Entrained flow coal gasification method employing solid state slag-tap suitable for high ash content and high ash melting point coal

A high ash melting point, solid state slagging technology, applied in the field of coal gasification, can solve the problems of increasing oxygen consumption, slagging heat loss, inability to gasify coal with high ash melting point, and reducing the content of cold coal gas, etc. The effect of good chemical index, resource saving and less exhaust emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

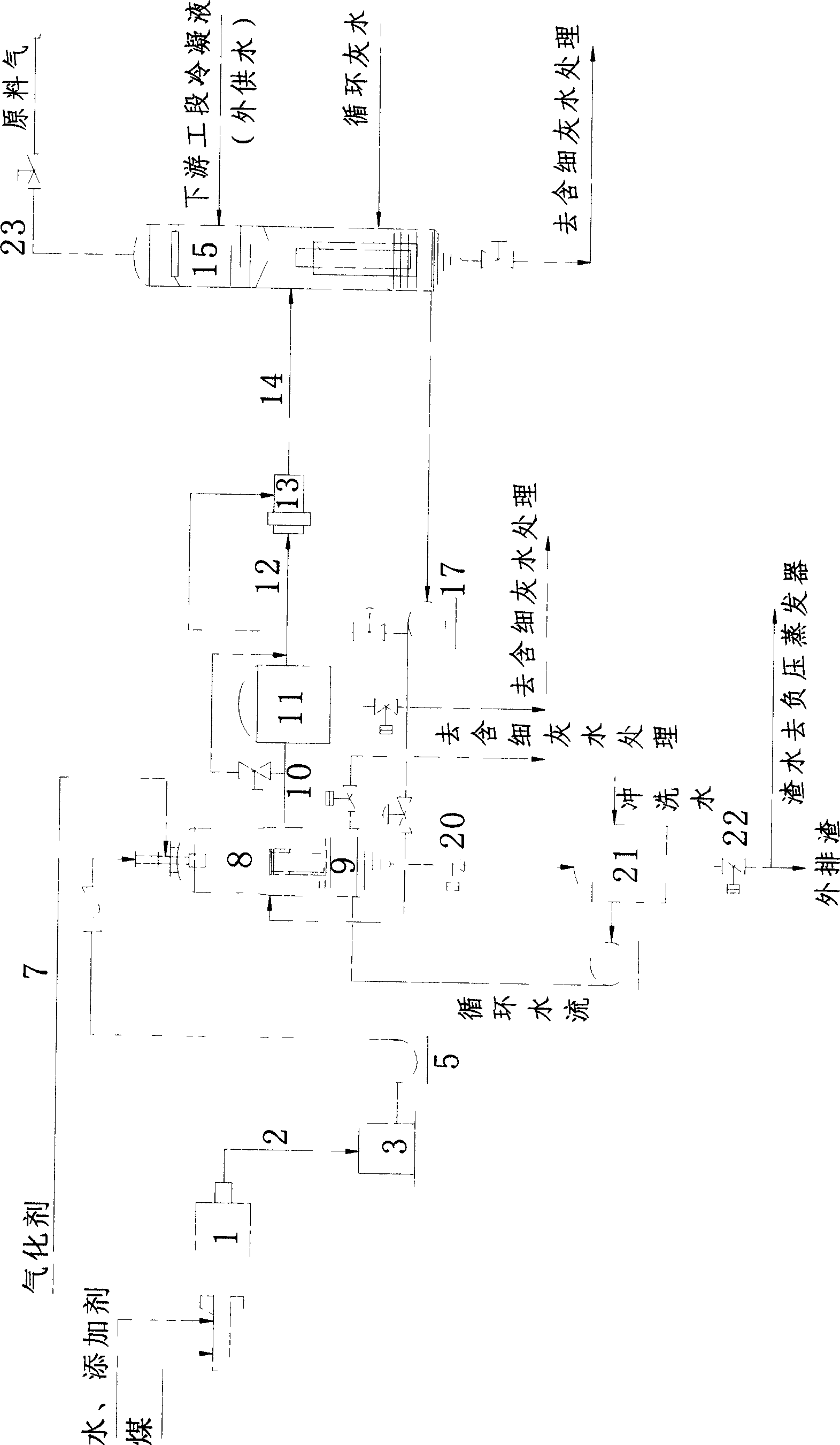

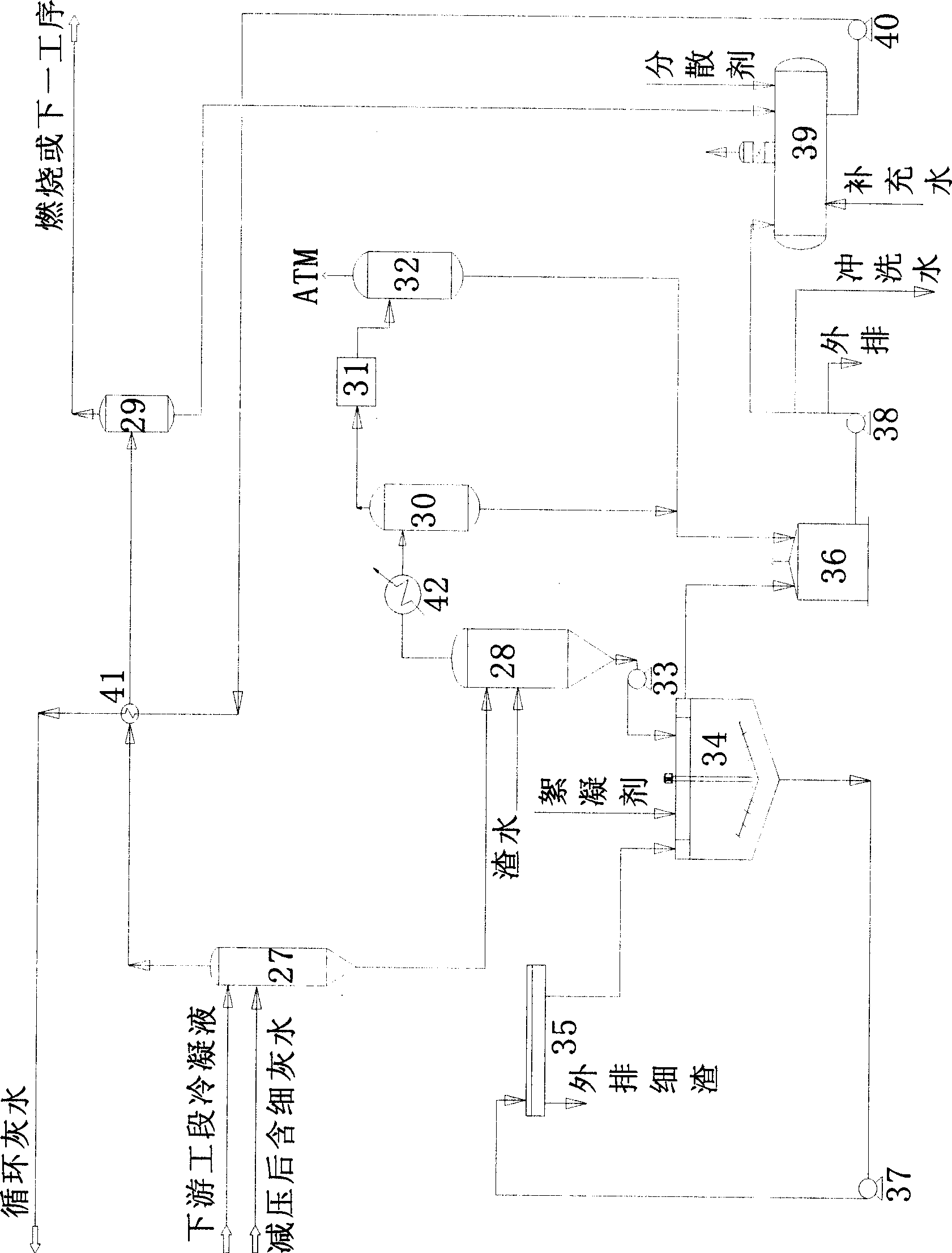

Method used

Image

Examples

Embodiment 1

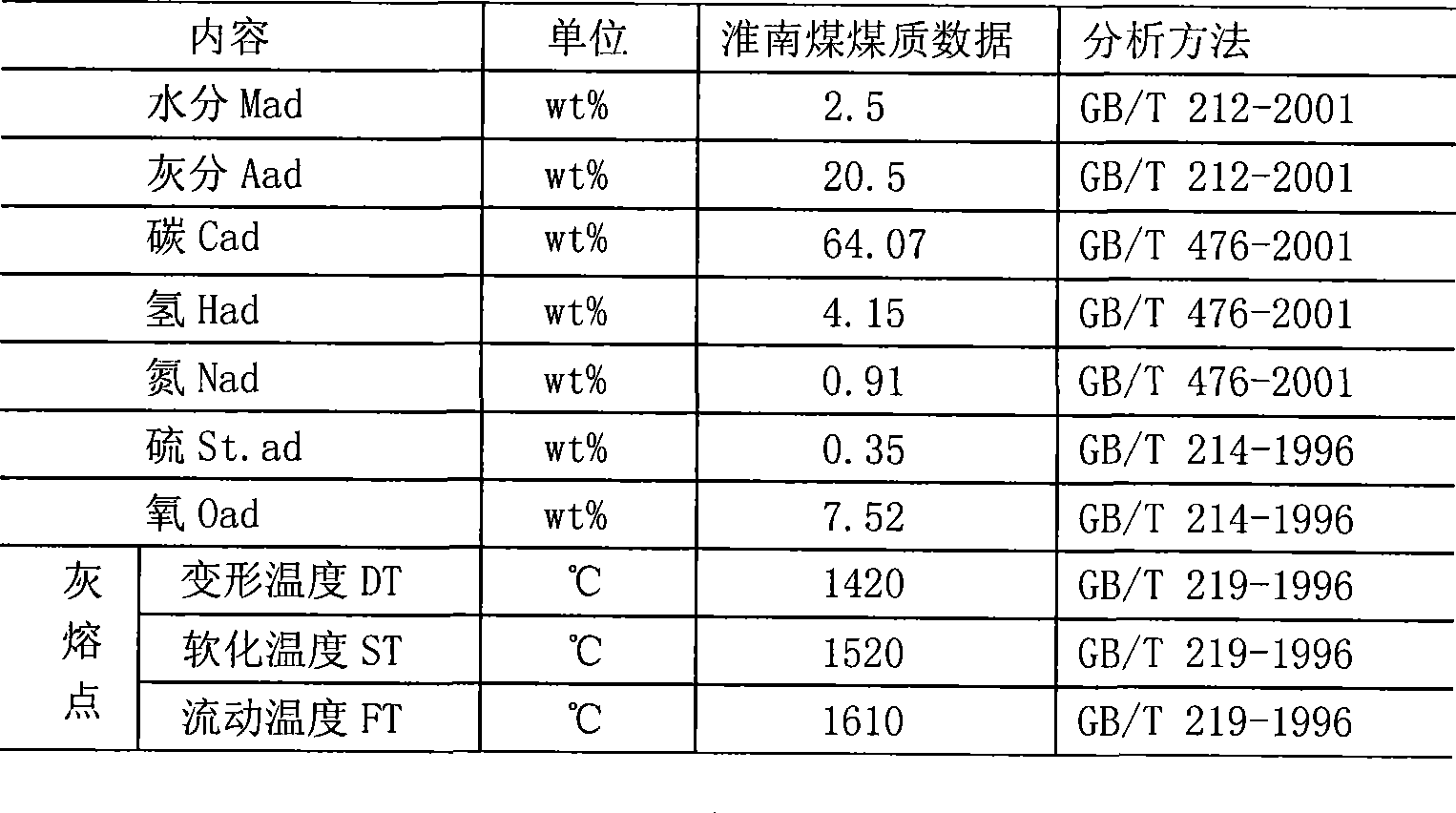

[0040] Embodiment 1: According to the method of the present invention, Huainan coal with high ash content and high ash melting point is used as raw material to produce synthesis gas.

[0041] The coal quality data analysis of Huainan coal is listed in Table 1 below.

[0042] Table 1

[0043]

