Patents

Literature

594results about How to "Increase internal pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System for withdrawing body fluid

ActiveUS20080021494A1Easily and reliably withdrawalReliable waySensorsBiological testingCompression deviceBody area

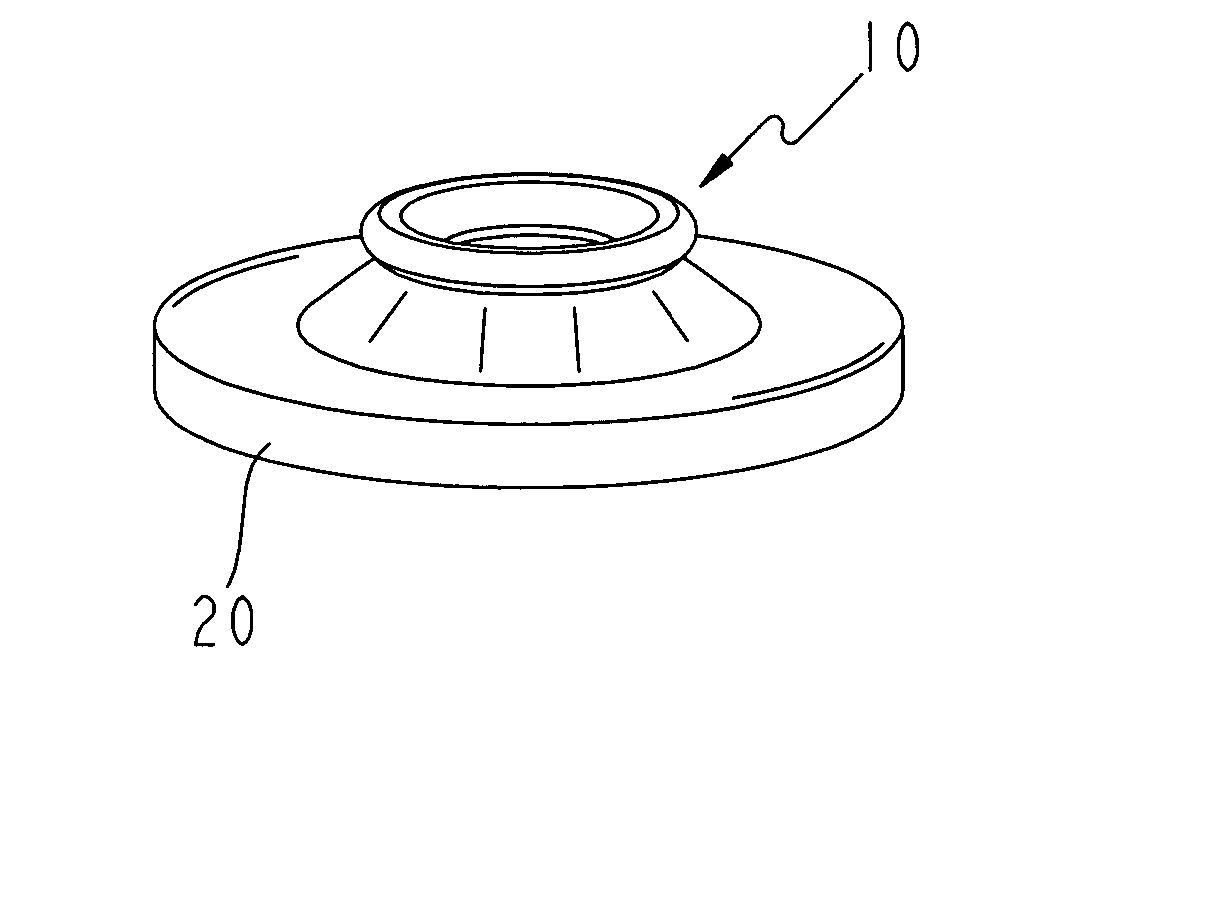

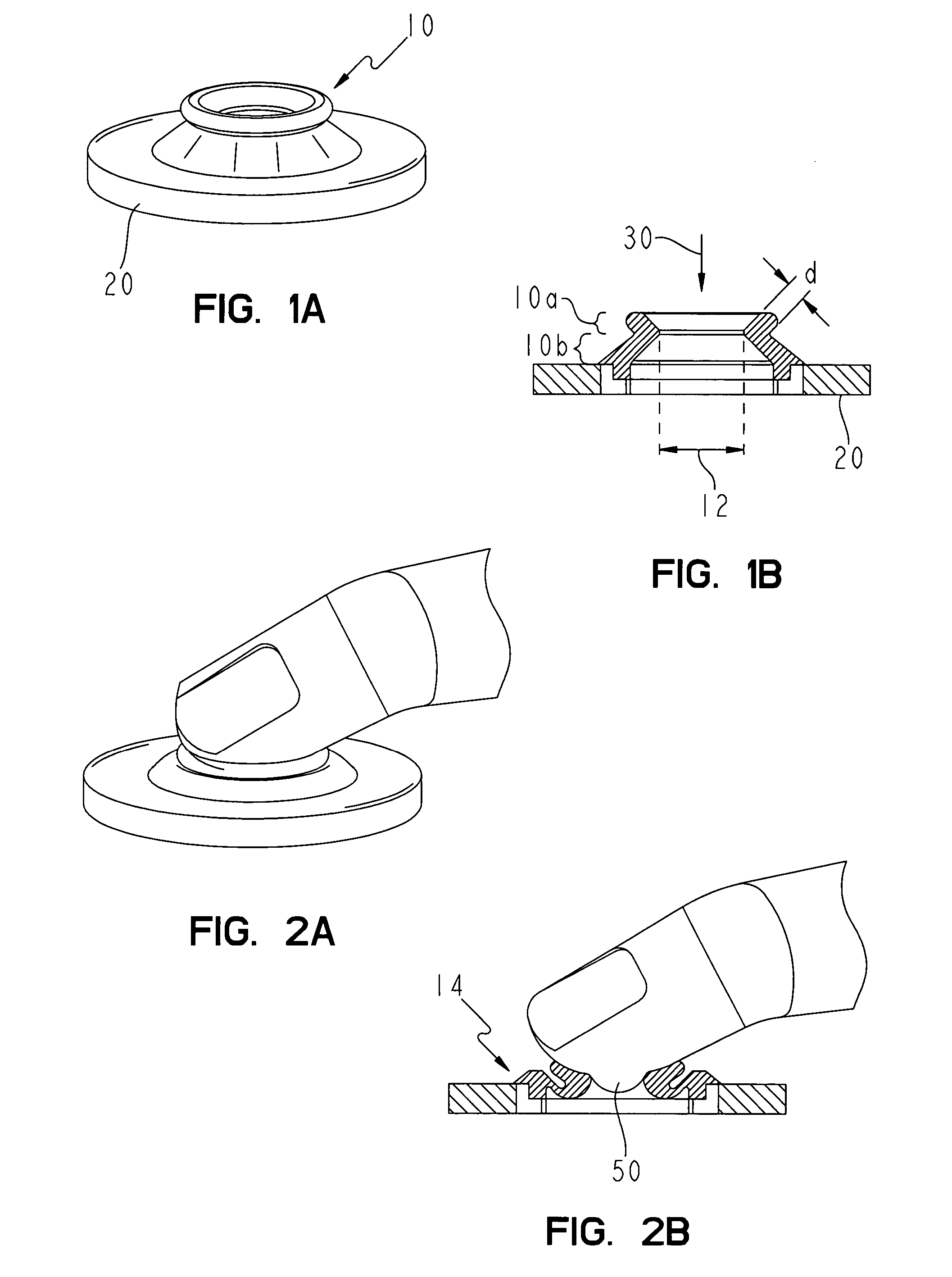

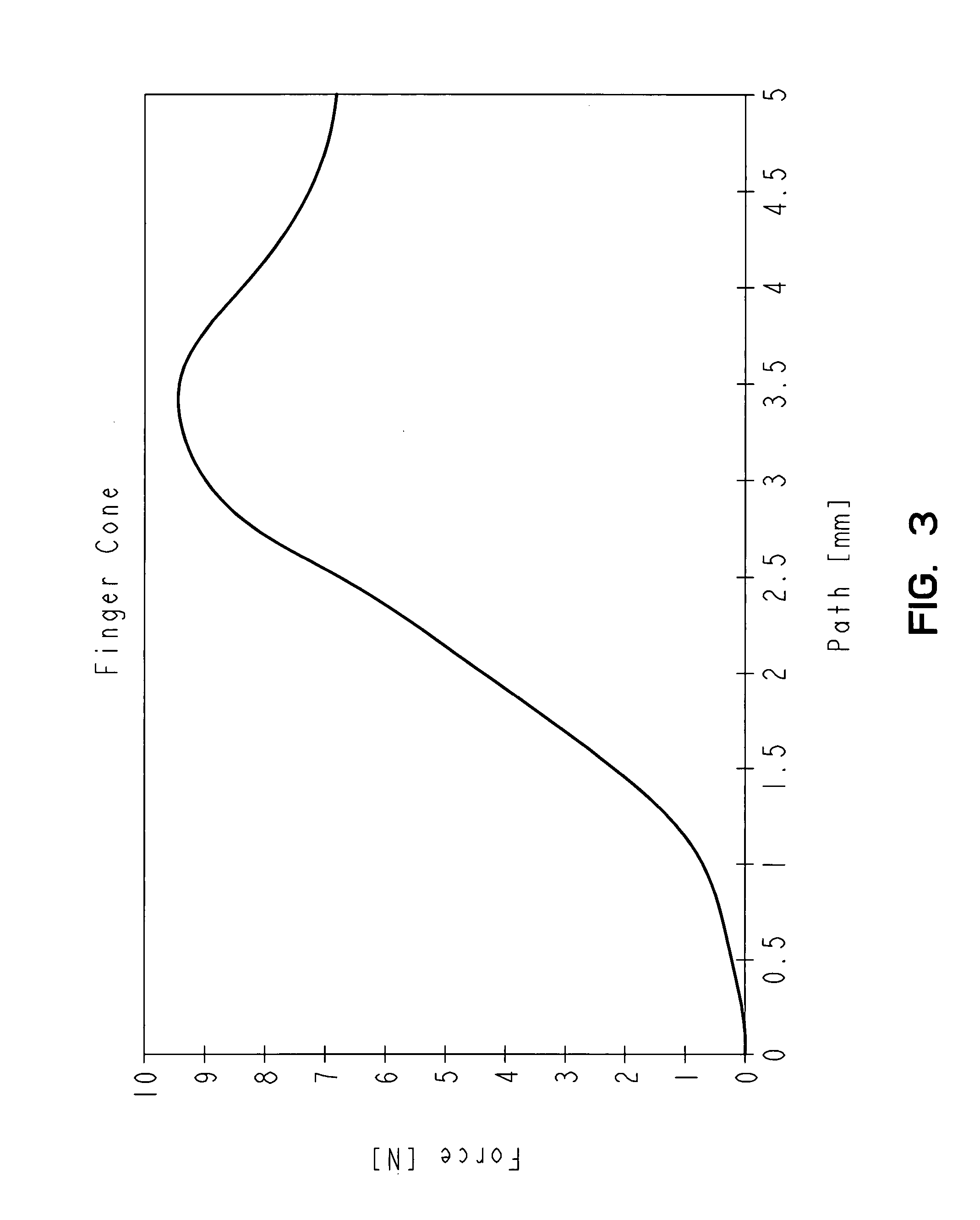

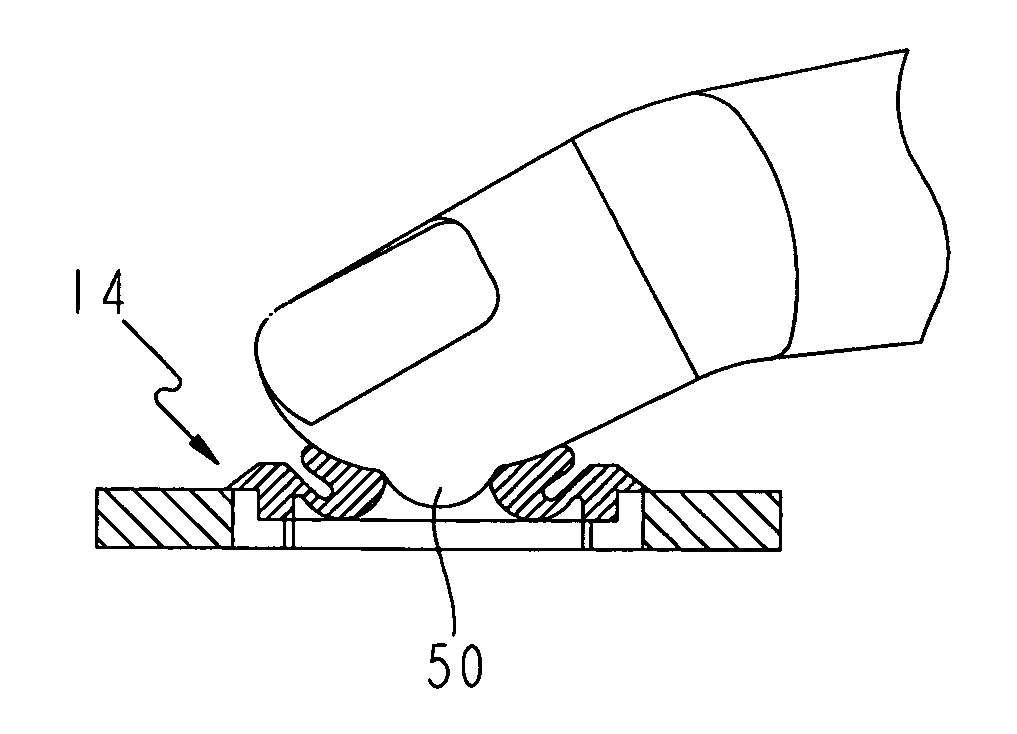

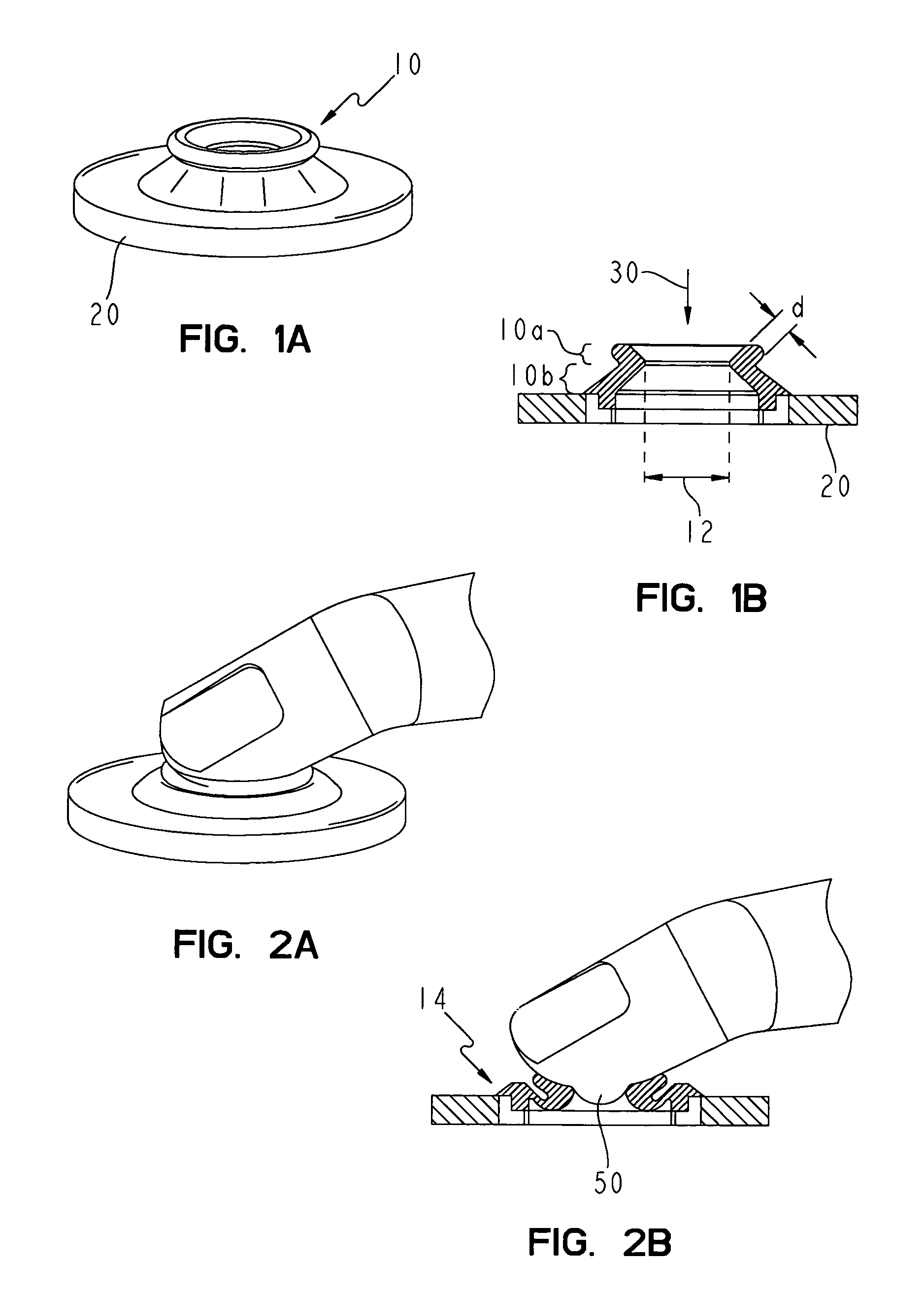

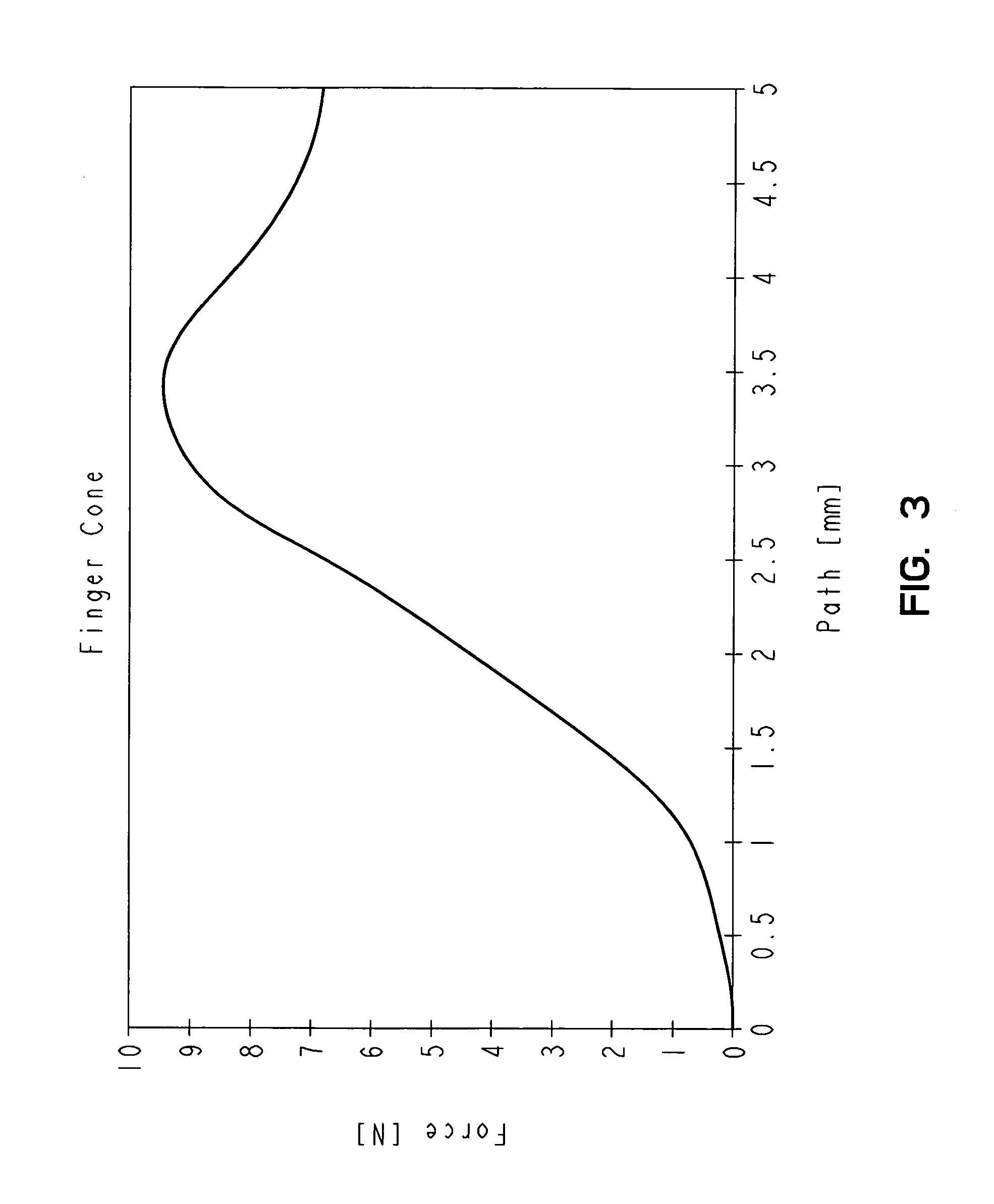

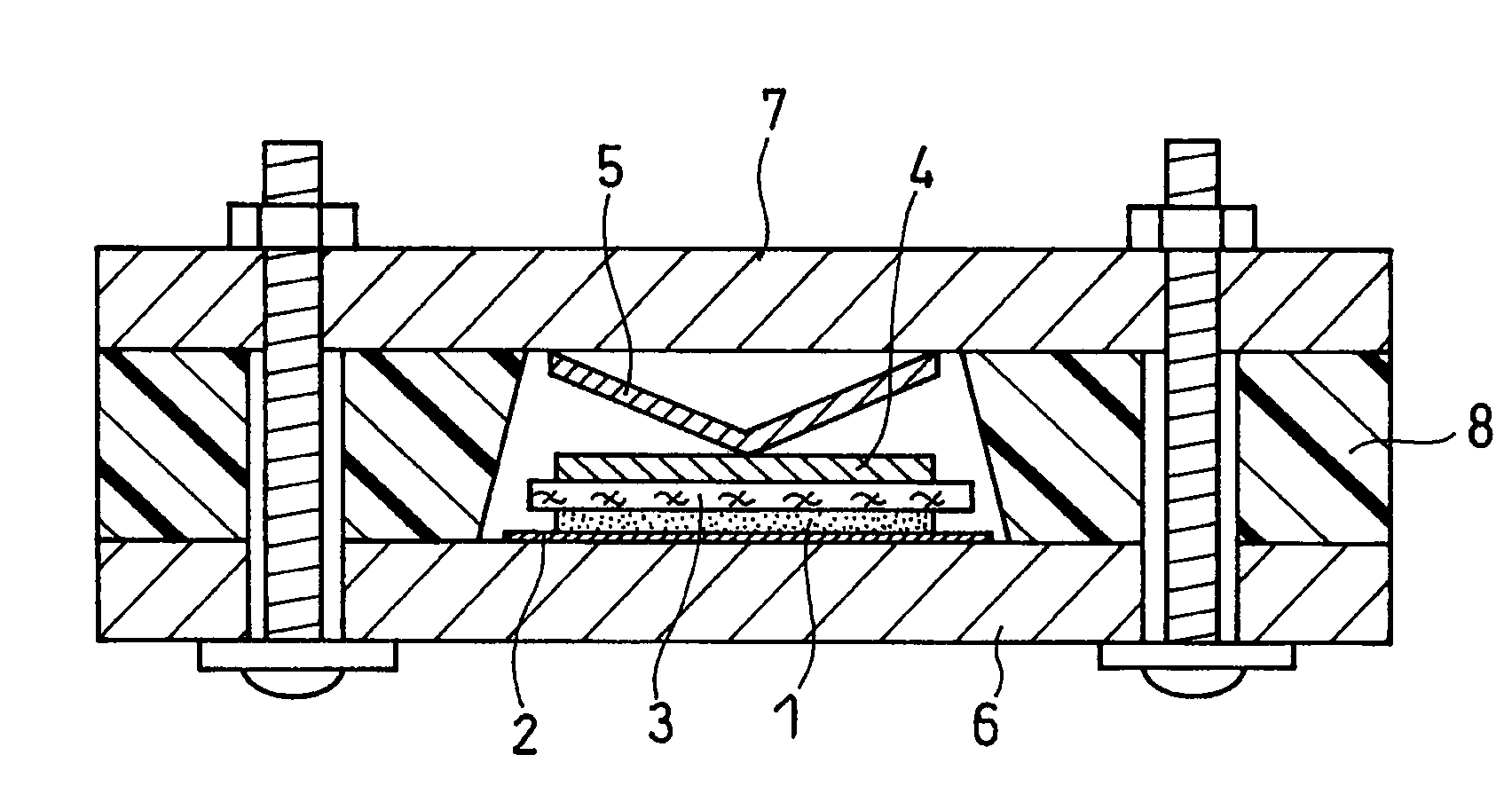

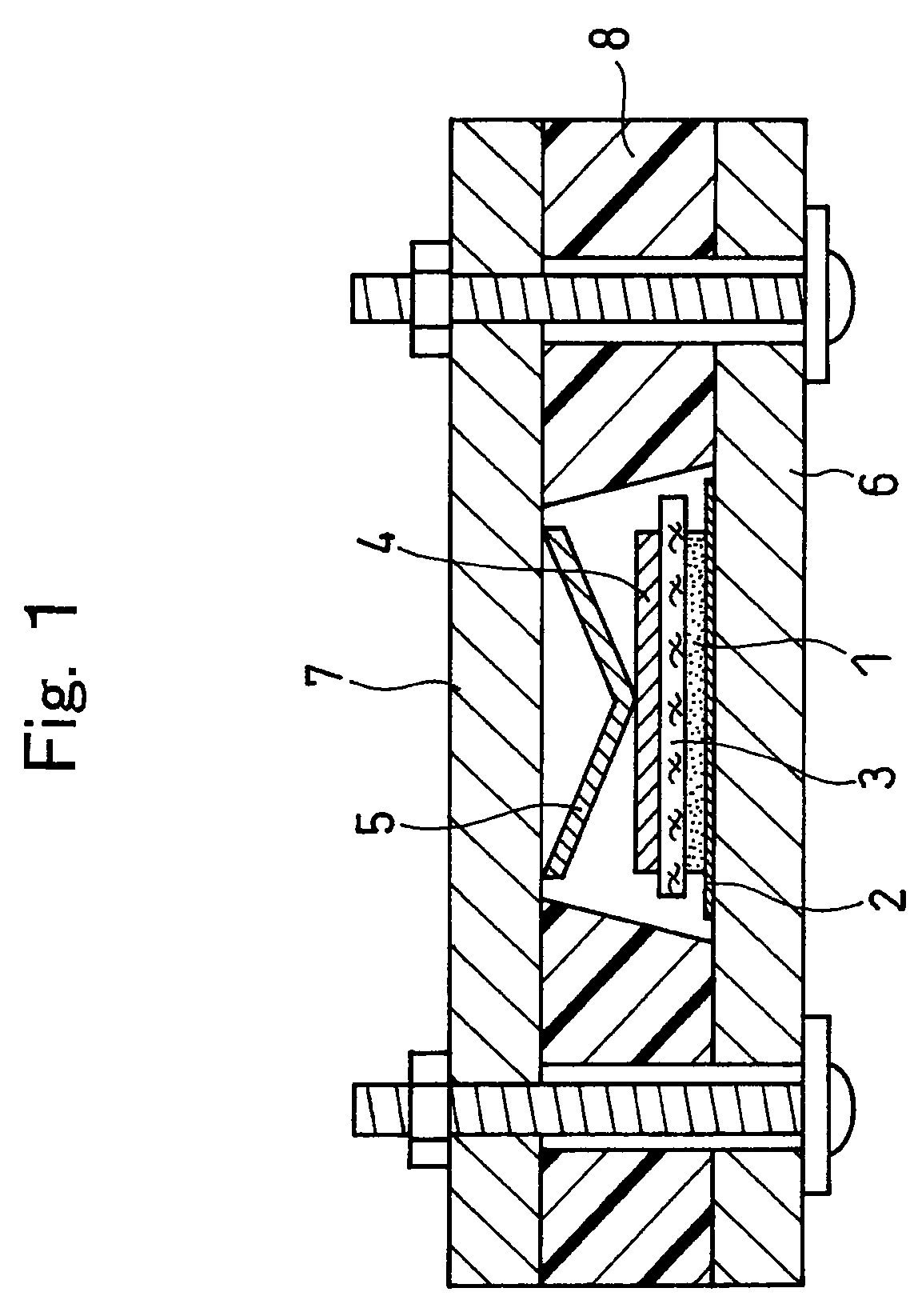

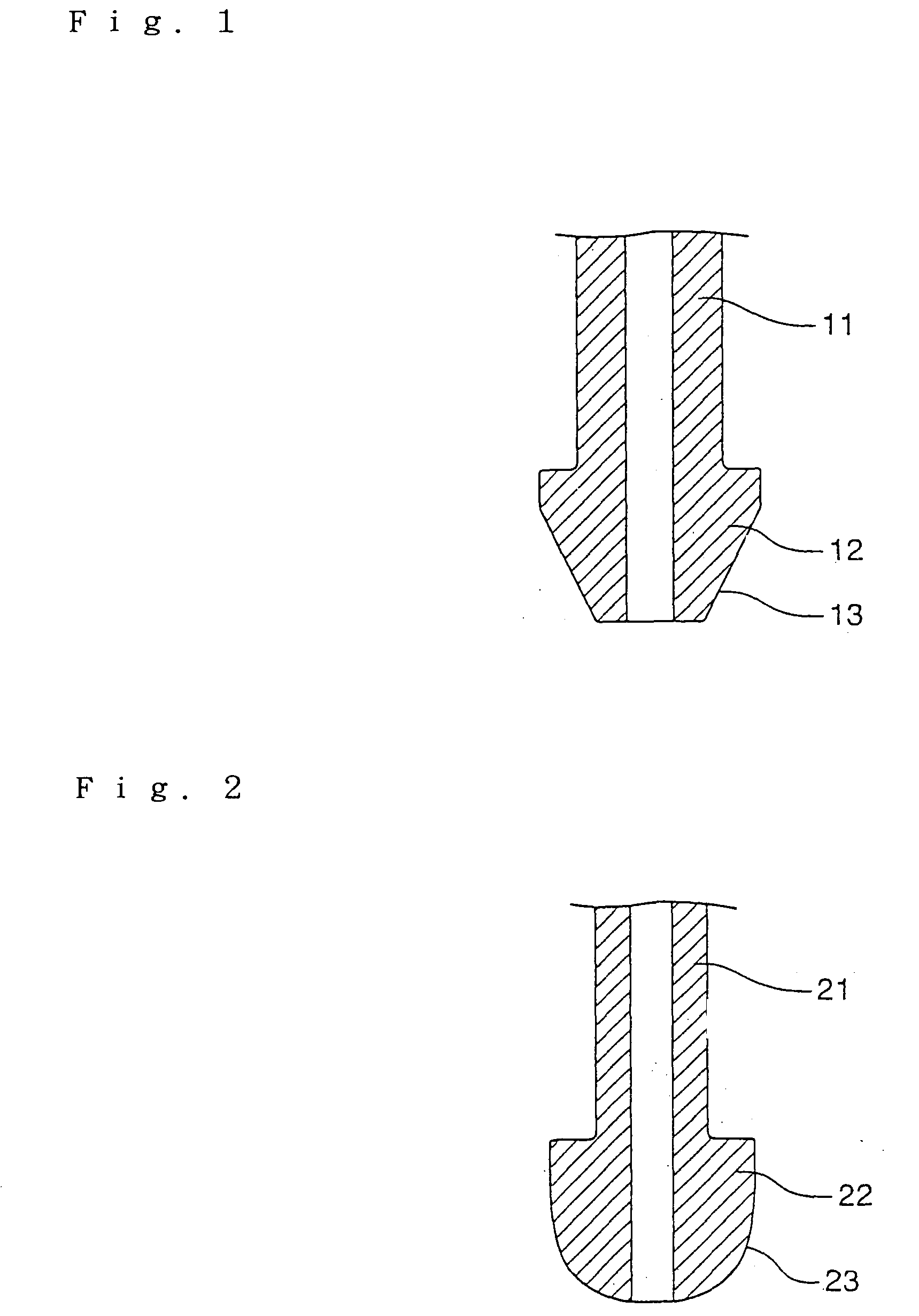

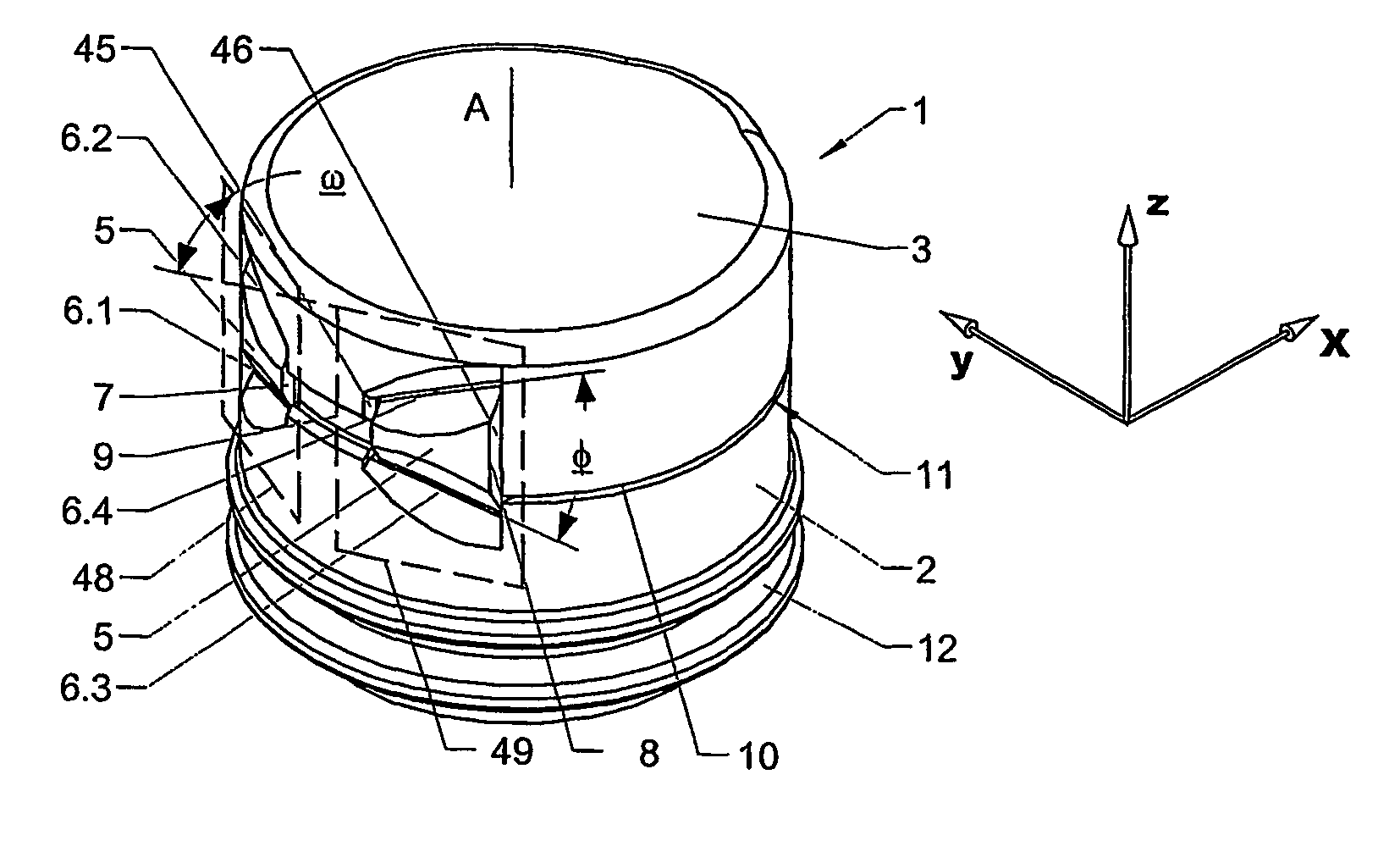

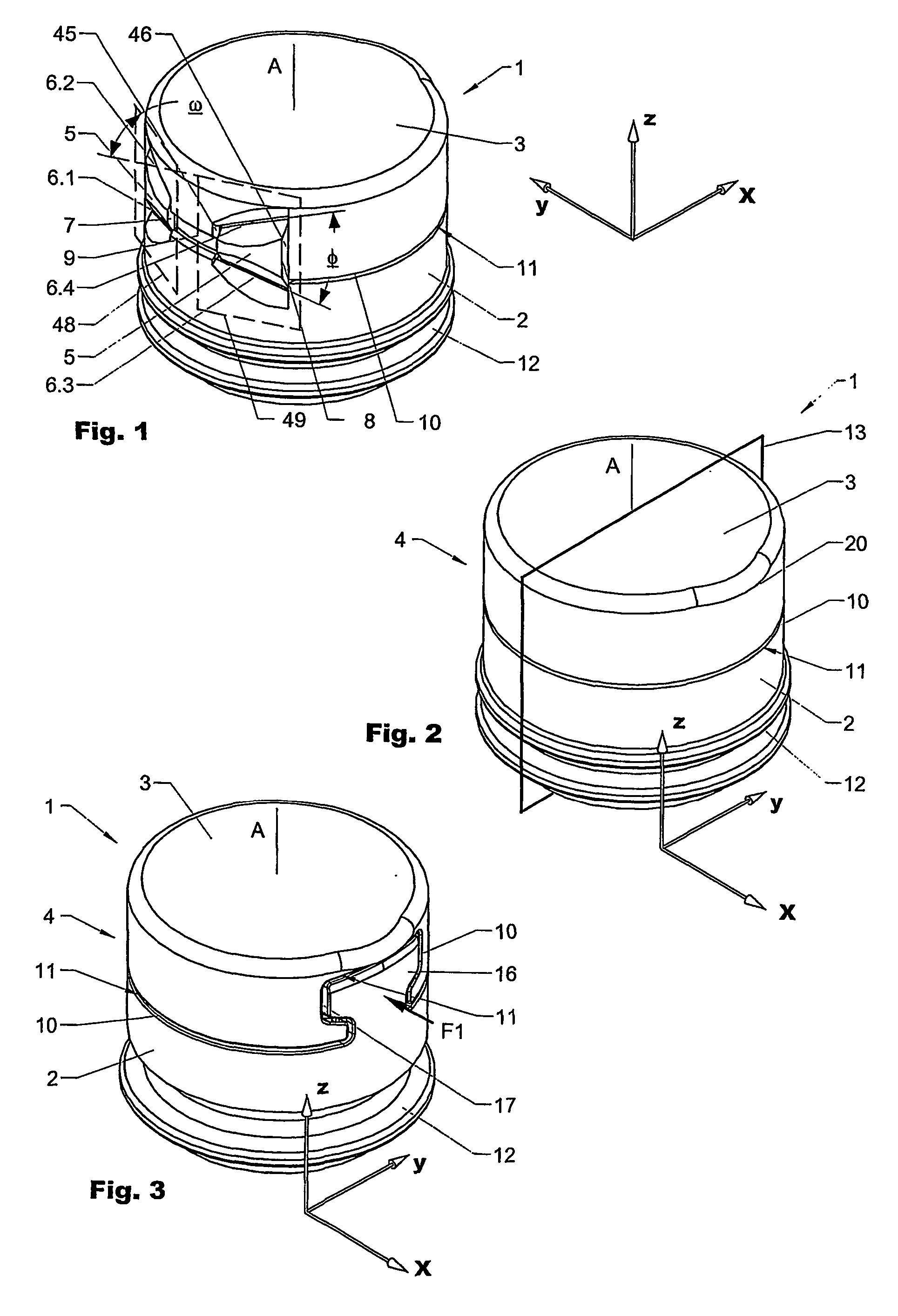

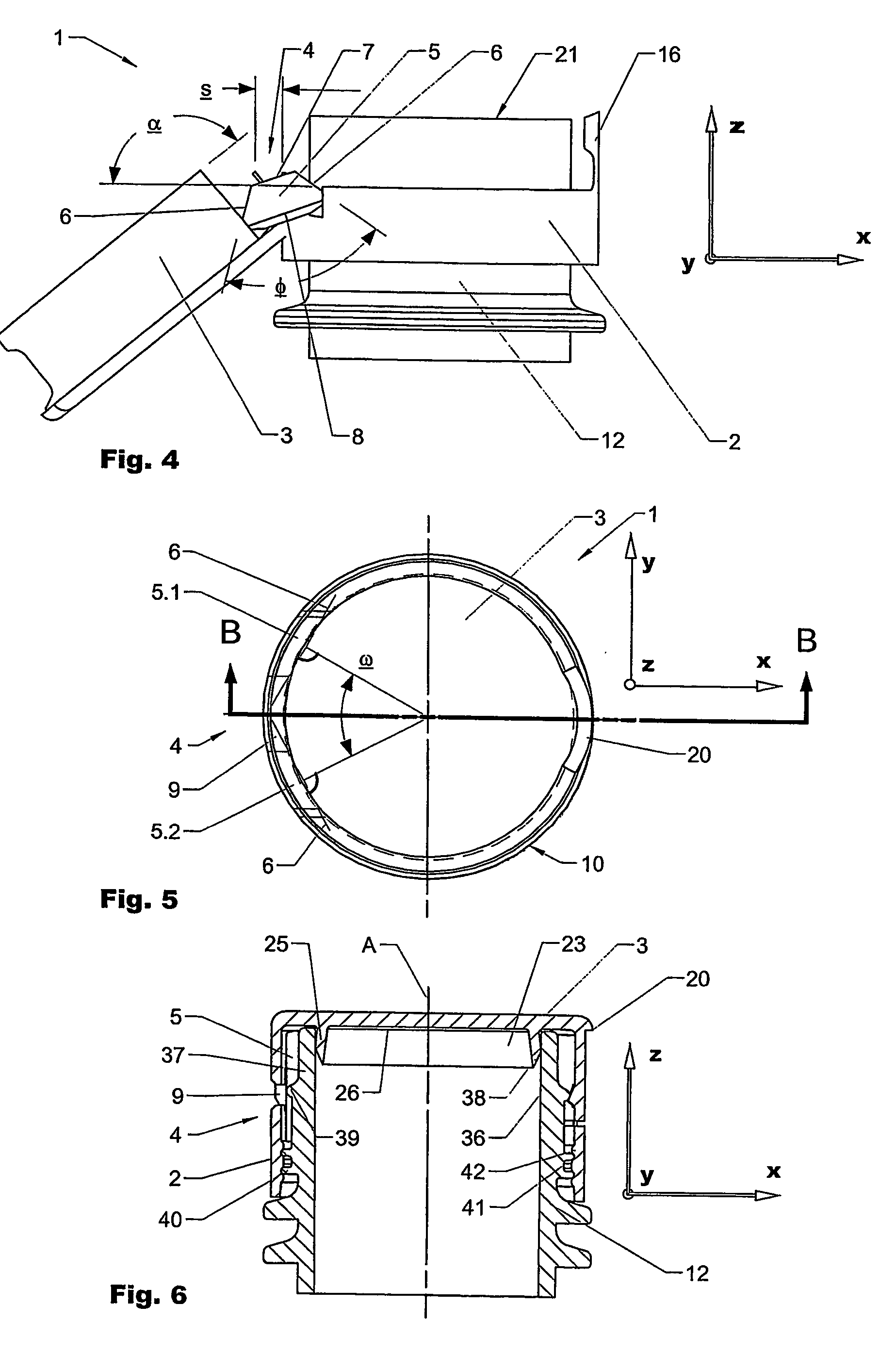

The present invention relates to a compression device for stimulating the efflux of a body fluid from a body part. The device has a compression unit with a pressure-application region made of a deformable material, the region being formed to generate a repulsive force between the body part and the compression unit. The repulsive force passes through a force maximum then decreases to serve as an indication that the body part is guided sufficiently firmly and far enough onto the compression unit.

