Breather structure for internal combustion engine

a technology for internal combustion engines and breather, which is applied in the direction of combustion engines, gearing details, belts/chains/gearings, etc., can solve the problems of making the impact of the fluctuation in the pressure in the crank chamber great, and achieve the effect of reducing the fluctuation of the pressure inside the auxiliary apparatus chamber, and reducing the fluctuation of the pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

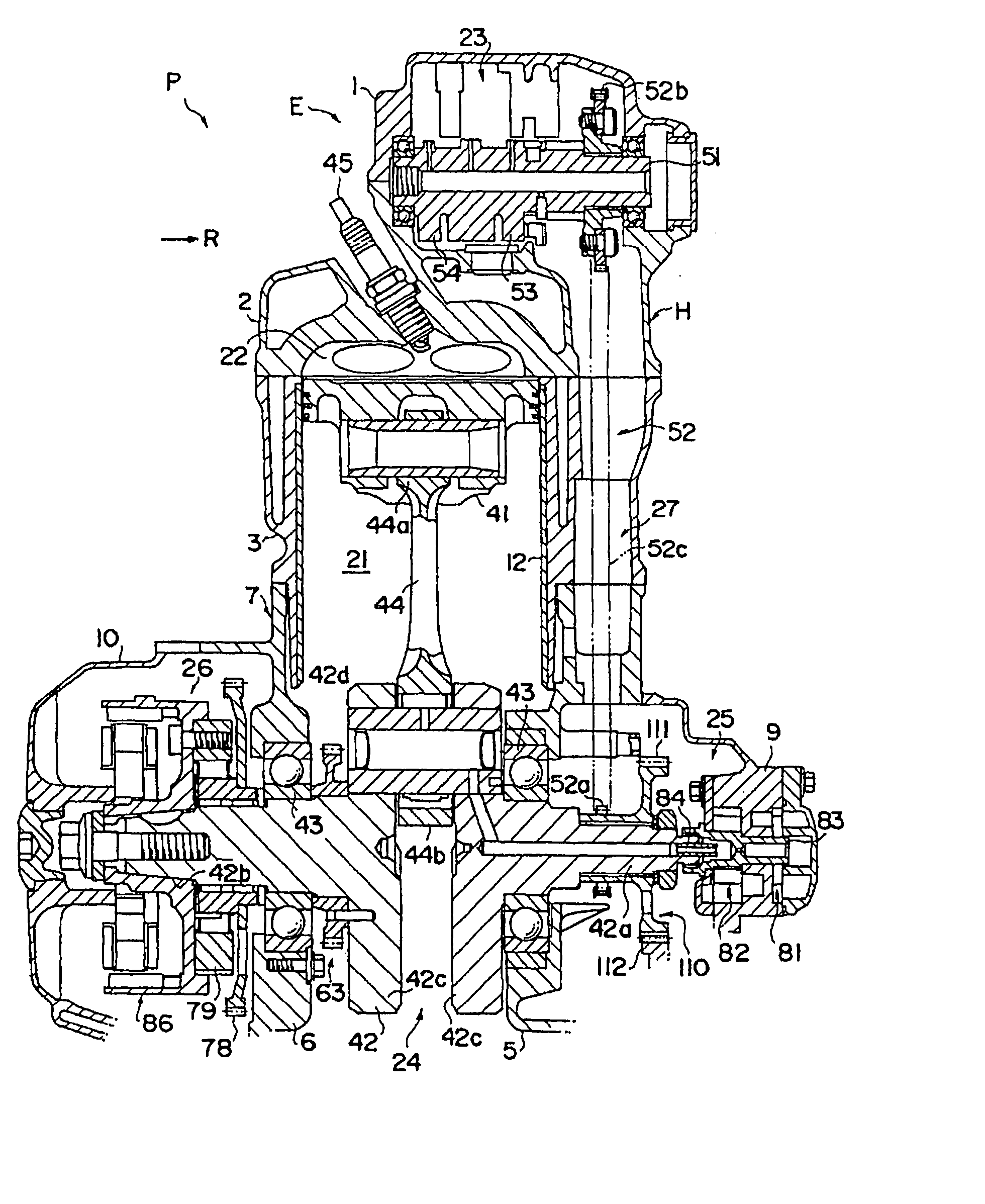

