Optical axis offset error compensation method and determination apparatus

A technology of optical axis offset and error compensation, applied in the direction of testing optical performance, etc., can solve problems such as affecting personnel operation, optical axis instability, and bad, etc., to ensure consistent alignment, optical axis instability correction, and beneficial effects. significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below with reference to the drawings and embodiments.

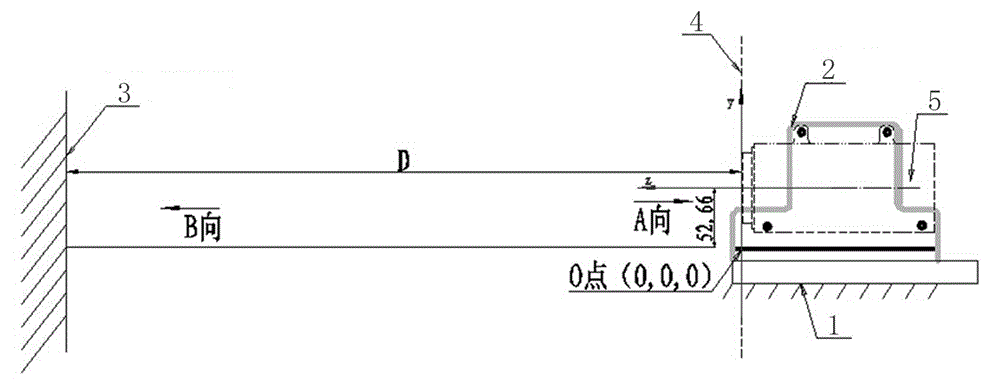

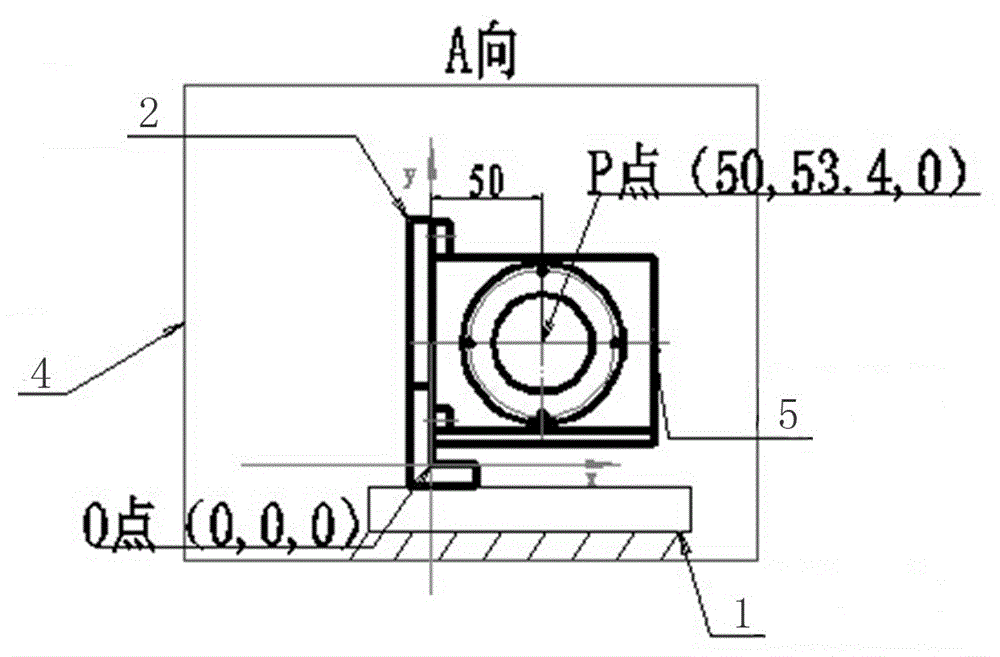

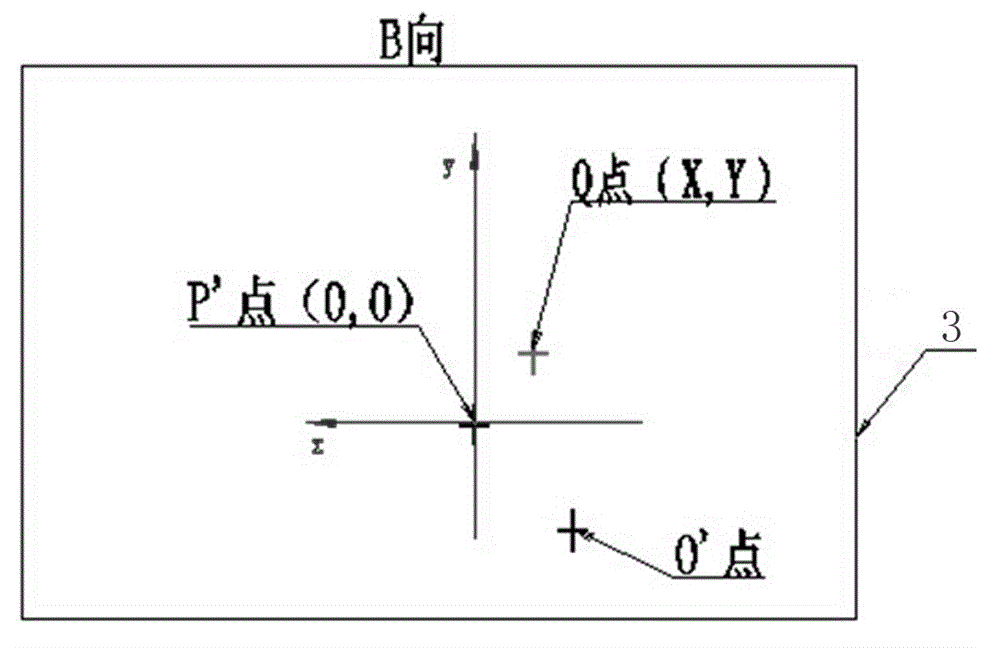

[0014] Such as figure 1 As shown, the structural principle diagram of the optical axis deviation error measuring device of the present invention is given. The installation platform 1 and the fixing device 2 shown constitute a tooling test piece, the installation platform 1 is fixed on the optical test bench, and the fixing device 2 Fixed with the installation platform 1, the optical imaging system 5 is arranged on the fixing device 2. Select the front end surface of the optical imaging system 5 as the reference plane 4, such as figure 2 As shown, gives figure 1 In the A-direction view in, the origin O and the center point P in the optical imaging system are both located in the reference plane 4. The reticle indicating board 3 shown is located at the front end of the reference plane 4, preferably at a distance of 10-30 m, and the reticle indicating board 3 is parallel to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com