Patents

Literature

557 results about "Hydraulic test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

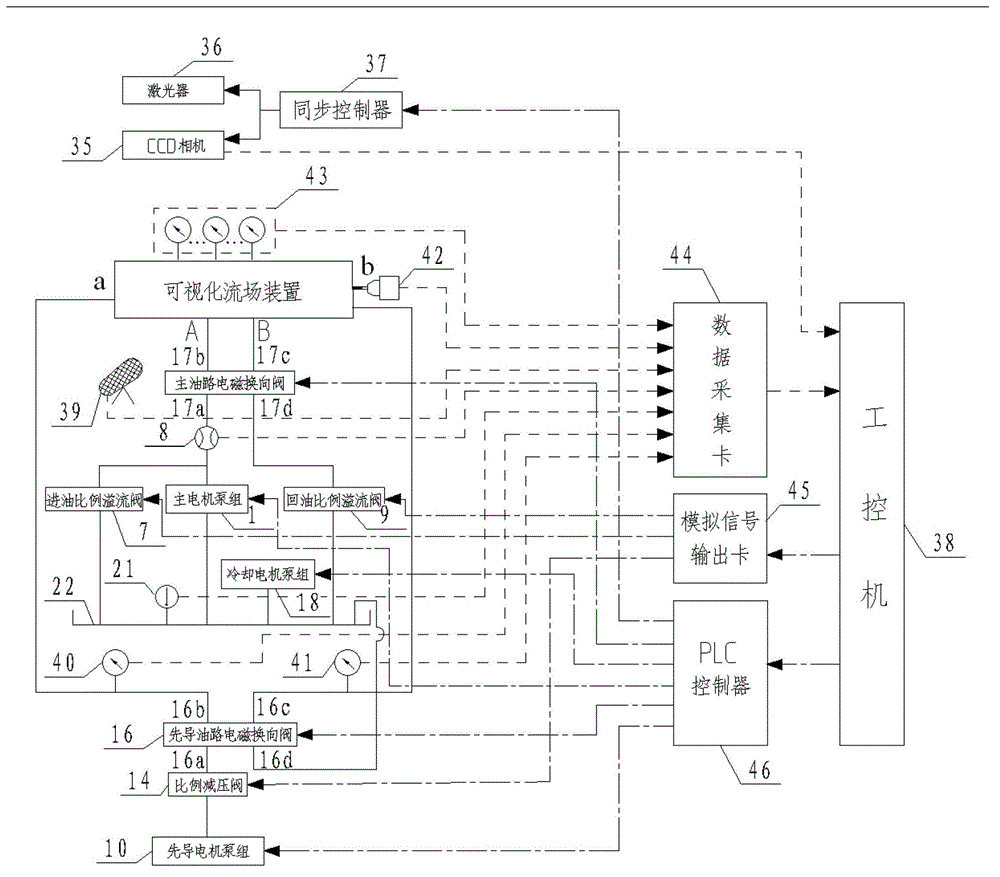

Servo valve test system

ActiveCN101813109AFully automaticQuick responseFluid-pressure actuator testingTest efficiencyData acquisition

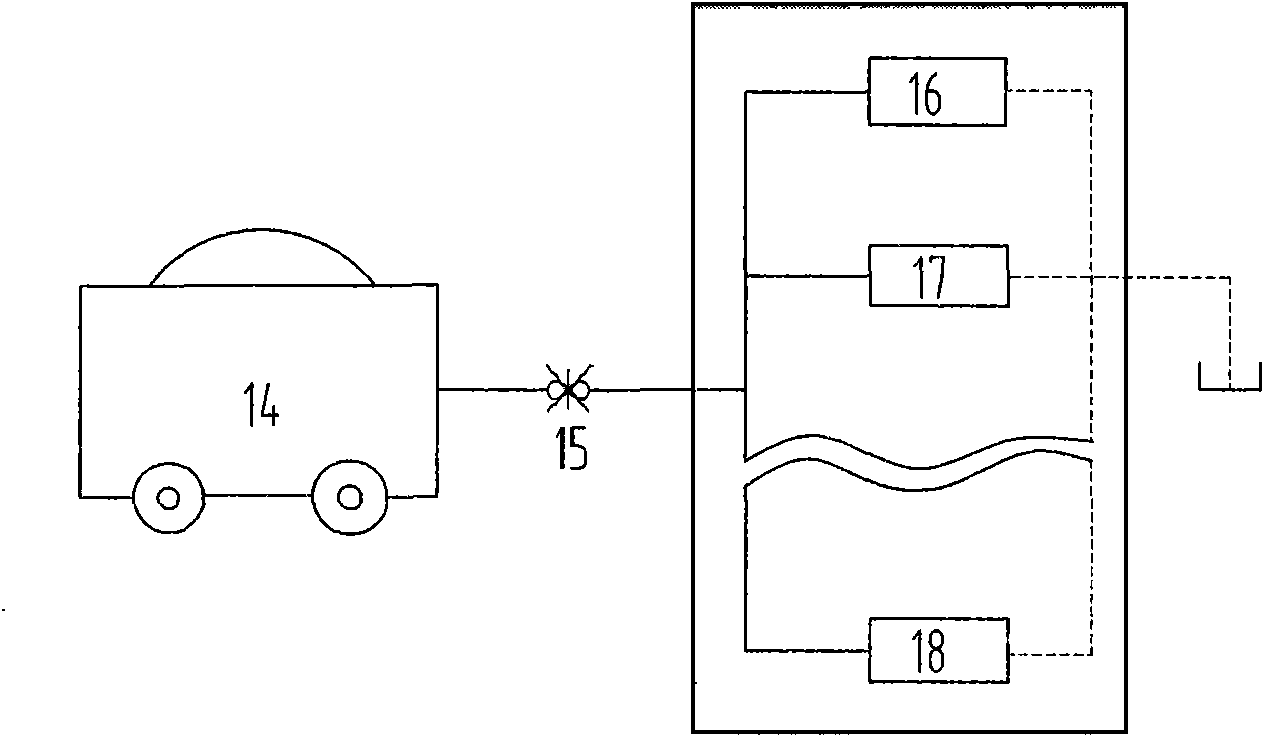

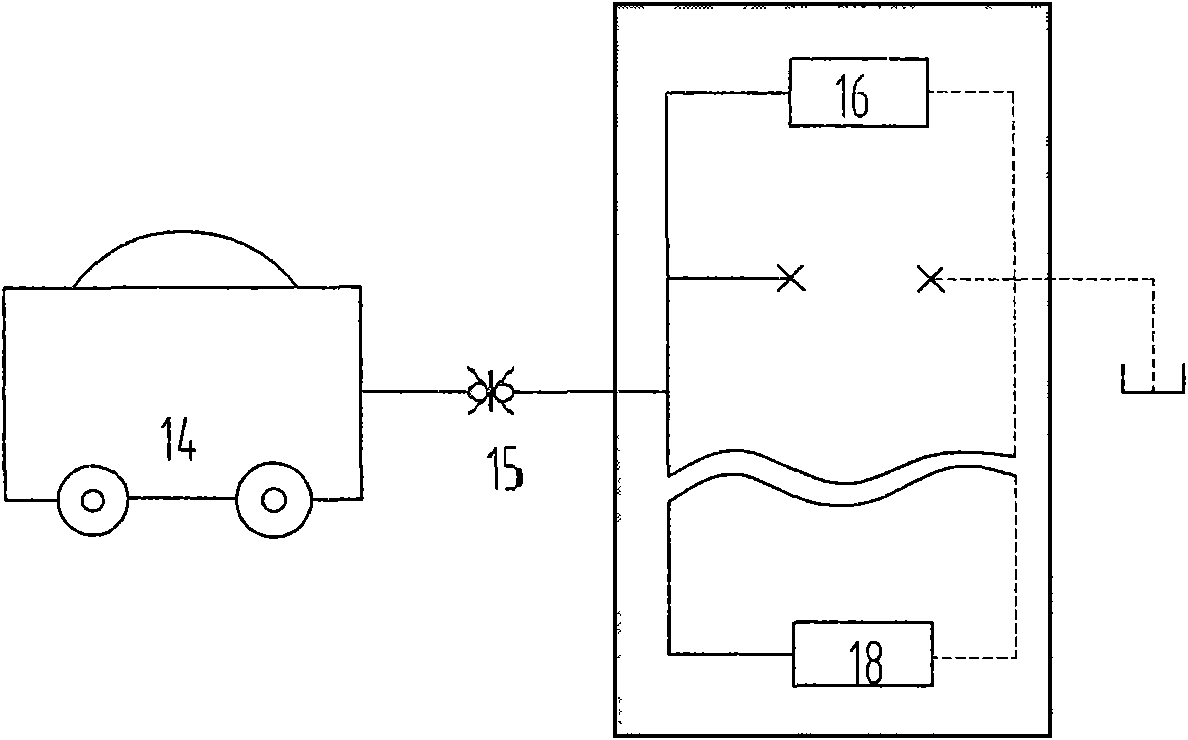

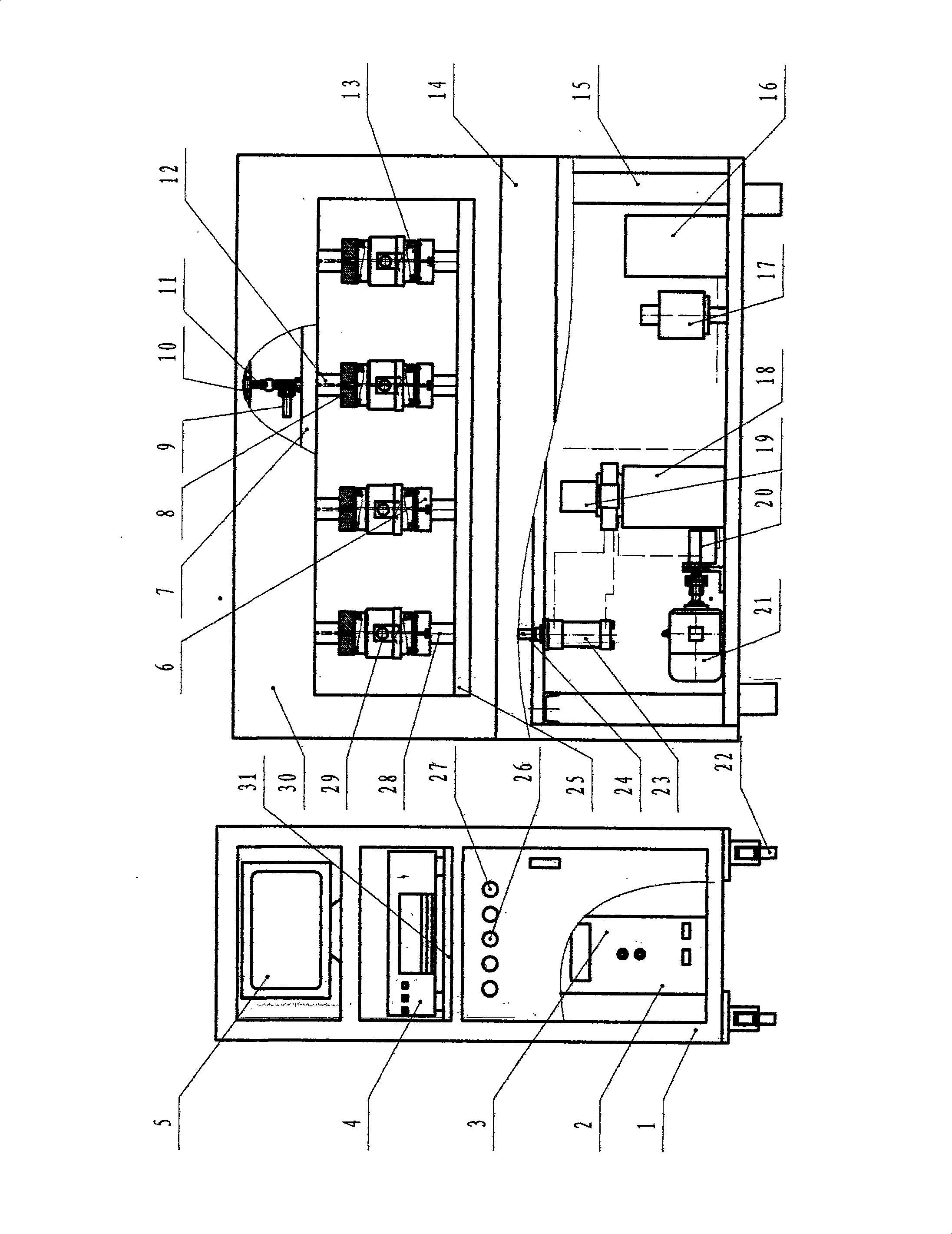

The invention relates to a servo valve test system. By adopting a cartridge valve to automatically switch static and dynamic oil lines, the servo valve test system can realize the full automatic one-step test and intelligent analysis of the static properties and the dynamic properties of an electro-hydraulic servo valve, improves the test efficiency of the electro-hydraulic servo valve, and increases the accuracy of the test results. Strictly based on the test standard of the electro-hydraulic servo valve GB / T15623-1995, the whole test method completes all the detection tests of the servo valve, and automatically displays and outputs the test results. The servo valve test system mainly comprises a hydraulic test system, an electrical control system and a data acquisition and processing system, wherein a servo valve to be tested is connected with the hydraulic test system and the electrical control system; a main oil line of the hydraulic test system is automatically switched to the dynamic oil line and the static oil line by a cartridge valve assembly, and the hydraulic test system is also provided with a dynamic cylinder for detecting the servo valve to be tested; and the data acquisition and processing system is connected with the electrical control system and the hydraulic test system.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

