Patents

Literature

57results about How to "Reduce fluid flow rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

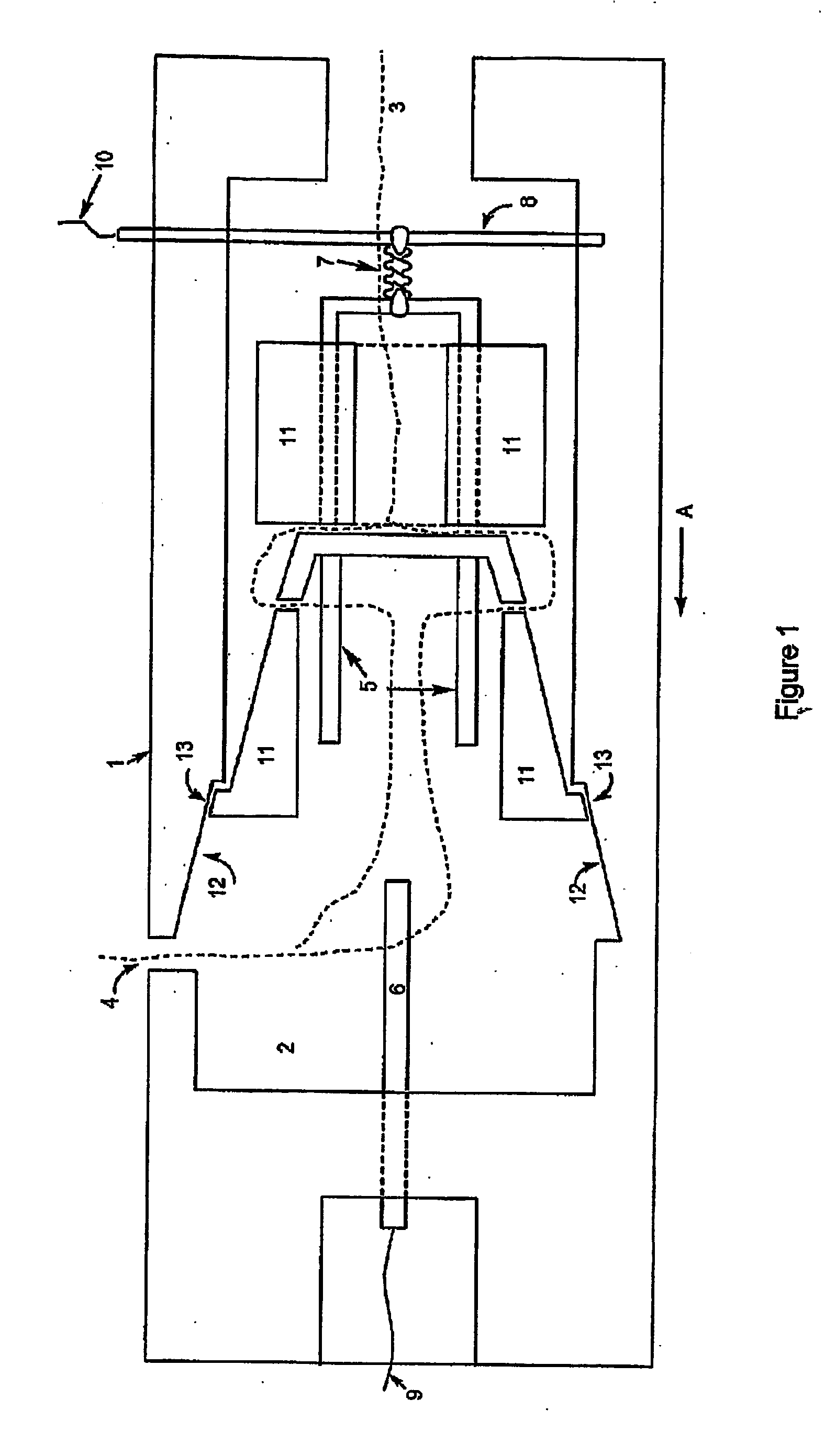

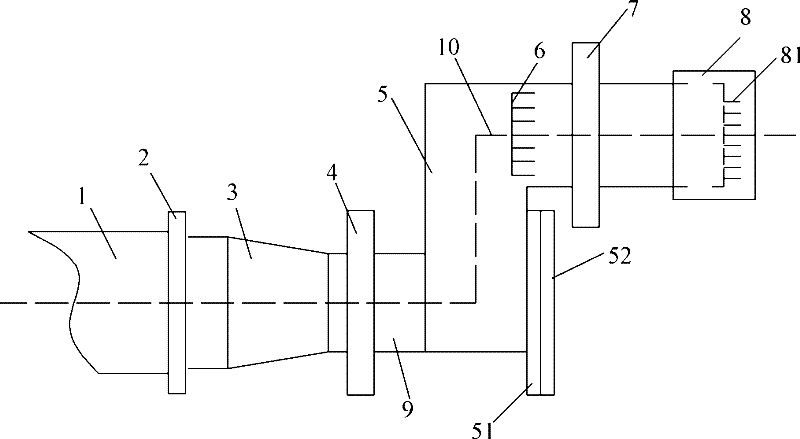

Apparatus for combusting a fuel at high pressure and high temperature, and associated system

ActiveUS9068743B2Reducing and eliminating needEliminate damage to and build-upGas turbine plantsDirect carbon-dioxide mitigationCombustion chamberWorking fluid

