Patents

Literature

400results about "Filling using counterpressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

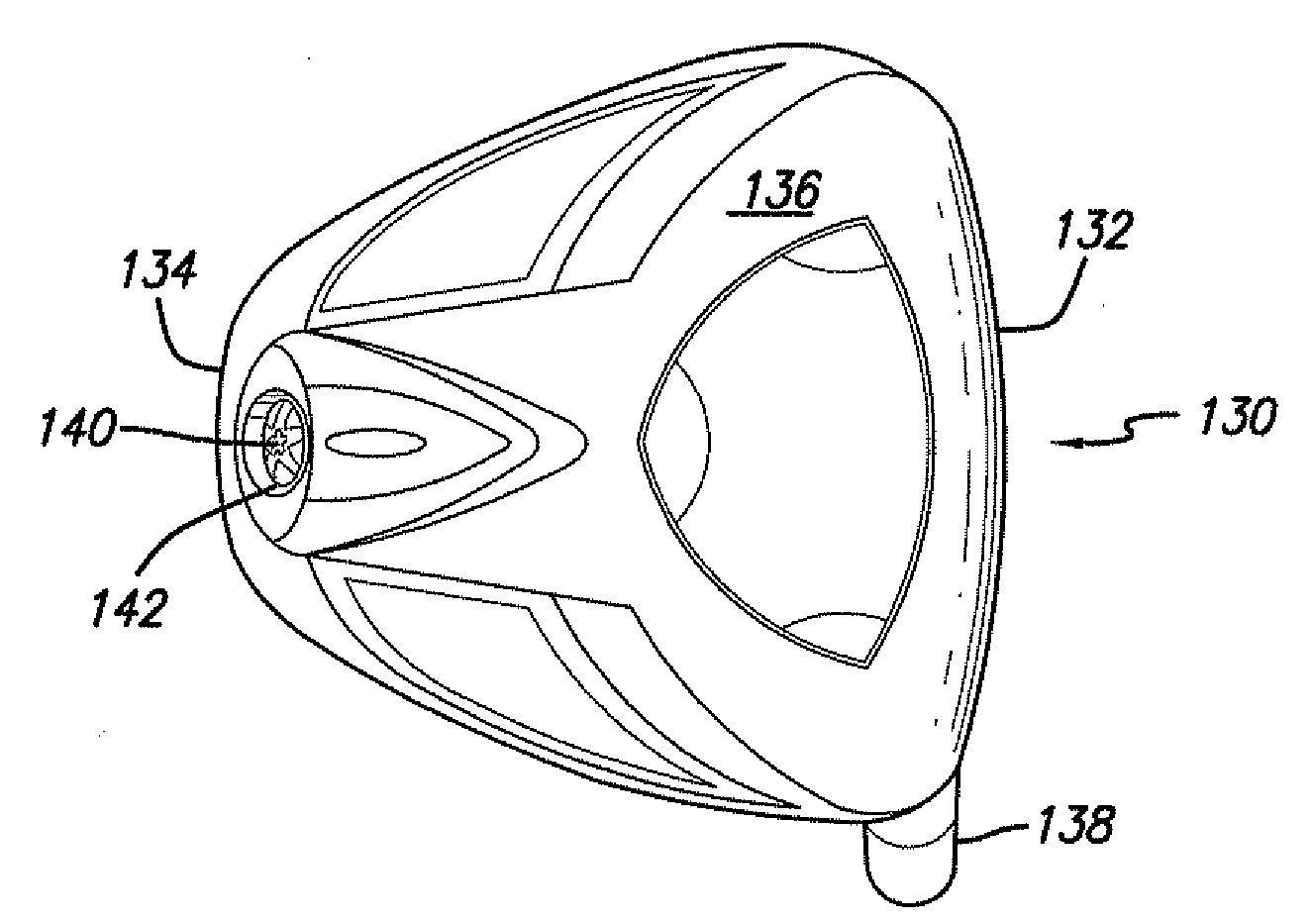

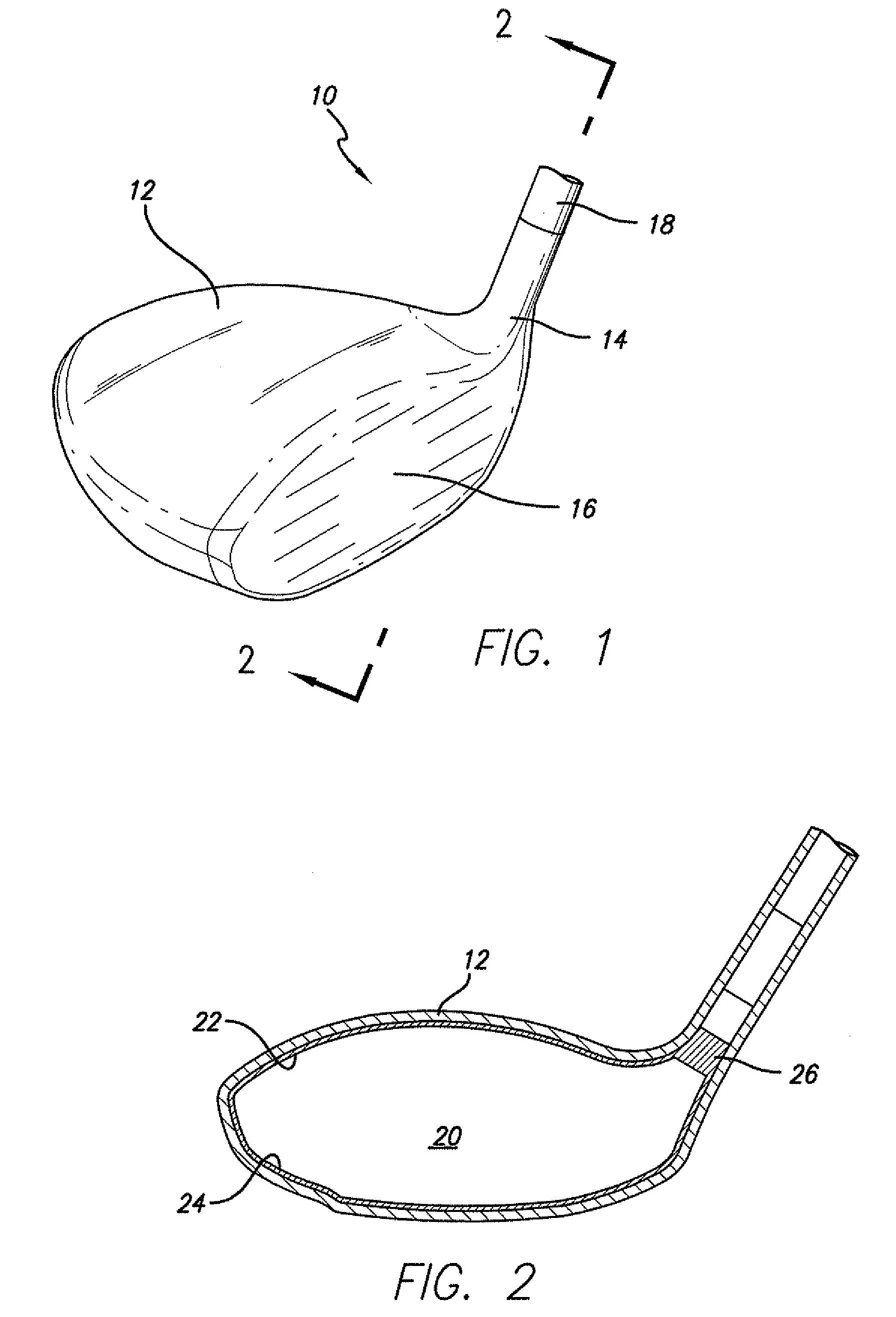

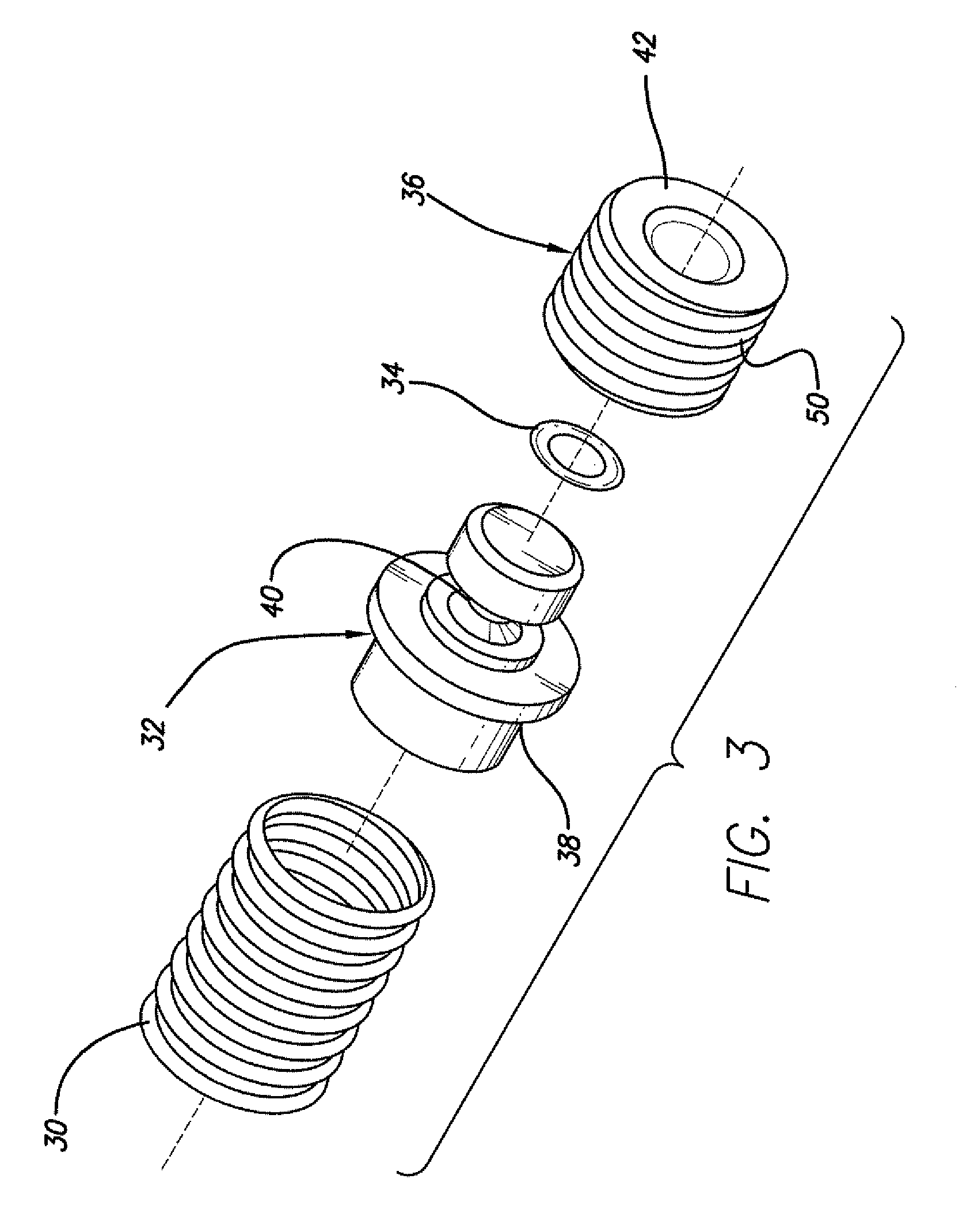

Golf club having a hollow pressurized metal head

ActiveUS20080188322A1Avoid passingPrevent escapeFilling using counterpressureMetal rolling stand detailsShell moldingPlastic materials

A golf club having a hollow golf club head which is filled with a gas under pressure. The interior surface of the golf club head is coated with a solidified layer of plastic material. The pressurized gas permits the use of thinner face plates by compensating for forces generated when the face plate strikes a golf ball. The plastic layer is preferably applied through the process of rotational molding using a thermoplastic material.

Owner:BLOWERS ALDEN J

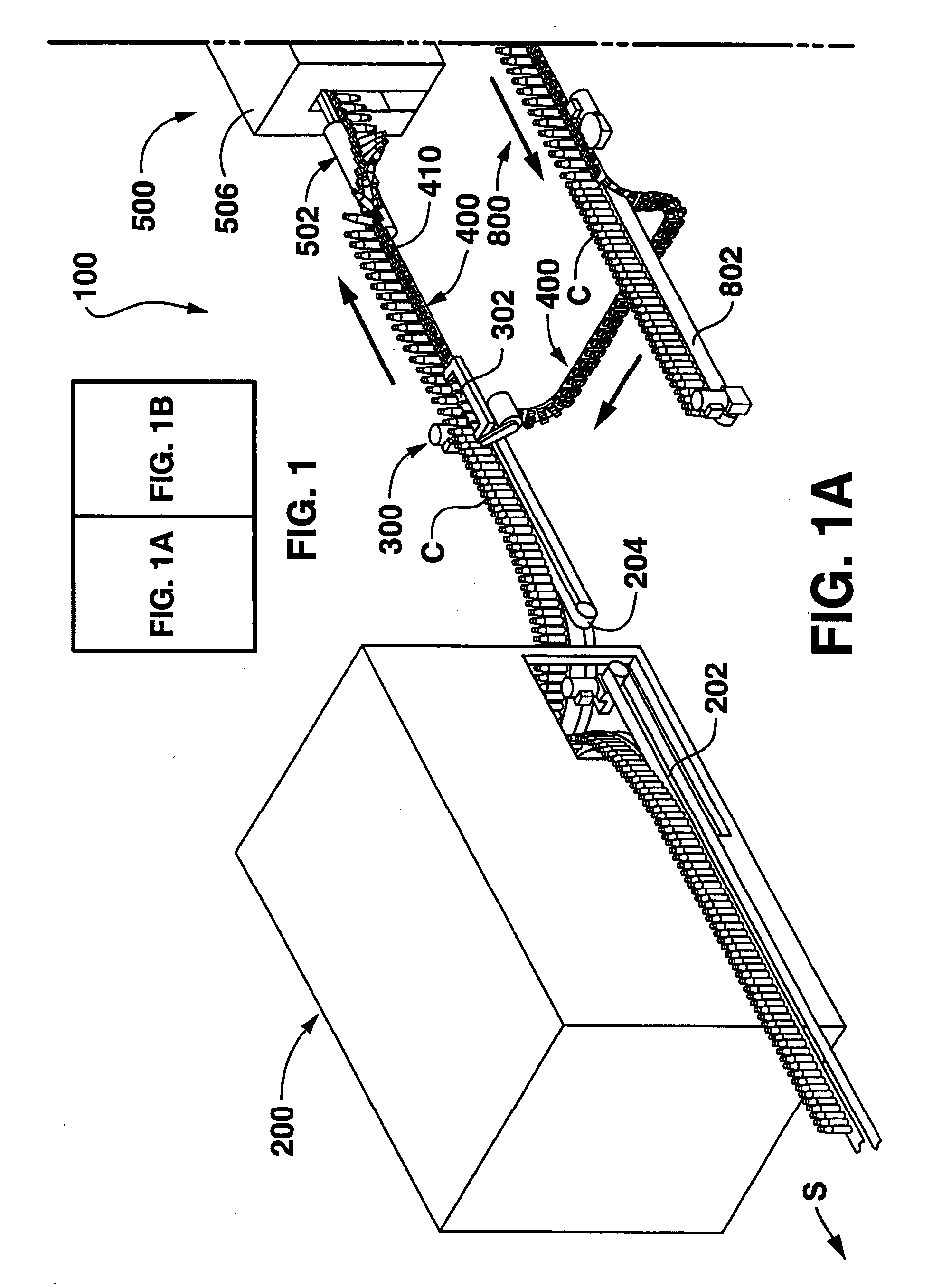

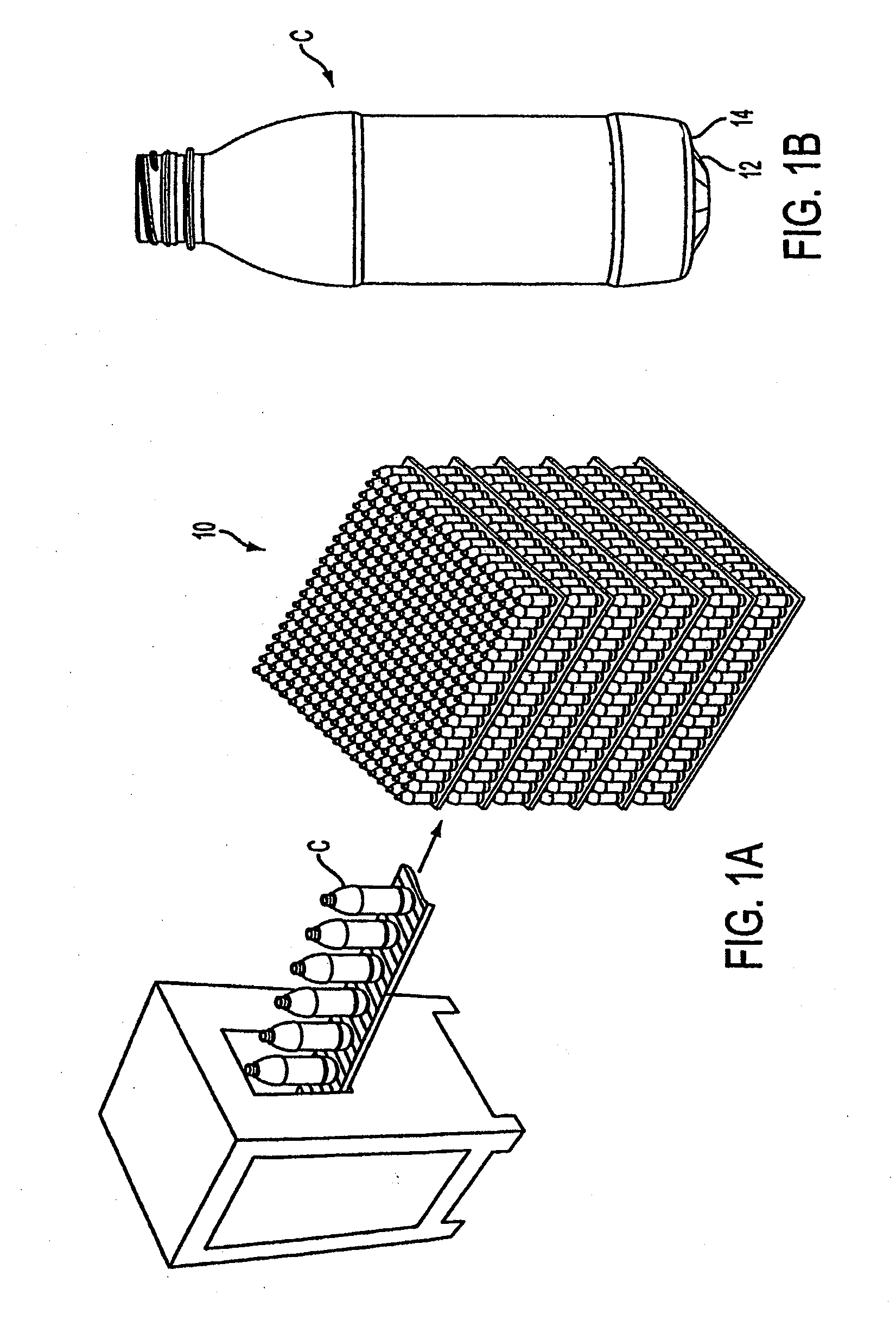

Container handling system

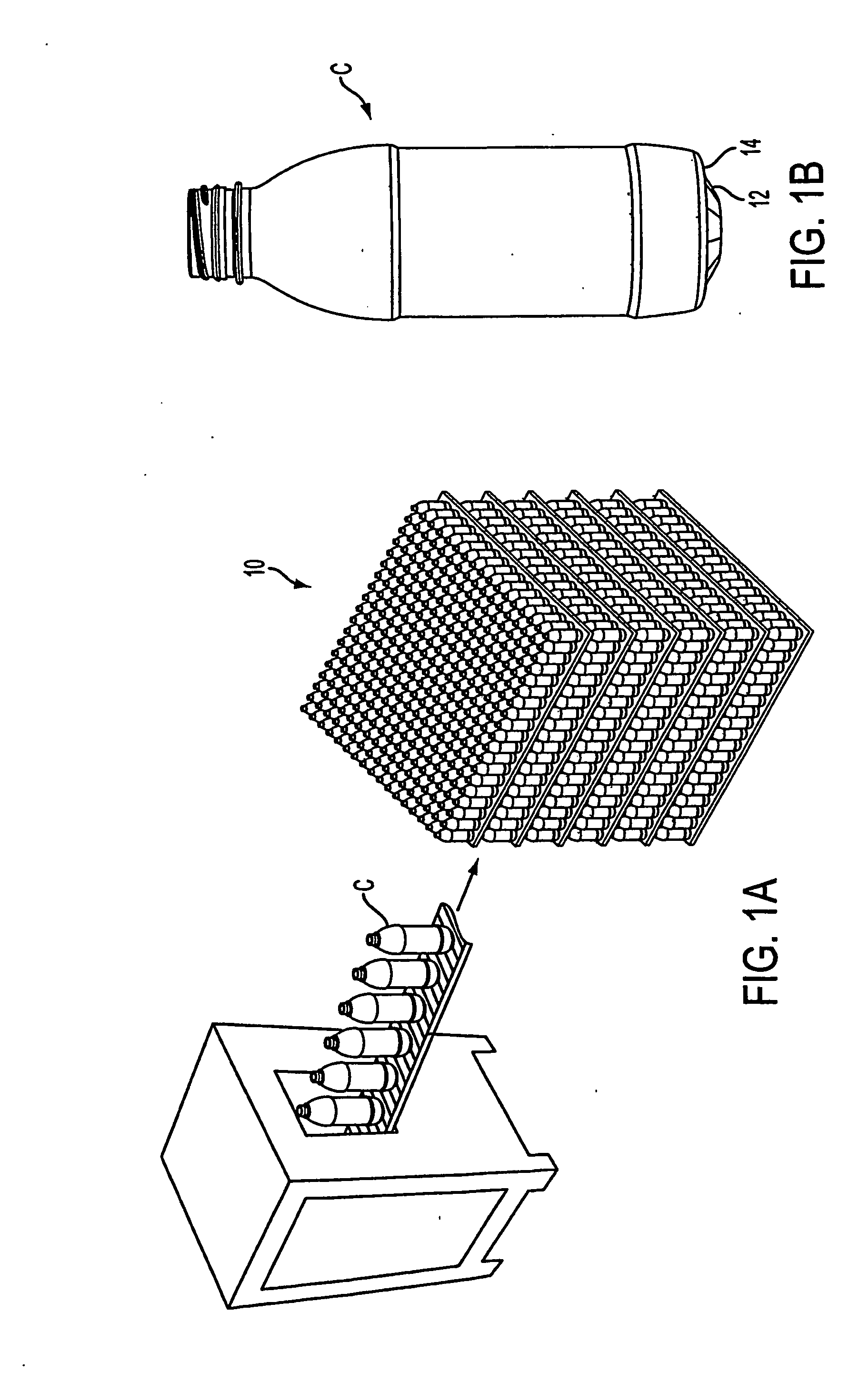

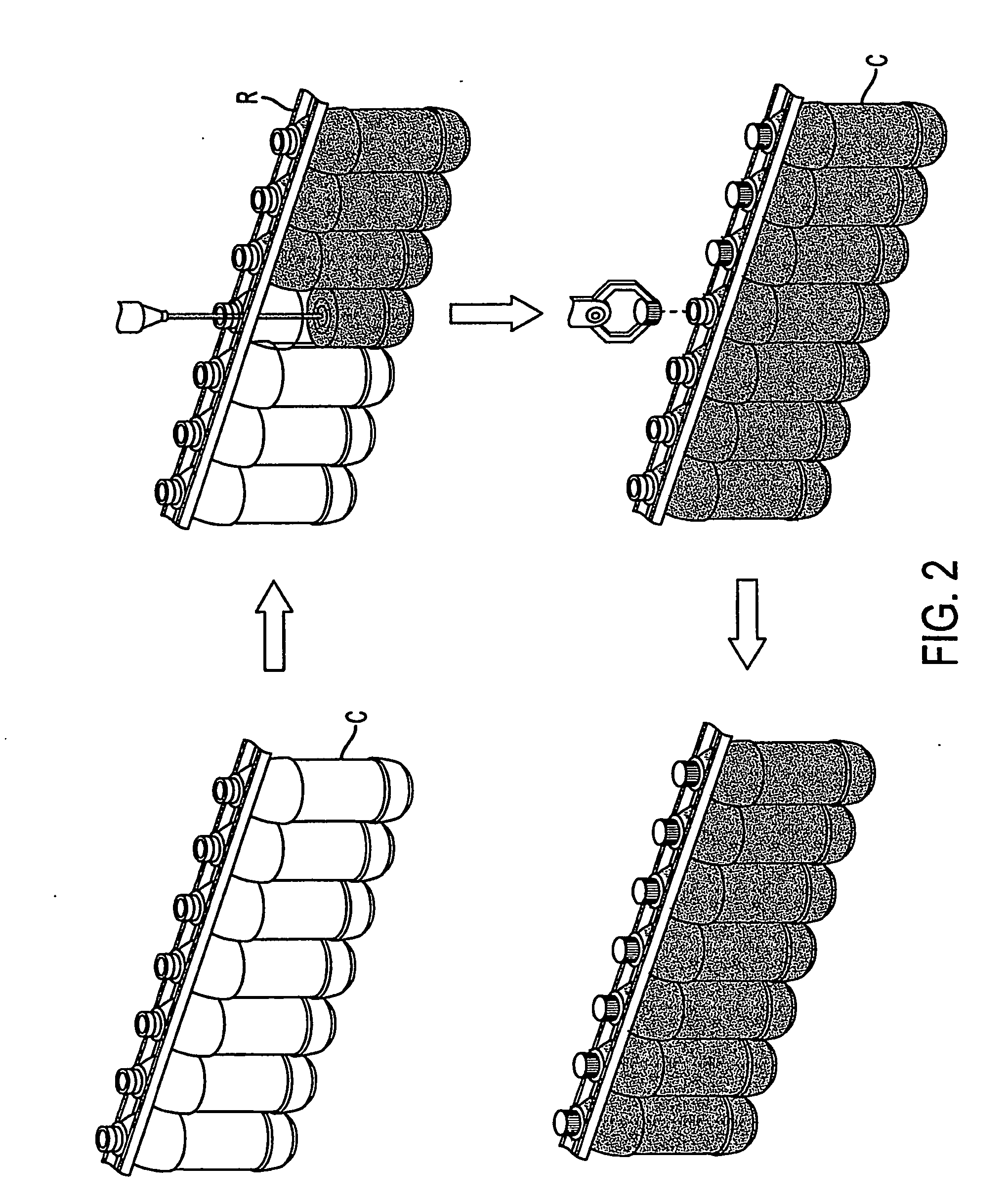

ActiveUS20070051073A1Smooth for label placementThorough removalCapsDecorative coversBlow moldingStructural geometry

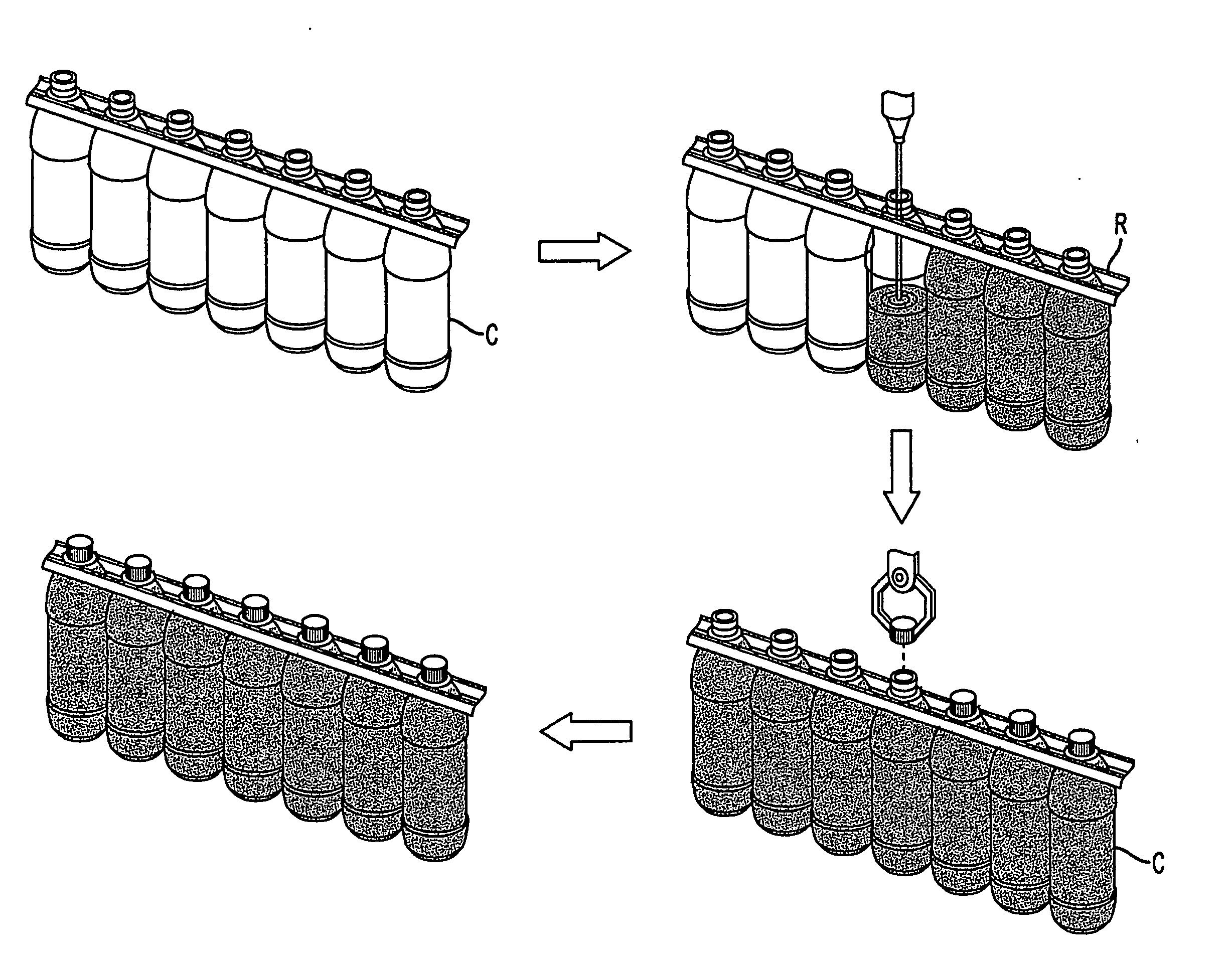

A system for processing a simplified plastic container (C) that is to be filled with a hot product includes the step of blow-molding parison to form a container body, where the container body has a neck, a base, a side surface relatively free of structural geometry that surrounds an interior of the container body and, prior to being filled with the hot product, a projection (12) extending from the container body. After the container body is filled with a hot product in a production line, the neck of the filled container body is capped with a cap and then, the container body is cooled. During the cooling operation, the hot product is contracted so that the projection extending from the container can be pushed (P) into the container body like a traditional push-up so that the resultant, filled and cooled container body is relatively free of structural geometry.

