Method for preparing general type coal series asphalt with spinnability by solvent extraction and oxidative thermopolymerization

A technology of spinnability and thermal polymerization, applied in processing tar pitch/petroleum pitch/natural pitch by selective extraction, processing tar pitch/petroleum pitch/natural pitch by distillation, processing tar pitch/petroleum pitch/natural pitch by chemical methods and other directions, it can solve the problems of low softening point, complex process and harsh conditions, and achieve the effects of narrow molecular weight distribution, high product yield and high softening point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

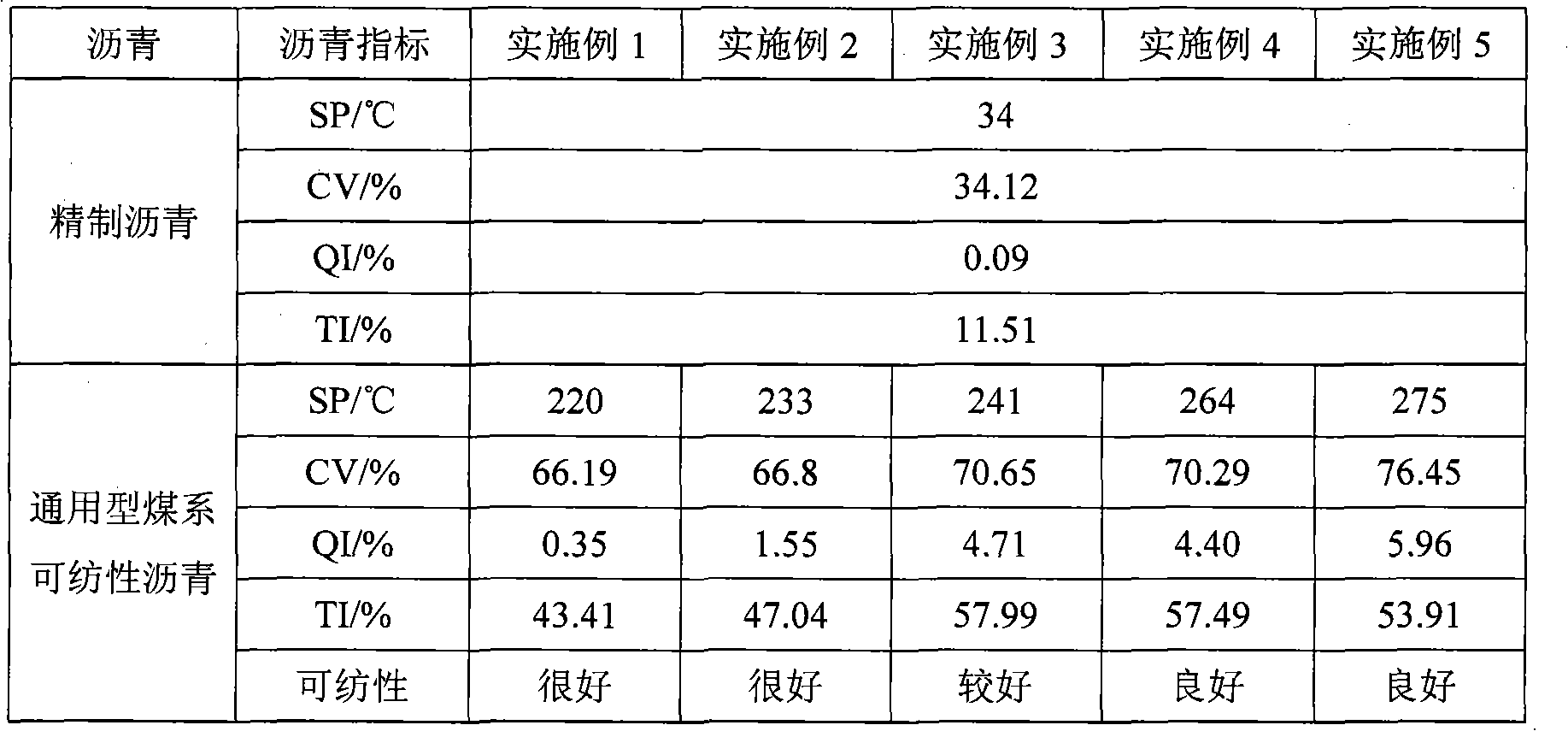

[0014] The first step: put 600g of coal tar soft pitch into a 1L three-necked bottle, the softening point of coal tar soft pitch is 22°C; the mass percentage of coking value is 32.2%; the mass percentage of quinoline insoluble matter is 2.95%; the mass percentage of toluene insoluble matter is 11.51% %, add a total of 480g of kerosene and heavy wash oil mixed solvent with a mass ratio of 0.8:1, heat and stir at 130°C for 30min, then stand still for 75min, separate the extract phase, and distill off the solvent to obtain refined pitch, the yield mass percentage is 50%, and the indicators are shown in Table 1.