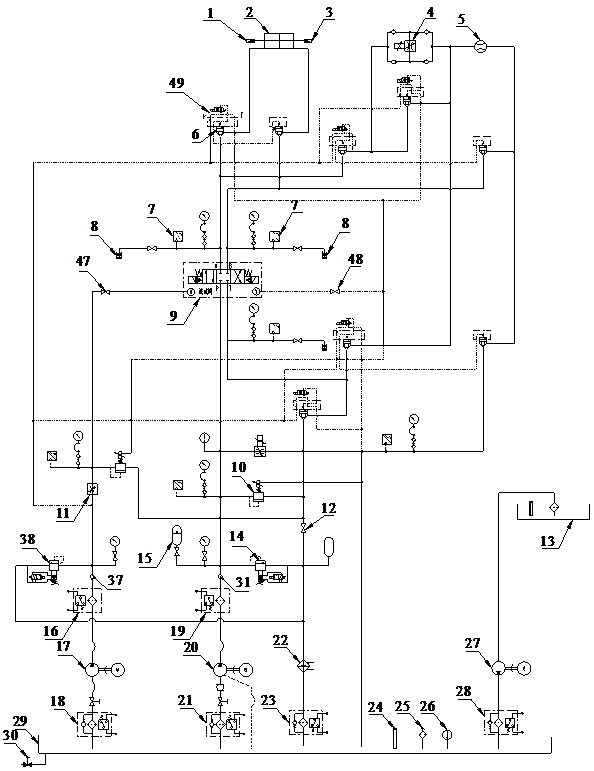

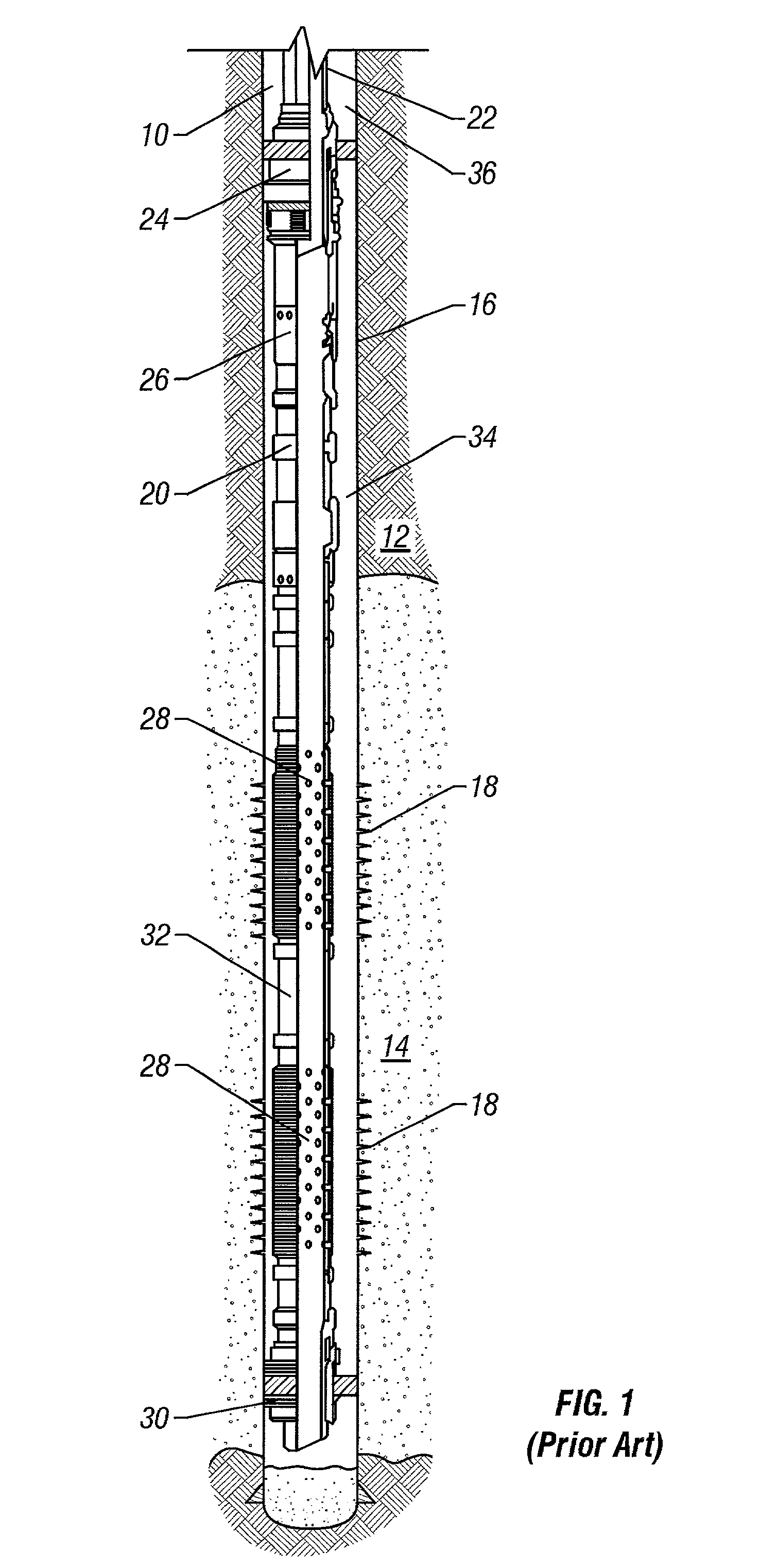

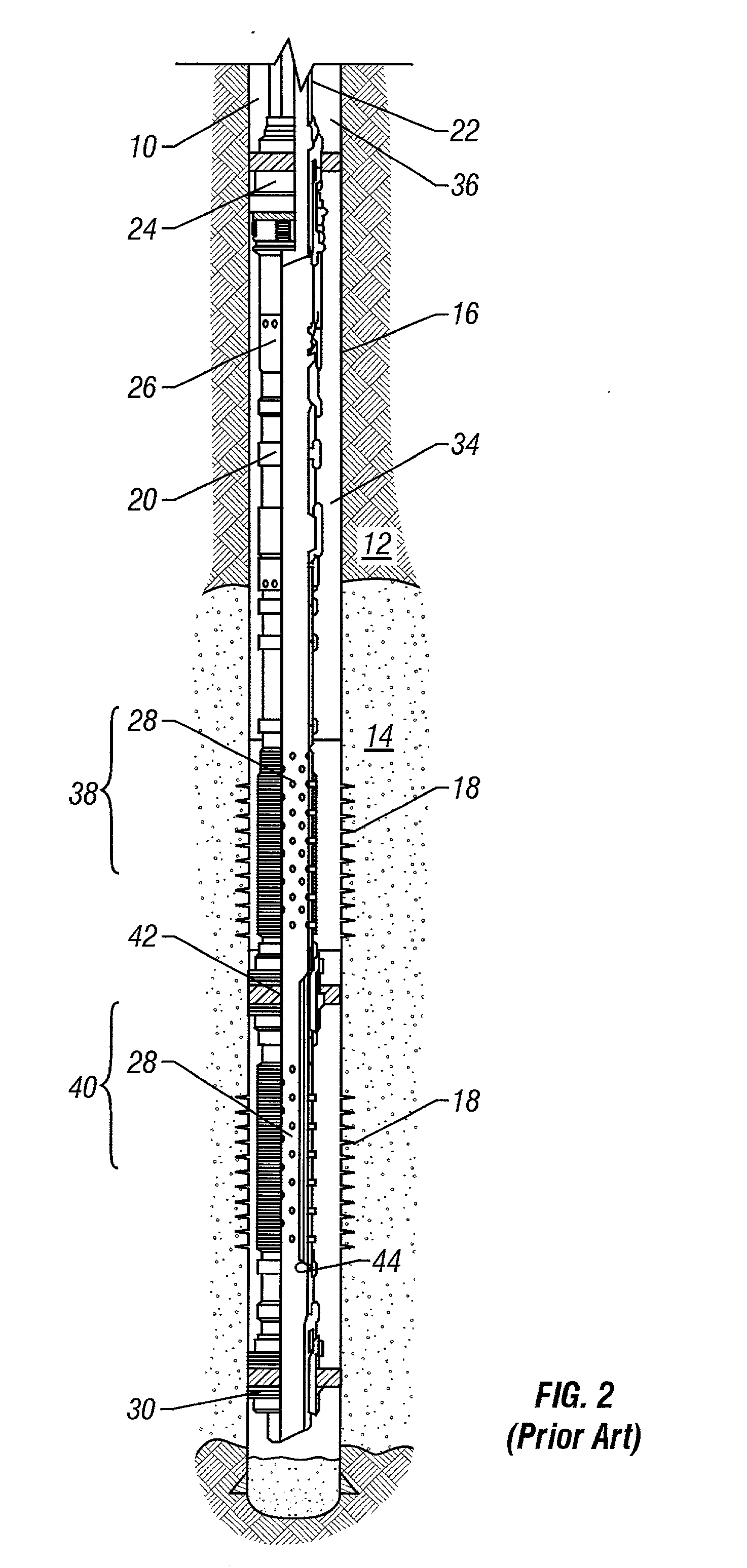

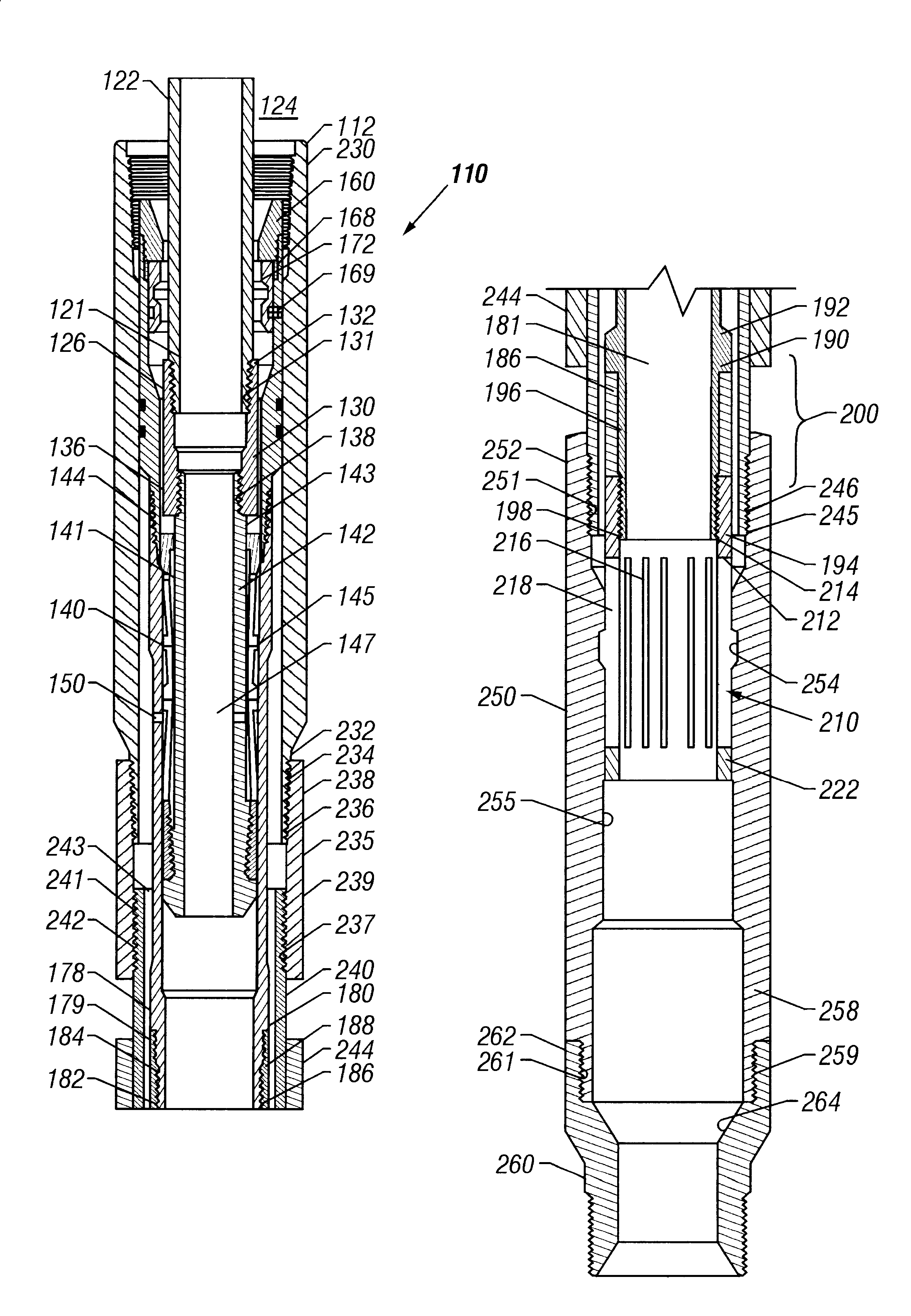

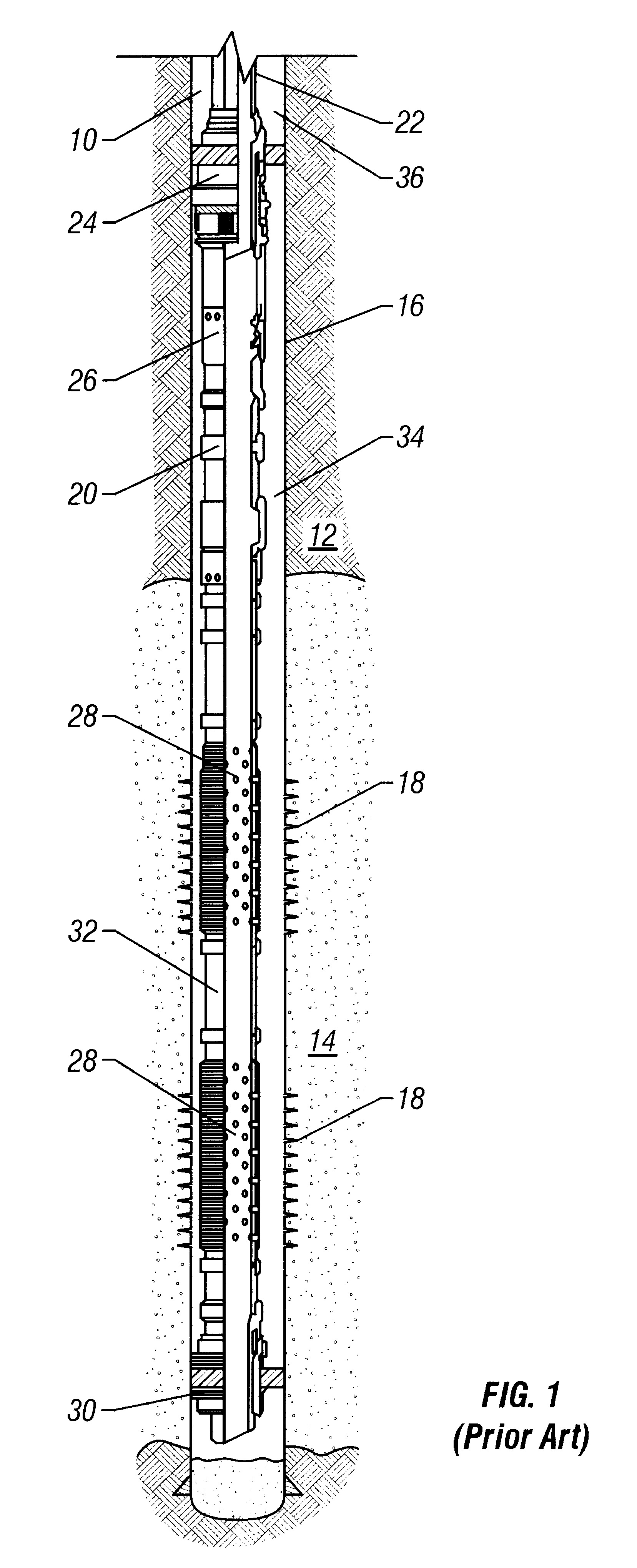

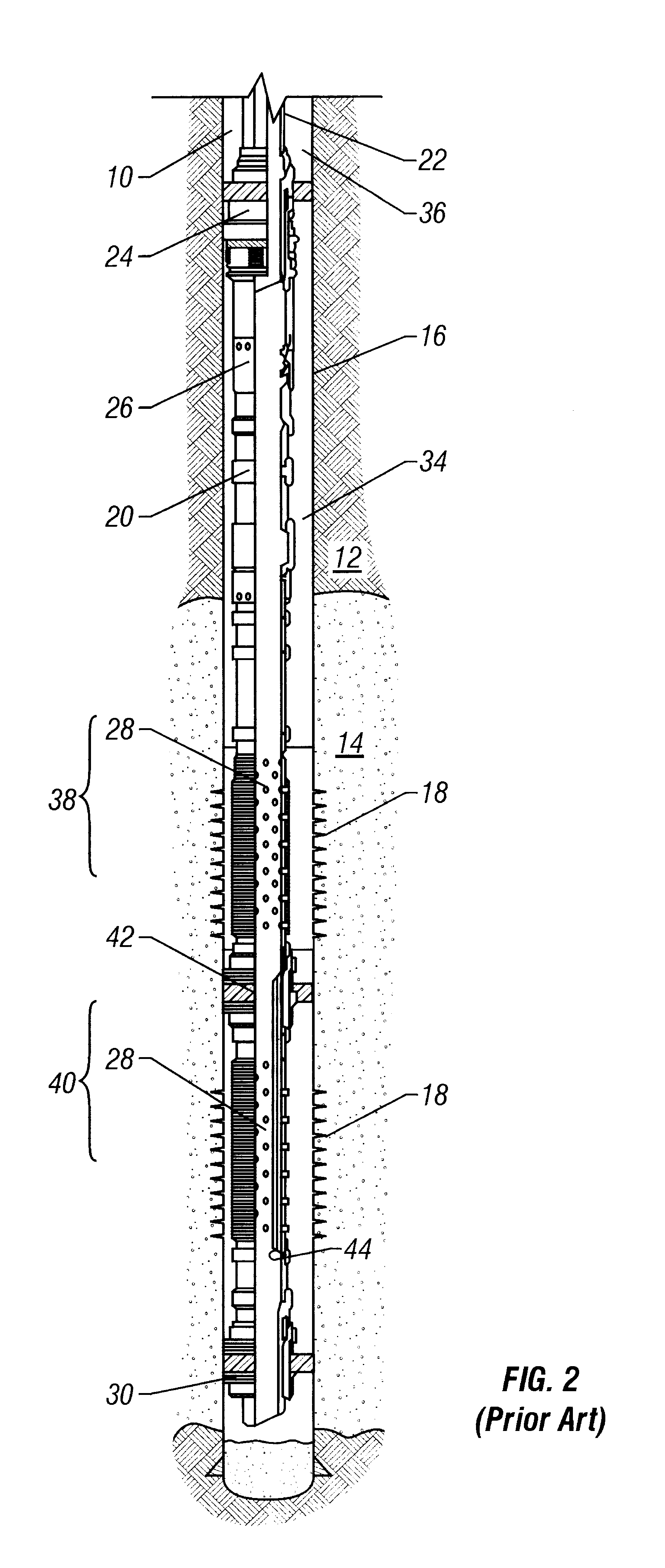

Zonal isolation tool with same trip pressure test

Apparatus and methods for gravel packing, isolating and testing a sand screen completion of a wellbore in a single trip are disclosed. One method comprises inserting into the wellbore a sand screen assembly, an isolation pipe, and a test assembly on a workstring. A gravel pack operation is performed, and the isolation pipe is shifted to a position in sealing contact with the sand screen assembly, thereby isolating the sand screen assembly. The test assembly is then shifted to a configuration that provides hydraulic communication between the interior of the isolation pipe and the workstring-wellbore annulus above the test assembly. Imposing pressure on the workstring-wellbore annulus then hydraulically tests the integrity of the seal between the isolation pipe and the sand screen assembly.

Owner:SCHLUMBERGER TECH CORP

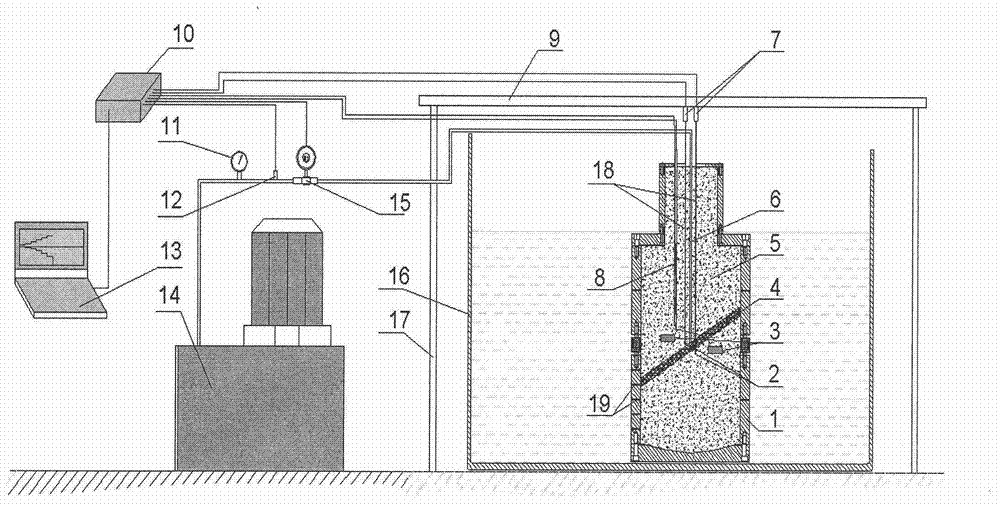

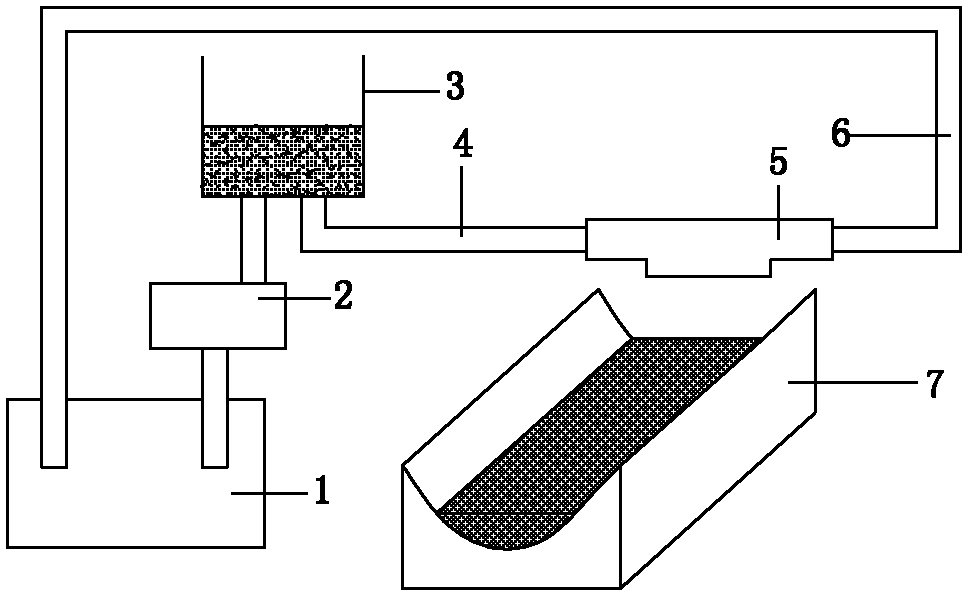

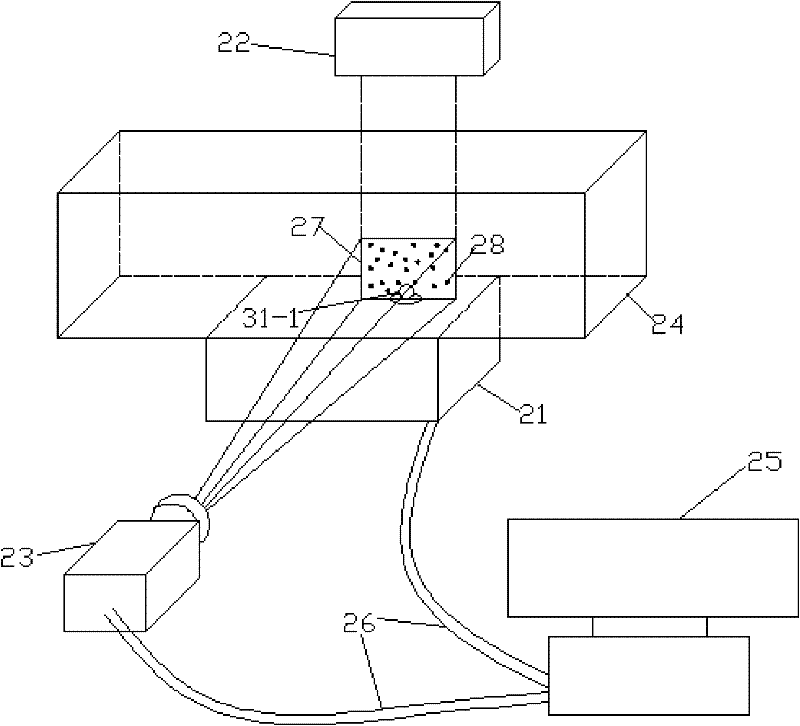

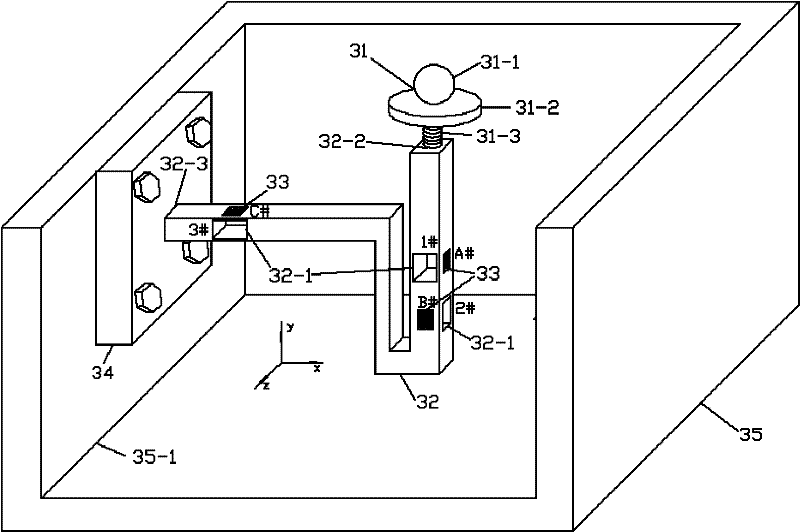

Indoor test system and test method for seepage characteristics of jointed rock mass

InactiveCN103033458AAvoid disturbanceReal-time synchronous display of trafficPermeability/surface area analysisPilot systemData acquisition

The invention discloses an indoor test system and a test method for seepage characteristics of jointed rock mass. Through carrying out seepage, deformation and stress coupling tests of seepage performance for a large scale jointed rock mass test piece under high pressure water to a given jointed rock mass, the test pressure, flow and displacement can be simultaneously displayed and collected in real time, and the test data can be stored. The test method comprises the following steps: a test rock piece with a fissure surface is placed into a mould, the mould is placed into water, and the fissure surface inclination of the rock is adjusted; a water filling pipe is installed on the fissure surface of the rock, the water filling pipe is connected with a high pressure pump, and pressure cells are installed on an upper plate and a lower plate of the fissure surface of the rock; anchorage points are arranged on the upper side and the lower side of the fissure surface, and the anchorage points are connected with a displacement meter; high flow and high pressure hydraulic test is carried out by the high pressure pump to the fissure surface through the water filling pipe, the collected data is transferred to a collector by a pressure sensor on the water filling pipe, a flow sensor, the press cells and the displacement meter respectively and then accesses to a computer, and the real-time pressure, flow, relative displacement of the fissure and coupling relationship are continuously recorded and displayed.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

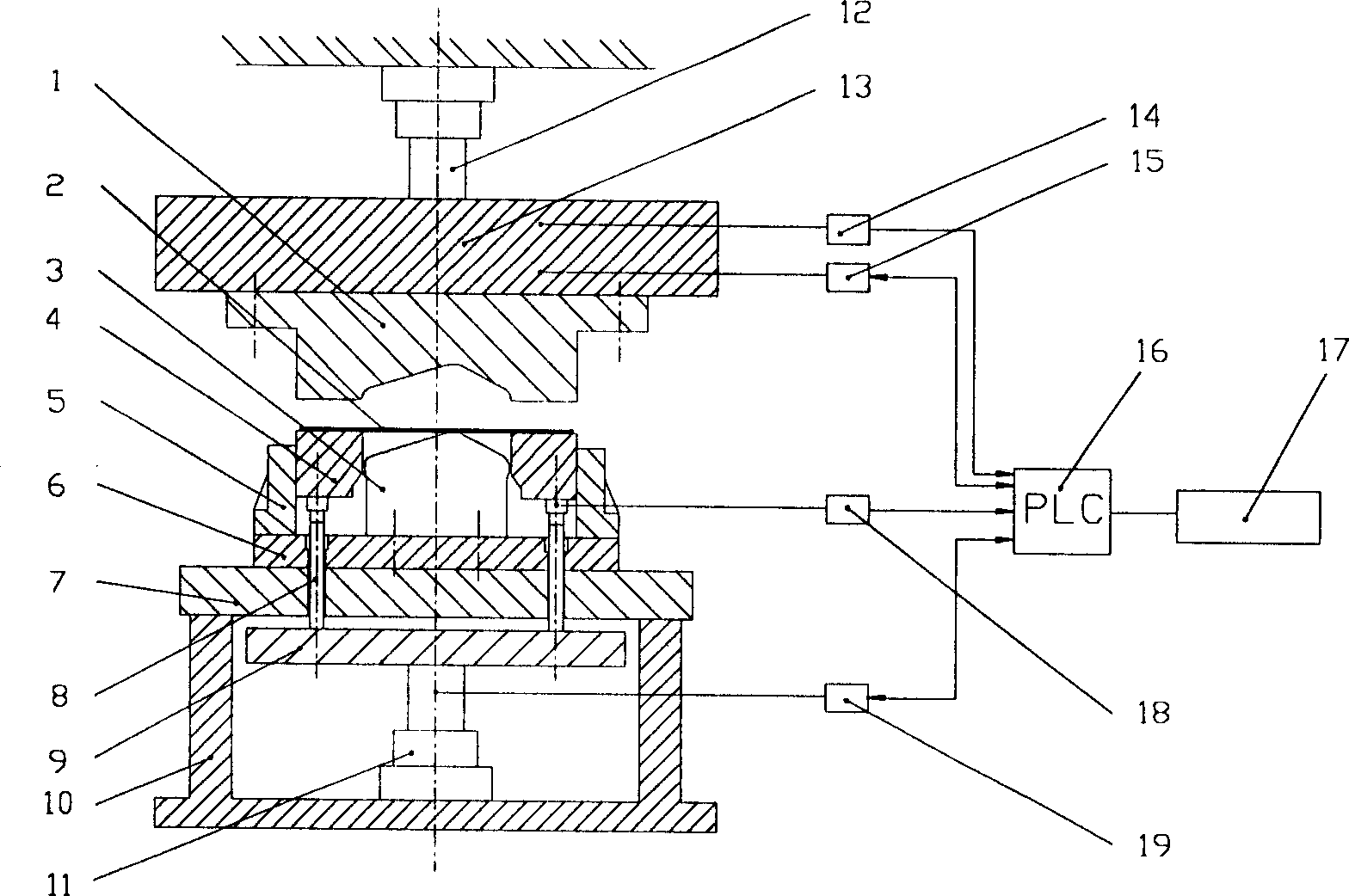

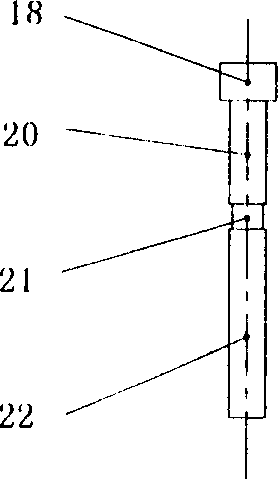

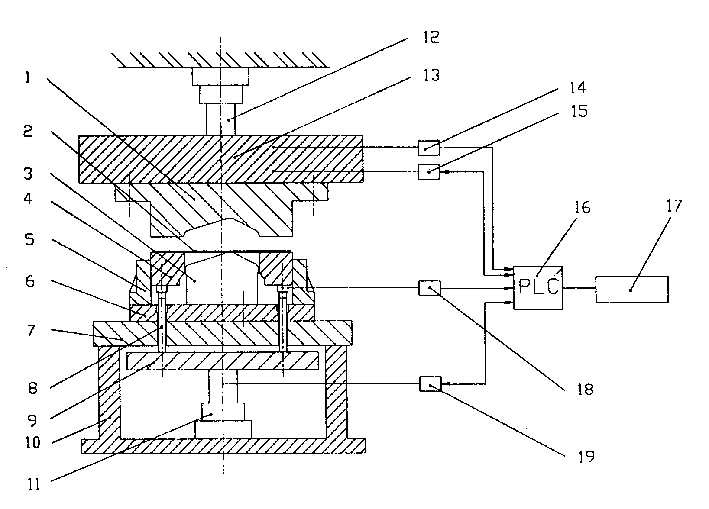

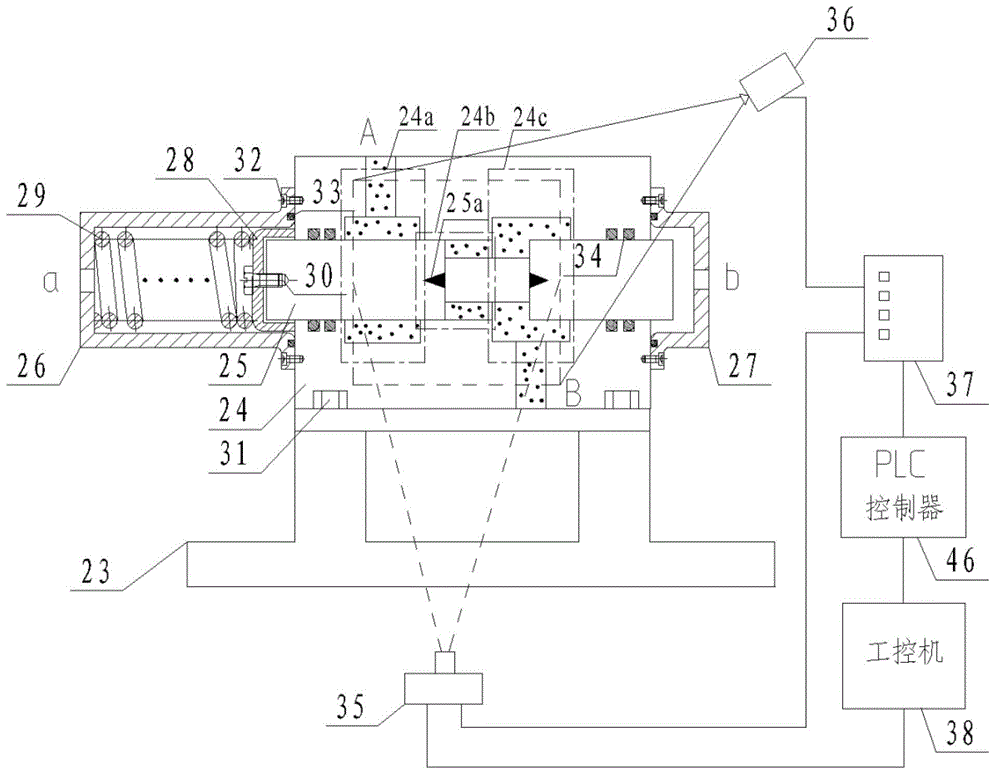

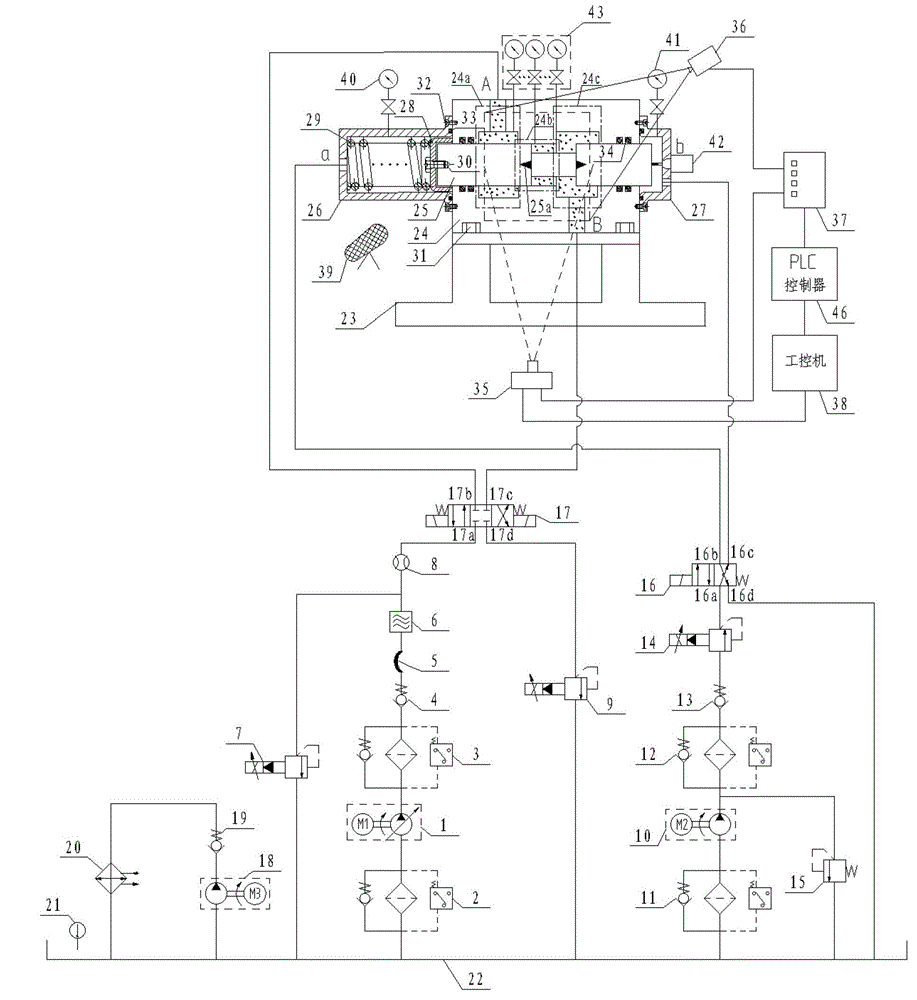

Edge pressing force and punching speed changeable single moving sheet hydraulic test machine

InactiveCN1434282AChange the total blank holder forceExcellent drawing performanceMaterial strength using tensile/compressive forcesLoop controlSheet steel

The invention is a single-acting sheet hydraulic test machine of variable border pressing force and press speed. It uses the displacement of the top slide block as the independent variable, accordingto the present working curve, uses the pressure and speed sensor to real-timely sample the pressure and speed data provide for the PLC to make close-loop control, which realize the continual variation of the border-pressing force within 150KN-1250KN and the adjustment of the press speed within 4-20 mm / s.

Owner:JIANGSU UNIV

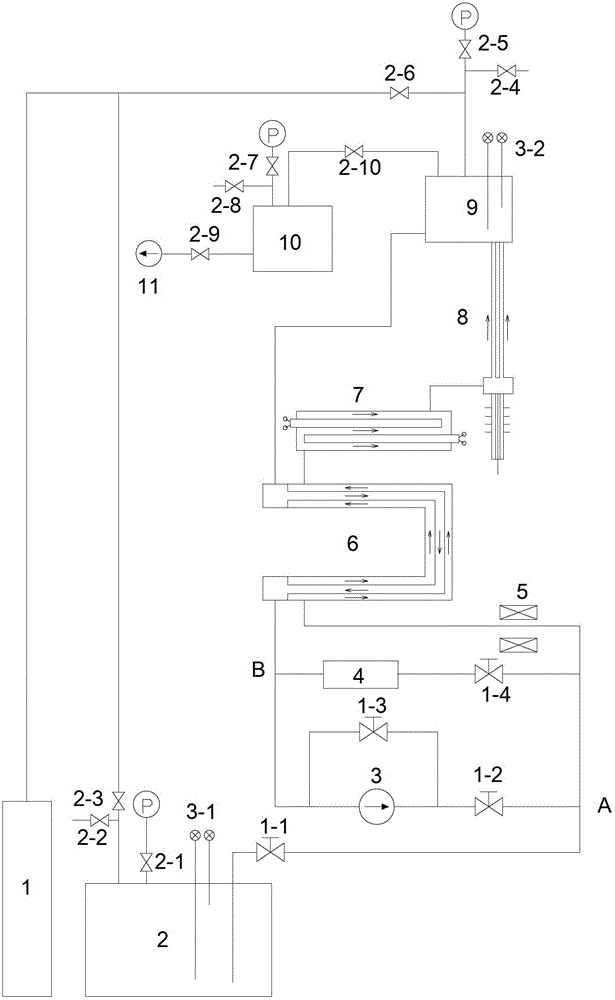

Liquid metal sodium boiling two-phase thermal-hydraulic test loop system and test method thereof

InactiveCN102915777AMeet the requirement of boiling two-phase testGuaranteed tightnessNuclear energy generationNuclear monitoringData acquisitionLiquid metal

The invention discloses a liquid metal sodium boiling two-phase thermal-hydraulic test loop system and a test method thereof. The loop system is divided into three parts comprising a high temperature part, a low temperature part and an argon branch, wherein the low temperature part comprises a sodium storage tank, an electromagnetic pump, an electromagnetic flowmeter, a purification cold trap, four sodium valves and corresponding connecting pipelines; the low temperature part is made of 316L stainless steel; the high temperature part comprises a regeneration heater, a preheater, a test section, an upper expansion box and corresponding connecting pipelines; the high temperature part is made of Incoloy 800 and allows the operating temperature to reach 1,200 DEG C; and the argon branch comprises an argon bottle, an expansion pressure stabilizing box, a vacuum pump, three pressure gauges, ten vacuum diaphragm valves and corresponding connecting pipelines. The system is suitable for operating at high temperature, has a good sealing property and can realize analysis and research on the liquid metal sodium boiling two-phase heat exchange flow characteristic by adding different test sections and a data acquisition system.

