Patents

Literature

387results about How to "Less wearing parts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Torsional impact drilling tool

ActiveCN102454364ATorque stability and balanceReduce torsional oscillationsVibration drillingImpact hammerPetroleum engineering

The invention discloses a torsional impact drilling tool which can apply high-frequency torsion impact to a drilling bit in the drilling engineering. The technical scheme of the torsional impact drilling tool is as follows: the torsional impact drilling tool mainly comprises a short section of a drill collar, a torsional impact generator and a connecting body, wherein the short section of the drill collar and the torsional impact generator are in clearance connection through the connecting body and are located by splines; a diversion cover is fixed on a hammer seat; a cavity is formed inside the diversion cover; a closure nozzle, a sieve tube, a locating sleeve and an impact hammer are sequentially arranged in the cavity from inside to outside; the sieve tube is fixed with the hammer seat; the impact hammer, the locating sleeve, the sieve tube and the hammer seat are provided with through holes in the circumferential direction; and an impact hammer head and a starting hammer head are processed on the impact hammer. The torsional impact drilling tool is arranged between the drill collar and the drilling bit; and the drilling bit receives the high-frequency torsional impact generated by the impact hammer under the driving of fluids while receiving the rotational torsion of a drill column. Compared with other drilling tools, the torsional impact drilling tool disclosed by the invention has the advantages that the high-frequency torsional impact can be generated, the sticking-sliding phenomenon of the drilling bit is eliminated, the mechanical drilling rate of harder or abrasive formation is increased, the service life of matched components, such as the drilling bit and the like of the drill column is prolonged, the drilling efficiency is improved and the drilling cost is reduced.

Owner:CHINA PETROCHEMICAL CORP +3

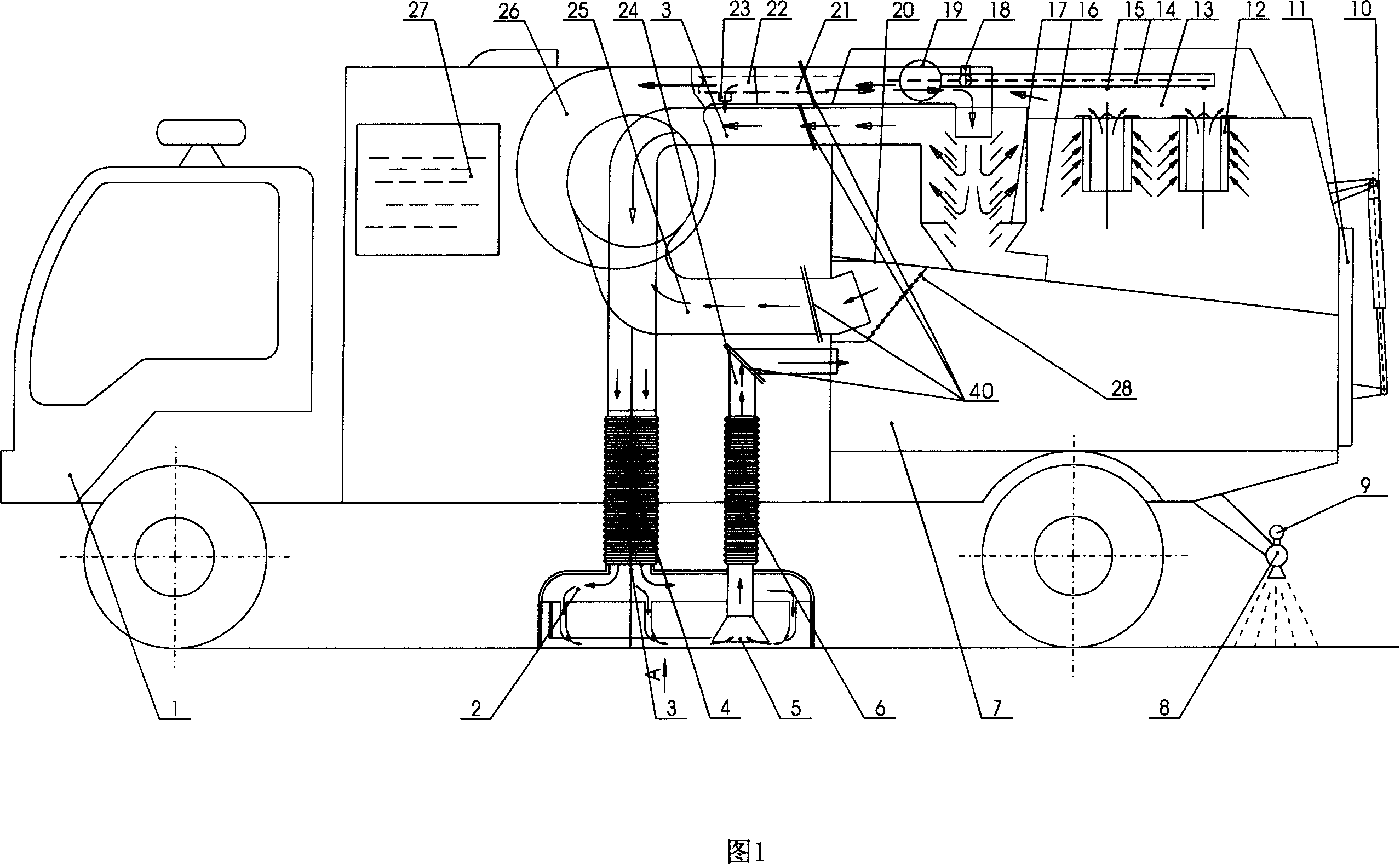

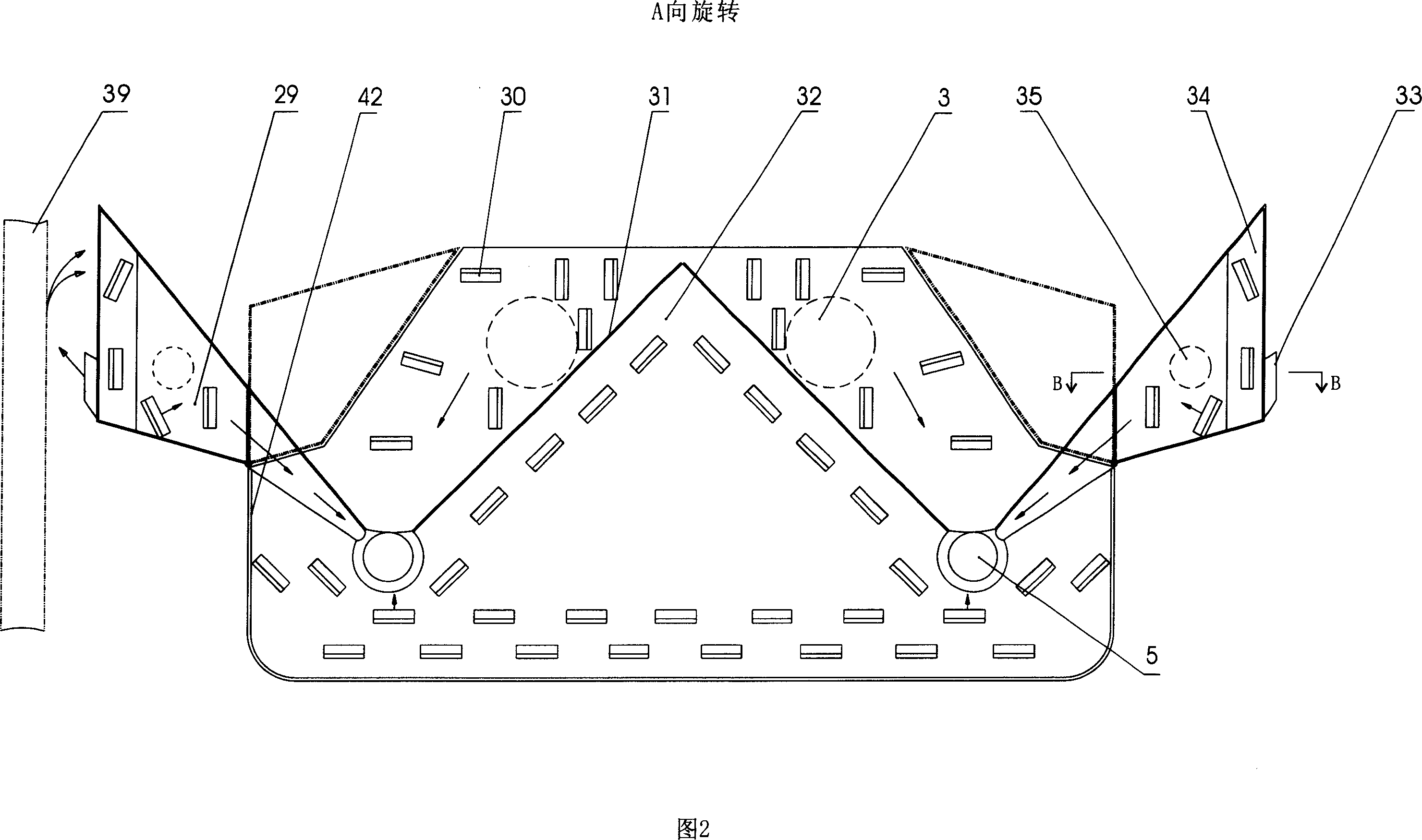

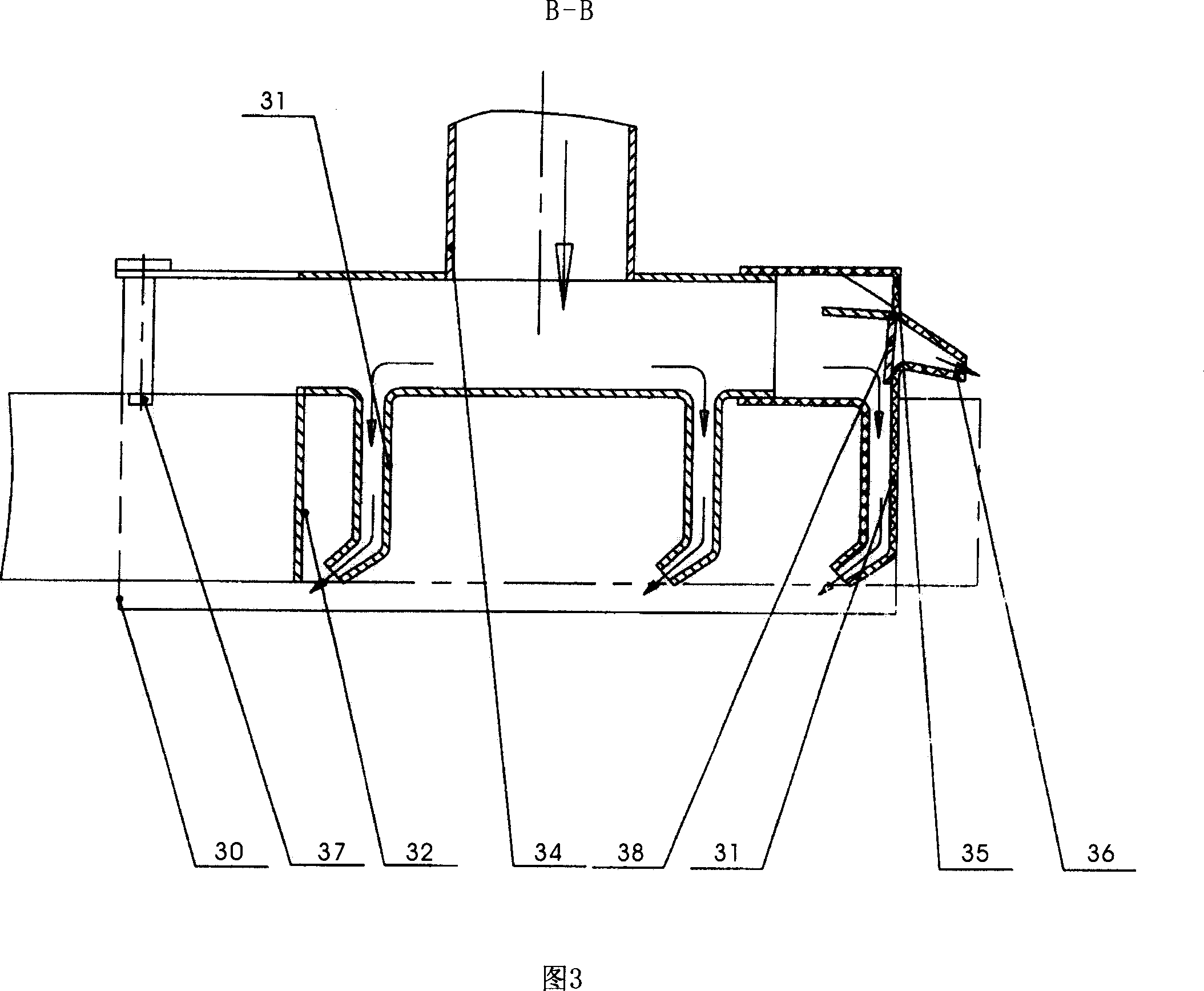

Multifunctional complete sucking type sweeping car

ActiveCN101003968AEfficient removalClean up thoroughlyRoad cleaningRefuse vehiclesParticulatesAir cleaning

The present invention relates to a multifunctional full-suction type roadsweeper. Said multifunctional fall-suction type roadsweeper includes the following several portions: upper dust-collecting tank, lower settlement negative-pressure tank, air-cleaning chamber, flower fan, air outlet pipe, air-blowing pipe, reverse-flow dust remover, filter dust-remover and power device. Said invention also provides the connection mode of all portions, also provides its working principle and concrete operation method.