Owner:ROCHE DIABETES CARE INC

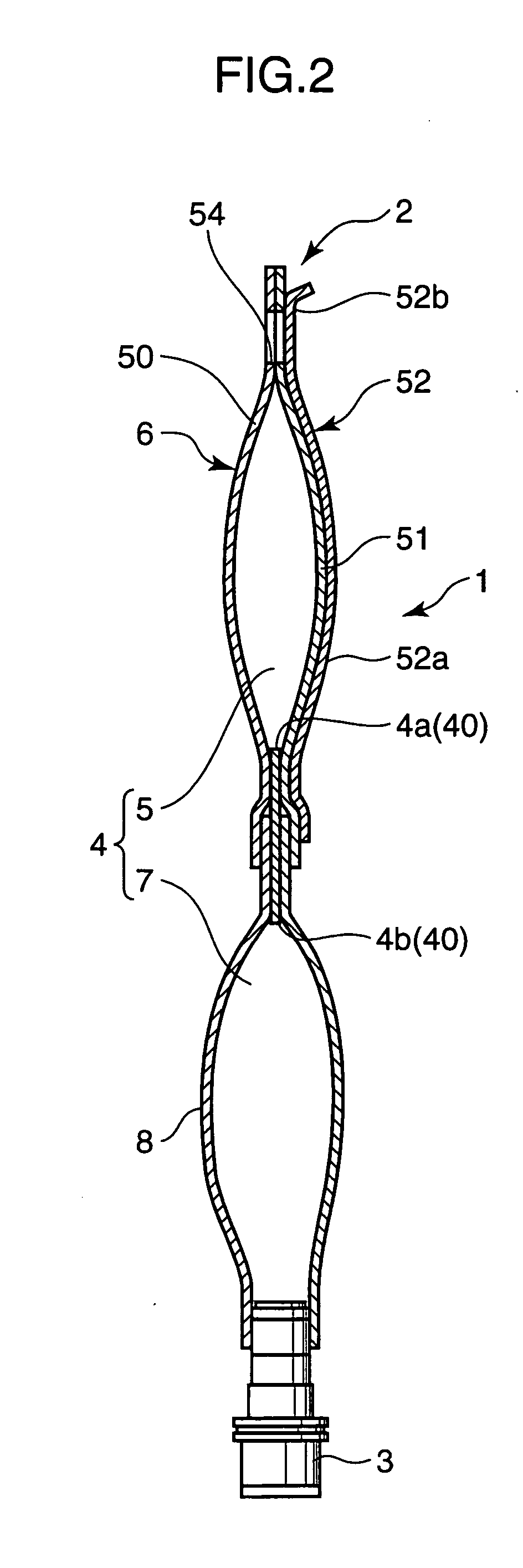

System for withdrawing body fluid

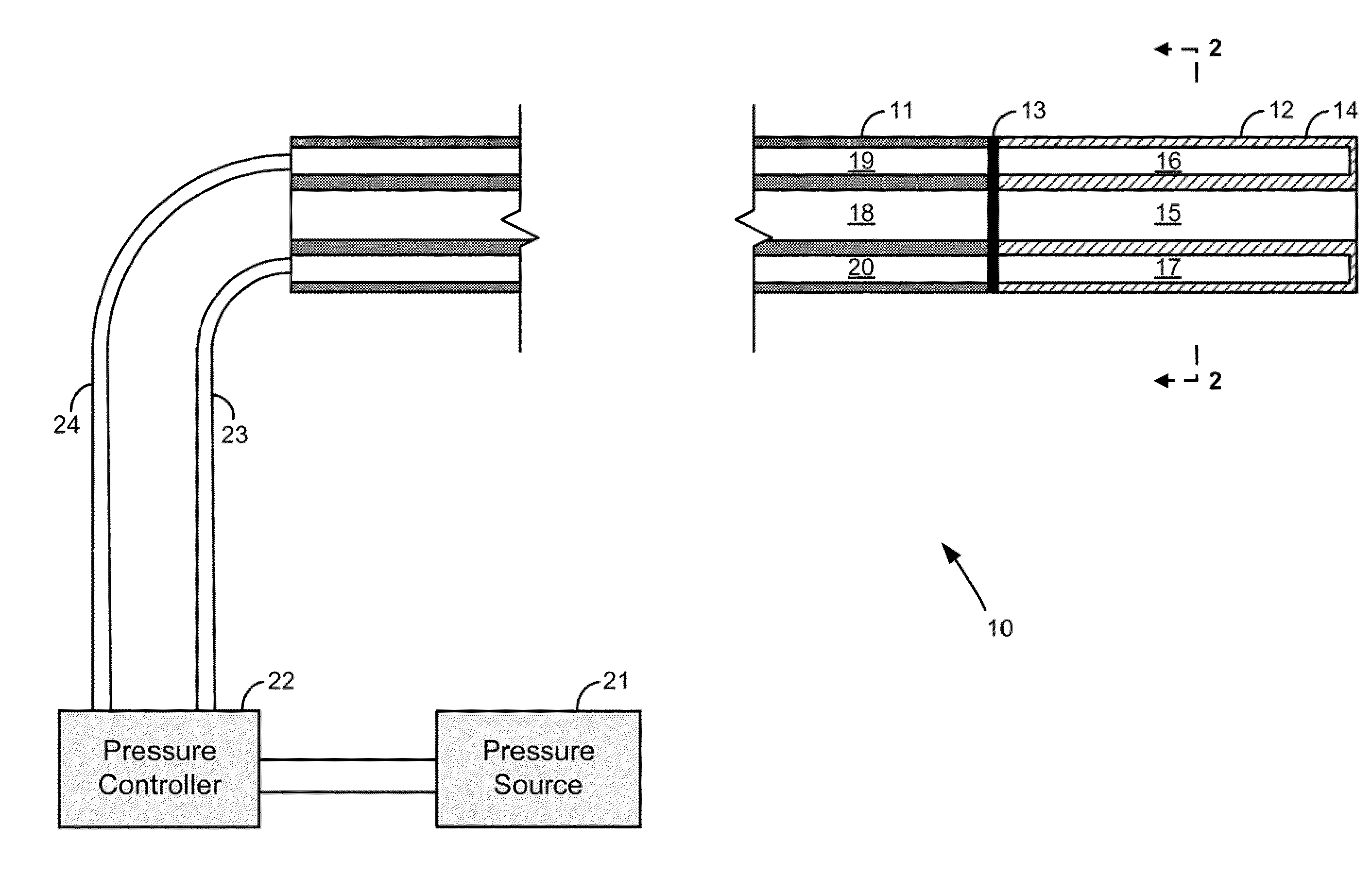

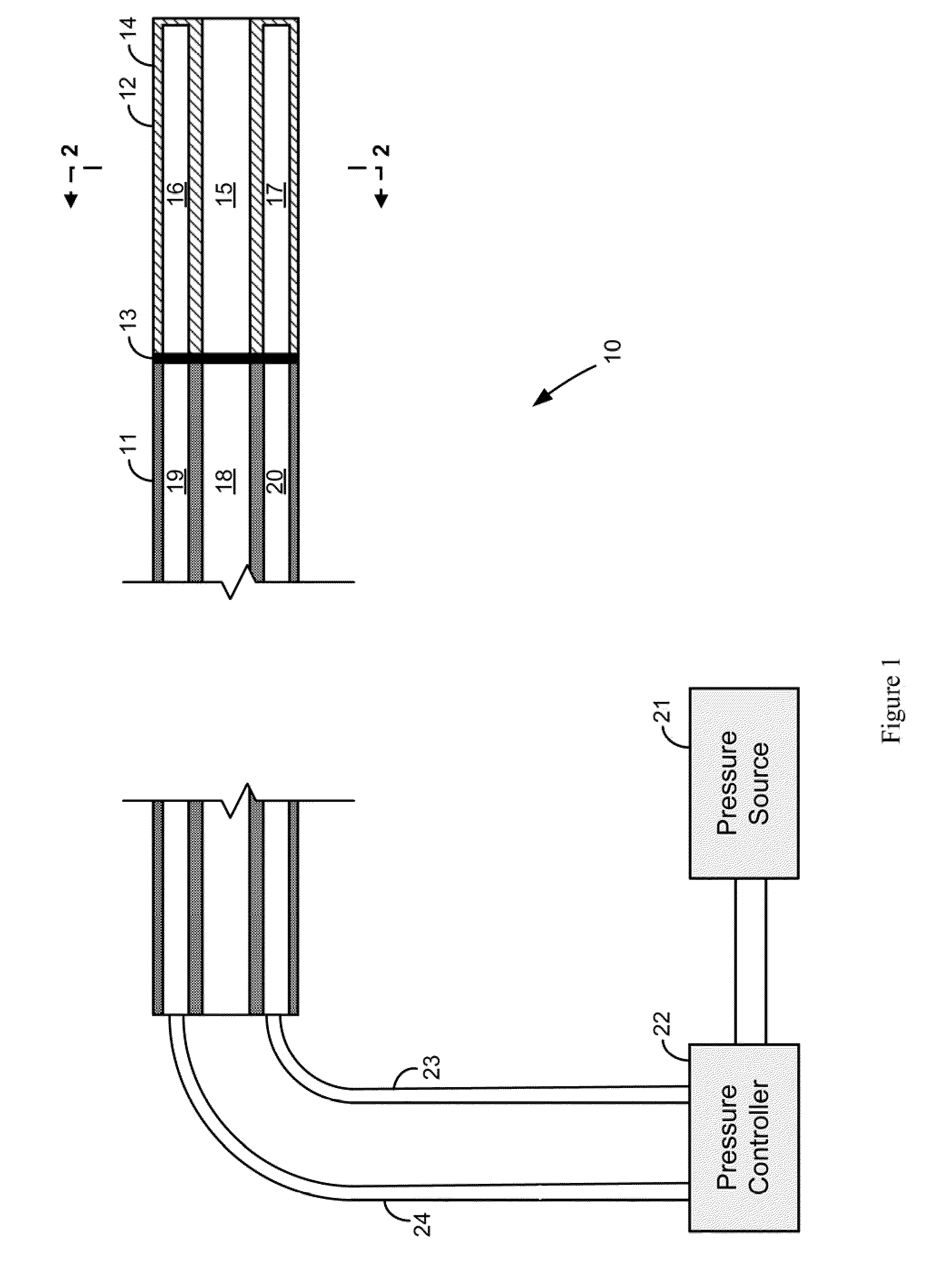

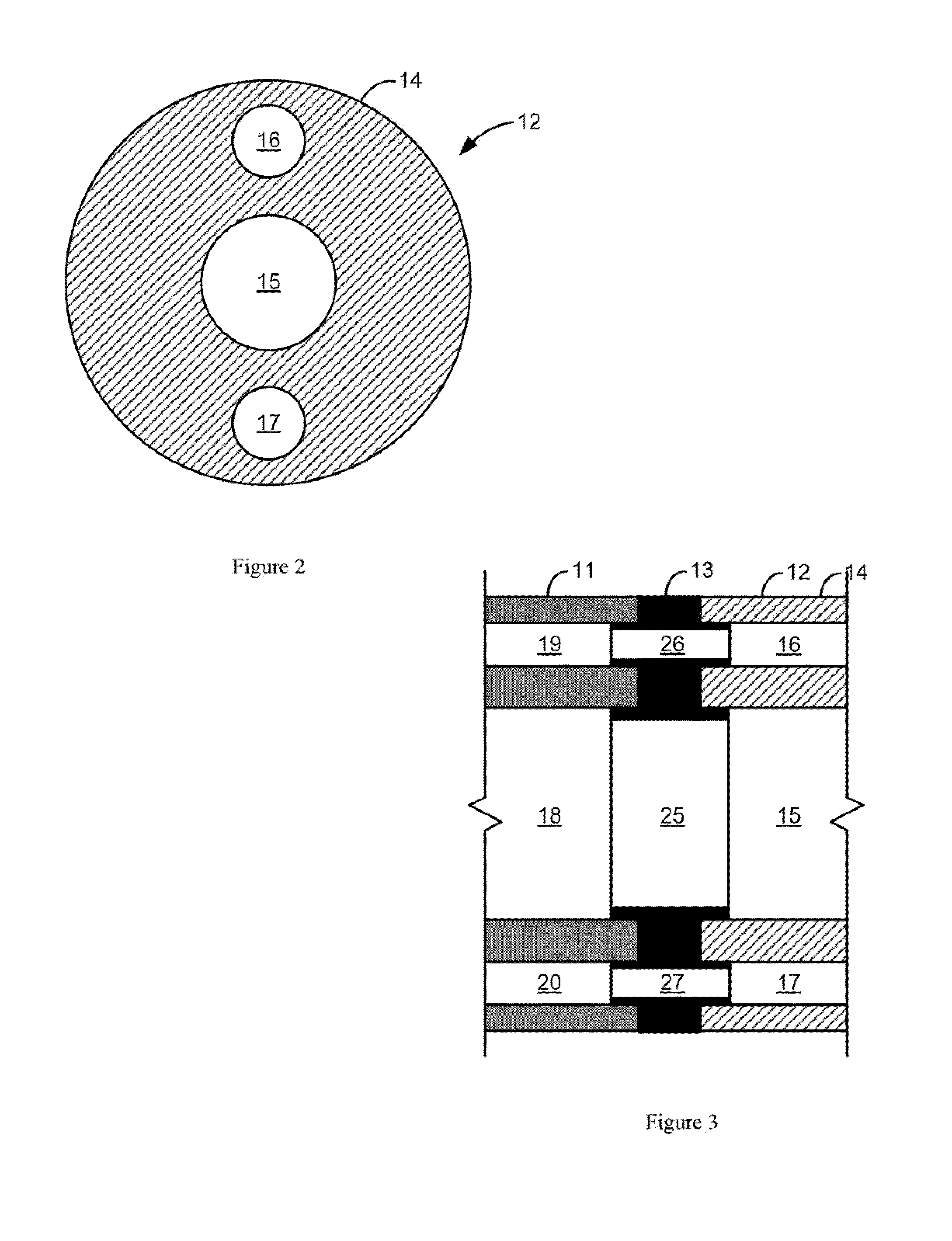

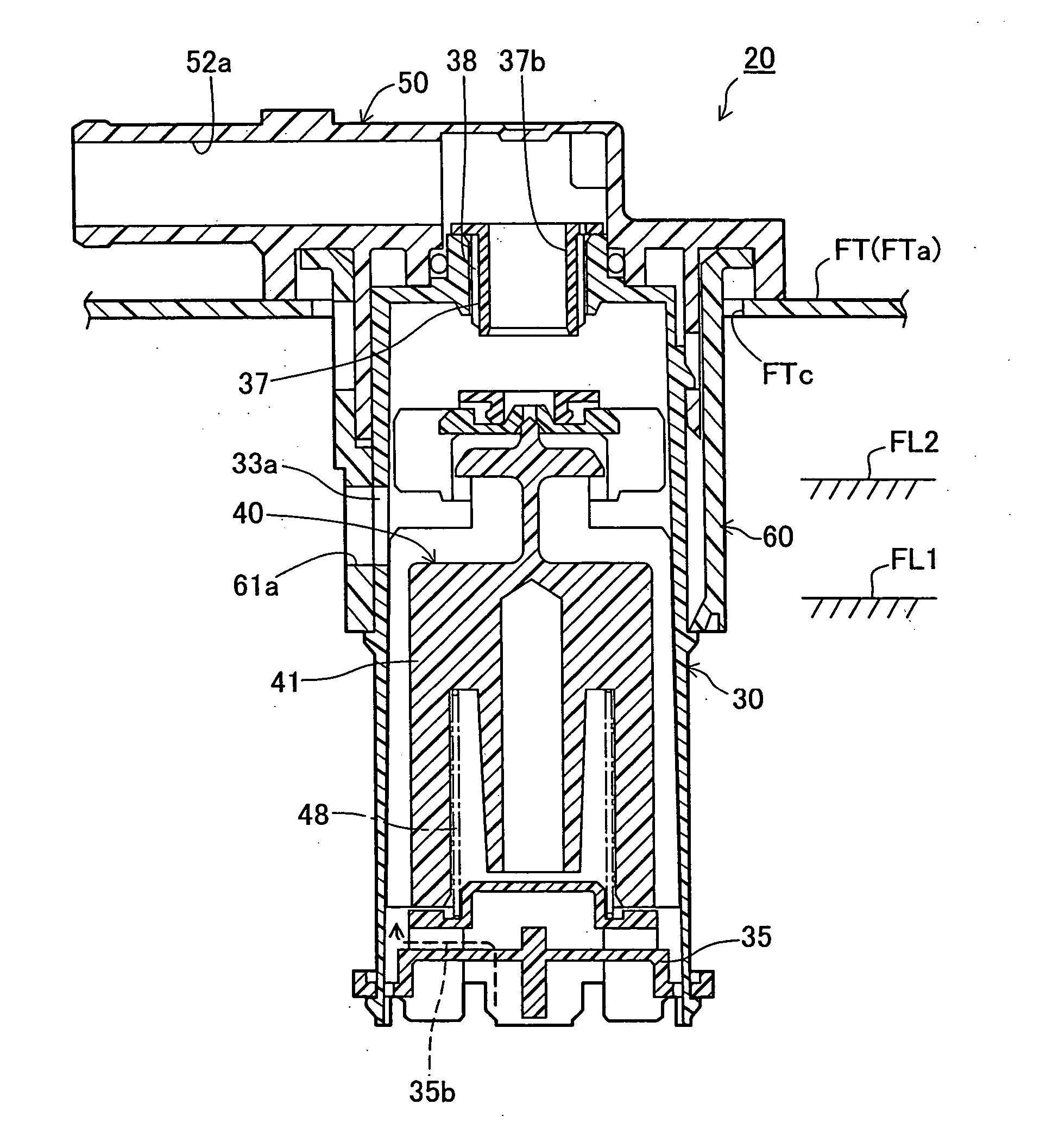

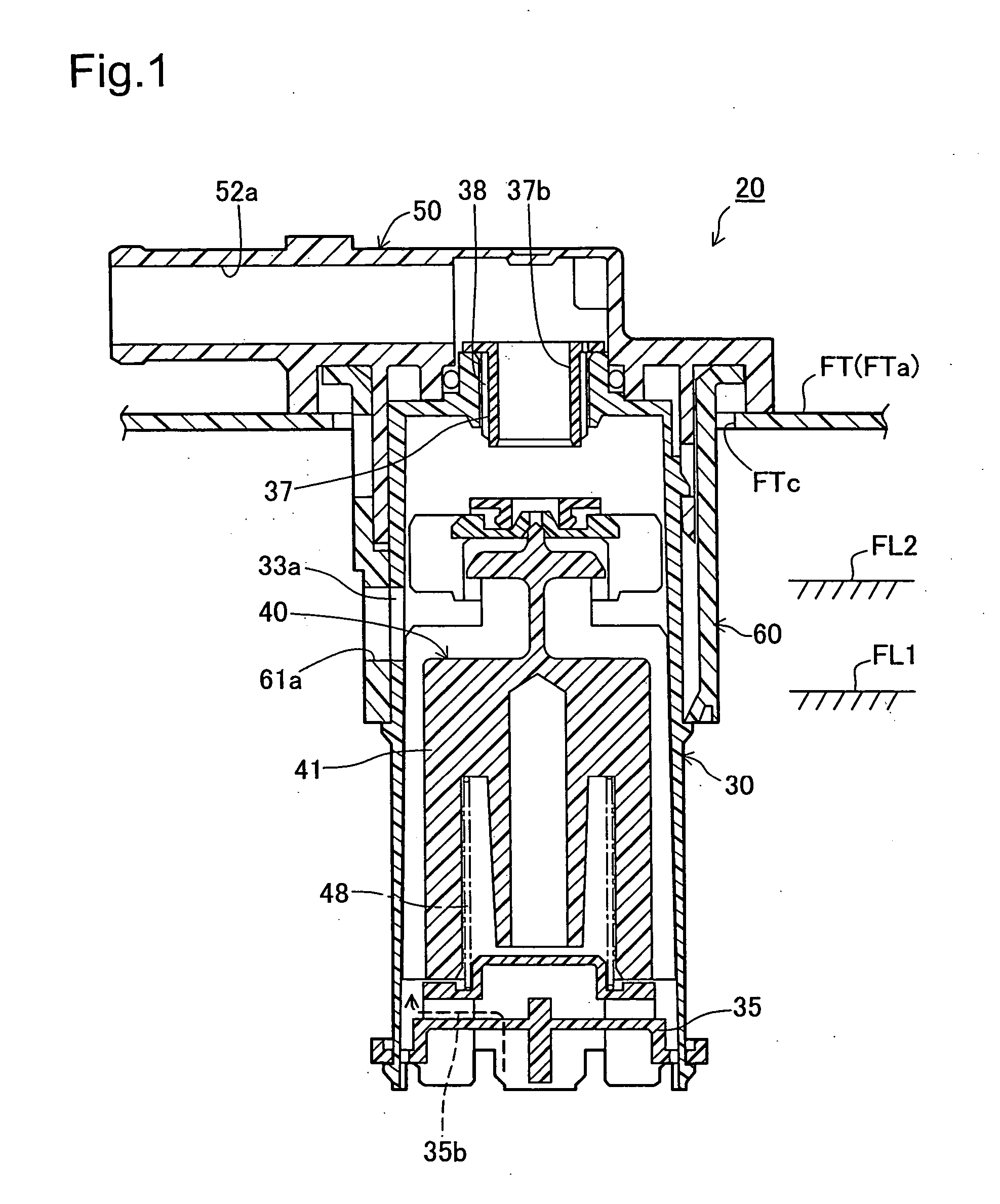

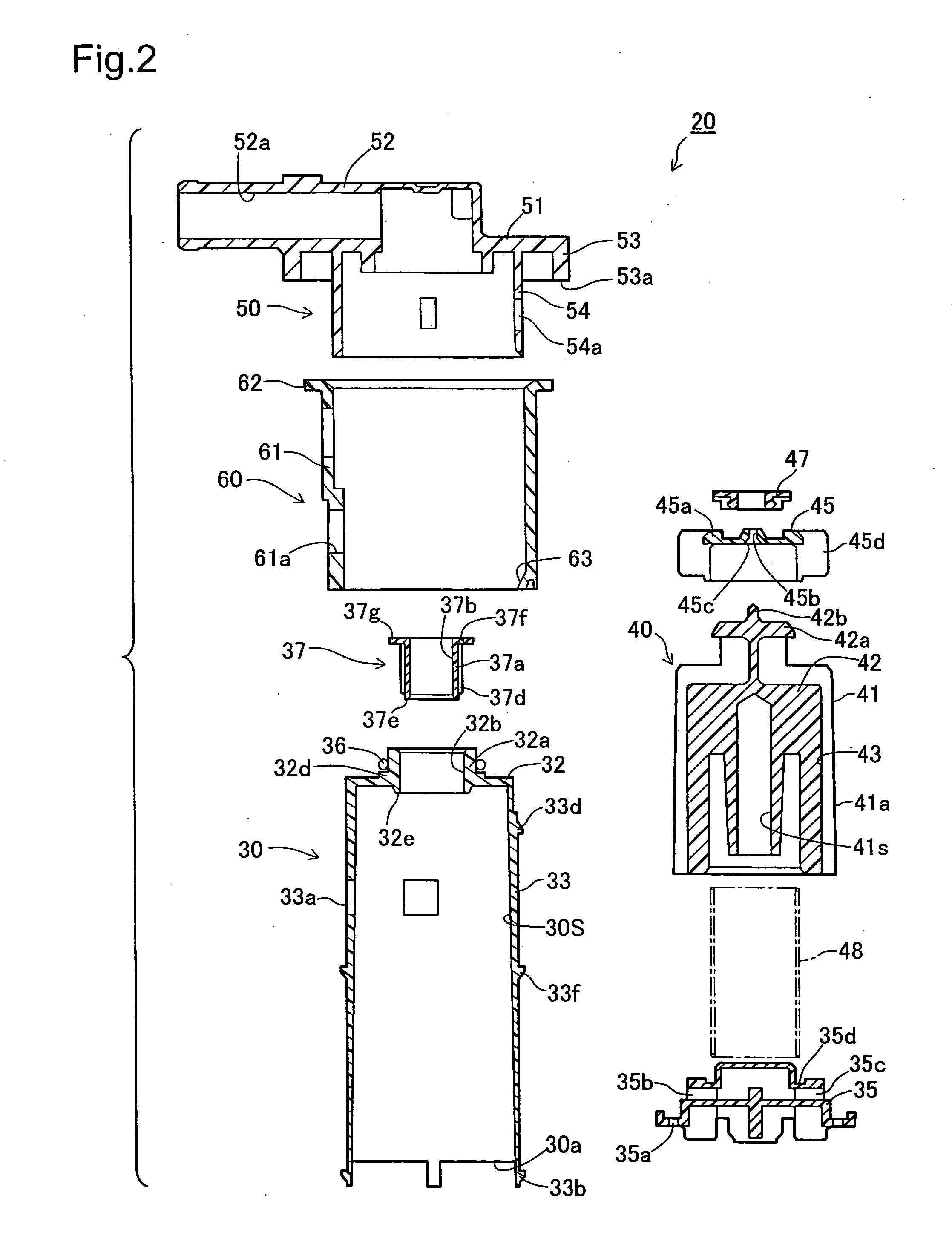

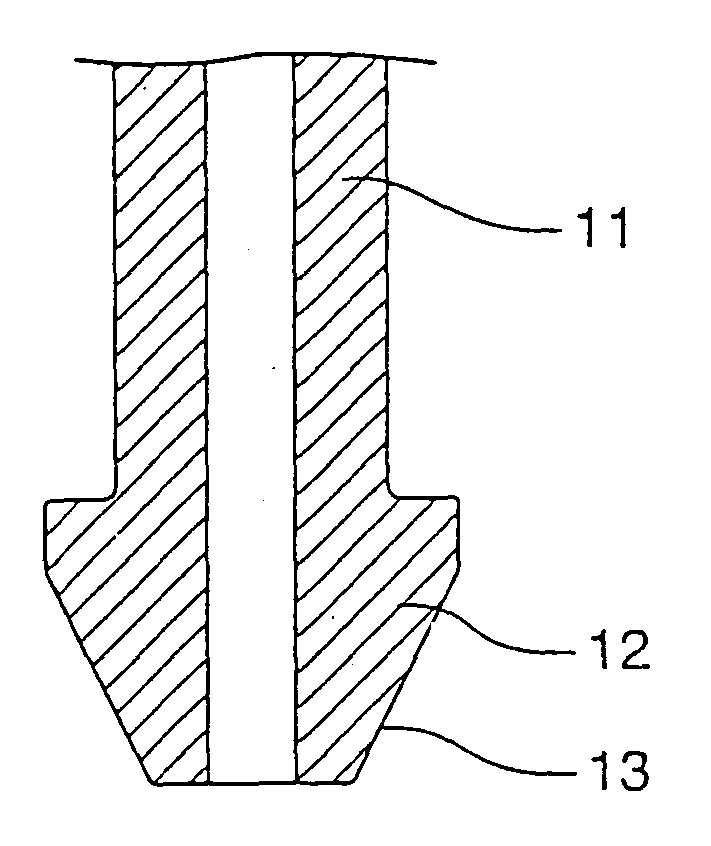

InactiveUS7291159B2Obtain goodIncrease internal pressureSensorsBiological testingInternal pressureBody area

System for withdrawing body fluid from a body part in particular the finger pad, comprising a compression unit that is deformed when the body part is pressed against it and increases the internal pressure in a region of the body part, and a withdrawal device. Deformation of the compression unit partially converts the primary pressing movement into a secondary movement which leads to an increase in the internal pressure in a region of the body part. The invention also comprises a system for stimulating the outflow of body fluid using a deformable compression unit.

Owner:ROCHE DIABETES CARE INC

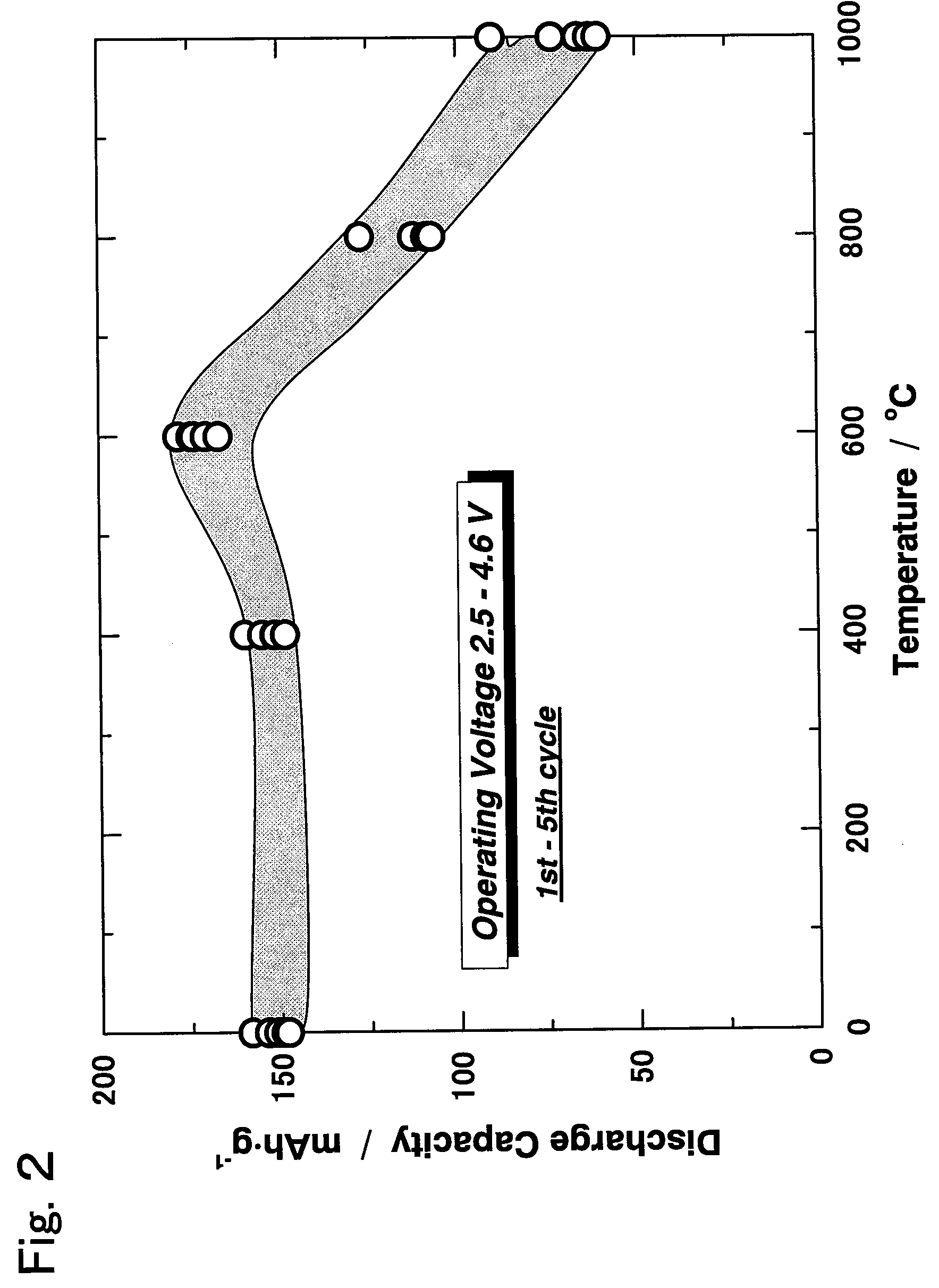

Active material for non-aqueous electrolyte secondary battery and manufacturing method therefore

ActiveUS20080268347A1Increase capacityReduces electron conductivity and lithium diffusing abilityElectrode manufacturing processesNon-aqueous electrolyte accumulatorsDesorptionX-ray

An active material for a non-aqueous electrolyte secondary battery including a lithium-containing transition metal oxide containing nickel and manganese and having a closest-packed structure of oxygen, wherein an atomic ratio MLi / MT between the number of moles of lithium MLi and the number of moles of transition metal Mt contained in the lithium-containing transition metal oxide is greater than 1.0; the lithium-containing transition metal oxide has a crystal structure attributed to a hexagonal system, and the X-ray diffraction image of the crystal structure has a peak P003 attributed to the (003) plane and a peak P104 attributed to the (104) plane; an integrated intensity ratio I003 / I104 between the peak P003 and the peak P104 varies reversibly within a range from 0.7 to 1.5 in association with absorption and desorption of lithium by the lithium-containing transition metal oxide; and the integrated intensity ratio varies linearly and continuously.

