Patents

Literature

456results about "Tar working-up by chemical refining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for converting carbon-based energy carrier material

InactiveUS20090308787A1Thermal non-catalytic crackingCatalytic crackingPtru catalystPhysical chemistry

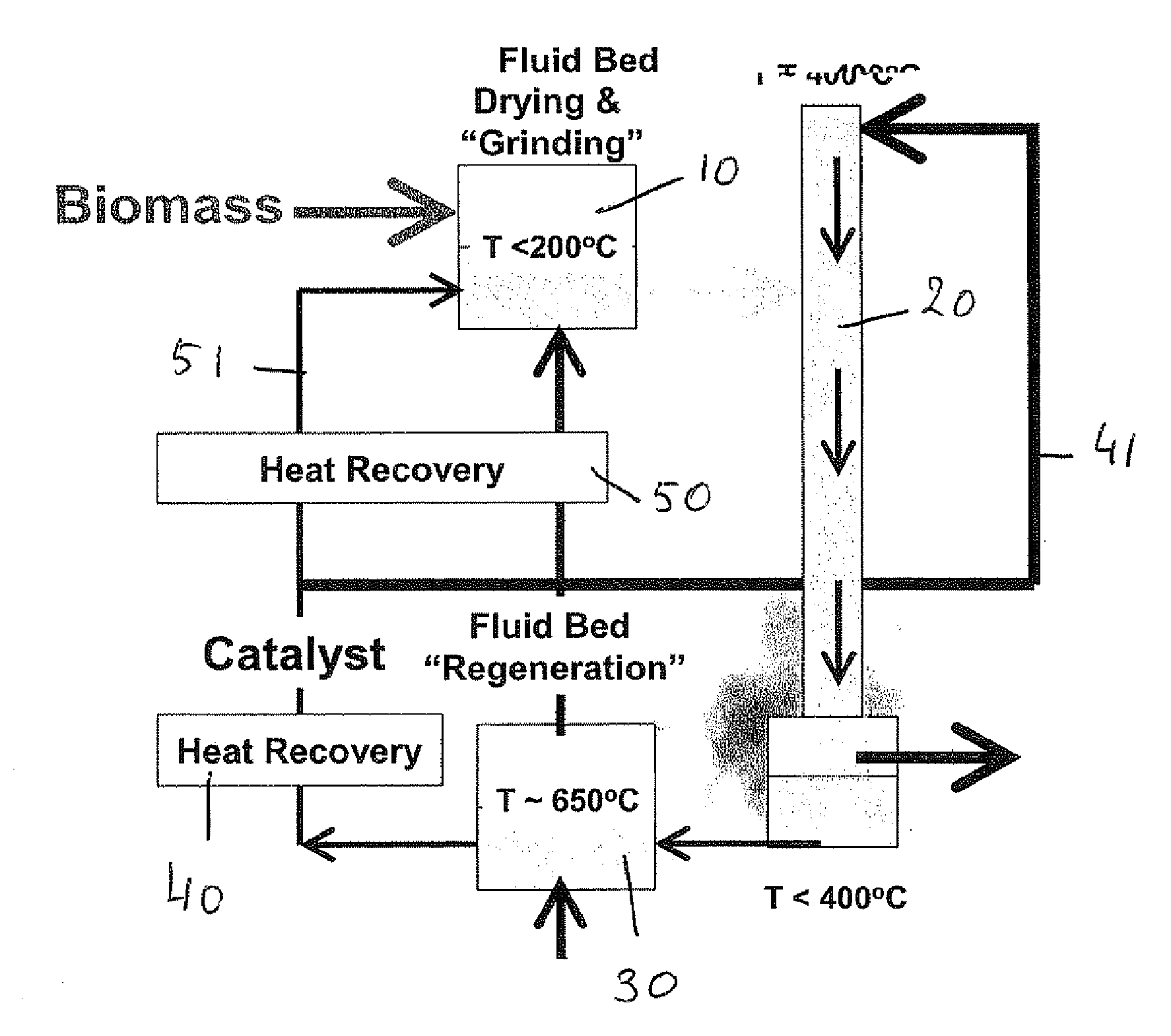

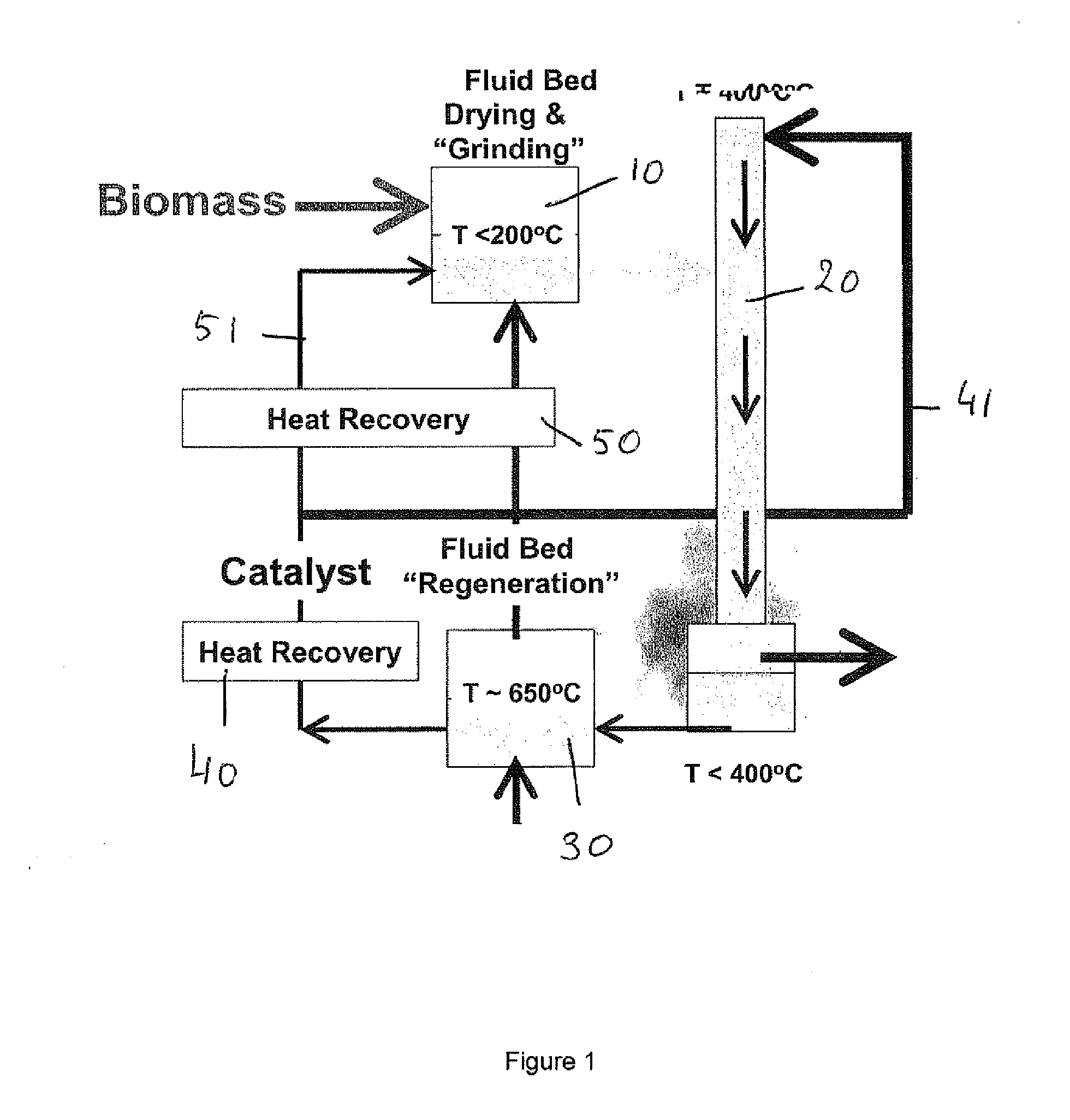

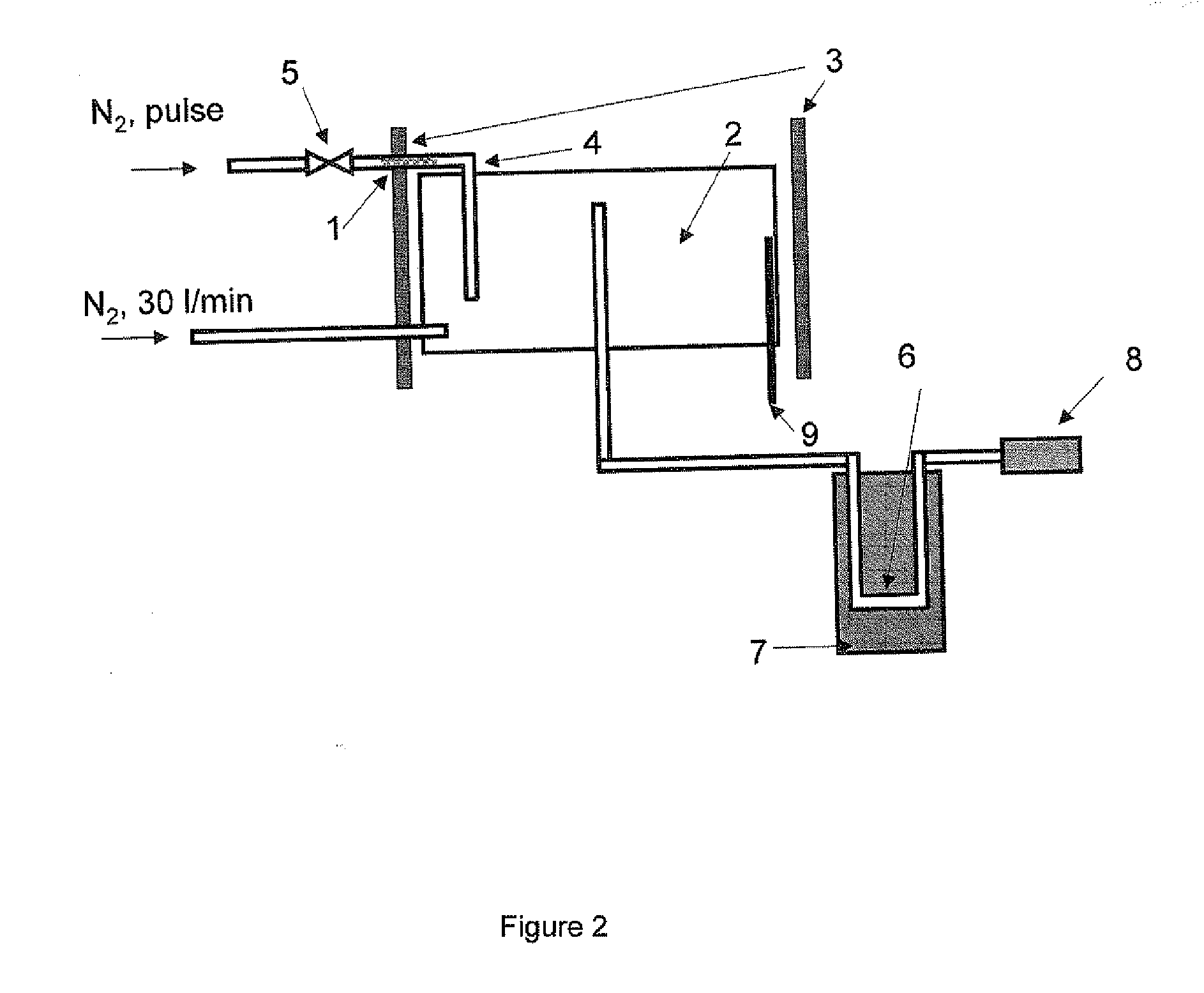

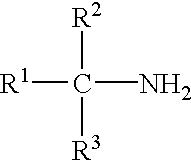

A process is disclosed process for converting a solid or highly viscous carbon-based energy carrier material to liquid and gaseous reaction products, said process comprising the steps of: a) contacting the carbon-based energy carrier material with a particulate catalyst material b) converting the carbon-based energy carrier material at a reaction temperature between 200° C. and 450° C., preferably between 250° C. and 350° C., thereby forming reaction products in the vapor phase. In a preferred embodiment the process comprises the additional step of: c) separating the vapor phase reaction products from the particulate catalyst material within 10 seconds after said reaction products are formed; In a further preferred embodiment step c) is followed by: d) quenching the reaction products to a temperature below 200° C.

Owner:MARD INC

Upgrading of tar using POX/coker

ActiveUS8083931B2Reduce and eliminate needThermal non-catalytic crackingTreatment with plural serial cracking stages onlyNaphthaPartial oxidation

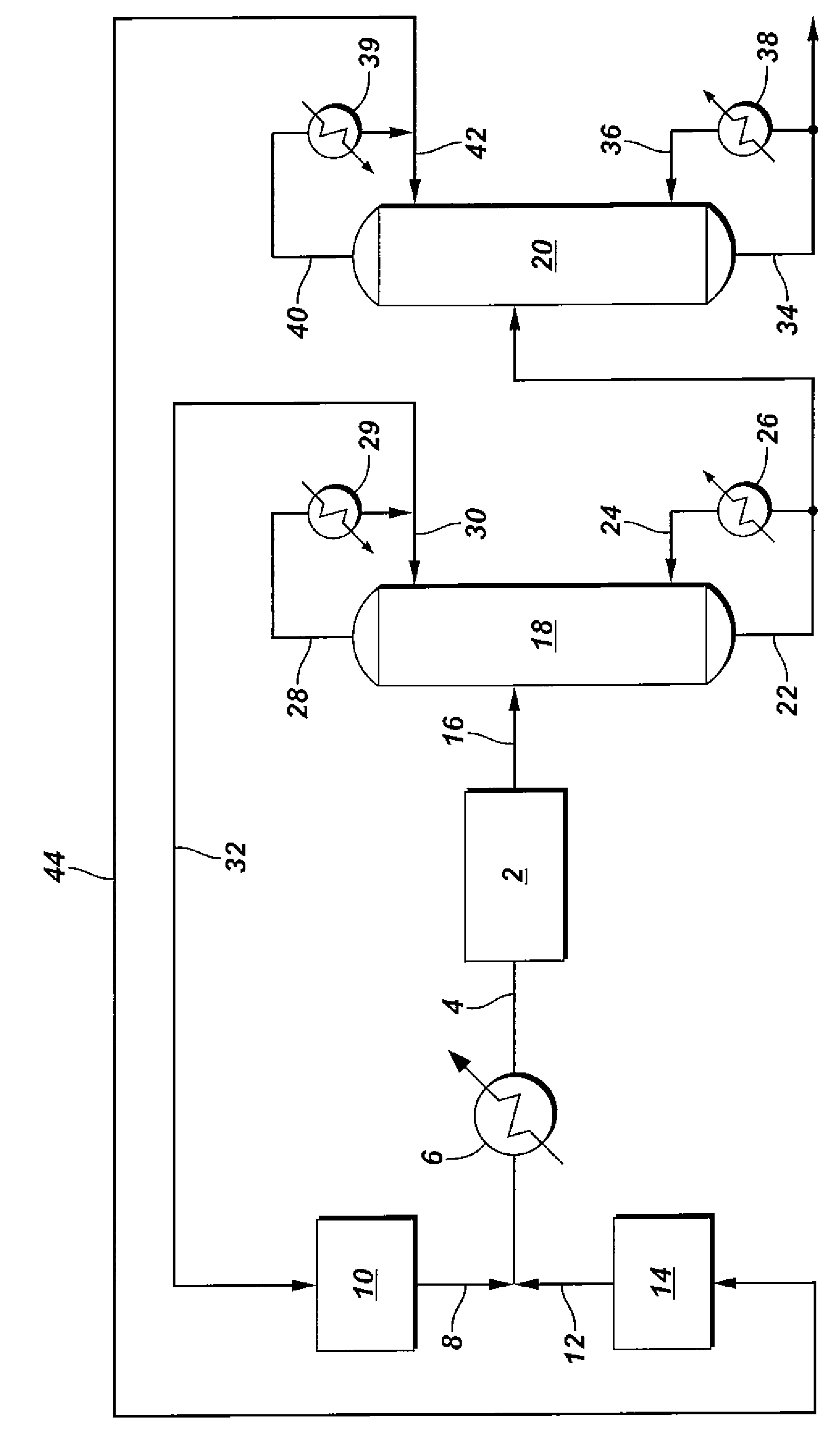

The invention is directed to a process wherein a feedstock or stream comprising steam cracker tar is passed to a vacuum pipestill. A deasphalted cut of tar is obtained as an overhead (or sidestream) and a heavy tar asphaltenic product is obtained as bottoms. In preferred embodiments, at least a portion of the bottoms product is sent to a partial oxidation unit (POX) wherein syn gas may be obtained as a product, and / or at least a portion of the bottoms product is used to produce a light product stream in a coker unit, such as coker naphtha and / or or coker gas oil. In another preferred embodiment at least a portion of the overheads product is added to refinery fuel oil pools and in yet another preferred embodiment at least a portion of the overheads product is mixed with locally combusted materials to lower soot make. Two or more of the aforementioned preferred embodiments may be combined.

Owner:EXXONMOBIL CHEM PAT INC

Compositions and methods of using same in producing heavy oil and bitumen

InactiveUS7691788B2Maximize the effectLarge volumeWorking-up pitch/asphalt/bitumen by chemical meansFluid removalFuel oilSolvent

Owner:SCHLUMBERGER TECH CORP

Compositions and Methods of Using Same in Producing Heavy Oil and Bitumen

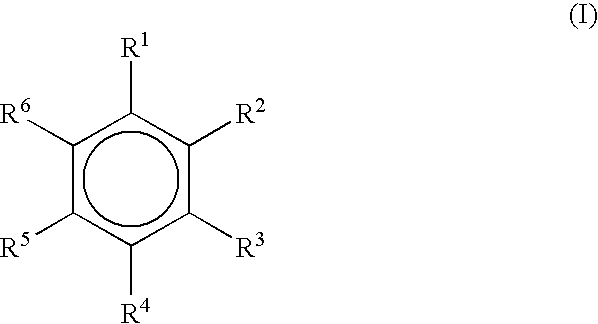

InactiveUS20070295640A1Reduce energy consumptionMinimal heat lossWorking-up pitch/asphalt/bitumen by chemical meansFluid removalFuel oilSolvent

deposition in a formation, wellbore, near wellbore region, and production tubing. Compositions of the invention comprise an asphaltene solvent and a viscosity reducing agent, the asphaltene solvent and viscosity reducing agent present in a ratio so as to substantially reduce viscosity of an asphaltene-containing material while substantially negating deposition of asphaltenes either in a reservoir, in production tubing, or both when mixed or otherwise contacting the asphaltene-containing material Methods of the invention comprise forcing a composition comprising an asphaltene solvent and a viscosity reducing agent to contact an asphaltene-containing hydrocarbon in an underground geologic formation, and producing from the formation a production composition comprising at least some of the treatment composition and at least some of the asphaltene-containing hydrocarbon under conditions sufficient to substantially negate deposition of asphaltenes in the formation.

Owner:SCHLUMBERGER TECH CORP

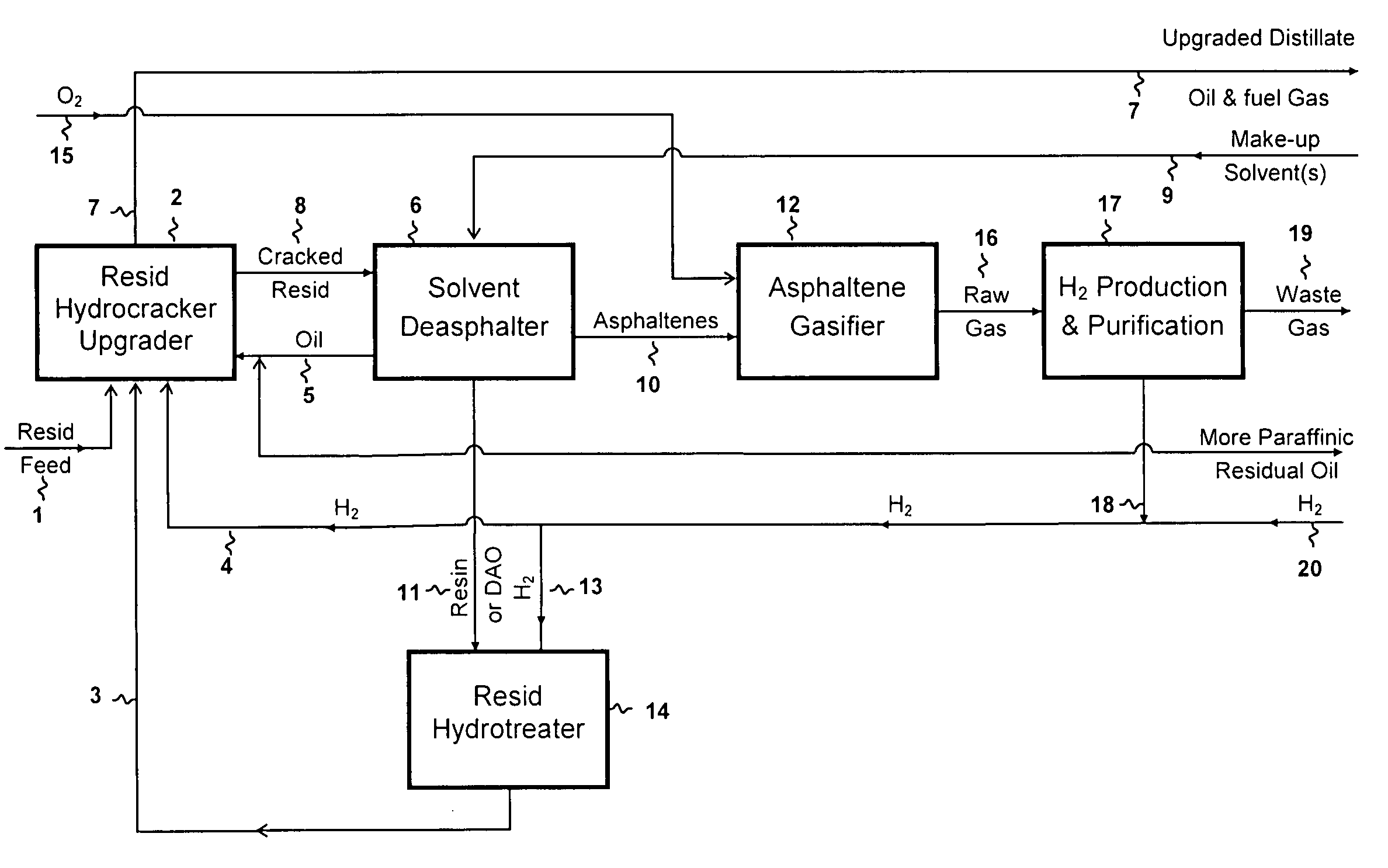

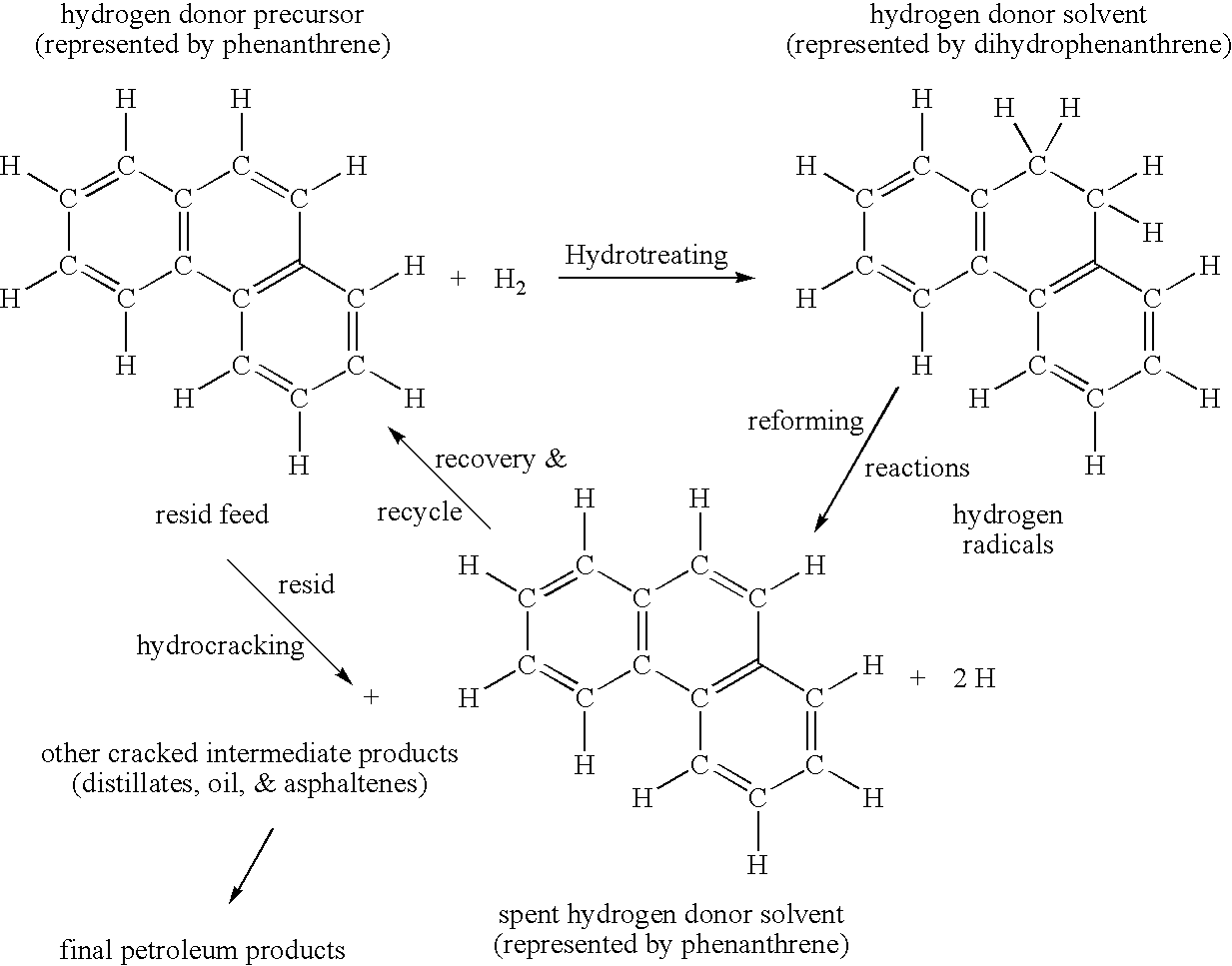

Hydrogen donor solvent production and use in resid hydrocracking processes

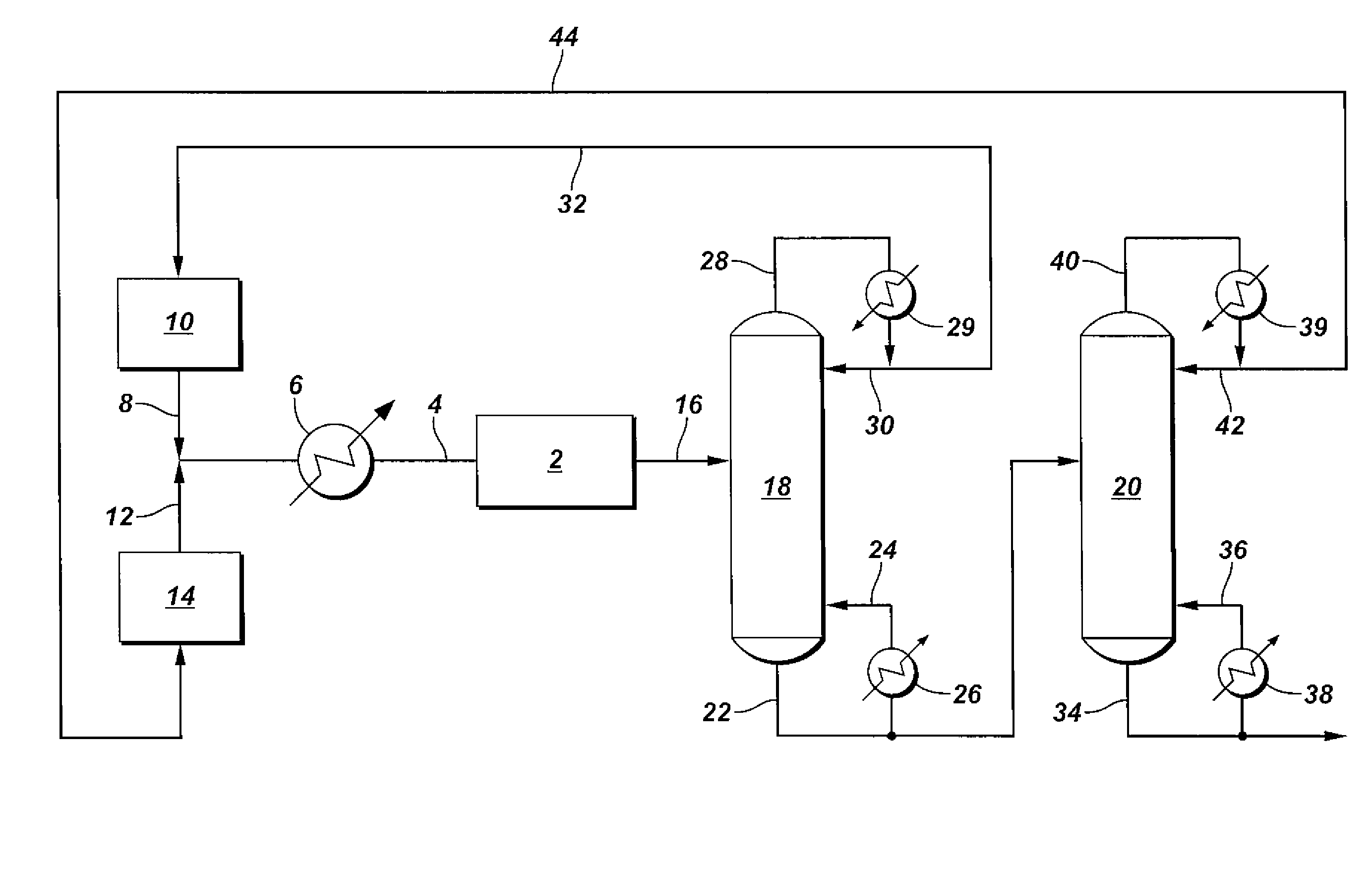

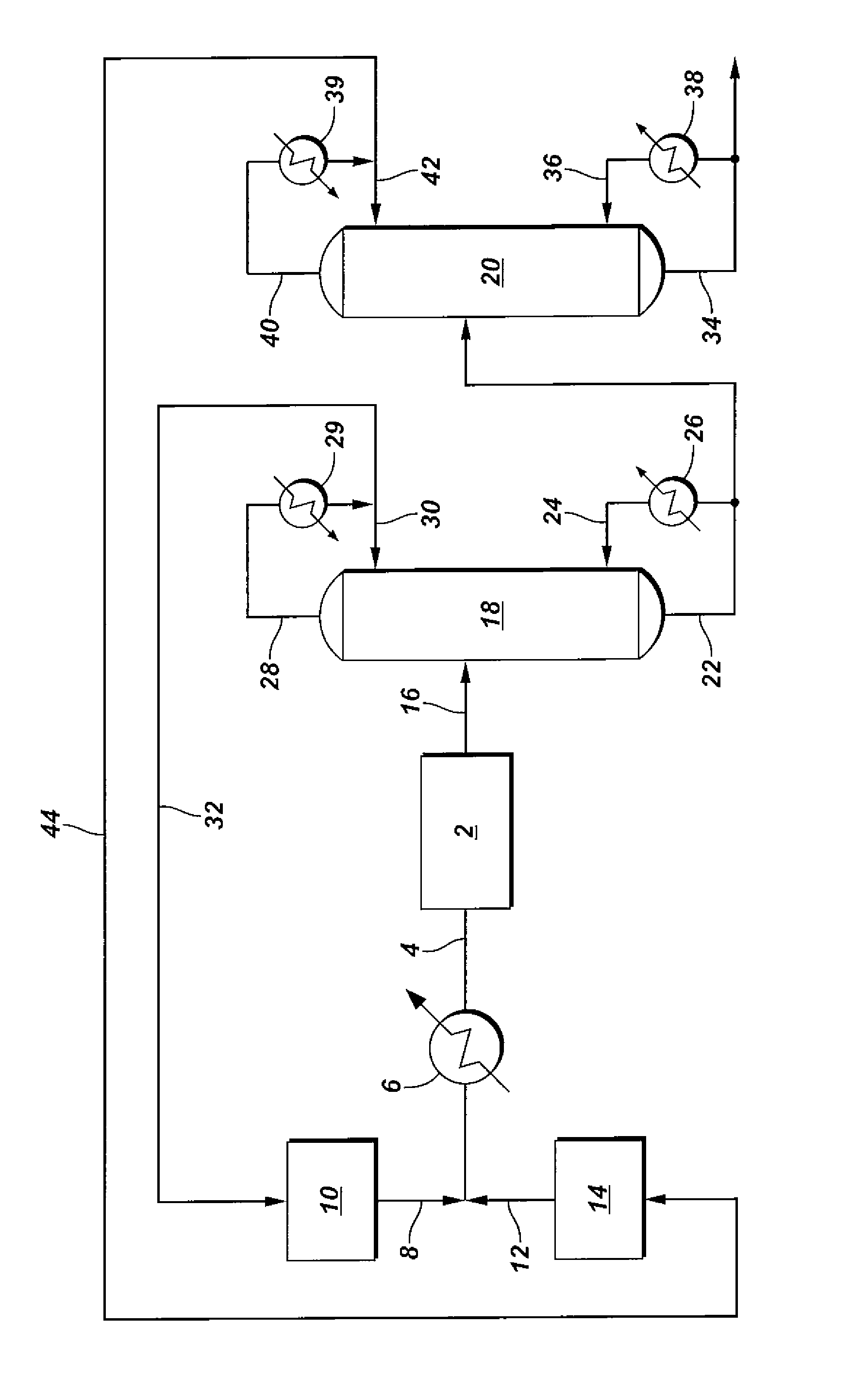

InactiveUS20070108100A1Treatment with plural serial cracking stages onlyCoke ovensHydrogenBoiling point

A process derived hydrogen donor solvent is used to increase the maximum resid conversion and conversion rate in an ebullated bed resid hydrocracker. The hydrogen donor solvent precursor is produced by hydroreforming reactions within the resid hydrocracker, recovered as the resin fraction from a solvent deasphalting unit, regenerated in a separate hydrotreater reactor, and recycled to the ebullated bed resid hydrocracker. The major advantage of this invention relative to earlier processes is that hydrogen is more efficiently transferred to the resin residual oil in the separate hydrotreater and the hydrogen donor solvent effectively retards the formation of coke precursors at higher ebullated bed resid hydrocracker operating temperatures and resid cracking rates.