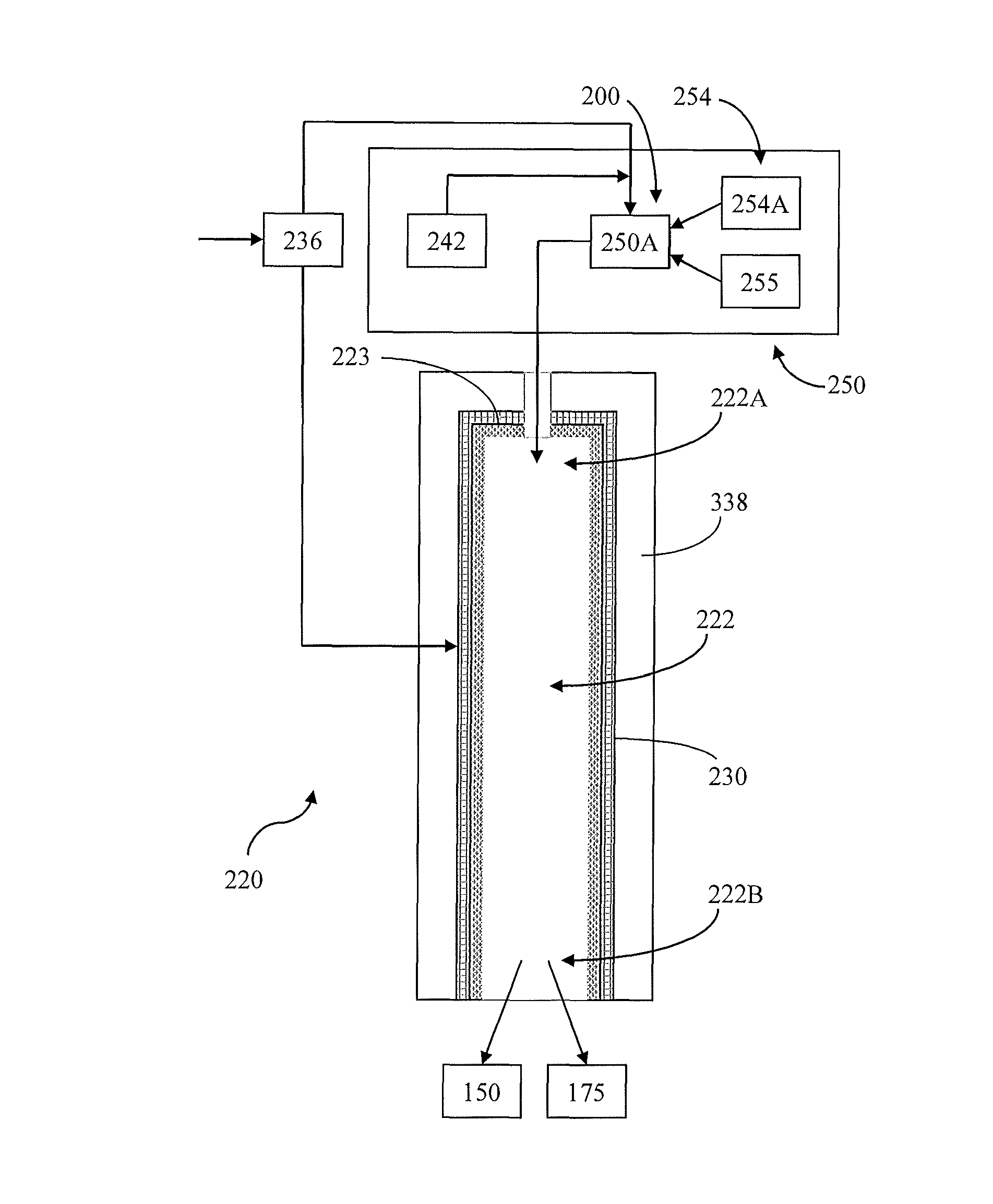

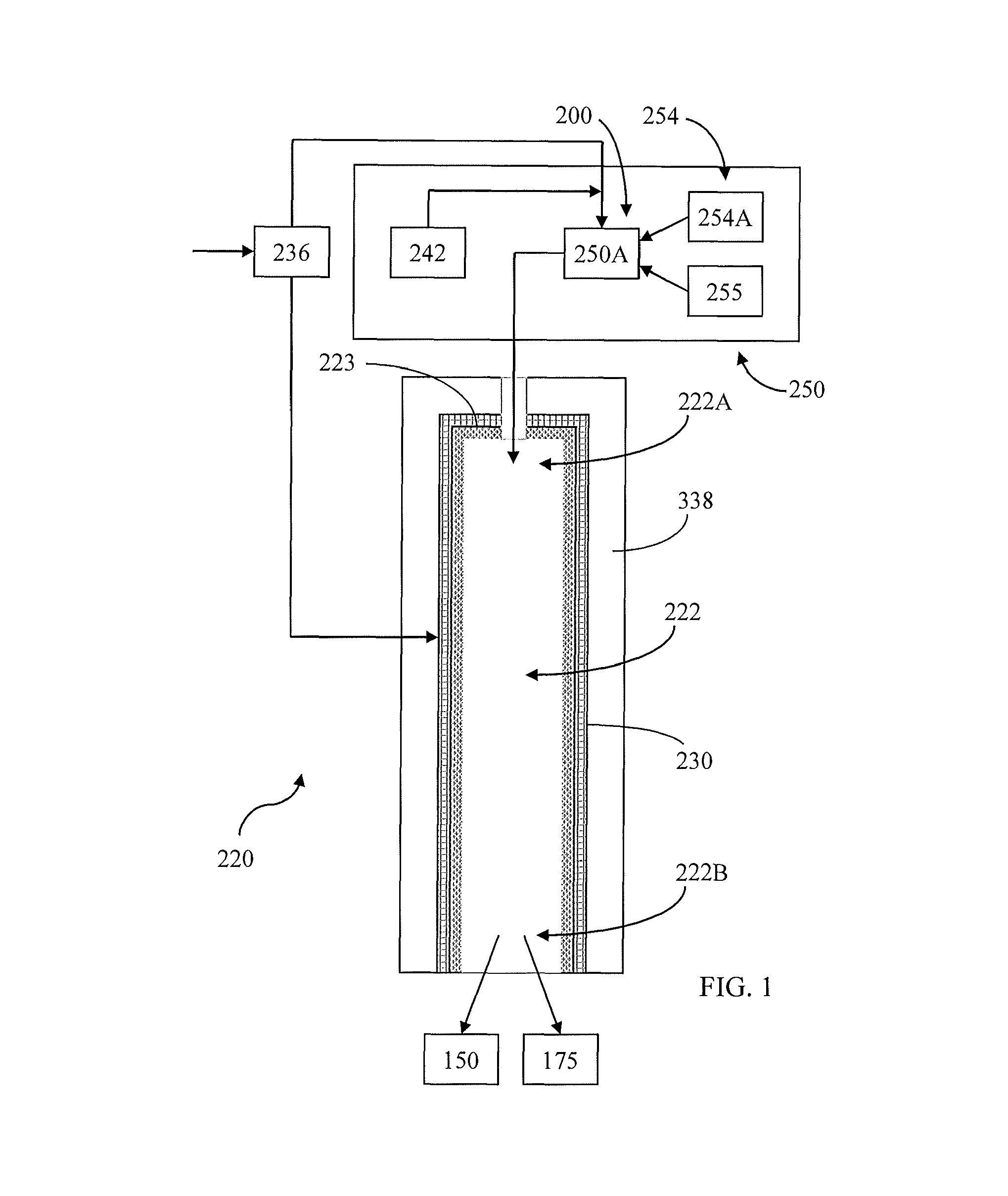

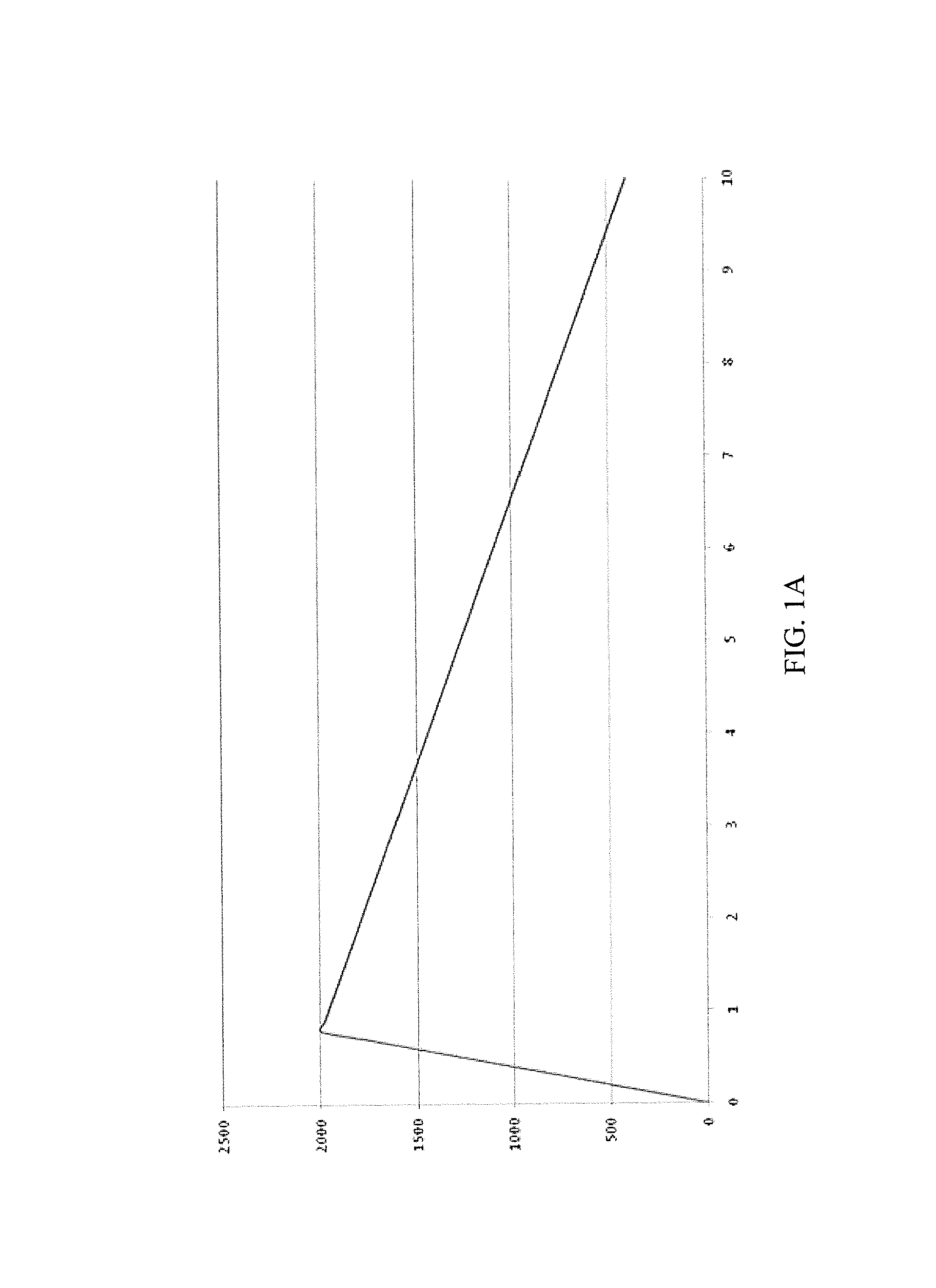

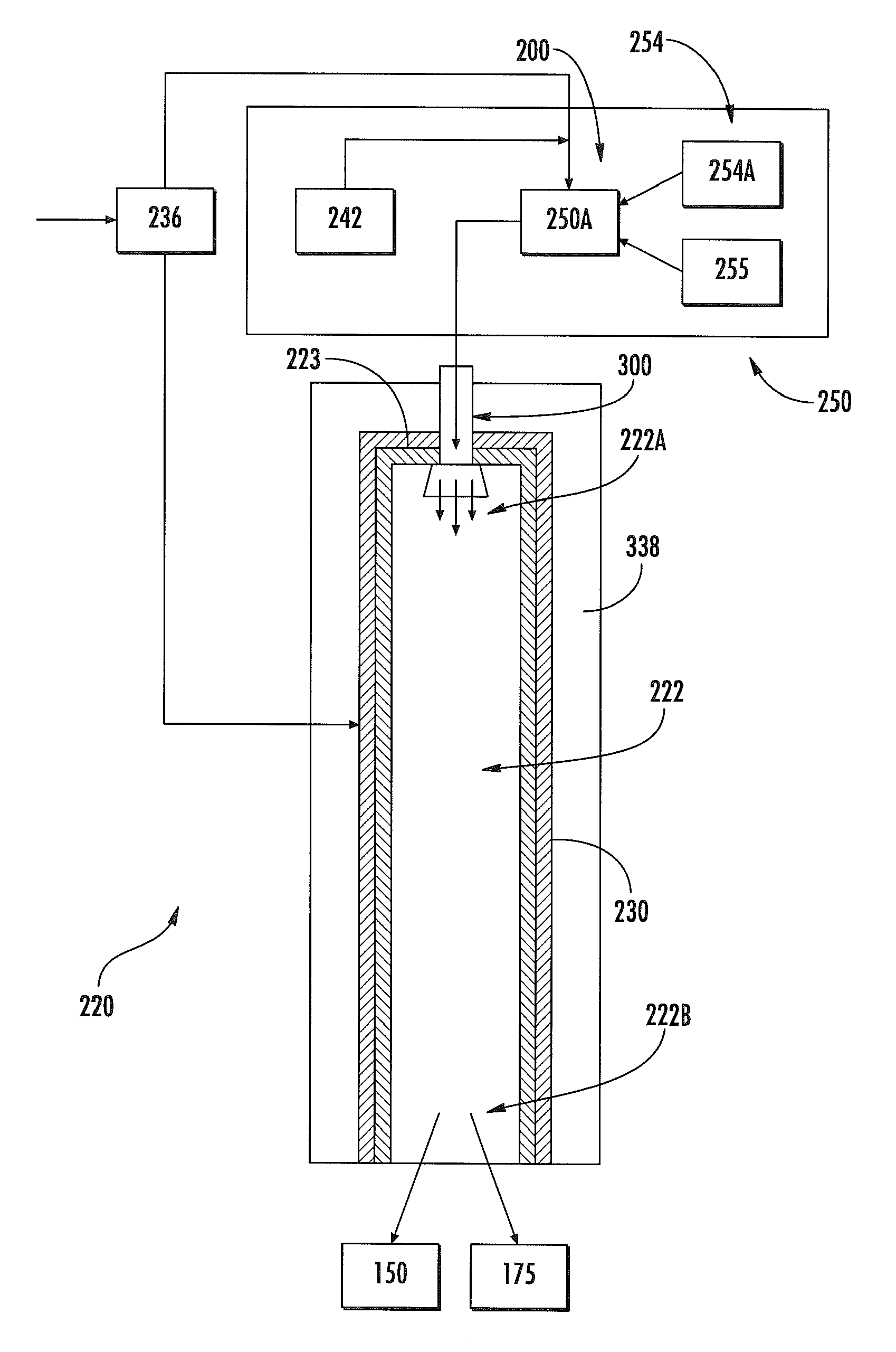

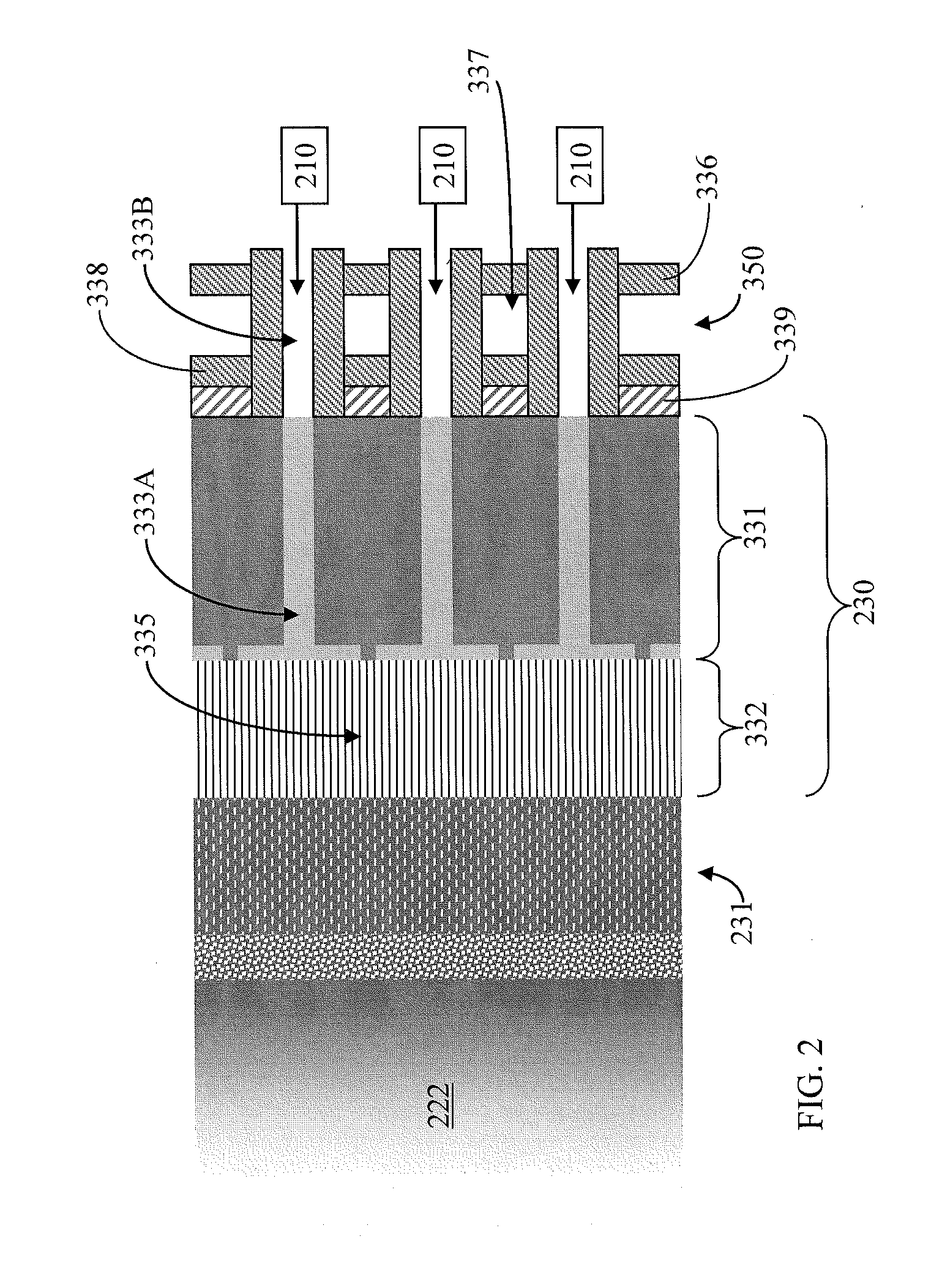

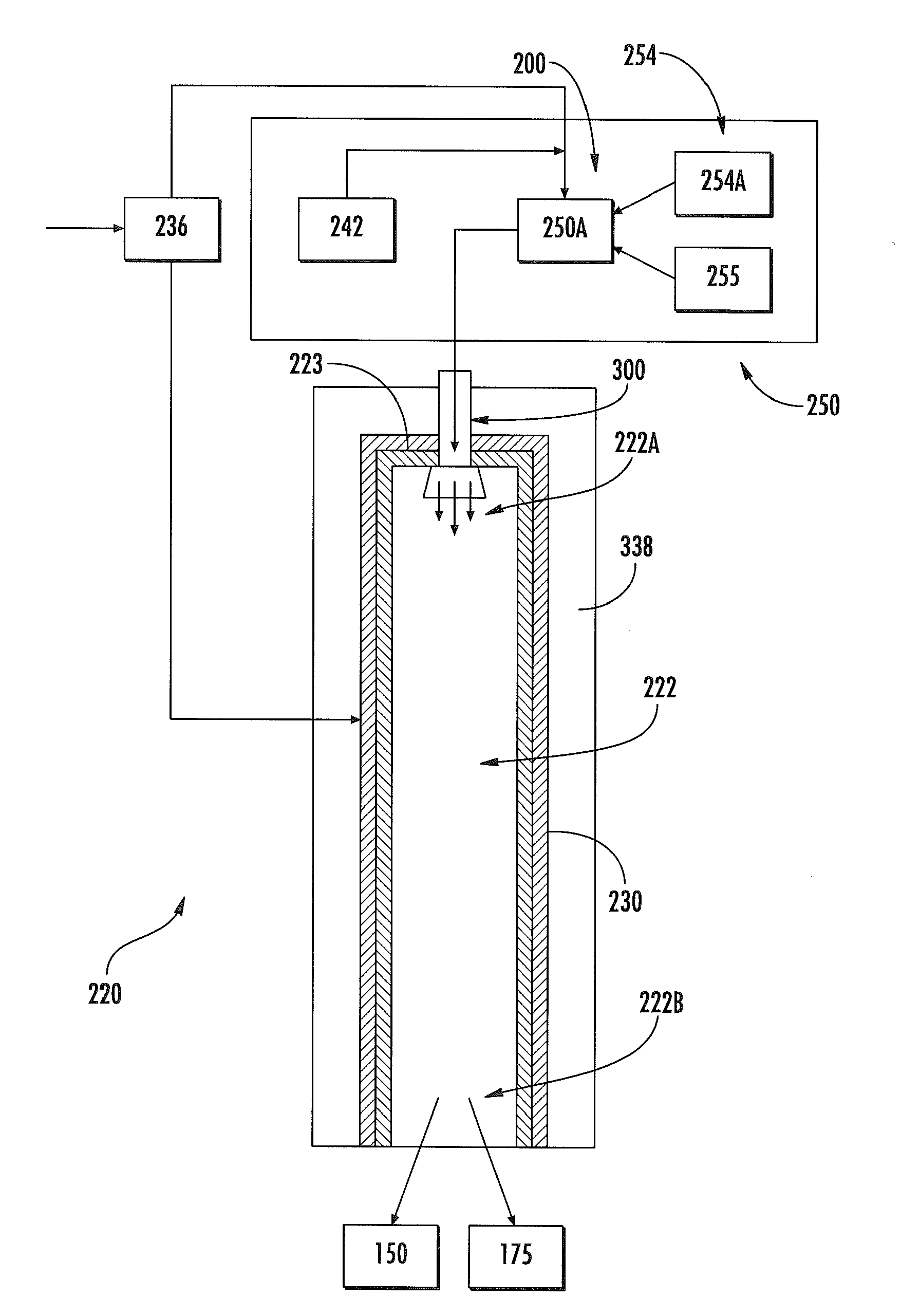

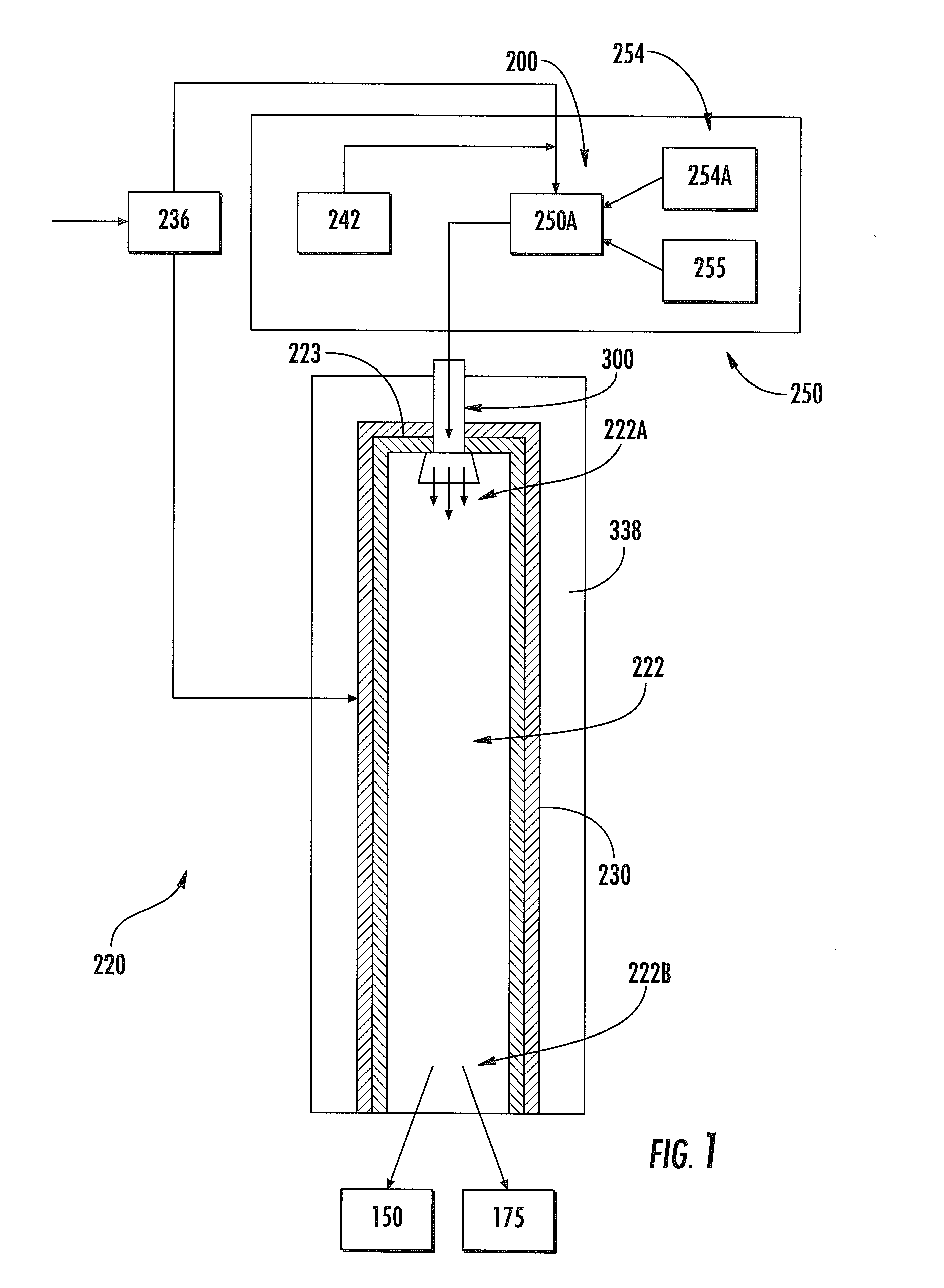

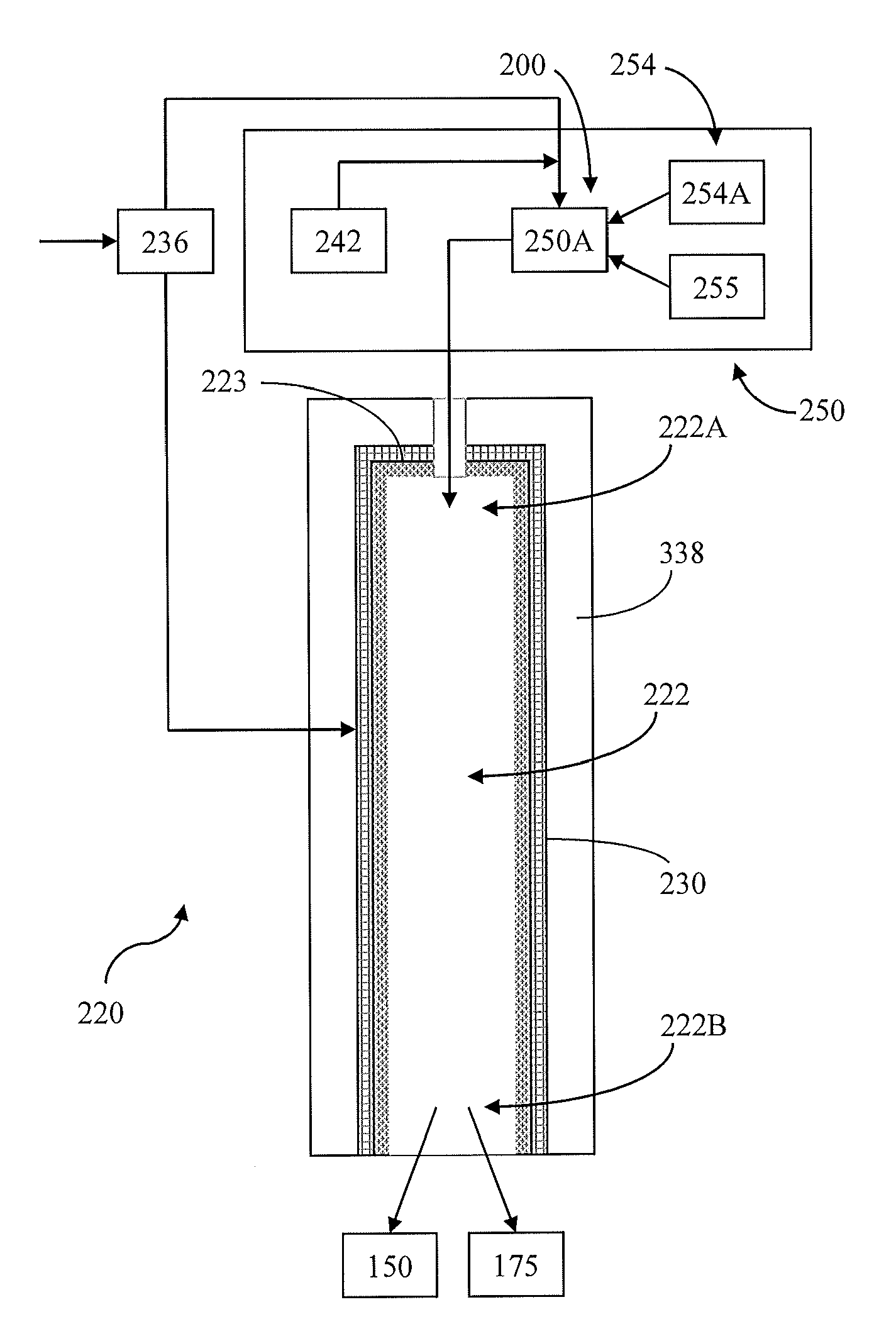

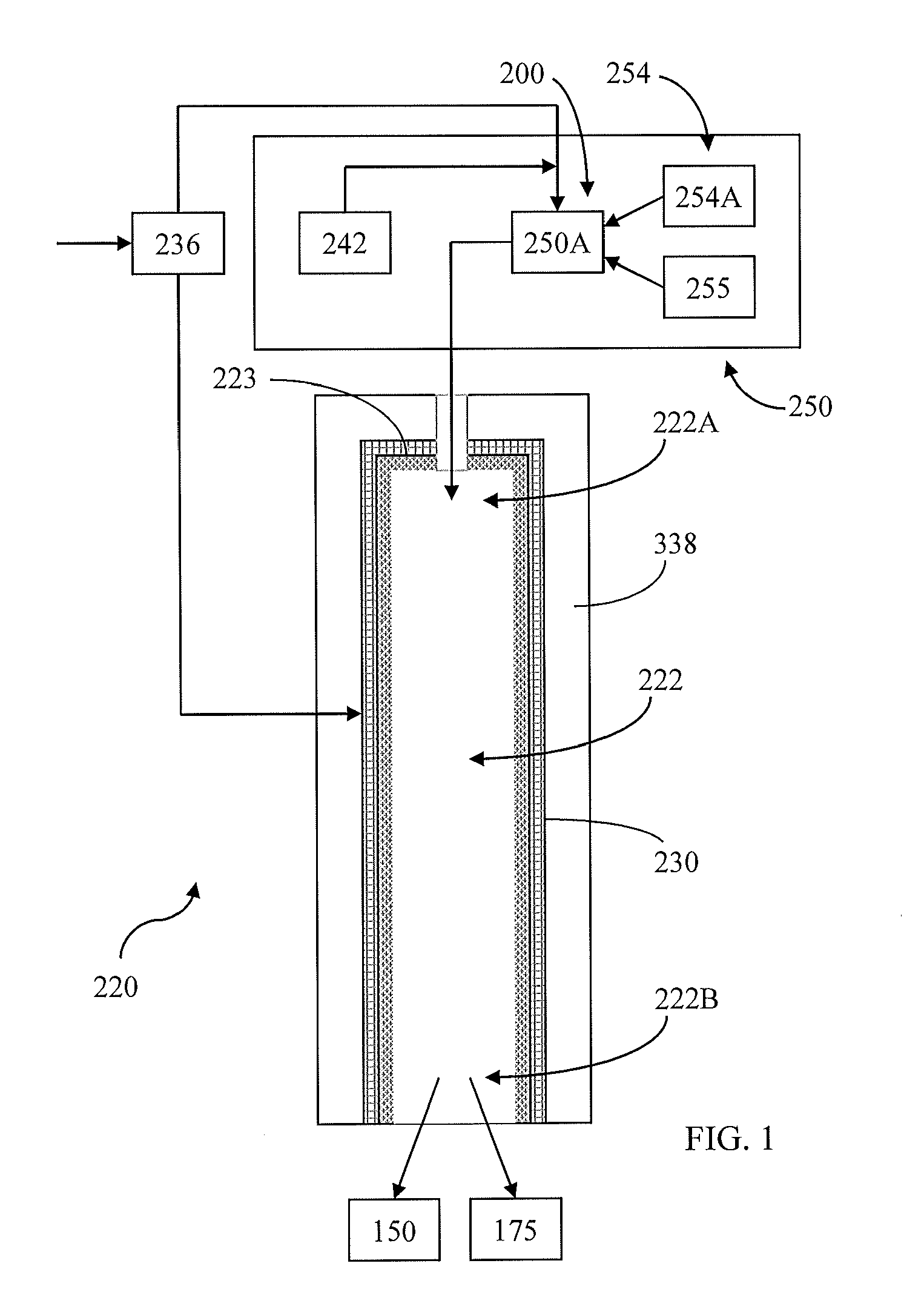

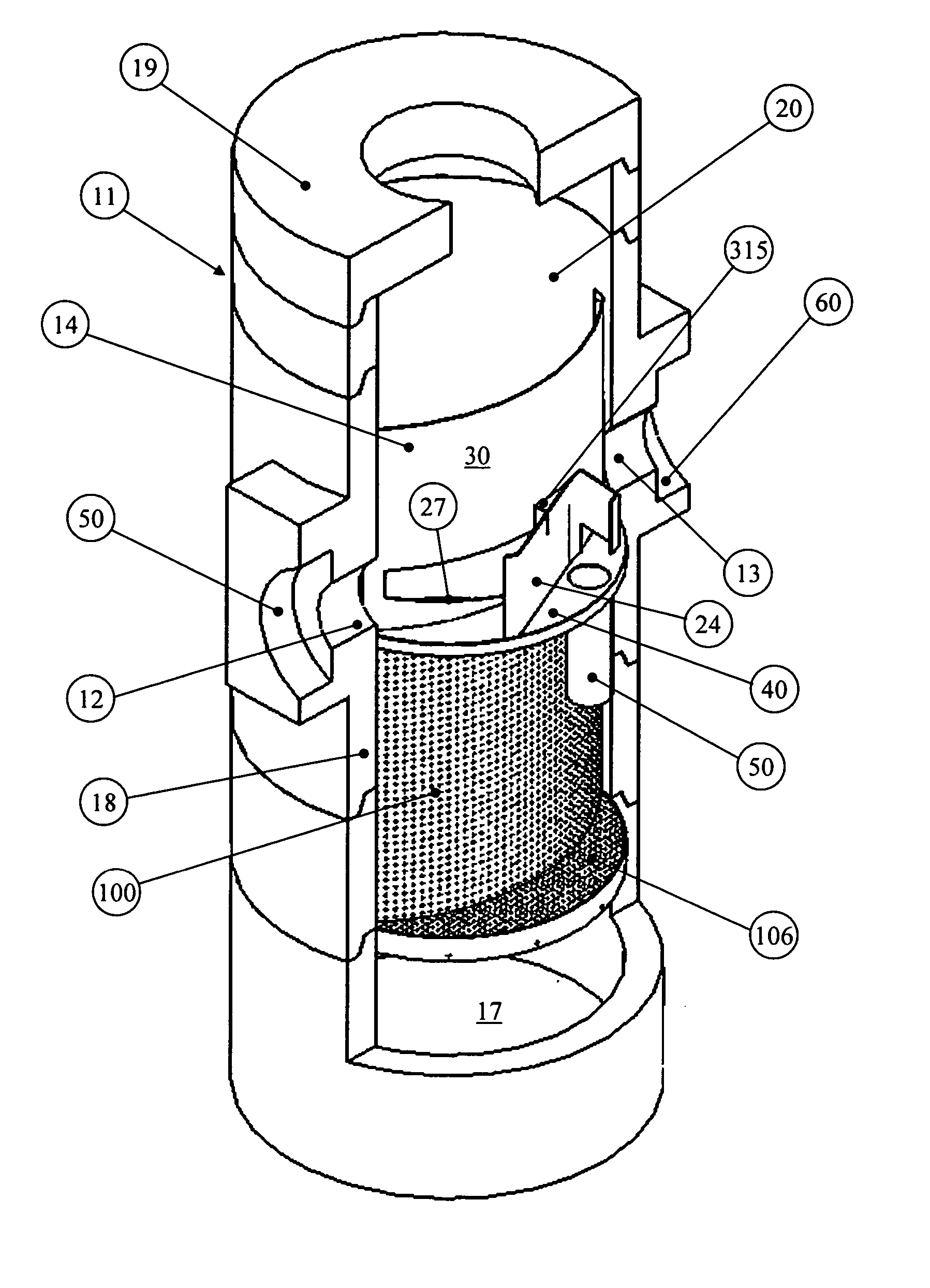

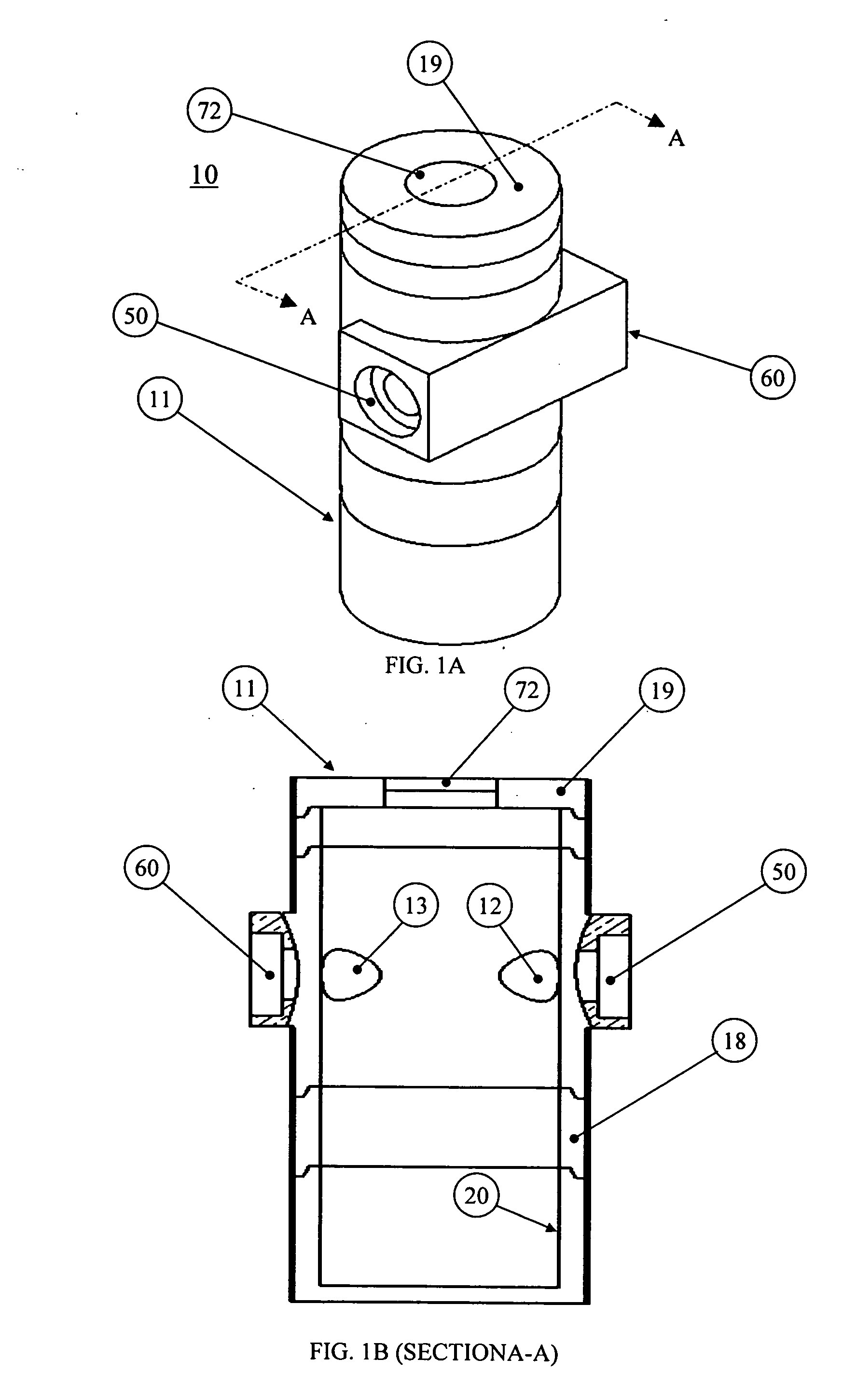

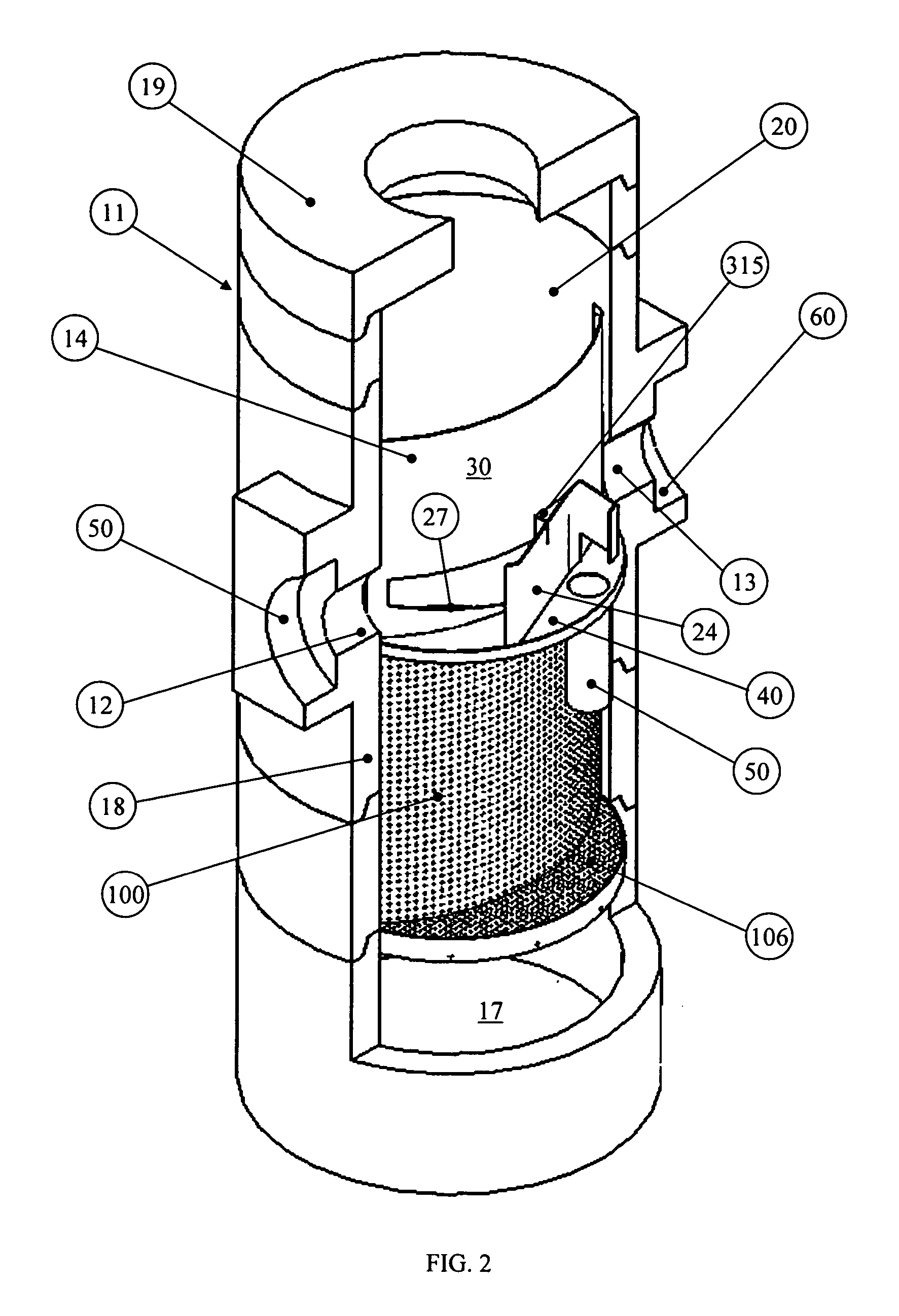

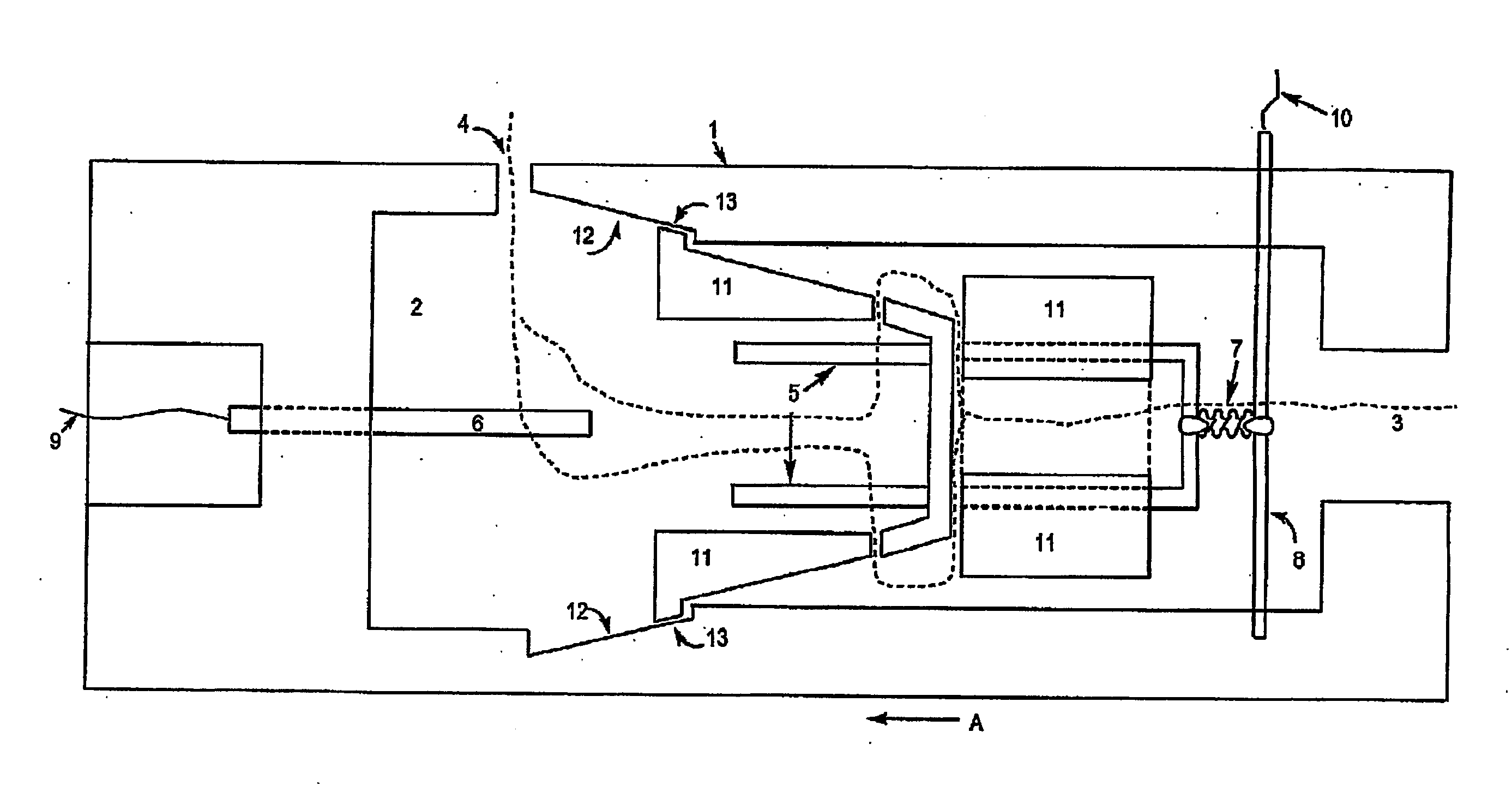

A combustor apparatus is provided, comprising a mixing arrangement for mixing a carbonaceous fuel with enriched oxygen and a working fluid to form a fuel mixture. A combustion chamber is at least partially defined by a porous perimetric transpiration member, at least partially surrounded by a pressure containment member. The combustion chamber has longitudinally spaced apart inlet and outlet portions. The fuel mixture is received by the inlet portion for combustion within the combustion chamber at a combustion temperature to form a combustion product. The combustion chamber further directs the combustion product longitudinally toward the outlet portion. The porous transpiration member is configured to substantially uniformly direct a transpiration substance laterally therethrough, about the perimeter thereof defining the combustion chamber and longitudinally between the inlet and outlet portions, toward the combustion chamber for buffering interaction between the combustion product and the porous transpiration member. Associated systems are also provided.

Owner:8 RIVERS CAPTTAL LLC

Apparatus for combusting a fuel at high pressure and high temperature, and associated system

ActiveUS8986002B2Reducing and eliminating needEliminate damage to and build-upContinuous combustion chamberGas turbine plantsWorking fluidCombustor

A combustor apparatus is provided, comprising a mixing arrangement for mixing a carbonaceous fuel with enriched oxygen and a working fluid to form a fuel mixture. A combustion chamber is at least partially defined by a porous perimetric transpiration member, at least partially surrounded by a pressure containment member. The combustion chamber has longitudinally spaced apart inlet and outlet portions. The fuel mixture is received by the inlet portion for combustion within the combustion chamber at a combustion temperature to form a combustion product. The combustion chamber directs the combustion product longitudinally toward the outlet portion. The transpiration member is configured to substantially uniformly direct a transpiration substance therethrough toward the combustion chamber, such that the transpiration substance is directed to flow helically about the perimeter and longitudinally between the inlet and outlet portions, for buffering interaction between the combustion product and the transpiration member. Associated systems are also provided.

Owner:8 RIVERS CAPTTAL LLC

Apparatus and Method for Combusting a Fuel at High Pressure and High Temperature, and Associated System and Device

ActiveUS20100300063A1Enhanced overall recoveryReducing and eliminating needSolidificationLiquefactionWorking fluidCombustion chamber

A combustor apparatus is provided, comprising a mixing arrangement for mixing a carbonaceous fuel with enriched oxygen and a working fluid to form a fuel mixture. A combustion chamber is at least partially defined by a transpiration member. The transpiration member is at least partially surrounded by a pressure containment member. The combustion chamber has opposed inlet and outlet portions. The inlet portion of the combustion chamber is configured to receive the fuel mixture for the fuel mixture to be combusted at a combustion temperature. The combustion chamber is further configured to direct the resulting combustion product toward the outlet portion. The transpiration member directs a transpiration substance therethrough toward the combustion chamber for buffering interaction between the combustion product and the transpiration member. Associated systems, apparatuses, and methods are also provided.