Owner:PUBLIC UNIVERSITY CORPORATION OSAKA CITY UNIVERSITY +1

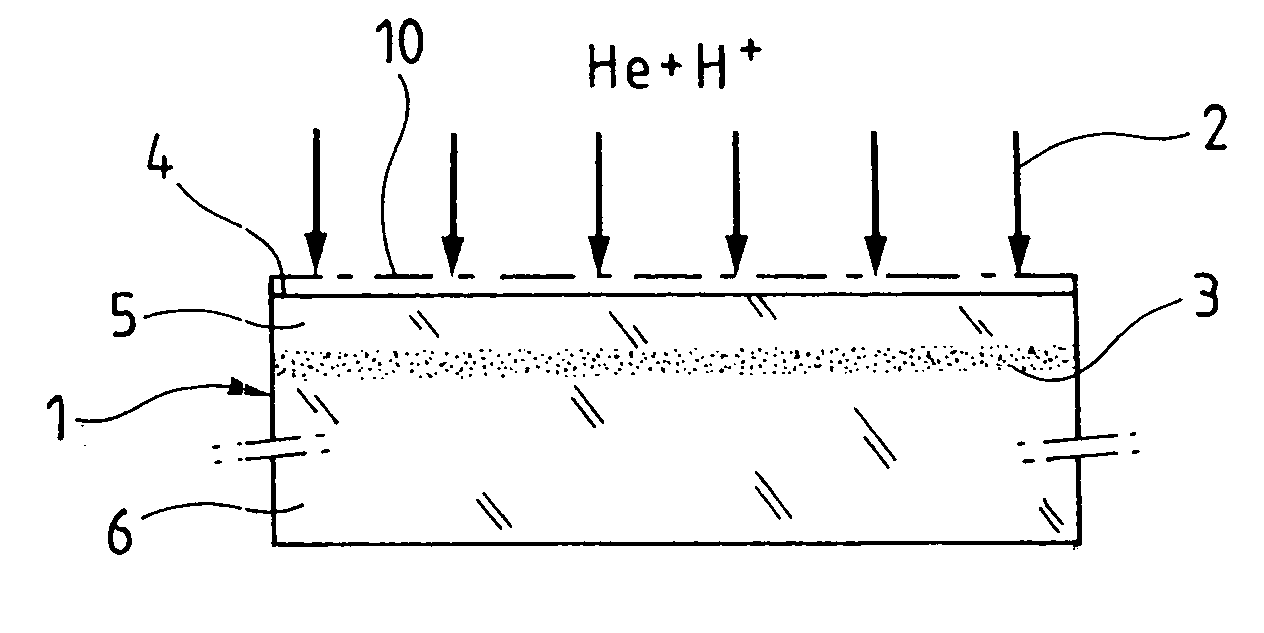

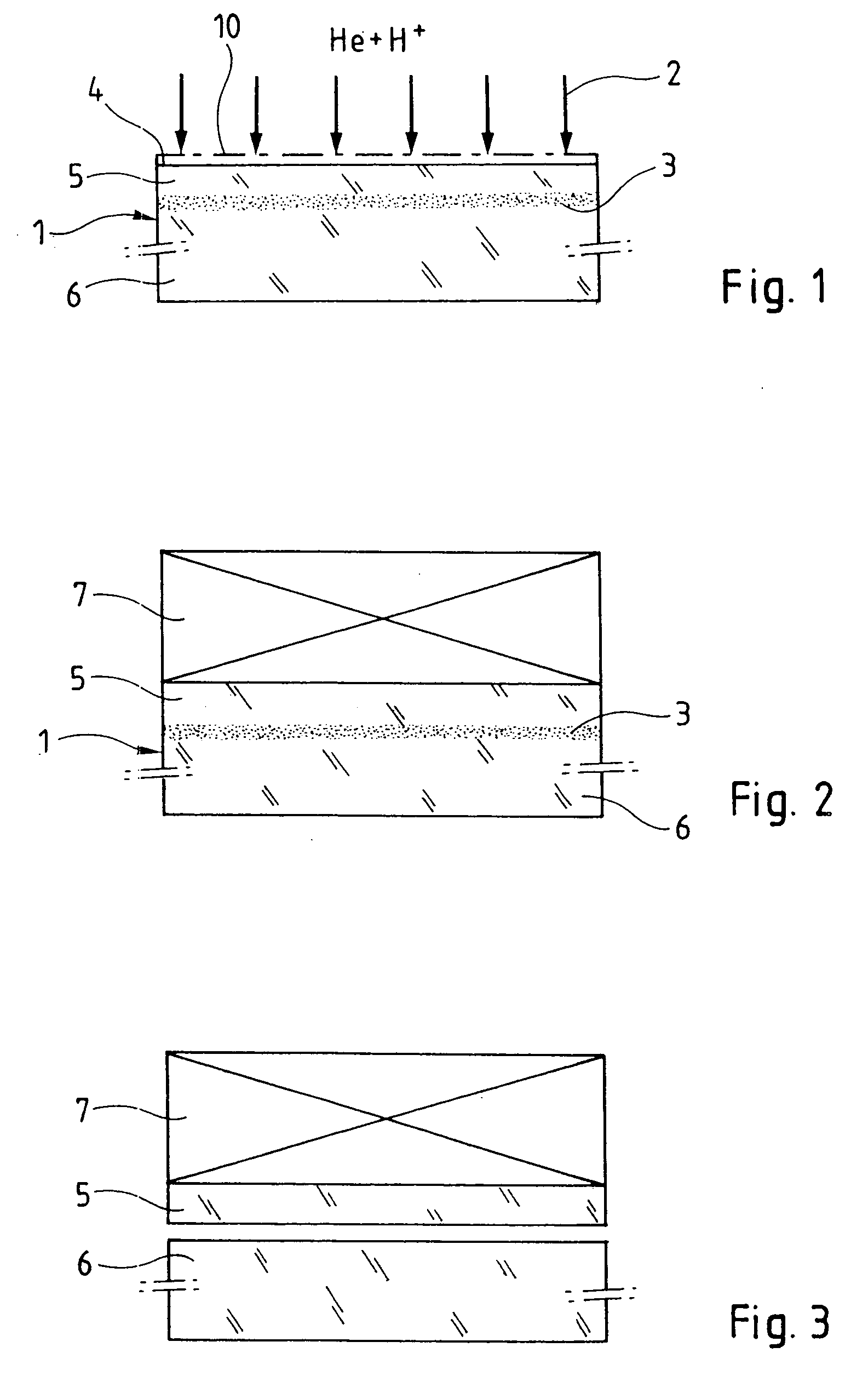

Method of detaching a thin film at moderate temperature after co-implantation

ActiveUS20040171232A1Increase internal pressureEasy to reinforceSemiconductor/solid-state device manufacturingAmount of substanceCo implantation

A method of detaching a thin film from a source substrate comprises the following steps: implanting ions or gaseous species in the source substrate so as to form therein a buried zone weakened by the presence of defects; splitting in the weakened zone leading to the detachment of the thin film from the source substrate. Two species are implanted of which one is adapted to form defects and the other is adapted to occupy those defects, the detachment being made at a temperature lower than that for which detachment could be obtained with solely the dose of the first species.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

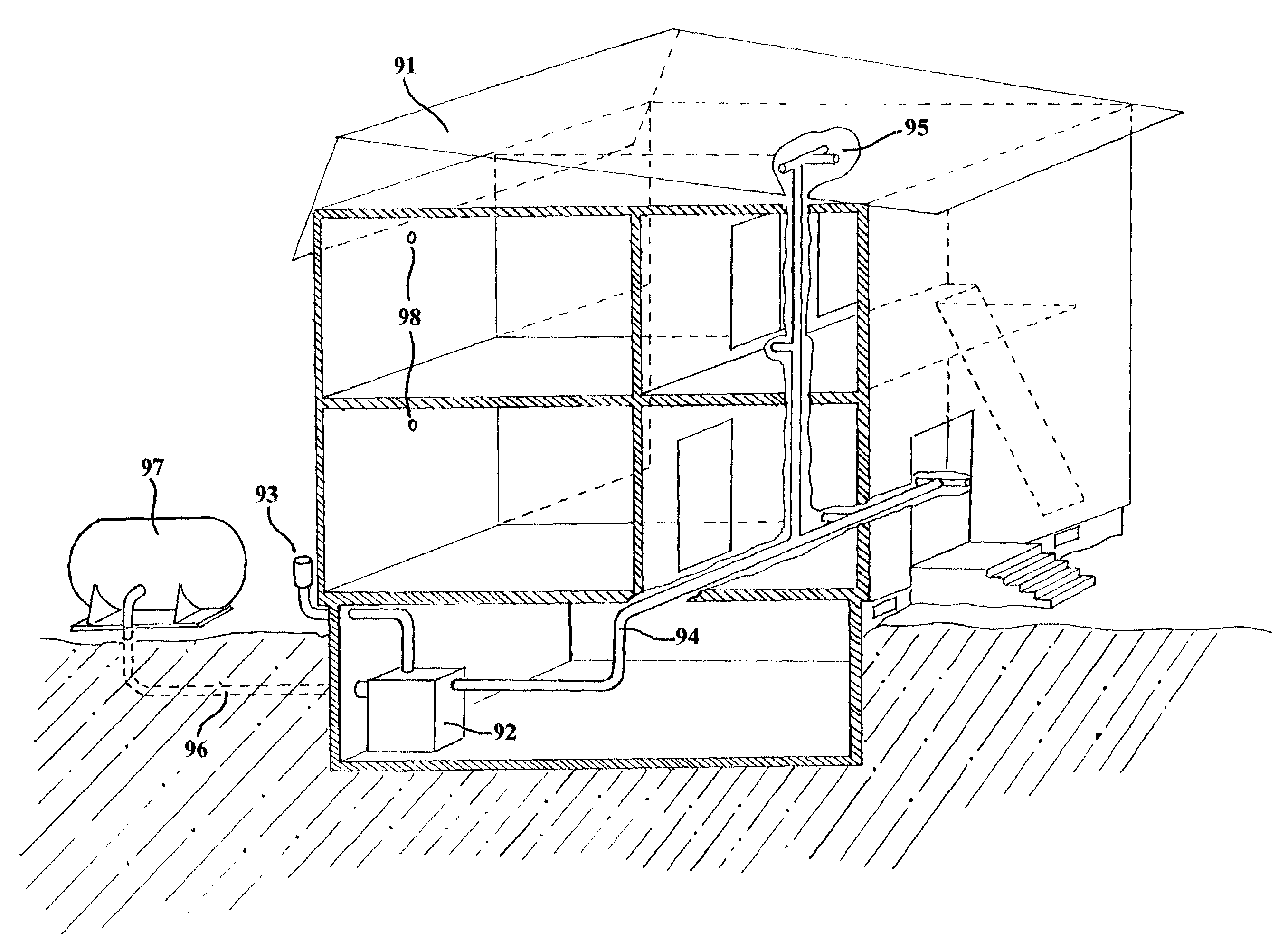

Hypoxic fire prevention and fire suppression systems with breathable fire extinguishing compositions for human occupied environments

InactiveUS20020023762A1Strong lightIncrease internal pressureSolidificationLiquefactionOn boardAmbient pressure

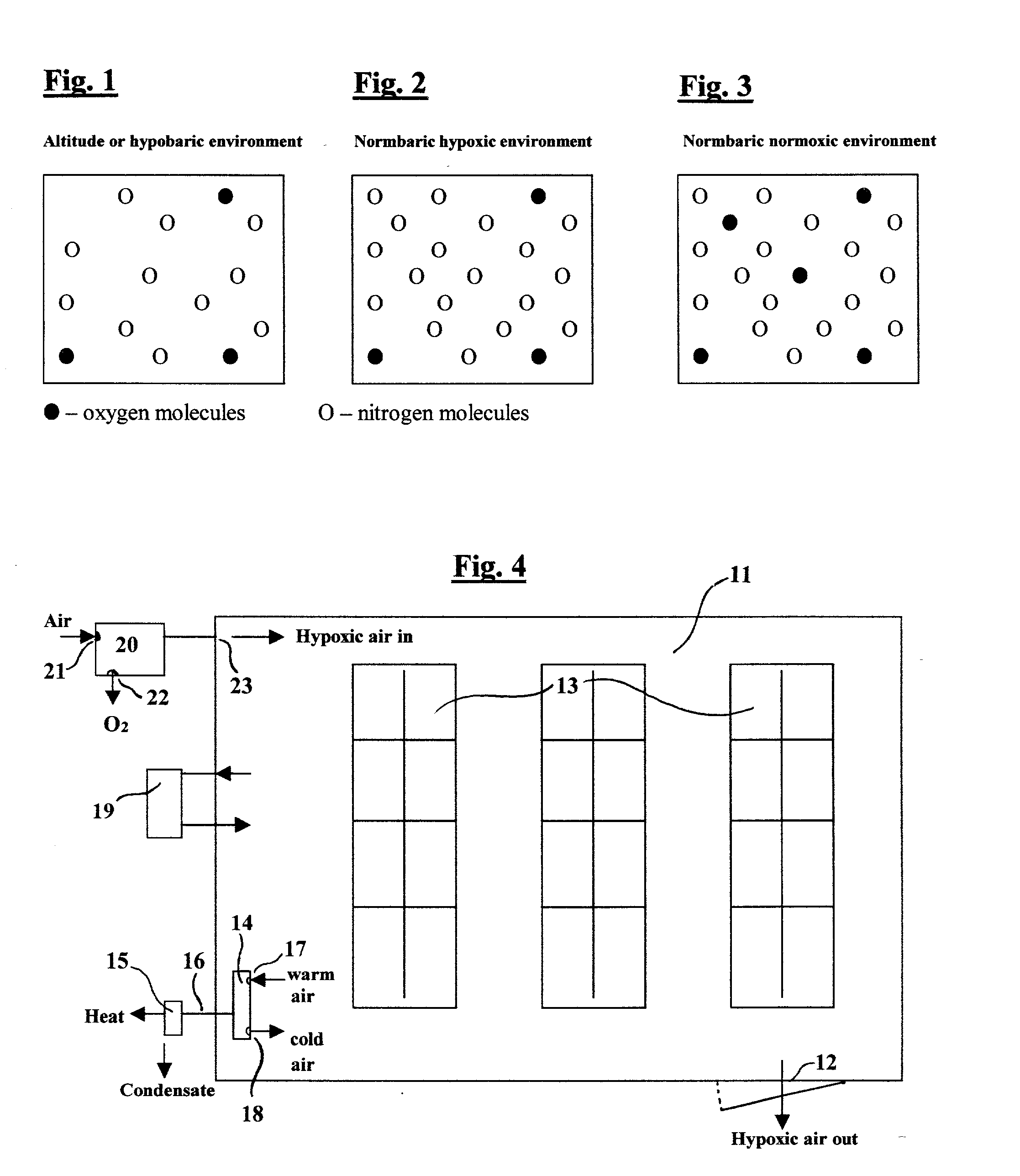

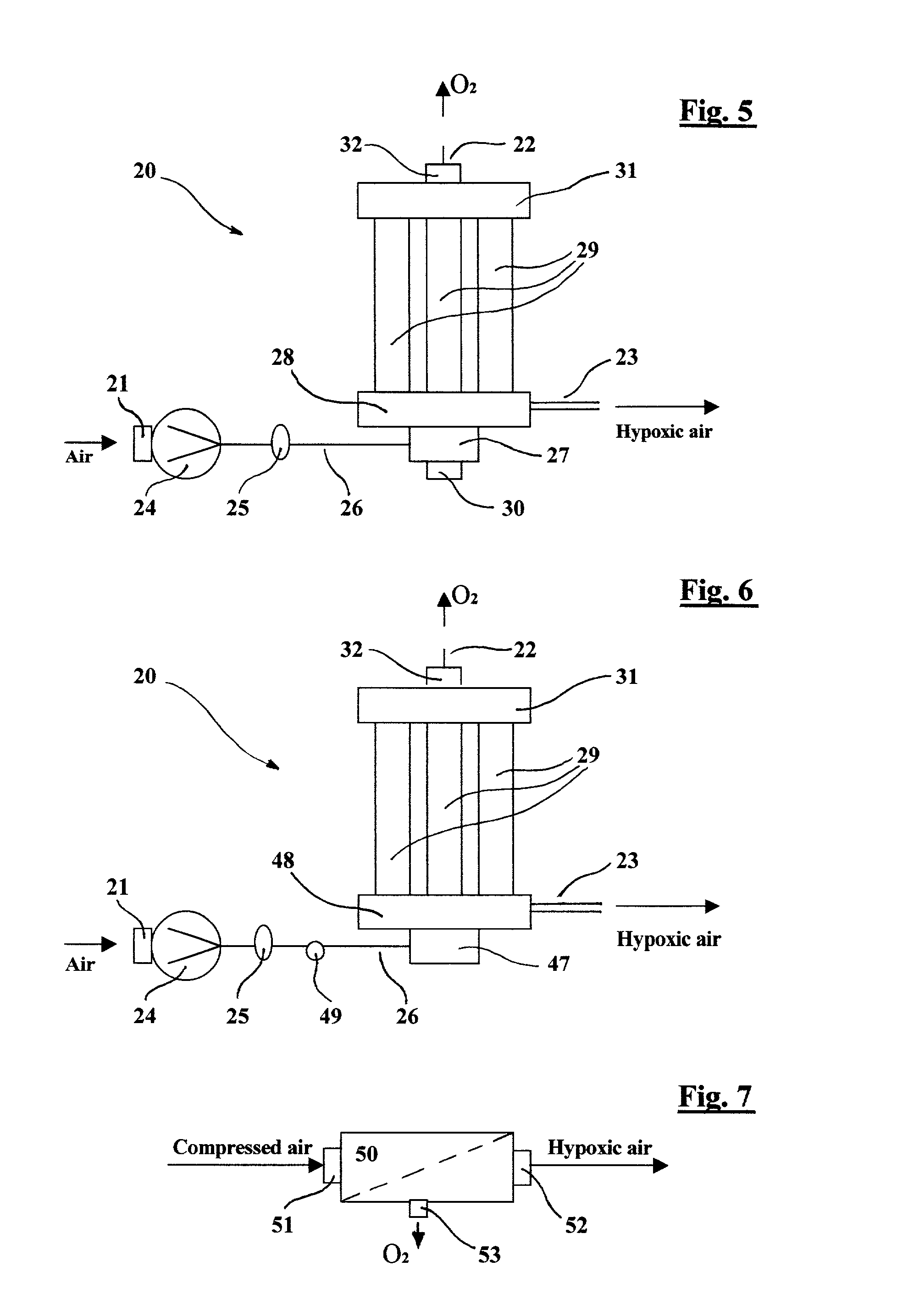

Fire prevention and suppression systems and breathable fire-extinguishing compositions are provided for rooms, houses and buildings, transportation tunnels and vehicles, underground and underwater facilities, marine vessels, submarines, passenger and military aircraft, space stations and vehicles, military installations and vehicles, and all other human occupied objects and facilities. The system provides a breathable hypoxic fire-preventative atmosphere at standard atmospheric or local ambient pressure. The system employs an oxygen-extraction apparatus supplying oxygen-depleted air inside a human-occupied area or storing it in a high-pressure container for use in case of fire. A breathable fire-extinguishing composition is introduced for constant fire-preventive environments, being mostly a mixture of nitrogen and oxygen and having oxygen content ranging from 12% to 17%. A fire-suppression system is provided employing a fire-extinguishing composition with oxygen concentration under 16%, so when released it creates a breathable fire-suppressive atmosphere having oxygen concentration of approximately 16% (or lower if needed) with possible addition of carbon dioxide. A technology for automatically maintaining a breathable fire-preventive composition on board a human-occupied hermetic object is provided by introducing inert ballast that automatically maintains oxygen content under the Hypoxic Threshold. An aircraft fire prevention and suppression systems are provided utilizing hypoxic fire extinguishing compositions for producing breathable atmosphere onboard having fire-retarding properties.

Owner:FIREPASS CORP

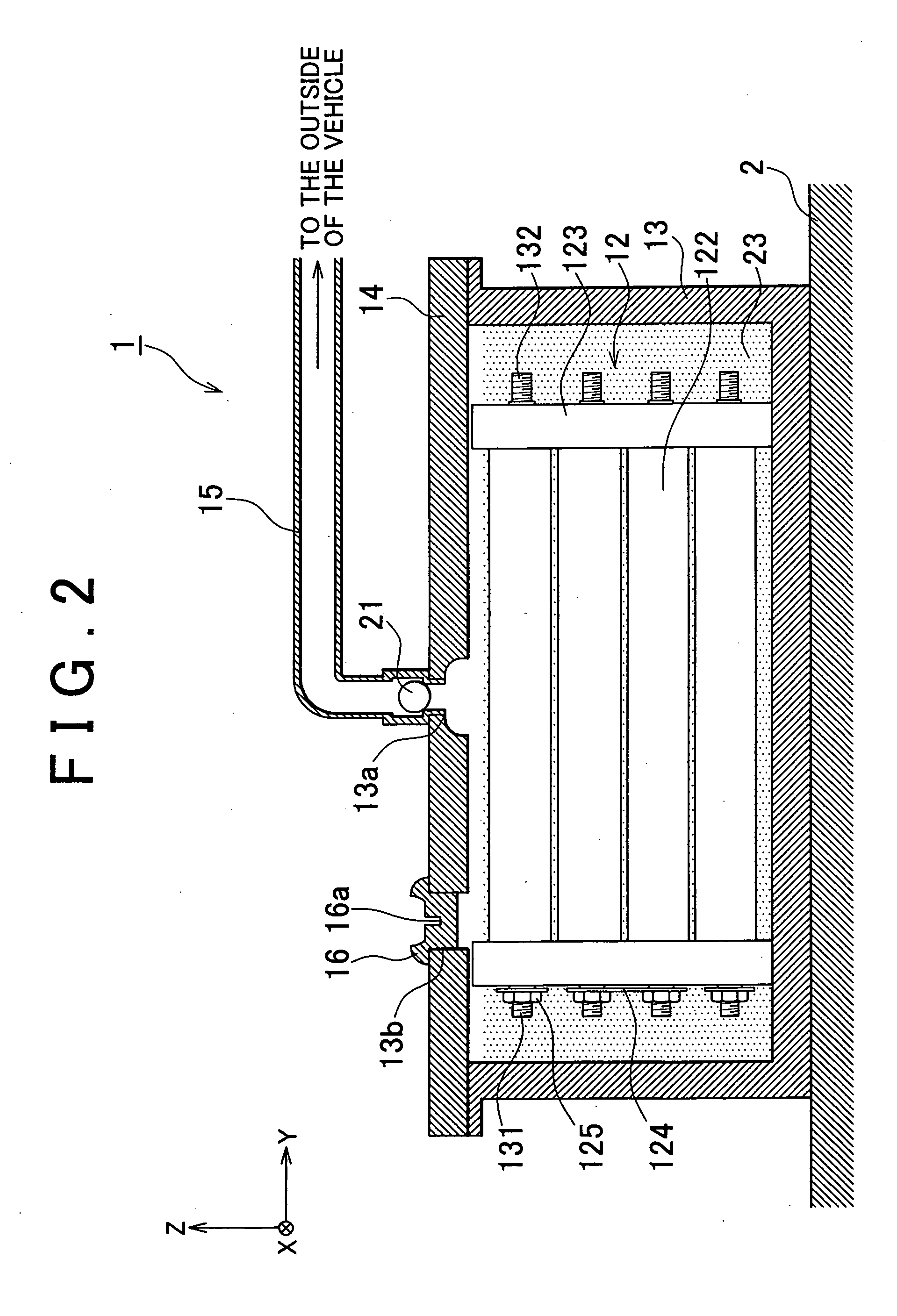

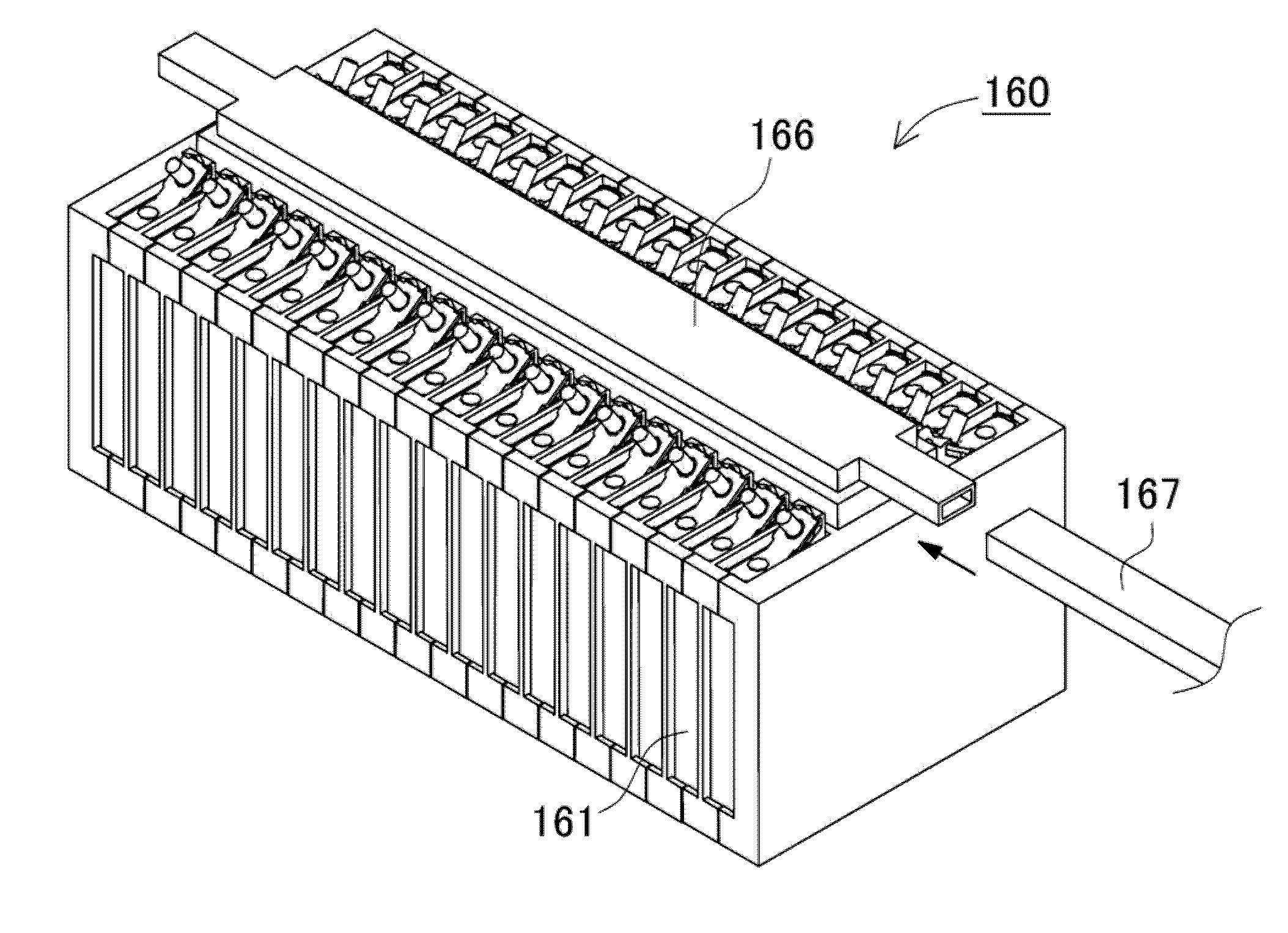

Vehicle power storage unit and vehicle

InactiveUS20080318121A1Increase internal pressureGrowth inhibitionElectric devicesCell temperature controlProduct gasCoolant

A vehicle power storage unit, has: a power storage assembly; a coolant for cooling the power storage assembly; a casing having a coolant inlet through which the coolant is filled into the casing and containing the coolant and the power storage assembly; a gas-discharge pipe through which gas produced by the power storage assembly is discharged from the casing to the outside of a passenger compartment or a trunk of the vehicle; and a first pressure-release valve which is provided at the coolant inlet and through which the pressure in the casing is released to the outside when gas is produced by the power storage assembly.

Owner:TOYOTA JIDOSHA KK

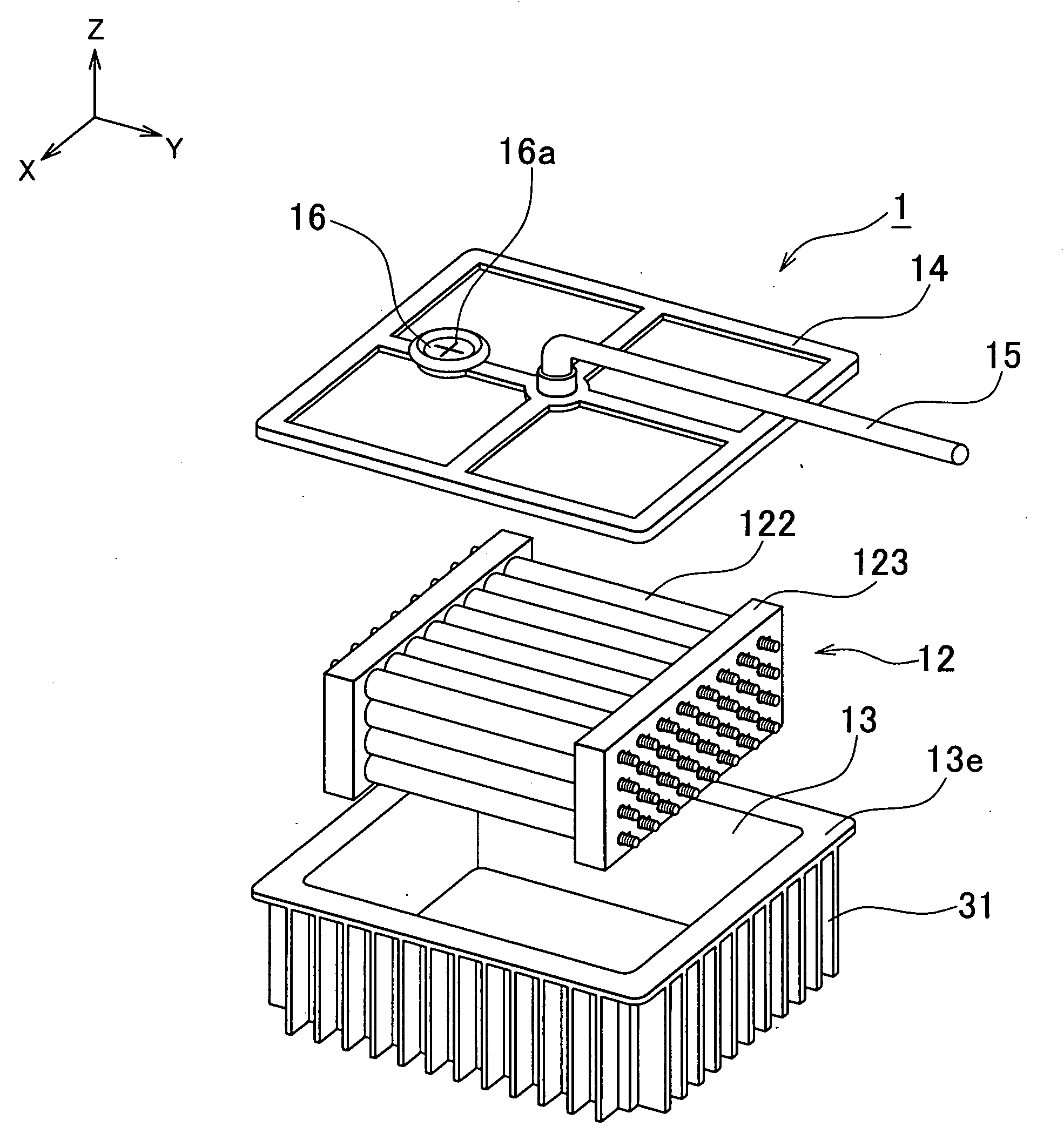

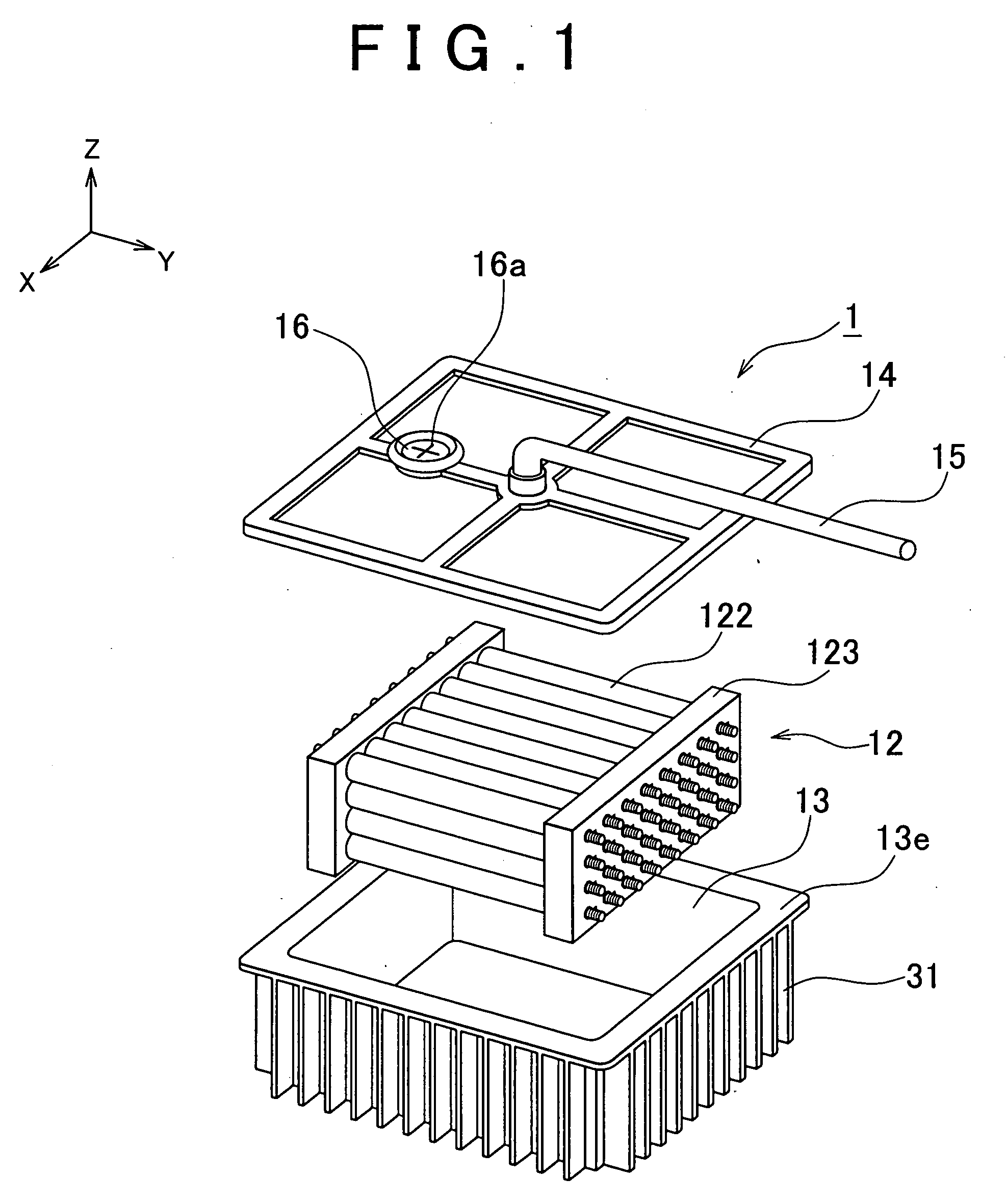

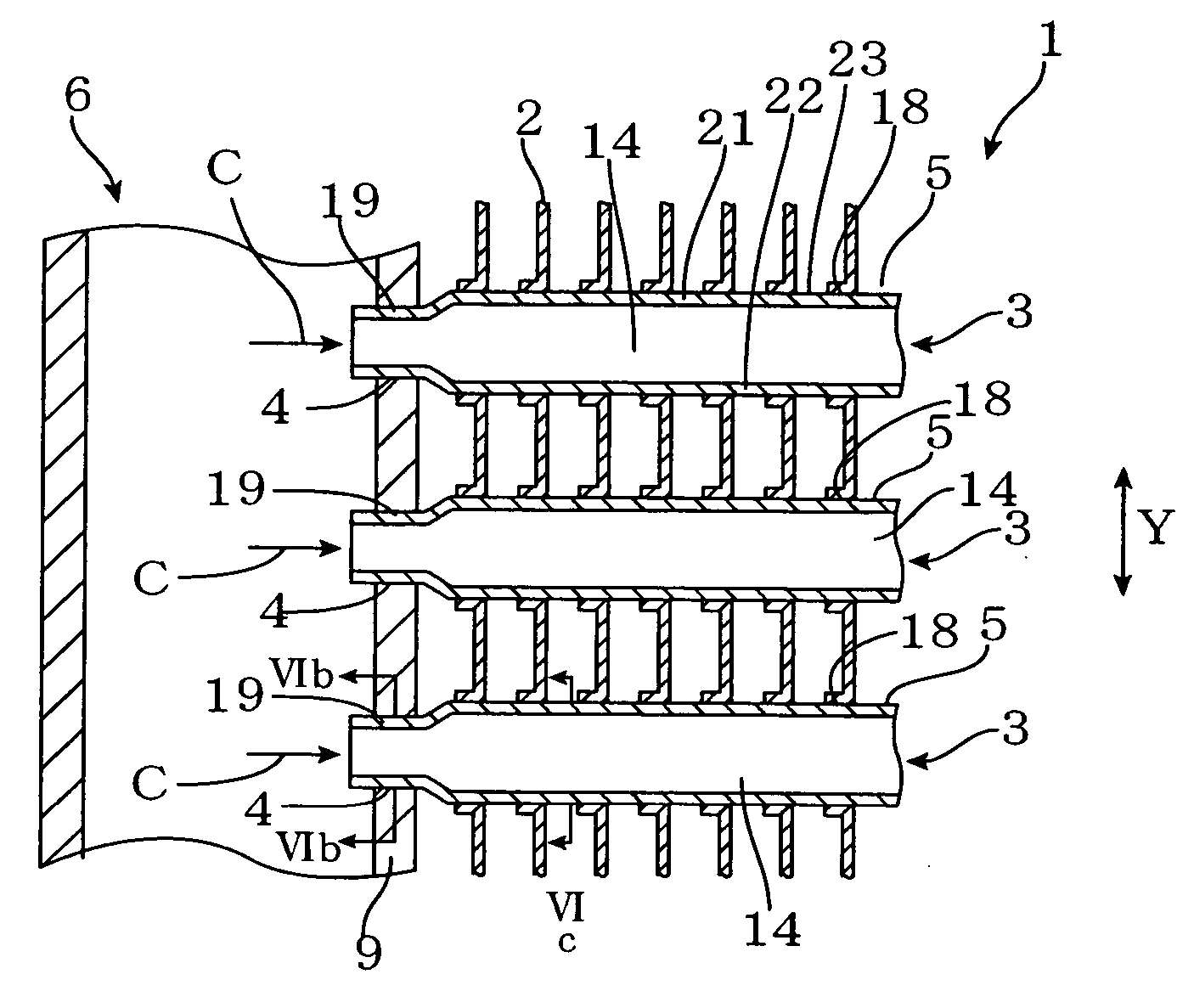

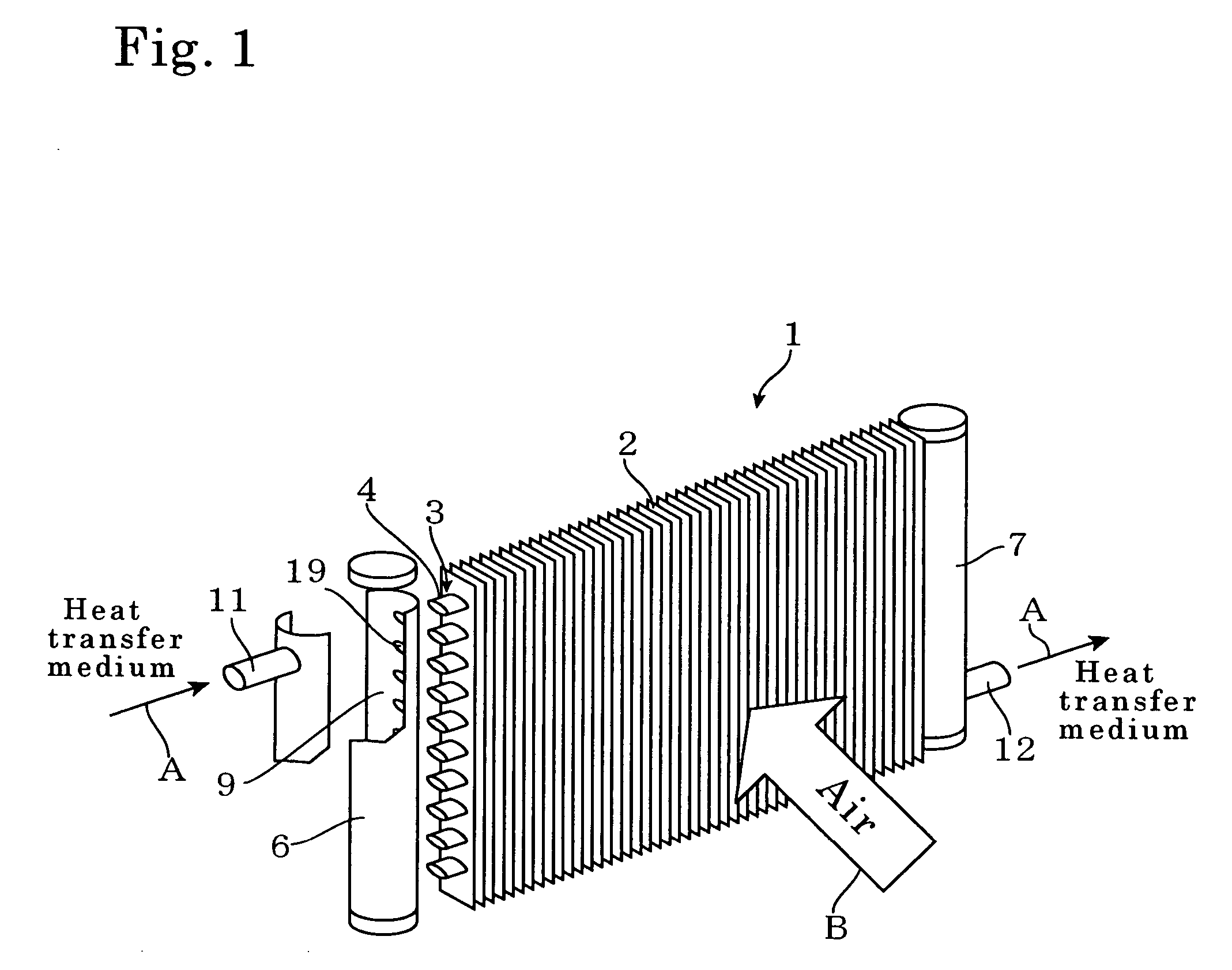

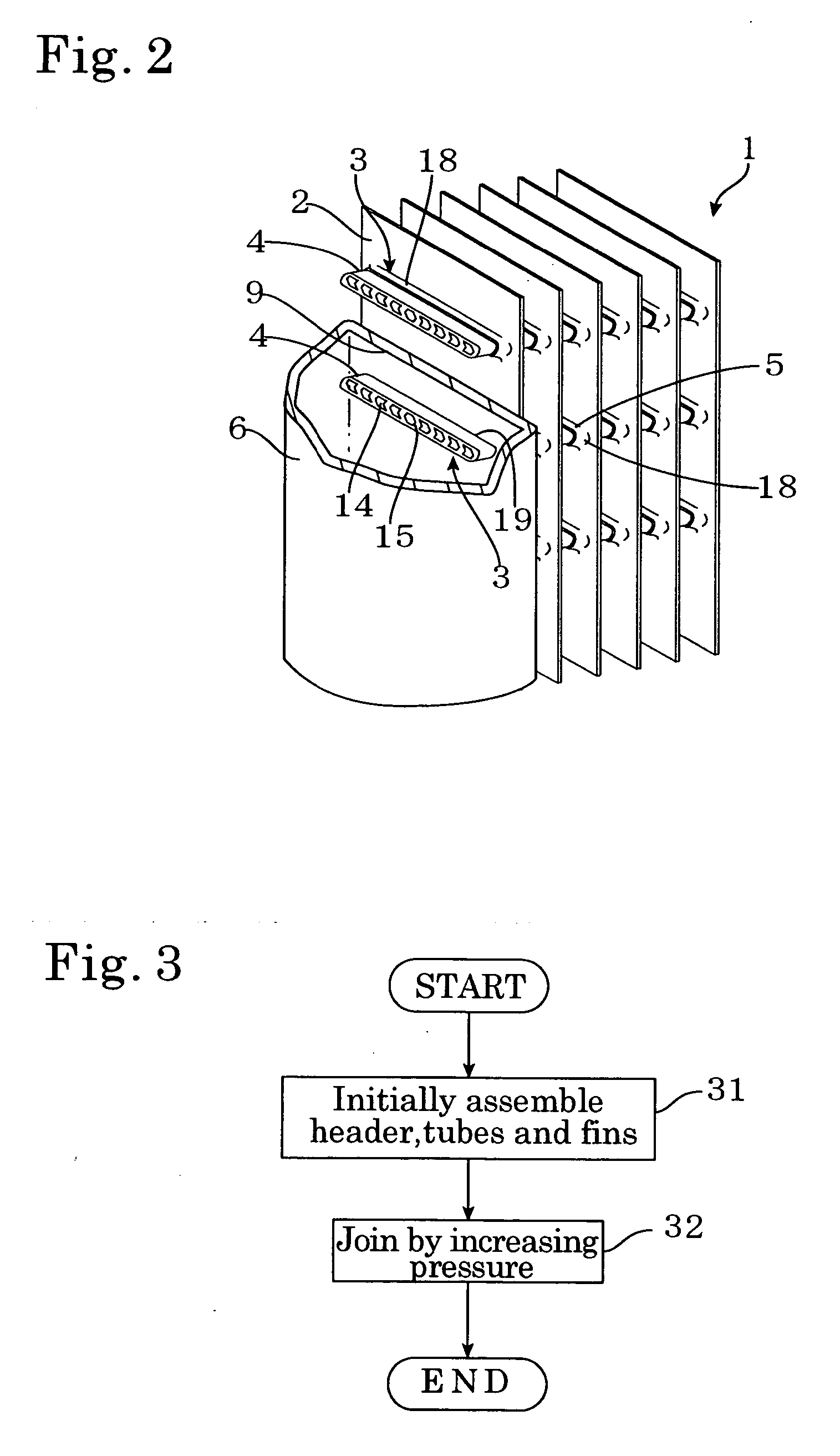

Heat exchanger and method of manufacturing the same

InactiveUS20050061494A1Increase internal pressureAdd partsStationary conduit assembliesHeat exchanger casingsInternal pressureEngineering

There is provided a method of manufacturing a heat exchanger, including a first step of mounting an end part of flat tube to a header, assembling the flat tube and fins, and sealing a part where the header and the end part is attached, and a second step of increasing an internal pressure of the flat tube to expand other part of flat tubes aside from the end parts with respect to the end part of the tube in order to make the fins and the other part of the flat tube in contact each other. According to this method of manufacturing, in the second step, the other part of the flat tube that passes through the fins is expanded, so that it is possible to mechanically join the flat tube and the fins, and a plate fin-type heat exchanger with high strength and heat exchange efficiency can be easily provided.

