Patents

Literature

892results about How to "Quick unloading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

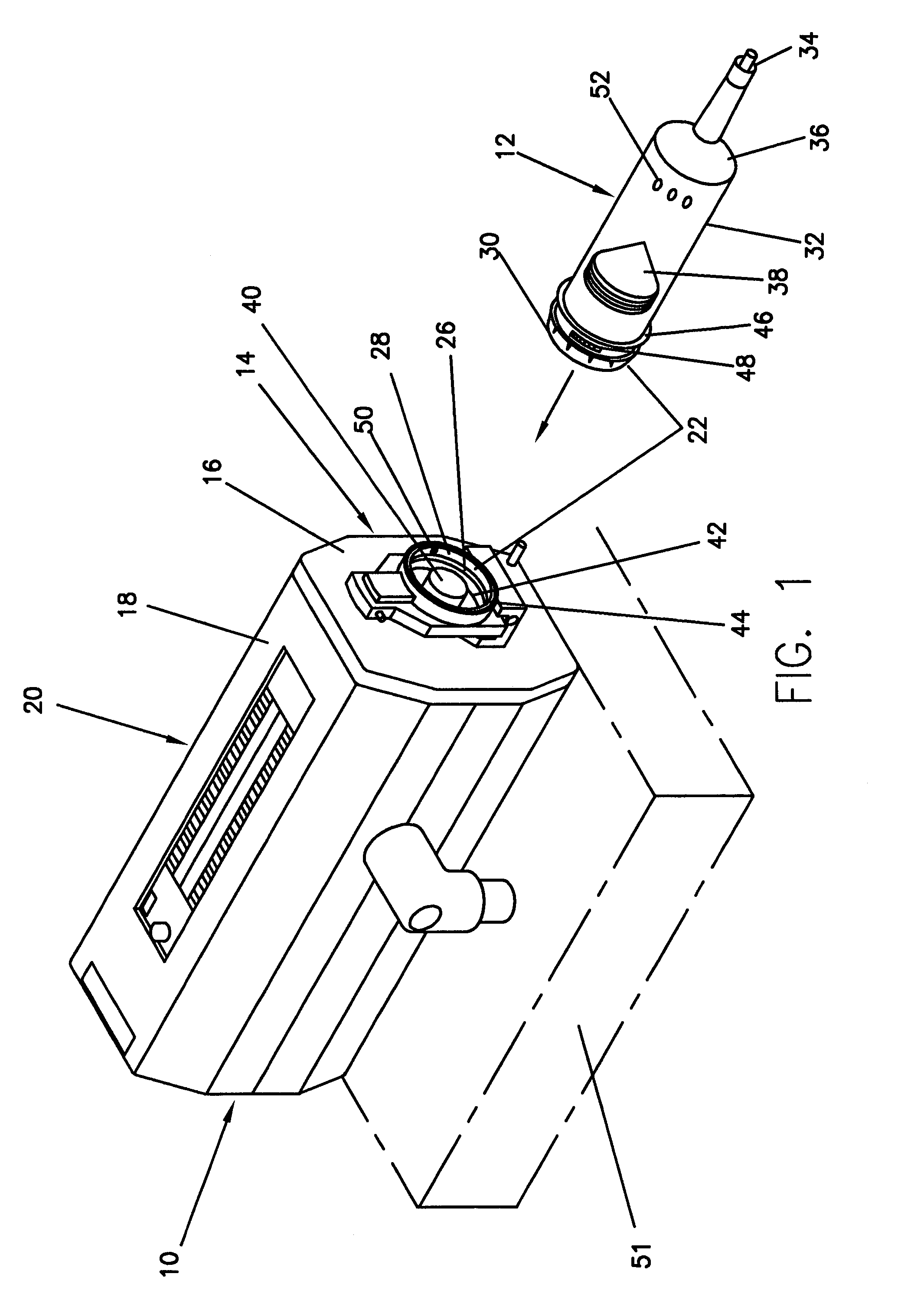

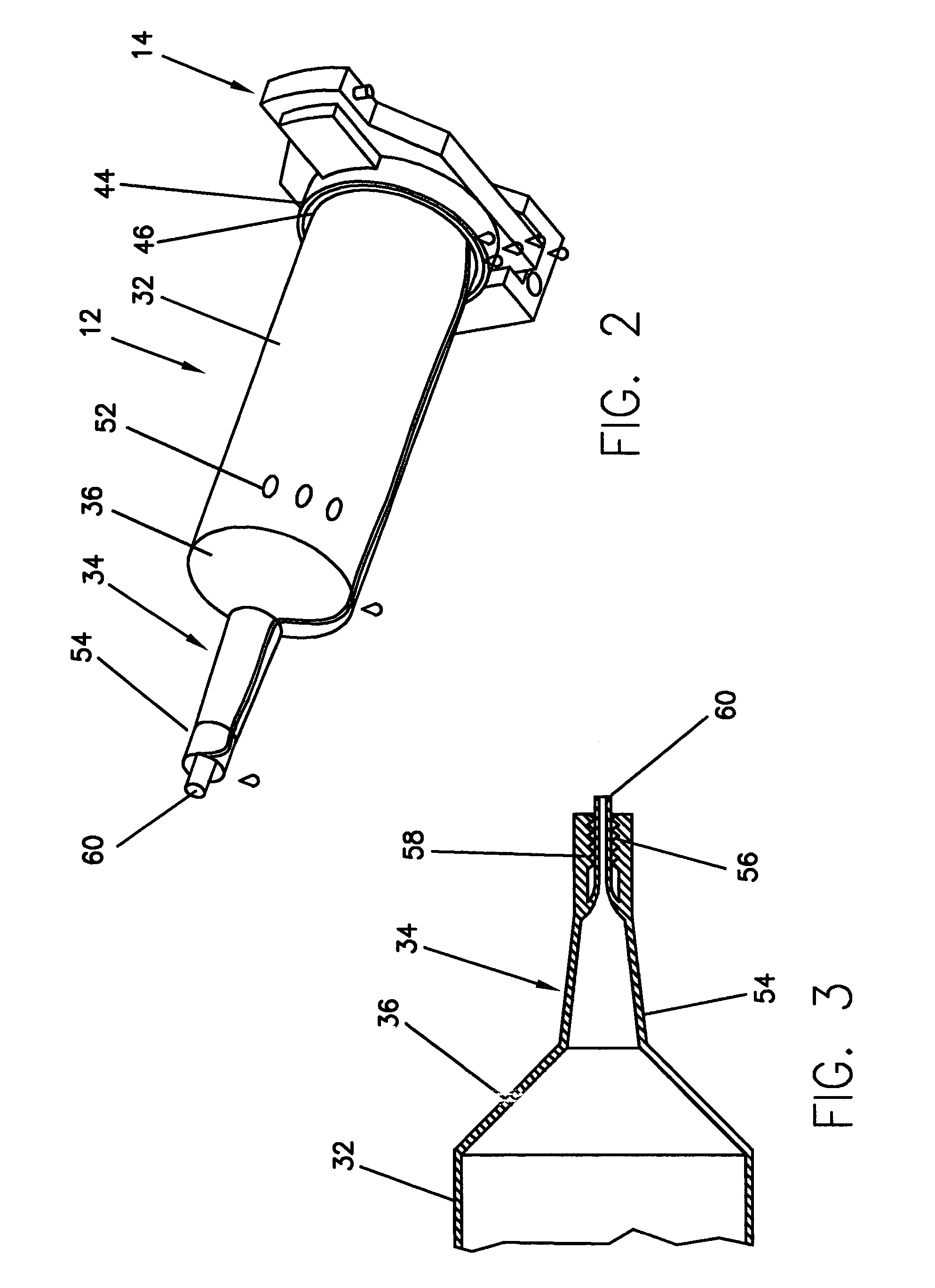

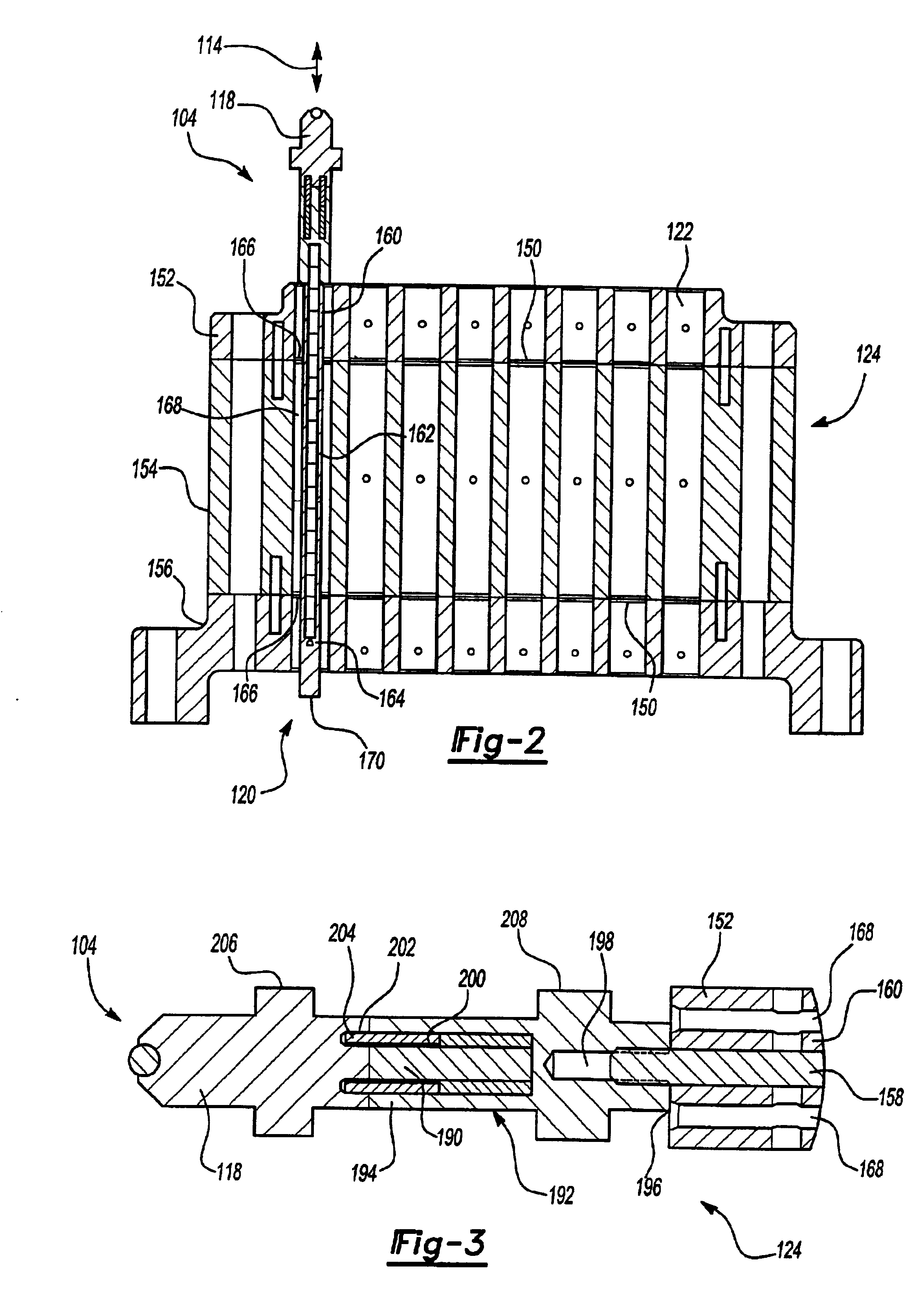

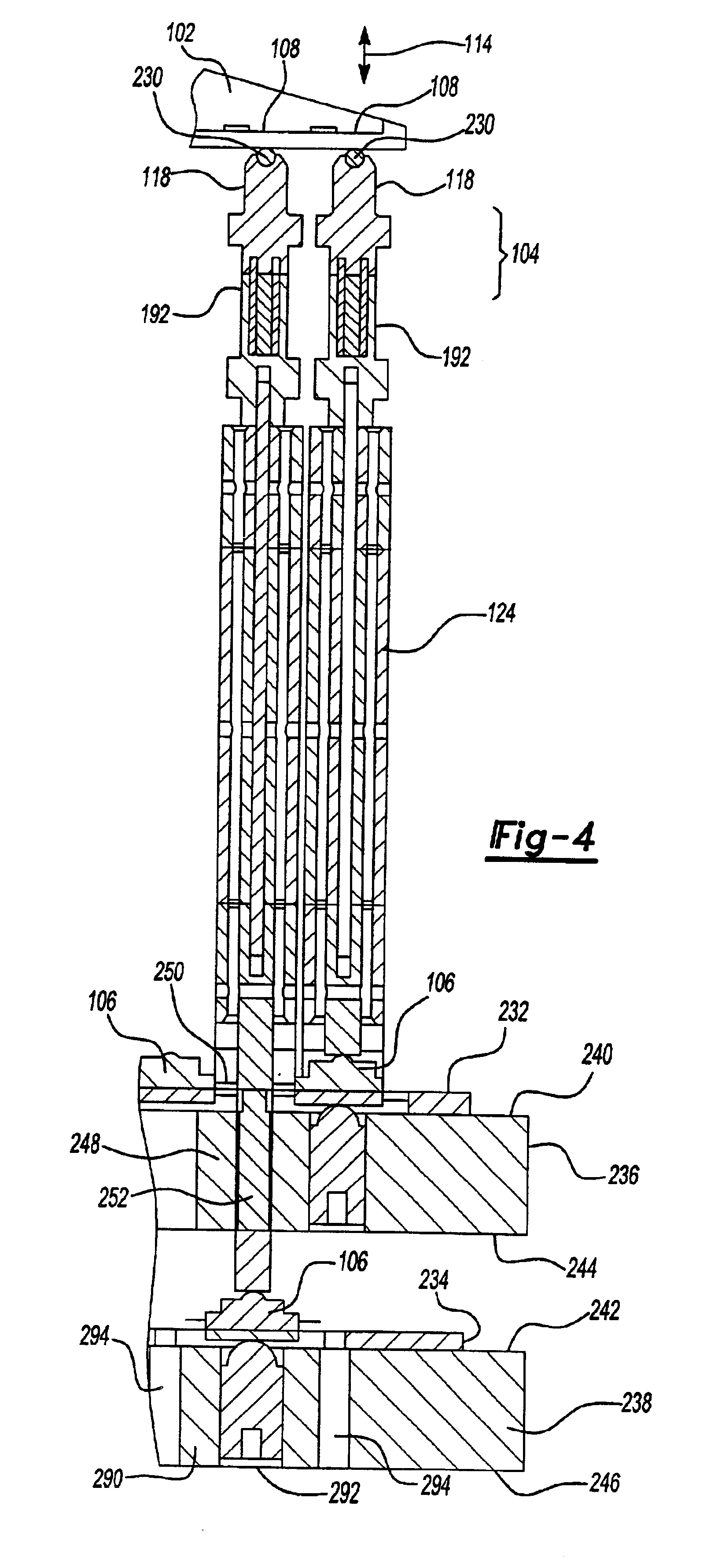

Front-loading syringe for medical injector having a flexible syringe retaining ring

InactiveUS7419478B1SimplerEasily and readily and securely fastenedInfusion syringesMedical devicesEngineeringFront loading

Embodiments of an injector, injector system, syringe, syringe interface, syringe adapter, and piston / plunger assembly for an injector (of contrast medium, for example) are described. Preferably, the syringe is adapted to engage a syringe interface mechanism such that the syringe may be seated within an injector without regard to any particular orientation of the syringe about its axis with respect to the injector.

Owner:BAYER HEALTHCARE LLC

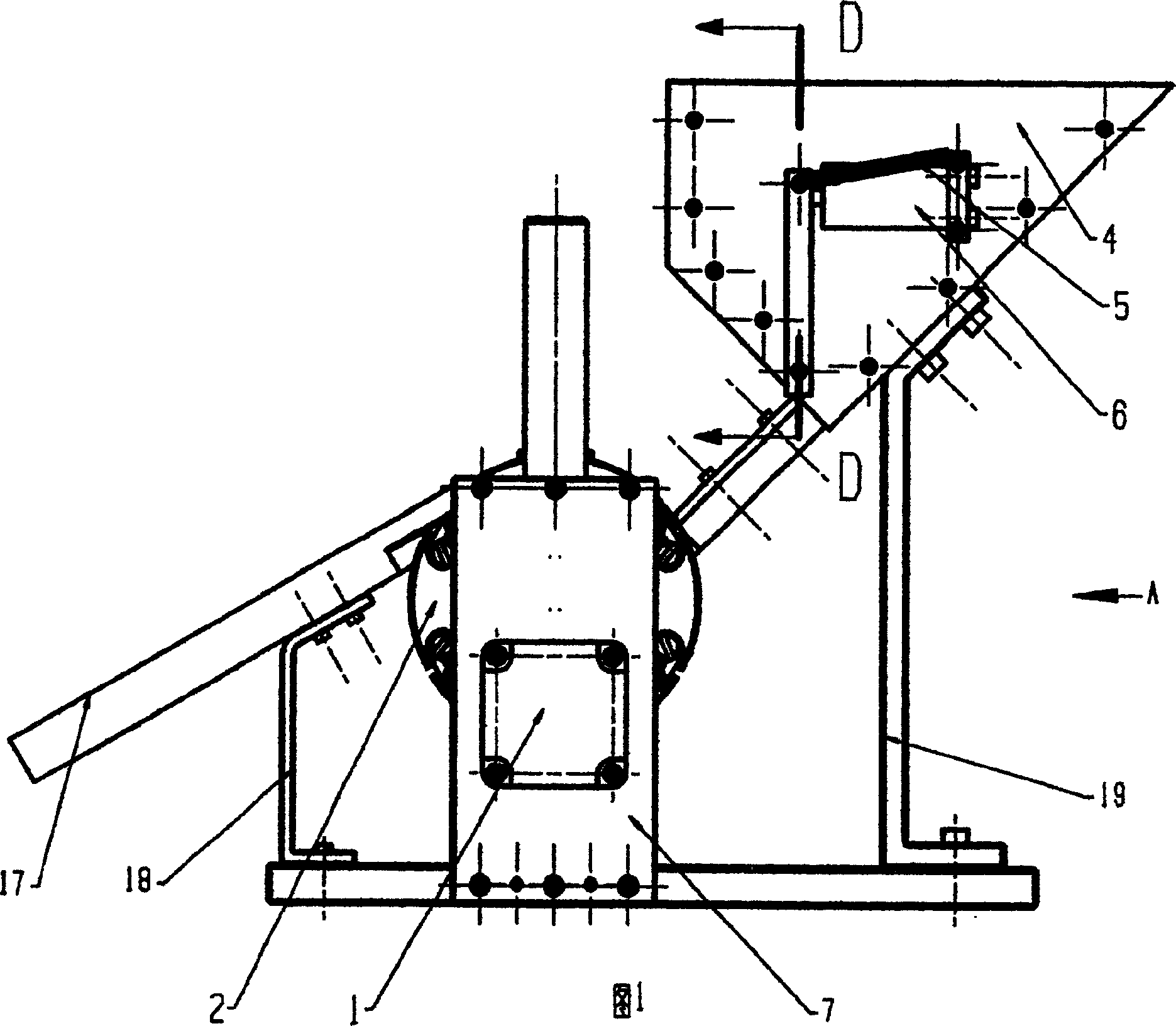

Cyclone suspension flash magnetized roasting-magnetic separating method for refractory ferric oxide ore

The present invention relates to a cyclone suspension flash magnetizing roast-magnetic separation method for difficult-separable ironoxide ore. Its concrete steps are as follow: firstly, roasting the powdered difficult-separable ironoxide ore granules or fire-ground strong-magnetically-separated chats in the separation process under the condition of high-temperature reduction atmosphere and cyclone suspension fluidized state to make them be quickly dynamically reduced into magnetite within 5-100 sec. then adopting weak magnetic separation process to obtain high-quality acceptable iron headings.

Owner:湖南长拓高科冶金有限公司

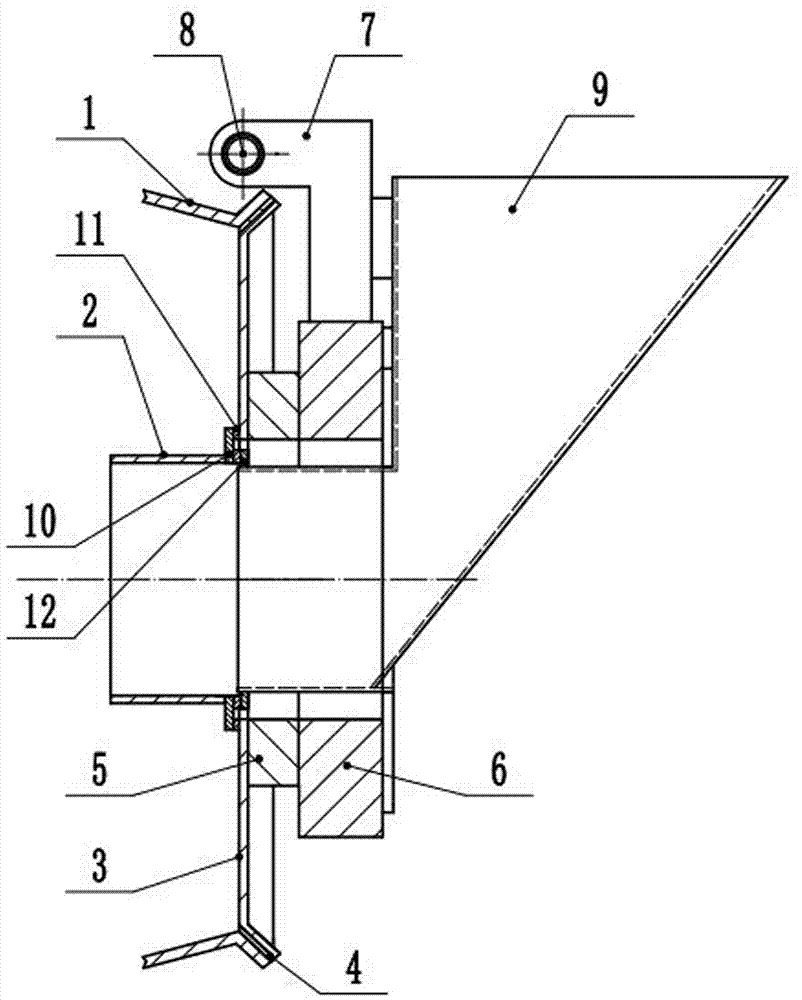

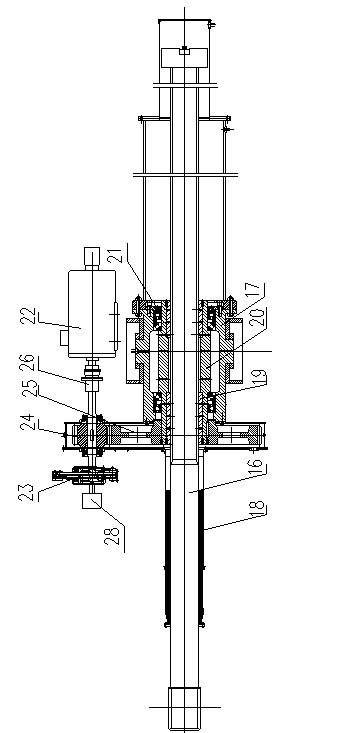

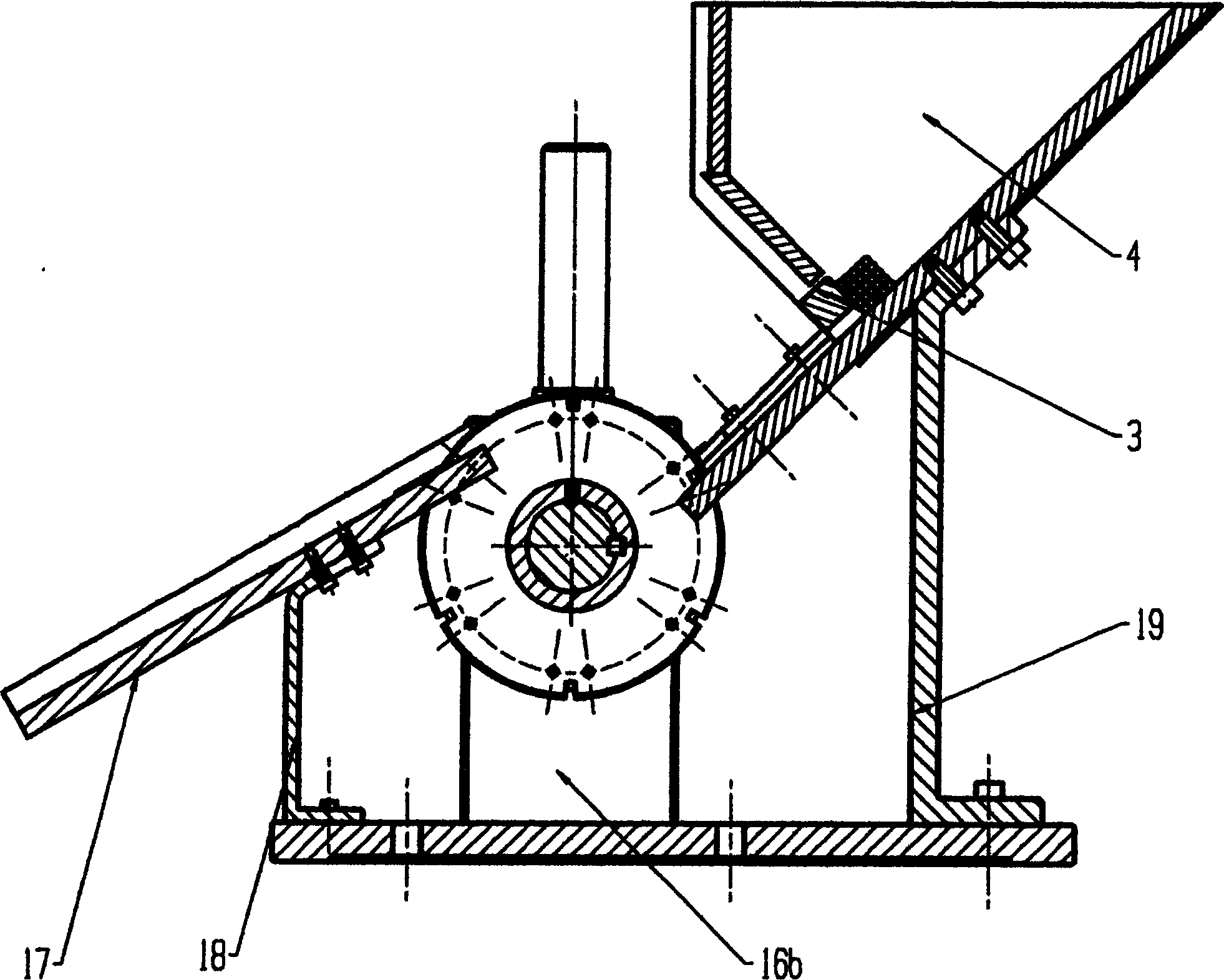

Hollow shaft rotary sealing concrete mixing truck

ActiveCN107344401ASmall turning radiusRelatively low linear speedCement mixing apparatusEngineeringTruck

The invention discloses a hollow shaft rotary sealing concrete mixing truck which comprises a mixing drum that is arranged on a truck body and can rotate relative to the truck body. A feeding cylinder is arranged in the middle of an outlet of the mixing drum. The hollow shaft rotary sealing concrete mixing truck further comprises a moving component which is arranged on the truck body and can move relative to the truck body; a sealing cover is arranged on the moving component through a rotary support; the external edge of the sealing cover is in contact with the external edge of the outlet of the mixing drum, and a first sealing device is arranged at the contact part; and the sealing cover, under the driving of the mixing drum, rotates relative to the moving component along with the mixing drum. The sealing cover for plugging the mixing drum is in a rotary structure and synchronously rotates along with the mixing drum, and a dynamic sealing part is changed to be positioned between the feeding cylinder and a feeding hopper accordingly, thus the rotating radius of the dynamic sealing part is reduced substantially, the relative linear velocity of the dynamic sealing part is reduced, the abrasion to a sealing component is reduced when the sealing effect is ensured, the reliability of the hollow shaft rotary sealing concrete mixing truck is improved, and the maintenance difficulty is lowered.

