Patents

Literature

56results about How to "Reduce chamber volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

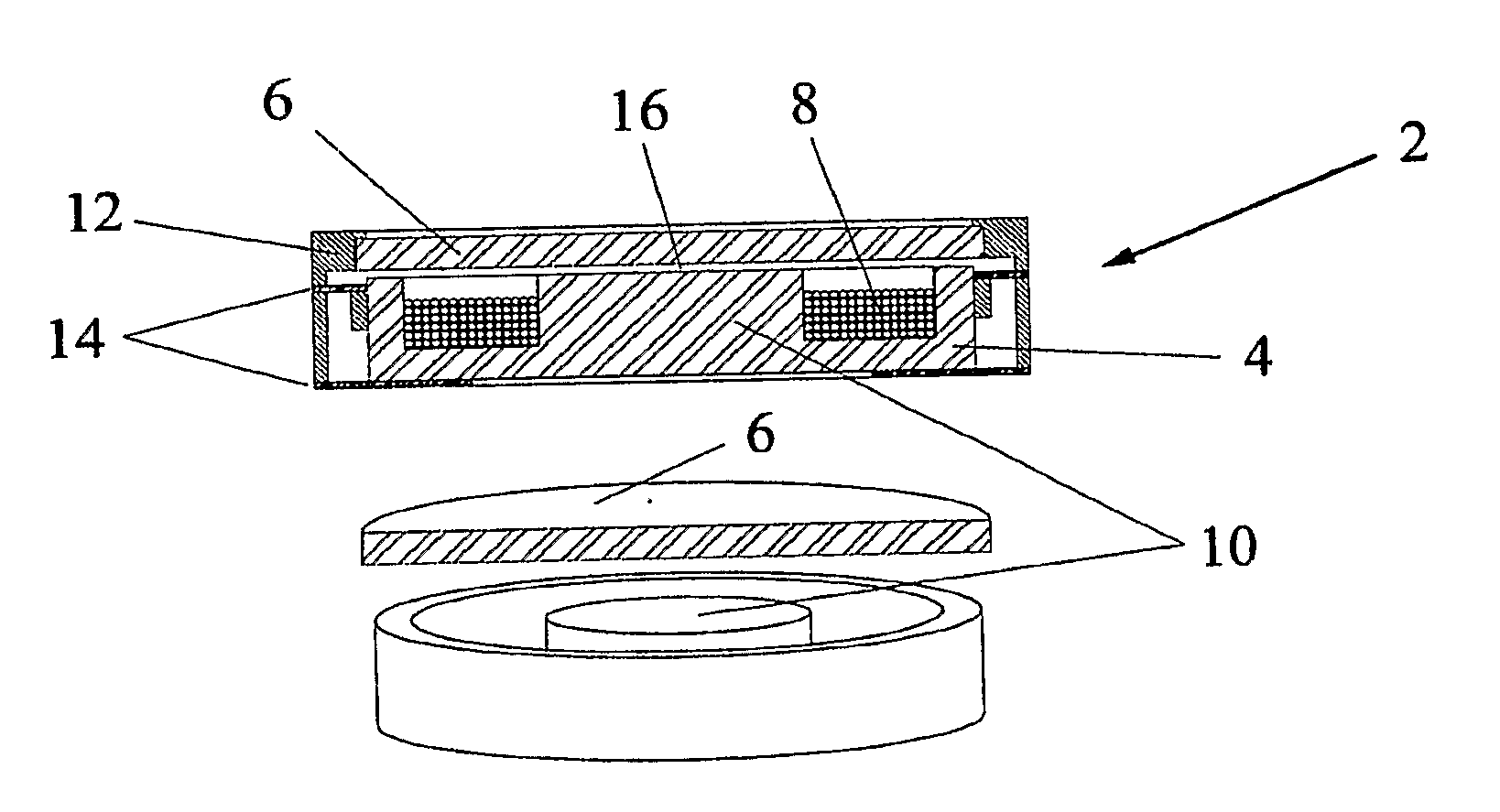

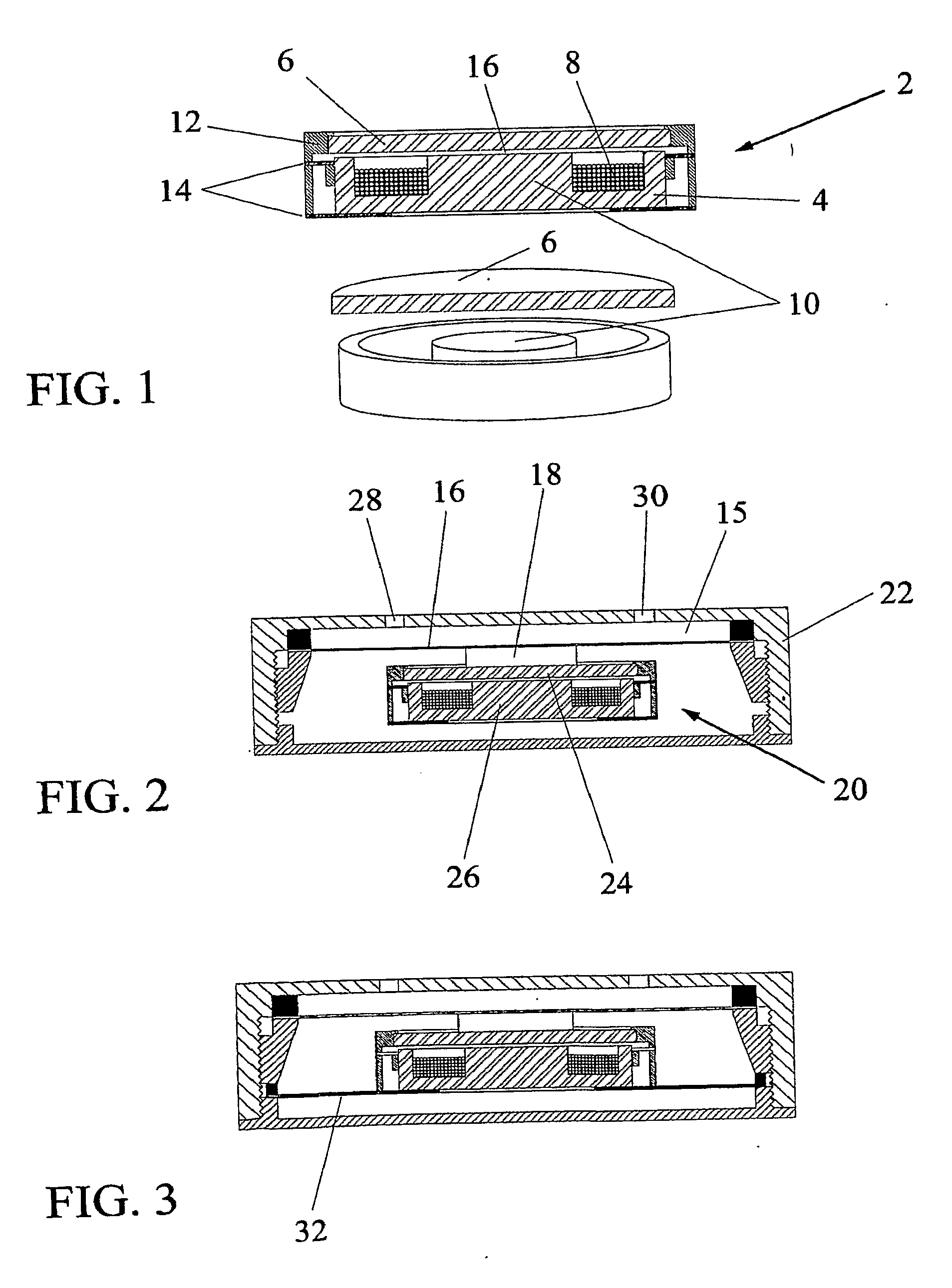

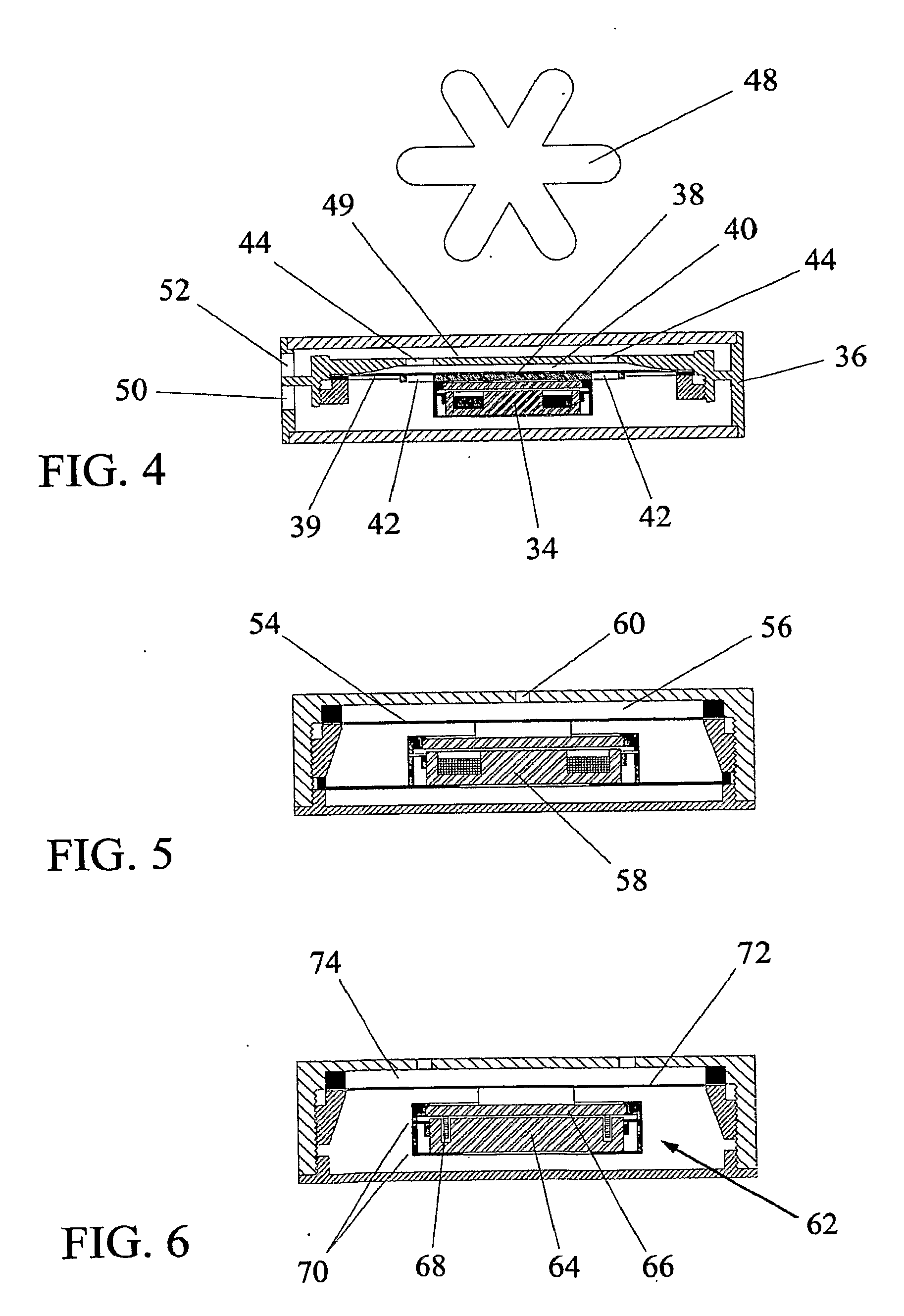

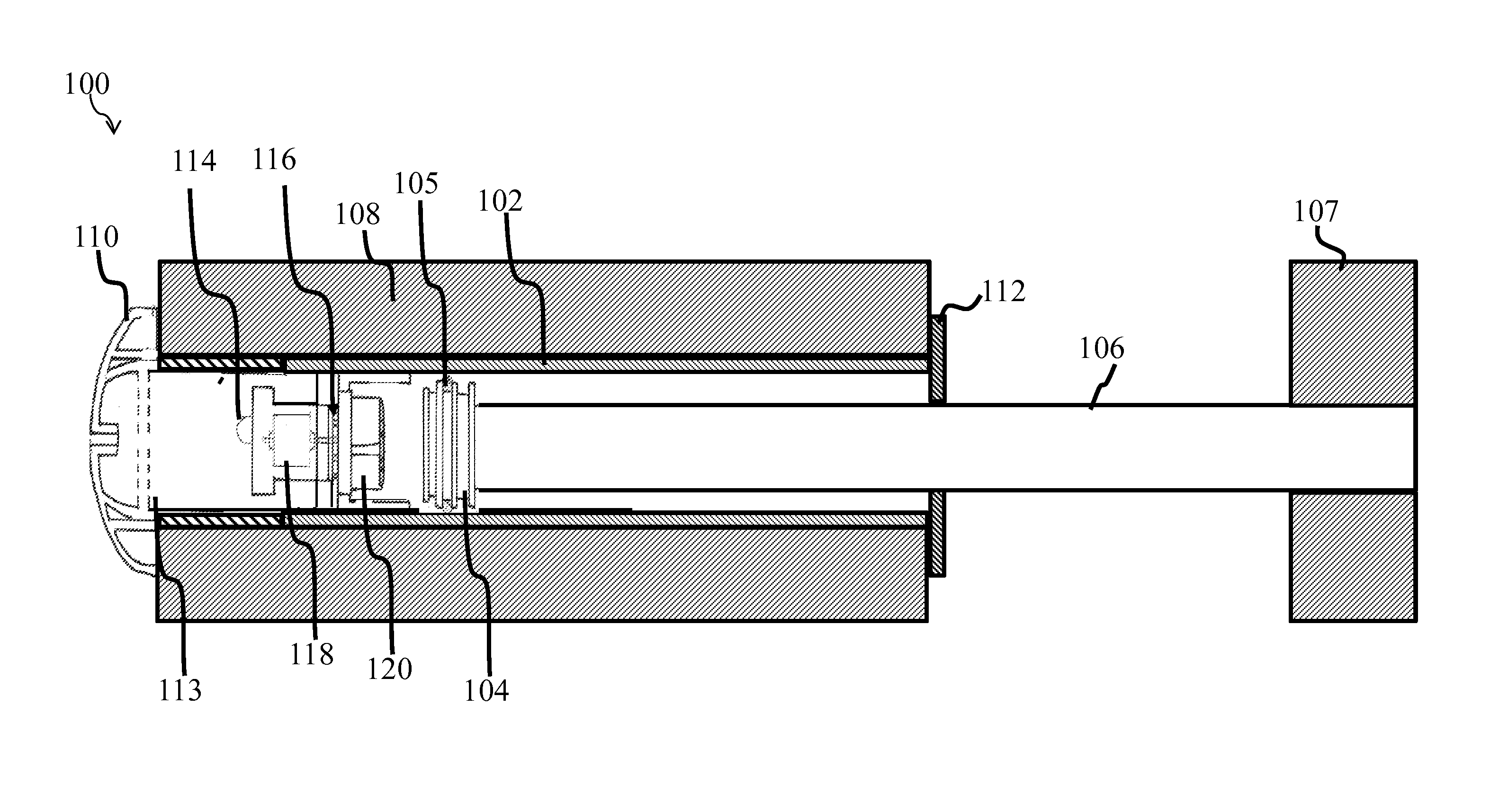

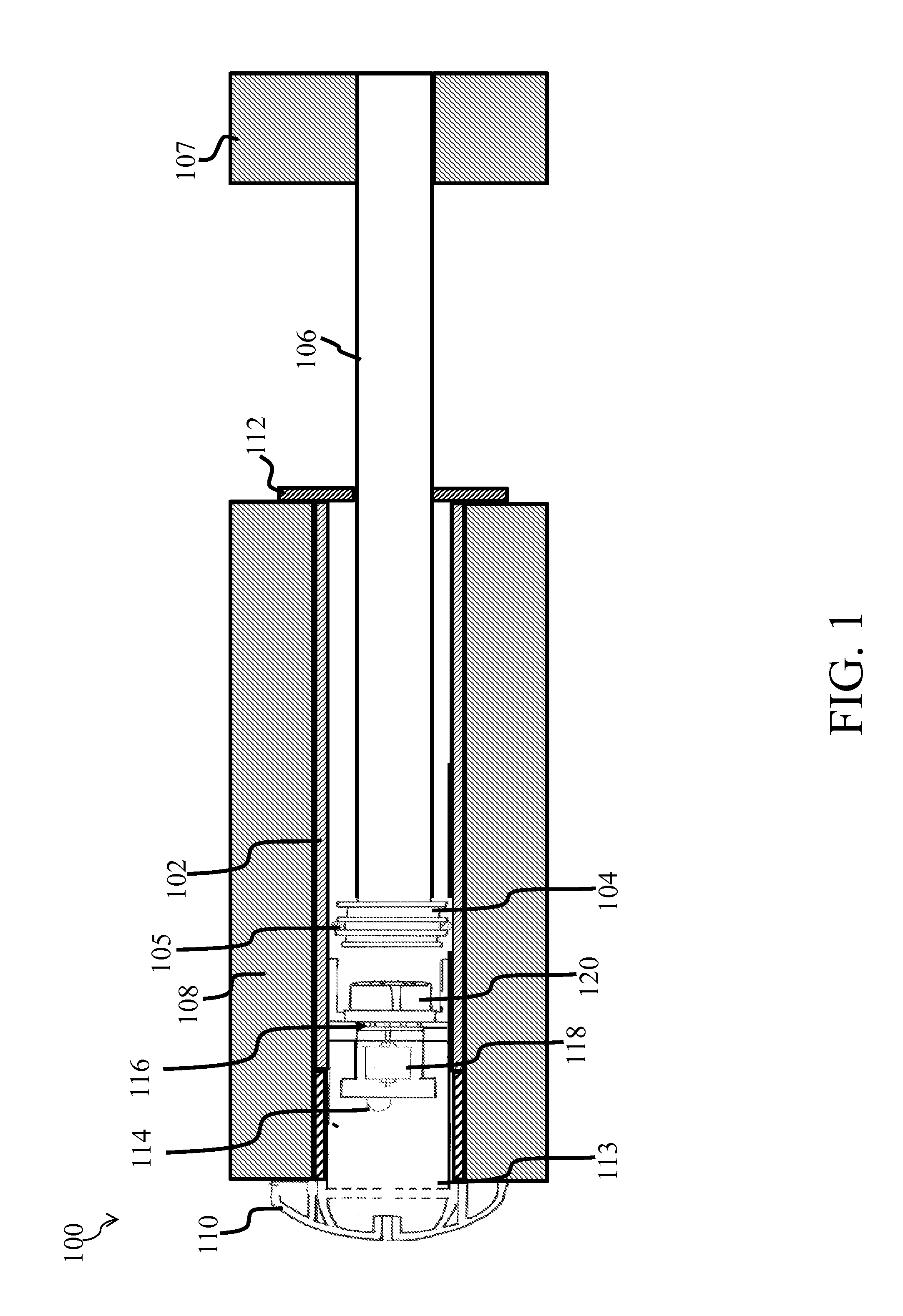

Fluidic Energy Transfer Devices

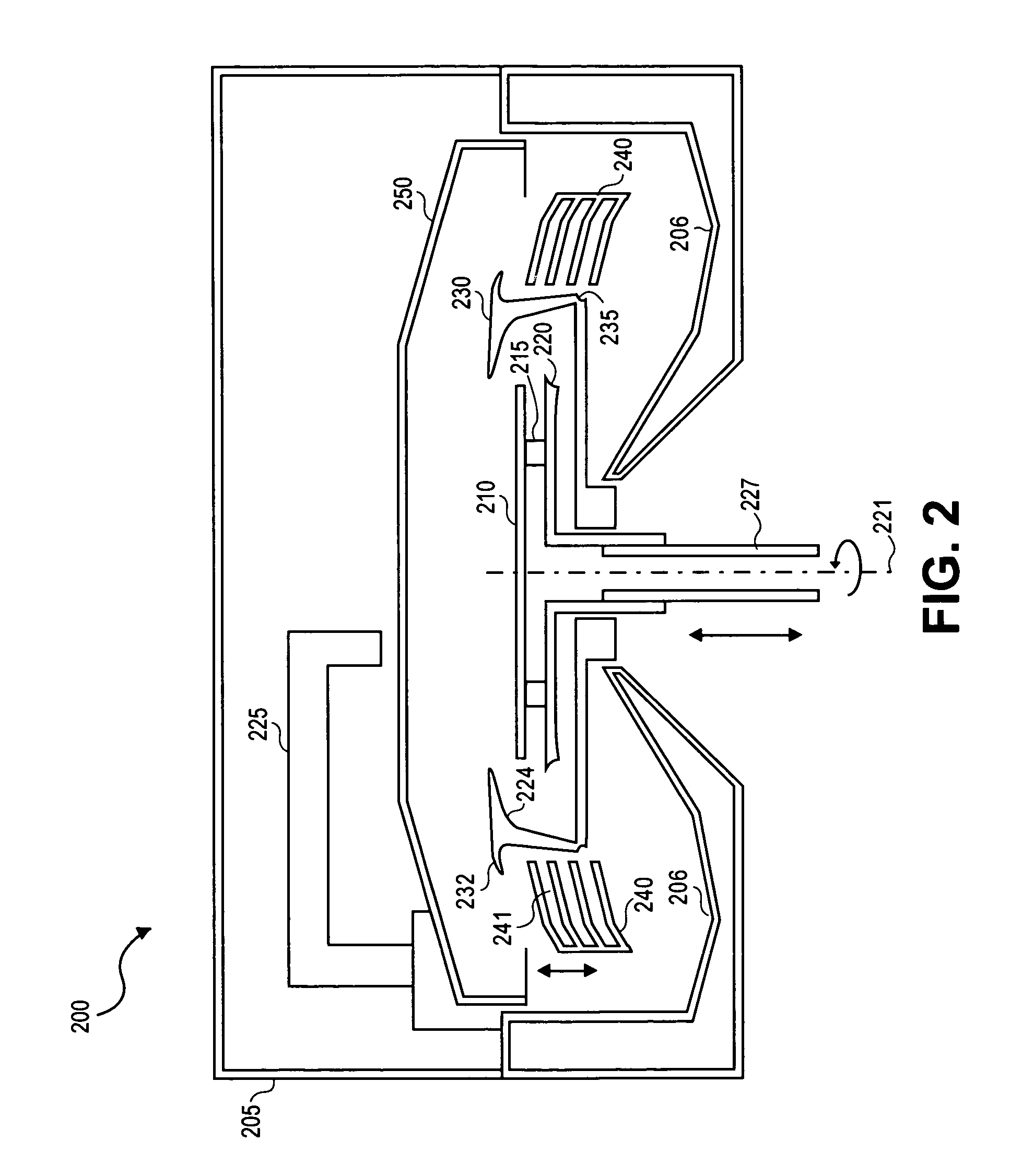

ActiveUS20090148320A1Increase volume of chamberReduce chamber volumeFlexible wall reciprocating enginesOscillating piston pumpsEngineeringActuator

A fluid energy transfer device, including a chamber for receiving a fluid, at least a portion of the chamber comprising a movable portion relative to another portion of the chamber, the movable portion being adapted to change the volume of the chamber from a first volume to a second volume by movement of the movable portion. The device further includes an actuator attached to the movable portion, wherein the displacements of the movable portion can be larger than the displacement of the actuator.