Owner:DENSO AIRCOOL CORP

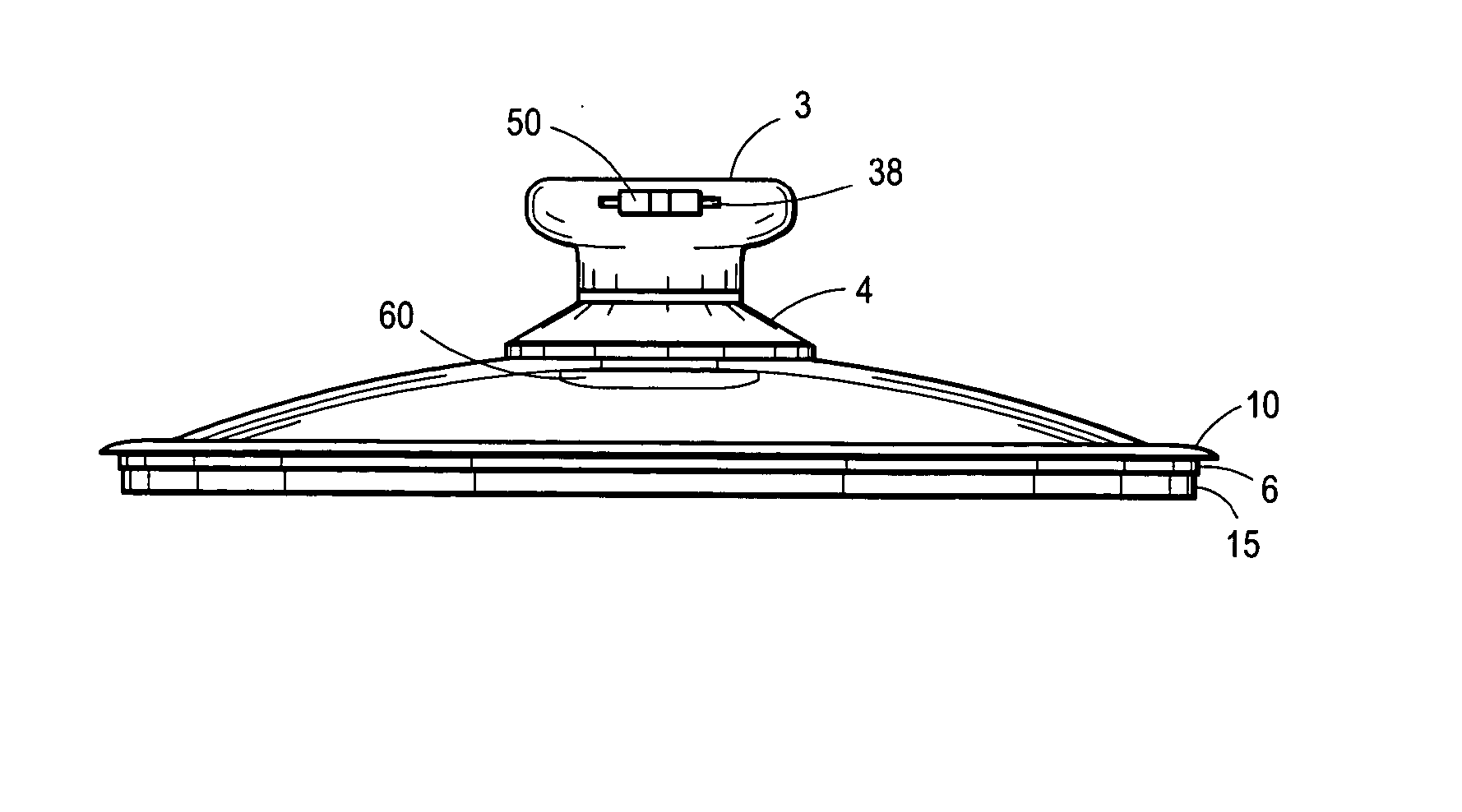

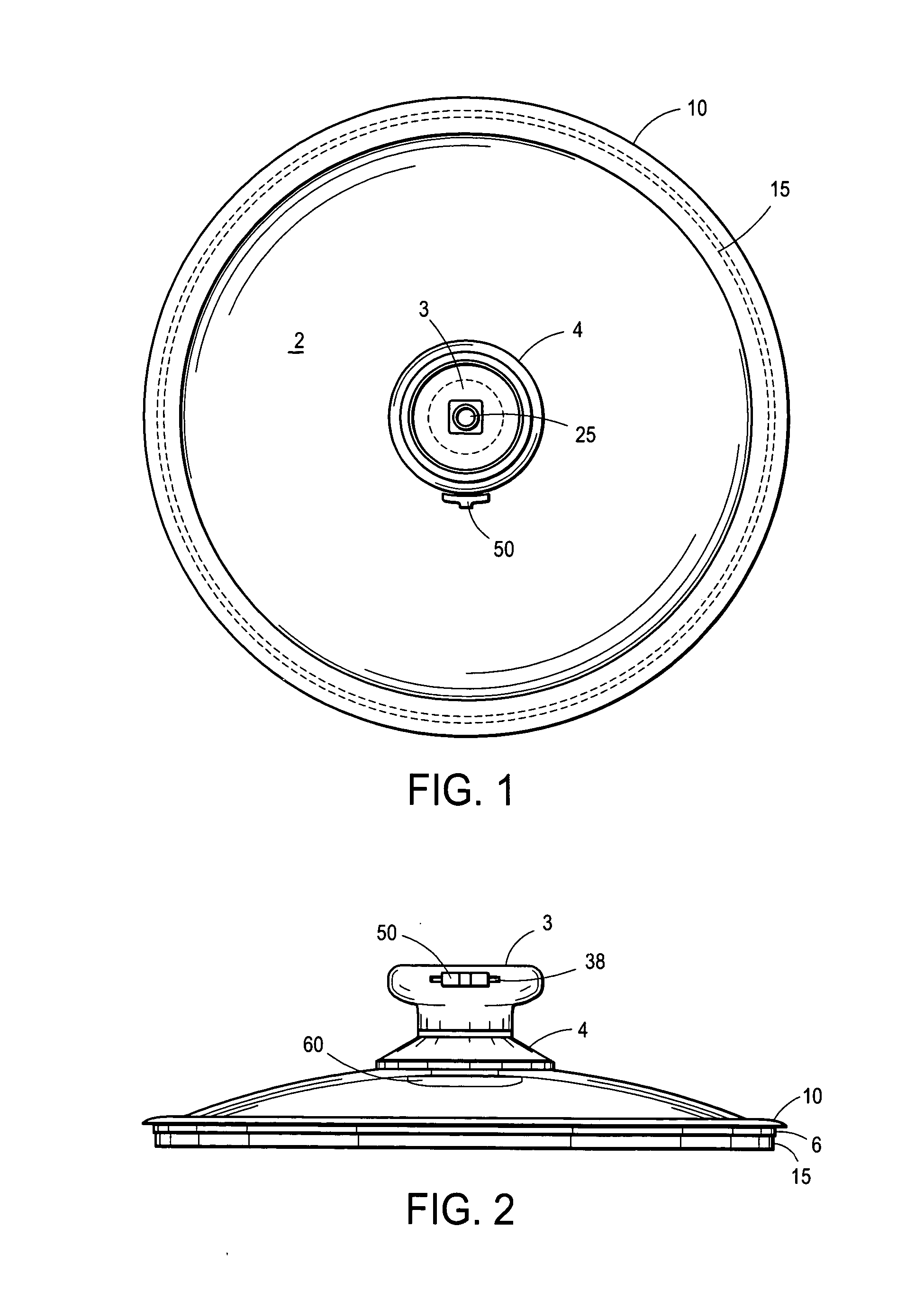

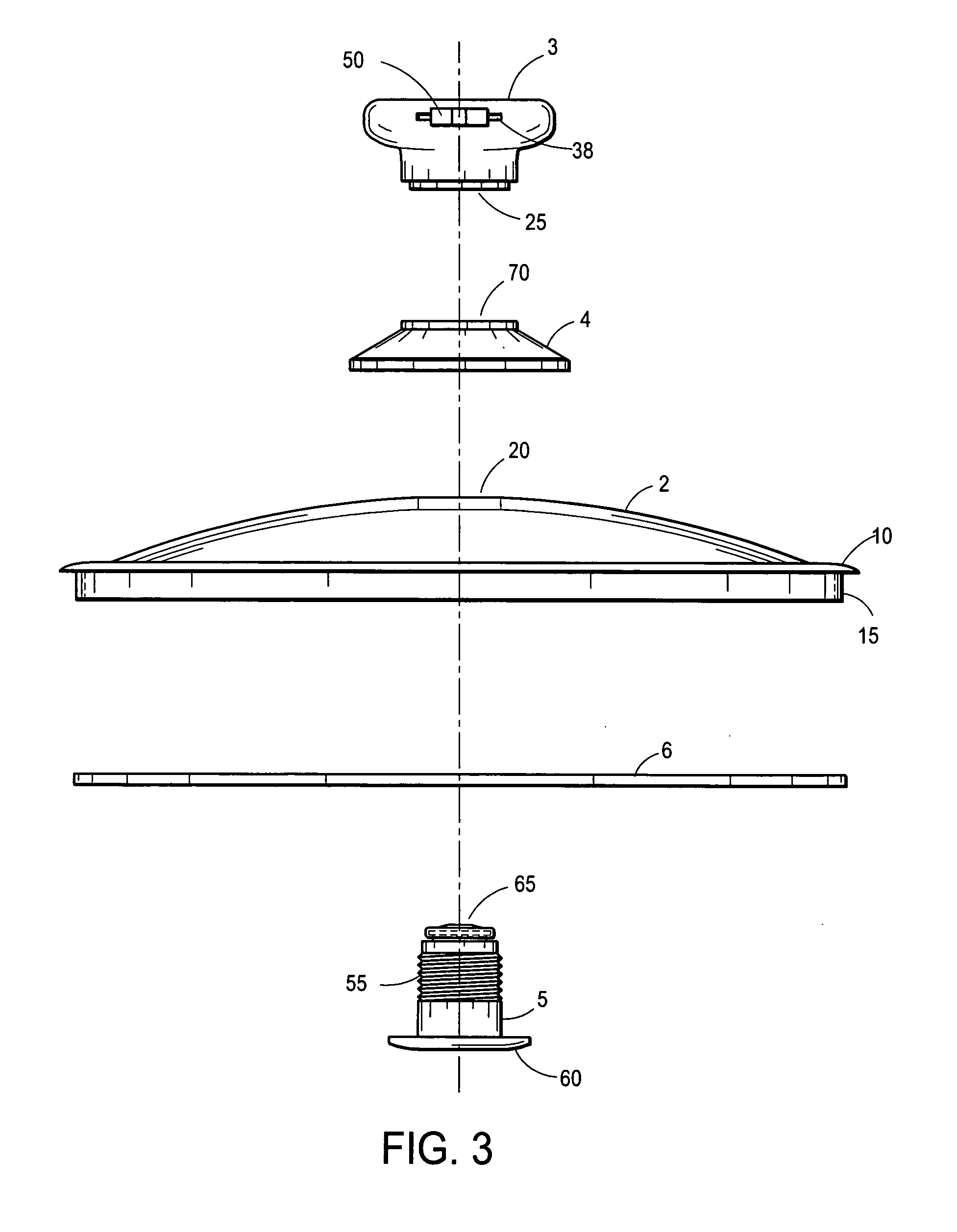

Cookware lid assembly with sealing band and whistling handle

InactiveUS20050205577A1Reduce heatEasy to disassembleBoiling over preventionCooking-vessel lids/coversEngineeringFlange

A cookware lid assembly having a whistling handle and a removable flexible sealing band that extends around a flange on the lid. The sealing band secures the lid to the cookware to prevent the lid from being dislodged from the cookware as pressure inside the cookware increases or as water in the cookware comes to a boil. The handle has a hole in it that generates as whistling noise when the pressure in the cookware increases. A movable slide in the handle allows the hole in the lid to be closed or remain fully or partly open. The slide also allows the volume and pitch of the whistle to be adjusted.

Owner:INNOVATION IP HLDG

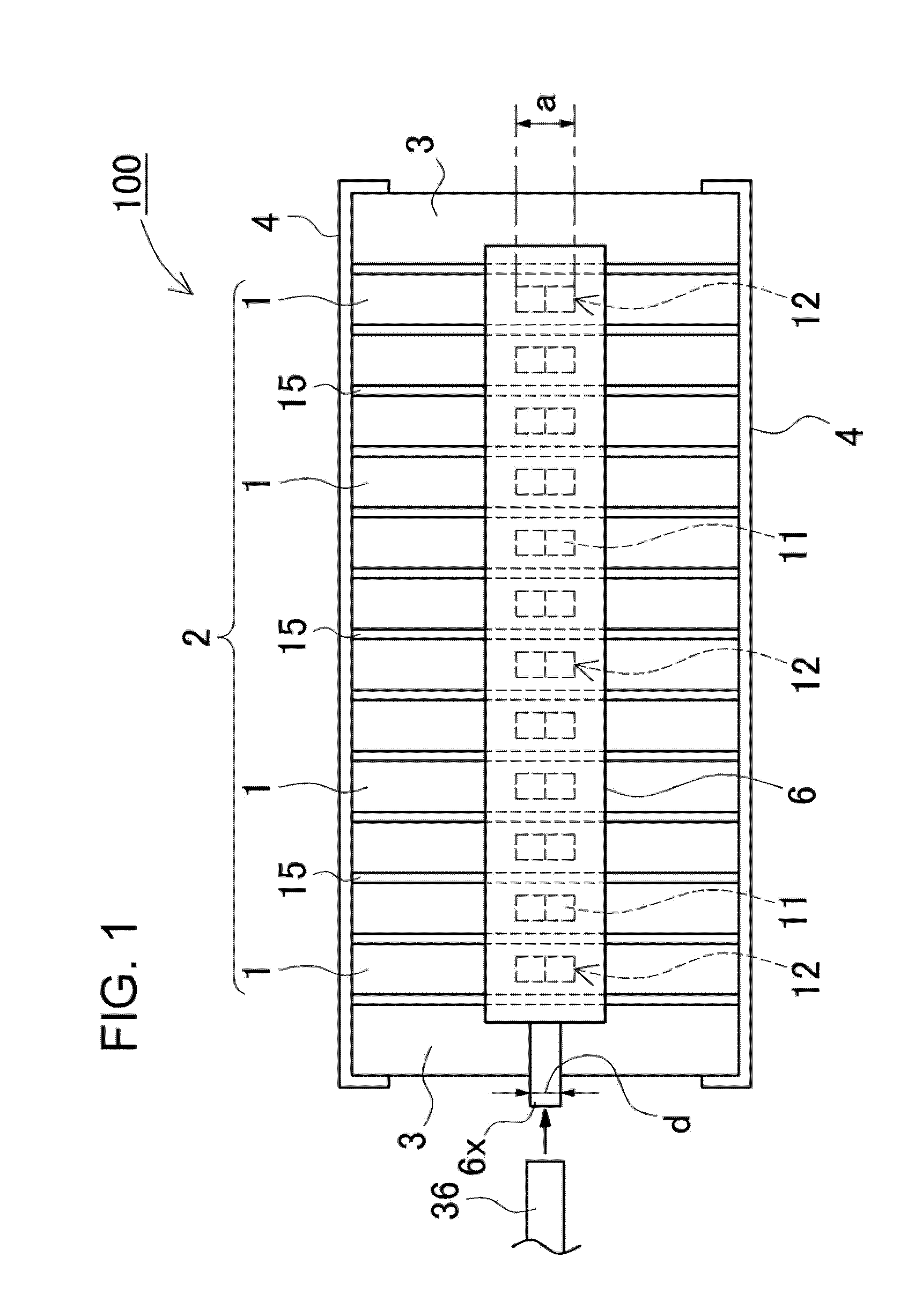

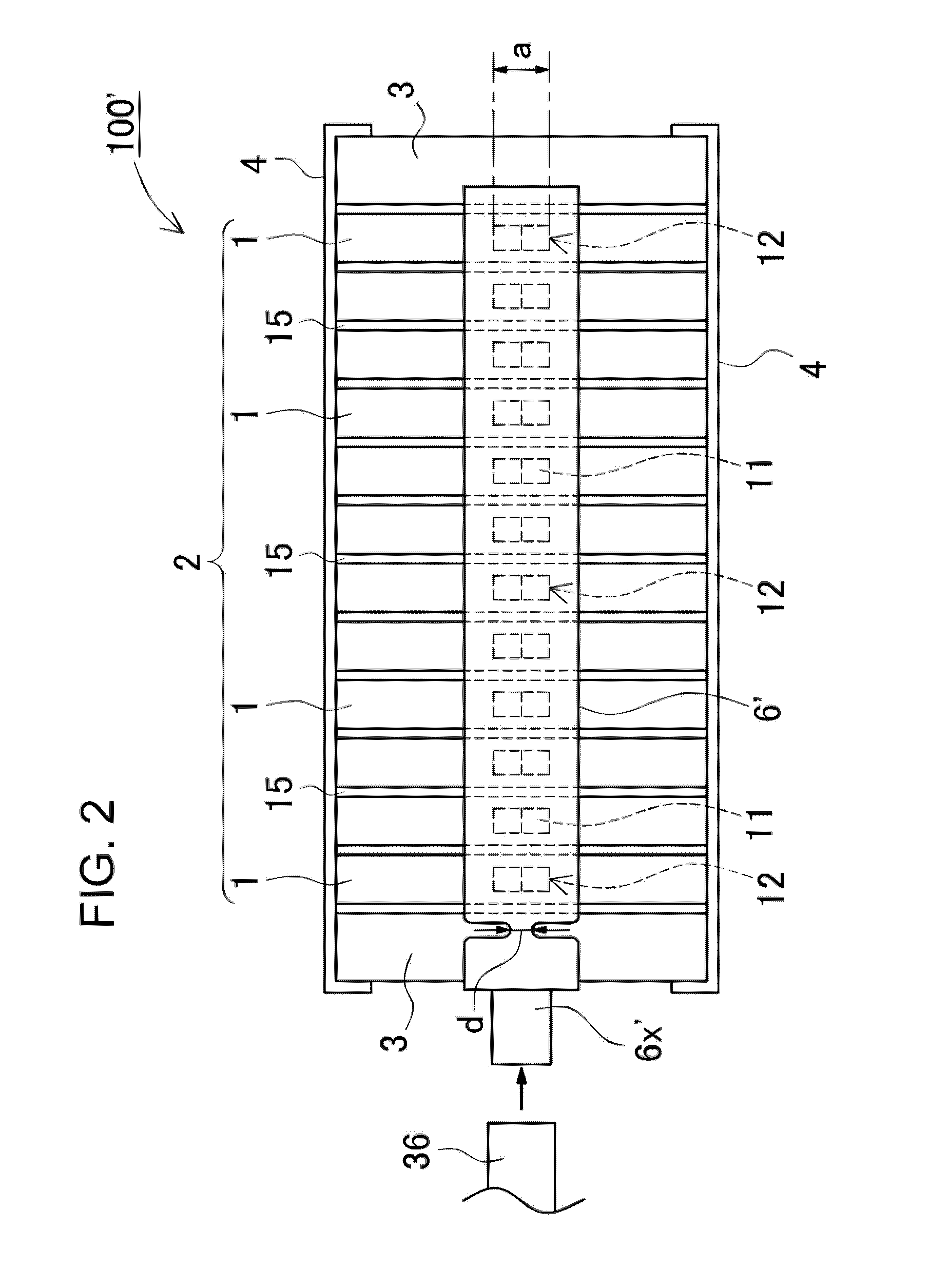

Power source device, electric vehicle provided with same, and electricity storage device

InactiveUS20150125720A1Trouble by a broken piece is preventedAvoid troubleElectric devicesCell component detailsElectricityInternal pressure

In a power supply device, the gas exhaust valve is integrally coupled to the outer can at the time of opening the gas exhaust valve, and the connecting portion between the outer can and the gas exhaust valve is partially broken at the time of opening the gas exhaust valve by an internal pressure of the outer can, and the gas duct further comprises a joining aperture being connected airtight to the gas exhaust valve, and a duct exhaust portion being connected to the external gas exhaust duct, and the inner diameter d inside the gas duct is at least partially smaller than the outer diameter a of the gas exhaust valve between the joining aperture and the duct exhaust portion.

Owner:SANYO ELECTRIC CO LTD

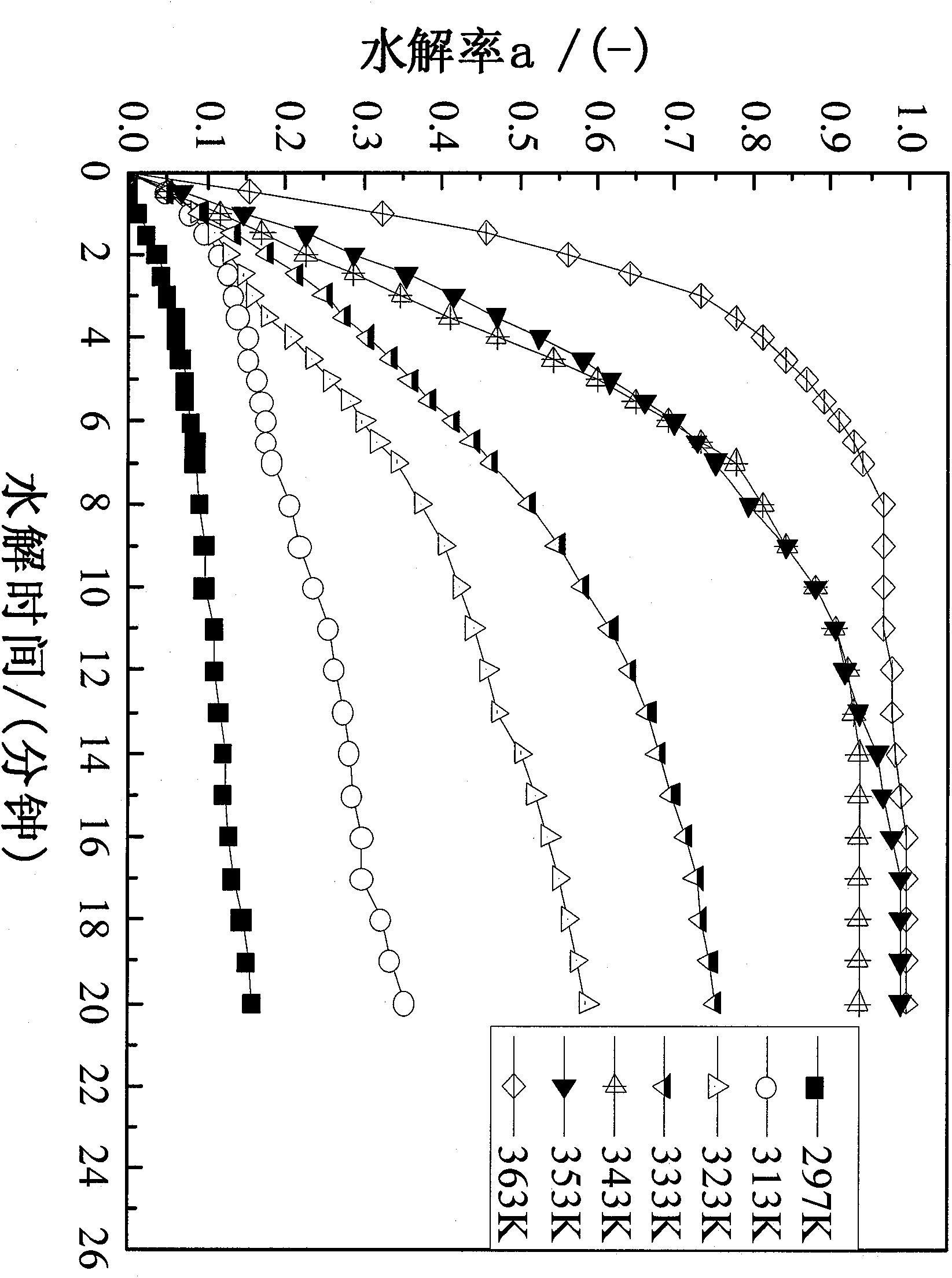

Low-temperature two-step method for preparing composite anatase type titanium dioxide visible light catalyst

InactiveCN102500426APromote crystallizationIncrease internal pressureCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsRoom temperatureWater baths

The invention discloses a low-temperature two-step method for preparing a composite anatase type titanium dioxide visible light catalyst, and belongs to the visible light catalyst. The preparation method comprises the following steps of: 1, adding titanium-containing precursor into alcohol, uniformly mixing and then adding a dopant, fully stirring, then adding an inhibitor and de-ionized water respectively, and performing water bath heating to prepare colloid containing titanium and doping element; and 2, cooling the prepared colloid to room temperature, transferring into a high-pressure-resistant container, adding a thermal decomposition type compound into the colloid, then quickly sealing the container, heating to perform reaction, preserving heat, obtaining precipitate after the reaction is finished, filtering the precipitate and washing with the de-ionized water and then drying to prepare the composite anatase type titanium dioxide visible light catalyst. The method has the advantages that: 1, the catalyst is prepared under the condition of 80-100 DEG C, and the energy consumption is favorably reduced during preparation; and 2, subsequent high-temperature treatment is not required in the method, the defect of high probability of losing the doping element through the high-temperature treatment is avoided, and the photo-catalytic performance is favorably improved.

Owner:CHINA UNIV OF MINING & TECH

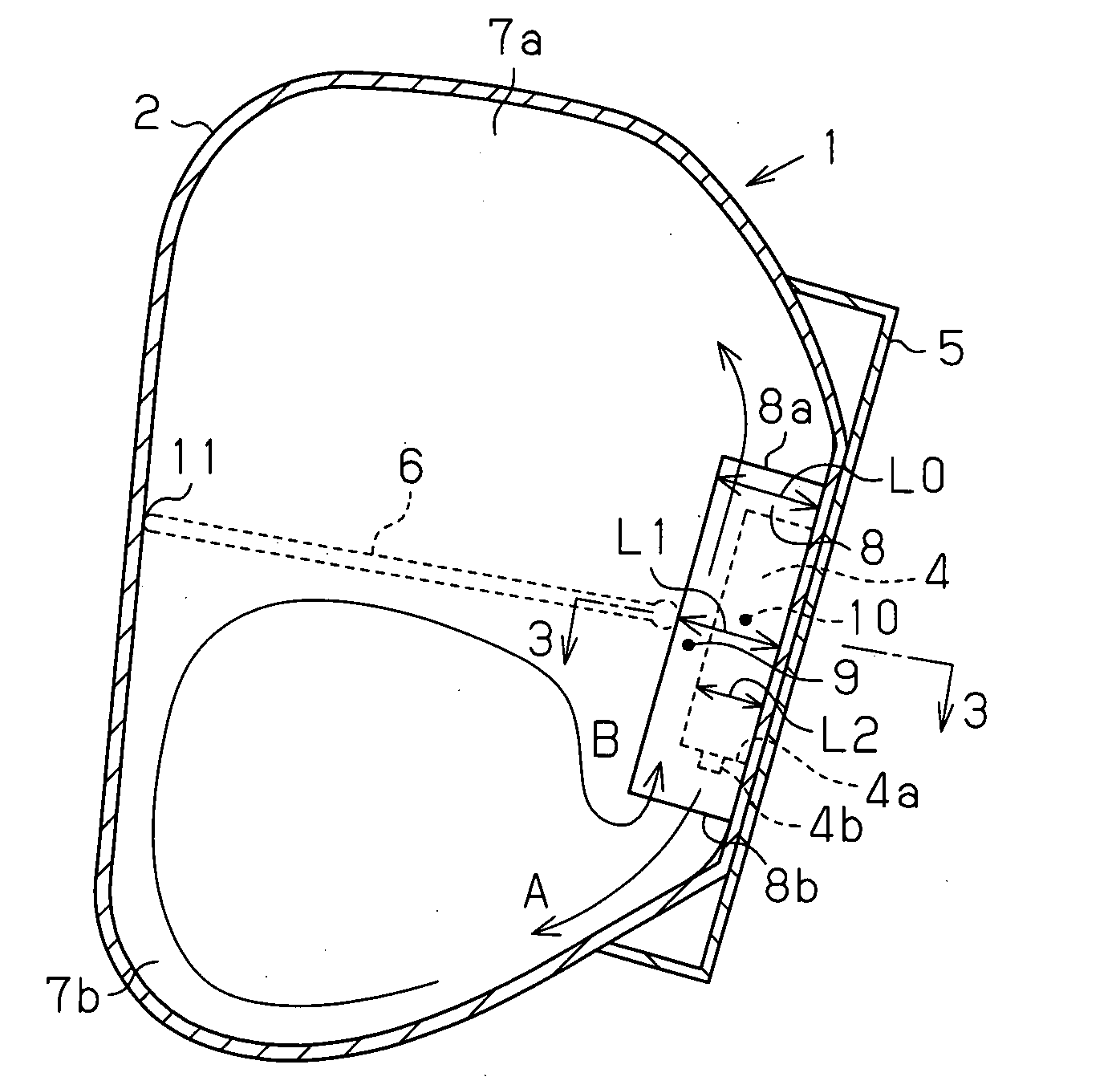

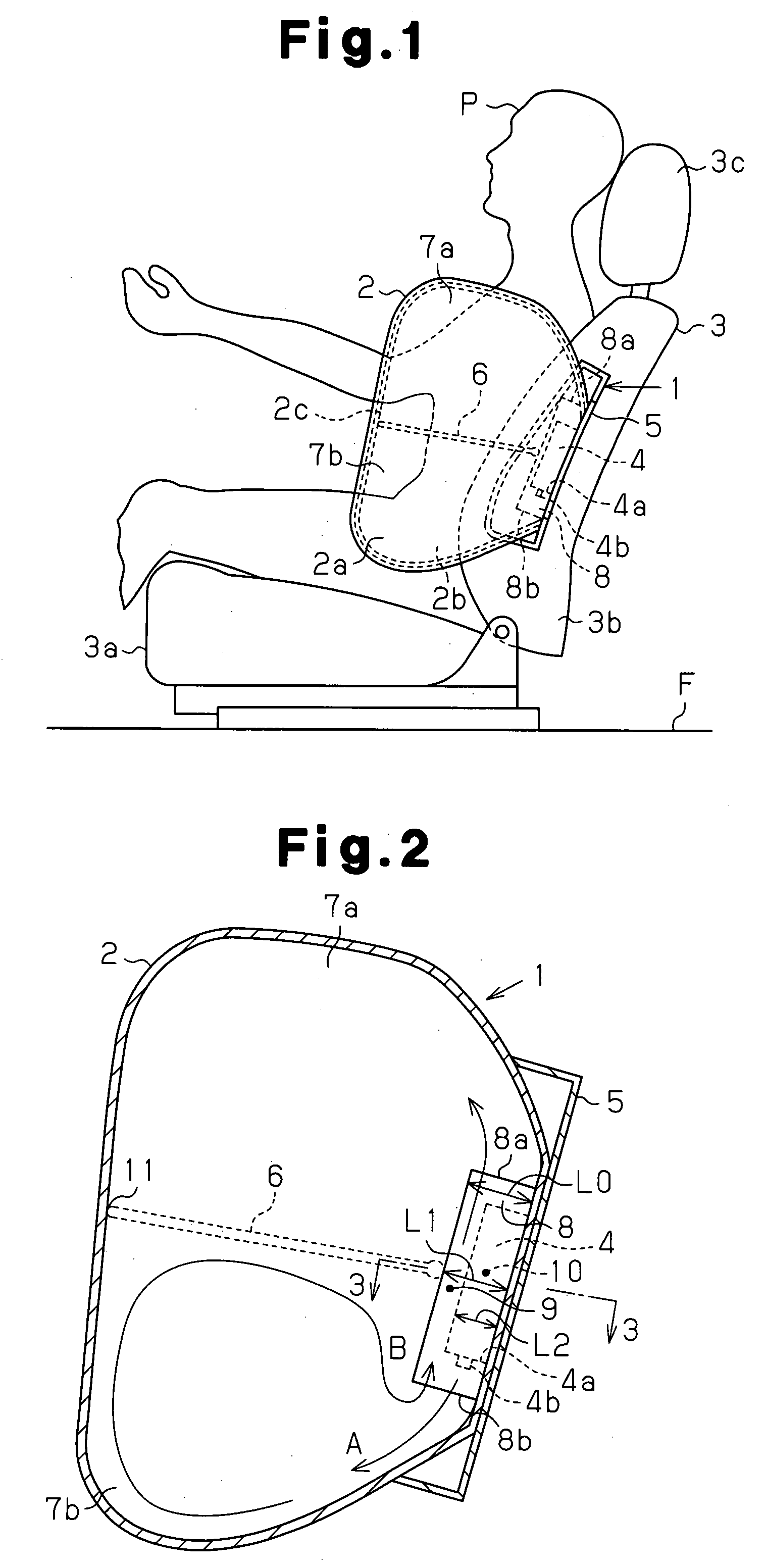

Side airbag apparatus

InactiveUS20070228701A1Increase internal pressureStable statePedestrian/occupant safety arrangementClosed chamberEngineering

An airbag includes a seam, which divides the airbag into an upper chamber and a lower chamber. An inner tube is provided inside the airbag such that openings are each located in one of the chambers. An inflator is inserted in the inner tube such that gas blown out from a gas port is oriented toward the lower chamber. A gap formed between an outer circumferential surface of the inflator and an inner circumferential surface of the inner tube during inflation and deployment of the airbag connects the upper chamber to the lower chamber.

