not required, no wastewater or waste residues are produced in the technological process, the operation temperature is low, operation is reliable, energy is saved, the environmentis protected, and the operation efficiency of a factory is improved.

Owner:ZHEJIANG GREAT CHEM SCI & TECH

Manufacturing of nitrogen-containing materials

InactiveUS20150321967A1Low operating temperatureEliminate expense associateSolid waste managementOrganic fertilisersScrapPhenols

It has been discovered that waste cross-linked polymer materials both synthetic (scrap tire rubber, used polyurethane, and epoxy and phenol resins in discarded printed circuit boards) and natural (wood biomass, keratin, and chitin) can be conveniently depolymerized at slightly elevated temperatures and moderate pressures by the action of a liquid chemical reagent. The proposed inexpensive process results in a substantial to total depolymerization of synthetic polymers and thereby recovers valuable liquid and solid materials. When applied to lignocellulosic biomass, the proposed process, depending on the reaction conditions, either unlocks the lignin-hemicellulose matrix making cellulose more available for fermenting microorganisms or results in carbonization, or coalification of the biomass that may be desirable in terms of sequestering excessive carbon from the Earth's biosphere.

Owner:GESTALT CHEMICAL PRODUCTS INC

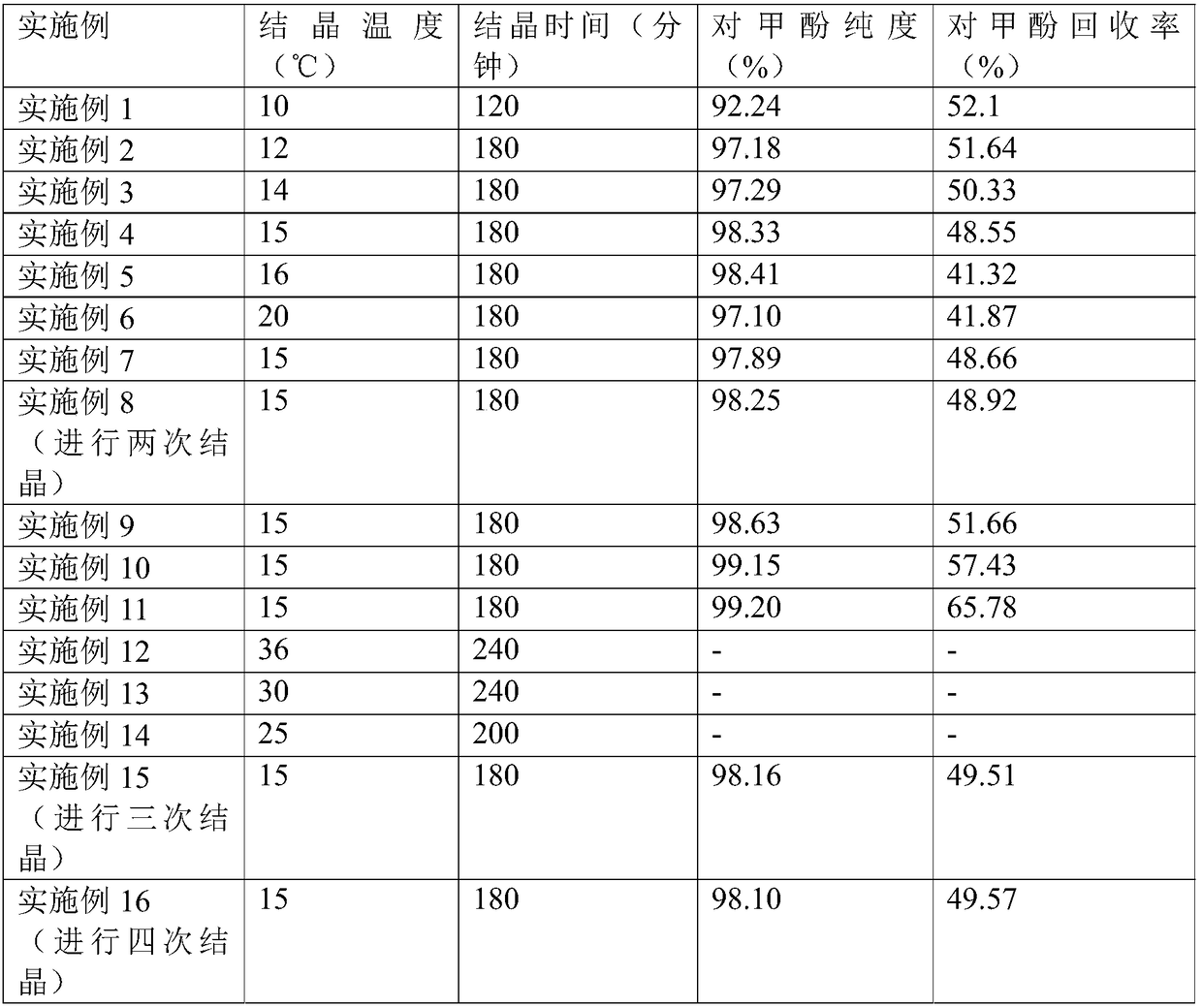

Paracresol separation method

ActiveCN109232192AEasy to operateLow operating temperatureOrganic chemistryOrganic compound preparationSolventChemistry