Owner:8 RIVERS CAPTTAL LLC

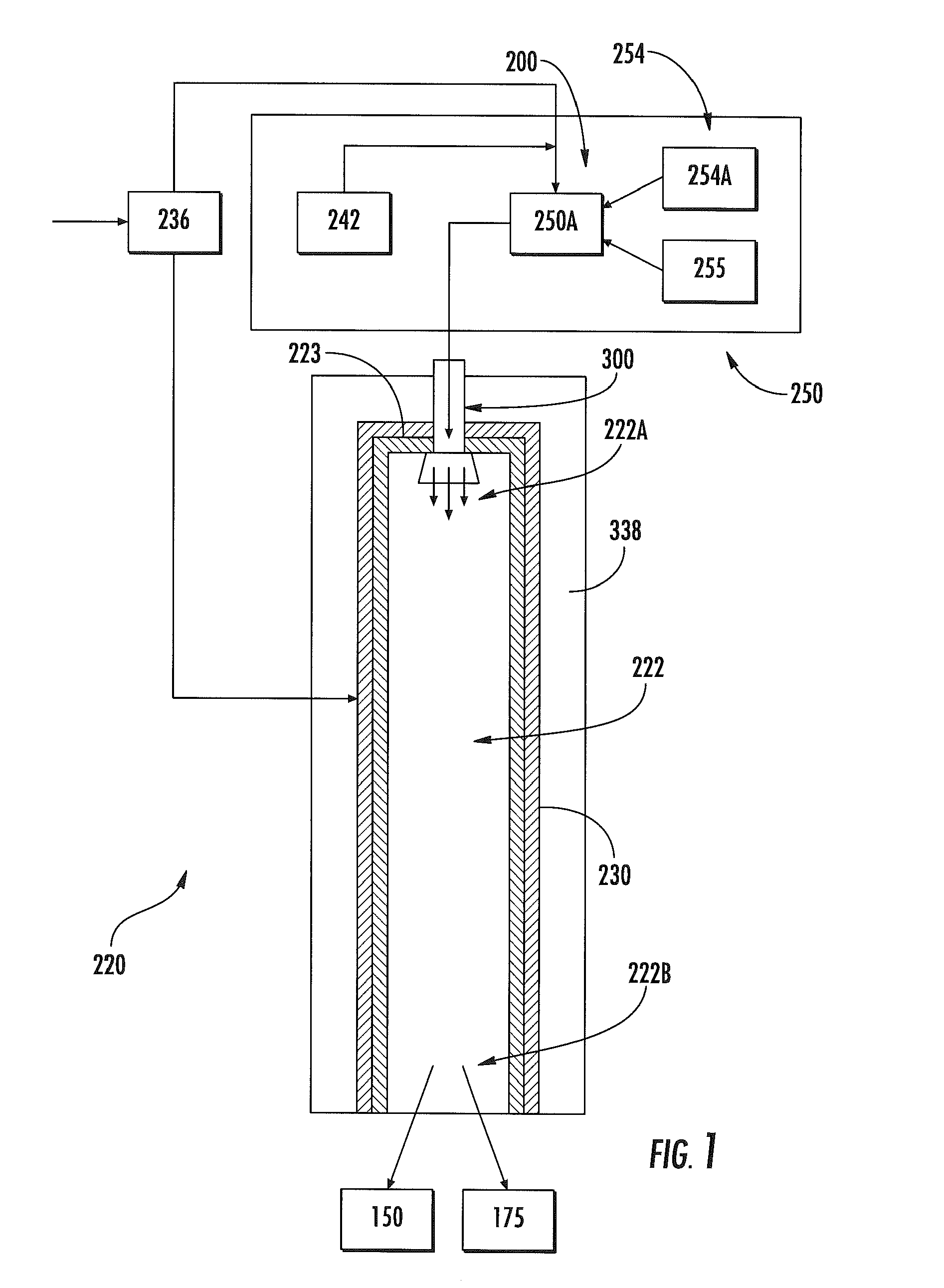

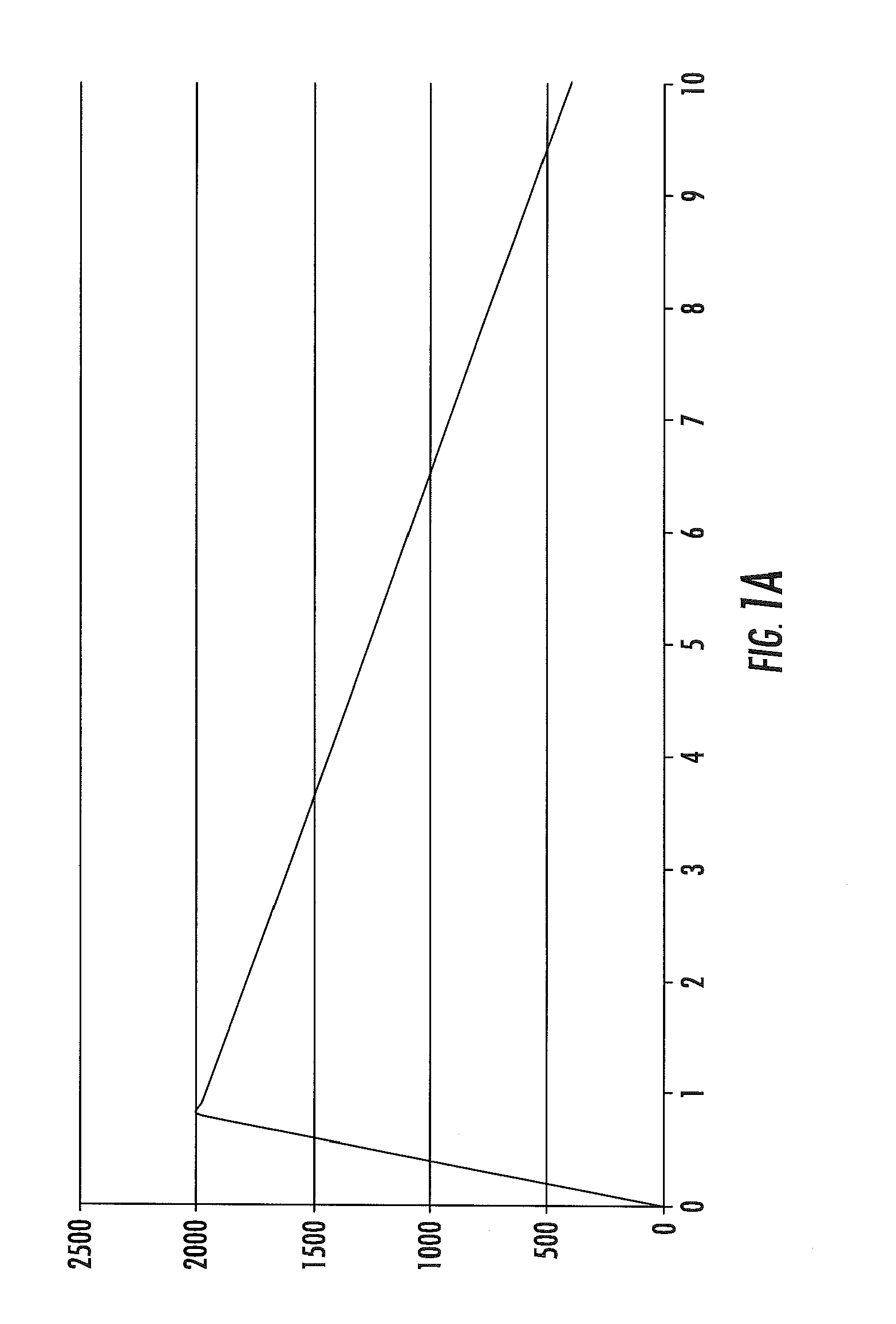

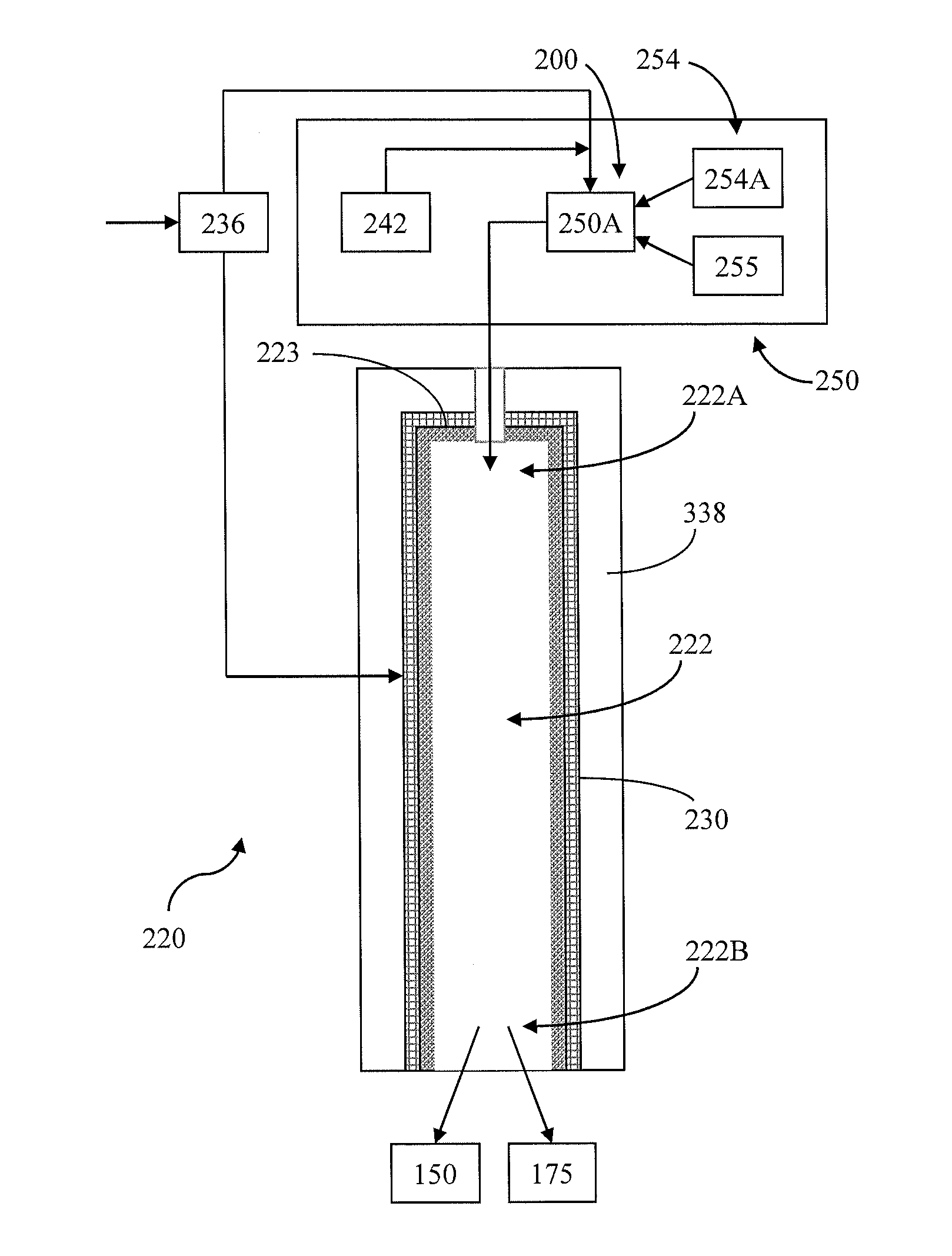

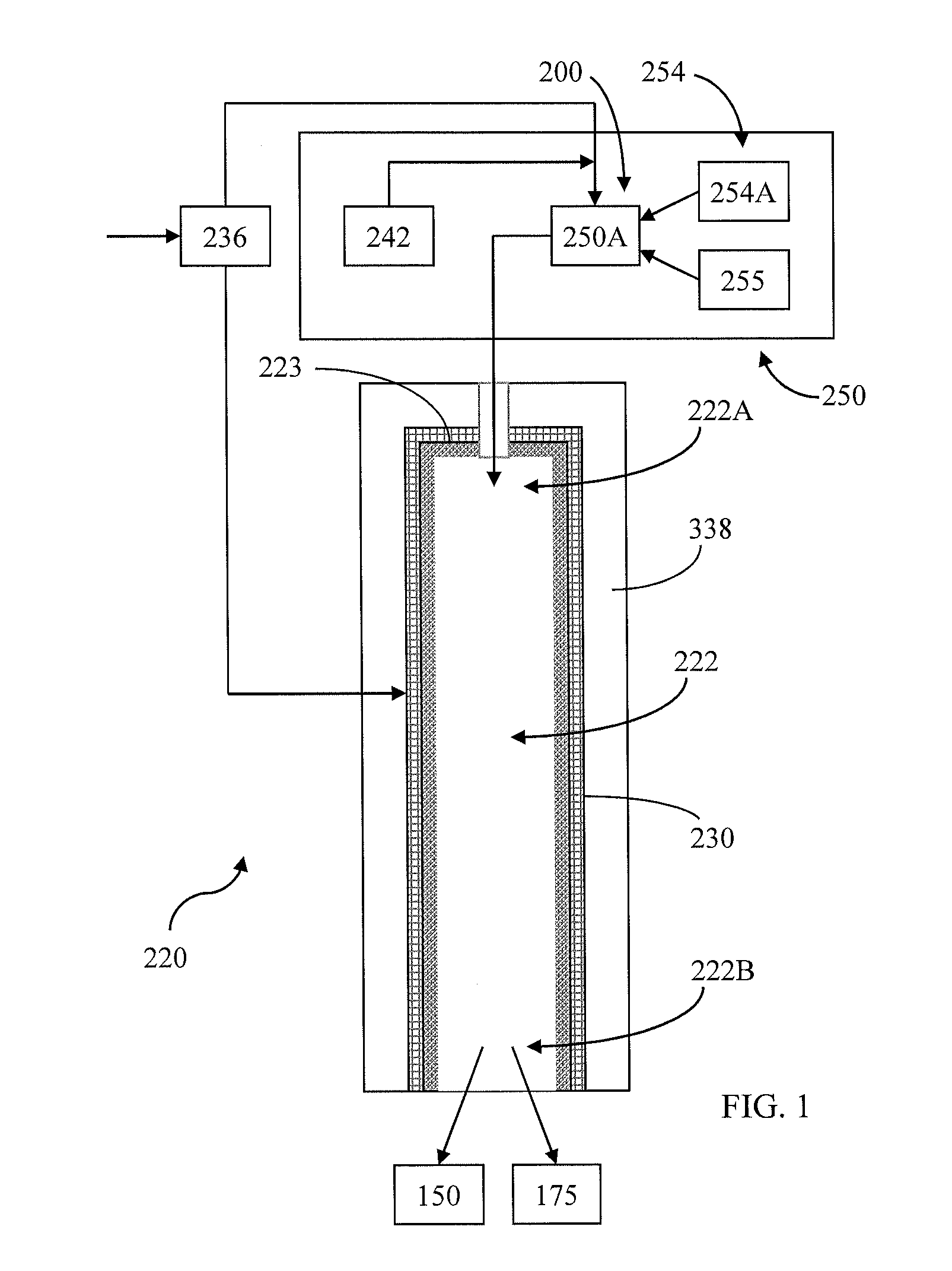

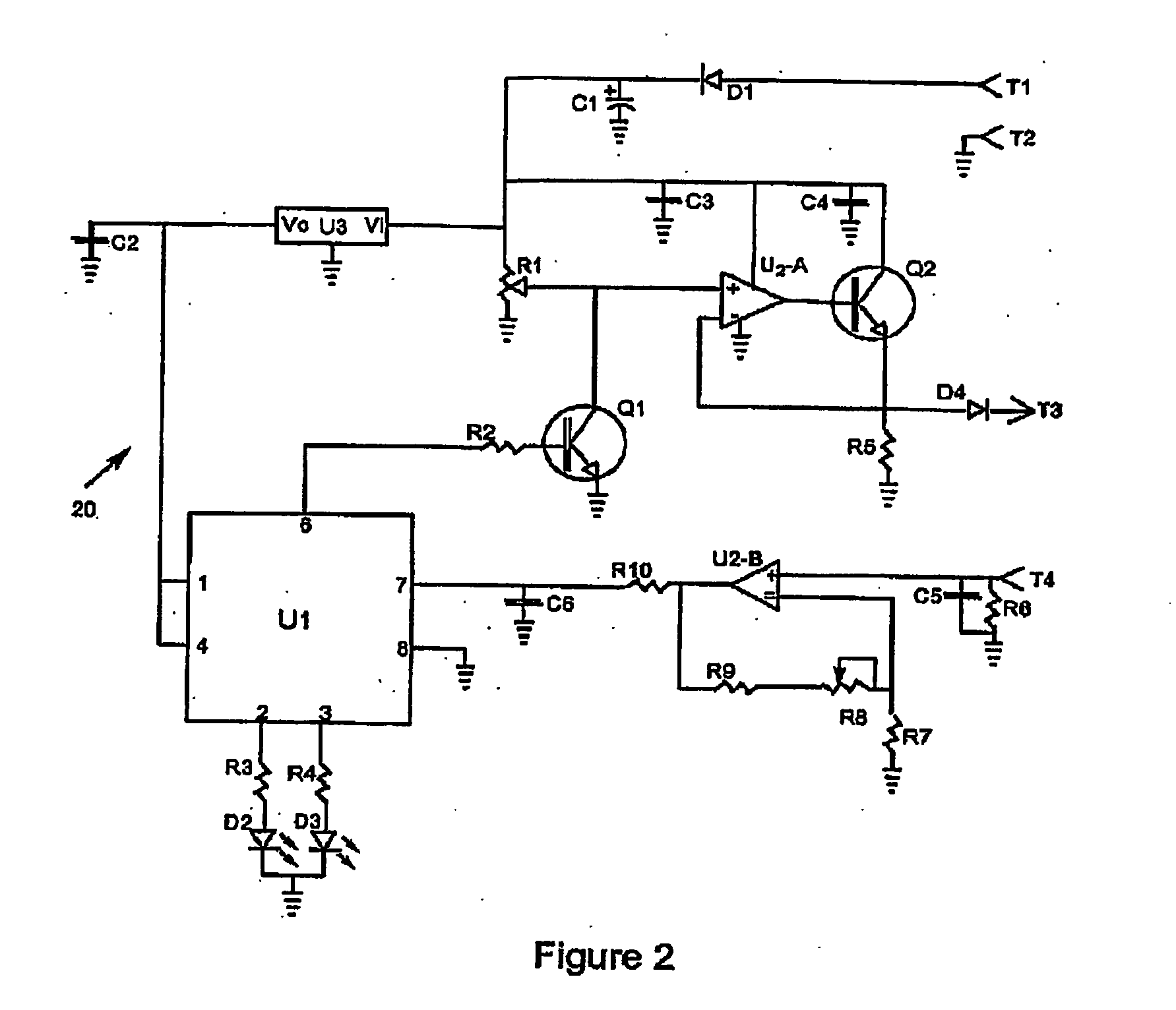

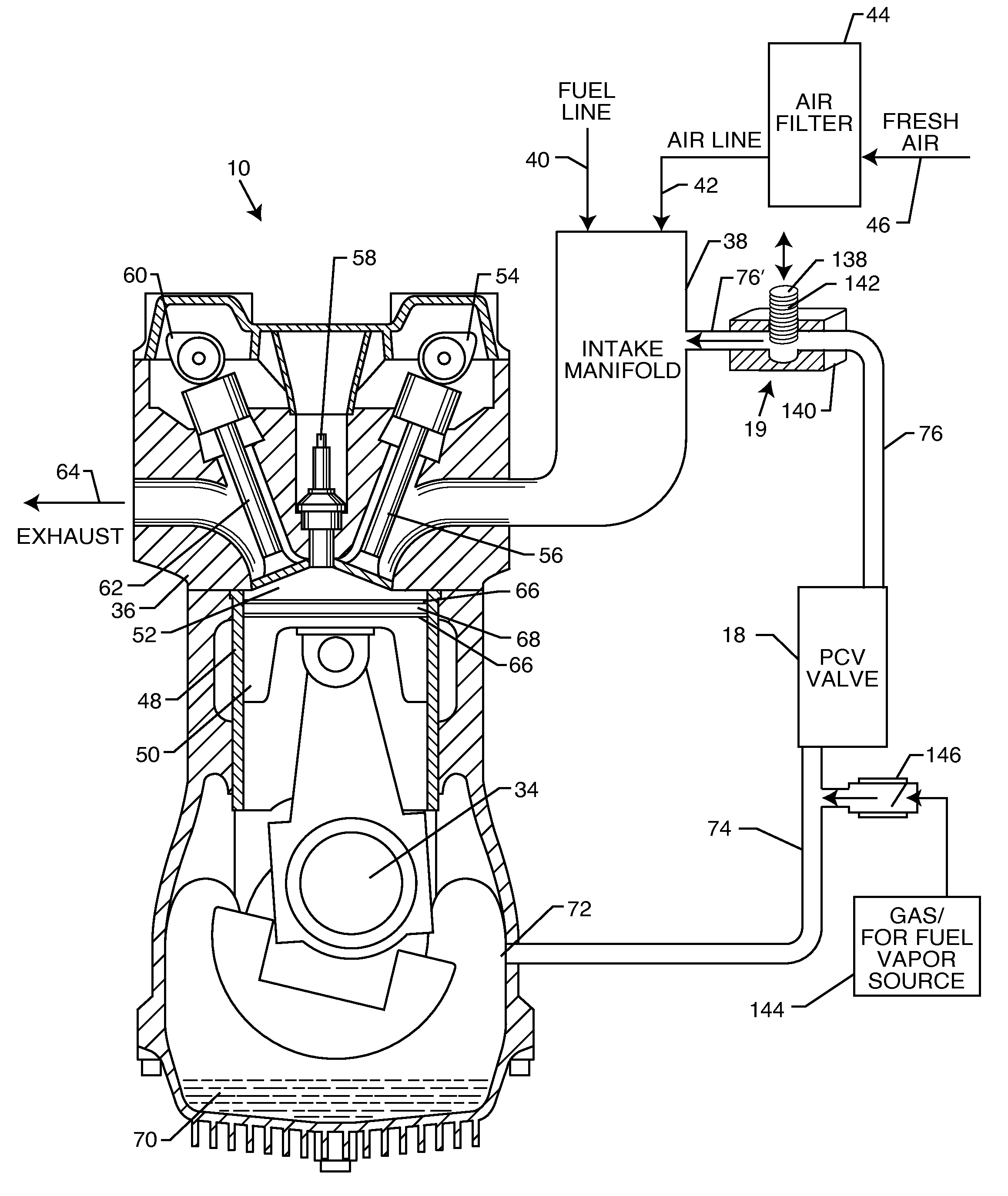

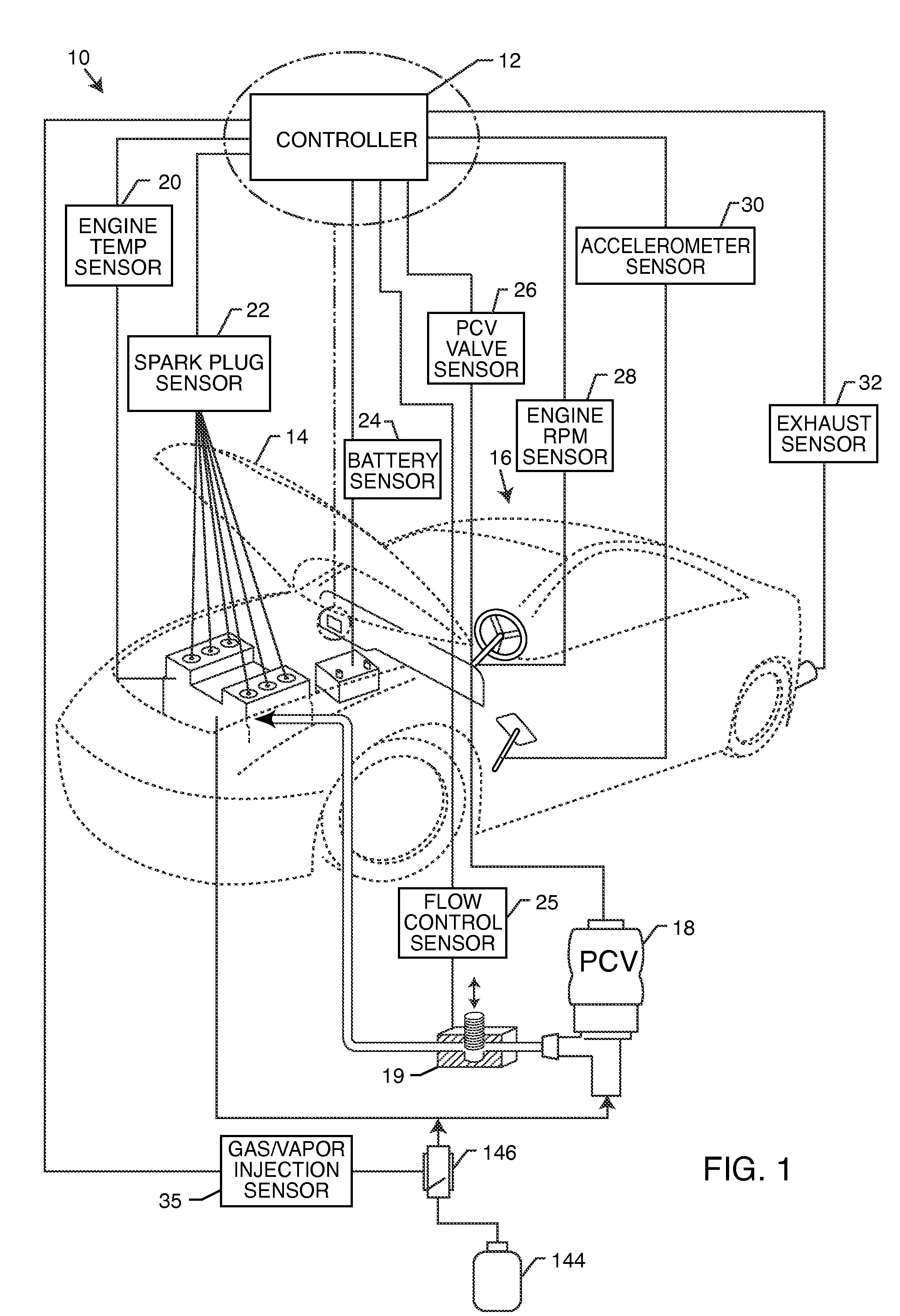

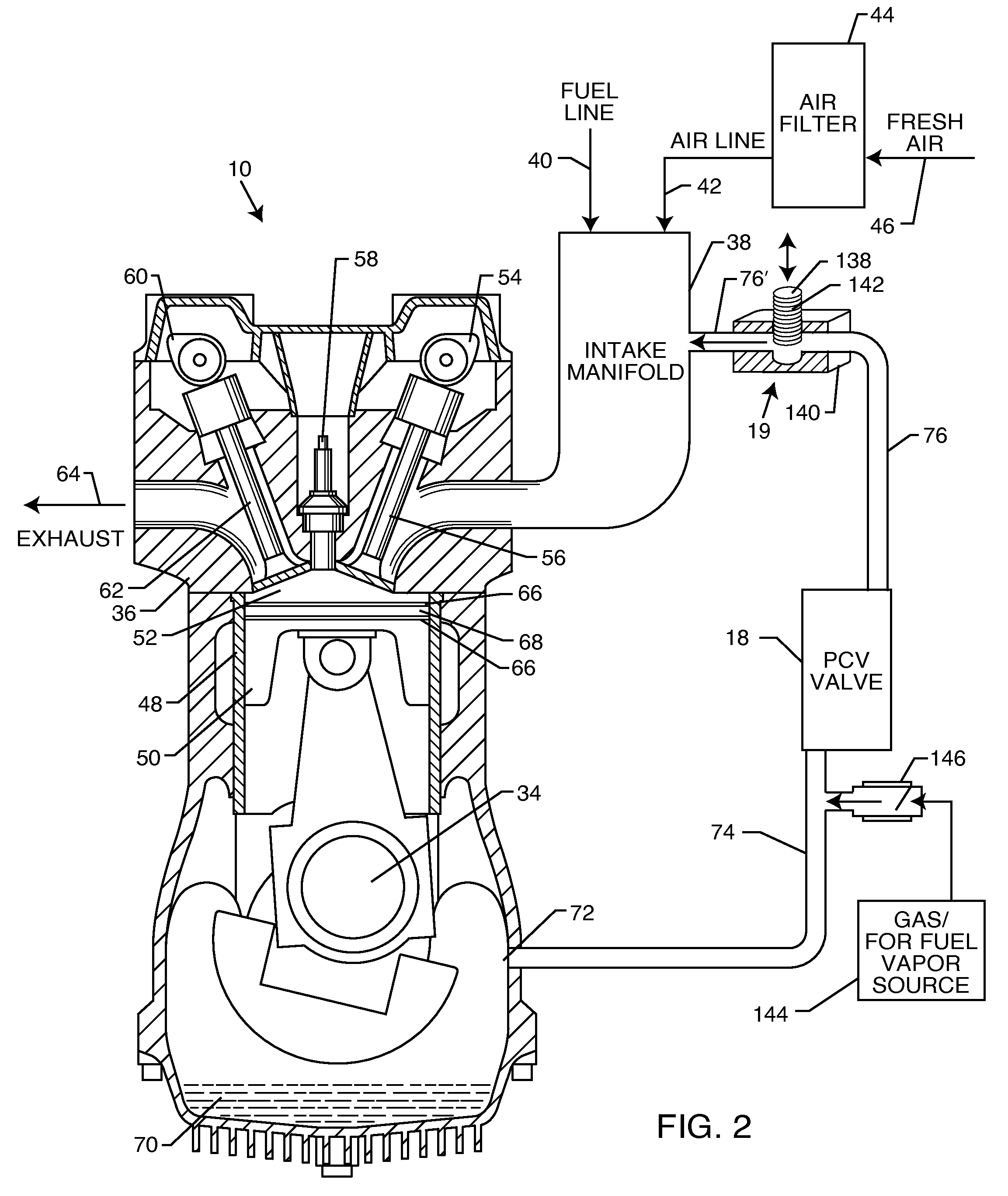

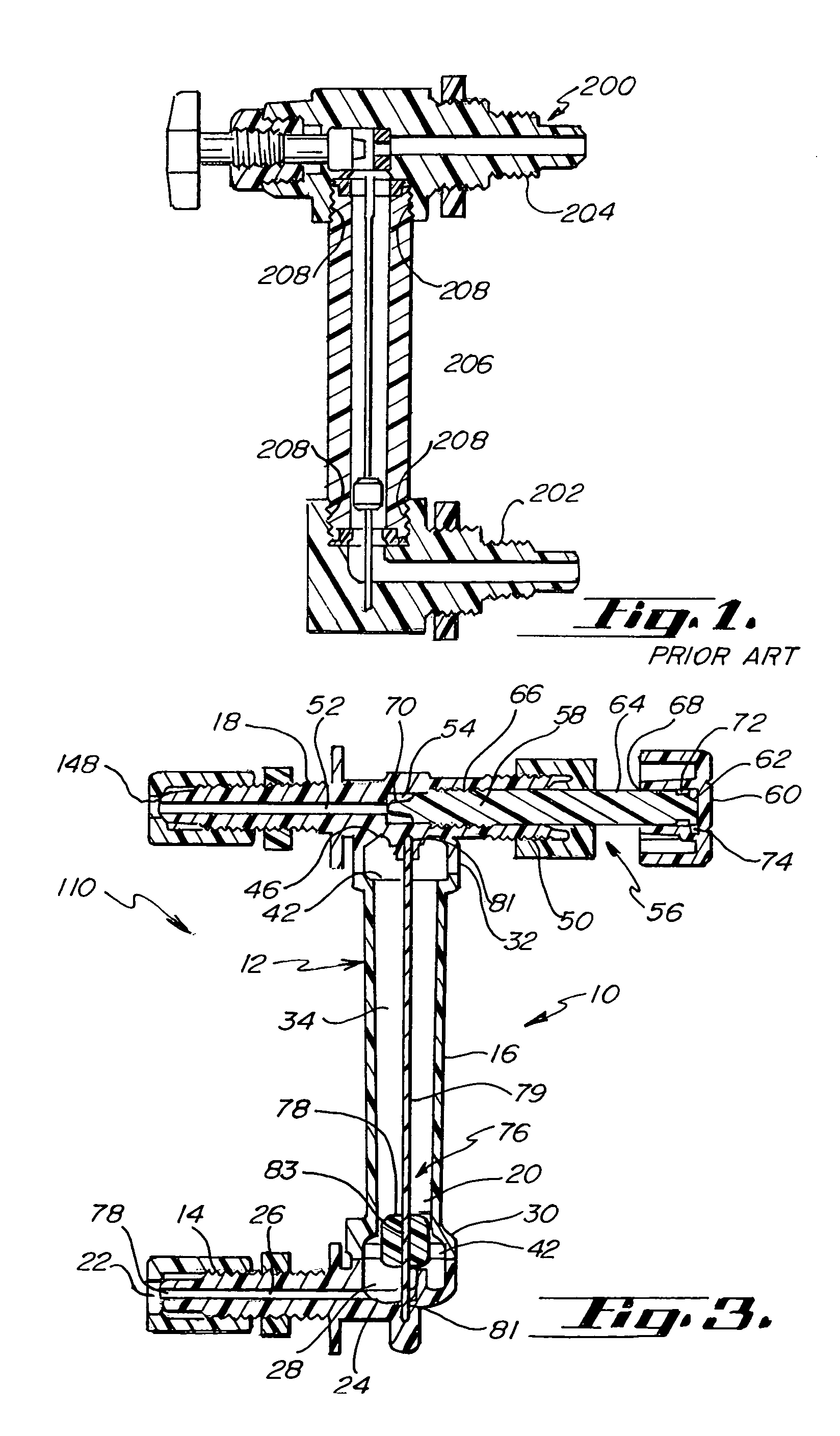

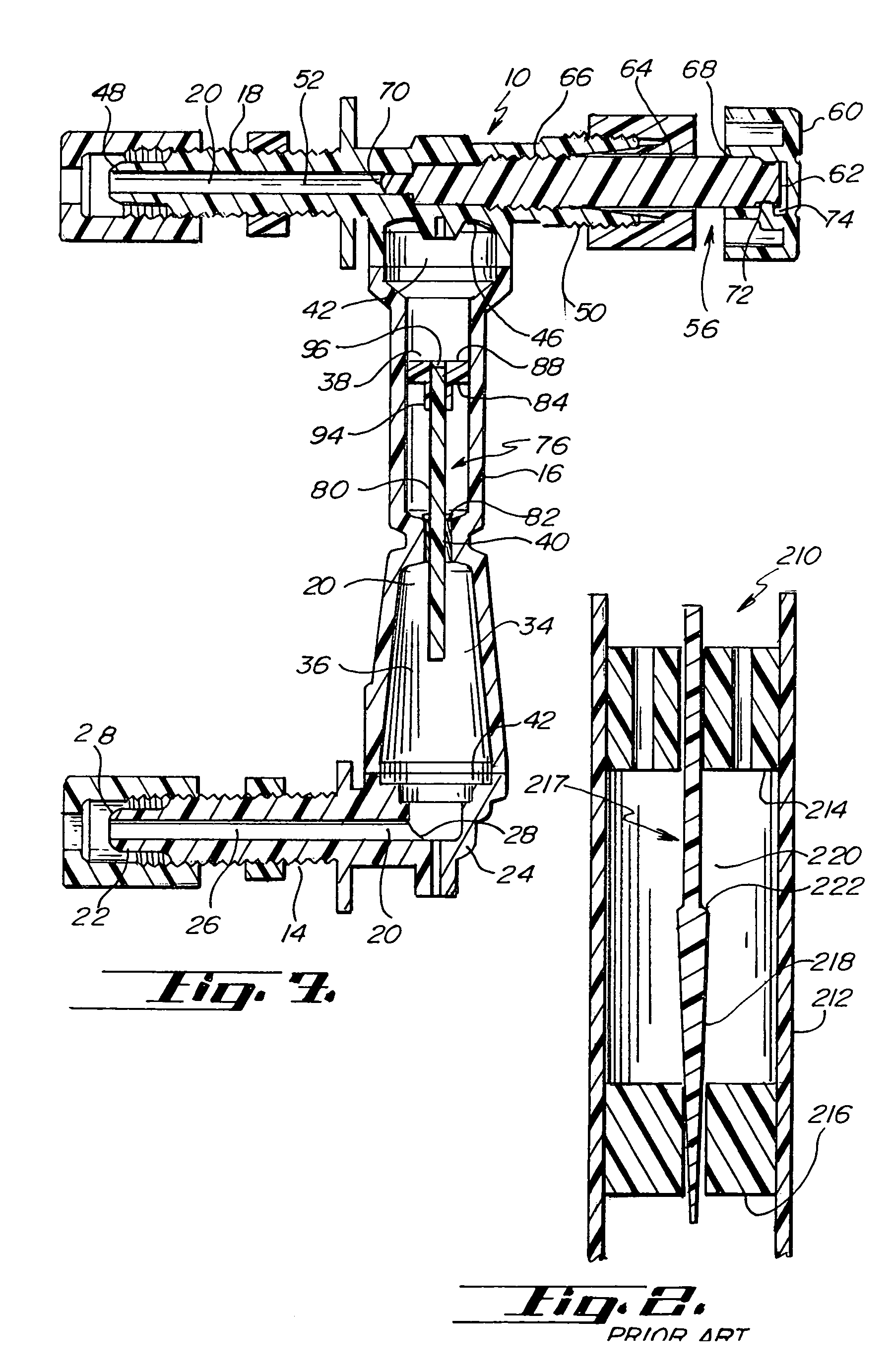

Pollution control system

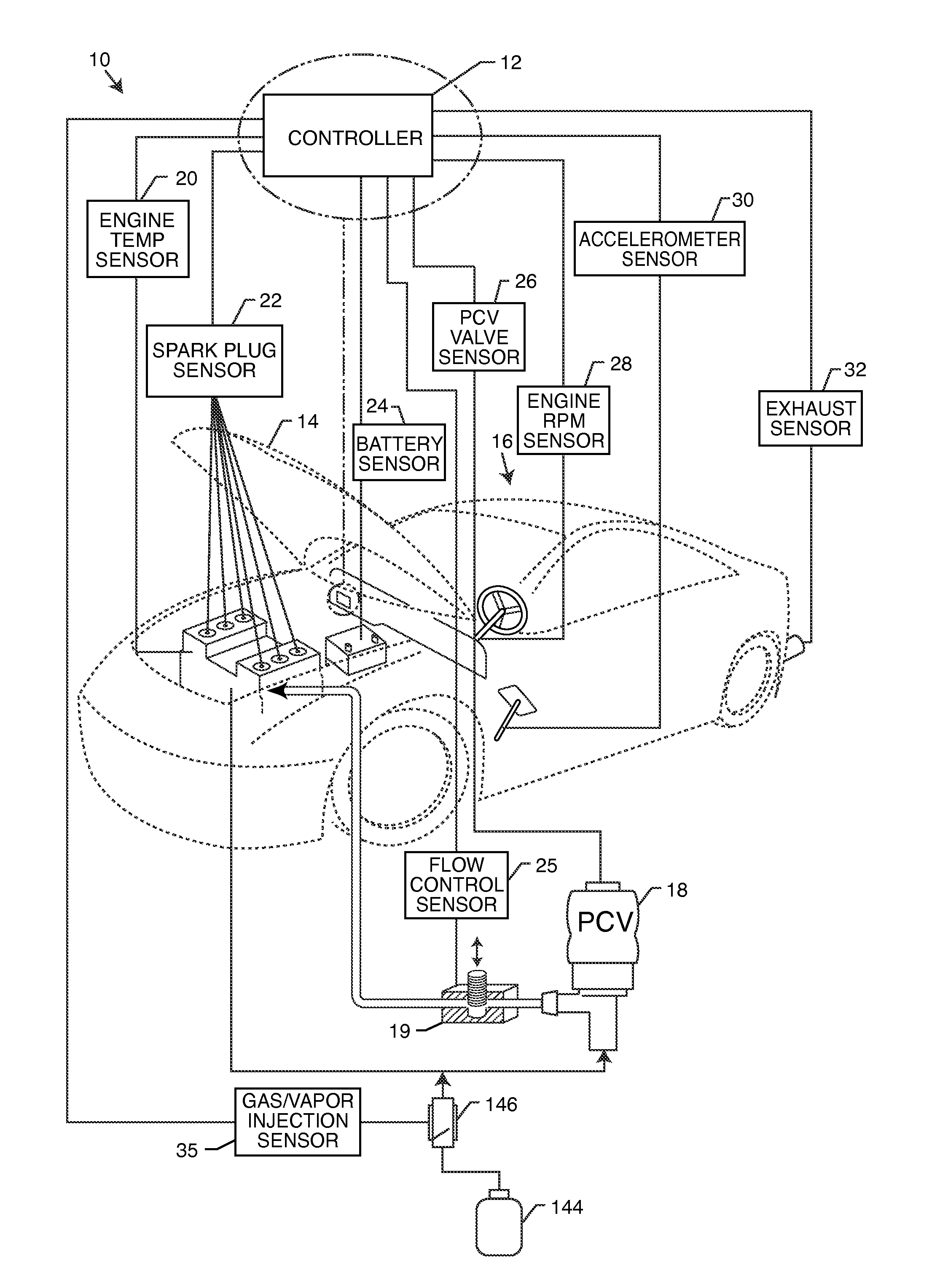

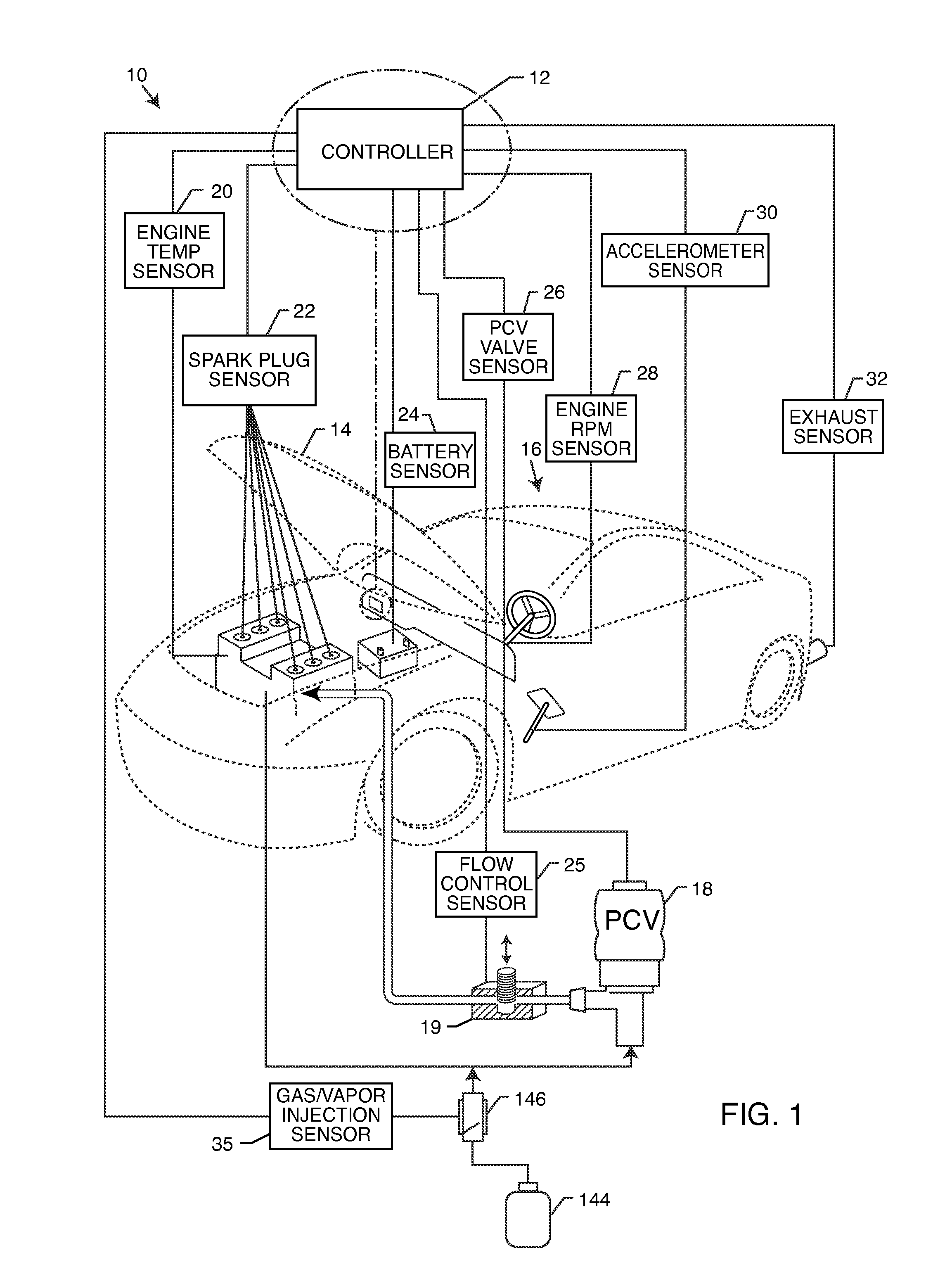

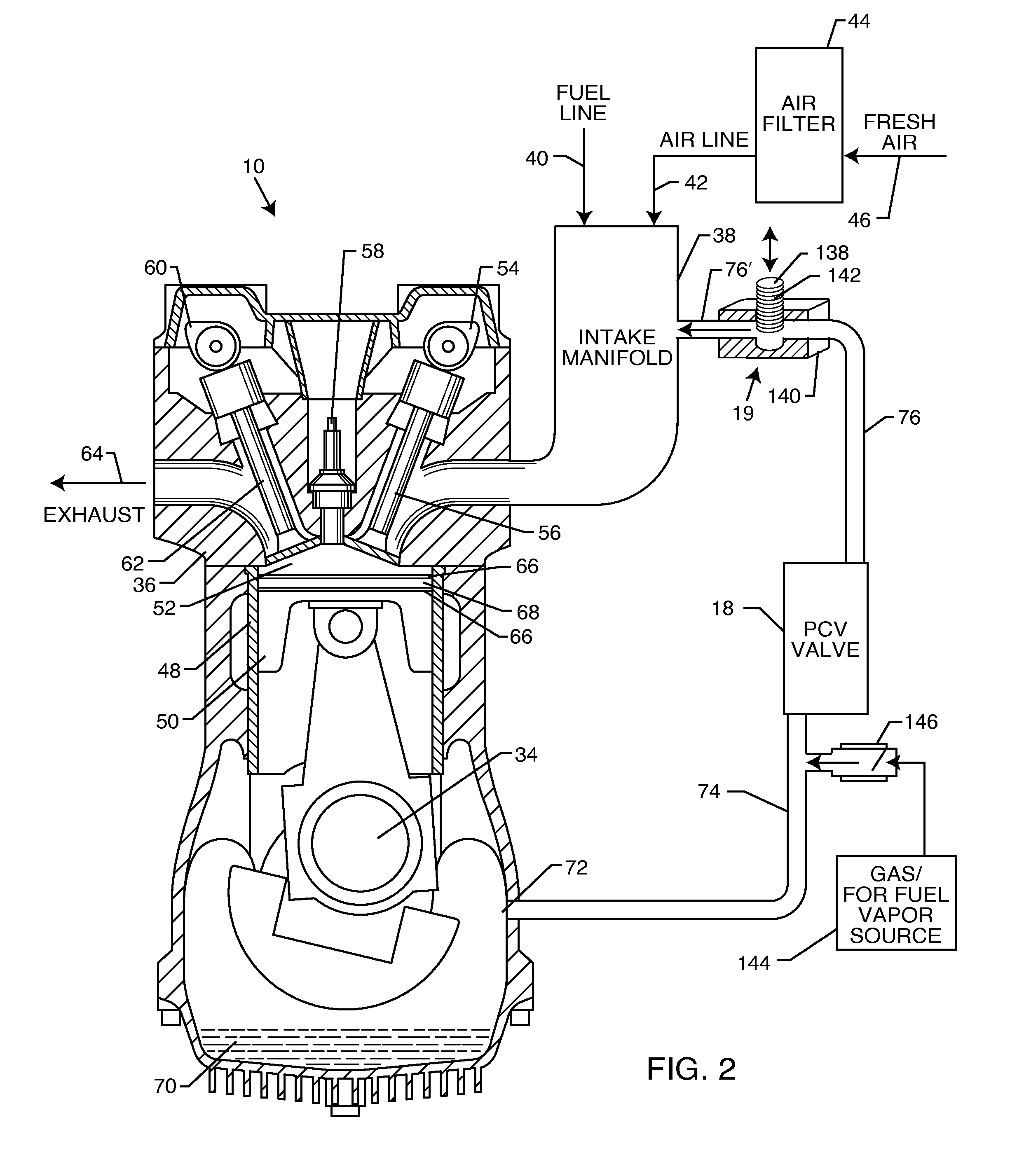

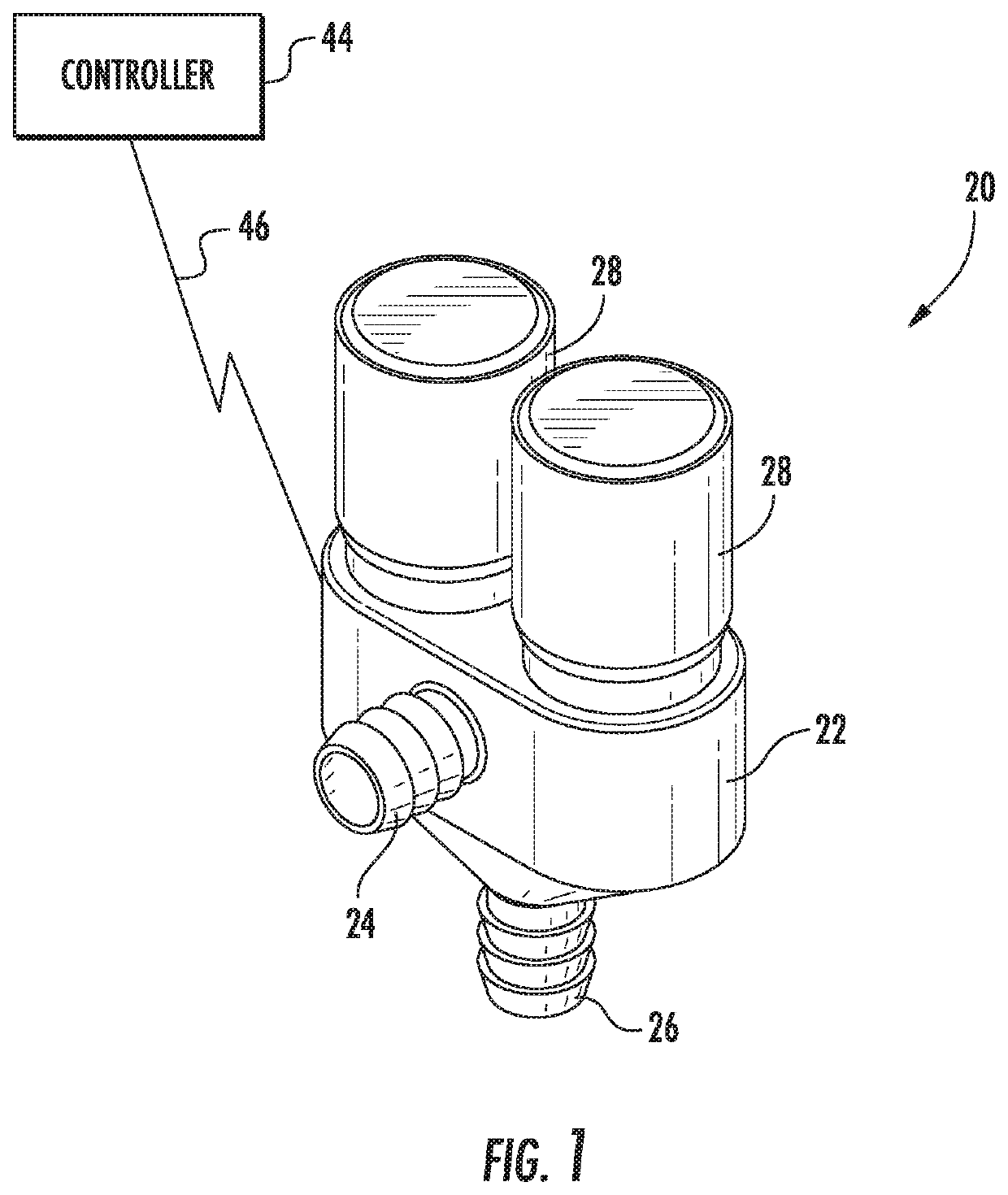

ActiveUS20100076664A1Reduce fluid flow rateIncrease fluid velocityAnalogue computers for vehiclesInternal combustion piston enginesVacuum pressureCombustion

The pollution control system includes a controller coupled to a sensor monitoring an operational characteristic of a combustion engine, such as engine RPM. A PCV valve having an inlet and an outlet is adapted to vent blow-by gas out from the combustion engine. A fluid regulator associated with the PCV valve and responsive to the controller selectively modulates engine vacuum pressure to adjustably increase or decrease a fluid flow rate of blow-by gas venting from the combustion engine. The controller selectively adjustably positions the fluid regulator to vary the degree of vacuum pressure to optimize the recycling of blow-by gases.