Owner:BOC GRP INC

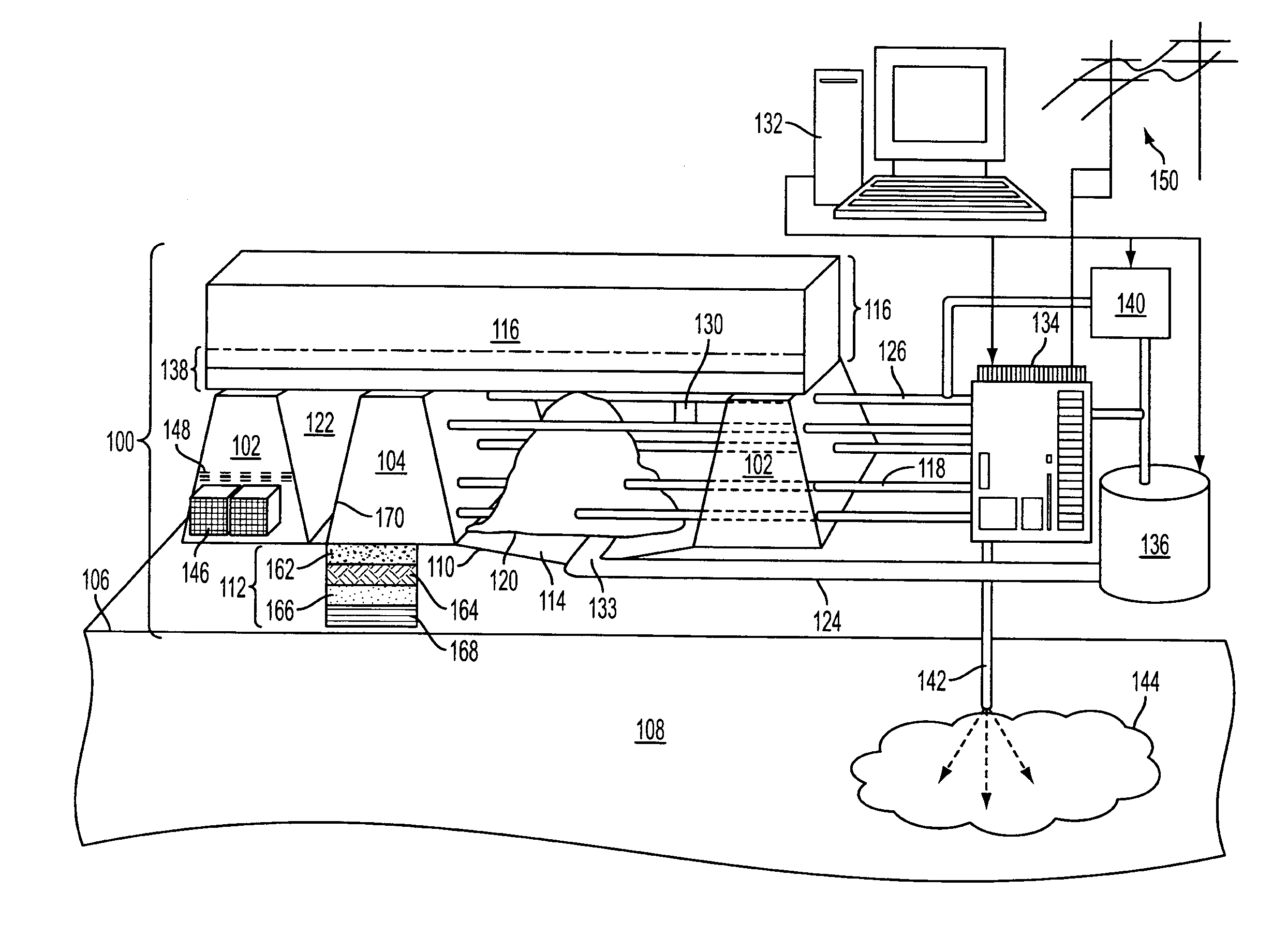

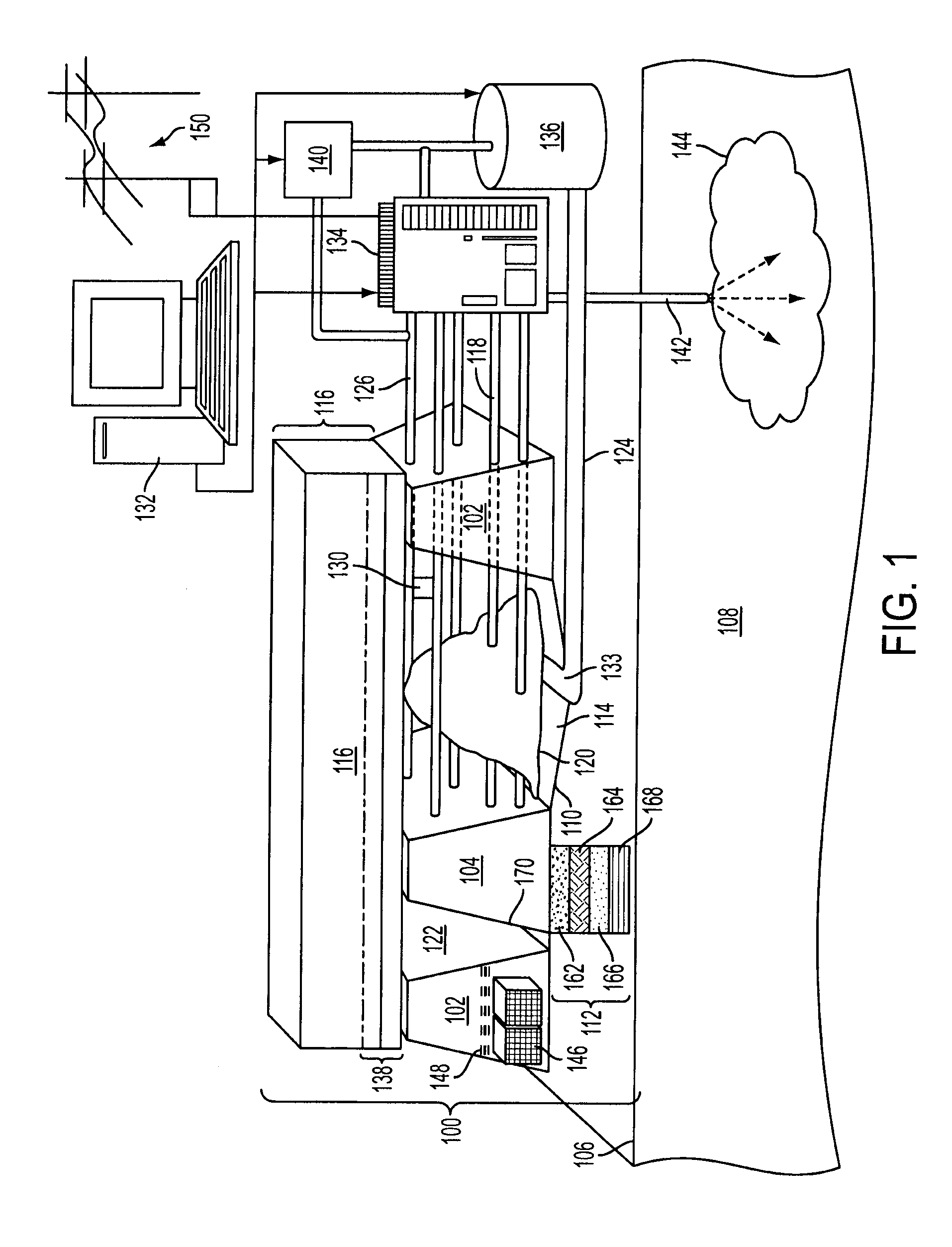

Methods of recovering hydrocarbons from hydrocarbonaceous material using a constructed infrastructure and associated systems

ActiveUS20080190818A1Reduce processing costsIncrease volume outputThermal non-catalytic crackingSolid waste disposalEngineeringHydrocarbon

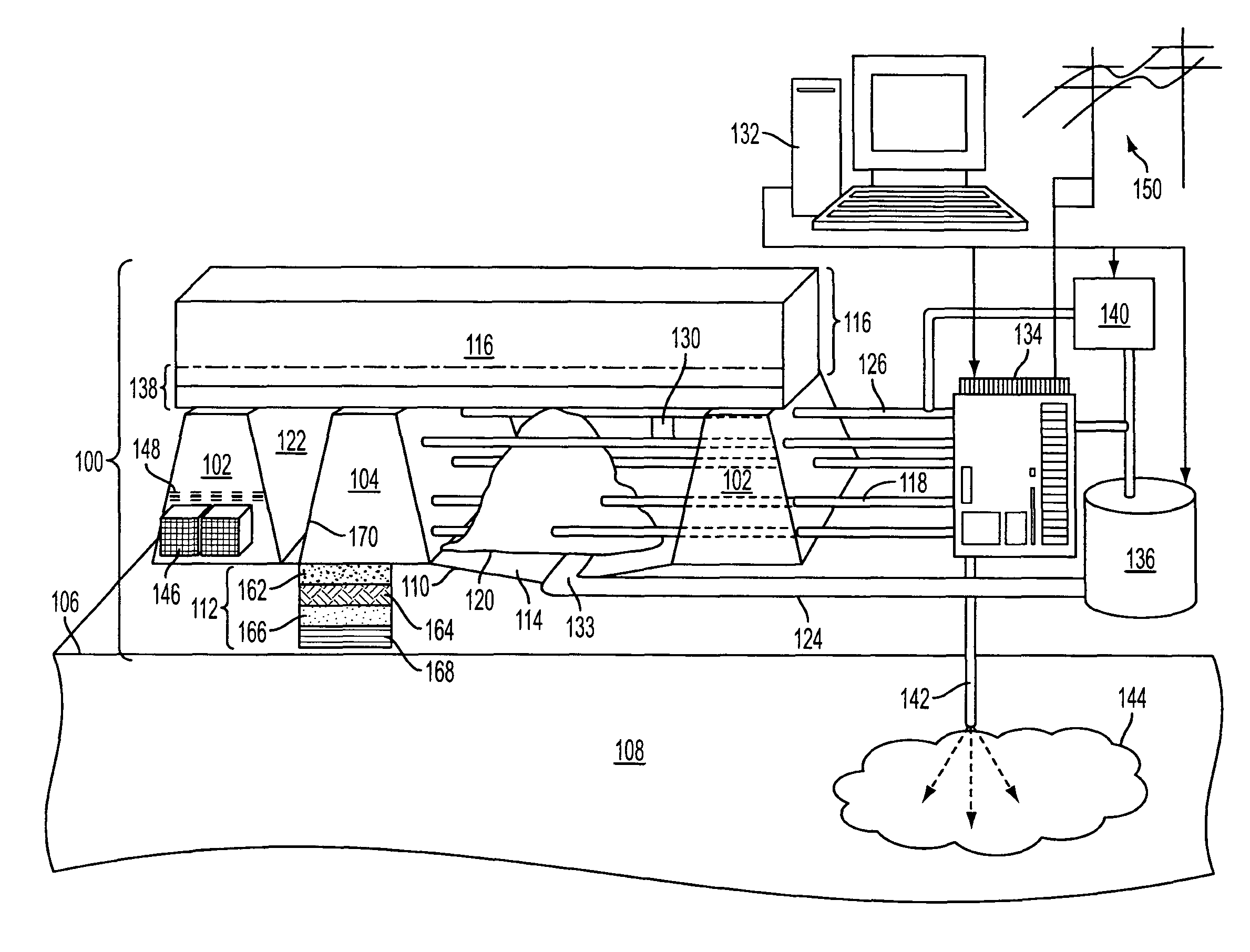

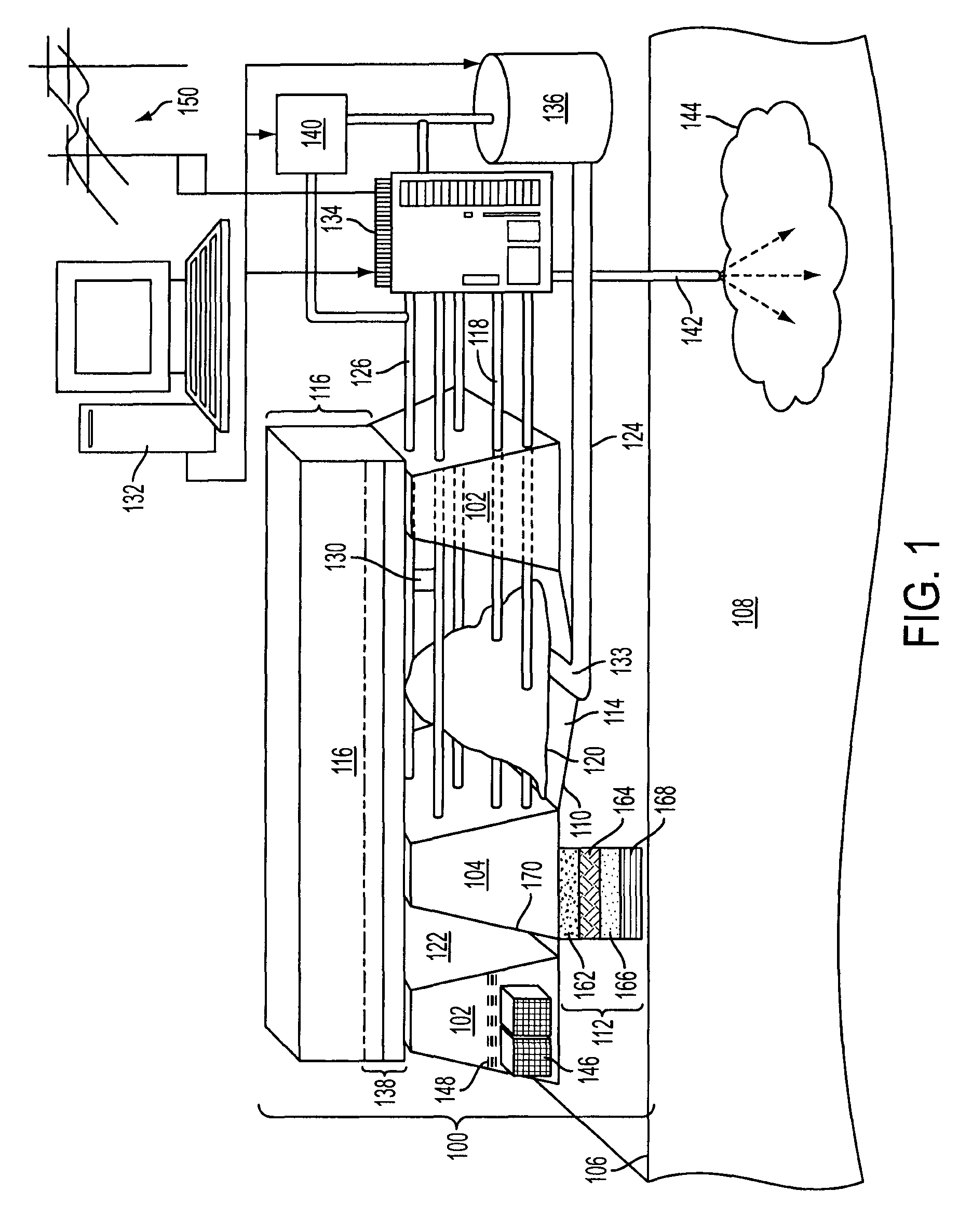

A method of recovering hydrocarbons from hydrocarbonaceous materials can include forming a constructed permeability control infrastructure. This constructed infrastructure defines a substantially encapsulated volume. A comminuted hydrocarbonaceous material can be introduced into the control infrastructure to form a permeable body of hydrocarbonaceous material. The permeable body can be heated sufficient to remove hydrocarbons therefrom. During heating the hydrocarbonaceous material is substantially stationary as the constructed infrastructure is a fixed structure. Removed hydrocarbons can be collected for further processing, use in the process, and / or use as recovered.

Owner:RED LEAF RESOURCES

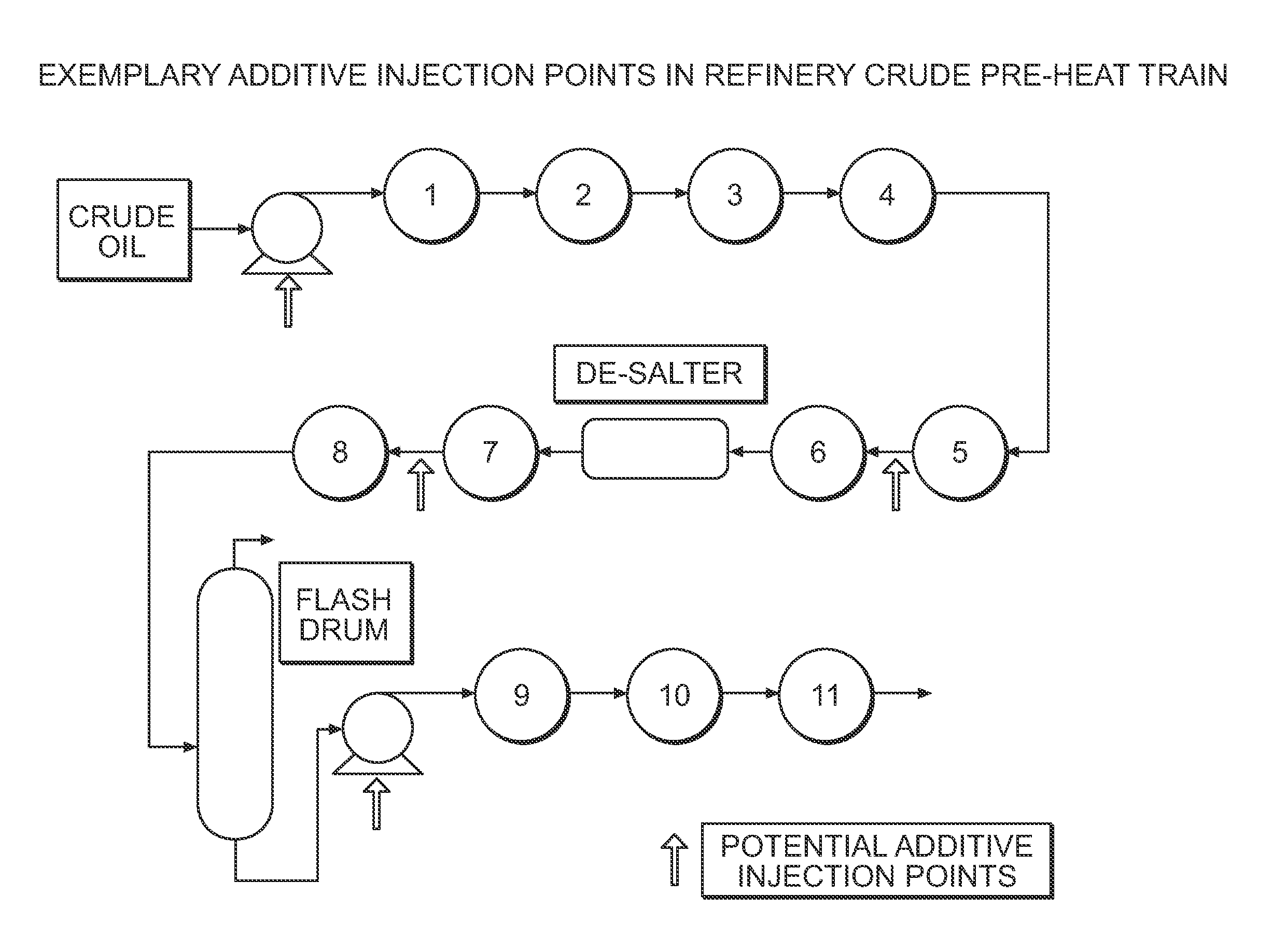

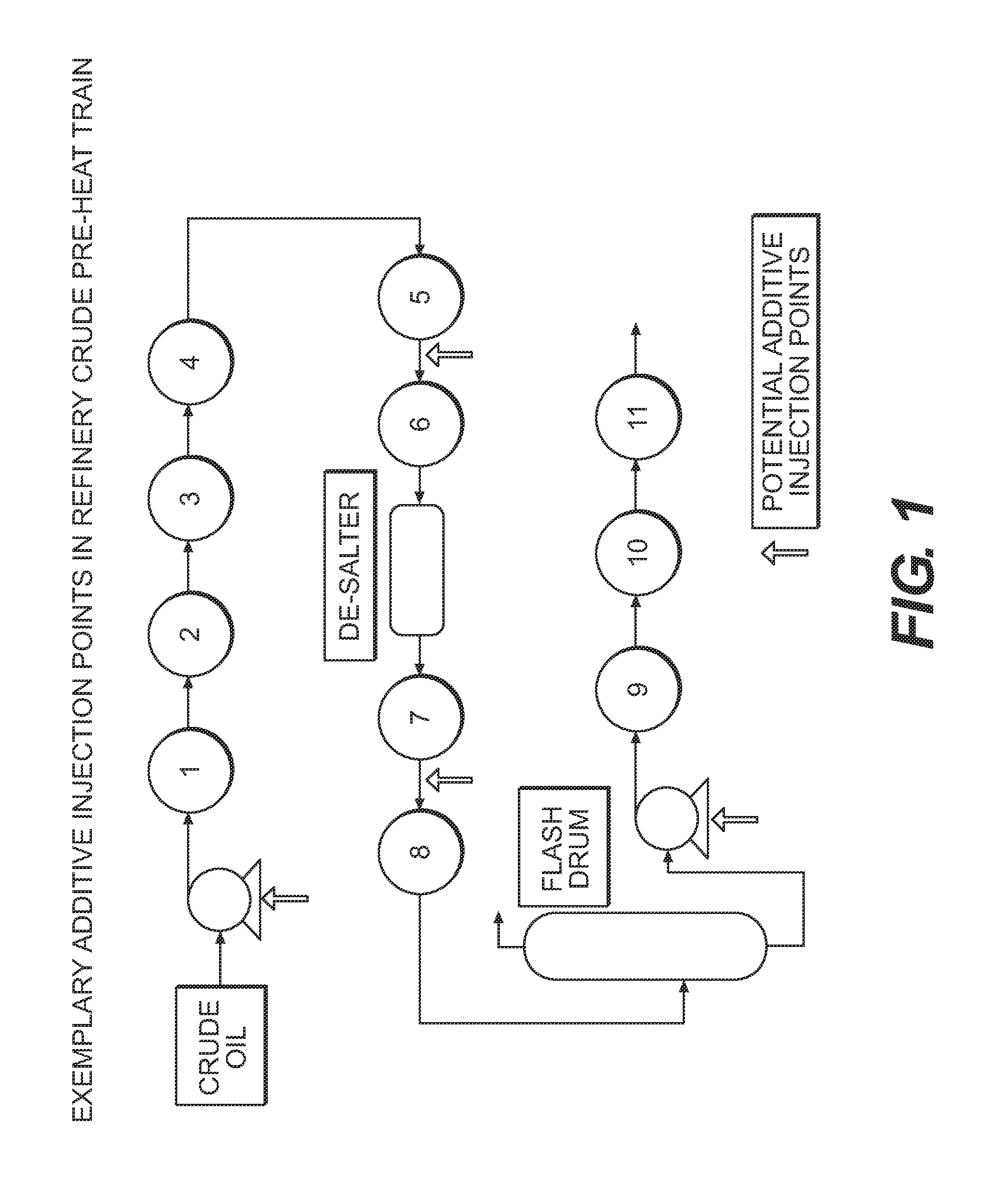

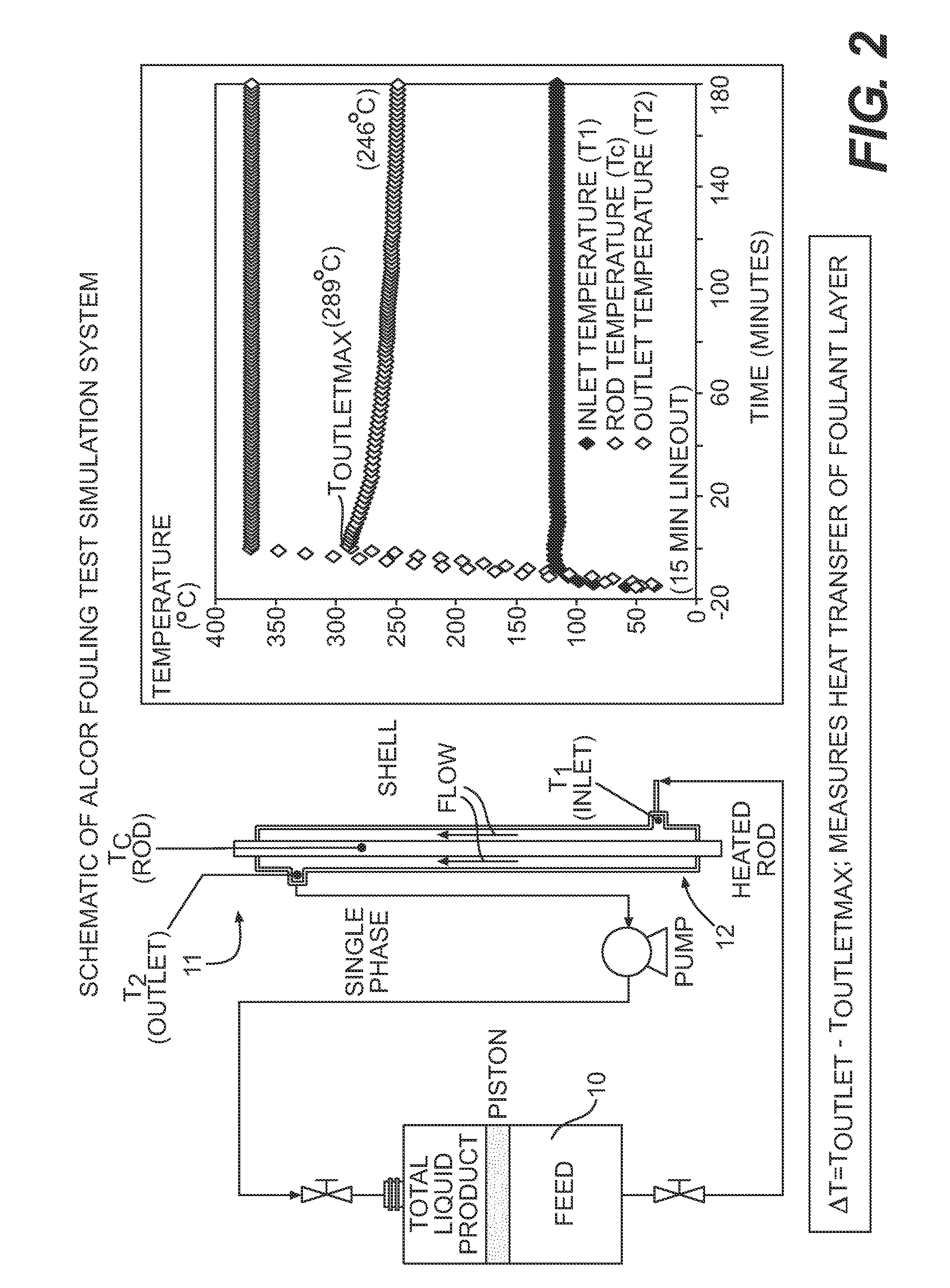

Polyalkyl succinic anhydride derivatives as additives for fouling mitigation in petroleum refinery processes

InactiveUS20100170829A1Thermal non-catalytic crackingOrganic chemistryParticulatesFouling mitigation

The present invention provides a method for reducing fouling, including particulate-induced fouling, in a hydrocarbon refining process including the steps of providing a crude hydrocarbon for a refining process; adding at least one polyalkyl succinic anhydride derivative additive disclosed herein. The additive can be complexed with a boronating agent, such as boric acid, to yield a boron-containing polyalkyl succinic anhydride derivative.

