Patents

Literature

2973results about "Crankcase ventillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

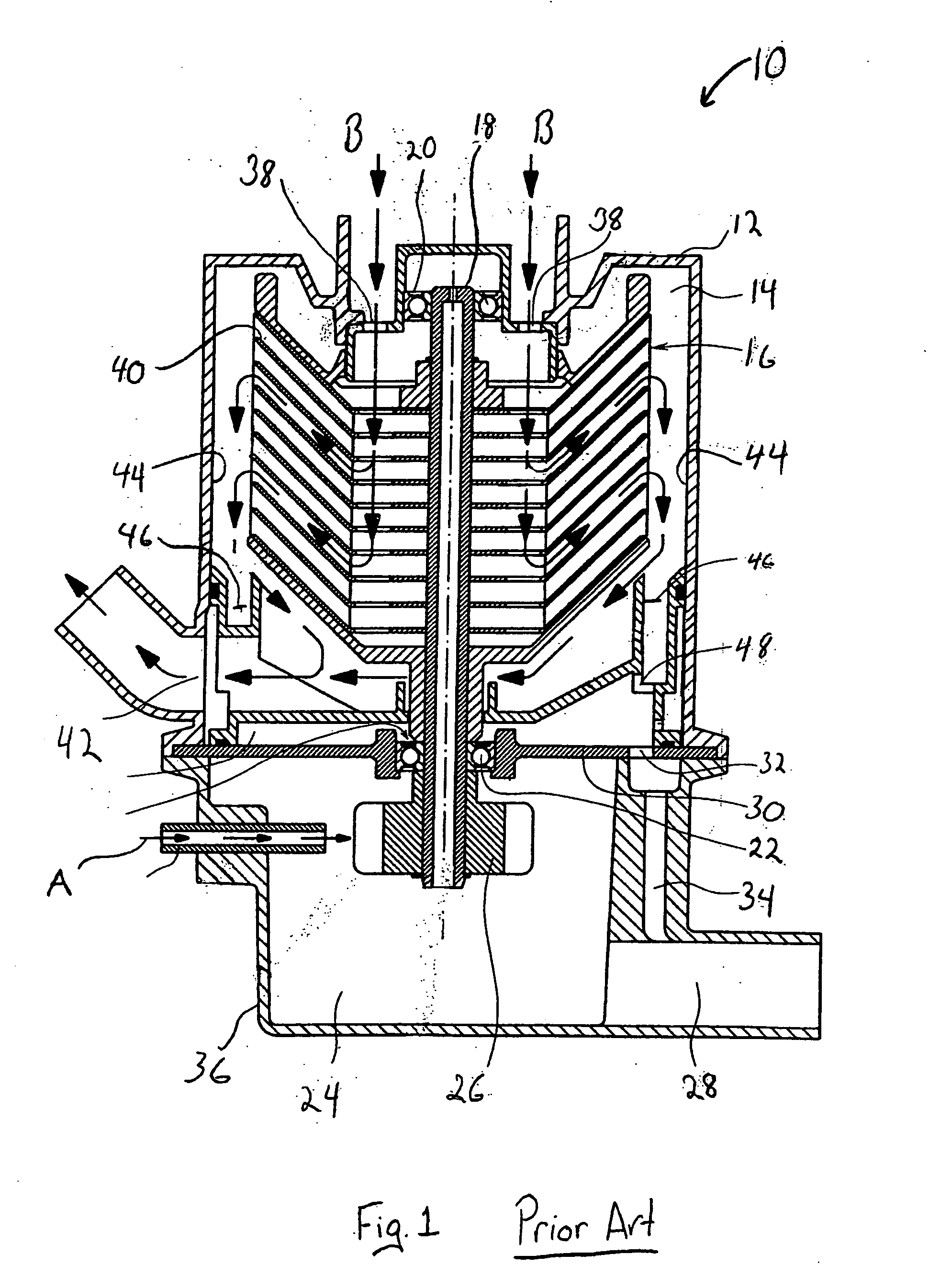

Air cleaner; aerosol separator; and method

InactiveUS6187073B1Easy collection and removalAvoid flowCombination devicesNon-fuel substance addition to fuelCoalescerFilter element

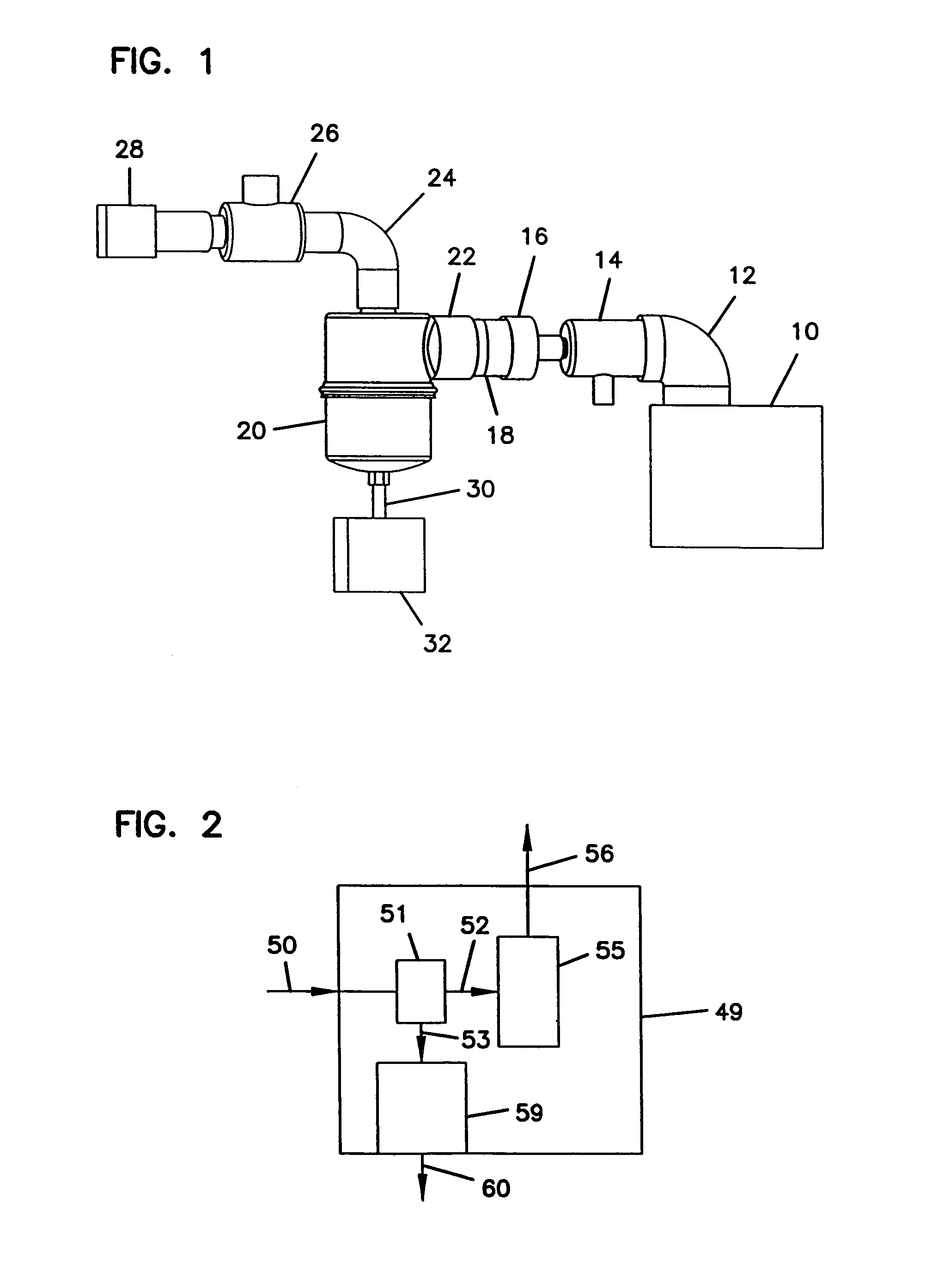

A filter arrangement includes a tubular first filter element having a first media pack defining a first open filter interior and an air flow outlet. The air flow outlet is in gas flow communication with the first open filter interior. A housing construction has a gas flow inlet and a gas flow outlet. The air flow outlet of the first filter element is in gas flow communication with the gas flow outlet. A coalescer filter element is oriented in the housing construction in fluid communication with the gas flow inlet. A tubular second filter element is oriented in the housing construction and has a second media pack defining a second open filter interior. The second open filter interior is in gas flow communication with the gas flow outlet.

Owner:DONALDSON CO INC

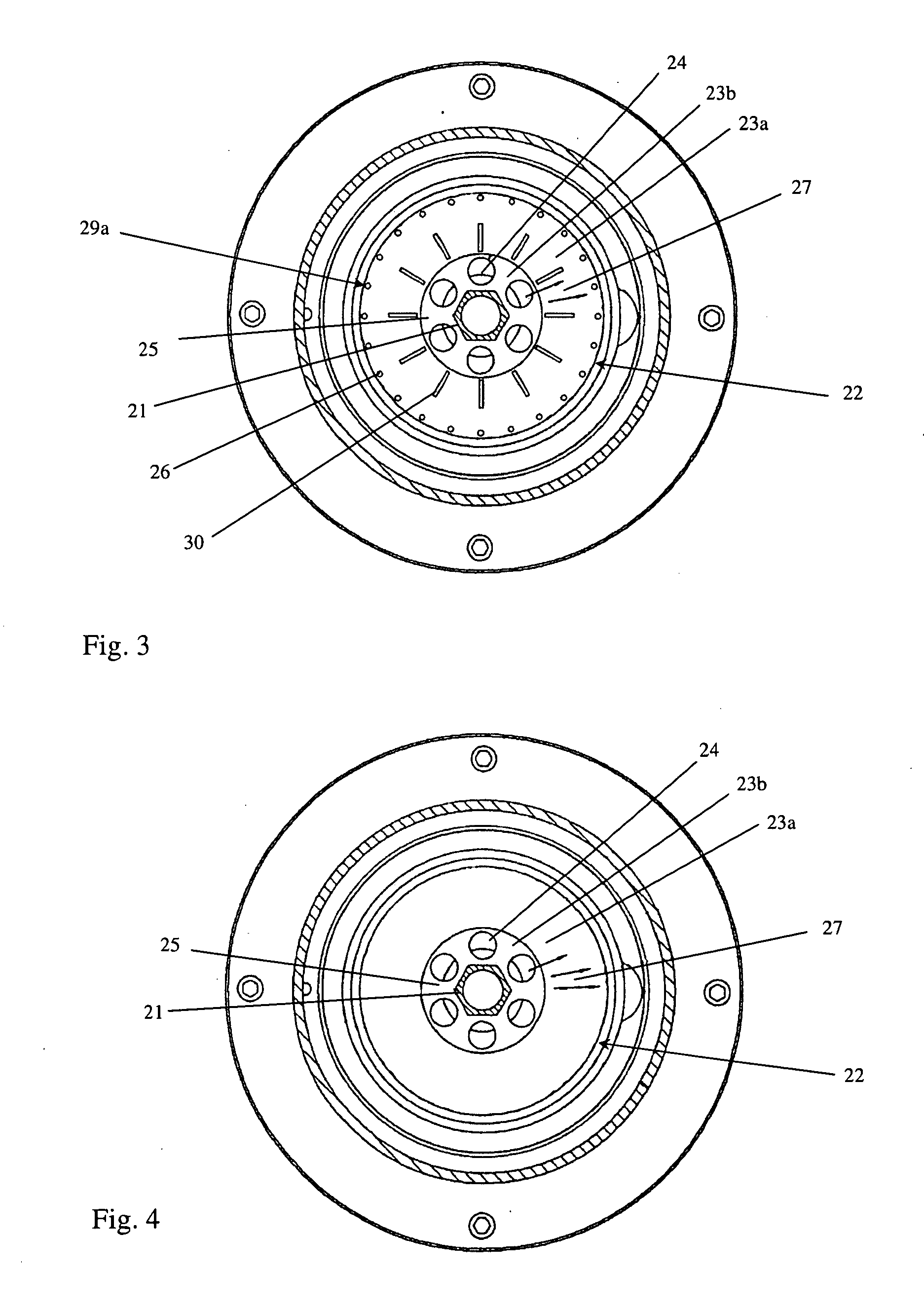

Aerosol separator; and method

InactiveUS6290739B1Reduce the overall diameterReduce pressureCombination devicesNon-fuel substance addition to fuelFiberCoalescer

An arrangement for separating a hydrophobic liquid phase from a gaseous stream includes a coalescer filter, a housing, a gas flow direction arrangement, and a liquid collection arrangement. The coalescer filter includes a non-woven media of fibers. The housing includes an interior having a gas flow inlet and a gas flow outlet. The liquid collection arrangement is positioned within the housing construction and is oriented for receiving liquid collected from the coalescer filter and drained therefrom.

Owner:DONALDSON CO INC

Aerosol separator; and method

InactiveUS6530969B2Reduce pressureIncrease pressureCombination devicesNon-fuel substance addition to fuelFiberCoalescer

Owner:DONALDSON CO INC

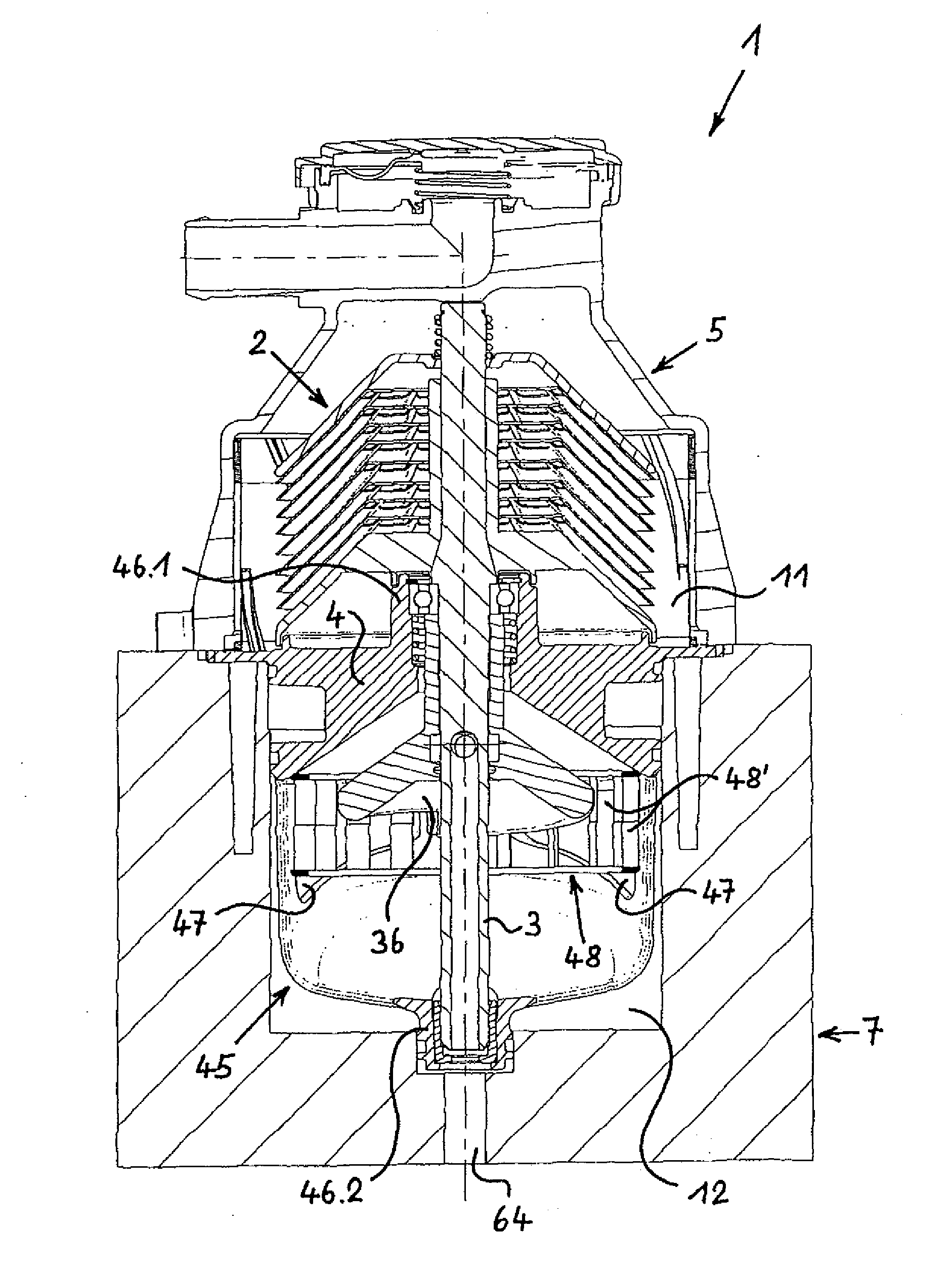

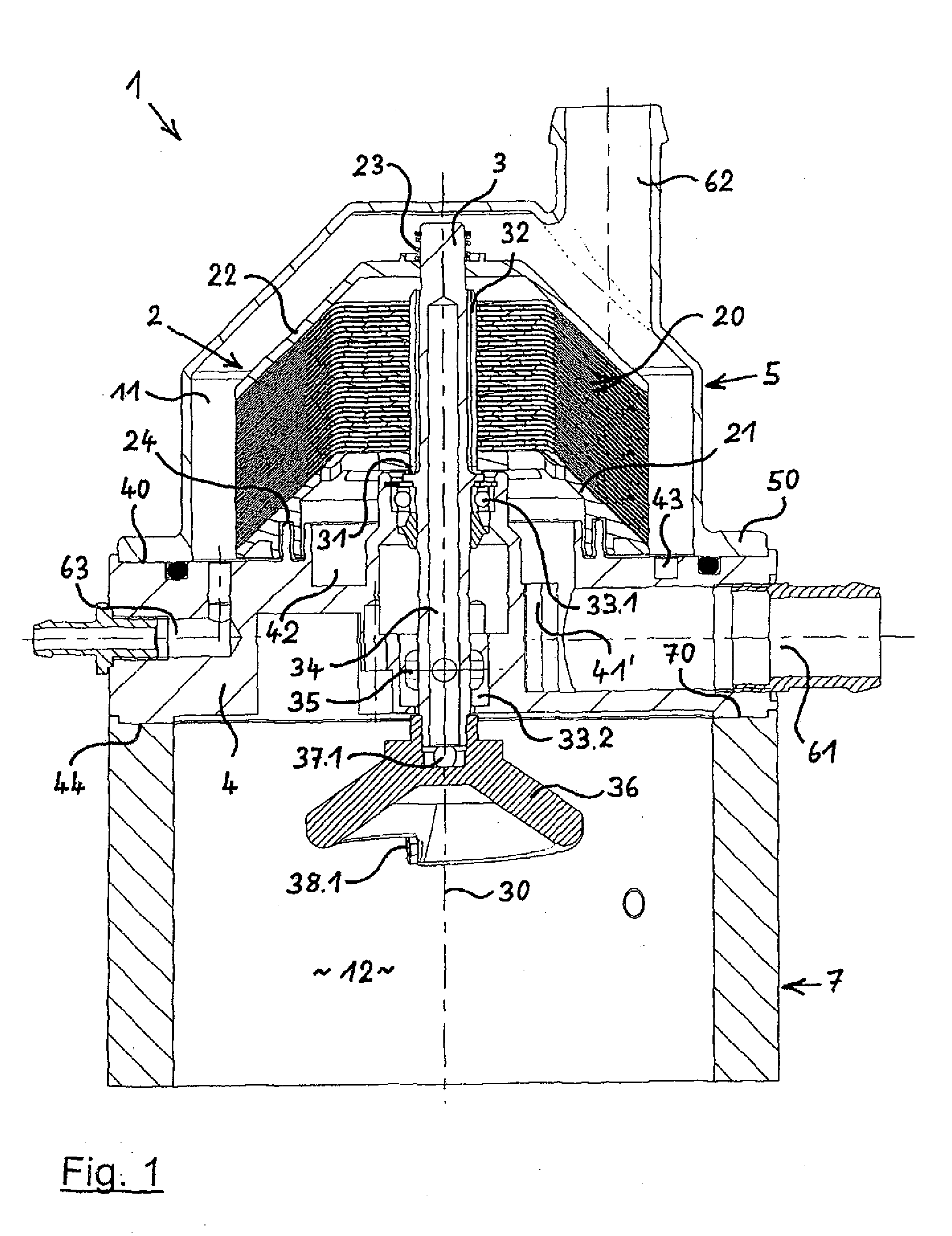

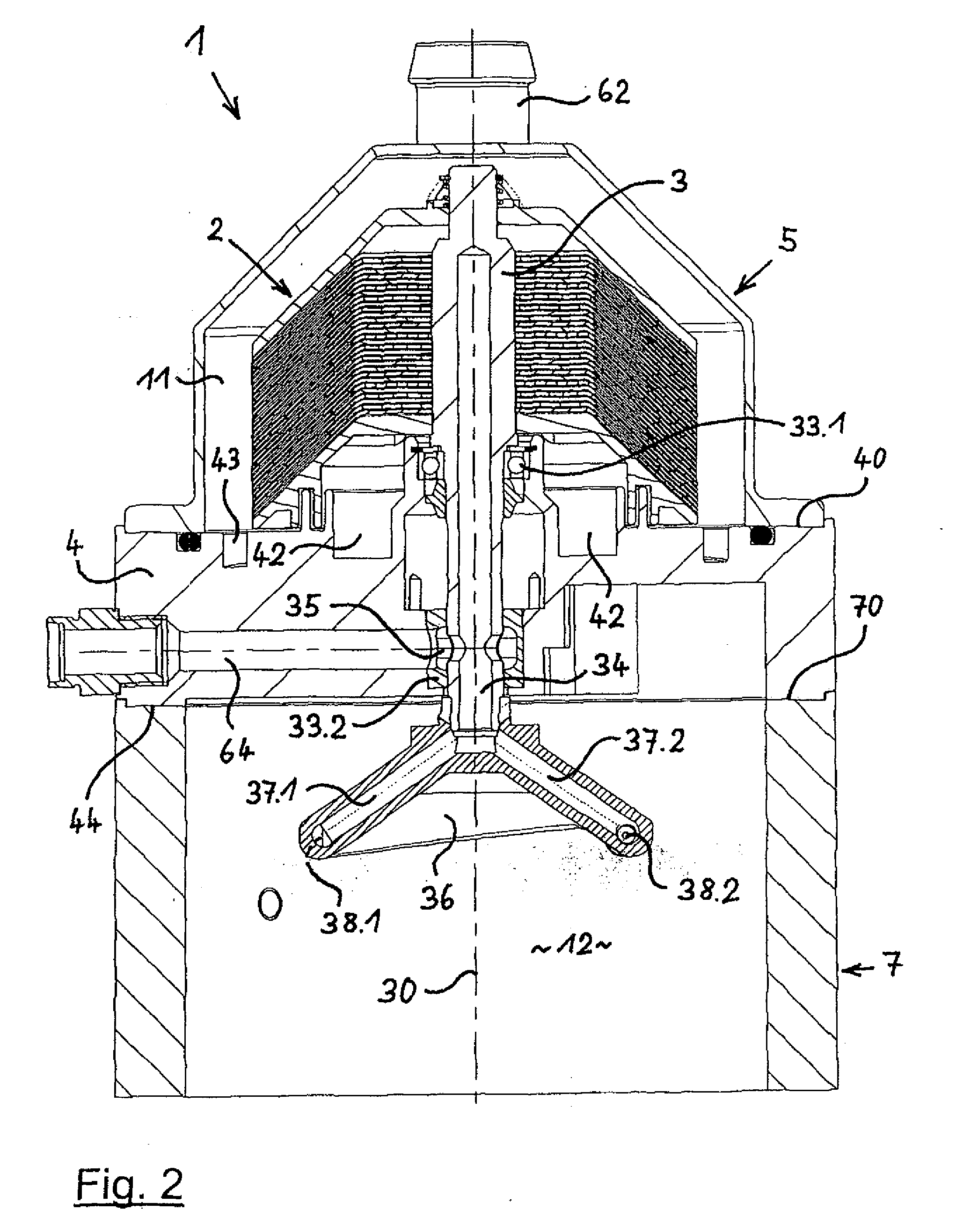

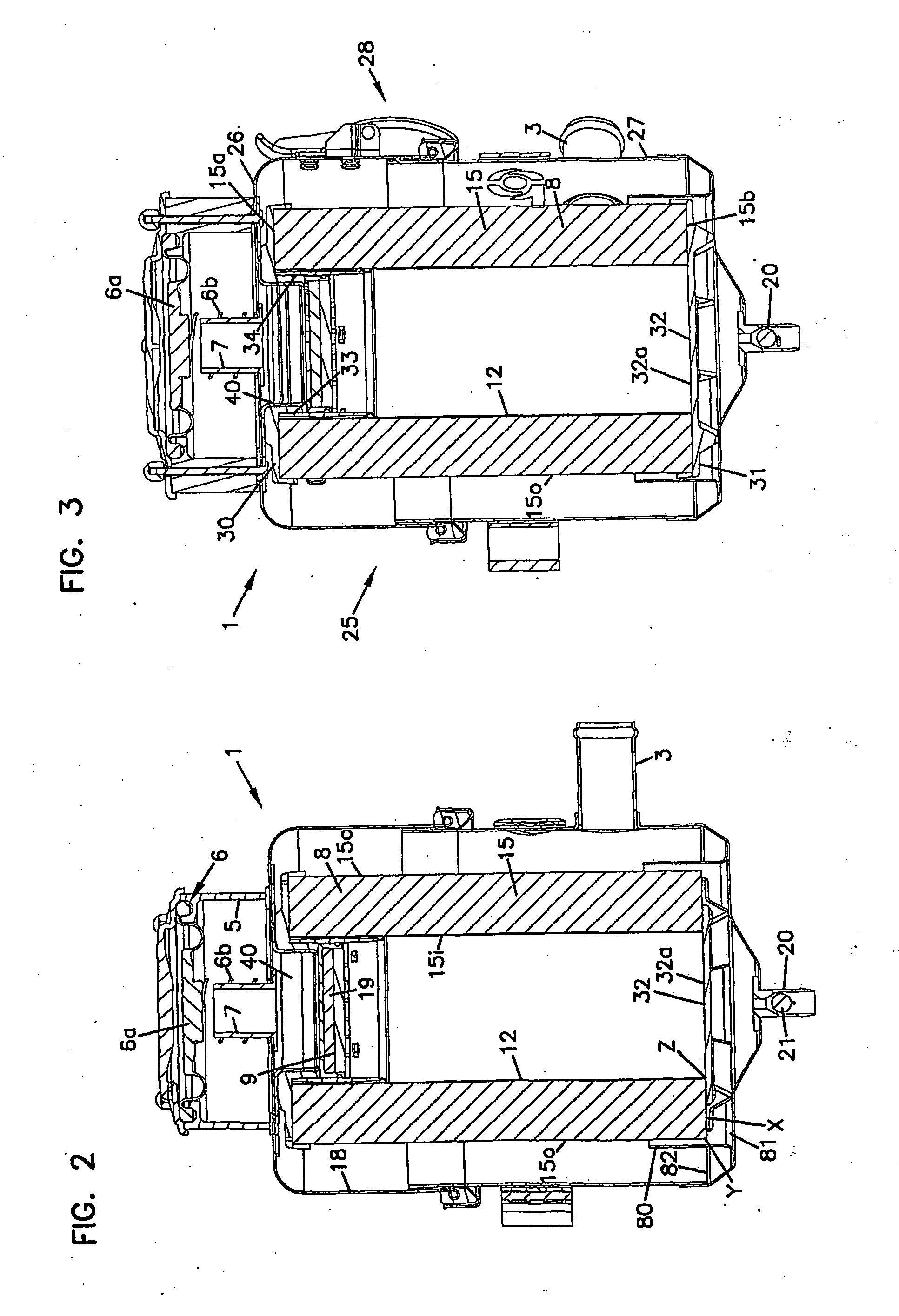

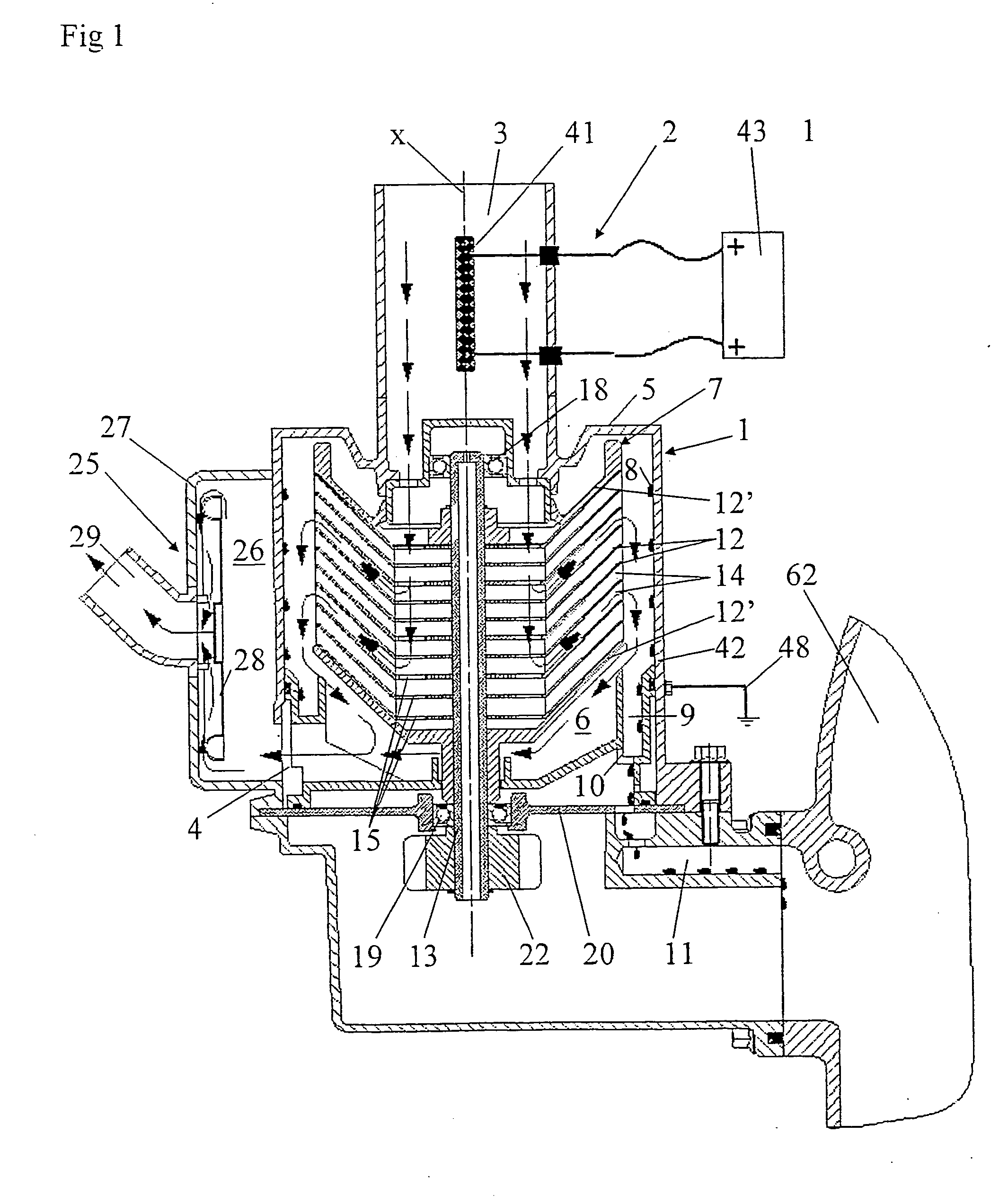

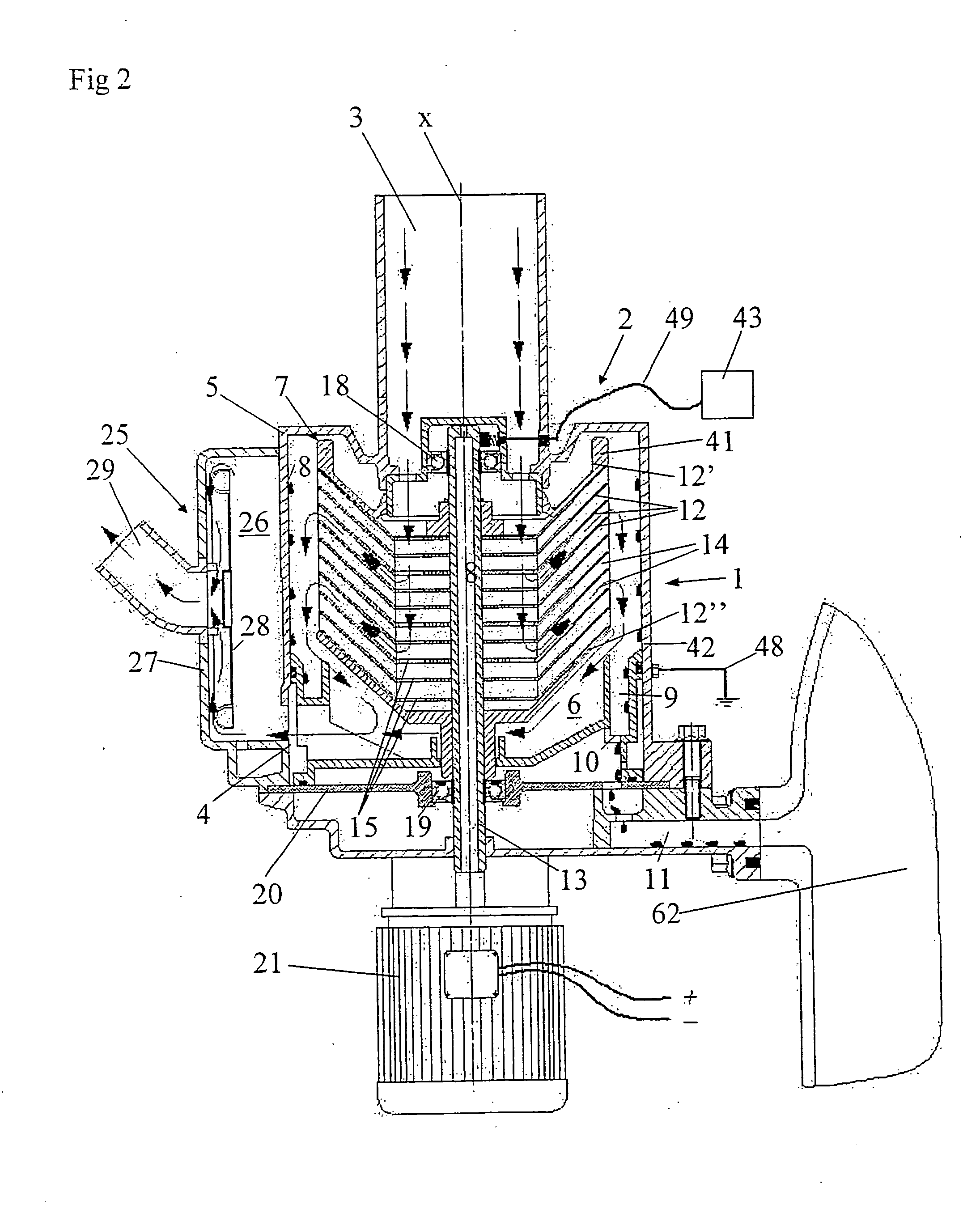

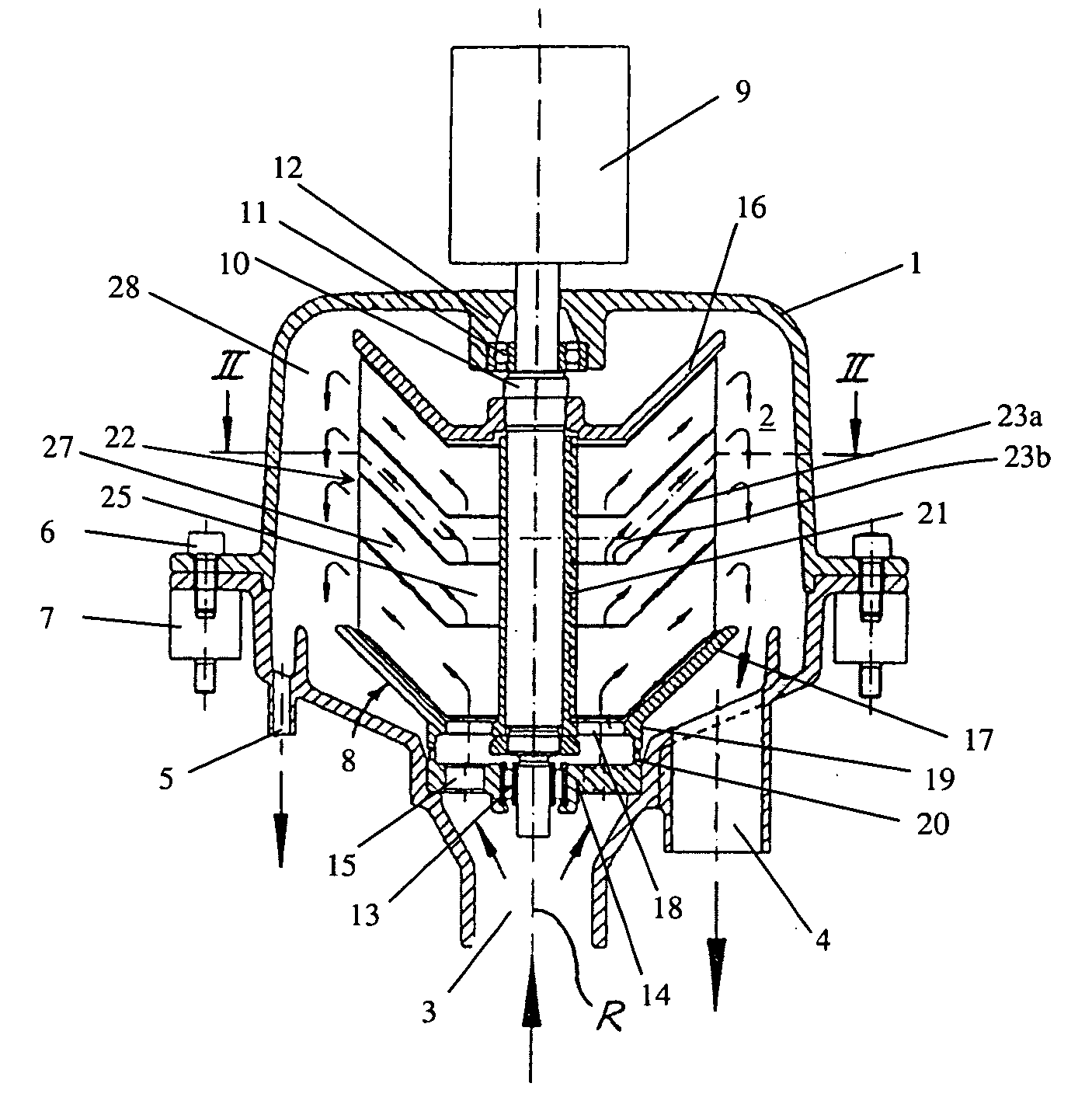

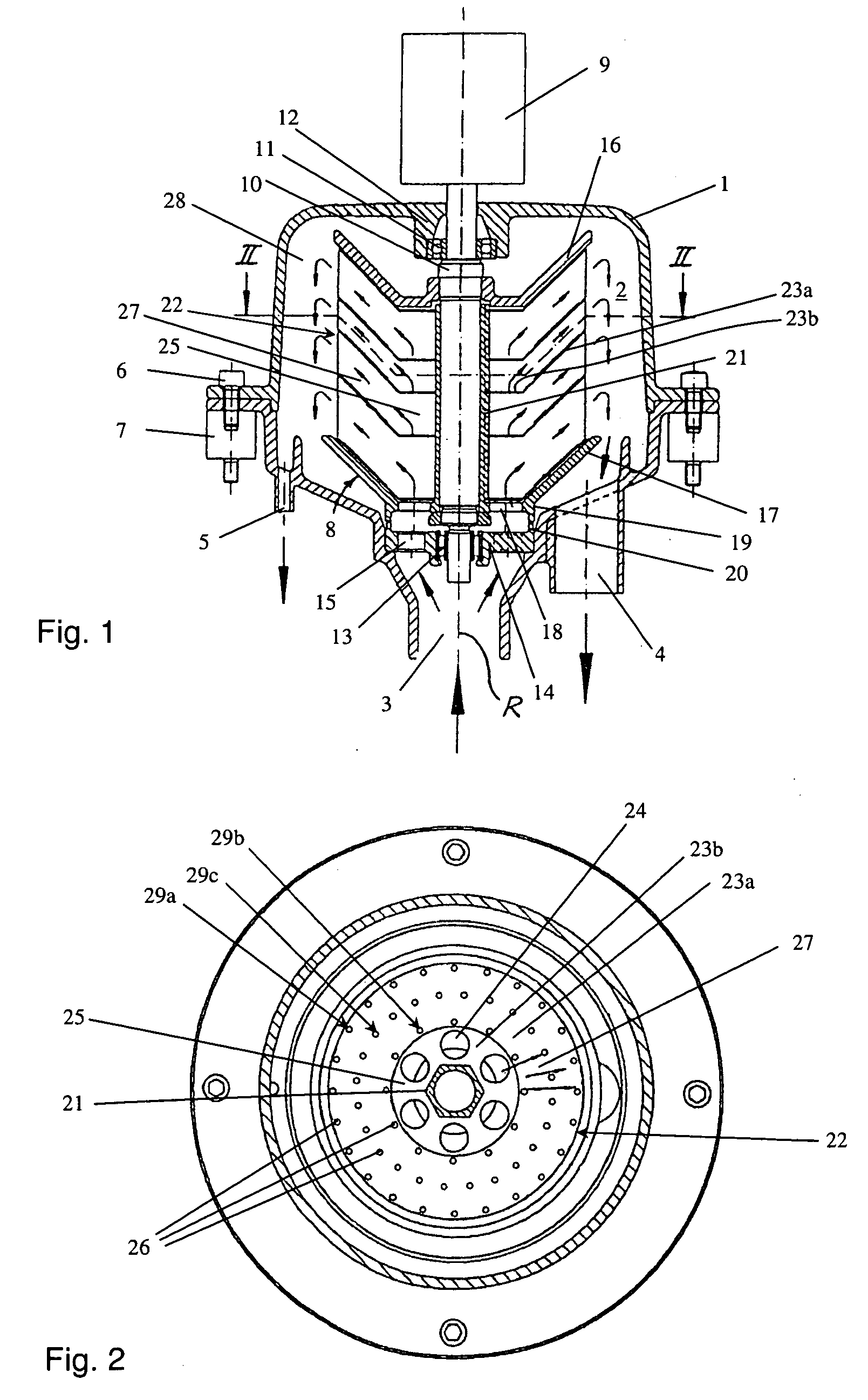

Separator for separating oil mist from the crankcase ventilation gas of an internal combustion engine, and functional module and internal combustion engine comprising a separator

ActiveUS20100180854A1Increase speedEasy to separateCombination devicesLubrication of auxillariesExternal combustion engineEngineering