Owner:SVMTECH

Apparatus for combusting a fuel at high pressure and high temperature, and associated system

ActiveUS20120073261A1Improve efficiencyLower cost of capitalGas turbine plantsDirect carbon-dioxide mitigationNuclear engineeringCombustion chamber

A combustor apparatus is provided, comprising a mixing arrangement for mixing a carbonaceous fuel with enriched oxygen and a working fluid to form a fuel mixture. A combustion chamber is at least partially defined by a porous perimetric transpiration member, at least partially surrounded by a pressure containment member. The combustion chamber has longitudinally spaced apart inlet and outlet portions. The fuel mixture is received by the inlet portion for combustion within the combustion chamber at a combustion temperature to form a combustion product. The combustion chamber directs the combustion product longitudinally toward the outlet portion. The transpiration member is configured to substantially uniformly direct a transpiration substance therethrough toward the combustion chamber, such that the transpiration substance is directed to flow helically about the perimeter and longitudinally between the inlet and outlet portions, for buffering interaction between the combustion product and the transpiration member. Associated systems are also provided.

Owner:8 RIVERS CAPTTAL LLC

Apparatus for combusting a fuel at high pressure and high temperature, and associated system

ActiveUS20110083435A1Enhance oil recoverySave powerGas turbine plantsDirect carbon-dioxide mitigationNuclear engineeringCombustion chamber

A combustor apparatus is provided, comprising a mixing arrangement for mixing a carbonaceous fuel with enriched oxygen and a working fluid to form a fuel mixture. A combustion chamber is at least partially defined by a porous perimetric transpiration member, at least partially surrounded by a pressure containment member. The combustion chamber has longitudinally spaced apart inlet and outlet portions. The fuel mixture is received by the inlet portion for combustion within the combustion chamber at a combustion temperature to form a combustion product. The combustion chamber further directs the combustion product longitudinally toward the outlet portion. The porous transpiration member is configured to substantially uniformly direct a transpiration substance laterally therethrough, about the perimeter thereof defining the combustion chamber and longitudinally between the inlet and outlet portions, toward the combustion chamber for buffering interaction between the combustion product and the porous transpiration member. Associated systems are also provided.

Owner:8 RIVERS CAPTTAL LLC

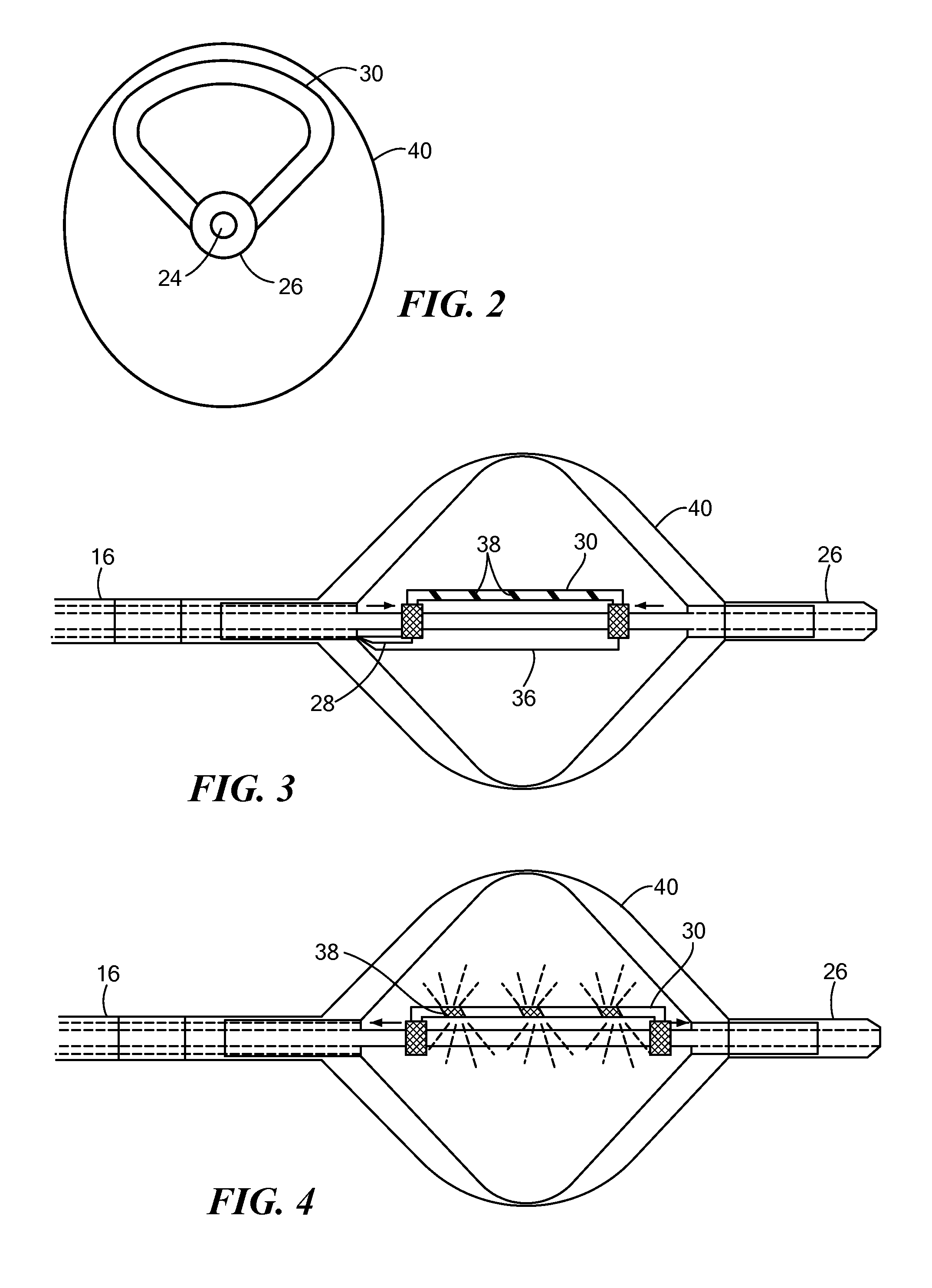

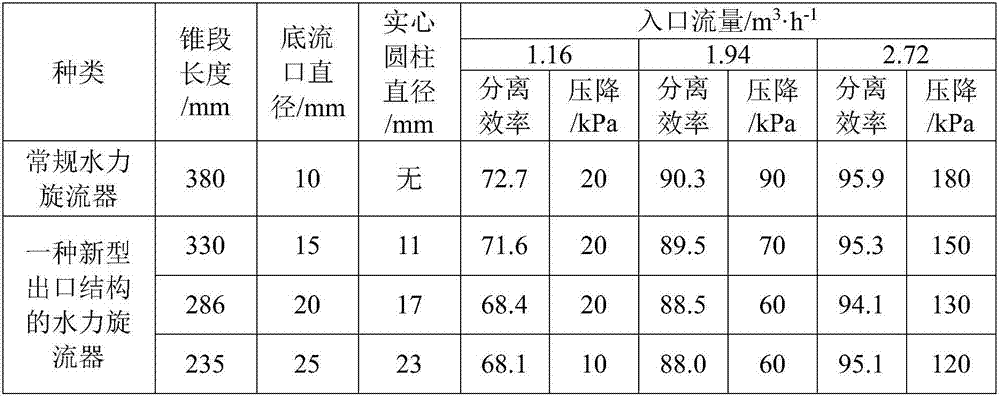

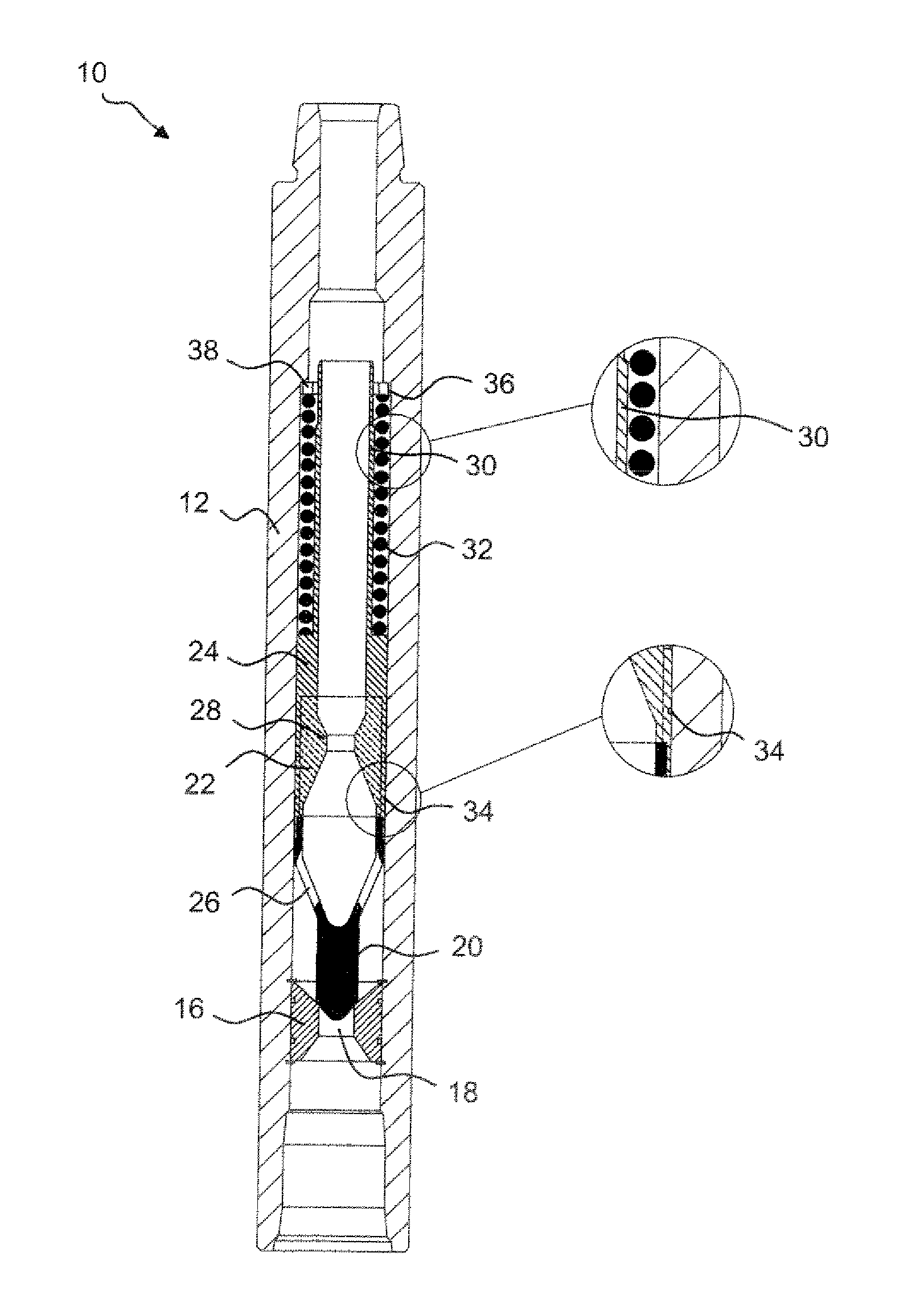

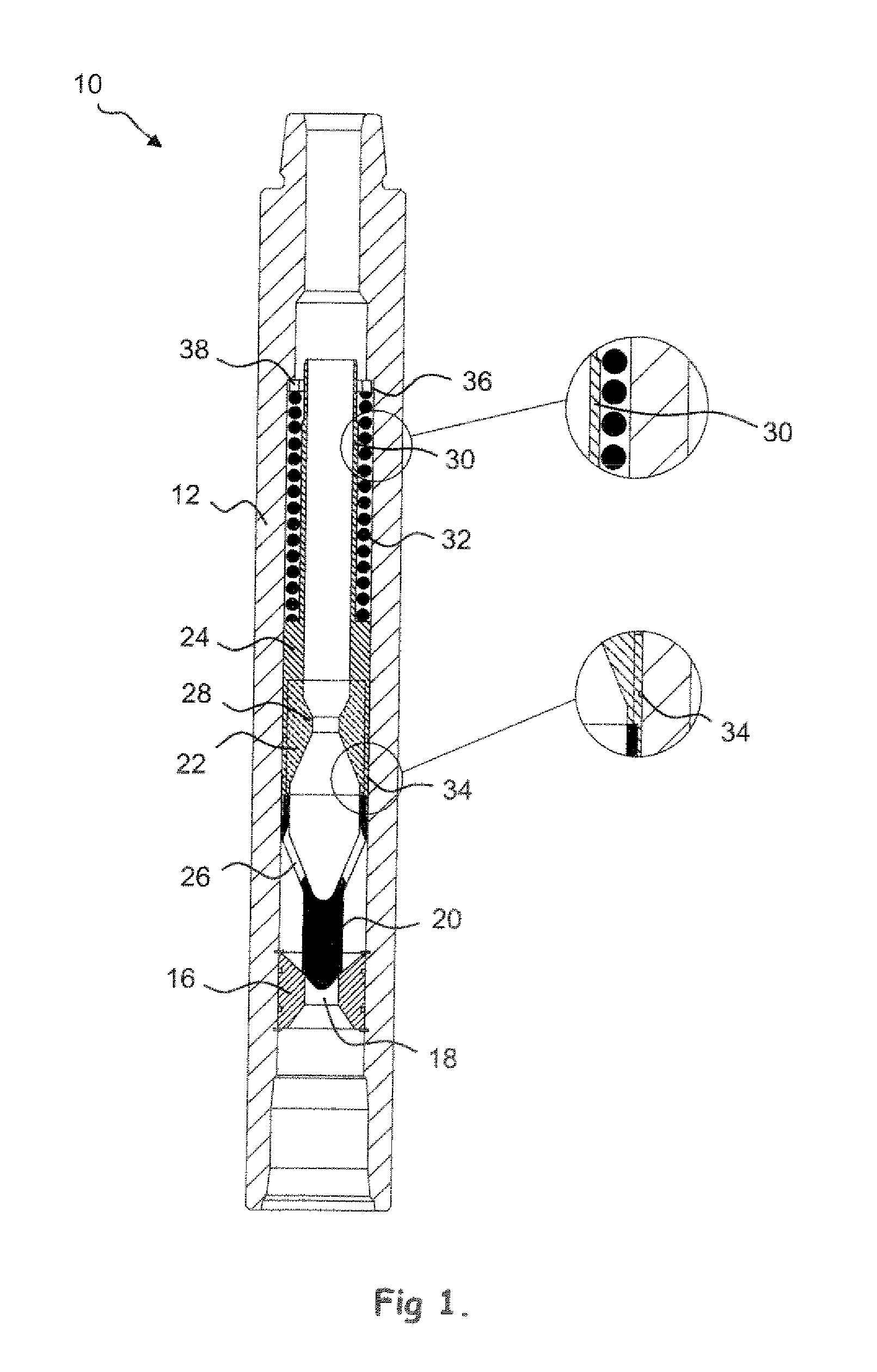

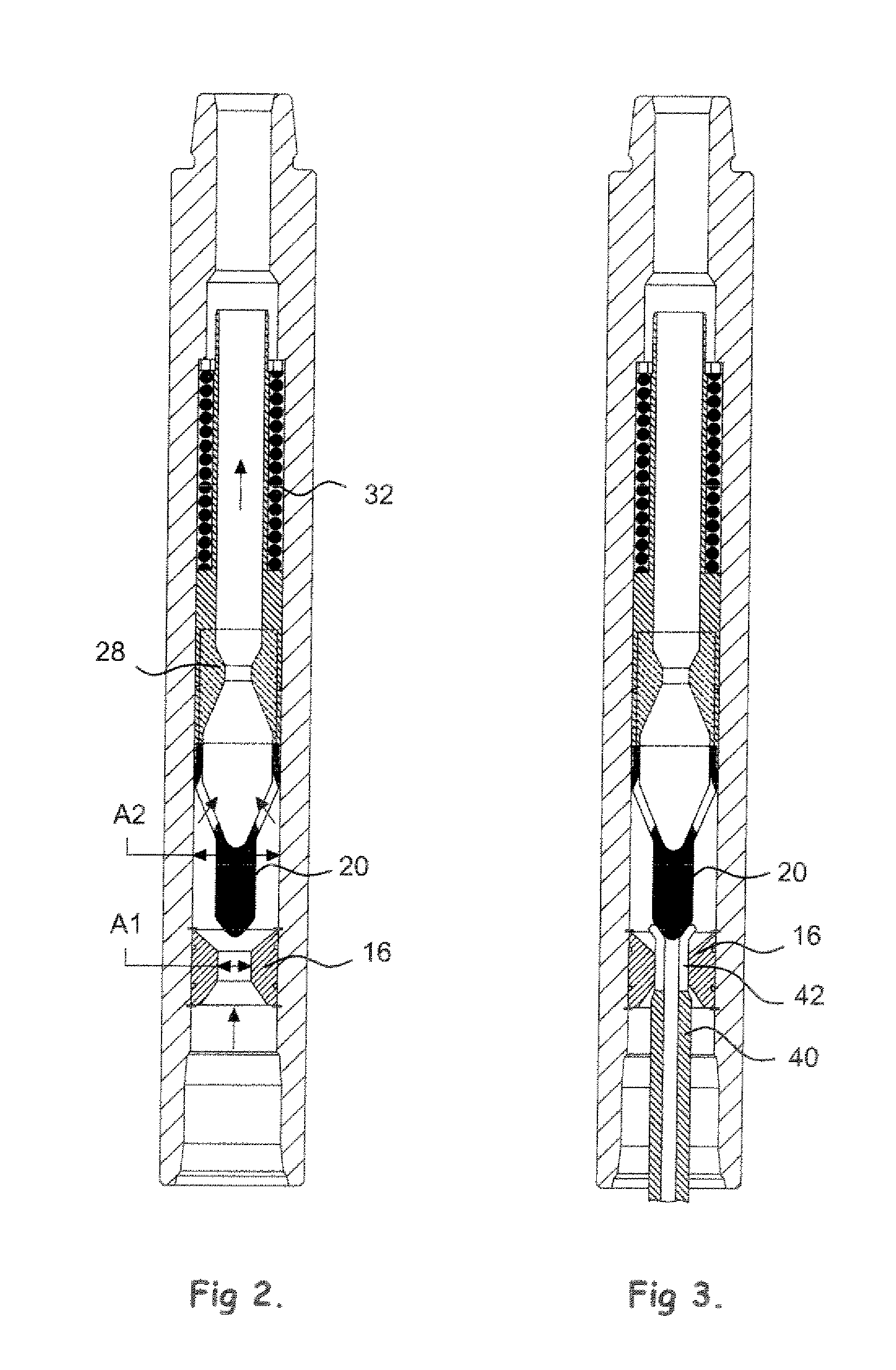

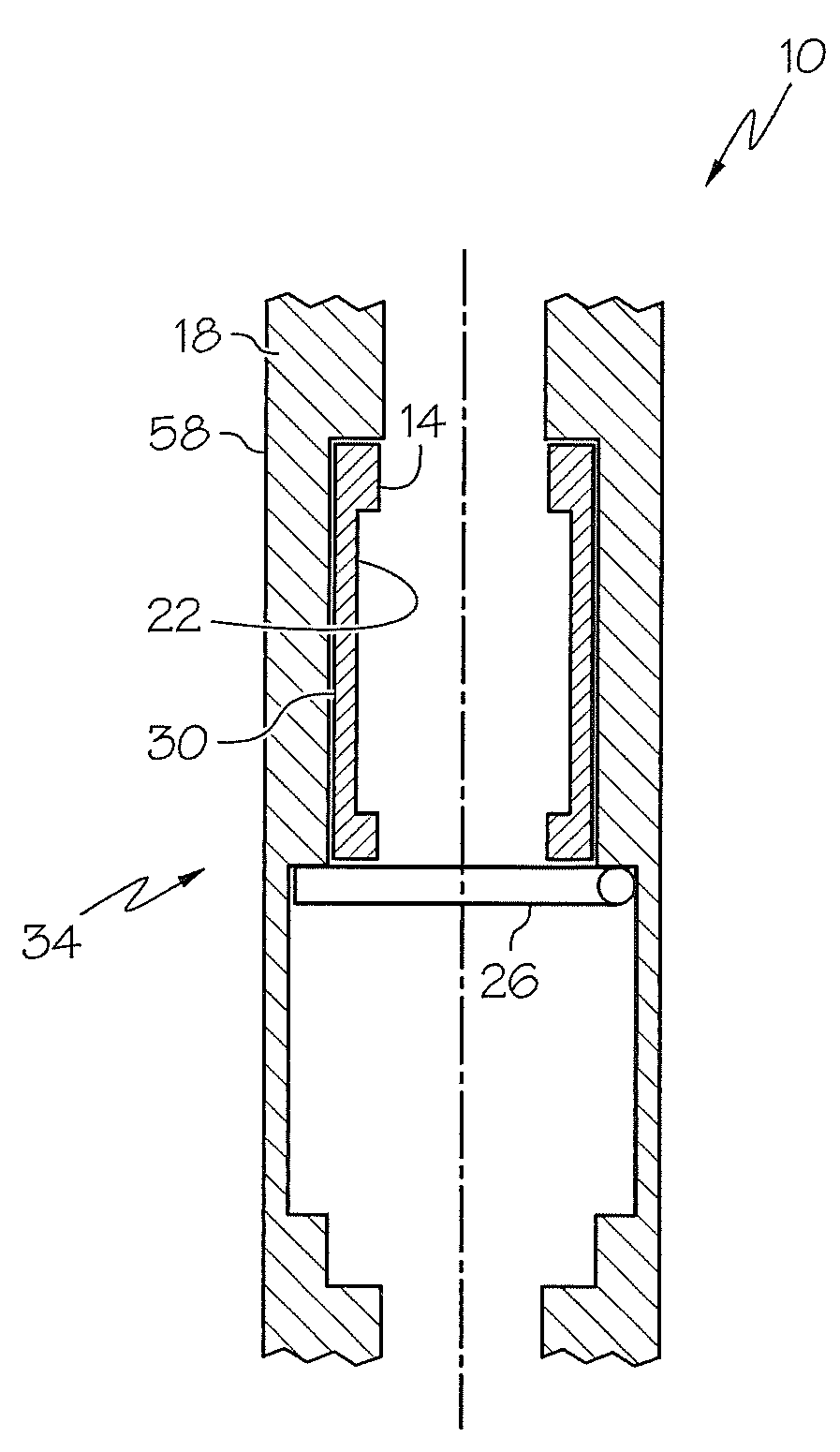

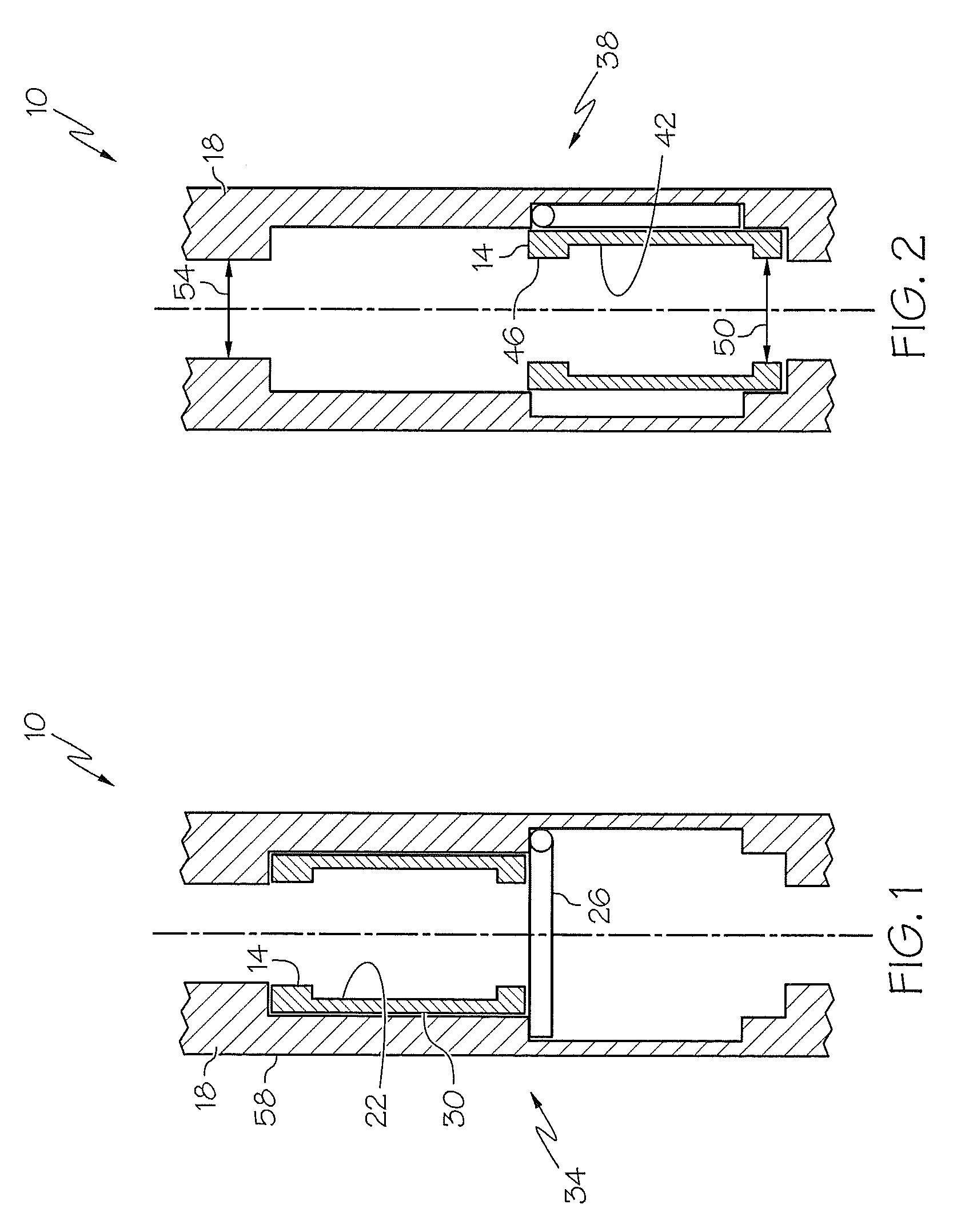

Balloon catheter with deformable fluid delivery conduit

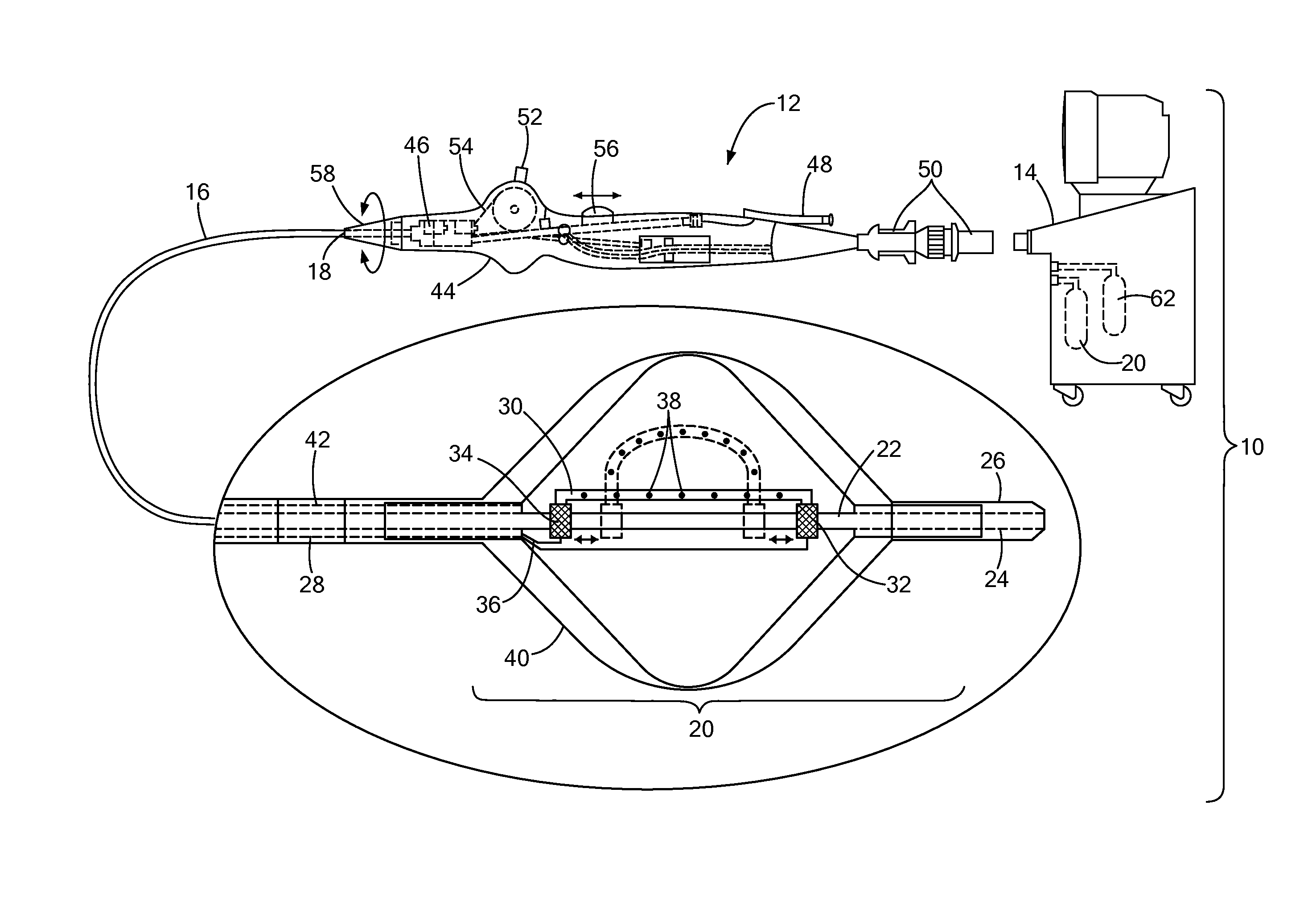

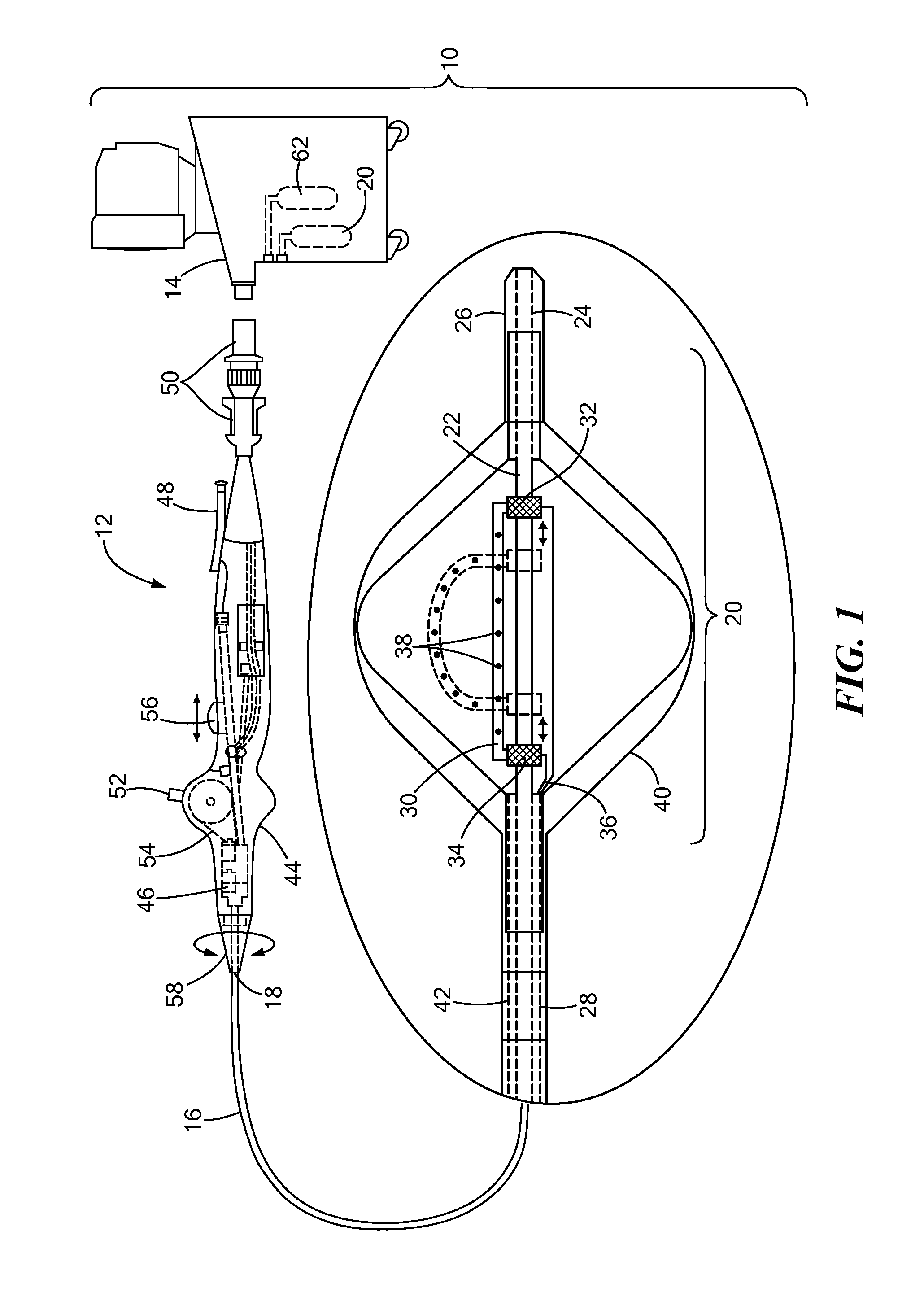

InactiveUS8911434B2Increase fluid velocityReduce fluid flow rateStentsCatheterDistal portionLinear configuration

A medical device, including an elongate body having a proximal portion and a distal portion; a shaft at least partially disposed within the elongate body; an expandable element at the distal portion of the elongate body; and a fluid delivery conduit defining a deflectable segment movably coupled to the shaft, the deflectable segment being transitionable from a substantially linear configuration to a substantially curvilinear configuration.