Owner:YANTAI SHENGLIDA ENG TECH

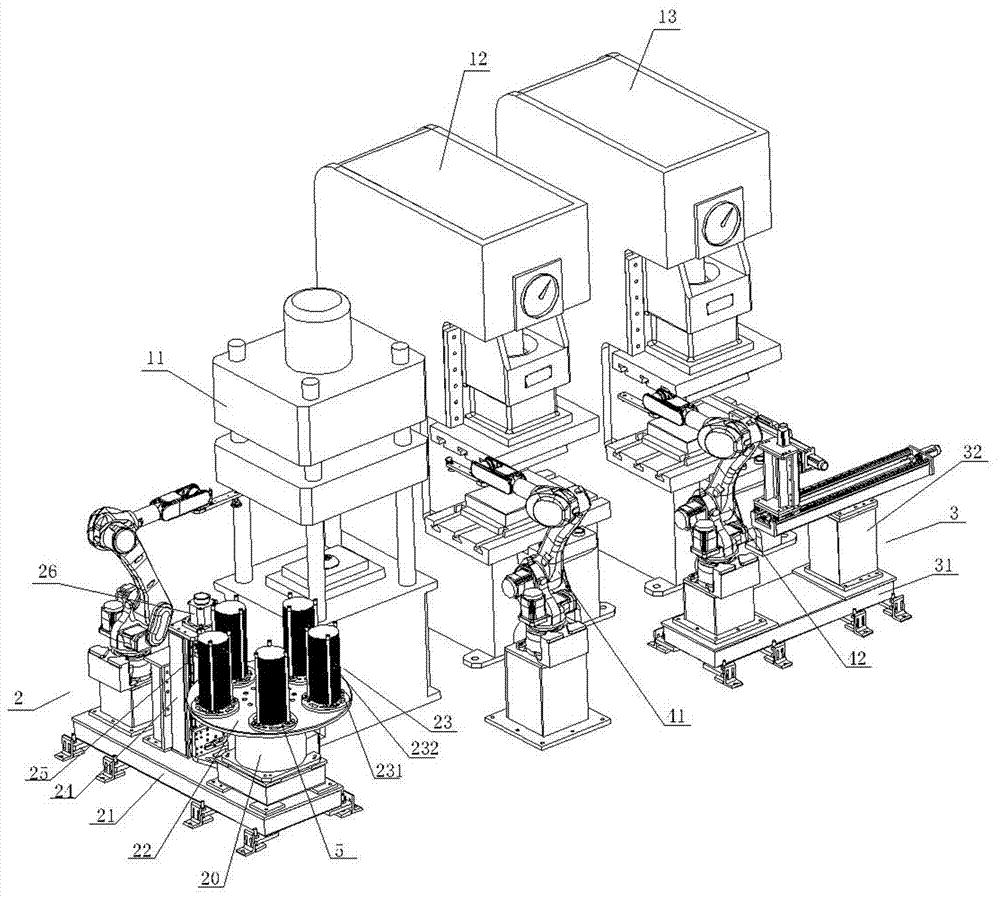

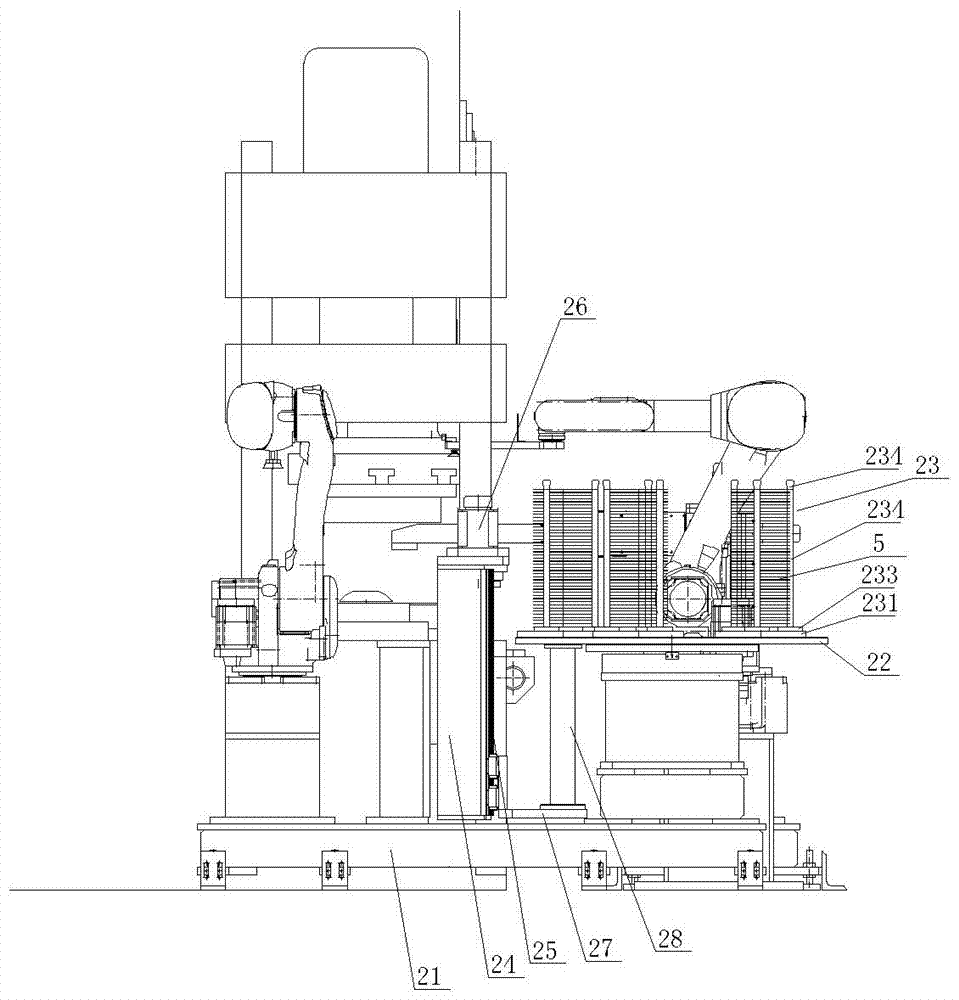

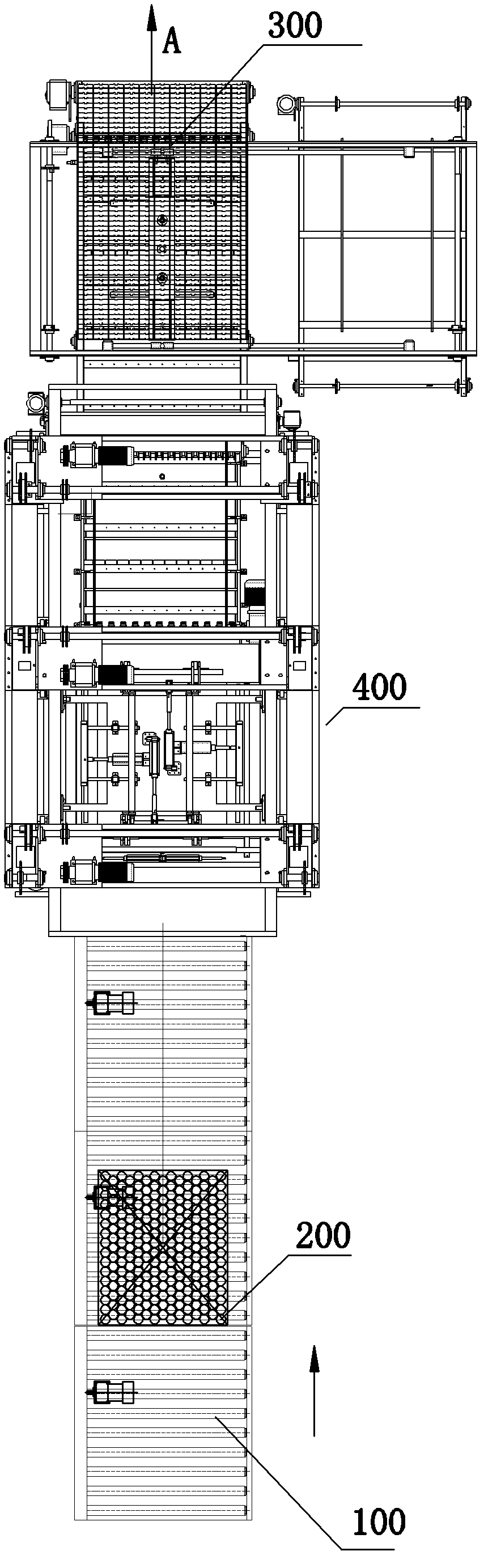

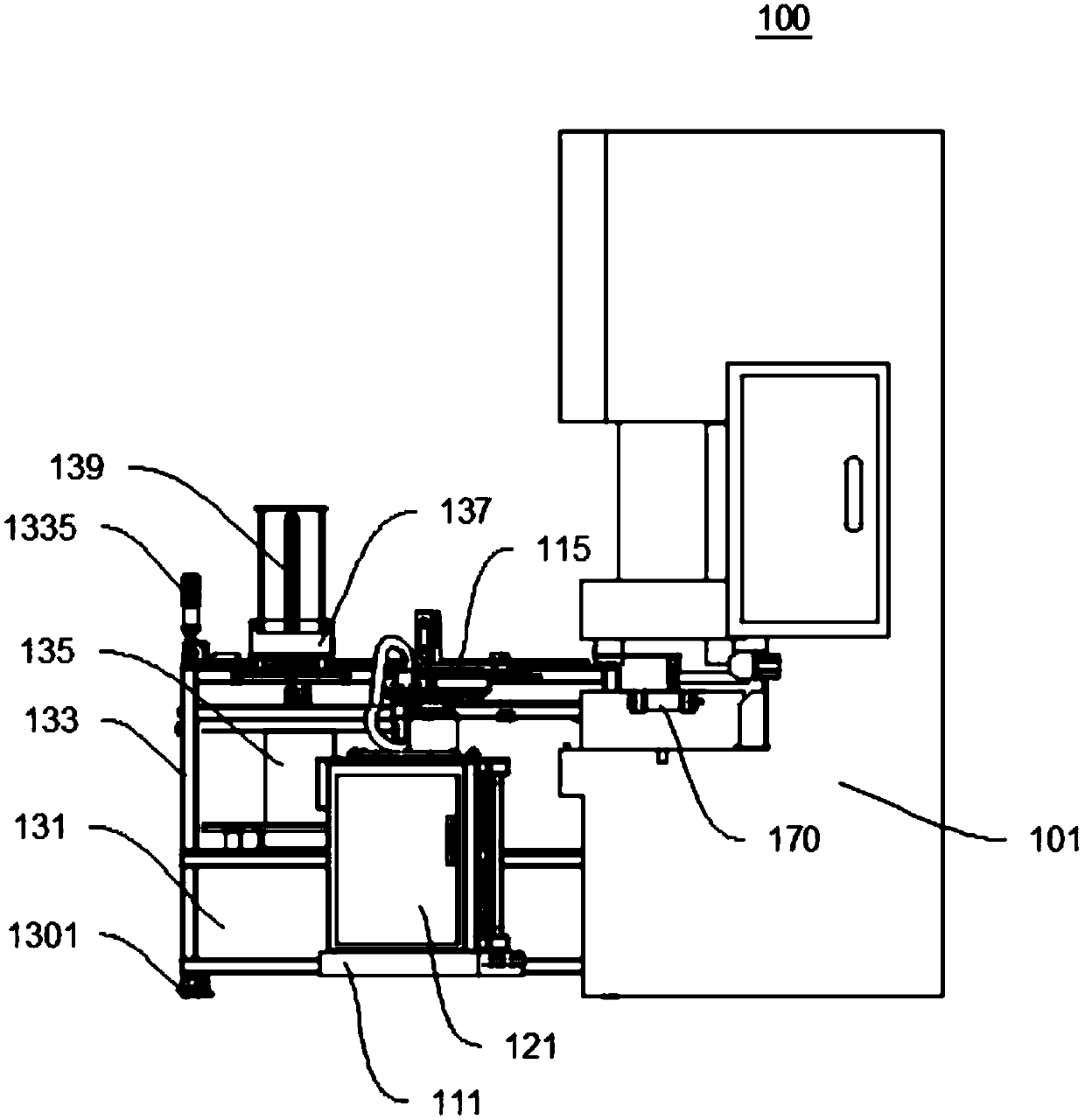

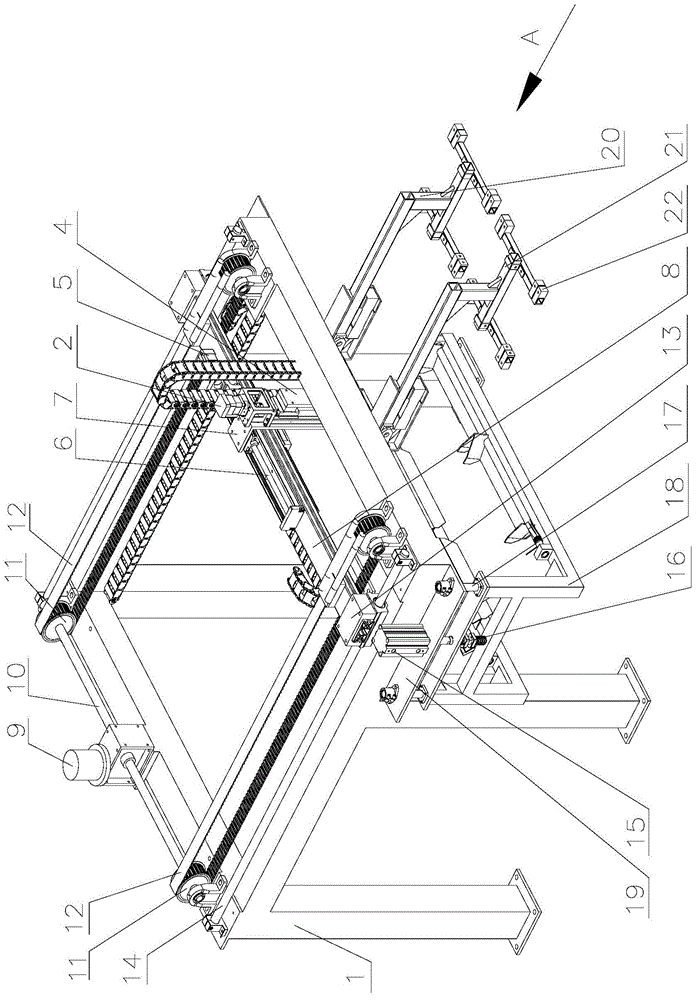

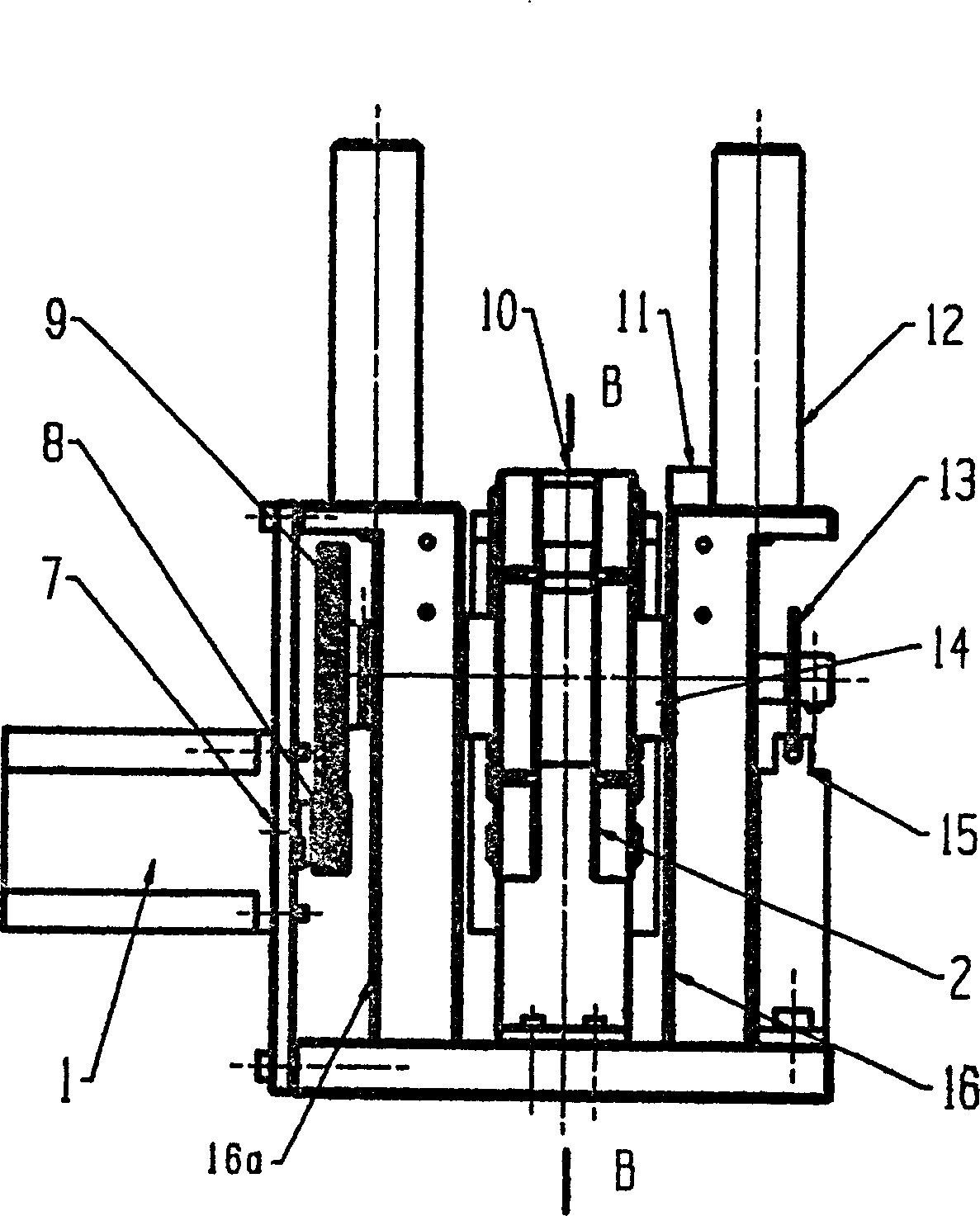

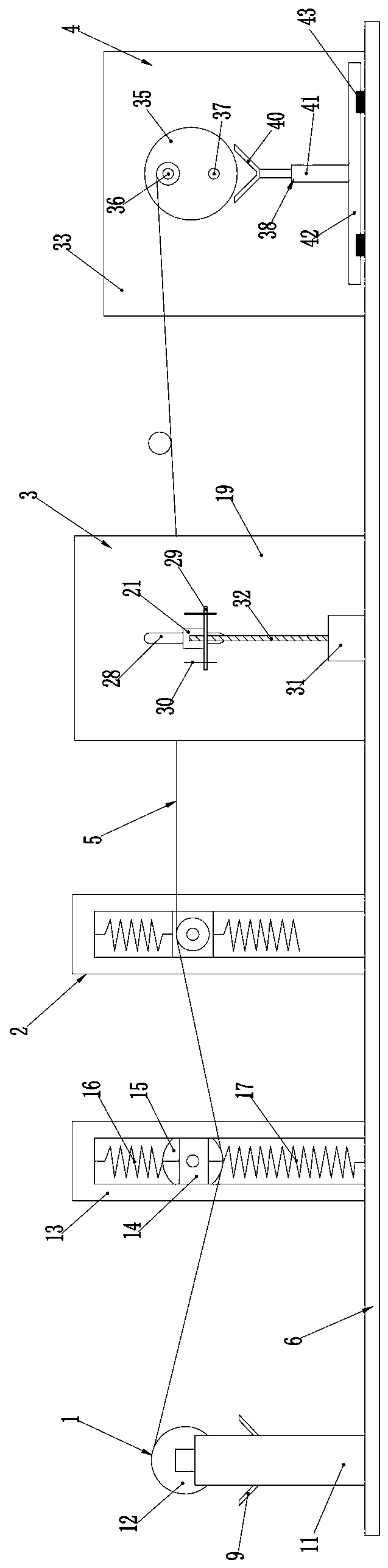

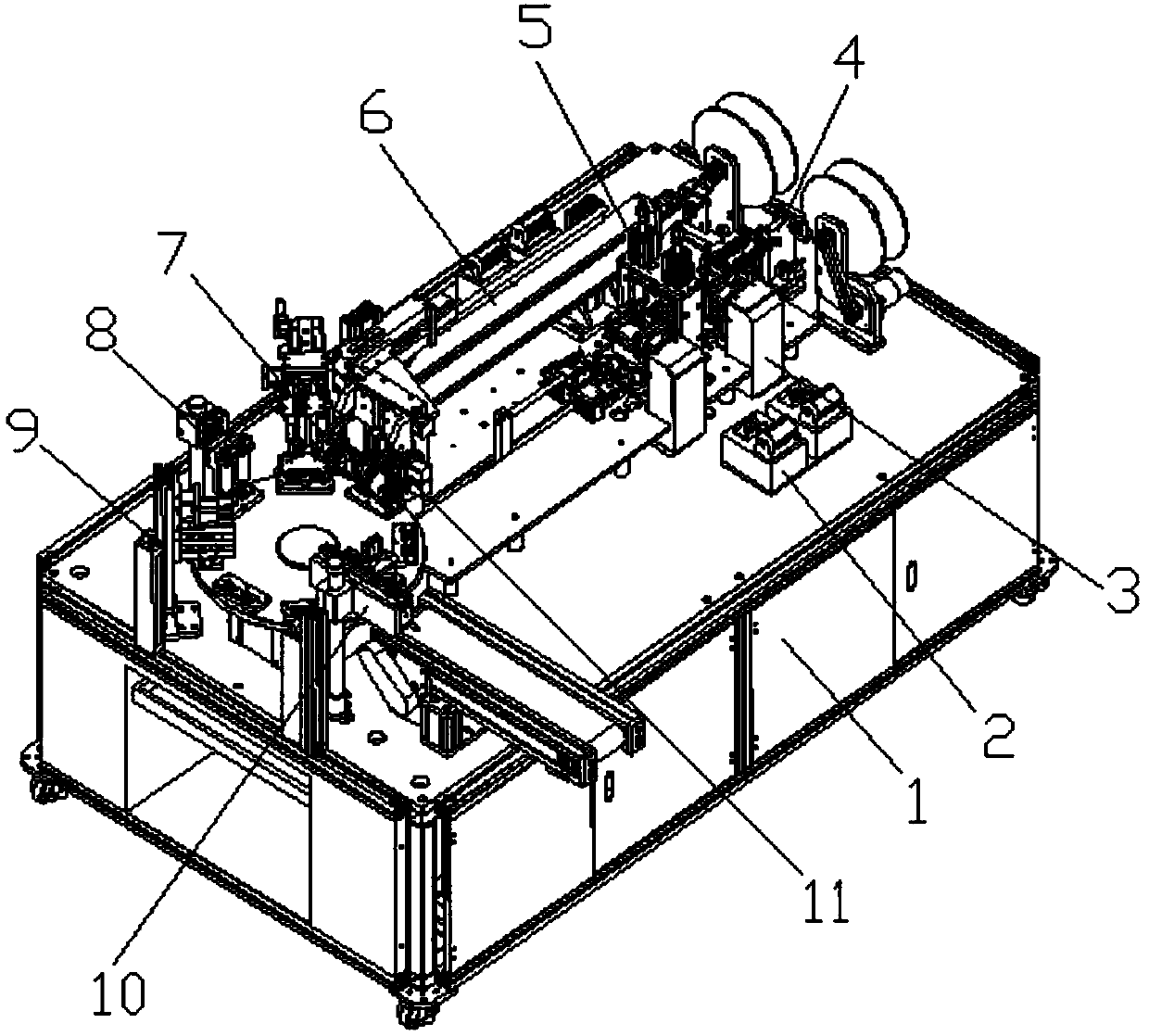

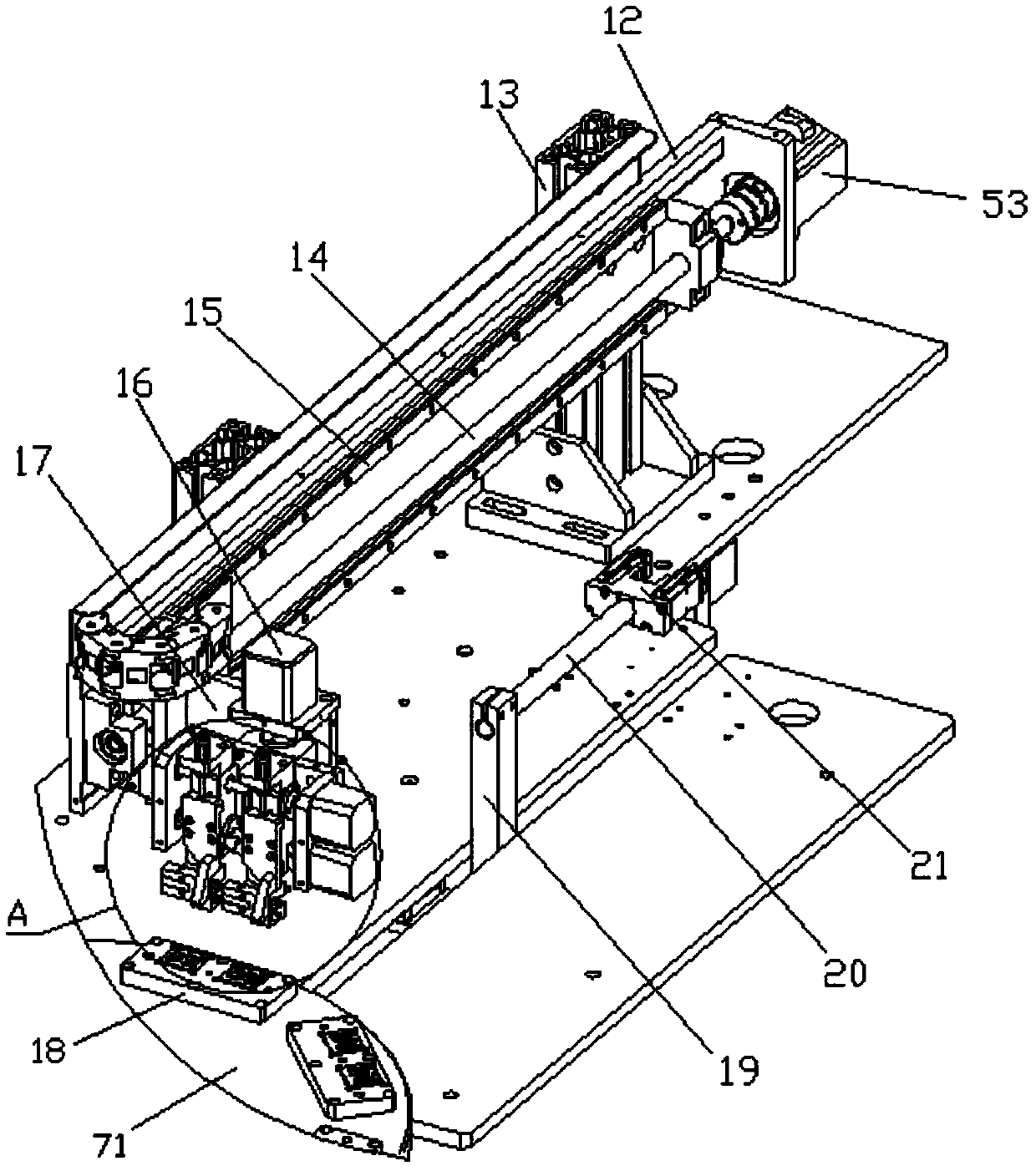

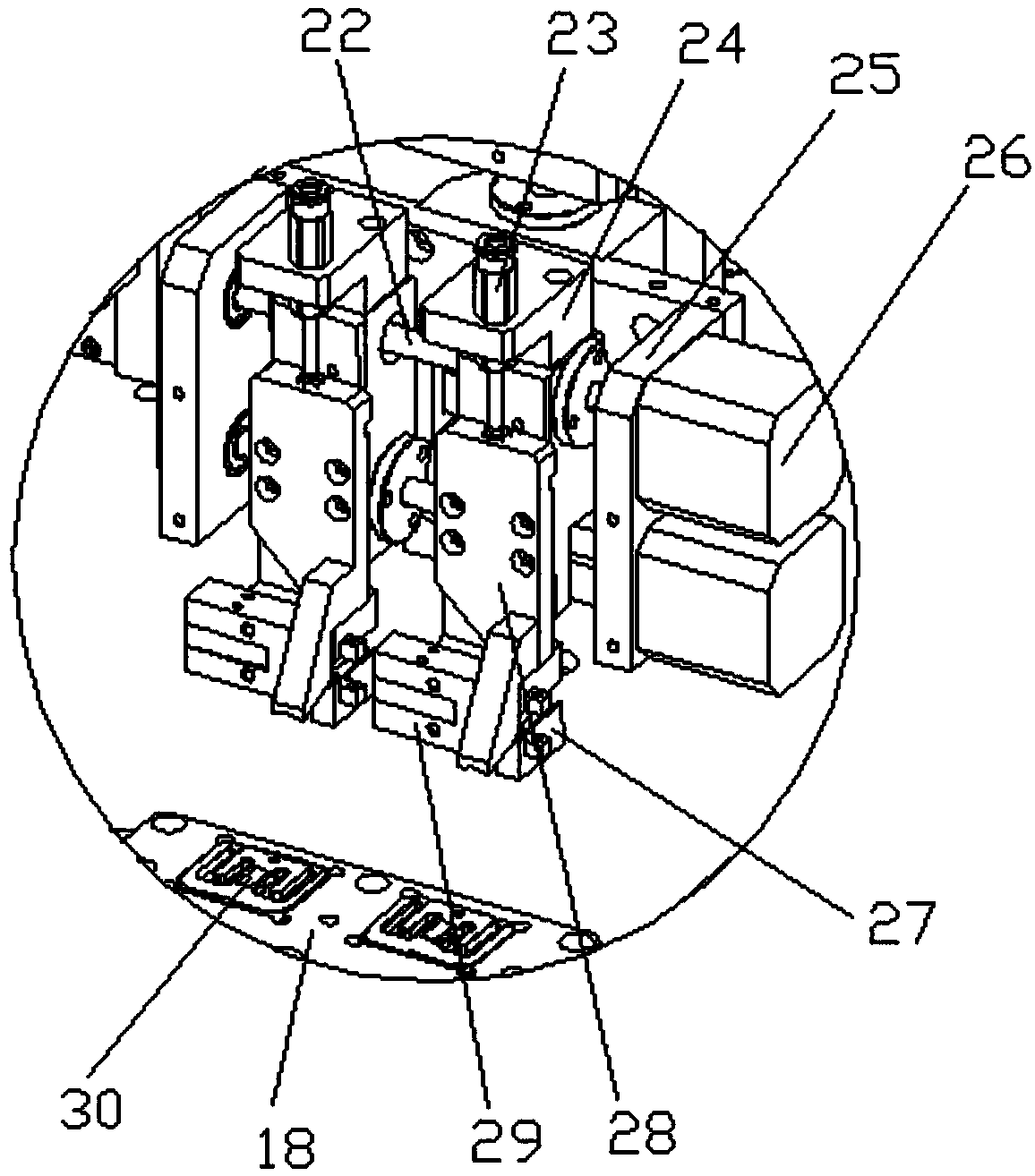

Automatic feed and discharge system of press robot

InactiveCN107159803AConvenient continuous feedingImprove feeding efficiencyMetal-working feeding devicesPositioning devicesNumerical controlAutomatic control

The invention relates to an automatic feed and discharge system of a press robot. The automatic feed and discharge system comprises at least one punch press, an automatic feed device, an automatic discharge device and a computer automatic-control system. The automatic feed device comprises a rotary feeding mechanism and a feed manipulator device, and the computer automatic-control system comprises an integrated chip, a numerical control circuit, a display screen and a control panel; automatic feed, stamping forming and automatic discharge of the punch press, the rotary feeding mechanism, the feed manipulator device and the automatic discharge device are achieved through the computer automatic-control system. By adopting the above structure, the automatic feed and discharge system has the advantages that the machining is quick and accurate, and the machining accuracy is even; the production efficiency is improved, and the manpower cost is reduced; and manual feed and discharge are avoided, and the production safety is improved.