Owner:XI AN JIAOTONG UNIV

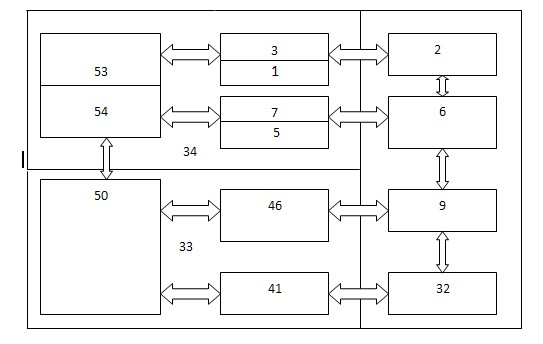

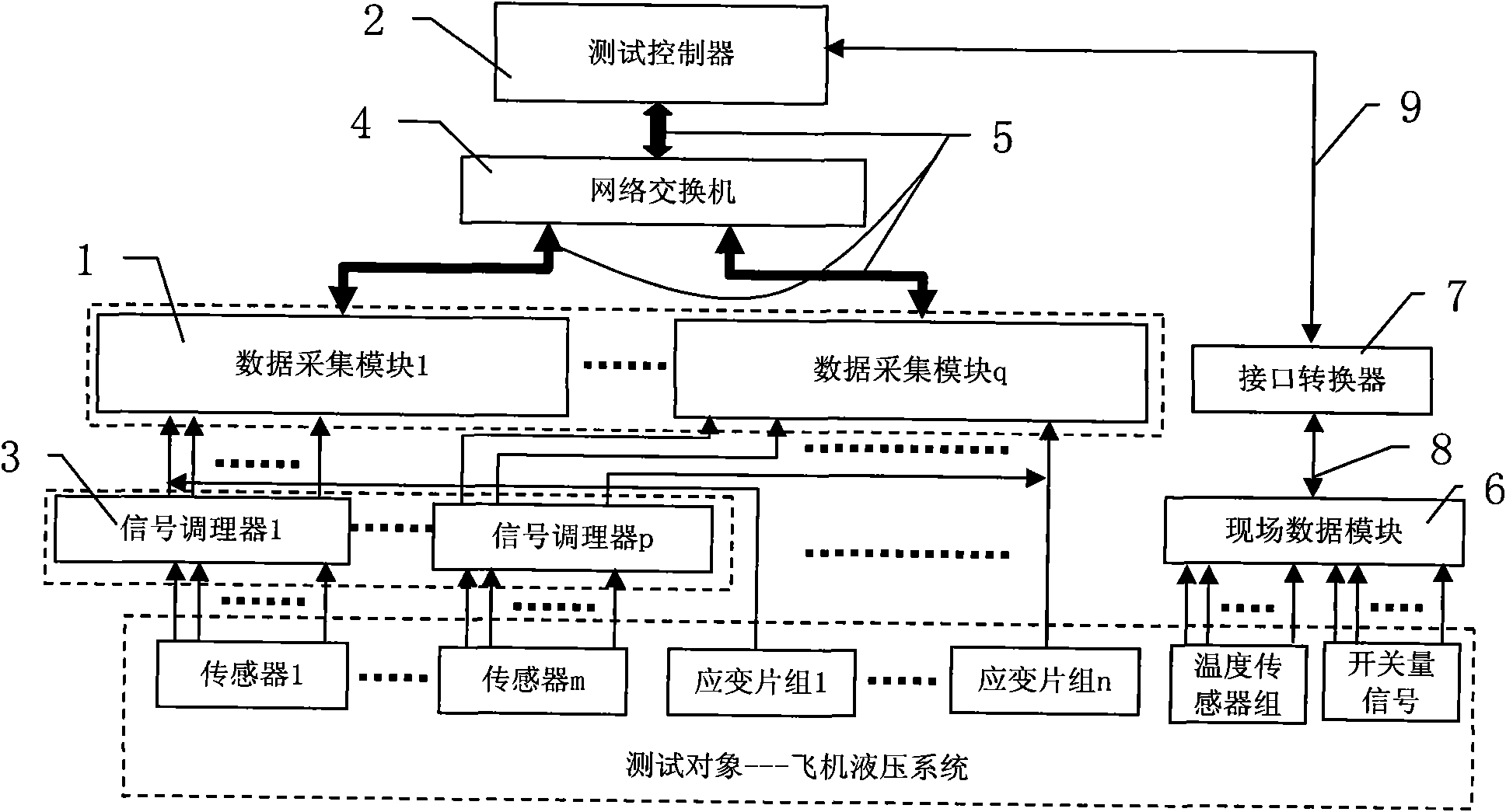

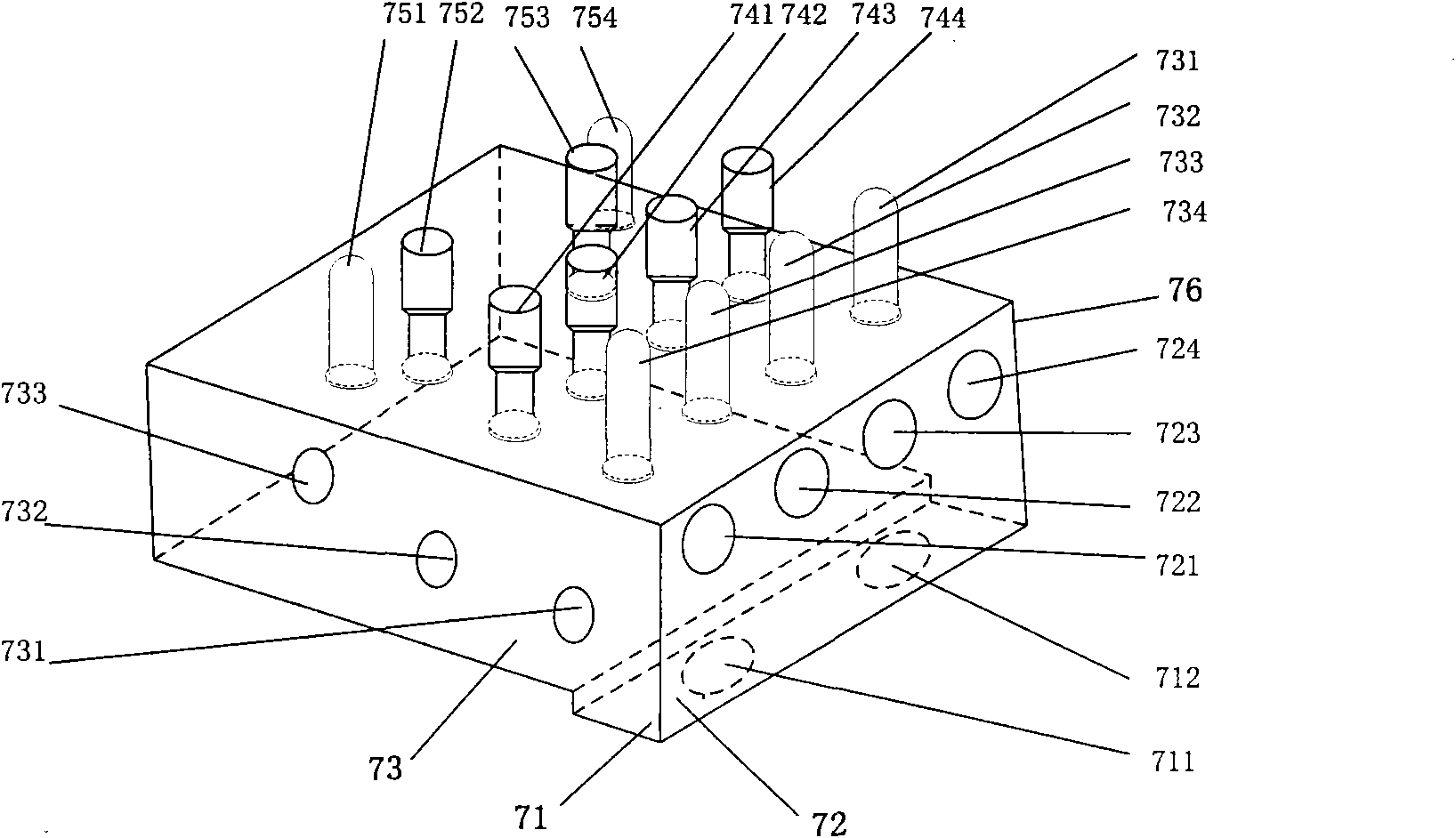

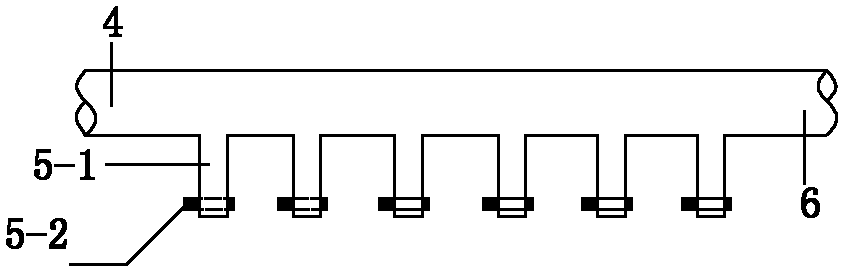

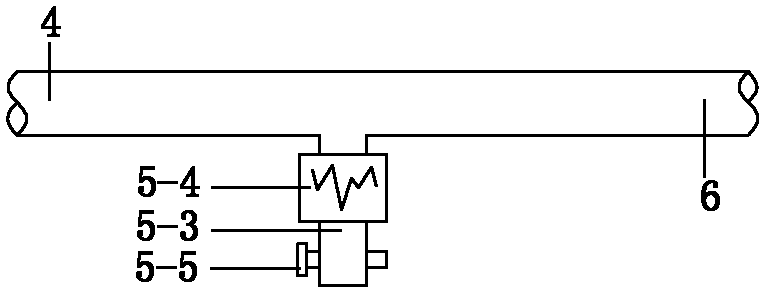

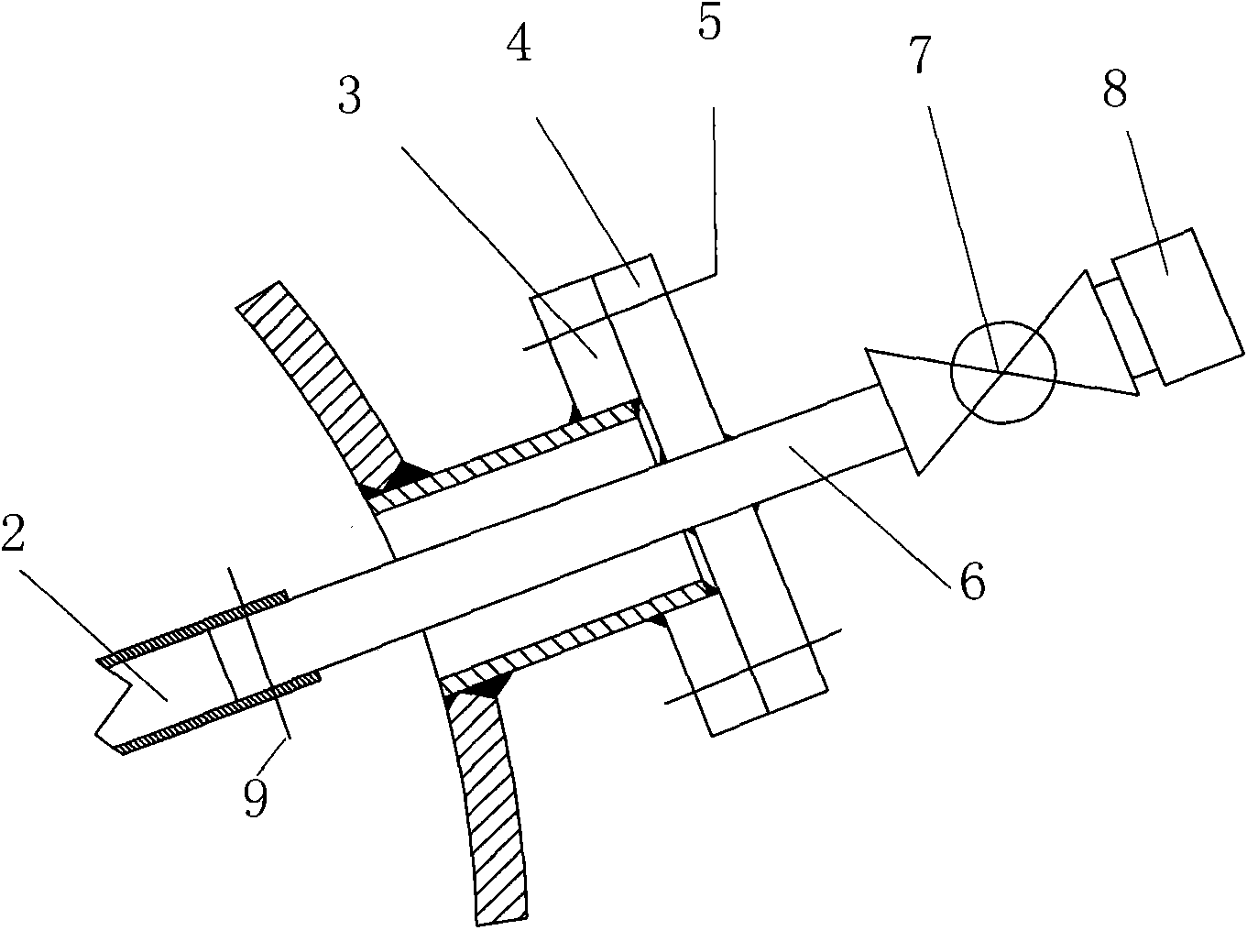

Airplane hydraulic test distributed test system and method thereof

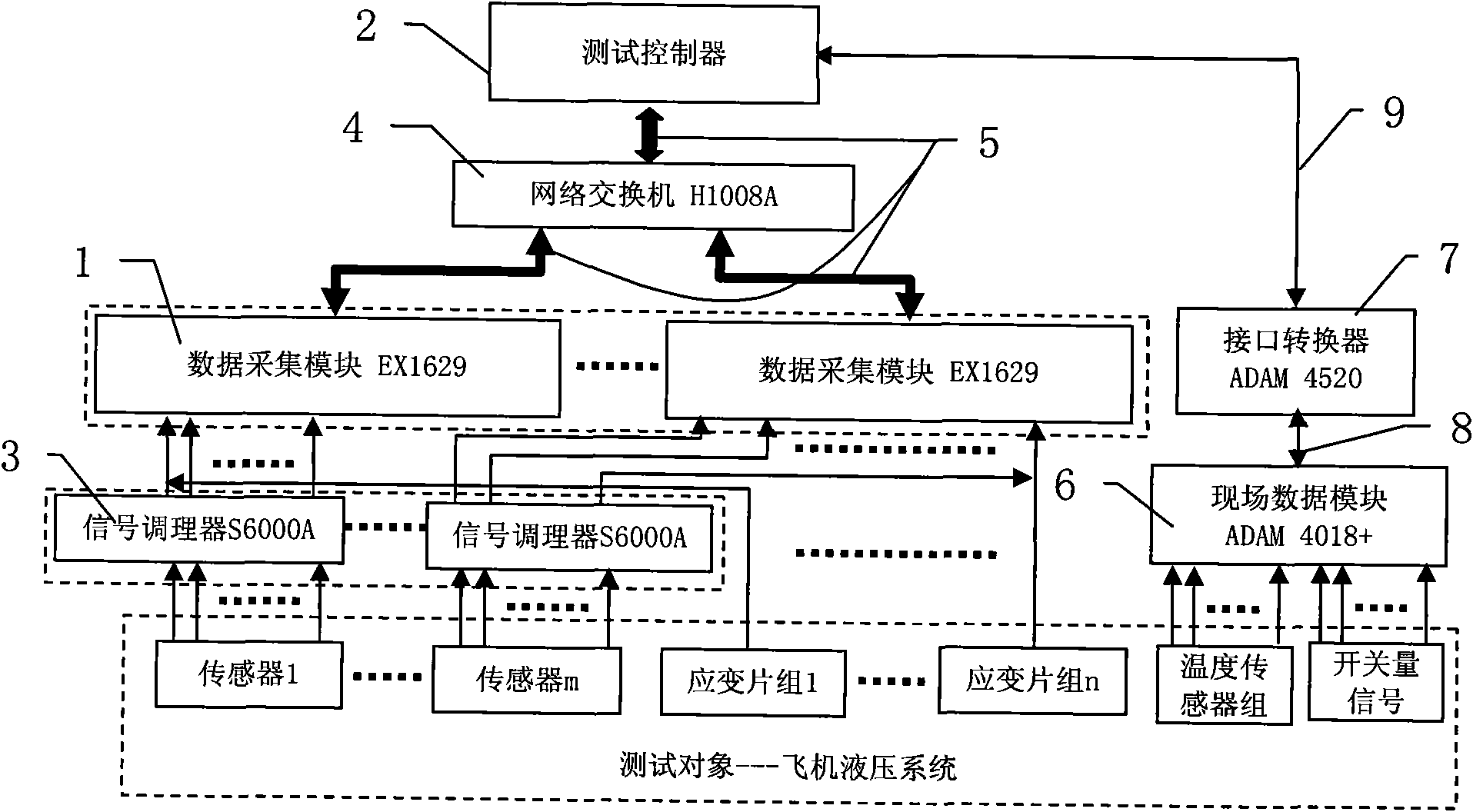

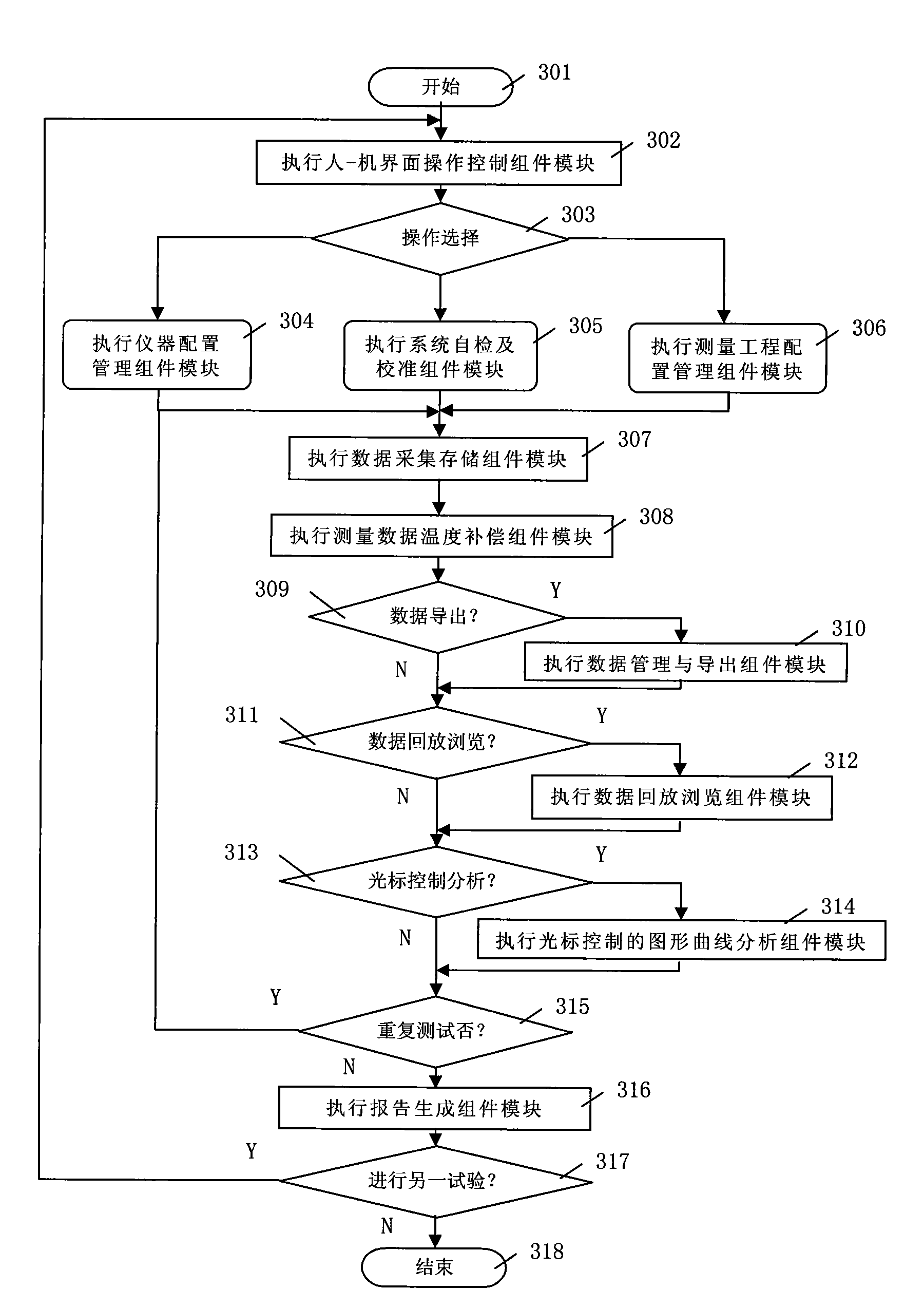

InactiveCN101865182ACompact structureSmall space sizeFluid-pressure actuator testingData acquisitionE communication

The invention discloses an airplane hydraulic test distributed test system and a method thereof, belonging to the technical field of measurement and control. The test system comprises a data acquisition instrument module (1), a test controller (2), a signal conditioner (3), a network switch (4), an LXI instrument control data bus (5), a field data module (6), an interface conversion module (7), a field data bus (8), a series communication data bus (9) and test software and is characterized in that a plurality of data buses are simultaneously used, and various data acquisition modules are adopted in the test system to finish the data acquisition in the measurement of various signals and the long-line transmission of the measured signals. The system of the invention has compact and simple structure, small space size, reliable operation, high test accuracy and favorable expansibility and tailorability.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

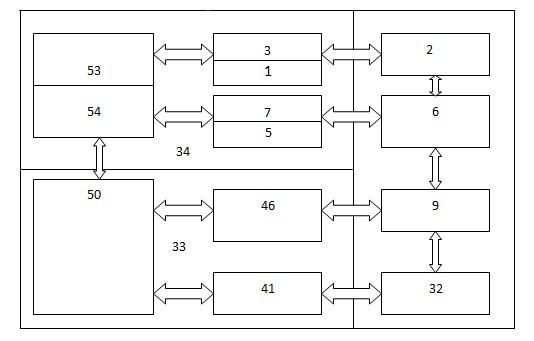

Hydraulic oil circuit suitable for tests of multiple kinds of hydraulic components

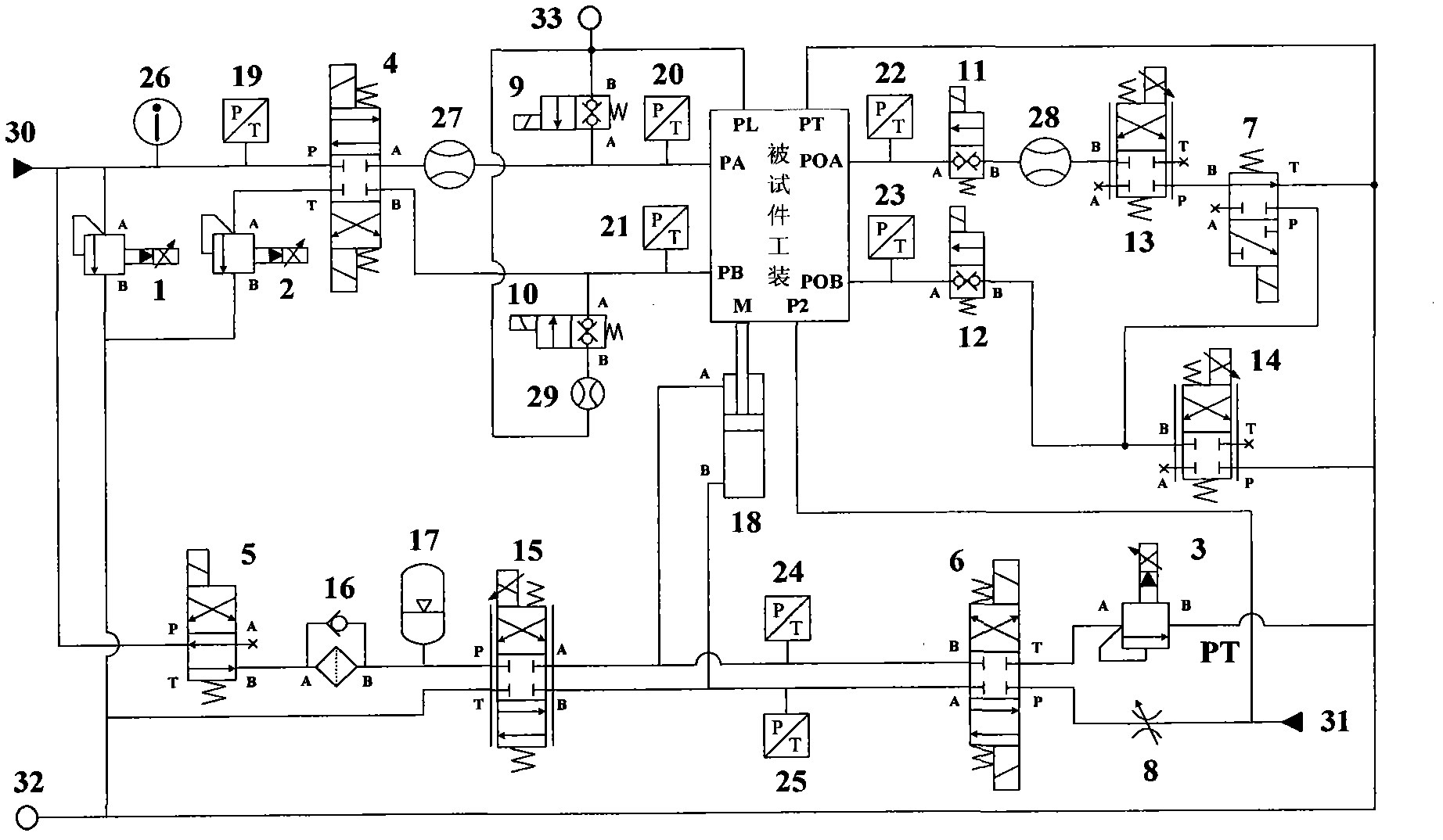

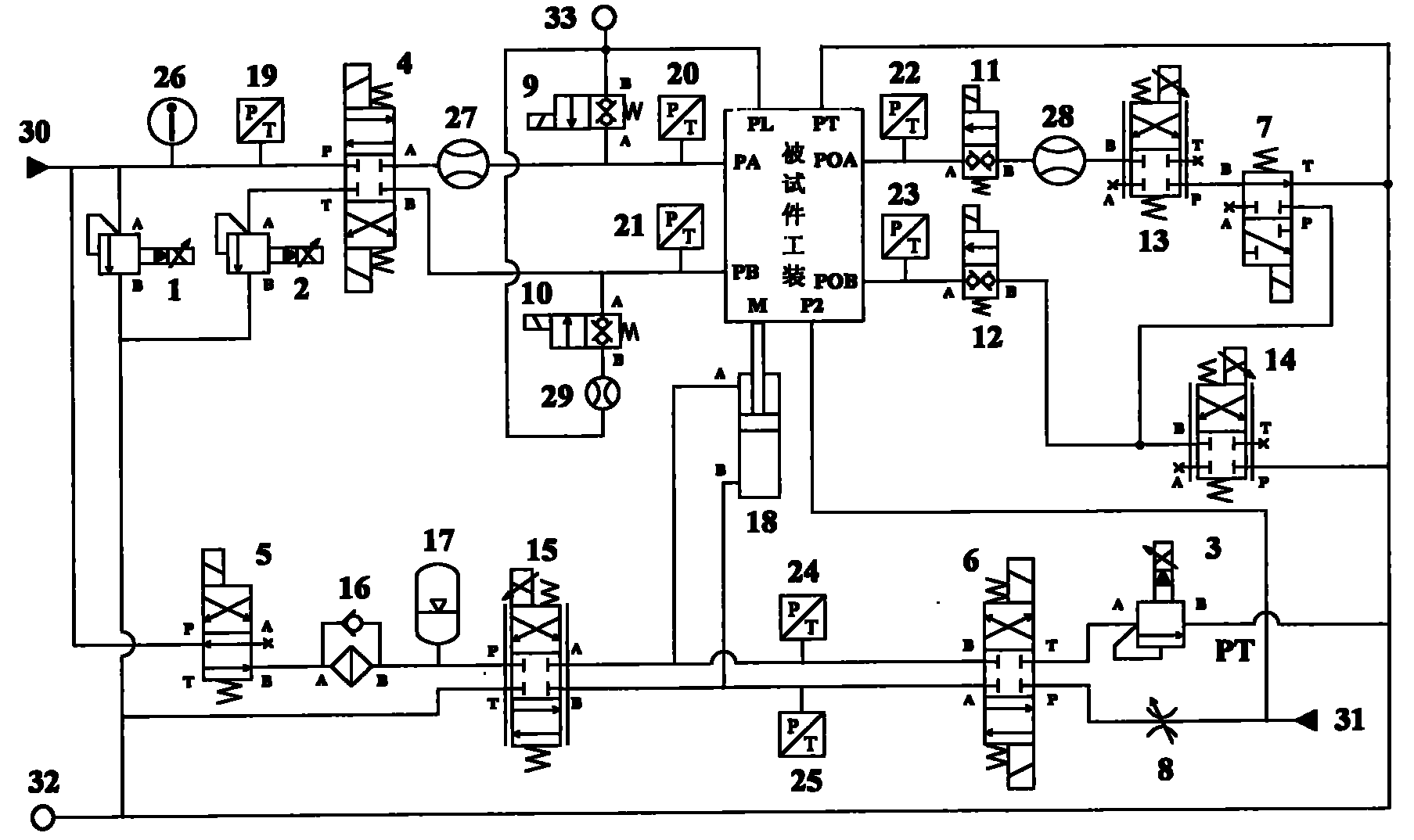

InactiveCN102493974AMeet the needs of comprehensive testingHigh degree of automationFluid-pressure actuator testingElectro hydraulicTest requirements

The invention relates to a hydraulic oil circuit suitable for tests of multiple kinds of hydraulic components, and belongs to the technical field of hydraulic test. The hydraulic oil circuit suitable for the tests of the multiple kinds of hydraulic components comprises a proportional relief valve, an electromagnetic directional valve, a throttling valve, an electromagnetic ball valve, a proportional directional valve, an electro-hydraulic servo valve, a fine filter, an accumulator, a servo oil cylinder, a pressure sensor, a temperature sensor, a flow sensor, a high-pressure oil source P1, a low-pressure oil source P2, an oil return port PT, an oil drain port PL and a test piece tooling. The invention solves the problems that standard hydraulic test oil circuits have single functions and are low in generality. The hydraulic oil circuit has high automation degree and a strong comprehensive test ability, and can meet the comprehensive test requirements of the multiple kinds of hydraulic components.

