Patents

Literature

399results about "Working-up pitch/asphalt/bitumen by distillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Systems, methods, and catalysts for producing a crude product

InactiveUS20050139522A1Working-up pitch/asphalt/bitumen by distillationCatalytic crackingHydrogenProduct system

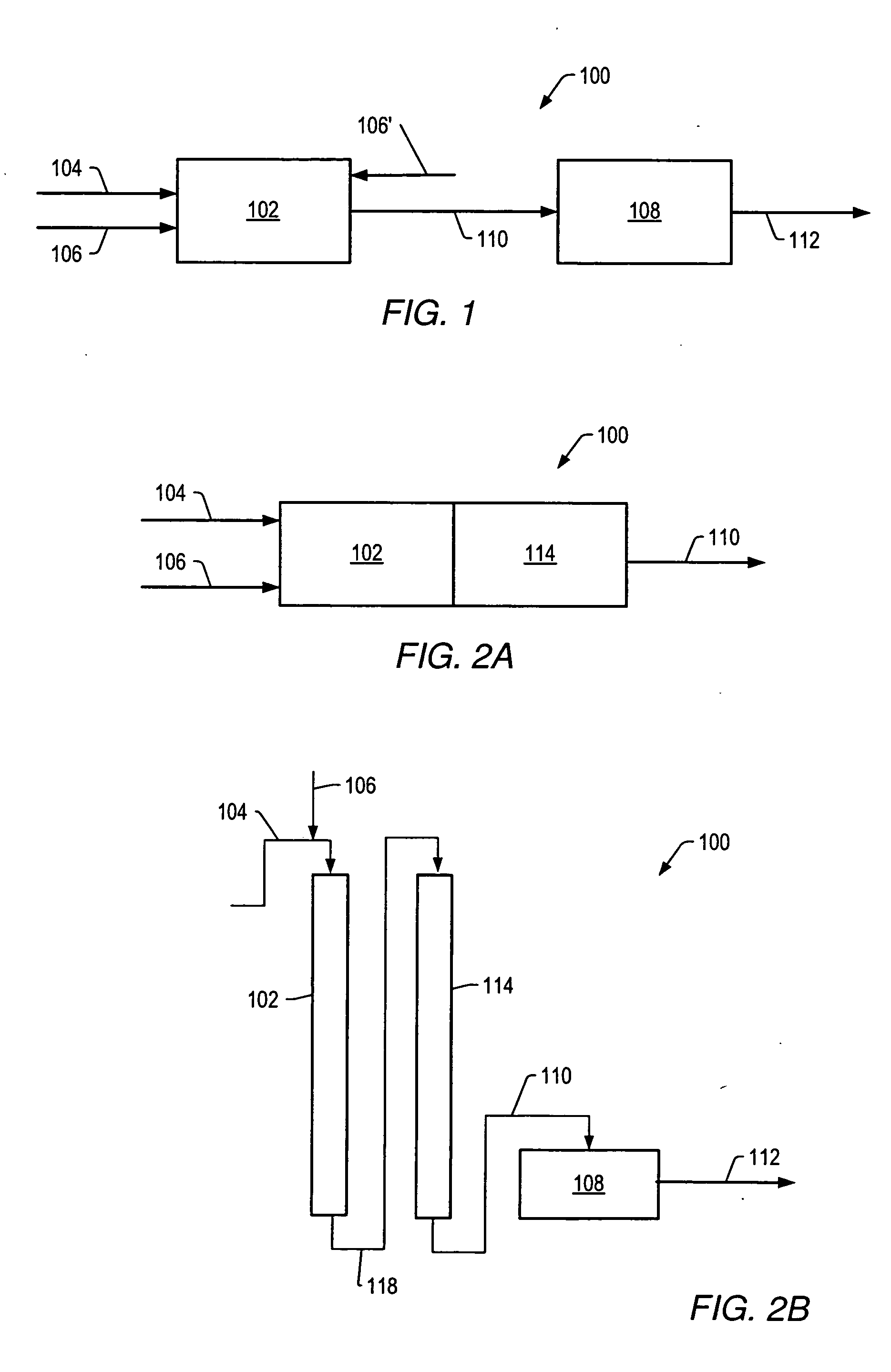

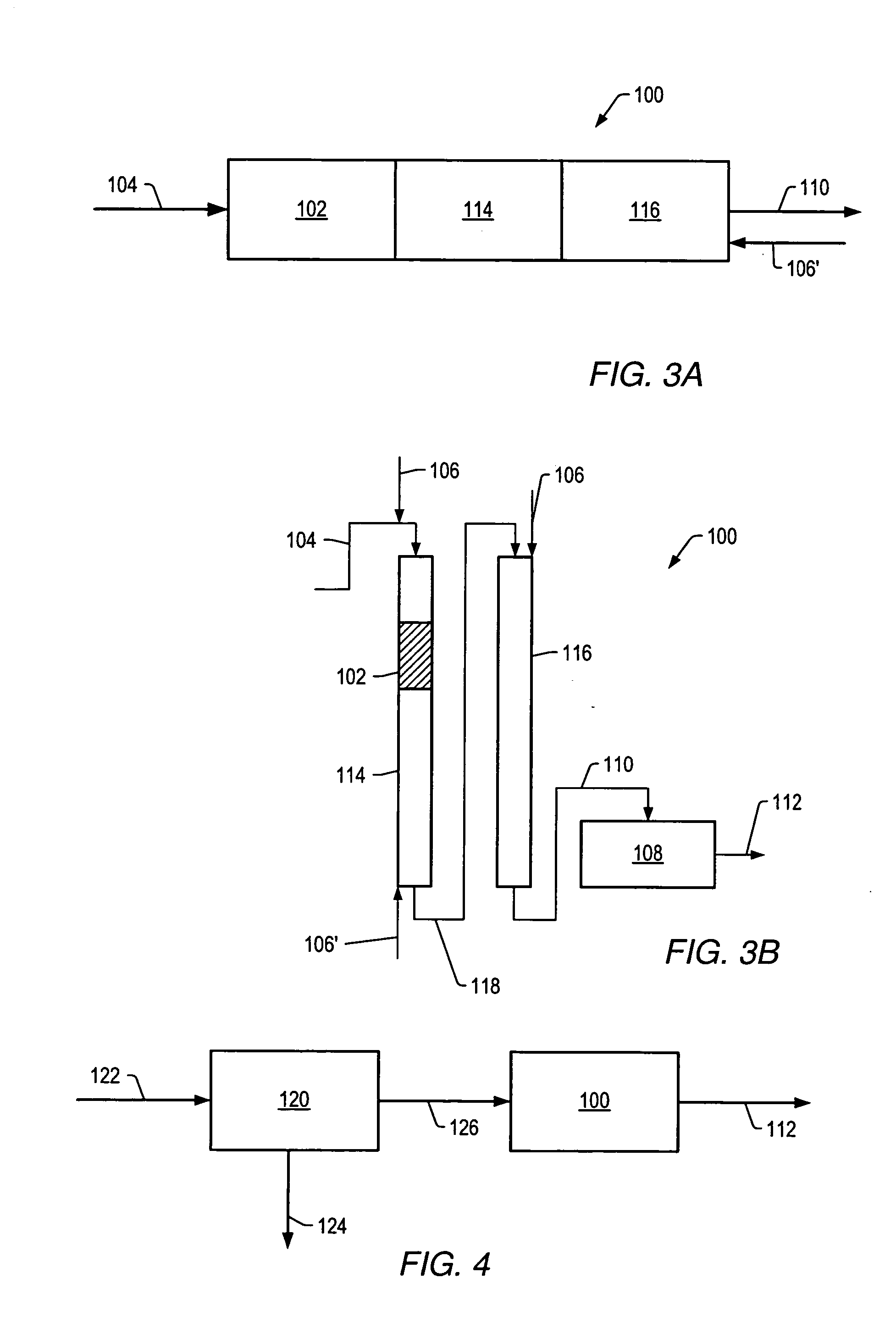

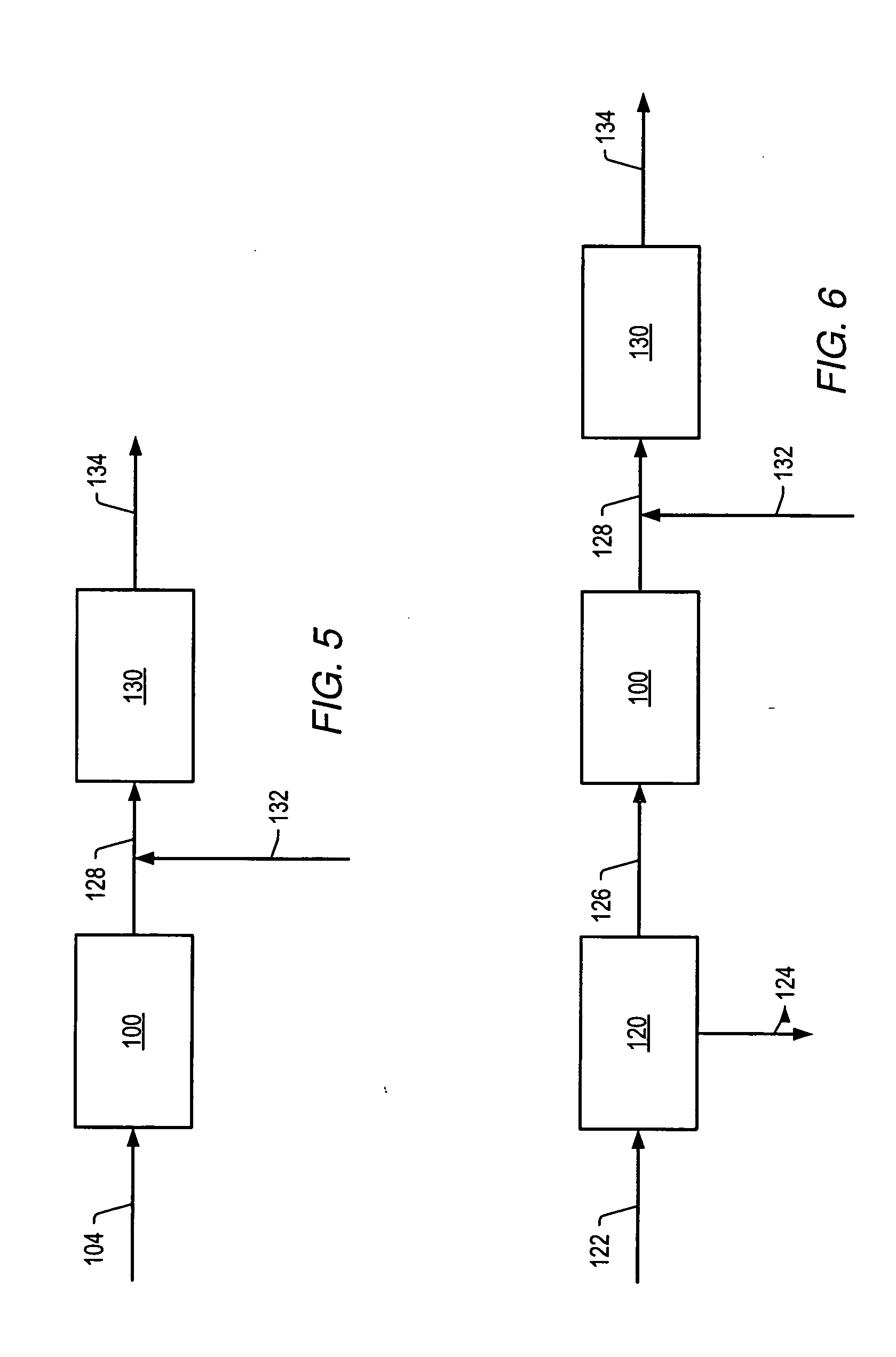

Systems and methods for contacting a crude feed with one or more catalysts produces a total product that include a crude product are described. The crude product is a liquid mixture at 25° C. and 0.101 MPa. The one or more catalysts may include one or more vanadium catalysts. Methods and compositions of the one or more vanadium catalysts are described. One or more properties of the crude product may be changed by at least 10% relative to the respective properties of the crude feed. In some embodiments, hydrogen is generated.

Owner:SHELL OIL CO

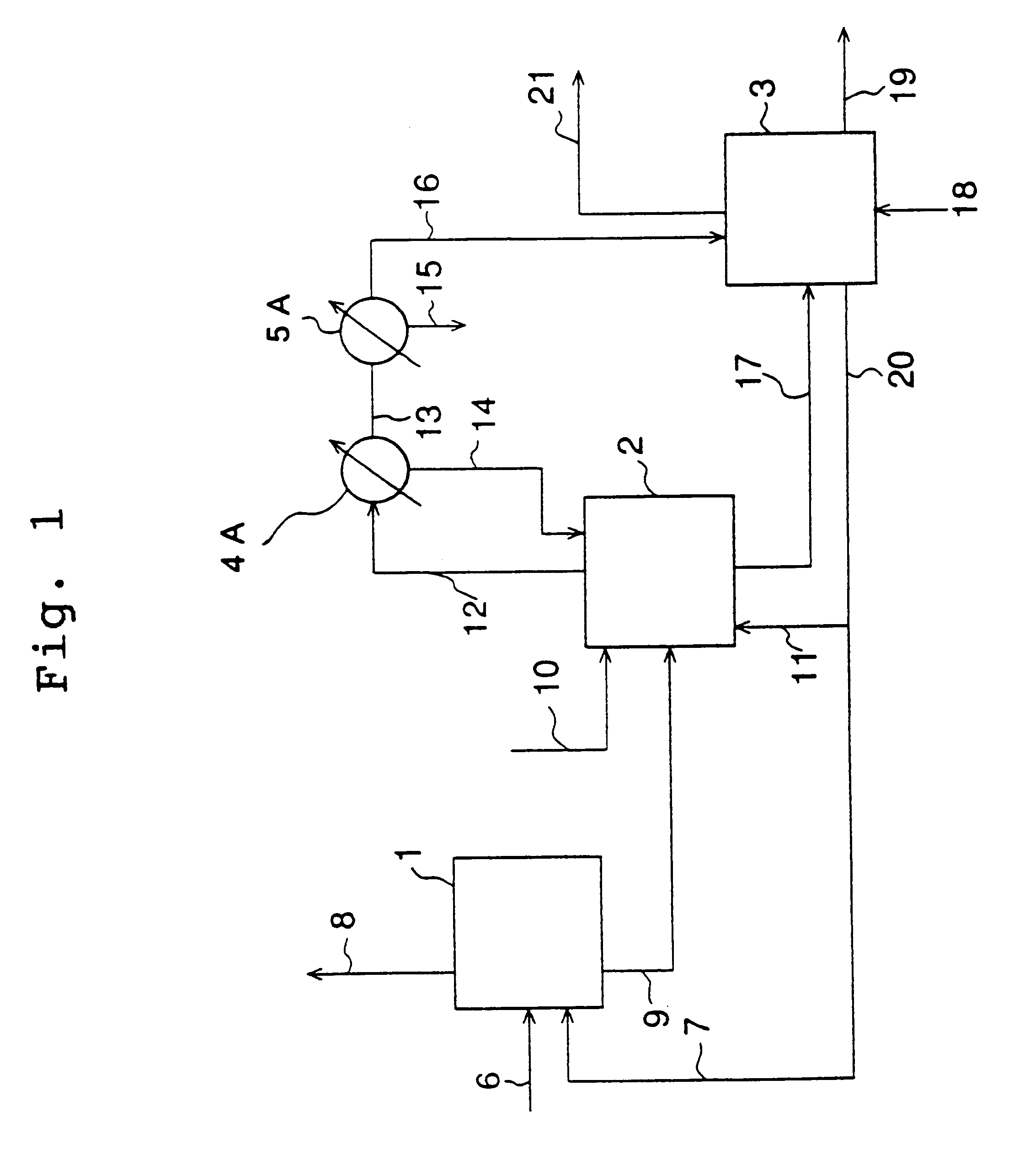

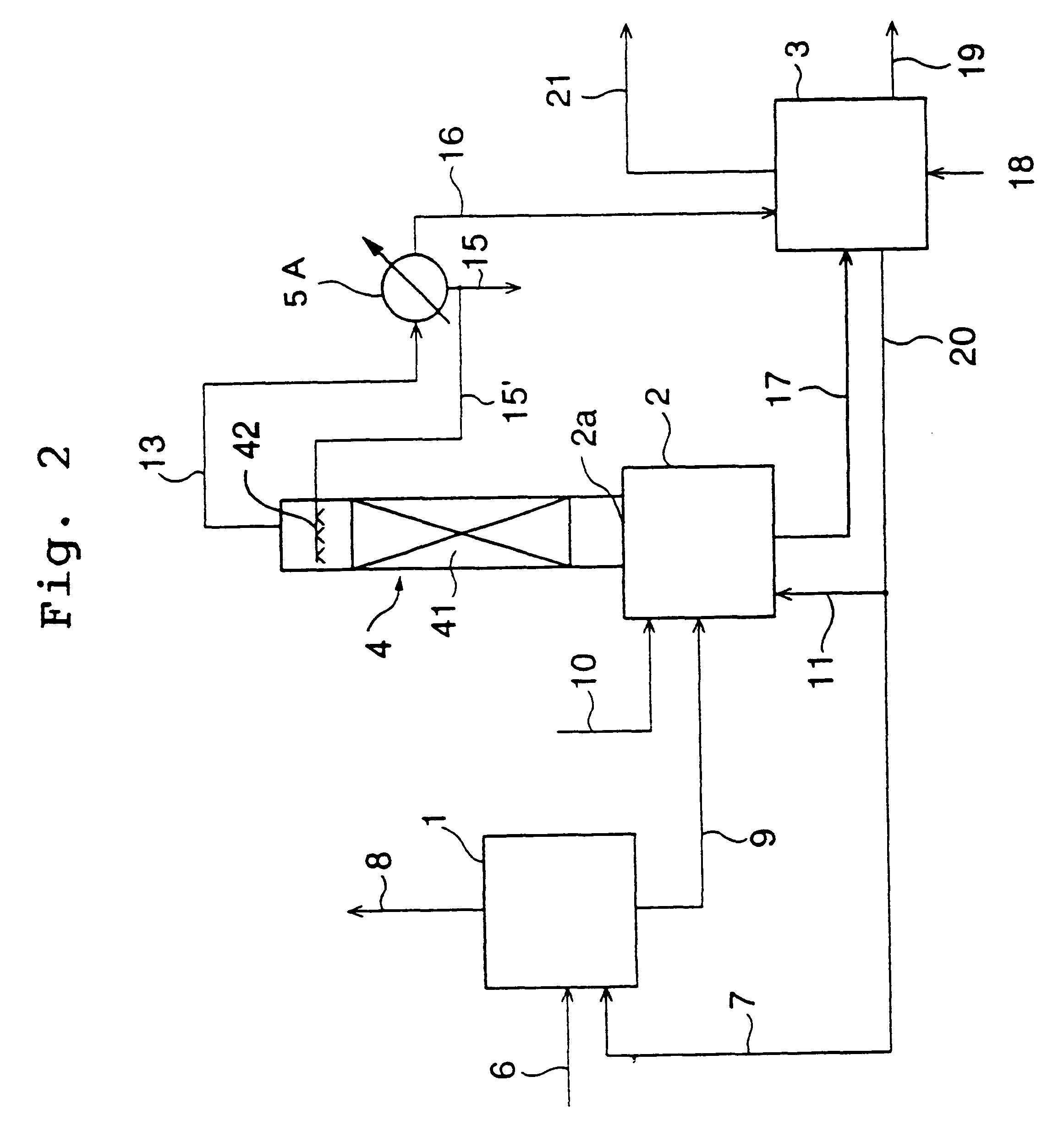

Method and apparatus for reclaiming oil from waste plastic

InactiveUS6172271B1Increase productionContinuous operationThermal non-catalytic crackingHydrocarbon distillationForeign matterBoiling point