Owner:GUANGZHOU ZHENGBAO PRECISION MACHINERY +1

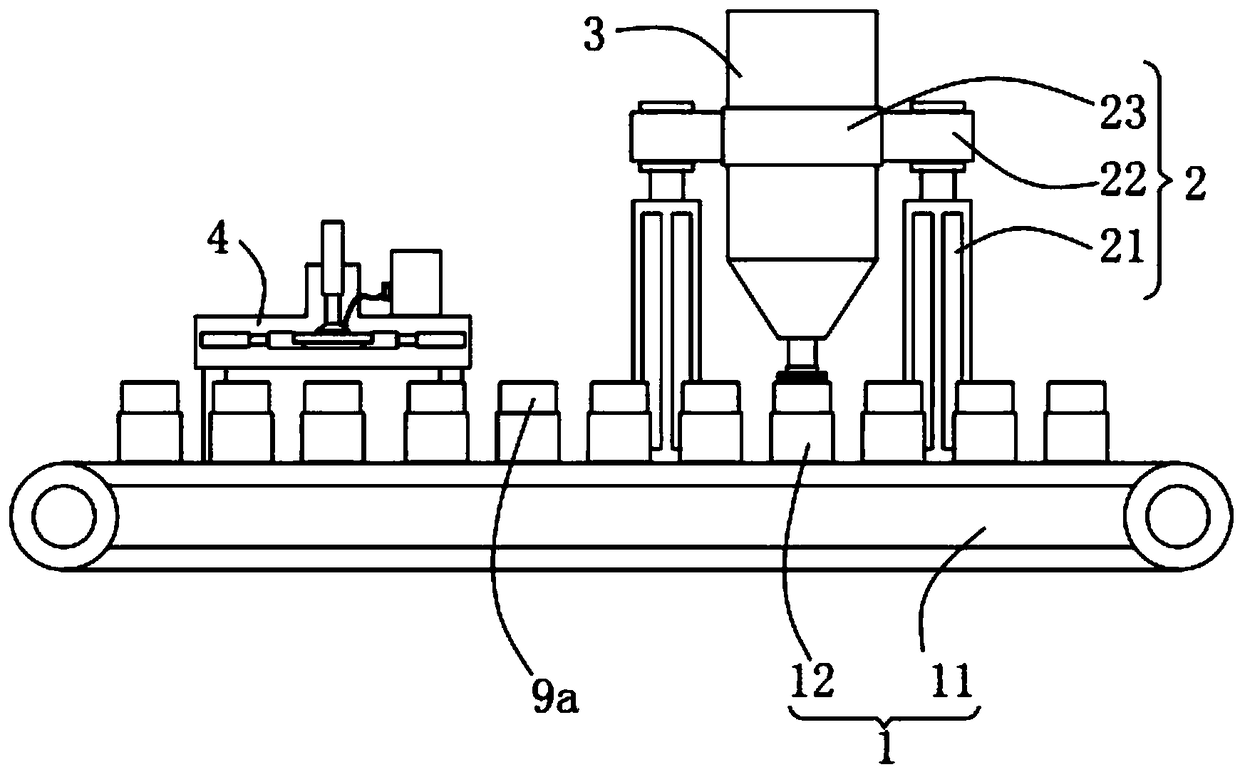

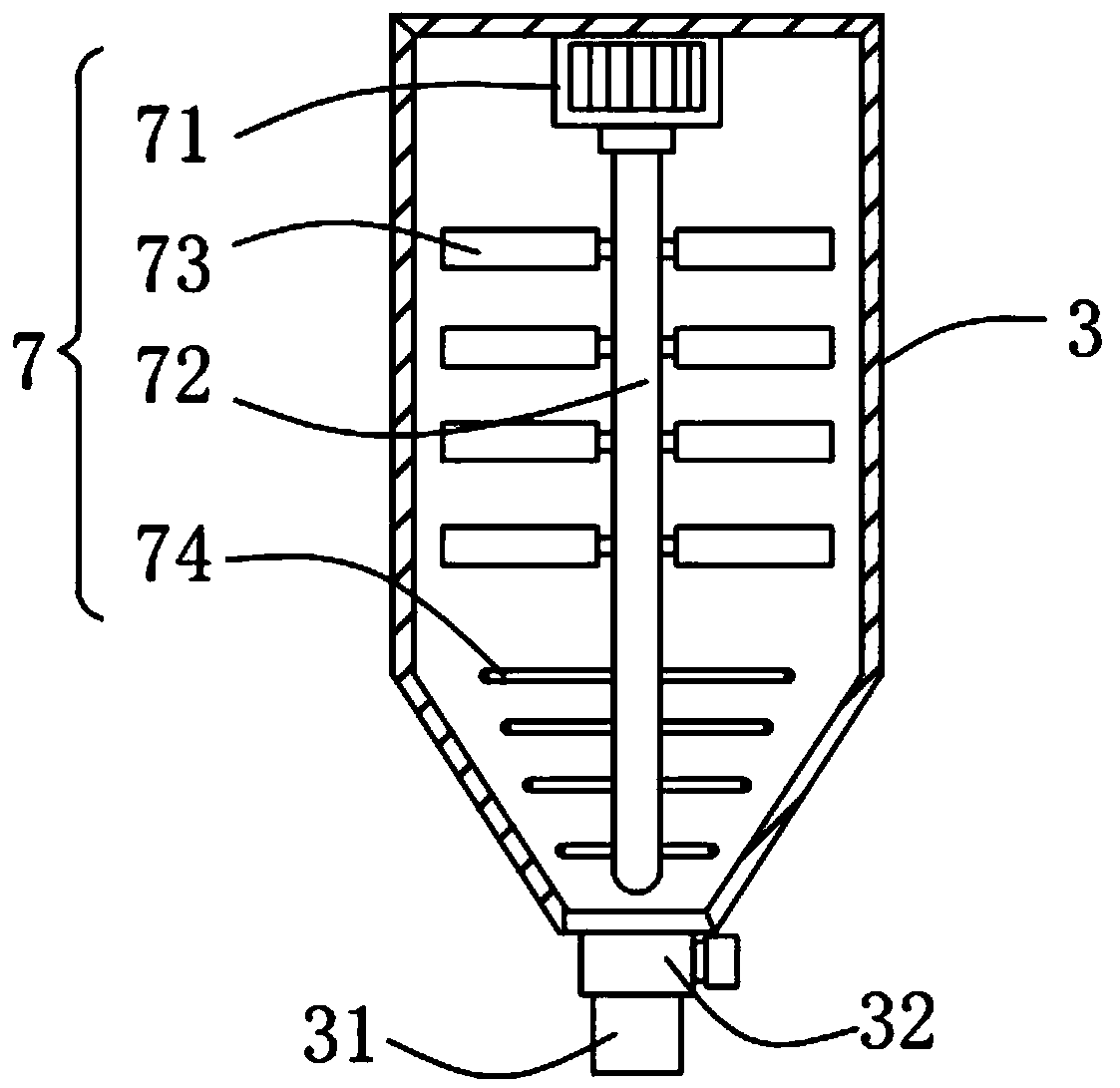

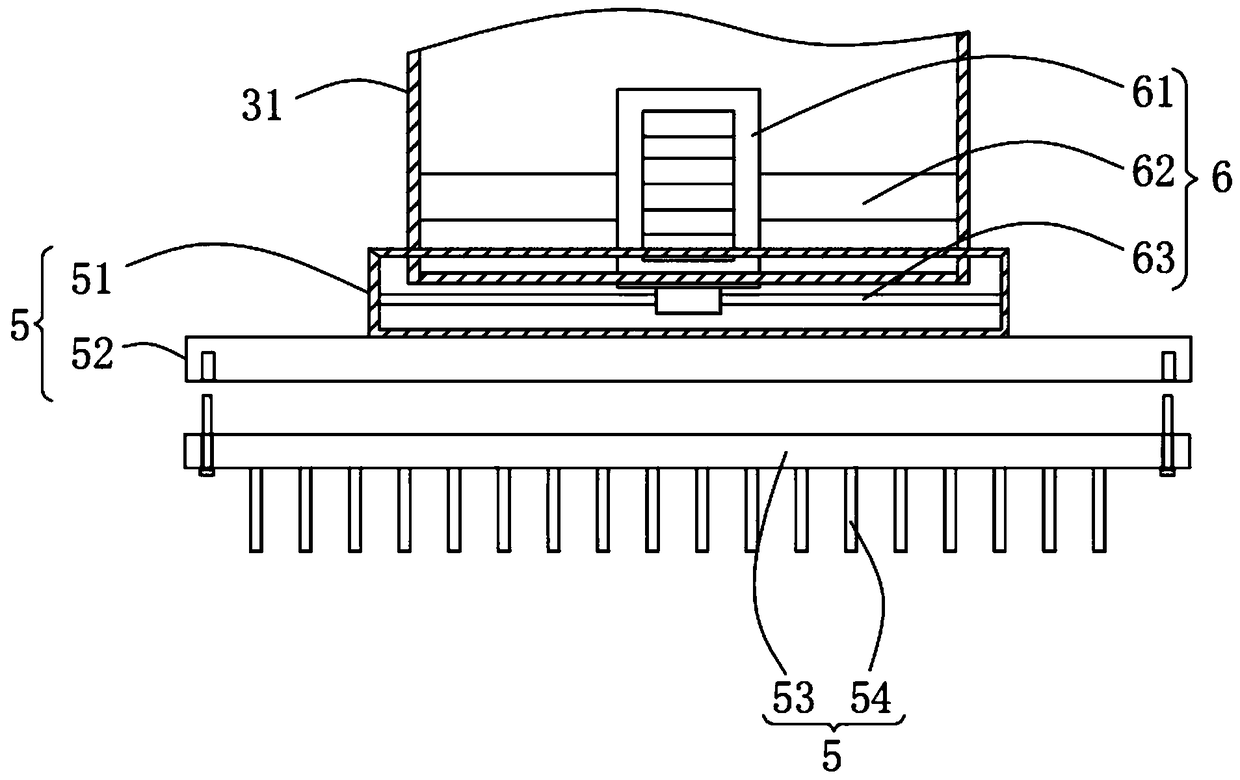

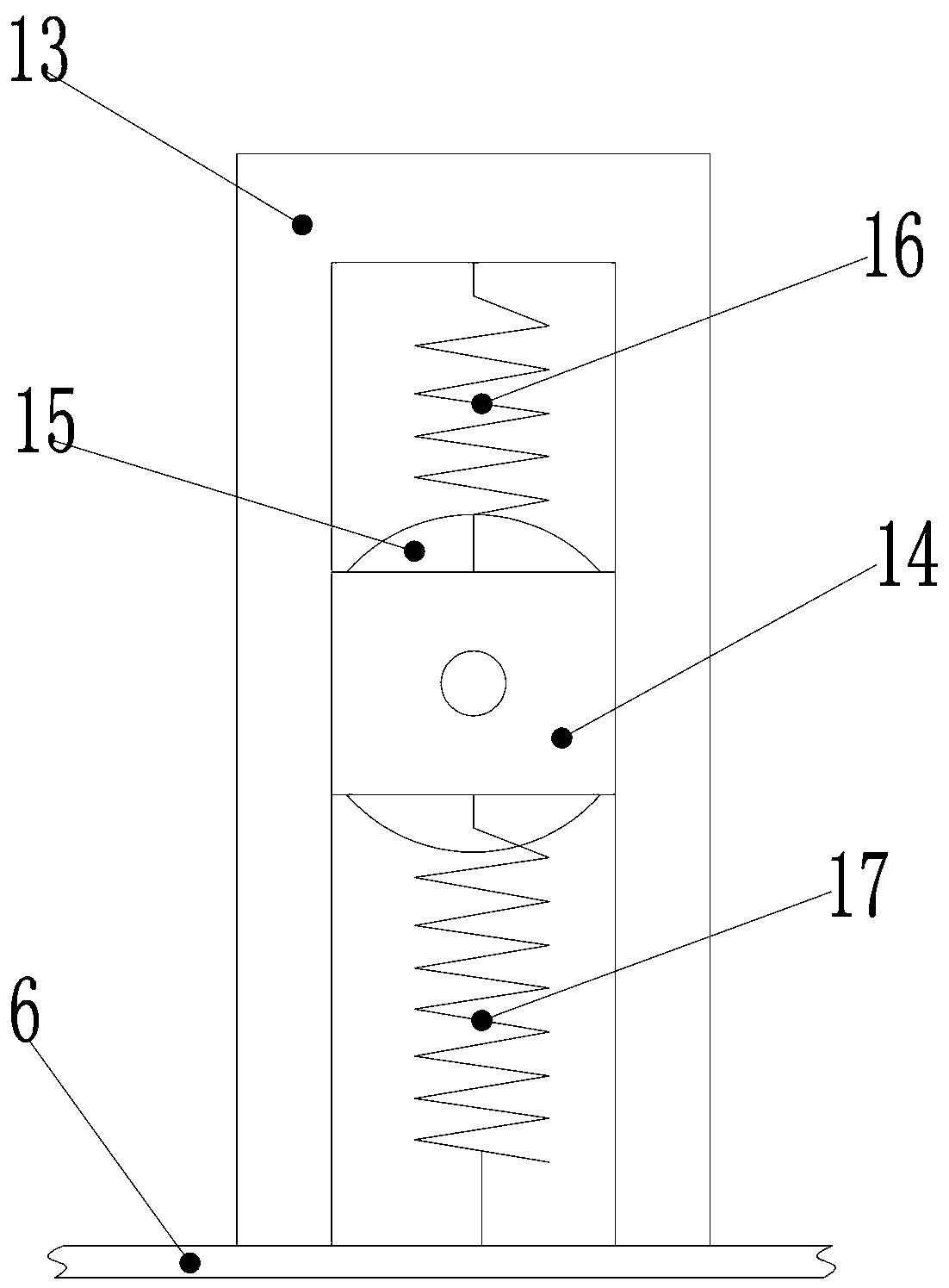

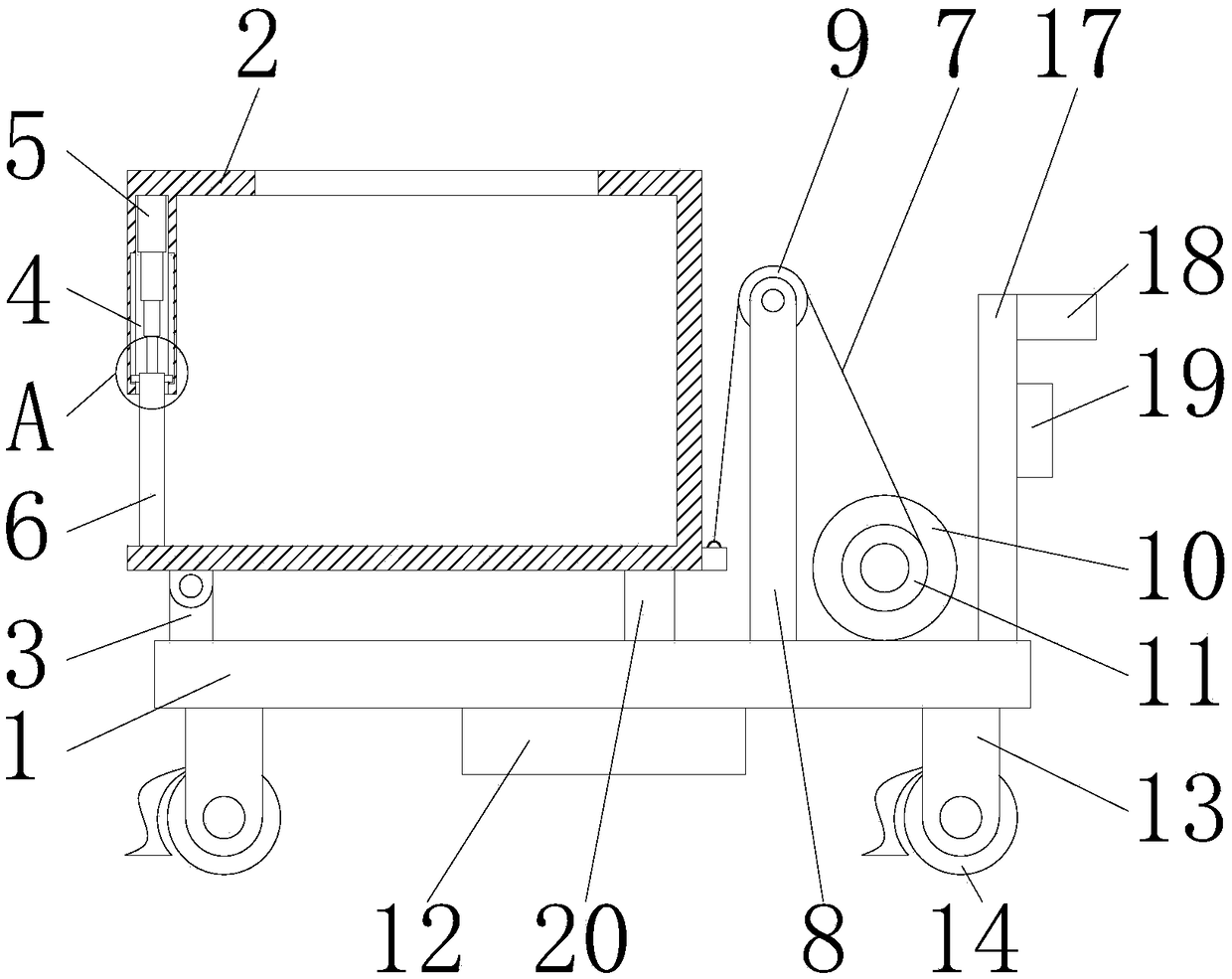

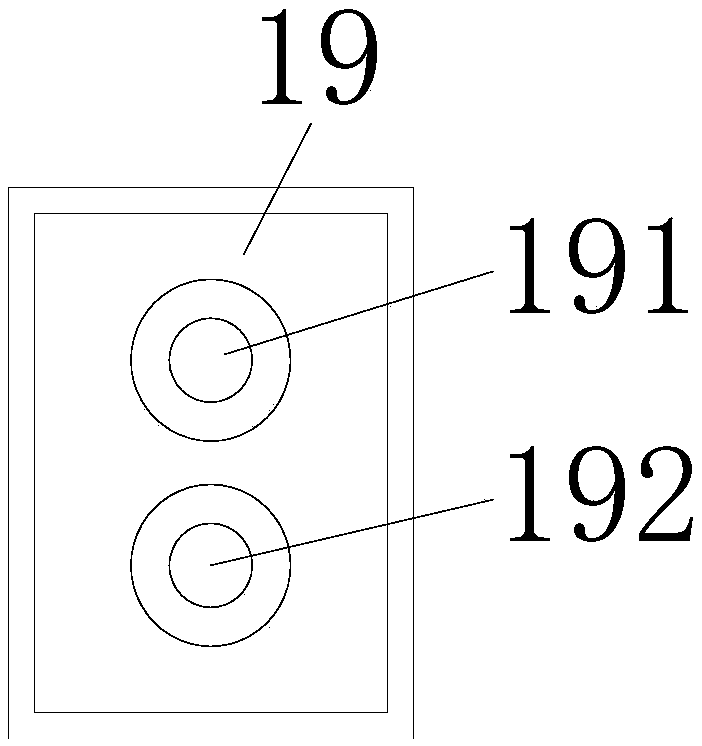

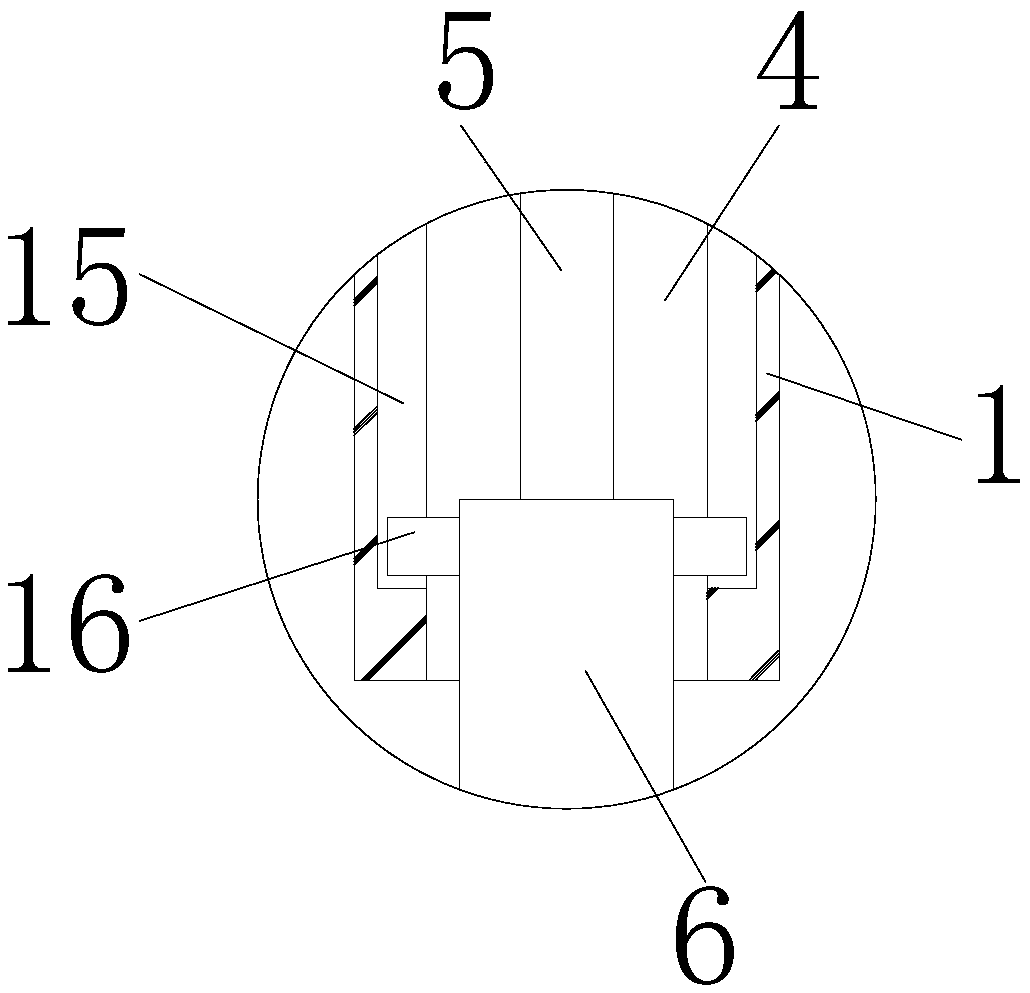

Powder material packaging machine

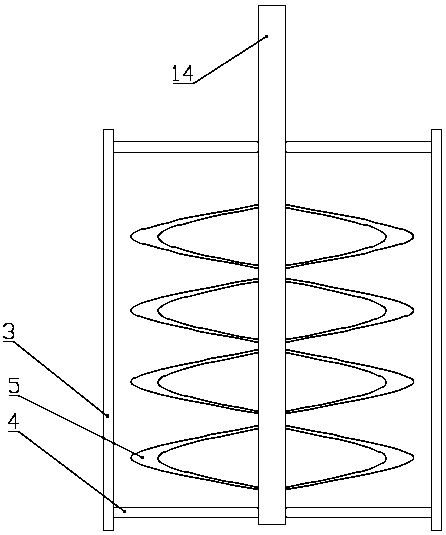

ActiveCN109335113AEvenly stackedQuick unloadingRotary stirring mixersSolid materialPackaging TankEngineering

The invention relates to the technical field of food processing equipment, in particular to a powder materials packaging machine. The powder material packaging machine comprises a conveying mechanism,a lifting mechanism, a material storage cylinder, a sealing mechanism, a flattening mechanism, a rotating mechanism, a stirring mechanism and a feeding mechanism. According to the machine, a discharging pipe can be driven to move upwards gradually from the bottom layer in a packaging tank through the lifting mechanism, so that the materials are gradually accumulated from bottom to top, and the accumulation is more uniform; meanwhile, the rotating mechanism can drive the flattening mechanism to rotate, a shifting rod can shift and scatter the materials, a flattening plate can flatten the materials, so that the powder materials can fully fill the whole packaging tank; in the discharging process, stirring blades can stir the top area of the packaging tank, stirring rods which are distributedin a funnel shape can stir the outlet area of the packaging tank, so that the discharging is more rapid and the blockage is prevented; and automatic feeding and packaging can be realized.

Owner:台州佑辅机械实业有限公司

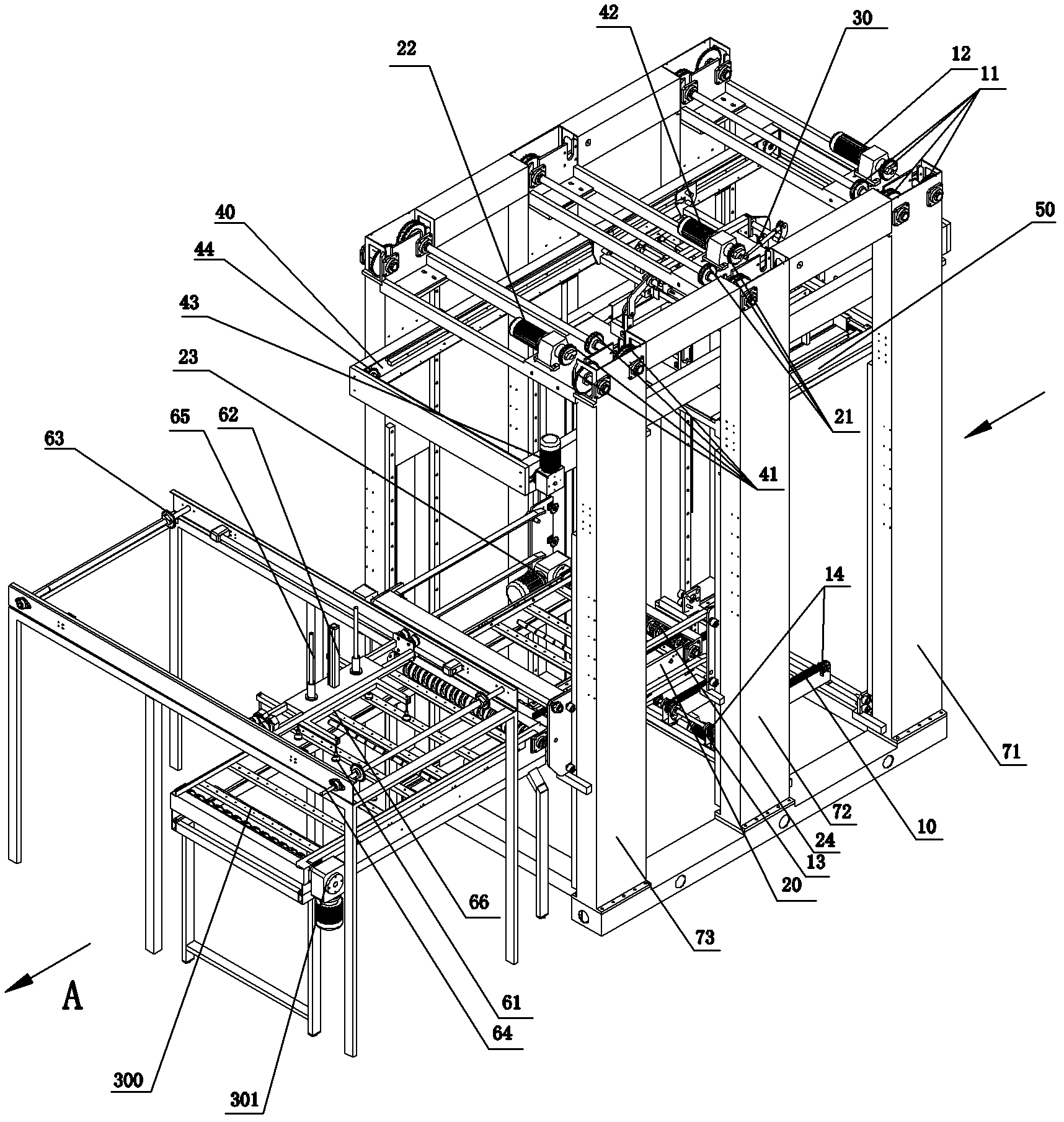

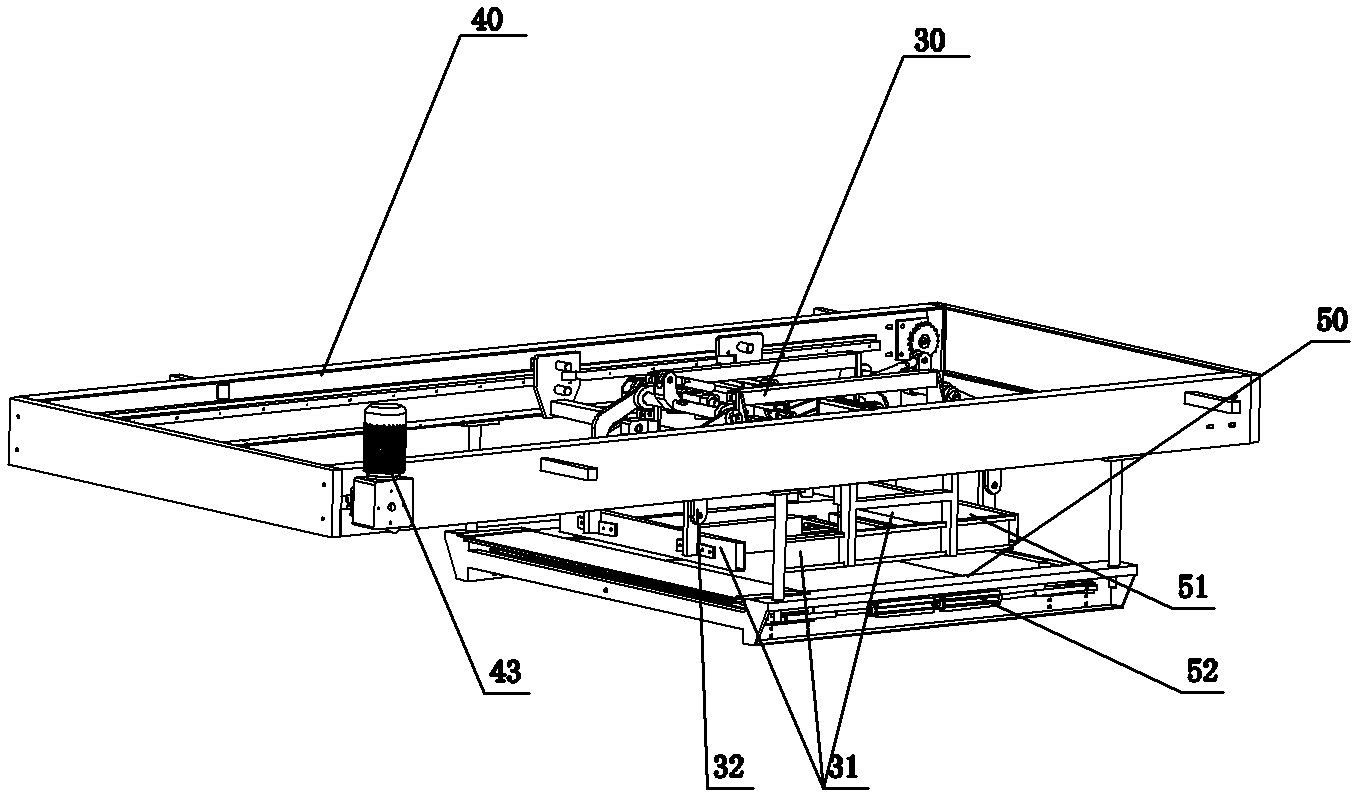

Bottle unloading machine

ActiveCN102616575AStable structureCompact structureStacking articlesDe-stacking articlesEngineeringBottle

The invention provides a bottle unloading machine which comprises a first liftable platform for bearing the whole stack of bottles, a liftable transitional platform for bearing the whole layer of bottles, a mechanical gripper for the whole layer of bottles, a lifting frame, a clamping mechanism and a separation board moving-away device, wherein the transitional platform is a conveying mechanism; the lifting frame is positioned above the first platform and the transitional platform; the conveying mechanism is arranged in the lifting frame; the mechanical gripper is connected onto the conveying mechanism; and the clamping mechanism is arranged on the lifting frame and is positioned below the mechanical gripper. According to the bottle unloading machine disclosed by the invention, the first platform, the transitional platform and the lifting frame are interactive in full time in a two-dimensional space and are separately and efficiently matched in parallel, so that the low-in and low-out quick bottle unloading process is realized.

