Patents

Literature

482results about How to "Slow flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

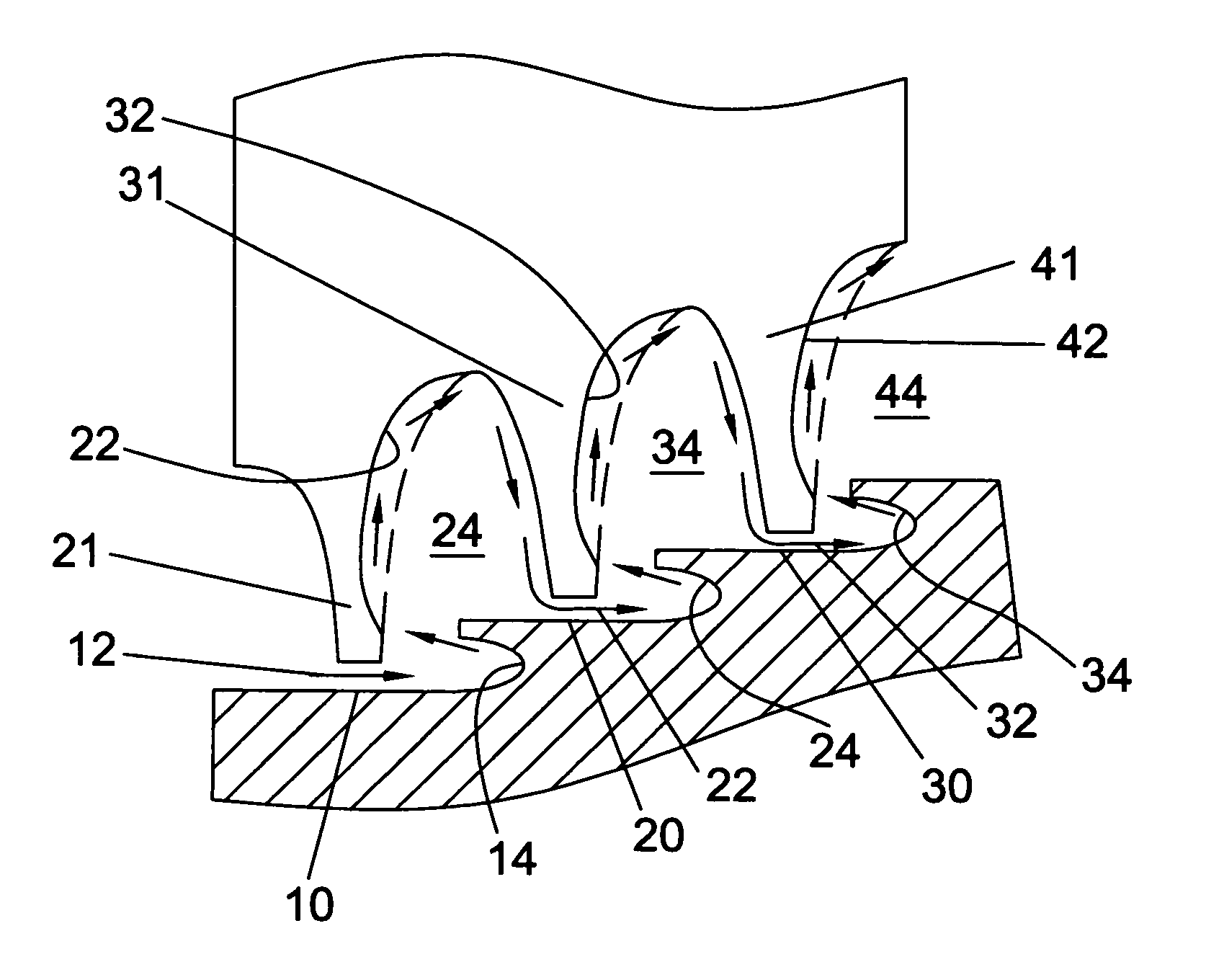

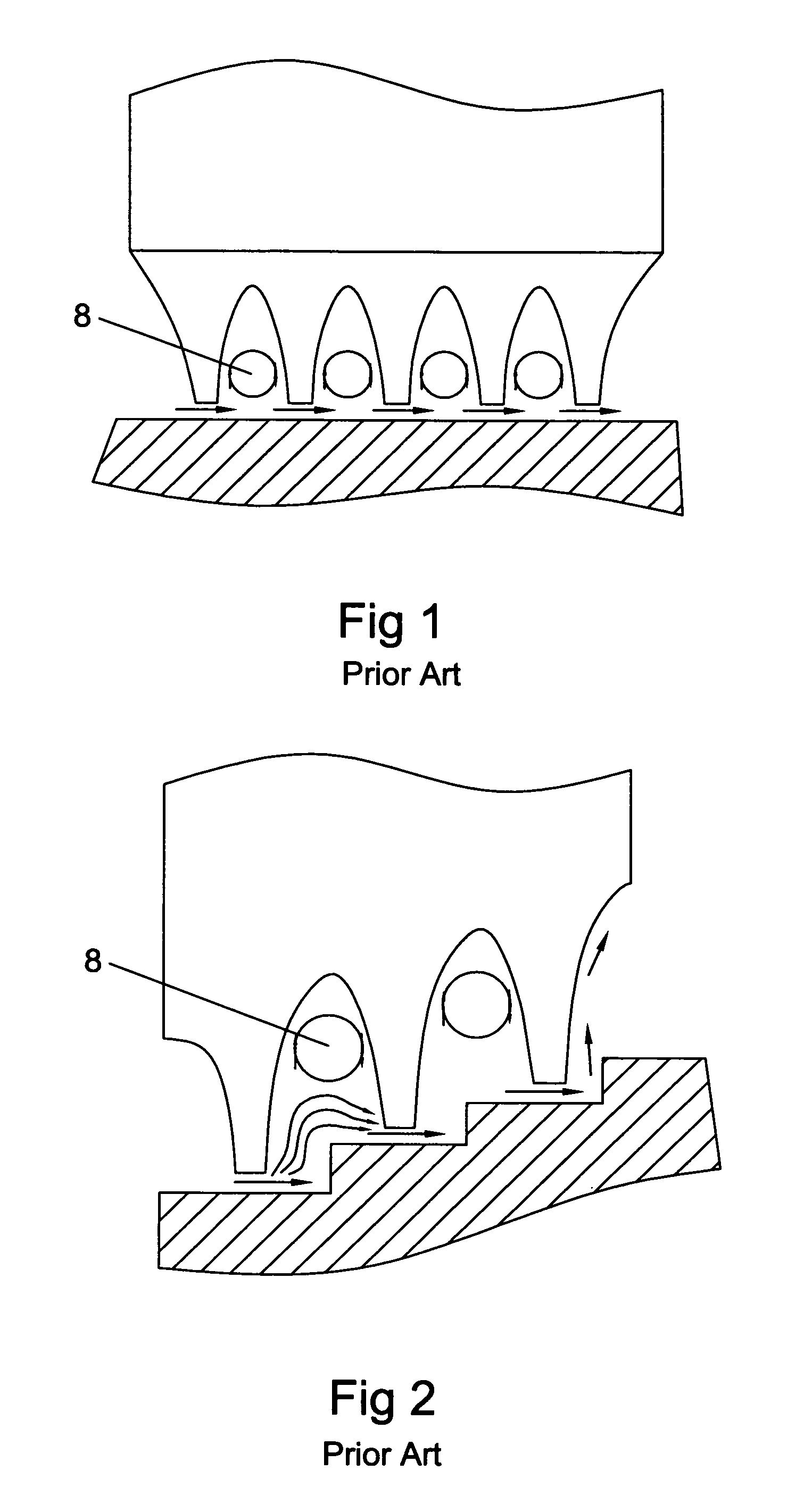

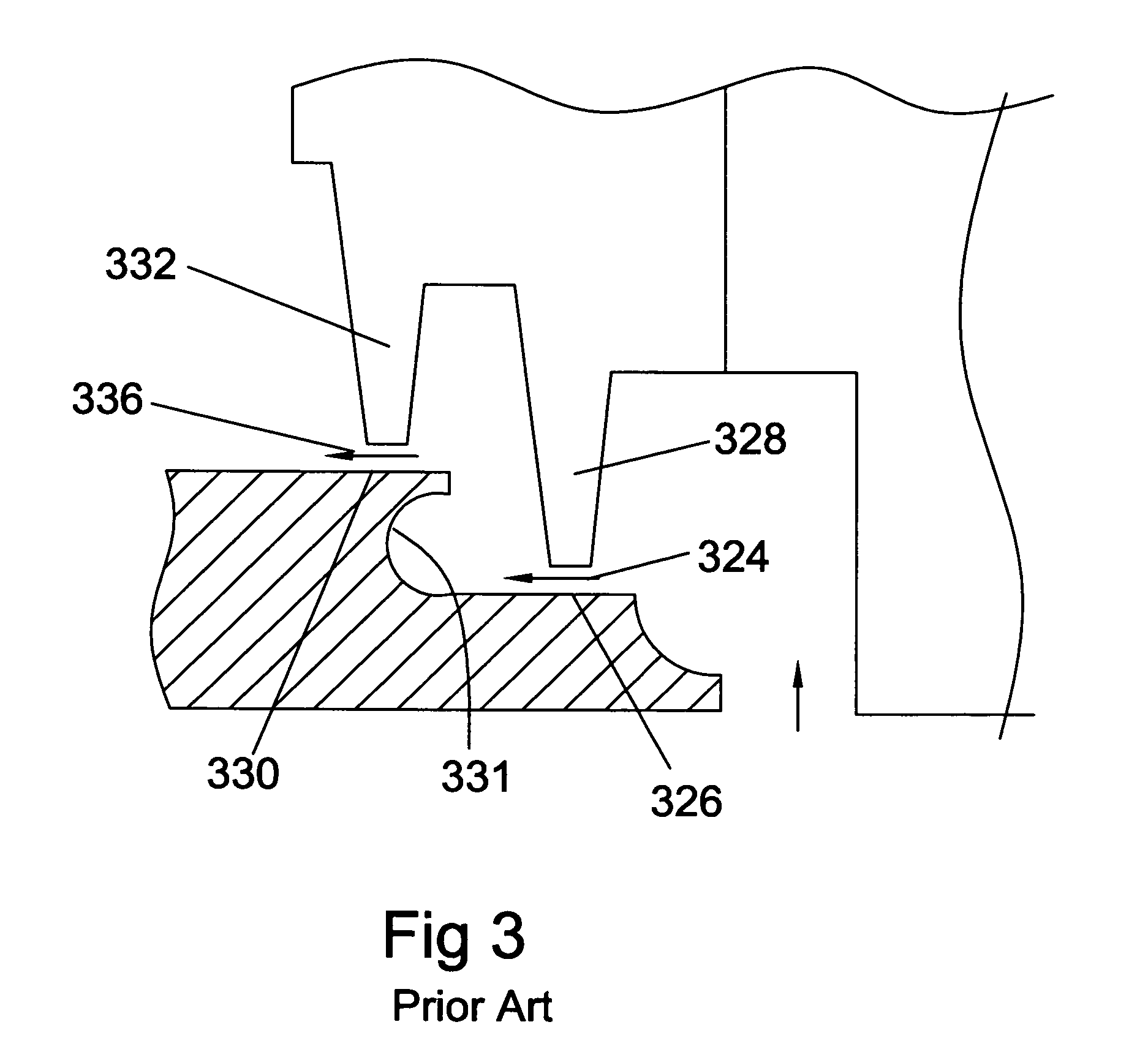

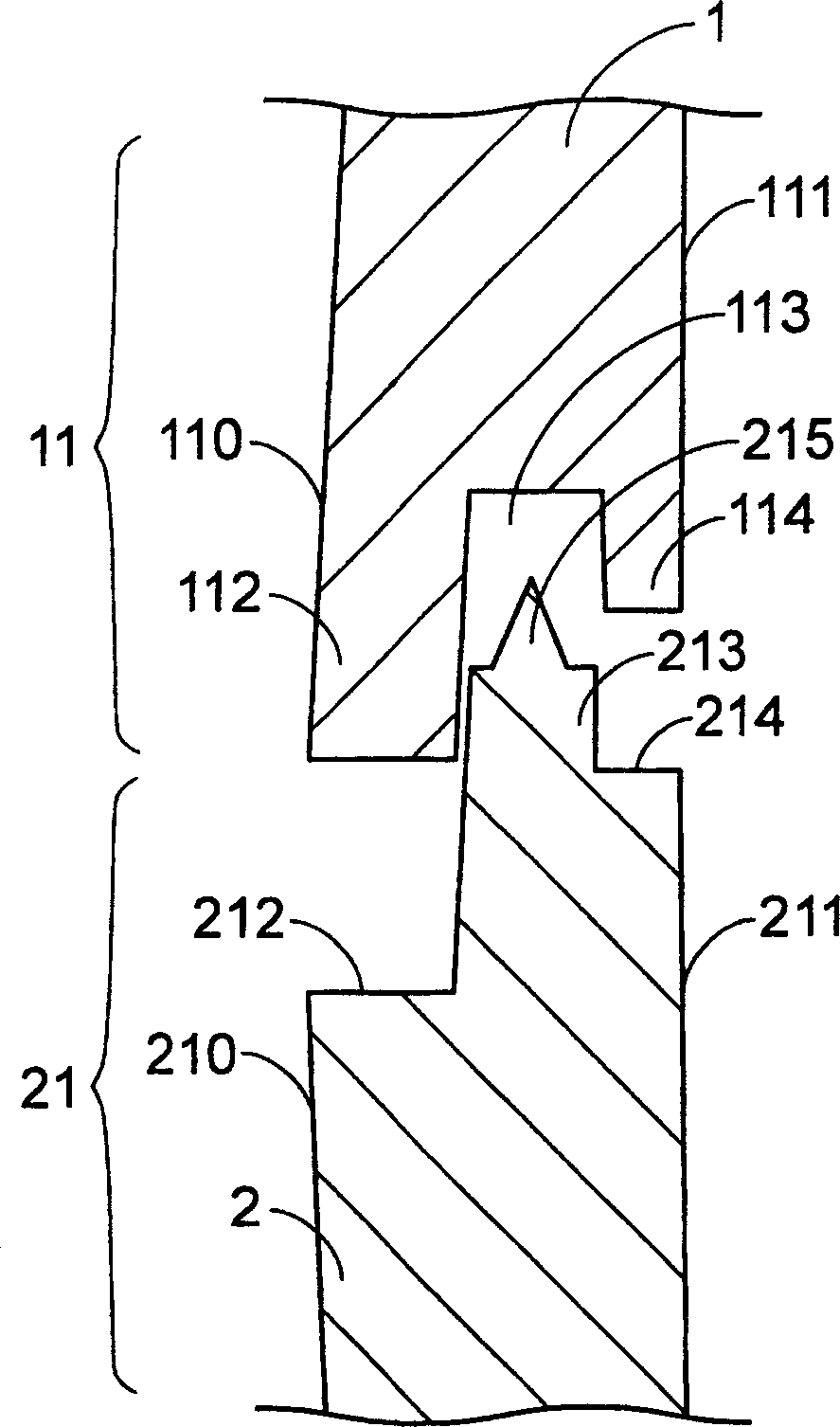

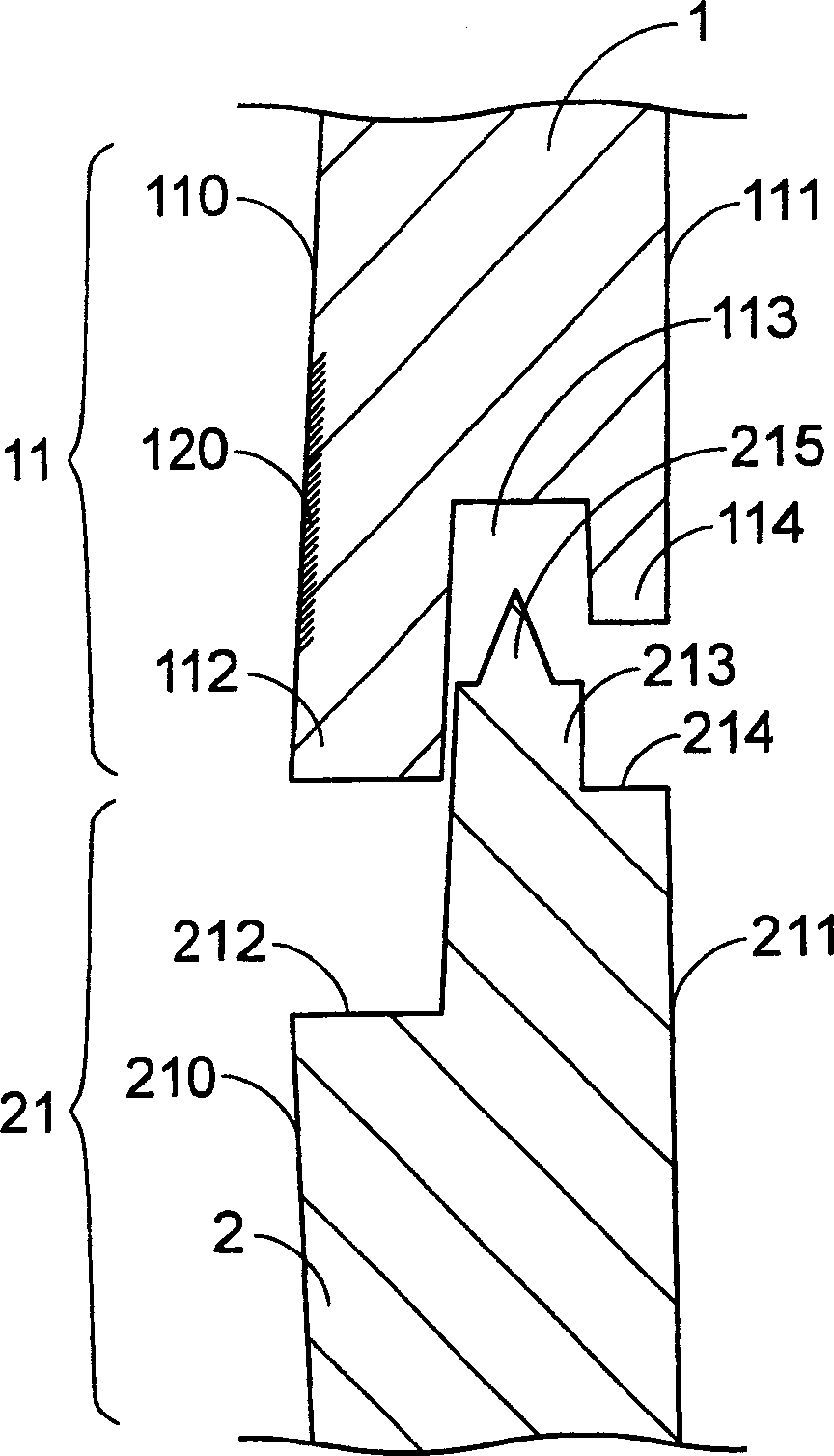

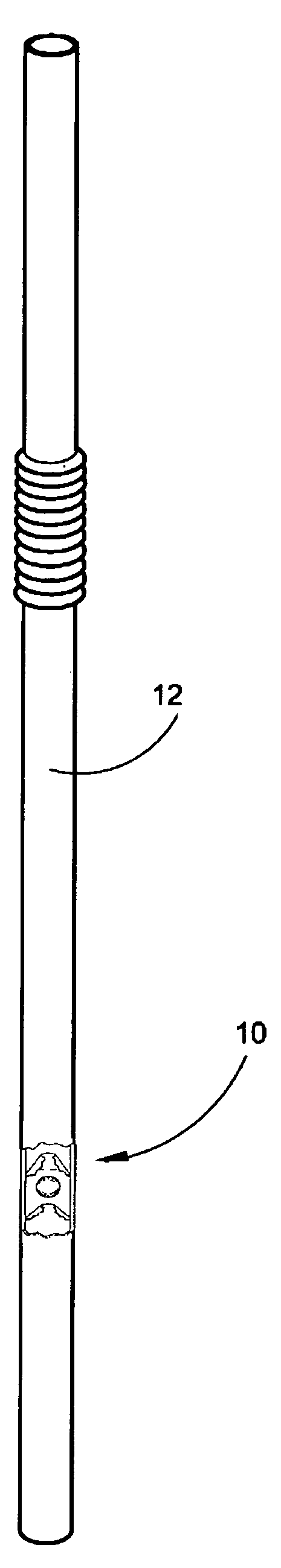

Stepped labyrinth seal

InactiveUS7445213B1Without slowing leakage flowReduce the impactEngine sealsEngine manufactureEngineeringLeakage flow

A stepped labyrinth seal for a turbomachine, the seal having a stepped portion with a redirecting groove formed thereon to redirect a leakage flow through the gap in substantially a reverse direction and onto a surface of the finger such that the dynamic pressure of the leakage flow is not substantially reduced and the static pressure increased. The cavity formed between adjacent fingers has a flow guiding surface that maintains the dynamic pressure of the flow, thereby keeping the flow at high velocity and low static pressure.

Owner:FLORIDA TURBINE TECH

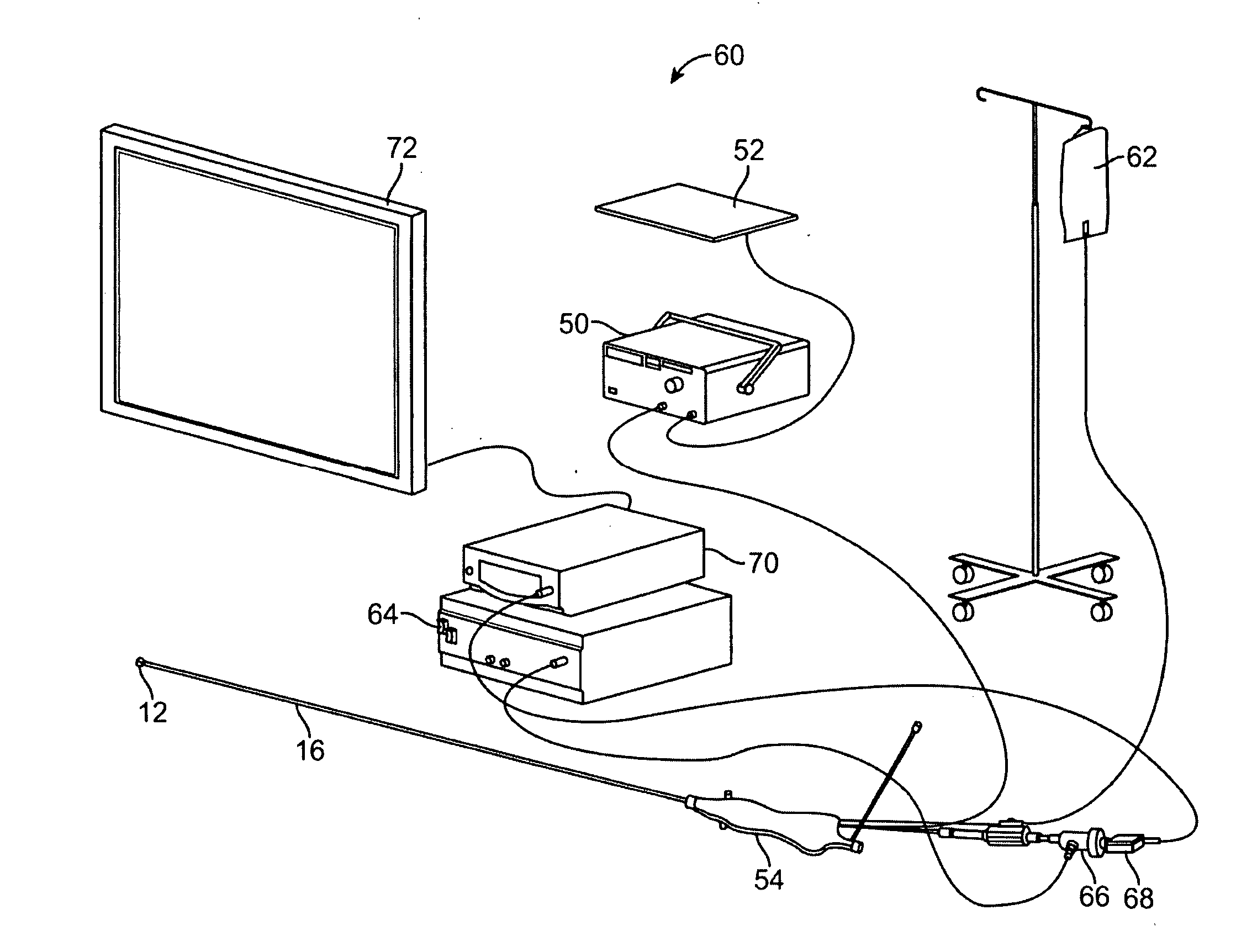

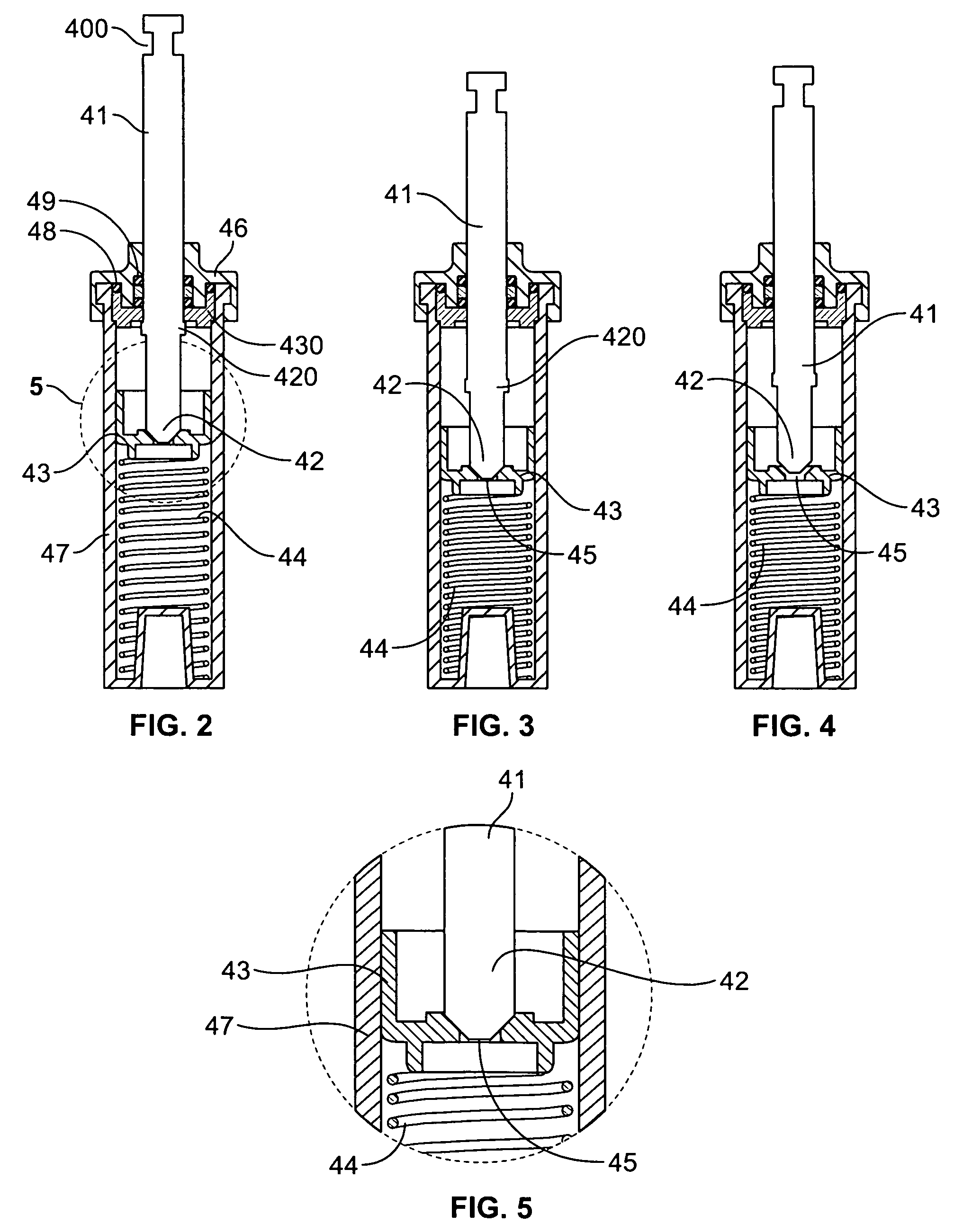

Tissue visualization and ablation systems

InactiveUS20090125022A1Facilitate conductionSlow flowBioelectric signal measurementEndoscopesRf ablationControl manner

Visualization and ablation system variations are described which utilize various tissue ablation arrangements. Such assemblies are configured to facilitate the application of energy delivery, such as RF ablation, to an underlying target tissue for treatment in a controlled manner while directly visualizing the tissue during the bipolar ablation process.