The invention provides a paracresol separation method. The method comprises the following steps of S1, providing a mixture containing 60 to 90 weight percent of paracresol; S2, adding paracresol seedcrystals into the mixture at 10 to 36 DEG C so that paracresol is crystallized; separating out paracresol crystals; S3, separating the paracresol crystals. By using the technical scheme provided by the invention, the operation is simple; the operation temperature and the operation pressure of the technical process are lower; the equipment and operation cost is reduced. Meanwhile, by using the technical scheme, higher crystallizing temperature and shorter cooling time are used; the energy consumption reduction is facilitated. In addition, by using the technical scheme, the simple technical process is used; the use of a great number of solvents is not needed, so that the problem of complicated separation process and great consumption of solvents can be avoided.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

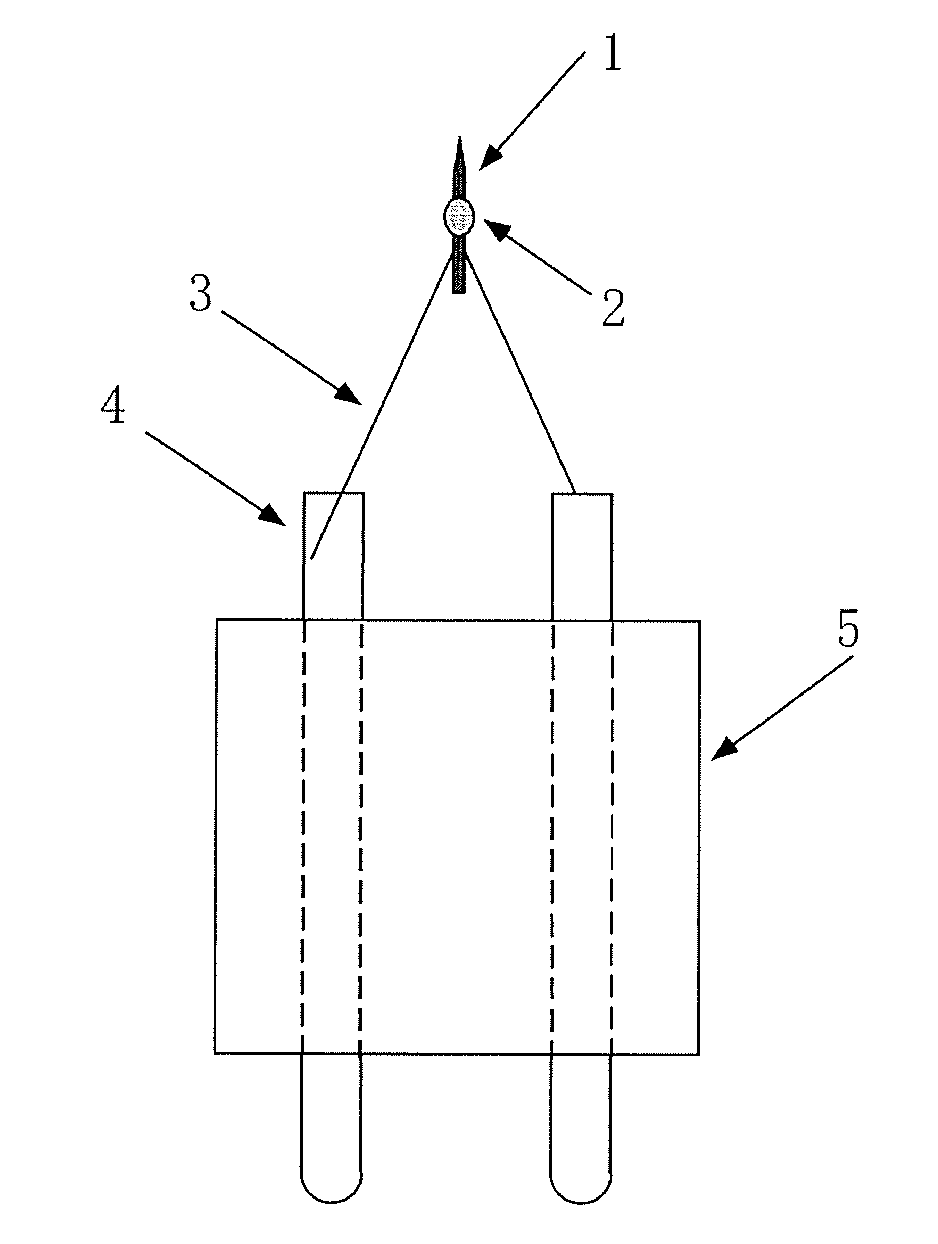

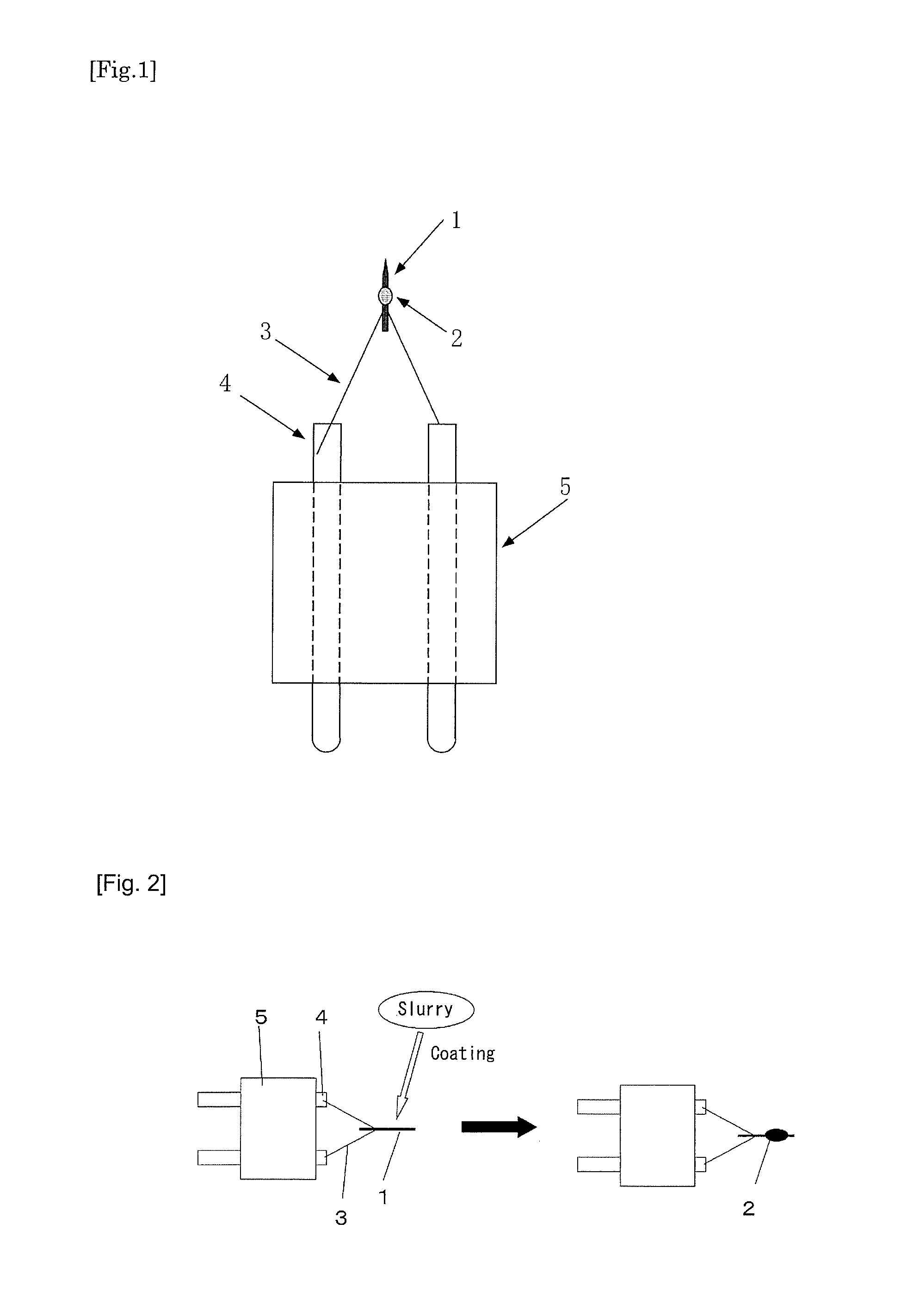

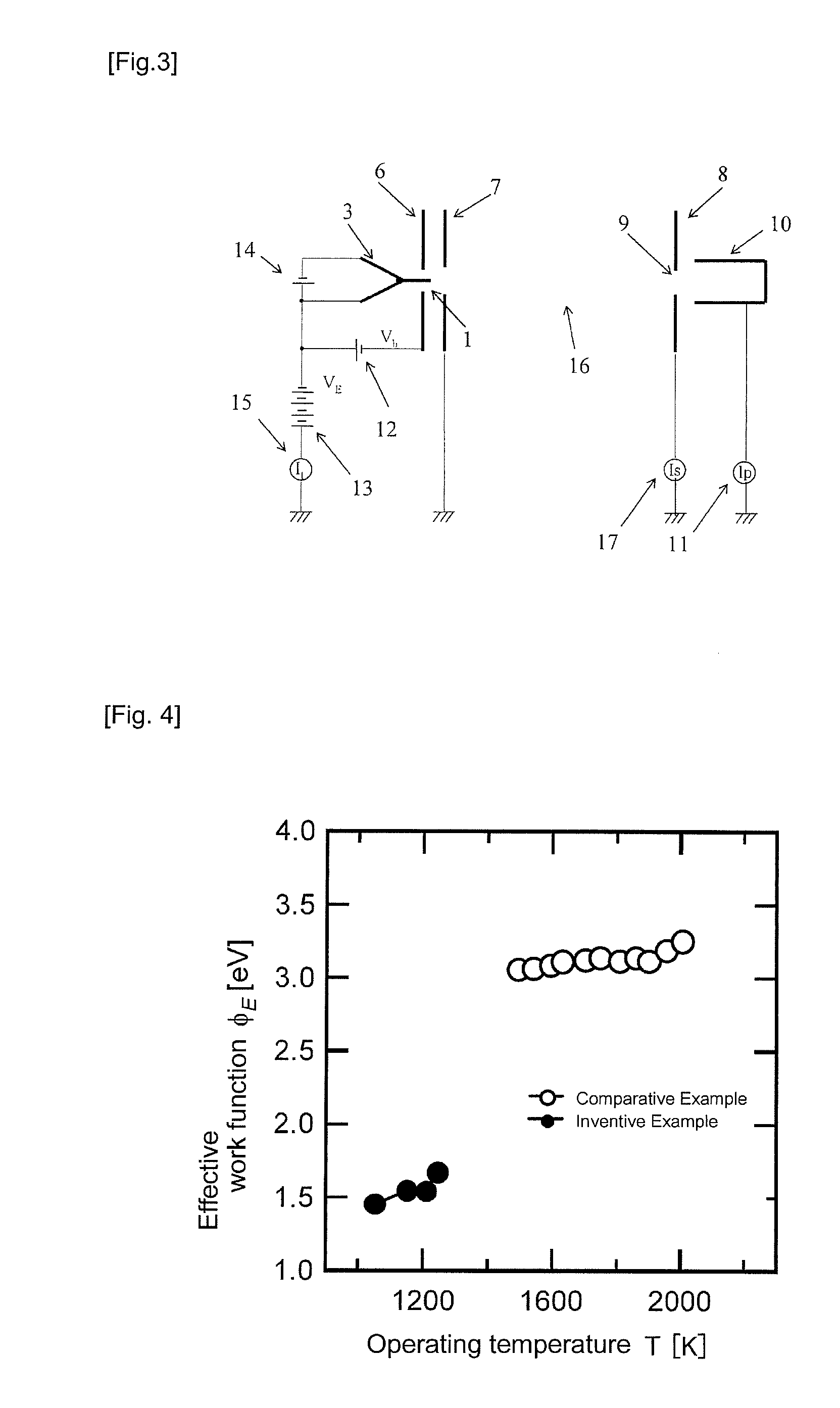

Electron-source rod, electron source and electronic device

InactiveUS20120169210A1Low operating temperatureHigh densityElectric discharge tubesDischarge tube solid thermionic cathodesComposite oxideTungsten

An electron source is provided that operates at lower temperature and has a low work function and a narrower energy width. The electron source includes a porcelain insulator, two conductive terminals connected to the porcelain insulator, a filament formed between the conductive terminals, and a <100> orientation single crystal rod of at least one metal selected from the group consisting of tungsten, molybdenum, tantalum and rhenium connected to the filament. The rod has an electron-emitting face formed in at its tip region with its {100} crystal face exposed. The rod further includes a diffusion source in its central region that is made of a composite oxide formed from barium oxide and scandium oxide wherein the proportion of barium oxide being 50 mol % or more of BaO and the proportion of scandium oxide being 10 to 50 mol % as Sc2O3 when the mixed oxide is prepared.