Owner:高亚峰

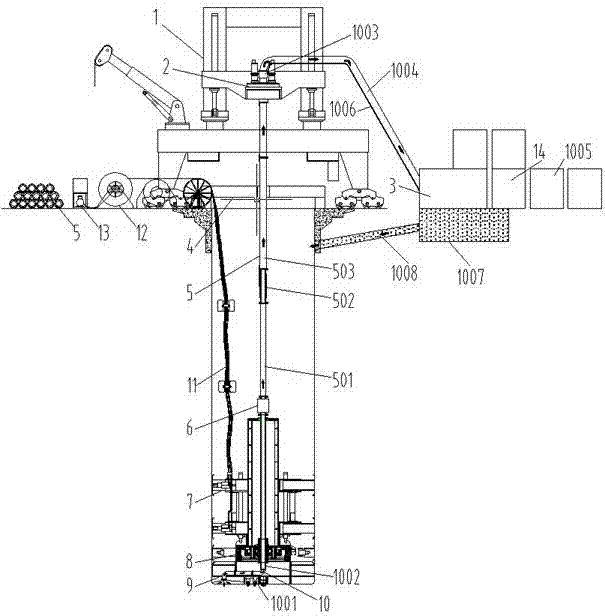

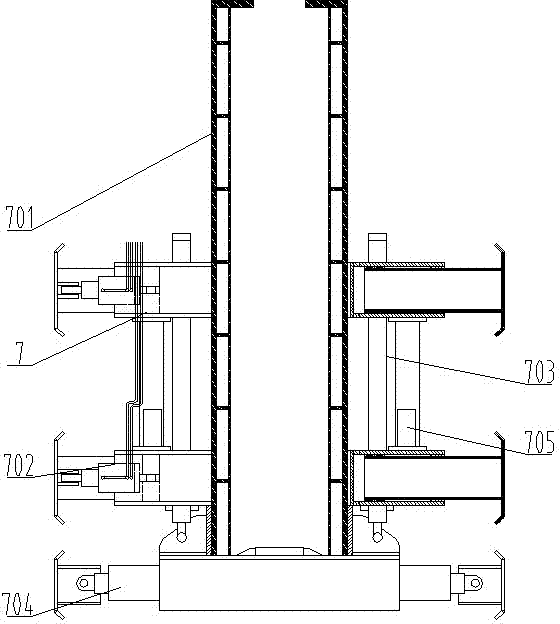

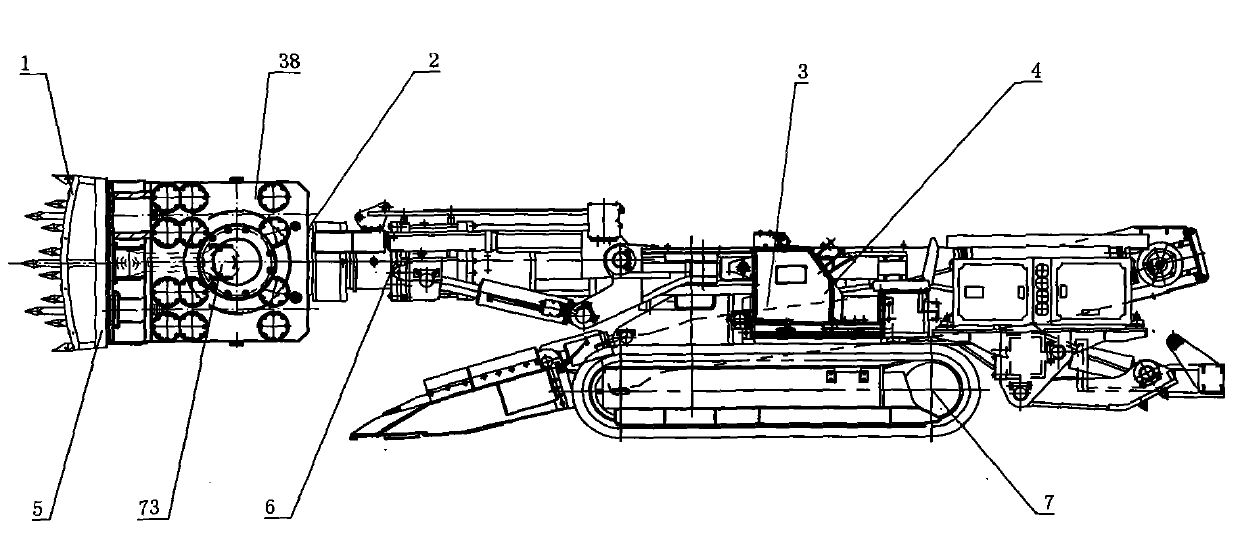

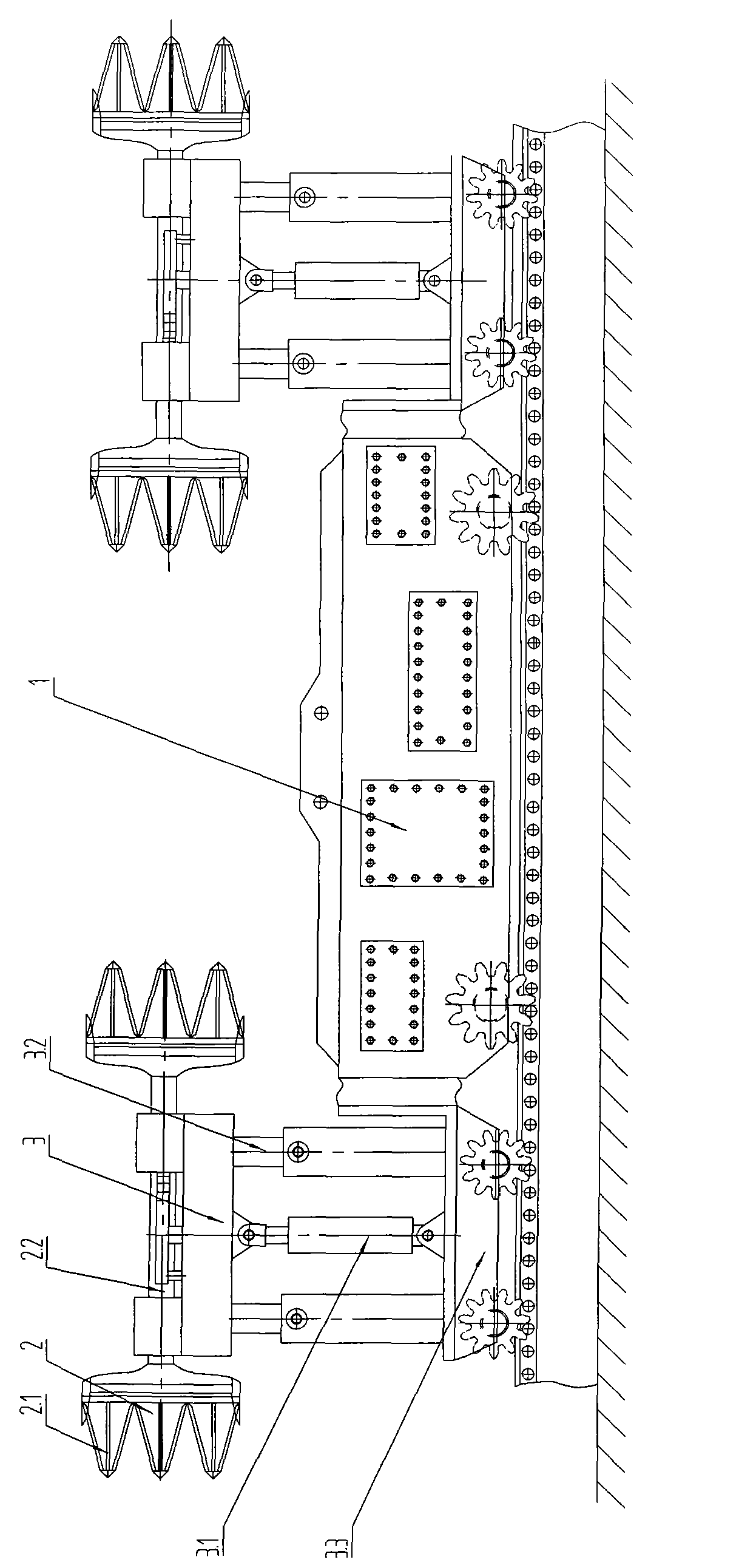

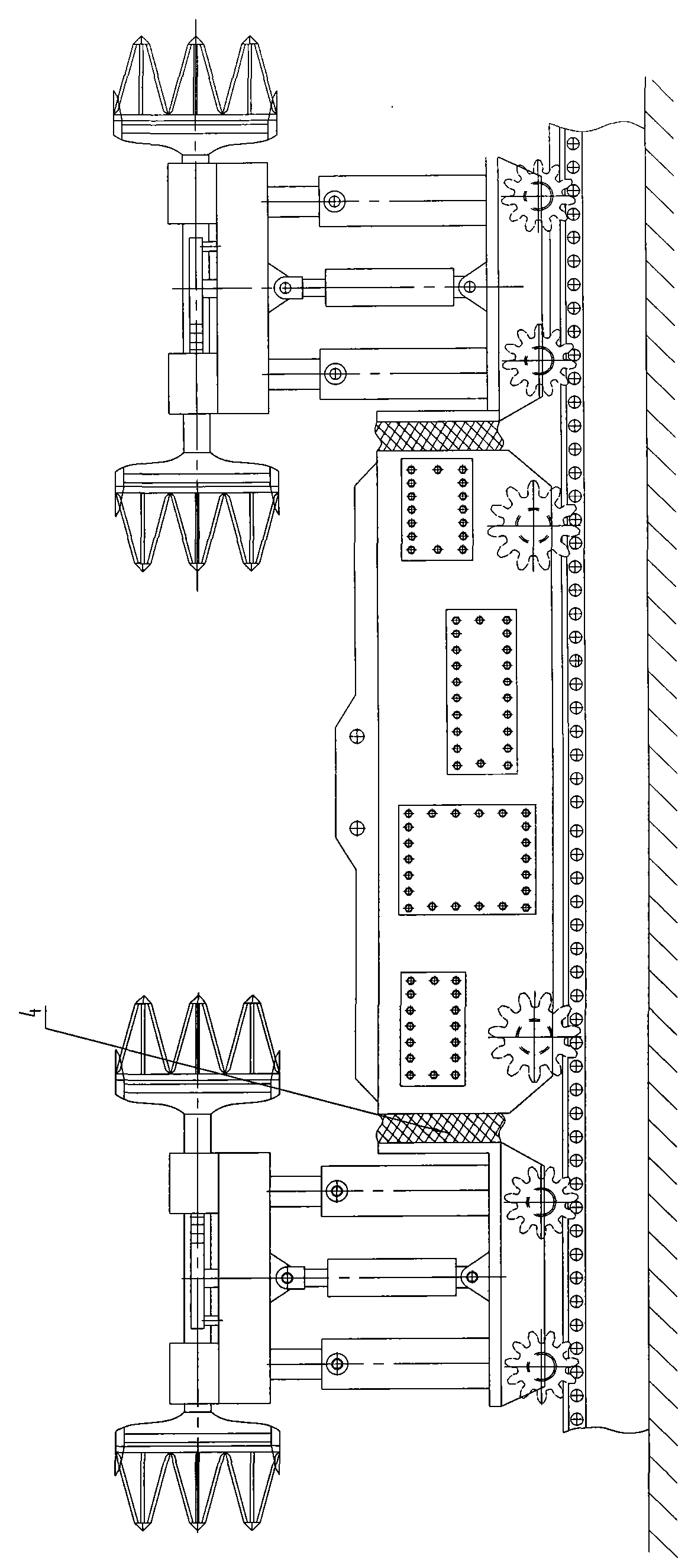

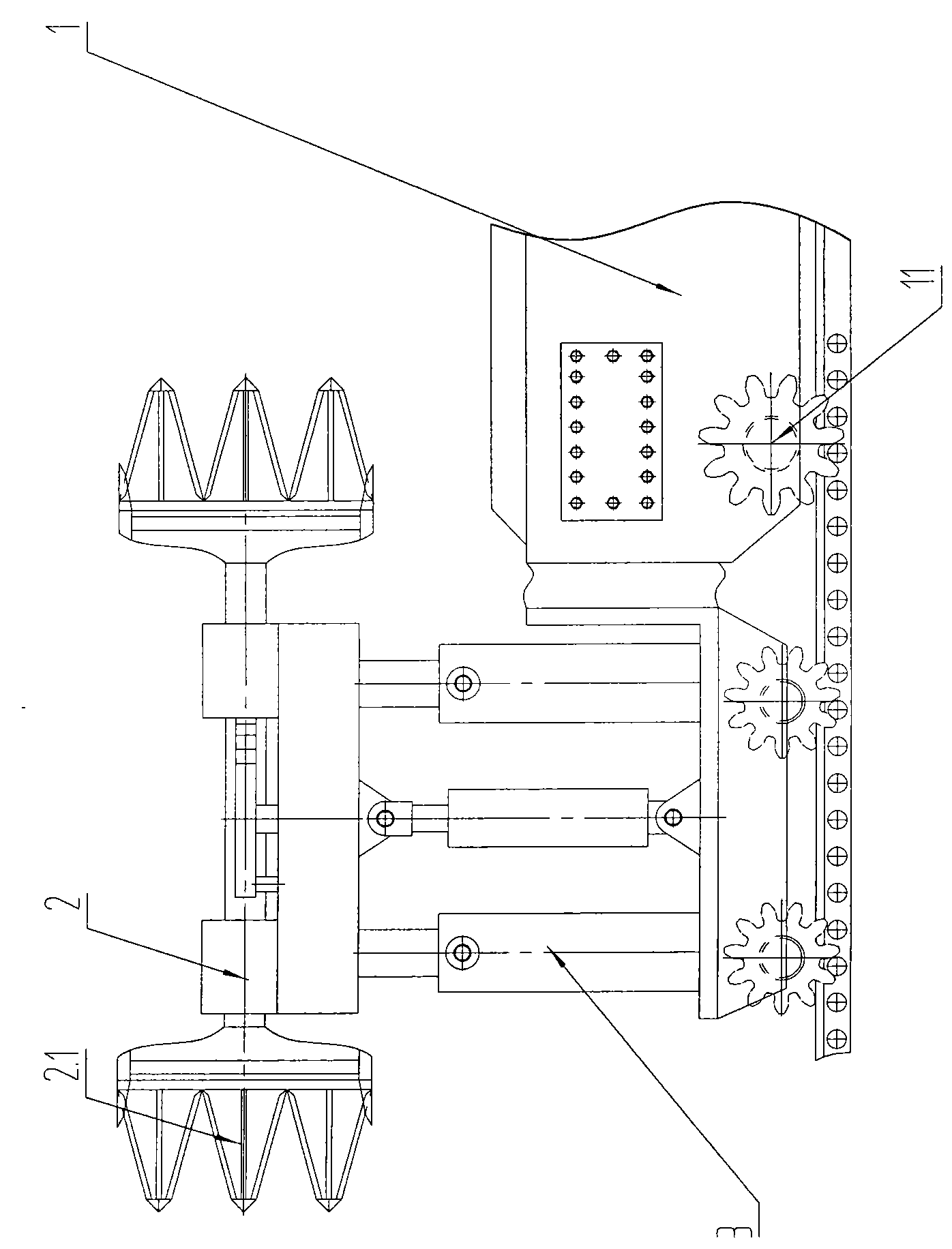

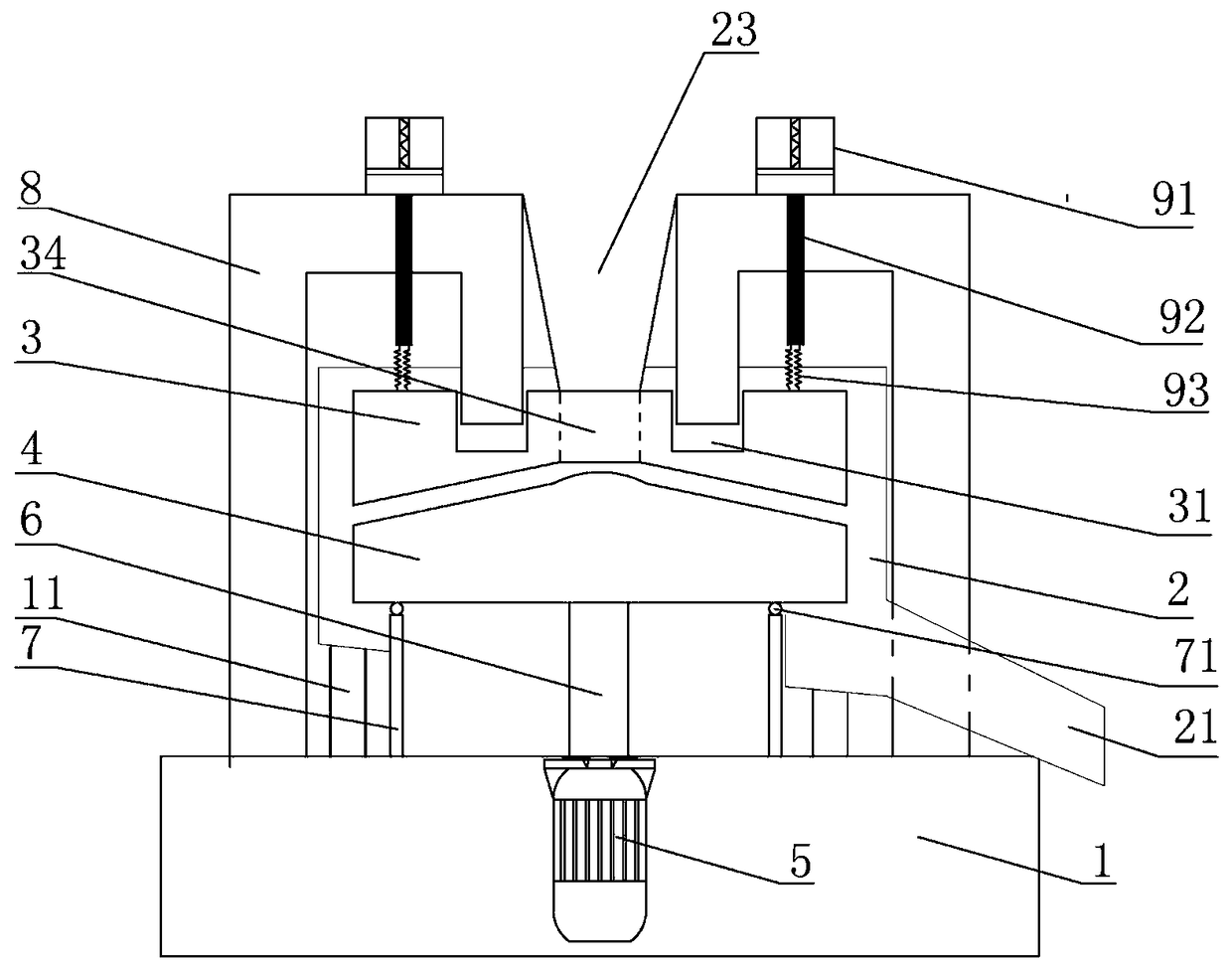

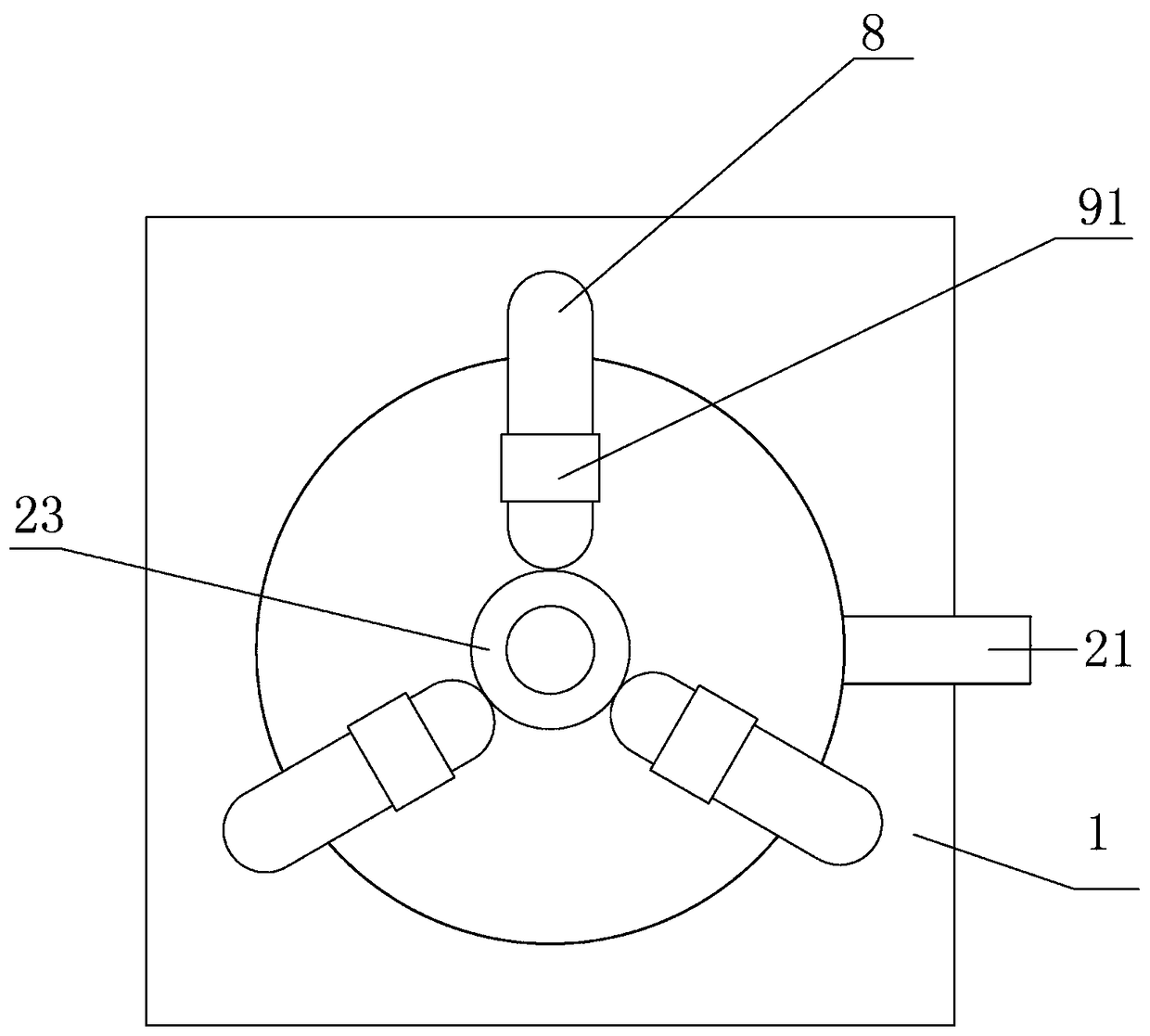

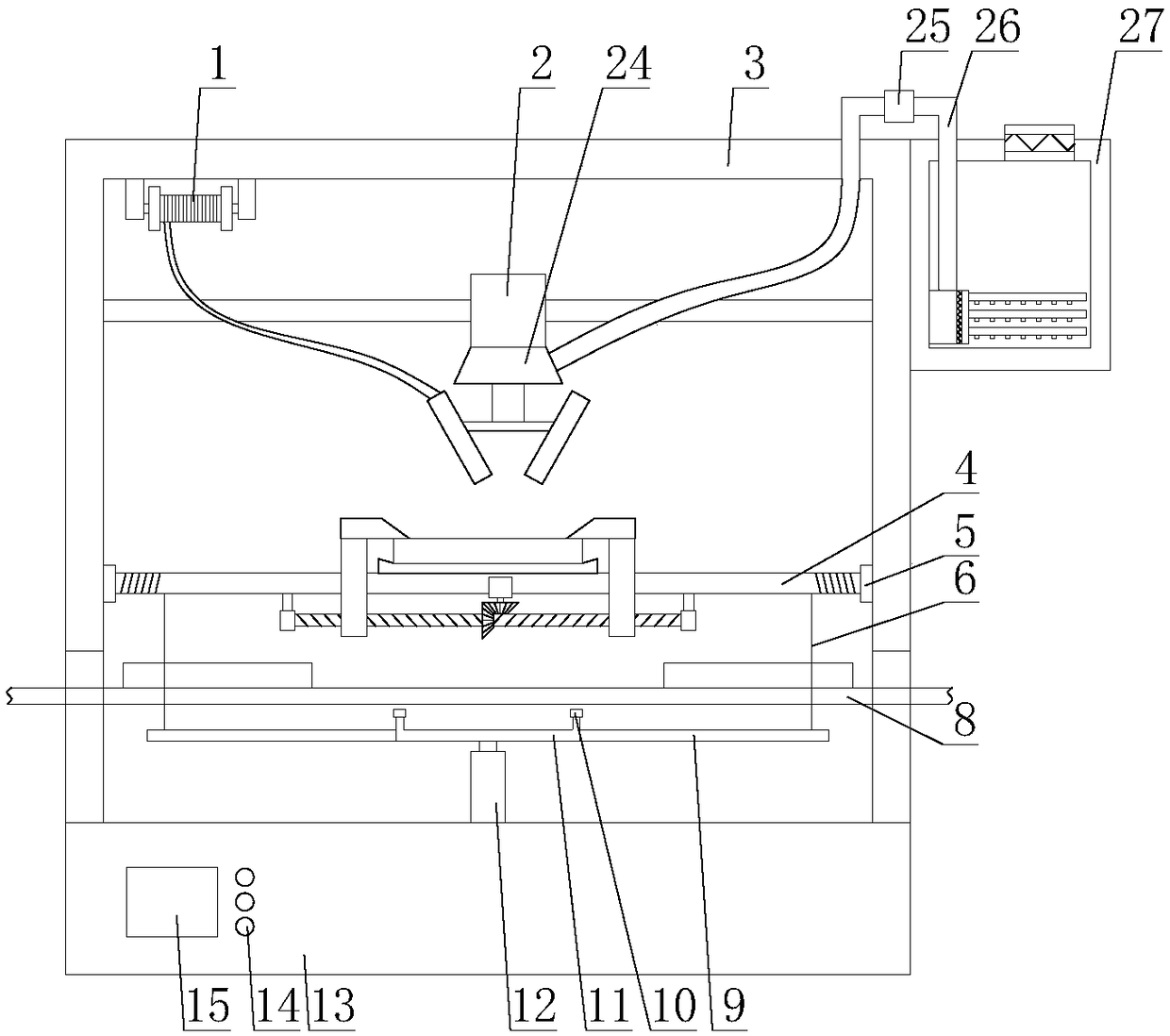

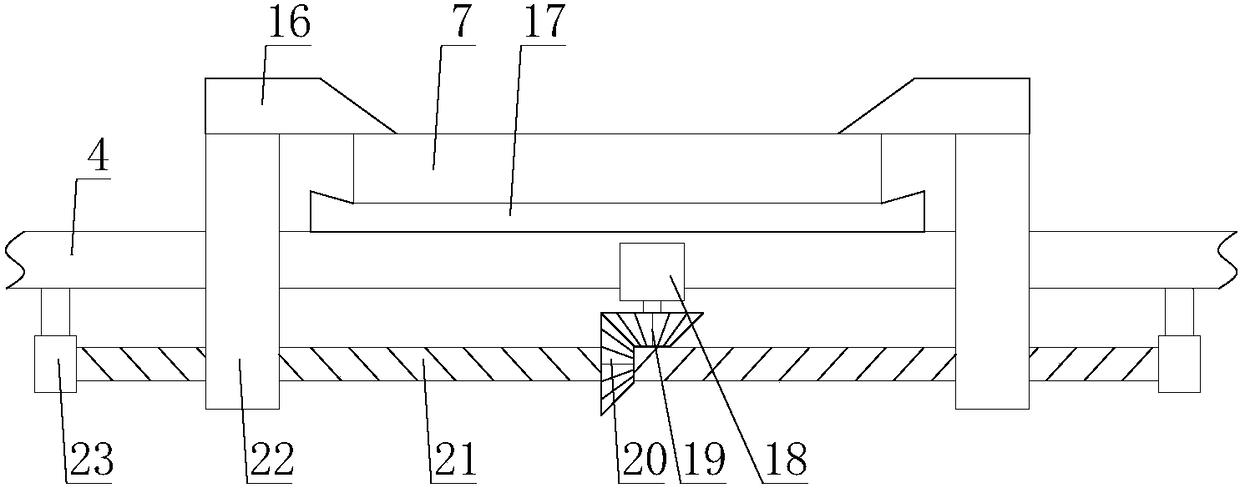

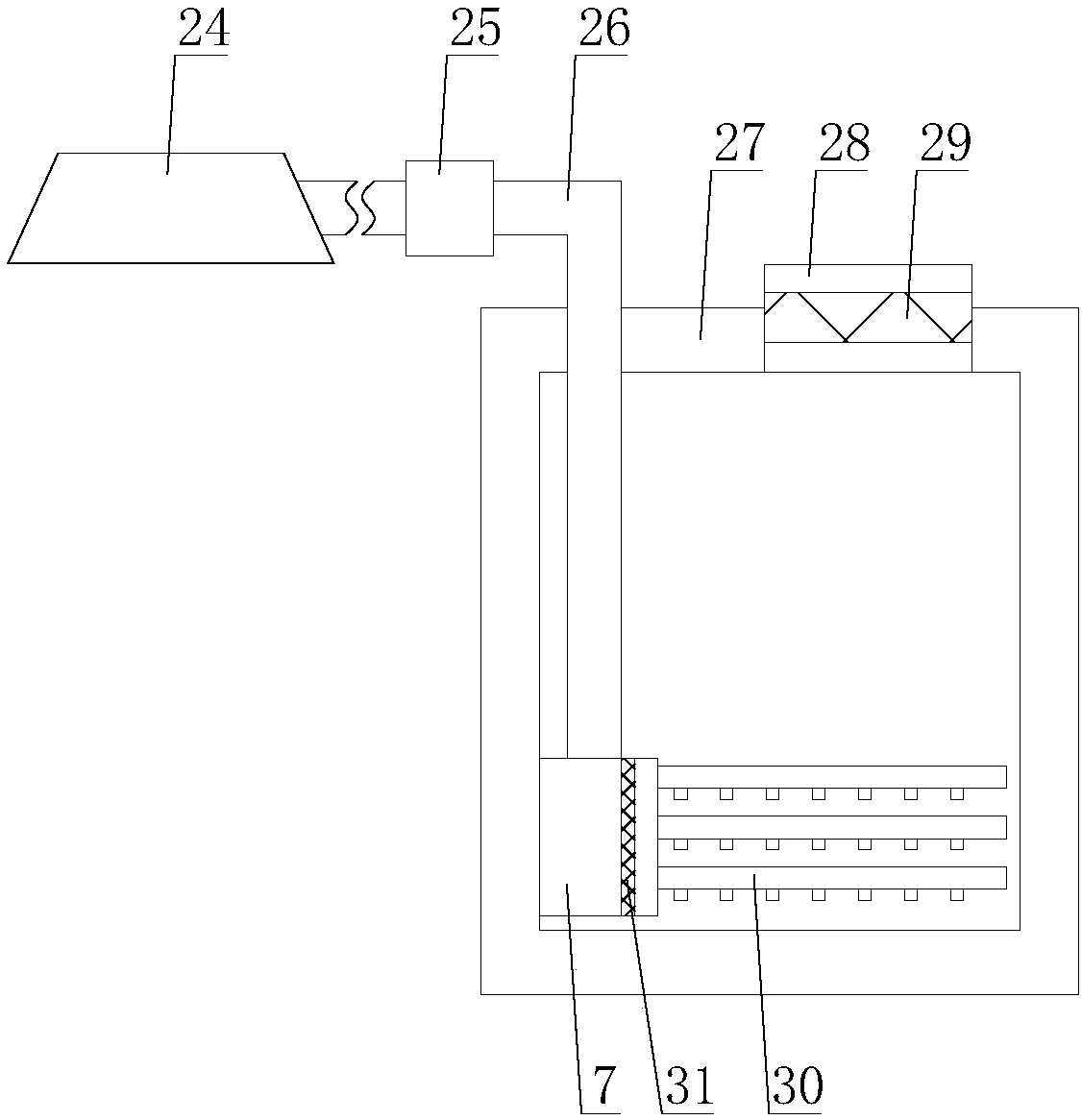

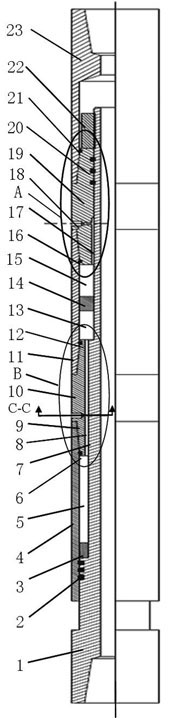

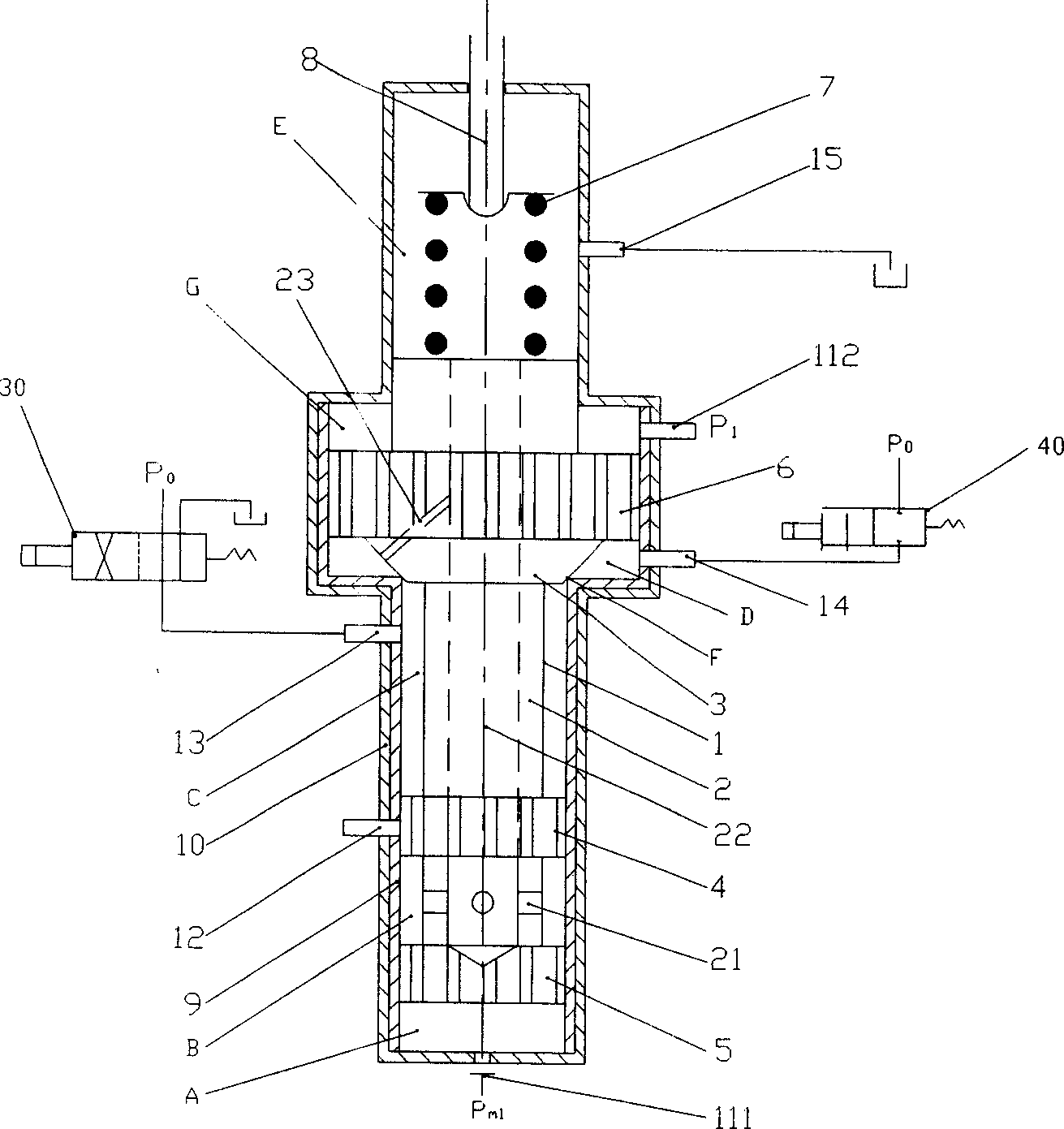

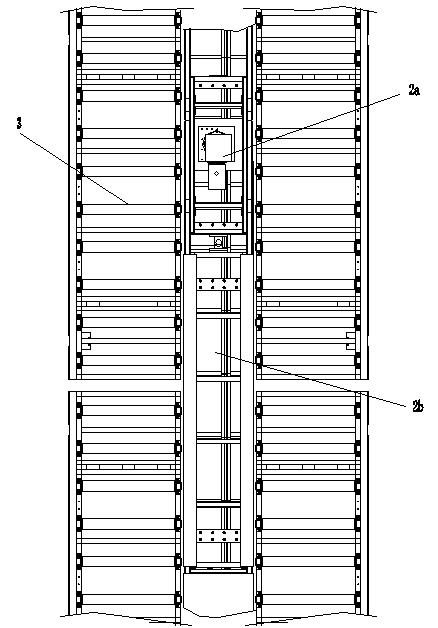

Novel drilling method for shaft drilling machine

ActiveCN103899316AImprove stabilityImprove construction efficiencyDerricks/mastsBorehole drivesSlagWell drilling