Owner:EXXON RES & ENG CO

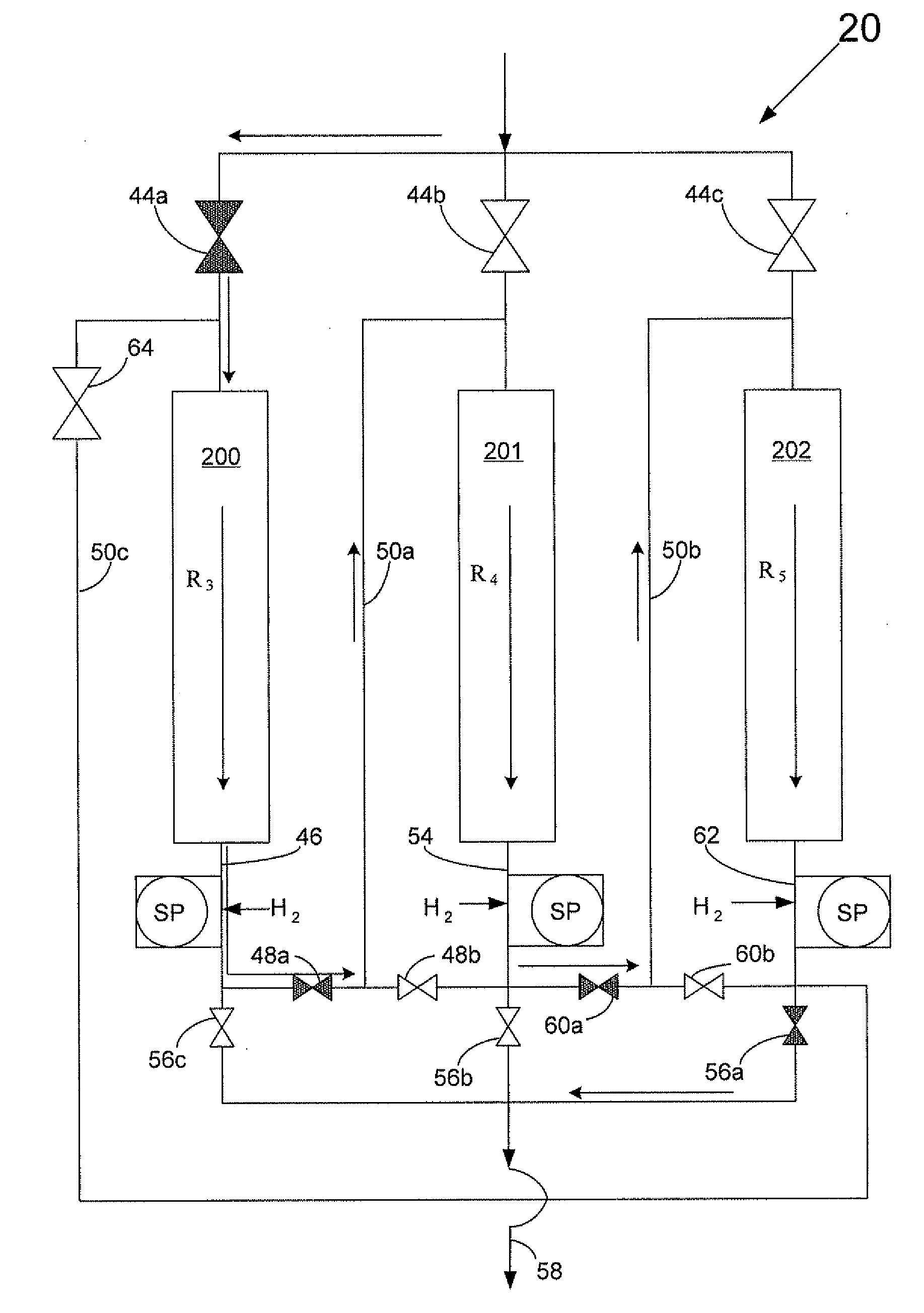

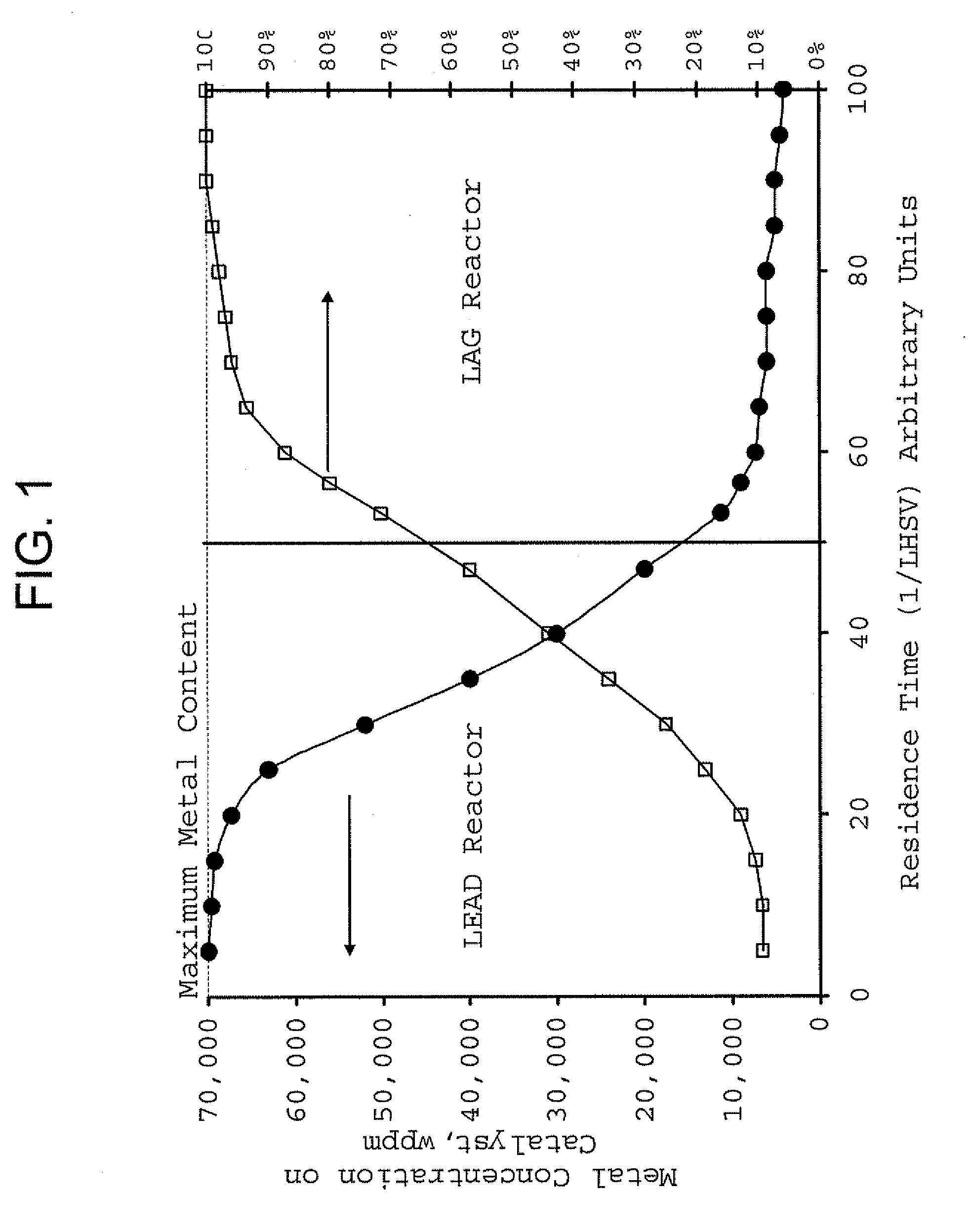

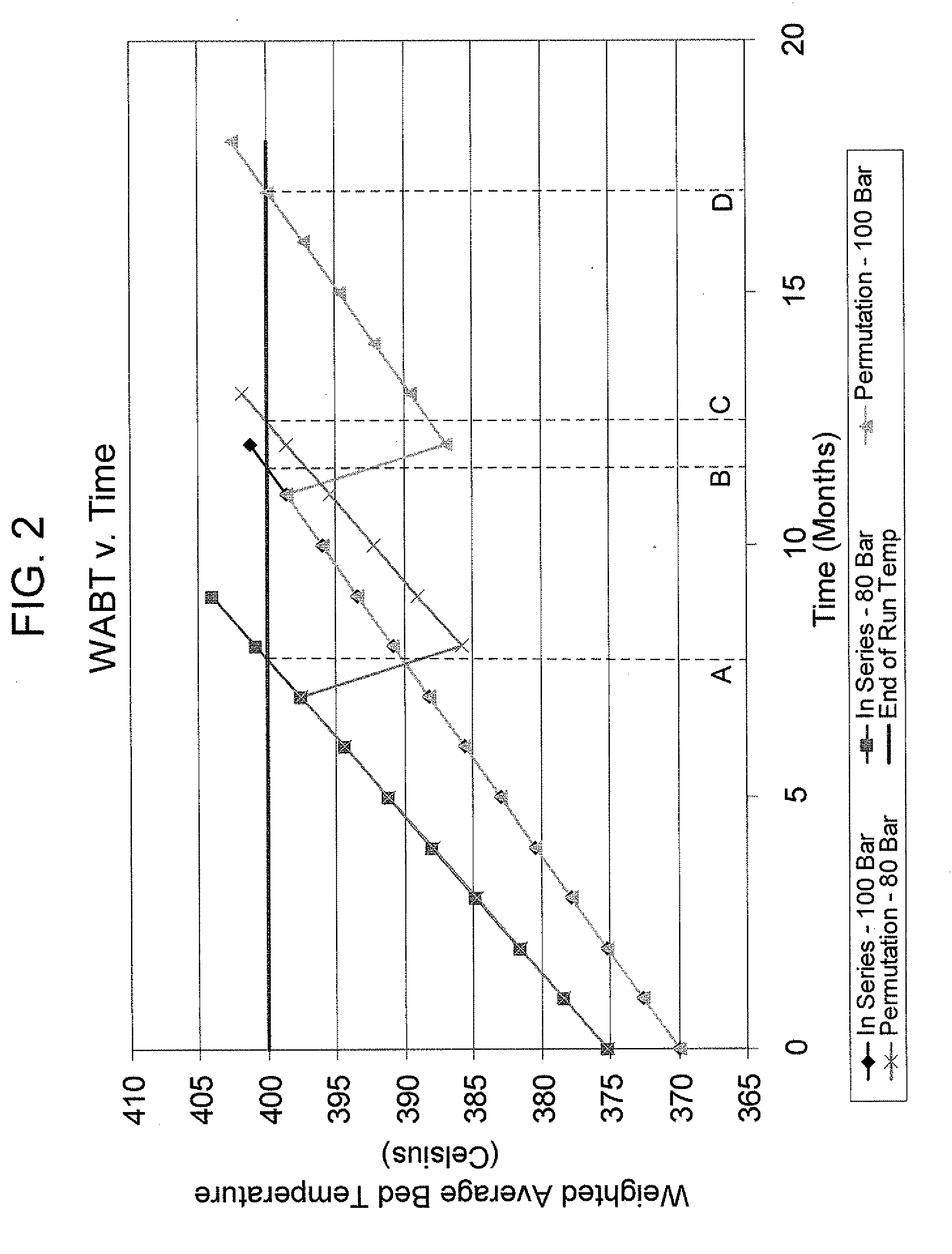

Process for catalytic hydrotreating of sour crude oils

ActiveUS20090139902A1Improve catalyst utilizationImproves HDS activityTreatment with hydrotreatment processesFilter regenerationHydrodesulfurizationSulfur

A continuous process for upgrading sour crude oil by treating the sour crude oil in a two step process that includes a hydro-demetallization section and a hydro-desulfurization section, both of which are constructed in a permutable fashion so as to optimize the operating conditions and catalyst lifespan to produce a high value crude oil having low sulfur and low organometallic impurities.

Owner:SAUDI ARABIAN OIL CO

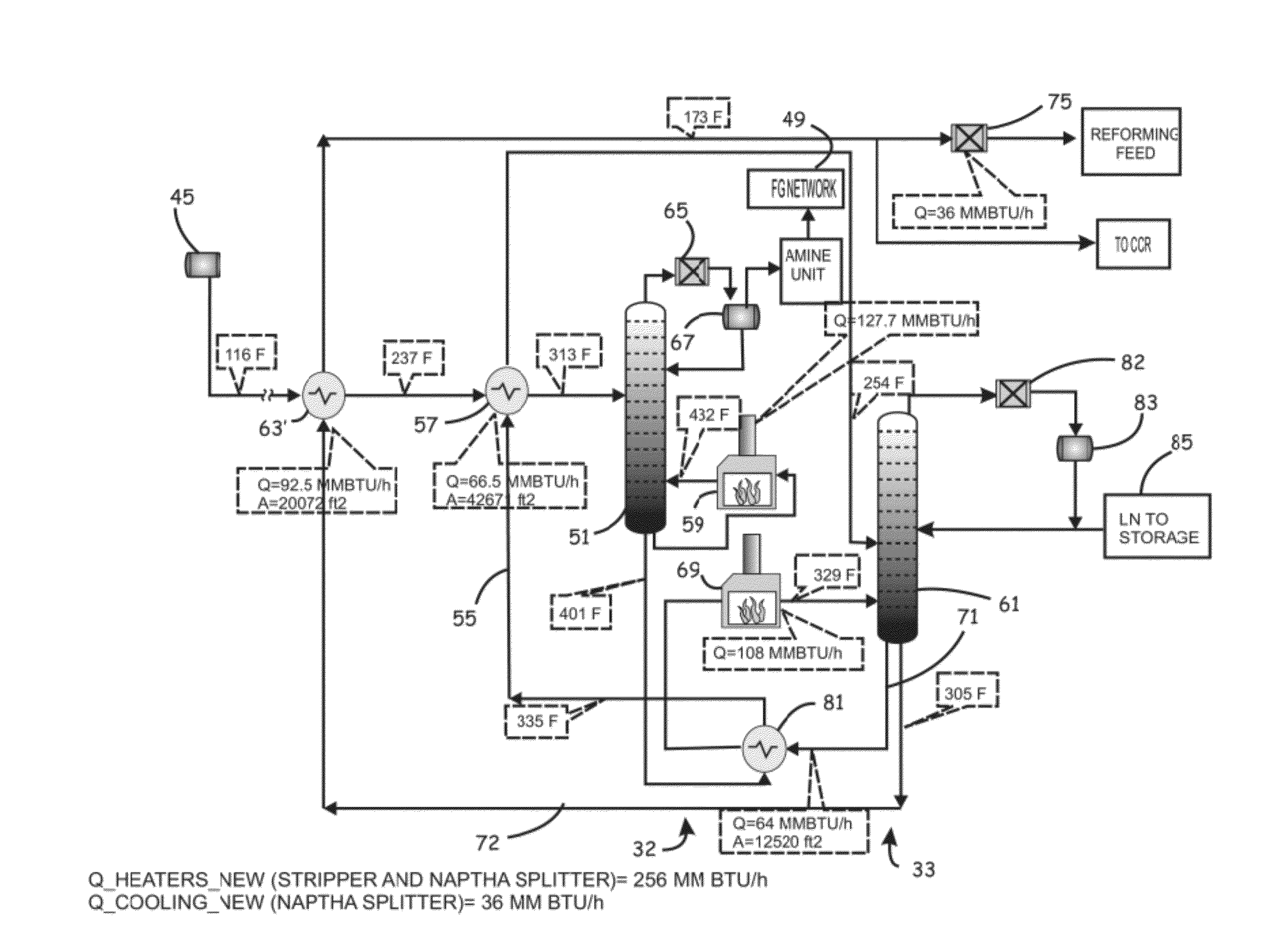

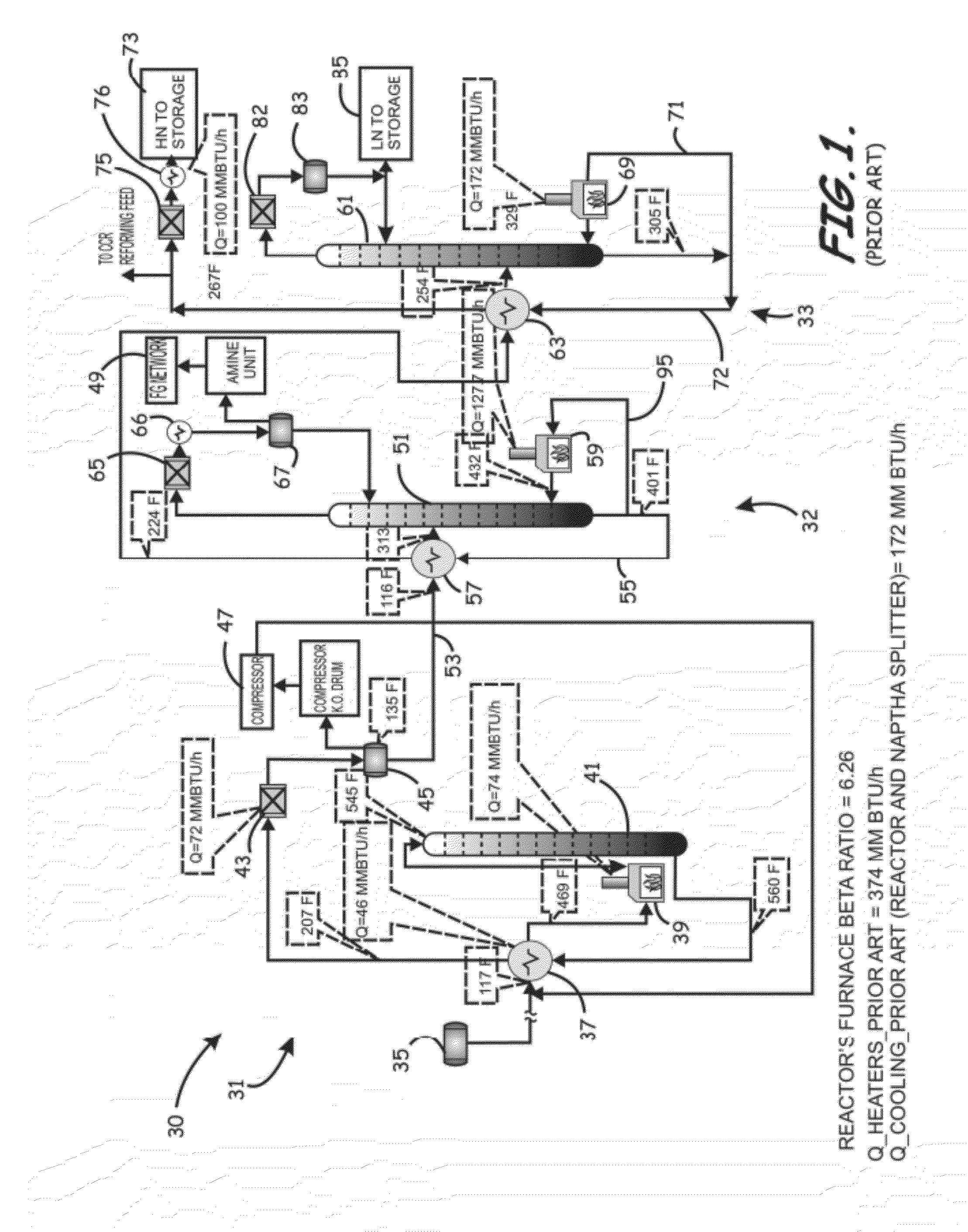

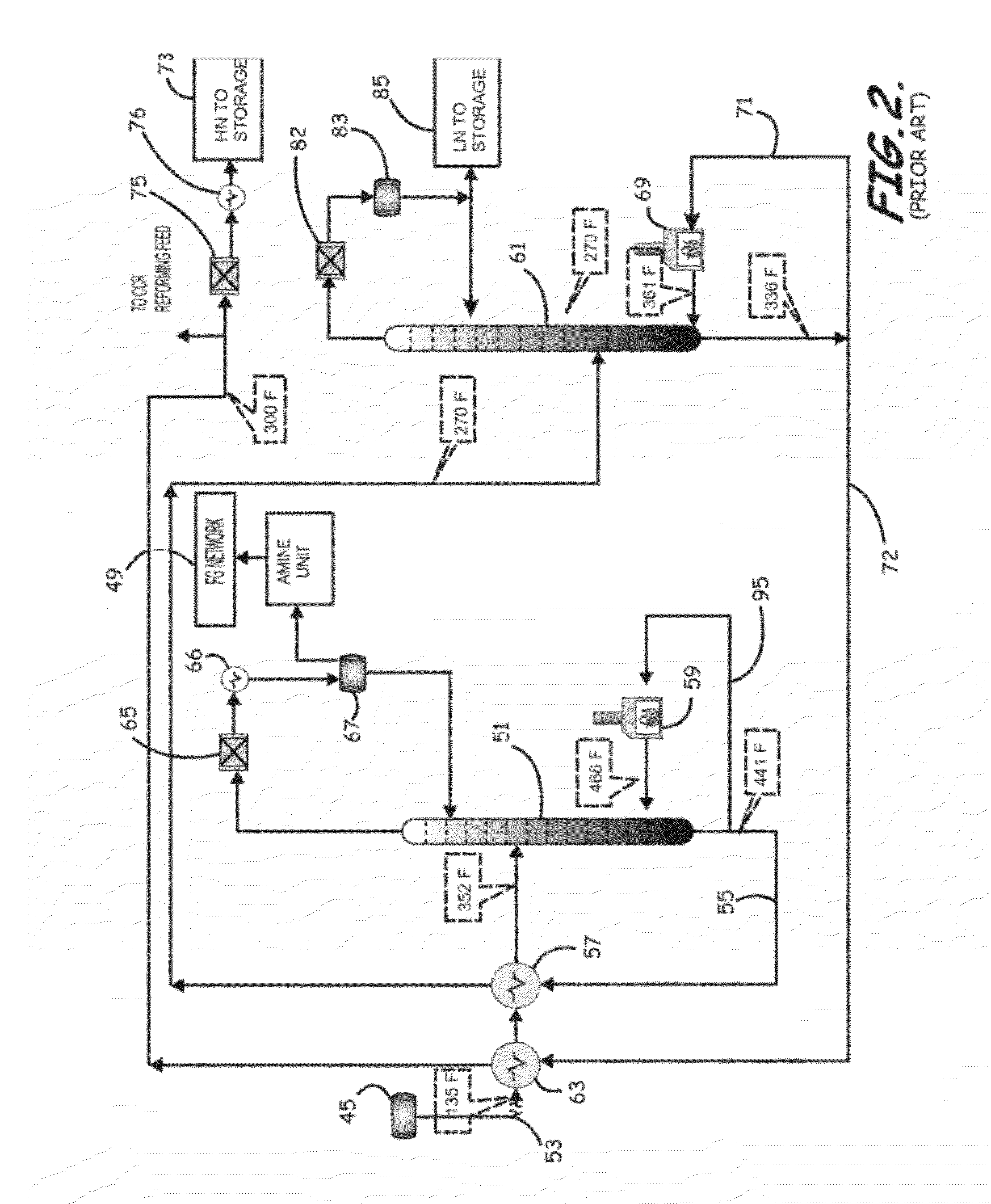

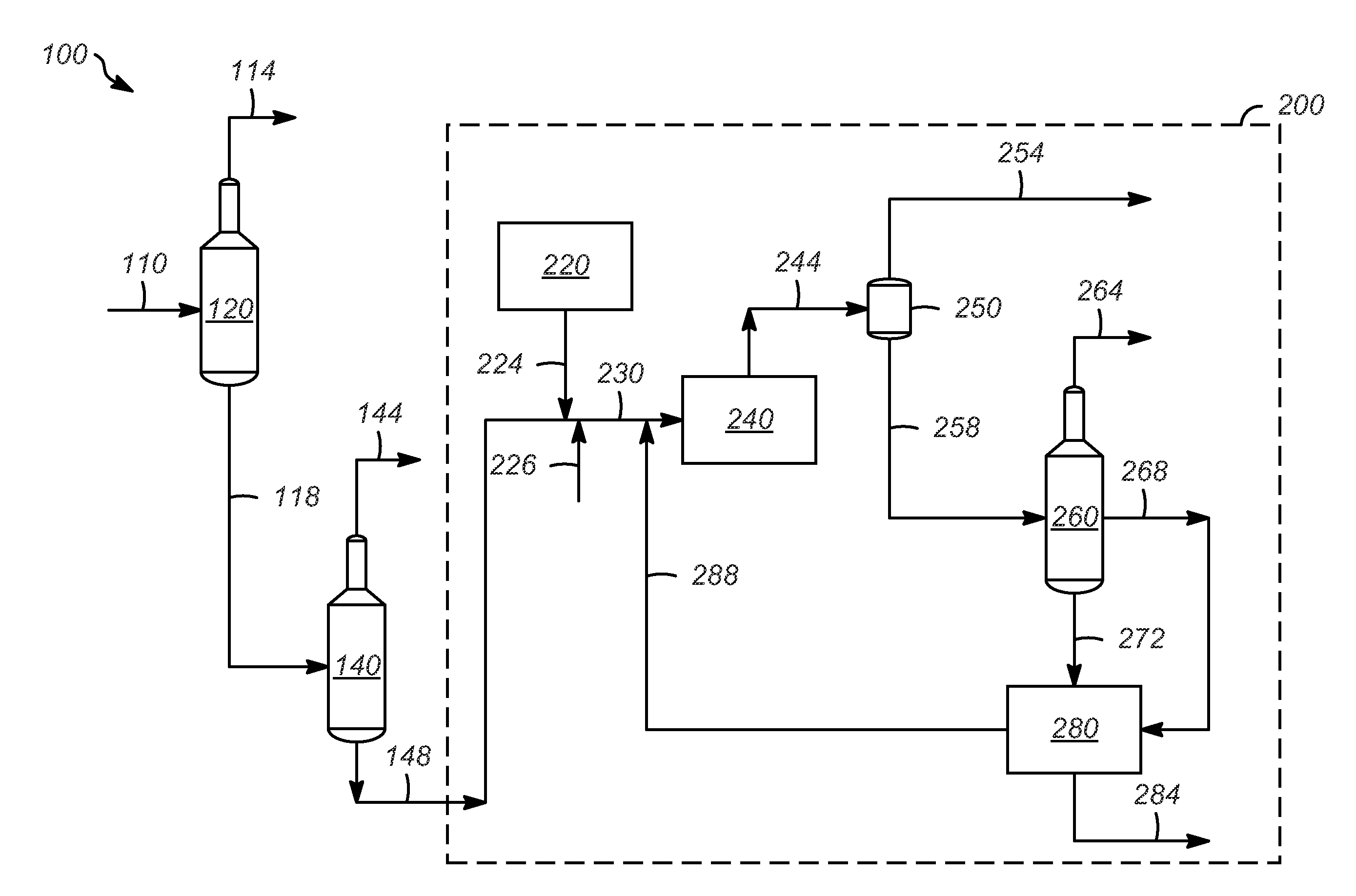

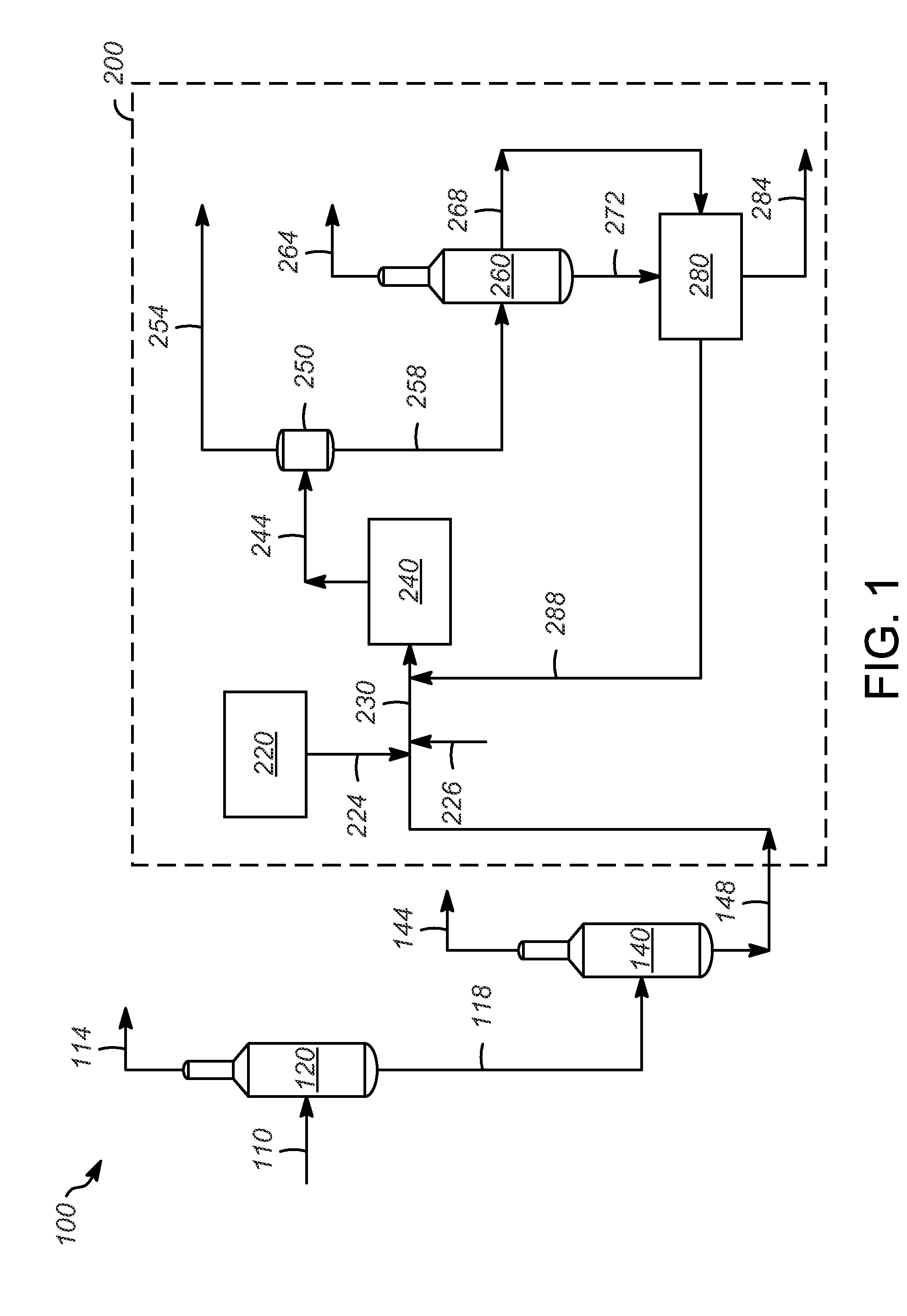

Energy-Efficient and Environmentally Advanced Configurations For Naptha Hydrotreating Process

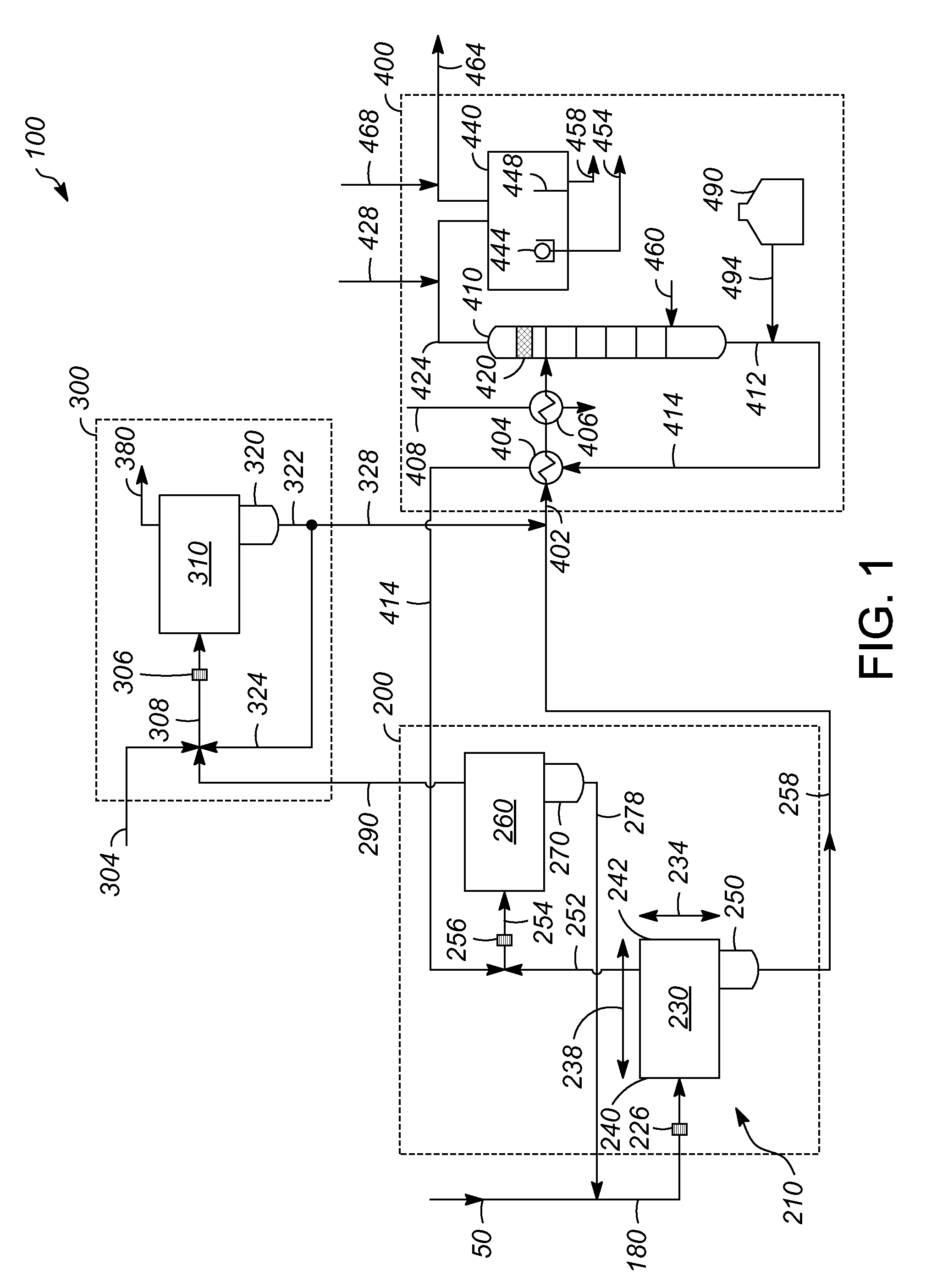

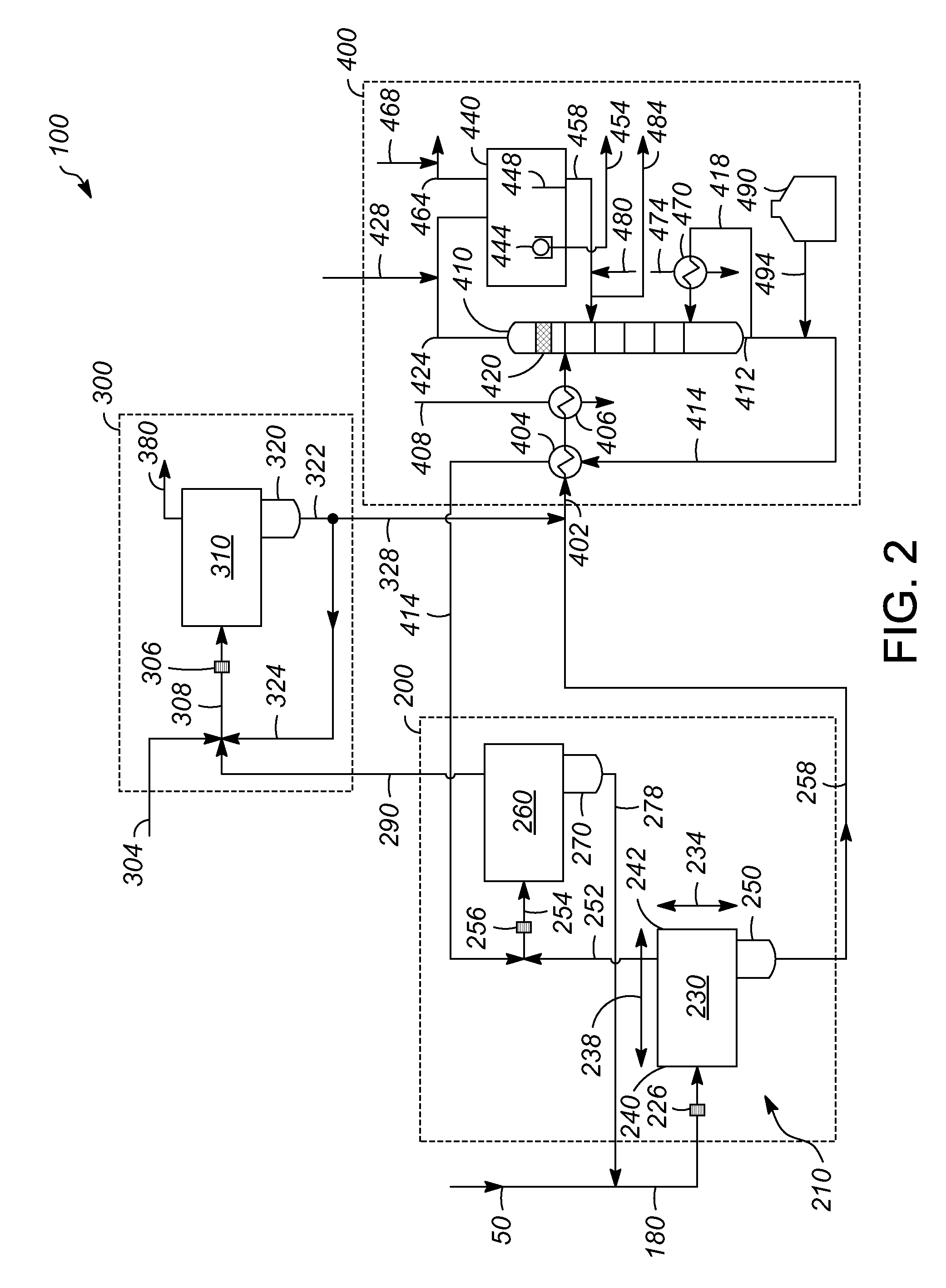

ActiveUS20120279900A1Less emissionsLower ratioRecuperative heat exchangersThermal naphtha reformingProcess systemsNaphtha

Systems and methods of hydrotreating different naphtha feed stocks destined for a refining reforming unit and other applications with less energy consumption than conventionally possible, while producing less greenhouse gas emissions, and / or using a lesser number of heaters and correspondingly less capital investment in such heaters, air coolers, and water coolers, are provided. According to the more examples of such systems and methods, such reductions are accomplished by directly integrating a naphtha stripping process section with a naphtha splitting process section. Additional reductions can also be accomplished through directly integrating a naphtha hydrotreat reaction process section with the naphtha stripping process section.