Owner:HANGZHOU YOUNGSUN INTELLIGENT EQUIP

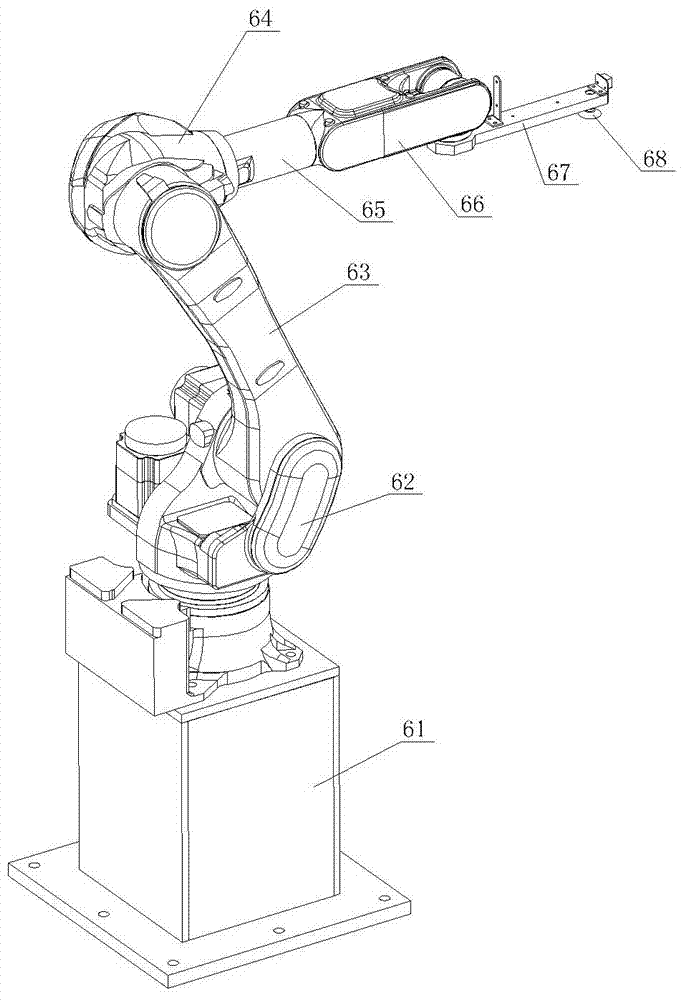

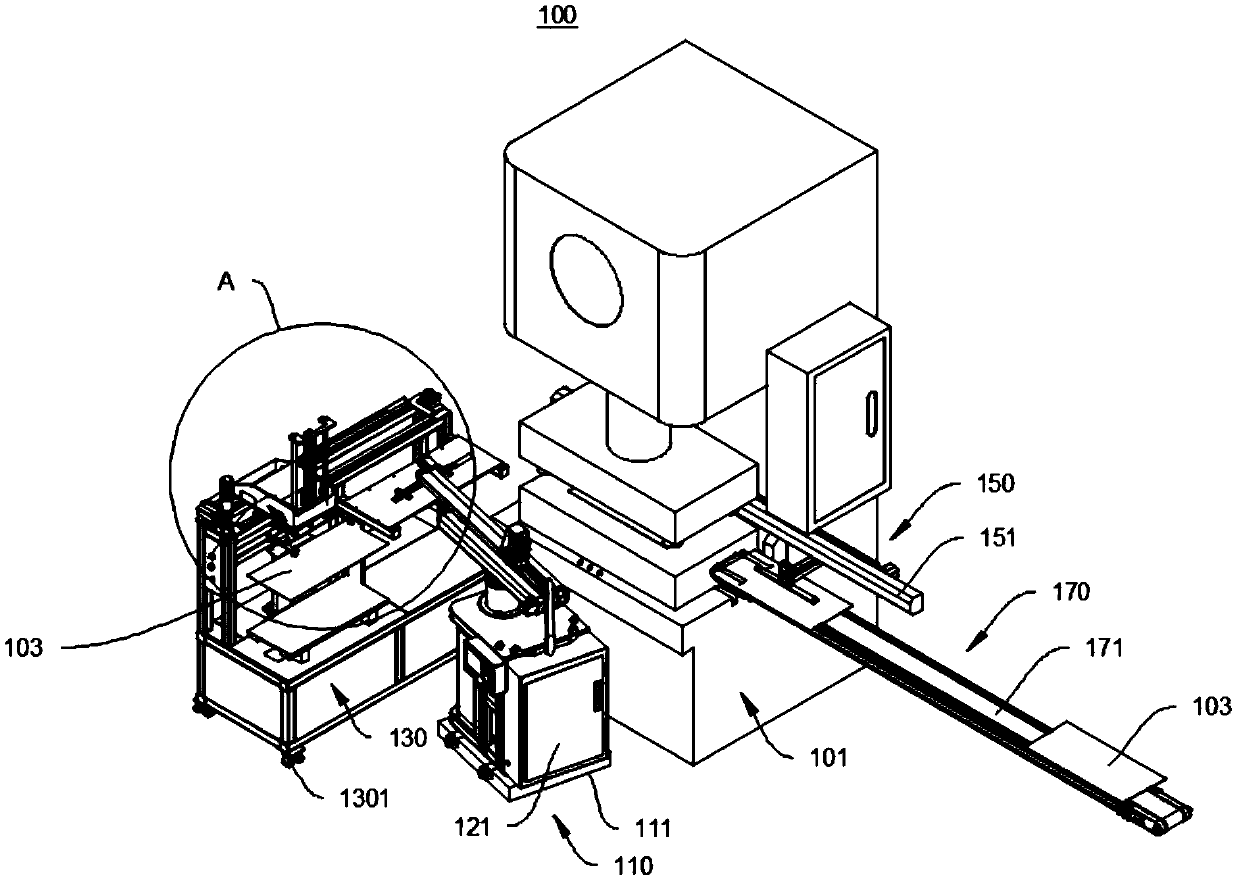

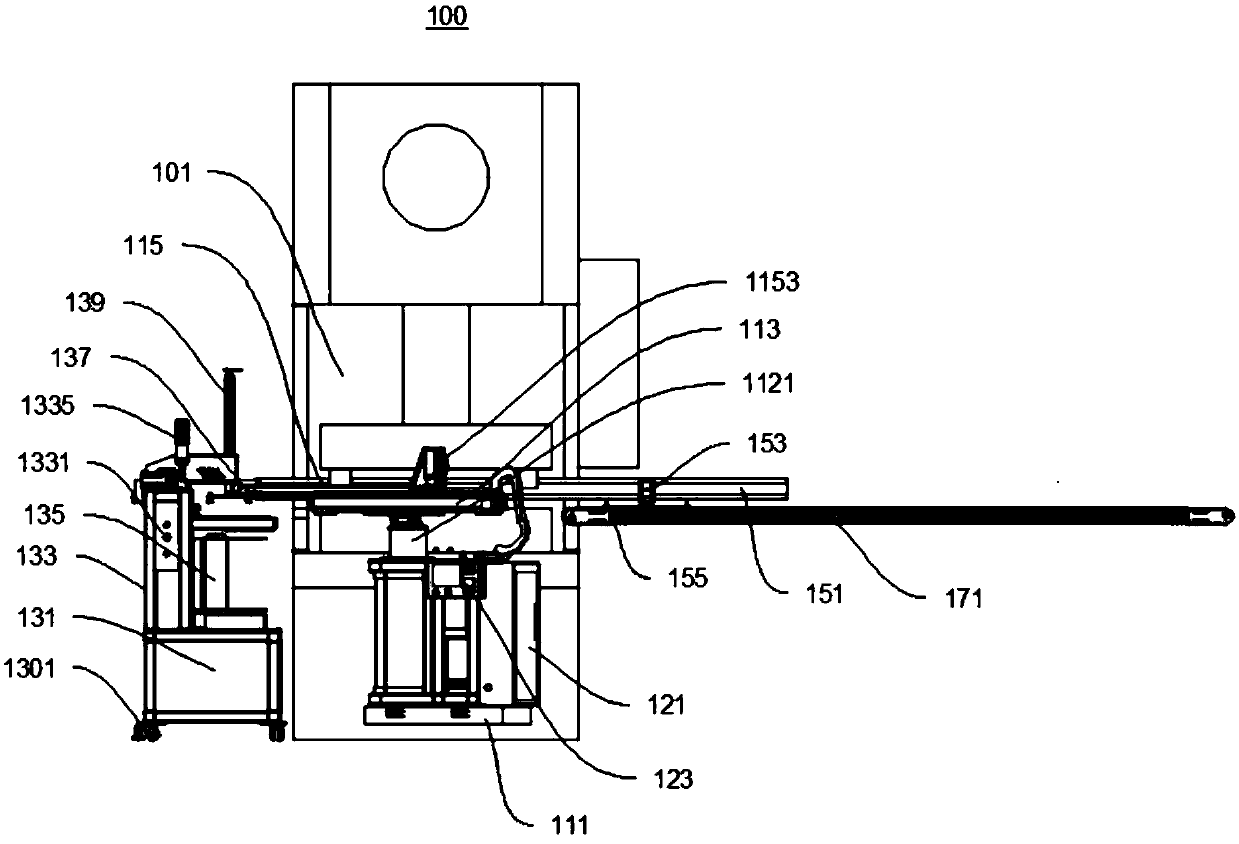

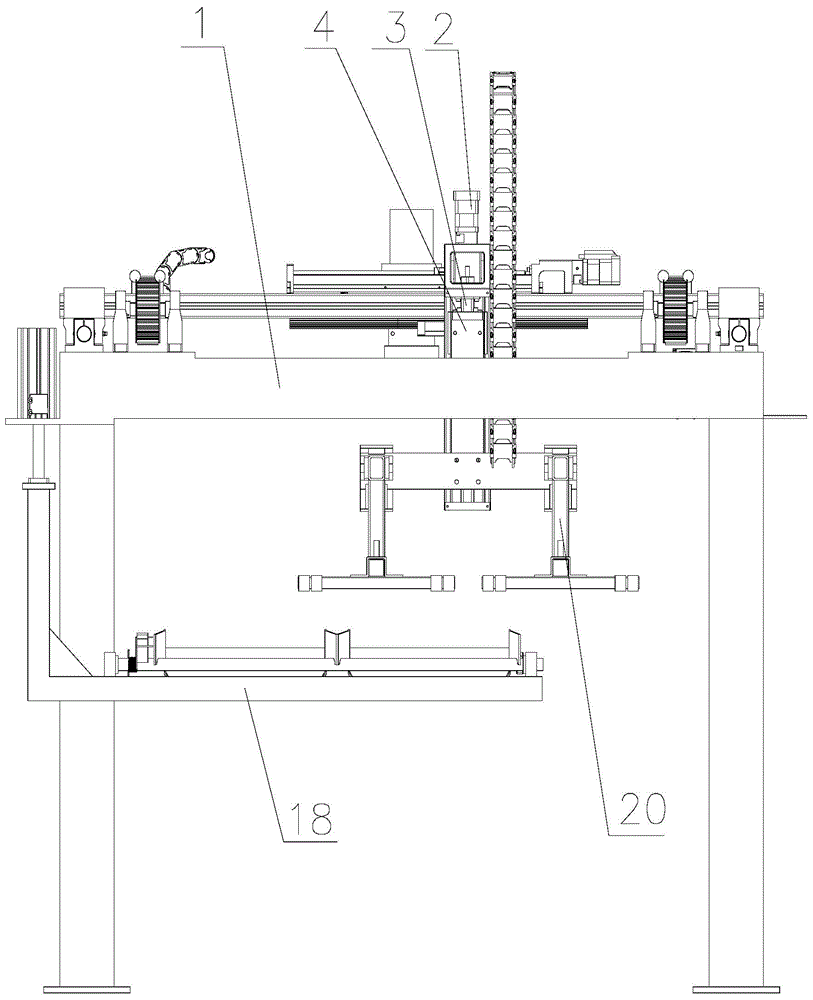

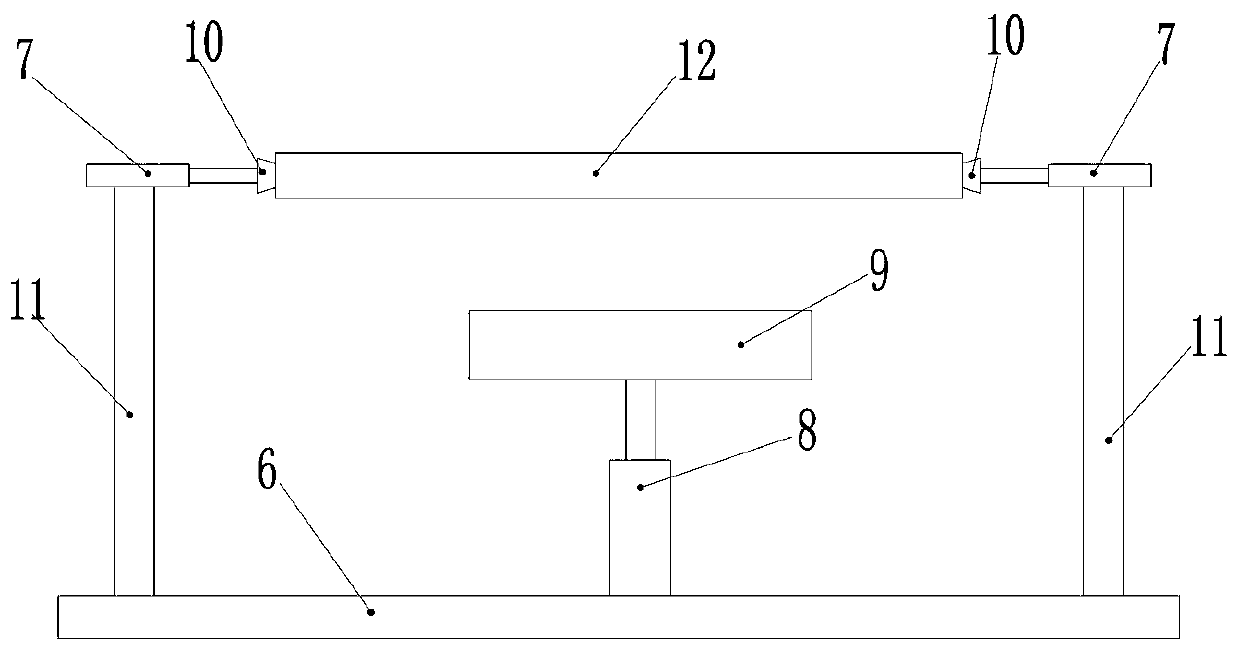

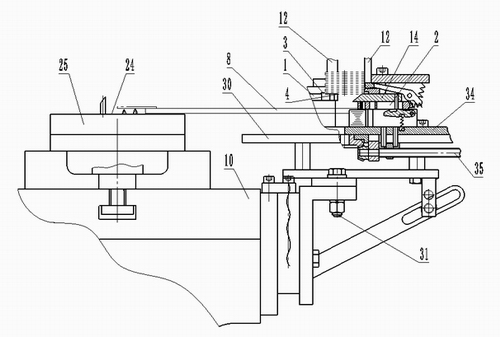

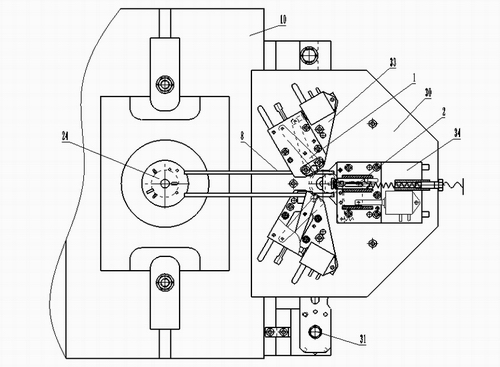

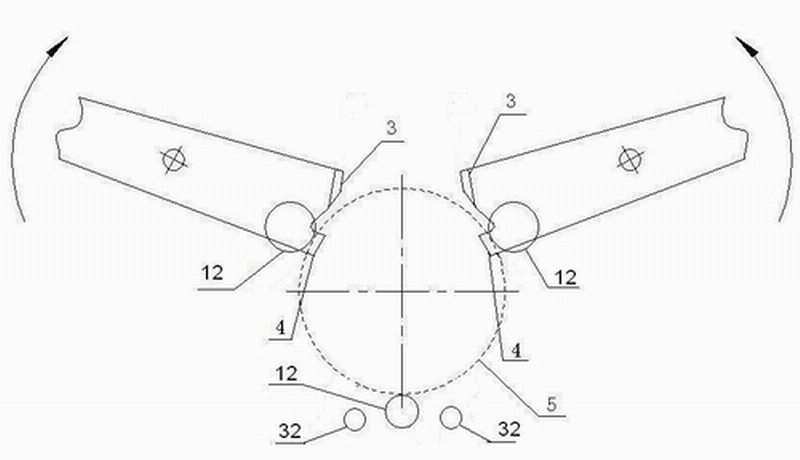

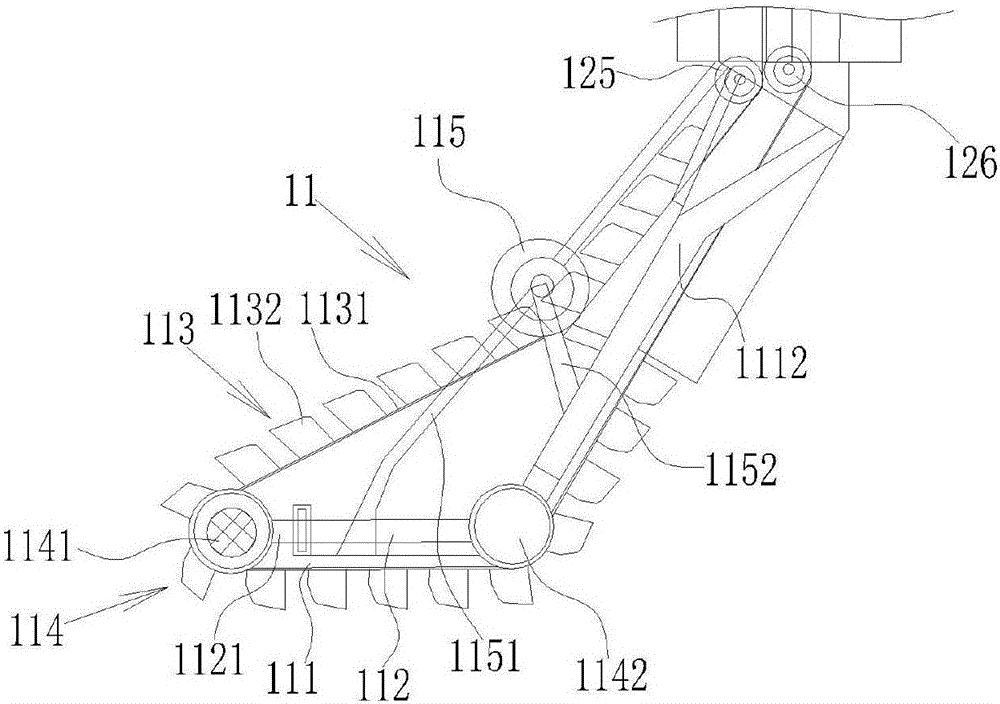

Automatic feeding and discharging mechanical arm of punching machine

ActiveCN107900245ARealize dynamic adjustmentEasy to operateMetal-working feeding devicesPositioning devicesDischarge efficiencyPunch press

The invention provides an automatic feeding and discharging mechanical arm of a punching machine and relates to the technical field of mechanical automation. The automatic feeding and discharging mechanical arm of the punching machine comprises a feeding platform, a feeding mechanical arm and a horizontal auxiliary arm. The feeding mechanical arm body conveys a product to a punching platform. Thehorizontal auxiliary arm moves the product out from the punching platform. The feeding mechanical arm comprises a first operation platform, a servo motion module, a control system, a manipulator arm and a manipulator hand, wherein the servo motion module, the control system, the manipulator arm and the manipulator hand are installed on the first operation platform. The servo motion module is electrically connected with the control system. The servo motion module is connected with the manipulator arm. The manipulator arm is connected with the manipulator hand. The horizontal auxiliary arm comprises a horizontal beam, a first transmission assembly, a support and a grabbing assembly. The horizontal beam is installed on the punching platform. The first transmission assembly is installed on thehorizontal beam. The support is connected with the first transmission assembly. The grabbing assembly is connected with the support. The automatic feeding and discharging mechanical arm of the punching machine is convenient to manipulate, high in feeding and discharging efficiency, high in control precision, safe and reliable.

Owner:绵阳海迪机器人科技有限公司

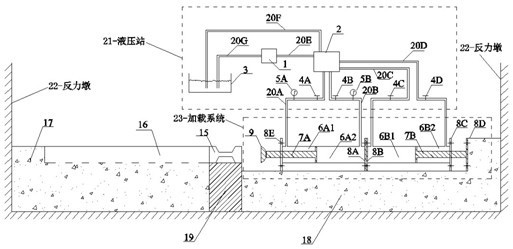

Transient unloading loose simulating system for excavating jointed rock mass

The invention discloses a transient unloading loose simulating system for excavating a jointed rock mass. The transient unloading loose simulating system for excavating the jointed rock mass comprises counterforce piers, a jointed rock mass model, an experimental table provided with displacement scale marks, a transitional block cushioning box, a transitional block arranged on the transitional block cushioning box, a hydraulic station, a loading device, a loading device supporting table and a monitoring system, wherein the counterforce piers are fixed on the outer sides of the loading device supporting table and the experimental table; the transitional block cushioning box is arranged on the other side of the experimental table; a slot for accommodating the jointed rock mass model is formed on the upper surface of the experimental table; the transitional block (15) is a square column with a variable cross section, and the section areas of the two ends of the transitional block are larger than the section area of the middle section; the width and height of the jointed rock mass model are matched with those of the transitional block (15); the loading device is horizontally arranged on the loading device supporting table; and the monitoring system is used for monitoring the simulating process. By the system, the load on the jointed rock mass model is quickly unloaded, and the actual unloading condition in an engineering is met well.