Owner:中国人民解放军65185部队 +1

Zonal isolation tool with same trip pressure test

Apparatus and methods for gravel packing, isolating and testing a sand screen completion of a wellbore in a single trip are disclosed. One method comprises inserting into the wellbore a sand screen assembly, an isolation pipe, and a test assembly on a workstring. A gravel pack operation is performed, and the isolation pipe is shifted to a position in sealing contact with the sand screen assembly, thereby isolating the sand screen assembly. The test assembly is then shifted to a configuration that provides hydraulic communication between the interior of the isolation pipe and the workstring-wellbore annulus above the test assembly. Imposing pressure on the workstring-wellbore annulus then hydraulically tests the integrity of the seal between the isolation pipe and the sand screen assembly.

Owner:SCHLUMBERGER TECH CORP

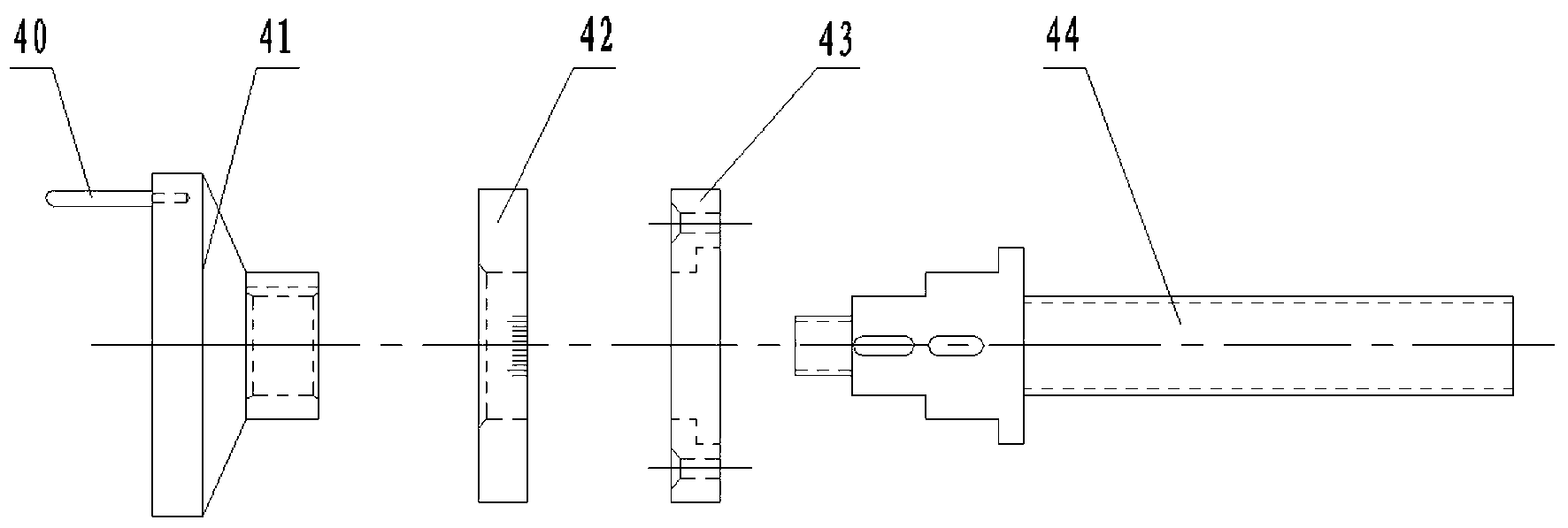

Throttle valve port performance test device

InactiveCN103335834ASimple structureReduce distractionsMachine part testingCavitationData acquisition

The invention discloses a throttle valve port performance test device which comprises a visualized flow field, a hydraulic test loop and a data acquisition control system, wherein the hydraulic test loop comprises a main oil circuit, a pilot control oil circuit and a cooling oil circuit; the visualized flow field comprises a valve cavity made of transparent material, a valve core provided with a throttle valve port of which the performance is to be tested, a laser, a CCD camera and a synchronous control device; movement of the valve core is controlled through reset springs at two ends and controlled oil together; the data acquisition control system comprises pressure sensors placed near the throttle valve port in the visualized flow field and in control oil cavities at two ends of the valve core, a flow sensor, a displacement sensor, a sound-level meter and a temperature meter in an oil tank. The device can directly observe cavitation form and flow phenomenon in the visualized flow field, and completes measurement of various parameters such as valve port noise, steady flow force of the valve core, pressure distribution of the flow field, flow and displacement of the valve core at the same time.

Owner:NANJING UNIV OF TECH +1

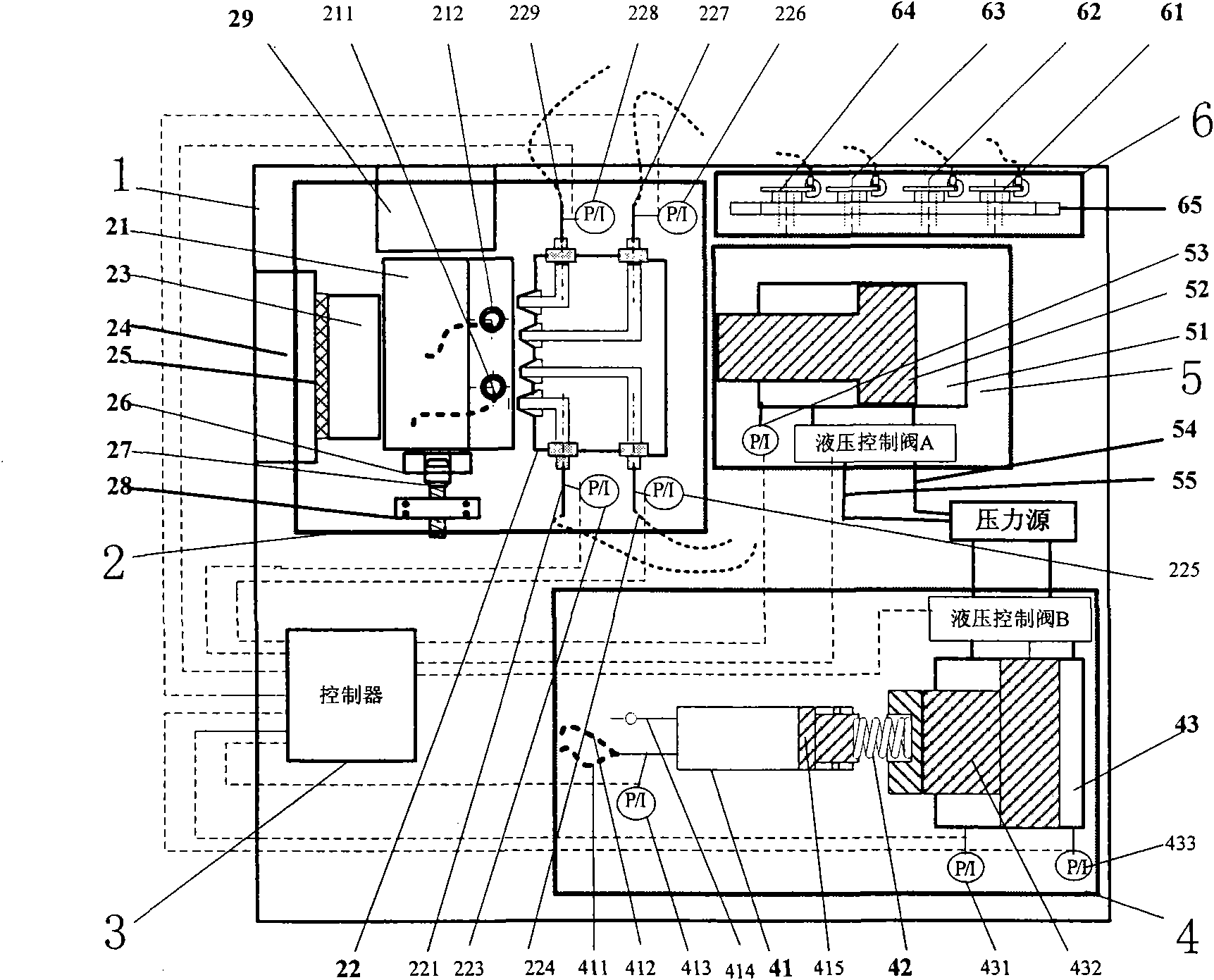

Hydraulic control unit performance test station for stability control system in vehicle dynamics

ActiveCN101566527ARapid positioningQuick dockingVehicle testingFluid-tightness measurementHydraulic cylinderHydraulic control unit

The invention relates to a hydraulic control unit performance test station for a stability control system in vehicle dynamics and belongs to the technical field of automobile manufacturing. The test station comprises a flat workbench, an HCU fast limiting and oil circuit sealing platform which is arranged on the workbench, a controller, a sealing feeding differential hydraulic cylinder, a hydraulic test system, a vehicle braking system, and a pressure source; the controller is respectively connencted with the HCU fast limiting and oil circuit sealing platform, the differential hydraulic cylinder and the hydraulic test system by a circuit; the differential hydraulic cylinder contacts the HCU fast limiting and oil circuit sealing platform; the hydraulic test system is connencted with the HCU fast limiting and oil circuit sealing platform by a test oil circuit; the vehicle braking system is connencted with the HCU fast limiting and oil circuit sealing platform by a braking fluid interface pipeline; and the hydraulic test system and the oil circuit sealing differential hydraulic cylinder are connencted with the pressure source by a hydraulic pipeline. The invention meets the delivery inspection needs of HCU, has easy and quick operation, and achieves low cost.

Owner:TSINGHUA UNIV

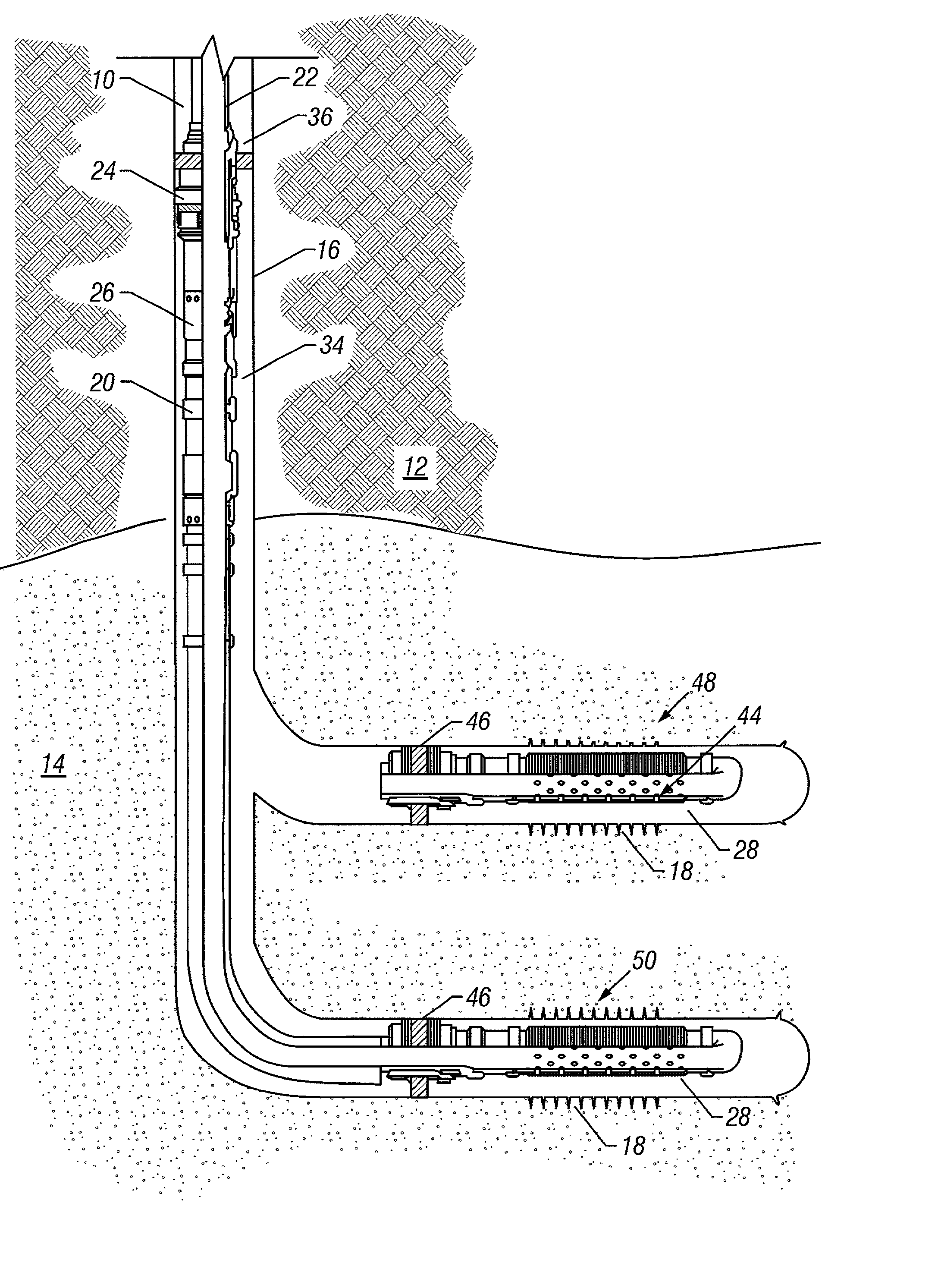

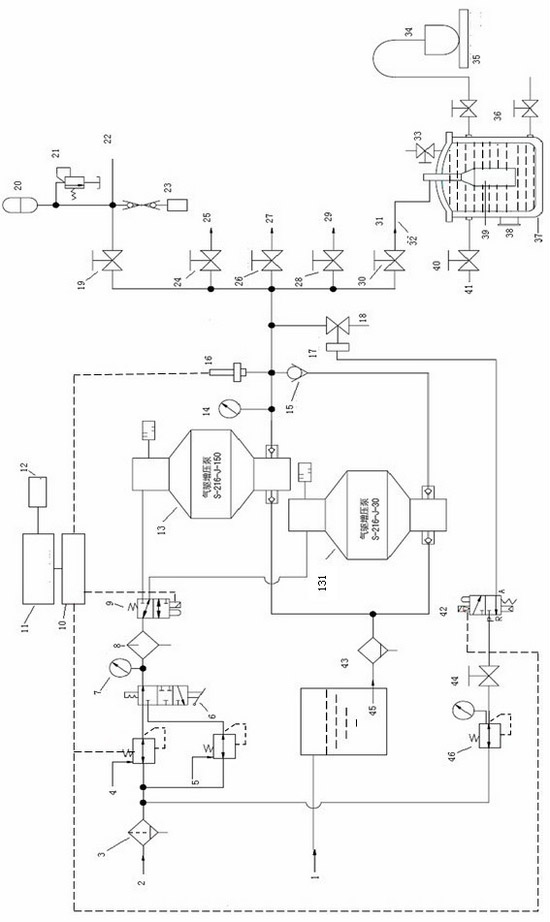

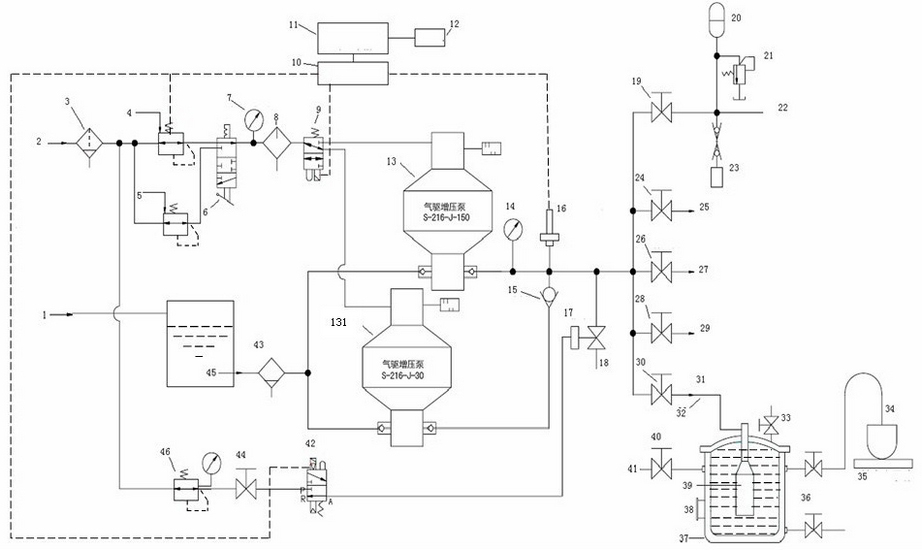

Measurement and control system for hydraulic test

ActiveCN102607960ABoost rate adjustableReal-time detection of pressure changesMaterial strength using tensile/compressive forcesSimultaneous control of multiple variablesAutomatic controlControl signal

The invention relates to a measurement and control system for a hydraulic test. A system control part is composed of a PLC (programmable logic controller) control cabinet, an industrial personal computer and a printer, a PLC is included in the PLC control cabinet, and the industrial personal computer is used as an upper computer of the PLC and connected with the PLC via a communication cable; a measurement and control pipeline part comprises a gas source supply pipeline, a gas-driving booster pump A, a gas-driving booster pump B, a liquid source supply pipeline, a high hydraulic output pipeline and a liquid unloading pipeline; and the PLC outputs a current control signal to the output end of an electric proportional valve, and the electric proportional valve controls gas pressure and gas flow rate by adjusting the position of a gas inlet valve according to the current control signal and a gas pressure signal which is output in proportion. The measurement and control system can performvarious pressure tests including an intensity test, a burst test for a safety relief device of a container, and a test for the residual deformation rate of the container; automatic control and manualcontrol in the hydraulic test for a fire-fighting product are independent from each other and can be used independently; pressure-boosting speed is adjustable, pressure change and dynamic curve output are detected in time; the measurement and control system is high in pressure control accuracy, small in volume, light in weight and low in energy consumption; multi-level pressure-boosting can be realized; and the measurement and control system has the characteristics of being high in reliability, high in accuracy, easy in operation etc.

Owner:应急管理部天津消防研究所

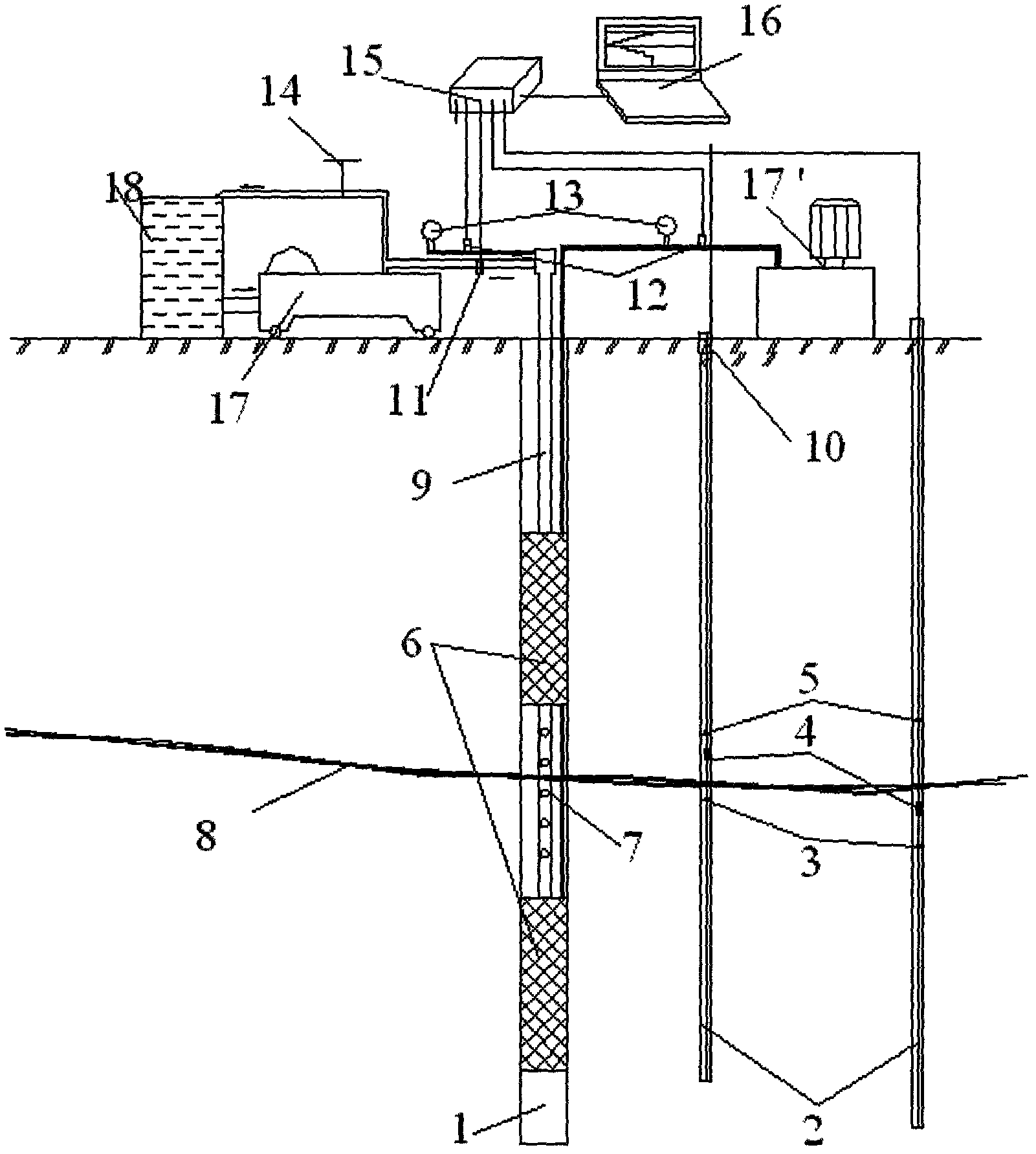

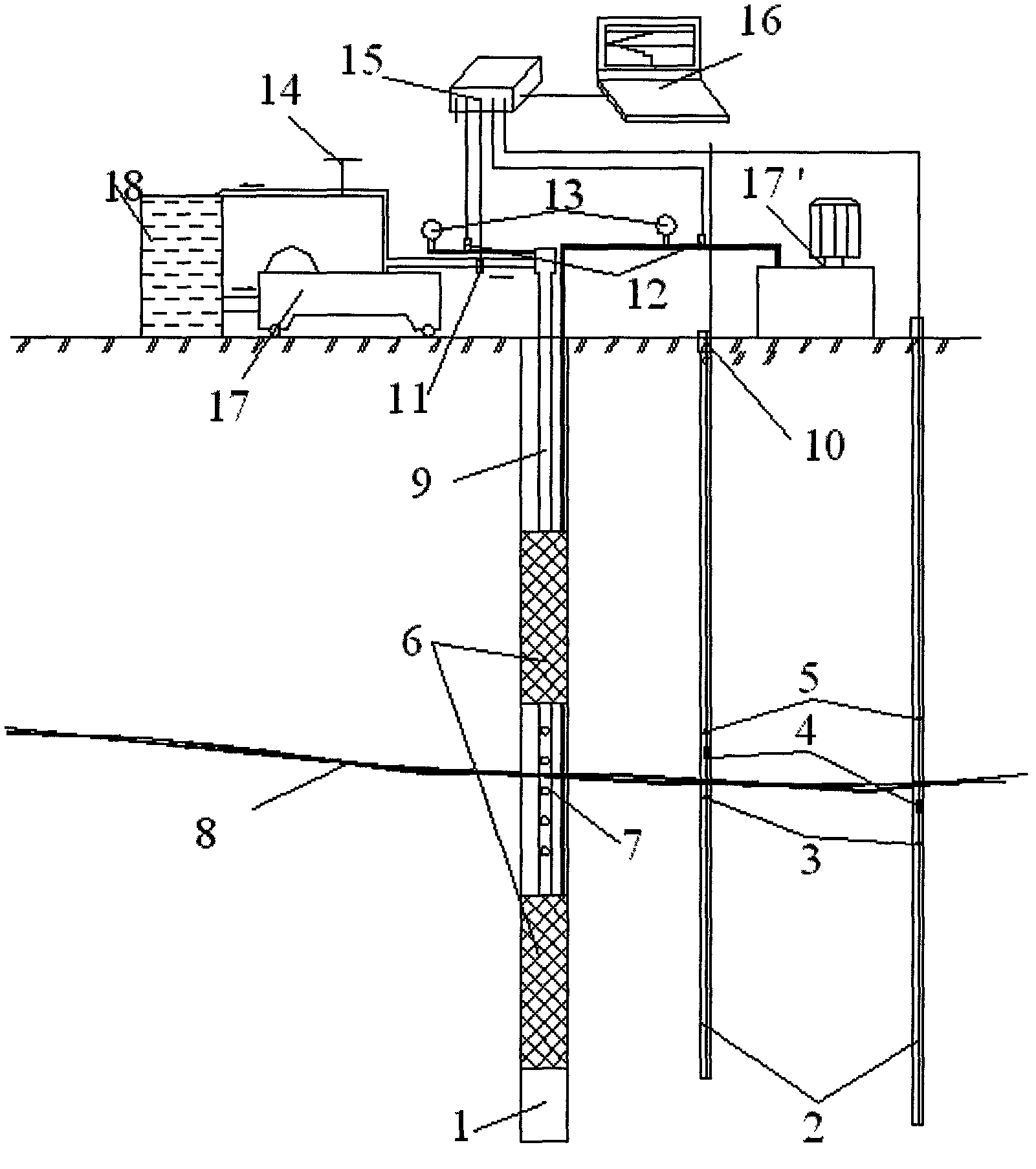

Field test system for transfusion, stress and deformation coupling characteristics of jointed rock mass

InactiveCN102621002ATightly boundFlow synchronization measurementMaterial strength using tensile/compressive forcesPermeability/surface area analysisData acquisitionField tests

The invention discloses a field test system for transfusion, stress and deformation coupling characteristics of a jointed rock mass. A given crack which passes through a drill hole is subjected to a permeability test under different pressure conditions by virtue of the drill hole, hydraulic power pressure, penetration flow and crack stress deformation can be measured, acquired and tested at the same time, and data can be stored by a high pressure hydraulic test system. A hole is drilled at a rock mass at a crack, a packing capsule is filled in the hole up and down, a test section is remained at the crack, a high pressure water pump pipe is provided with a pressure sensor which is connected into the packing capsule, and the packing capsule is pressurized, thus the packing capsule and hole wall are tightly combined, the high pressure water pump pipe is provided with a flow sensor and a pressure sensor, and a high pressure water pump carries out a flow high pressure hydraulic test on the test section in the drill hole by virtue of a drill pipe; an observation hole is drilled on the rock mass, a multi-point displacement anchor head and a strain gauge are arranged in the hole, the anchor head is connected with a displacement sensor, and the displacement sensor, the flow sensor and the pressure sensor are respectively connected into a data acquisition storage instrument and are respectively controlled by a computer.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

Device for adding sand to suspended load in river model test

InactiveCN102493390ARealize fully automatic controlAccurate measurementHydraulic modelsAutomatic controlControl line

The invention relates to a device for adding sand to suspended load in a river model test, and belongs to the field of hydraulic tests. The device mainly comprises a sand supply power system, a sand release device, a sand supply pipe and a return pipe, and is characterized by also comprising an integrated automatic control system, wherein the inlet and outlet of the sand supply power system is connected with the sand release device through the sand supply pipe and the return pipe to form a suspended load slurry conveying loop; and the integrated automatic control system is connected with the sand supply power system and the sand release device through a control line to monitor and adjust the suspended load slurry conveying process of the sand supply power system and the sand release device. By the device, the sand supply system is not blocked, backflow of a bypass pipe and the return pipe stirs a slurry tank, and a sand adding hole is not clogged under any experiment conditions; and the device can accurately meter the sand adding flow, and can fully automatically control to add the sand.