Owner:CO2 PAC

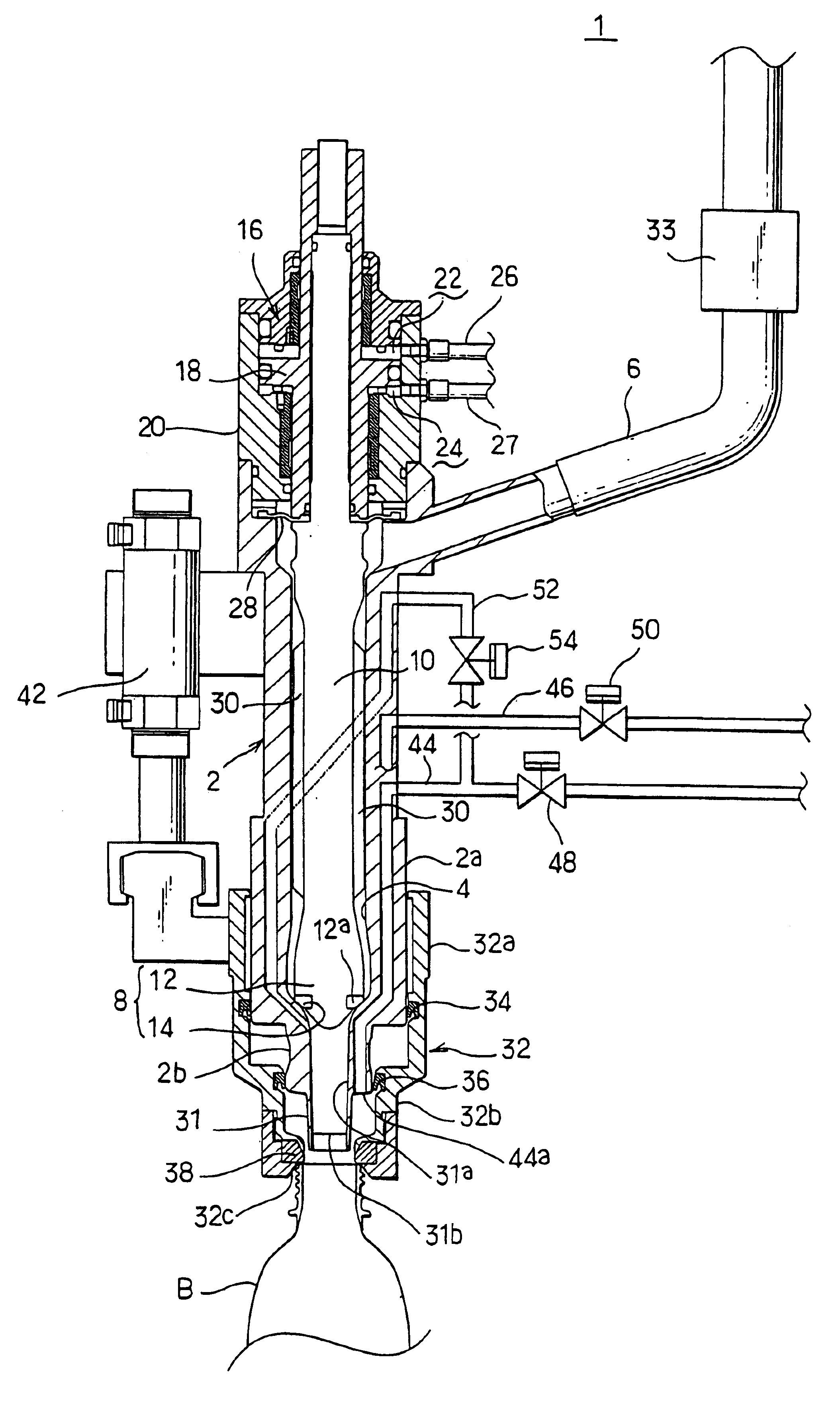

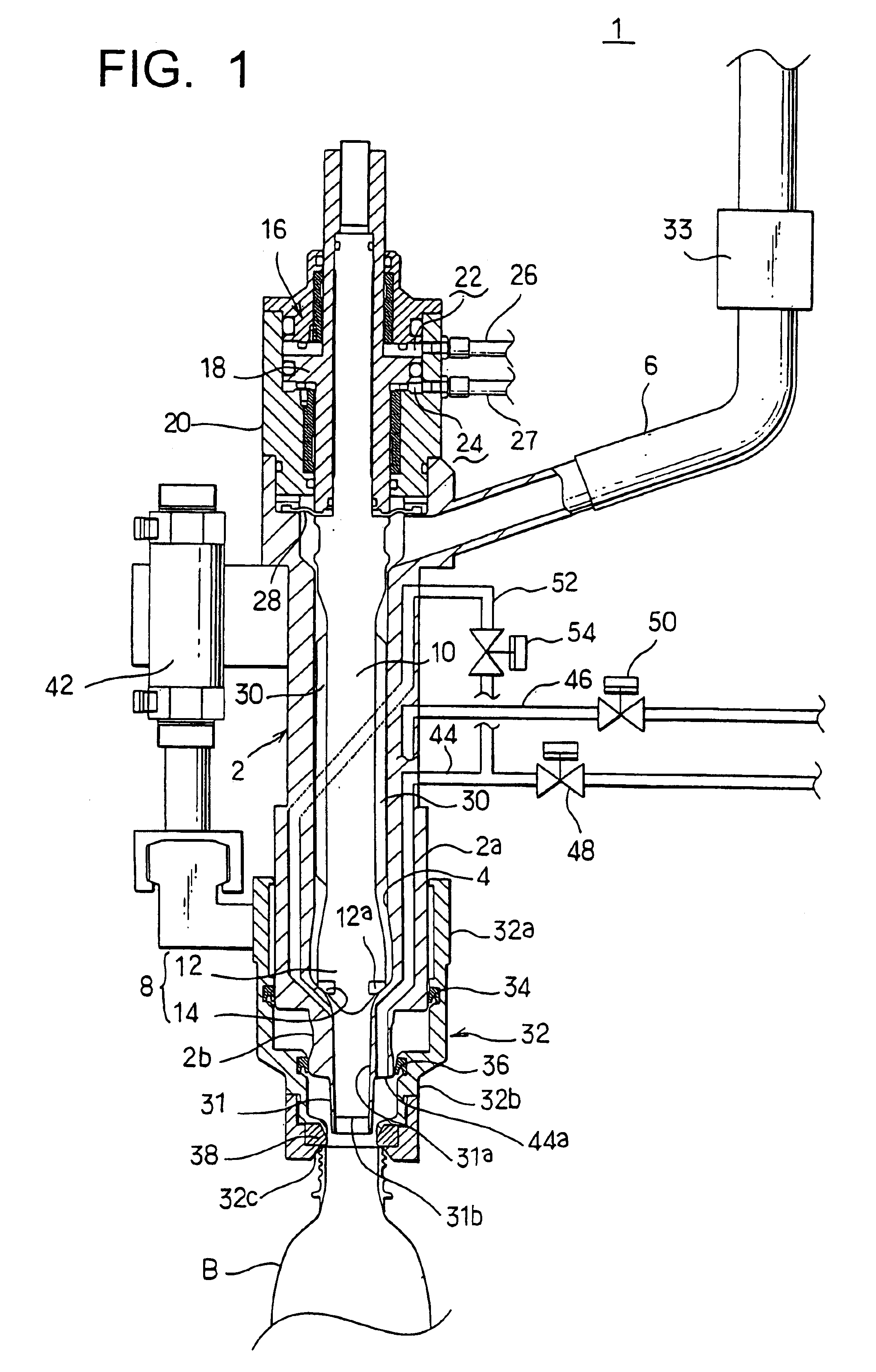

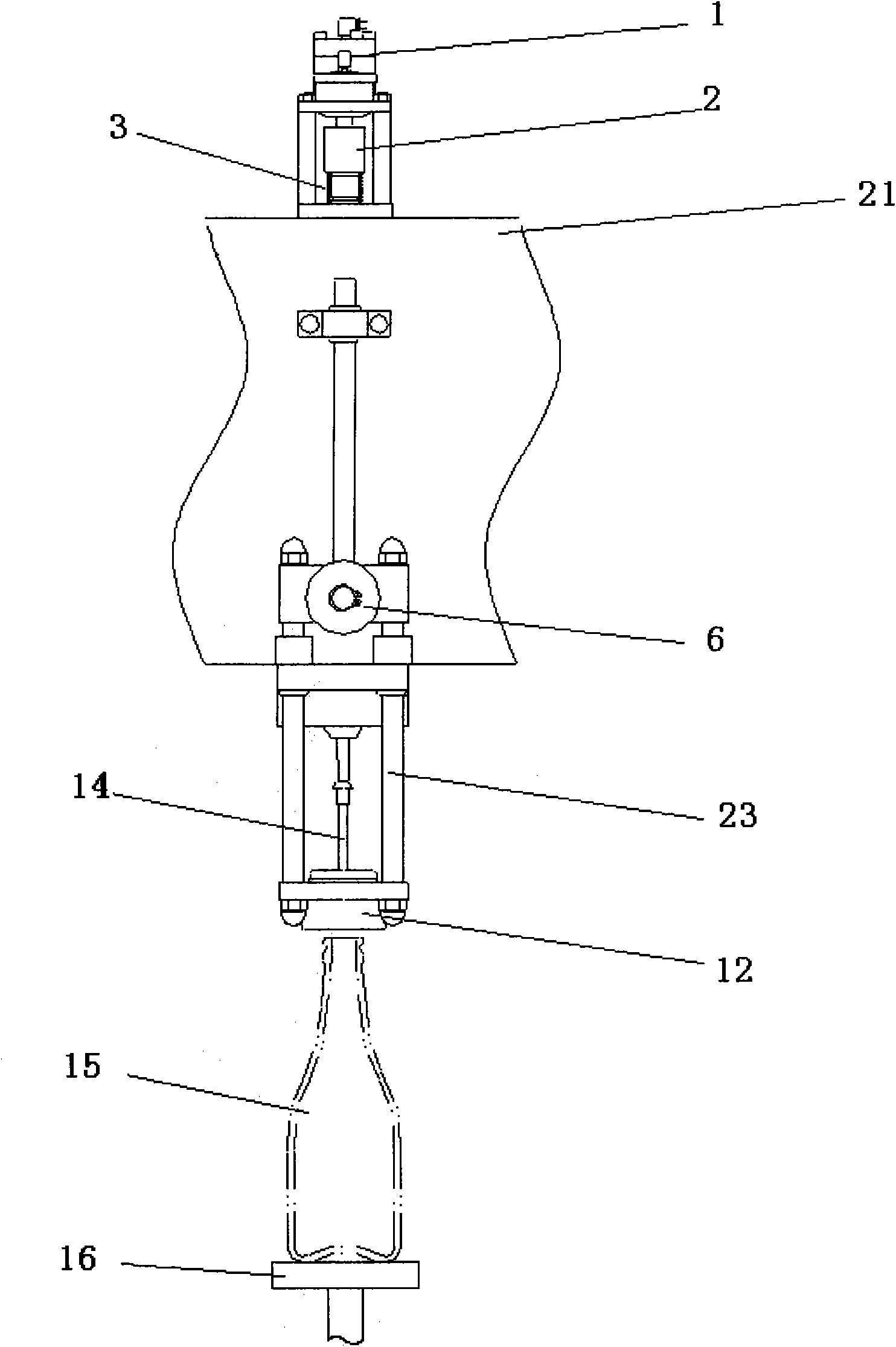

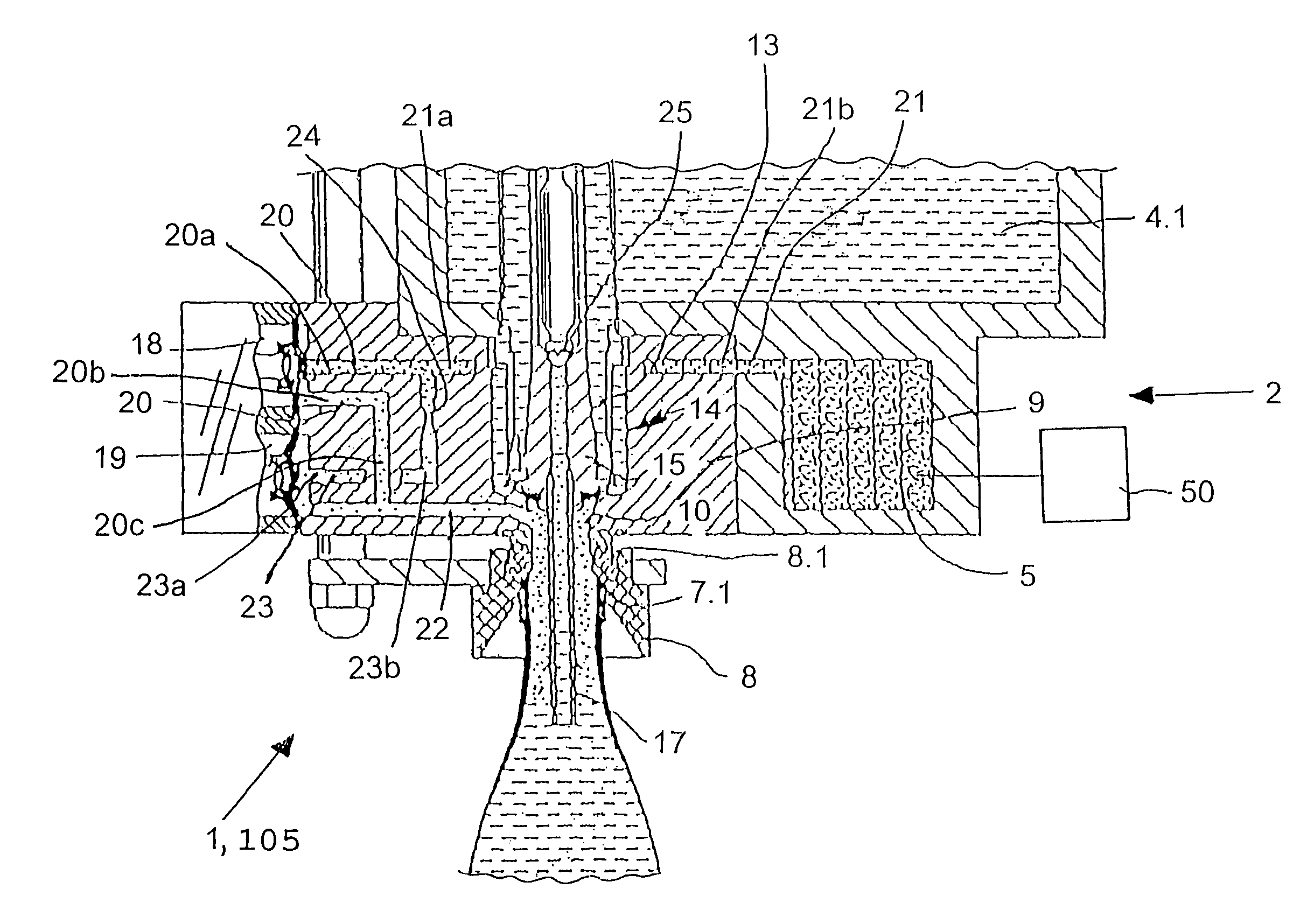

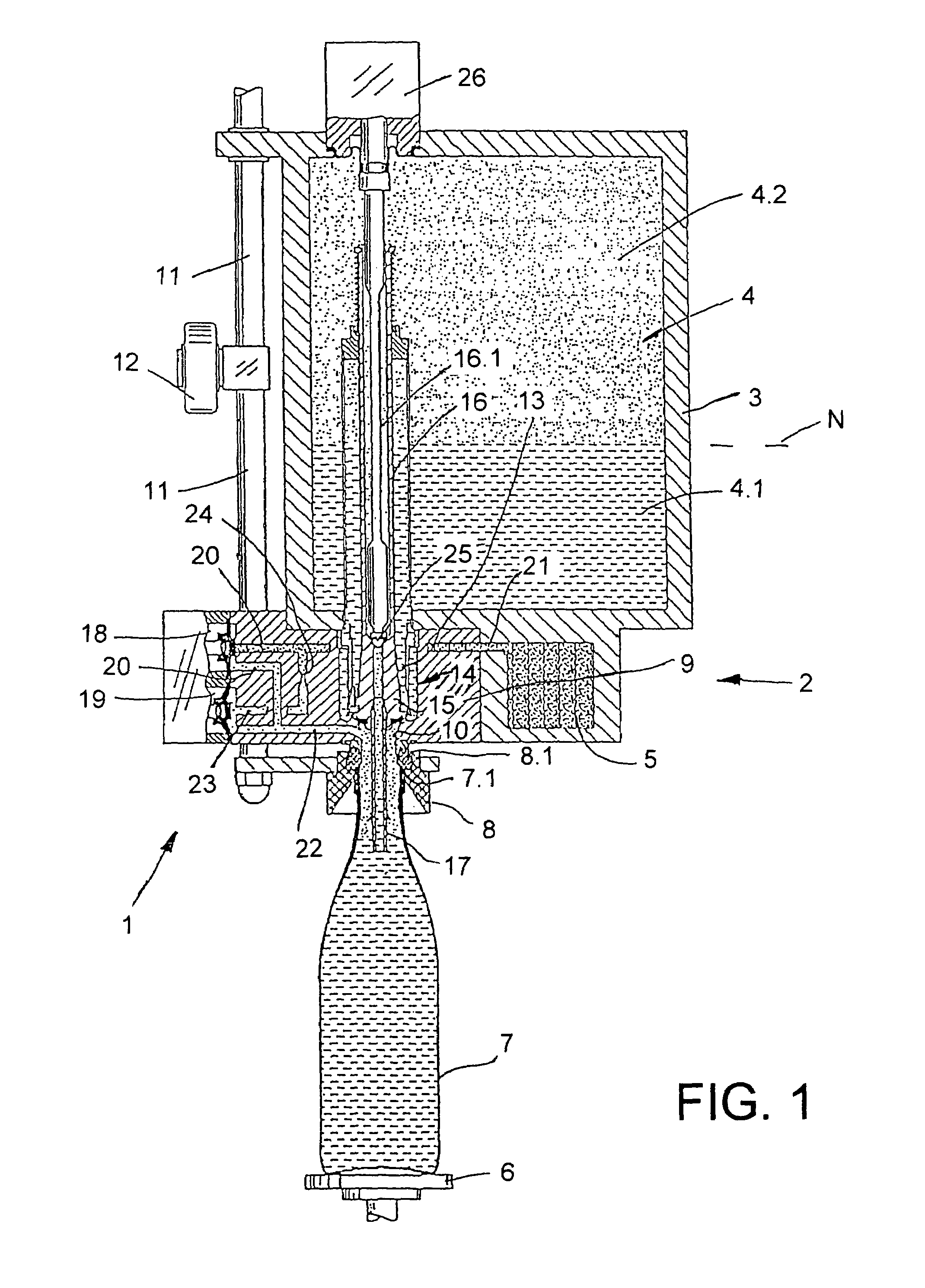

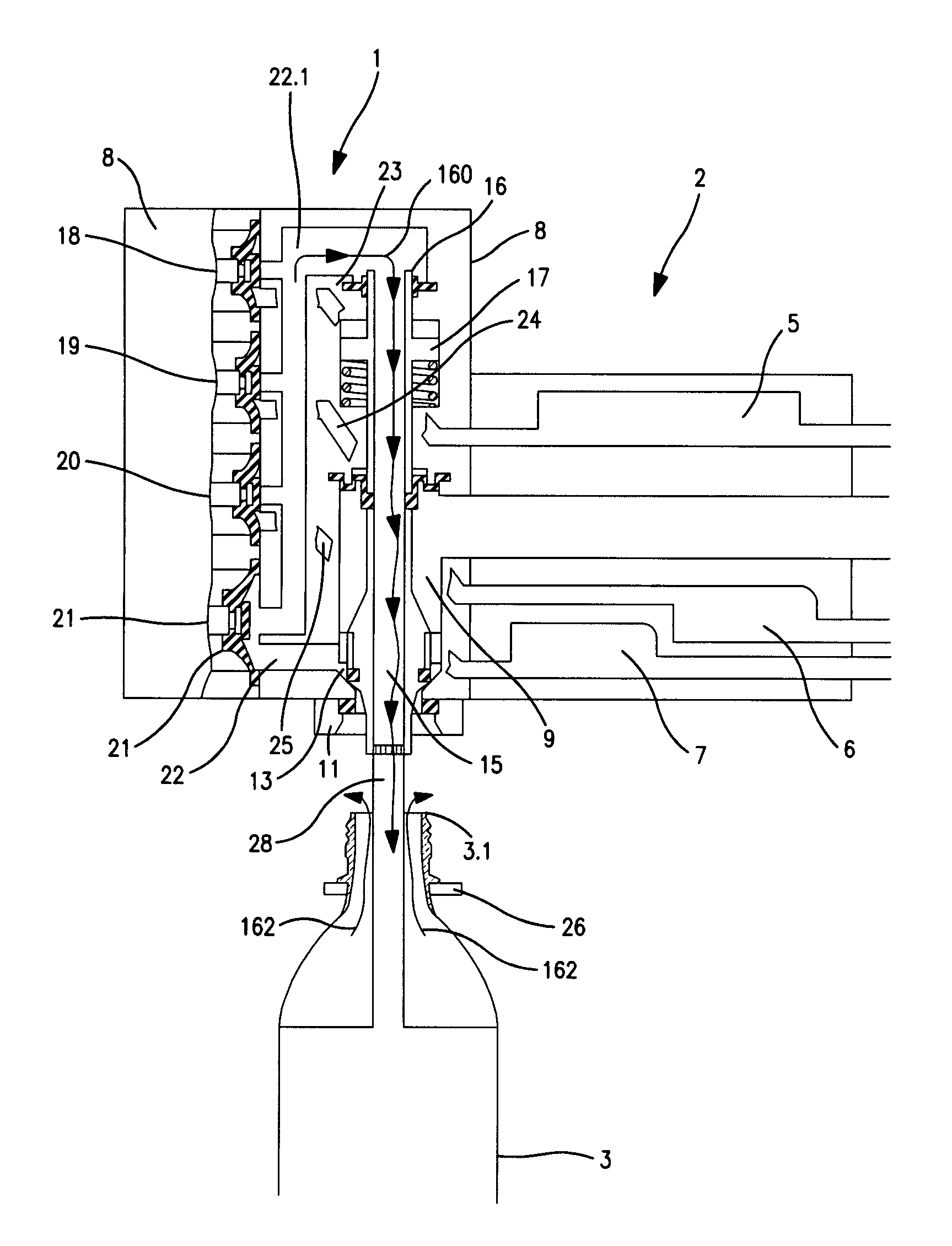

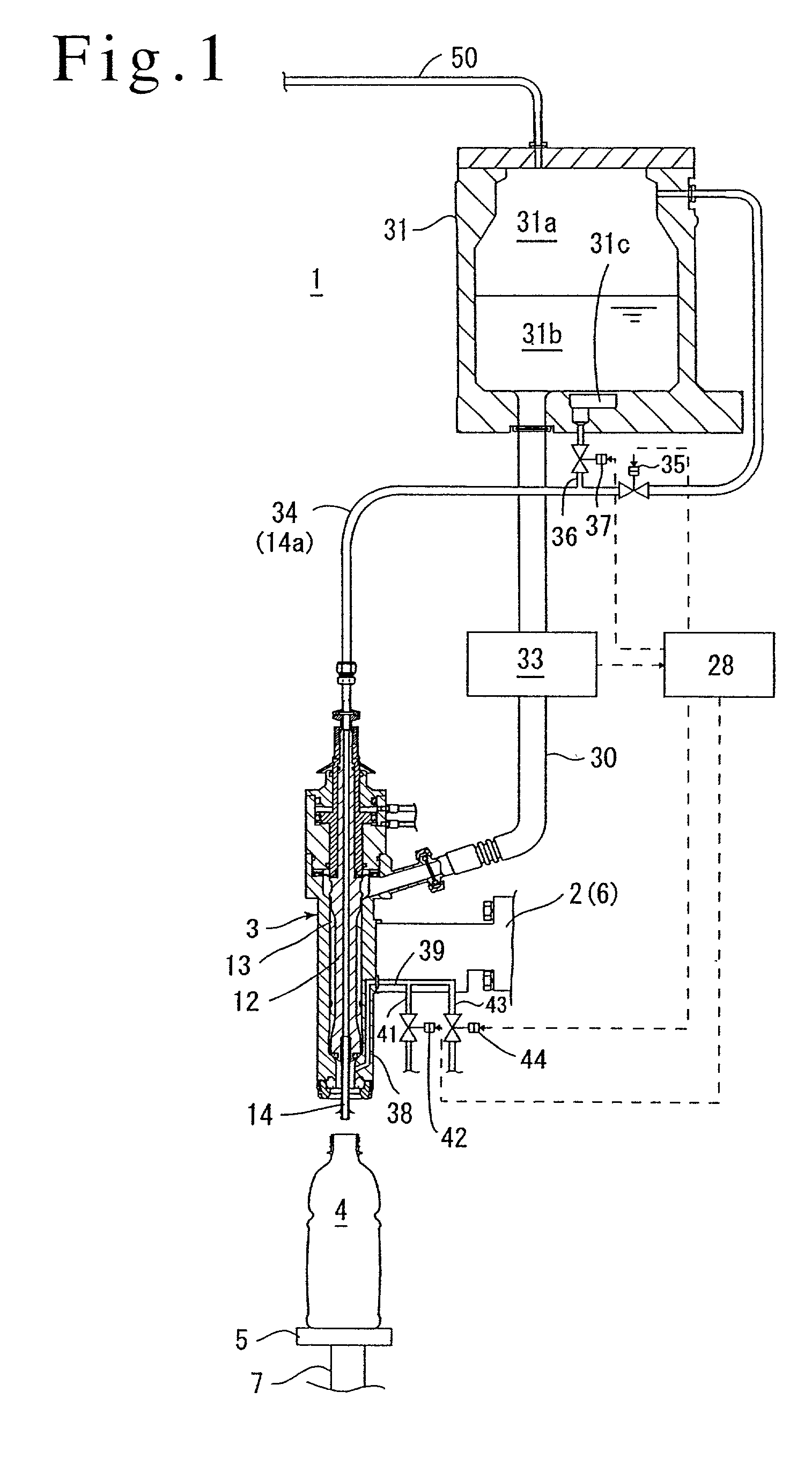

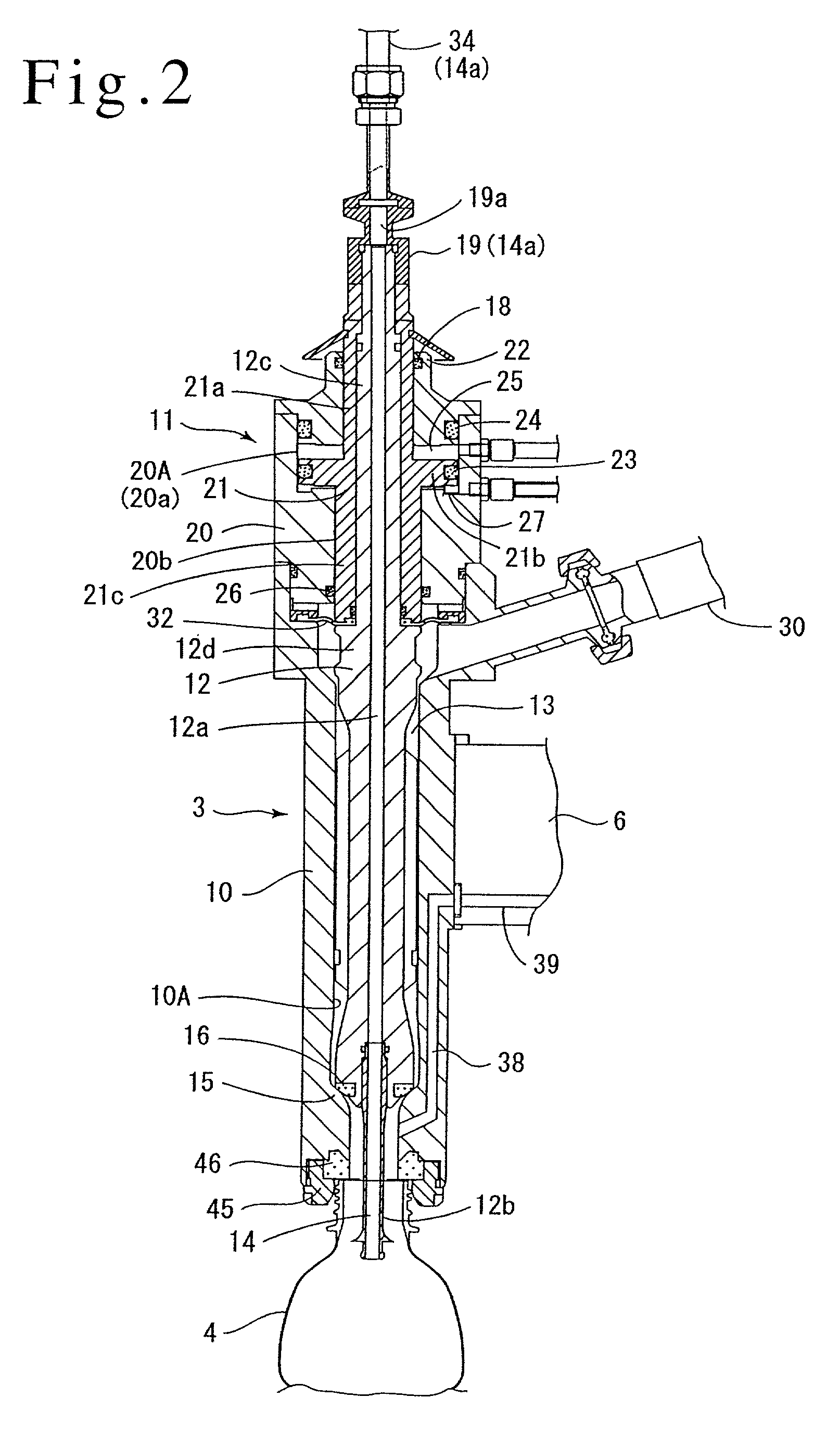

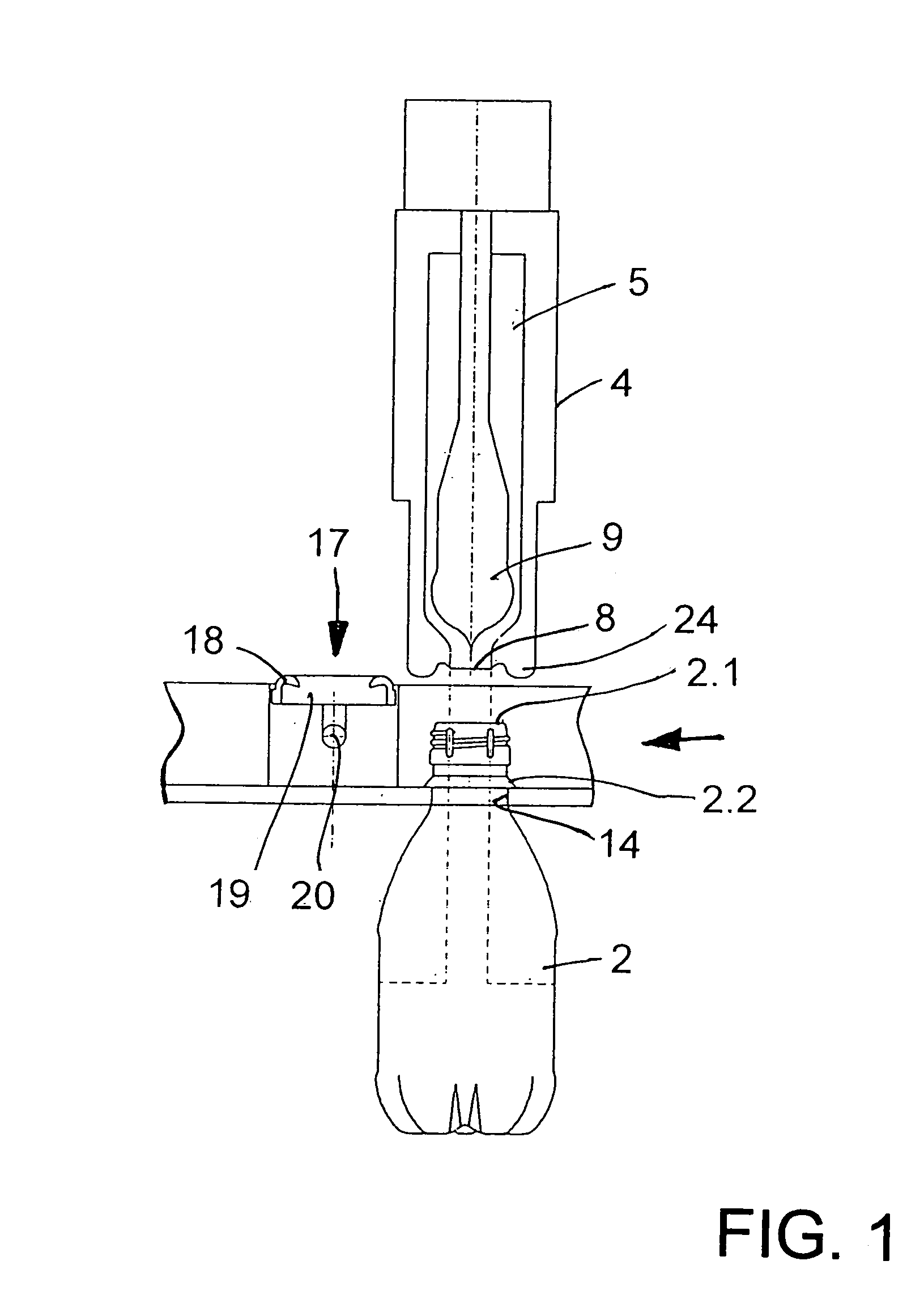

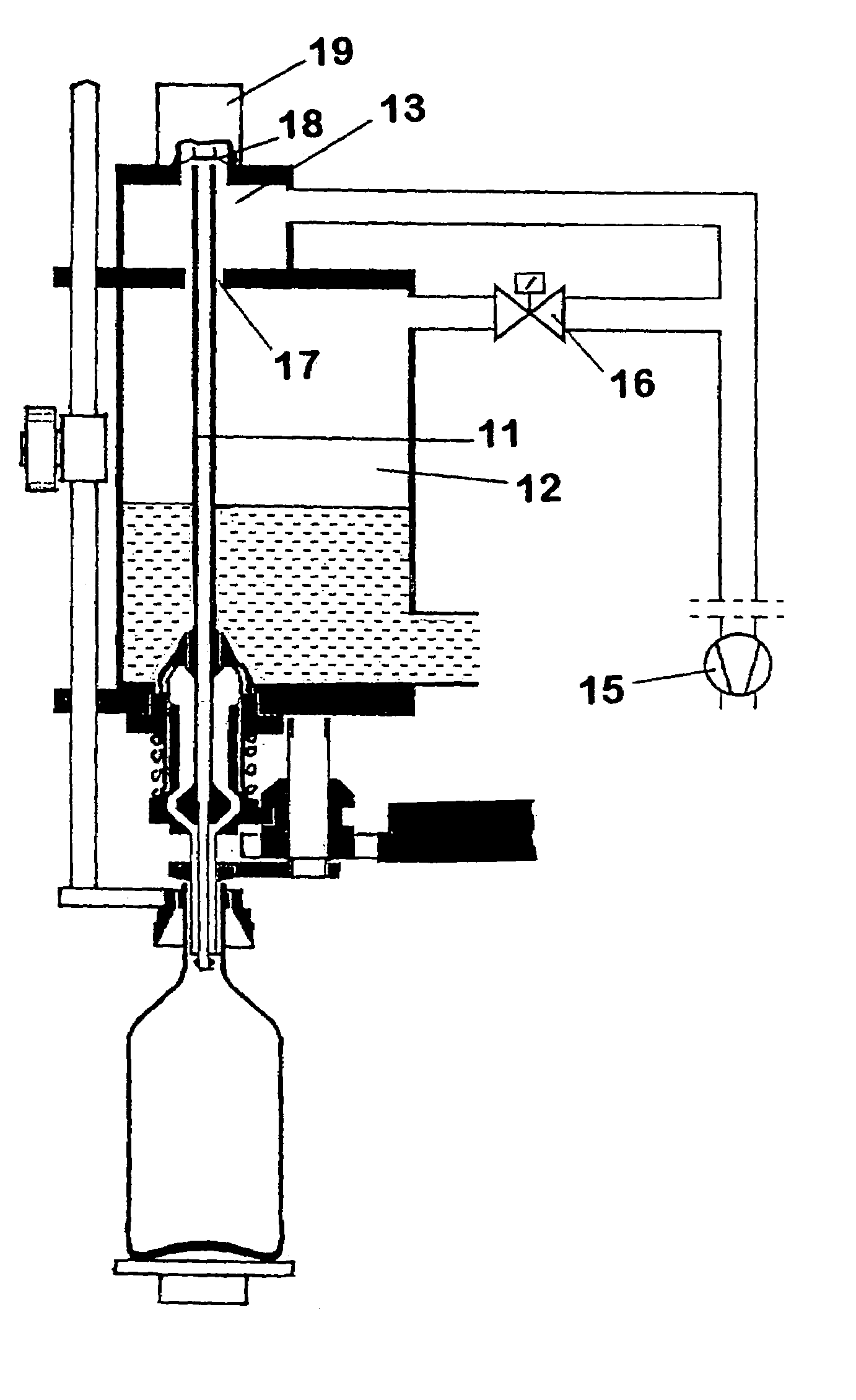

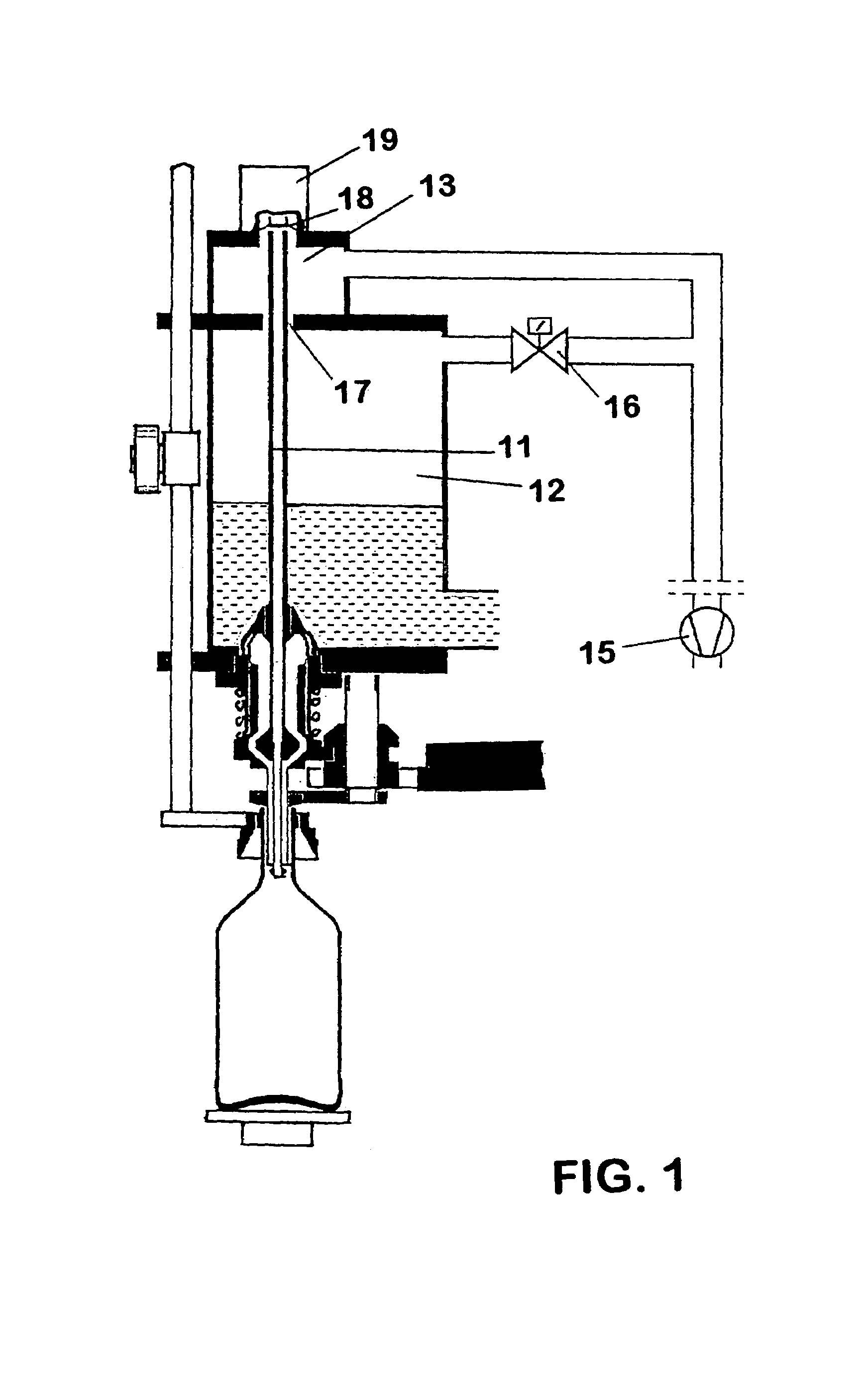

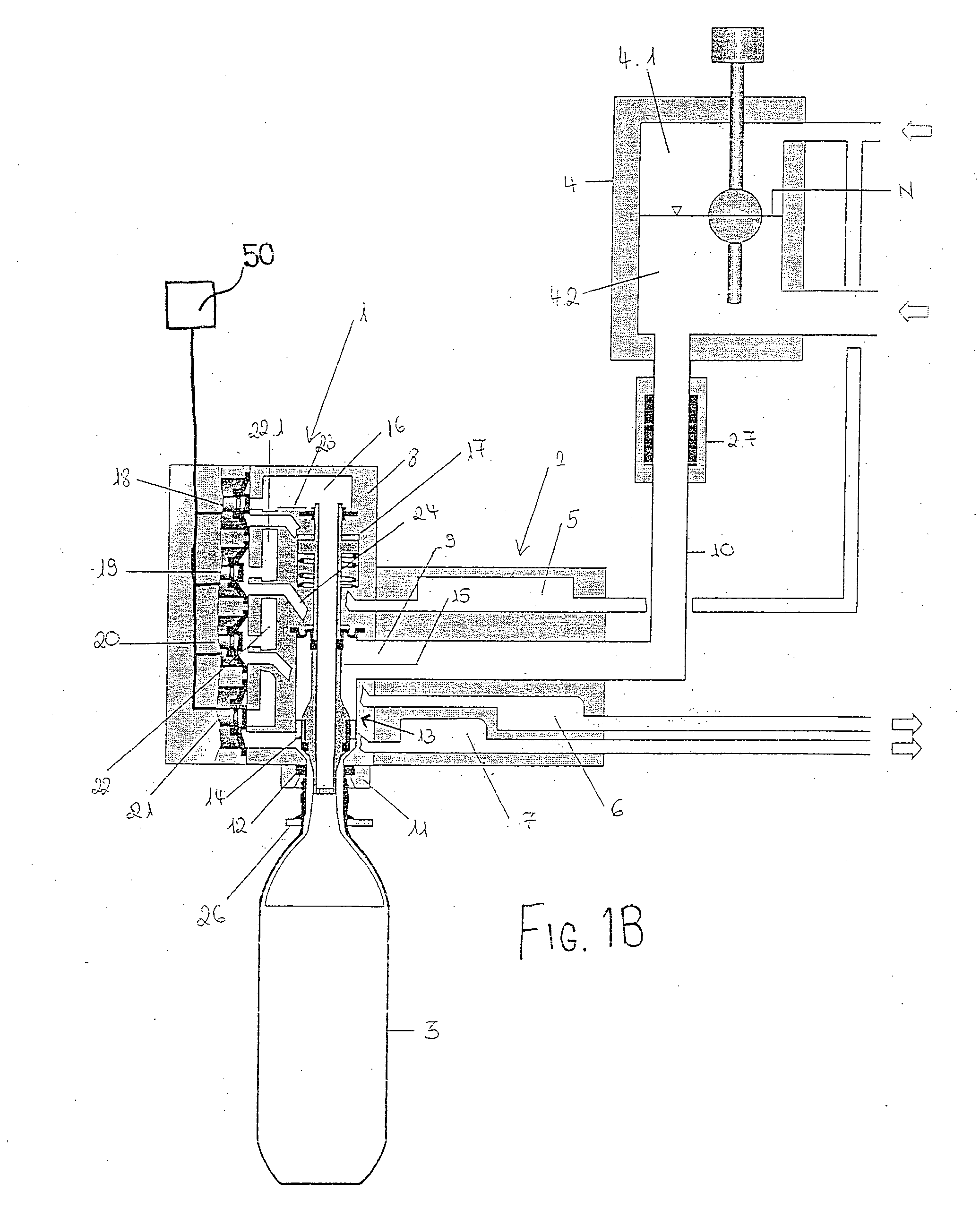

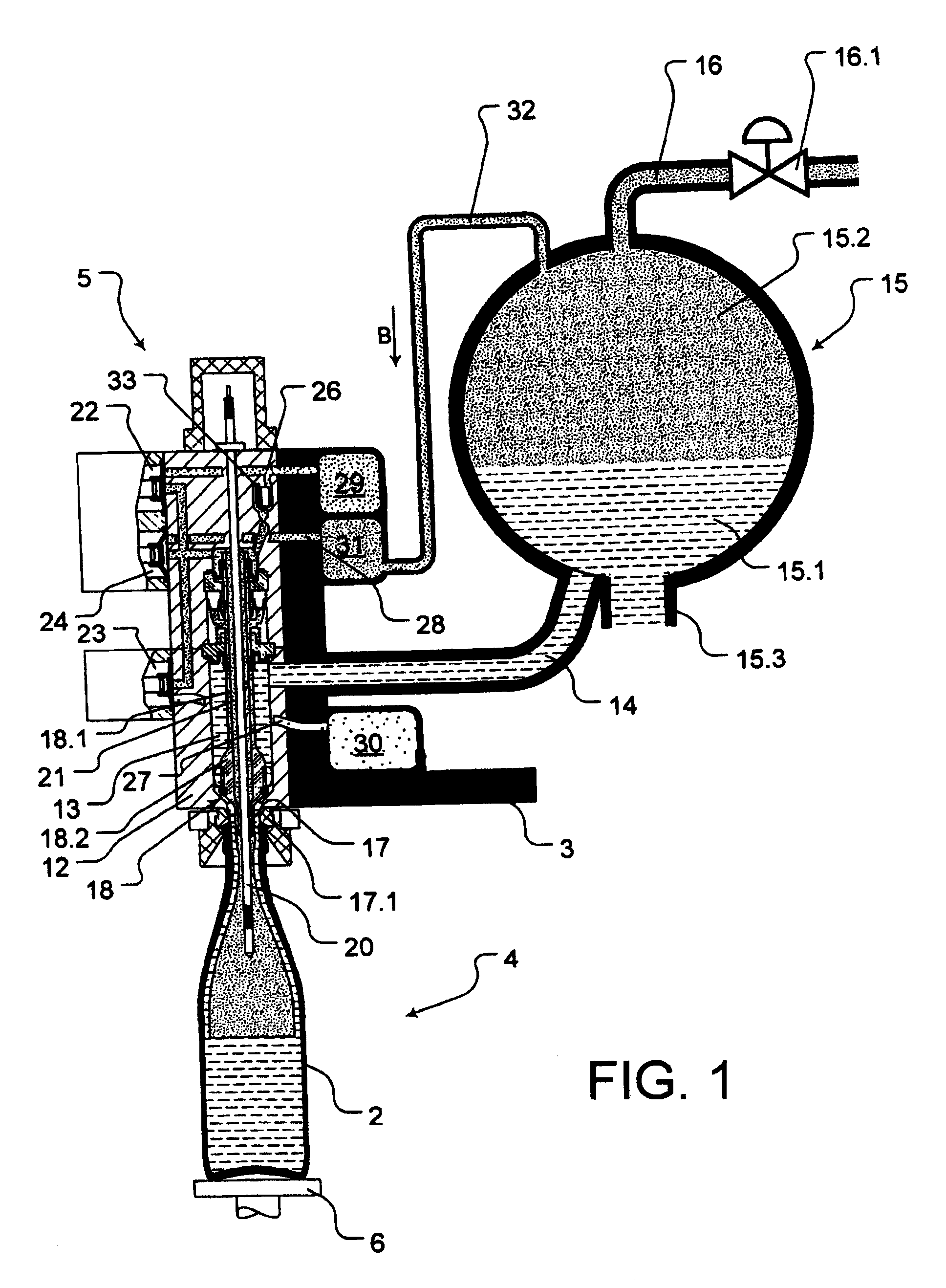

Filling valve

InactiveUS6817386B2Improve hygieneGuaranteed uptimeFilling using counterpressureFilling without pressureEngineeringMechanical engineering

A liquid passage 4 for filling which communicates with a liquid supply piping 6 for filling is formed within a valve housing 2 and carries a filling nozzle 31 at its lower end. The liquid passage 4 is opened or closed by a liquid valve. A packing 38 which seals the mouth of a vessel B, a cylinder 42 which elevates the packing 38, a flow meter 33 which detects a filled content of the liquid which is filled into the vessel B, and an exhaust passage 44 formed in the valve housing 2 are provided. The exhaust passage 44 has an opening disposed toward the vessel which is disposed outside an opening of the filling nozzle 31, and the opening of the filling nozzle 31 is maintained above the elevation of the liquid level which is filled into the vessel B during the filling operation. The filling valve assures a sanitary excellence and is usable with vessels B of differing sizes and shapes.