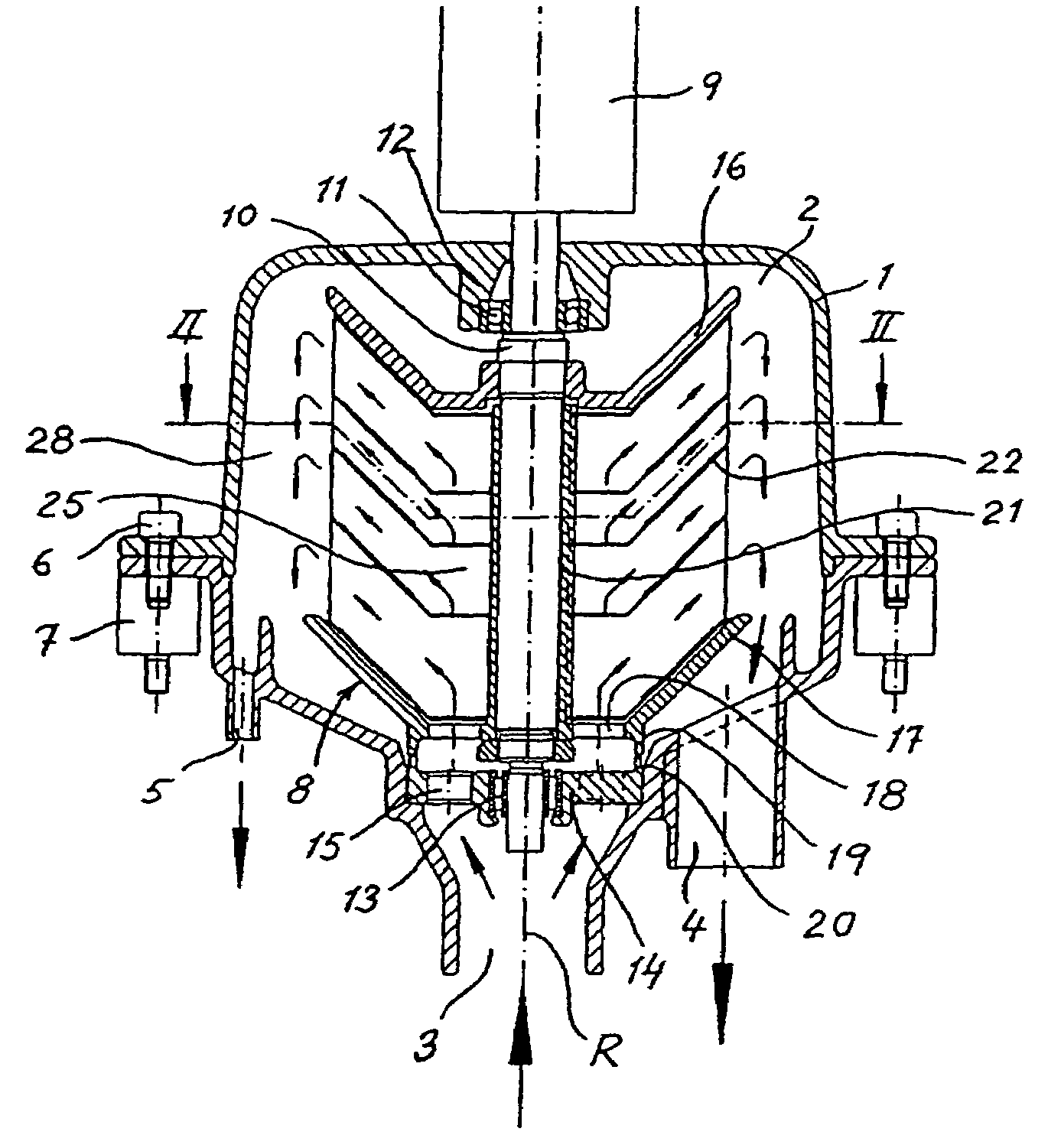

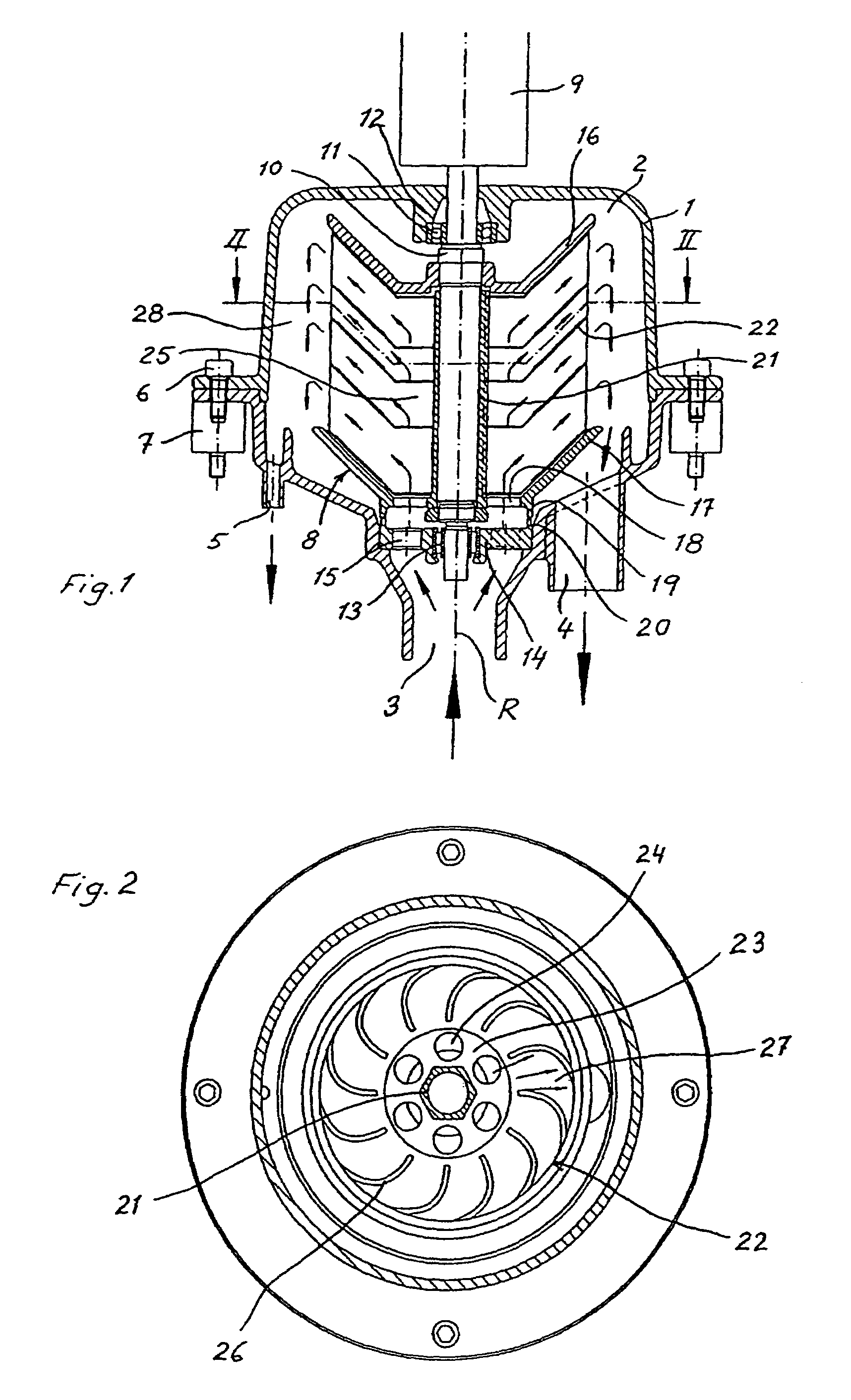

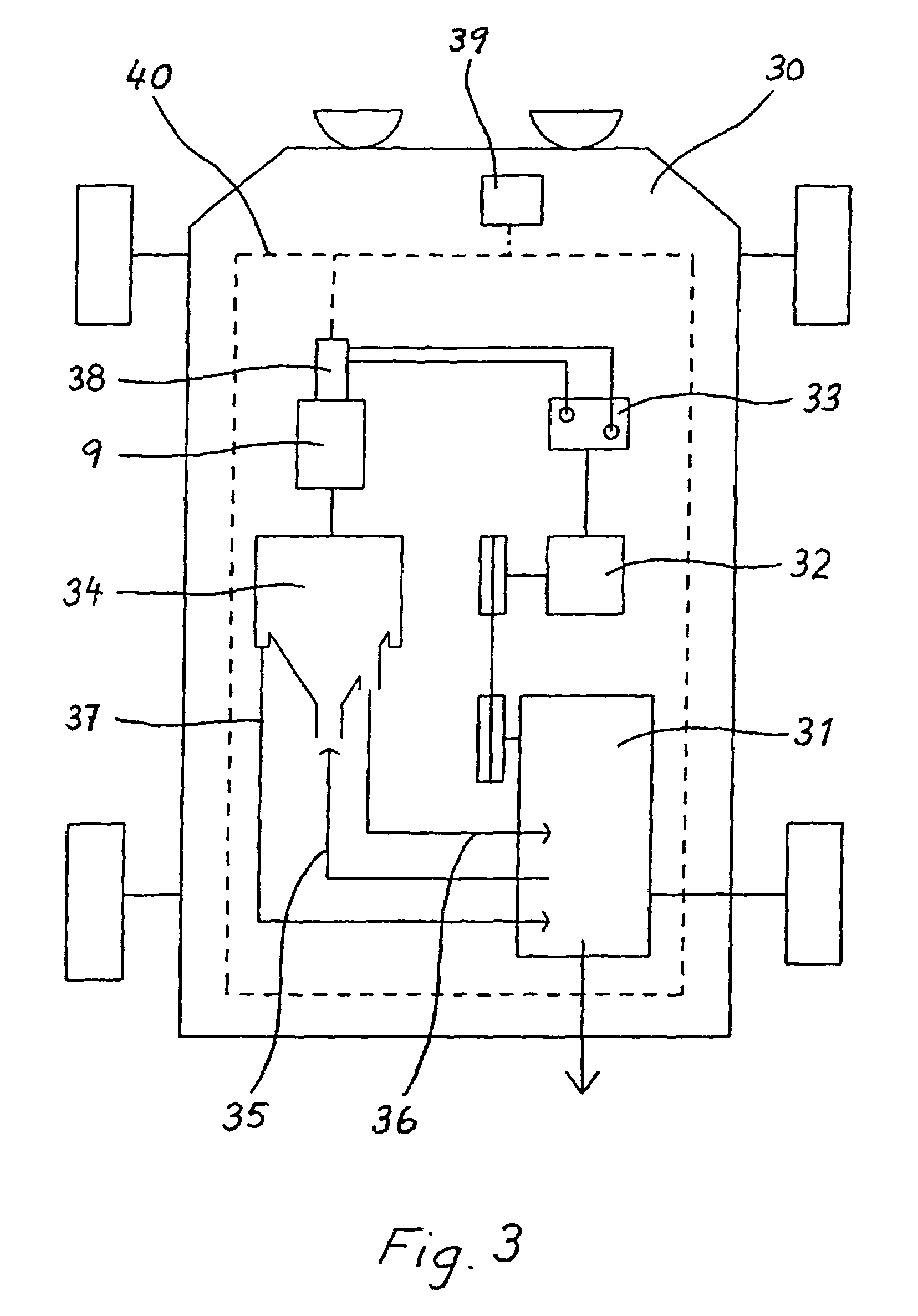

A separator for separating oil mist from the crankcase ventilation gas of an internal combustion engine, especially of a motor vehicle. The separator includes a gas purification chamber inside which a rotatably mounted centrifugal rotor is arranged. The gas purification chamber has a crude gas inlet, a pure gas outlet, and an oil outlet. The crankcase ventilation gas can be conducted into a radially internal zone of the centrifugal rotor via the crude gas inlet, while pure gas that is liberated from oil mist can be discharged from the gas purification chamber via the pure gas outlet, and oil separated from the gas can be discharged from the gas purification chamber via the oil outlet. The separator further includes a rotary drive for the centrifugal rotor. The rotary drive is disposed in a drive chamber of the separator, can be operated using pressurized lubrication oil of the internal combustion engine, and is connected to the centrifugal rotor by means of a shaft extending from the drive chamber into the gas purification chamber, from which the drive chamber is separated. The rotary drive is formed by at least one thrust nozzle which is connected to the shaft and to which the pressurized lubrication oil of the internal combustion engine can be fed. The separator includes at least one part of a base that forms the separation between the gas purification chamber and the drive chamber and extends into the drive chamber, the part of the base being fitted with a seat for a bearing of the shaft. The bearing is located at a distance from the centrifugal rotor.

Owner:HENGST WALTER

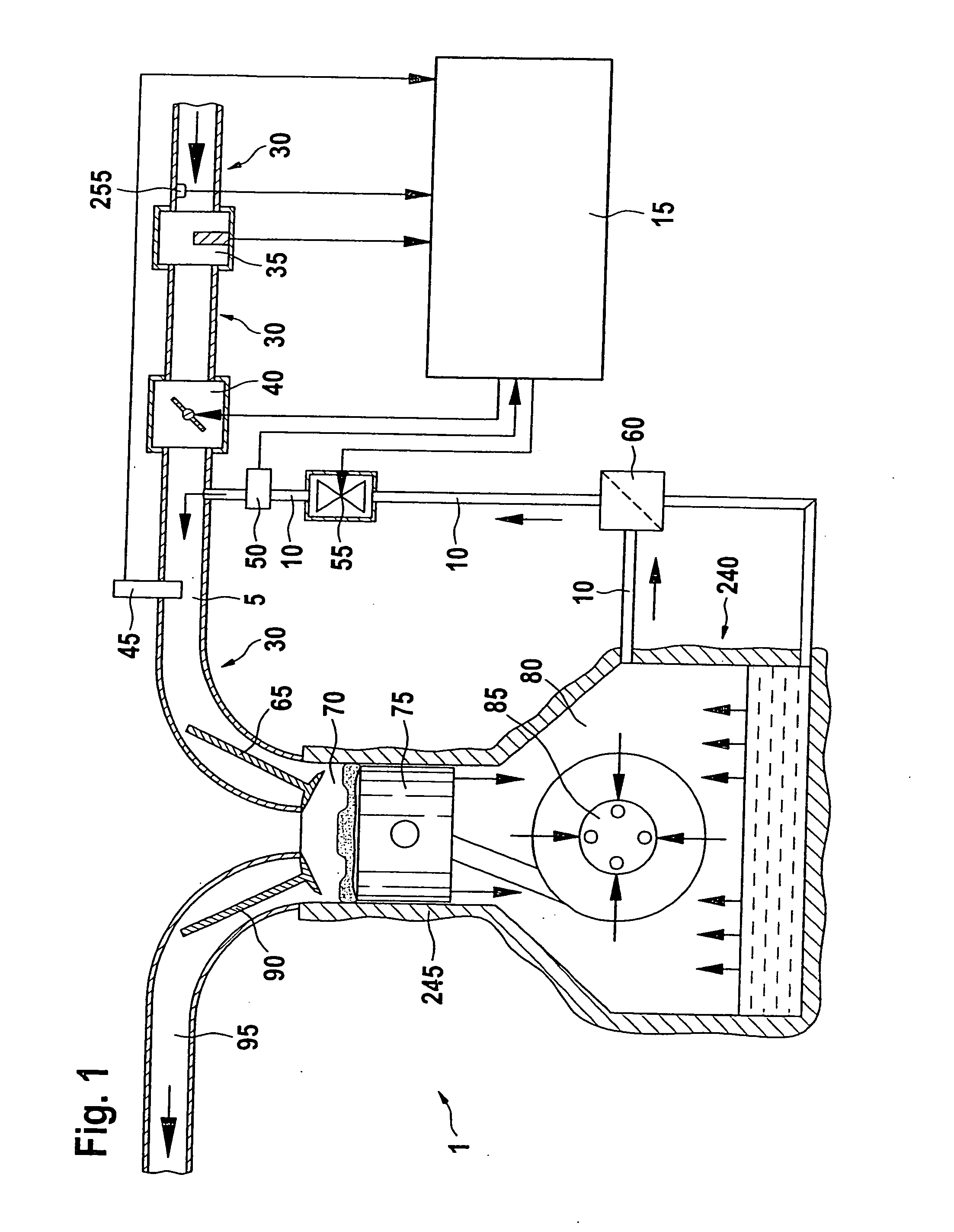

Method and a device for cleaning of crankcase gas

InactiveUS7152589B2Satisfy cleanlinessShorten speedDispersed particle separationCombustion enginesCombustionUnit of time

Owner:ALFA LAVAL CORP AB

Aerosol separator; and method

An arrangement for separating a hydrophobic liquid phase from a gaseous stream includes a coalescer filter, a housing, a gas flow direction arrangement, and a liquid collection arrangement. The coalescer filter includes a non-woven media of fibers. The housing includes an interior having a gas flow inlet and a gas flow outlet. The liquid collection arrangement is positioned within the housing construction and is oriented for receiving liquid collected from the coalescer filter and drained therefrom. Methods for conducting the separations are also provided.

Owner:DONALDSON CO INC

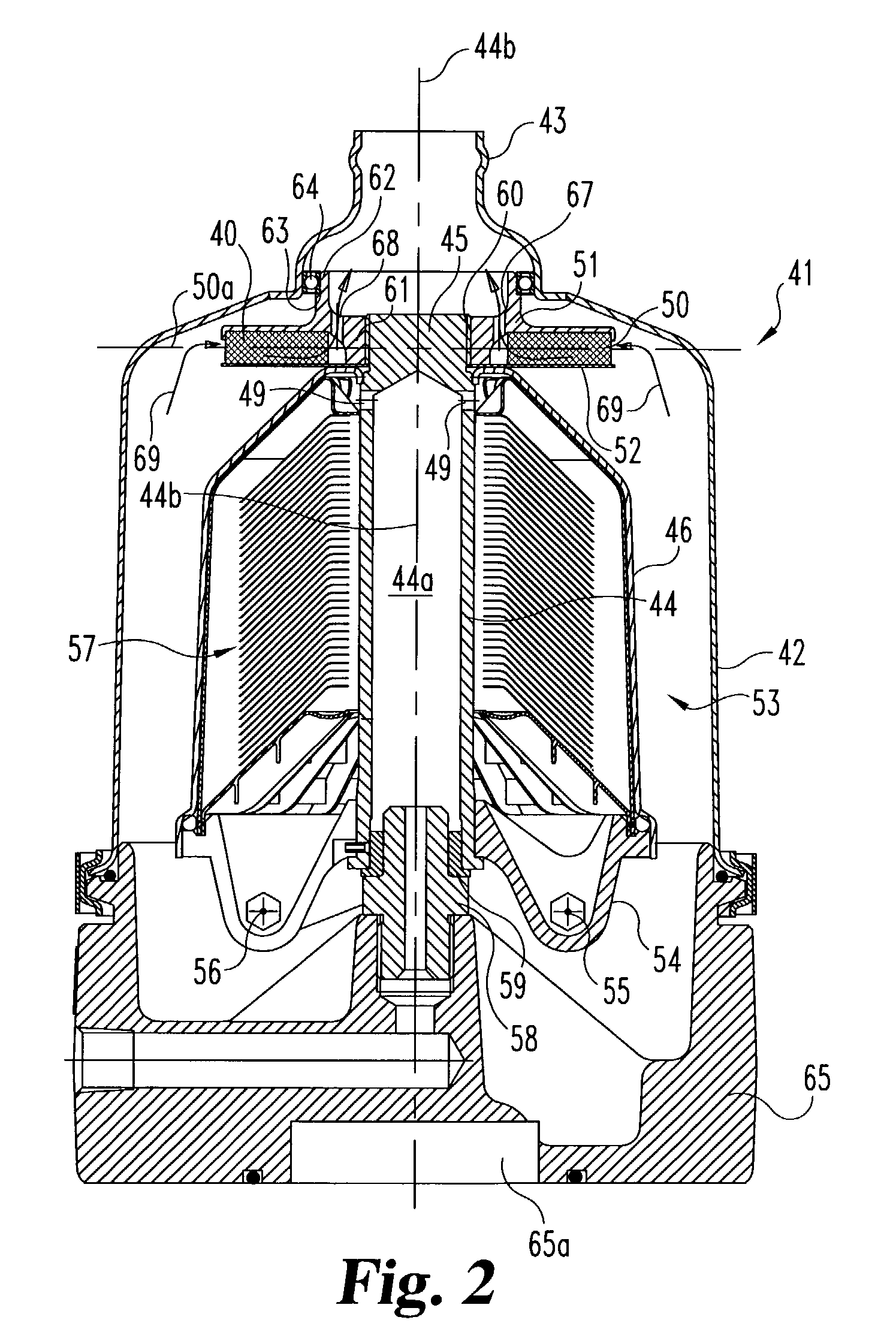

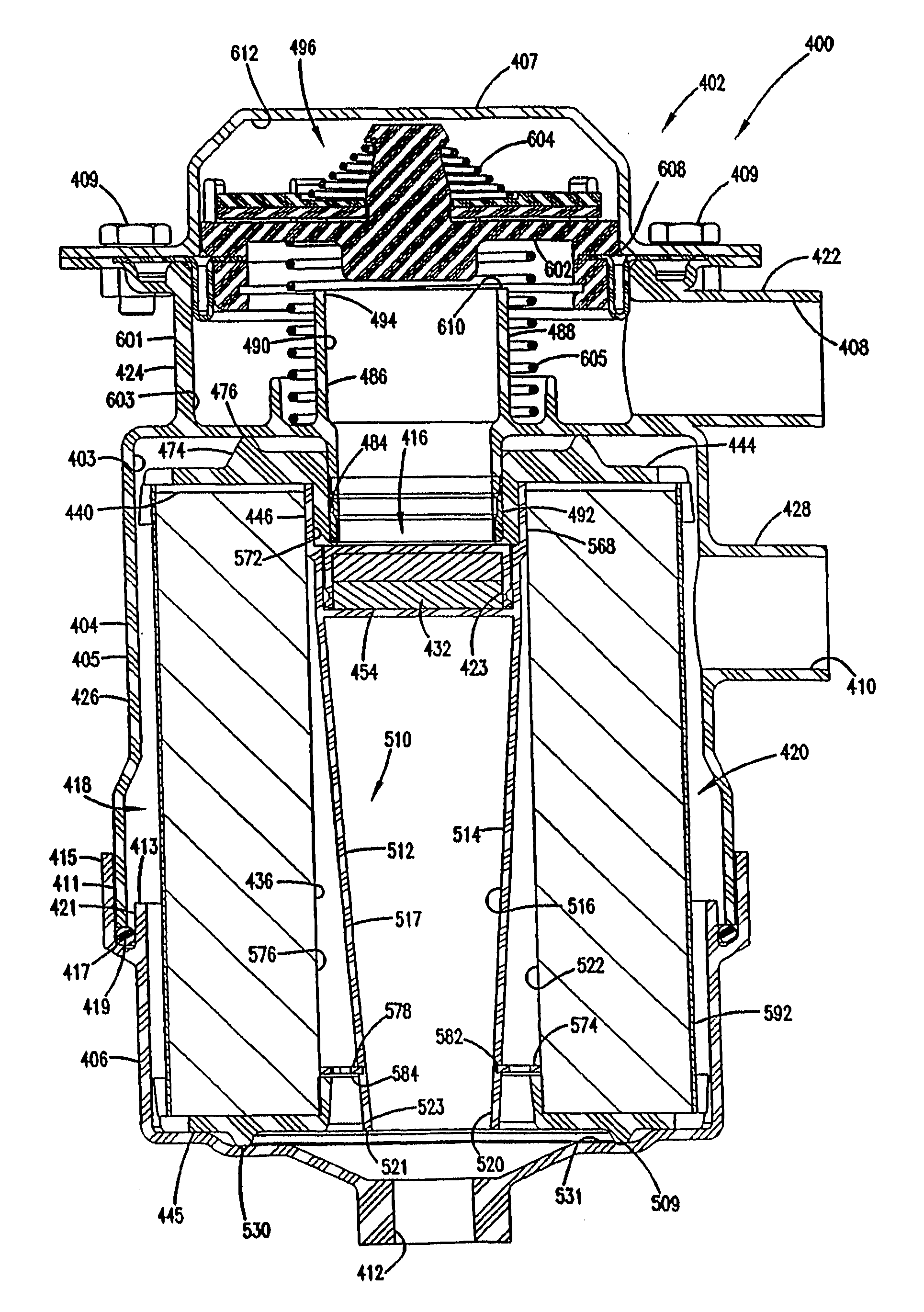

Integral air/oil coalescer for a centrifuge

InactiveUS7235177B2Combination devicesDispersed particle filtrationParticulatesMechanical engineering

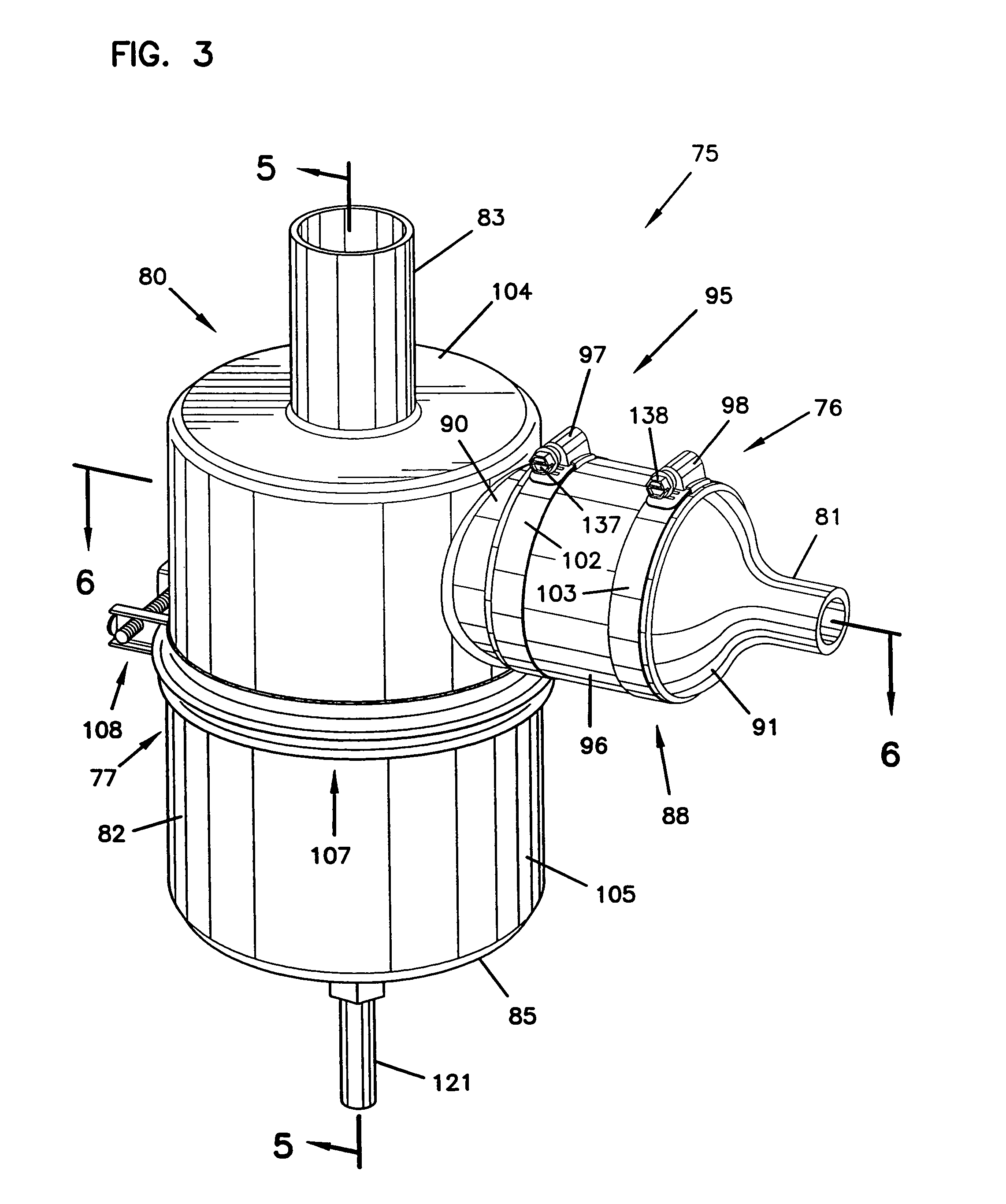

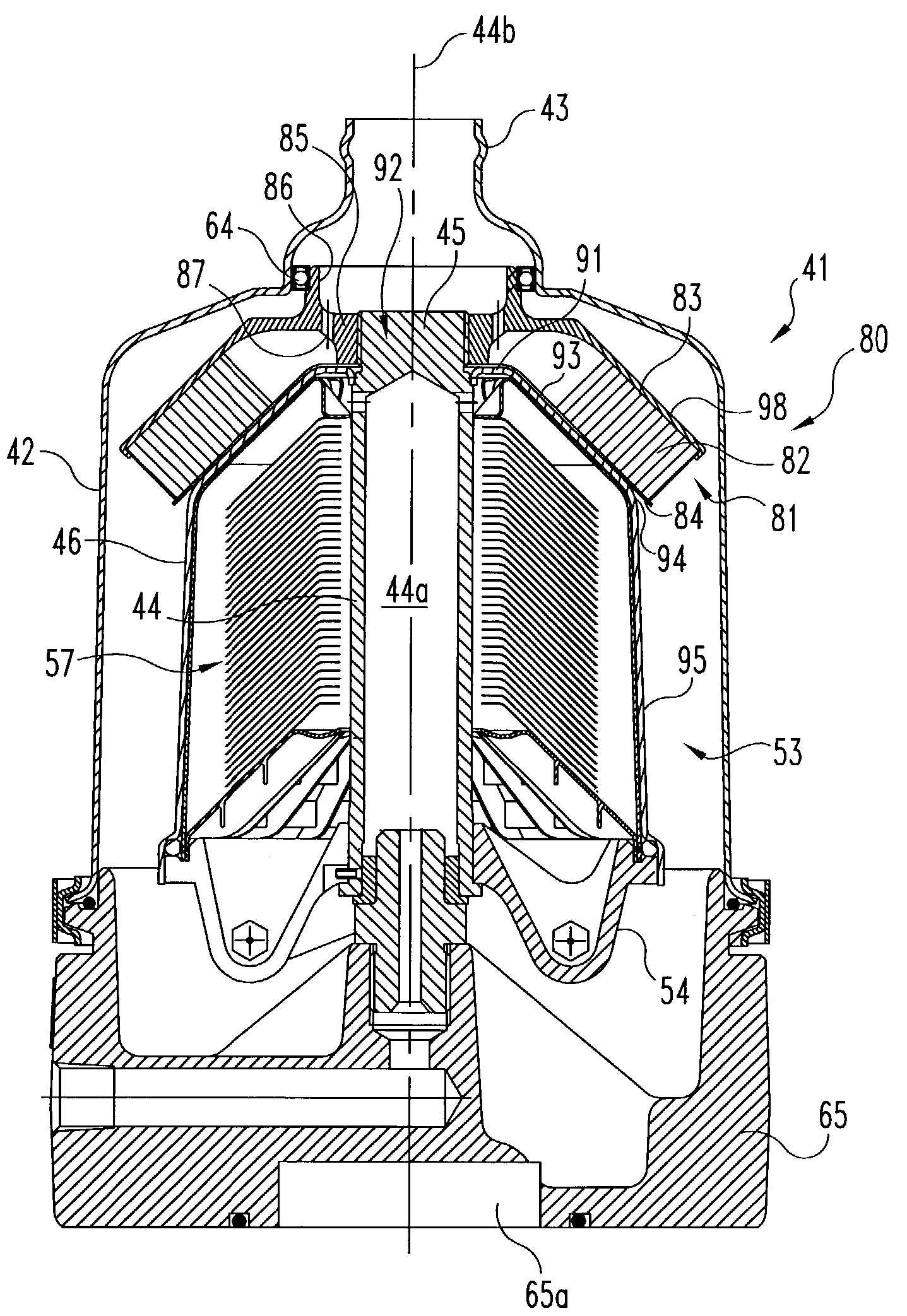

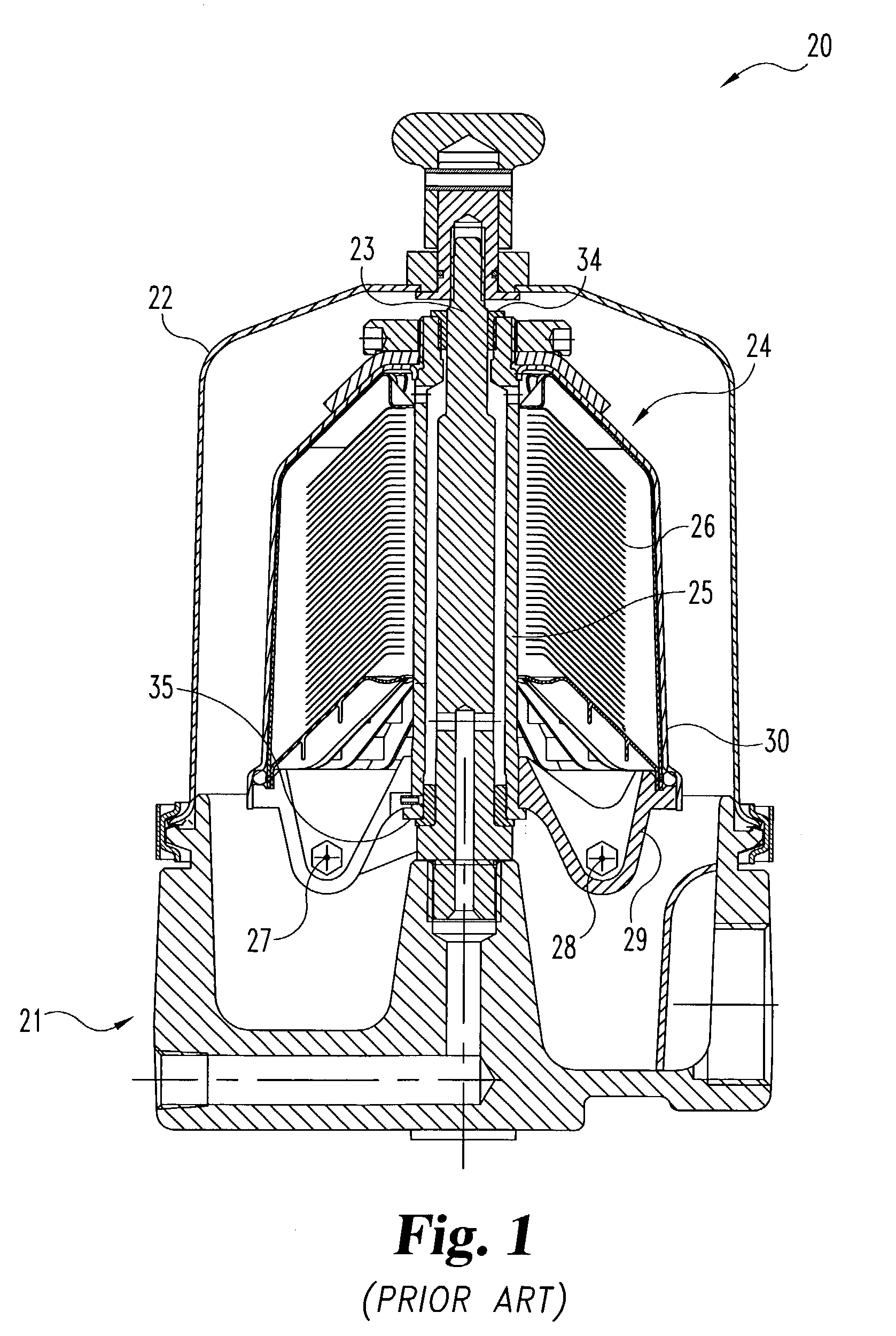

A centrifuge for separating particulate matter from circulating fluid includes a centrifuge enclosure including a housing and a base joined together so as to define a hollow interior. A rotor is positioned in the hollow interior and is supported by the base in a manner to permit rotary motion of the rotor relative to the centrifuge enclosure. A coalescing filter assembly is secured to the rotor and is constructed and arranged for removing oil aerosol from a blowby gas which is introduced into the centrifuge. A roller bearing, press fit into the centrifuge housing, receives a portion of the coalescing filter assembly.

Owner:FLEETGUARD INC

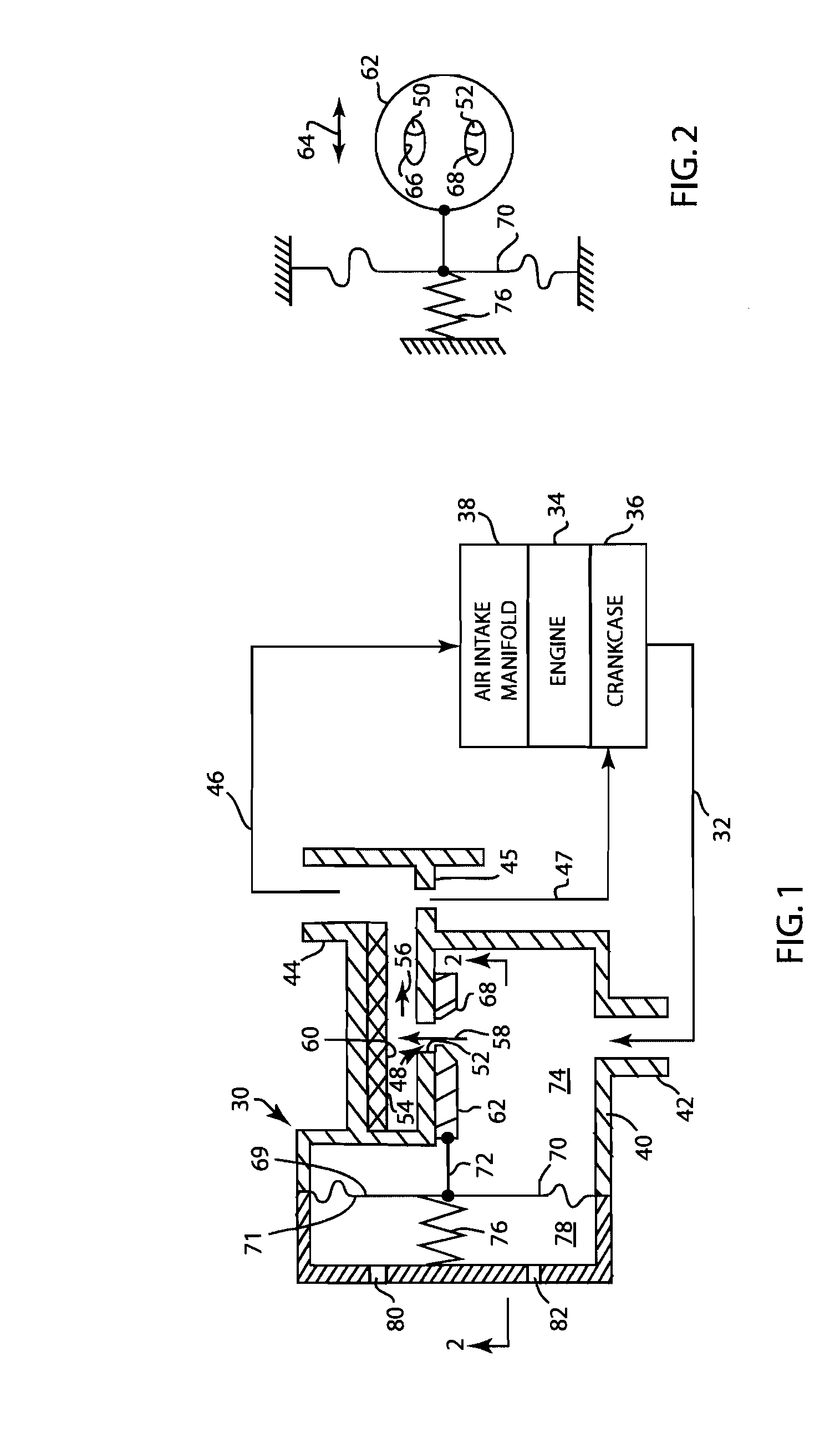

Multistage Variable Impactor

ActiveUS20070256566A1Improve performanceConsistent efficiencyCombination devicesLiquid degasificationEngineeringPlunger

An inertial gas-liquid separator and method is provided, including variable orifice jet nozzle structure having a variable orifice area dependent upon axial movement of a plunger relative to a housing sleeve, and in another embodiment having first and second flow branches, with the first flow branch being continuously open, and the second flow branch having a variable flow controller controlling flow therethrough.