Owner:MITSUBISHI HEAVY IND LTD

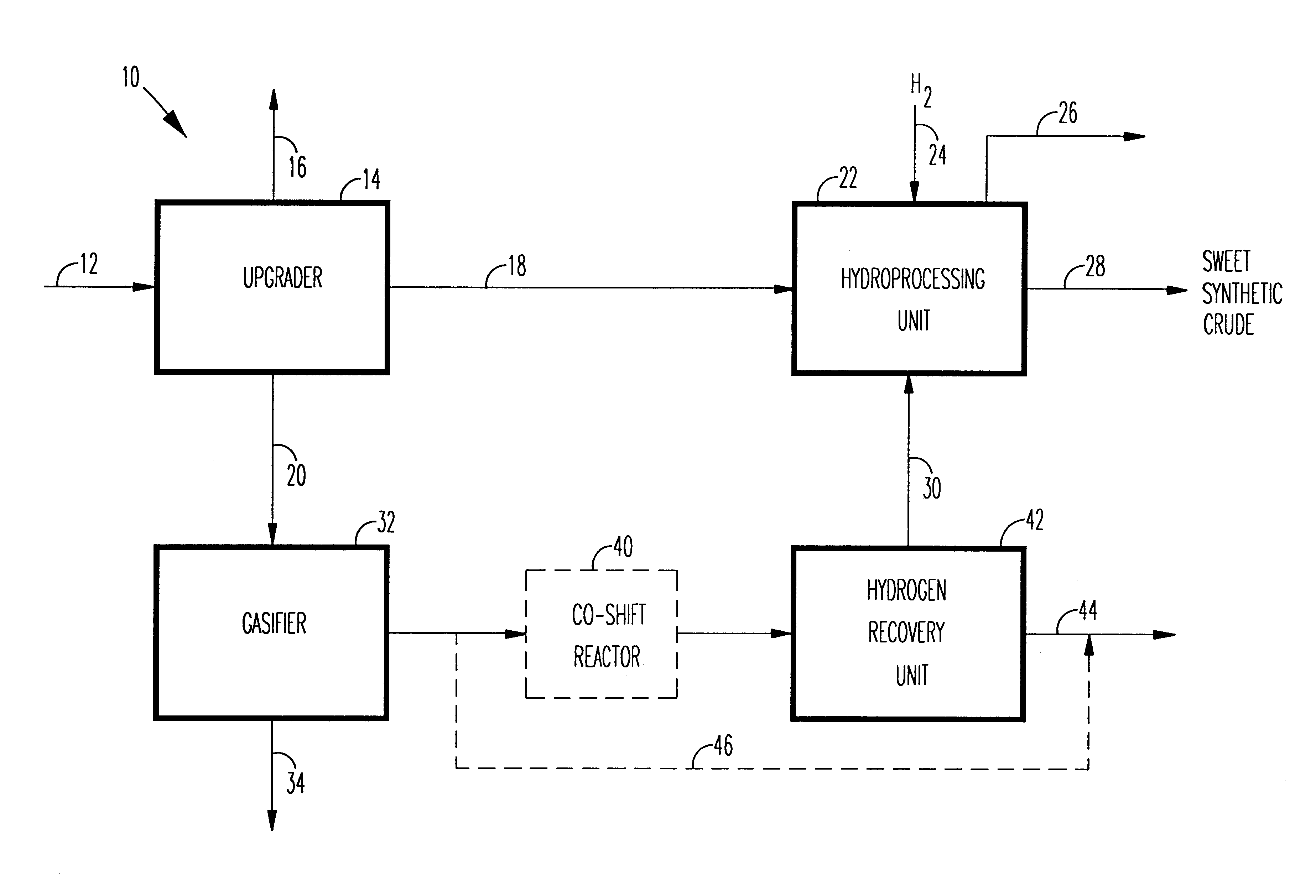

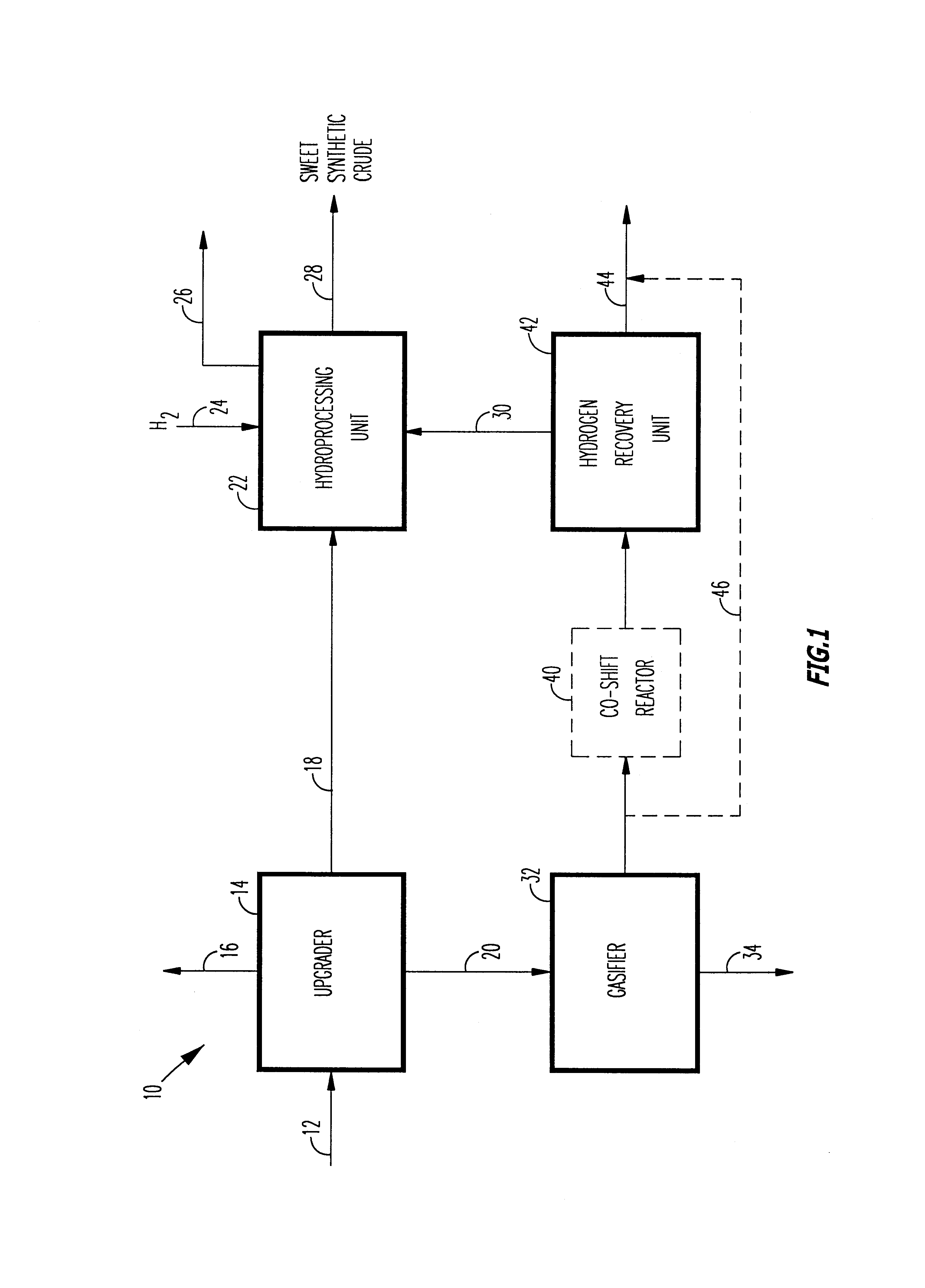

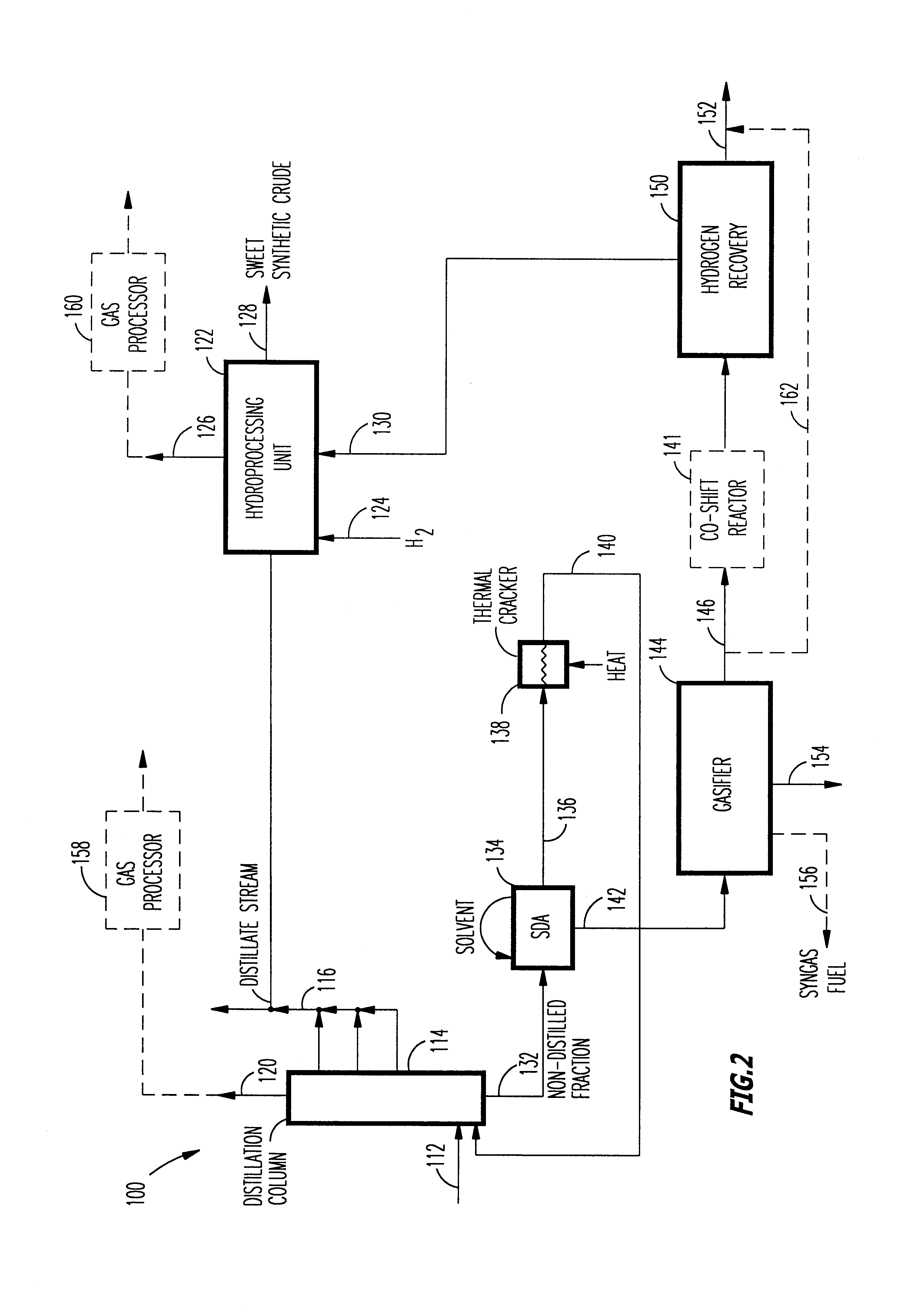

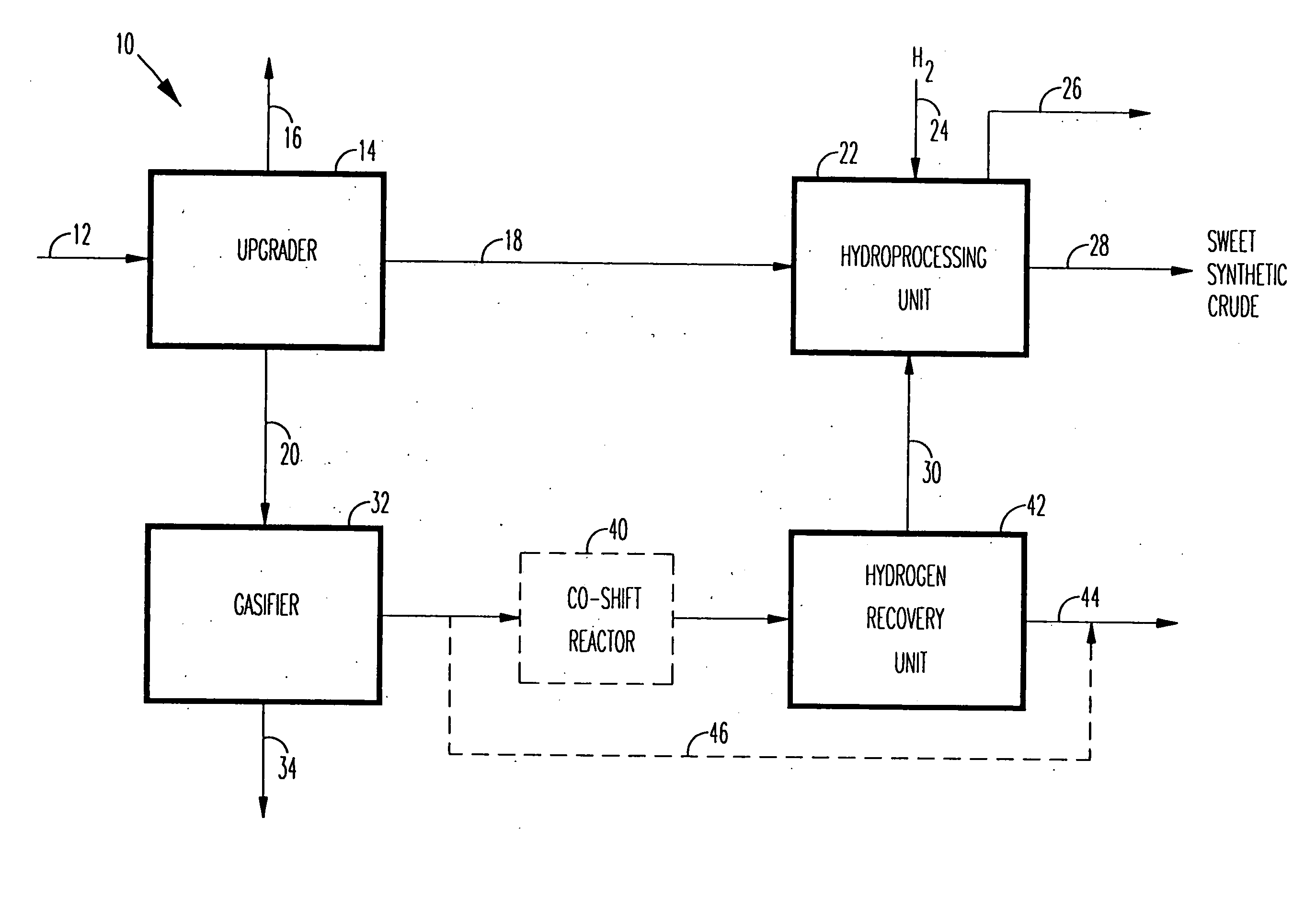

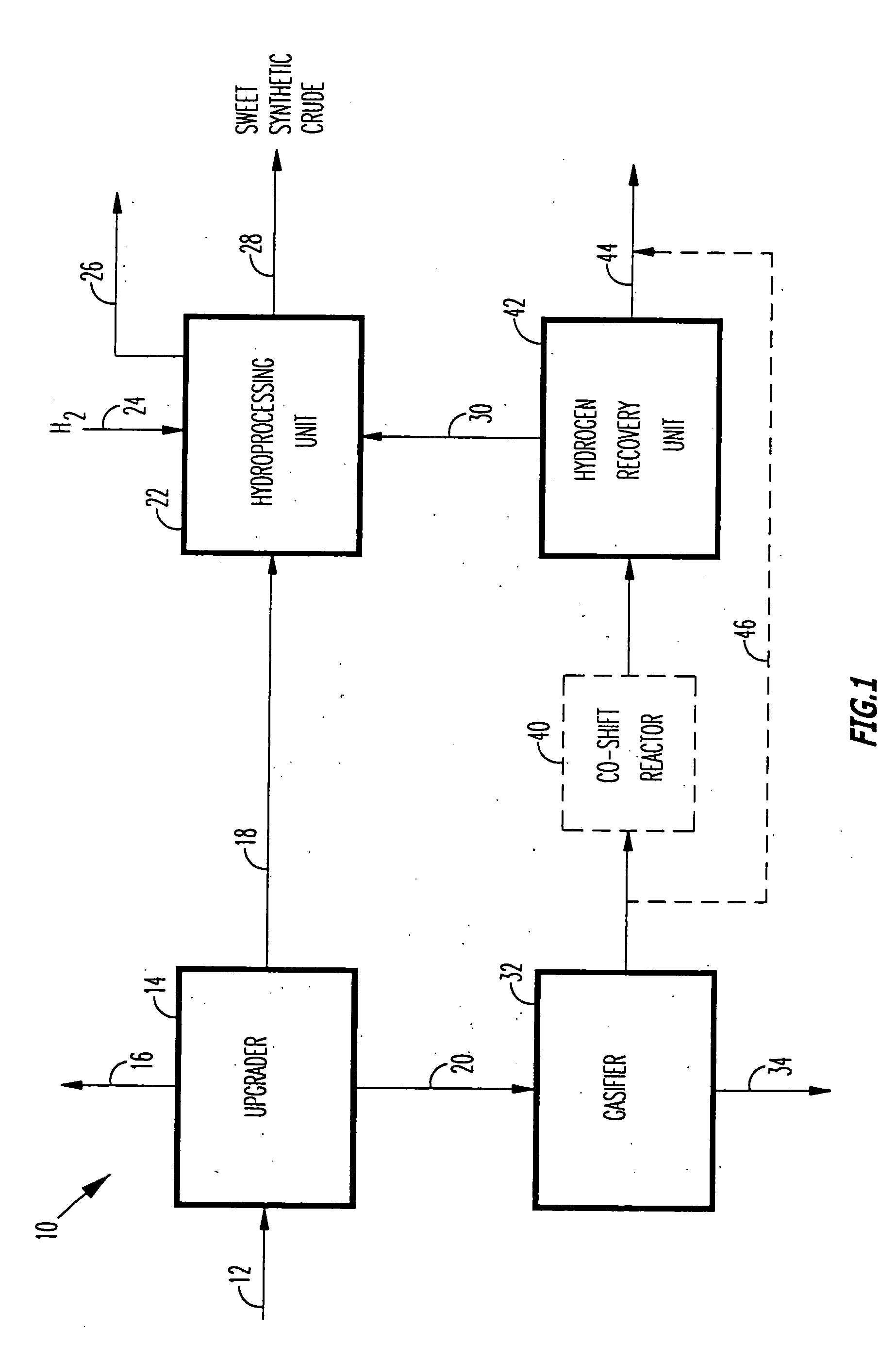

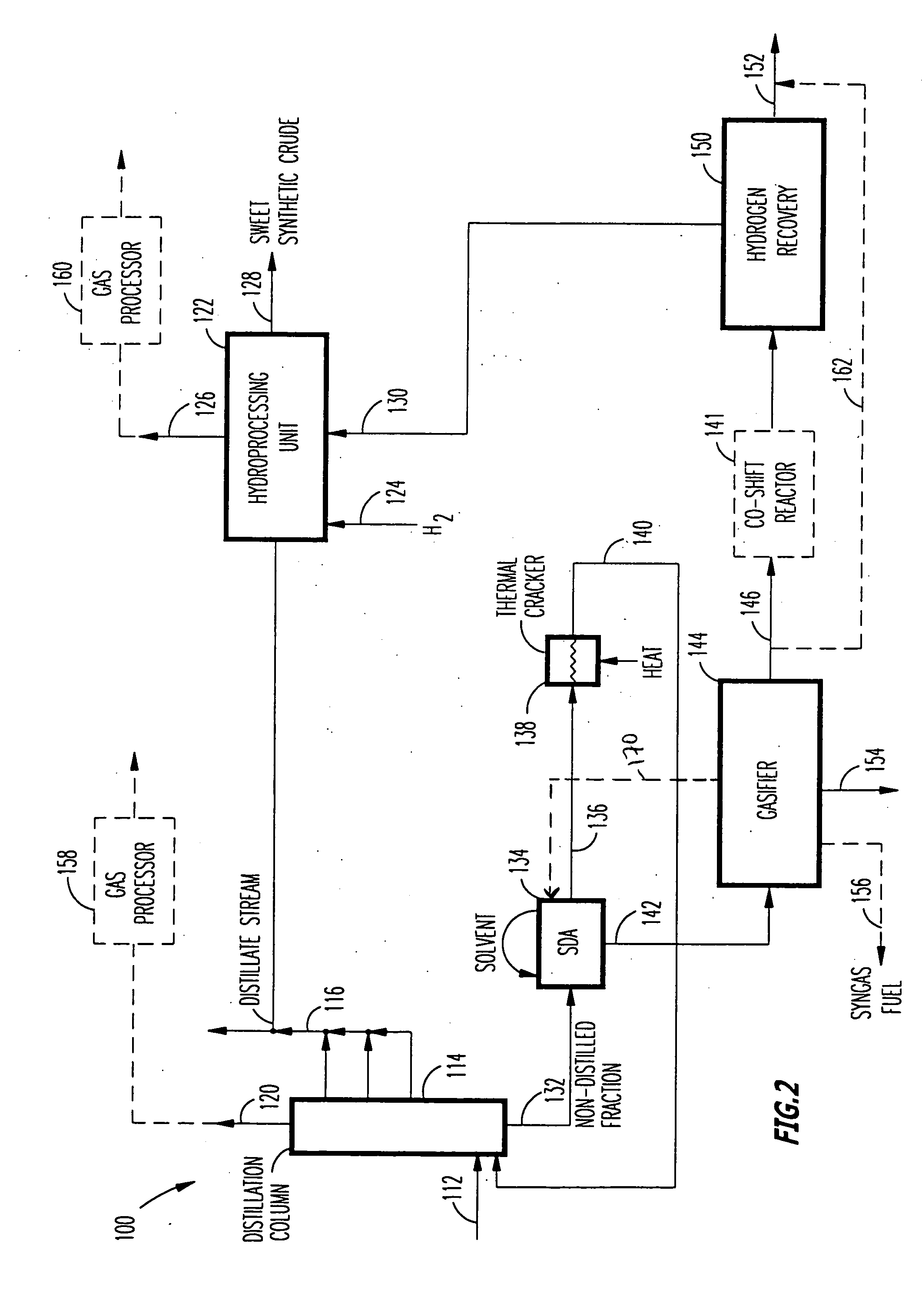

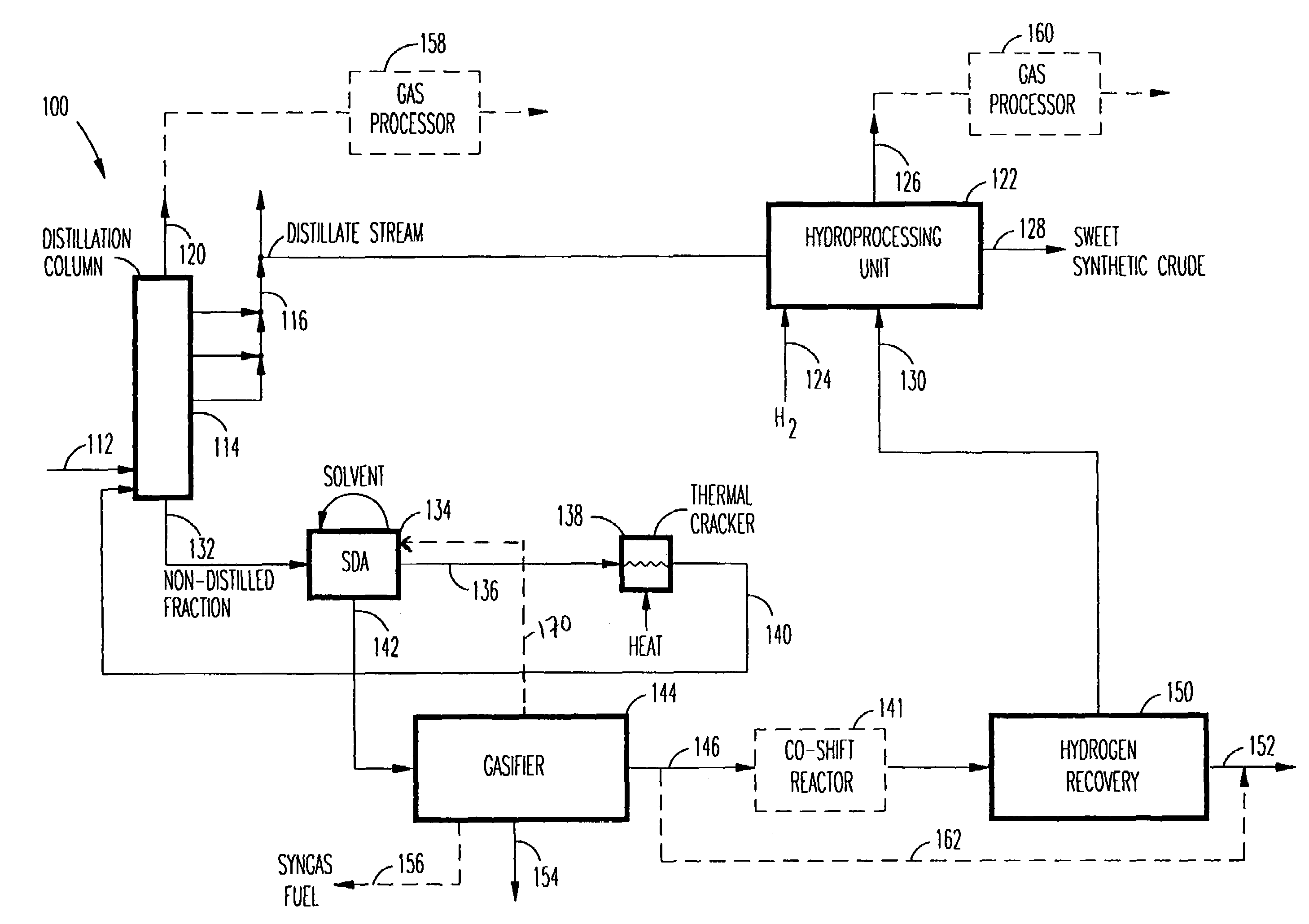

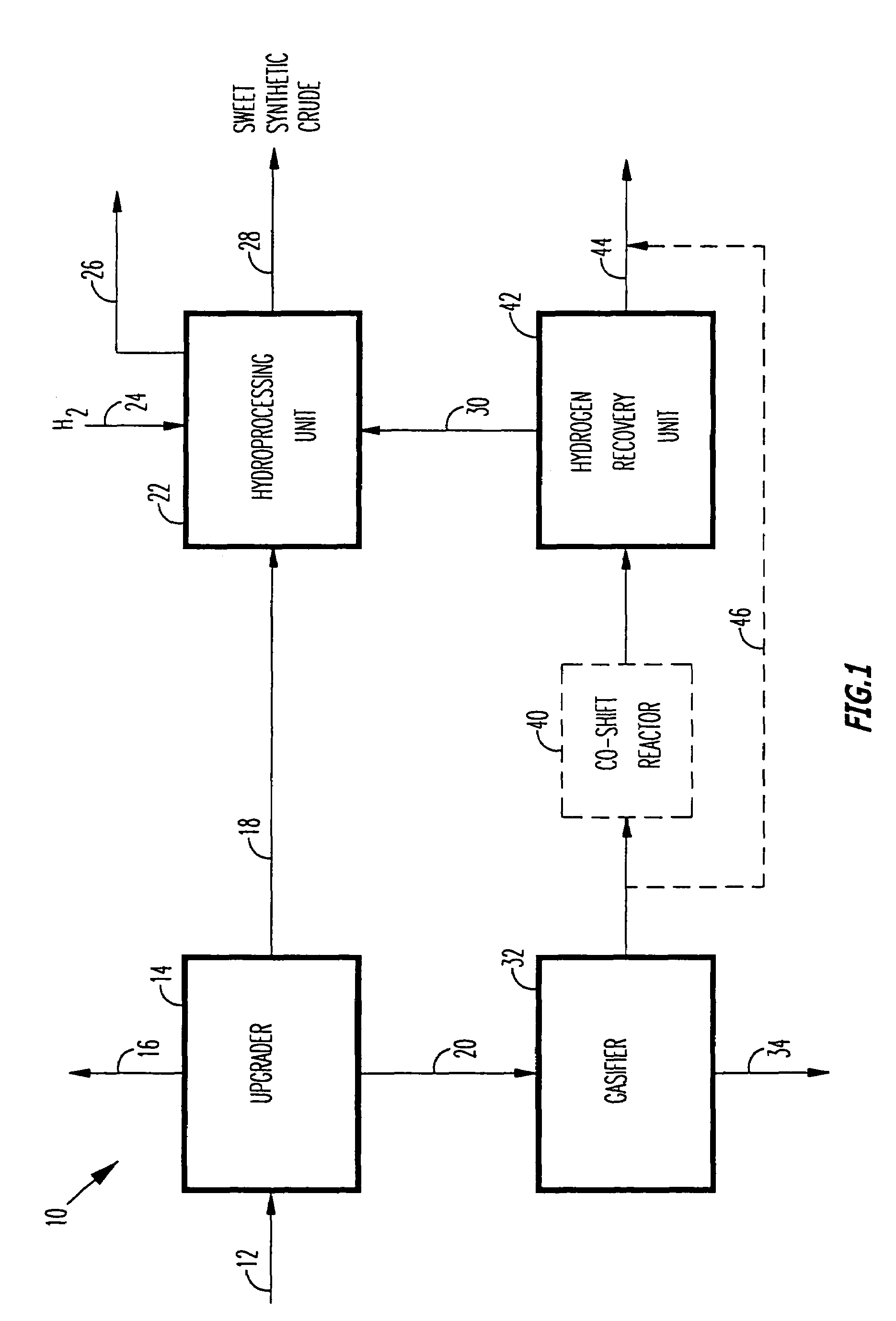

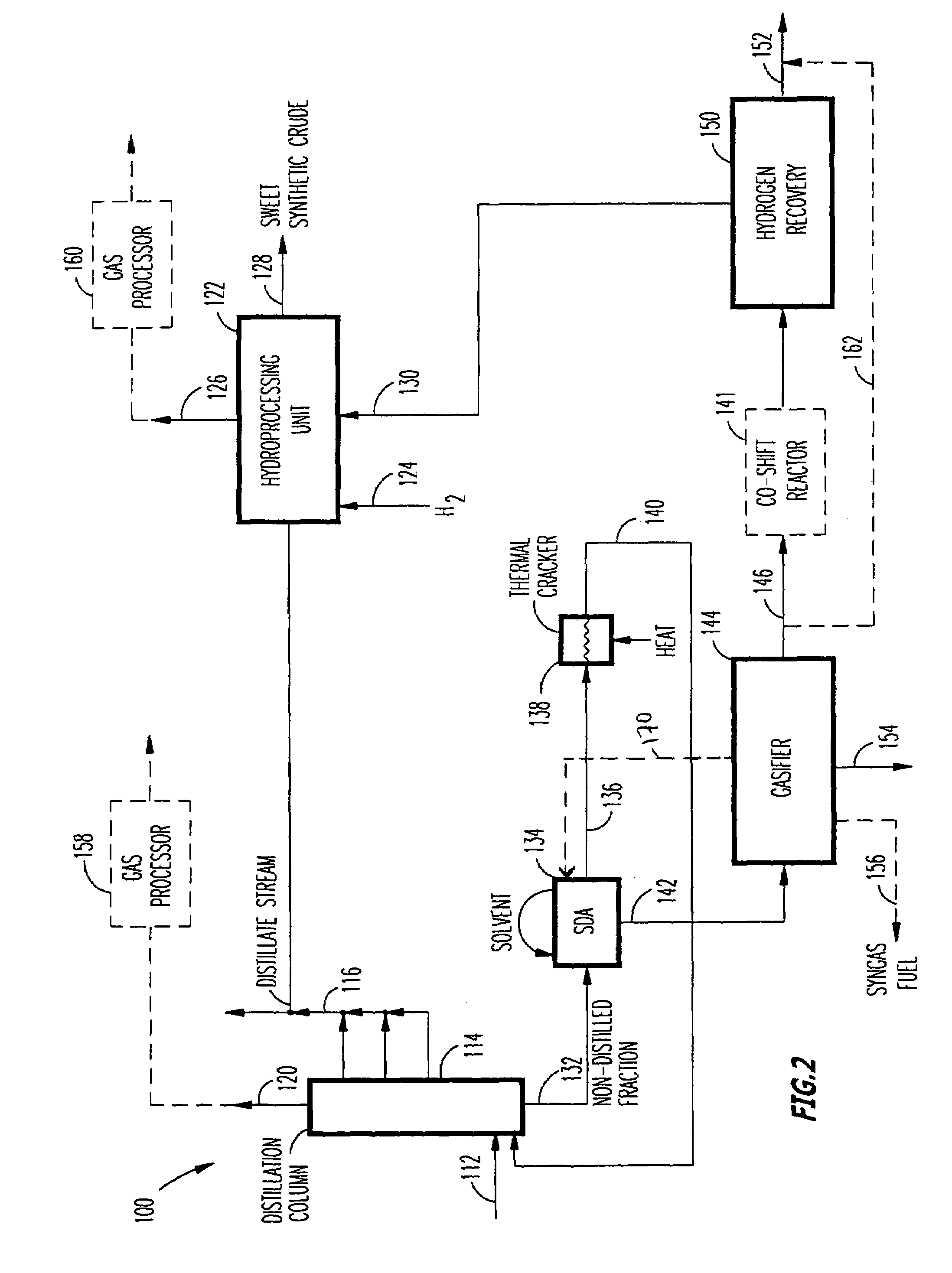

Method of and apparatus for upgrading and gasifying heavy hydrocarbon feeds

A novel apparatus for producing sweet synthetic crude from a heavy hydrocarbon feed comprising: an upgrader for receiving said heavy hydrocarbon feed and producing a distillate fraction including sour products, and high-carbon content by-products; a gasifier for receiving the high-carbon content by-products and producing synthetic fuel gas and sour by-products; a hydroprocessing unit for receiving the sour by-products and hydrogen gas, thereby producing gas and sweet crude; and a hydrogen recovery unit for receiving said synthetic fuel gas and producing further hydrogen gas and hydrogen-depleted synthetic fuel gas, said further hydrogen gas being supplied to said hydroprocessing unit.

Owner:ORMAT IND LTD

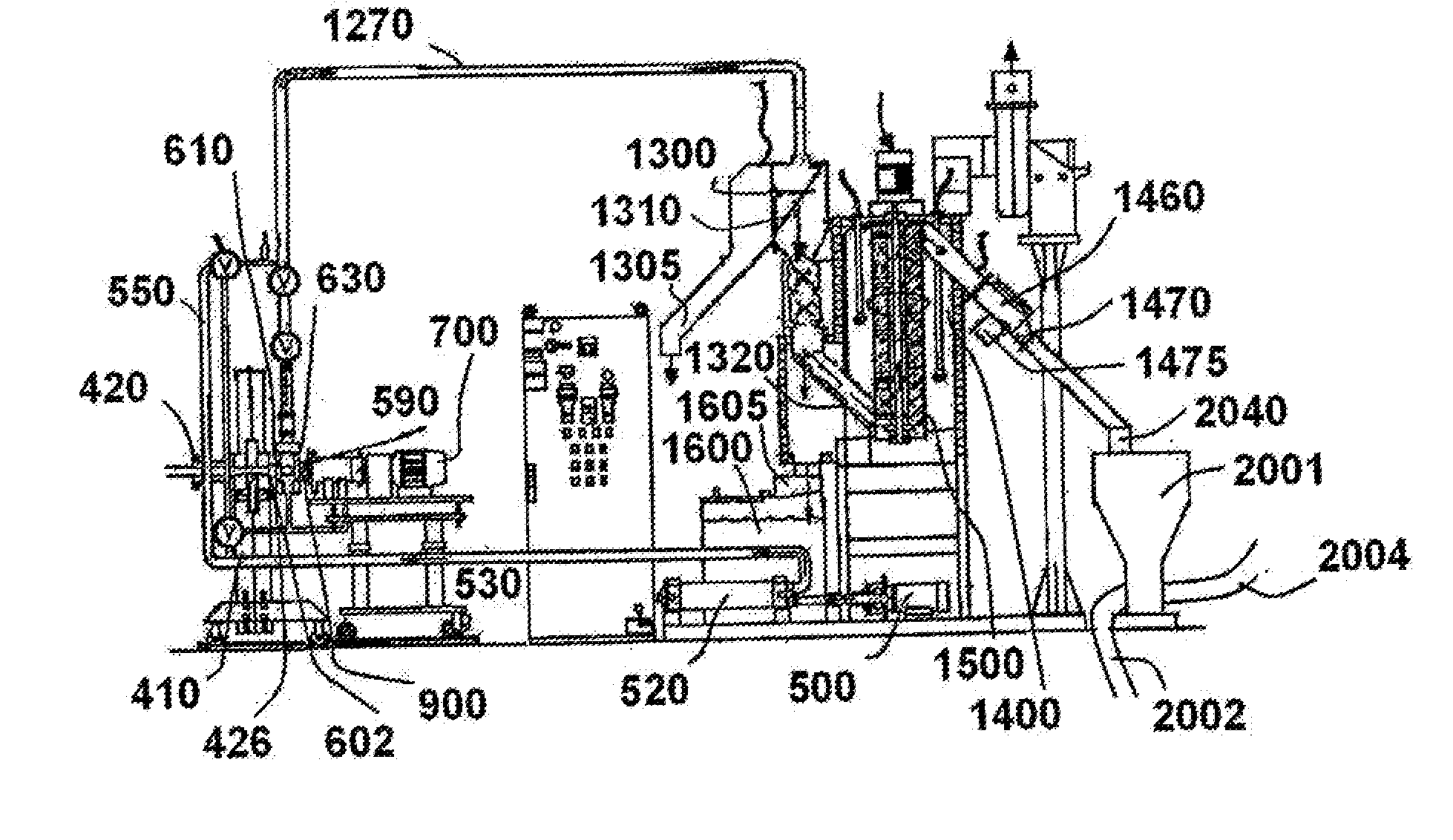

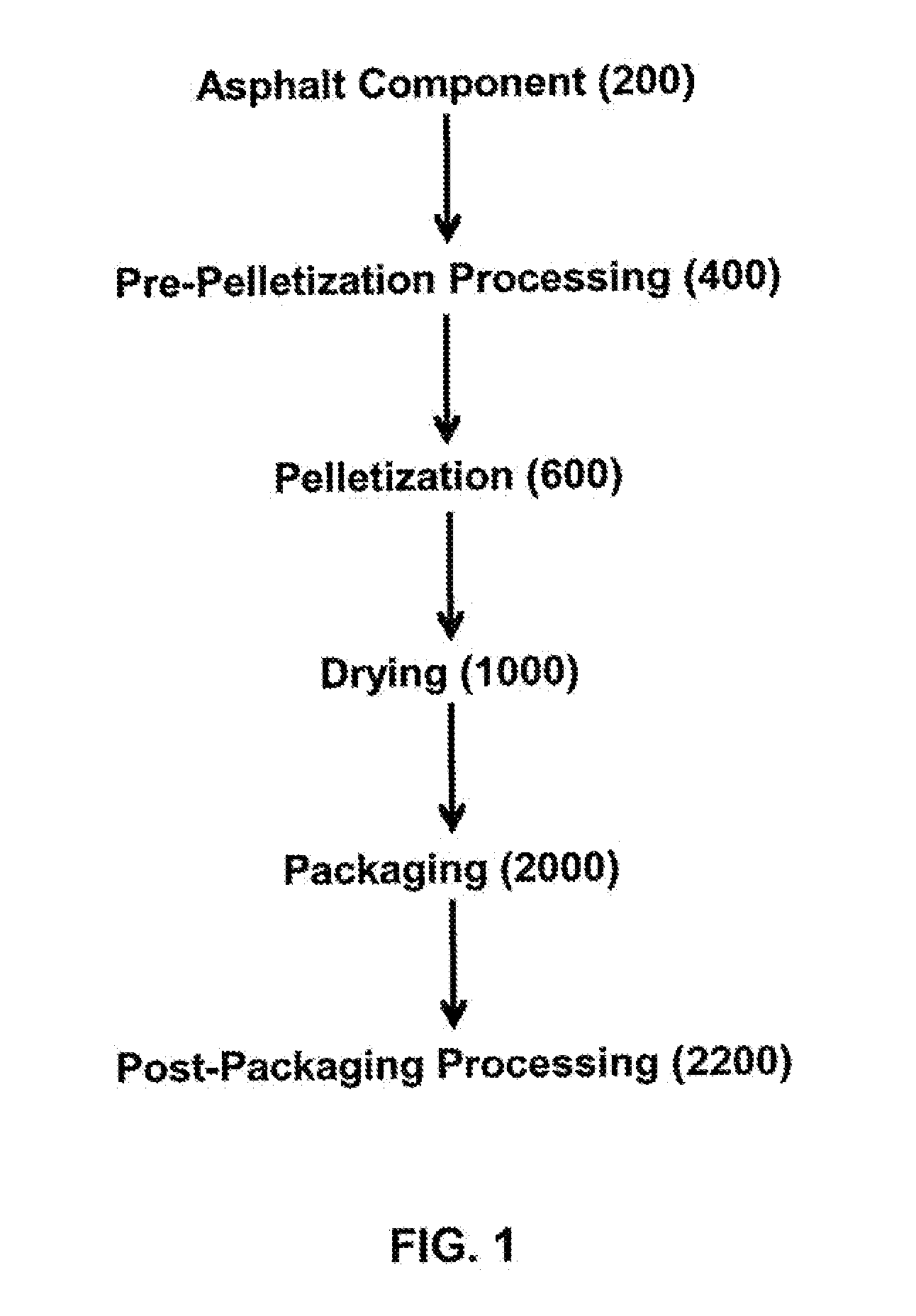

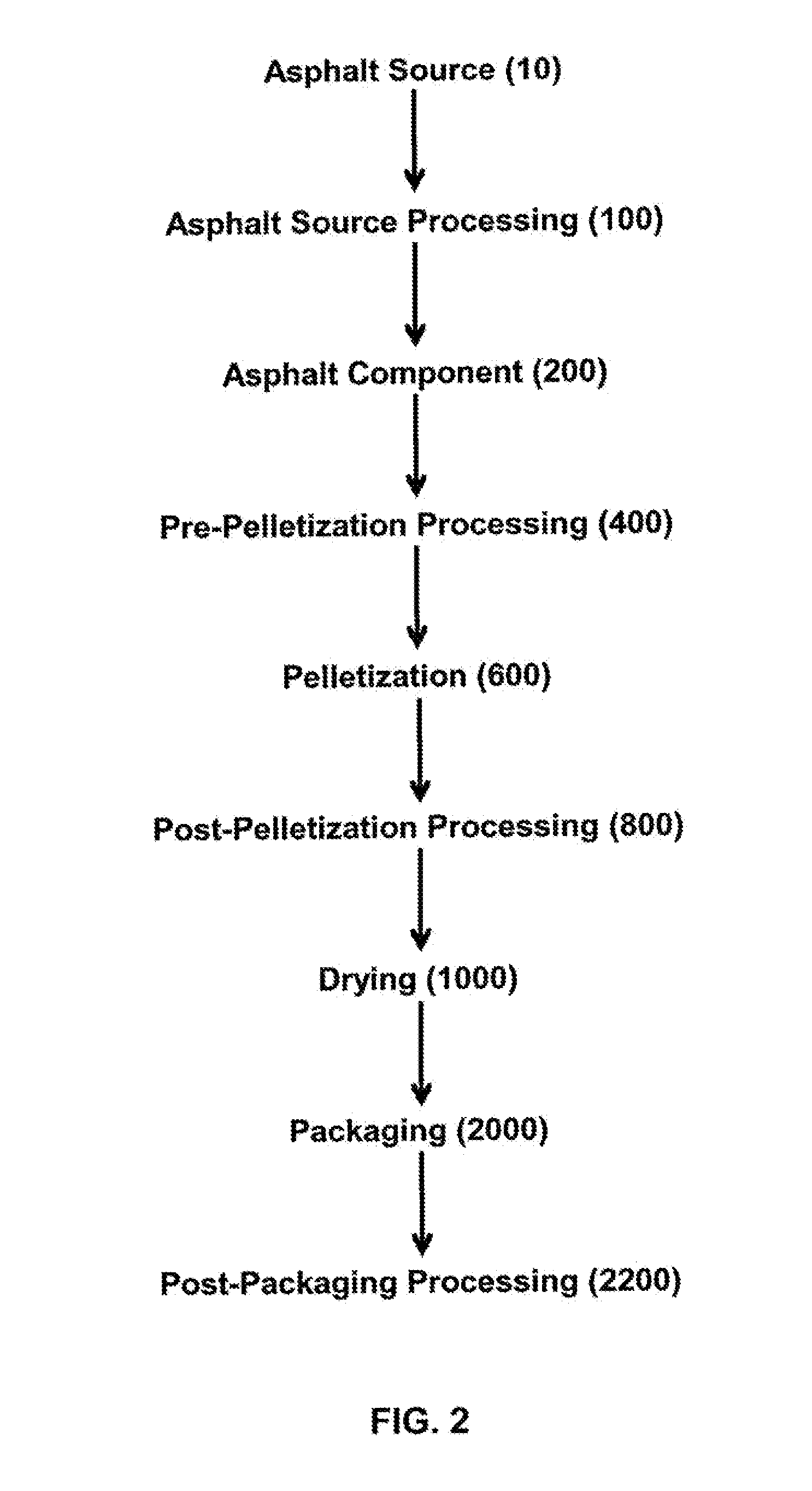

Continuous process for fractioning, combination, and recombination of asphalt components for pelletization and packaging of asphalt and asphalt-containing products

ActiveUS20130036714A1Prevent movementWorking-up pitch/asphalt/bitumen by distillationLiquid surface applicatorsEngineeringAsphalt

A continuous process for fractioning, combination, and recombination of asphalt sources into asphalt components for pelletization of asphalt and asphalt-containing products such that the pellets formed are generally uniform in dimension, freely flowing, free from agglomeration, and the pelletized asphalt is packaged, and preferably compatibly packaged, for additional processing and applications.