A novel drilling method for a shaft drilling machine mainly comprises a derrick and an opening-sealing flat wagon which are arranged at a well opening, and further comprises a drill rod, a flexible connector, a stable pressing device, a torque amplification driving device, a cutter head, a slag discharging system, a mud treatment station, an electric appliance cabinet, a hydraulic pressure station and a power pipeline. A main drive is arranged on the derrick, the lower portion of the main drive is connected with the drill rod, the flexible connector is arranged on the drill rod, the lower end of the drill rod is connected with the torque amplification driving device, the lower end of the torque amplification driving device is connected with the cutter head, the stable pressing device is arranged outside the torque amplification driving device; muck dug by the cutter head in a well is delivered to the mud treatment station on the ground through the slag discharging system. According to the novel drilling method for the shaft drilling machine, stability of the whole machine is increased, pressing force of equipment is improved, drilling torque is increased, construction in soft soil layers is available and construction in rock stratums of high hardness is also available, guide is more accurate, so that shaft construction efficiency can be improved, shaft construction cycle is shortened, and finished well quality is improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

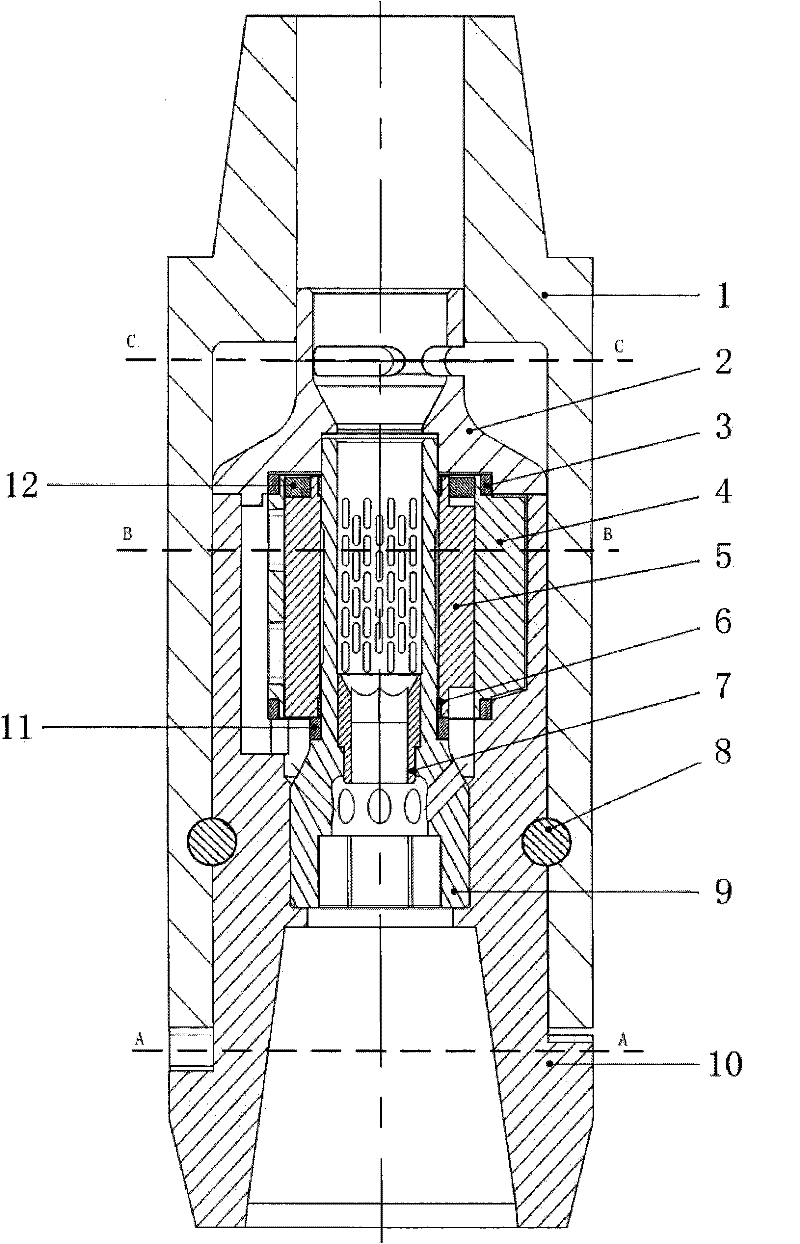

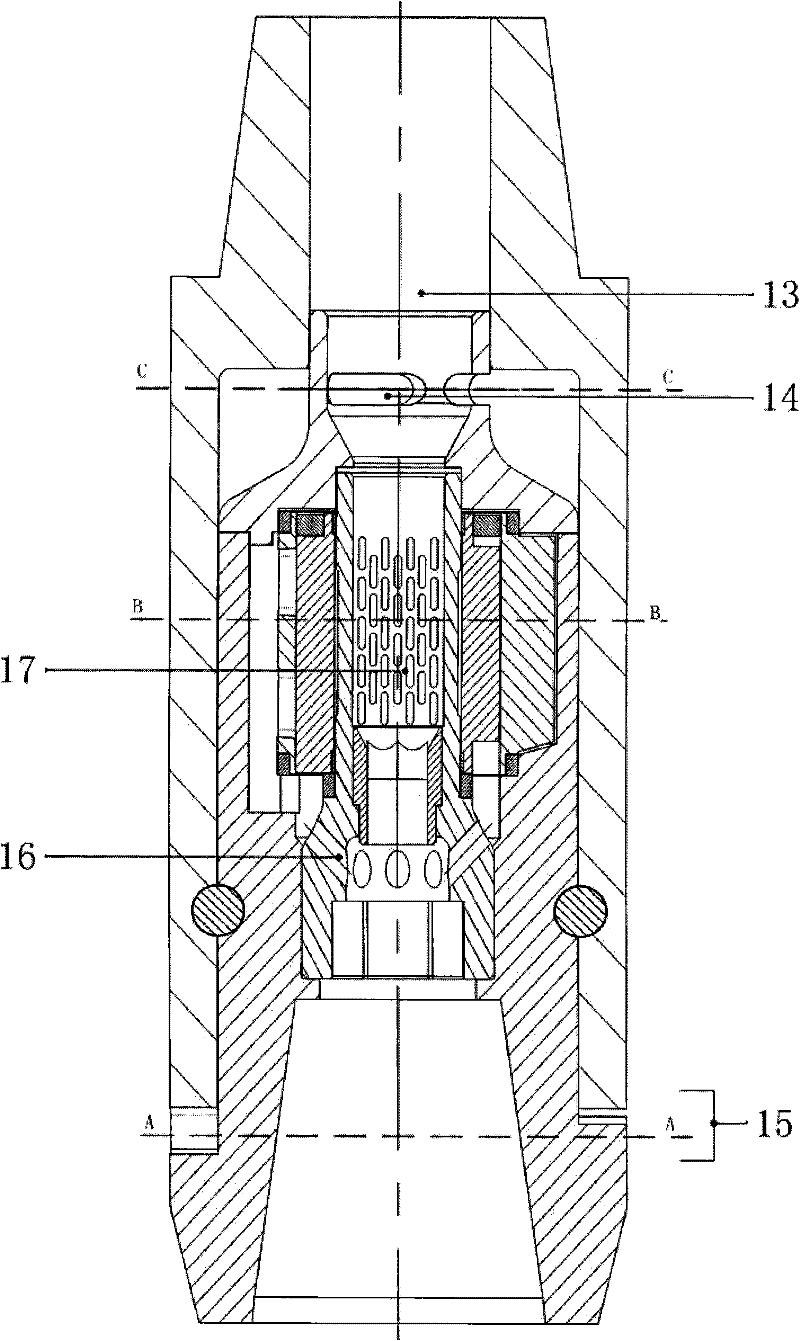

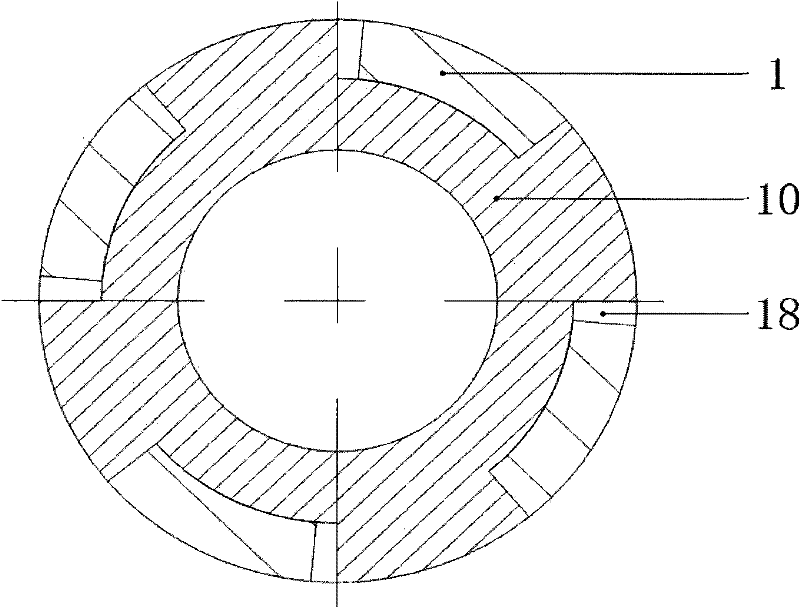

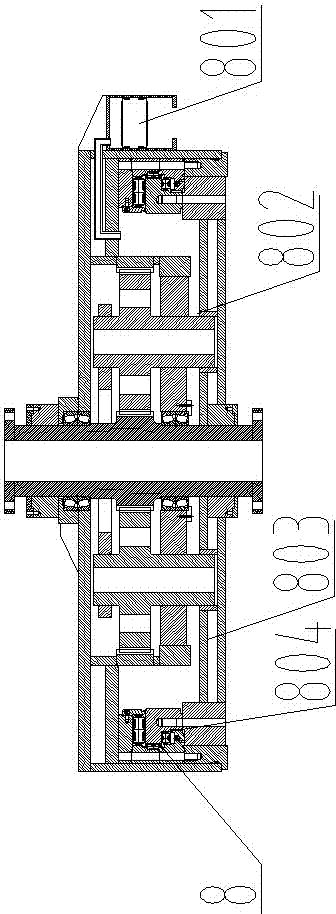

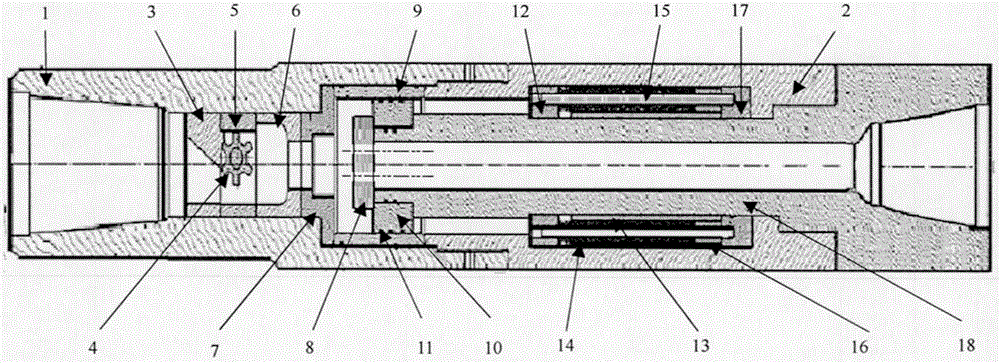

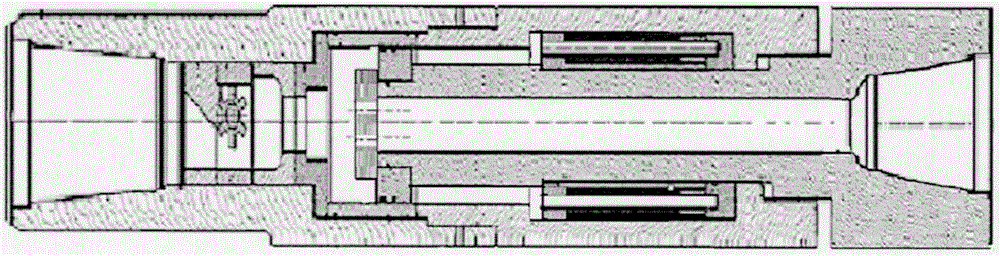

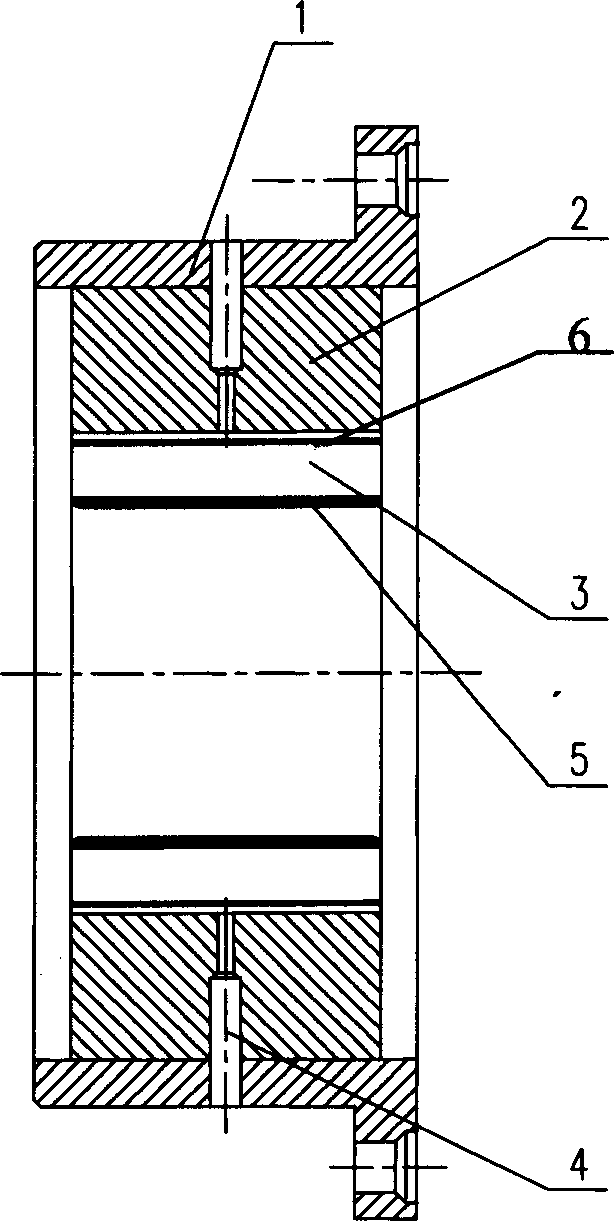

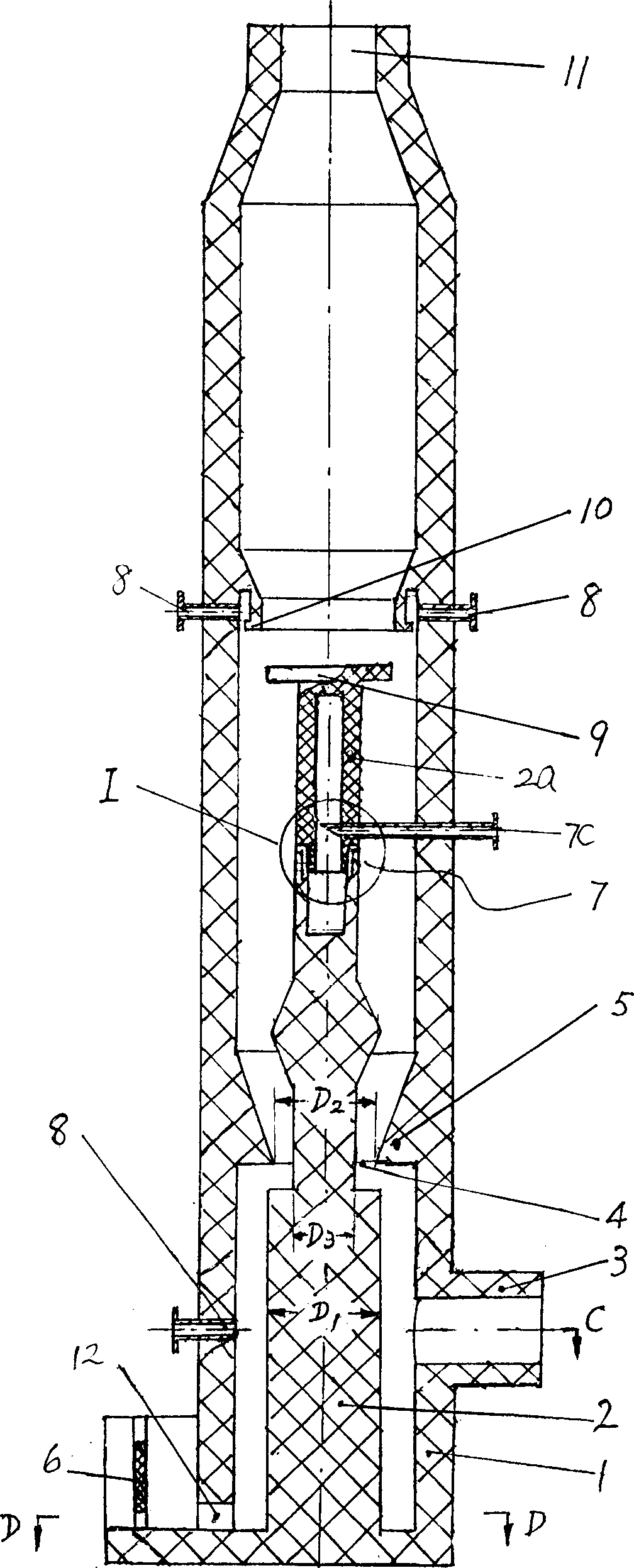

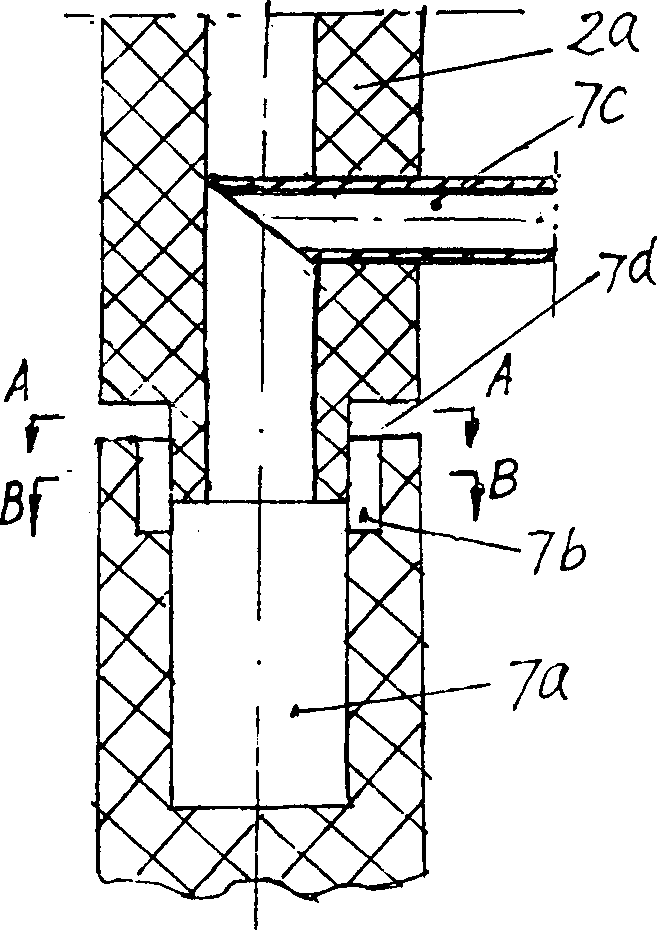

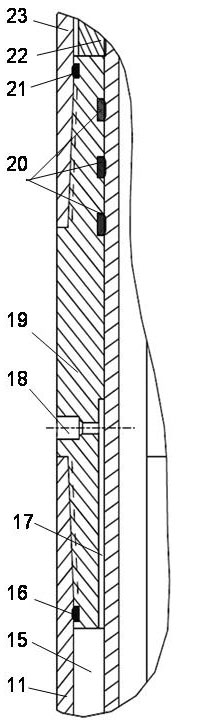

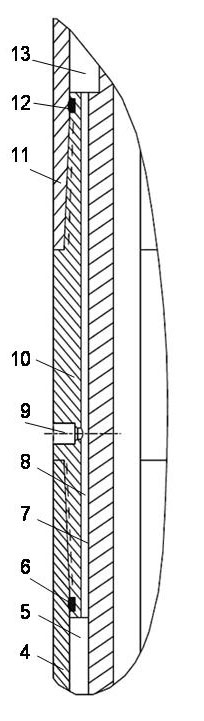

Near-bit torsion impactor

InactiveCN103628819AStable jobEliminate stick-slipDrill bitsVibration drillingElectricityWell drilling

The invention discloses a near-bit torsion impactor. The near-bit torsion impactor comprises a drill collar pup joint, a splitter, a torsion impactor body and an impact transmission pup joint. The lower portion of the drill collar pup joint is connected with the impact transmission pup joint, the splitter and the torsion impactor body are installed between the drill collar pup joint and the impact transmission pup joint; a lower port of the splitter is communicated with an inlet of the torsion impactor body; an outlet of the torque impactor body is communicated with the transmission pup joint. The near-bit torsion impactor has the advantages that due to the fact that high-frequency low-amplitude torque impact which is stable in periodicity is generated, impact torque can eliminate the phenomena of PDC bit stick slip and intermittent bit sticking; due to the fact that the near-bit torsion impactor is provided with no electronic part and is of a full-hydraulic mechanical structure, the size is small and the impact process has no interference to an electric instrument which conducts measurement while drilling. The near-bit torsion impactor guarantees that in the drilling process, torque in a drill stem is stable and balanced, drill stem torsion oscillation is reduced and stable work of electric MWD devices, electric LWD devices and the like is facilitated. Parts which are prone to being damaged are few in the near-bit torsion impactor, and the near-bit torsion impactor is stable in work, long in service life and beneficial for lowering well drilling cost.