Owner:DENKA CO LTD

Method for performing ultrasonic-assisted supercritical carbon dioxide extraction on vanilla bean essential oil

InactiveCN107974351AIncrease productivityLow operating temperatureEssential-oils/perfumesSolid solvent extractionSolventChemistry

The invention discloses a method for performing ultrasonic-assisted supercritical carbon dioxide extraction on vanilla bean essential oil. The method comprises the following steps: crushing dried vanilla beans into 60 to 90 meshes; performing ultrasonic treatment and adding a solvent, so that the solid-liquid ratio is 1:(0.2-1), the temperature is normal temperature, the power is 200 to 400 W andthe time is 4 to 8 minutes; putting into a supercritical carbon dioxide extraction tank and performing extraction, wherein the flow quantity of the carbon dioxide is 16 to 20 L / h, the extraction temperature is 35 to 45 DEG C, the extraction pressure is 10 to 14 Mpa and the extraction time is 160 to 180 minutes; separating for the first time, wherein the separation pressure is 6 to 8 Mpa and the separation temperature is 35 to 45 DEG C; separating for the second time, wherein the separation pressure is 4 to 5 Mpa and the separation temperature is 25 to 30 DEG C. By the method, the problem thatthe flavor and the aromaticity of perfume are changed by the traditional ethanol extraction method can be solved, the production efficiency of the vanilla bean essential oil is high and the product has pure and natural fragrance.

Owner:丽华(广州)香精香料股份有限公司

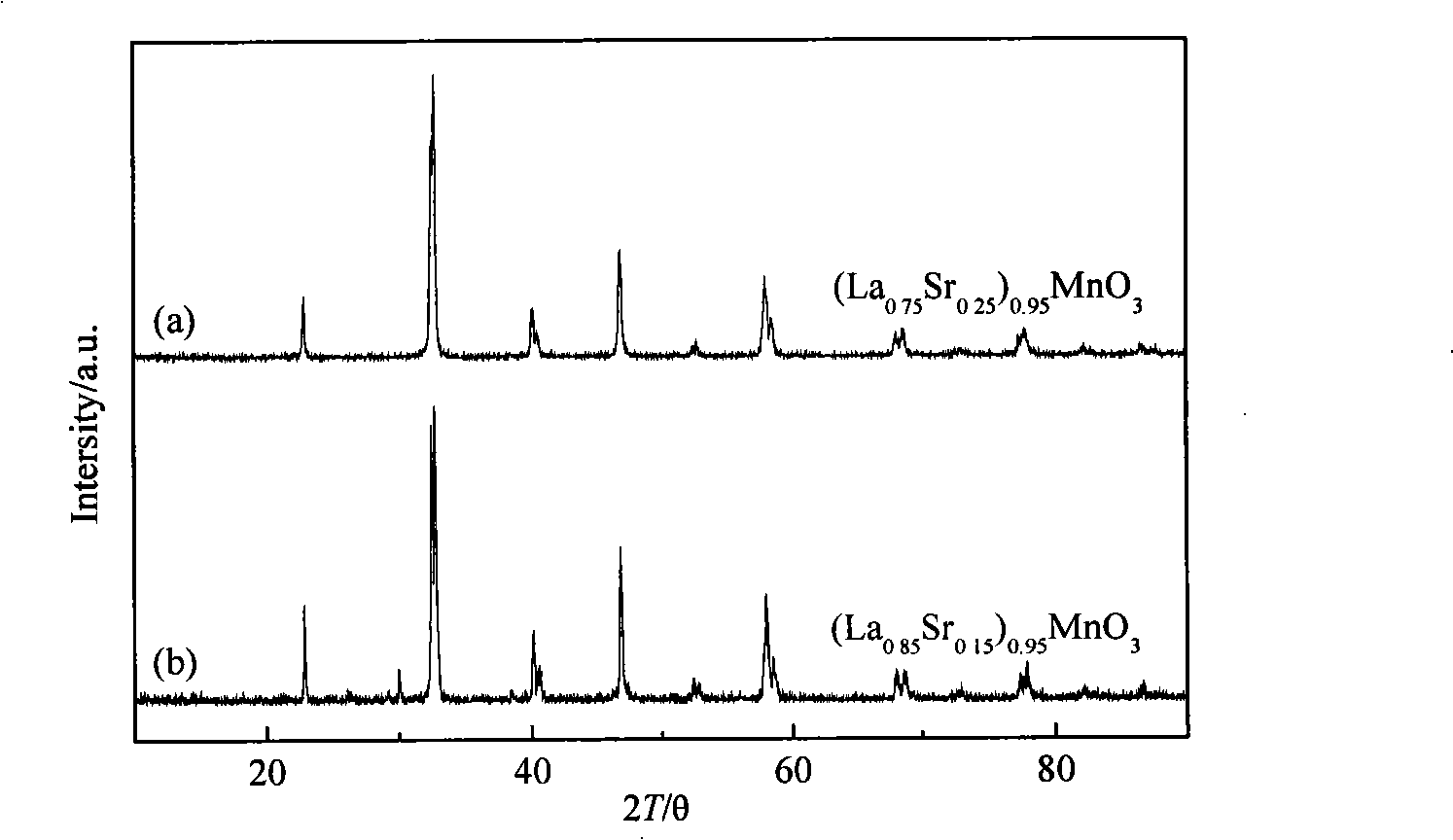

Solid-oxide fuel battery cathode powder preparation method

ActiveCN101310898ALow operating temperatureInlet temperature and outlet temperature decreaseIonSolvent