Owner:GALA INDUSTRIES INC

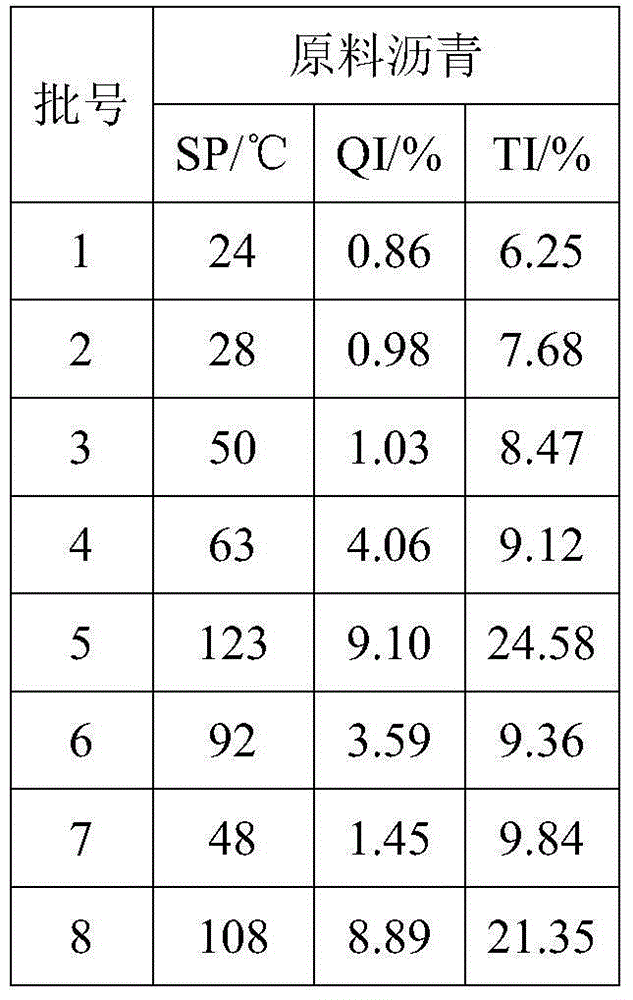

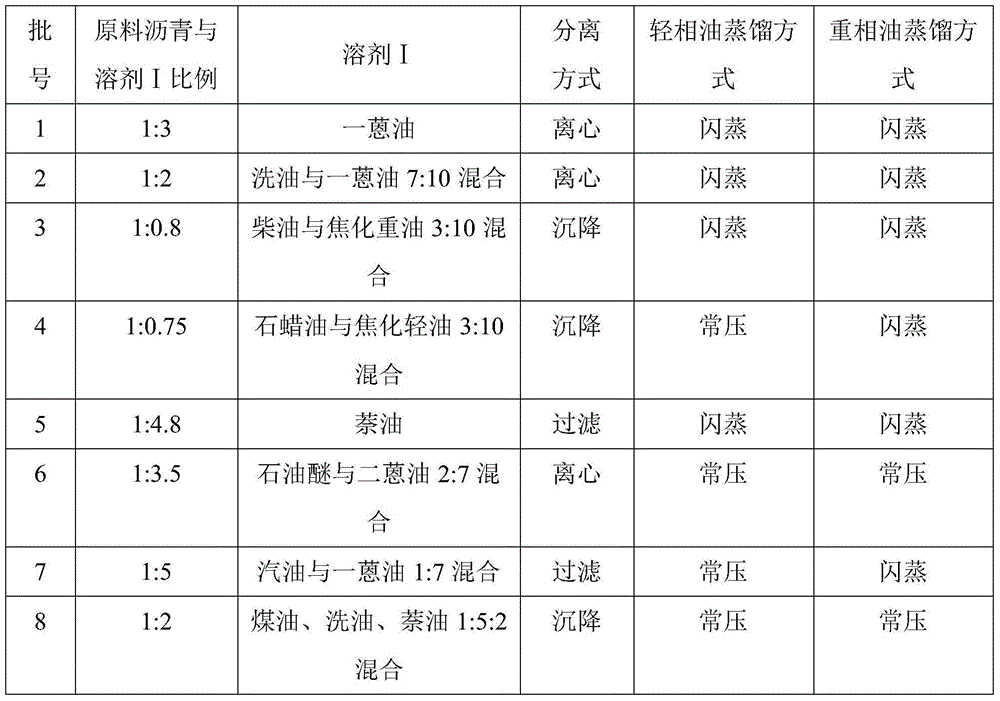

Novel process for eliminating quinoline insoluble substances in coal tar medium temperature pitch

InactiveCN101824329AAvoid power consumptionReduce manufacturing costWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionQuinolineAliphatic hydrocarbon

The invention discloses a novel process for eliminating quinoline insoluble substances in a coal tar medium temperature pitch. The invention comprises the following steps: using the coal tar pitch as raw material, mixing with a solvent according to a certain proportion, and continuous extracting and settling separation for the settling separation of the quinoline insoluble substances in the pitch to obtain a clarified liquid and sediments. The invention is characterized in that the coal tar pitch material uses the coal tar medium temperature pitch; the coal tar medium temperature pitch and a mixed solvent of an aromatic hydrocarbon solvent and an aliphatic hydrocarbon solvent according to a certain proportion are preheated and respectively sent to a multi-level static mixer for even mix according to a proportion of 1:0.8-1.2 by weight to produce a mixing oil; and the continuous extracting and settling separation is carried out for eliminating the quinoline insoluble substances in the coal tar medium temperature pitch. Since the technical proposal is used, the invention has low cost and high separation efficiency, and the refine pitch after clarifying fully satisfies the requirement of producing needle coke or as an impregnant pitch.

Owner:朱兴建

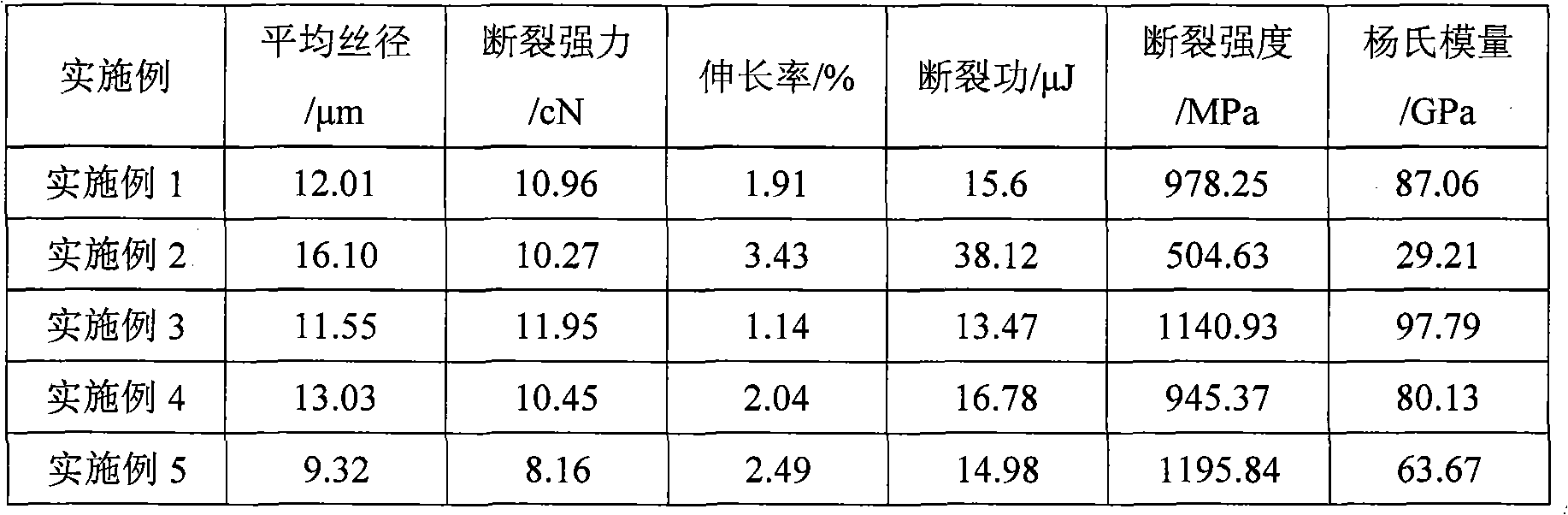

Preparation method of soluble mesophase pitch

InactiveCN102942945AImprove solubilityFacilitate subsequent processingWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionFiberCarbon fibers

The invention belongs to the technical field of a preparation method of spinning raw materials of high-performance pitch-based carbon fibers, and particularly relates to a preparation method of soluble mesophase pitch, which mainly solves the problems of the existing mesophase pitch preparation method that the process is complicated, requirements on the equipment are high, the cost is high, the industrialization process is difficult and the like. The invention adopts the technical scheme that the preparation method of the soluble mesophase pitch comprises the following steps of (1) thermally treating raw material pitch or ethylene bottom oil with a low softening point in an inert atmosphere, then distilling the material in a short distance or flashing the material, removing light ends, and collecting heavy fraction, i.e. heavy end pitch; (2) preparing the heavy enbd pitch into mesophase pitch; and (3) cooling the mesophase pitch to 320DEG C to 400DEG C, removing internal light ends, and collecting the heavy fraction, i.e. the mesophase pitch. The preparation method has the advantages of simplicity in process, moderate in reaction condition, low equipment requirement, low cost and adaptability to industrialized production.

Owner:SICHUAN CHUANGYUE CARBON MATERIAL

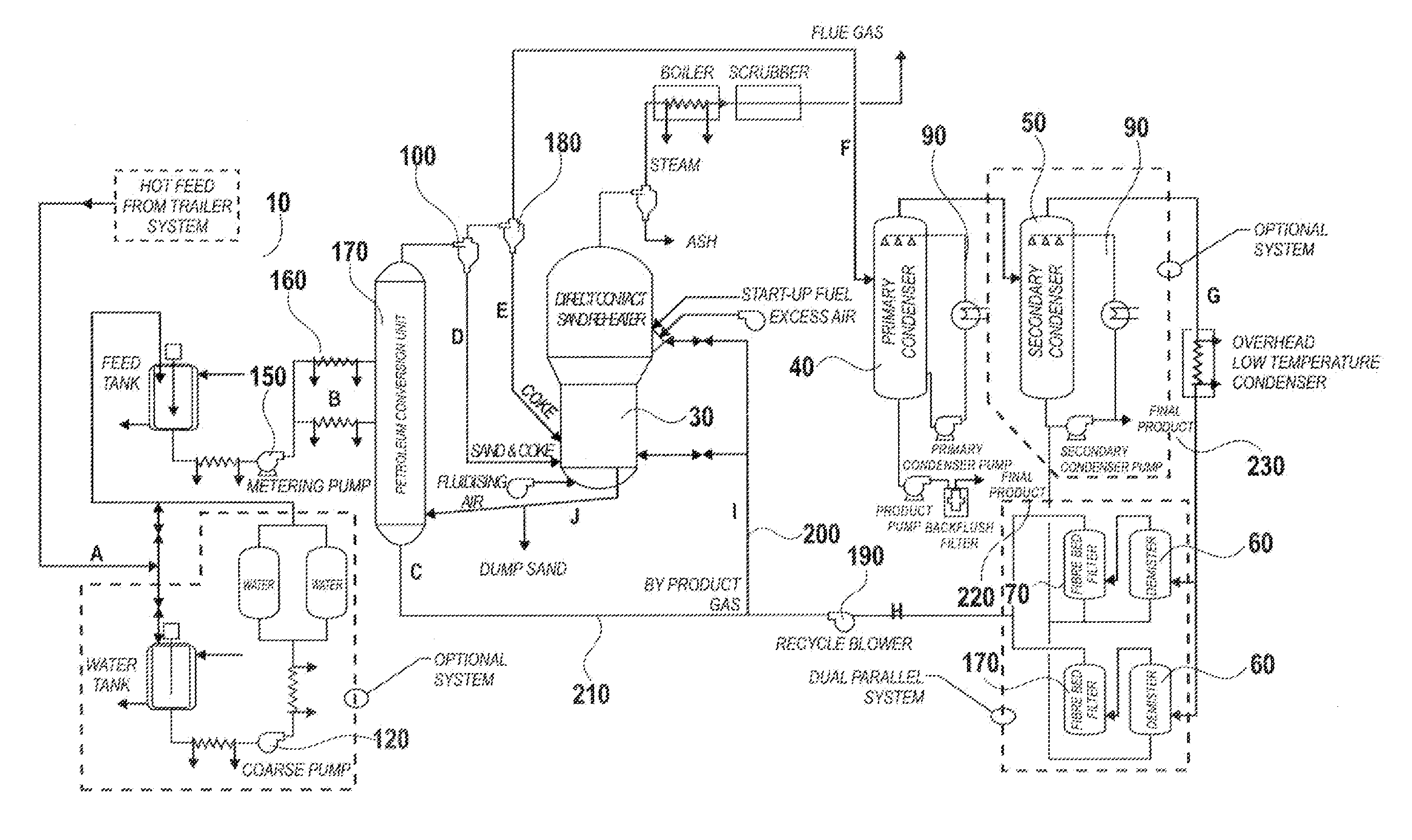

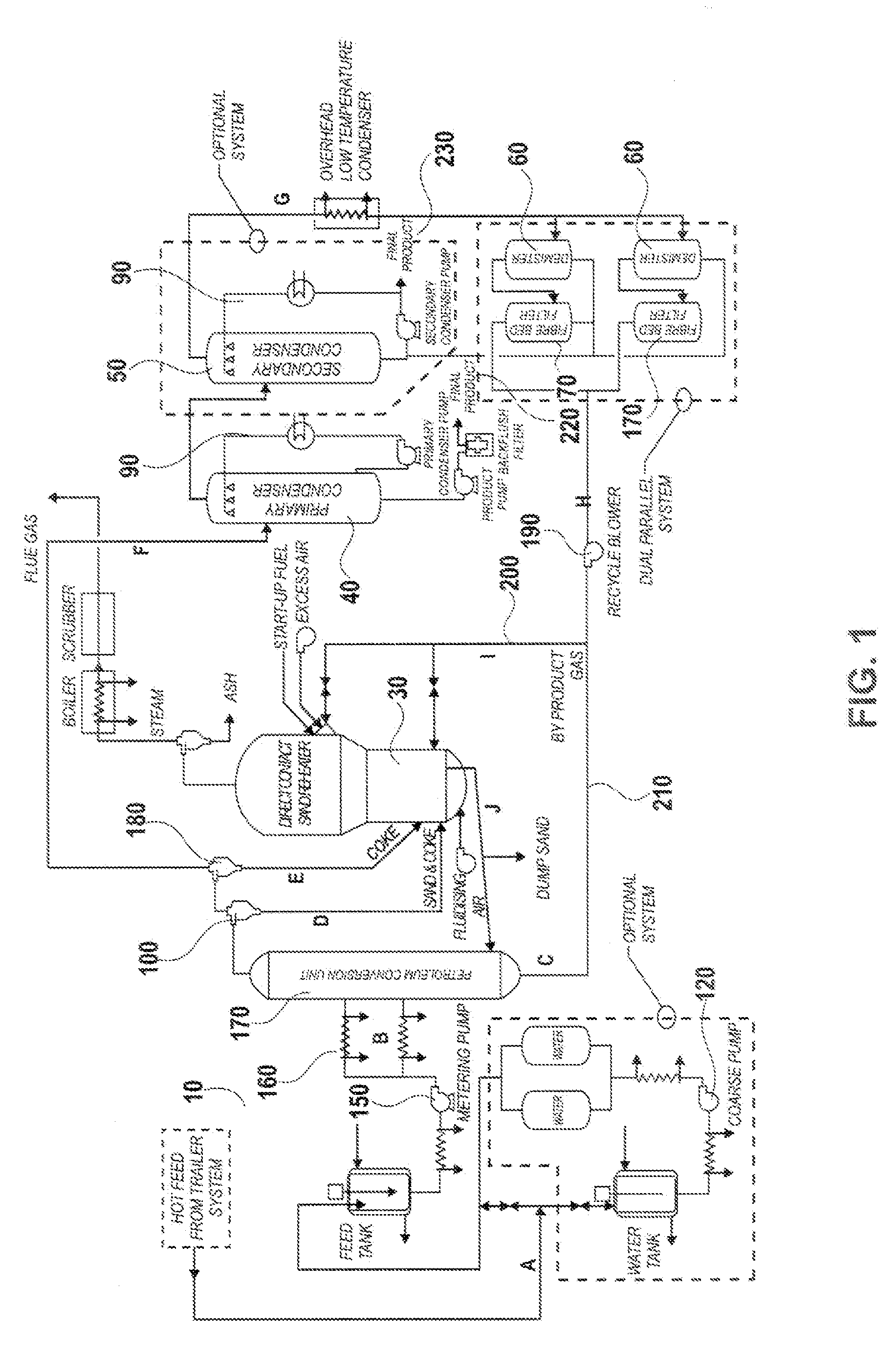

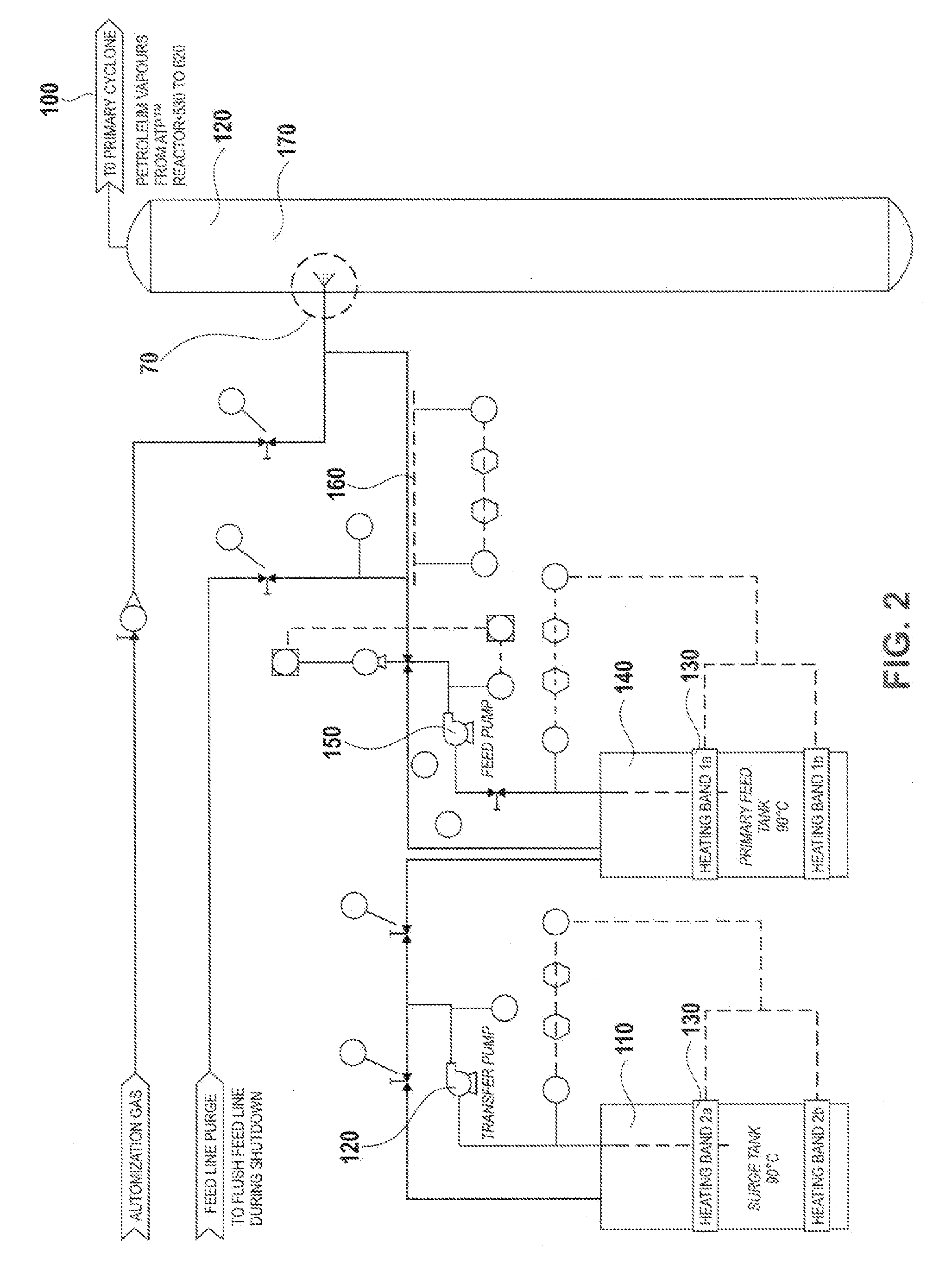

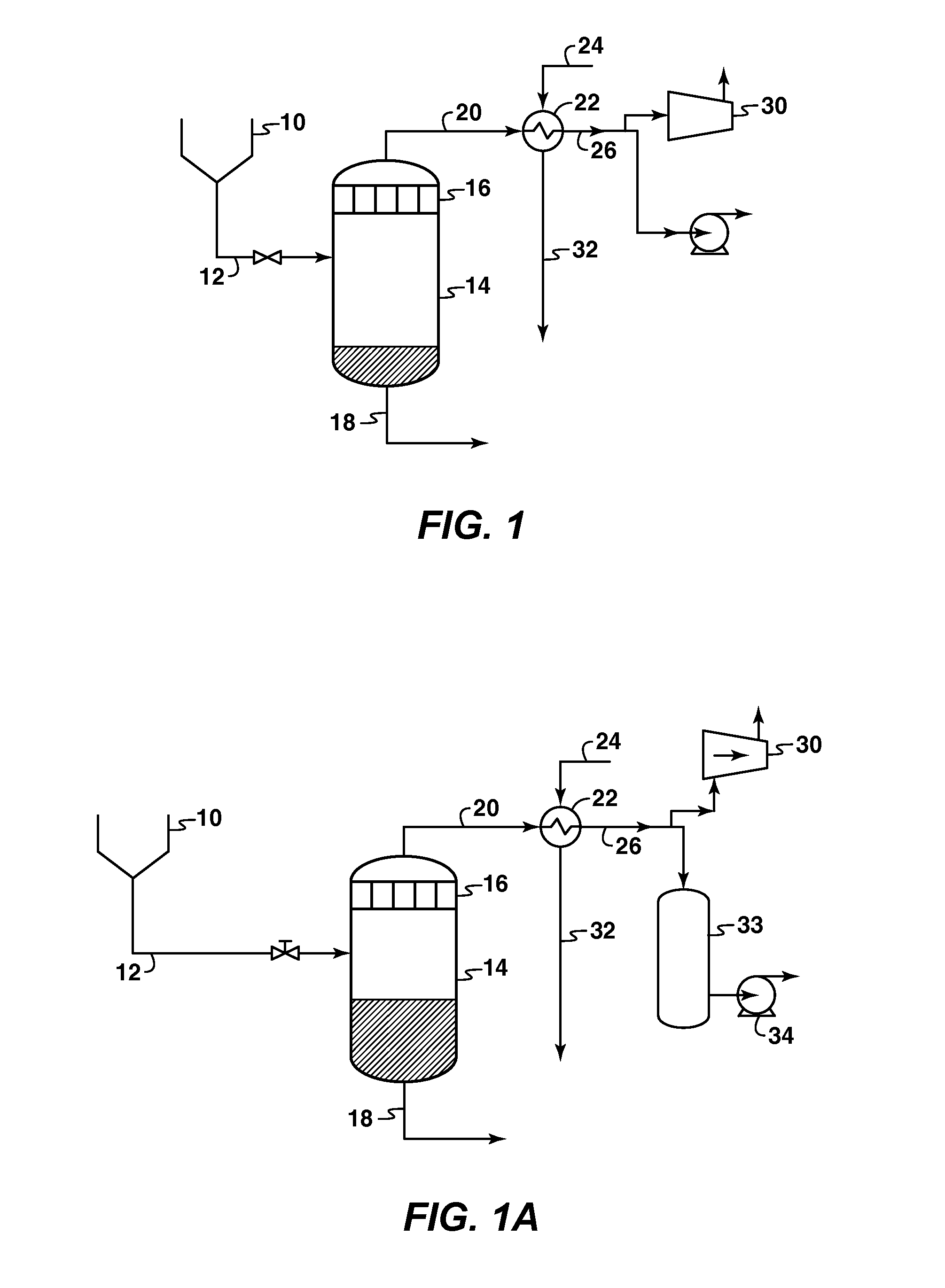

Rapid thermal processing of heavy hydrocarbon feedstocks

InactiveUS20120279825A1Upgrade and reduce viscosityRapid heat treatmentWorking-up pitch/asphalt/bitumen by distillationThermal non-catalytic crackingParticulatesLiquid product

The present invention is directed to the upgrading of heavy hydrocarbon feedstock that utilizes a short residence pyrolytic reactor operating under conditions that cracks and chemically upgrades the feedstock. The method for upgrading a heavy hydrocarbon feedstock comprises introducing a particulate heat carrier into an upflow reactor, introducing the heavy hydrocarbon feedstock into the upflow reactor at a location above that of the particulate heat carrier so that a loading ratio of the particulate heat carrier to feedstock is from about 15:1 to about 200:1, allowing the heavy hydrocarbon feedstock to interact with the heat carrier with a residence time of less than about 1 second, to produce a product stream, separating the product stream from the particulate heat carrier, regenerating the particulate heat carrier, and collecting a gaseous and liquid product from the product stream.