Owner:INTUITIVE SURGICAL OPERATIONS INC

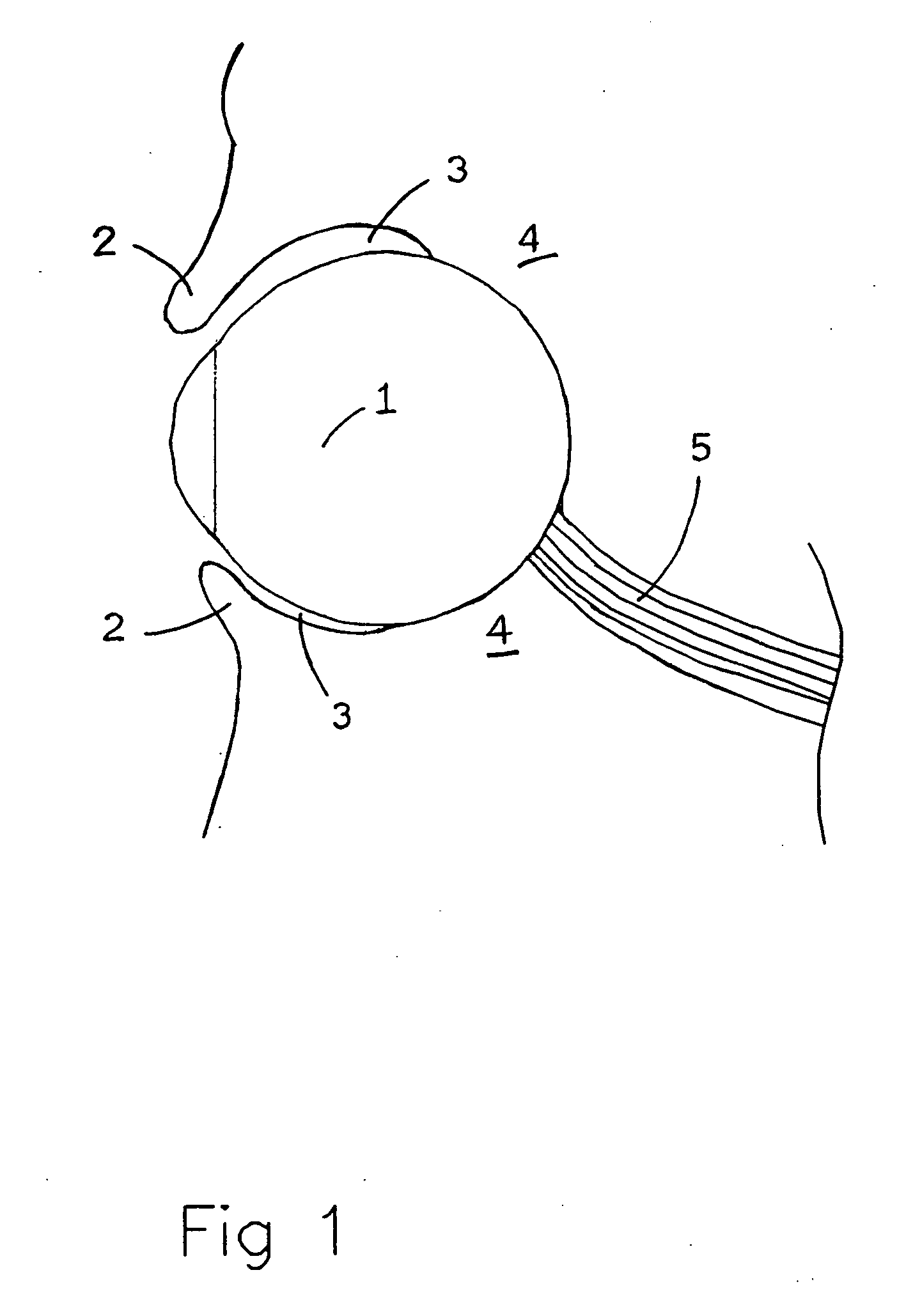

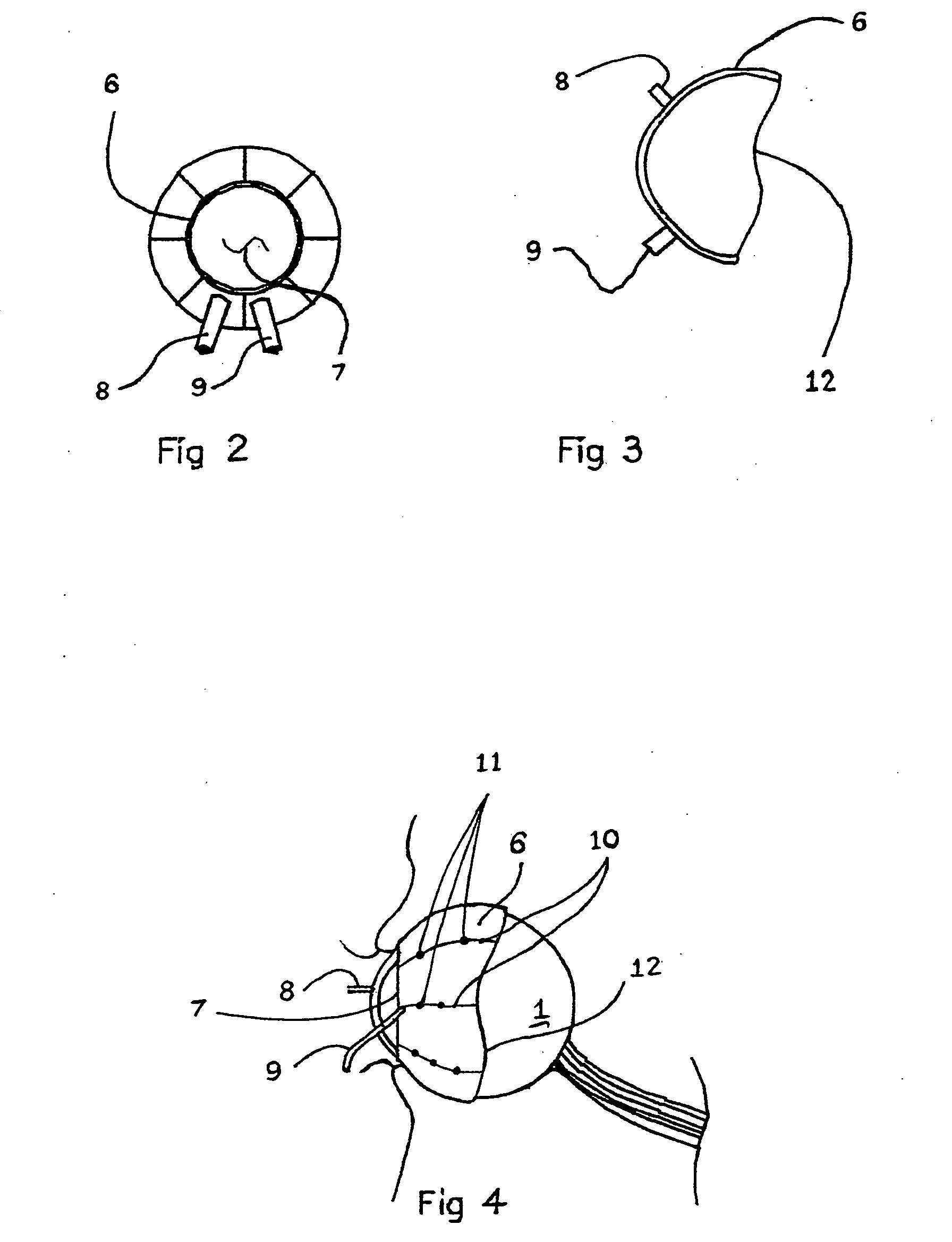

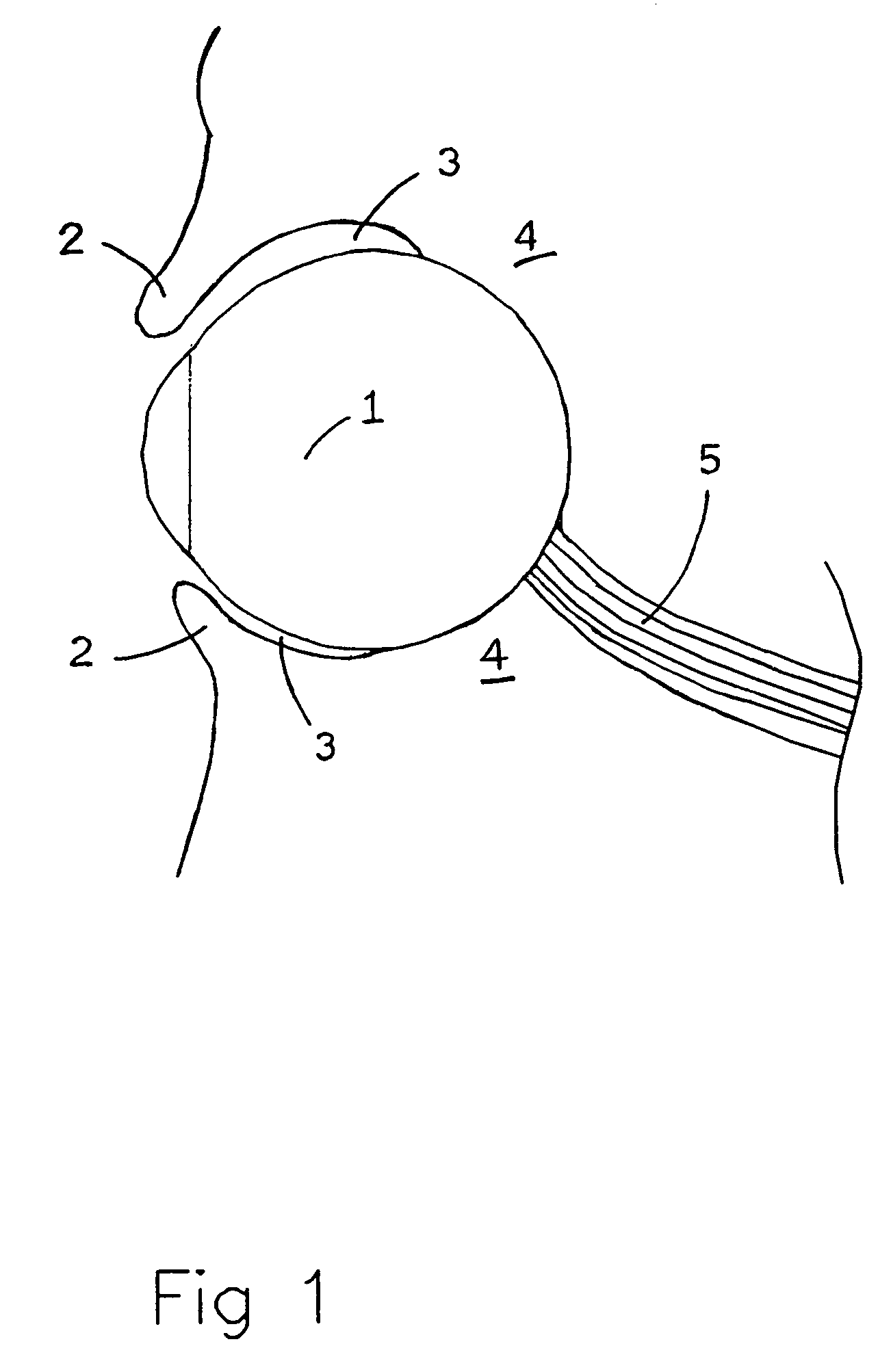

Medical device and method for temperature control and treatment of the eye and surrounding tissues

ActiveUS20060136022A1Easily penetrate sclera of eyeImprove the level ofEye surgerySurgeryDiseaseIntraocular pressure

The invention provides a medical device having a thermister for temperature measurement, irrigation / aspiration ports for fluid exchange and application of therapeutic modalities, a pressure manometer for pressure measurement, and an external system for control of temperature, pressure, and flow rate. When applied to the eye and orbit, this device can be used in hypothermia or hyperthermia applications, the control of intraocular pressure (IOP), and the application of treatment modalities. Methods of using the device in treating patients suffering from central retinal artery occlusion, anterior optic nerve disease, pathology of the choroid and retina including the macula, inflammation of the eye including the vitreous and anterior segment, glaucoma, inflammation and / or infections of the anterior and / or posterior segment of the eye, treatment before / during / after surgery of the eye, and the application of treatment modalities through a semi-permeable membrane are described.

Owner:WONG JR EDWARD K +2

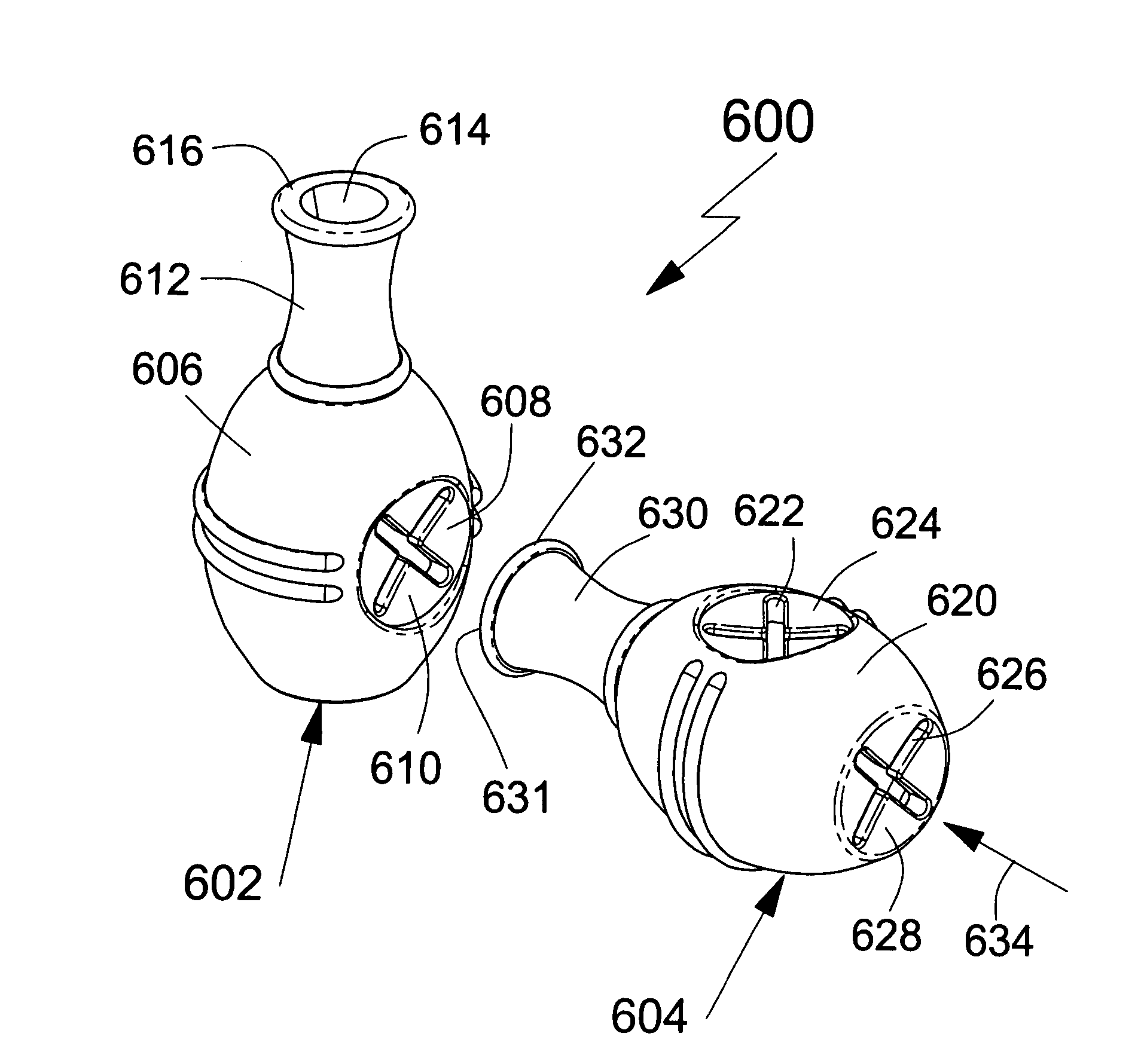

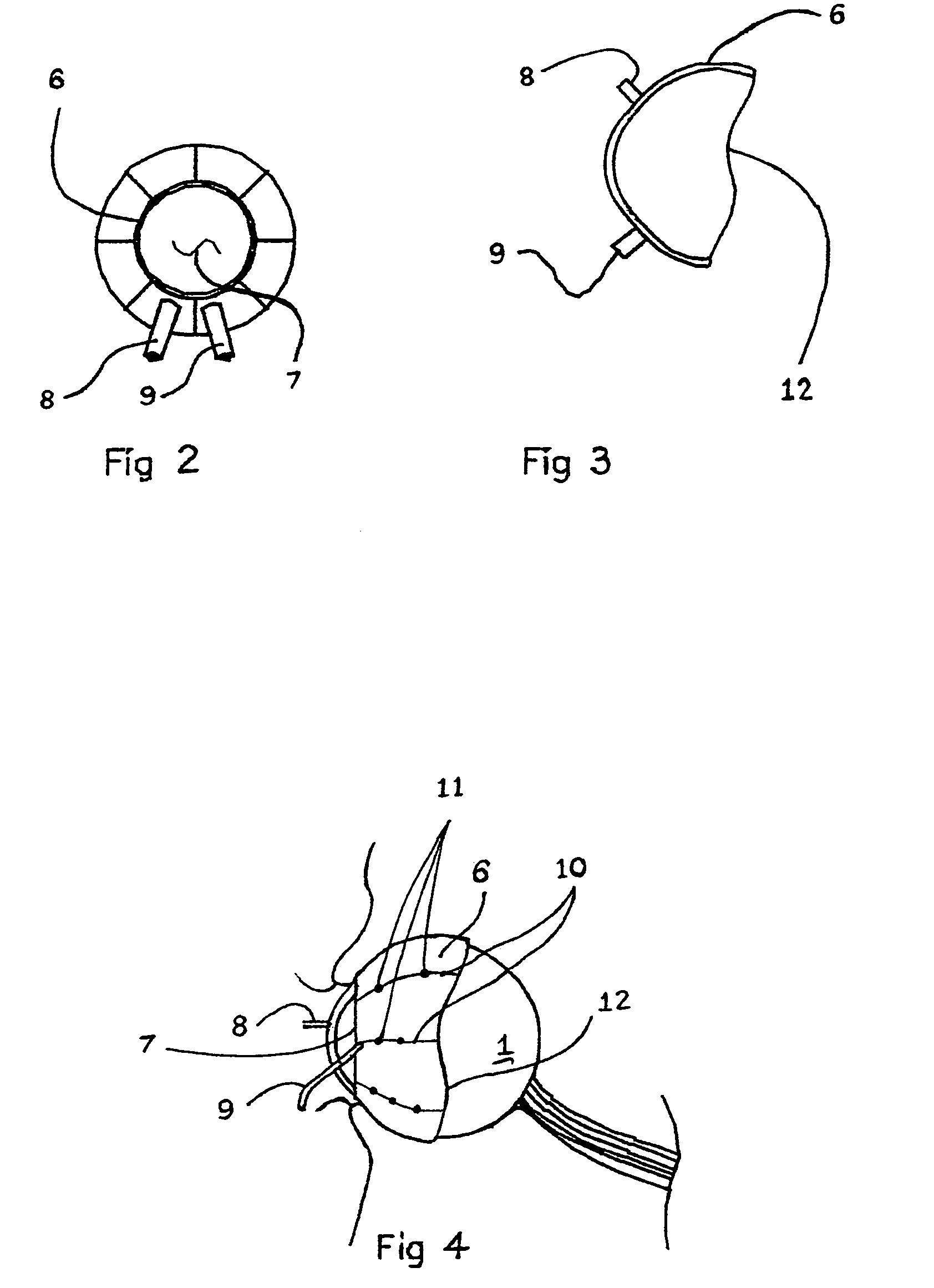

Food dispensing interlocking animal toy system

ActiveUS7389748B2Increase level of difficultySlow flowDollsAnimal feeding devicesEngineeringRandom combination

An animal toy features the ability to connect two or more separate toys of varying shape, size, color, and / or texture, together to create larger and more complex toy systems. The animal toy allows an almost endless variety of toy systems to capture the interest as well as challenge and develop the animal's problem solving skills. The animal toys are either solid or include internal chambers for holding and ultimately dispensing food. When two or more toys with the internal chambers are combined the food may flow from the chamber of one toy into another toy several times before exiting the toy system. The increased problem of extracting the food challenges and develops the animal's skills. Morever, by combining solid and food dispensing toys in random combinations further increases the problem solving skills required to completely extract the food from the toy system.

Owner:CANINE GENIUS

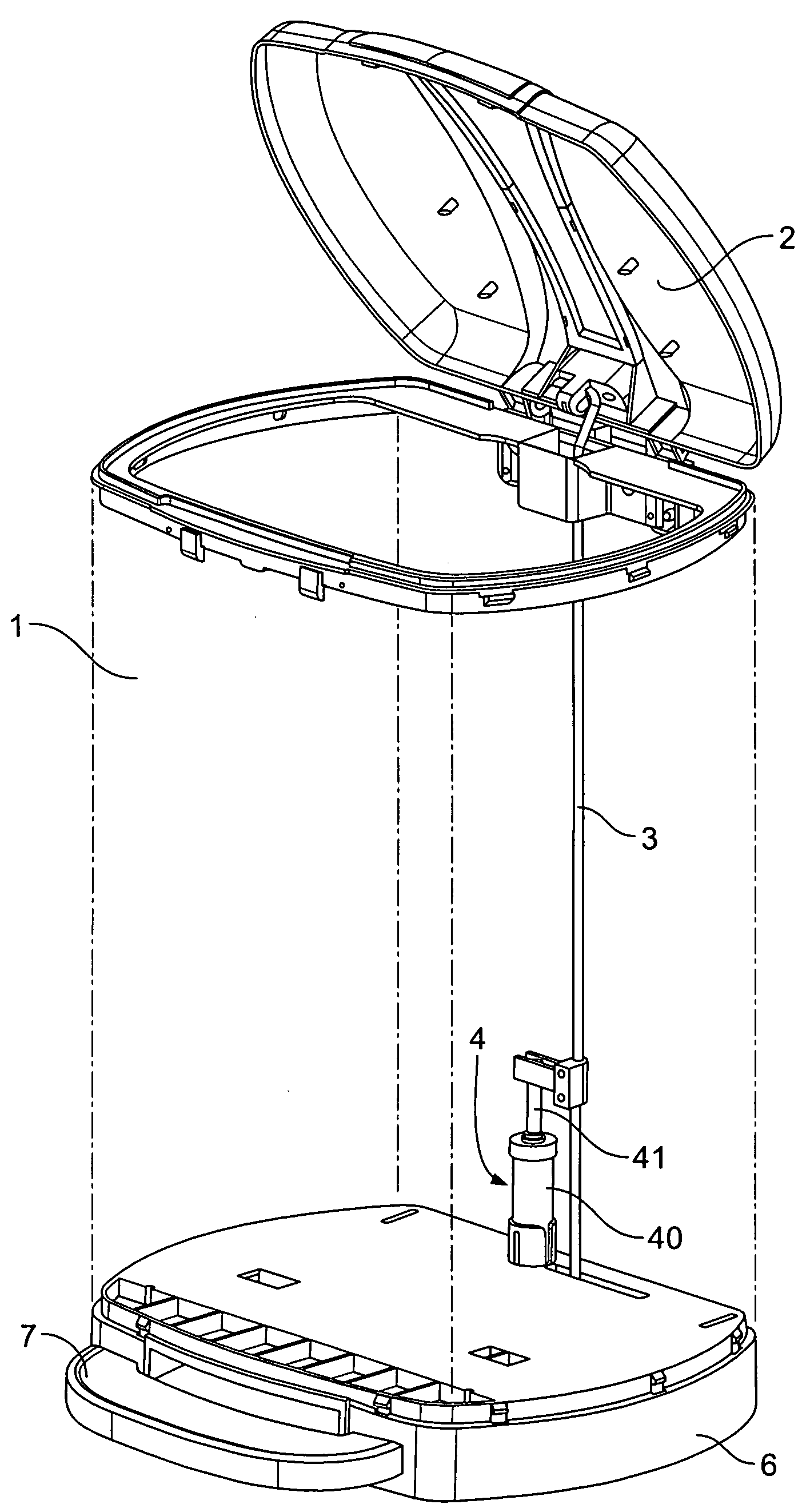

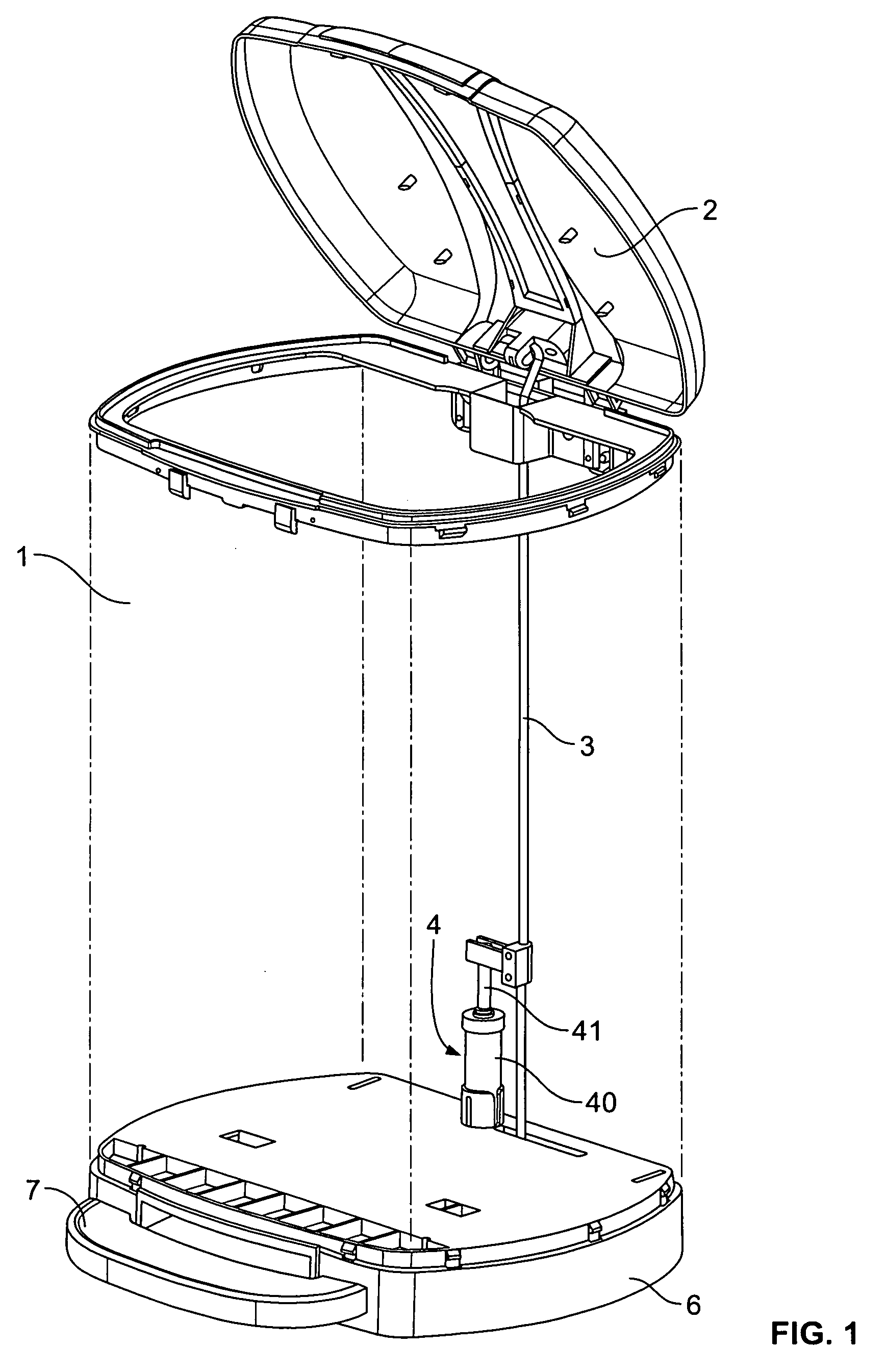

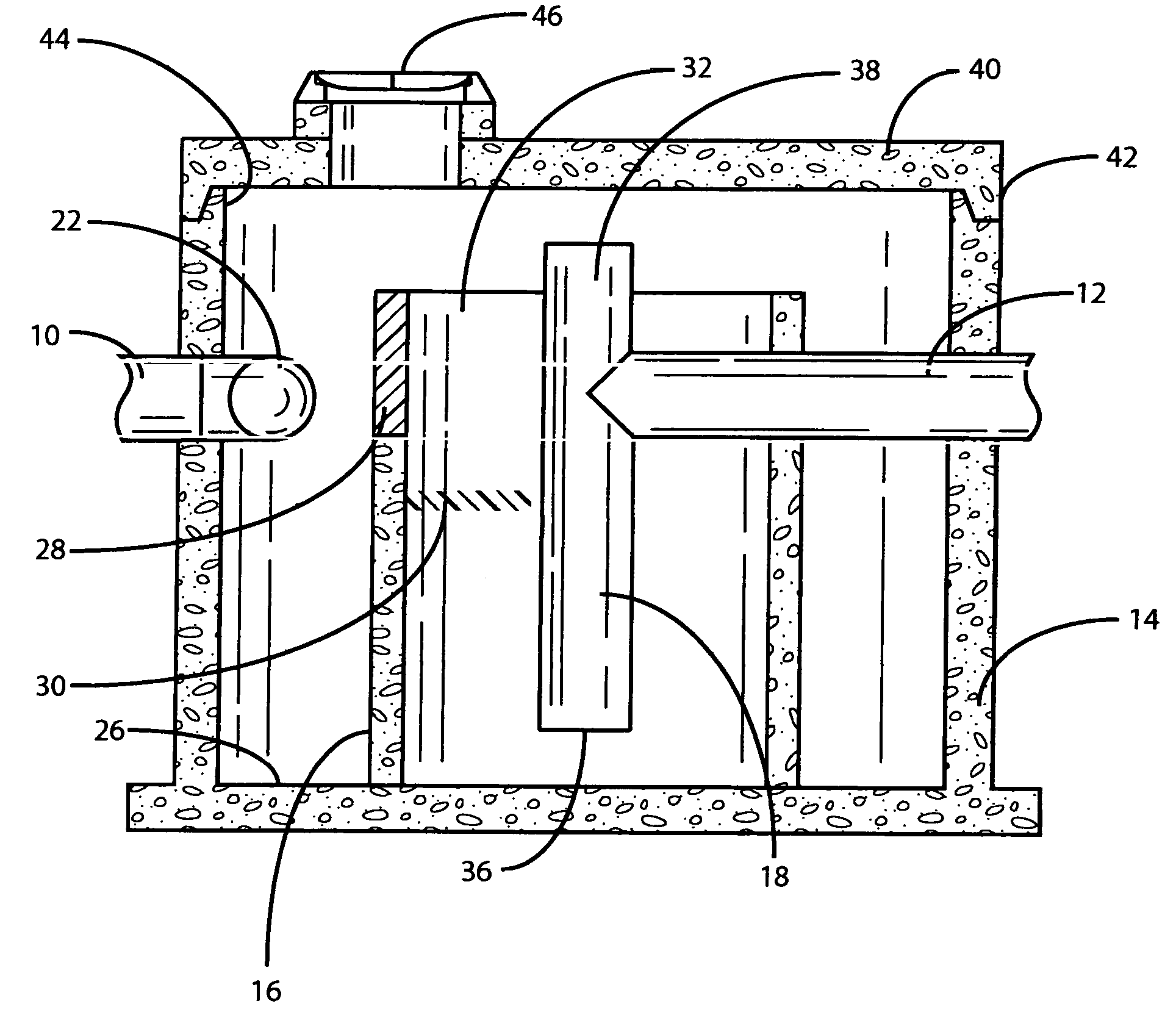

Trashcan with hydraulic lid deceleration

A trashcan has a hydraulic drop-deceleration mechanism including a can body, a lid, and a connection pole for push-open connection. The lid is connected to the connection pole at a top connection pole end. The connection pole is connected to the foot pedal via a lever at a bottom connection pole end. A hydraulic mechanism is for drop-deceleration. The hydraulic mechanism is connected to the connection pole by a connector. The hydraulic mechanism has a chamber filled with hydraulic fluid. The hydraulic mechanism has a gliding rod moving within the chamber. The gliding rod forms a tip at a gliding rod lower end. The mechanism has upper and lower fluid storage chambers. A piston is slidingly mounted in the hydraulic mechanism is biased in a lid open position by a spring.

Owner:LU HUANBANG

Medical device and method for temperature control and treatment of the eye and surrounding tissues

Owner:WONG JR EDWARD K +2

Environmentally-friendly barium-free thixotropic antirust oil

The invention discloses an environmentally-friendly barium-free thixotropic antirust oil, which is characterized by comprising the following components in percentage by weight: antirusting agent 4.0-25.0, thixotropic agent 0.1-5.0, antioxidant 0.1-3.0 and base oil 72.0-94.0. The preparation method of the environmentally-friendly barium-free thixotropic antirust oil comprises: firstly, adding the base oil into a reaction kettle, stirring the base oil, heating the base oil to 110 to 120 DEG C, adding the antirusting agent, stirring the mixture for continuous dehydration for 1 hour, and cooling the mixture to 50 to 60 DEG C; and secondly, adding the antioxidant, stirring the mixture for 3 hours at a constant temperature of 50 to 60 DEG C, adding the thixotropic agent, stirring the mixture for1 hour at 50 to 60 DEG C, cooling the resulting product to 40 DEG C, filtering the resulting product and discharging the resulting product. For obtaining antirust oil films that are insusceptible toflow and free from heavy metal barium, the antirust oil selects a proper barium-free corrosion inhibiter to ensure excellent antirust performance besides the thixotropic agent added for quickly forming stable oil films of antirust oil.

Owner:沈阳防锈包装材料有限责任公司

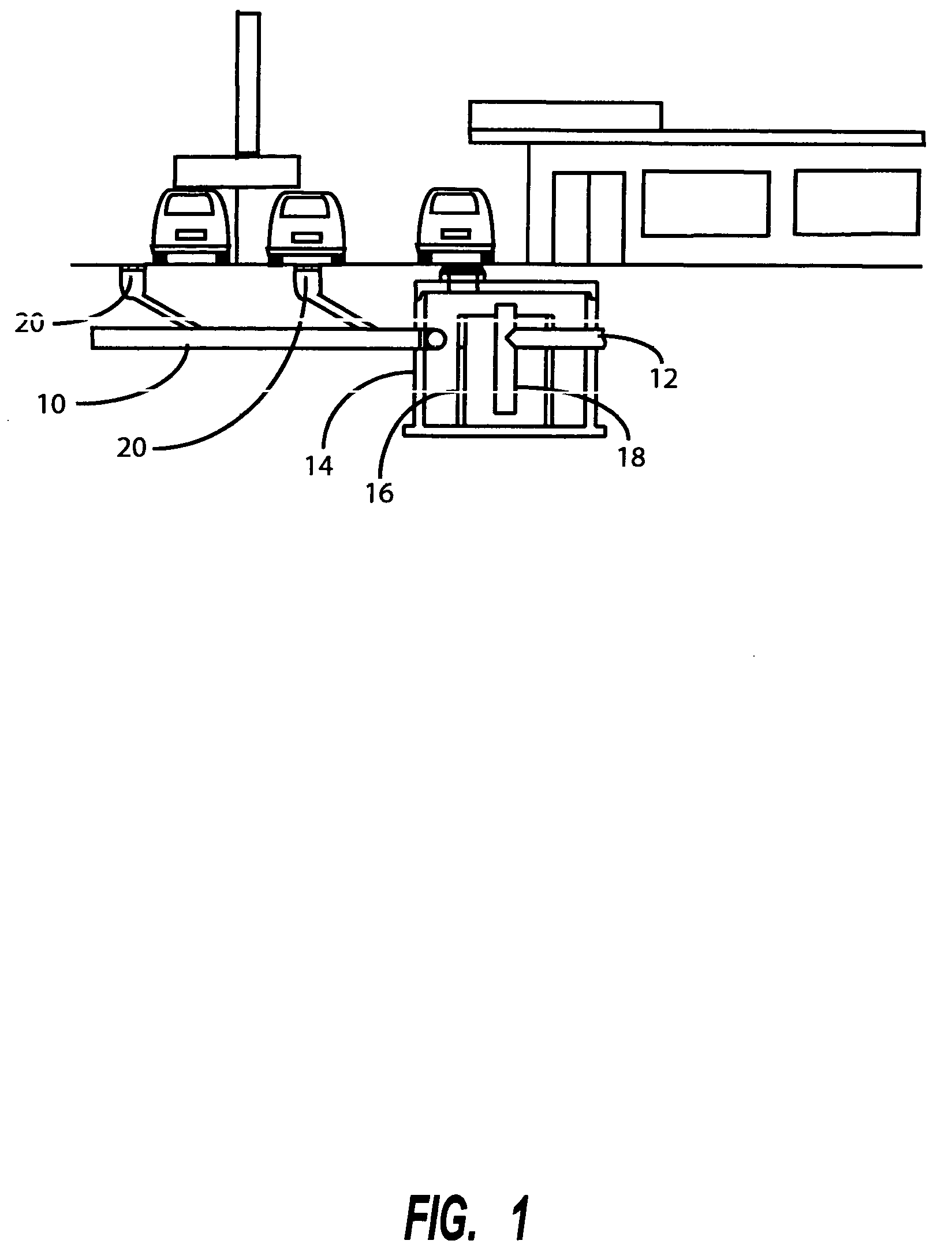

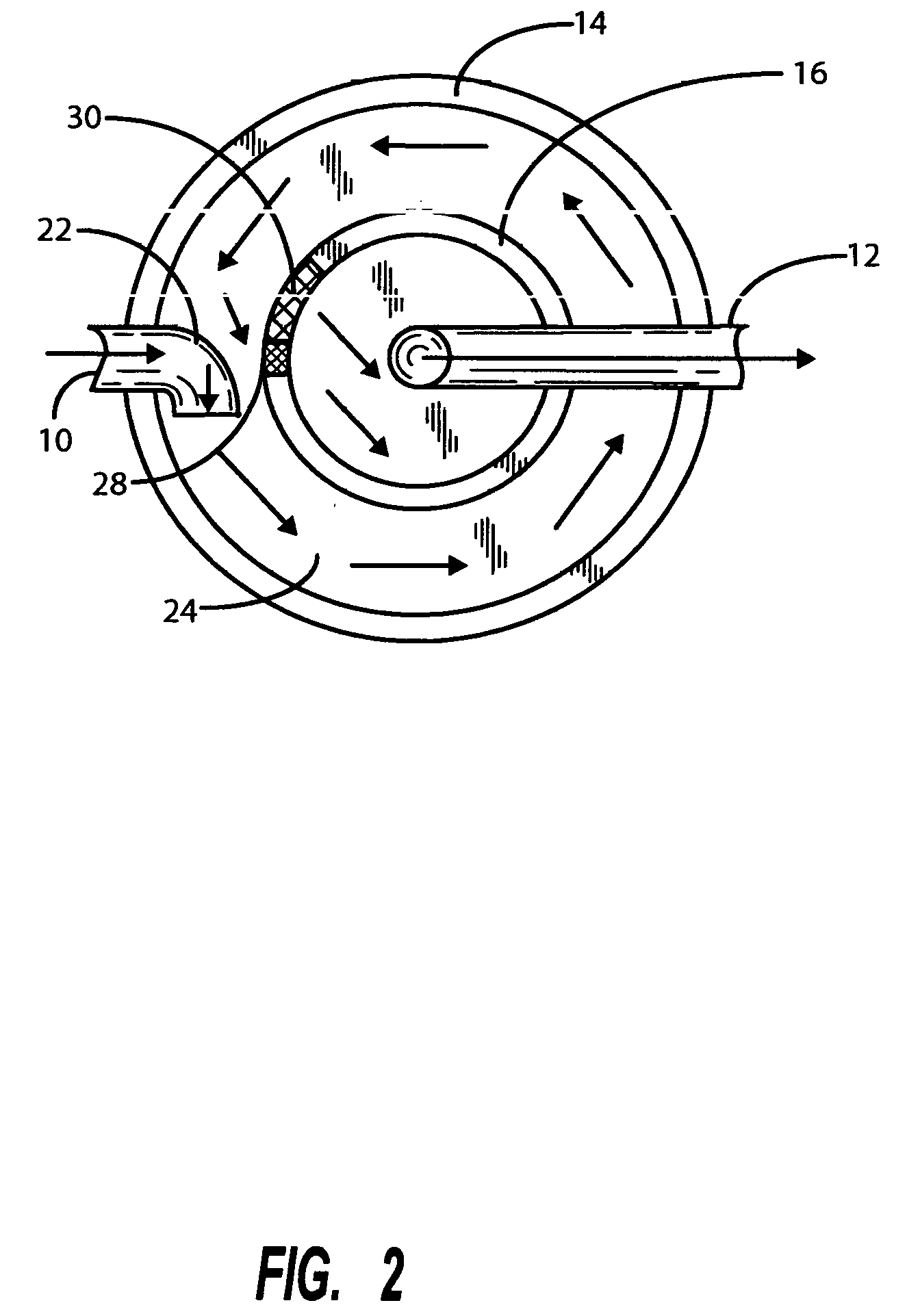

Stormwater treatment system for eliminating solid debris

ActiveUS20050077248A1Slow flowWater/sewage treatment by centrifugal separationWater cleaningWater treatment systemSystems design

A stormwater treatment system designed to separate floating pollutants, liter, and contaminated settling solids from drainage discharge. The system uses a cylindrical tank, buried below the ground, which enables separation of the pollutants. The stormwater flows around the inside perimeter of the tank until it flows into an inner cylinder through a weir (or weirs). This causes a delayed flow due to the limited entry point through the vertical weir. The extended amount of resonance time allows for separation of pollutants, liter, and contaminated solids. The stormwater continues to separate itself as it flows around the inner cylinder, up through a vertical pipe and out an outlet pipe. The solid contaminants which are left behind are stored and able to be removed later.