Owner:CUMMINS FILTRATION IP INC

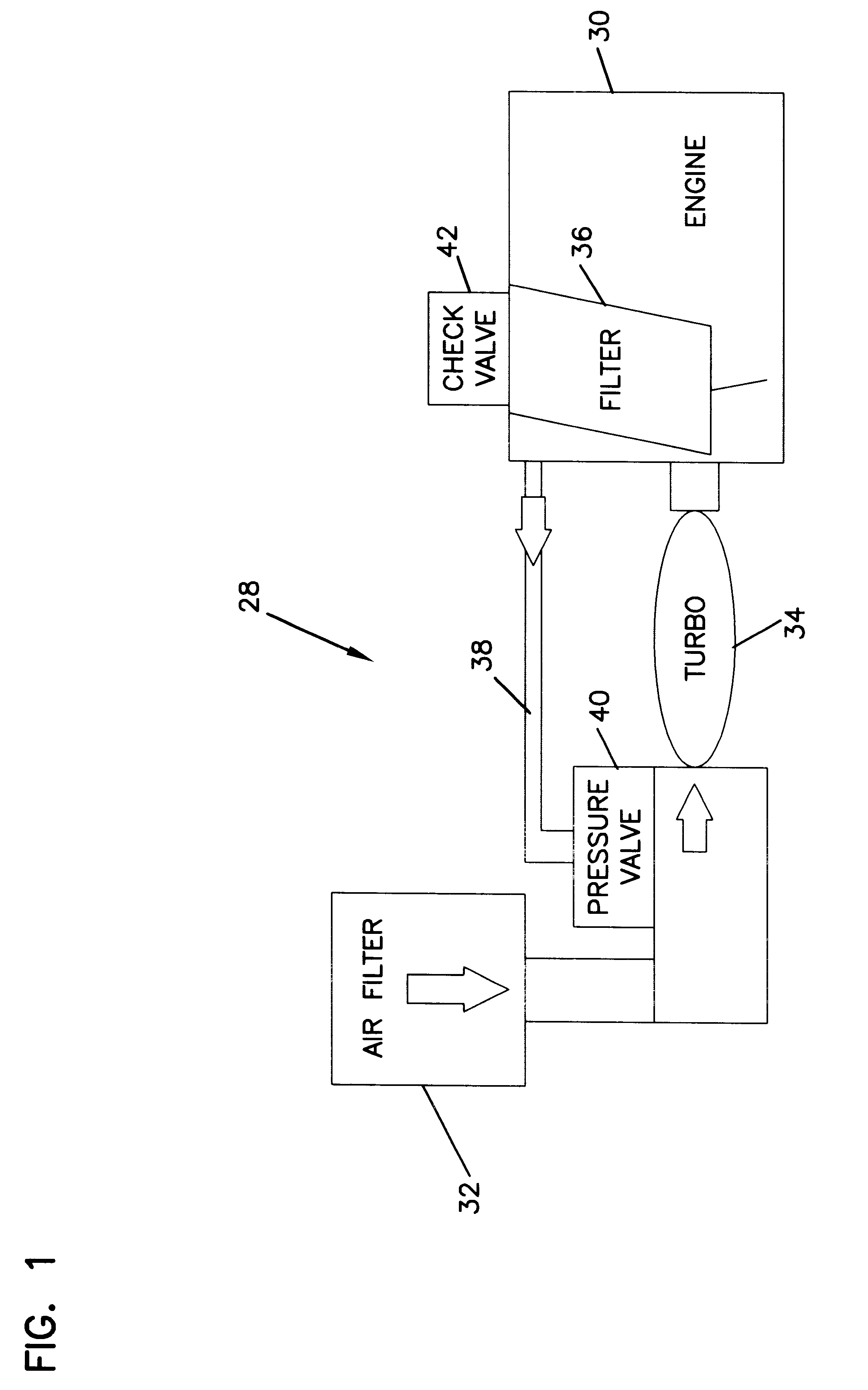

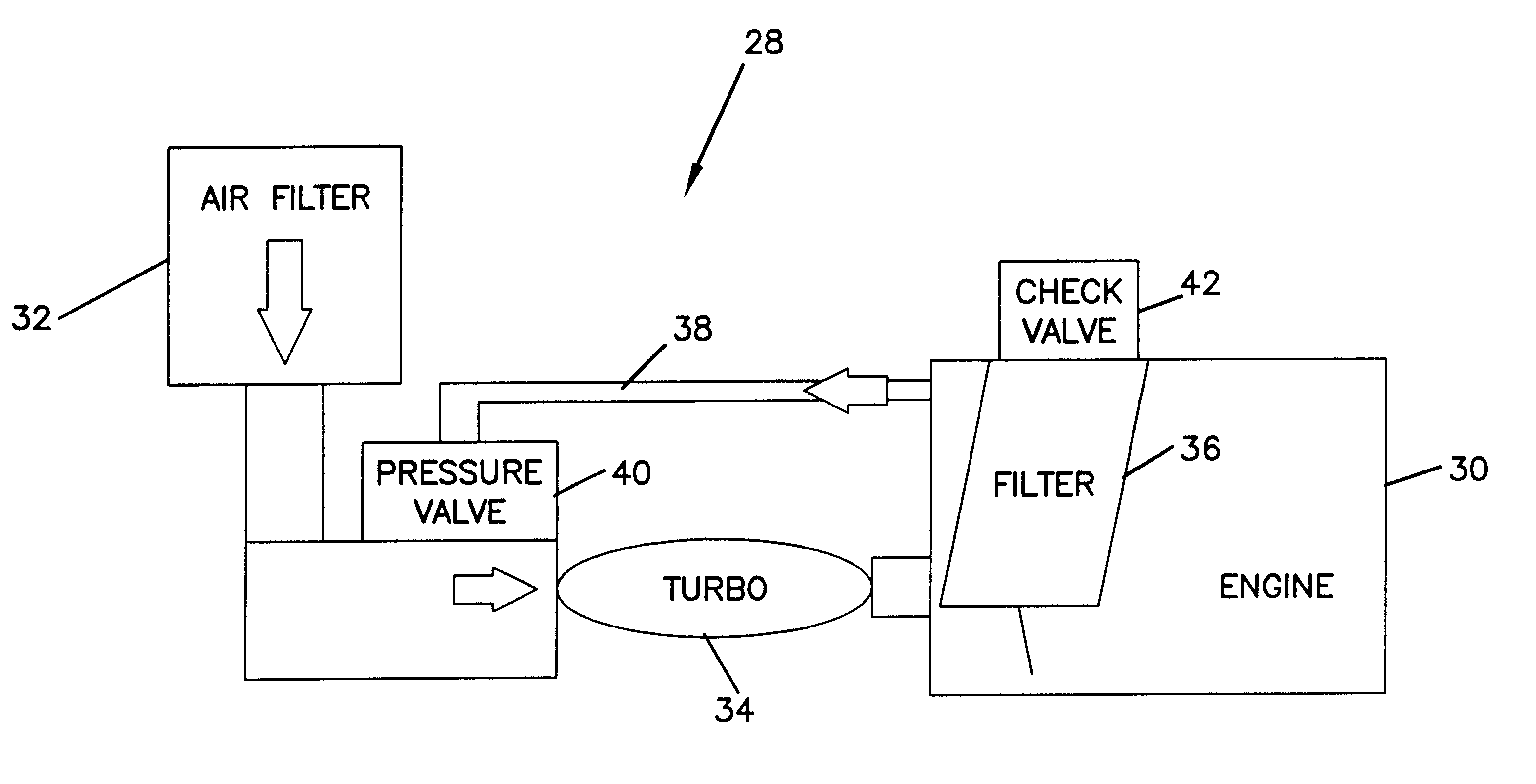

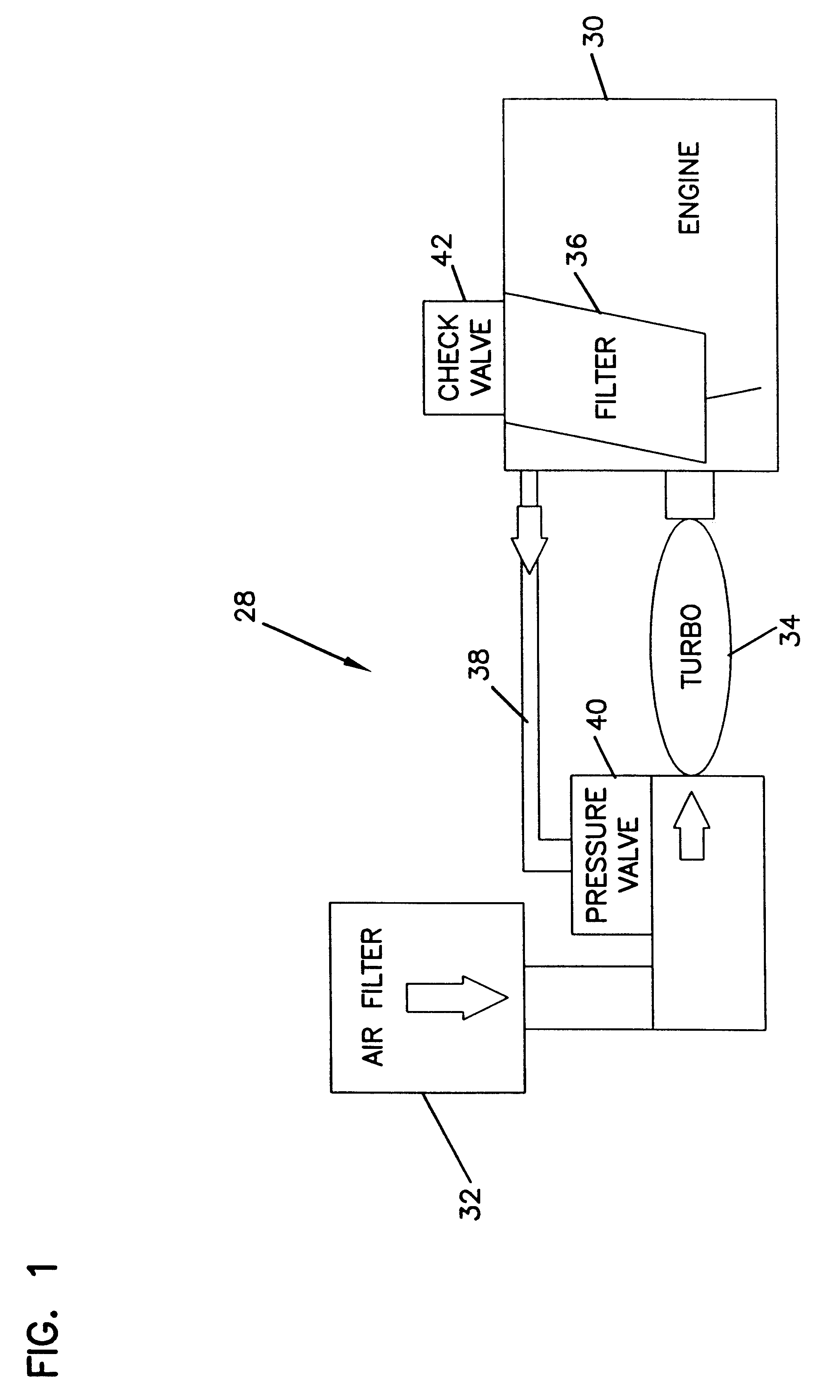

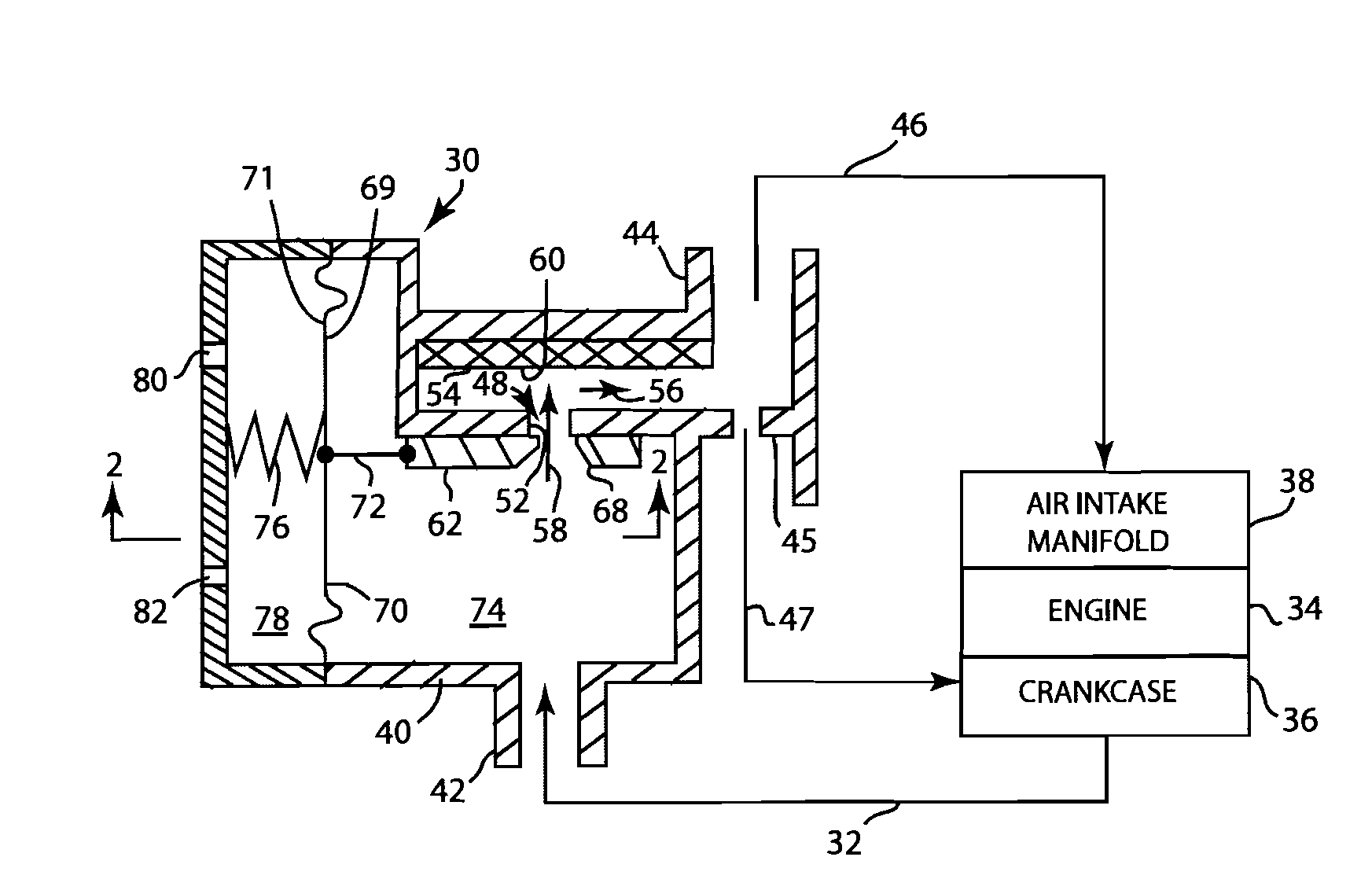

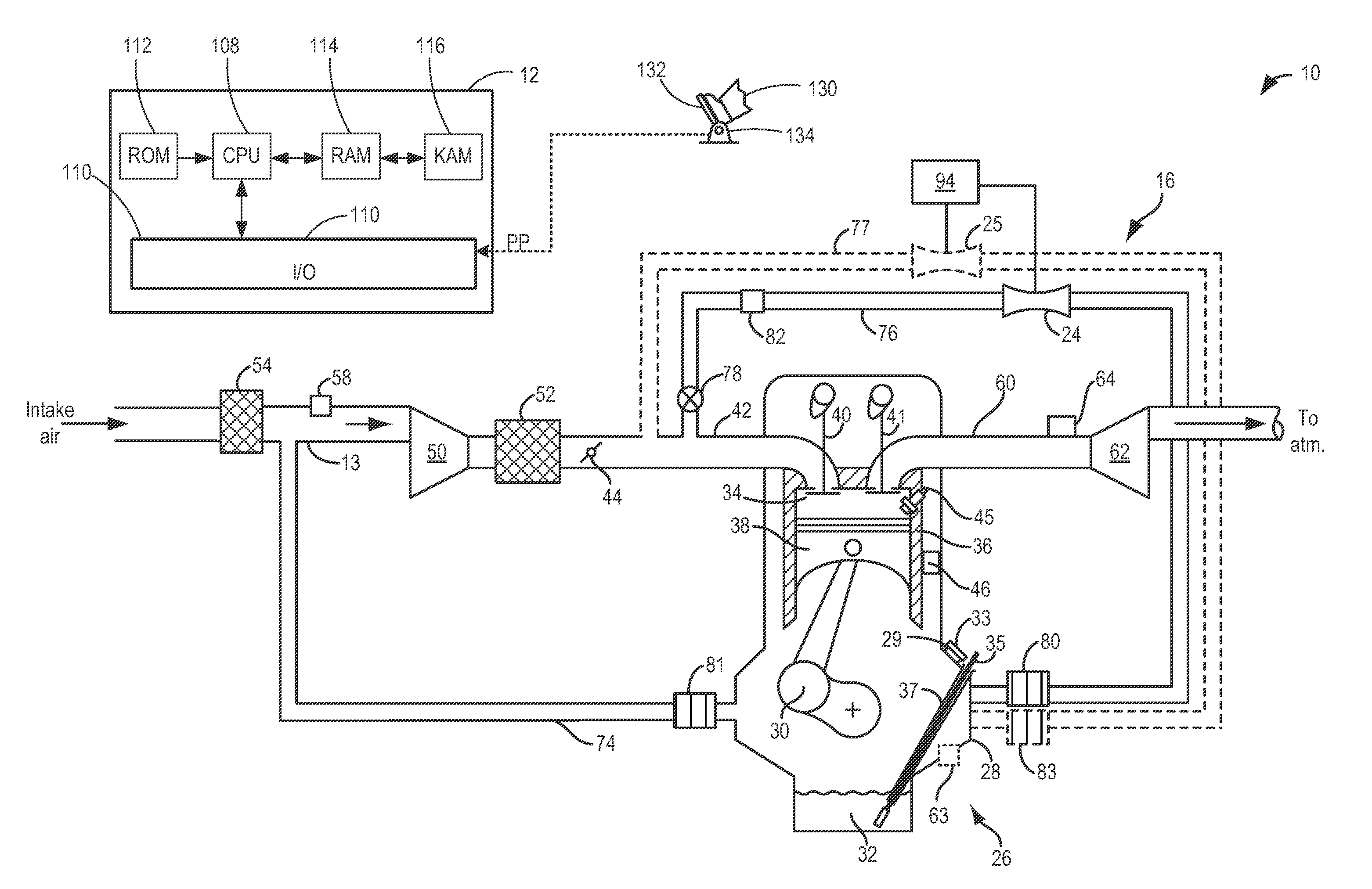

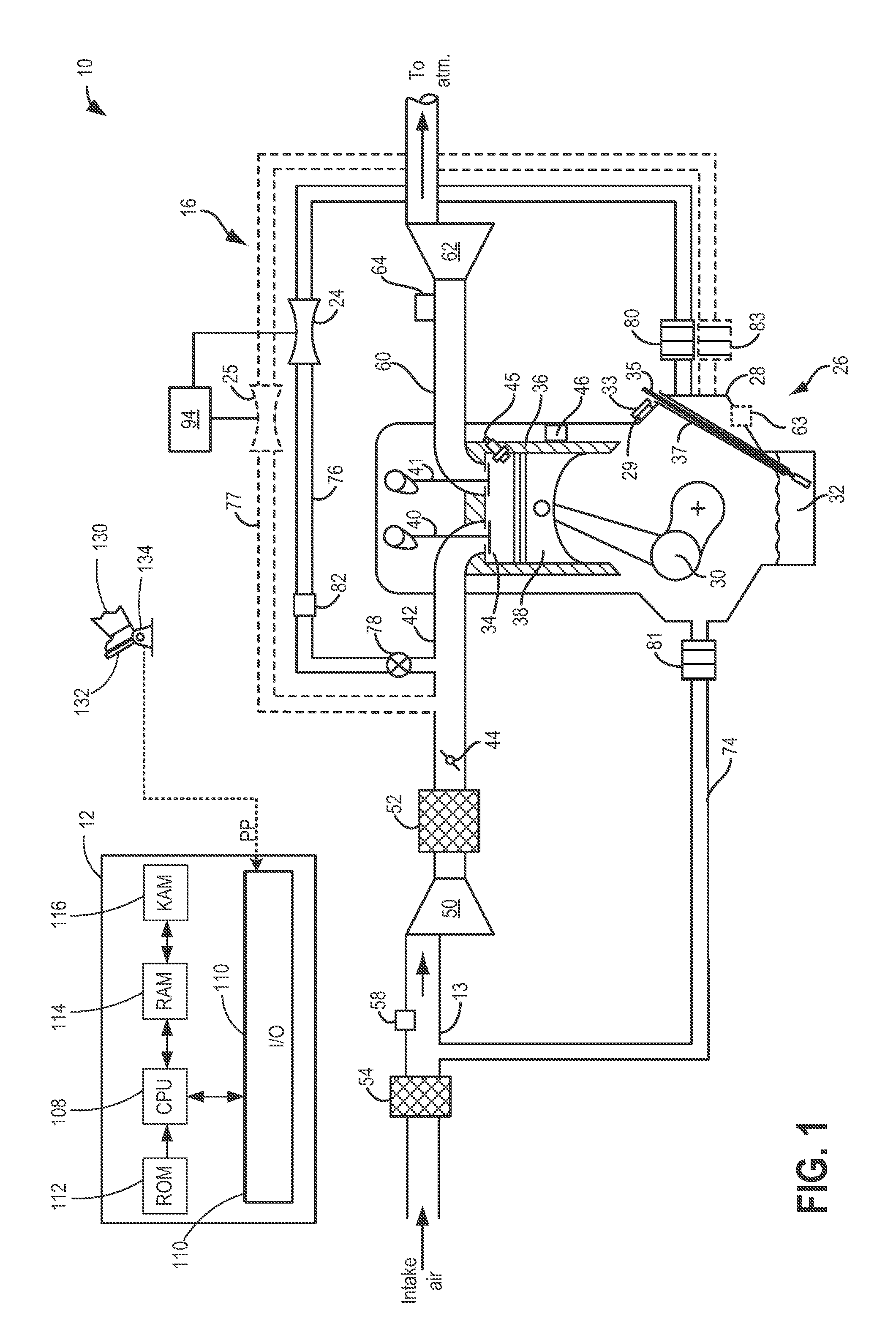

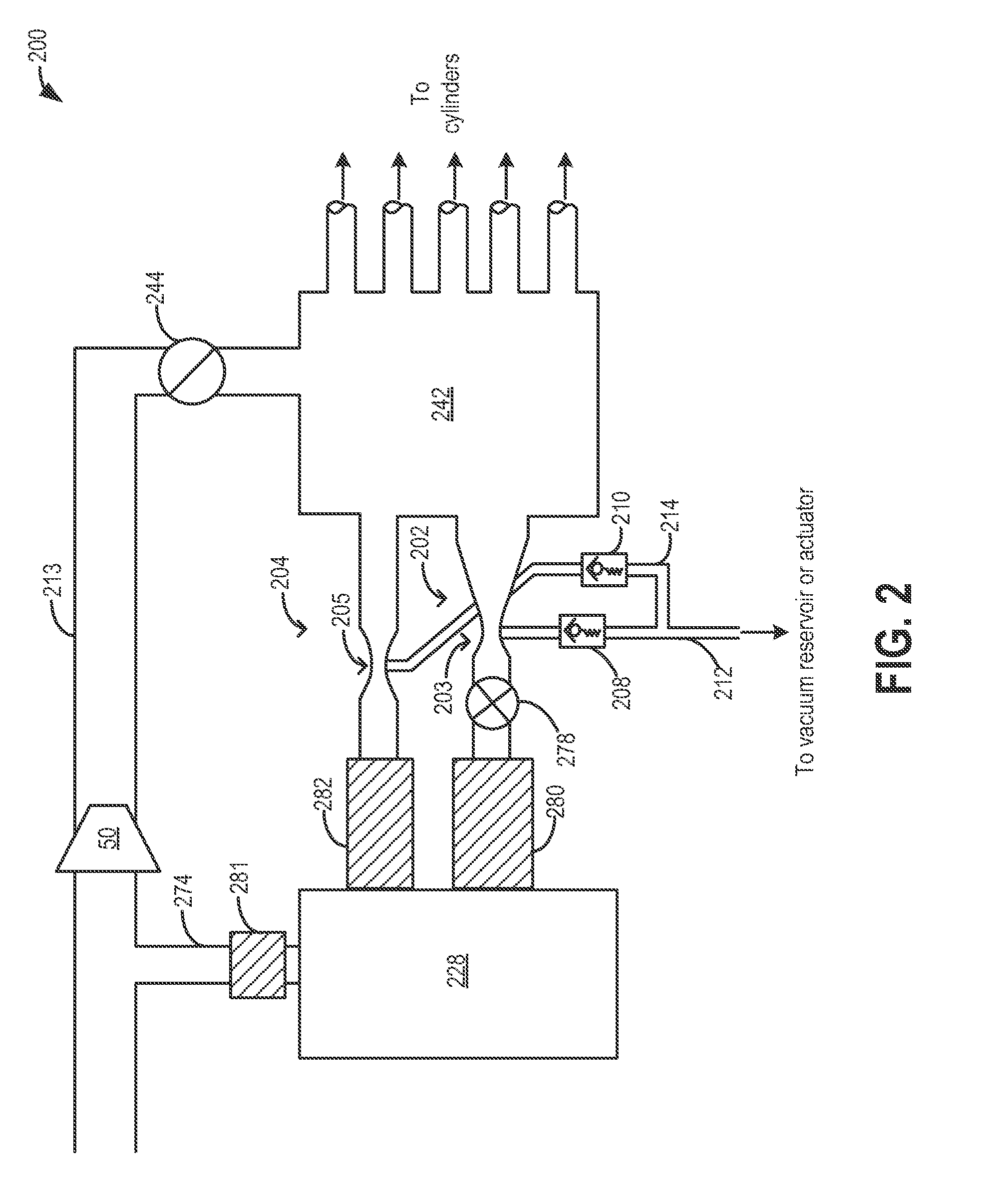

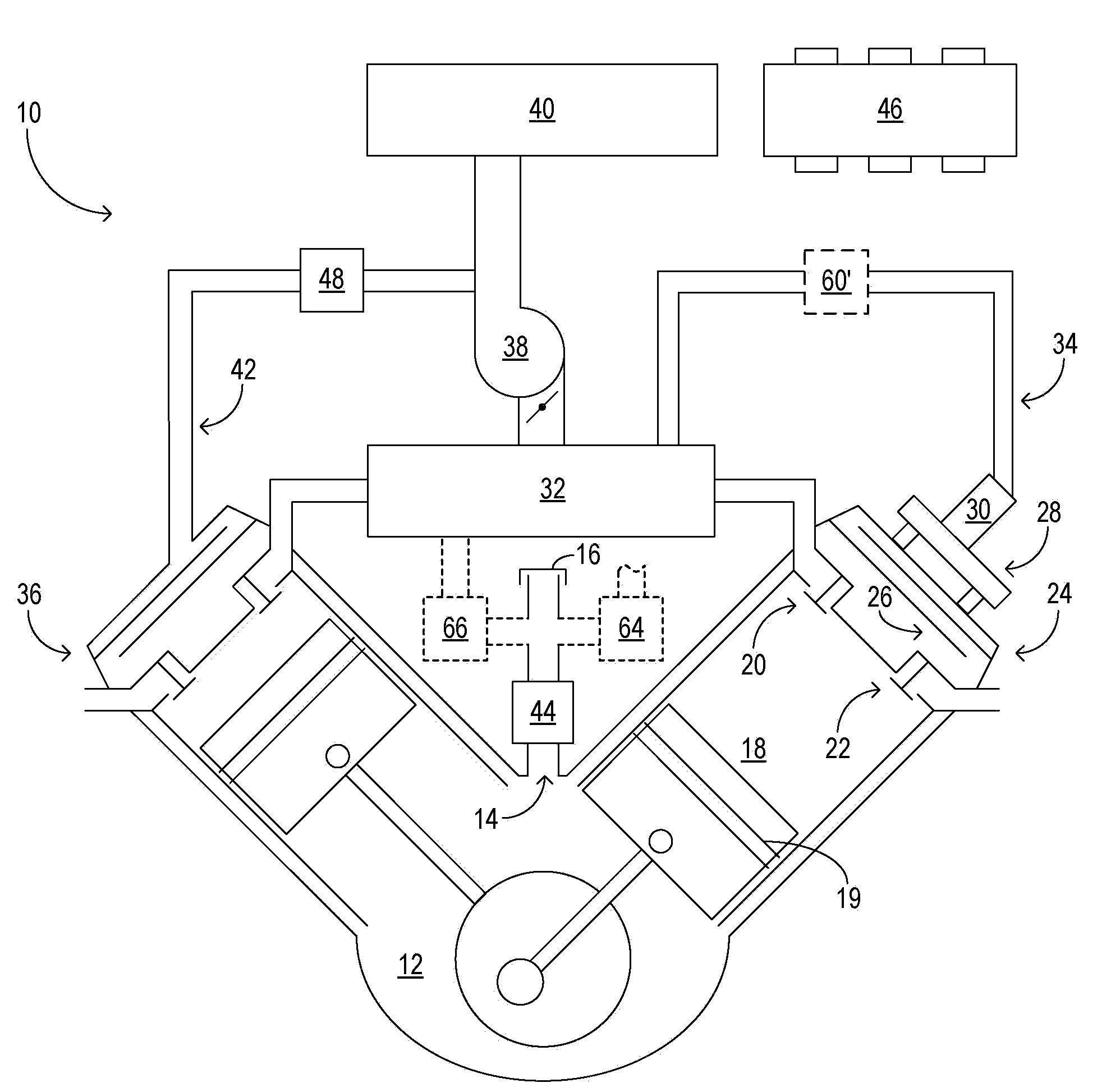

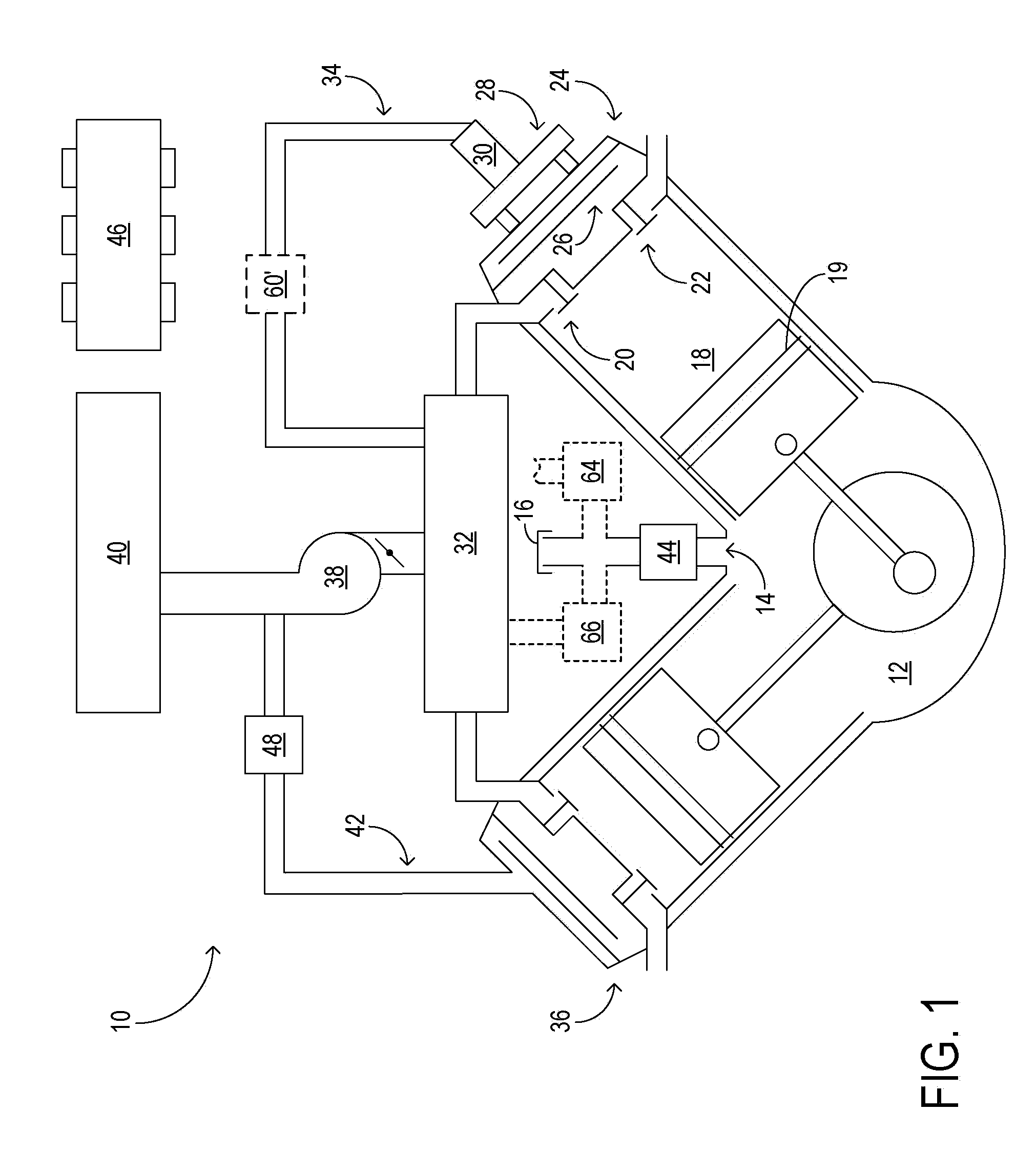

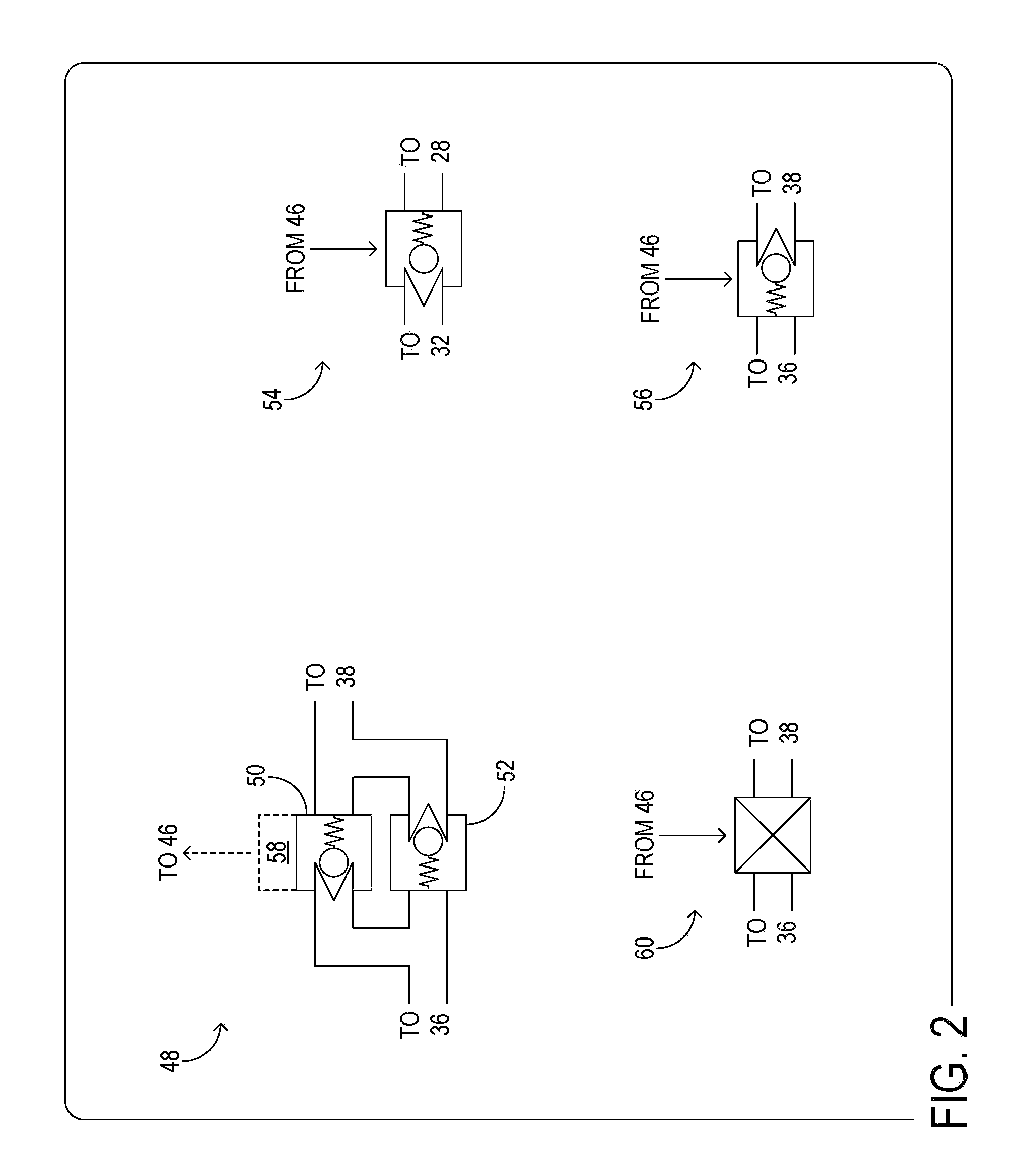

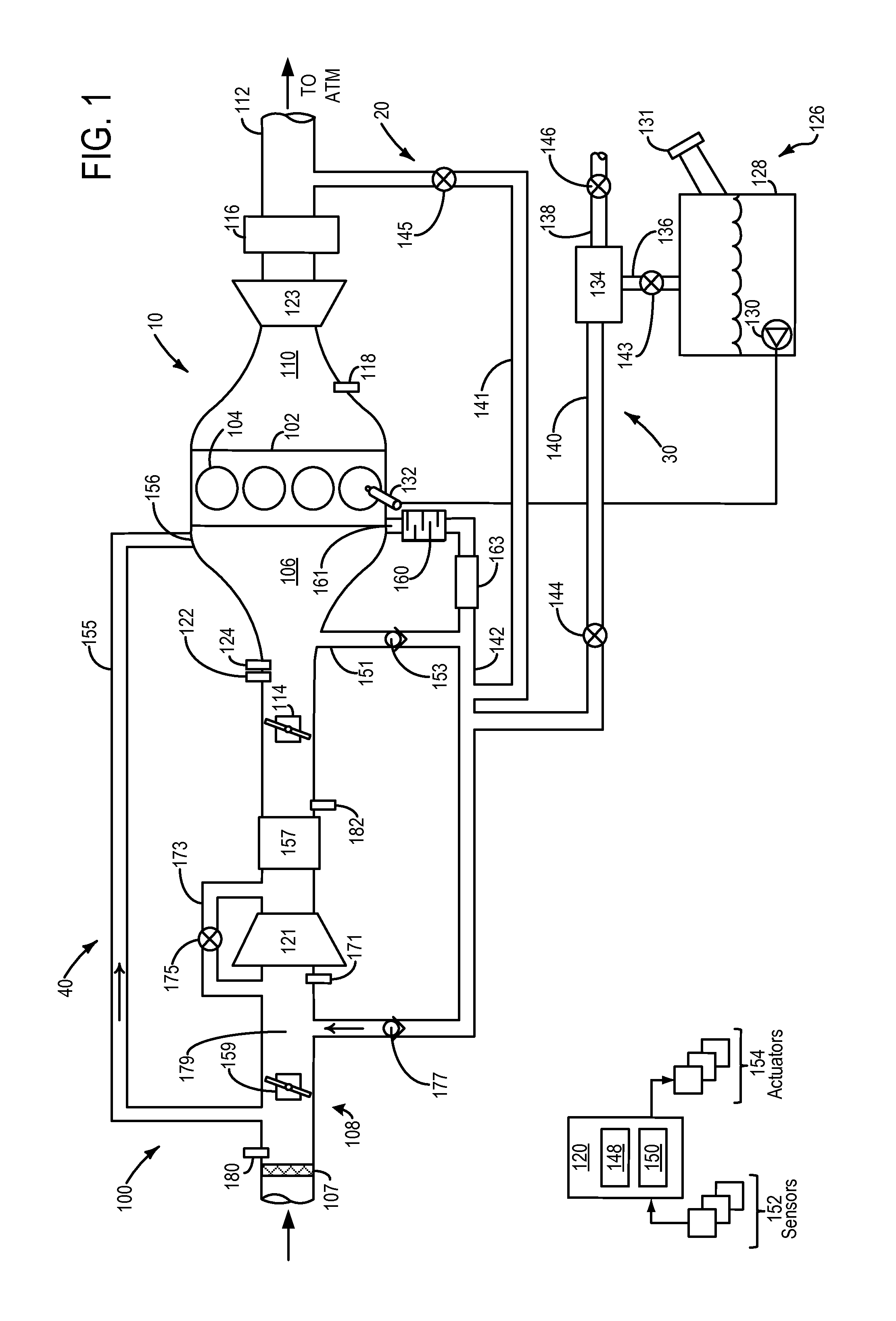

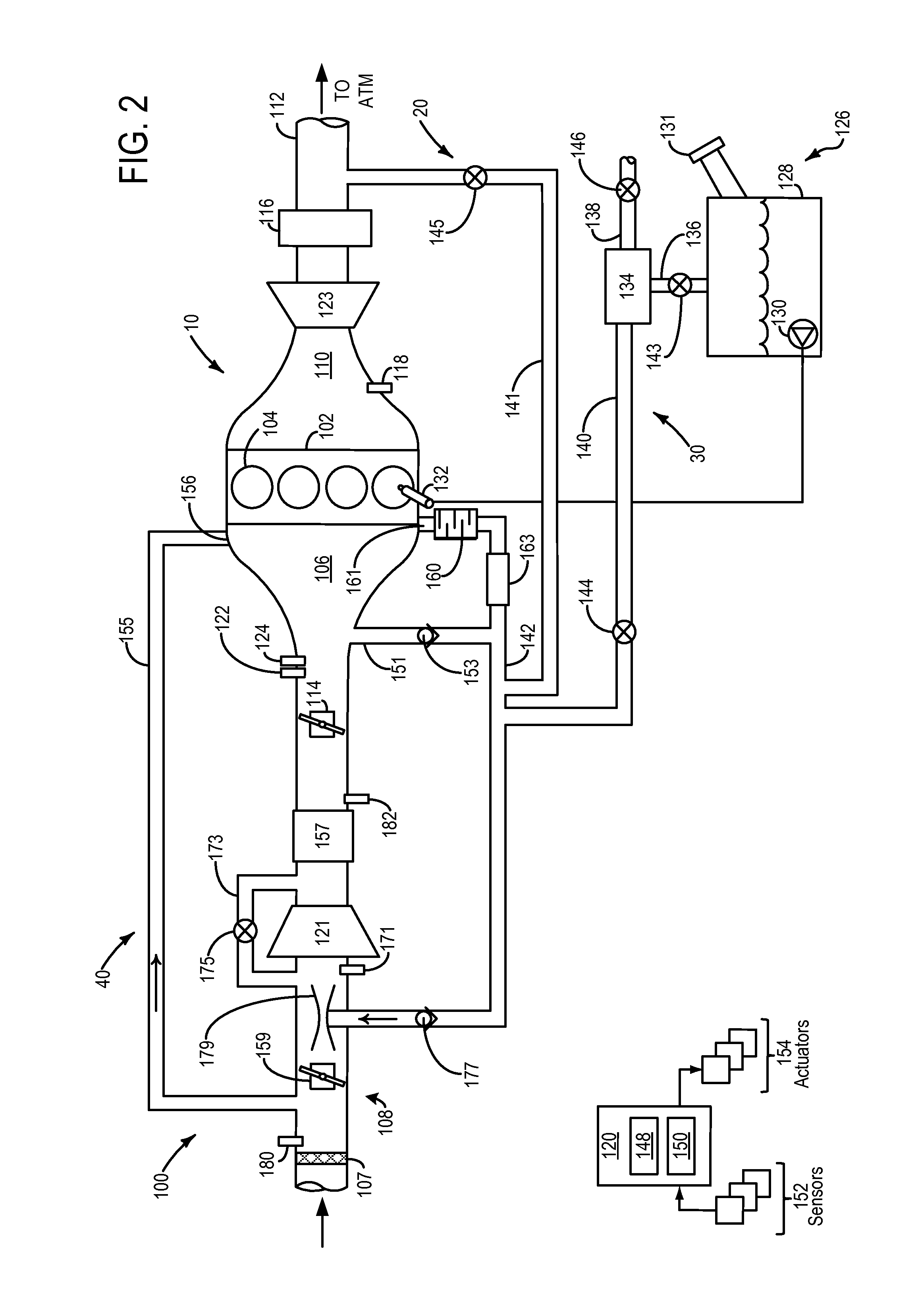

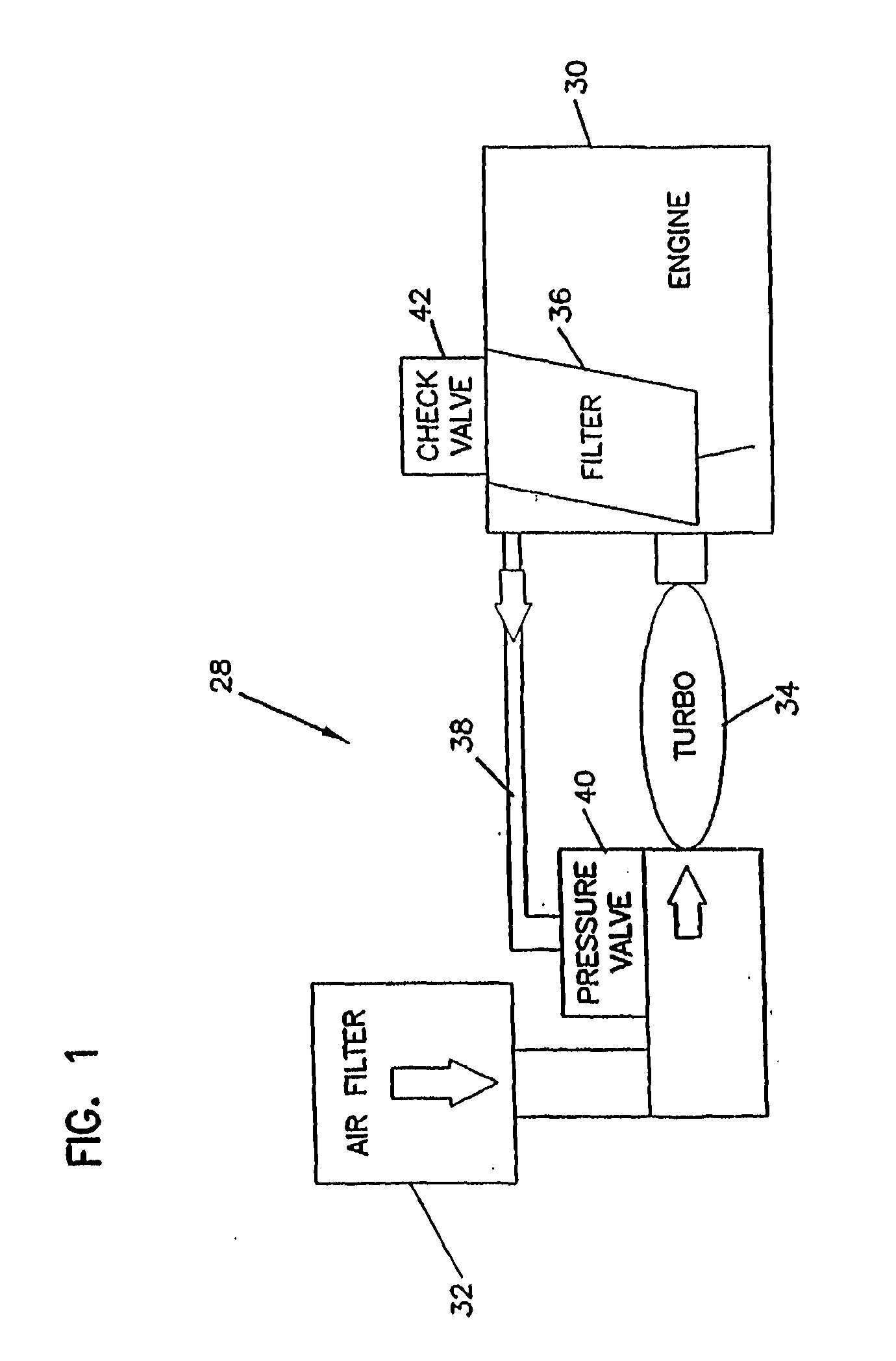

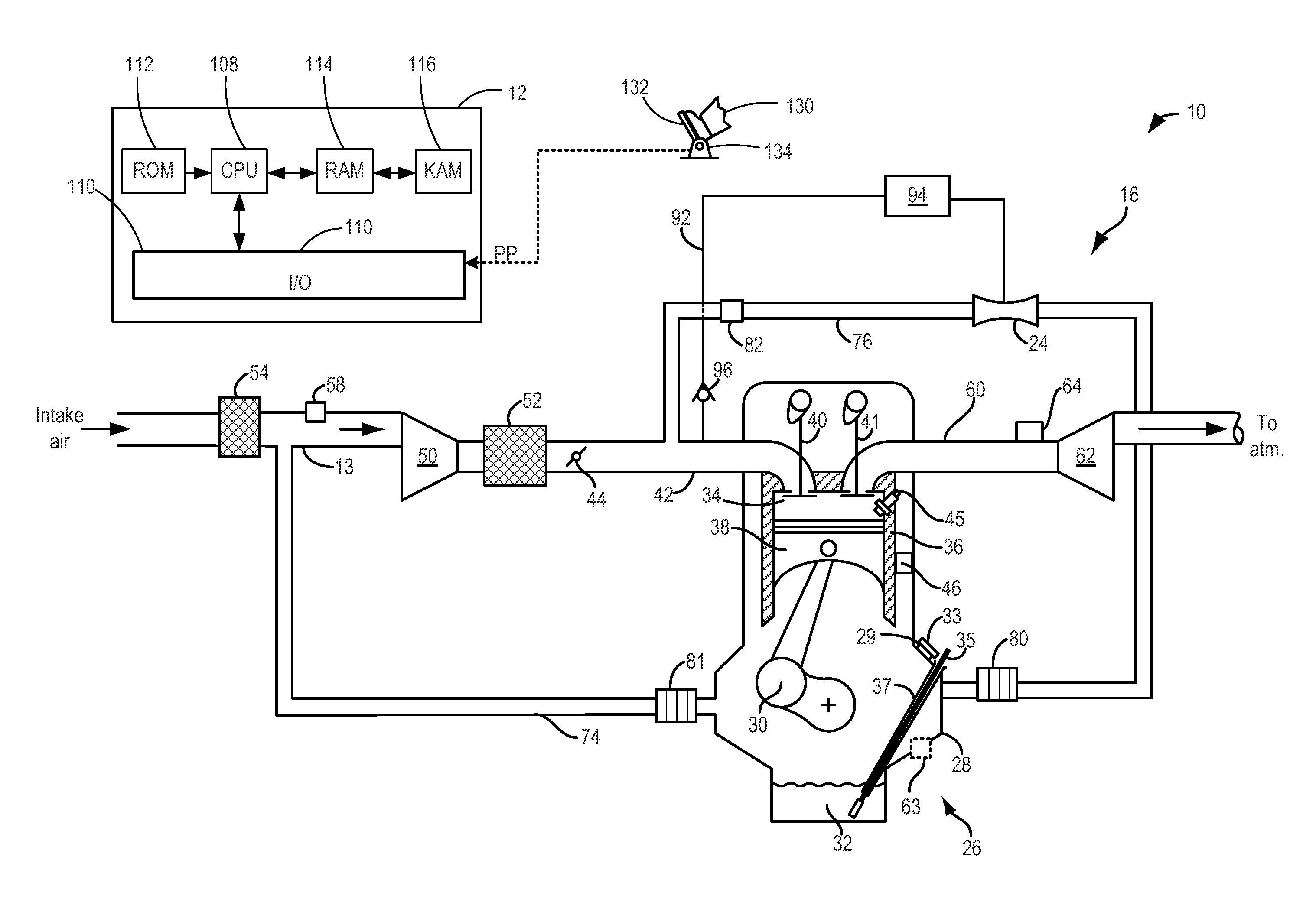

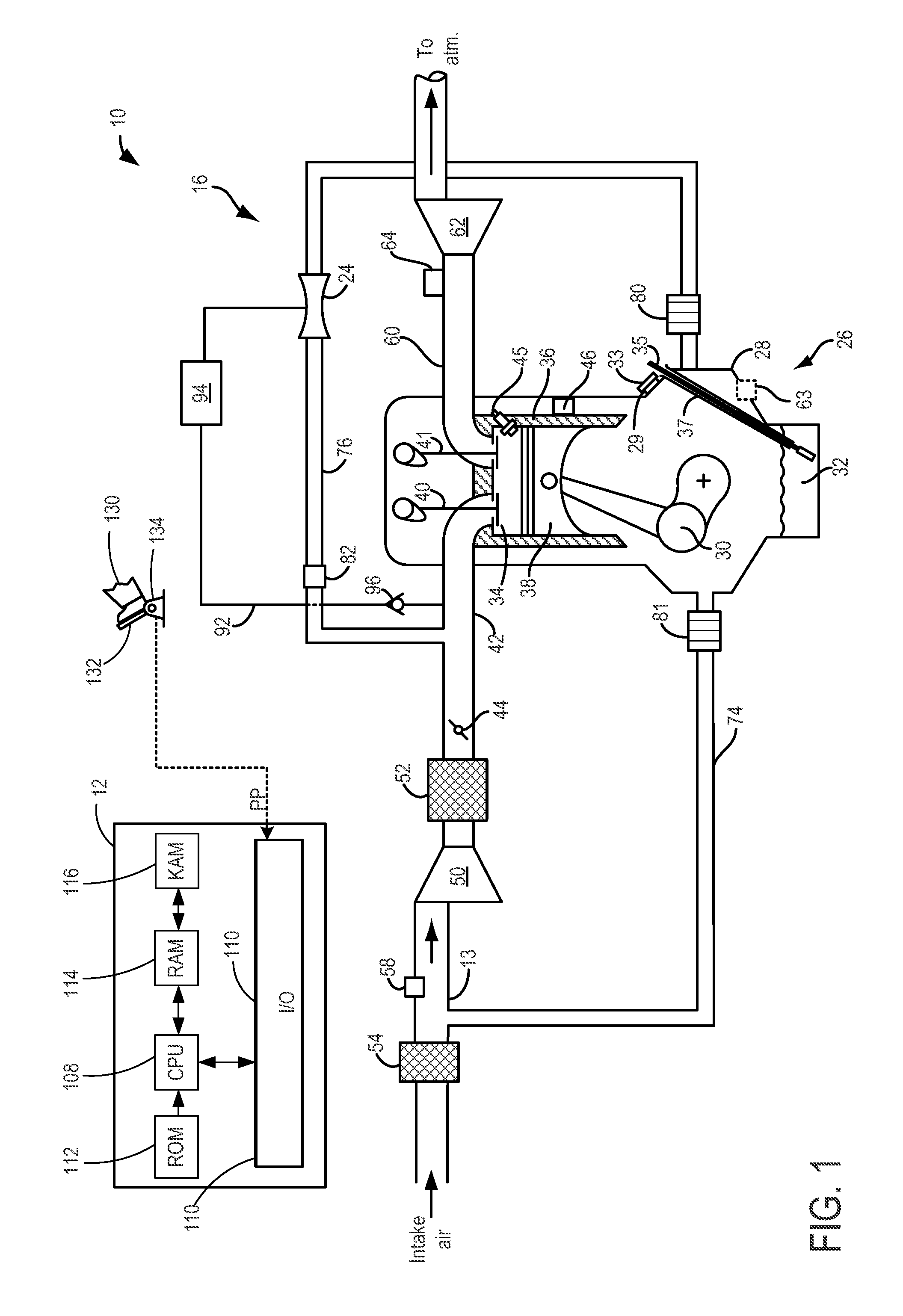

Crankcase ventilation and vacuum generation

InactiveUS20130340732A1Increase vacuum generationImprove power generation efficiencyInternal combustion piston enginesNon-fuel substance addition to fuelInspiratorProcess engineering

Methods and systems are provided for generating vacuum from crankcase ventilation flow. During both directions of gas flow between an engine intake manifold and a crankcase, gases are directed through one or more aspirators to produce vacuum. The drawn vacuum may then be used to operate various engine vacuum actuators.

Owner:FORD GLOBAL TECH LLC

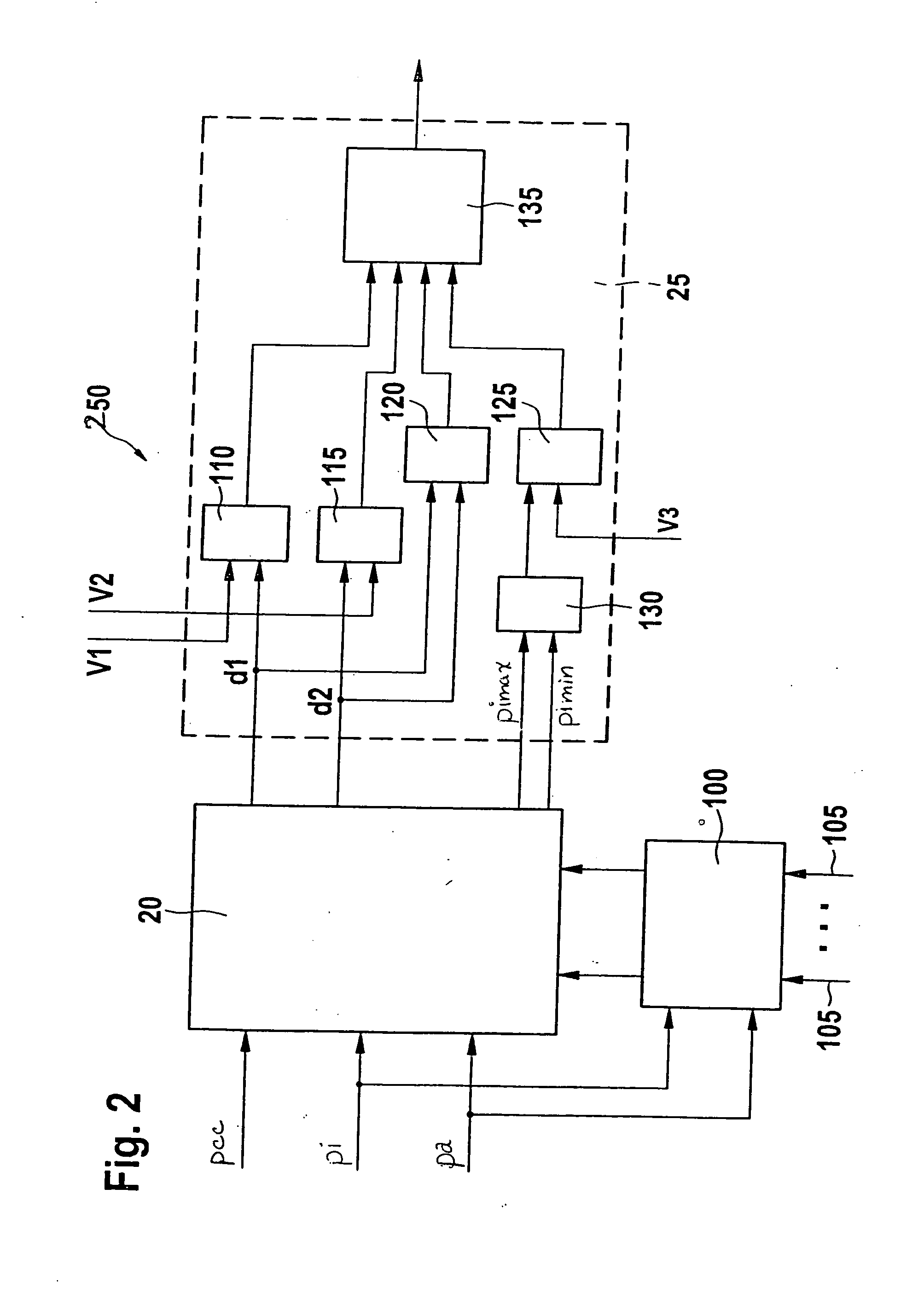

Method and device for operating an internal combustion engine

InactiveUS20050022795A1Reliable detectionReduce riskEngine pressureElectrical controlFuel tankAmbient pressure

