Anti-layering saline-alkali soil improvement and improvement method

A saline-alkali soil improvement, saline-alkali soil technology, applied in chemical instruments and methods, soil conditioning materials, organic fertilizers, etc., can solve problems such as less research on saline-alkali geological improvement methods, achieve easy implementation, facilitate drainage and salt washing, and low production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Select iron tailings, then add polyacrylic acid with a molecular weight of 2000-5000, a solid content of 30%, and a 1% aqueous solution with a pH value of 3.0, stir evenly, adjust the pH of the iron tailings to 6.5, and obtain modified iron tailings.

[0038] Take soil samples from the plow layer (0-20cm) in the sandy clay loamy saline-alkali soil area to be improved, and analyze the mechanical composition after air drying (see Table 1). The soil bulk density is 1.32g / cm 3 .

[0039] Table 1. Mechanical composition of sandy clay loamy saline-alkali soil

[0040] Particle size classification

<0.002mm

0.002≤~<0.05mm

0.05≤~<2mm

content(%)

23.1

24.0

52.9

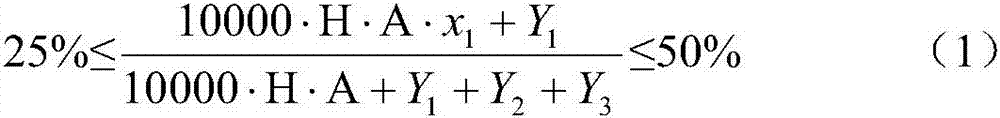

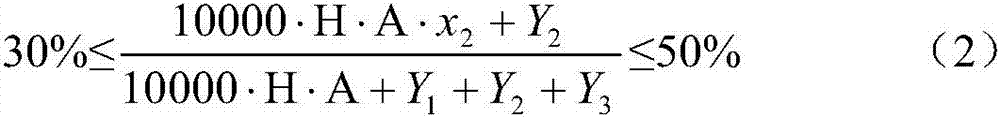

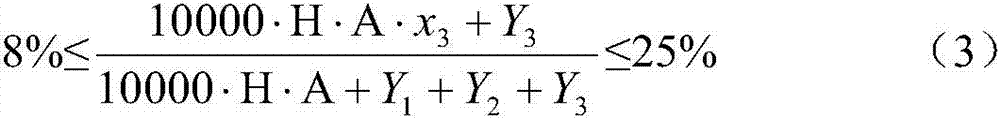

[0041] Select 30m in the area to be improved 2 In the plot, add modified iron tailings sand to the soil after leveling, and calculate according to formulas (1), (2) and (3), the addition amount is clay 0kg, silt 700kg, sand 0kg, and then mix with the plow layer soil (20cm depth...

Embodiment 2

[0048] Dewatered sludge with a water content of 80%±5 and a pH of 8.5±0.5 from a domestic sewage treatment plant was mixed evenly with corn stalk powder. After composting, decomposed sludge with a water content of 25.7% and a pH of 8.3 was obtained.

[0049] Take the plow layer soil (0-20cm) in the clay loamy saline-alkali soil area to be improved, and analyze the mechanical composition after air-drying (see Table 4). The soil bulk density is 1.41g / cm 3 .

[0050] Table 4. Mechanical composition of clay loamy saline-alkali soil

[0051] Particle size classification

<0.002mm

0.002≤~<0.05mm

0.05≤~<2mm

content(%)

28.2

42.3

29.5

[0052] Select 30m in the area to be improved 2 For the plot, add iron tailings sand to the soil after leveling, and calculate according to the formulas (1), (2) and (3), the addition amount is clay 0kg, silt 510kg, sand 420kg, and the plow layer (20cm depth) soil Stir evenly, then add 60kg of decomposed sludge...

Embodiment 3

[0059] Mix the residue obtained from anaerobic fermentation with cow dung as raw material in the biogas digester and straw at a C / N ratio of 25 to 35:1, and undergo static aerobic composting to obtain a decomposed material with a water content of 27.3% and a pH of 8.5. Biogas residue.

[0060] Take the plow layer soil (0-20cm) in the sandy loam saline-alkali soil area to be improved, and analyze the mechanical composition after air-drying (see Table 7). The soil bulk density is 1.30g / cm 3 .

[0061] Table 7. Mechanical composition of sandy loamy saline-alkali soil

[0062] Particle size classification

<0.002mm

0.002≤~<0.05mm

0.05≤~<2mm

content(%)

6.4

41.0

52.6

[0063] Select 30m in the sandy loamy saline-alkali soil area to be improved 2 In the plot, add iron tailings sand to the soil after leveling, and calculate according to formulas (1), (2) and (3). ) and stir evenly, then add 60kg of decomposed biogas residue, stir evenly wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com