Owner:CNPC BOHAI DRILLING ENG

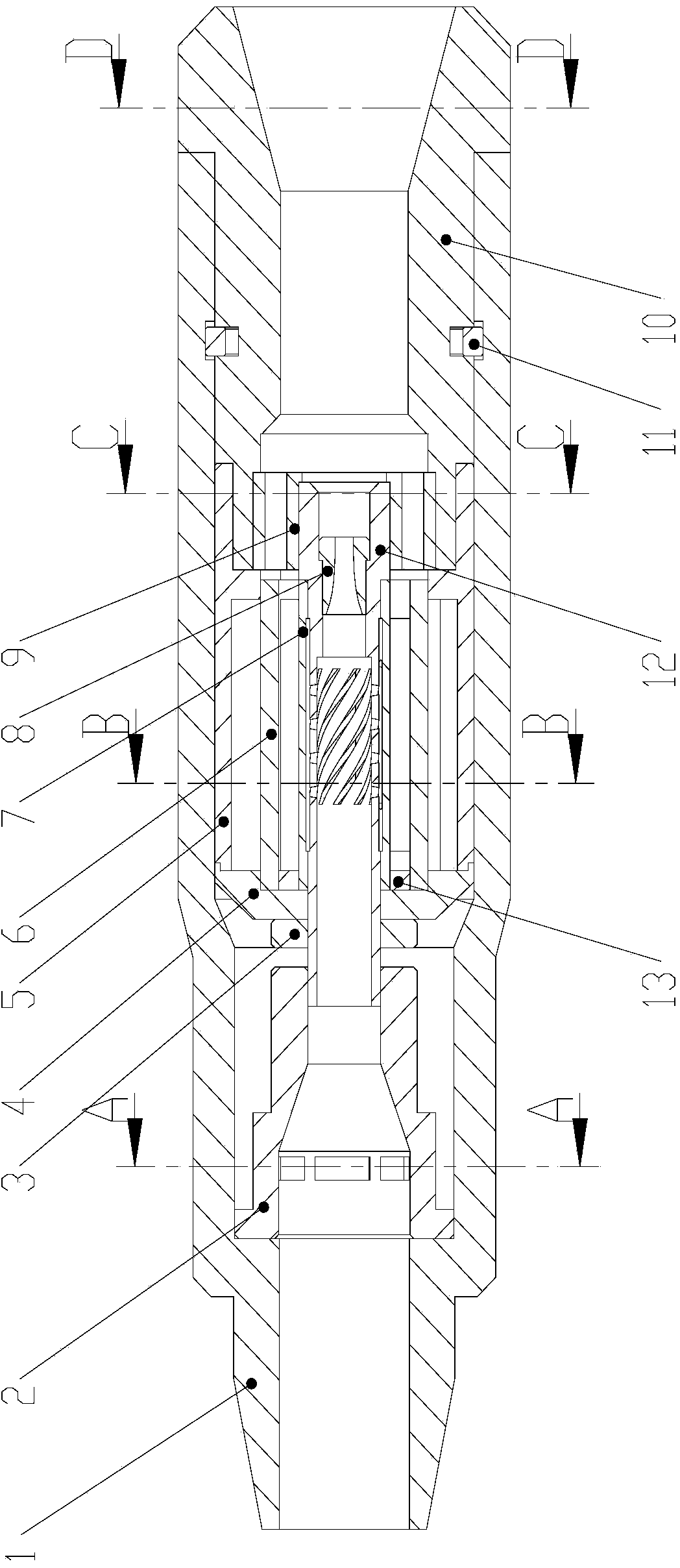

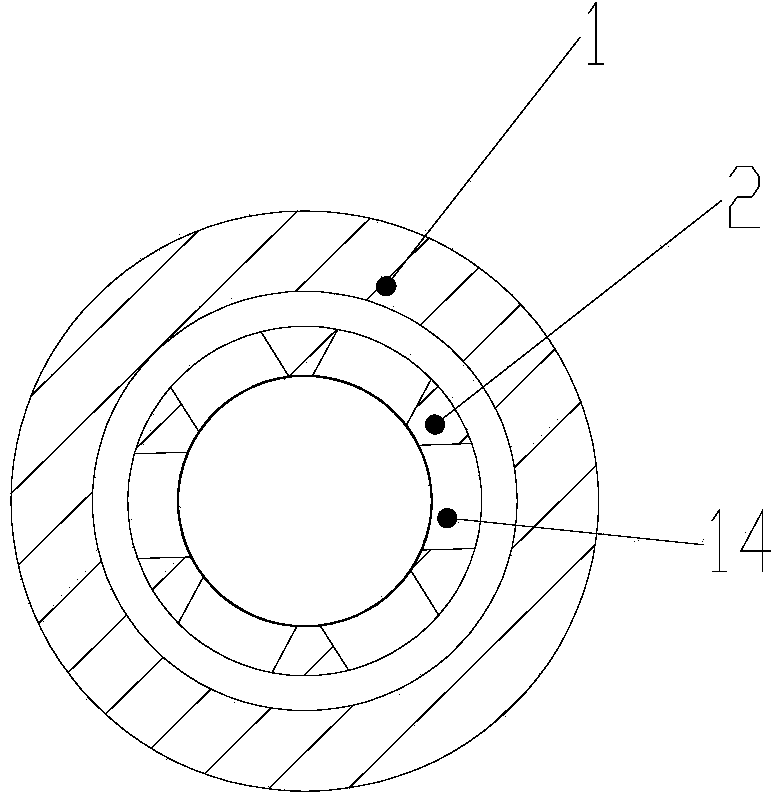

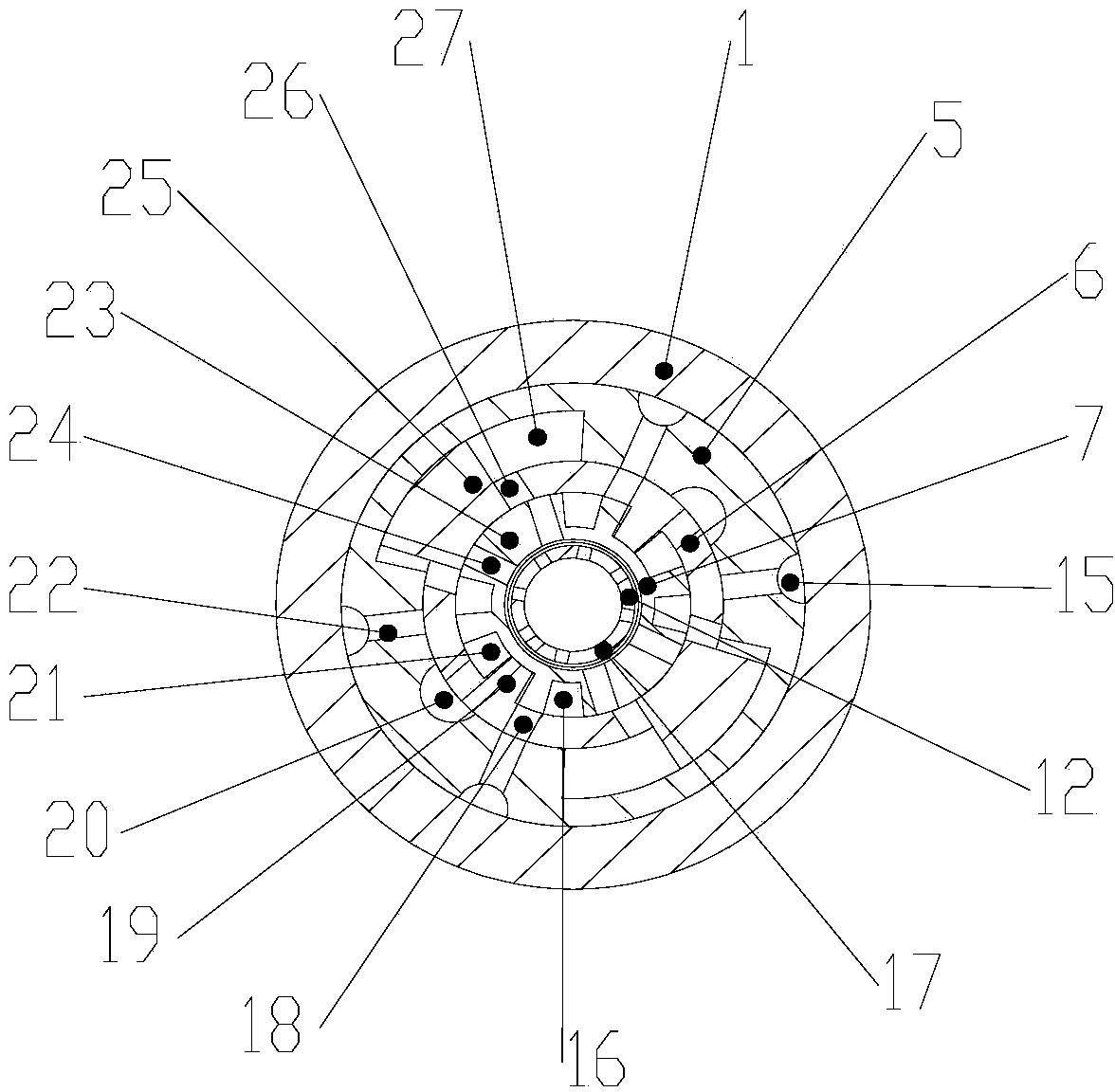

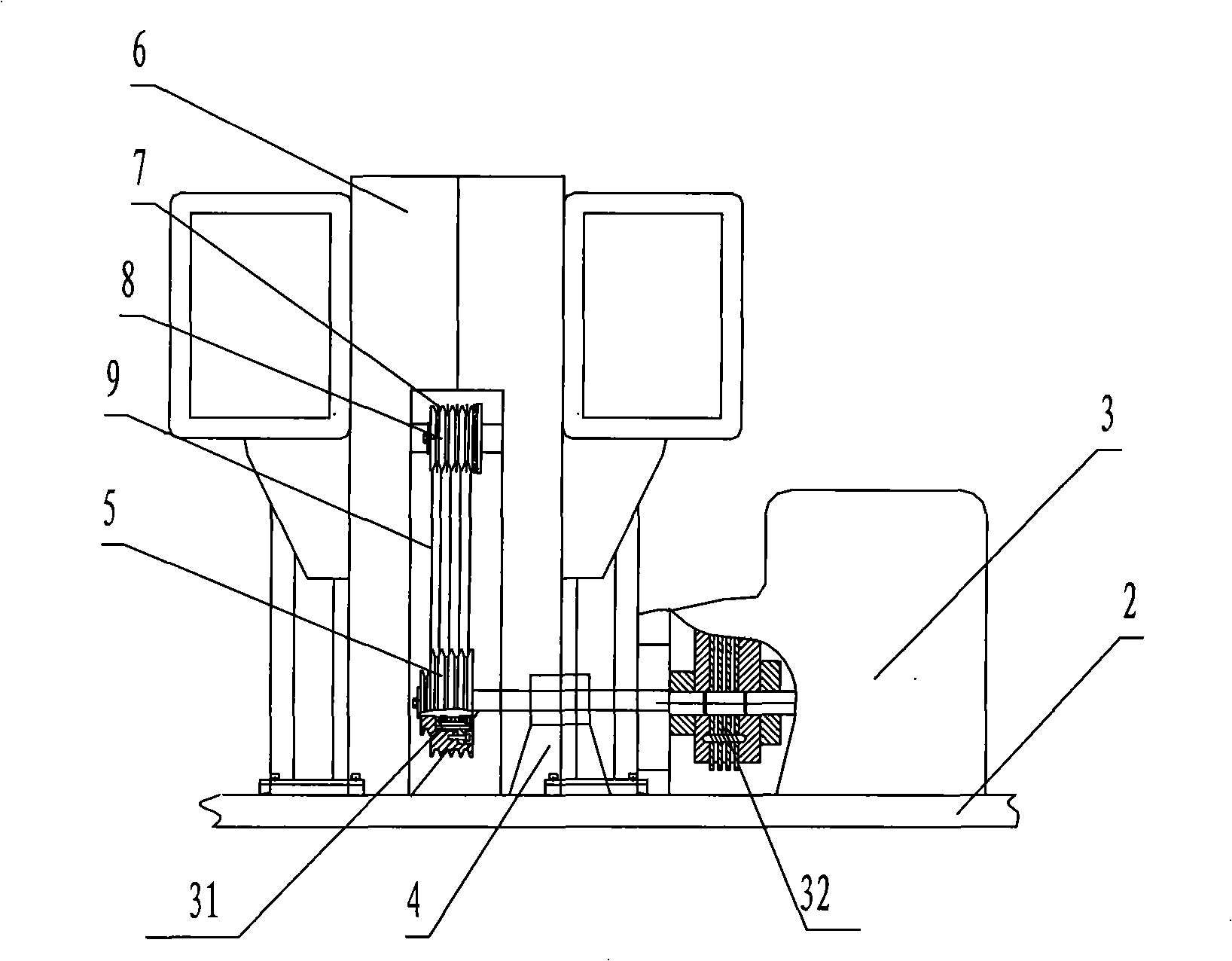

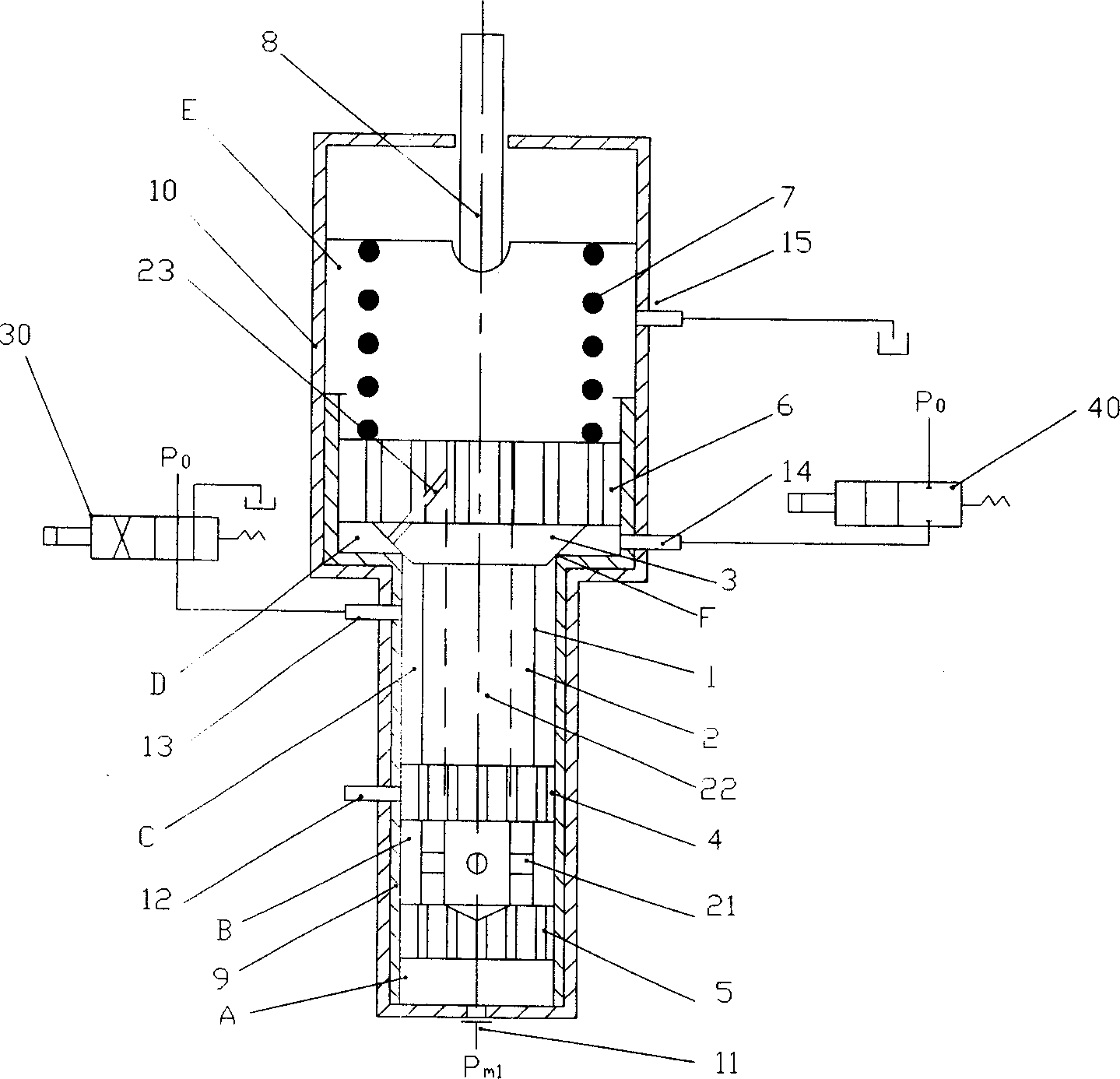

Well drilling method and device through hydraulic power and disc spring coupling driving and axial vibration

The invention discloses a well drilling method and device through hydraulic power and disc spring coupling driving and axial vibration. By means of the method and device, axial impact vibration can be uniformly applied to a drill bit or a pipe column in the welling drilling process. According to the technical scheme, the device is mainly composed of a body, a pulse generating device and an axial vibration device; the pulse generating device is composed of a guiding object, an impeller seat, impellers and a vibration nozzle; the axial vibration device is composed of a pressure stressed face, a piston portion, a central rod and a disc spring portion; the piston portion is composed of a piston bush, an oil seal and a piston; the disc spring portion is composed of a disc spring upper pressing sleeve, a disc spring adjusting sleeve, a disc spring protecting sleeve, a disc spring set, a disc spring core bar and a disc spring seat. Compared with other well drilling tools, by means of the well drilling method and device, stable and uniform axial vibration can be generated, and frictional resistance generated by 'pressure supporting' in a horizontal well is lowered; when the device is installed between a drill collar and a drill bit, stable and uniform axial force can be provided for the drill bit, and well drilling efficiency is improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