Owner:SAUDI ARABIAN OIL CO

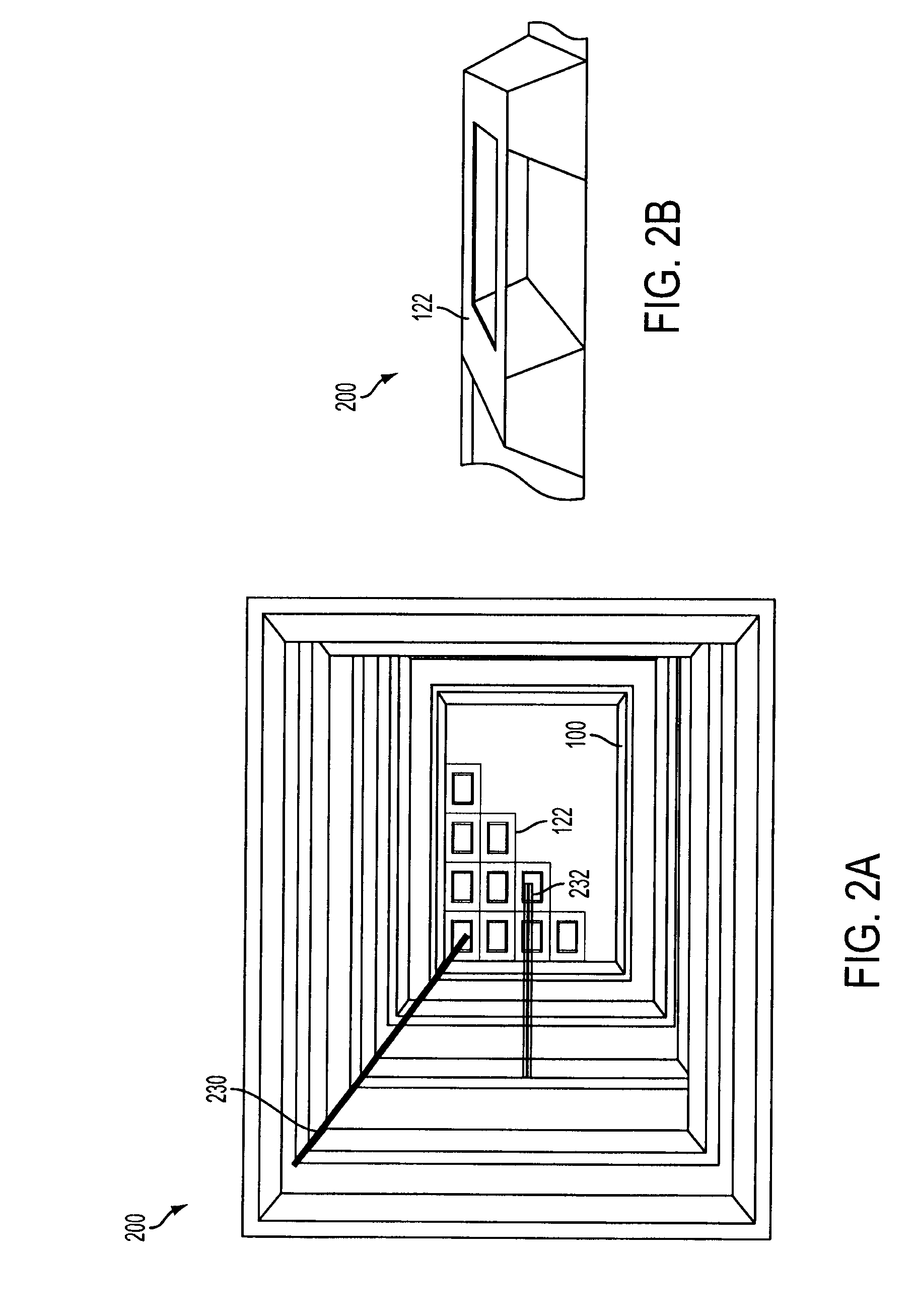

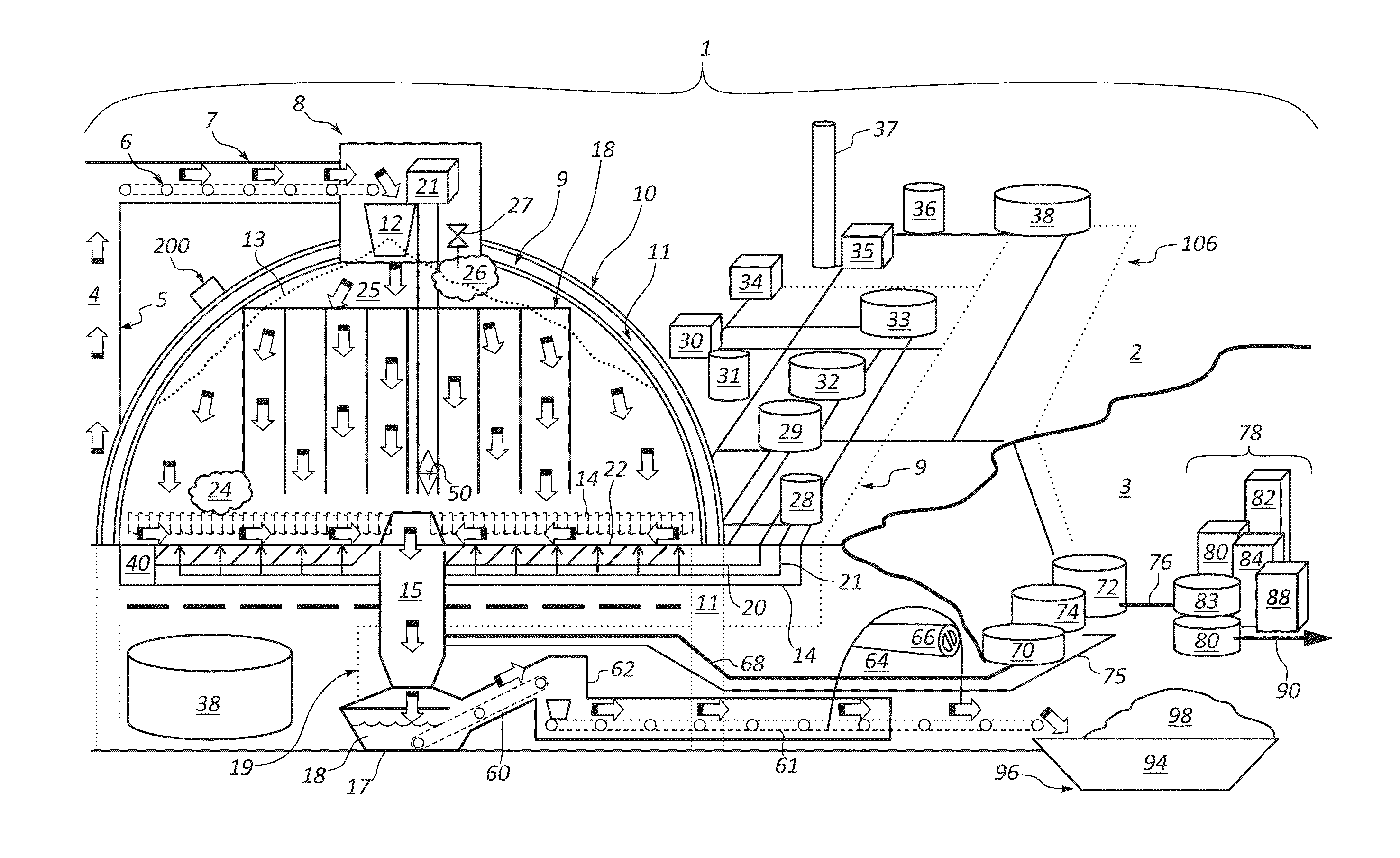

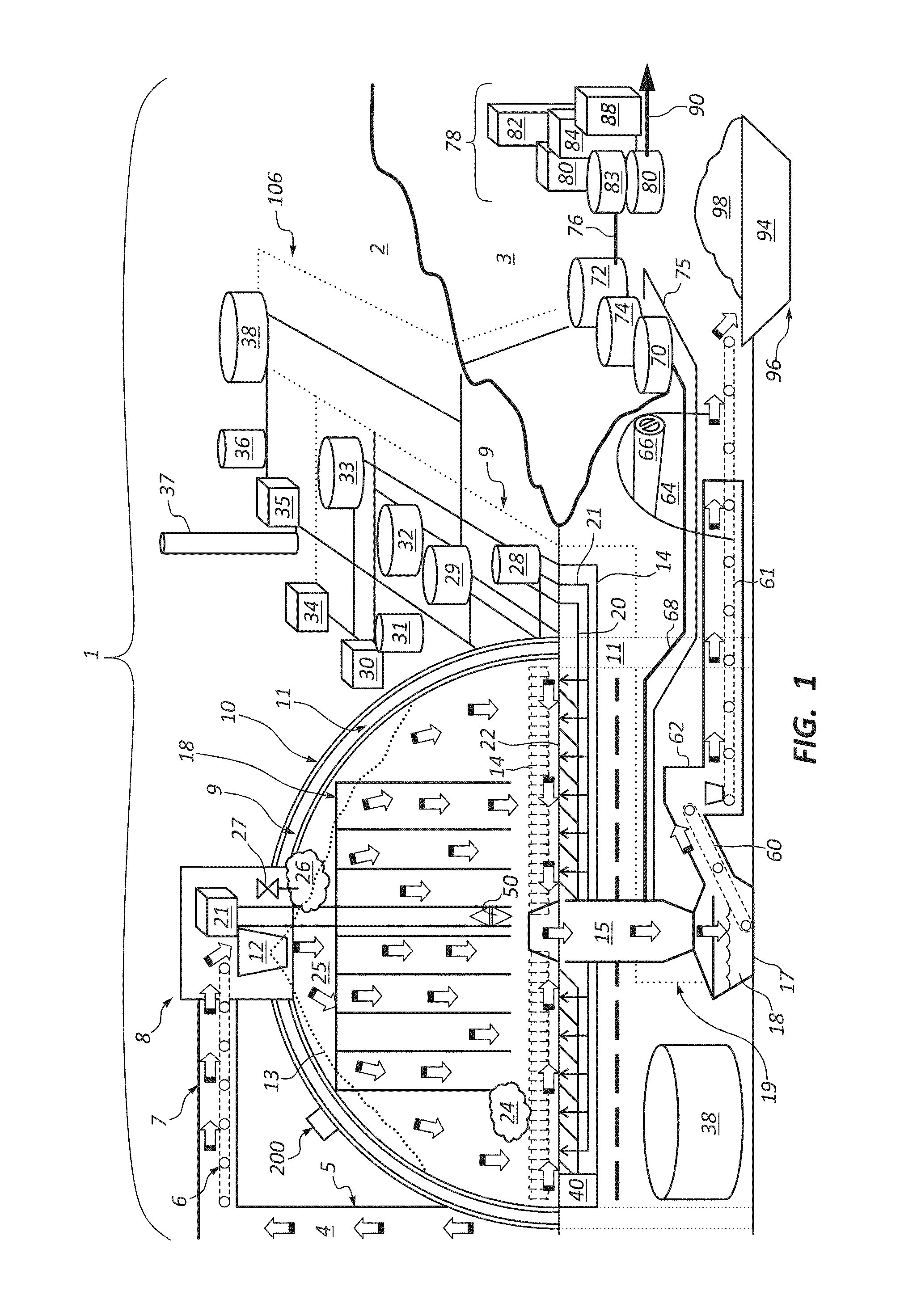

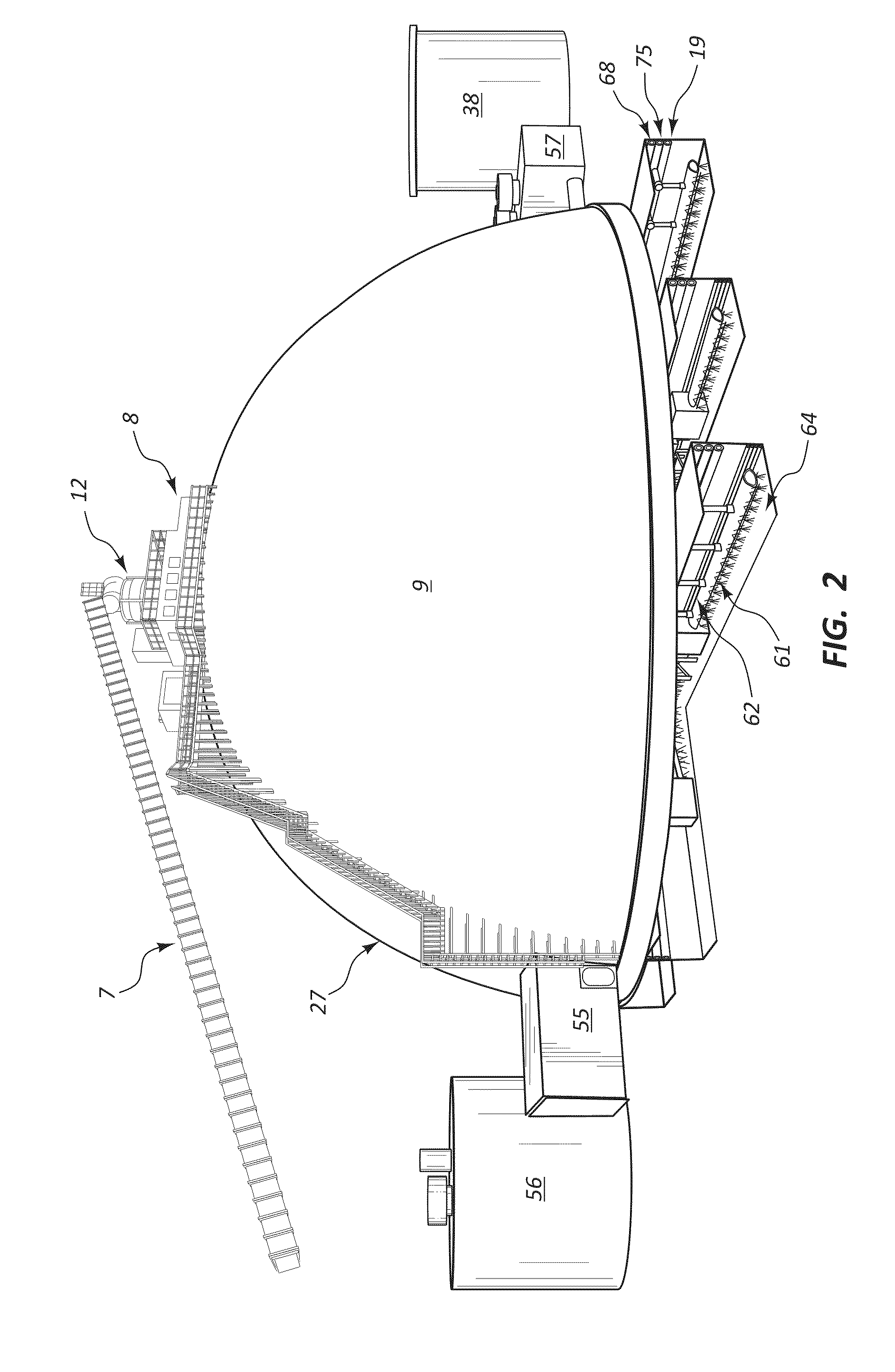

Systems, Apparatus and Methods of a Dome Retort

InactiveUS20110313218A1Increased material throughputLower cost of capitalPressurized chemical processDirect heating destructive distillationBasementControl system

A system, apparatus and method for hydrocarbon extraction from feedstock material that is or includes organic material, such as oil shale, coal, lignite, tar sands, animal waste and biomass. A retort system including at least one retort vessel may include a monolithic dome structure surrounded by a process isolation barrier, the dome structure being sealingly engaged with the process isolation barrier. The dome structure and the process isolation barrier define a retort chamber, at least a portion of which may comprise a subterranean chamber. A lower end of the dome retort structure provides an exit for collected hydrocarbons and spent feedstock material. Systems may include a plurality of such dome retort structures. A control system may be used for controlling one or more operating parameters of a retorting process performed within such a dome retort structure for extraction and collection of hydrocarbons.

Owner:DANA TODD C

Slurry hydrocracking apparatus or process

InactiveUS20110303580A1Easy to separateAvoid disintegrationWorking-up pitch/asphalt/bitumenHydrocarbon oil crackingSlurryProcess engineering

One exemplary embodiment can include a slurry hydrocracking process. The process can include combining one or more hydrocarbons and a slurry hydrocracking catalyst as a feed to a slurry hydrocracking reaction zone, fractionating an effluent from the slurry hydrocracking reaction zone, separating the pitch from at least a portion of the slurry hydrocracking catalyst, and recycling the suspension to the slurry hydrocracking reaction zone. The slurry hydrocracking catalyst may include a support. Fractionating the effluent may provide a light vacuum gas oil, a heavy vacuum gas oil, and a mixture comprising a pitch and the slurry hydrocracking catalyst. Generally, the separated slurry hydrocracking catalyst is comprised in a suspension.

Owner:UOP LLC

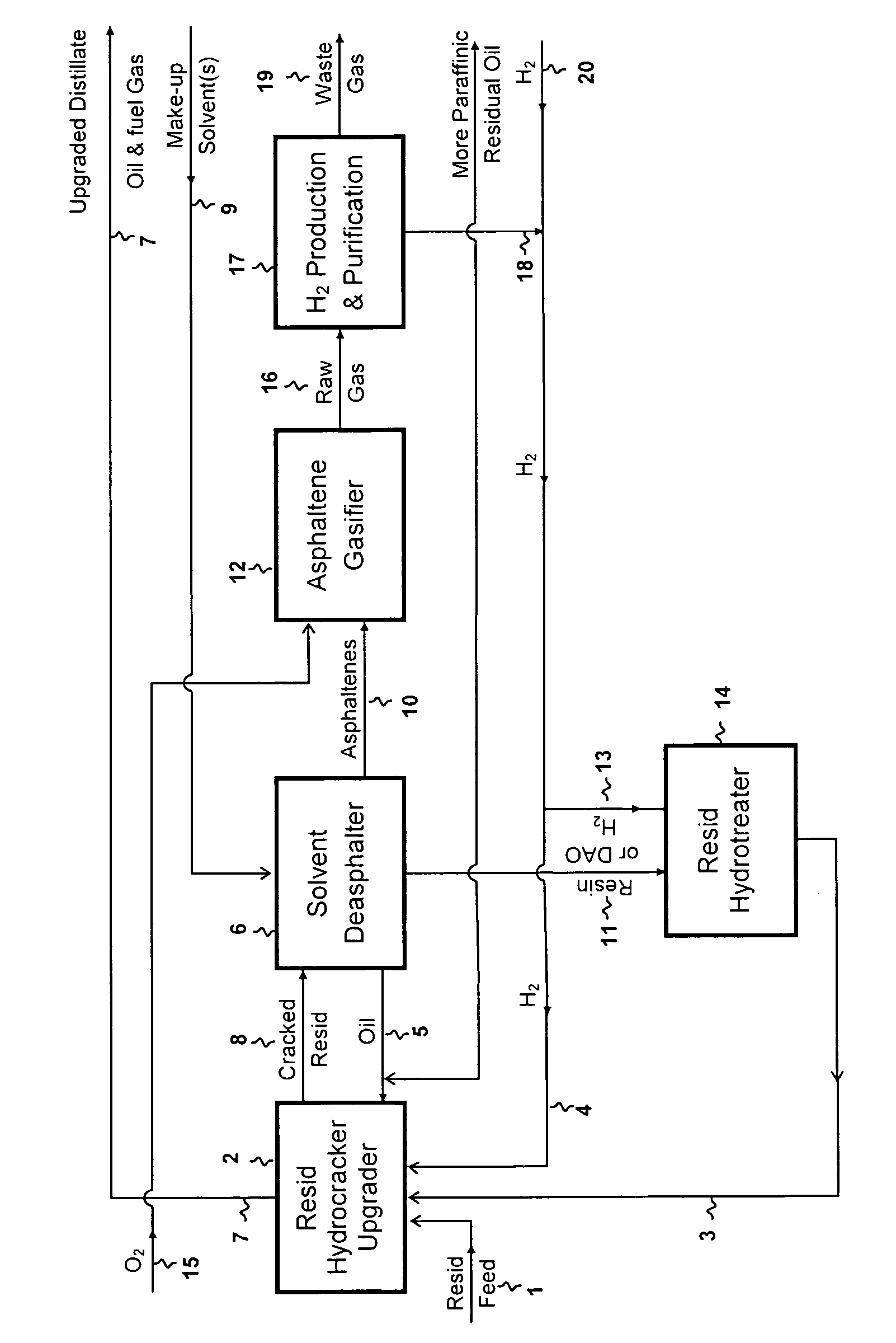

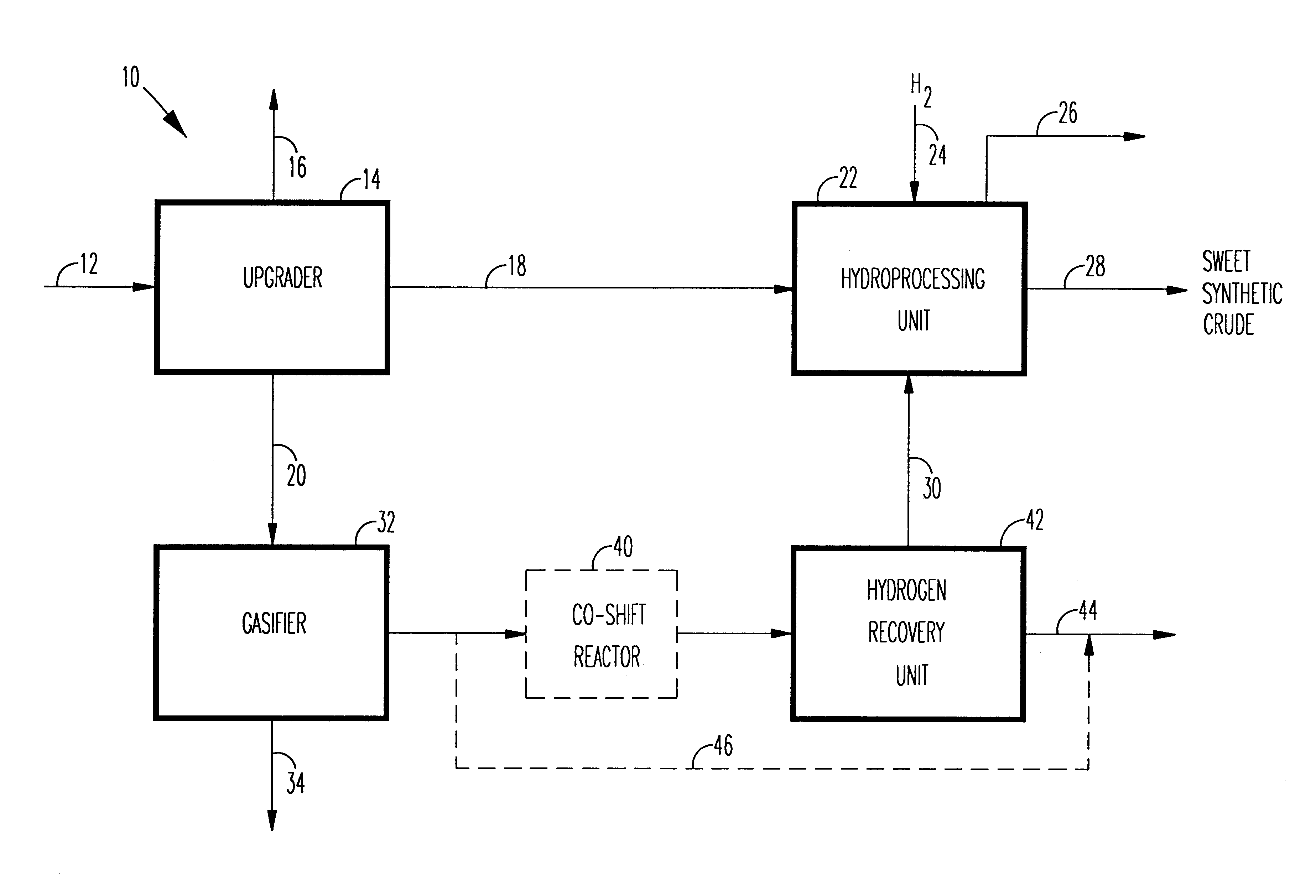

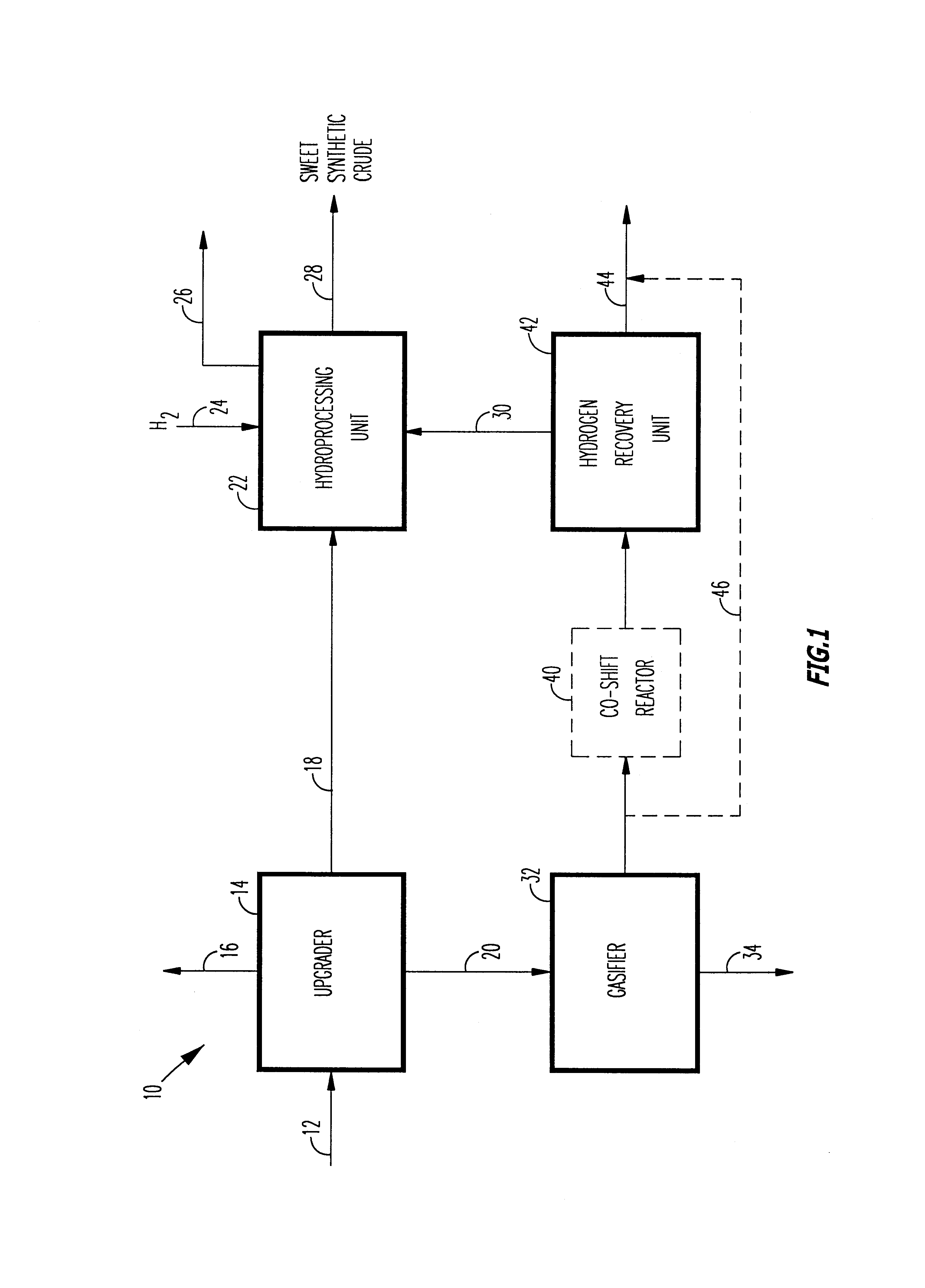

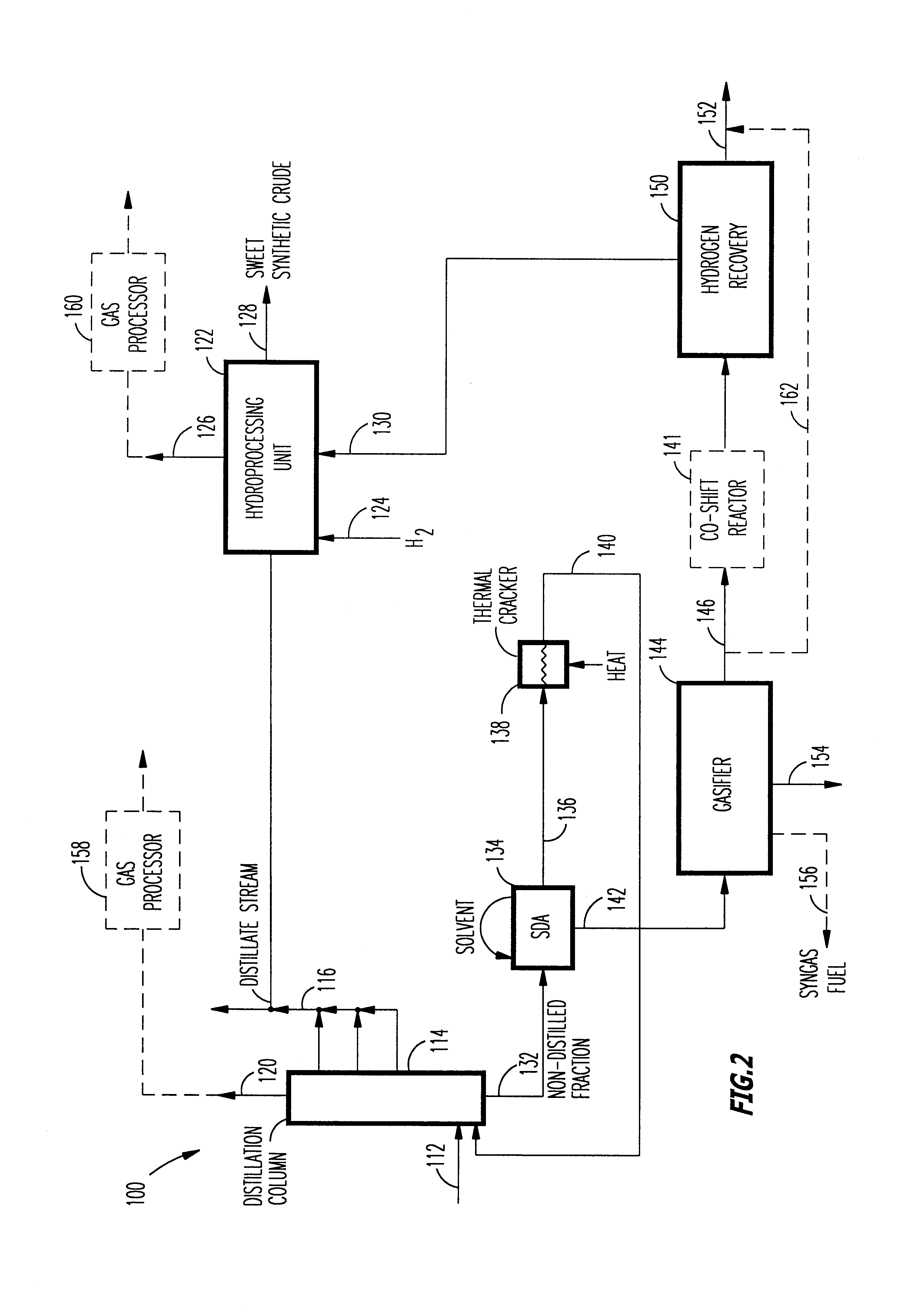

Method of and apparatus for upgrading and gasifying heavy hydrocarbon feeds

A novel apparatus for producing sweet synthetic crude from a heavy hydrocarbon feed comprising: an upgrader for receiving said heavy hydrocarbon feed and producing a distillate fraction including sour products, and high-carbon content by-products; a gasifier for receiving the high-carbon content by-products and producing synthetic fuel gas and sour by-products; a hydroprocessing unit for receiving the sour by-products and hydrogen gas, thereby producing gas and sweet crude; and a hydrogen recovery unit for receiving said synthetic fuel gas and producing further hydrogen gas and hydrogen-depleted synthetic fuel gas, said further hydrogen gas being supplied to said hydroprocessing unit.