Owner:IVANHOE HTL GASOLINEEUM

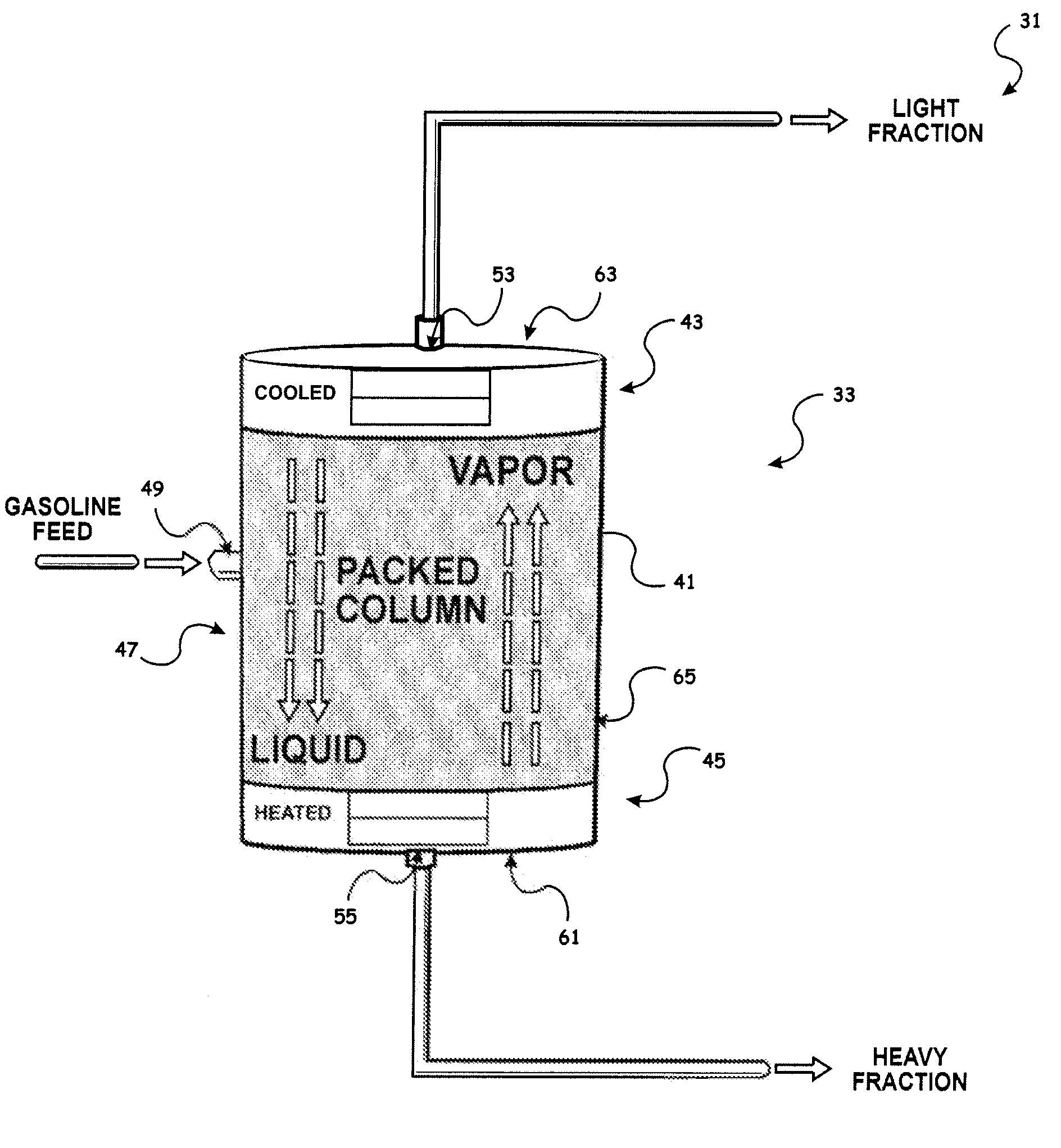

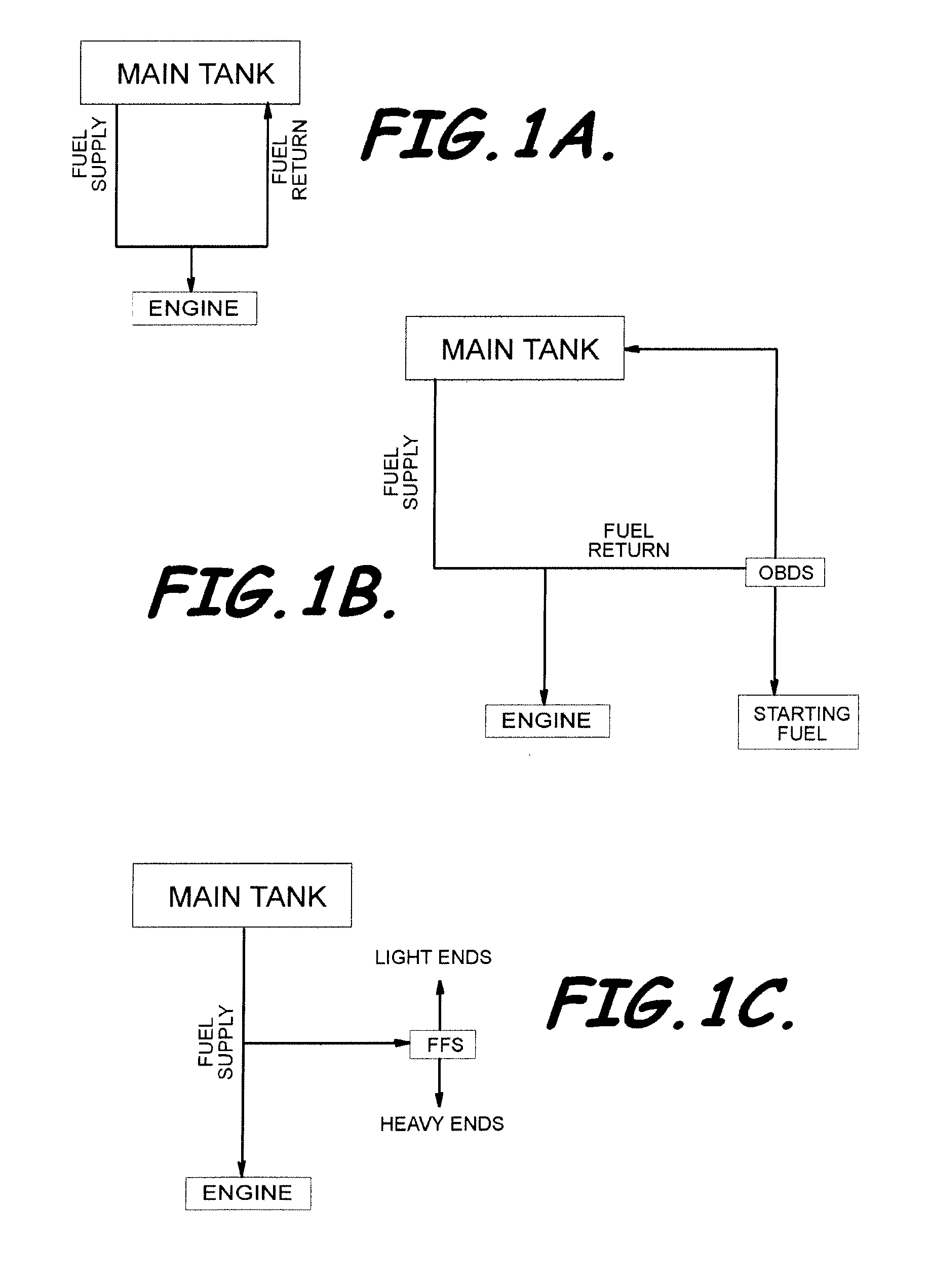

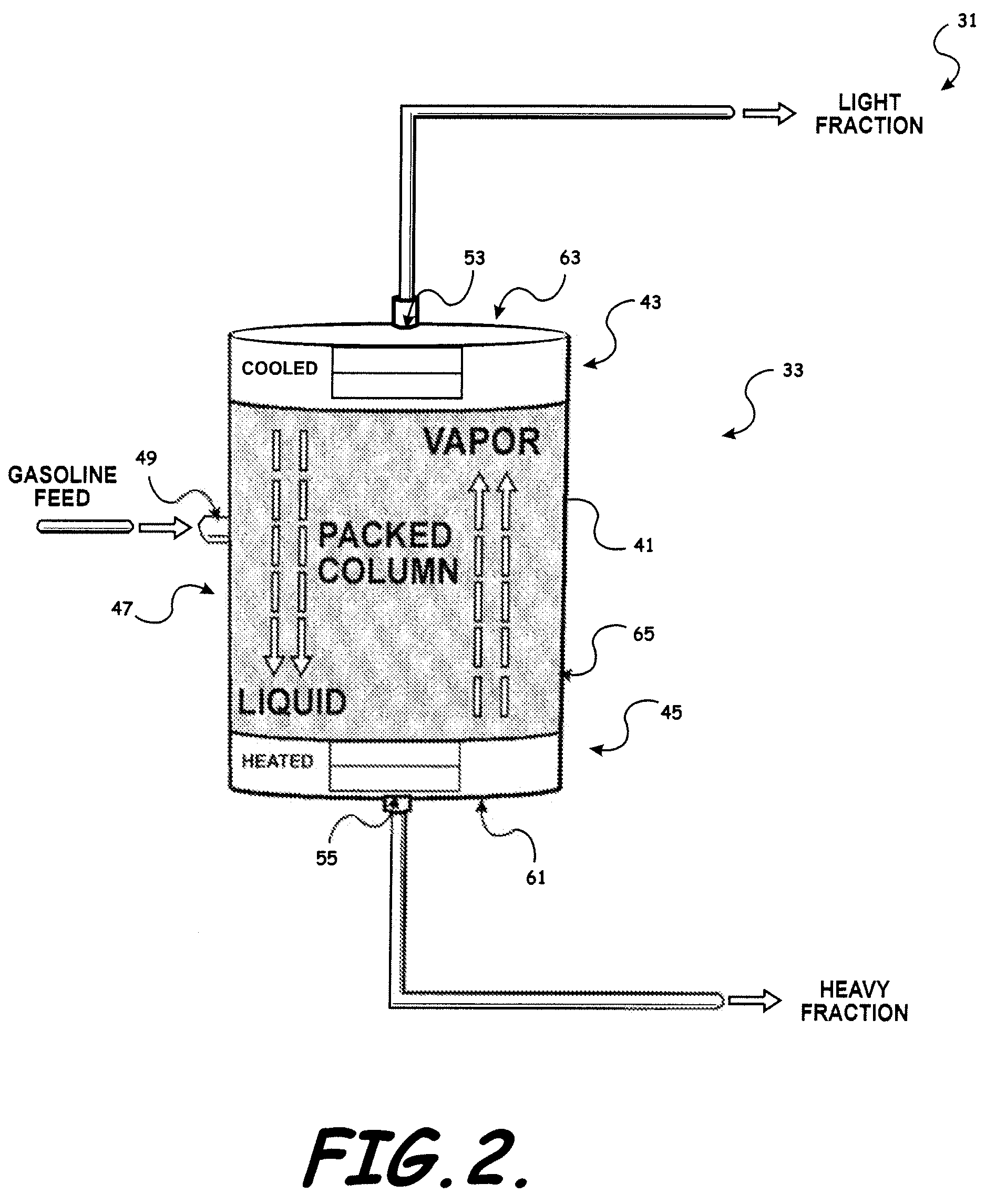

On-board fuel fractionation system and methods to generate an engine starting fuel

InactiveUS7370610B2Efficient separationAccelerate emissionsThermal non-catalytic crackingDistillation regulation/controlDistillationFractionation

A Fuel Fractionation System (FFS) and associated methods to generate and store a fuel for internal combustion engines is provided. FFS provides a distillation column assembly to distill liquid fuel to form a volatile light fraction secondary fuel. The distillation column assembly includes a vaporization module to vaporize a feed fuel in the distillation column and includes a condensation module to condense heavy fraction components of the vaporized feed fuel. FFS also provides a controller positioned to control the vaporization of feed fuel in the distillation column to thereby control the separation of the feed fuel into light fraction fuel and heavy fraction fuel components, and positioned to control the condensation of the heavy fraction components so that fuel exiting a light fraction output port in the distillation column is substantially light fraction fuel components by volume.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Continuous sedimentation process for production of needle coke

InactiveCN101531909AGood for long-term operationEasy to operateWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionTarQuinoline

The invention relates to a continuous sedimentation process for production of needle coke. Under the continuous condition of in-out materials, the process carries out settling separation on an insoluble substance of quinoline to obtain a qualified light phase of the insoluble substance of the quinoline. The mixed ratio of an aliphatic solvent to an aromatic solvent is (0.6-1.2) to 1; the mixed ratio of a mixed solvent to soft coal-tar asphalt is (0.6-1.2) to 1; the mixed oil is pumped into settling separation equipment by a pump for the settling separation; light liquid slowly rises; and after the insoluble substance of the quinoline reaches the requirement, the light liquid is continuously discharged from the upper part and distilled to obtain refined asphalt. The continuous sedimentation process has the advantages that the prior intermittent sedimentation process is improved into the continuous sedimentation process, namely the in-out materials are processed under the continuous operating condition. The continuous operation can simplify operation, reduce equipment, the floor space and the blocking of the equipment, and is favorable for long-period operation of the process.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

Method for producing environment-friendly rubber softening oil

InactiveCN101560330ANo pollutionNo or only pollutionWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by chemical meansPolycyclic aromatic hydrocarbonFiltration

The invention relates to a method for producing environment-friendly rubber softening oil. The method is characterized by comprising the following steps: decompressing and distilling mineral oil; adding a catalyst into cut fraction at a temperature of between 280 and 340 DEG C to carry out a high-pressure hydrogenation reaction; adding the obtained product into carclazyte to be refined, and carrying out vacuum filtration to obtain refined mineral oil; treating bottom oil of a vacuum tower by the conventional propane deasphalting process to obtain an asphalt solution; distilling the asphalt solution under reduced pressure, taking cut fraction at a temperature of between 270 and 330 DEG C to be oxidized to obtain oxidized asphalt; mixing and stirring the obtained refined mineral oil and the oxidized asphalt in proportion by weight of 2.5-3.5:1.2-1.5 at a temperature of between 50 and 80 DEG C. The environment-friendly rubber softening oil has the advantages that the softening property, the compatibility and the intermiscibility are the same as or similar to the prior product high aromatic oil, but as the rubber softening oil does not contain or contains trace polycyclic aromatic hydrocarbon, so the rubber softening oil does not have carcinogenicity, does not pollute human body and environment, and meet the requirement of environment-friendly rubber extending oil.

Owner:SHANGHAI FUWODI LUBRICANT

High-softening-point coal-tar pitch production method

ActiveCN102732280AHigh purityLow impurity contentWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by chemical meansFiberCarbon fibers

The invention relates to a high-softening-point coal-tar pitch production method, which is mainly and technically characterized in that the method comprises the following steps of: (1) adding low-QI (Quality Index) purified coal-tar pitch into a stirring tank, continuously feeding air into the stirring tank, carrying out stirring in the process of feeding air, and carrying out air oxidation under the condition of 200-300 DEG C, wherein the oxidation time is 4-12 h; and (2) after the oxidation is completed, adding the pitch into a film evaporator, carrying out thin-film distillation on the pitch at a temperature of 300-350 DEG C and under a vacuum negative pressure of 0.05-0.099 Mpa, removing light components in the pitch, and carrying out distillation treatment on the obtained product for one to four hours so as to obtain high-softening-point coal-tar pitch. The method disclosed by the invention is reasonable in design; and the softening point of high-softening-point coal-tar pitch produced by taking the low-QI purified coal-tar pitch as raw materials reaches 270-290 DEG C, and the high-softening-point coal-tar pitch is low in impurity content, high in purity, simple in production process, energy-saving and environmental-friendly, and can be widely applied to the production of cathode materials jackets for lithium ion batteries and carbon fibers.

Owner:内蒙古隆通碳纤维技术有限公司

Method of producing high softening point pitch

InactiveUS7220348B1Reduce partial pressureMinimizes decompositionWorking-up pitch/asphalt/bitumen by distillationCatalytic crackingSuperheated steamHydrocarbon

The present invention provides a way to increase the softening point of heavier hydrocarbons in a relatively low cost and low pressure process using superheated steam to i) increase the carbon yield of the heavier hydrocarbons, while simultaneously ii) removing volatile components with a steam stripping process.

Owner:MARATHON PETROLEUM

Purification method for coal pitch

InactiveCN101475820AImprove solubilityImprove purification effectWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionFiberPurification methods

The invention relates to a method for purifying coal tar pitch, which is characterized in that the method comprises the following steps: using mid-temperature coal tar pitch or coal tar maltha as a raw material, and using a mixed solvent consisting of arene from coking and coal oil or light diesel fuel from petrifaction to perform sufficient mixing and dissolving at certain temperature; performing centrifugal separation to remove the residue, and distilling the obtained clear solution to remove and reclaim the solvent so as to obtain the purified pitch with the content of quinoline undissolved substances of between 0.01 and 0.04 percent. The method has the advantages of simple process, low production cost, high separation efficiency and lower QI content; besides, the purified pitch can completely meet the requirements on producing the products of needle coke, carbon fiber and the like.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Process for Separating Pitch from Slurry Hydrocracked Vacuum Gas Oil

InactiveUS20100326887A1Easy to manageLess stickyWorking-up pitch/asphalt/bitumen by distillationHydrocarbon oil crackingParticulatesSlurry

A process is disclosed for converting heavy hydrocarbon feed into lighter hydrocarbon products. The heavy hydrocarbon feed is slurried with a particulate solid material to form a heavy hydrocarbon slurry and hydrocracked in a slurry hydrocracking unit to produce vacuum gas oil (VGO) and pitch. A first vacuum column separates VGO from pitch, and a second vacuum column further separates VGO from pitch. As much as 15 wt-% of VGO can be recovered by the second vacuum column and recycled to the slurry hydrocracking unit. A pitch composition is obtained which can be made into particles and transported without sticking together.

Owner:UOP LLC

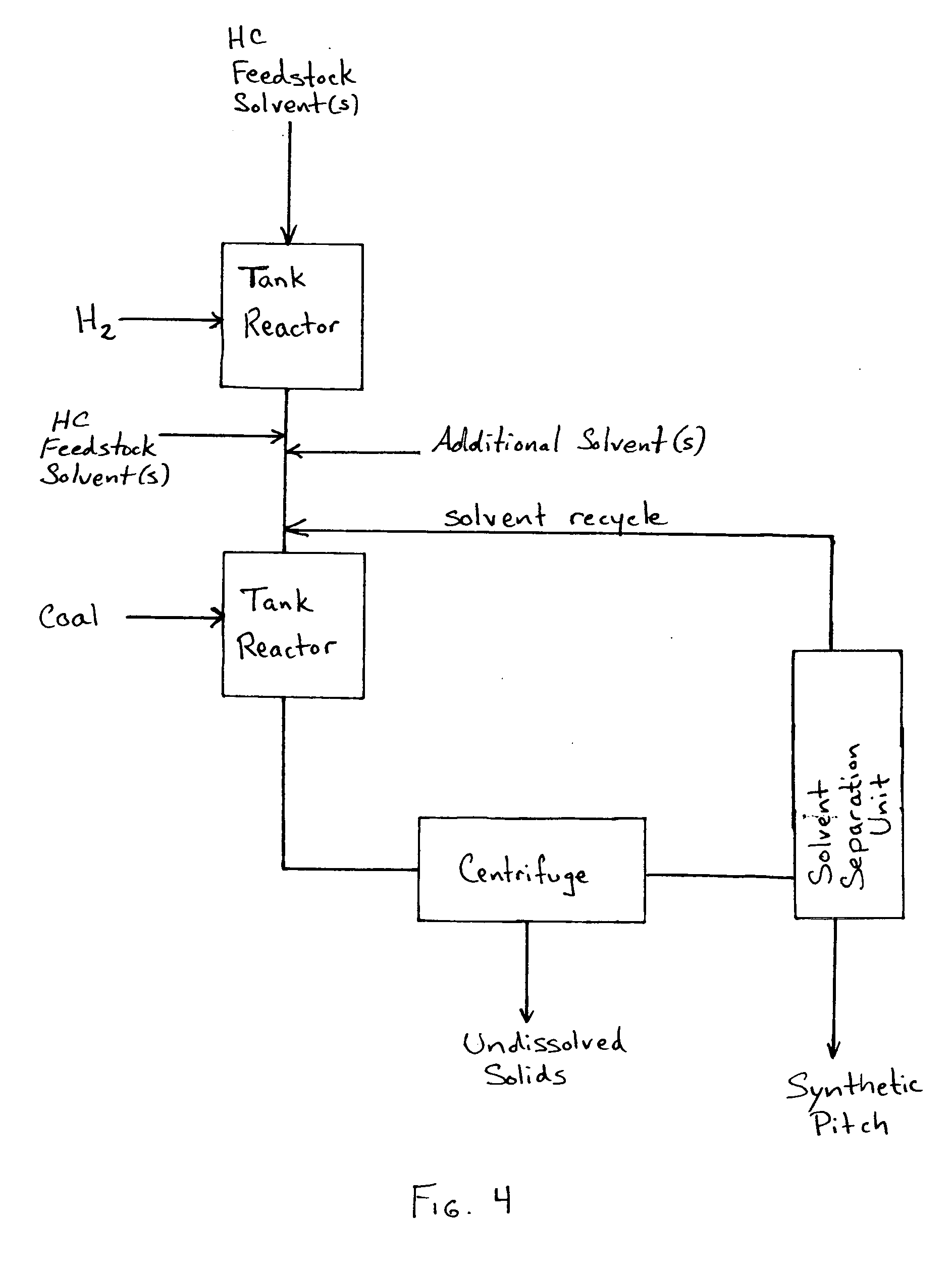

Method of producing synthetic pitch

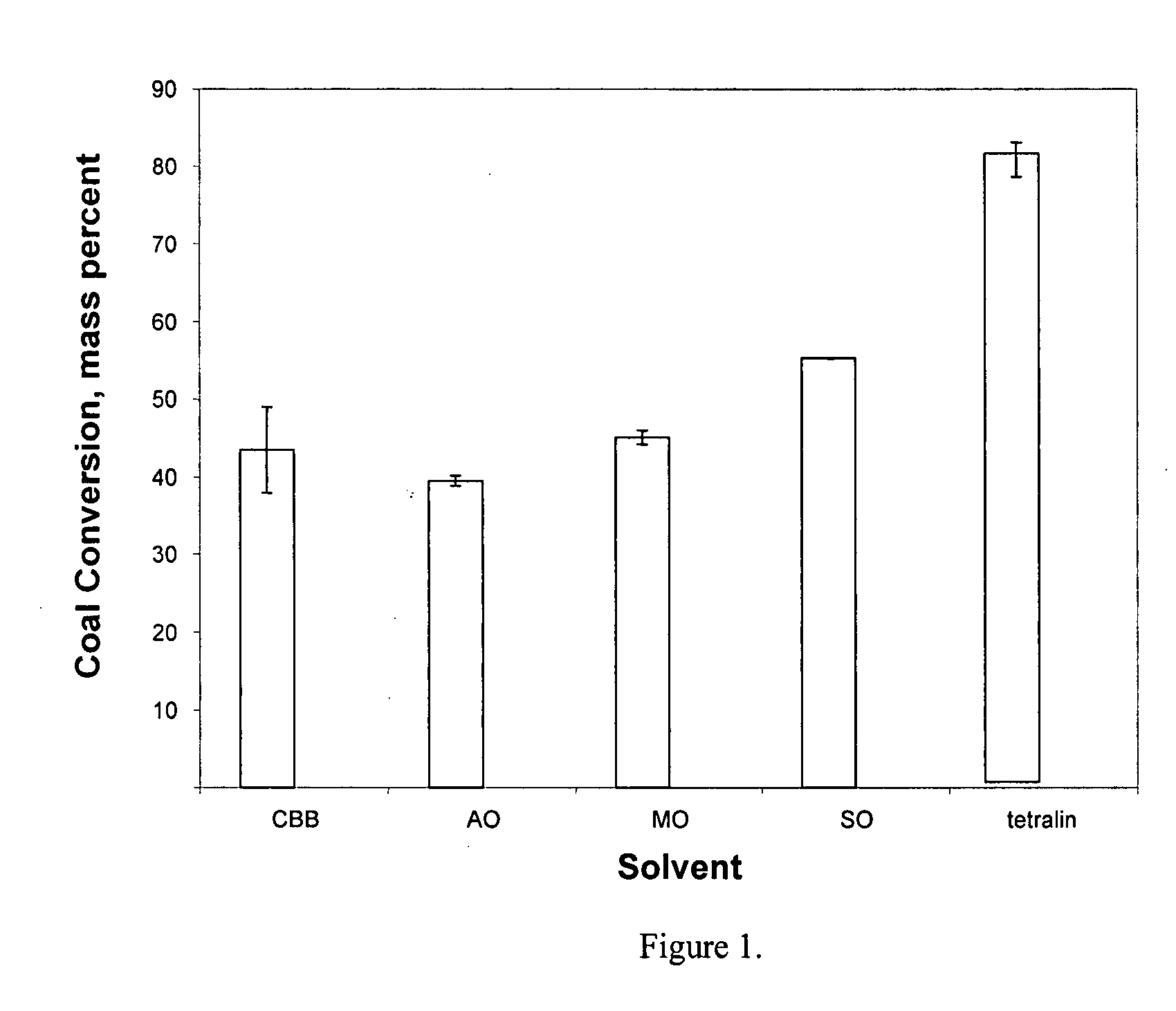

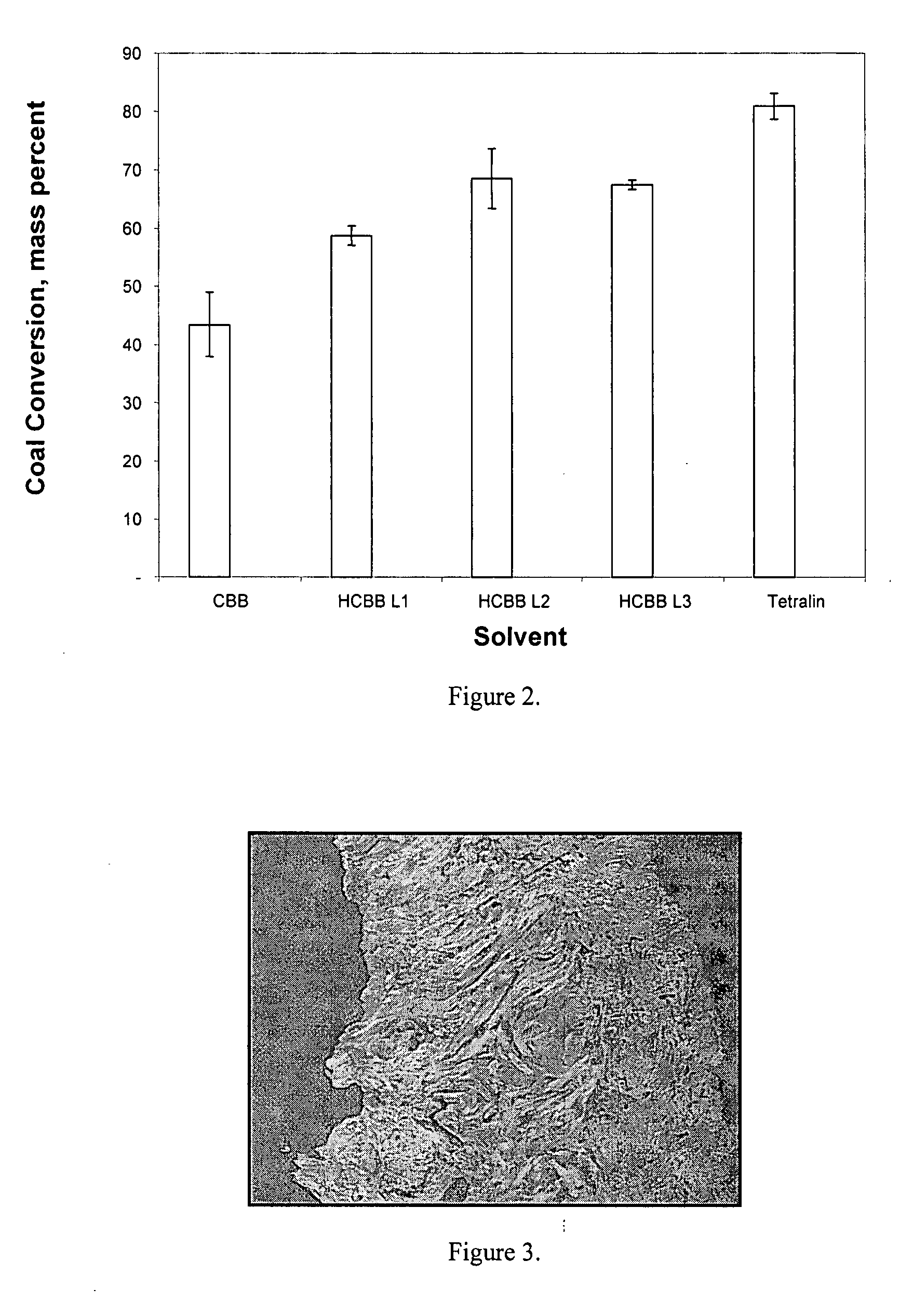

ActiveUS20080017549A1Working-up pitch/asphalt/bitumen by distillationLiquid hydrocarbon mixture productionTarSolvent

Embodiments of a method are described for modifying pitches, oils, tars, and binders by using these materials as solvents to extract organic chemicals from coal.

Owner:WEST VIRGINIA UNIVERSITY

Mesophase pitch and preparation method thereof

ActiveCN104004536AHigh carbon contentModerate carbon-hydrogen ratioWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionOrganic solventSolvent

The invention provides a method for preparing mesophase pitch from direct coal liquefaction residues. The method mainly comprises the following steps: 1, extracting the direct coal liquefaction residues by using an organic solvent I to obtain extracted pitch; 2, dissolving the extracted pitch by using a polar organic solvent II, and carrying out solvent recovery on the soluble part to obtain refined pitch; 3, carrying out thermal polycondensation on the obtained refined pitch at a high temperature to obtain a thermal polycondensation product; and 4, carrying out reduced pressure flash evaporation on the thermal polycondensation product to obtain the mesophase pitch. The invention also provides the mesophase pitch. The spinnable indexes of the mesophase pitch are characterized in that the softening point, the aromatic carbon rate and the quinoline insoluble substance content of the mesophase pitch are 250-280DEG C, not lower than 0.9 and 35-45% respectively.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

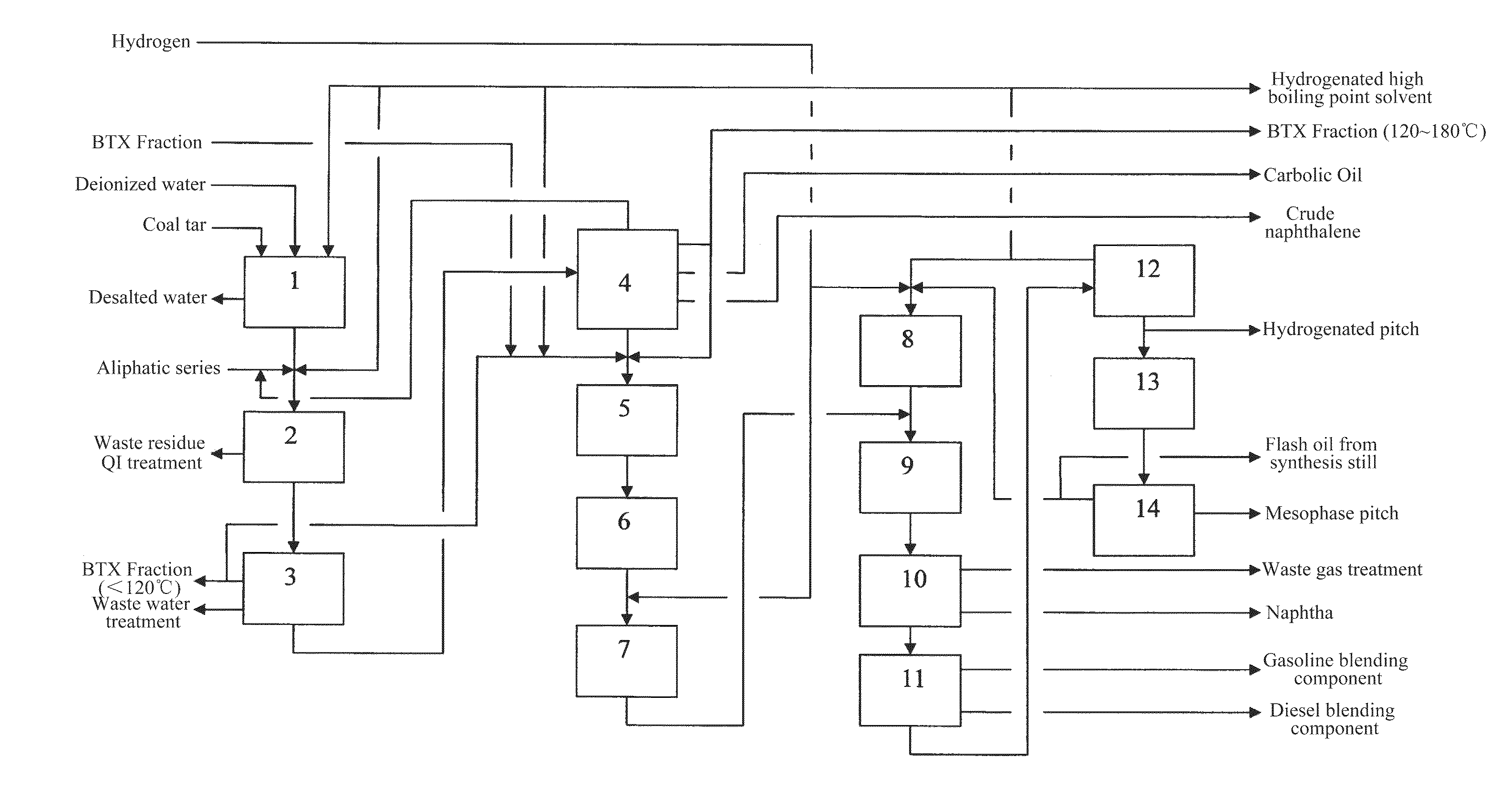

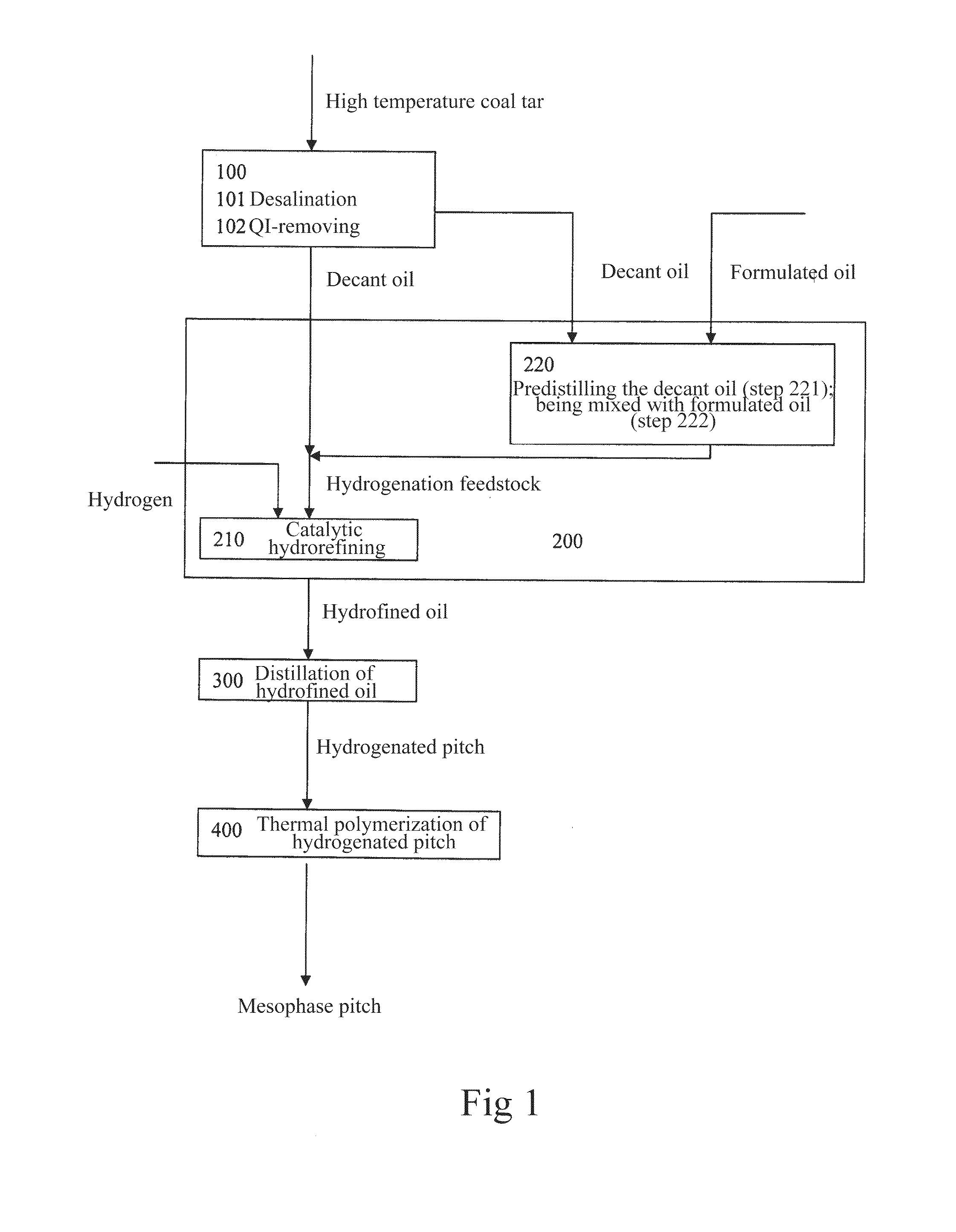

Process for Producing Mesophase Pitch by Hydrogenation of High-temperature Coal Tar

ActiveUS20150076031A1Increase H/C ratioHigh content of mesophase pitchWorking-up pitch/asphalt/bitumen by distillationLiquid hydrocarbon mixtures productionBoiling pointCoal tar

A process for producing mesophase pitch from high-temperature coal tar comprises: removing salts and quinoline insoluble fraction from a high-temperature coal tar to obtain a decant oil; using the decant oil as a hydrogenation feedstock, or pre-distilling the decant oil to obtain a residue with a boiling point higher than 230 and formulating the residue into a hydrogenation feedstock; catalytic hydrorefining the hydrogenation feedstock to obtain a hydrofined oil; distilling the hydrofined oil to obtain hydrogenated pitch; and subjecting the hydrogenated pitch to the thermal polymerization to obtain the mesophase pitch. The process has features such as an easily controllable degree of hydrogenation, complete removal of impurities, good raw material flowability, not tending to form the carbon deposition and the coking during the process, and not tending to jam the reactor. The product has a high content of mesophase pitch, a low softening point and a low impurity content.