Owner:TOYODA GOSEI CO LTD

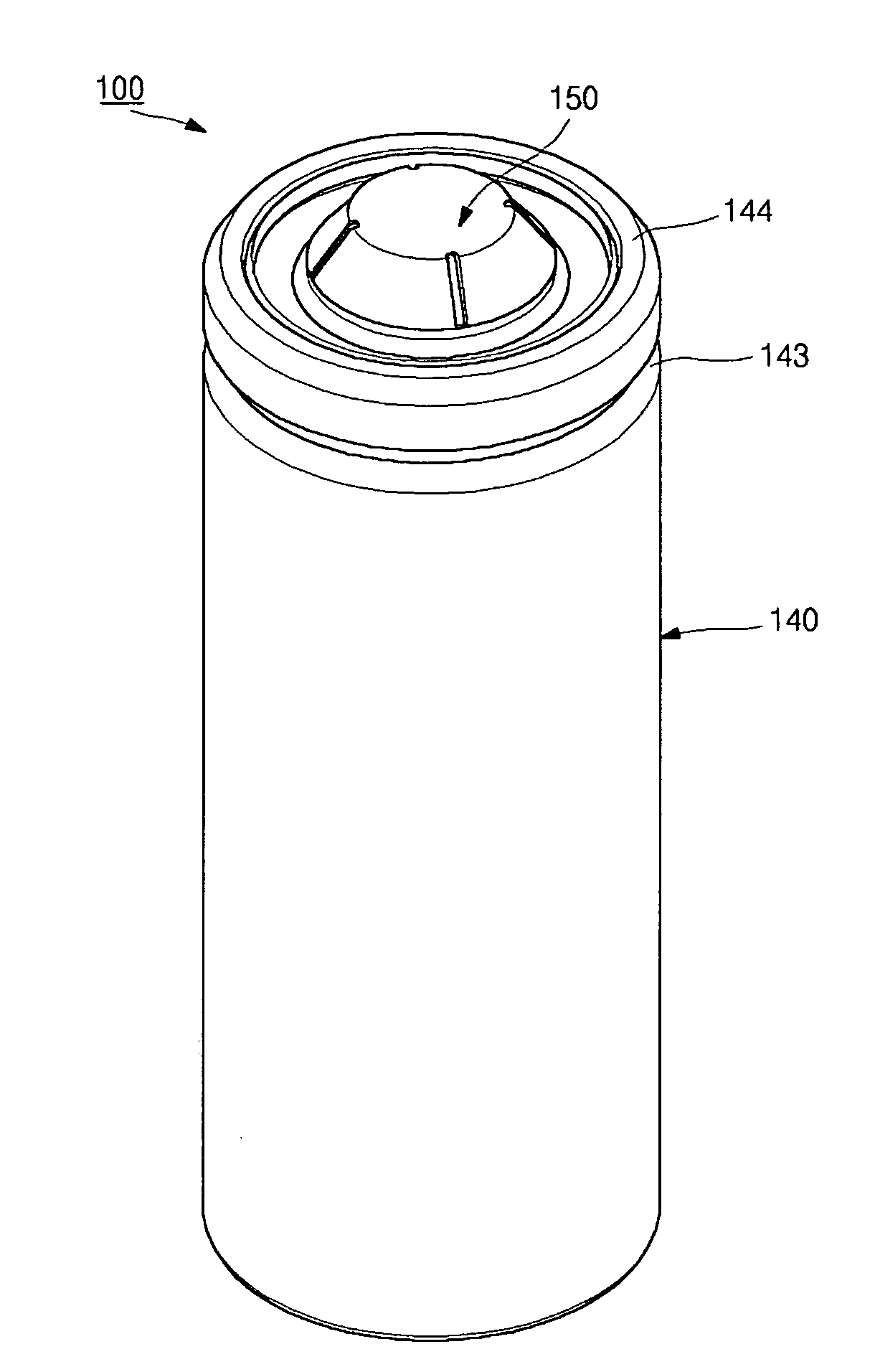

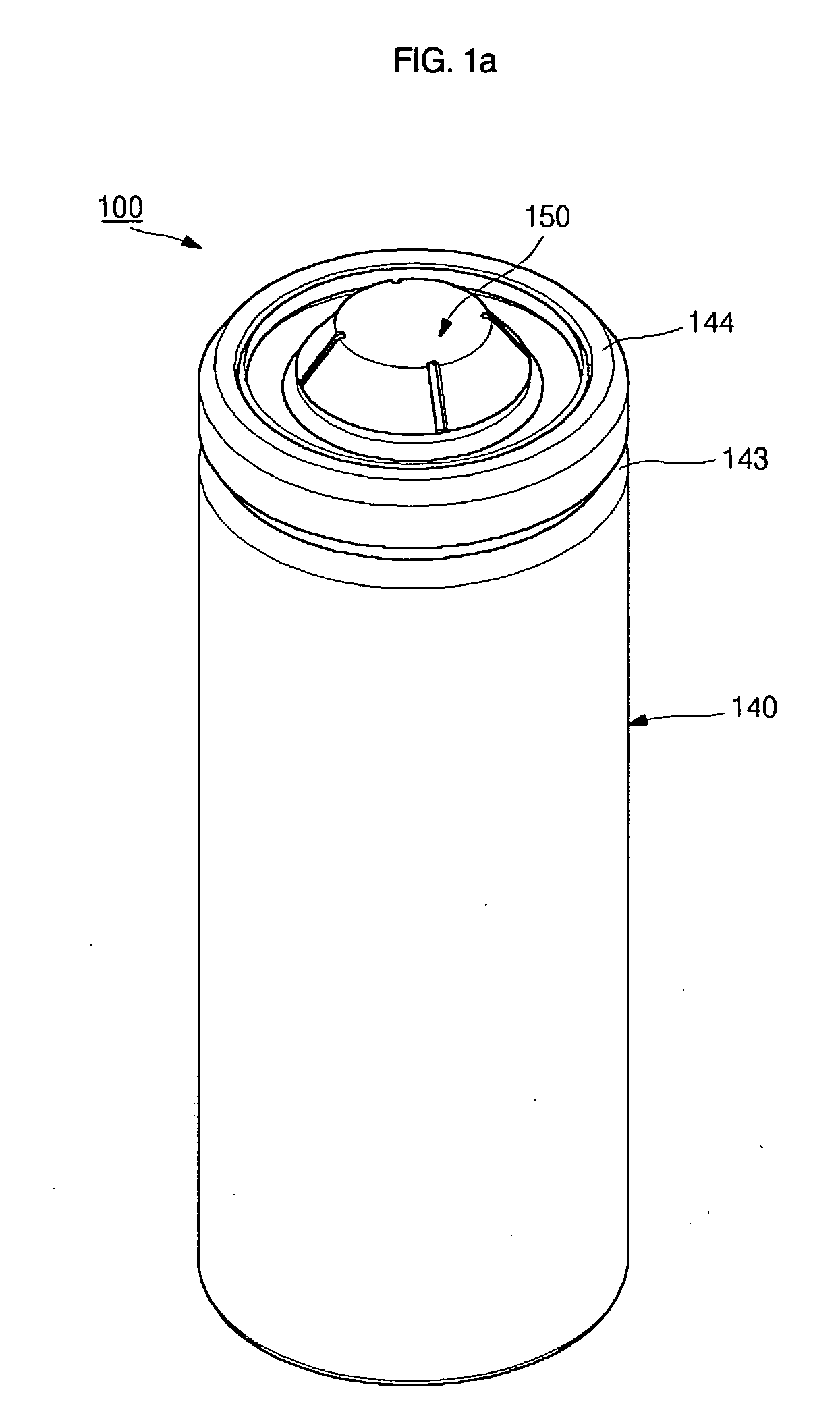

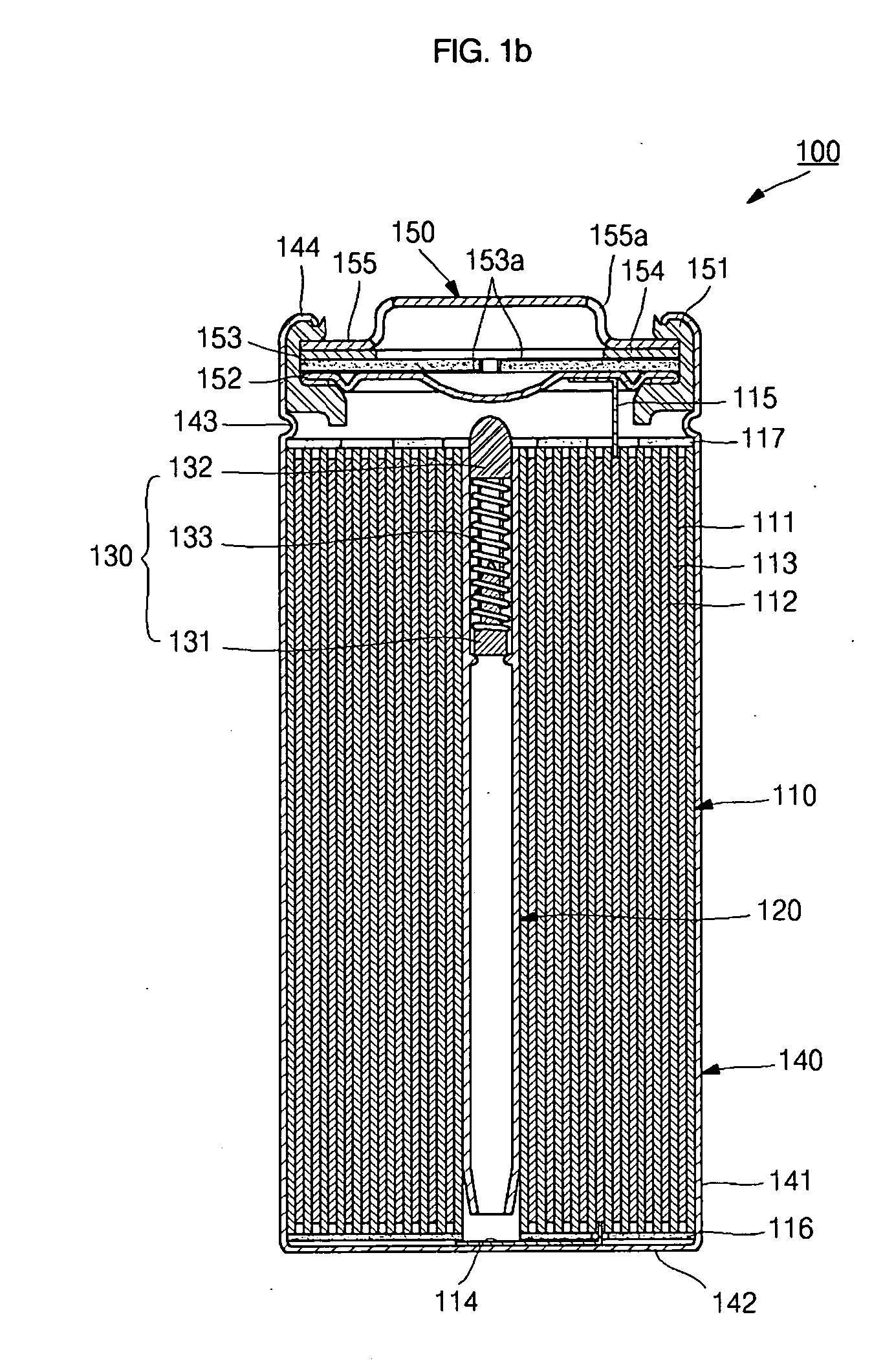

Cylindrical lithium ion secondary battery having functional center pin

InactiveUS20060263676A1Increase internal pressureExtended interruption timeSmall-sized cells cases/jacketsWound/folded electrode electrodesVariable lengthBiomedical engineering

A lithium ion secondary battery including an electrode assembly, a center pin positioned within the electrode assembly, a variable-length member coupled to the center pin, the variable-length member adapted to increase in length when an interior temperature of the center pin reaches a critical temperature, a can containing the electrode assembly, the center pin, and the variable-length member, and a cap assembly coupled to the can, the cap assembly having safety means fracturable in response to the variable-length member being increased in length.

Owner:SAMSUNG SDI CO LTD

Steerable catheter with distending lumen-actuated curling catheter tip

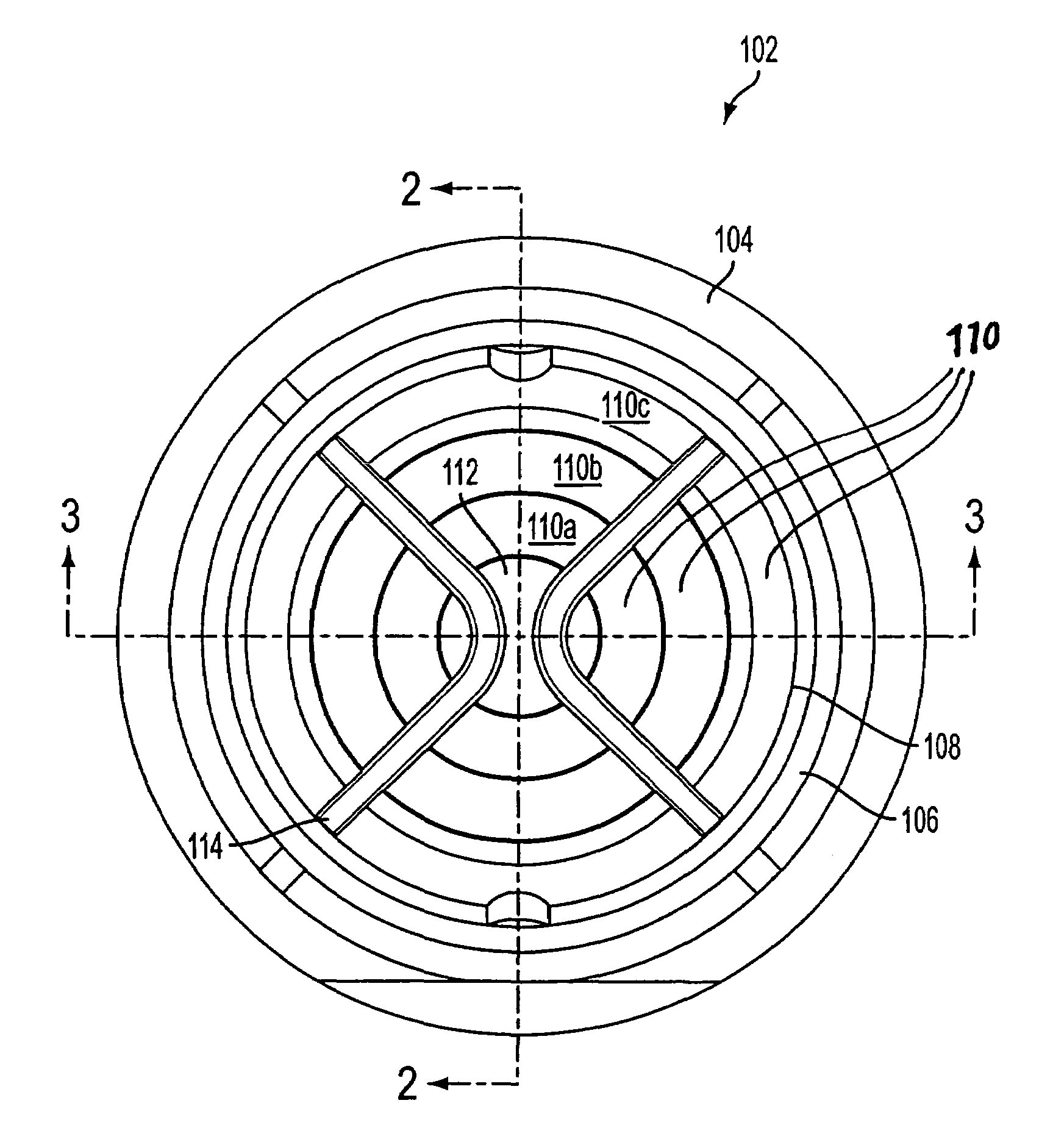

InactiveUS20100010437A1Minimize possibility of hyperthermiaFacilitate deployment/positioningMedical devicesCatheterInternal pressureGuide tube

A steerable catheter having a catheter tip connected to an elongated catheter body, with the catheter tip having an elastomeric cylindrical body and one or more steering lumens each offset from the longitudinal axis of the elastomeric cylindrical body and extending substantially the length of the elastomeric cylindrical body so that increasing the internal pressure of one or more of the steering lumens using, for example, a pneumatic or hydraulic pressure source or heating a thermally expandable media in the steering lumens, operates to curl the longitudinal axis of the elastomeric cylindrical body towards the internally pressurized steering lumen or lumens for steering the catheter tip.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

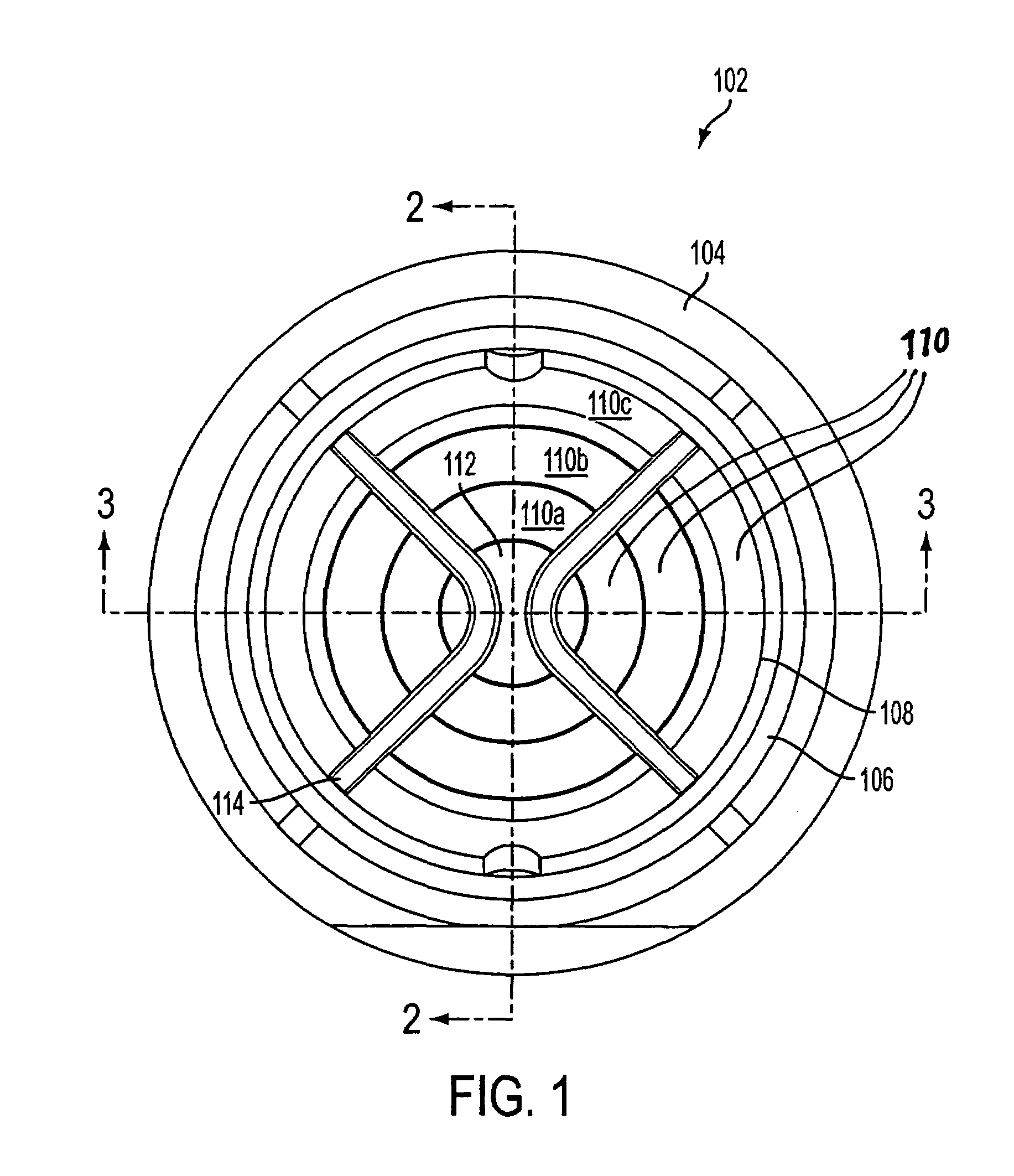

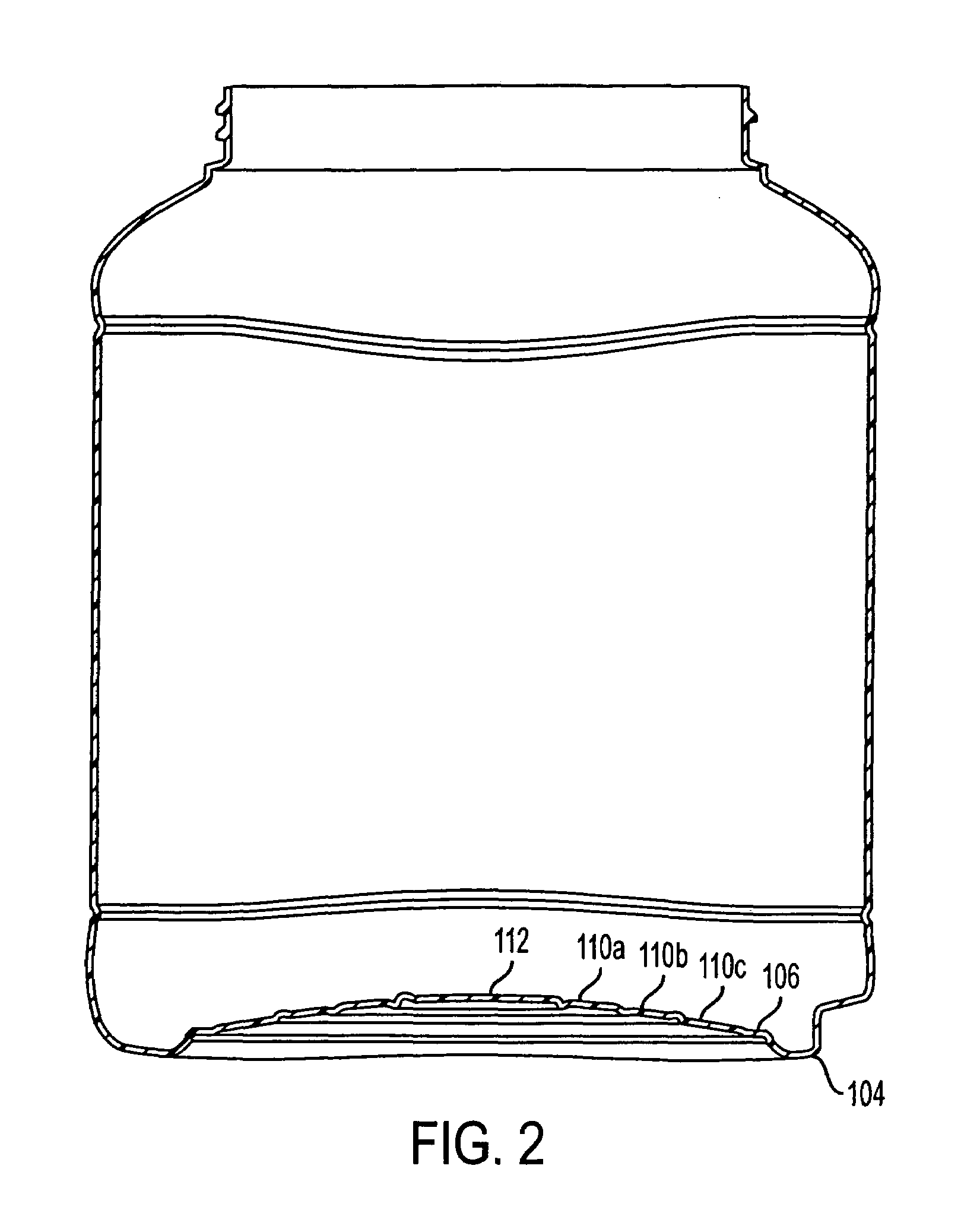

Base design for pasteurization

ActiveUS7140505B2Efficient stackingIncrease internal pressureLarge containersRigid containersEngineeringPasteurization

Owner:GRAHAM PACKAGING CO LP

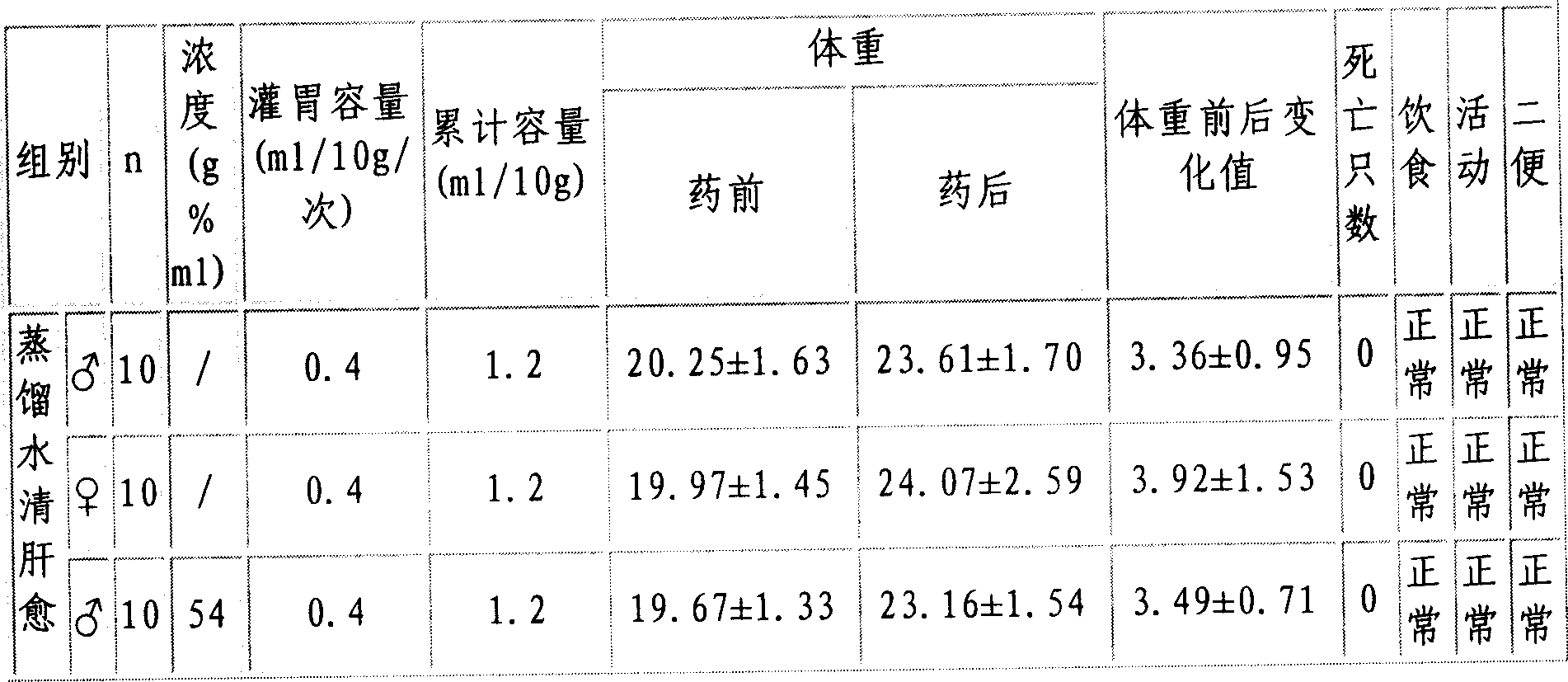

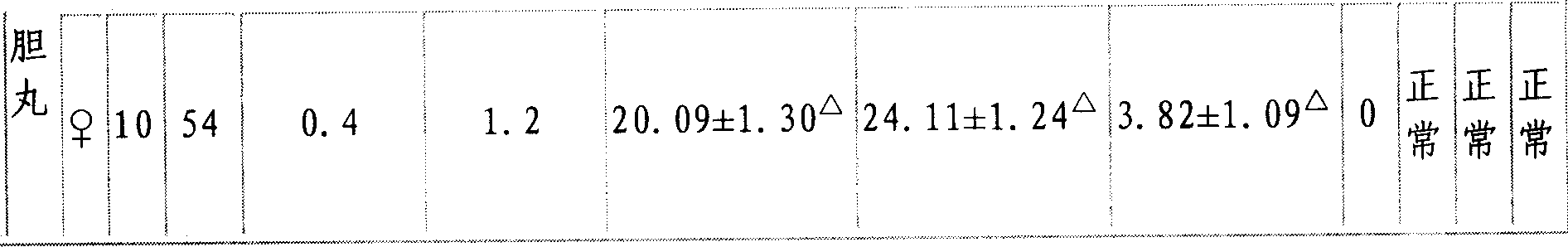

Medicinal composition for treating cholecystitis

InactiveCN100998843ANo side effectsWith preventionDigestive systemPlant ingredientsMedicineLiver function

A Chinese medicine for preventing and treating cholecystitis, cholelithiasis and the inflammation of biliary tract, and improving the function of gallbladder and liver is prepared from 23 Chinese-medicinal materials including tackahoe, capejasmine fruit, white peony root, cyprus tuber, etc.

Owner:曹国胜

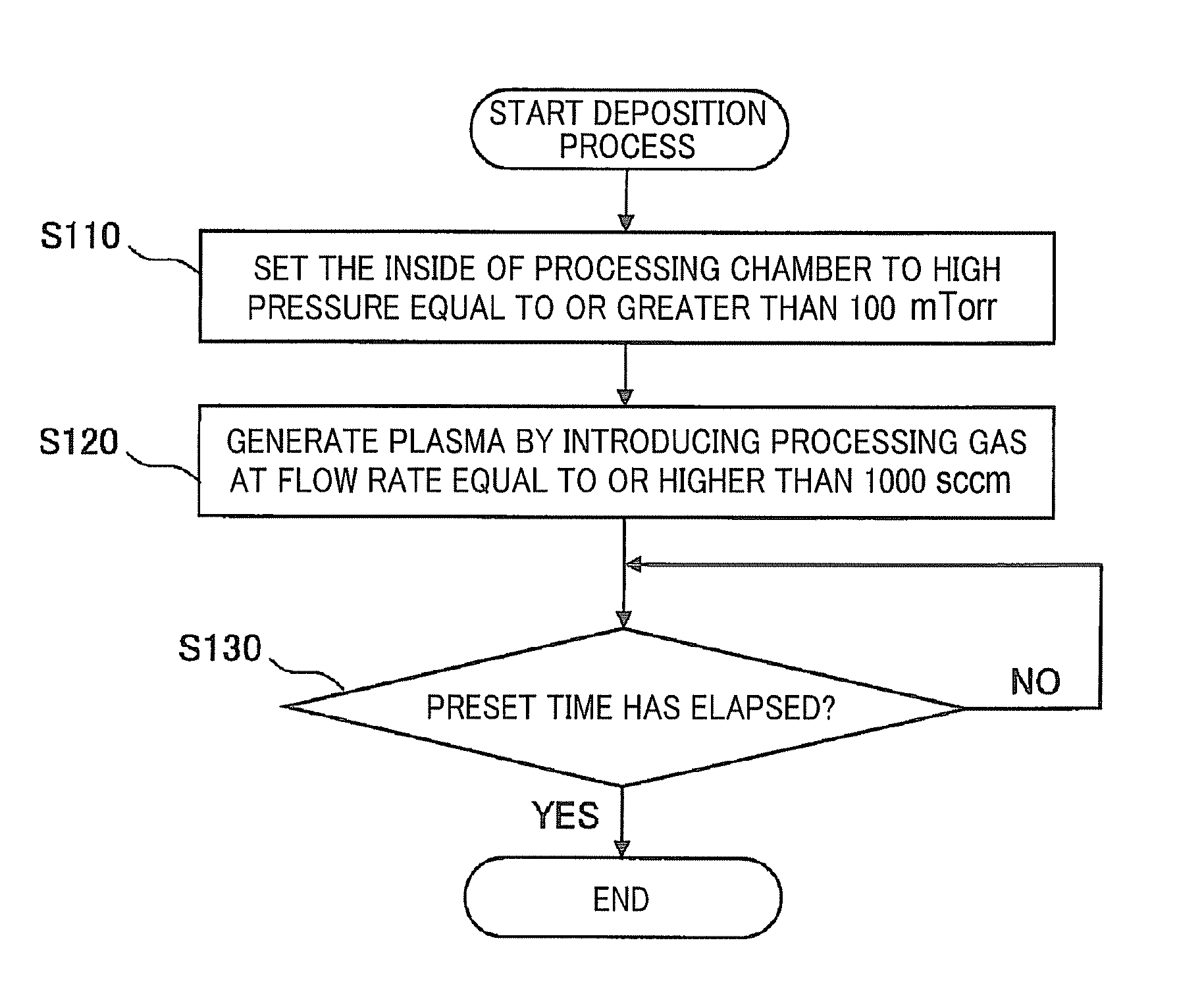

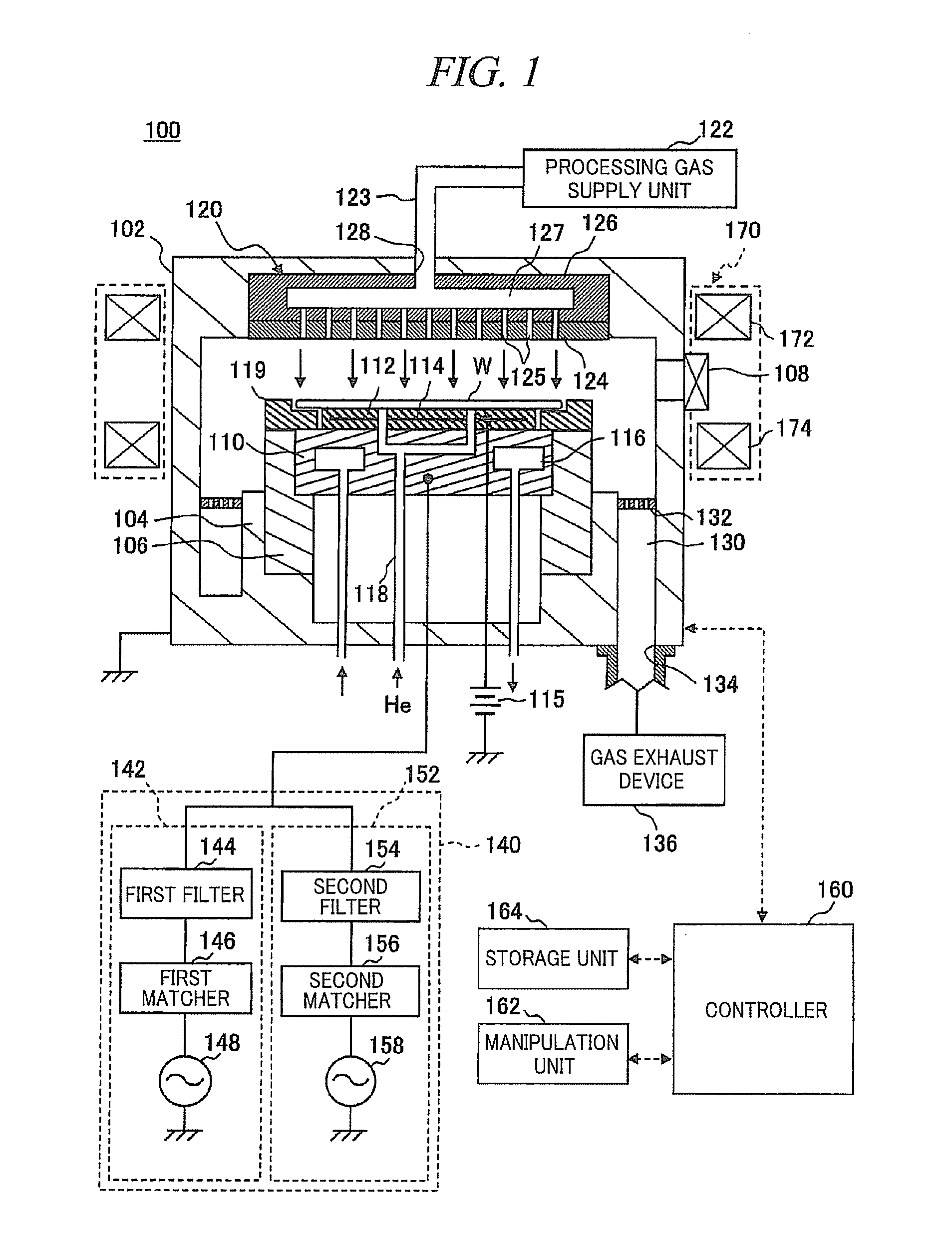

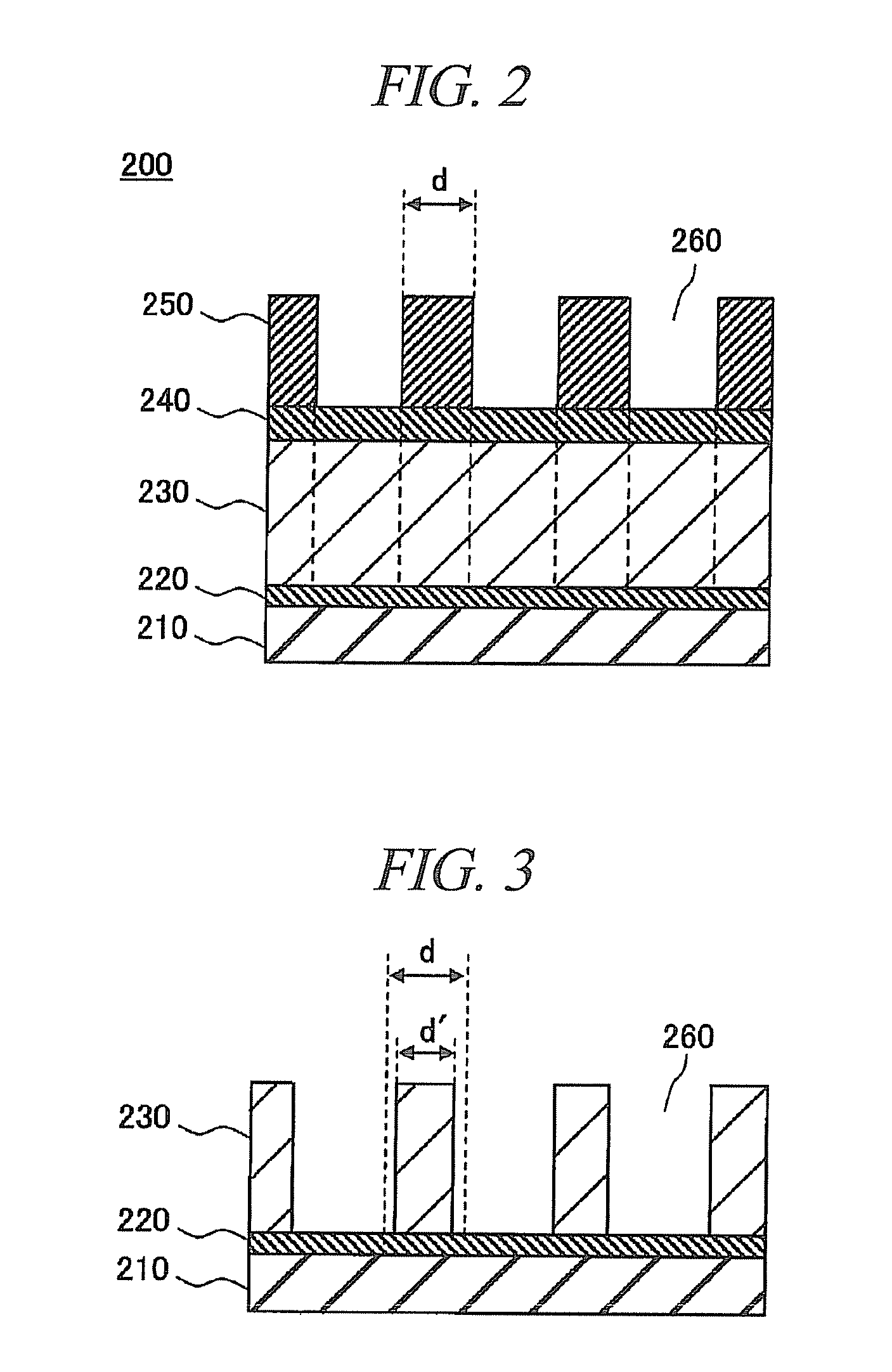

Substrate processing method

InactiveUS8524331B2Effectively suppressing non-uniformity in deposition degreeIncrease flow rateElectric discharge tubesLiquid/solution decomposition chemical coatingResistMetallurgy

A substrate processing method effectively suppresses non-uniformity in deposition degree on a surface of a substrate. The substrate processing method includes depositing a deposit on a sidewall of each opening of a resist pattern, which is formed on an antireflection film on an etching target film of the substrate and is provided with a plurality of openings, before etching the etching target film of the substrate. Plasma is generated in the depositing process by introducing a CHF-based gas into the processing chamber at a flow rate equal to or higher than about 1000 sccm while a pressure in the processing chamber is set to equal to or higher than about 100 mTorr.