Owner:AAVID THERMALLOY LLV

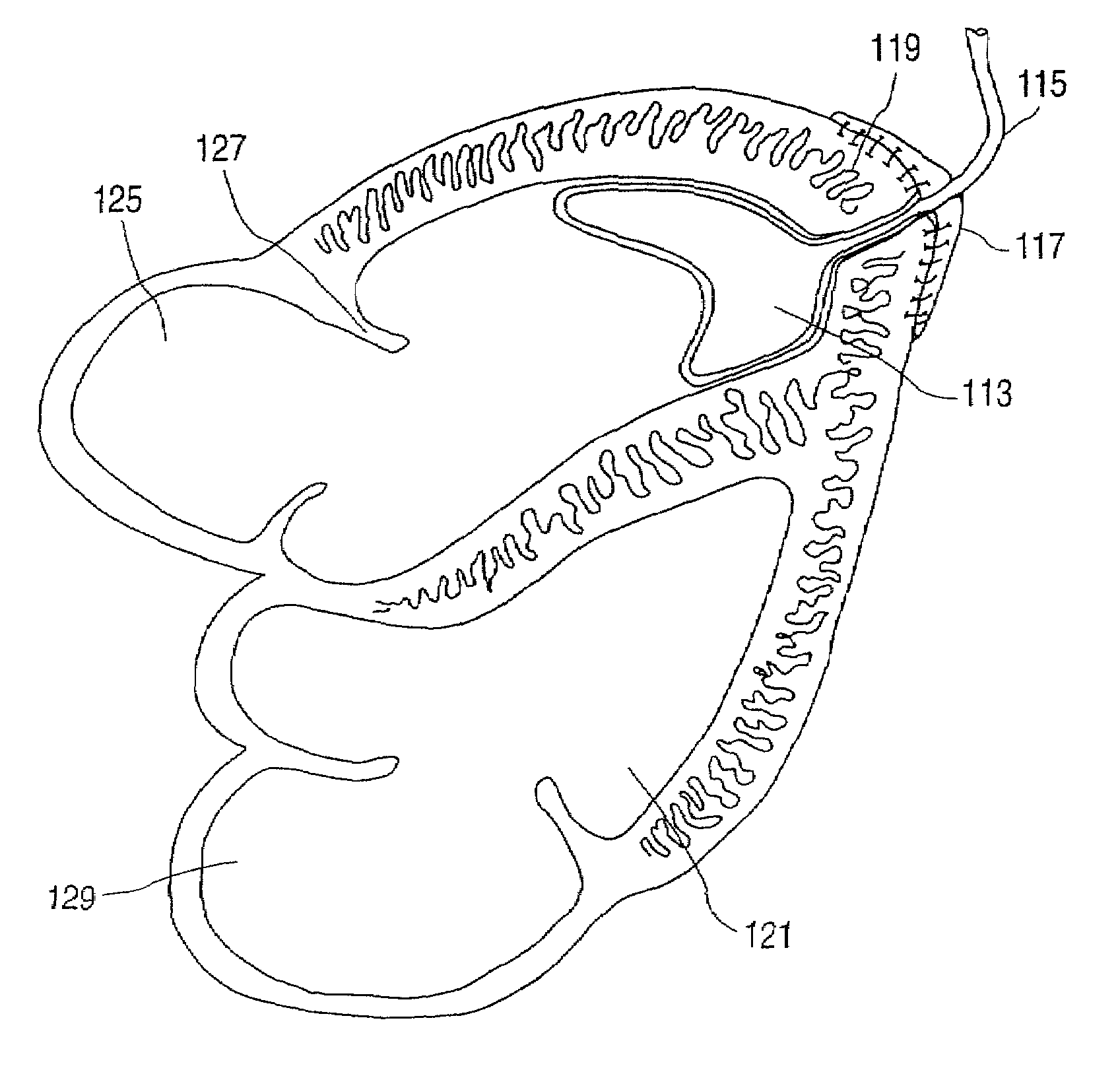

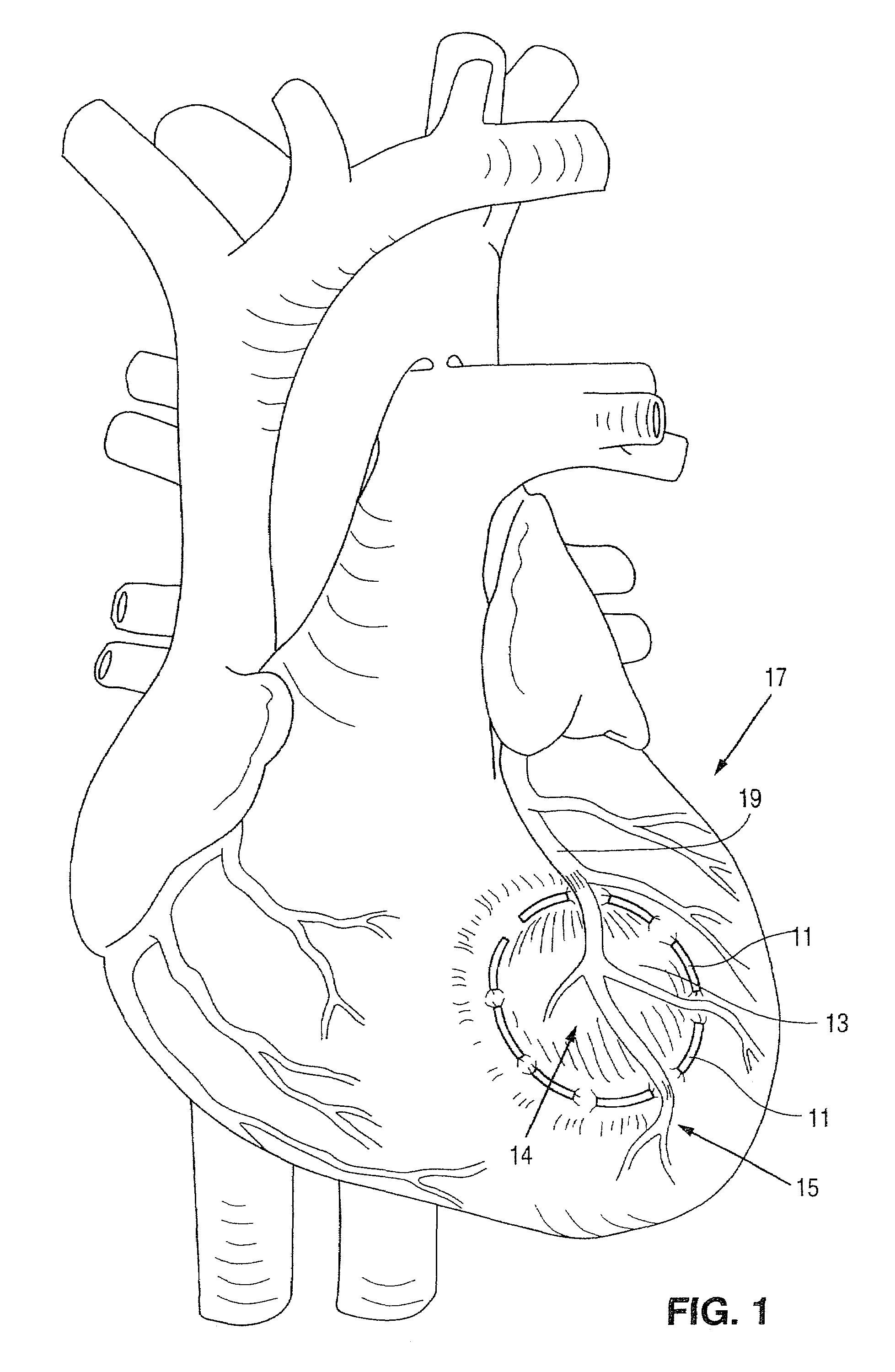

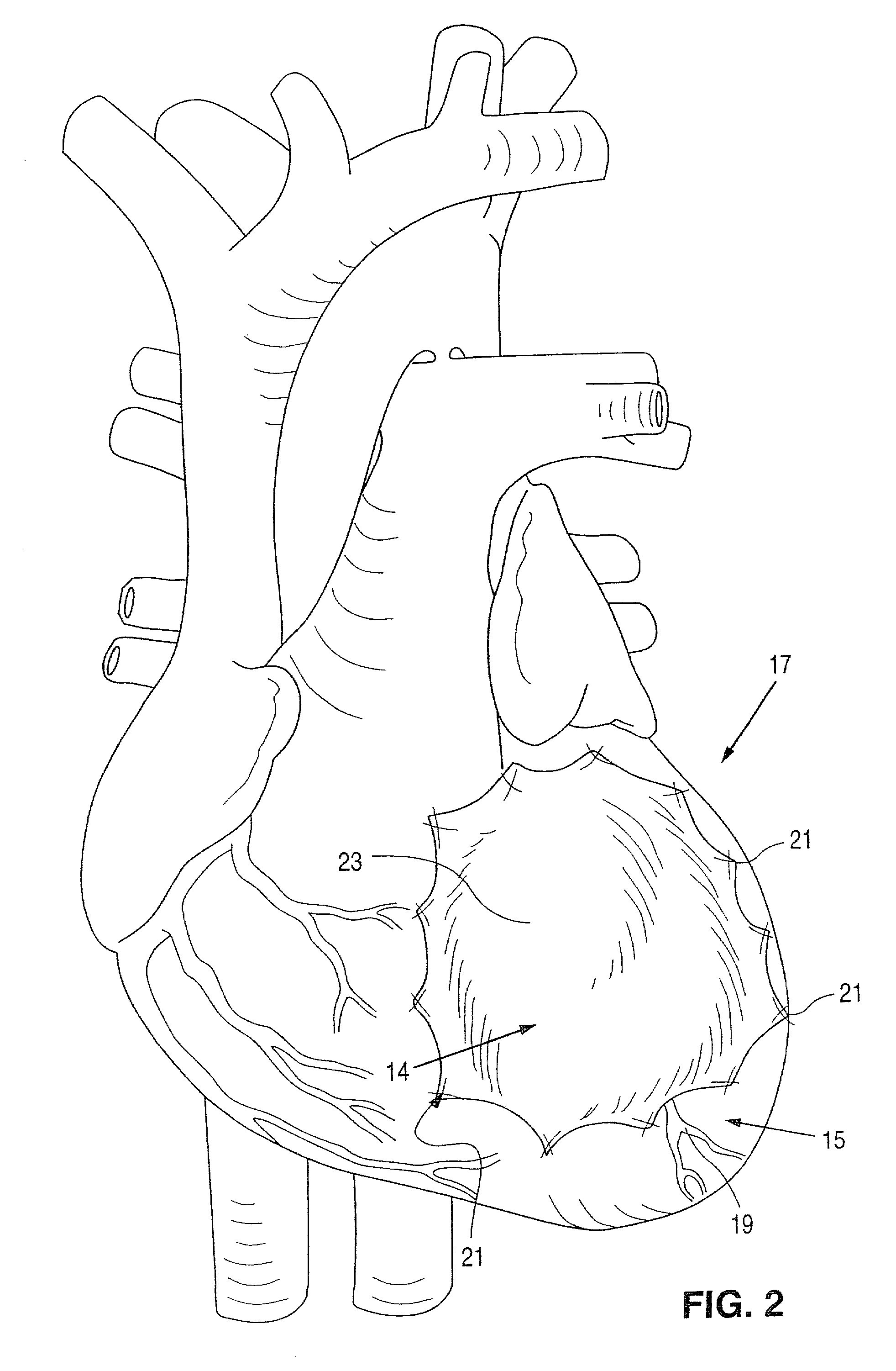

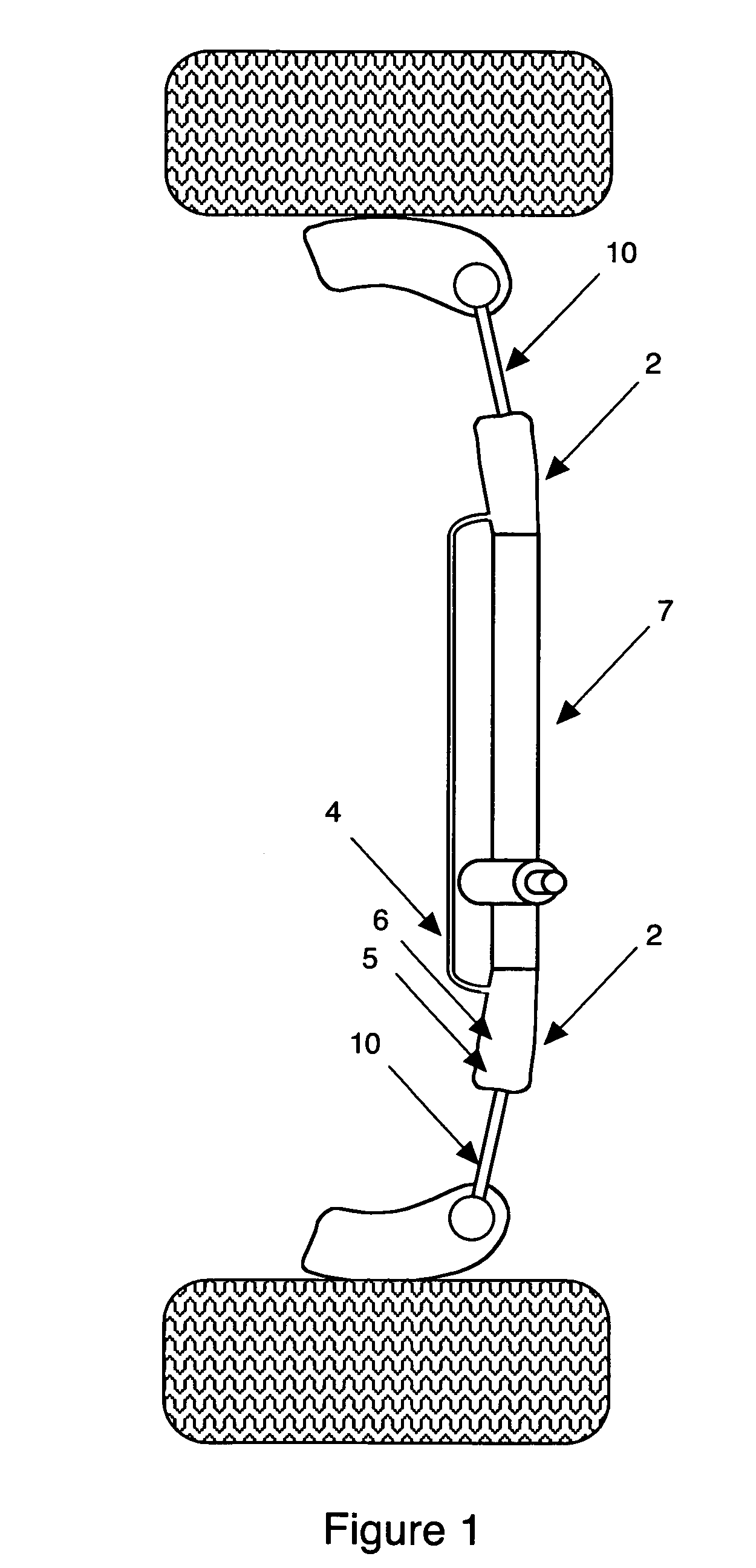

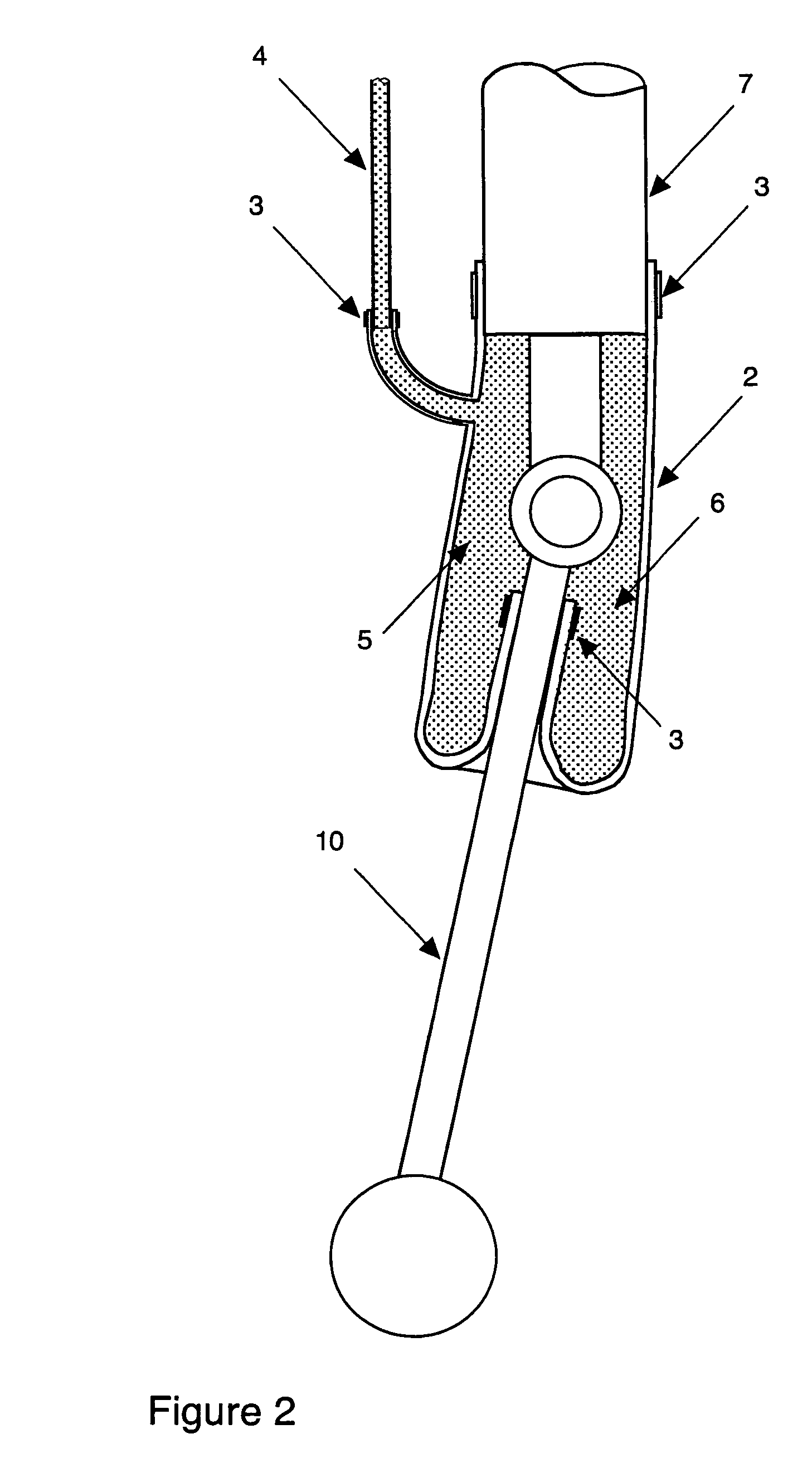

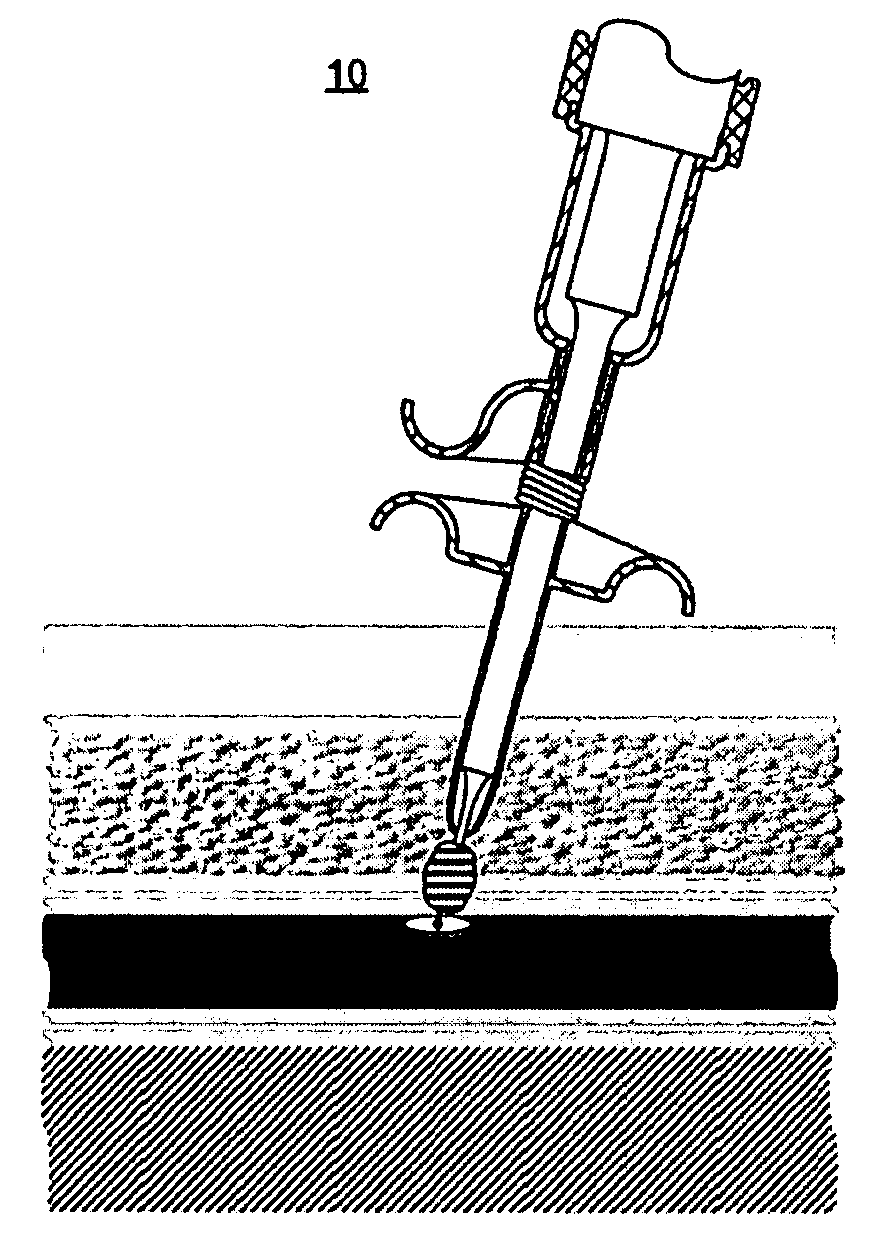

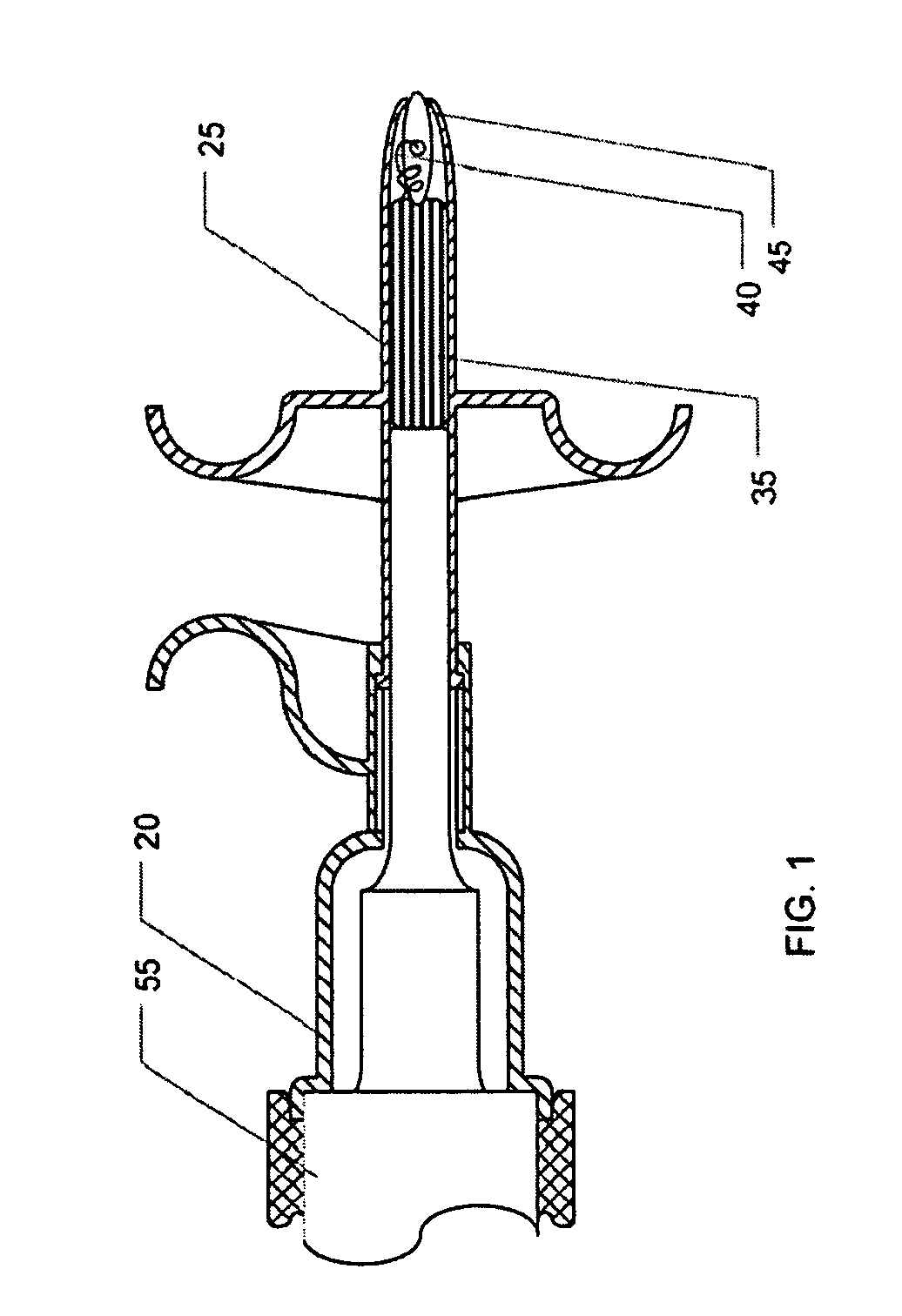

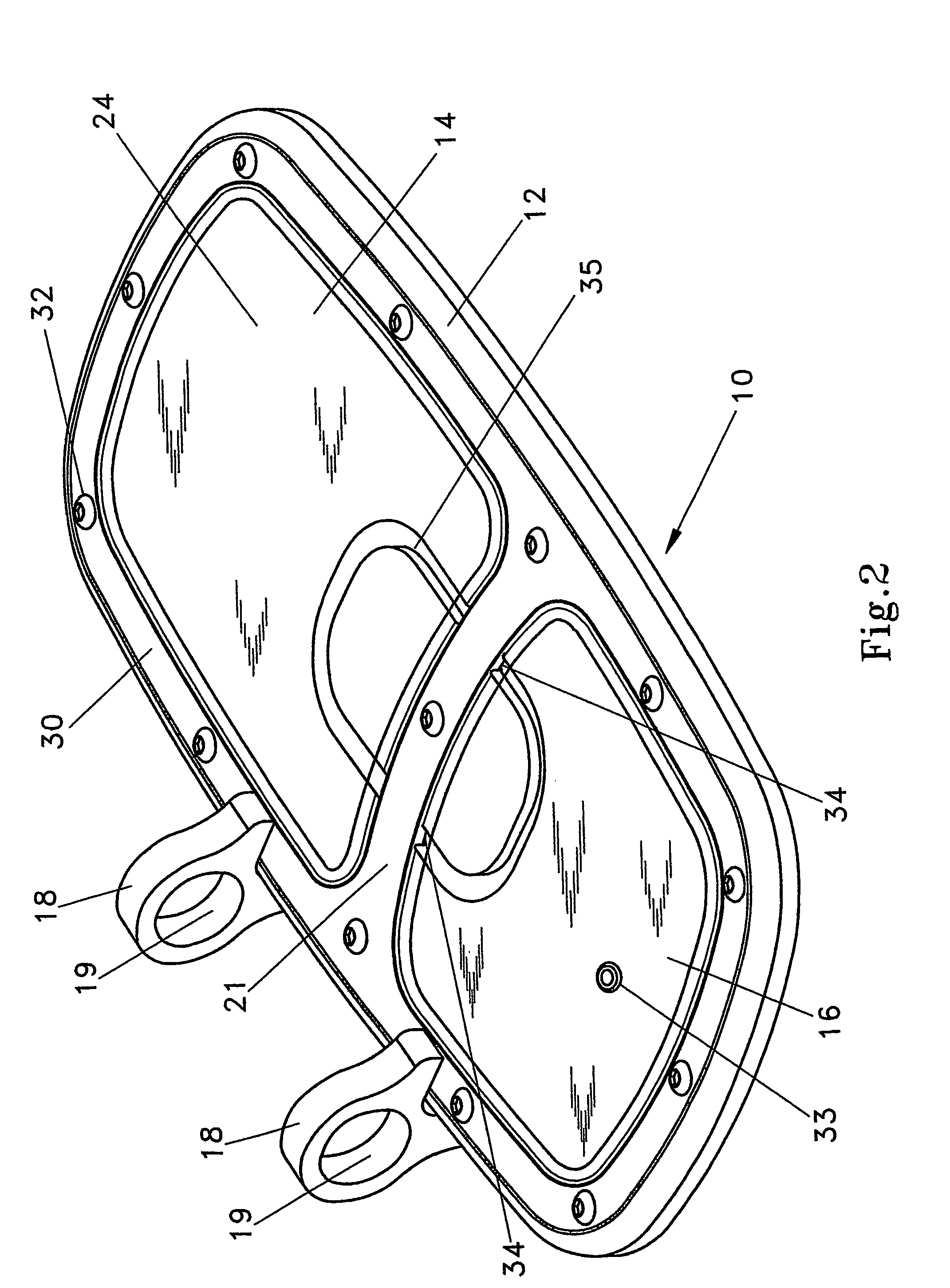

Surgical procedures and devices for increasing cardiac output of the heart

InactiveUS7361137B2Reduce available blood volume of chamberReduce chamber volumeSuture equipmentsDiagnosticsCardiac functioningSurgical department

Methods and devices for passively assisting the cardiac function of the heart are disclosed. A method of increasing the cardiac output of a heart includes providing a site of surgical access to the portion of the heart to be restrained, reducing the cardiac expansion of the portion of the heart to be restrained, and maintaining the reduction of cardiac expansion of the portion of the heart to be restrained for a substantial amount of time. Cardiac assist devices for increasing the cardiac output of the heart are disclosed comprising a reinforcing portion configured to contact a portion of the heart tissue wherein the reinforcing portion restricts the expansion of the portion of the heart tissue. The reinforcing portion can be a number of structures, including pads, frames, straps, and other retaining means for limiting cardiac expansion of the portion of the heart tissue to be restrained.

Owner:MAQUET CARDIOVASCULAR LLC

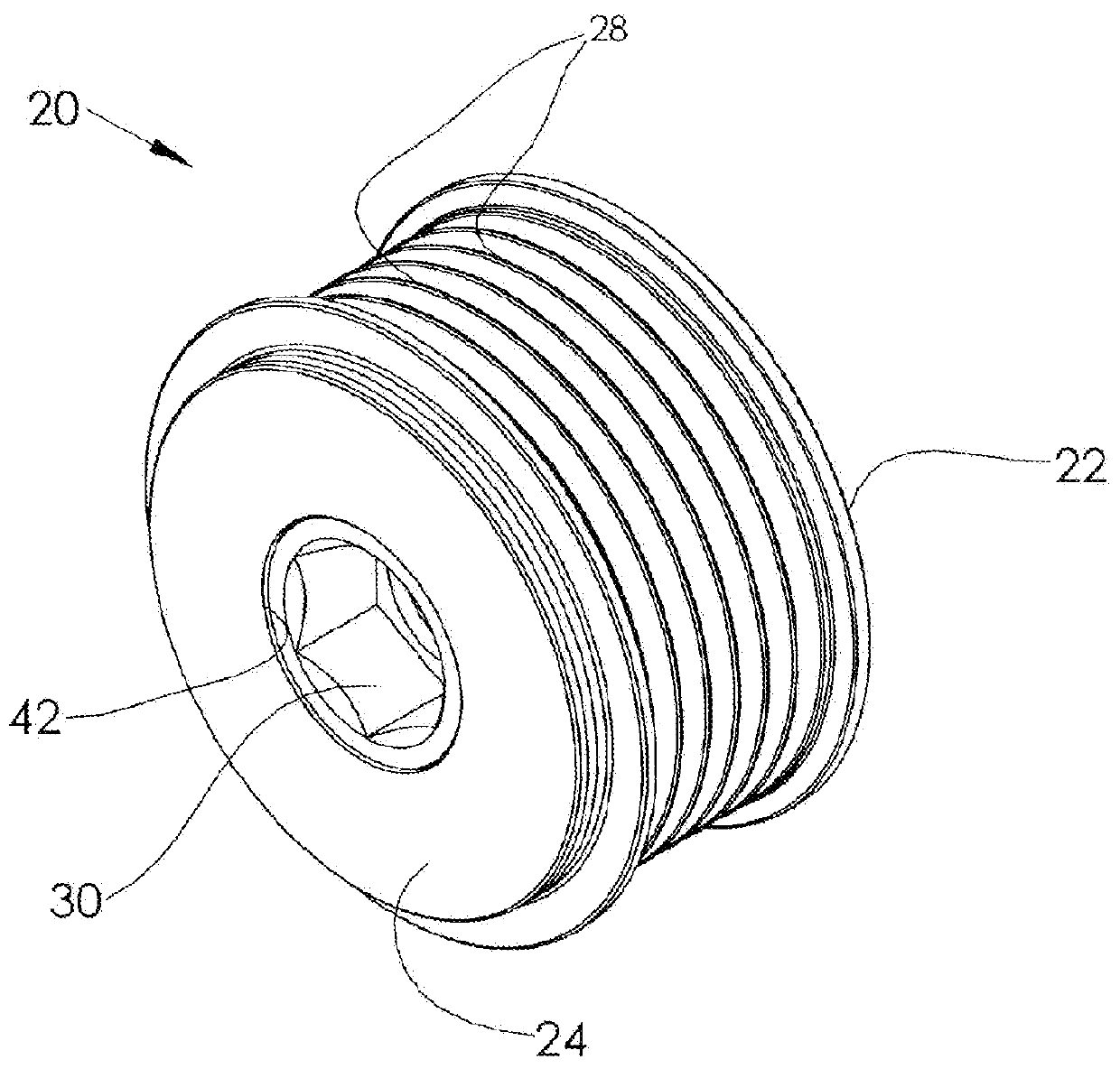

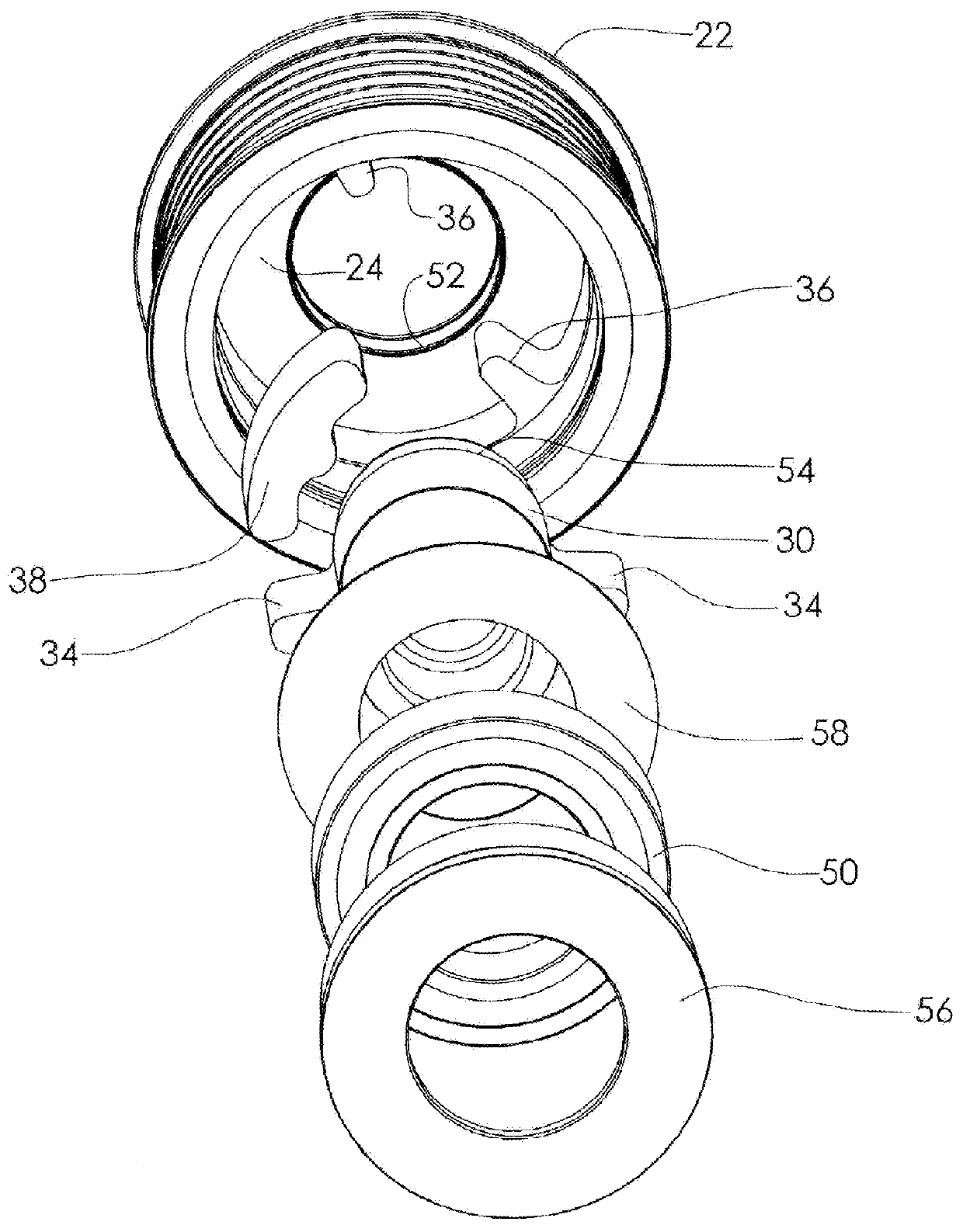

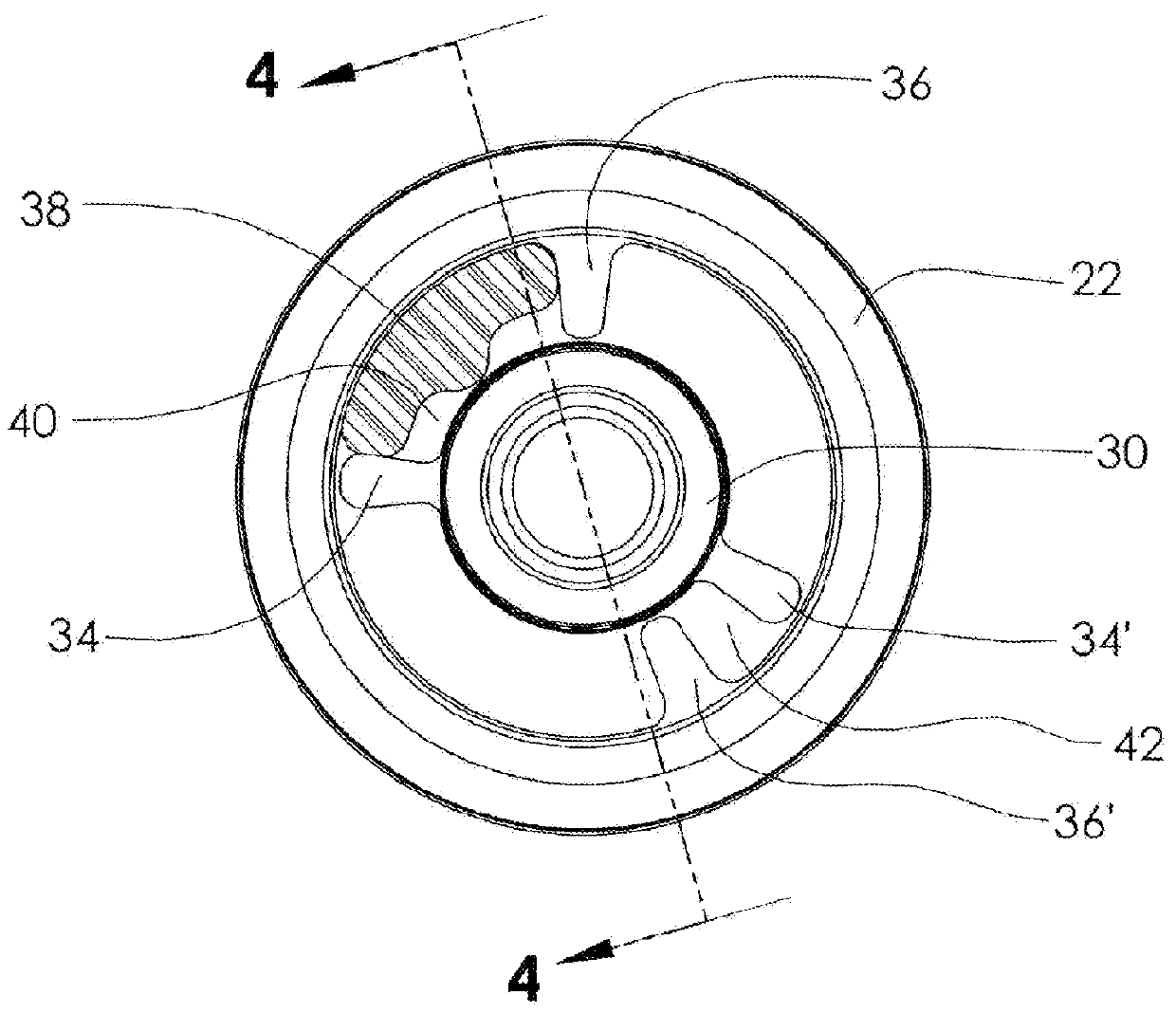

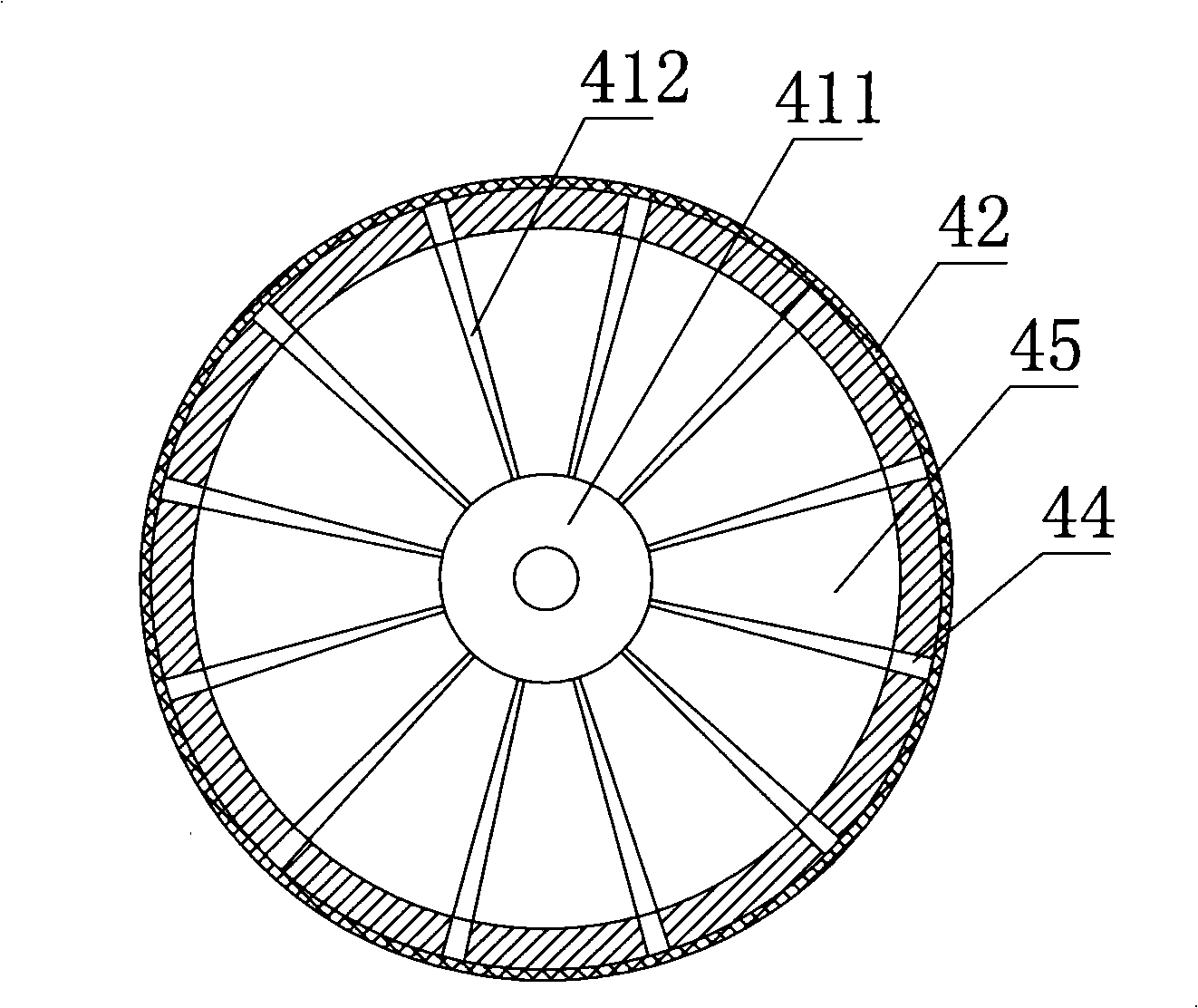

Elastomeric spring pulley assembly for rotary devices

InactiveUS20120172163A1Smoothly counteracts changeGreat control of relative rotationYielding couplingPortable liftingAlternatorEngineering

A pulley assembly for a rotary device such as an automotive alternator comprising a pulley, a hub, and one or more elastomeric springs to cushion and attenuate the effect of sudden rotational velocity variations of the pulley and the hub. Premature spring failure is prevented by a mechanical stop arrangement that limits the amount of relative rotation between the pulley and hub to prevent over-compression of the springs.

