Disc unloading mechanism of dual take-up machine

A wire take-up machine and frame technology, applied in the field of cable equipment, can solve problems such as unsmooth reel unloading, stuck wire reel production efficiency, thrust deviation from the center of gravity of the wire reel, etc., so as to achieve fast unloading and avoid wire reel The effect of jamming and unloading force is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

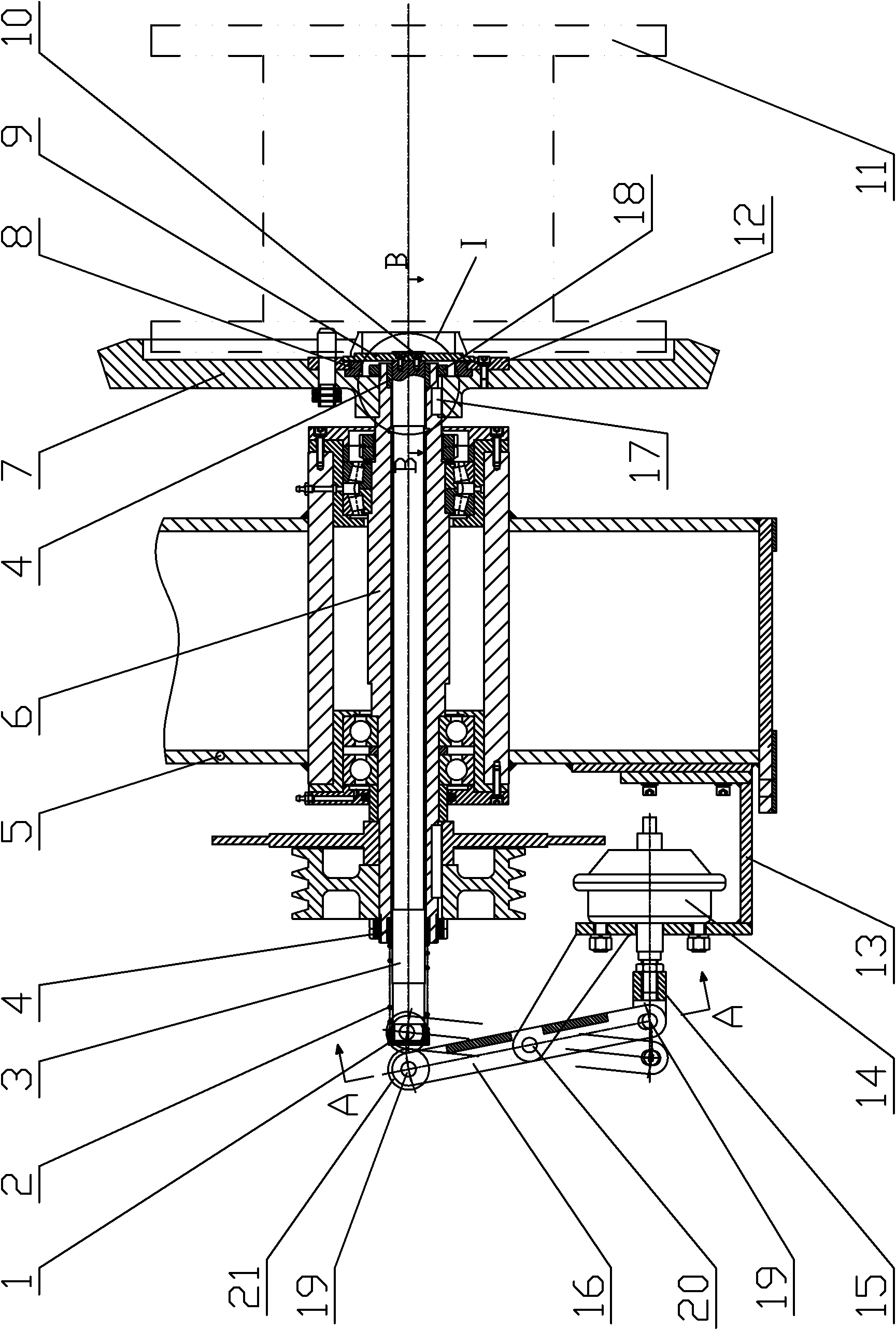

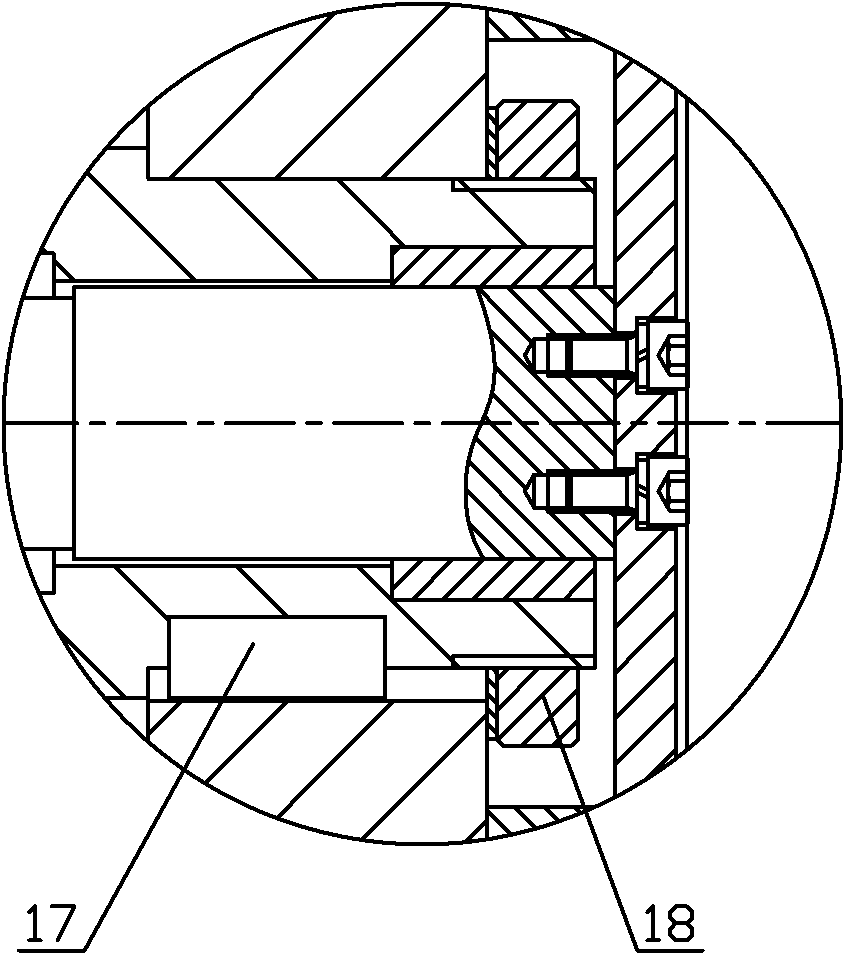

