Liquid metal sodium boiling two-phase thermal-hydraulic test loop system and test method thereof

A technology of liquid metal sodium and experimental circuit, which is applied in the field of liquid metal sodium boiling two-phase thermal hydraulic experimental circuit system, can solve the problems that are not suitable for the analysis and research of liquid metal sodium boiling two-phase flow heat transfer characteristics, so as to ensure the overall sealing sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

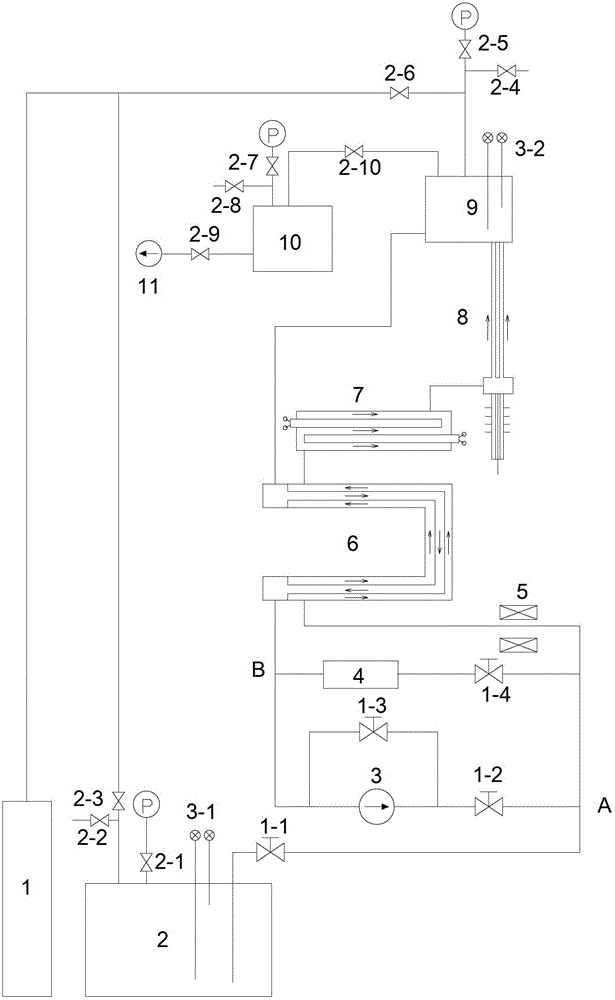

[0043] The liquid metal sodium boiling two-phase thermal hydraulic experiment circuit system of the present invention is divided into three parts: a high temperature part, a low temperature part, and an argon branch circuit. The low-temperature part includes sodium storage tank 2, electromagnetic pump 3, purification cold trap 4, electromagnetic flowmeter 5, 4 sodium valves and corresponding connecting pipes. These parts are all made of 316L stainless steel, and the upper limit of the allowable operating temperature is 400°C (depending on The allowable operating temperature of the electromagnetic pump 3); the high temperature part includes the regenerative heater 6, the preheater 7, the test section 8, the upper expansion tank 9 and the corresponding connecting pipes, this part is manufactured by Incoloy800, and the allowable operating temperature can reach 1200 °C; the argon branch The circuit includes an argon gas cylinder 1, an expansion tank 10, a vacuum pump 11, 3 pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com