Patents

Literature

53results about How to "Relatively low linear speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

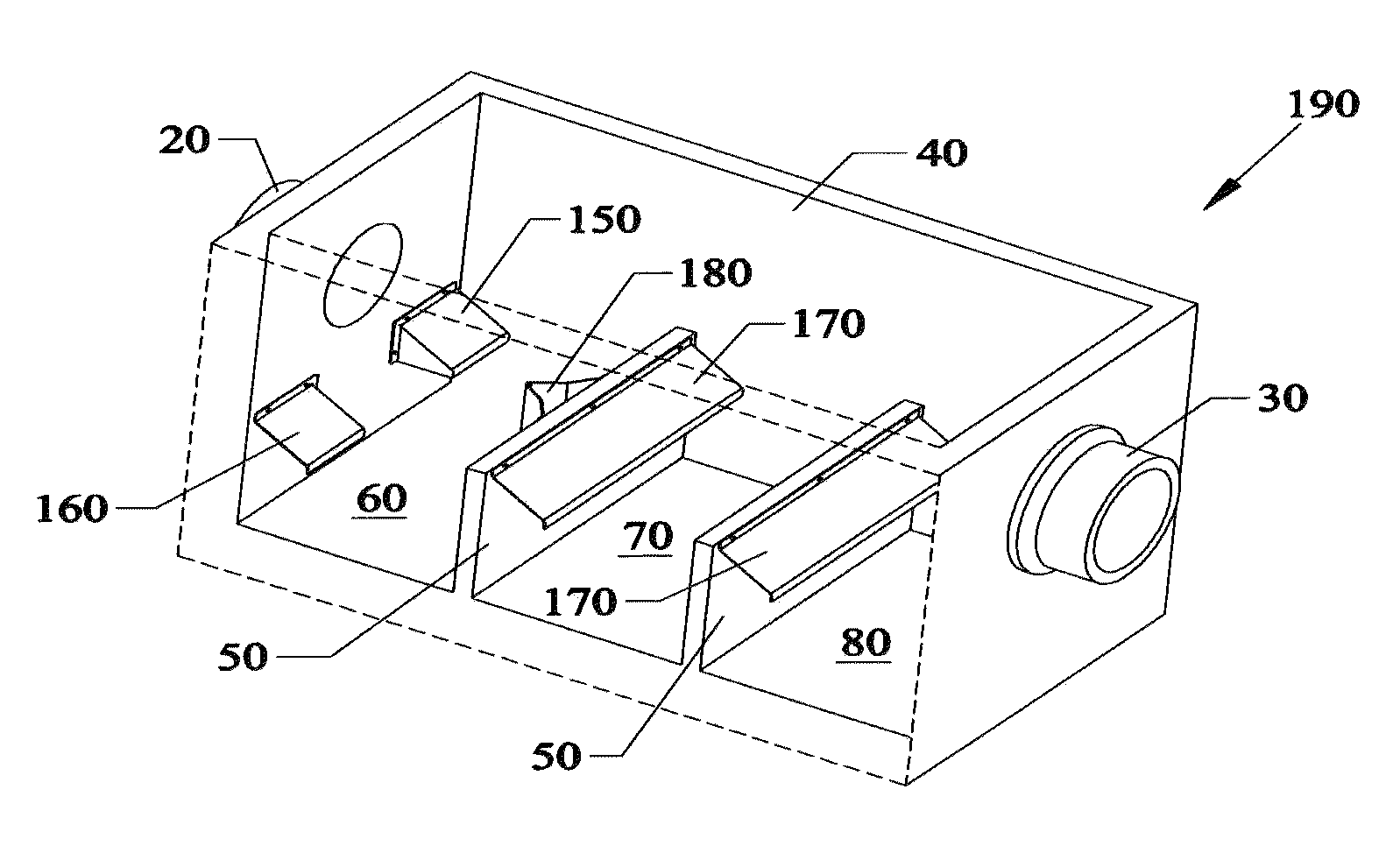

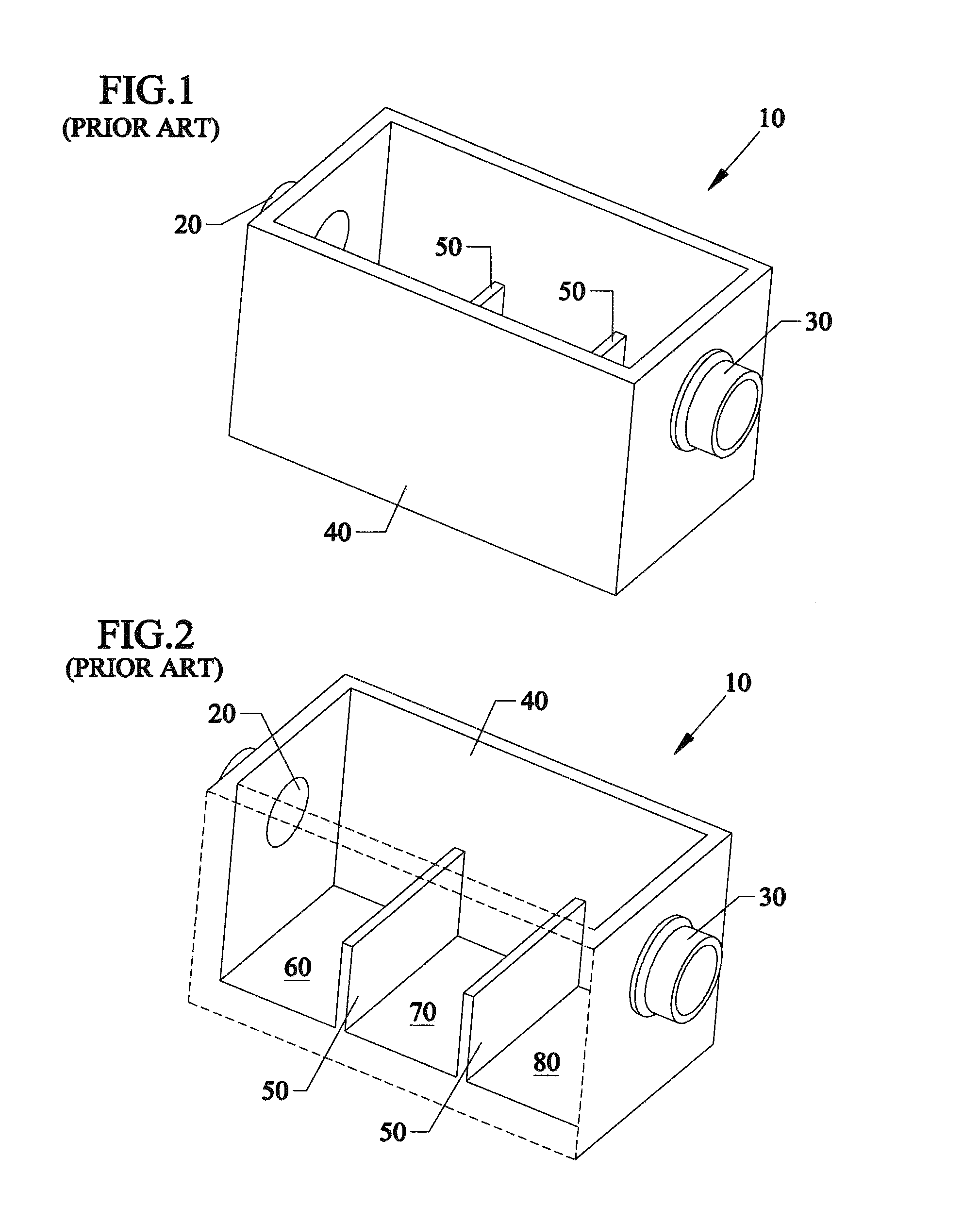

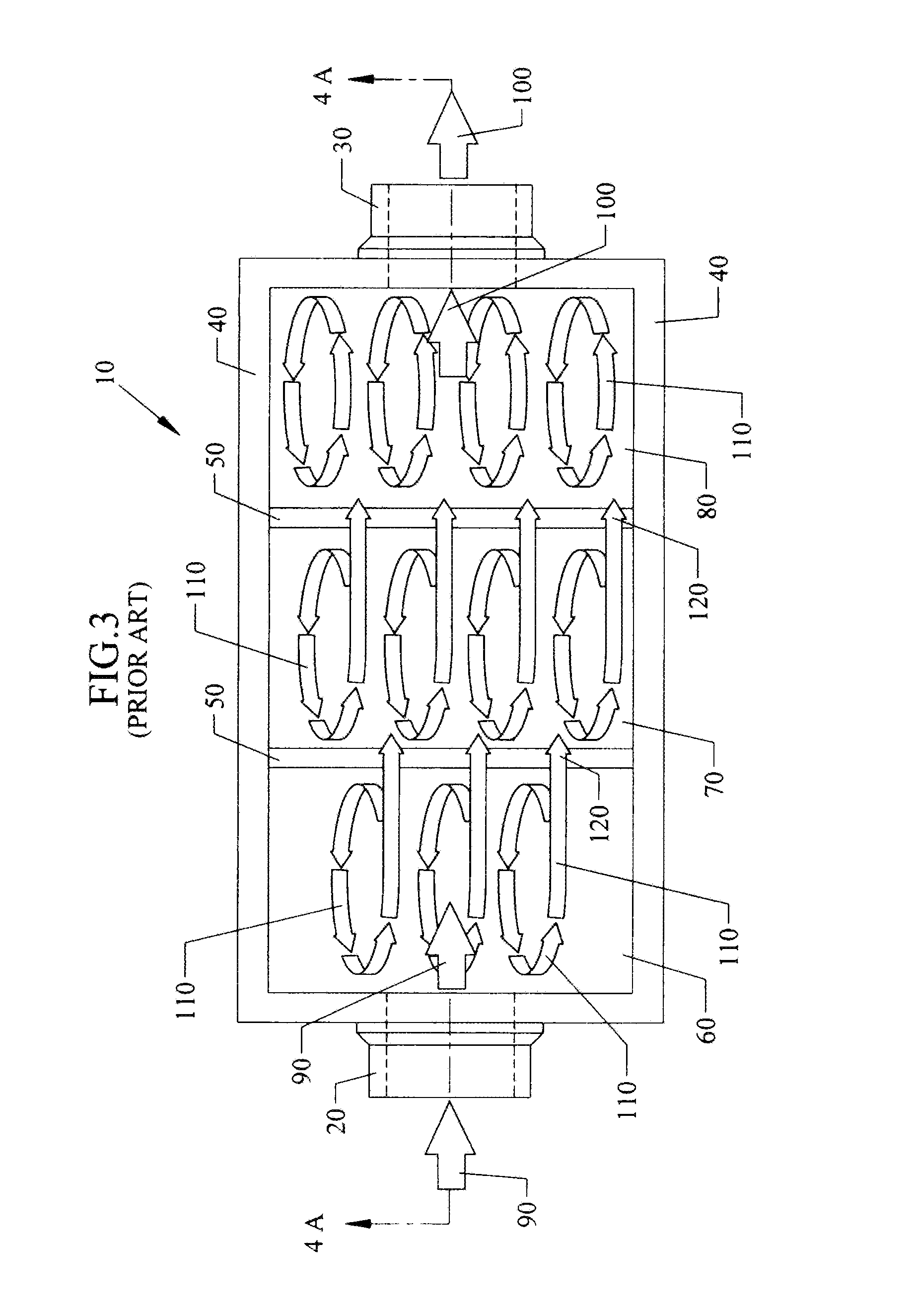

Baffle box deflectors and flow spreaders

ActiveUS8142666B1Improve removal efficiencyReduce and prevent conveyanceFatty/oily/floating substances removal devicesWater cleaningWater flowUltra fine

Devices, apparatus, systems and methods of using baffle boxes with turbulence deflectors and flow spreaders. Turbulence deflectors are added about the inlet port of a baffle box, and a flow spreader is added centrally beneath an outlet port to increase removal efficiency of pollutants and prevent the conveyance of pollutants down stream. The turbulence deflectors and the flow spreader will increase the removal efficiency of particles, especially fine and ultra fine particles without impeding the water flow. The turbulence deflectors will significantly reduce the turbulence within the sediment chambers which will lead to better settling and less re-suspension. The flow spreader spreads the flow wide sooner within the baffle box to reduce the linear velocity of the water current, and directs water flow away from the area of greatest turbulence adjacent to the inflow, and will increase the settling of particles and minimize re-suspension. By increasing the removal efficiency of the first sediment chamber the shielding will prevent the re-suspension of fine and ultra fine particles.

Owner:OLDCASTLE INFRASTRUCTURE INC

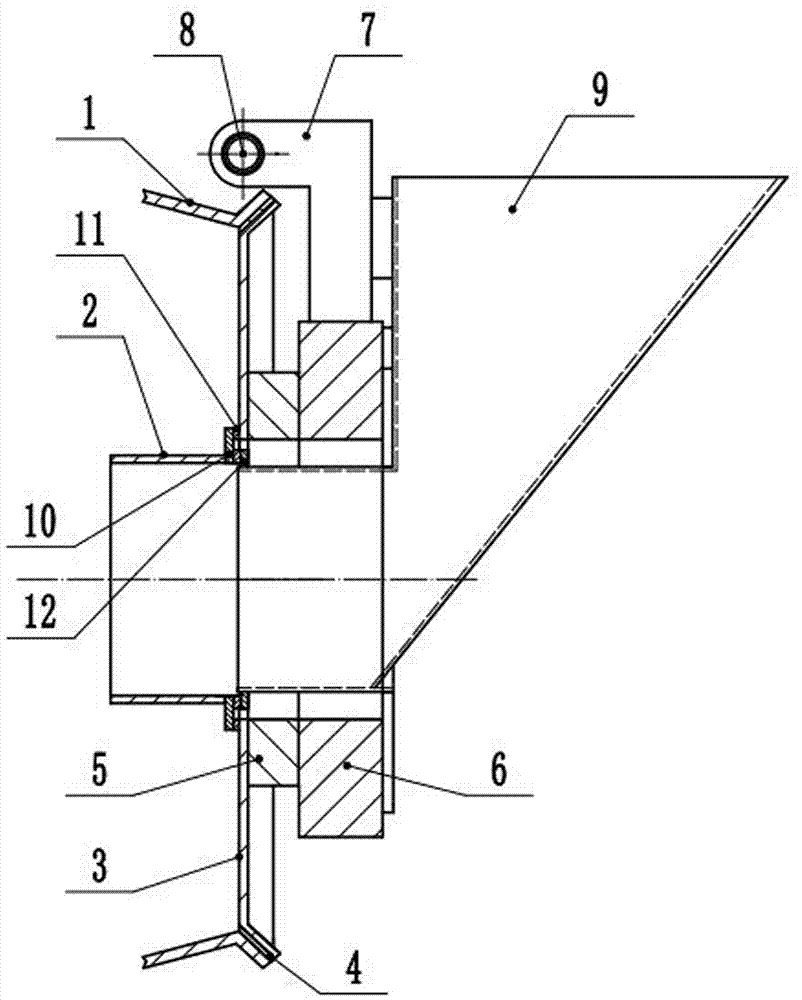

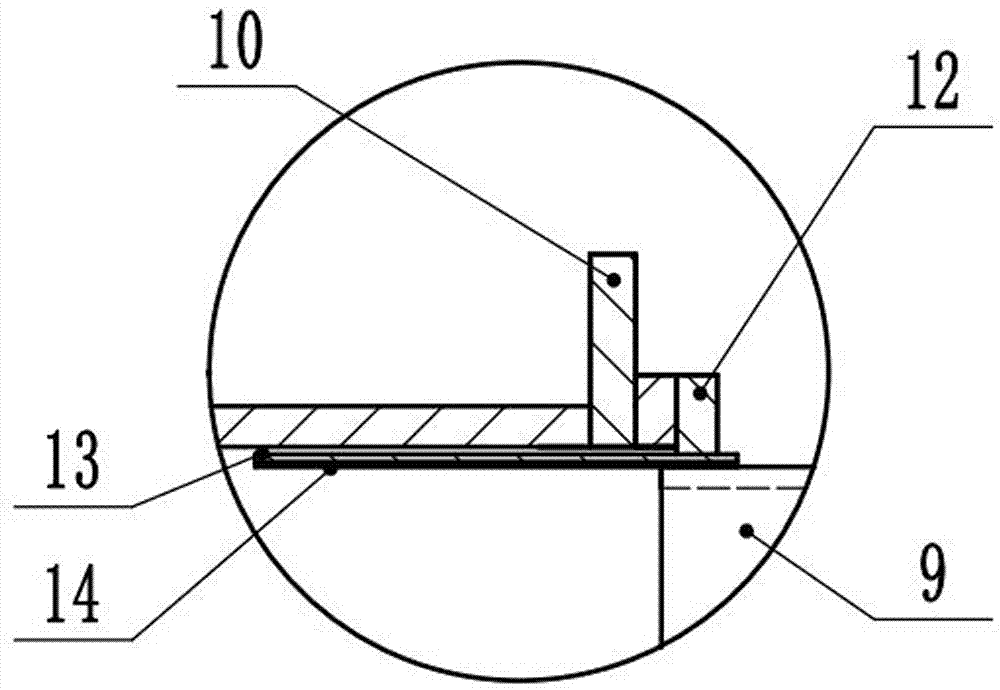

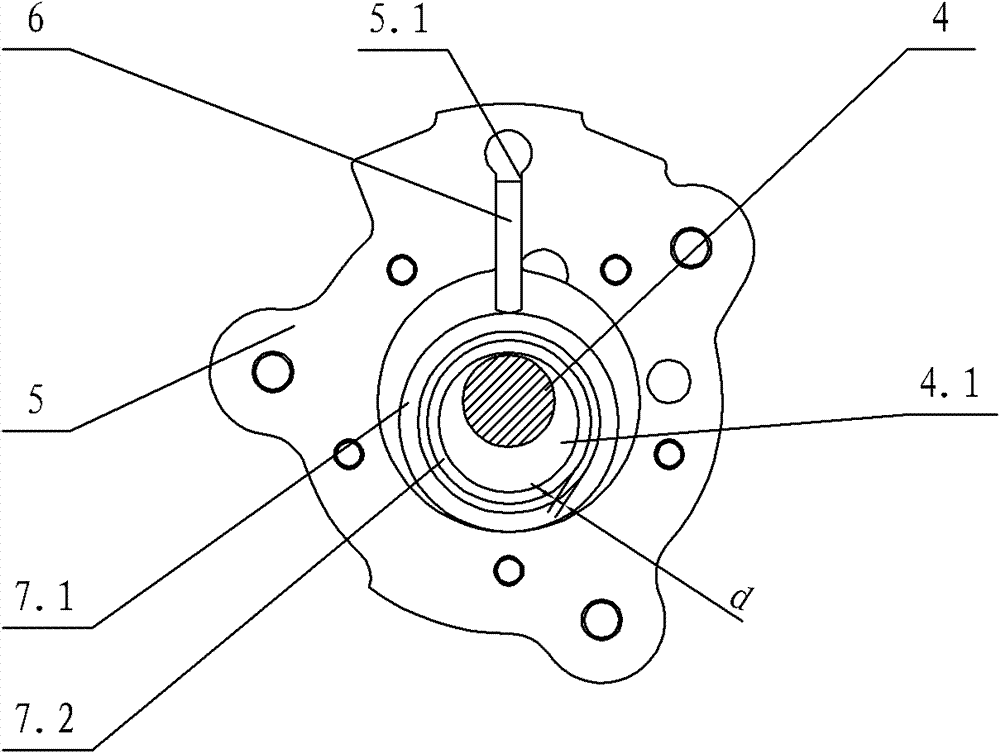

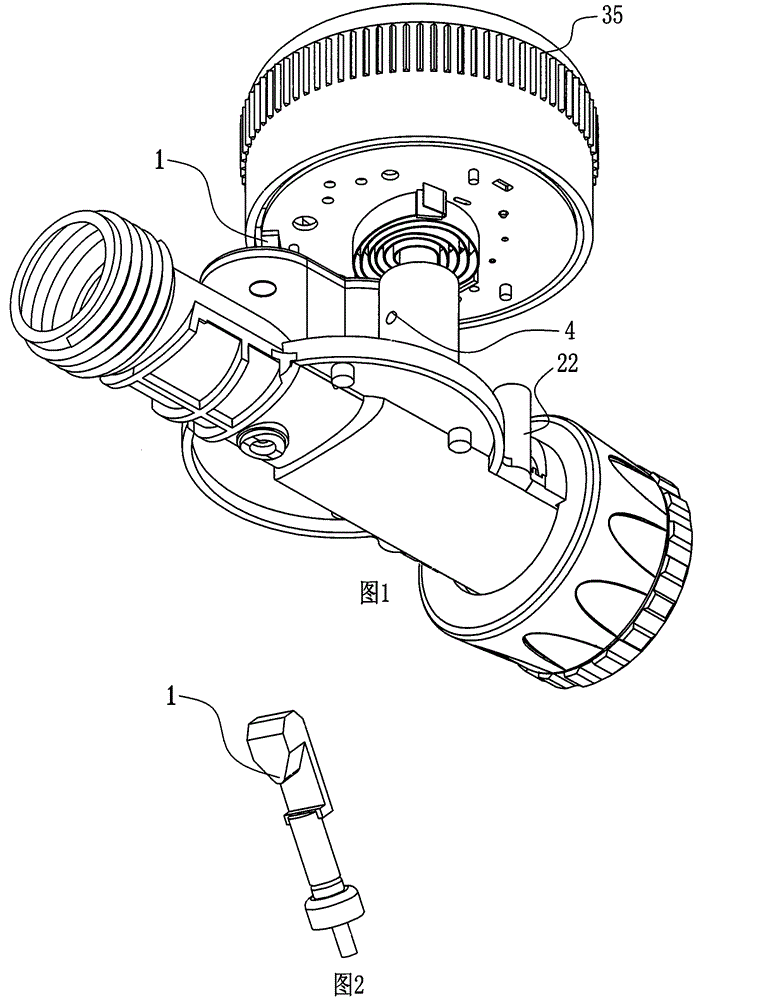

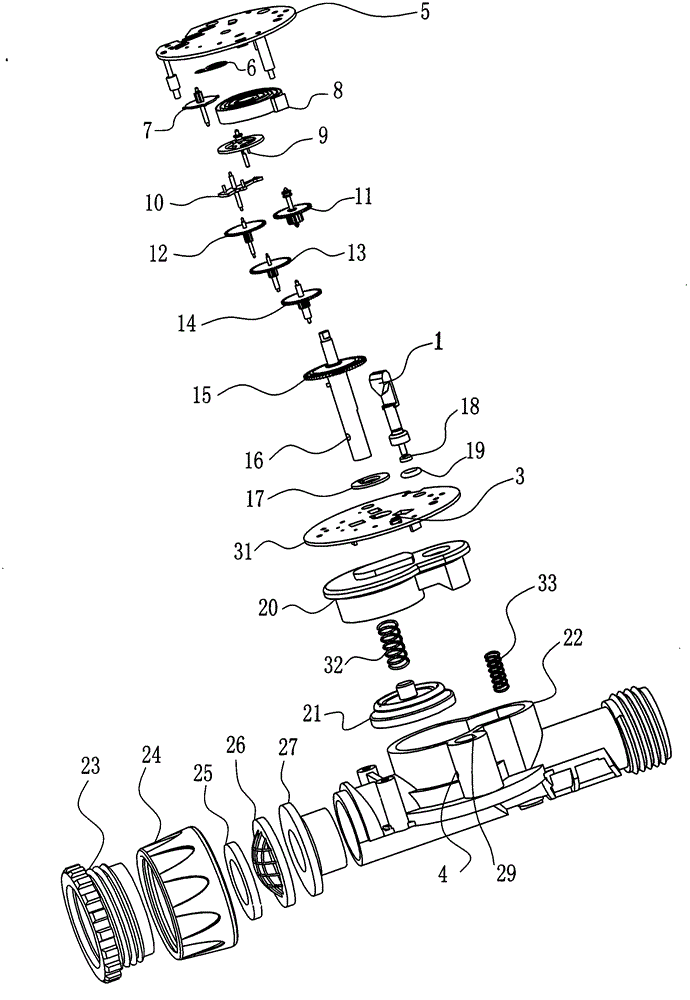

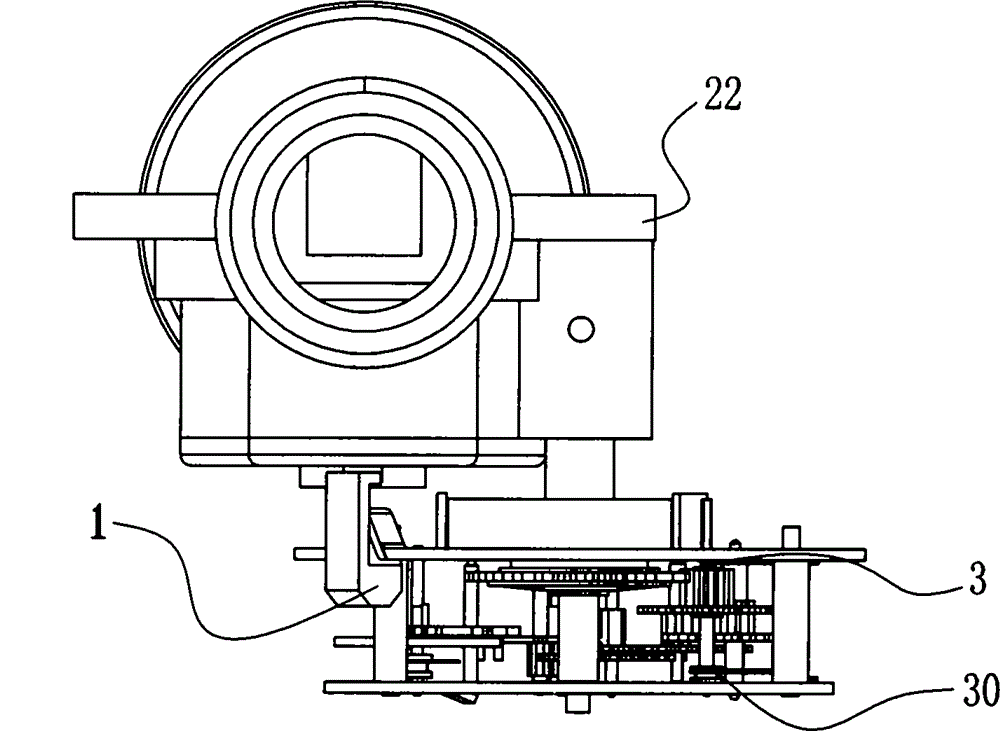

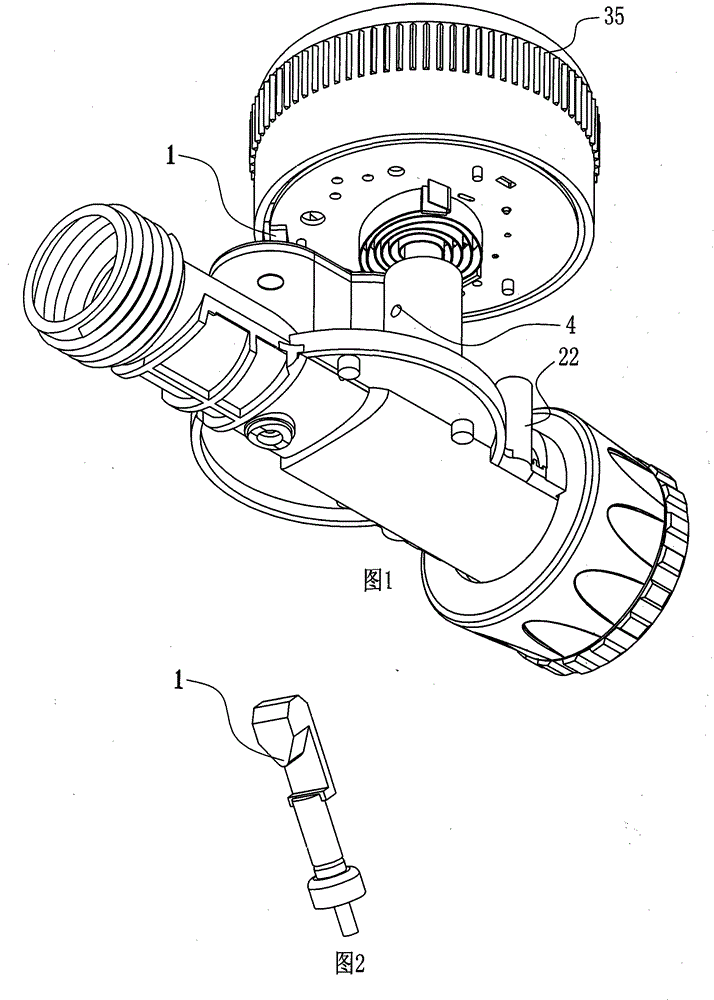

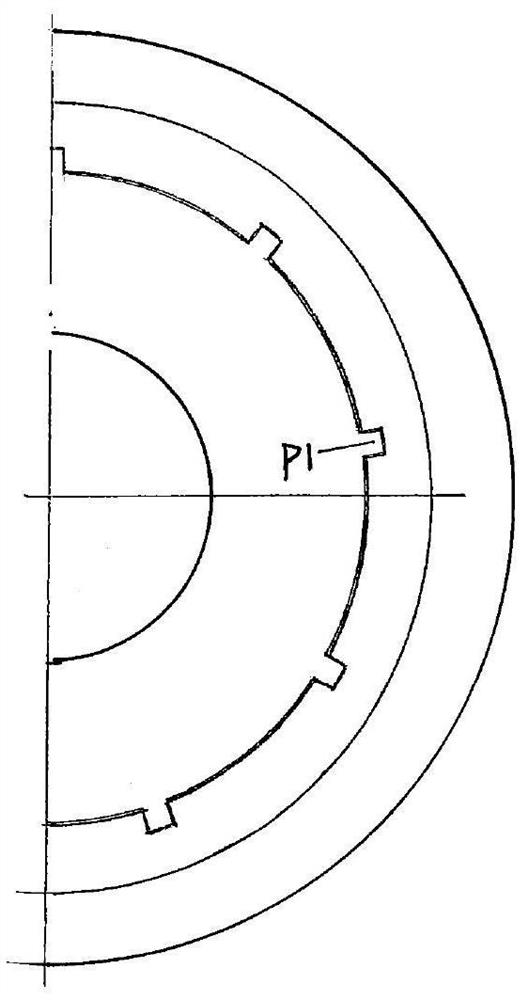

Hollow shaft rotary sealing concrete mixing truck

ActiveCN107344401ASmall turning radiusRelatively low linear speedCement mixing apparatusEngineeringTruck

The invention discloses a hollow shaft rotary sealing concrete mixing truck which comprises a mixing drum that is arranged on a truck body and can rotate relative to the truck body. A feeding cylinder is arranged in the middle of an outlet of the mixing drum. The hollow shaft rotary sealing concrete mixing truck further comprises a moving component which is arranged on the truck body and can move relative to the truck body; a sealing cover is arranged on the moving component through a rotary support; the external edge of the sealing cover is in contact with the external edge of the outlet of the mixing drum, and a first sealing device is arranged at the contact part; and the sealing cover, under the driving of the mixing drum, rotates relative to the moving component along with the mixing drum. The sealing cover for plugging the mixing drum is in a rotary structure and synchronously rotates along with the mixing drum, and a dynamic sealing part is changed to be positioned between the feeding cylinder and a feeding hopper accordingly, thus the rotating radius of the dynamic sealing part is reduced substantially, the relative linear velocity of the dynamic sealing part is reduced, the abrasion to a sealing component is reduced when the sealing effect is ensured, the reliability of the hollow shaft rotary sealing concrete mixing truck is improved, and the maintenance difficulty is lowered.

Owner:YANTAI SHENGLIDA ENG TECH

Gas-phase oxidization process and process for the preparation of phthalic anhydride

InactiveUS6369240B1Change activityHigh activityOrganic oxidationOrganic compound preparationMaleic anhydrideChemistry

This invention relates to the vapor-phase oxidation of hydrocarbons by passing a gaseous mixture comprising of a molecular oxygen-containing gas and hydrocarbons which may contain substituents to a fixed bed of catalyst and provides a process for vapor-phase oxidation to be effected by passing a gaseous mixture of raw materials to a fixed bed of catalyst in which the void ratio of the catalyst layers increases by stages in one step or more from upstream downward in the flow of the gaseous mixture of raw materials. For example, the process can oxidize in vapor phase such hydrocarbons as naphthalene, xylene, benzene, toluene, durene, butene, acenaphthene, anthracene, indene and their derivatives in high yields with high productivity. Moreover, the process can prepare phthalic anhydride in high yields with high productivity by the vapor-phase oxidation of naphthalene or ortho-xylene.