Owner:WUHAN UNIV

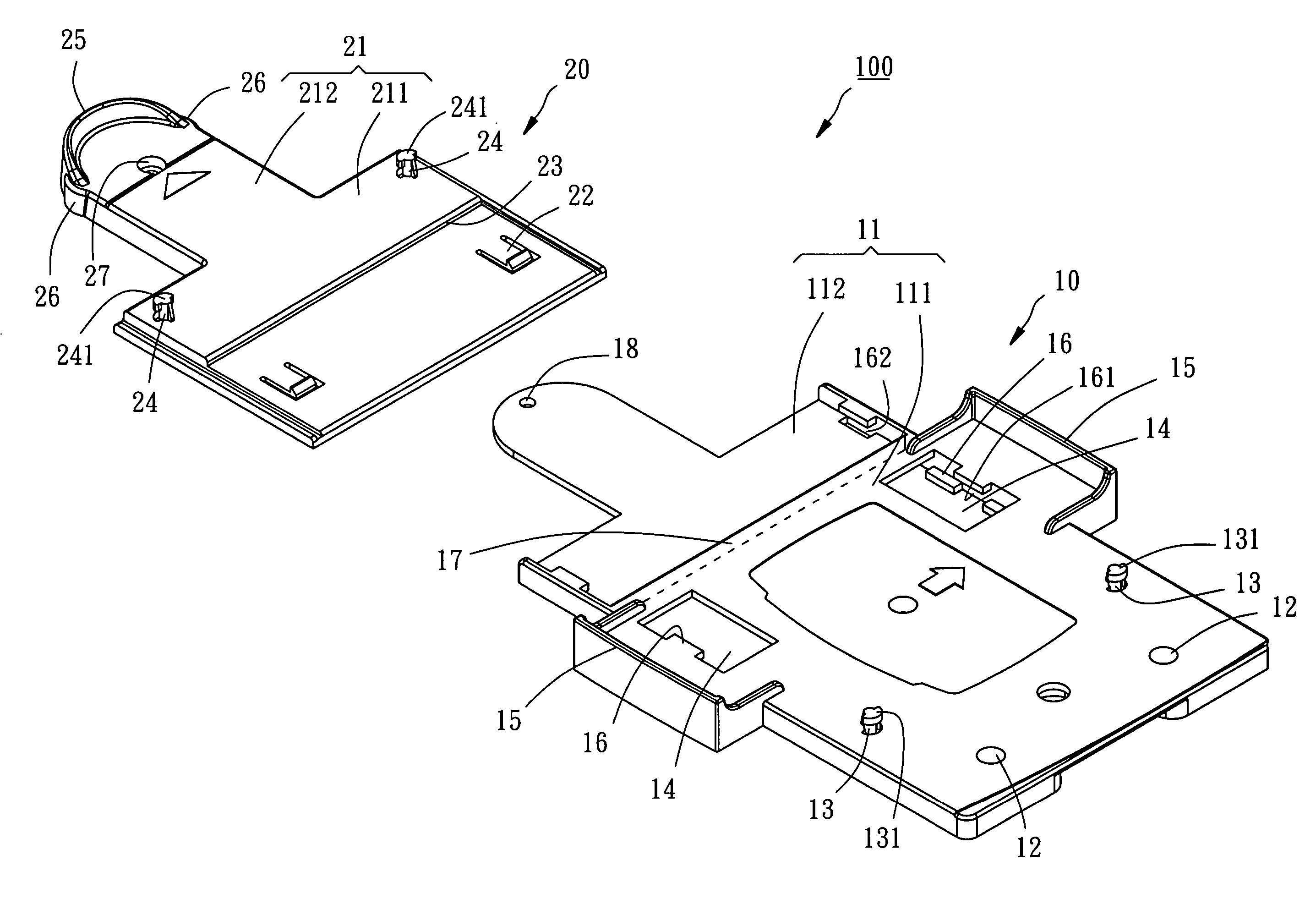

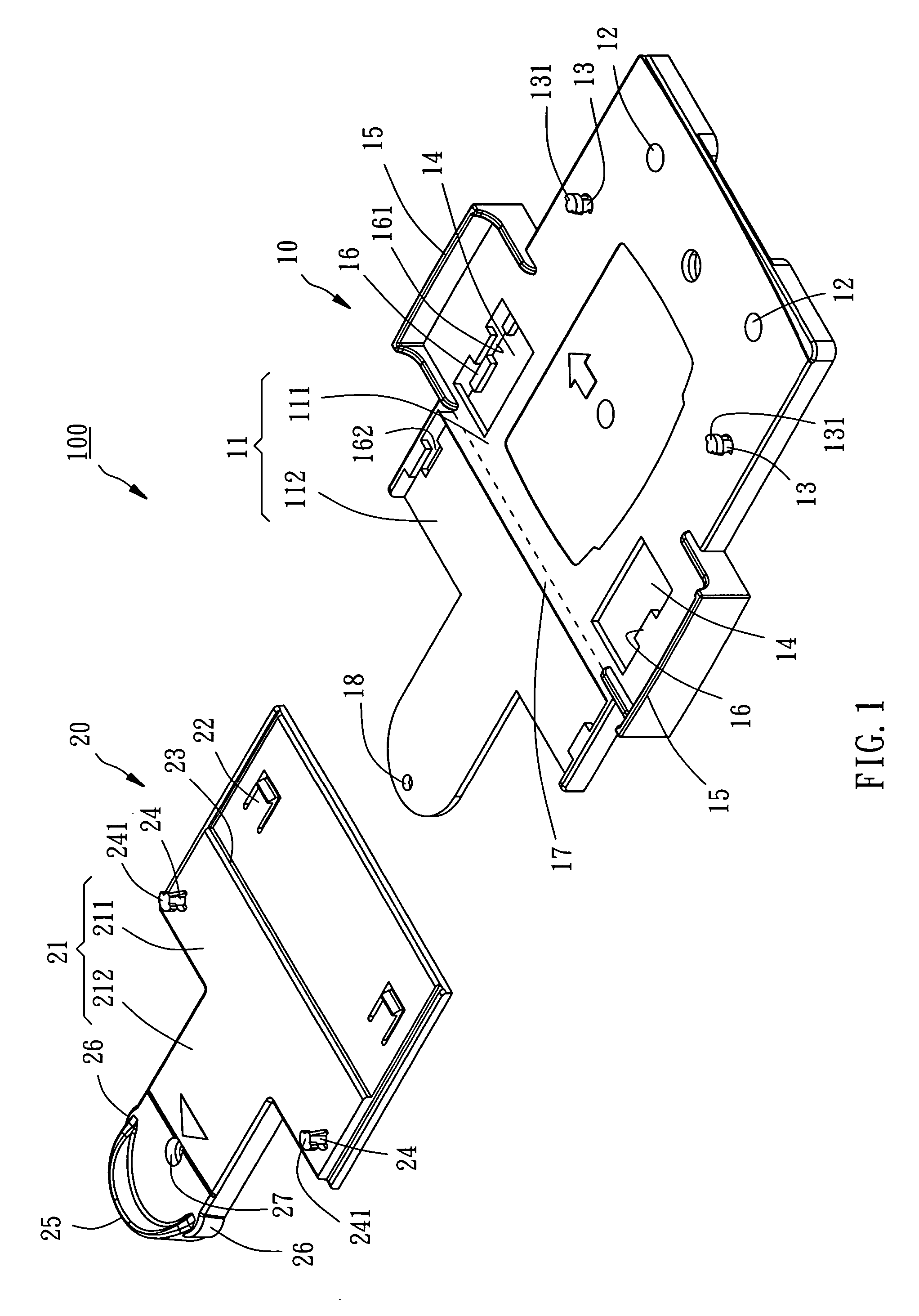

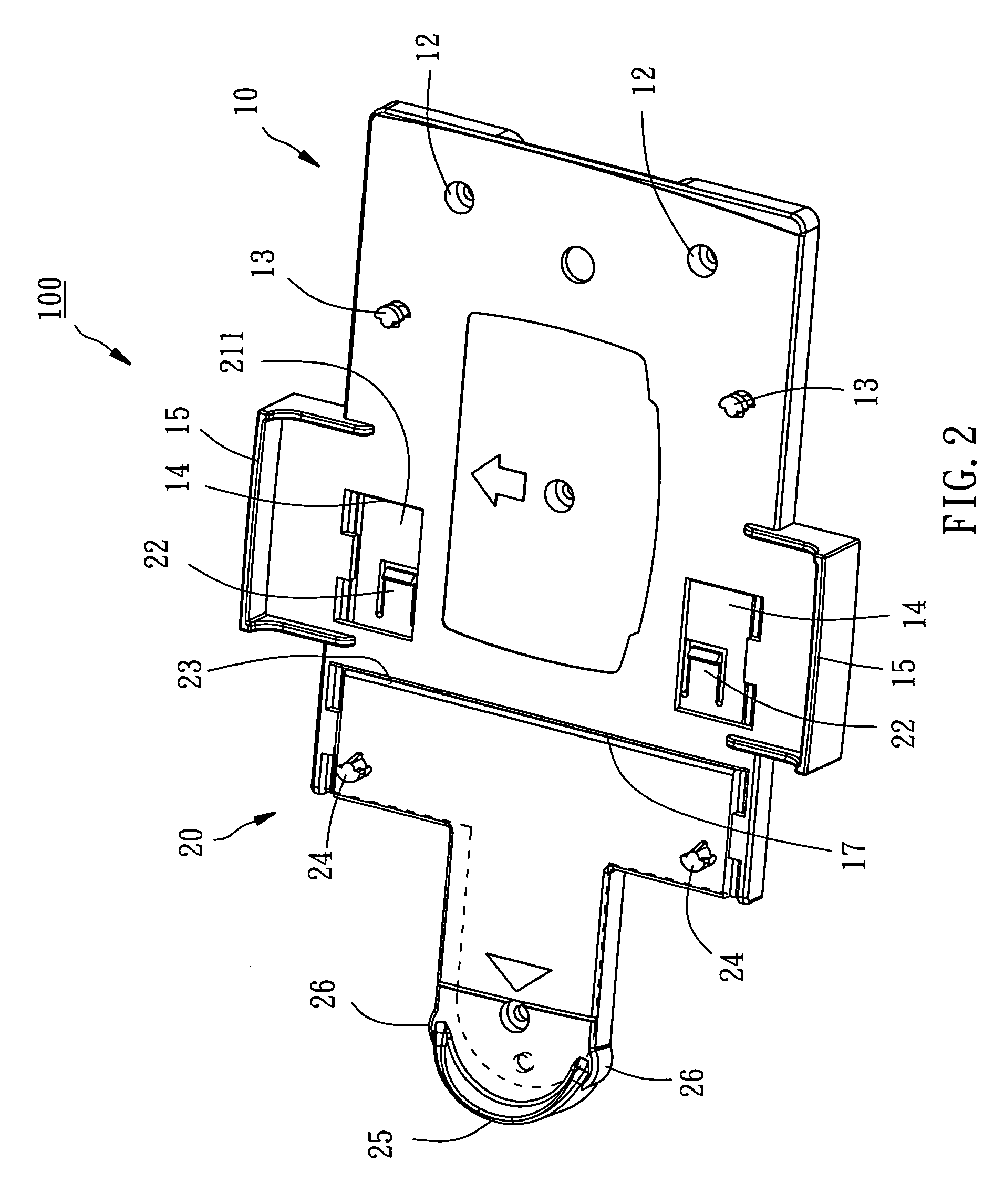

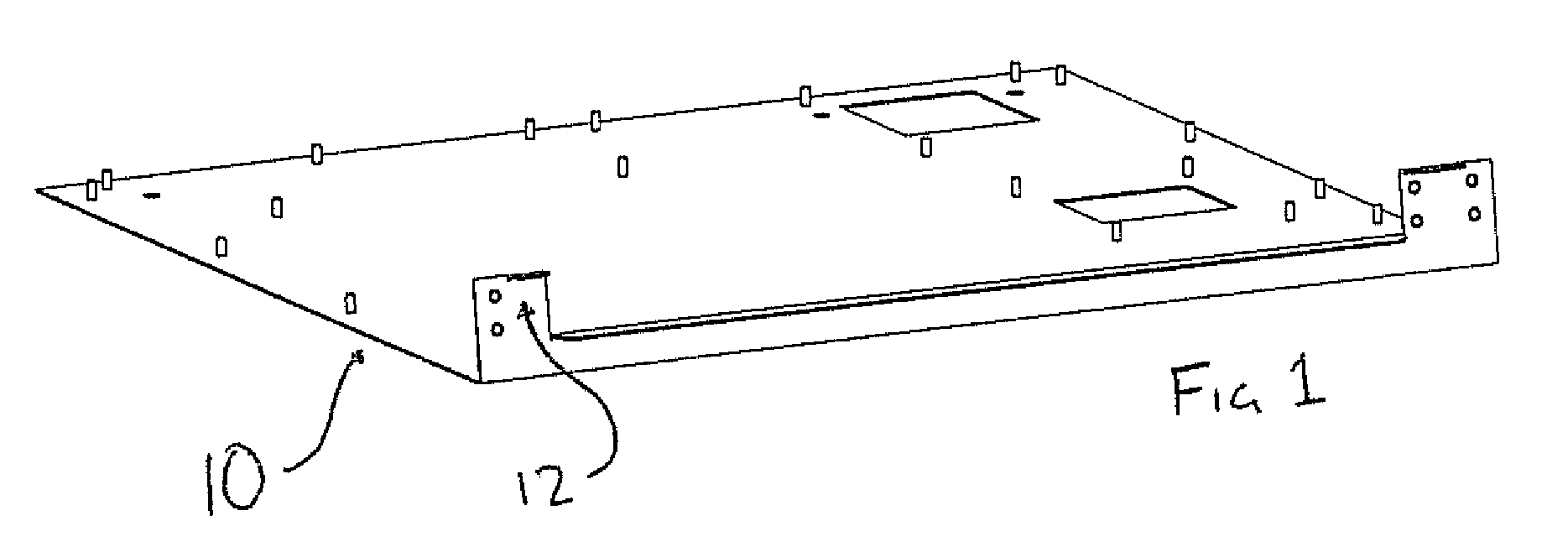

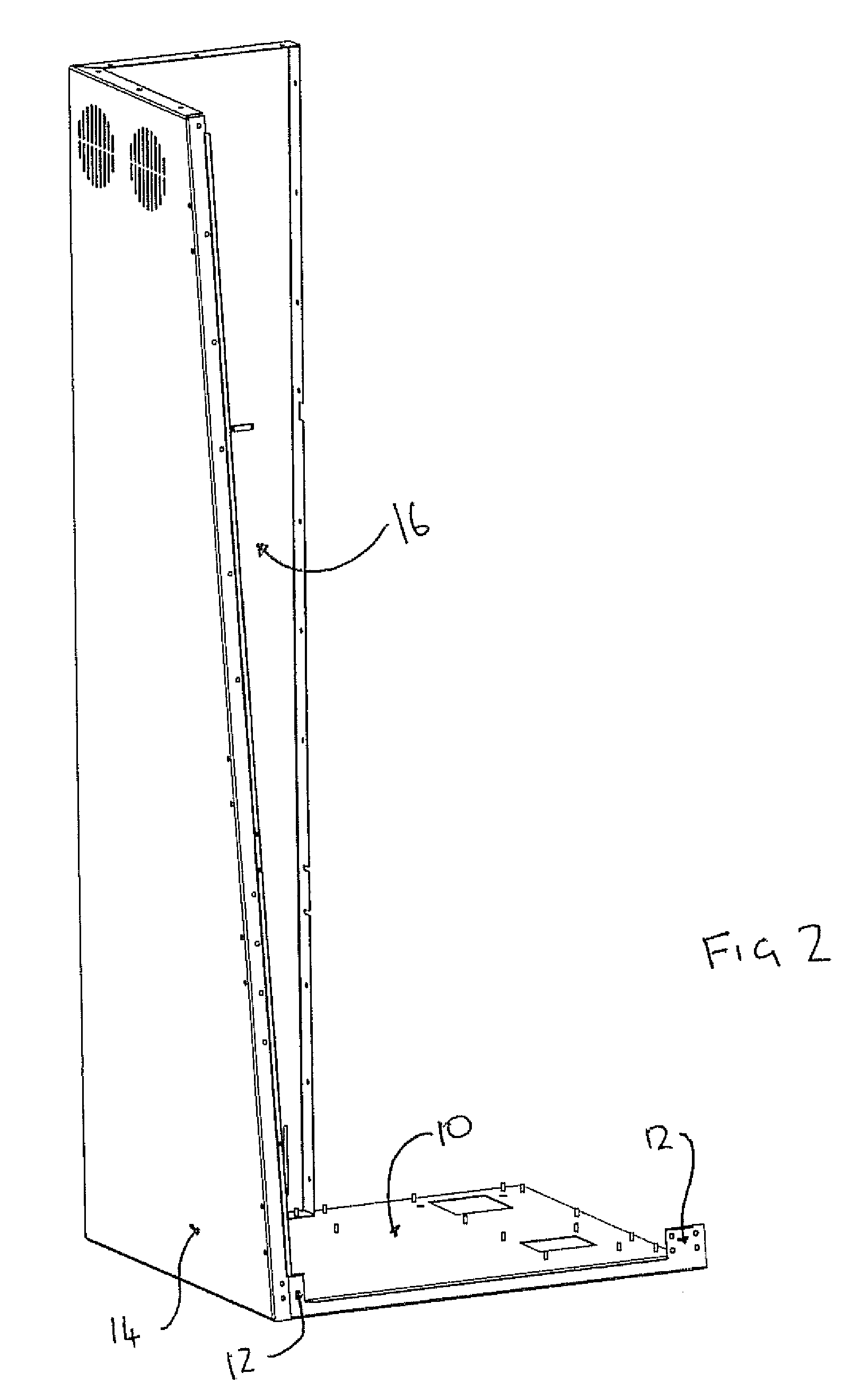

Electronic device holder

InactiveUS20070018067A1Quick unloadingQuick loading and unloadingCasings/cabinets/drawers detailsStands/trestlesEngineeringMechanical engineering

Owner:ASKEY COMP

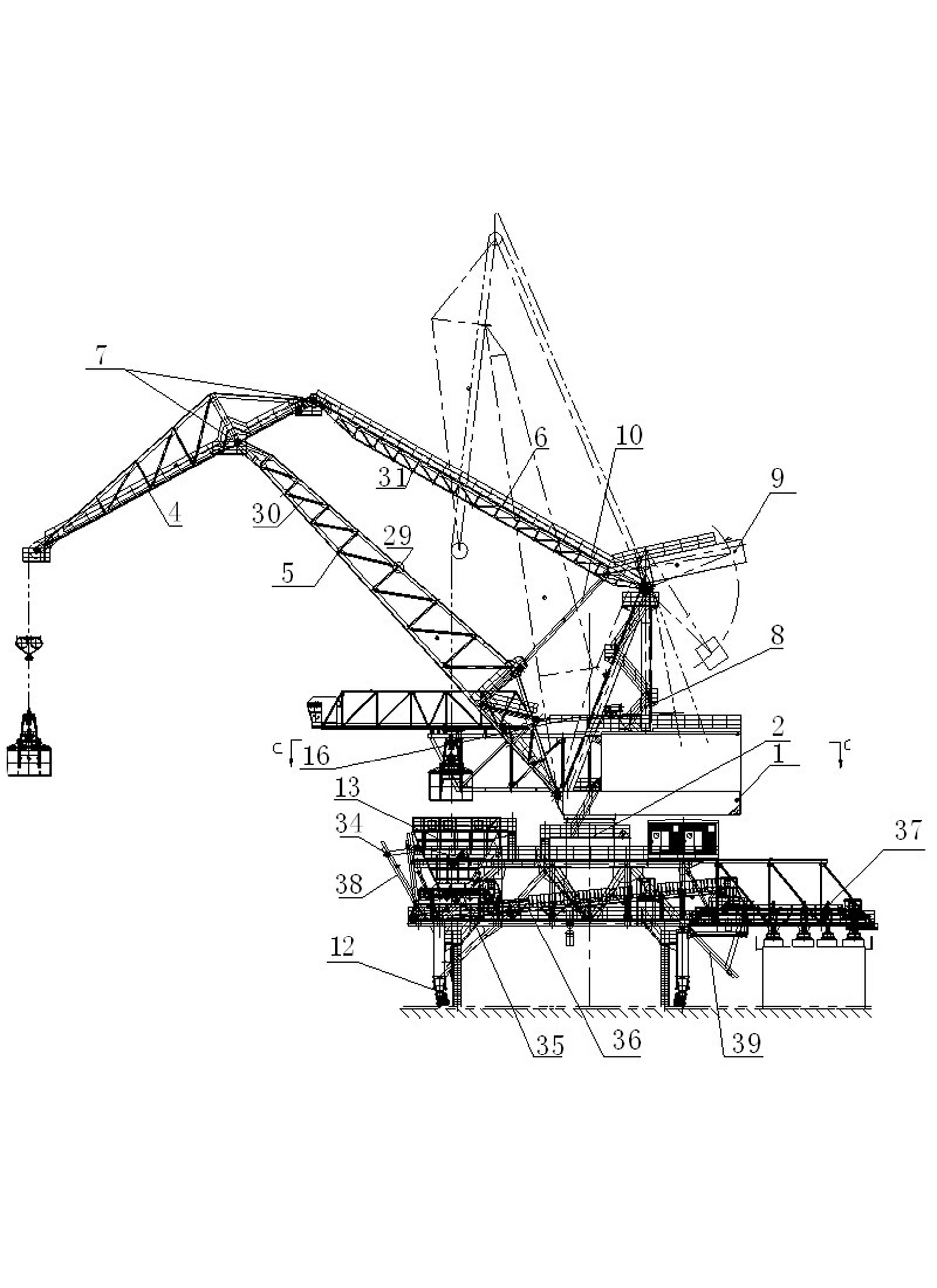

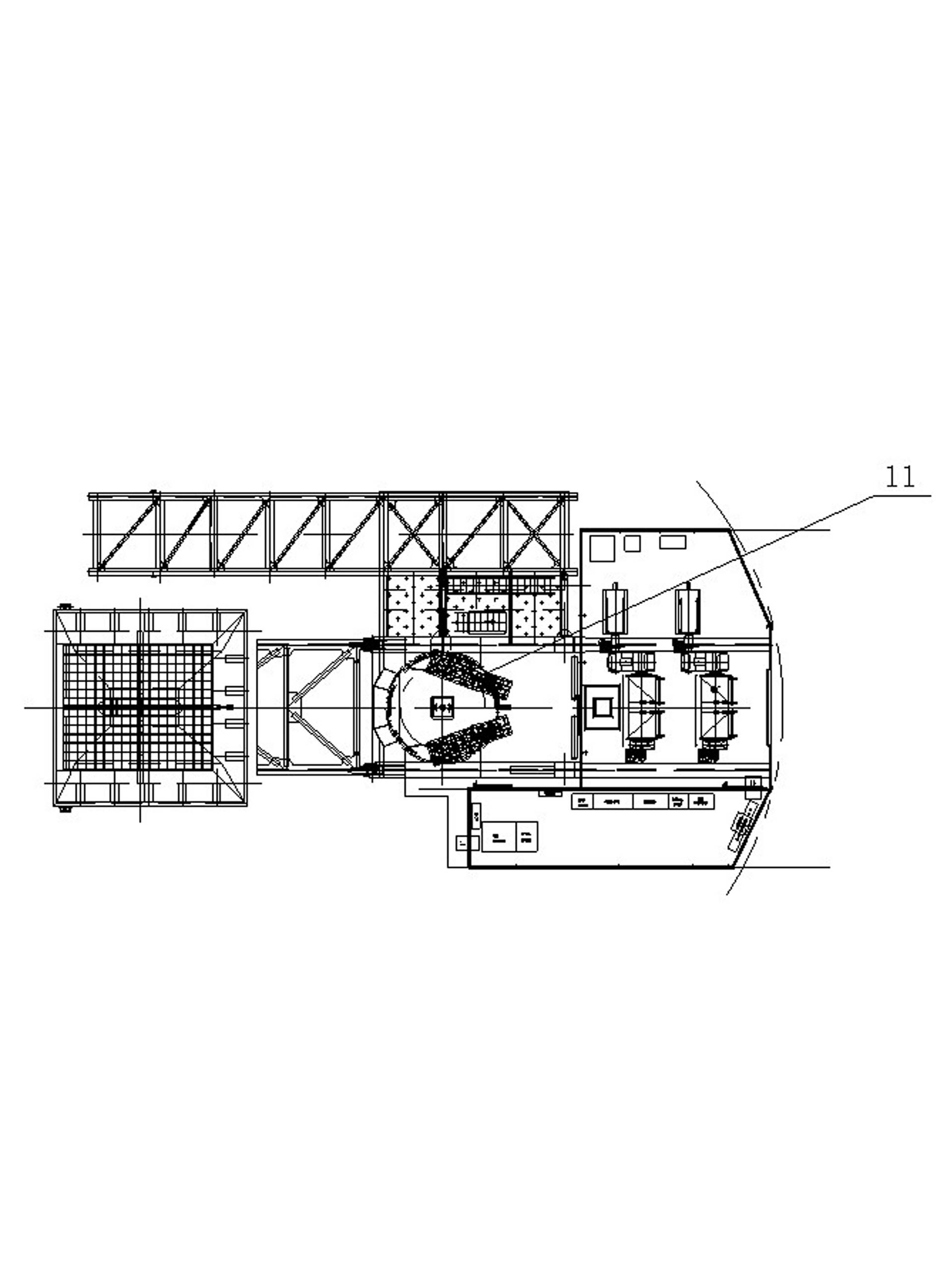

Horizontal luffing grab portal crane

InactiveCN102229412AImprove transmission efficiencyHigh transmission efficiency and high telescoping speedCranesNumerical controlGusset plate

The invention relates to a horizontal luffing grab portal crane, including a four-bar linkage level luffing boom system, a travelling mechanism and a gantry structure. The crane is characterized in that: a luffing mechanism comprises a triple screw, a screw pedestal and an electric transmission mechanism. The outside of the triple screw is provided with a telescopic cover, the inside of the screw pedestal is equipped with a sleeve with nuts, and two ends outside the sleeve are provided with bearings in the screw pedestal. The electric transmission mechanism comprises a motor, a driving gear and a brake apparatus. The end of the triple screw is hinged to a boom, and the luffing mechanism is equipped with a speed adjustable control system. The four-bar linkage boom system and a gantry beam are both girder construction which employs a T-shaped structure and a rectangular pipe. The T-shaped structure is a main chord member, and the rectangular pipe as a web member is welded on a web member gusset plate. In the blanking process, the T-shaped structure and the web member gusset plate are integrated through numerical control cutting. The crane of the invention has high operating cycle frequency which can reach 6 million times, high luffing speed, smooth running of grab bucket, high operating efficiency and long service life.

Owner:江苏海隆重机有限公司

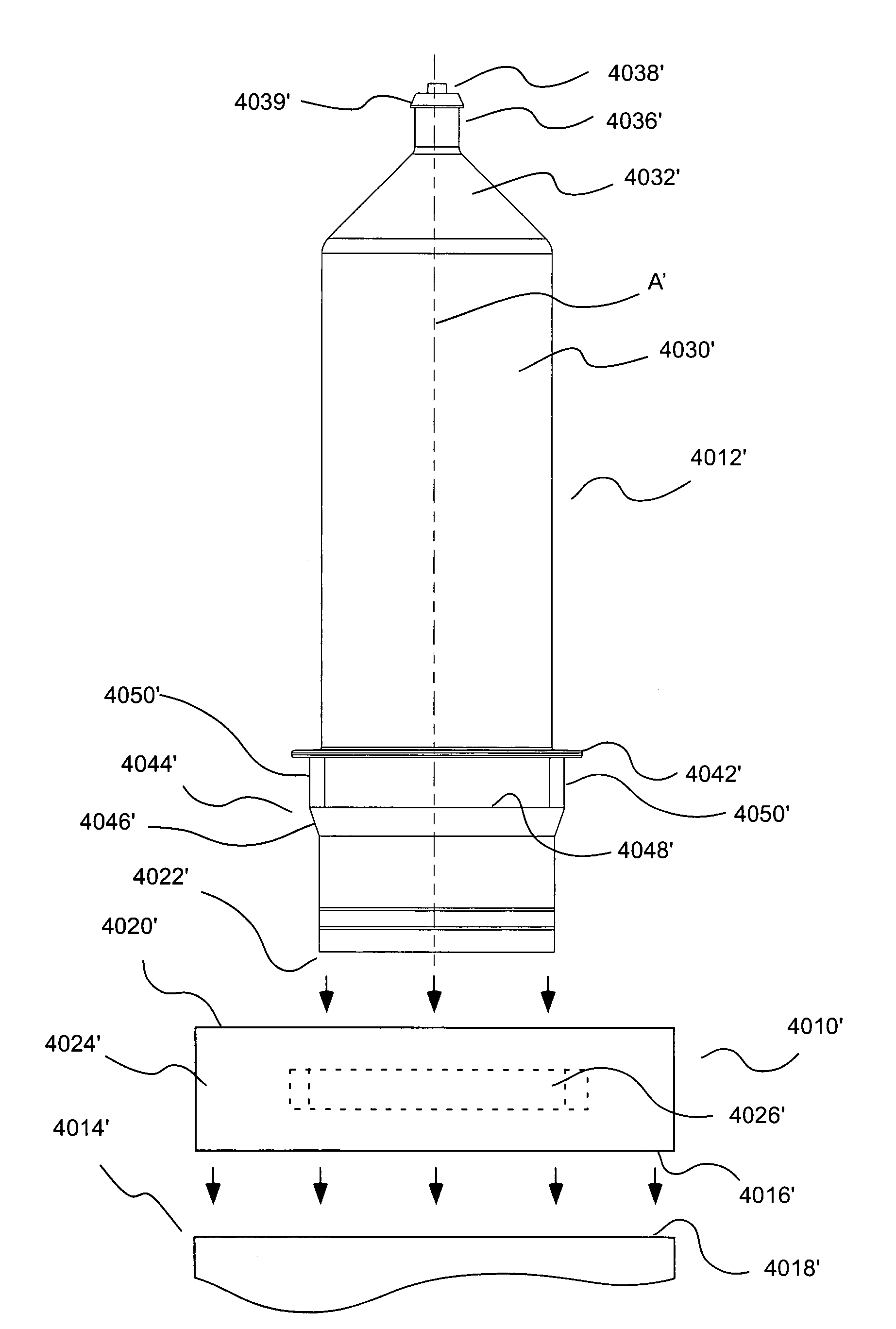

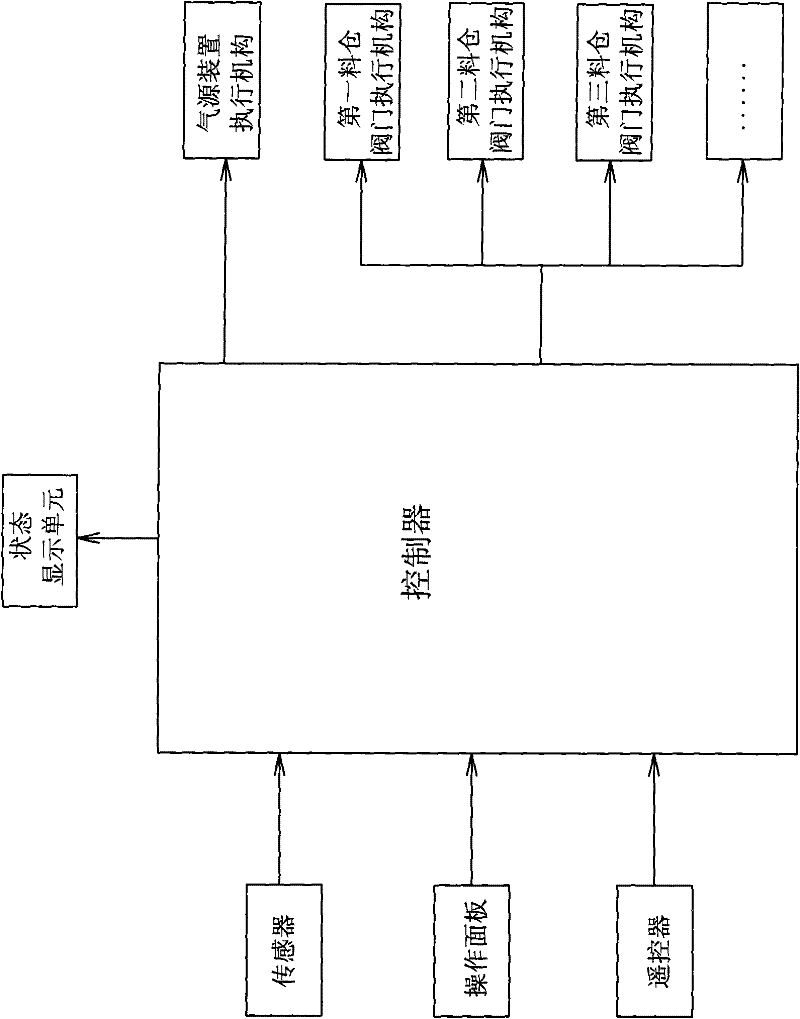

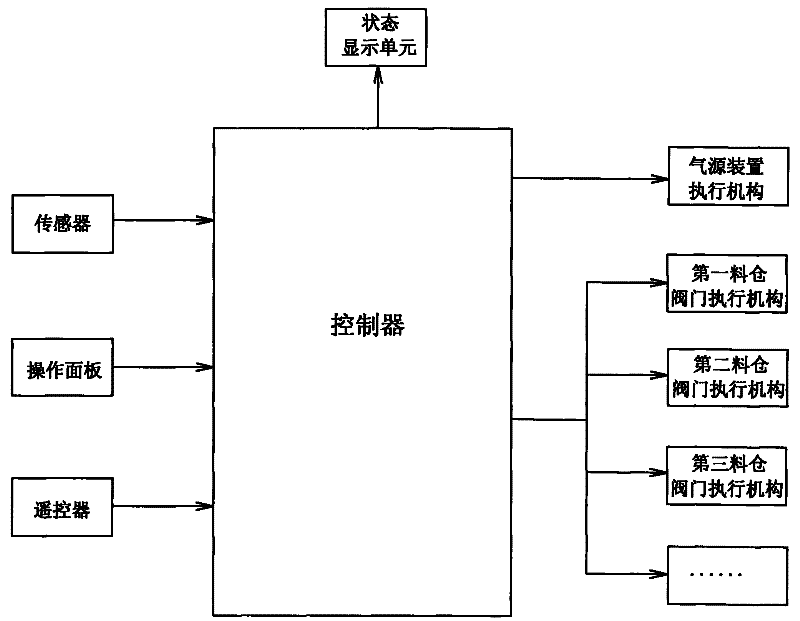

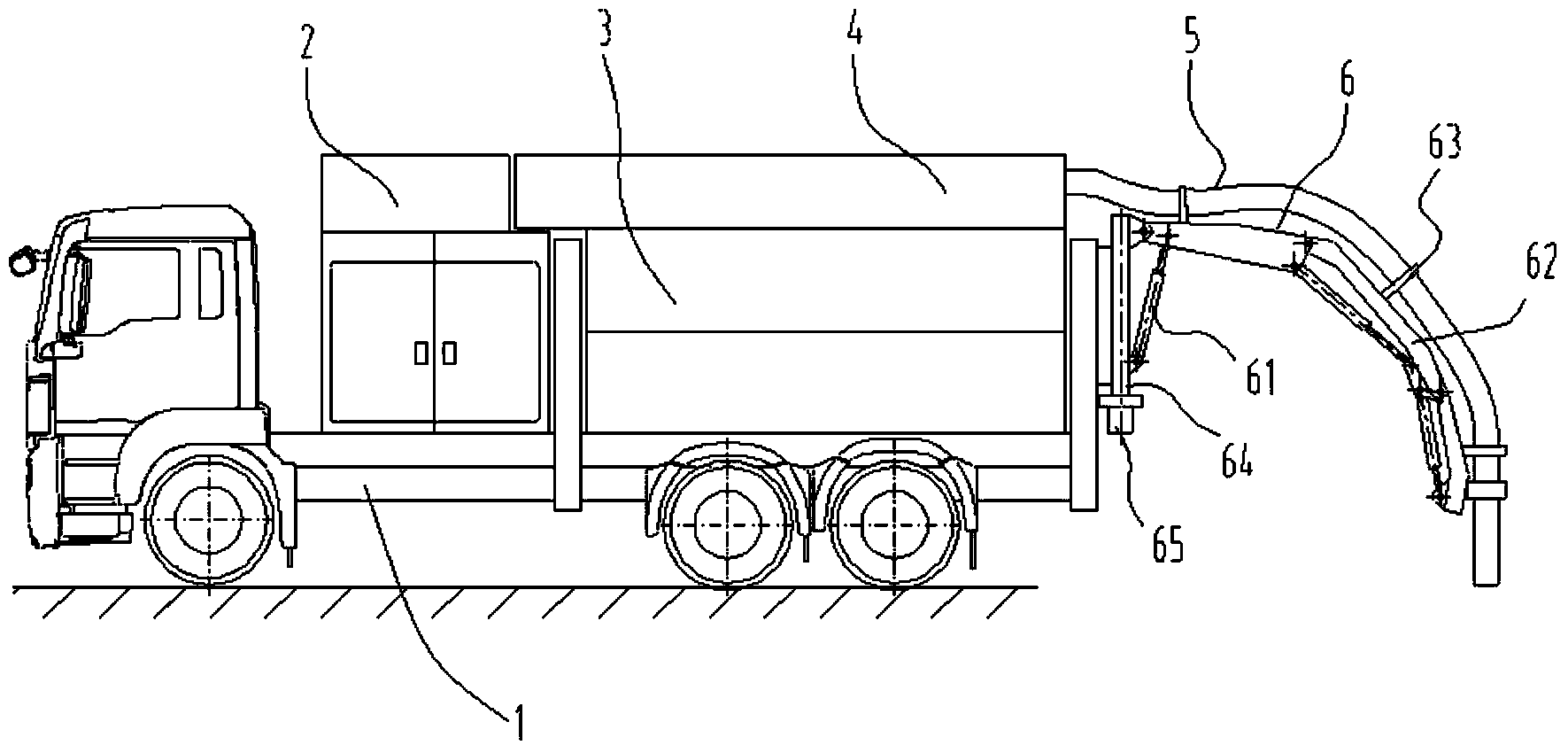

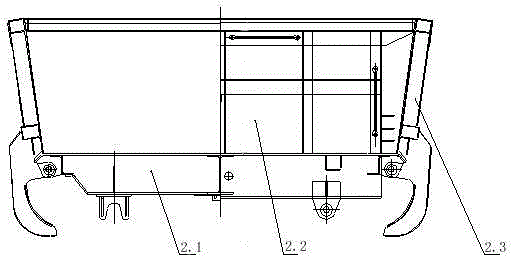

Intelligent unloading system, multi-silo tank container and multi-silo tank car

ActiveCN102234027AReduce labor intensityImprove unloading efficiencyLoading/unloadingControl signalValve actuator

The invention discloses an intelligent unloading system, a multi-silo tank container and a multi-silo tank car. The intelligent unloading system comprises a sensor which is arranged in a tank body and is used for timely acquiring a pressure signal in the tank body, multiple valve actuators which are respectively connected with multiple unloading valves of multiple silos and are used for opening or closing the unloading valves, a controller and an input unit, wherein the controller is used for receiving the pressure signal input by the sensor, comparing a pressure value with multiple opening pressure set values and multiple closing pressure set values in the controller and then controlling multiple actuators to sequentially open and close the unloading valves of all the silos according to the comparison result, thus all the silos sequentially unload; and the input unit is connected with the controller and is used for inputting a control signal to the controller. By adopting the intelligent unloading system disclosed by the invention, the labour intensity can be greatly reduced, and the unloading efficiency can be improved. A tank container or tank car provided with the intelligent unloading system disclosed by the invention is convenient and rapid to unload.

Owner:CIMC VEHICLES (GROUP) CO LTD +1

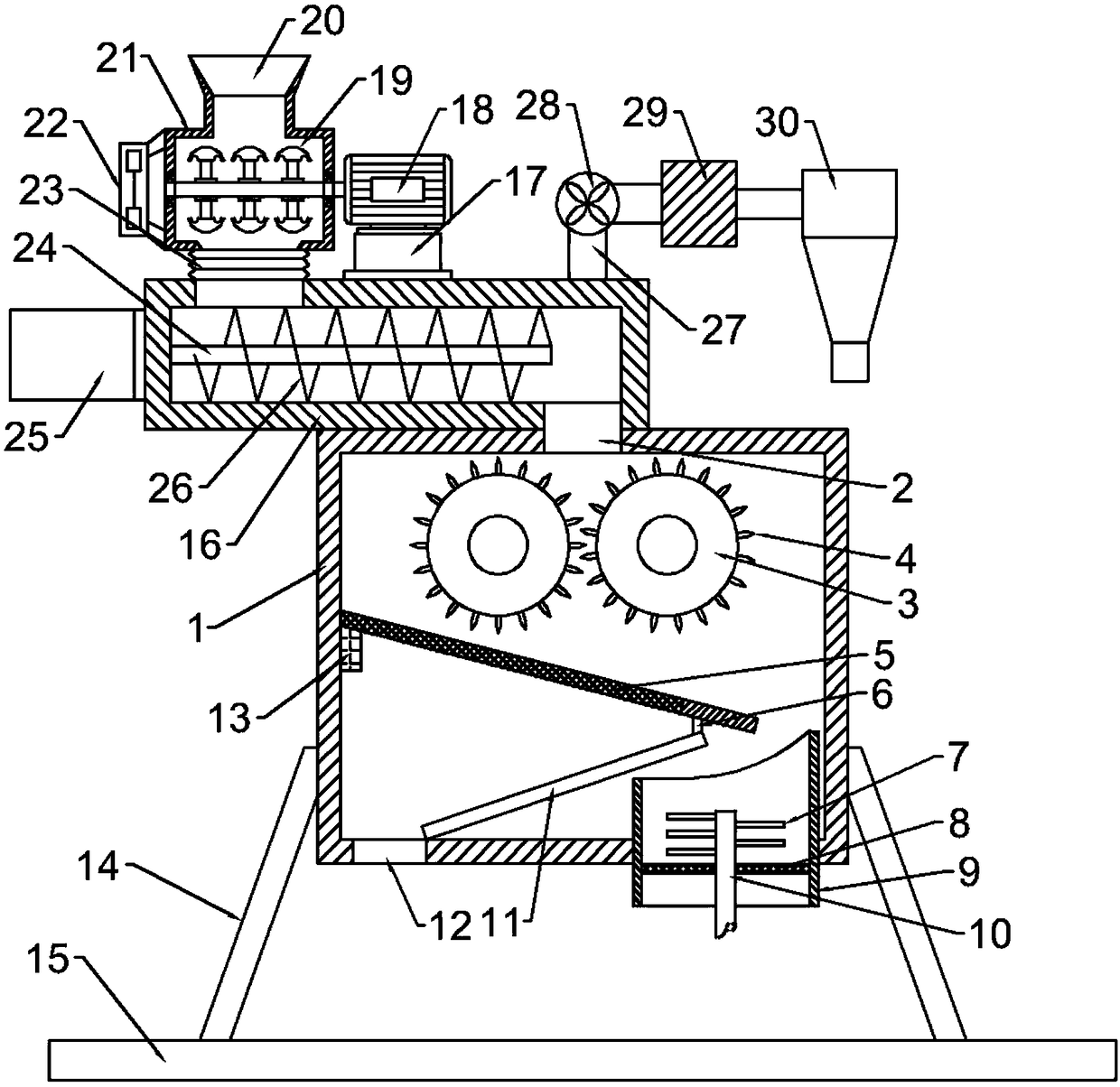

Environment-friendly and efficient coal grinding device

The invention discloses an environment-friendly and efficient coal grinding device. The environment-friendly and efficient coal grinding device comprises a shell, a falling inlet, cutting rollers, crushing blades, a screening plate, a first discharging end, a sending plate, a second discharging end, a cylinder, a rotary-type crushing mechanism, a vibrating screen, a feeding pipe, an elastic pipe,a hard compression spring, a pre-crushing cylinder and a feeding hopper, a vibration motor is arranged on the left side of the pre-crushing cylinder, and a plurality of crushing devices are evenly arranged on the positions, in the pre-crushing cylinder, on an output shaft of the motor. Raw materials are pre-crushed through the crushing devices in the pre-crushing cylinder, and large blocks of caked raw materials are removed; the pre-crushing cylinder is vibrated through the vibrating motor, and thus falling can be quicker; the coal blocks are fully crushed through the crushing blades and the cutting rollers, the crushing effect is good, and the efficiency is high; and the screening function is achieved, the unqualified coal blocks can also continue being further crushed and screened, thusthe coal block processing efficiency is improved, the moisture can further be discharged, and dust is collected.