A method and a device for operating an internal combustion engine having an intake manifold and a ventilation system may allow a reliable and fault-free diagnosis of a fault in the ventilation. The ventilation system may be a tank ventilation or a crankcase ventilation. The ventilation duct is conducted to the intake manifold of the internal combustion engine. At least one pressure differential may be determined between an intake-manifold pressure or an ambient pressure, on the one hand, and a pressure in the ventilation duct, on the other hand. A fault in the ventilation may be diagnosed as a function of the at least one pressure differential.

Owner:ROBERT BOSCH GMBH

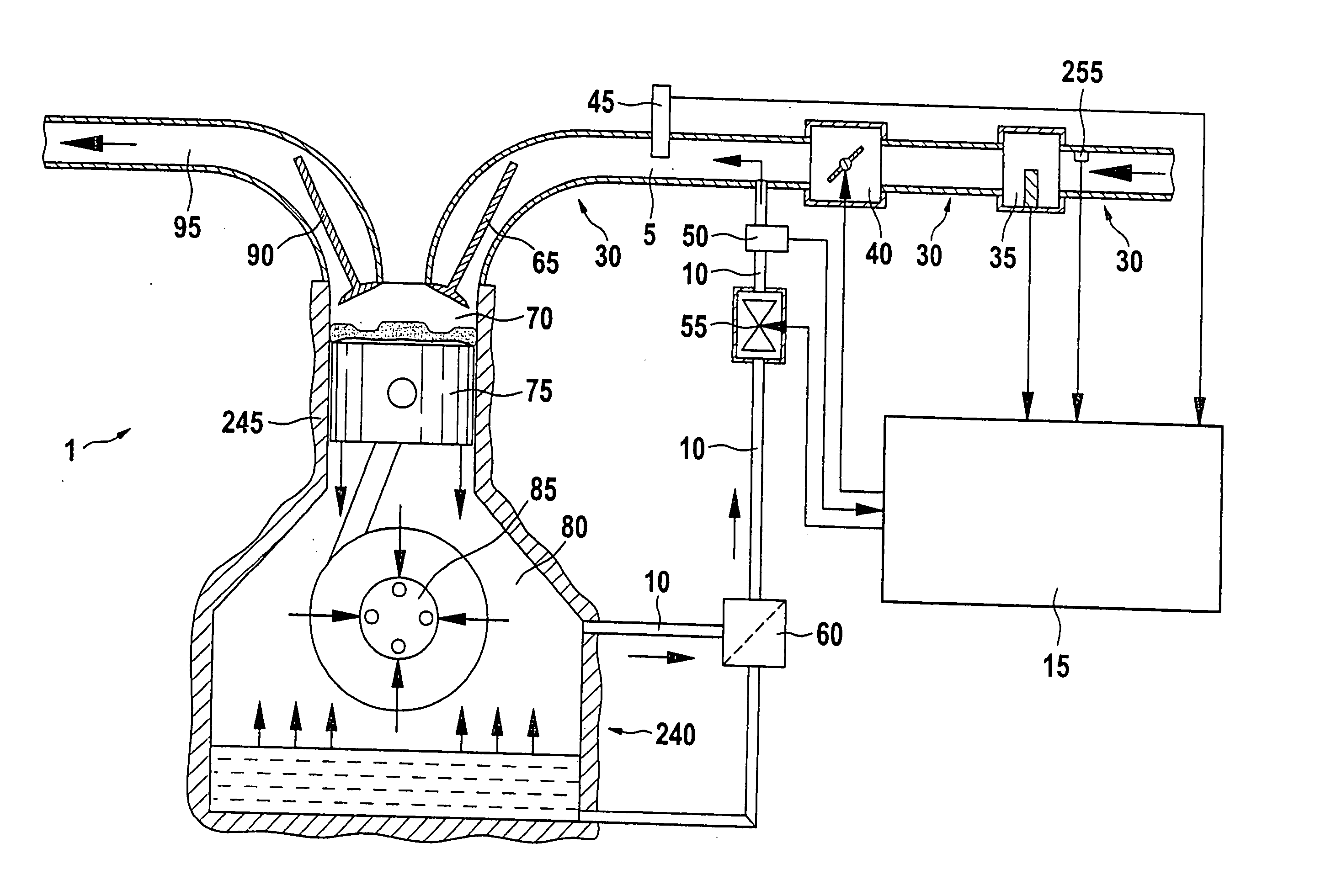

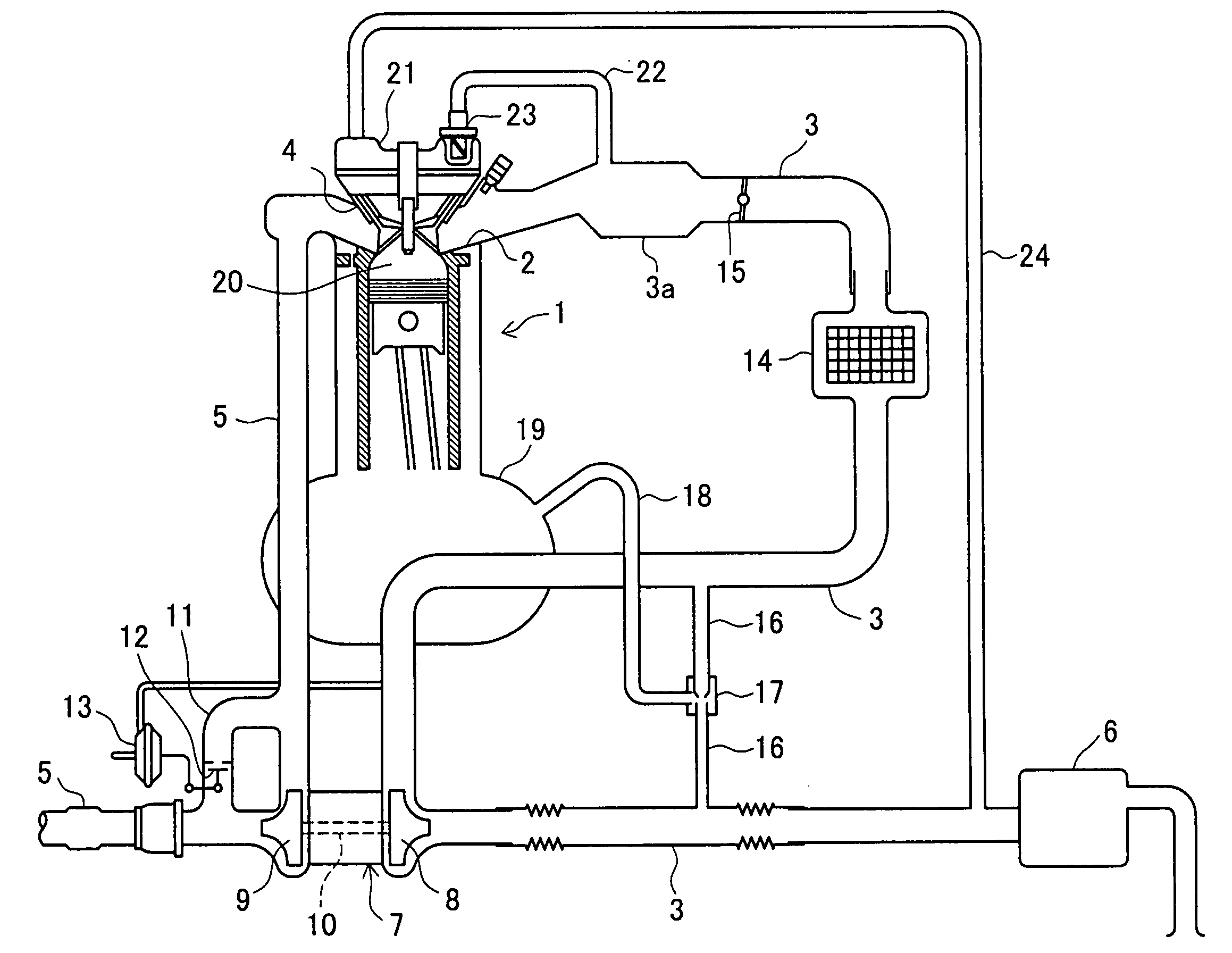

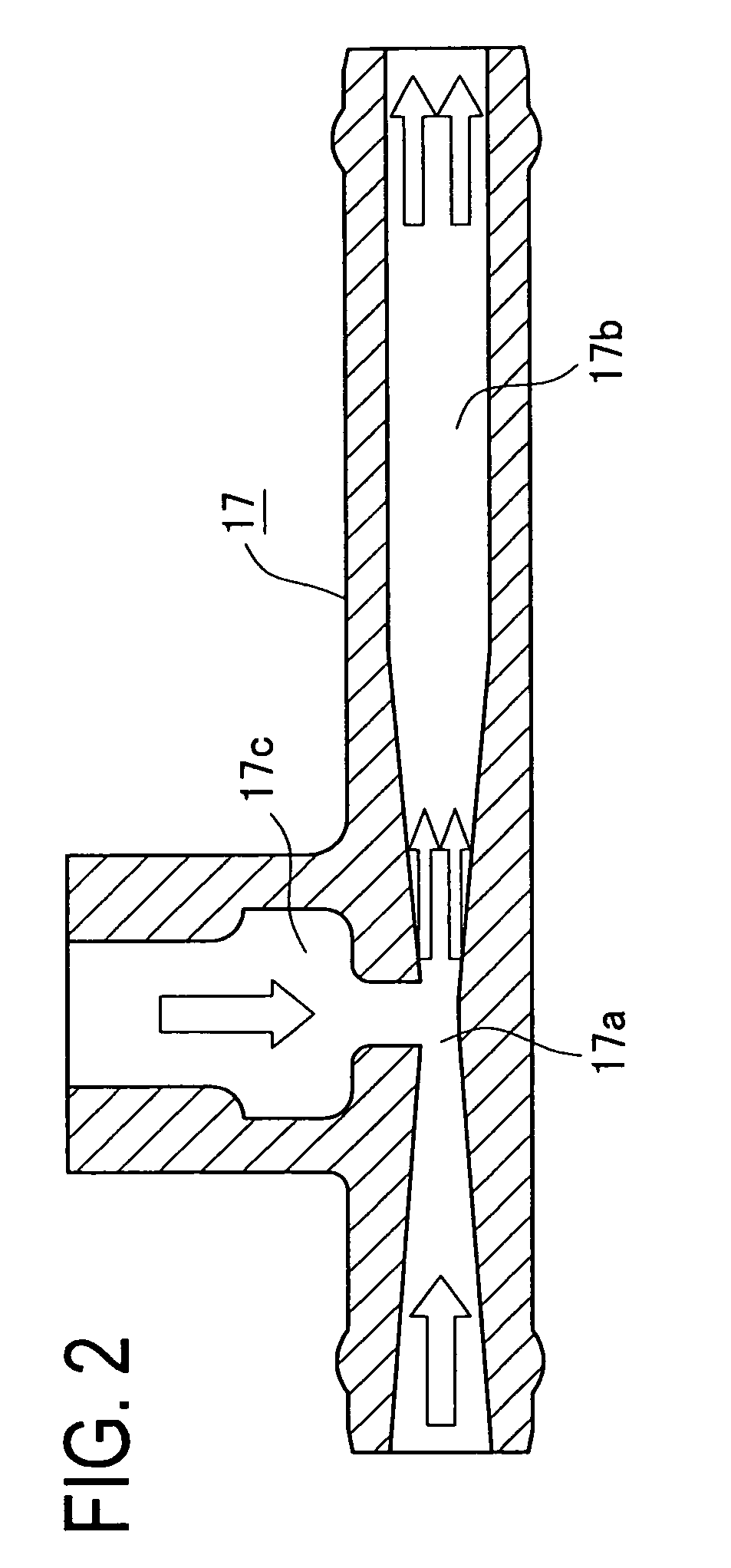

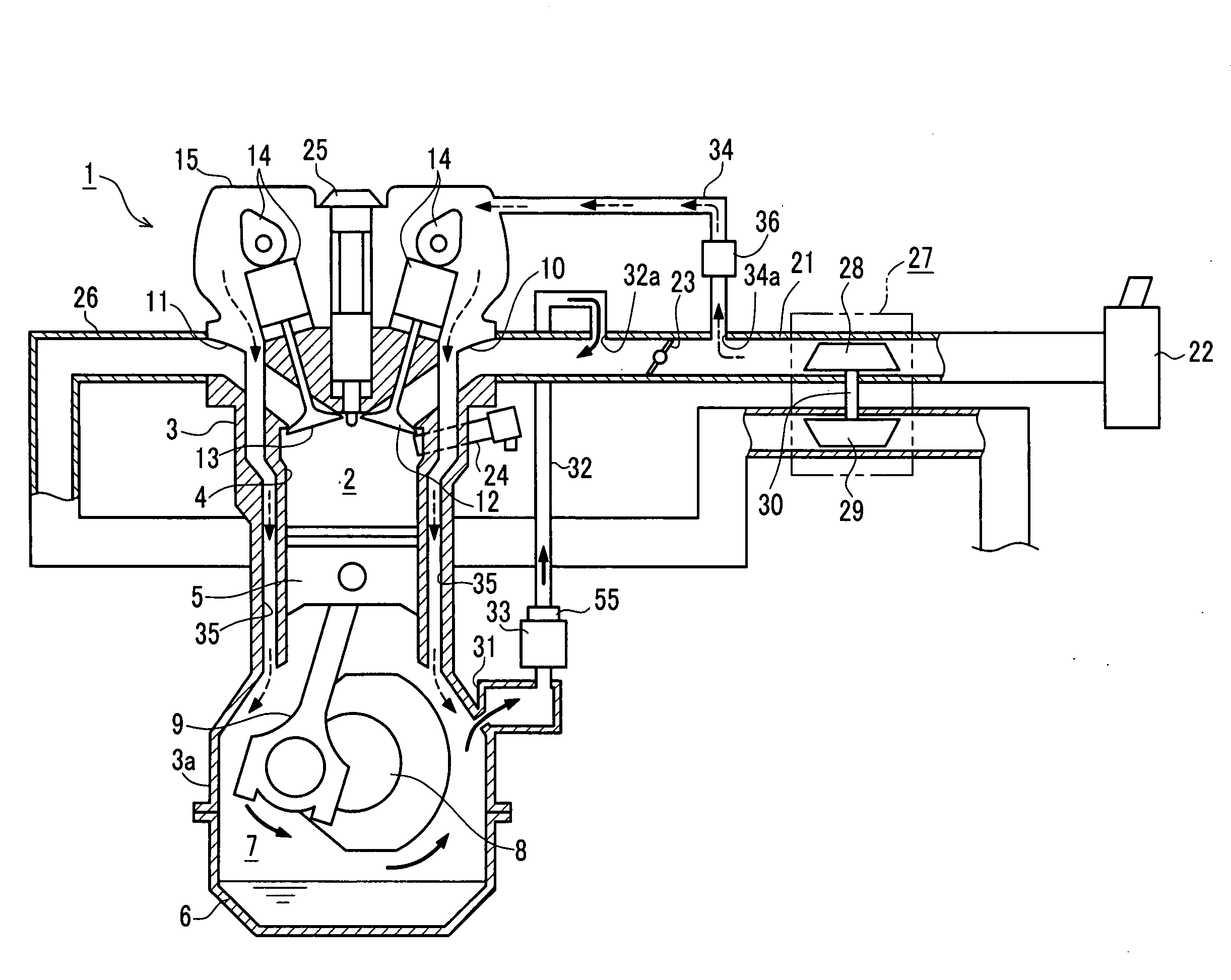

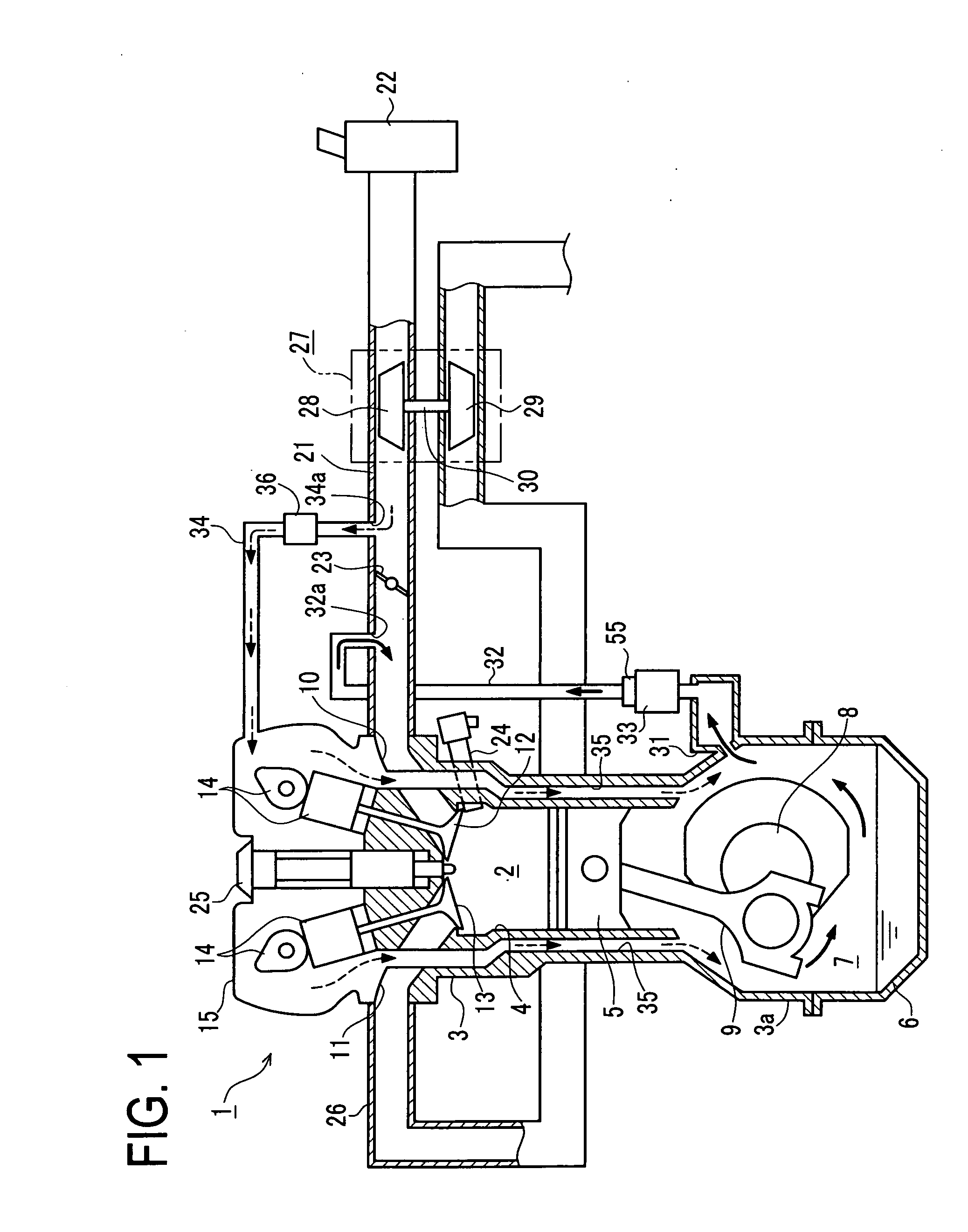

Blowby gas returning apparatus

ActiveUS20090308364A1Increase intake resistanceIncrease boost pressureNon-fuel substance addition to fuelInternal combustion piston enginesTurbochargerEngineering

A blowby gas returning apparatus is mounted in an engine provided with a turbocharger in an intake passage and provided with a blowby gas returning passage for flowing blowby gas generated in the engine to return to the engine. This apparatus comprises an intake bypass passage connecting an upstream side and a downstream side of the intake passage with respect to the turbocharger, and a jet pump for generating negative pressure in the intake bypass passage. An exit of the first blowby gas returning passage is connected to the intake bypass passage through the jet pump. The apparatus further includes a second blowby gas returning passage connecting the intake passage downstream of the throttle valve to a head cover. In the head cover, a PCV valve is placed at an entrance of the second blowby gas returning passage.