Owner:NIPPON MICROMETAL

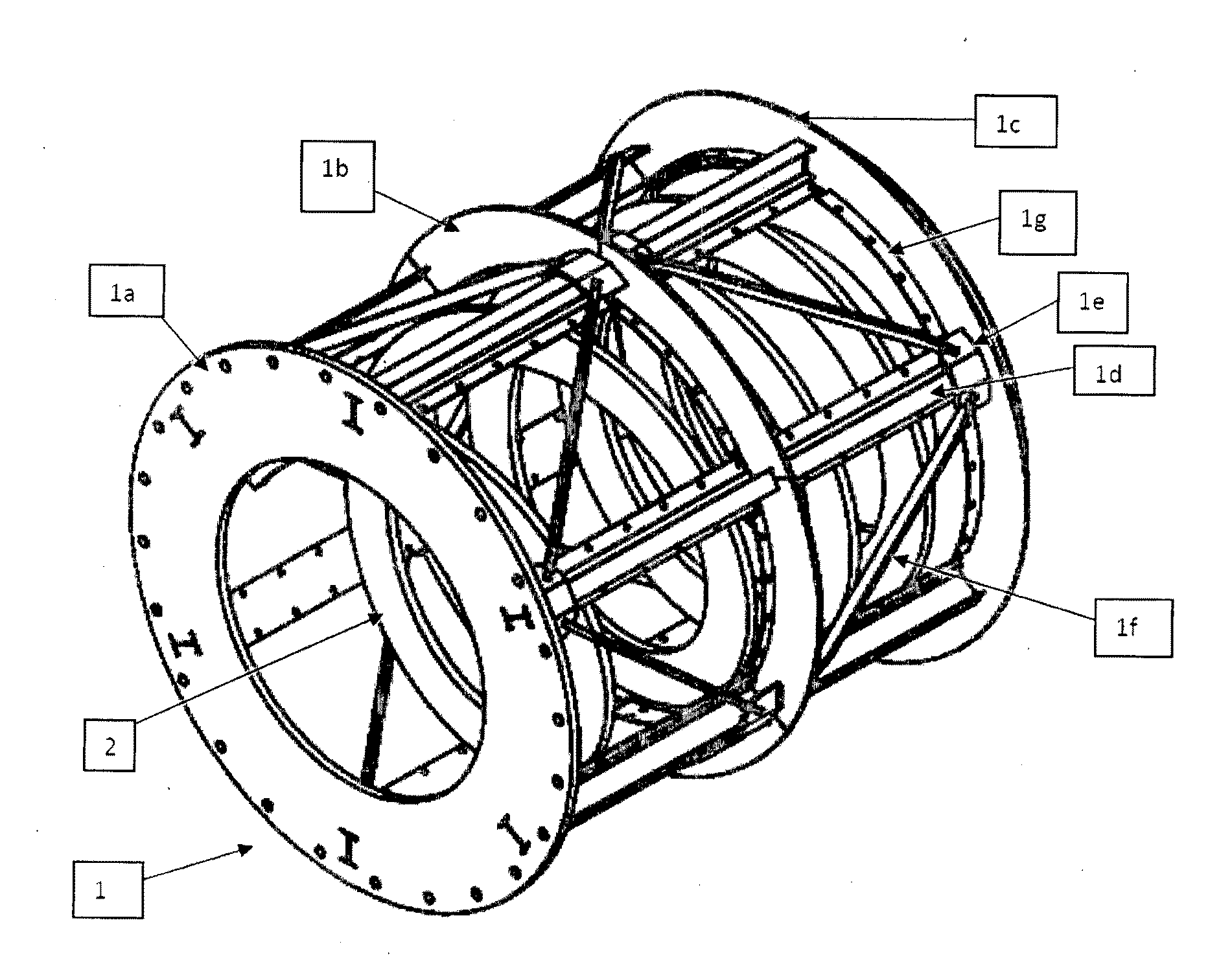

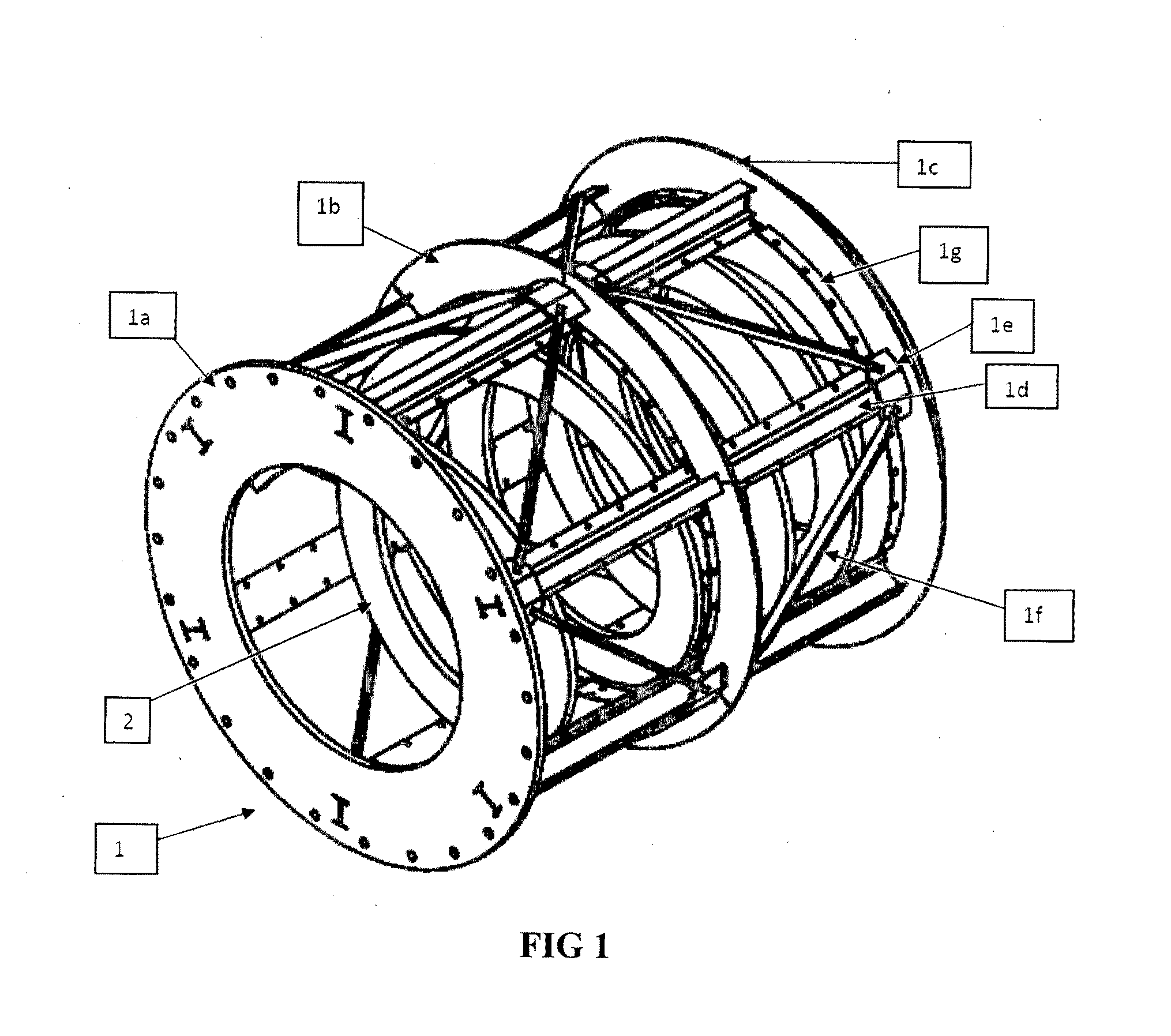

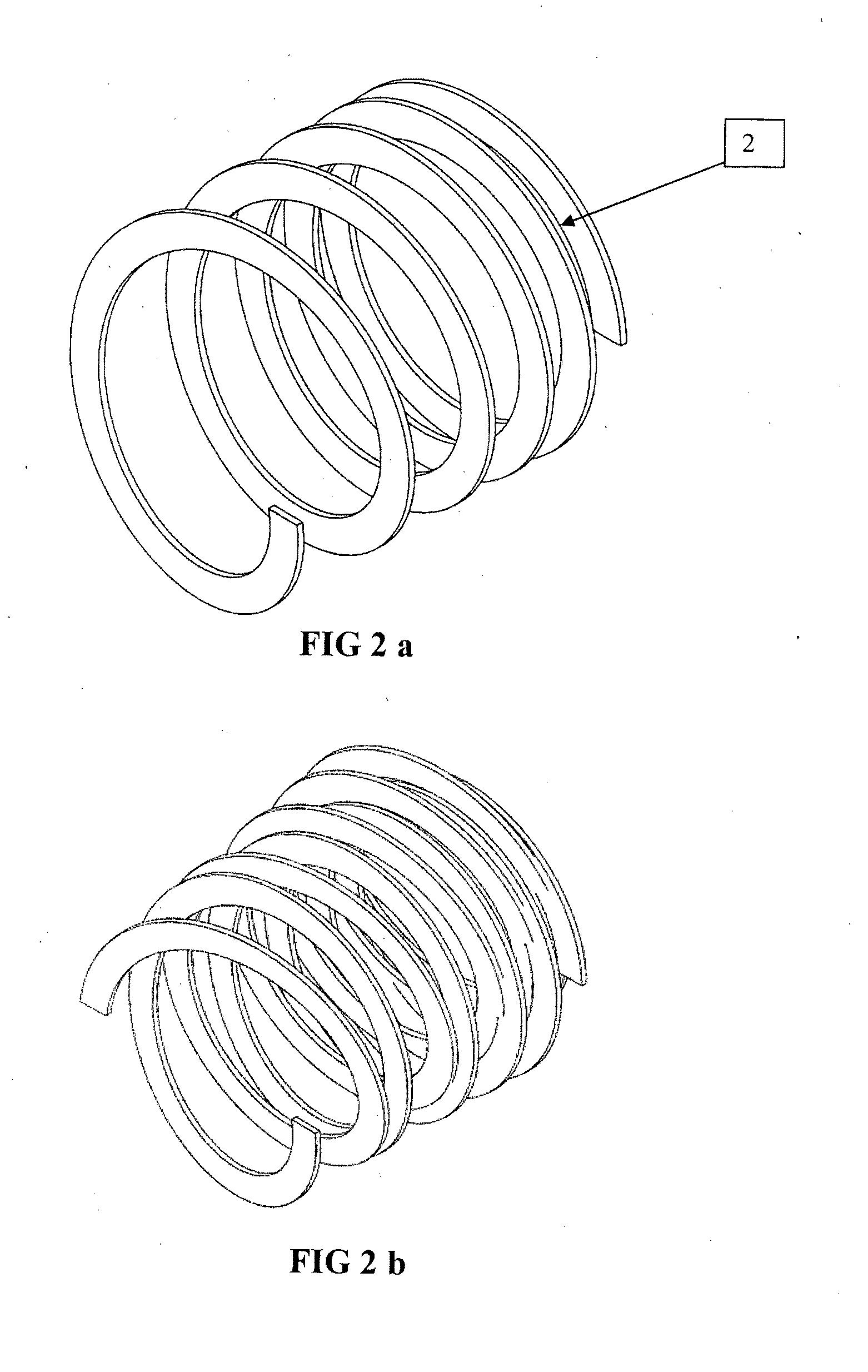

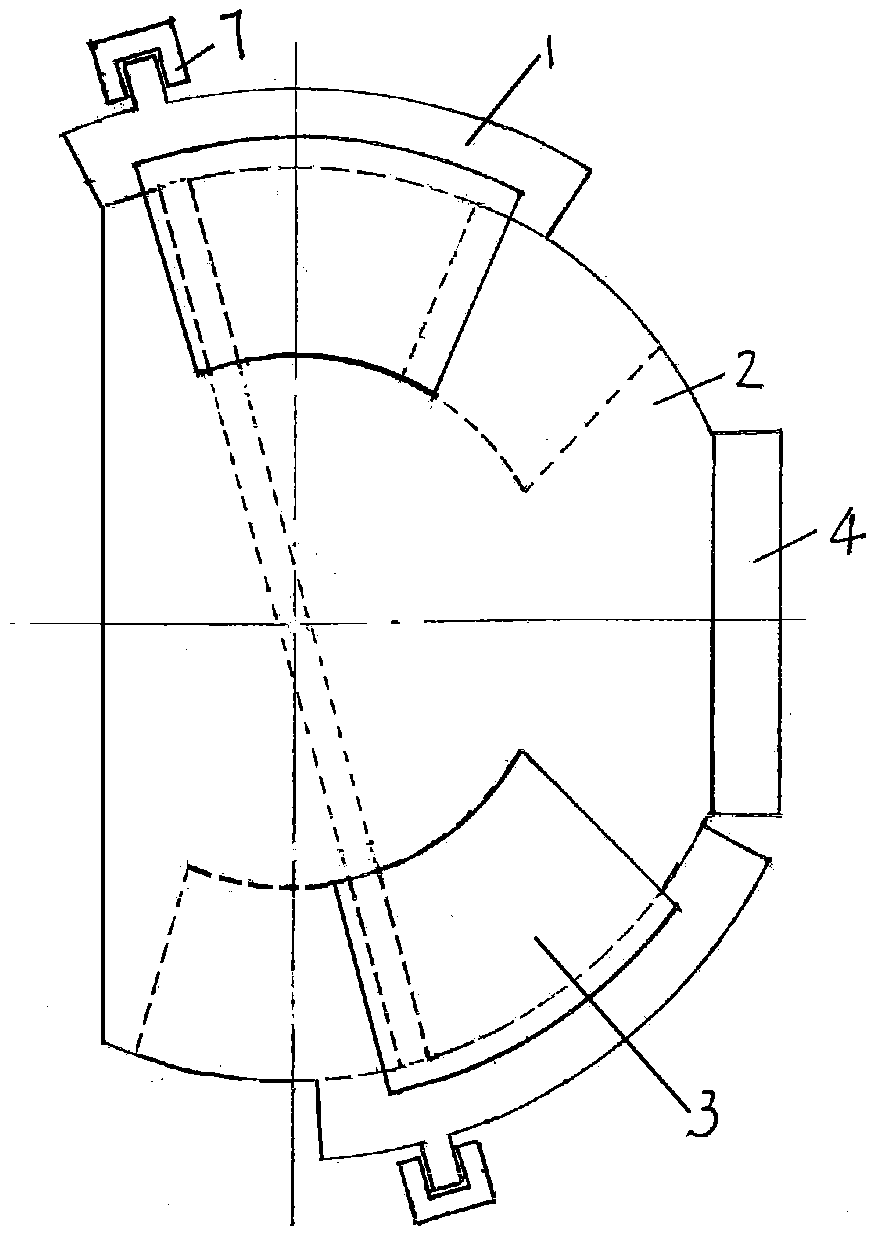

Trommel assembly having a spiral assembly with decaying pitch

InactiveUS20160129477A1Improve screening efficiencyReduce the overall heightSievingScreeningRetention timeEngineering

The trommel assembly (1) with a spiral assembly having a decaying spiral pitch (3) comprises rotating drum structure with the decaying spiral assembly (2) and screen panels (6) made of polymeric material or rubber compounds. The pitch (3) is at a maximum at the inlet and at a minimum at the outlet providing increased screening efficiency. Maximum pitch produces low media height with increased inlet velocity and minimum pitch increases media height. The spiral (2) is of single start, double start or multi start configuration. The pitch (3) decreases along the trommel such that screening efficiency is improved without affecting the retention time.

Owner:TEGA IND LTD +1

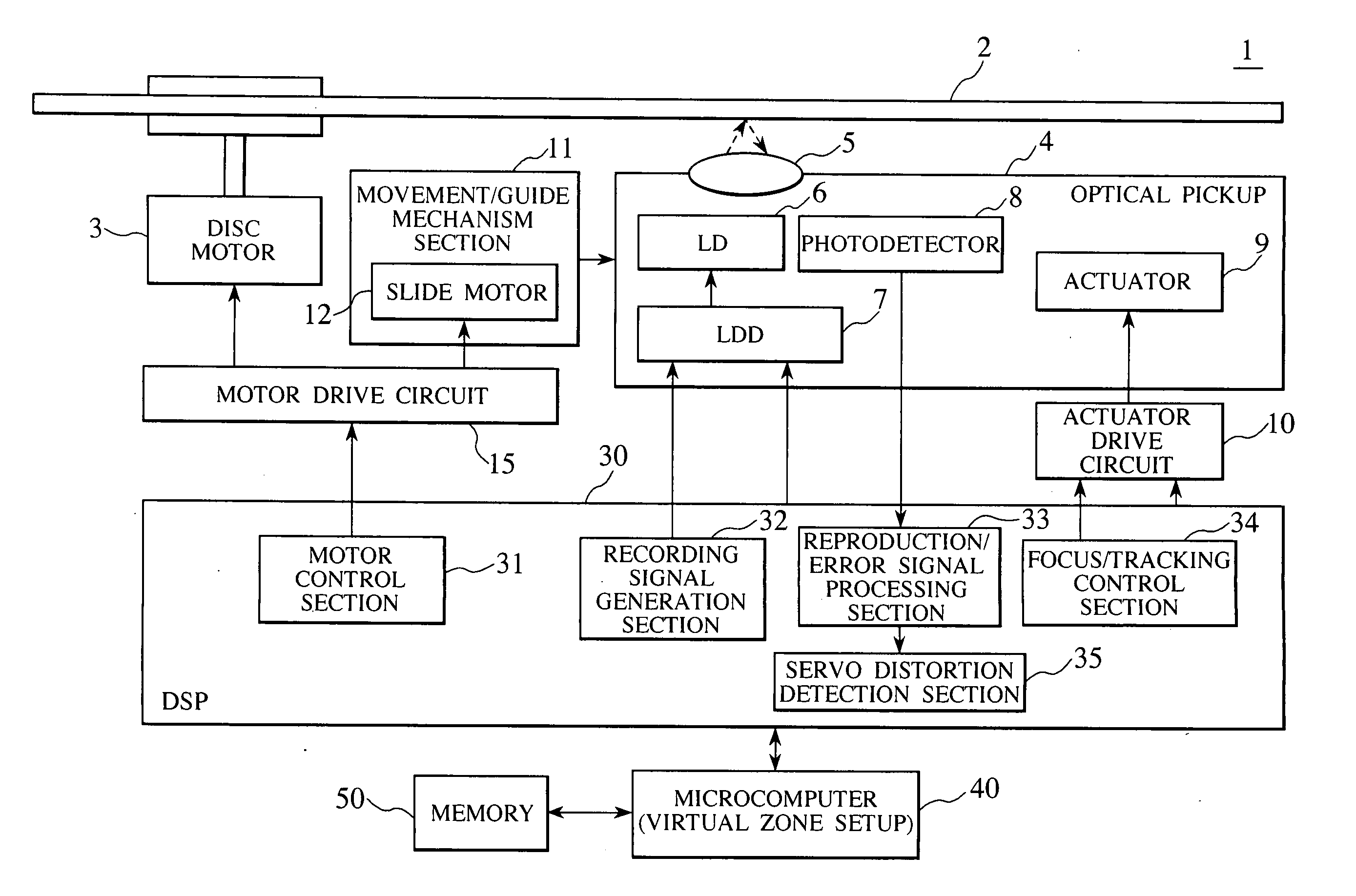

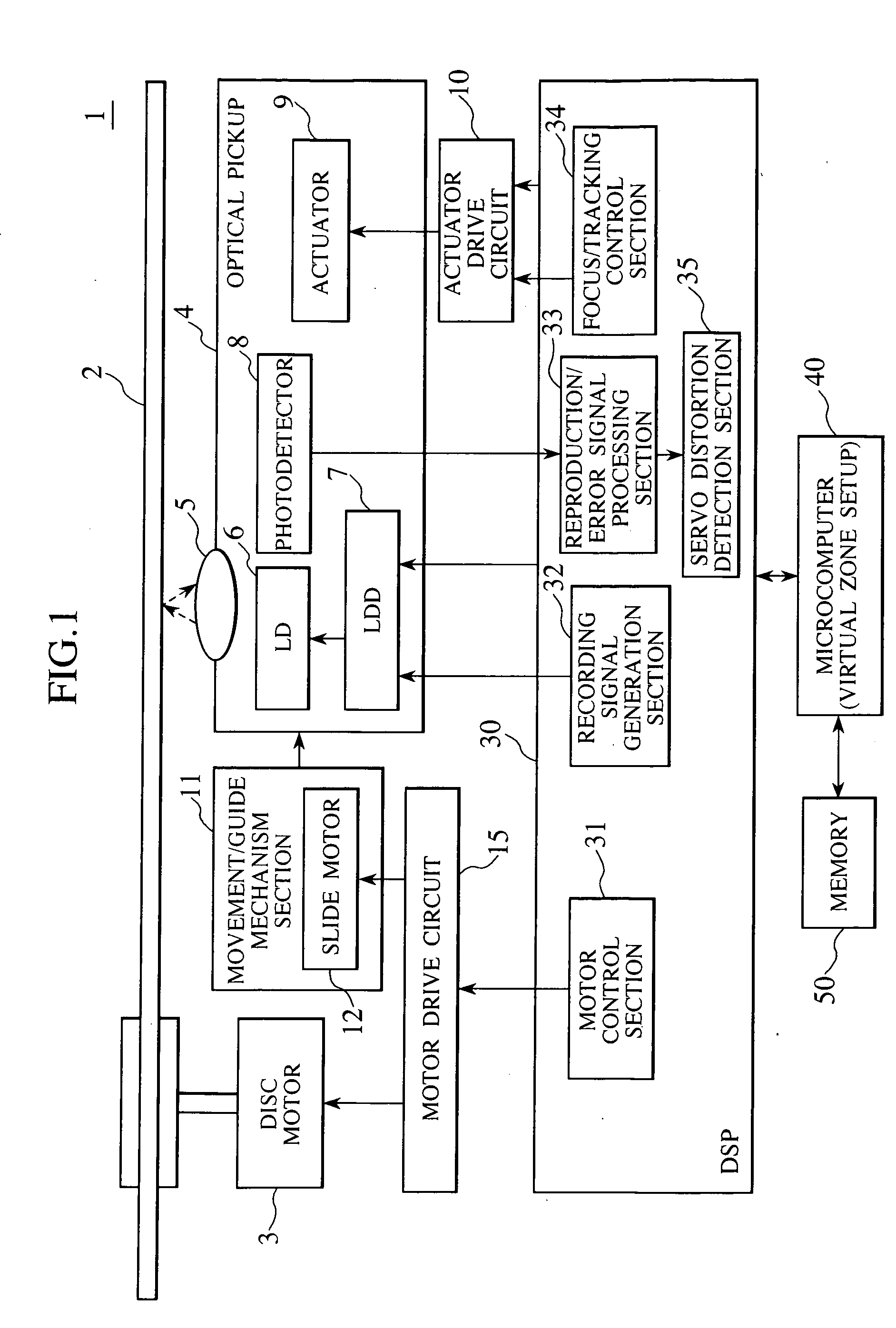

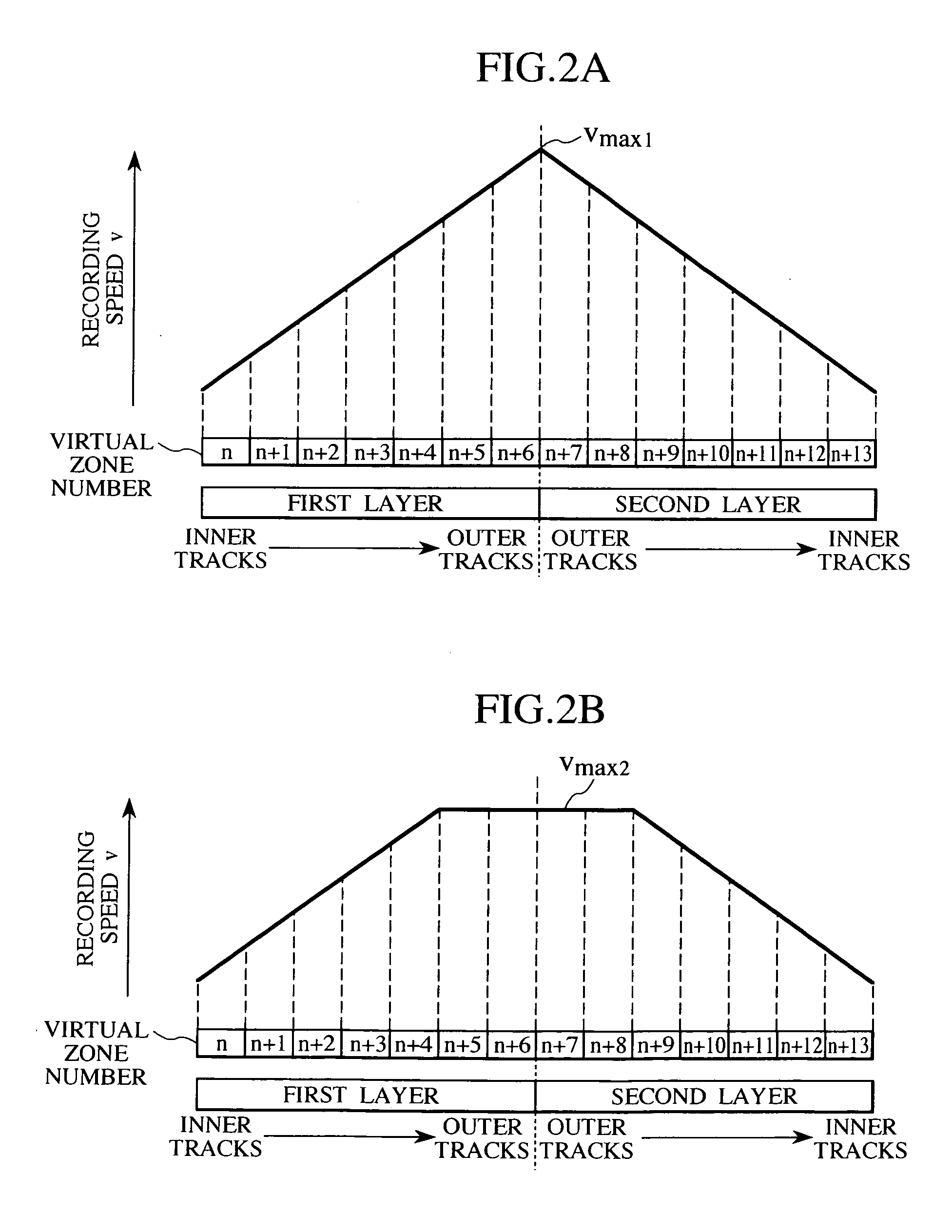

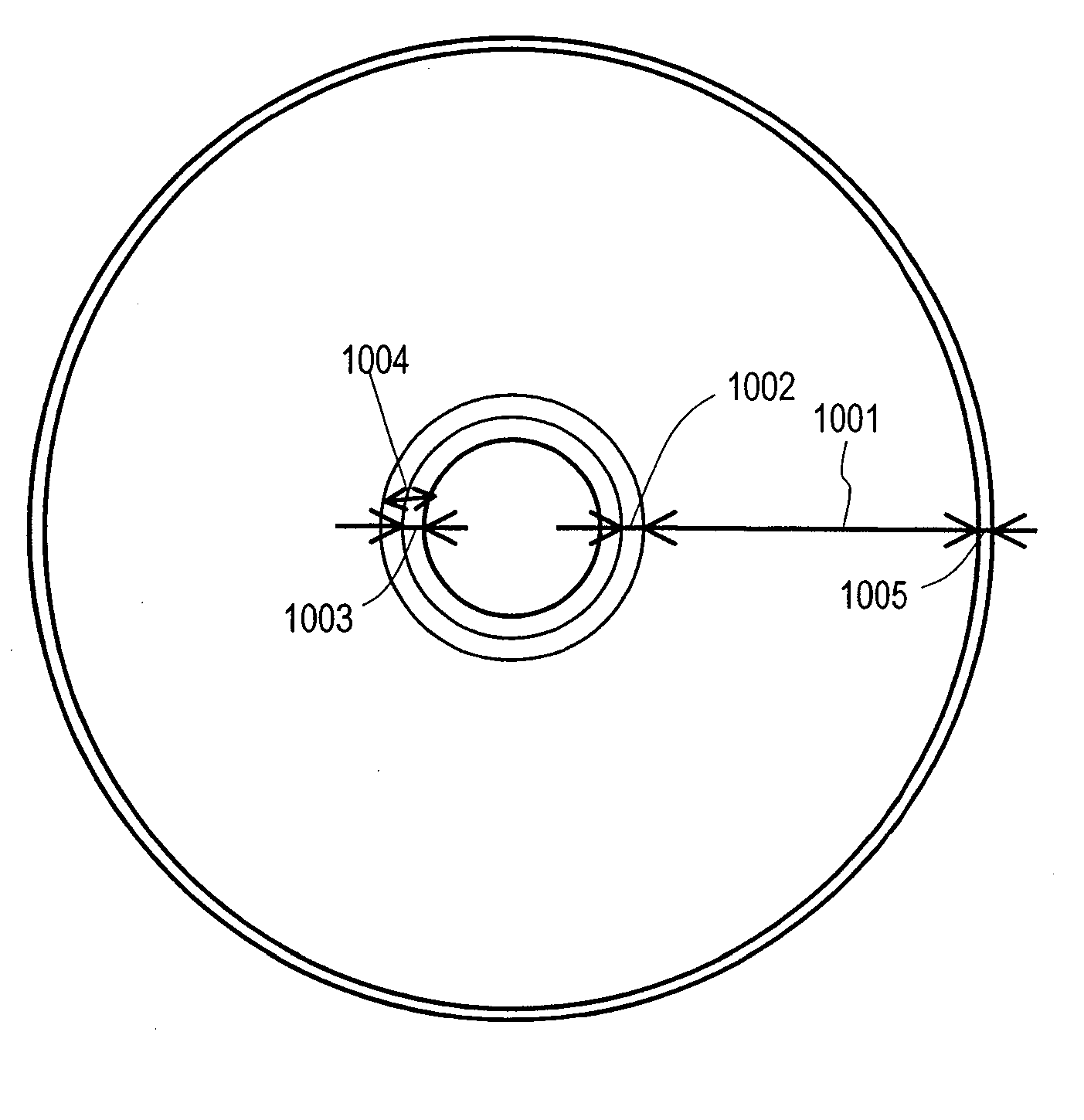

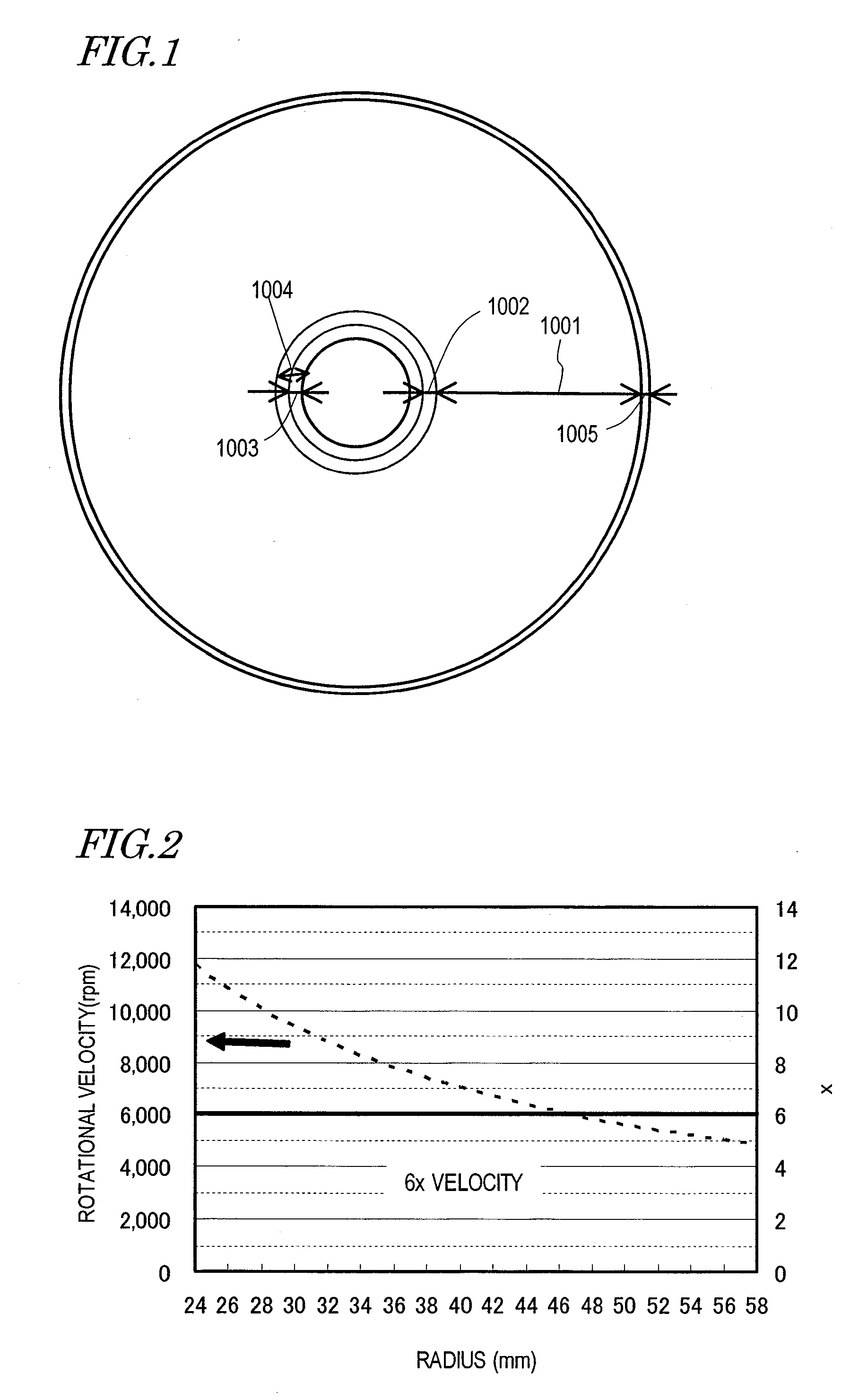

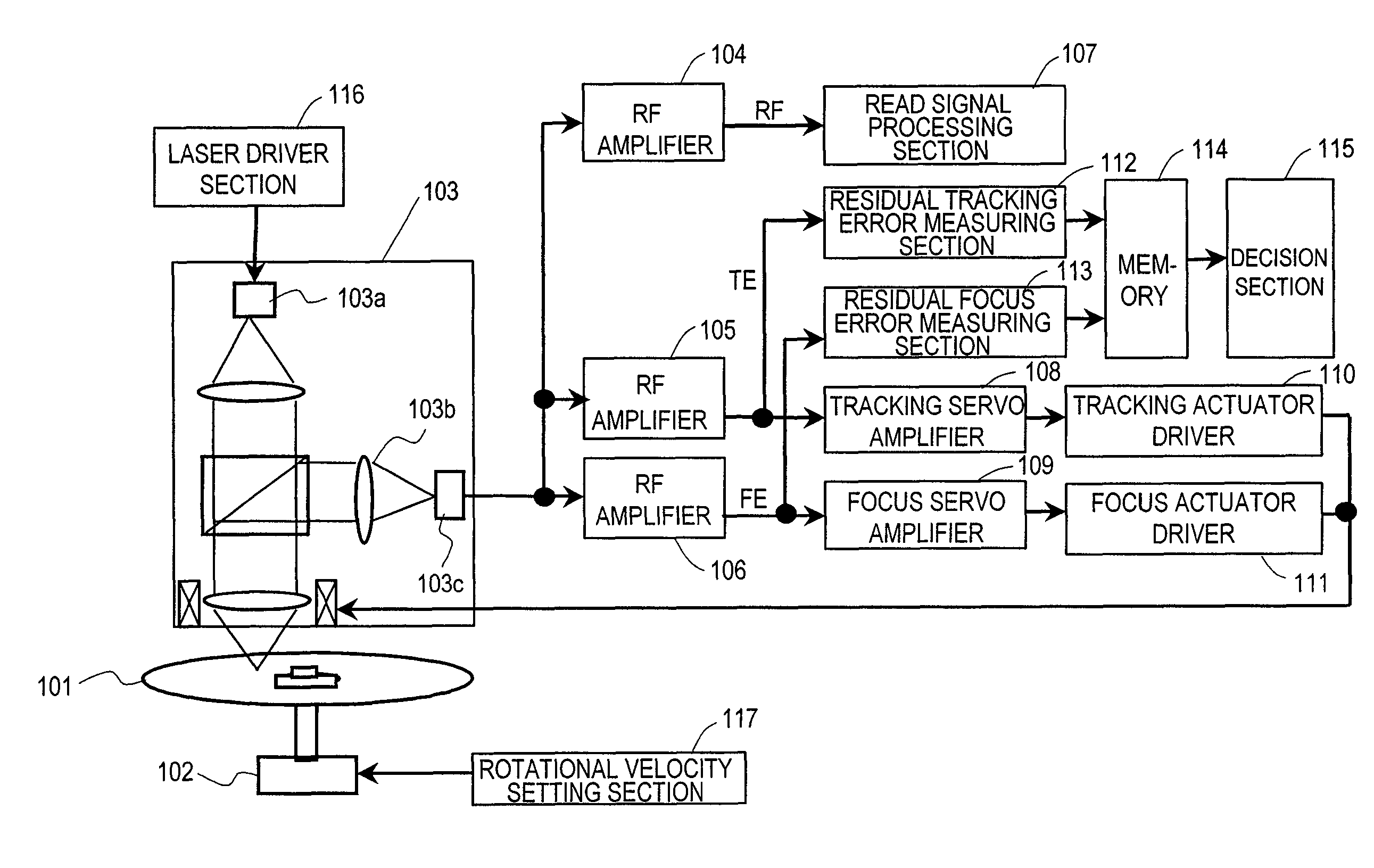

Optical disc apparatus and information recording and reproducing method

InactiveUS20070121444A1Recording speed is reducedExtend recording timeCombination recordingDisposition/mounting of recording headsComputer hardwareLow speed

Disclosed is an optical disc apparatus that sets a plurality of virtual zones, which correspond to a plurality of zones that are arranged in the radial direction of an optical disc, for a plurality of recording layers of the optical disc. When a servo signal distortion is detected in a virtual zone to change the rotation speed of the optical disc to a low speed in the virtual zone during an information recording or reproduction operation relative to a first recording layer, the optical disc apparatus stores the change information. When a recording or reproducing operation is to be performed in a virtual zone of a second recording layer, which is in the same disc radial position as the virtual zone of the first layer, the optical disc apparatus changes the rotation speed of the optical disc for the virtual zone to a low speed in accordance with the change information.