Owner:ROYAL ENVIRONMENTAL SYST

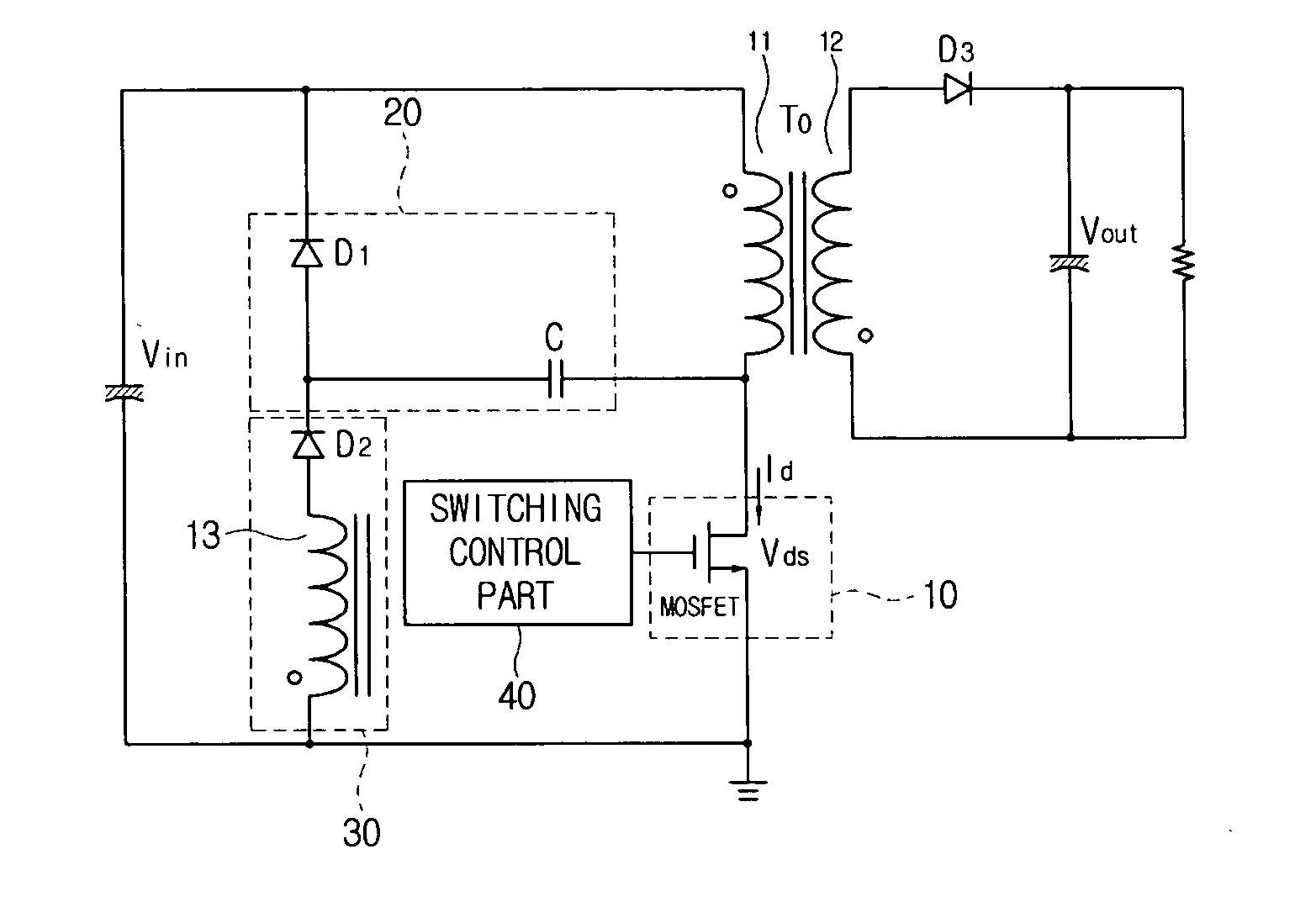

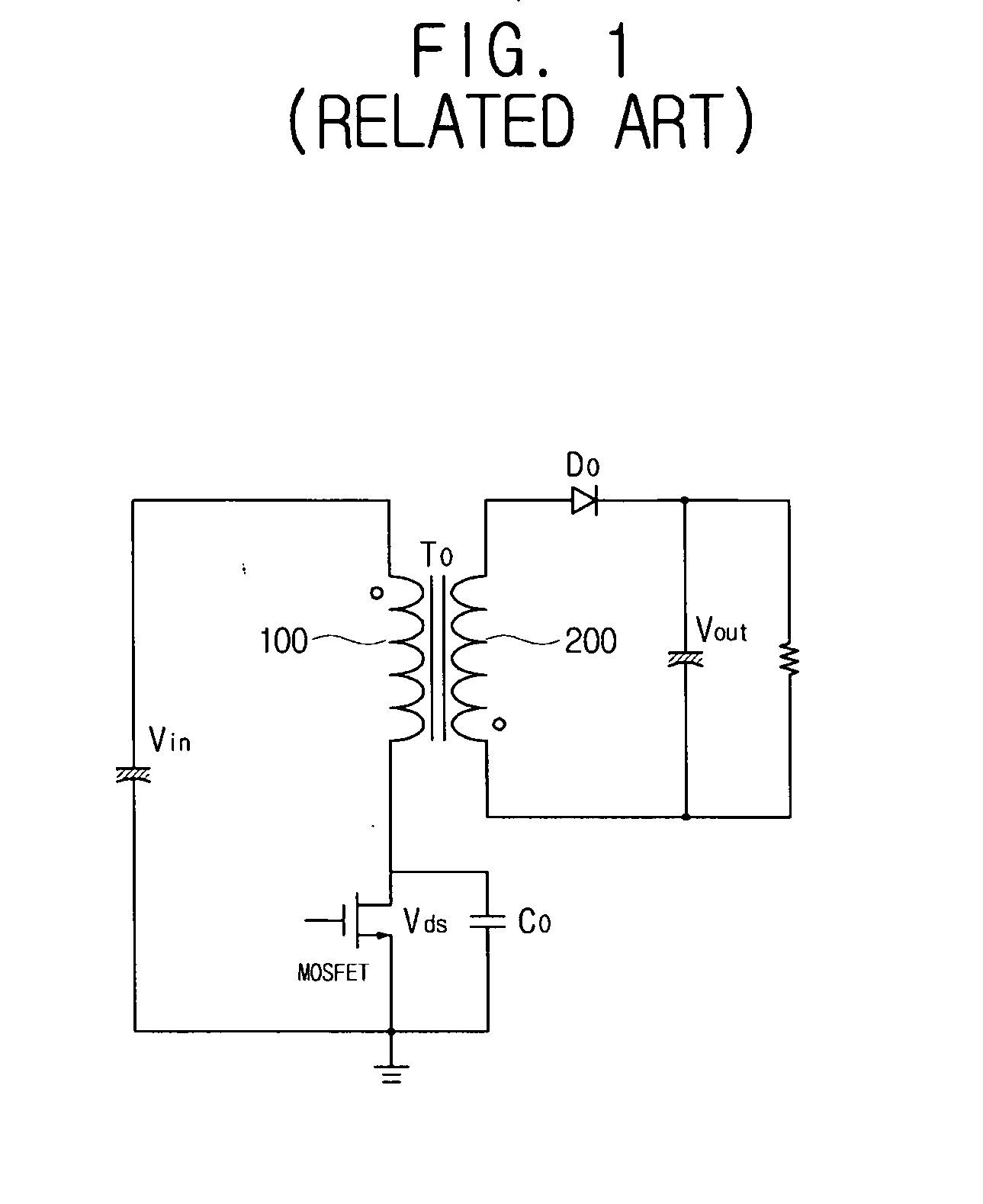

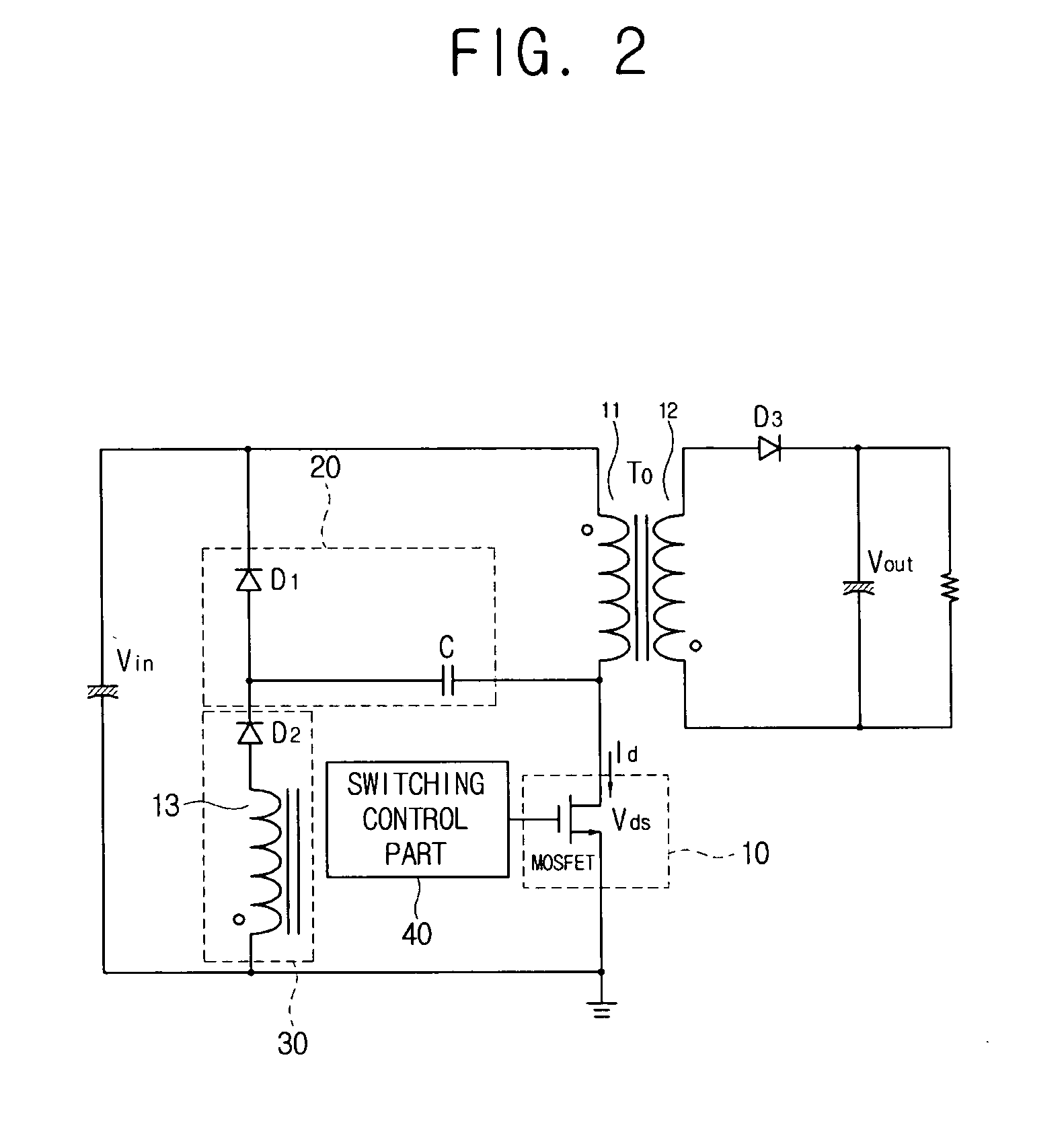

DC to DC converter

InactiveUS20070159857A1Slow flowReduce switching lossesEfficient power electronics conversionConversion with intermediate conversion to dcTransformerControl signal

A direct current (DC) to DC converter is provided. The DC to DC converter includes: a transformer which comprises a primary winding which is connected in series with an input voltage and a secondary winding which generates induced current when the input voltage is applied to the primary winding; a switching part which is connected to the primary winding and performs a switching operation according to a predetermined control signal; a first delay part which delays an increasing rate of voltage between open nodes according to a turned-off state of the switching part and supplies a discharge current when the switching part is turned-on; and a second delay part which delays current flow in the switching part when the first delay part discharges the current when the switching part is turned-on.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for preparing polyacrylonitrile-based carbon fiber precursor fiber

ActiveCN101161880AConducive to smoothHigh tensile strengthMonocomponent synthetic polymer artificial filamentWet spinning methodsElastic modulusAmmonium hydrogen sulfite

The invention provides a preparation method for polyacrylonitrile base carbon fiber protofilament. ammonium persulfate-ammonium sulfite or ammonium hydrogen sulfite is used as the aqueous phase suspension copolymerization of a initiation system for preparing polyacrylonitrile base carbon fiber protofilament which uses polymers as raw materials; polymers are made into 16-20Wt percent of slurry at -18-0 DEG C, vacuumized to 40-95 Kpa and dissolved for 1-2 hours at 40-55 DEG C; then spinning stock solution at 70-80 DEG C is extruded into a spinning pipe in coagulation bath via a spinneret to be shaped, and PAN nascent fiber is obtained through the minus elongation of the coagulation bath; the PAN nascent fiber has desolventize flushed away by hot water, and is simultaneously stretched, oiled, dried for densification, baked and elongated to obtain PAN base protofilament, and the tensile strength is no lower than 6.60N / dtex; the carbon fiberstrength is 3.30-4.01Gpa, and the elastic modulus is 210-262Gpa. The main technical indexes of the present invention are equivalent to the similar products in America, Japan and other countries.