Owner:SHIBUYA IND CO LTD

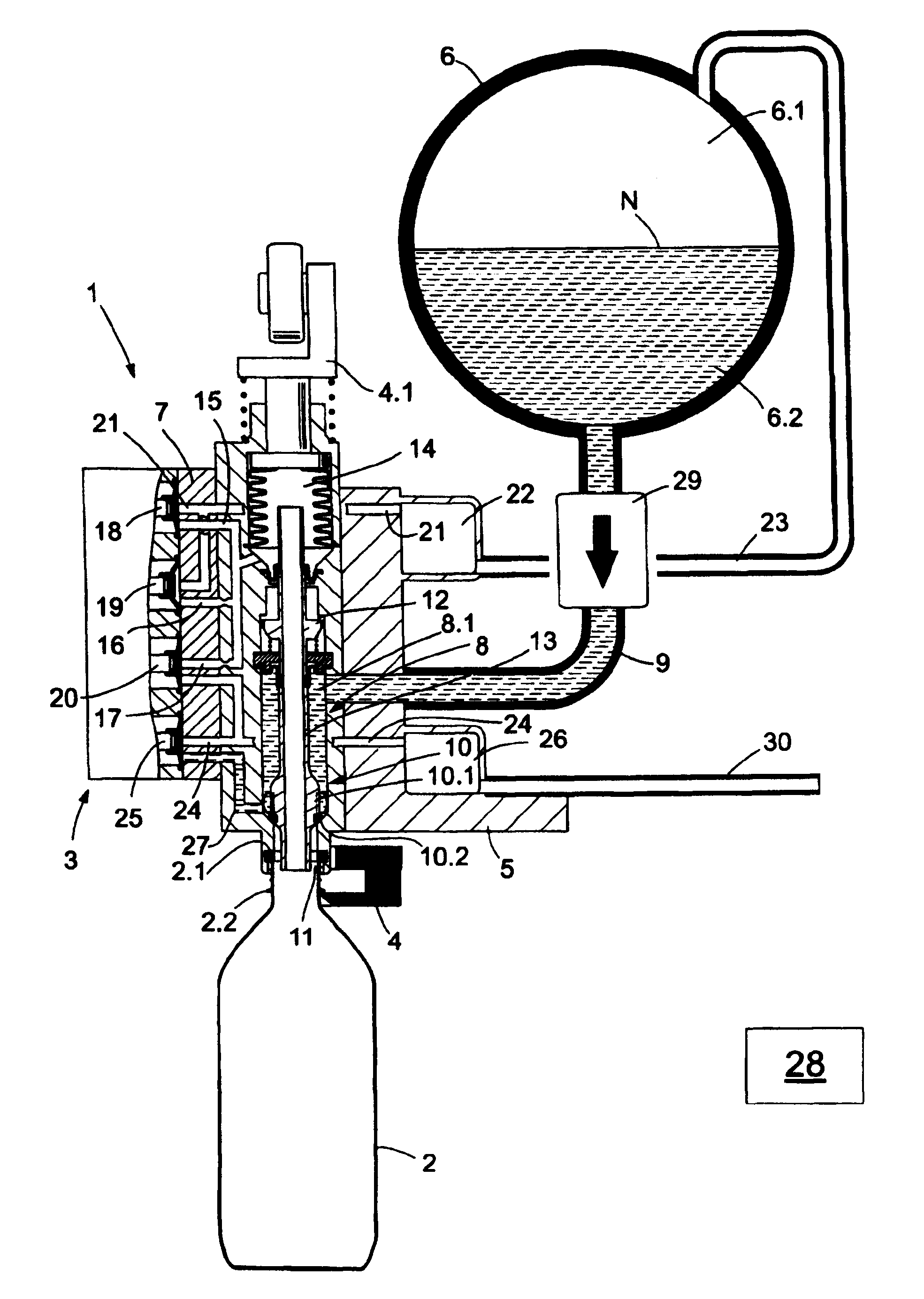

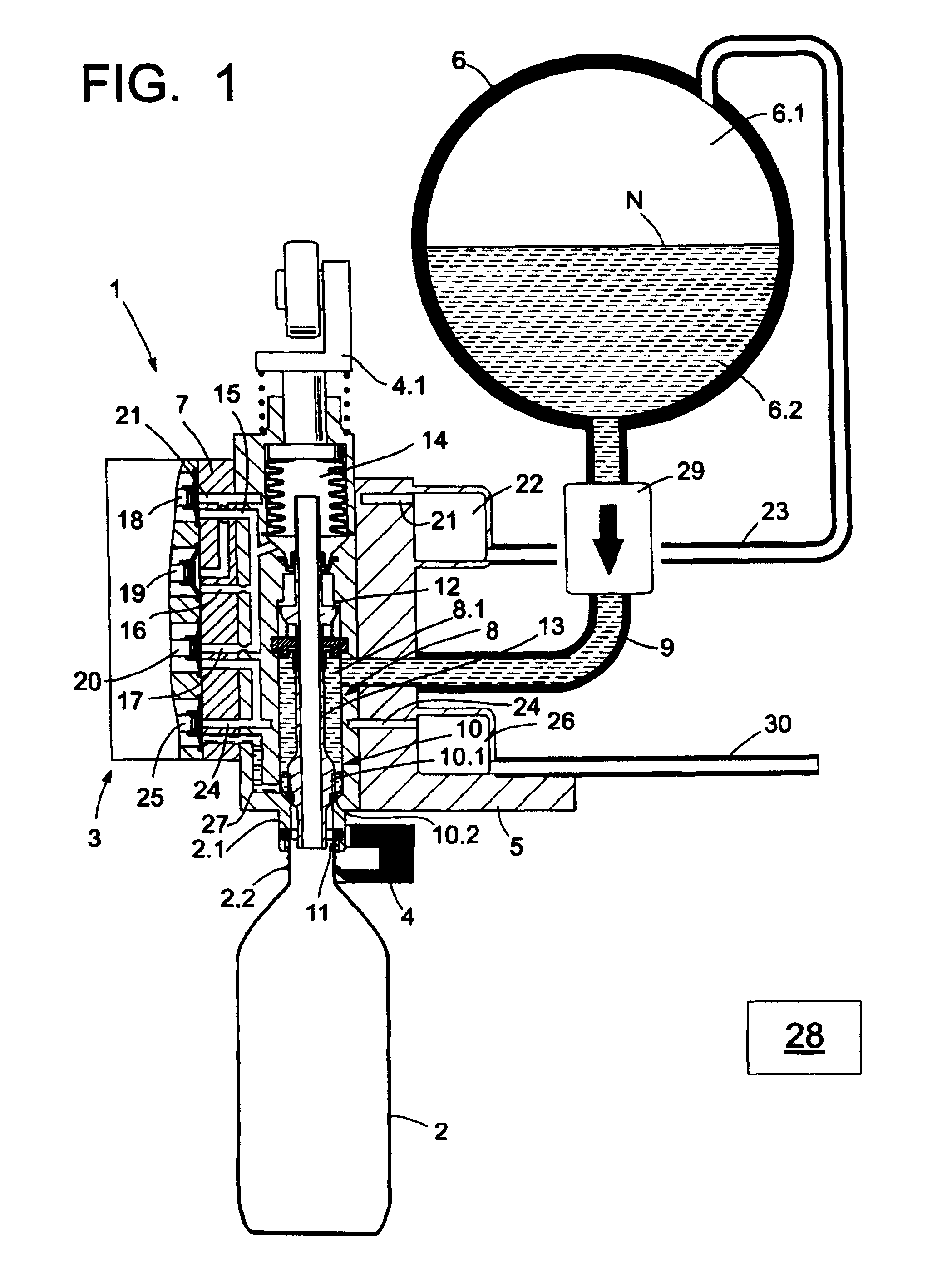

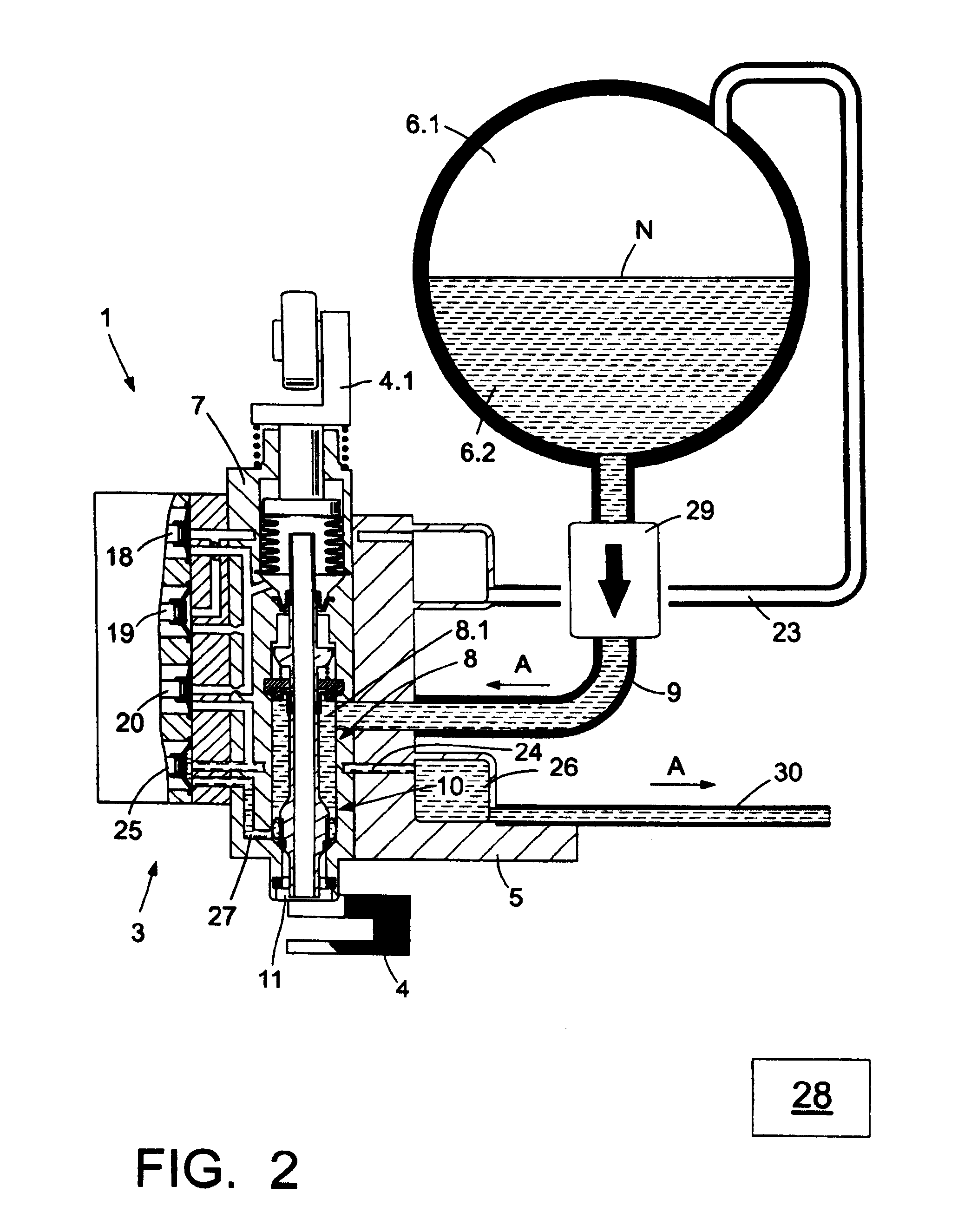

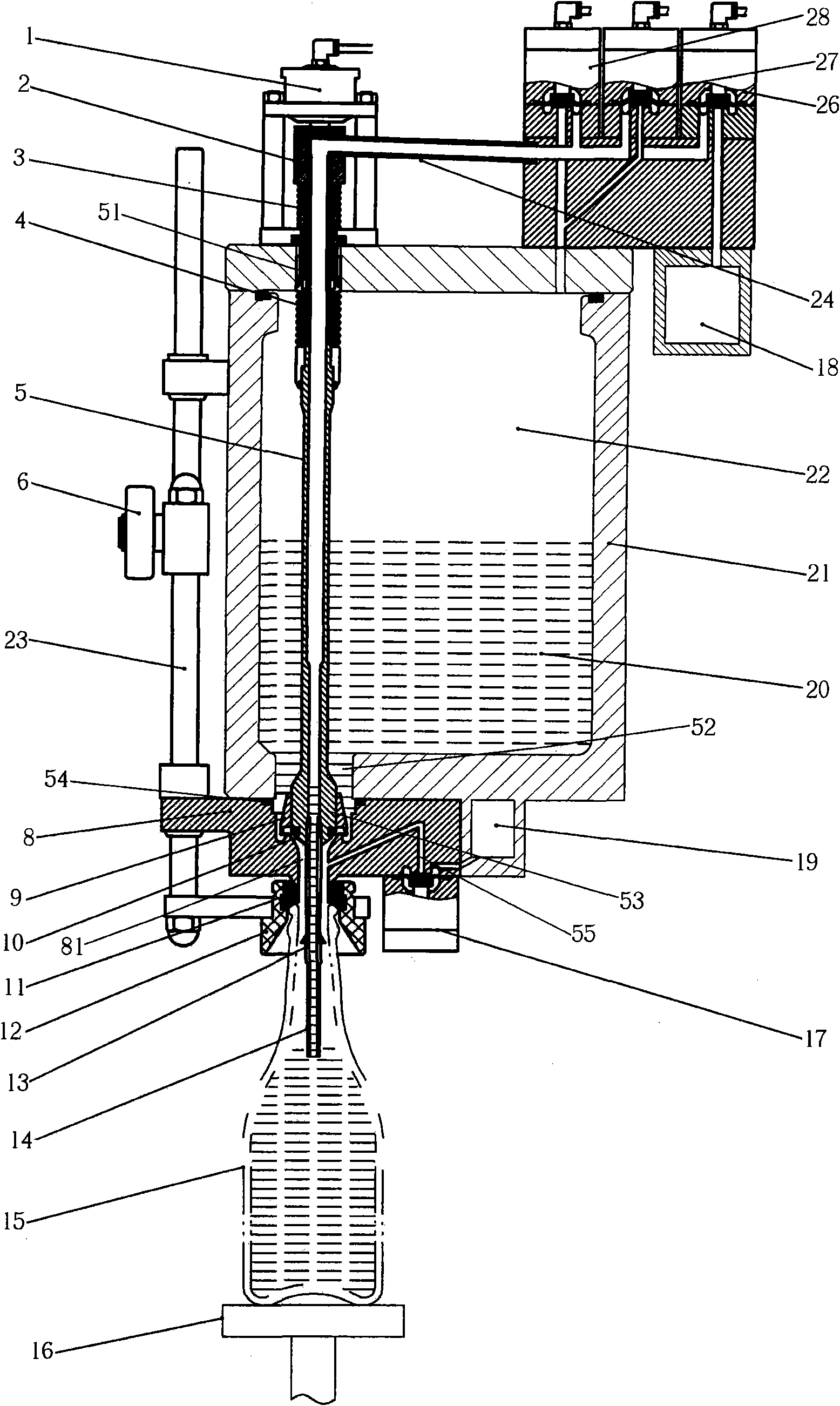

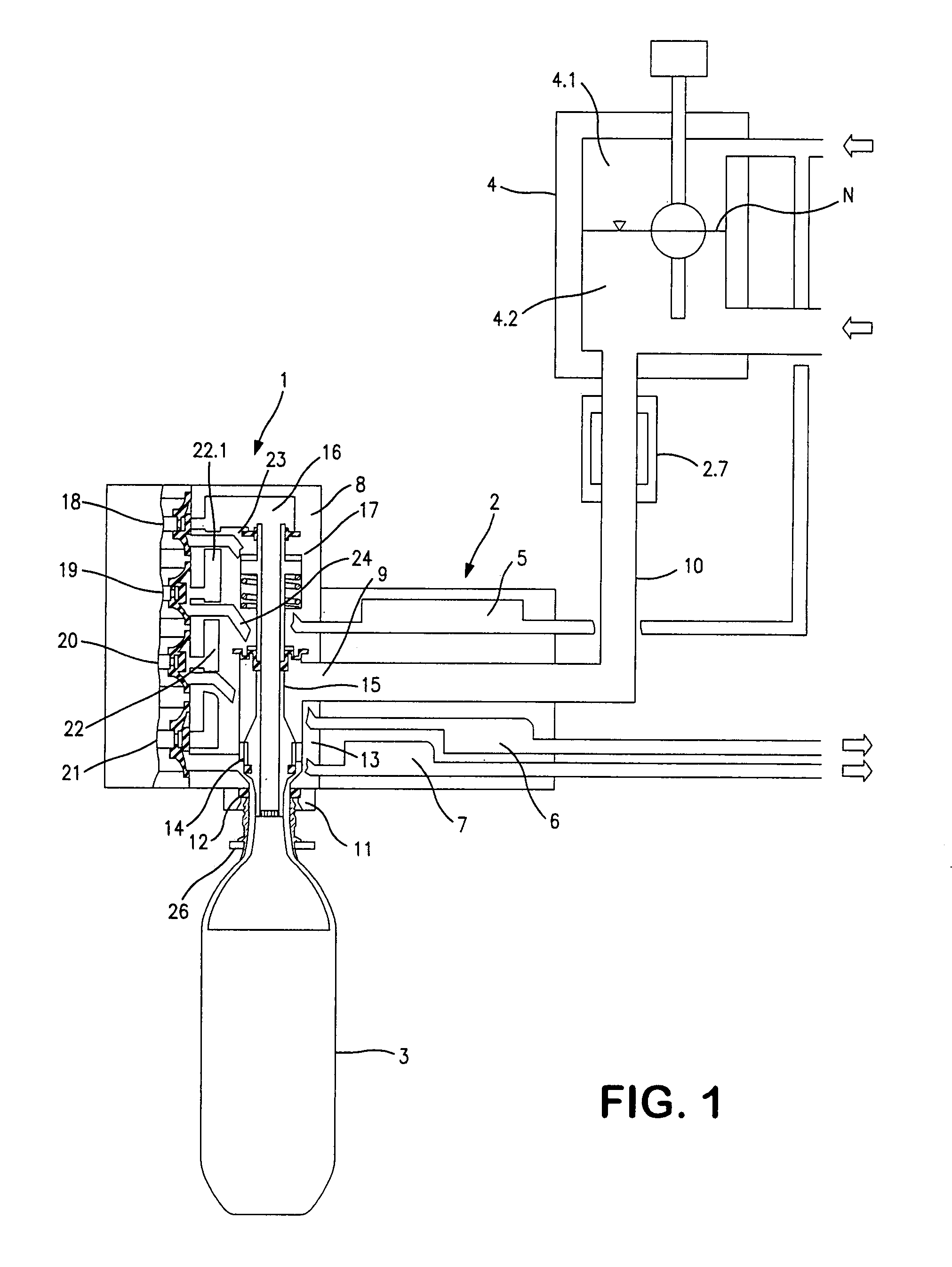

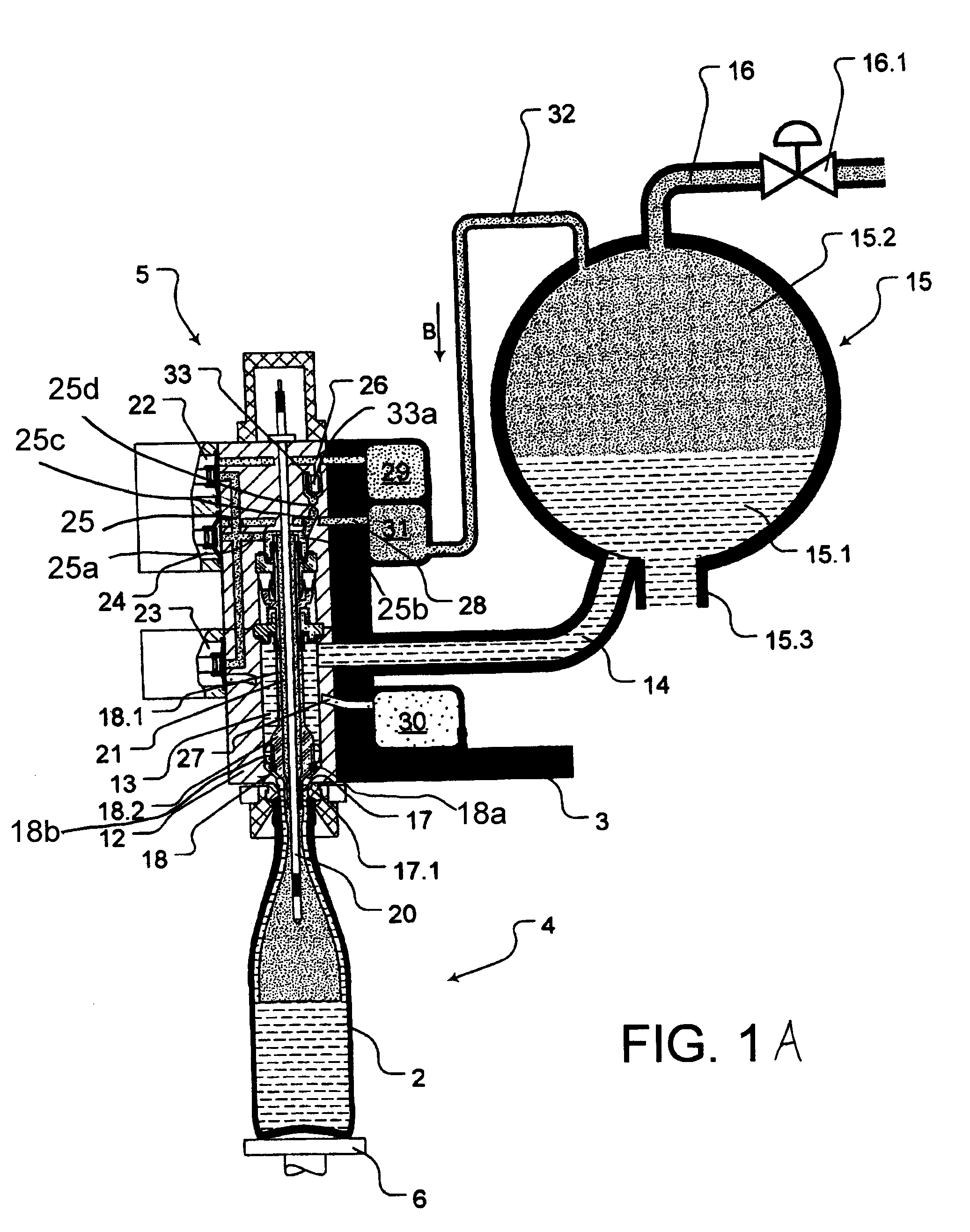

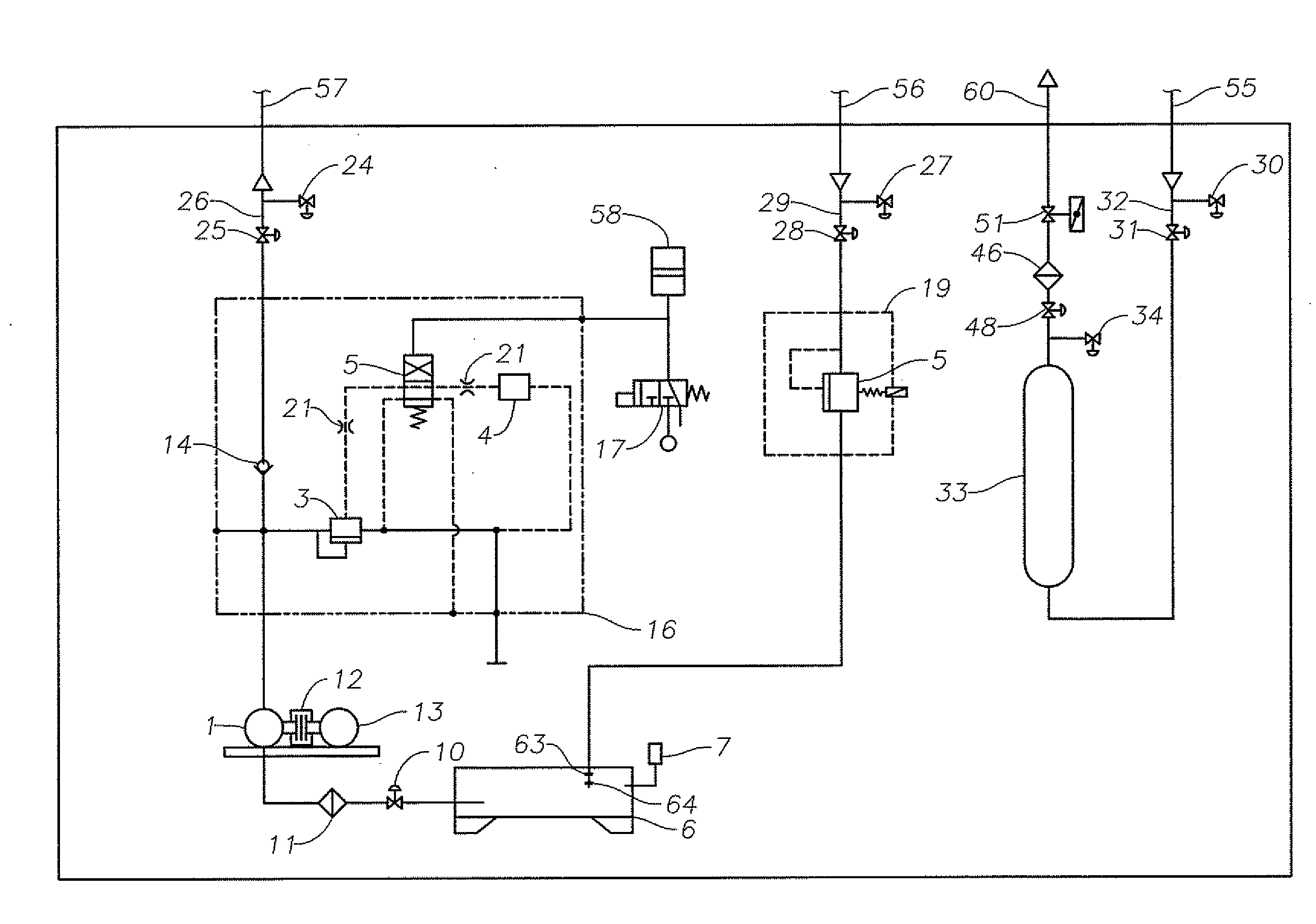

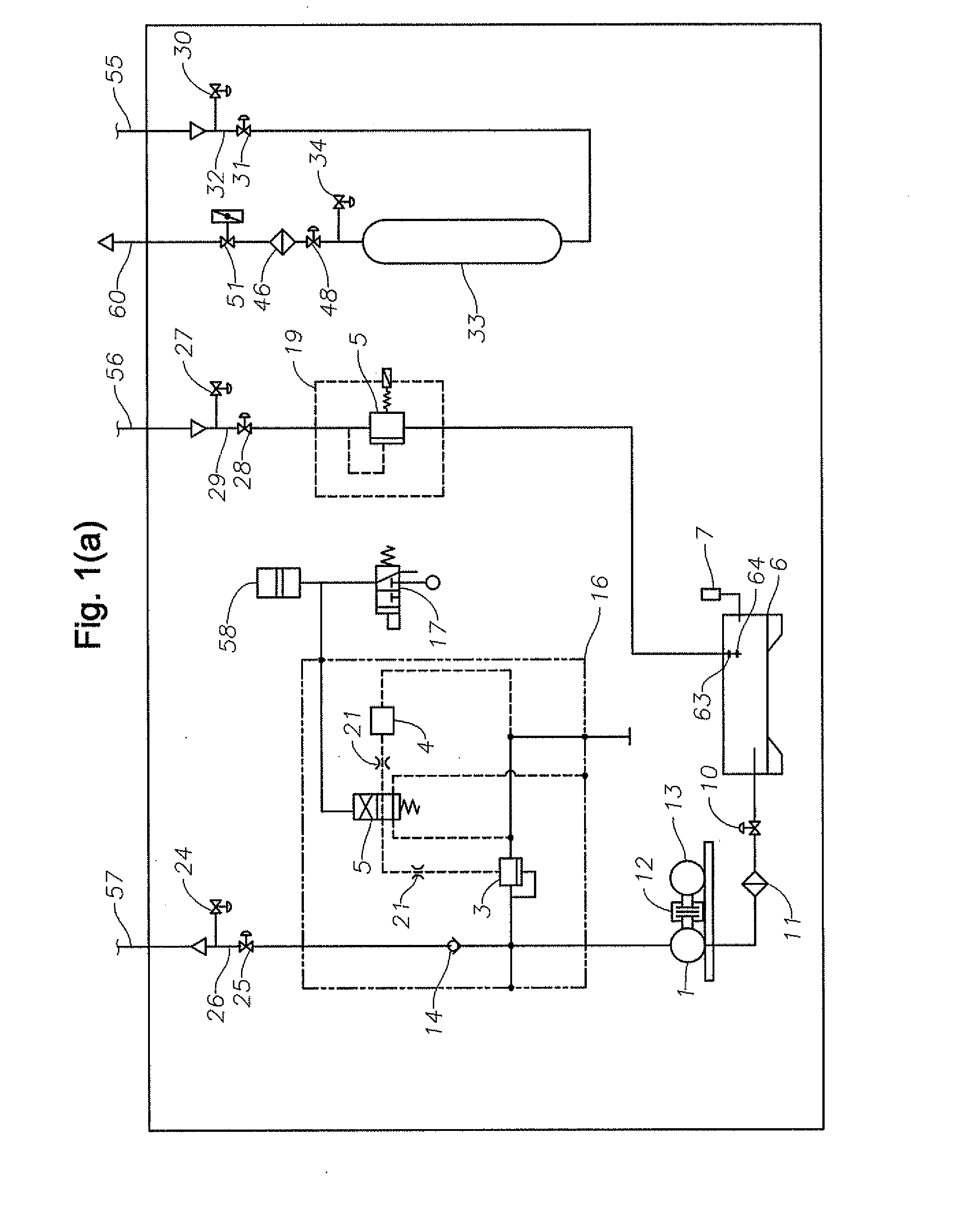

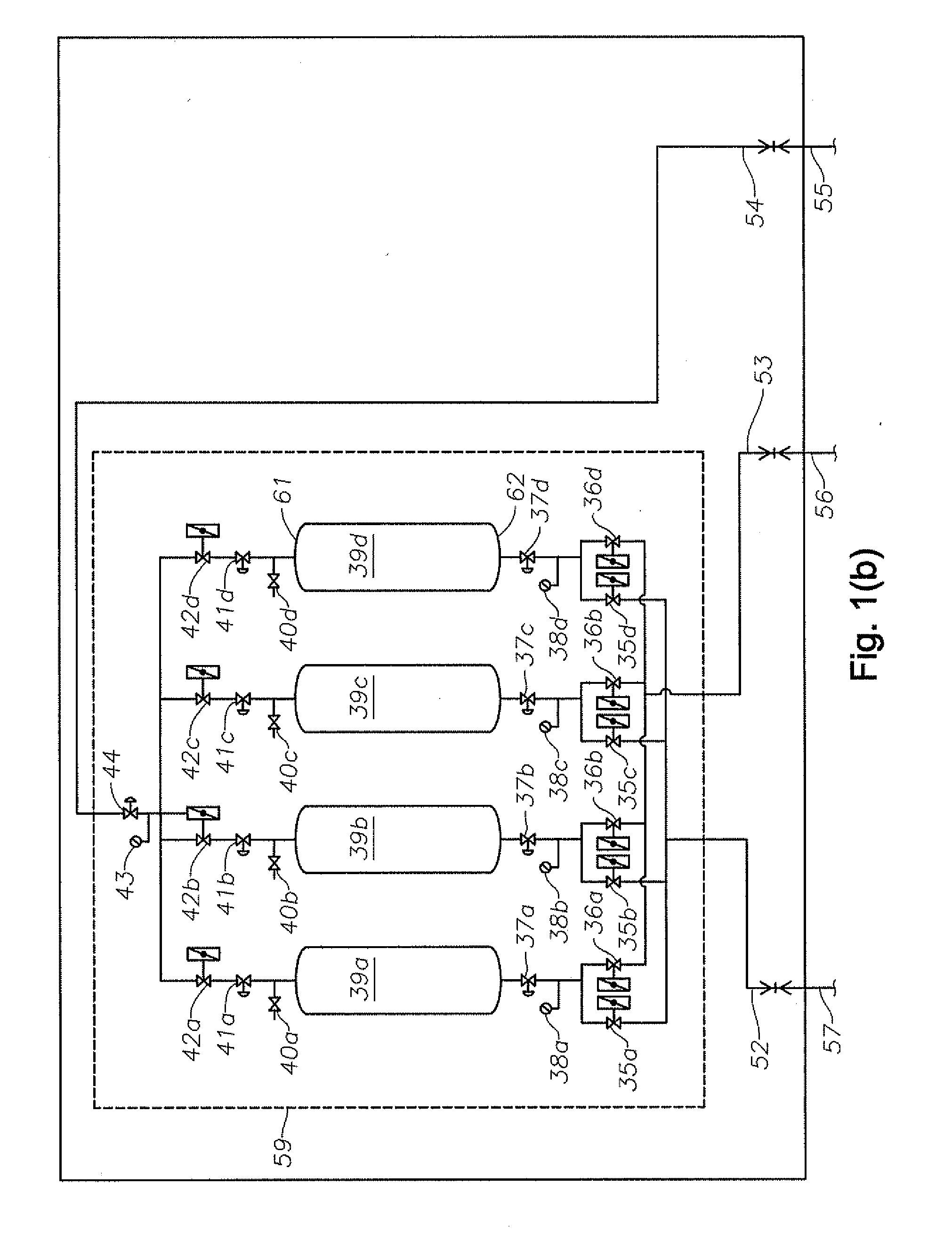

Filling apparatus and filling method therefor

A filling apparatus 1 is made up of a gas passage 14 connected to a storage tank 31 via a connection passage 14a, a first gas valve 35 that opens and closes the gas passage, a pressure gas passage 41 connected to a pressure gas supply source, a pressure gas valve 42 that opens and closes the pressure gas passage, an exhaust passage 43 that allows an interior of a container 4 to communicate with the exterior thereof, and an exhaust valve 44 that opens and closes the exhaust passage. With this filling apparatus, before a pressurized filling operation, both the gas passage and the pressure gas passage are opened to pressurize the interior of the container with a carbonated gas supplied through both passages. Further, also before a unpressurized filling operation, both the gas passage and the pressure gas passage are opened to perform a flushing operation in which droplets are discharged from the gas passage with air exhausted from the container into the storage tank via the gas passage. Then, after the filling operation, both the gas passage and the exhaust passage are opened to discharge a certain amount of filling liquid remaining in the gas passage, into the container.