Owner:HITACHI-LG DATA STORAGE

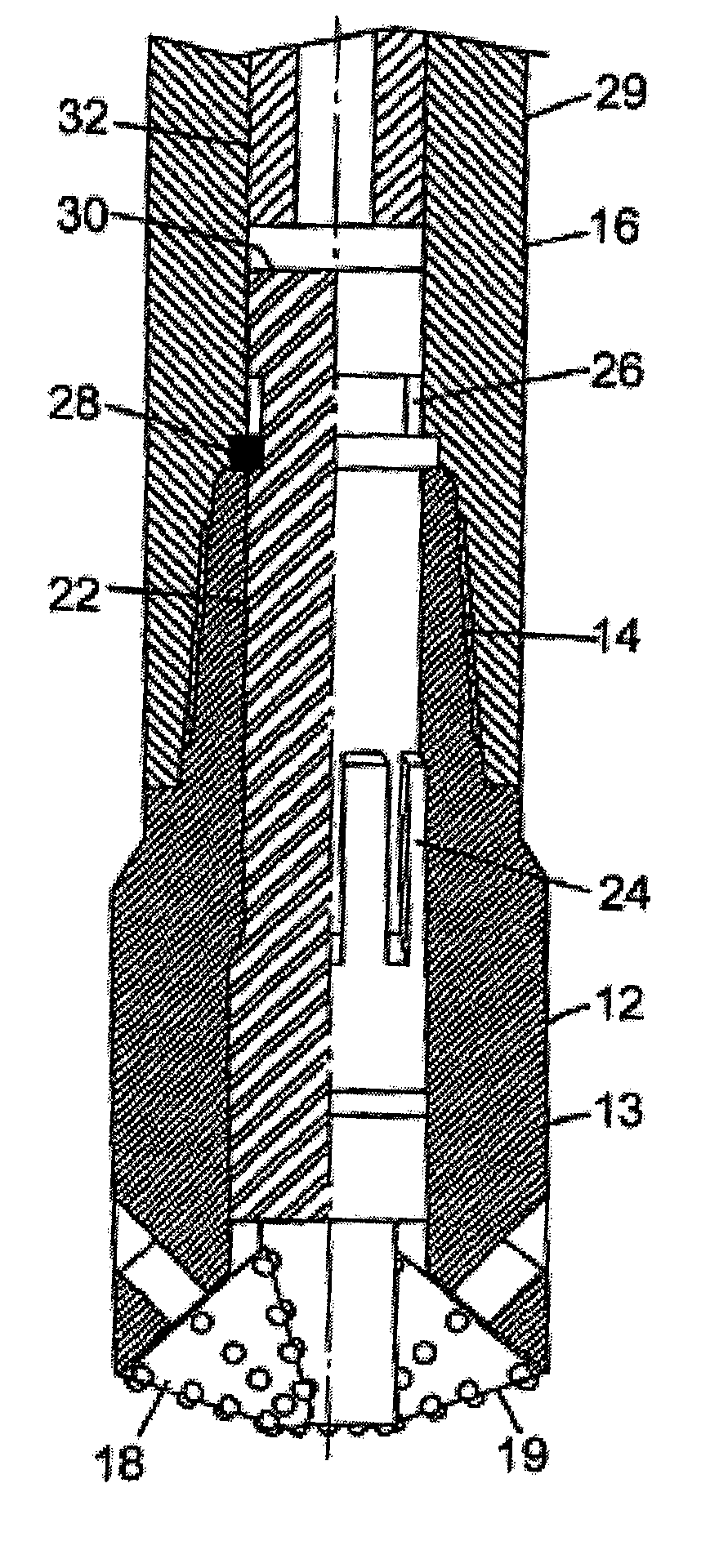

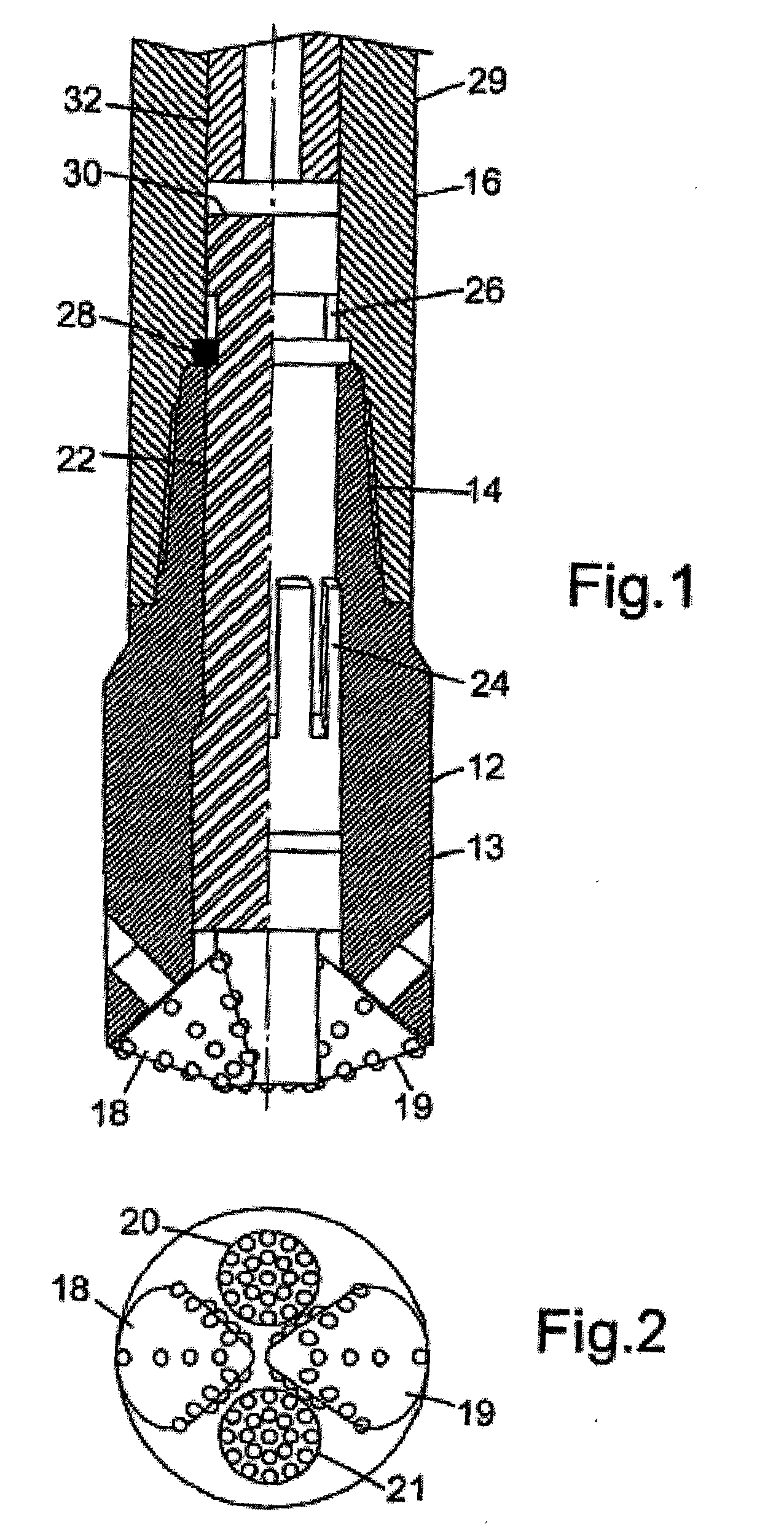

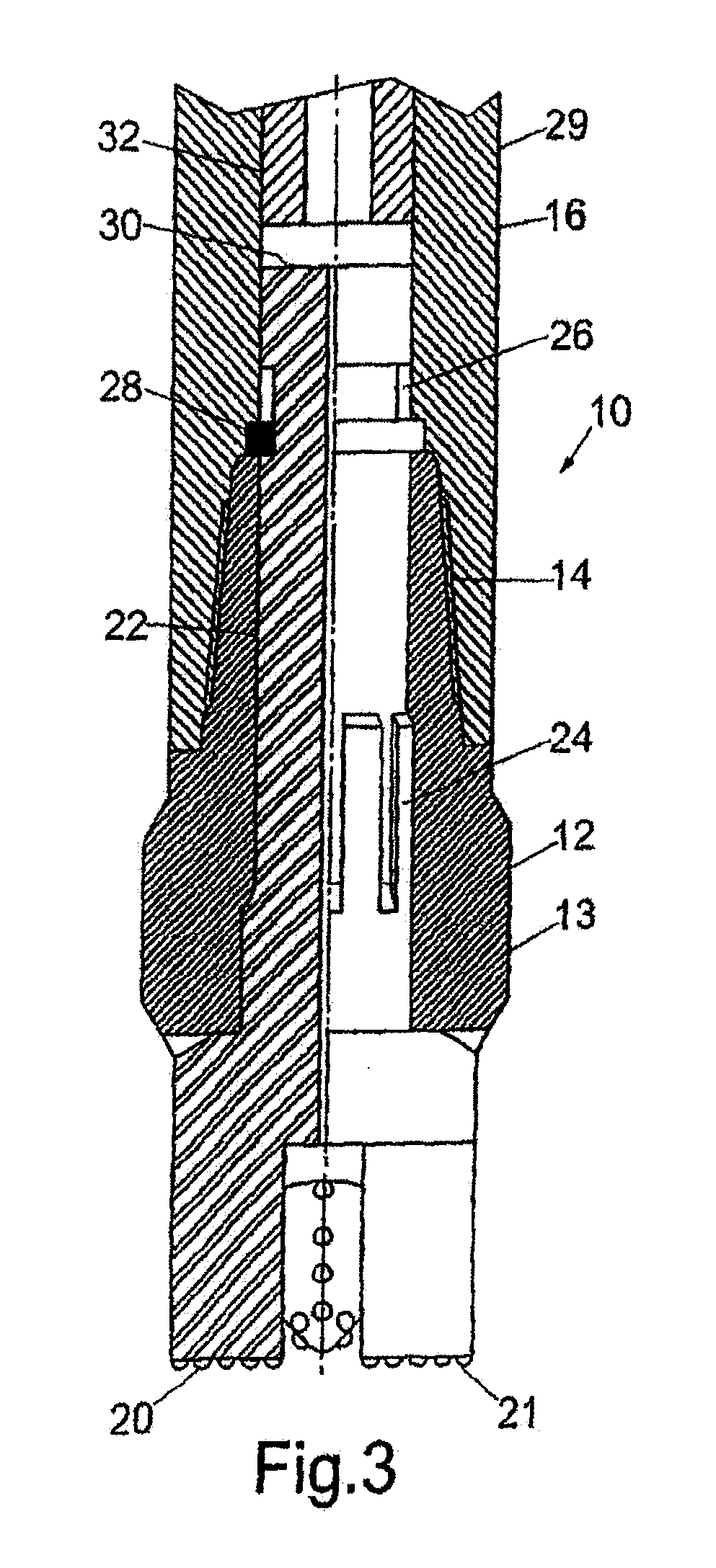

Drilling apparatus with percussive action cutter

InactiveUS20070181340A1Easy to controlLimit cutting effectivenessSurveyDrill bitsMechanical engineeringHydraulic pressure

A drilling apparatus includes a cutting structure defined by a percussive action cutter and at least one other cutter. The percussive action cutter is adapted to be urged in a drilling direction by hydraulic pressure force, while the other cutter is urged in a drilling direction by mechanical force.

Owner:ANDERGAUGE

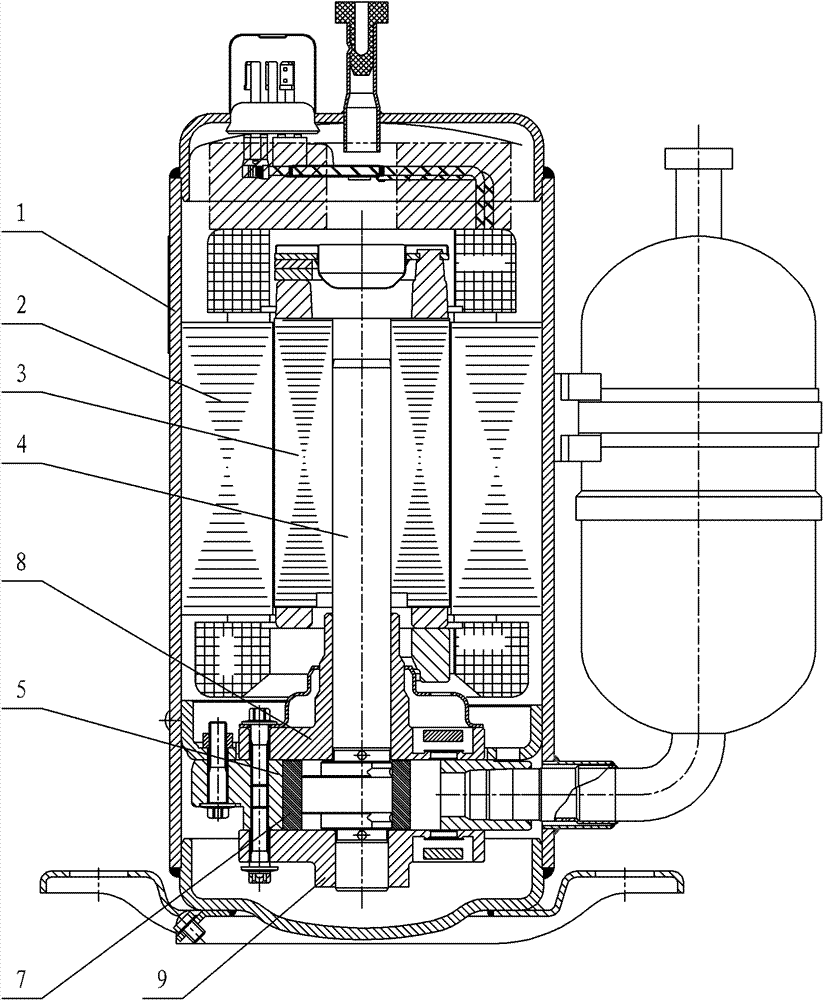

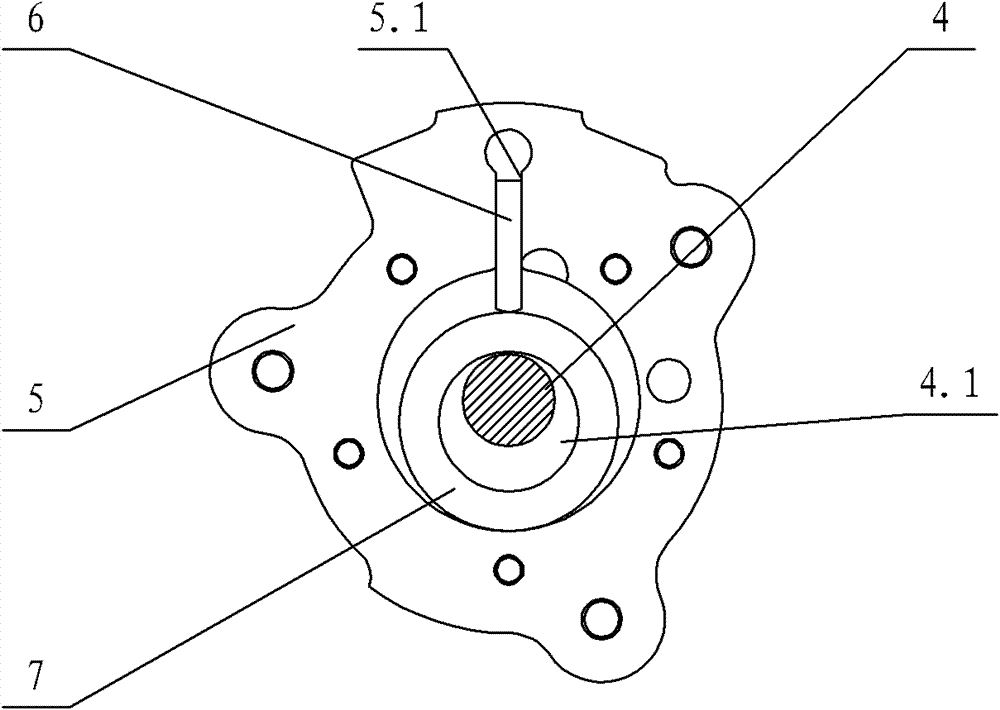

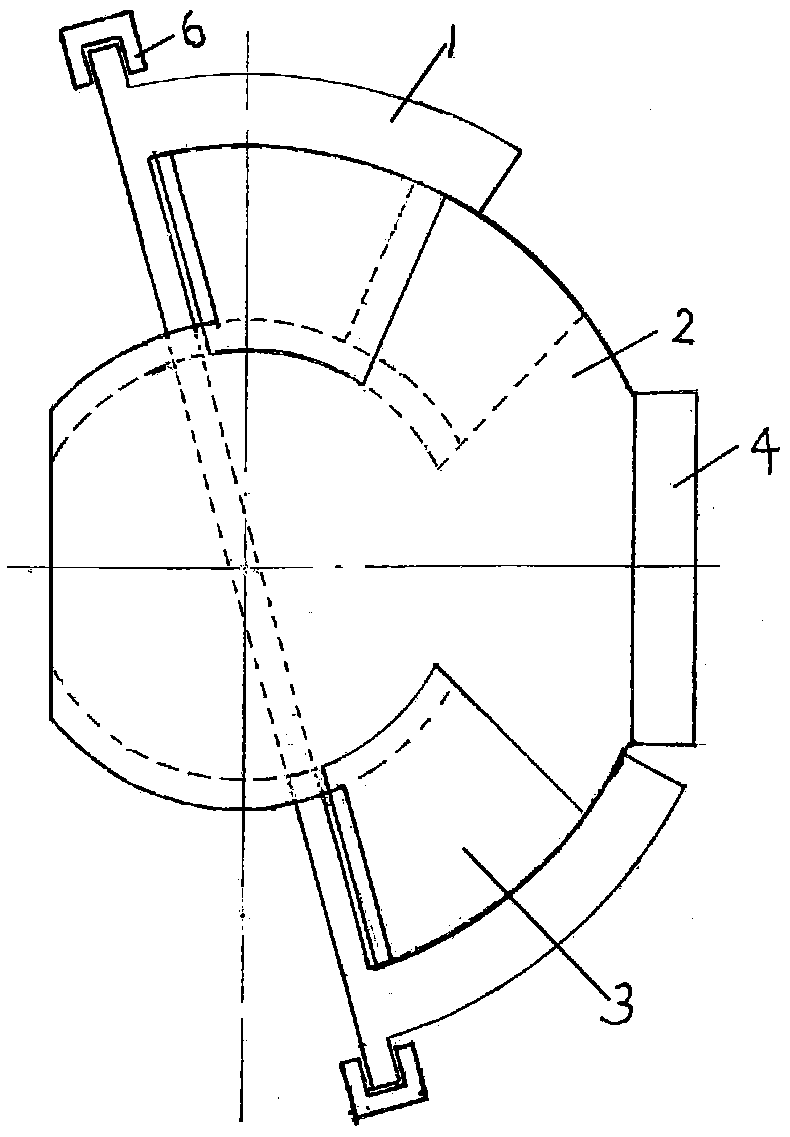

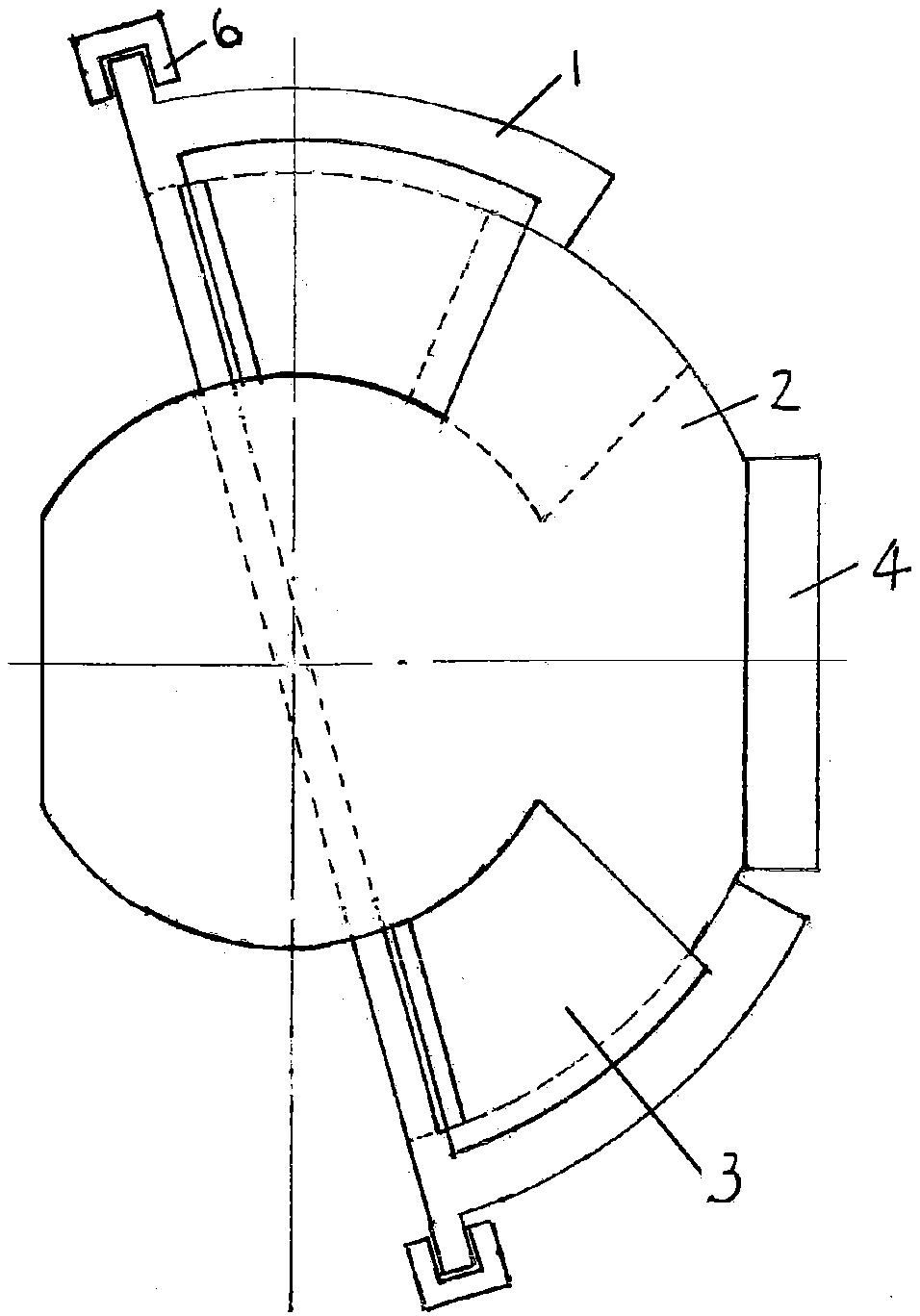

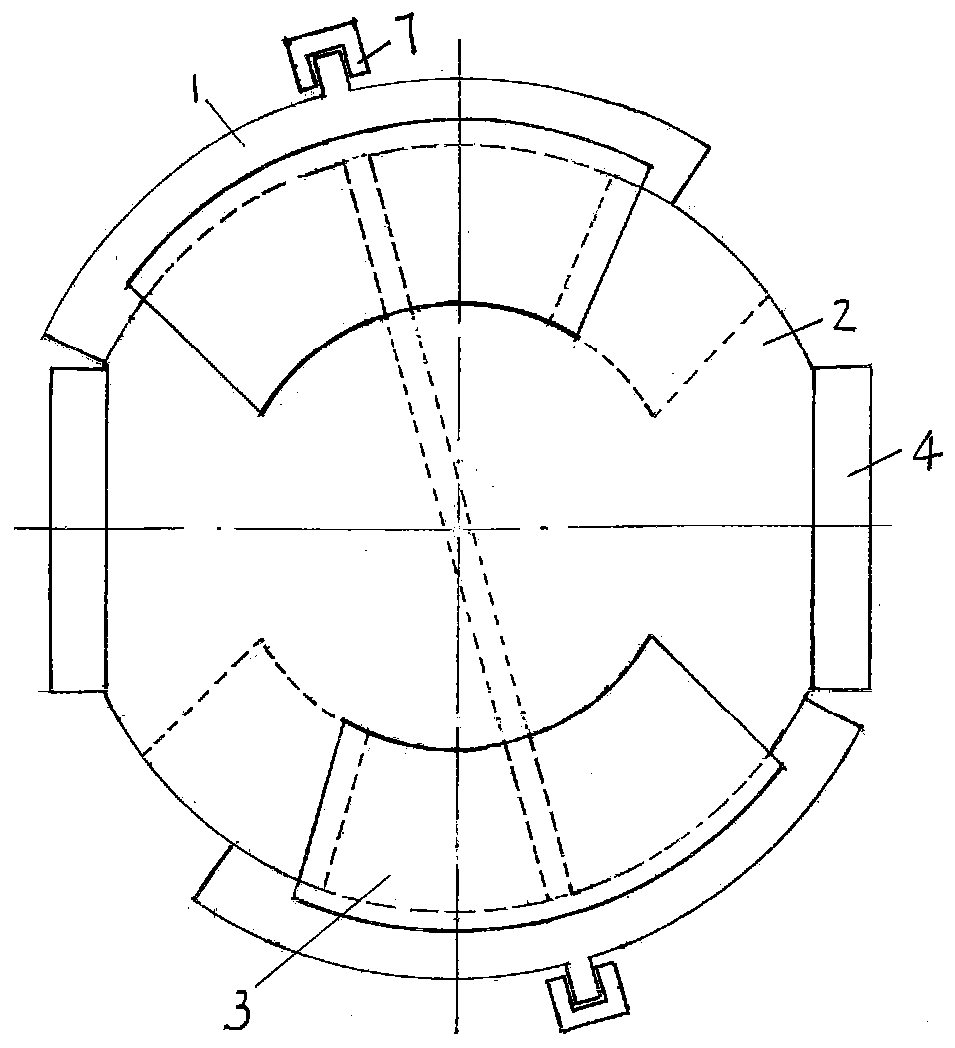

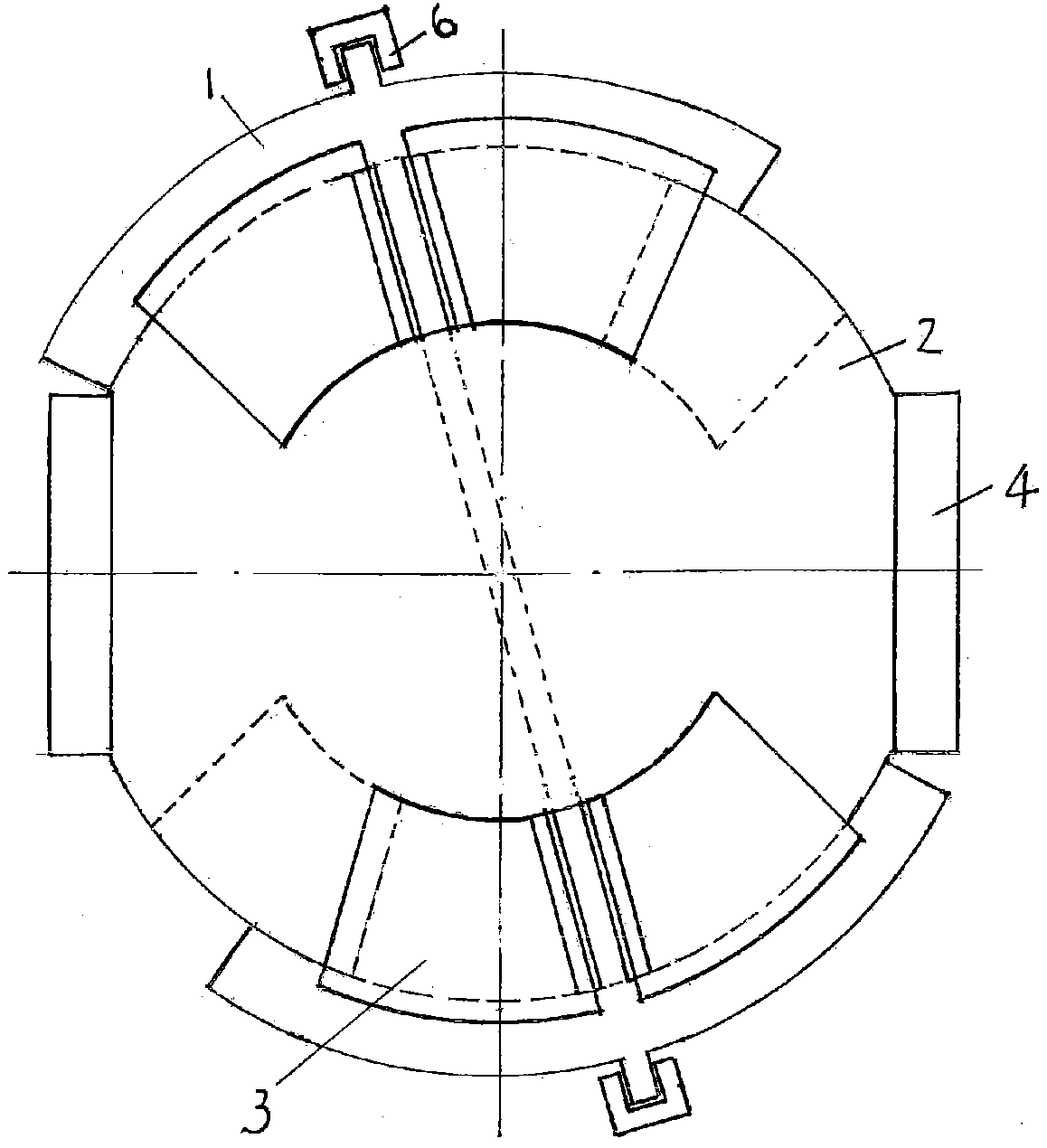

Rotary compressor

InactiveCN102767519AImprove relative linear velocityIncrease power consumptionRotary piston pumpsRotary piston liquid enginesBusiness efficiencyPiston ring

A rotary compressor comprises a housing. A motor and a compressing mechanism are arranged in the housing. The motor comprises a stator and a rotor. The stator is fixedly connected with the inner wall of the housing. The rotor is connected with a crankshaft in the compressing mechanism. The compressing mechanism also comprises a cylinder. A slide plate chute for holding a slide plate and a piston which is sleeved on the periphery of an eccentric shaft of the crankshaft and rotates together with the crankshaft to compress a refrigerant are arranged in the cylinder. The front end of the slide plate contacts with the periphery of the piston. A base bearing and an auxiliary bearing which are used for supporting the crankshaft are arranged at upper and lower sides of the cylinder. The piston comprises a large piston ring and a small piston ring which are concentrically arranged, wherein the small piston ring is sleeved on the periphery of the eccentric shaft; the large piston ring is sleeved on the periphery of the small piston ring; the inner circumference of the large piston ring is in clearance fit with the periphery of the small piston ring and the fit clearance is less than or equal to 40m. The rotary compressor provided by the invention has characteristics of simple and reasonable structure, flexible operation, low manufacturing cost, small frictional power consumption, high energy efficiency ratio and wide application range.