Owner:MEDTRONIC CRYOCATH LP

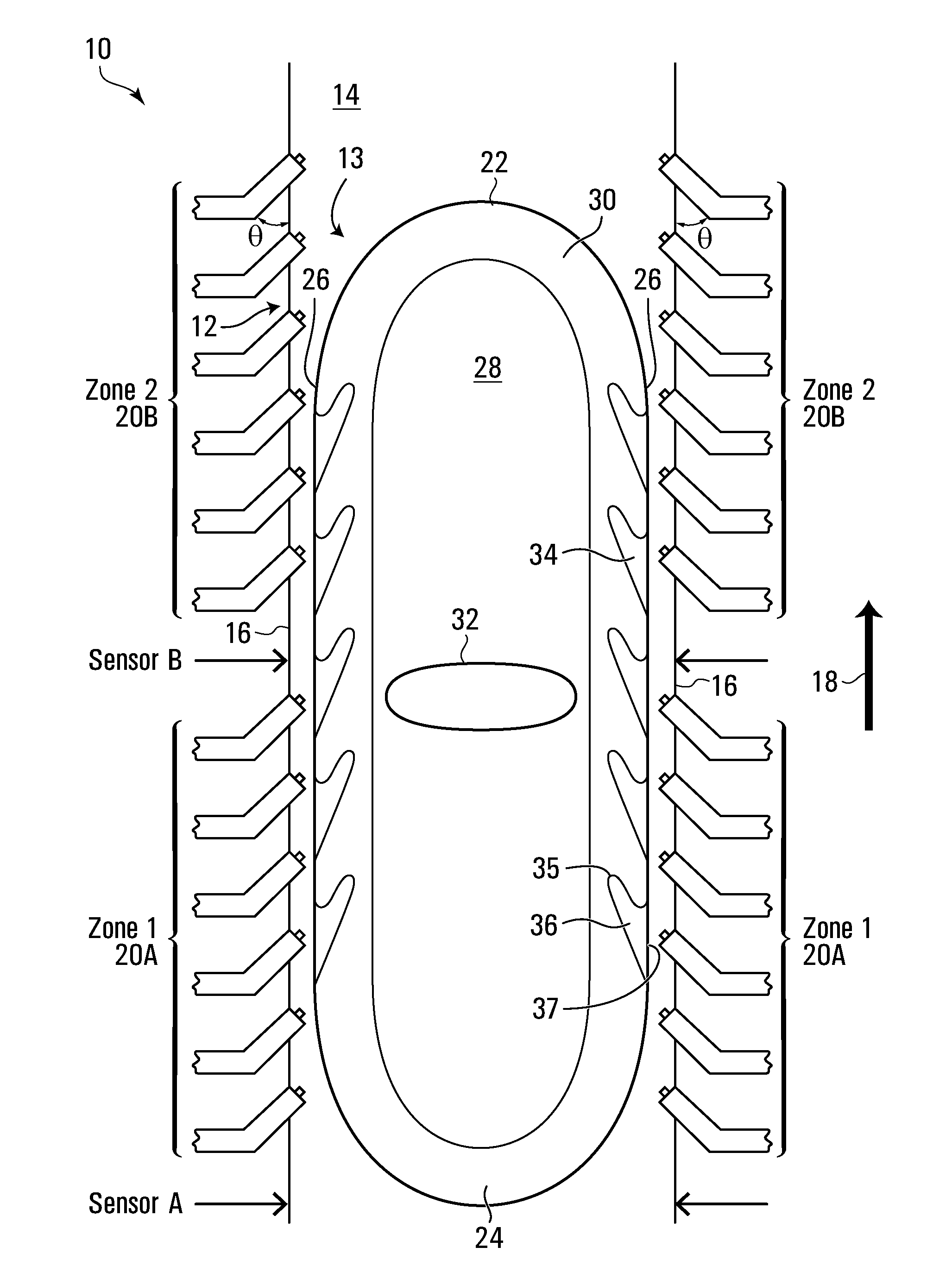

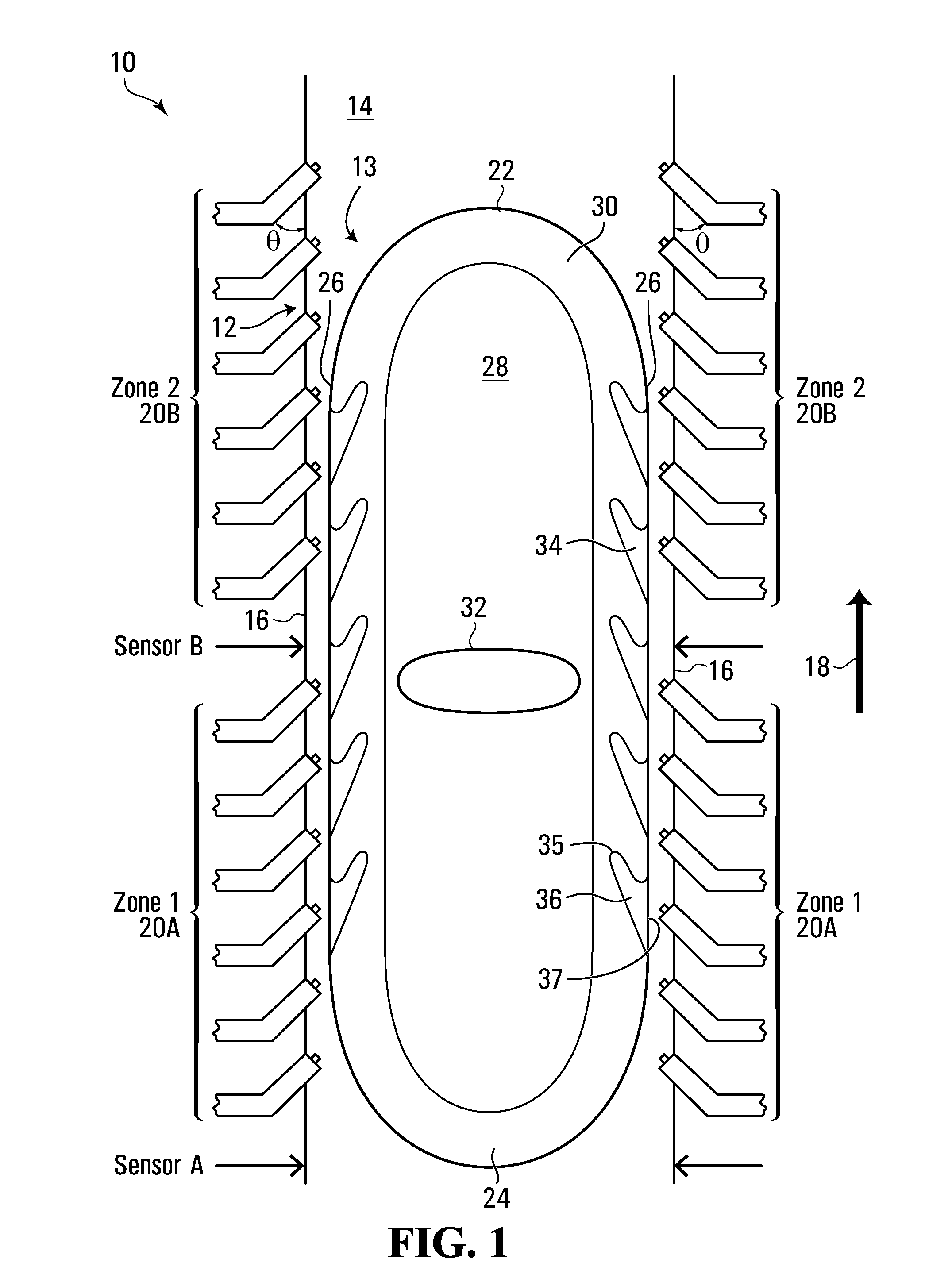

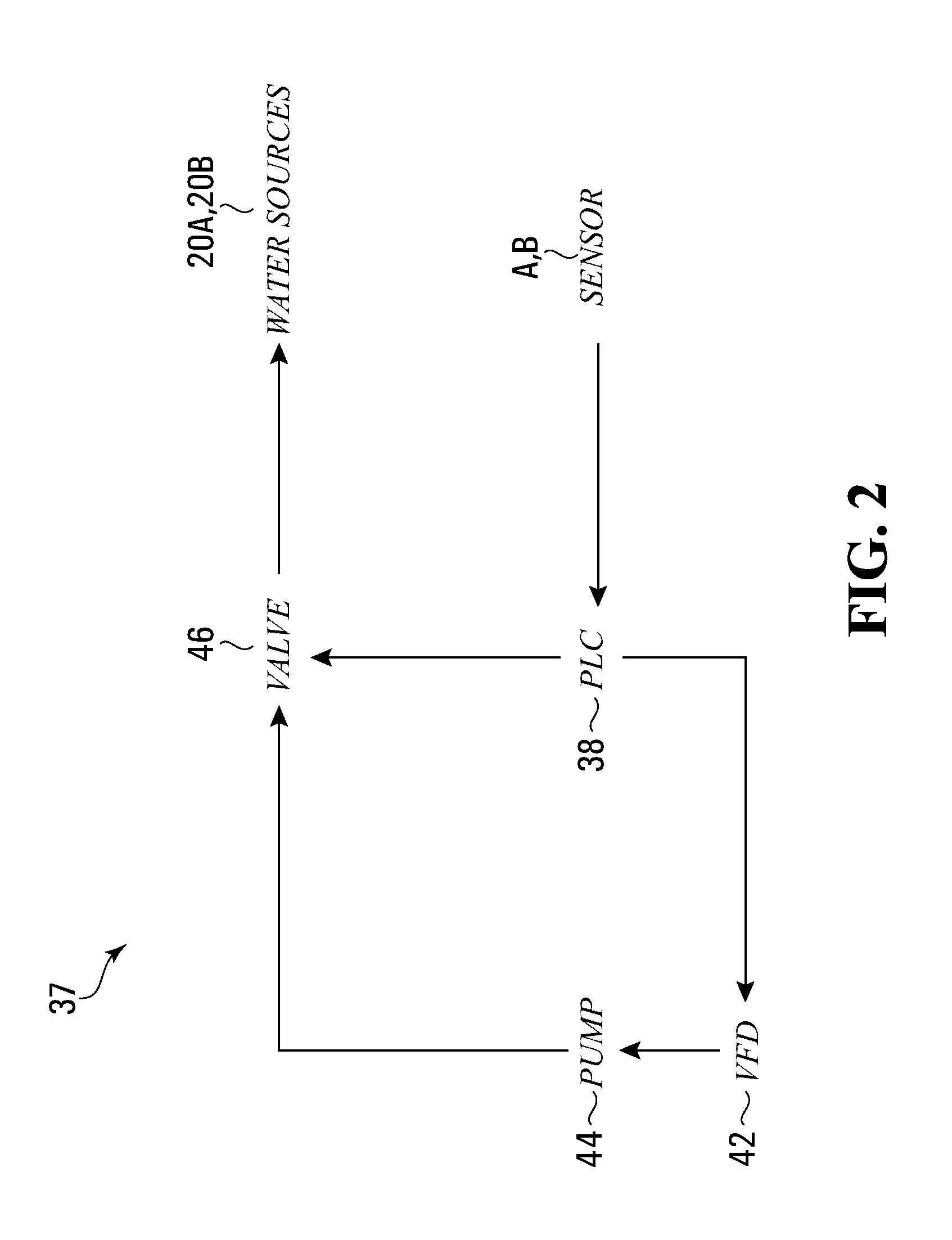

Amusement attraction fluid control system

An amusement attraction fluid control system comprises a fluid source, at least one pump, at least one fluid feature, a plurality of conduits interconnecting the fluid source and the at least one pump to the at least one fluid feature, and a controller; wherein the at least one pump is configured to pump fluid through the conduits to the at least one fluid feature. The controller is adapted to control the at least one pump to deliver fluid to each respective fluid feature.

Owner:PROSLIDE TECHNOLOGY

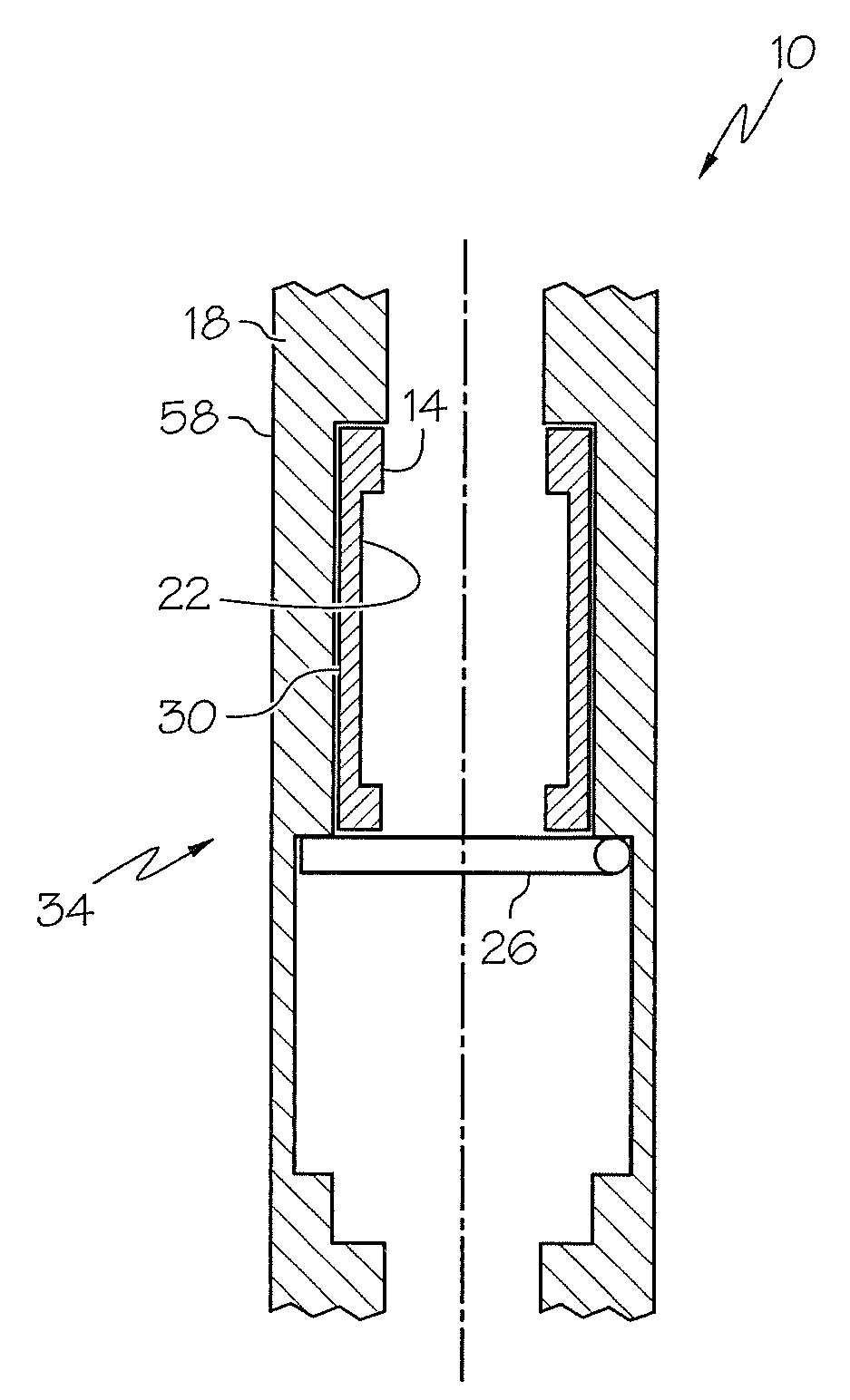

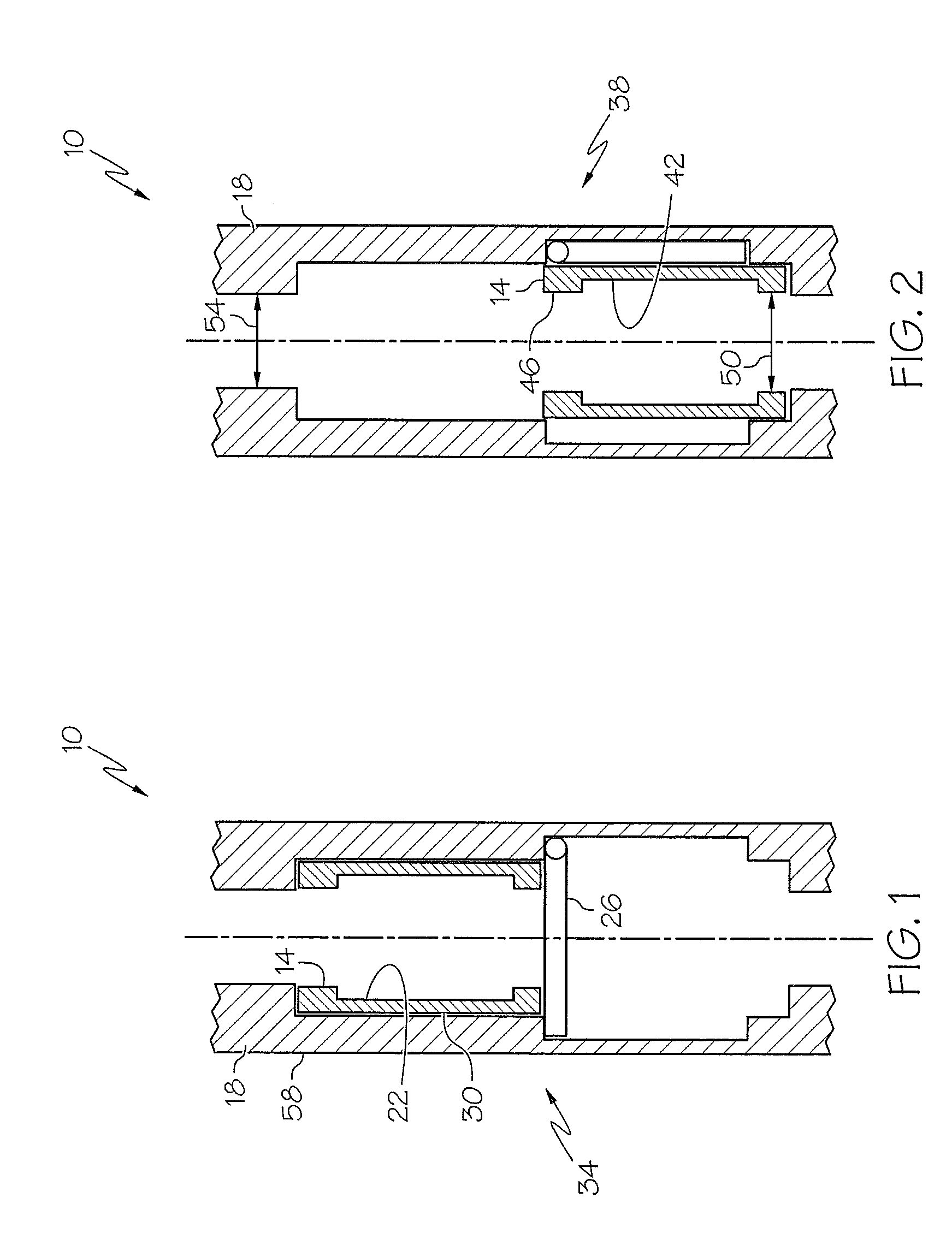

Two-way actuator and method

InactiveUS20100294376A1Reduce fluid flow rateDrill bitsCheck valvesEngineeringVolumetric Mass Density

Disclosed herein is a two-way actuator. The actuator includes, a tubular, movably positionable within a structure between at least a first position and a second position, the tubular having a first density selected such that buoyancy forces urge the tubular toward the first position in response to submersion of the tubular within a fluid having a second density that is greater than the first density, and at least one flow resistor disposed at the tubular configured to urge the tubular toward the second position in response to fluid flow interacting with the at least one flow resistor.

Owner:BAKER HUGHES INC

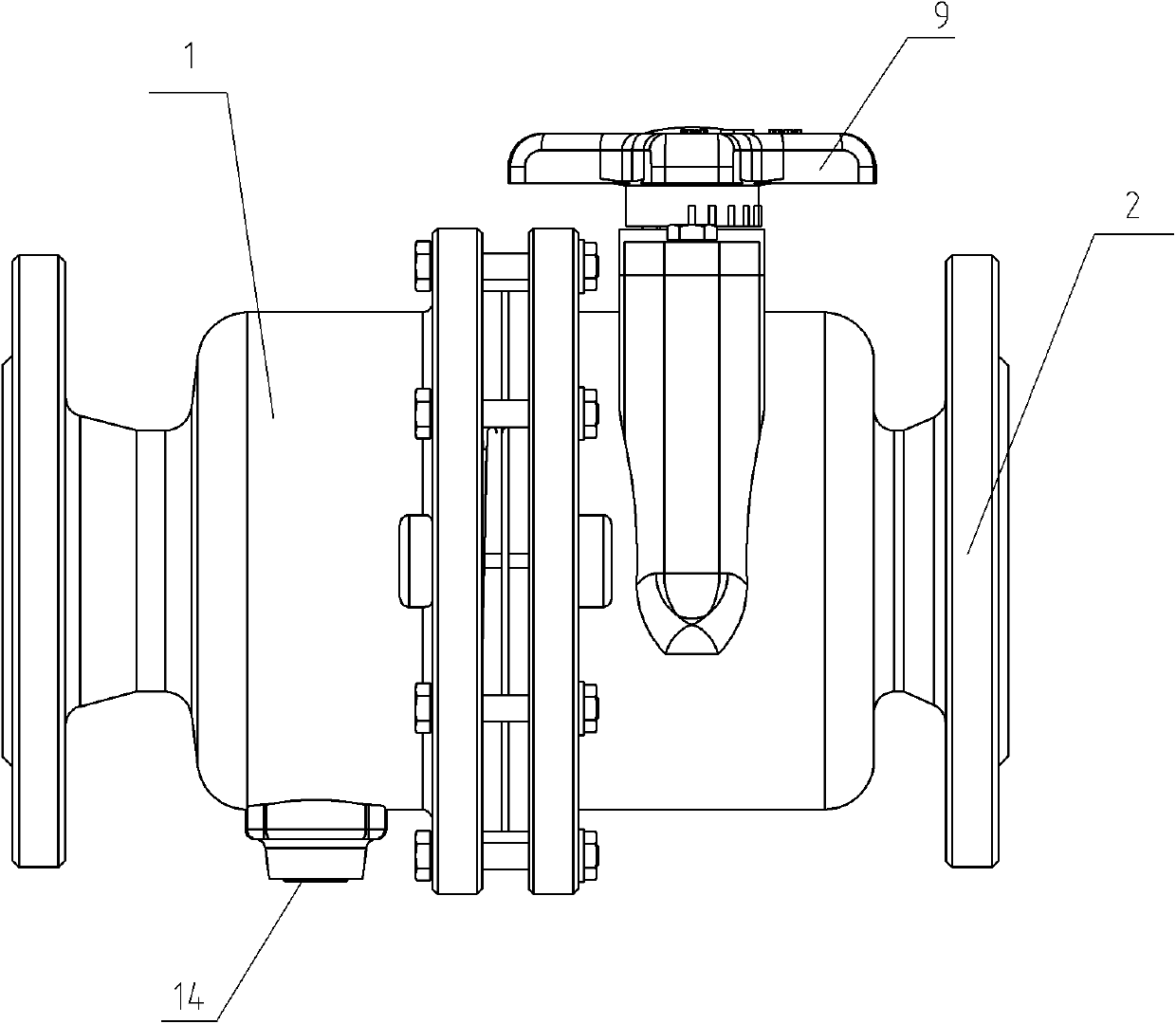

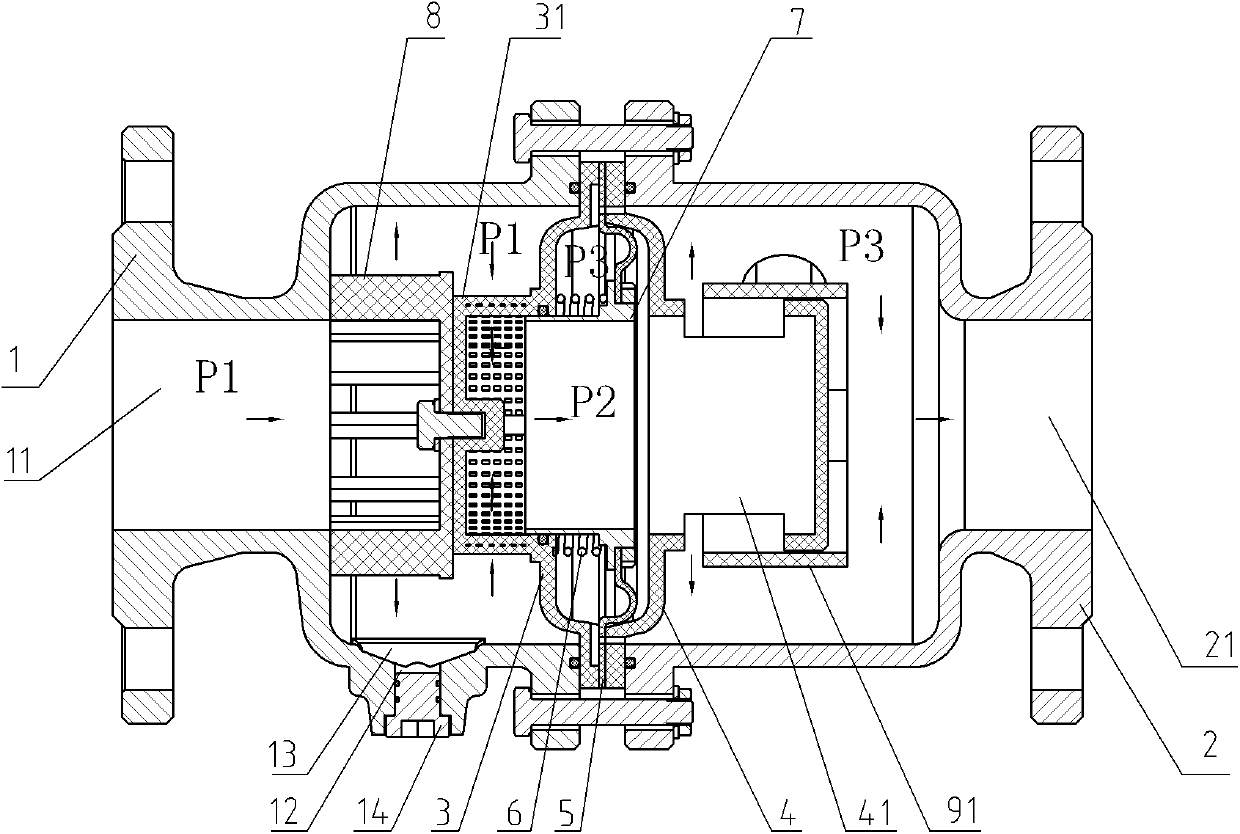

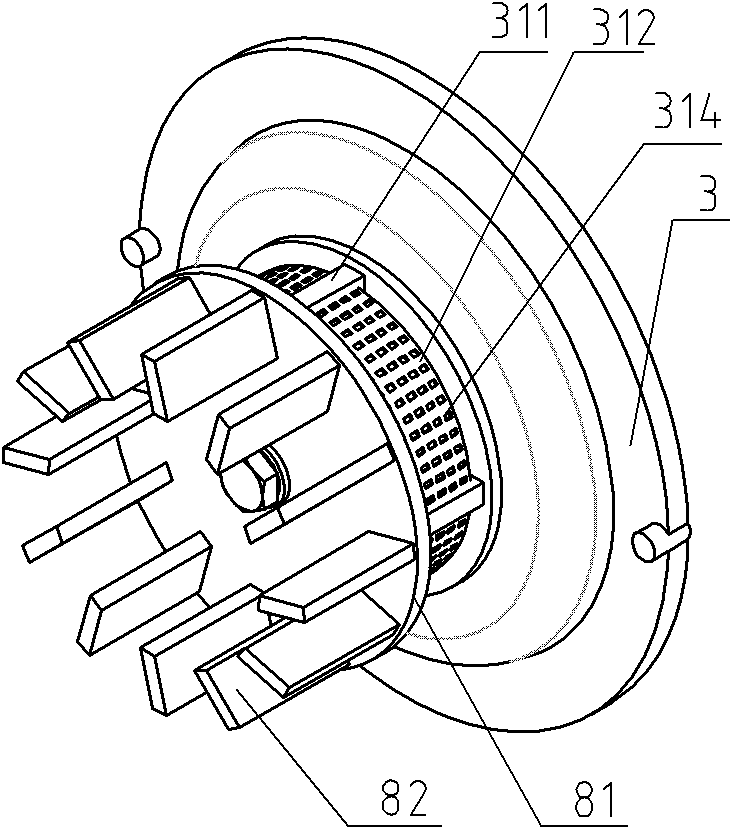

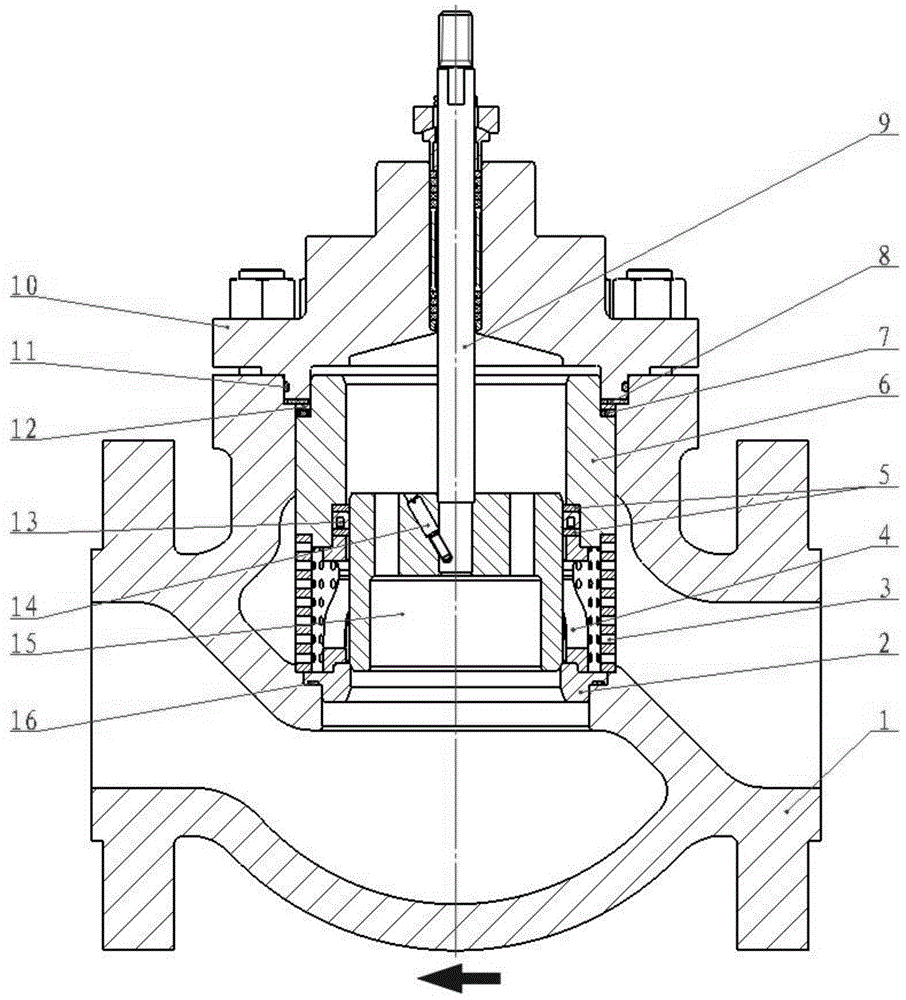

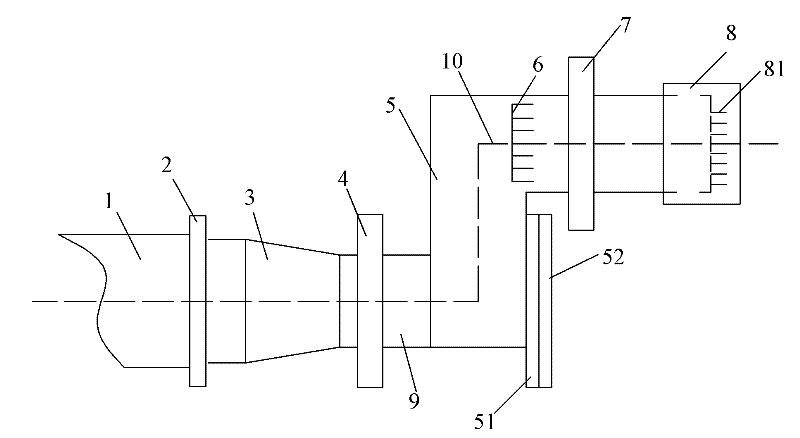

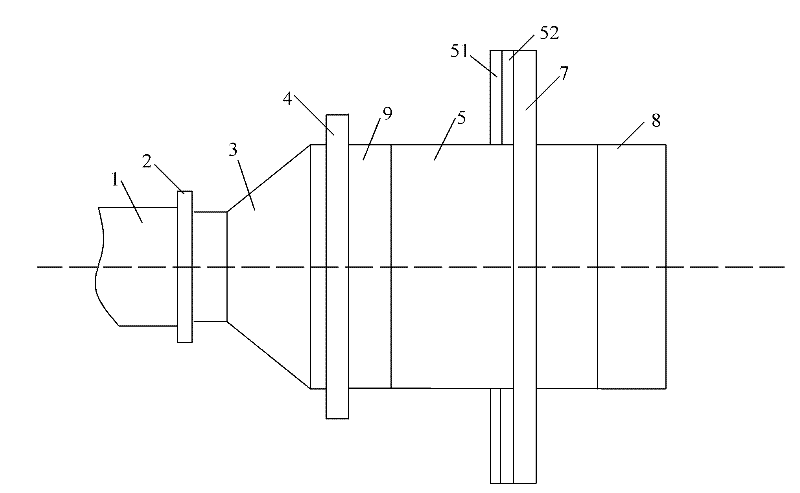

Axial flow type flow quantity control valve with dual filtering function

ActiveCN103470798AKeep water cleanReduce fluid flow rateOperating means/releasing devices for valvesValve members for absorbing fluid energyWater flowEngineering

The invention discloses an axial flow type flow quantity control valve with dual filtering functions, which solves the technical problems that the control valve of the prior art has poor performance and has no filtering function. The control valve comprises a valve body and a valve frame, wherein the valve frame is fixedly arranged in the valve body and is used for adjusting the flow quantity of the control valve, the valve body comprises a left valve body and a right valve body, the left valve body is provided with a flow inlet, the right valve body is provided with a flow outlet, the interior of the left valve body is provided with a flow disturbance cover, the flow disturbance cover is positioned between the flow inlet and the valve frame, one side, facing the flow disturbance cover, of the valve frame is provided with filtering holes, and the left valve body is provided with a blowoff port which can be opened and closed. When the fluid flowing into the valve body via the flow inlet of the left valve body flows through the flow disturbance cover, the speed reduction function is realized, and the large impurities in the fluid are settled under the action of gravity. When the fluid flows through the valve frame, the secondary filtering function is realized by the filtering holes, and the fine impurities are filtered. The impurities are settled in the filtering process, and after the blowoff port is opened, the impurities in the valve body are removed under the action of the water flow pressure. The filtering device is directly arranged in the valve body, and the structure of a flow passage is simplified.

Owner:ZHEJIANG DUNAN INTELLIGENT CONTROL TECH CO LTD

Apparatus for separating particulates from a fluid stream

ActiveUS20050145555A1Minimize the possibilityMaximize removal capabilityLiquid displacementLoose filtering material filtersParticulatesLeading edge

A screen apparatus for improved separation of particulates from a fluid stream. The screen is configured and arranged to filter relatively large particulates from the fluid stream as the fluid stream passes from a storage chamber of the tank to a tank outlet. The screen is removably affixed to a diverter, such as a baffle, used to divert a portion or all of the fluid into the storage chamber. The screen is preferably shaped to substantially conform to the shape of the diverter to aid in the smoothing of the fluid flow within the retention section of the tank. The screen may be entirely porous, or it may be non-porous at its leading edge to minimize particulate build-up at the transition from the tank interior wall to the screen. The apparatus may optionally include a second screen to provide additional filtering of floating particulates as the fluid level in the tank exceeds the crown elevation of the inlet. The second screen may be substantially horizontally oriented and may be combined with a collection weir. Alternatively, the second screen may be conical in shape. A high flow bypass arrangement for the separation system may include an upper baffle and a lower baffle or a screen instead of the lower baffle. The upper baffle is set closer to the center of the tank than the lower baffle or screen, thereby providing more volume for flow diversion behind the upper baffle.