Owner:AISAN IND CO LTD

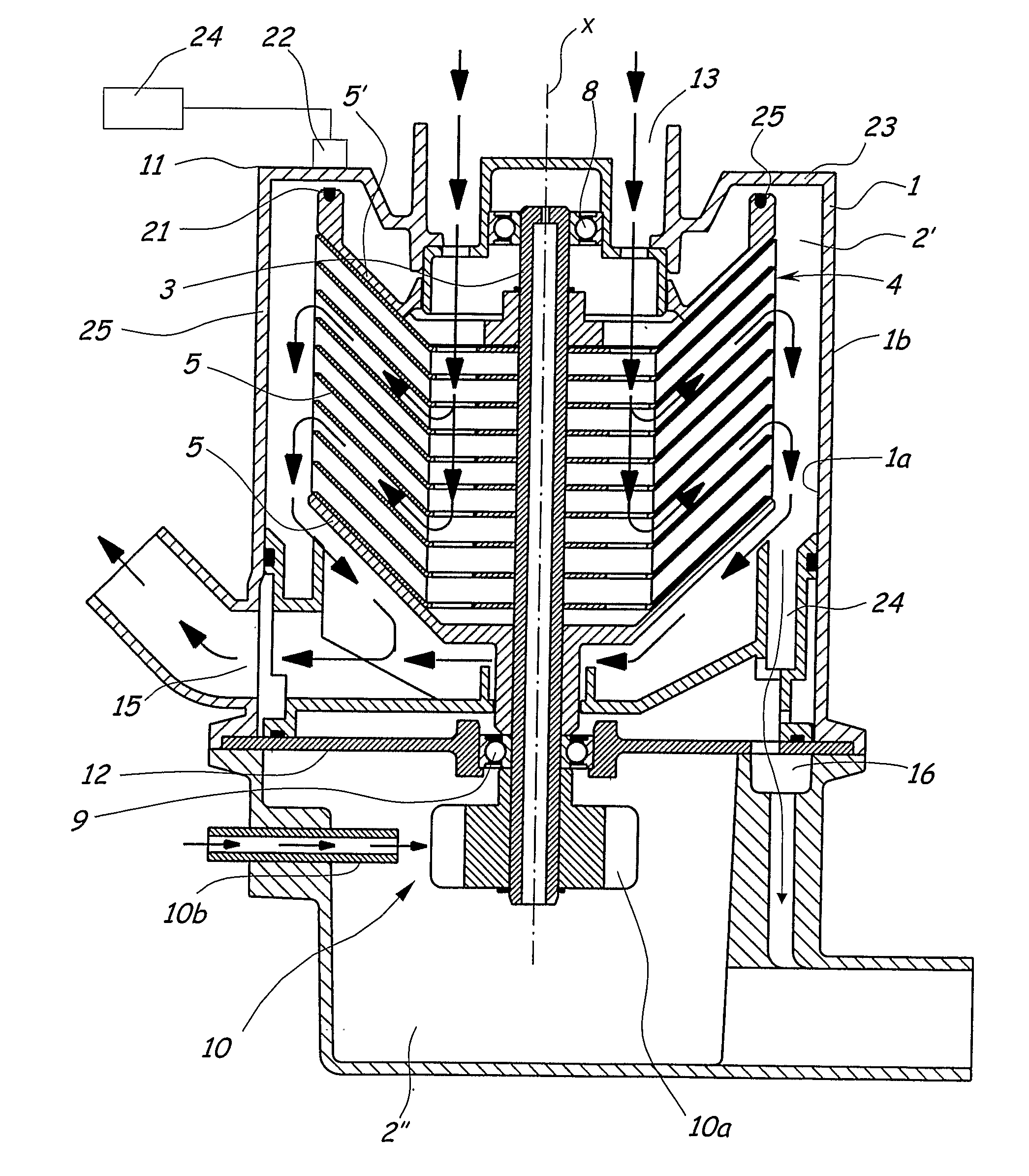

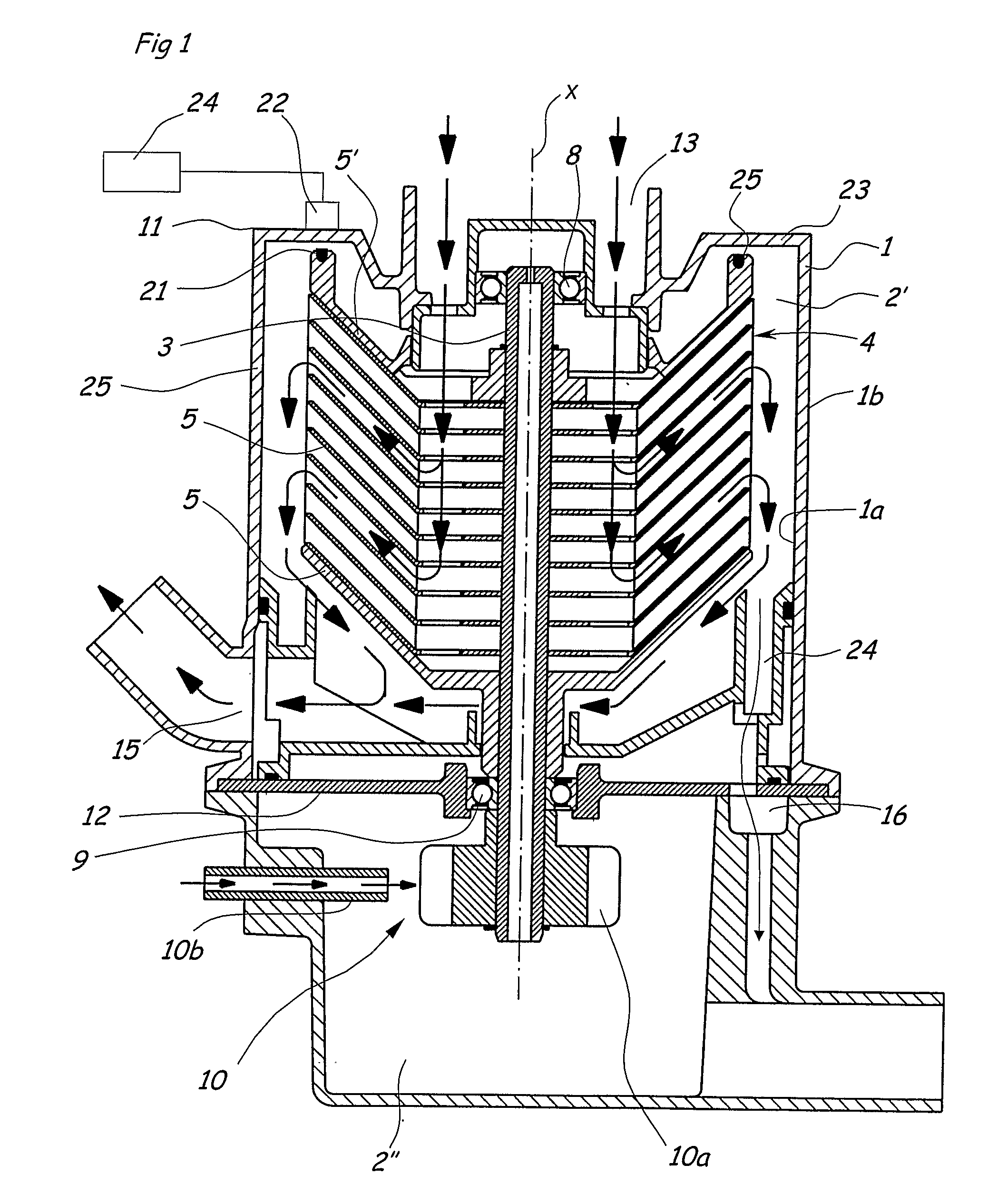

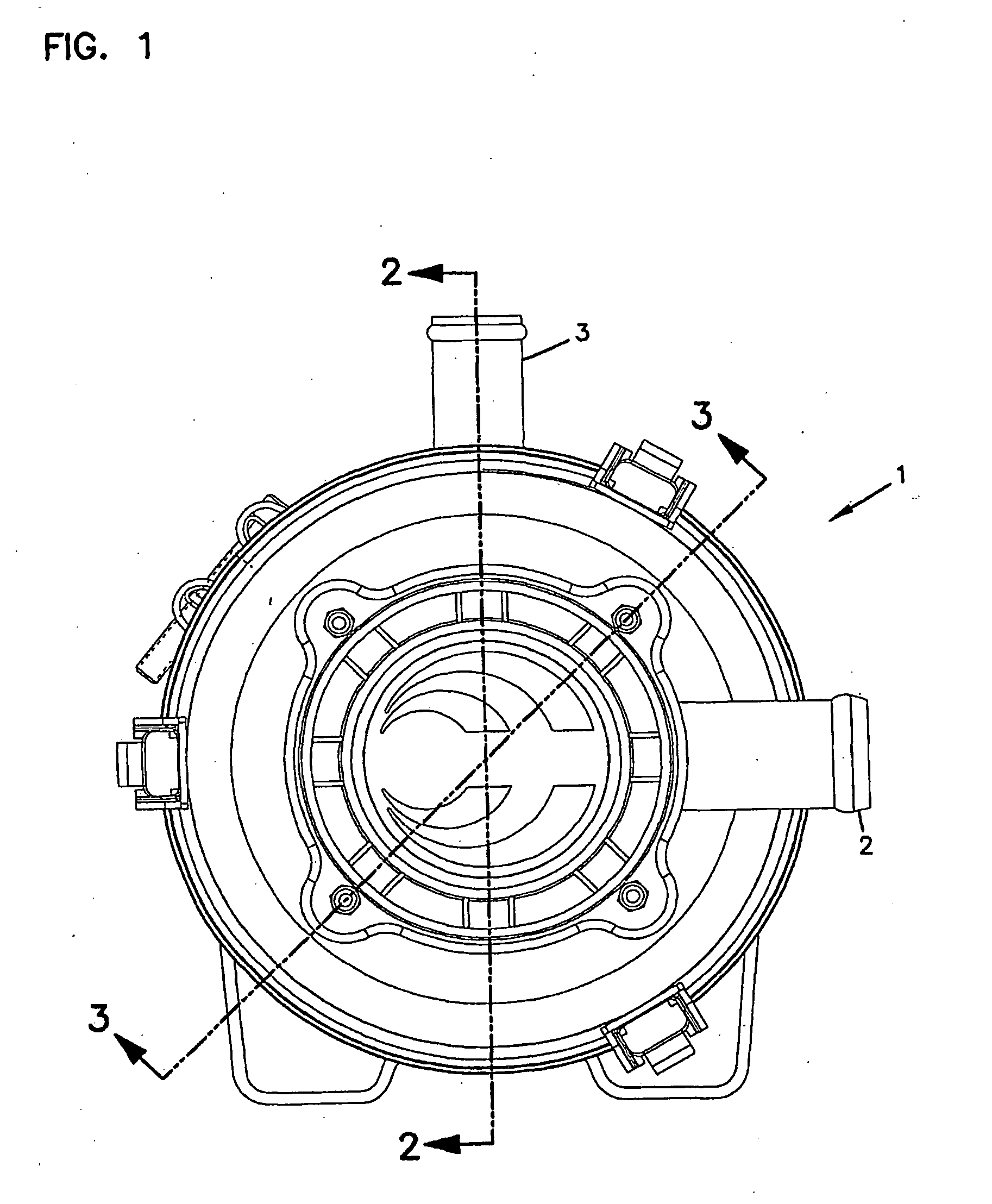

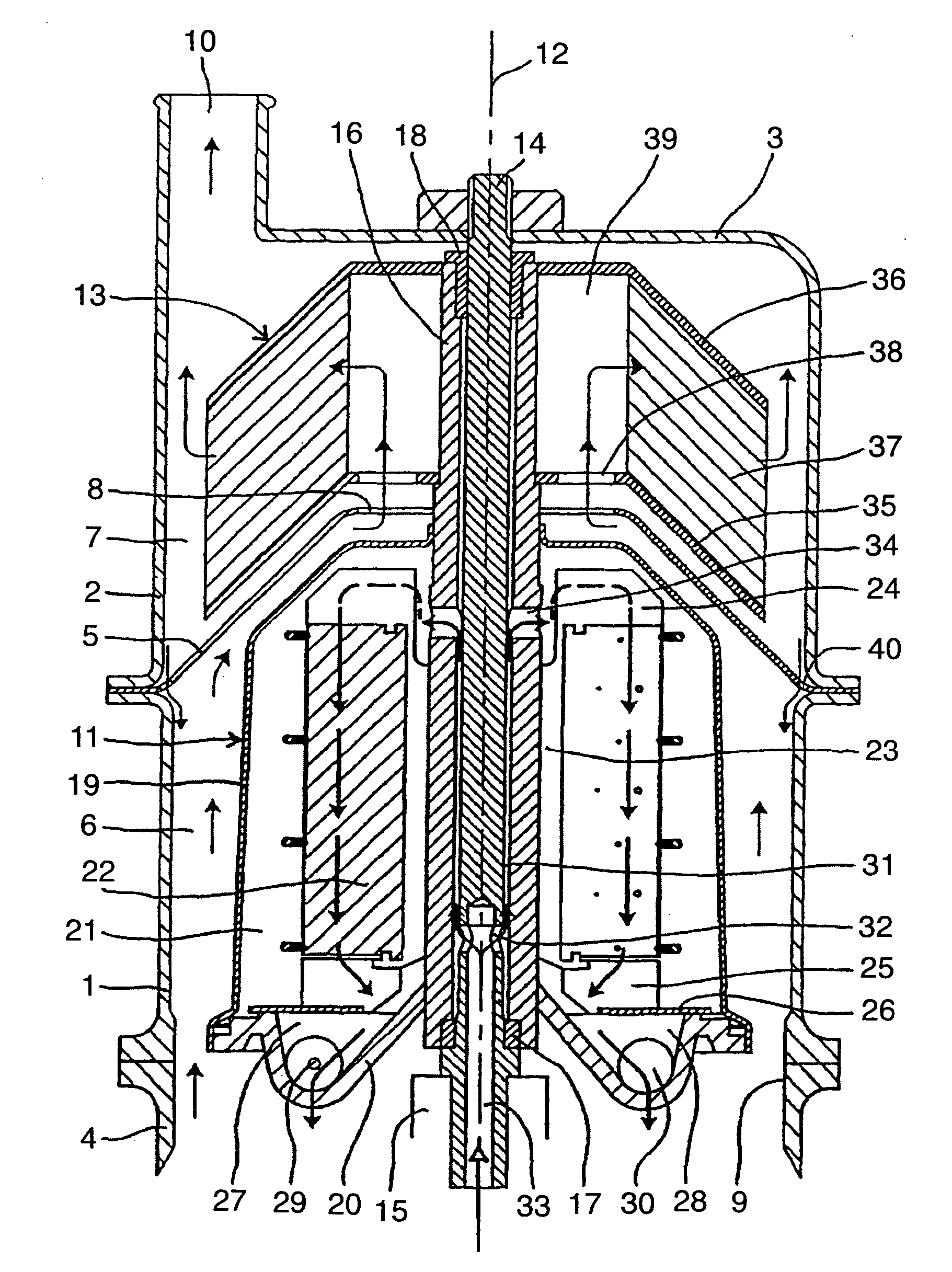

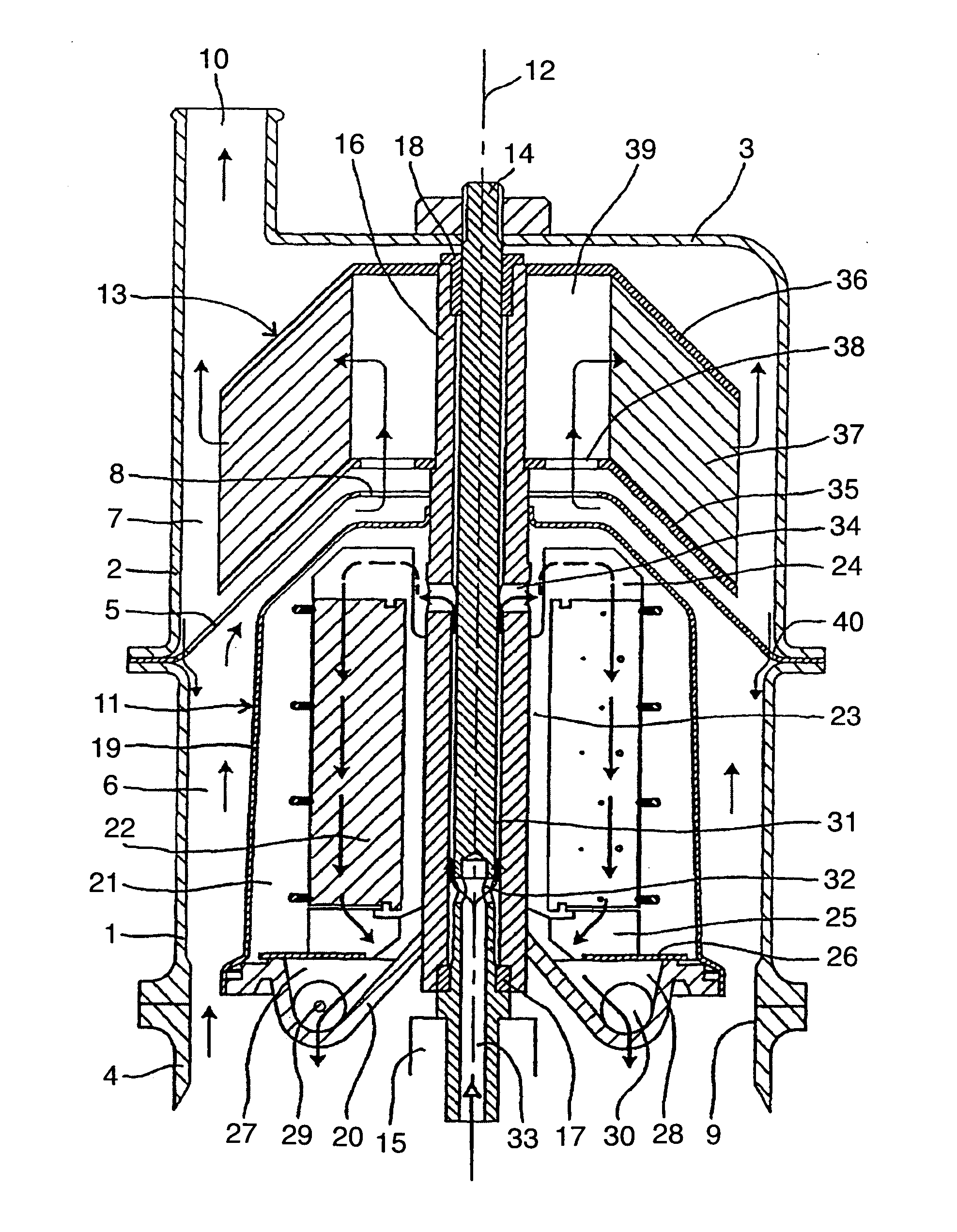

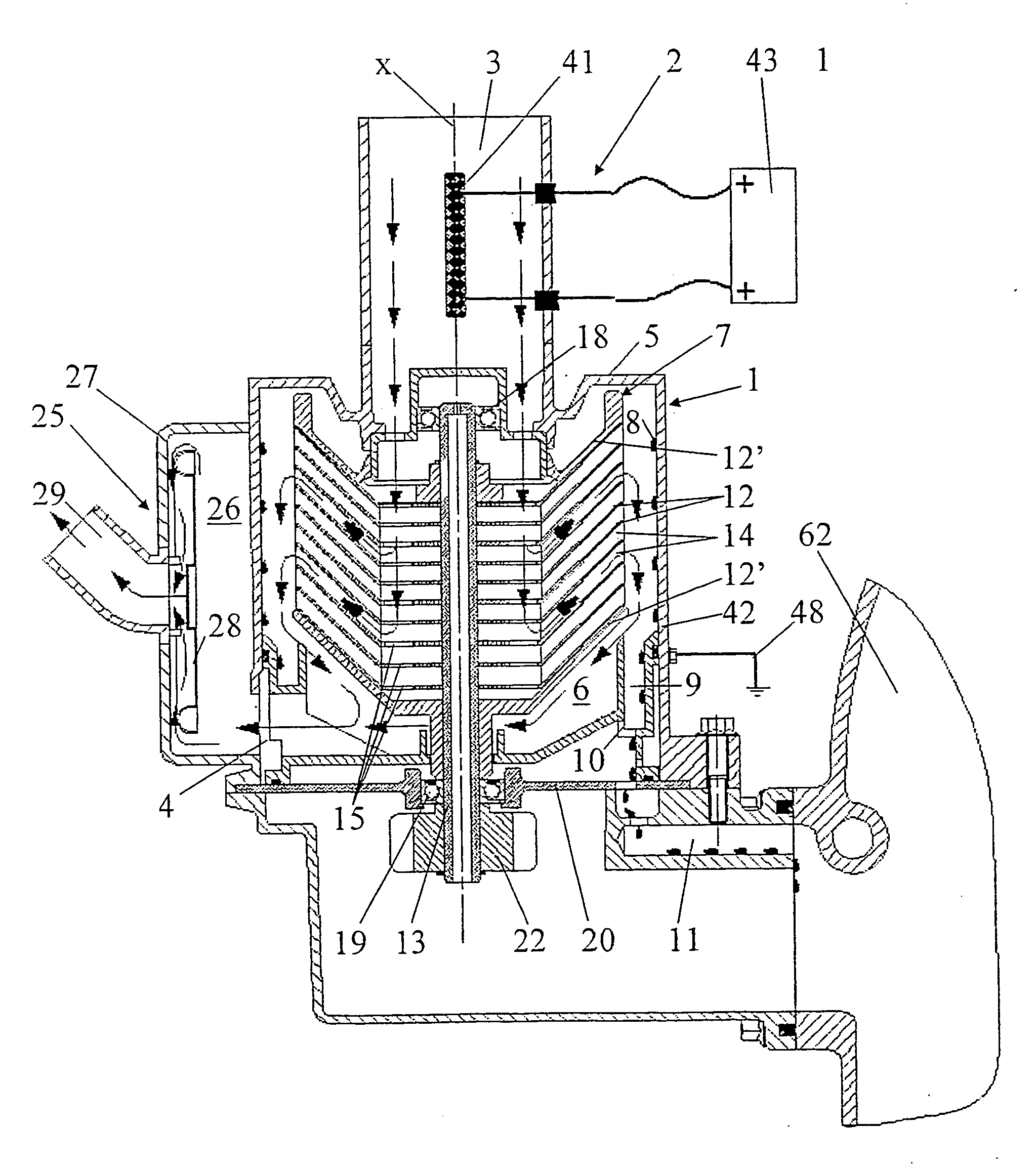

Centrifugal separator for cleaning gas generated by an internal combustion engine and a method for operating the same

ActiveUS20070249479A1Minimizes for egressMinimize potentialCombination devicesAuxillary pretreatmentEngineeringCentrifugal force

In a centrifugal separator for cleaning gases generated by an internal combustion engine a housing defines an interior separation chamber. A centrifugal rotor is coupled for rotation to the housing and extends into the separation chamber. A drainage chamber is positioned adjacent the separation chamber and is delimited therefrom by a partition wall. A flow path is provided through which oil, separated from gases generated by the internal combustion engine and collecting on the partition wall, can travel from the separation chamber to the drainage chamber. A pump wheel is coupled to a shaft portion defined by the rotor and extends radially outwardly therefrom. During operation the oil, upon exiting the separation chamber, contacts the pump wheel. Centrifugal forces generated due to the rotation of the pump wheel cause the oil to be thrown into the drainage chamber. The pump wheel also minimizes the potential for oil resident in the drainage chamber to re-enter the separation chamber.

Owner:ALFA LAVAL CORP AB

Centrifugal separator for cleaning of gas

ActiveUS20090025562A1Reliable and secure determinationReliable readCombination devicesAuxillary pretreatmentInterior spaceEngineering

The invention refers to a centrifugal separator comprising a stationary casing defining an inner space, a spindle and a rotating member, which is attached to the spindle and arranged to rotate around an axis of rotation with a rotary speed. The rotating member comprises a number of separating discs which are provided in the inner space. A drive member drives the spindle and the rotating member with said rotary speed. A sensor device senses the rotation of the rotating member in relation to the casing. The sensor device comprises at least one transmitter element which is provided in the inner space on the rotating member and a receiver element which is provided at the casing and arranged to sense the transmitter element. The receiver element is provided on the casing outside the inner space.

Owner:ALFA LAVAL CORP AB

Crankcase breech detection for boosted engines

InactiveUS20100147270A1Prolonged duty cycleIncreased blow-byCombustion enginesLubrication pressure controlMobile vehicleAtmospheric air

Methods for indicating whether a crankcase of an engine is breeched are provided. One example method comprises restricting a communication of the crankcase with atmosphere, acting to increase or decrease a crankcase pressure, and indicating whether the crankcase is breeched based on the crankcase pressure. Another example method comprises sensing a crankcase pressure component, and indicating whether the crankcase is breeched based on the crankcase pressure component, the crankcase communicating with atmosphere via a conduit, a restrictedness of the conduit responsive to one or more of a crankcase pressure and a signal from an electronic control unit of the motor vehicle. Still other examples provide more particular methods for indicating whether the crankcase is breeched, and example configurations that enable the various methods.