Owner:TSINGHUA UNIV

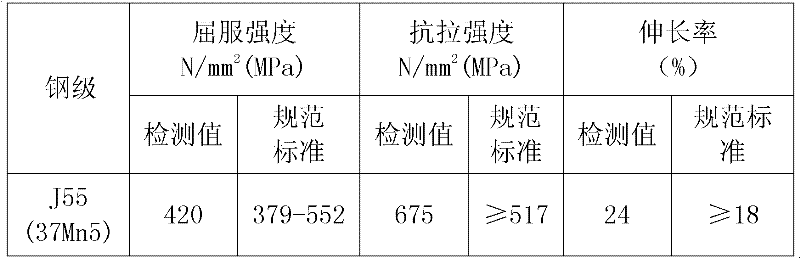

Spiral molded large-deformation-resistant submerged-arc welding pipe and manufacture method thereof

ActiveCN103192234ASmall sizeImprove construction efficiencyArc welding apparatusStress–strain curveLandslide

The invention discloses a spiral molded large-deformation-resistant submerged-arc welding pipe and a manufacture method thereof. A large-deformation-resistant hot rolled coil plate is unrolled and straightened, a welding groove is respectively machined on two sides of the plate, then the plate is placed into a spiral steel pipe molding unit to be molded and bent into a pipe shape gradually, the submerged-arc welding process is adopted to conduct welding pipe welding, and the welding pipe is subjected to following treatment such as hole enlargement, detection, hydraulic test and ultrasonic detection to form a product. The submerged-arc welding pipe has low yield ratio, larger even elongation, high deformation hardening exponent and Round-House type stress-strain curve under the premise that the welding pipe meets the requirement for high strength and high flexibility. The welding pipe is mainly applied to regions such as frozen earth zones, landslide zones, earthquake zones and the like where geological movement happens easily, serves as a steel pipe in oil and gas delivery pipes which can bear large deformation and stress, and ensures safe service of the pipes.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

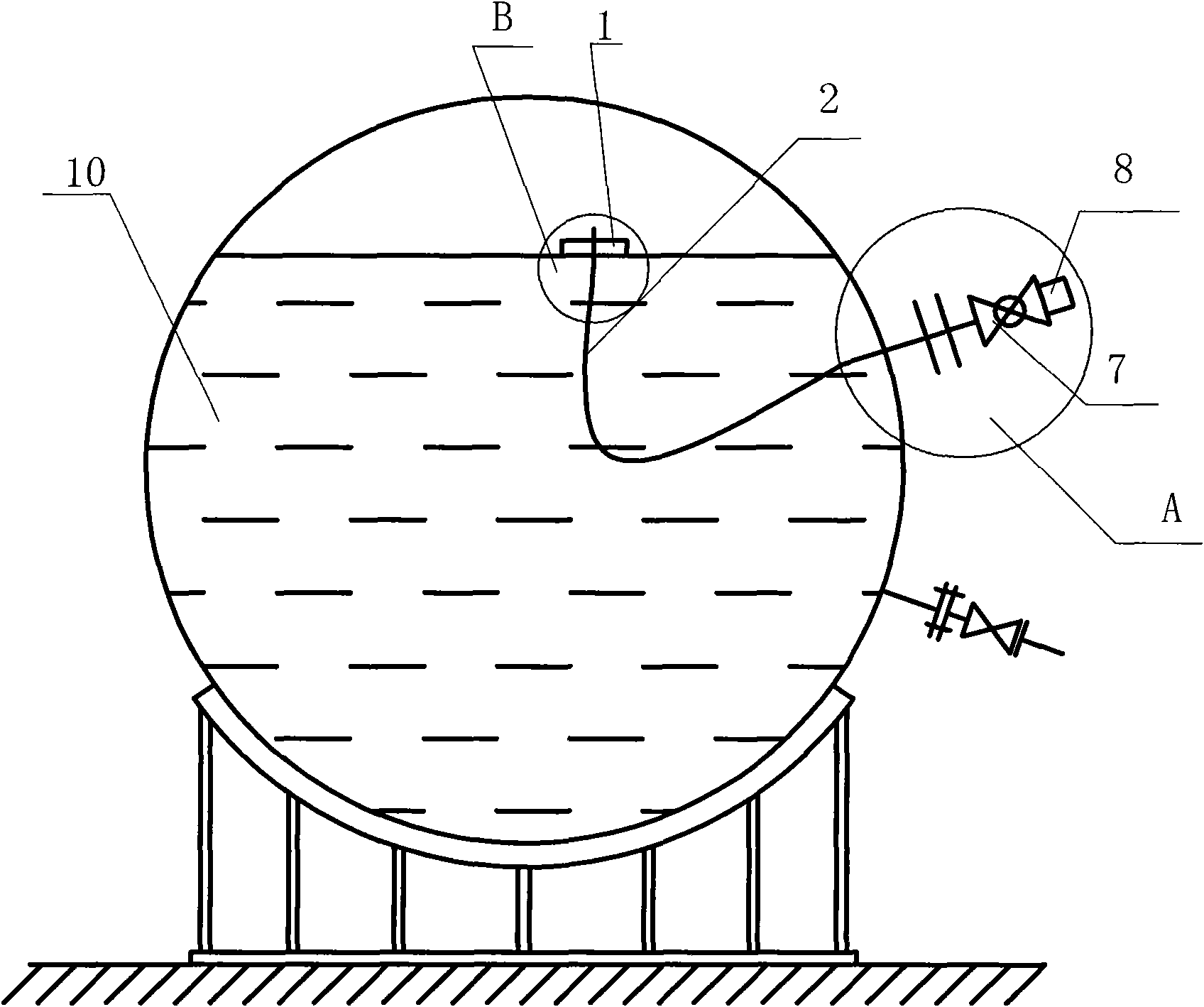

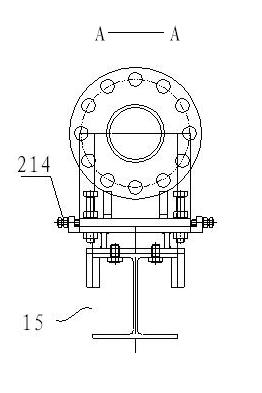

Exhaust device used for hydraulic test of pressure vessel

ActiveCN101672742ADischarge in timeEasy dischargeMaterial strength using tensile/compressive forcesEngineeringExhaust pipe

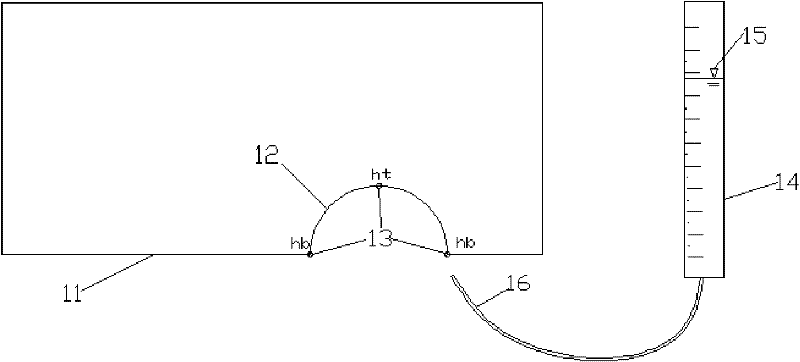

The invention relates to an exhaust device used for a hydraulic test of a pressure vessel, which comprises an exhaust pipe, a connecting mechanism and a globe valve, wherein the exhaust pipe is arranged inside the pressure vessel and used for guiding the gas inside the pressure vessel out of the pressure vessel; the connecting mechanism is arranged on the wall of the pressure vessel and is connected with the exhaust pipe; the globe valve is arranged outside the pressure vessel, connected with the connecting mechanism and used for cutting off or adjusting the flux of the gas exhausted out of the exhaust pipe. The exhaust device is characterized in that the exhaust pipe is a flexible soft pipe; and the other end of the exhaust pipe is fixed on a floating part that can float on water. Compared with the prior art, the exhaust device solves the problem that the large pressure vessel equipment has no suitable discharging exhaust point during the water-filling process of the hydraulic test, has good exhaust effect, avoids the hidden safety problem caused by the gas accumulated on top of the vessel during the water-filling process, and shortens the pressurizing time of the hydraulic test;furthermore, the exhaust device has simple structure, is safe and feasible, is convenient for manufacturing, has low cost, can be applicable to the hydraulic tests of the equipments of various specifications and has wide application prospect.

Owner:SINOPEC NINGBO ENG +1

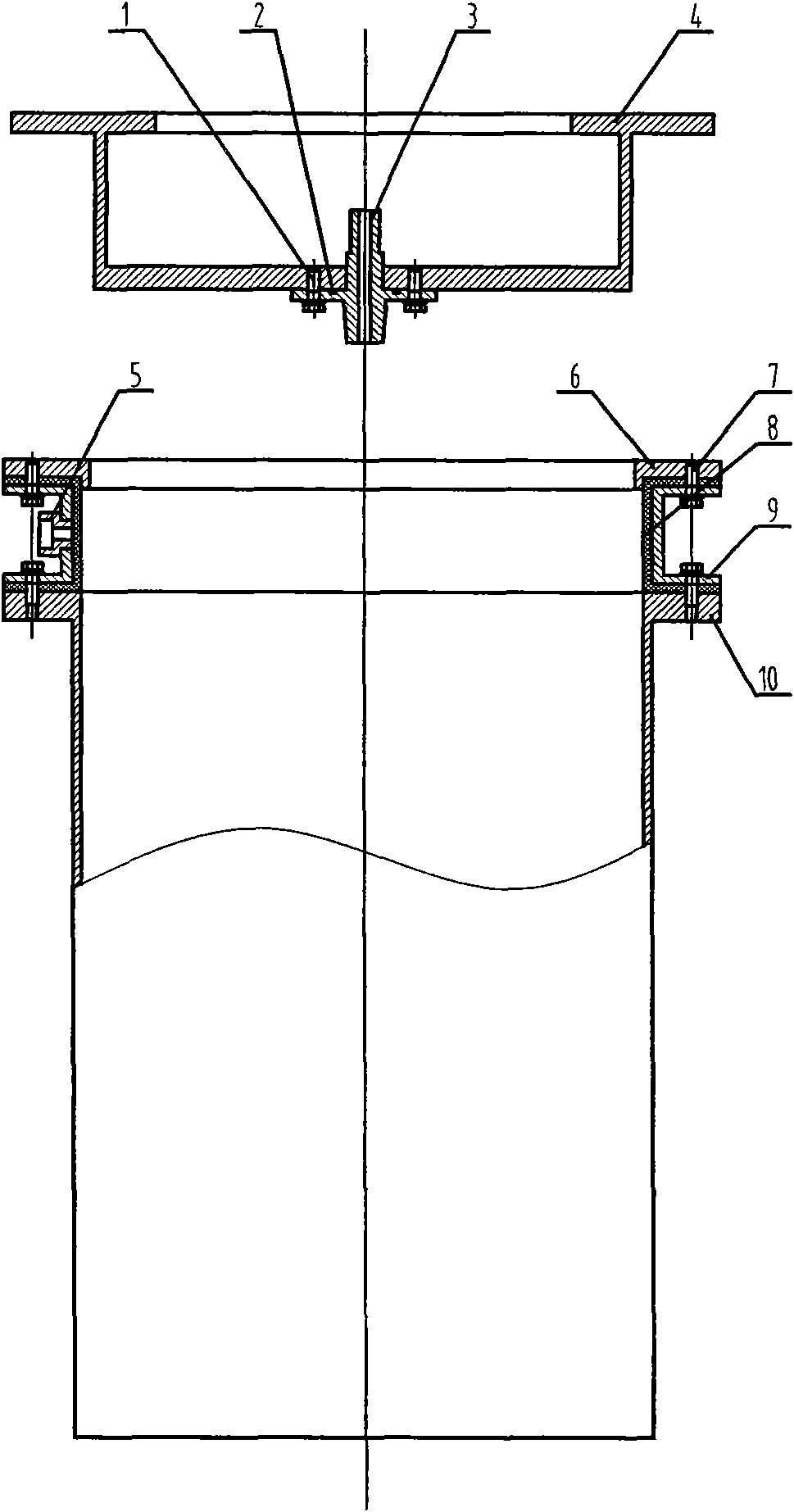

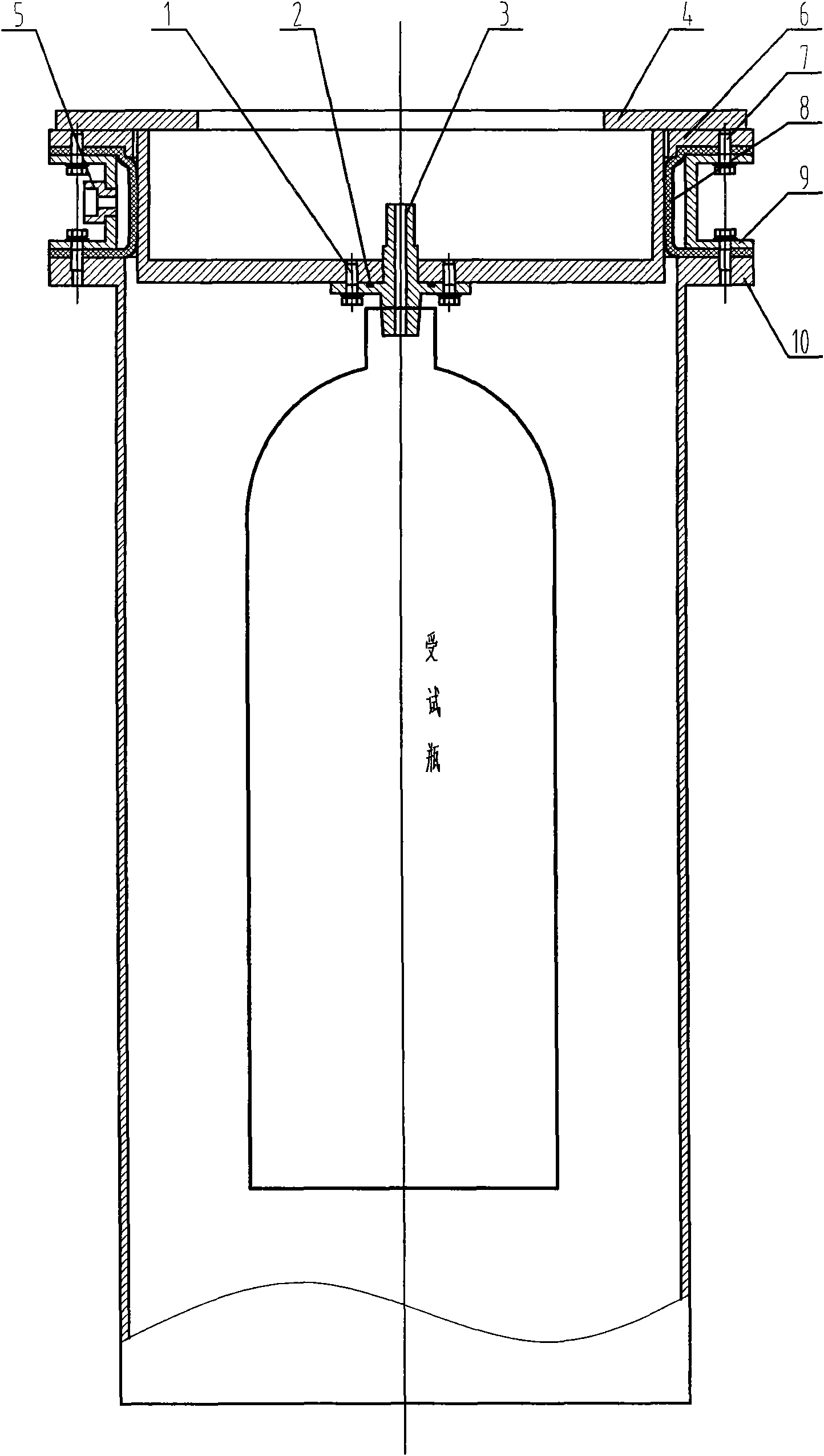

Water jacket and air bag type sealing device for hydraulic test of air bottle outside measuring method

InactiveCN101581643AQuick sealImprove sealingMaterial strength using tensile/compressive forcesGas cylinderEngineering

The invention relates to a water jacket and air bag type sealing device for hydraulic test of an air bottle outside measuring method, in particular to a test container for forming seal between a water jacket and a water jacket cover. The sealing device mainly comprises a pressure test joint, the water jacket cover, a pneumatic joint, a flange, a rubber air bag, a connecting flange and the water jacket, wherein the pressure test joint is fixedly connected with the water jacket cover through a connecting bolt and an O-shaped ring which seals the connecting part; the pneumatic joint is fixedly connected to an outer circular face of the connecting flange; the rubber air bag and the connecting flange are placed between the flange and the water jacket and fixed through the connecting bolts; and the connecting faces of the connecting flange, the flange and the water jacket are sealed through an upper end face and a lower end face of the rubber air bag. The sealing device has a simple, compact and reasonable structure, has simple and convenient operation, is quick, effective and reliable to form a water jacket seal, can ensure smooth hydraulic test of the air bottle outside measuring method, and greatly improves the production efficiency.

Owner:无锡昌华机电制造有限公司

Ultrasonic vibration three-point bending test device suitable for observing crisp and hard material on line

ActiveCN103217347AAchieve multi-dimensional vibrationMaterial strength using steady bending forcesMaterial strength using repeated/pulsating forcesAlloyEngineering

The invention discloses an ultrasonic vibration three-point bending test device suitable for observing a crisp and hard material on line. The ultrasonic vibration three-point bending test device comprises a cubical support, and a three-point bending device is fixed on a dynamometer placed on a hydraulic test machine; quartz glass is arranged at the front side of a flat plate on the support; a bottom plate of the support is provided with a movable observing device, and a high-speed photographic tens of the movable observing device corresponds to the quartz glass in position; the flat plate on the support is transversely provided with a dovetail groove guide rail, and a movable supporting seat is connected with the flat plate on the support through the dovetail groove guide rail and is in transmission fit with a lead screw; a semicircular groove is formed in the top surfaces of the movable supporting seat and a fixed supporting seat, a test piece is arranged in the semicircular groove, and a round hard alloy bar is exposed out of the semicircular groove and used for supporting the test piece; and the support at the right side of the fixed supporting seat is provided with a horizontal ultrasonic vibration system, and a longitudinal ultrasonic vibration system is arranged on a main shaft of the hydraulic test machine. By using the ultrasonic vibration three-point bending test device, multi-dimensional vibration of a workpiece can be realized, and the research on ultrasonic vibration grinding cracks can be conveniently carried out through simulating the stress state of a ceramic material in the actual machining process.