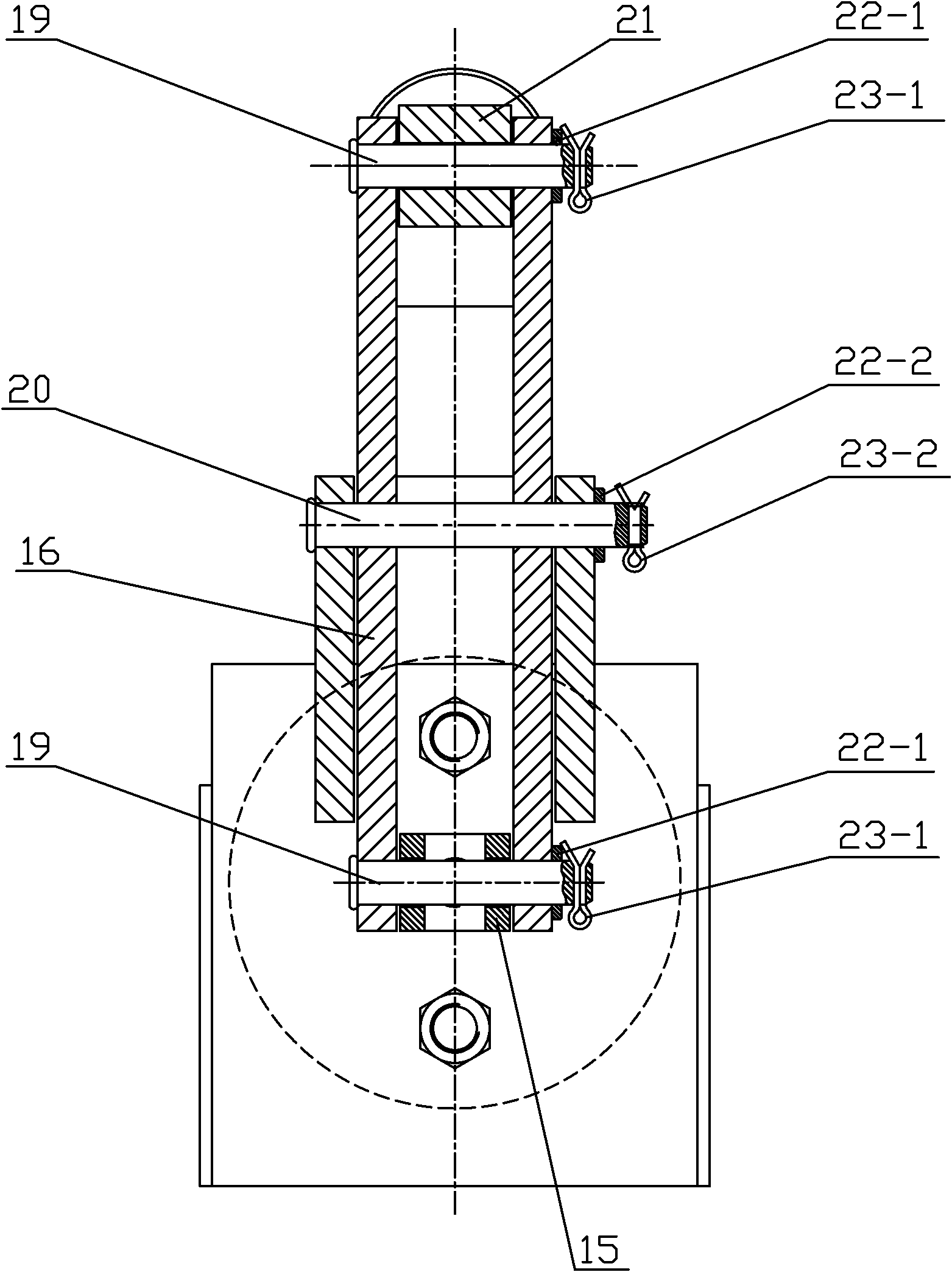

[0033] Such as Figure 1 to Figure 4 As shown, the present invention is composed of a first unloading mechanism and a second unloading mechanism arranged in parallel in the front and rear. The first and second unloading mechanisms have the same structure and both include an end cover 1, a compression spring 2, and a shaft. 3. Frame 5, hollow shaft 6, large turntable 7, push plate 9, bracket 13, film cylinder 14, hinge 15, lever 16 and pressure wheel 21, said hollow shaft 6 is installed on frame 5, said large The turntable 7 is installed at the right end of the hollow shaft 6. The shaft 3 is arranged in the hollow shaft 6, and the push plate 9 is arranged on the right of the hollow shaft 6 and is fixedly connected to the shaft 3; the left end of the shaft 3 is located on the hollow shaft 6. In addition, the end cover 1 is installed at the left end of the shaft 3, the compression spring 2 is arranged between the end cover 1 and the hollow shaft 6; the thin film cylinder 14 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com