Owner:ORMAT IND LTD

Hydrotreated hydrocarbon tar, fuel oil composition, and process for making

InactiveUS20140174980A1Thermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by chemical meansBoiling pointTar

Provided is a hydrocarbon tar. The tar has 75 wt % or more of aromatics of 10 carbons to 75 carbons based on the total weight of the tar. The aromatics exhibit 40% to 80% aromaticity. The tar has a boiling point of from 300° F. to 1350° F. There is also a fuel oil composition having the tar therein. There are also processes for making the hydrocarbon tar.

Owner:EXXONMOBIL CHEM PAT INC

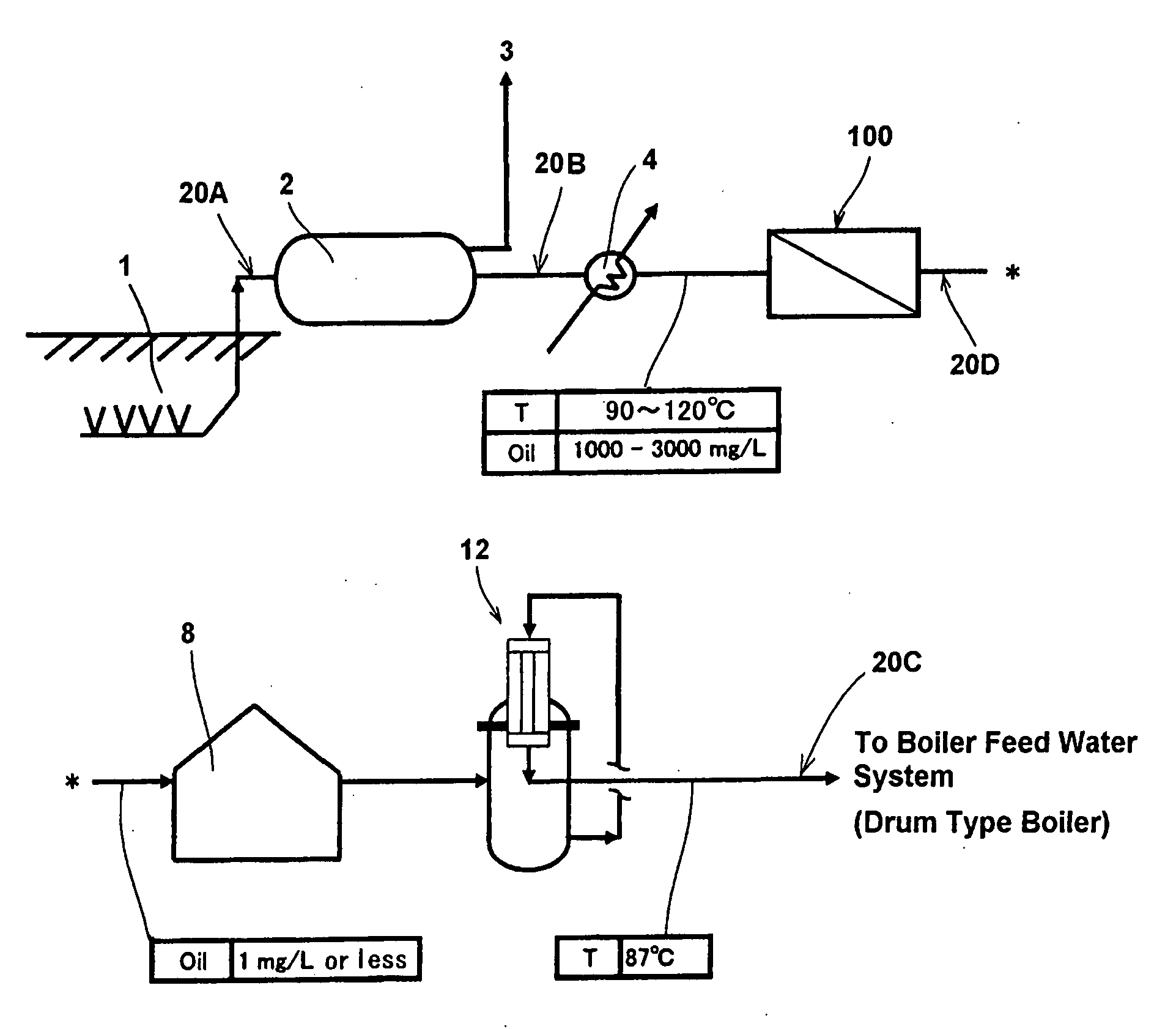

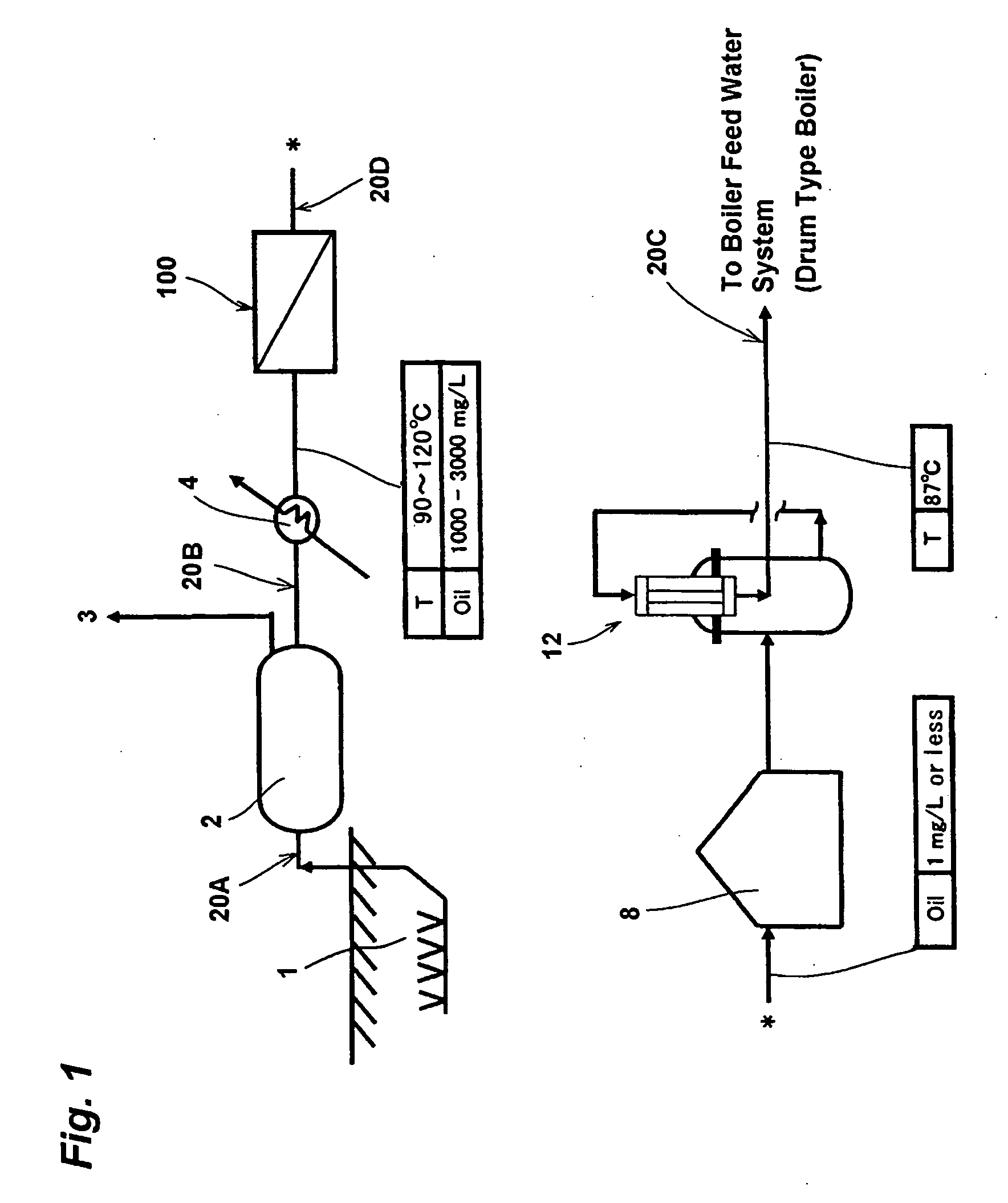

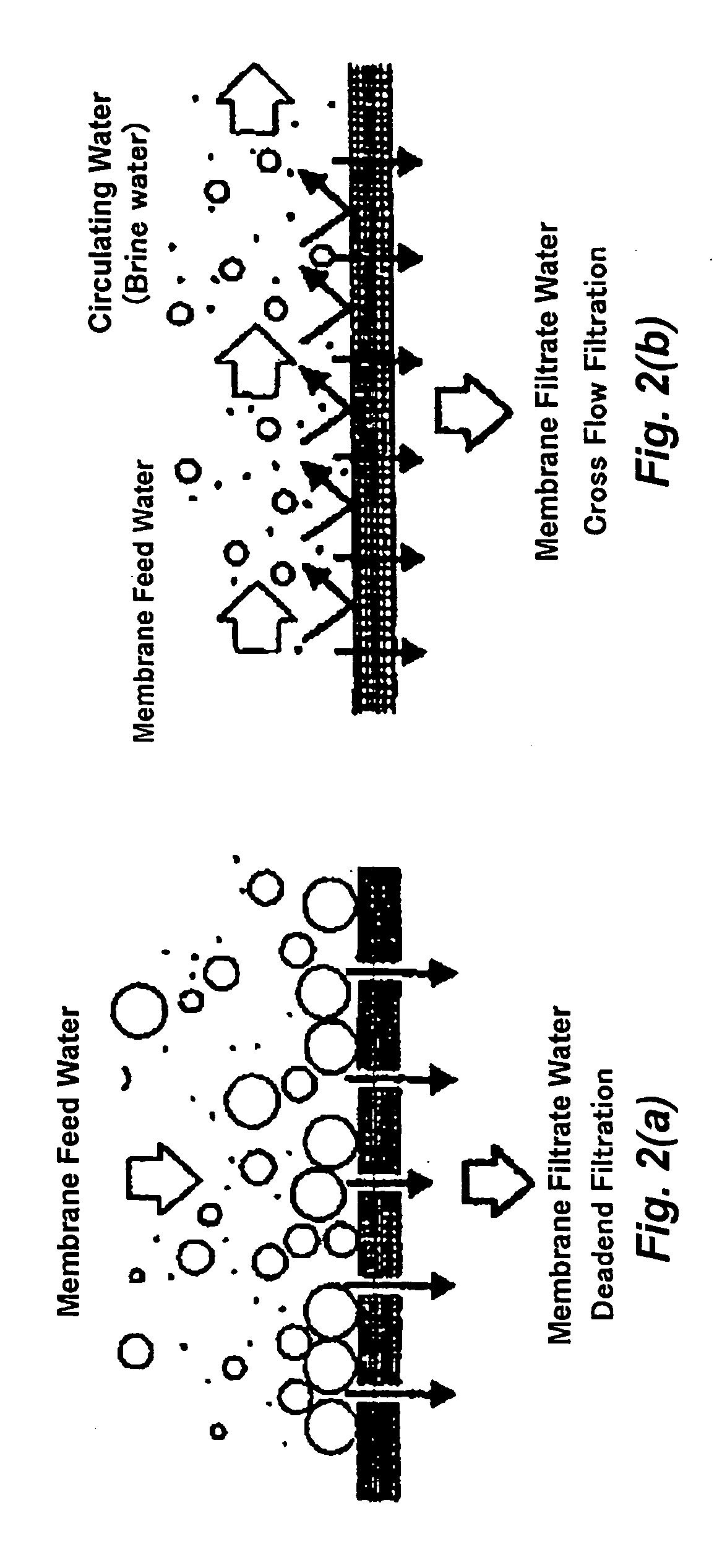

Method of produced water treatment, method of water reuse, and systems for these methods

ActiveUS20100264068A1Fatty/oily/floating substances removal devicesDewatering/demulsification with mechanical meansRecovery methodMicrofiltration membrane

A method of produced water treatment in an in-situ recovery method of producing bitumen from oil sand, the method has the steps of: separating bitumen from bitumen-mixed fluid so as to leave produced water, the bitumen-mixed fluid having been recovered from the oil sand wells; and filtering the produced water via a microfiltration membrane made of polytetrafluoroethylene.

Owner:SUMITOMO ELECTRIC IND LTD +1

Apparatus and process for treating a hydrocarbon stream

InactiveUS20100243532A1Minimizes inventoryQuantity minimizationLiquid degasificationSolvent extractionBoiling pointIonic liquid

One exemplary embodiment can be an apparatus for treating a hydrocarbon stream having one or more compounds with a boiling point of about 140-about 450° C. The apparatus can include an extraction zone and a regeneration zone. The extraction zone can include at least one settler. Each settler can have a height and a length. Typically the length is greater than the height. Also, the settler can form a boot, which can be adapted to receive a feed at one end. The regeneration zone may include a regenerator for an ionic liquid. The regenerator can include a column adapted to provide a regenerated ionic liquid to the extraction zone.

Owner:UOP LLC

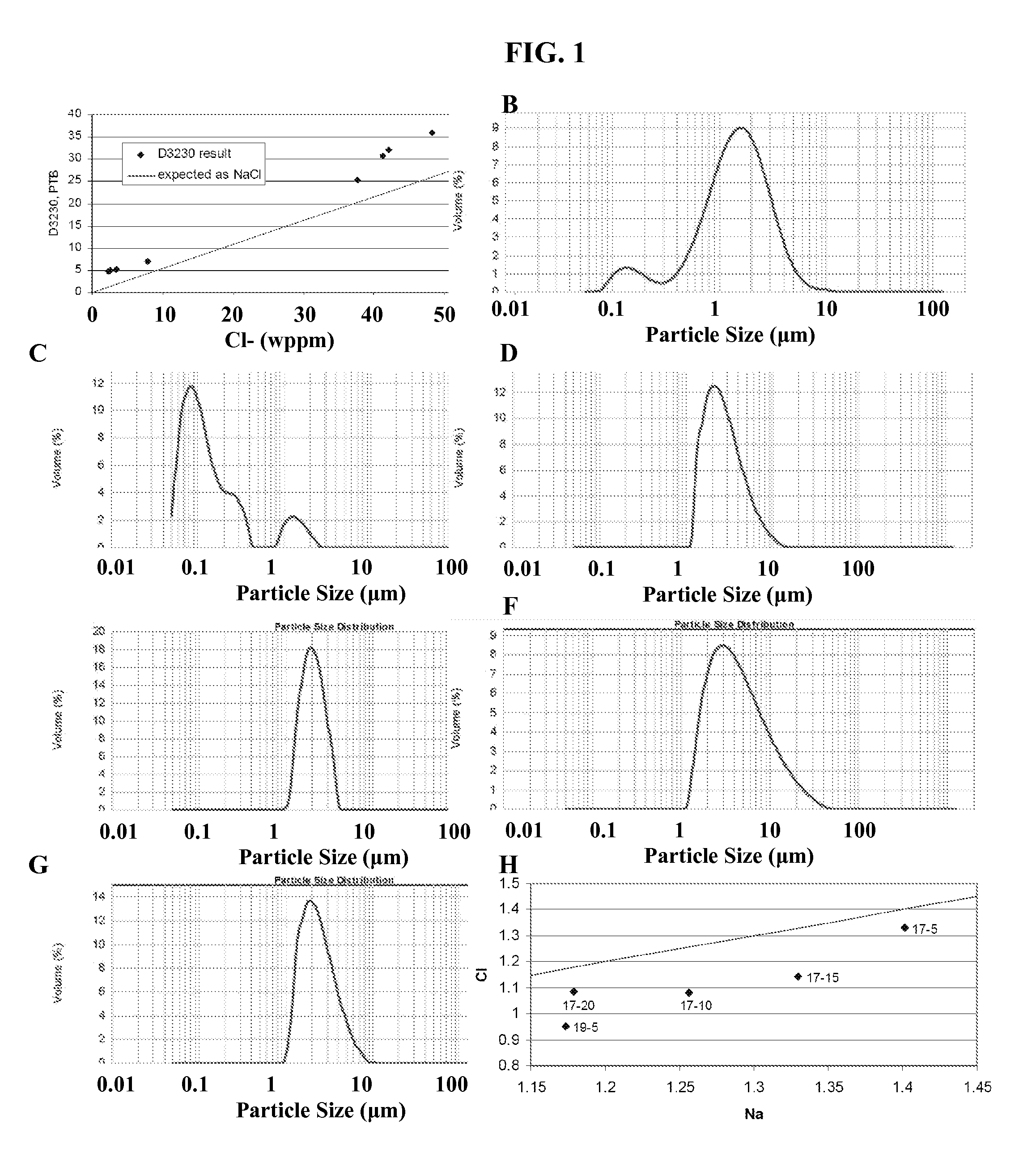

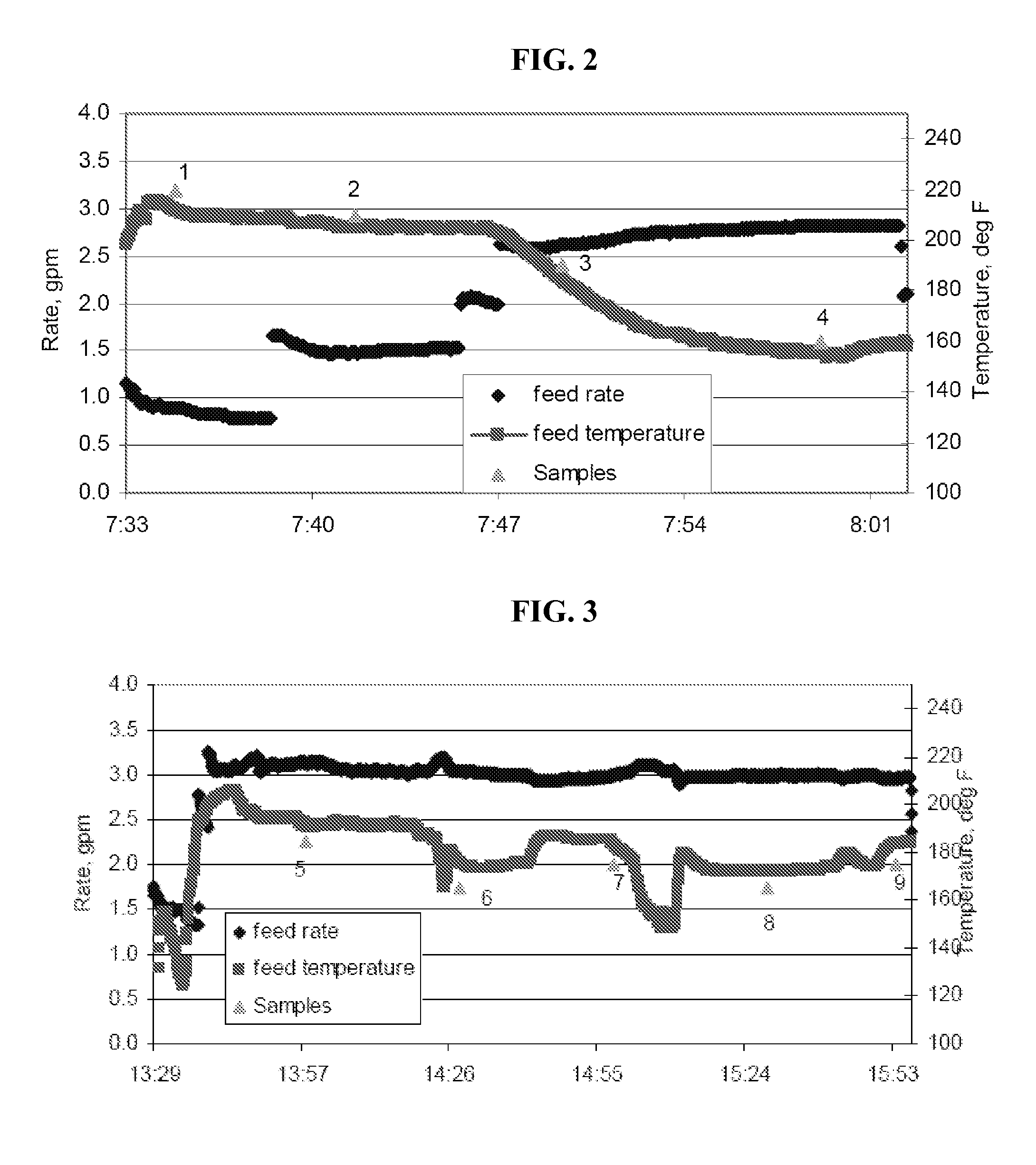

Refinery desalter improvement

ActiveUS20120024758A1Increase capacityEasy to separateDewatering/demulsification with mechanical meansRefining by water treatmentDesalinationDesalter

The invention relates to improved methods of desalting hydrocarbon feeds using a separator with a stacked disk centrifuge to separate an emulsified oil and water rag layer. This method is effective for desalting heavy, high ionic, and non-traditional crude oils.