Owner:ECO CARBON MATERIALS HLDG (SHENZHEN) CO LTD +1

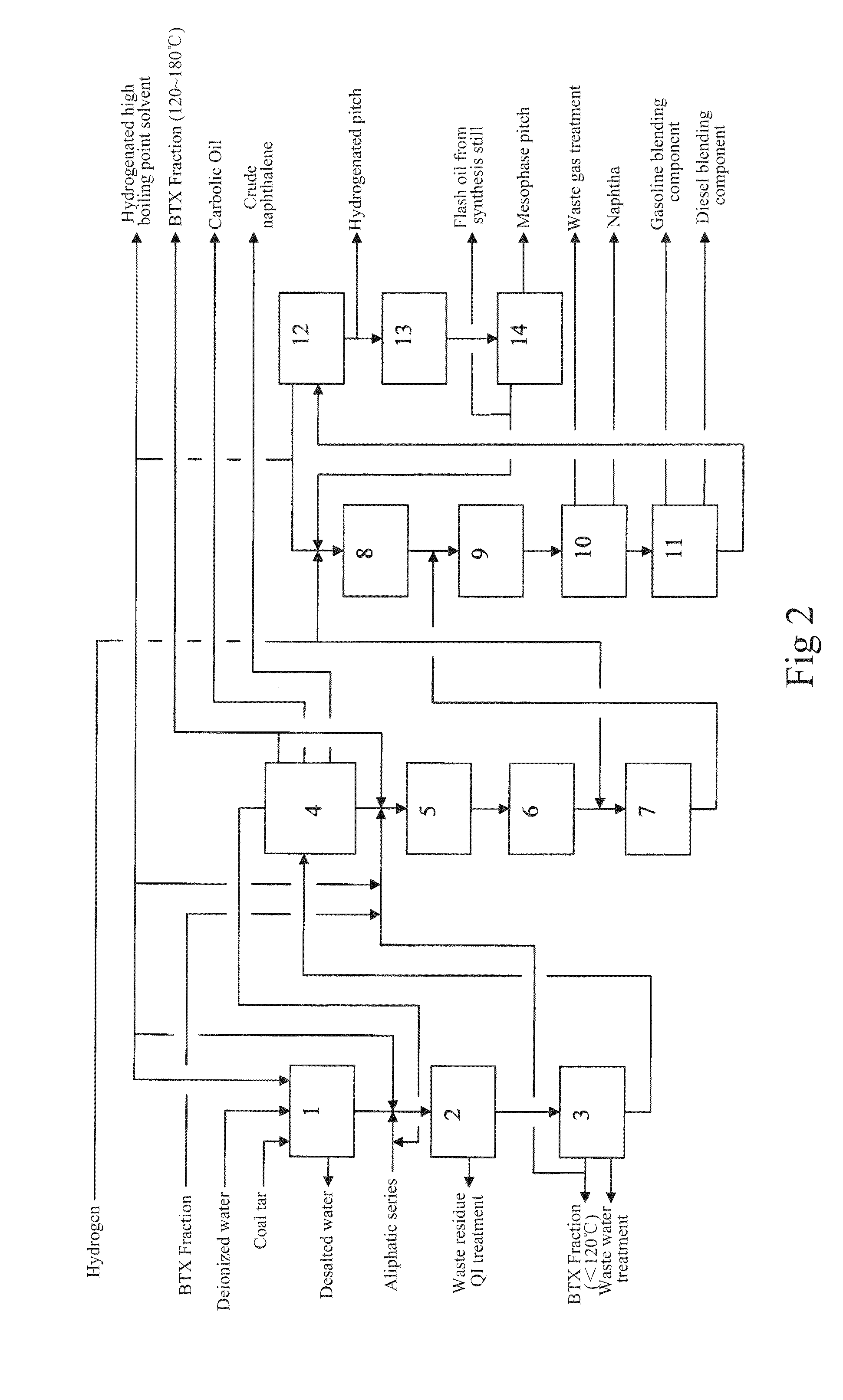

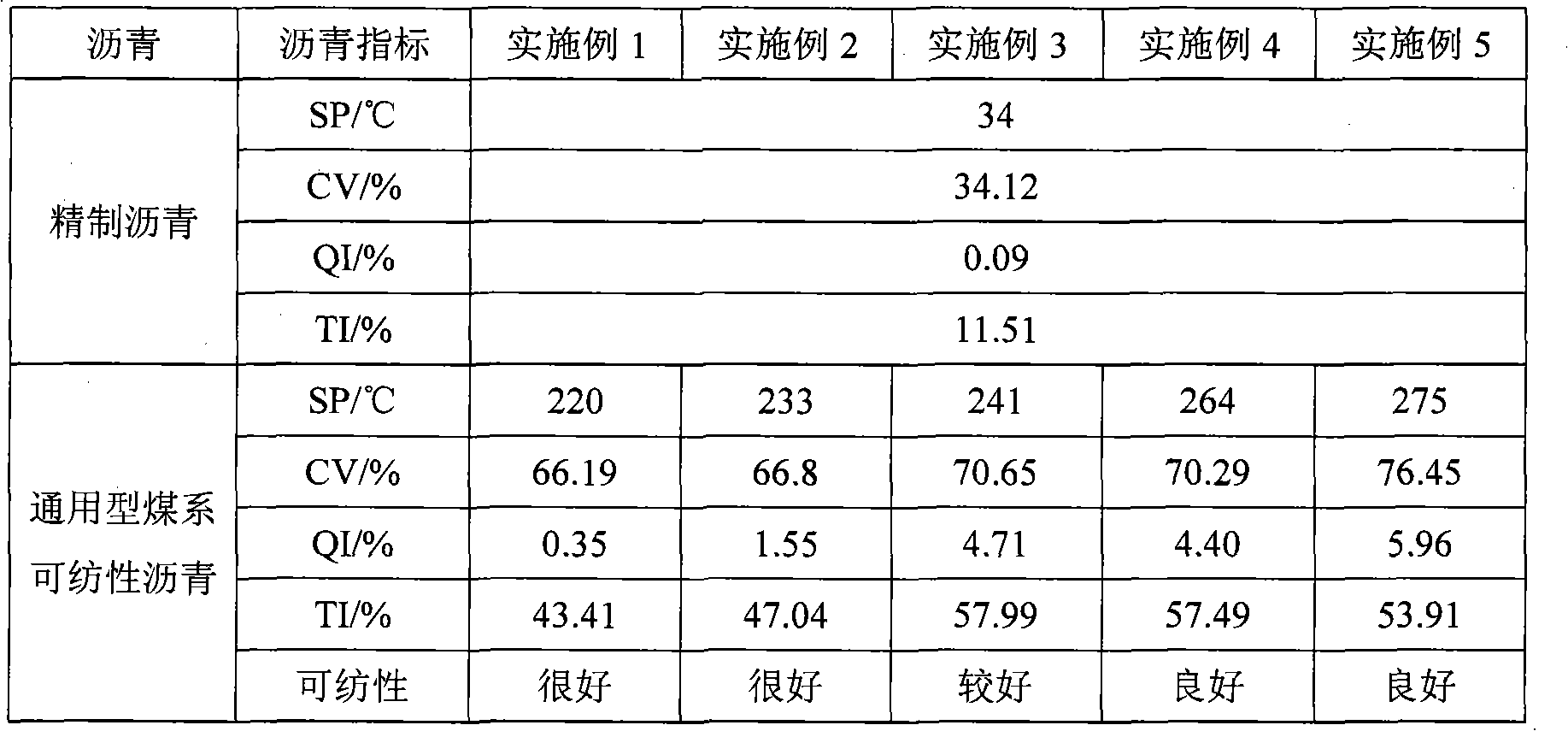

Method for preparing general type coal series asphalt with spinnability by solvent extraction and oxidative thermopolymerization

InactiveCN102399563AObvious beneficial effectNarrow molecular weight distributionWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionFiberPolymer science

The invention discloses a method for preparing general type coal series asphalt with spinnability by solvent extraction and oxidative thermopolymerization. The method comprises the following steps: tasking coal tar soft asphalt as a raw material, extracting and separating by using a mixed solvent of aliphatic hydrocarbon and aromatic hydrocarbon; taking the obtained refined asphalt as a raw material, carrying out oxidative thermopolymerization in a stainless steel reaction vessel, performing flash evaporation after finishing the oxidative thermopolymerization to obtain the general type coal series asphalt with spinnability. According to the invention, a solvent extraction method is used for removing a first quinoline insoluble substance of the asphalt, a process of oxidative thermopolymerization and flash evaporation is used to obtain the product, so that the disadvantages of wide molecular weight distribution of asphalt during the heat treatment process and high secondary quinoline insoluble substance content can be overcome. The general type coal series asphalt with spinnability has optical isotropy under the spinning temperature, has the characteristics of narrow molecular weight distribution, high softening point, good spinnability and high product yield, and is suitable for preparing general carbon fiber.

Owner:UNIV OF SCI & TECH LIAONING

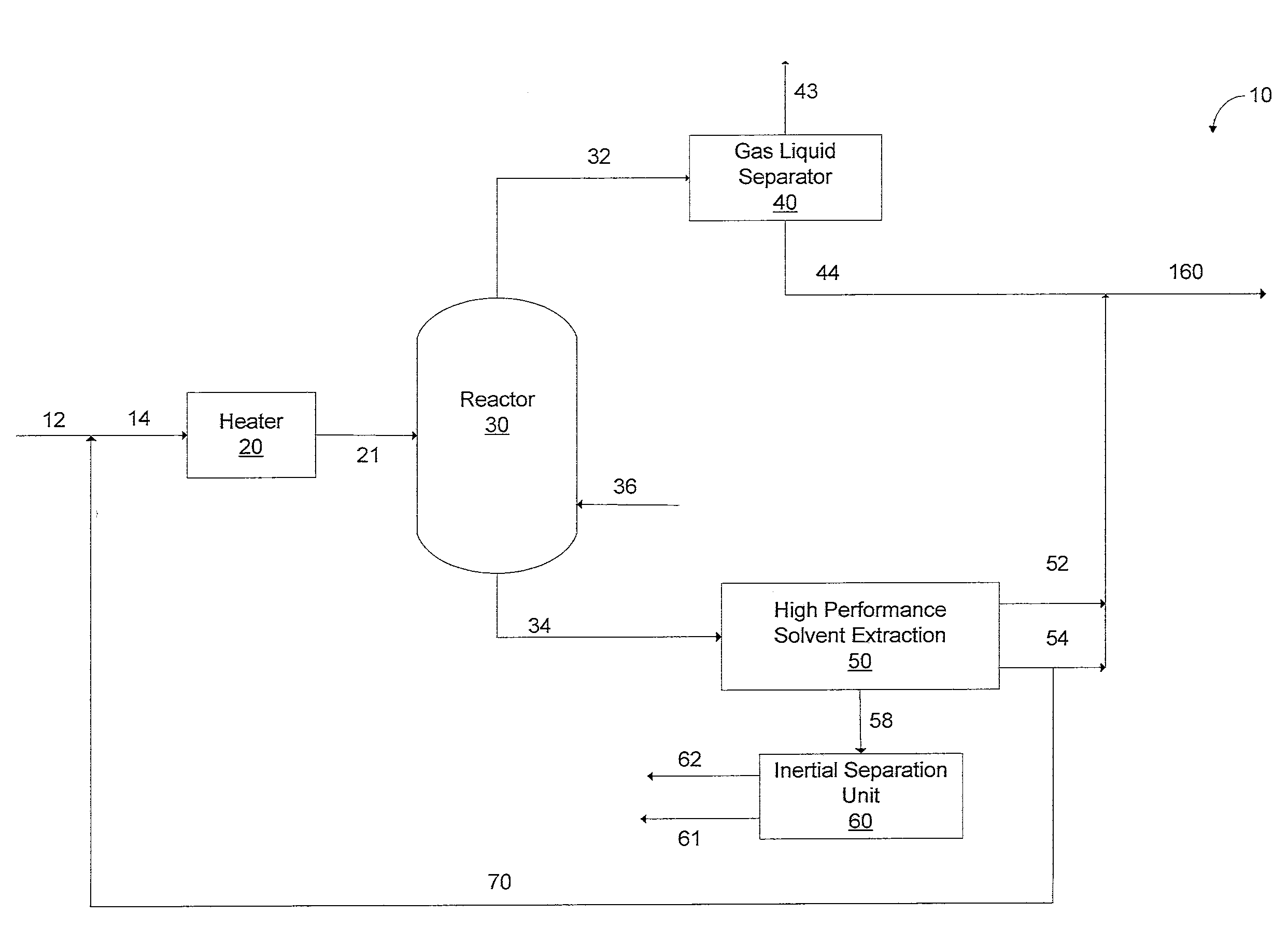

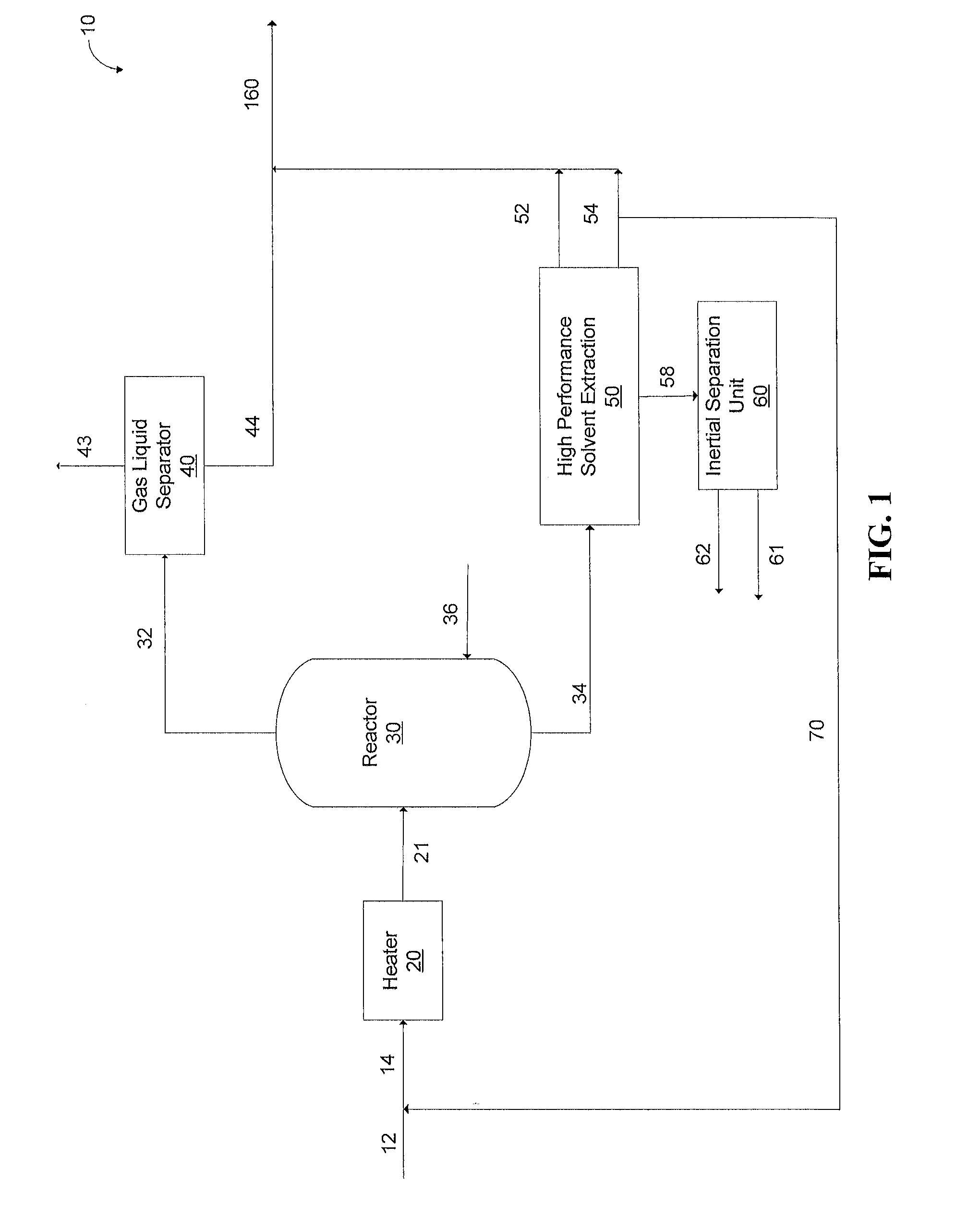

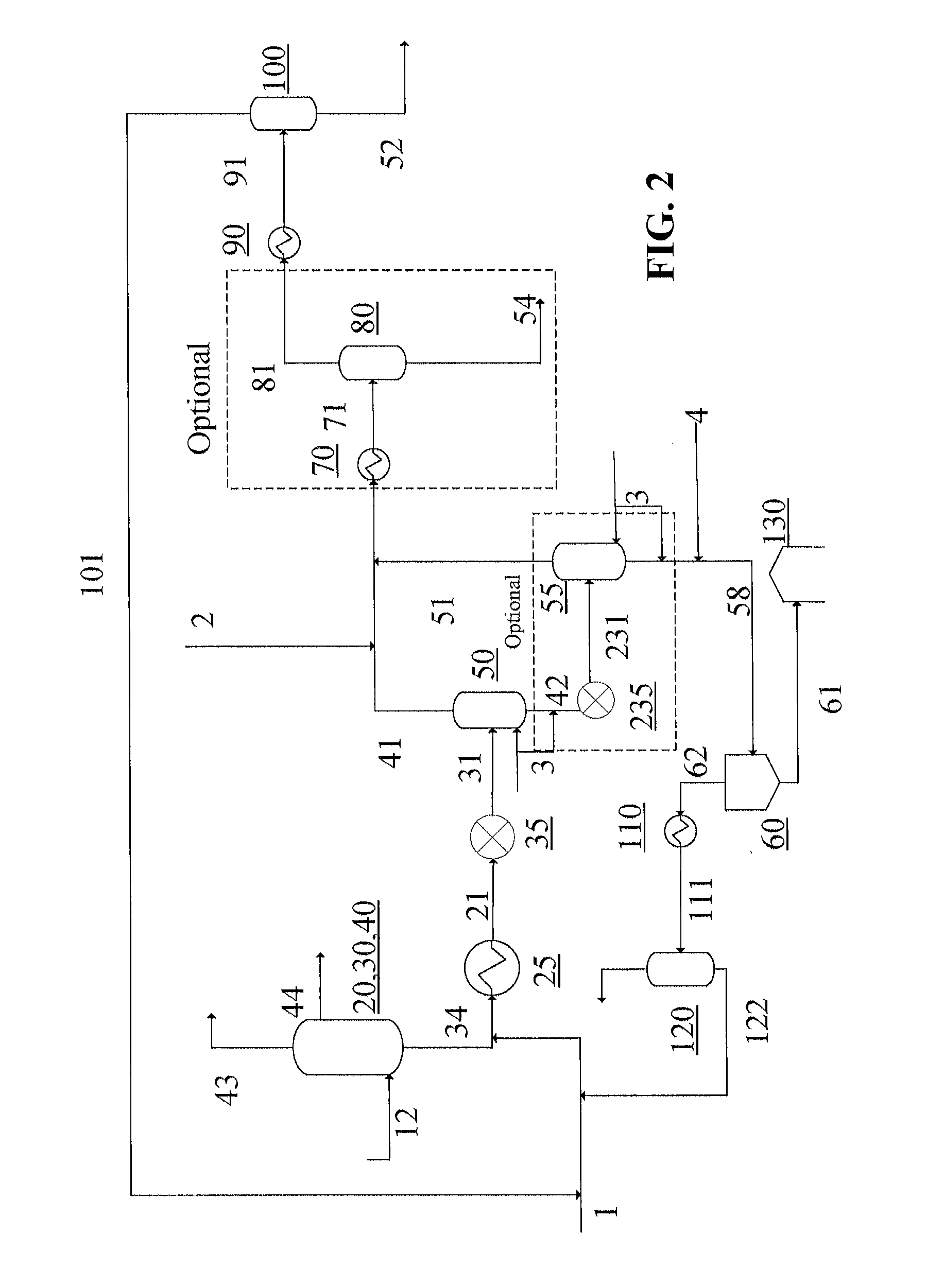

Low complexity, high yield conversion of heavy hydrocarbons

ActiveUS20130180888A1Assist in removingImproved solvent-extraction performanceWorking-up pitch/asphalt/bitumen by distillationThermal non-catalytic crackingSolventAsphaltene

A process for producing pipeline-ready or refinery-ready feedstock from heavy hydrocarbons using a high-performance solvent extraction process with high local solvent-to-process fluid ratios yet maintaining low overall solvent-to-process fluid ratios, by first performing mild thermal cracking on the heavy hydrocarbons and then separating asphaltene-rich fractions from a resulting thermally affected fluid so that the high solvent-to-oil ratio portion of the process acts only on those asphaltene-rich fractions, and producing a dry, solid asphaltene as an end-product.