Owner:吉林碳谷碳纤维股份有限公司

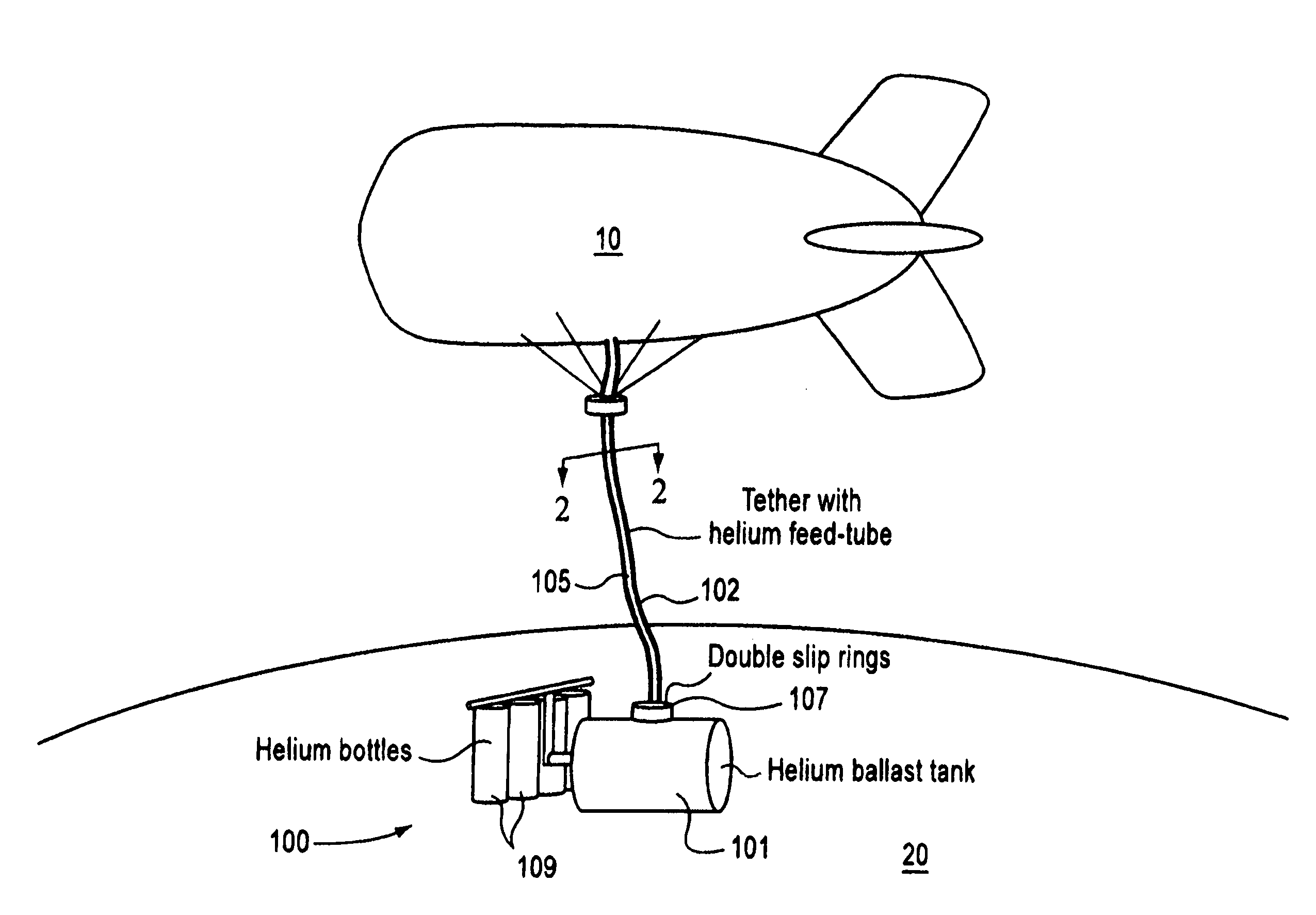

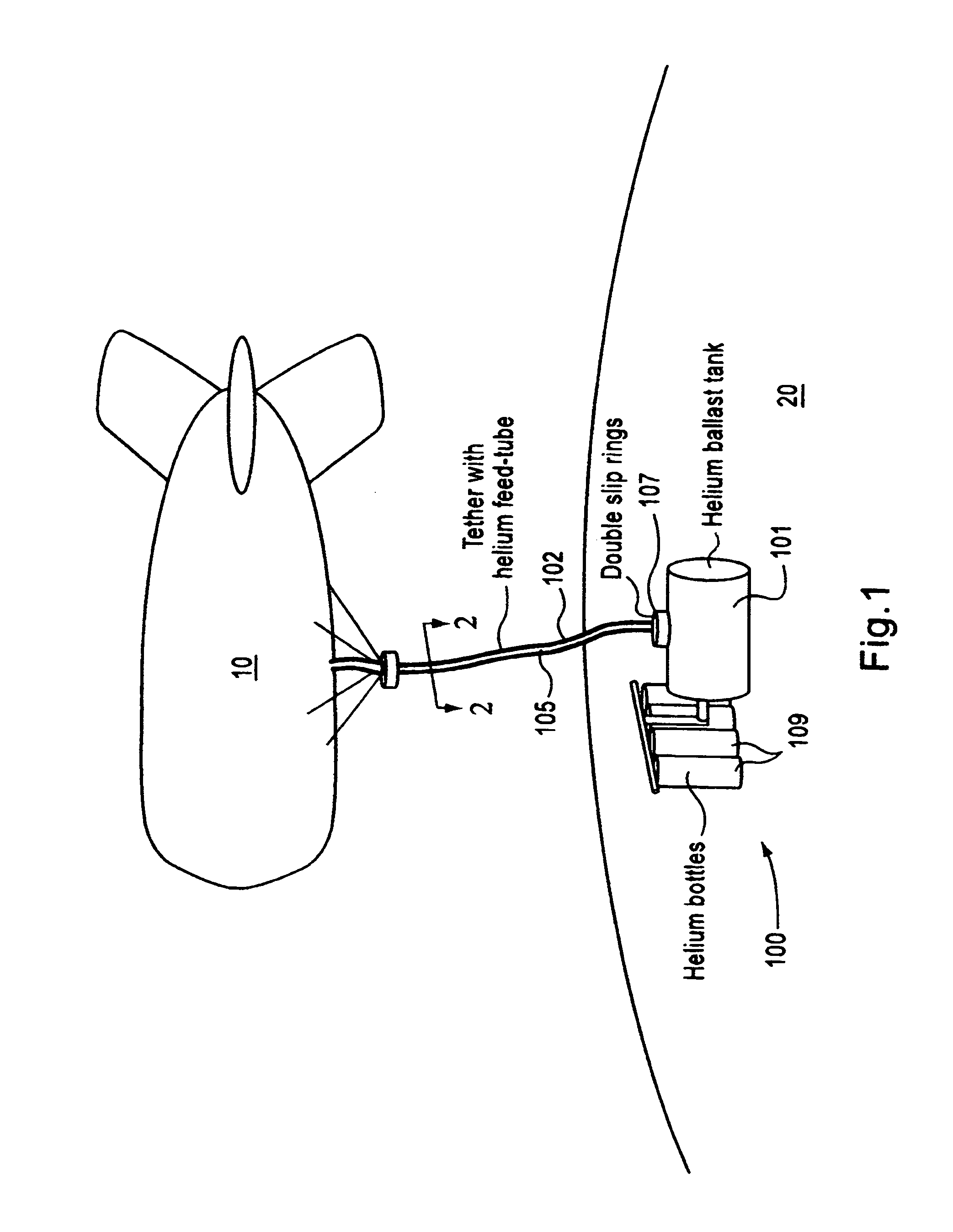

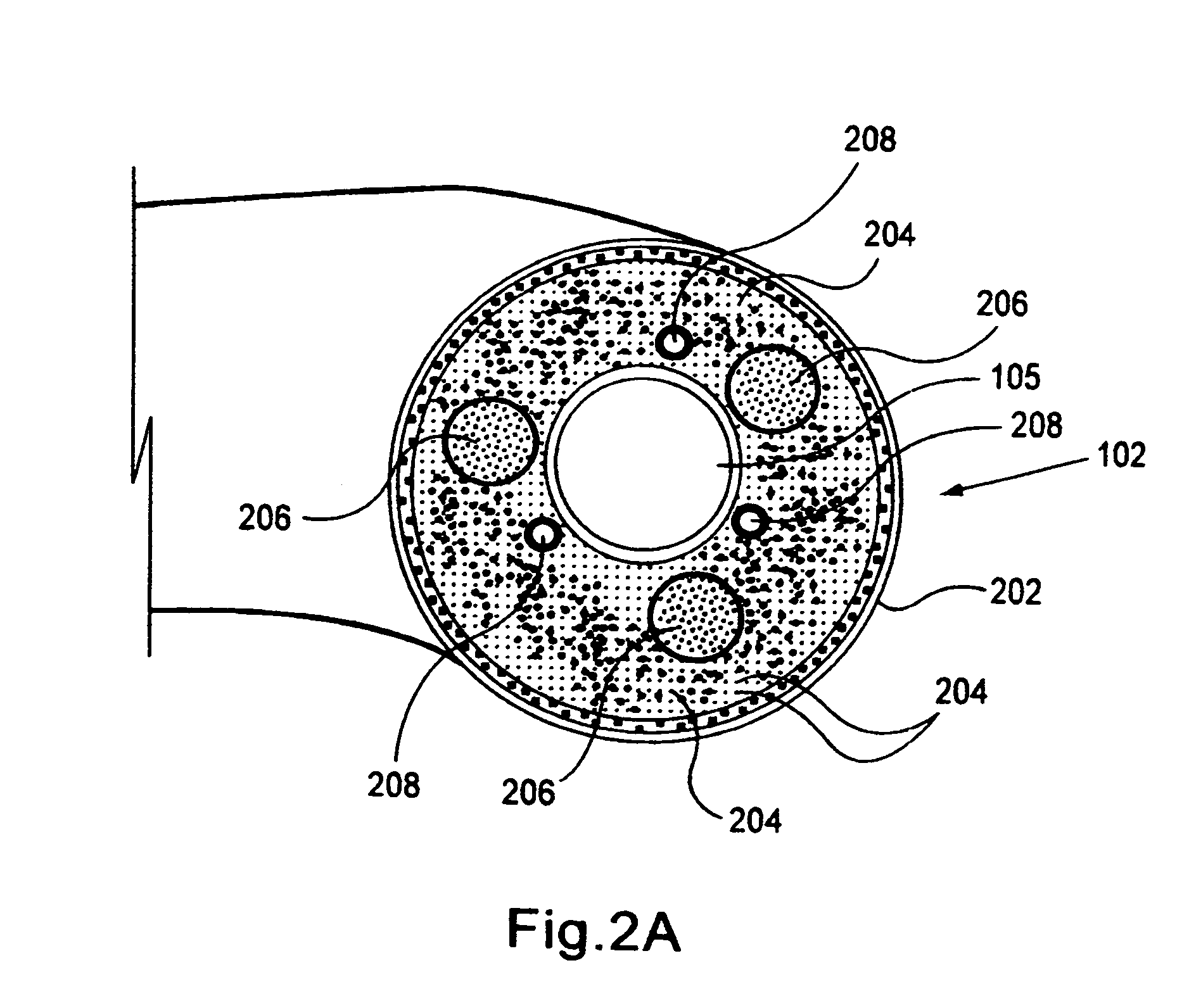

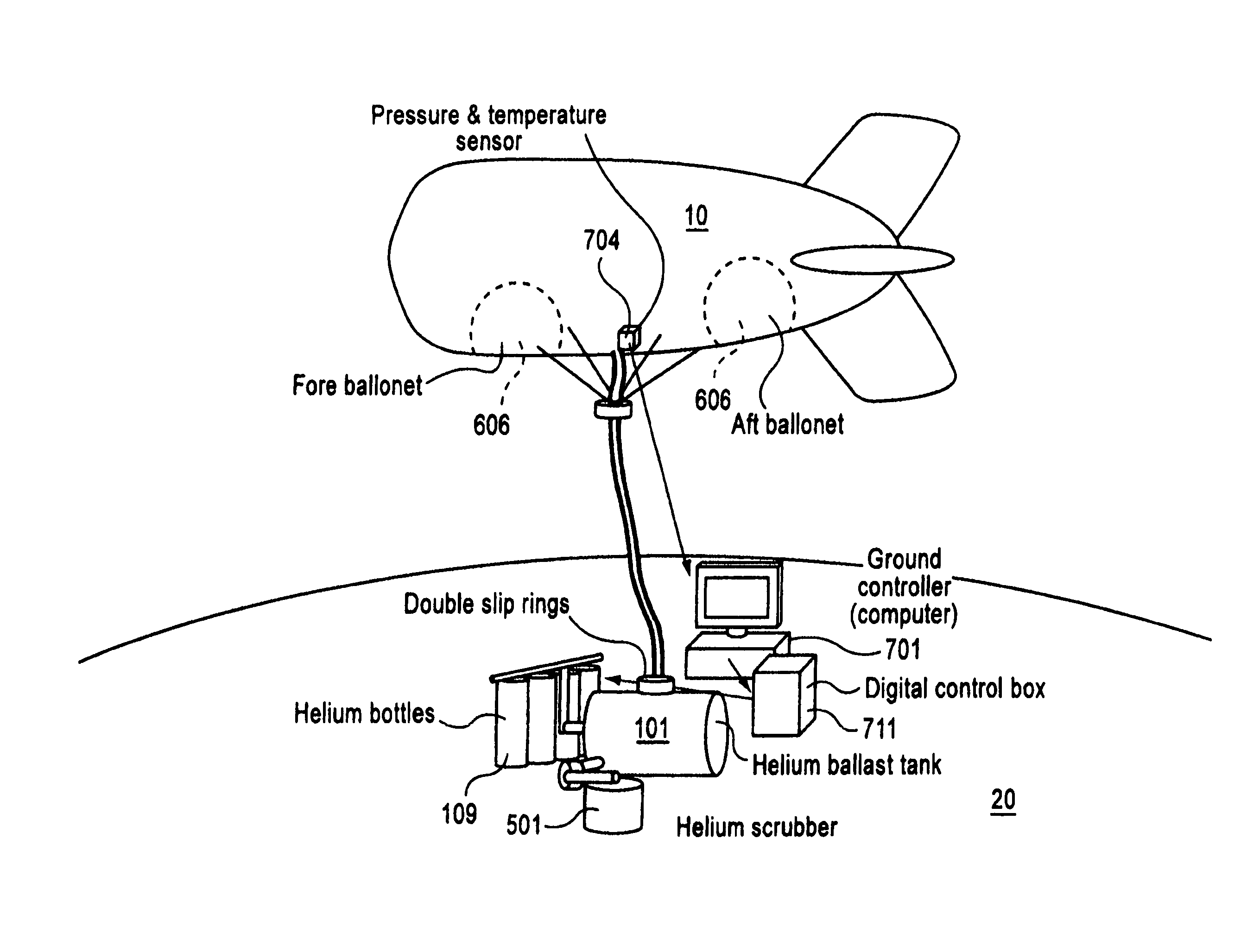

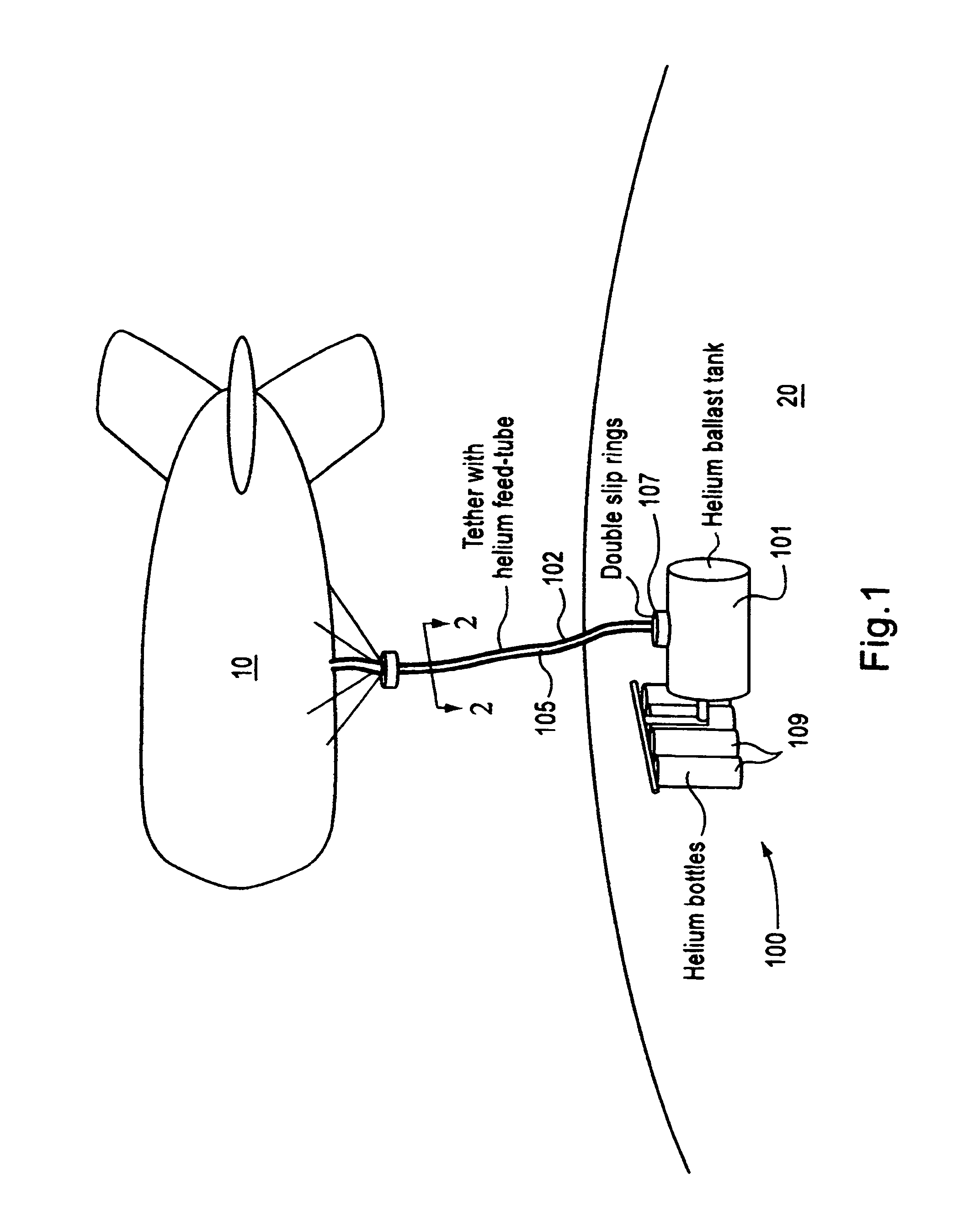

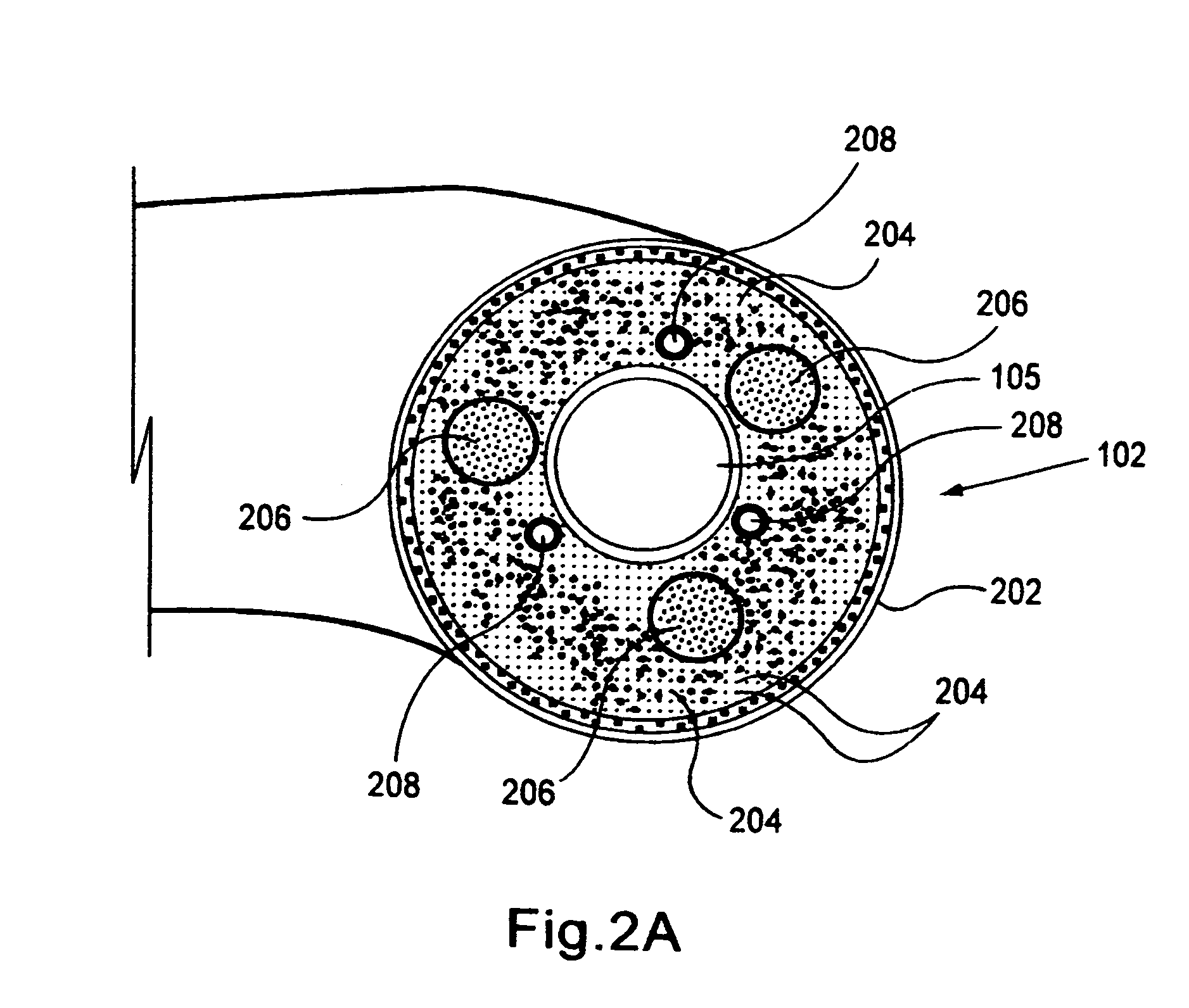

Long mission tethered aerostat and method of accomplishing

ActiveUS20120091261A1Stay rigidReducing reliance on ballonetsNon-rigid airshipsMovable targetsEngineeringGround station

Apparatus and method for a continuous replenishing of the lift gas and maintaining the proper pressure and lift of a tethered medium altitude aerostat utilizing a novel feed tube running the entire length of the tether. A first end of the feed tube is connected to the aerostat while a second end is connected through a novel slip ring means to a pressure controlled helium ballast chamber and scrubber on the ground to maintain pressure and lift by a reversible compressing pump. A plurality of pressure and temperature sensors and tension gauges strategically placed inside and around the airship continuously monitor the temperature and pressure changes in the aerostat. A data retrieval and communication unit mounted on the aerostat collects measurement data from the pressure, temperature and tension sensors which is relayed to the ground station and the data is used to regulate lifting gas pressure inside the aerostat.

Owner:STRATOCOMM CORP

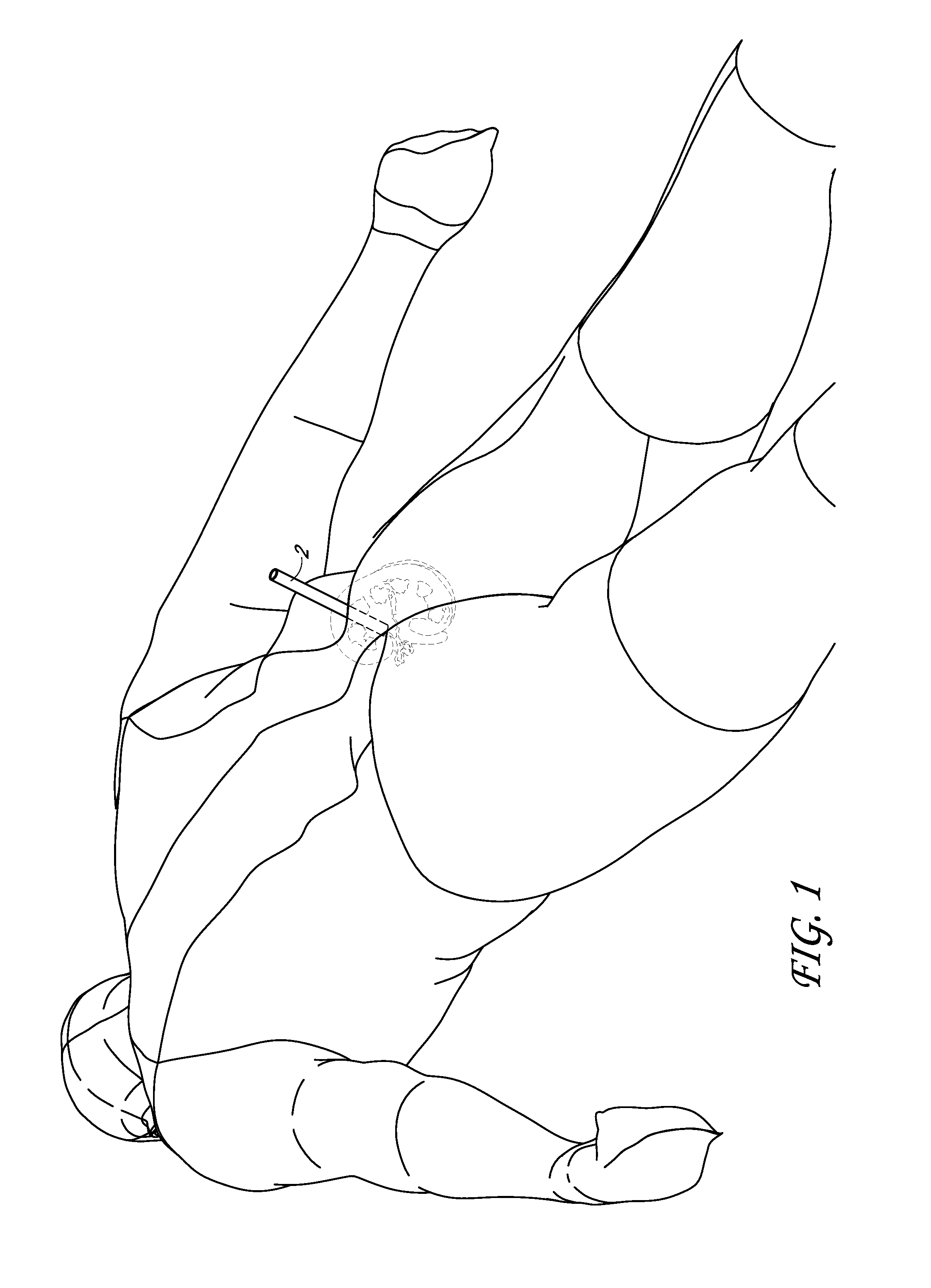

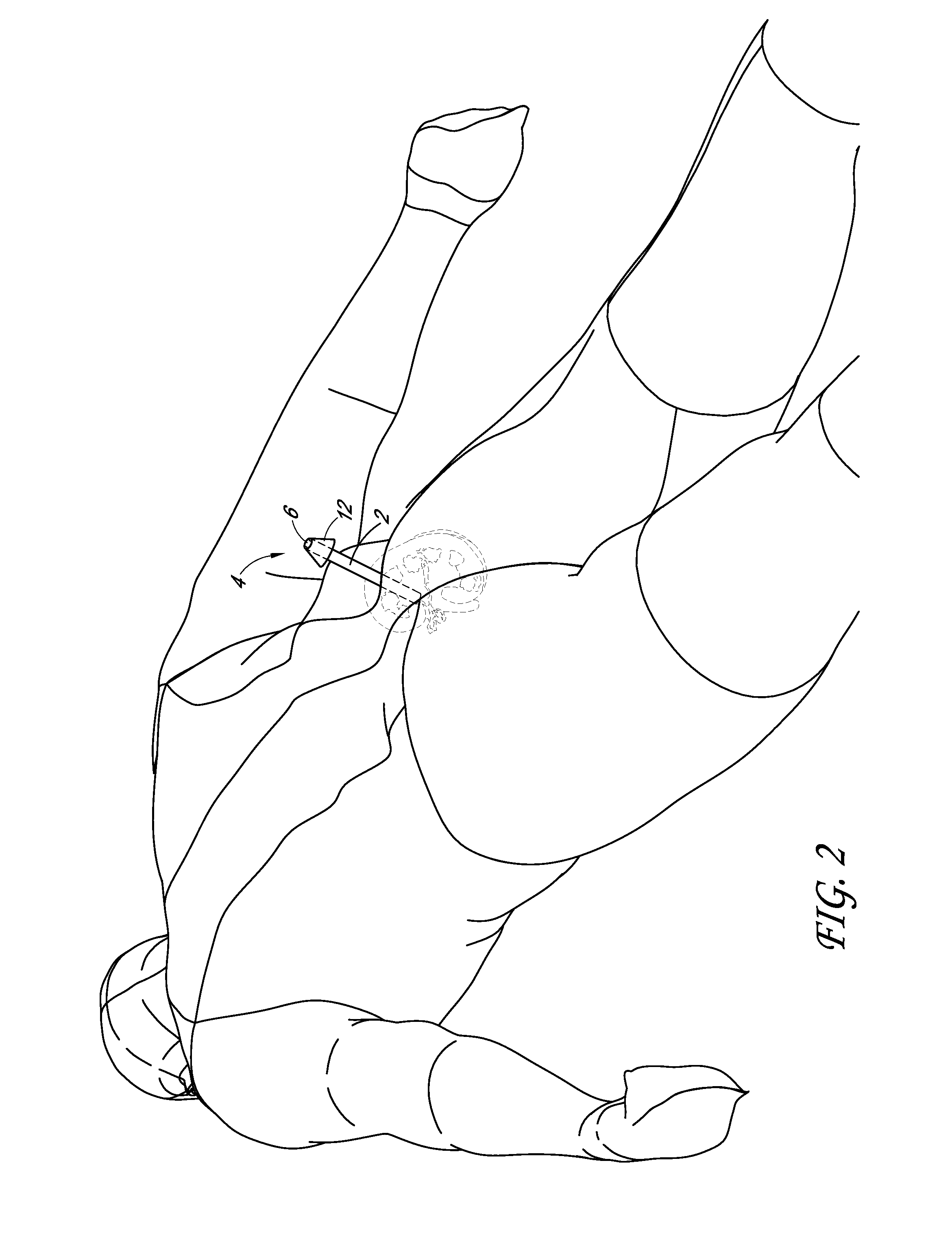

Controlled pressure endoscopic and percutaneous surgery

ActiveUS20150119645A1Good for fast flowMinimal bleedingCannulasEndoscopesEndoscopic sinus surgeryDistal portion

The present disclosure relates to systems and methods for controlling pressure during percutaneous and endoscopic surgeries, including percutaneous renal procedures, endoscopic uterine procedures, transurethral endoscopic procedures for the bladder or prostate, or any percutaneous or endoscopic procedure. The system can include a sheath and / or endoscope each having an inflow port providing access to an inflow channel extending from the inflow port to a distal portion of the sheath, and an outflow port providing access to an outflow channel extending from the outflow port to the distal portion of the sheath. The sheath can also include a pressure sensor configured to generate a pressure measurement, and an electronic processor configured to control fluid through at least one of the inflow port and the outflow port based on the pressure measurement.

Owner:FACULTY PHYSICIANS & SURGEONS OF LOMA LINDA UNIV SCHOOL OF MEDICINE

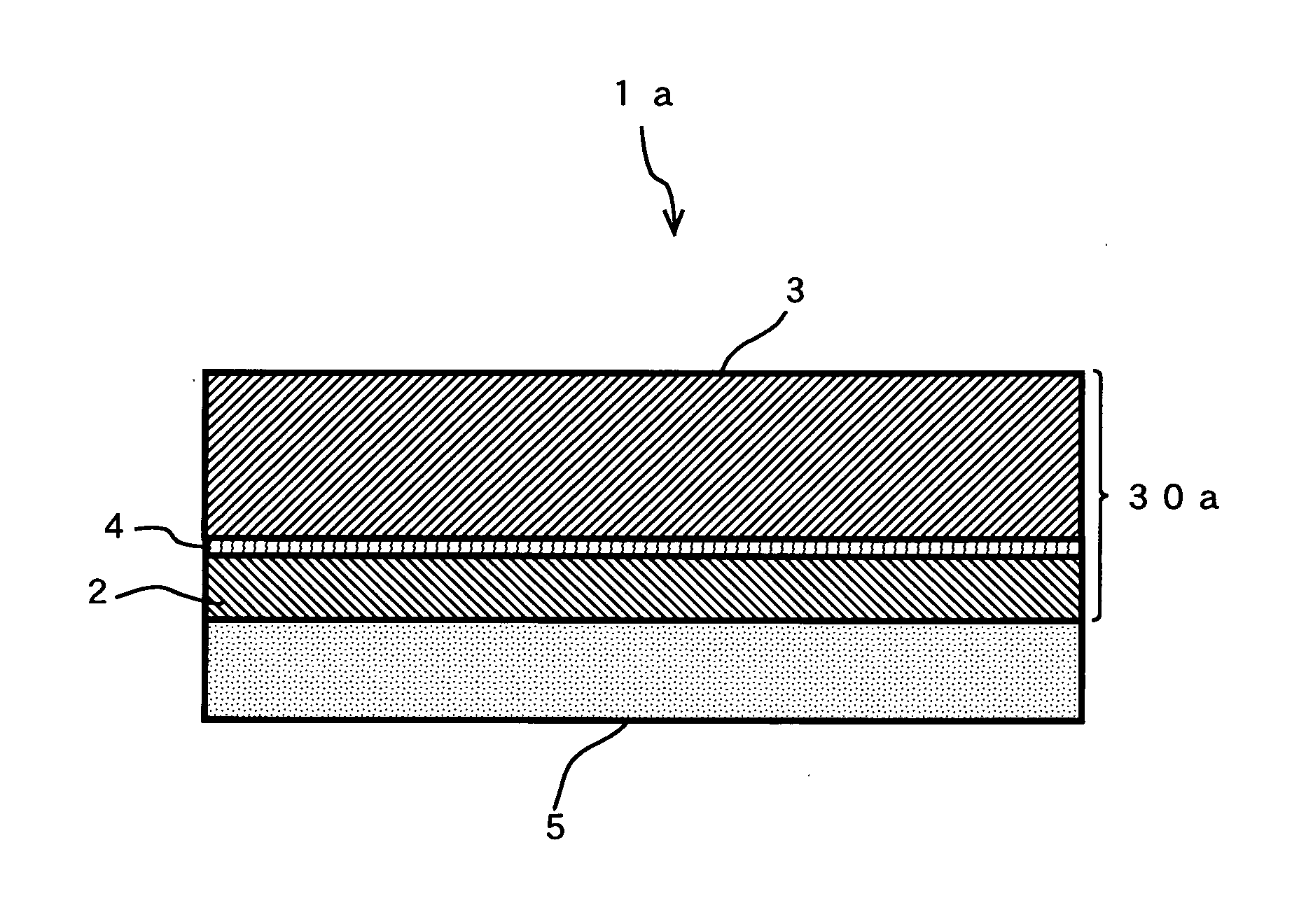

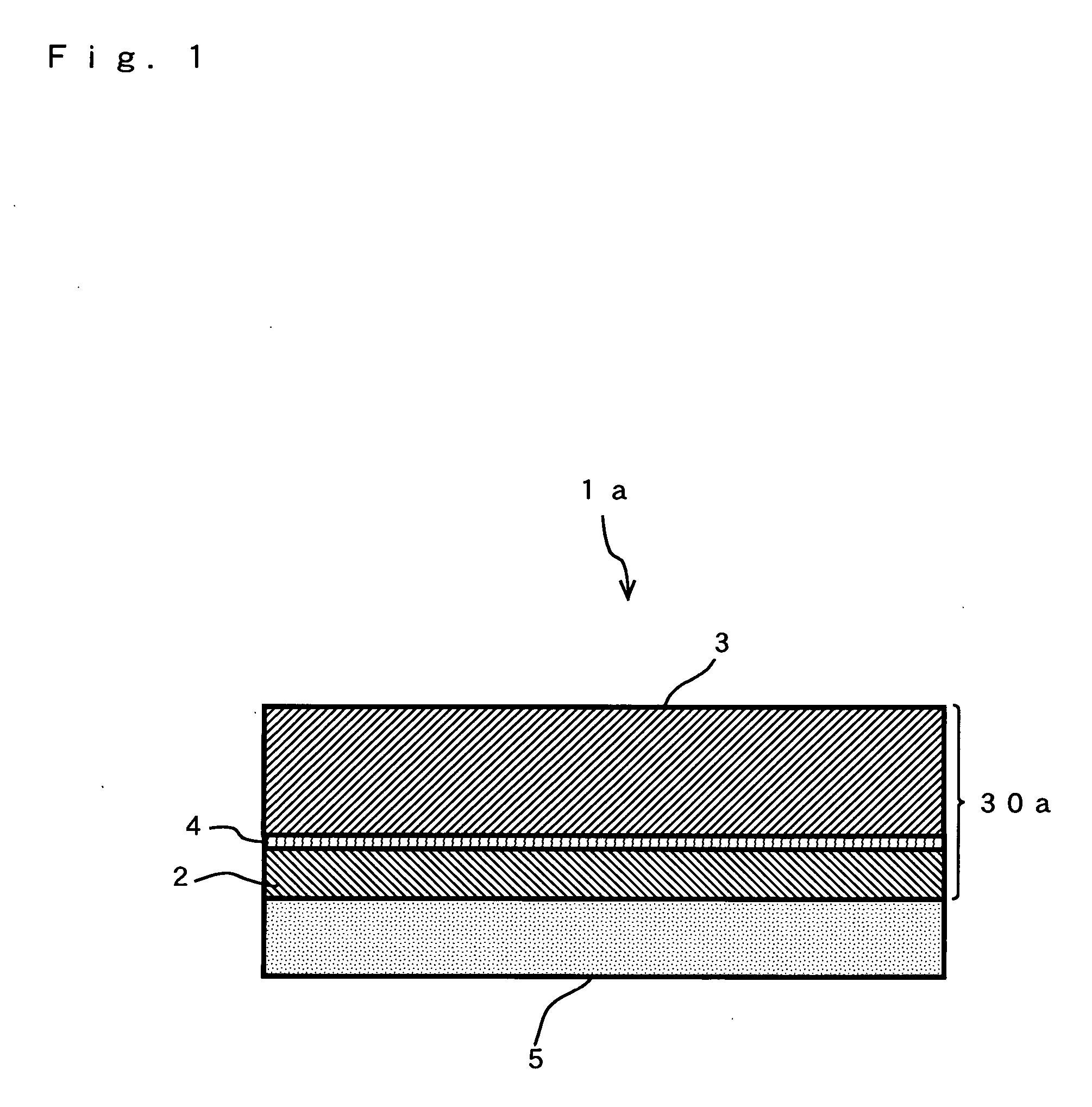

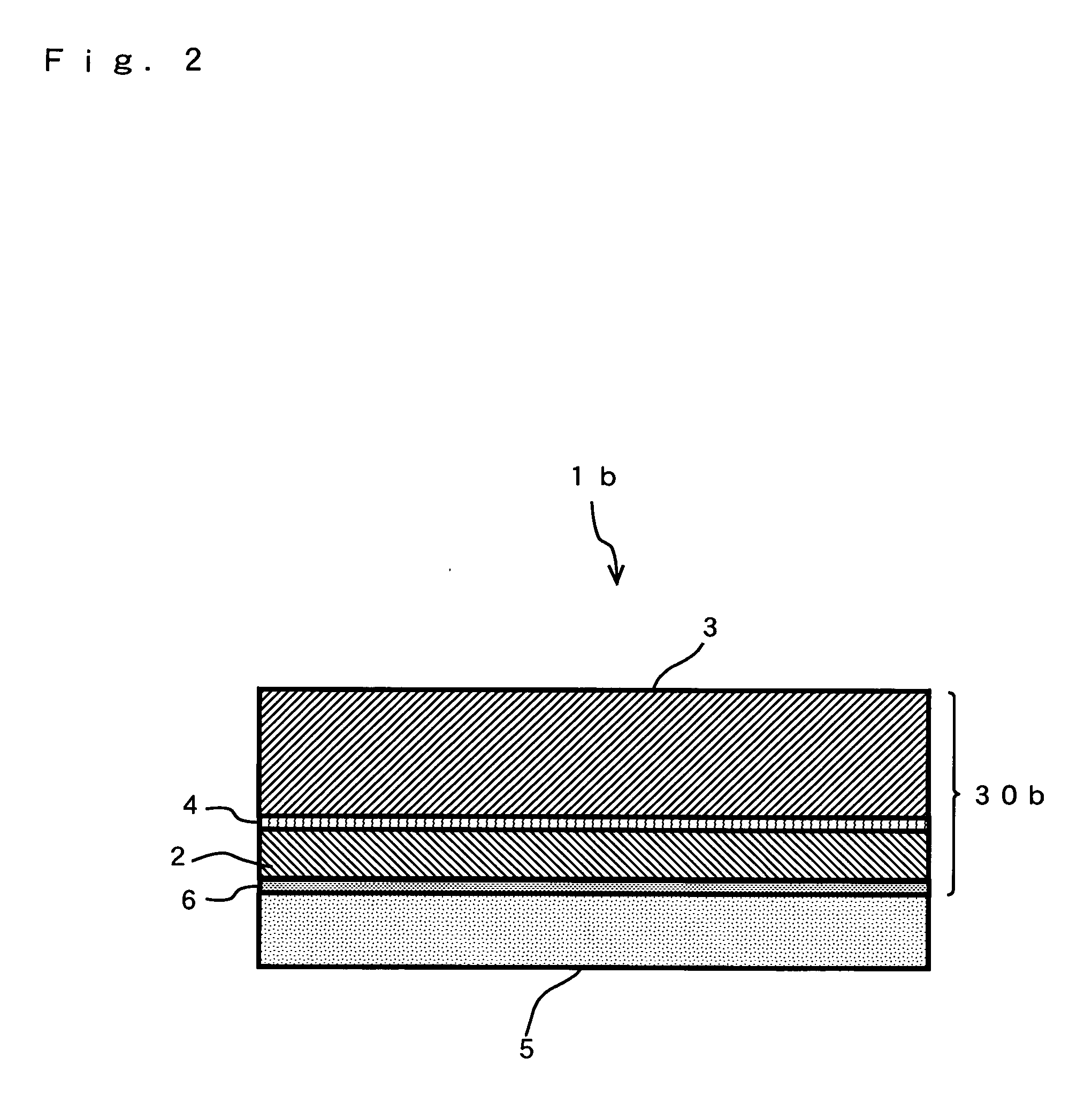

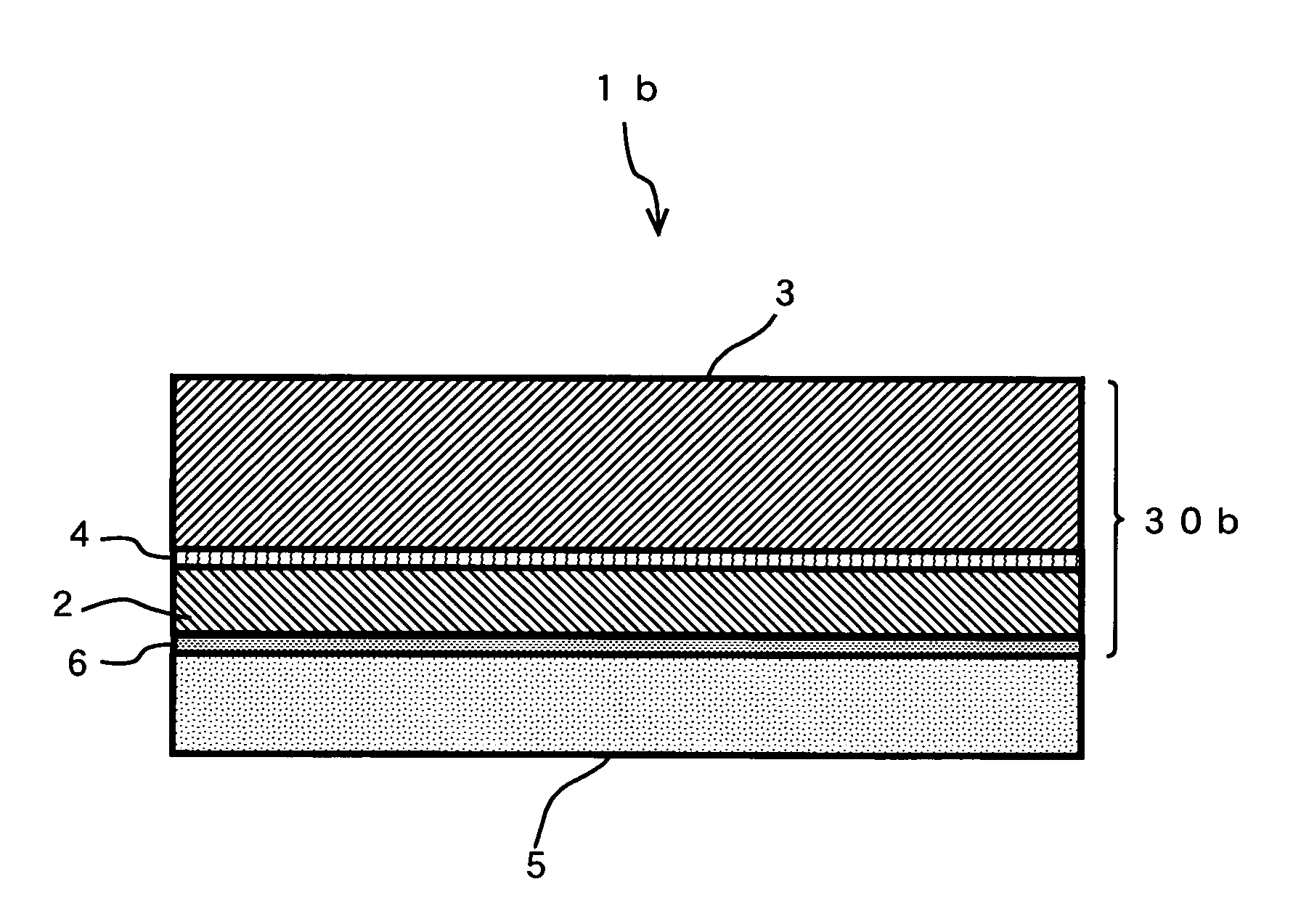

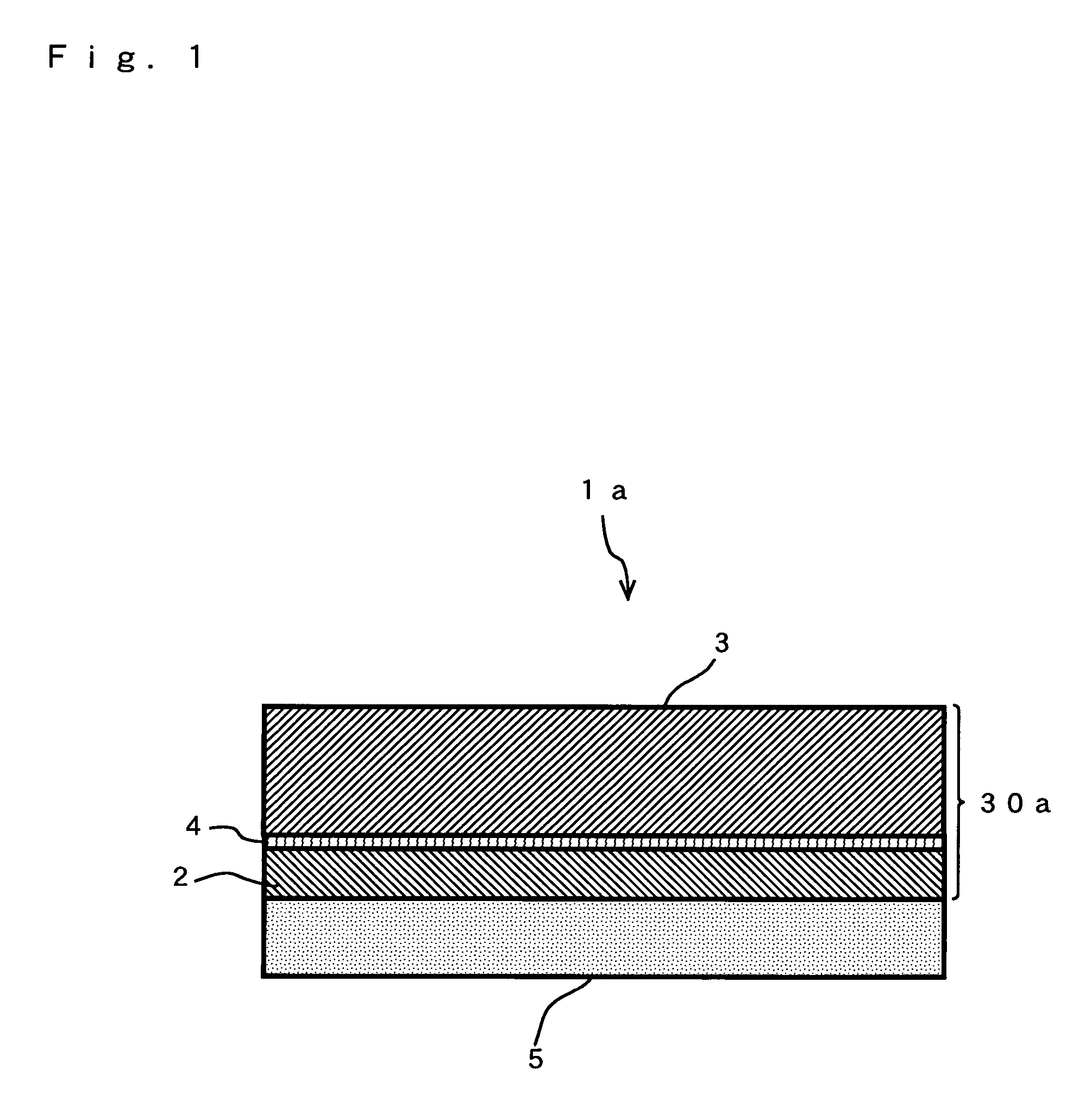

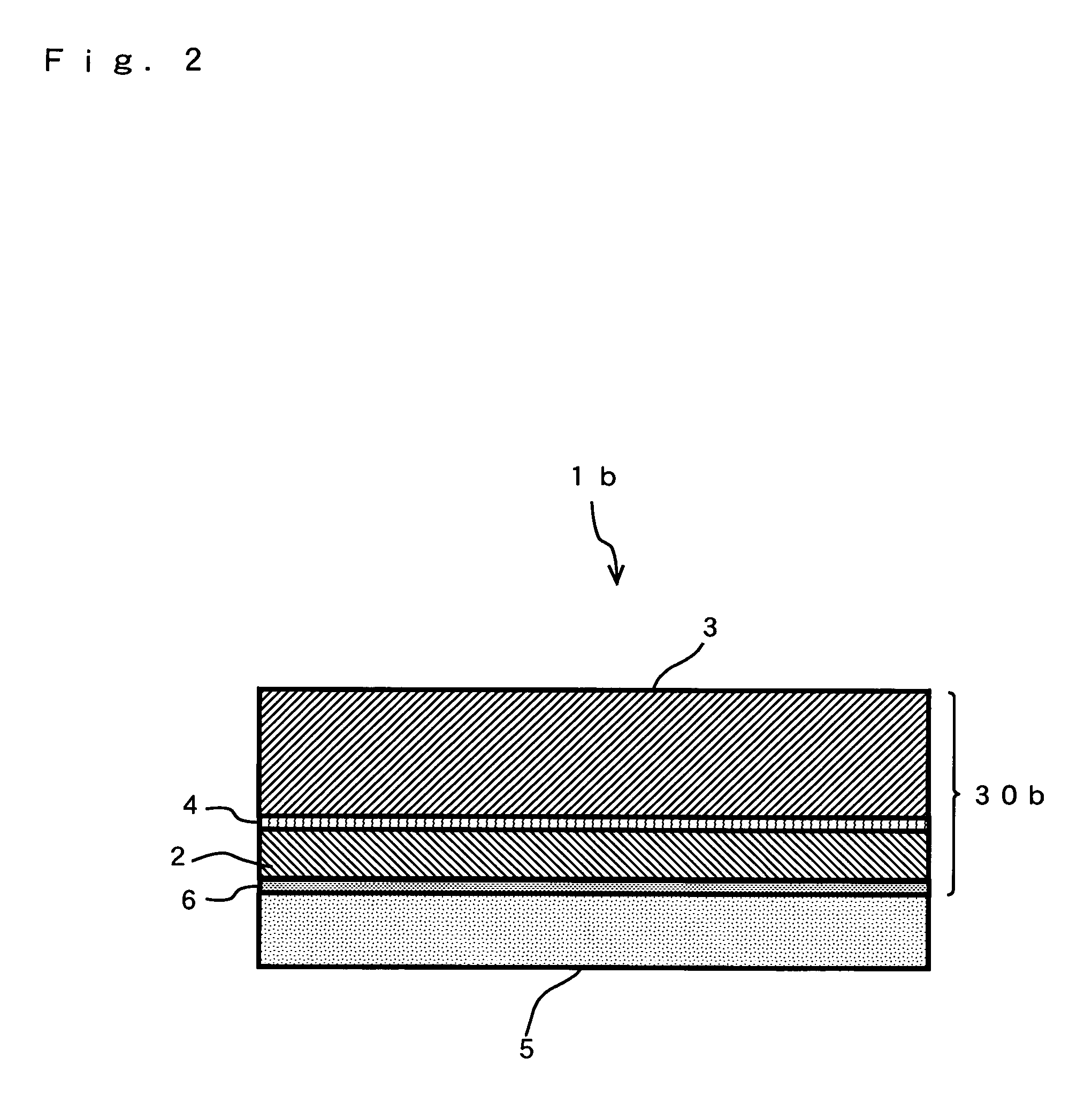

Electrodeposited Copper Foil with Carrier Foil on which a Resin Layer for Forming Insulating Layer is Formed, Copper-Clad Laminate, Printed Wiring Board, Method for Manufacturing Multilayer Copper-Clad Laminate, and Method for Manufacturing Printed Wiring Board