Owner:PHILLIPS 66 CO

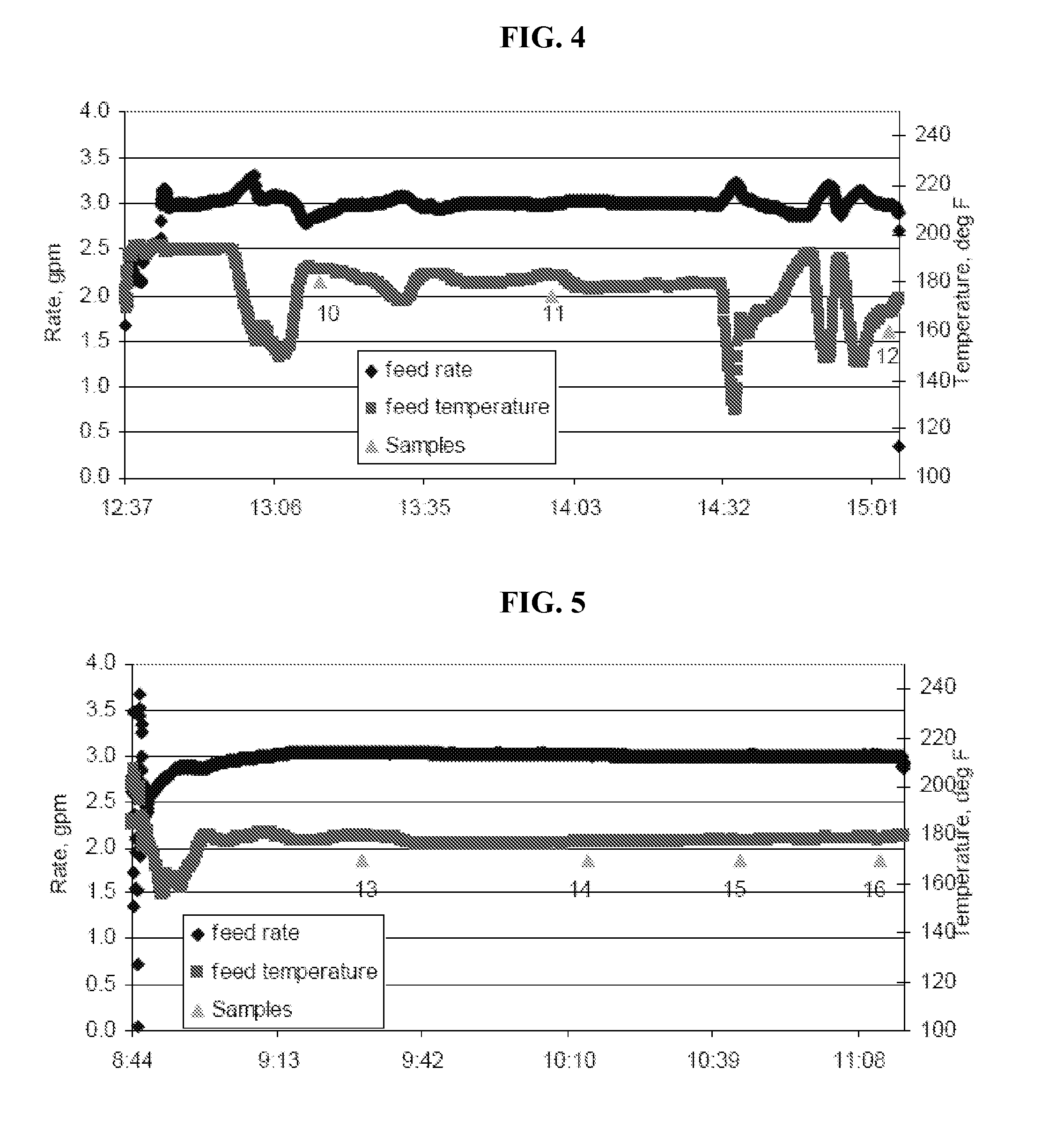

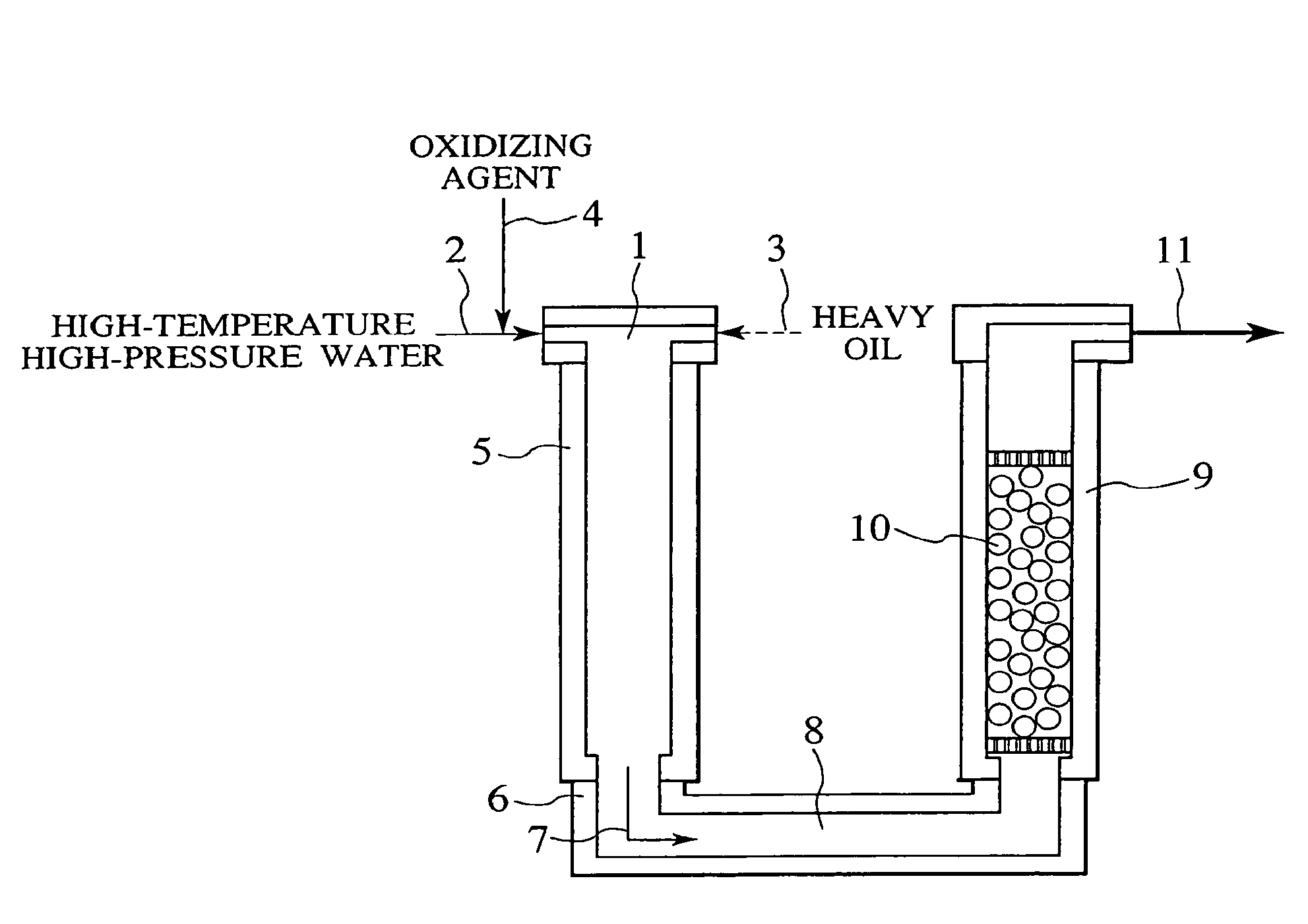

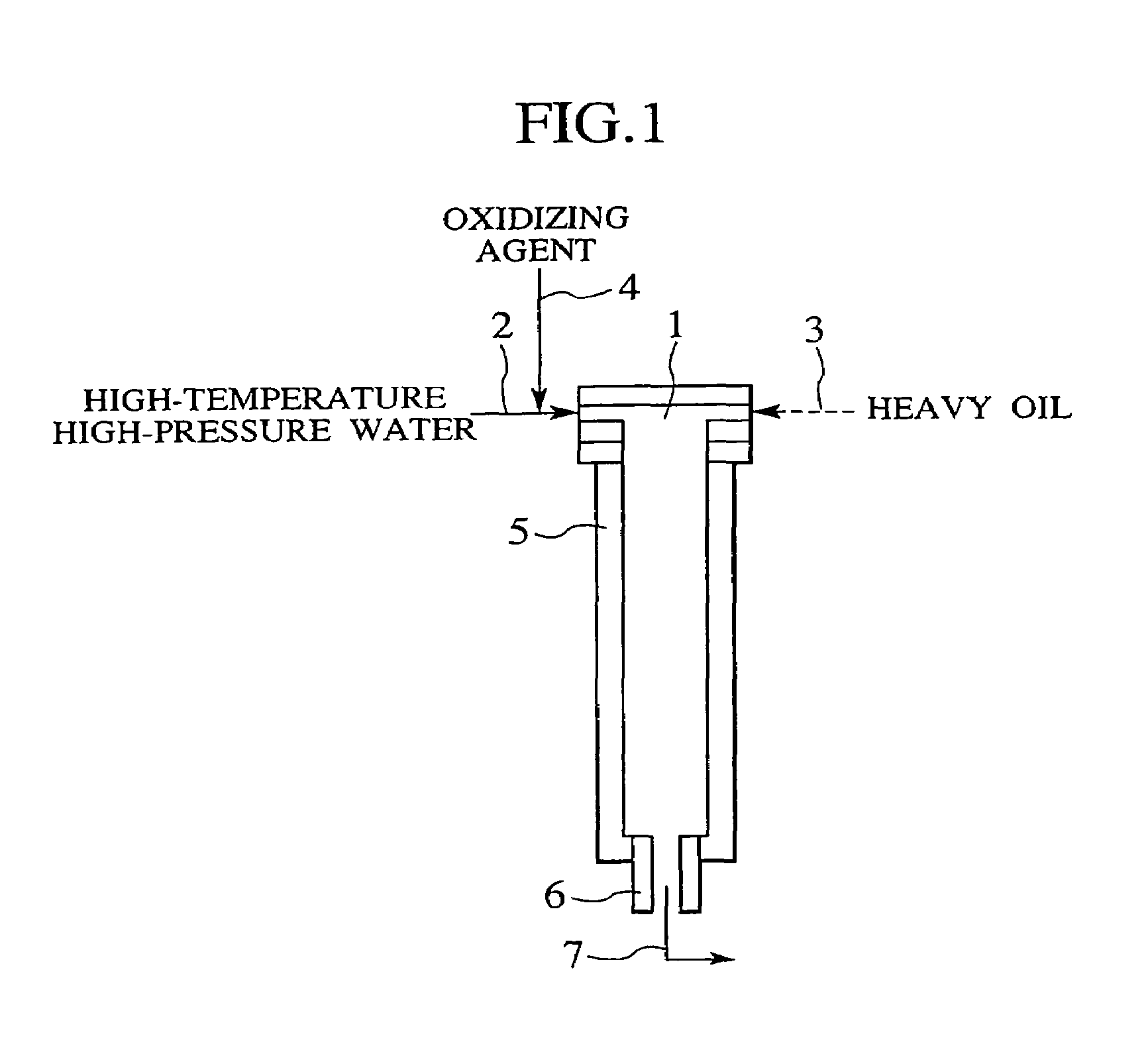

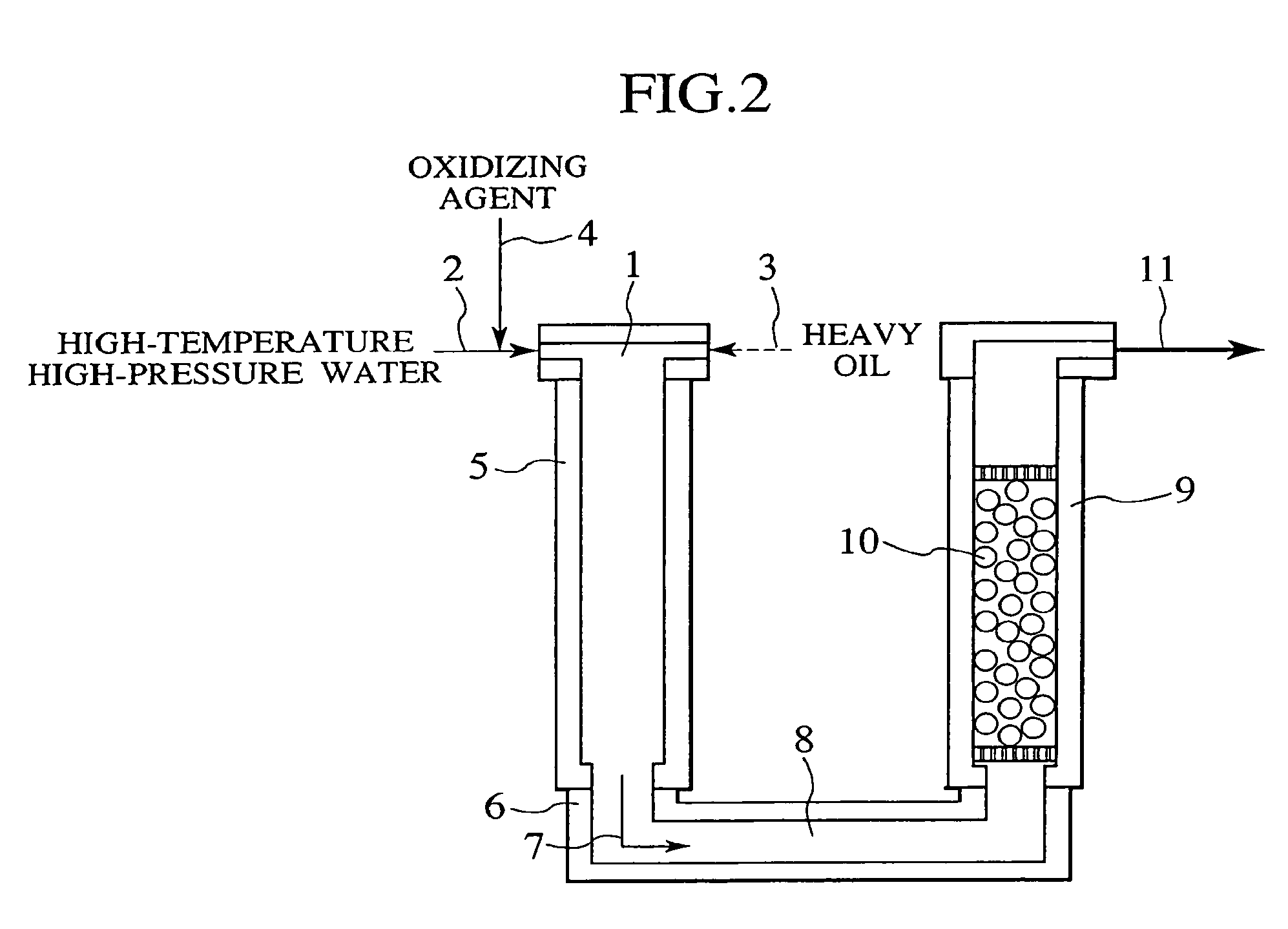

Process and apparatus for treating heavy oil with supercritical water and power generation system equipped with heavy oil treating apparatus

InactiveUS7264710B2Thermal non-catalytic crackingPressurized chemical processScavengerAfter treatment

The reforming of heavy oil with supercritical water or subcritical water is accomplished by mixing together supercriticai water, heavy oil, and oxidizing agent, thereby oxidizing vanadium in heavy oil with the oxidizing agent at the time of treatment with supercritical water and separate vanadium oxide. The separated vanadium oxide is removed by the scavenger after treatment with supercritical water. In this way it is possible to solve the long-standing problem with corrosion of turbine blades by vanadium which arises when heavy oil is used as gas turbine fuel.

Owner:HITACHI LTD

Recovery and transportation of heavy crude oils

InactiveUS6402934B1Low viscosityWorking-up pitch/asphalt/bitumen by chemical meansLiquid carbonaceous fuelsHeavy crude oilSequestering Agent

Owner:ROHM & HAAS CO

Fragmentation of heavy hydrocarbons using an ozone-containing fragmentation fluid

InactiveUS20060163117A1Thermal non-catalytic crackingCatalytic crackingChemical speciesChemical compound

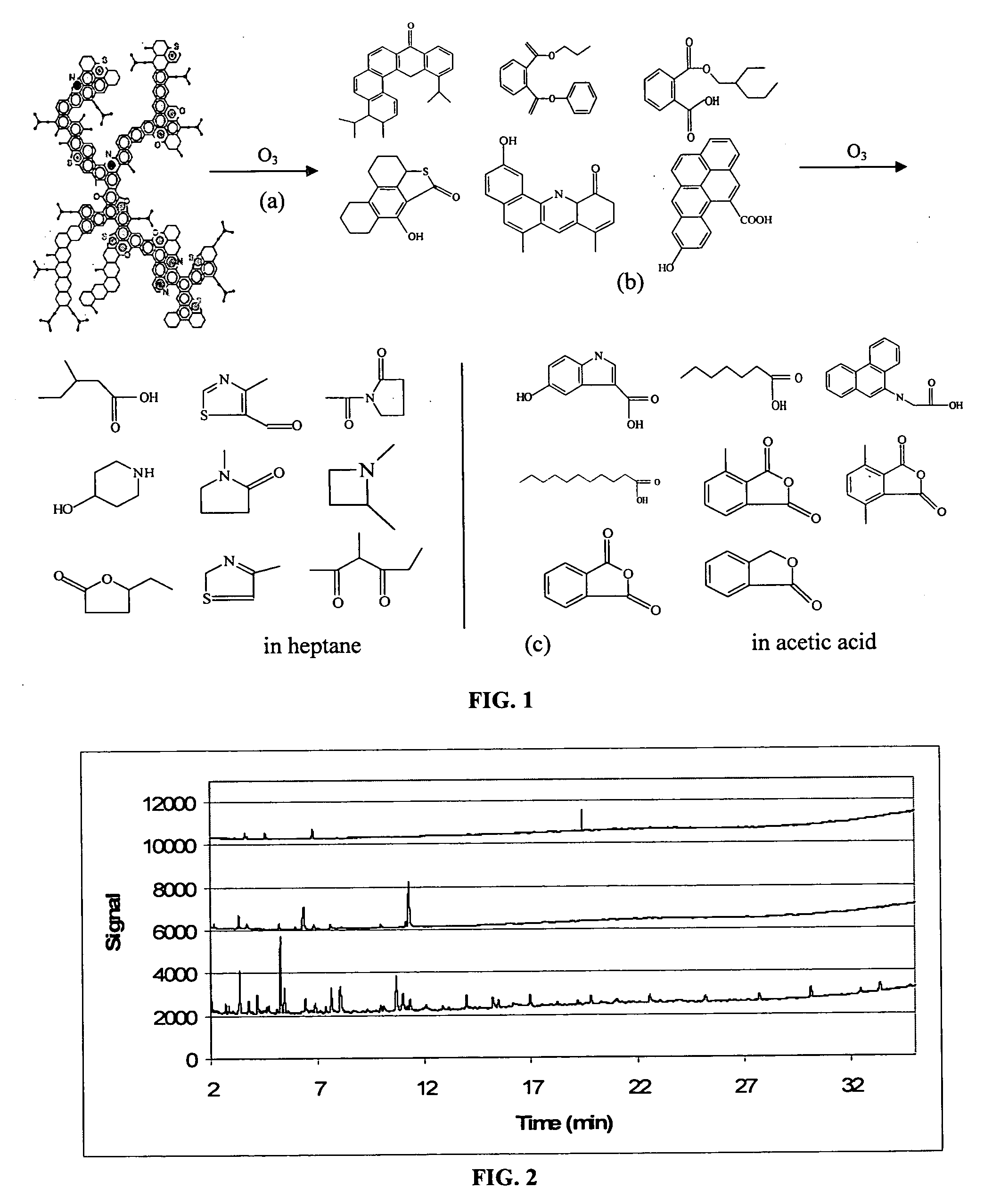

A method for recovering valuable chemical products from heavy hydrocarbons such as tar sand or petroleum waste products is disclosed and described. Heavy hydrocarbons can be contacted with a fragmentation fluid which includes ozone and a solvent carrier. The fragmentation fluid can be provided at supercritical conditions. For example, supercritical CO2 can be an effective liquid solvent carrier for ozone. During contact with the fragmentation fluid, the heavy hydrocarbons are reduced in size to form a product mixture of chemical compounds. This product mixture typically includes chemical species which are more suitable than the original heavy hydrocarbons to commercial uses and / or further separation to provide useful starting materials for a wide variety of synthesis and industrial applications.

Owner:MARATHON OIL CANADA

Use of steam cracked tar

ActiveUS20070163921A1Catalytic crackingWorking-up pitch/asphalt/bitumen by chemical meansTarPulp and paper industry

Owner:EXXONMOBIL CHEM PAT INC

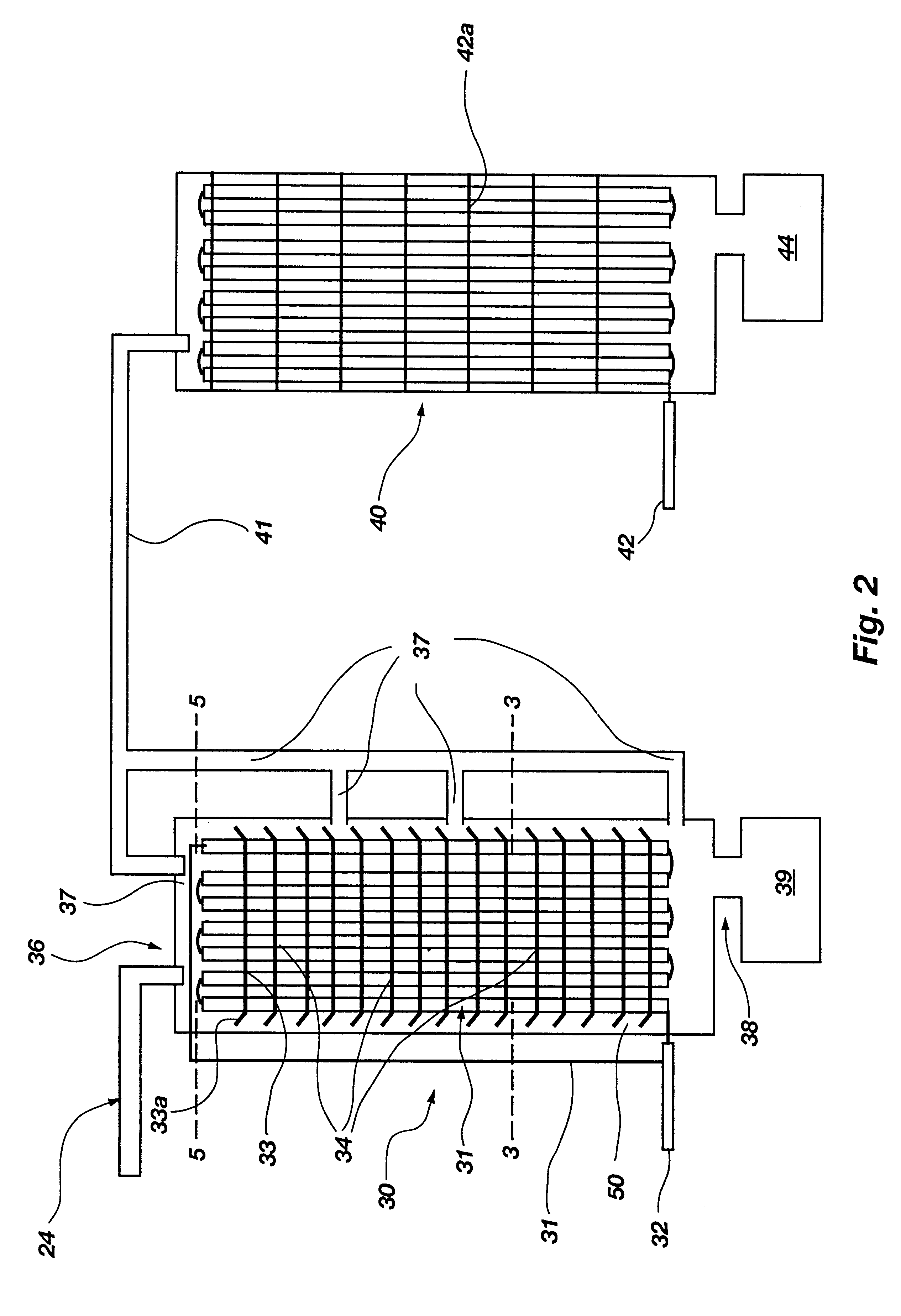

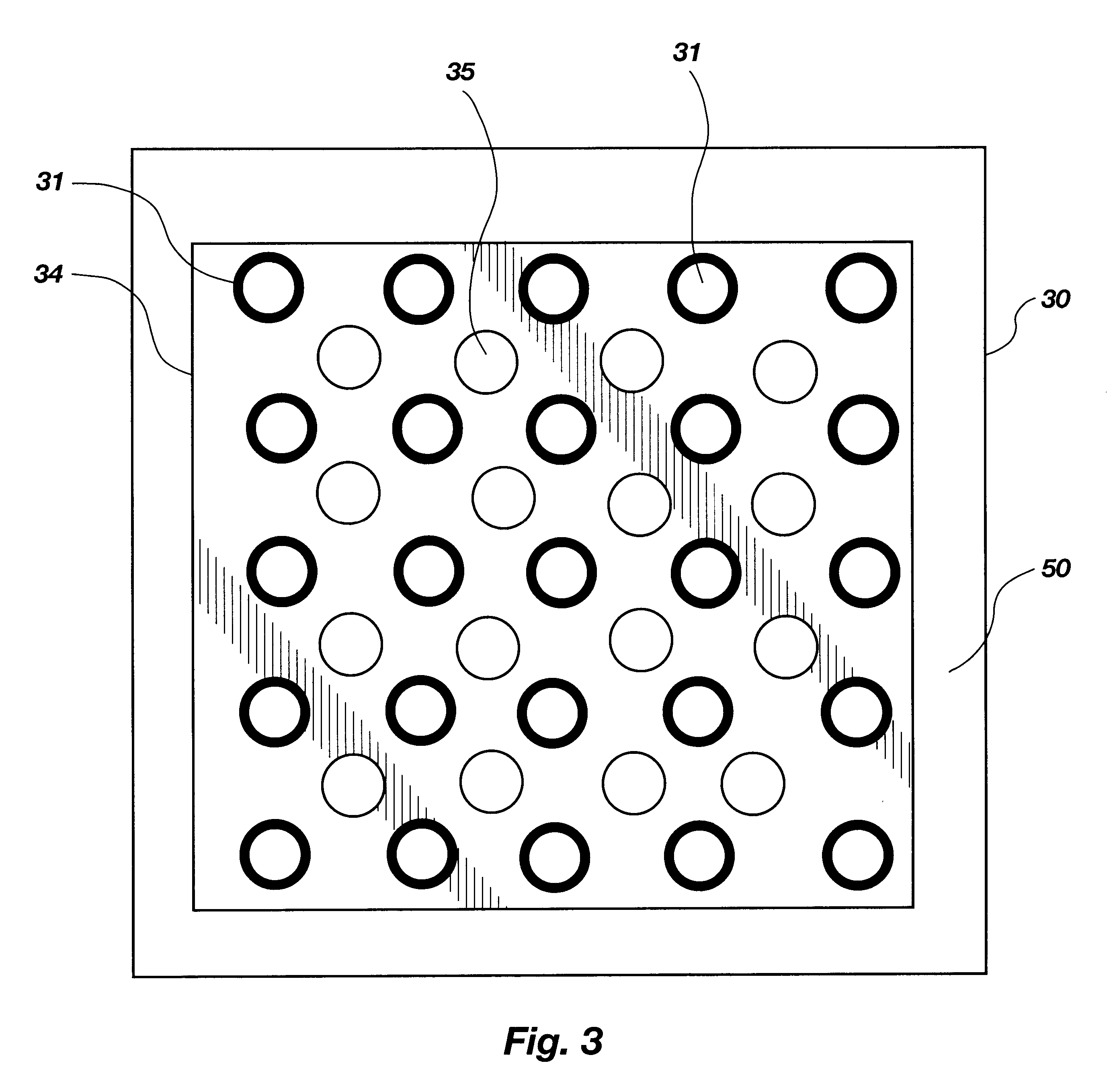

Methods of recovering hydrocarbons from hydrocarbonaceous material using a constructed infrastructure and associated systems

ActiveUS7862705B2Low costHigh outputThermal non-catalytic crackingSolid waste disposalEngineeringHydrocarbon

A method of recovering hydrocarbons from hydrocarbonaceous materials can include forming a constructed permeability control infrastructure. This constructed infrastructure defines a substantially encapsulated volume. A comminuted hydrocarbonaceous material can be introduced into the control infrastructure to form a permeable body of hydrocarbonaceous material. The permeable body can be heated sufficient to remove hydrocarbons therefrom. During heating the hydrocarbonaceous material is substantially stationary as the constructed infrastructure is a fixed structure. Removed hydrocarbons can be collected for further processing, use in the process, and / or use as recovered.

Owner:RED LEAF RESOURCES

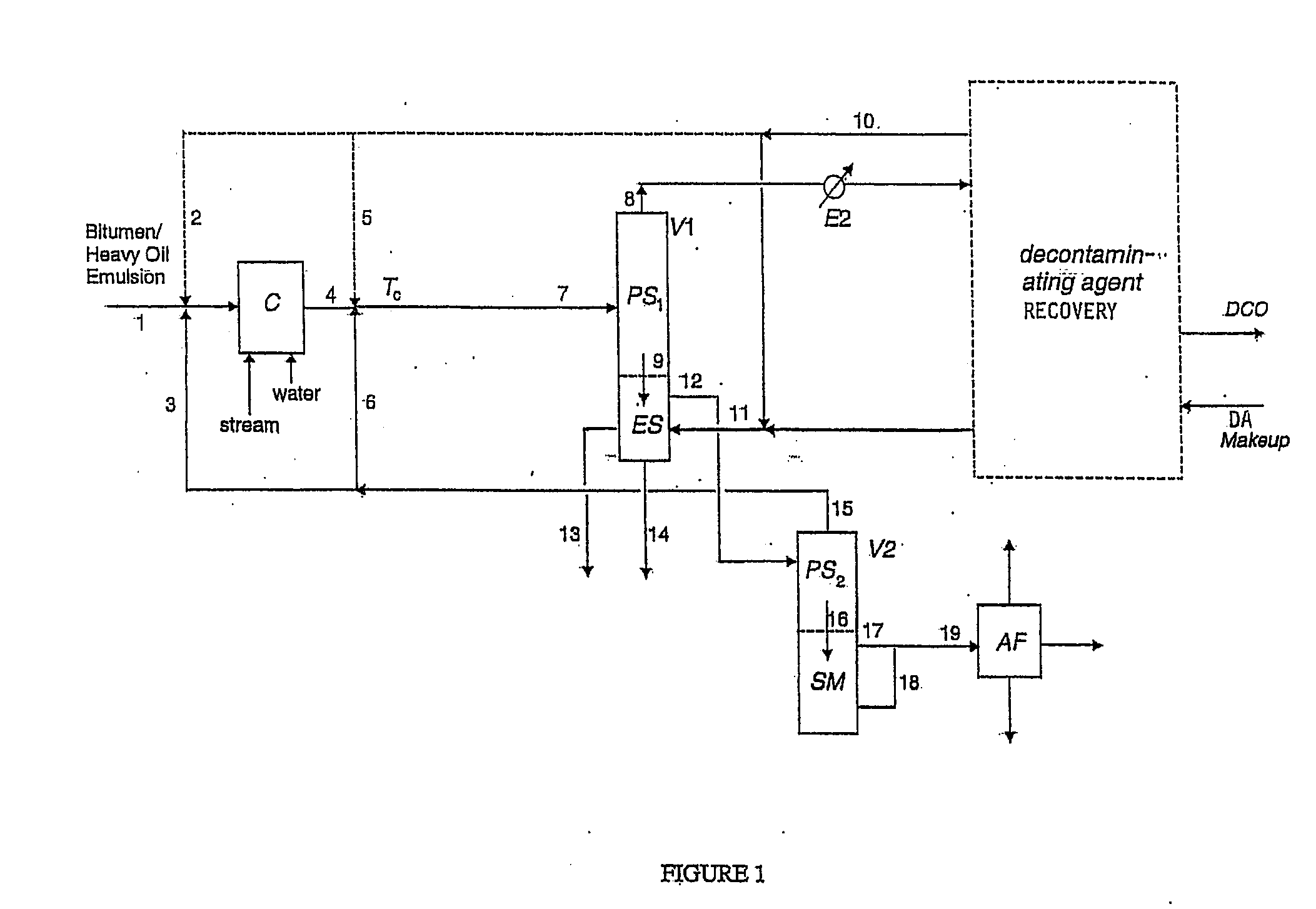

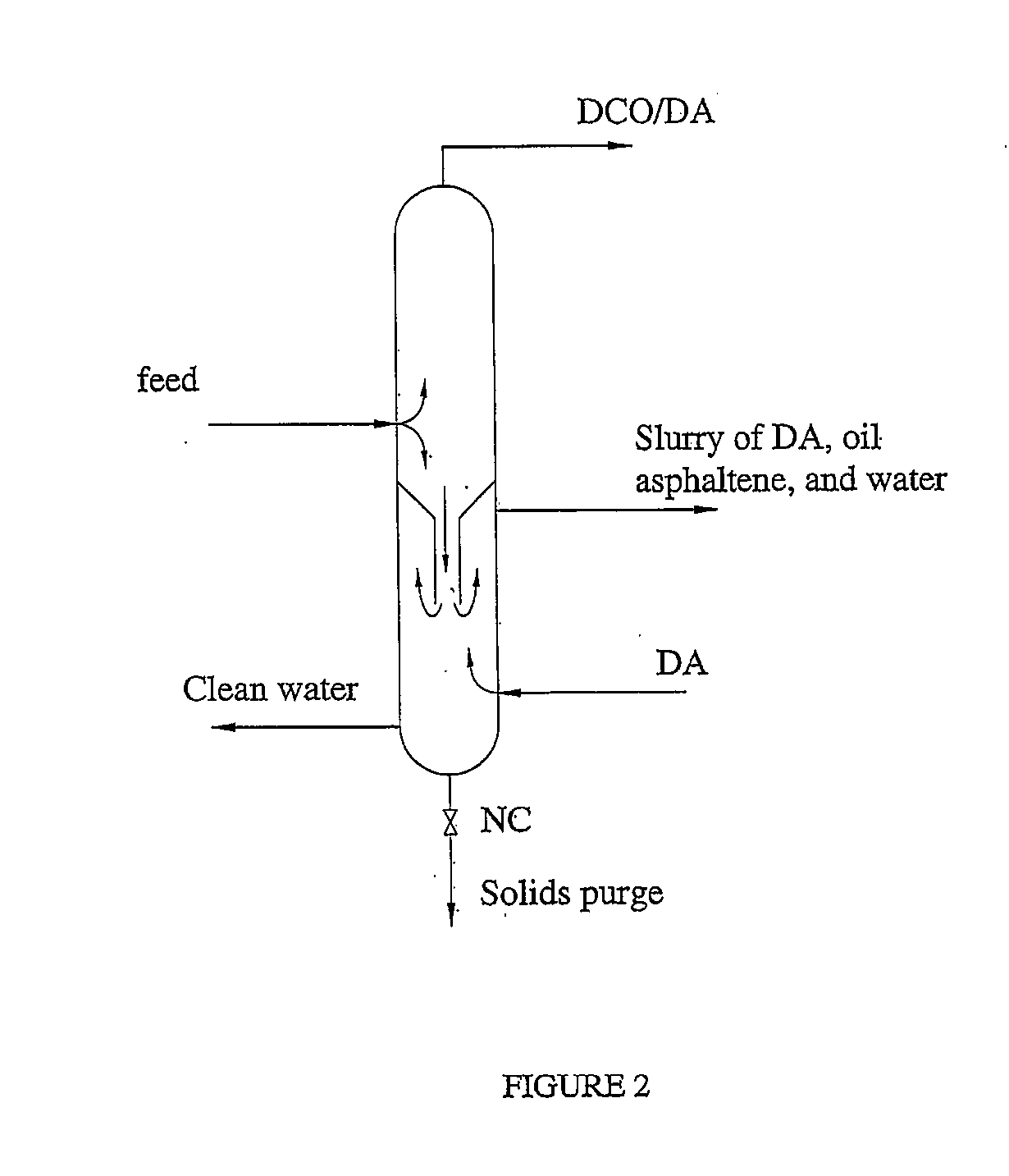

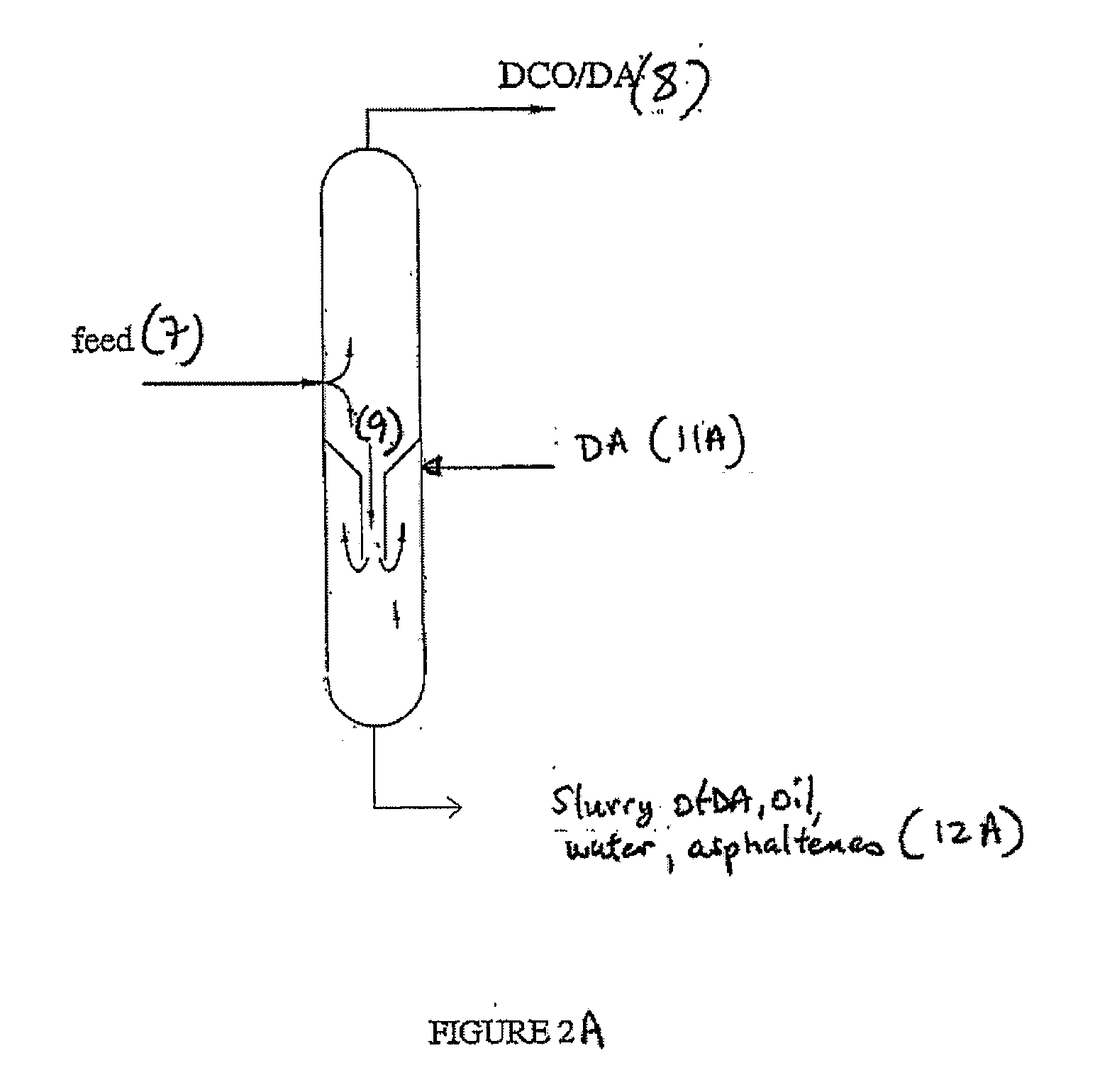

Decontamination of asphaltic heavy oil and bitumen

ActiveUS20060260980A1Distillation regulation/controlHydrocarbon distillationPetroleum productFuel oil

Owner:VALUE CREATION +1

Solvent extraction of hydrocarbons from inorganic materials and solvent recovery from extracted hydrocarbons

InactiveUS6207044B1No pollution to the environmentIncrease surface areaLiquid organic insulatorsWorking-up pitch/asphalt/bitumen by chemical meansHydrocarbon solventsSolvent vapor

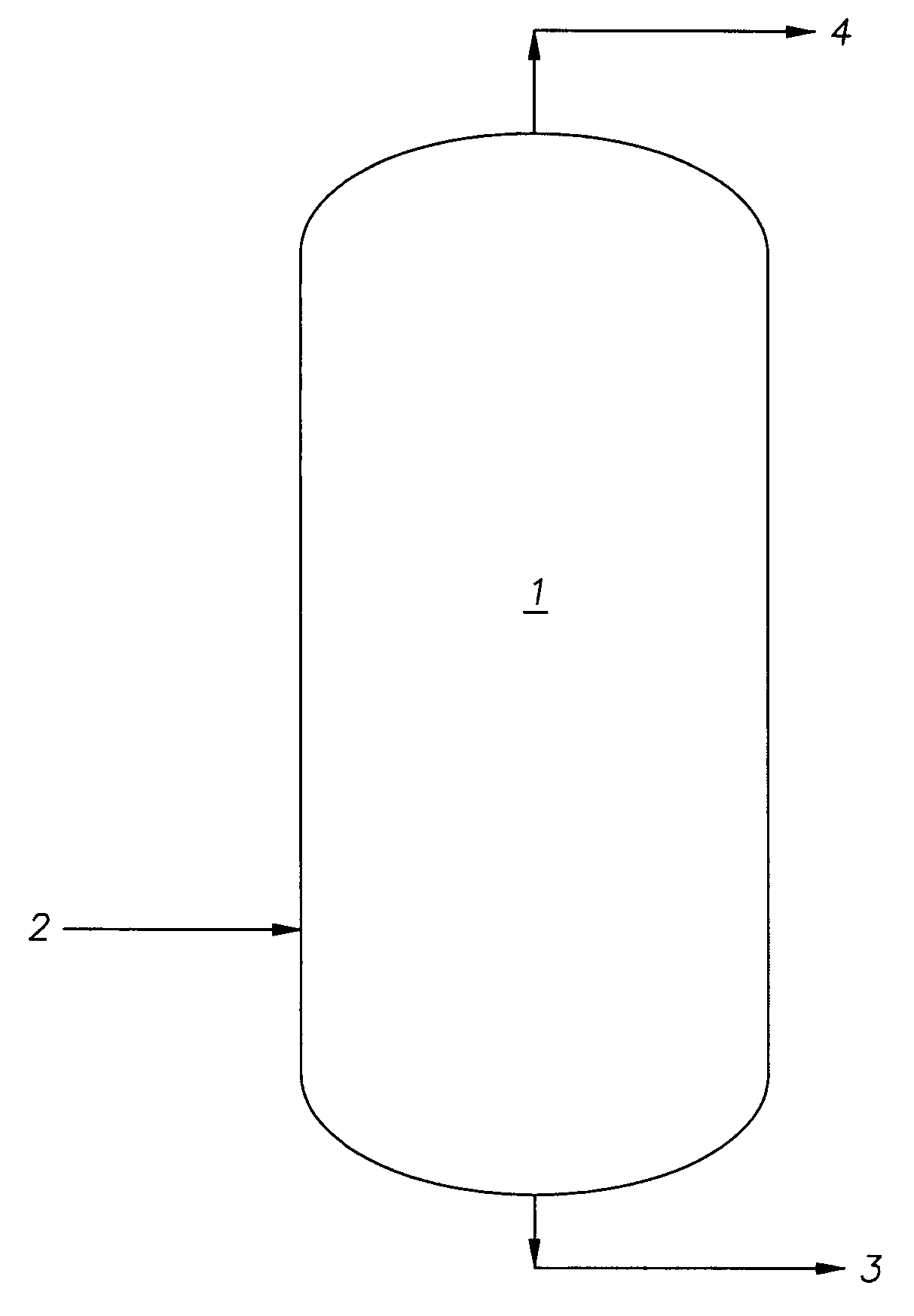

A process for the solvent separation of hydrocarbons from tar sand or contaminated soils comprises extracting the hydrocarbons from the sand or soil in a solvent extraction means to form a hydrocarbon rich solvent solution. The rich solvent is separated from the hydrocarbon in a process that utilizes flashing of the solvent in a heated flashing column at ambient pressure. The hydrocarbon is withdrawn from the bottom of the column and the flashed solvent vapors are strategicly withdrawn and passed into a condensation column from which the condensed solvent may be recycled. The flashing column is divided by a series of horizontal, vertically aligned apertured trays. The solution is introduced into the top of the column and the flashing operation is facilitated by the increase in the surface area of the solution as it flows by gravity from tray to tray. The column is maintained at a temperature, preferably above the boiling temperature of the solvent. The process is particularly adapted to the use of chlorinated hydrocarbon solvents and most particularly to the use of methylene chloride.