Owner:C T DRIVES

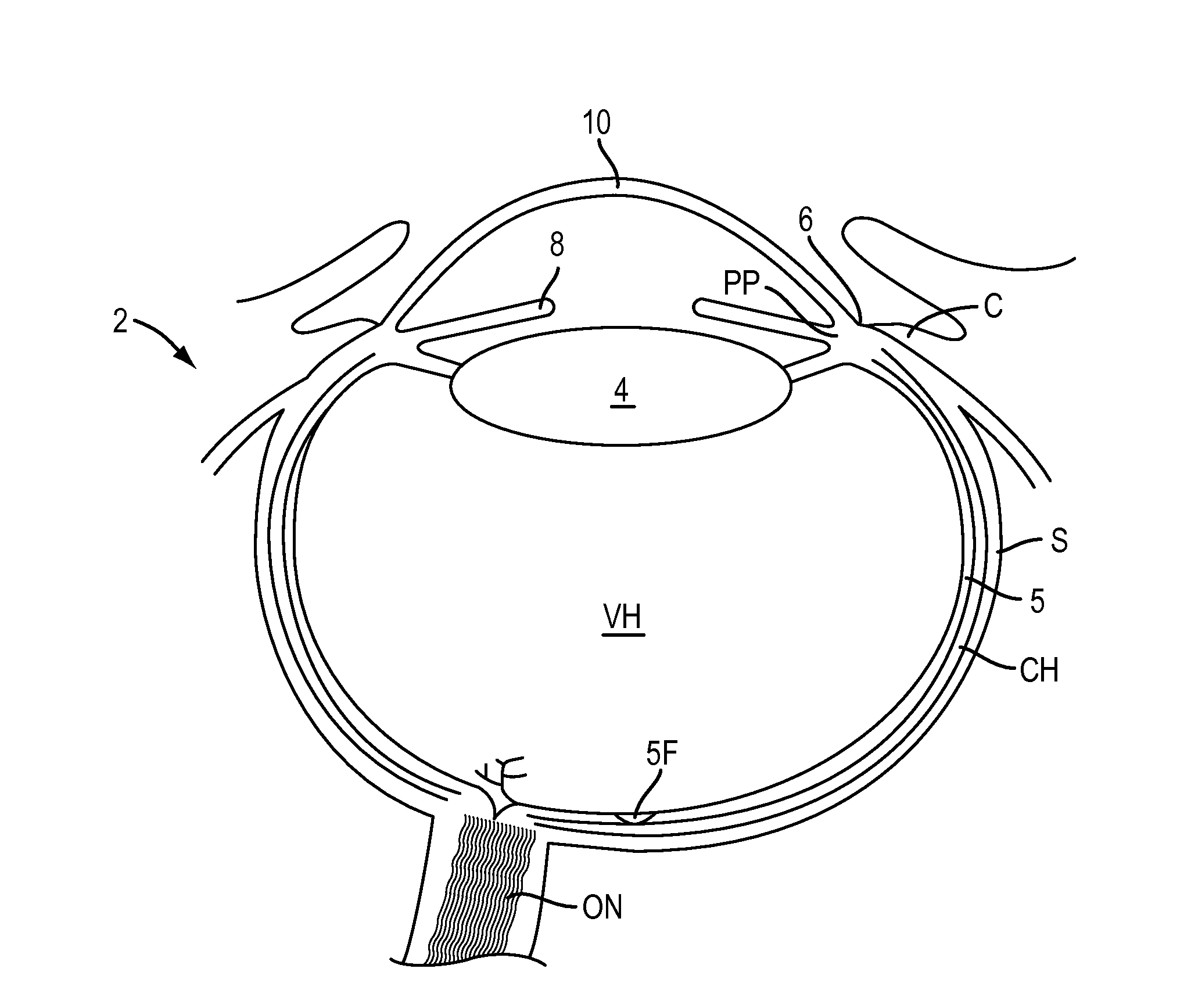

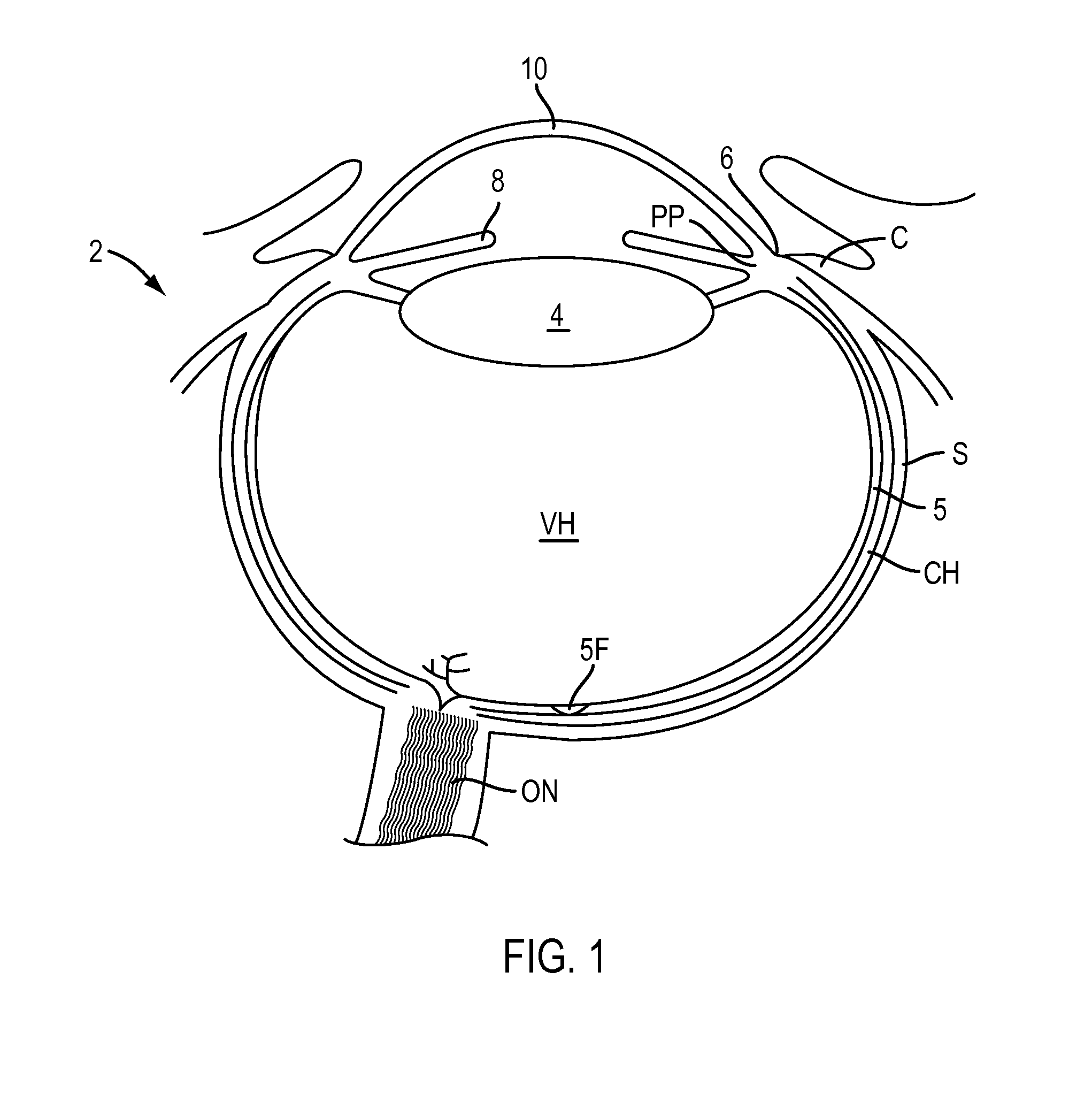

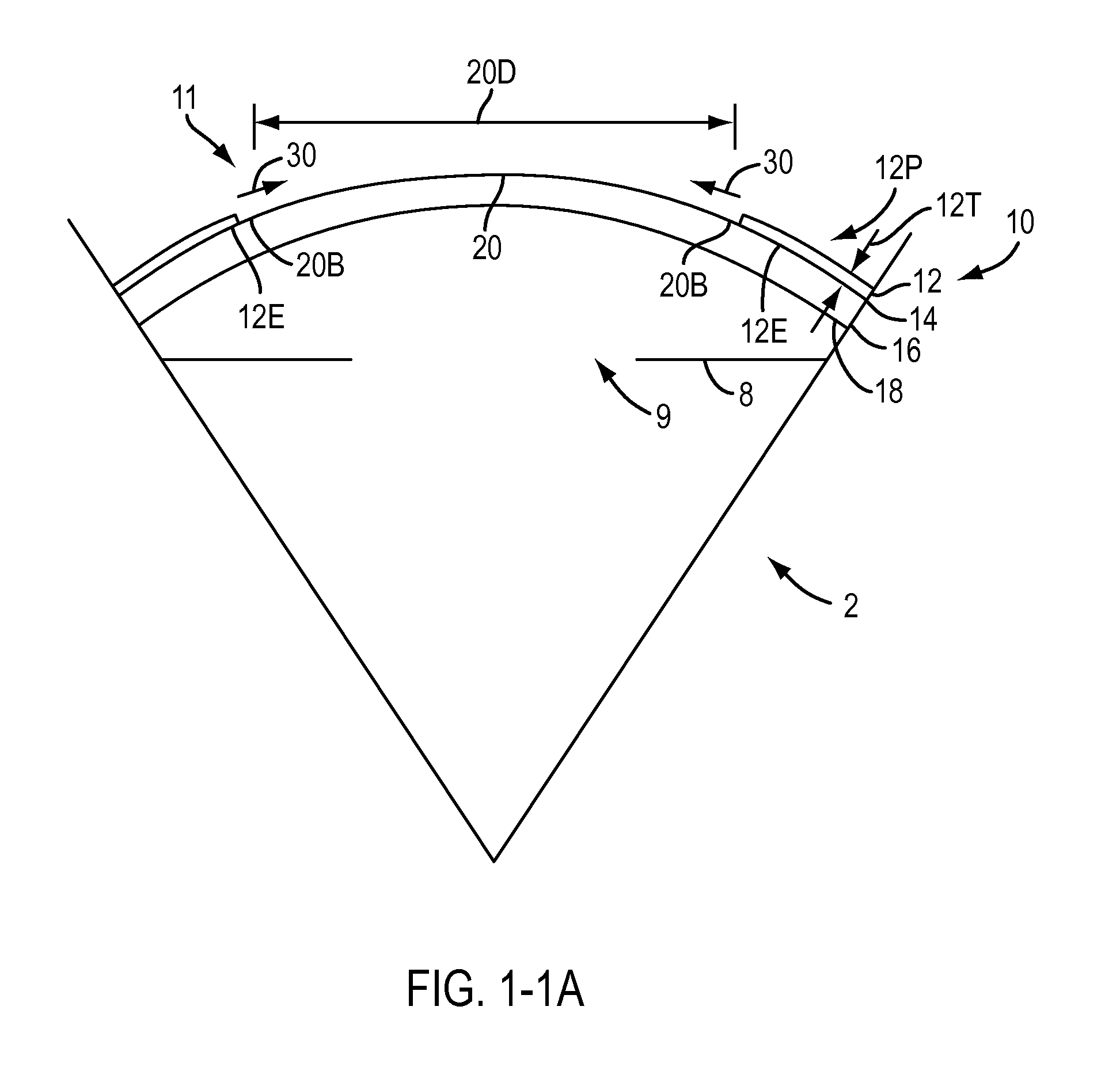

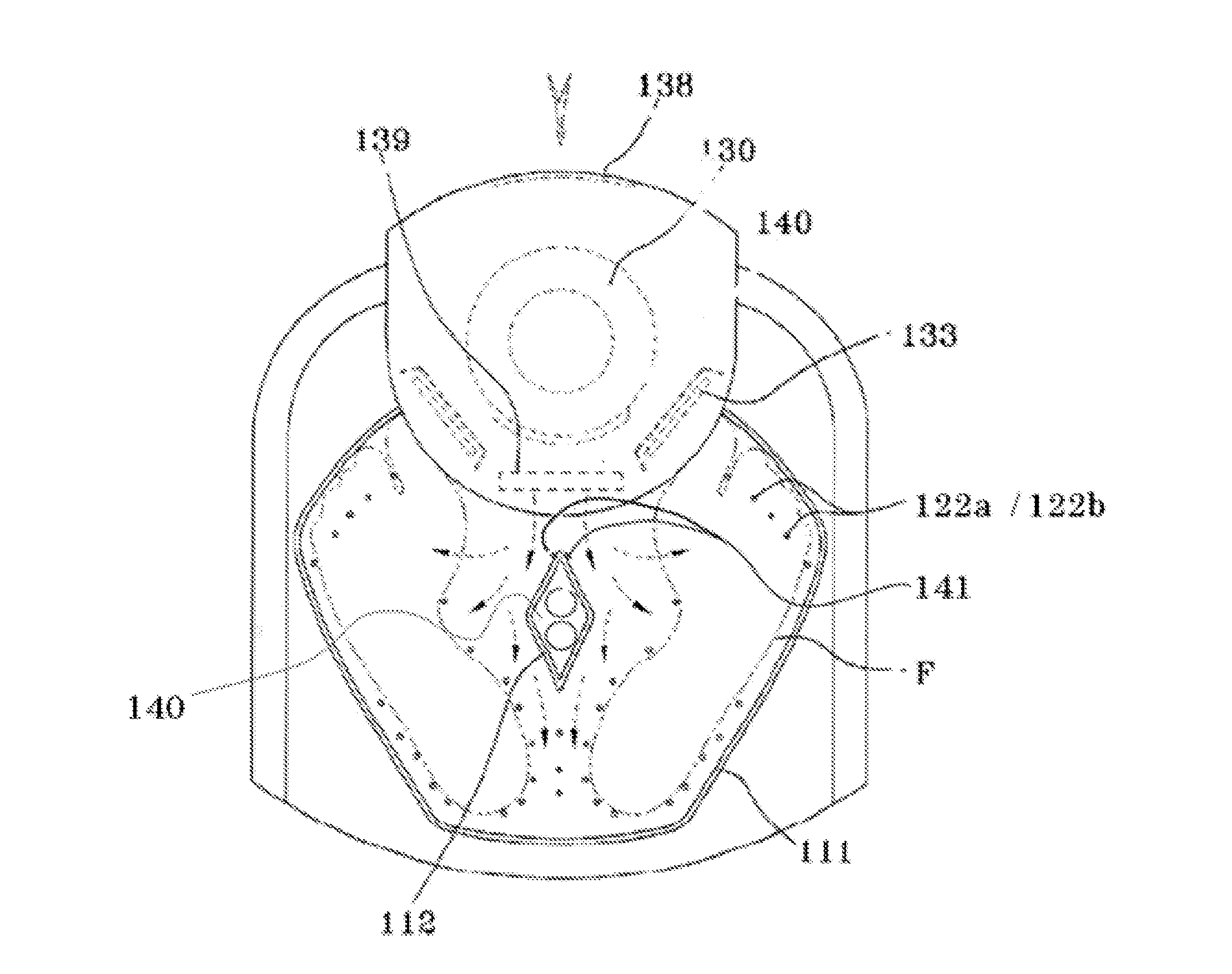

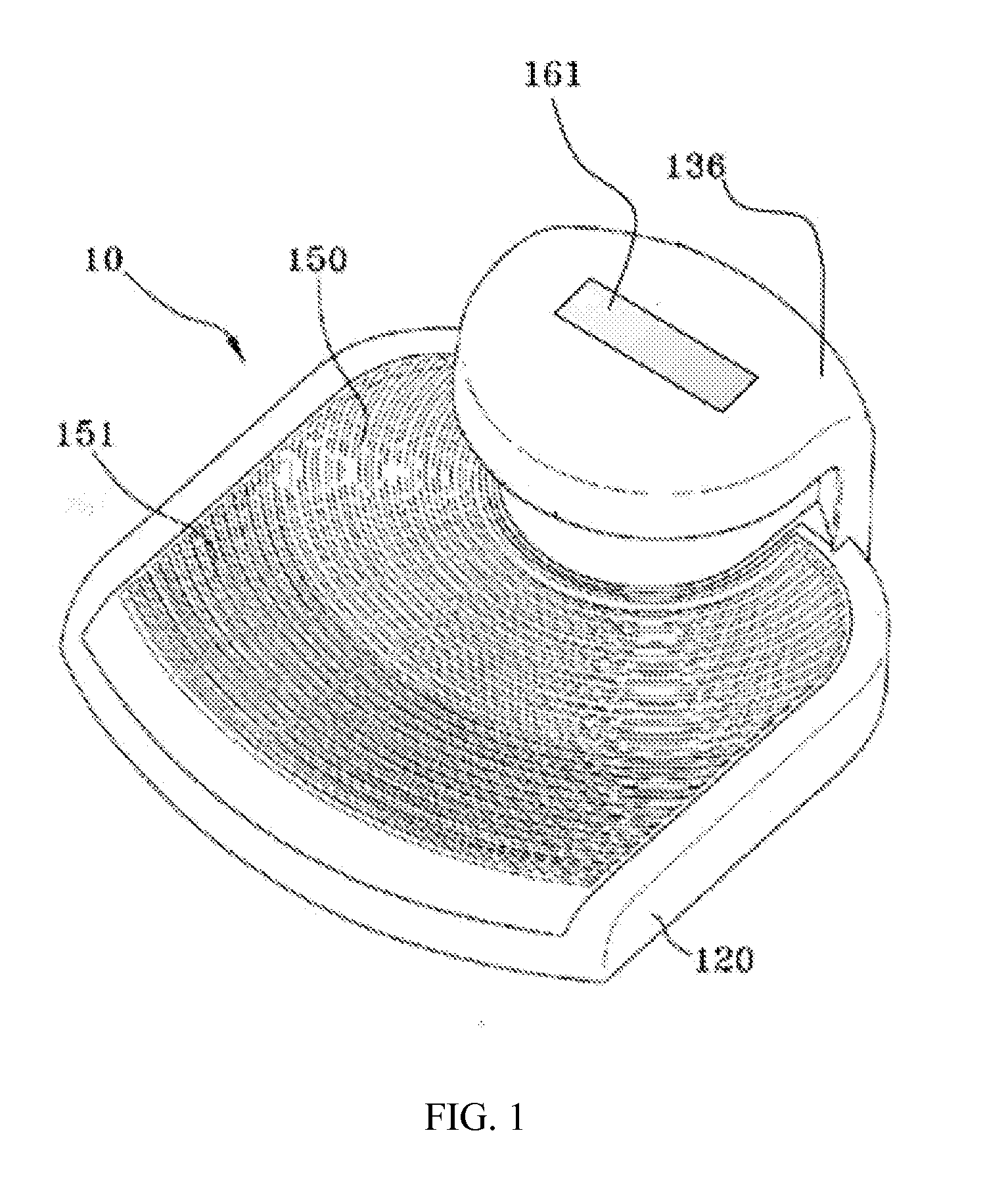

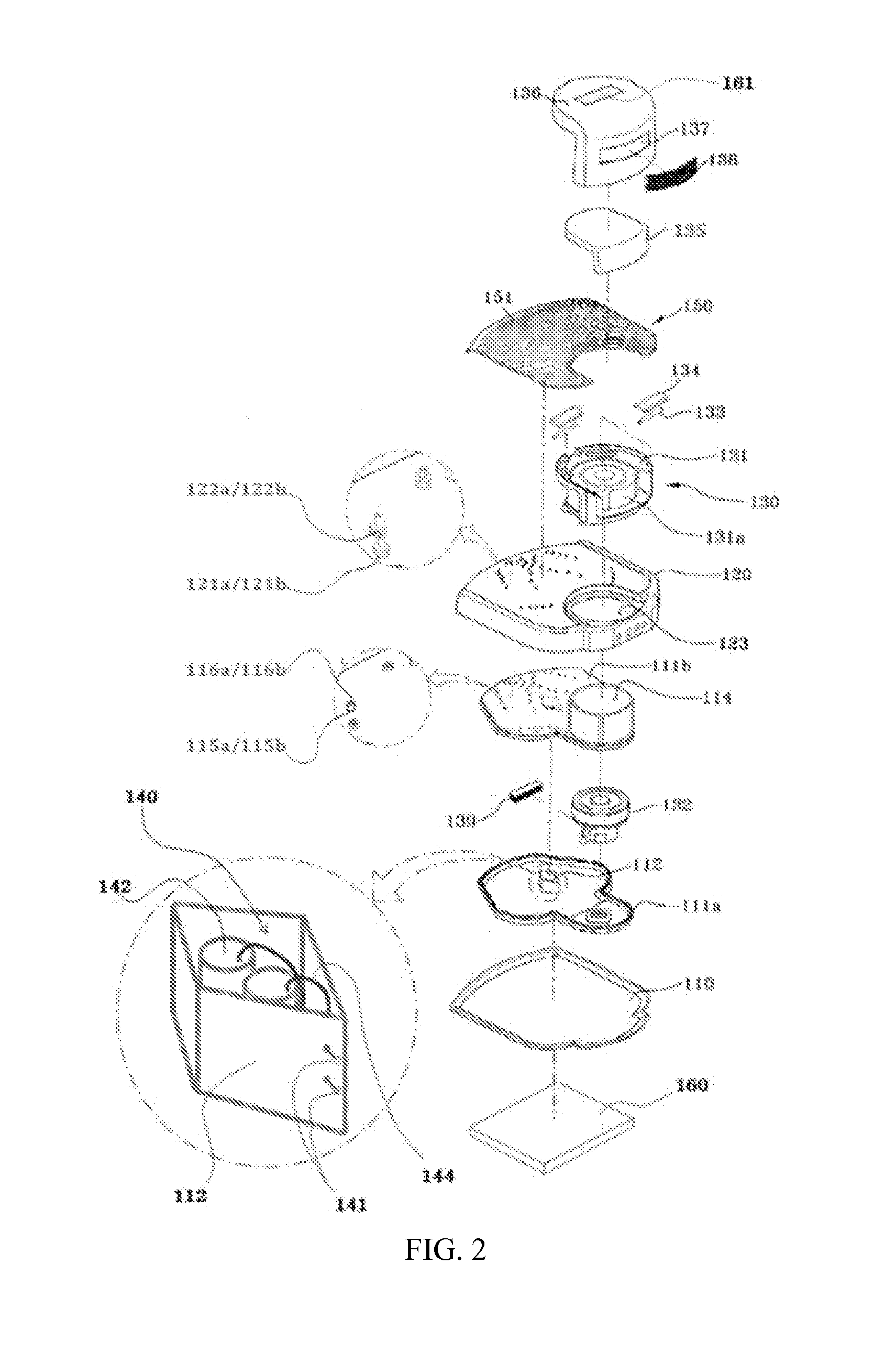

Eye Covering and Refractive Correction Methods and Apparatus Having Improved Tear Flow, Comfort, and/or Applicability

ActiveUS20130077044A1Reduce pressureHigh oxygen permeabilityOptical articlesEye treatmentConjunctivaEyelid

An eye covering such as a contact lens may comprise one or more structures to pump tear liquid under the covering such that the covering can remain in the eye and correct vision for an extended amount of time. In many embodiments, the covering comprises a material having fenestrations to draw tear liquid under the covering and an outer portion shaped to contact the conjunctiva over the sclera, such that when the eye closes pressure of one or more eyelids urges tear liquid through one or more fenestrations and under the outer portion shaped to contact the conjunctiva. When the eye blinks, the pressure of the one or more eyelids can urge the covering toward the cornea such that tear liquid can pass through the fenestrations.

Owner:JOURNEY1 INC

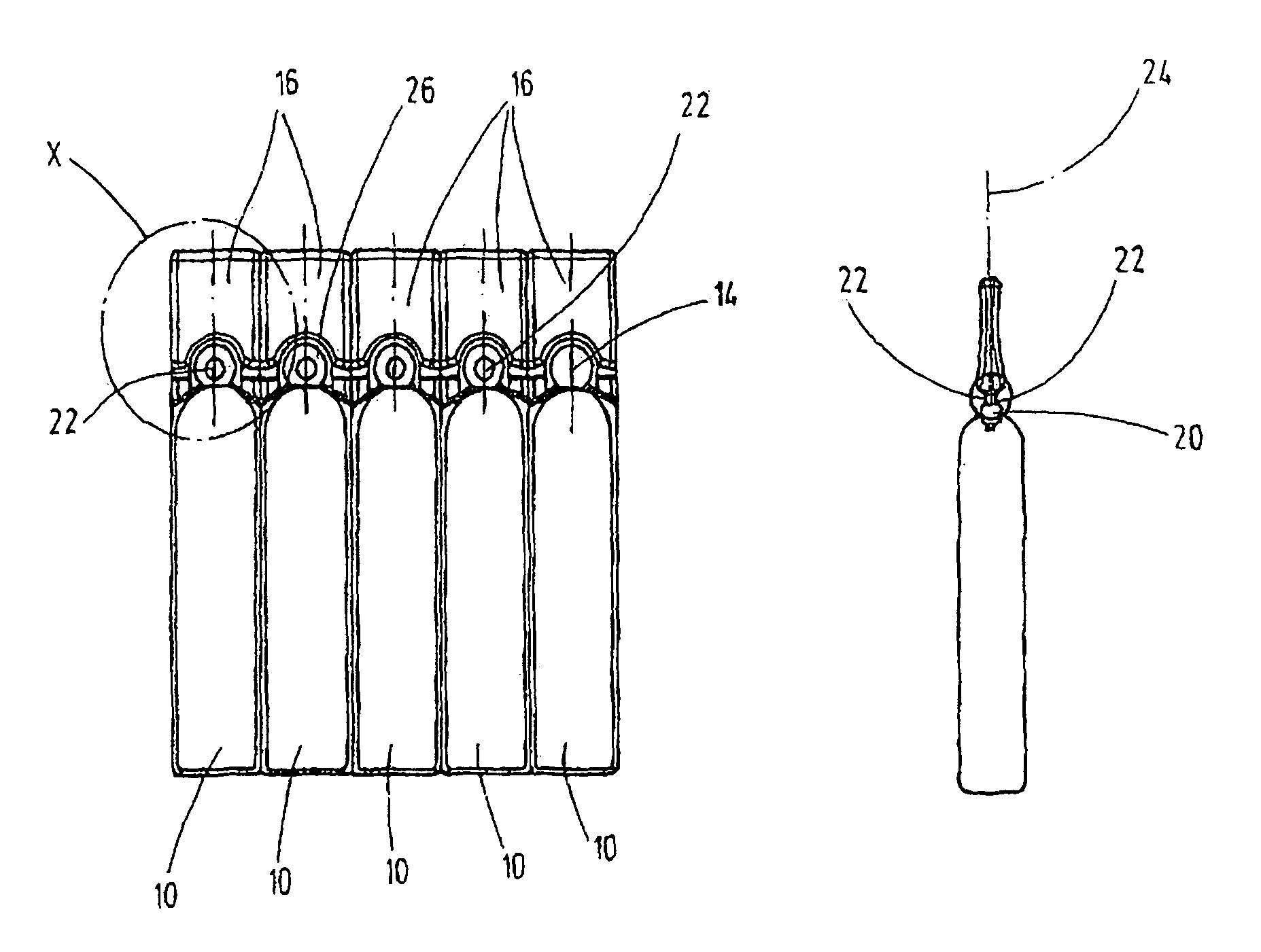

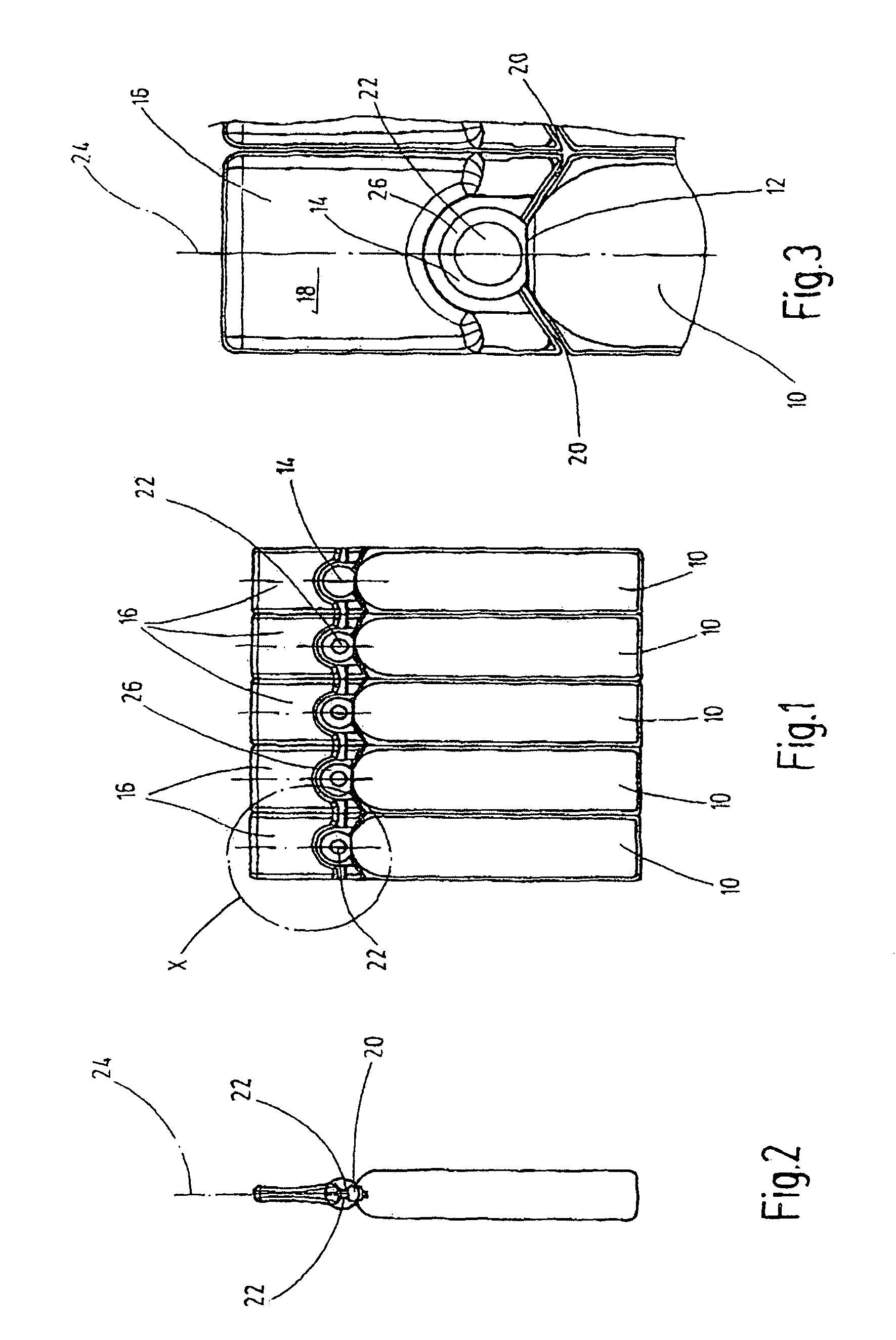

Container and device for production of such container

Owner:HANSEN BERND

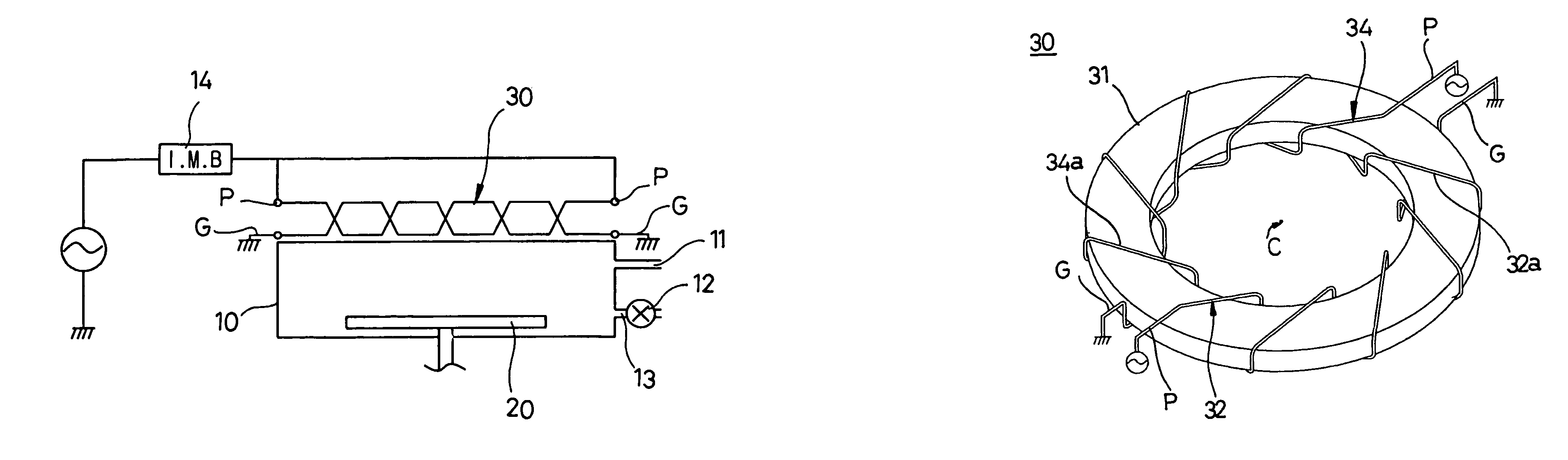

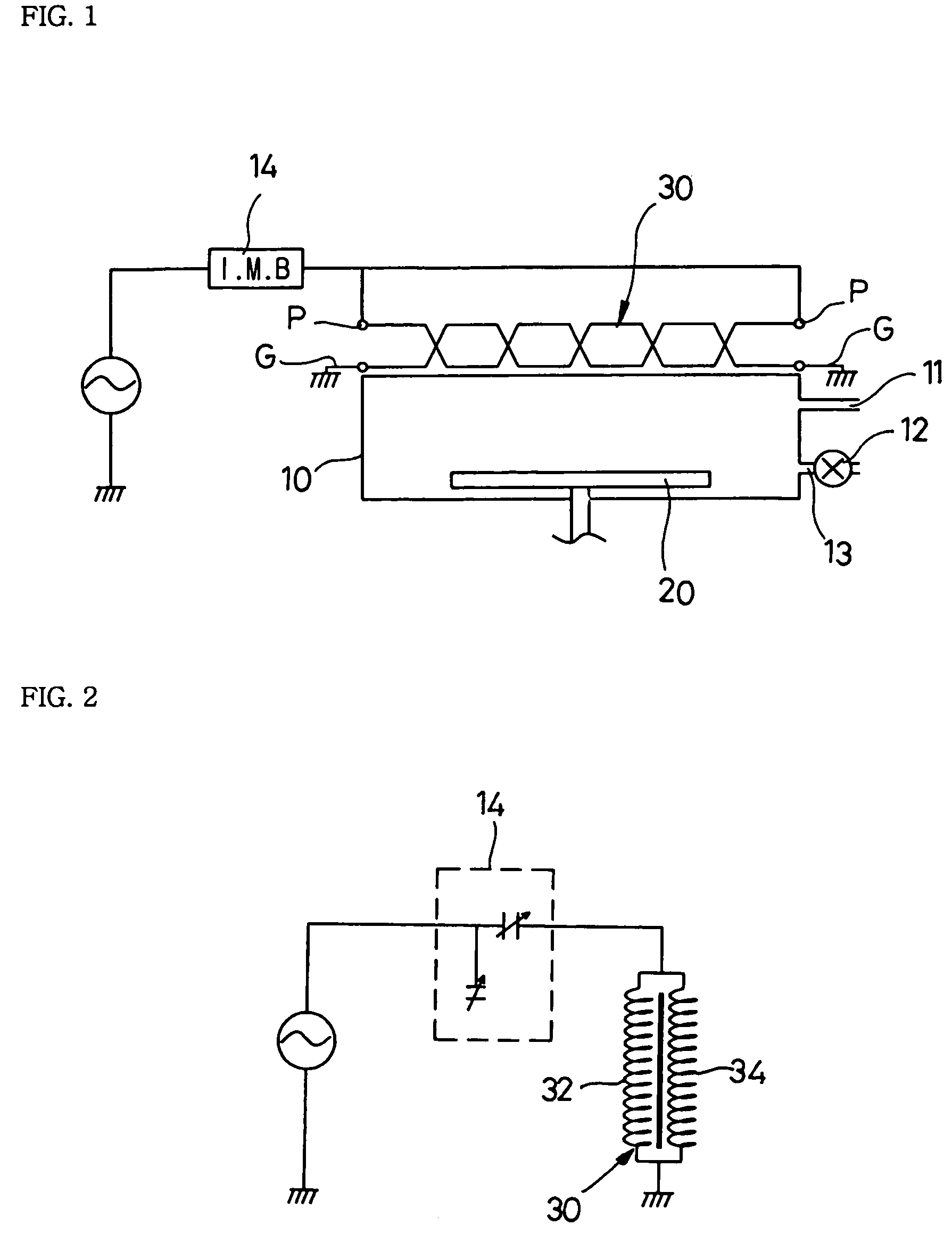

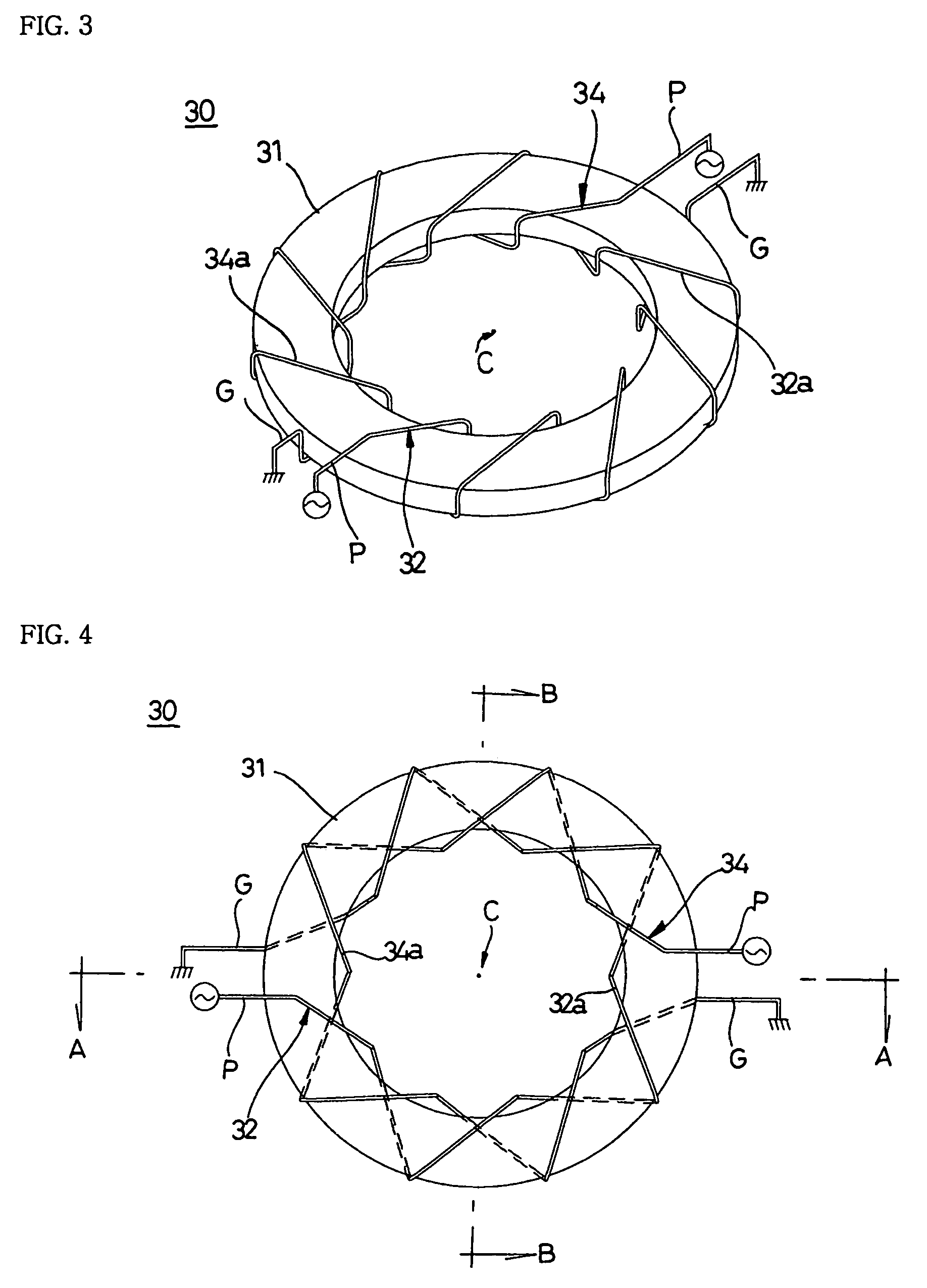

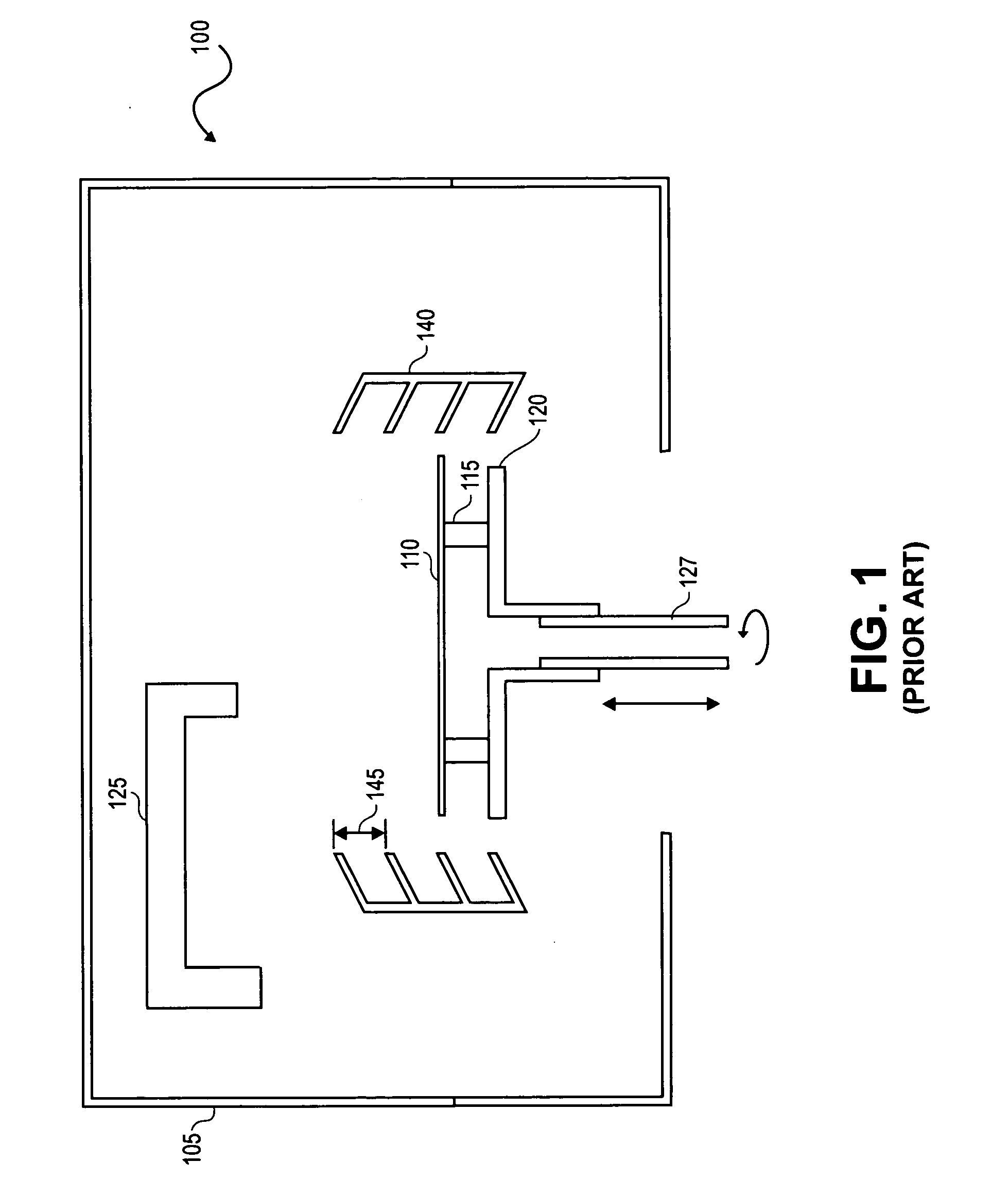

Inductively coupled plasma generator having low aspect ratio

InactiveUS7088047B2Made preciselyHigh selectivityElectric discharge tubesDecorative surface effectsPlasma densityHigh frequency power

An inductively coupled plasma generator having a lower aspect ratio reaction gas, comprising a chamber having a gas inlet through which a reaction gas is supplied, a vacuum pump for maintaining the inside of the chamber vacuum and a gas outlet for exhausting the reaction gas after completion of the reaction, a chuck for mounting a target material to be processed inside the chamber, and an antenna to which high-frequency power is applied, the antenna provided at the upper and lateral portions of the chamber, wherein the antenna has parallel antenna elements in which a discharge of a high frequency can be allowed and impedance is low to ensure a low electron temperature, the antenna is disposed such that a powered end of each of the antenna elements and a ground end of each of the antenna elements opposite to the powered end are symmetrical in view of the center of an imaginary circle formed by the antenna to establish rotation symmetry of plasma density profiles, the antenna elements are twisted in a helical manner, and the powered end of each of the antenna elements is positioned to be far from the chamber and the ground end of each of the antenna elements is positioned to be close to the chamber, thereby compensating for a drop in the plasma density due to ion loss occurring at the powered end.

Owner:SEMES CO LTD

Hydraulic damper integrated into steering rack for attenuating steering nibble

InactiveUS7484743B2Lower the volumeIncrease volumeSpringsSteering linkagesSteering wheelHydraulic pump

The present invention provides a damping system for use with a mechanism such as a steering system wherein one element moves relative to another element. The system includes a variable volume chamber, a collection chamber, and an inertia track providing fluid communication between the two chambers. A fluid is disposed in the chambers and the inertia track. A compliant tuning member is in fluid communication with the variable volume chamber. The damping system is capable of attenuating vibration at chosen frequencies without adding undesired damping at other frequencies. In the preferred embodiment, the damping system is used to attenuate steering wheel torsional vibration without increasing low frequency damping that would deteriorate steering feel.