Owner:TOKYO ELECTRON LTD

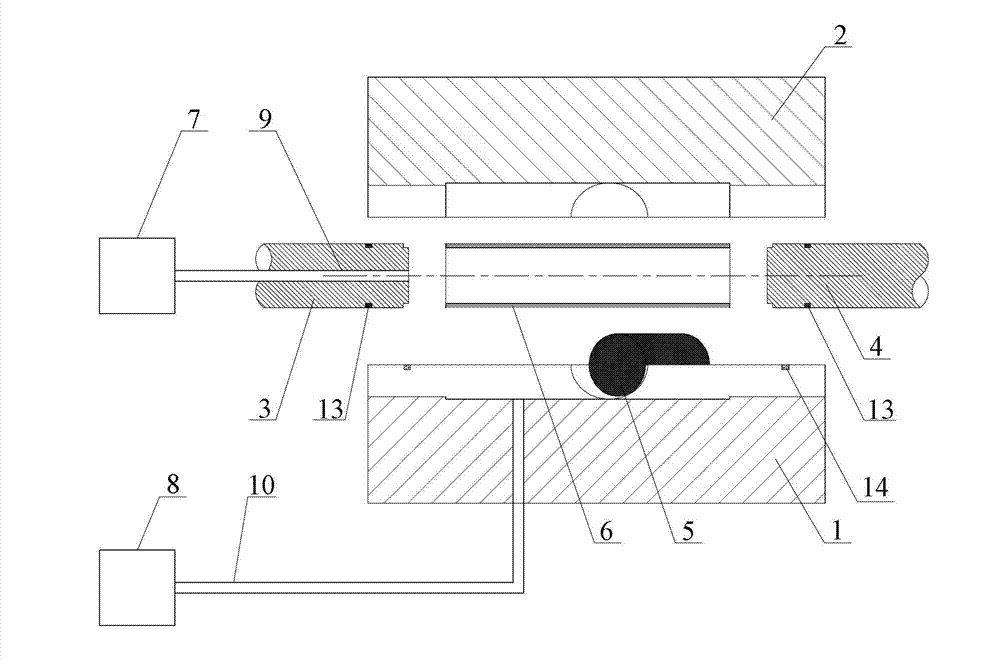

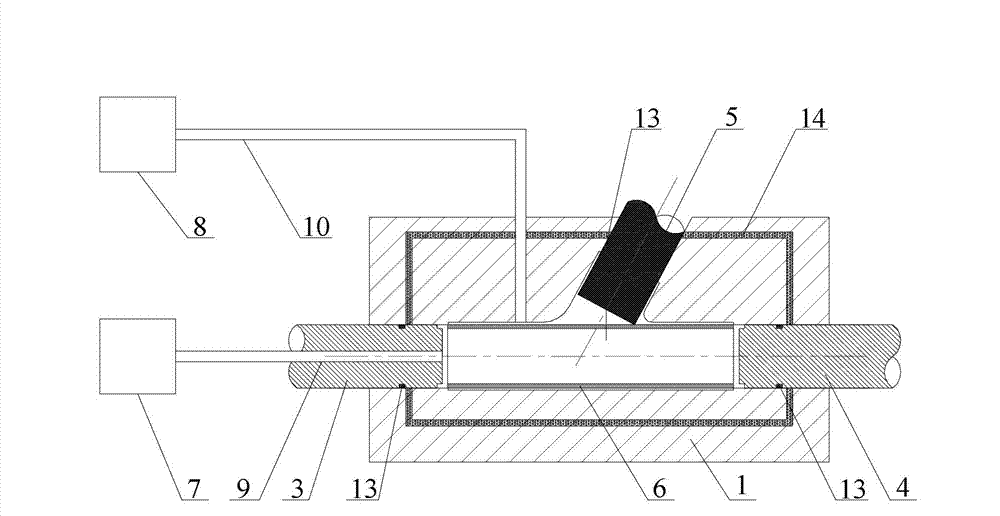

Composite inner and outer hydraulic pressure forming method for high-branch height thin-wall three-way pipe

ActiveCN102921792AReduce frictionImprove axial critical wrinkling stressInternal pressureHigh pressure

The invention discloses a composite inner and outer hydraulic pressure forming method for a high-branch height thin-wall three-way pipe, belongs to the technical field of inner high pressure forming and aims to solve the problem that the branch height of the formed three-way pipe is limited in the conventional inner high pressure forming method. The method comprises the following steps of: filling liquid media inside a pipe billet and discharging gases through a supercharger, and moving a left-side punch and a right-side punch forwards to finish pipe end seal, so that inner pressure of the pipe billet is insufficient, and the pipe billet deforms; filling liquid media on the outer side of the pipe billet through holes on a die, wherein outside hydraulic pressure is sealed by a sealing groove on the die and a sealing ring on the punch, so that the pipe billet has plastic deformation under the action of inner pressure, outer pressure, axial feeding of the left and right punches and retreating of the branch punch, and obtaining the high-branch height three-way pipe. Compared with the traditional inner high pressure forming method, the method has the advantages of high branch pipe height and high pipe surface quality, and is particularly suitable for thin-wall three-way pipe forming.

Owner:抚顺三方机械制造有限公司

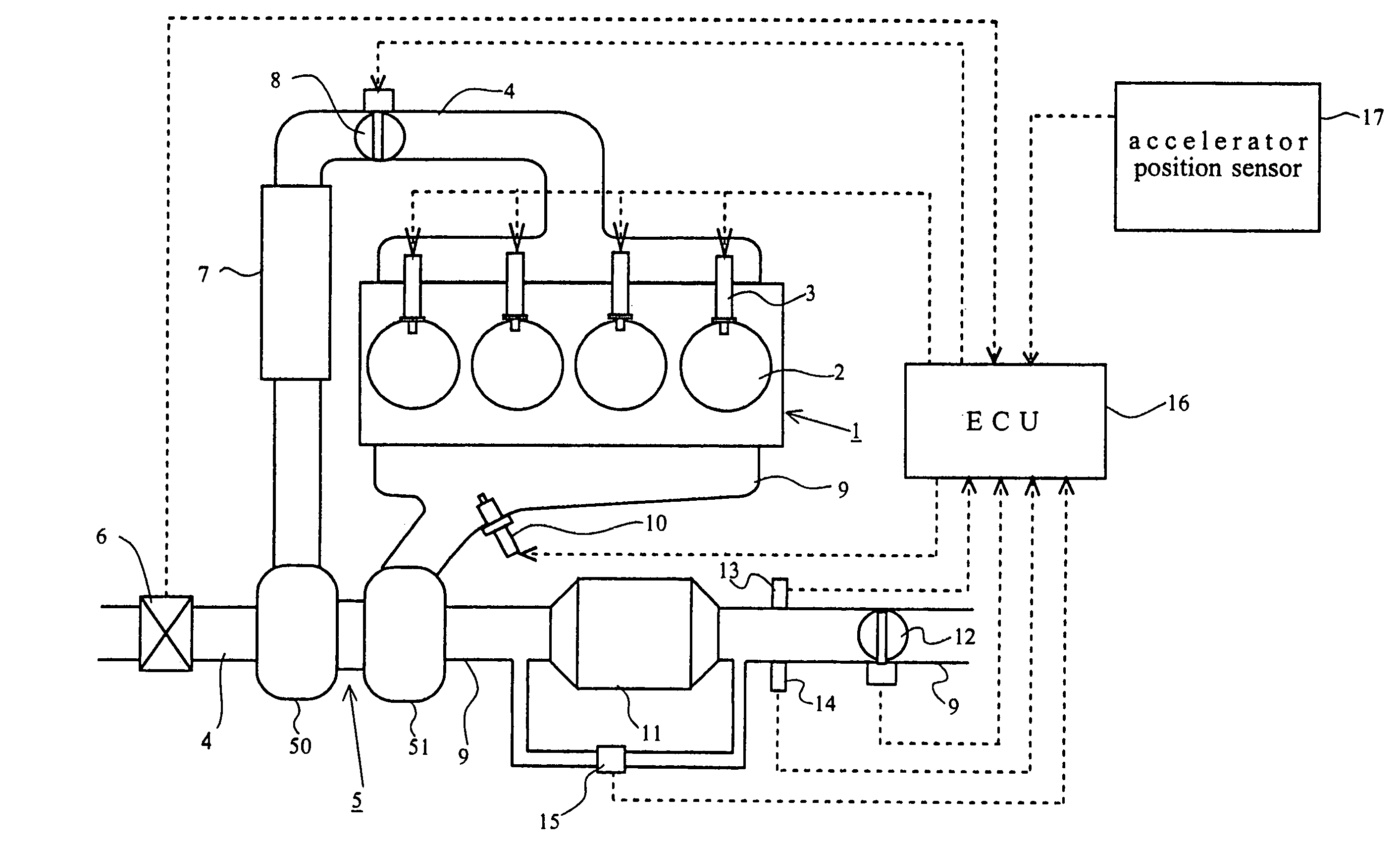

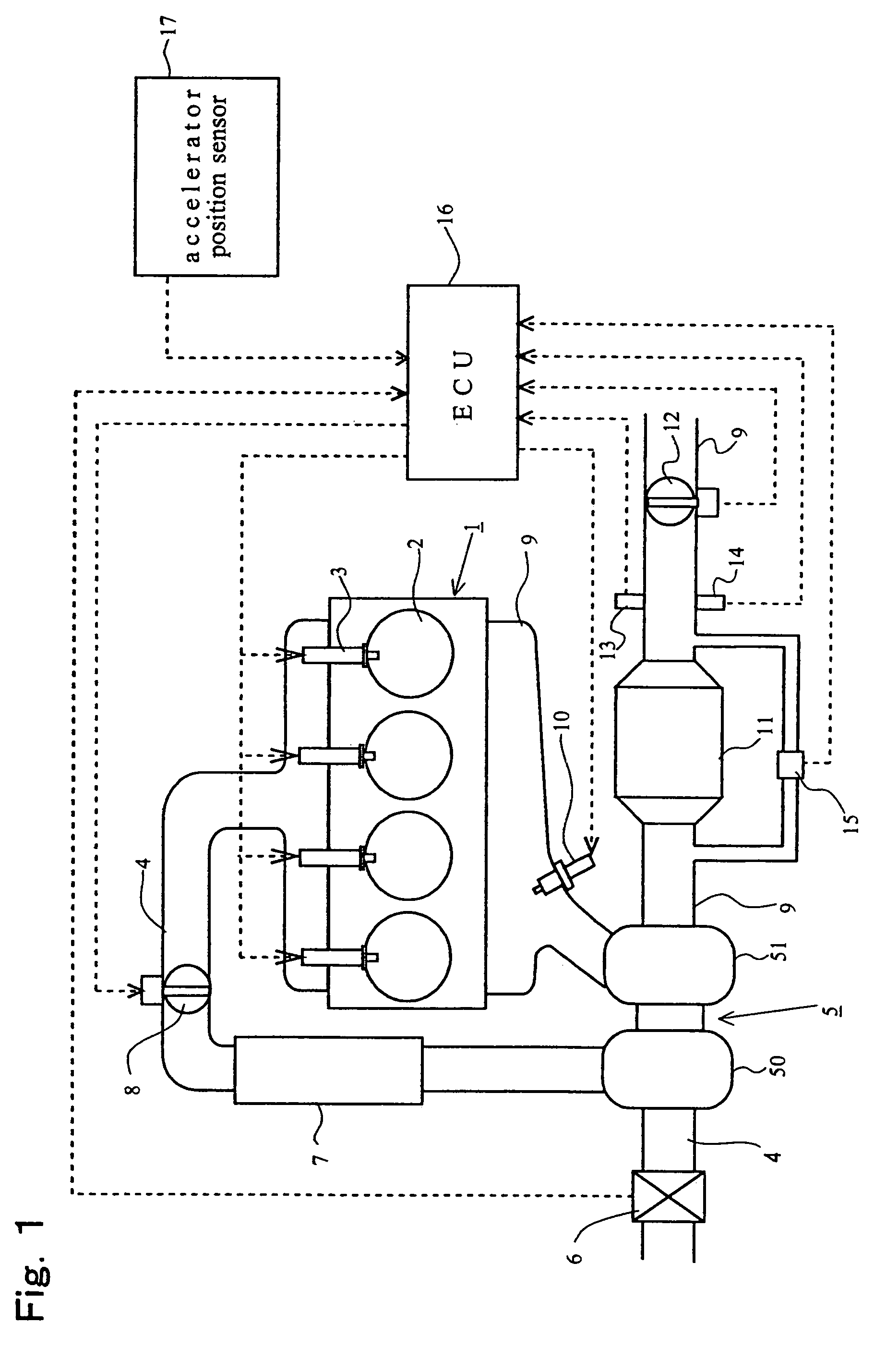

Exhaust Gas Purification System For Internal Combustion Engine

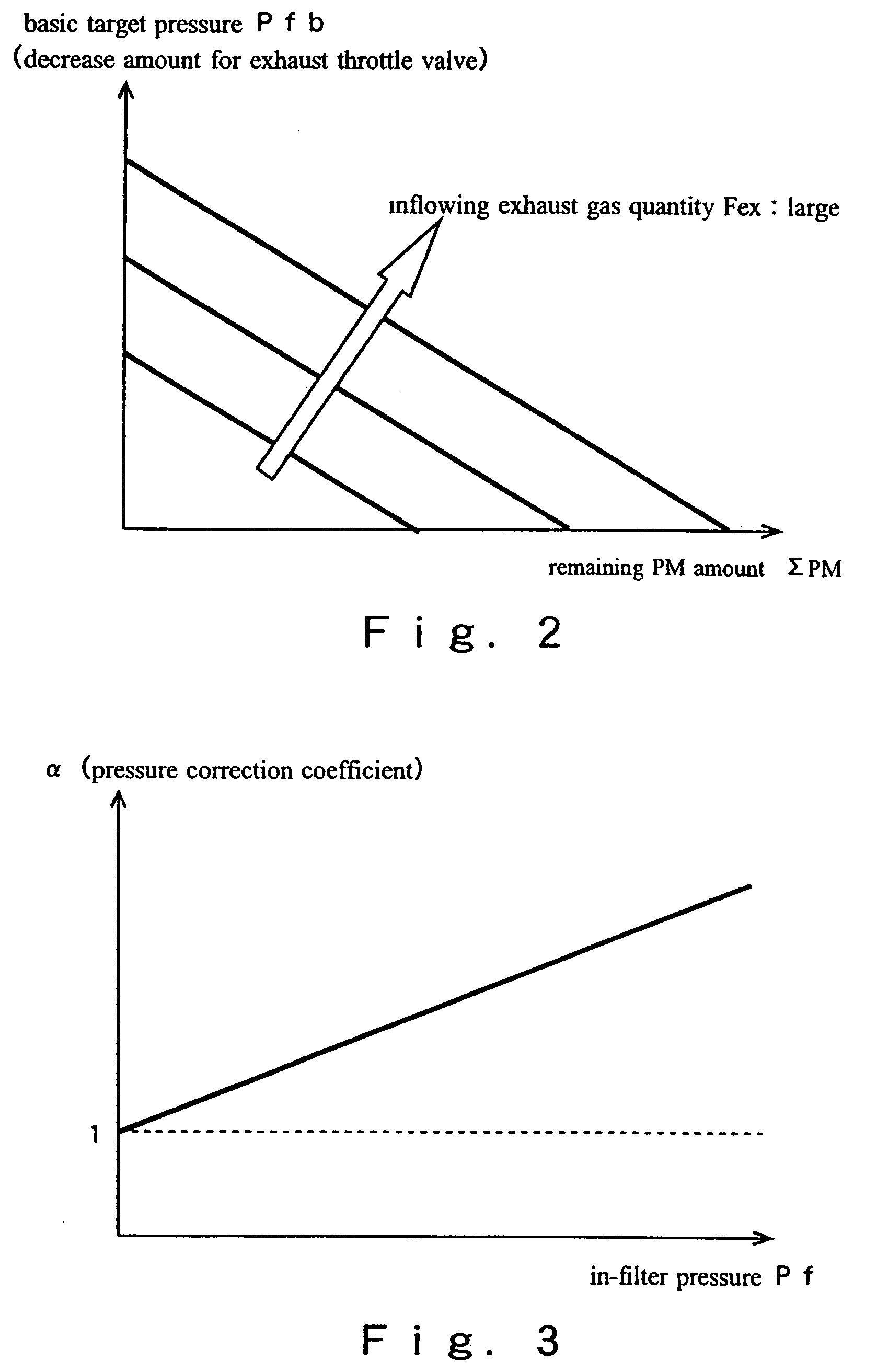

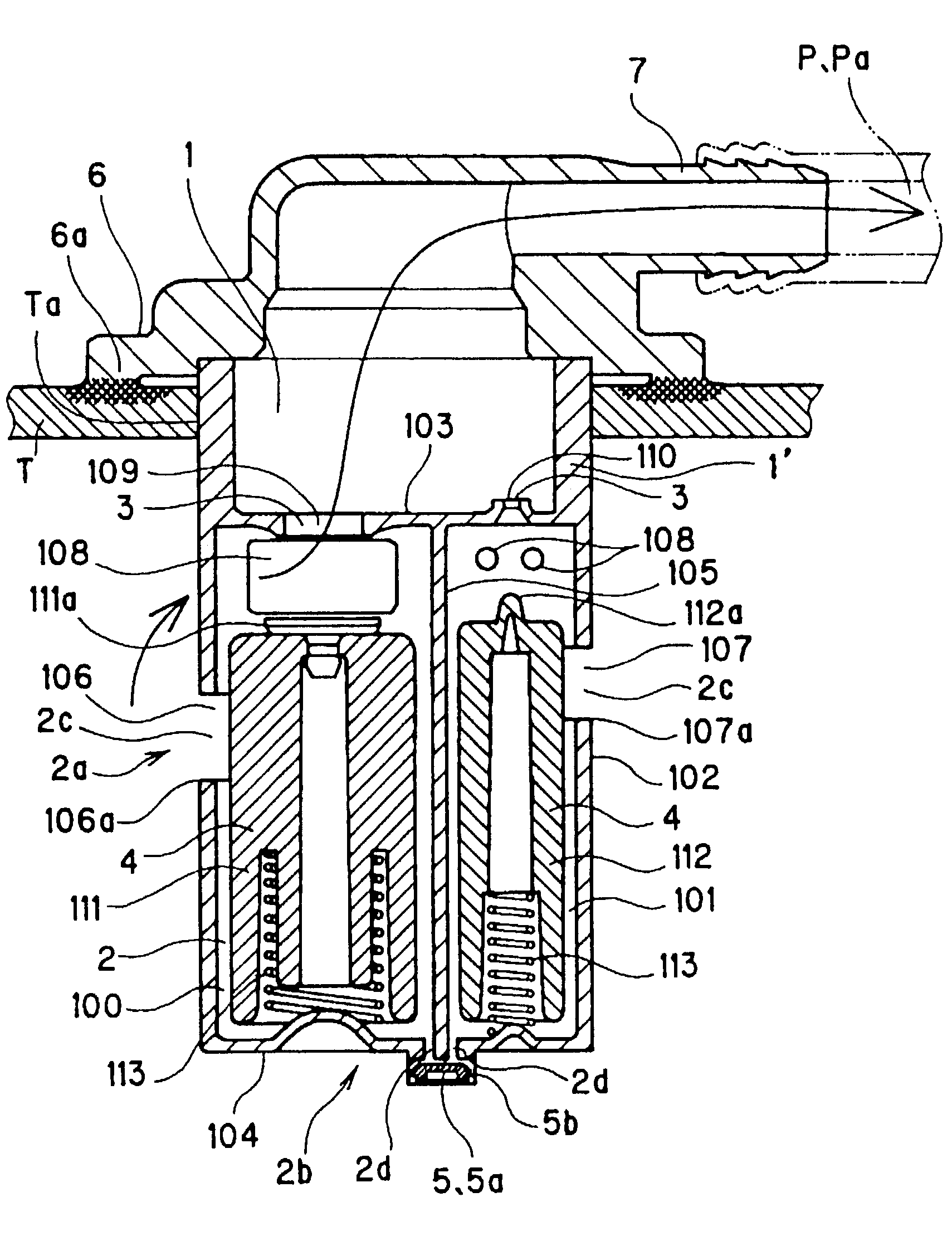

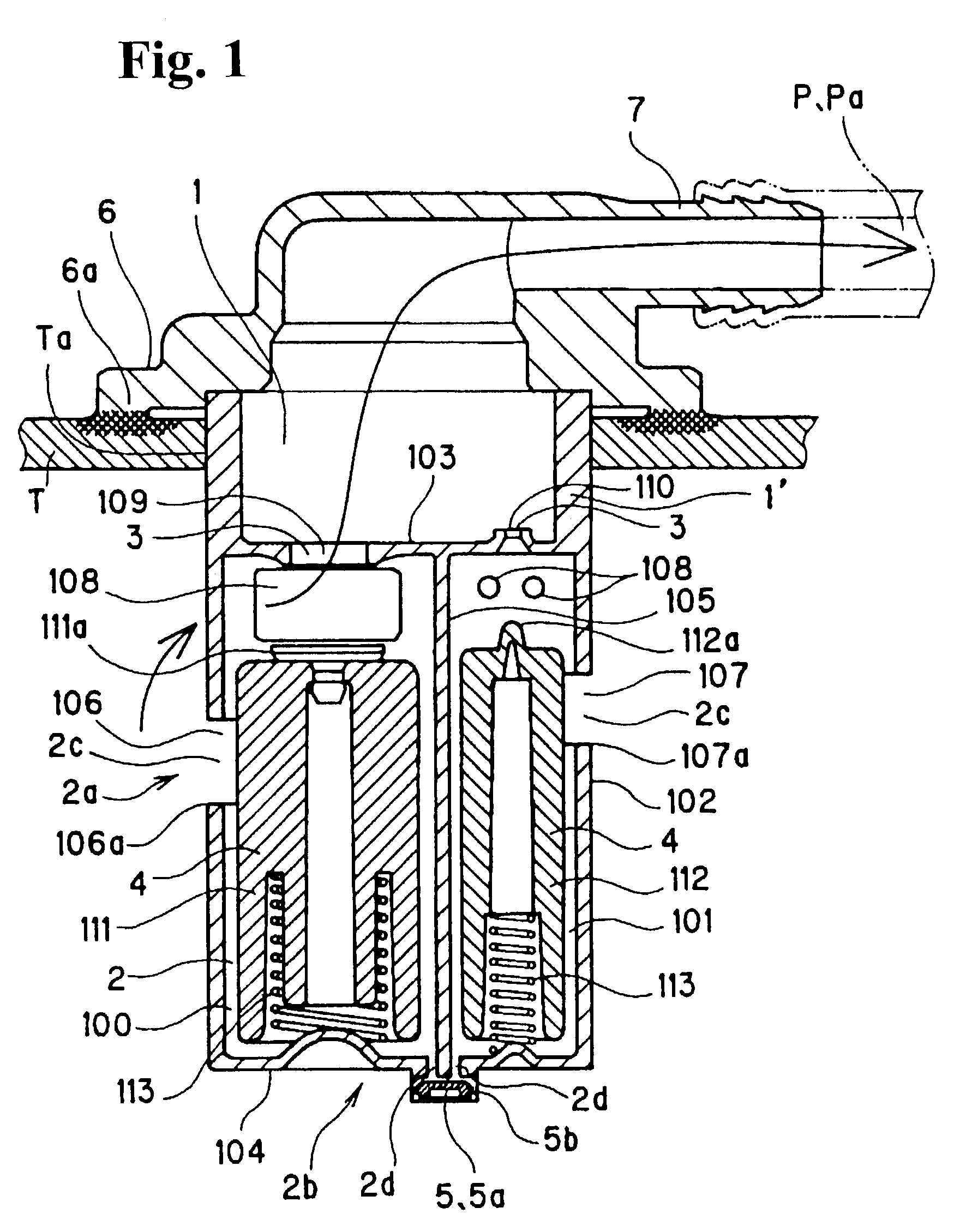

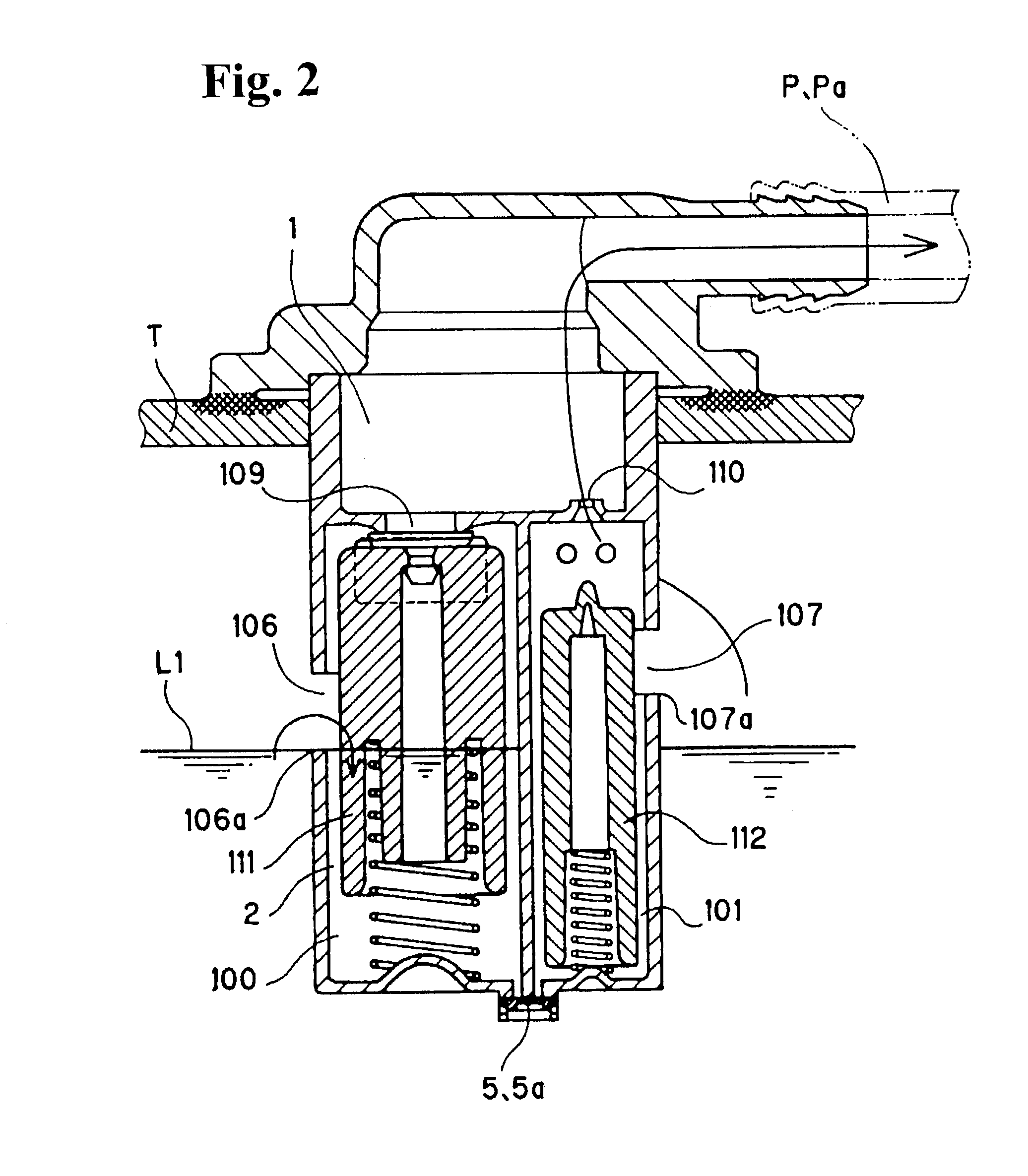

InactiveUS20080196395A1Easy to changeIncrease internal pressureElectrical controlInternal combustion piston enginesRegenerative processExhaust fumes

The present invention is directed to an exhaust gas purification system for an internal combustion engine that performs high pressure PM filter regeneration process by decreasing the degree of opening of an exhaust throttle valve in regenerating the particulate matter trapping capacity of a particulate filter and has as an object to provide a technology that enables to perform the high pressure PM filter regeneration process while suppressing excessive temperature rise of the particulate filter even while the vehicle is moving. According to the invention, a prediction is made, when the high pressure PM filter regeneration process is performed, as to whether there is a possibility that the temperature of the particulate filter will reach a predetermined upper limit temperature, and the pressure inside the particulate filter is controlled in accordance with the prediction.

Owner:TOYOTA JIDOSHA KK

Over-fueling prevention valve

InactiveUS6959720B2Increase internal pressureImprove the level ofNon-fuel substance addition to fuelLarge containersInternal pressureFuel tank

A fuel valve includes an upper chamber communicating with a ventilation passage of a canister; a lower chamber to be disposed inside a fuel tank; a communicating port between the upper chamber and the lower chamber; and a float member disposed in the lower chamber for blocking the communicating port when fuel flows into the lower chamber. The lower chamber includes a one-way valve formed at a bottom thereof for allowing the fuel to flow out only through the one-way valve, and a fuel inlet formed in a side wall of the lower chamber. When a fuel level inside the fuel tank reaches the main fuel inlet, the fuel flows into the lower chamber to raise the float member. As a result, an internal pressure of the fuel tank increases, so that a sensor at a fueling nozzle side can detect that the fuel tank is filled-up.

Owner:NIFCO INC

Safety device for secondary battery and battery pack employed with the same

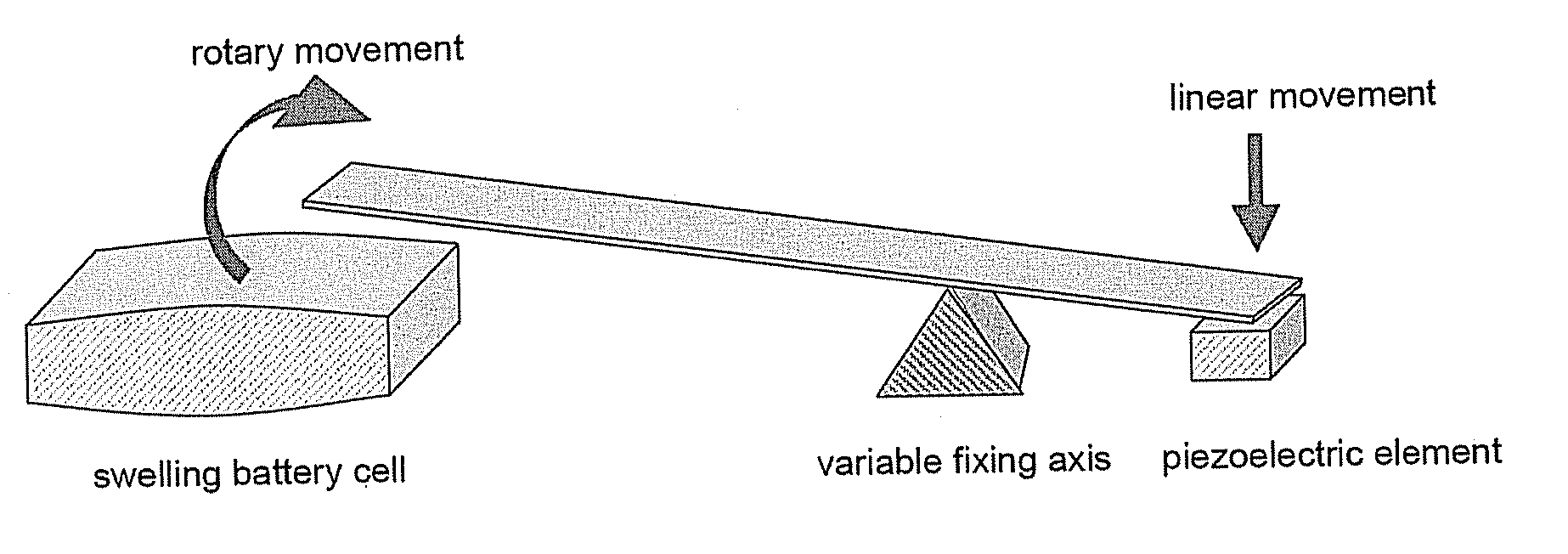

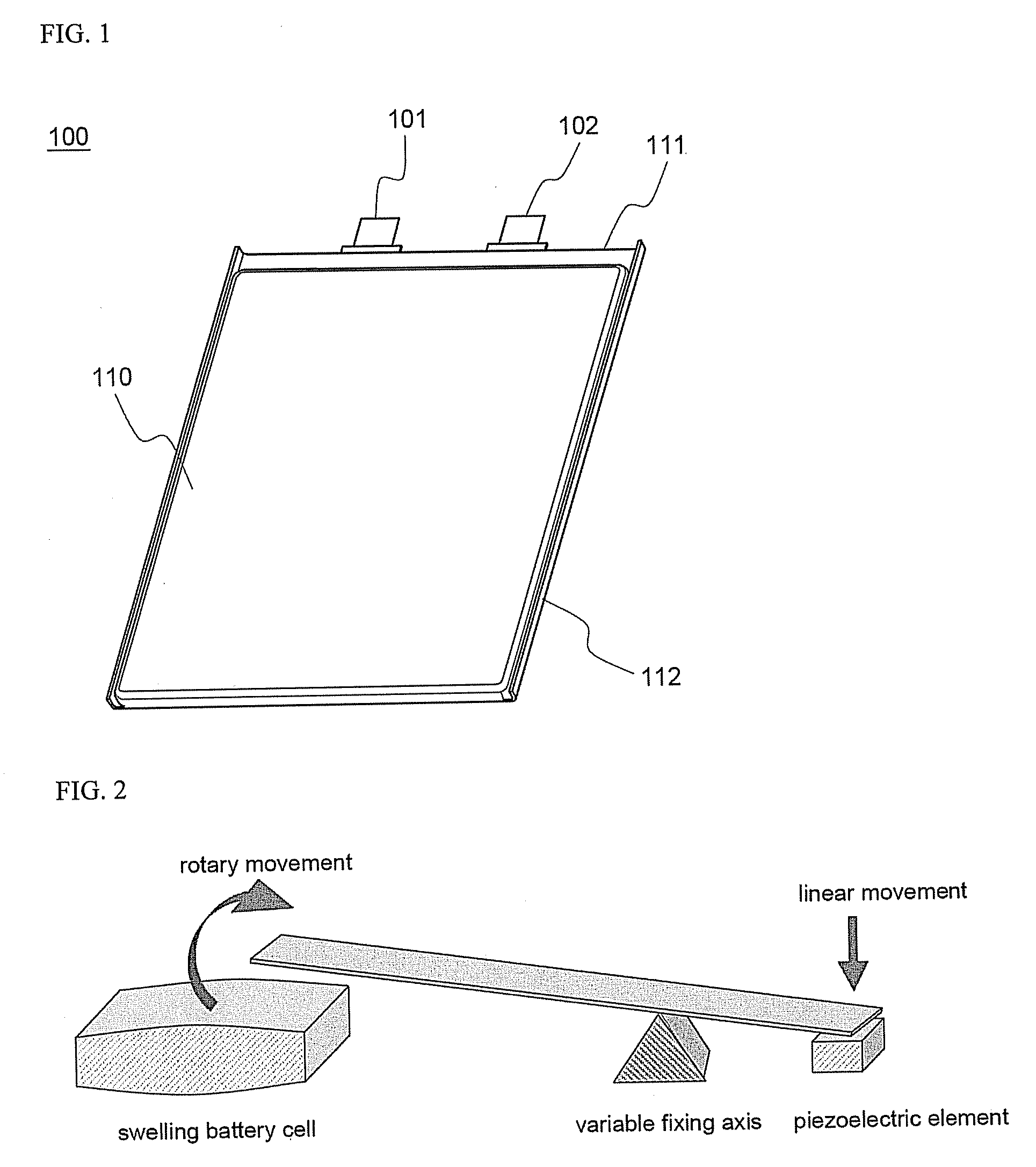

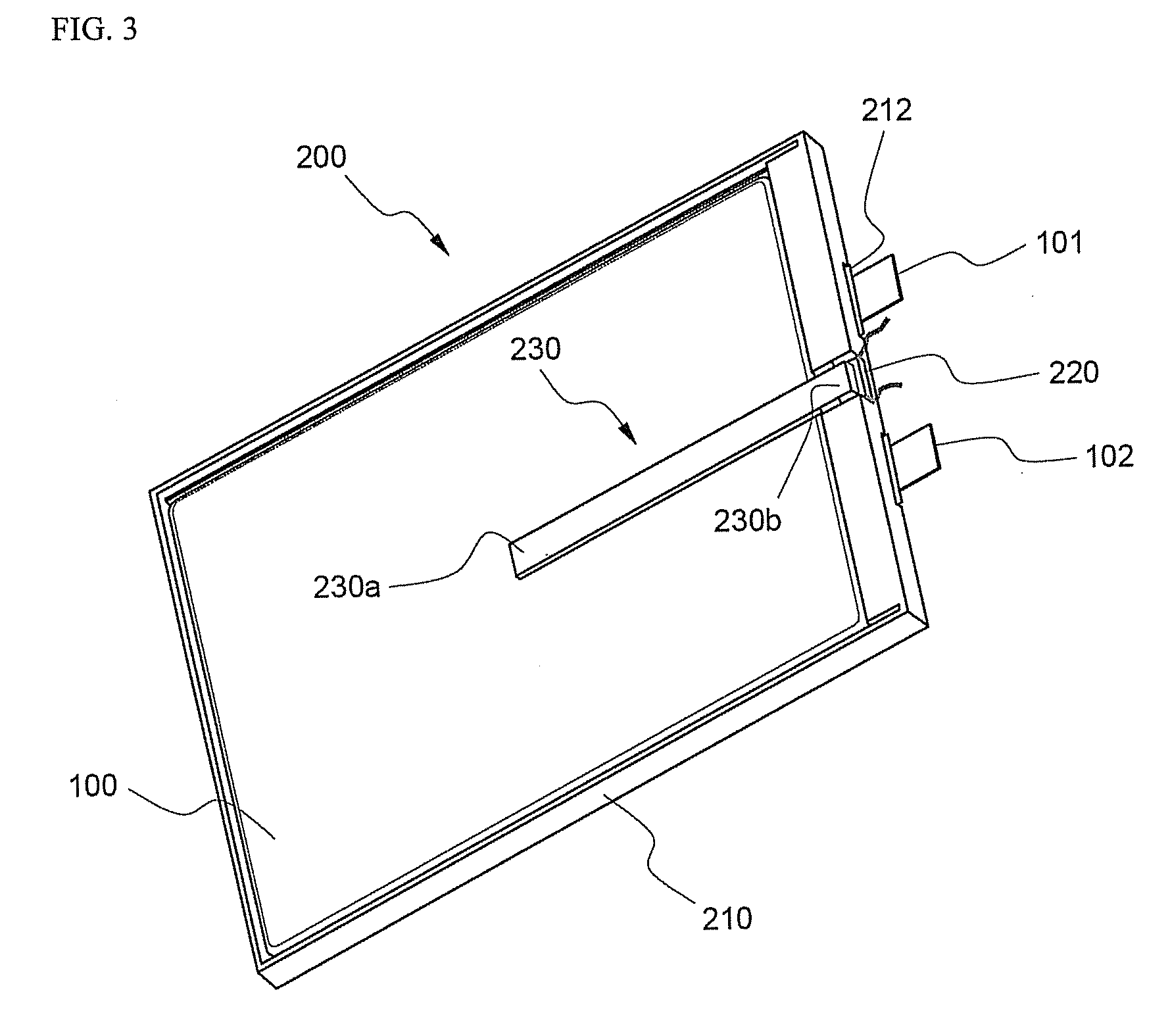

ActiveUS20070122691A1Increase in sizeIncreased battery sizeCells structural combinationLi-accumulatorsHemt circuitsControl theory

Disclosed herein are a safety device for secondary batteries that is capable of pressing a piezoelectric element using a seesaw member, which is constructed in a variable fixing structure, to generate electric current when a battery cell swells due to the abnormal operation or the degradation of the battery, and controlling the operation of the battery according to the generated electric current using a protection circuit module, thereby securing the safety of the battery, and a battery pack including a battery cell, which has low mechanical strength and high deformability, mounted in a frame member having the safety device, whereby the safety of the battery is improved and the assembly efficiency of the battery pack is improved.