The invention relates to a method for preparing cathode powder of solid oxide fuel batteries. The method is characterized in that lanthanum nitrate solution, manganese nitrate solution and strontium nitrate solution are prepared according to the proportion requirements of the metal elements in the cathode powder of the fuel battery and the solvent of the solution can be ethanol or / and hydrosolvent, and then the solutions are mixed evenly; the mixed solution is dried by spraying with a spray dryer to obtain white powder or gel matters; afterwards, the white powder or gel matters are put into a box-typed resistor furnace for baking to obtain the cathode powder of the solid oxide fuel battery. During the preparing course, technique ethanol is taken as the solvent, thus greatly reducing the temperature of an inlet and an outlet for the spraying drying and effectively preventing the decomposition of nitrate with low decomposition temperature. If deionized water is adopted as the solvent, by adjusting the feeding rate, not only can the decomposition of the nitrate be prevented, but also the preparing rate is increased and the cost is reduced.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

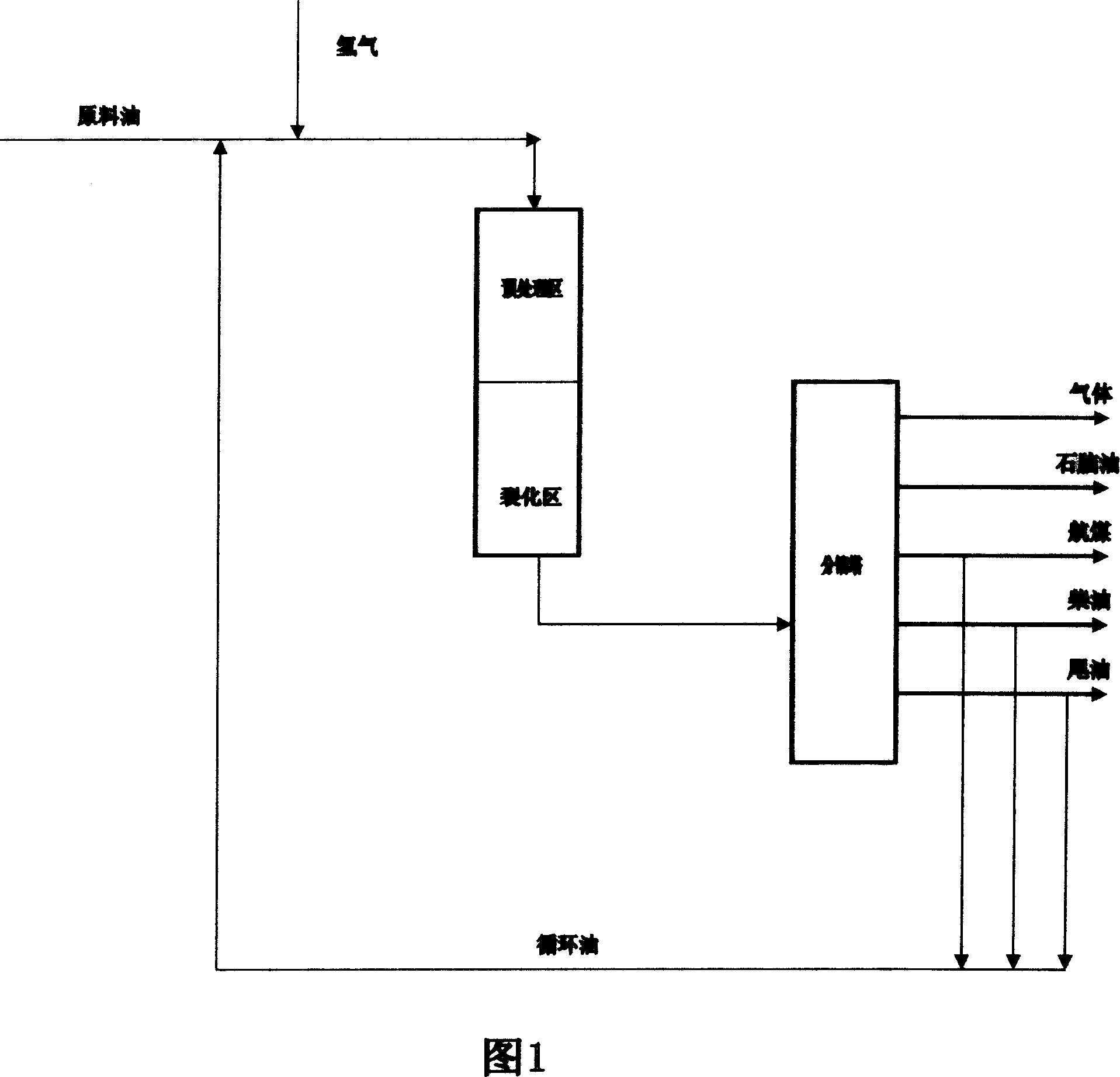

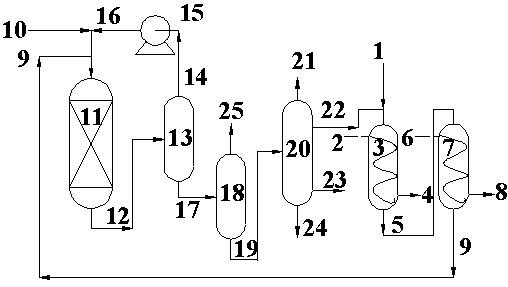

Coal tar hydrotreatment process

ActiveCN111154505ALow operating temperatureReduce nitrogen contentTar working-up by distillationTar working-up by chemical refiningProcess engineeringFuel oil

The invention discloses a coal tar hydrotreatment process. The process comprises the following steps: (1) mixing a coal tar raw material with a diesel fraction obtained by a hydrotreating unit to obtain a mixture flow A, and then sequentially carrying out acid pickling treatment and water washing treatment to obtain a hydrotreating unit feed; and (2) feeding the hydrotreating unit feed obtained instep (1) and hydrogen into the hydrotreating unit, contacting the hydrotreating unit feed with a hydrotreating catalyst, carrying out a hydrogenation reaction, and fractionating the obtained hydrogenation reaction product to obtain naphtha, diesel oil, fuel oil, tail oil and other fractions. High-quality fuel oil can be produced, the problem that the operation period of a hydrogenation device isinfluenced due to the fact that the content of metal, mechanical impurities and the like in the coal tar raw material is high is solved, the reaction temperature in the hydrotreatment process is reduced, energy consumption is reduced, and safety is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

