Hydrostatic test compensator and method of carrying out pipe hydrostatic tests by using same

A hydrostatic test and compensator technology, applied in the direction of applying stable tension/pressure to test the strength of materials, using liquid/vacuum to measure liquid tightness, etc., can solve problems such as large water intake, low efficiency, and long time , to achieve the effect of improving efficiency, reducing overall time and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

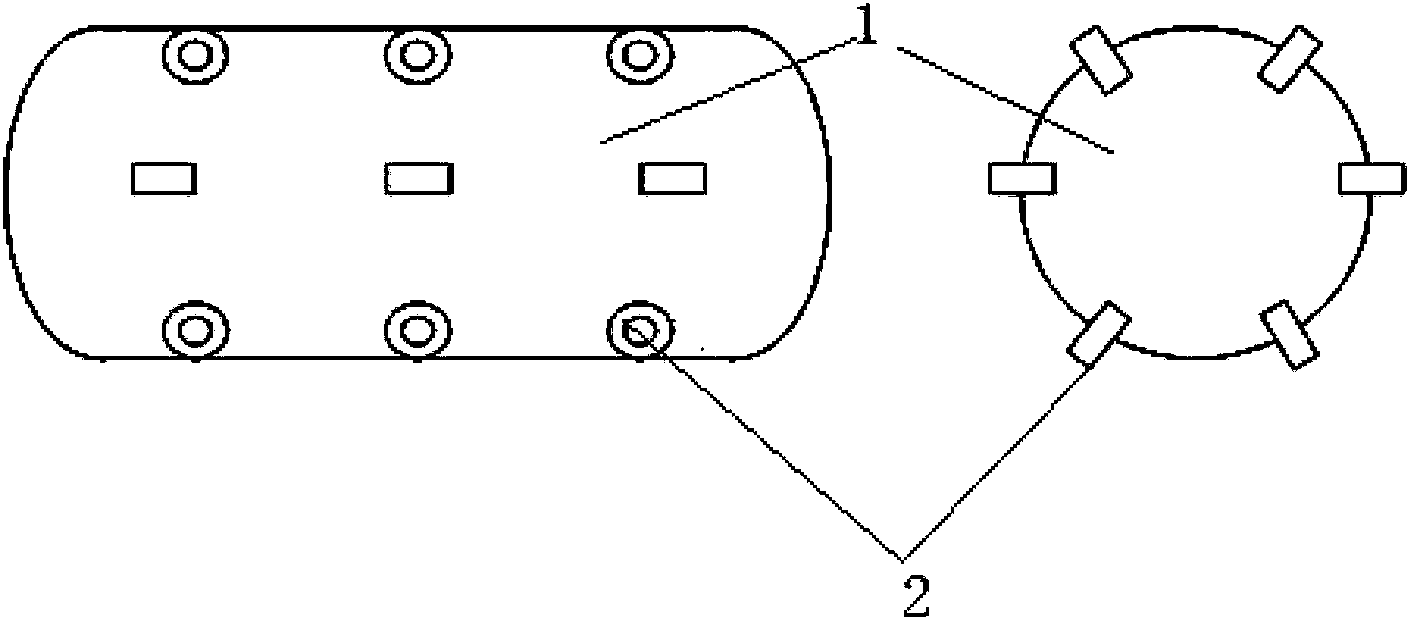

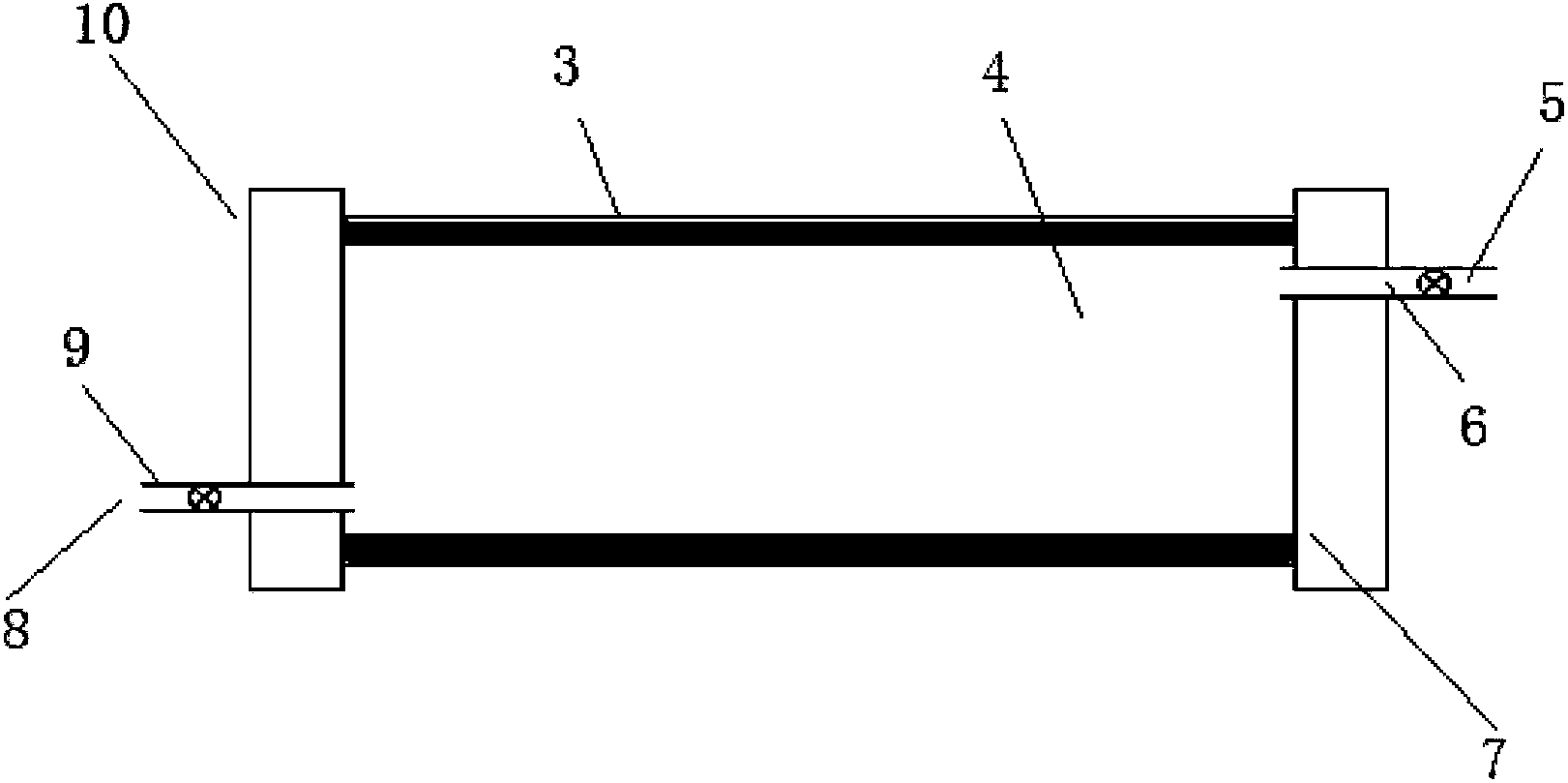

[0028] Such as Figure 1 to Figure 4 A hydraulic test compensator is shown, the hydraulic test compensator is a cylinder that can withstand an external pressure not lower than the pressure of the pipe hydraulic test without damage, and the cylinder is a solid cylinder , in other embodiments, it can also be a hollow shell structure with sealed heads at both ends; the envelope outer diameter of the hydrostatic test compensator is 96% of the inner diameter of the corresponding hydrostatic test pipe, and the outermost two ends The length of the flange is 50mm to 150mm short...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com