Owner:IQ ISOLATION QUALITY

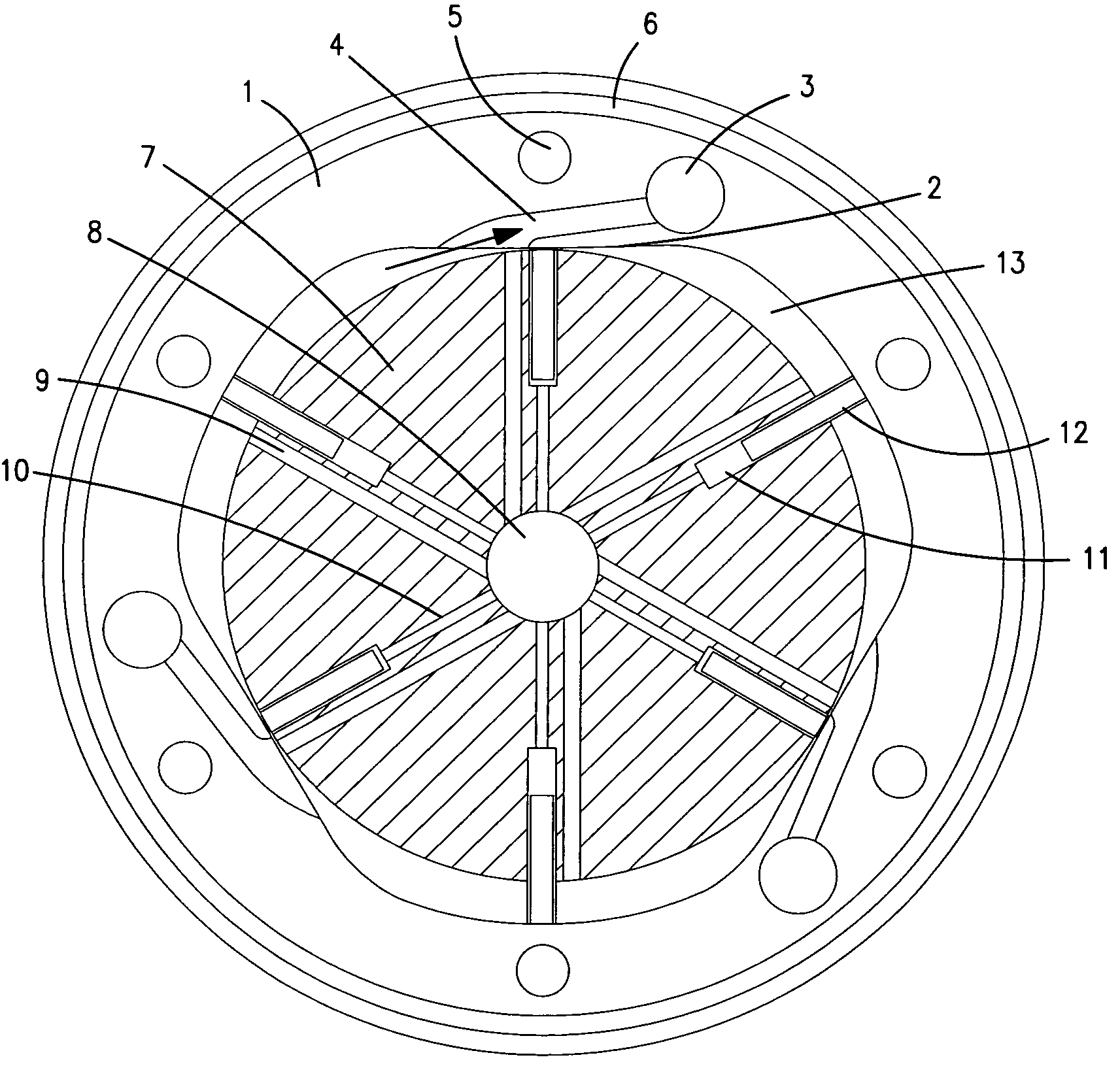

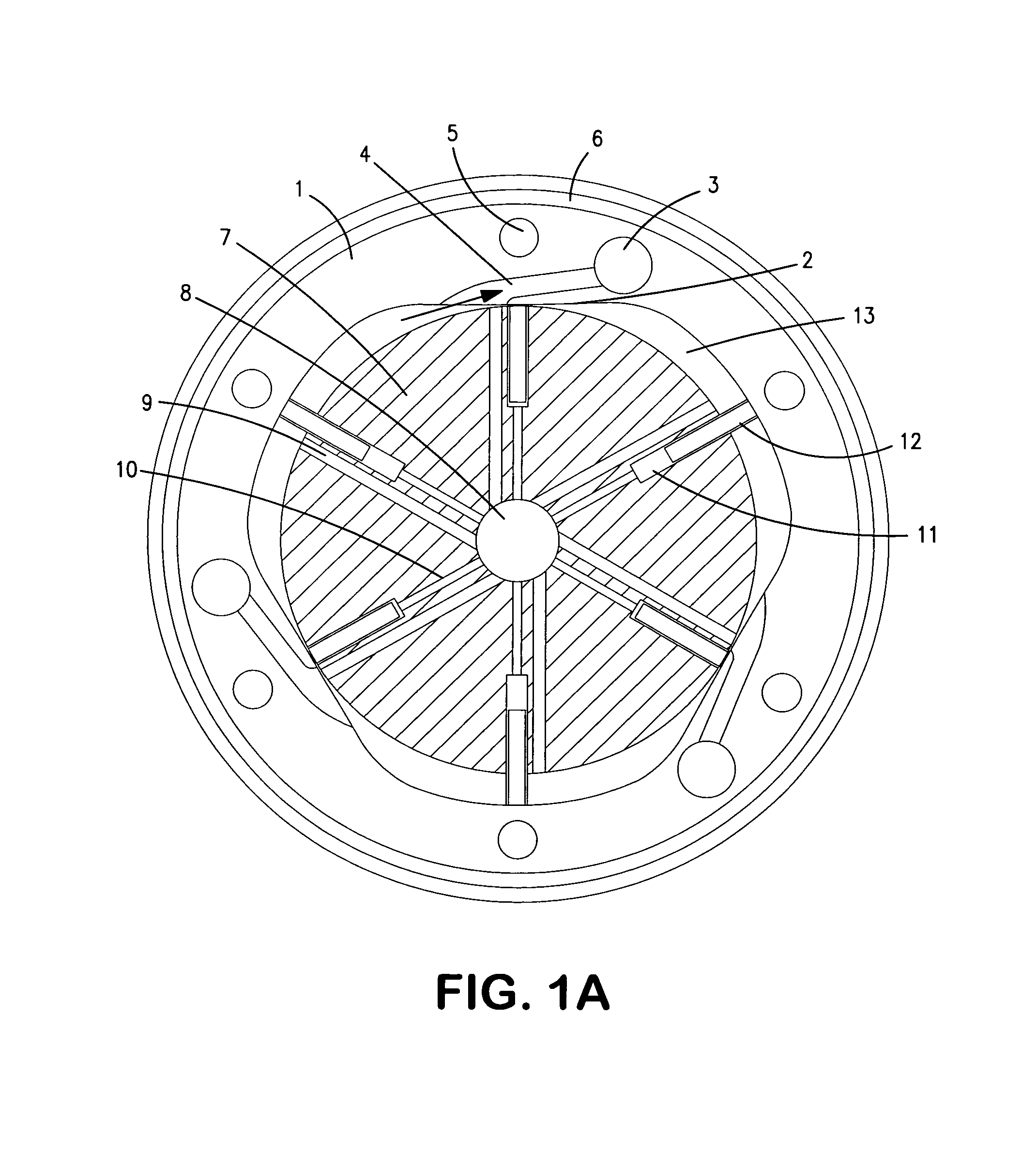

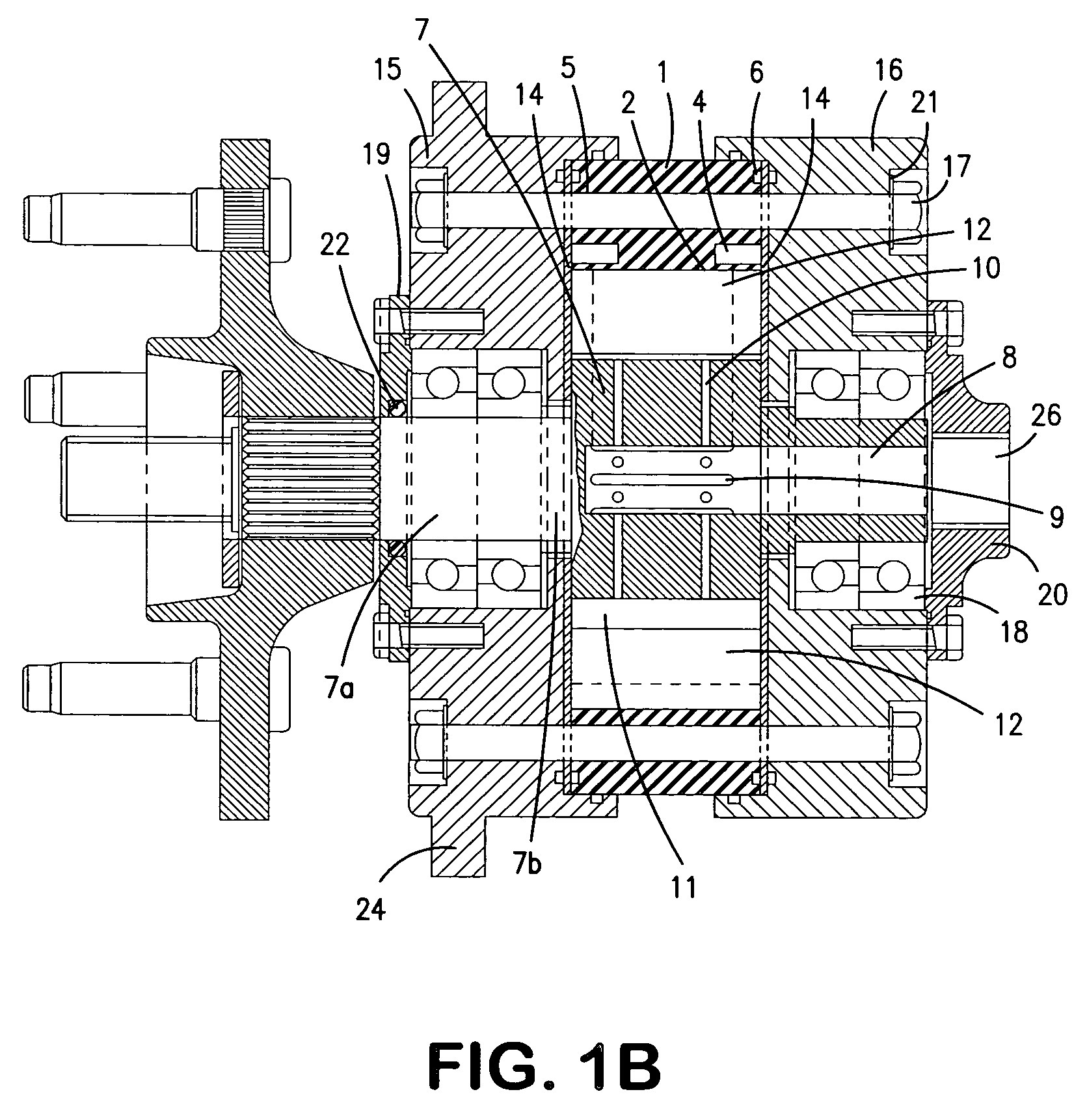

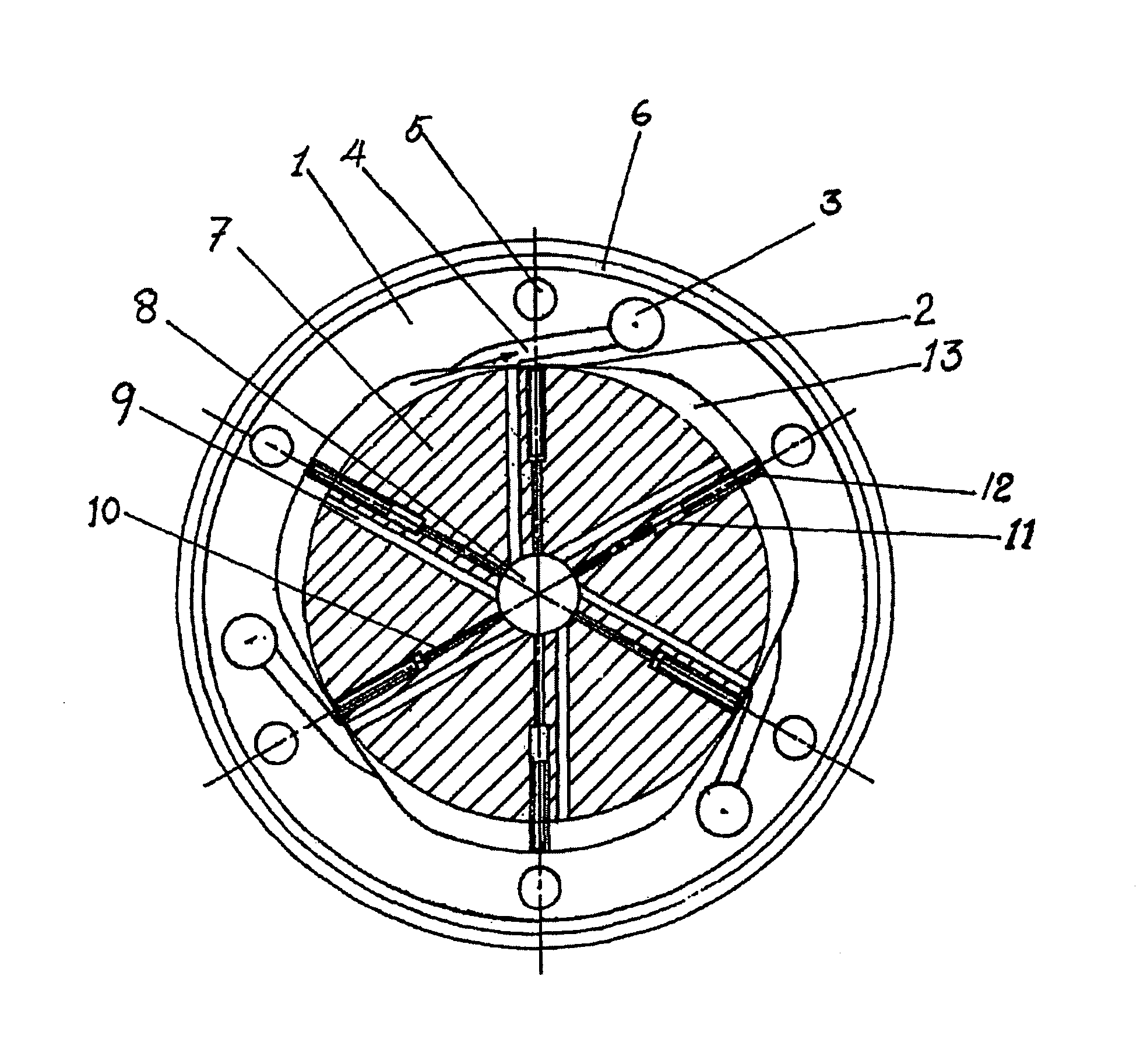

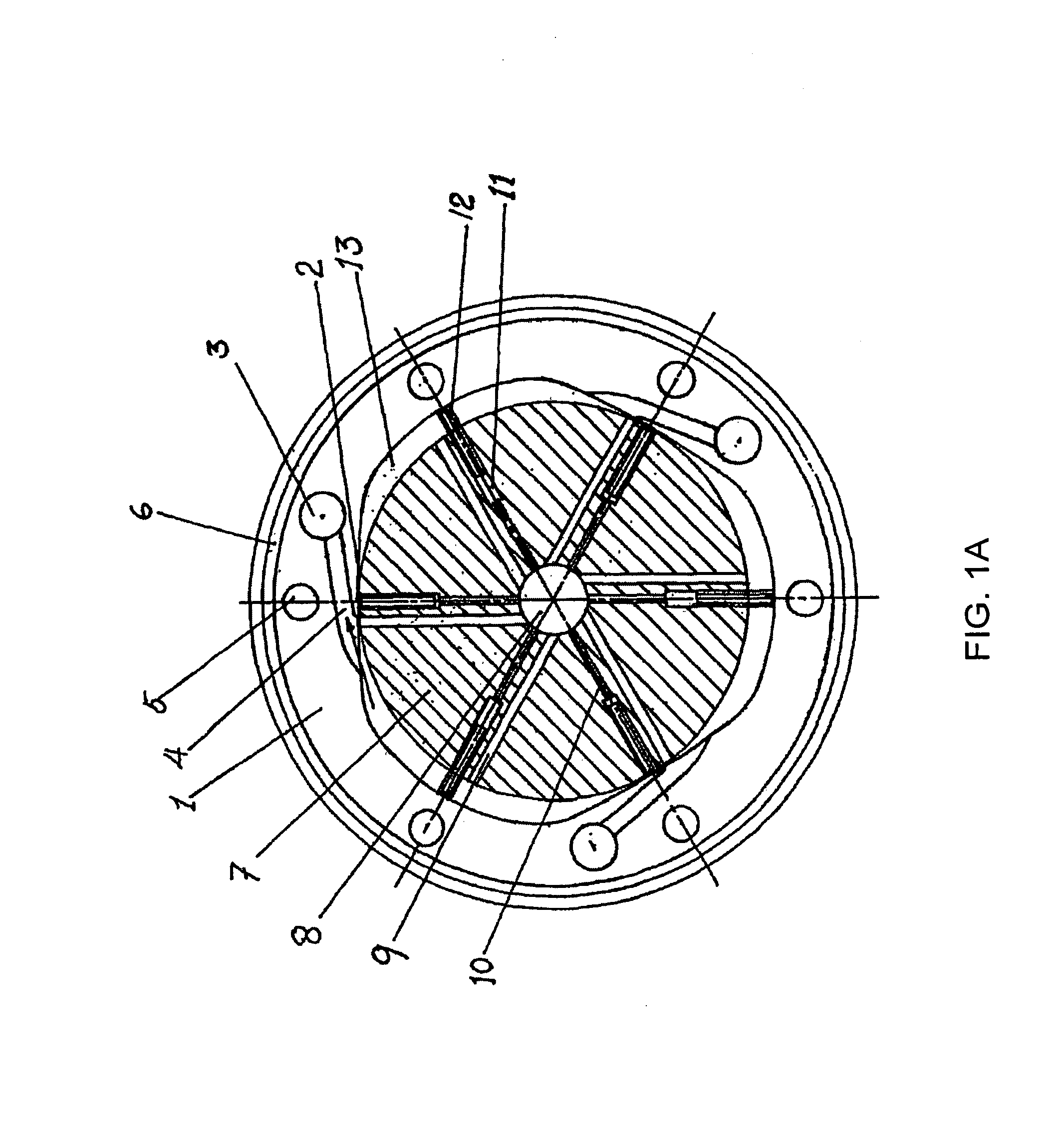

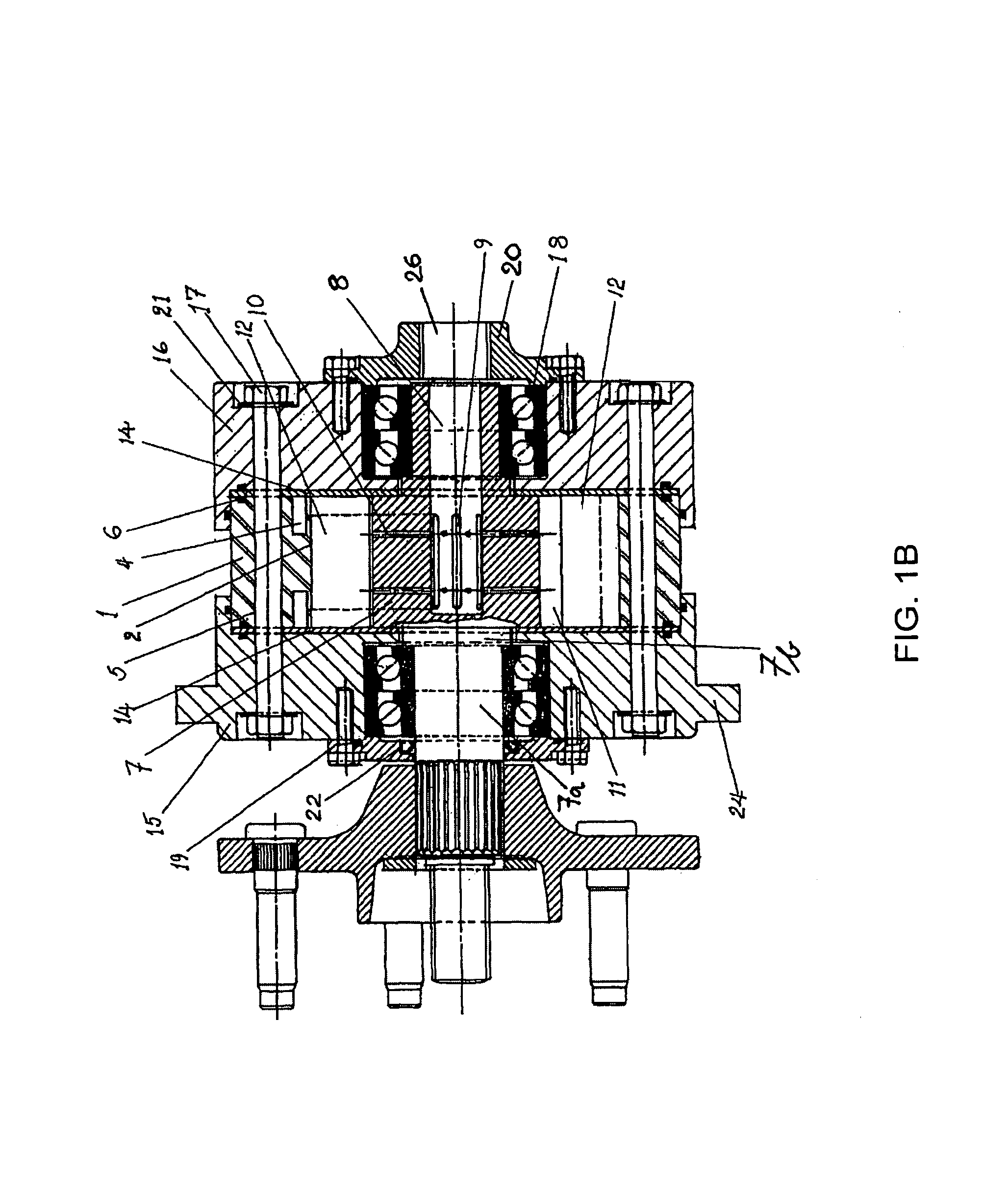

Hydraulic traction system for vehicles

InactiveUS20080202842A1Reduce the displacement angleReduce chamber volumeDigital data processing detailsAutomatic steering controlHydraulic motorTraction system

A hydraulic traction system for vehicles is described. The system comprises a hydraulic vane motor mounted at each wheel of the vehicle, and equal number of identical hydraulic vane motors operated as engine driven pumps, and a control system for regulating the flow and direction of hydraulic oil during operation. The hydraulic motor is of a novel design that has a hollow non-drive shaft that accepts incoming hydraulic oil, this allows internal components of the hydraulic motor to be arranged in such a way to improve the efficiency of the hydraulic traction system.

Owner:SHEVKET ALPER

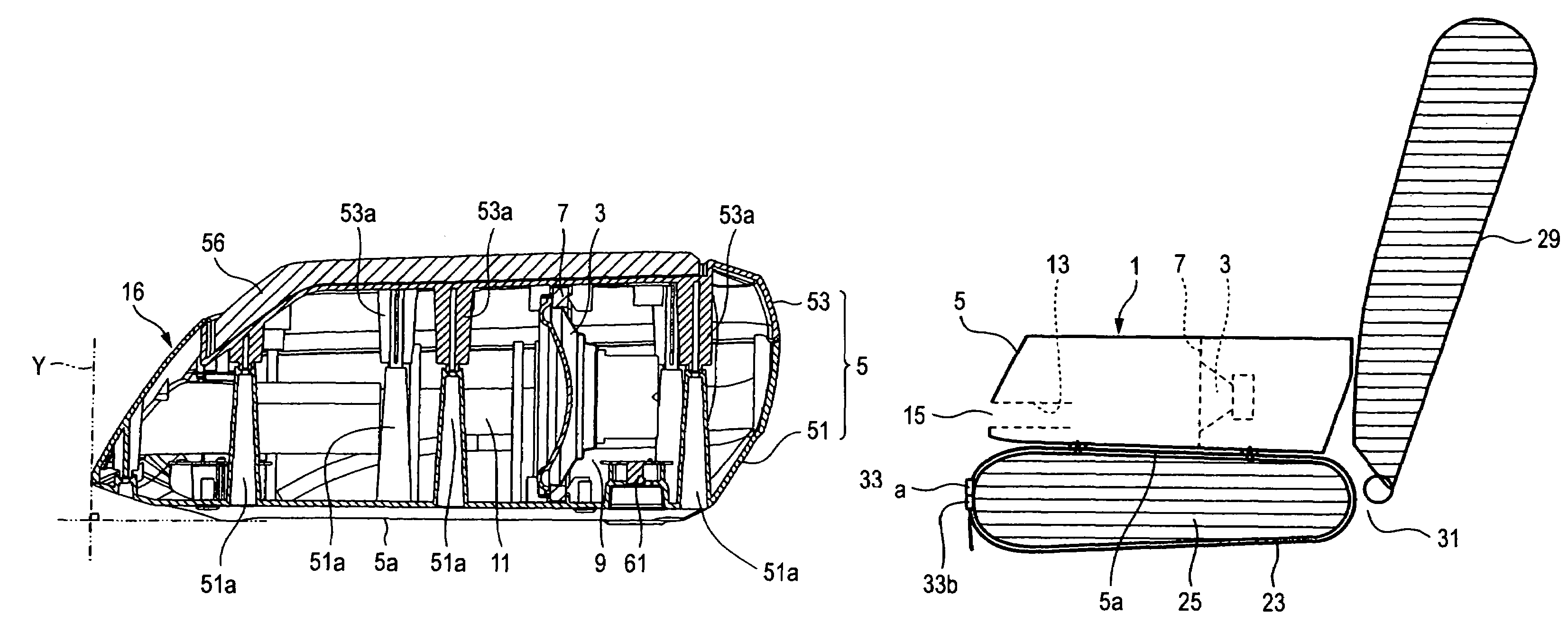

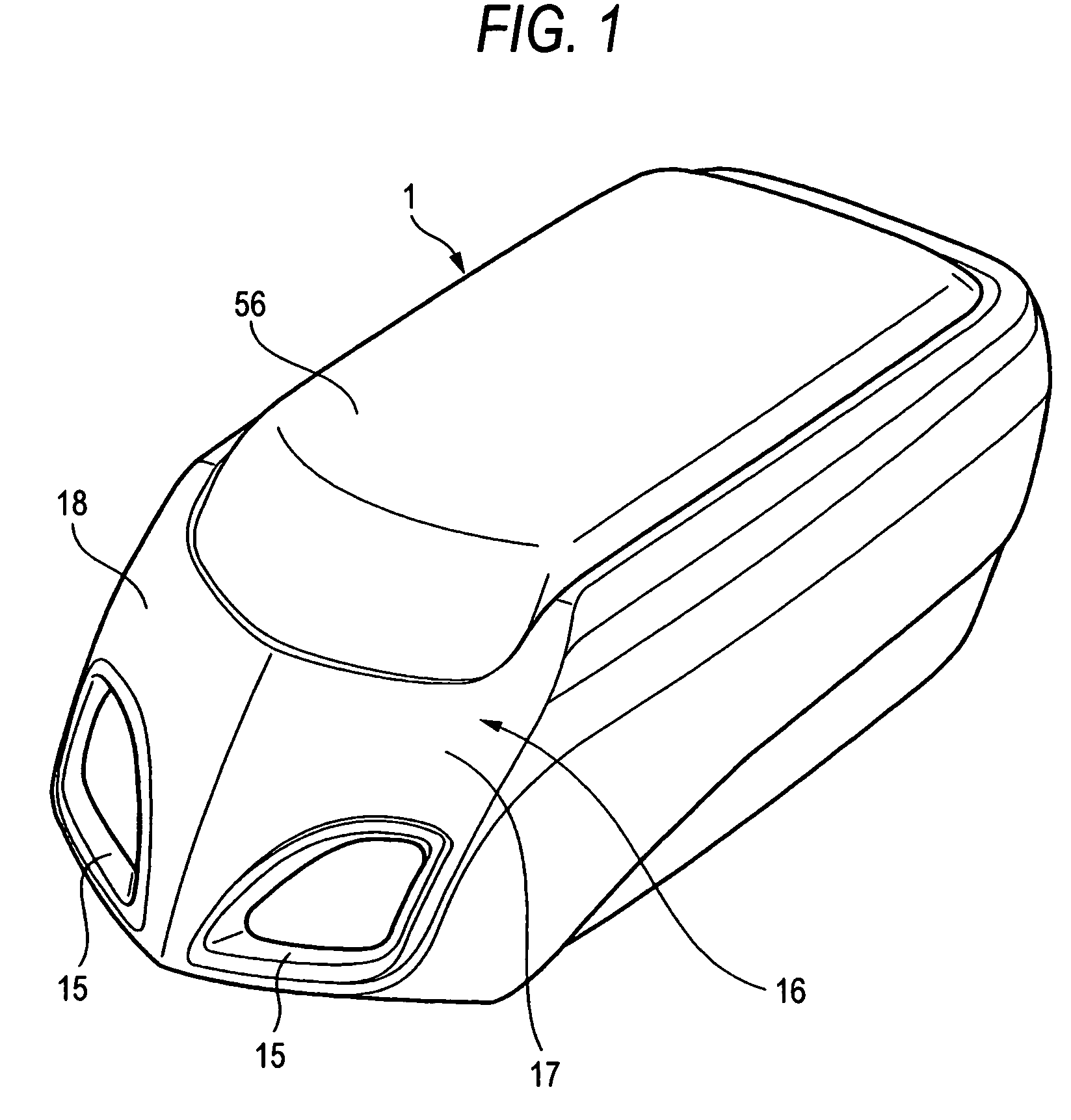

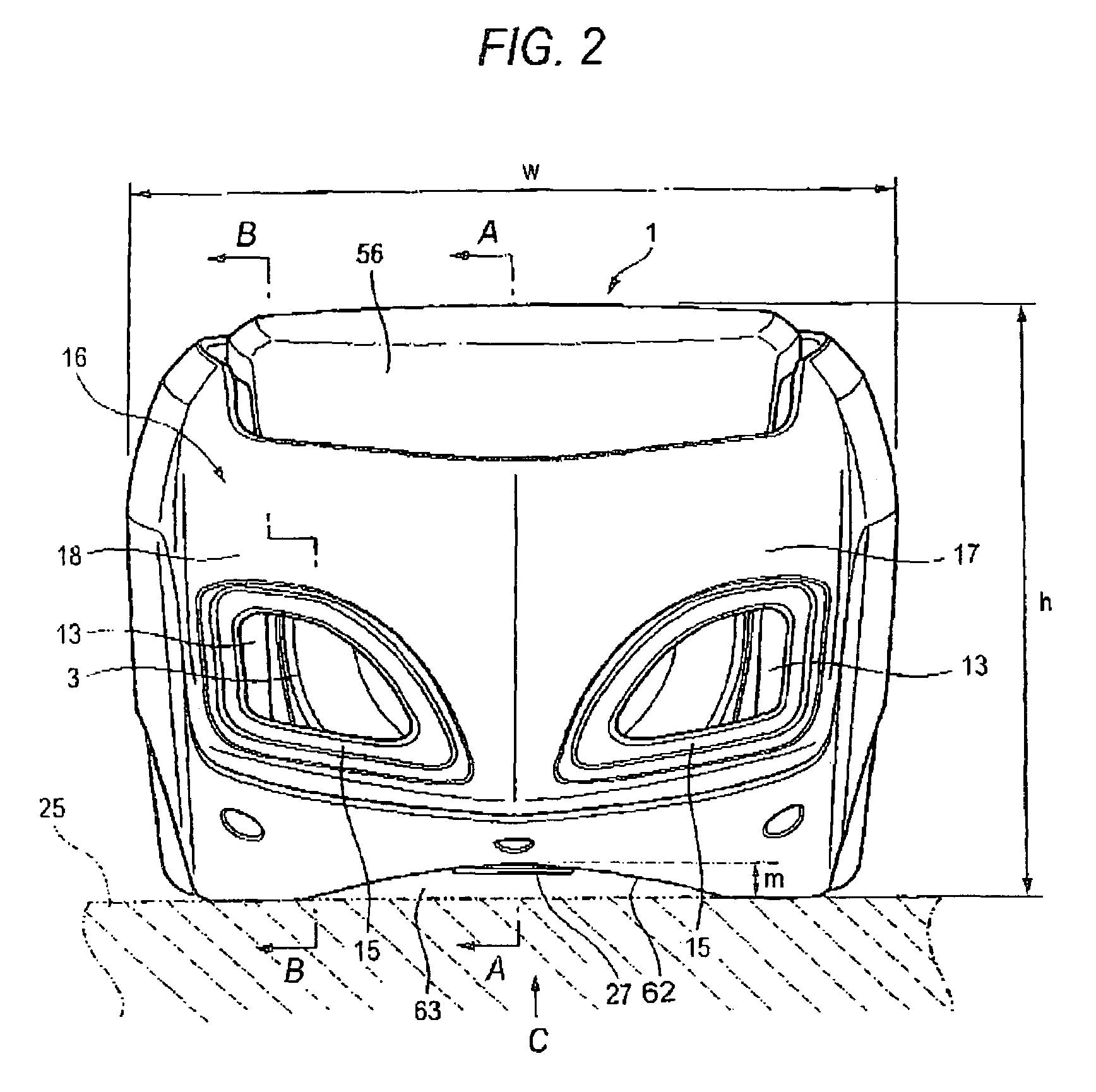

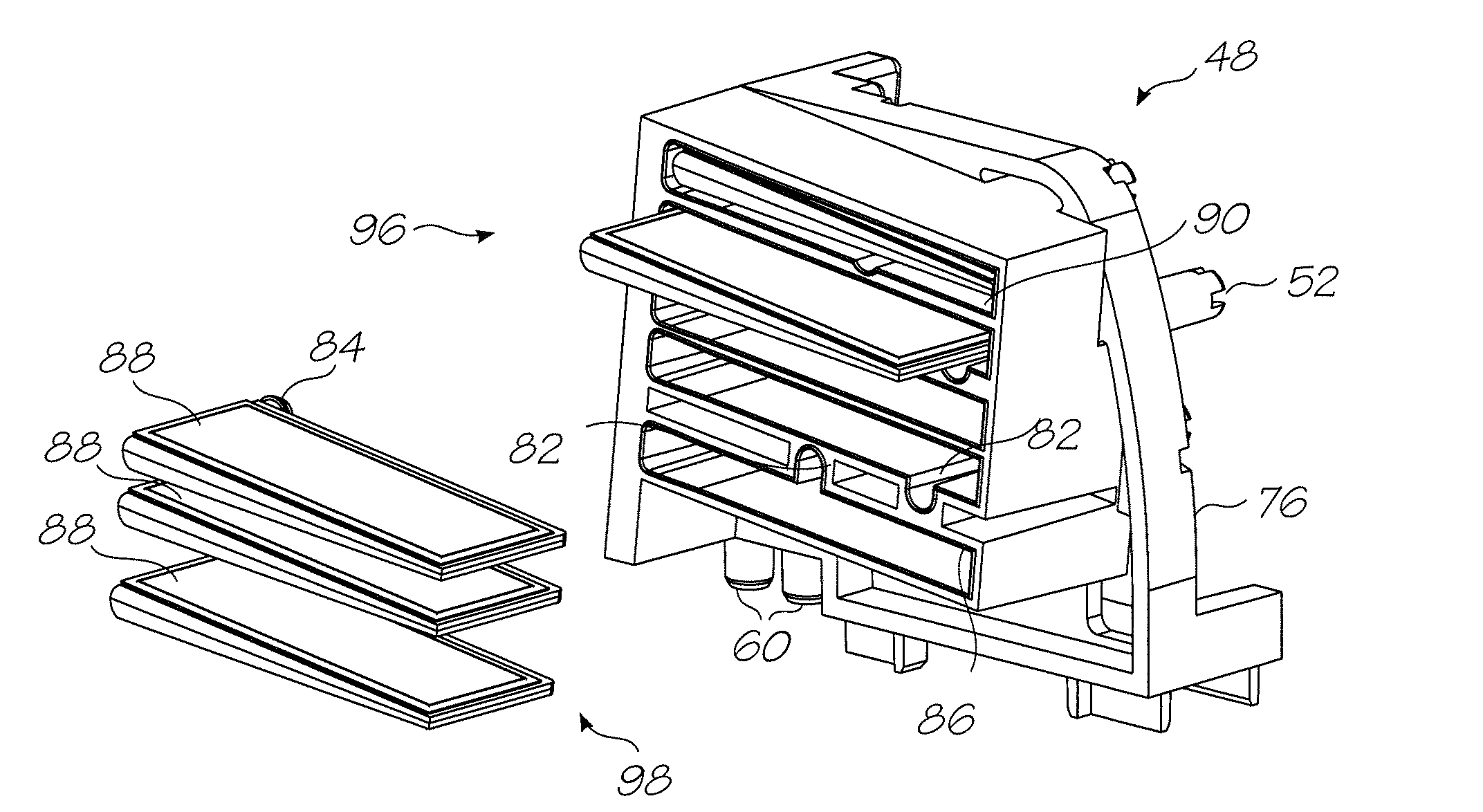

Low-frequency sound reproducing speaker apparatus

InactiveUS7284637B2Simply be removedCapacity of the cabinet can comparatively freelyCabinetsHermetically-sealed casingsEngineeringLoudspeaker

In a low-frequency sound reproducing speaker apparatus of Kelton type, a cabinet for containing a speaker unit is constituted by a shape of substantially a parallelepiped slender in a front and rear direction, a length dimension in the front and rear direction is set to a value substantially near to a depth dimension of a seat cushion of a vehicle, the speaker unit is attached to a partition plate for partitioning inside of the cabinet into front and rear air chambers, and a lower face of the cabinet is fixed to the seat cushion by a fixing belt laid along the front and rear direction.

Owner:PIONEER CORP

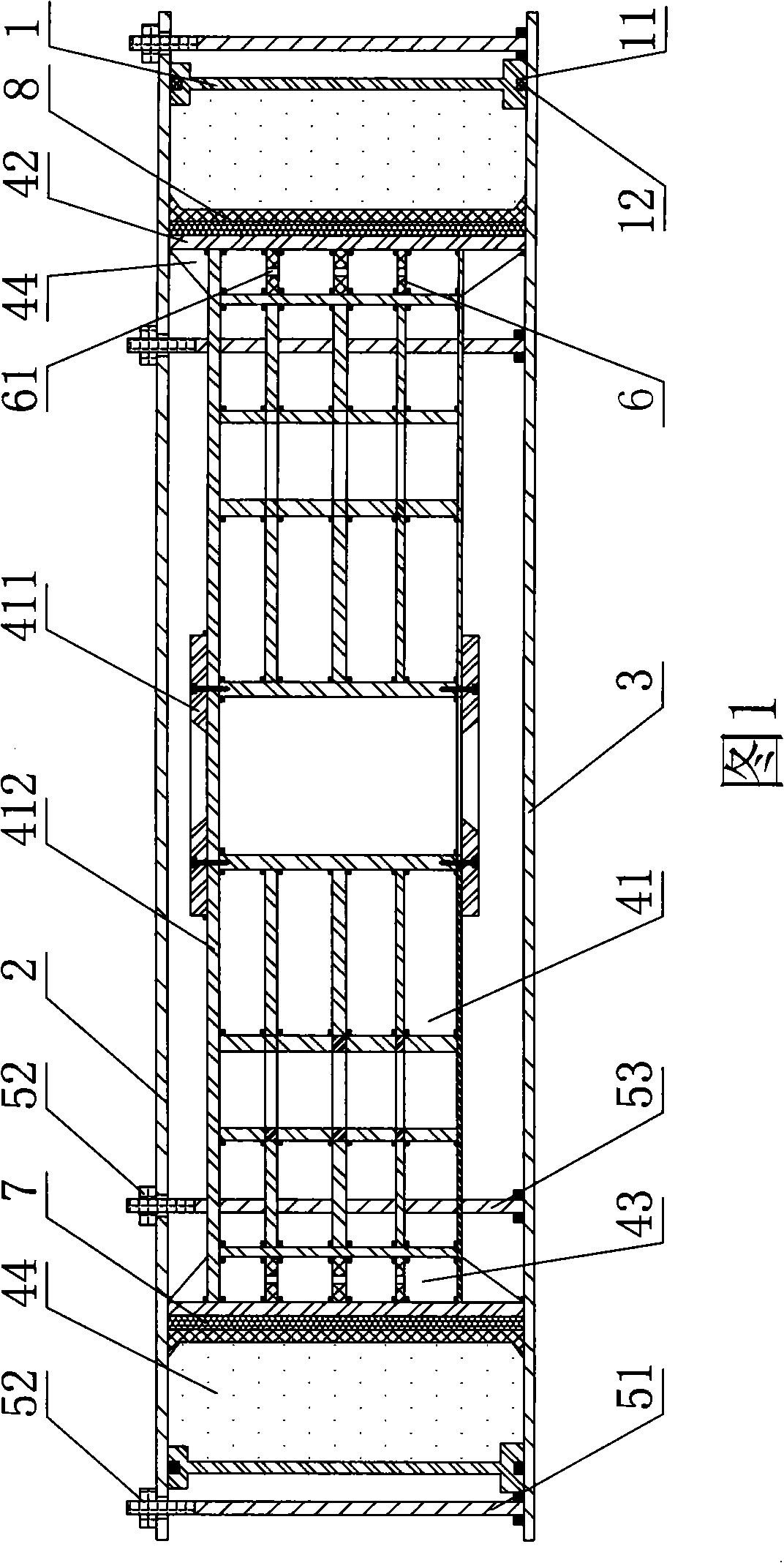

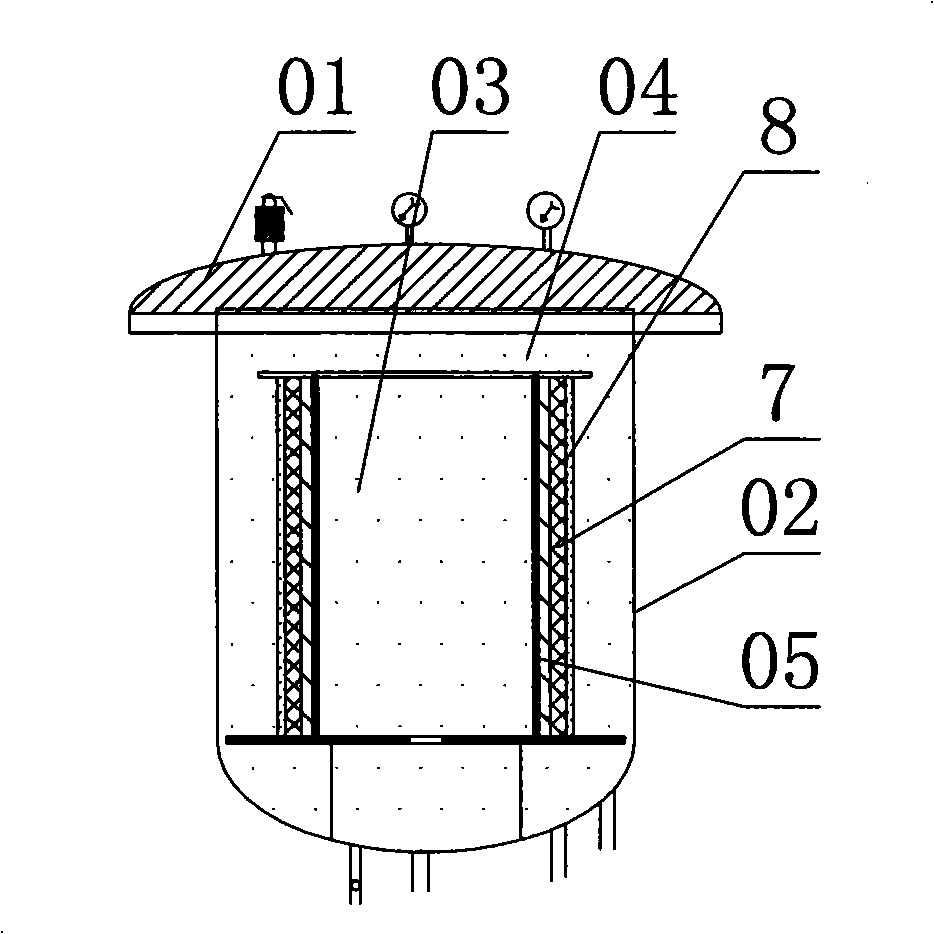

Rubber transmission belt vulcanizing device and vulcanizing method thereof

The invention discloses a rubber driving belt vulcanizing device which comprises an outer sleeve, and an upper cover plate, a lower bottom plate and a die component which are connected with the upper end surface and the lower end surface of the outer sleeve in a sealing manner. The die component comprises a pivot holder body and a die arranged at the outer ring end of the pivot holder body, a circularly communicated steam chamber is arranged on the inner surface of the die and close to the pivot holder body, an external pressure cavity is formed between the outer sleeve and the die, and the upper cover plate is adjustably connected with the lower bottom plate through a locking bolt, an inner locking bolt and a locking nut. The vulcanizing medium in the external pressure cavity is mixed with high-pressure compressed air through saturated steam, which can ensure the vulcanizing pressure and a certain temperature, the steam chamber is arranged between the die and the outer ring end of the pivot holder body, the volume of the steam chamber is greatly reduced than the volume of the internal pressure air chamber of the prior vulcanizing boiler, so that the consumption of saturated steam is greatly reduced; therefore, the steam consumption for the boiler is low, and the energy consumption is low. The device does not need a special vulcanizing boiler, so that the equipment investment is saved.