Owner:SUNCOR ENERGY INC

Residuum Oil Supercritical Extraction Process

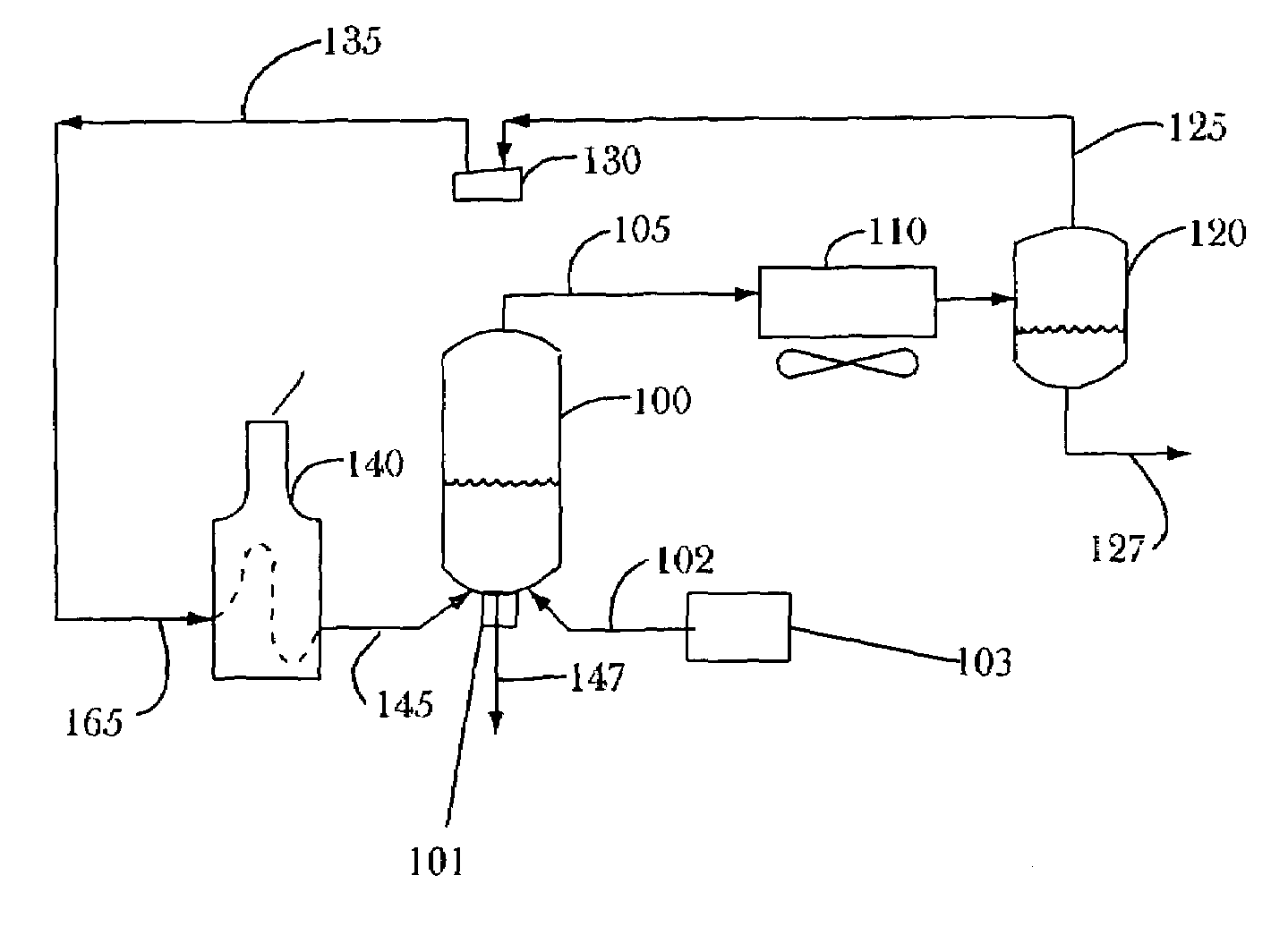

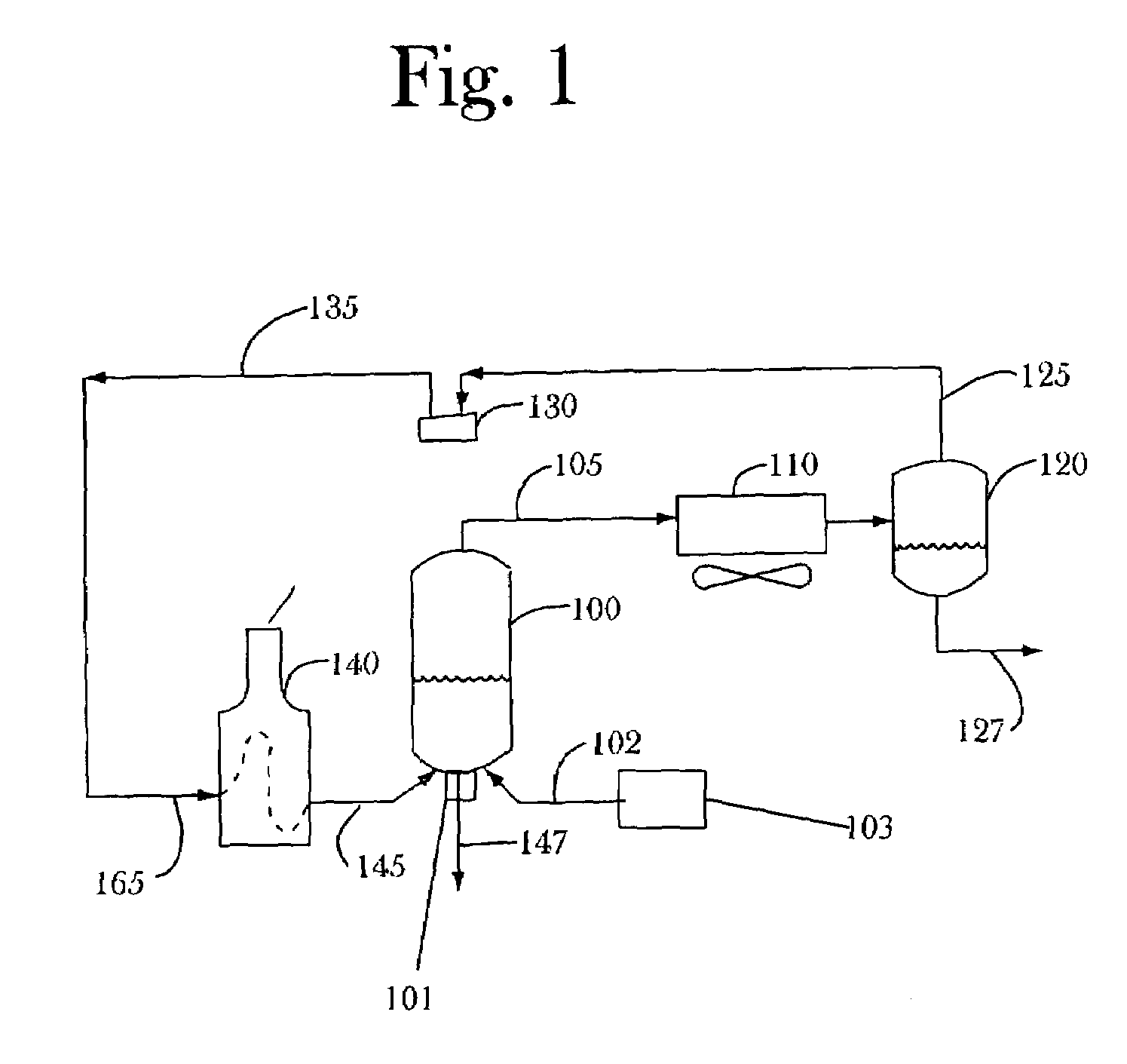

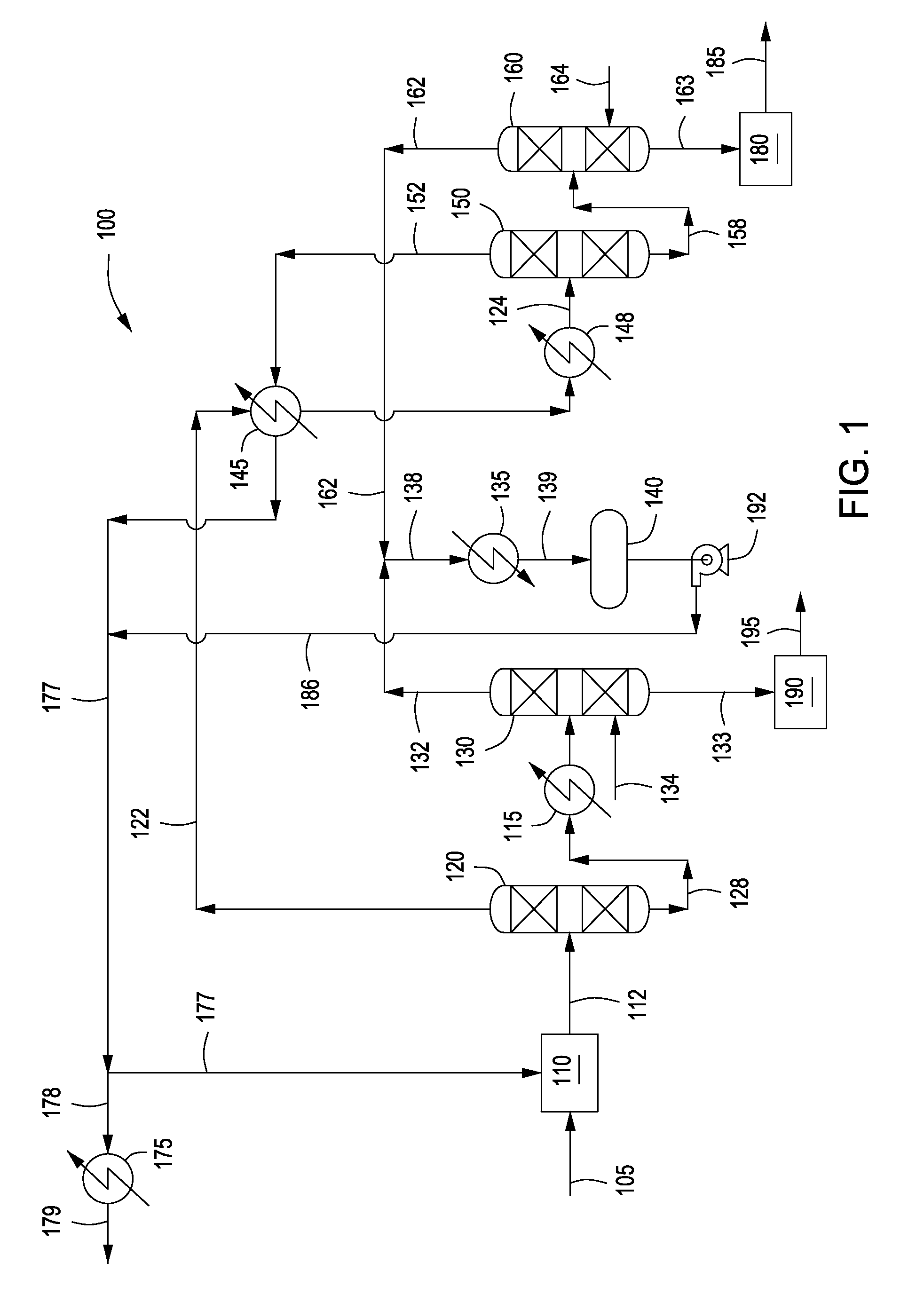

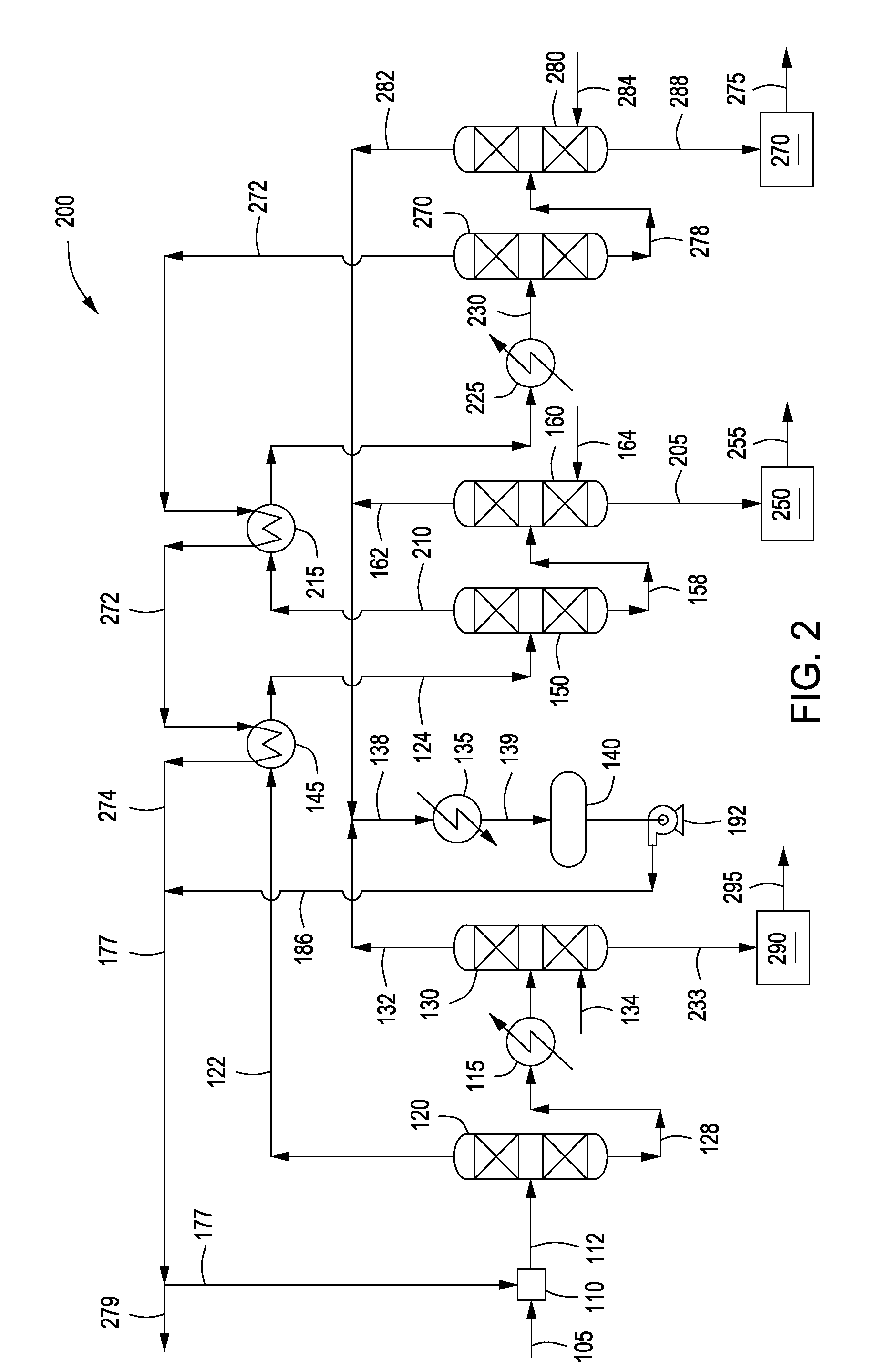

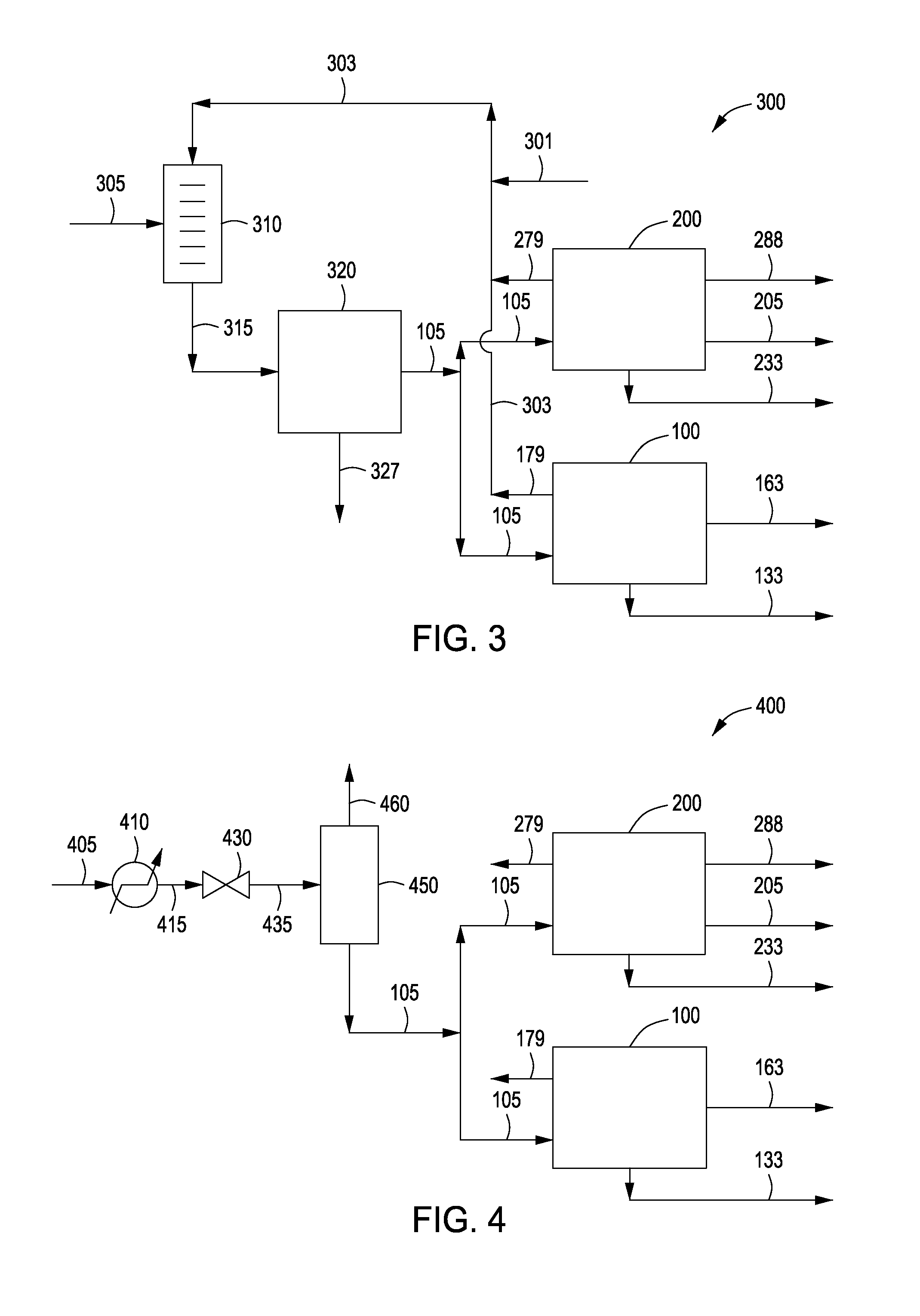

InactiveUS20110094937A1Working-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by chemical meansProcess systemsAsphaltene

Systems and methods for processing one or more hydrocarbons are provided. A hydrocarbon can be selectively separated to provide one or more finished products and an asphaltenic hydrocarbon using a pretreatment process. The asphaltenic hydrocarbon can be selectively separated to provide a deasphalted oil and one or more asphaltenes. At least a portion of the deasphalted oil can be converted to one or more first products using a first post-treatment process. At least a portion of the one or more asphaltenes can be converted to one or more second products using a second post-treatment process.

Owner:KELLOGG BROWN & ROOT LLC

Co-production technique of needle coke, mesocarbon microbeads and high-quality asphalt

ActiveCN104650938AHigh degree of processingLow costWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionMicrosphereEconomic benefits

The invention relates to a co-production technique of needle coke, mesocarbon microbeads and high-quality asphalt; heavy phase asphalt generated by raw material asphalt pre-treatment and raw material asphalt are mixed to produce mesocarbon microbeads, the byproduct asphalt of the production of misocarbon microbeads and the refined asphalt obtained by the raw material asphalt pre-treatment are mixed as a needle coke raw material; the technique comprises the steps of raw material asphalt pre-treatment, polymerization, polymerization product separating and drying, byproduct asphalt processing, coking and sintering. Compared with the prior art, the technique related by the invention has the following beneficial effects: (1) the coal tar asphalt processing degree is high, the cost is low, the varieties are diversified, the added value of the product is high, and the maximal economic benefit is realized; (2) the waste discharge is avoided during the whole production process, and the optimal environmental benefit is realized; (3) the process is flexible, the operation is simple, and the high-efficiency combination of needle coke, mesocarbon microbeads and high-quality asphalt is realized; and (4) the product index is flexible and adjustable, so as to adapt to market variations in time and improve the market risk resisting capability of an enterprise.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