InactiveUS20070207337A1Improve adhesionSufficiently applicable peel strengthDecorative surface effectsCoatingsEpoxyBond interface

The present invention discloses a technology for a printed wiring board which uses a copper foil without roughening treatment. Therefore, electrodeposited copper foil with carrier foil which is sequentially constituted with carrier foil, bonding interface layer, electrodeposited copper foil with smooth surface on both side and a resin layer is employed. The resin composition constituting the resin layer is composed of 20 to 80 parts by weight of an epoxy resin which includes curing agent, 20 to 80 parts by weight of a solvent soluble aromatic polyamide resin polymer and curing accelerator in a suitable amount if required.

Owner:MITSUI MINING & SMELTING CO LTD

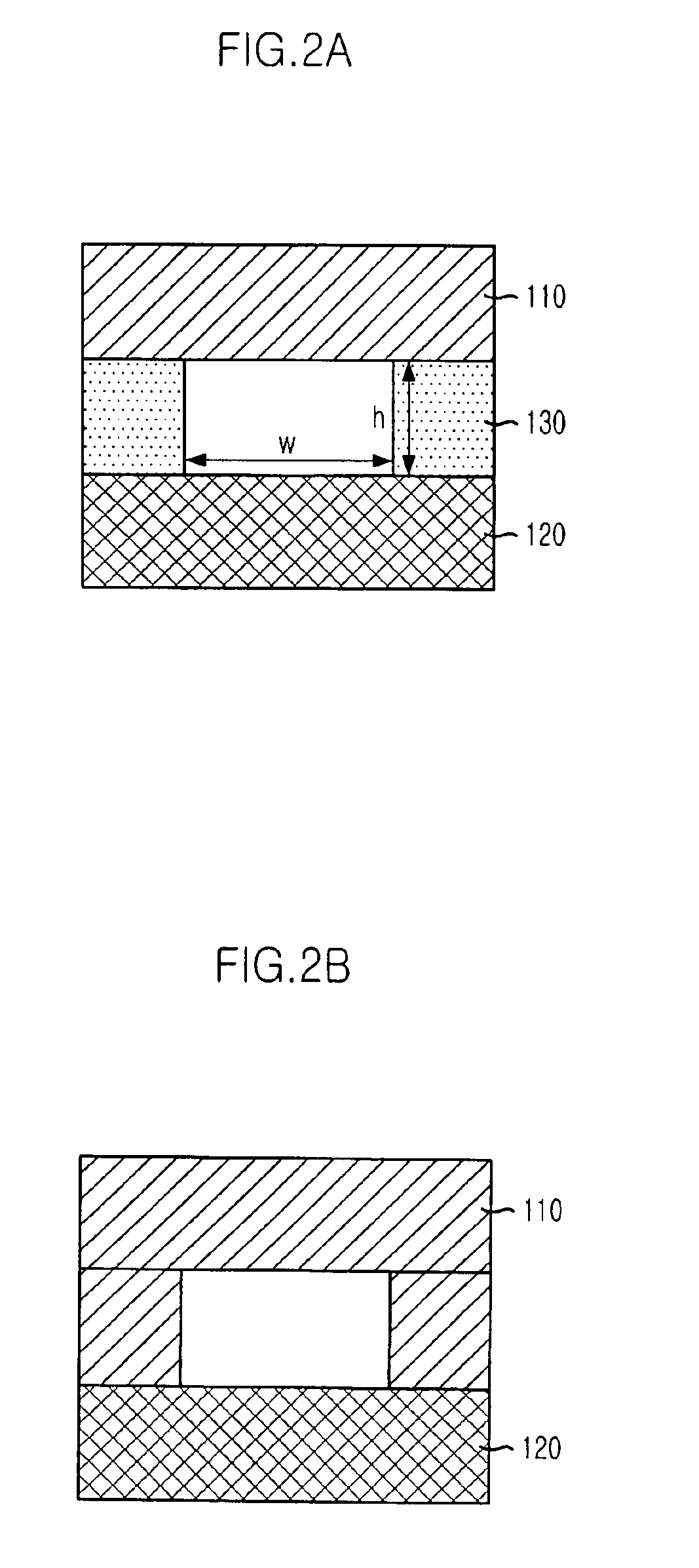

Micro fluidic device for controlling flow time of micro fluid

ActiveUS6901963B2Simple principleSimple structureAmpoule syringesCircuit elementsControl flowEngineering

Provided is a micro fluidic device that can control a flow time of micro fluid by using a capillary phenomenon. The micro fluidic device includes: a flow channel for flowing fluid, the flow channel being formed between a top substrate and a bottom substrate or between a top substrate, a bottom substrate, and a middle substrate; a flow blocking surface for stopping a flow of the fluid in the flow channel temporarily; and a hump for delaying the flow formed in the line of continuity with the flow blocking surface. The micro fluidic device of the present research can control the flow time in a simple manner.

Owner:INTELLECTUAL DISCOVERY CO LTD

Glufosinate separation and purification method

ActiveCN104860988ASlow flowFast flowGroup 5/15 element organic compoundsPurification methodsCentrifugation

The invention belongs to the field of pesticide production and particularly relates to a glufosinate separation and purification method. According to the method, the separation and purification is started when a glufosinate hydrochloride reaction solution in the steps of distilling the glufosinate hydrochloride reaction solution under reduced pressure to remove dilute hydrochloric acid, adding ammonia water to adjust the pH to maximally produce ammonium chloride, distilling under reduced pressure to remove water, adding a flotation solvent for dispersion, placing the material into a chute at specific temperature and speed, performing flotation separation according to the difference in the proportion of a principal component and subsidiary salt, removing the solvent, dissolving the material in aqueous methanol to remove trace ammonium chloride, filling ammonia gas to adjust the pH value to 8, performing centrifugation and drying to obtain a final product. The glufosinate separation and purification method uses a flotation method for separating the principal component glufosinate and an intermediate of the principal component from the subsidiary salt ammonium chloride and the aqueous methanol for purification and is high in yield, good in purity, simple in process, low in cost and is suitable for industrial production.

Owner:石家庄瑞凯化工有限公司

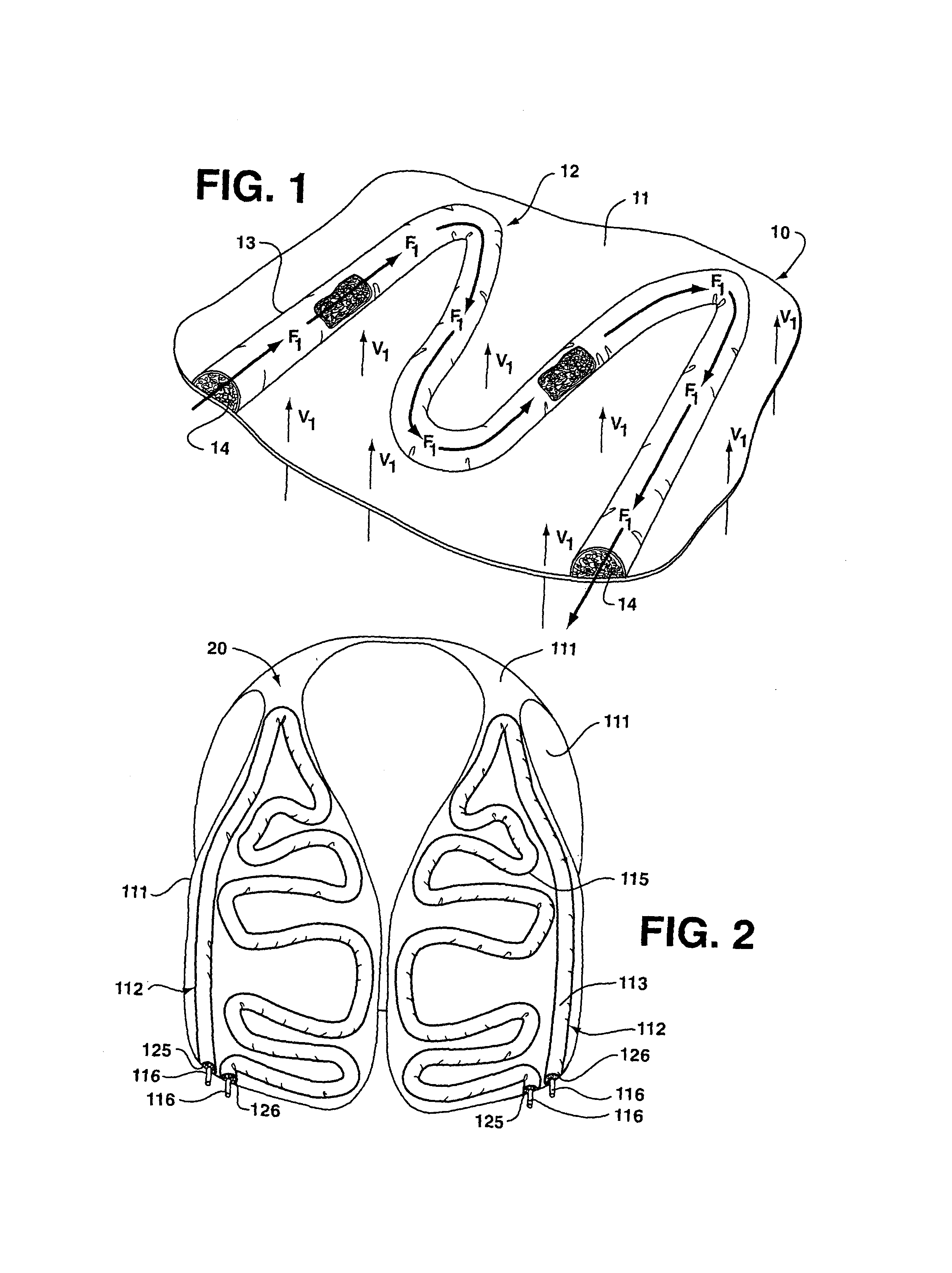

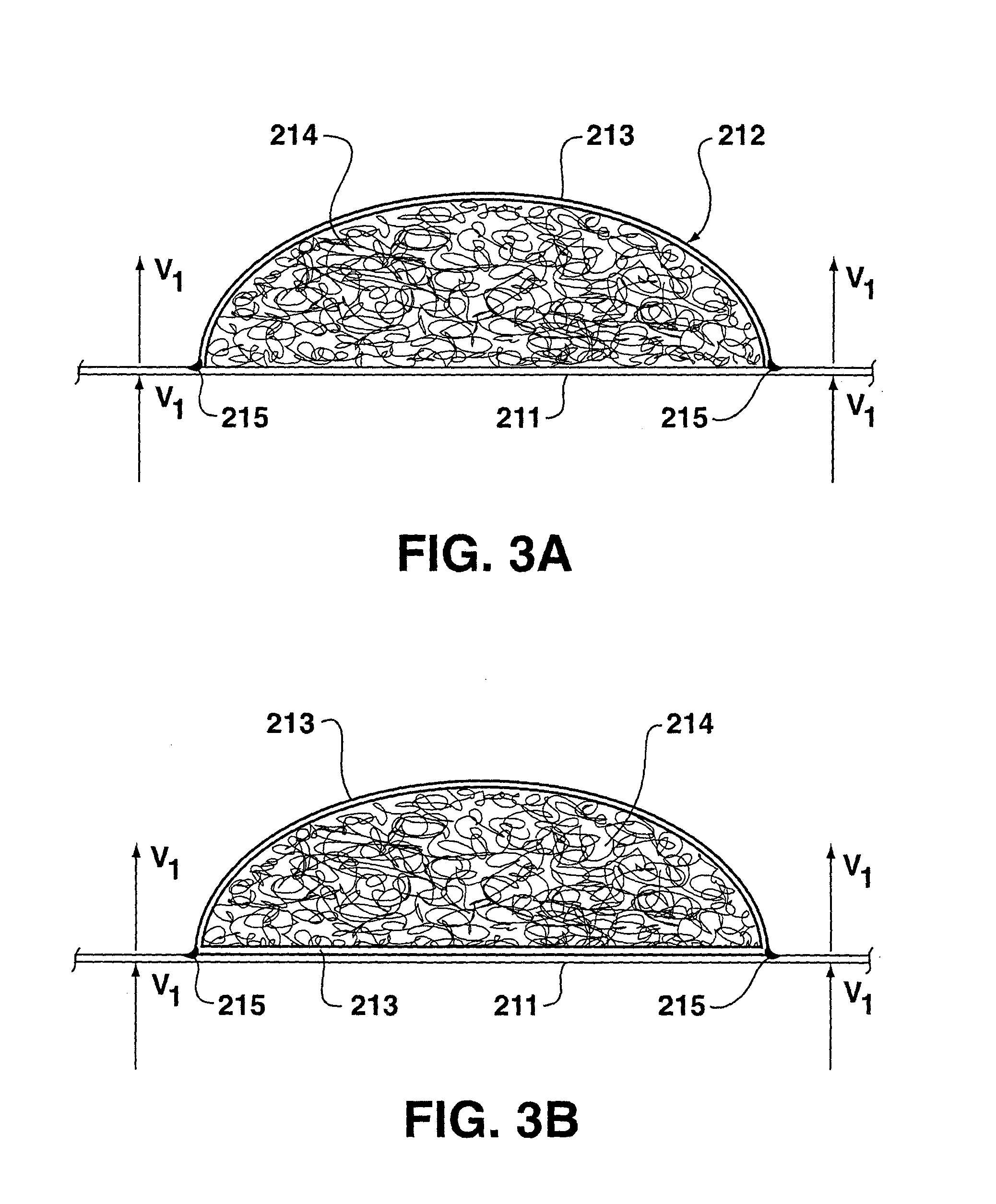

Microclimate regulating garment and composite structure

InactiveUS7735149B2Avoid water retentionLessens wear-cycle timeChemical protectionHeat protectionThermal insulationFilling materials

This invention is for a composite structure and a garment constructed from the composite structure which can be worn next to the skin or as outerwear as well as a process for making the composite structure and garment. The garment provides microclimate control for the wearer by means of at least one three-dimensional passageway formed by an outer cover material which is secured to a first substrate layer. The passageway contains a filler material which adds support to the walls of the passageways and allows a fluid to flow through the filler material. The passageway provides a thermal insulation by its bulk or by allowing a fluid to be pumped through it. The first substrate layer is breathable to increase the comfort level of the wearer.

Owner:CLEMSON UNIV RES FOUND

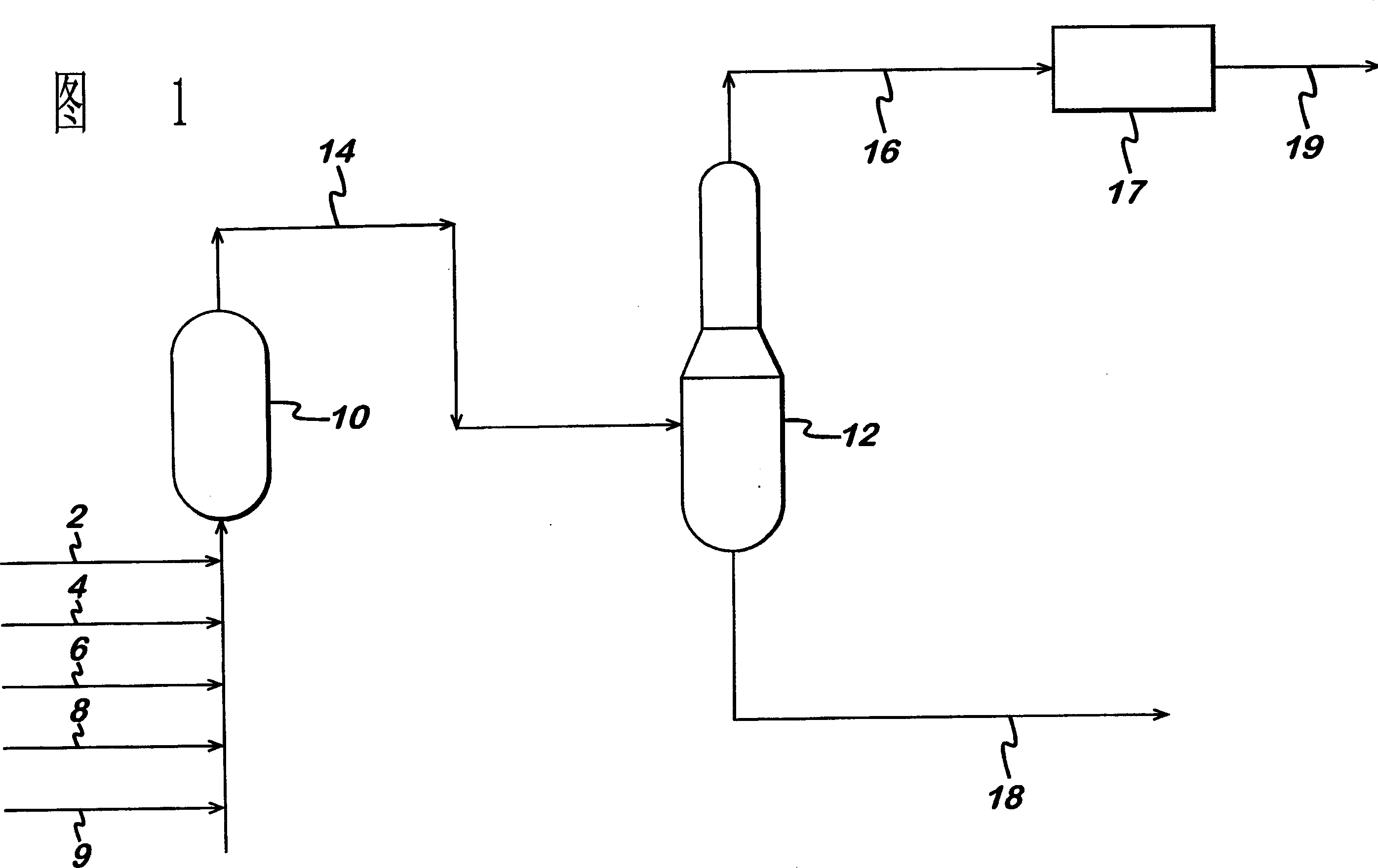

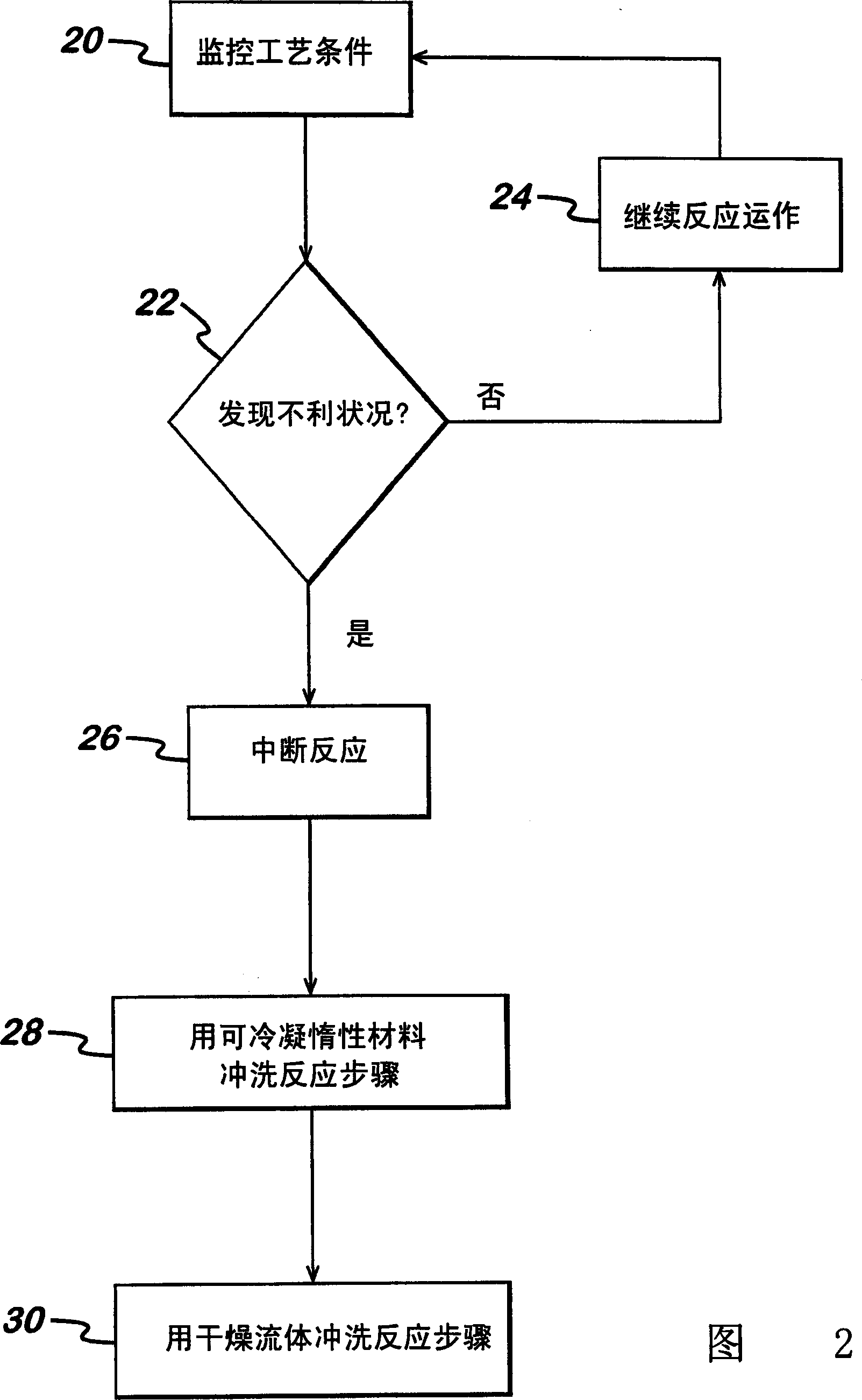

Non-routine reactor shutdown method

InactiveCN1781594ASlow flowGuaranteed trafficProcess control/regulationOrganic compound preparationChemical reactionAdverse conditions

Abnormal (i.e., emergency) shutdown of a chemical reaction process is accomplished by a method of safely operating a chemical reaction process that includes the steps of detecting adverse conditions that can affect the reaction process, minimizing the reaction of reactants, and maintaining The flow of material in the reaction zone of the process to displace the reaction mixture from the reaction zone. The flow of material is maintained for a period of time to displace substantially all of the reaction mixture from the reaction zone, thereby flushing the reaction zone. The reaction mixture can then be flushed into an auxiliary vessel, such as an absorption column.

Owner:ROHM & HAAS CO

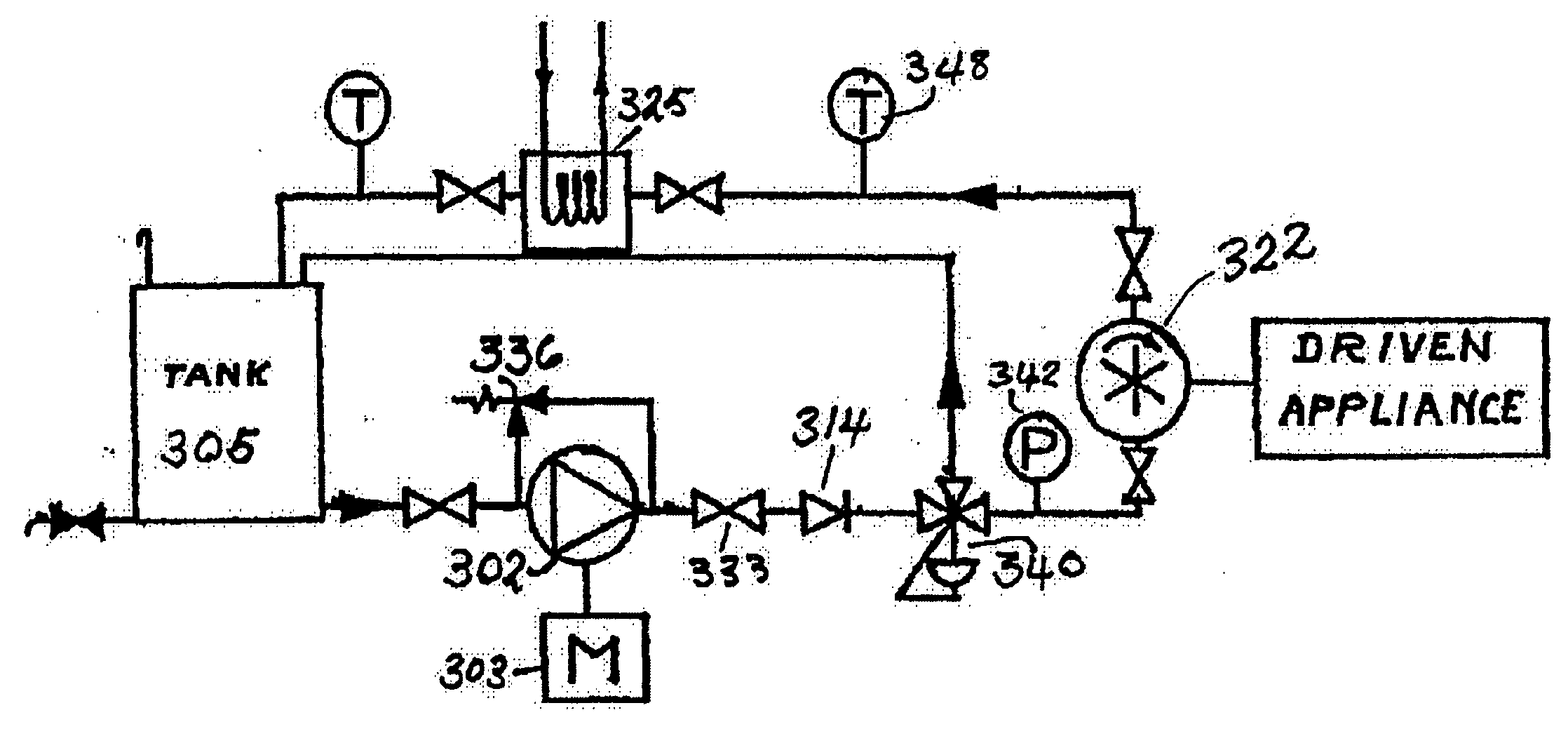

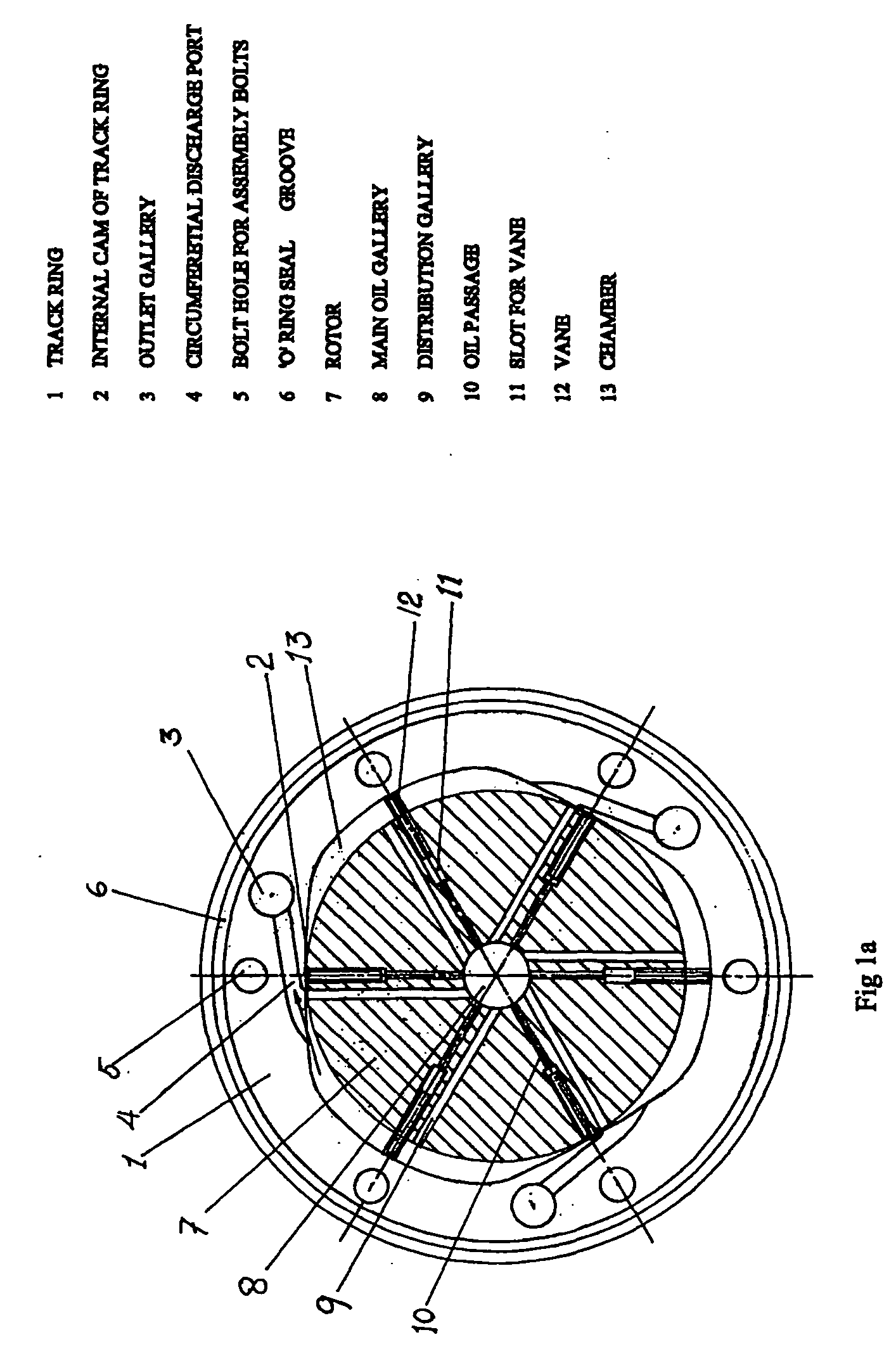

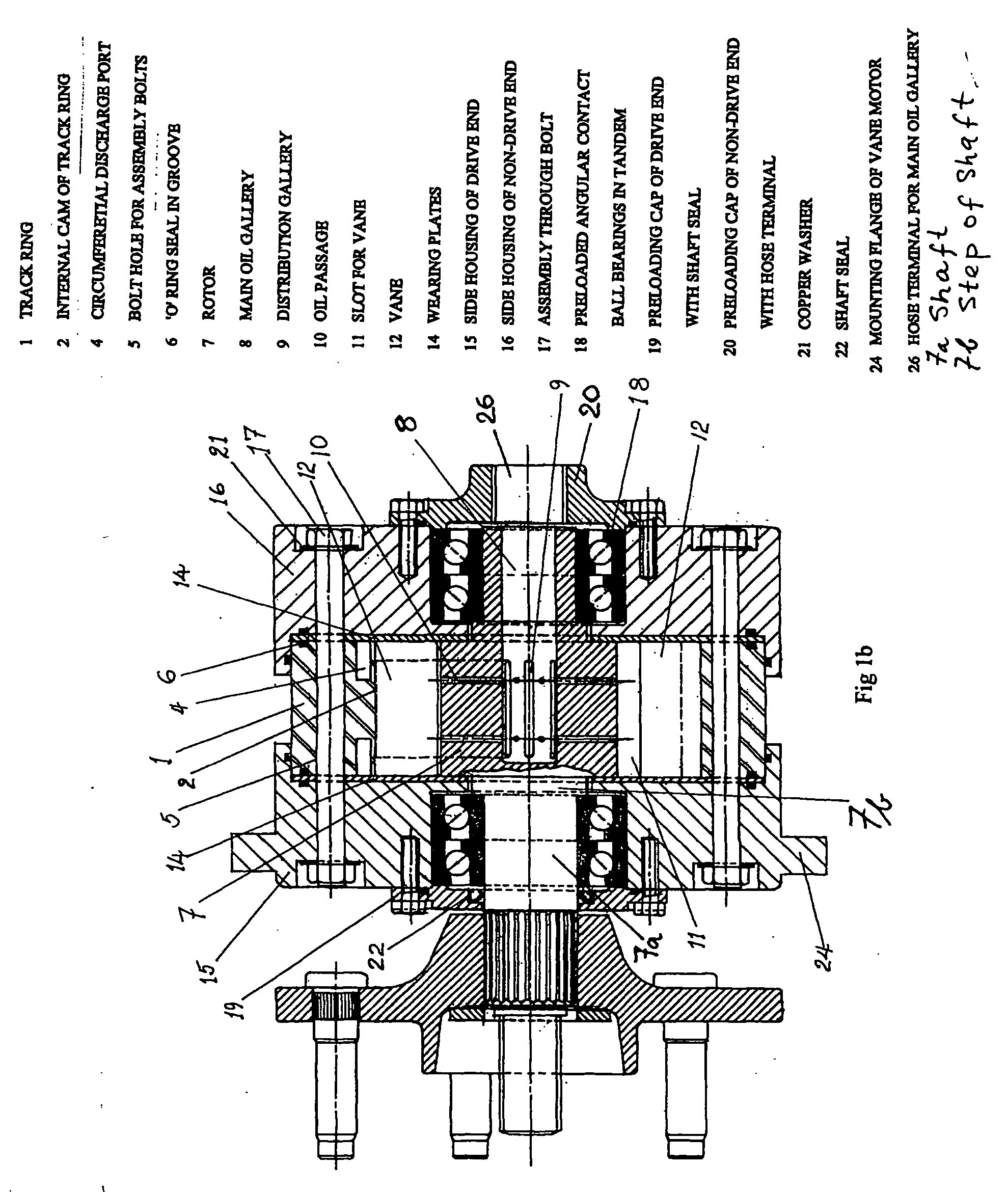

Hydraulic traction system for vehicles

InactiveUS20060059904A1Reduce the displacement angleReduce chamber volumeRotary piston pumpsMotor depositionHydraulic motorTraction system