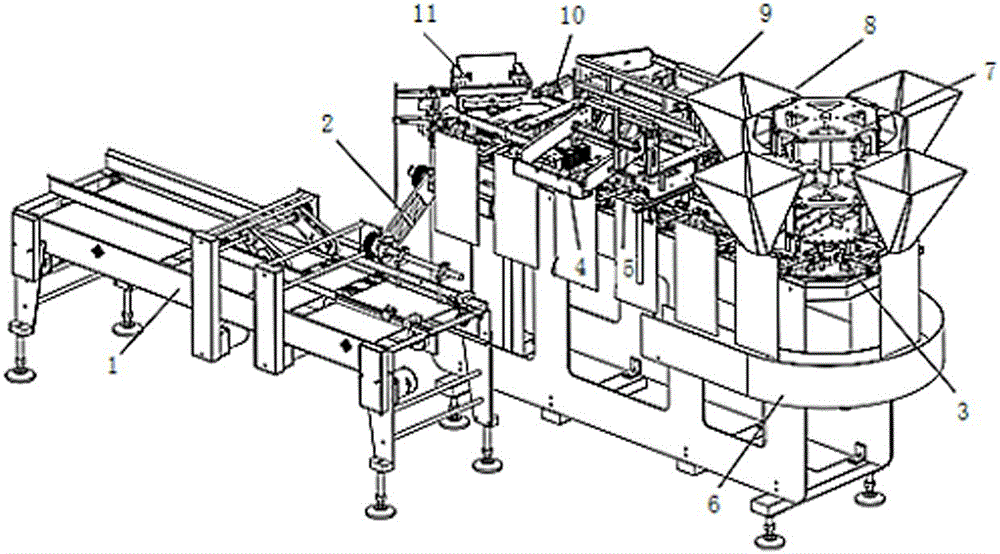

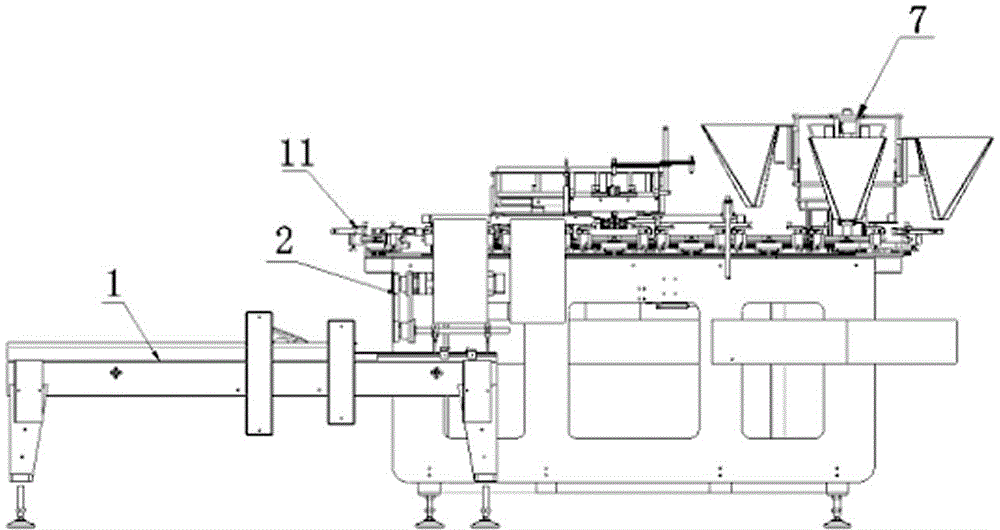

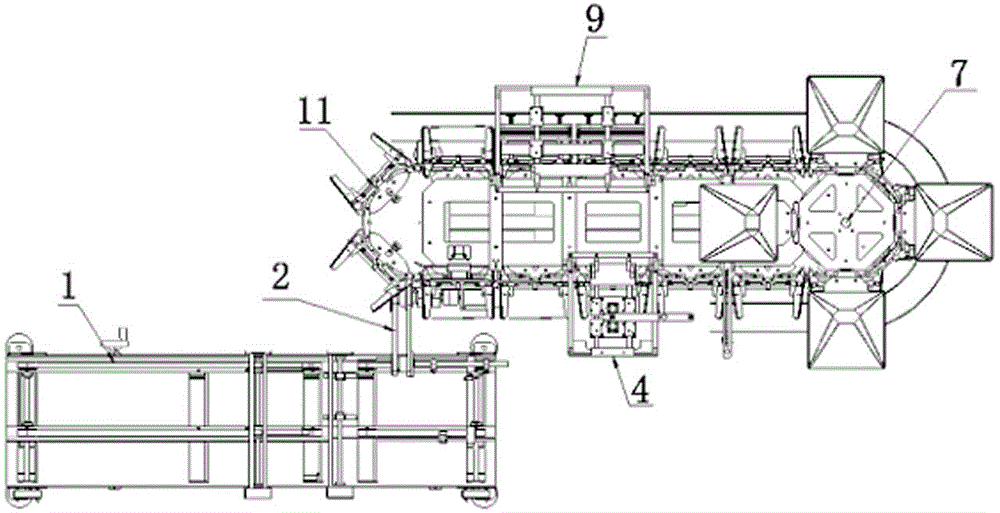

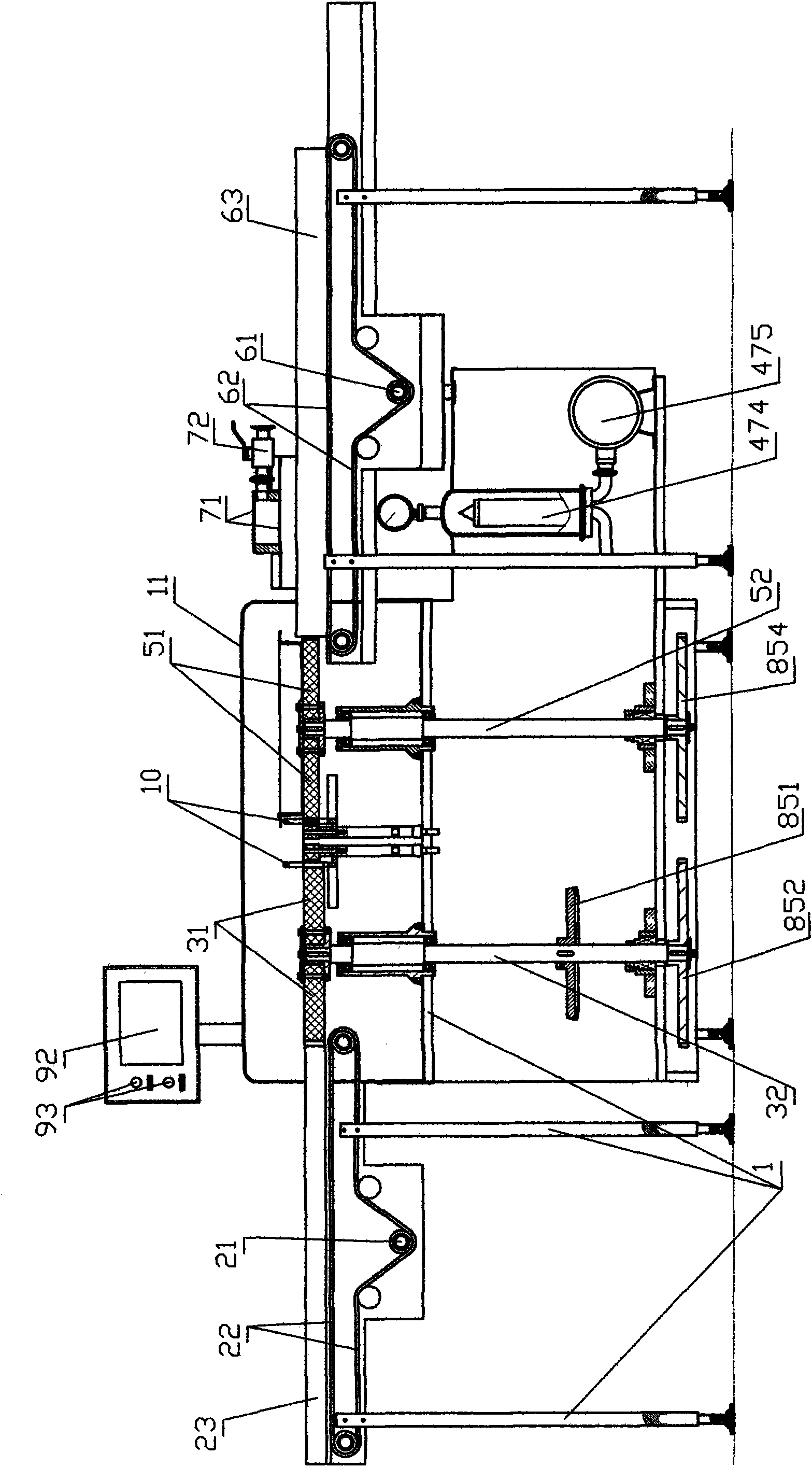

Full-automatic prefabricated bag feed type packing machine

InactiveCN104627394ALarge package sizeLarge packing capacityWrapper twisting/gatheringPackaging automatic controlOutput deviceMechanical engineering

The invention discloses a full-automatic prefabricated bag feed type packing machine which comprises a bag conveying and releasing device, a bag taking device, a rotary driving device, a bag opening device, an air blowing device, an auxiliary conveying belt, a discharge device, a finished product detecting device, an upper sealing device and a finished product output device. The bag taking device is located above the right end of the bag conveying and releasing device. The bag taking device is fixedly installed below the left end of the rotary driving device. The rotary driving device drives and is connected with a plurality of clamping devices which are evenly distributed on the rotary driving device. The bag opening device and the upper sealing device are located on the two sides of the middle section of the rotary driving device. The air blowing device is fixedly installed at the upper end of the right side of the bag opening device. The discharge device and the finished product detecting device are located at the right end of the rotary driving device. The finished product detecting device is located on the left side of the discharge device. The auxiliary conveying belt is located at the right end of the rotary driving device and located below the discharge device. The finished product output device is located at the left end of the rotary driving device. The full-automatic prefabricated bag feed type packing machine is larger in packing size and higher in packing capacity.

Owner:SHANGHAI GOFLYING PACKING MACHINERY MFGCO LTD

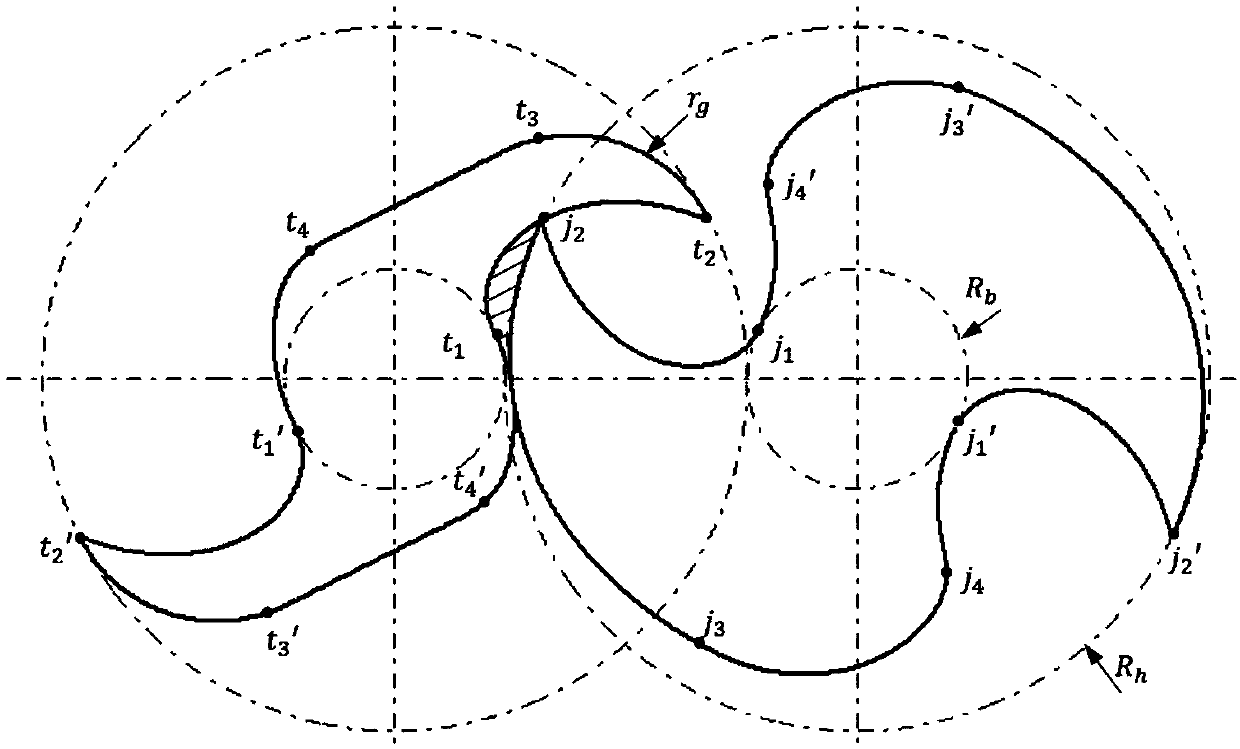

Method and apparatus for converting rotary motion into reciprocating impact motion

ActiveCN103498673APass smoothlySmooth nestingDriving meansPercussion drillingDrive shaftReciprocating motion

A method and device for converting rotary motion to reciprocating percussion motion. The device comprises a machine body (4), a travel portion (7), and a reciprocating percussion portion (5). The reciprocating percussion portion (5) comprises a percussion drive mechanism (2), a rocker arm (6), and a percussion head (1). The percussion drive mechanism (2) comprises a percussion power source member (11), a transmission component, and a crankshaft (10). The percussion power source member (11) comprises a motor, and the motor comprises a power output shaft (14). The transmission component comprises a power gear (13) and a transmission gear (12). The power gear (13) is mounted on the power output shaft (14). The transmission gear (12) drives the crankshaft (10). The transmission component comprises a transmission shaft. The power output shaft (14) is perpendicular to the rocker arm (6), and is parallel to the transmission shaft and the crankshaft (10) so that the transmission gear (12) drives the crankshaft (10) to convert rotary motion to reciprocating motion; or the power output shaft (14) is parallel to the rocker arm (6), the crankshaft (10) is driven to convert rotary motion to reciprocating motion after the power direction is changed by a power bevel gear and a transmission bevel gear. The crankshaft (10) drives the percussion head (1) to perform reciprocating percussion. The travel portion (7) drives the machine body to travel. The machine body (4) drives the reciprocating percussion portion (5) to move and work continuously. The device applies to the mining field or mechanical engineering field, and has advantages such as strong structural strength and a small amount of maintenance.

Owner:刘素华

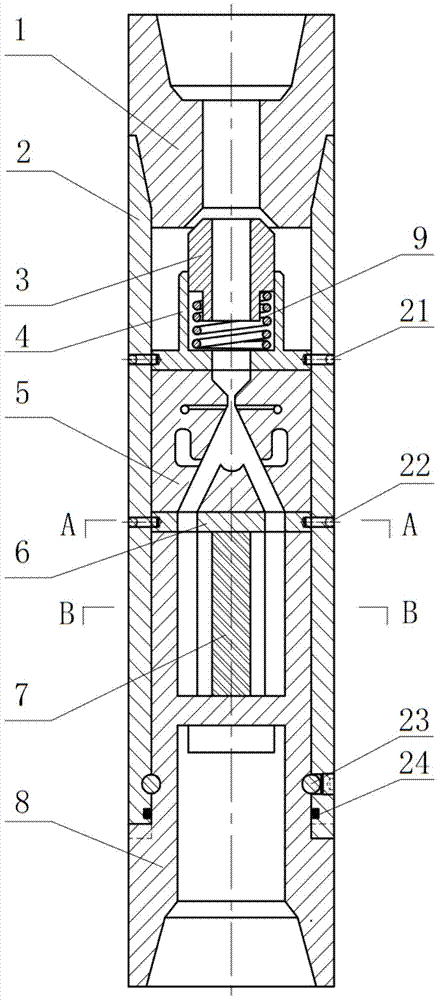

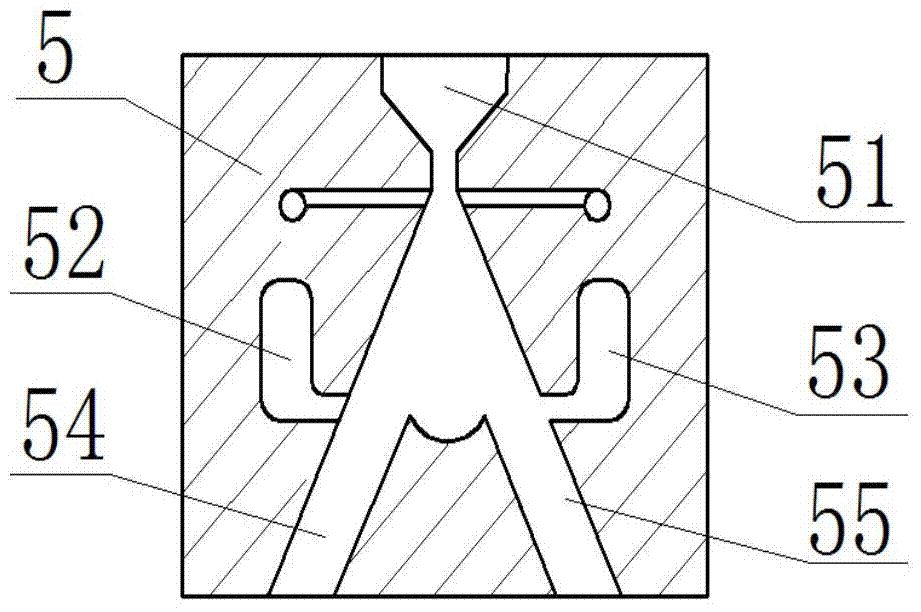

Jet type torsional impact drilling tool

ActiveCN103774983AIncreased torque averageReduce stick-slipReciprocating drilling machinesConstructionsWorking lifeWell drilling

The invention relates to a jet type torsional impact drilling tool. The jet type torsional impact drilling tool comprises an upper connector, an outer shell, a float valve, a valve seat spreader plate, a jet element, a jet spreader plate, a punch hammer, an impact transmission cylinder and a spring. The upper connector is fixedly connected with the outer shell, the outer shell is fixedly connected with the impact transmission cylinder, the float valve, the valve seat spreader plate, the jet element, the jet spreader plate and the spring are located in the outer shell, and the punch hammer is arranged in the transmission cylinder. According to the jet type torsional impact drilling tool, the attachment jet element generates alternating jet to drive the punch hammer to swing left and right, and the punch hammer collides with and impacts on the transmission cylinder to make underground torque greatly fluctuate; compared with a conventional drilling mode, the mean value of the torque of an underground drill bit is increased, the torque of the underground drilling tool is made to greatly fluctuate at high frequency in the drilling process, the stick slip phenomenon of the drill bit is alleviated, the probability of bit bouncing is reduced, and drilling efficiency is improved. The drilling tool is fewer in movable parts and quick-wear parts, long in normal work life, and high in safe reliability.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

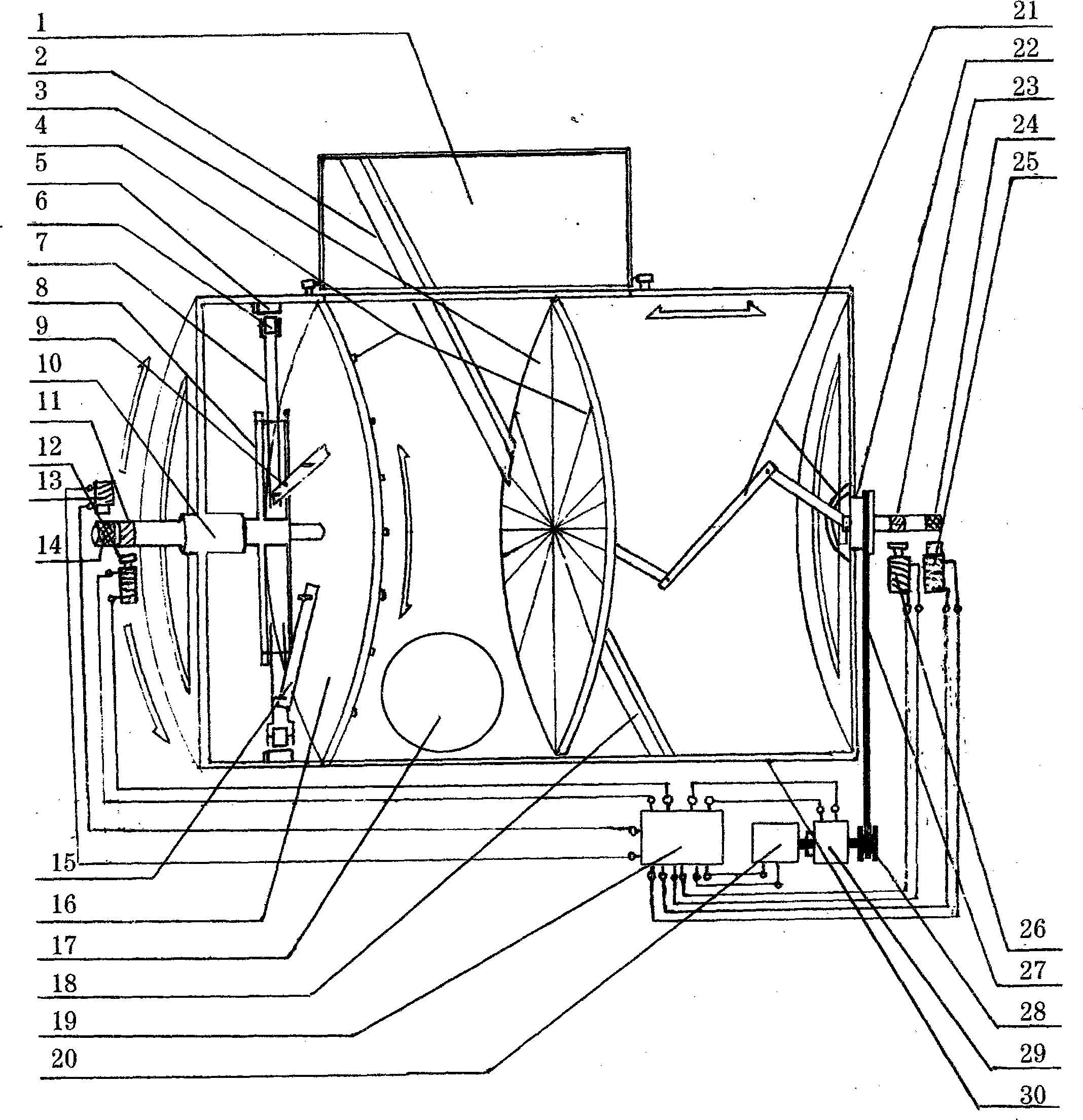

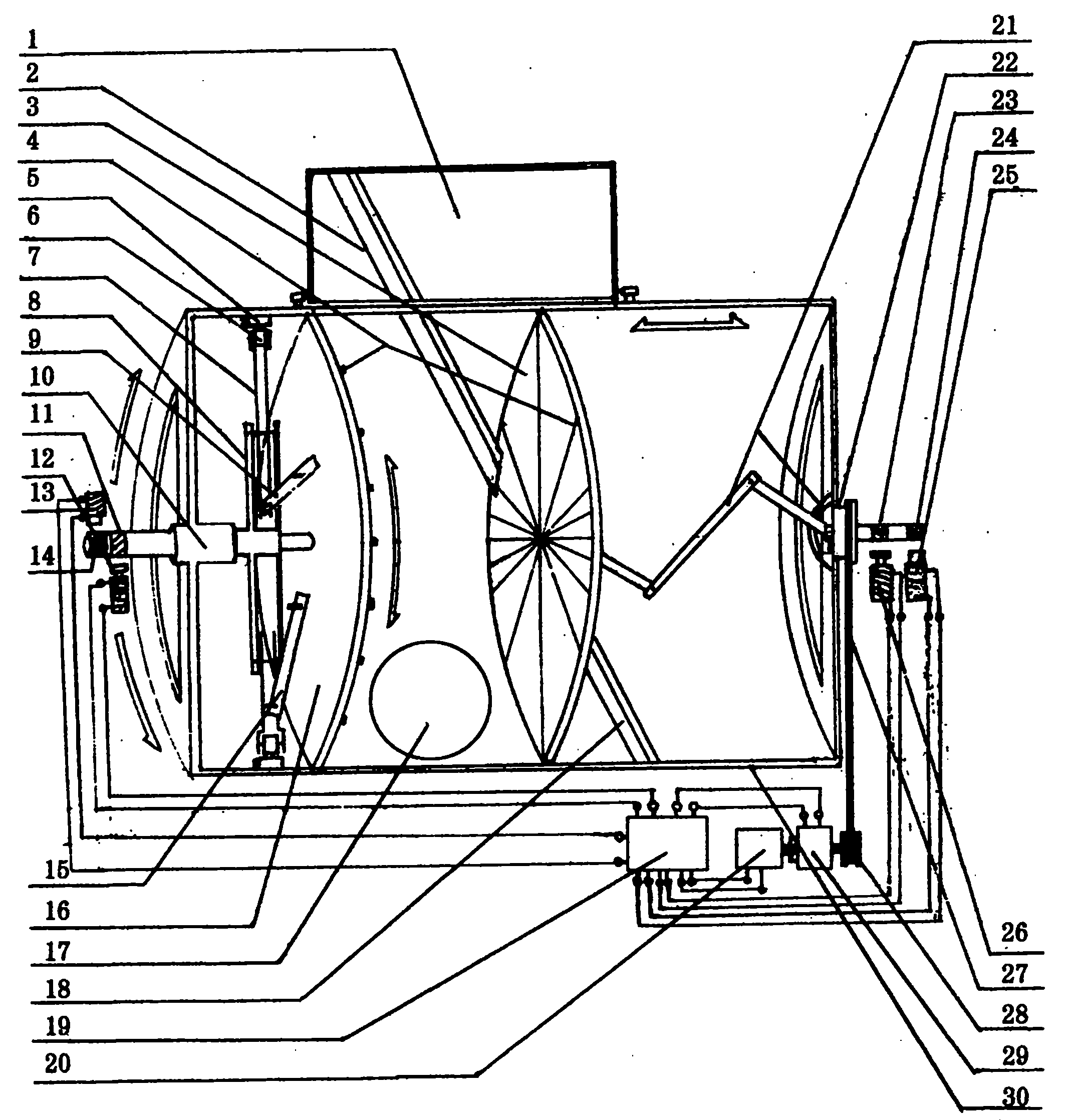

Roller washing machine

InactiveCN102094304ASimple structureLess wearing partsOther washing machinesWashing machine with receptaclesEngineeringMechanical engineering

The invention relates to a roller washing machine. A roller body is provided with a spiral slide way which is provided with a movable rolling disc, a rubbing disc capable of clockwise and counterclockwise alternately rotating is opposite to the rolling disc, and the roller body can rotate. When having the effect of rolling and rubbing washing, the roller washing machine has simple structure and less quick-wear parts and is beneficial to cost reduction and maintenance.