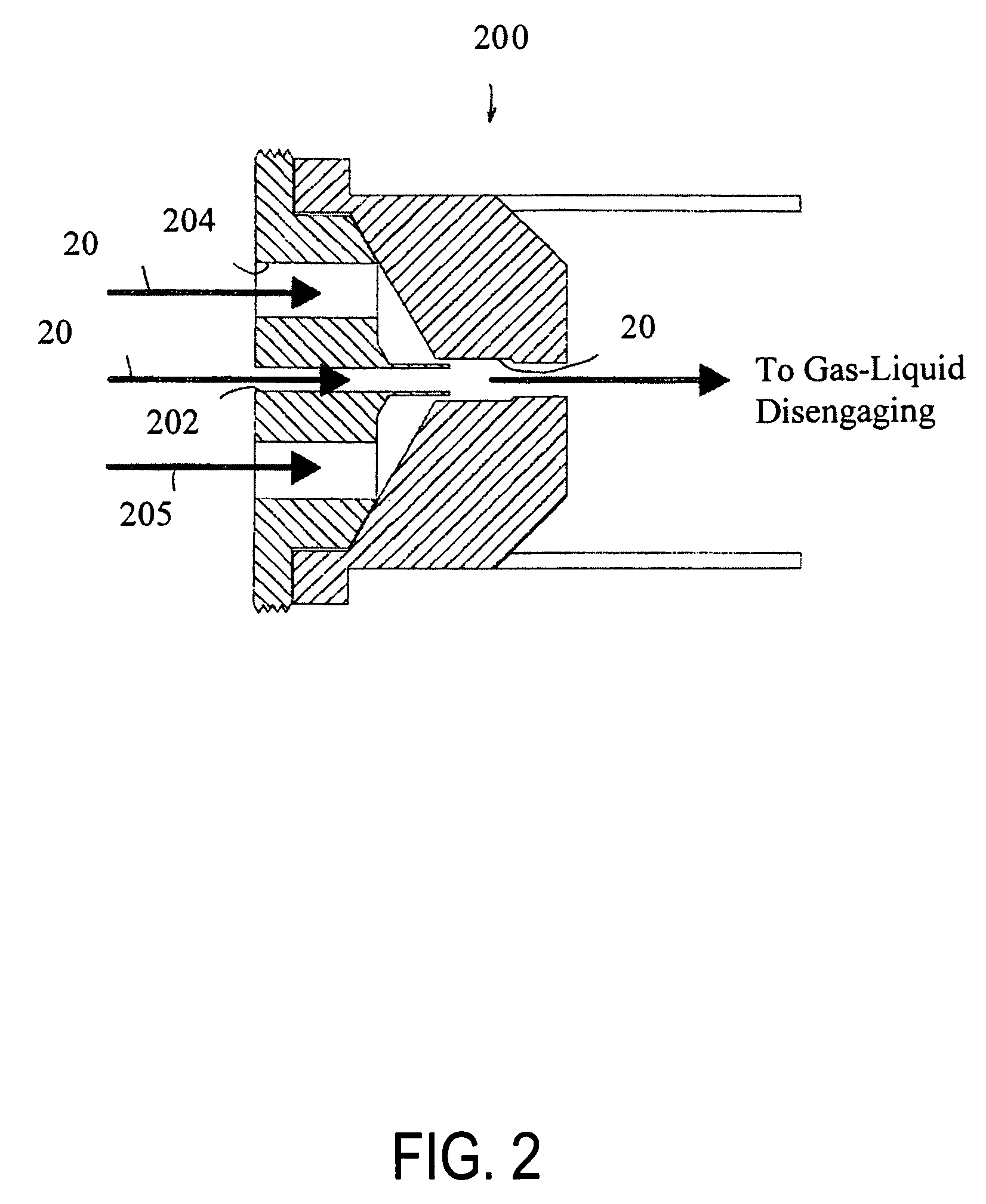

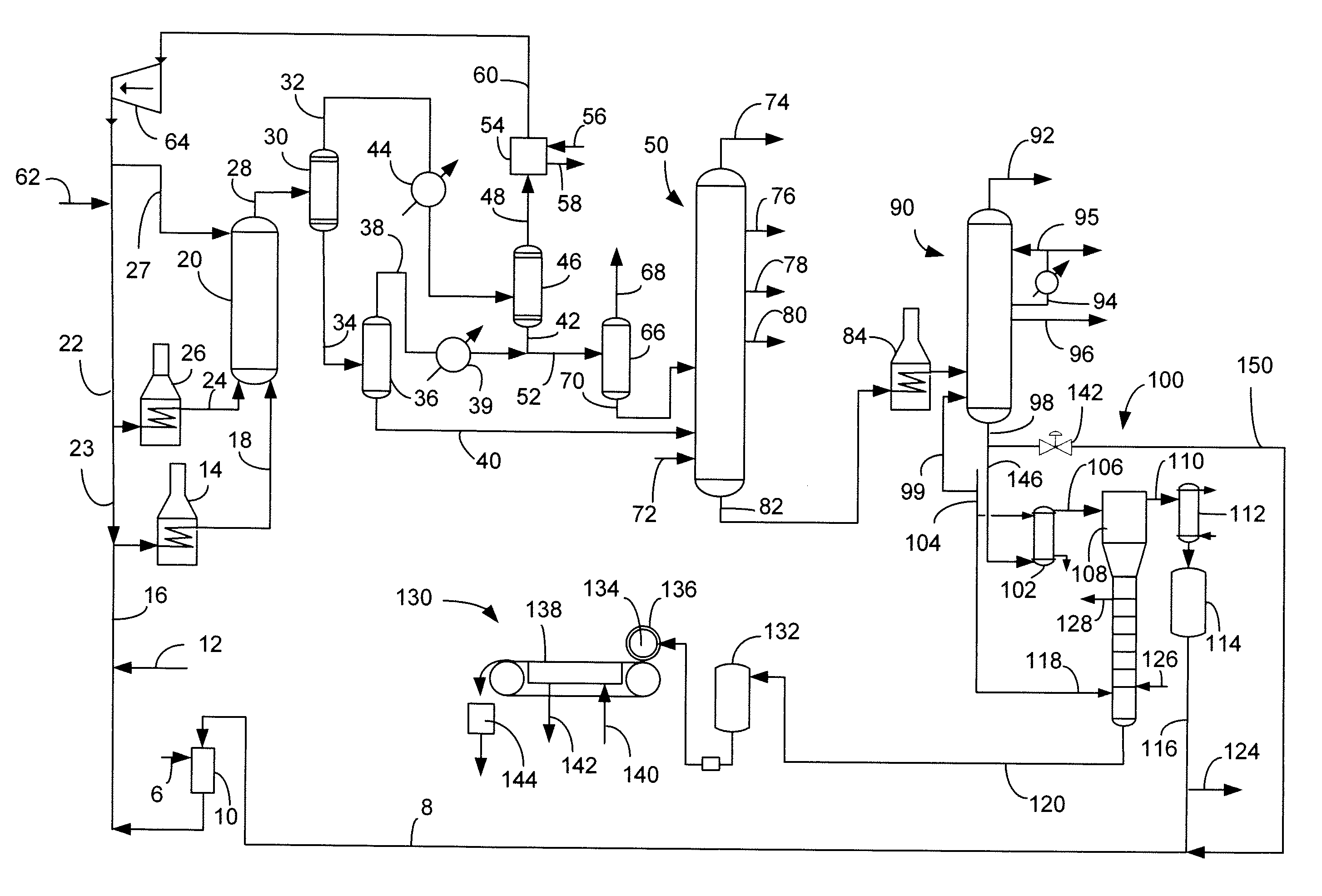

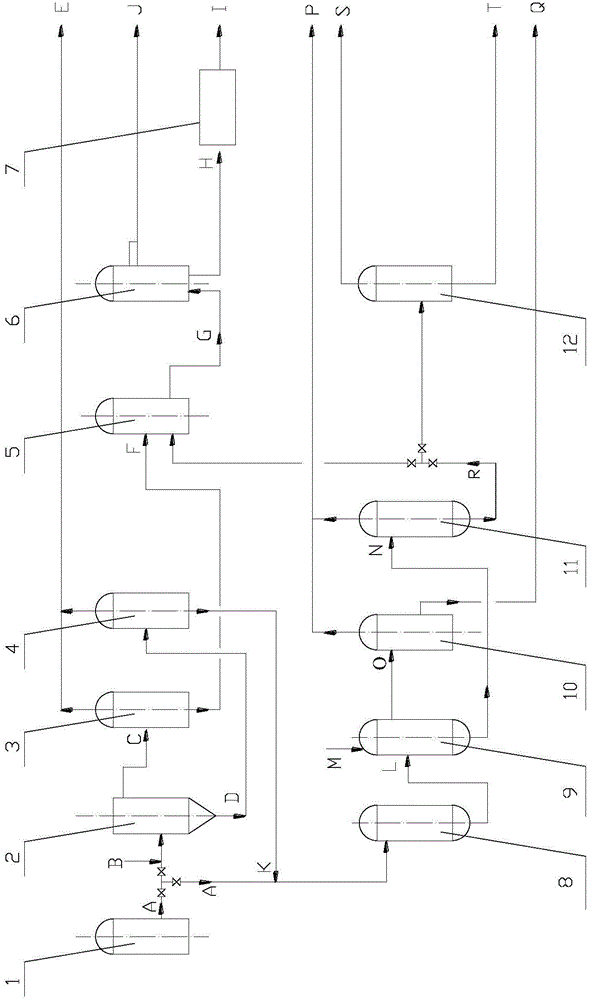

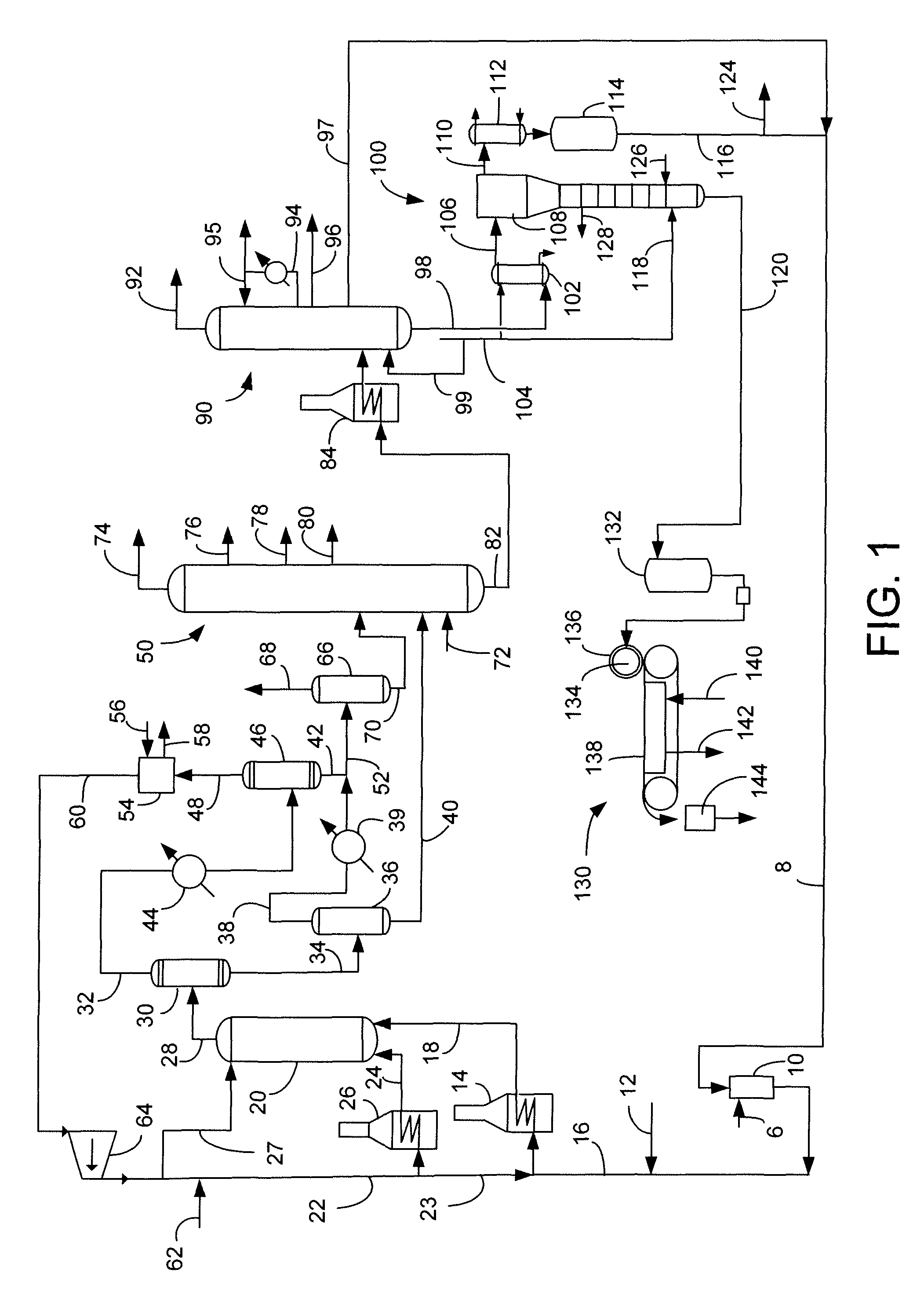

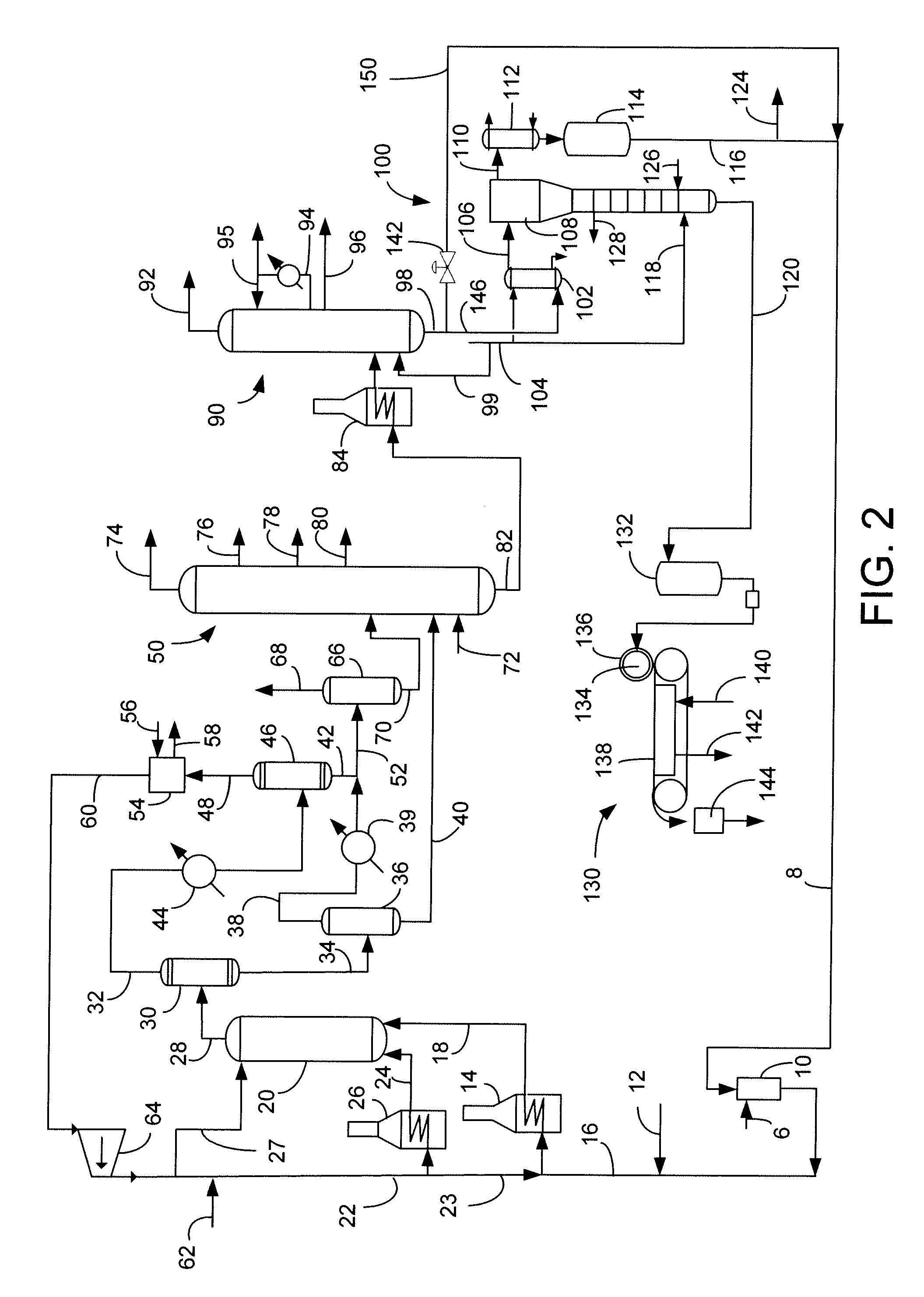

Method of and apparatus for upgrading and gasifying heavy hydrocarbon feeds

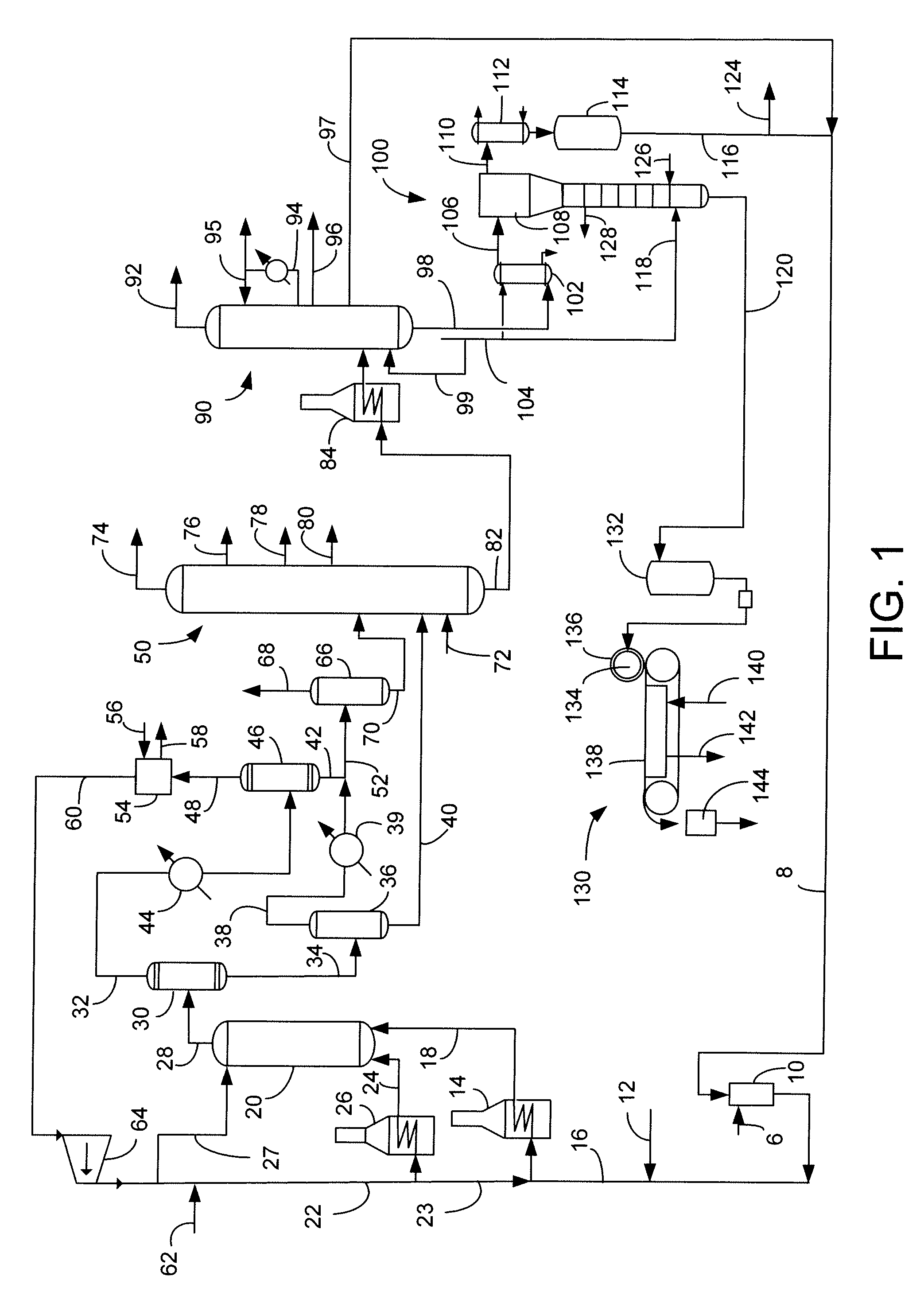

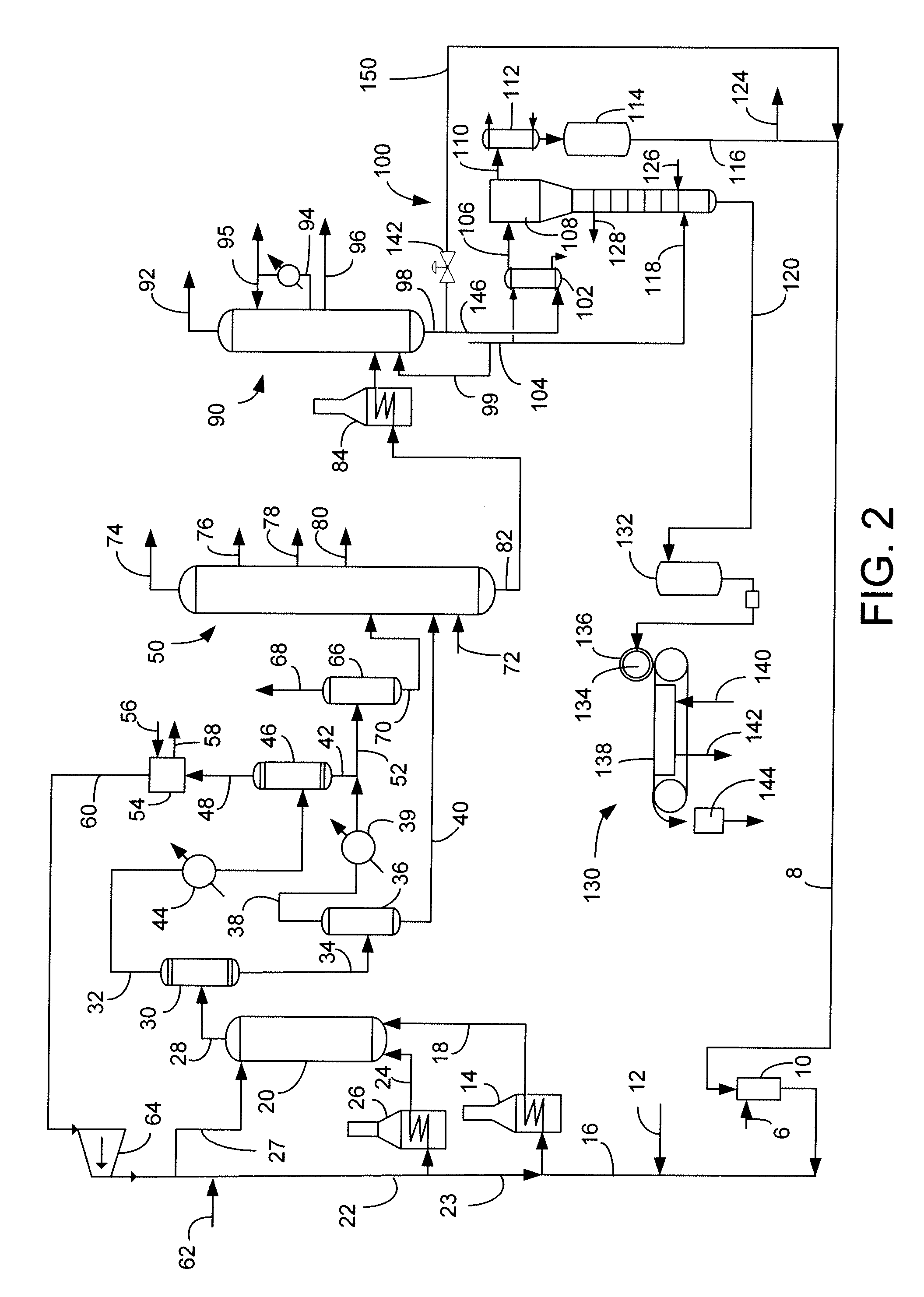

InactiveUS20040118745A1Thermal non-catalytic crackingSolvent extractionThermodynamicsProcess engineering

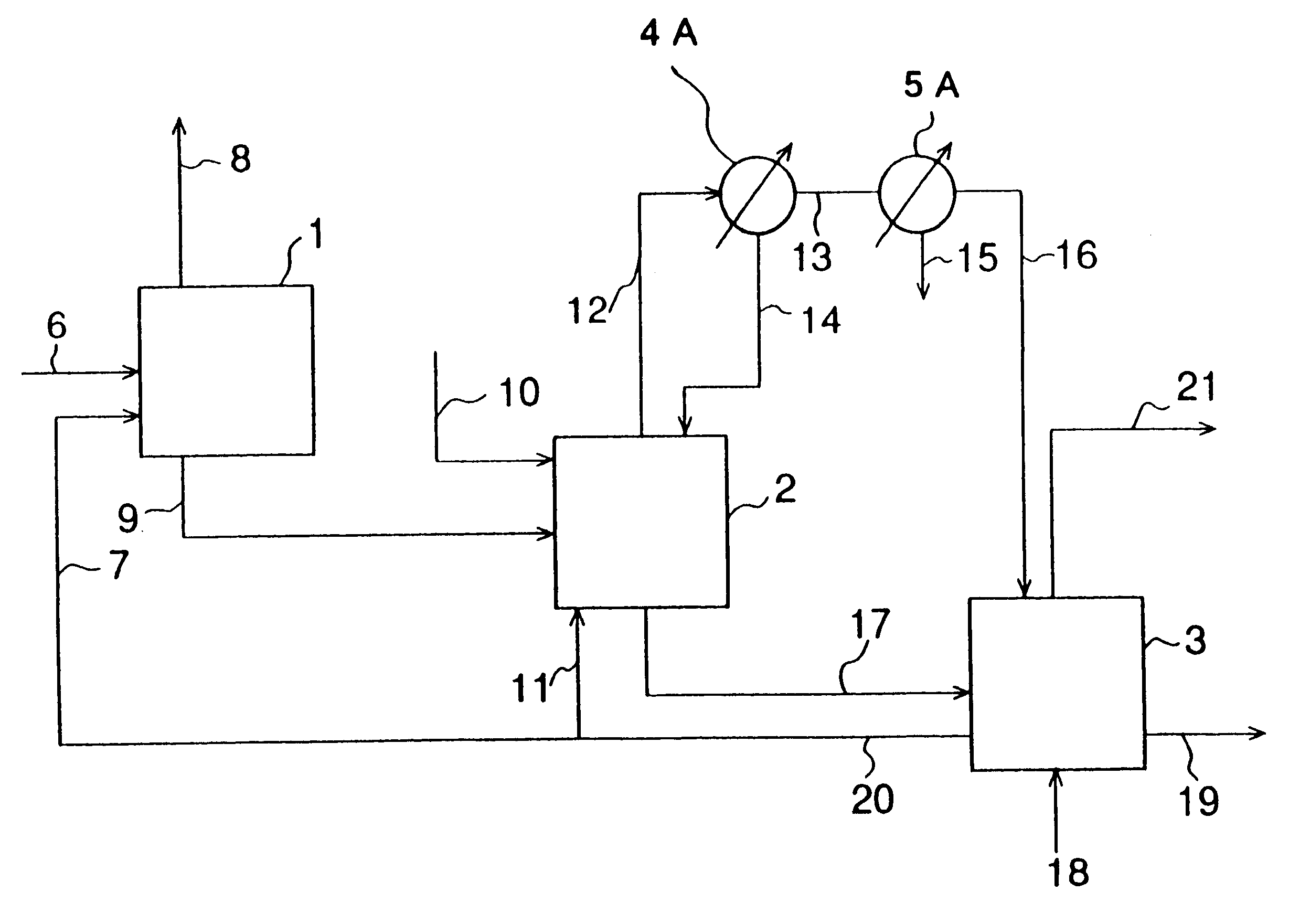

A novel apparatus for producing sweet synthetic crude from a heavy hydrocarbon feed includes: an upgrader for receiving the heavy hydrocarbon feed and producing a distillate fraction including sour products, and high-carbon content by-products; a gasifier for receiving the high-carbon content by-products and producing synthetic fuel gas and sour by-products; a hydroprocessing unit for receiving the sour by-products and hydrogen gas, thereby producing gas and sweet crude; and a hydrogen recovery unit for receiving the synthetic fuel gas and producing further hydrogen gas and hydrogen-depleted synthetic fuel gas, the further hydrogen gas being supplied to the hydroprocessing unit.

Owner:ORMAT IND LTD

Method of and apparatus for upgrading and gasifying heavy hydrocarbon feeds

A novel apparatus for producing sweet synthetic crude from a heavy hydrocarbon feed includes: an upgrader for receiving the heavy hydrocarbon feed and producing a distillate fraction including sour products, and high-carbon content by-products; a gasifier for receiving the high-carbon content by-products and producing synthetic fuel gas and sour by-products; a hydroprocessing unit for receiving the sour by-products and hydrogen gas, thereby producing gas and sweet crude; and a hydrogen recovery unit for receiving the synthetic fuel gas and producing further hydrogen gas and hydrogen-depleted synthetic fuel gas, the further hydrogen gas being supplied to the hydroprocessing unit.

Owner:ORMAT IND LTD

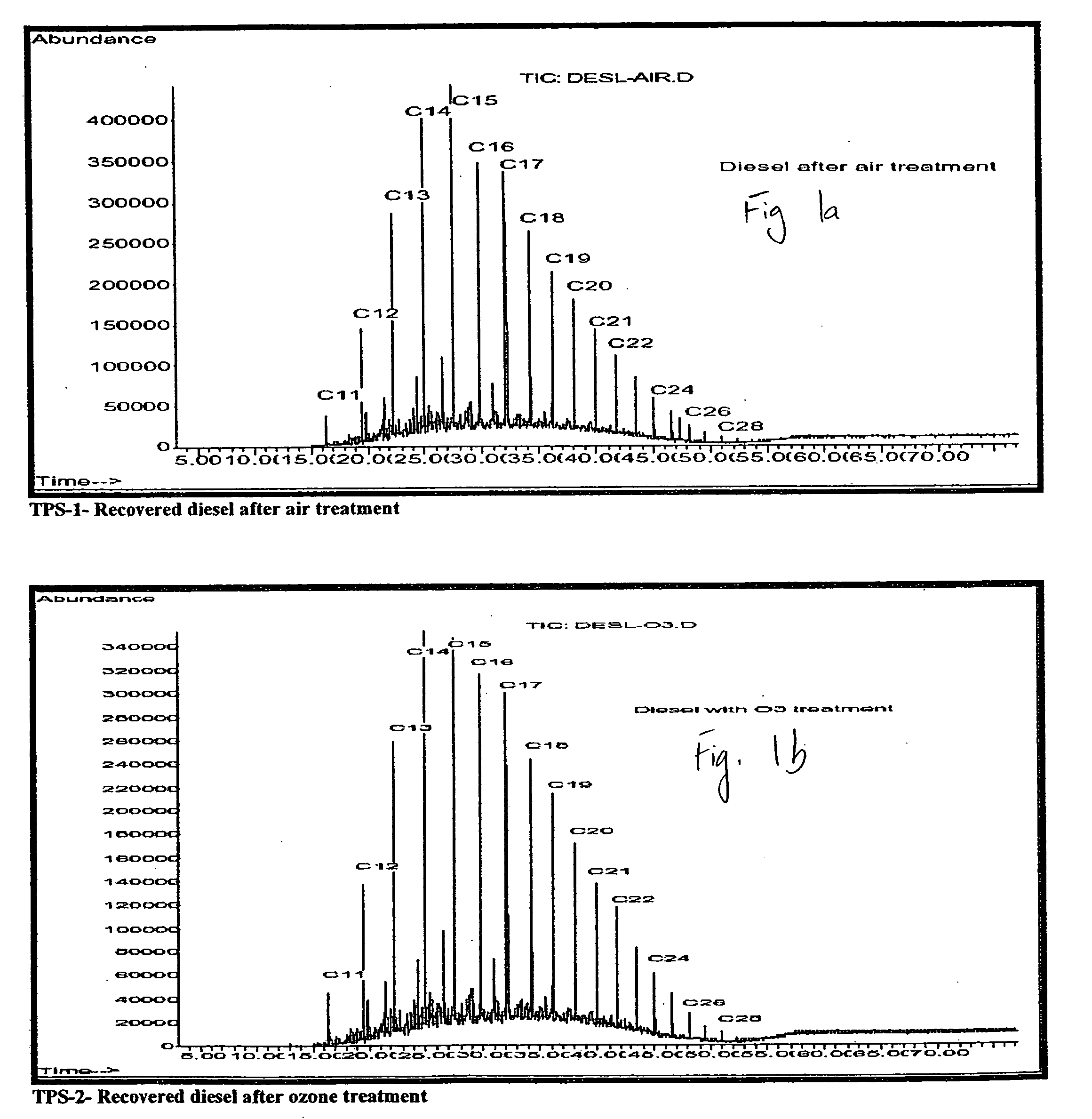

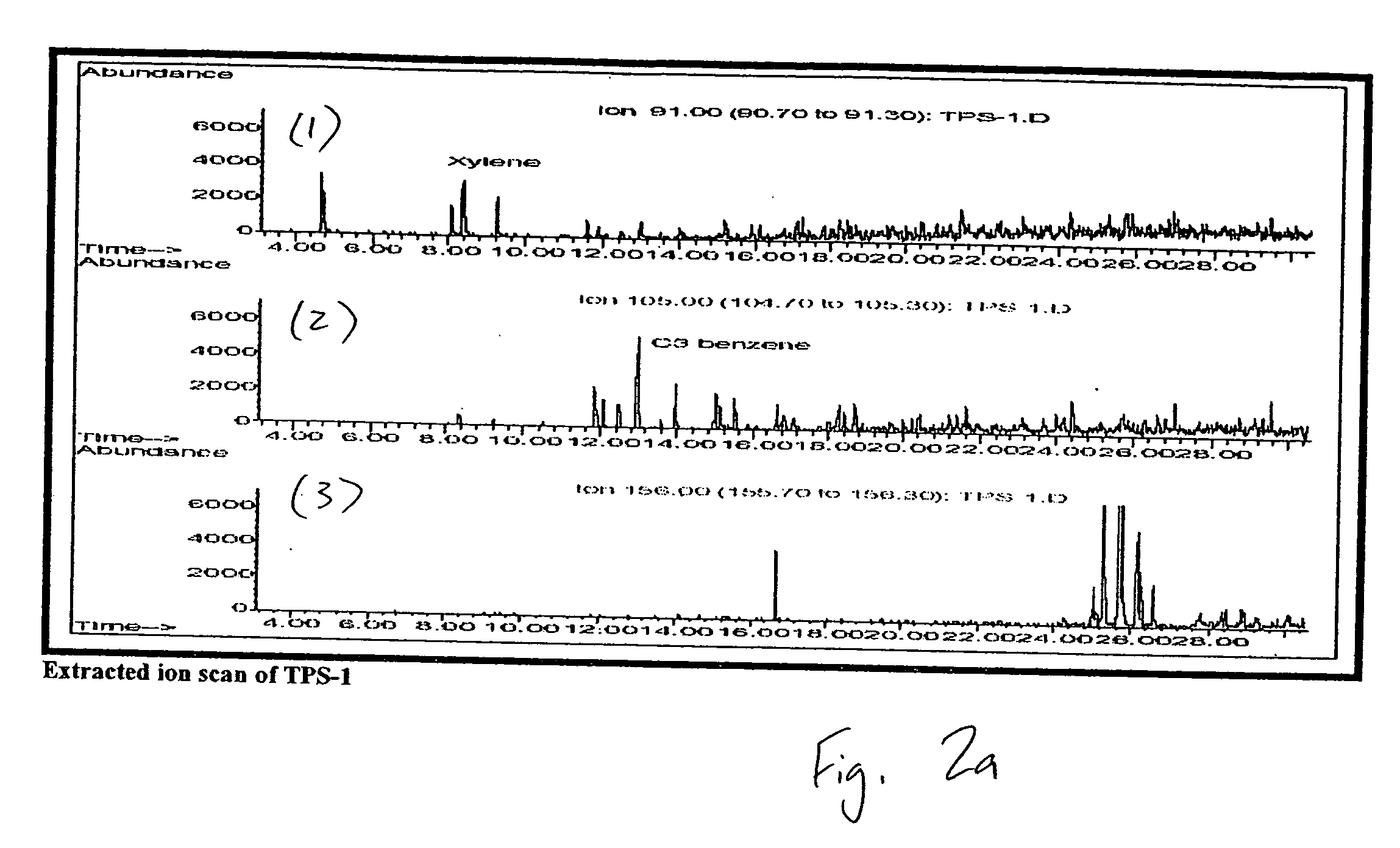

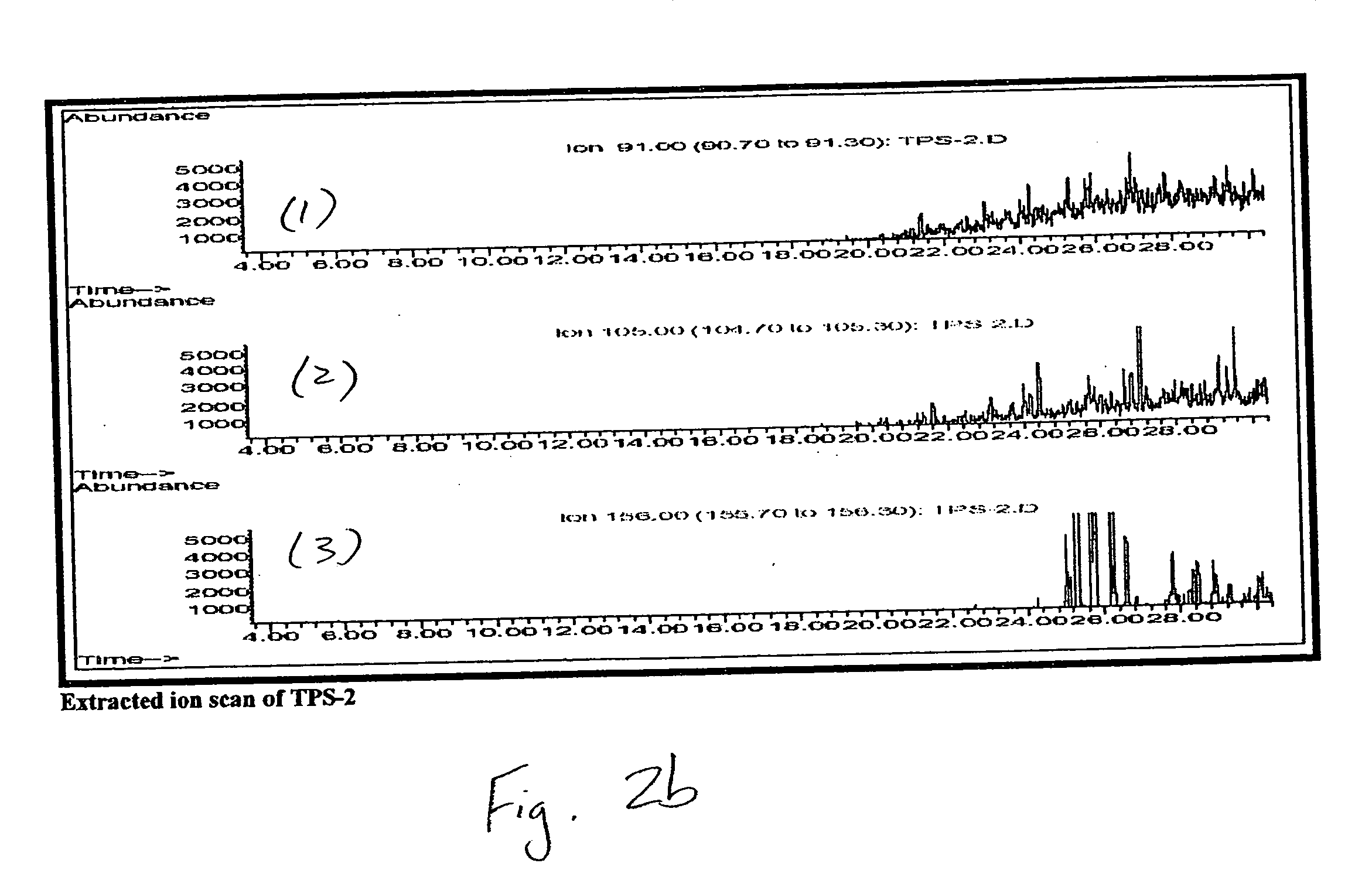

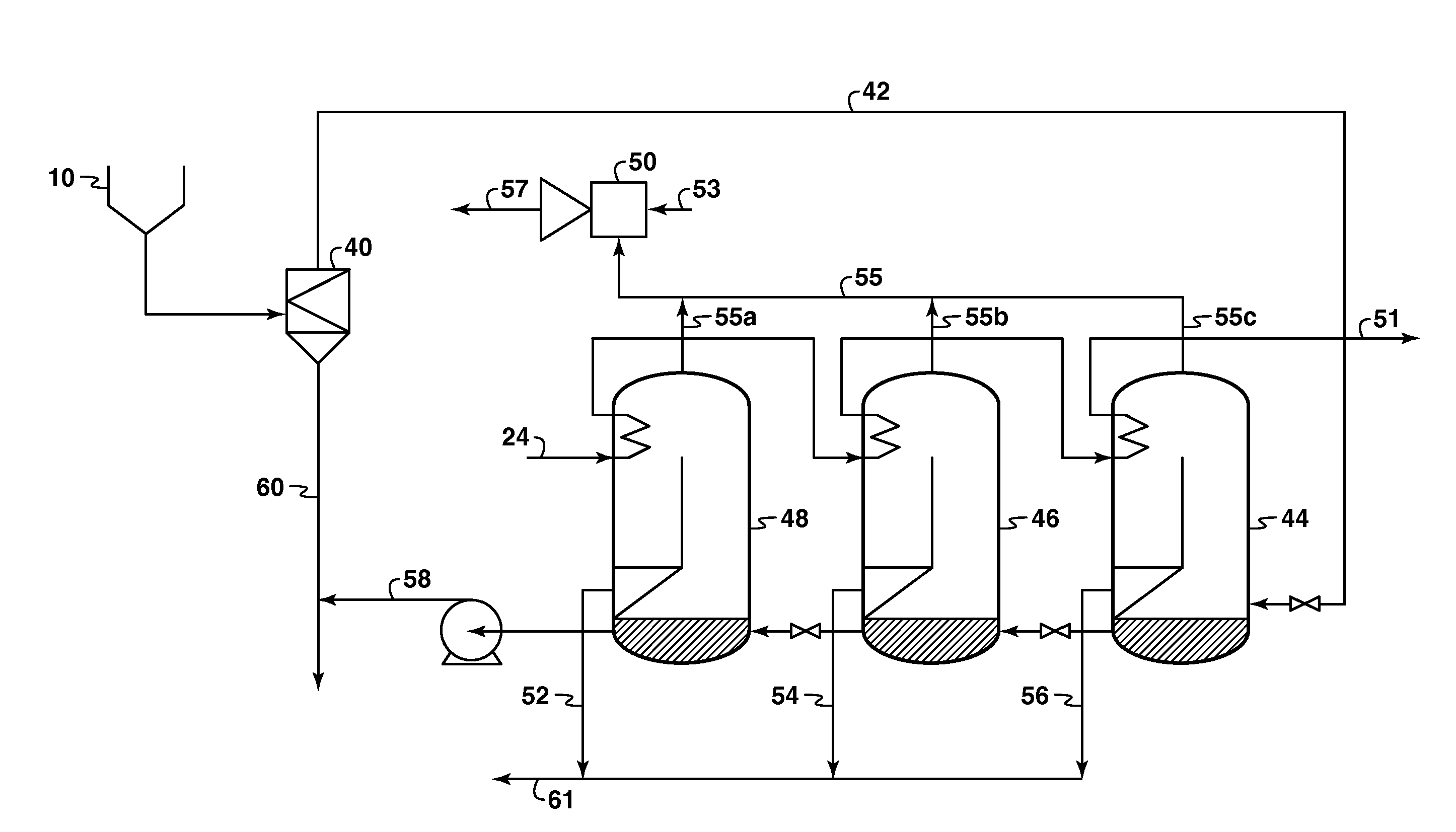

Treatment of hydrocarbon fluids with ozone

InactiveUS20050247599A1Thermal non-catalytic crackingDrying using combination processesHydrocarbonOzone

A method of treating a hydrocarbon fluid that includes contacting the hydrocarbon fluid with an effective amount of ozone. A method for separating contaminants from a contaminated material includes supplying the contaminated material to a processing chamber, moving the contaminated material through the processing chamber, heating the contaminated material by externally heating the processing chamber so as to volatilize the contaminants in the contaminated material, removing vapor resulting from the heating, wherein the vapor comprises the volatilized contaminants, collecting, condensing, and recovering the volatilized contaminants, and contacting the volatilized contaminants with an effective amount of ozone.

Owner:MI

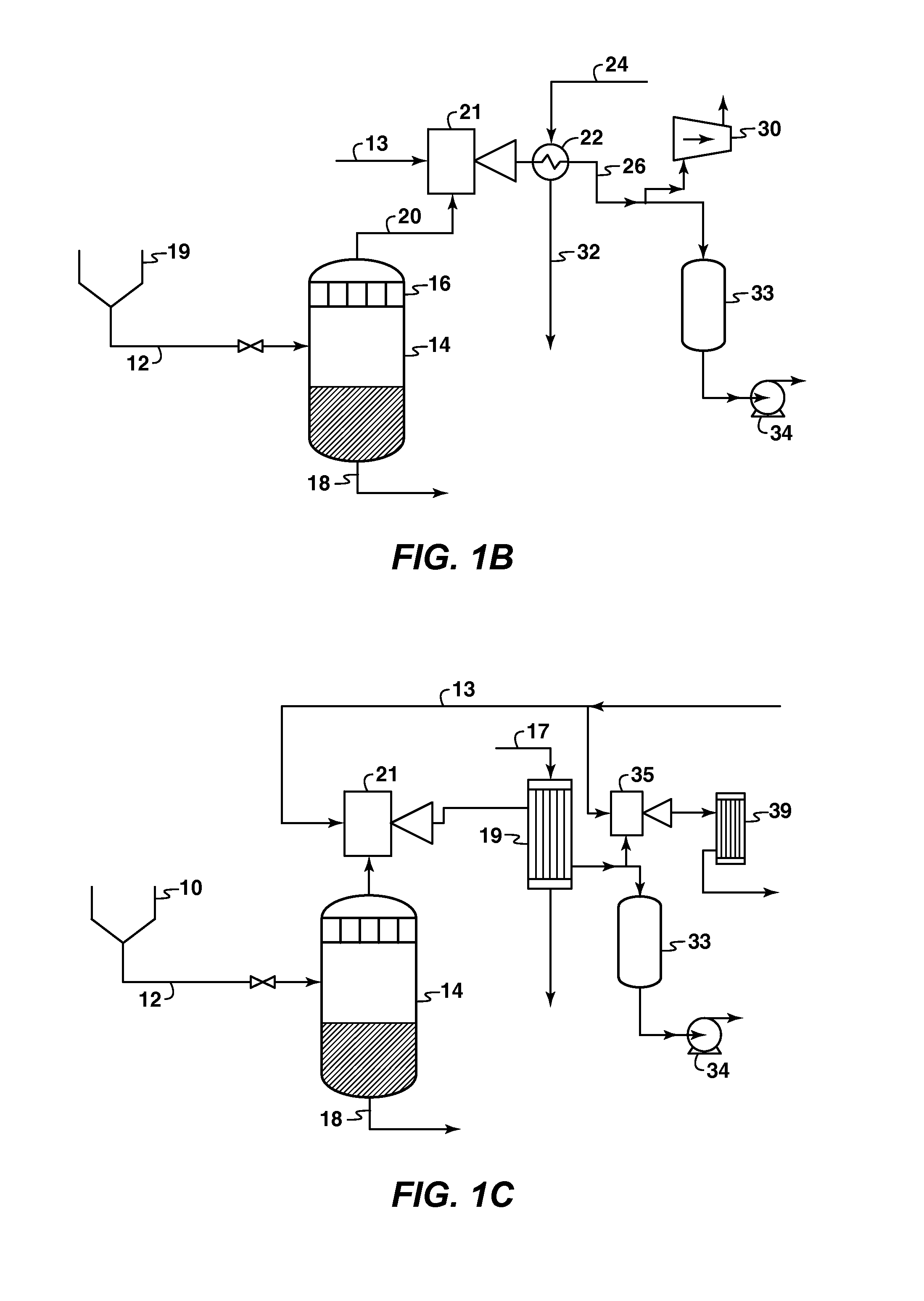

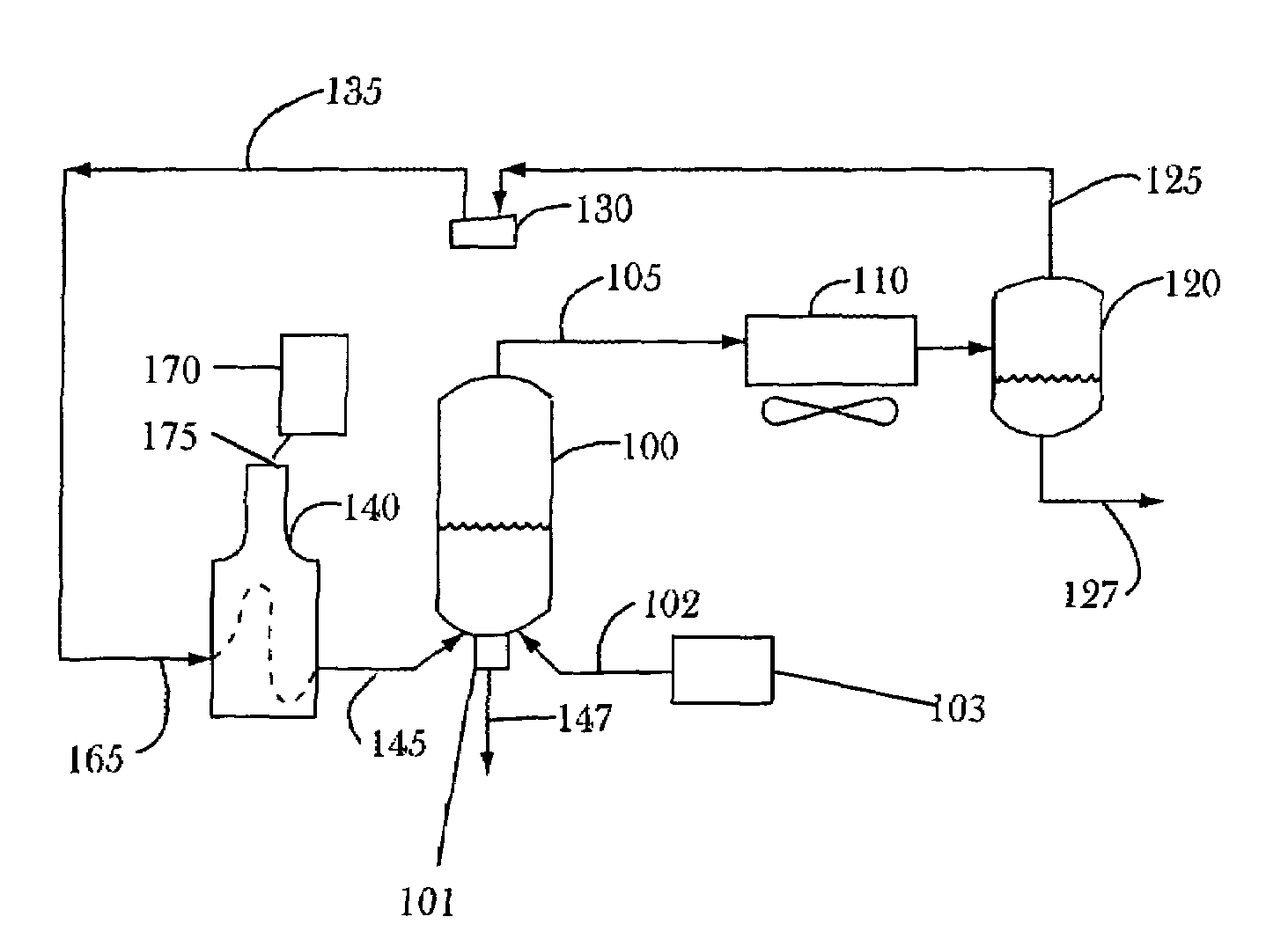

System and method of recovering heat and water and generating power from bitumen mining operations

InactiveUS20100275600A1Improve environmental performanceReducing greenhouse gas emissionThermal non-catalytic crackingAuxillariesEngineeringSlurry

A method recovering heat and water from a warm slurry, such as warm tailings from a oil sands extraction mining operation, is provided. The method comprises providing the tailings to a vacuum vessel, removing, from the vacuum vessel, warm vapor derived from the tailings, condensing the warm vapor in a condenser to produce water, and recovering the water from the condenser. Cool river or pond water can be warmed with the heat from the vapor for additional uses in the mining operation. Essentially pure water can be obtained in the process. This can also be achieved using one or flash vessels in series to condense the vapor. Power can also be generated from the vapor using a turbine.