[0015] The second step: the refined asphalt prepared in the first step is subjected to oxidative thermal polymerization, the reaction temperature is 260°C, the reaction time is 5h, and the air flow rate is 0.16m 3 / h to obtain oxidized pitch, the mass percentage yield is 92%.

[0016] The third step: the oxidized pitch obtained in the second step is subjected to vacuum ...

Embodiment 2

[0020] The first step: it is exactly the same as the first step in Example 1, except that 540 g of paraffin oil and light wash oil mixed solvent are added with a mass ratio of 0.75: 1.

[0021] The second step: the refined asphalt prepared in the first step is subjected to oxidative thermal polymerization, the reaction temperature is 260°C, the reaction time is 6h, and the air flow rate is 0.16m 3 / h to get oxidized pitch.

[0022] The third step: exactly the same as the third step in Example 1.

[0023] The fourth step; it is exactly the same as the fourth step in the implementation case 1.

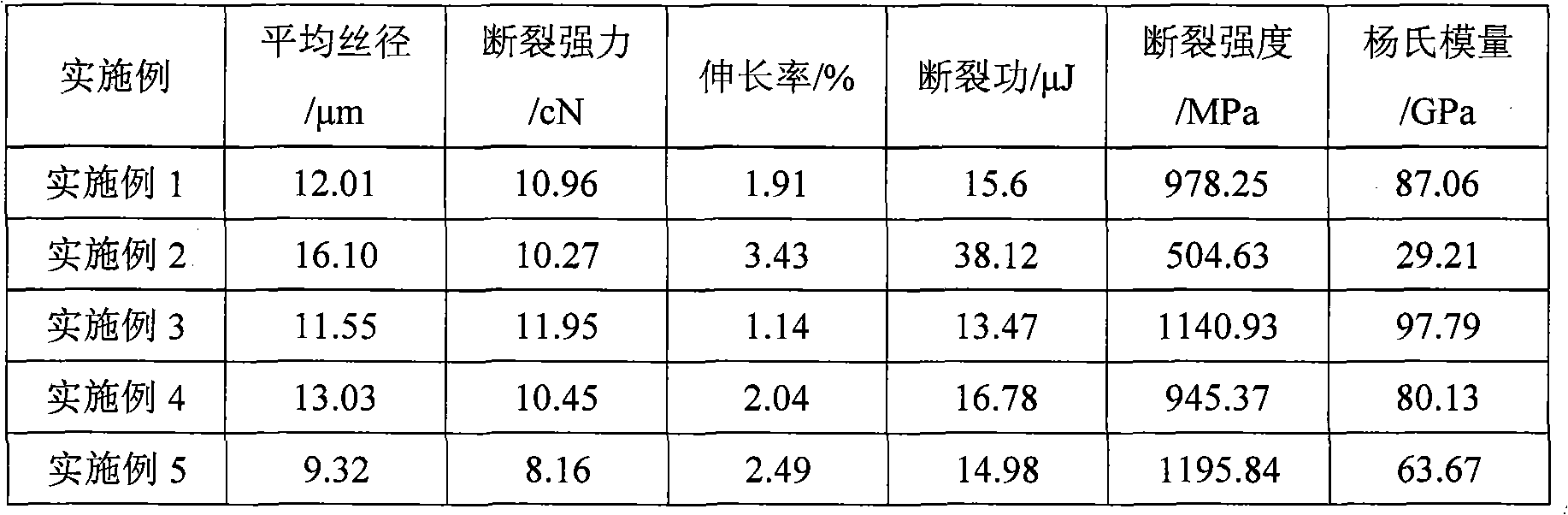

[0024] The obtained spinnable pitch is evaluated by spinning equipment, and has good spinnability. After stabilization and carbonization treatment, carbon fibers are made, and the indicators are shown in Table 1 and Table 2.

Embodiment 3

[0026] The first step: It is exactly the same as the first step in the implementation case 1, except that a total of 450 g of diesel oil and heavy washing oil mixed solvent with a mass ratio of 0.85: 1 are added.

[0027] The second step: oxidative thermal polymerization of refined pitch, reaction temperature 260°C, reaction time 7h, air flow 0.16m 3 / h, to get oxidized asphalt.

[0028] Step 3: Exactly the same as Step 3 in Implementation Case 1.

[0029] Step 4: Exactly the same as Step 4 in Implementation Case 1.

[0030] The obtained spinnable pitch was evaluated by spinning, and the spinnability was good. After stabilization and carbonization treatment, carbon fibers are made, and the indicators are shown in Table 1 and Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com