[0044] The present invention was carried out using the coal described in Table 1 as the main raw material. It can be seen from the above table that the softening temperature (ST) of the coal is 1520°C, so the selected gasification temperature is 1300°C. According to the gasification method of the present invention, the Huainan high ash content and high ash melting point coal gasification method is carried out under the conditions of an operating pressure of 4.0 MPa and a gasification temperature of 1300°C.

[0045] Put Huainan coal with high ash content and high ash melting point after crushing, mix it with water and sodium lignin sulfonate additive aqueous solution into the mill (1...

Embodiment 2

[0051] Embodiment 2 (comparison)

[0052] The above-mentioned Huainan coal was used, and the gasification technology of liquid slag discharge in the prior art was adopted, that is, the gasification technology of adding flux and increasing the gasification temperature was used to carry out the same test as before.

[0053] The existing liquid slagging technology adopts the method of adding flux to lower the gasification temperature.

[0054] This embodiment requires the use of a large amount of flux, the amount of flux added is 50% (weight) of the ash content, the operating temperature of the gasification reactor is 1400°C, and the gasification pressure is 4.0Mpa.

[0055] Analyze according to GB / T17132-1997. The effective gas in the syngas (CO+H 2 ) is 77.65%, producing 1000Nm 3 (CO+H 2 ) coal consumption is 753kg, production is 1000Nm 3 (CO+H 2 ) Oxygen consumption is 456Nm 3 .

[0056] The prior art adopts a liquid slagging gasification method of increasing the gasific...

Embodiment 3

[0058] Embodiment 3: The present invention is carried out using Huainan coal with high ash content and high ash melting point in Embodiment 1.

[0059] Carry out in the same manner as in Example 1, except that the gasification conditions in this example are gasification pressure 4.0 MPa and gasification temperature 1250°C.

[0060] The effective gas components obtained in this embodiment were analyzed according to GB / T17132-1997, and the data analysis results are listed in Table 3 below.

[0061] table 3

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com