Owner:杭州金瀚能源科技有限公司

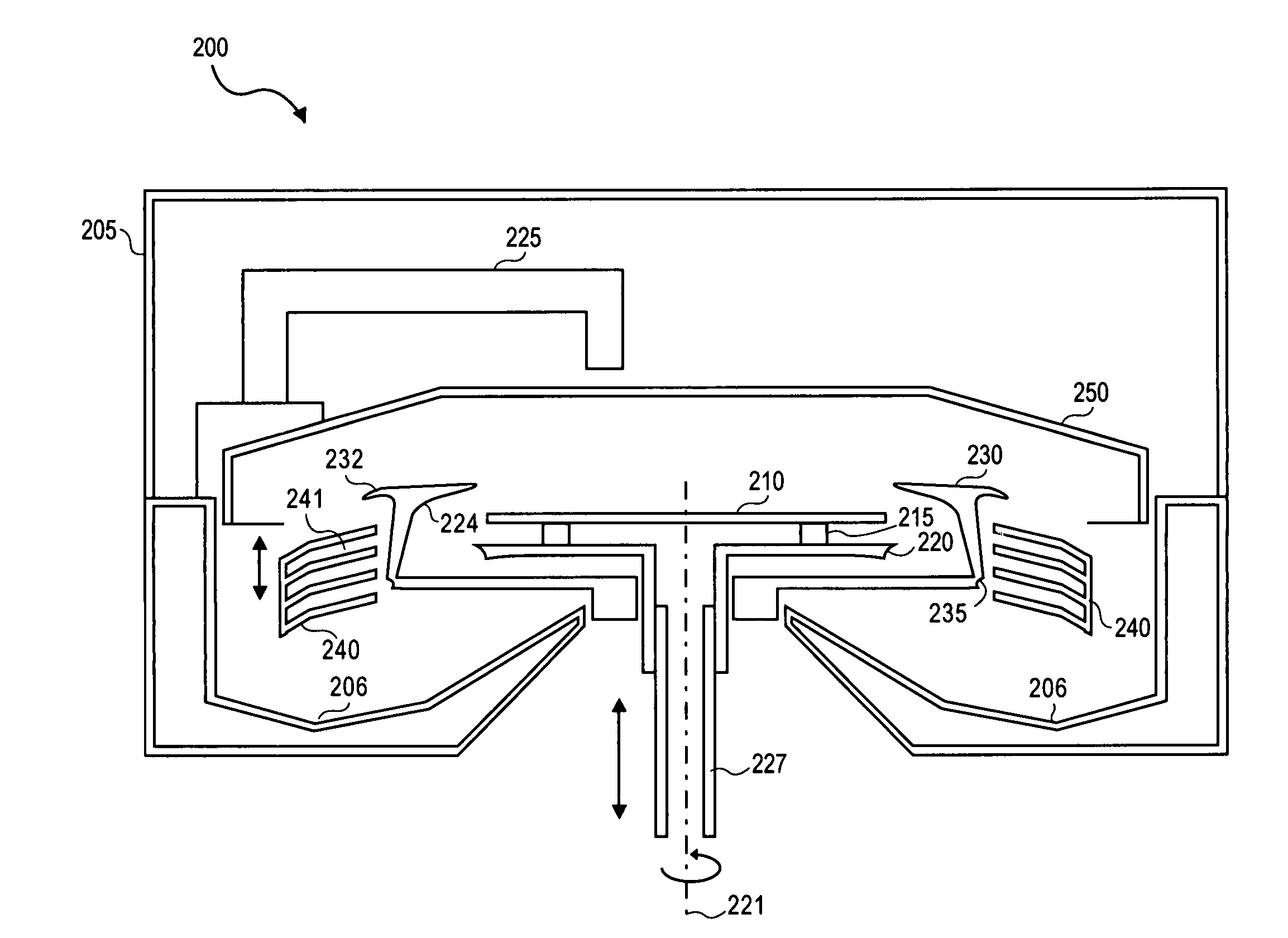

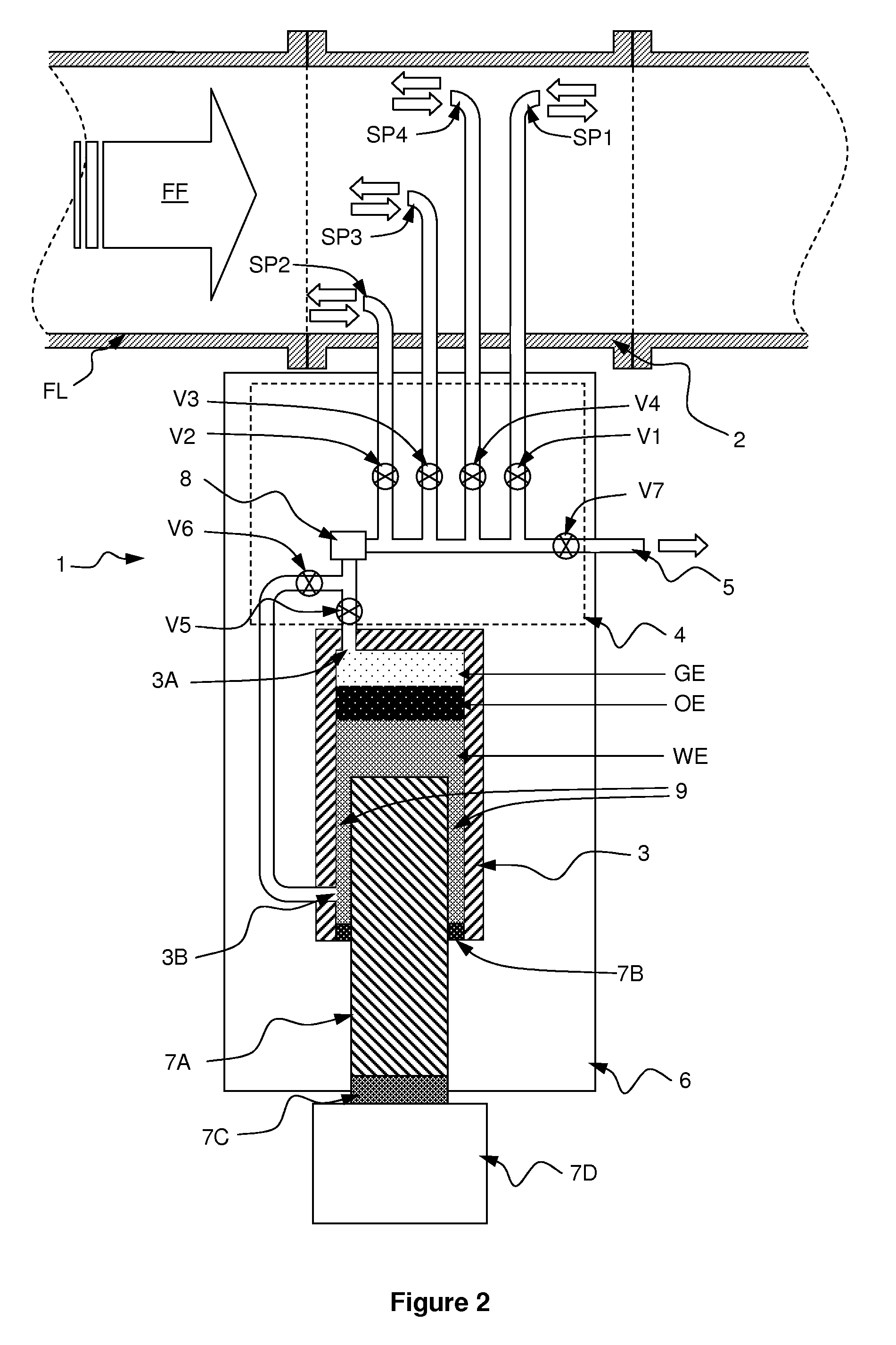

Apparatus for single-substrate processing with multiple chemicals and method of use

InactiveUS20070254098A1Reduced spray angleLower Level RequirementsPretreated surfacesSemiconductor/solid-state device manufacturingCompound (substance)Engineering

A single-substrate apparatus for wet chemical processing of one or multiple sides of a substrate is described. Embodiments of the present invention enable multiple chemicals to be applied to the substrate in succession and reclaimed substantially free of cross contamination between chemicals. In an embodiment of the present invention, a rotatable fluid diverter is positioned between a rotatable pedestal and a nonrotatable multi-level catch cup to funnel fluid shed from a substrate to a predetermined level of the catch cup. The rotatable fluid diverter is designed to expel fluid over a narrow spray angle and thereby enable the pitch of the levels in the catch cup to be reduced so that the chamber volume of the single-substrate apparatus is reduced. In another embodiment of the present invention, the rotatable pedestal is moveable so that the fluid shed from the substrate can be directed to away from the multi-level catch cup.

Owner:APPLIED MATERIALS INC

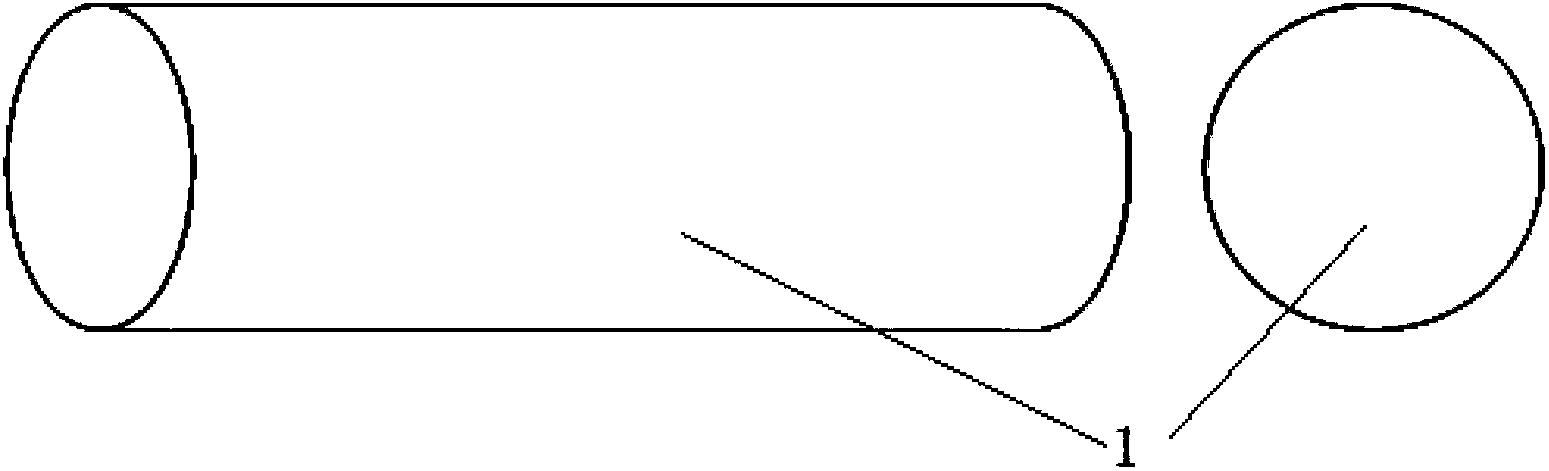

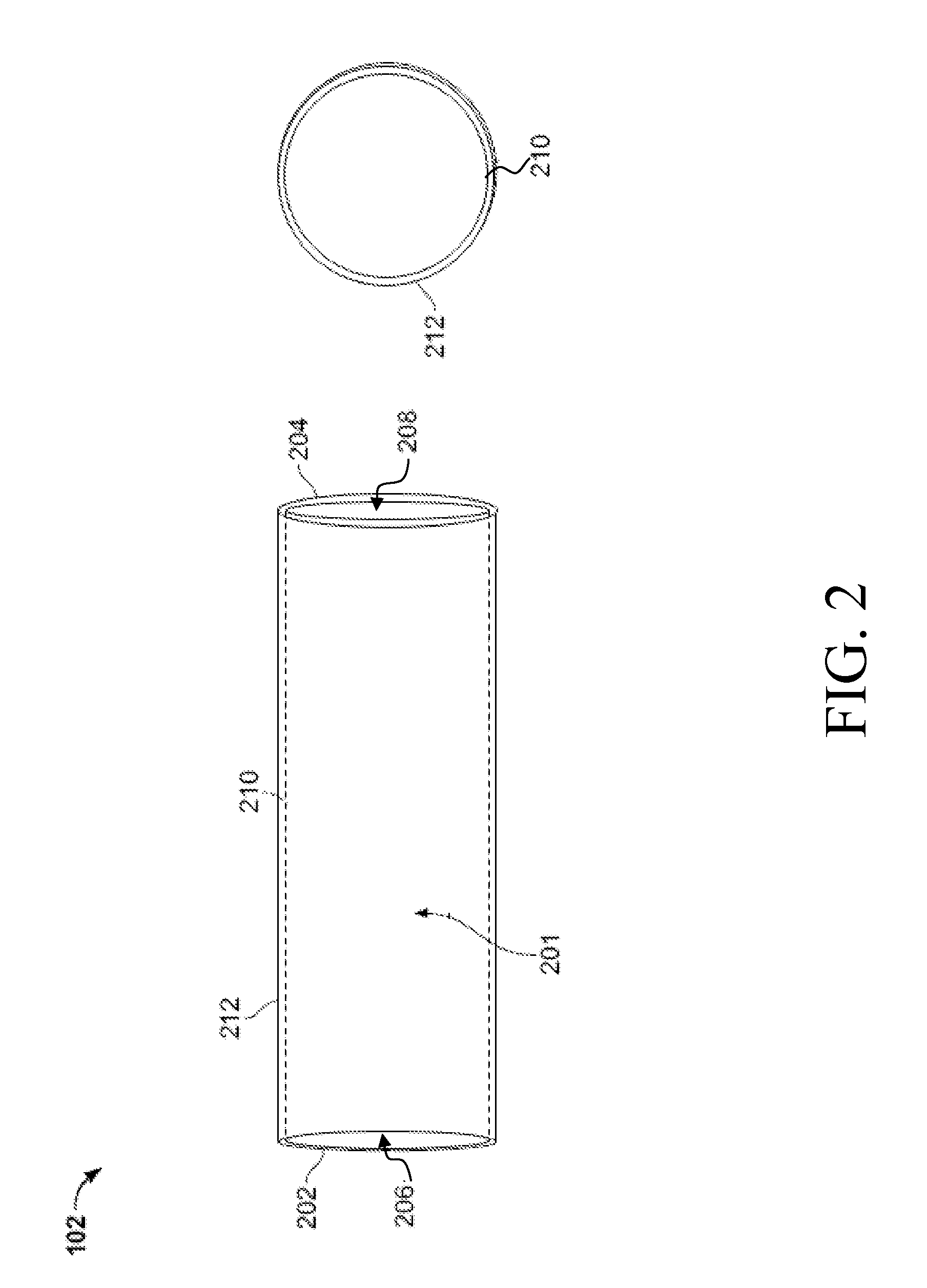

Hydrostatic test compensator and method of carrying out pipe hydrostatic tests by using same

InactiveCN103424314AShorten the timeImprove efficiencyMaterial strength using tensile/compressive forcesFluid-tightness measurement using fluid/vacuumWater dischargeEngineering

The invention discloses a hydrostatic test compensator. The hydrostatic test compensator is a cylinder which can bear the external pressure not less than the pressure size of the hydrostatic test for a pipe without damage; the cylinder is a solid cylinder or is in a hollow shell structure with the two ends sealed by adopting sealing heads. The invention also discloses a method of carrying out pipe hydrostatic tests, and the method comprises following steps: propelling the hydrostatic test compensator into a pipe to be tested, then fixing the pipe to be tested, which has been stuffed with the hydrostatic test compensator, and the hydrostatic test compensator to a hydrostatic test machine, and then carrying out hydrostatic tests according to normal methods. When the hydrostatic-test compensator is used for the hydrostatic test of the pipe, due to the capability of bearing the external pressure, the hydrostatic-test compensator is not deformed in the process of the hydrostatic test of the pipe, so that the water feeding time and the water discharging time in the hydrostatic test can be greatly reduced, and therefore the whole time for the hydrostatic test of the pipe is reduced and the efficiency of the hydrostatic test is increased.

Owner:BEIJING LONGSHINE OIL TUBULAR TECH

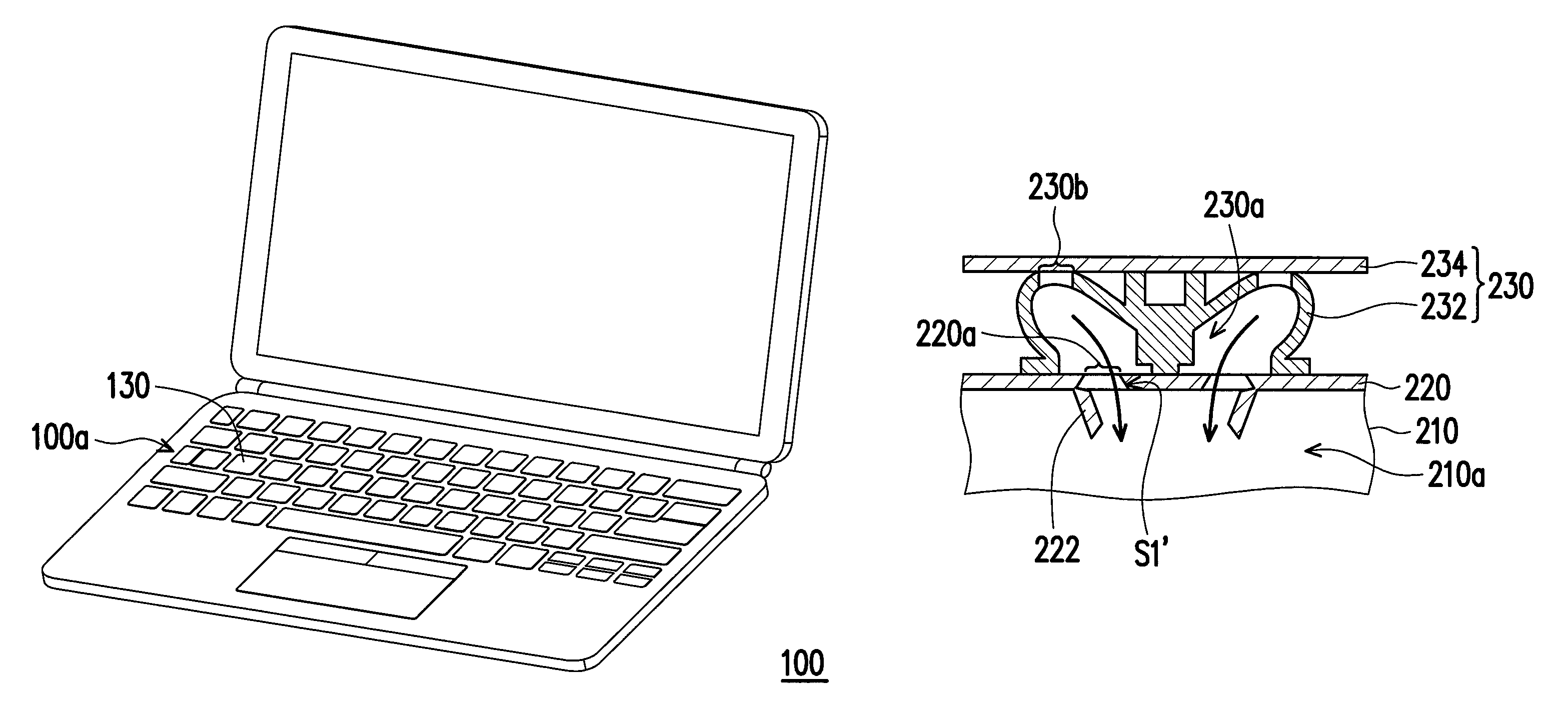

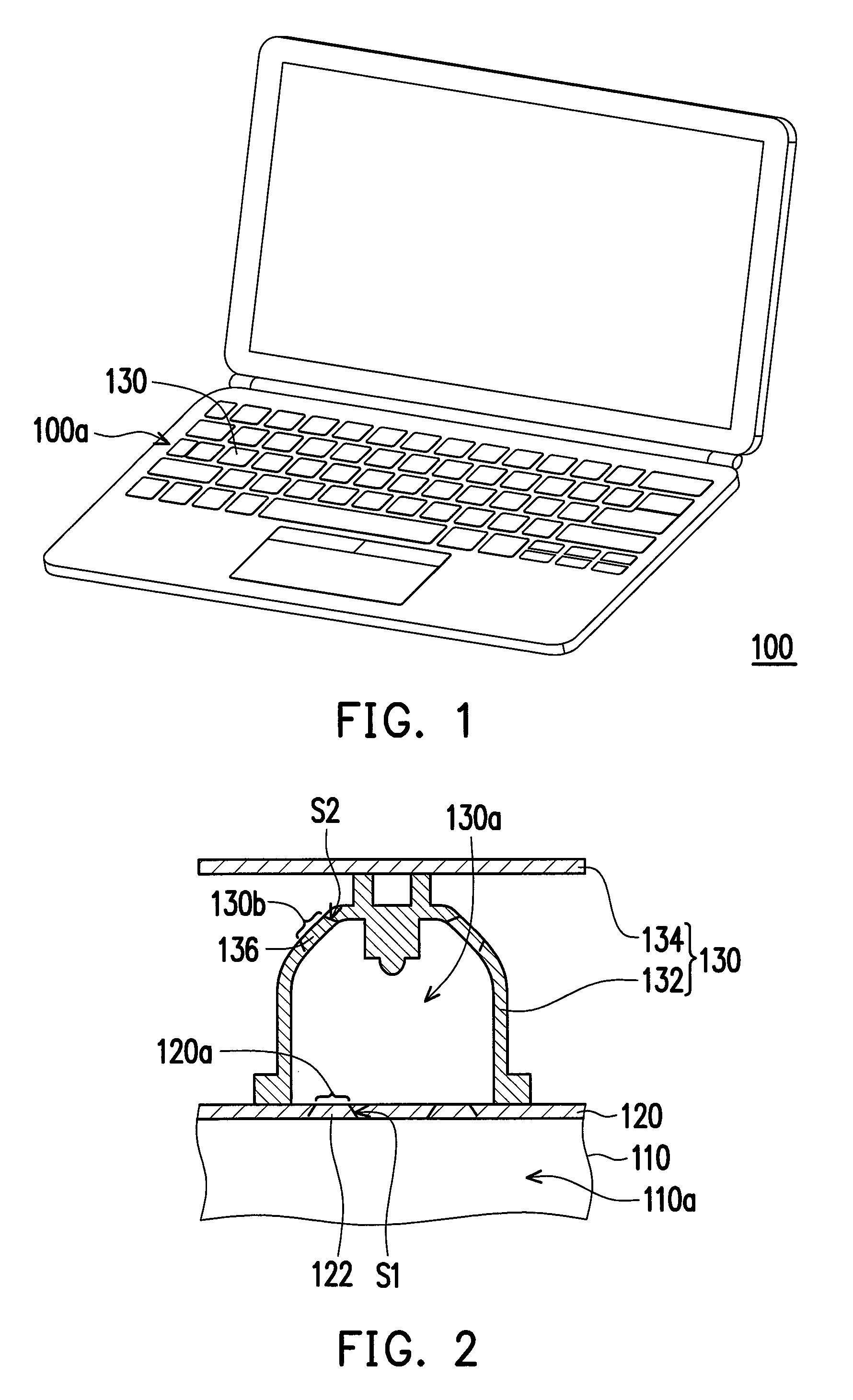

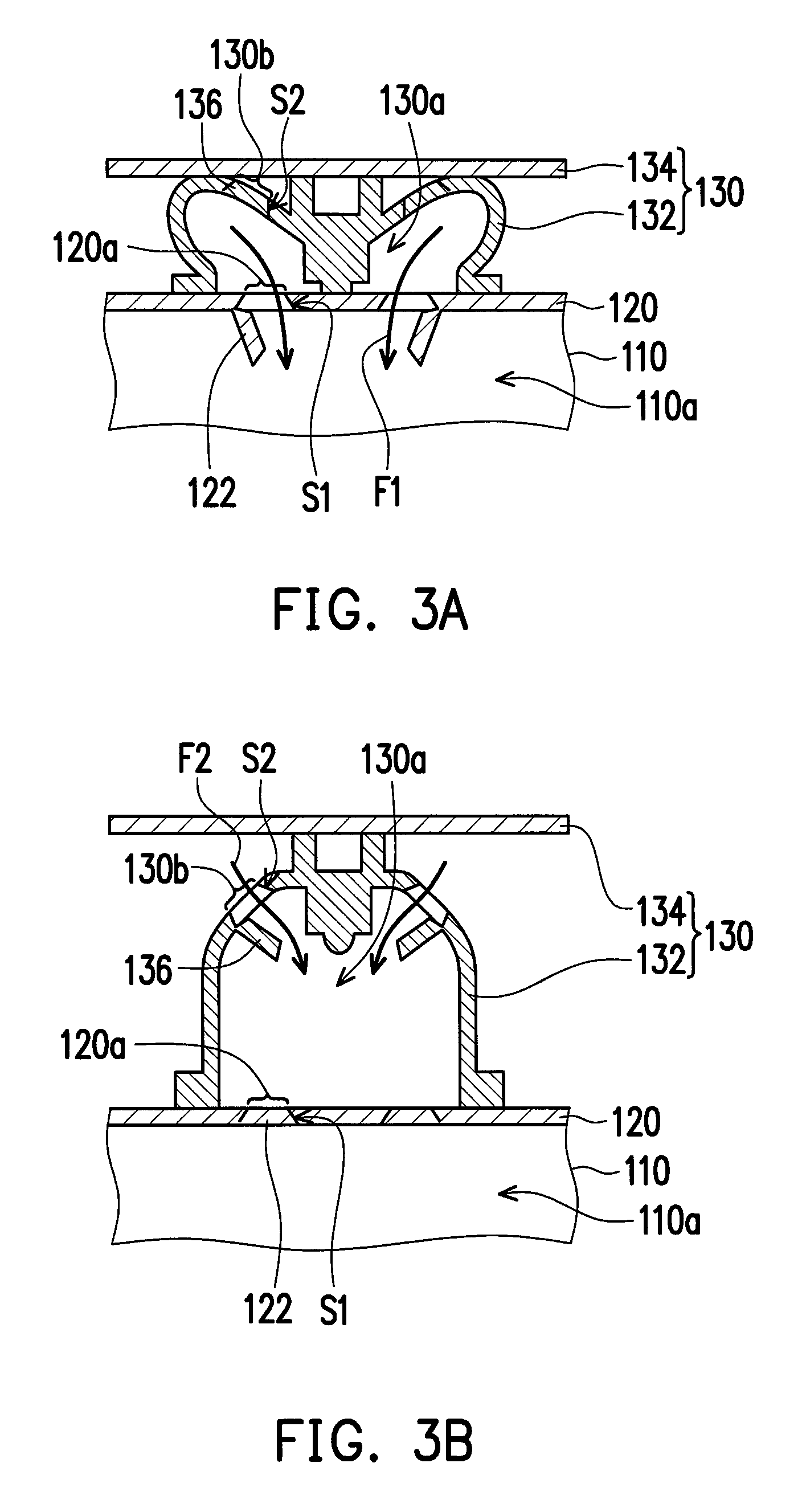

Electronic device and heat dissipation method

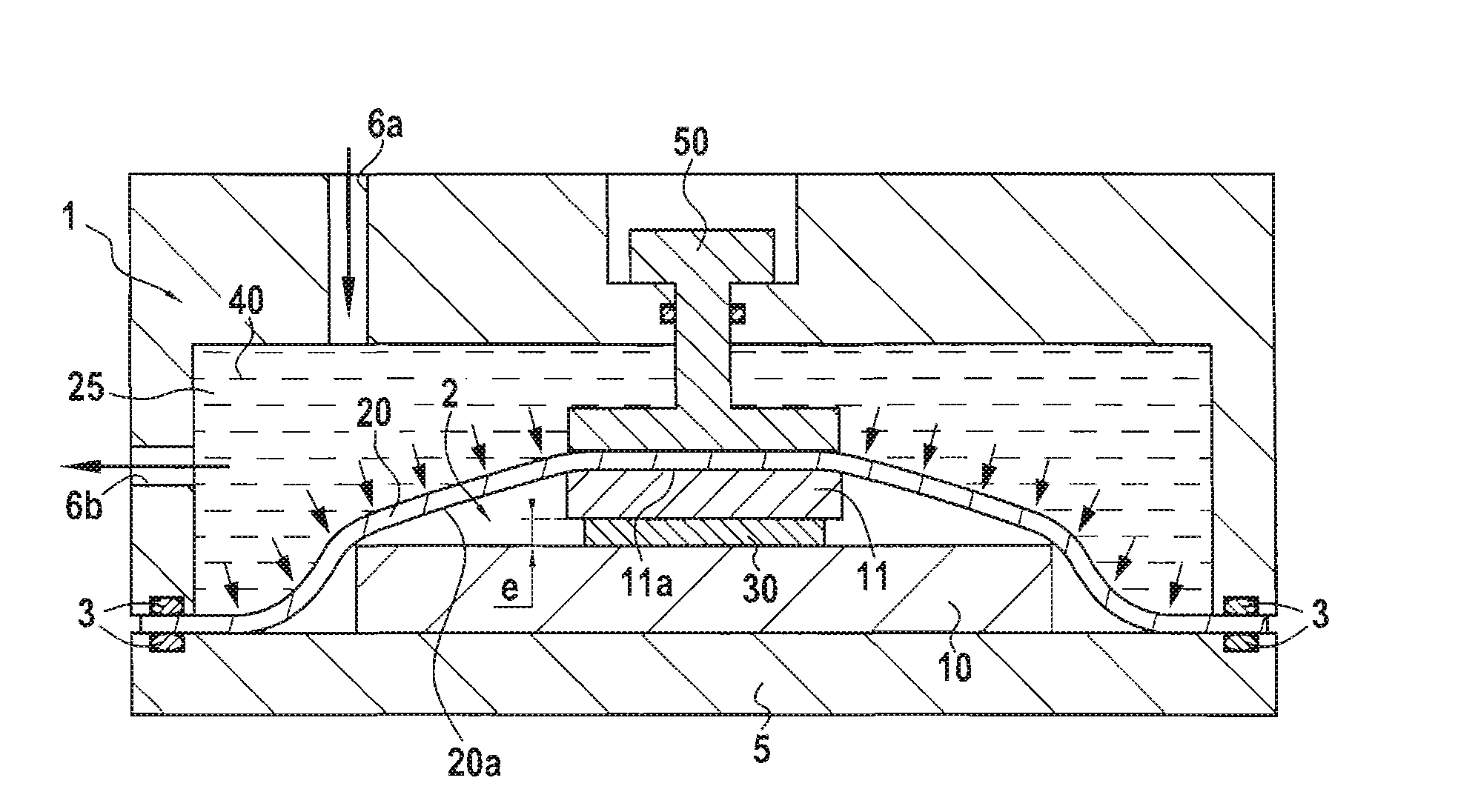

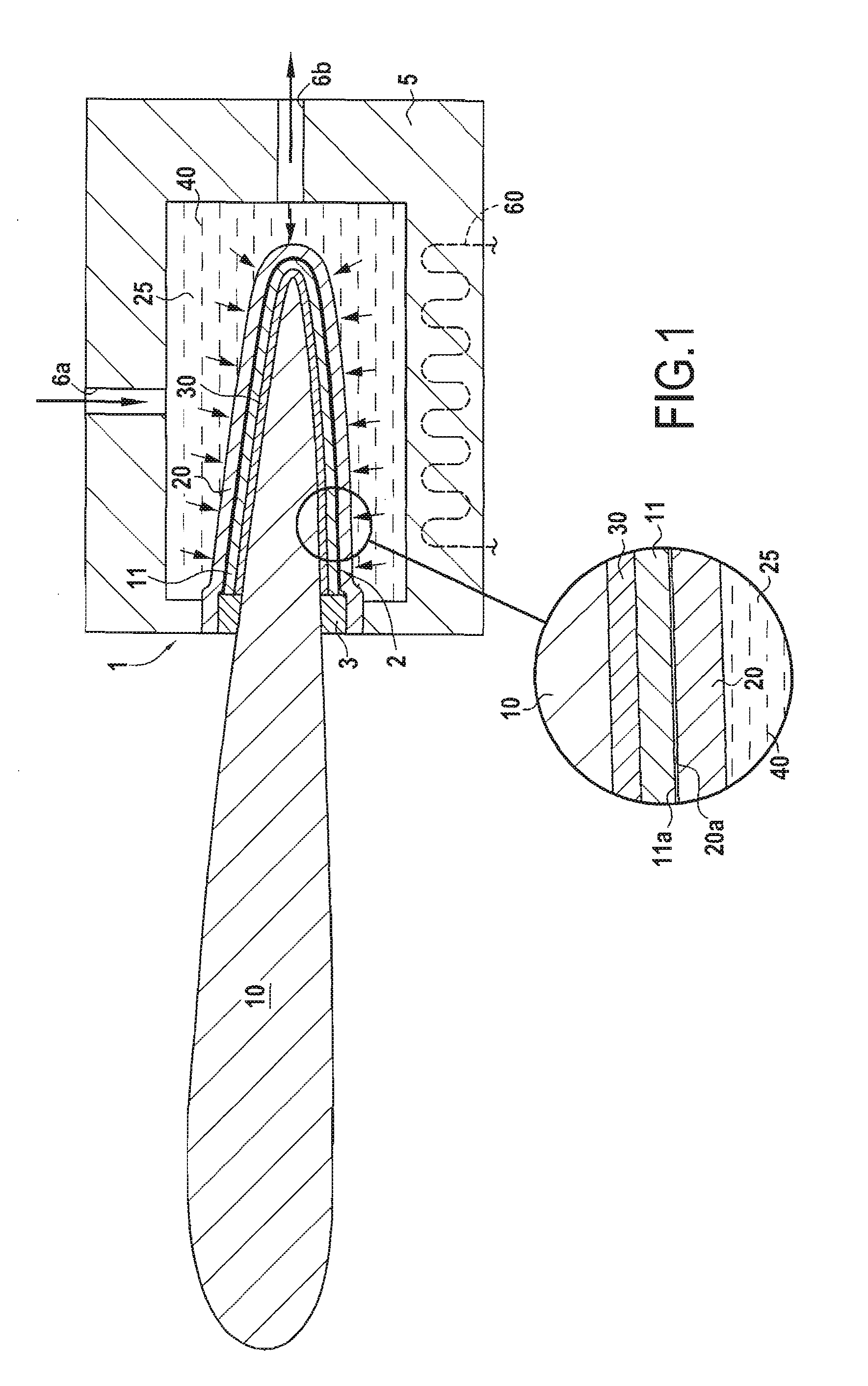

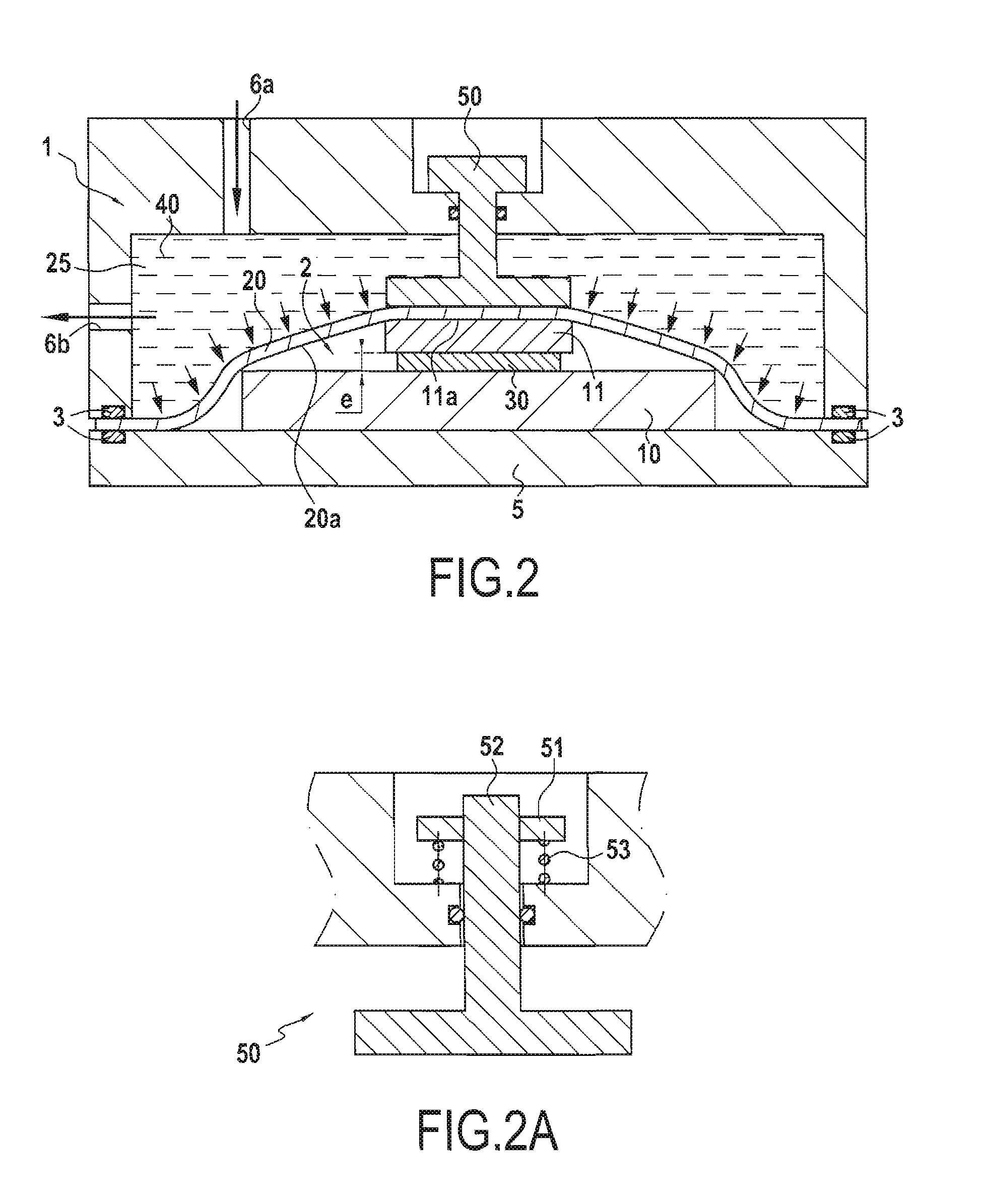

ActiveUS9367104B2Reduce chamber volumeIncrease volumeDigital data processing detailsElectric switchesEngineeringMechanical engineering

Owner:ACER INC

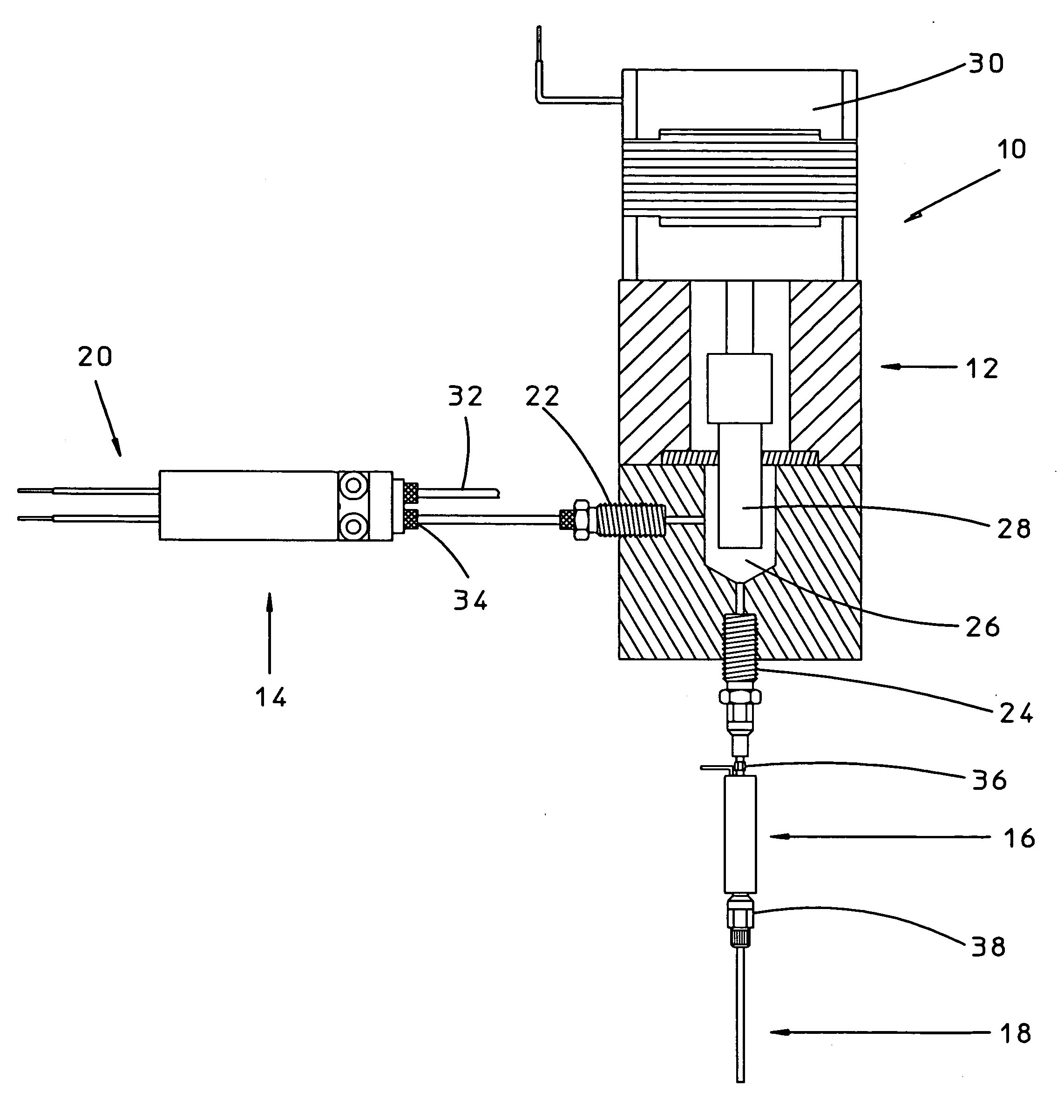

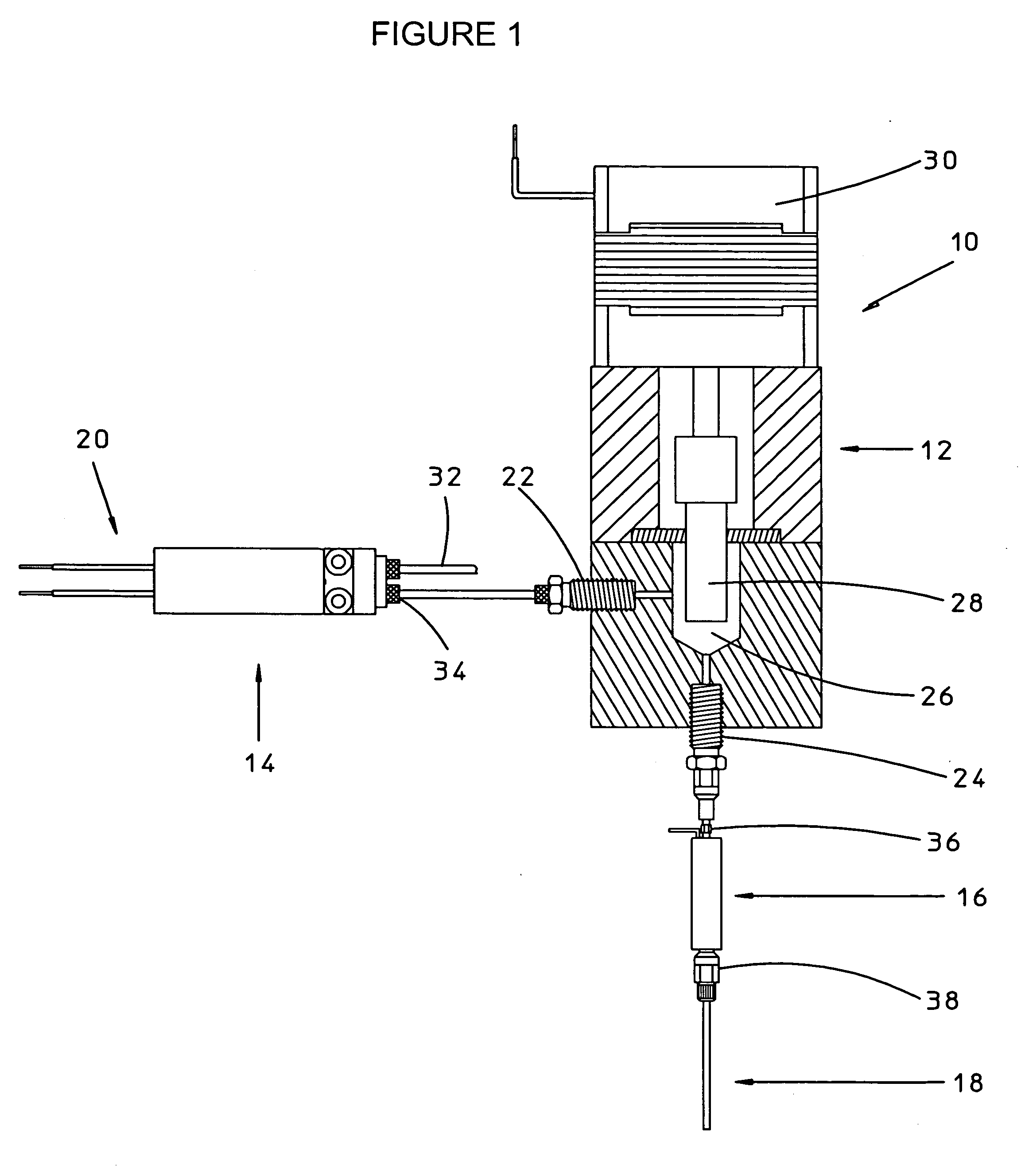

Method and apparatus for dispensing small volumes of fluid

InactiveUS20050238500A1Cheap manufacturingEconomical to maintainPower operated devicesPressure pumpsPump chamberStream flow

A method and apparatus for dispensing small volumes of fluid using a pneumatic control valve connected to the intake port of a pump having a chamber of variable volume, connecting the outlet port of the pump to the inlet port of a high speed flow control valve and a long, small diameter nozzle to the outlet port of the flow control valve, to aspirate a fluid to be dispensed into a long, small diameter nozzle by closing the pneumatic control valve, opening the flow control valve and partially expanding the volume of the pump chamber, then closing the flow control valve and further expanding the volume of the pump chamber to increase the gaseous volume within the pump chamber, pressurizing the gas within the pump chamber by closing the pneumatic control valve and reducing the volume of the pump chamber, finally dispensing a measured amount of fluid by briefly opening the flow control valve for a measured time to allow controlled amounts of fluid to be dispensed through the nozzle.