Owner:GUANGDONG MEIZHI COMPRESSOR

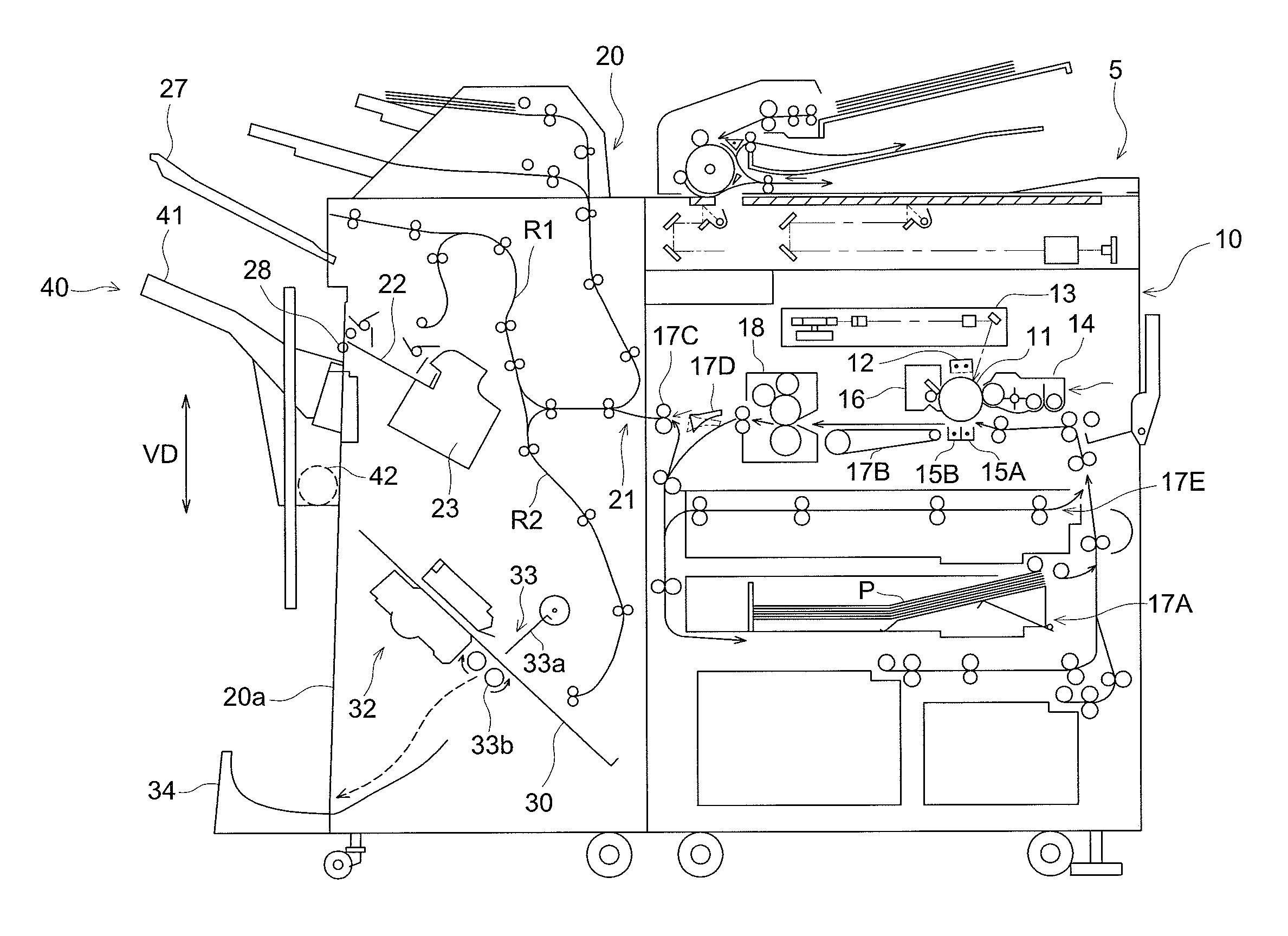

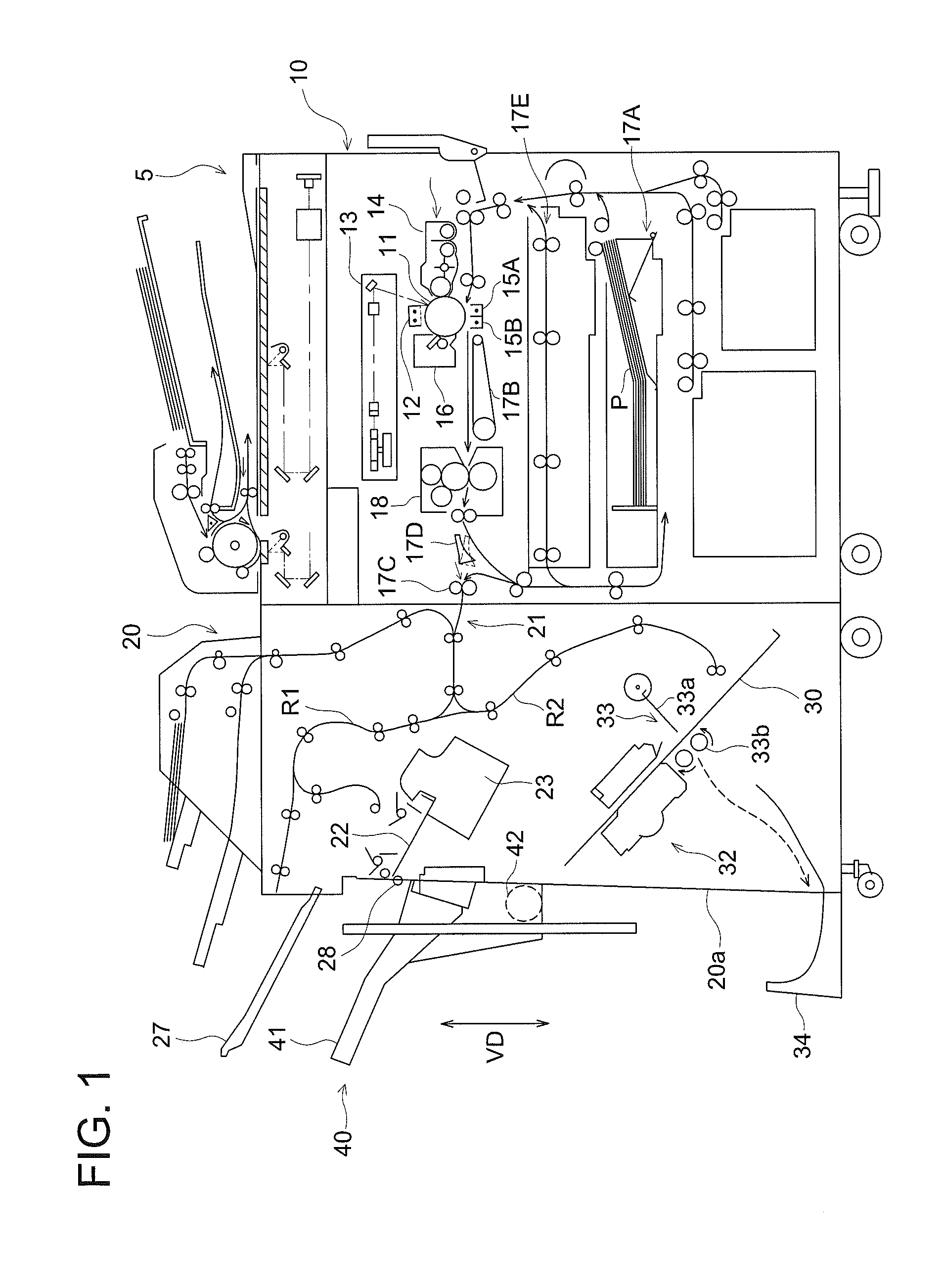

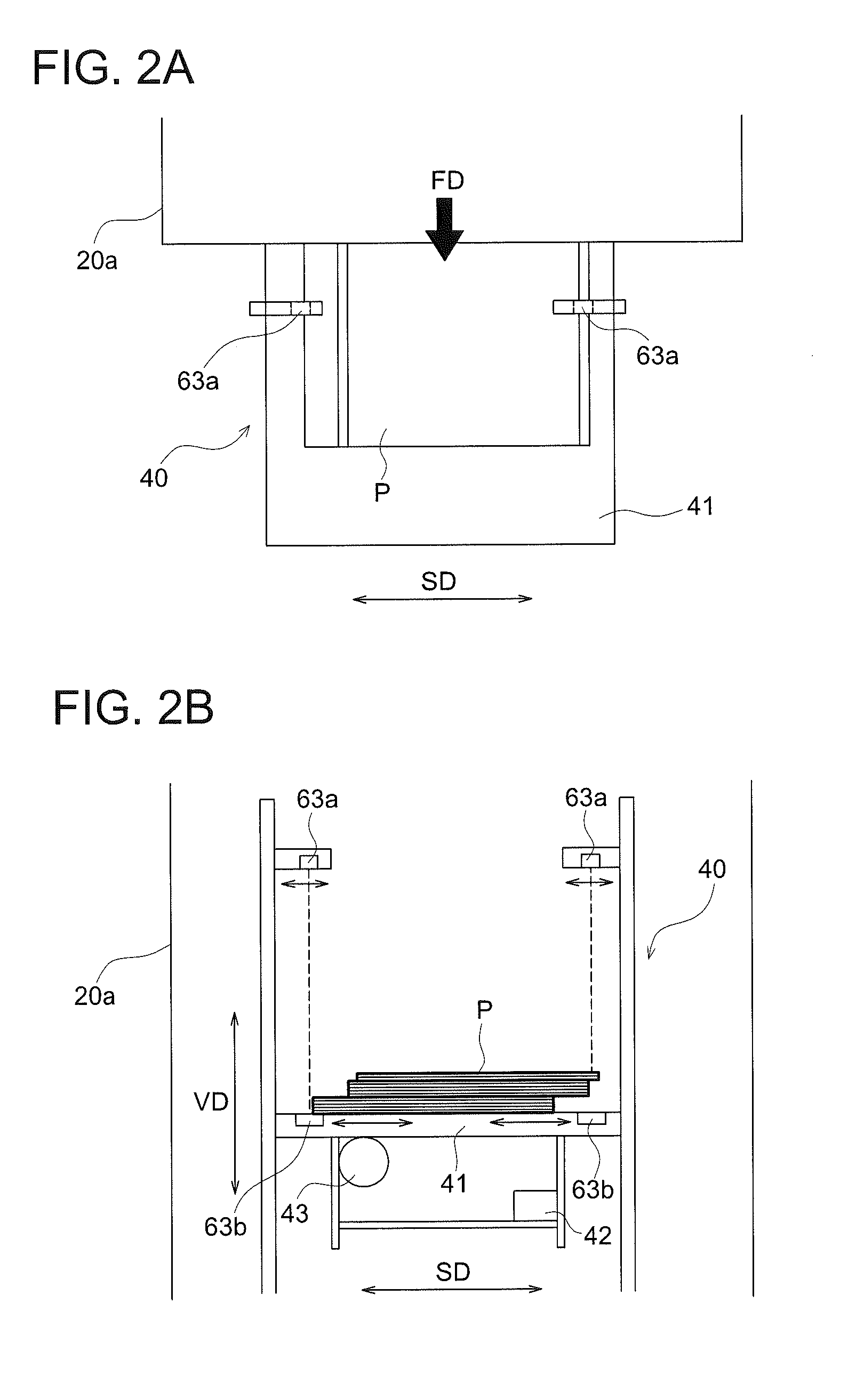

Sheet discharging tray device and image forming system provided therewith

ActiveUS20120104689A1Relatively low linear speedReduce distanceFunction indicatorsPile receiversImage formationEngineering

Owner:KONICA MINOLTA BUSINESS TECH INC

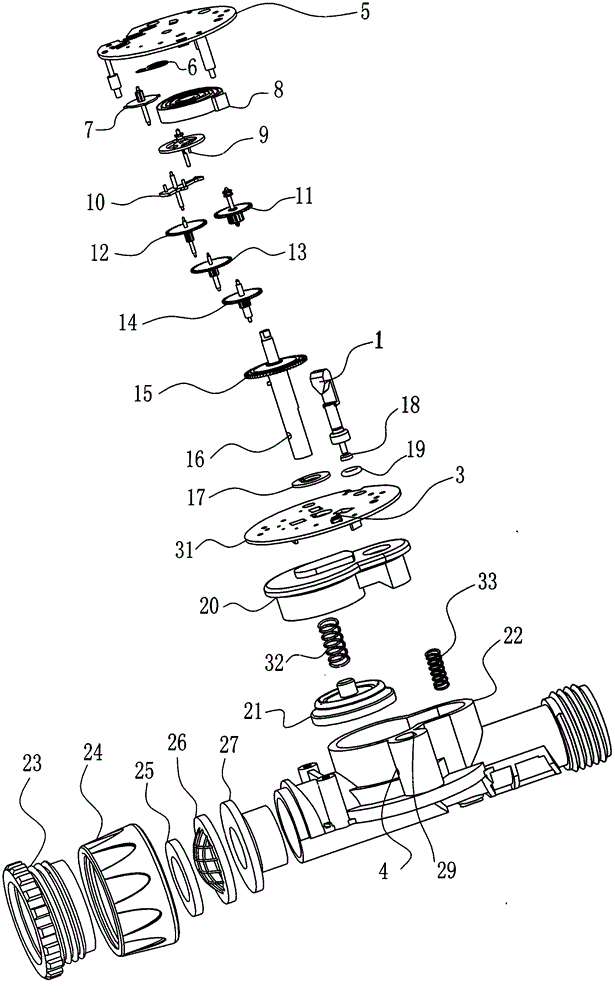

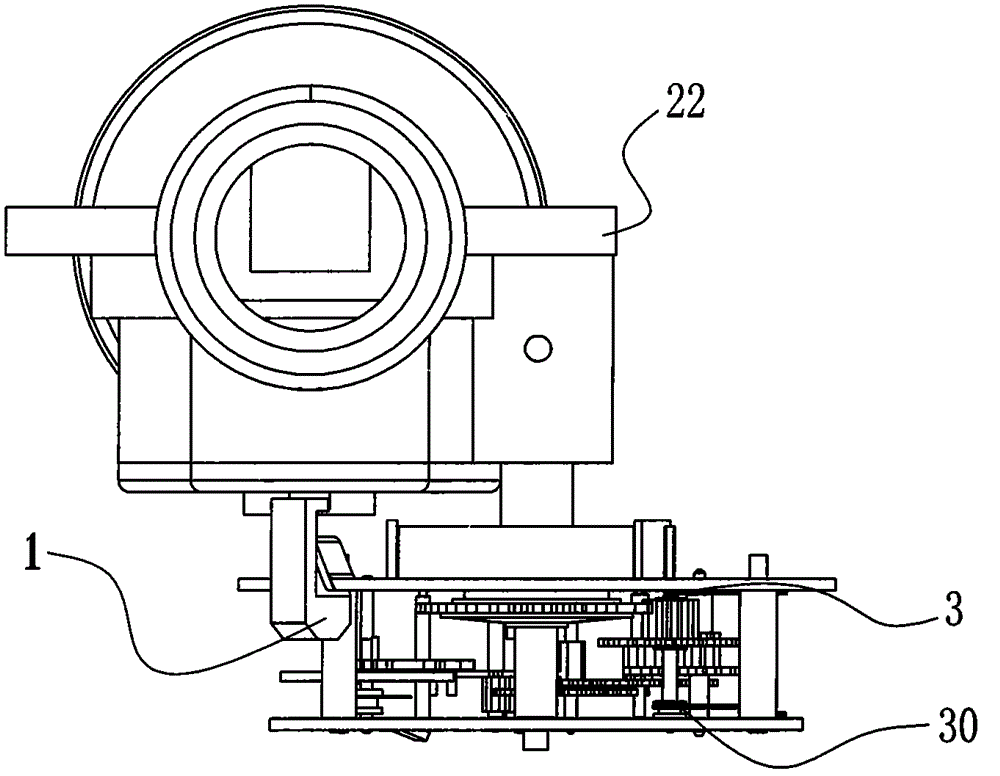

Energy-saving single-magnet type electromagnetic flowmeter, circuit and magnetic circuit all for agricultural irrigation

InactiveCN104957006AEasy to irrigateWide applicabilityWatering devicesCultivating equipmentsWater savingImpeller

The invention relates to a watering control method for environment protection and garden greening, relates an energy-saving single-magnet type impeller suspension electromagnetic flowmeter, a circuit and a magnetic circuit all for agricultural irrigation, and discloses a novel electromagnetic flowmeter, a circuit and a water-saving method. The electromagnetic flowmeter comprises a flow adjustable water dropper, a 360-degree nozzle, a joint which can be finely turned, a spraying timer and a water distributor. By the aid of stepped rolling, a one-stage rotation manner for an impeller turns to be a multiple-stage rotation manner, the relative linear velocity is decreased, the friction is smaller, and the precision is higher by the use of the single-magnet type impeller. The electromagnetic flowmeter can be used for efficient garden irrigation, saves energy and water, and can be used for high-precision flow metering. Single-magnet steel needles (581) are arranged on blades of the impeller, so that the counting precision can be higher. The length of the single-magnet steel needle (581) on each blade of the impeller is in the radial direction of the diameter of the impeller. The magnetic tip portion of each single-magnet steel needle is higher than the external diameter of the impeller by more than 0.1mm, so that a monopole of a magnetic field is closer to a magnetic induction strips without faults.

Owner:NINGBO DAYE GARDEN IND

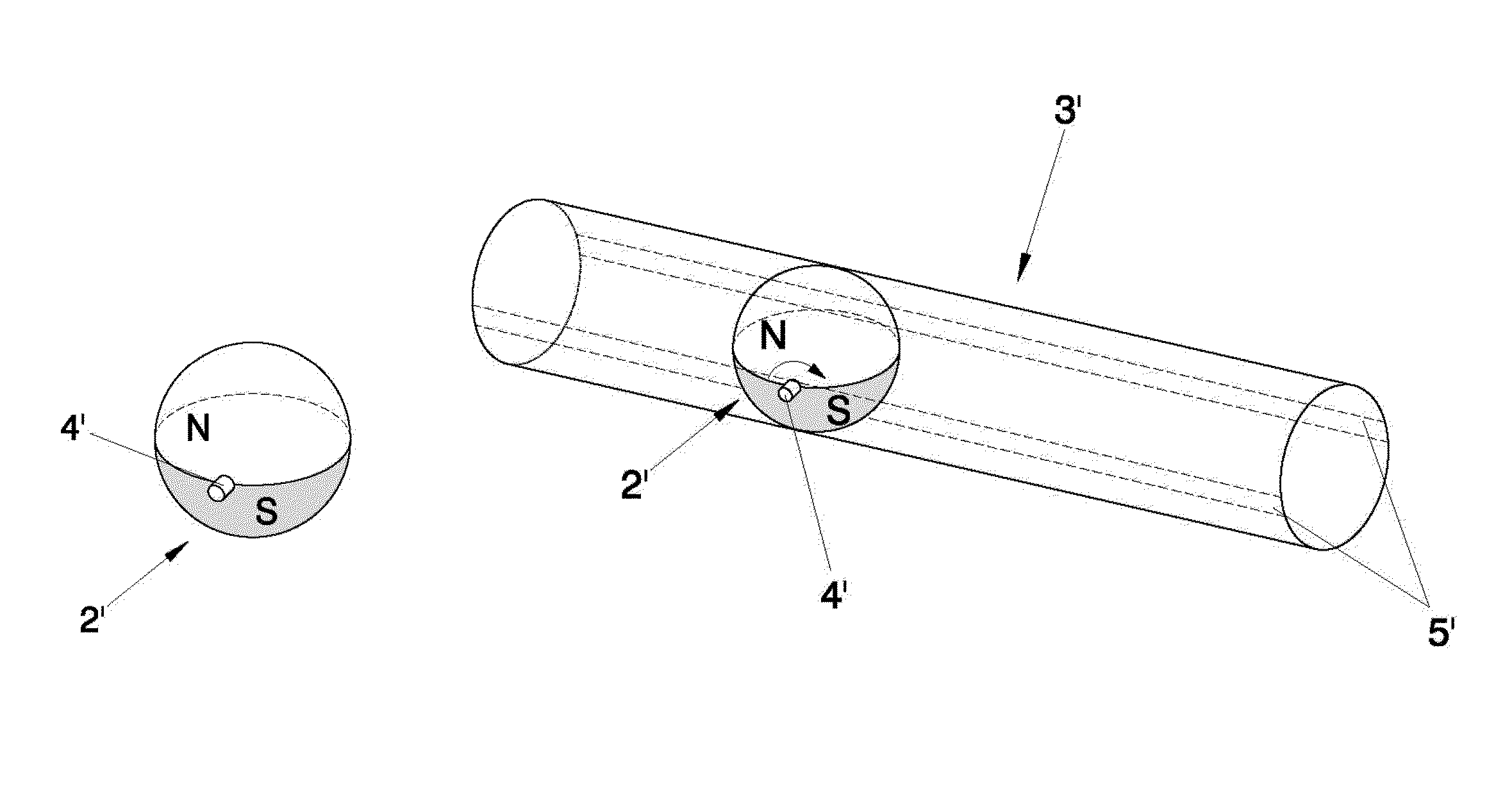

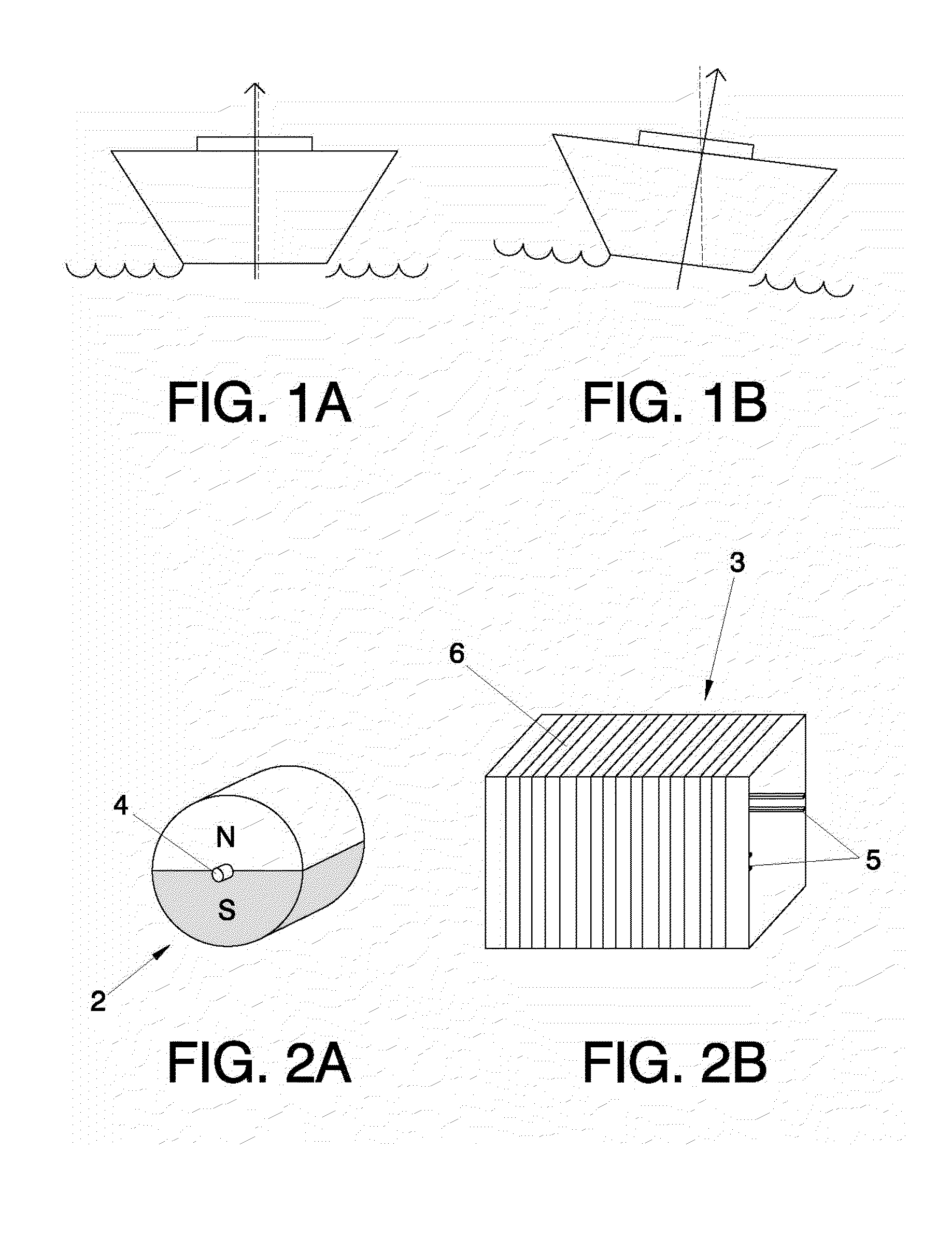

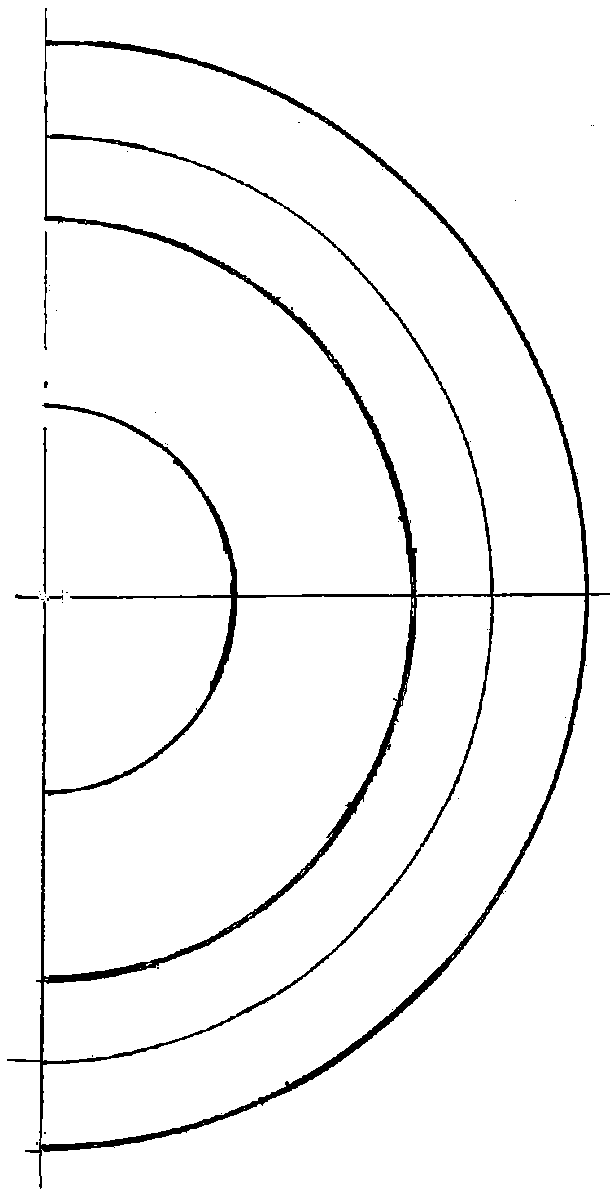

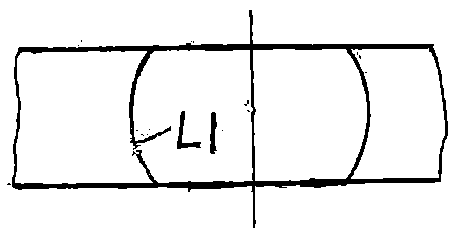

Magnetic flux power generation based on oscilating movement

InactiveUS8633605B2Extreme simplicityLow priceMachines/enginesMechanical energy handlingMotion generationConductor Coil

This invention describes a device for the generation of electric energy from small movements which comprises: a magnet with the shape of a solid of revolution which comprises at least a couple of poles (N, S) placed around an axis of revolution; a tube whose transversal section is complementary to the shape of the magnet, and which comprises a winding rolled transversally around it, with the magnet placed in the interior of the tube so that an inclination of the tube causes the magnet to roll, traveling along the interior of the tube and inducing tension on the winding.

Owner:UNIV DE BARCELONA +1

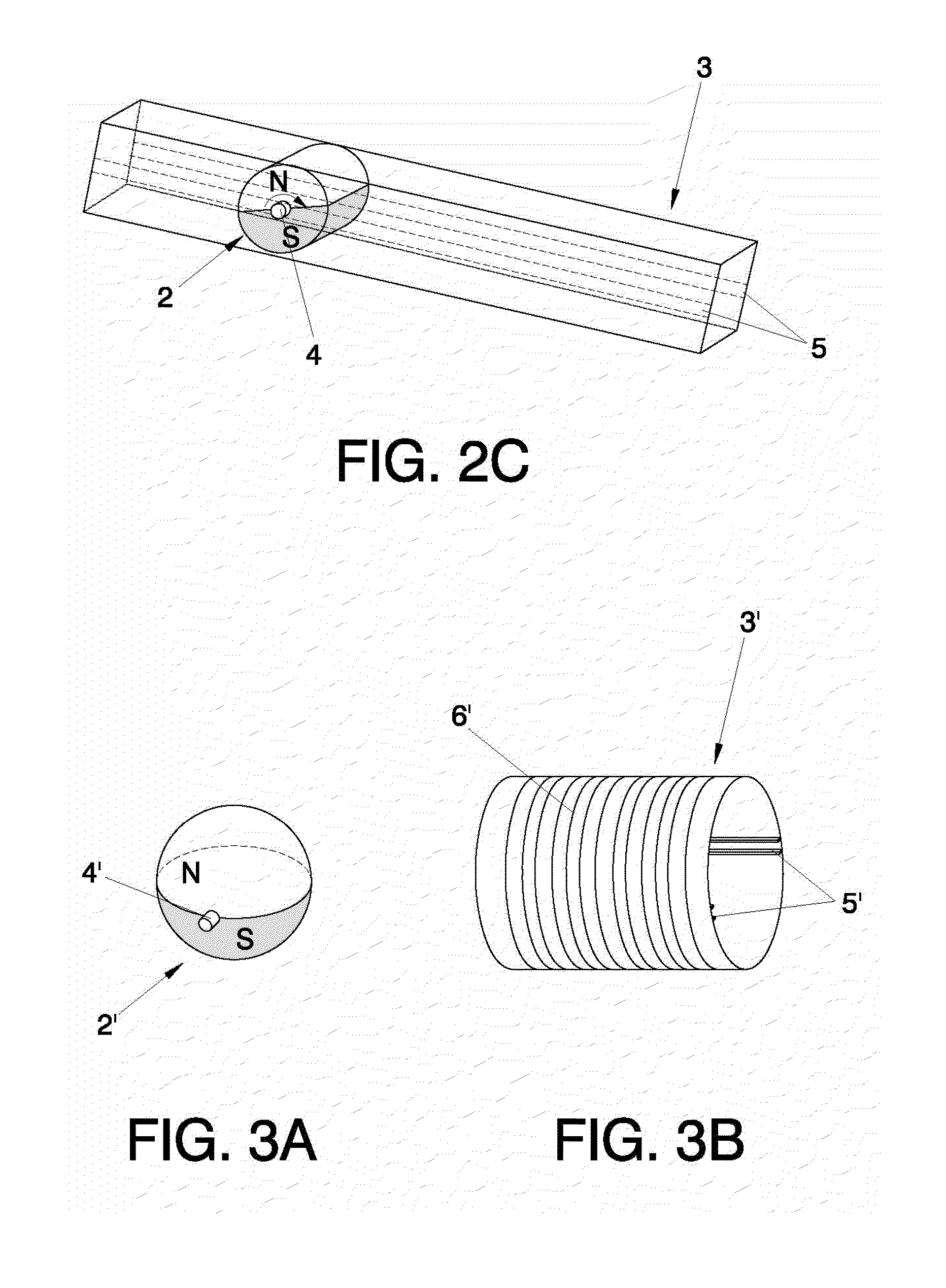

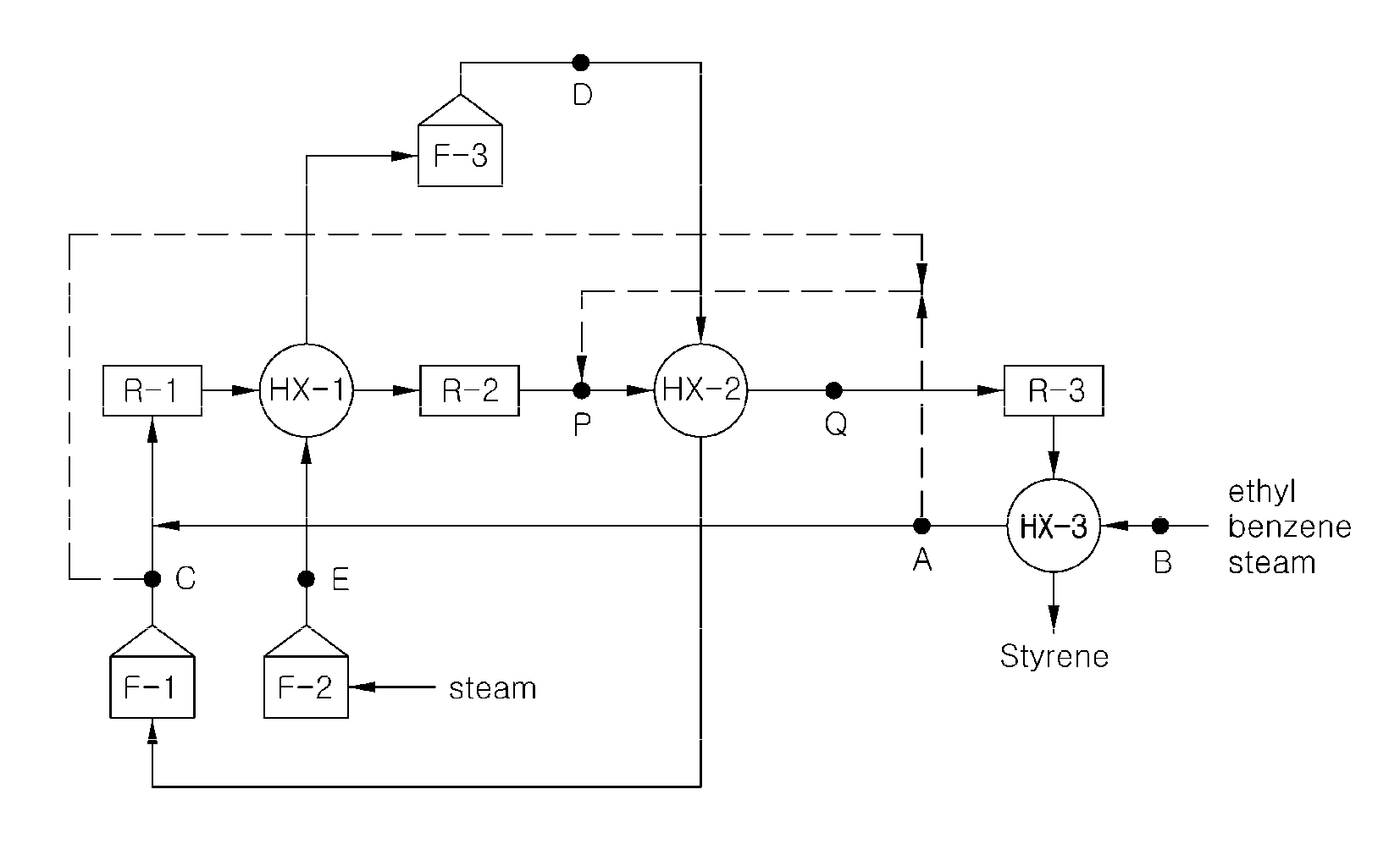

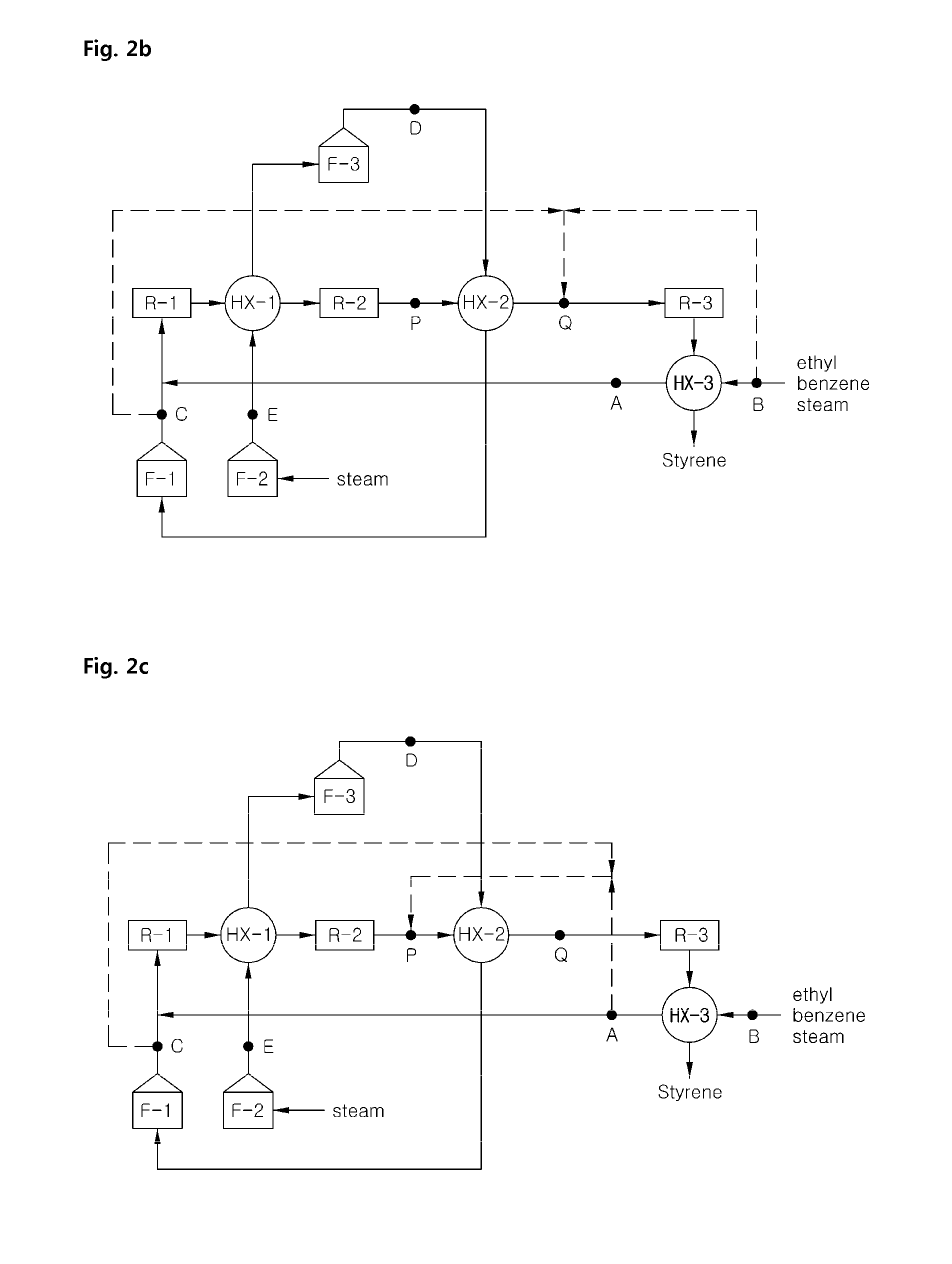

Method for improving productivity and process stability in styrene manufacturing system having multiple reactors connected in series

ActiveUS8802909B2Solution to short lifeReduce catalysisHydrocarbon by hydrogenationHydrocarbonsProduction rateReaction system

A method for improving productivity and process stability in styrene monomer manufacturing system using a reaction system having multiple reactors connected in series, which can prevent destruction of the embedded catalyst and bending of a screen which supports catalyst and achieve homogeneous catalyst inactivation during the reaction by divergence of some portions of the feed containing steam and ethylbenzene and injection thereof into a certain point of the system.