Owner:CONTECH ENGINEERED SOLUTIONS

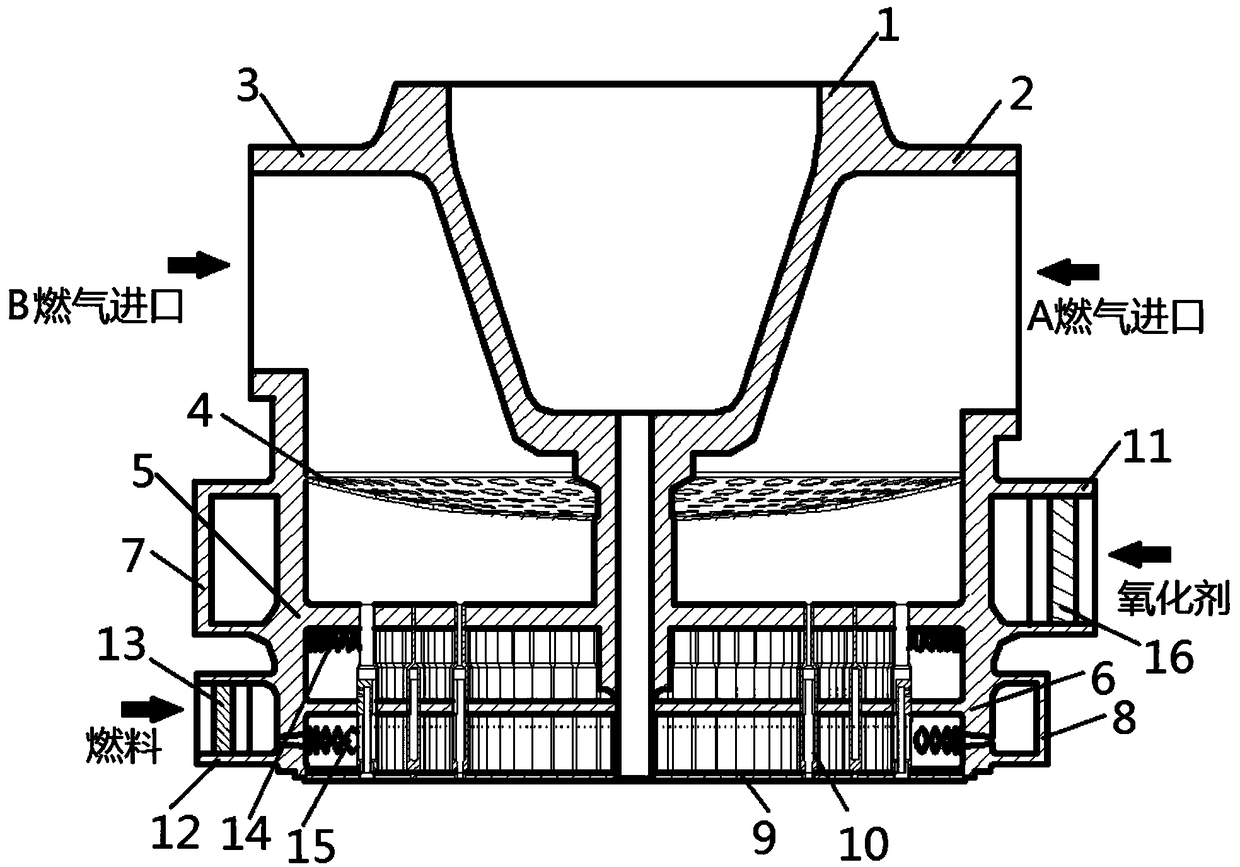

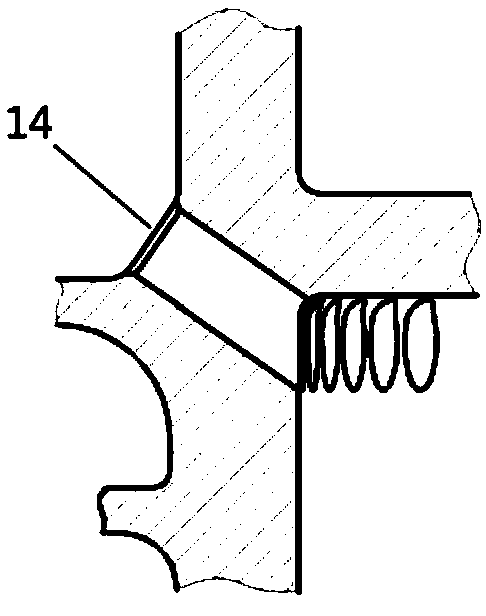

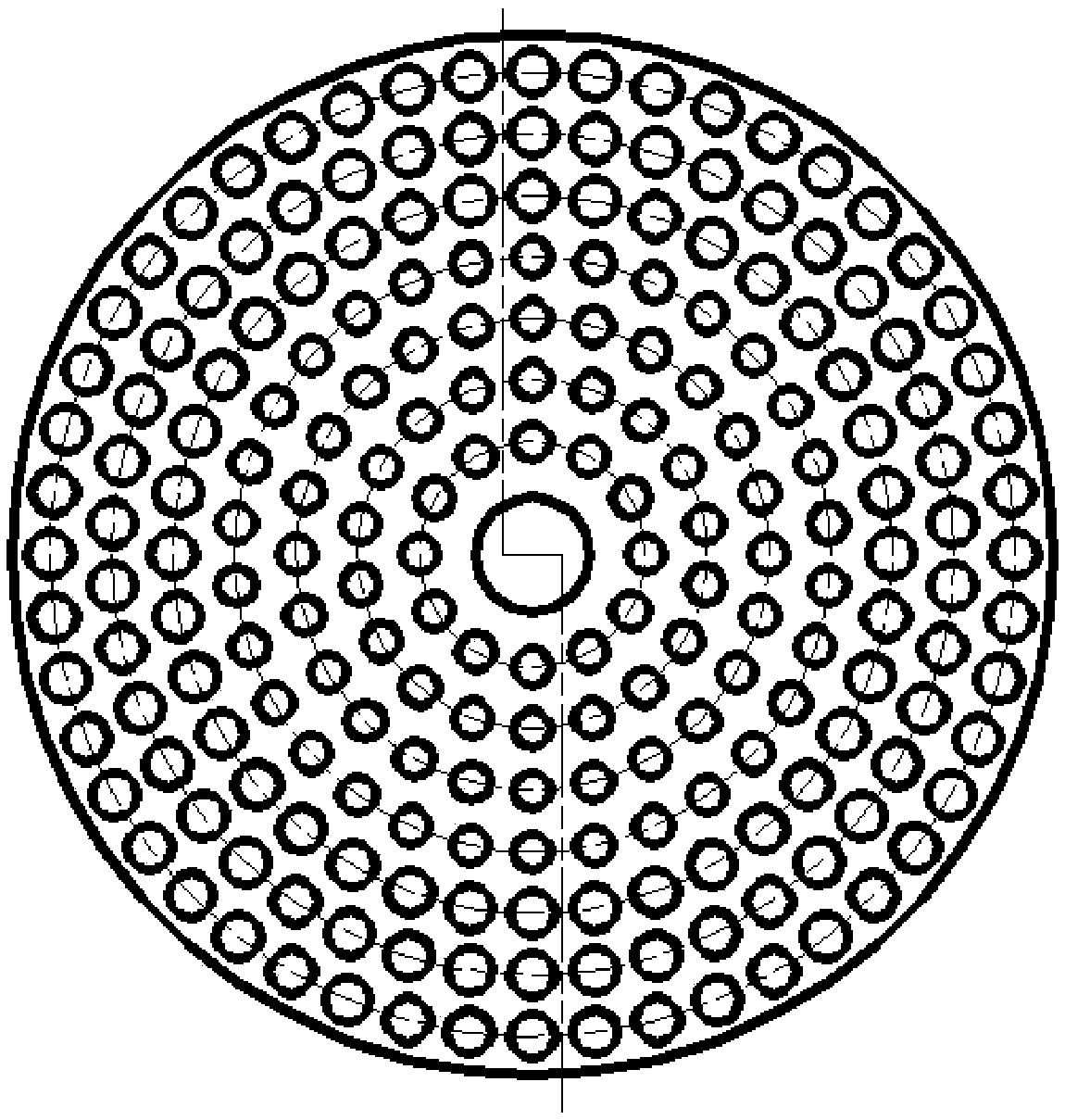

Four-bottom three-cavity injector

ActiveCN108915899ADissipated moreEliminate vortex phenomenonRocket engine plantsSpray nozzleEngineering

Provided is a four-bottom three-cavity injector. A bearing seat and gas top cover integrated piece and a belt ring three-bottom and fuze integrated piece form a gas chamber; a chamber jointly definedby the belt ring three-bottom and fuze integrated piece and a belt ring two-bottom jointly is an oxidant chamber, an oxidant inlet section is an inlet of an oxidant and is communicated with an oxidantcollector, and the oxidant inlet section is provided with a flow deflector that divides an incoming flow oxidant into two strands that flow into the two sides of the oxidant collector respectively. Achamber defined by a belt ring two-bottom and a one-bottom is a fuel chamber, a fuel inlet section is a fuel inlet and is communicated with a fuel collector, and the fuel inlet section is provided with a flow deflector that divides incoming flow fuel into two strands that flow into the two sides of the fuel collector respectively; and nozzle assemblies are mounted on the belt ring three-bottom and fuze integrated piece, the belt ring two-bottom and the one-bottom. The gas chamber, the oxidant chamber and the fuel chamber are sequentially distributed from top to bottom.

Owner:BEIJING AEROSPACE PROPULSION INST

Method and apparatus for processing fluids

InactiveUS20070158176A1Easily monitorIncrease fluid flow rateWater/sewage treatment by electrochemical methodsDispersed particle separationChemical activityIon

The present invention relates generally to the processing of fluids and / or their carriers. Carriers may comprise pipes, tubes and the like or reservoirs for the distribution and / or storage of fluids. In one form, the present invention relates to a method and apparatus that is suitable for use in the treatment of various fluids, such as water, by introducing at least one chemically active metal into the water and its carriers for disinfection of the water in a controlled manner. The invention also relates to a biasing means for displacement of an electrode arrangement to allow for the introduction of ions into a fluid at a controlled or easily monitored rate that is commensurate with the amount of fluid flow.

Owner:WONDER WATER

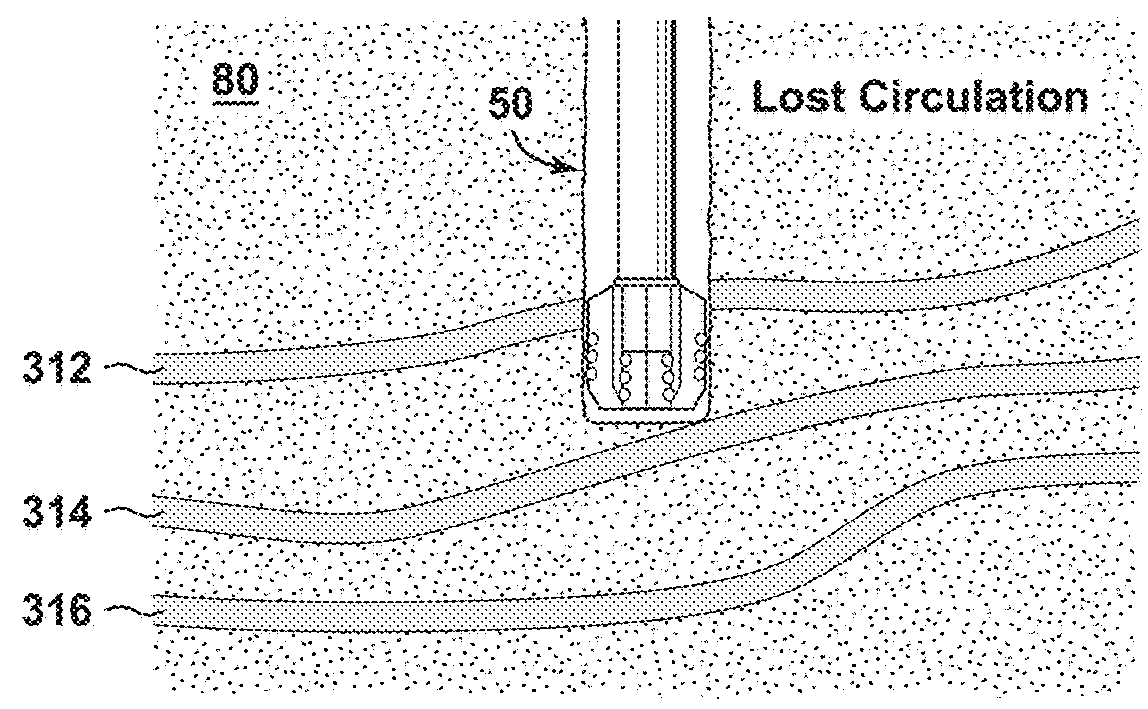

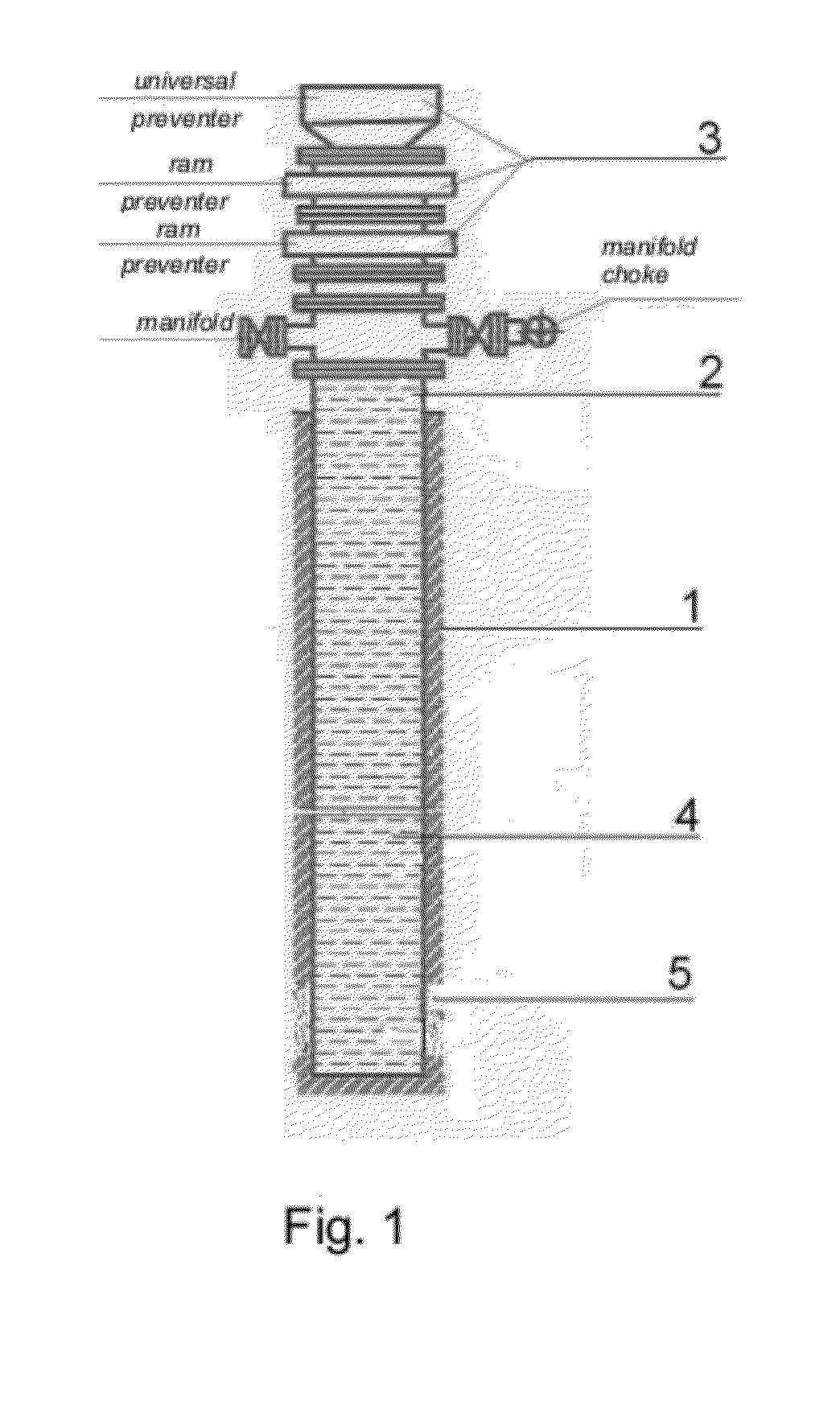

Polymers for Wellbore Plugs and Wellbore Stability

InactiveUS20180274326A1Reduce flow rateQuick implementationOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsBlowout preventerGuide tube

Apparatus, compositions, and methods for creating polymer plugs in wellbores and / or for enhancing wellbore stability, comprising: a flow control device such as a blowout preventer on a wellbore; a control fluid aperture fluidly connected with the wellbore for introducing a control fluid and / or a plug-forming agent such as a polymer, monomer, resinous, and / or crosslinkable material, through a control fluid aperture and into the primary throughbore while wellbore blowout fluid flows through the wellbore; and optionally, a weighted fluid aperture positioned in the wellbore conduit below the control fluid aperture for introducing a weighted fluid or another fluid or plug-forming agent into the wellbore. Exemplary plug-forming agents include dicyclopentadiene and norborene, and exemplary catalysts include Grubbs catalysts. The polymer plugs also may be utilized to hydraulic sealing within wellbores, such as during P&A and drilling operations for providing wellbore stability.

Owner:EXXONMOBIL UPSTREAM RES CO

Pollution control system

ActiveUS8370048B2Reduce pressureReduce gas productionAnalogue computers for vehiclesInternal combustion piston enginesVacuum pressureCombustion

The pollution control system includes a controller coupled to a sensor monitoring an operational characteristic of a combustion engine, such as engine RPM. A PCV valve having an inlet and an outlet is adapted to vent blow-by gas out from the combustion engine. A fluid regulator associated with the PCV valve and responsive to the controller selectively modulates engine vacuum pressure to adjustably increase or decrease a fluid flow rate of blow-by gas venting from the combustion engine. The controller selectively adjustably positions the fluid regulator to vary the degree of vacuum pressure to optimize the recycling of blow-by gases.

Owner:SVMTECH

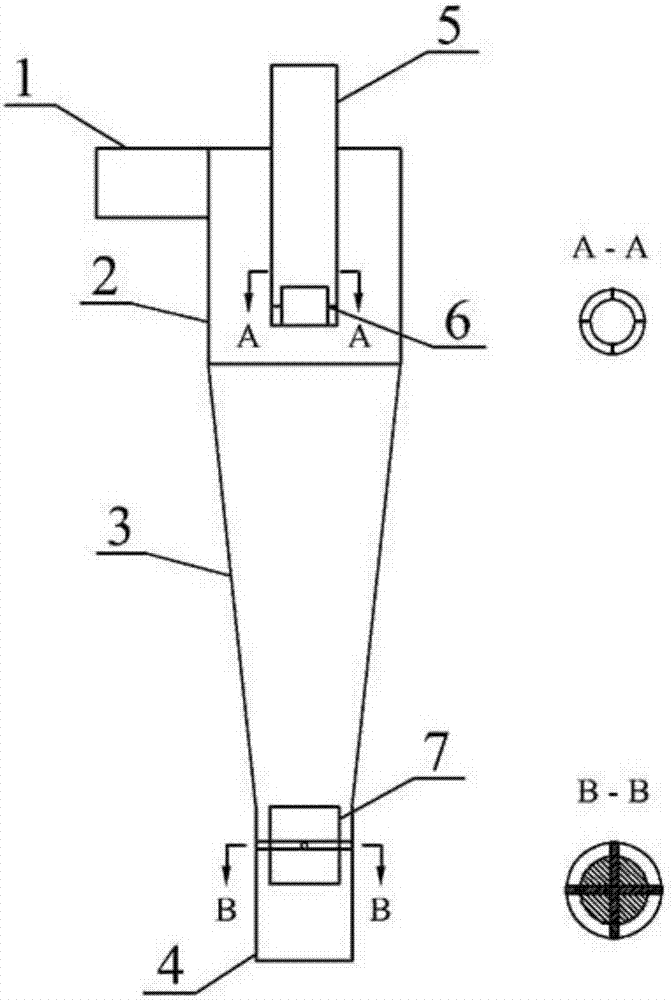

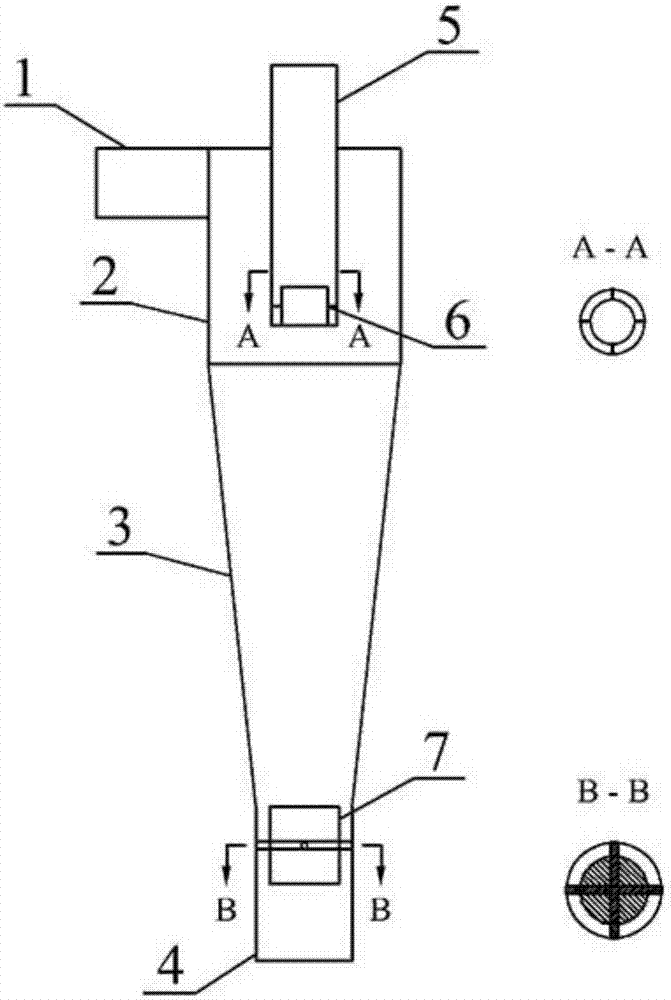

Hydrocyclone with novel outlet structure

The invention discloses a hydrocyclone with a novel outlet structure. The hydrocyclone comprises a feed pipe, a cylindrical section, a conical section, an underflow pipe, an overflow pipe, a sleeve and a solid cylinder body, wherein the sleeve is fixed at the inner part of the lower end of the overflow pipe through a thin sheet, the hydrocyclone adopts the design of a short cone and a large-diameter underflow port, and a solid cylinder is inserted into the center of the underflow pipe, so that the area of the annular space underflow port and the area of the underflow port of the common hydrocyclone having the same cone angle are the same. Compared with the common hydrocyclone, the length of the conical section is reduced, the occupied space of the hydrocyclone is saved, and in addition, due to the design of the thin sheet sleeve at the lower end of the overflow pipe of the hydrocyclone and the large-diameter underflow port, the pressure drop is greatly reduced without reducing the separating efficiency.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI +1

Fluoropolymer flowmeter

InactiveUS6973705B2Improve effectivenessImprove reliabilityElectronic circuit testingVolume meteringEngineeringCatheter

In one embodiment, a sight tube flowmeter is formed of a plurality of fluoropolymer components welded together to form a unitary flowmeter body. The components can comprise a PFA upright sight tube having two end portions, a flow conduit extending therethrough and two fitting portions that are uniquely welded onto each end of the sight tube, and a fluoropolymer float device movable to various positions within the flow conduit depending on the flow level of the fluid flowing therethrough. The float device can be of conventional design or for those flowmeter embodiments where low fluid flow rates are to be measured, an elongate float can be utilized. The floats and, in particular, a designated portion thereof, are visible through the sight tube to provide visual indication of the position, and thus the flow rate of fluid flowing through the flowmeter. In addition, alternative embodiments include the implementation of the unique sight tube and elongate float design in conventional flowmeters.

Owner:ENTEGRIS INC

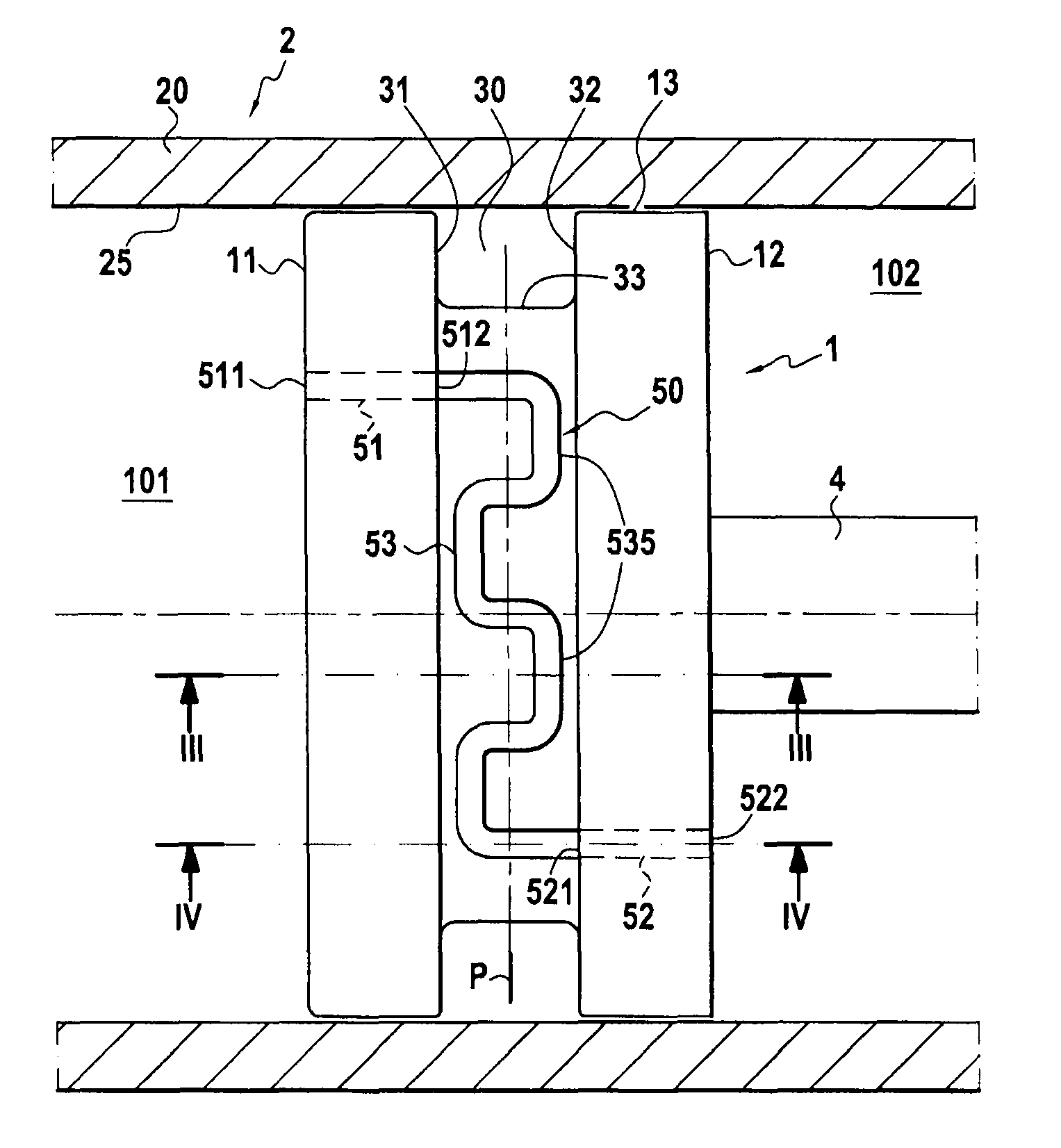

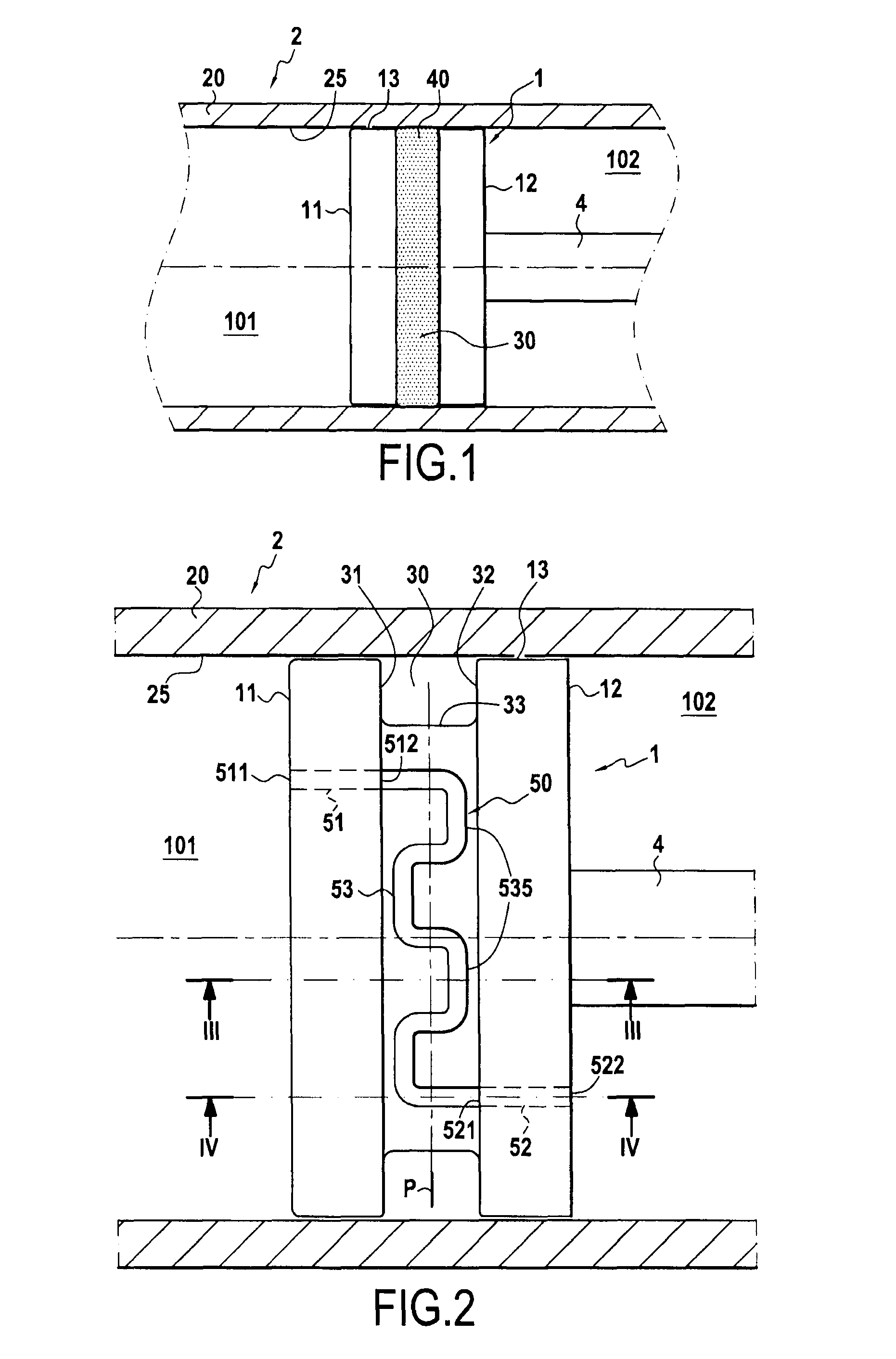

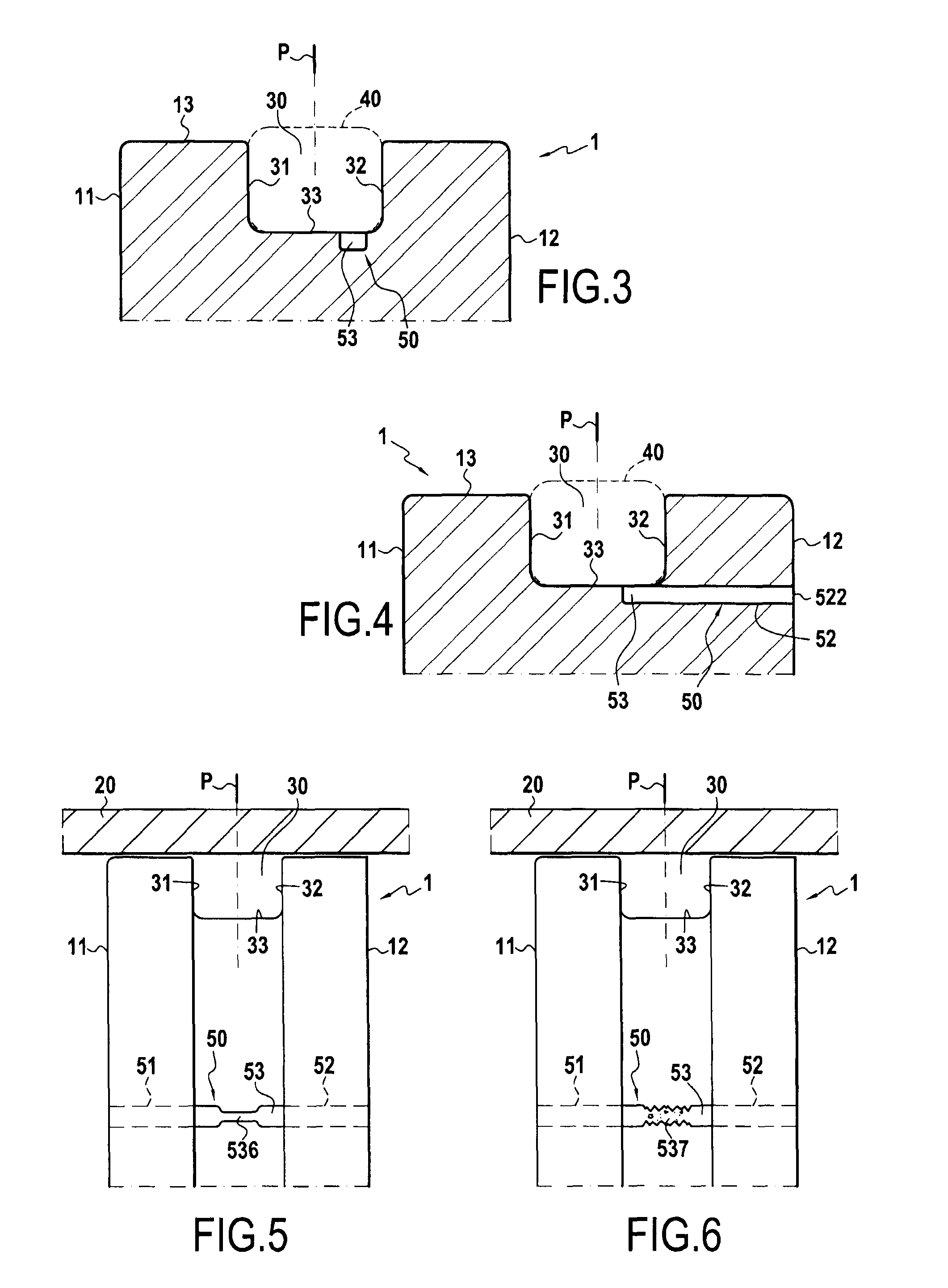

Piston with a duct under a gasket

The invention relates to a piston having a first face, a second face opposite to the first face, a third face connecting said first and second faces together and presenting a groove, and a sealing gasket housed in said groove. The piston includes a duct constituted by a first segment situated inside the piston and connecting said first face to said groove, by a second segment situated inside the piston and connecting said second face to said groove, and by an intermediate segment connecting together said first and second segments and crossing said groove, the walls of said intermediate segment being formed by the walls of said groove and by said sealing gasket in such a manner that said intermediate segment forms a leaktight tube that opens out solely via the first segment and via the second segment, said intermediate segment presenting at least one obstacle suitable for impeding the flow of fluid that flows along said intermediate segment.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