Owner:LEE COMPANY THE

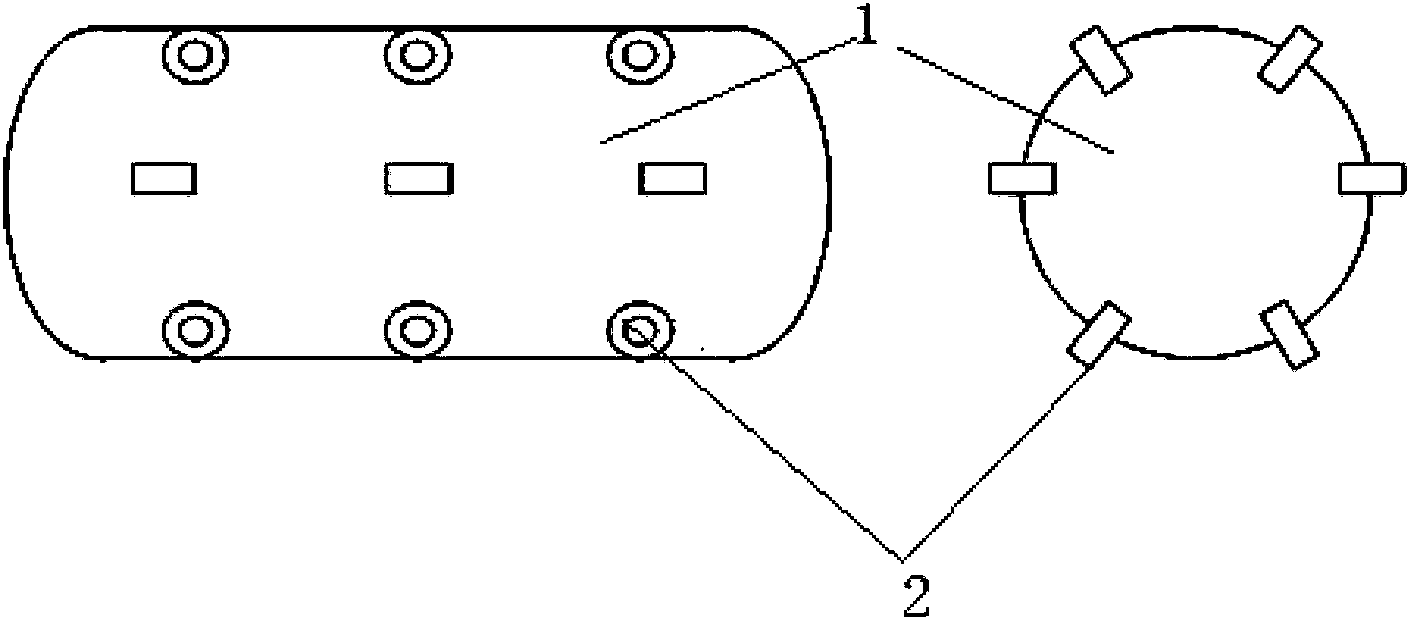

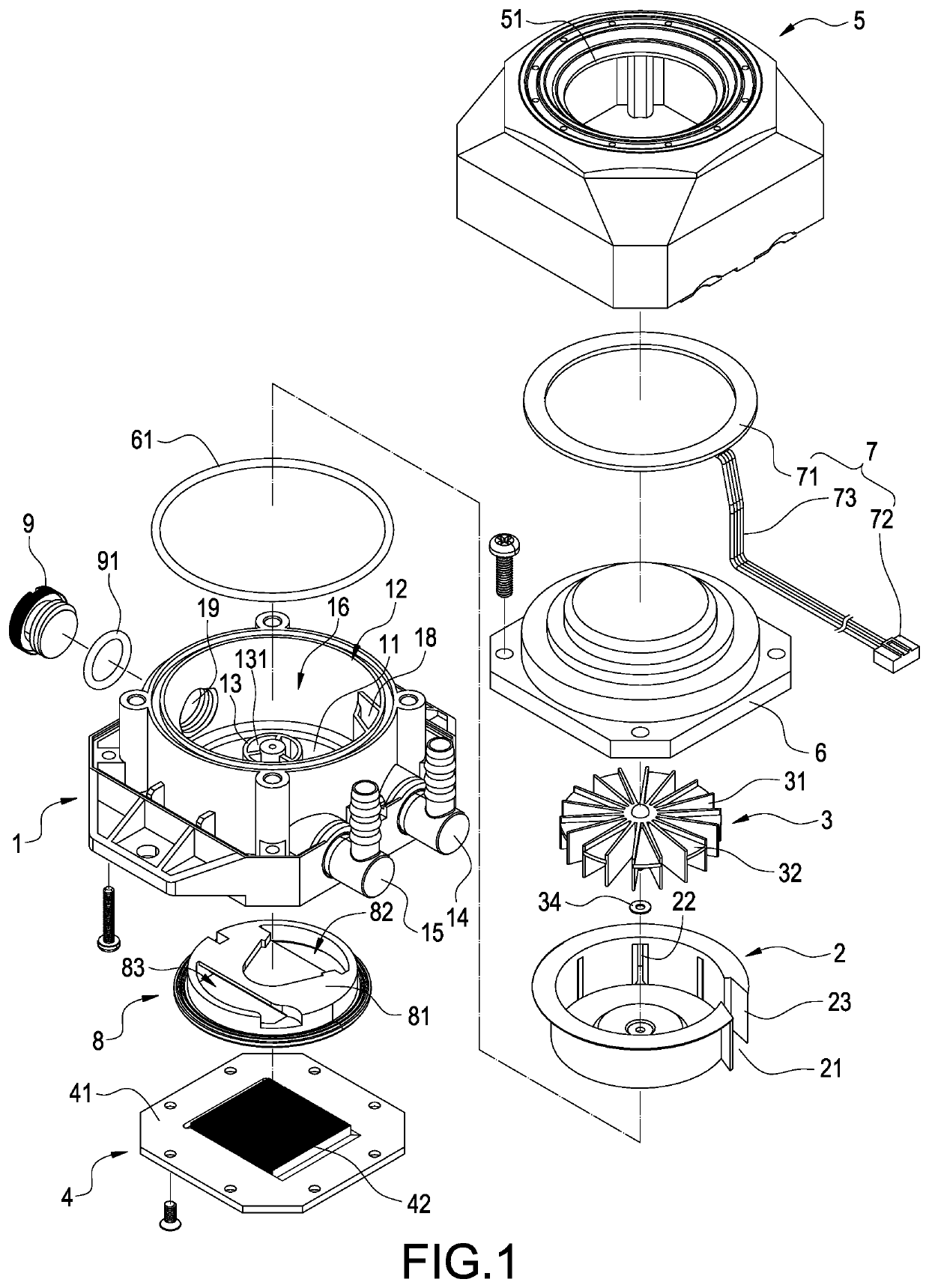

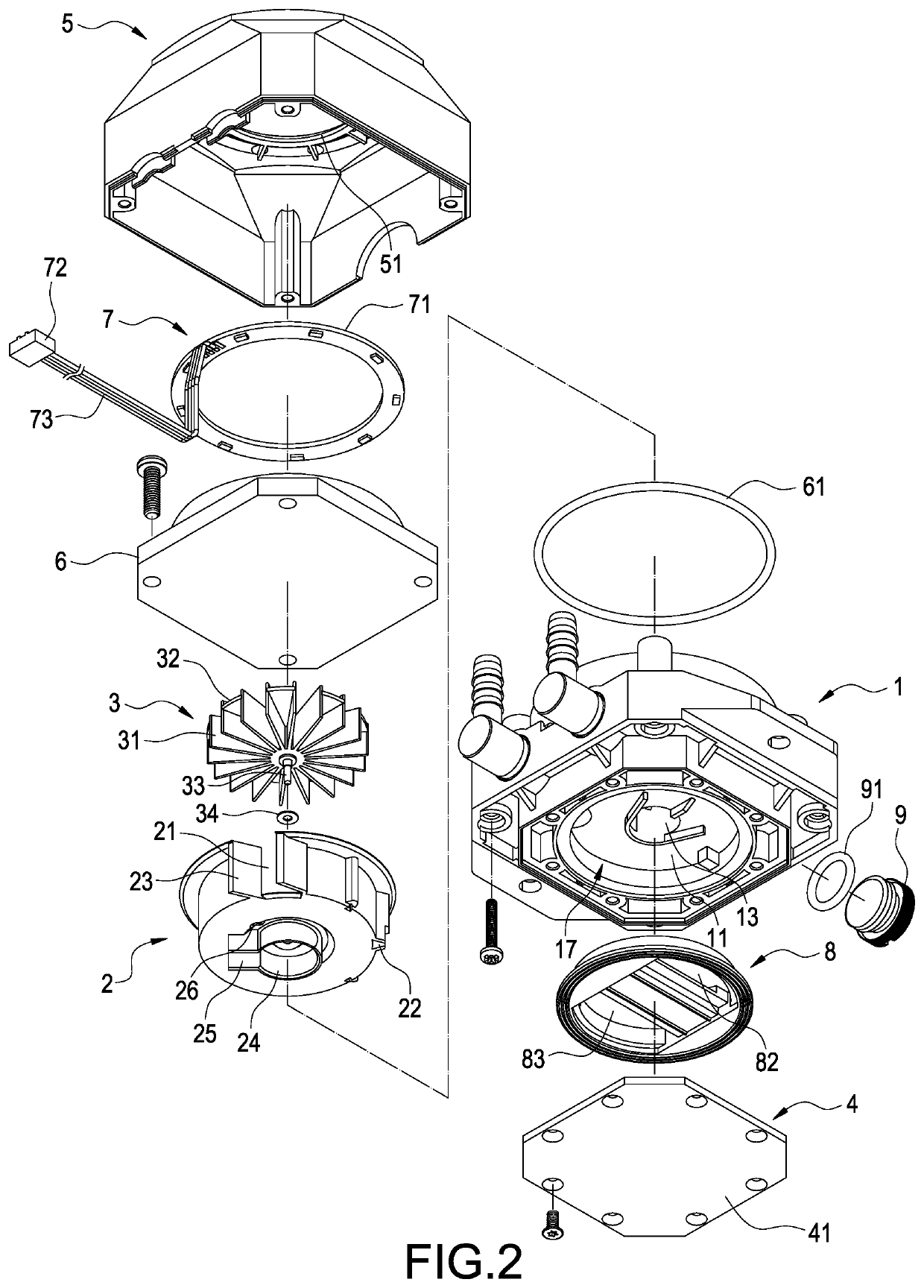

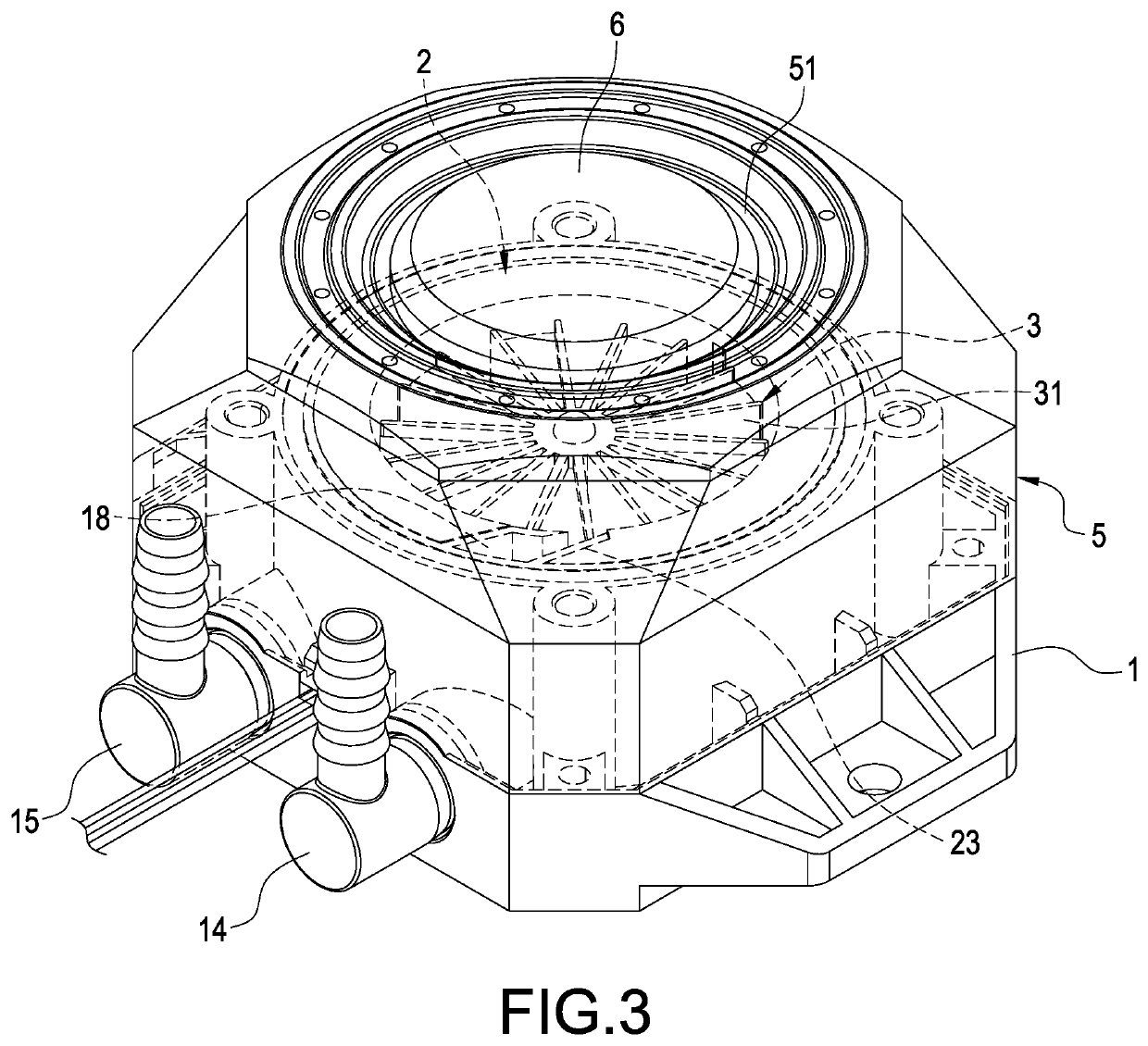

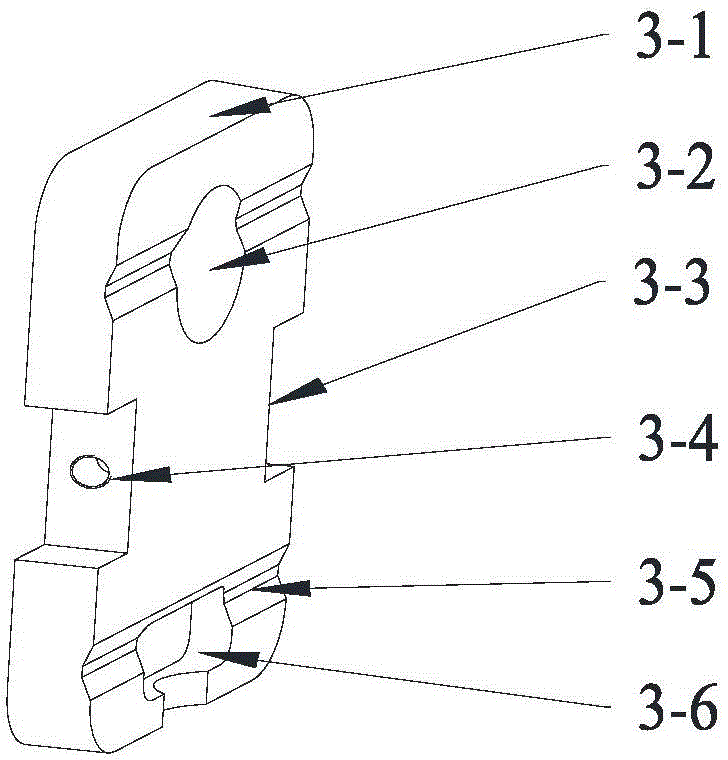

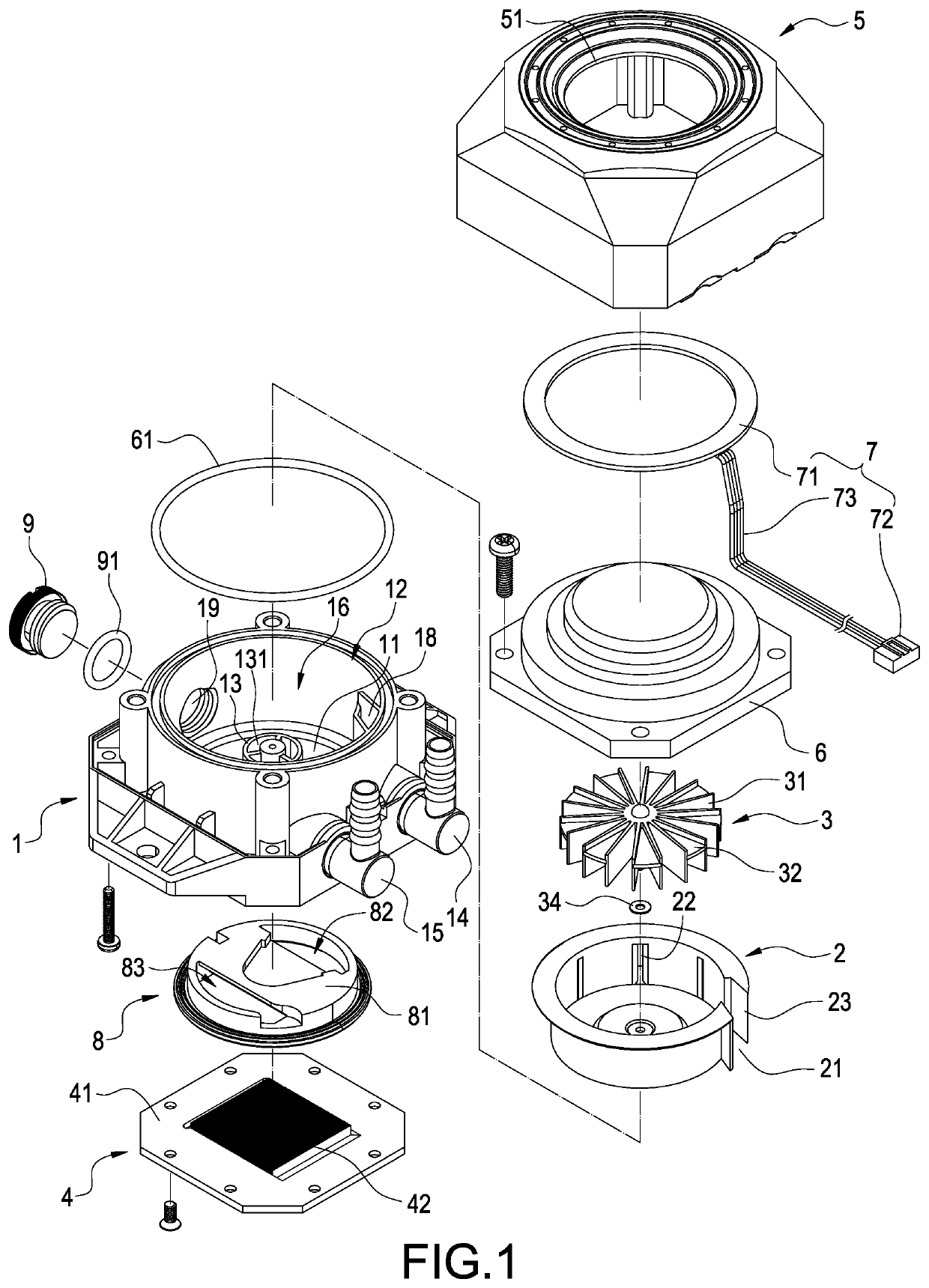

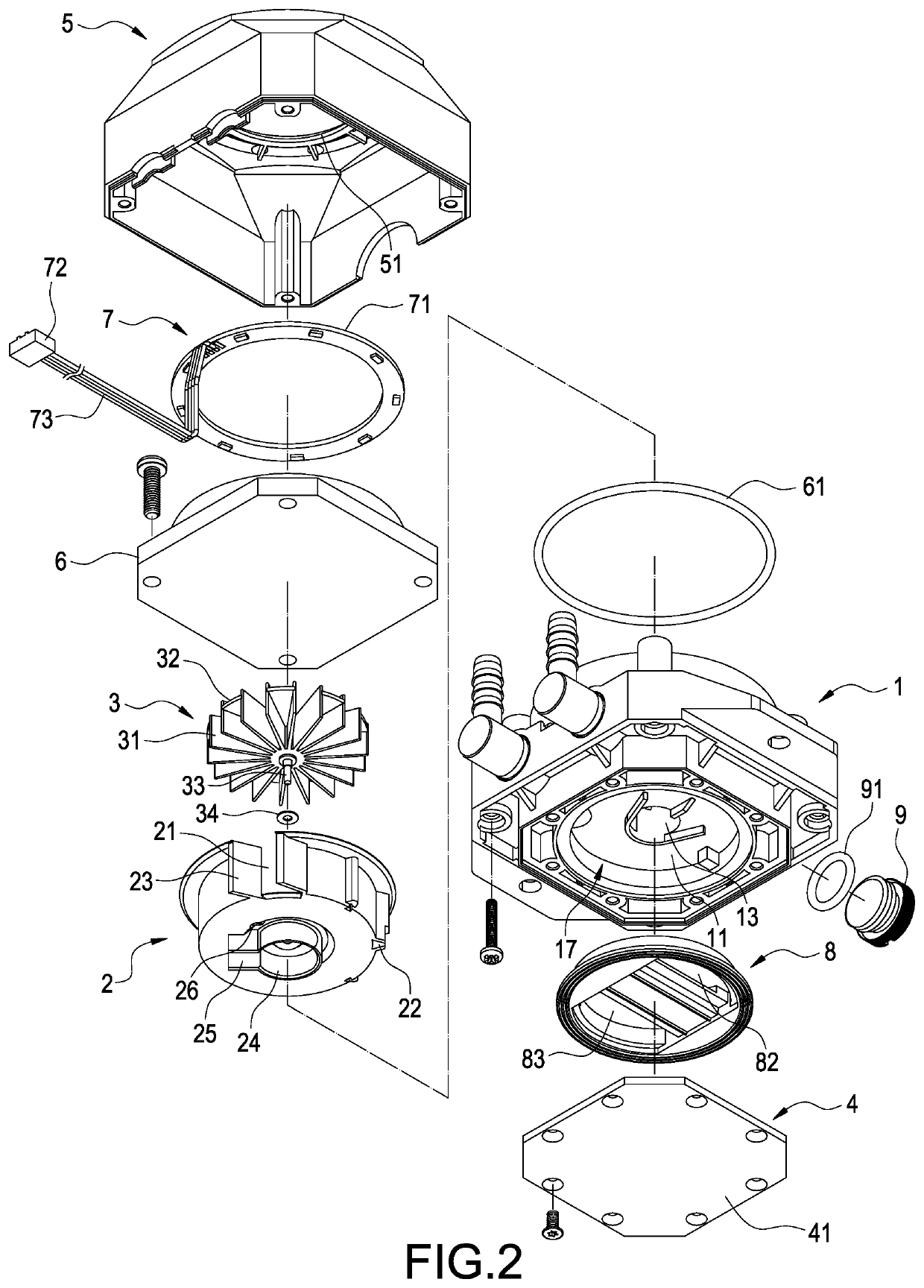

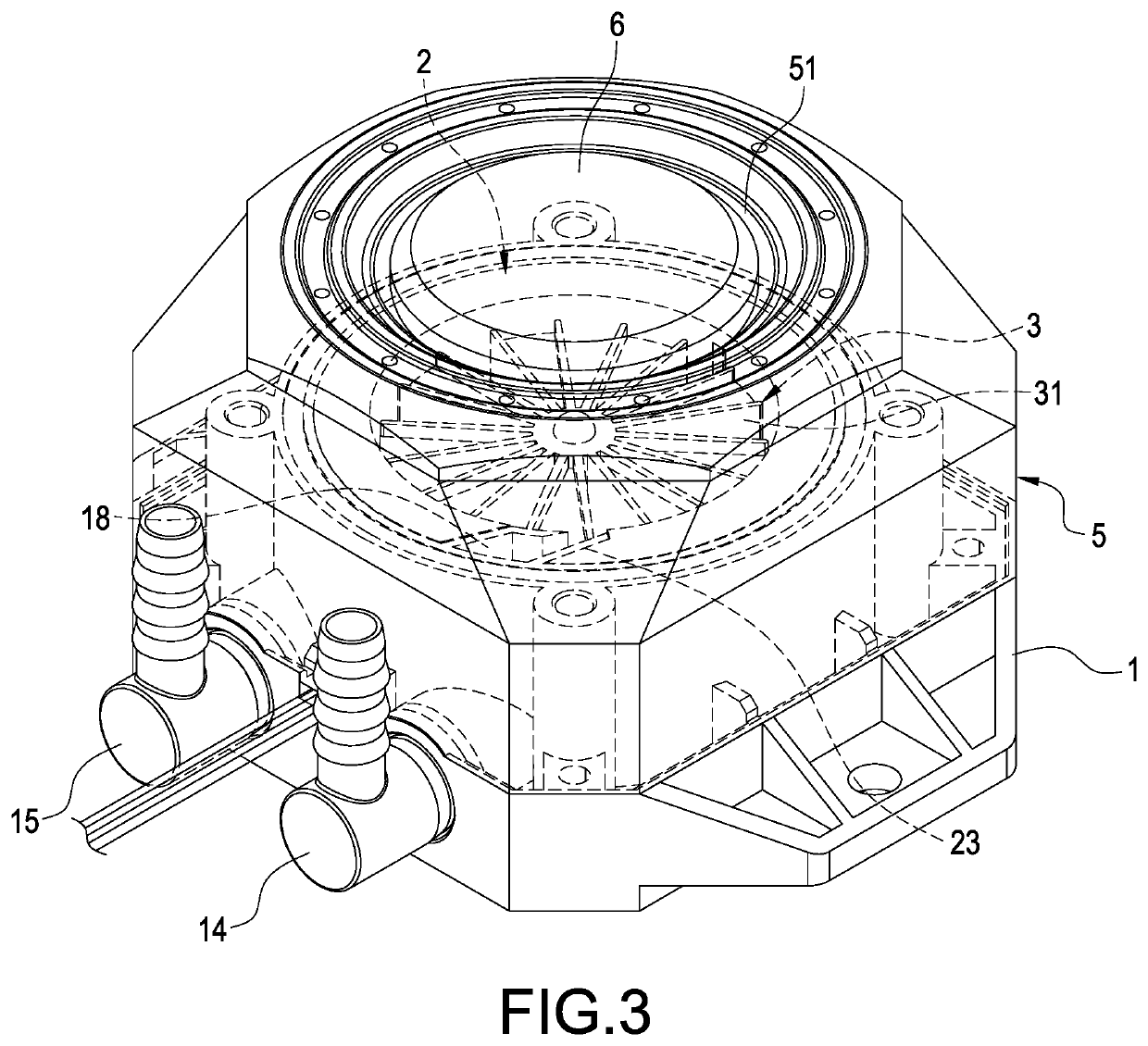

Water-cooled heat dissipating device

ActiveUS20200173728A1Reduce chamber volumeSufficiency can be reliablyDigital data processing detailsSemiconductor/solid-state device detailsImpellerWorking fluid

A liquid cooling device includes a base (1), a passive impeller (3) and a cold plate (4). The base (1) includes a division plate (11), a chamber (12) and a flow guiding pole (13). The division plate (11) divides the chamber (12) into a catchment portion and a heat exchanging portion (17). The flow guiding pole (13) communicates with both the catchment portion (16) and the heat exchanging portion (17). The passive impeller (3) is received in the chamber (12) and radially driven to rotate by the working fluid. The cold plate (4) is arranged correspondingly to the heat exchanging portion (17) and fastened to the base (1).

Owner:KUAN DING TECH

Apparatus to dry, weigh and sanitize body

InactiveUS20150343166A1Easy to useReduce chamber volumeRespiratorsBathroom accessoriesPlastic materialsWhole body

A full body drying system is an apparatus that can dry a full body with forced air, measure the weight of the body, and provide other health enhancing functions. The apparatus comprises a lower frame, and an upper frame, a blower unit, a foot plate, and a weighing scale. The lower frame and the upper frame provide the other components of the apparatus with the proper structural support. Once the user steps onto the foot plate, the blower unit provides the motorized forced air carrying massive amount of anions, which is used to dry and also to invigorate the body, and simultaneously the body weight is measured and displayed. In addition, around the user's feet area, UV light combined with antimicrobial plastic material used for the foot plate provide effective disinfection of the user's feet, which is further enhanced by the disinfecting ability of anions in the forced air stream.

Owner:RYU JASON +2

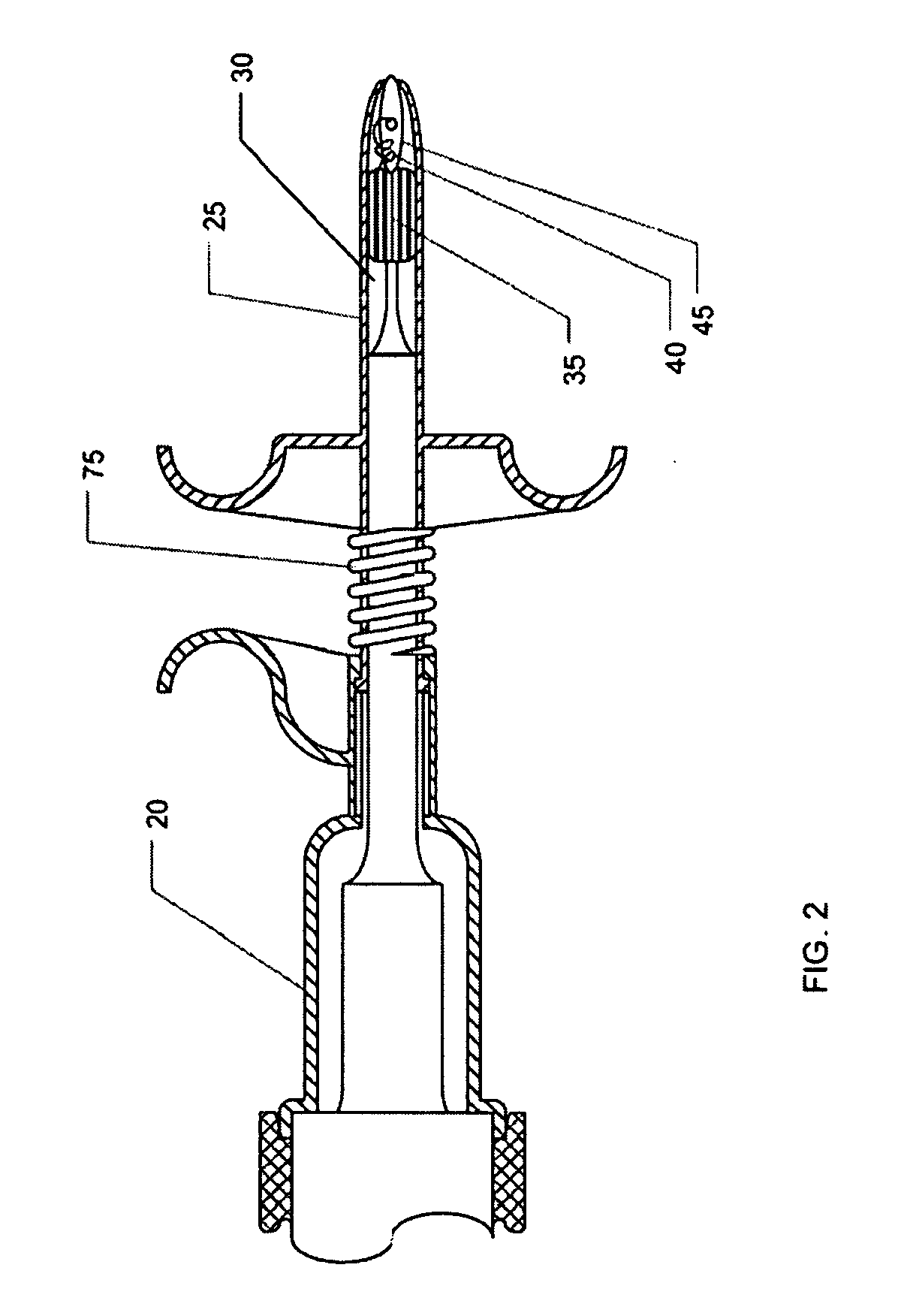

Squirting toy including a dynamo system and methods thereof

ActiveUS20140252035A1Reduce turbulenceSpeed up the flowSighting devicesLiquid ejecting gunsElectricityWater source

A squirting toy capable of squirting water received from a reservoir and / or from an external source. The squirting toy can include a housing, a piston, a shaft, and an handle portion. As the piston is slidably moved through the housing the water can be squirted out of the housing. Further, as the piston is slidably moved through the housing an electrical assembly including a turbine can be activated generating electricity to power an electric device (e.g., a light).