Owner:FORD GLOBAL TECH LLC

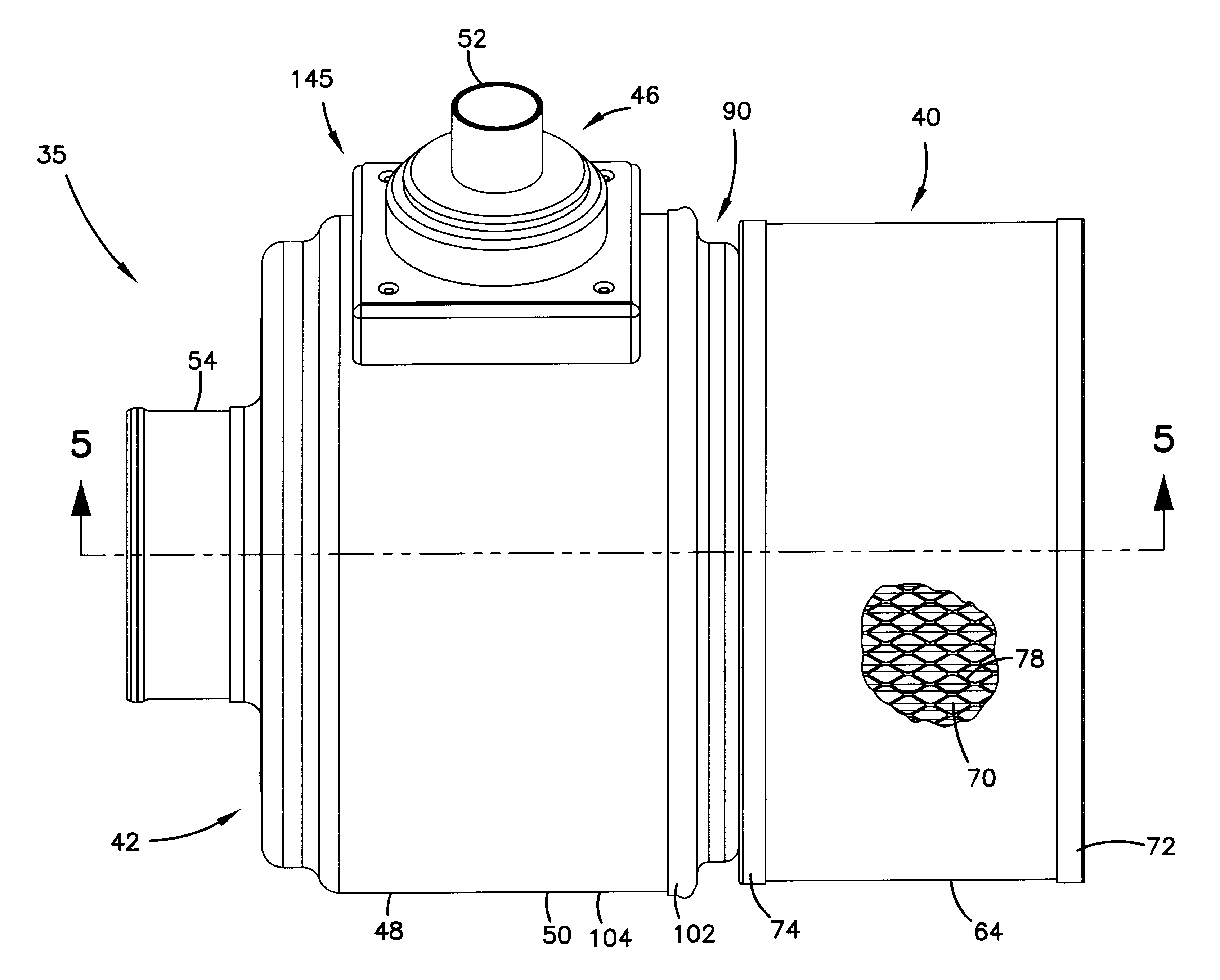

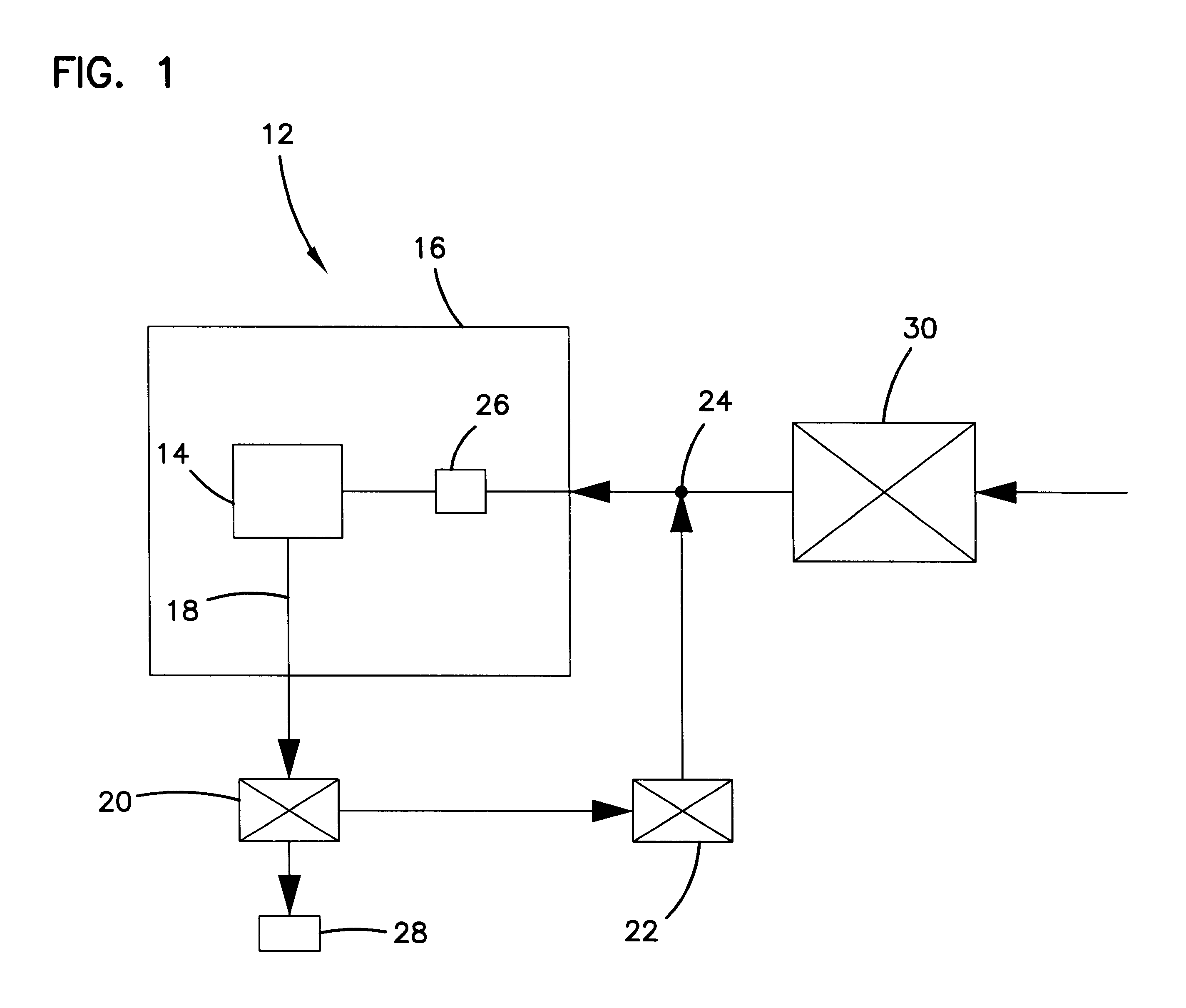

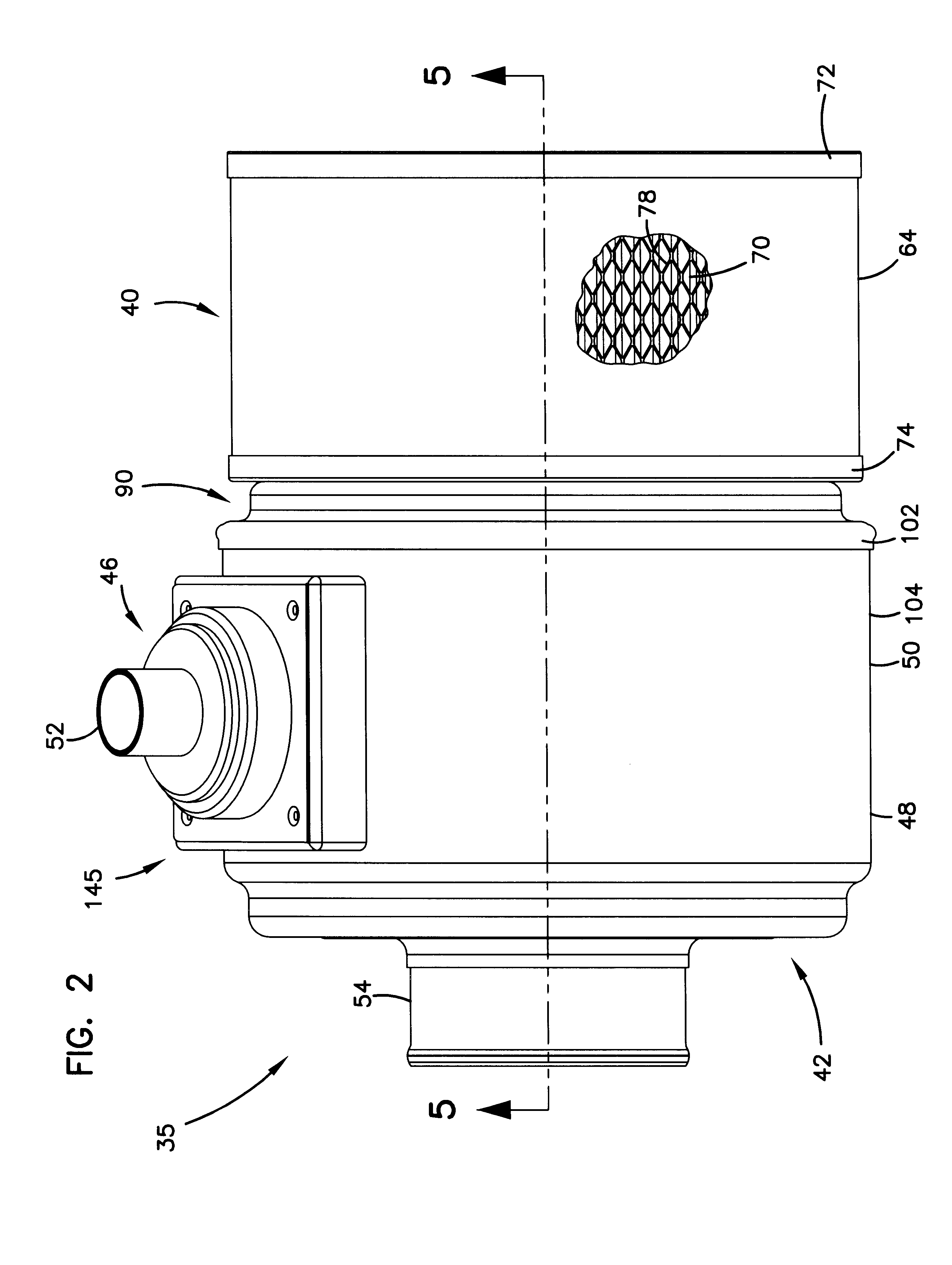

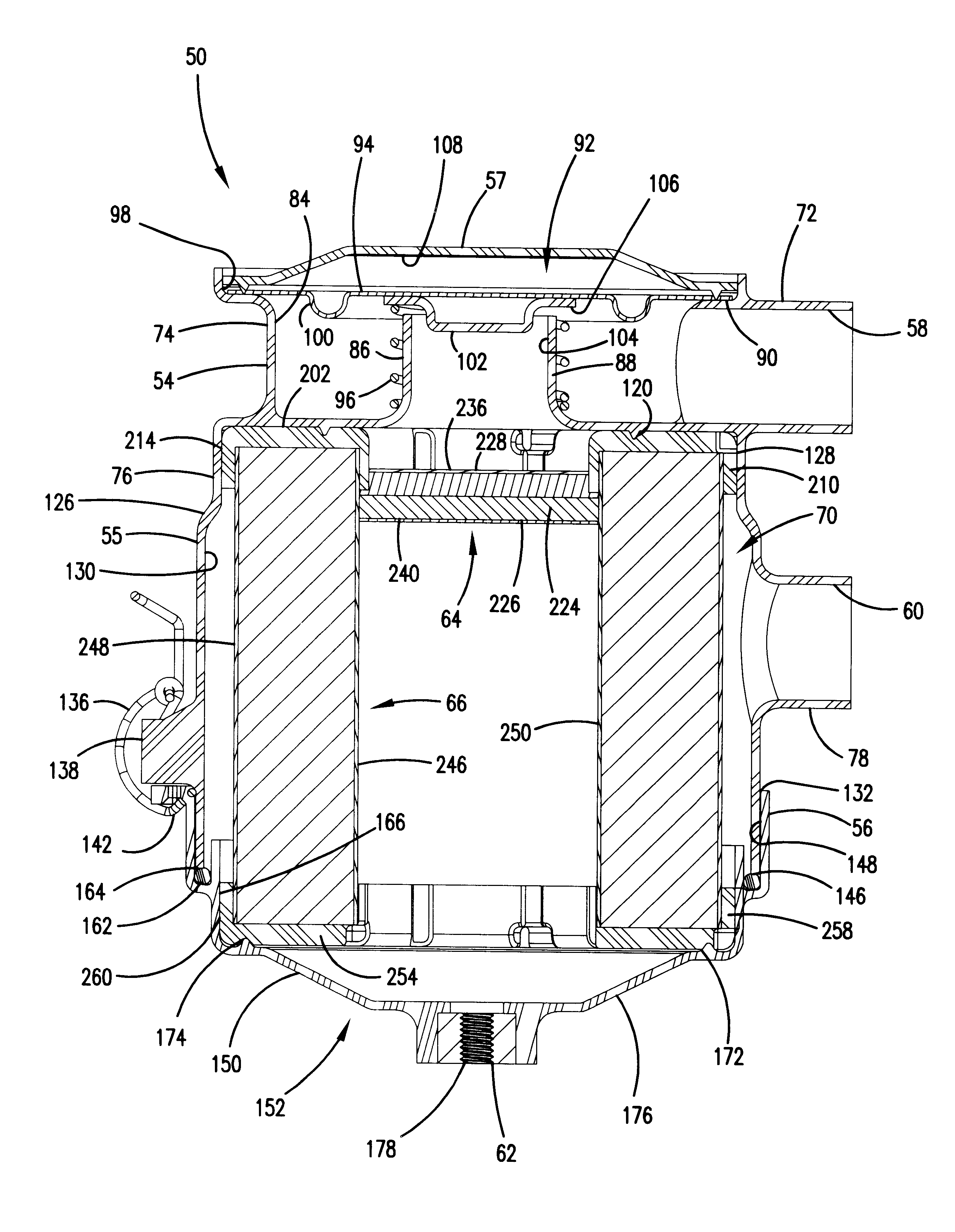

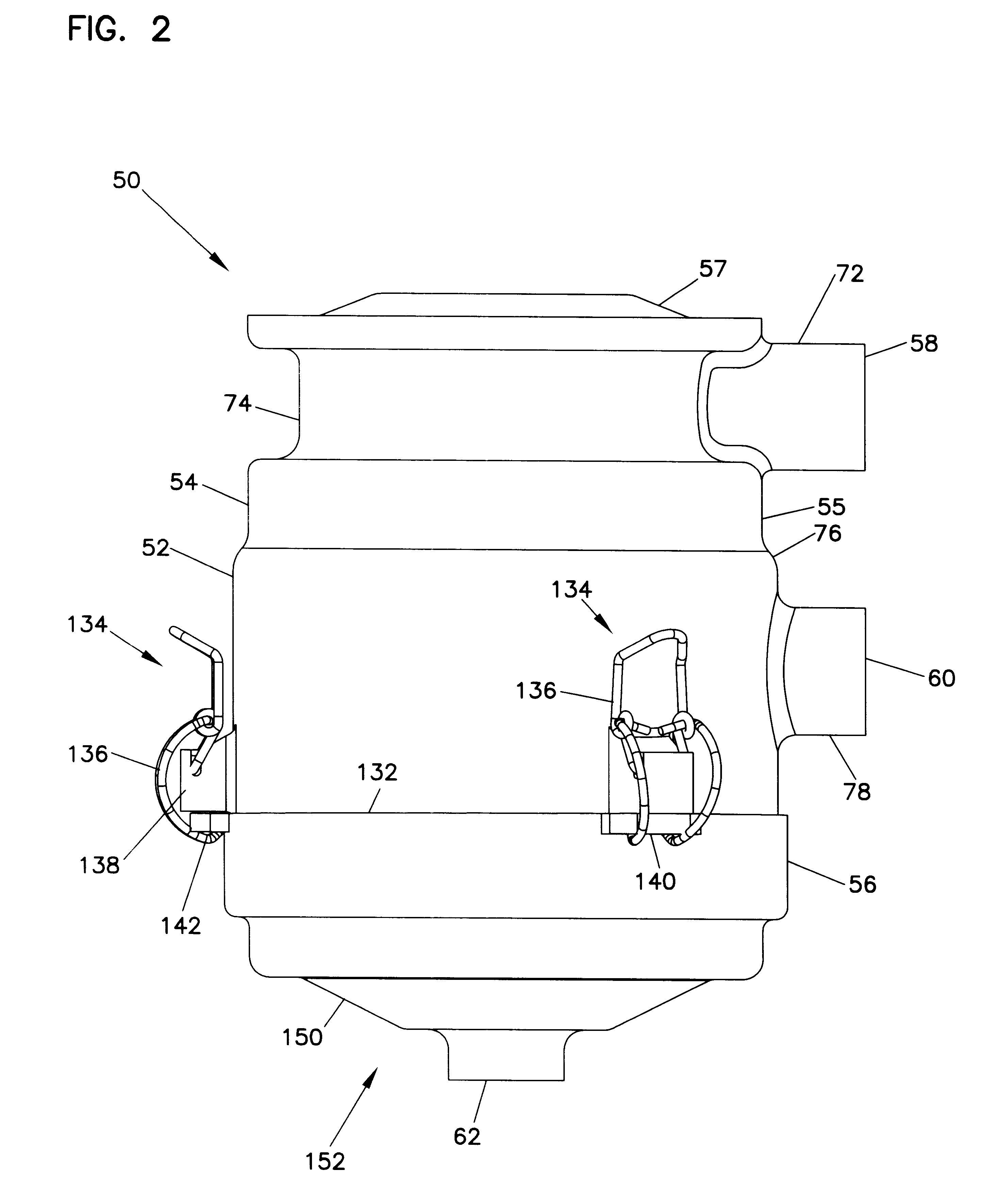

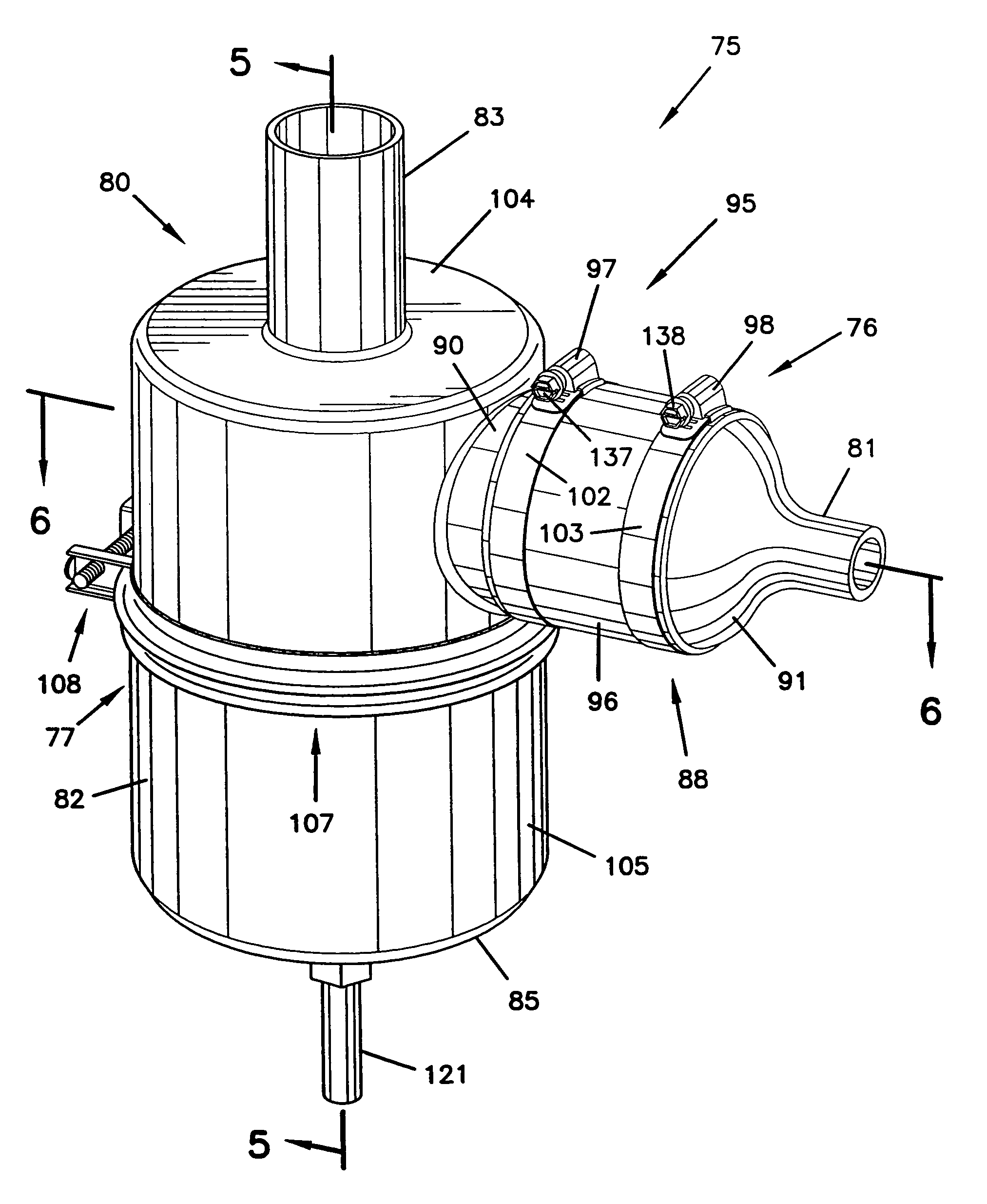

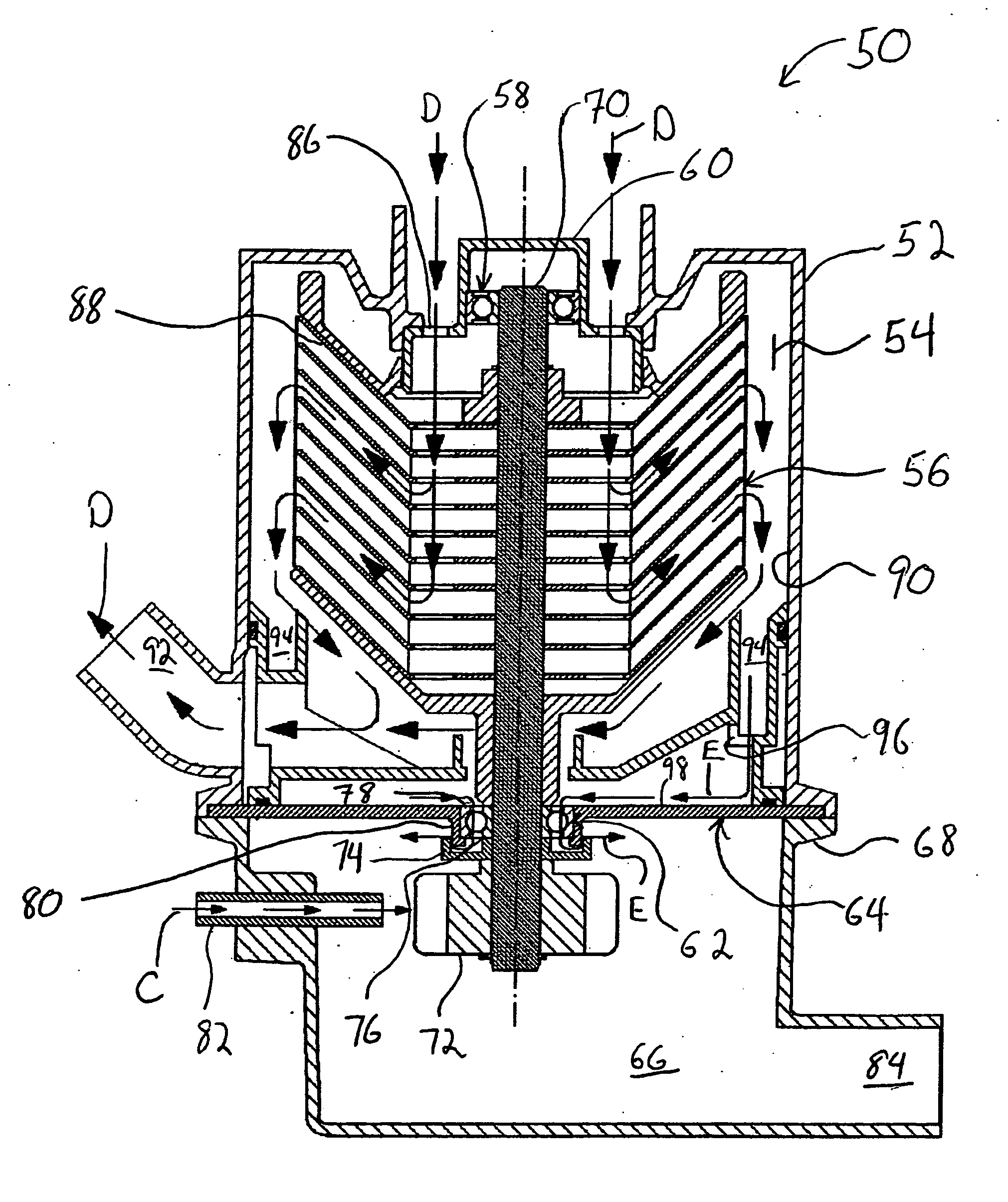

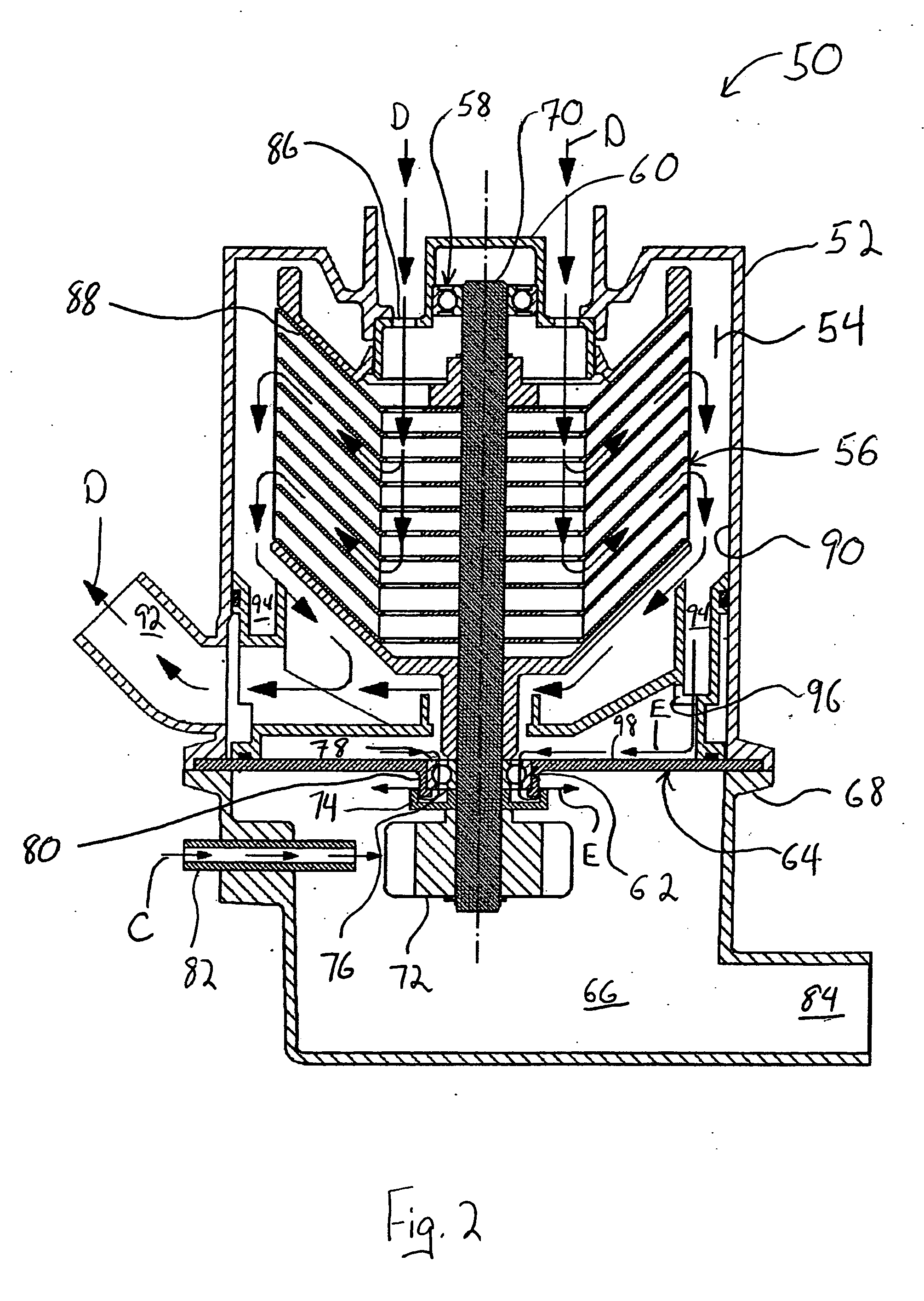

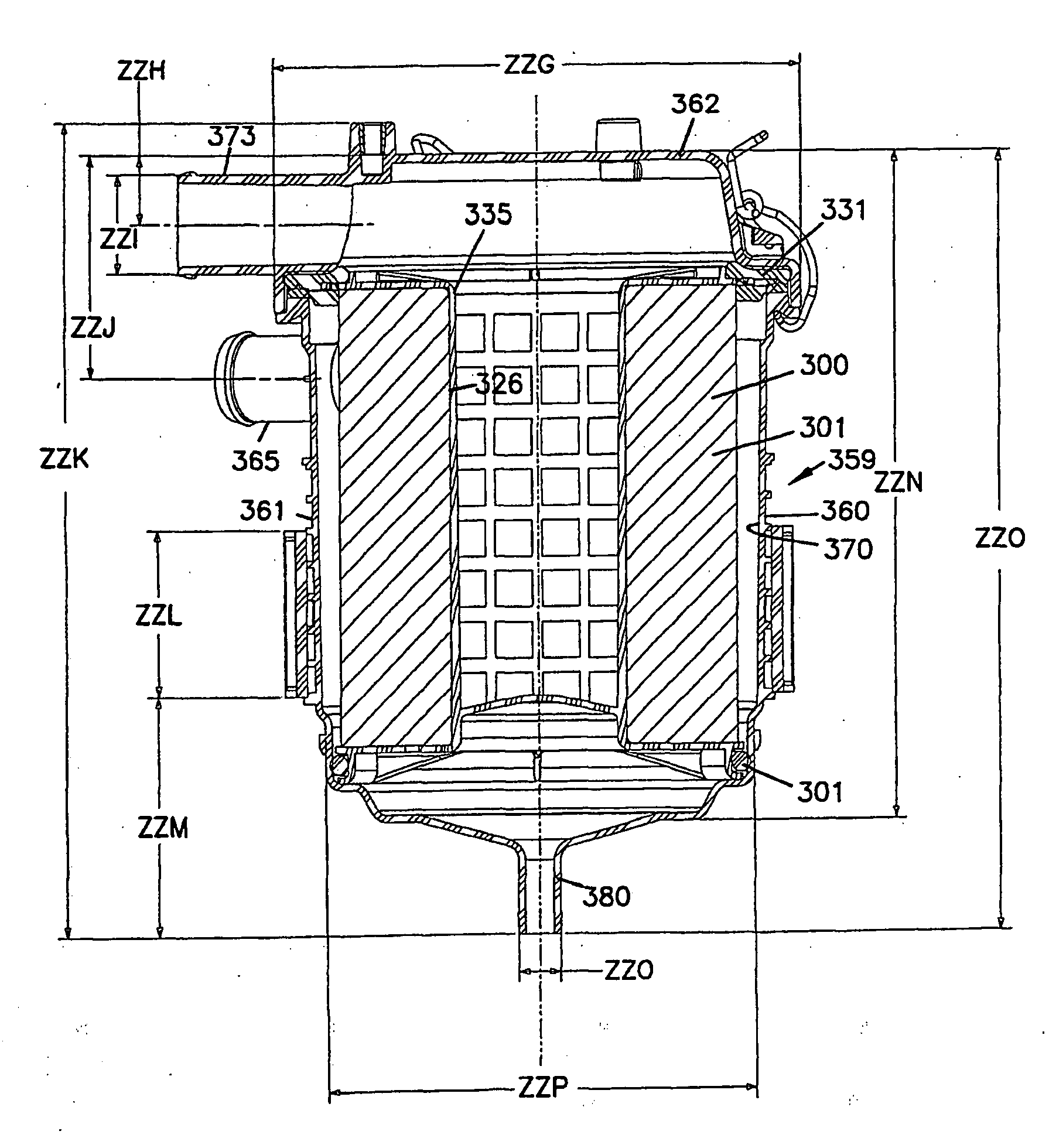

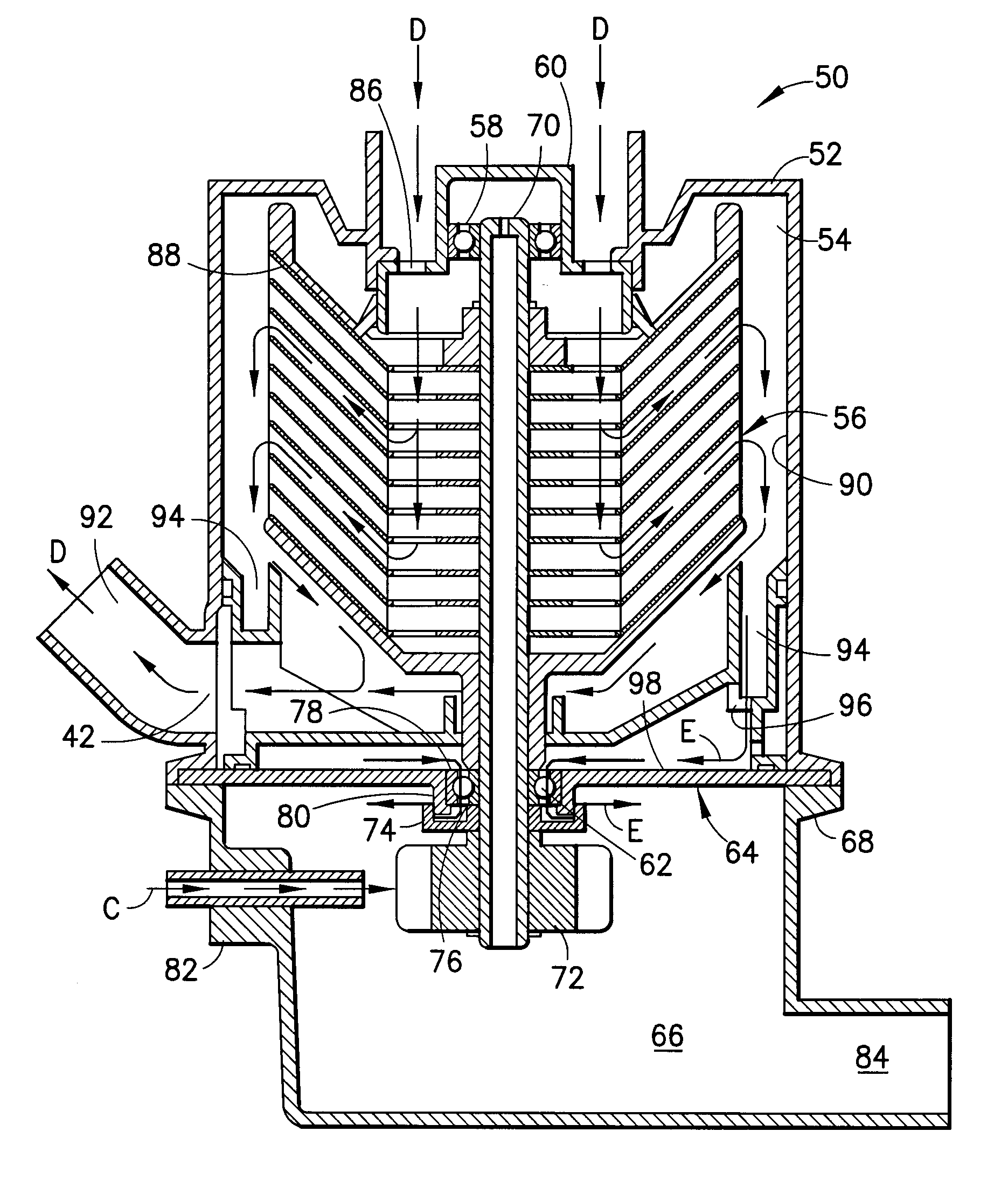

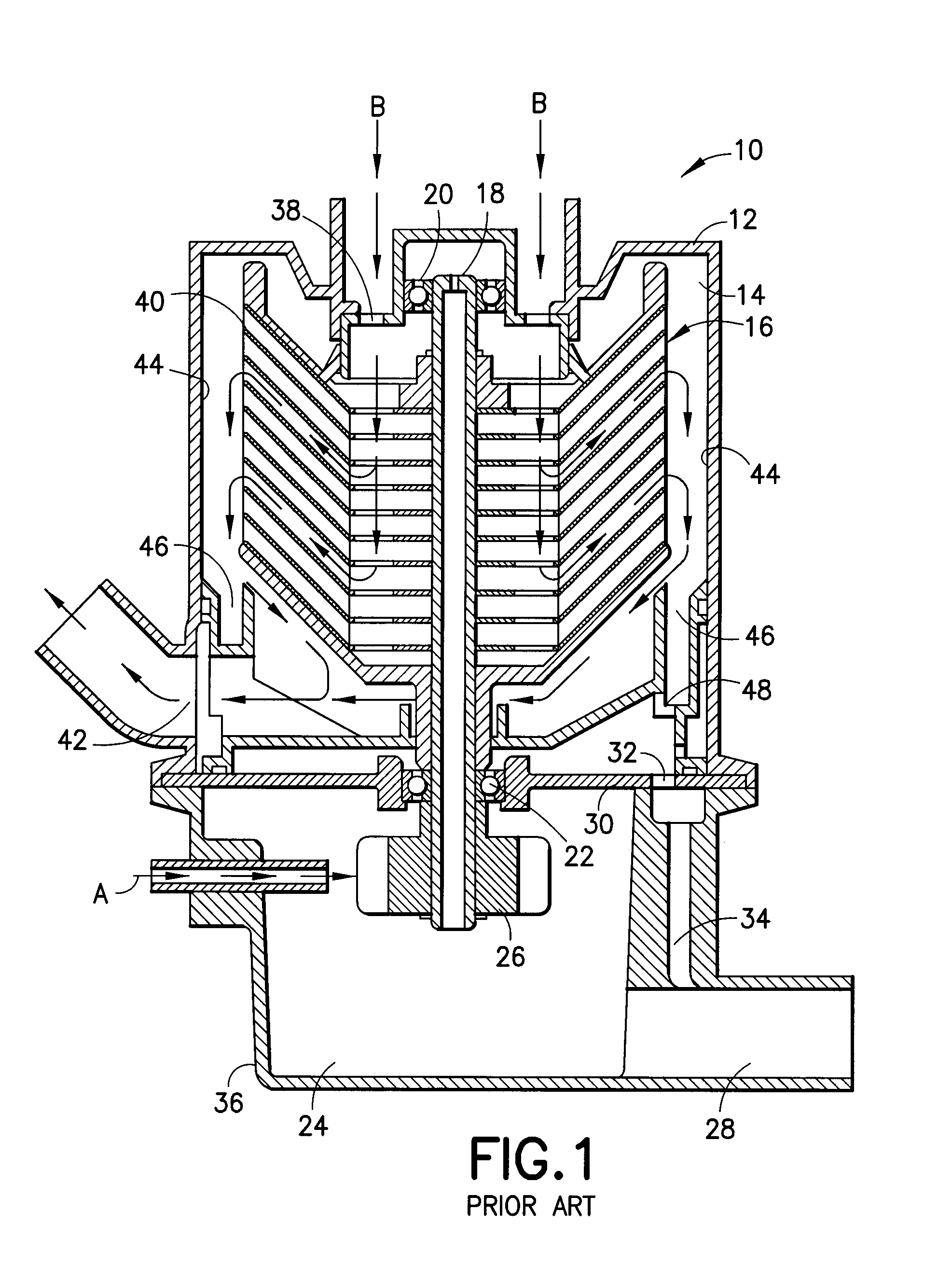

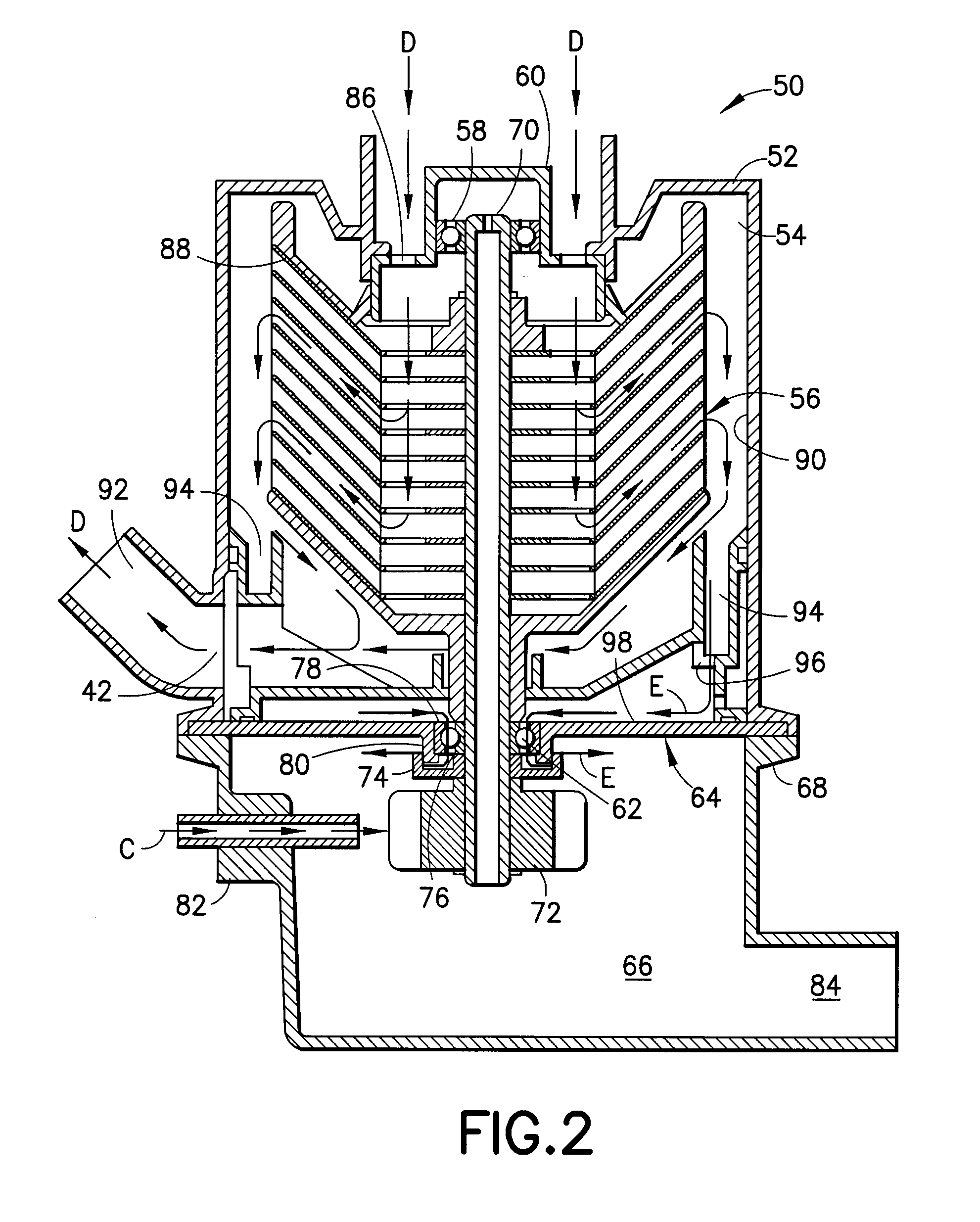

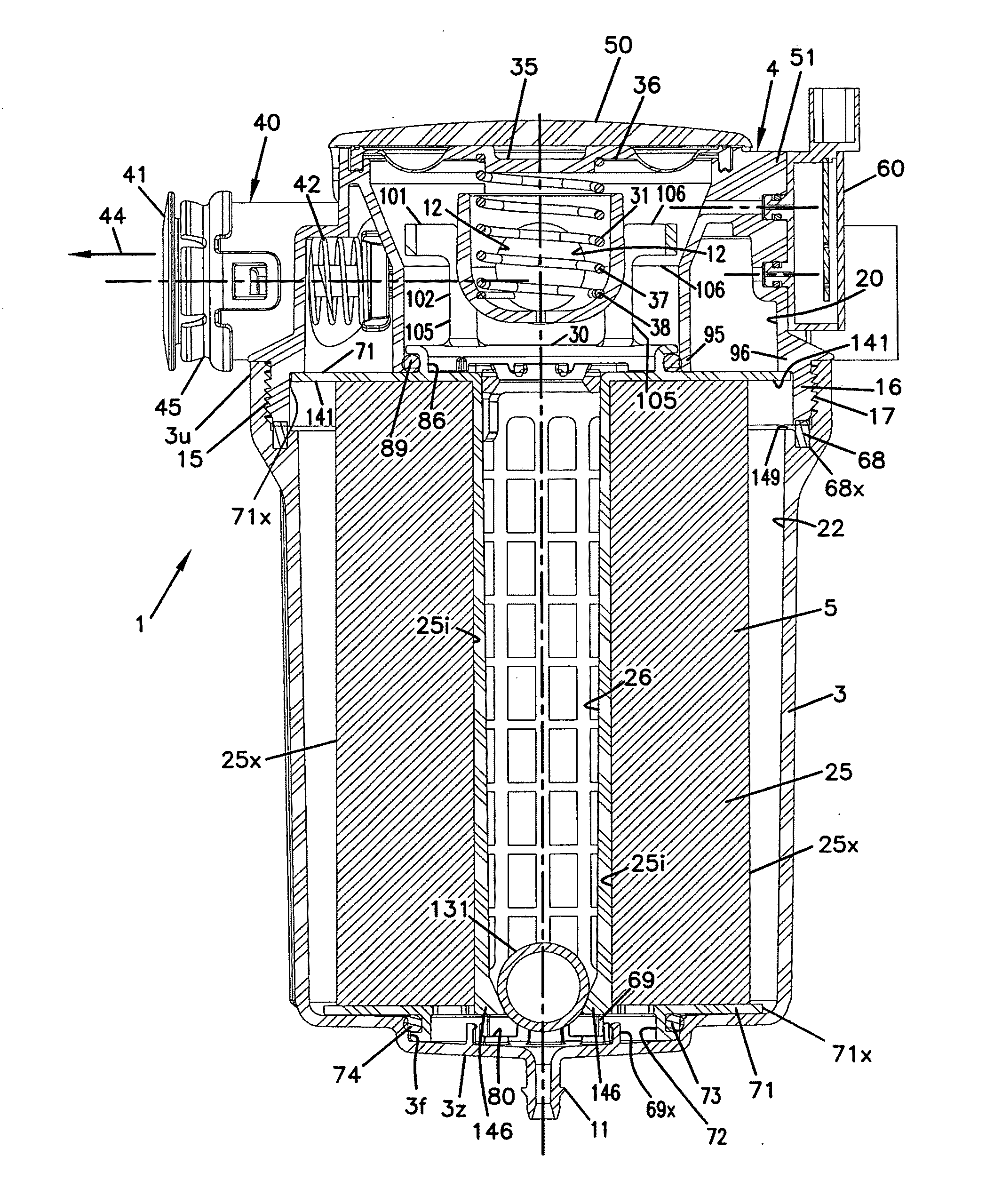

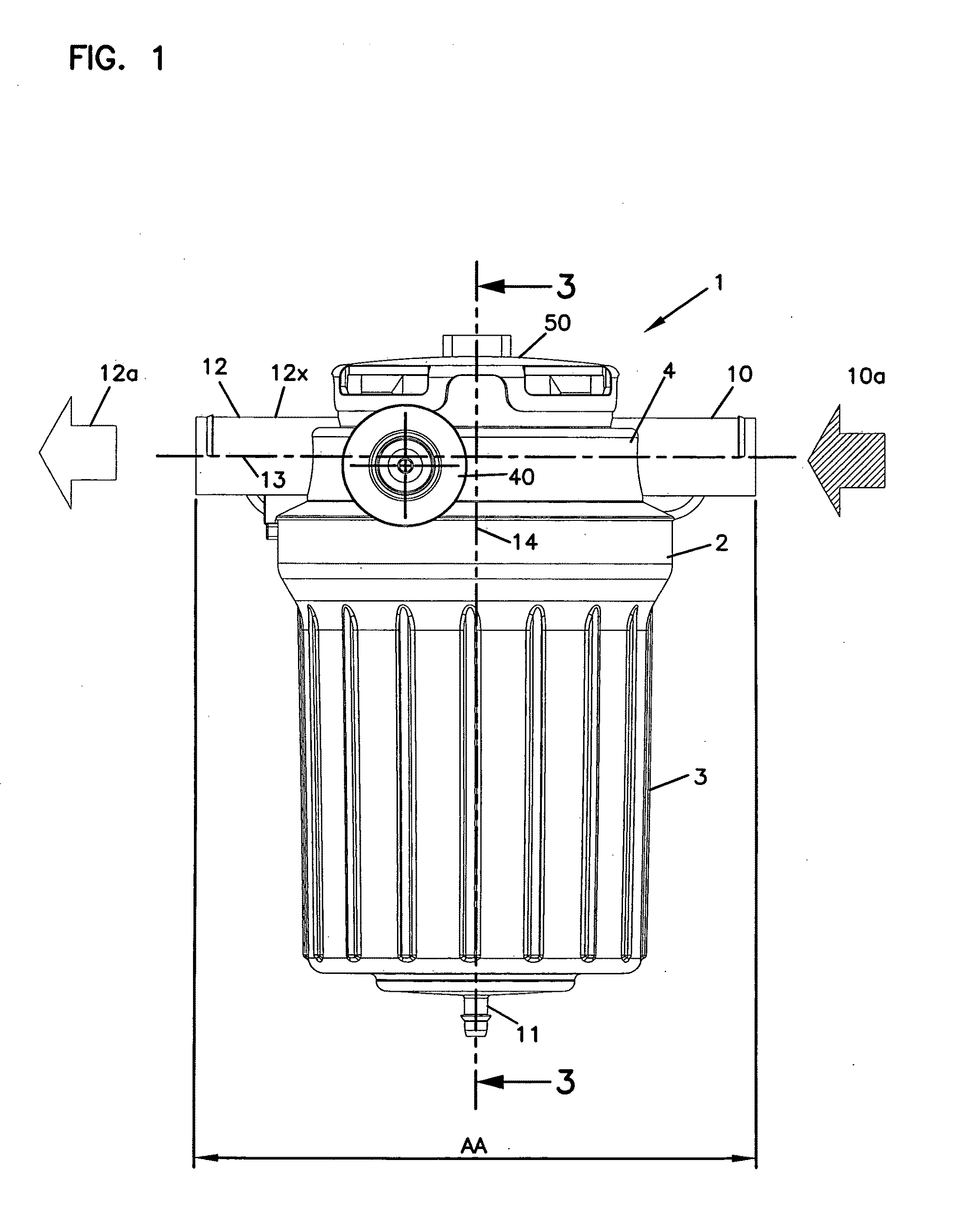

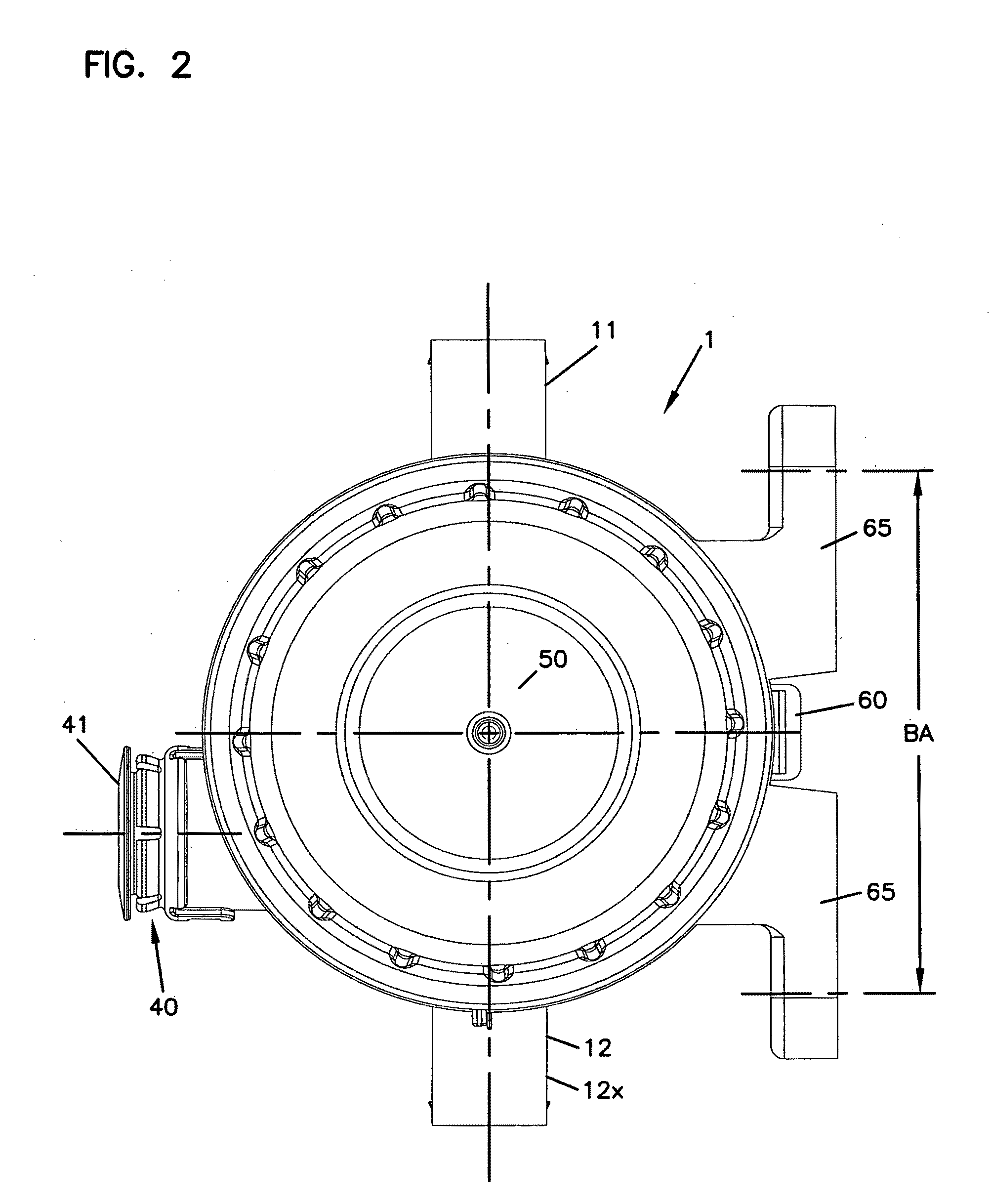

Aerosol Separator; Components; and, Methods

Arrangements for use in crankcase ventilation are described and shown. Included are serviceable crankcase ventilation filter cartridges which include a media pack axial drain arrangement, for preferred, efficient, operation. A crankcase ventilation filter arrangements including a housing and such a serviceable cartridge is shown. Also shown and described are methods of assembly, operation and use.

Owner:DONALDSON CO INC

Centrifugal separator for cleaning gas generated by an internal combustion engine and a method for operating the same

ActiveUS7338546B2Minimize potentialUniform pressureCombination devicesAuxillary pretreatmentExternal combustion engineEngineering

In a centrifugal separator for cleaning gases generated by an internal combustion engine a housing defines an interior separation chamber. A centrifugal rotor is coupled for rotation to the housing and extends into the separation chamber. A drainage chamber is positioned adjacent the separation chamber and is delimited therefrom by a partition wall. A flow path is provided through which oil, separated from gases generated by the internal combustion engine and collecting on the partition wall, can travel from the separation chamber to the drainage chamber. A pump wheel is coupled to a shaft portion defined by the rotor and extends radially outwardly therefrom. During operation the oil, upon exiting the separation chamber, contacts the pump wheel. Centrifugal forces generated due to the rotation of the pump wheel cause the oil to be thrown into the drainage chamber. The pump wheel also minimizes the potential for oil resident in the drainage chamber to re-enter the separation chamber.

Owner:ALFA LAVAL CORP AB

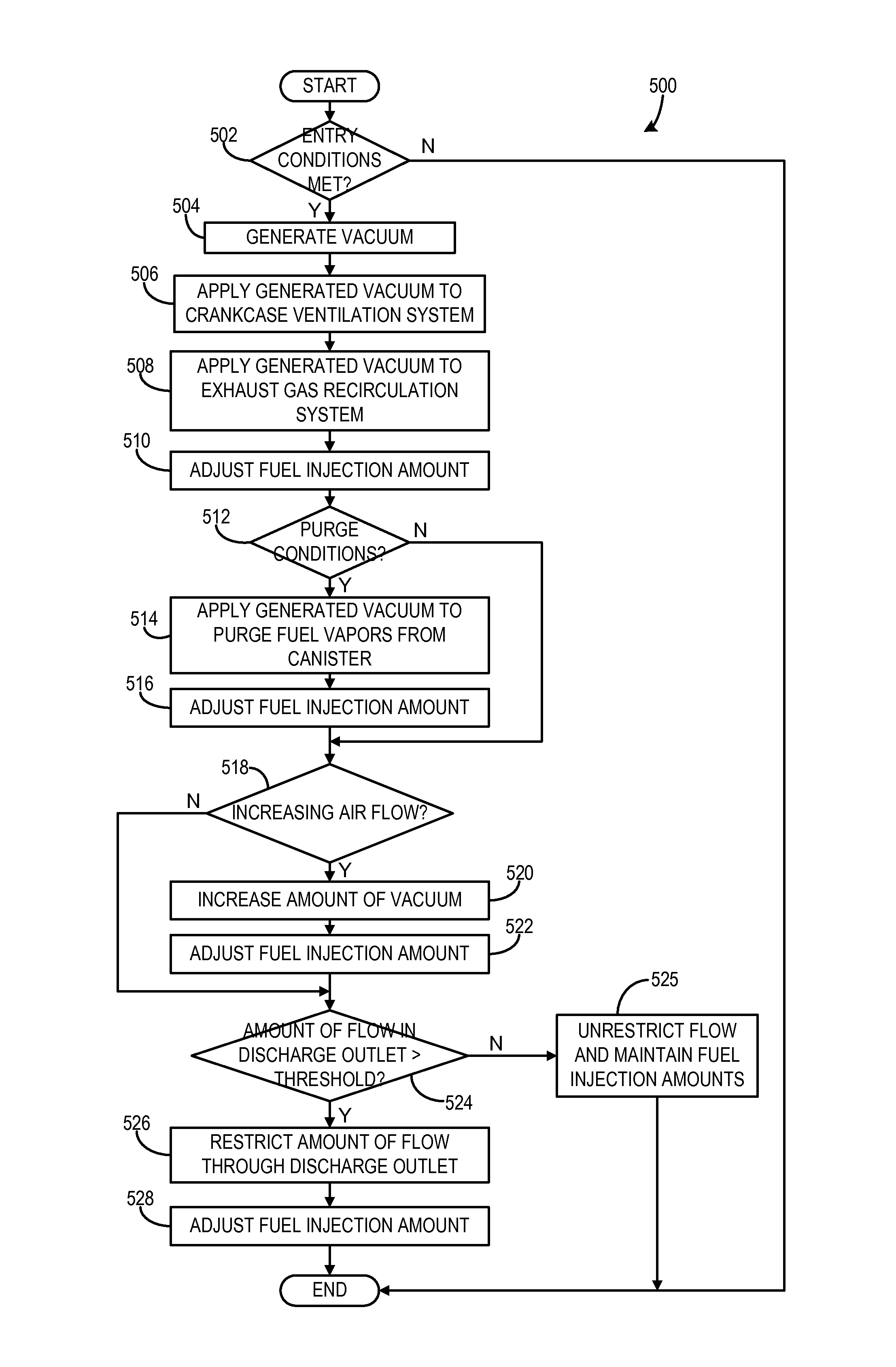

System and method for gas purge control

ActiveUS20140318514A1Reduce trafficAmount of vacuum in the intake manifold mayElectrical controlInternal combustion piston enginesControl systemEngineering

Systems and methods for providing vacuum to one or more of a crankcase ventilation system, an emission control system, and an exhaust gas recirculation (EGR) system included in a turbocharged engine system are provided. In one example, approach, a method comprises drawing vacuum from a vacuum source located in an intake of the engine downstream of a pre-compressor throttle and upstream of an intake throttle, and applying the drawn vacuum to a discharge outlet of a uni-directional crankcase ventilation system, where an inlet of the crankcase ventilation system is coupled to the intake of the engine upstream of the pre-compressor throttle.

Owner:FORD GLOBAL TECH LLC

Apparatus for simultaneous cleaning of a liquid and a gas

InactiveUS20050198932A1Suitable for useReduce manufacturing costCombination devicesDispersed particle filtrationEngineeringElectrical and Electronics engineering

