Movable type chain bucket ship unloader

A ship unloader, mobile technology, applied in the field of mobile chain bucket ship unloader, can solve the problems of large wear of the reclaiming head and screw blade, narrow application range, high energy consumption, etc., and achieve fast unloading speed and wide application range wide, low system energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

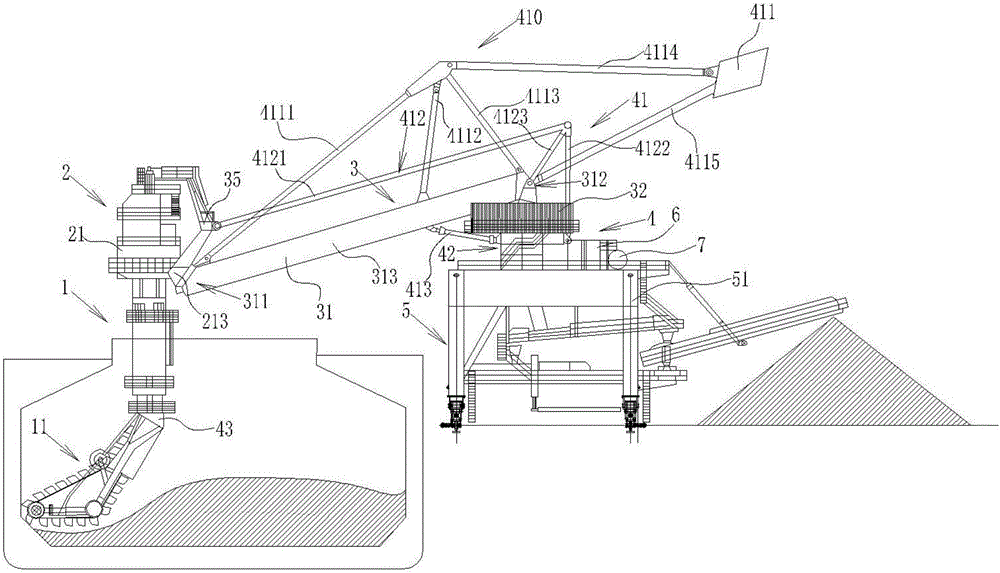

[0046] Cantilever pitching mechanism 41 adopts hydraulic system, such as figure 1As shown, the cantilever pitching mechanism 41 includes a balancing mechanism 410 , a stretching arm 412 and a push rod 413 . The balance mechanism 410 includes a balance piece 411, the balance piece 411 is connected and fixed by five balance beams, the balance piece 411 is located on the extension direction of the cantilever output end 312 of the cantilever delivery system 31; its five balance beams are respectively the first balance beam 4111, The second balance beam 4112, the third balance beam 4113, the fourth balance beam 4114 and the fifth balance beam 4115; wherein, the first balance beam 4111, the second balance beam 4112, the third balance beam 4113 and the fourth balance beam 4114 One end is connected to a point, which is located above the cantilever conveying system 31, the other end of the first balance beam 4111 is connected above the cantilever input end 311 of the cantilever conveyi...

Embodiment 2

[0048] The cantilever pitching mechanism 41 adopts a winch system, and its structure is basically the same as that of Embodiment 1, including a balancer 410 and a push rod 413. The structures of the balance mechanism 410 and the push rod 413 are the same as those in Embodiment 1, the difference is , also includes a hoisting mechanism, the hoisting mechanism includes a pull rope and a hoist, the pull rope is located at the position of the first stretch rod 4121 and the second stretch rod 4122 in Embodiment 1, and also includes a pole 4123, and the end of the pole 4123 is provided with One end of the pulley is connected to the connecting arm 35 of the reclaiming part, and is arranged along the length direction of the cantilever conveying system 31, bypasses the pulley, and is wound on the hoist. The hoist applies force to the connecting arm 35 of the reclaiming part and the cantilever conveying system 31 by retracting or releasing the pull rope, so that the cantilever conveying s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com