Owner:SHIBUYA IND CO LTD

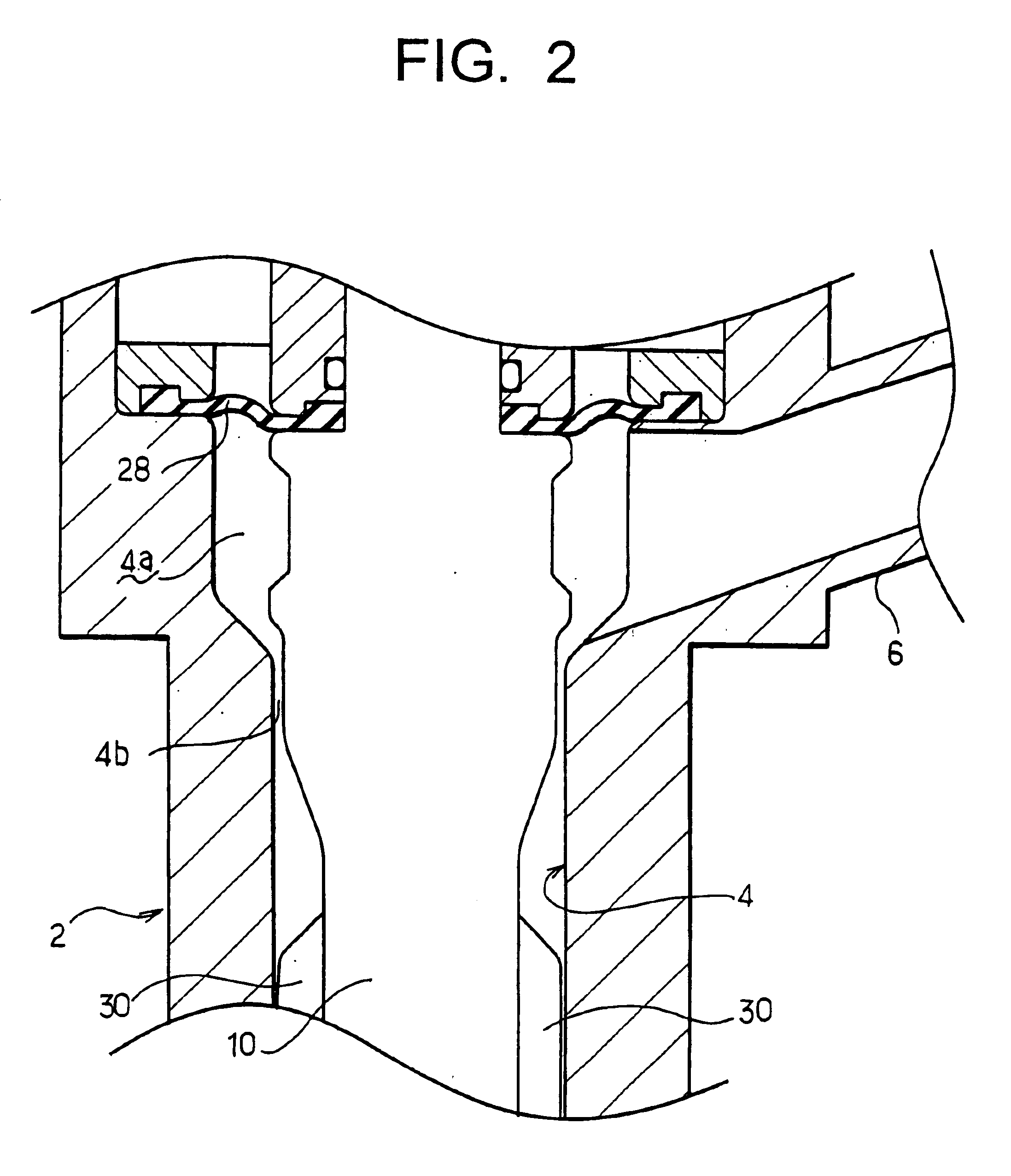

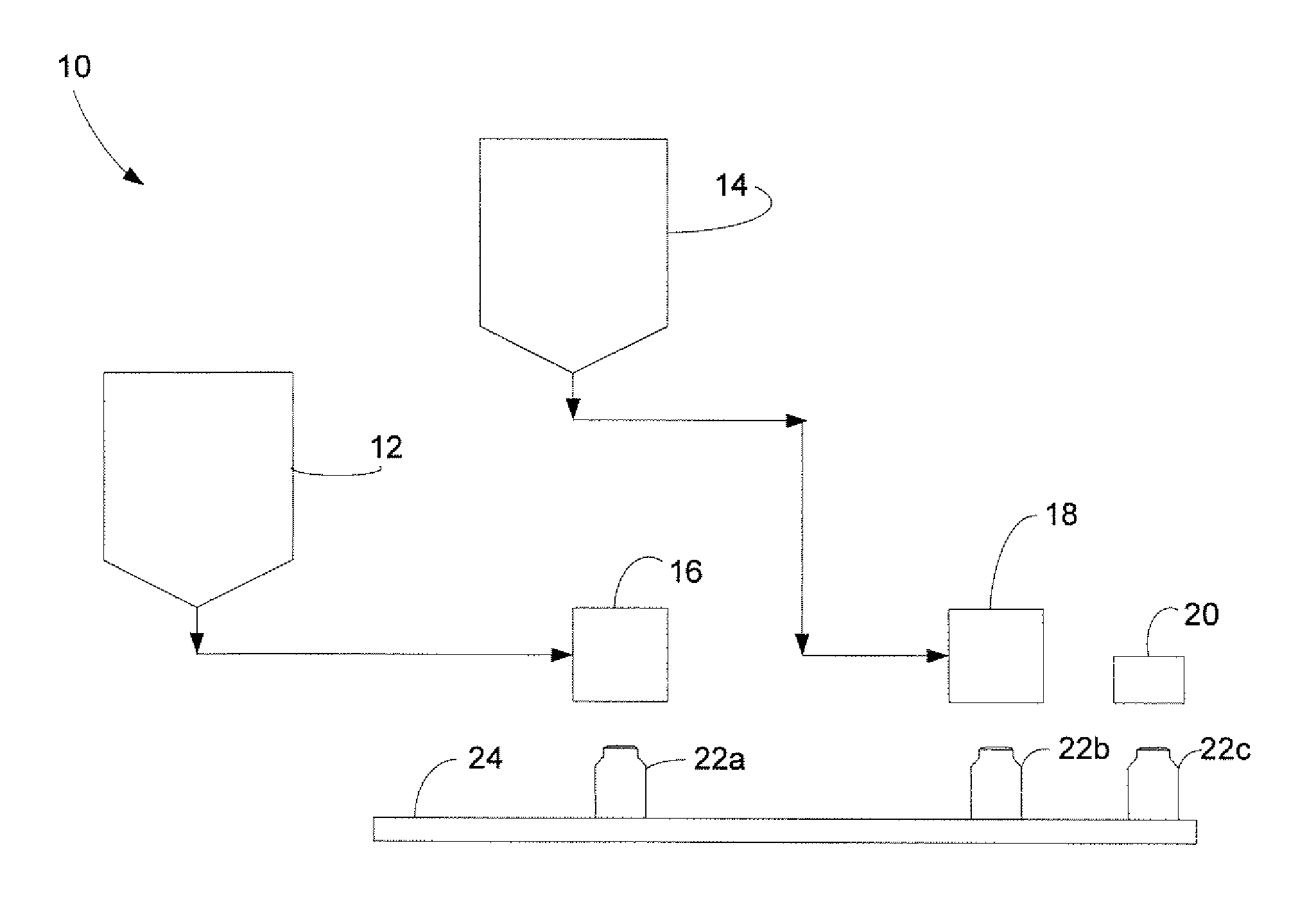

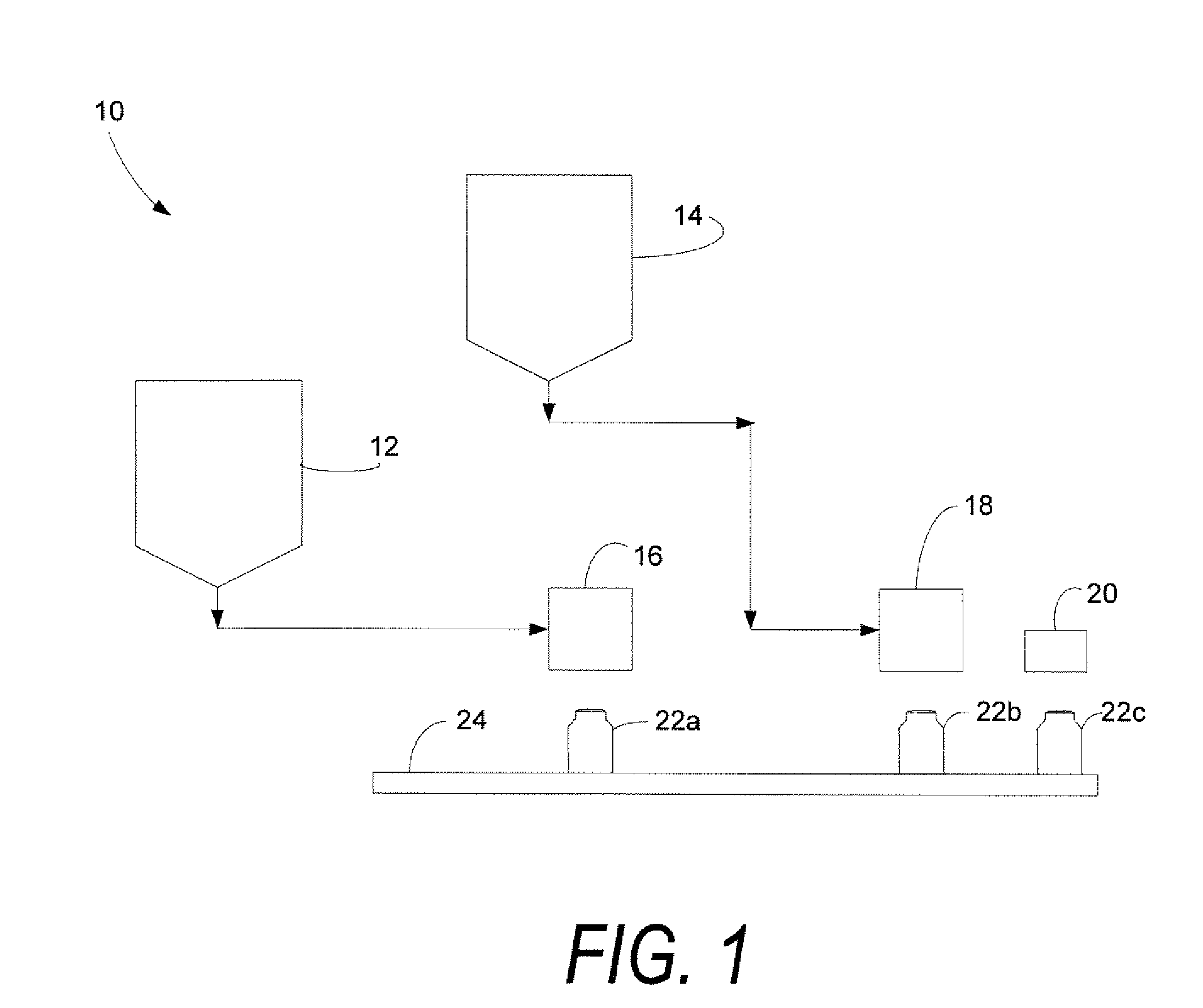

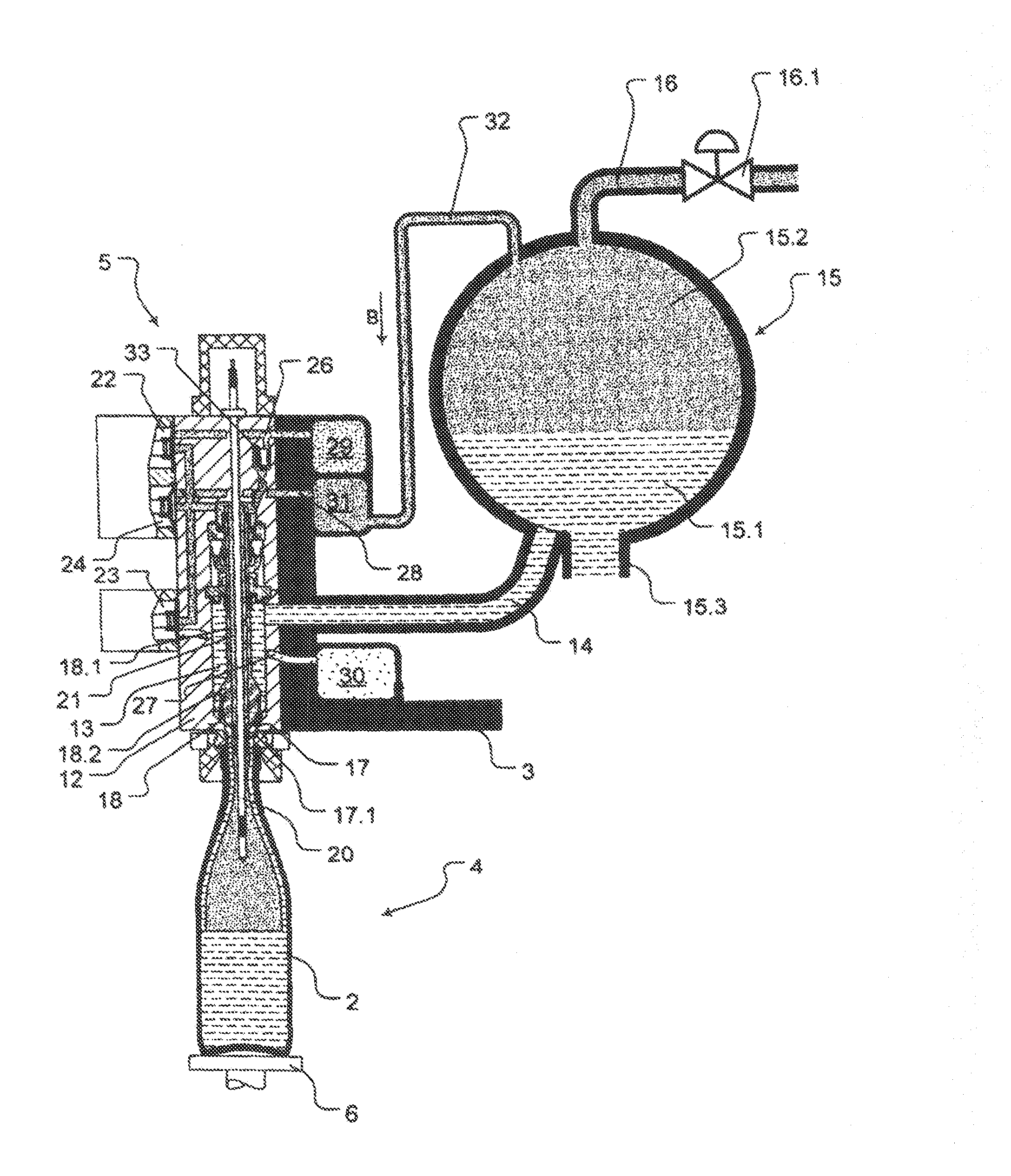

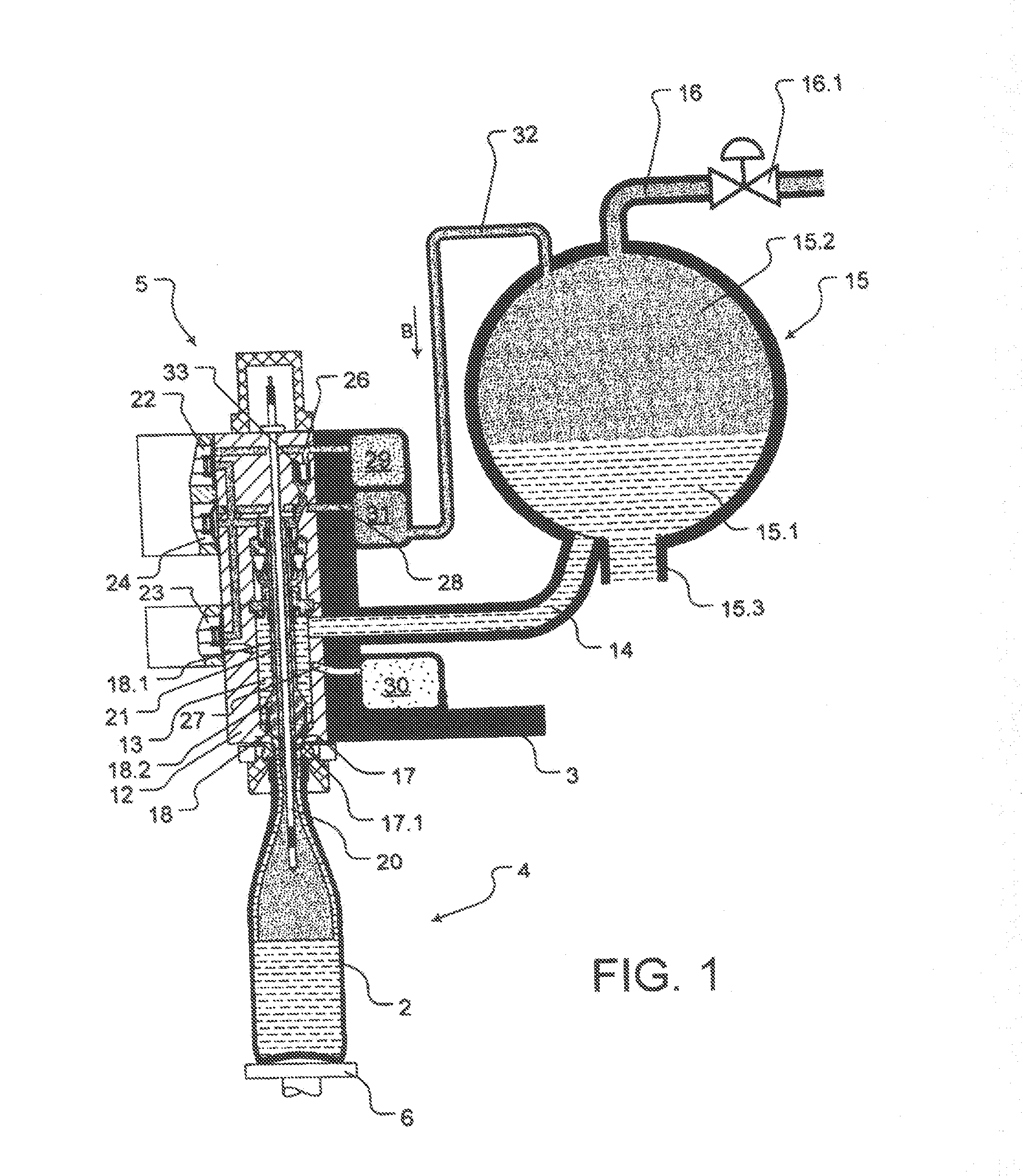

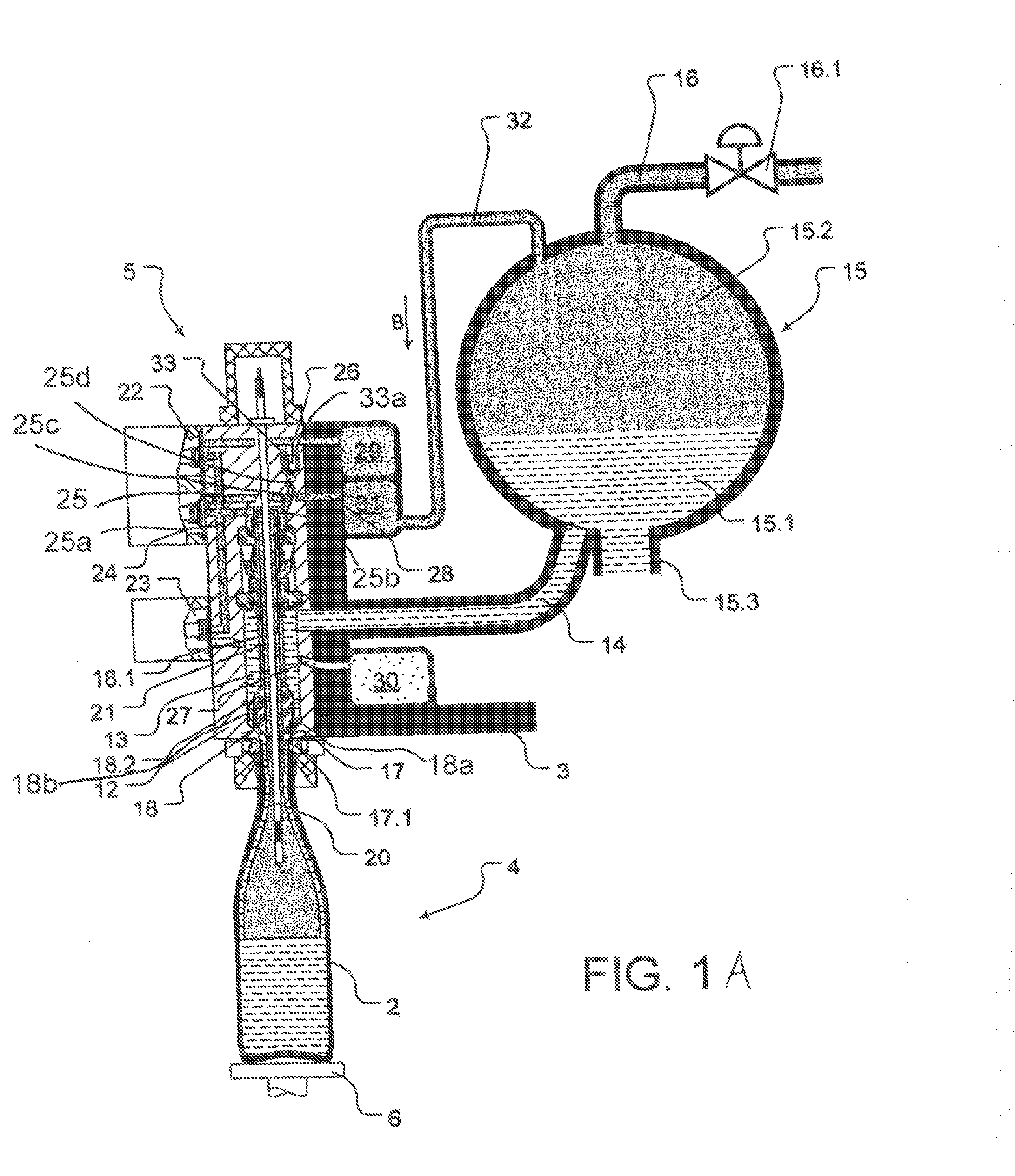

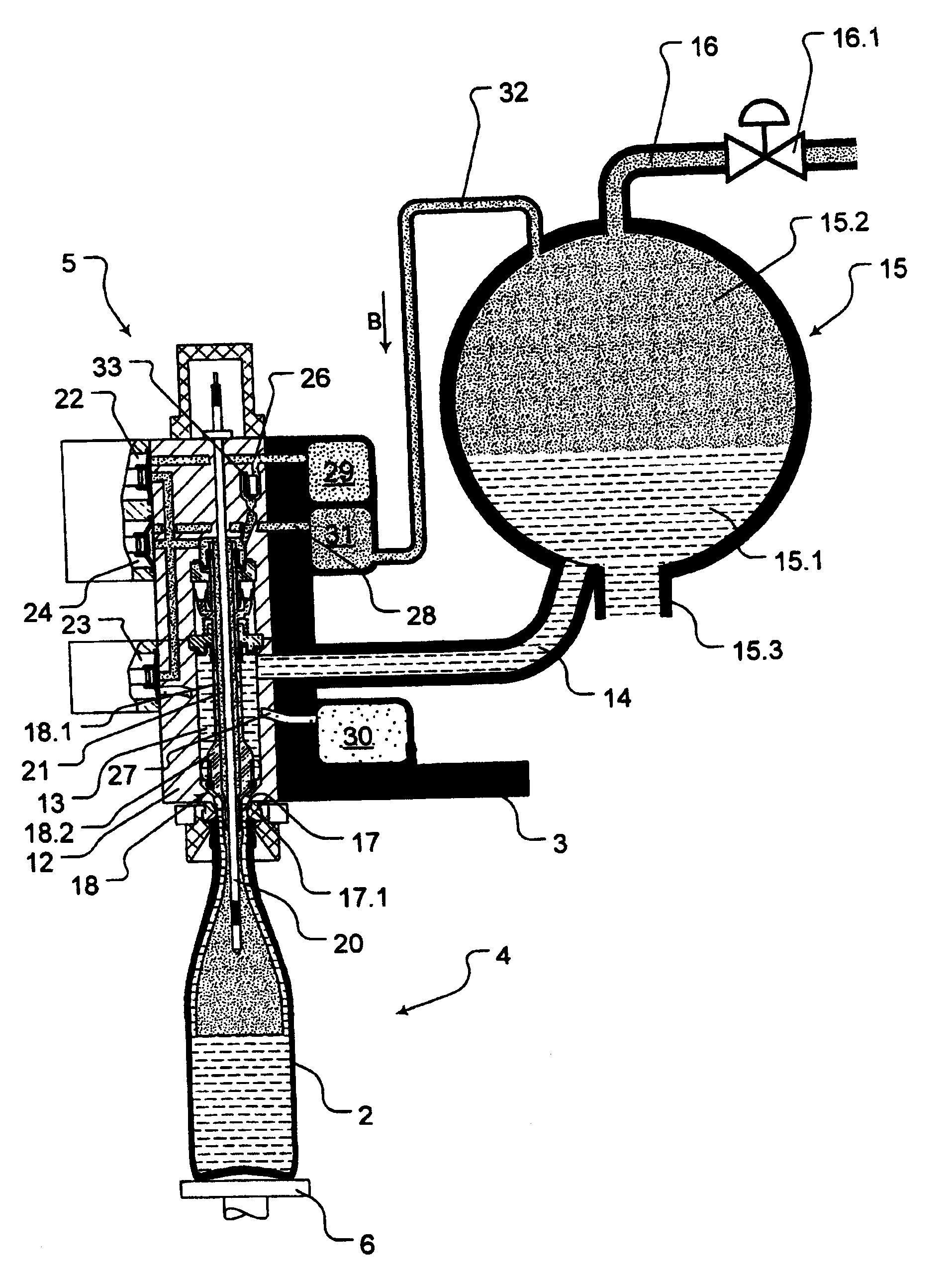

Filling system for hot filling of beverage bottles or containers in a bottle or container filling plant

InactiveUS20100071802A1Simply constructedSimply designedFilling using counterpressureSolid materialTrademarkEngineering

A filling system for hot filling of beverage bottles or containers in a bottle or container filling plant. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

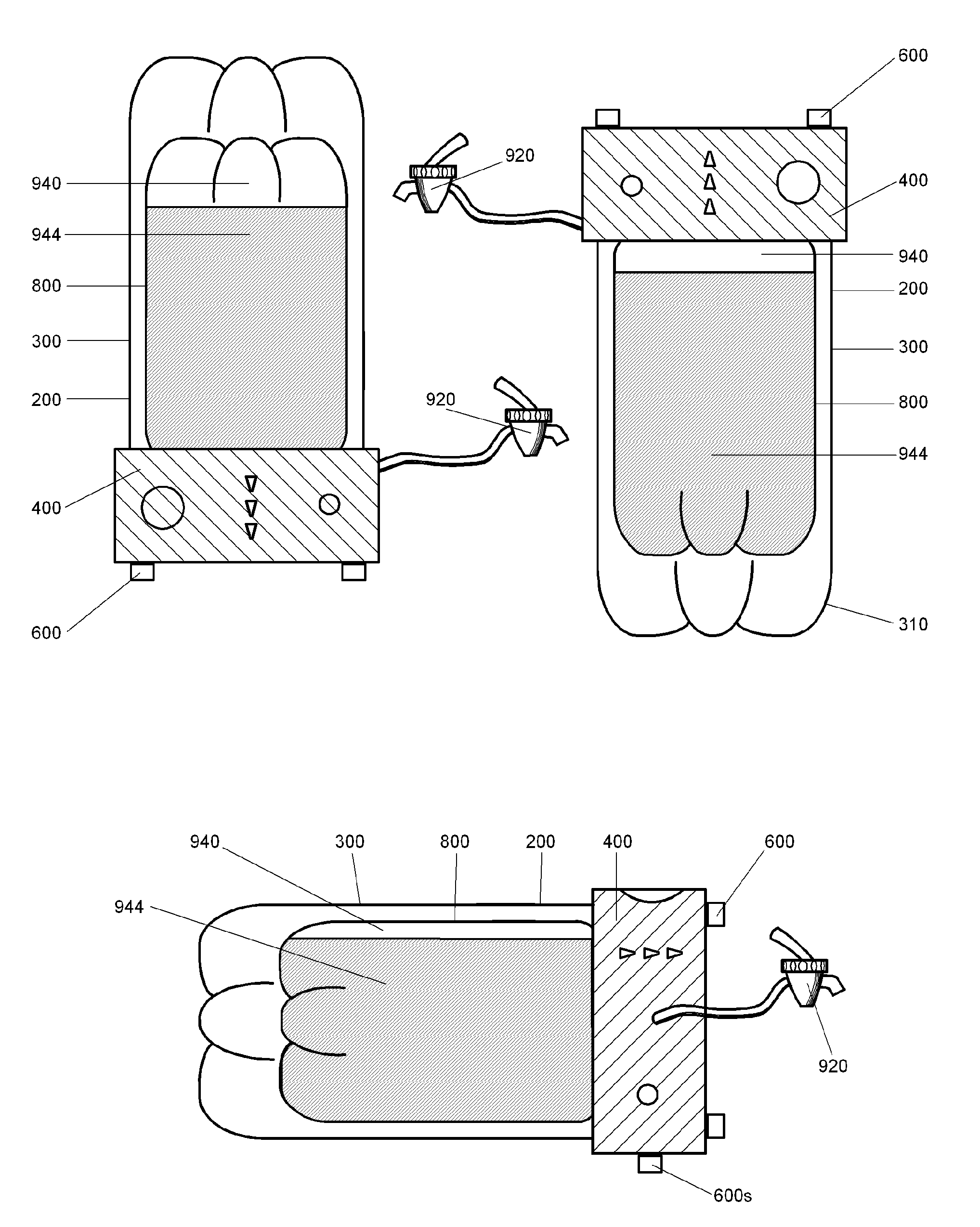

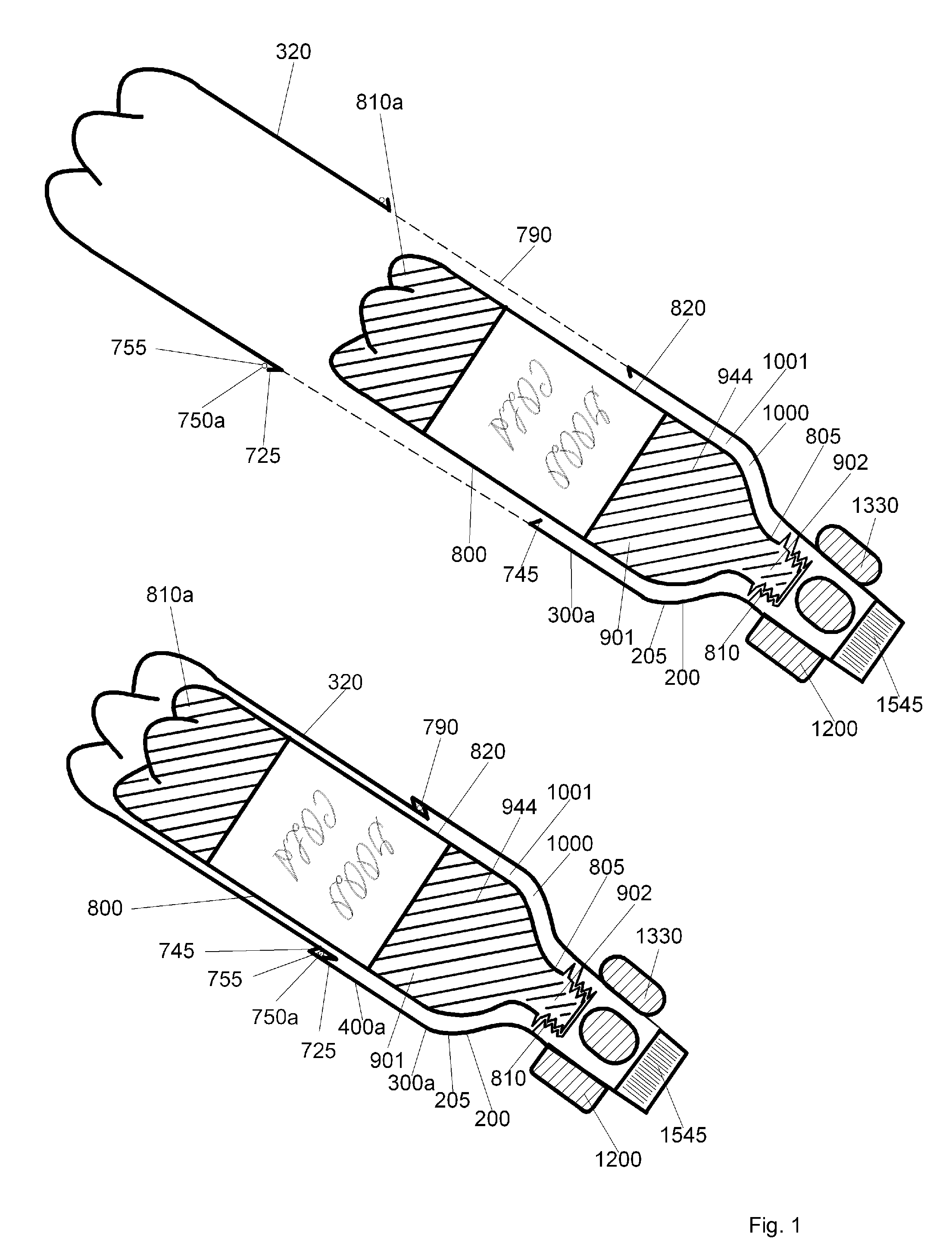

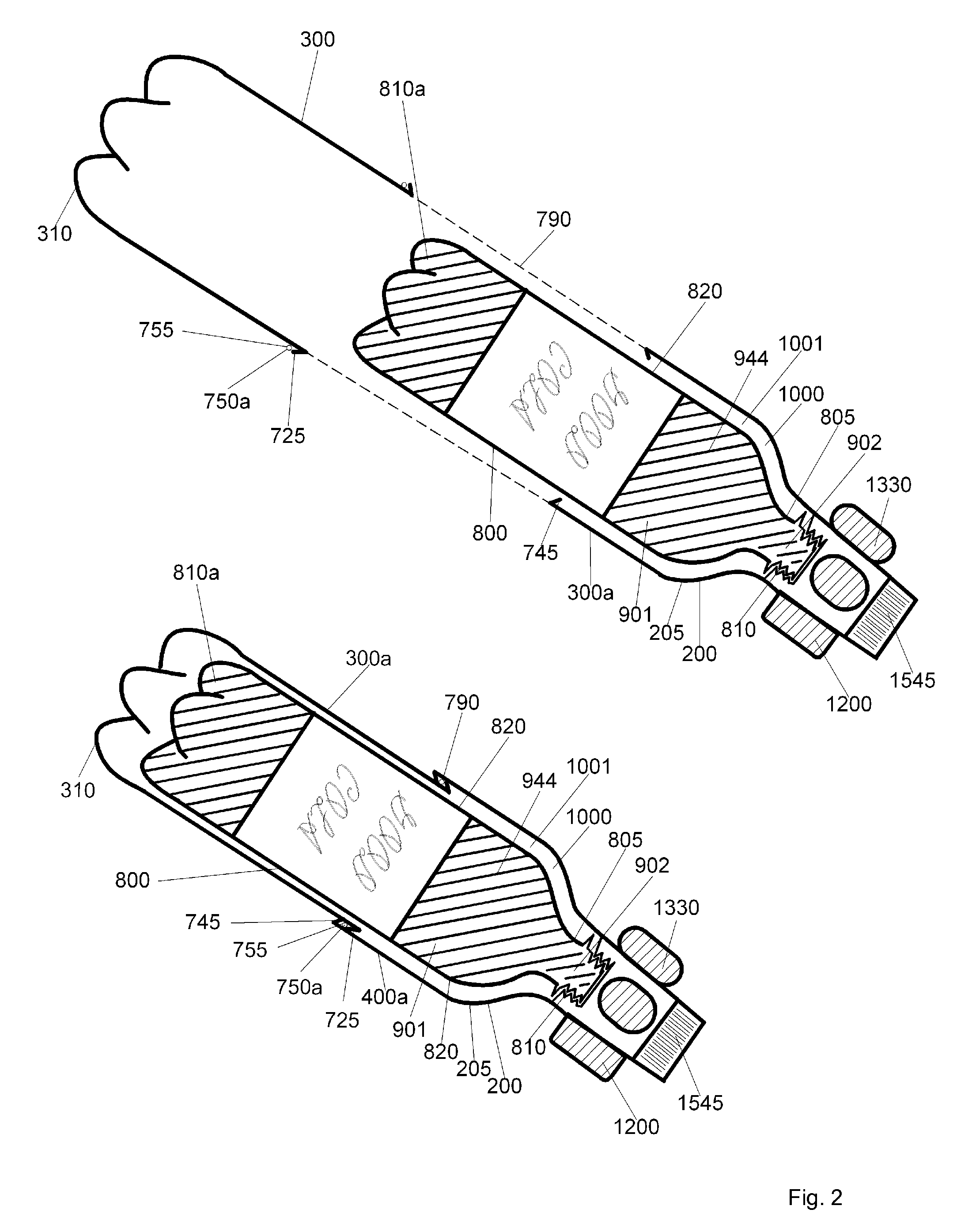

Flexible Bottle Wrapper for Preservation and Dispensation of Air Sensitive Materials

A volumetric displacement device, especially good for preserving and dispensing carbonated beverages has been constructed that is extremely light, small, safe, attractive, easy to use, energy efficient and inexpensive. It can use battery power, has an ovaloid shape, can be constructed of thin flexible plastics, and operates in various positions that eliminate the need for a pickup tube. The controls of the device have been linked both electronically and mechanically for ease of operation.

Owner:LITTO CLAUDE RAMON

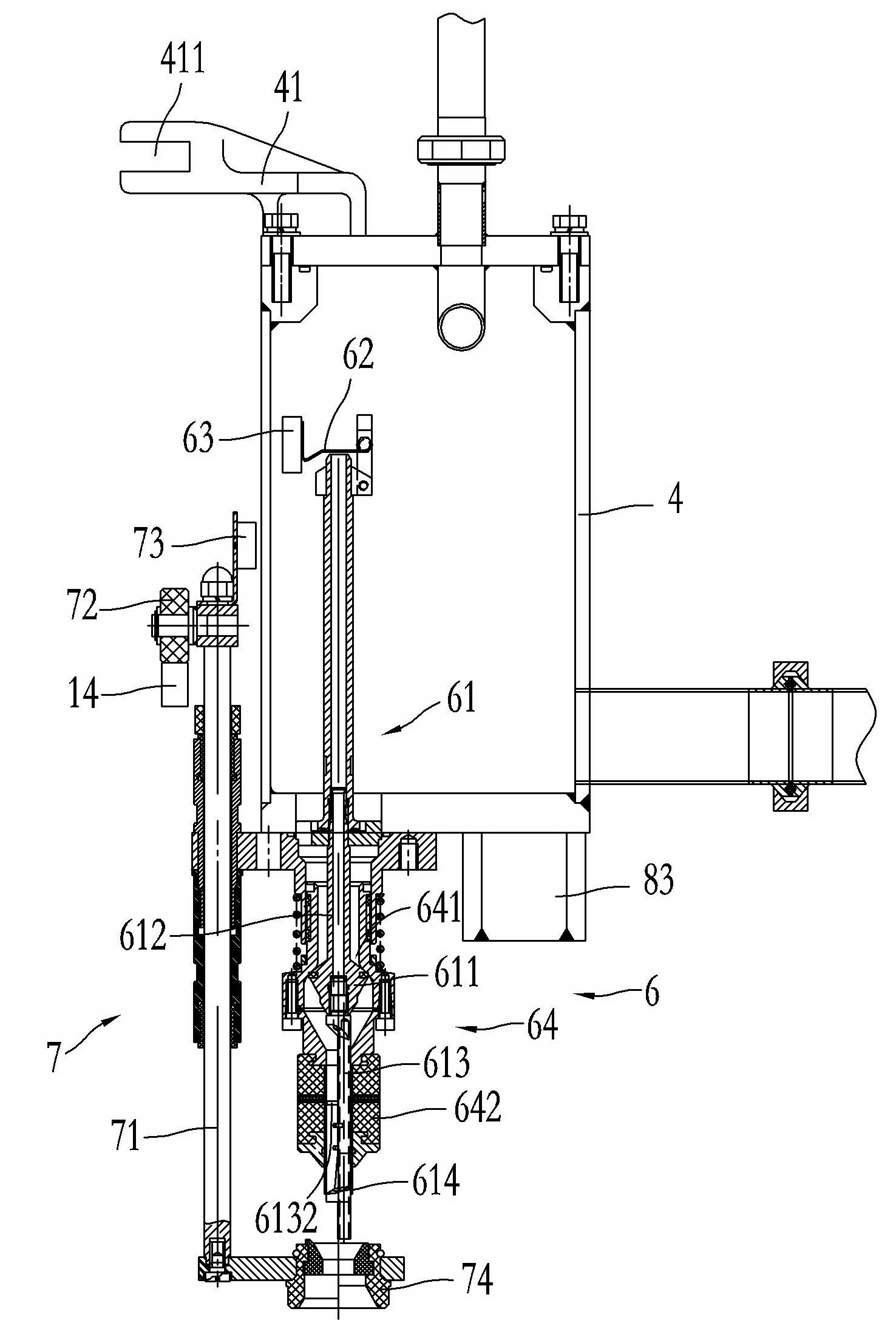

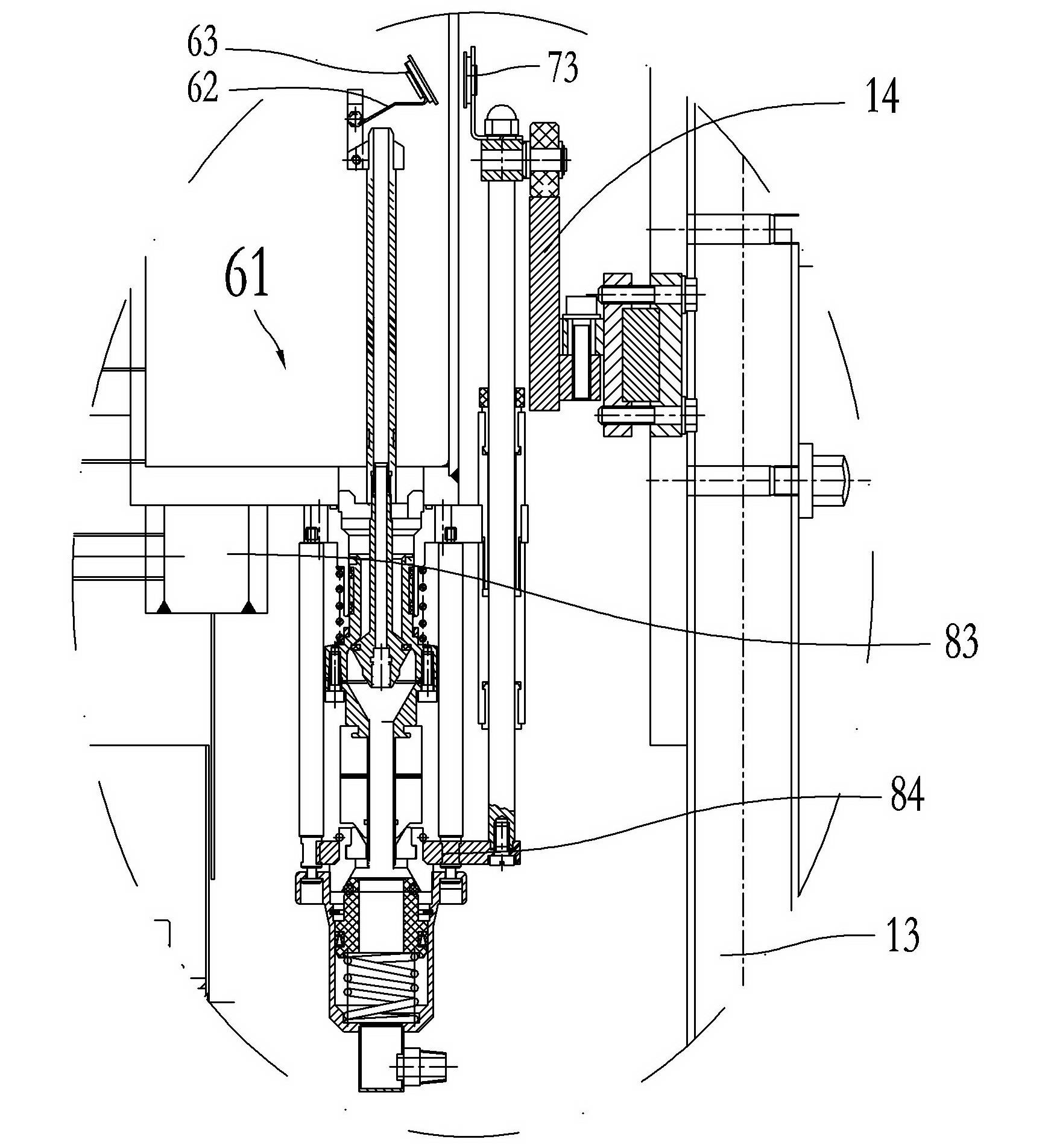

Electronic liquid filling device

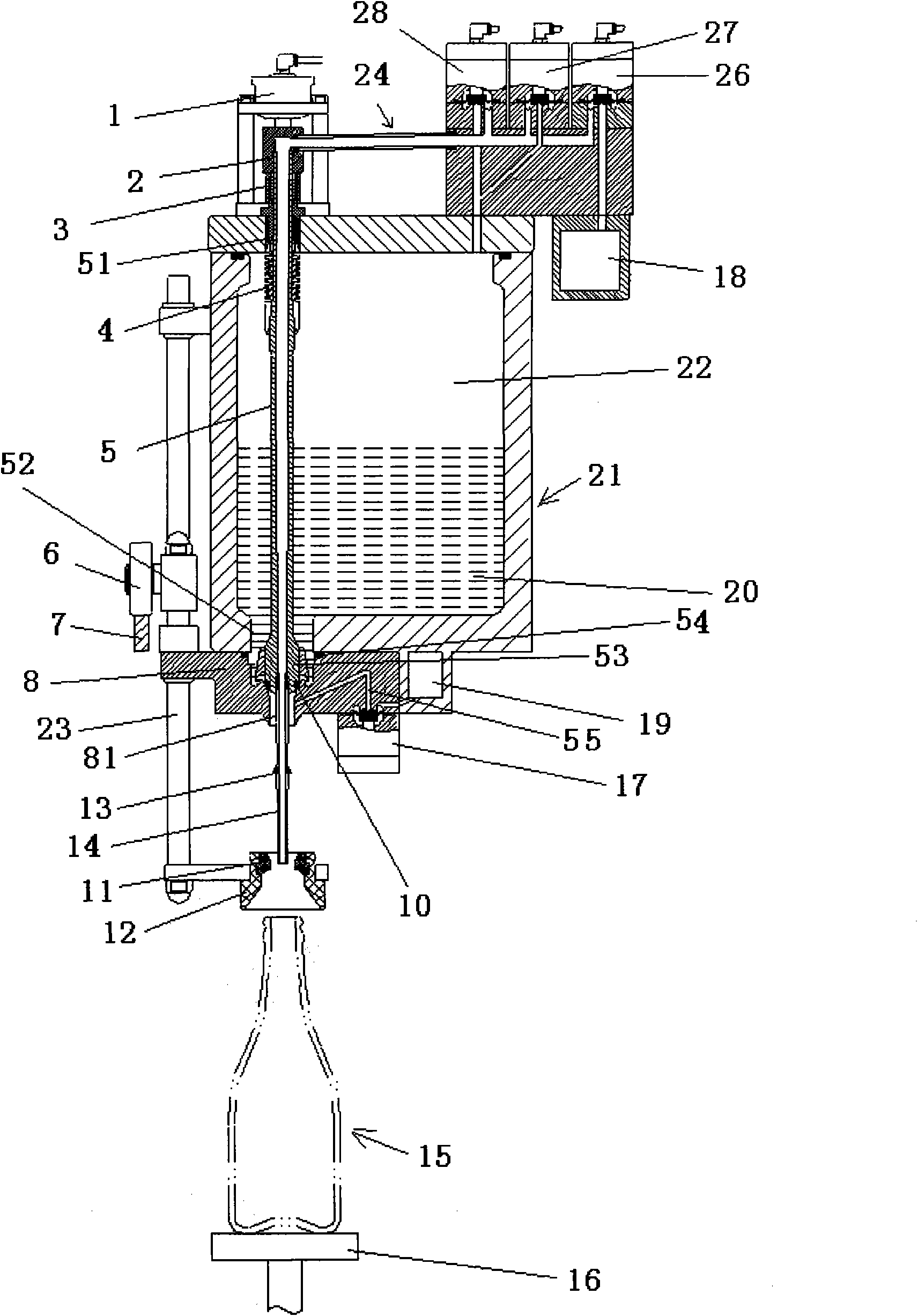

ActiveCN101941664AFilling does not affectThere will be no phenomenon of blocking the pressure relief channelFilling using counterpressureEngineeringVacuum chamber

The invention provides an electronic liquid filling device which is used for filling a liquid material (20) in a material cylinder (21) into a liquid container (15) and comprises a vacuumizing passage and a pressure-relieving passage. In a working state, one end of the vacuumizing passage is communicated with the liquid container (15), the other end of the vacuumizing passage is connected with a vacuum chamber (18) through a vacuum valve (26), one end of the pressure-relieving passage is communicated with the liquid container (15), and the other end of the pressure-relieving passage is connected with a pressure-relieving chamber (19) through a pressure-relieving valve (17). The pressure-relieving passage and the vacuumizing passage are two mutually independent passages. In a state when the liquid filling is finished, one end of the vacuumizing passage is arranged below the liquid level of the liquid container (15), and one end of the pressure-relieving passage is arranged above the liquid level of the liquid container (15).