Owner:LUCENT TECH INC

Preparation method of soluble mesophase pitch

InactiveCN102942945AImprove solubilityFacilitate subsequent processingWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionFiberCarbon fibers

The invention belongs to the technical field of a preparation method of spinning raw materials of high-performance pitch-based carbon fibers, and particularly relates to a preparation method of soluble mesophase pitch, which mainly solves the problems of the existing mesophase pitch preparation method that the process is complicated, requirements on the equipment are high, the cost is high, the industrialization process is difficult and the like. The invention adopts the technical scheme that the preparation method of the soluble mesophase pitch comprises the following steps of (1) thermally treating raw material pitch or ethylene bottom oil with a low softening point in an inert atmosphere, then distilling the material in a short distance or flashing the material, removing light ends, and collecting heavy fraction, i.e. heavy end pitch; (2) preparing the heavy enbd pitch into mesophase pitch; and (3) cooling the mesophase pitch to 320DEG C to 400DEG C, removing internal light ends, and collecting the heavy fraction, i.e. the mesophase pitch. The preparation method has the advantages of simplicity in process, moderate in reaction condition, low equipment requirement, low cost and adaptability to industrialized production.

Owner:SICHUAN CHUANGYUE CARBON MATERIAL

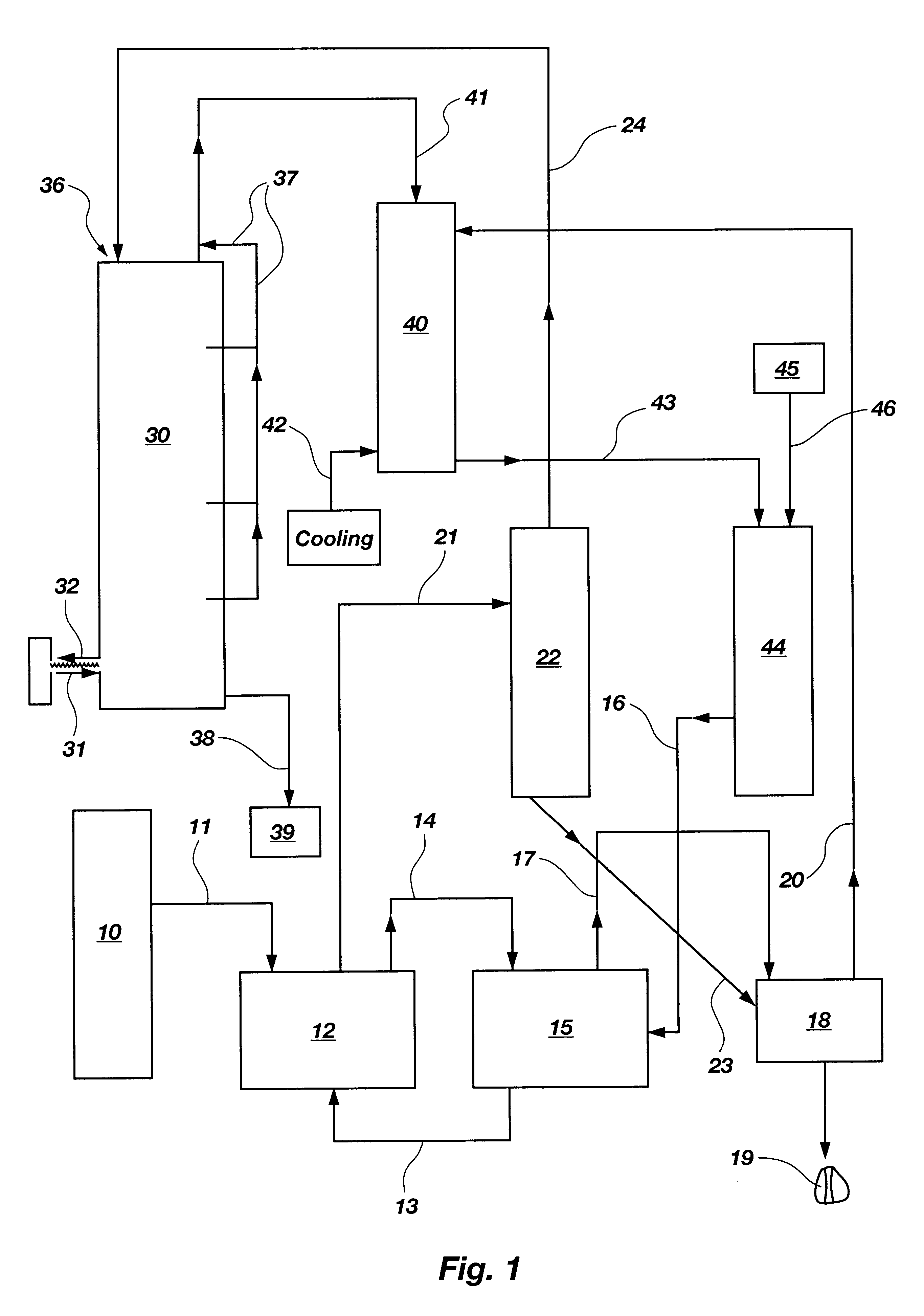

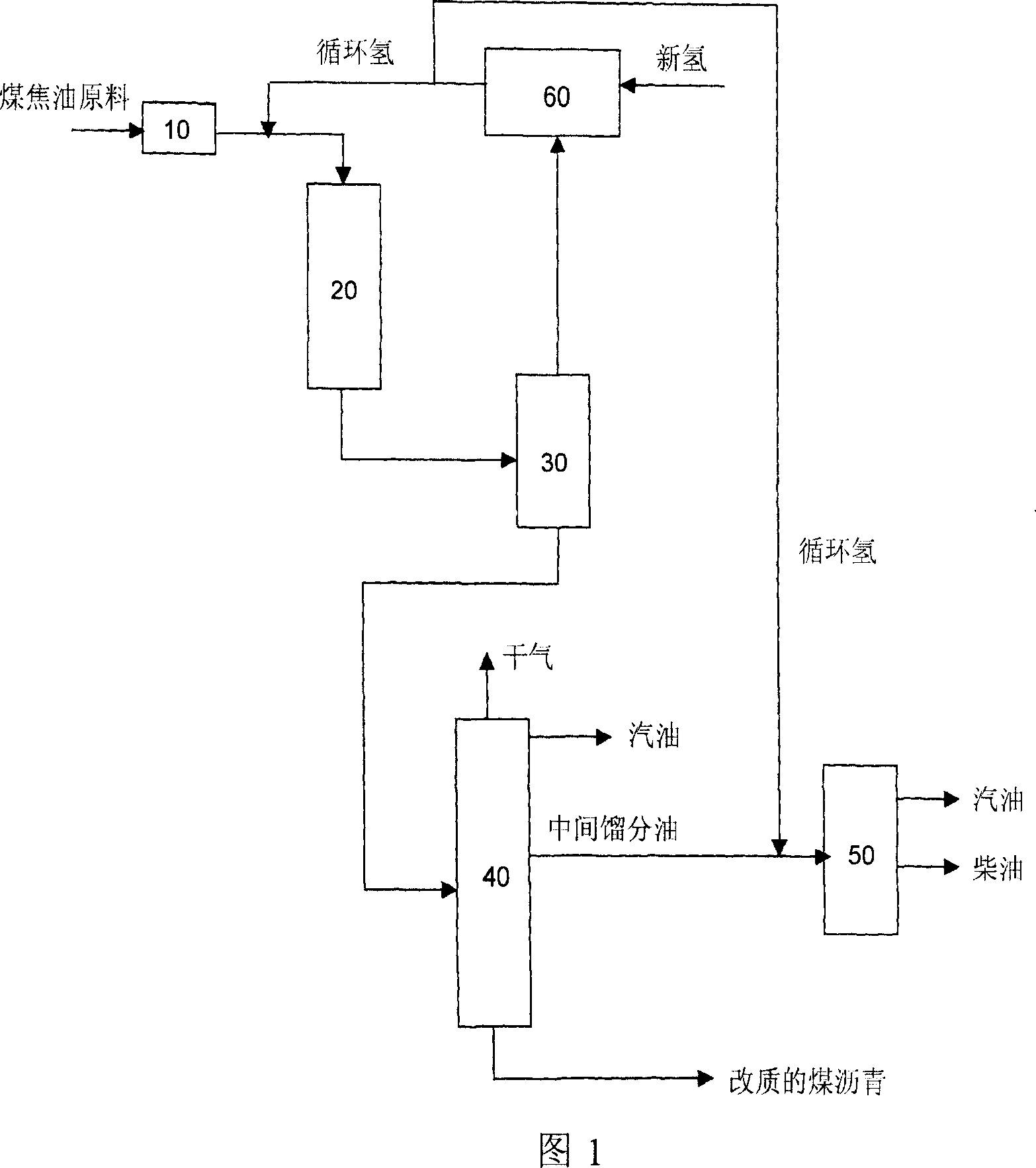

Hydrogenation for processing and utilizing coal tar

InactiveCN101074381ATake advantage ofHigh PAH contentTar working-up by chemical refiningHydrogenGas phase

Hydrogenation for processing and utilizing coal tar is carried out by dewatering for coal tar raw material to water content<0.05%, removing mechanical impurities to obtain purified coal tar raw material, mixing cal tar with hydrogen at 300-427 degree, 10.0-17.0 MPa and 0.15-1.0h-1 liquid volume air speed, hydrogenation reacting to obtain gas-phase and liquid-phase products under hydrogenation protector and loaded hydrogenation catalyst existence, in proportion of hydrogen: coal tar=1000:1-3500:1, and fractioning to obtain gasoline, middle fraction oil and modified coal asphalt. It's reasonable and flexible and has high supplementary value.

Owner:大连圣安煤化工有限公司

Method for removing asphaltene deposits

InactiveUS20080020949A1Reduce and prevent formationPreventing and reducing precipitationWorking-up pitch/asphalt/bitumen by chemical meansFlushingKeroseneFuel oil

Compositions comprising at least one C4-C30 olefin or oxidation product thereof and kerosene or an aromatic solvent are particularly effective for use in removing asphaltene and asphaltene-containing organic deposits and in preventing or reducing the precipitation and deposition of asphaltenes from hydrocarbon fluids. When added to heavy oils comprising asphaltenes, alone or in combination with dispersants and further inhibitors, the invented compositions lower viscosity and pour point, and aid in preventing asphaltene precipitation during transport and in combustion.

Owner:INEOS USA LLC

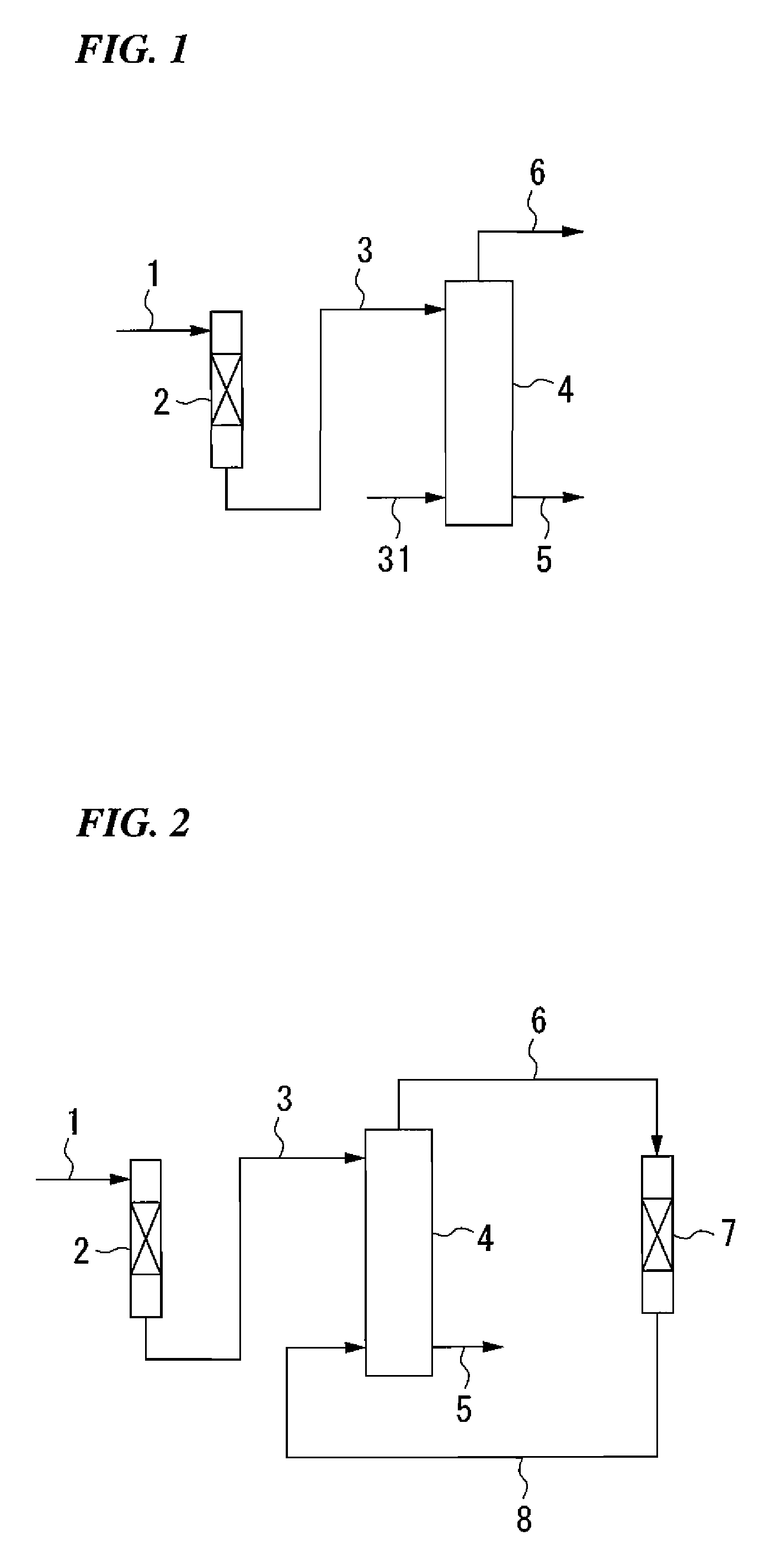

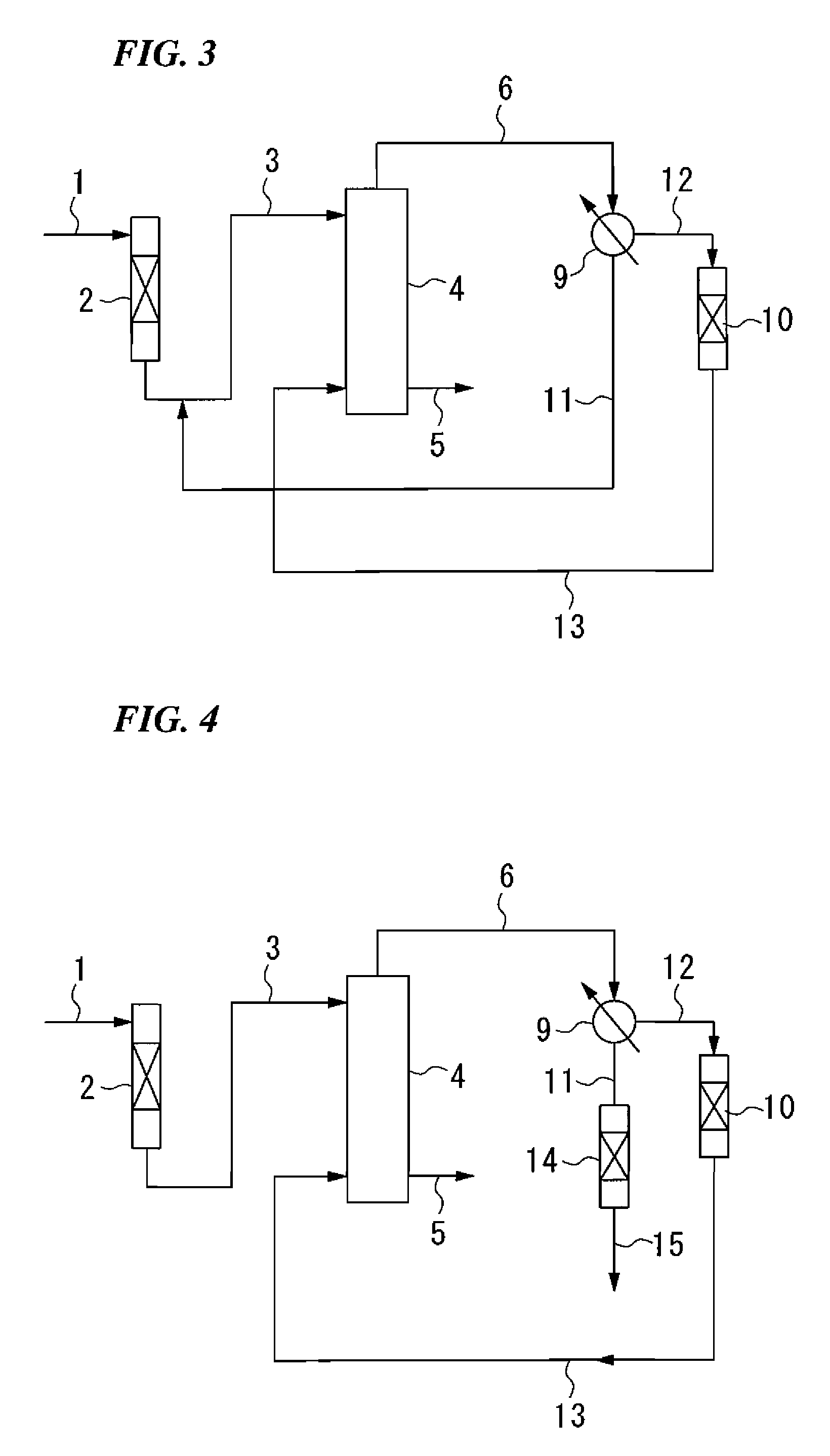

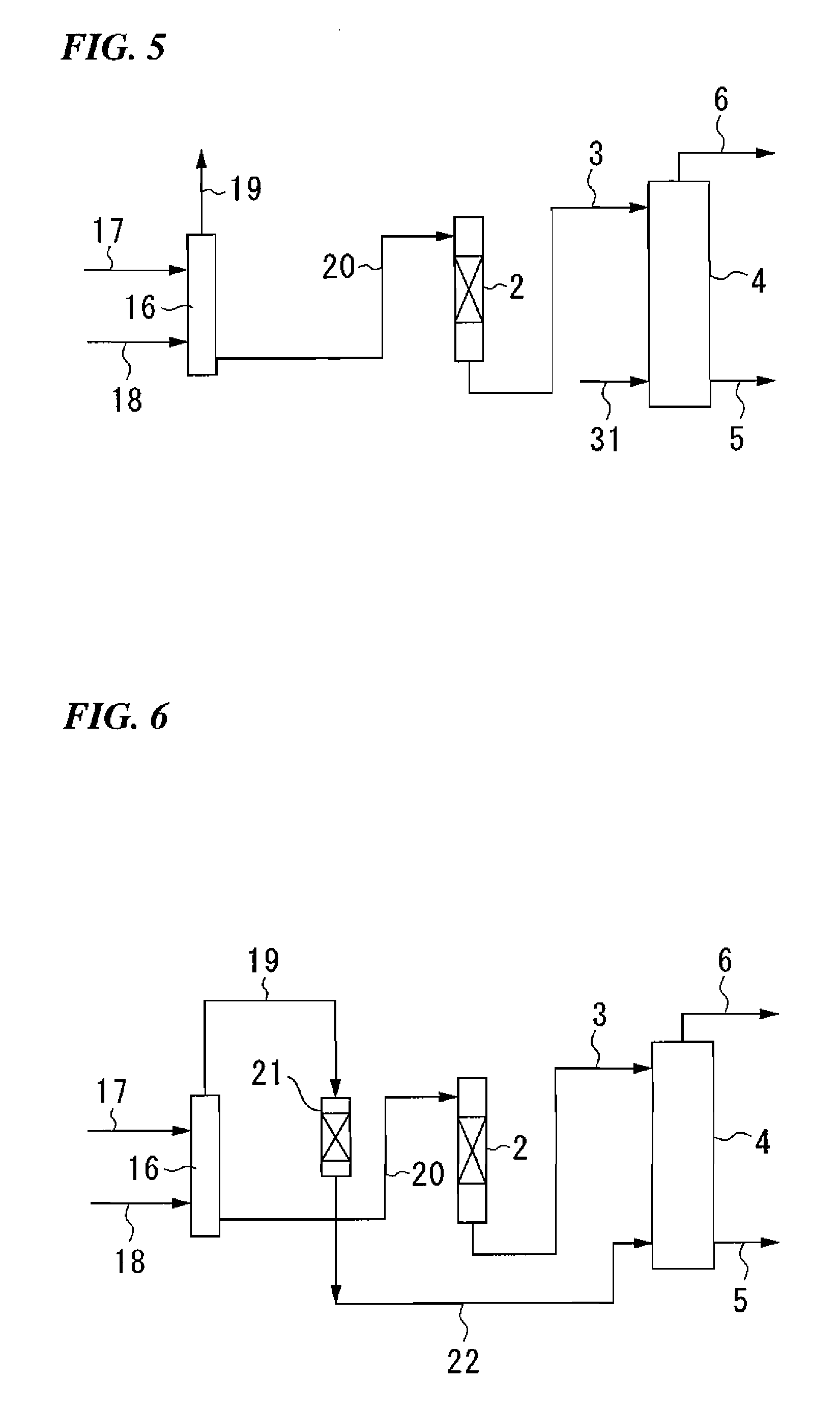

Mercury removal apparatus for liquid hydrocarbon

InactiveUS20100025184A1Easy to useComponent can be removedPhysical/chemical process catalystsUsing liquid separation agentLiquid stateLiquid hydrocarbons

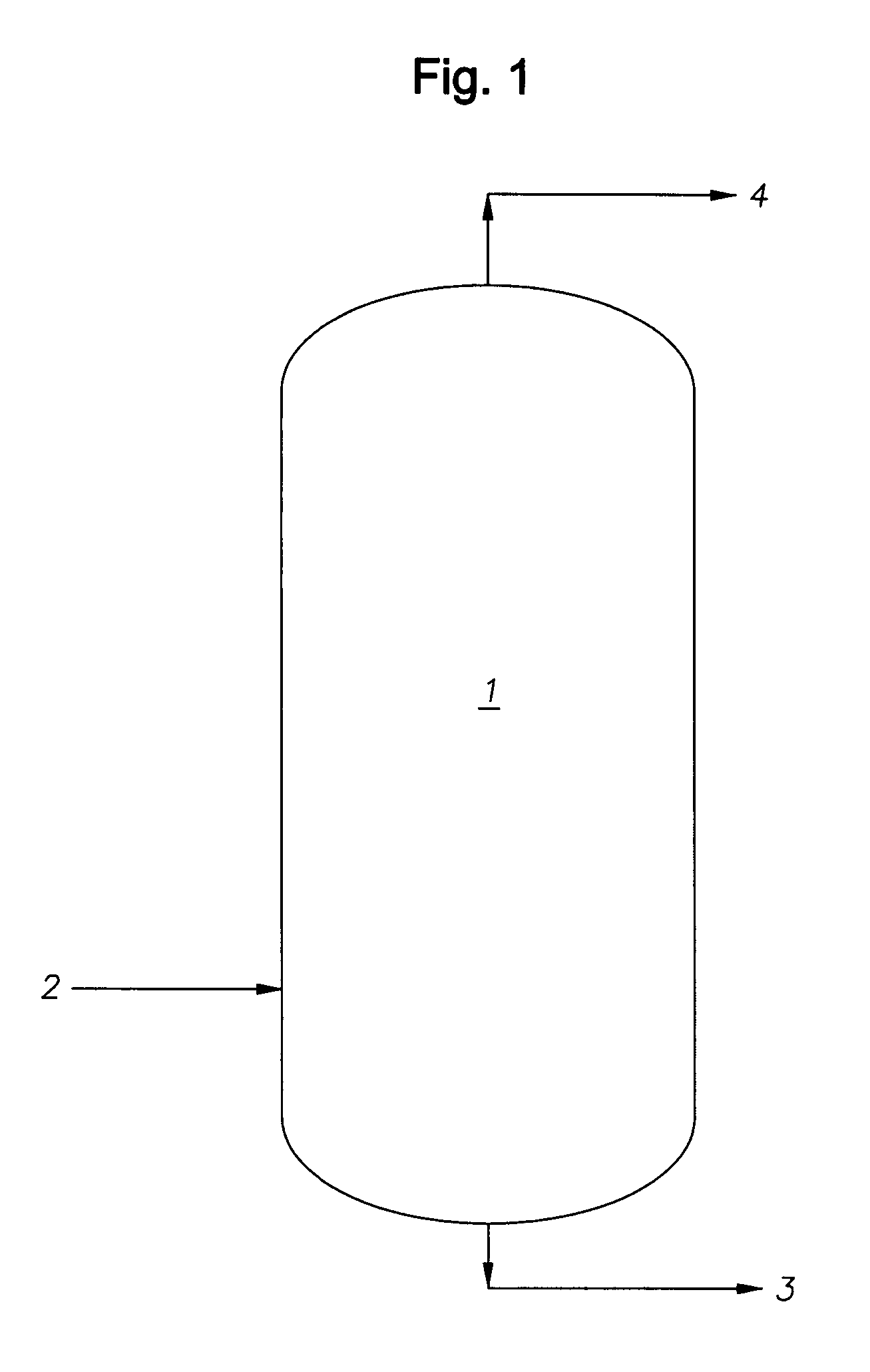

A mercury removal apparatus for a liquid hydrocarbon of the present invention includes a conversion device 2 which converts a mercury component in a raw liquid hydrocarbon into elemental mercury to obtain a first liquid hydrocarbon containing the elemental mercury; and a first stripping device 4 which brings the first liquid hydrocarbon into counter-current contact with a first stripping gas, thereby transferring the elemental mercury in the first liquid hydrocarbon to the first stripping gas to obtain a second liquid hydrocarbon in which the amount of the elemental mercury decreases and a first gaseous hydrocarbon containing the elemental mercury.