Owner:LG ENERGY SOLUTION LTD

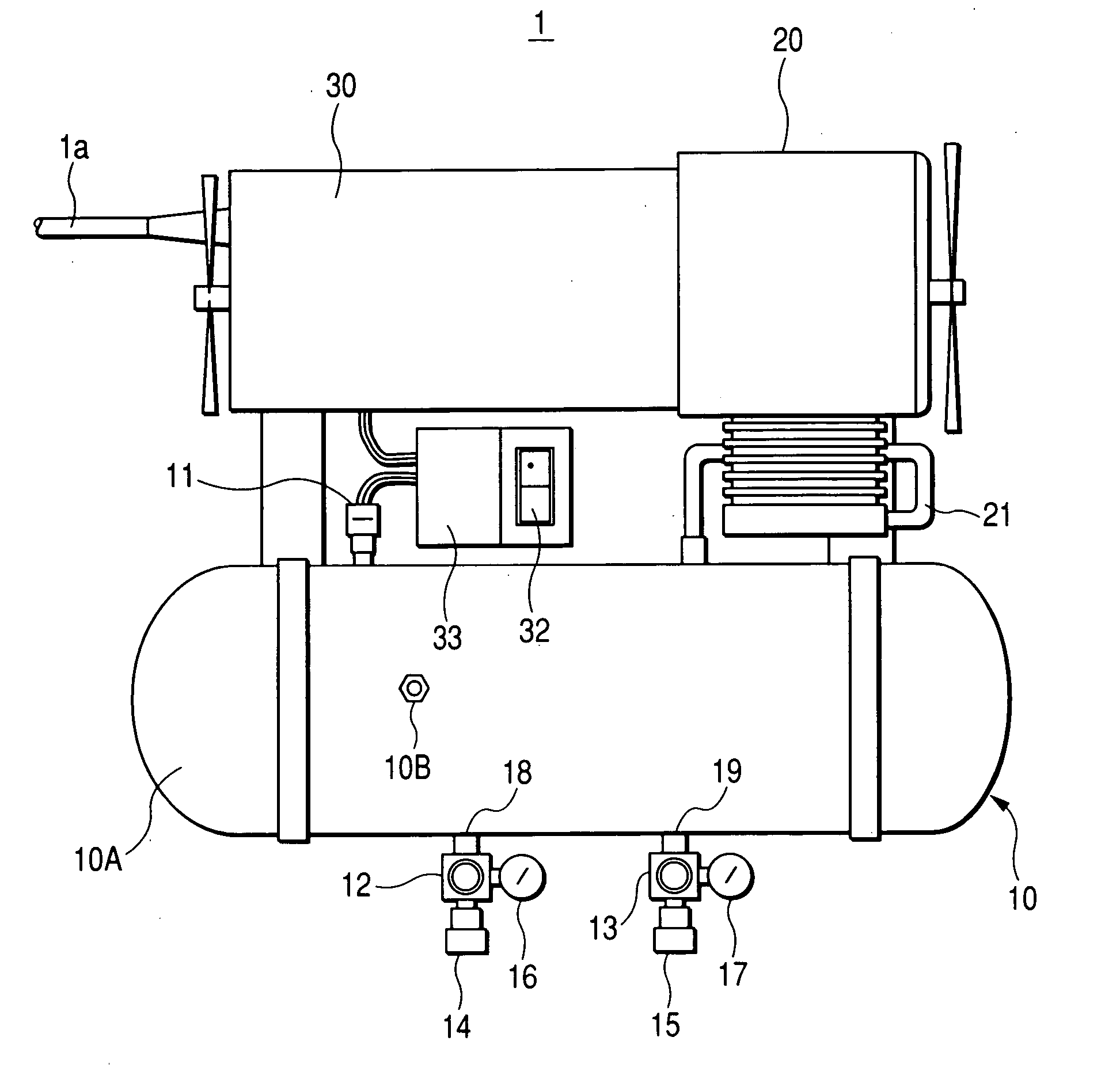

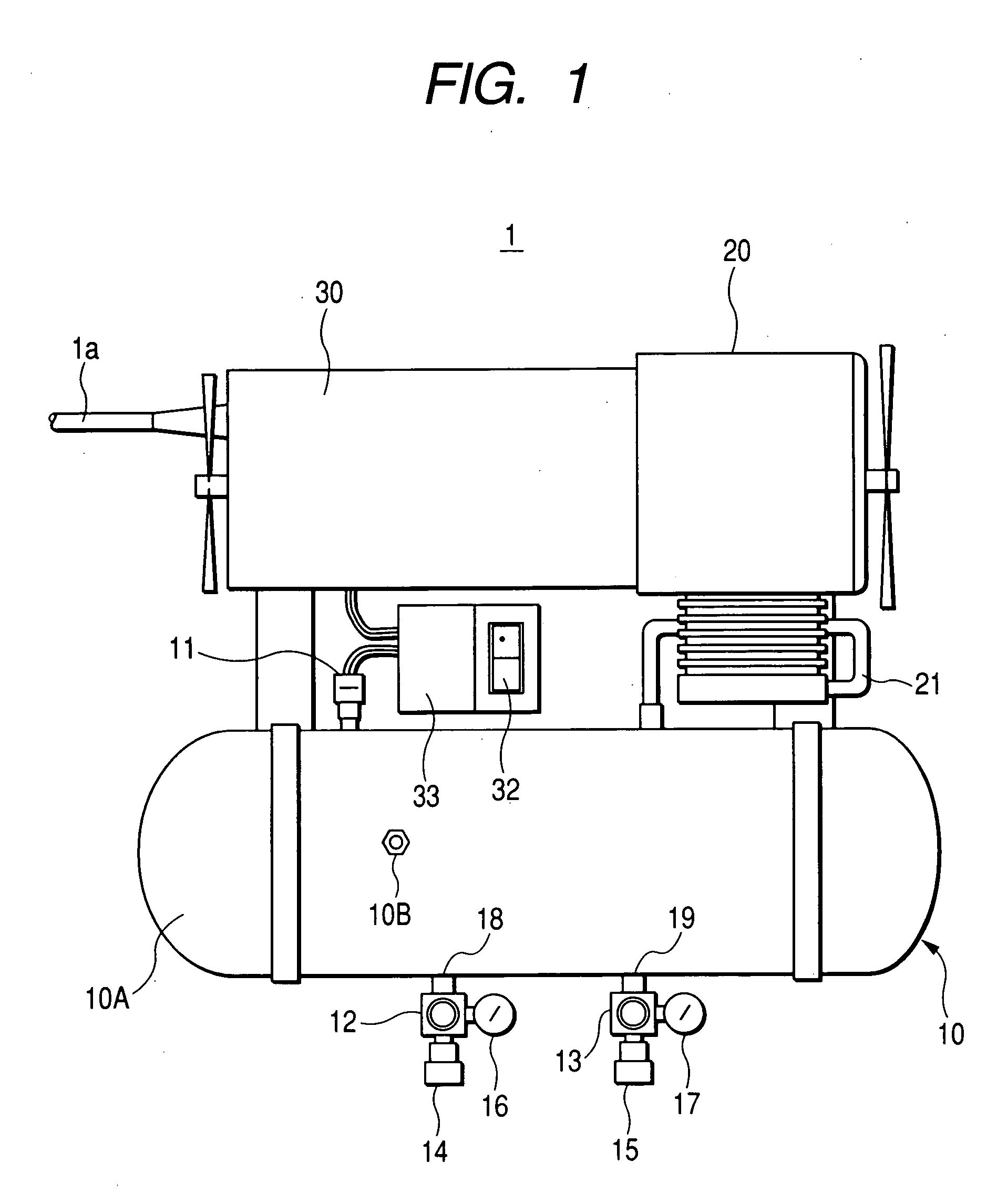

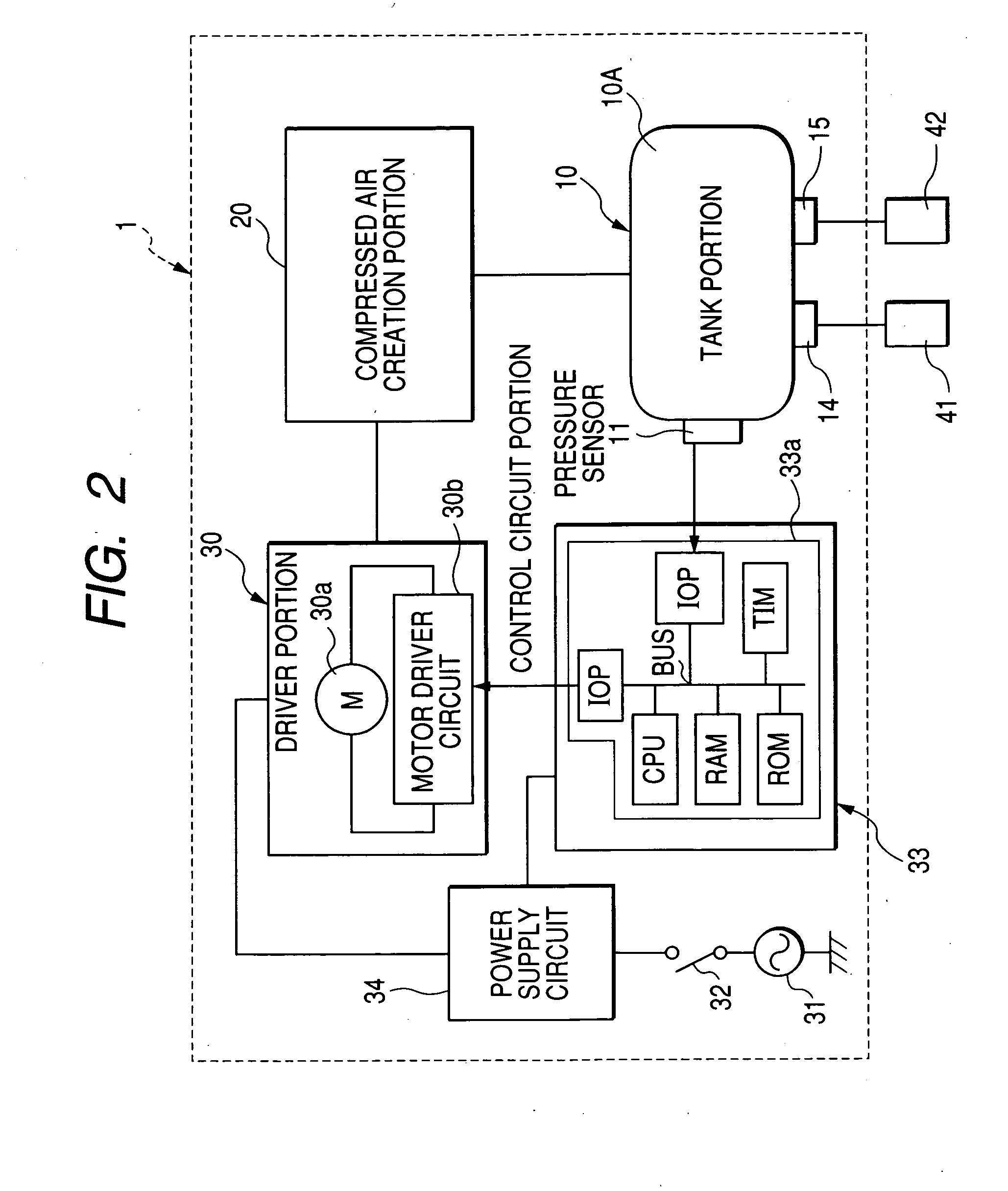

Air compressor

InactiveUS20060110258A1Increase internal pressureFrictional forcePump controlPositive-displacement liquid enginesDecreased pressureEngineering

A control circuit portion in an air compressor finds the rate of decrease of pressure inside a tank portion when a motor is at rest relative to the time based on a detection signal from a pressure sensor. Where the rate of decrease of pressure is greater than a given value, the motor is started without waiting for the pressure inside the tank to decrease to a motor restart pressure value, the pressure inside the tank portion rises to a given motor stop pressure value and the motor is then controlled to come to a stop. Where the rate of decrease of pressure is less than the given value, the motor is started when the pressure inside the tank has decreased to the motor restart pressure value. After the start of the motor, the motor is controlled such that it comes to a stop when the pressure inside the tank portion increases to a given value lower than the motor stop pressure value.

Owner:KOKI HLDG CO LTD

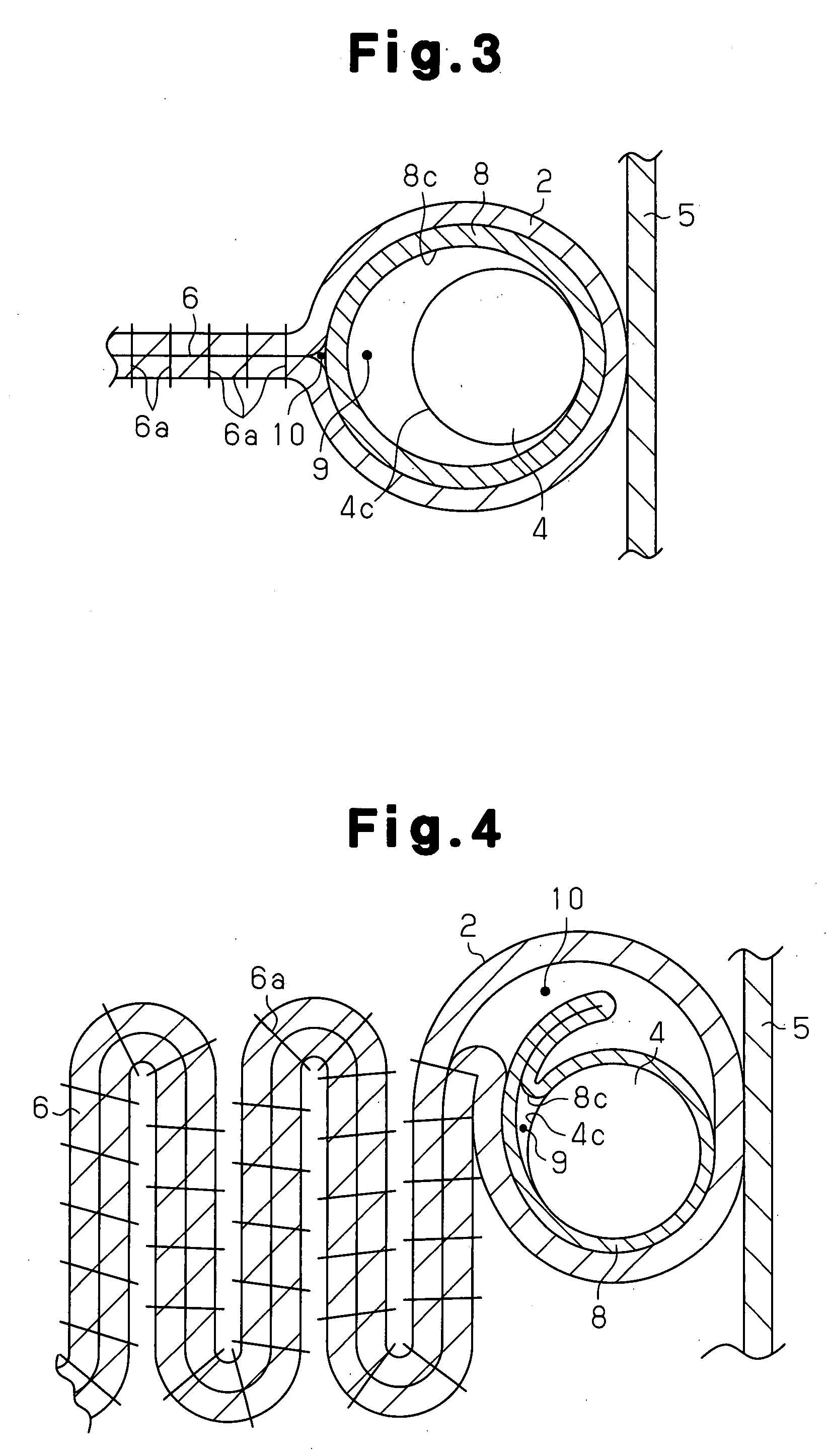

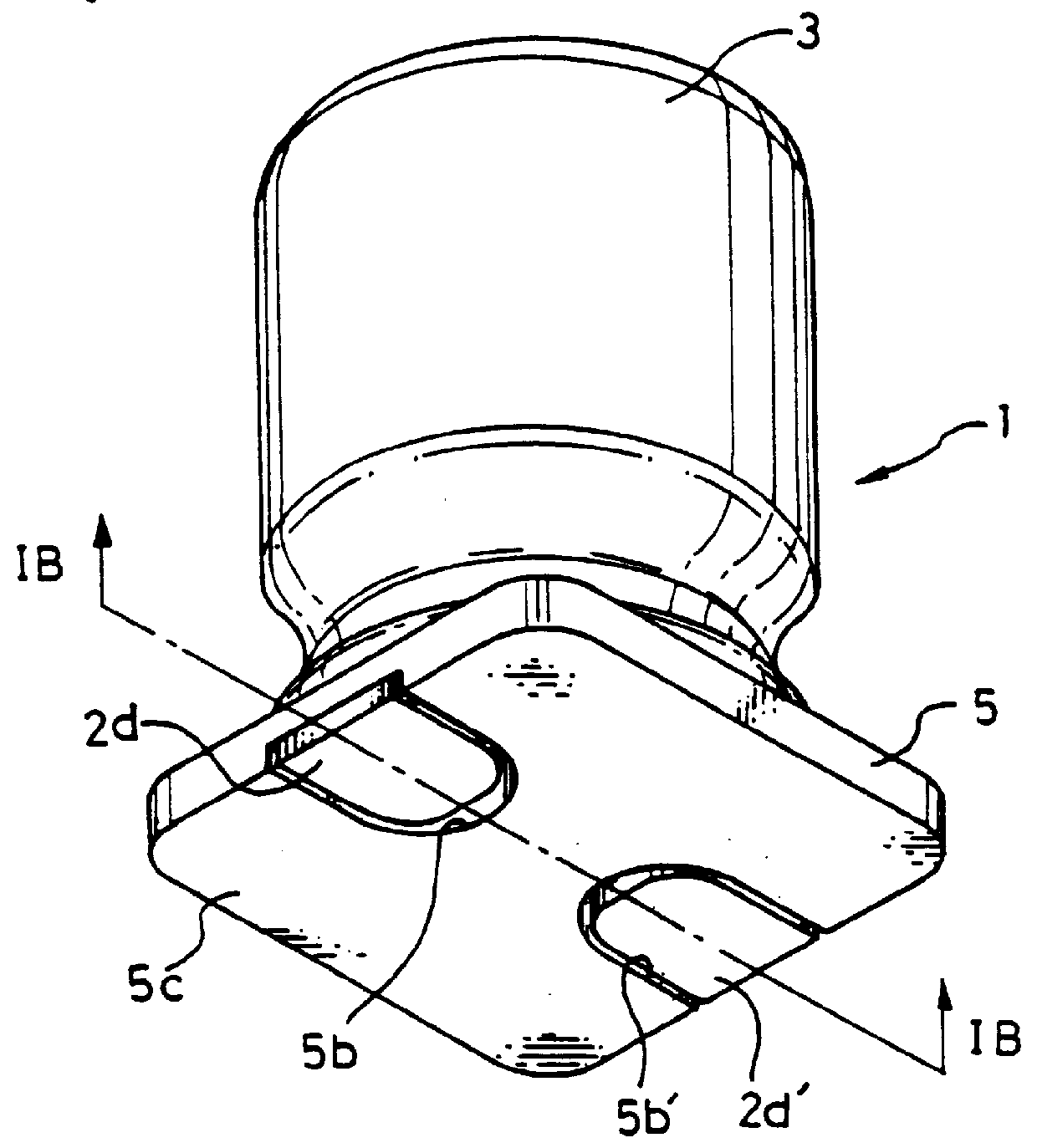

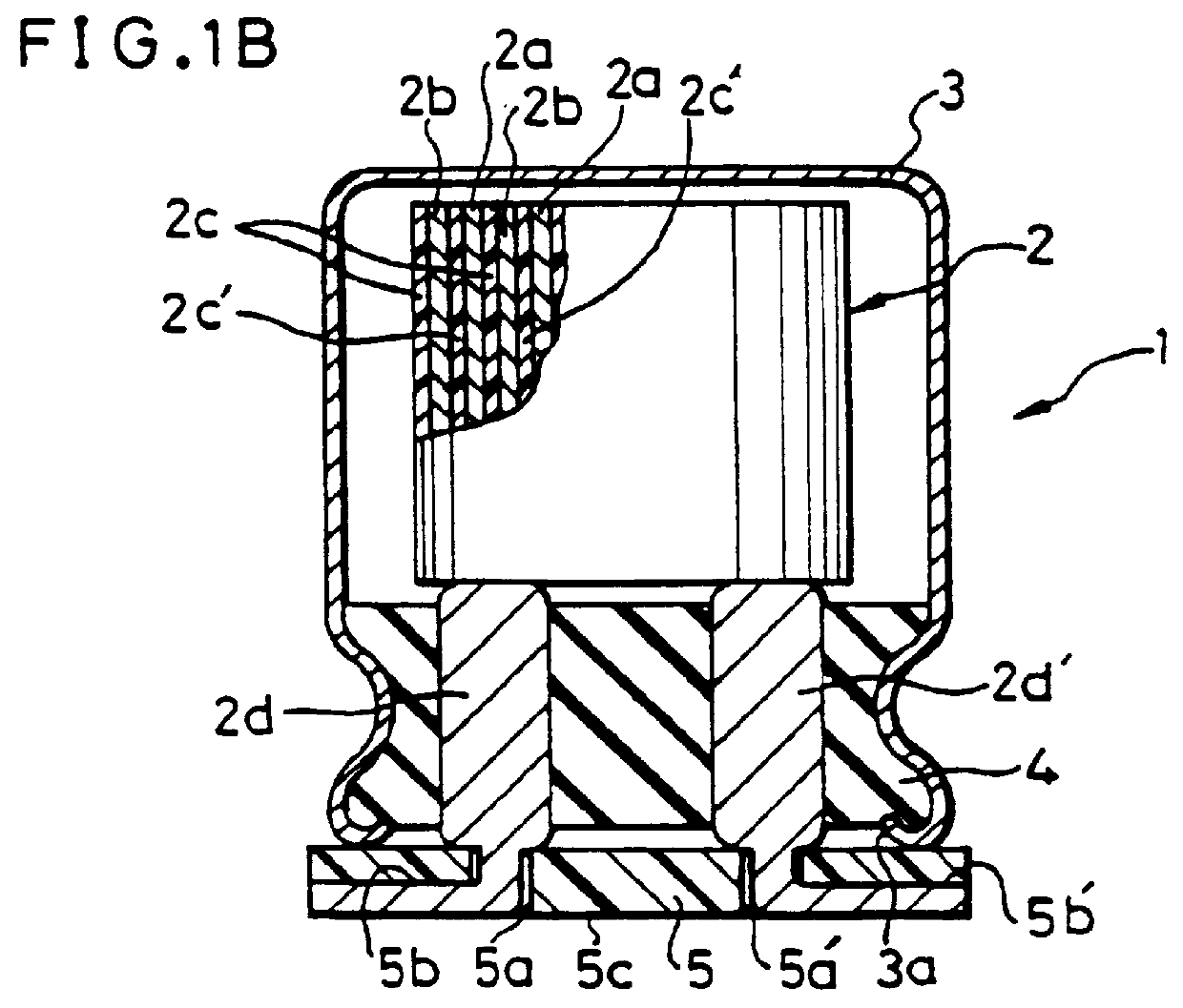

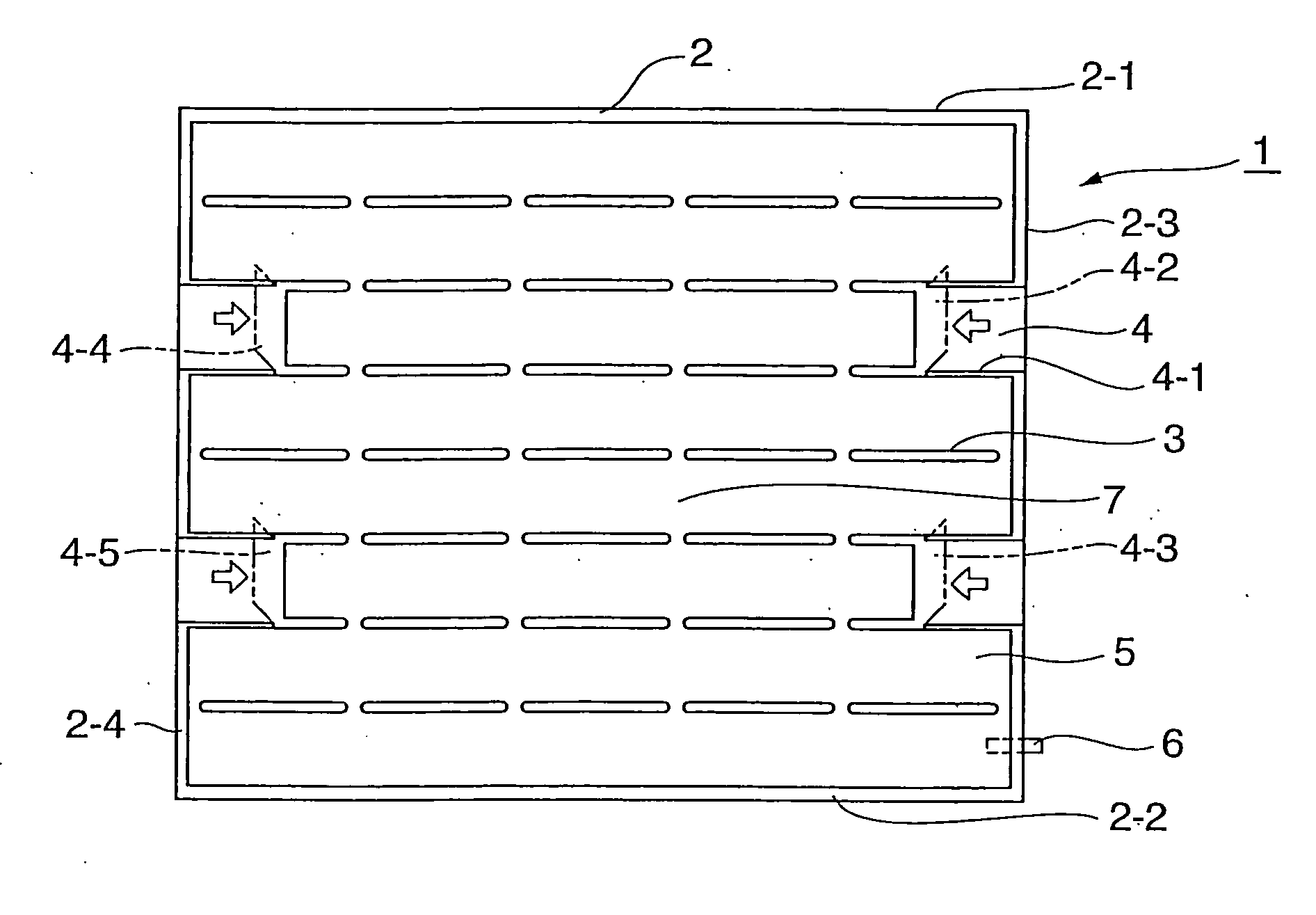

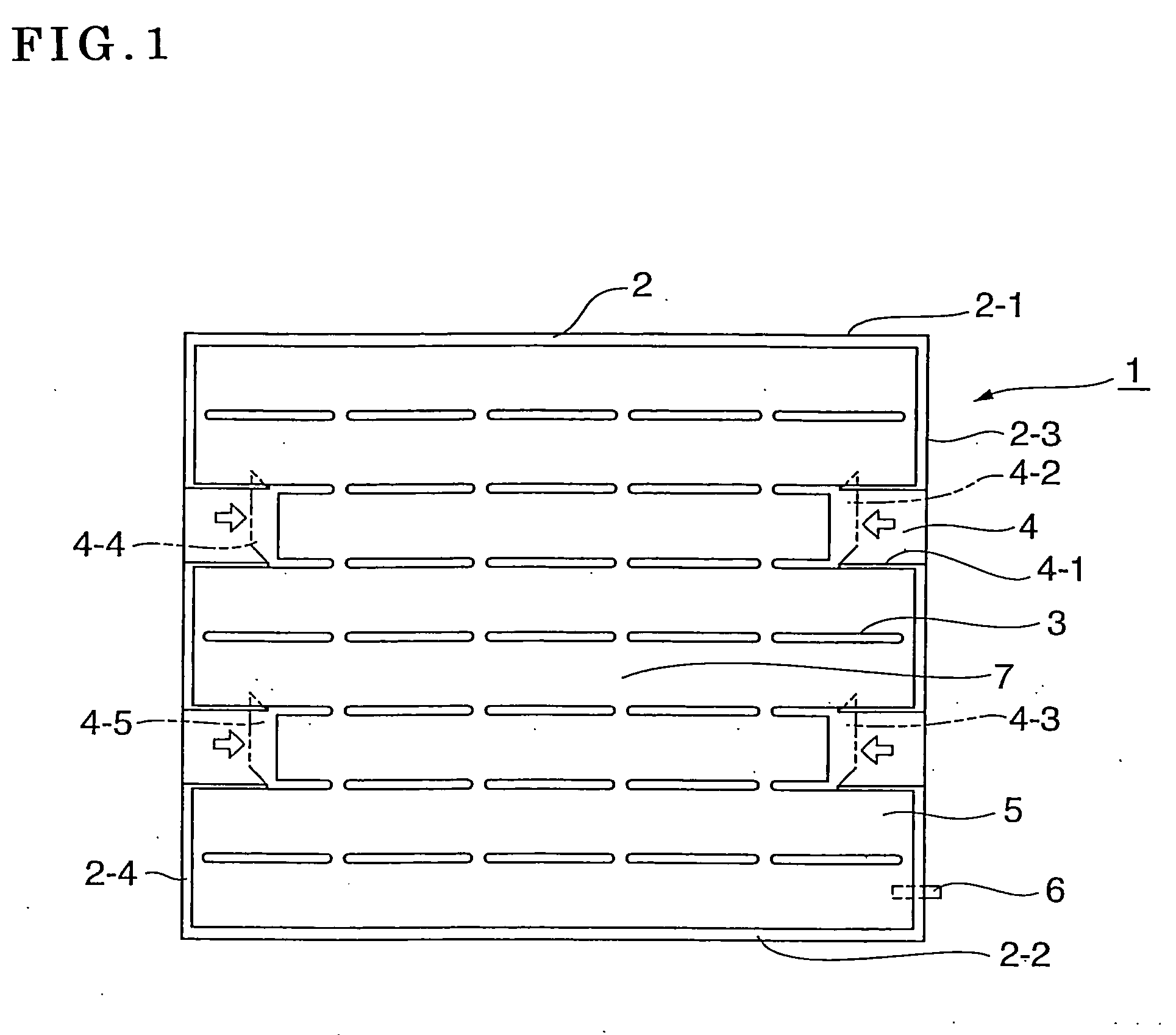

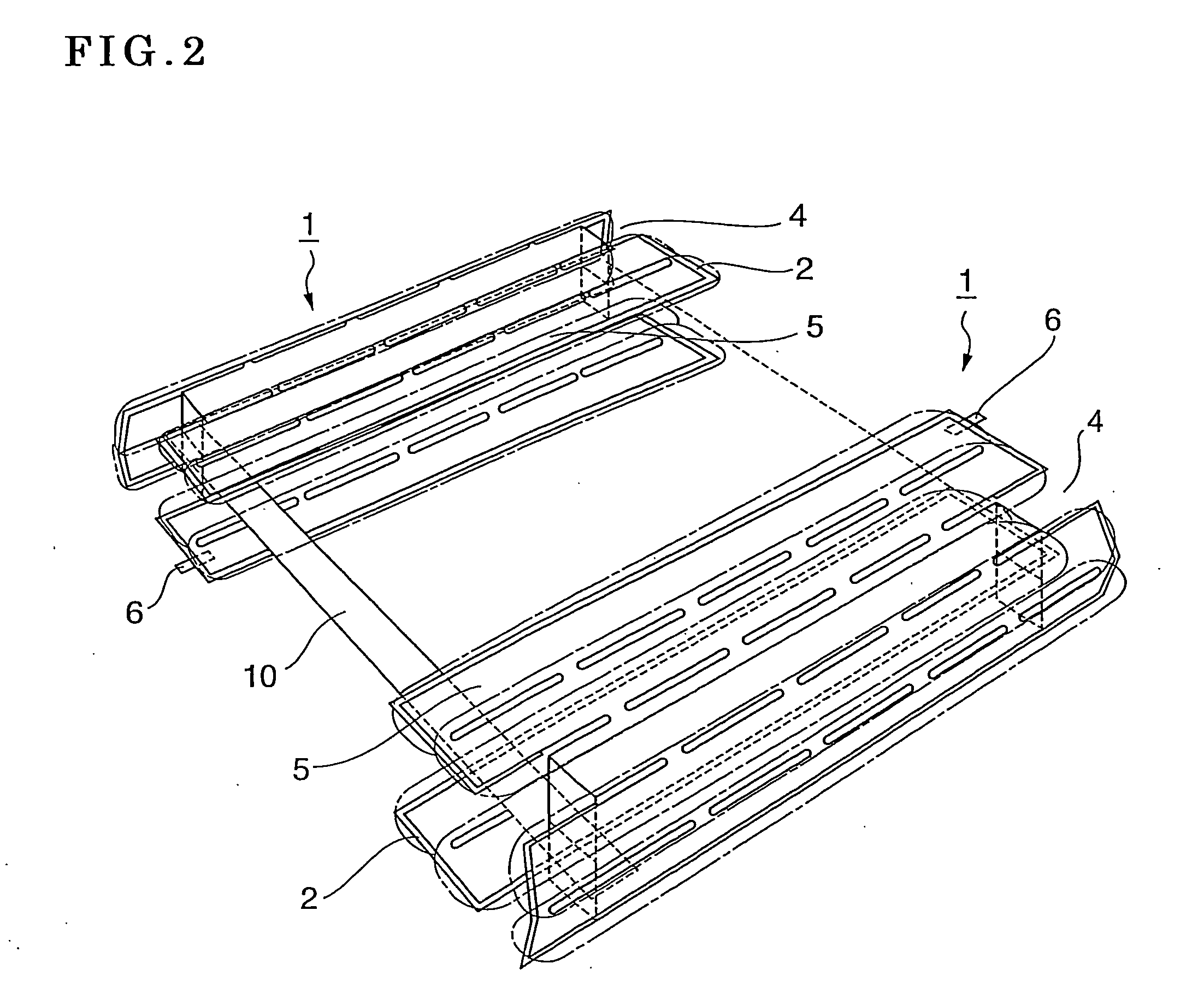

Chip type aluminum electrolytic capacitor

InactiveUS6017367AAvoid deformationIncrease internal pressureClosuresCasings/cabinets/drawers detailsCapacitorAluminum electrolytic capacitor

A chip type aluminum electrolytic capacitor (1) has a capacitor element (2) impregnated with an electrolytic solution, a cylindrical case (3) for containing the capacitor element (2), a sealing member (4) for sealing the cylindrical case (3), and an insulating board (5) having a mounting surface (5c) to be fixed to an electronic circuit board; and vapor pressure of the electrolytic solution is regulated to a predetermined value to prevent deformations of the cylindrical case (3) and the sealing member (4).

Owner:PANASONIC CORP

Fuel cutoff valve

InactiveUS20040238033A1Increase internal pressureLittle strengthOperating means/releasing devices for valvesLarge containersFuel tankFluid level

A fuel cutoff valve of the invention includes a casing body having a valve chamber and a holder element, a float having a seat member on its top, a movable valve element that is fitted in the holder element in a vertically movable manner, and a first connection conduit and a second connection conduit that connect inside of the valve chamber with outside. When the fuel level in a fuel tank rises to a preset first fluid level, the float moves up to shut off the first connection conduit. When the fuel level further rises to a preset second fluid level, the float further moves up to press the movable valve element up and shut off the second connection conduit. The fuel cutoff valve of this simple structure effectively prevents a blowing back flow of fuel in the course of fuel supply without requiring any subtle setting of a spring load.

Owner:TOYODA GOSEI CO LTD

High-pressure fuel injection pipe

InactiveUS20050005913A1Improve fatigue strengthIncrease internal pressureMachines/enginesSpecial fuel injection apparatusInternal pressureCavitation

A high pressure fuel injection pipe is provided for a diesel engine and has excellent internal pressure fatigue resisting characteristics, vibrational fatigue resisting characteristics and cavitation resisting property and sheet face flawing resisting property, and can be made thin and light in weight. In the high pressure fuel injection pipe, pipe extension and heat treatment are repeated by using a header manufactured by transformation induced plastic type strength steel, and processing for depositing residual austenite is then performed and final pipe extension processing is performed, and a joint portion is molded and bending processing is performed without performing perfect annealing at the size of a product.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

Hinged closure moulded in closed position

InactiveUS20060163188A1Increase internal pressureIncrease pressureCapsClosure using stoppersHinge angleEngineering

Owner:CREANOVA

Universal air-cushioning material

InactiveUS20070131575A1Broad mutual contact areaStable cushioning functionBagsSacksCushioningWadding

The invention intends to cheaply provide a cushioning material that can pack articles to be packed different in shapes and dimensions with a simple structure and stably and that can withstand transportations for long periods under severe conditions. A universal air cushioning material is formed in such a manner that side portions forming end portions of above and below and left and right external frames of two superposed rectangular synthetic resin films made of a same raw material are thermally fused and, between the side portions, an intermediate portion thereof is arbitrarily thermally fused in accordance with a dimension and shape of the article to be packed to dispose a plurality of partitioned peripheral portions; at arbitrary positions in the vicinity of the side portions of the peripheral portions, at least a pair of notches is disposed horizontally symmetrically in accordance with a dimension and shape of the article to be packed and, in the peripheral portions, at least one air passage port is disposed to form a plurality of mutually communicated air chambers to enable to arbitrarily vary a contact area between the air chambers and the article to be packed or an inner wall of the transporting vessel; to at least one of the air chambers an air inlet port is disposed to inject air from the air inlet port to expand an entirety of the air chambers; and thereby an inside thereof is pressed against the article to be packed and an outside thereof is pressed against an inner wall of the transporting vessel.