Owner:NANJING LEHUI LIGHT IND EQUIP

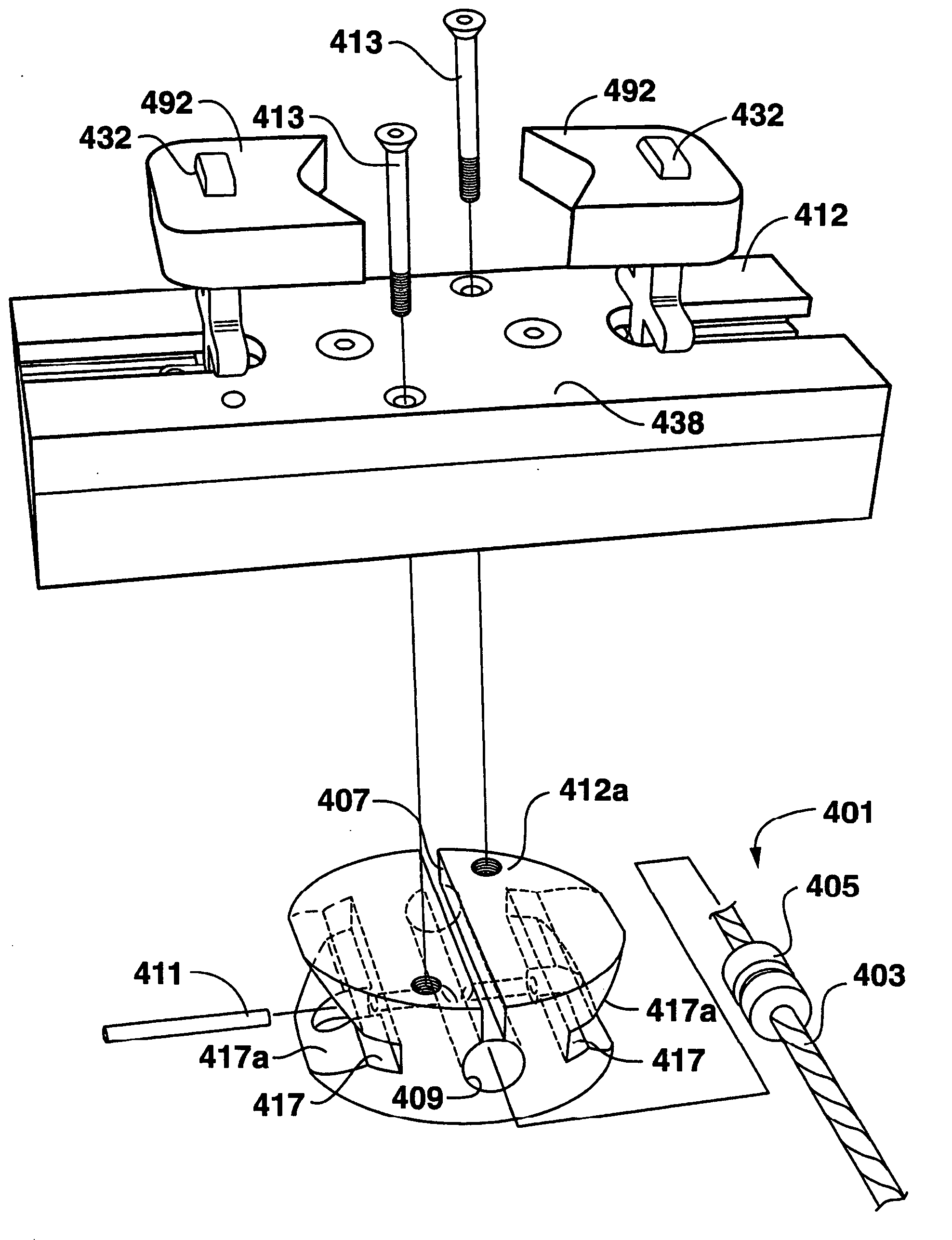

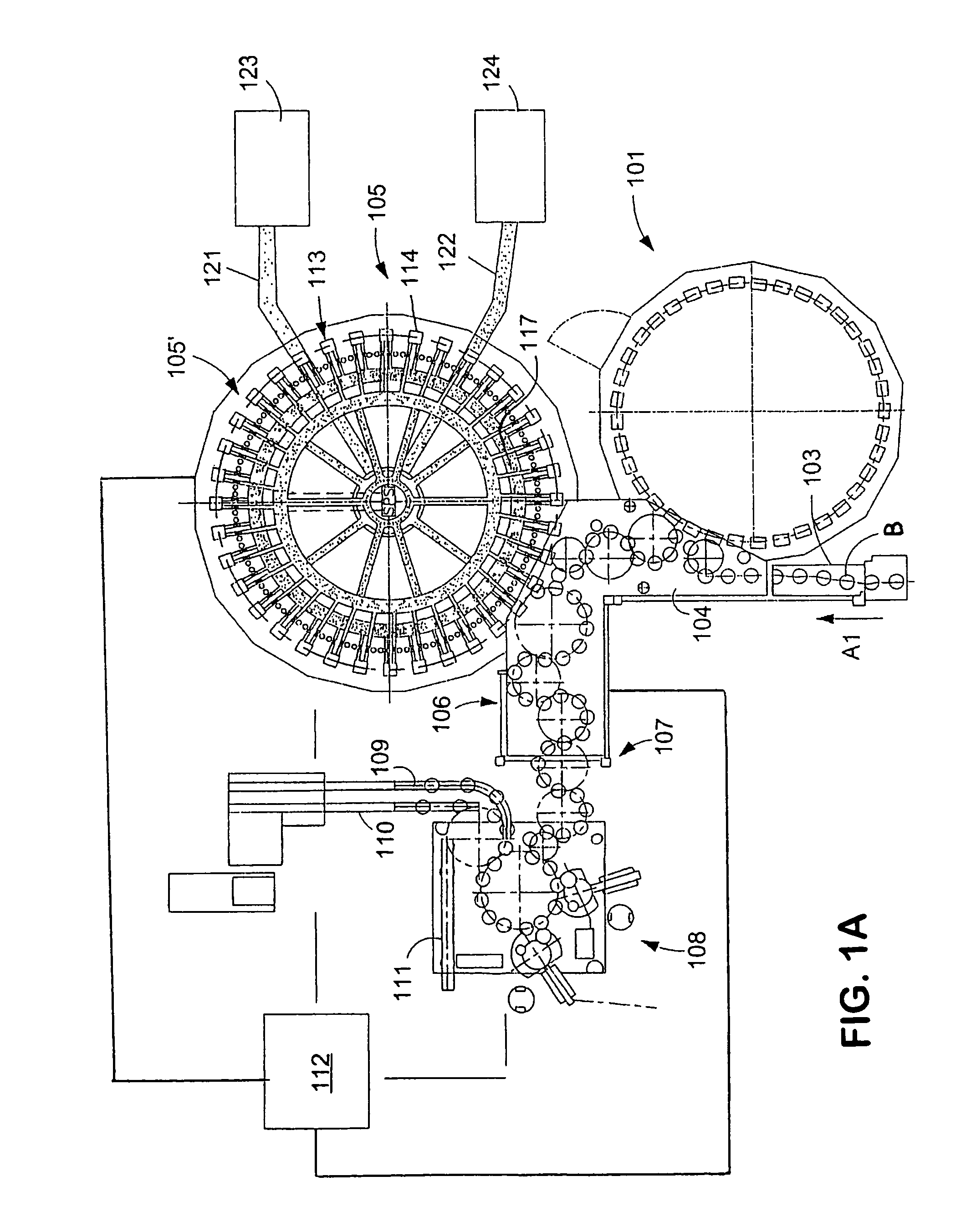

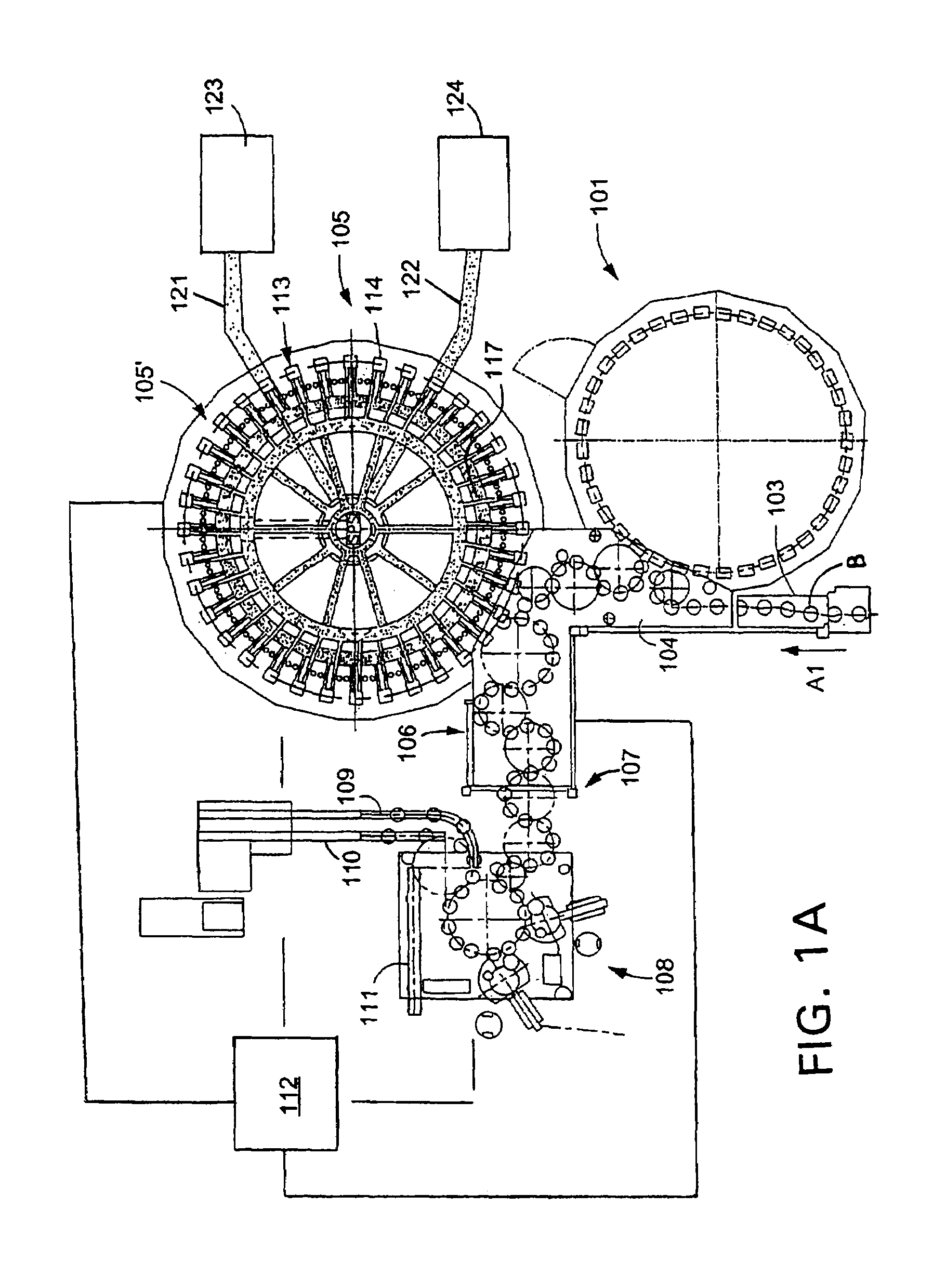

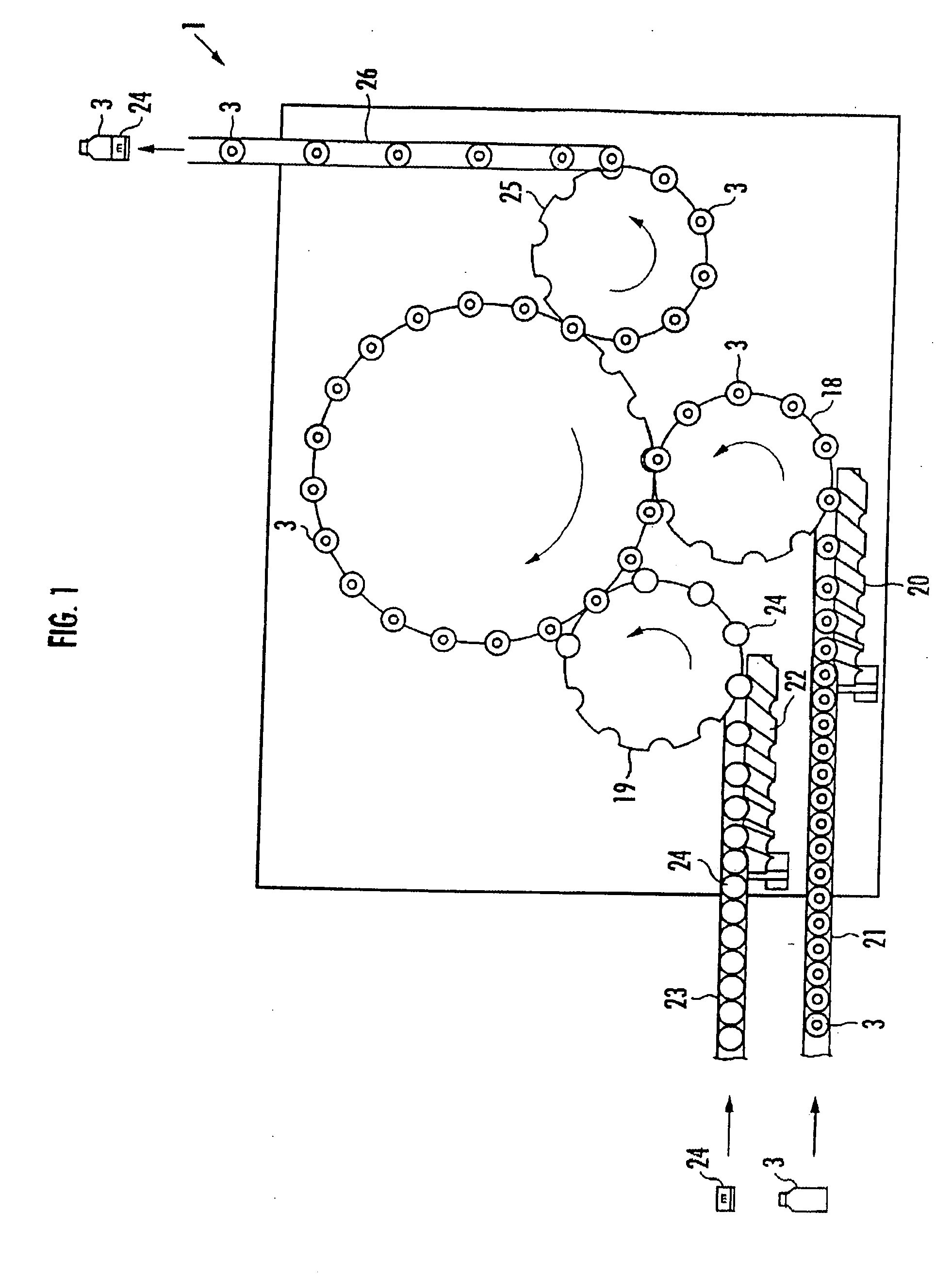

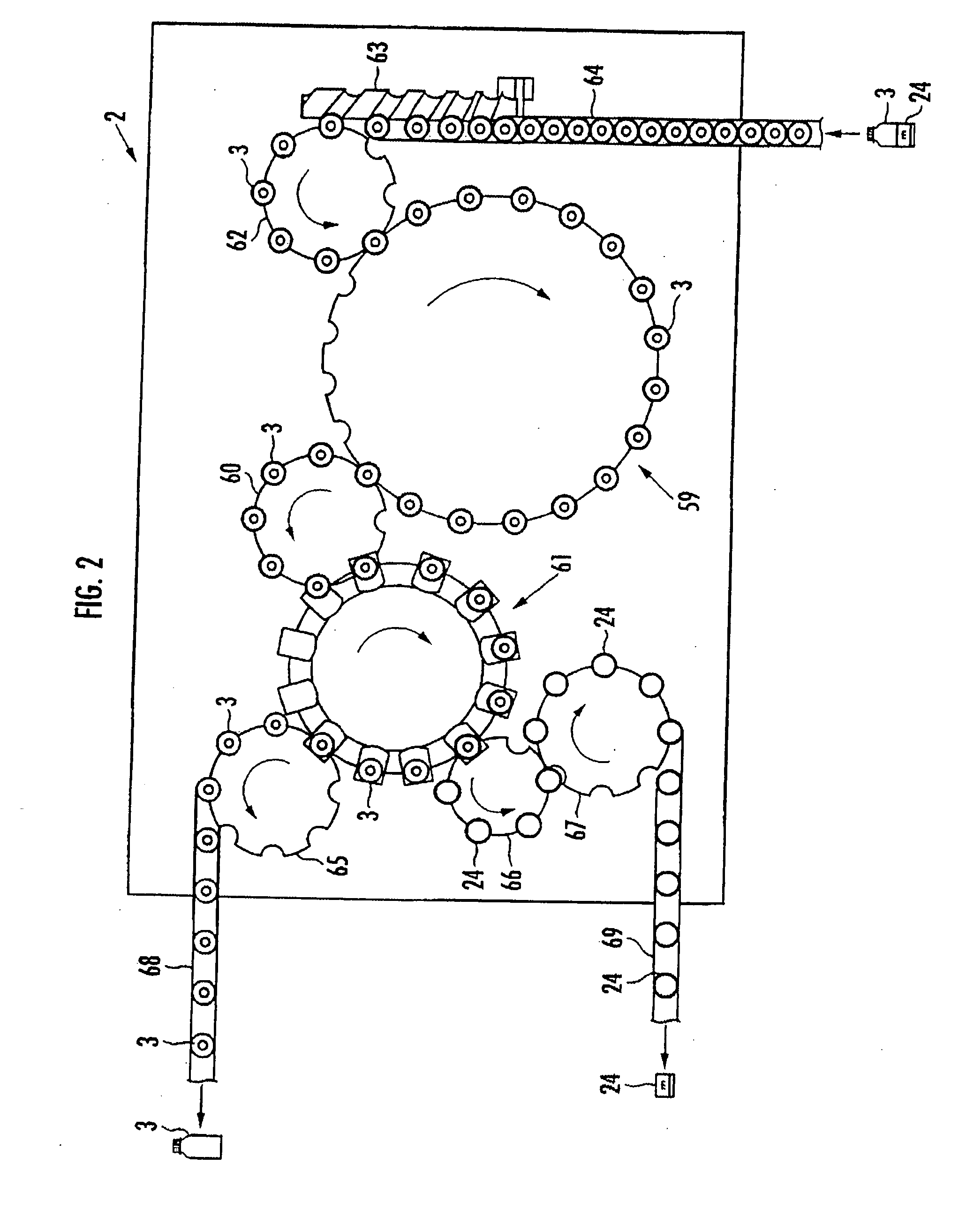

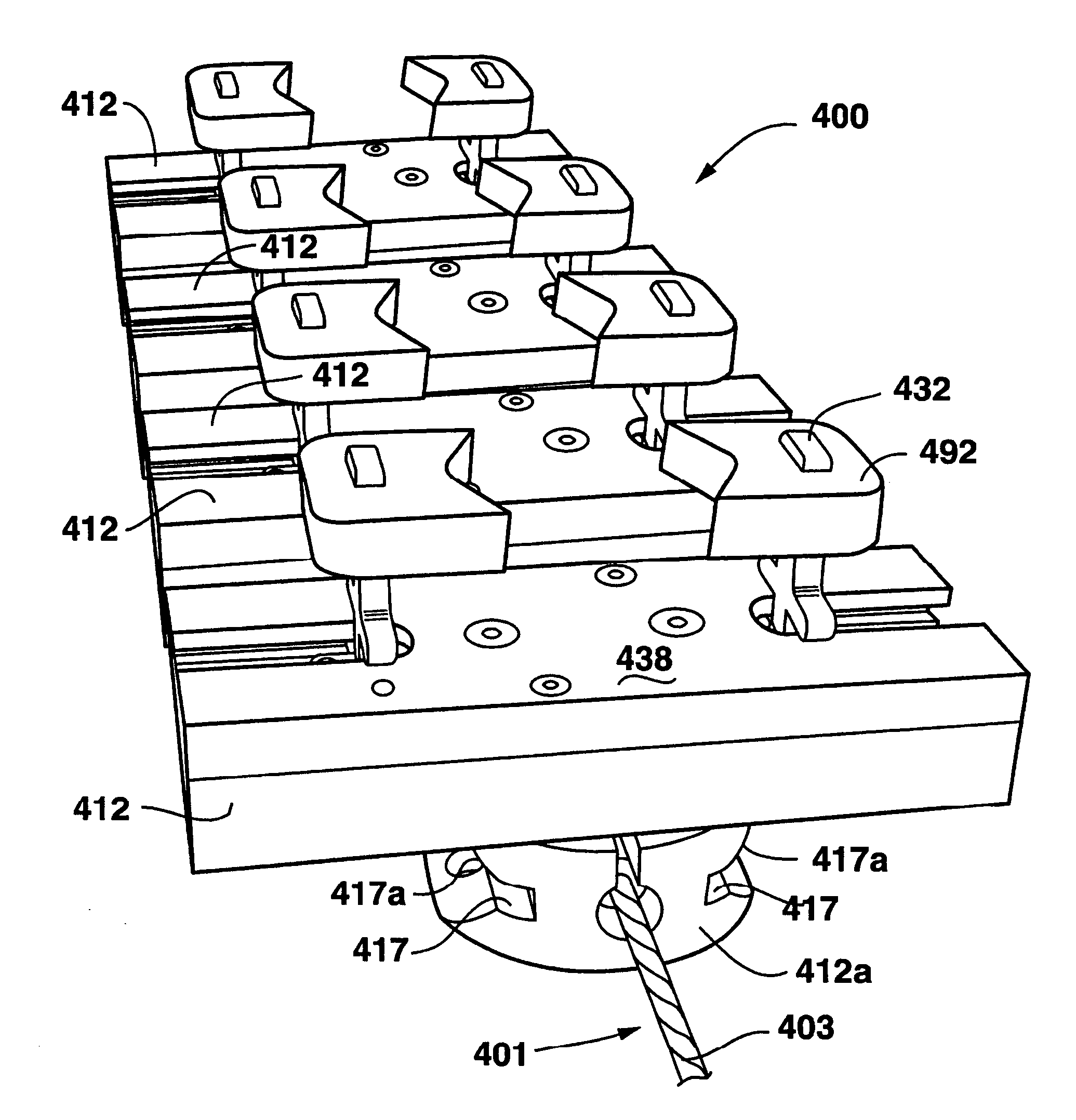

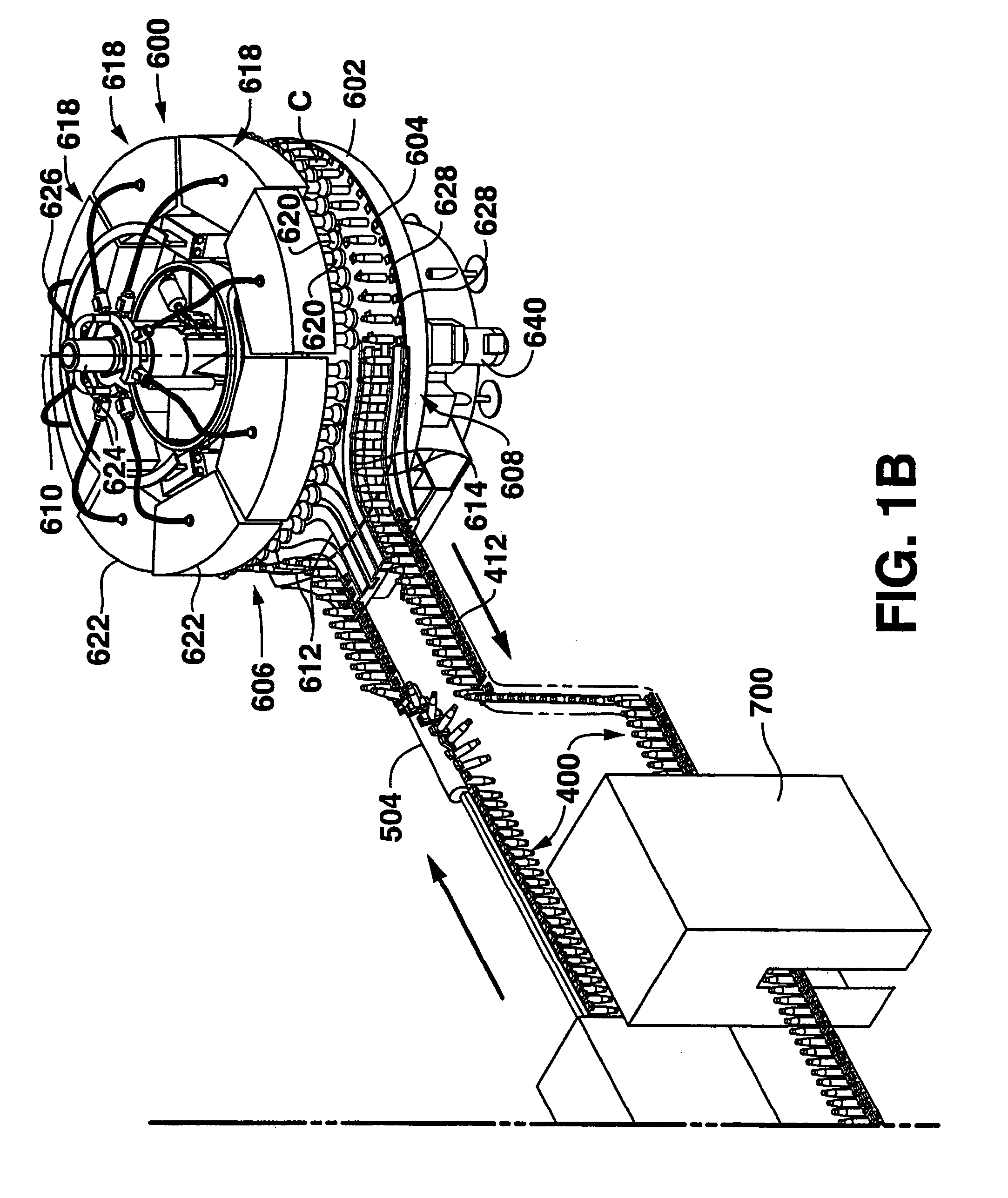

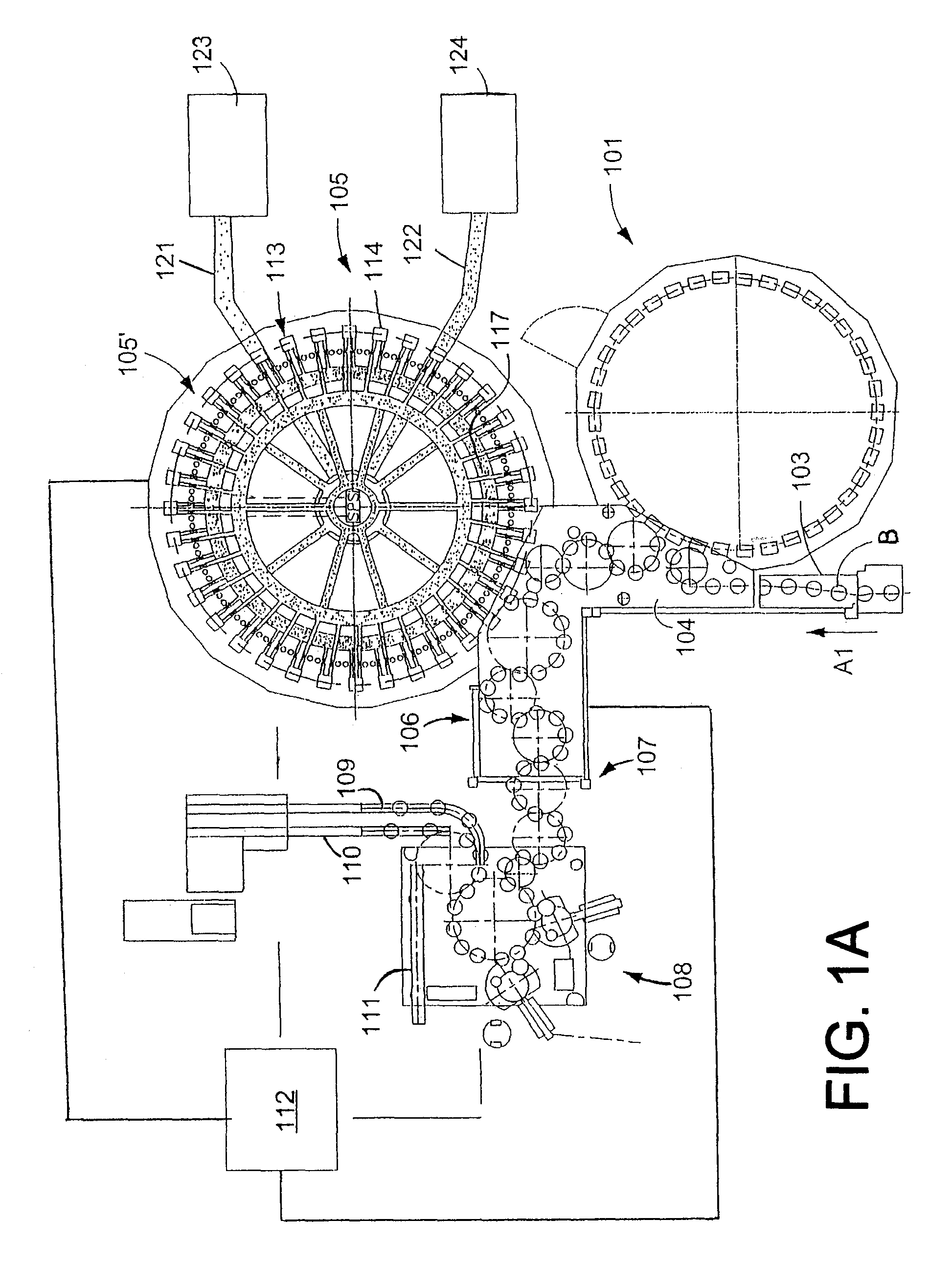

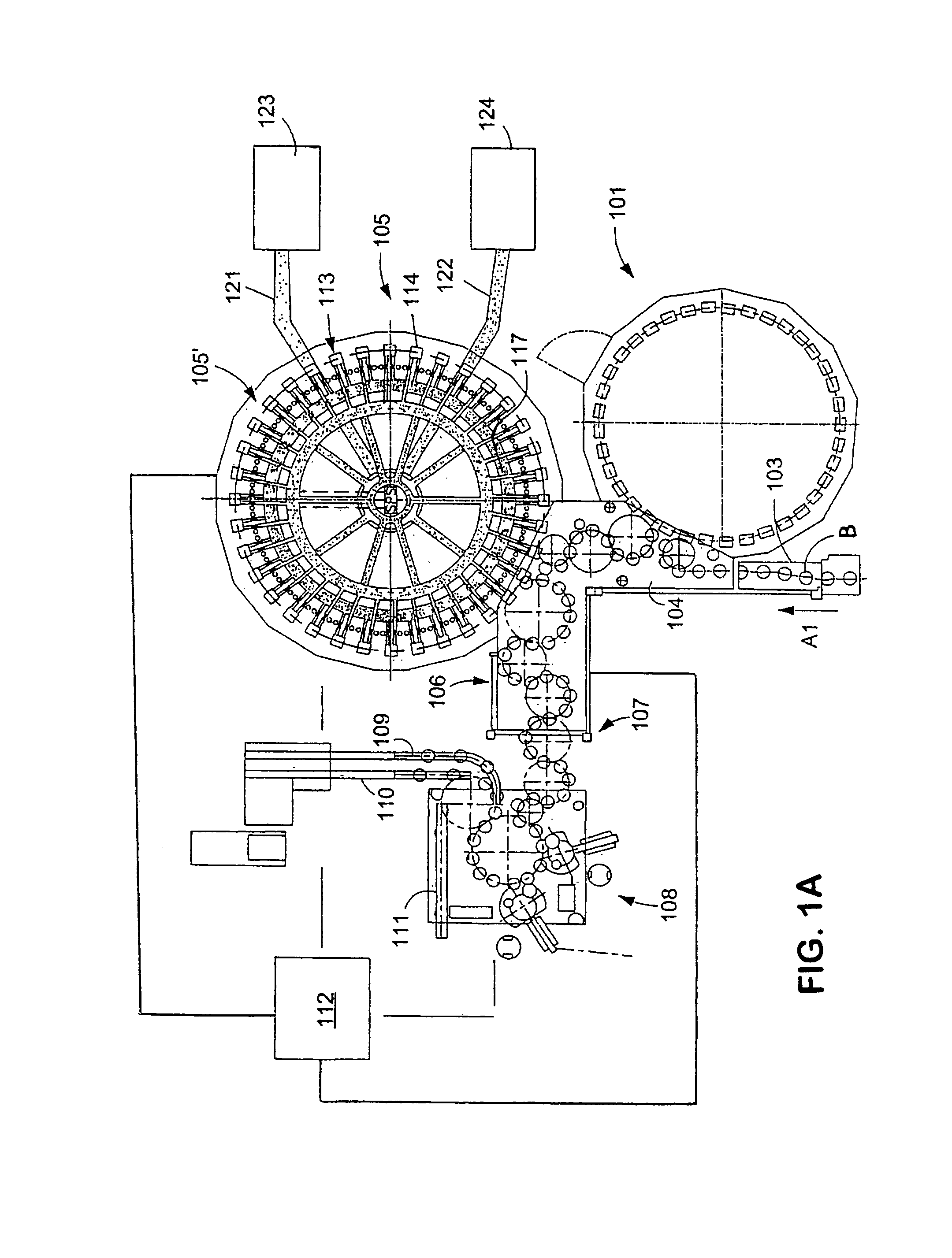

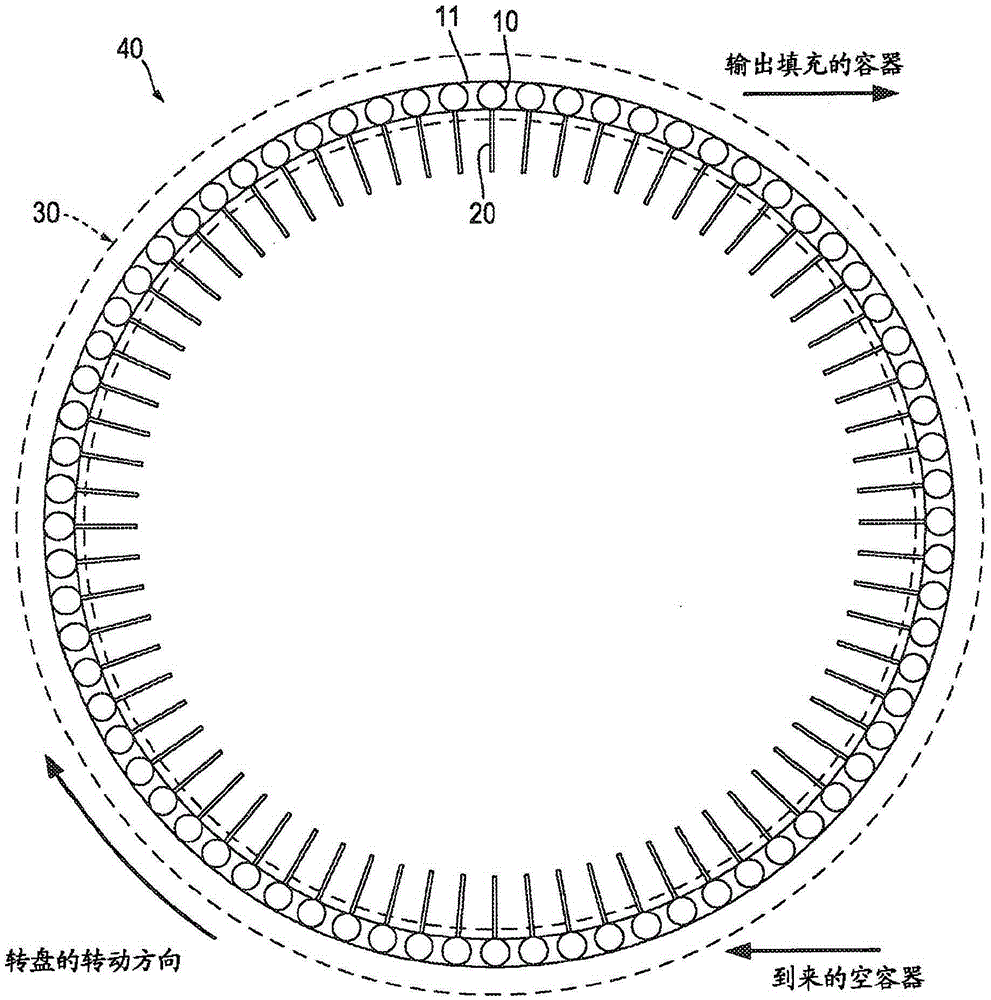

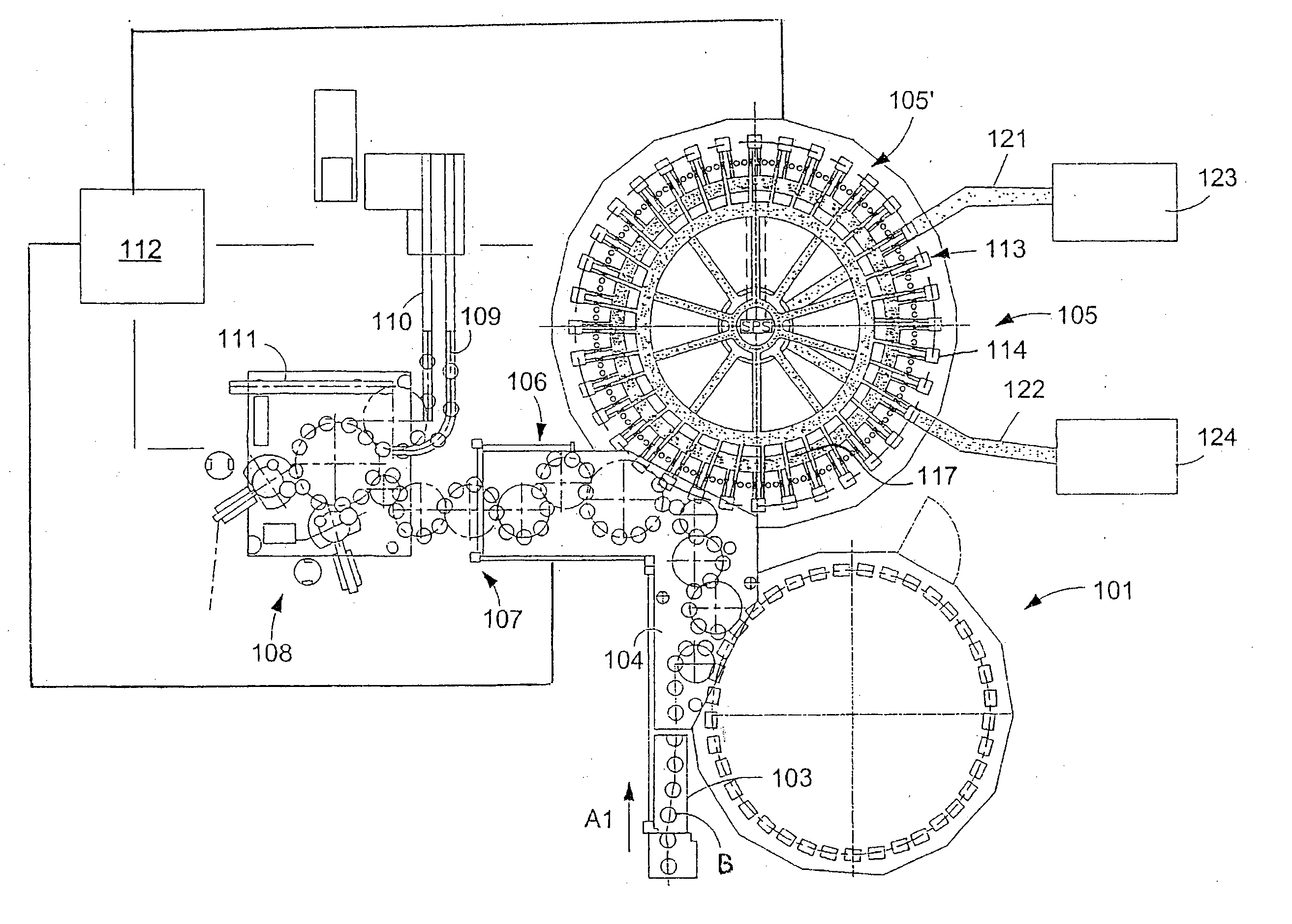

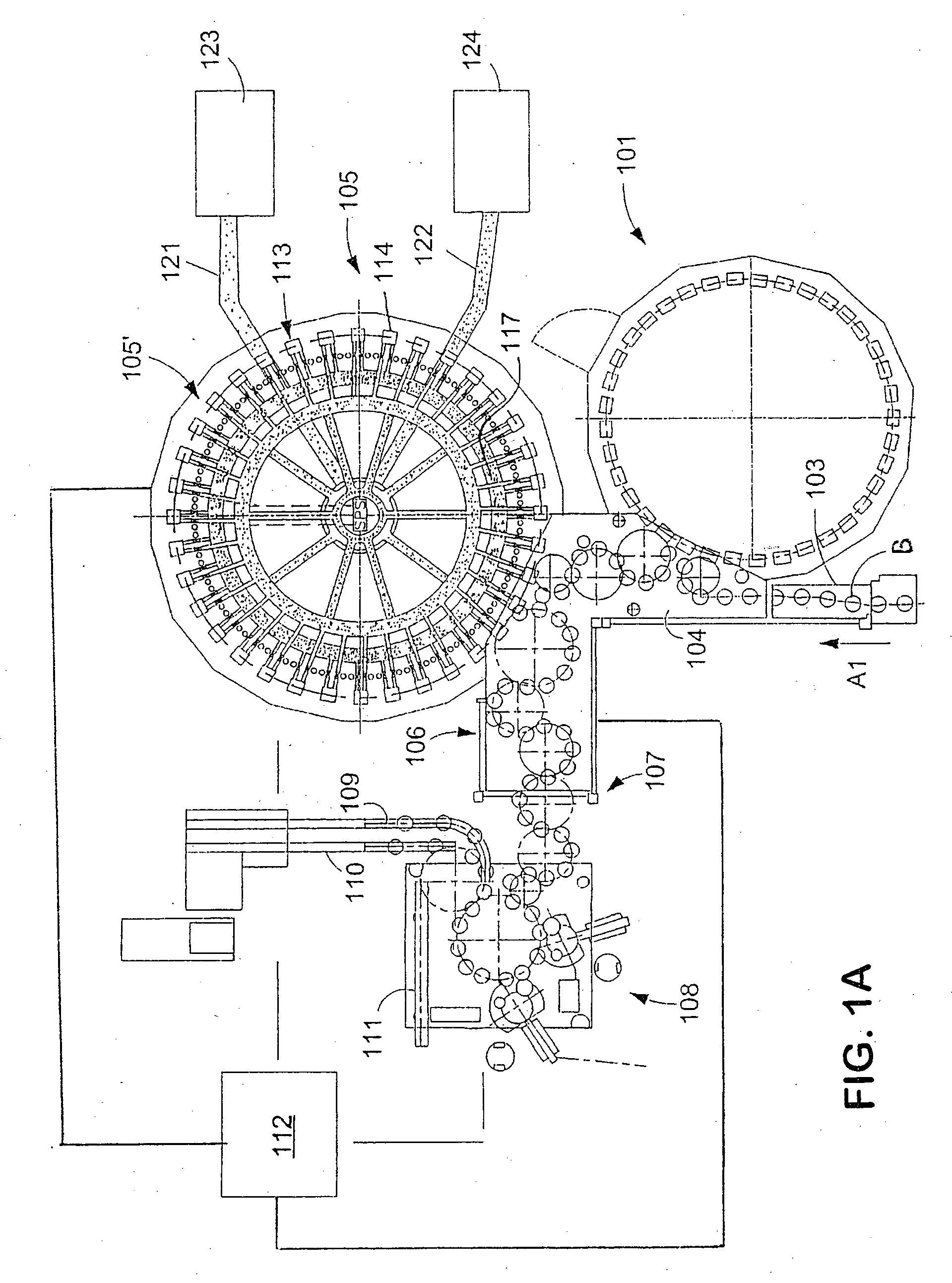

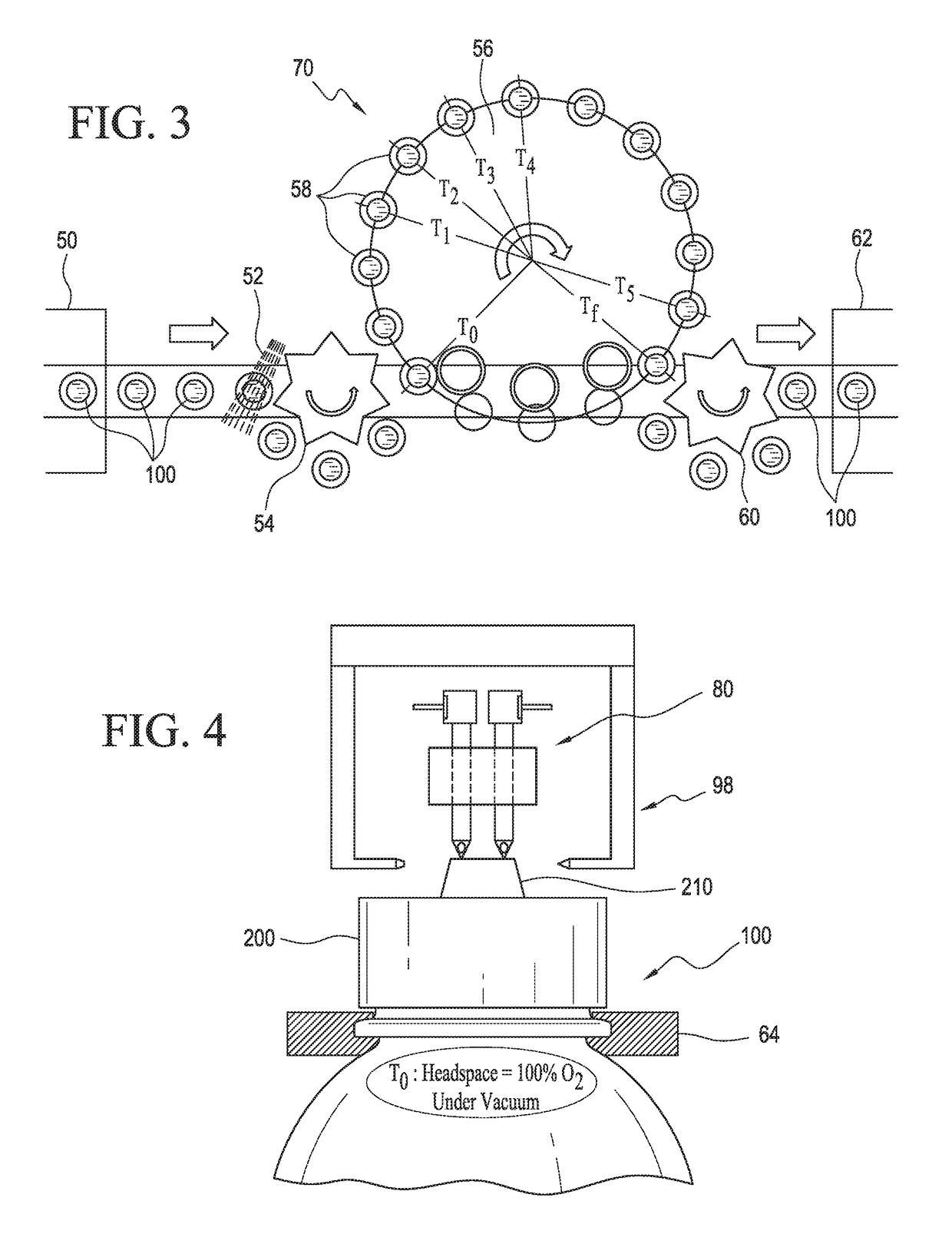

Neck gripping conveyor and link, and related rotary filler and system

InactiveUS20050284731A1Synchronising machinesFilling using counterpressureMechanical engineeringDelivery system

A conveyor is disclosed suitable for conveying objects such as containers to a processing station. The conveyor includes a plurality of connected links, and at least one gripping member extending from each of the links. Each gripping member is movable relative to its respective link for gripping a container by the neck of the container. A guide structure is disposed on the link for mating a component of the processing station to the neck of the container for processing the container. The processing station may be a filler such as a rotary filler, a capper, or a rinser. Related individual links, conveying systems, and filler components are also disclosed.