Owner:CONPROFE TECH GRP CO LTD +1

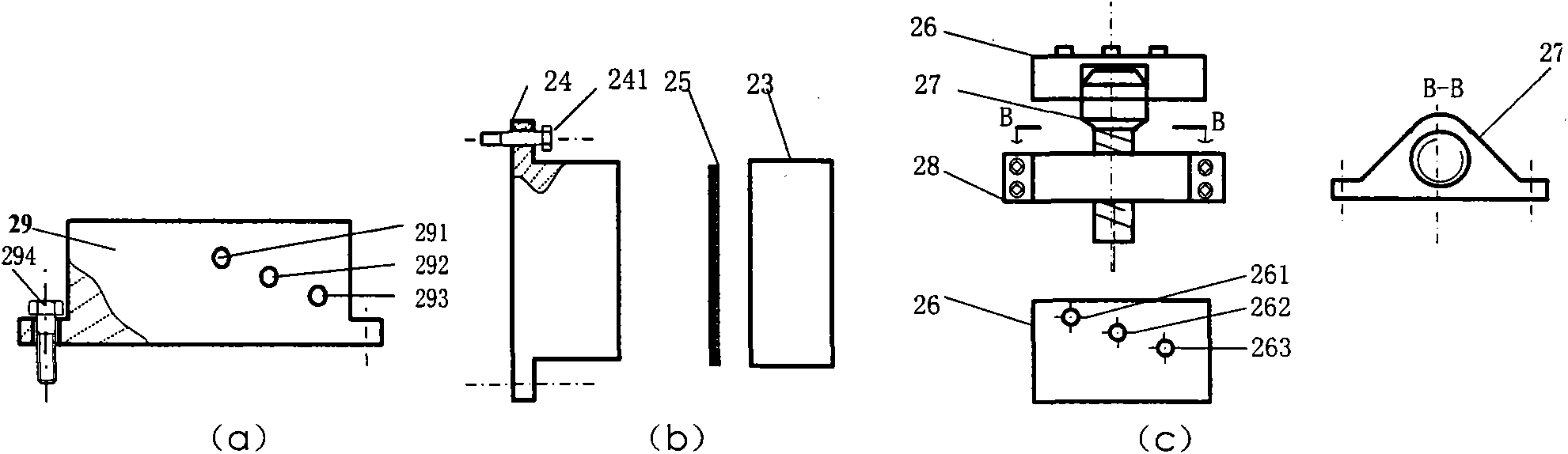

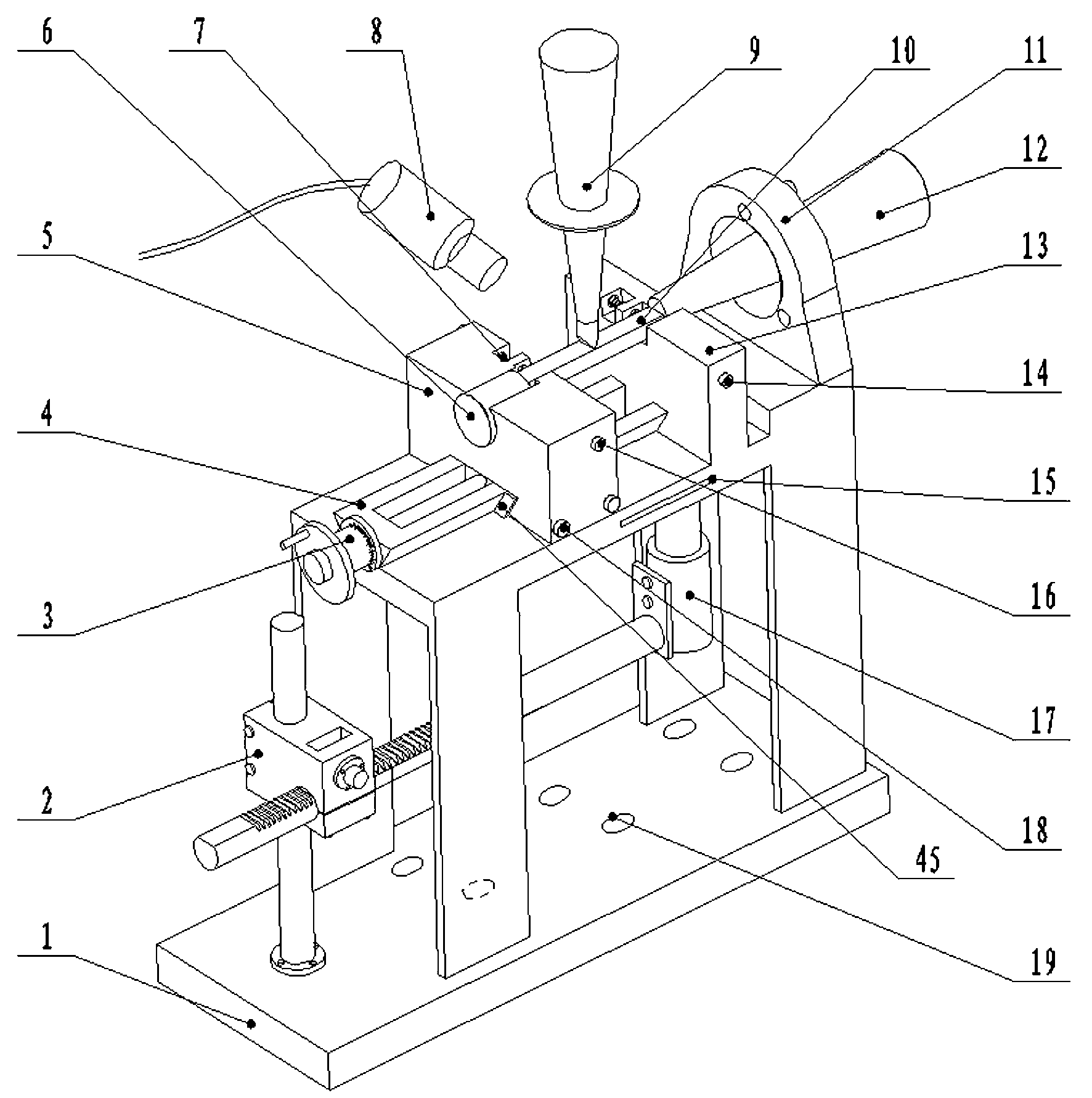

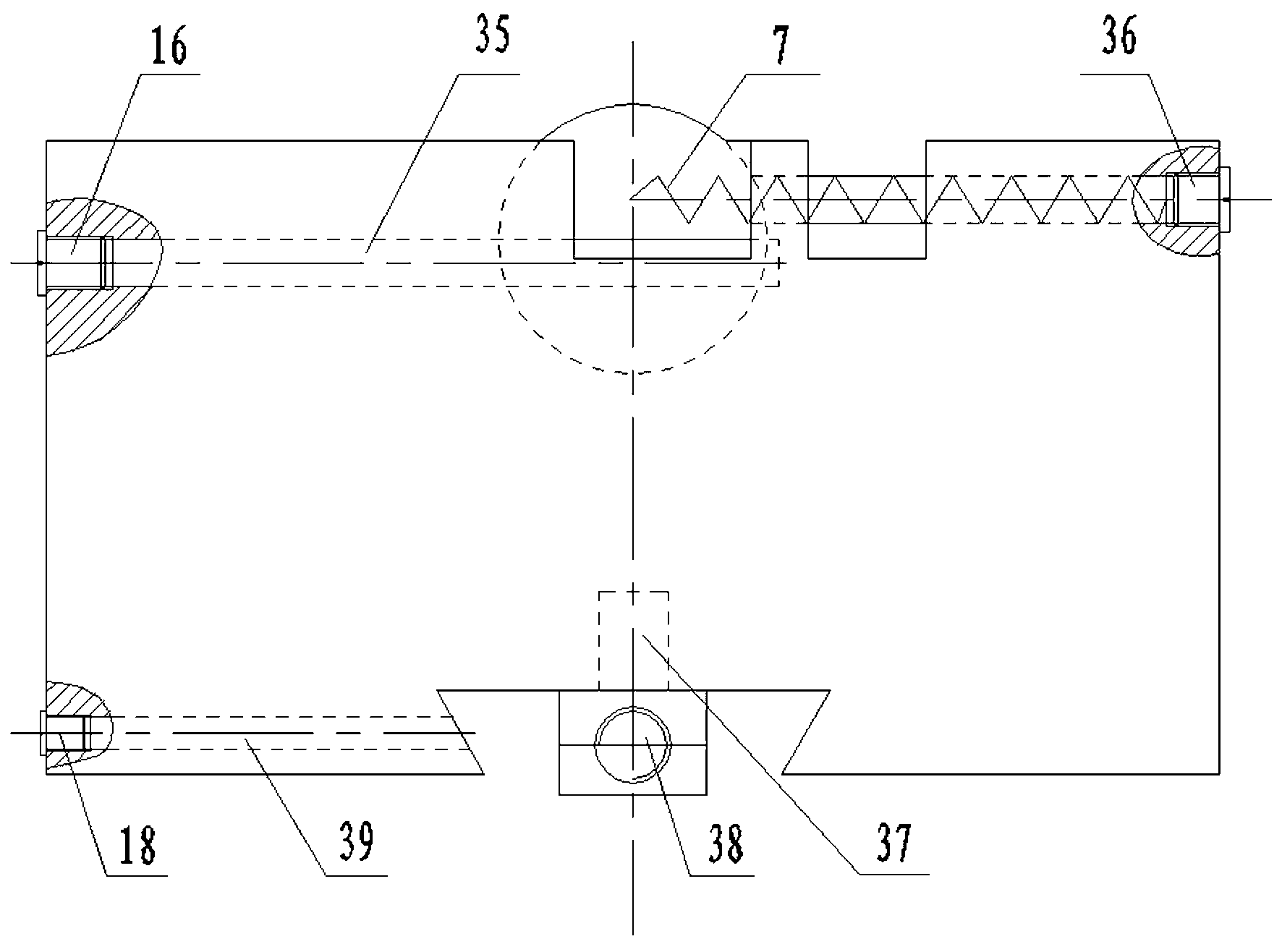

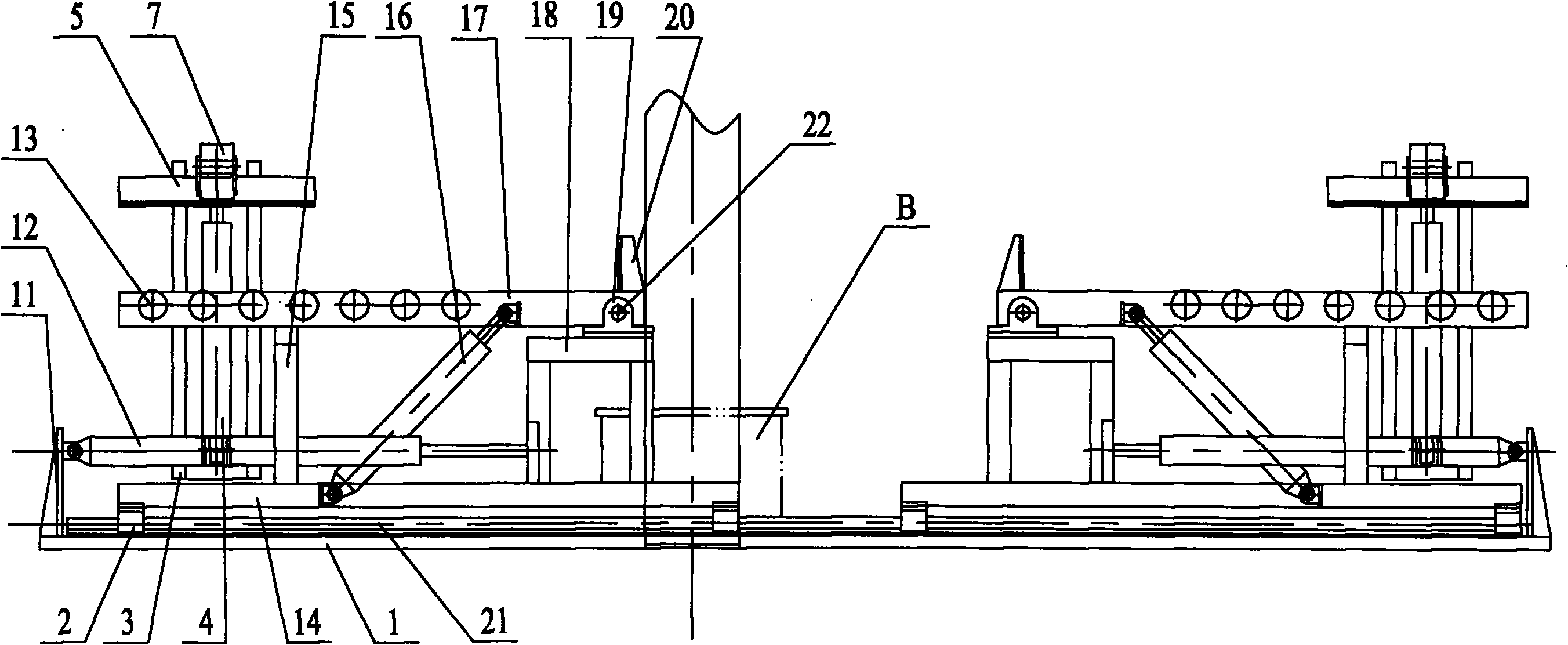

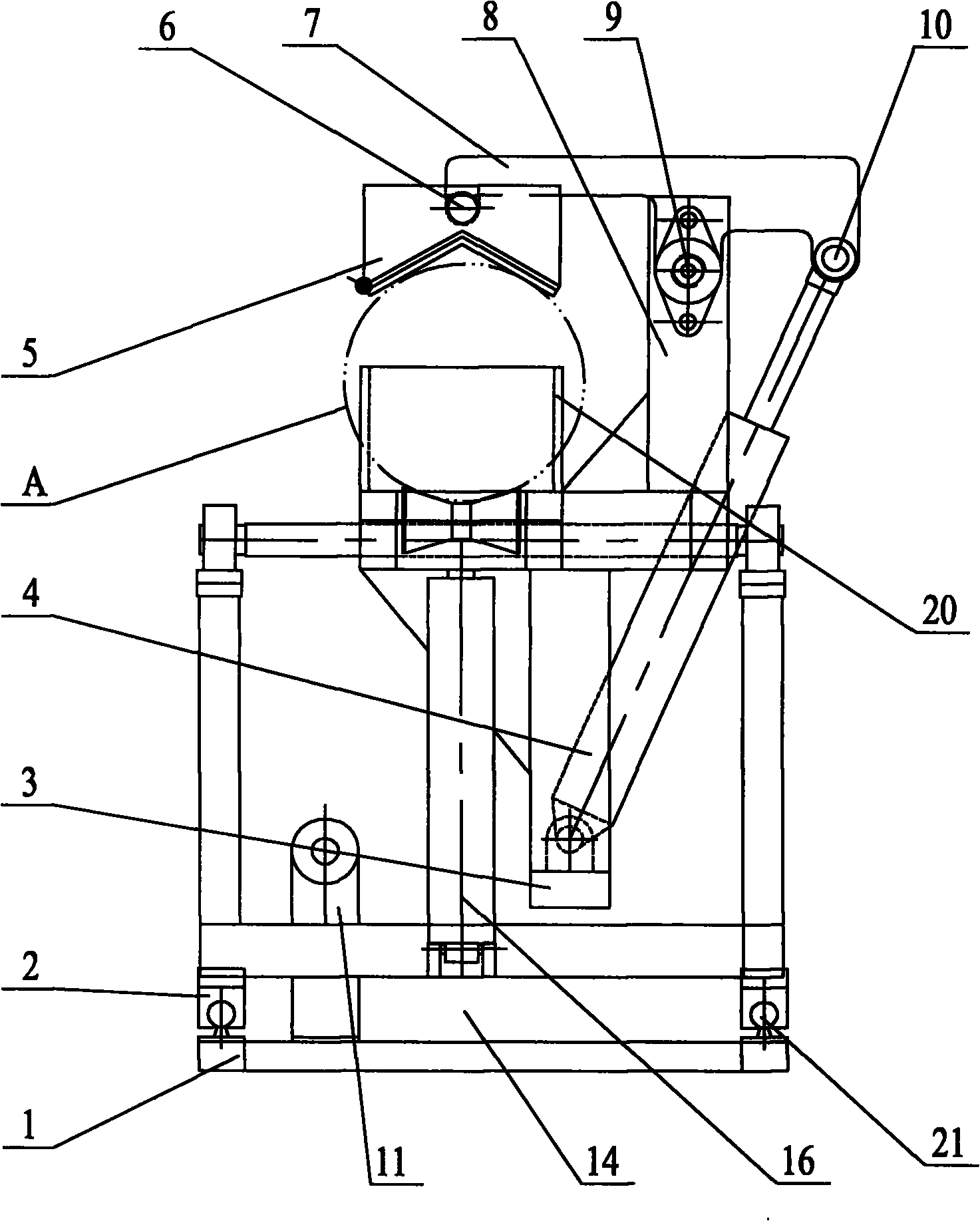

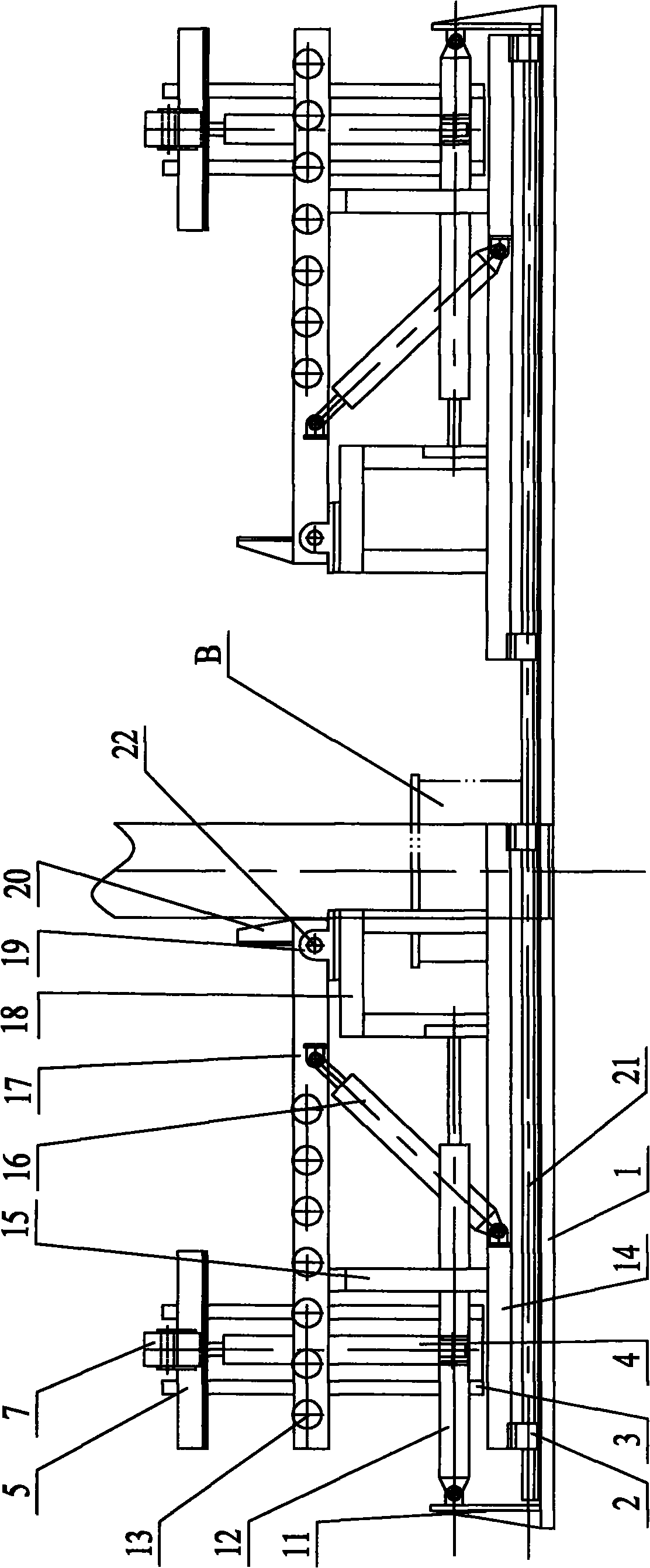

Mechanical clamping type automatic feeding and discharging device

InactiveCN101813585AGuarantee personal safetyIngenious and reasonable structureStructural/machines measurementStrength propertiesGas cylinderWater jacket

The invention relates to a mechanical clamping type automatic feeding and discharging device, which is applied on a production line of hydraulic tests in a water jacket method for gas cylinders. The device comprises a linear guide rail mechanism, an automatic feeding device and an automatic discharging device, wherein the automatic feeding device and the automatic discharging device are supported by the linear guide rail mechanism and can freely slide on the linear guide rail. The device is characterized in that the automatic feeding device and the automatic discharging device are of identical structures and are symmetrically arranged on the two ends of the linear guide rail; the automatic feeding device and the automatic discharging device are respectively driven by a power mechanism to slide in a reciprocating way along the linear guide rail; and the automatic feeding device and the automatic discharging device respectively comprise a base, an overturning frame and an overturning cylinder; the overturning cylinder are used for driving the overturning frames to overturn; the overturning frames comprise a roller frame, a roller and a clamping mechanism; the rollers are used for supporting an air cylinder to be tested; and the clamping mechanisms are used for fixing the air cylinder to be tested. The invention has the advantages of delicate and reasonable structure, convenient operation and high degree of automation, and can greatly improve the production efficiency, effectively reduce the labor intensity and ensure the personal safety of the operating personnel.

Owner:无锡昌华机电制造有限公司

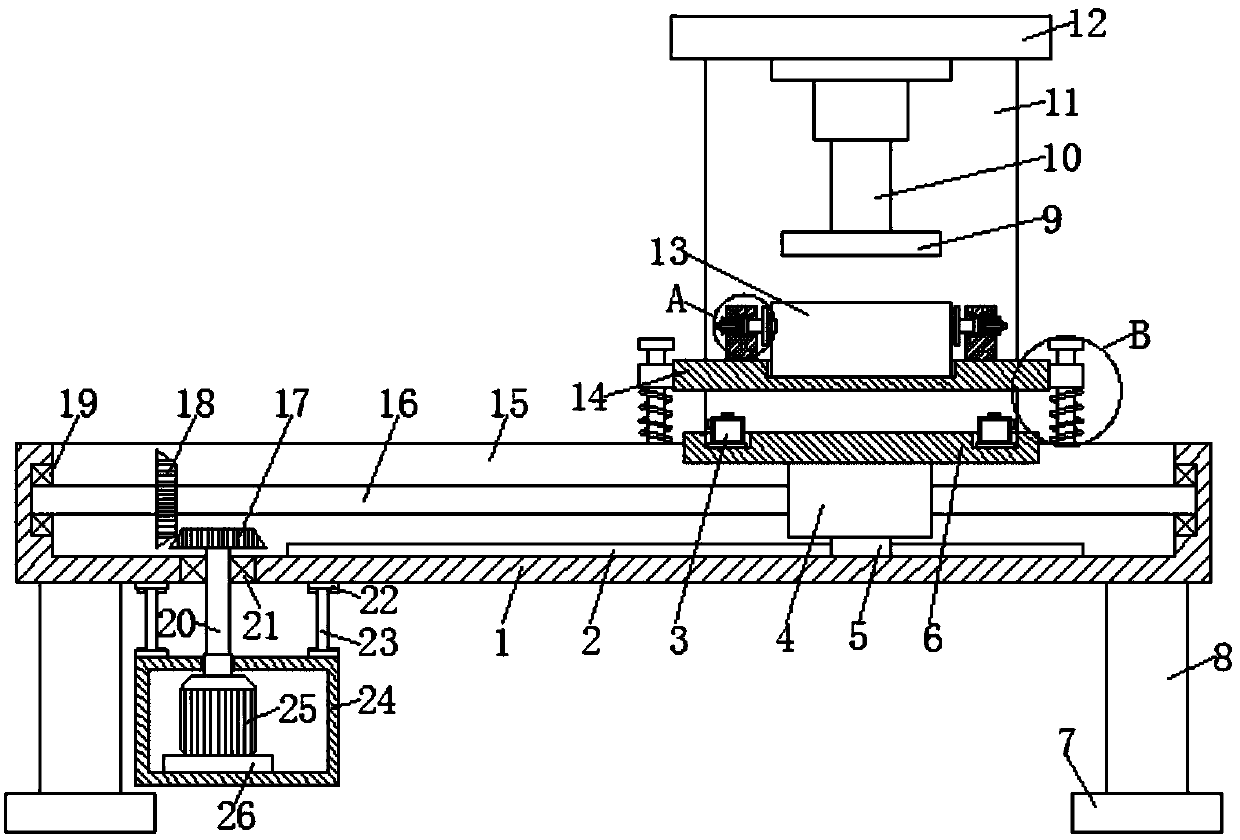

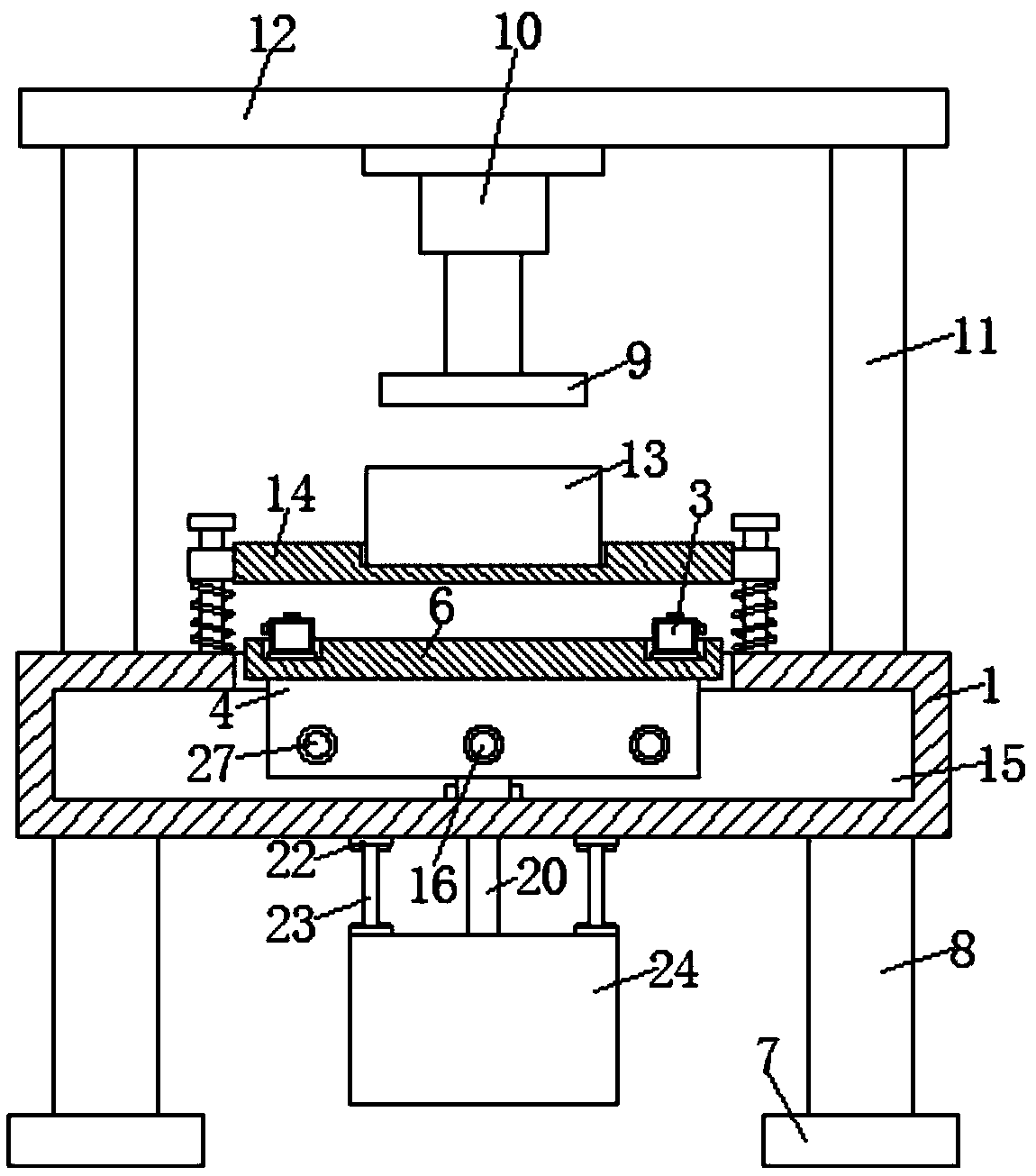

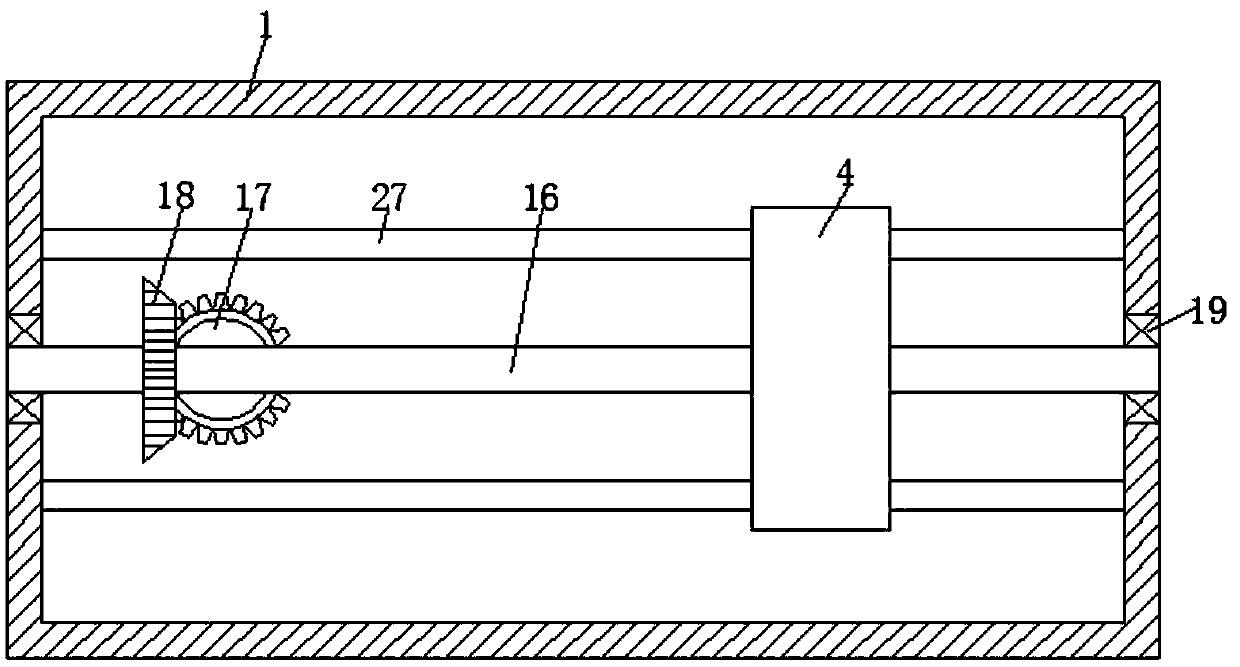

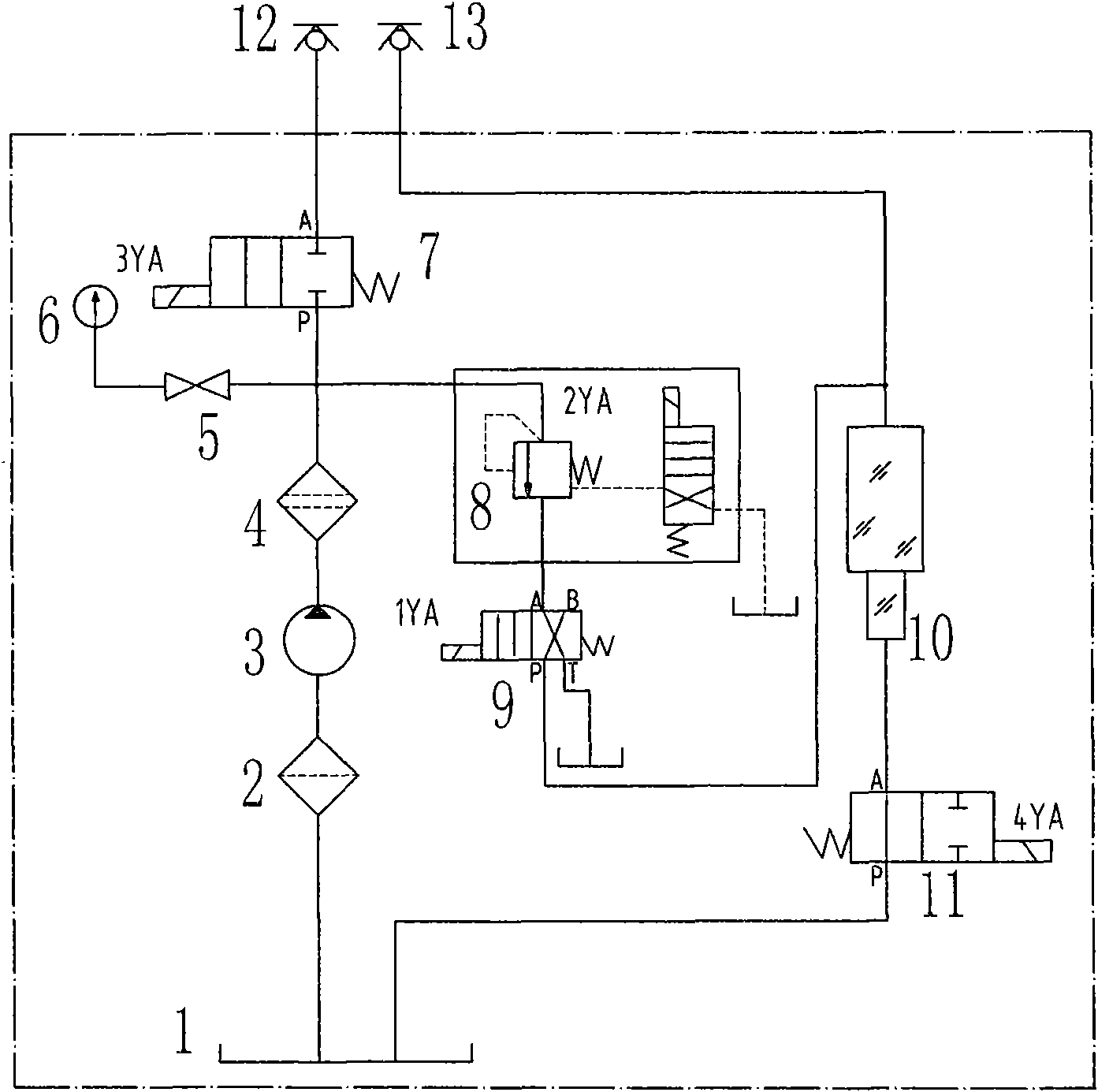

Multifunctional hydraulic comprehensive test bench

ActiveCN109612703AReduce the risk factorPlay a protective effectMachine valve testingMaterial strength using tensile/compressive forcesCombined testEngineering

The invention relates to the technical field of hydraulic test equipment, in particular to a multifunctional hydraulic comprehensive test bench, comprising a platen. A groove is formed on the upper surface of the platen. A first bearing is though provided on the middle of each of the two sides of the inner wall of the groove. An adjusting rod is rotationally provided between the two first bearings. A pressure sensor is fixedly mounted at each of the four corners of the upper surface of the movable plate. A supporting plate is fixedly mounted on each of the two ends of one side of the upper surface of the platen. A top cover is fixedly mounted on the upper end of each of the supporting plates. A hydraulic push rod is fixedly mounted at the middle of the lower surface of the top cover. A pressing plate is fixedly mounted at the lower end of the hydraulic push rod. Four positioning mechanisms are fixedly mounted on one side of the upper surface of the platen. A placing plate is fixedly mounted among the four positioning mechanisms. A mounting groove is formed on the upper portion of one side of the fixed block. A second sliding groove is fixedly mounted on each of the two sides of theinner wall of the mounting groove. According to the multifunctional hydraulic comprehensive test bench, a test piece can be fixed and adjusted, the operation is simple, the use is convenient and thepracticability is high.