Owner:张德胜

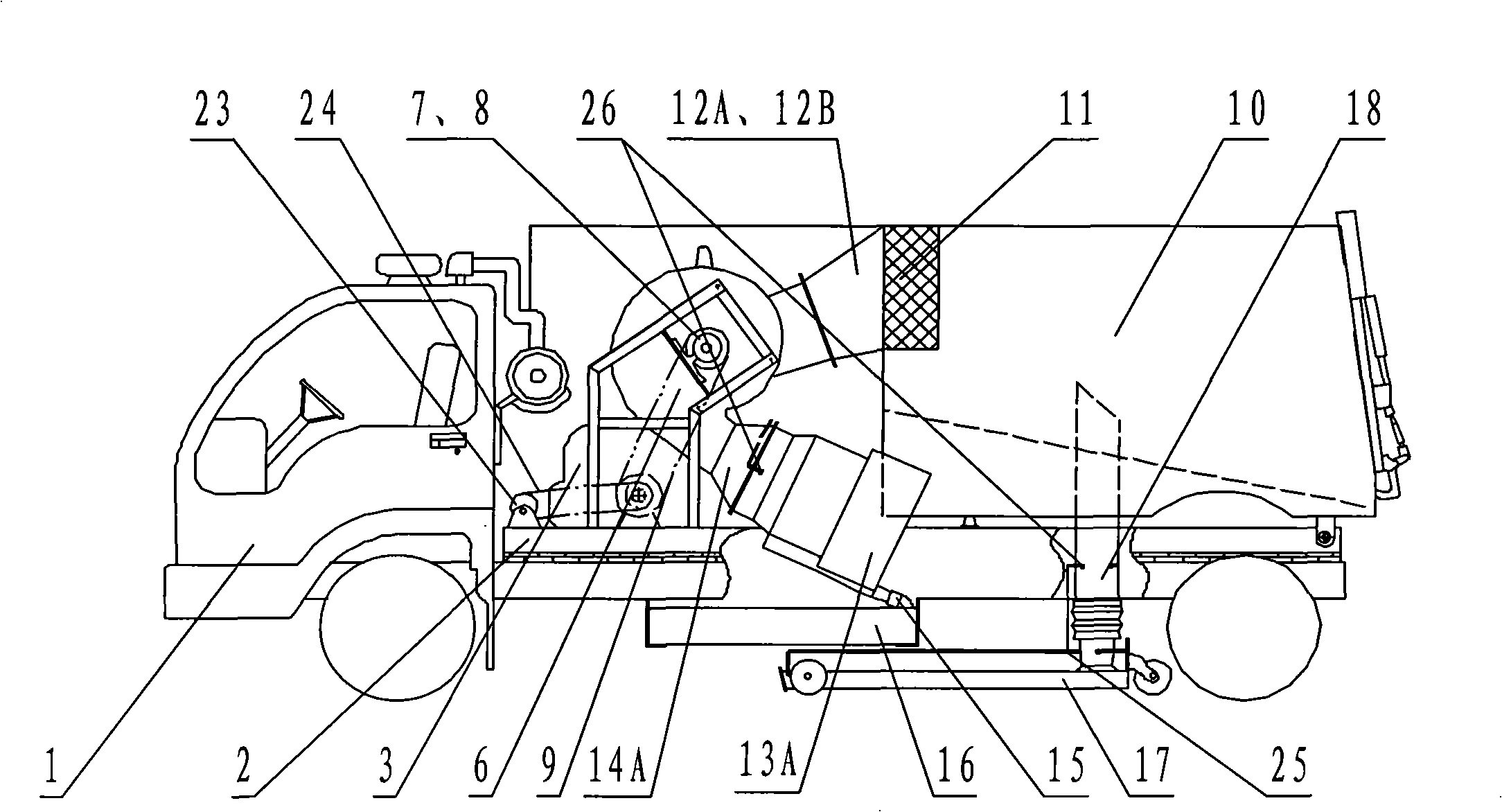

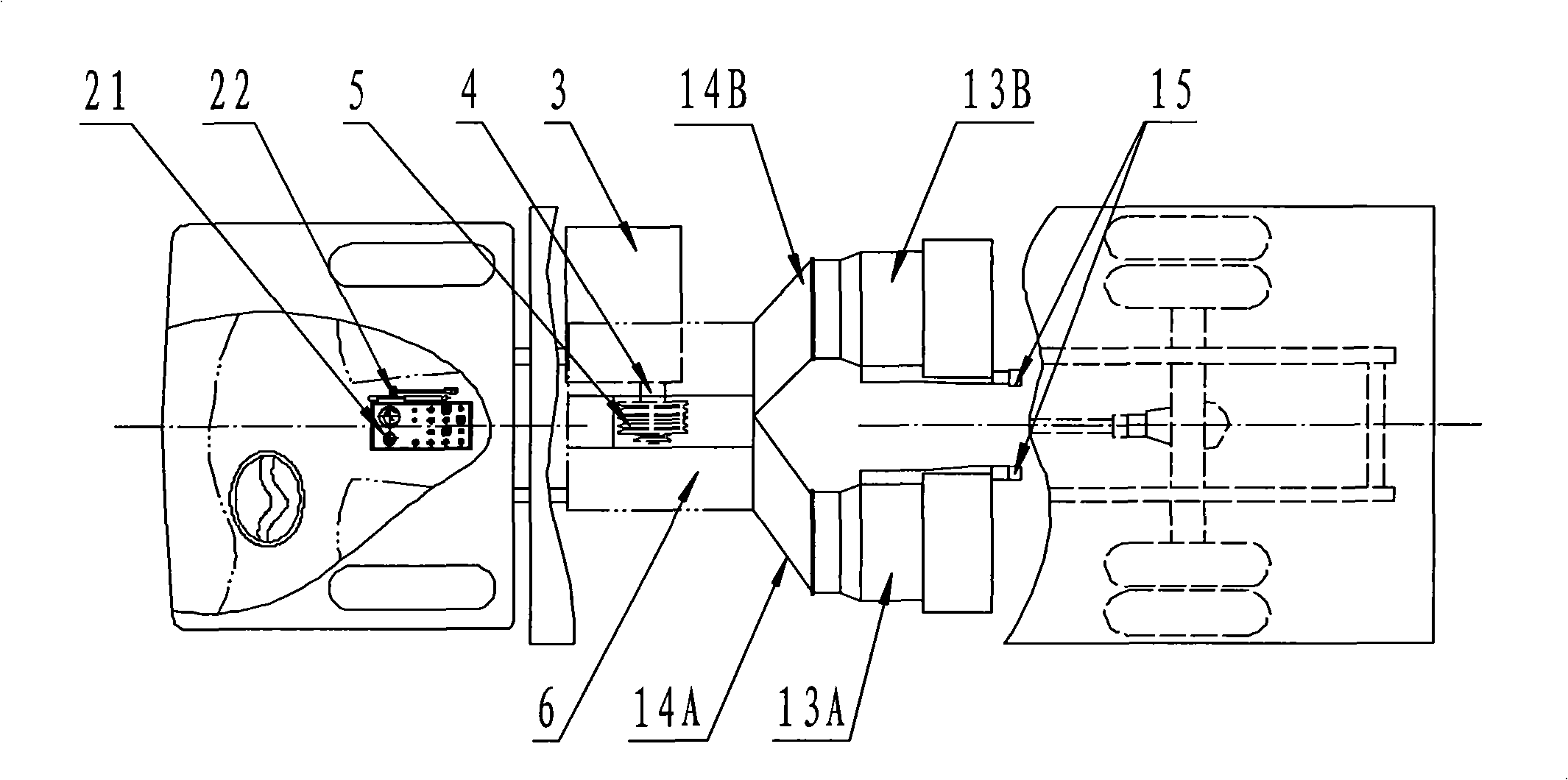

Dry and wet two-purpose road sweeper

InactiveCN101349043ASolve the icingSolve the problem of not being able to spray waterRoad cleaningVehicle frameRoad sweeper

The invention relates to a dry-wet dual purpose road sweeper, which comprises a vehicle frame as well as an auxiliary engine, a garbage bin, a suction fan, a chuck and dust removers which are arranged on the vehicle frame, wherein the chuck is arranged at the lower part of the vehicle frame and is connected to a garbage inlet of the garbage bin through a suction tube, the suction fan is connected with an air outlet of the garbage bin through an air duct, an air vent of the suction fan is connected with the dust removers, the auxiliary engine drives the suction fan, the suction fan is a double suction fan which is respectively communicated with the wet type diagonal flow dust removers. The road sweeper remedies the disadvantages that a suction sweeping road sweeper widely used on the market fails to be normally used in winter and is easy to spray ash and fly dust, and a suction road sweeper fails to perform wet operation and has poor sweeping efficiency and high use cost. The dry-wet dual purpose road sweeper uses a technology that the dry operation and the wet operation can both be performed, the design of the double suction fan with ultra-strong suction, and a unique wet type diagonal flow dust removal technology, and is the all-weather road sweeper.

Owner:江苏飞球专用车制造有限公司

Method for retaining vertical impact of impacting mechanism and vertical-lift impact-cutting digger implementing same

InactiveCN103206213AIncrease arm lengthReduce farewellDriving meansCutting machinesEngineeringFuselage

The invention specifically relates to a method for retaining vertical impact of an impacting mechanism and a vertical-lift impact-cutting digger implementing the method, belonging to the field of machinery, especially to the field of mining. The digger comprises a body, the impacting mechanism and a vertical lift mechanism, wherein the impacting mechanism comprises a guiding member and an impacting head, the vertical lift mechanism comprises a vertical lift driving unit, a lifting and moving part, a supporting seat and the like, the lifting and moving part is movably connected with the supporting seat, the supporting seat is connected with the body, the impacting mechanism is arranged on the lifting and moving part, the vertical lift driving unit drives the lifting and moving part to vertically move up and down, and the lifting and moving part drives the impacting mechanism to vertically rise and fall. The digger provided by the invention has the advantages of a long service life, a small amount of maintenance, high work efficiency, shortened body length and applicability to a complex usage occasion.

Owner:刘素华

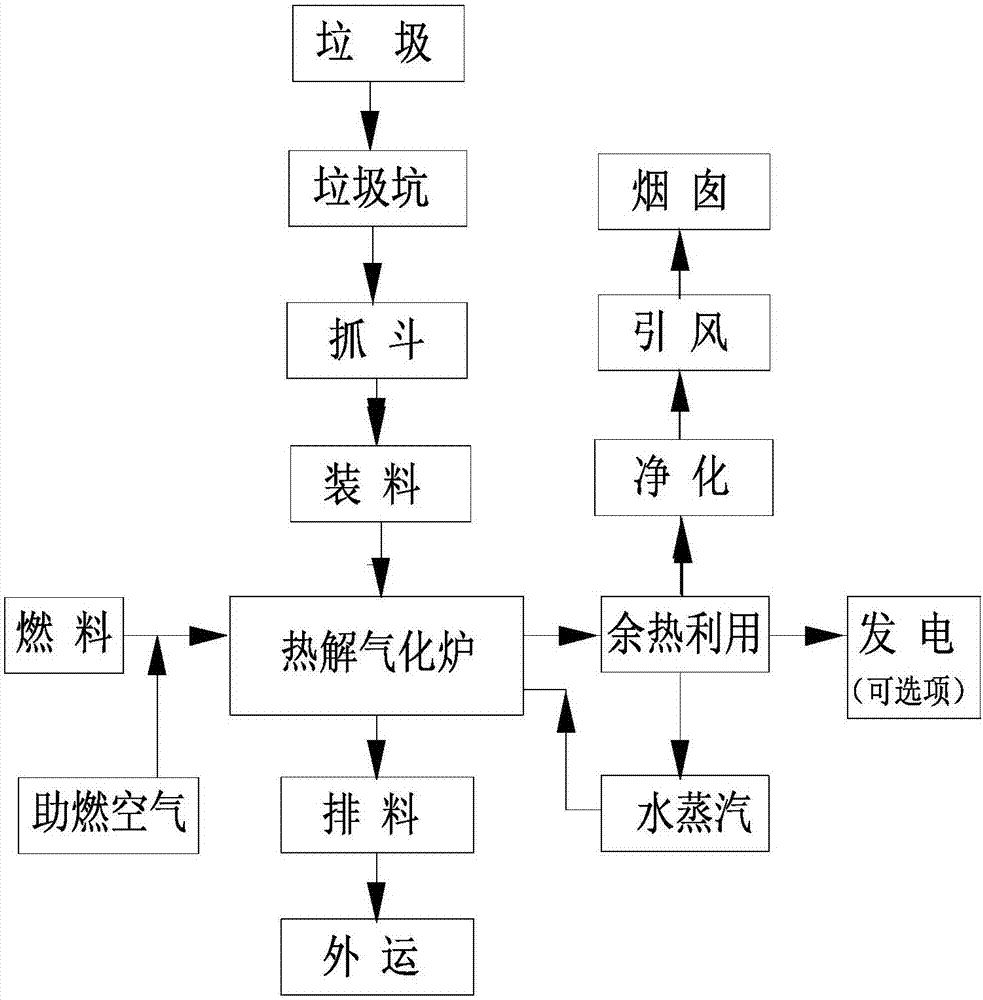

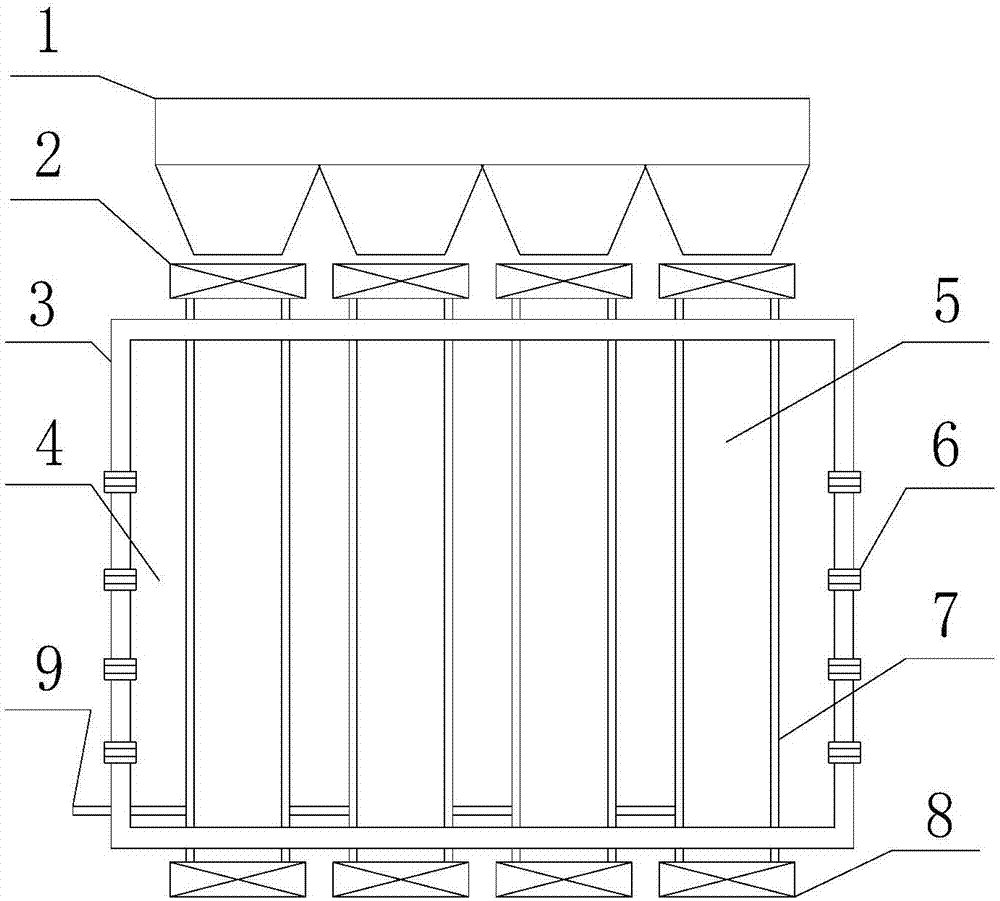

Large-scale domestic garbage pyrolysis and gasification technology

InactiveCN107490008AAdaptableSimple loading processIncinerator apparatusCombined combustion mitigationCombustion chamberPyrolysis

The invention relates to a large-scale domestic garbage pyrolysis and gasification technology. The large-scale domestic garbage pyrolysis and gasification technology includes the following steps that after domestic garbage is transported to a garbage pit, a grab bucket is used for grabbing the domestic garbage to the top of a pyrolysis and gasification furnace and loading the domestic garbage into a pyrolysis and gasification tank in the pyrolysis and gasification furnace through a loading device. Pyrolysis and gasification of the domestic garbage are completed in the tank, and ash obtained after pyrolysis and gasification is loaded into an ash tank through a discharging device and then is transported outwards. Heat needed by the pyrolysis and gasification tank is transmitted in from a combustion chamber in the pyrolysis and gasification furnace through a partition wall, and high-temperature flue gas in the combustion chamber passes through waste heat utilizing and purifying devices and other devices and then is discharged into the air. Compared with existing domestic garbage incineration, pyrolysis and gasification melting technologies and other technologies, the large-scale domestic garbage pyrolysis and gasification technology has the obvious beneficial effects that the domestic garbage adaptability is high, large-scale production is achieved, environment friendliness is good, cost is low, and the investment is small.

Owner:许志英

Integral multi-oil-wedge tiltable bush hydrodynamic sliding bearing

InactiveCN1776241AImprove vibration resistanceExtended service lifeSliding contact bearingsInterference fitWire cutting

This invention relates to an integral multi-oil wedge inclined bush dynamic pressure sliding bearing, which contains bearing seat and several bearing bushes, said bearing seat and central bush are integrated structure worked by wire cutting, the inner surface of bush made from Babbitt alloy to increase wearing resistance, bearing seat using interference fit to mounting in bearing flange with oil filling hole. Said invention insures the normal formation of wedge shape pressure oil film, reduces vibration and noise of whole machine set, increases rigidity of rotation pair, raises anti vibration ability and prolongs service of bearing and bearing bush.