Owner:陈景英

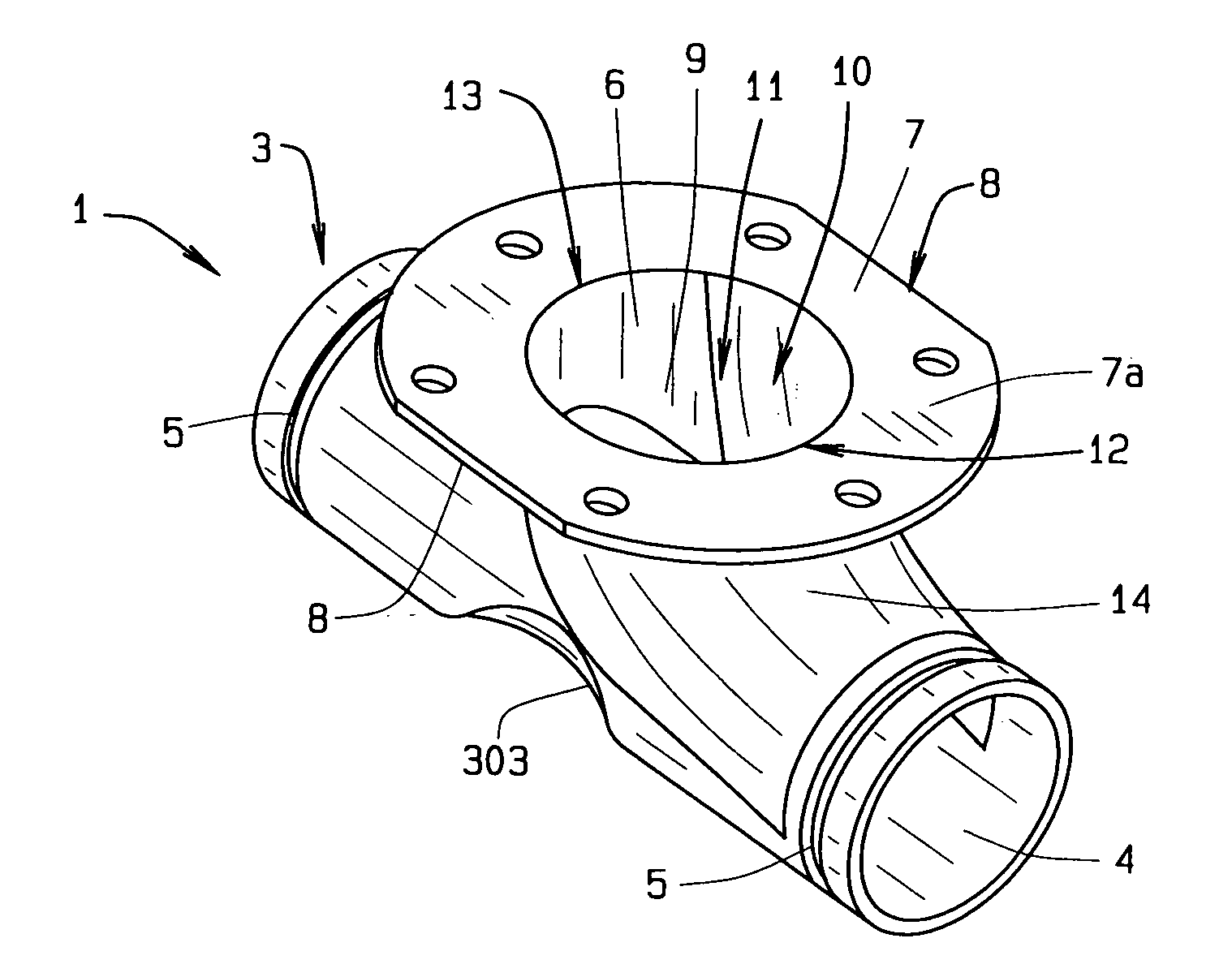

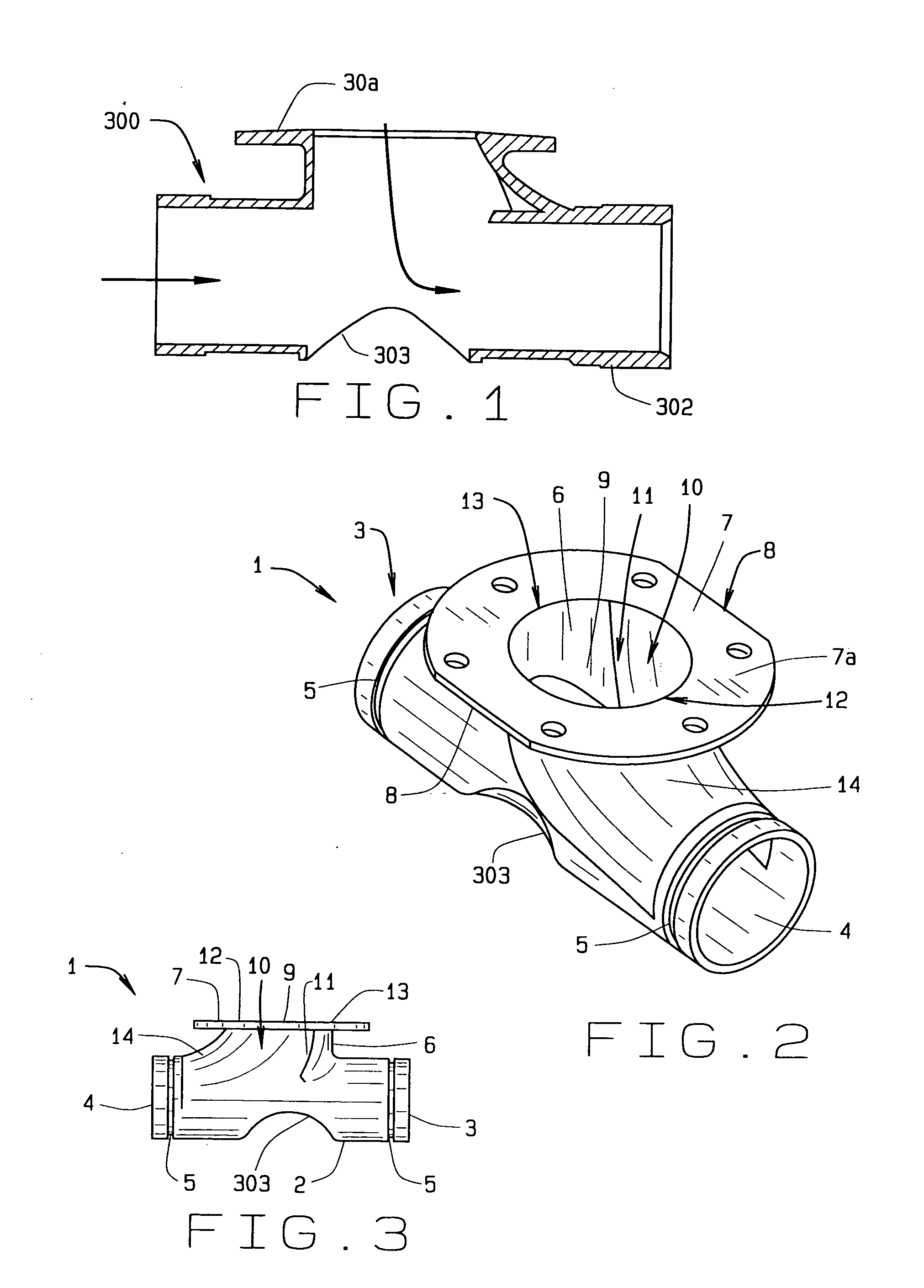

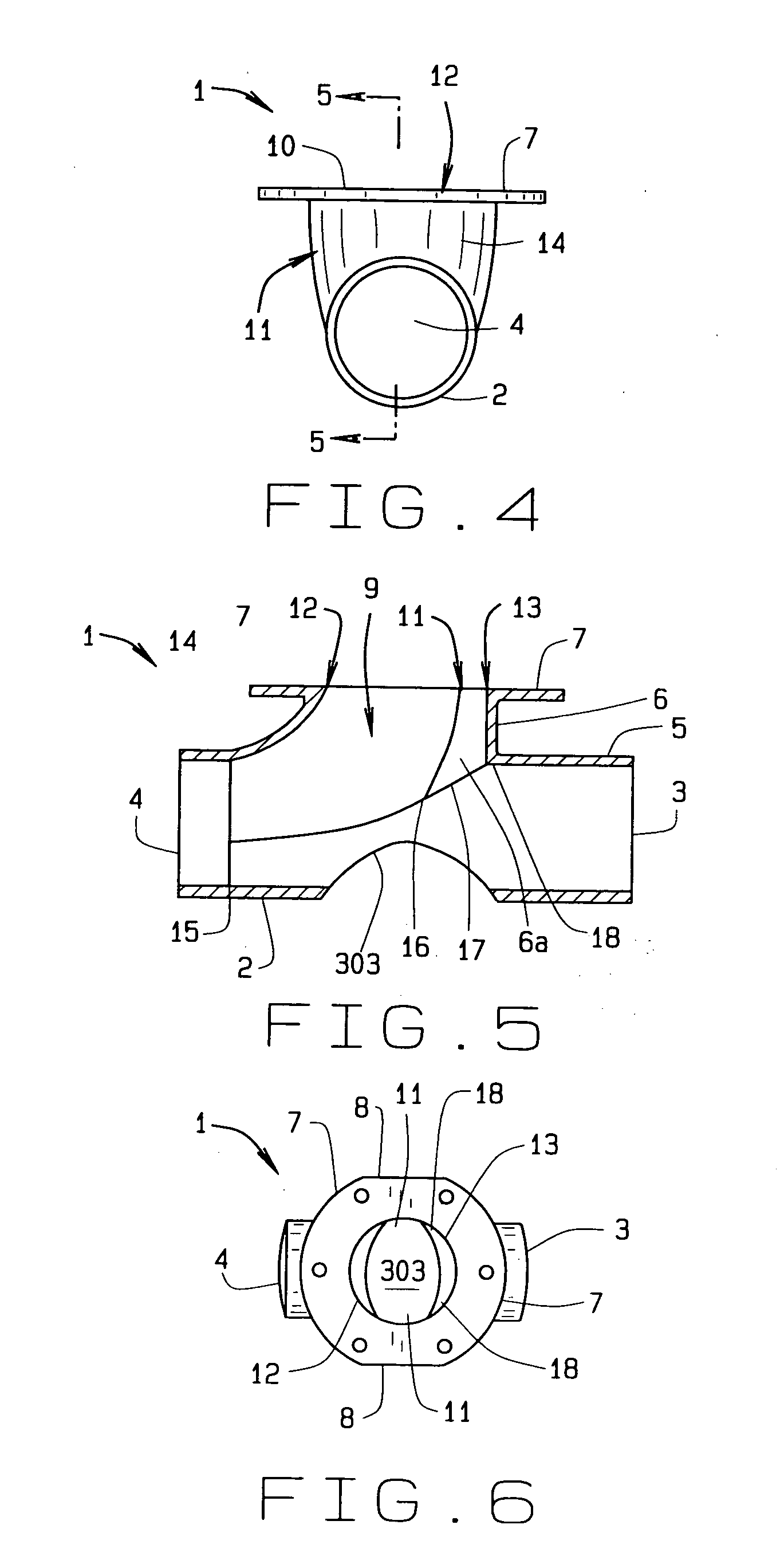

Hopper tee with comformable arcuate closure member

InactiveUS20130168956A1Reduce frictionIncrease frictionPipeline expansion-compensationLarge containersEngineeringCam

A directional hopper tee has a fluted interior vertical pipe that merges into a horizontal pipe. The horizontal pipe has an inlet that may receive bulk material, and subject to pressurized air that conveys the bulk material through the hopper tee. Bulk material may be discharged from a hopper through the vertical pipe, for conveyance for discharge from the horizontal pipe of the tee. A closure gate or door is provided through the bottom of the tee, generally in alignment with the vertical pipe, to allow for discharge or dropping of the granular material directly downwardly through and from the tee. The arcuate door is hinged on one side, and is locked by a cam lock on the opposite side, when located into closure against the bottom of the tee, but can be forced opened, through its cam mechanism, to provide for opening of the arcuate door and allow a direct downward discharge of the granular bulk material, from any hopper, and through the drop opening of the tee, as required.

Owner:BULK TANK

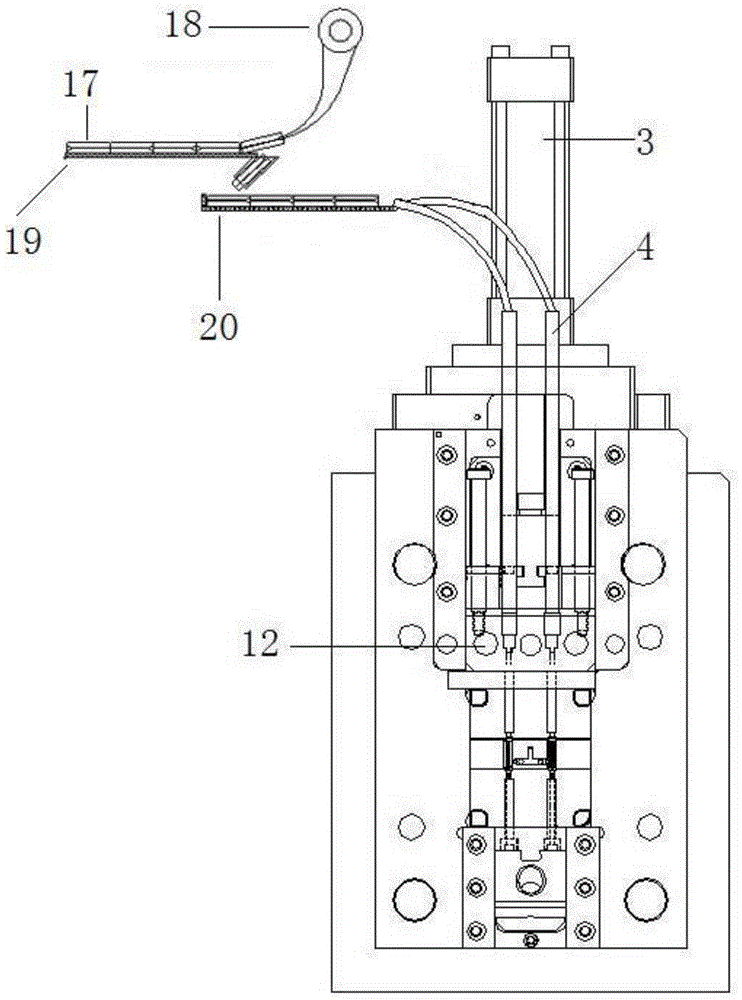

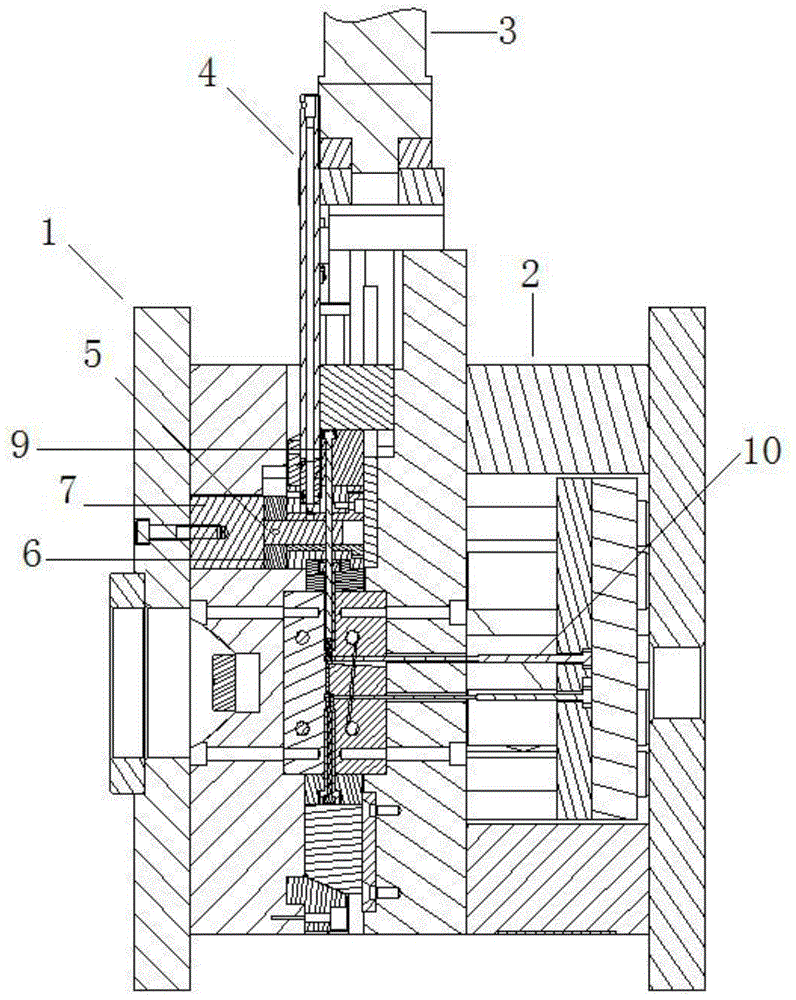

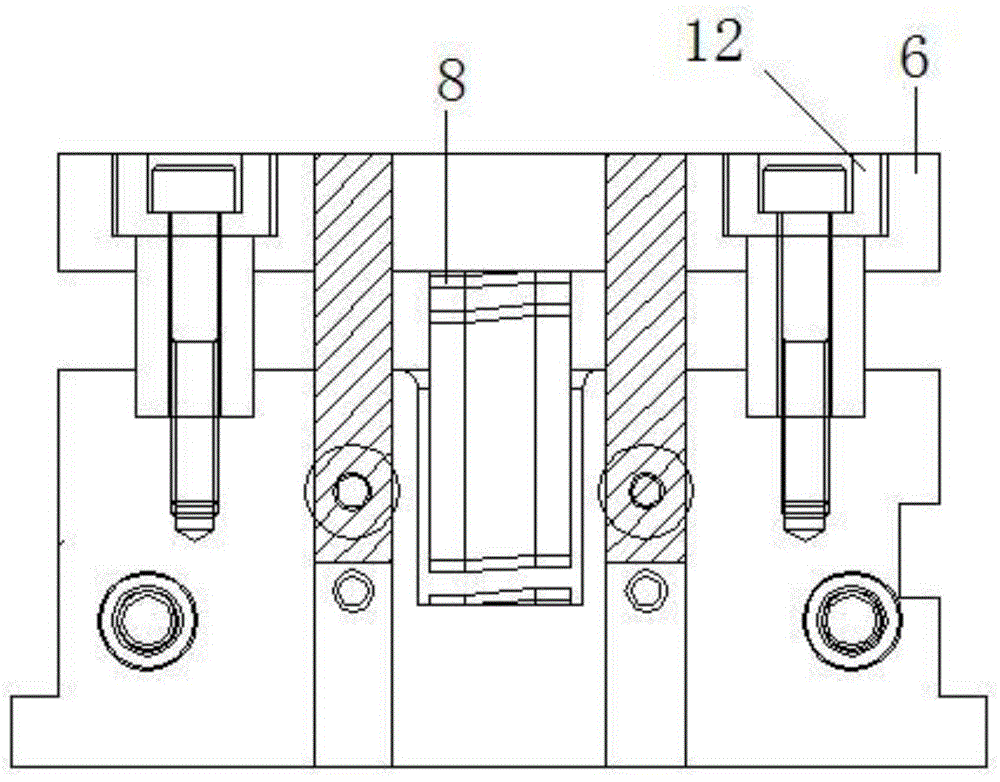

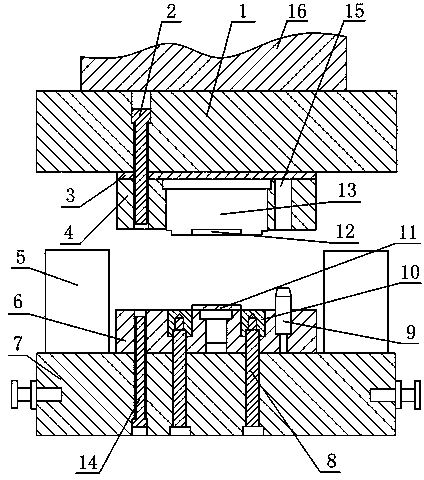

Automatic member-embedding injection mould

The invention discloses an automatic member-embedding injection mould. The automatic member-embedding injection mould has the advantages of automatic blanking, accurate positioning, high cooperation precision, and continuous and high efficiency injection moulding process. The automatic member-embedding injection mould comprises an upper die, a lower die, a cylinder and a blanking mechanism; the blanking mechanism comprises a blanking tube, a feeding push block with an accommodation hole is arranged at the lower part of the blanking tube, the feeding push block is positioned in a block pushing groove connected to the feeding push block in a slide mode, a compression extrusion plate is arranged besides the feeding push block, the right side of the compression extrusion plate is contacted to an upper die briquetting in the upper die, a spring is provided at the back of the compression extrusion plate, the spring is in a compaction state while the mould is closed, the blanking mechanism also comprises a feeding push rod driven by the cylinder, the lower end of the feeding push rod just faces to one end of the accommodation hole, a pre-embedding position in the mould cavity is positioned at the lower part of the accommodation hole, and a discharging push rod is provided on the lower die. The automatic member-embedding injection mould has the advantages of automatic feeding and blanking, rapid blanking in place and accurate positioning, the stability is high while injection moulding, and the cooperation precision of the molded product is guaranteed.

Owner:NINGBO BEILONG PRECISION MOLDING

Automobile air-conditioner sucking cup punch forming die

InactiveCN103962456AMolding stabilityQuality improvementShaping toolsStripping-off devicesEngineeringMechanical engineering

Owner:AIMBON (CHENGDU) ELECTRIC APPLICANCE CO LTD

Automatic picking and assembling machine and automatic picking and assembling method for small tile paster groups

InactiveCN103552703AReduce manual operationsImprove production efficiency and mechanizationPackaging automatic controlShock-sensitive articlesManipulatorEngineering

The invention discloses an automatic picking and assembling machine and an automatic picking and assembling method for small tile paster groups. The picking and assembling machine comprises a support frame, a case supporting mechanism and a sucking mechanism, wherein the case supporting mechanism is arranged on one side of the support frame; the sucking mechanism is arranged above the case supporting mechanism, is of a triaxial manipulator structure and is connected with an X-axis moving mechanism, a Y-axis moving mechanism and a Z-axis moving mechanism. The picking and assembling method comprises the following steps: after the sucking mechanism sucks the small tile paster groups, performing three-way control by virtue of the X-axis moving mechanism, the Y-axis moving mechanism and the Z-axis moving mechanism; conveying the small tile paster groups to an empty case of a qualified product packaging area or a defective product placement area. By applying the automatic picking and assembling machine and the automatic picking and assembling method to a small tile packing line, automatic picking and intelligent sorting of the small tile paster groups can be realized, manual operation is reduced, the production efficiency and the degree of mechanization are effectively improved, and the automatic picking and assembling machine and the automatic picking and assembling have great significance in realizing the purposes of improving the quality and lowering the cost for small tile production enterprises.

Owner:SHENYANG INST OF AUTOMATION GUANGZHOU CHINESE ACAD OF SCI +1

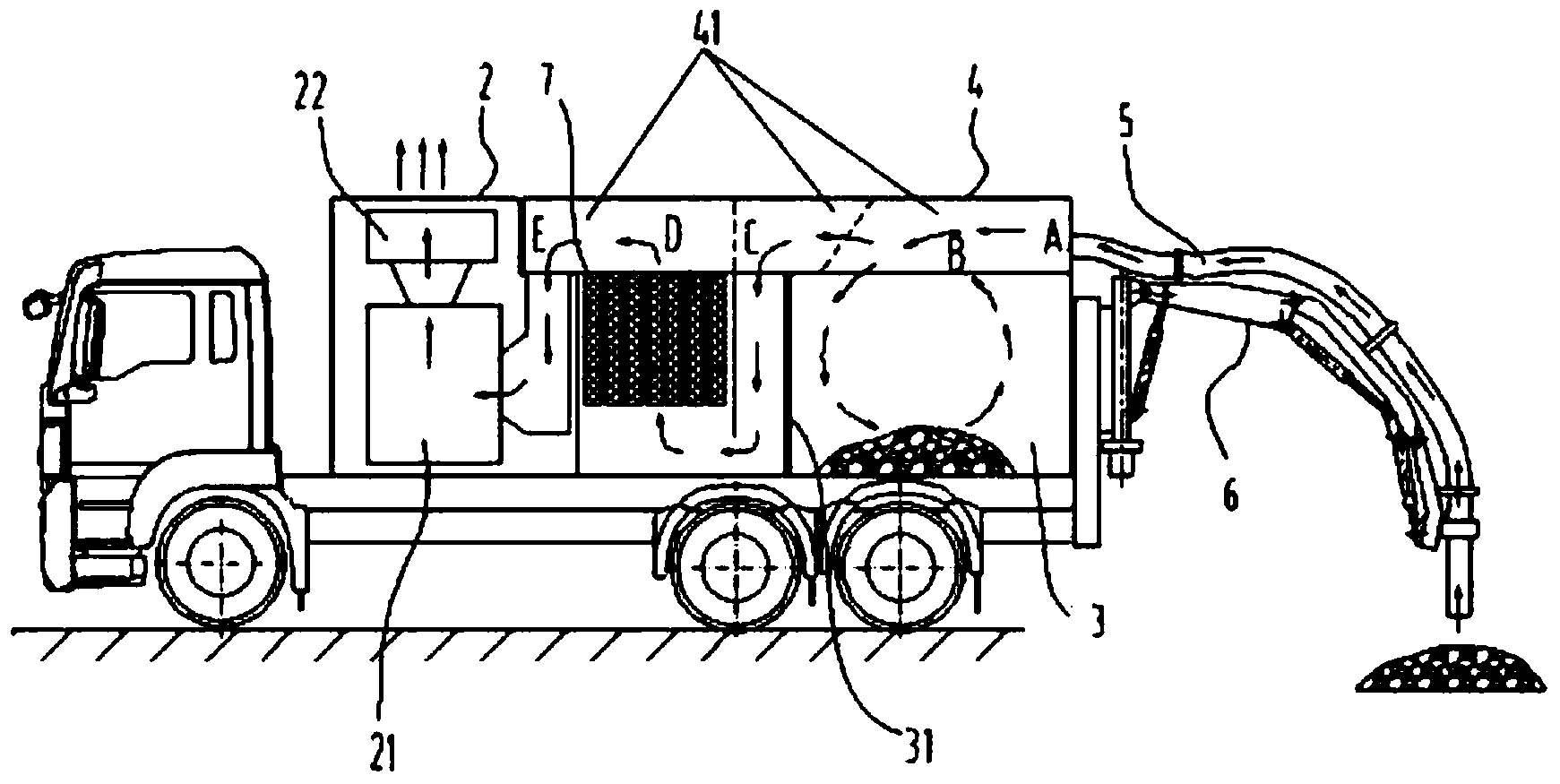

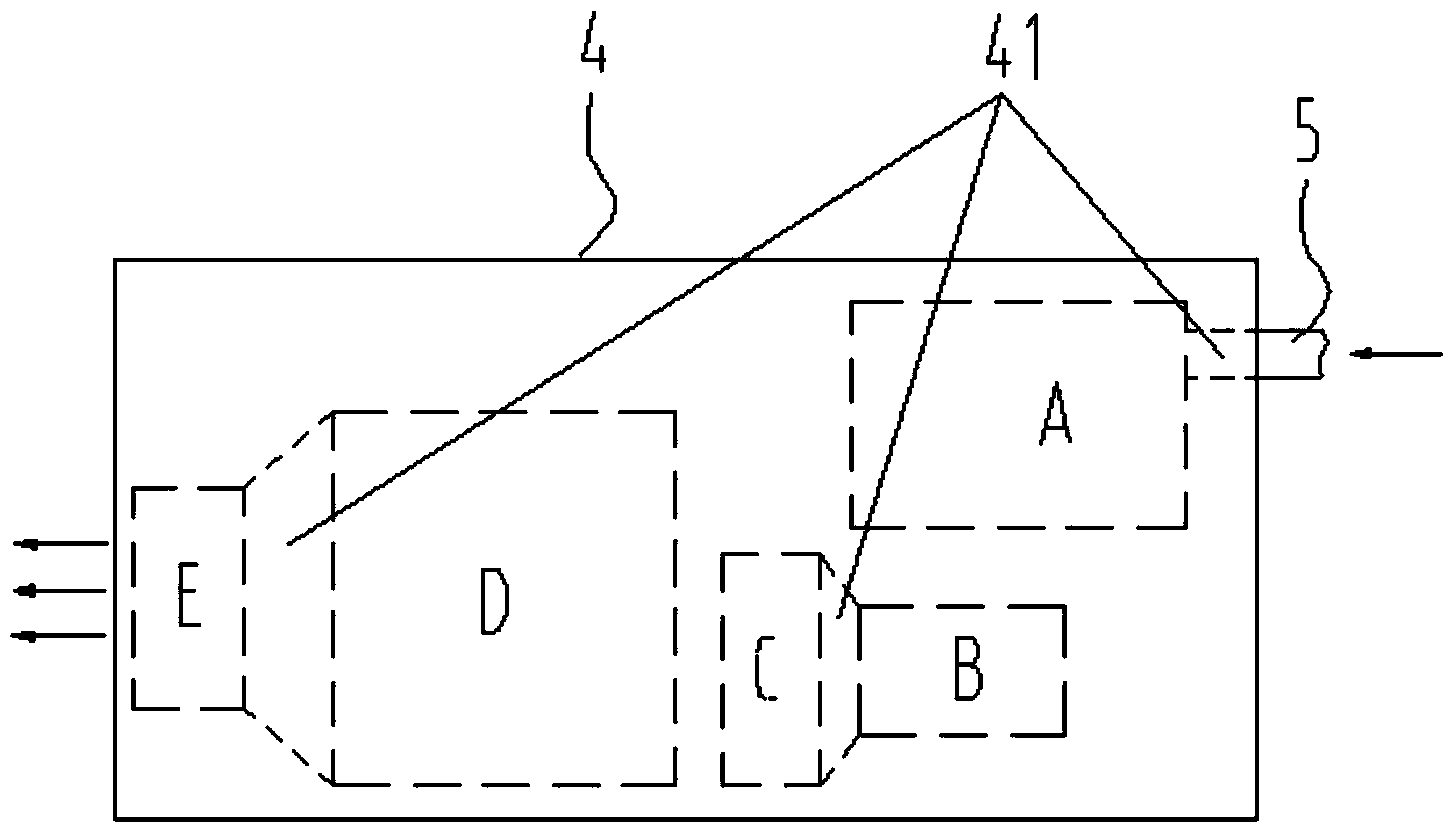

Pumping conveying vehicle

ActiveCN104175939ABig spaceVacuum Negative PressureItem transportation vehiclesRefuse vehiclesSpatial OrientationsAtmospheric air

The invention provides a pumping conveying vehicle. The pumping conveying vehicle comprises a vacuum unit, a filtering device, a material storing chamber, a pumping arm and an unloading device which are arranged on a vehicle chassis, wherein the filtering device is respectively communicated with the vacuum unit and the material storing chamber; a material storing chamber top cover which can be opened is designed at the top of the material storing chamber, a channel where air flow is transmitted is designed in the material storing chamber top cover, and the filtering device is communicated with the material storing chamber by the aid of the channel; a pumping tube is attached to the pumping arm, spatial orientation is performed with the movement of the pumping arm, the vacuum unit passes through the filtering device and the channel in the material storing chamber top cover, an inner cavity of the material storing chamber is pumped to form a semi-vacuum state, by means of pressure difference of the inner cavity of the material storing chamber and atmosphere, the pumping arm drives the pumping tube to move so that a material to be pumped is pumped into the material storing chamber, and during unloading, the unloading device turns over the material storing chamber so that the material is unloaded by the aid of gravity of the material.