A hydraulic traction system for vehicles is described. The system comprises a hydraulic vane motor mounted at each wheel of the vehicle, and equal number of identical hydraulic vane motors operated as engine driven pumps, and a control system for regulating the flow and direction of hydraulic oil during operation. The hydraulic motor is of a novel design that has a hollow non-drive shaft that accepts incoming hydraulic oil, this allows internal components of the hydraulic motor to be arranged in such a way to improve the efficiency of the hydraulic traction system.

Owner:SHEVKET ALPER

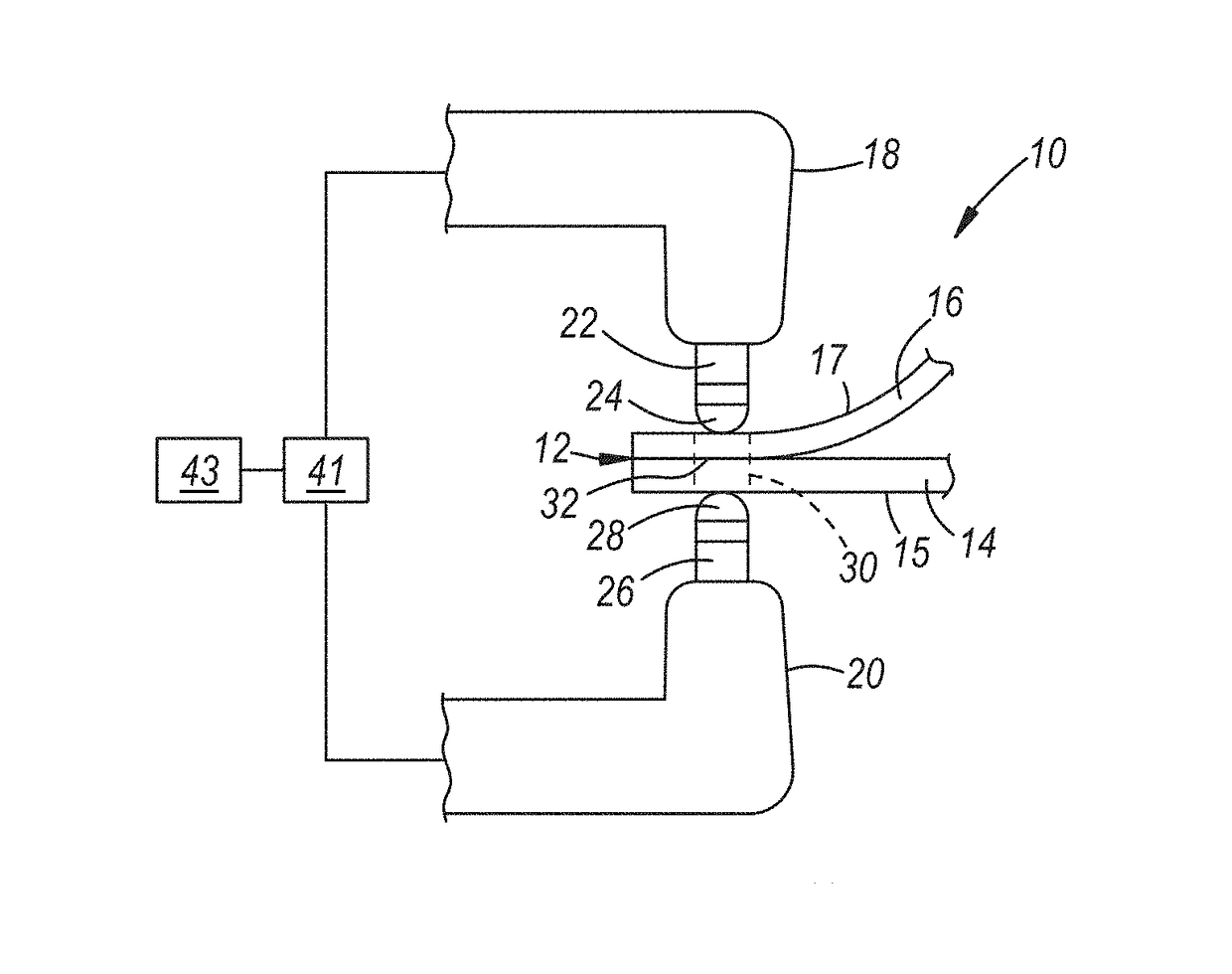

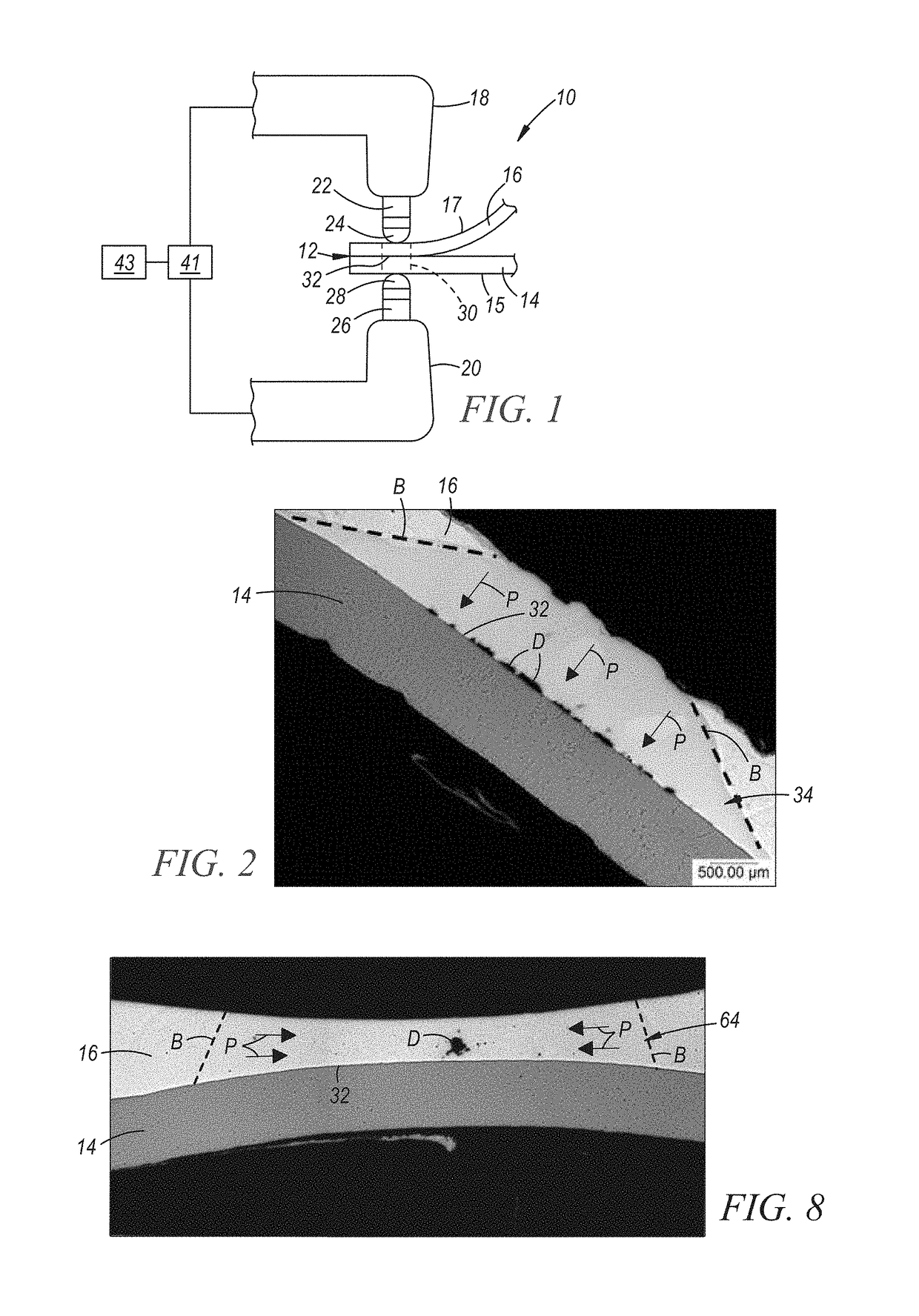

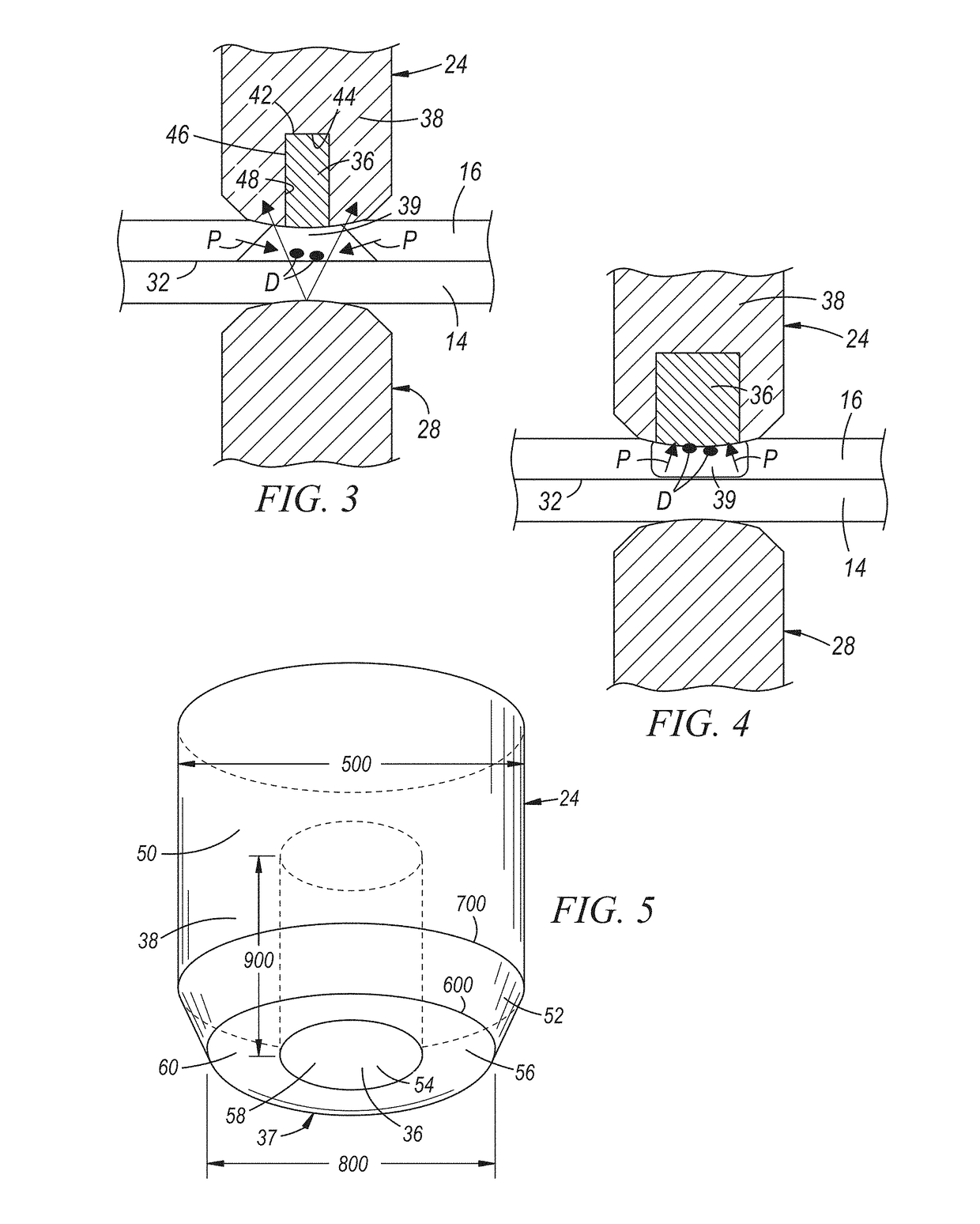

Resistance spot welding steel and aluminum workpieces with electrode having insert

ActiveUS20170297135A1Increased durabilityHigh strengthPressure electrodesWelding/soldering/cutting articlesElectrical resistance and conductanceSpot welding

A method of resistance spot welding a steel workpiece and an aluminum or aluminum alloy workpiece, and a welding electrode used therein. In one step of the method a workpiece stack-up is provided. The workpiece stack-up includes a steel workpiece and an aluminum or aluminum alloy workpiece. Another step of the method involves contacting the aluminum or aluminum alloy workpiece with a weld face of the welding electrode. The welding electrode has a body and an insert. The insert is composed of a material having an electrical resistivity that is greater than an electrical resistivity of the material of the body. The weld face has a first section defined by a surface of the insert and has a second section defined by a surface of the body. Both the first and second sections make surface-to-surface contact with the aluminum or aluminum alloy workpiece amid resistance spot welding.

Owner:GM GLOBAL TECH OPERATIONS LLC

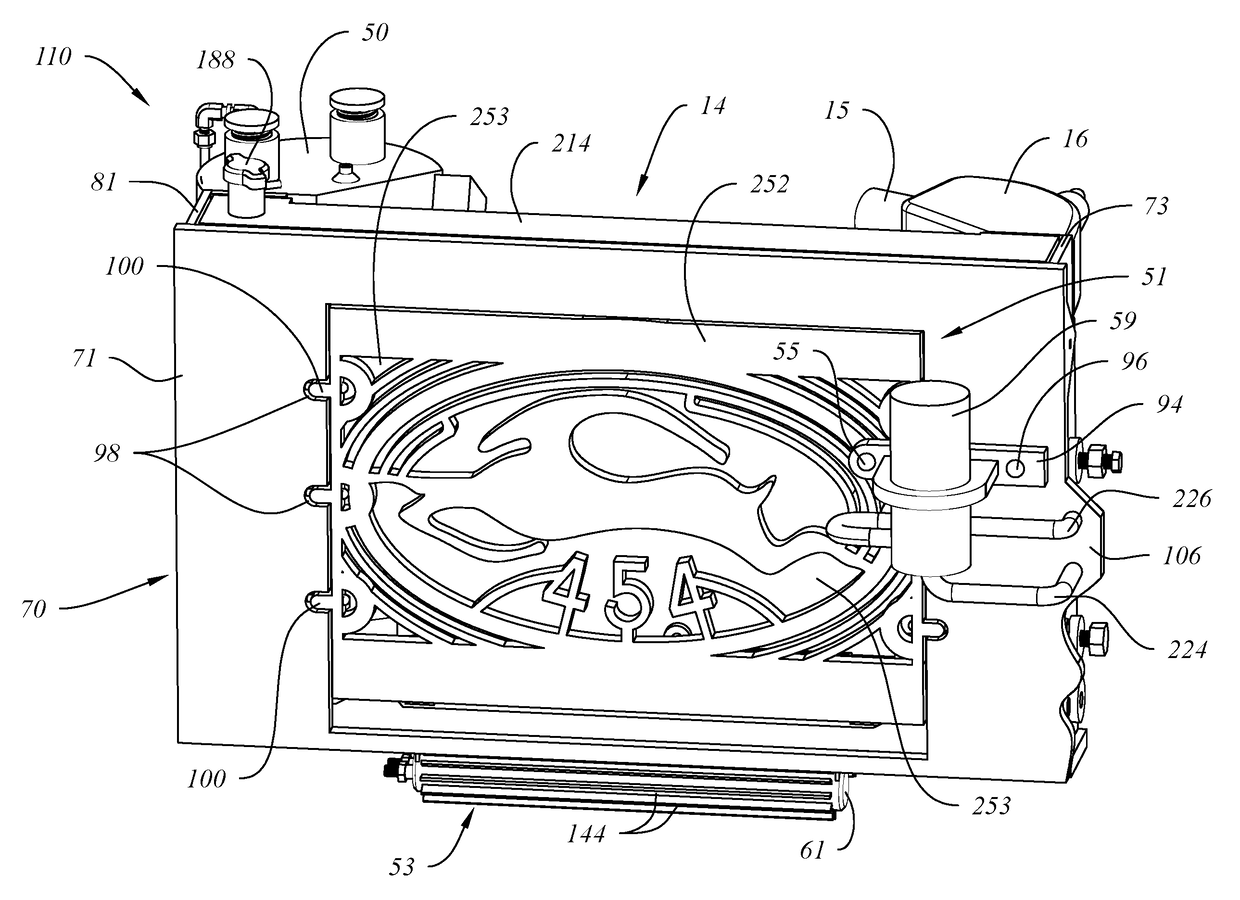

Shell body joint structure and jointing method thereof

ActiveCN1547427AReduce shadowsSlow flowCouplings bases/casesElectrical apparatus casings/cabinets/drawersBody jointsEngineering

The invention relates to a kind of shell joint structure and its joint method. The joint structure consists at least two parts: upper shell, which bears a joint including(from its outside to its inside orderly) first concave, first convex, first flute and second convex; and lower shell, which also bears a joint including(from its outside to its inside orderly) first concave, first convex and second concave. In addition, the first concave and the first convex of the upper shell are relative to the first convex of the lower shell, and the first flute and the first convex of the upper shell are relative to the first convex and the second concave of the lower shell respectively, thus jointing the upper shell and the lower one together. Through the use of this type of shell joint structure and its joint method, shell shadow and line flows can be reduced and the increase of the electricity climbing distance of the electric clearance after the combination of the shells will enhance the appearance of the shells of electric devices and their components as well as their electric characteristic.

Owner:DELTA ELECTRONICS INC +1

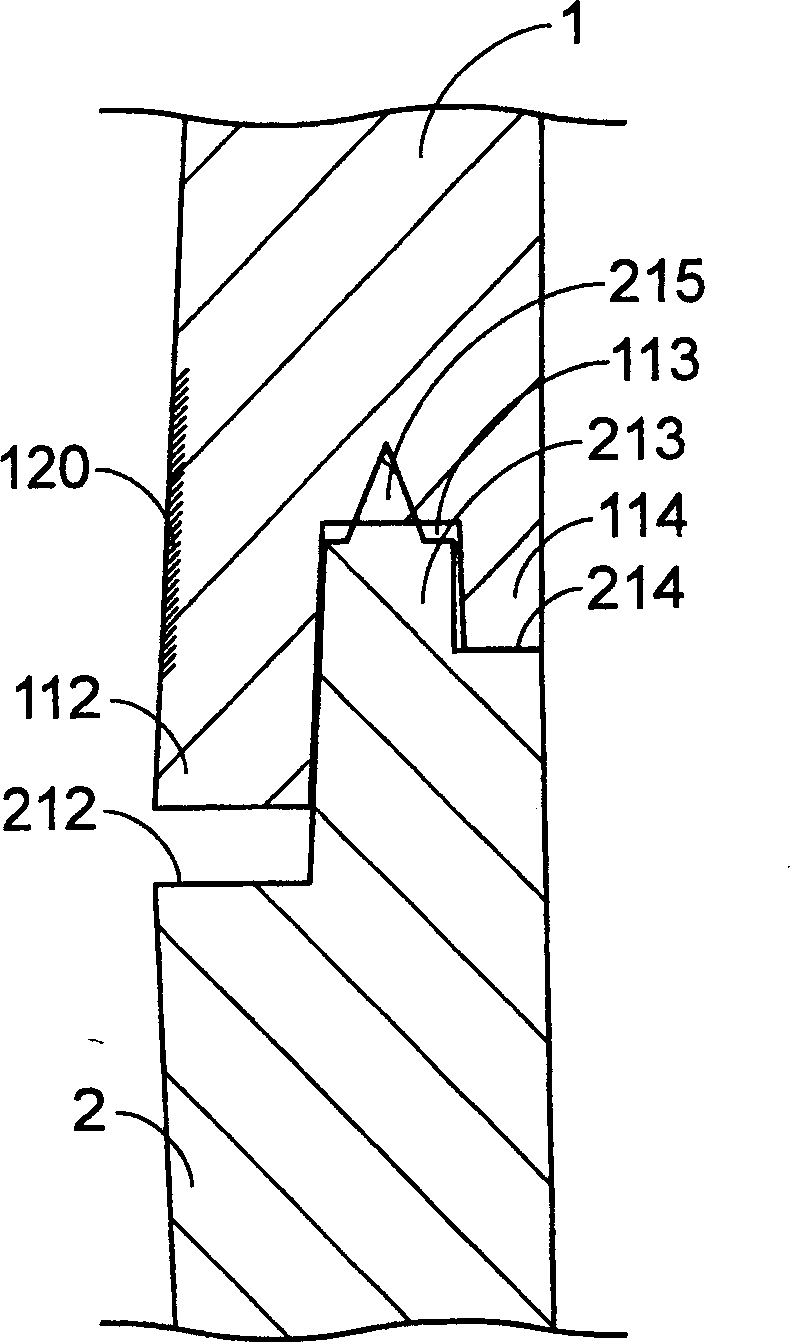

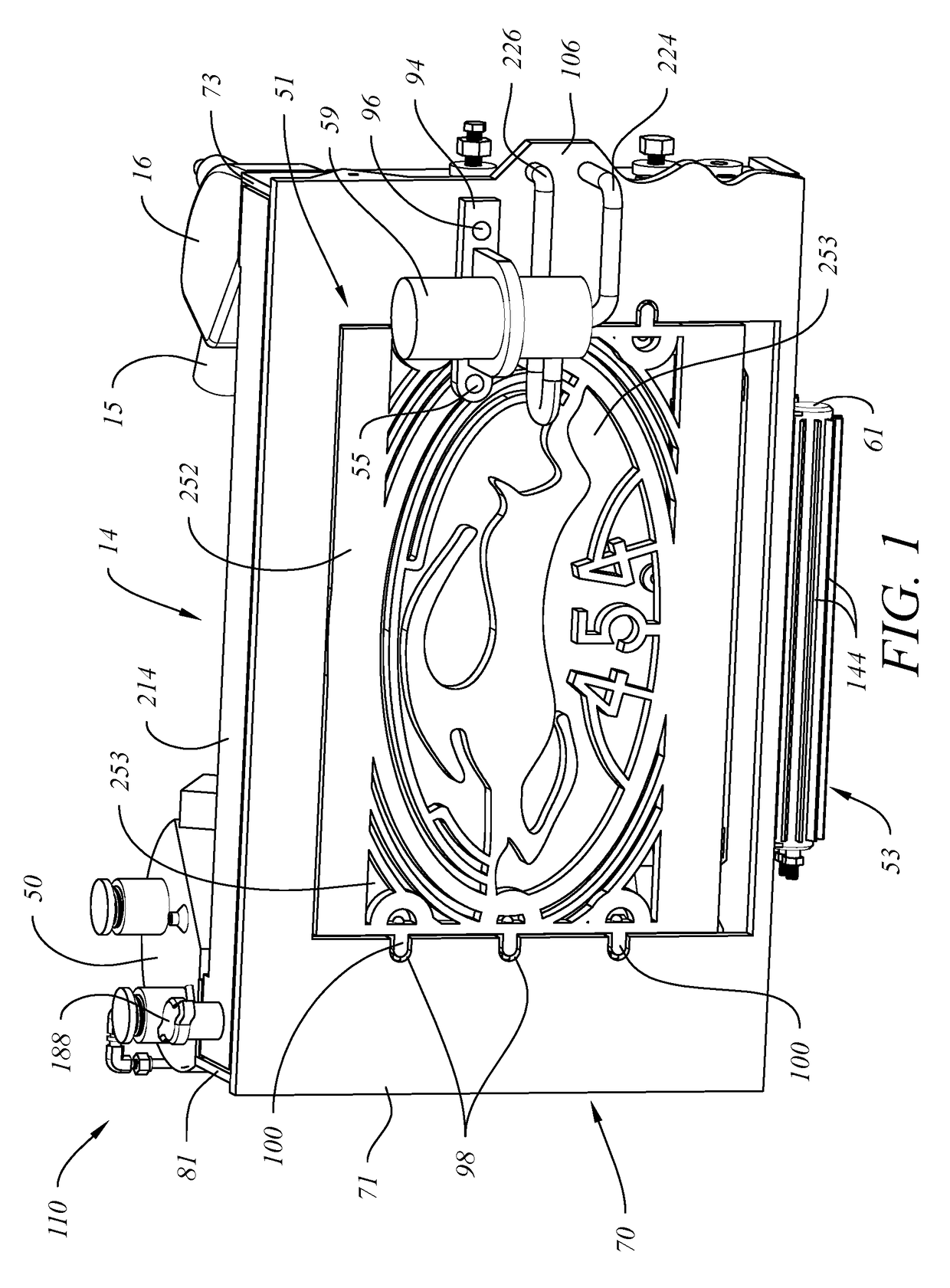

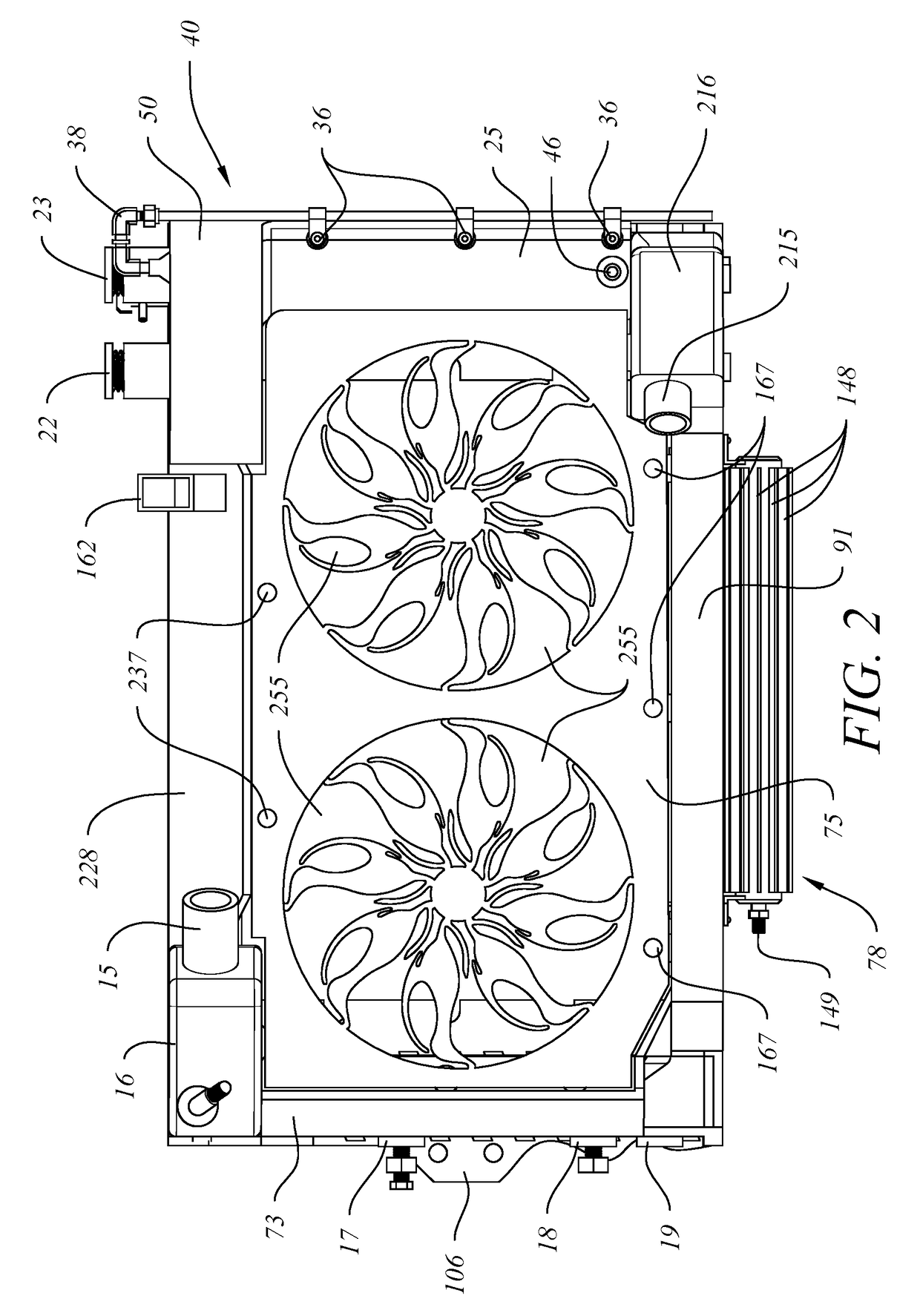

Radiator System

ActiveUS20180022209A1Reduce the likelihood of failureGood flexibilityLiquid coolingPump componentsNuclear engineeringControl system

An improved radiator mounting and cooling system for use in automobiles allows multiple components to be incorporated into the same unit, limiting the need for accessories to be mounted to inner fenders or firewall. A circulating vortex of air is pulled through a front grill and vortex tubes disposed through sides of the radiator system to improve cooling efficiency. An outer shroud protects interior components and creates a sealed core cavity allowing air to only enter through vortex tubes and front grill and exit through a rear grill. A self-circulating cooling system provides additional cooling of coolant. A fan system pulls around 5000 CFM of air through the core cavity. An optional secondary coolant pumping system allows coolant to be pumped when needed. A control system controls activation of the fan system and secondary coolant pumping system based on signals from sensors.