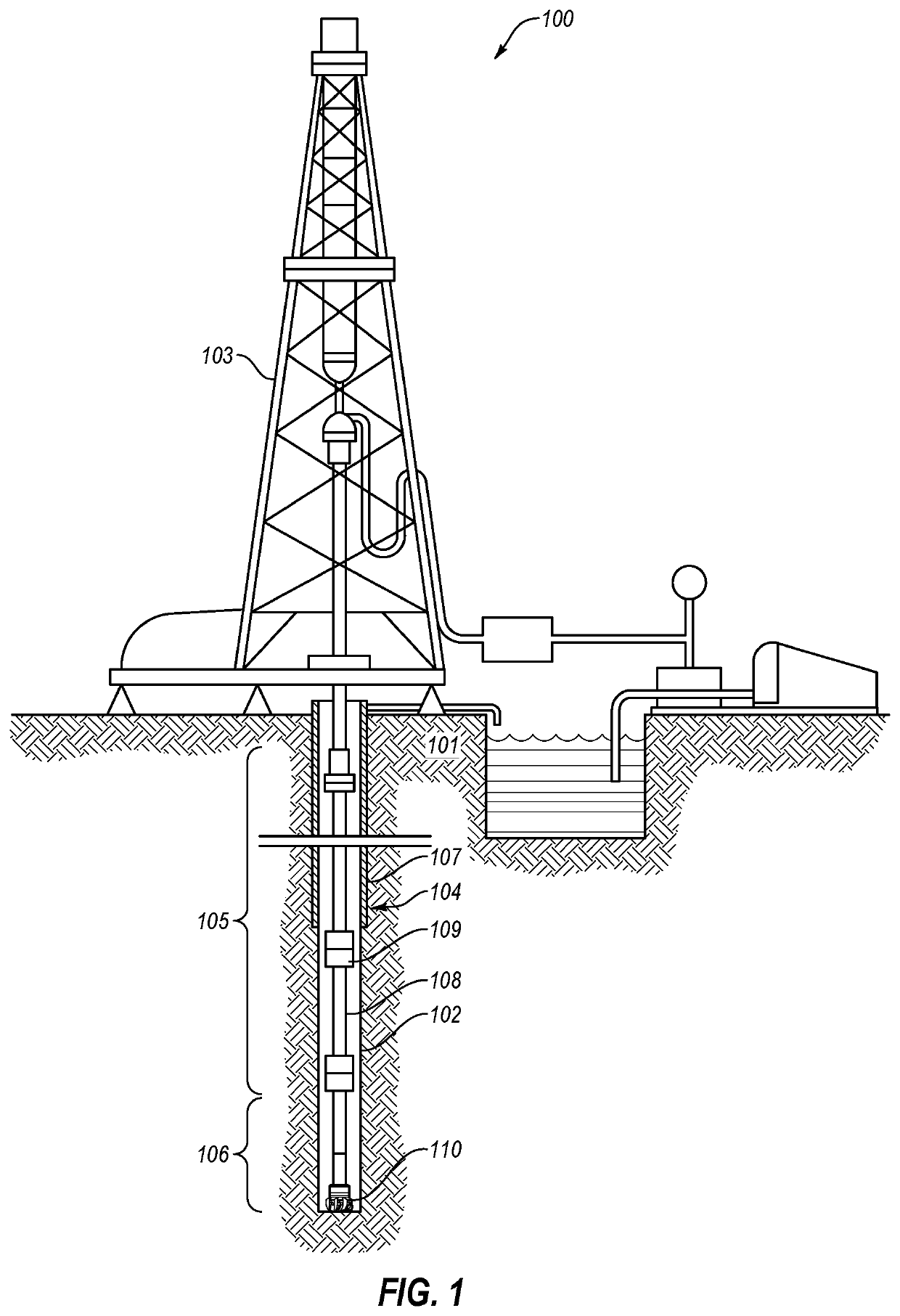

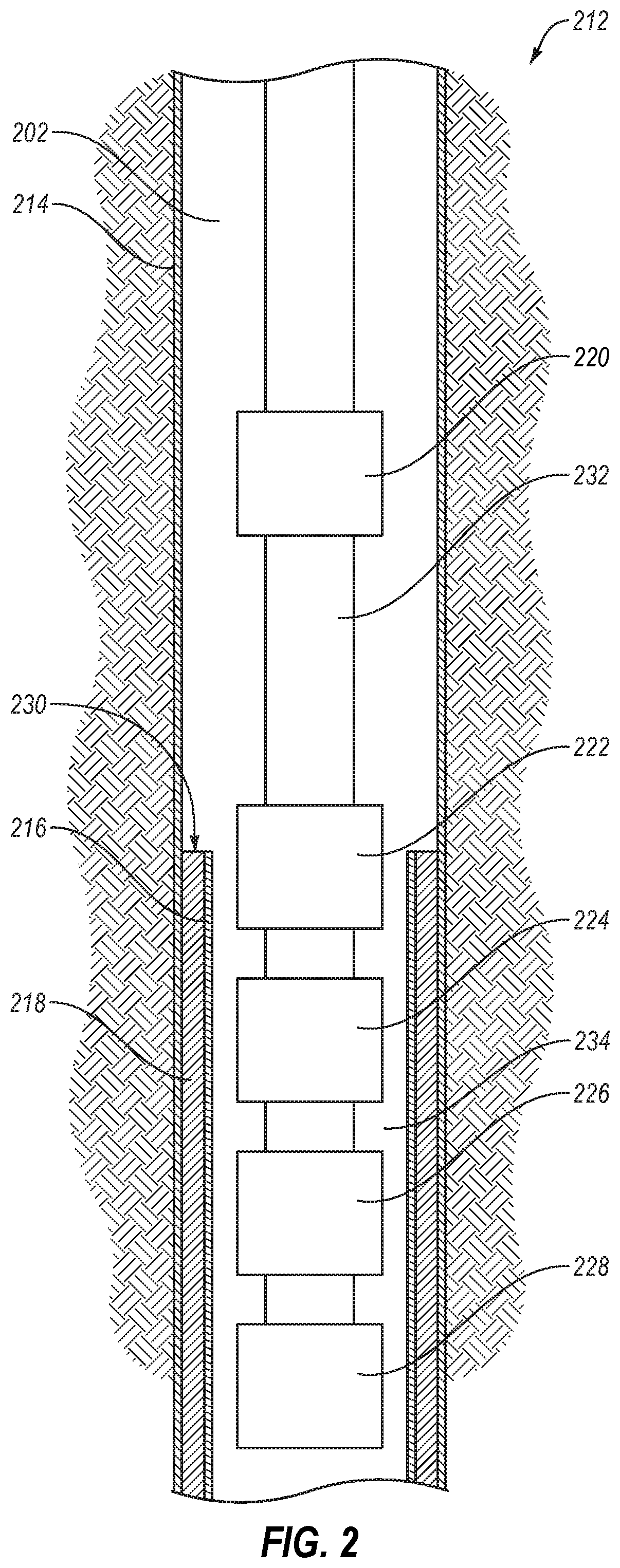

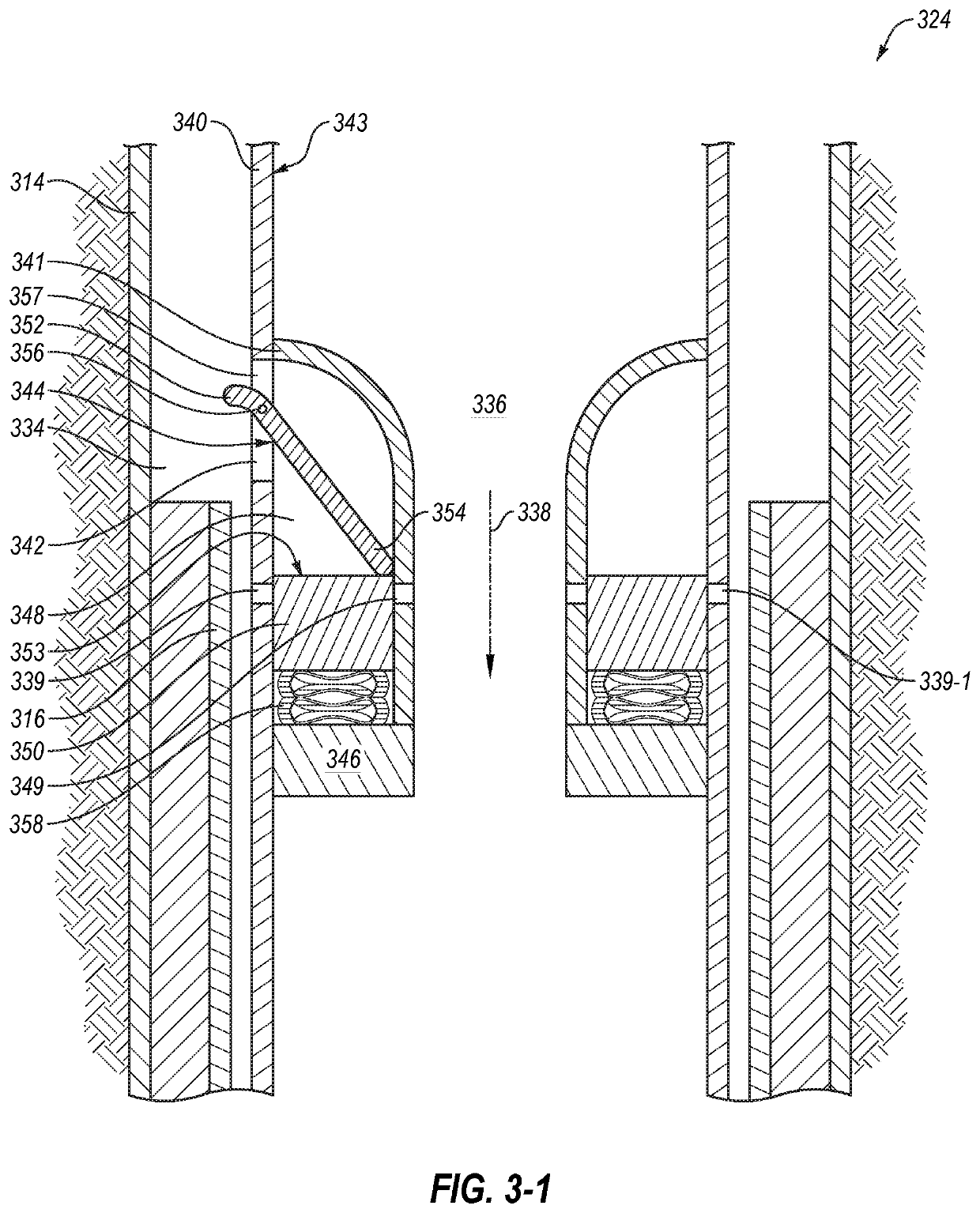

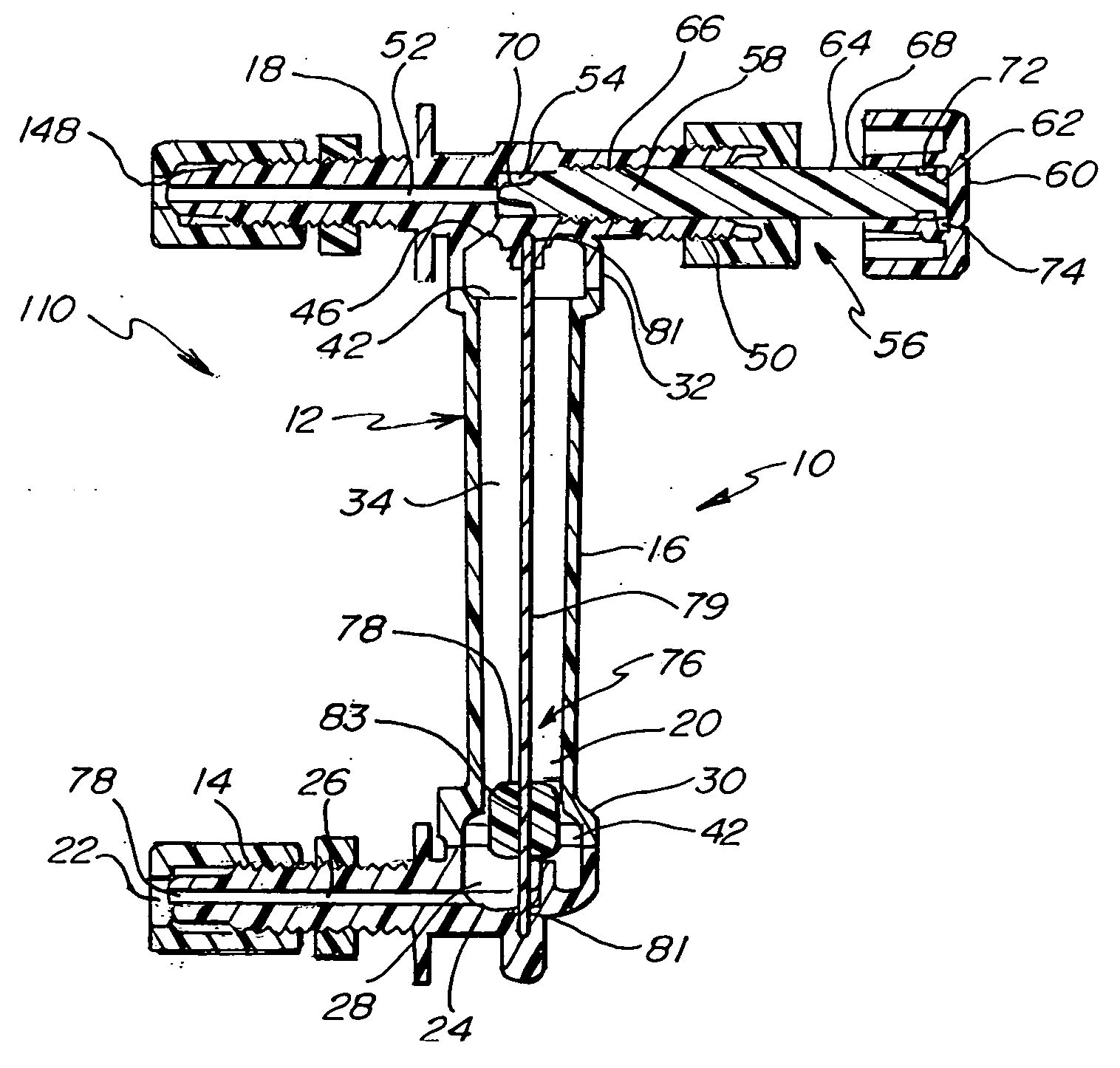

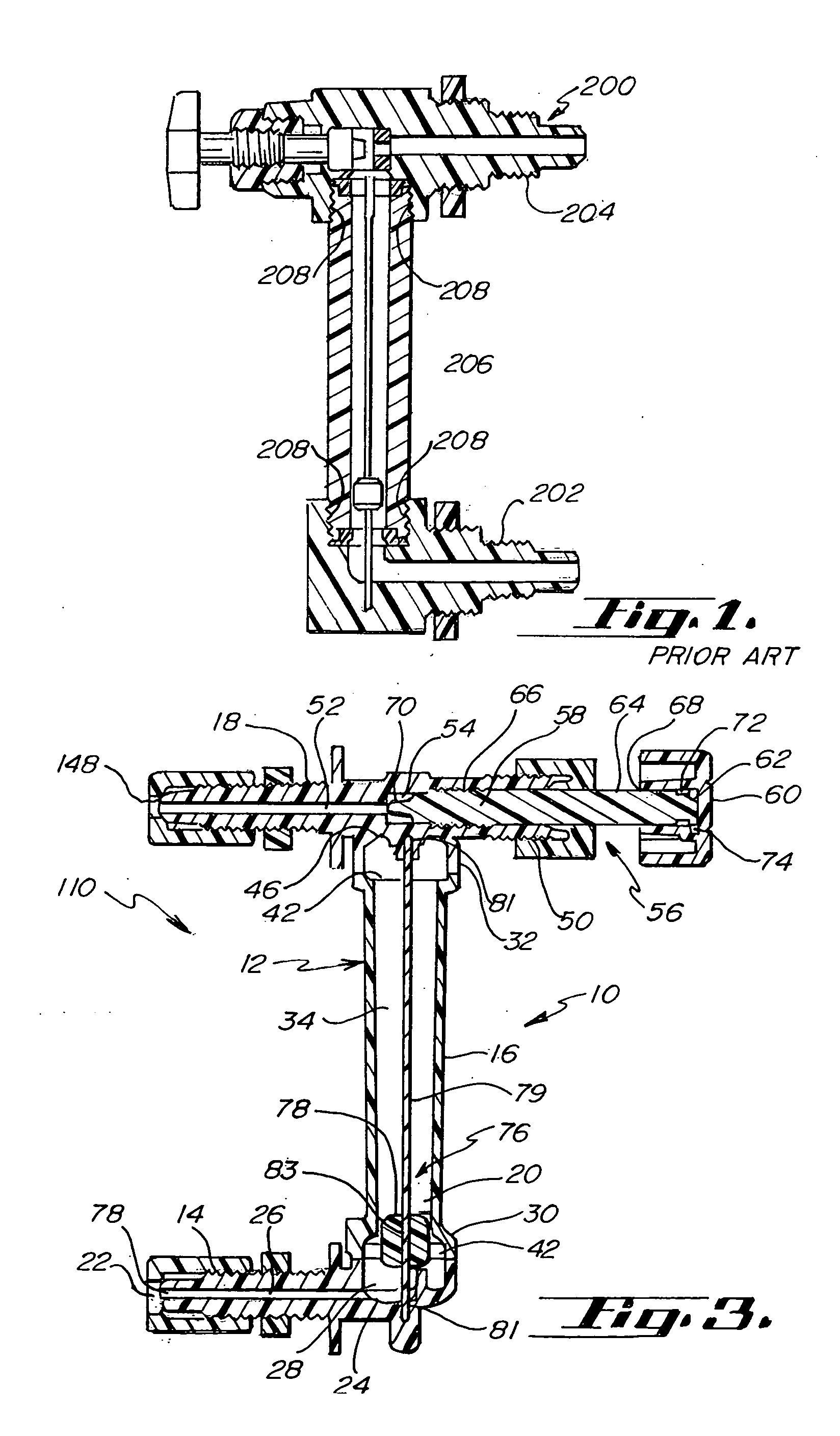

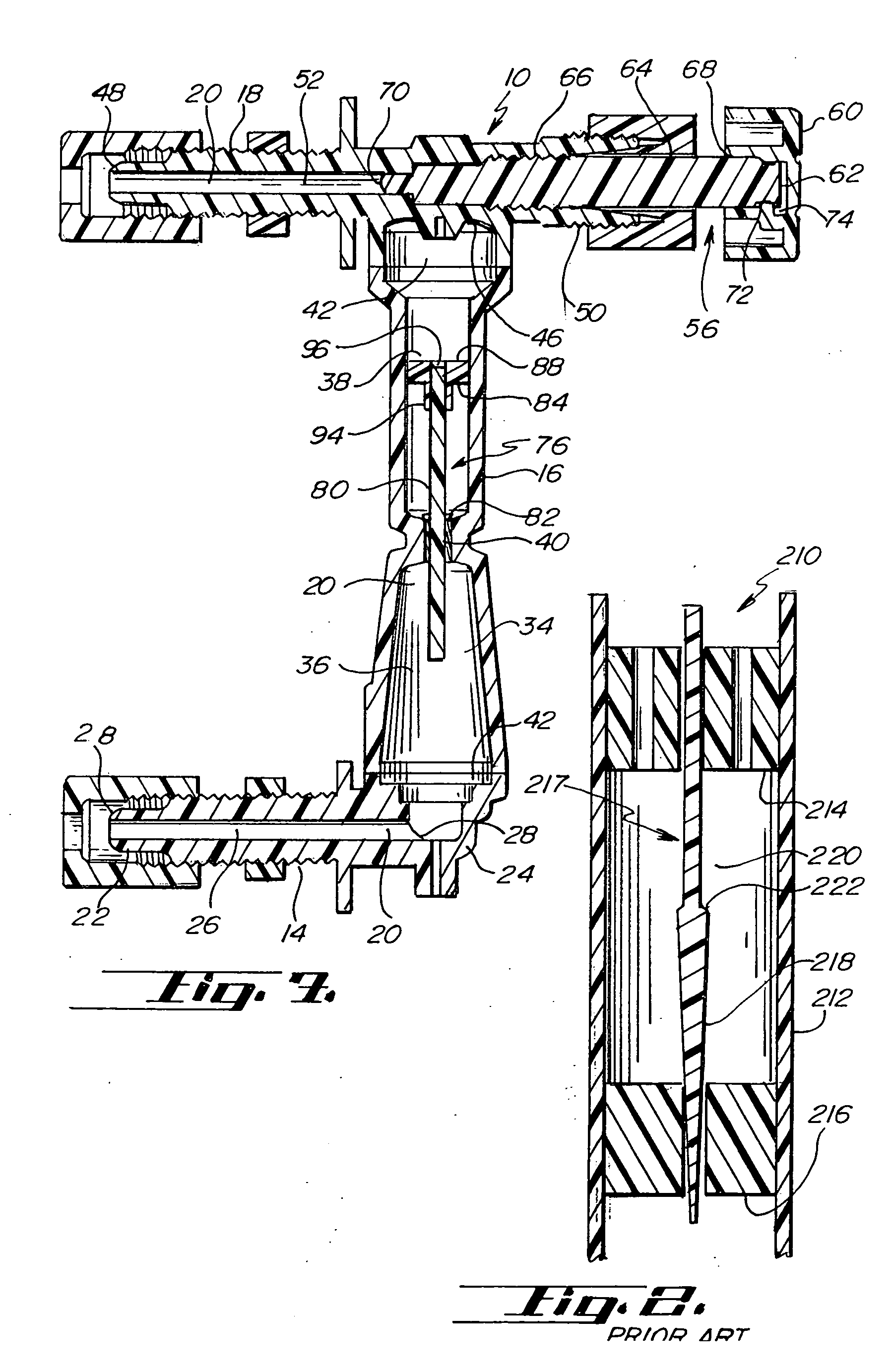

Flow Diversion Valve for Downhole Tool Assembly

InactiveUS20210115747A1Rate to changeReduce fluid flow rateTubing catchersFlushingStream flowMud motor

A casing removal system includes a flow diversion valve. The flow diversion valve includes a flow switch that engages an upper end of an inner casing. When the flow switch engages the upper end of the inner casing, the flow diversion valve opens and at least a portion of the fluid flow through the casing removal system exhausts to the annulus. The remaining fluid flow below the flow diversion valve is insufficient to operate a mud motor that drives a casing cutter. In other embodiments, when the flow switch is not engaged with the inner wall of casing, the flow diversion valve prevents fluid flow to components that are downhole of the valve and when the flow switch is engaged with the inner wall of casing, the flow diversion valve allows for fluid flow to components that are downhole of the valve.

Owner:STOKES DAVID A +3

Low-noise single-seat cage type regulating valve

The invention discloses a low-noise single-seat cage type regulating valve. The low-noise single-seat cage type regulating valve comprises a valve body, a valve seat, a valve cage, a supporting cylinder, a sealing ring, a sealing gasket, a valve rod, a valve deck, a sealing washer, a flat gasket, a set screw, a valve element and a valve seat sealing gasket. A window is arranged on the valve cage and can allow fluid to circulate and allow the flow to be accurately controlled, and two guide rings and an elastic sealing washer are further arranged in an annular groove in the lower side of the inner wall of the supporting cylinder, so that sealing is achieved. The two guide rings are located on the two sides of the elastic sealing washer. The inner cylindrical surface of each guide ring makes contact with the outer cylindrical surface of the valve element. Both the radial width of each guide ring and the radial width of the elastic sealing washer are slightly larger than the radial depth of the annular groove in the lower side of the inner wall of the supporting cylinder, so that the inner surface of the valve cage is made to be in clearance fit with the outer cylindrical surface of the valve element, and in this way, abrasion of the surface of the valve element is reduced while both the guiding function and the sealing function are achieved. The low-noise single-seat cage type regulating valve has the advantages of being compact in structure, reliable in sealing performance, low in noise, high in regulating precision and the like.

Owner:CHANGZHENG ENG +1

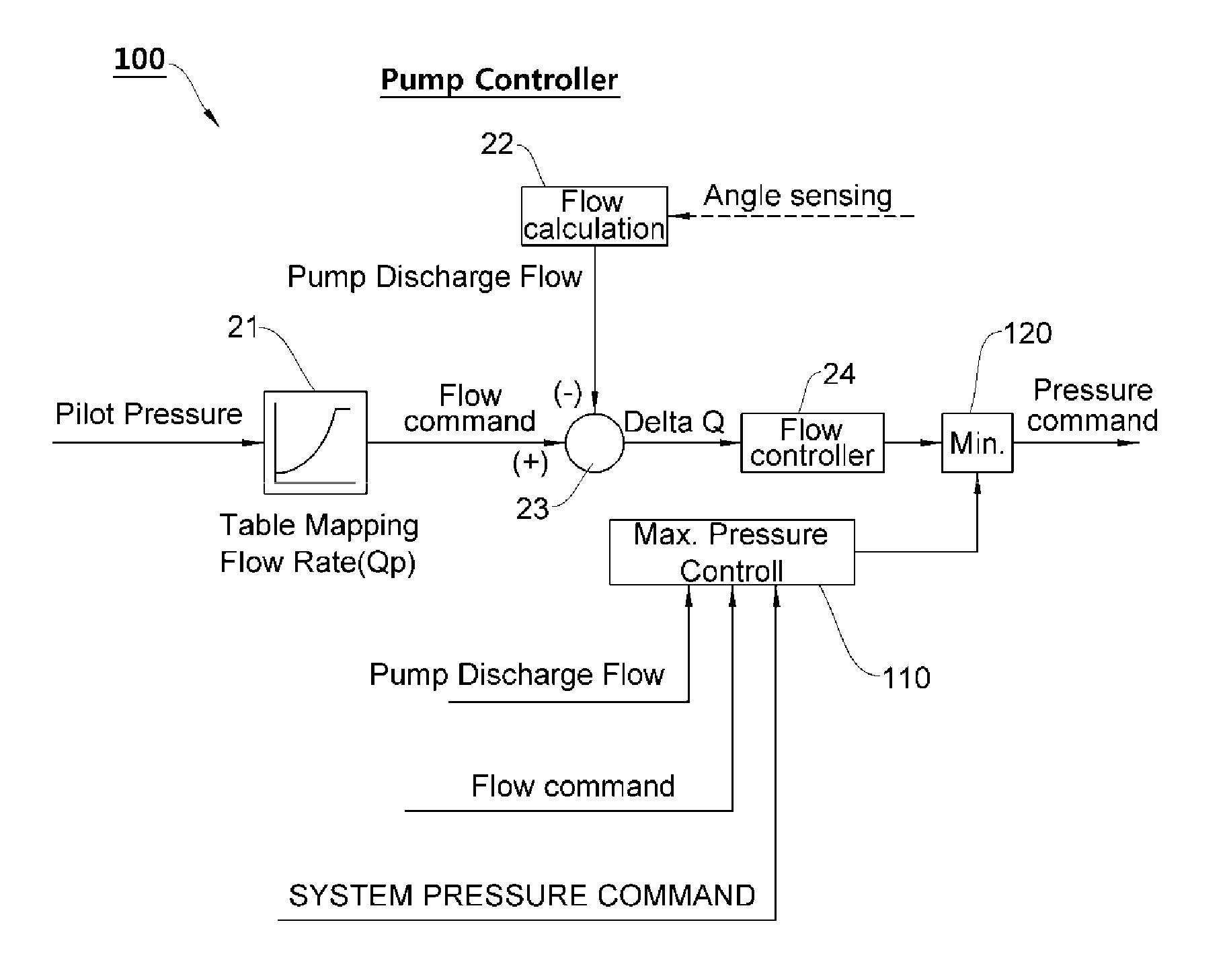

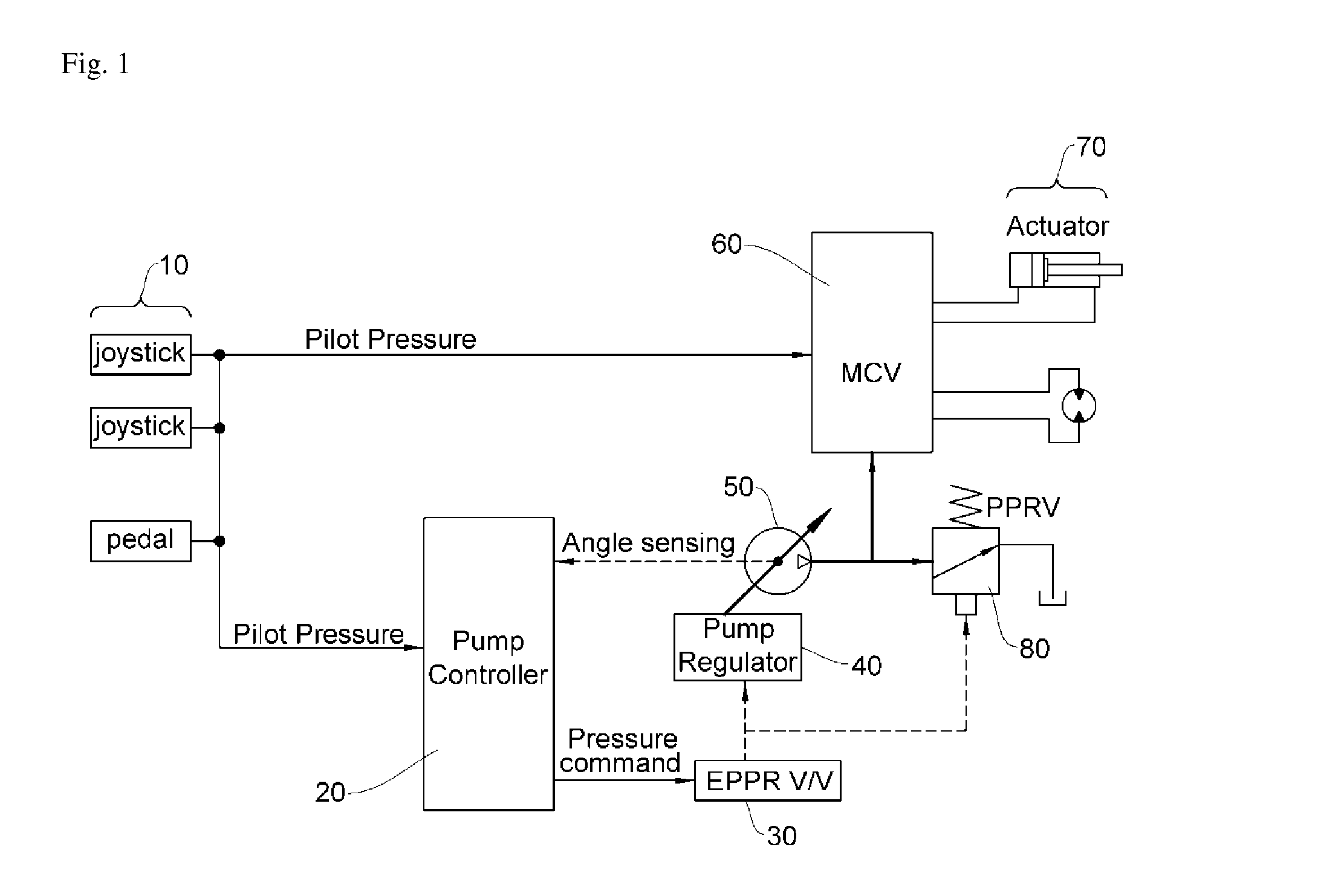

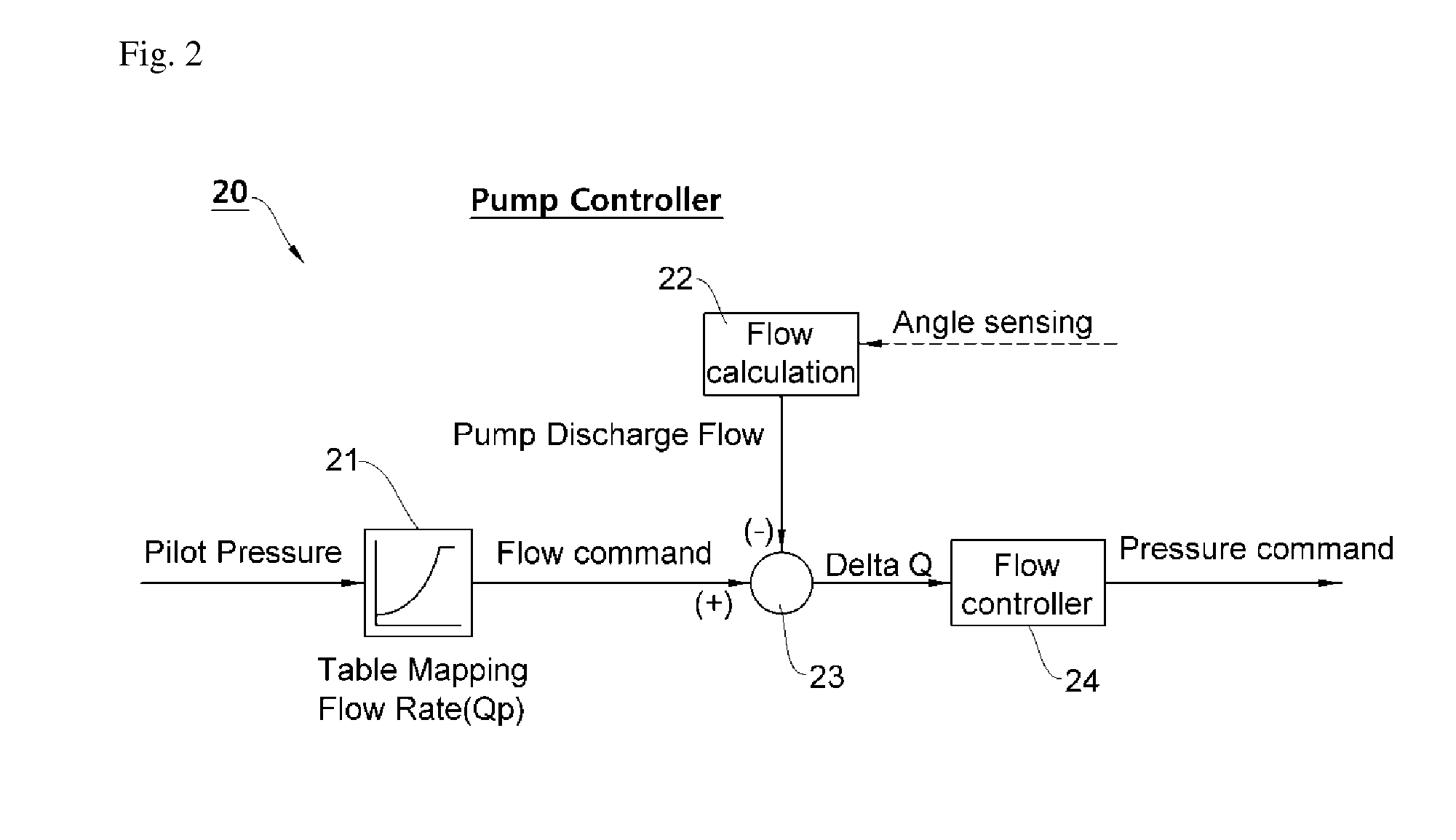

Pressure overshooting prevention system for electronic hydraulic pump in hydraulic system

InactiveUS20150017029A1Process stabilityReduce the discharge flow rateServomotorsServometer circuitsProportional controlWorking fluid

The present disclosure relates to a pressure overshooting prevention system for an electronic hydraulic pump in a hydraulic system, in which a flow rate command is added (+), a discharge flow rate is subtracted (−), a displacement flow rate (Delta Q) is calculated, a first pressure command corresponding to the displacement flow rate (Delta Q) is generated, a working fluid pressure value corresponding to the discharge flow rate is generated, a limit pressure command is generated to limit an increasing gradient of the working fluid pressure value, a stall is determined based on a first rate of change of the flow rate command, and a second rate of change of the discharge flow rate, and the limit pressure command is set to a second pressure command when the stall is determined, and a small value of the first pressure command and the second pressure command is selected as a final pressure command so as to control an electronic proportional control valve, thereby reducing overshooting of the electronic hydraulic pump.