Owner:湖北泰和电气有限公司

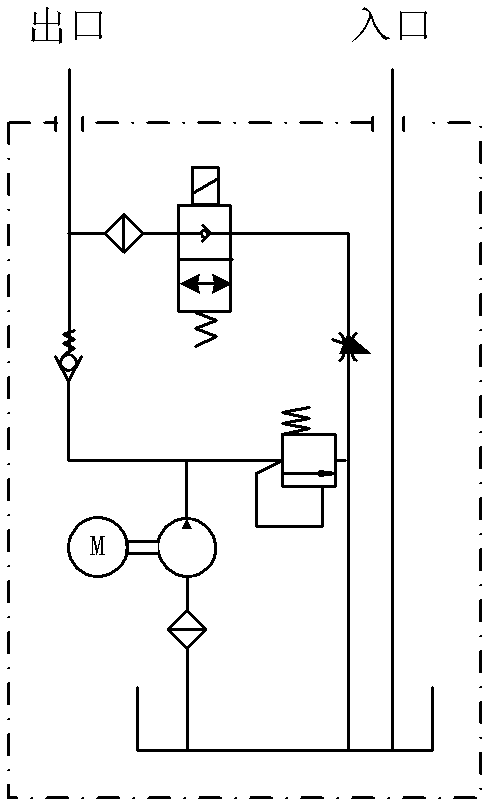

Portable active hydraulic tester and test method

InactiveCN101598159AAccurately judge the pros and cons of performanceFirmly connectedFluid-pressure actuator testingHydraulic pumpTester device

The invention discloses a portable active hydraulic tester and a test method. A coarse filter of the tester is connected with a hydraulic pump, and the hydraulic pump is connected with a fine filter; the fine filter is connected with a normally-off two-position two-way electromagnetic directional valve, a pressure gauge switch and an electromagnetic relief valve; the normally-off two-position two-way electromagnetic directional valve is connected with a quick connector; the electromagnetic relief valve is connected with a two-position four-way electromagnetic directional valve, and the two-position four-way electromagnetic directional valve is connected with an oil return quick connector and a metering cylinder; the two-position four-way electromagnetic directional valve is connected with an oil tank; the metering cylinder is connected with a normally-on two-position two-way electromagnetic directional valve; and the normally-on two-position two-way electromagnetic directional valve is connected with the oil tank. The test method comprises the following steps: debugging the pressure and flow parameter calibrated by the tester; testing the pressure and flow parameters under the condition that tested hydraulic systems and components are removed respectively, drawing a coordinate graph and analyzing a test result; and completing the performance calibration of a new-manufactured hydraulic system and the performance testing of an online hydraulic system, listing the sequence of hydraulic component spare parts, and removing faults. The tester and the method have simple, convenient and fast operation.

Owner:杨成刚 +1

Production process of special steel pipe for air-conditioning compressor casing

ActiveCN101885136AOptimize width sizeOptimizing the size design of the opening angleStrip steelEngineering

The invention relates to a production process of a special steel pipe for an air-conditioning compressor casing. The production process comprises the following steps of selecting materials, cutting into band steel, loading, forming rolled pipes, extruding into pipes through high-frequency welding, post-processing welding seams, detecting the welding seams, finishing, correcting and performing a hydraulic test according to the technical scheme provided by the invention. The production process optimizes the design of the width dimension of the band steel and the size of an opening angle and improves the precision of the final product; current, voltage and rolling speed are rationally adjusted according to the size of the steel pipe and the sheet thickness, thus ensuring reliable welding quality; and a compressor unit is carefully combined, a rolling line is lengthened and deformation of steel bands among each unit is reduced so as to ensure welding quality of the steel pipe and control rebounding of the steel pipe.

Owner:无锡天龙钢管有限公司

Multi-station ball-valve bursting test machine

InactiveCN101339111AVersatileImprove work efficiencyFluid-tightness measurement using fluid/vacuumStrength propertiesAutomatic controlUltimate tensile strength

The invention discloses a multi-work station ball valve blasting testing machine which belongs to the field of testing device. The testing machine comprises a testing host and a control cabinet. The testing host is divided into two layers; a testing table is arranged on the upper layer and a machine base is arranged on the lower layers. The testing table is provided with 3 to 10 testing work stations which are arranged in parallel and which can simultaneously test the pressure and blasting performance of 1 to 10 ball valves. In the test, hydraulic oil uses a solenoid directional control valve to push each piston; the compression rod of each piston can rise simultaneously; a special sealing fixture is used for sealing and clamping two ends of the ball valve. A hydraulic test pump is used for pouring the testing medium into the tested ball valve and boosting the pressure of the tested ball valve so as to test the ball valve. The testing machine can simultaneously seal, clamp, pour the testing medium into and test a plurality of ball valves. In the whole test process, a computer is used for automatically controlling the test through a PLC controller. And the testing machine has the advantages of stable performance, high work efficiency, low labor intensity, simple structure, high security, and so on.

Owner:于常友 +1

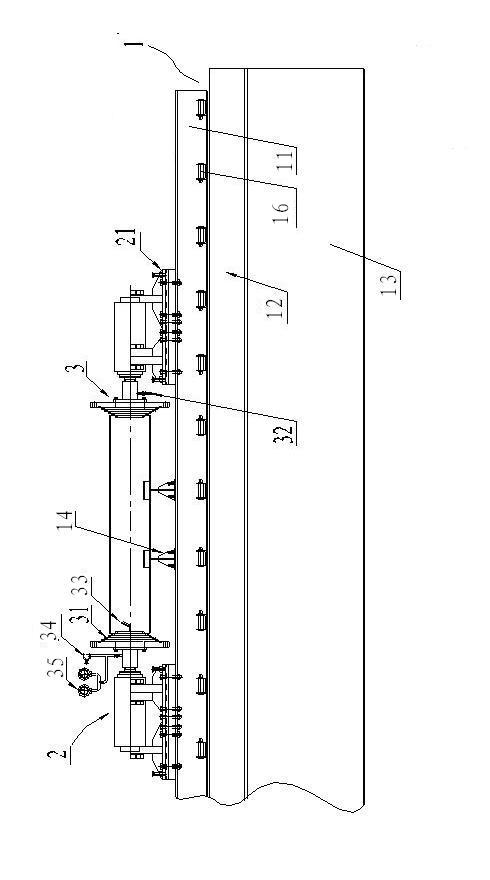

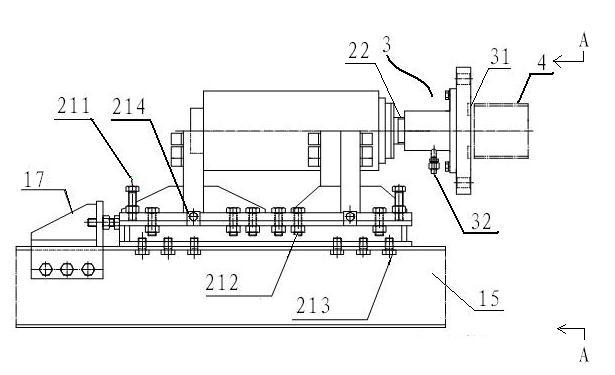

Coupling measurement device of particle three-dimensional stress and two-dimensional fluid velocity field

The invention relates to a coupling measurement device of particle three-dimensional stress and a two-dimensional fluid velocity field, belonging to the field of hydraulic tests. The device comprises a computer, a PIV (Particle Image Velocimetry) fluid velocity measurement unit and a three-dimensional force measurement unit, wherein the PIV fluid velocity measurement unit and the three-dimensional force measurement unit are respectively connected with the computer; the PIV fluid velocity measurement unit is positioned outside the side wall of an experimental water tank; the three-dimensional force measurement unit mainly comprises a stressed particle assembly, a three-dimensional force measurement framework, a fixed part and three force measurement strain gauges; the stressed particle assembly is composed of stressed particles and a particle support plate which are fixedly connected into a whole; the three force measurement strain gauges are respectively installed in three axial directions of the three-dimensional force measurement framework and used for measuring three-dimensional stress of particles; and the computer is respectively connected with the PIV fluid velocity measurement unit and the three-dimensional force measurement unit and used for synchronously controlling, collecting and storing measurement data of the PIV fluid velocity measurement unit and the three-dimensional force measurement unit. The device disclosed by the invention is capable of synchronously collecting the particle three-dimensional stress and the two-dimensional fluid velocity field around the particles at high frequency and high quality, thus, an experimental foundation is laid for researching internal relation and interaction mechanism between the particle three-dimensional stress and the two-dimensional fluid velocity field.

Owner:TSINGHUA UNIV

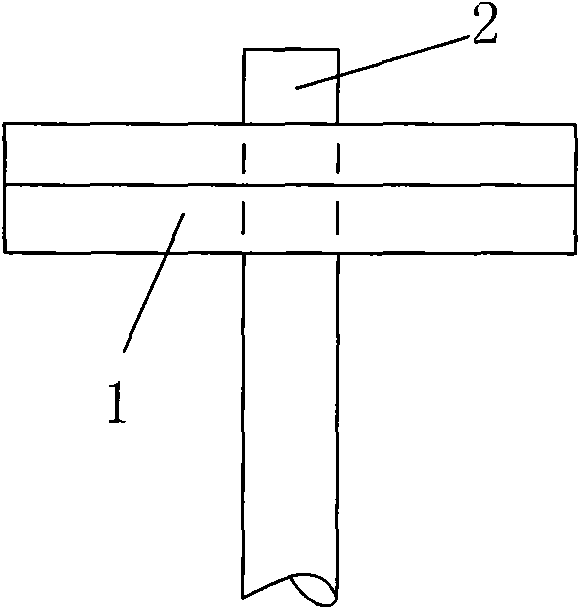

Pipeline hydraulic test device

ActiveCN101984337AAchieve axial sealingMaterial strength using tensile/compressive forcesFluid-tightness measurement using fluid/vacuumCouplingStructural engineering

The invention provides a pipeline hydraulic test device, which consists of beds, hydraulic thrust power units, pipeline connecting pieces, composite sealing elements and supports. Two hydraulic power units are removably fixed to beds by universal adjusting bases based on the lengths of the pipelines to be tested. Seal flange is used as the conduit coupling. One end of the conduit coupling is connected to the thrust bar of hydraulic thrust power units. Composite sealing elements are arranged at the connection place of the sealing surface of the other end of the conduit coupling and tube walls. The composite sealing elements are compounded of high toughness rubber bases and flexible metal anti-shear layers. Being connected with the pipelines to be tested, flexible metal anti-shear layers can resist the edge cutting of pipelines against the sealing elements, and high toughness rubber bases make up the deviation between sections generated from tack cutting of pipelines and axial verticality of pipelines. The axial sealing is realized without considering on the high requirements of inner and outer diameter surface smoothness or other parameters of the pipelines to be tested by adopting other sealing types. The device provided by the invention acts more effectively with less input.

Owner:NANJING BAOSE

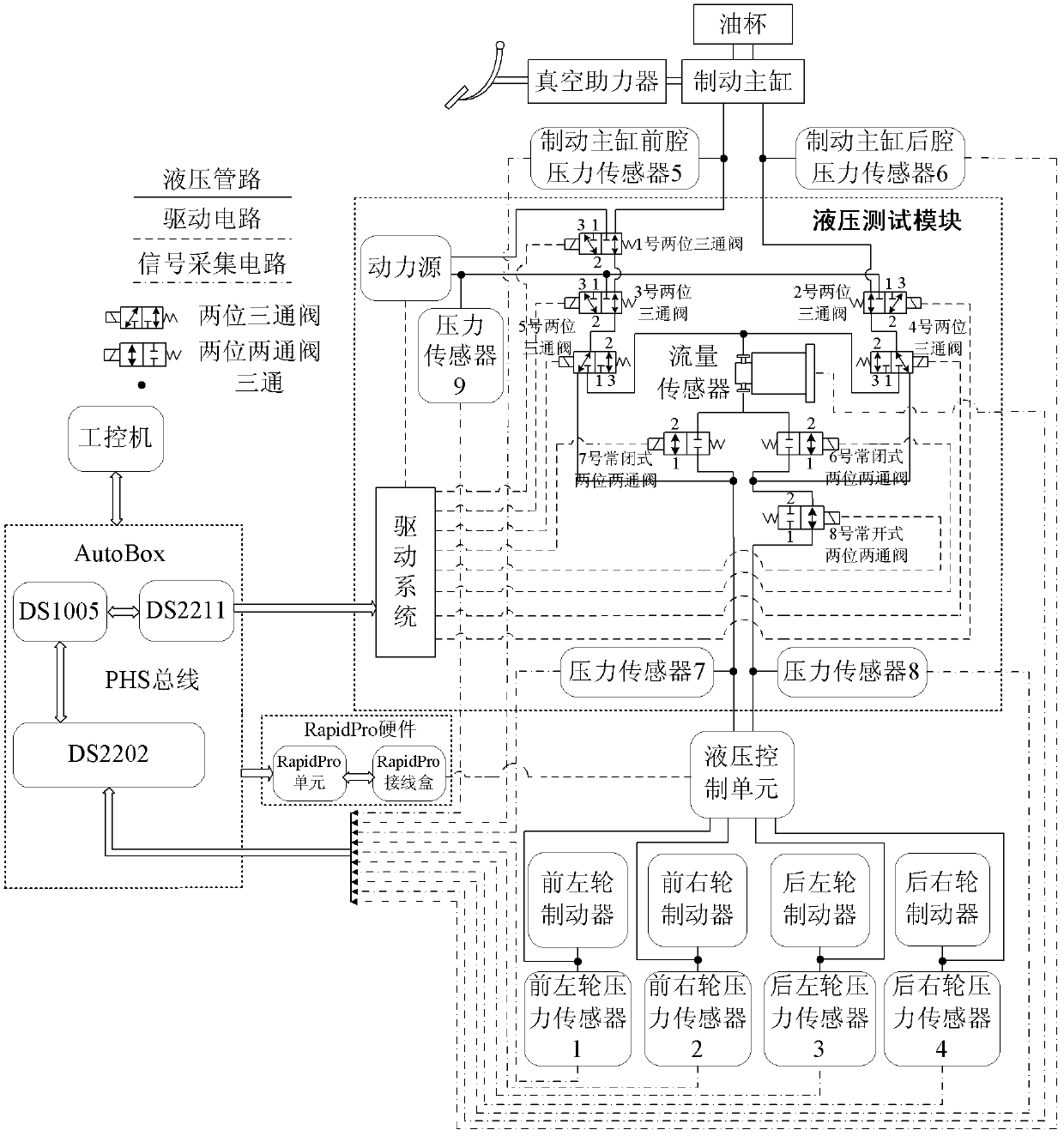

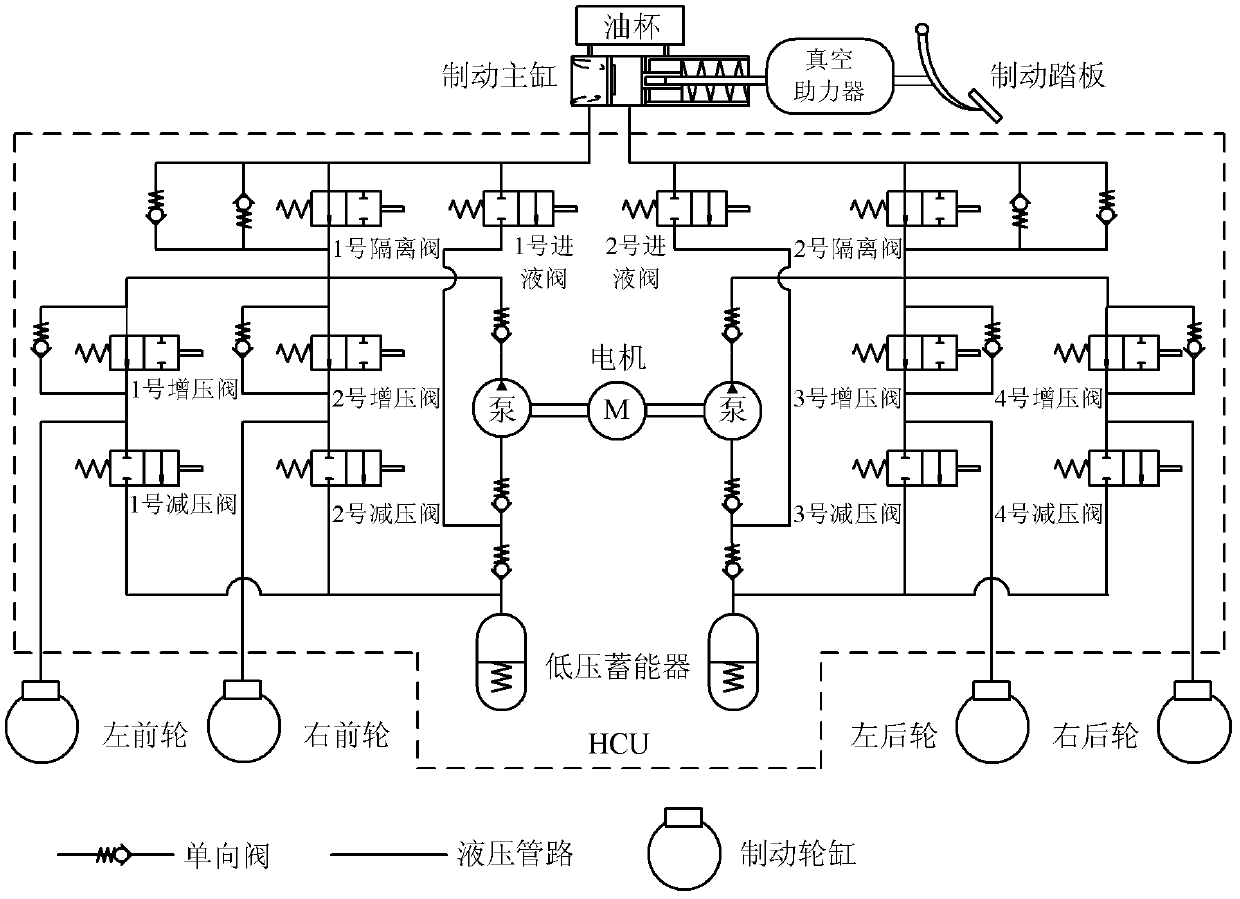

Test bed for hydraulic brake actuating mechanism

InactiveCN102608995AGet Orifice CoefficientAccurate estimateMachine part testingElectric testing/monitoringComputer moduleEngineering

The invention discloses a test bed for a hydraulic brake actuating mechanism, which comprises a real-time platform, an ICC (integrated circuit card) hydraulic brake system and a hydraulic test module. The hydraulic test module comprises a power source, a flow sensor, three pressure sensors with the same structures, five two-position and three-way valves with the same structures, a normally open two-position and two-way valve, two normally closed two-position and two-way valves with the same structures and a driving system. The driving system comprises eight relays with the same structures, wherein the relays include a power source relay, a first electromagnetic valve relay, a second electromagnetic valve relay, a third electromagnetic valve relay, a fourth electromagnetic valve relay, a fifth electromagnetic valve relay, a sixth electromagnetic valve relay, a seventh electromagnetic valve relay and an eighth electromagnetic valve relay. The real-time platform is connected with the ICC hydraulic brake system through an electric wire and connected with the hydraulic test module through a DS2211 type multi-way I / O (input / output) board and a driving system, and the ICC hydraulic brake system is connected with the hydraulic test module through a pipeline.

Owner:JILIN UNIV

Waste and old oil well pipe performance recovery process

ActiveCN102581542ADense tissueAchieve energy saving and consumption reductionPulp and paper industryPerformance recovery

The invention discloses a waste and old oil well pipe performance recovery process which comprises the following steps: (1) heating; (2) sorting; (3) carrying out constant-diameter wall reducing; (4) carrying out heat diffusion; (5) carrying out negative-tension diameter reducing; (6) sorting and dimensioning; (7) stretching and carrying out a hydraulic test: stretching the sorted and dimensioned waste and old oil well pipes, and carrying out the hydraulic test; and (8) packaging: packaging the detected and qualified waste and old oil well pipes, and putting into service. The waste and old oil well pipe performance recovery process has the advantages that the waste and old oil well pipes are reforged, so that the repaired oil well pipes are more compact in internal structures, higher in corrosion resistance and higher in wear resistance, the waste and old oil well pipes are subjected to same-specification regenerative repair to meet the specification and the API (American Petroleum Institute) standard requirements, and the purposes of saving energy, reducing consumption and changing waste materials into valuable materials are achieved.