Owner:ABE TOMEMATSU

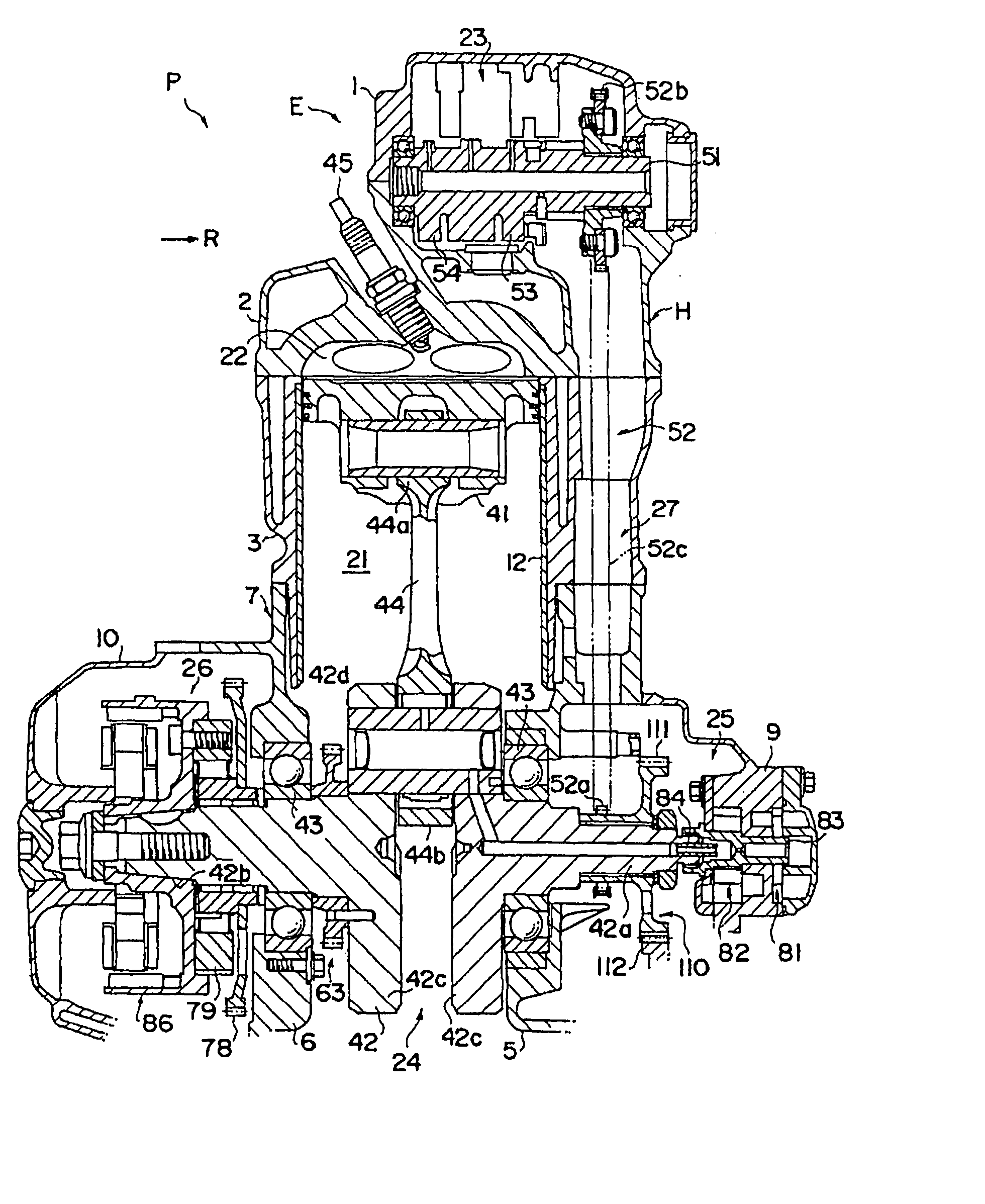

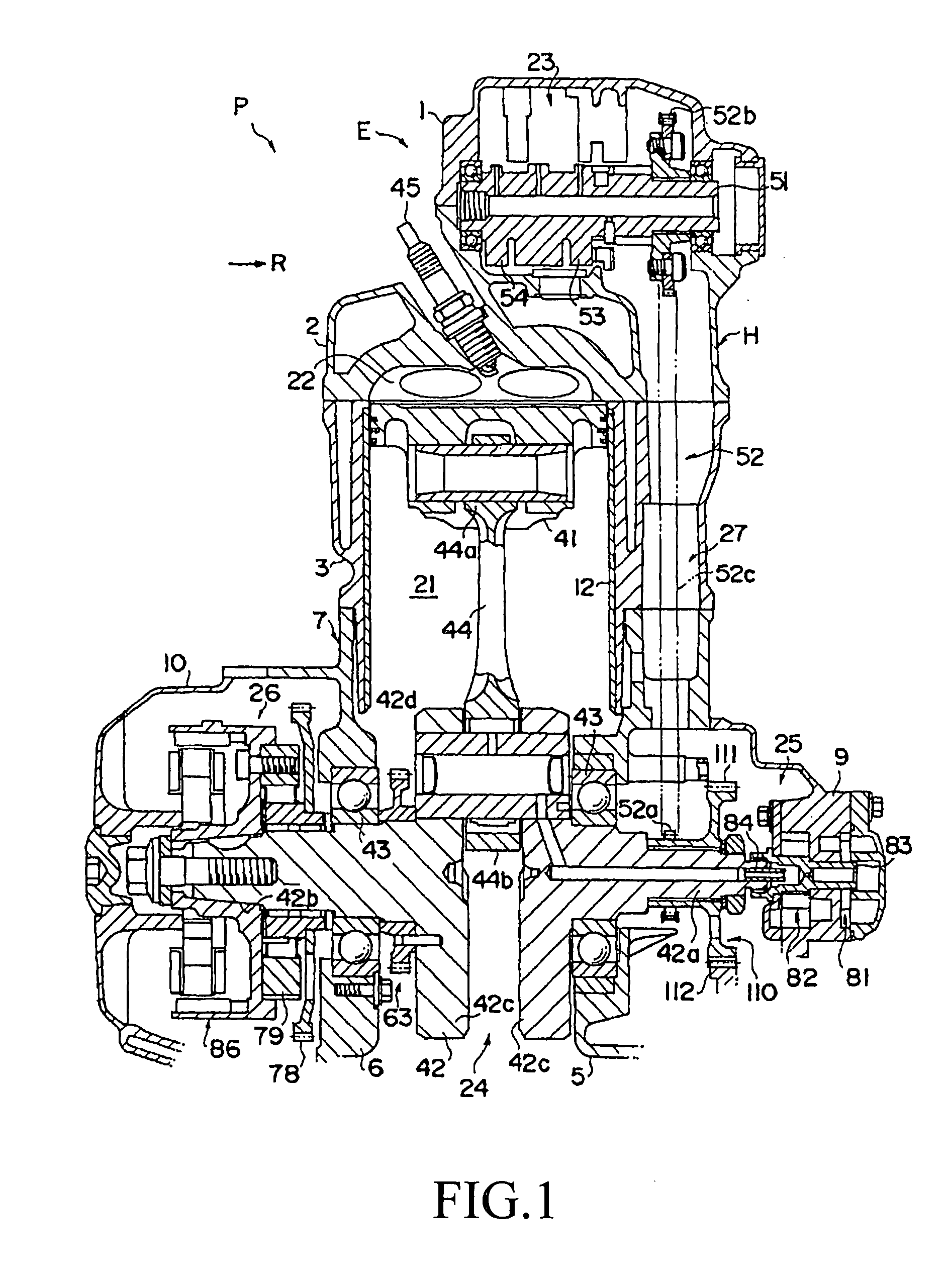

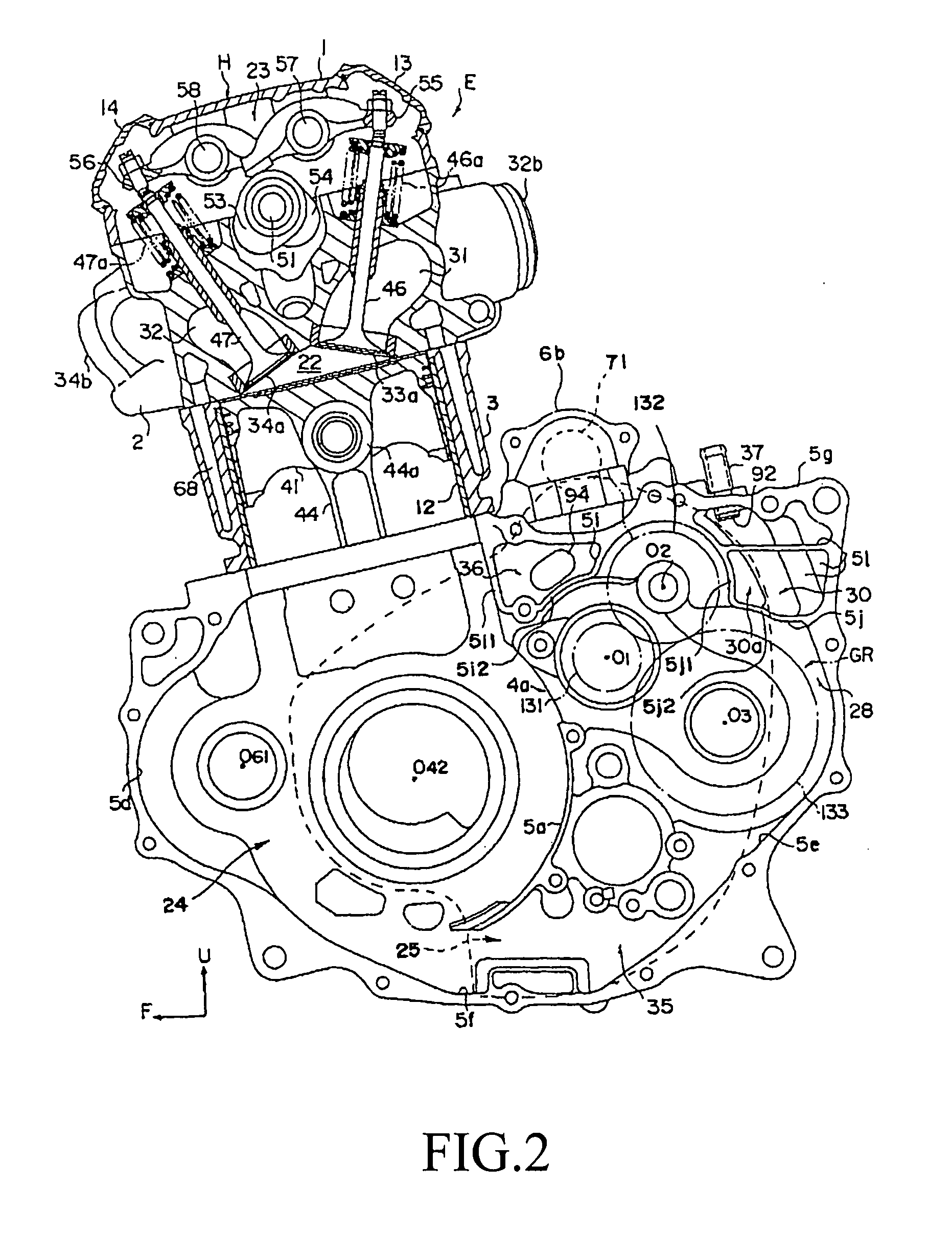

Breather structure for internal combustion engine

InactiveUS20080022981A1Sufficient breathing effectLarge capacityCombustion enginesGearing detailsBreatherEngineering

A breather structure for internal combustion engine, the structure making a breather chamber smaller and thus making an internal combustion engine as a whole smaller. A breather chamber and a small chamber are formed. The breather chamber includes a first side face cover. The first side face cover is joined to a case to cover a first one of the right and left side faces of the case. Inside the first side face cover, an auxiliary apparatus chamber is formed. The auxiliary apparatus chamber houses a clutch mechanism connecting or disconnecting the power transmission route. Additionally, formed inside a housing are an external communication port communicating to the outside of the housing, and the small chamber communicating to a crank chamber and to the auxiliary apparatus chamber. Moreover, the auxiliary apparatus chamber communicates to the breather chamber.

Owner:HONDA MOTOR CO LTD

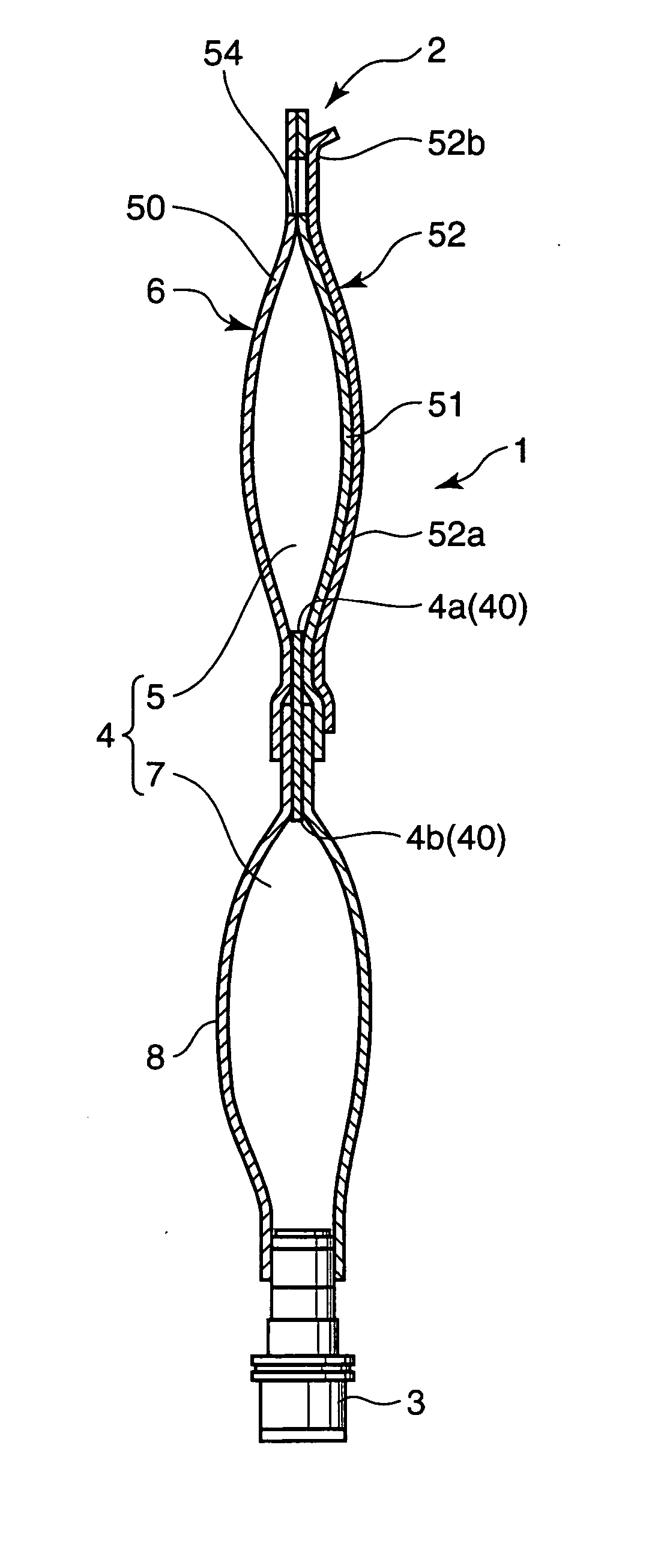

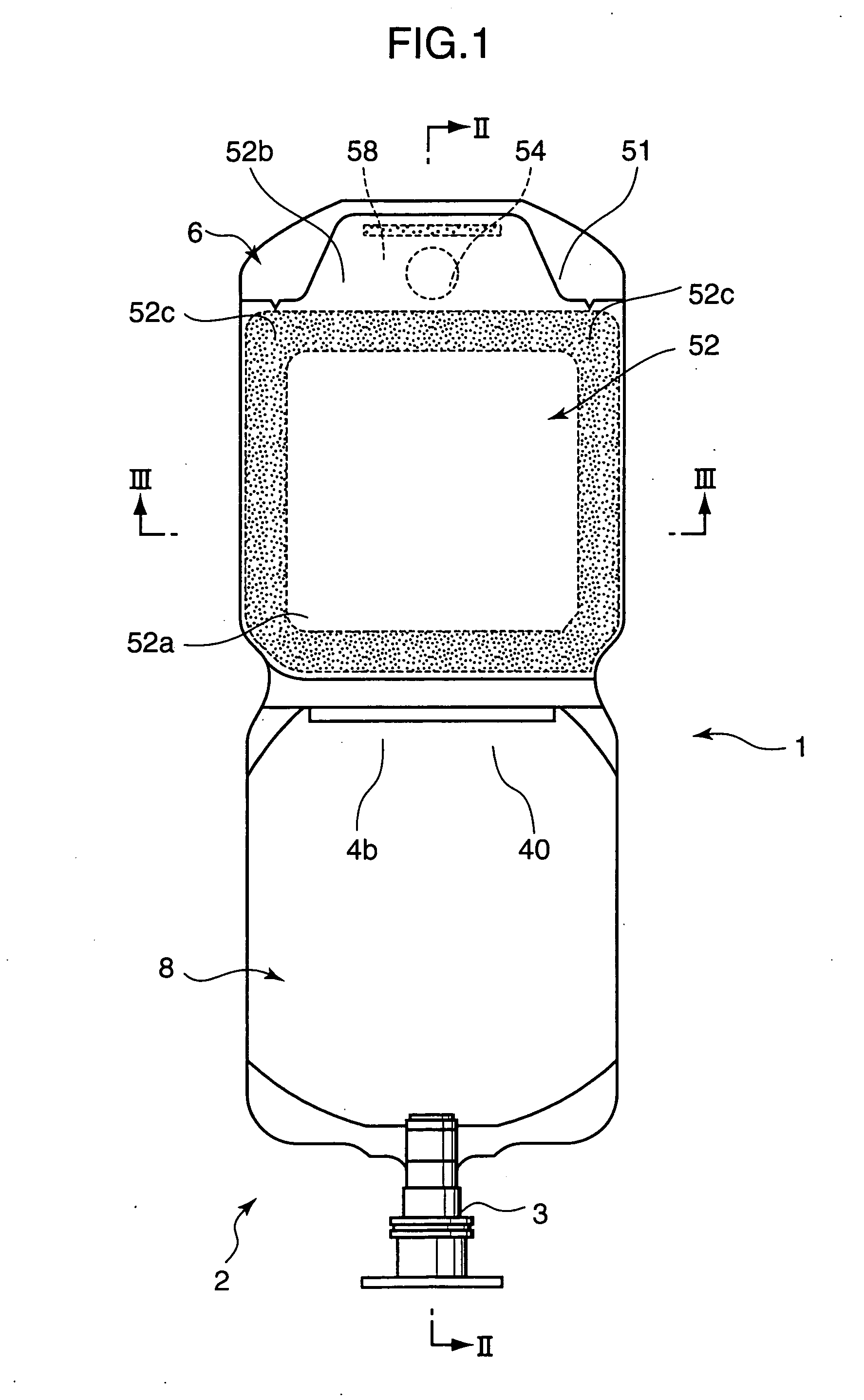

Medicine bag

ActiveUS20040188281A1Increase internal pressureElectrical apparatusSynthetic resin layered productsInternal pressureBiomedical engineering

A medicine bag, which includes a bag body having a medicine storage chamber that stores a medicine in such a way that the medicine is visually confirmed through a light-transmission portion provided in at least one part of the bag body, the bag body having a weak seal portion that divides the medicine storage chamber into a plurality of division spaces, and the sealing of the weak seal portion adjacent to a specific division space being removed by increasing the internal pressure of that division space, including: a cover sheet which is peelably attached to the bag body; and a requisitely-used portion which is used in the process shortly before the medicine is administered, in which the cover sheet includes: a light-shielding portion which shields from the light the medicine stored in at least one division space by covering a predetermined part of the light-transmission portion; and a continuously-formed portion which is continuously formed in the light-shielding portion and is placed so that the requisitely-used portion is prevented from being used with the cover sheet kept attached.

Owner:NIPRO CORP

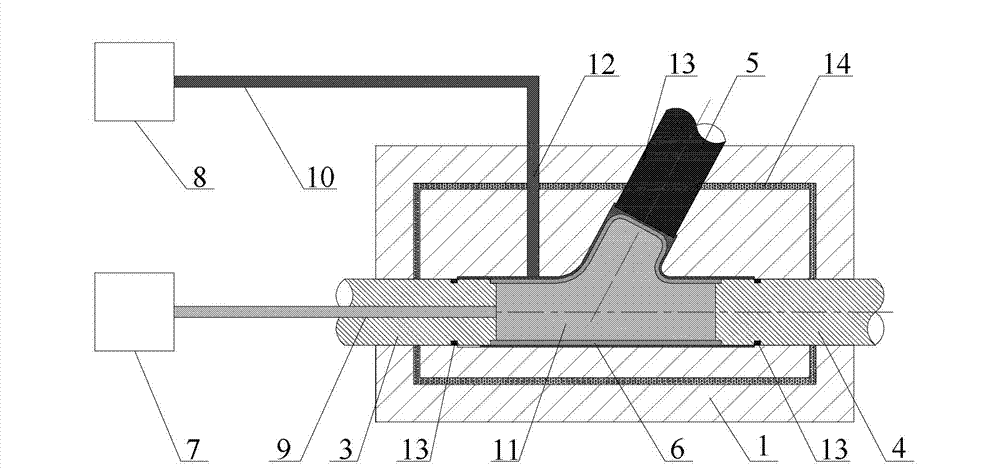

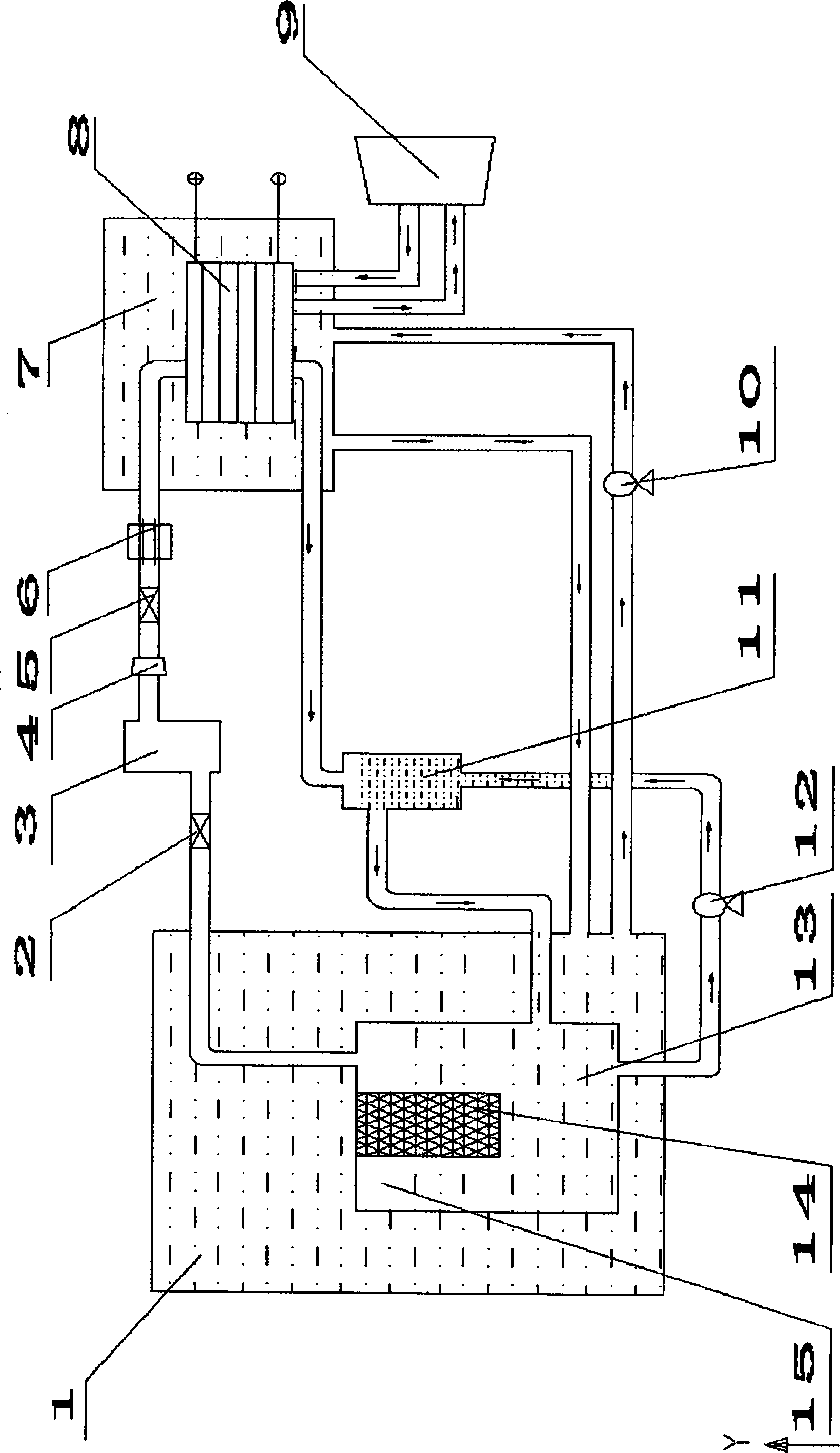

Fuel-cell power generation system for supplying hydrogen by hydrolyzing magnesium hydride

ActiveCN103579652ALarge amount of hydrogen releaseLow densityElectrolysis componentsFuel cell auxillariesMagnesium hydrideNuclear engineering

The invention relates to a fuel-cell power generation system for supplying hydrogen by hydrolyzing magnesium hydride. The fuel-cell power generation system comprises the combination of hydrogen generation by hydrolyzing MgH2 and a proton membrane fuel cell. The fuel-cell power generation system utilizes a Kipps apparatus principle and can realize a hydrogen generation immediate supplying / stopping technology. A hydrolysis reactor water bath (1) is communicated with a fuel cell cooling water bath (7) by a pipeline; working residual heat of a fuel cell set is used for heating a reactor to carry out hydrolysis reaction. In the working process, the water baths are communicated to keep the working temperature of a hydrolysis reactor and the working temperature of a fuel cell constant so as to be good for carrying out the reaction. The hydrolysis reactor is connected with a proton exchange membrane fuel cell by a pipeline; water generated by the working of the proton membrane fuel cell can be balanced with water consumed by hydrolyzing the MgH2 so as to realize the cyclic utilization of the water; theoretically, the water does not need to be injected from the outside. A hydrolysis reaction product, namely magnesium hydroxide sediments, can be filtered and recycled by a hydrolysis reactor filtering machine and is industrially utilized to reduce the cost.

Owner:HARBIN INST OF TECH AT WEIHAI

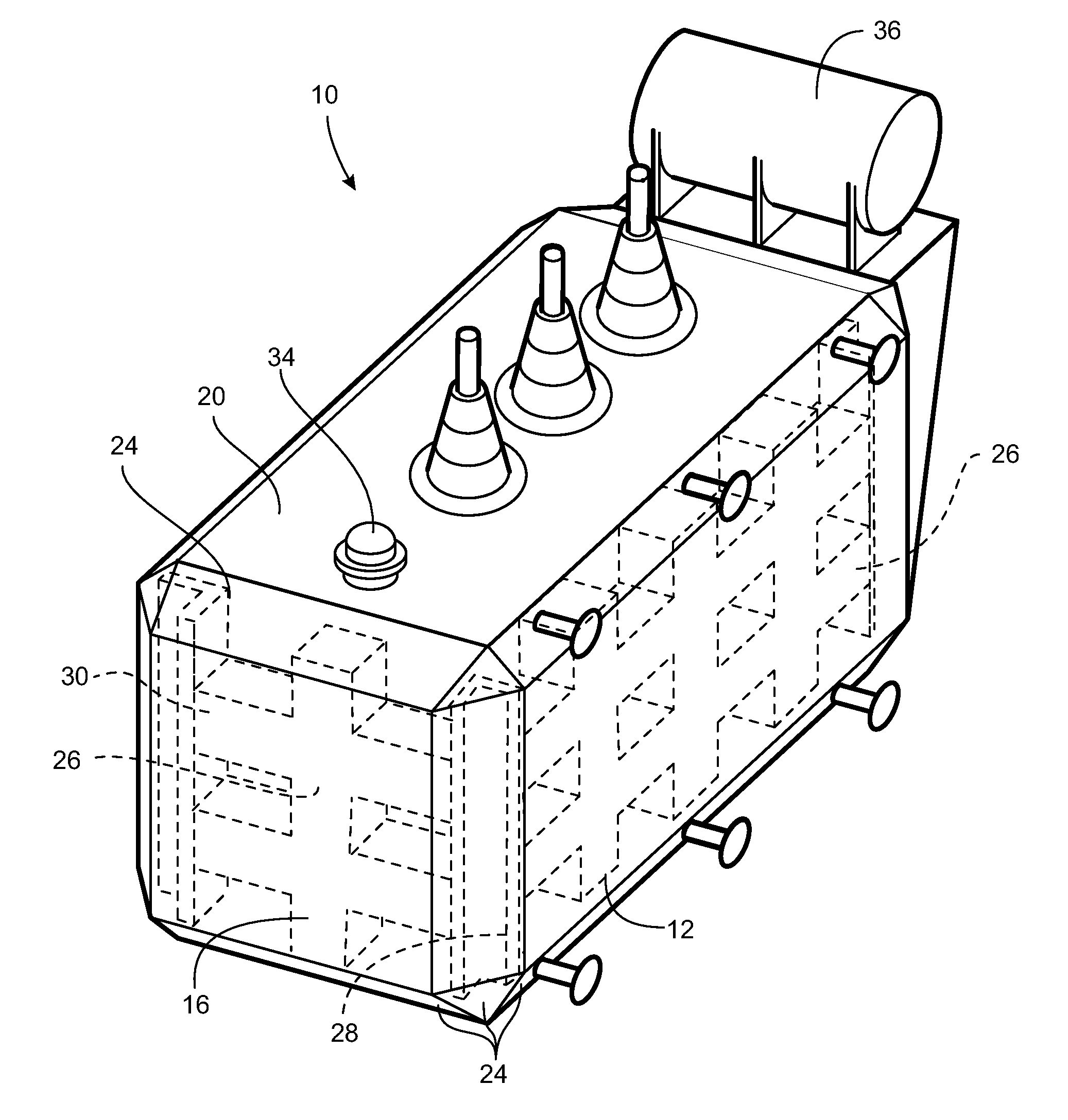

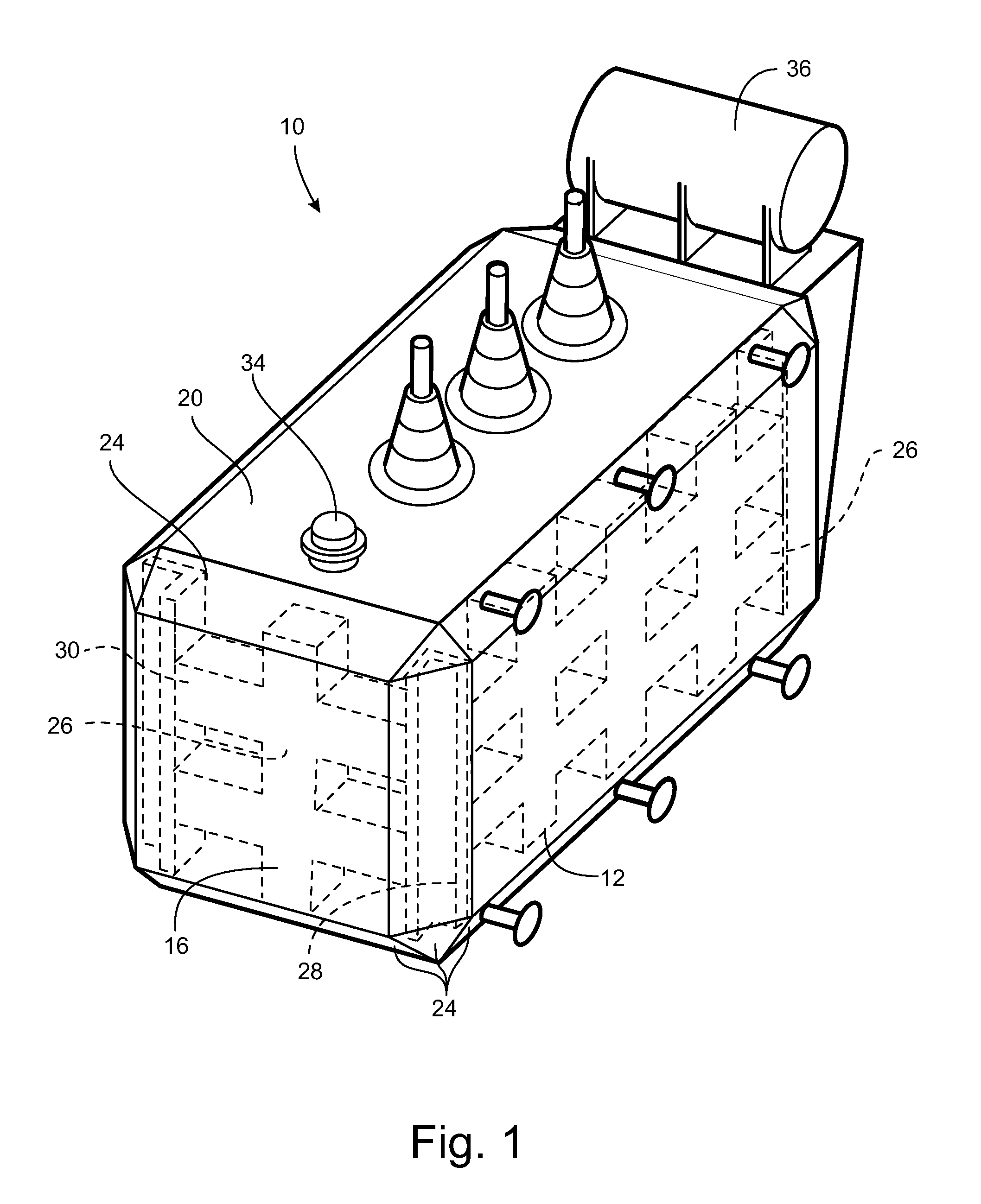

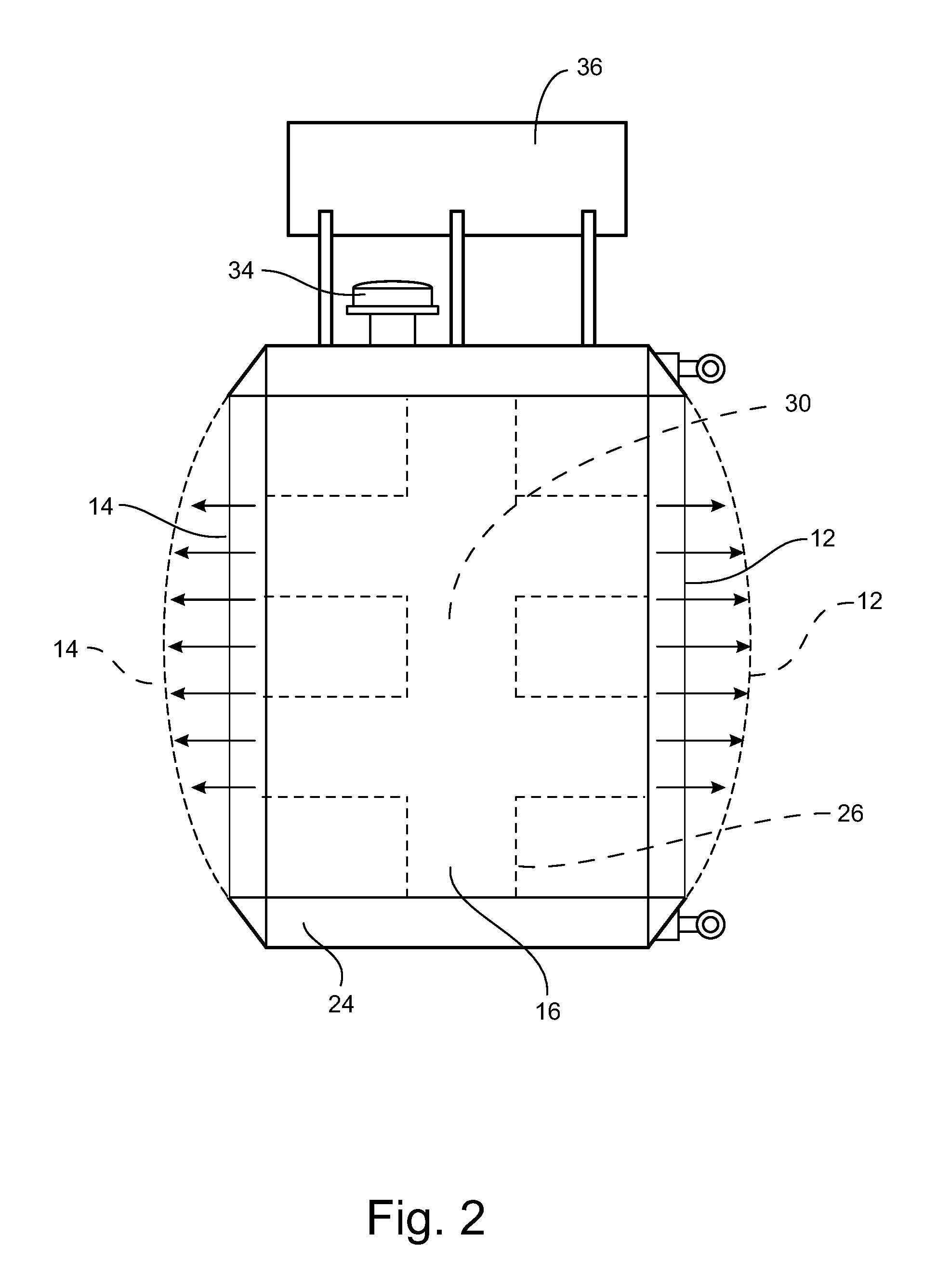

Endoskeletal transformer tank

InactiveUS20110273255A1Increase internal pressureIncrease the volume of the water tankTransformers/inductances casingsRigid containersFuel tankPositive pressure

A transformer tank having opposing walls and junctions between adjacent tank walls being intermediate walls defining obtuse angles with respect to each of their respective adjacent tank walls such that the tank is free from perpendicular wall intersections. Internal framework is disposed within the tank for preventing inward wall deflections and is anchored to the intermediate walls and is substantially free from attachment to the opposing walls. The tank undergoes volumetric expansion in response to increases in internal positive pressure to avoid tank rupture.

Owner:THOMPSON ROBERT SAMUEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com