Owner:ILLINOIS TOOL WORKS INC

Beverage bottling plant with a beverage bottle filling machine for filling beverage bottles, and filling elements for the beverage bottle filling machine

ActiveUS7647950B2Easy constructionPromoting orFilling using counterpressurePackaging under special atmospheric conditionsEngineeringBottle

Owner:KHS GMBH

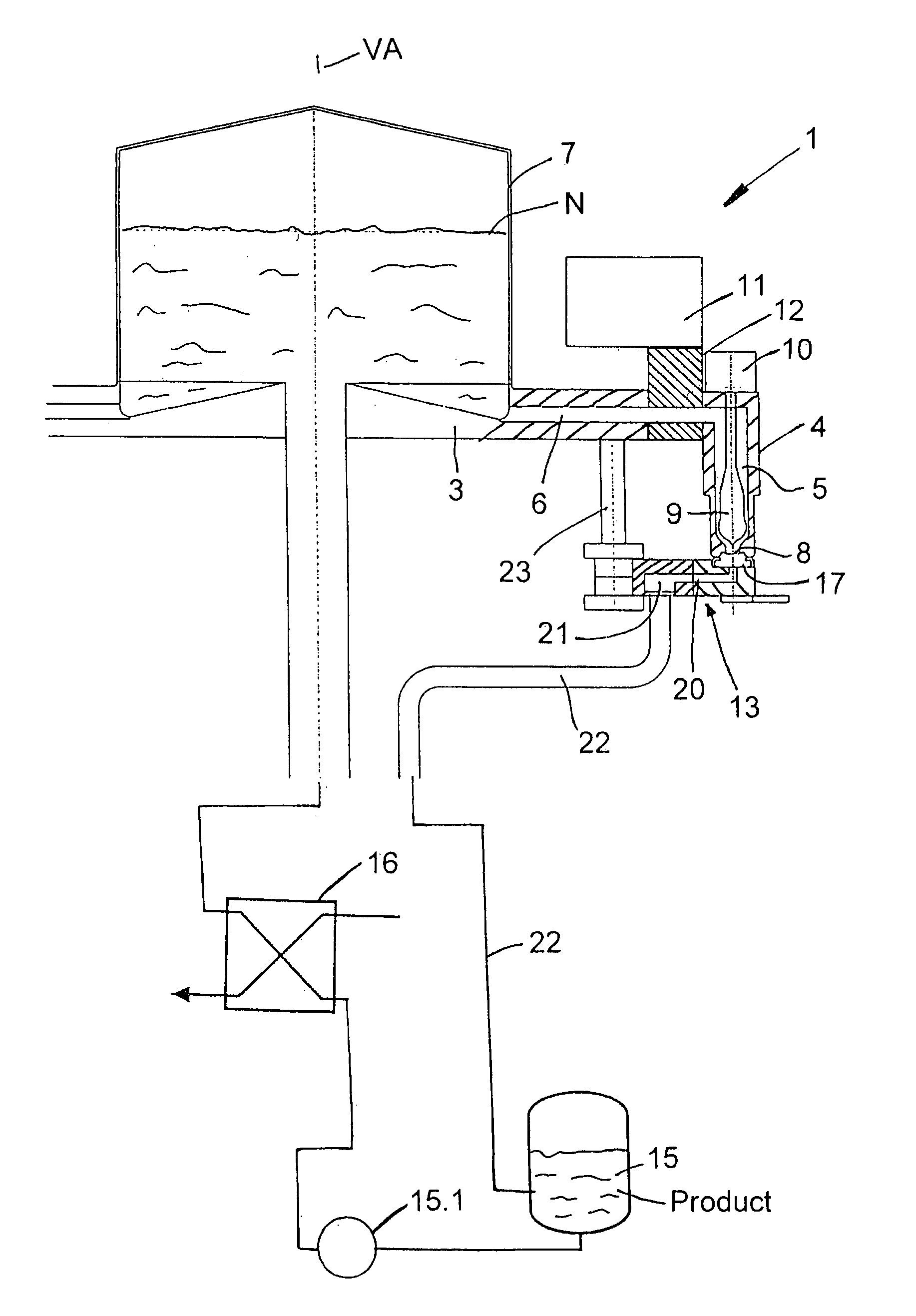

Beverage bottling plant for filling bottles with a liquid beverage filling material having a filling device and a filling machine having such a filling device

ActiveUS7353848B2Reduce manufacturing costFilling using counterpressureFilling without pressureFilling materialsTrademark

A beverage bottling plant for filling bottles with a liquid beverage filling material having a filling device and a filling machine having such a filling device. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

Filling apparatus and filling method therefor

A filling apparatus 1 comprises a gas passage 14 connected to a storage tank 31 via a connection passage 14a, a first gas valve 35 that opens and closes the gas passage, a pressure gas passage 41 connected to a pressure gas supply source, a pressure gas valve 42 that opens and closes the pressure gas passage, an exhaust passage 43 that allows an interior of a container 4 to communicate with an exterior thereof, and an exhaust valve 44 that opens and closes the exhaust passage. With this filling apparatus, before a pressurized filling operation, both the gas passage and the pressure gas passage are opened to pressurize the interior of the container with a carbonated gas supplied through both passages. Further, also before a unpressurized filling operation, both the gas passage and the pressure gas passage are opened to perform a flushing operation in which droplets are discharged from the gas passage with air exhausted from the container into the storage tank via the gas passage. Then, after the filling operation, both the gas passage and the exhaust passage are opened to discharge a certain amount of filling liquid remaining in the gas passage, into the container.

Owner:SHIBUYA IND CO LTD

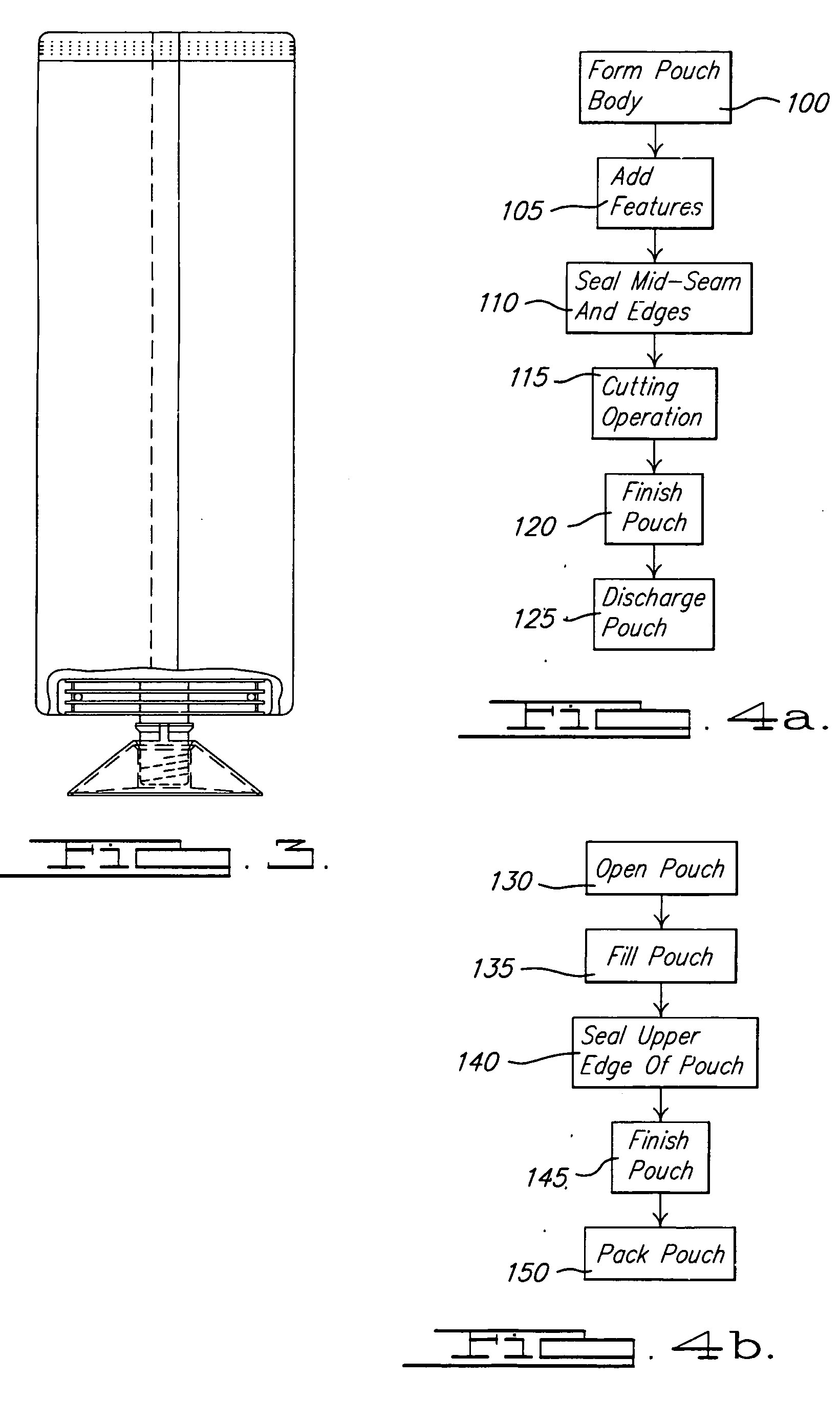

Apparatus and method of filling a flexible pouch with extended shelf life

InactiveUS20090095369A1Increased cost-effectivenessAvoids excessive film creepageEnvelopes/bags making machineryBag making operationsPasteurizationShelf life

A compact apparatus and method for filling a flexible pouch having an extended shelf life is provided. The machine includes a frame, a transport means disposed on the frame for transporting a pouch holder containing the flexible pouch. The machine also includes a receiving station for placing the pouch into the pouch holder, and an opening station for opening the pouch to separate the walls of the pouch, a filling station for filling the pouch and a closing station for closing the filled pouch. The machine further includes a pasteurization station. The flexible pouch includes a panel having an upper edge, an opposed lower edge and a first side edge and a second side edge extending therebetween the upper edge and the lower edge, the upper edges are sealed along an upper seam and a fitment opening means is disposed in the upper seam for accessing the product.

Owner:POUCH PAC INNOVATIONS

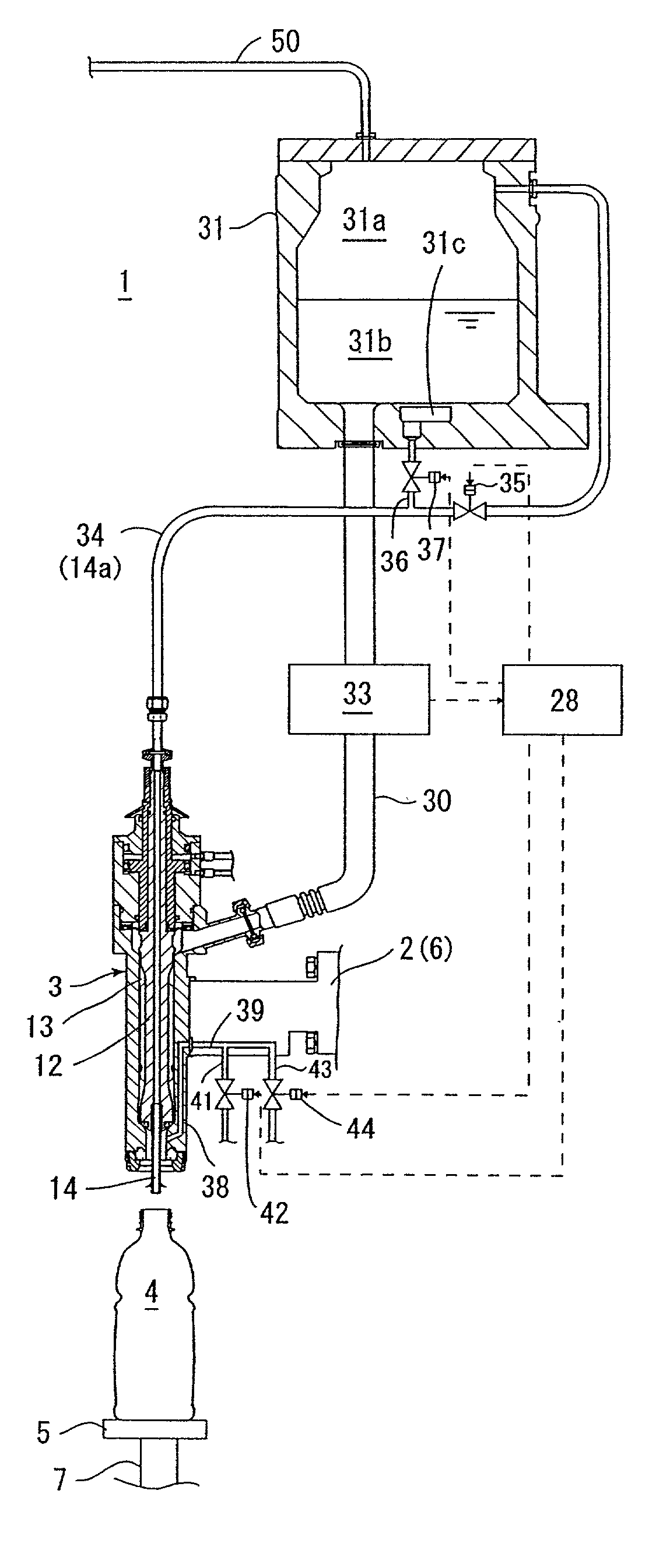

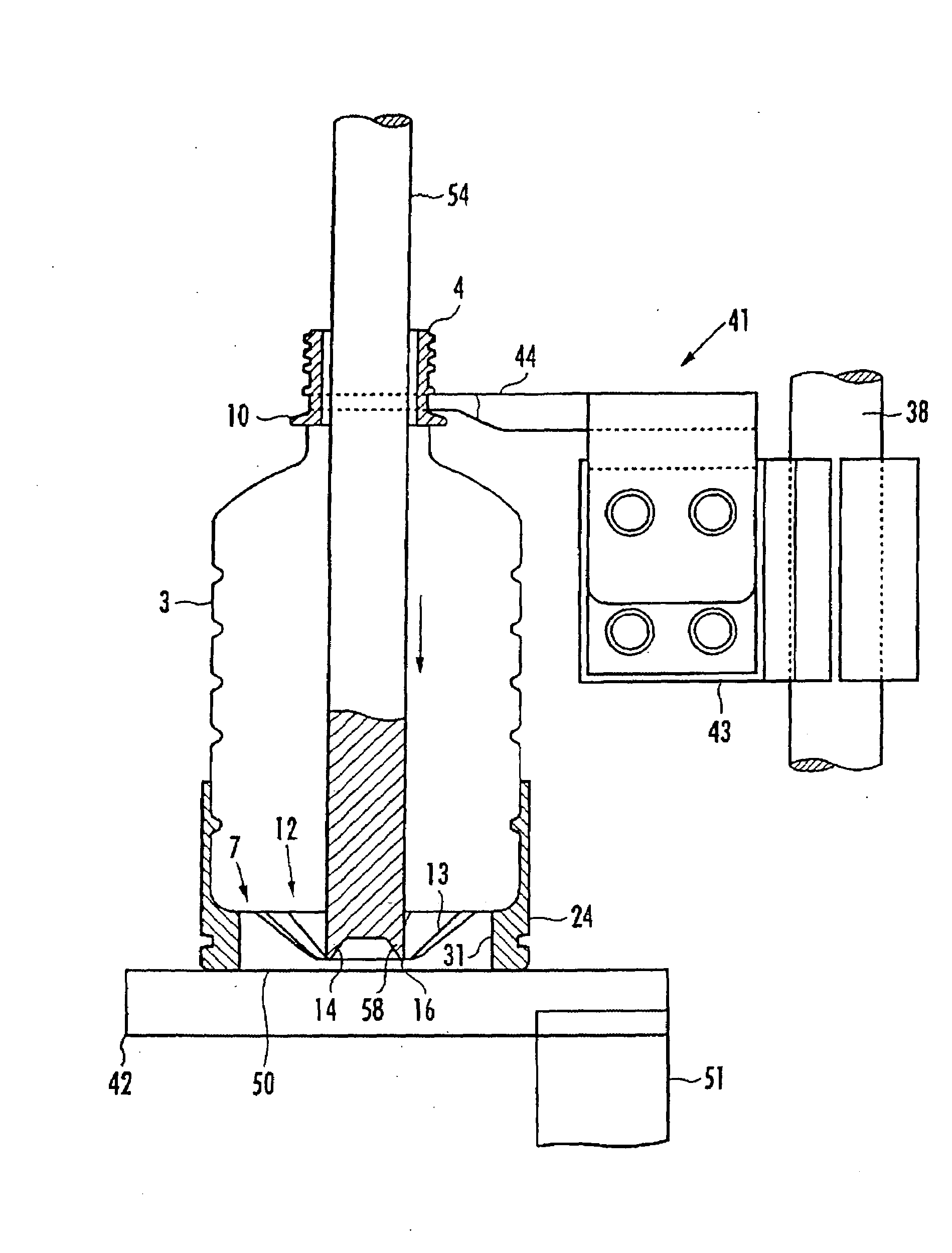

Method and Device for Manufacturing Content-Filled Bottle

InactiveUS20090218003A1High strengthWithout adversely affecting product quality of bottleFilling using counterpressureSolid materialBottlePressure reduction

A method and device for manufacturing a content-filled bottle having an inversion part at its bottom. In producing the bottle, the inversion part is inverted to prevent deformation of a body part caused by a pressure reduction in the bottle, and as a result, inappropriate deformation and buckling of the bottle are prevented, enabling efficient manufacturing of the bottle with high quality. The bottle (3) is held from the outside by an empty-bottle chuck (41) of auxiliary device mounting means in such a way that the bottle (3) is held at its a mouth part (4) by the chuck along the upper surface of a flange part (10) of the bottle (3). Next, an empty-bottle support table (42) on which an assistance device (24) is placed is raised, the assistance device (24) is mounted on a bottom part (7) of the bottle (3), and the bottle (3) is placed on the empty-bottle support table (42). After that, with the empty bottle (3) held positioned by the empty-bottle chuck (41) and the empty-bottle support table (42), the inversion part (12) is projected to the outside of the body part (6) by a push-down member (54) of bottom projecting means. Then, the bottle (3) is filled with contents and sealed by a cap. The inverted part (12) is recessed into the body part (6), and the assistance device (24) is separated from the bottle (3).