Owner:JAPAN PETROLEUM EXPLORATION CO LTD +1

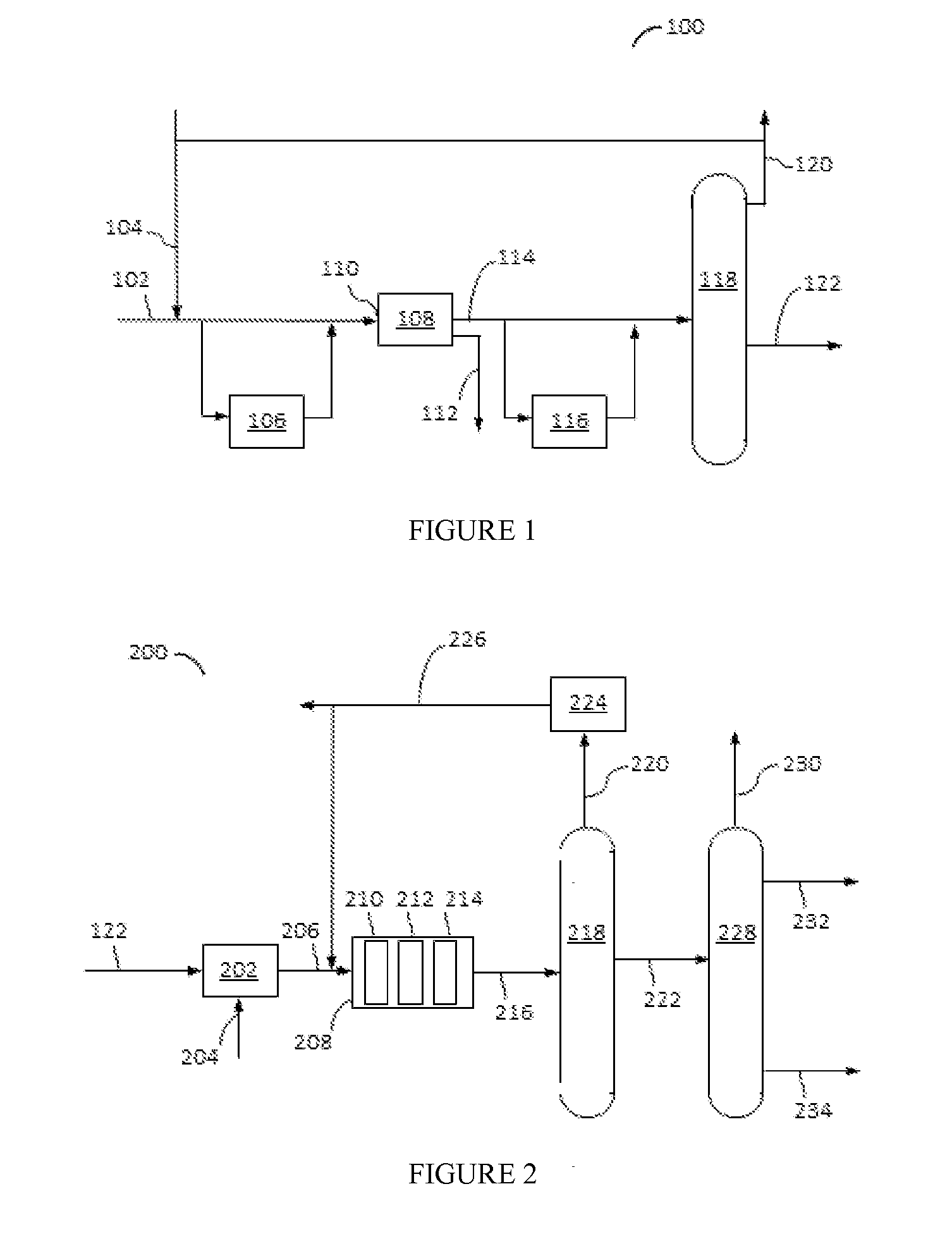

Method and Apparatus for Improving A Hydrocarbon Feed

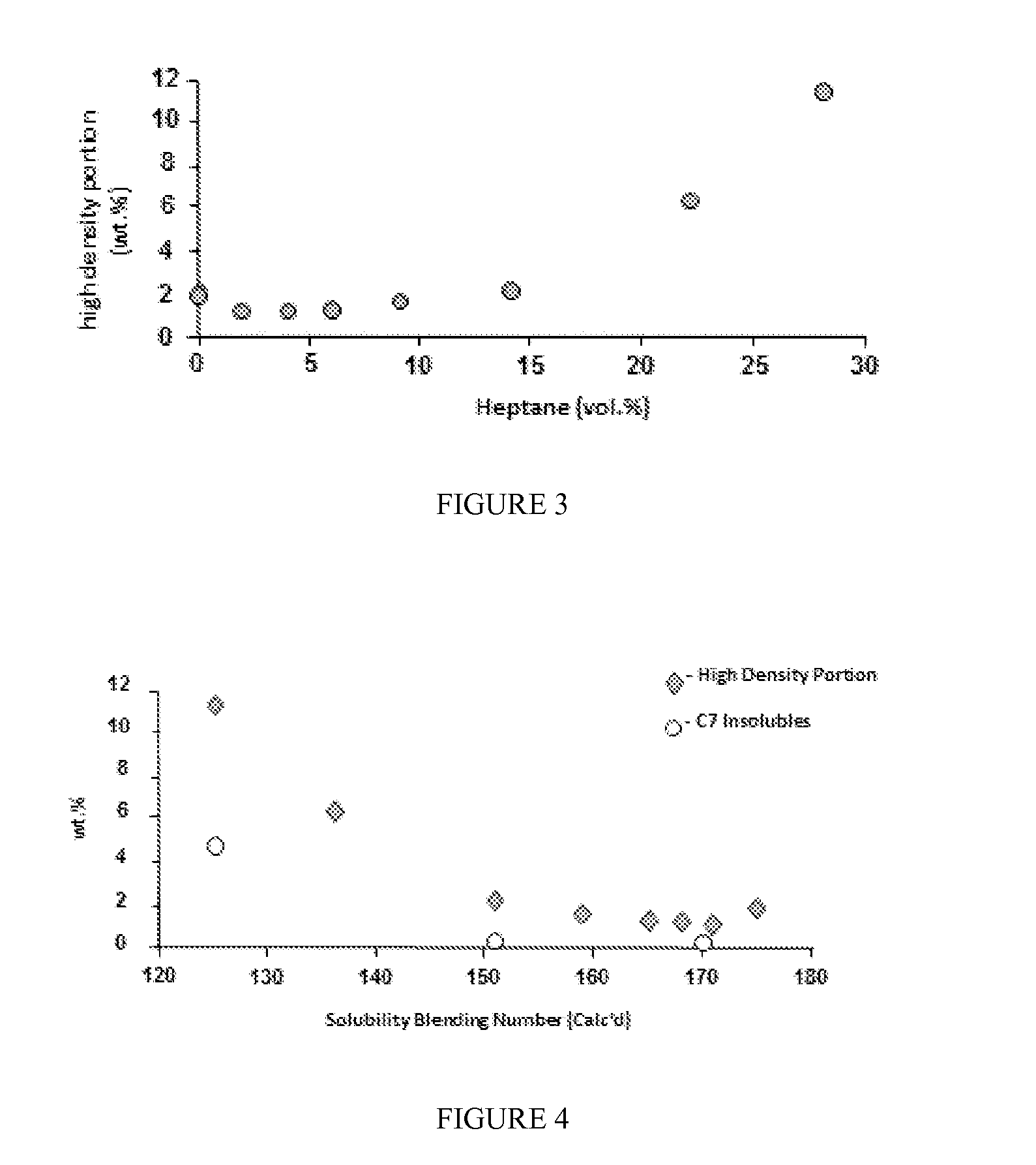

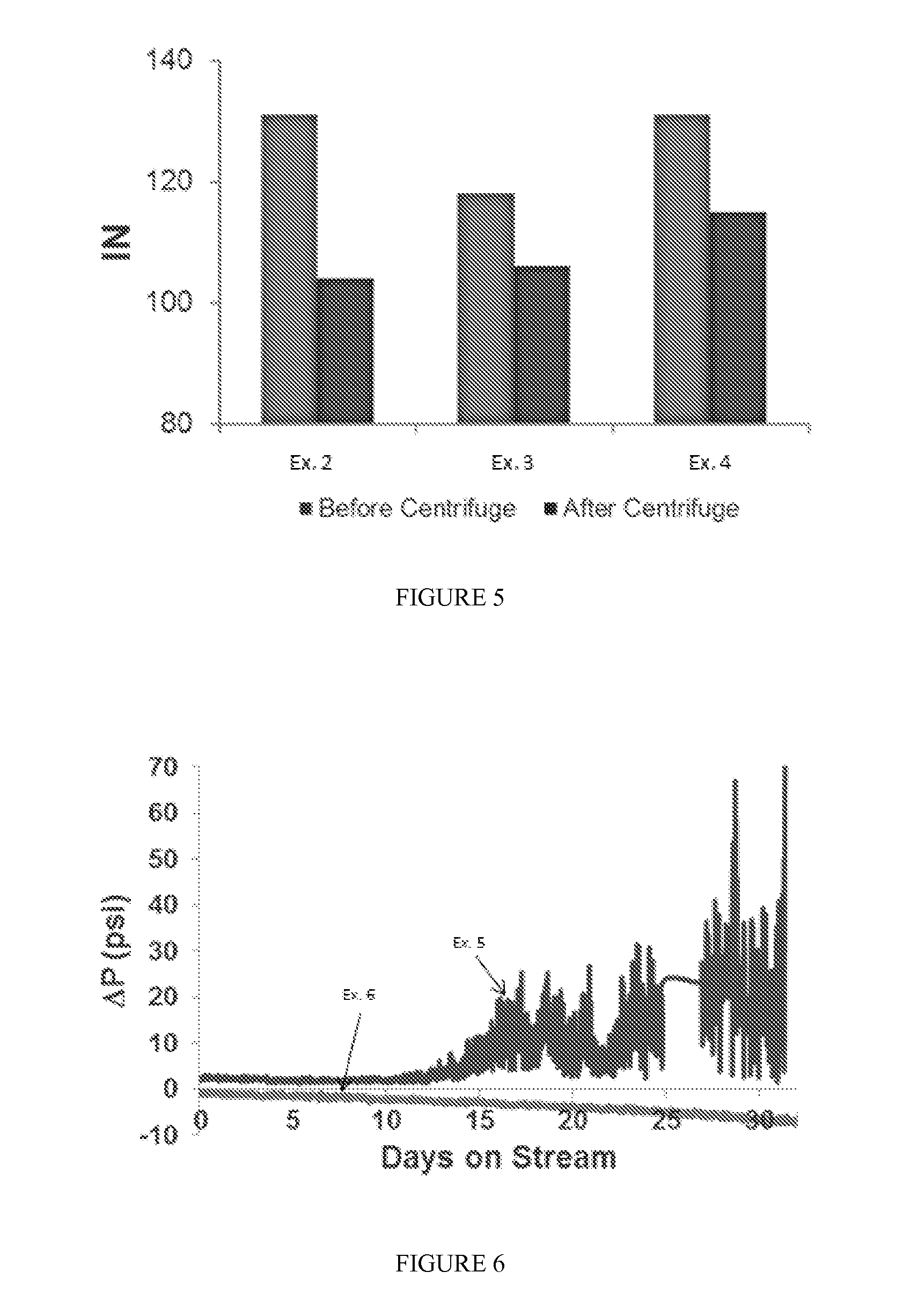

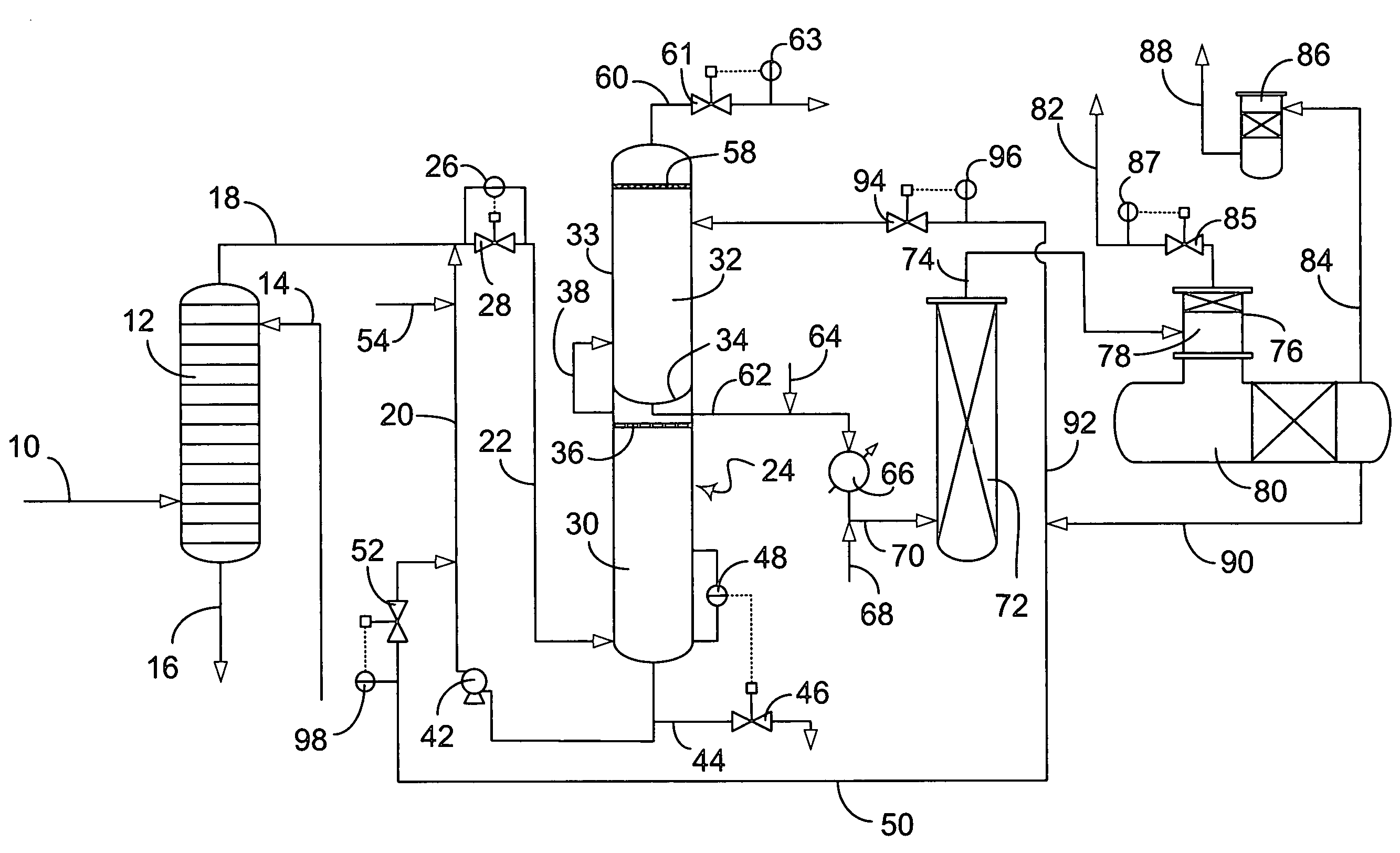

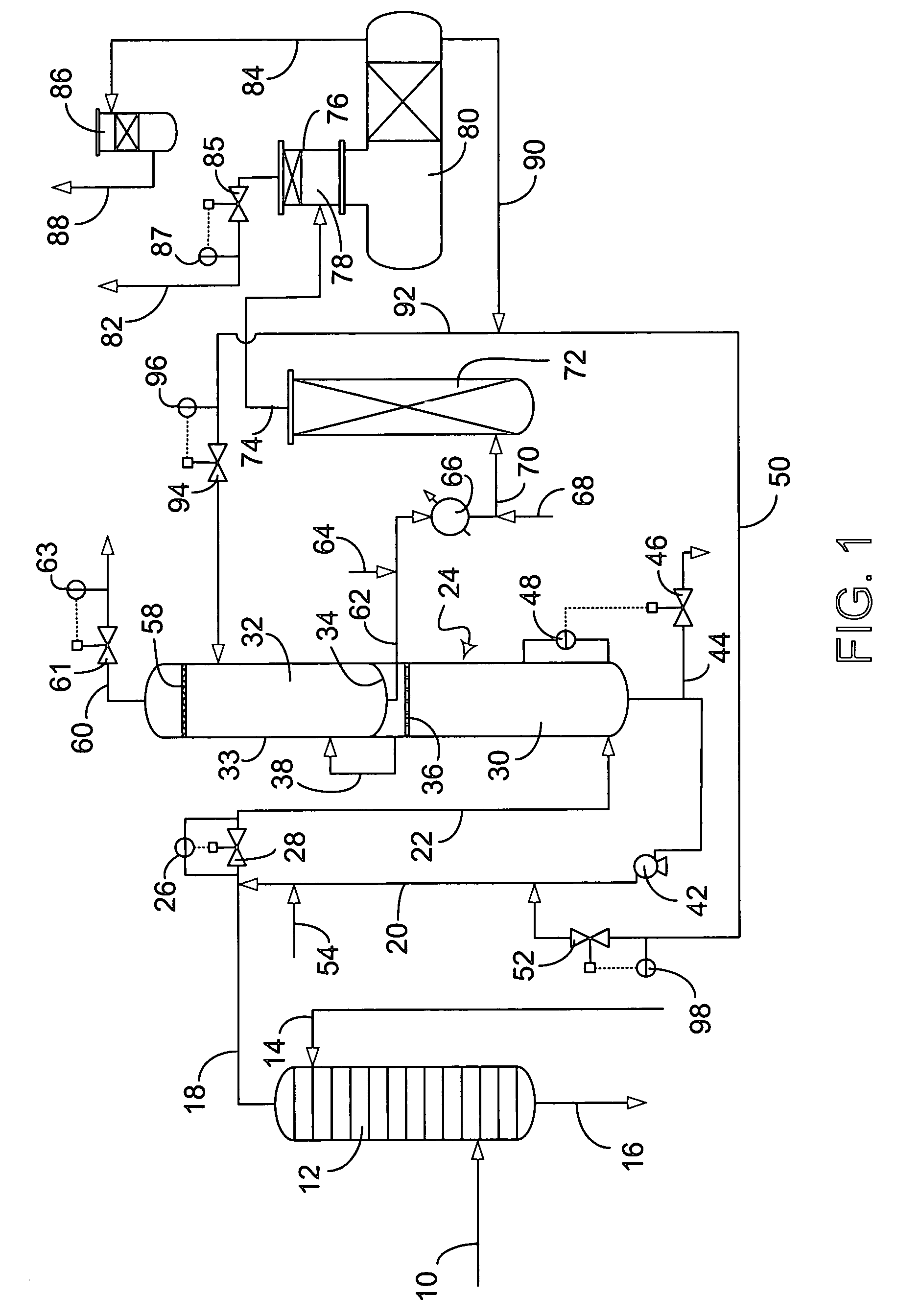

ActiveUS20150361354A1Improve compatibilityImprove scalabilityTreatment with plural serial stages onlyRotary centrifugesHigh densityVolumetric Mass Density

Methods for upgrading a hydrocarbon feed are disclosed. The methods include a hydrocarbon feed having an insolubility number, Ifeed, with at least a first fluid to form a fluid-feed mixture; and inducing a centrifugal force to the fluid-feed mixture sufficient to form at least a higher density portion and a lower density portion, said lower density portion having an insolubility number, ILD, wherein ILD / Ifeed≦0.95. Methods and apparatus for hydroprocessing the treated feed and blending with a fuel oil blend-stock are also described.

Owner:EXXONMOBIL CHEM PAT INC

Apparatus for prewashing a hydrocarbon stream containing hydrogen sulfide

Disclosed is an apparatus for extracting sulfur compounds from a hydrocarbon stream. A prewash section for converting hydrogen sulfide to sodium sulfide by reaction with an alkali such as caustic prepares the hydrocarbon stream for extraction. Spent alkali is continuously withdrawn and regenerated alkali is continuously added to the prewash section.

Owner:UOP LLC

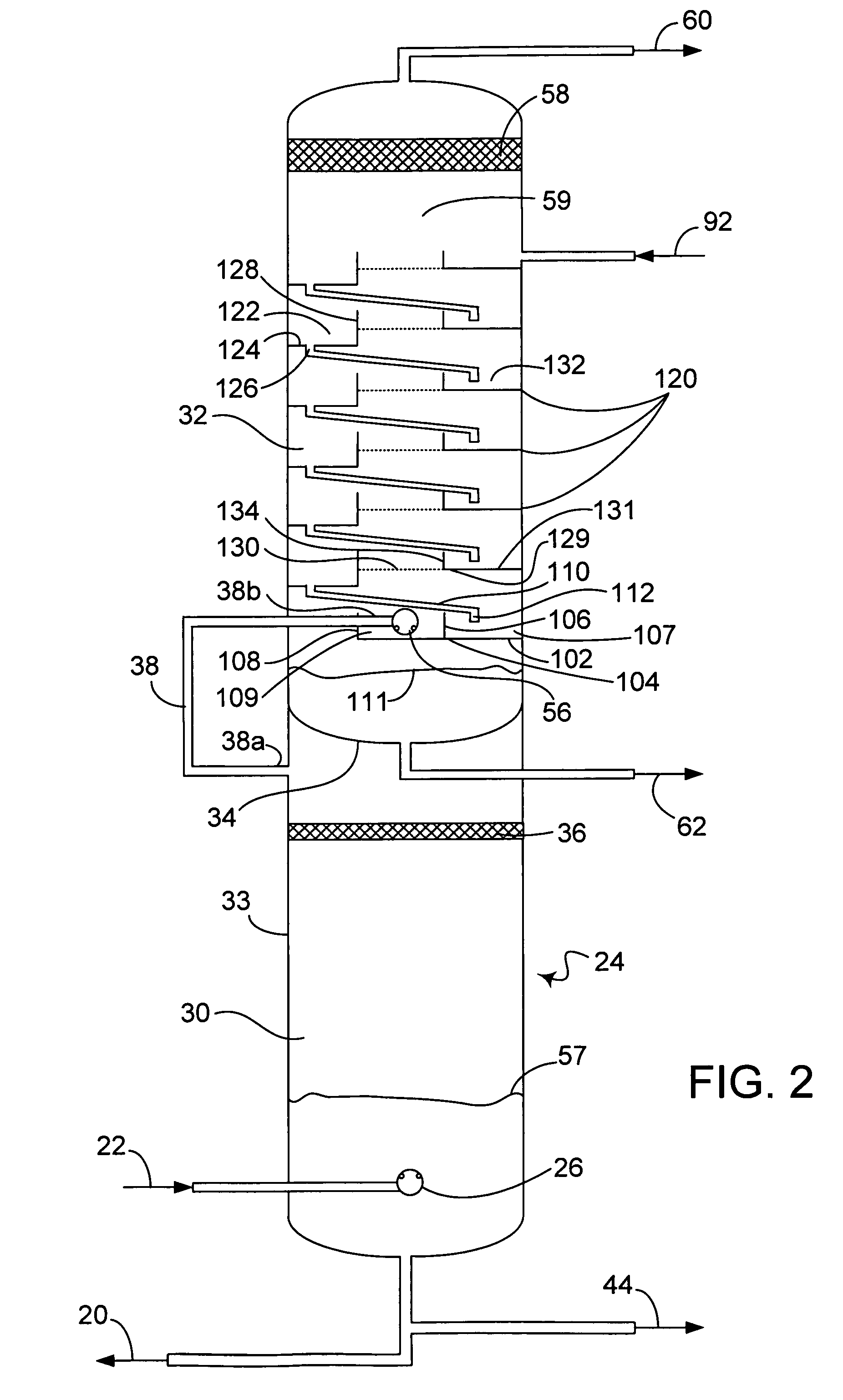

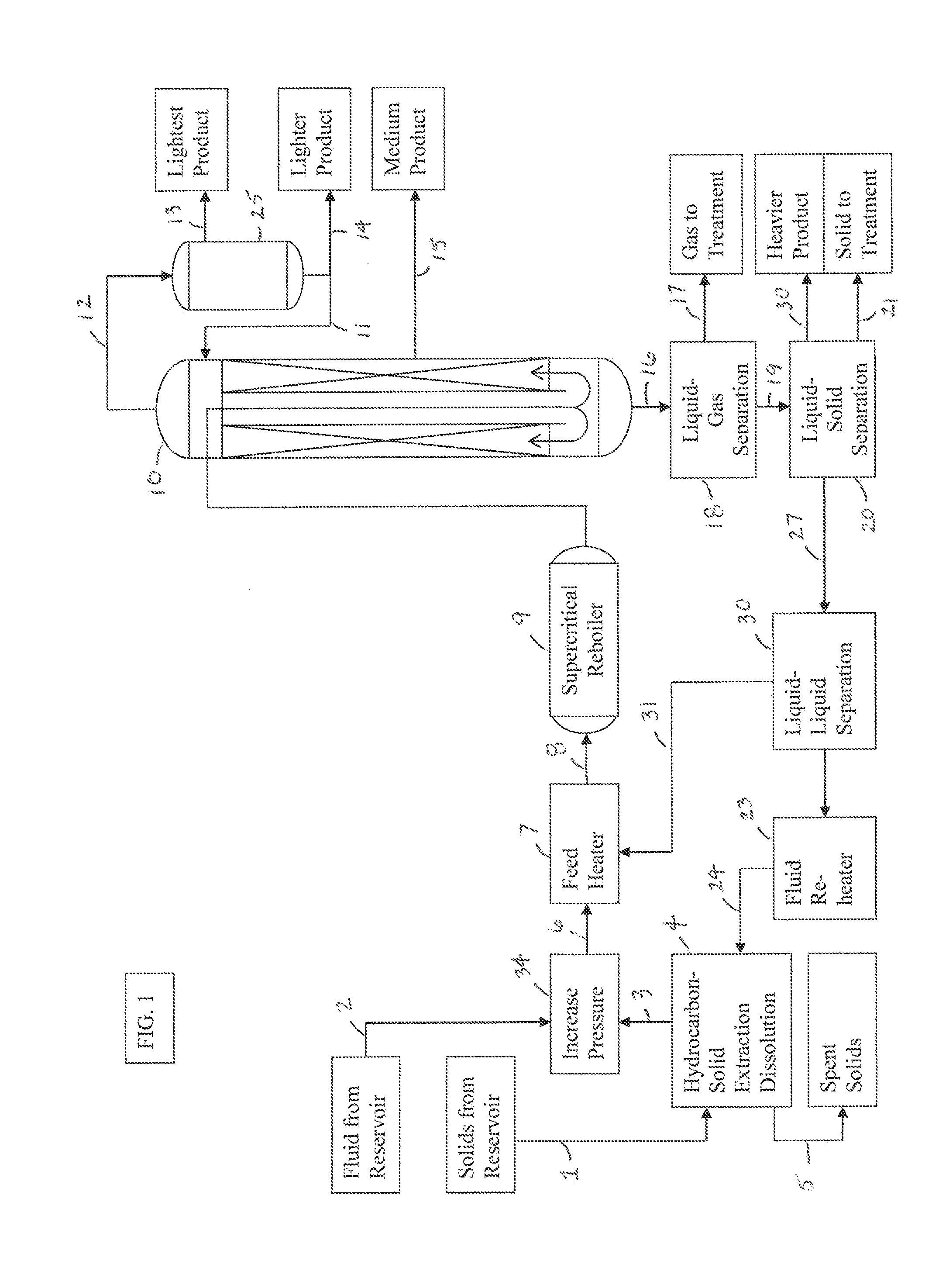

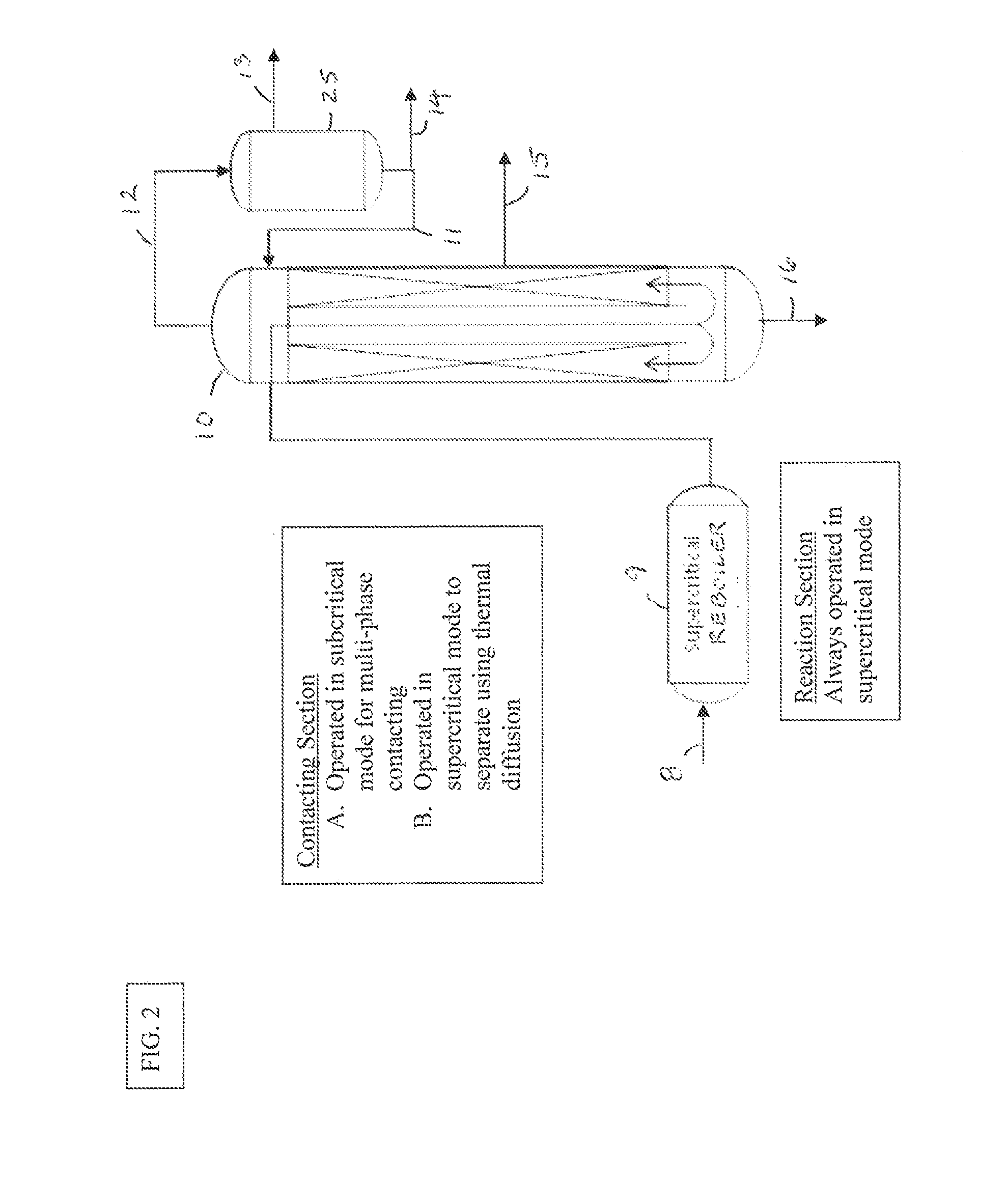

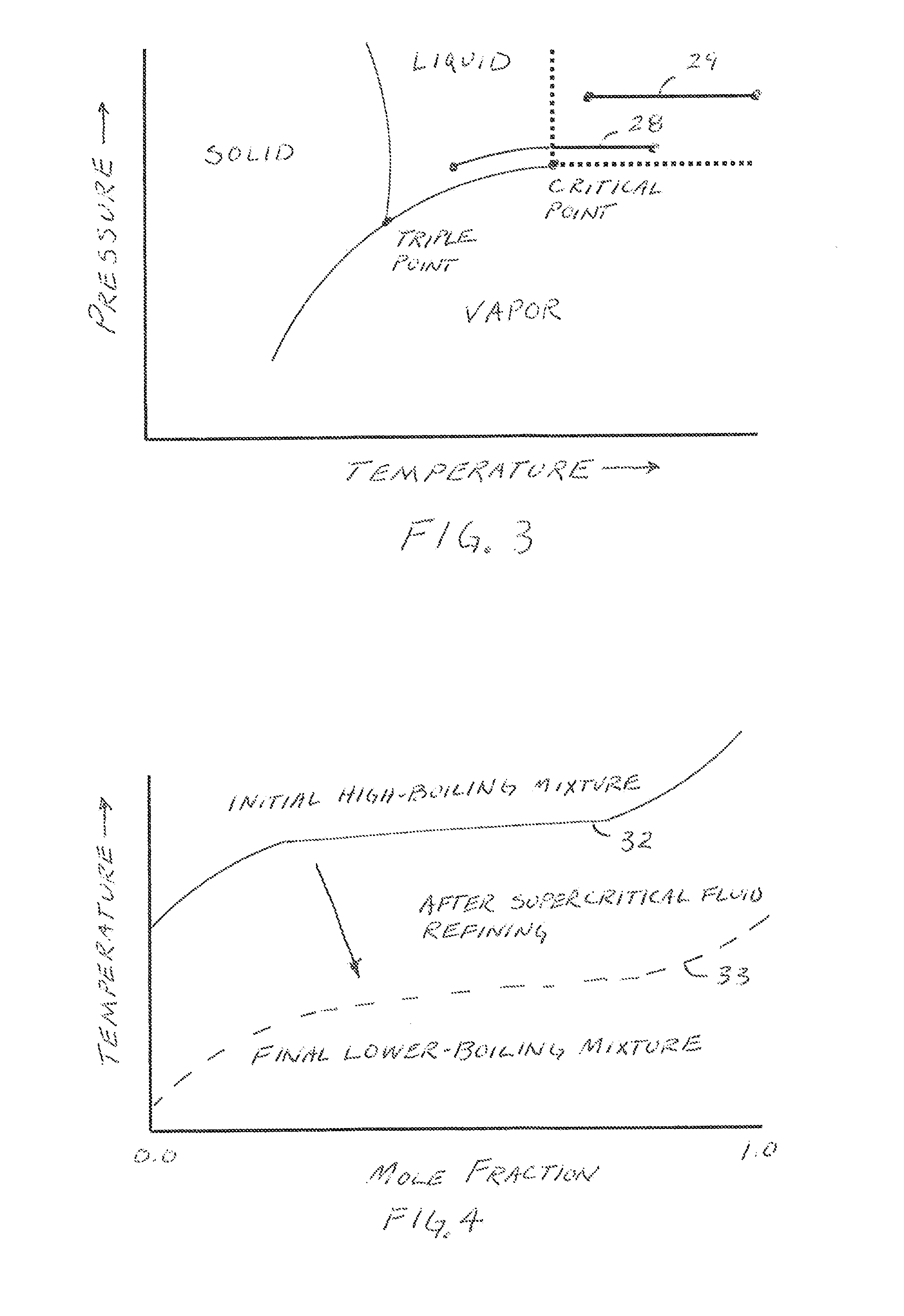

Using supercritical fluids to refine hydrocarbons

ActiveUS20110163011A1Light weightImprove securityRefining by water treatmentLiquid hydrocarbon mixture productionHydrocotyle bowlesioidesAPI gravity

This is a method to reactively refine hydrocarbons, such as heavy oils with API gravities of less than 20° and bitumen-like hydrocarbons with viscosities greater than 1000 cp at standard temperature and pressure using a selected fluid at supercritical conditions. The reaction portion of the method delivers lighter weight, more volatile hydrocarbons to an attached contacting device that operates in mixed subcritical or supercritical modes. This separates the reaction products into portions that are viable for use or sale without further conventional refining and hydro-processing techniques. This method produces valuable products with fewer processing steps, lower costs, increased worker safety due to less processing and handling, allow greater opportunity for new oil field development and subsequent positive economic impact, reduce related carbon dioxide, and wastes typical with conventional refineries.

Owner:HEAVY OIL SOLUTIONS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com