Owner:DOOSAN INFRACORE CO LTD

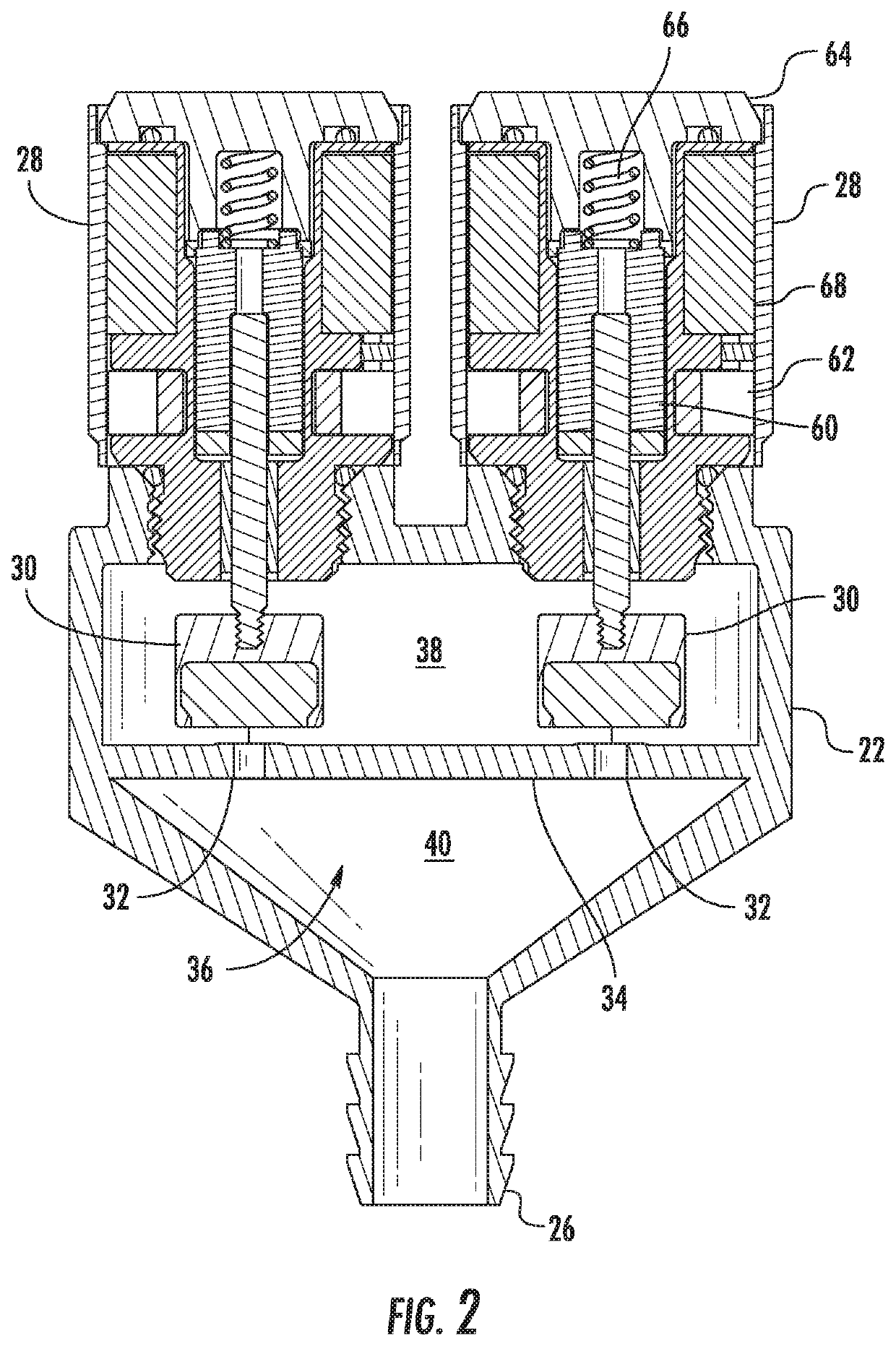

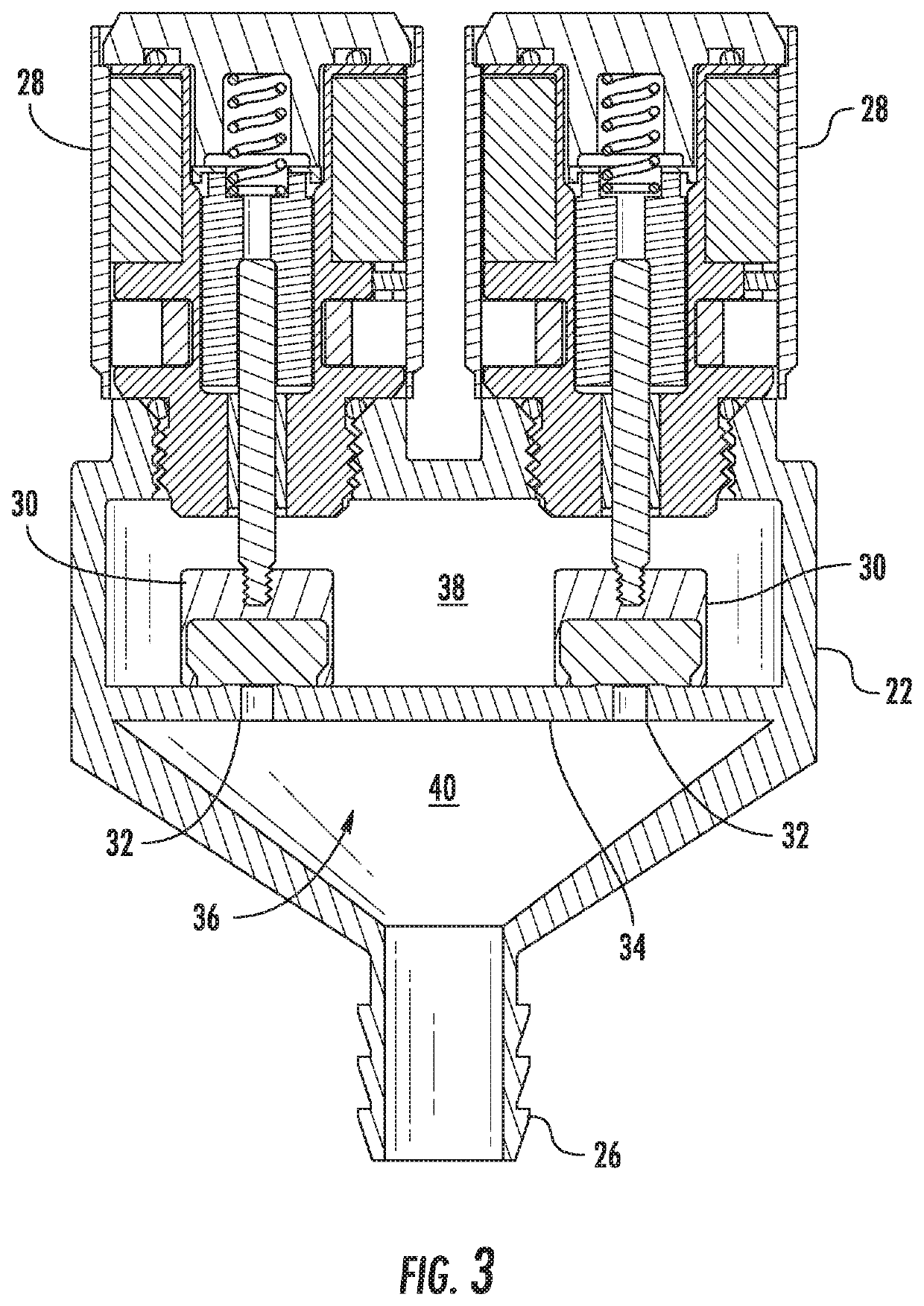

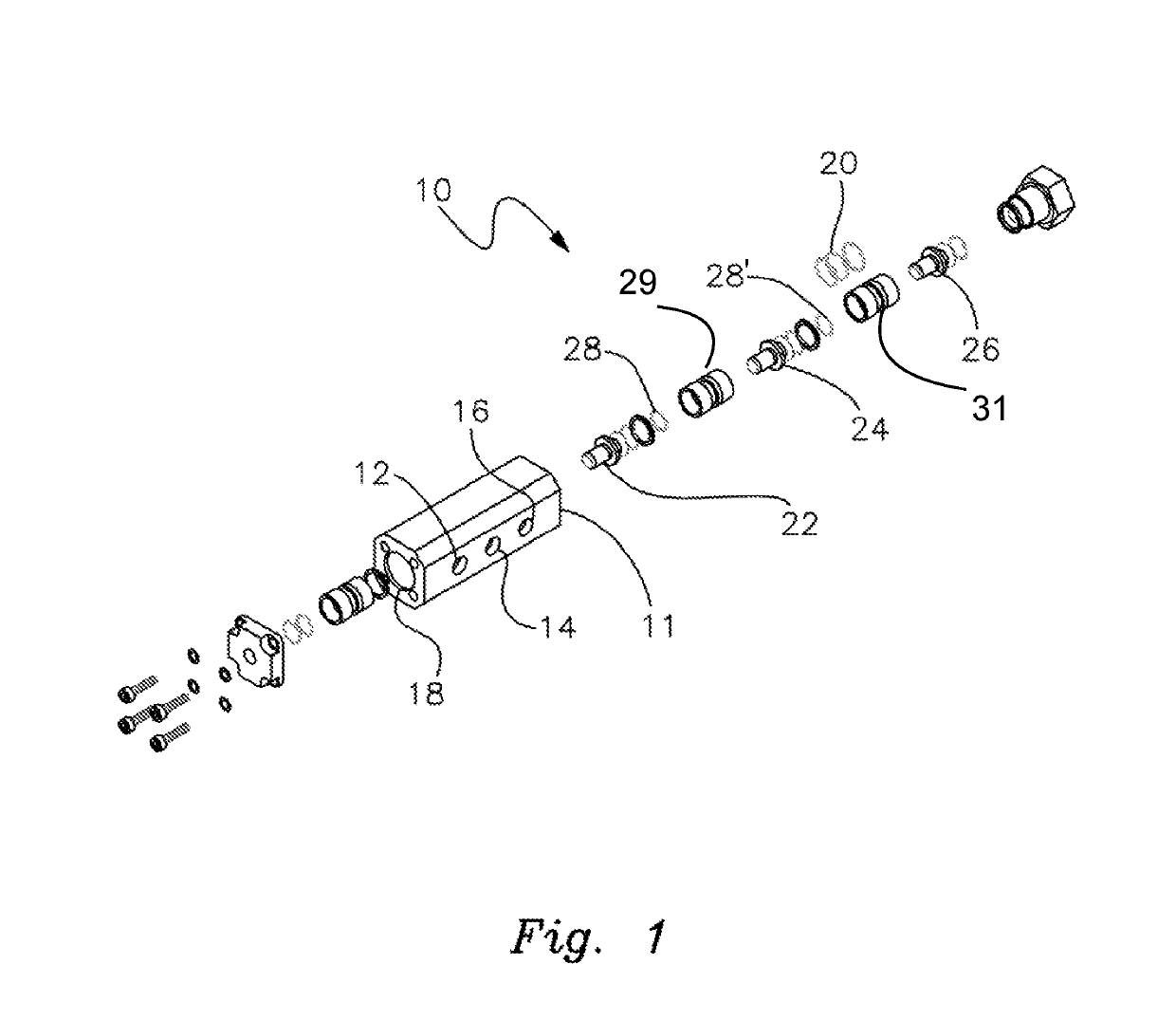

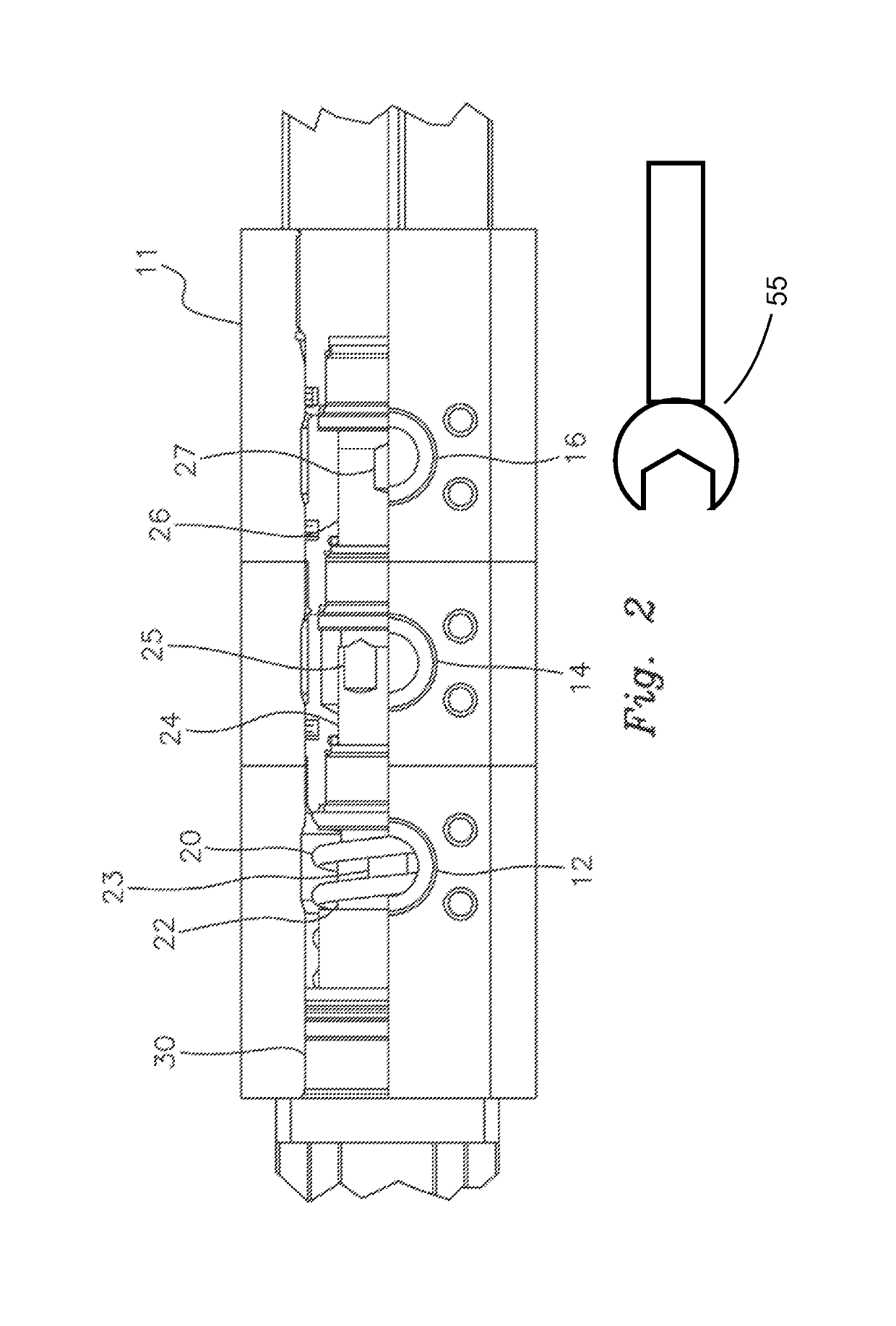

Multivalve member flow control apparatus and method

InactiveUS20190346065A1Increase fluid velocityReduce fluid flow rateOperating means/releasing devices for valvesCheck valvesEngineeringLeakage flow

A solenoid operated valve constructed in accordance with the teachings herein utilizes multiple solenoids which each actuate their own respective valve member. There is a one-to-one relationship of valve members to solenoids. This same one-to-one relationship exists between the valve members and a plurality of passages arranged along a flow path through the valve. Each solenoid is operable to independently move its associated valve member from a closed position, where the valve member is seated against a partition wall defining the passage to entirely prevent fluid flow through its associated passage (or only allow for a controlled leakage flow), and an open position, where the valve member allows fluid flow through its associated passage.

Owner:TLX TECH

Valve

ActiveUS20100212912A1Lower overall pressure dropReduce erosionOperating means/releasing devices for valvesCheck valvesWorking fluidEngineering

A downhole valve comprises a tubular body and a valve member. The valve member is normally closed and in the closed position may prevent or restrict passage of a working fluid through the body. The valve member is movable to an open position, a first working fluid pressure differential being necessary to move the valve member from the closed position and a lower second working fluid pressure differential being necessary to maintain the valve member in the open position.

Owner:ANDERGAUGE

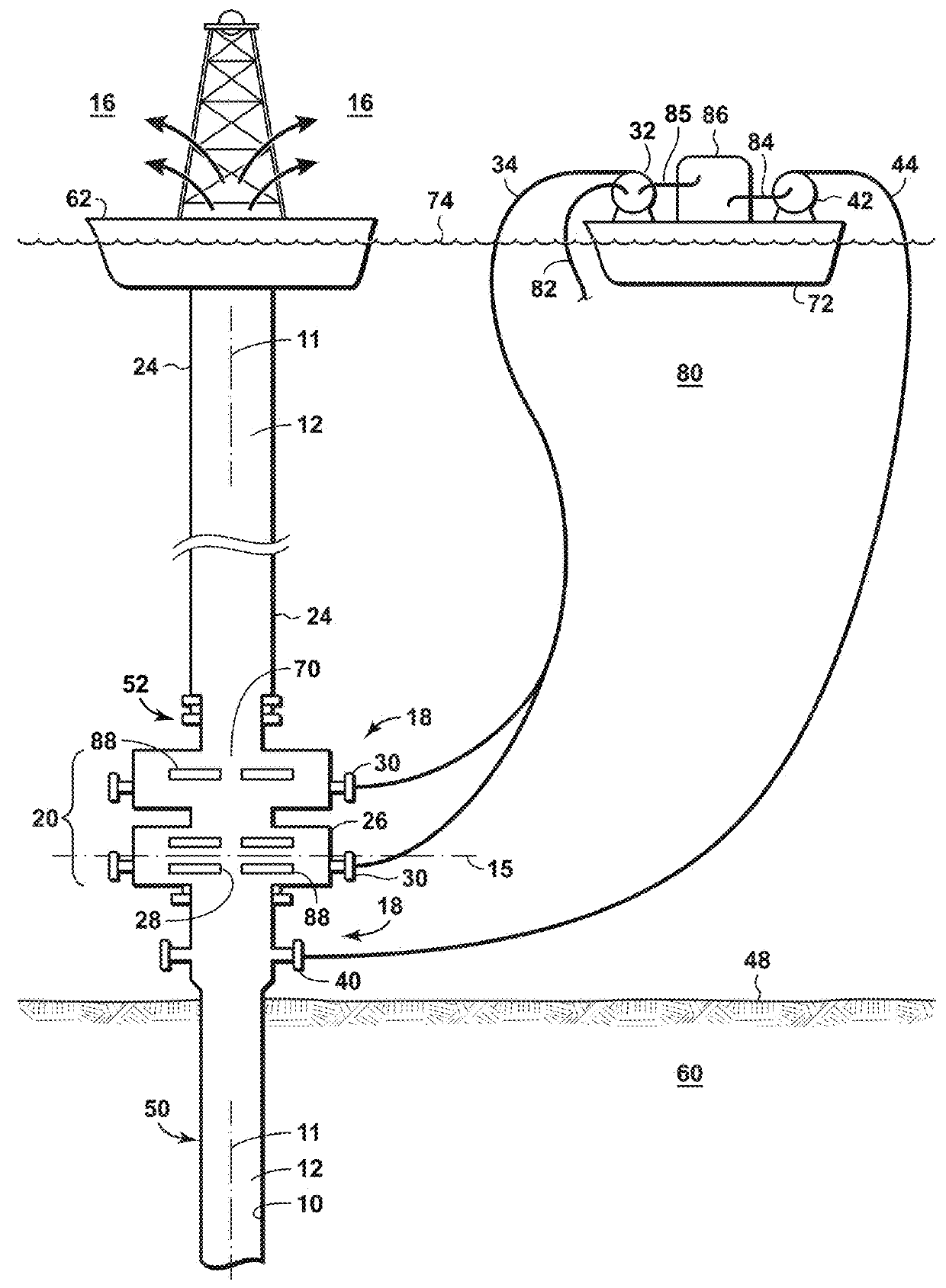

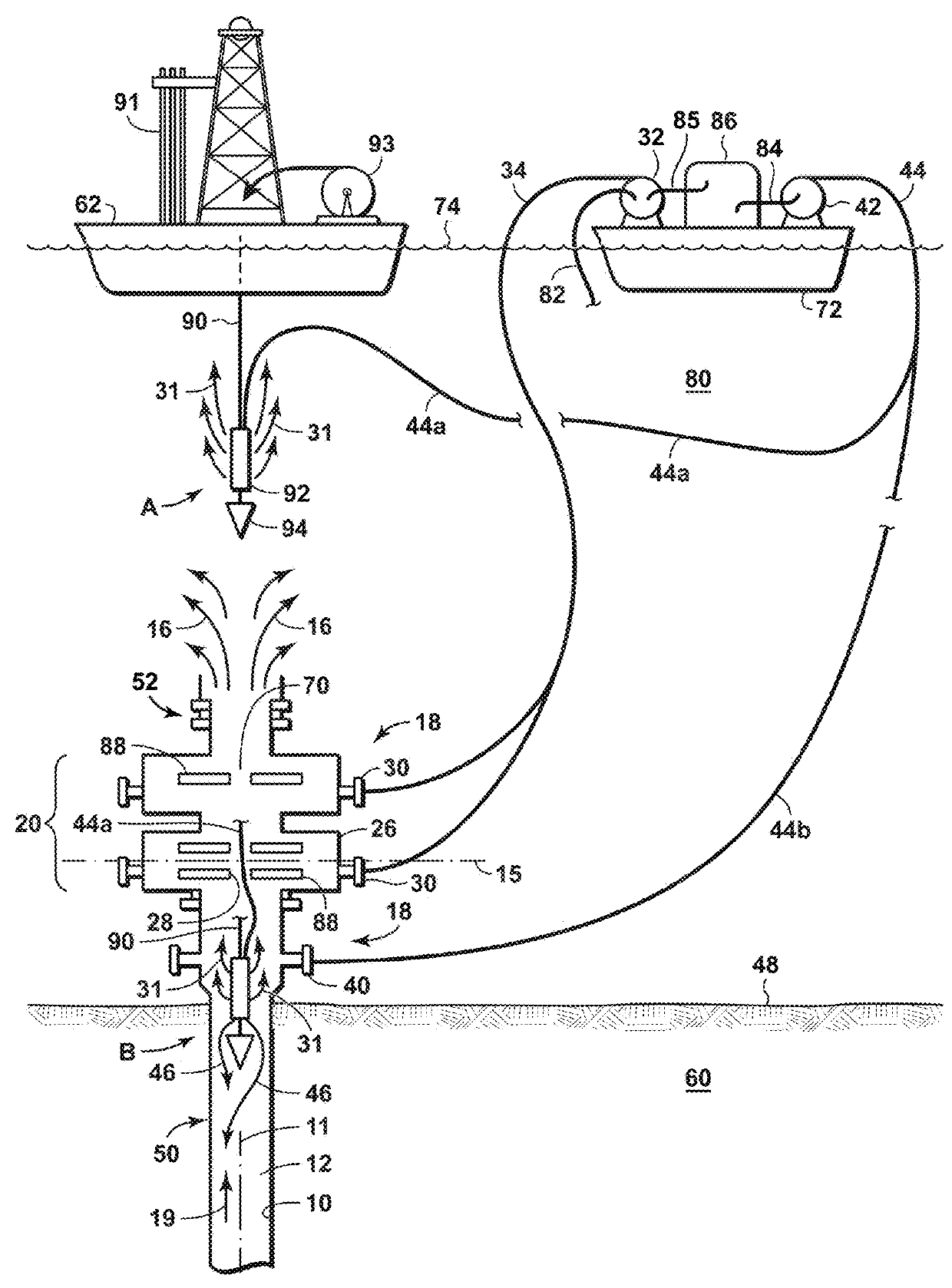

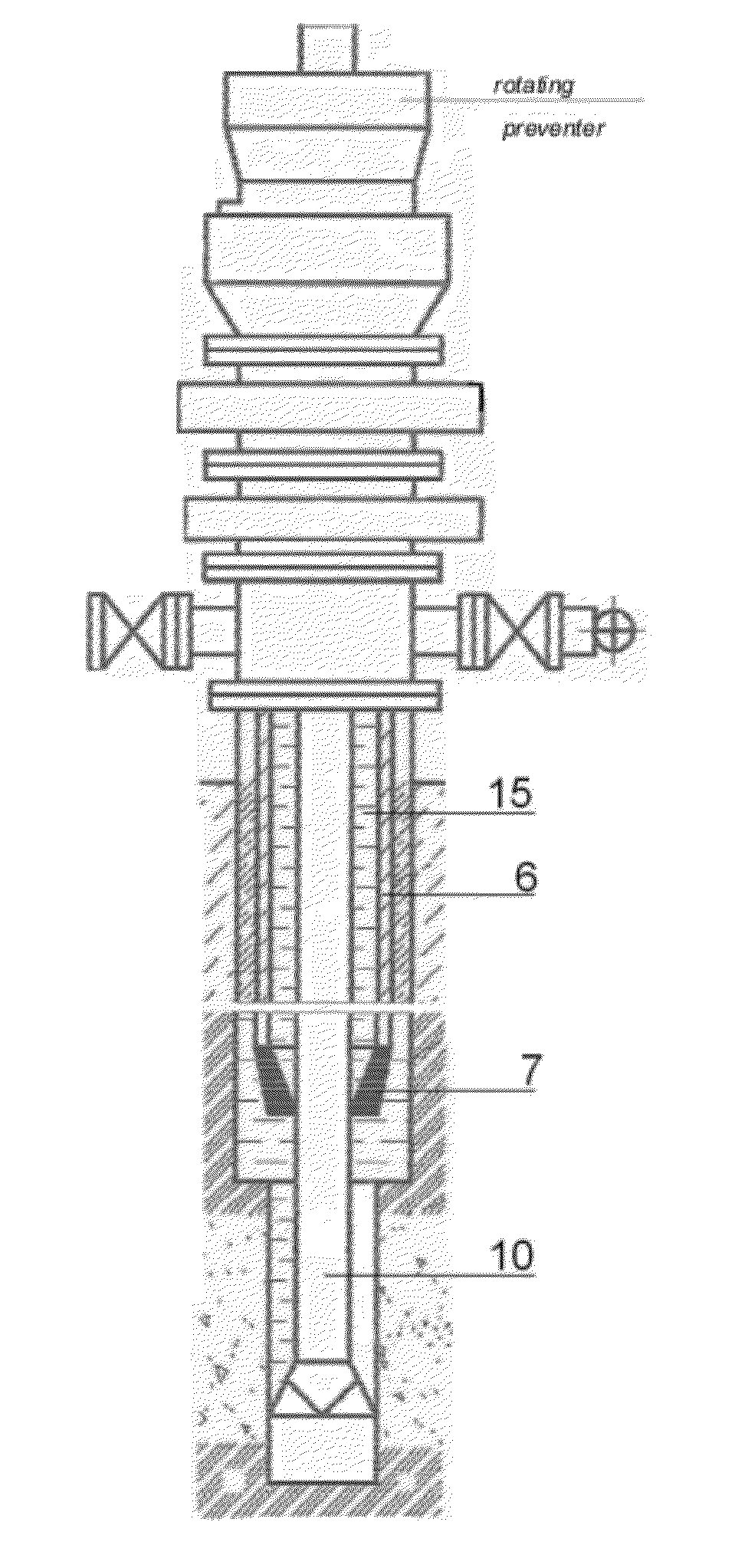

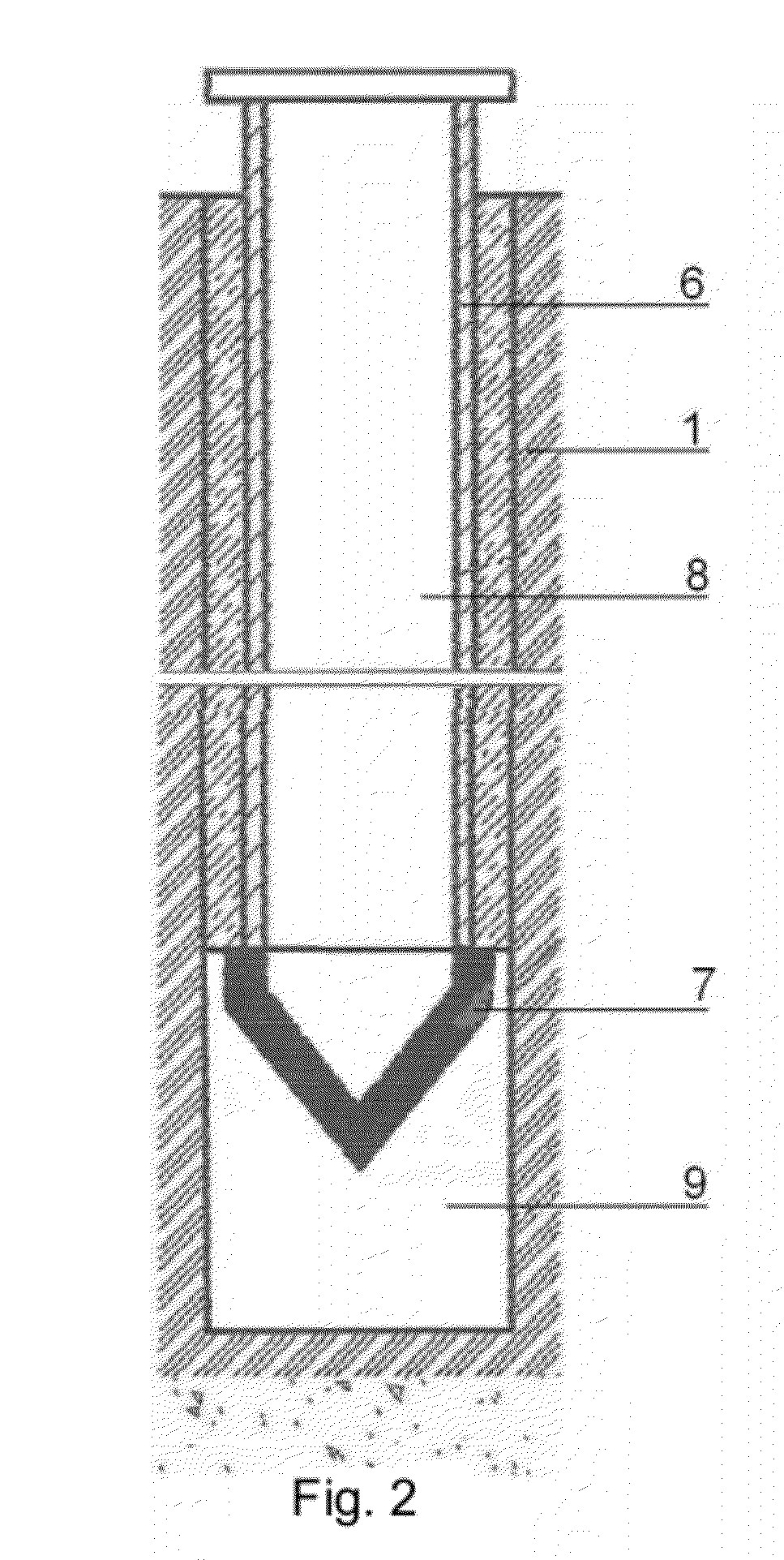

A well completion method

InactiveUS20120103626A1Improve efficiencyQuality improvementFluid removalSealing/packingWellheadGas industry

The method pertains to the oil and gas industry and can be used in the development of producing formations. A producing string (6) together with a sealing device (7) are lowered into a well (1) and the well (1) is divided into an upper cavity (8) and a lower cavity (9) with the aid of said sealing device (7) to establish a hydraulic connection between the well opening and the upper cavity and between the lower cavity and the producing formation, respectively. The installation of equipment (10) and a check valve is carried out stepwise. A washer fluid (4) is replaced by a washer fluid (15). The equipment (10) is passed through the sealing device (7) and the hydraulic connection between the well opening, the lower cavity and the producing formation is re-established along the annular channel. The well (1) is deepened using the equipment (10) until an inflow of formation fluids occurs, the differential pressure in the hydraulic system “well opening—producing formation” being adjusted using the check valve and a blowout preventer (3). The equipment (10) is withdrawn from the lower cavity (9) upon completion of deepening, the device (7) is closed during separation of the cavity (9) from the cavity (8) and cutting-off the hydraulic connection between the producing formation and the upper cavity. The technical solution increases the efficiency and quality of technical operations and prevents the undesired inflow of formation fluids.

Owner:PAVEL DMITRIEVICH ALEKSANDROV

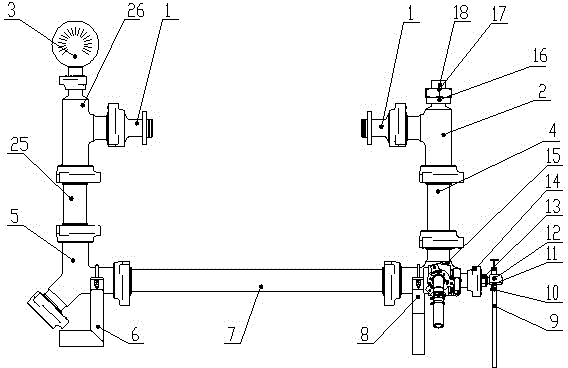

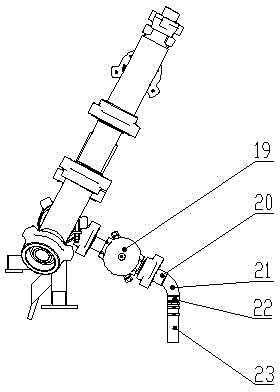

A dual-discharge high-pressure manifold for fracturing

The invention provides a double-discharging high pressure pipe manifold for fracturing. A first pressure relief pipe manifold and a second pressure relief pipe manifold are respectively connected at two ends of a four-way connection assembly, the other two ends of the four-way connection assembly are respectively connected with a first dual male reducer union and an integral dual male straight pipe assembly, one end of the integral dual male straight pipe assembly is connected with a Y-shaped tee joint, a second dual male reducer union and a second T-shaped tee joint in sequence, the other two ends of the second T-shaped tee joint are respectively connected with a Marti-Decker gauge and a discharging flange assembly, the other end of the first dual male reducer union is connected with a first T-shaped tee joint and the discharging flange assembly in sequence, and the other end of the first T-shaped tee joint is connected with an adapter, a transducer adapter and a pressure sensor in sequence. The double-discharging high pressure pipe manifold is capable of overcoming the defects and disadvantages of existing discharging pipe manifolds. Further, the structural functions of the discharging pipe manifold are increased, and the water power efficiency of a fracturing pump truck is improved.

Owner:中石化四机石油机械有限公司 +2

Shuttle valve

ActiveUS10371272B2Slow flowReduces vacillationServomotor componentsMultiple way valvesEngineeringShuttle valve

A shuttle valve has a housing with a plurality of inlet ports, an outlet port for fluid flow, and a passageway for fluid to flow from any one of the inlet ports to the outlet port. Each Inlet port has an associated plunger configured one to the other such that when sufficient pressurized fluid is flowing into any one of the inlet ports, fluid is prevented from flowing into any other inlet port. The plungers include male and female mating portions with a radial seal between them. A biasing spring allows one of the plungers to allow backward fluid flow through the associated inlet port when not under pressure.

Owner:THE SUBSEA

Two-way actuator and method

Owner:BAKER HUGHES HLDG LLC

Fluoropolymer flowmeter

InactiveUS20050022610A1Improve effectivenessImprove reliabilityElectronic circuit testingVolume meteringEngineeringCatheter

In one embodiment, a sight tube flowmeter is formed of a plurality of fluoropolymer components welded together to form a unitary flowmeter body. The components can comprise a PFA upright sight tube having two end portions, a flow conduit extending therethrough and two fitting portions that are uniquely welded onto each end of the sight tube, and a fluoropolymer float device movable to various positions within the flow conduit depending on the flow level of the fluid flowing therethrough. The float device can be of conventional design or for those flowmeter embodiments where low fluid flow rates are to be measured, an elongate float can be utilized. The floats and, in particular, a designated portion thereof, are visible through the sight tube to provide visual indication of the position, and thus the flow rate of fluid flowing through the flowmeter. In addition, alternative embodiments include the implementation of the unique sight tube and elongate float design in conventional flowmeters.

Owner:ENTEGRIS INC

Abrasion-resistant flow guide device

InactiveCN102226663AReduce fluid flow rateModerate local abrasionCorrosion preventionHeat exchanger casingsEngineeringStreamflow

The invention discloses an abrasion-resistant flow guide device which comprises a suction flange, a buffer channel and a first rectangular flange connected with the inlet of a heat exchanger, wherein the suction flange, the buffer channel and the first rectangular flange are sequentially connected with a system pipeline; the buffer channel comprises a Z-shaped buffer distribution channel; and at least a flow guide vane is arranged in the outlet of the Z-shaped buffer distribution channel. In the abrasion-resistant flow guide device disclosed by the invention, the buffer distribution channel is in a Z shape, thus the flowing angel change of the solid-liquid phase fluid in the Z-shaped buffer distribution channel is great and the buffer effect is good. Furthermore, the effective flow space in the Z-shaped buffer distribution channel is large and the flow velocity of the fluid when the flow is the same is low, thereby effectively reducing the partial abrasion of the plate beam of a heat exchanger by a solid-liquid phase flow.

Owner:SHANGHAI HEAT TRANSFER EQUIP

Condenser flow path structure, condenser flow path control method and air conditioner

ActiveCN111637583AImprove heat transfer effectIncrease the number of branchesMechanical apparatusSpace heating and ventilation safety systemsControl valvesControl theory

The invention discloses a condenser flow path structure, a condenser flow path control method and an air conditioner, and relates to the field of air conditioners. The condenser flow path structure comprises a first flow path, a second flow path and a four-way valve assembly a, the four-way valve assembly a comprises a first valve pipe, a second valve pipe, a third valve pipe and a fourth valve pipe, and the first valve pipe is in communication with the third valve pipe; a first control valve is arranged on the first valve pipe, the second valve pipe is in communication with the fourth valve pipe, and a second control valve is arranged on the fourth valve pipe; the first valve pipe is in communication with the fourth valve pipe through a first connecting pipe, a third control valve is arranged on the first connecting pipe, the first valve pipe and the second valve pipe communicate with the first flow path, and the third valve pipe and the fourth valve pipe communicate with the second flow path. The number of branches of an internal pipeline of a condenser and flow of each branch are controlled through a control valve, so that the temperature value of each branch is balanced, and the heat exchange performance is improved.

Owner:NINGBO AUX ELECTRIC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com