Filling system for hot filling of beverage bottles or containers in a bottle or container filling plant

a filling system and beverage bottle technology, applied in the directions of liquid handling, packaging goods, transportation and packaging, etc., can solve the problems of complex construction, high construction cost, time-consuming, etc., and achieve the effect of requiring and/or requiring a great deal of control effor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

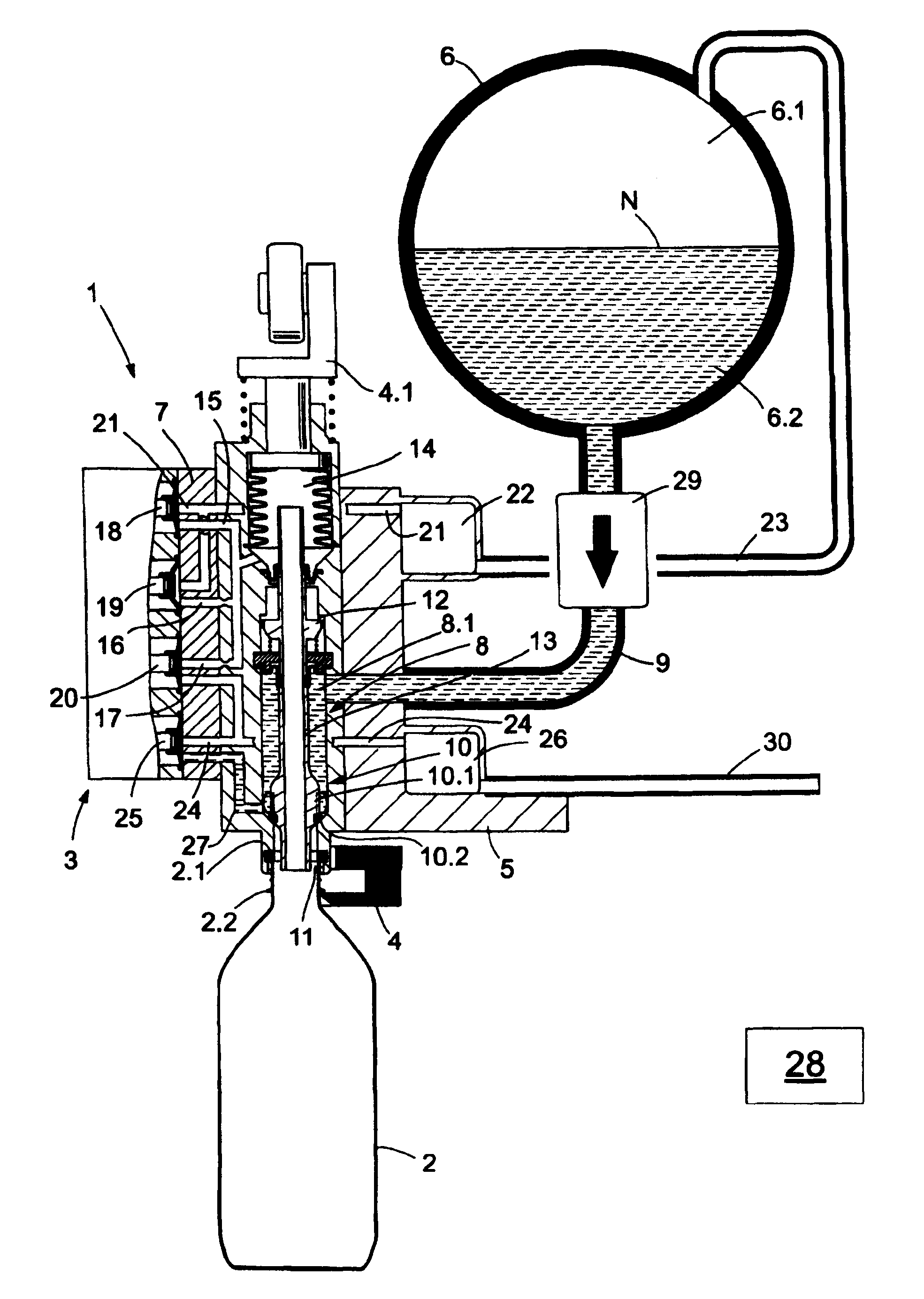

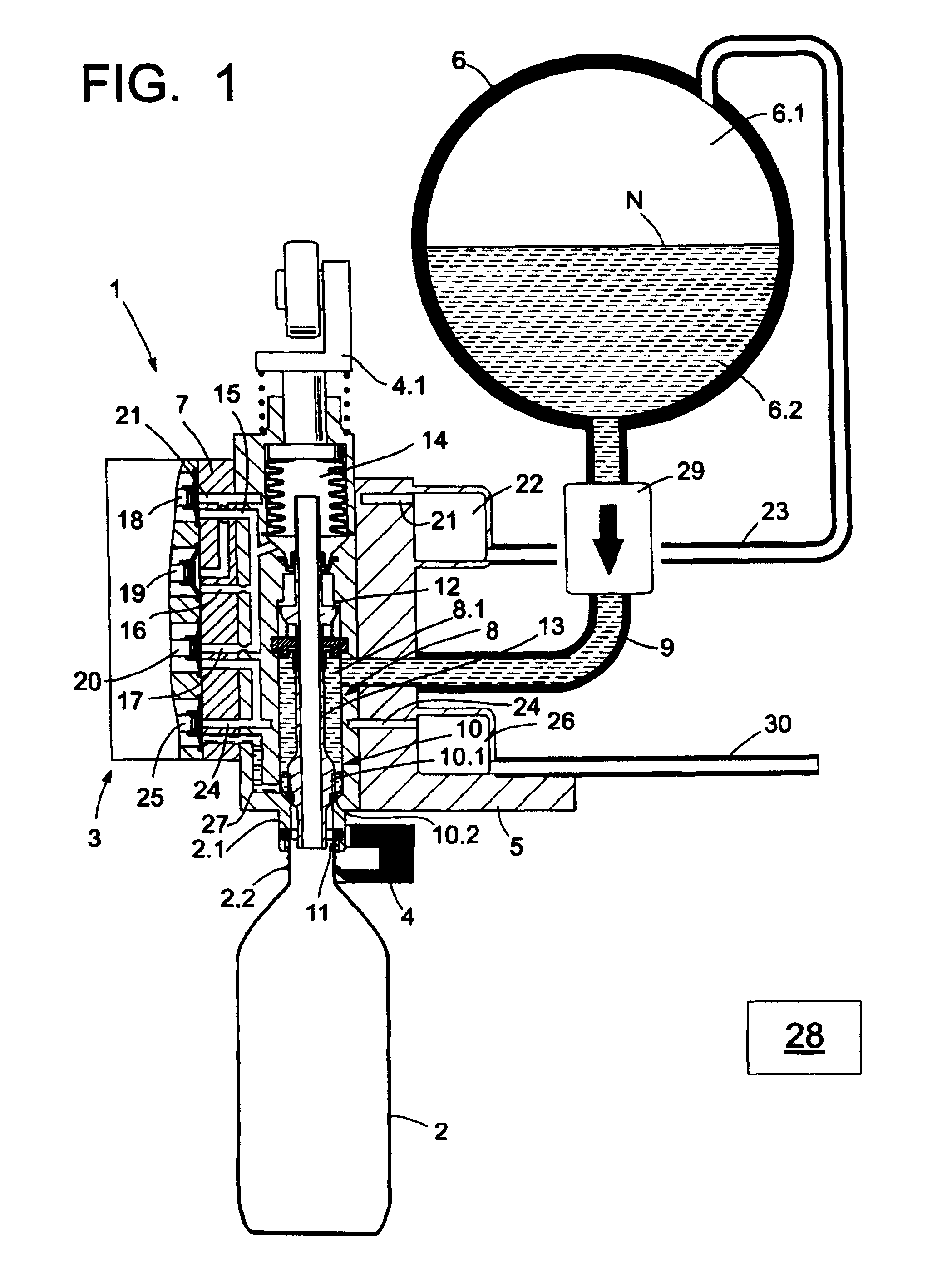

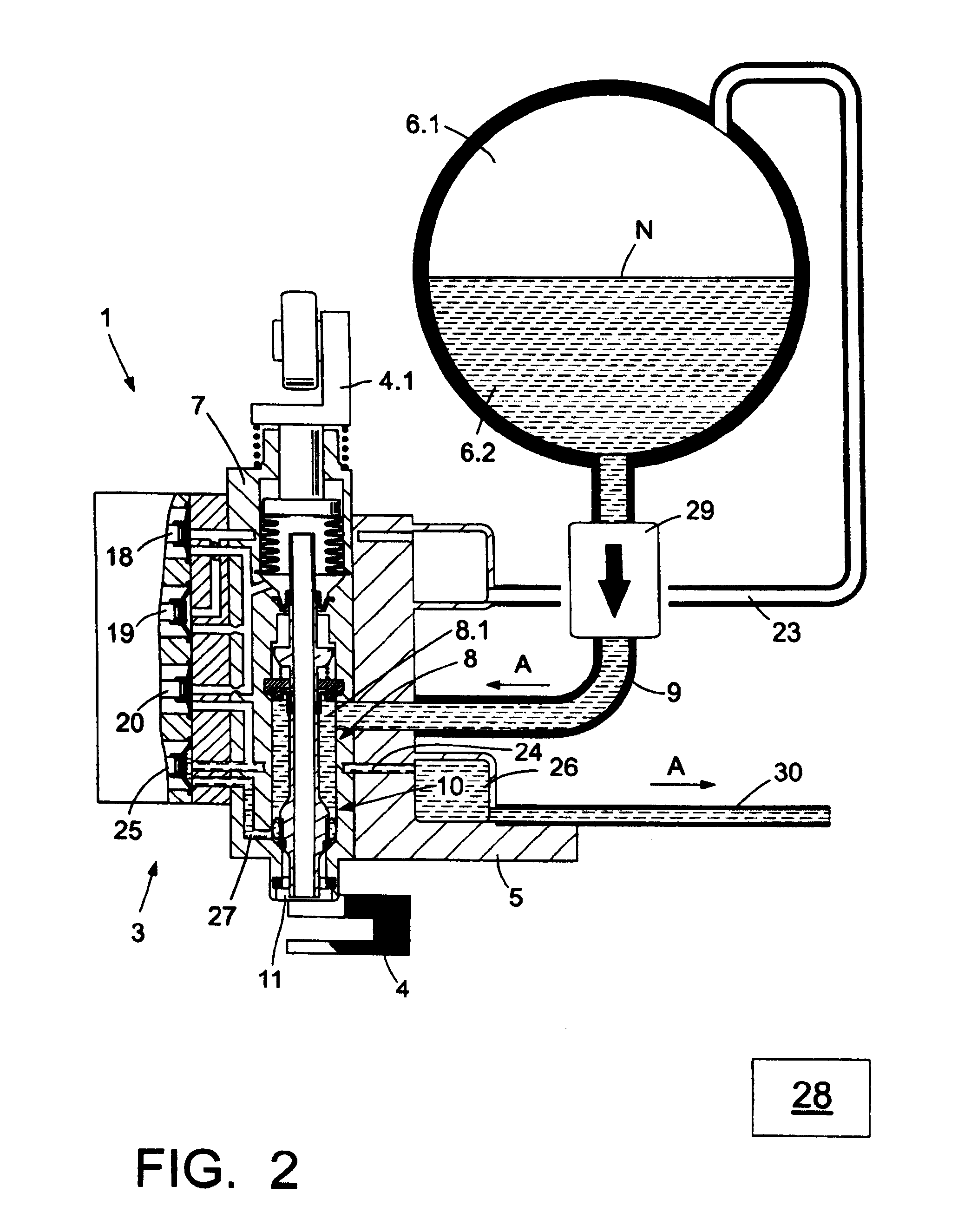

[0020]The filling system, identified in general in FIGS. 1 and 2 by the reference 1, is a component of a filling machine of the rotary type for filling a liquid product into bottles 2 or similar containers. The filling system 1, for this purpose, essentially comprises a filler element 3 and a bottle or container carrier 4 that is associated with said filler element, said bottle or container carrier, in the possible embodiment represented, serving to hold the bottle 2 at a mouth flange 2.2 that is formed below the bottle mouth 2.1 and, for this purpose, being realized, for example, in the manner of a fork. The filler element 3 and the associated container carrier 4 are provided with a plurality of identical-type filler elements 3 and container carriers 4 at the periphery of a rotor 5 that is rotatingly driveable about a vertical machine axis. A reservoir 6 that is common to the filler elements is situated at the rotor 5 above the filler elements 3, said reservoir being realized, for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flow rate | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Perimeter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com