Owner:EXXONMOBIL UPSTREAM RES CO

Continuous oxidation and distillation process of heavier hydrocarbon materials

InactiveUS7341656B1Low costLow facility requirementsWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by chemical meansDistillationPhysical chemistry

The present invention provides a way to process heavier hydrocarbons in a relatively low cost and low pressure process using a combination of superheated steam and at least one reaction gas to i) promote oxidation and thermal reaction of heavier hydrocarbons, while simultaneously ii) removing volatile components with a steam stripping process.

Owner:MARATHON PETROLEUM

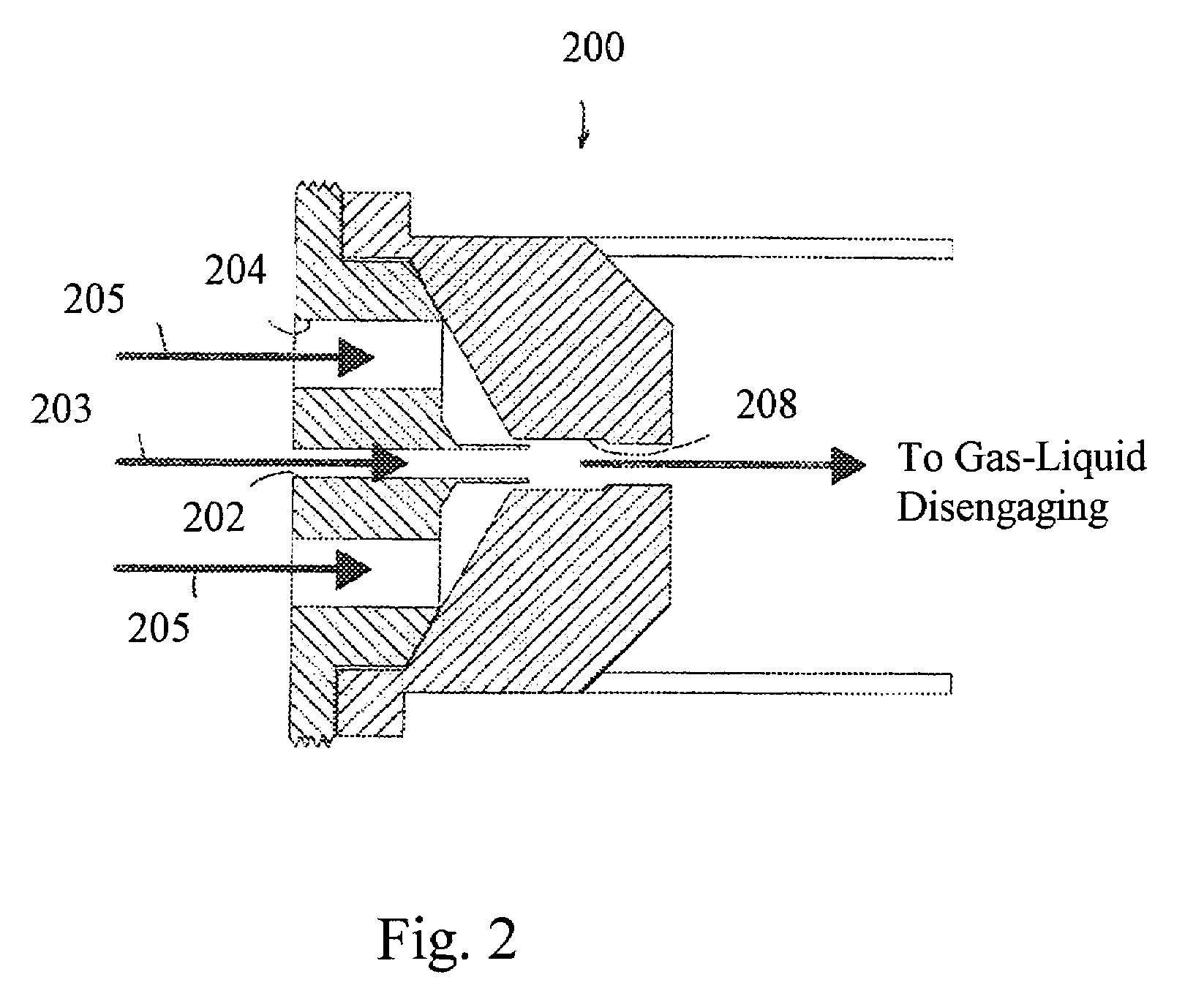

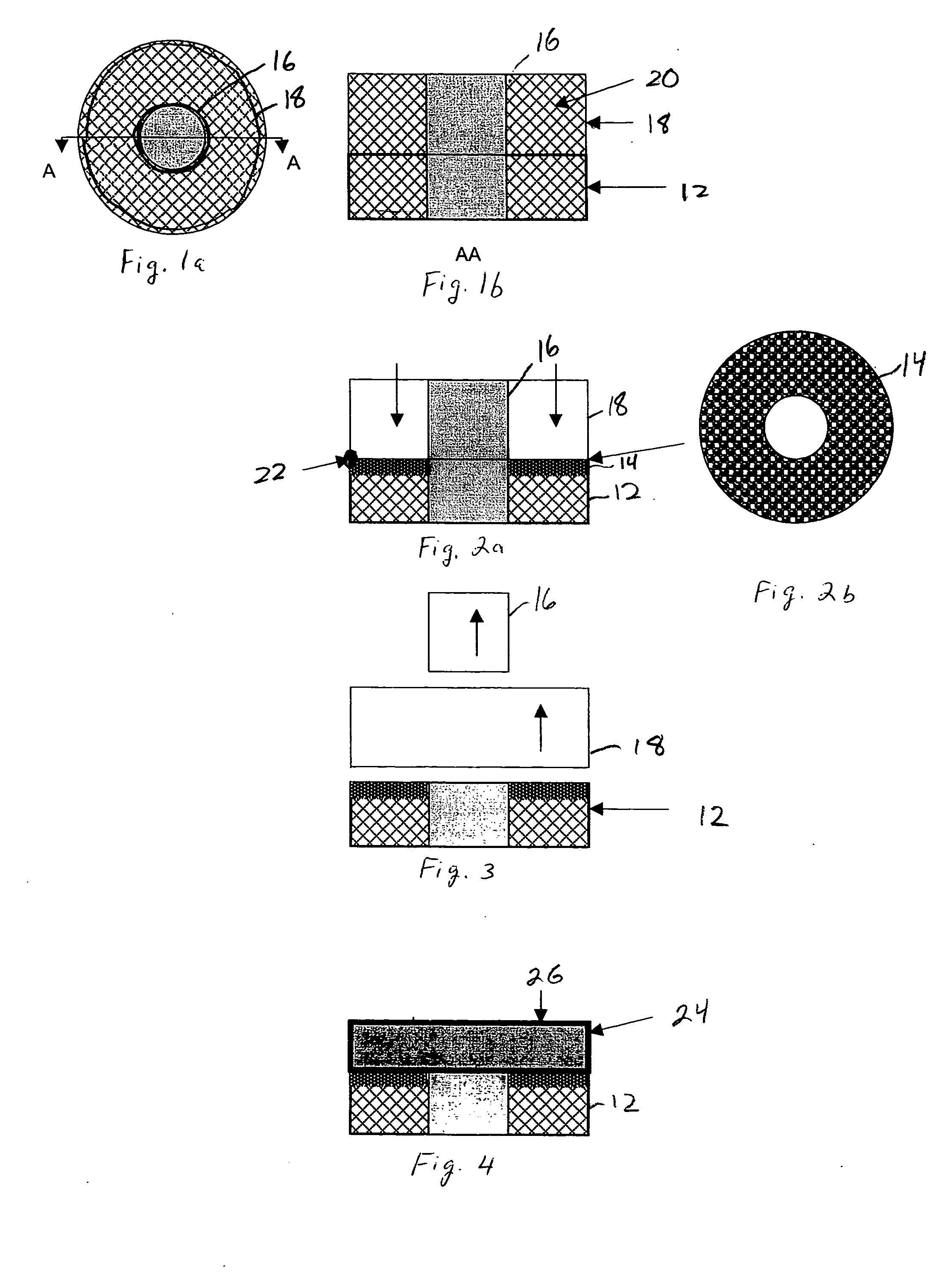

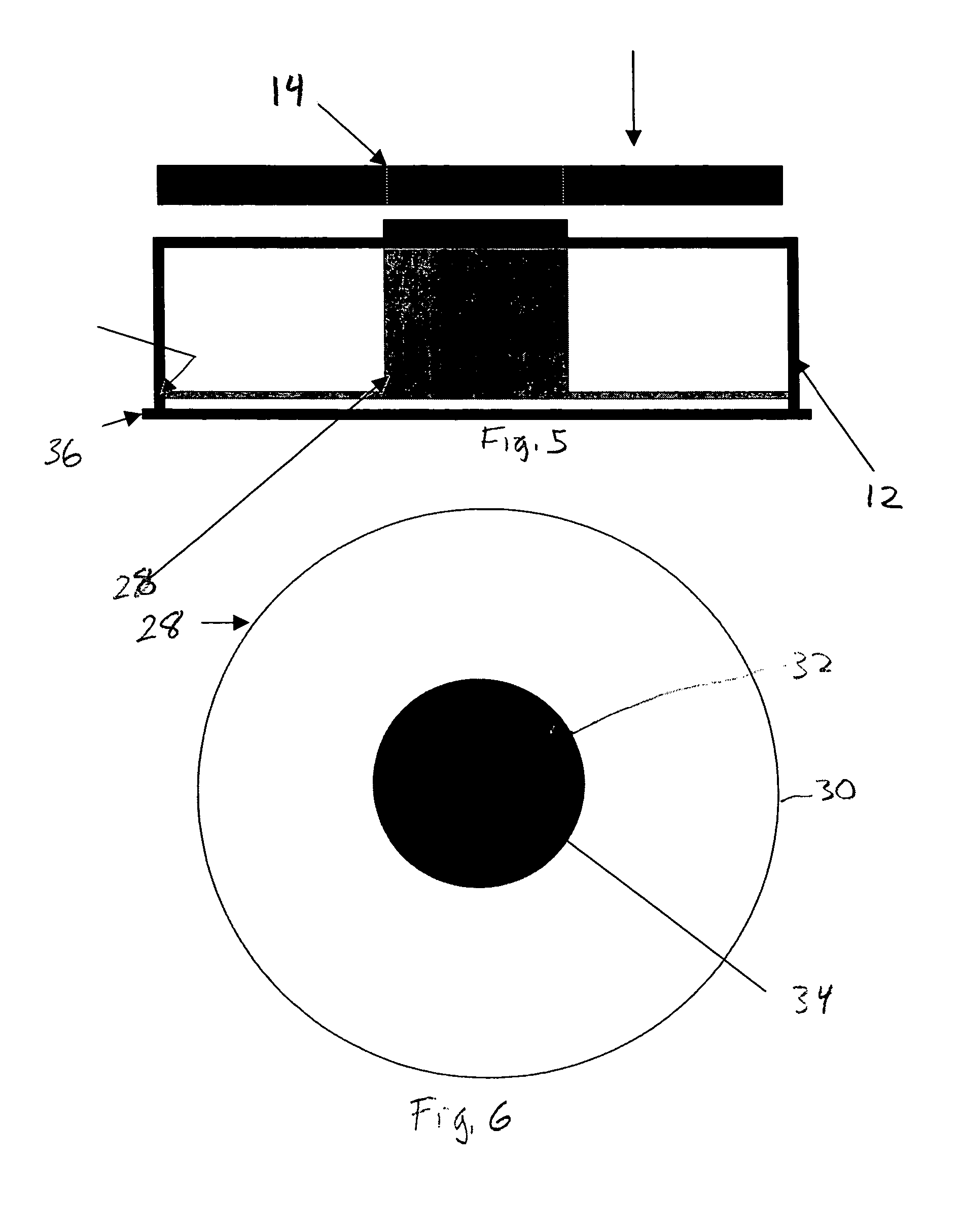

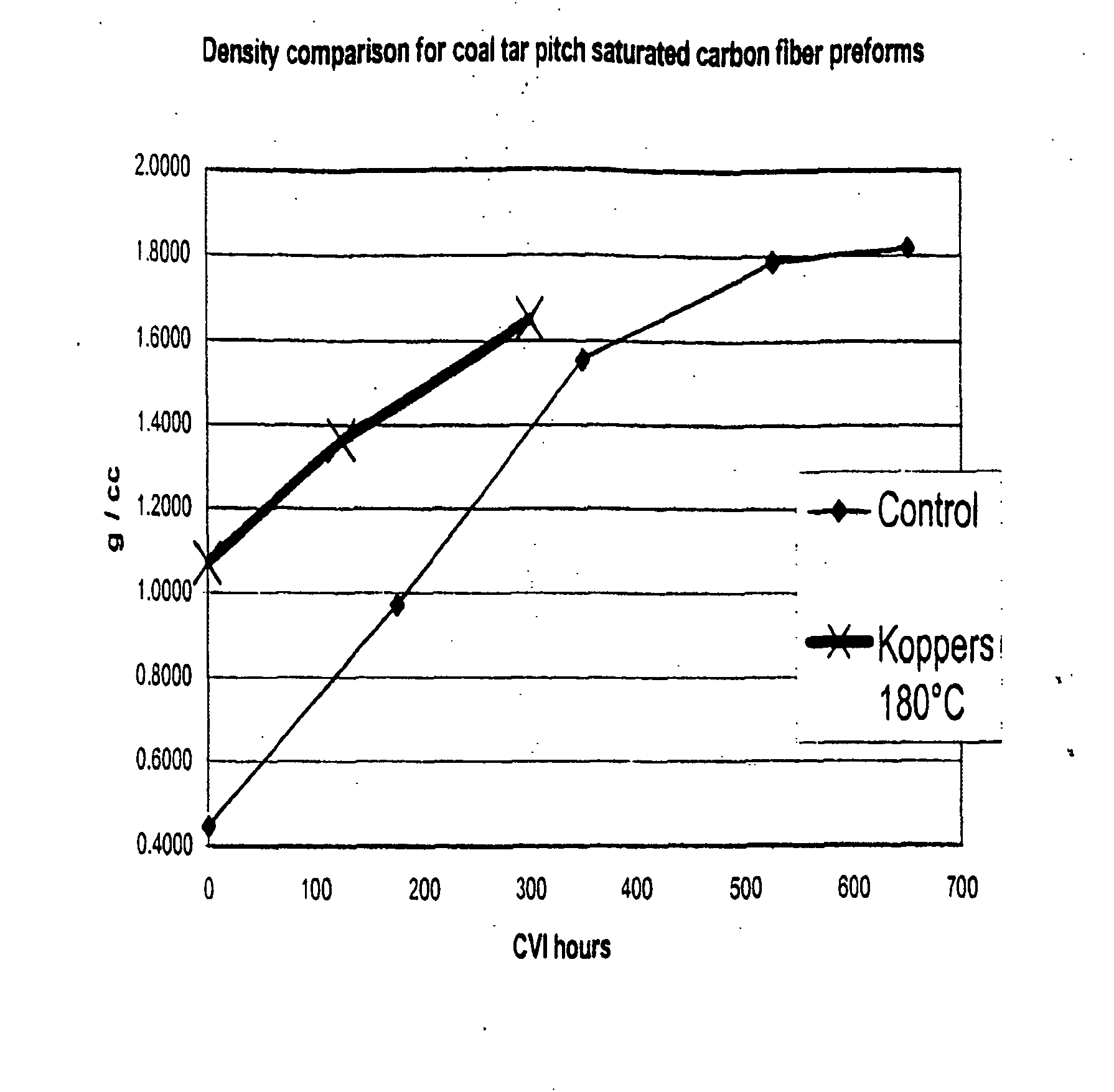

Chopped carbon fiber preform processing method using coal tar pitch binder

InactiveUS20050081752A1High densityExcellent propertyWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by chemical meansFiberCarbon fibers

Owner:KOPPERS DELAWARE INC

Process for separating pitch from slurry hydrocracked vacuum gas oil

InactiveUS8540870B2Easy to manageLess stickyWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by solidifying/disintegratingParticulatesSlurry

A process is disclosed for converting heavy hydrocarbon feed into lighter hydrocarbon products. The heavy hydrocarbon feed is slurried with a particulate solid material to form a heavy hydrocarbon slurry and hydrocracked in a slurry hydrocracking unit to produce vacuum gas oil (VGO) and pitch. A first vacuum column separates VGO from pitch, and a second vacuum column further separates VGO from pitch. As much as 15 wt-% of VGO can be recovered by the second vacuum column and recycled to the slurry hydrocracking unit. A pitch composition is obtained which can be made into particles and transported without sticking together.

Owner:UOP LLC

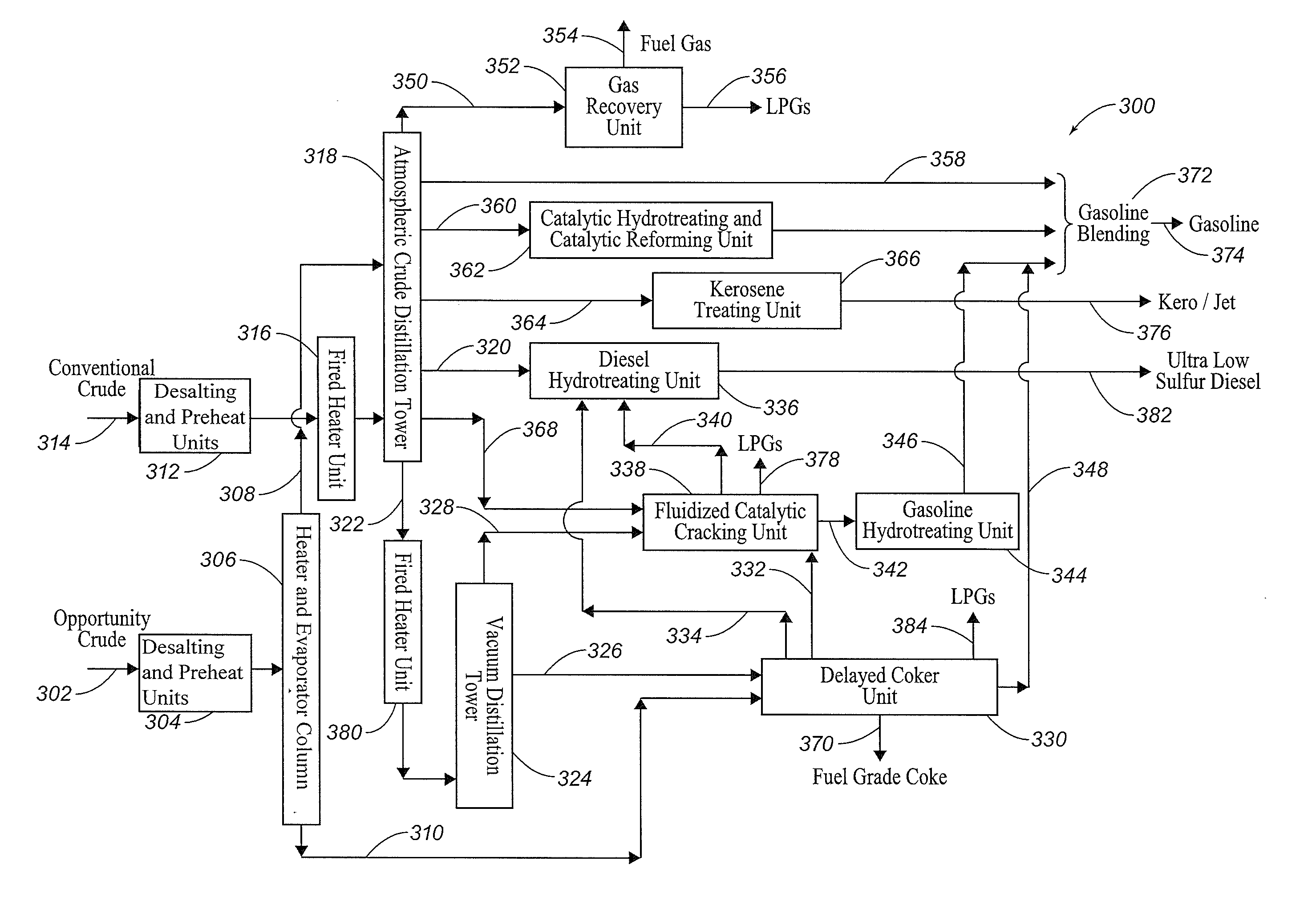

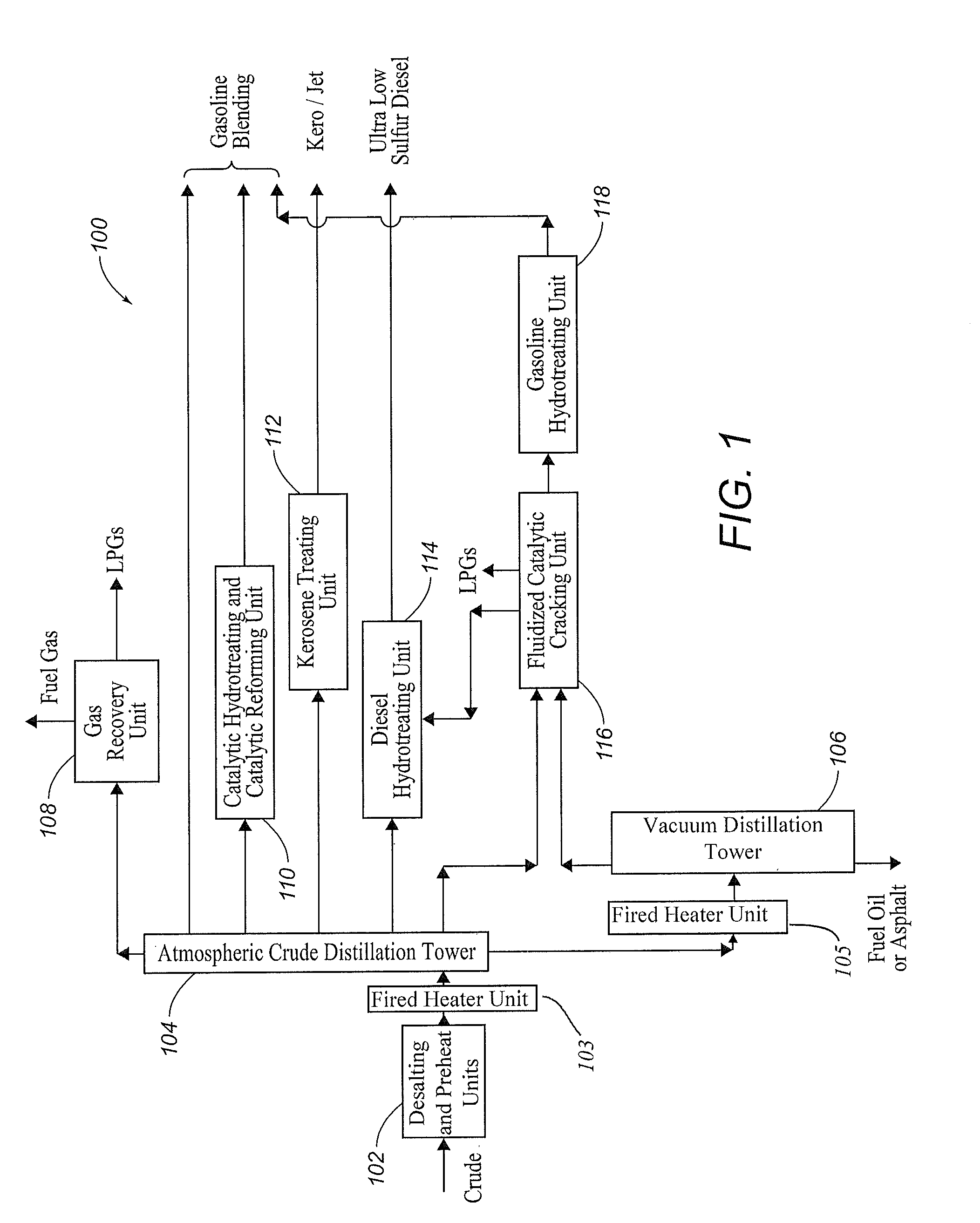

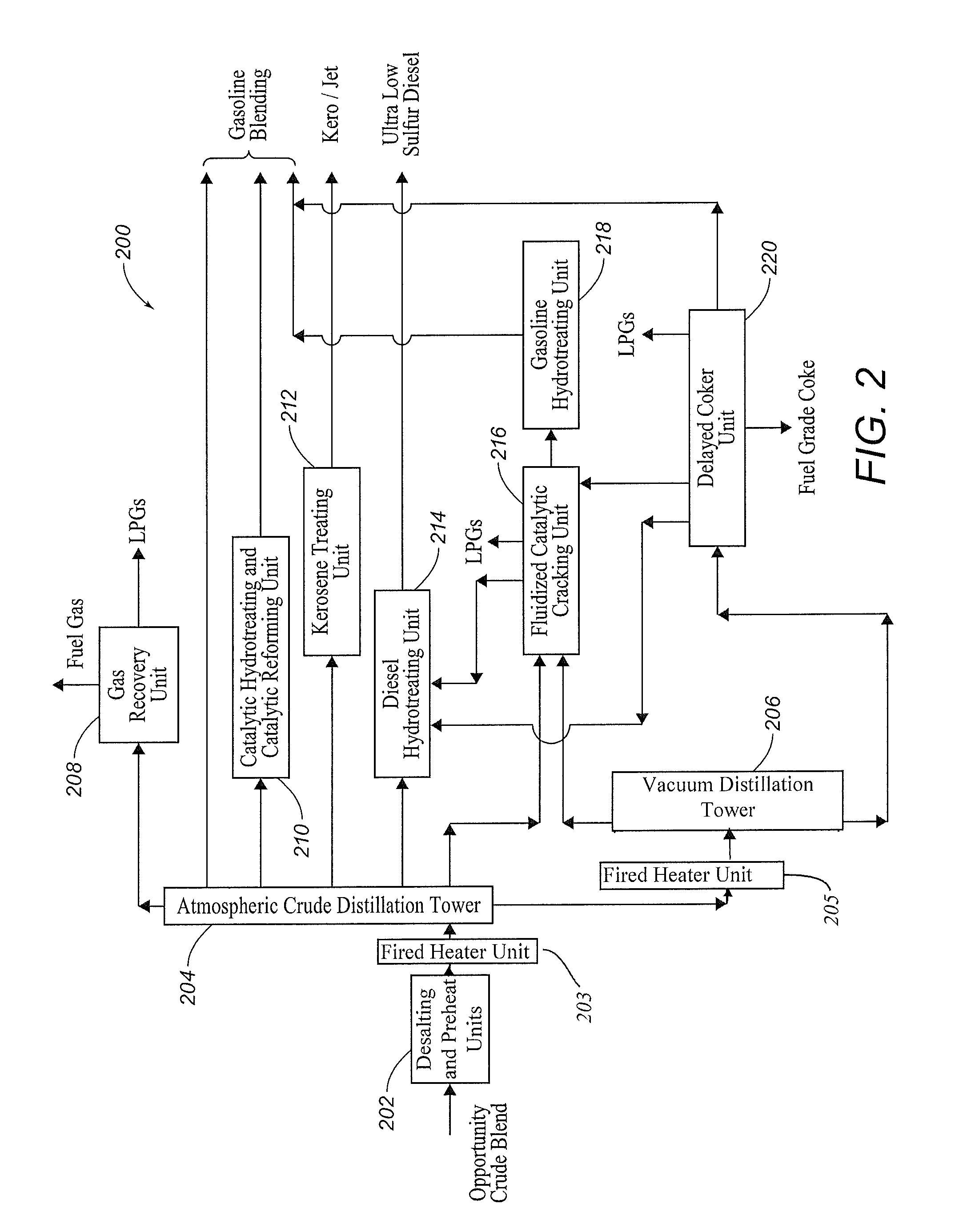

Systems and Methods for Refining Corrosive Crudes

ActiveUS20120261308A1Thermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by distillationMaterials scienceCrude oil

Owner:BECHTEL ENERGY TECH & SOLUTIONS INC

Method for increasing asphalt softening point

InactiveCN102363731AImprove liquidityImprove uniformityWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by chemical meansPolymer scienceTower

The invention discloses a method for increasing an asphalt softening point. Firstly, asphalt is added into a reaction kettle, the reaction kettle is heated to a temperature of 200 to 280 DEG C, and melting asphalt is confected; then an air blower is used to feed oxidizing agents into the reaction kettle from the bottom of the reaction kettle, and the melting asphalt is oxidized at a high temperature and a high speed; afterwards, the oxidized melting asphalt is added into an atomizing and conditioning tower at a temperature of 380 to 550 DEG C and is rapidly flashed under a high temperature condition; later, the flashed melting asphalt is imported into an emulsifying machine at a temperature of 300 to 400 DEG C, and emulsifying agents are added into the emulsifying machine to emulsify the flashed melting asphalt at a high speed; and finally, after the emulsified melting asphalt is cooled and the temperature is reduced to below 300 DEG C, materials are emptied and the asphalt with a high softening point is acquired. According to the method, through adopting a manner of oxidizing the asphalt melt at a high speed and a high temperature, rapidly flashing the asphalt melt and emulsifying the asphalt melt at a high speed, the asphalt with the high softening point is obtained; and the method has the characteristics of simple preparation process, short time consumption, high product softening point and low comprehensive cost.

Owner:BEIJING ZHONGSHIHONG INSTALLATION ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com