Owner:ALFA LAVAL CORP AB

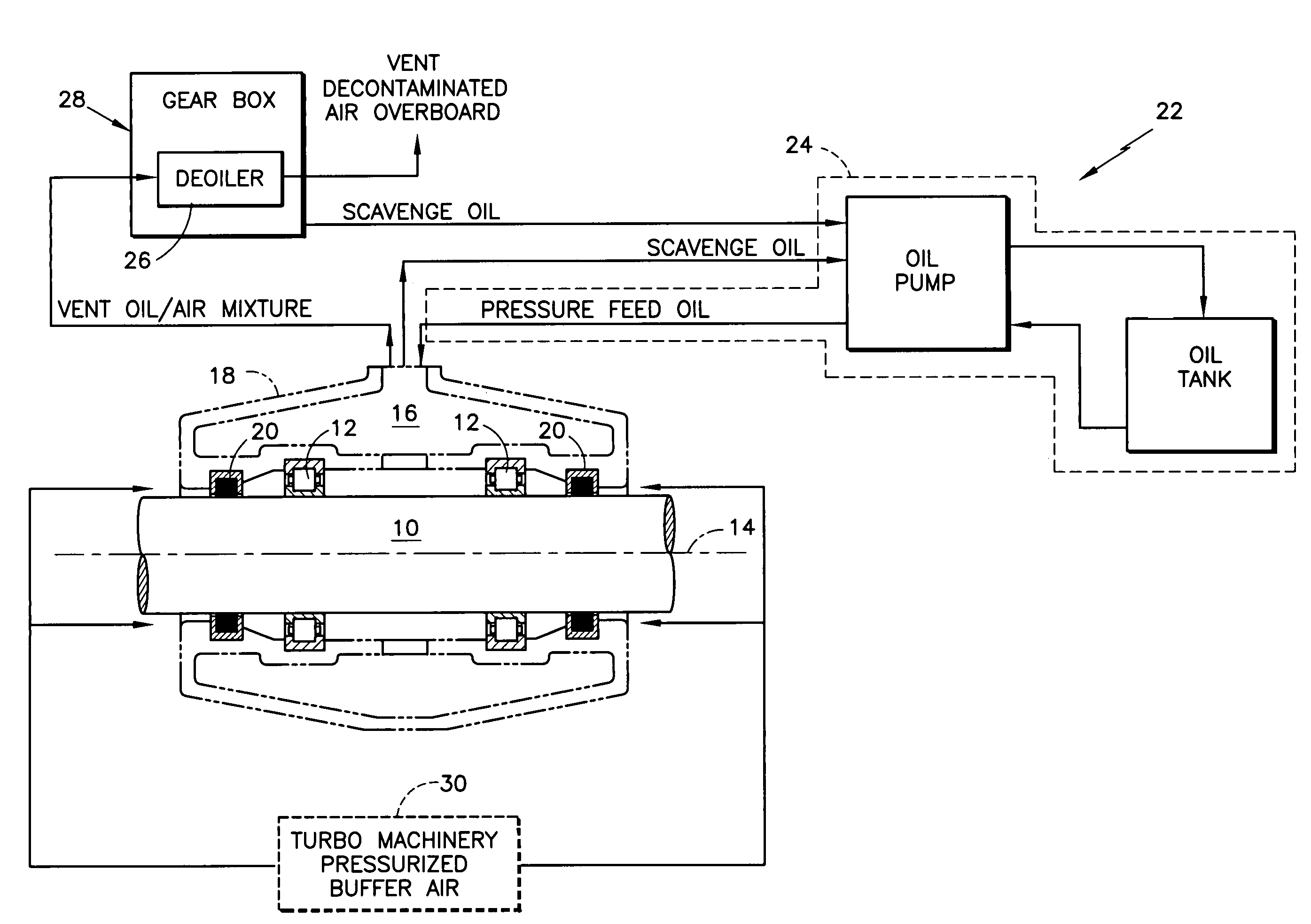

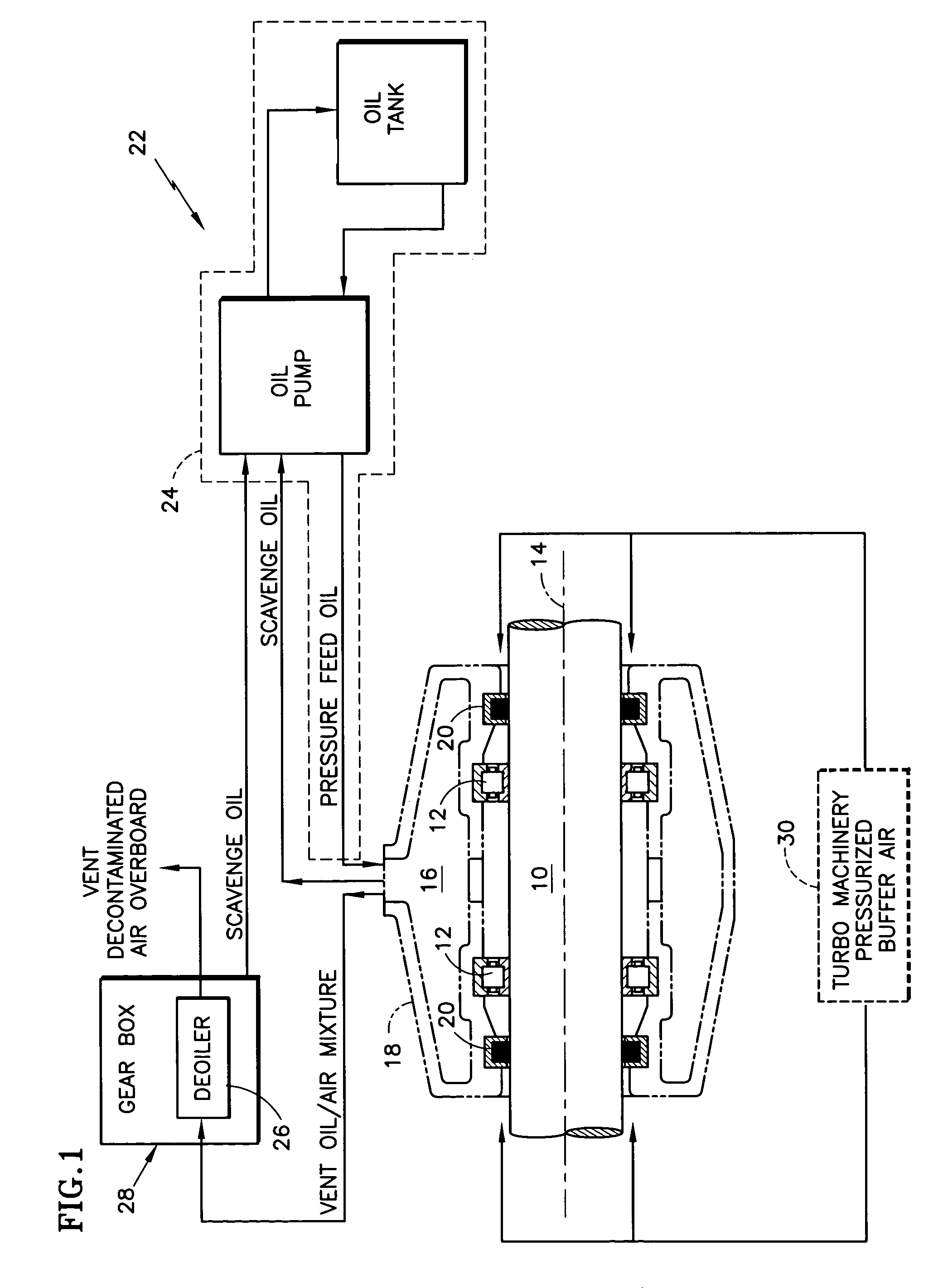

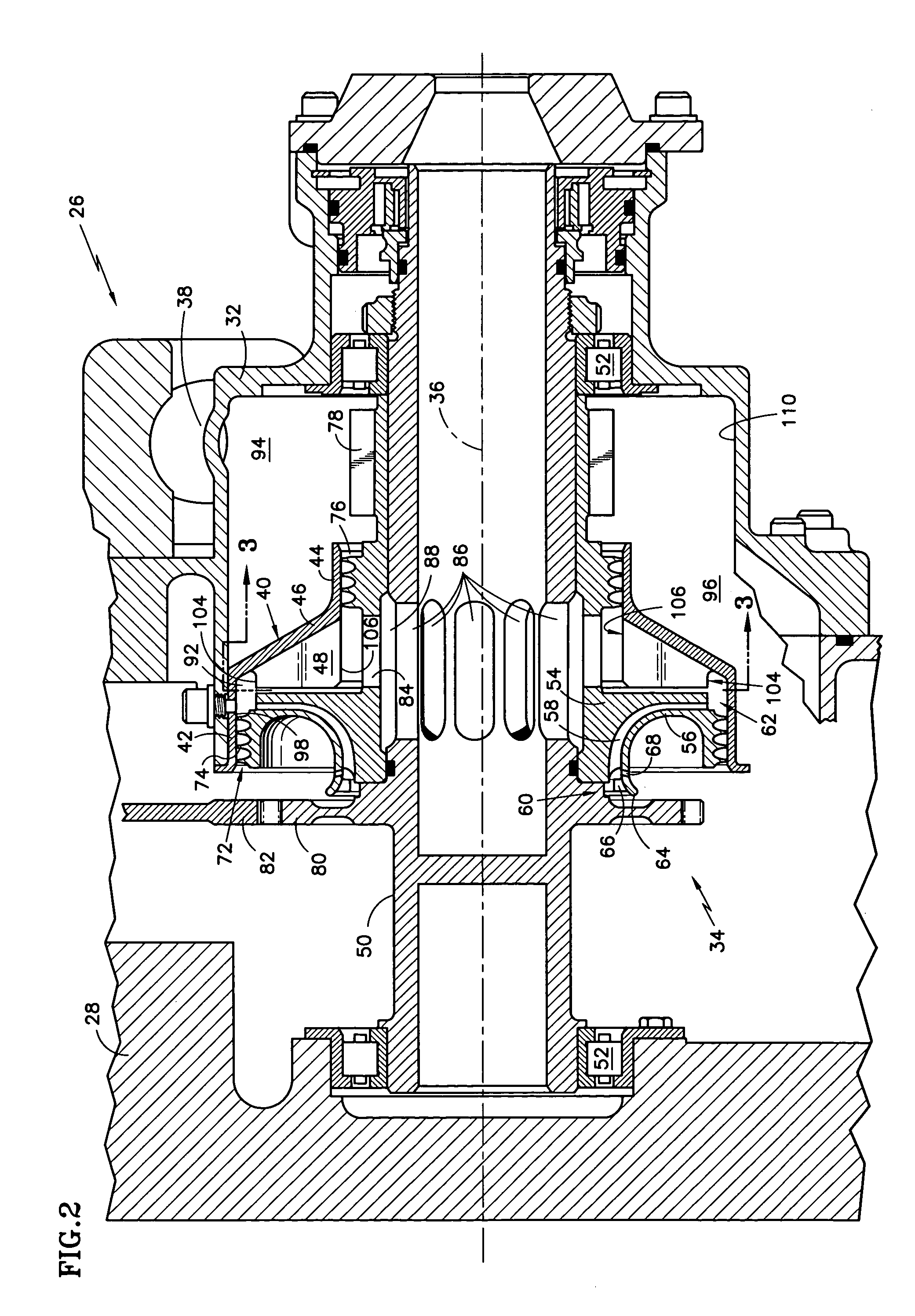

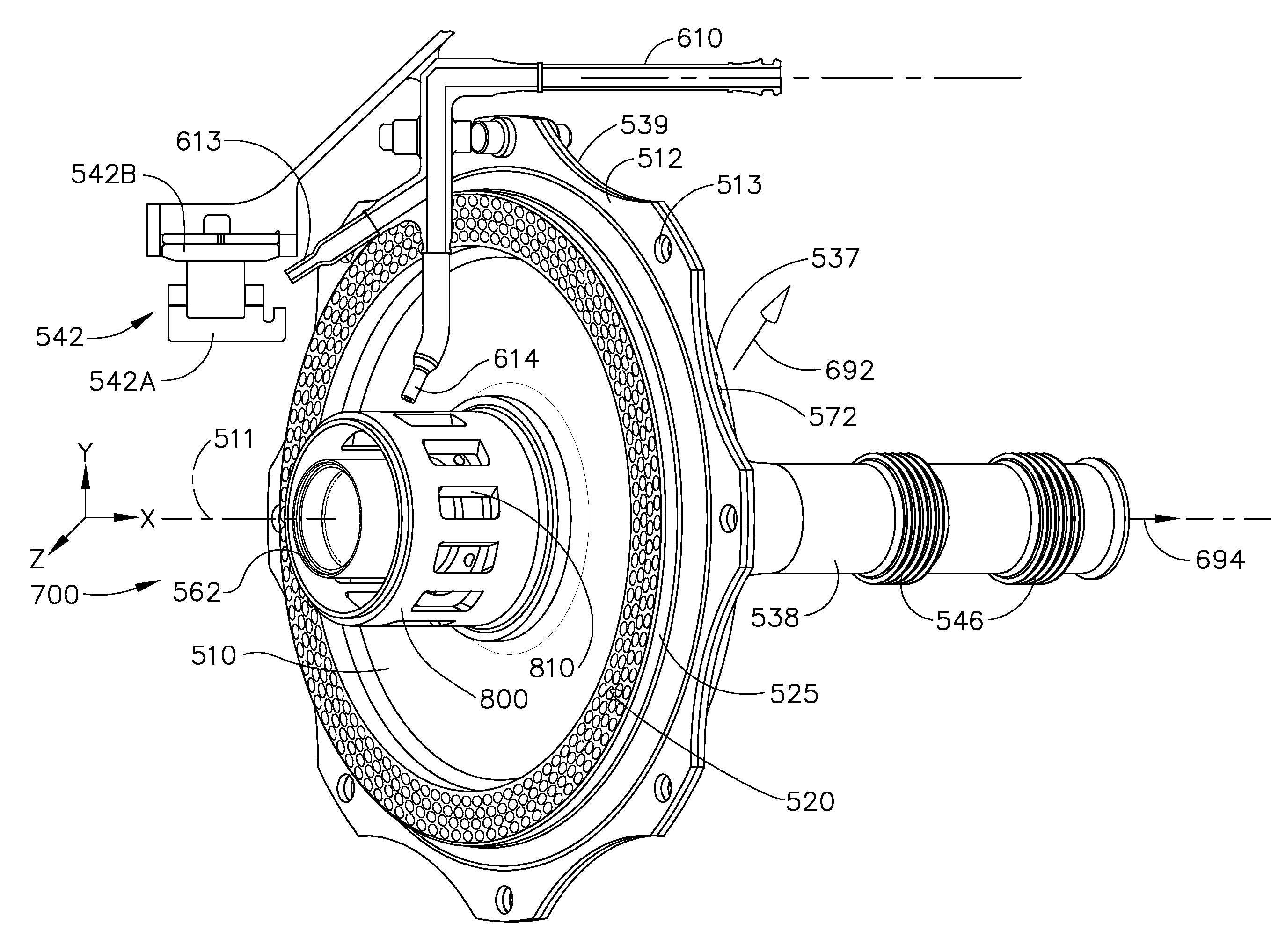

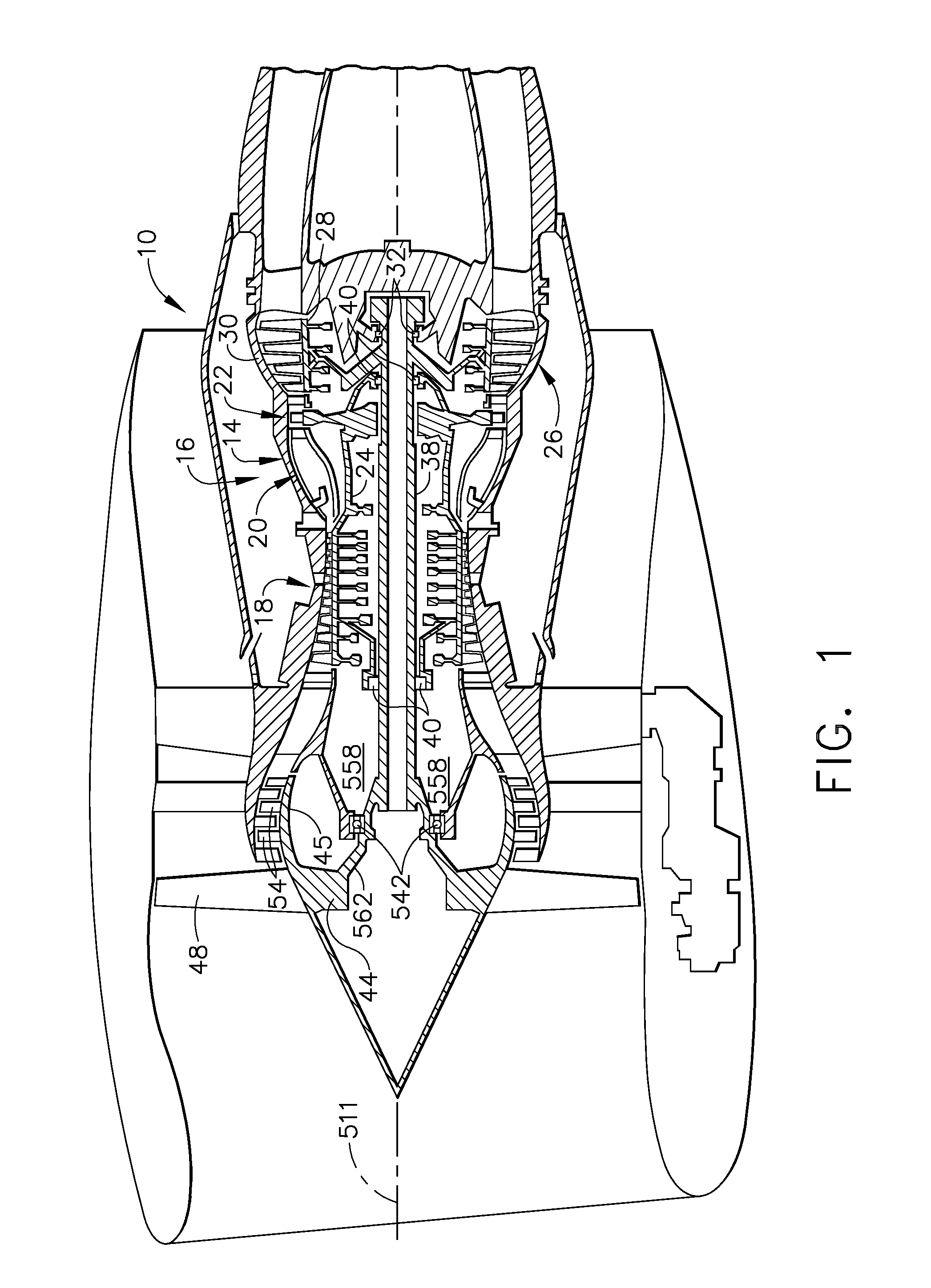

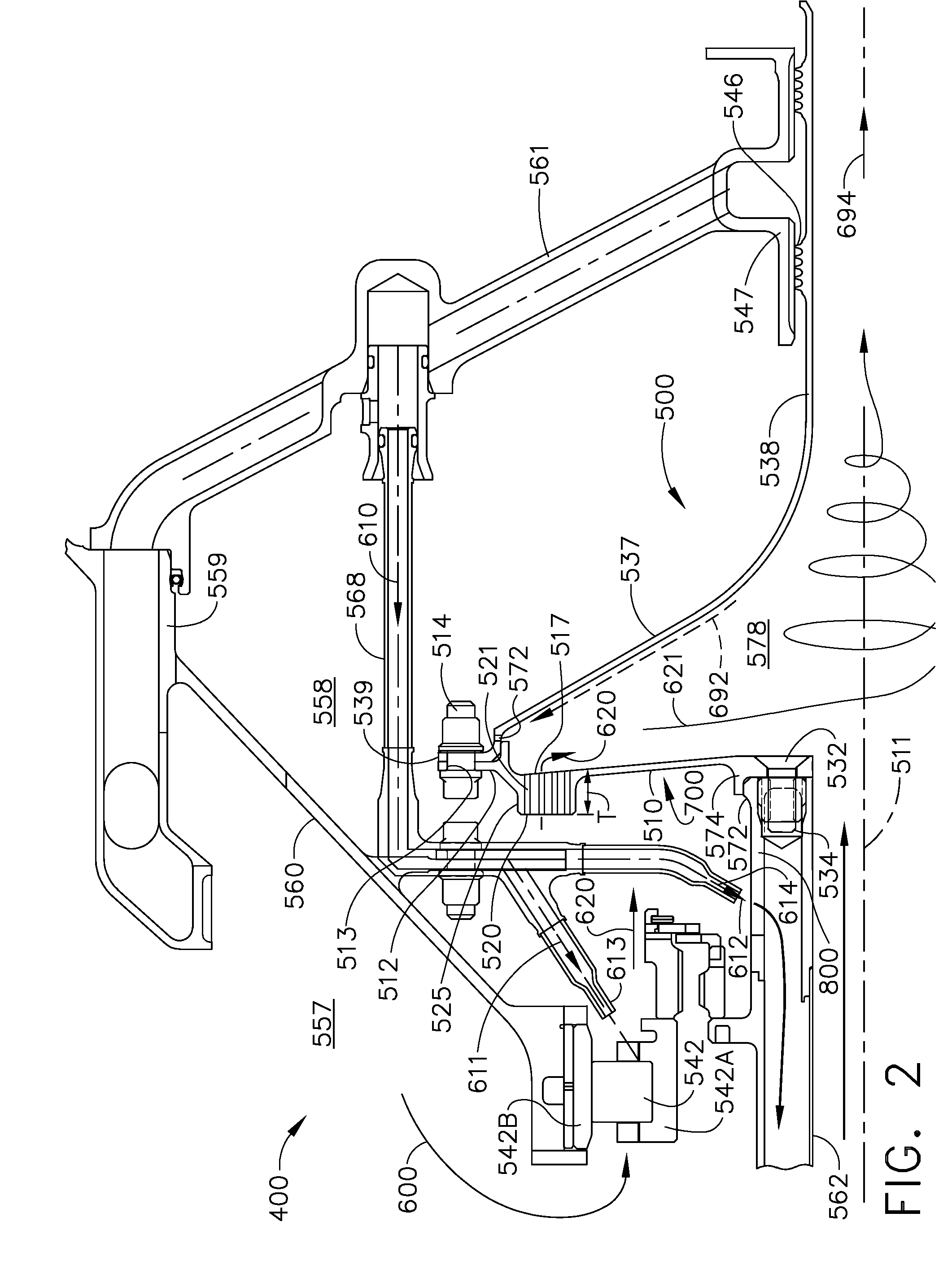

Deoiler for a lubrication system

ActiveUS7377110B2Reduce pressureHigh power settingPump componentsEngine fuctionsPositive pressureEngineering

A deoiler 26 for separating oil from air contaminated with the oil has at least one separator for separating the oil from the air and also has a source of suction for reducing air pressure at the source of the air. In an exemplary embodiment, the deoiler 26 creates the suction at a first operating condition, but acts as a restrictor at a second operating condition. A deoiling method according to the invention creates suction at a first operating condition to reduce the air pressure at the source of the oil-contaminated air, establishes a flow restriction at a second operating condition to pressurize the air source, and encourages oil to separate from the air at both operating conditions. When used as a component of a turbine engine lubrication system 22, the source of contaminated air may be a buffered bearing compartment 16. The inventive deoiler ensures a positive pressure difference across the bearing compartment seals 20 at the engine's idle power setting without requiring the idle setting to be undesirably high, and without requiring the use of buffer air whose pressure at higher engine power is high enough to be detrimental. In an exemplary embodiment, the deoiler pressurizes the bearing compartment at higher power settings to resist excessive buffer air infiltration into the bearing compartment.

Owner:RTX CORP

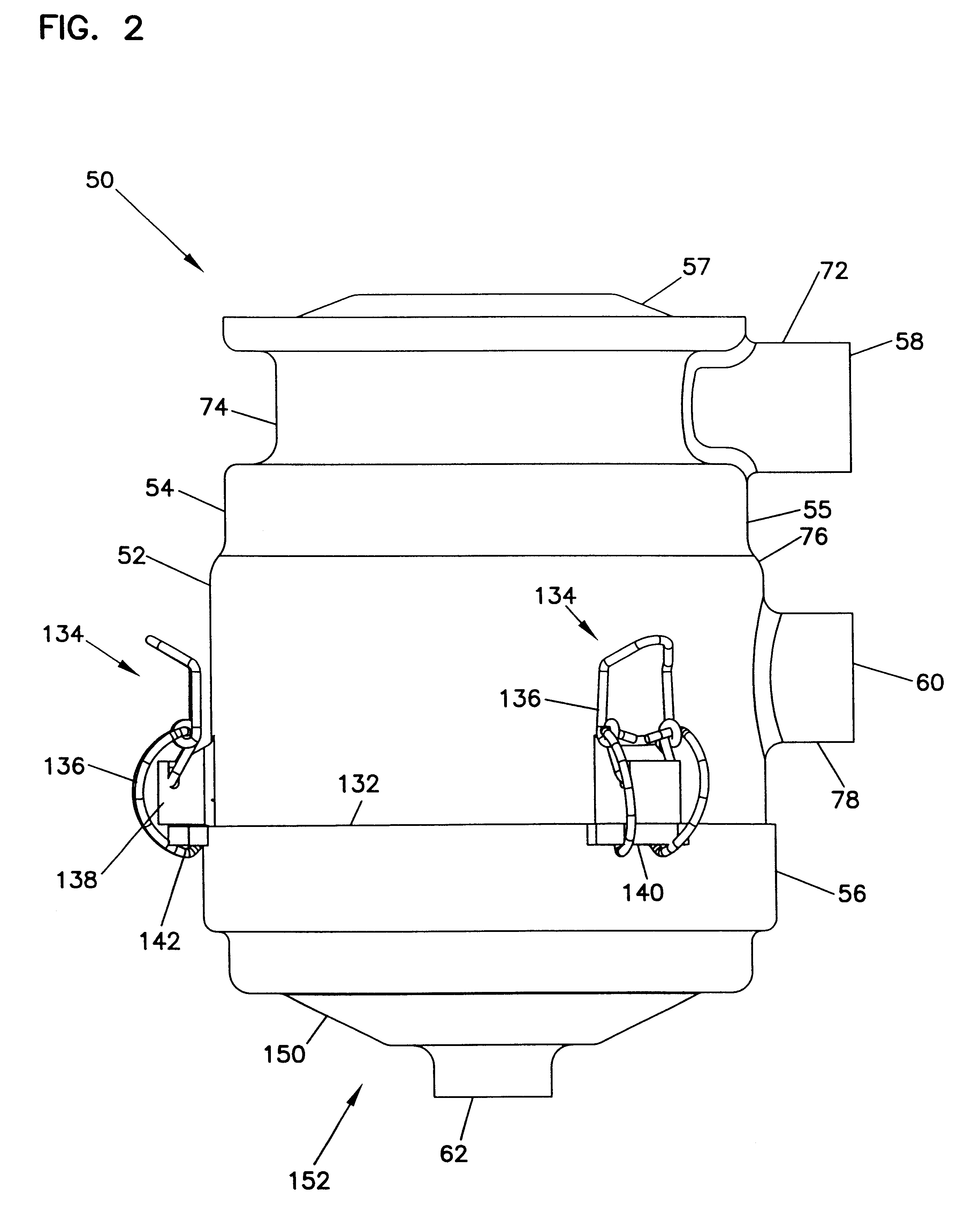

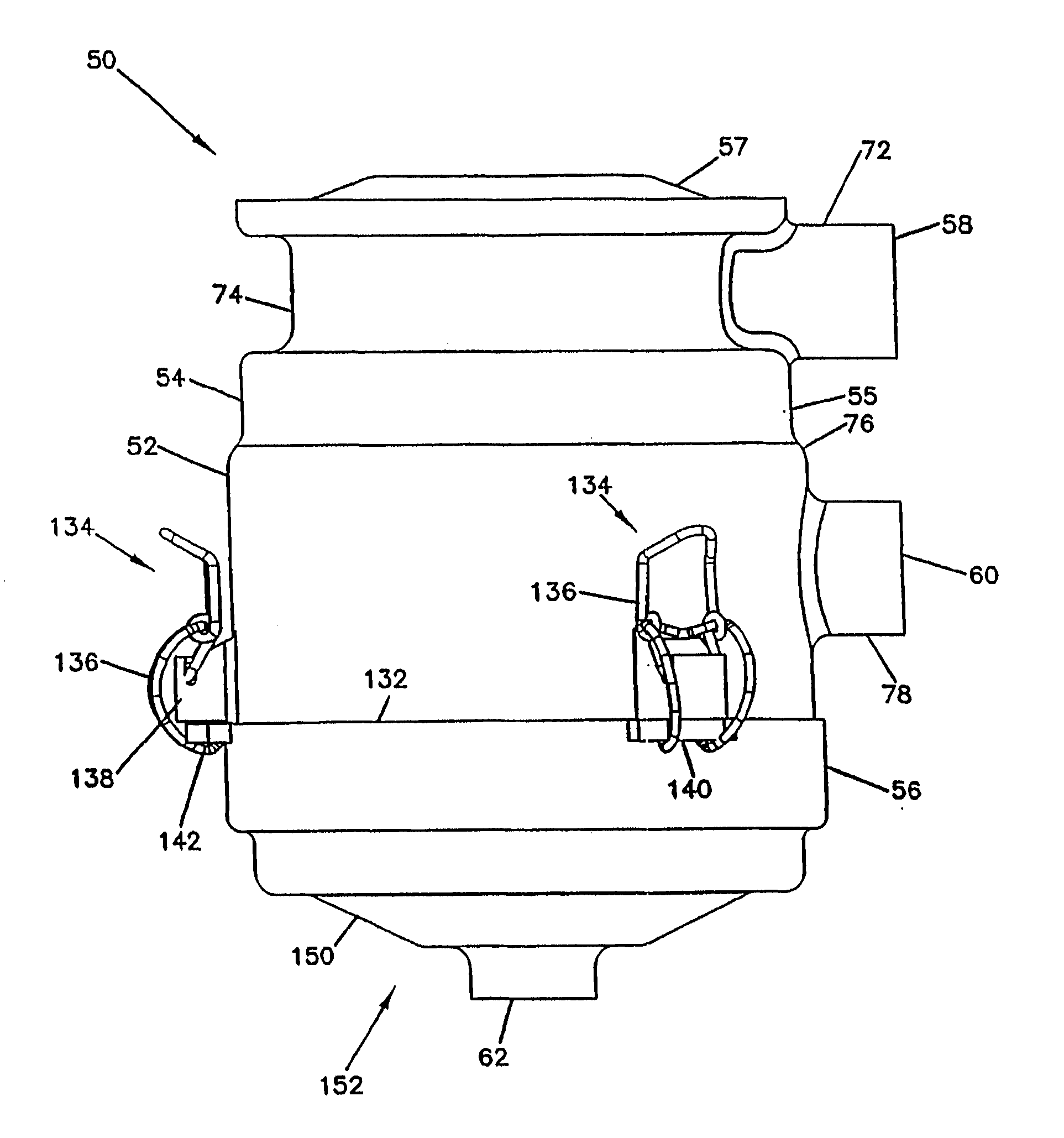

Crank case ventilation filter assembly; and methods

Crankcase ventilation filter arrangements and components therefore are described. Example arrangements are described. In one, a serviceable filter cartridge includes a check valve therein, for protection during vehicle rollover. Handle arrangements are also described. Methods of use are described.

Owner:DONALDSON CO INC +1

Crankcase Ventilation Filter

A crankcase ventilation filter includes a media stage comprising continuous, extruded fibres having a largest cross sectional size of at least 10 microns, a calculated pore size in the x-y direction of 10-60 microns, an added binder resin content if any of no greater than 7% by weight of the total fibre material; the continuous fibres being bonded at spaced locations. An assembly comprising the filter and a housing including a gas flow inlet, a gas flow outlet and a liquid drain.

Owner:DONALDSON CO INC

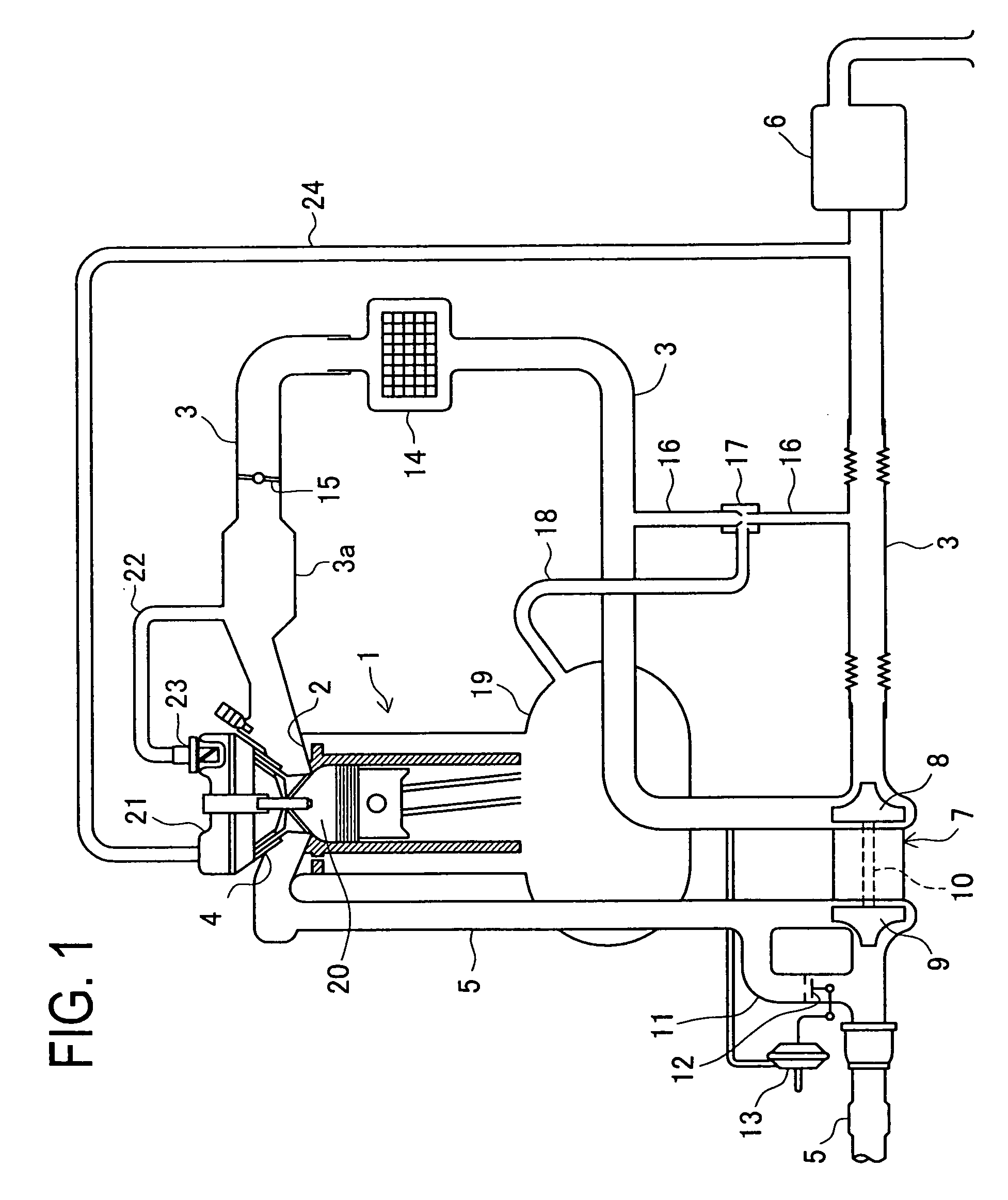

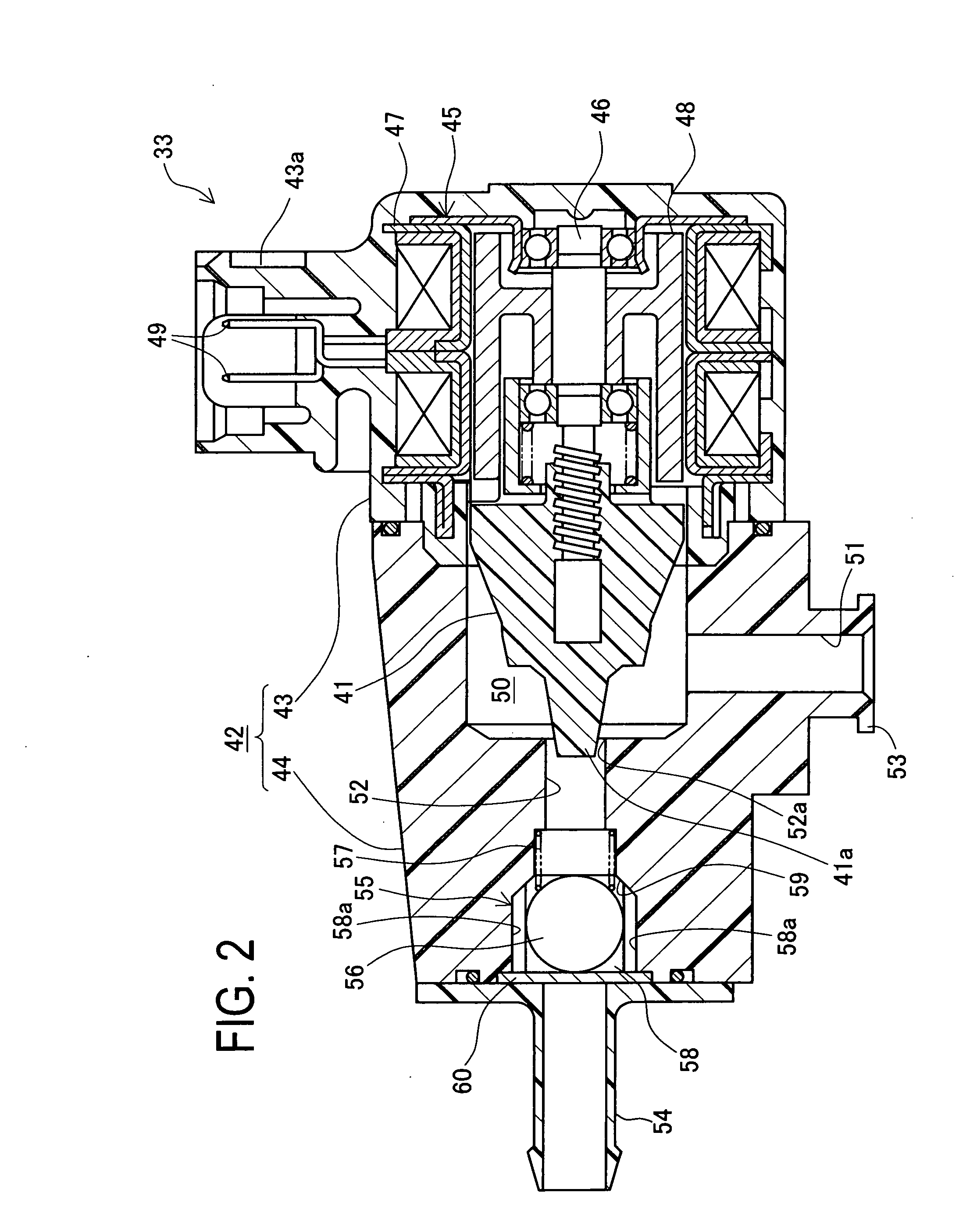

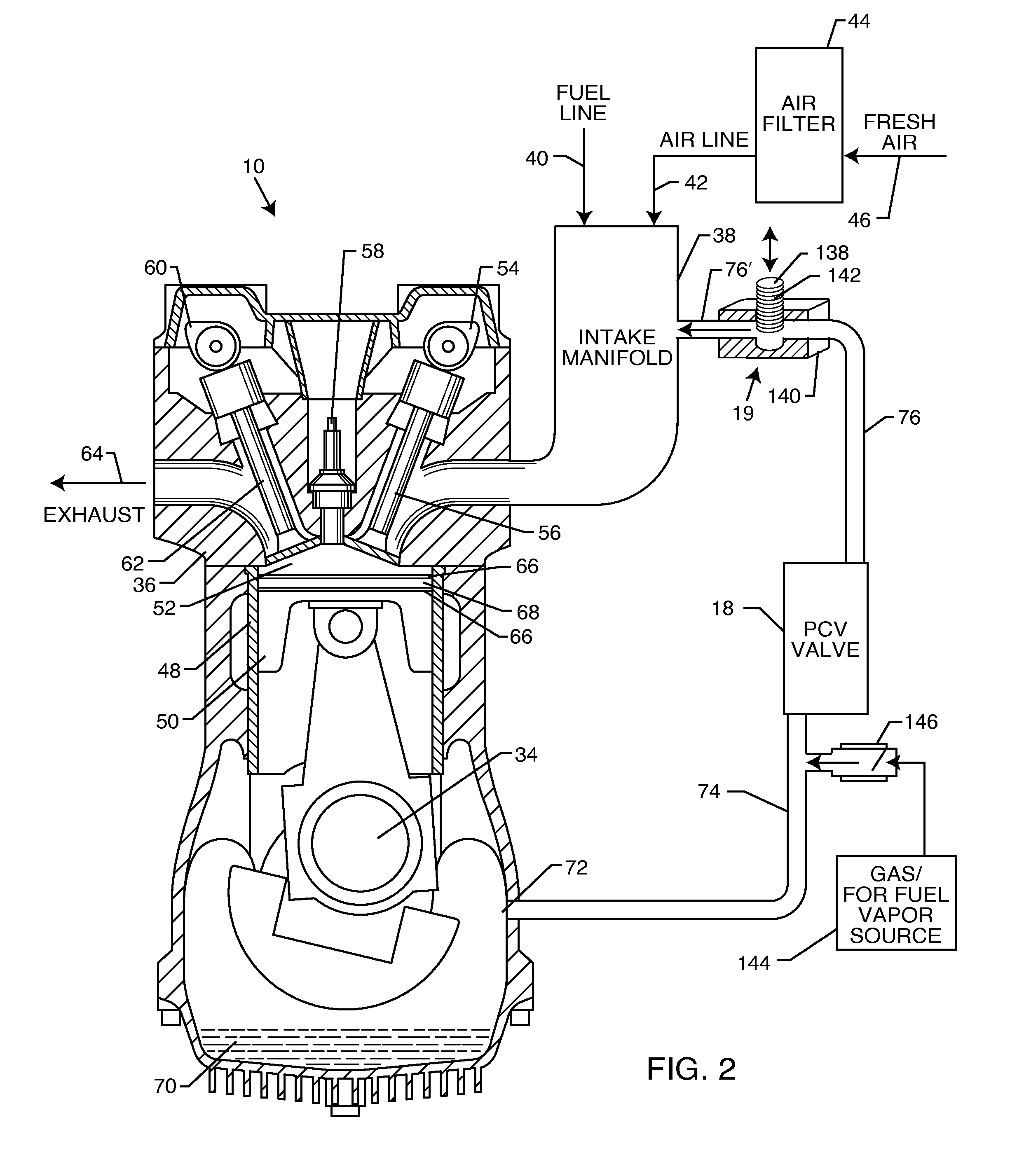

Engine blow-by gas returning apparatus

A blow-by gas returning apparatus is arranged to allow blow-by gas leaking from a combustion chamber of an engine into a crank chamber to flow in an intake passage through a returning passage, and to regulate a flow rate of the blow-by gas by a PCV valve placed in the returning passage. A supercharger is placed in the intake passage. The PCV valve is adapted to change a position of the valve element by electromagnetic force to change a passage opening area. A check valve is placed integral with the PCV valve in the returning passage between the valve element of the PCV valve and the intake passage. The check valve is arranged to inhibit back-flow of the gas from the intake passage.

Owner:AISAN IND CO LTD

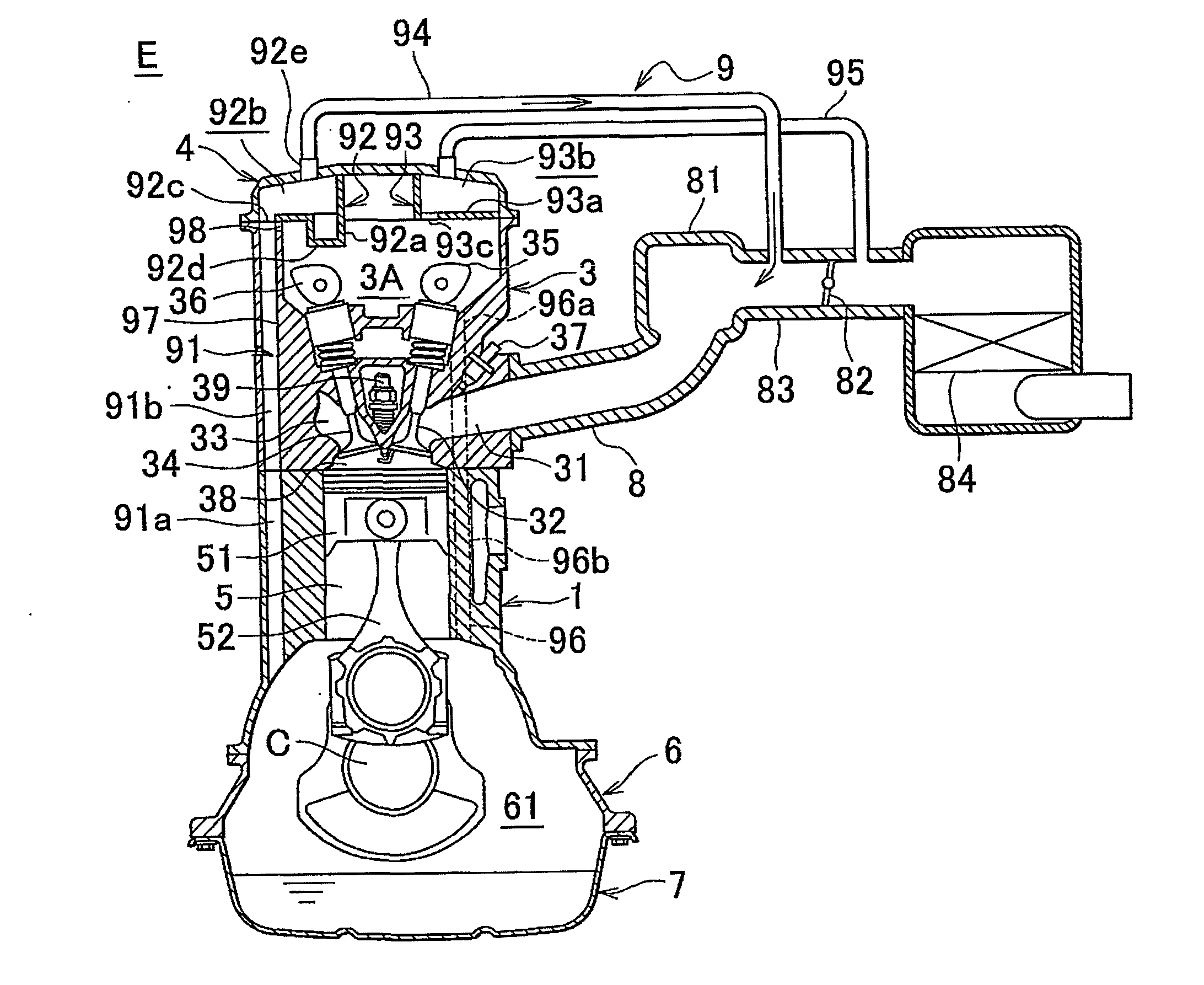

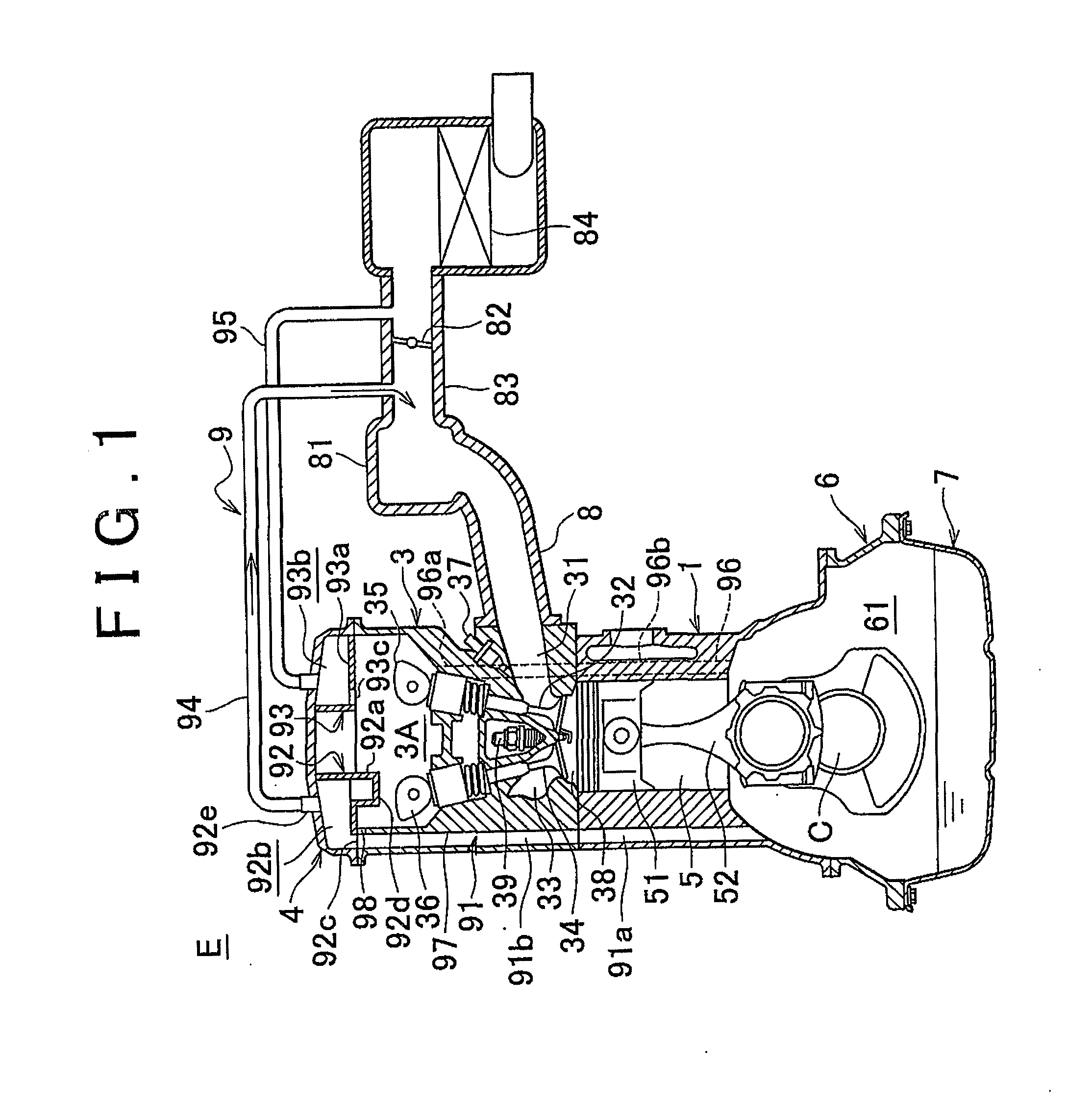

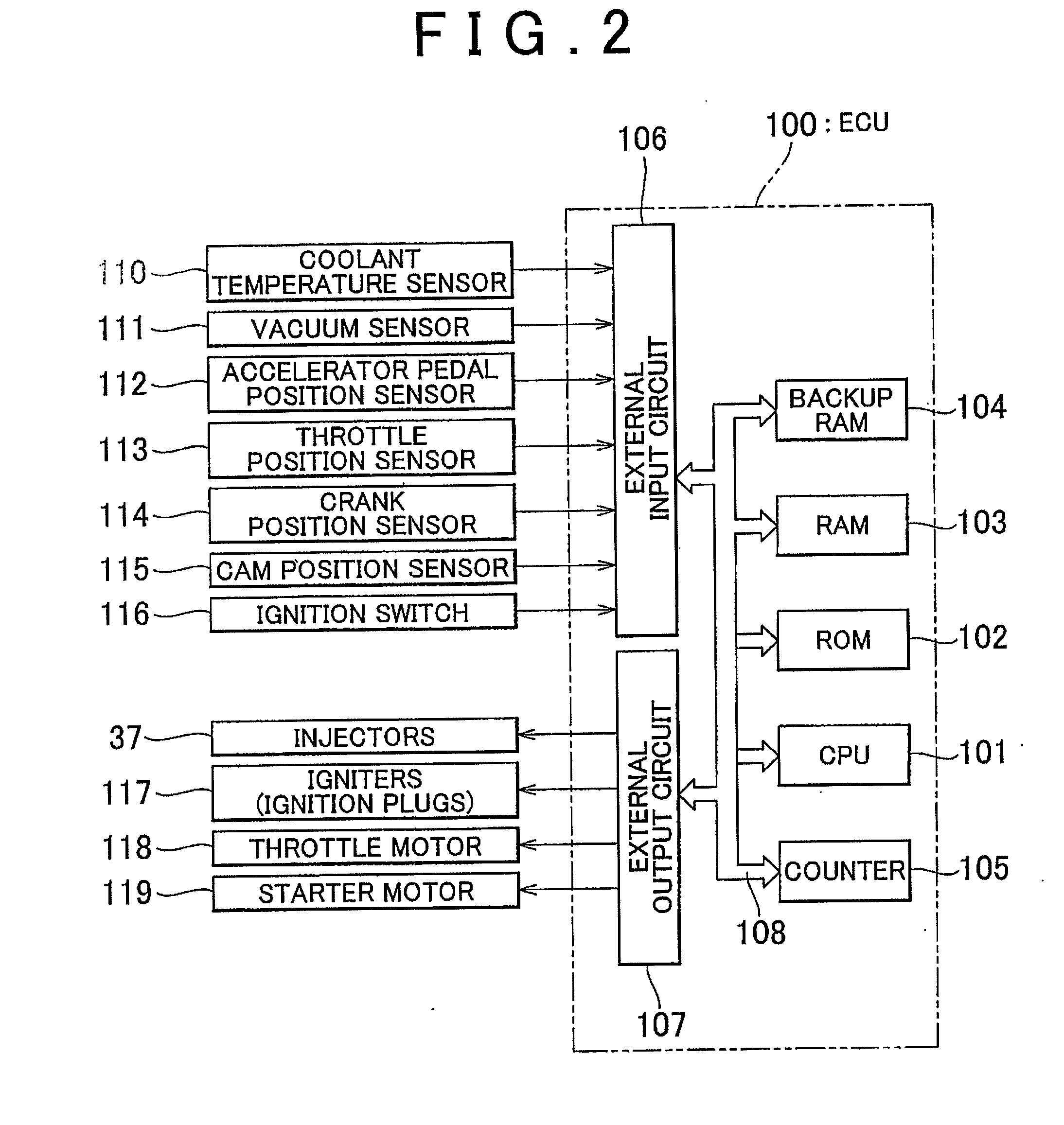

Positive crankcase ventilation system, cylinder head used for positive crankcase ventilation system, internal combustion engine including positive crankcase ventilation system, and positive crankcase ventilation method

InactiveUS20100101514A1Reduce manufacturing costSimple processCylinder headsCombustion enginesCylinder headEngineering

A blow-by gas collection passage (91) extends in a cylinder block (1) and a cylinder head (3). A crank chamber (61) is connected to an oil separator (92) through the blow-by gas collection passage (91). A cutout portion is formed in an upper end portion of a wall portion (97) of the blow-by gas collection passage (91), and the oil separator (92) contacts an upper surface of the cylinder head (3) to form a connection portion (98) through which the blow-by gas collection passage (91) is connected to a cam chamber (3A). Thus, new air in the cam chamber (3A) flows into the blow-by gas collection passage (91) at an inlet portion of the oil separator (92) through the connection portion (98) to dilute the blow-by gas.