Owner:梅河口市弘业无缝钢管有限公司

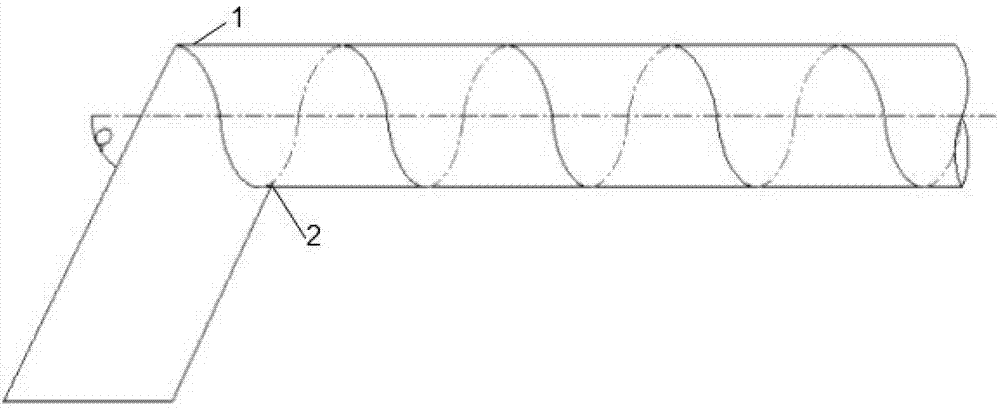

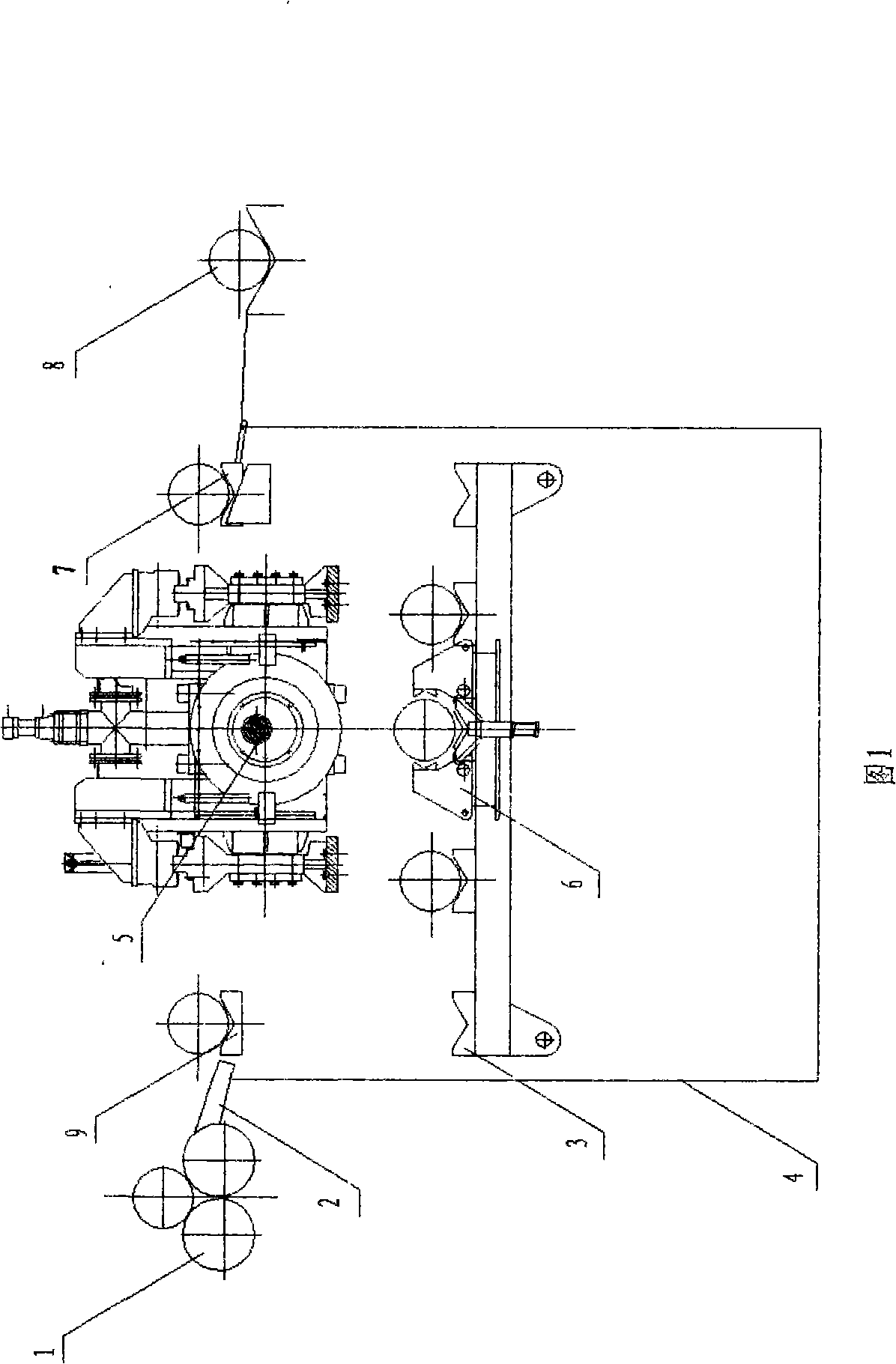

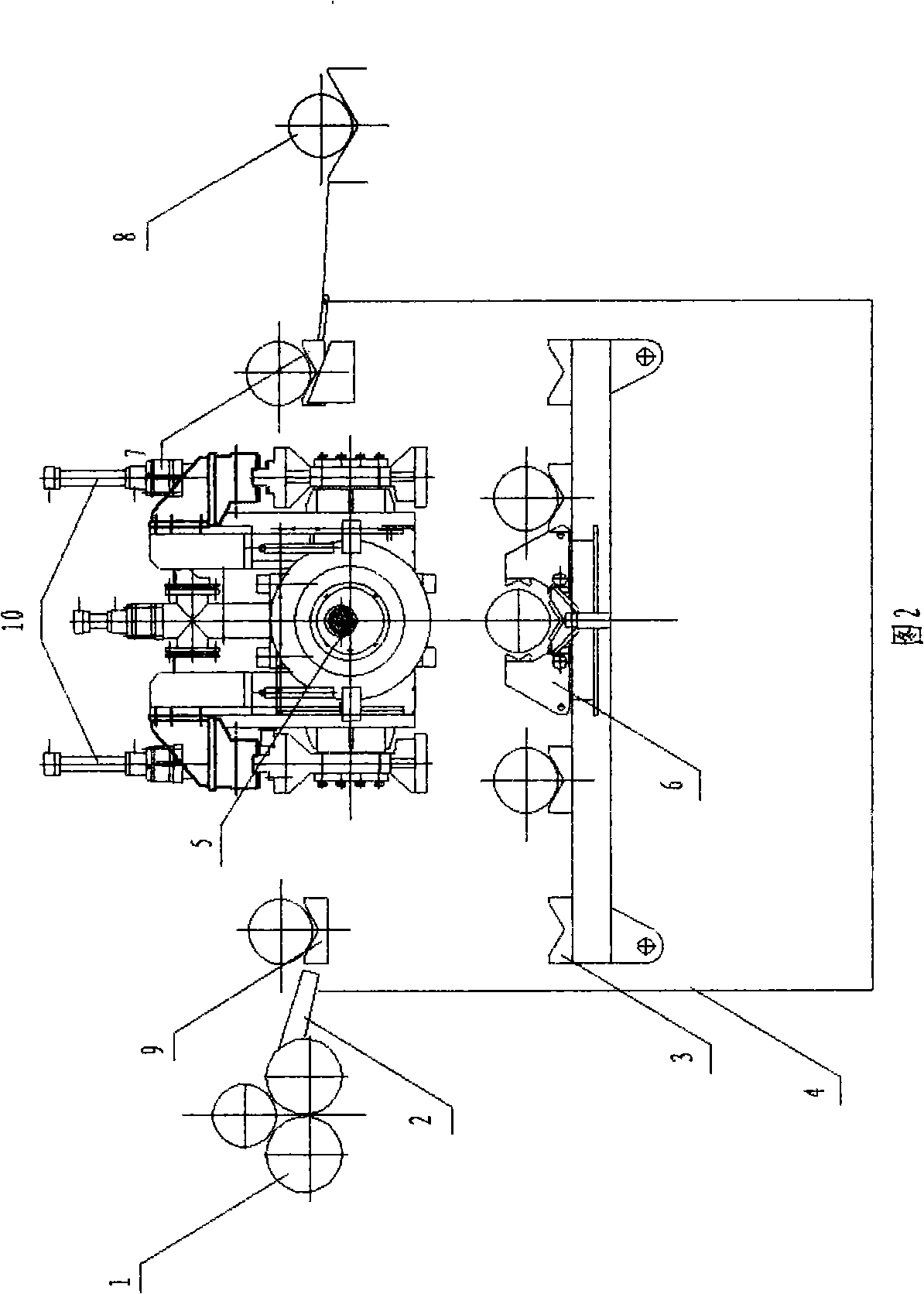

Pre-water filling steel tube hydraulic test method and special-purpose equipment thereof

InactiveCN101281084AOutstanding FeaturesHighlight significant progressMeasurement of fluid loss/gain rateEngineeringSteel tube

The invention discloses a hydrostatic test method and the dedicated device thereof for a water pre-filling steel pipe, comprising a rotary type washing mechanism (1) connected with one end of a feed mechanism (2), the other end of the feed mechanism (2) is connected with a elevating mechanism (9), a media tank (4) is arranged below the elevating mechanism (9), a pipe-moving mechanism (3) is arranged in the media tank (4),a clamping mechanism (6) is arranged on the pipe-moving mechanism (3), a hydrostatic test mechanism (5) is arranged above the clamping mechanism (6),the pipe-moving mechanism (3) is corresponding to a discharging mechanism (7) arranged upside, the discharging mechanism (7)is connected with a water control mechanism (8);the hydrostatic test method utilizing the device is showed as follows: rinsing the internal surface of the steel pipe, immerging the steel pipe in bulge medium, sealing the two ends of the steel pipe by a bulge head when the inside cavity of the steel pipe is filled with bulge medium, bulging and dwelling directly, and then discharging last; the method mentioned above does not take up the effective operation time and the device has high hydrostatic test efficiency.

Owner:烟台鲁宝钢管有限责任公司

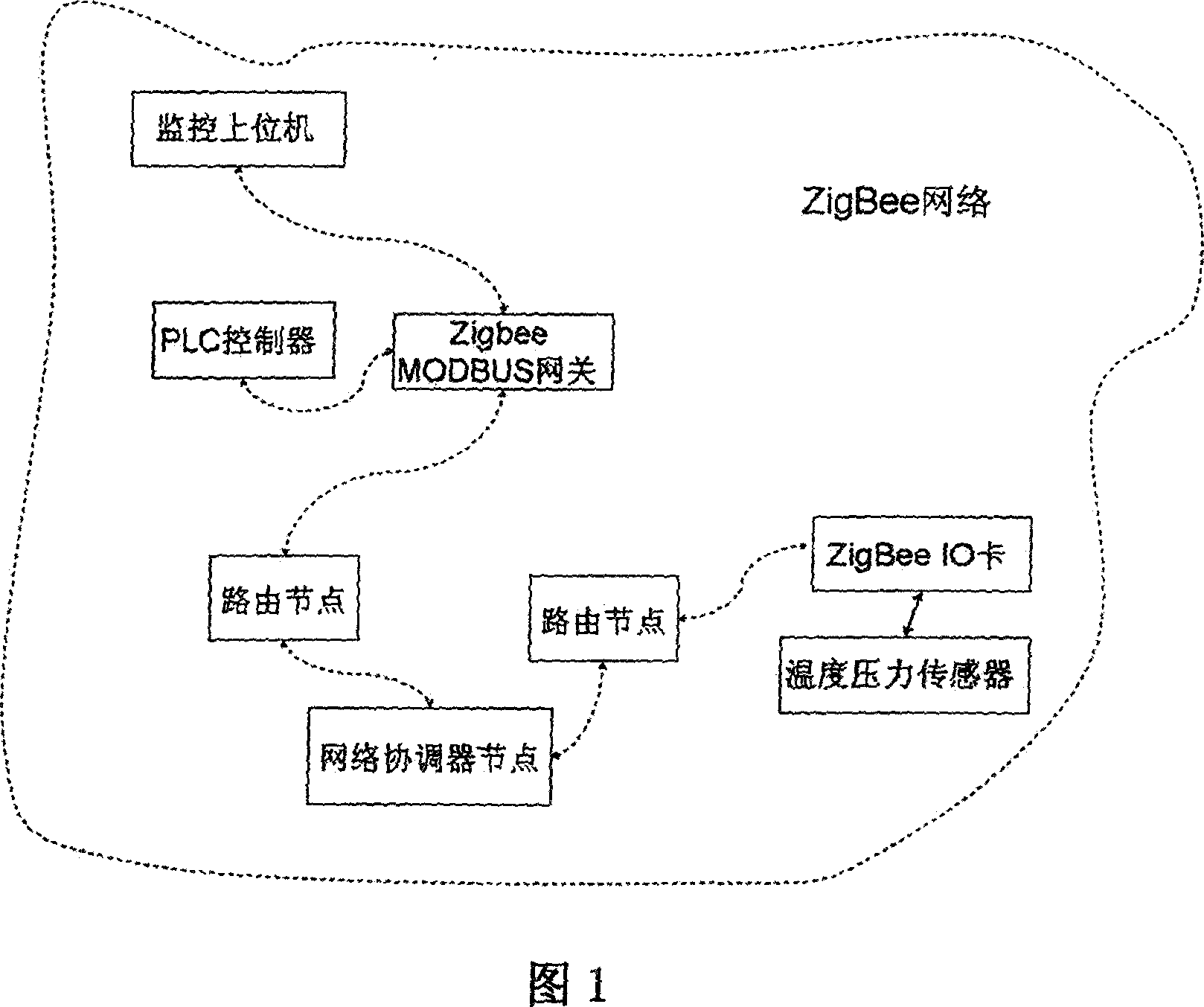

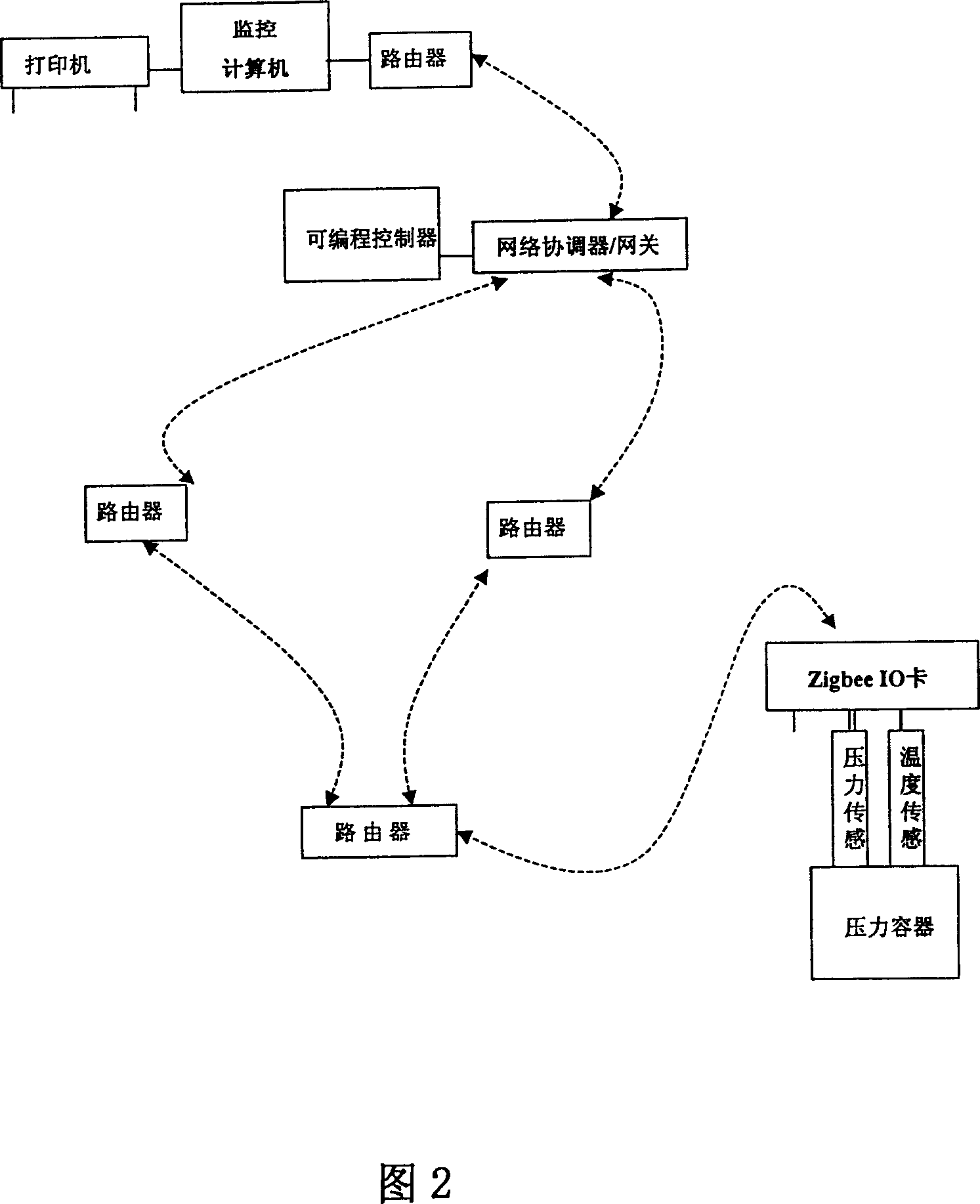

Automatic control system for nucleonic product hydraulic pressure test using Zigbee wireless communication

ActiveCN1921446AImprove normativeHigh precisionTransmission systemsNetwork topologiesModbusAutomatic control

The invention relates to a nuclear product hydraulic test automatic control system, which uses Zigbee wireless communication. Wherein, it is formed by pressure temperature sensor, Zigbee I / O card, Zigbee route node, Zigbee network consulter, PLC controller, Zigbee MODBUS gateway and detector; the pressure temperature sensor and the terminal node, and one PLC controller are at the site of hydraulic test, via network consulter, route node and Zigbee IO card, to form one Zigbee wireless network, and via Zigbee-Modbus gateway, to transmit relative data to the detector and PLC control system that detecting and recording data, to be compared with the data collected and transmitted via line. The invention can realize full-automatic program control, to improve the test accuracy.

Owner:SHANGHAI INST OF PROCESS AUTOMATION & INSTR

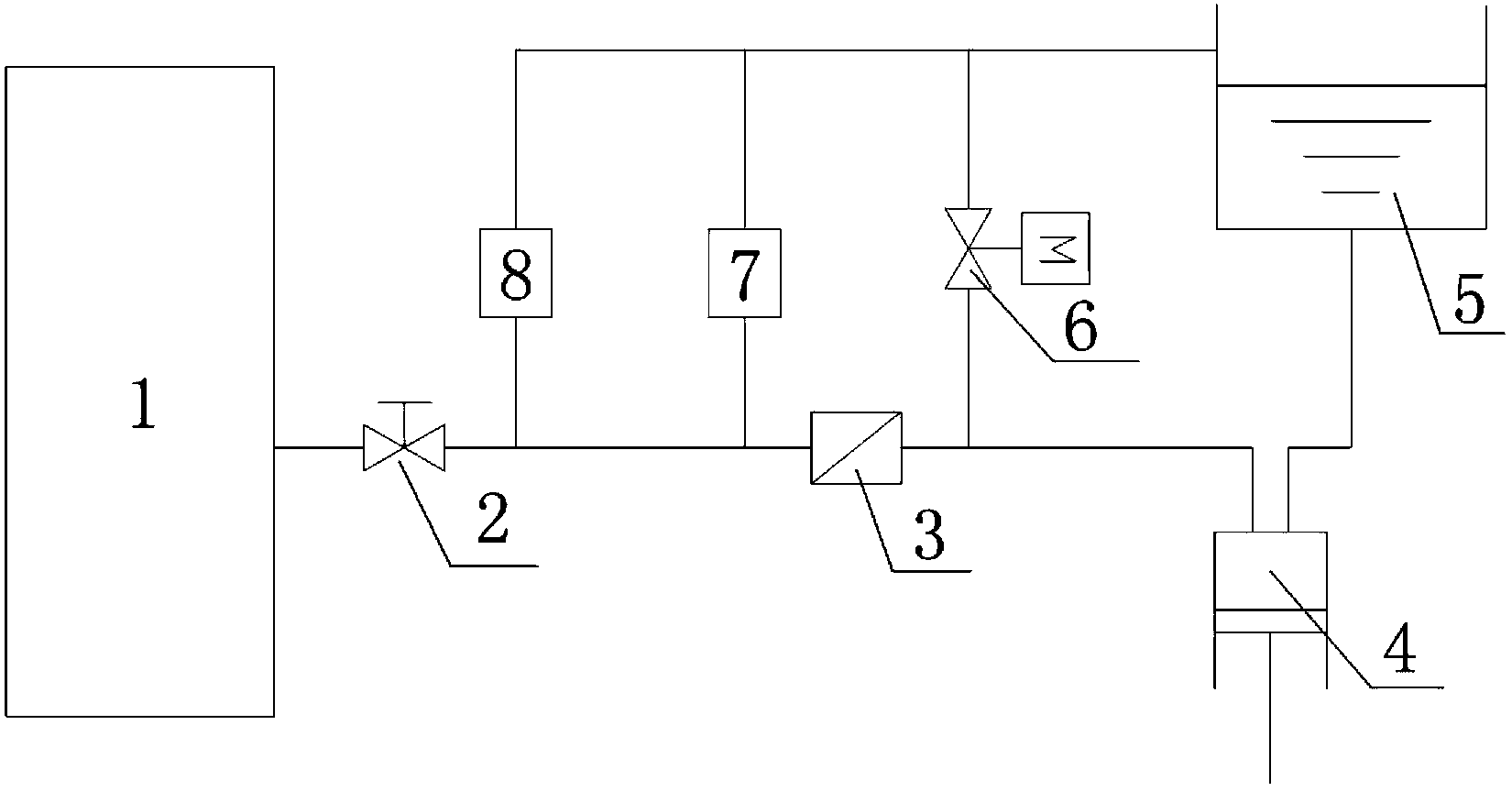

Hydraulic test pressure control system

InactiveCN103424233AImprove securityEnsure safetyMeasurement of fluid loss/gain rateFluid pressure controlControl systemTested time

The invention relates to the technical field of a container hydraulic test and particularly relates to a hydraulic test pressure control system. The control system comprises a test body, a stop valve, a pressure pump and a water tank, wherein the test body is connected with the water tank through the pressure pump, the pipeline where the stop valve and the pressure pump are connected is also provided with a flow direction control unit, and the pipeline of the pressure pump and the flow direction control unit is also provided with a pipeline which is communicated with the upper end of the water tank through an adjusting valve. The control system can effectively realize operation such as establishing initial pressure, boost, dwell, pressure relief and the like; the pressure of the test body can be boosted stably and the safety of a hydraulic test is improved through effective adjustment during a boost process; and during a pressure relief process, a pressure relief rate can be controlled through a pressure reduction rate control unit so that not only can the test time be shortened, the safety of the test body is also ensured.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

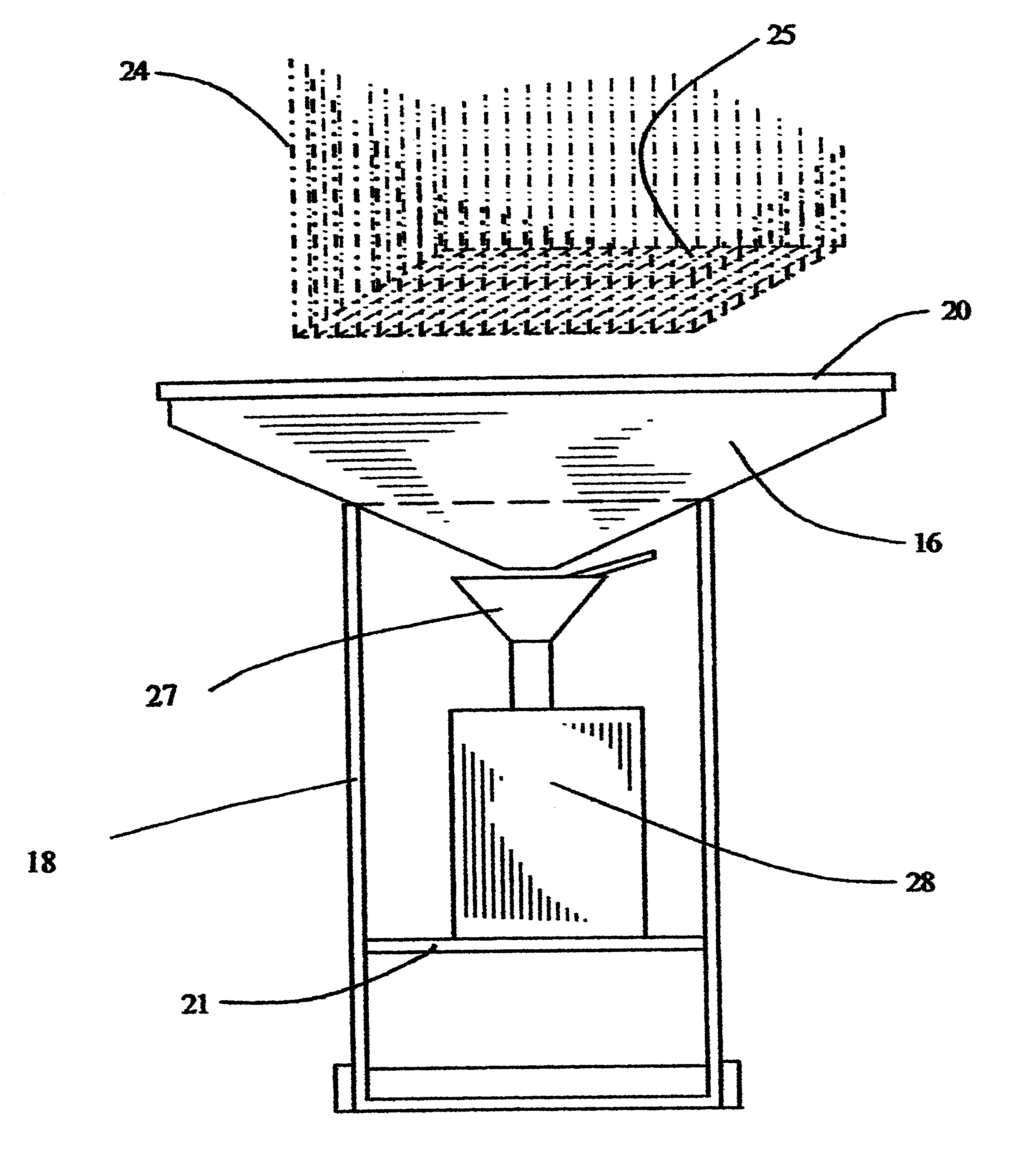

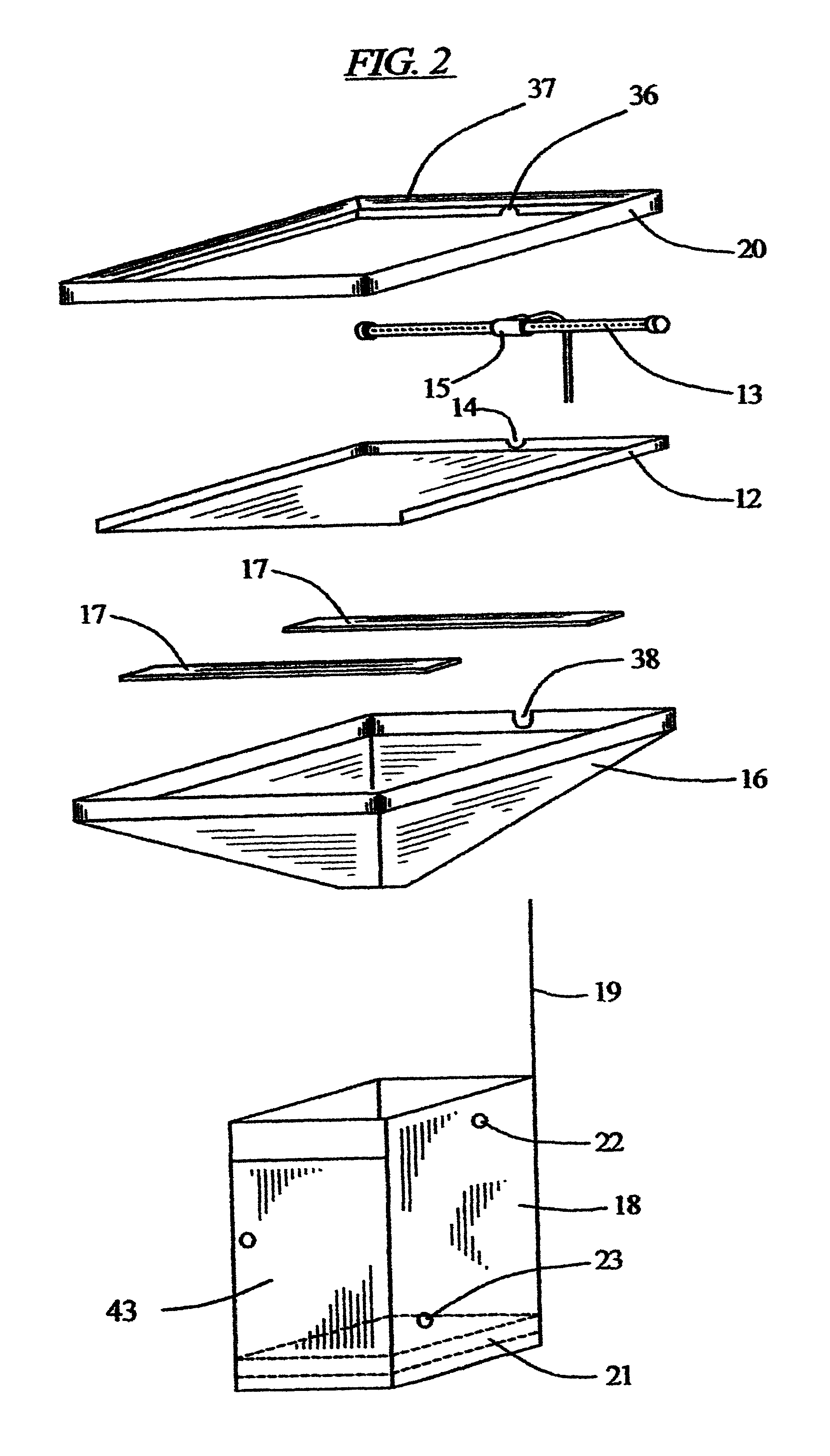

Aqua clean birdcage companion

The Aqua Clean BirdCage Companion is a hydraulic waste and airborne contaminant containment system disposed beneath a birdcage, occupying a bird. The birdcage, having a grid floor retains and separates the bird from the system, while allowing the waste and airborne contaminants from the caged bird to gravitate to the system's constant medium being a hydraulic body of water contained in a tray beneath the birdcage. Our constant medium traps, contains and moves waste and airborne contaminants within it's water to a plurality of filters. The waste filled water passes through the filters. The filters remove the waste materials. The now filtered water is returned by electric pump and discharged into the tray's constant medium creating the hydraulic body, which traps and contains new waste for removal. The filters continually renew the water in this closed hydraulic waste and airborne contaminant containment system.

Owner:SCHRADER RHONDA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com