Owner:HOKKAN HLDG

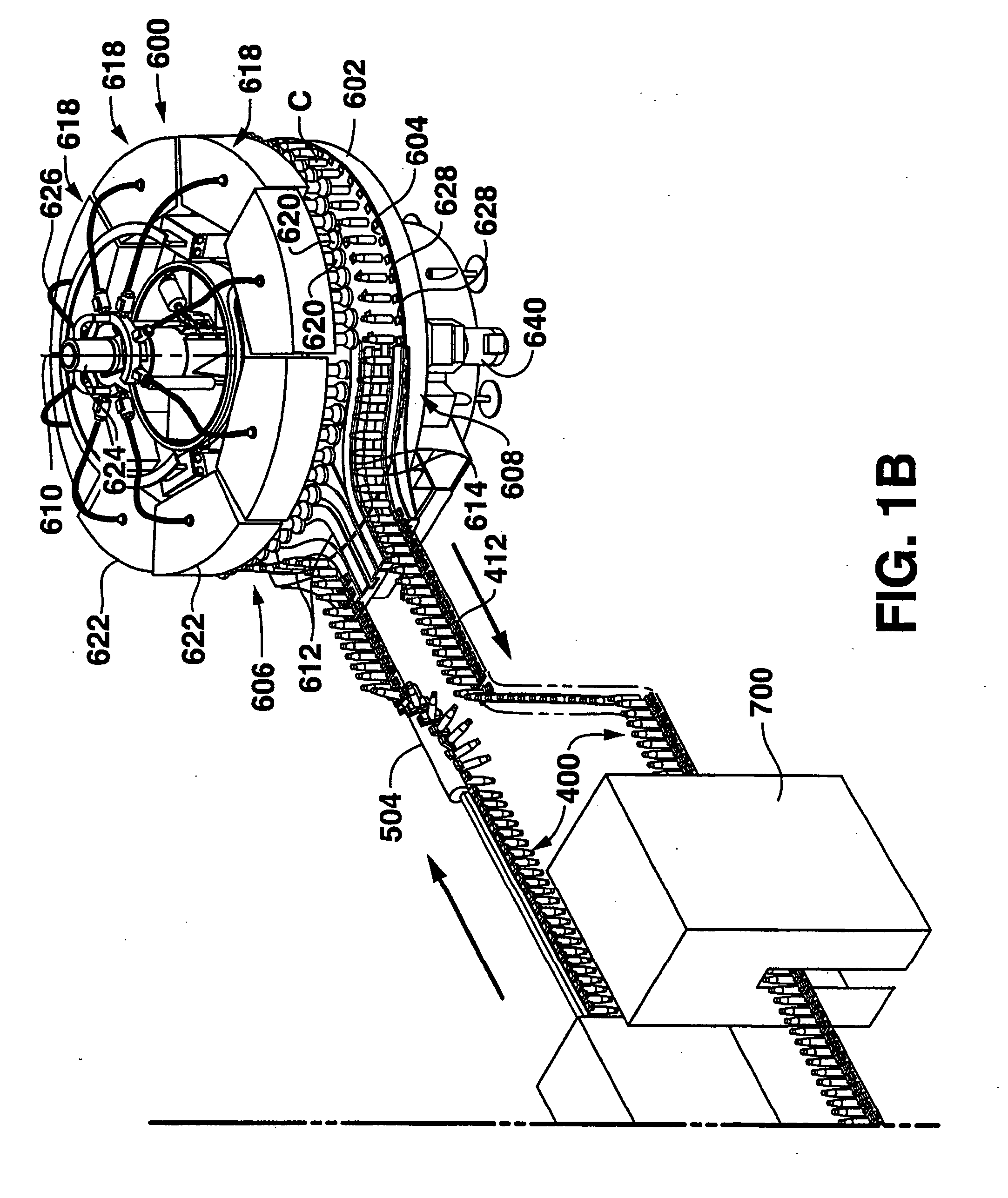

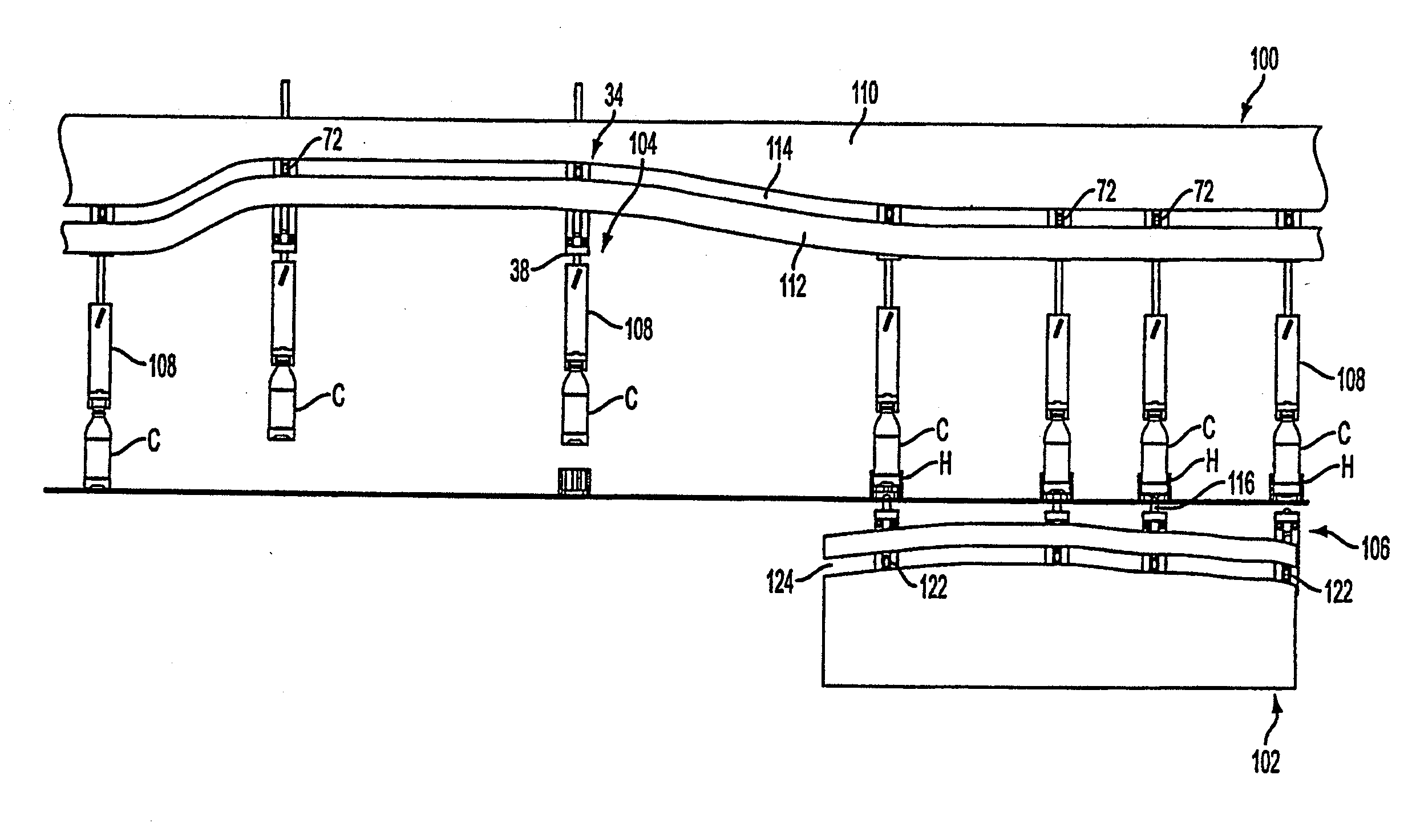

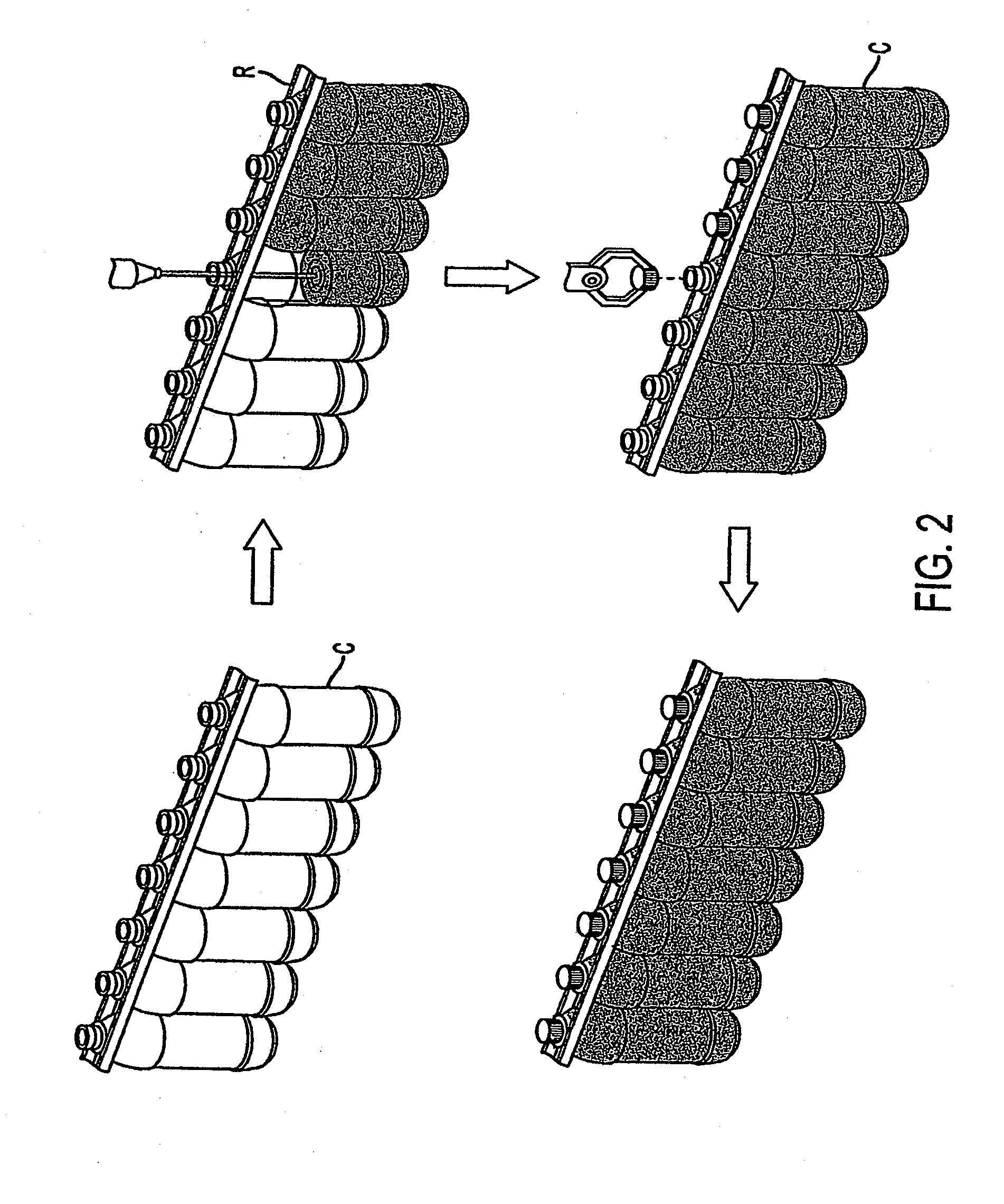

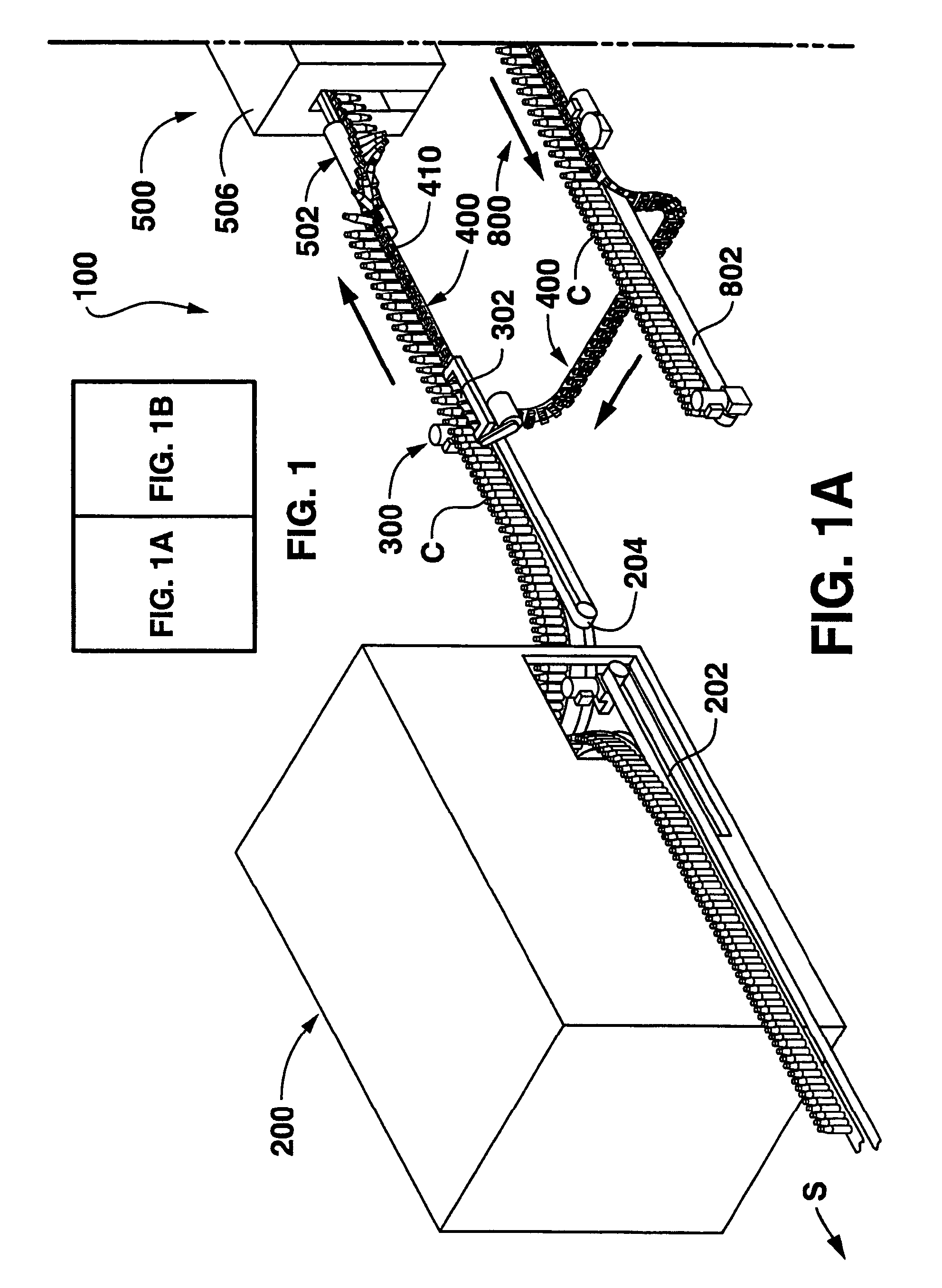

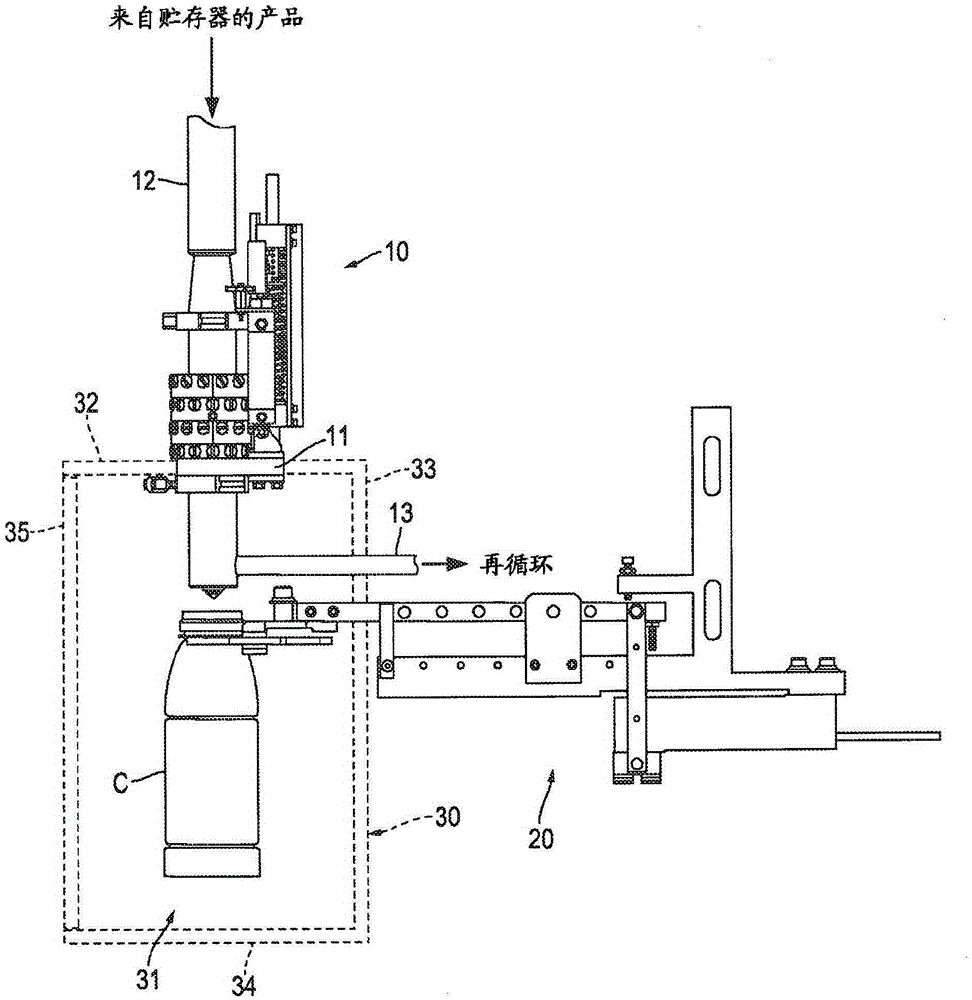

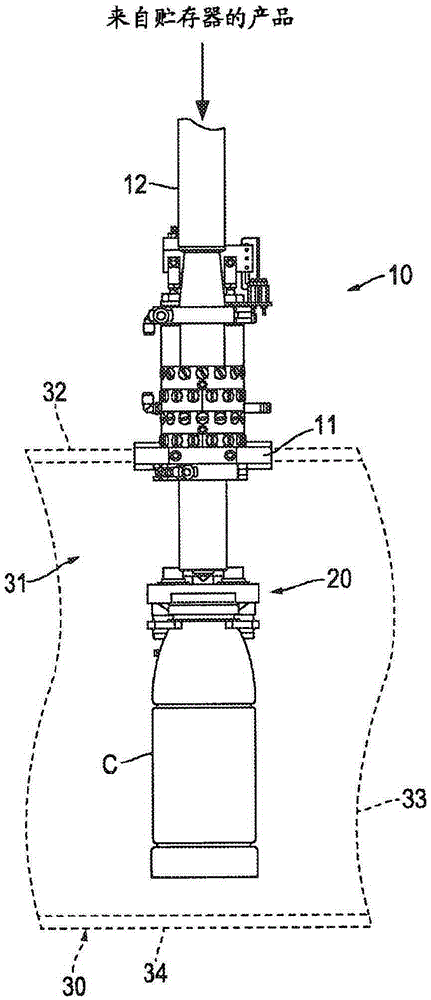

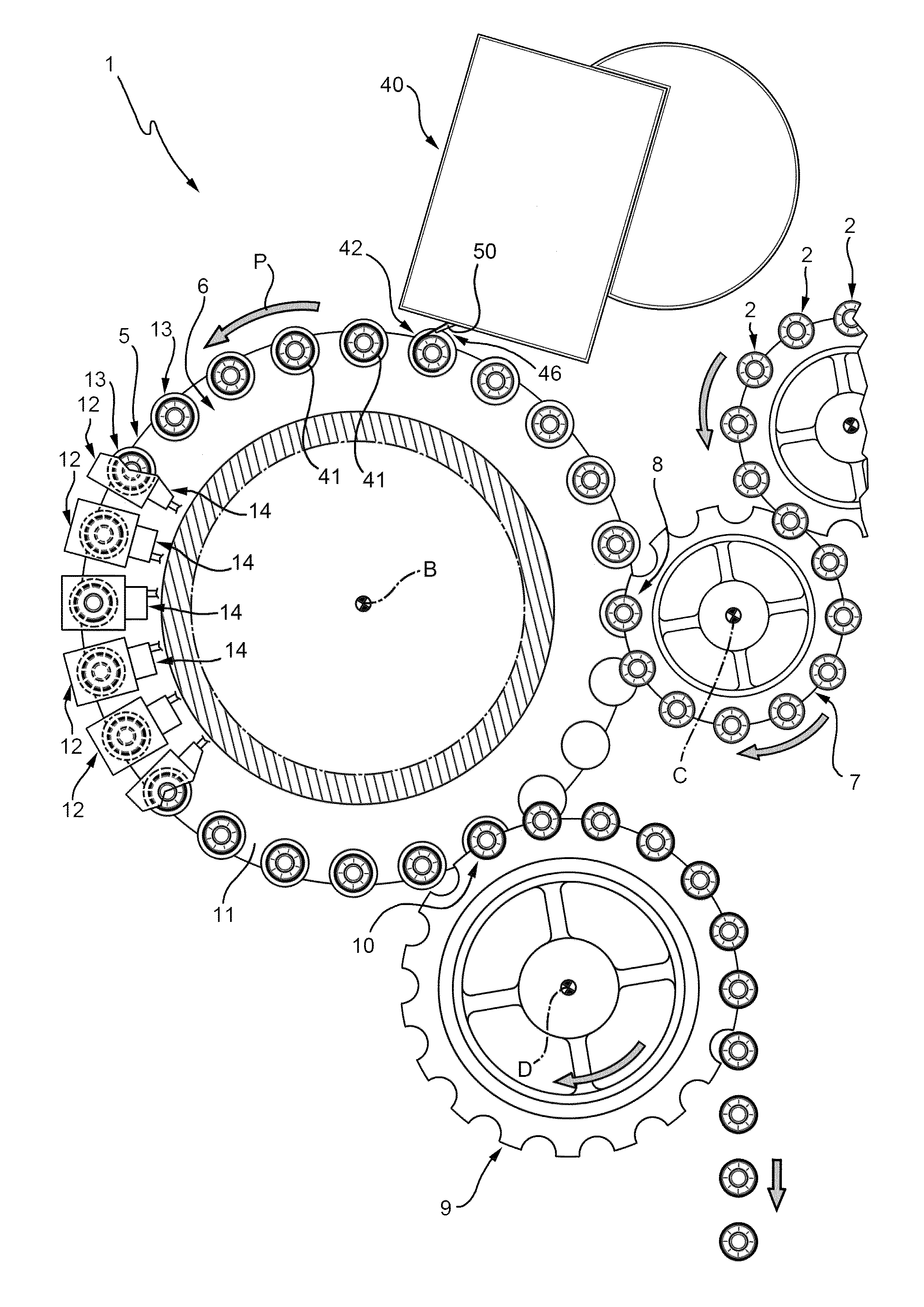

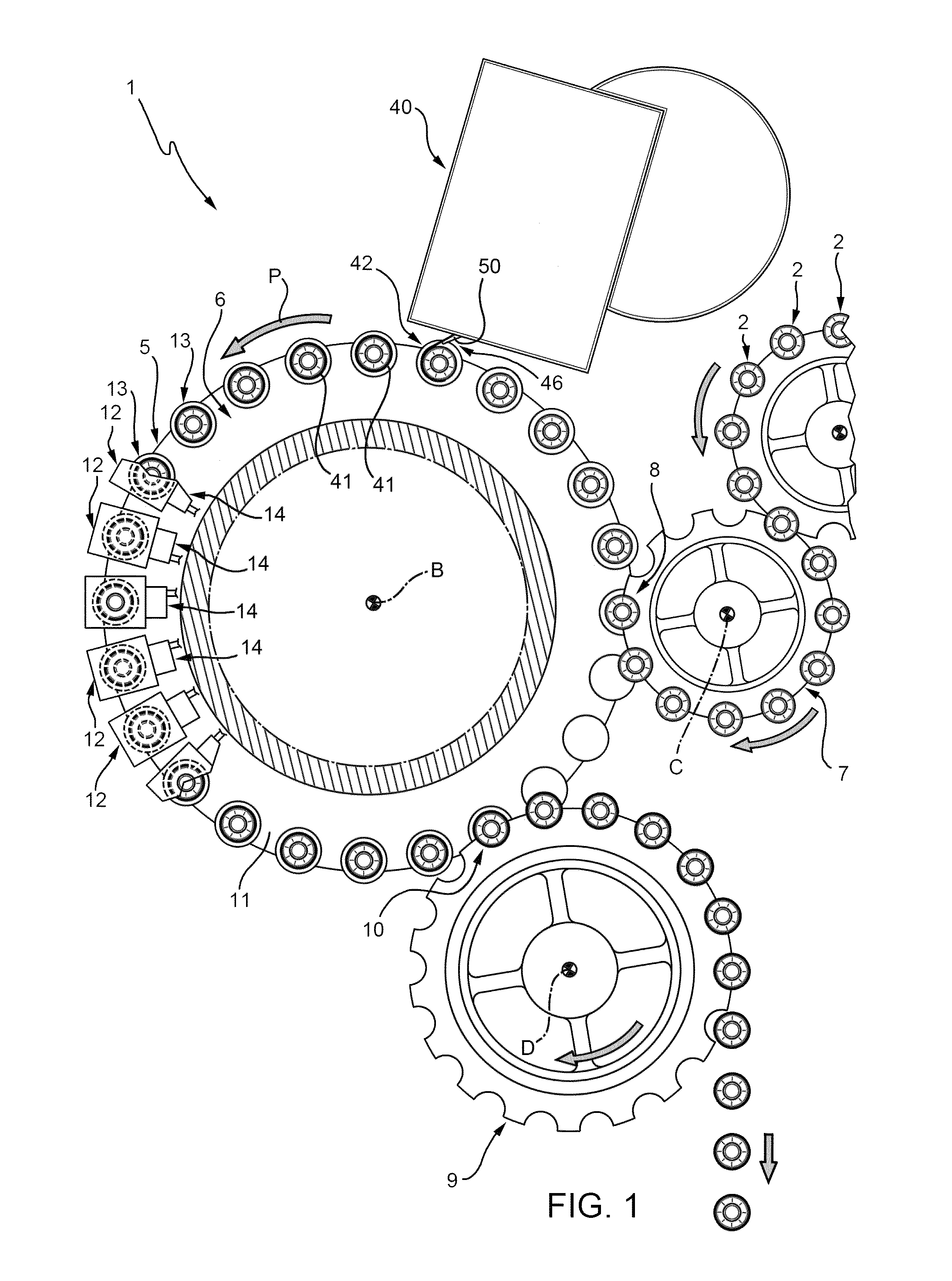

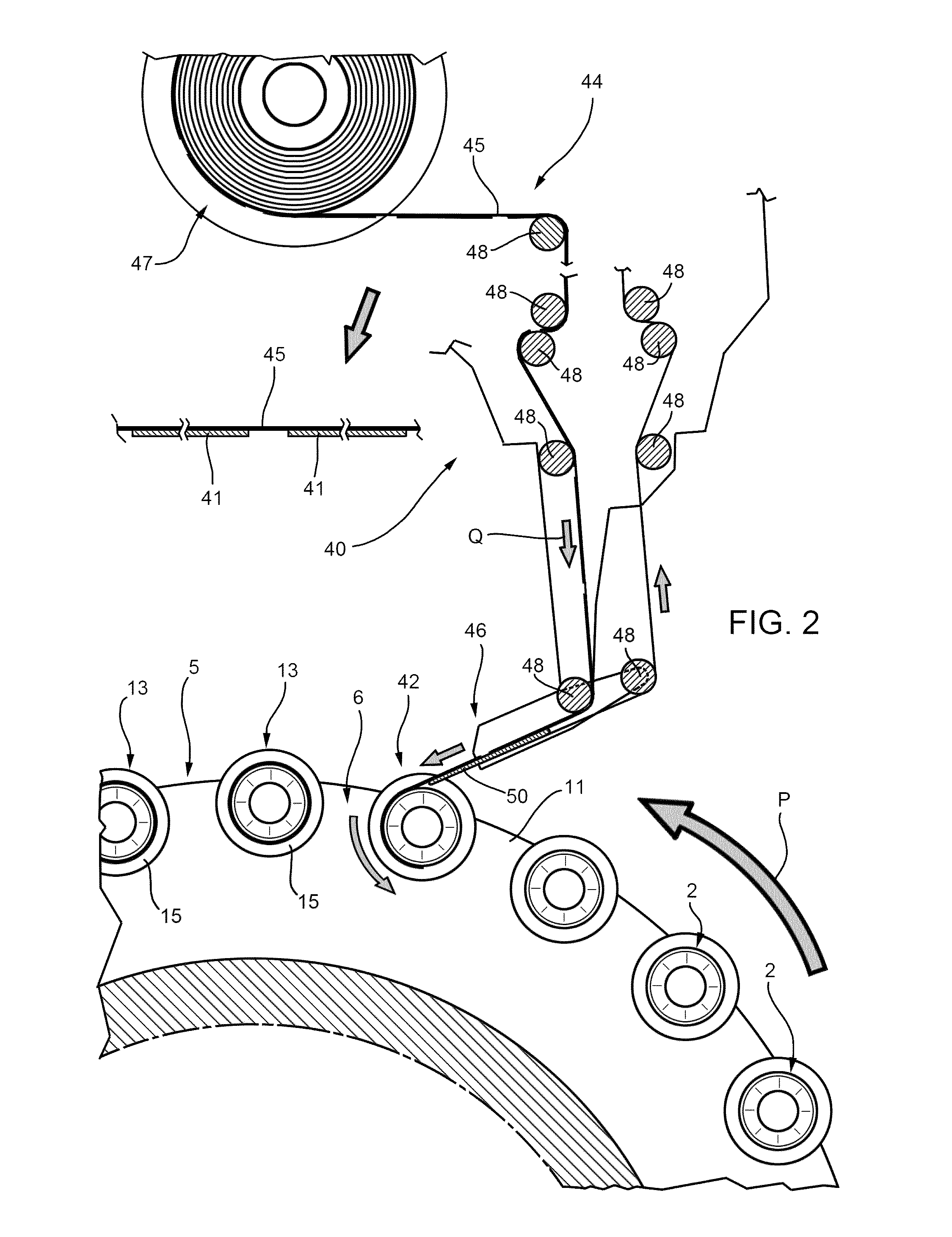

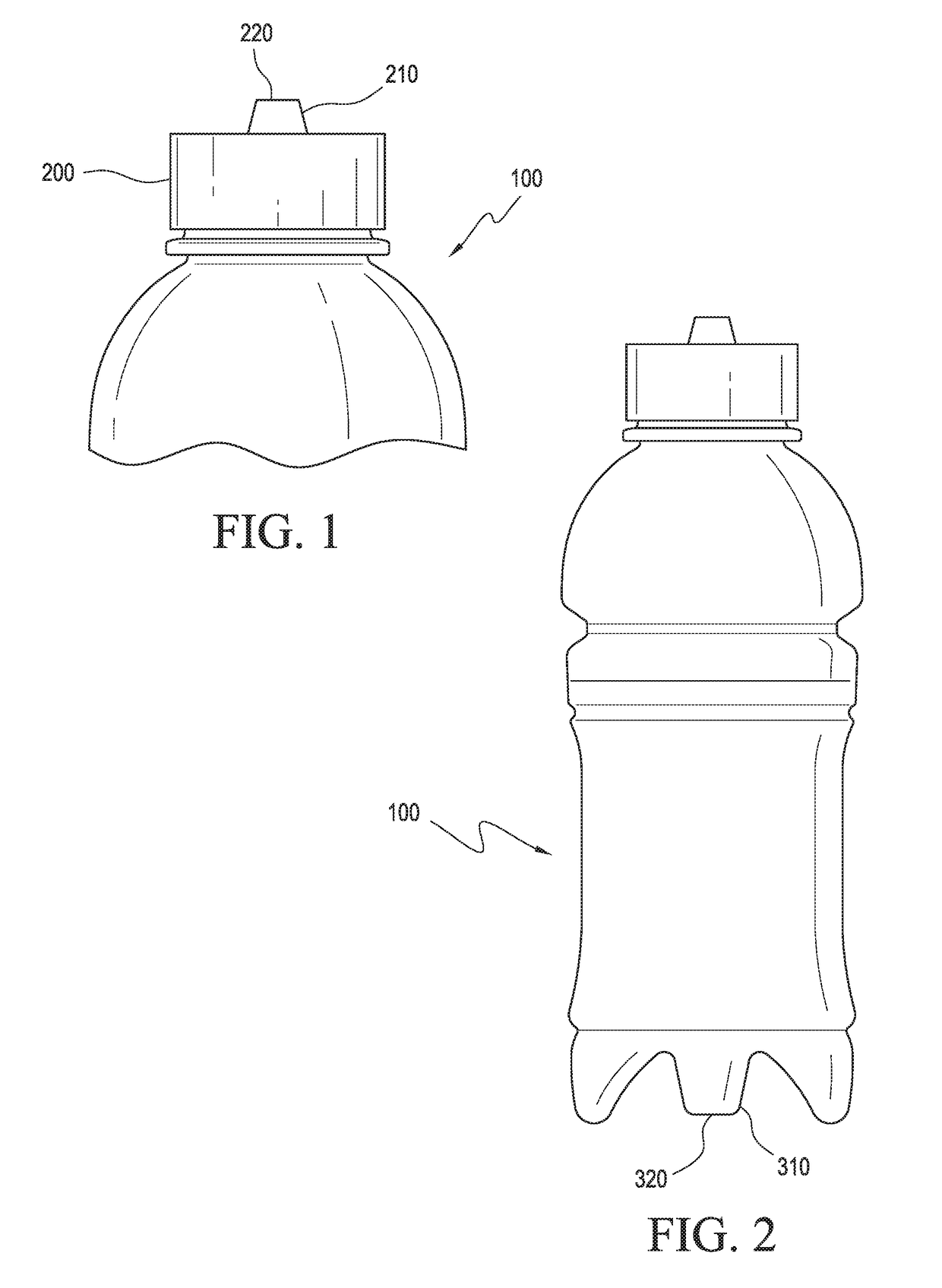

Container Handling System

ActiveUS20090120530A1Smooth for label placementThorough removalSynchronising machinesFilling using counterpressureBlow moldingStructural geometry

A system for processing a simplified plastic container (C) that is to be filled with a hot product includes the step of blow-molding parison to form a container body, where the container body has a neck, a base, a side surface relatively free of structural geometry that surrounds an interior of the container body and, prior to being filled with the hot product, a projection (12) extending from the container body. After the container body is filled with a hot product in a production line, the neck of the filled container body is capped with a cap and then, the container body is cooled. During the cooling operation, the hot product is contracted so that the projection extending from the container can be pushed (P) into the container body like a traditional push-up so that the resultant, filled and cooled container body is relatively free of structural geometry.

Owner:CO2 PAC

Neck gripping conveyor and link, and related rotary filler and system

InactiveUS7261199B2Synchronising machinesFilling using counterpressureEngineeringMechanical engineering

A conveyor is disclosed suitable for conveying objects such as containers to a processing station. The conveyor includes a plurality of connected links, and at least one gripping member extending from each of the links. Each gripping member is movable relative to its respective link for gripping a container by the neck of the container. A guide structure is disposed on the link for mating a component of the processing station to the neck of the container for processing the container. The processing station may be a filler such as a rotary filler, a capper, or a rinser. Related individual links, conveying systems, and filler components are also disclosed.

Owner:ILLINOIS TOOL WORKS INC

Beverage bottling plant for filling containers, such as bottles and cans, with a liquid beverage, a filling machine for filling containers with a liquid, and a method for filling containers with the filling machine

A method for hot bottling of a liquid in bottles, kegs or similar containers using a filling machine that has a plurality of filling elements, each filling element has a liquid duct disposed at a dispensing opening and a valve for dispensing the hot liquid to the container, the liquid being bottled in the filling elements is substantially continuously conveyed in the hot condition in a circuit comprising a flow path that includes the filling elements and the liquid ducts from a source for the hot liquid being bottled to a reservoir during an interruption of the filling process in order to reduce the cooling of the liquid being bottled in the filling elements and / or to prevent the cooling of the filling elements.

Owner:KHS GMBH

Beverage bottling plant for filling bottles with a liquid beverage having a filling machine for filling bottles with a liquid beverage

ActiveUS7347231B2Filling using counterpressurePackaging under special atmospheric conditionsEngineeringBottle

Beverage bottling plant for filling bottles with a liquid beverage having a filling machine for filling bottles and other beverage containers with a liquid beverage. The filling machine having a gas tube being configured and disposed to permit evacuation of gas from a beverage bottle to a chamber of a return gas duct without the gas contacting liquid beverage material in a beverage storage reservoir to essentially prevent contamination of the liquid beverage material in said beverage storage reservoir by the gas being evacuated from the beverage bottle.

Owner:KHS GMBH

Container filling system and valve for same

ActiveCN105229353AFilling using suctionOperating means/releasing devices for valvesControl systemMechanical engineering

A container filling valve may include a shuttle and a drive sleeve that are magnetically coupled. Movement of the drive sleeve may move the shuttle from a position in which the filling valve is closed to a position in which the filling valve is open. A container handling arm may include a distal end configured to hold a container and a proximal end that includes a load cell. A low flow setpoint system may be configured to arrest closing of a filling valve when that filling valve is partially closed. A pressure control system may be configured to maintain a desired pressure in a reservoir or in a flow path from that reservoir. A product recirculation system may be configured to adjust flow rate in the product recirculation system.

Owner:PEPSICO INC

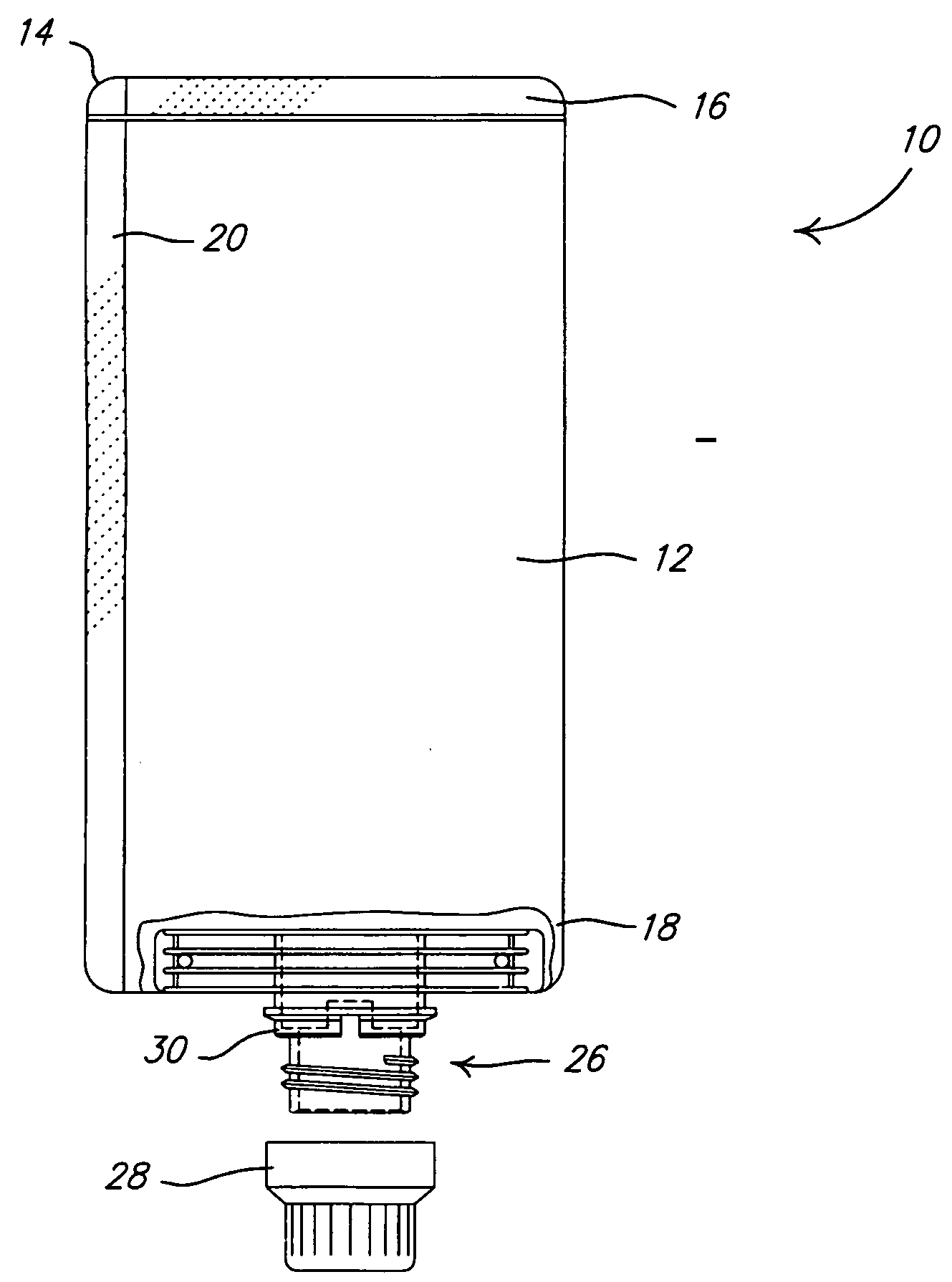

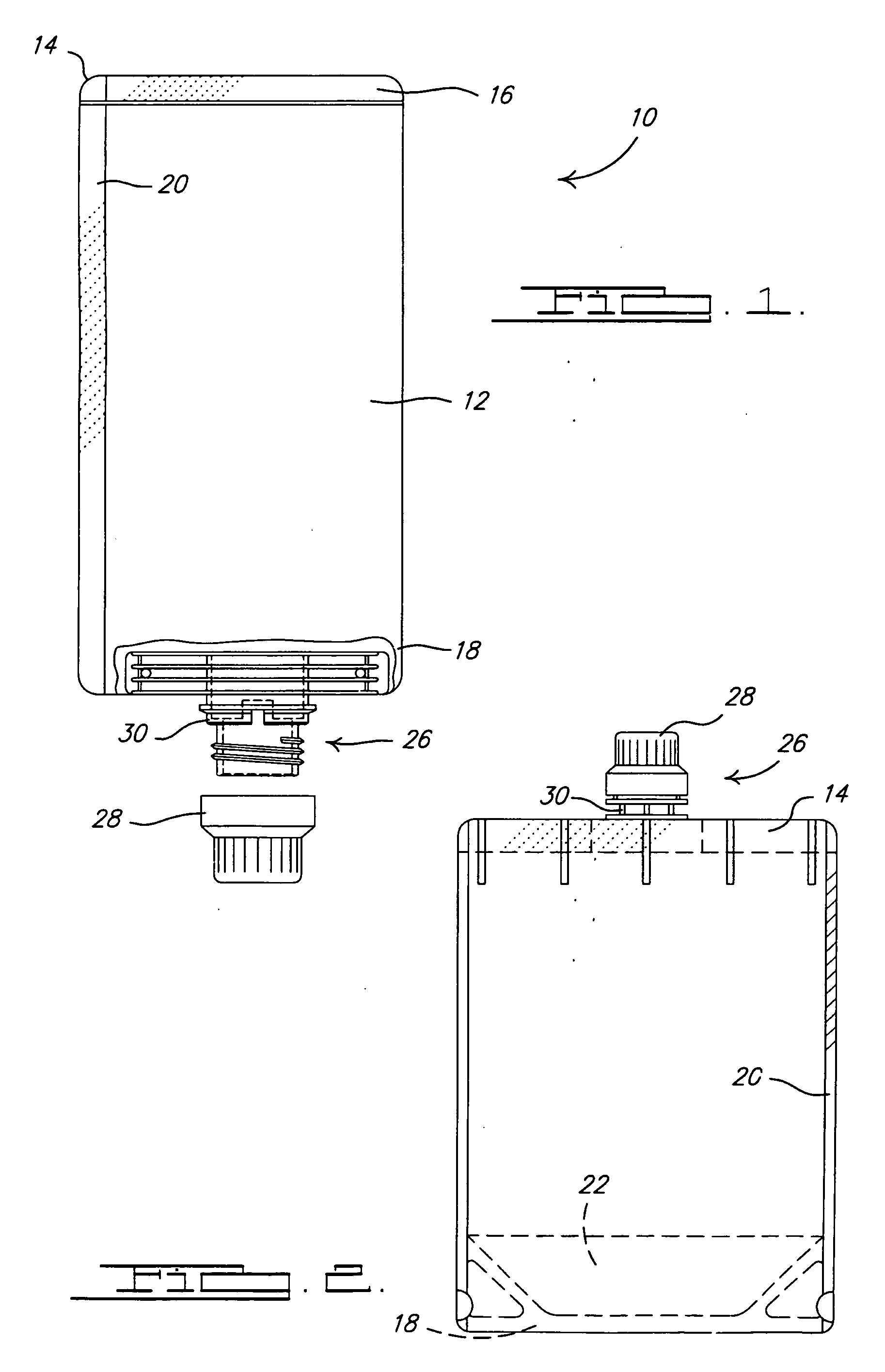

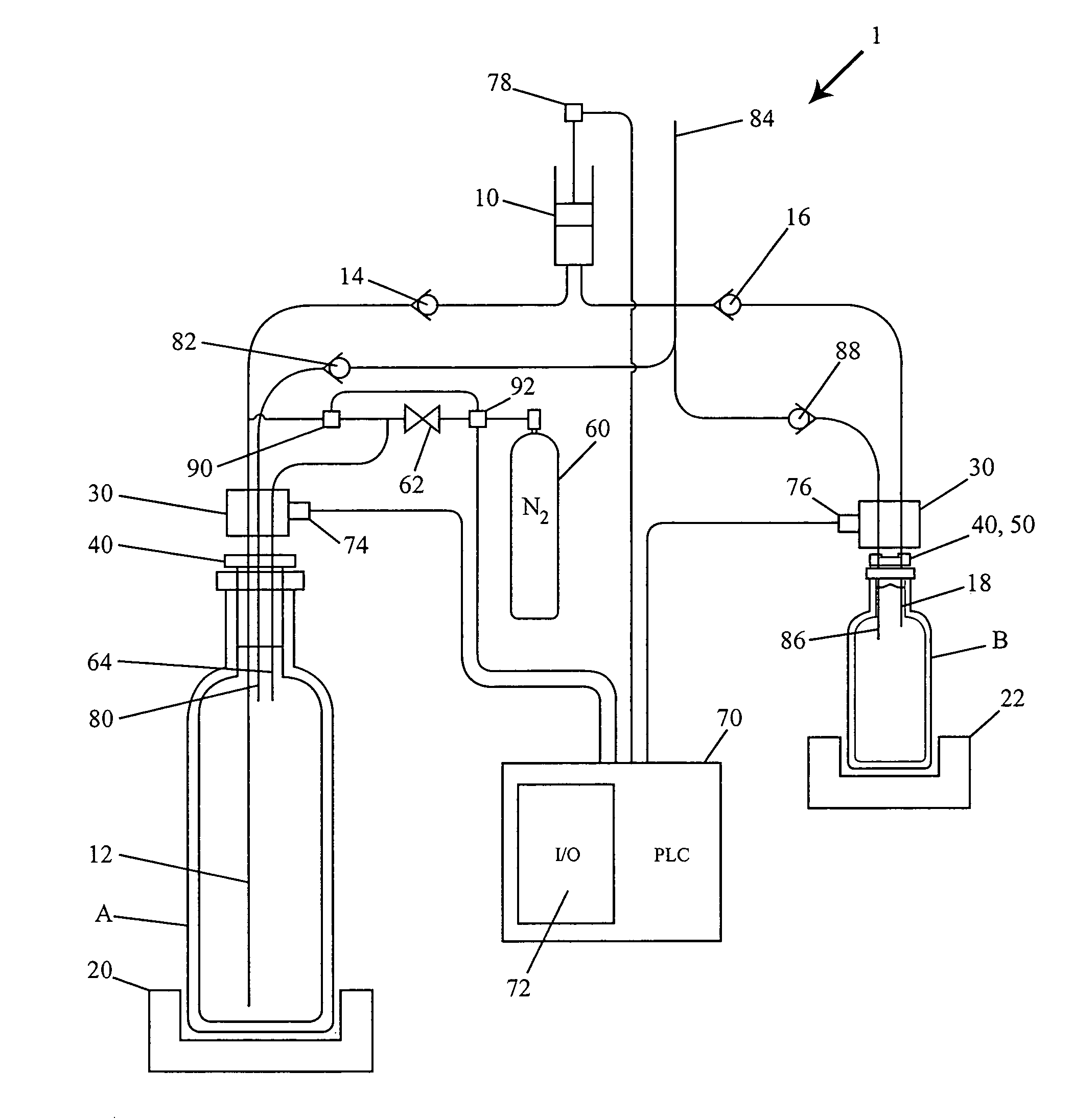

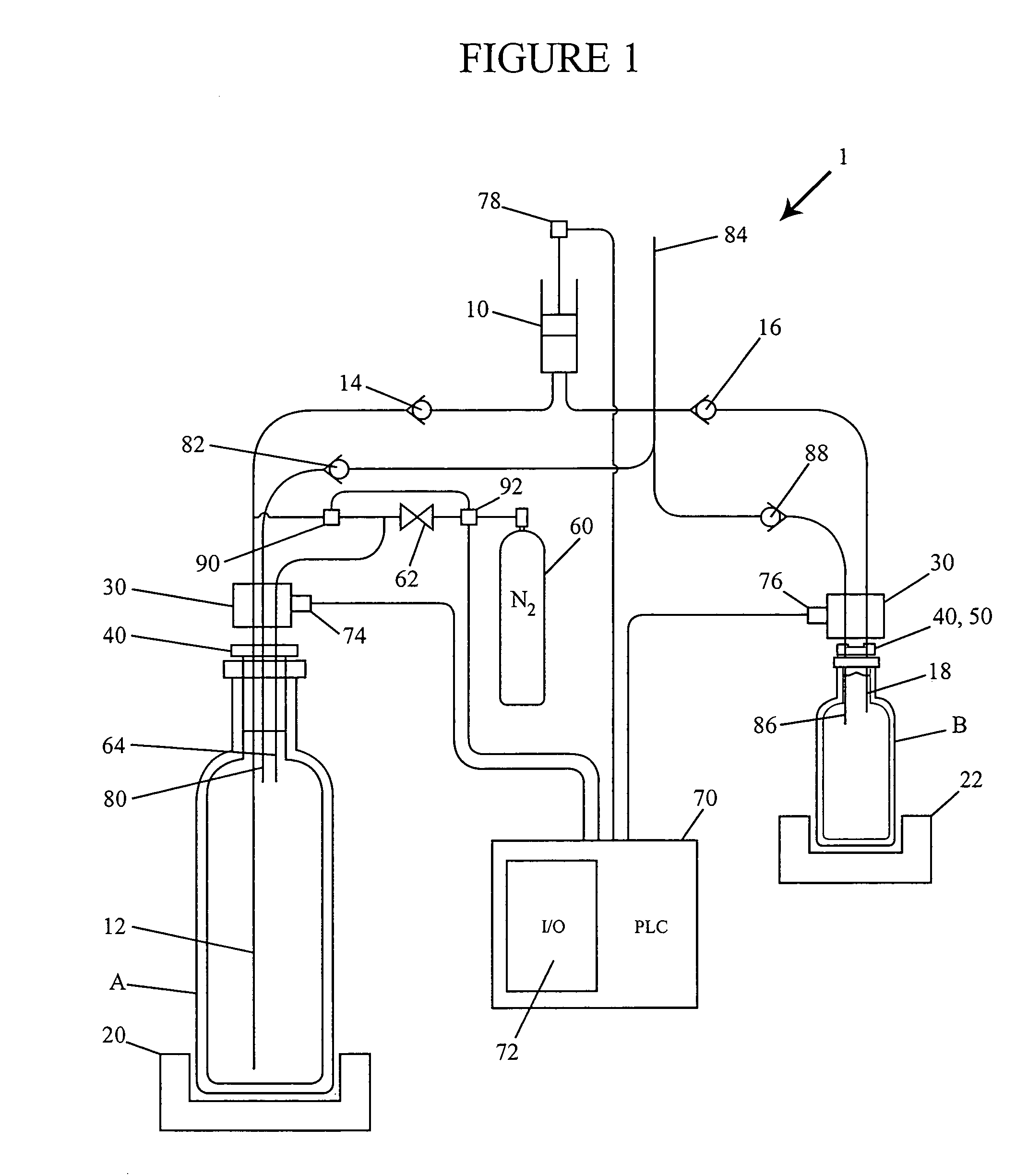

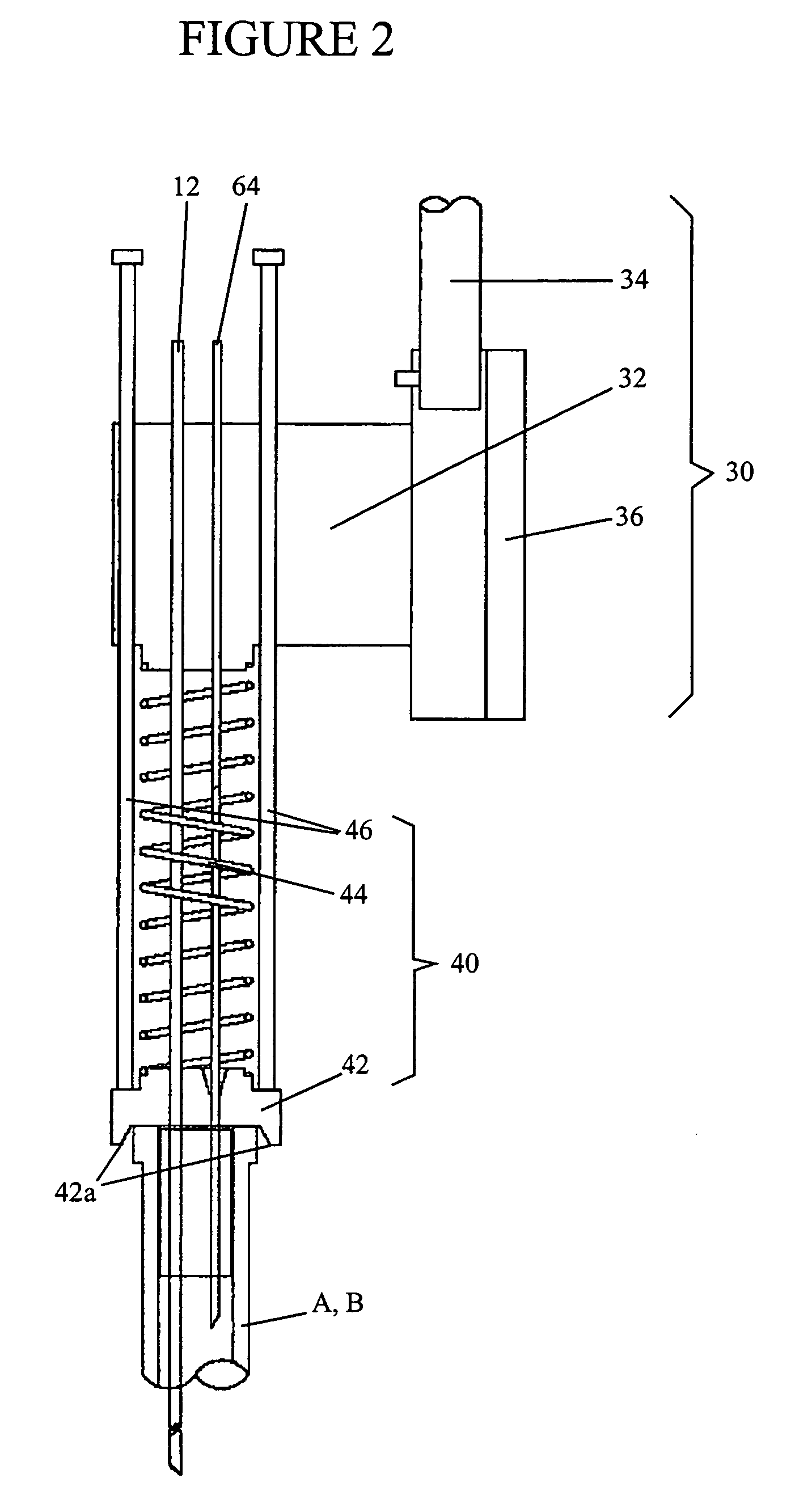

Method and apparatus for the storage and preservation of liquids compounds

InactiveUS7533701B2Prevent backflowFilling using counterpressurePackaging by pressurising/gasifyingEngineeringCheck valve

The present invention is directed to an apparatus for transferring a liquid from a source container to a destination container including a liquid transfer mechanism; at least one unidirectional valve preventing backflow into the source container; a source needle, inserted into a sealed closure of the source container, withdrawing the liquid from the source container; a destination needle, inserted into a sealed closure of the destination container, depositing the liquid into the destination container; an inert gas container supplying an inert gas to the source container; and at least one vent check valve releasing pressure from at least one of the containers when the pressure in the container exceeds a predetermined pressure limit. The present invention transfers liquids such as wine from an original sealed container into various new containers under controlled conditions without compromising the original composition of the liquids.

Owner:WINE FLOW

A machine and a method for filling containers

ActiveUS20160194189A1Cheap and easy to implementLabelling non-rigid containersFilling using counterpressureEngineeringActuator

A machine for filling a container having a longitudinal axis is disclosed. The machine comprises a conveying device, and at least one handling unit moved by the conveying device along a path. The at least one handling unit comprises a support device configured to receive and retain the container, and at least one filling device configured to feed a pourable product into the container as the at least one handling unit travels along the path. The machine further comprises an actuator configured to rotate the container about the longitudinal axis while the container is filled with the pourable product by the at least one filling device.