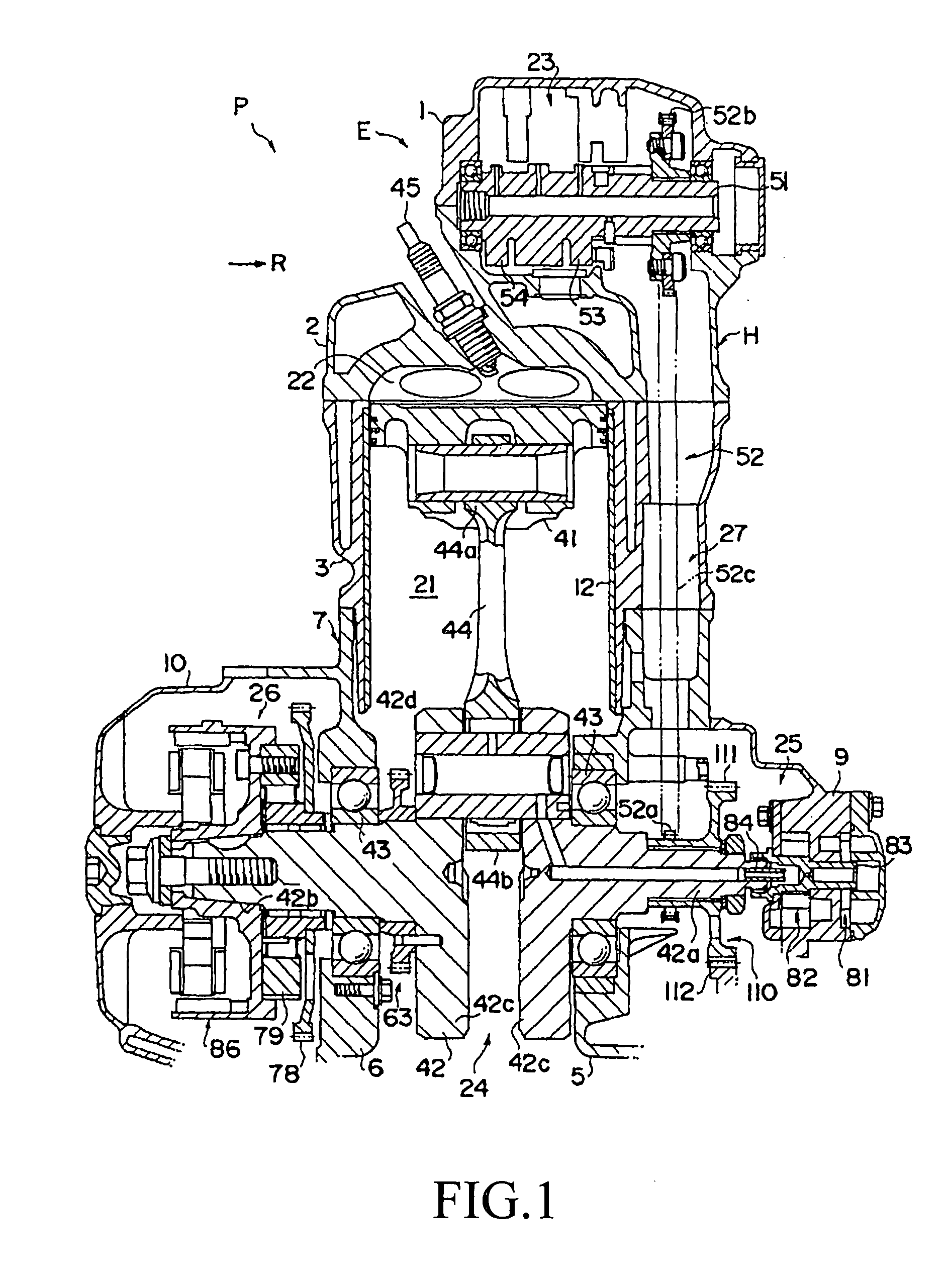

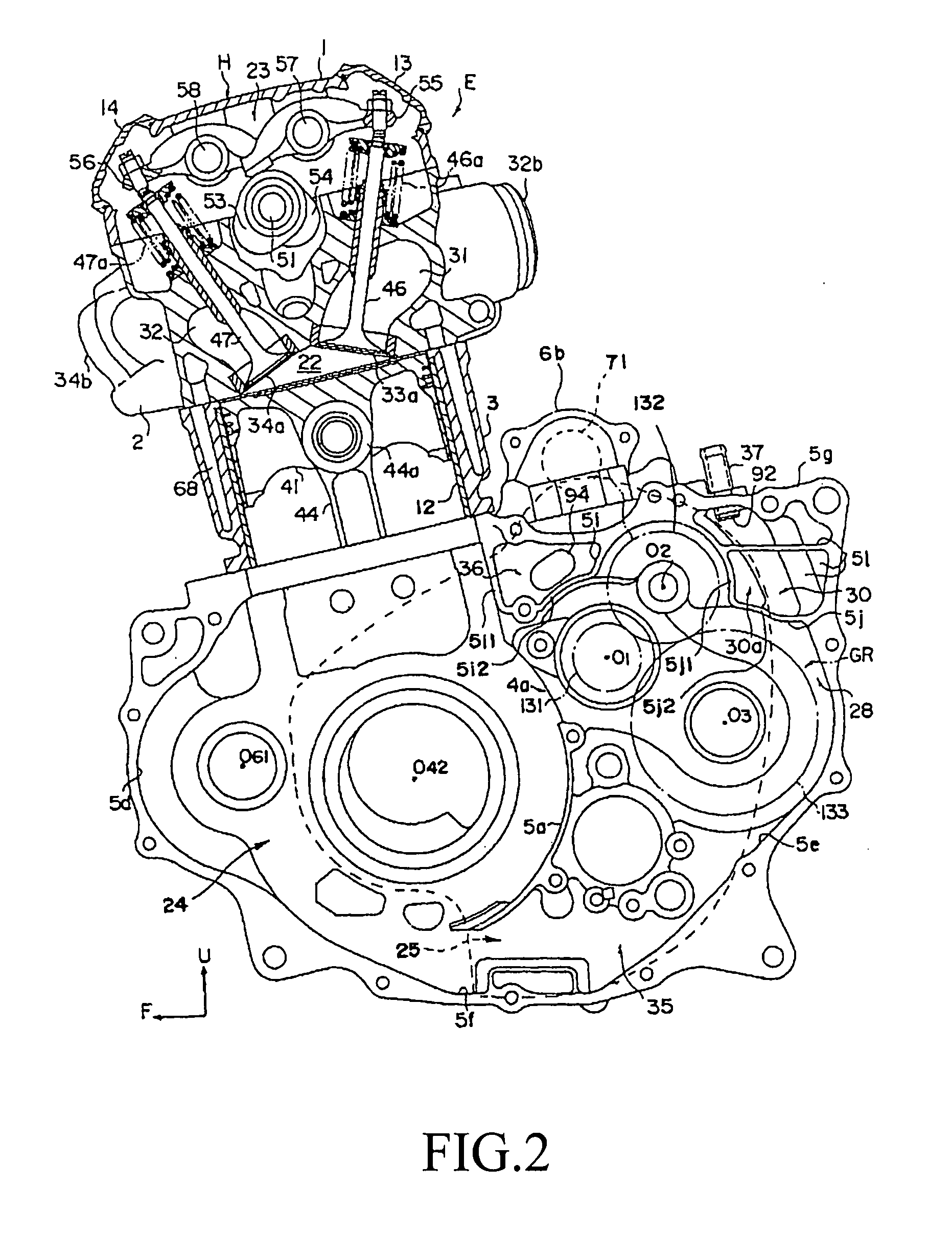

[0026]FIG. 1 to FIG. 5 illustrate a power unit P of a saddle-ride type vehicle equipped with a breather structure for internal combustion engine according to the present invention. In the figures, an arrow U indicates the upward direction; an arrow F, the forward direction; and an arrow R, the rightward direction. The directions indicated by these arrows correspond to the directions from the viewpoint of the driver of the saddle-ride type vehicle. Examples of the saddle-ride type vehicle include a motorcycle and an all-terrain buggy.

[0027] The power unit P includes components in and outside of a housing H. The housing H is formed by assembling a head cover 1, a cylinder head 2, a cylinder block 3 and a crankcase 4 into one. Specifically, the cylinder head 2 is joined to the top of the cylinder block 3. The head cover 1 is joined to the cylinder head 2 so as to cover the cylinder head 2. The crankcase 4 is joined to the bottom of the cylinder block 3.

[0028]FIG. 2 and FIGS. 6 to 8 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com