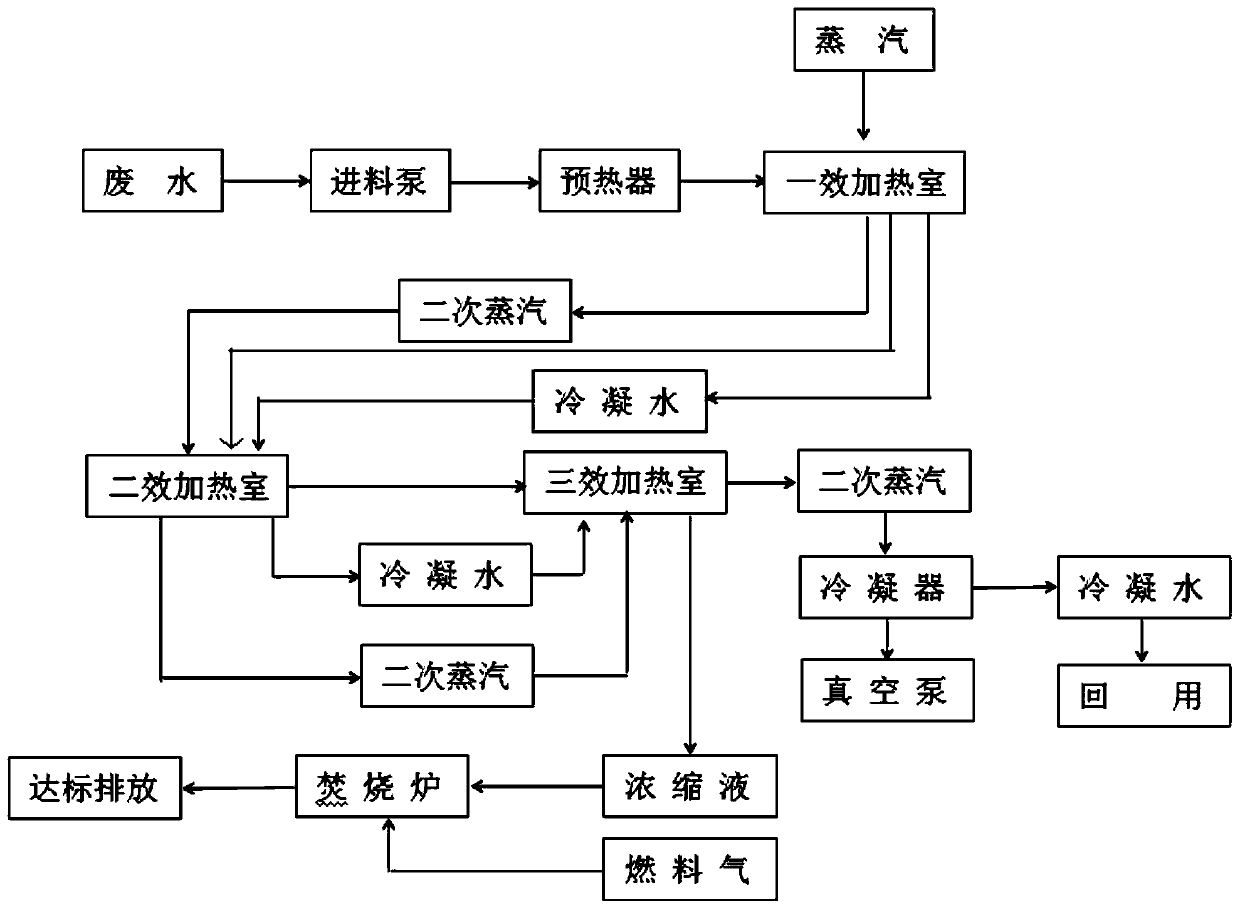

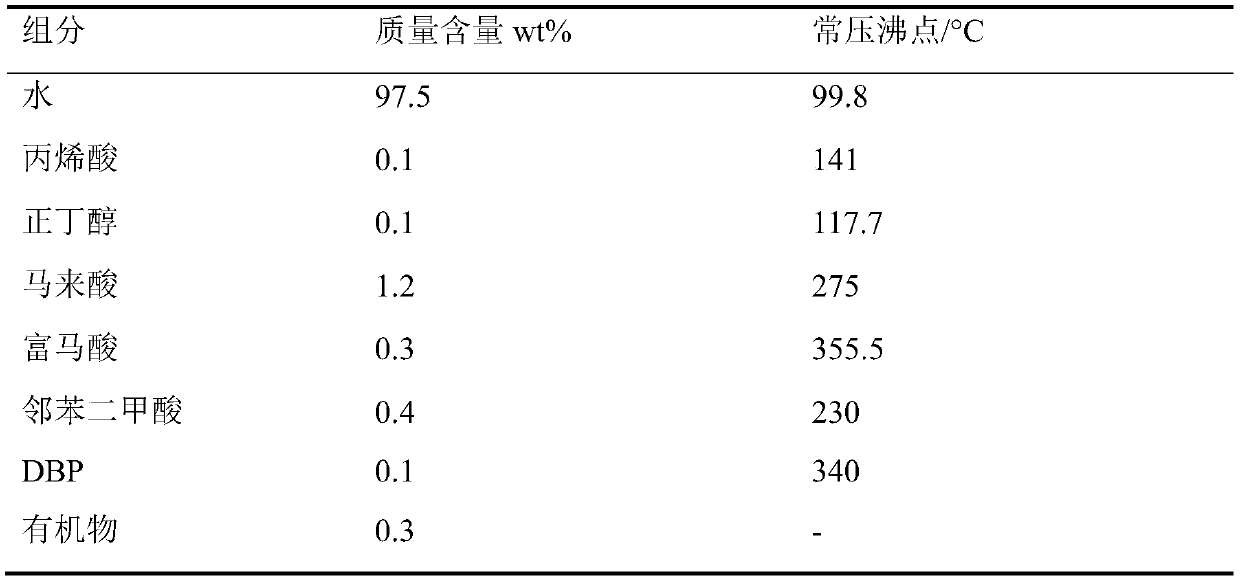

Treatment method of maleic anhydride production waste liquid

InactiveCN111072086AReduce production and operation costsLow operating temperatureWater contaminantsWater/sewage treatment by heatingMaleic anhydrideChemistry

The invention discloses a treatment method of maleic anhydride production waste liquid. The treatment method comprises the steps: waste liquid is pumped into a preheater for preheating, the preheatedwaste liquid sequentially enters a first-effect heating chamber, a second-effect heating chamber and a third-effect heating chamber for evaporating and concentrating, and then the concentrated liquidenters an incinerator to be treated and the gas phase enters a condenser to be condensed, wherein the first-effect heating chamber uses live steam for evaporation, steam generated by the first-effectheating chamber is used as a heat source of the second-effect heating chamber, steam generated by the second-effect heating chamber is used as a heat source of the third-effect heating chamber, and avacuum pump is used for maintaining negative pressure operation of the third-effect heating chamber. According to the treatment method, multiple-effect evaporation is adopted to concentrate the wasteliquid, the amount of used steam is small, the production operation cost can be reduced and the energy-saving and consumption-reducing principle is met.

Owner:惠州宇新新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com