Owner:SIDEL SPA

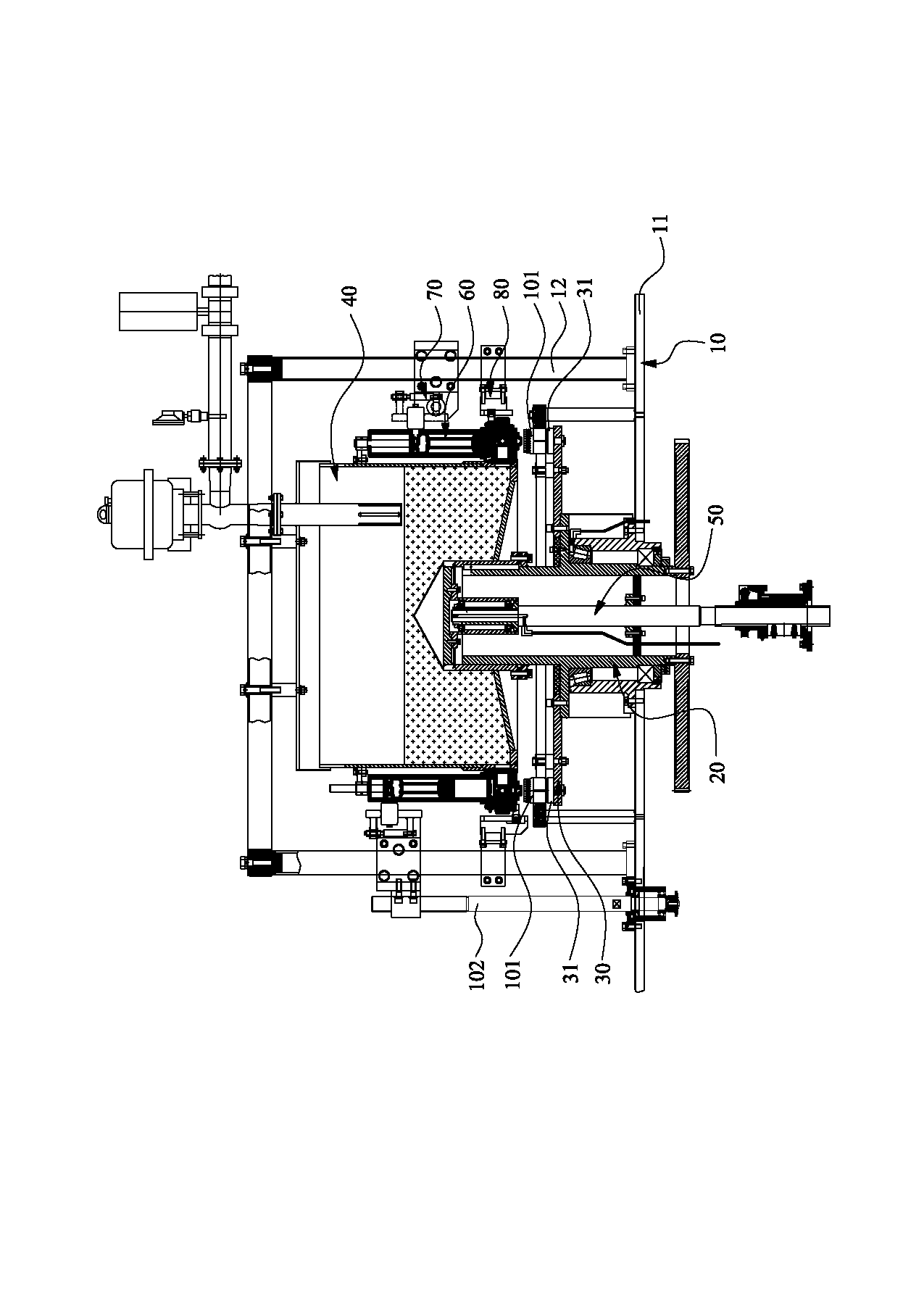

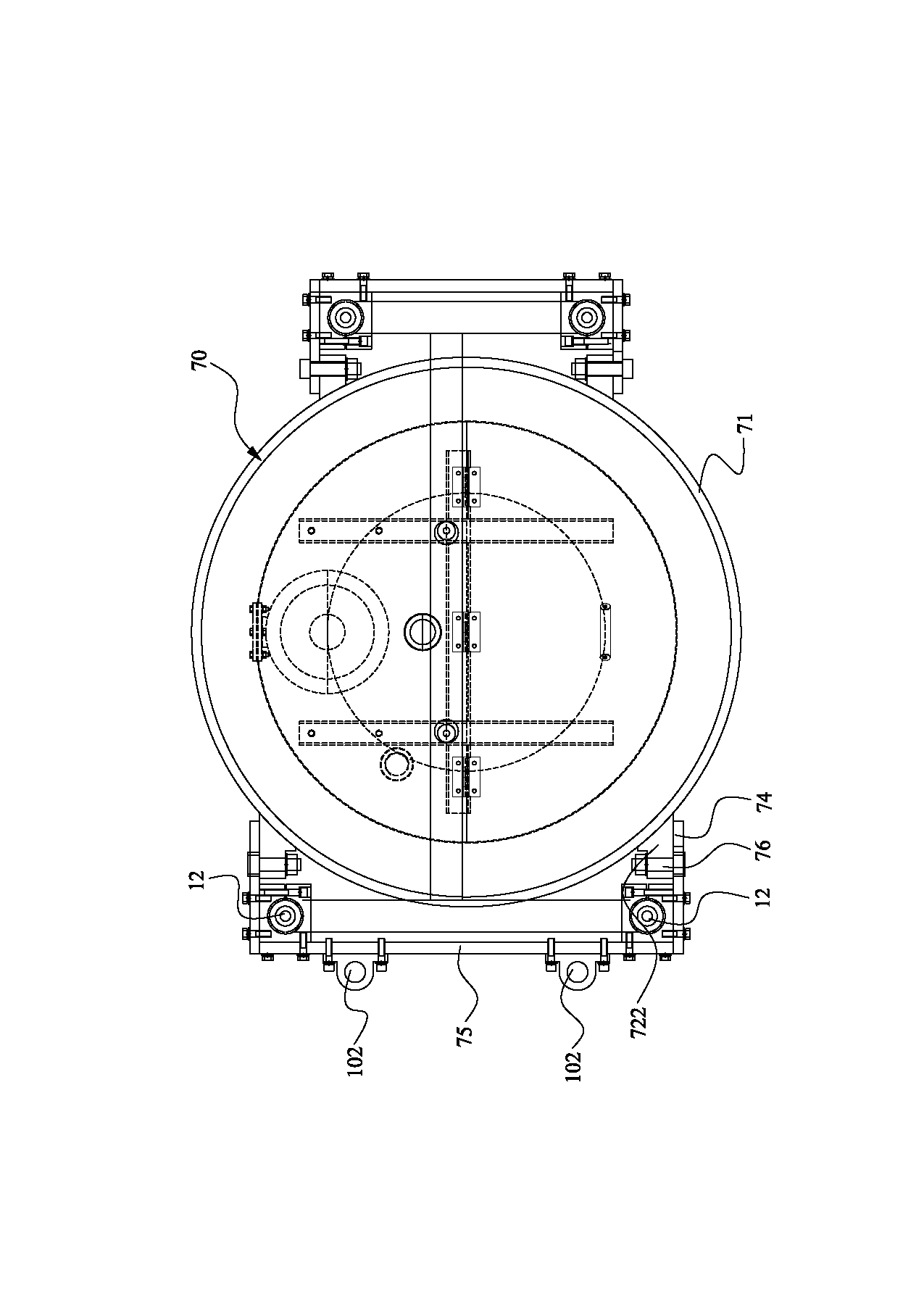

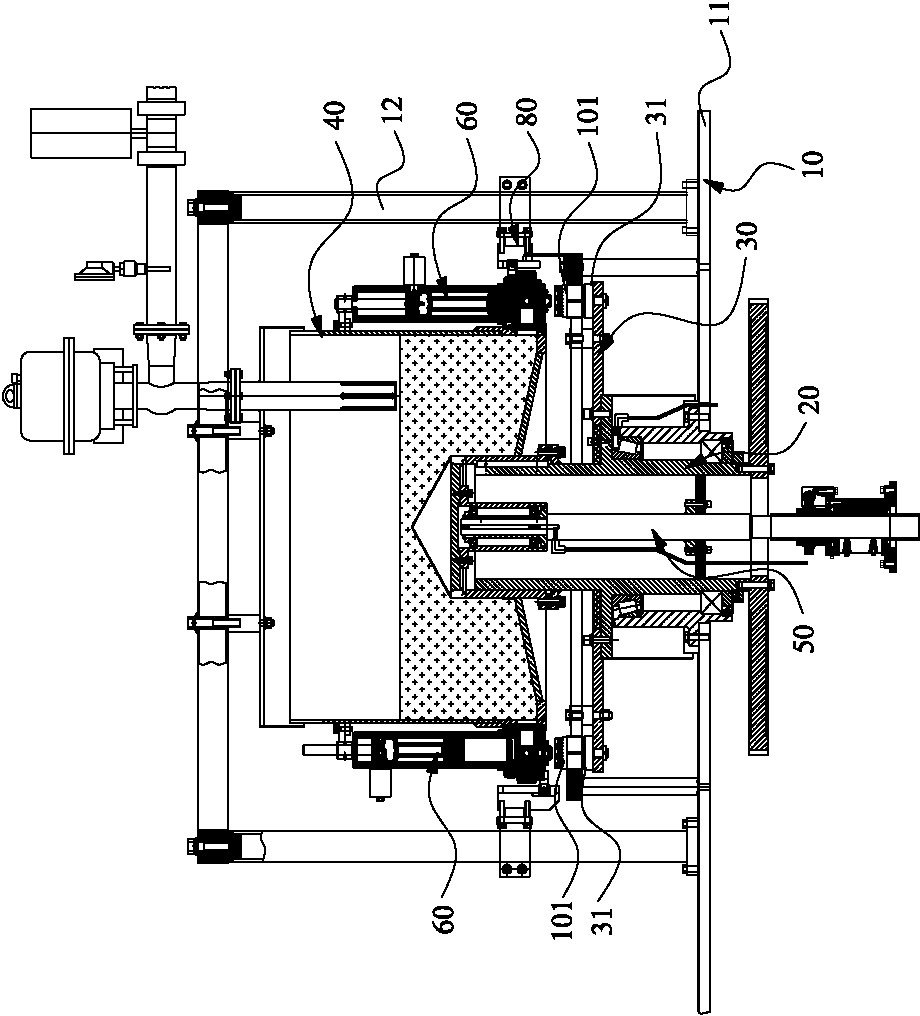

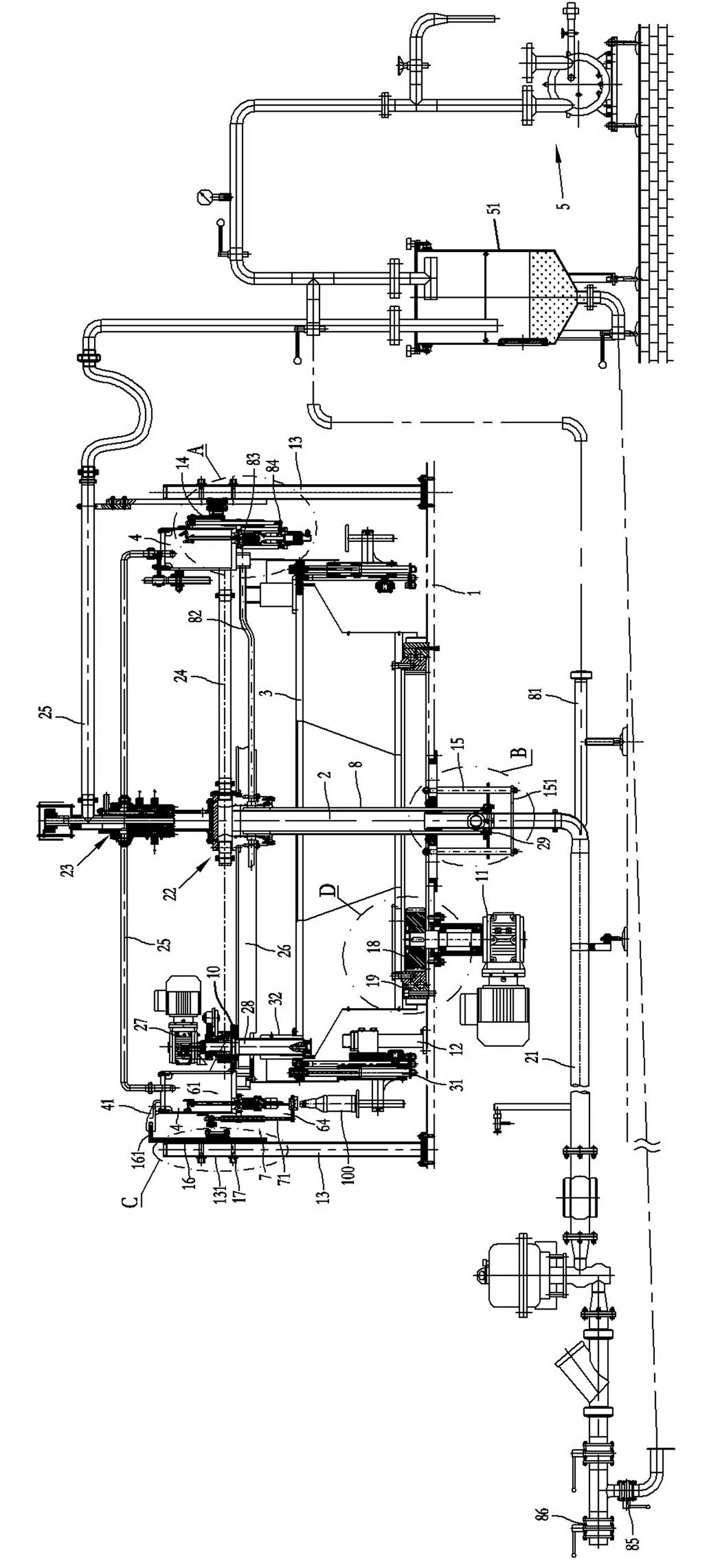

Quantitative filling machine of viscous material

ActiveCN102838069AImprove filling efficiencyEasy to installFilling using counterpressureEngineeringBottle

The invention discloses a quantitative filling machine of a viscous material. The quantitative filling machine comprises a rack, a revolving seat, a revolving platform and a material cylinder, wherein the circumferential face of the material cylinder is provided with a filling valve; a track which is arranged slantwise is constituted by an upper ring and a lower ring; a piston is controlled to alternately suck the material into a material cavity or press the material in the material out and fill in a bottle by using the track; meanwhile, a sensor is cooperatively used for controlling work of a driving mechanism, so that an ascending passage is opened or closed by a swing rod, thereby communicating a feed port and the material cavity by a feeding passage or communicating a filling port and the material cavity by a filling passage, effectively controlling output of the material and preventing a mistaken filling phenomenon; and thus, inlet and outlet of the material of all filling valves can be simultaneously and effectively controlled by using a piston control device and a switching control device, the quantitative filling machine has a simple structure and is convenient to operate, mount, debug and maintain, the degree of automation of the machine is greatly improved, and the filling efficiency of the material is effectively increased.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

Devices and methods for packaging beverages

ActiveUS20080023099A1Decreasing container-to-container variationReduce buildFilling using counterpressureMixing methodsEngineering

A method for packaging a beverage comprising particulates in a liquid, the method comprising dispensing a first portion of the beverage from a first source into containers, wherein the first portion of the beverage comprises at least a majority of the particulates and a first portion of the liquid, dispensing from a counterpressure filler a second portion of the beverage from a second source into the containers, wherein the second portion of the beverage comprises a second portion of the liquid, and sealing the containers to form packaged beverages. An apparatus for packaging a beverage comprising particulates in a liquid. A method for packaging, in sequence, a first beverage comprising particulates in a liquid and a second beverage comprising a carbonated beverage. A method for packaging a beverage comprising a dairy component and a liquid.

Owner:THE COCA-COLA CO

Beverage bottling plant for filling bottles with a liquid beverage filling material having a filling device and a filling machine having such a filling device

ActiveUS20050217753A1Reduce manufacturing costFilling using counterpressureFilling without pressureTrademarkEngineering

A beverage bottling plant for filling bottles with a liquid beverage filling material having a filling device and a filling machine having such a filling device. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

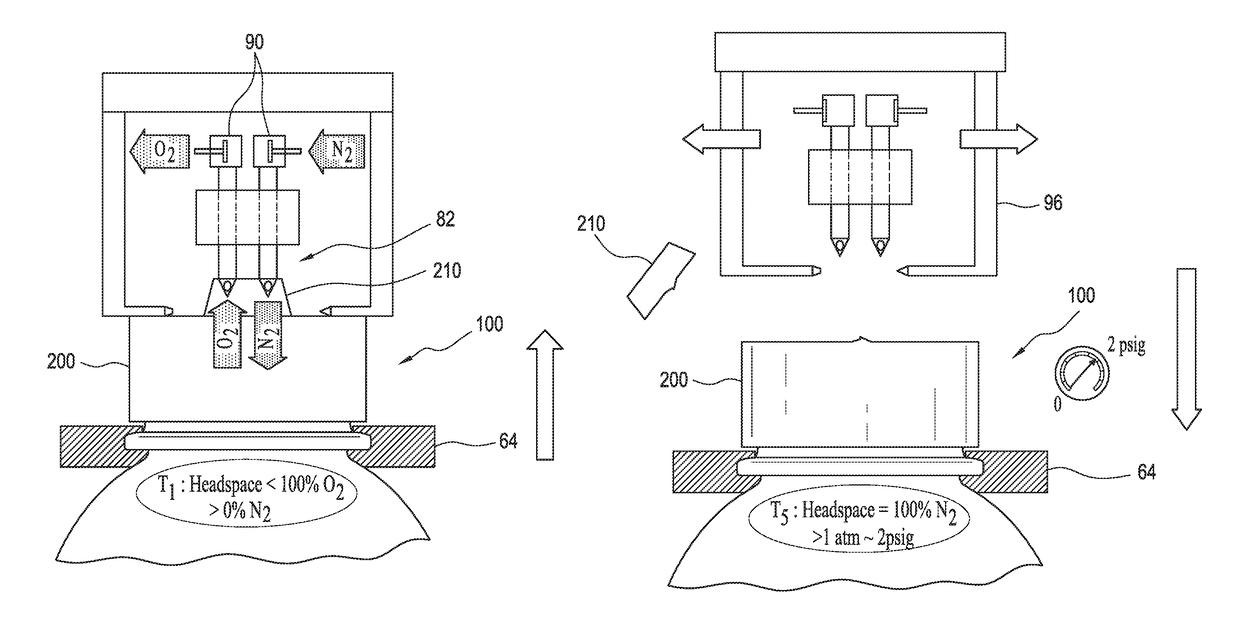

System and method of transferring matter through a sealed container

ActiveUS9643746B1Filling using counterpressurePackaging by pressurising/gasifyingEngineeringInert gas

A method and system of transferring matter through a sealed container during a bottling process are provided. The method includes accessing a headspace of the filled and sealed container by creating at least one opening. An inert gas is provided within the headspace while allowing O2 to exit from the headspace until substantially all of the O2 has been flushed out of the headspace. The headspace is then pressurized by continuing to direct the inert gas into the headspace after it has been flushed of O2. The at least one opening of the container is then sealed while the headspace is under pressure. The filled and sealed container can be a hot-filled container.

Owner:PEPSICO INC

Method for filling bottles or similar containers with an oxygen sensitive effervescent liquid beverage filling material under counterpressure and filling machine for the performance of this method

ActiveUS20130180619A1Reduce consumptionAvoid and restrict and minimize absorptionFilling using counterpressurePackaging under special atmospheric conditionsTrademarkBottle

A method for filling bottles or similar containers with an oxygen sensitive effervescent liquid beverage filling material under counterpressure and filling machine for the performance of this method. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

Method for filling bottles or similar containers with an oxygen sensitive effervescent liquid beverage filling material under counterpressure and filling machine for the performance of this method

InactiveUS20100212773A1Reduce consumptionAvoid and restrict and minimize absorptionFilling using counterpressurePackaging by pressurising/gasifyingTrademarkBottle

A method for filling bottles or similar containers with an oxygen sensitive effervescent liquid beverage filling material under counterpressure and filling machine for the performance of this method. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

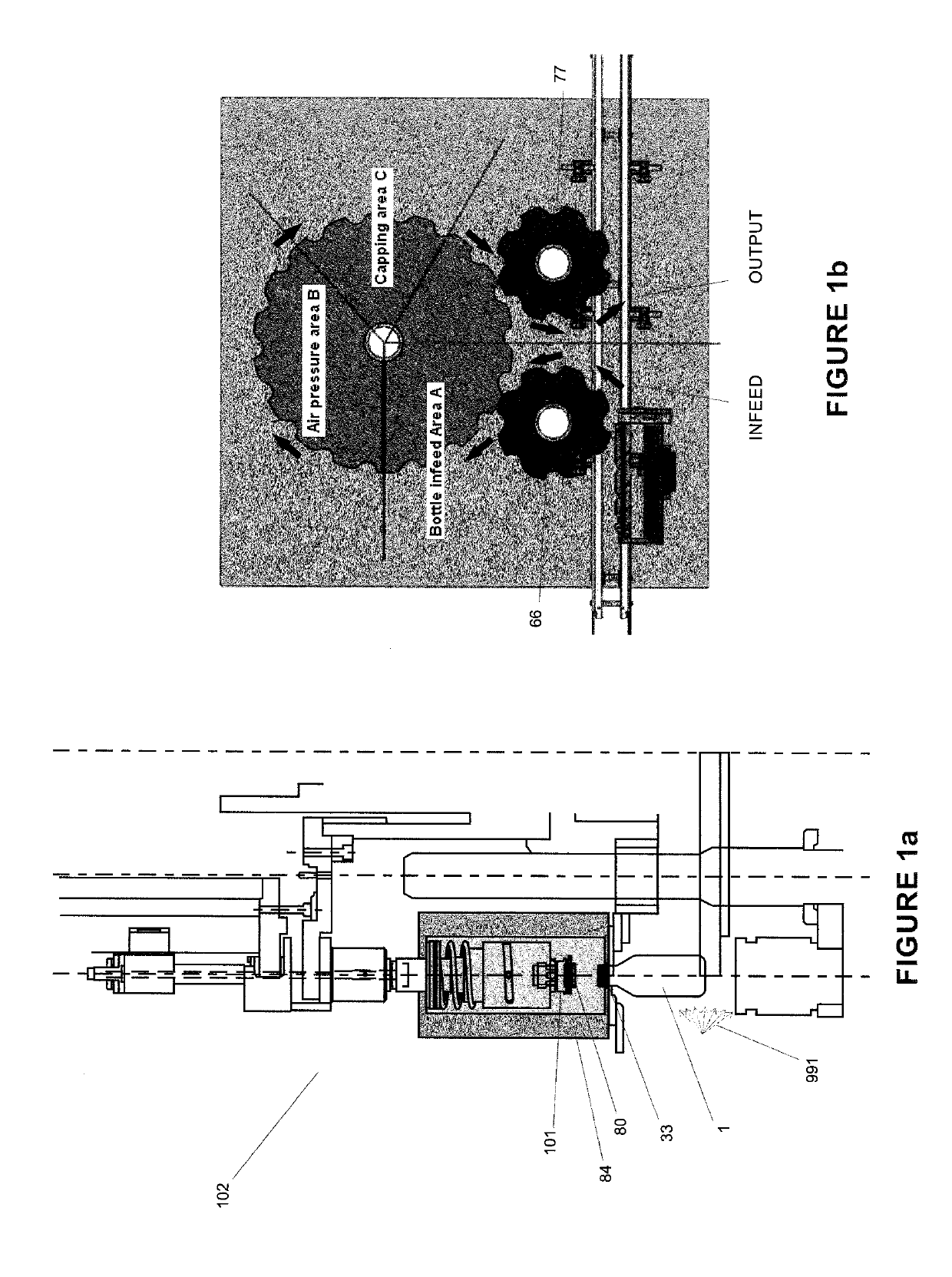

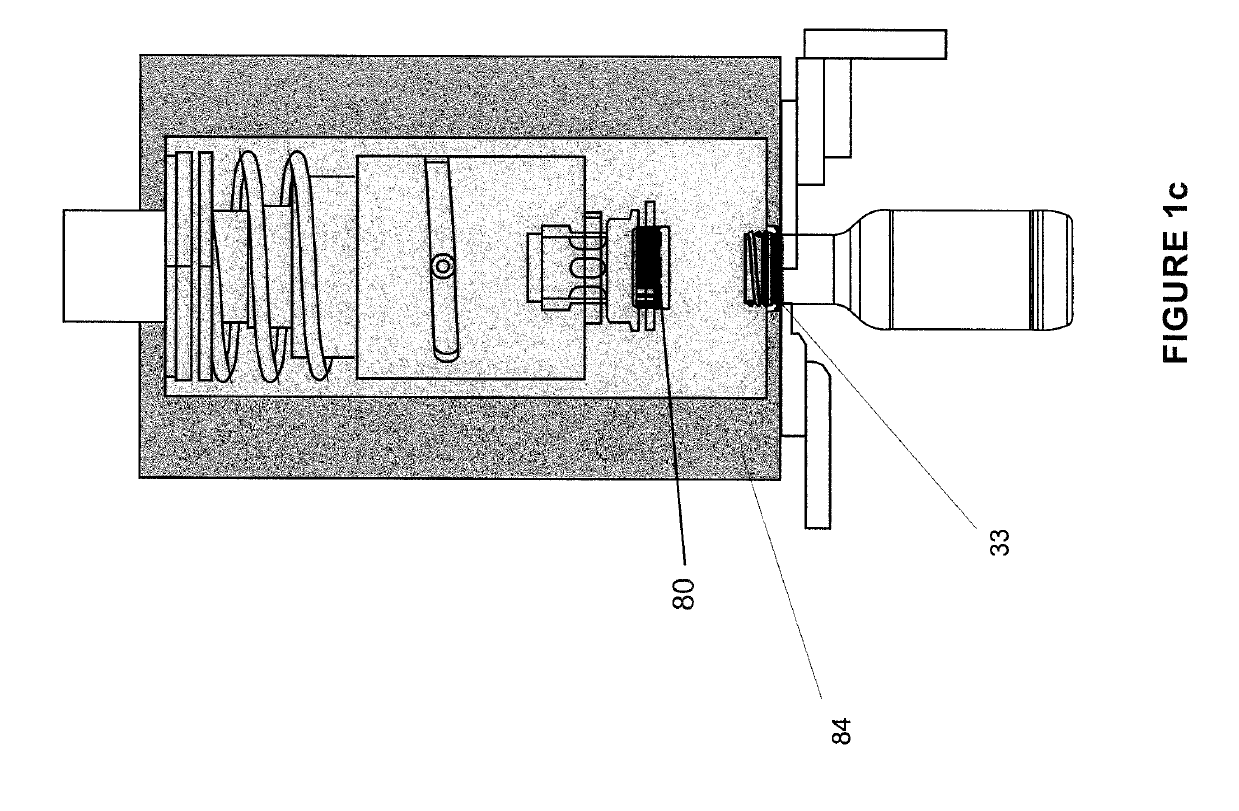

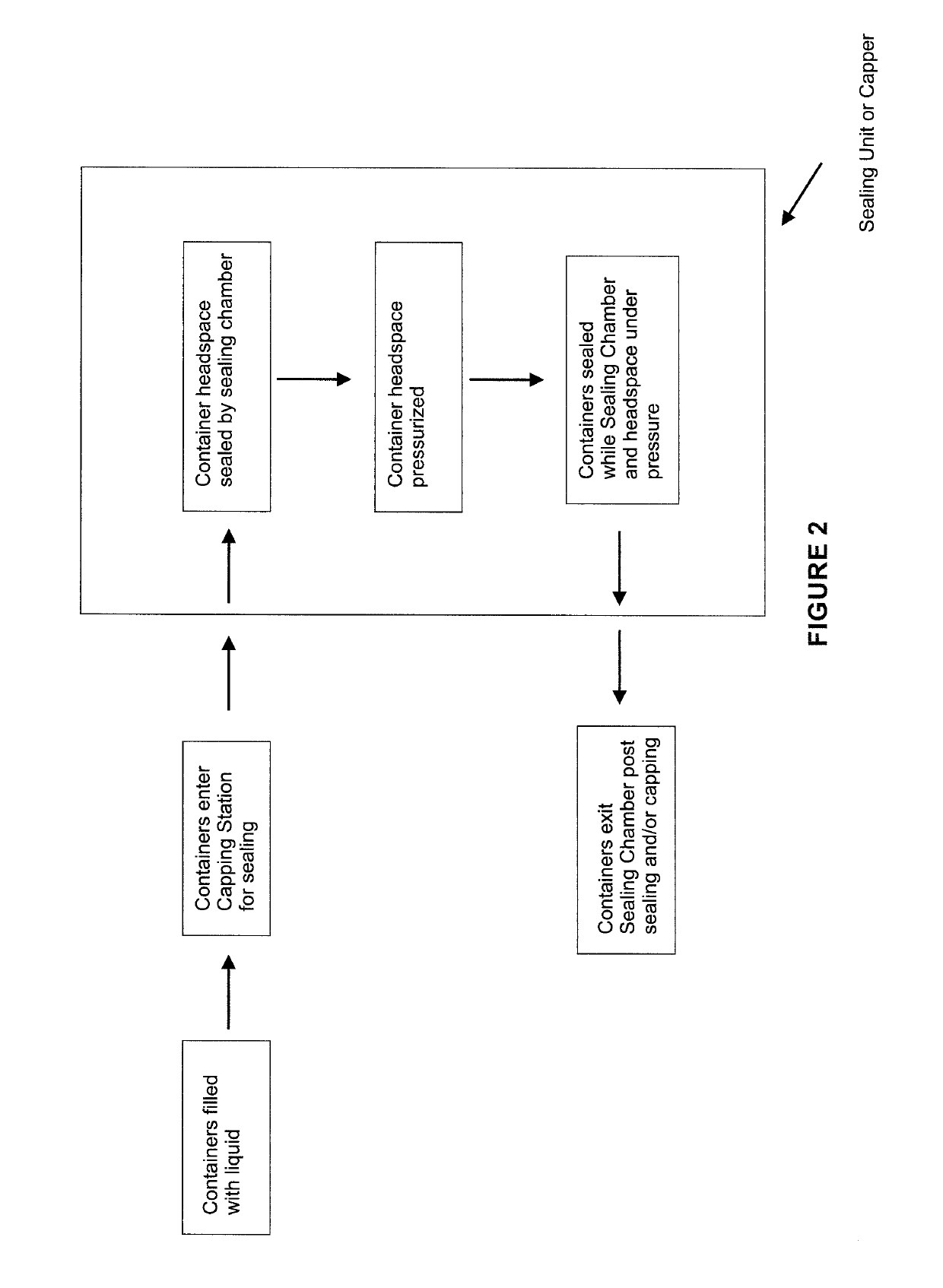

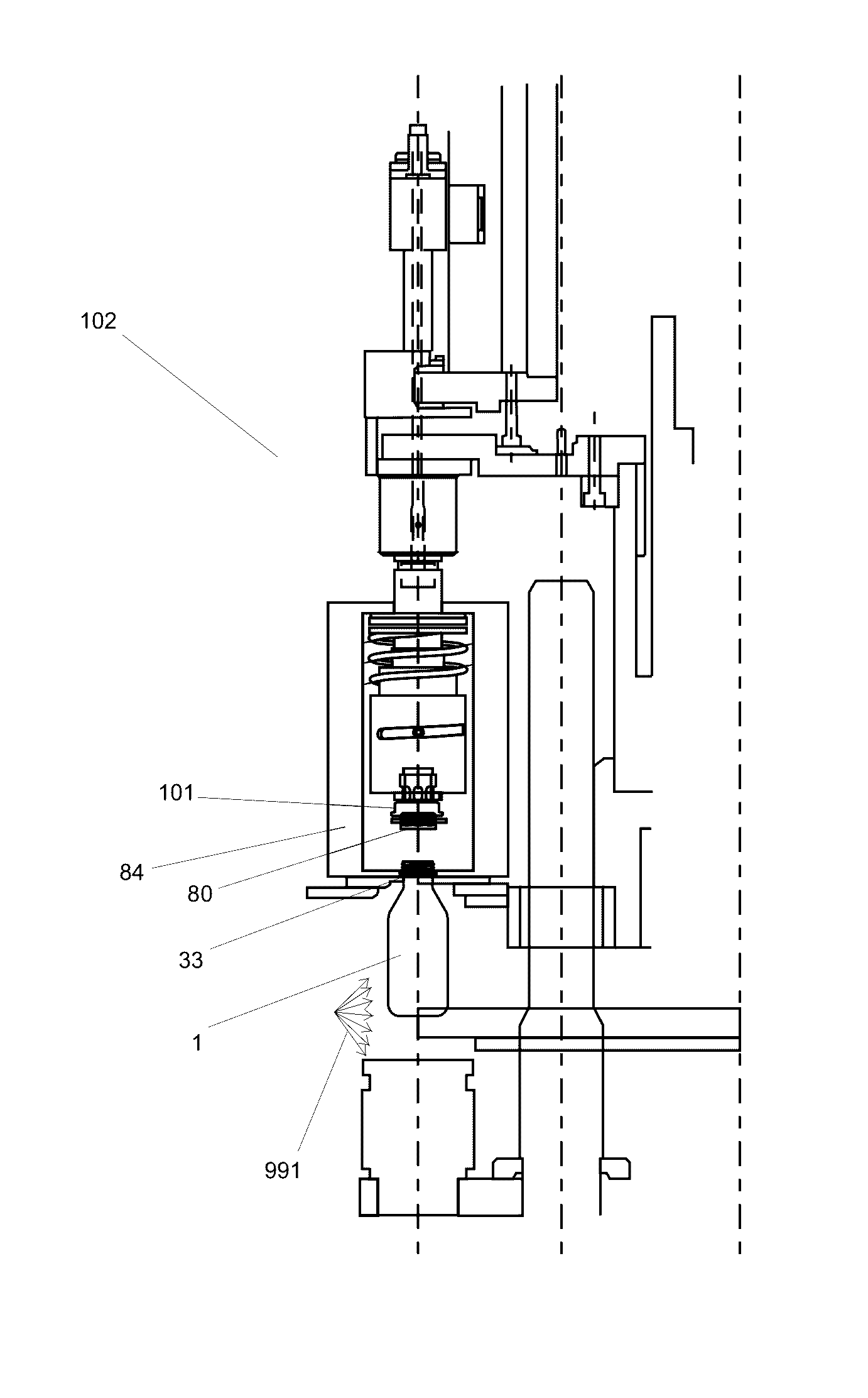

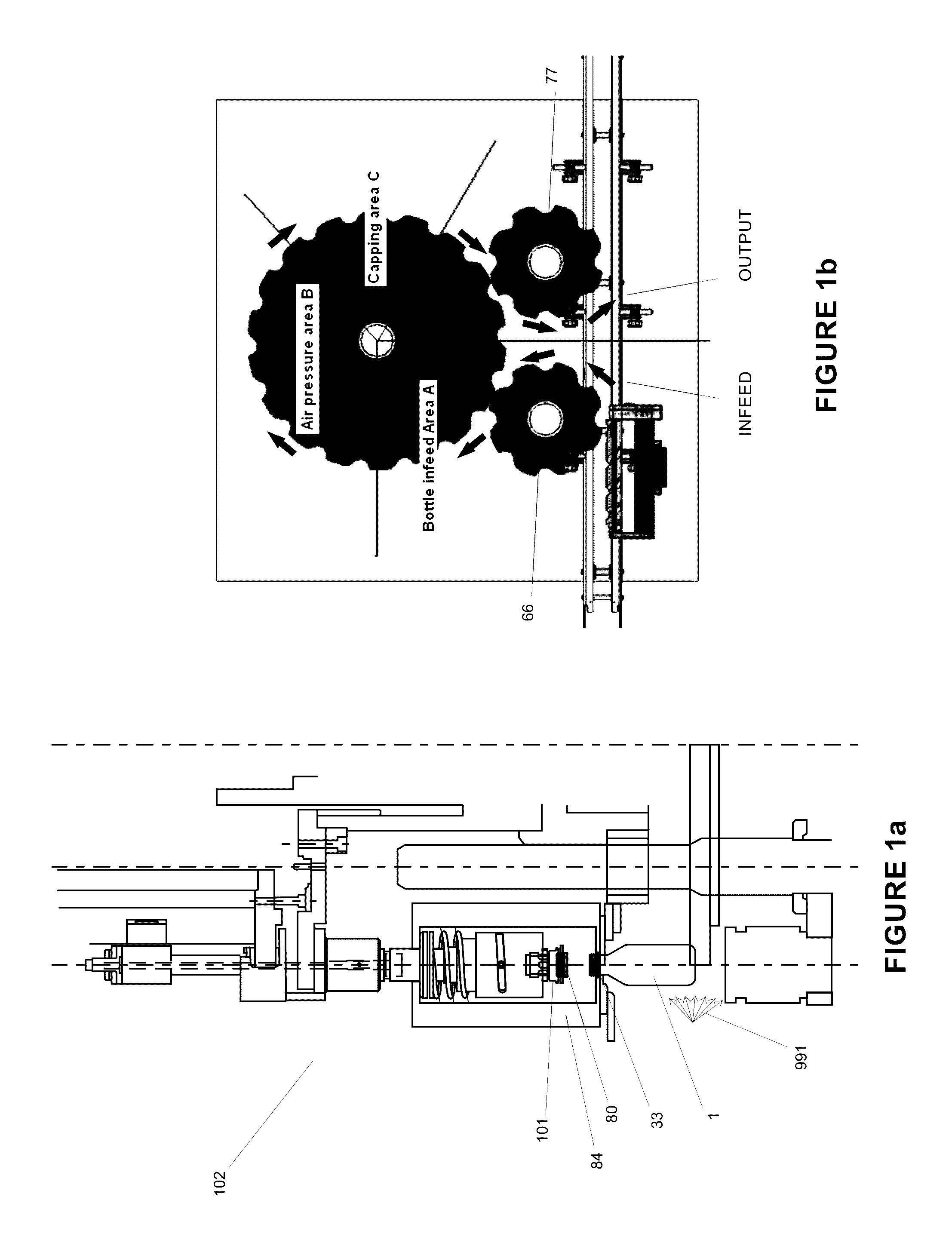

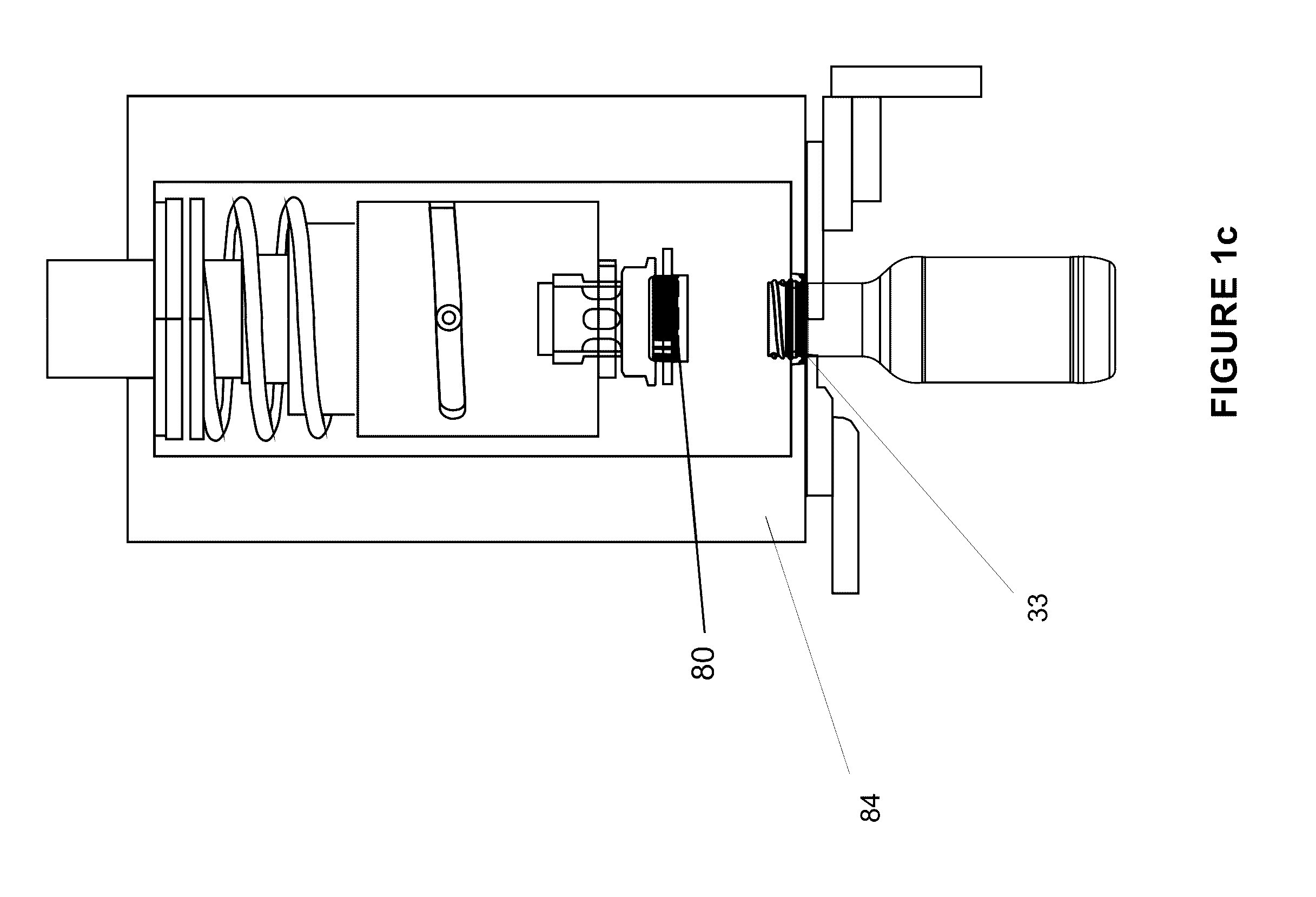

Controlled container headspace adjustment and apparatus therefor

InactiveUS20190330038A1Relieve stressIncrease pressureCapsThreaded caps applicationEngineeringMechanical engineering

A sealing and pressure dosing apparatus, and container filling method, including a capping machine (102) which receives containers (1). Closures (80) are applied to the containers (1) immediately following the raising of pressure within the containers (1) by a pressure dosing system in a pressure sealing chamber (84). Preferably a cooling system is integrated with the capping machine.

Owner:MELROSE DAVID MURRAY

Soy sauce filling machine

ActiveCN102320540AQuality assuranceSimple structureFilling using counterpressureVacuum pumpingBottle

The invention discloses a soy sauce filling machine; a first magnet is fixed on an upper end of a guide rod; a cover plate is engaged with an upper end of a steam-return pipe and can cover an opening of the steam-return pipe; a second magnet is fixed at one side of the cover plate near the guide rod; the facing surfaces of the first magnet and the second magnet have the same magnetism; when the guide rod is lifted to the highest position, the first magnet and the second magnet are approximately on the same horizontal line. The invention can control the opening or closing of the channel between a material cylinder and external air by the interaction between the first magnet and the second magnet, realizes no vacuum pumping when no bottle is provided, ensures the filling quality, and has a simple structure.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

System for Charging and Purging a Compressed Gas Cylinder

A fixed and / or stationary modular unit consists of a hydraulic fluid tank, a pressurization pump, and a compressed gas transportation system consisting of a cylinder or set of cylinders. Each cylinder has two ends, a charging end and a dispensing end, with actuated valves positioned at each end. A pair of valves are located at each charging end of each cylinder, with one valve connected to an incoming hydraulic fluid line and the other valve connected to a hydraulic fluid return line. A valve is connected at the dispensing end of each cylinder. Adapters at each end of the cylinder have curved J-tubes that extend into the cylinder. The J-tube on the charging end curves downward and the J-tube on the dispensing end curves upward. The cylinder or sets of cylinders are inclined to a desired level for the dispensing process.

Owner:NEOGAS INC

Controlled container headspace adjustment and apparatus therefor

ActiveUS20170008745A1Increase internal pressureNegative effectCapsFilling using counterpressureMechanical engineeringEngineering

A sealing and pressure dosing apparatus, and container filling method, including a capping machine (102) which receives containers (1). Closures (80) are applied to the containers (1) immediately following the raising of pressure within the containers (1) by a pressure dosing system in a pressure sealing chamber (84). Preferably a cooling system is integrated with the capping machine.

Owner:MELROSE DAVID MURRAY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com