Owner:EASEBON SERVICES

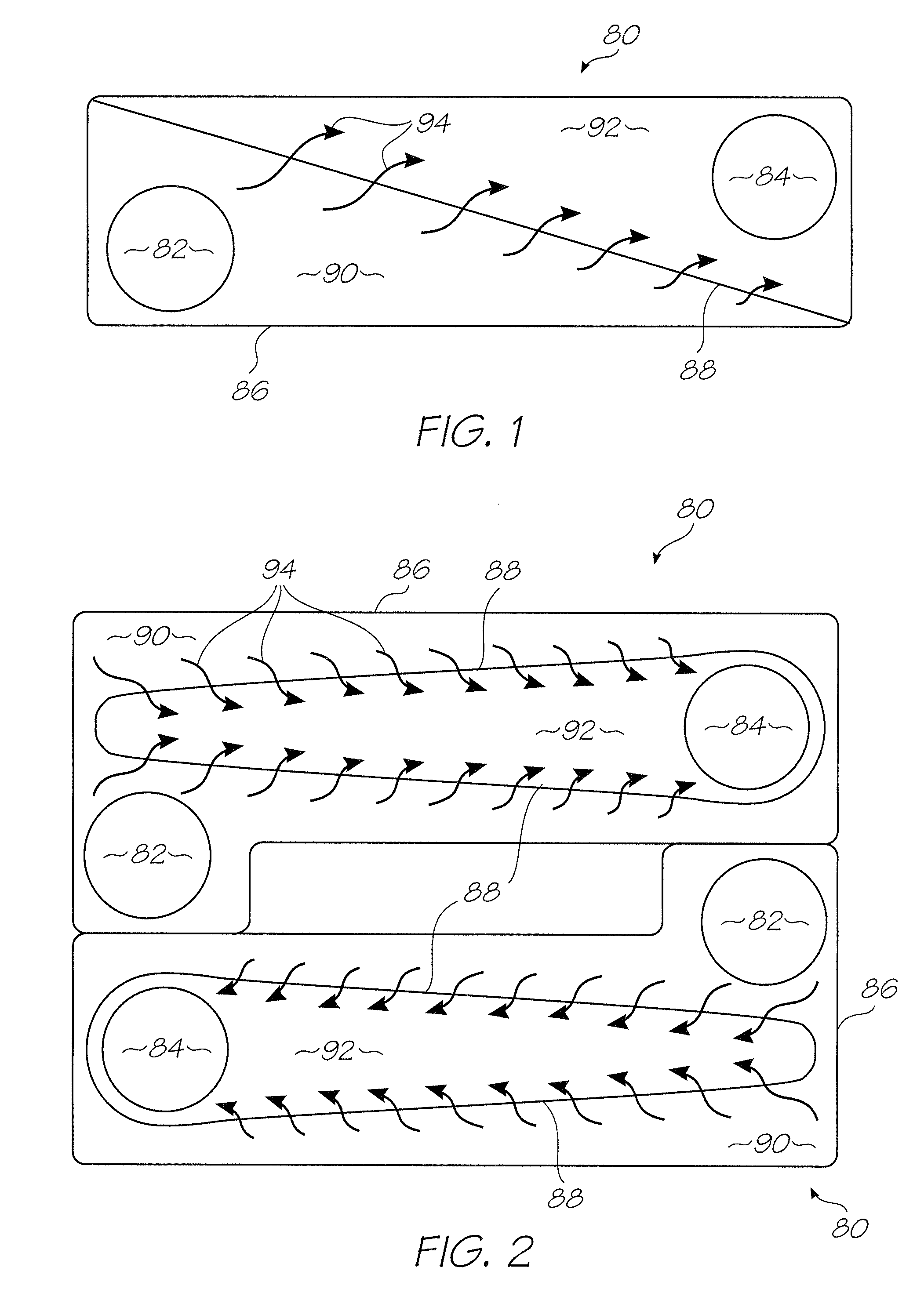

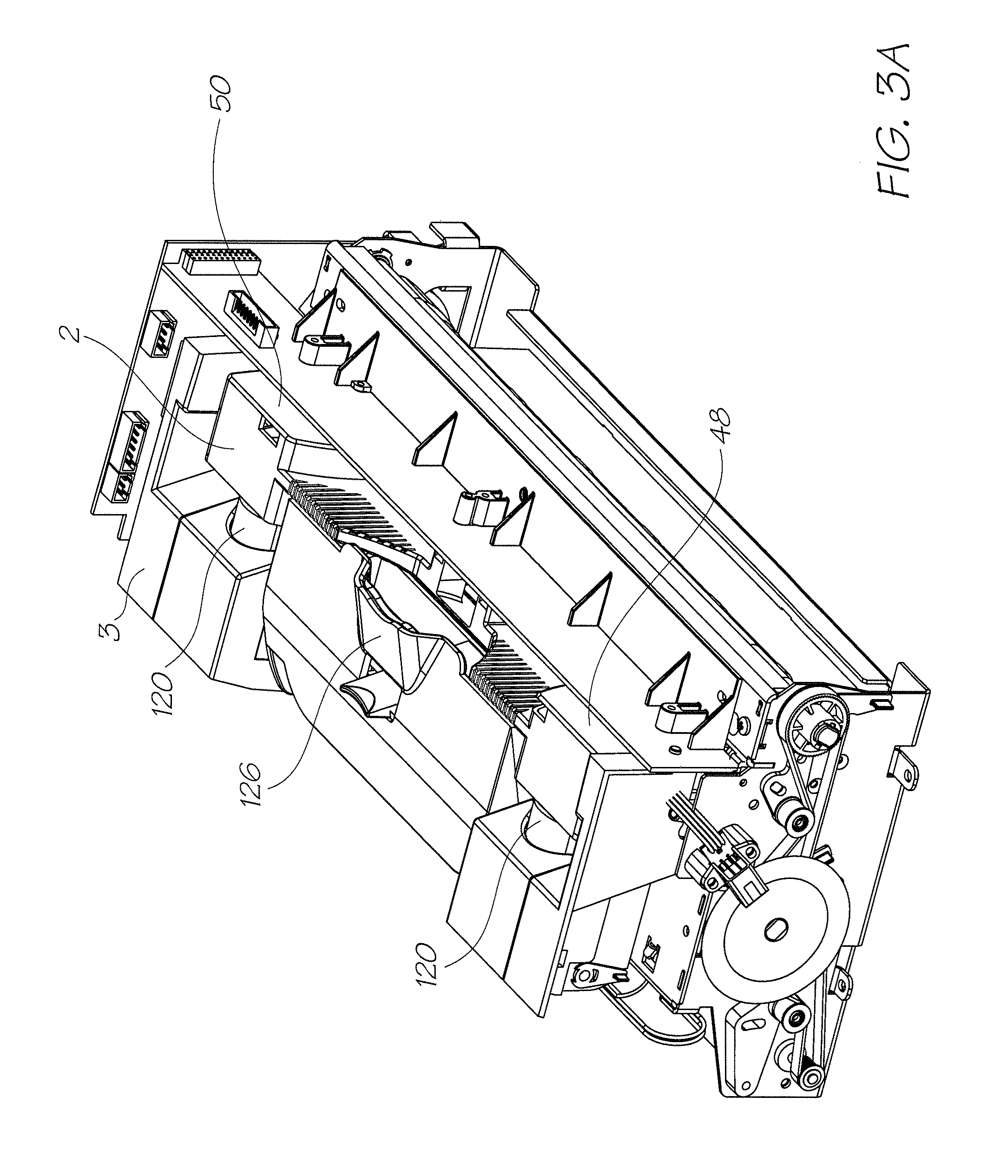

Compact ink filter assembly

InactiveUS20090179977A1No-flow or low-flow zones are minimizedReduce chamber volumePrintingWaste management

A filter assembly for an inkjet printhead, that has an inlet for connection to an ink supply, an outlet for connection to an inkjet printhead, a filter membrane for filtering ink flowing from the inlet to the outlet, and a chamber to house the filter membrane. The filter membrane divides the chamber into an upstream portion for holding a quantity of the unfiltered ink, and a downstream portion for holding a quantity of the filtered ink. The upstream portion tapers towards the outlet and the downstream portion tapers towards the inlet.

Owner:ZAMTEC +1

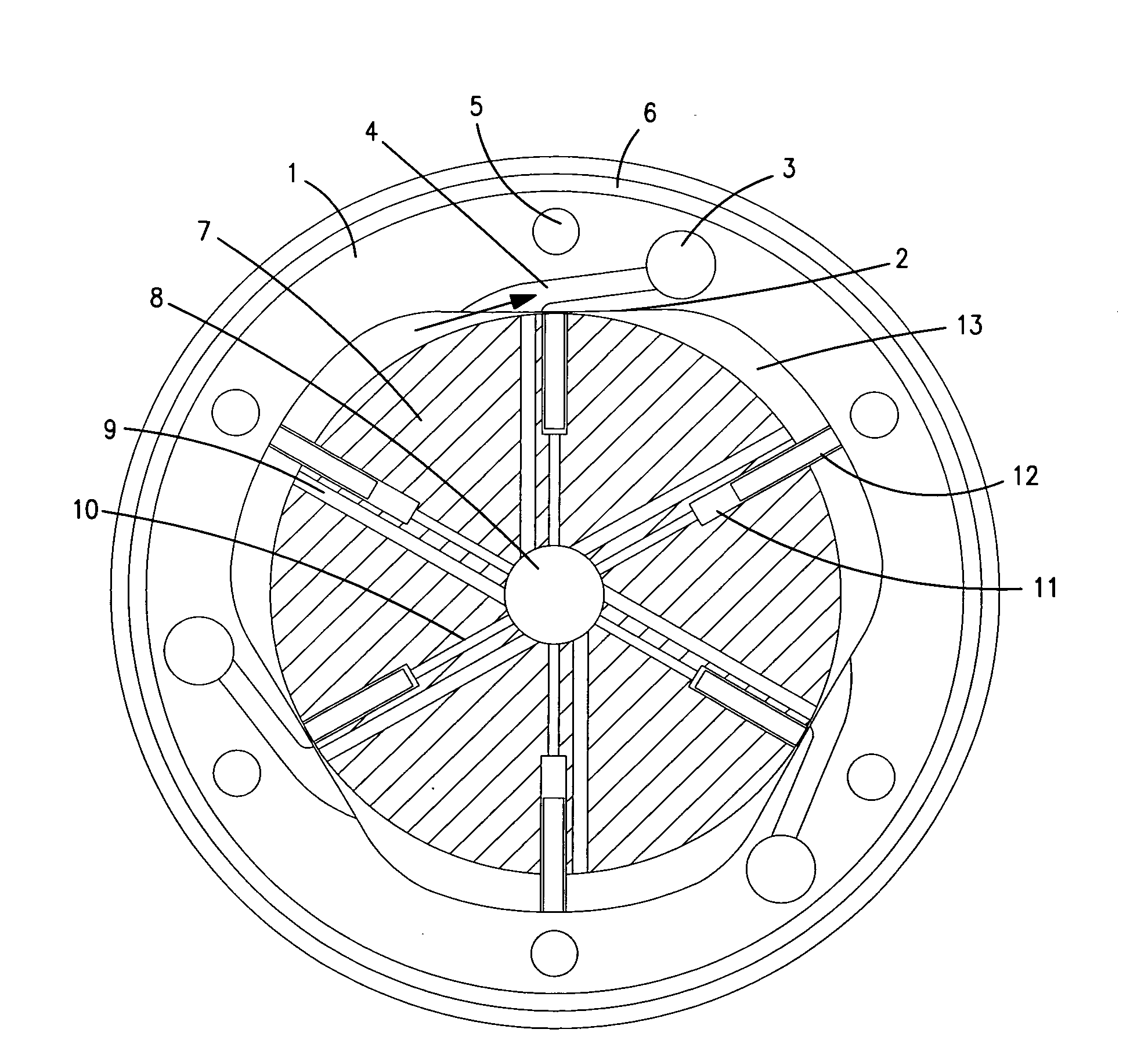

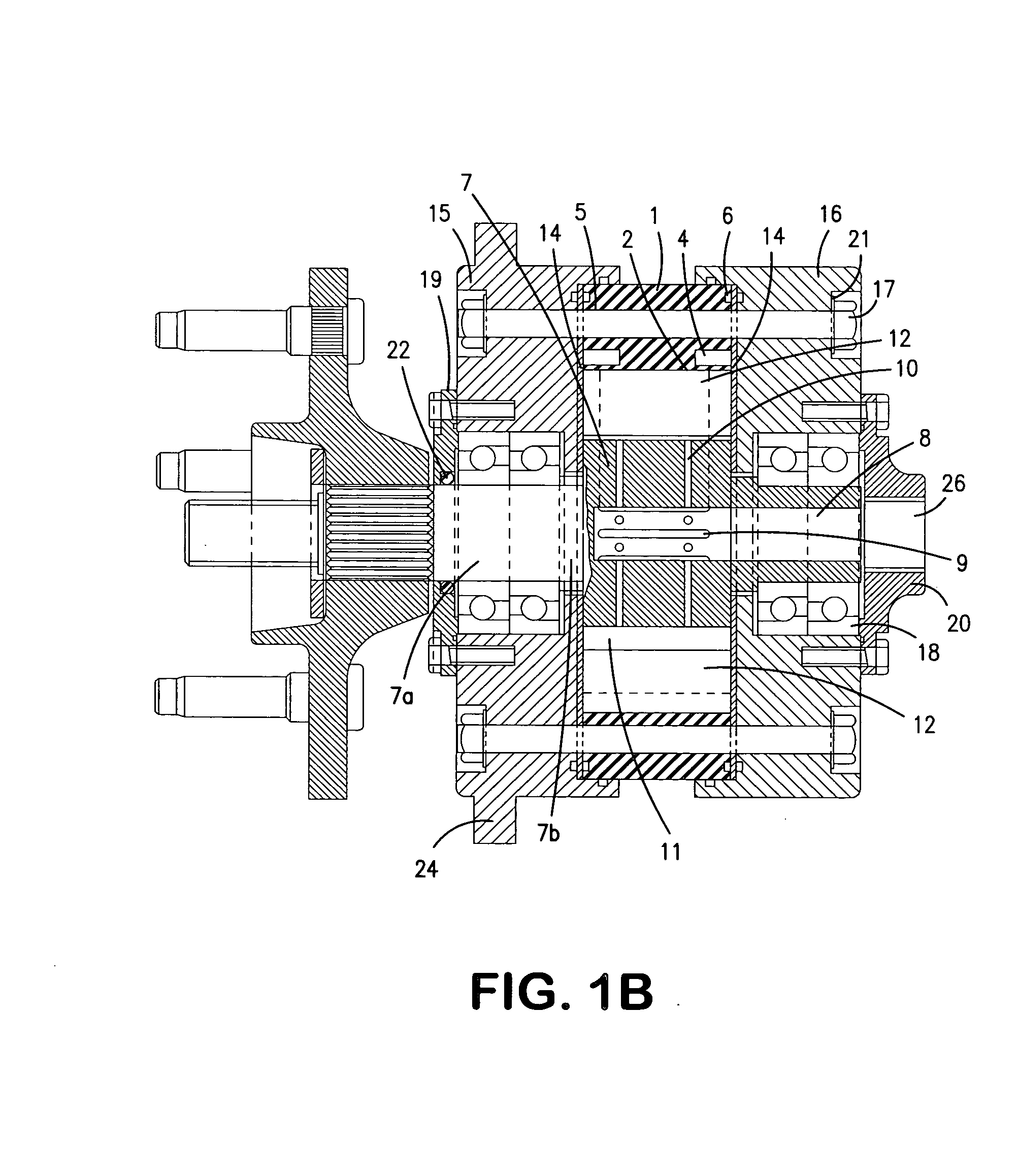

Hydraulic traction system for vehicles

InactiveUS7814999B2Reduce the displacement angleReduce chamber volumeDigital data processing detailsAutomatic steering controlHydraulic motorTraction system

A hydraulic traction system for vehicles is described. The system comprises a hydraulic vane motor mounted at each wheel of the vehicle, and equal number of identical hydraulic vane motors operated as engine driven pumps, and a control system for regulating the flow and direction of hydraulic oil during operation. The hydraulic motor is of a novel design that has a hollow non-drive shaft that accepts incoming hydraulic oil, this allows internal components of the hydraulic motor to be arranged in such a way to improve the efficiency of the hydraulic traction system.

Owner:SHEVKET ALPER

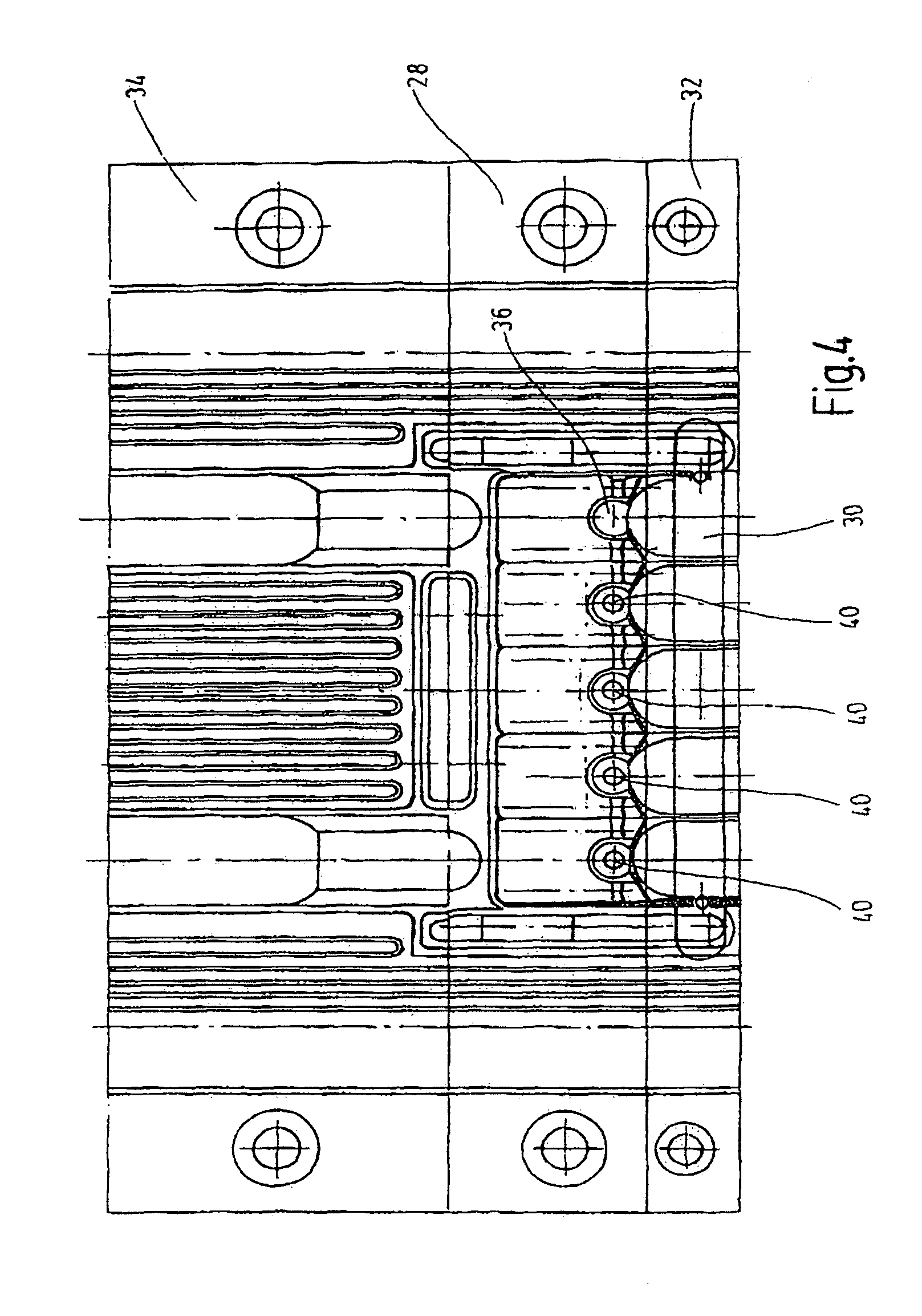

Method for adhering parts and device for implementing said method

A method is provided of bonding together at least two parts. The method includes assembling together at least two parts and at least one adhesive layer, the adhesive being configured so that its adhesive power increases on heating as a result of it polymerizing, at least one of the parts being made of composite material or of metal, the adhesive layer being present, after assembly, between the parts, the assembled together parts and the adhesive being present in a chamber defined by a wall, the wall having an inside face situated facing a first part present between the adhesive layer and the wall, the first part being intended to be bonded to a second part and only a fraction of the second part being present inside the chamber; and applying a liquid against the wall on its side opposite from the chamber.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

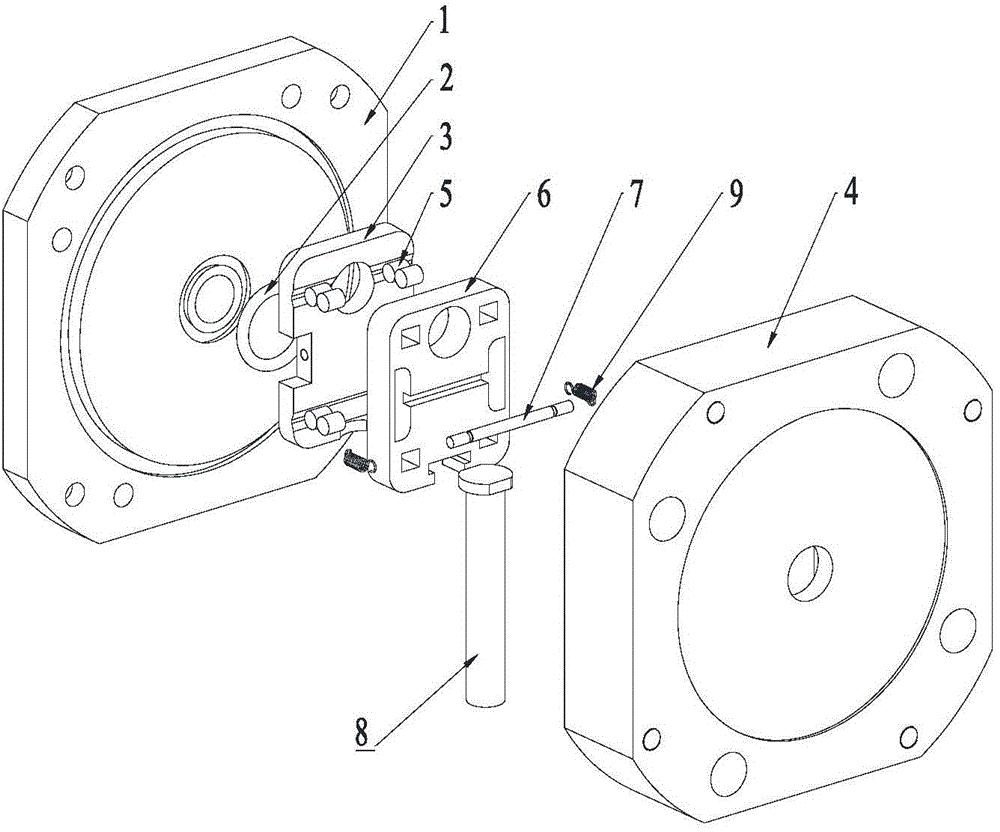

Vacuum gate valve, mass spectrometry instrument and method for establishing high vacuum environment in mass spectrometry sample change

InactiveCN104455506AImprove sealingSimple structureSlide valveMass spectrometersMass Spectrometry-Mass SpectrometryMass analyzer

The invention discloses a vacuum gate valve for a mass spectrometer. The vacuum gate valve comprises a valve seat and a valve element, and a sealing ring is arranged between the valve seat and the valve element. The valve element is provided with a squeezing mechanism used for enabling the valve element to tightly press the sealing ring. The invention further discloses a mass spectrometry instrument, the mass spectrometry instrument comprises an ion source cavity and an analysis chamber which is communicated with the ion source cavity, and a communicated channel of the ion source cavity and the analysis chamber is provided with the vacuum gate valve. In addition, the invention discloses a method for establishing a high vacuum environment in mass spectrometry sample change. The method includes the steps that the communicated channel of the ion source cavity and the analysis chamber is closed through the vacuum gate valve, the ion source cavity is opened for changing samples, after the samples are changed, the ion source cavity is pre-vacuumized, the vacuum gate valve is opened so that the ion source cavity and the analysis chamfer can be communicated with each other, and vacuumizing is conducted. According to the devices and the method, the vacuum needed by detection of the mass spectrometer can be established quickly after the samples are changed, the sealing effect is good, and the sample changing efficiency is high.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

Ultrasonic vascular closure method

InactiveUS20090228039A1Extended stayLow costChiropractic devicesEye exercisersPuncture WoundVascular tissue

Owner:BACOUSTICS LLC

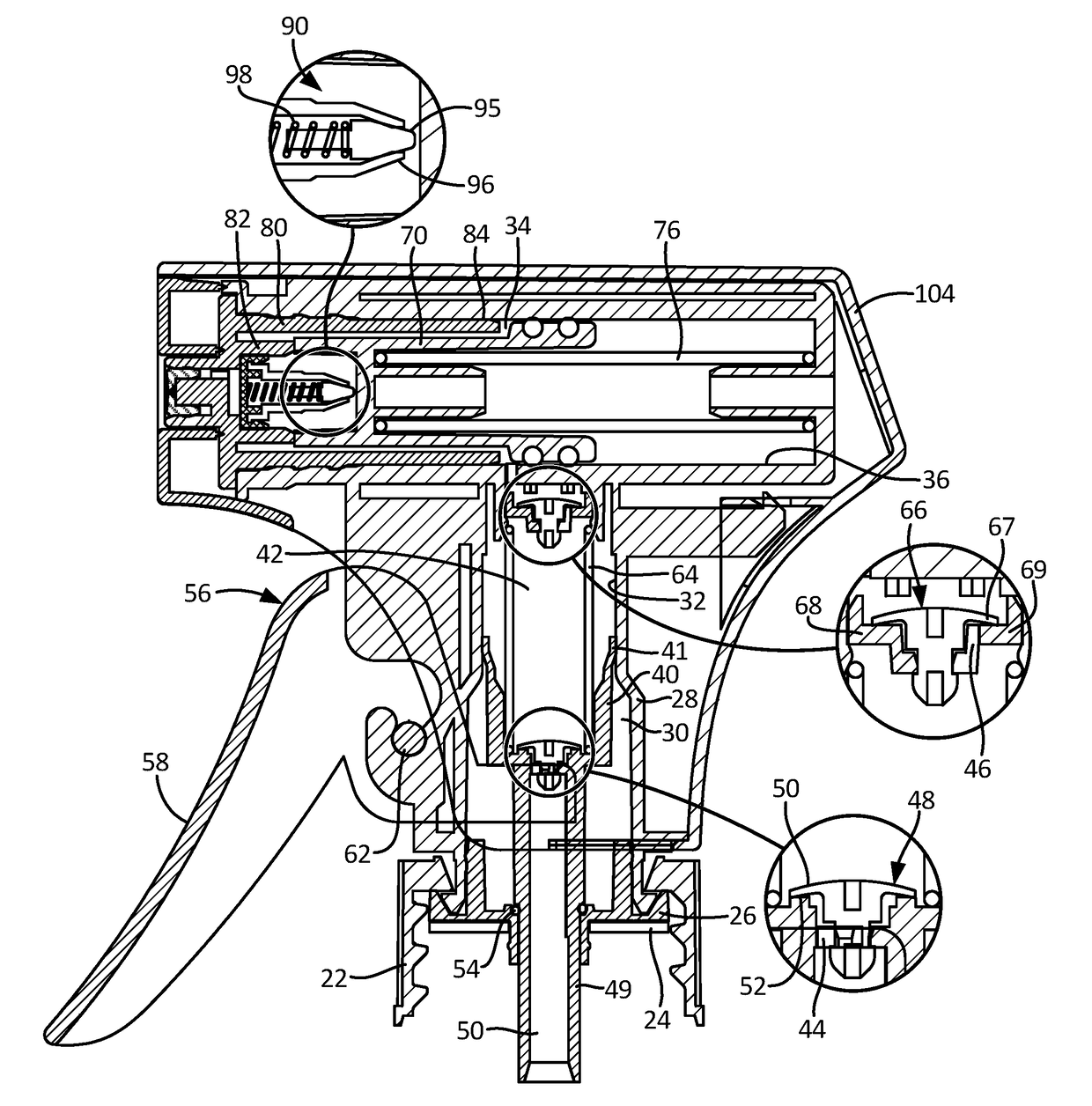

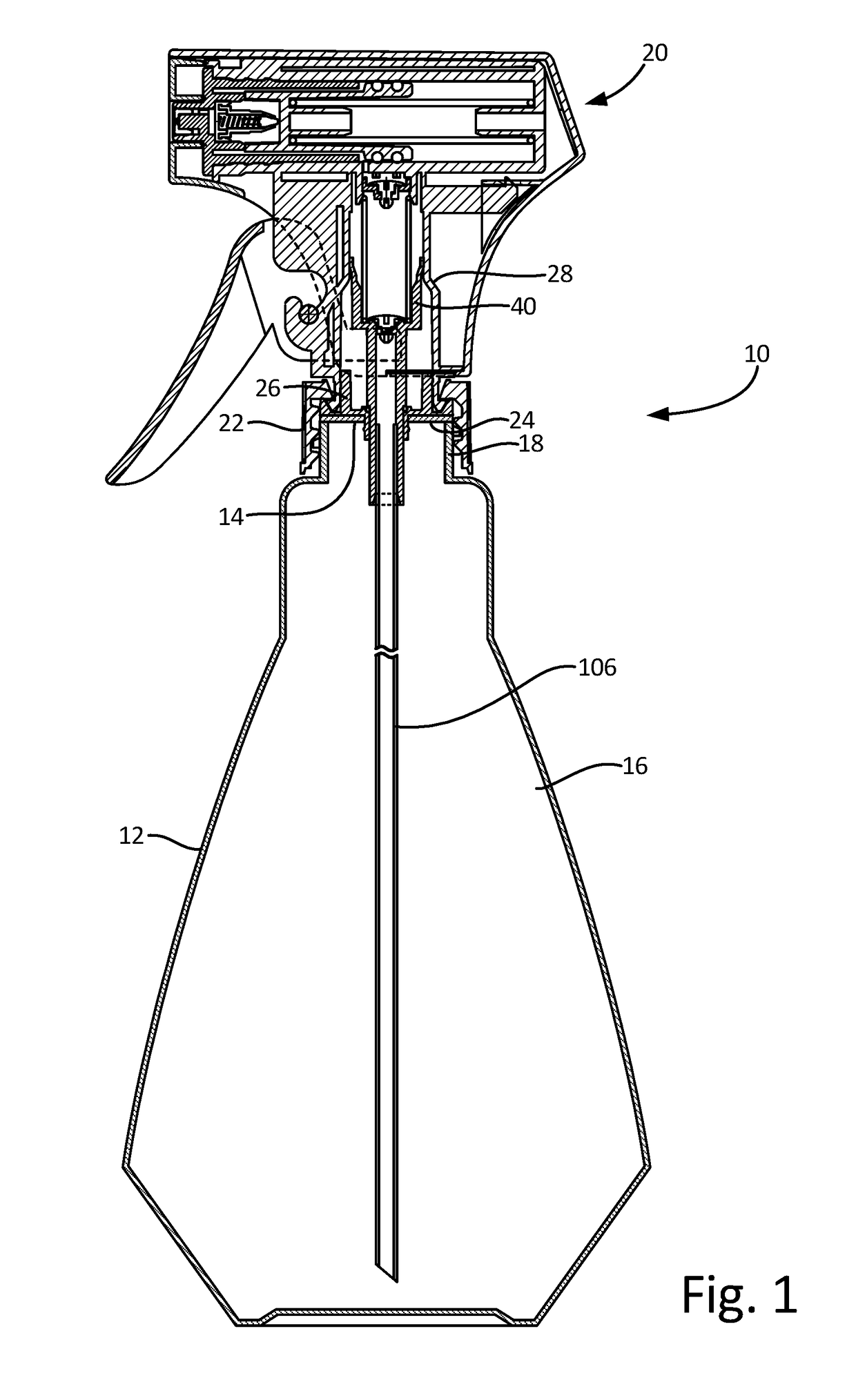

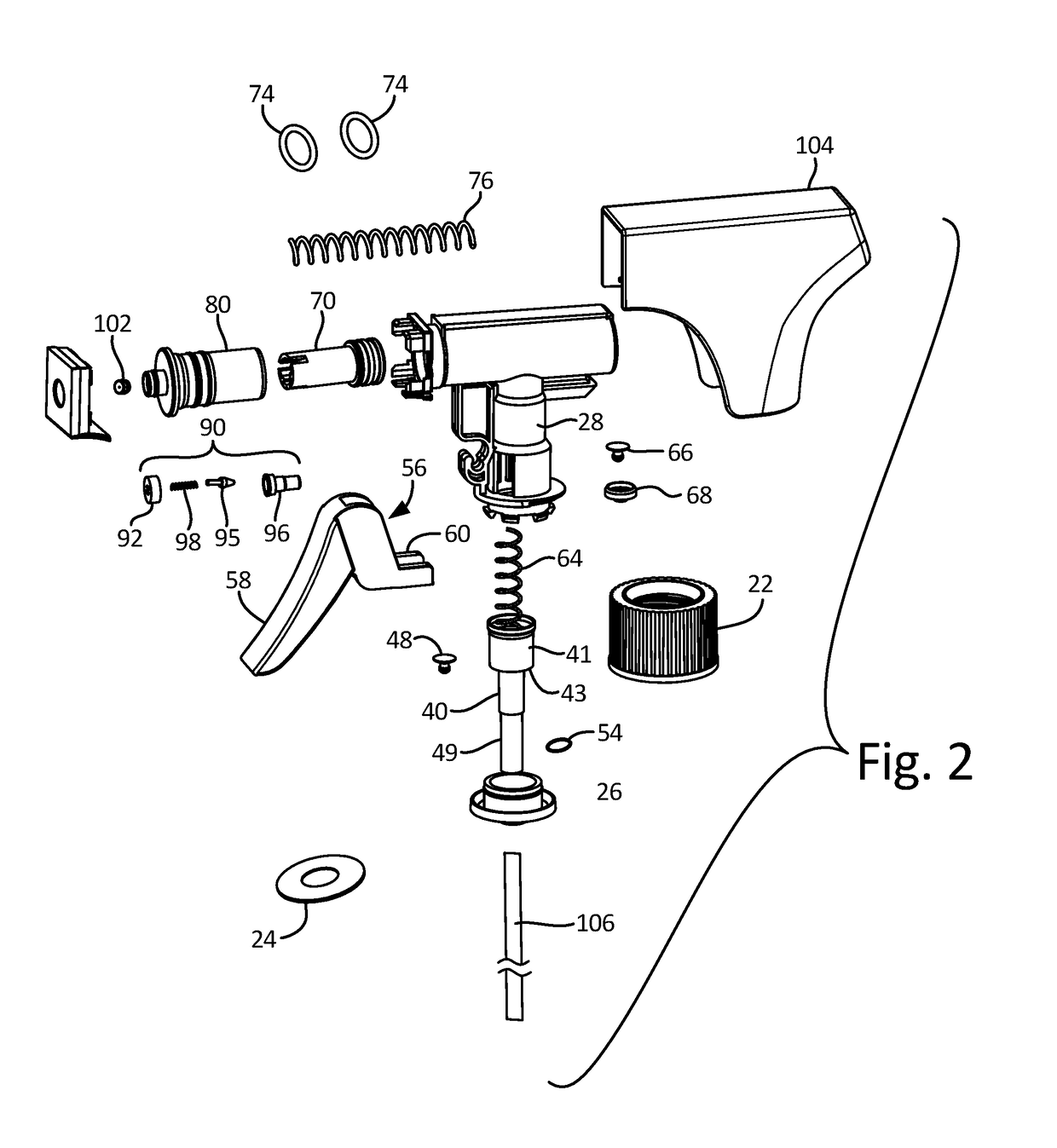

Fluid Pump

InactiveUS20170328361A1Reduce chamber volumePositive displacement pump componentsSingle-unit apparatusSpray nozzleEngineering

A fluid pump apparatus includes a multi-chamber pump mechanism, with an actuator having a nozzle portion defining a nozzle chamber that has a controlled opening through a discharge valve, which is calibrated to open in response to a fluid pressure in the nozzle chamber exceeding the threshold pressure.

Owner:ZHEJIANG JM IND

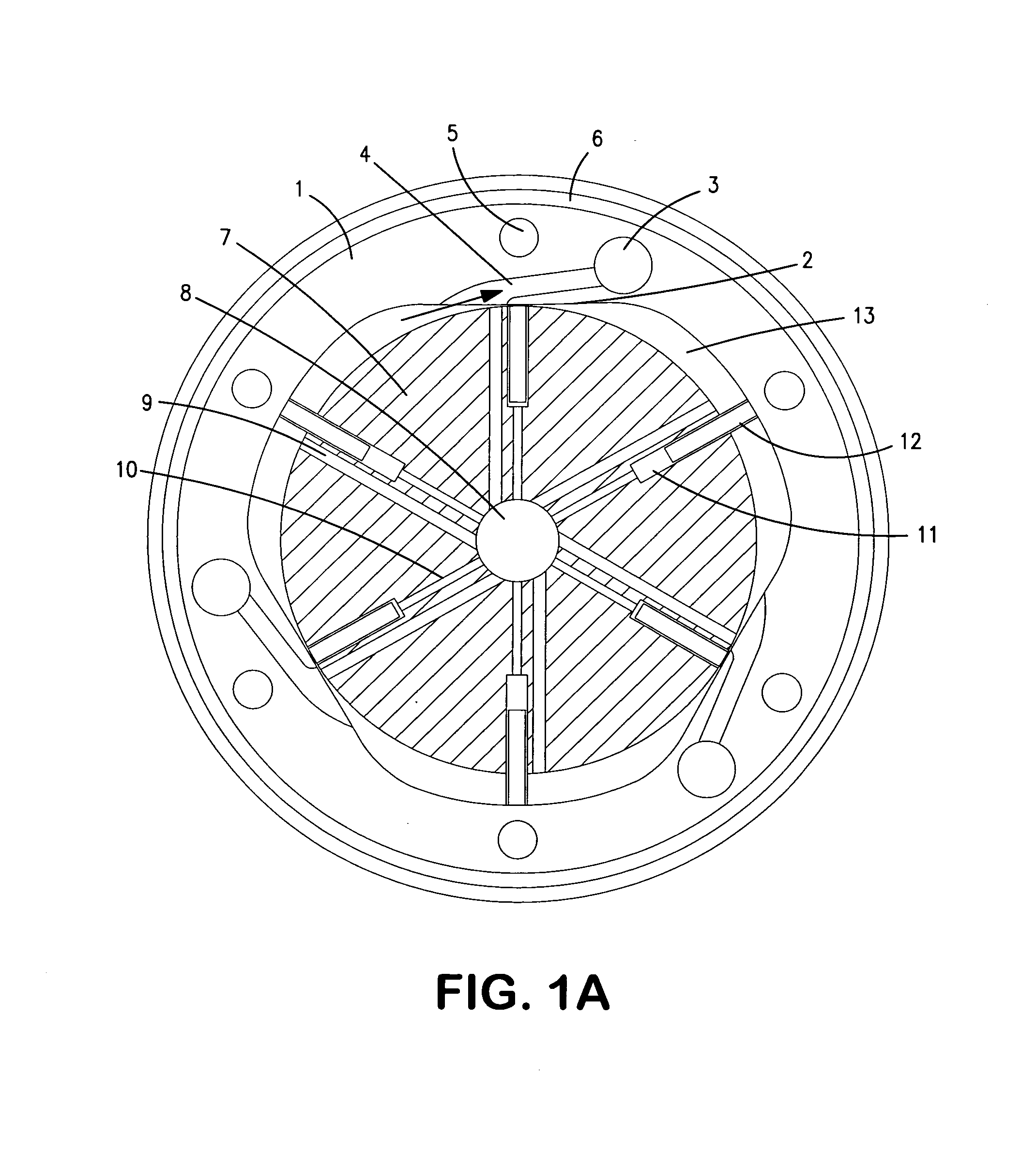

Hydraulic traction system for vehicles

InactiveUS7331411B2Reduce the displacement angleReduce chamber volumeRotary piston pumpsMotor depositionHydraulic motorTraction system

A hydraulic traction system for vehicles is described. The system comprises a hydraulic vane motor mounted at each wheel of the vehicle, and equal number of identical hydraulic vane motors operated as engine driven pumps, and a control system for regulating the flow and direction of hydraulic oil during operation. The hydraulic motor is of a novel design that has a hollow non-drive shaft that accepts incoming hydraulic oil, this allows internal components of the hydraulic motor to be arranged in such a way to improve the efficiency of the hydraulic traction system.