Owner:SHIHEIBER NIMER IBRAHIM

Long mission tethered aerostat and method of accomplishing

ActiveUS8485465B2Reducing reliance on ballonetsReducing the demands on blowersNon-rigid airshipsMovable targetsEngineeringGround station

Apparatus and method for a continuous replenishing of the lift gas and maintaining the proper pressure and lift of a tethered medium altitude aerostat utilizing a novel feed tube running the entire length of the tether. A first end of the feed tube is connected to the aerostat while a second end is connected through a novel slip ring means to a pressure controlled helium ballast chamber and scrubber on the ground to maintain pressure and lift by a reversible compressing pump. A plurality of pressure and temperature sensors and tension gauges strategically placed inside and around the airship continuously monitor the temperature and pressure changes in the aerostat. A data retrieval and communication unit mounted on the aerostat collects measurement data from the pressure, temperature and tension sensors which is relayed to the ground station and the data is used to regulate lifting gas pressure inside the aerostat.

Owner:STRATOCOMM CORP

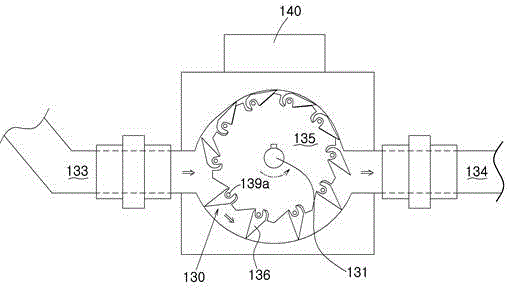

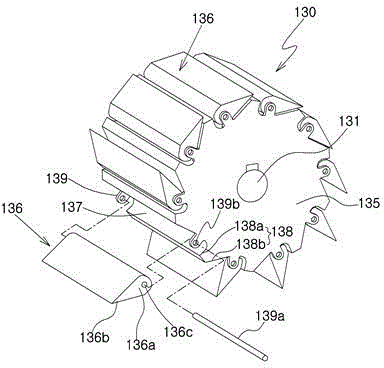

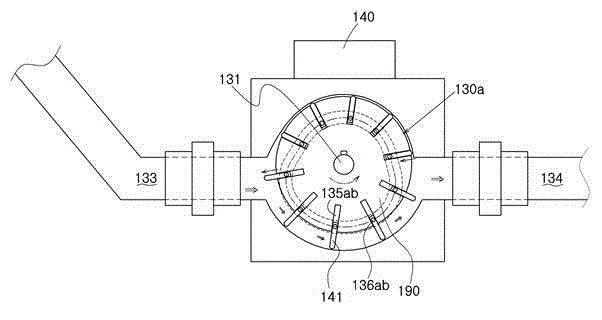

Simple hydraulic power unit

InactiveCN104100450AReduce flow rateReduce water flowWind motor controlEngine componentsTelescopic cylinderElectric energy

The present invention relates to a simple hydraulic power unit which comprises a foldable-wing type waterwheel generating device arranged between pipes and rotates under inflow water pressure. The generating device comprises a cam-type water wheel, a rotating shaft arranged in the center of the cam-type water wheel, and a generating mechanism arranged at one end of the rotating shaft and converting kinetic energy into electricity. The cam-type water wheel comprises a cylindrical body having a rotating shaft inserted in the center and rotating with the rotating shaft, two telescopic blades spacedly arranged on the periphery of the cylindrical body and making the cylindrical body to rotate under inflow water pressure, and cam type slot covers arranged at two side surfaces of the cylindrical body and allowing the telescopic blades to withdraw or protrude along the inner side surface as rotation of the cylindrical body. The simple hydraulic power unit enables the generation of a substantial amount of electricity with a low flow rate and speed.

Owner:CHEONG JUNG TECH

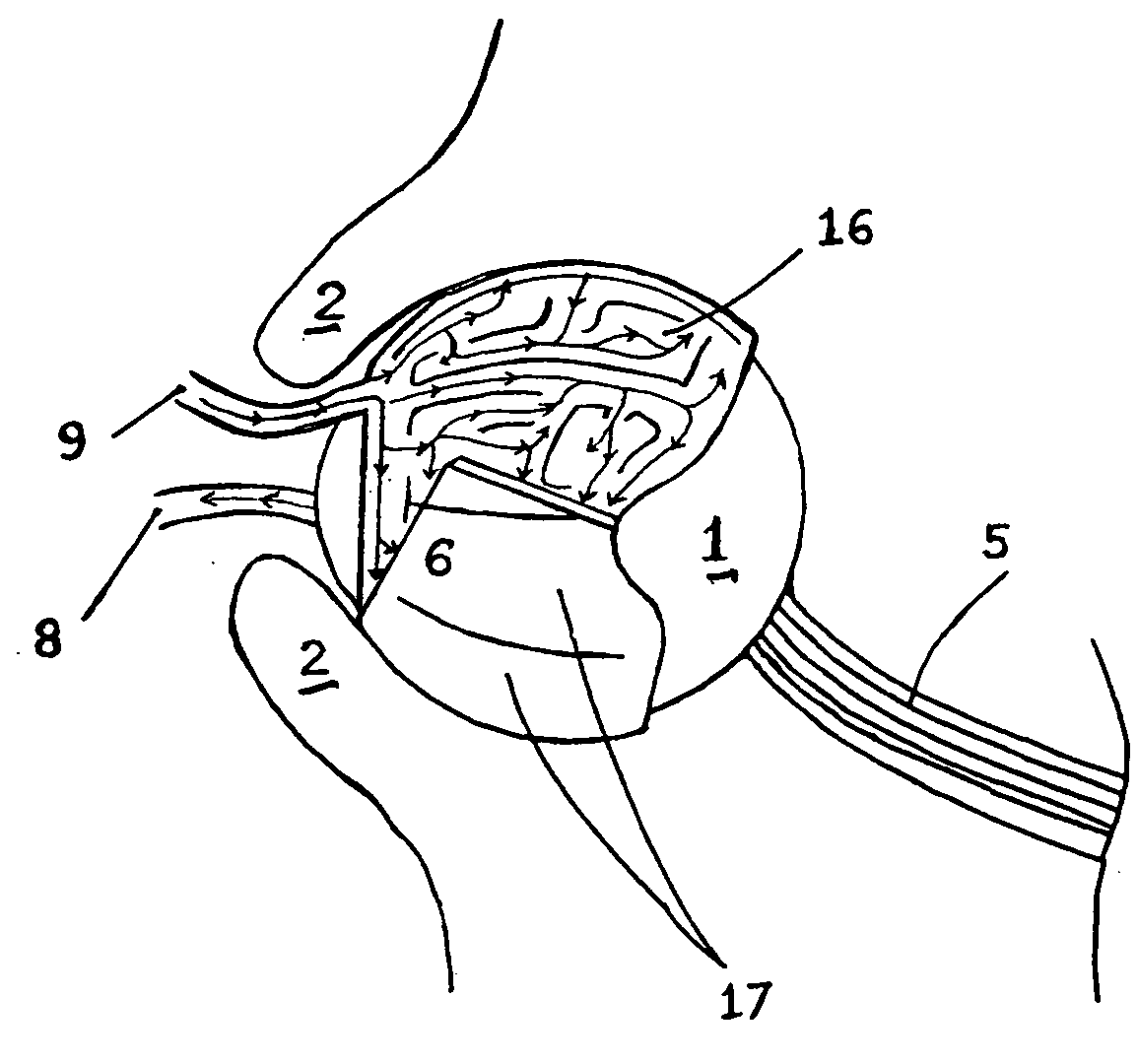

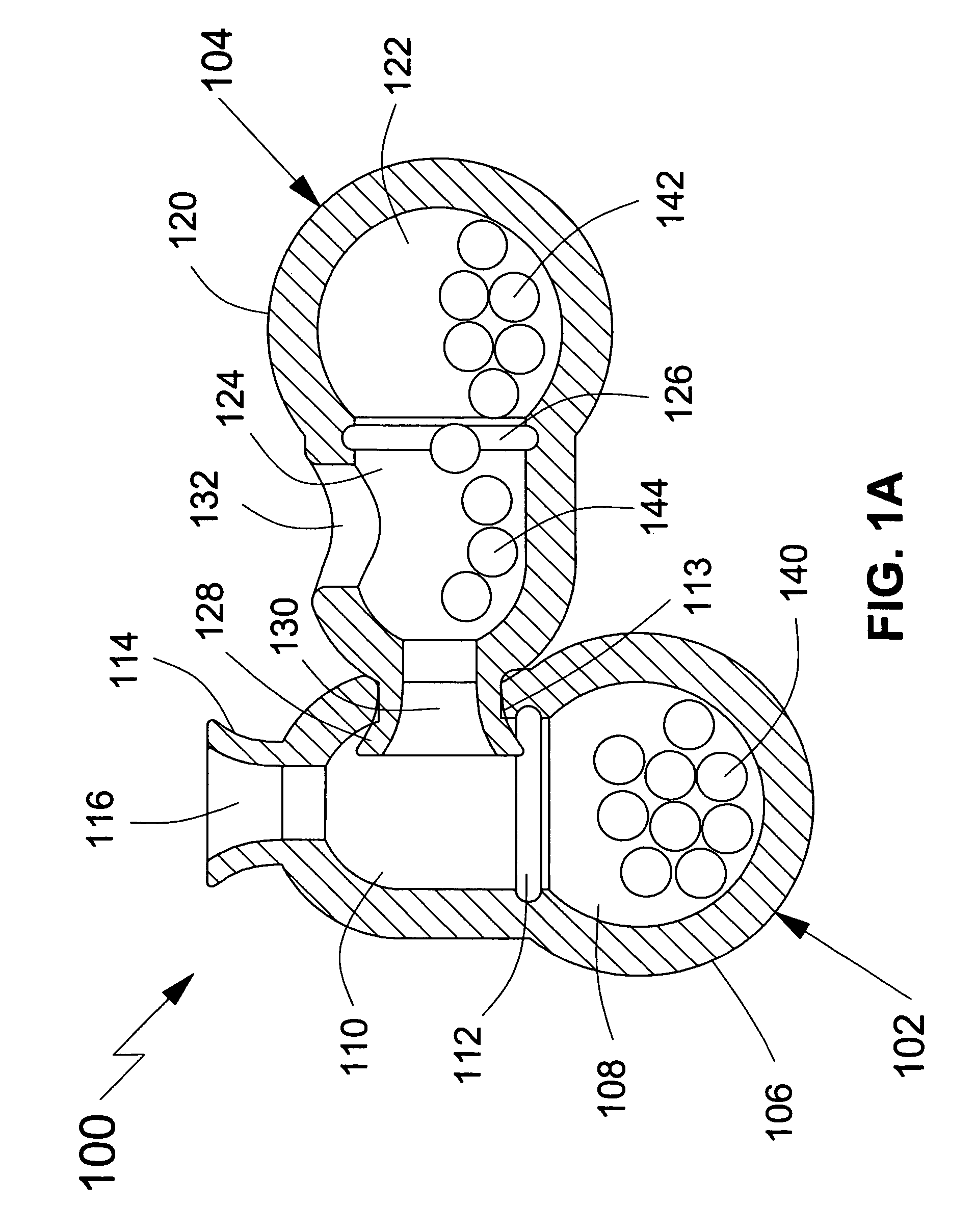

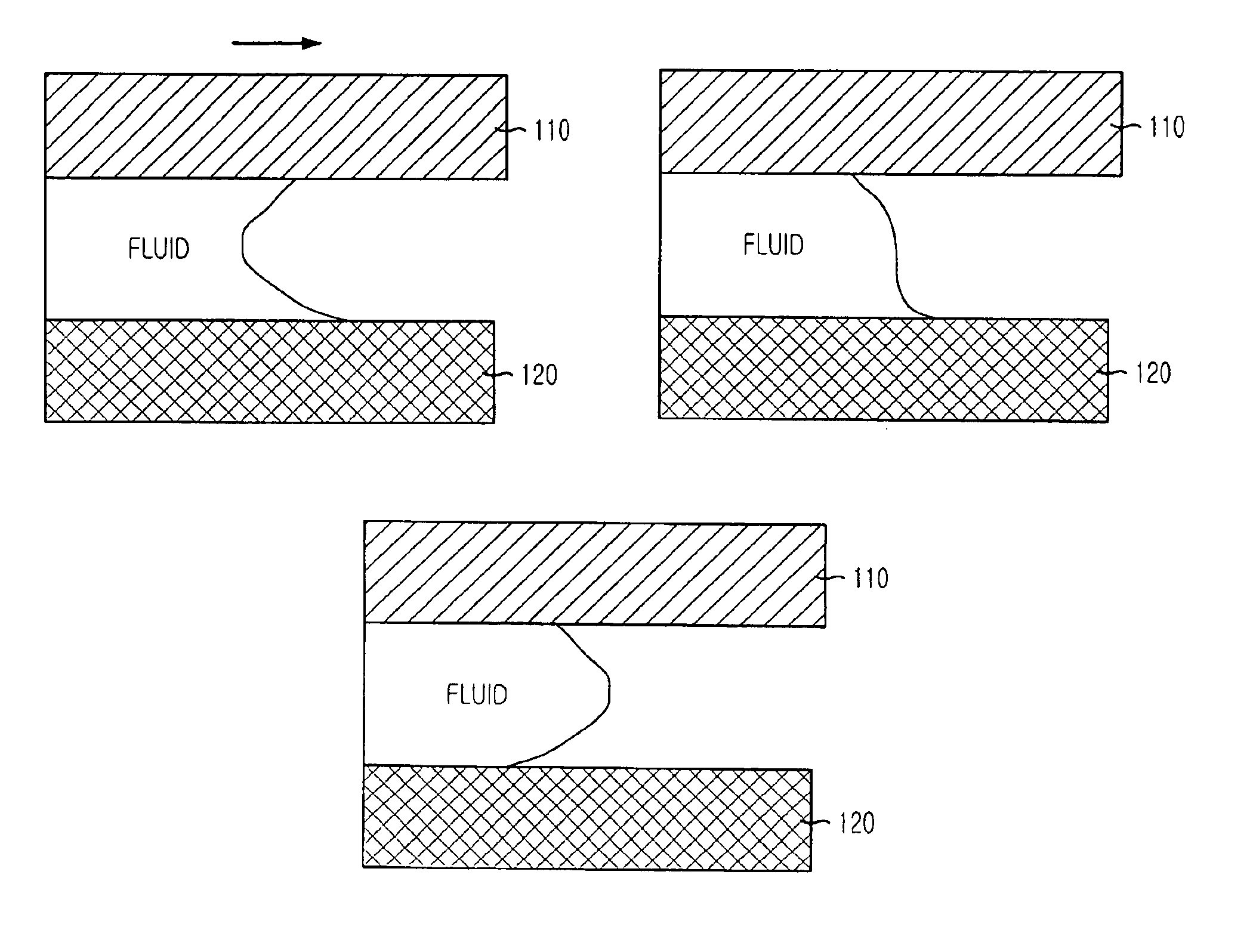

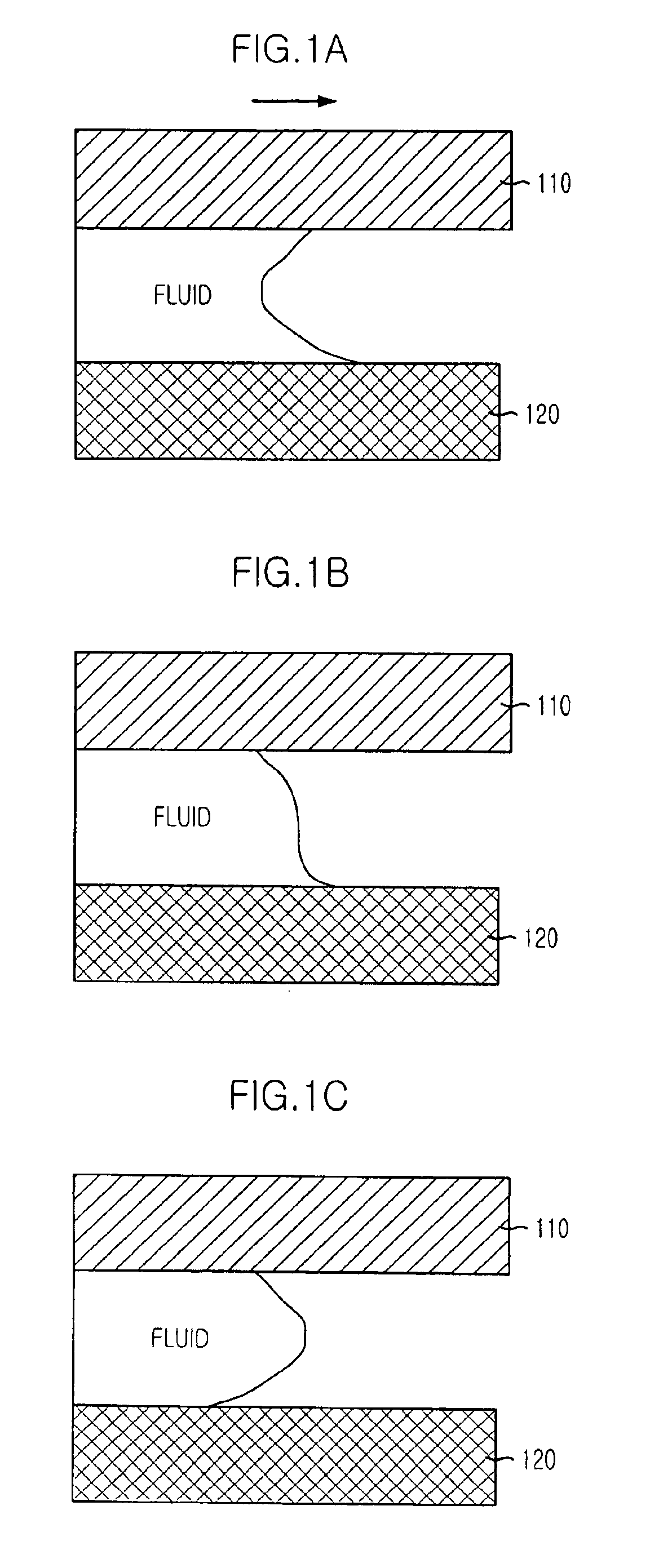

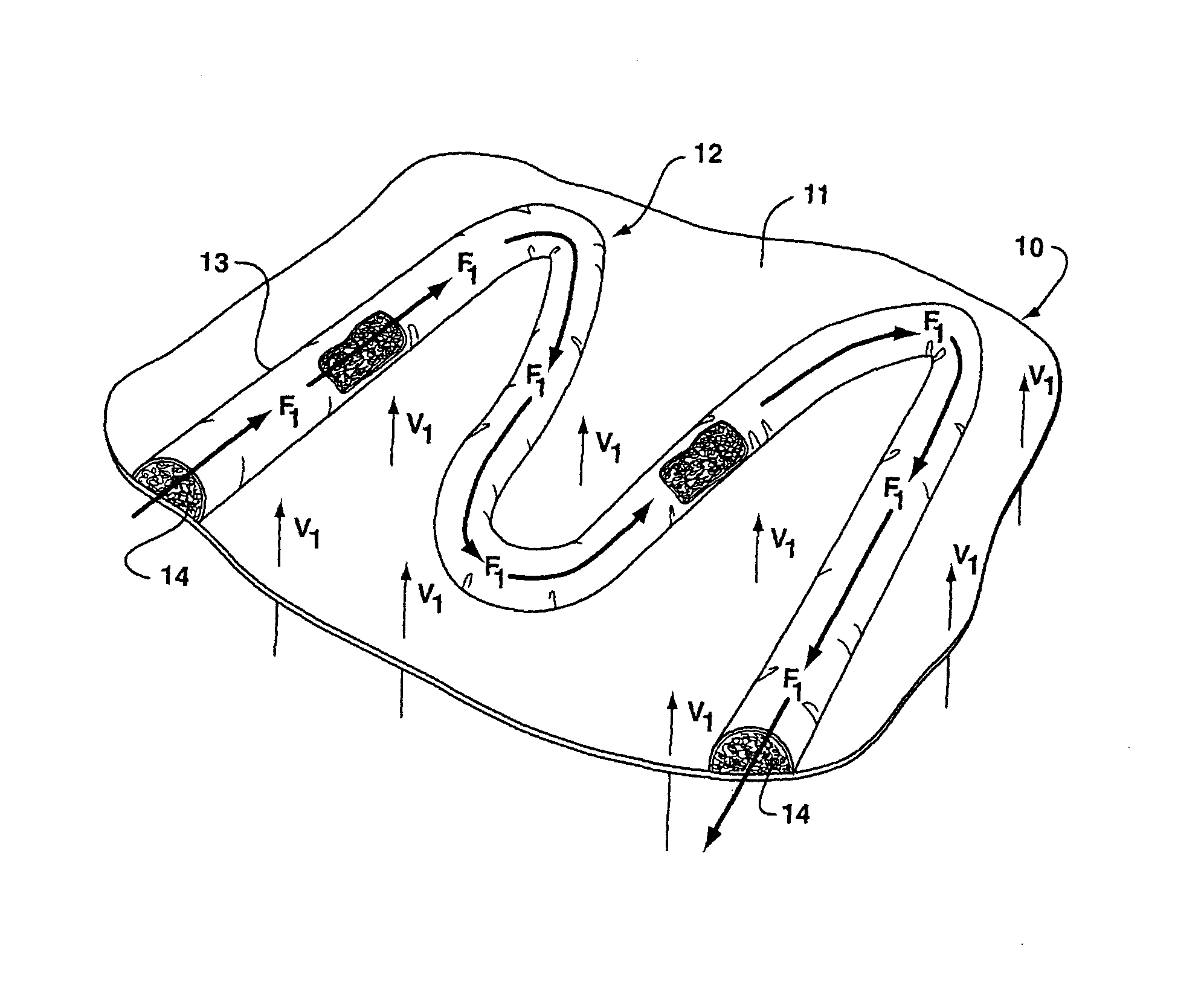

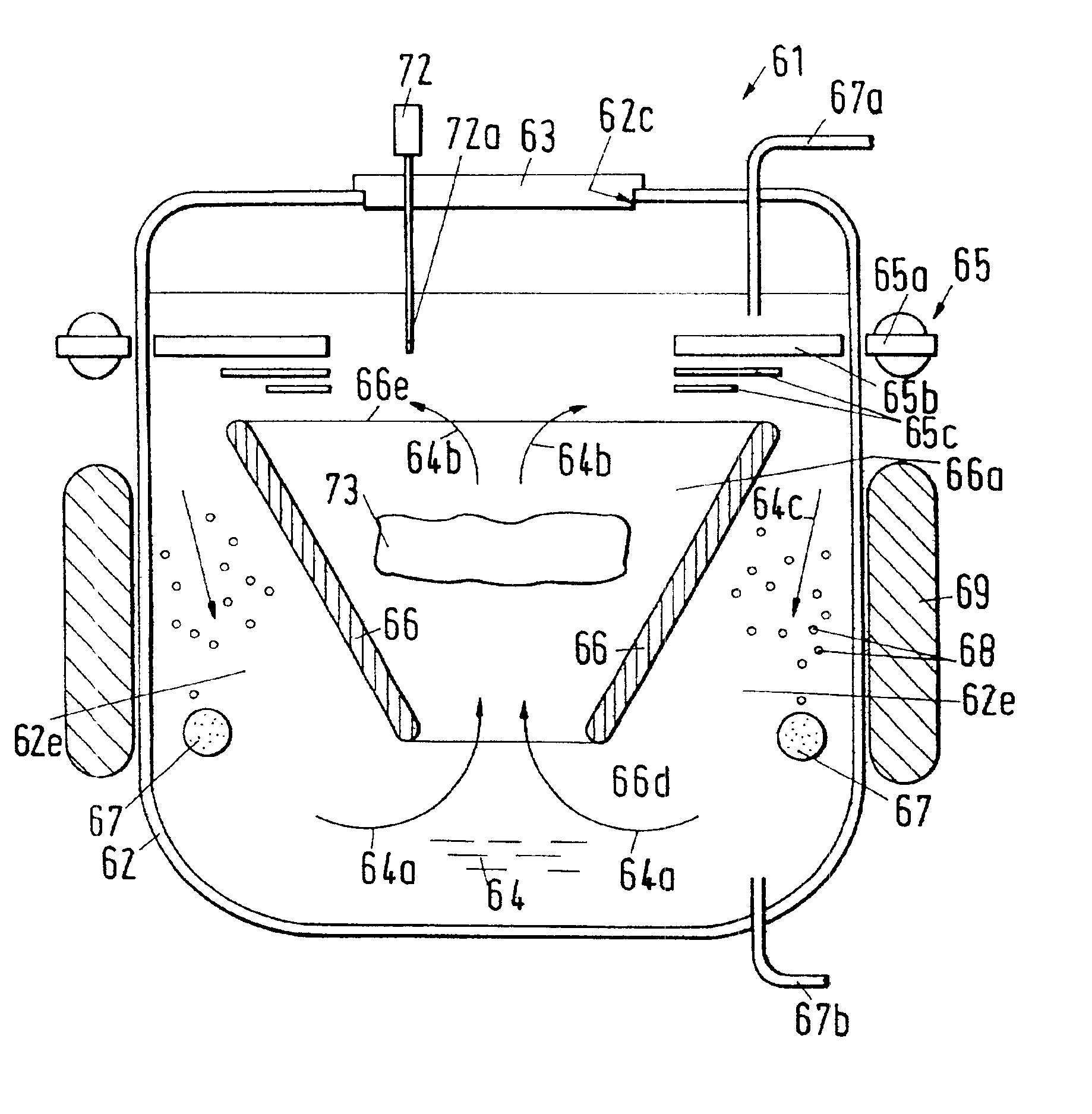

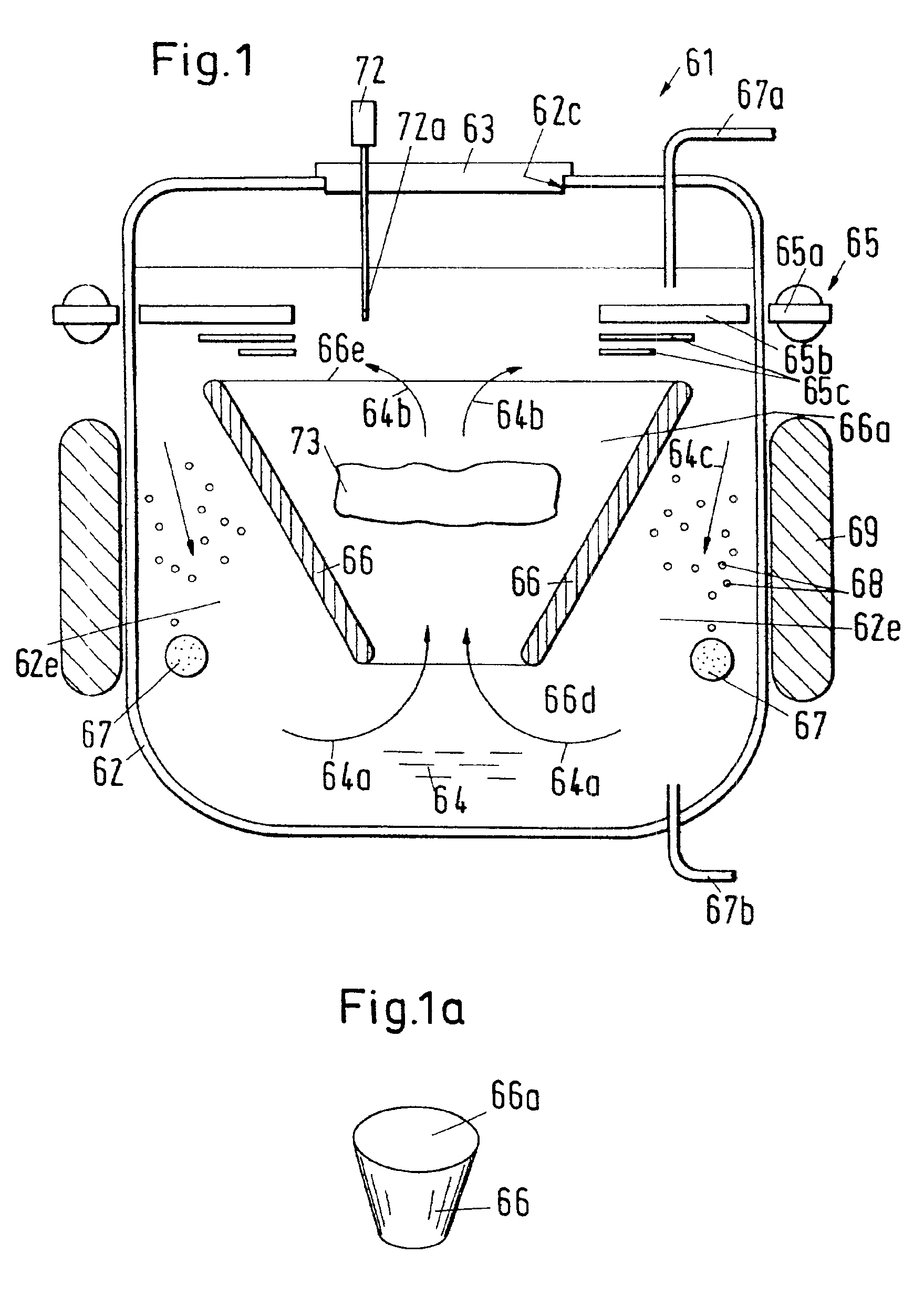

Bioreactor and method for fluidly suspending a product

InactiveUS6864084B2No laborious cleaning processEconomically and reliably producedBioreactor/fermenter combinationsBiological substance pretreatmentsVolumetric Mass DensityBioreactor

A method for floating at least one substance for growing a tissue part in a bioreactor. The method includes providing at least one substance consisting of one of a tissue part, a scaffold having cells deposited thereon, and a scaffold including a tissue part thereon. The method further includes further acting upon the substance with fluid, wherein the fluid holds the substance in free floatation. The fluid flows in a direction counter to gravity when a density of the substance is greater than a density of the fluid, and in a direction counter to buoyancy when a density of the substance is less than a density of the fluid. The bioreactor for floating at least one substance for growing a tissue part includes a container including a first flow chamber and at least one substance consisting of one of a tissue part, a scaffold having cells deposited thereon, and a scaffold including a tissue part thereon. The substance is acted upon with fluid. The bioreactor further includes an apparatus for conveying the fluid. The substance is arranged in the first flow chamber in such a manner that the fluid holds the substance in free floatation.

Owner:QUALCOMM INC +2

Environment-friendly thixotropic anti-rust oil

ActiveCN103992858AImprove performanceImprove washing resistanceLubricant compositionBobbinPhenyl Ethers

The invention discloses an environment-friendly thixotropic anti-rust oil. The anti-rust oil comprises the following raw materials by weight: 81 to 90 parts of bobbin oil, 0.1 to 0.3 part of hydroxyethylpyrrolidone, 1 to 2 parts of 1-hydroxyethyl-2-oleic imidazoline, 5 to 7 parts of dinonyl-naphthalene sulfonic acid calcium salt, 1 to 2 parts of organic bentonite, 0.7 to 1 part of polyoxyethylene nonyl phenyl ether, 3 to 4 parts of epoxidized soybean oil, 0.6 to 2 parts of decyl primary amine, 0.6 to 2 parts of Span-80 and 5 to 6 parts of an anti-rust auxiliary agent. The anti-rust oil provided by the invention has excellent performance and cleaning performance, certain lubricity and good thixotropy, so the anti-rust oil can form a stable oil film on the surface of metal, hardly flows and can maintain the stable oil film when a steel plate is rolled up, thereby reducing the application amount of the oil.