Owner:SHANGHAI JIAO TONG UNIV

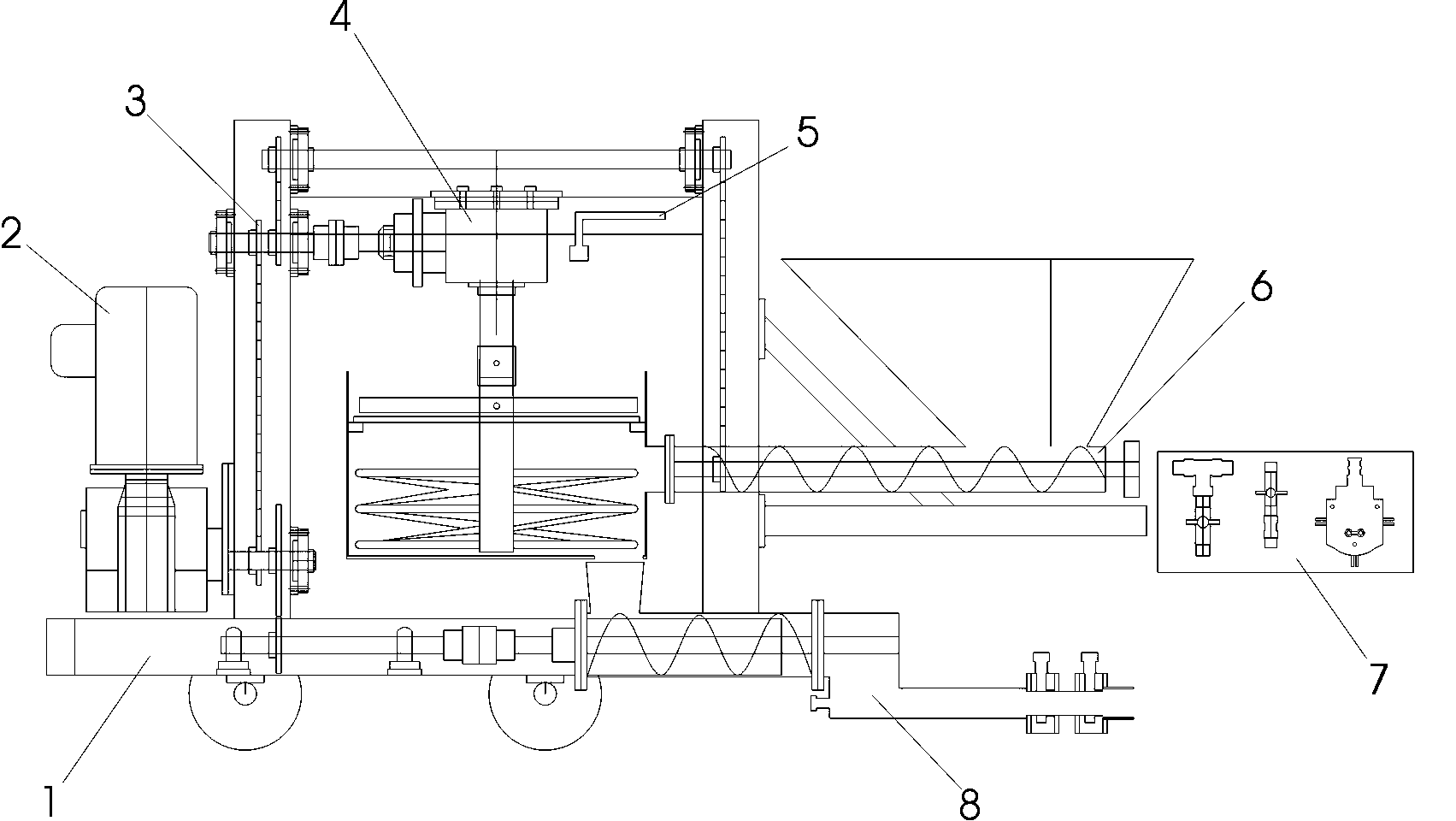

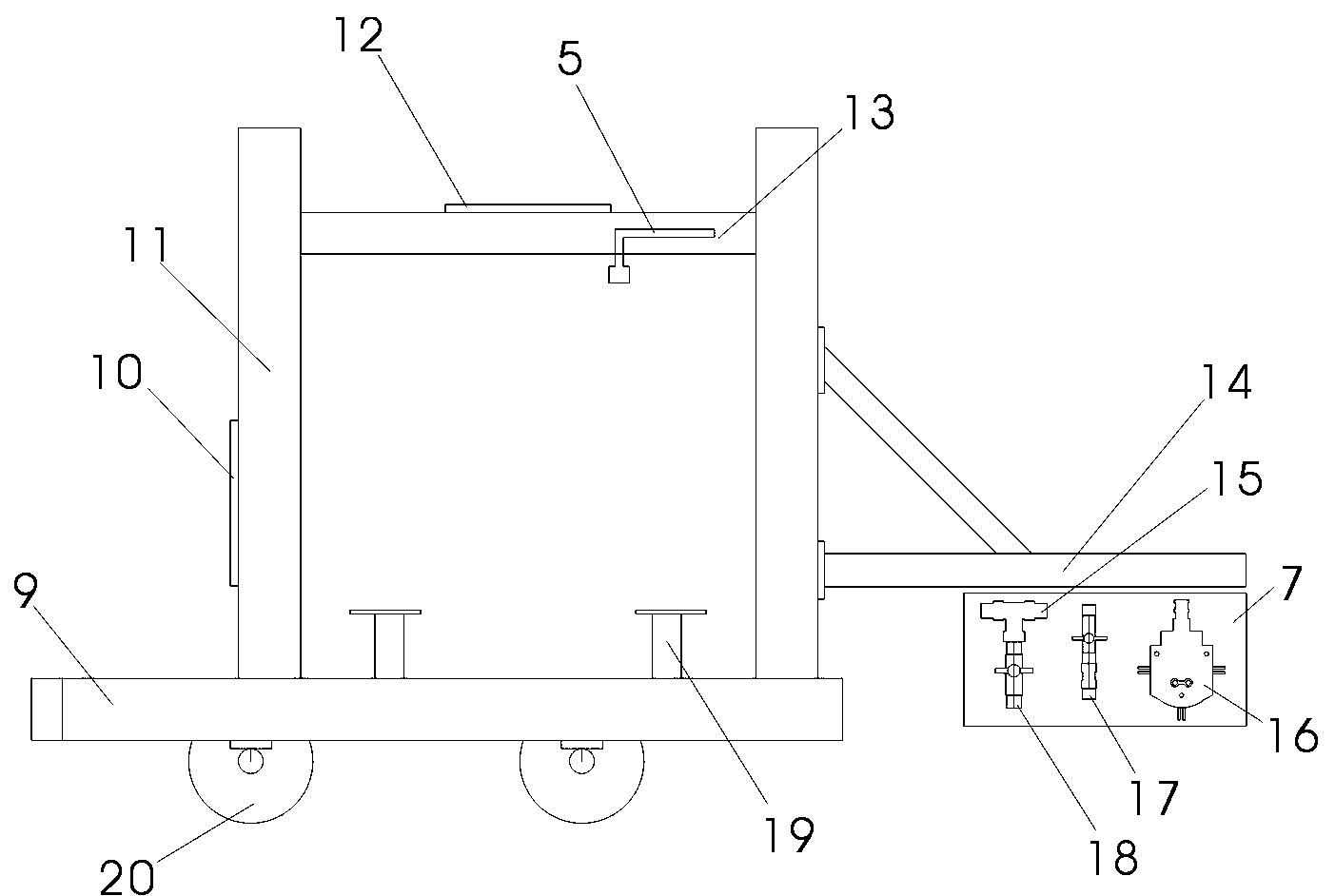

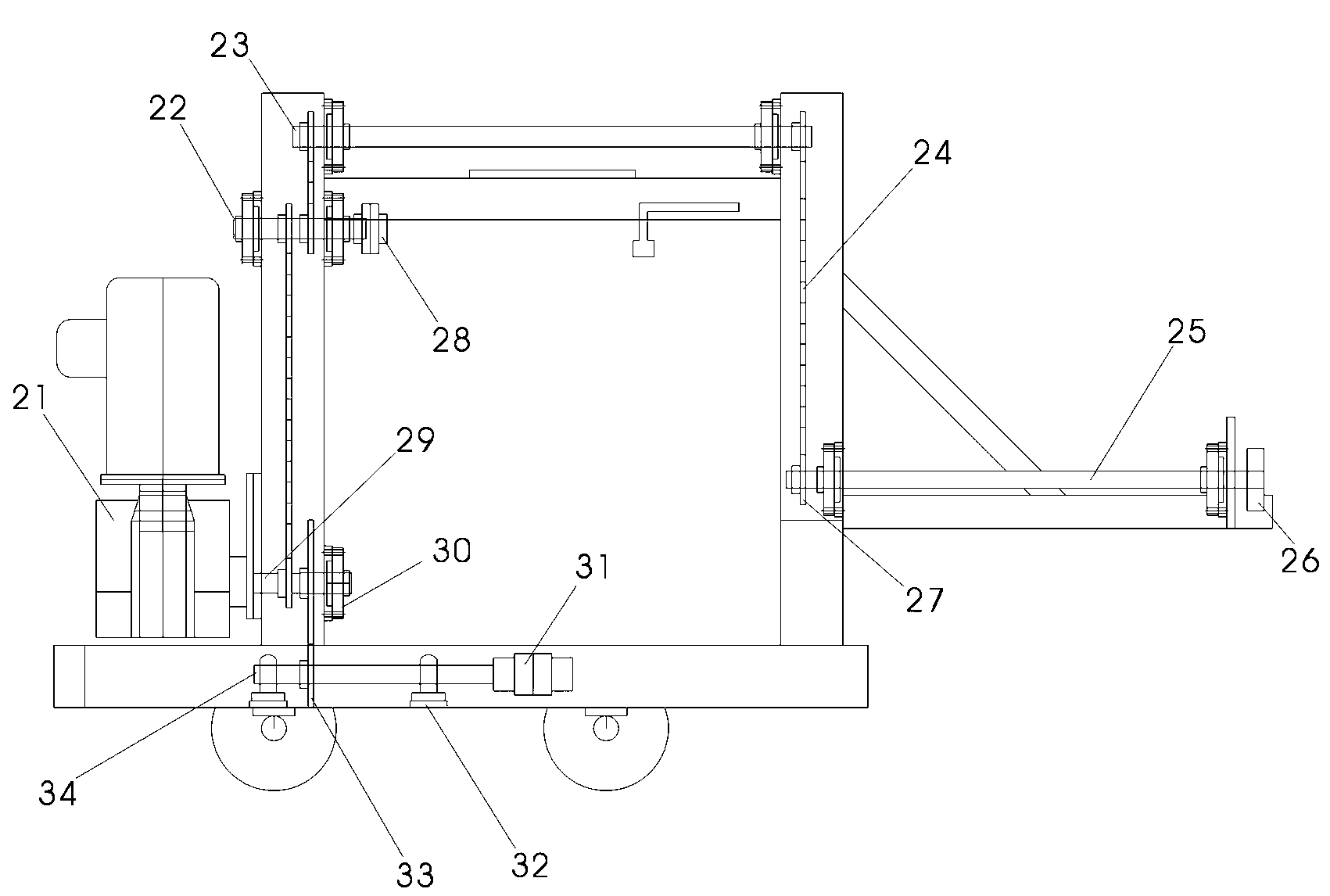

Wet type shotcrete machine

InactiveCN103216248ASolve the ratio problemReduce volumeUnderground chambersTunnel liningShotcreteReducer

Provided is a wet type shotcrete machine. The wet type shotcrete machine comprises a rack portion, a power portion, a driving portion, a stirring machine portion, a watering device portion, a quantitative screw conveyor portion, a control portion and a spraying mechanism portion. The rack portion is a main body supporting piece, and is integrally of a frame structure, a pair of tramcar wheels which make contact with rails are arranged on the lower portion of the rack portion, a speed reducer component of the stirring machine is arranged in the middle of the upper portion of the rack portion, the watering device portion is arranged on one side of the speed reducer component, the driving portion is arranged on the connection between the watering device portion and the speed reducer component, the power portion is arranged at one end of the rack portion and is connected with the driving portion, the quantitative screw conveyor portion is arranged at the other end of the rack portion, the control portion is arranged on one side of the quantitative screw conveyor portion, and the spraying mechanism portion is arranged on the lower portion of a stirring barrel of the stirring machine portion. The wet type shotcrete machine combines a function of stirring and a function of spraying into a whole, and is small in size, convenient to move and wide in applicability.

Owner:胡方志

High efficiency wet desulfuration and dust-removing device

InactiveCN1391978AWell mixedFull desulfurization and dust removalUsing liquid separation agentFlue gasEngineering

The efficient wet desulfurizing and dusting device especially for coal burning boiler in power plant has one vertical tower with inner tower in its center, tangent flue gas inlet pipe and flue gas outlet pipe, lime water and cinder output pipe, tangent chemical nozzle and water retaining ring. It features the inwards protruding ring set over the flue gas inlet pipe to make fluid passage turned first to tower center and then upwards, and one overflowing unit in the center of the tower to overflow downwards the showing chemical liquid. The present invention has high desulfurizing and dusing effect.

Owner:ZHEJIANG BOHUA ENVIRONMENTAL TECH & ENG

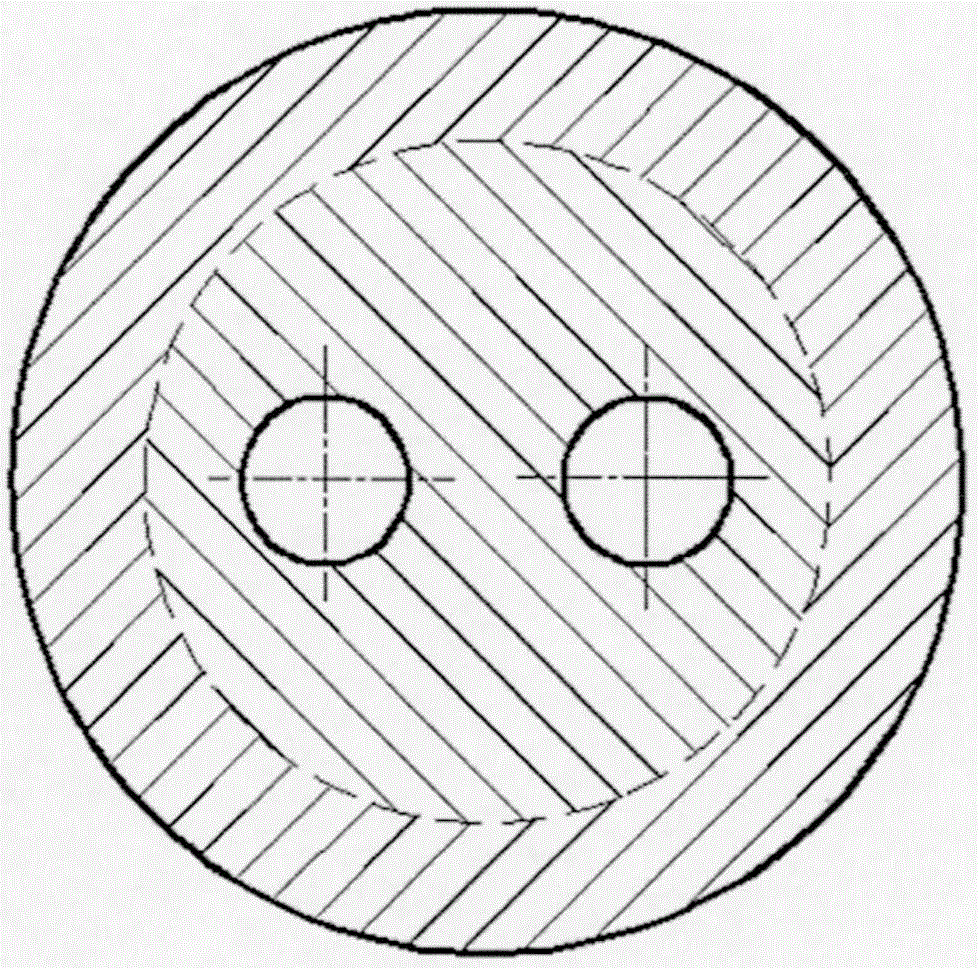

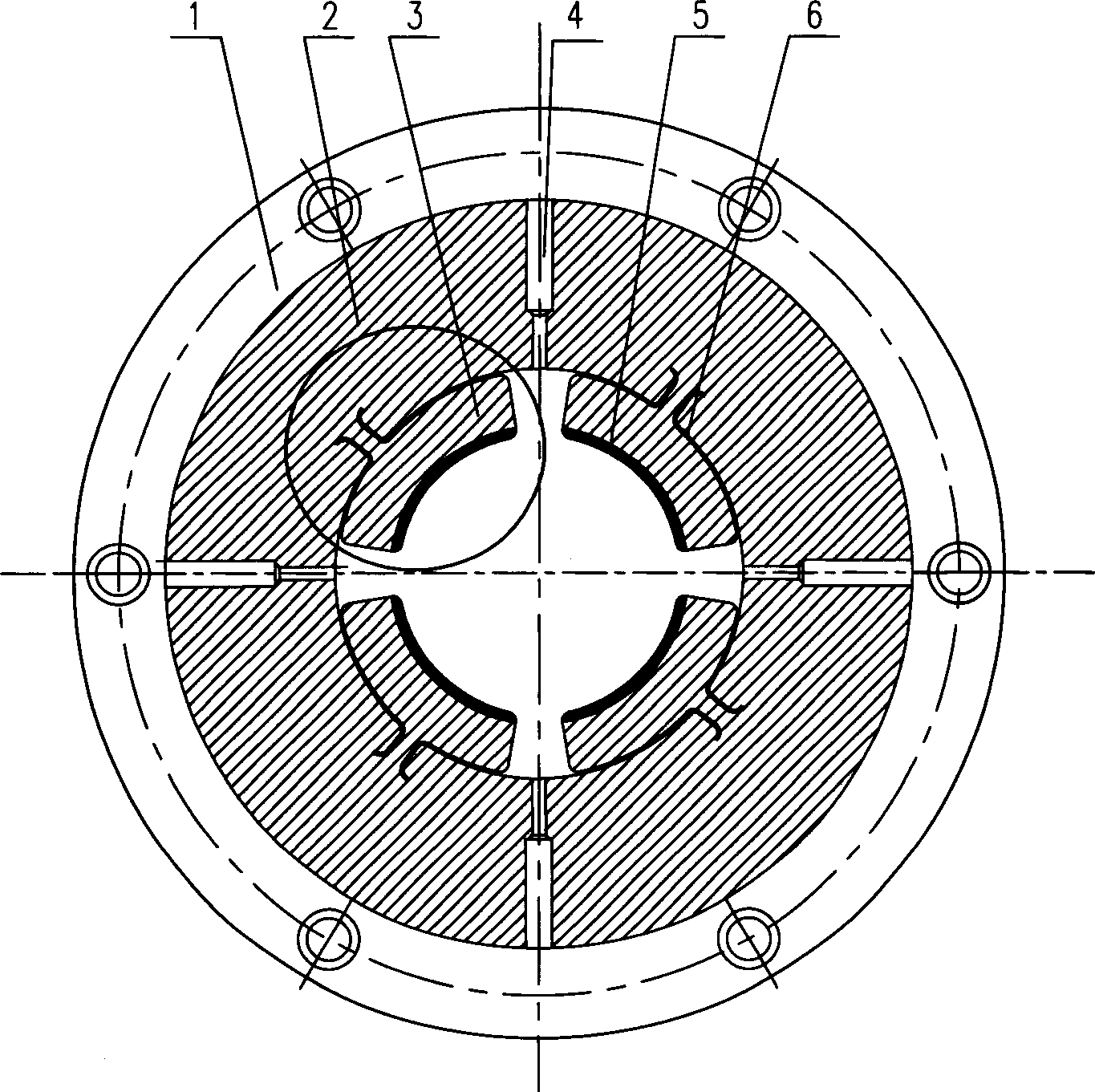

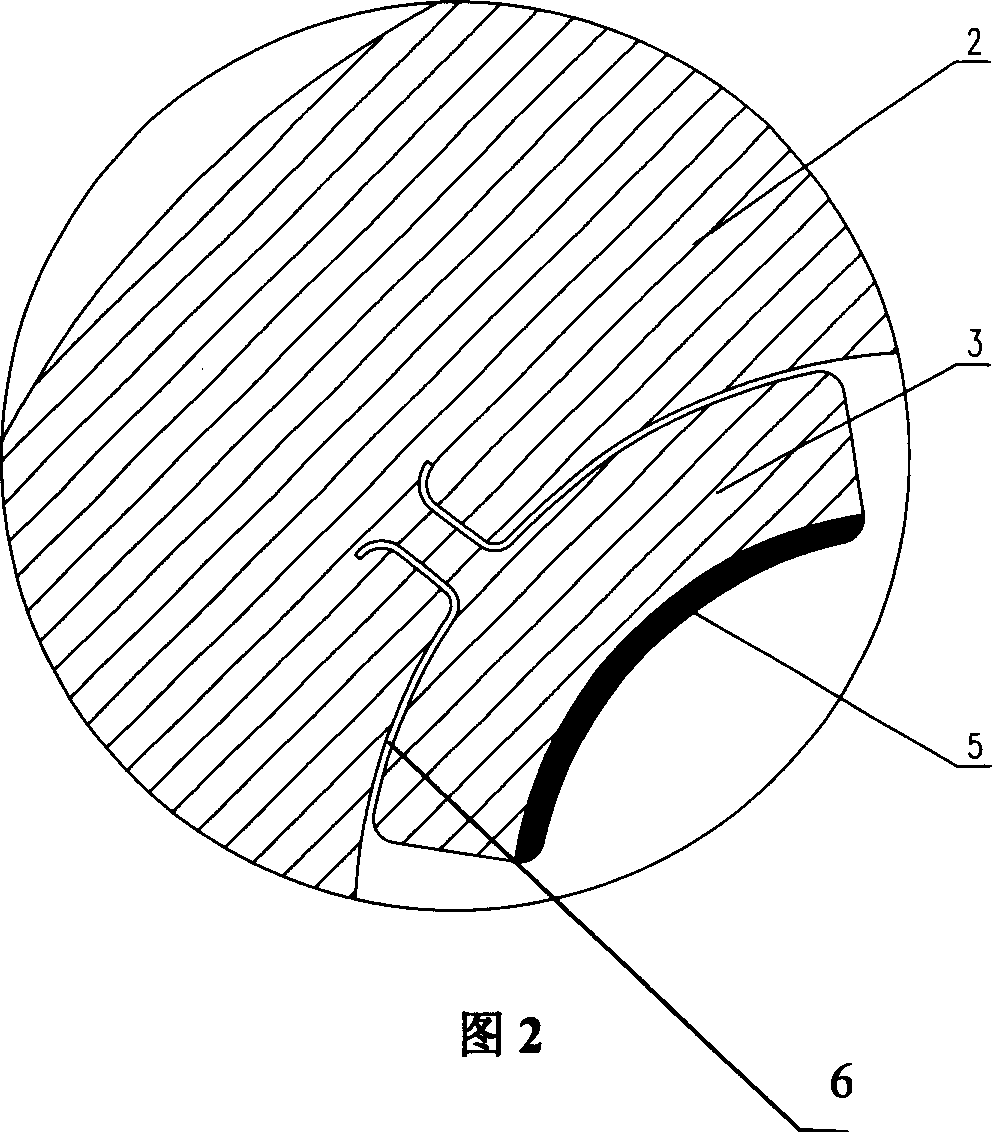

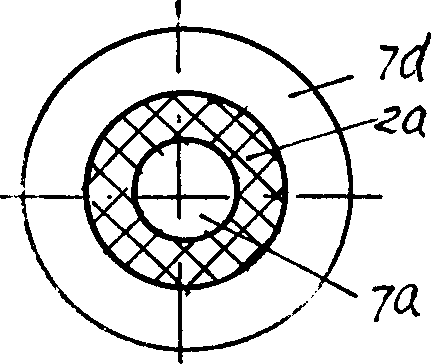

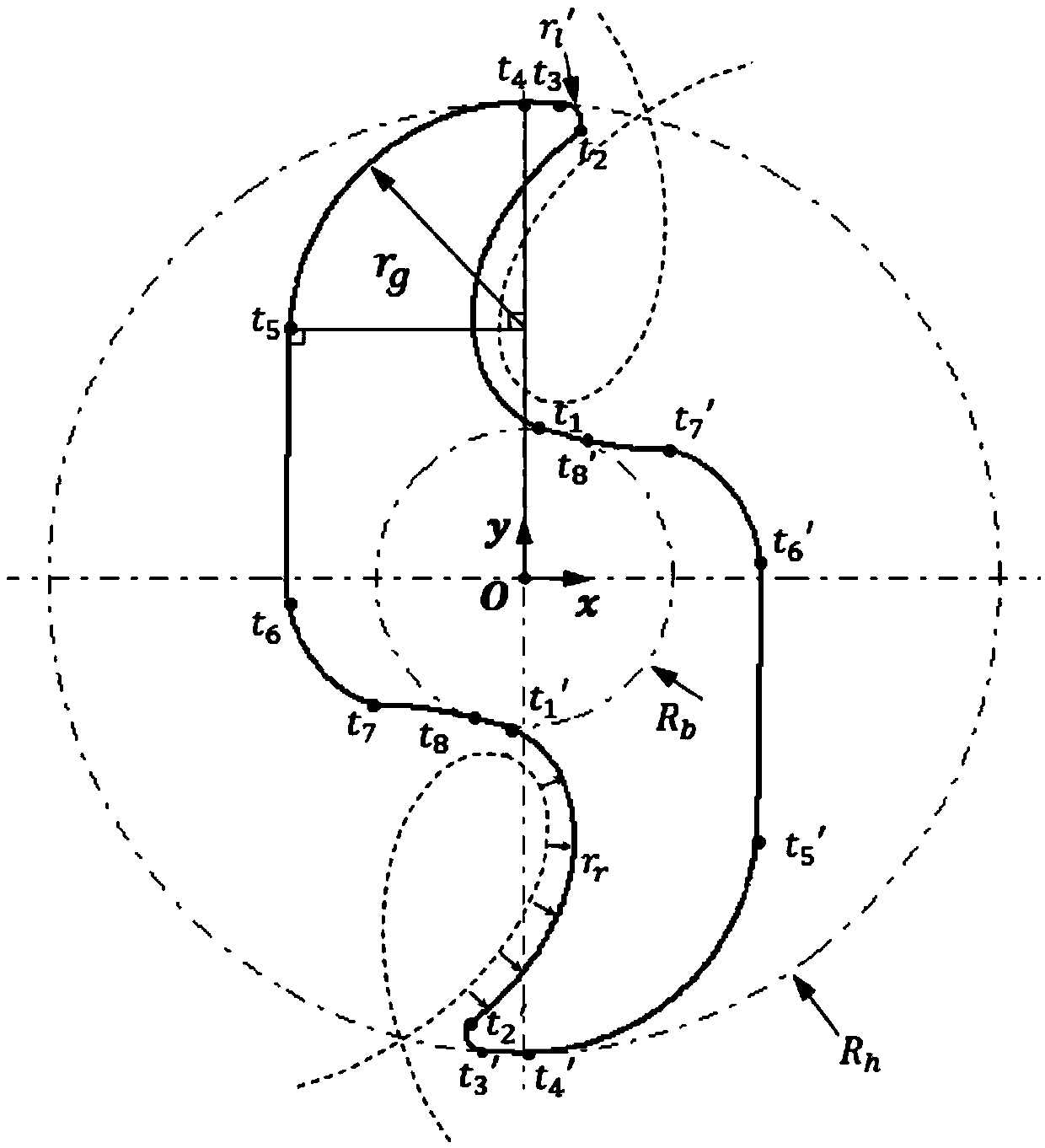

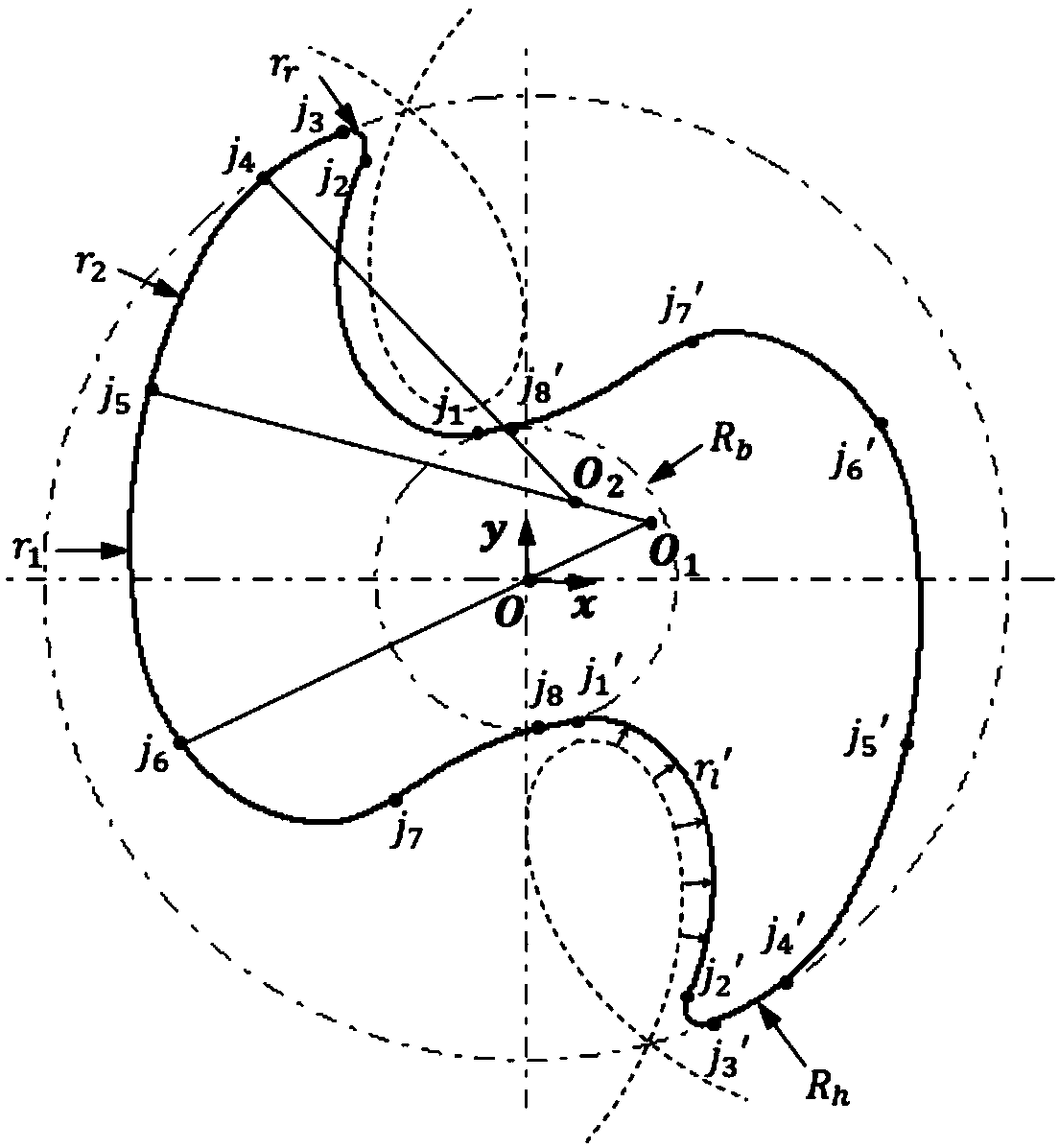

Double-head claw pump rotor and its molded line

ActiveCN108930650AAvoid severe wear and tearIncrease design parameter spaceRotary piston pumpsRotary piston liquid enginesEngineeringSharp point

The invention relates to a double-head claw pump rotor and its molded line. The molded line comprises an equidistance curve of a point meshing epicycloid, a modified arc segment, a tooth top arc segment, an intermediate connecting arc segment, an arc conjugate curve segment, and a tooth root arc segment. Two rotors adopt a central symmetrical structure. By setting the modified arc segment, the sharp points are eliminated, and severe wearing phenomenon of the rotors during operation can be avoided. The equidistance curve of the point meshing epicycloid and the modified arc segment are always spaced apart to avoid the formation of suction and exhaust closed volume, and a design parameter space of the rotor molded line is increased, the power consumption is reduced, and the pump efficiency isimproved. The molded line is designed in the double-head claw pump, compared with the other conventional pumps, the pump in the invention has the advantages of less wearing parts, compact structure,high pumping rate, no surge, and low vibration noise.