Owner:HANWHA TOTALENERGIES PETROCHEMICAL CO LTD

Energy-saving advanced type impeller suspension type electromagnetic flowmeter for agriculture and forestry irrigation

InactiveCN104782451AEasy to irrigateWide applicabilityWatering devicesCultivating equipmentsImpellerCollocation

Provided is an energy-saving advanced type impeller suspension type electromagnetic flowmeter for agriculture and forestry irrigation. The energy-saving advanced type impeller suspension type electromagnetic flowmeter for agriculture and forestry irrigation comprises an electromagnetic flowmeter and circuit of a novel energy-saving impeller suspension non-shaft support, and further comprises a novel flow adjustable water dropper, a novel 360-degree shower nozzle, a connector capable of finely adjusting the size and screw pitch of a thread ring, an electromagnetic flowmeter body, and interfaces between an energy-saving type sprinkler timer with multiple interfaces and a water knockout drum, optional collocation is easy, and the components are matched for the water-saving method and used for the garden efficient irrigation energy and water conservation. The advanced type rolling assisting enables one-stage rotation of impellers to be changed into multi-stage rotation between inner pipes of an outer shell, so that the relative linear velocity of every two adjacent rotary pairs is reduced. A rolling body has the magnetism used for magnetic suspension, the magnetic induction impellers are matched, a support, having resistance on fluid flow, of six rods of a conventional center shaft is omitted, the magnetic suspension and advanced type rolling assisting are used, the resistance of the flowmeter to the fluid flow is smaller, less idle work is consumed, friction is smaller, and accuracy is higher.

Owner:NINGBO DAYE GARDEN IND

High-performance variable multi-blade pump

ActiveCN109185125ALarge displacementIncrease pressureRotary piston pumpsRotary piston liquid enginesMechanical engineeringEngineering