Owner:福建海山机械股份有限公司

Steel bar automatic feeding device

ActiveCN1699954AAutomatic feeding and high efficiencyPrecise positioningMaterial strength using steady bending forcesLocation detectionSolenoid valve

The invention provides a bar stock automatic feeding device which comprises mechanical transmit part including pack house, framework, discharge hole, fore-and-aft frame, stepping motor, gear set, gear shaft, loading turntable conveyor with spout, coaxial survey posit plate, two photoelectric sensors and positing column connected with external device; pneumatic master part including cylinder, deflector rod and restoring spring; and electric control component whose position detecting circuit connected with gauge control circuit, stepping motor-dive, stepping motor and turntable position control circuit, with information inputting test being output the computer while react to positing measuring circuit; and speed control circuit being connected with gauge control circuit, air value control circuit and magnetic value; computer output information of testing output reacting to position detecting circuit and gauge control circuit.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

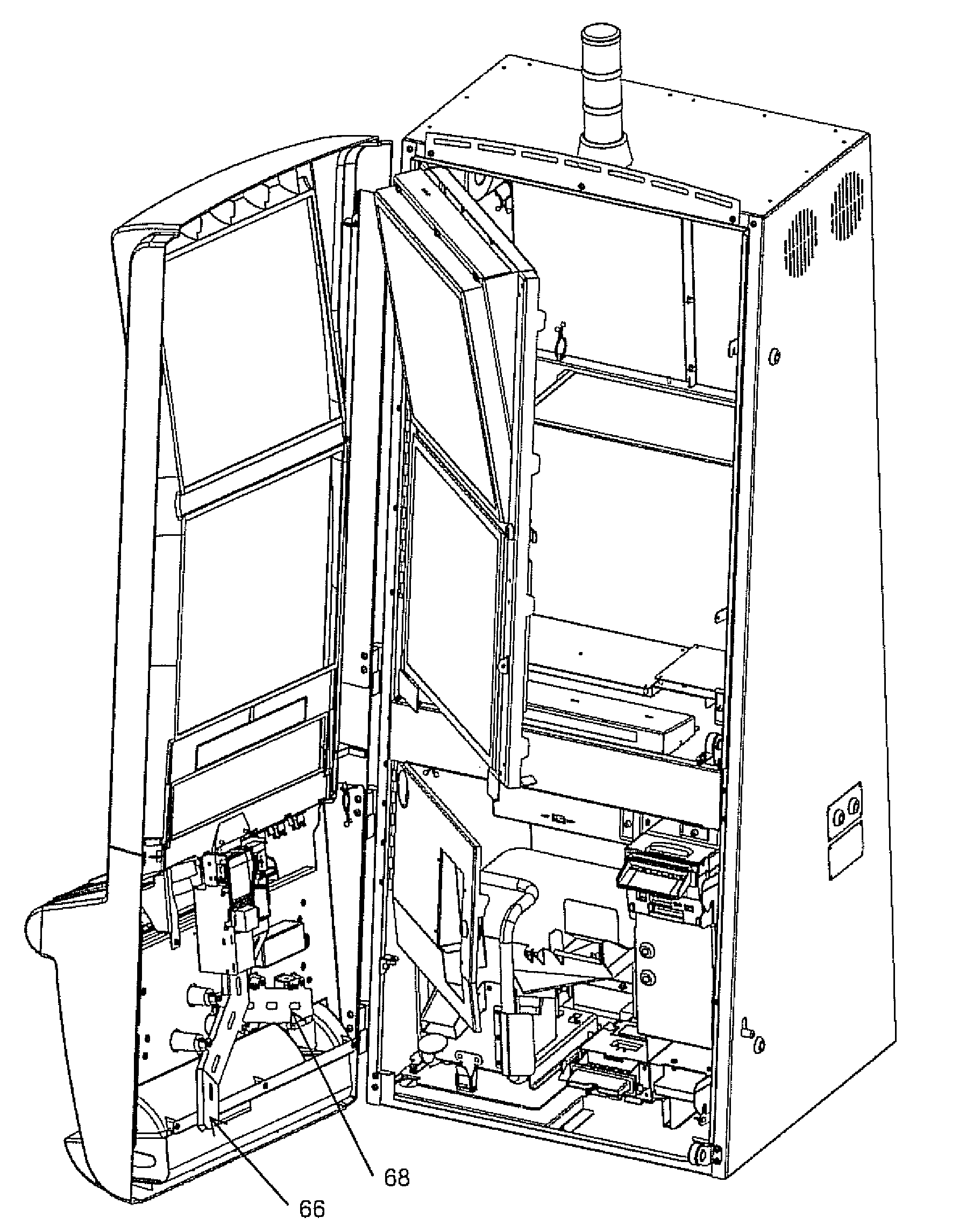

Gaming machine and cabinets therefor

InactiveUS20090009041A1Small footprintEasy to handleApparatus for meter-controlled dispensingFolding cabinetsBiomedical engineeringGame machine

Owner:OCTAVIAN INT

Nonwoven fabric slitting device

ActiveCN109811537ARealize automatic liftingRealize unloadingSevering textilesEngineeringNonwoven fabric

The invention discloses a nonwoven fabric slitting device and belongs to the technical field of nonwoven fabric production equipment. The nonwoven fabric slitting device aims to solve the technical problem of low production efficiency of an existing slitting machine. The nonwoven fabric slitting device comprises an unwinding mechanism, a tensioning mechanism, a slitting mechanism and a rewinding mechanism which are sequentially arranged on a base in the forward direction of nonwoven fabric, the unwinding mechanism tightly clamps an unwinding cylinder through a coaxially-arranged tip cone, rising and falling of the unwinding cylinder are realized through a V-shaped storing table, the slitting mechanism completes slitting of the nonwoven fabric through cooperation of a circular blade and a cutter groove shaft, the circular blade slides on a square shaft to realize adjusting of the nonwoven fabric slitting width, and the rewinding mechanism quickly mounts and demounts a rewinding cylinderthrough an unloading frame. The nonwoven fabric slitting device has the advantages of easy operation, high production efficiency, small workload and wide use range.

Owner:信阳颐和非织布有限责任公司

Practical building stirrer

InactiveCN108297281AEasy to moveReduce wearTransportation and packagingMixing operation control apparatusWear resistantEngineering

The invention discloses a practical building stirrer. The practical building stirrer comprises a main body. A wear-resistant layer is arranged on the inner wall of the main body. An upper cover plateis arranged on the upper portion of the main body and provided with a water inlet opening, a motor, a rotating shaft and an upper cover plate body. A first rotating wheel is arranged on the rotating shaft, and a second rotating wheel is arranged on the motor. A stirring device is arranged on the rotating shaft. Connecting rods are arranged at the upper end and the lower end of the rotating shaft.The other ends of the connecting rods are arranged on two scraping plates. Support legs are arranged on the lower portion of the main body and used for supporting the main body. Universal wheels are arranged at the bottoms of the support legs. A discharging plate is arranged at the bottom o the main body through hinges. An extending-and-contracting device is arranged at the bottom of the other endof the discharging plate and mounted on the discharging plate through hinges. The other end of the extending-and-contracting device is mounted at the bottoms of the support legs through hinges. The practical building stirrer is simple in structure, convenient to discharge, capable of achieving self-leaning and long in service life.

Owner:陈伟平

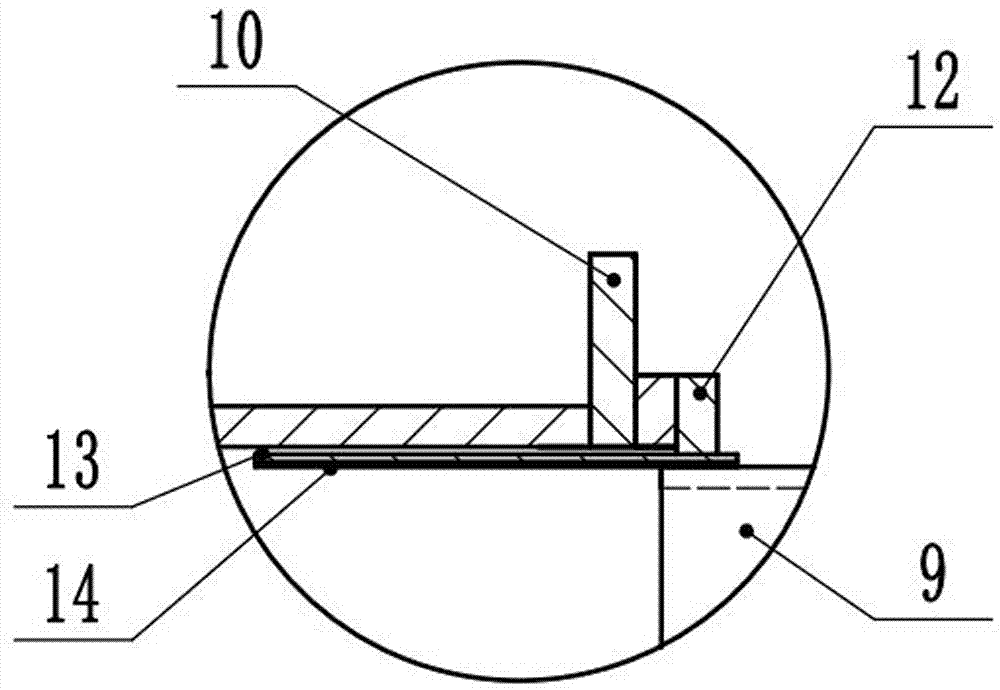

Sheet stock blank feeding equipment for punching process

InactiveCN101879561AAvoid separationAvoid the effects of plastic deformationMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention relates to sheet stock blank feeding equipment for punching process, comprising a rack. The sheet stock blank feeding equipment is characterized in that the rack is provided with a material delivery platform; a longitudinal blanking guide bracket is arranged above the material delivery platform; the lower port of the longitudinal blanking guide bracket is provided with a single-sheet separation device of a sheet stock blank stacking part; one side of the blanking end of the material delivery platform is provided with an elastic striking mechanism; the single-sheet separation device of the sheet stock blank stacking part comprises at least one pair of single-sheet sidewise shifting rocking blocks, and each single-sheet sidewise shifting rocking block is correspondingly provided with a longitudinal limiting rocking block along a rotating direction; the other side of the lower end part of the sheet stock blank stacking part is correspondingly provided with a supporting telescopic slide block; and the rack is provided with a stop block preventing other sheet stock blank stacking parts from being shifted. The invention has the advantages of simple structure, convenient use, reliable work, high commonality, easy and convenient installation of connecting with a punching machine and capability of high-efficient automatic punching production.

Owner:陈石云

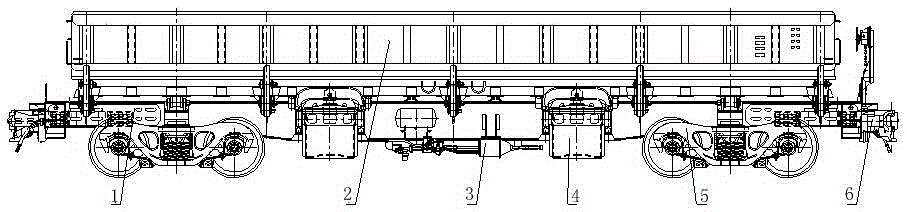

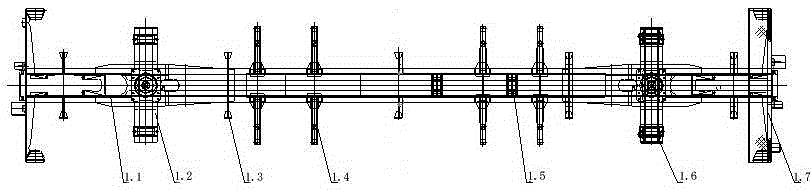

Novel self-dumping car with axle load of 27t

InactiveCN105235695AImprove transportation economicsExtended maintenance cycleTipping wagonsTruckHeavy duty

The invention belongs to the technical field of railway freight cars, specifically relates to a novel self-dumping car with an axle load of 27t, and solves the problem that a requirement of running of heavy-duty railway freight cars with an axle load of 27t respectively on the existing universal lines cannot be met in the existing self-dumping cars. The novel self-dumping car with the axle load of 27t comprises an underframe assembly, a compartment assembly, a wind-hand braking device, a dumping device, car coupler buffering devices and bogies, wherein the bogies are arranged at the two ends of the underframe assembly; the compartment assembly is arranged at the upper side of the underframe assembly; two rows of wheels are arranged at the lower side of each of the left end and the right end of the underframe assembly; one car coupler buffering device is arranged between each two rows of wheels; the wind-hand braking device used for braking is further arranged on the underframe assembly; and the dumping device capable of dumping the compartment assembly is arranged between the underframe assembly and the compartment assembly.

Owner:CRRC TAIYUAN CO LTD

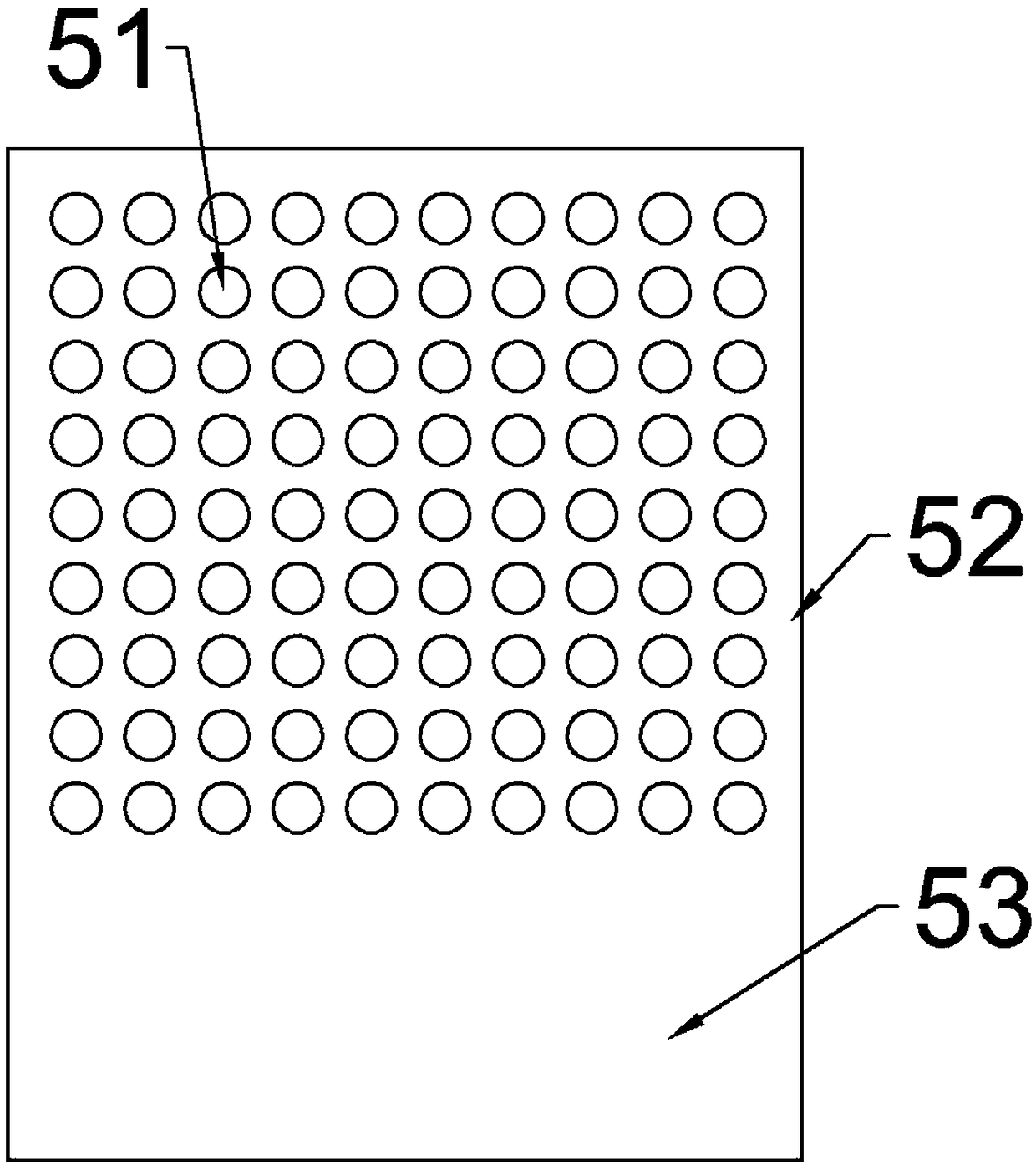

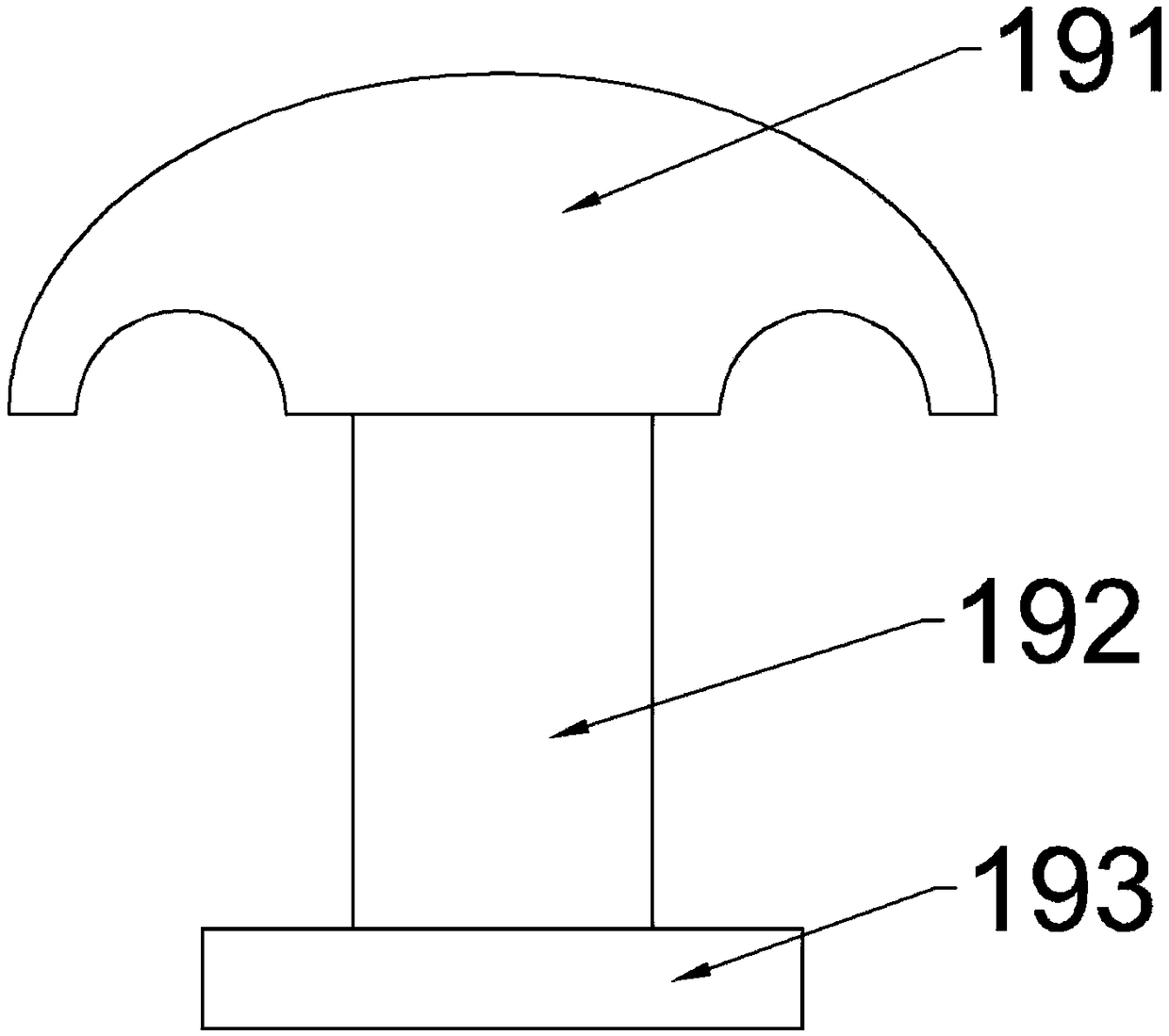

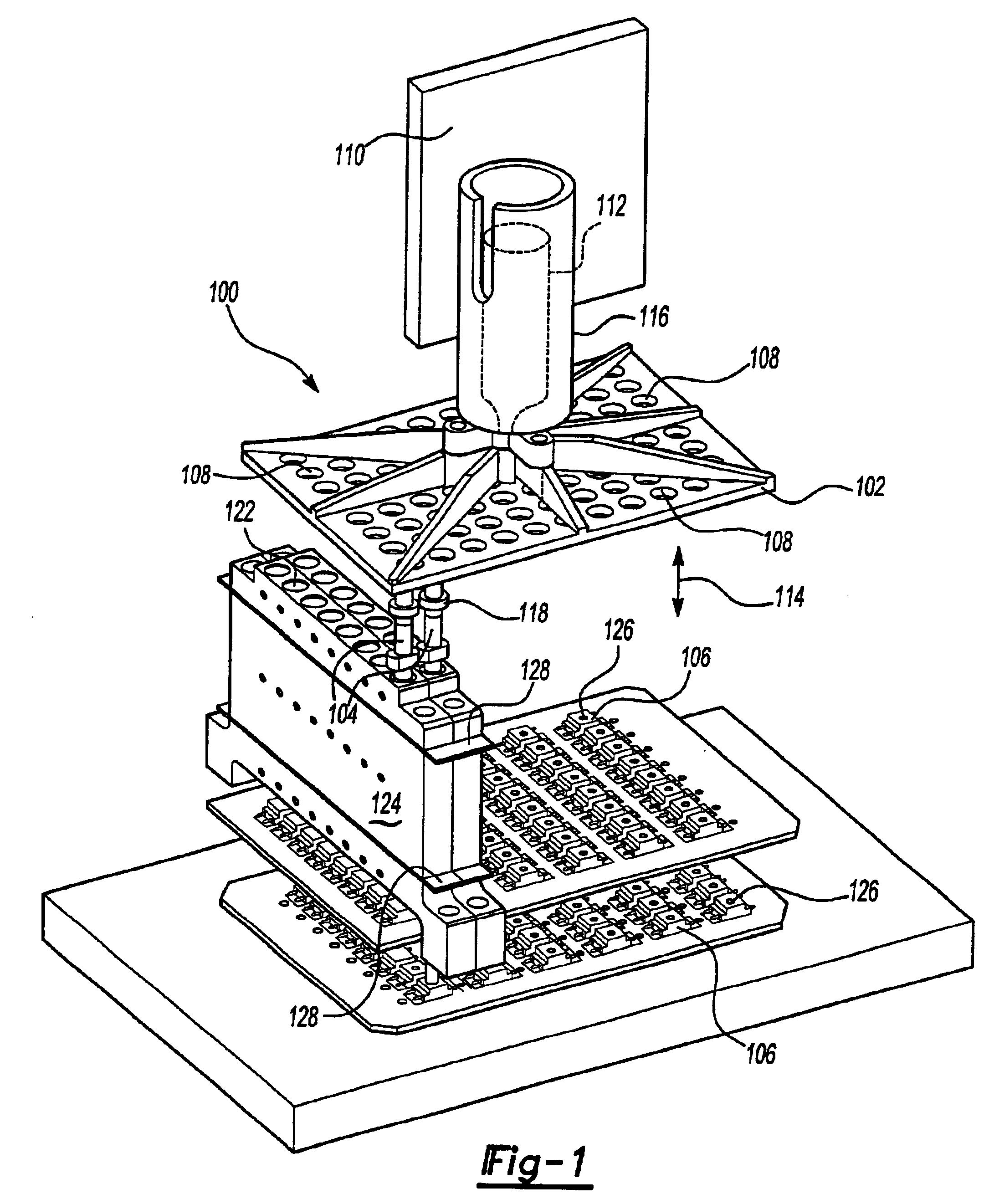

Instrument for high throughput measurement of material physical properties and method of using same

InactiveUS6936471B2Easy to prepareFaster sample loadingAnalysing fluids using sonic/ultrasonic/infrasonic wavesFlow propertiesSensor arrayYoung's modulus

An apparatus and method for screening combinatorial libraries of materials by measuring the response of individual library members to mechanical perturbations is described. The apparatus generally includes a sample holder for containing the library members, an array of probes for mechanically perturbing individual library members, and an array of sensors for measuring the response of each of the library members to the mechanical perturbations. Library members undergoing screening make up a sample array, and individual library members constitute elements of the sample array that are confined to specific locations on the sample holder. During screening, the apparatus mechanically perturbs individual library members by displacing the sample array (sample holder) and the array of probes. Typically, all of the elements of the sample array are perturbed simultaneously, but the apparatus also can also perturb individual or groups of sample array elements sequentially. The flexible apparatus and method can screen libraries of materials based on many different bulk physical properties, including Young's modulus (flexure, uniaxial extension, biaxial compression, and shear); hardness (indentation), failure (stress and strain at failure, toughness), adhesion (tack, loop tack), and flow (viscosity, melt flow indexing, and rheology), among others.

Battery pole piece slitting and welding integration machine

InactiveCN107803664AAvoid misalignmentImprove product qualityOther manufacturing equipments/toolsWelding apparatusMotor drivePole piece

The invention relates to a battery pole piece cutting and welding integrated machine, which includes a frame, a conveying mechanism and a control box, a pole piece cutting device is arranged on the frame, a pushing device is arranged on the left side of the conveying mechanism, and the pushing device includes The pusher connecting seat that cooperates with the conveying mechanism is provided with a lifting screw rod, and the lifting screw rod is connected with the lower end of the output shaft of the pushing material lifting motor arranged on the pushing material connecting seat, and the thread on the lifting screw rod It is equipped with a pusher installation seat, a pusher positioning motor is installed on the front side of the pusher installation seat, and a pressing device matching with the product is installed on the left side of the pusher positioning seat; the pole piece raw material is cut into individual pieces by the pole piece cutting device At the same time, the push positioning motor drives the push positioning screw, cooperates with the push positioning seat to precisely position the welding position of the pole piece, and presses the pole piece on the pole piece through the pressing device, effectively preventing the pole piece from being dislocated during welding , to ensure precise welding, thereby improving product quality.

Owner:DONGGUAN UNIV OF TECH

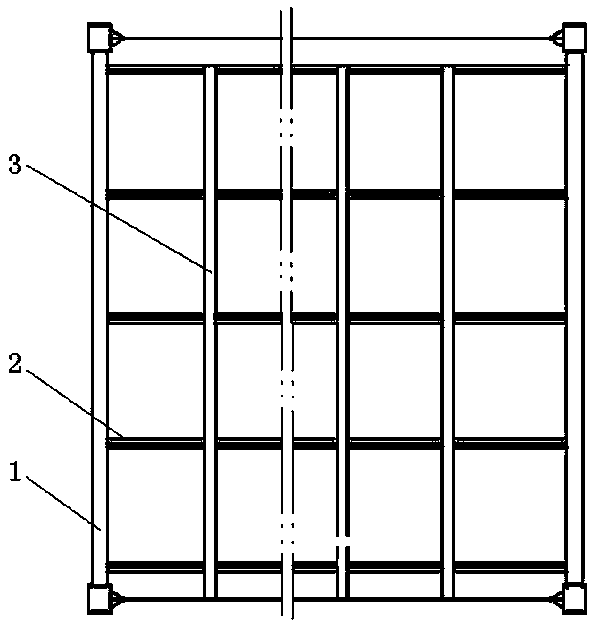

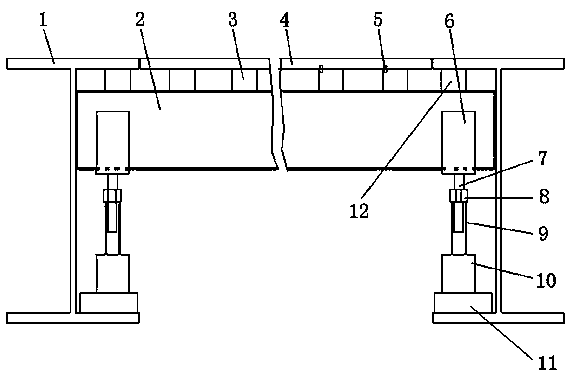

Concrete formwork supporting device for floor slab concreting

ActiveCN103967273AEasy to adjustFulfill pouring requirementsAuxillary members of forms/shuttering/falseworksFloor slabKeel

The invention provides a concrete formwork supporting device for floor slab concreting. The device comprises main steel-structure beams and a formwork and is characterized in that height adjustable key keels are arranged between the two opposite main steel-structure beams at intervals, auxiliary keels are arranged on the key keels at intervals, and the formwork is placed on the auxiliary keels; a vertical bolt is made to move upwards or downwards by rotating a nut, so that rising or descending of a horizontal beam is realized, the whole key keels are finally made to be stably fixed between the two steel-structure beams by replacing upper cushion blocks and / or lower cushion blocks in different heights or thicknesses, floor slab or floor clapboard concreting requirements are met, and embedding of embedded parts such as cable tubes or cable boxes is facilitated during concreting. According to the device, cross construction such as wall construction can be conducted, working efficiency is improved effectively while construction quality is guaranteed, construction progress is accelerated, and form removal and frame unloading are extremely convenient and fast. The device has the advantages of being capable of making construction convenient and fast, safe and reliable in cross construction, short in construction duration, convenient to dismount, capable of being used repeatedly, low in cost and the like.