Owner:TOYOTA JIDOSHA KK

Device and a Method for Cleaning of a Gas

ActiveUS20080264251A1Efficient separationEasy and efficient removalCombination devicesDispersed particle filtrationParticulatesEngineering

Owner:ALFA LAVAL CORP AB

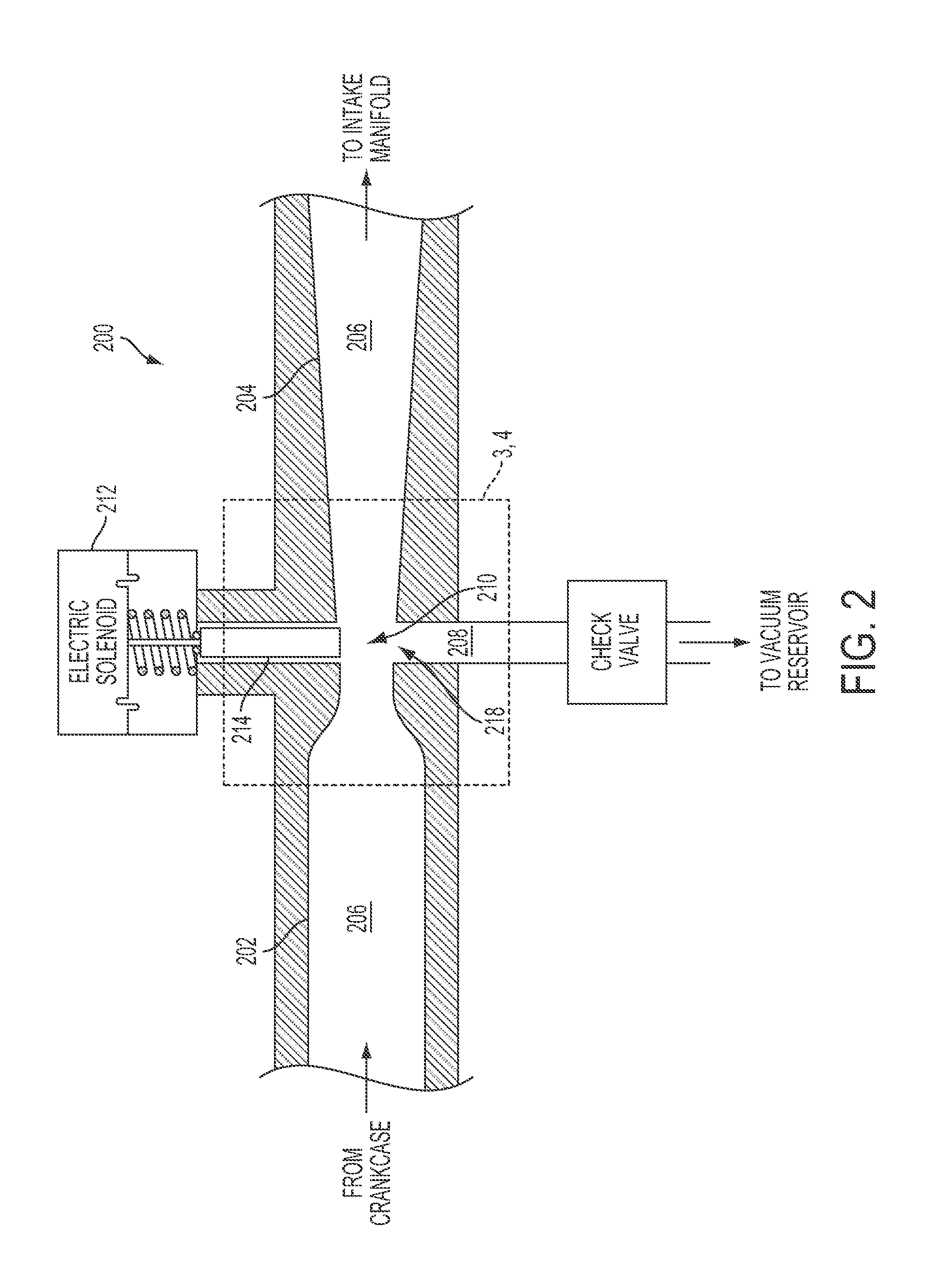

Aspirator for crankcase ventilation and vacuum generation

InactiveUS20140014080A1Avoid problemsCommunication is limitedInternal combustion piston enginesCrankcase ventillationCrankcaseEngineering

Methods and systems are provided for flowing crankcase gases through an aspirator arranged in a PCV line. The aspirator regulates PCV flow, and may also generate vacuum depending on a position of a pintle extendable across a horizontal passage of the aspirator. When regulating PCV flow and not generating vacuum, the aspirator is fully closed and crankcase gases in the horizontal passage are metered through an orifice in the pintle. When generating vacuum, the aspirator is at least partially opened and PCV flow through the horizontal passage generates vacuum at a vacuum port of the aspirator.

Owner:FORD GLOBAL TECH LLC

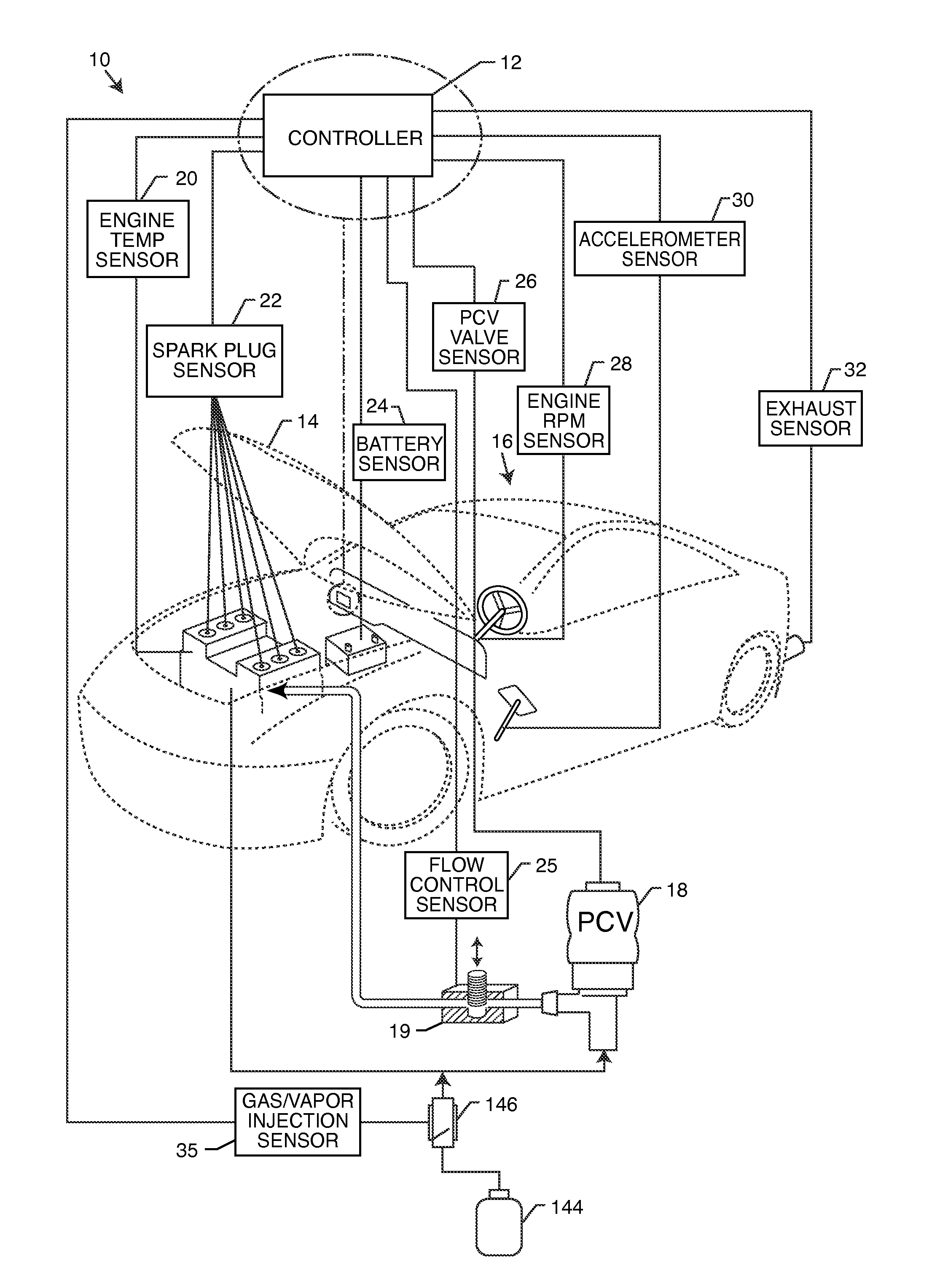

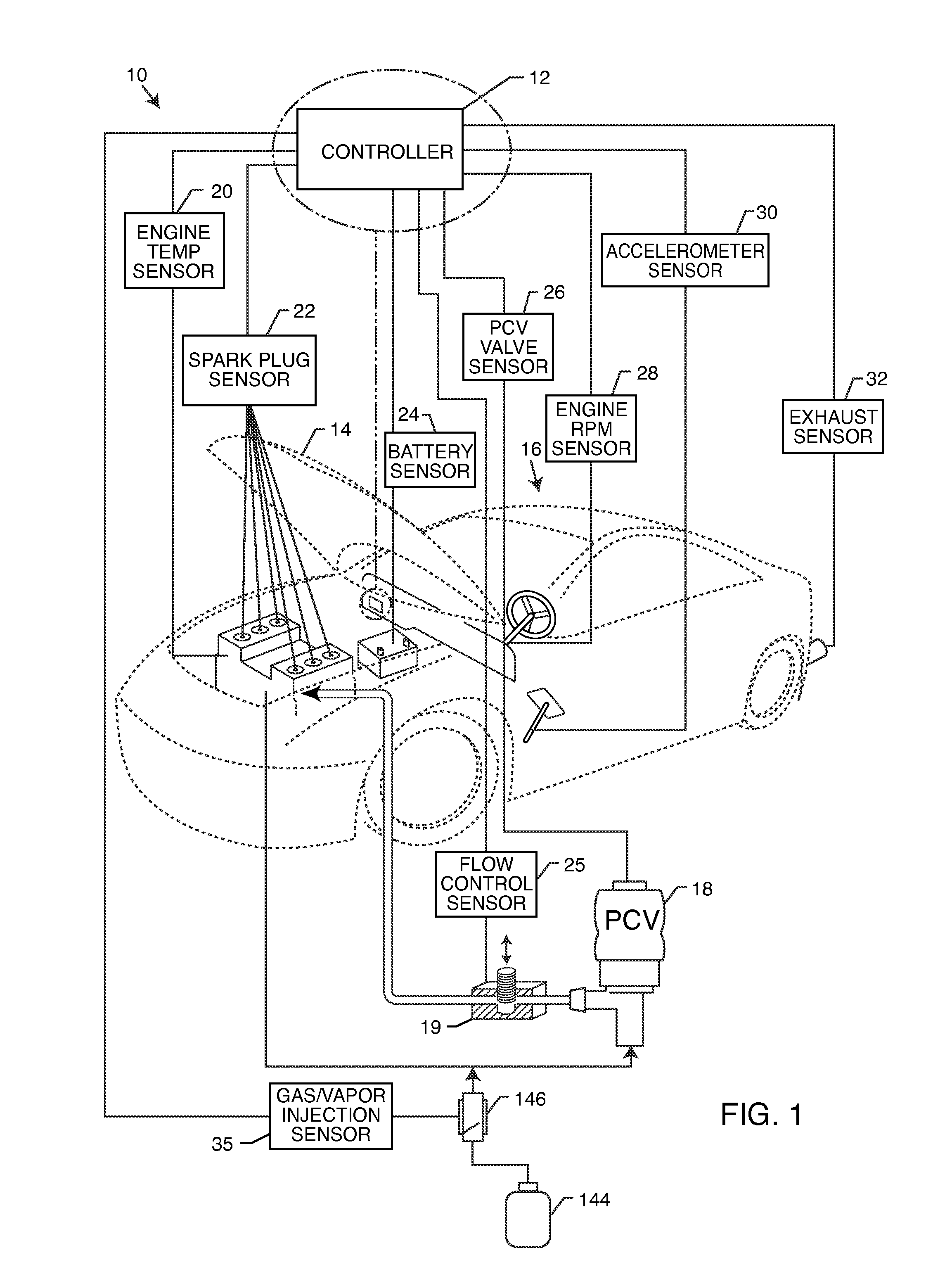

Pollution control system

ActiveUS20100076664A1Reduce fluid flow rateIncrease fluid velocityAnalogue computers for vehiclesInternal combustion piston enginesVacuum pressureCombustion

The pollution control system includes a controller coupled to a sensor monitoring an operational characteristic of a combustion engine, such as engine RPM. A PCV valve having an inlet and an outlet is adapted to vent blow-by gas out from the combustion engine. A fluid regulator associated with the PCV valve and responsive to the controller selectively modulates engine vacuum pressure to adjustably increase or decrease a fluid flow rate of blow-by gas venting from the combustion engine. The controller selectively adjustably positions the fluid regulator to vary the degree of vacuum pressure to optimize the recycling of blow-by gases.

Owner:SVMTECH

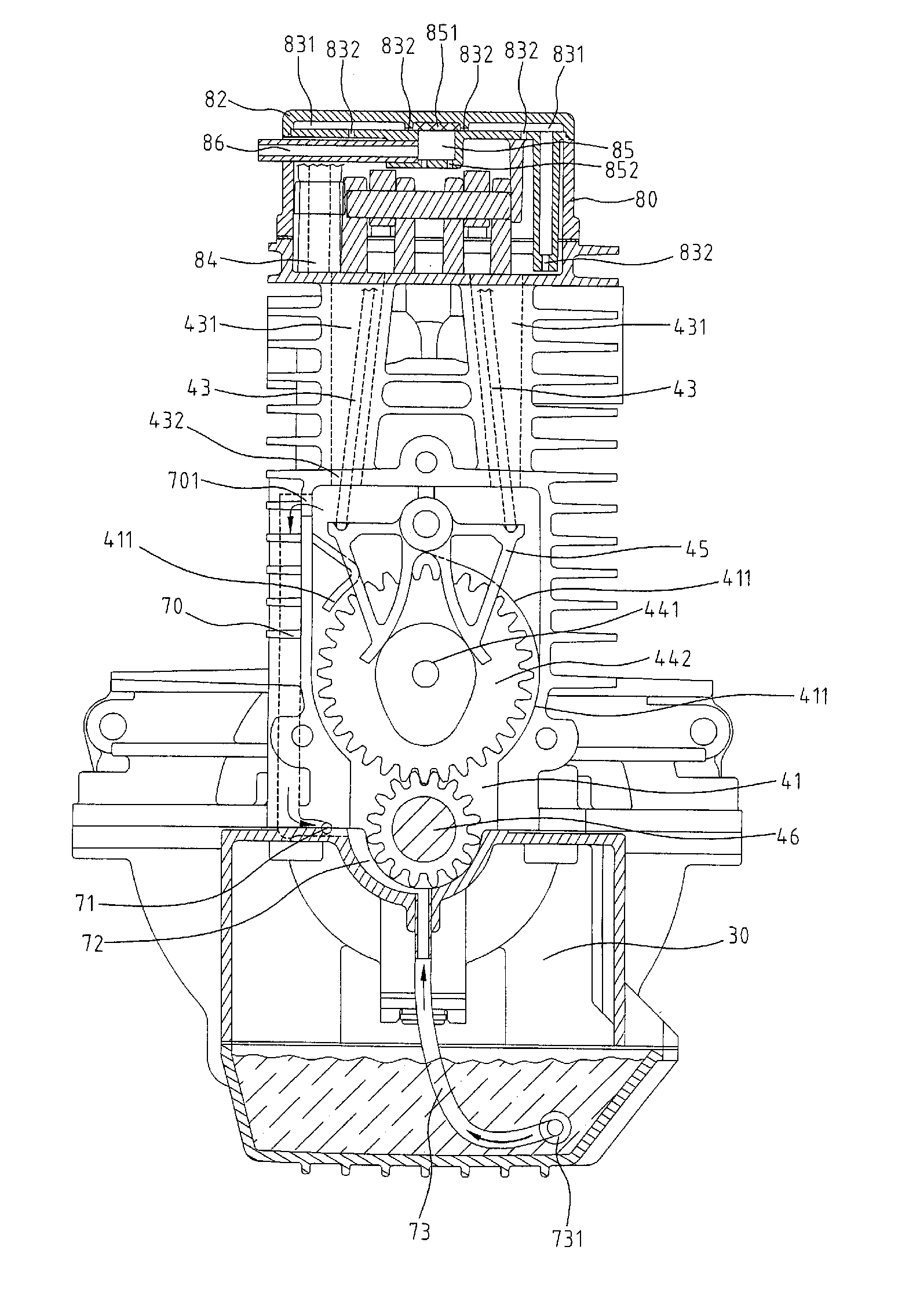

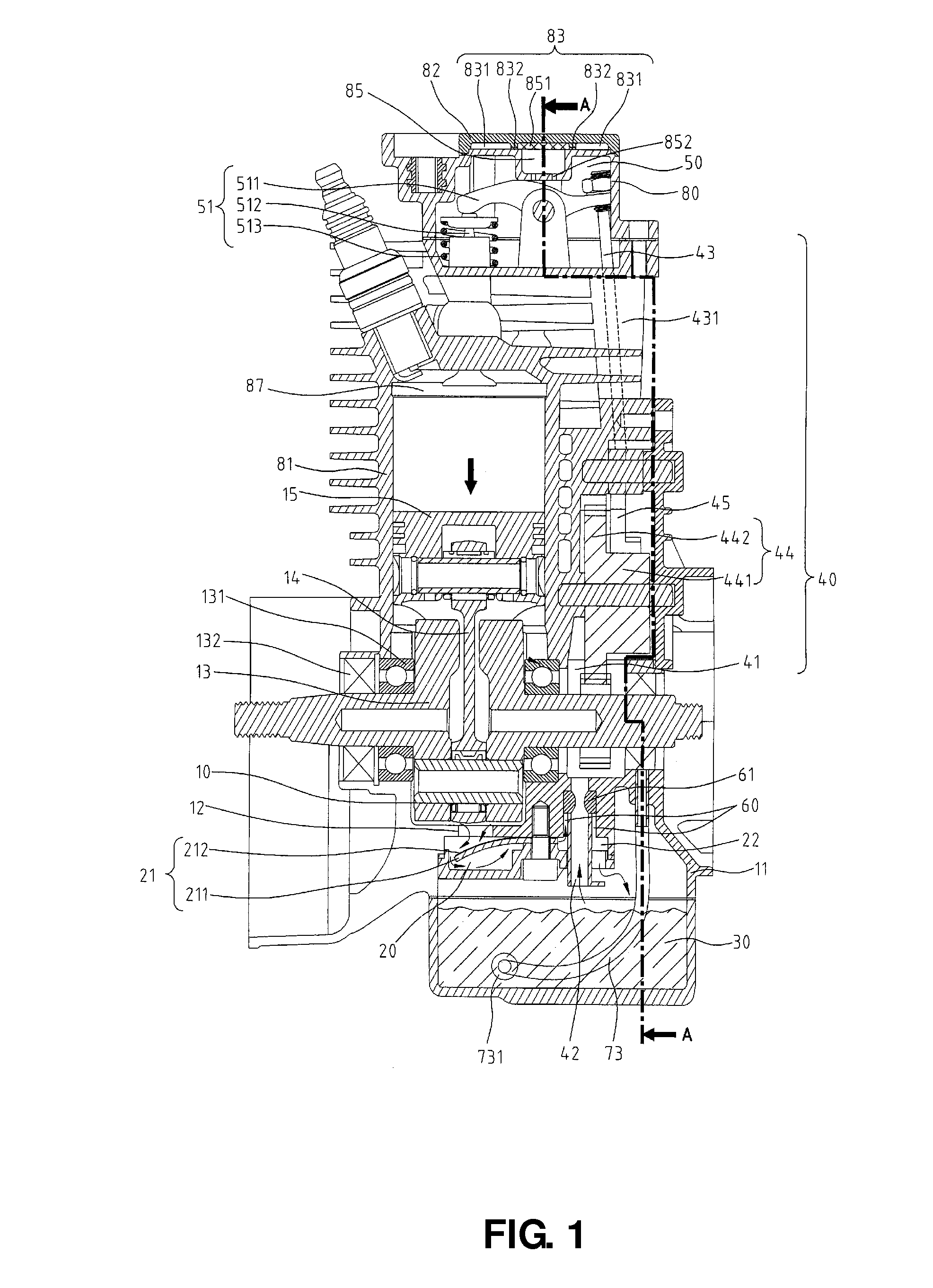

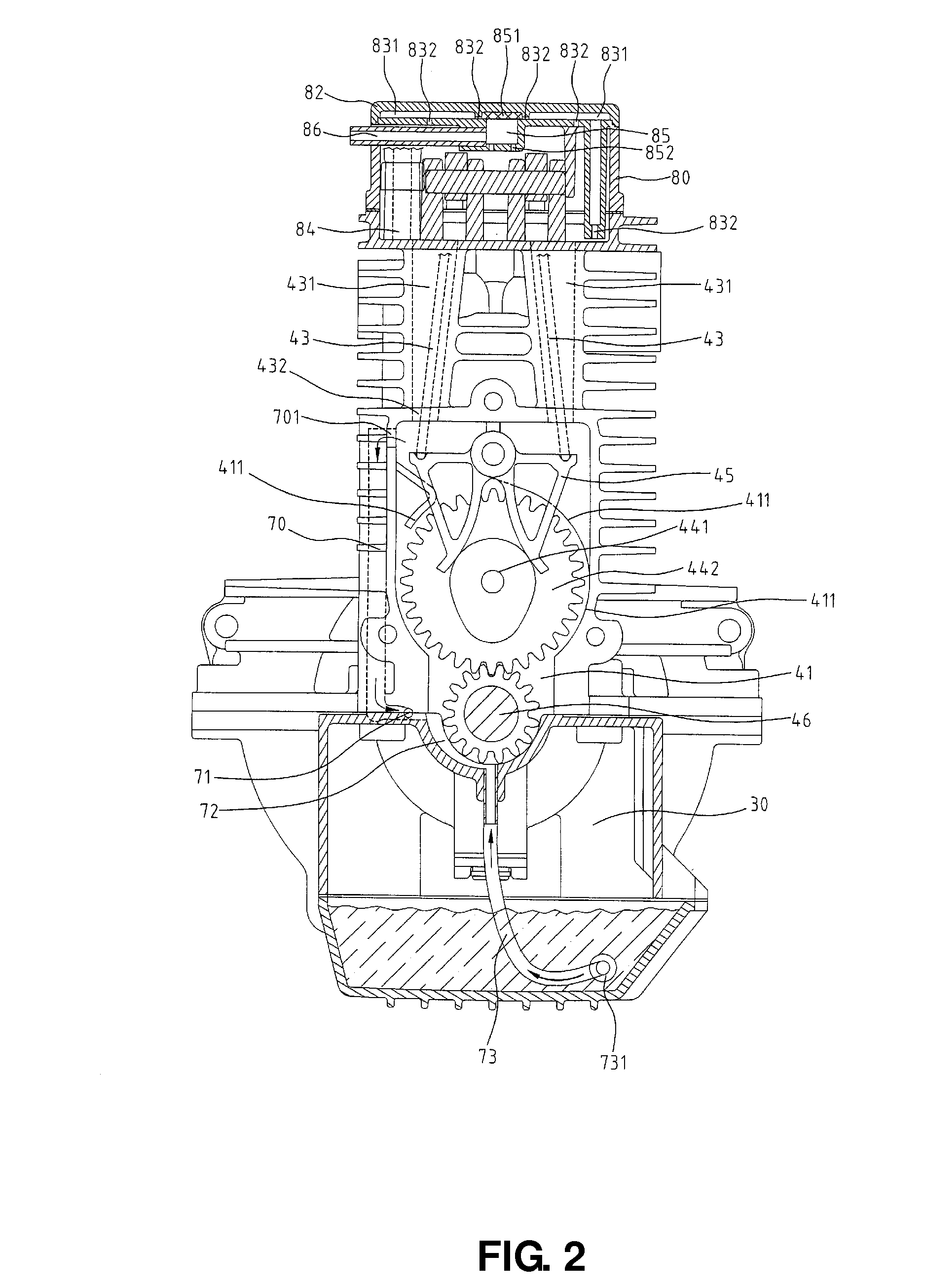

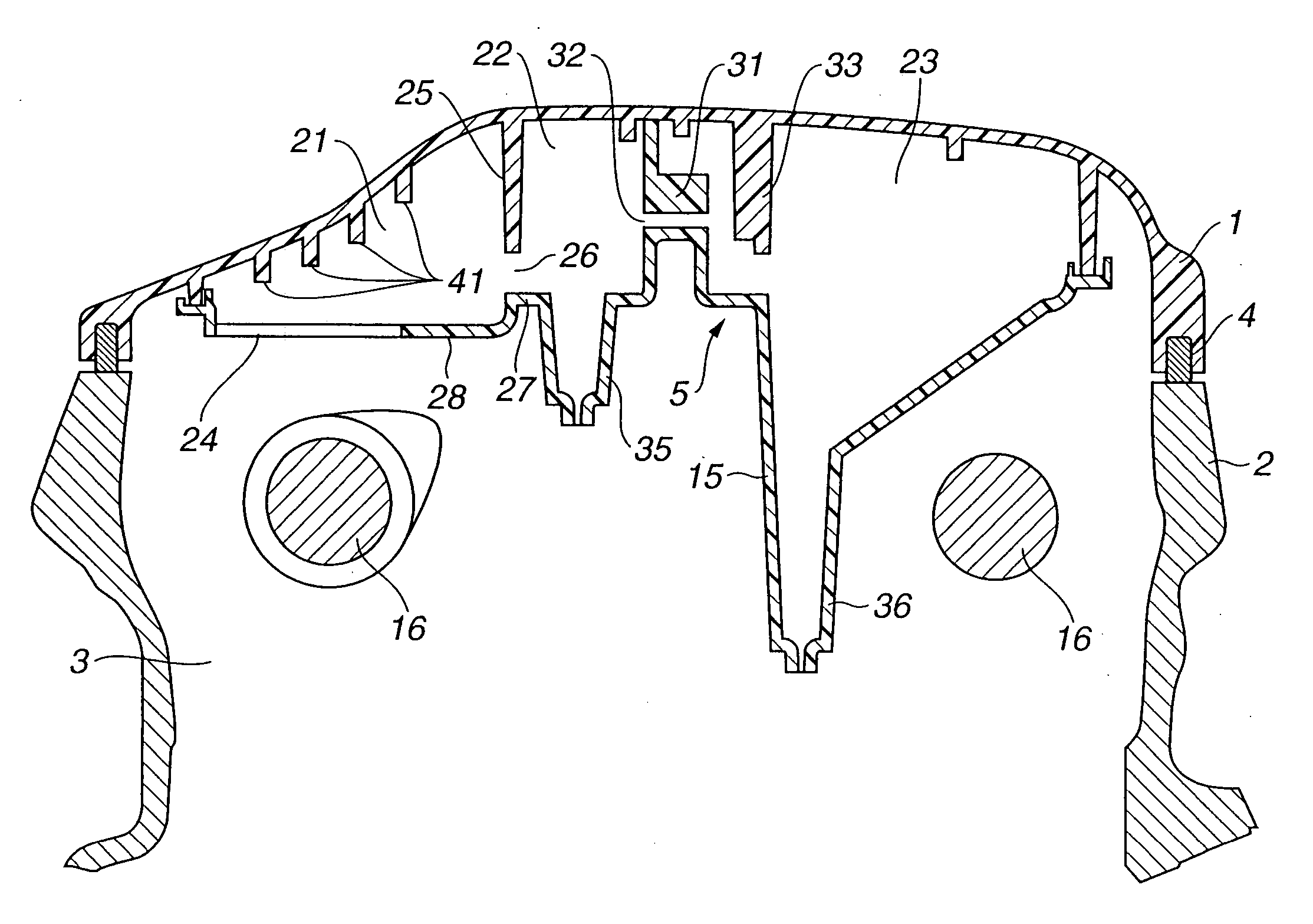

Lubrication system for an engine

ActiveUS20090013959A1Fully lubricatedCombustion enginesPressure lubricationFour-stroke engineEngineering

A lubrication system for a small lightweight four-stroke engine is disclosed. The lubrication system, provided with a weight at one end of a flexible oil tube inserted into an oil reservoir, is capable of providing a sufficient lubrication to components of the engine which may operate in a horizontal posture, a vertical posture, or any posture therebetween.

Owner:LIN SZU LIANG

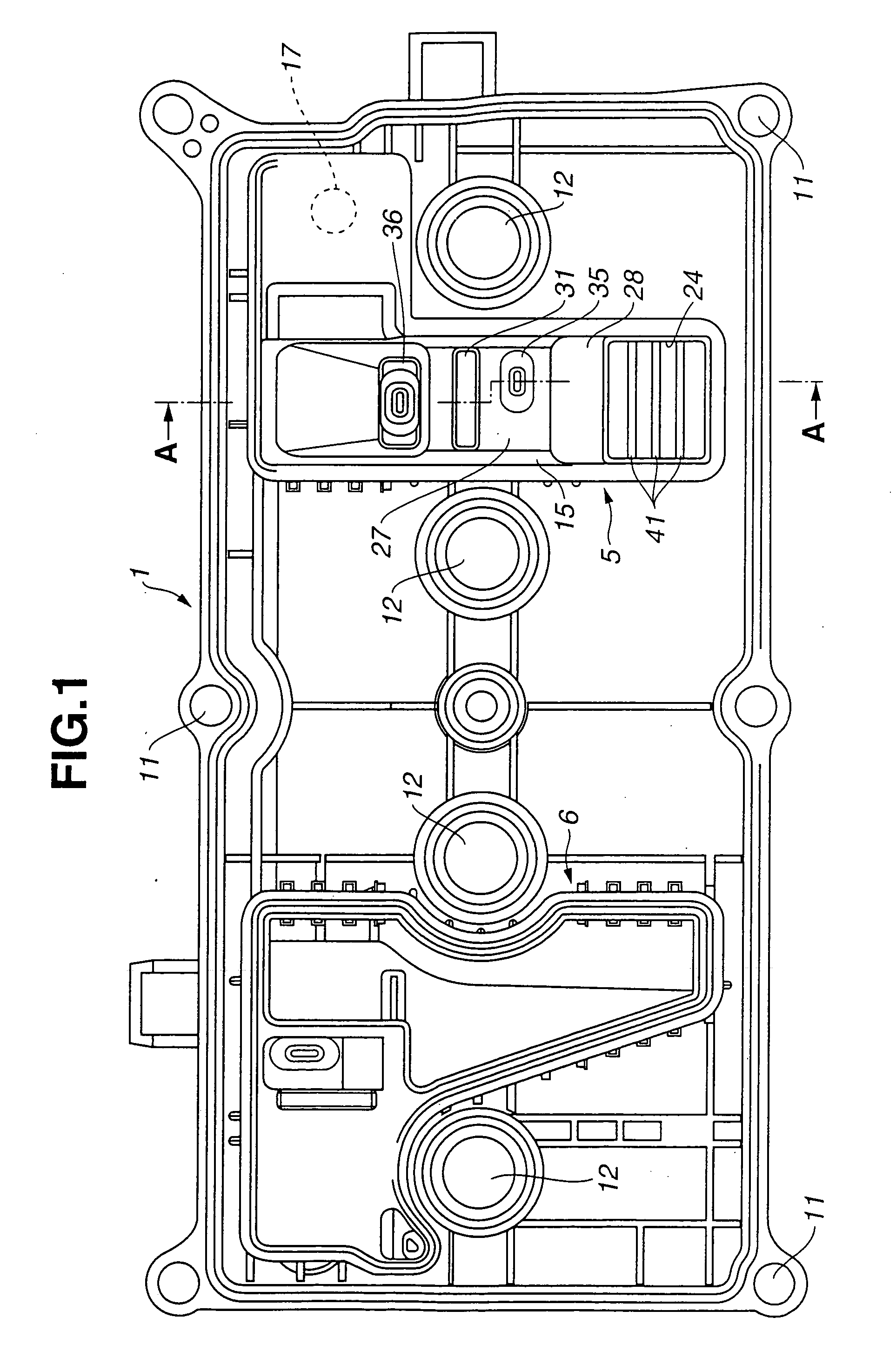

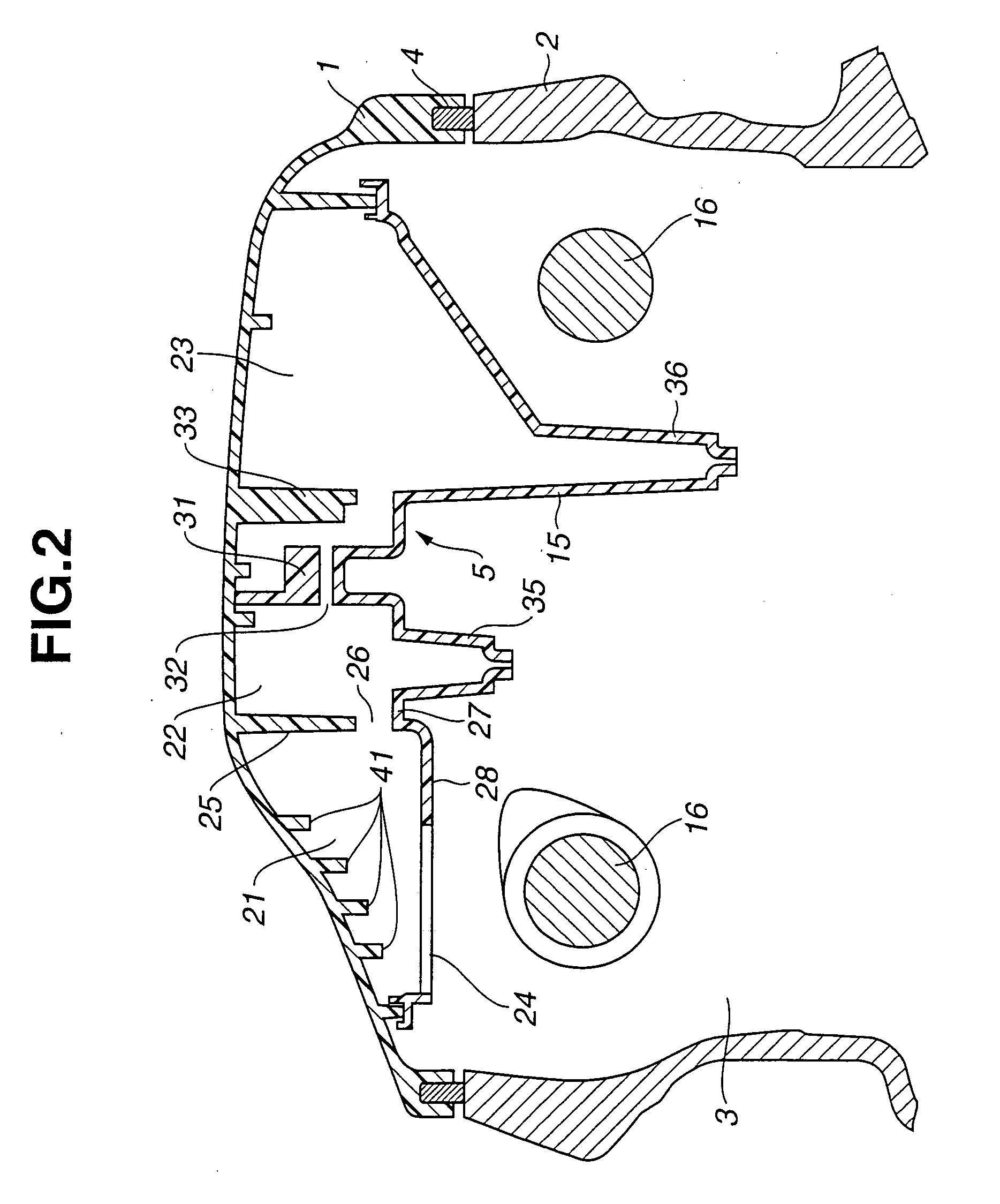

Oil separator combined with cylinder head cover

InactiveUS20050092267A1Effectively overcome drawbacksReduce the overall heightCasingsLubrication of auxillariesCylinder headEngineering

An oil separator provided in combination with a cylinder head cover of an internal combustion engine. The oil separator includes a separator cover fixed to an inner surface of the cylinder head cover defining a space extending in a first direction perpendicular to axis of a camshaft in plan, between the separator cover and the cylinder head cover. The separator cover has an opening through which the space is opened to a valve operating chamber. A partition wall is provided to define in the space an inlet-side separator chamber and an outlet-side separator. The partition wall extends in a second direction parallel with the axis of the camshaft and being formed with a plurality of fine passages. Additionally, a plurality of projection walls project from a part of the inner surface of the cylinder head cover which faces the valve operating chamber through the opening.

Owner:MAHLE FILTER SYST JAPAN CORP

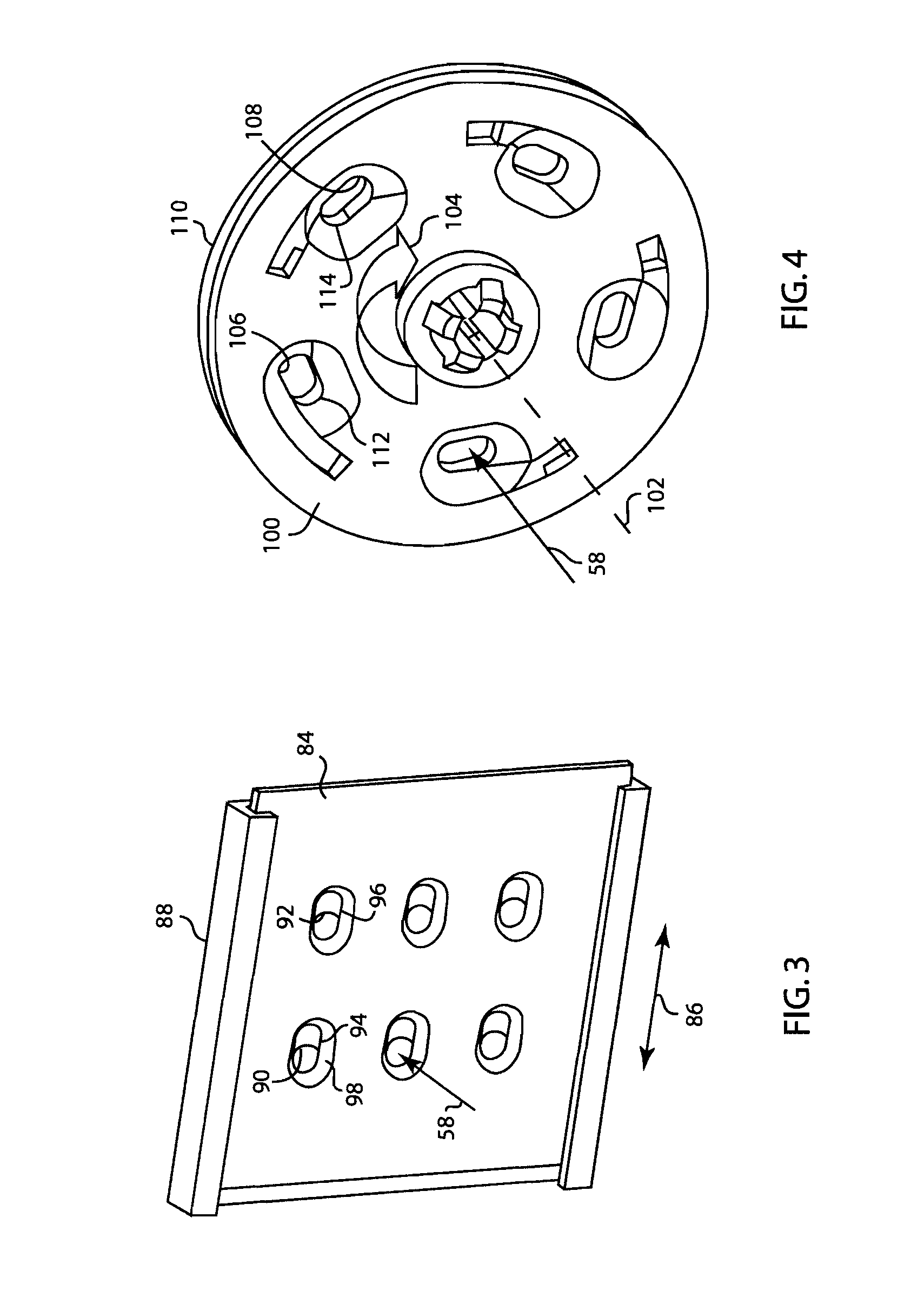

Centrifugal separator

ActiveUS20100011723A1Evenly distributedImprove pumping capacityDispersed particle separationRotary centrifugesParticulatesProduct gas

The invention relates to a centrifugal separator for cleaning of gas from solid or liquid particles suspended therein which are of greater density than the gas. A main object of the present invention is to accomplish a centrifugal separator which does not have said inactive regions and thereby achieves efficient separation of particulate contaminants from a gas. This object is achieved by the centrifugal separator initially defined, which is characterised in that the interspaces between the separation discs at least at their radially outer parts are substantially open for flow of the gas in the circumferential direction and that mutually adjacent separation discs are arranged at mutual spacing such that rotation of the rotor causes a pumping action in the interspaces, which pumping action drives the gas from the gas inlet, through the interspaces between the separation discs and out via the gas outlet.

Owner:ALFA LAVAL CORP AB

Vortex air-oil separator system

The present invention provides a vortex generator that may be used in systems for separating oil from air oil mixtures. The vortex generator comprises a rotating disk having a rim having a plurality of passages extending through it and a cavity formed by the rotating disk and a cavity wall wherein a vortex is created when there is a flow through the plurality of passages into the cavity.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com