Owner:诺土(上海)新材料技术有限公司

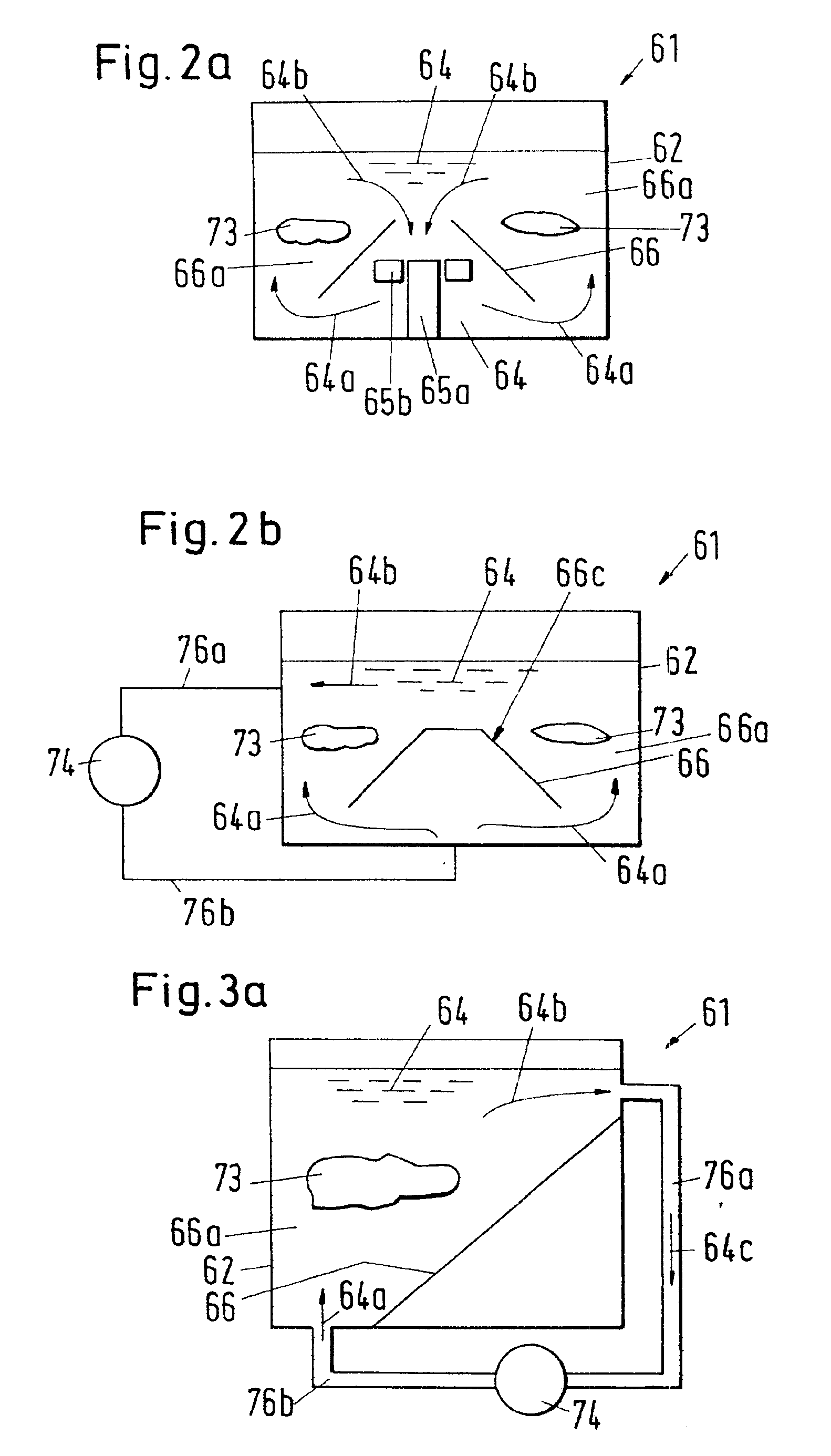

Negative pressure soda liquor absorption technique for oxides of nitrogen waste gas

ActiveCN101244364AGood governanceReduce acid consumptionDispersed particle separationThree levelAtmospheric air

The invention relates to a negative-pressure soda lye absorption craft for the nitrogen-oxide waste gas, belonging to the environment protecting, emission reducing and energy saving technical field, which is characterized in that: the NOx gas brought by nitration reaction flows in a direction under the function of vacuum power, that is, the gas flows through the condenser, the receive pot, the primary absorption pot, the secondary absorption pot, the three-level soda lye pond orderly; the evaporative nitric acid is condensing from gas to liquid into receive pot to store through the condenser; the NOx not condensing enters into the negative-pressure absorption workshop section; the whole working procedure are in series and enclosed totally without leaking; the three levels absorption can assure the tail gas NOx absorbed entirely and not diffused to the atmosphere to pollute the environment, meanwhile the zero-emission is realized.

Owner:HUNAN JINWANG BISMUTH

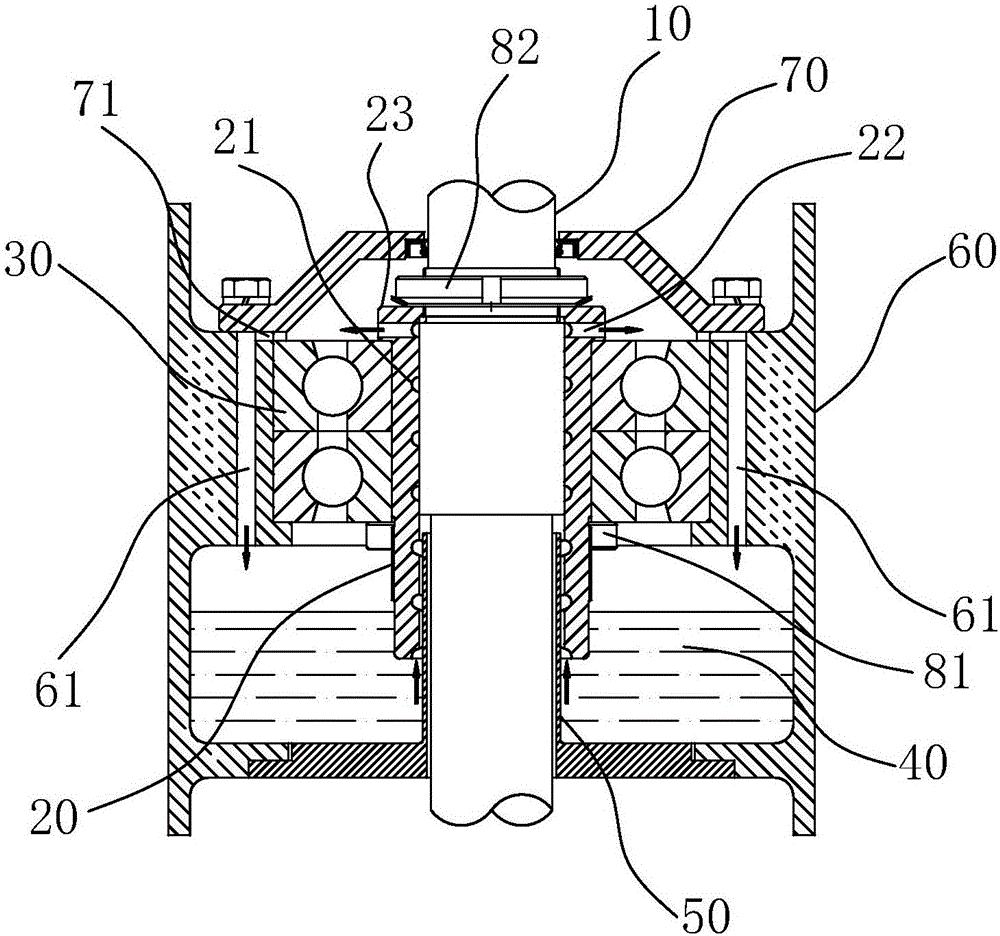

Self-sucking type bearing lubricating device

InactiveCN106438725ARealize oil bath heat dissipationFast coolingBearing coolingEngine lubricationDrive shaftEngineering

The invention relates to a self-sucking type bearing lubricating device. The self-sucking type bearing lubricating device comprises a self-sucking shaft sleeve and a bearing, wherein the self-sucking shaft sleeve is fixed to the peripheral face of a transmission shaft in a sleeving manner and can axially rotate around the self-sucking shaft sleeve along with the transmission shaft, and the bearing is arranged on the peripheral face of the self-sucking shaft sleeve in a sleeving manner. A spiral oil sucking groove spirally elevating lubricating oil in an oil storage cavity in the lower end of the self-sucking shaft sleeve to the upper end of the self-sucking shaft sleeve is formed in the inner wall of the self-sucking shaft sleeve. The self-sucking shaft sleeve is further provided with an oil throwing channel throwing lubricating oil elevated to the upper end of the self-sucking shaft sleeve to the upper end face of the bearing. The self-sucking type bearing lubricating device is provided for vertical equipment, oil bath heat dissipation of the bearing is achieved, the cooling speed of the lubricating oil on the bearing is high, the cooling effect of the lubricating oil on the bearing is good, product input and using cost is low, and safety is high; and the service life of the bearing is greatly prolonged, and running stability of corresponding devices is greatly improved.

Owner:合肥华升泵阀股份有限公司

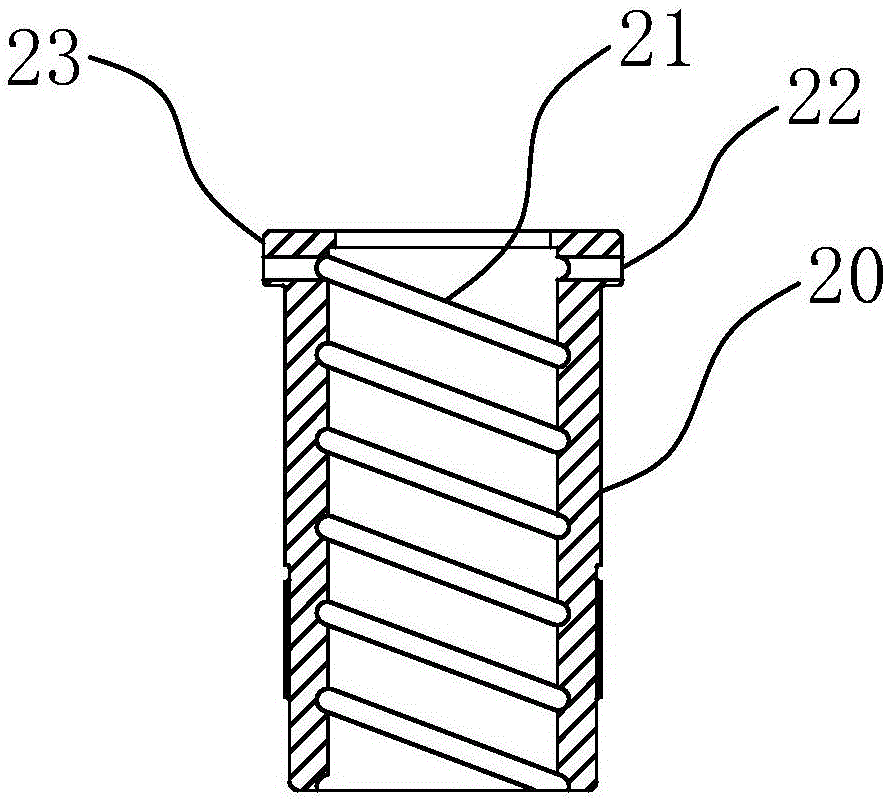

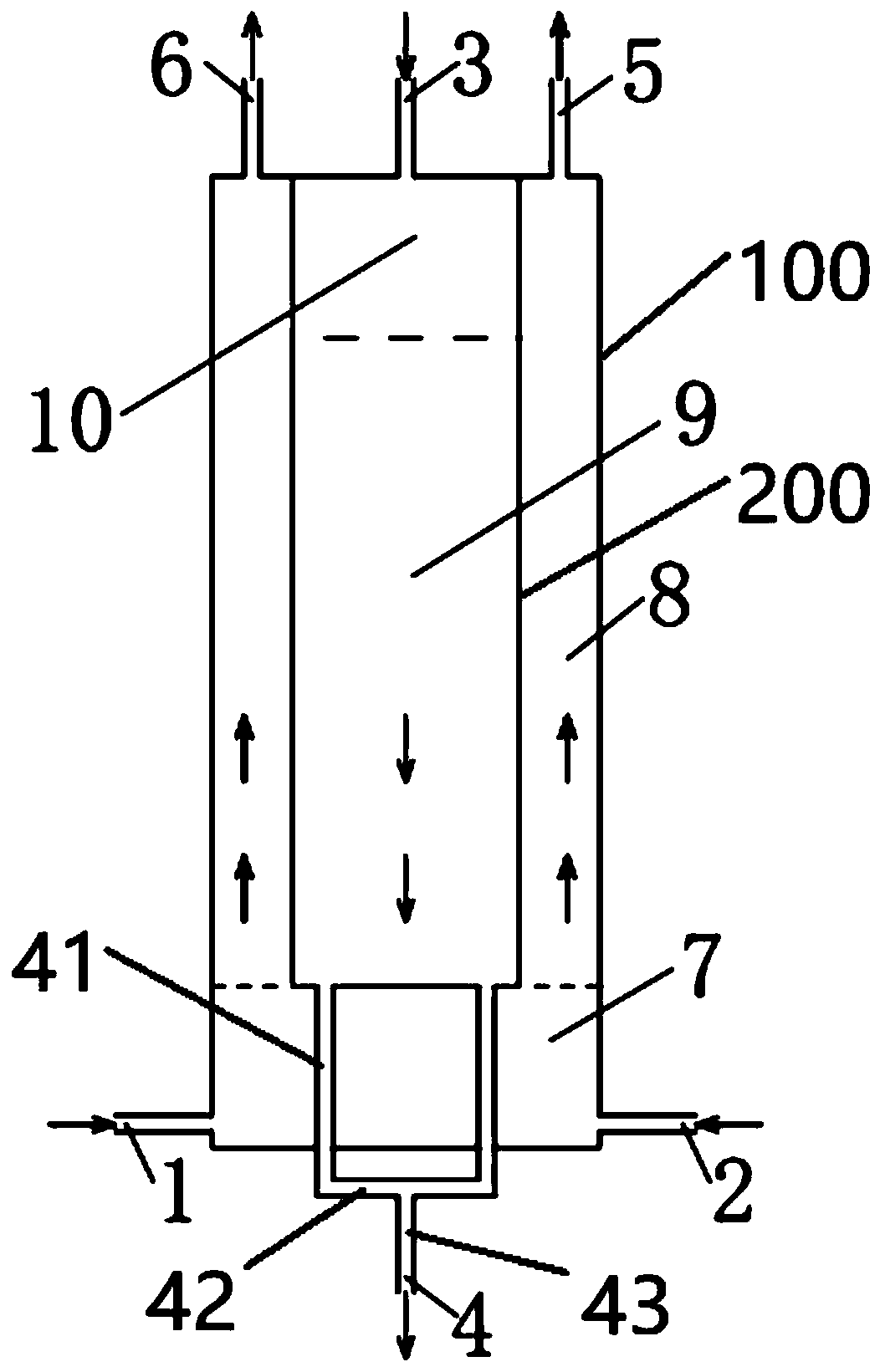

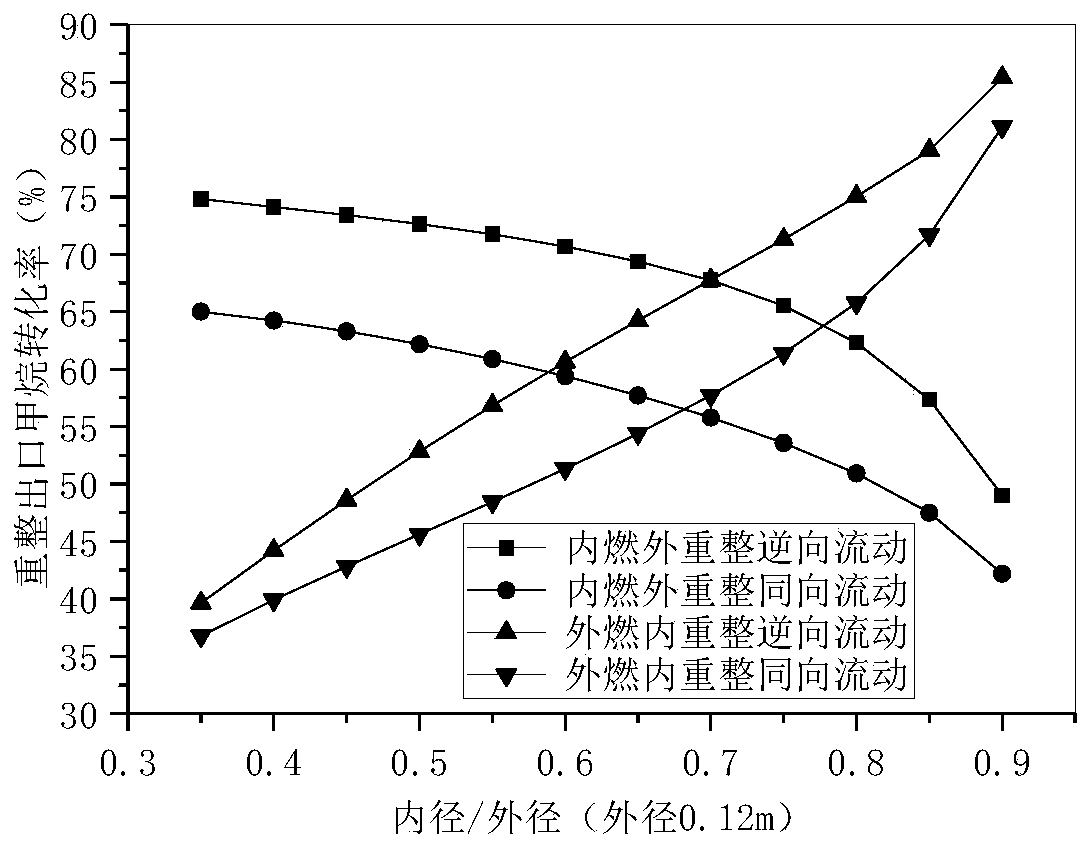

Efficient reformer for autothermal reforming of methane

The invention discloses an efficient reformer for autothermal reforming of methane. The efficient reformer for autothermal reforming of methane comprises an external cylinder body and an internal cylinder body; the external cylinder body and the internal cylinder body are concentrically arranged cylinders; an annular space between the external cylinder body and the internal cylinder body comprisesa combustion chamber and a combustion buffering chamber, wherein the combustion chamber is formed in the upper part and used for supplying heat to combustion, and the combustion buffering chamber isformed in the lower part; and the cylindrical space in the internal cylinder body comprises a reforming buffering chamber and a reforming chamber, wherein the reforming buffering chamber is formed inthe upper part, and the reforming chamber is formed in the lower part of the reforming buffering chamber and used for hydrogen production by reforming. As an external combustion chamber of a reactor has a small section, and a reforming chamber of the reactor has a big section, the heat transfer resistance from the combustion chamber to the reforming chamber is reduced, the staying time of reforming gas in the reforming chamber is also increased, and the strong heat of combustion is sufficiently absorbed; moreover, compared with a common internal combustion and external reforming form, the efficient reformer for autothermal reforming of methane, disclosed by the invention, has the advantages that the heat exchanging areas of the combustion chamber and the reforming chamber are also increased, and the heat exchanging efficiency is made higher.

Owner:XI AN JIAOTONG UNIV

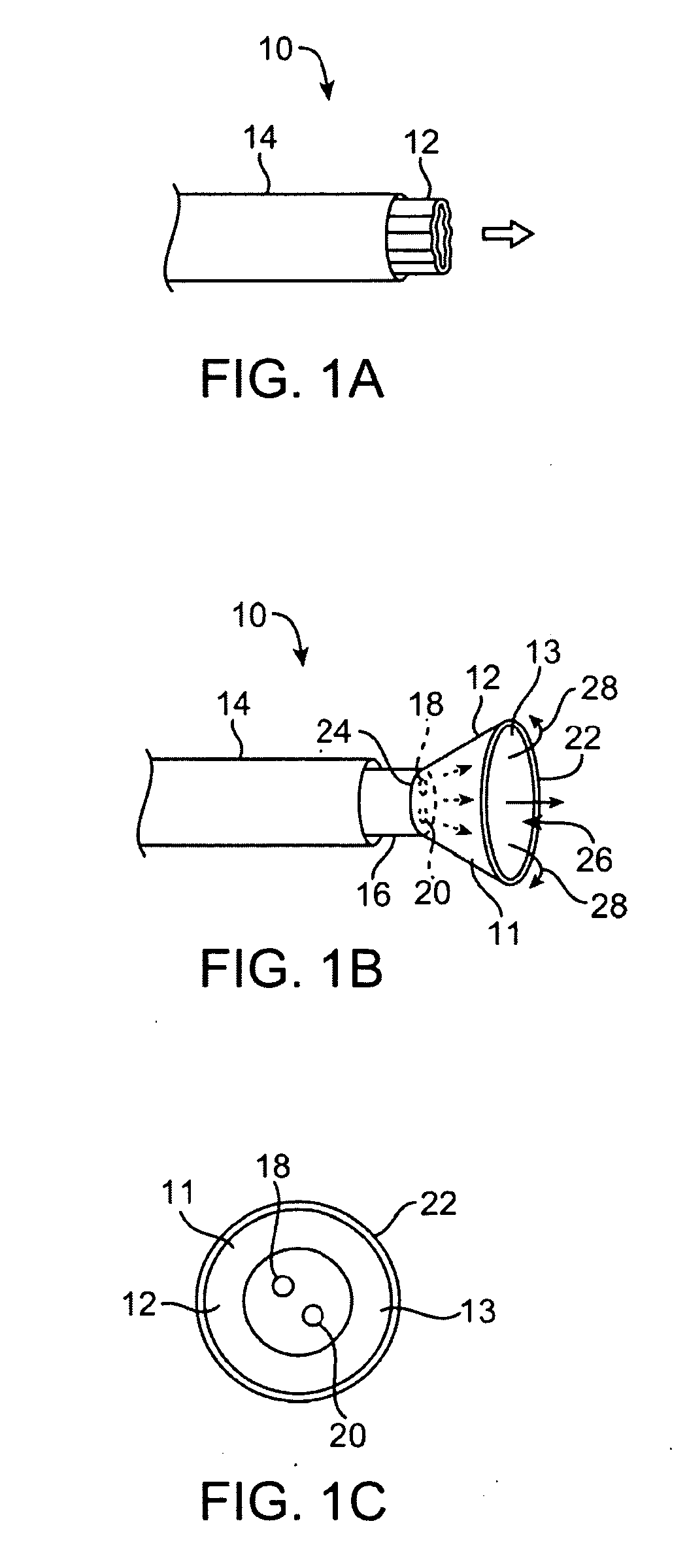

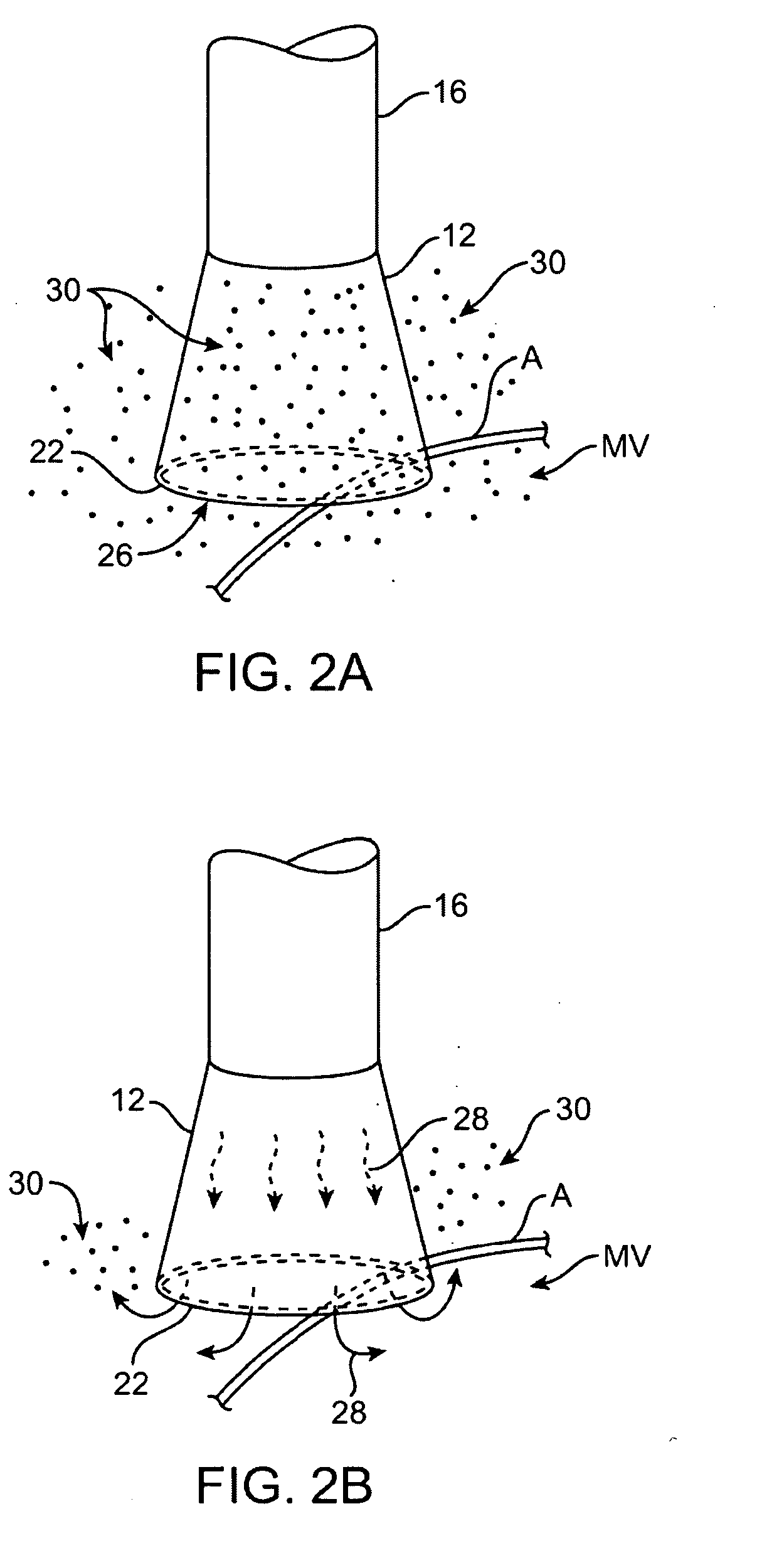

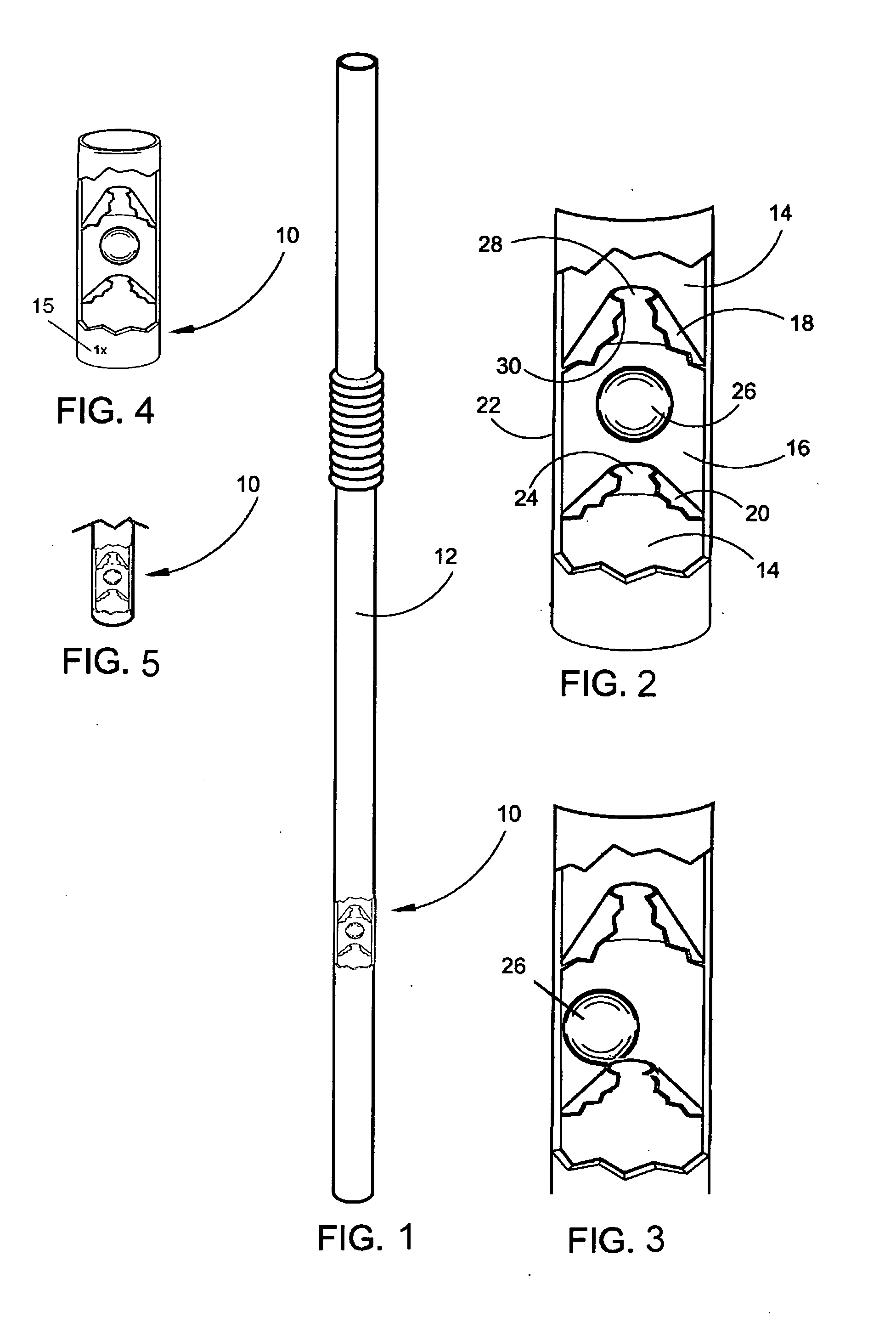

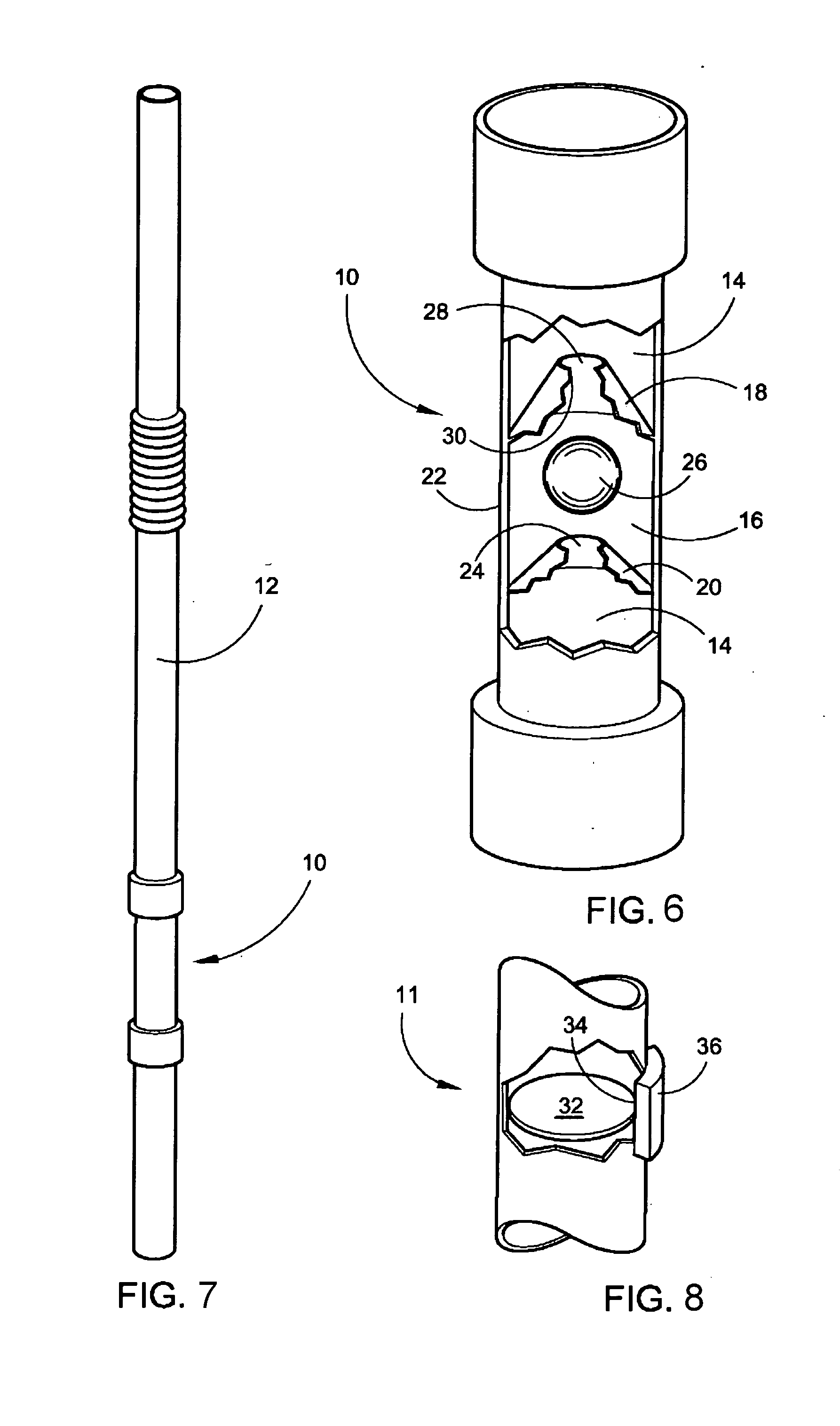

Apparatus and method for regulation of fluid flow from a straw

InactiveUS20080023567A1Faster sealSlow flow of fluidCheck valvesSpray nozzlesDrinking strawEngineering

A regulating component to regulate fluid flow through the axial passage communicating between the intake end, and mouth engageable distal end, of a drinking straw. The component has an upper wall separated from a lower wall by an engaged sidewall all defining a restriction chamber. When engaged in the axial passage of a drinking straw, fluid traversing the straw all traverses through apertures in the lower and upper wall and thereby through the restriction chamber. Force of the moving fluid on a ball in the restriction chamber acts to raise the ball to seal the aperture in the upper wall. If the fluid reaches too high a speed or continues long enough at a lower speed to move the ball upward it seals the restriction chamber from the exit end of the straw.

Owner:BYERLY JENNIFER

Electrodeposited copper foil with carrier foil on which a resin layer for forming insulating layer is formed, copper-clad laminate, printed wiring board, method for manufacturing multilayer copper-clad laminate, and method for manufacturing printed wiring board

InactiveUS7883783B2Improve adhesionSufficiently applicable peel strengthDecorative surface effectsCoatingsEpoxyBond interface

An electrodeposited copper foil with carrier foil on which a resin layer for forming an insulating layer is formed, comprising a carrier foil, a bonding interface layer, an electrodeposited copper foil with smooth surfaces on both sides and a resin layer. The resin layer is composed of 20 to 80 parts by weight of an epoxy resin and a curing agent, 20 to 80 parts by weight of a solvent soluble aromatic polyamide resin polymer and optionally a curing accelerator in a suitable amount.

Owner:MITSUI MINING & SMELTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com