Owner:ZHEJIANG UNIV

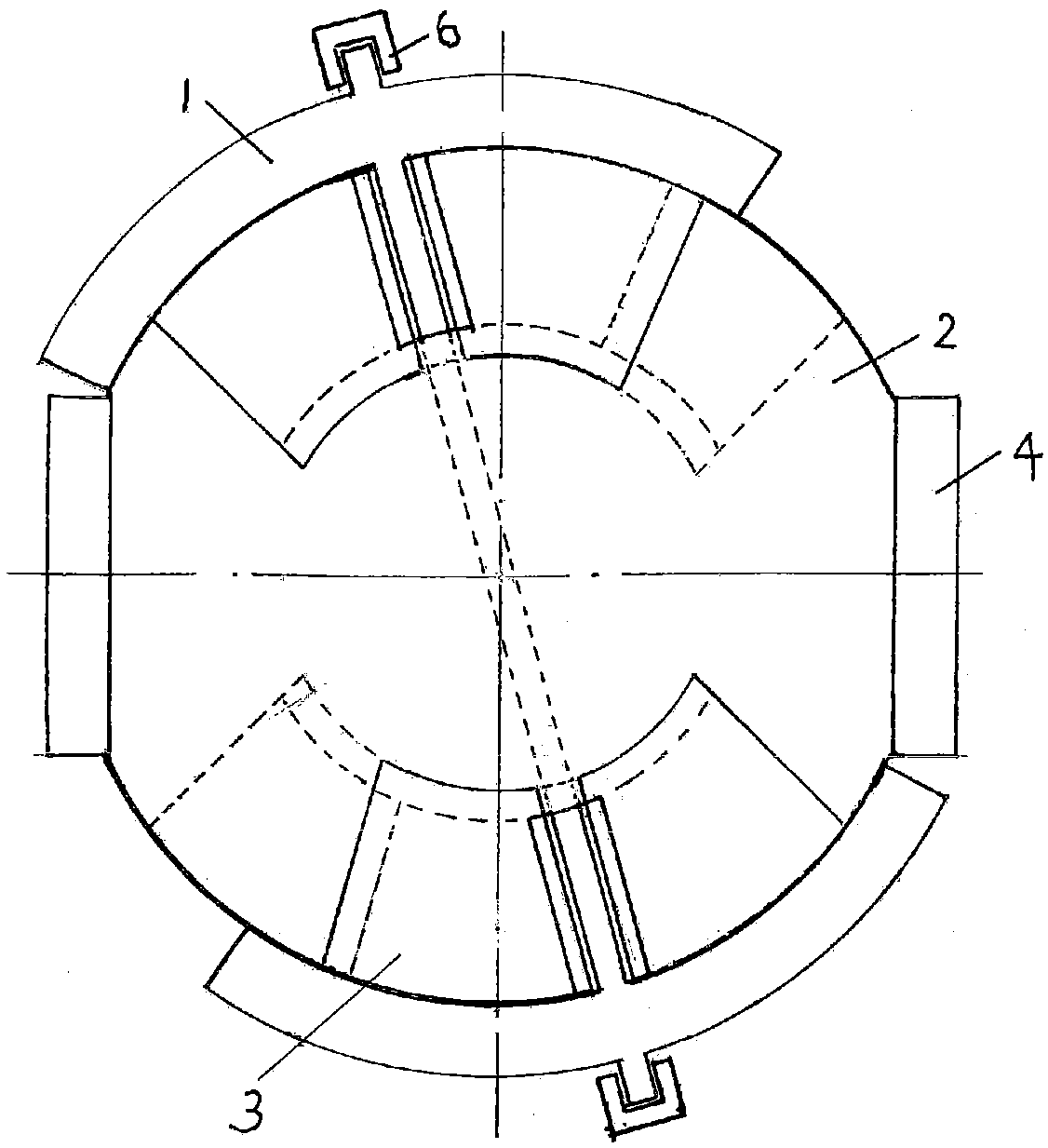

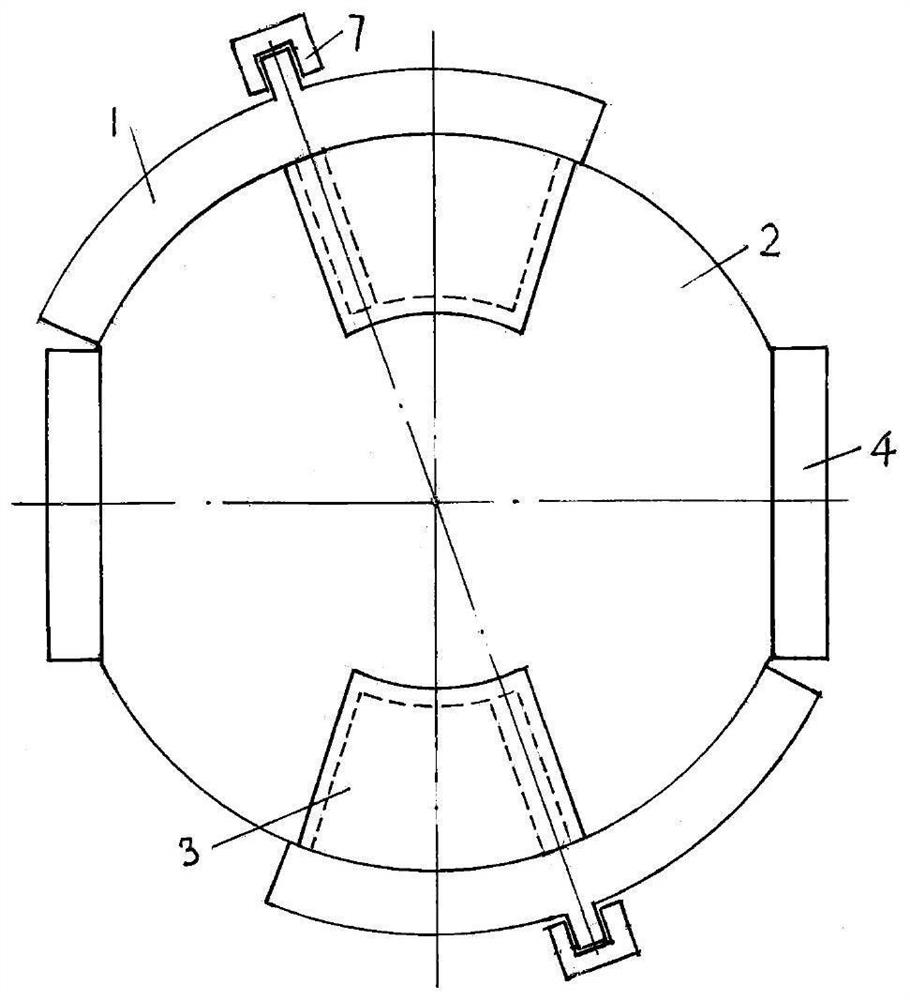

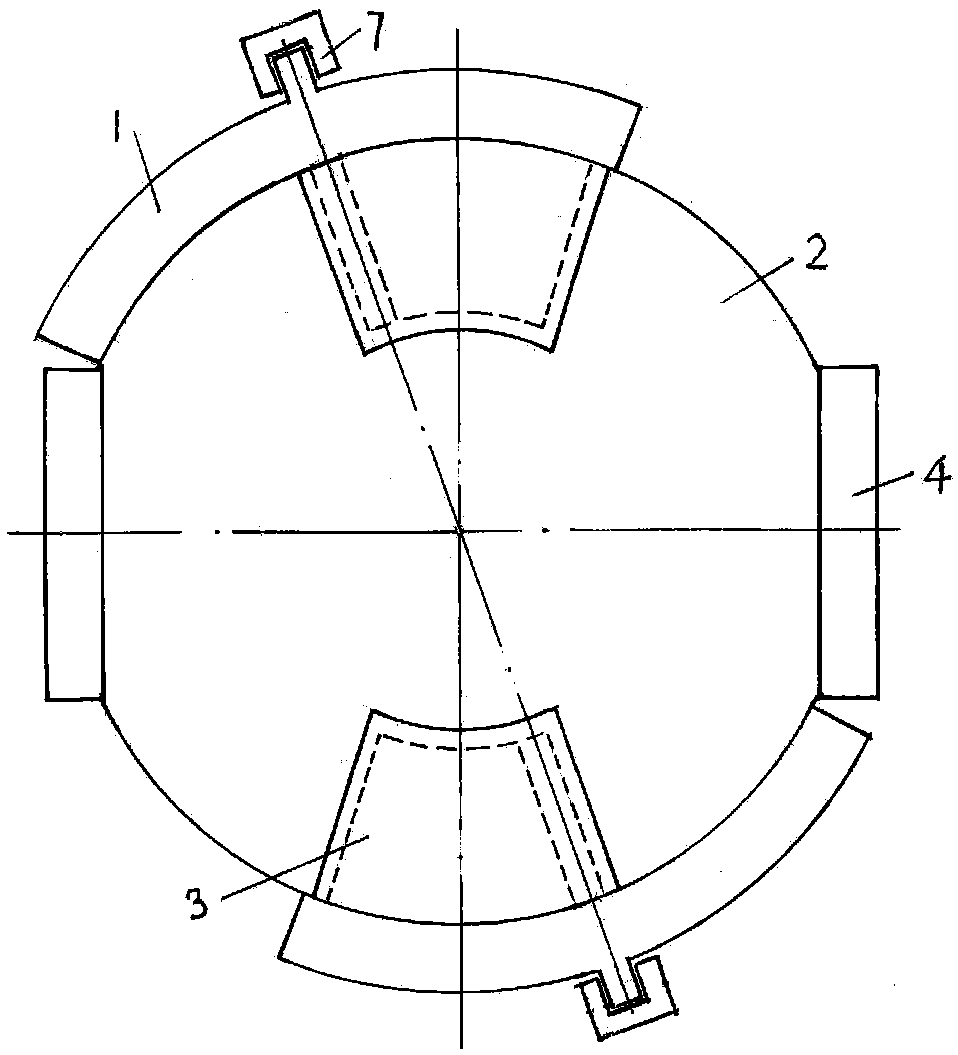

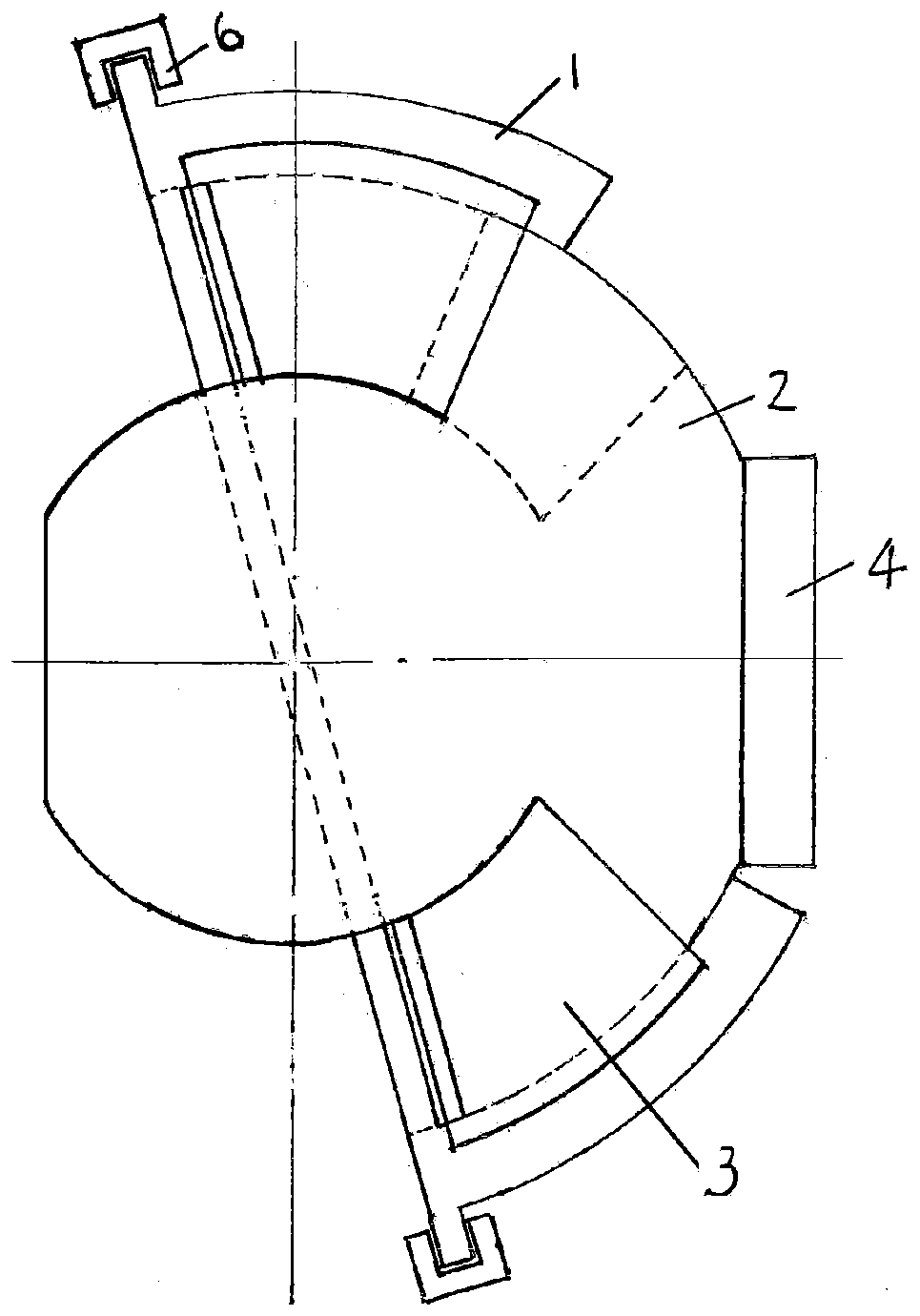

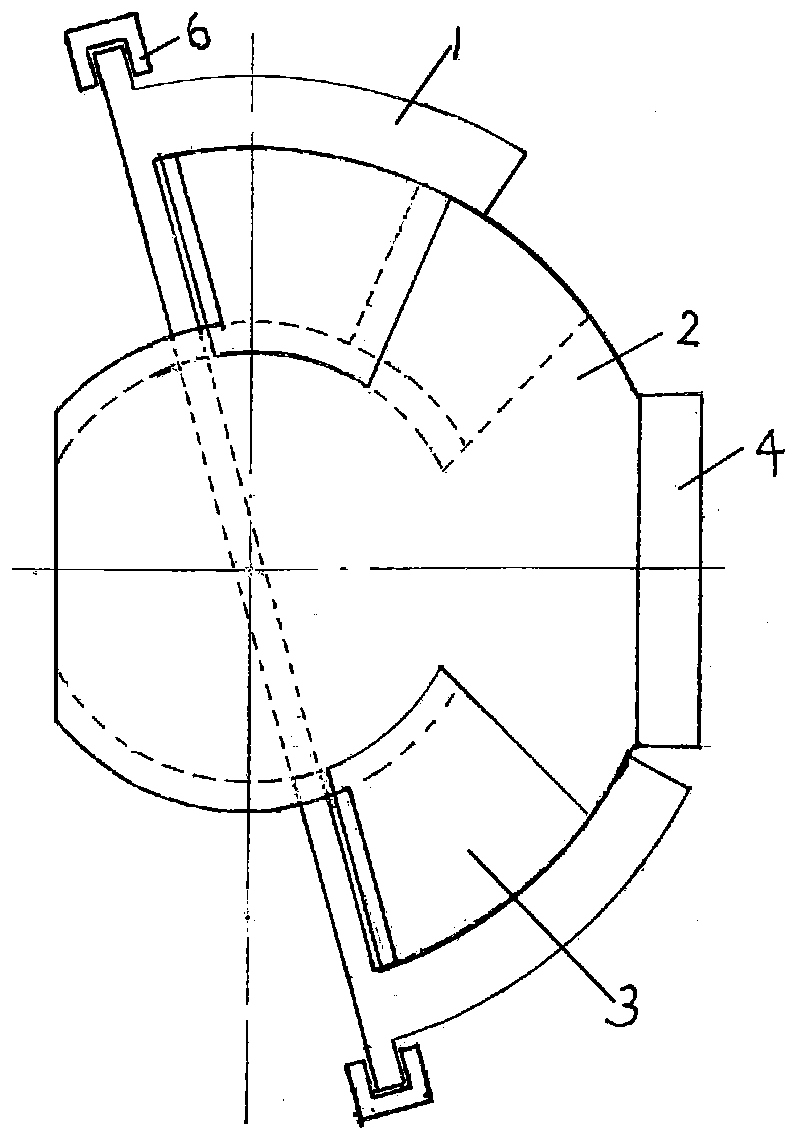

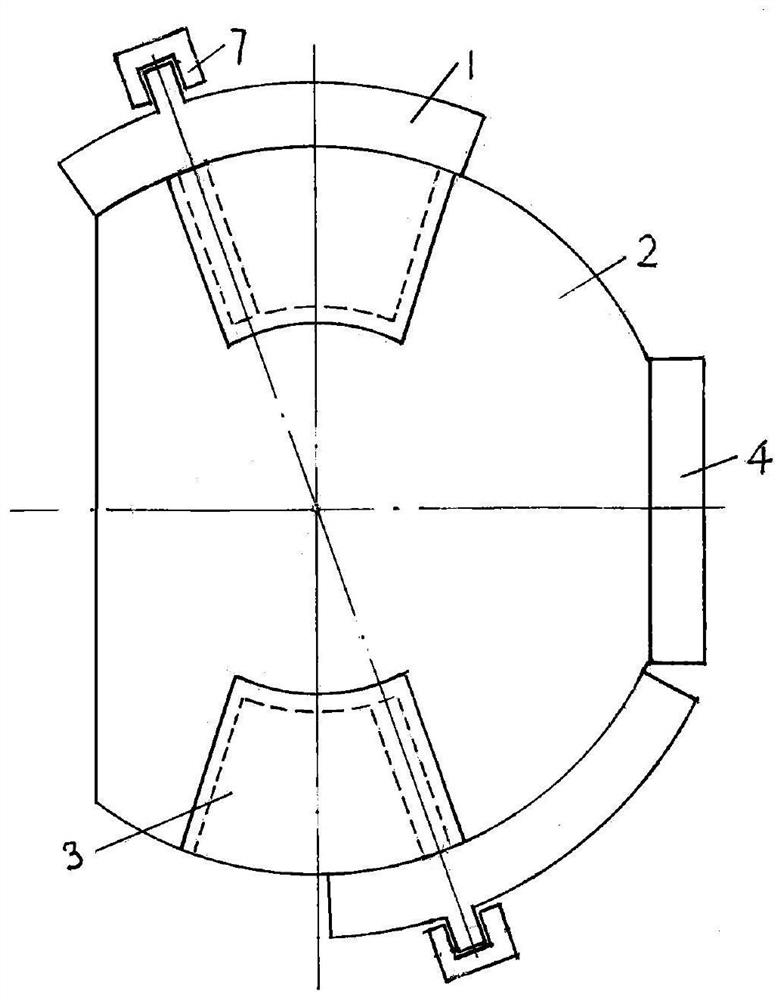

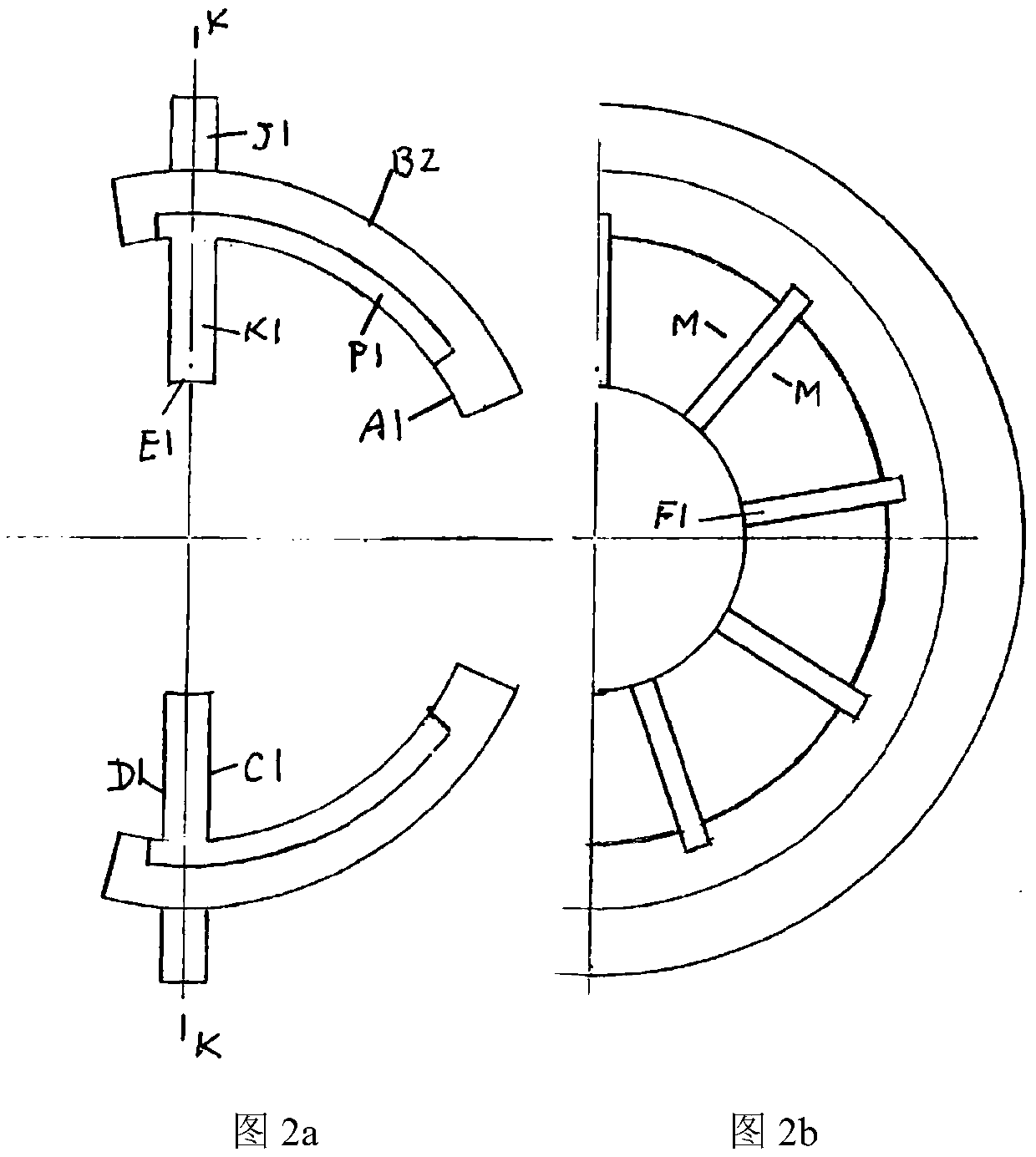

High-performance multi-blade motor

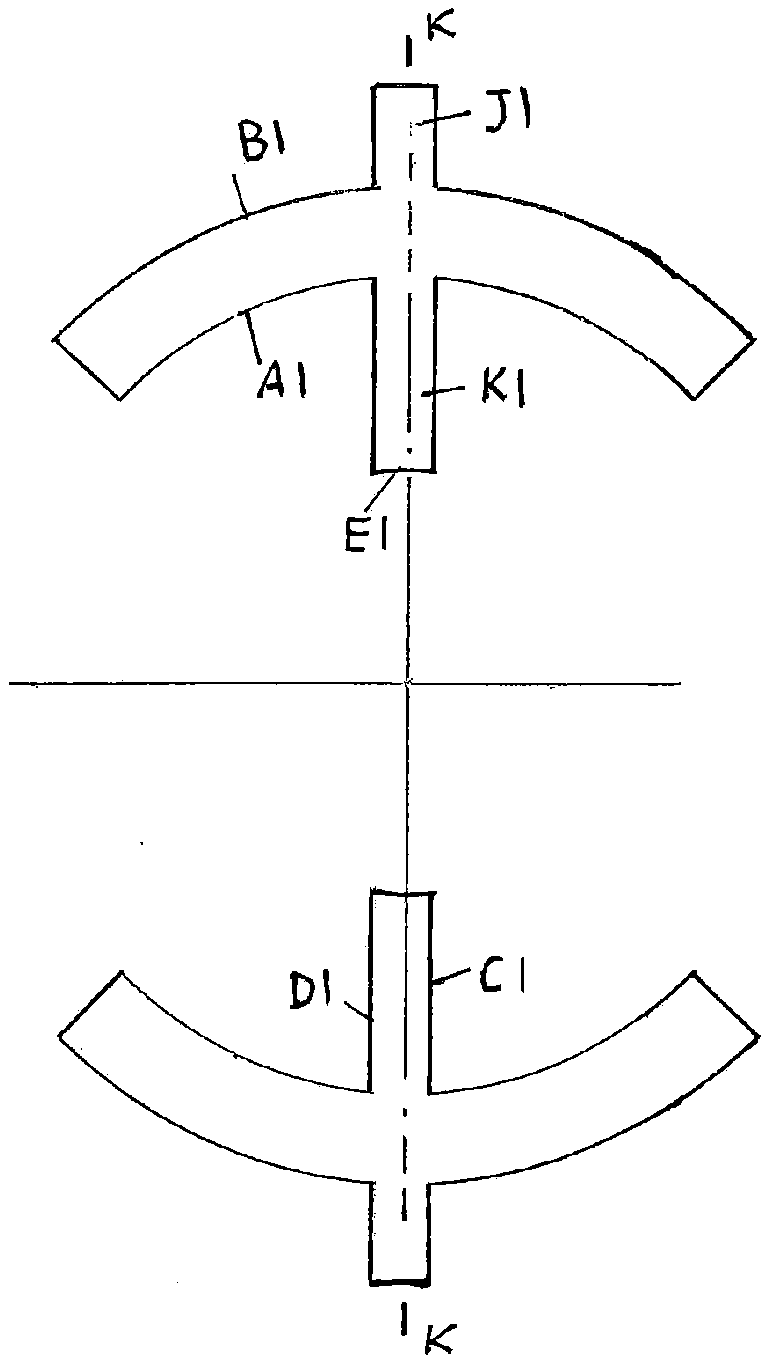

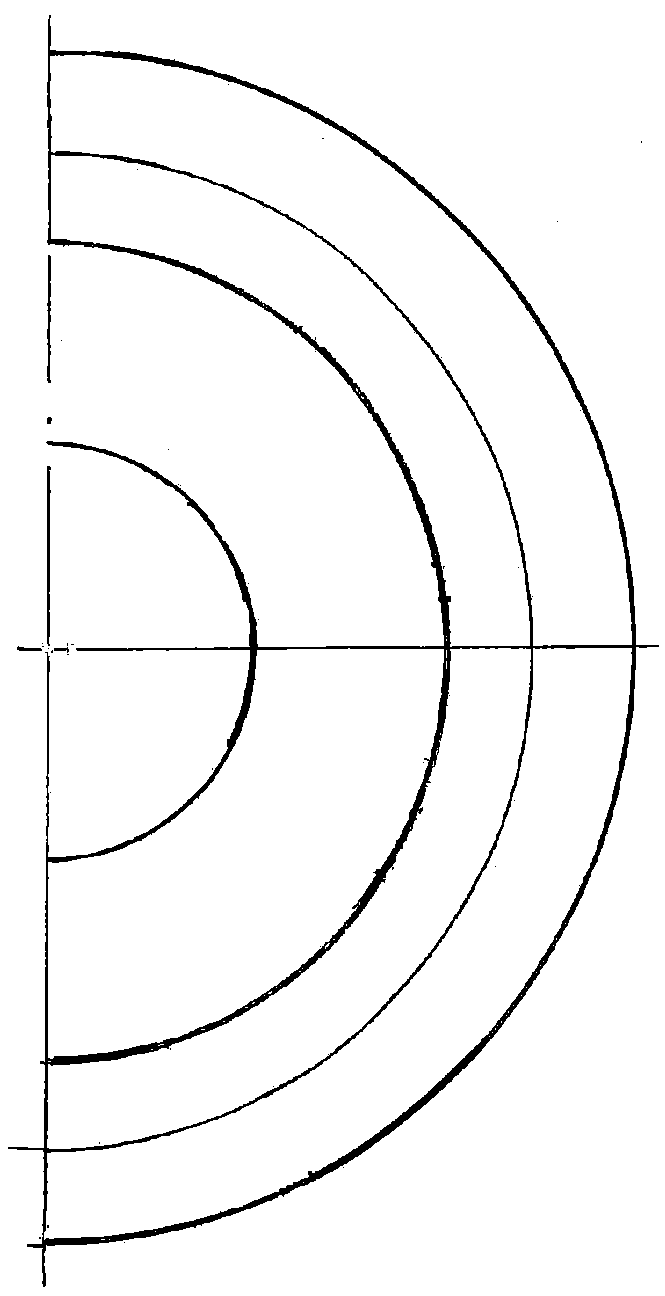

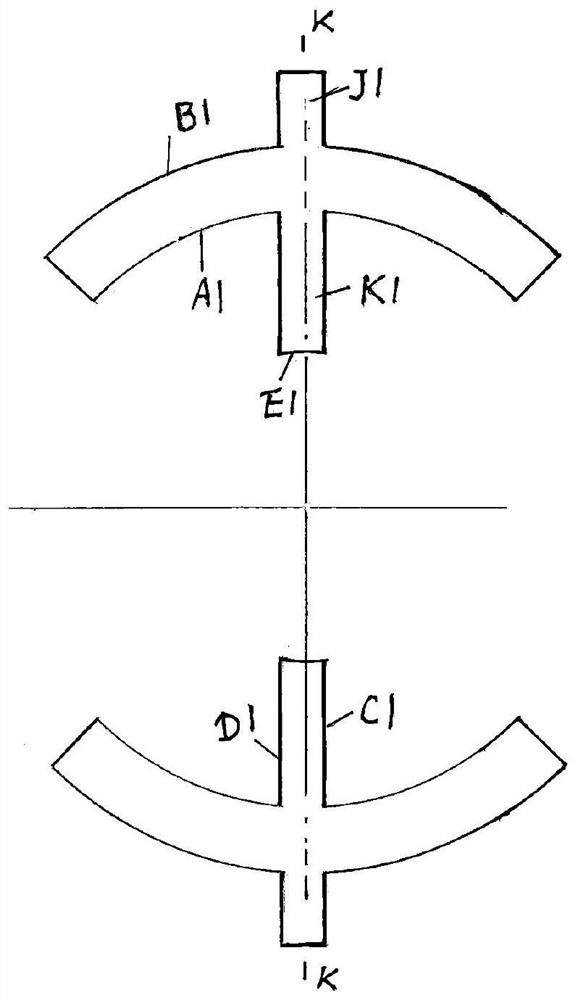

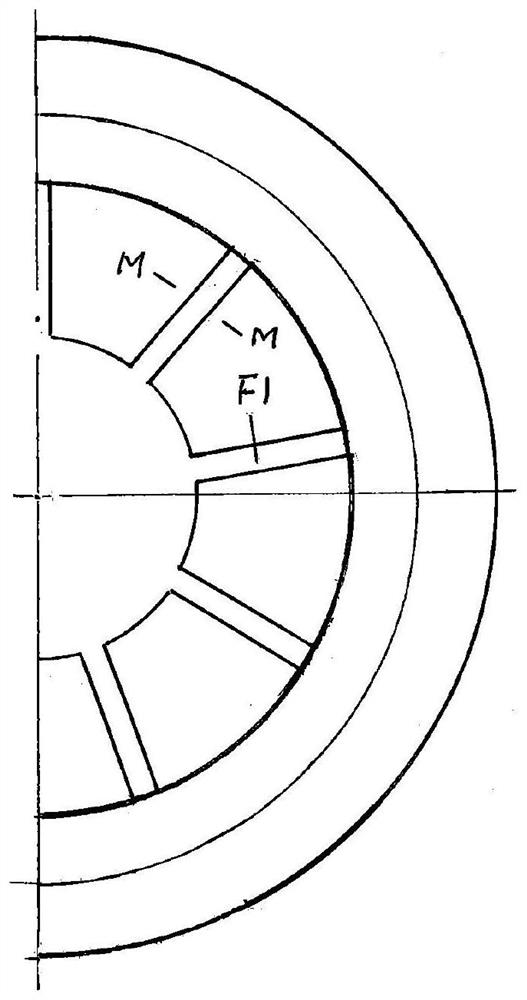

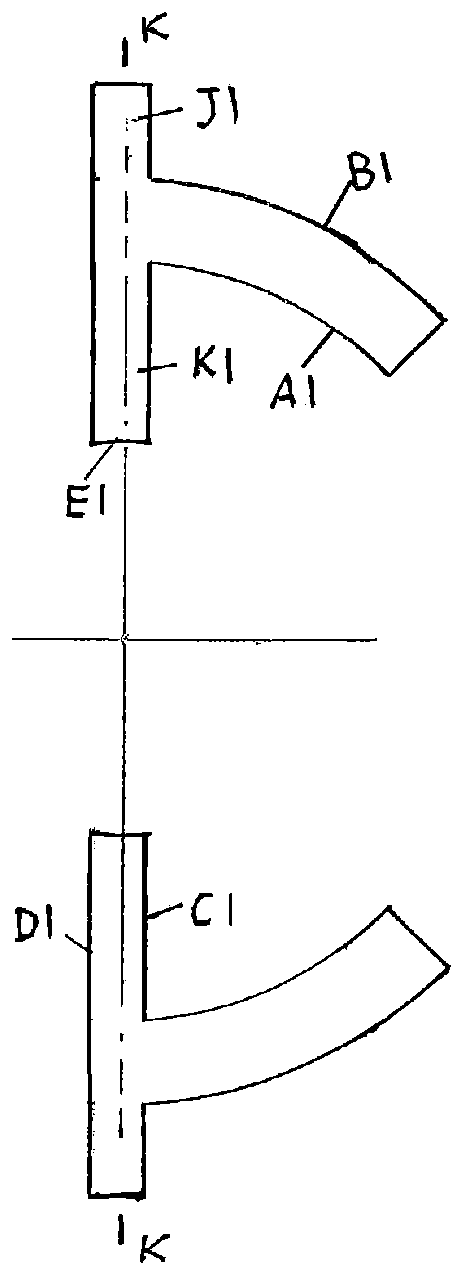

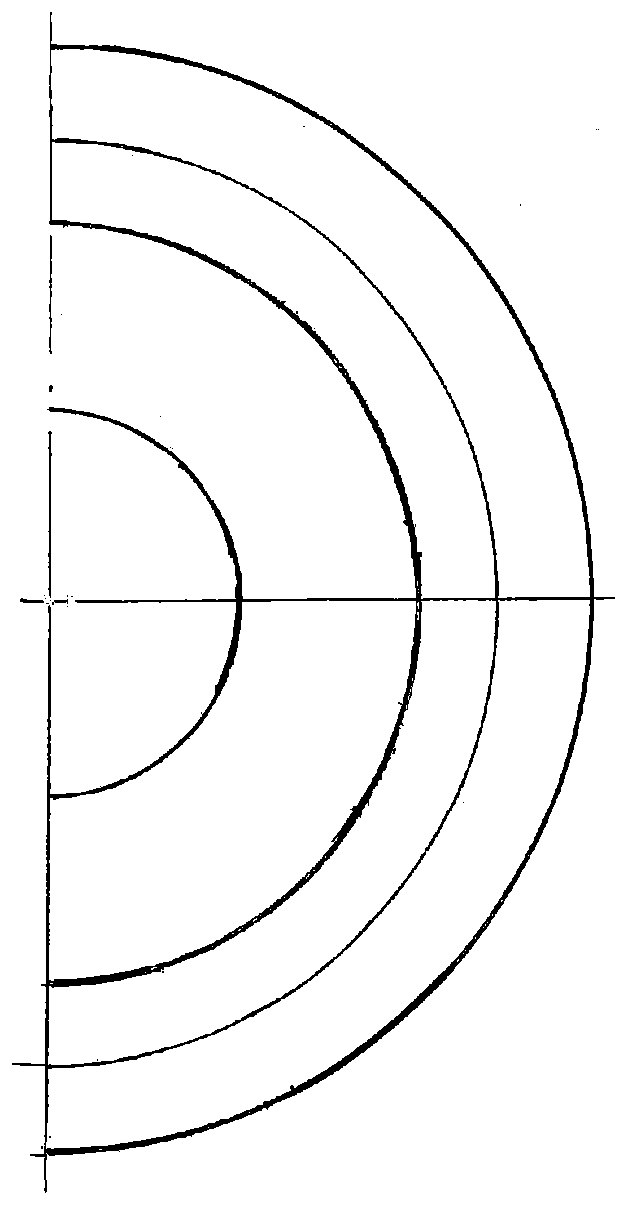

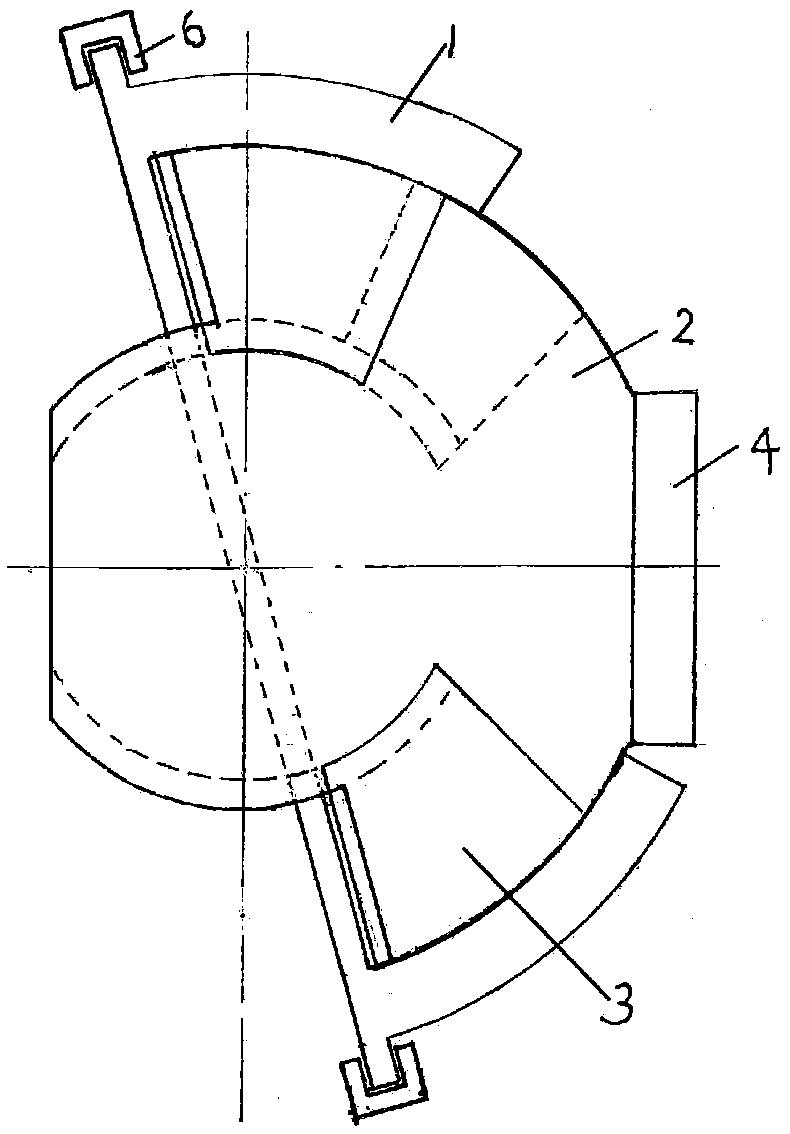

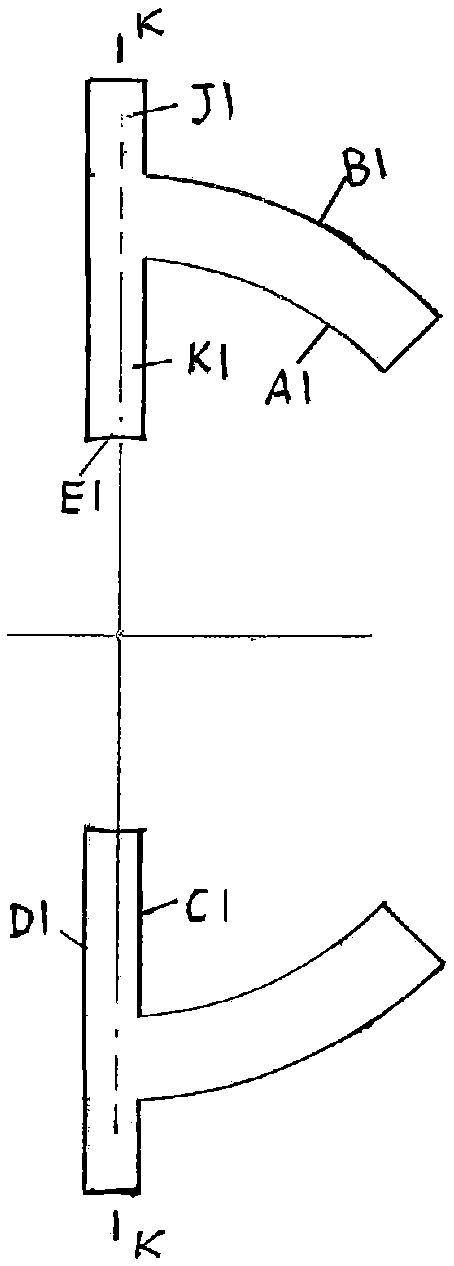

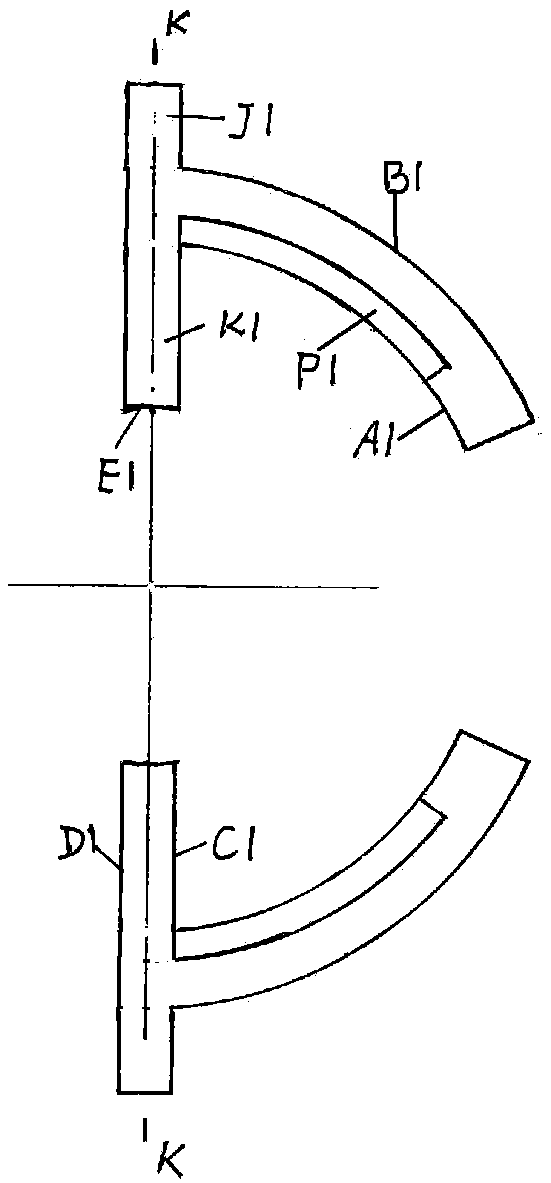

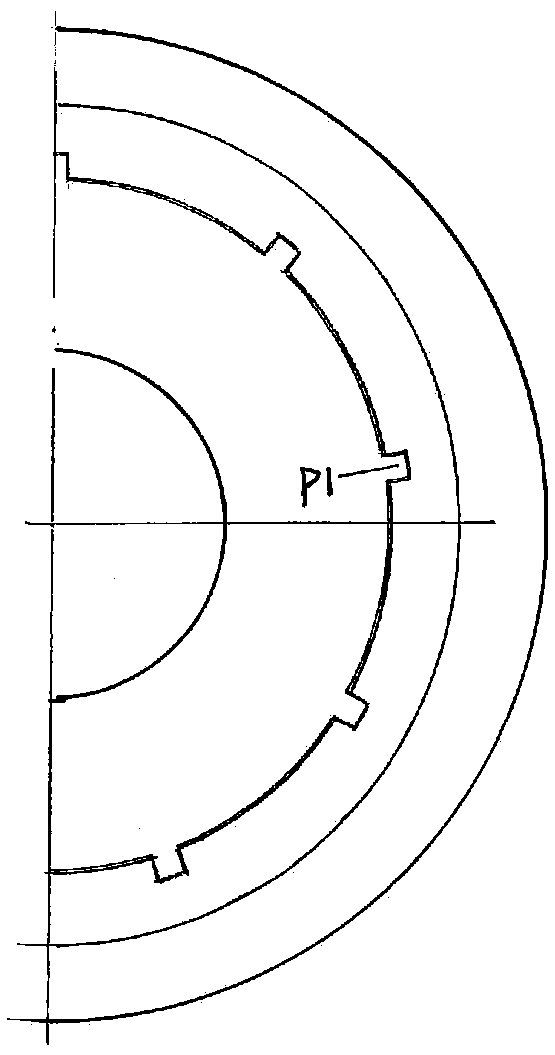

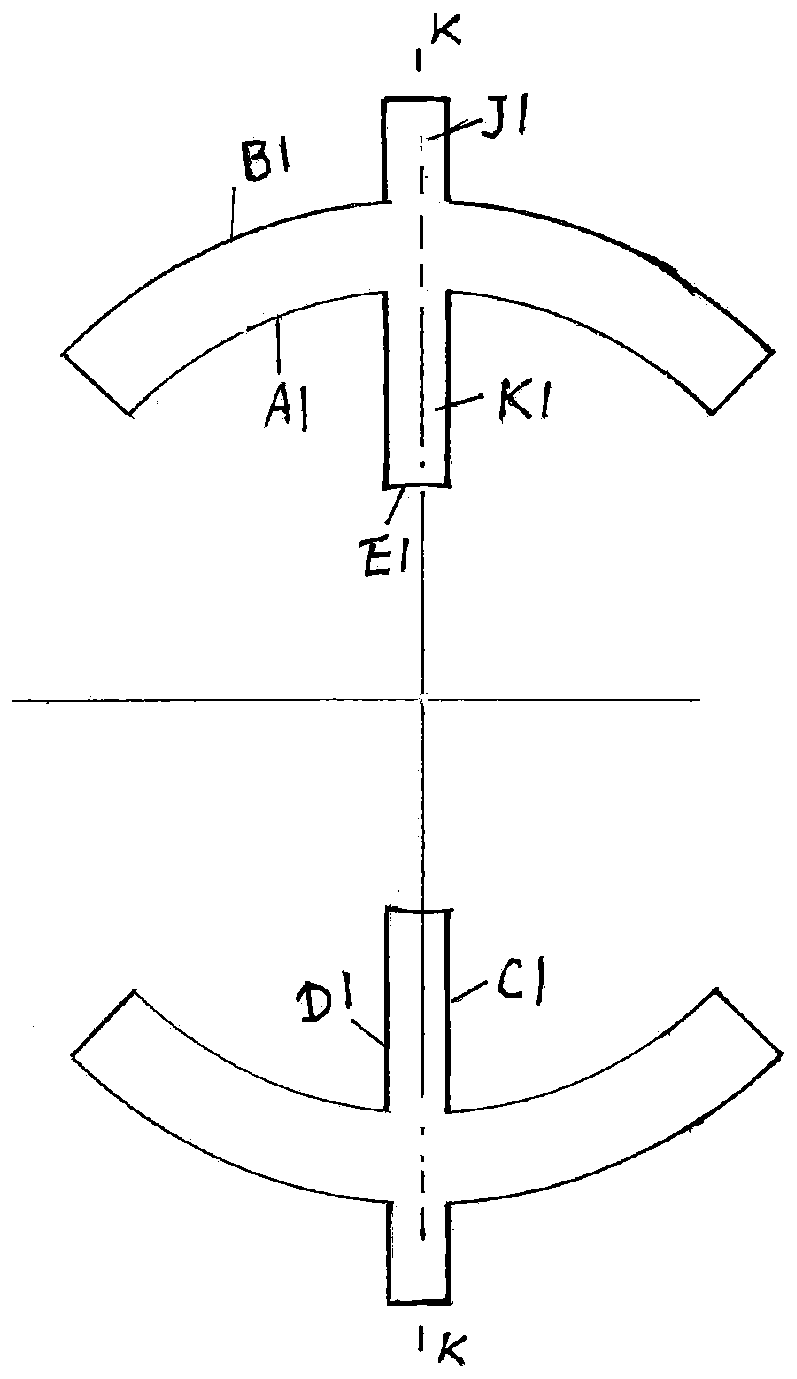

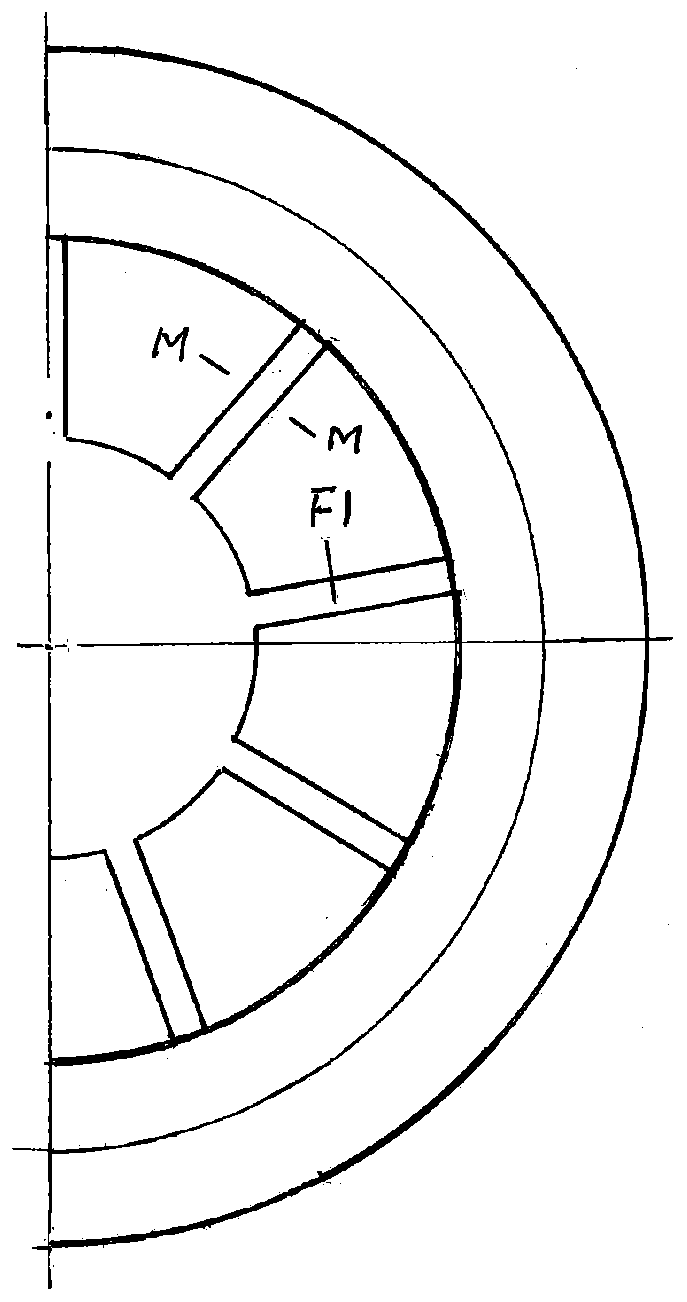

The invention discloses a high-performance multi-blade motor. The high-performance multi-blade motor comprises a shell, a rotor, blades and a sliding shoe; the shell covers the outer part of the rotor, and a circle of circular ring K1 is arranged in the middle of the inner wall of the shell in the direction of the sphere center; an annular groove is formed in the middle of the side wall of the rotor, at least three left sliding grooves which are uniformly distributed in the circumferential direction are formed in the left side surface of the annular groove, and the right side surface of the annular groove is provided with right sliding grooves which are the same as the left sliding grooves and correspond to the left sliding grooves in a one-to-one correspondence mode; the blades are arranged on the left sliding grooves and the right sliding grooves in a sliding mode, the circular ring K1 is clamped between blades of the left sliding grooves and the right sliding grooves, the outer endsof the blades are mounted on the sliding shoe, and the sliding shoe is connected to the side surface of the circular ring K1 in an abutting mode; a containing cavity is formed among the two adjacentblades, the surface of the annular groove, the inner wall of the shell and the side wall of the circular ring K1; and the axis of the rotor and the axis of the shell do not coincide. According to high-pressure oil drives the volume of the containing cavity to enlarge and reduce periodically, so that the rotor are drive to rotate, and therefore the power output is realized.

Owner:ZHEJIANG UNIV

Method for inspecting optical information recording medium, inspection apparatus, optical information recording medium and recording method

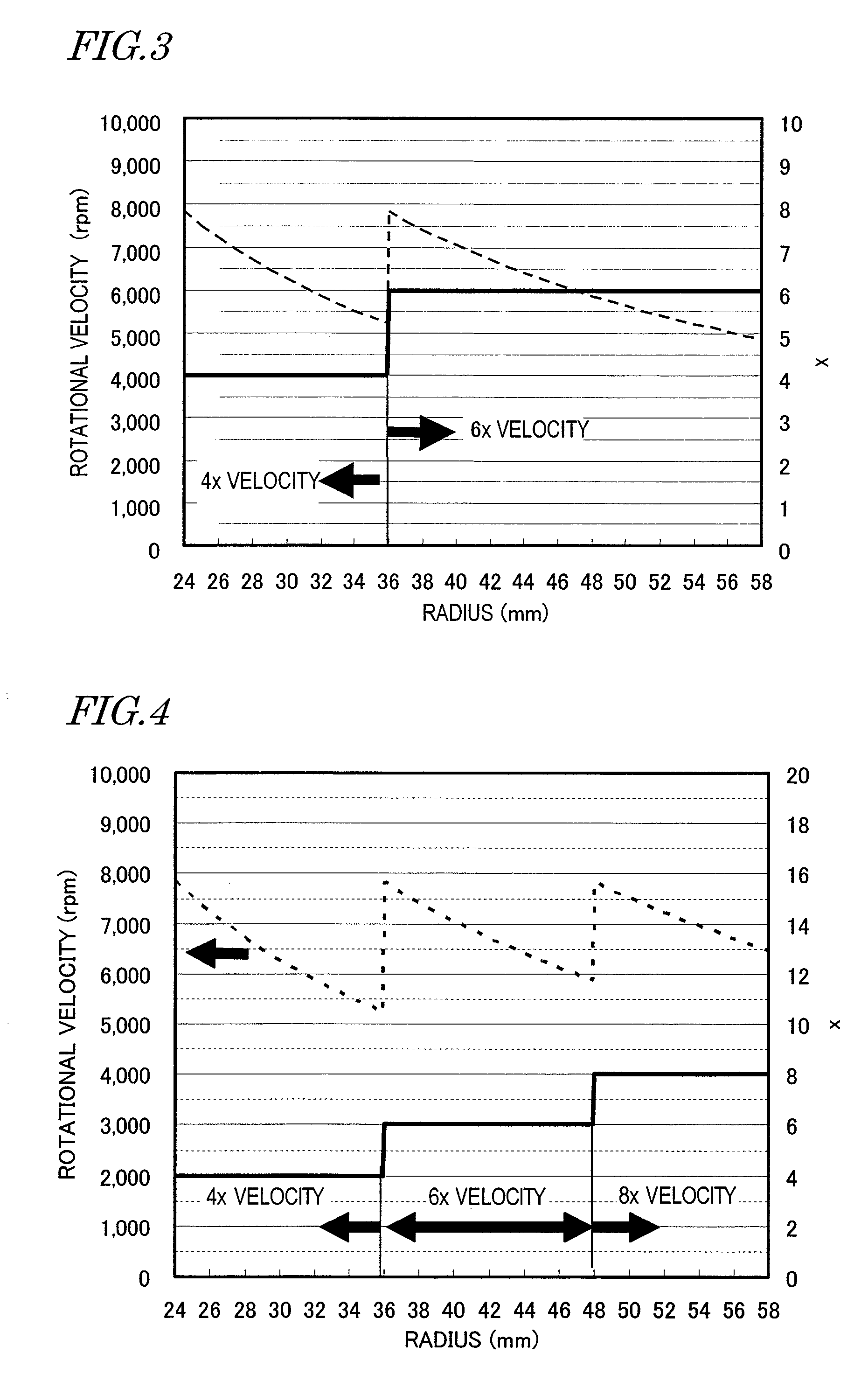

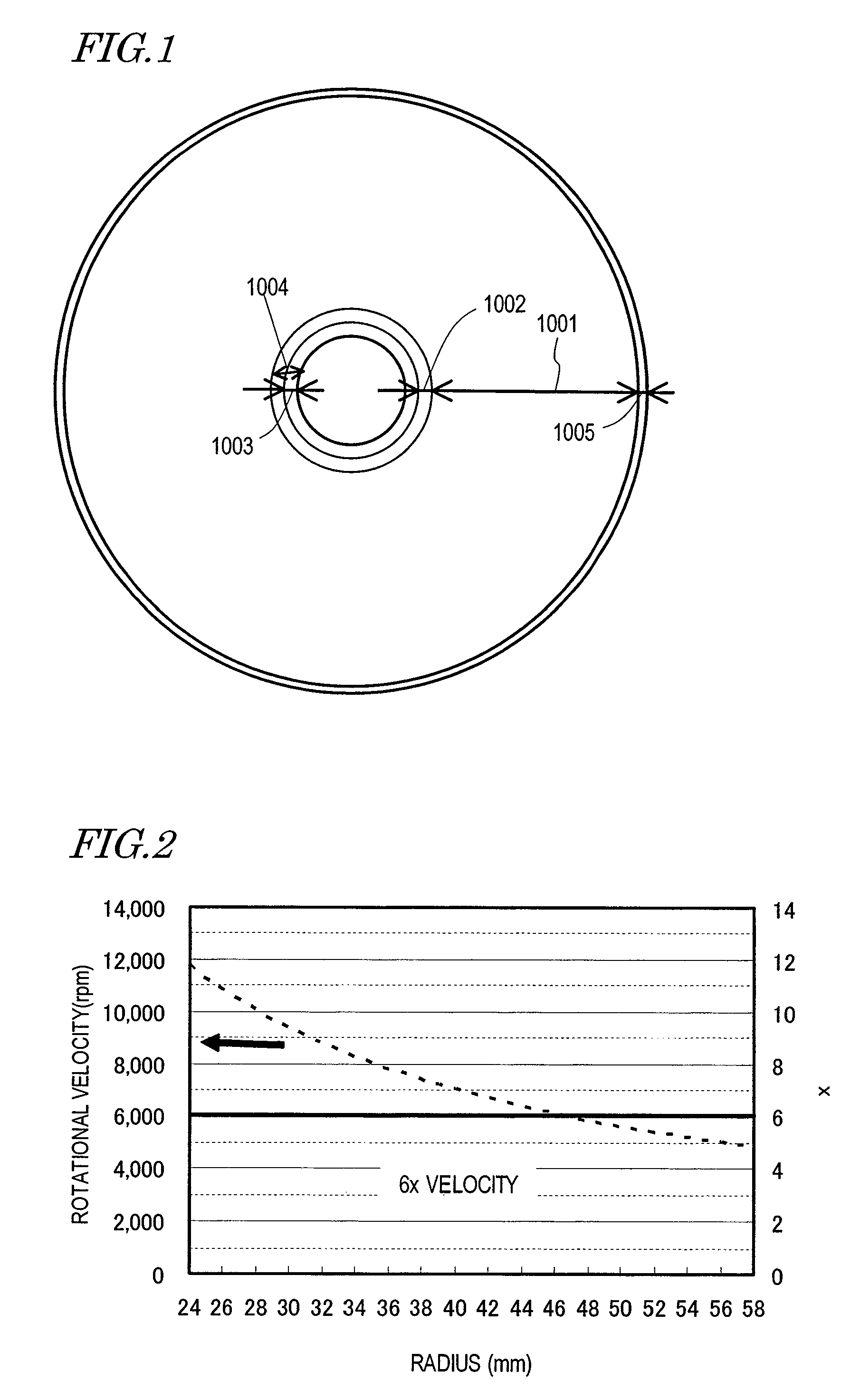

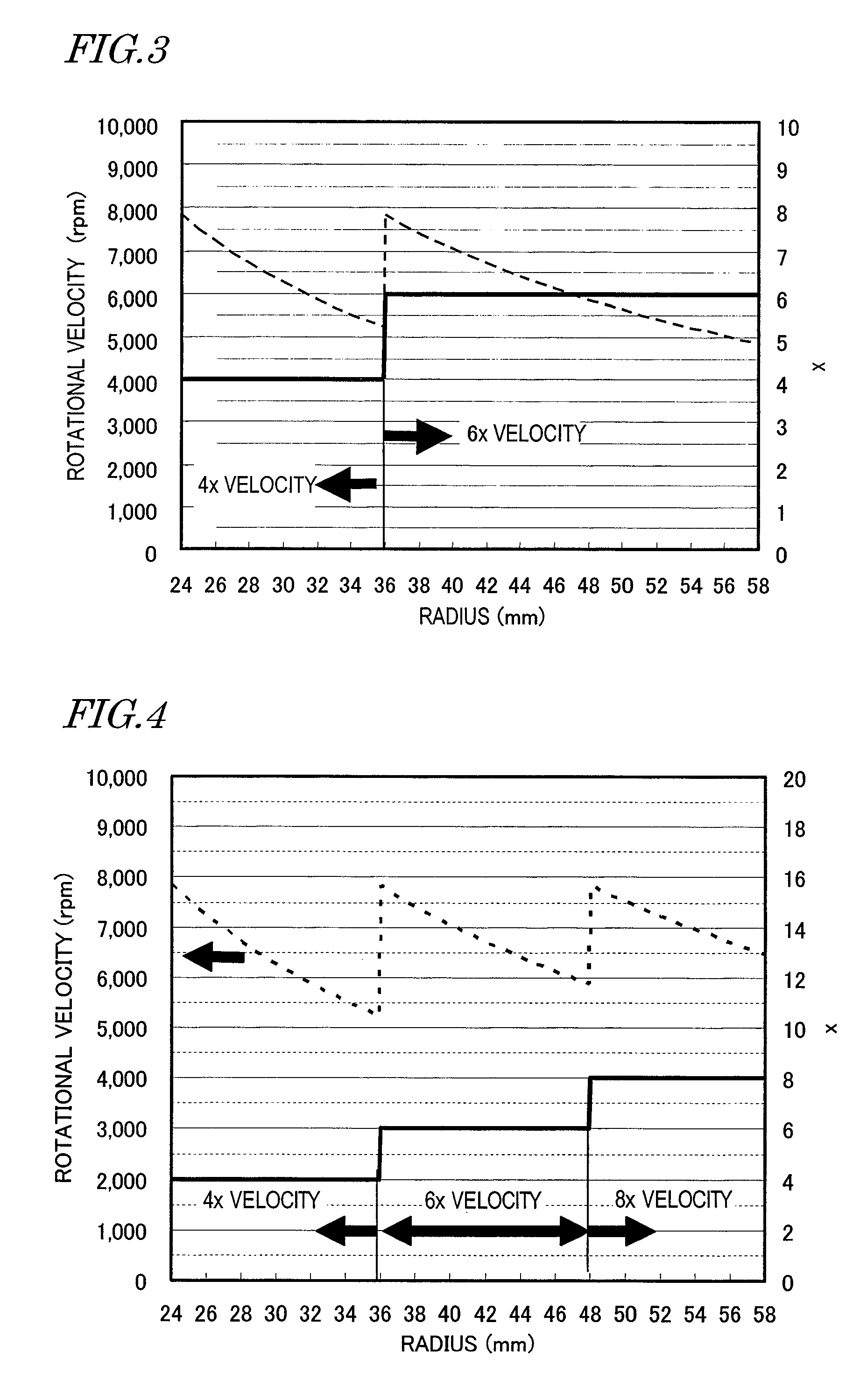

ActiveUS20100118673A1Relatively low linear speedIncrease chanceCombination recordingOptical discsConstant linear velocityComputational physics

A method for inspecting an optical information storage medium includes the steps of: irradiating the storage medium with a laser beam and rotating the medium by a constant linear velocity control technique by reference to the radial location at which the laser beam forms a spot on the medium; changing the rotational velocities according to the radial location on the medium between at least two linear velocities that include a first linear velocity Lv1 and a second linear velocity Lv2 higher than the first linear velocity Lv1; generating a focus error signal and / or a tracking error signal based on the light reflected from the medium; performing a focus control and / or a tracking control on the laser beam that irradiates the medium based on the focus and / or tracking error signal(s); and passing the branched outputs of control loops for the focus and / or tracking error signal(s) through predetermined types of frequency band-elimination filters for the focus and / or tracking error signal(s) to obtain residual errors of the focus and / or tracking error signal(s) and comparing the residual errors to predetermined reference values.