Owner:云南昆钢钢结构股份有限公司

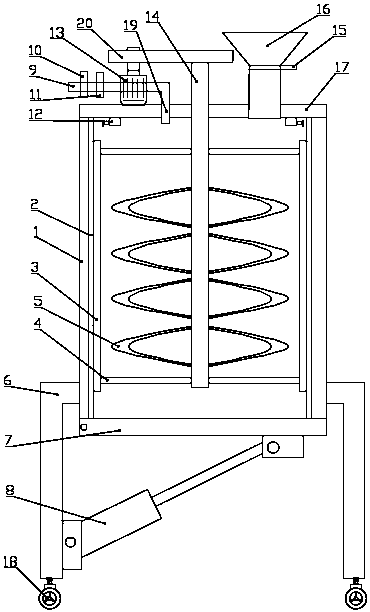

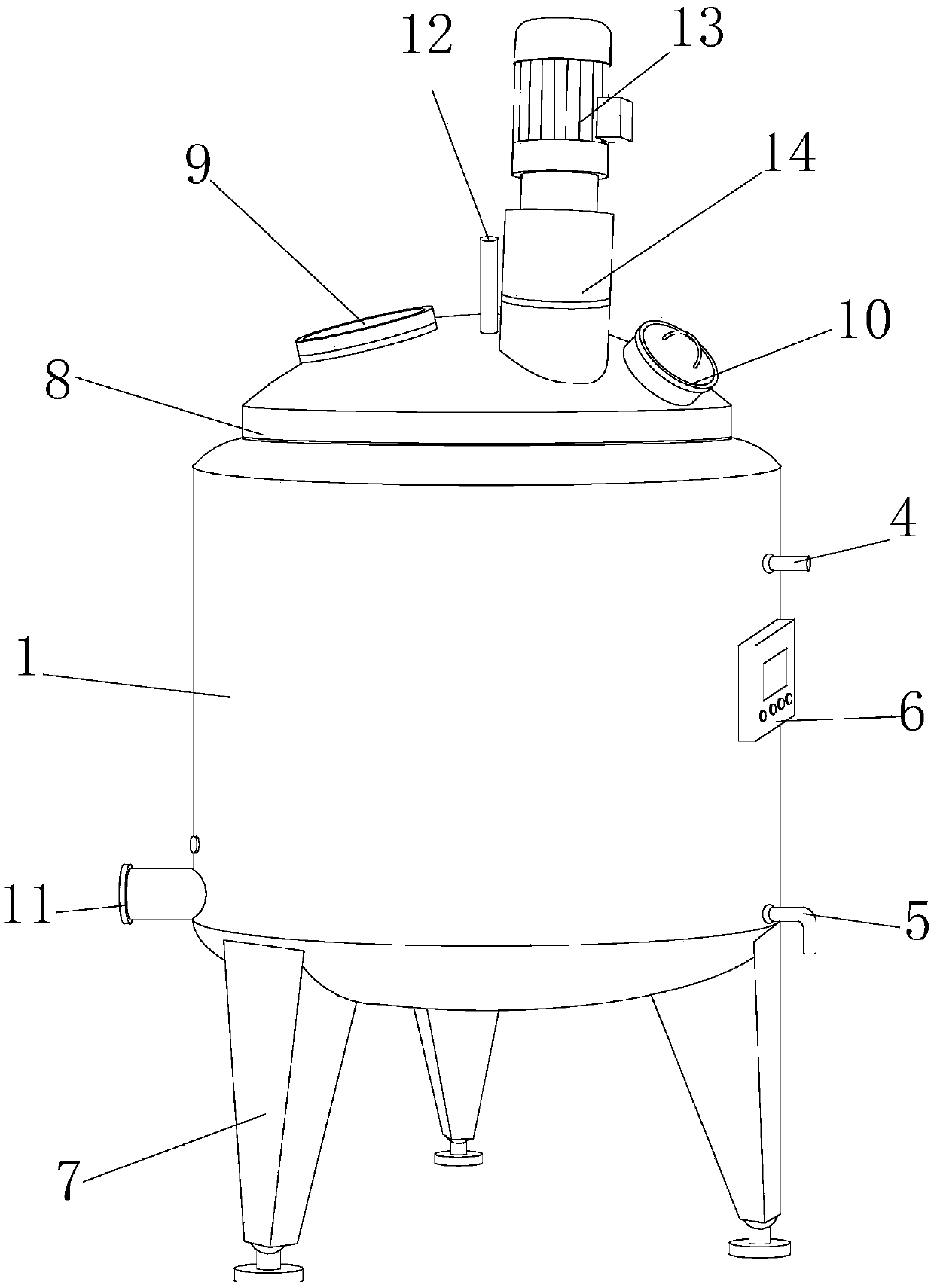

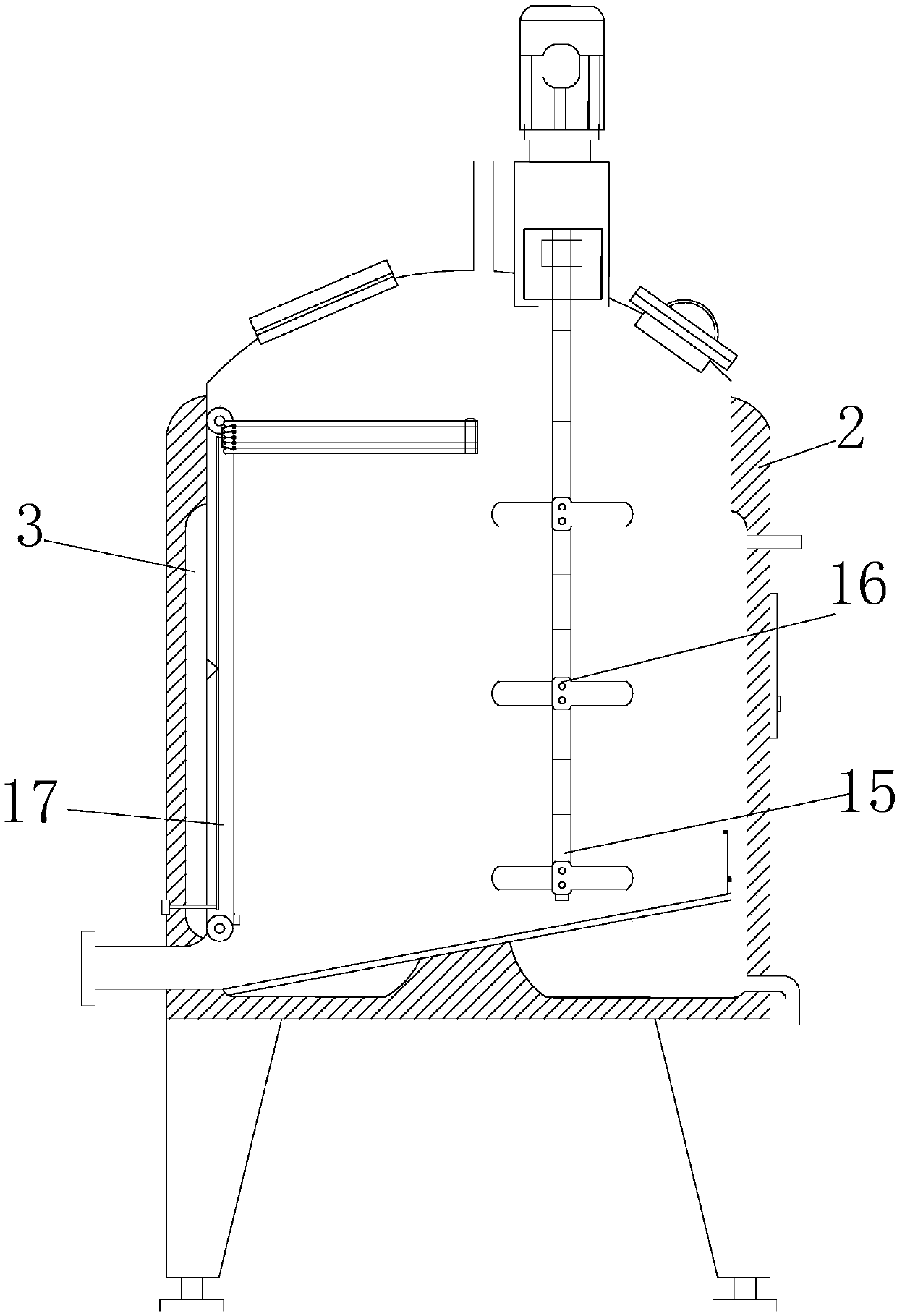

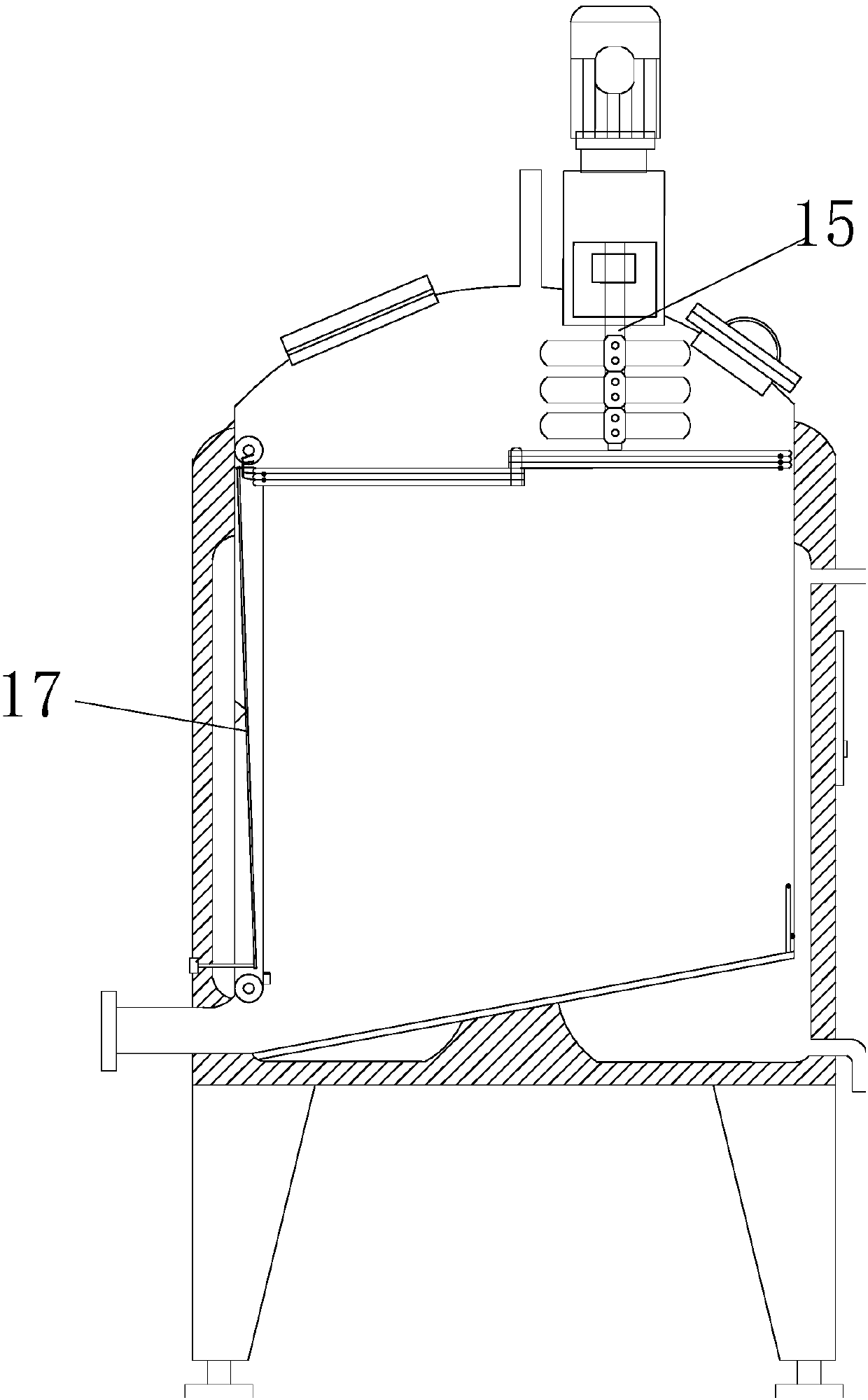

Food fermentation device

ActiveCN107760597AReduce manufacturing costIncrease unloading rateBioreactor/fermenter combinationsBiological substance pretreatmentsHeat conductingEngineering

The invention discloses a food fermentation device. The food fermentation device comprises a fermentation tank body, a heat conducting-insulating shell, a cooling interlayer, a cooling water inlet pipe, a cooling water outlet pipe, a control panel, a support leg frame, a sealing cover, a visible window, a charging hole, a discharging pipe, a gas discharging pipe, a driving motor, a stirrer, a telescopic stirring roller, stirring blades, a rapid discharging device, wherein the outer surface of the fermentation tank body is coated with the heat conducting-insulating shell, and the heat conducting-insulating shell is connected with the fermentation tank body through temperature-resistant glue; the cooling interlayer is an interlayer arranged between the heat conducting-insulating layer and the fermentation tank body. The food fermentation device has the beneficial effects that the rapid discharging device is provided, so that rapid discharging can be realized under the action of pushing force of a discharging plate, meanwhile, an inner wall of the fermentation tank is scraped, so that residual materials attached on the inner wall can be discharged for avoiding waste and inconvenient cleaning, the discharging rate of the food fermentation device is increased effectively, the working efficiency of the device is increased, meanwhile, waste is avoided, and the manufacturing cost of food is lowered.

Owner:ZHEJIANG QIANCAOSU BIOTECH CO LTD

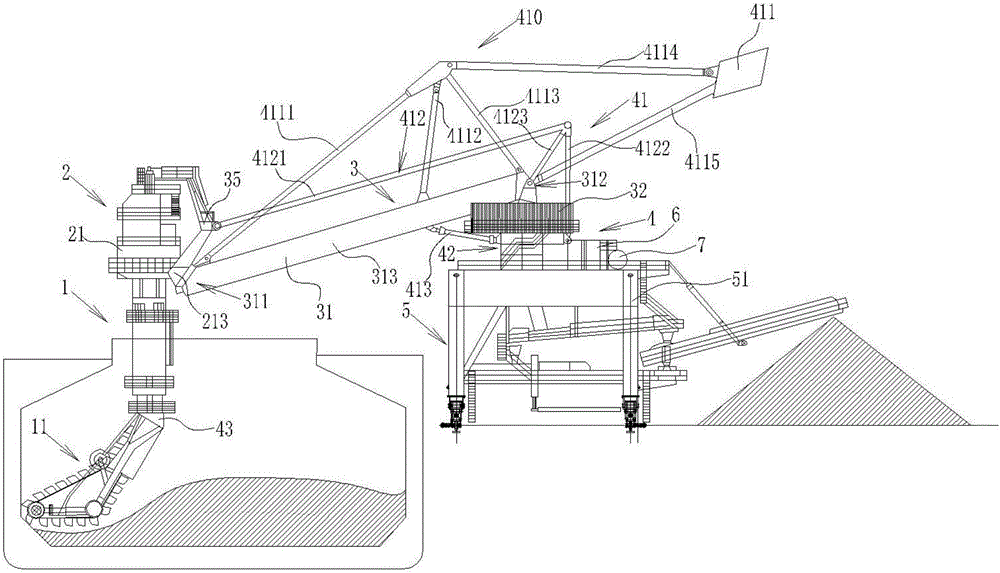

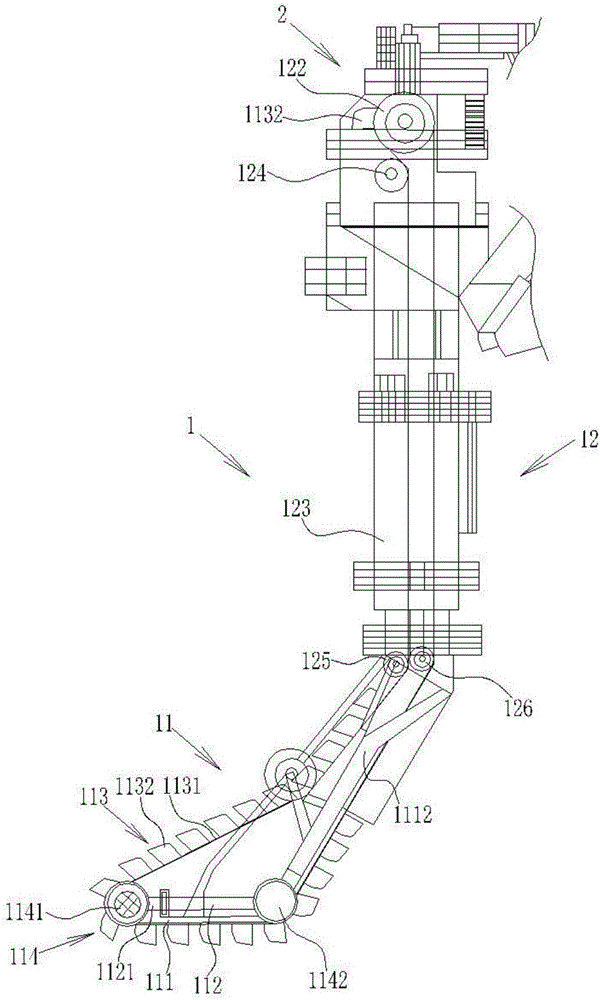

Movable type chain bucket ship unloader

The invention provides a mobile chain bucket ship unloader, which includes a retrieving mechanism, a conveying mechanism and a control mechanism. It is a chain-bucket reclaiming and lifting mechanism, and the conveying mechanism is a cantilever conveying mechanism. The chain-bucket reclaiming and elevating mechanism is connected with the cantilever conveying mechanism. A positioning mechanism is provided on the mechanism, and the positioning mechanism is controlled by a control mechanism. The positioning mechanism includes: a cantilever pitching mechanism and a cantilever turning mechanism. The invention provides a mobile chain-bucket ship unloader, which is a continuous type of retrieving and conveying, with fast unloading speed and wide application range; The unique swing mechanism can also take out the materials under the deck; the reclaiming section of the reclaiming system is equipped with a hydraulic tensioning device, which can reclaim the materials smoothly and completely remove the residual materials.

Owner:JIANGSU WANBAO MACHINERY

Textile discharging cart

InactiveCN108725549AQuick unloadingEasy to pushHand carts with multiple axesHand cart accessoriesMotor driveArchitectural engineering

The invention discloses a textile discharging cart, comprising a bottom plate and a conveyer box. A fixing block is fixedly connected to the top left of the bottom plate; the top of the fixing block is movably connected with the conveyer box through a rotary shaft; the left surface of the conveyer box is provided with a movement channel; an electric telescopic rod is fixedly connected to the top of an inner cavity of the movement channel; a retaining plate is fixedly connected to the bottom of the electric telescopic rod; the bottom of the retaining plate is passed through the movement channeland is in contact with the bottom of the inner cavity of the conveyer box. The bottom plate, the conveyer box, the fixing block, the movement channel, the electric telescopic rod, the retaining plate, a rope, a support post, a pulley, a motor, a reel and a battery jointly form the textile discharging cart, wherein the motor drives the rope to telescope so that the conveyer box is inclined; the electric telescopic rod pulls the retaining plate to rise so that fabric in the conveyer box can be discharged quickly. The structural fit above enables the problems of poor stability, troublesome discharging and waste of time and manpower to be solved.

Owner:SUZHOU RUIZHONG NEW MATERIAL TECH CO LTD

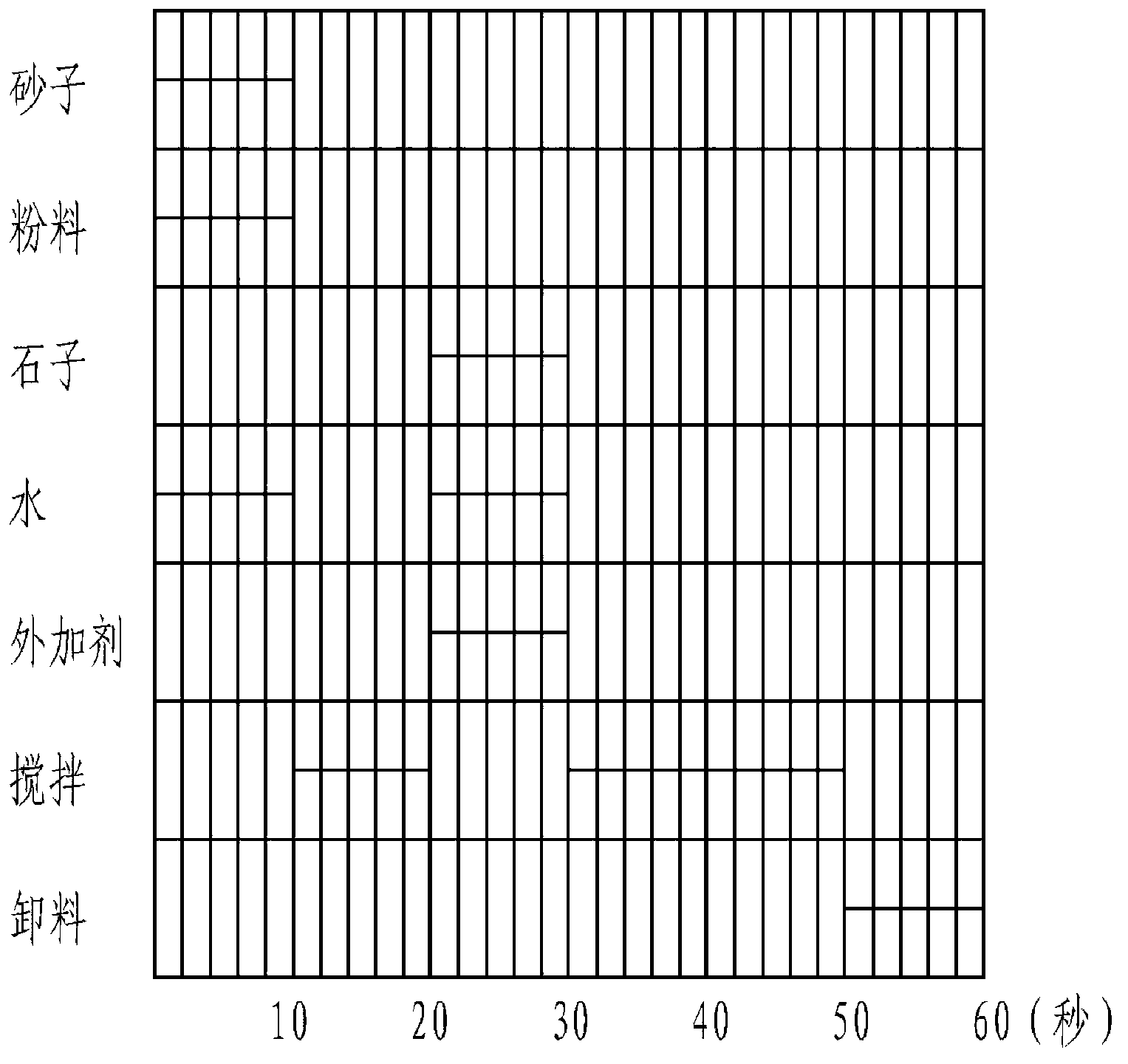

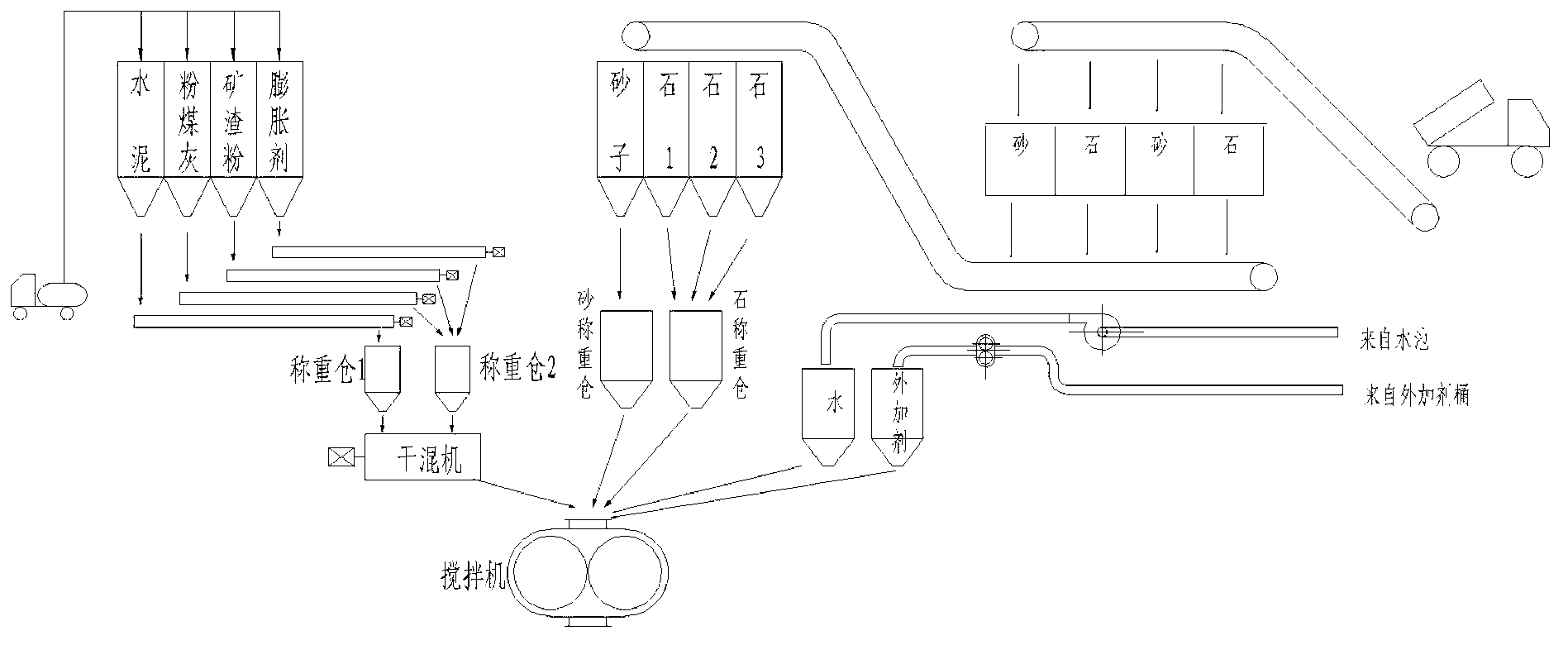

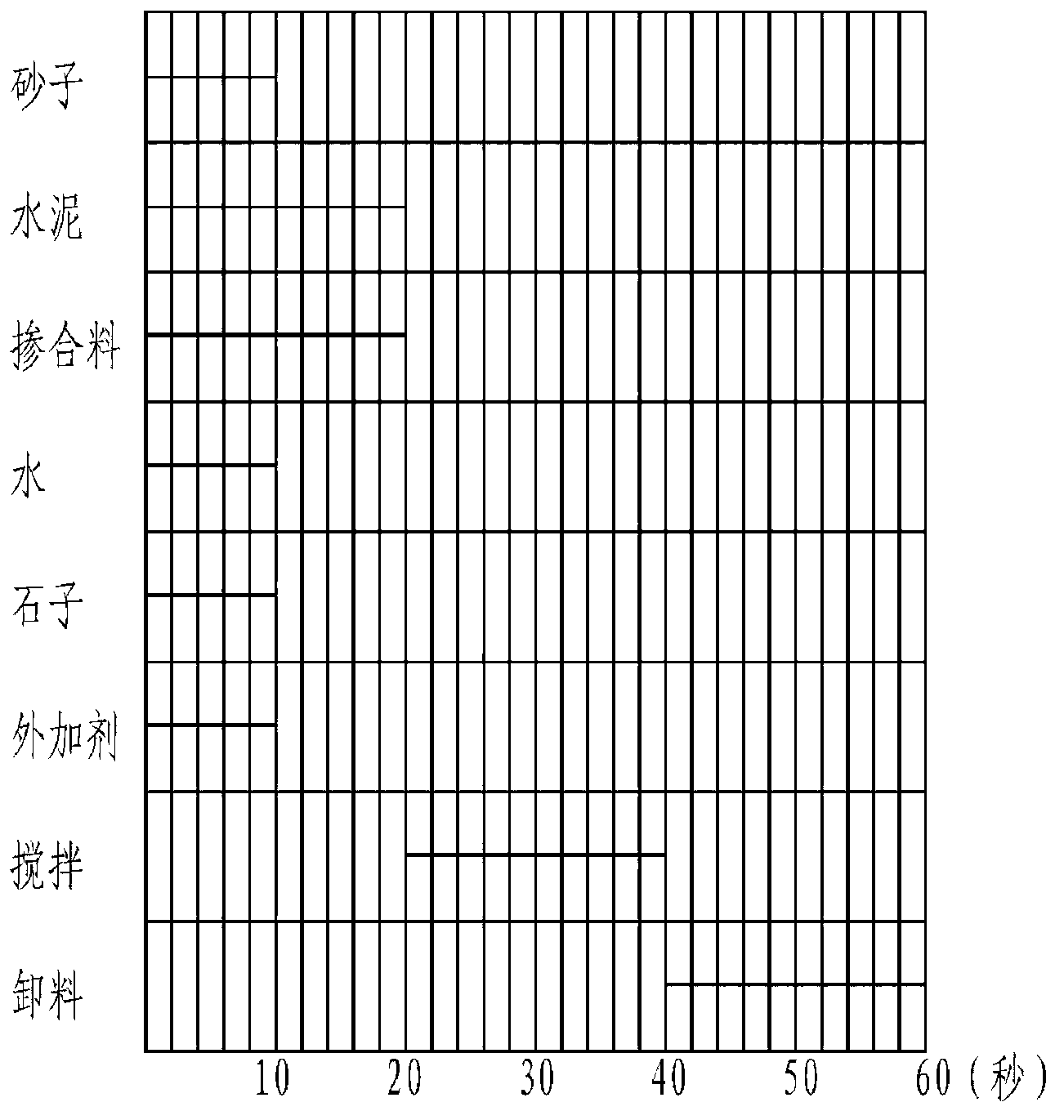

New concrete production technology

ActiveCN102837361AQuick unloadingReal-time effective automatic controlMixing operation control apparatusCement mixing apparatusMaterials preparationSlurry

A new concrete production technology consists of four steps of primary material preparation of dry mixed slurry, secondary material preparation of rear additive, stirring and discharging; through the optimization of feeding combination and blanking in concrete production, the problems of non-uniform distribution of powdery material in the concrete, bad compatibility of cement and additive and the like are efficiently solved, the internal defects of concrete are reduced, and the strength and quality stability of concrete products are improved; under the condition of maintaining the same mixing proportion, compared with the concrete produced by the traditional technique, the slump constant of the concrete produced by using the technology in the invention can be increased by more than 20mm, the concrete strength of C30 level can be improved by more than 10%; and under the conditions of maintaining the original strength and unchanging the flowability, more than 15Kg cement and 5Kg water can be saved in each square of concrete with the strength of C30 level.

Owner:北京新奥混凝土集团有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com