Owner:SHEVKET ALPER

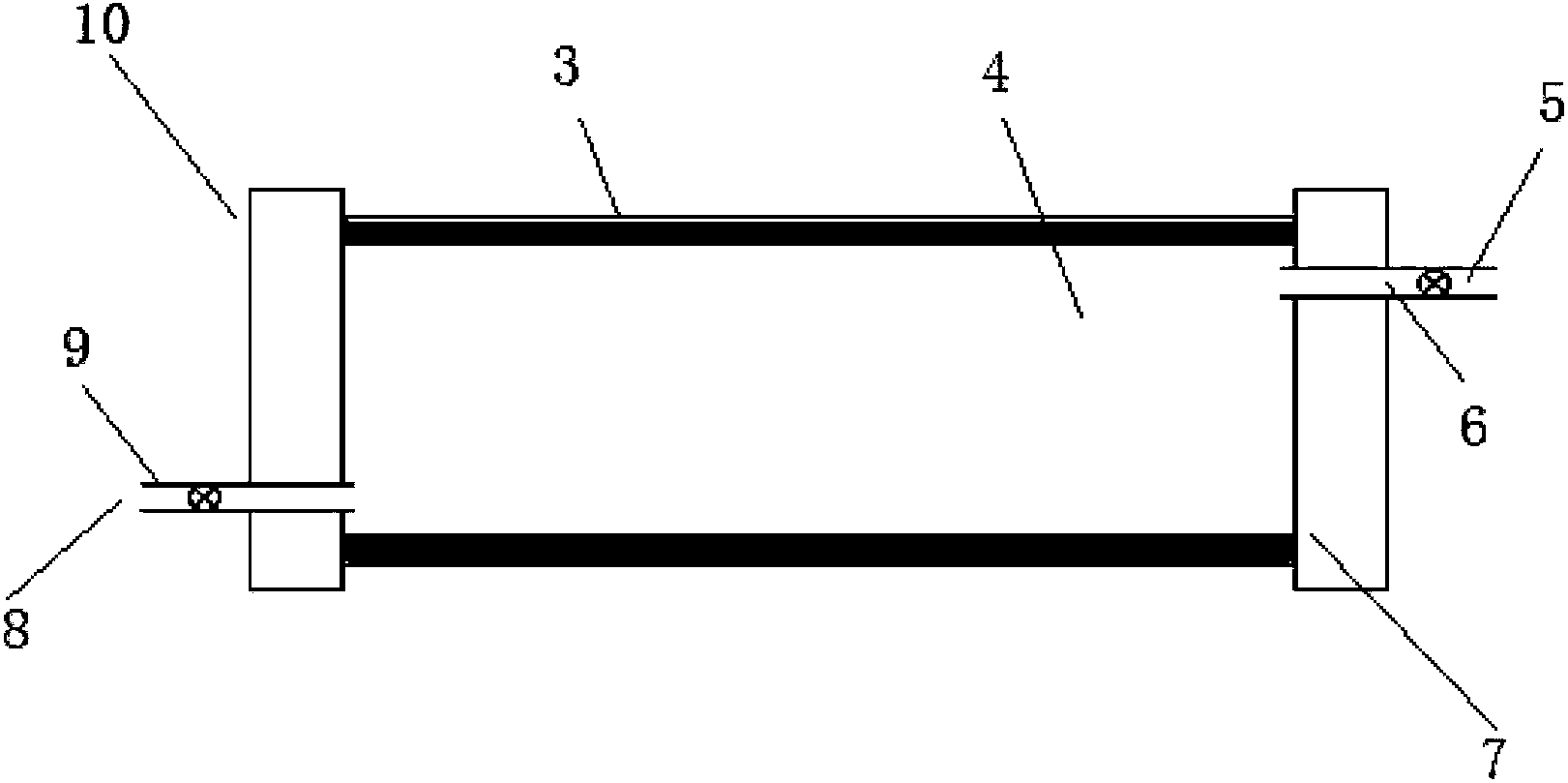

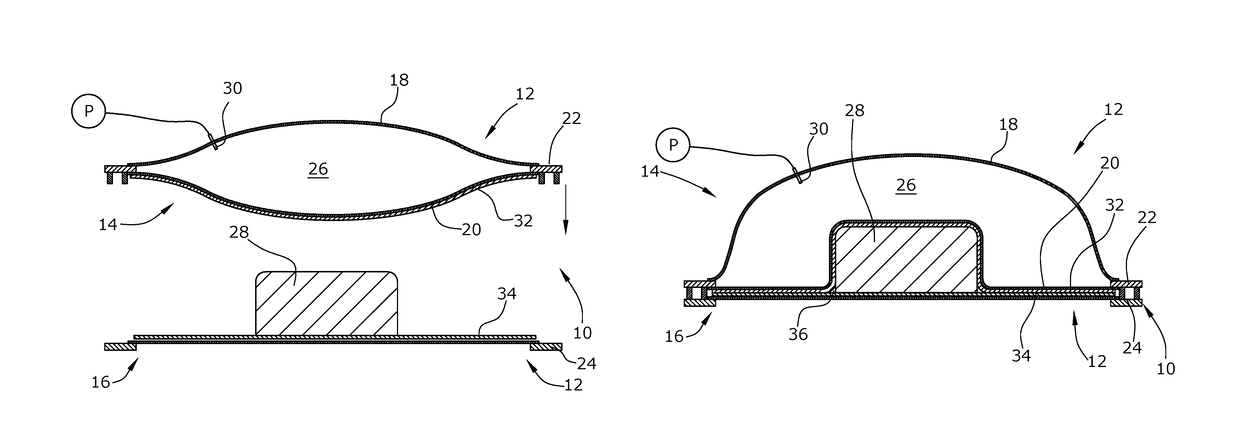

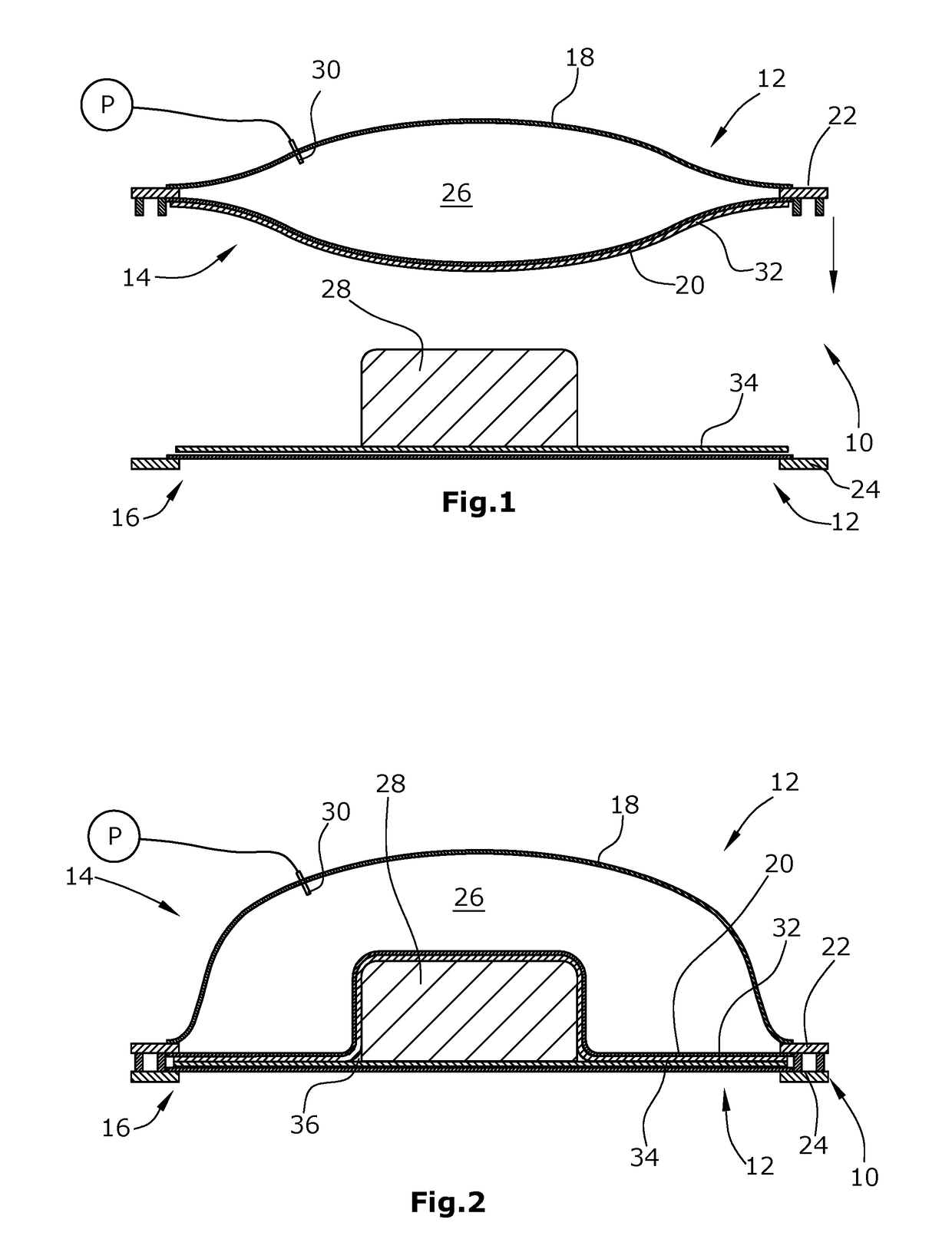

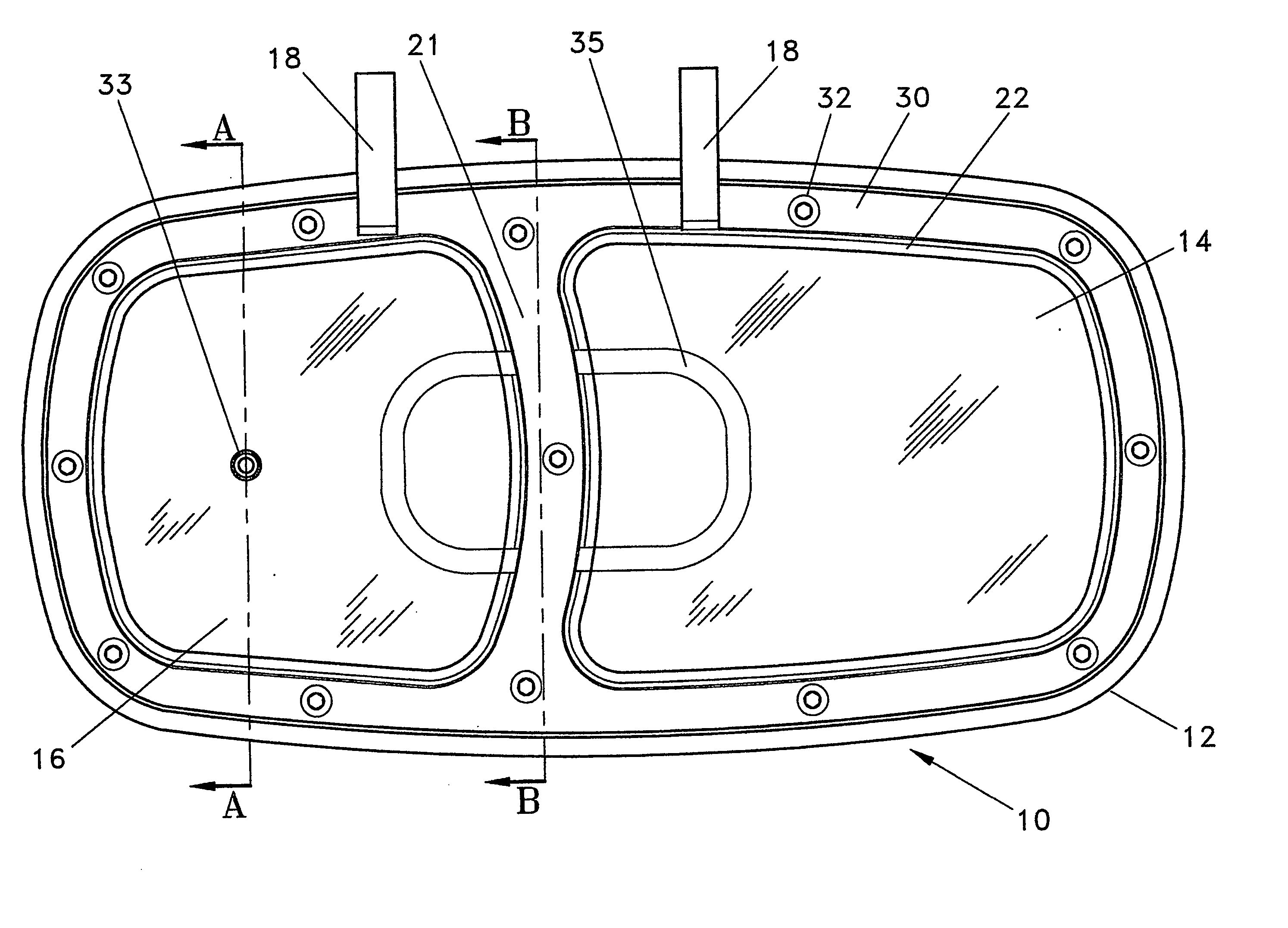

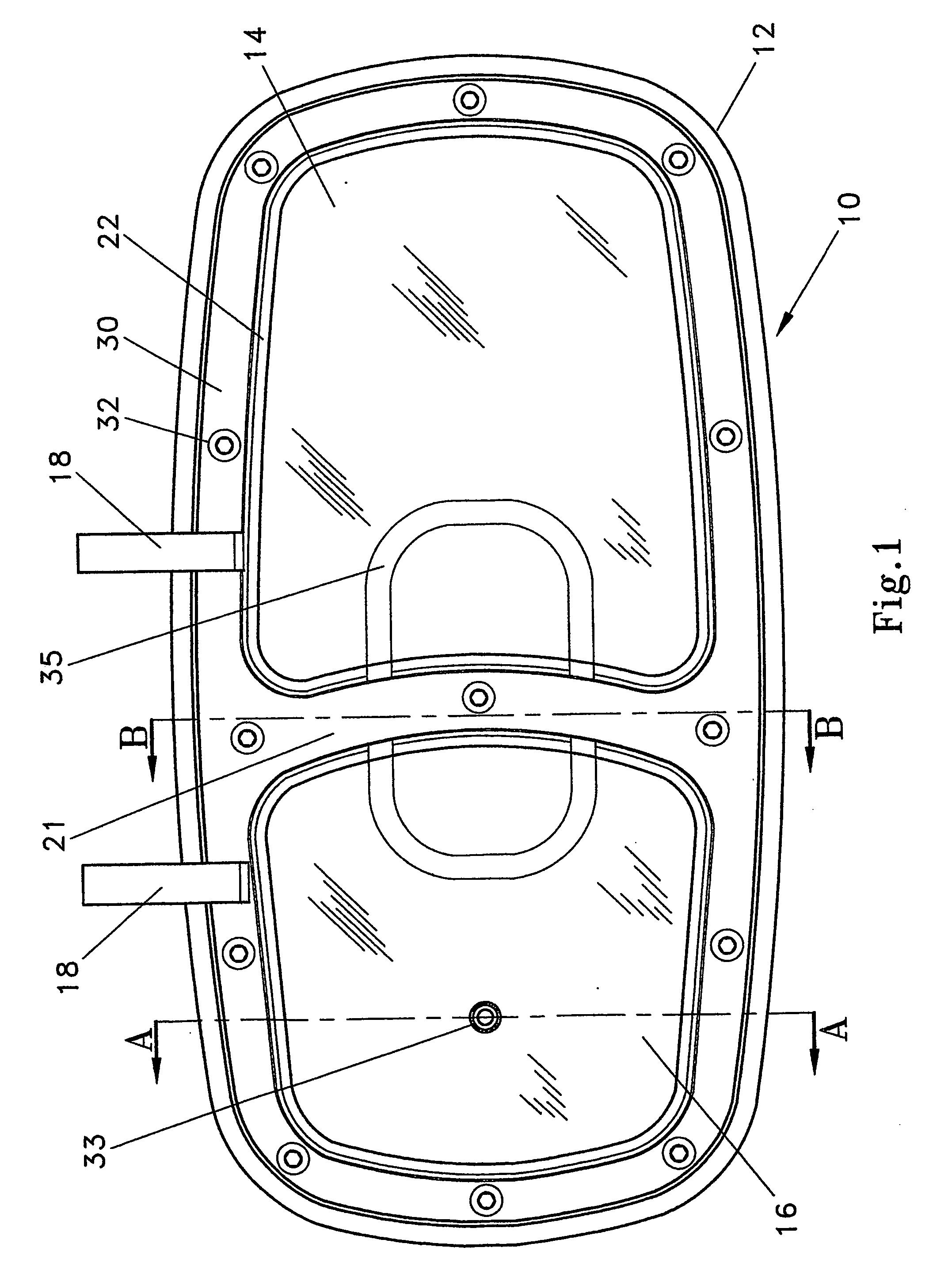

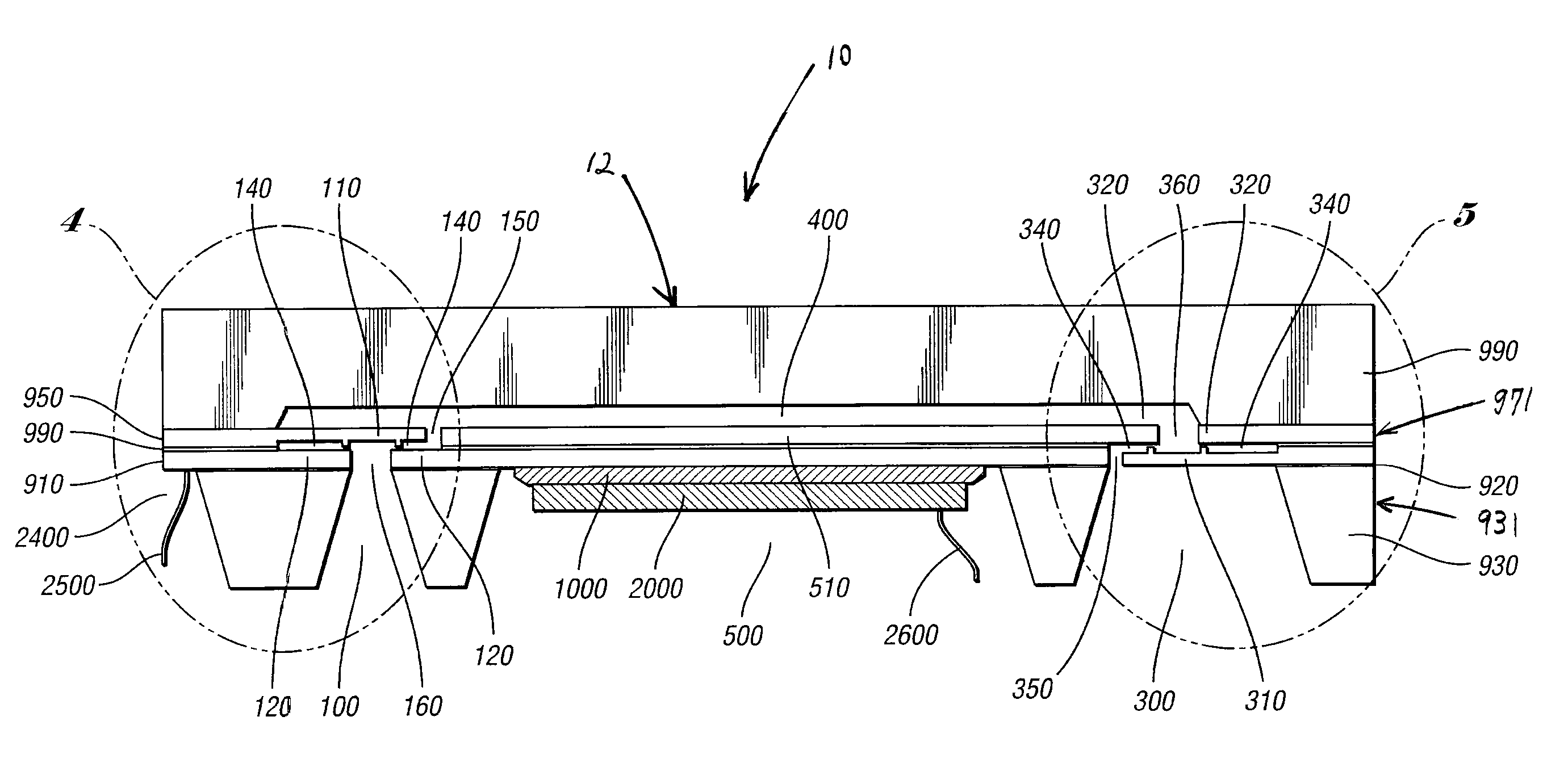

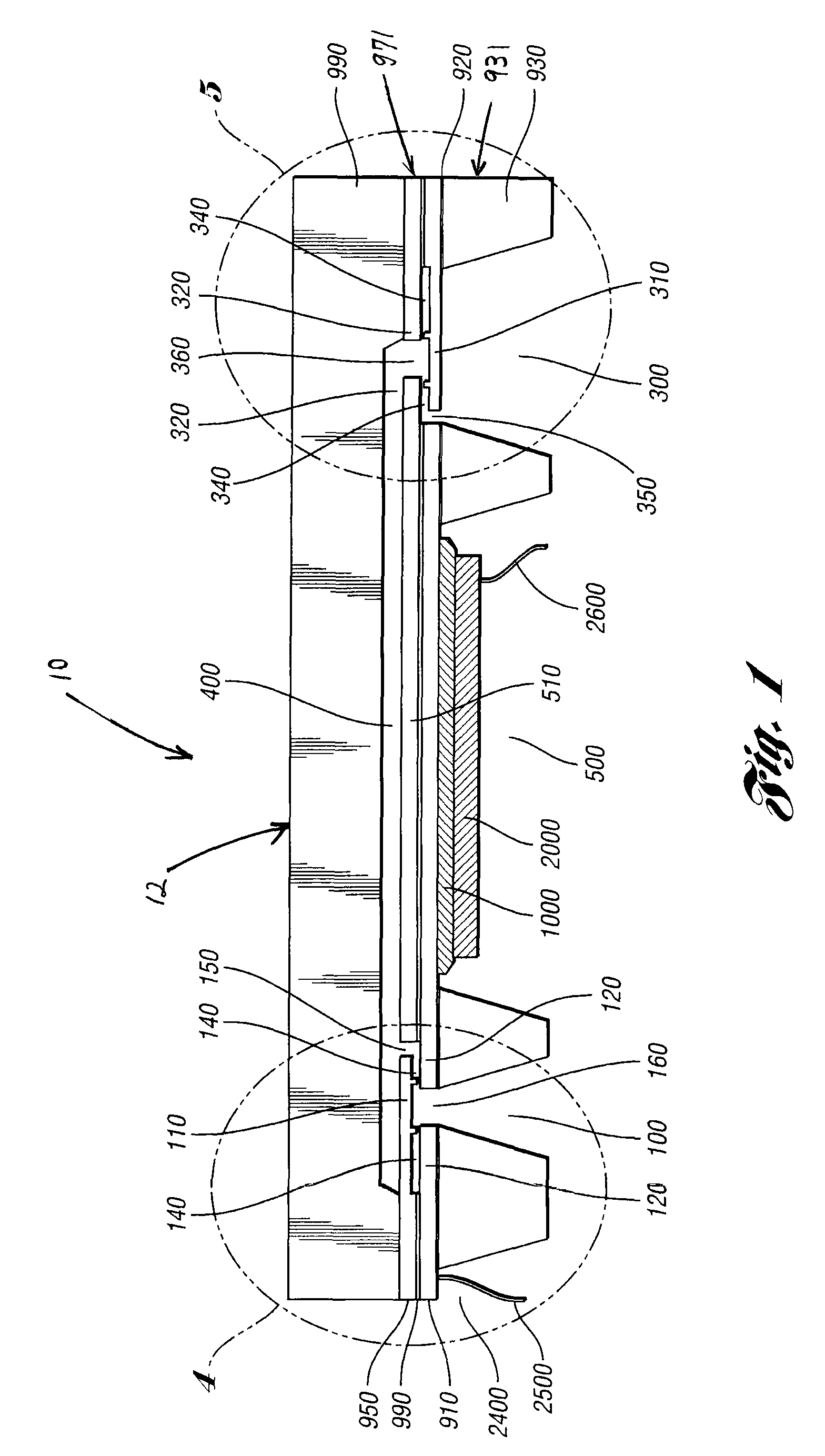

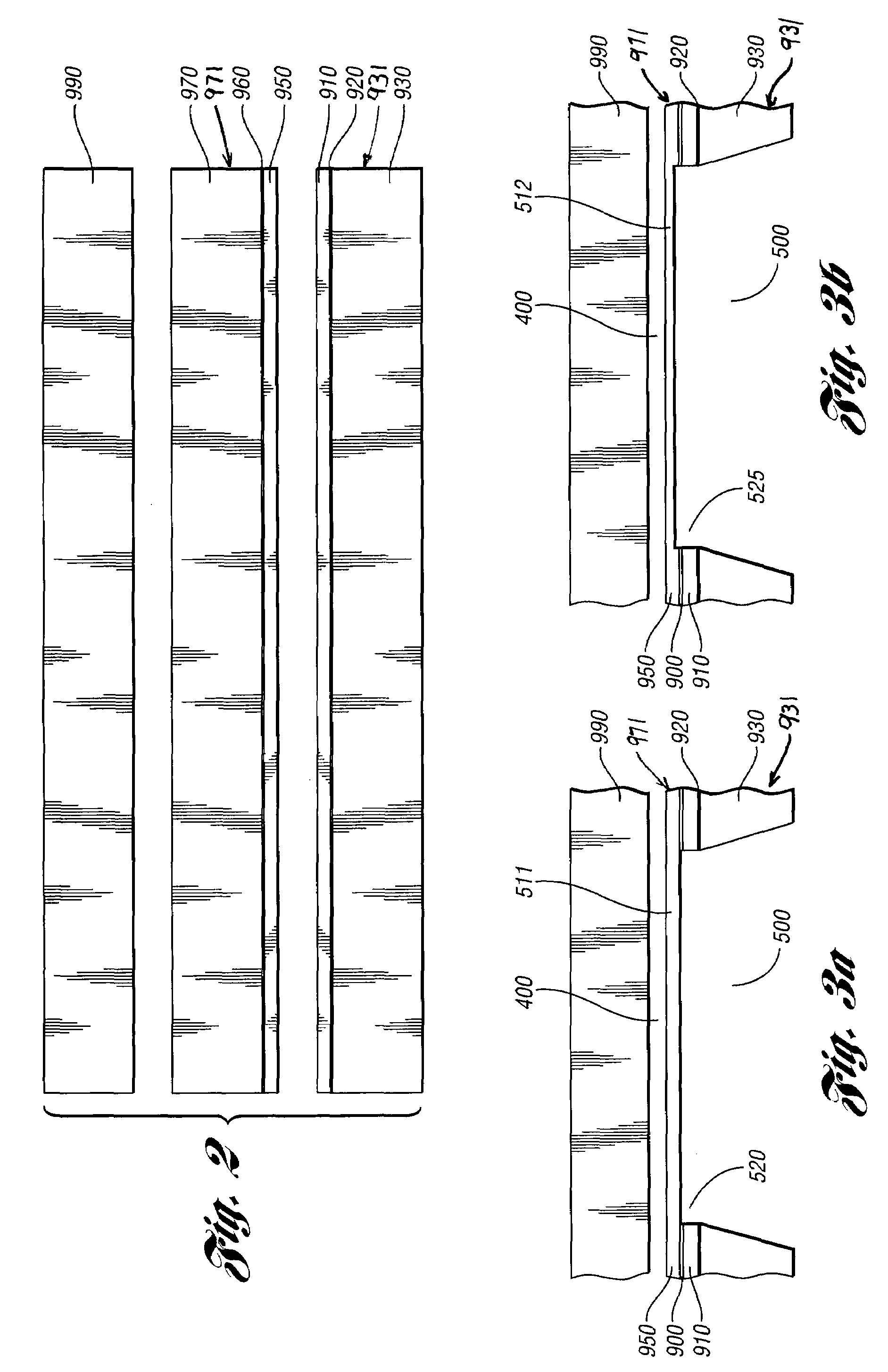

Evacuable flexible leakage test chamber

ActiveUS10119883B2Lower the volumeReduce chamber volumeMeasurement of fluid loss/gain rateEngineeringTest chamber

An evacuable flexible test chamber (10) for a leakage test of a test piece, having a wall (12) surrounding a test chamber volume (36), is characterized in that at least a portion of said wall is made up of two layers (18, 20) of wall material of which at least the layer (20) facing said test chamber volume (36) is made from a flexible material, and that between said two layers (18, 20) an overpressure as compared to the atmosphere surrounding said test chamber (10) is adapted to be created.

Owner:INFICON GMBH

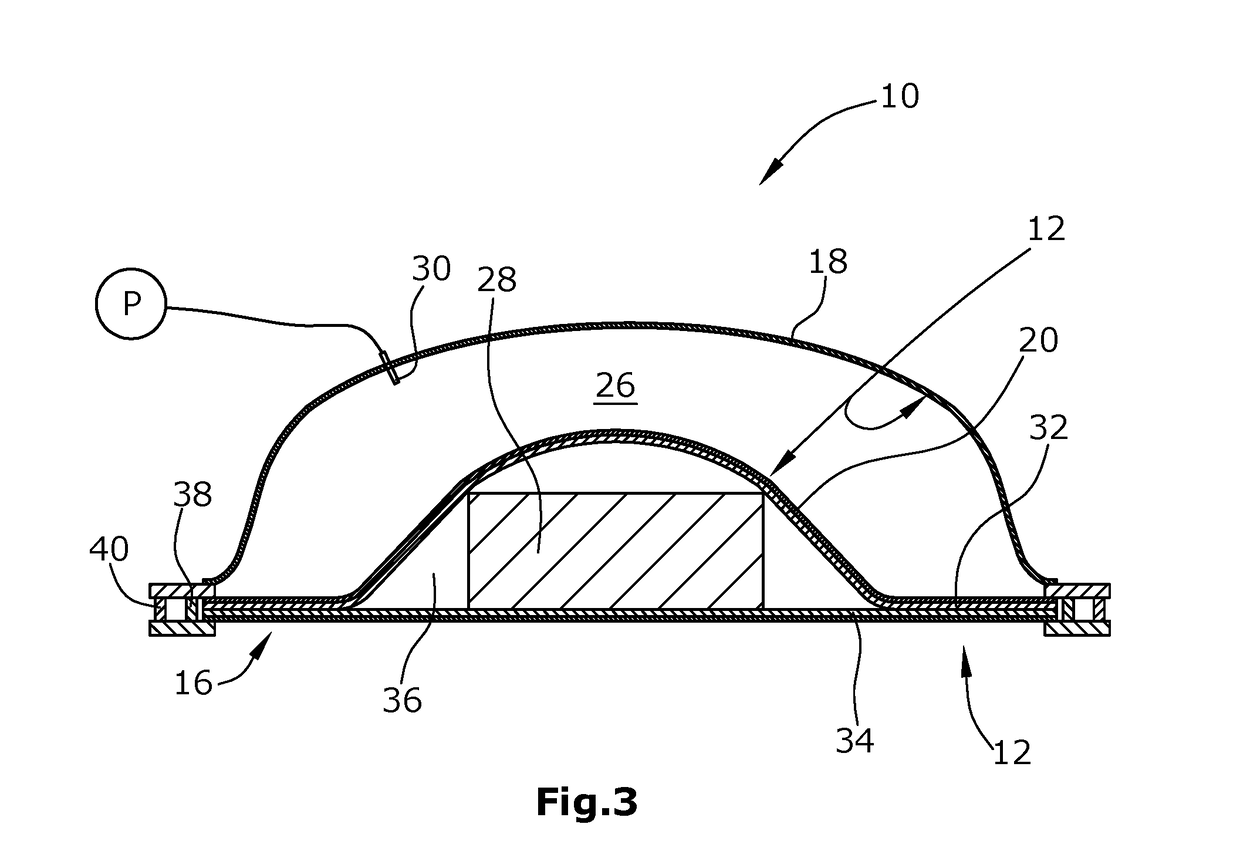

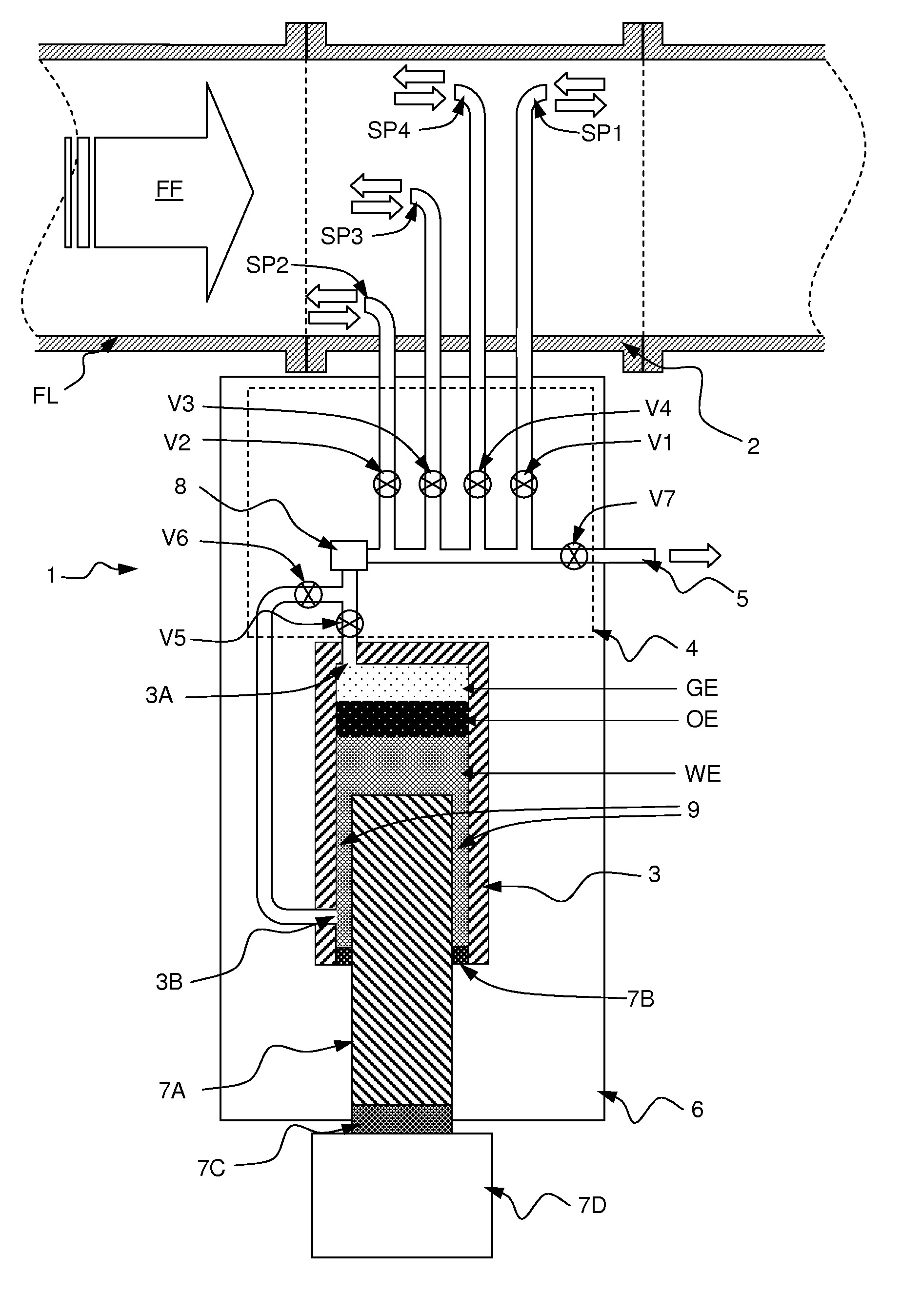

Sampling apparatus

ActiveUS8109158B2Avoid changeReduce chamber volumeWithdrawing sample devicesVolume/mass flow measurementSample chamberGravitation

Owner:SCHLUMBERGER TECH CORP

Technologic nozzle and thermal circulation heat-insulation device for same

InactiveCN103464311AIncrease the heat exchange areaImprove heat transfer efficiencySpray nozzlesLiquid temperatureSpray nozzle

A thermal circulation heat-insulation device for a technologic nozzle comprises a cavity, an upper comb-shaped flow stopping plate and a lower comb-shaped flow stopping plate, wherein a heat exchanging chamber is formed in the cavity; the upper comb-shaped flow stopping plate comprises a cover plate and a plurality of upper flow stopping sheets; the lower comb-shaped flow stopping plate comprises a bottom plate and a plurality of lower flow stopping sheets; the lower flow stopping sheets and the upper flow stopping sheets are distributed in the heat exchanging chamber in a staggered manner; a circulation liquid inlet and a circulation liquid outlet are respectively formed in two ends of the cover plate; and the heat exchanging chamber, the upper comb-shaped flow stopping plate and the lower comb-shaped flow stopping plate form a snakelike heat exchanging channel. The invention also provides a technologic nozzle comprising the thermal circulation heat-insulation device. The snakelike heat exchanging pipe is used in the thermal circulation heat-insulation device, the heat exchanging area is large, the heat exchanging efficiency is high, and an external circulation liquid delivery pipeline and the inner structure of the heat-insulation device are skillful, so that the thermal circulation heat-insulation device is easy to operate. The thermal circulation heat-insulation device is arranged in the technologic nozzle, therefore, sufficient heat exchange is guaranteed, the volume of the chamber in the technologic nozzle is reduced, and the temperature of work liquid stored in the chamber is well guaranteed.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

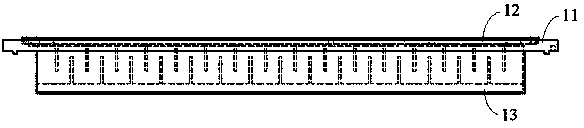

Water-cooled heat dissipating device

ActiveUS10866031B2Reduce chamber volumeSufficiency can be reliablyDigital data processing detailsSemiconductor/solid-state device detailsImpellerWorking fluid

A liquid cooling device includes a base (1), a passive impeller (3) and a cold plate (4). The base (1) includes a division plate (11), a chamber (12) and a flow guiding pole (13). The division plate (11) divides the chamber (12) into a catchment portion and a heat exchanging portion (17). The flow guiding pole (13) communicates with both the catchment portion (16) and the heat exchanging portion (17). The passive impeller (3) is received in the chamber (12) and radially driven to rotate by the working fluid. The cold plate (4) is arranged correspondingly to the heat exchanging portion (17) and fastened to the base (1).

Owner:KUAN DING TECH

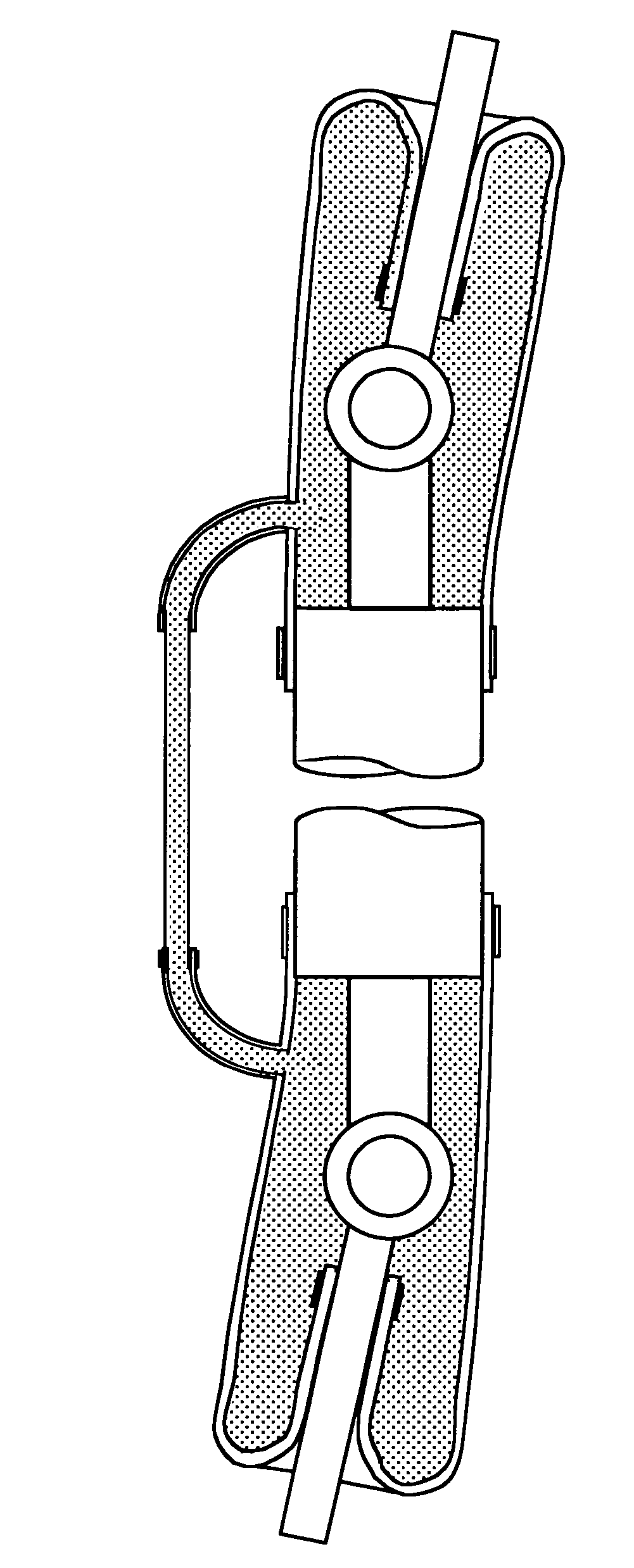

Leg exercise device

InactiveUS20060154789A1Decrease volume of firstReduces volume of secondBlood stagnation preventionMovement coordination devicesHeel-and-toeLeg exercise

A foot and / or leg-exercising device (10) has a first sealed chamber (14) and a second sealed chamber (16) that are interconnected via one or more passageways (34). The chambers (14, 16) are of variable volume and fluid within one chamber may be pumped to the other chamber using the feet and / or legs. In one embodiment each foot is provided with a first chamber and a second chamber and fluid is pumped by a heel and toe rocking action of each foot. The chambers for both feet may be interconnected to allow pumping by an up and down action of the legs.

Owner:SARMA VIMALA

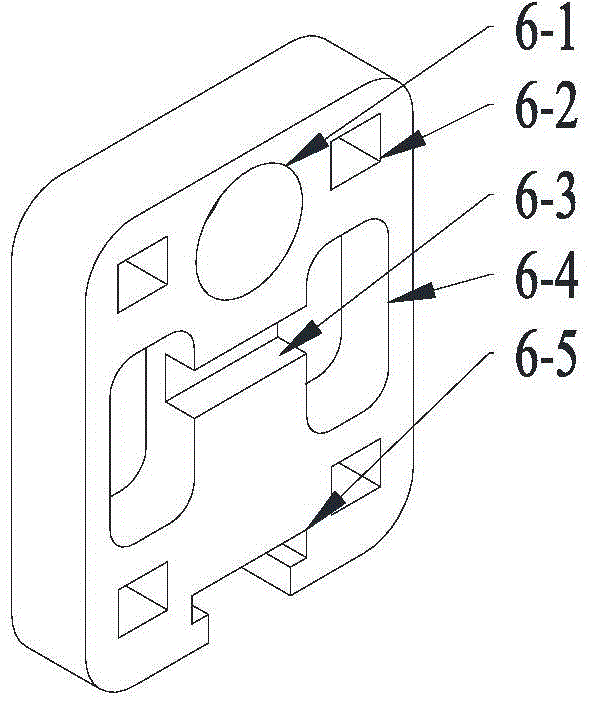

Check valve diaphragm micropump

A micropump device including a first wafer and a second wafer attached to the first wafer. The first and second wafers are configured to define a chamber therebetween having a predetermined volume. A third wafer is attached to the second wafer to define an inlet section and an outlet section in fluid communication with the chamber. At least one of the second and third wafers are formed to define a moveable diaphragm configured to change the predetermined volume of the chamber for pumping a fluid between the inlet section and the outlet section.

Owner:WAYNE STATE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com