Owner:PANASONIC CORP

Method for inspecting optical information recording medium, inspection apparatus, optical information recording medium and recording method

ActiveUS8018808B2Relatively low linear speedIncrease chanceCombination recordingModification of read/write signalsConstant linear velocityComputational physics

Owner:PANASONIC CORP

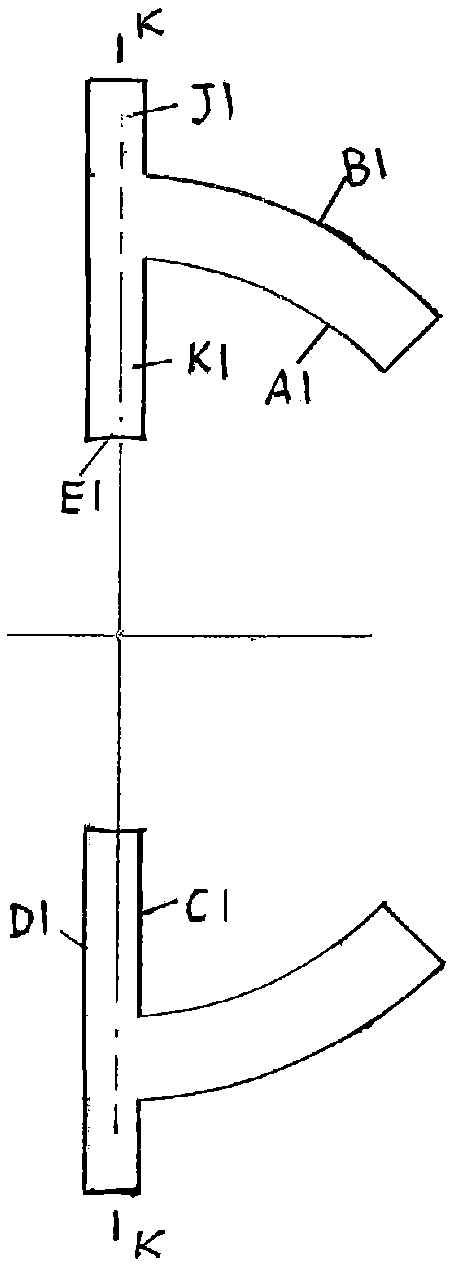

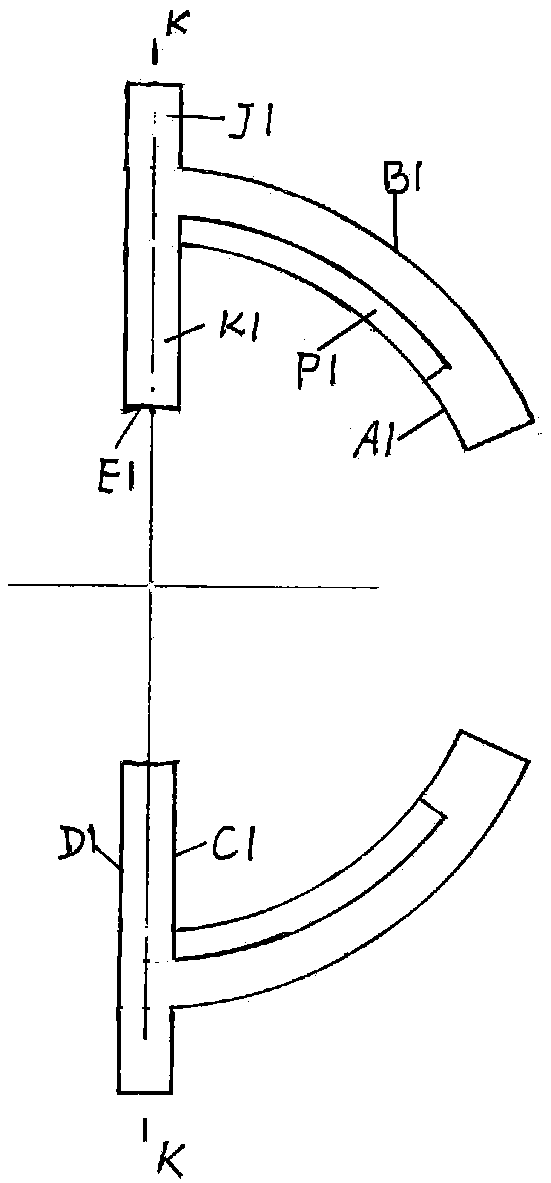

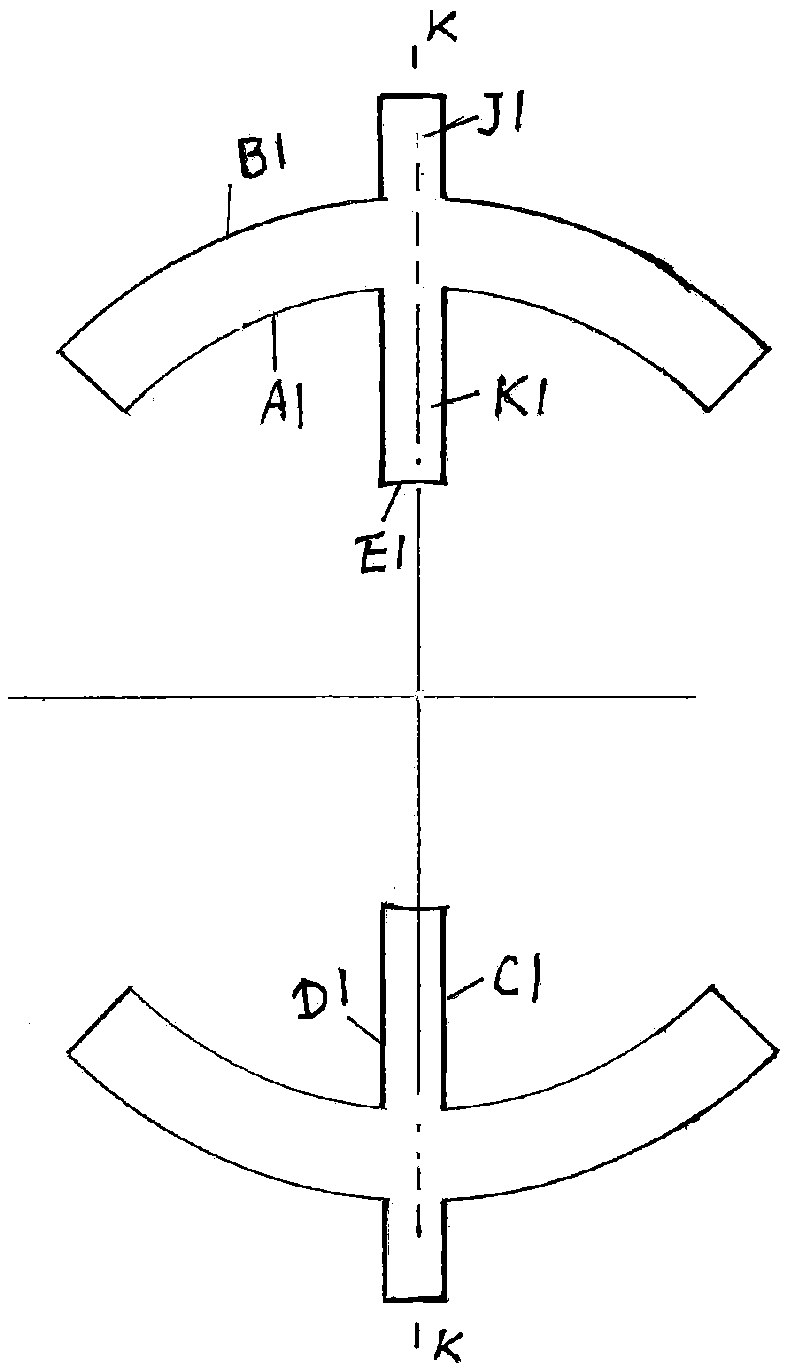

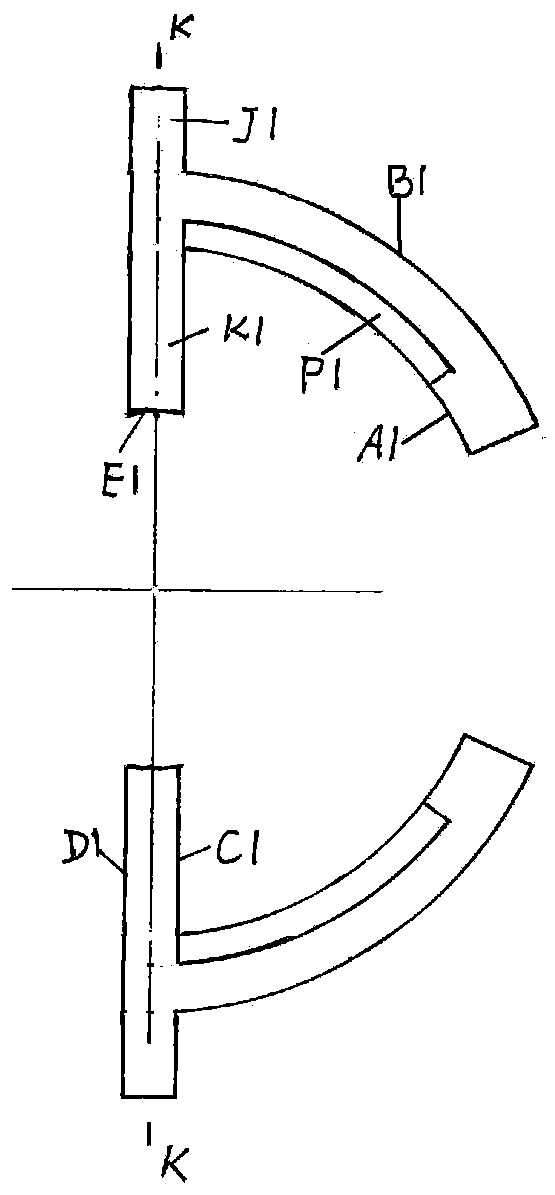

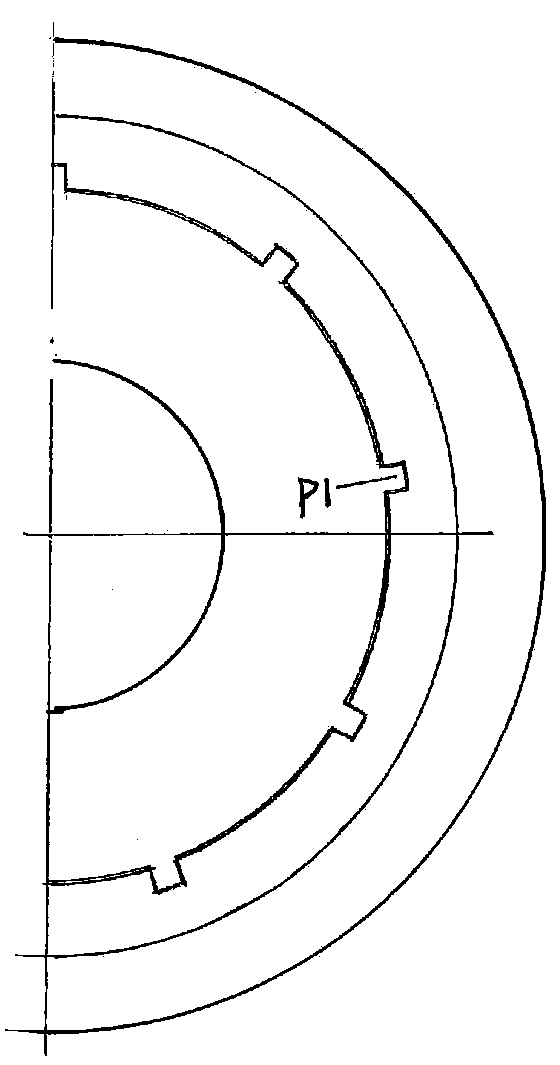

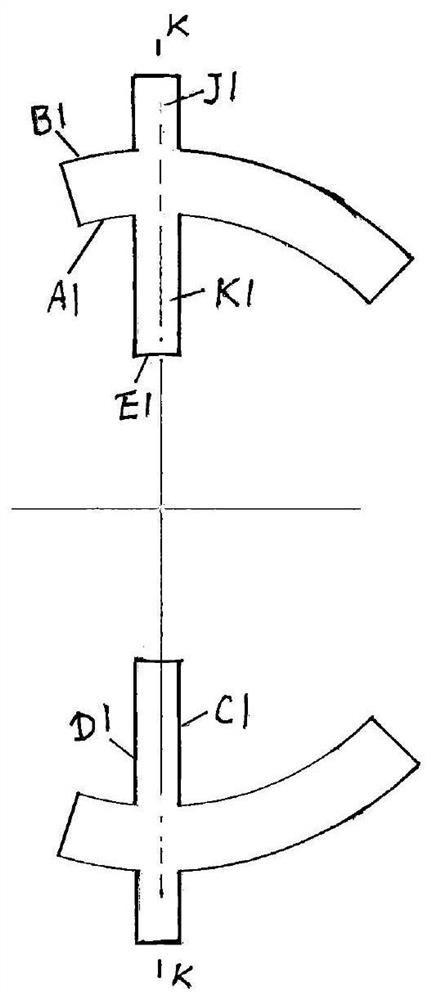

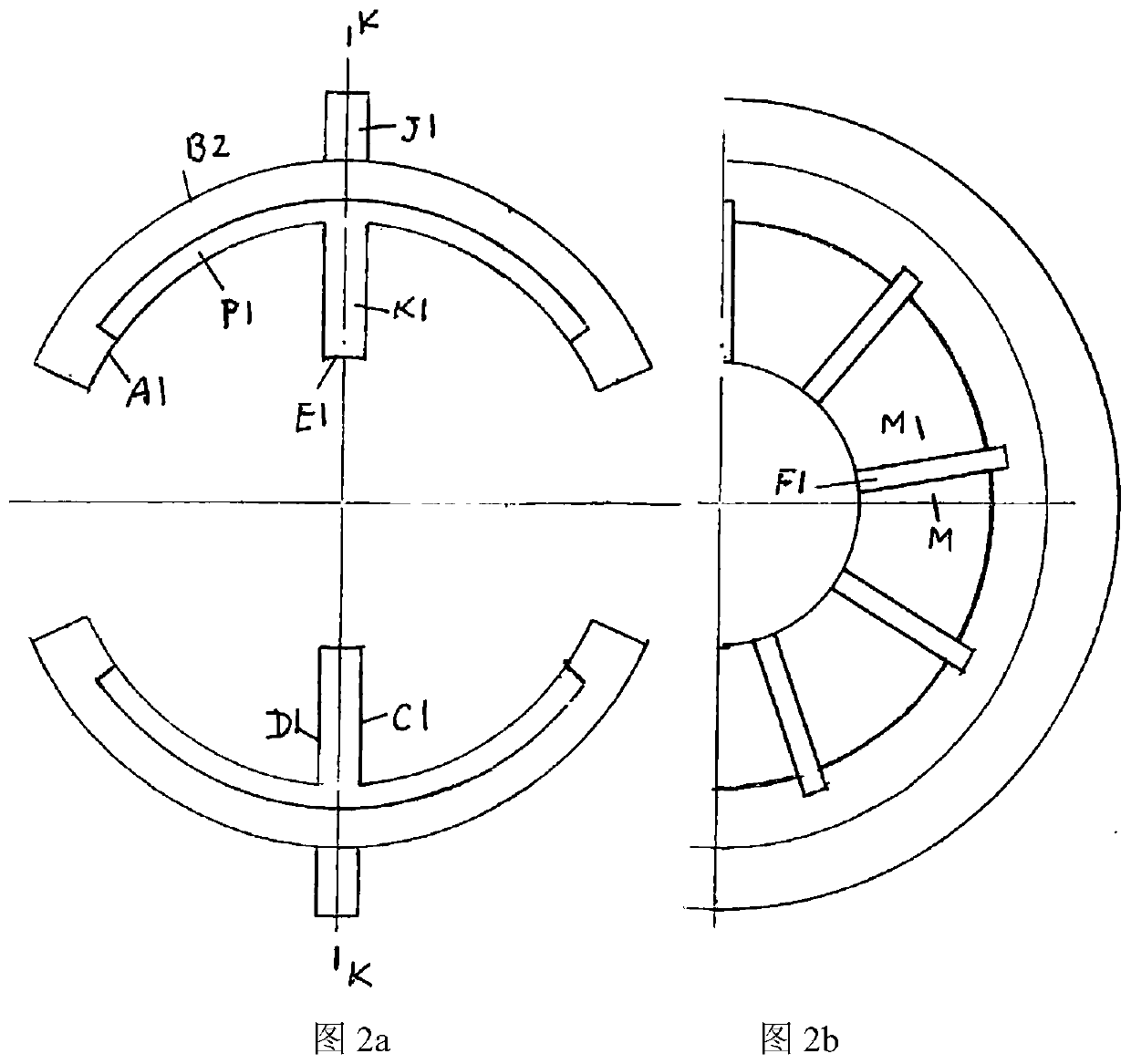

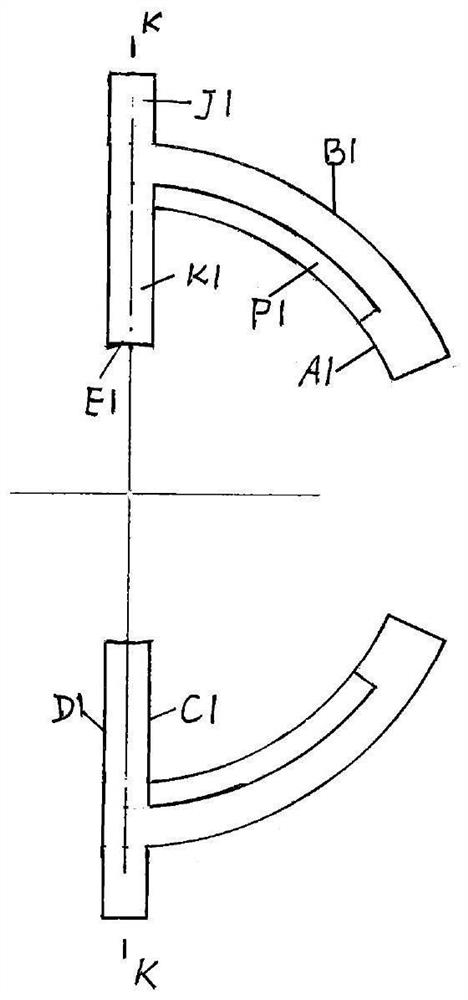

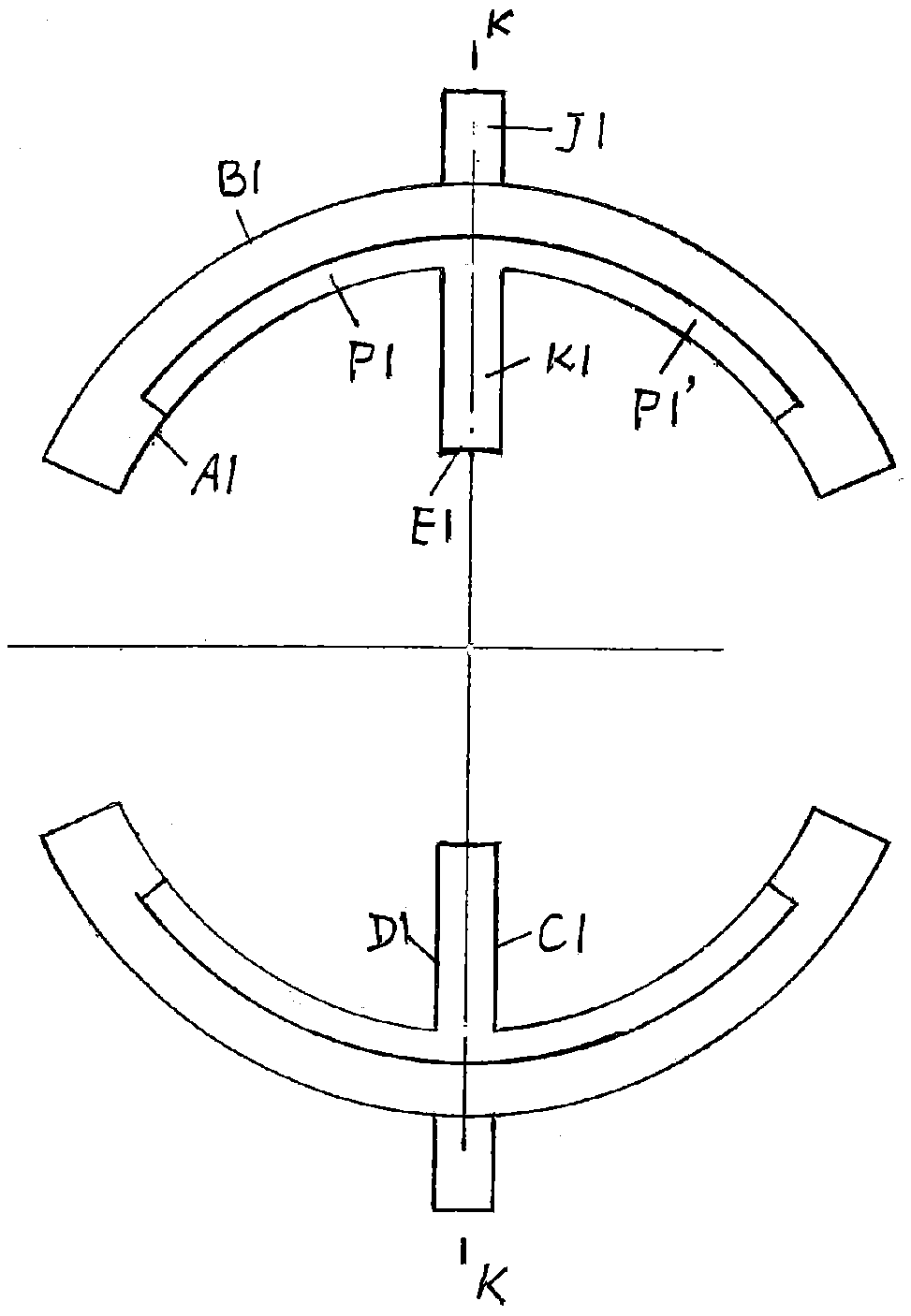

High-performance vane hydraulic motor

The invention discloses a high-performance vane hydraulic motor. The high-performance vane hydraulic motor comprises a housing, rotors and vanes, the rotors are covered with the housing, the housing is in a hemispheric shape, a lap of circular ring K1 is arranged on the end face of the housing in an inward extending mode, the vanes are mounted on locating grooves, sliding grooves corresponding tothe locating grooves in an one-to-one mode are formed in the rotors, the vanes on the locating grooves are further arranged on the sliding grooves in a sliding mode and are sealed through sealing elements, the outer ends of the vanes are mounted on sliding shoes, the sliding shoes abut against the side face of the circular ring K1, a containing cavity is formed among every two adjacent vanes, thesurface of a circular groove, the inner wall of the housing and the side wall of the circular ring K1, oil ports are formed in the rotors and are the same as the containing cavities in number, one oilport communicates with the corresponding containing cavity, the two ends of the rotors are connected with oil distribution blocks, a convex circular ring J1 is arranged on the outer wall of the housing, the convex circular ring J1 is arranged in a guide groove of a guide block, and the axis of the rotors and the axis of the housing do not coincide. The volume of a high-pressure oil driving chamber is increased or decreased periodically, thus the rotors are driven to rotate, and power output is realized.

Owner:ZHEJIANG UNIV

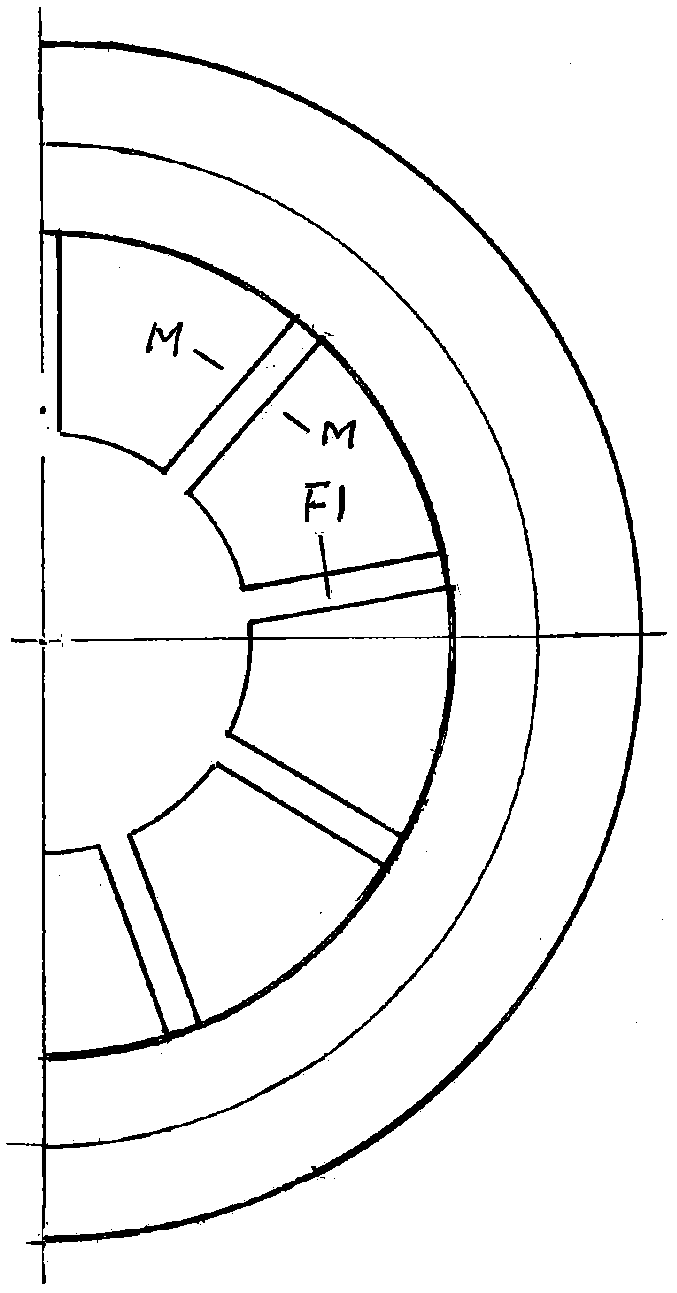

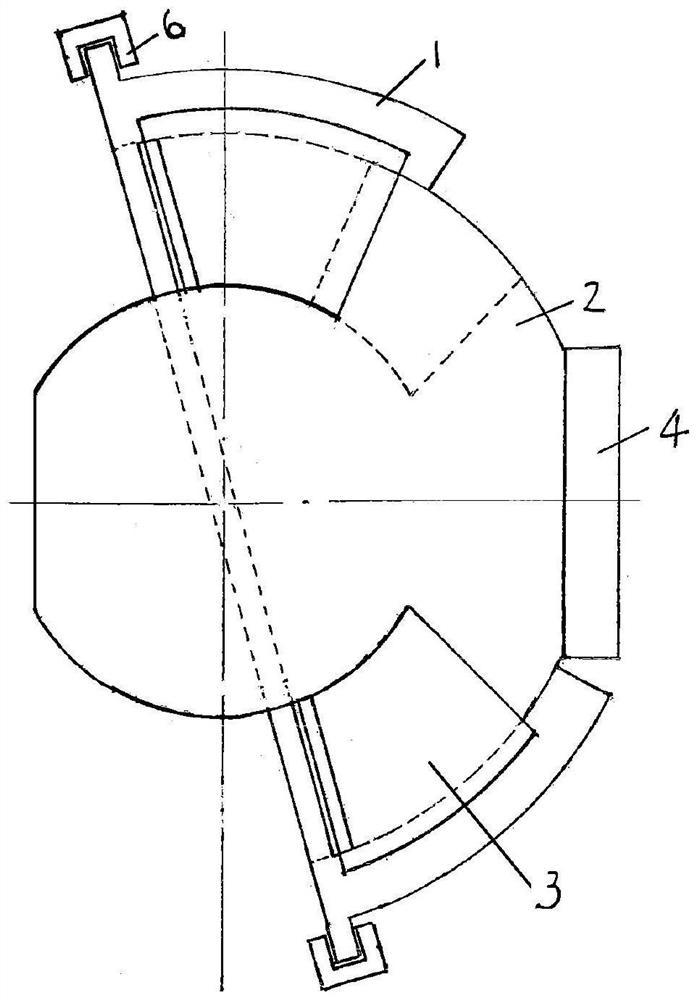

High performance multi-vane pump

ActiveCN109469610BLarge displacementIncrease pressureRotary piston pumpsRotary piston liquid enginesOil distributionPhysics

The invention provides a high-performance multi-blade pump, which includes a casing, a rotor, blades, an oil distribution block and a guide block. A chute is formed between the two shifting blocks, and a ring groove is opened at the center of the side wall of the rotor. In the ring groove, there are positioning slots with the same number as the shifting blocks evenly along the circumferential direction, and a blade is installed on each positioning slot. A cavity is formed between two adjacent blades, the surface of the ring groove and the inner wall of the housing. The blades are inserted into the chute, so that each cavity has a shifting block, and the shifting block divides the cavity into the first chamber and the second chamber. Two chambers; both ends of the rotor are connected with oil distribution blocks; the convex ring J1 on the outer wall of the housing is placed in the guide groove of the guide block; the axis of the rotor and the axis of the housing do not coincide; when the rotor rotates, dial The block slides back and forth between the two blades, so that the volumes of the first chamber and the second chamber change periodically, and the changes of the two are just opposite.

Owner:ZHEJIANG UNIV

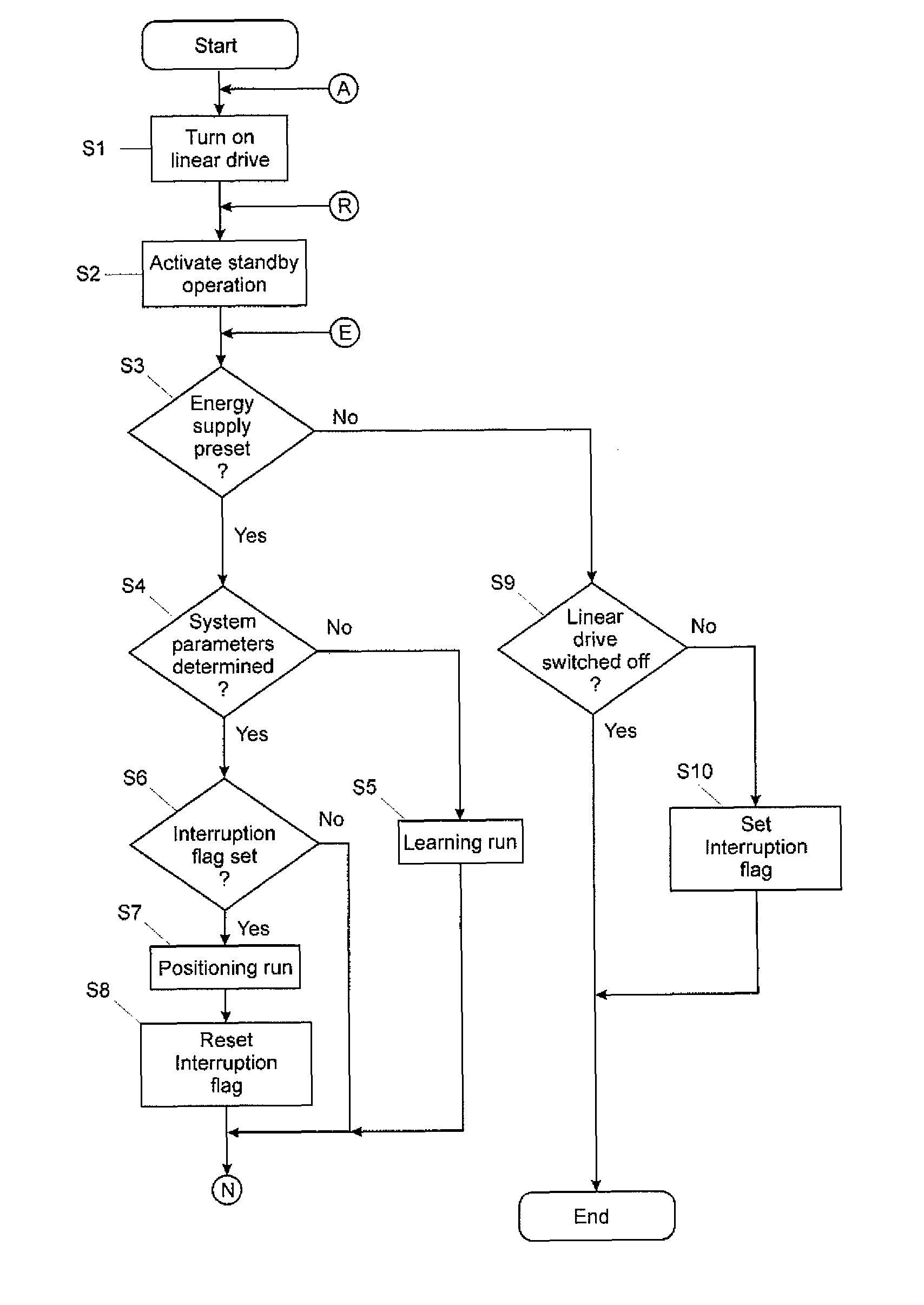

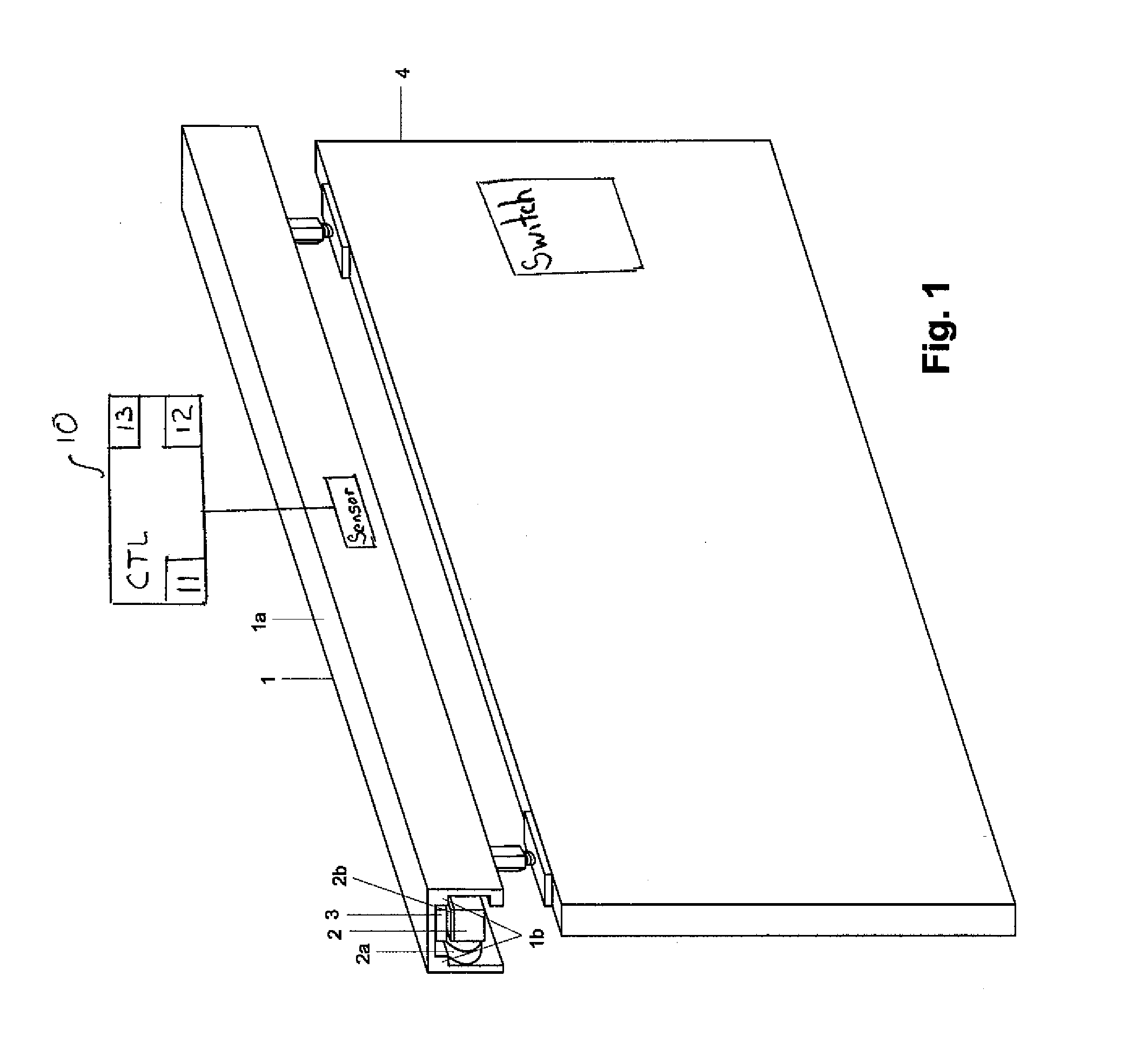

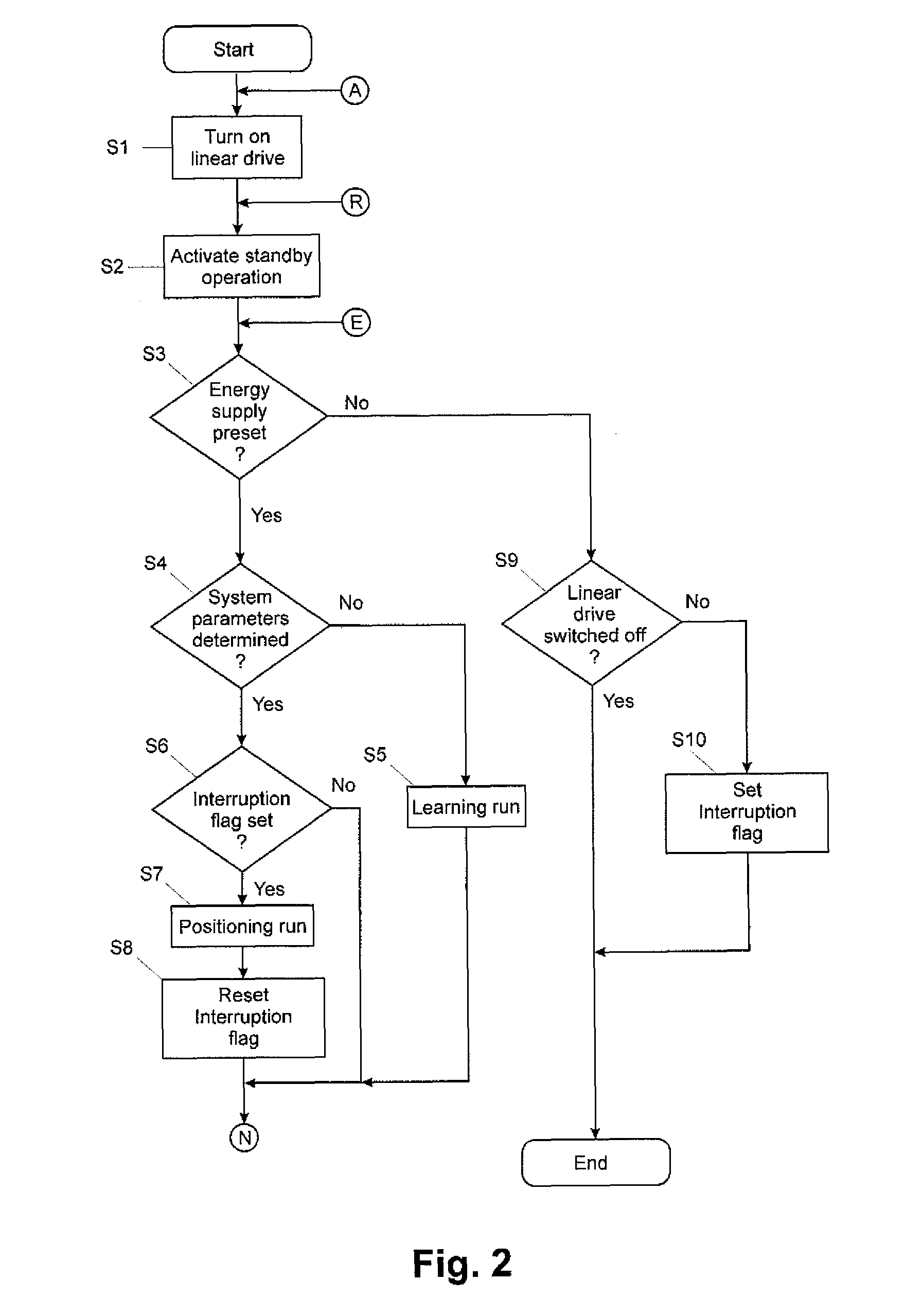

Linear drive for sliding doors or the like

ActiveUS8456111B2Improve securityDetect presenceTemperatue controlBuilding braking devicesEngineeringEnergy supply

A linear drive based on linear motors, for panels, in particular sliding doors, movable along a respective travel path. A linear drive for at least one panel, in particular a sliding door leaf, movable along a travel path, has at least one linear motor for this at least one panel. The linear motor is provided with a stator member and a carriage. Furthermore, the linear drive has a control circuit. The control circuit is adapted to stop the linear motor in the event of failure of power supply to the linear motor, by switching-off the linear motor and operating it as a generator. Thereupon, in terms of its displaceability, this movable panel is enabled by the control circuit. In addition, the linear drive has a switch for switching-off the energy supply to the at least one linear motor.

Owner:DORMAKABA DEUT GMBH

High-performance multiple-blade pump

ActiveCN109469610ALarge displacementIncrease pressureRotary piston pumpsRotary piston liquid enginesOil distributionEngineering

The invention provides a high-performance multiple-blade pump. The high-performance multiple-blade pump comprises a casing, a rotor, blades, oil distribution blocks and a guiding block. The casing isarranged outside the rotor in a covering mode. The casing is provided with at least three shifting blocks uniformly distributed in the circumferential direction. A sliding groove is formed between every two adjacent shifting blocks. An annular groove is formed in the center of the side wall of the rotor. Positioning grooves of which the number is equal to that of the shifting blocks are uniformlyformed in the annular groove in the circumferential direction. Each blade is mounted on the corresponding positioning groove. An accommodating cavity is formed among every two adjacent blades, the annular groove surface and the inner wall of the casing. The blades are inserted into the sliding grooves, so that each accommodating cavity is internally provided with the corresponding shifting block.Each accommodating cavity is divided into a first cavity and a second cavity through the corresponding shifting block. The two ends of the rotor are connected with the oil distribution blocks correspondingly. A convex ring J1 of the outer wall of the casing is placed in a guiding groove of the guiding block. The axis of the rotor and the axis of the casing do not coincide. When the rotor rotates,each shifting block slides back and forth between the two corresponding blades, thus the volumes of the corresponding first cavity and the corresponding second cavity periodically change, and the changes of the corresponding first cavity and the corresponding second cavity are opposite.

Owner:ZHEJIANG UNIV

A High Performance Vane Hydraulic Motor

The invention discloses a high-performance vane hydraulic motor. The high-performance vane hydraulic motor comprises a housing, rotors and vanes, the rotors are covered with the housing, the housing is in a hemispheric shape, a lap of circular ring K1 is arranged on the end face of the housing in an inward extending mode, the vanes are mounted on locating grooves, sliding grooves corresponding tothe locating grooves in an one-to-one mode are formed in the rotors, the vanes on the locating grooves are further arranged on the sliding grooves in a sliding mode and are sealed through sealing elements, the outer ends of the vanes are mounted on sliding shoes, the sliding shoes abut against the side face of the circular ring K1, a containing cavity is formed among every two adjacent vanes, thesurface of a circular groove, the inner wall of the housing and the side wall of the circular ring K1, oil ports are formed in the rotors and are the same as the containing cavities in number, one oilport communicates with the corresponding containing cavity, the two ends of the rotors are connected with oil distribution blocks, a convex circular ring J1 is arranged on the outer wall of the housing, the convex circular ring J1 is arranged in a guide groove of a guide block, and the axis of the rotors and the axis of the housing do not coincide. The volume of a high-pressure oil driving chamber is increased or decreased periodically, thus the rotors are driven to rotate, and power output is realized.

Owner:ZHEJIANG UNIV

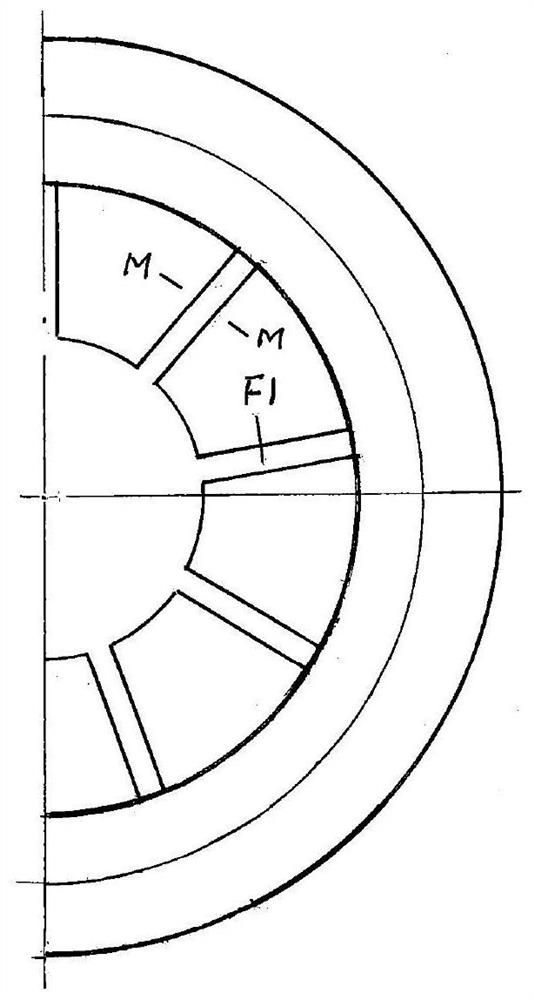

High performance variable multi-vane pump

ActiveCN109185125BLarge displacementIncrease pressureRotary piston pumpsRotary piston liquid enginesEngineeringMechanical engineering

Owner:ZHEJIANG UNIV

Multiple-blade hydraulic motor with high performance

The invention discloses a multiple-blade hydraulic motor with high performance. The multiple-blade hydraulic motor with high performance comprises a shell body, a rotor, blades and sliding shoes; theshell body covers the outer part of the rotor and is in a hemisphere shape, a circular ring K1 extends inwards from the end face of the shell body, and the circular ring K1 penetrates through the center of a sphere of the shell body; at least three sliding grooves are formed in the rotor and are uniformly distributed in the circumferential direction, the blades are slidably arranged in the slidinggrooves, the outer ends of the blades are installed on the sliding shoes, and the sliding shoes abut against the side surface of the circular ring K1; a containing cavity is formed among the adjacenttwo blades, the surface of the rotor, the inner wall of the shell body and the side wall of the circular ring K1; the axis of the rotor and the axis of the shell body are not coincident; and the volume of a cavity chamber is driven by high pressure oil to be increased and decreased periodically, and thus the rotor is driven to rotate, and the output of power is achieved.

Owner:ZHEJIANG UNIV

High performance vane hydraulic pump

ActiveCN109236640BLarge displacementIncrease pressureRotary piston pumpsRotary piston liquid enginesHydraulic pumpStructural engineering

Owner:ZHEJIANG UNIV

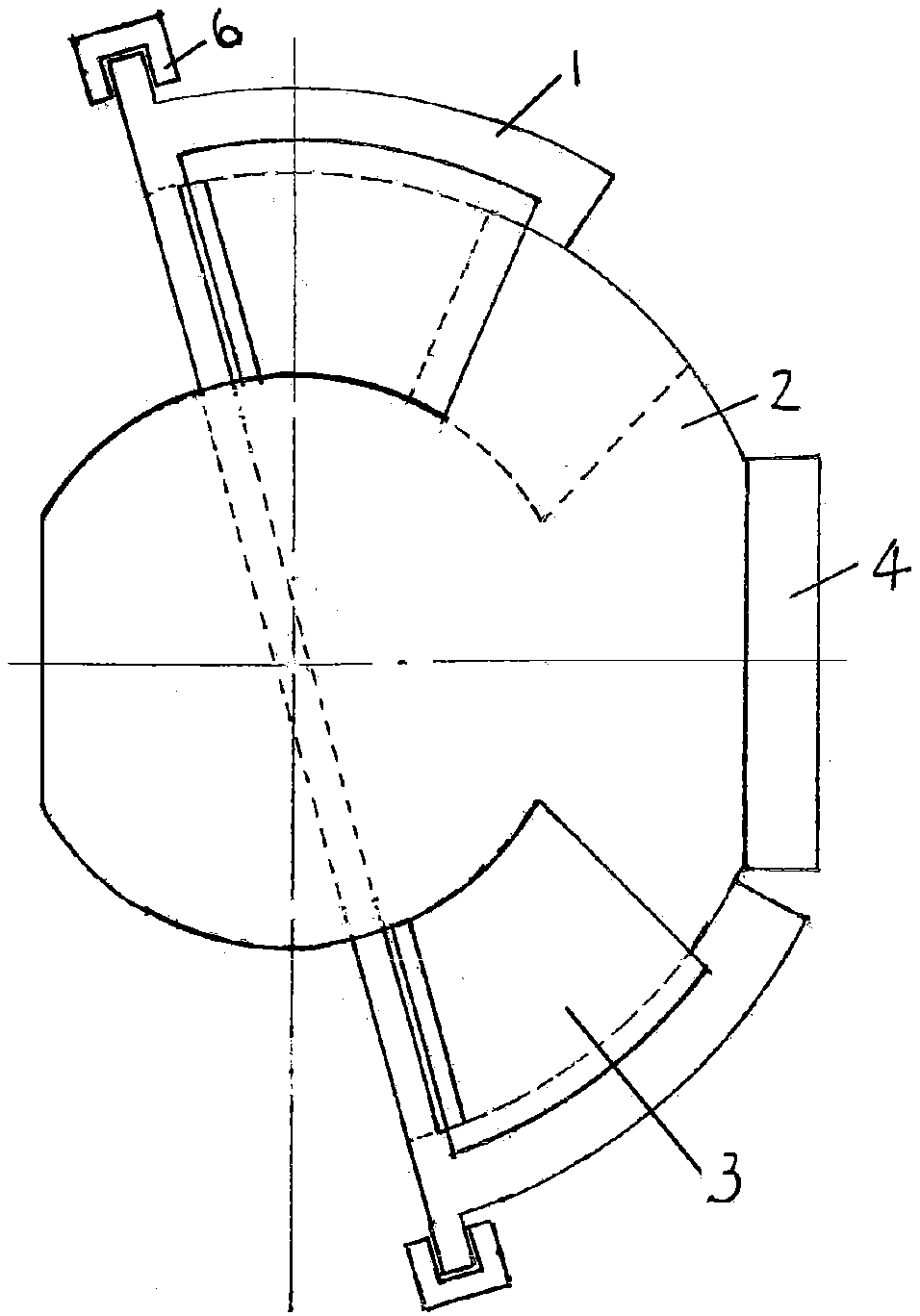

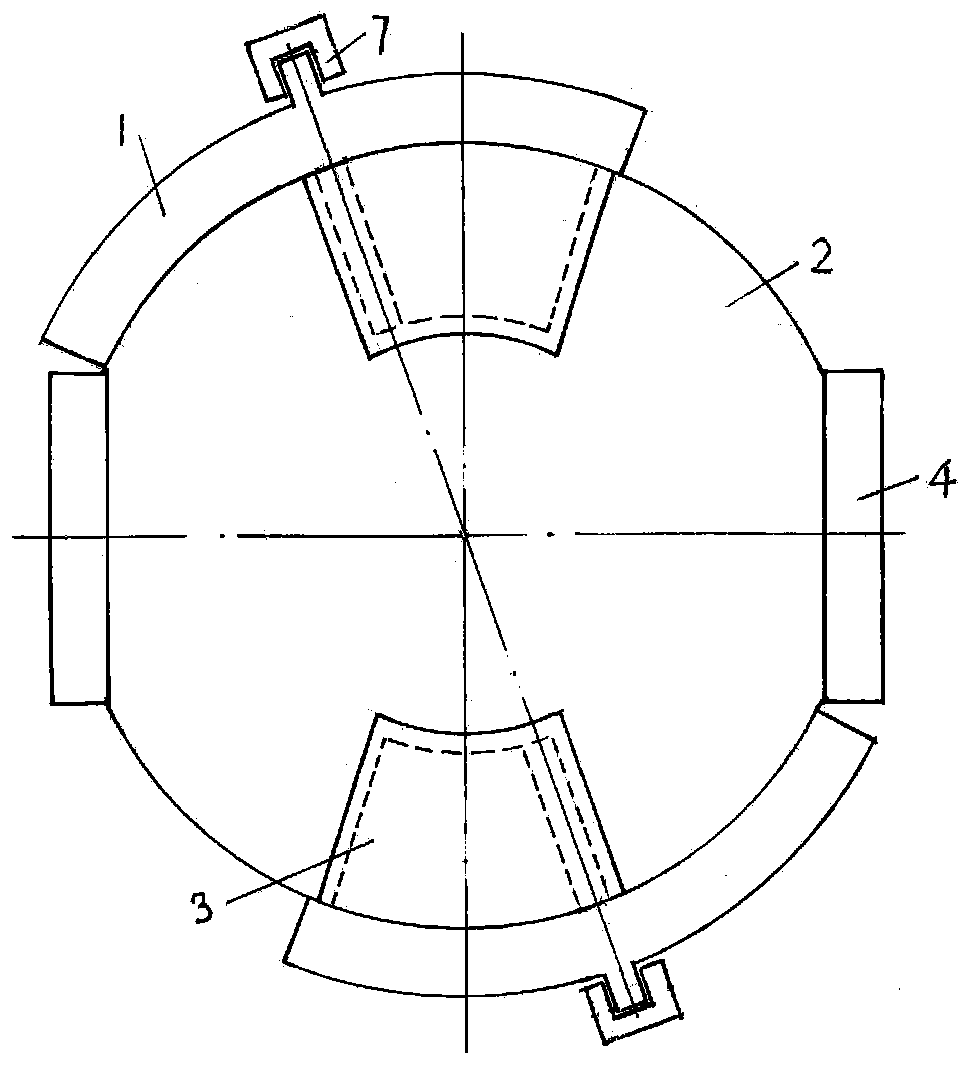

A high-performance high-torque multi-blade motor

The invention discloses a high-performance and large-torque multi-blade motor. The high-performance and large-torque multi-blade motor comprises a shell body, a rotor and blades, a round of ring K1 extends in the center of the inner wall of the shell body to the direction of center of a ball, and at least three first positioning grooves are evenly formed in the inner wall of the shell body in thecircumferential direction. A second positioning groove is formed in the ring K1, and the blades are arranged on the first positioning grooves and the second positioning groove at the same time. The second positioning groove divides the ring K1 into a plurality of partition plates, a ring groove is formed in the center of the rotor side wall, left sliding grooves corresponding to the first positioning grooves one by one are formed in the left side surface of the ring groove, right sliding grooves corresponding to the first positioning grooves one by one are formed in the right side surface of the ring groove, the two ends of the blades are separately placed on the left sliding grooves and the right sliding grooves in an accommodating mode. An accommodating cavity is formed between the adjacent two blades, the surface of the ring groove and the inner wall of the shell body, each partition plate is arranged in each accommodating cavity, and the partition plates divide the accommodating cavities into left accommodating cavities and right accommodating cavities. The volume of the accommodating cavities is driven by high pressure oil to increase and decrease periodically, so that the rotor is driven to rotate, and the output of power is realized.

Owner:ZHEJIANG UNIV

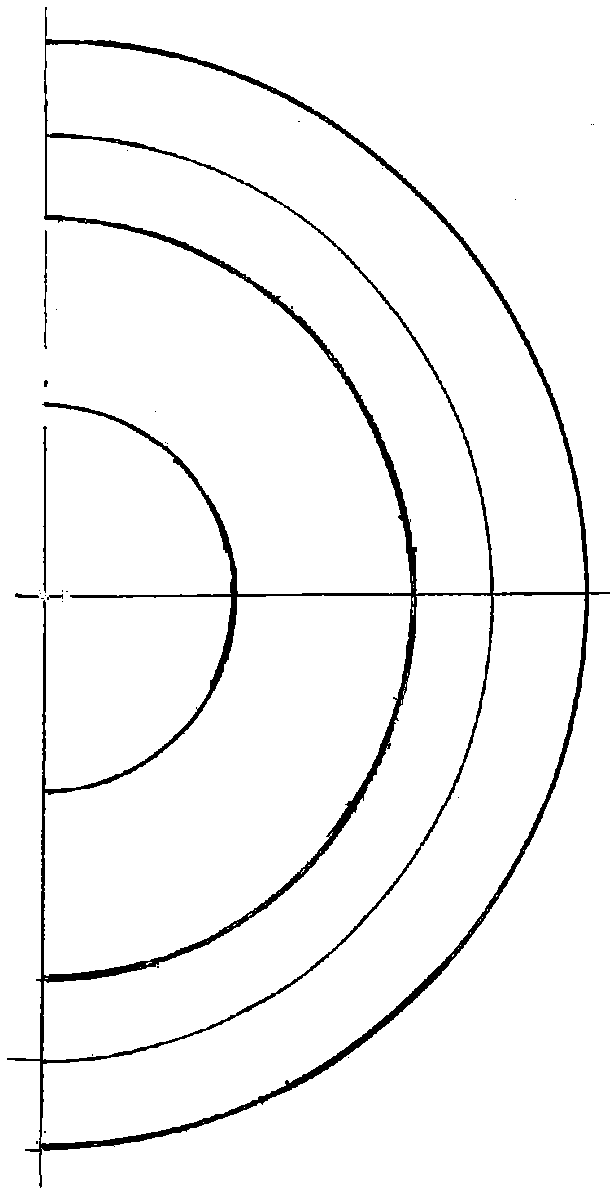

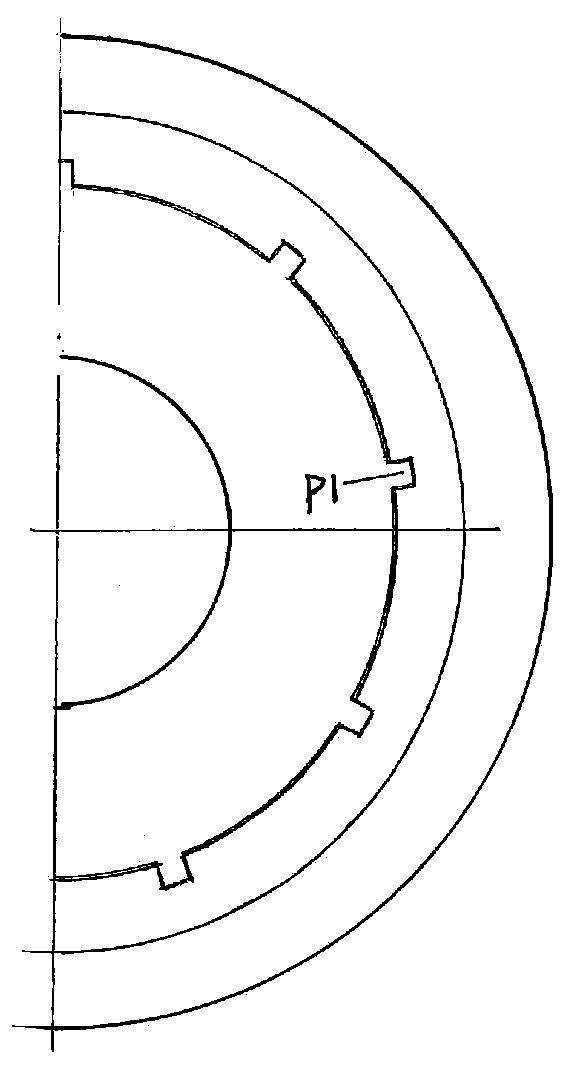

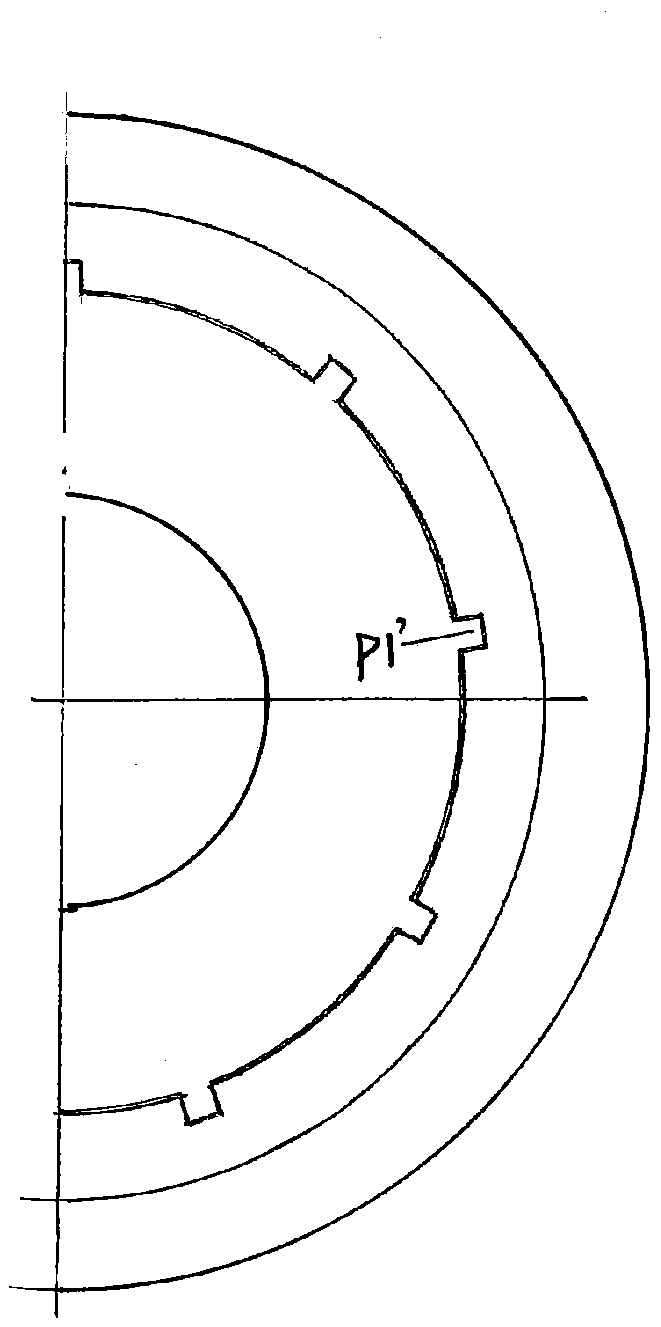

High-performance variable vane pump

ActiveCN109538467ALarge displacementIncrease pressureRotary piston pumpsRotary piston liquid enginesEngineeringOil distribution

The invention discloses a high-performance variable vane pump, which includes a housing, a rotor and blades. The housing covers outside the rotor, the housing is hemispherical, the end face of the housing extends inwards to be provided with a circle of circular rings K1, the circular rings K1 pass through the sphere center of the housing; positioning grooves are provided with the blades, the rotoris provided with sliding grooves corresponding to the positioning grooves one to one, and the blades on the positioning grooves are further slidably arranged on the sliding grooves and sealed throughsealing parts; the outer end tips of the blades are installed on sliding shoes, the sliding shoes abut against the side faces of the circular rings K1, an accommodating cavity is formed among every two adjacent blades, the surface of a ring groove, the inner wall of the housing and the side walls of the circular rings K1, the rotor is provided with oil ports with the same number as the accommodating cavities, each oil port communicates with the corresponding accommodating cavity, and both ends of the rotor are connected with oil distribution blocks correspondingly; and the outer wall of the housing is provided with a convex circular ring J1, the convex circular ring J1 is placed in a guide groove of a guide block, and the axis of the rotor do not coincide with that of the housing. According to the high-performance variable vane pump, the relative linear velocity between the blades and the housing is zero, and running at the extremely high speed can be achieved.

Owner:ZHEJIANG UNIV

High performance variable vane pump

ActiveCN109538467BLarge displacementIncrease pressureRotary piston pumpsRotary piston liquid enginesStructural engineeringOil distribution

The invention discloses a high-performance variable vane pump, which includes a housing, a rotor and blades. The housing covers outside the rotor, the housing is hemispherical, the end face of the housing extends inwards to be provided with a circle of circular rings K1, the circular rings K1 pass through the sphere center of the housing; positioning grooves are provided with the blades, the rotoris provided with sliding grooves corresponding to the positioning grooves one to one, and the blades on the positioning grooves are further slidably arranged on the sliding grooves and sealed throughsealing parts; the outer end tips of the blades are installed on sliding shoes, the sliding shoes abut against the side faces of the circular rings K1, an accommodating cavity is formed among every two adjacent blades, the surface of a ring groove, the inner wall of the housing and the side walls of the circular rings K1, the rotor is provided with oil ports with the same number as the accommodating cavities, each oil port communicates with the corresponding accommodating cavity, and both ends of the rotor are connected with oil distribution blocks correspondingly; and the outer wall of the housing is provided with a convex circular ring J1, the convex circular ring J1 is placed in a guide groove of a guide block, and the axis of the rotor do not coincide with that of the housing. According to the high-performance variable vane pump, the relative linear velocity between the blades and the housing is zero, and running at the extremely high speed can be achieved.

Owner:ZHEJIANG UNIV

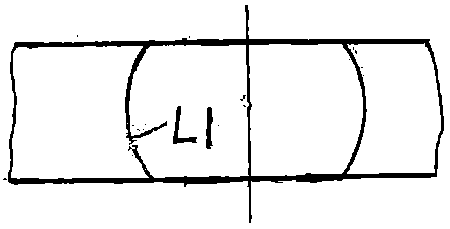

High pressure multi-blade pump

ActiveCN109538466APump specific powerFlow adjustableRotary piston pumpsRotary piston liquid enginesEngineeringHigh pressure

The invention discloses a high pressure multi-blade pump. The high pressure multi-blade pump includes a shell, rotors and blades, wherein the shell is located outside the rotors in a covering mode, the end surface of the shell inwards extends to be provided with a circle of circular ring K1, at least three first locating grooves are evenly formed in the inner wall of the shell in the circumferential direction, second locating grooves are evenly formed in the ring K1 in the circumferential direction, wherein the number of the second locating grooves is the same as the number of the first locating grooves, and the blades are mounted on the first locating grooves and the second locating grooves simultaneously; the ring K1 is divided into a plurality of shifting pieces by the second locking grooves, a ring groove is formed in the side walls of the rotors, the circular ring K1 is located in the ring groove, sliding grooves which correspond to the first locking grooves in a one-to-one mode are formed in the right side face of the ring groove, and the blades are slidably arranged on the sliding grooves; and a containing cavity is formed among every two adjacent blades, the ring groove surface, the shifting pieces and the inner wall of the shell, when the rotors rotate, the rotors drive the blades to rotate together, the blades push the shell to rotate around the axis of the shell, theblades slide on the sliding grooves in a reciprocating mode while rotating, and thus the volume of the containing cavity is periodically changed.

Owner:ZHEJIANG UNIV

Double acting variable vane pump

ActiveCN109538468BLarge displacementIncrease pressureRotary piston pumpsRotary piston liquid enginesStructural engineeringMechanical engineering

The invention discloses a double-acting variable vane pump. The double-acting variable vane pump comprises a housing, rotors and vanes, the rotors are located in the center and covered with the housing, a lap of ring K1 extends from the middle center position of the inner side wall of the shell housing extends to a lap of ring K1 in to the direction of the spherical center, three or more left locating grooves and right locating grooves are evenly formed in the inner sidewall of the housing in the circumferential direction, and the left locating grooves and the right locating grooves are both provided with the vanes; a circular groove is formed in the middle center position of the side wall of the each rotors, left sliding grooves are formed in the left side surfaces of the circular grooves, right sliding grooves are formed in the right side surfaces of the circular grooves, the vanes on the left locating grooves are further arranged on the left sliding grooves in a sliding mode, and the vanes on the right locating grooves are further arranged on the right sliding grooves in a sliding mode; the ring K1 is clamped between the vanes of the left locating grooves and the vanes of the right locating grooves, a chamber is formed among every two adjacent vanes, the surfaces of the circular grooves, the inner wall of the housing and the side wall of the ring K1 form a chamber, and the axis of the rotors and the axis of the housing do not coincide are in misalignment position. The relative linear velocity between the vanes and the housing is zero, and the double-acting variable vanepump is capable of working in at an extremely high velocity.

Owner:ZHEJIANG UNIV

A high-performance multi-vane hydraulic motor

The invention provides a high-performance multi-blade hydraulic motor. The high-performance multi-blade hydraulic motor comprises a shell, a rotor, blades, oil distribution blocks and guide blocks. The outer side of the rotor is covered with the shell. At least three shifting blocks which are uniformly distributed in the circumferential direction are arranged in the shell. A chute is formed between every two shifting blocks. A ring groove is formed in the centring position of the side wall of the rotor. Positioning grooves with the same number as the shifting blocks are uniformly formed in thering groove in the circumferential direction. A blade is mounted on each positioning groove. A cavity is formed among every two adjacent blades, the surface of the ring groove and the inner wall of the shell. The blades are inserted into the corresponding chutes. One shifting block is arranged in each cavity. Each cavity is partitioned into a first cavity body and a second cavity body by the corresponding shifting block. Both ends of the rotor are correspondingly connected with the oil distribution blocks, A convex ring J1 of the outer wall of the shell is arranged in guide grooves of the guide blocks. The axis of the rotor and the axis of the shell do not coincide. The volume of a high-pressure oil driving chamber periodically increases and decreases, so that the rotor is driven to rotate, and power output is realized.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com