Owner:宝风压缩机科技(浙江)有限公司

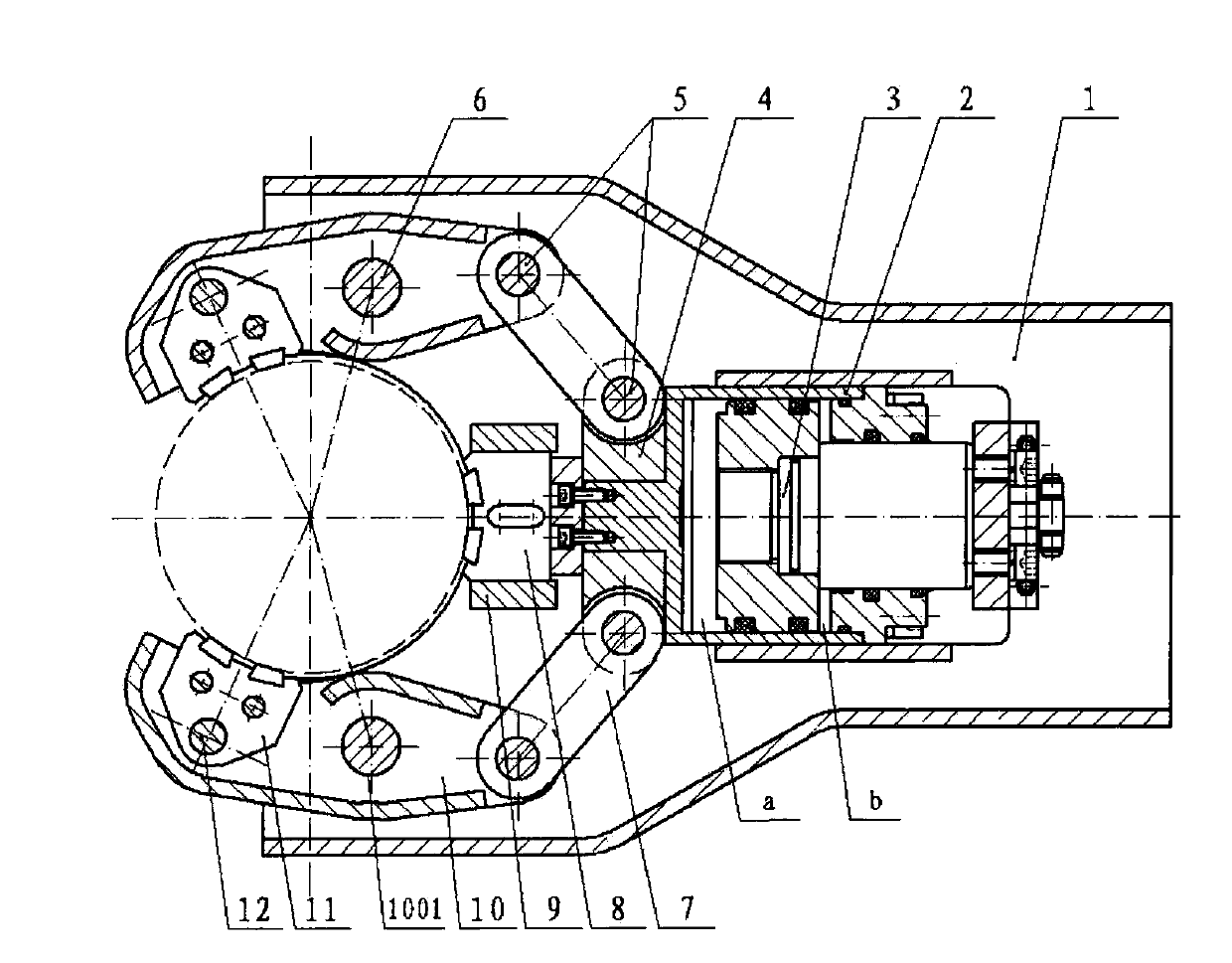

Linkage multi-jaw hydraulic power back-up wrench

InactiveCN103375139AReasonable designThe principle is simpleDrilling rodsDrilling casingsHydraulic cylinderEngineering

The invention relates to a linkage multi-jaw hydraulic power back-up wrench. Acting force of a hydraulic cylinder directly acts on a clamped string by the aid of a movement pair between a translation jaw assembly and a back-up wrench body of the linkage multi-jaw hydraulic power back-up wrench, at the moment, linear movement of a cylinder body or a piston rod of the hydraulic cylinder is converted into rotation of clamping arms by the aid of a fixed hinge form of two rotary pairs and a movable hinge form of two other rotary pairs, the rotary pairs are arranged among the hydraulic cylinder and rotary jaw assemblies, and the acting force outputted by the hydraulic cylinder acts on the clamped string, so that the purpose of clamping the clamped string in a three-point linkage manner is achieved. The linkage multi-jaw hydraulic power back-up wrench has the advantages of reasonable design, simple principle, compact structure, convenience in manufacture, good clamping stability and low quantity of easily damaged parts.

Owner:盐城特达钻采设备有限公司

Driving device for passage gates or thoroughfare gates and door or gate drives

InactiveCN1882757ALow manufacturing costLess wearing partsTurnstilesPower-operated mechanismDrive shaftElectric machine

Disclosed is a driving device for passage gates or thoroughfare gates and door or gate drives. Said driving device comprises a brushless DC servo motor to which a servo regulator is assigned. The output shaft of said DC servo motor is directly connected to the drive shaft of the locking element. The DC servo motor can be accurately regulated to a great extent regarding rotational speed, torque, etc. and can be adapted to different requirements via the servo regulator such that the same motor can be used for many different applications along with said servo regulator, i.e. a continuous drive system is created. Coupling gears and reduction gears, i.e. parts that are prone to malfunction and wear, can be dispensed with due to the fact that the locking element is directly driven, thus requiring less maintenance work at greater intervals.

Owner:MAGNETIC AUTOCONTROL

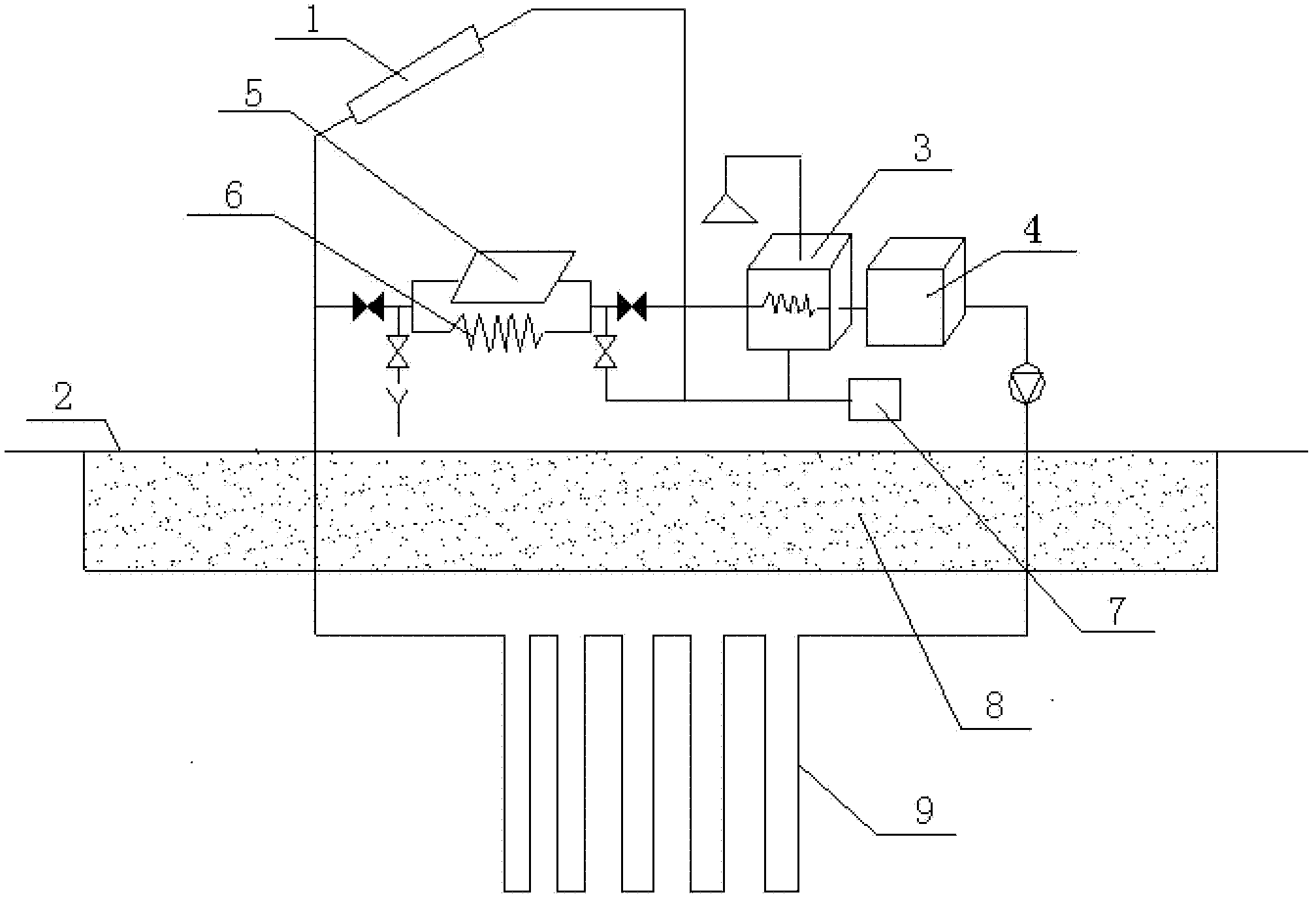

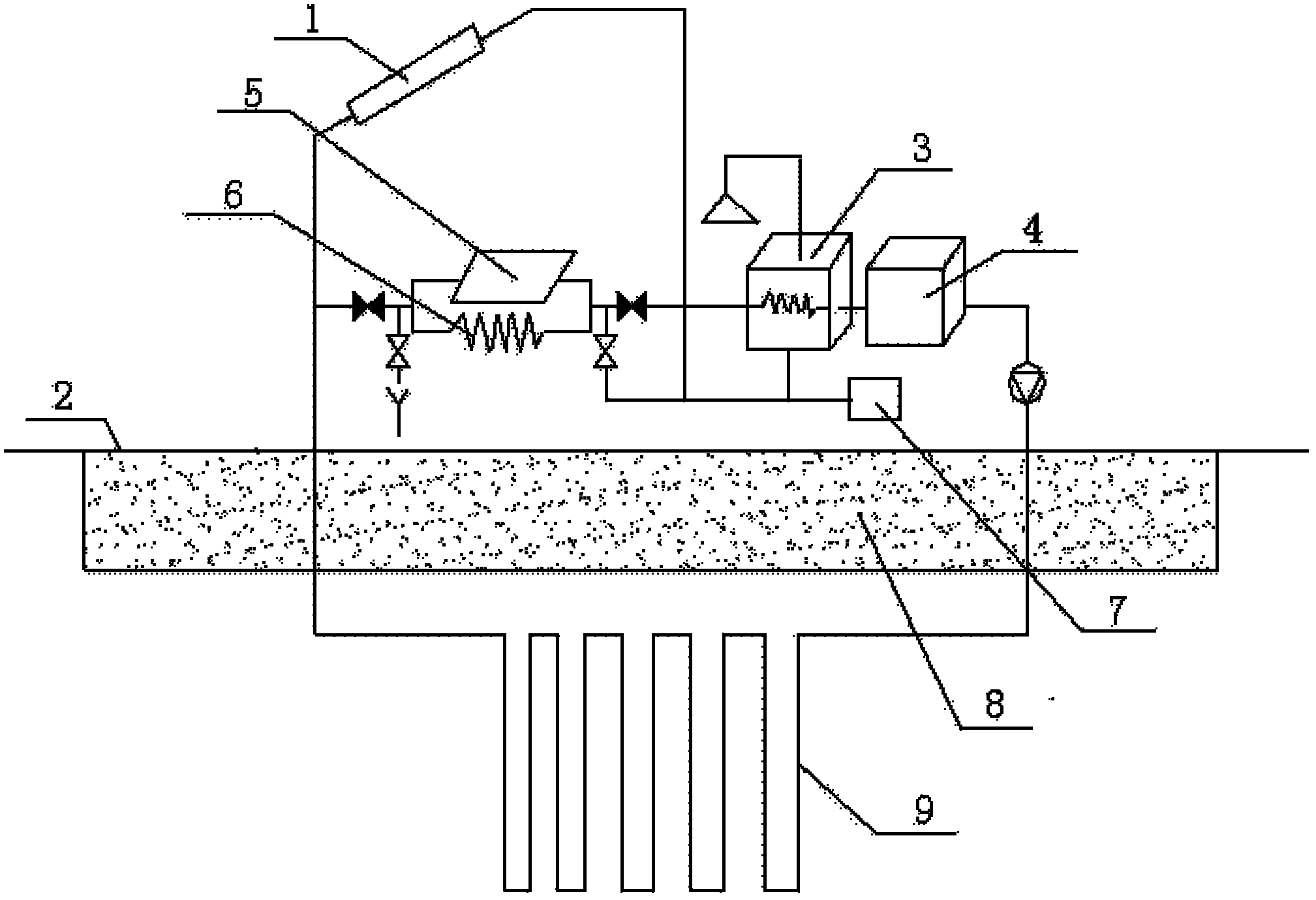

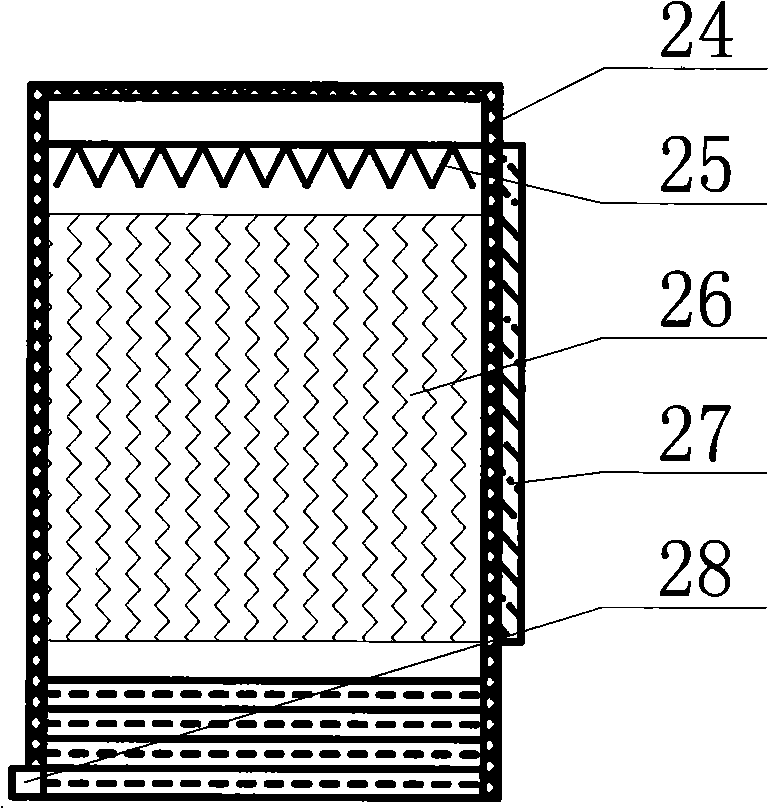

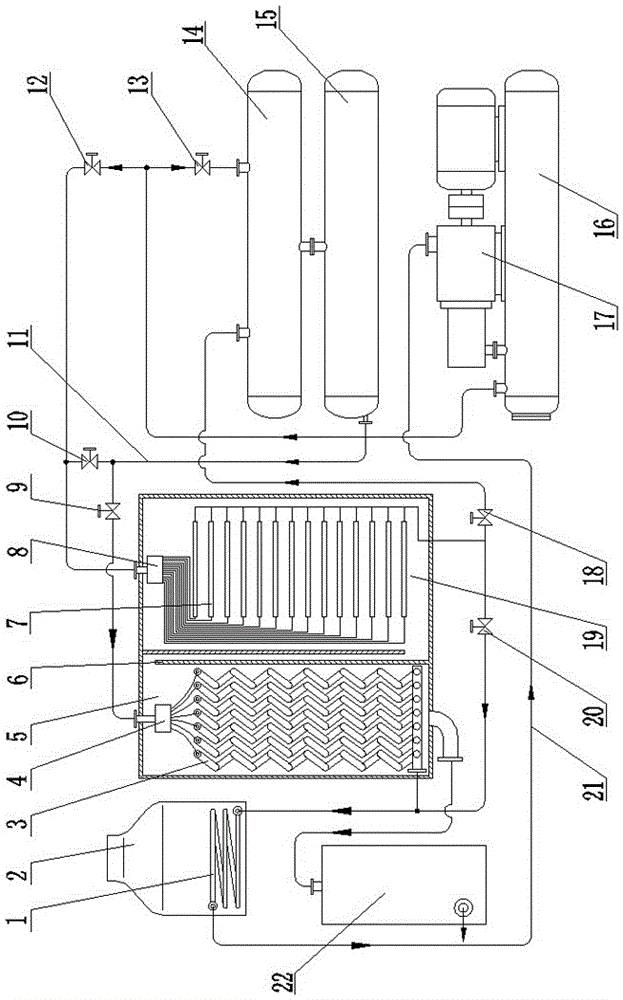

Solar energy full-year collection and storage supply system

InactiveCN102635953APrevent frost crackingSolution to short lifeSolar heat devicesAir conditioning systemsThermal energy storageCollection system

The invention discloses a solar energy full-year collection and storage supply system which comprises a solar collection system and a heating and refrigerating system connected with the solar collection system, wherein the solar collection system comprises a solar thermal collector and a thermal storage system, the thermal storage system is a buried U-shaped pipe arranged underground, and the solar thermal collector is connected with a thermal storage system in the underground soil of a building; the heating and refrigerating system is connected with the solar thermal collector and the thermal storage system, and the heating and refrigerating system comprises a heating and refrigerating fan coil system and a floor radiation heating system; and the solar collection system and the heating and refrigerating system are connected with tap water. The solar energy full-year collection and storage supply system has the advantages of low cost, high efficiency, long service life, increased heating efficiency and reduced cost.

Owner:TIANPU NEW ENERGY TECH

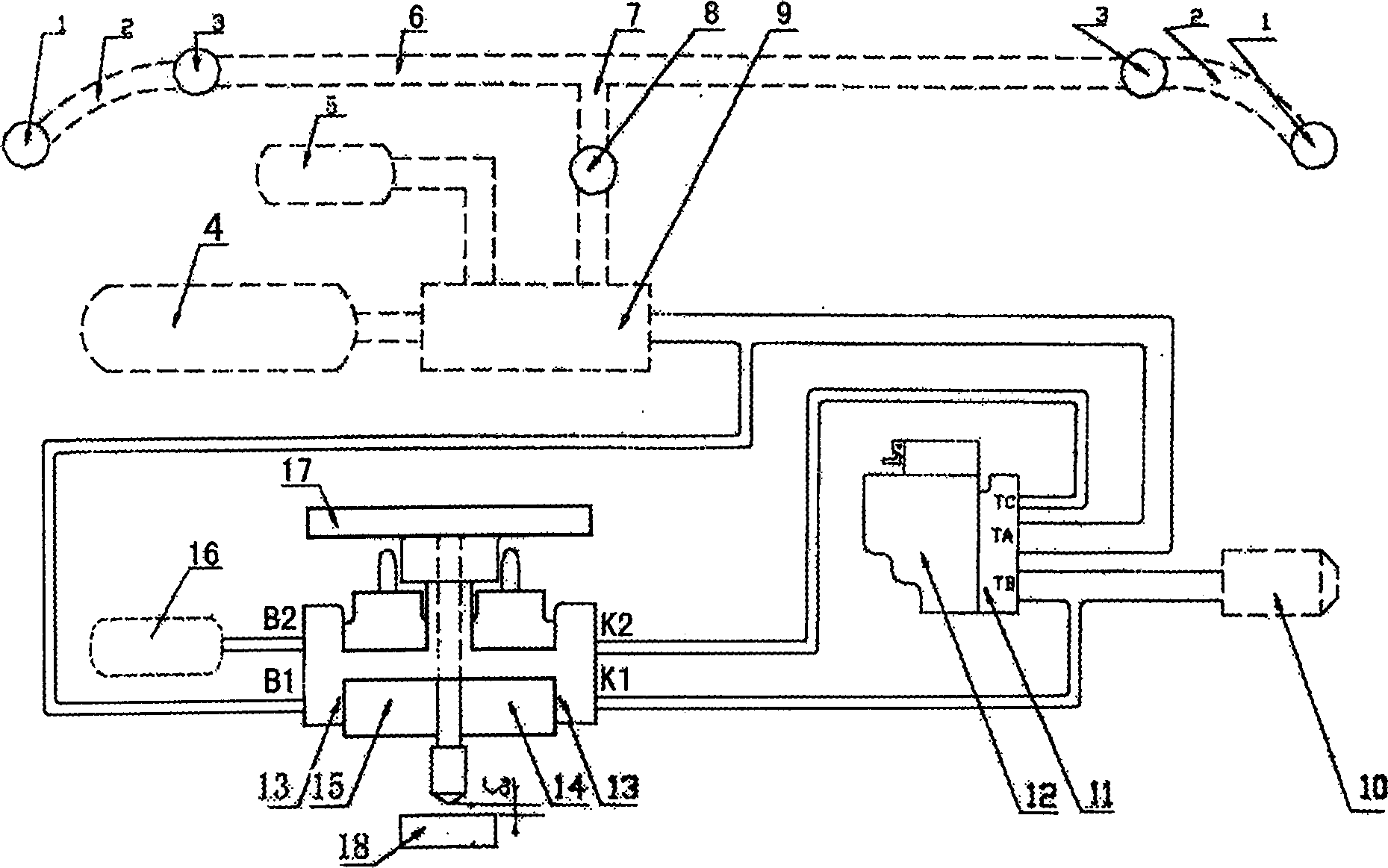

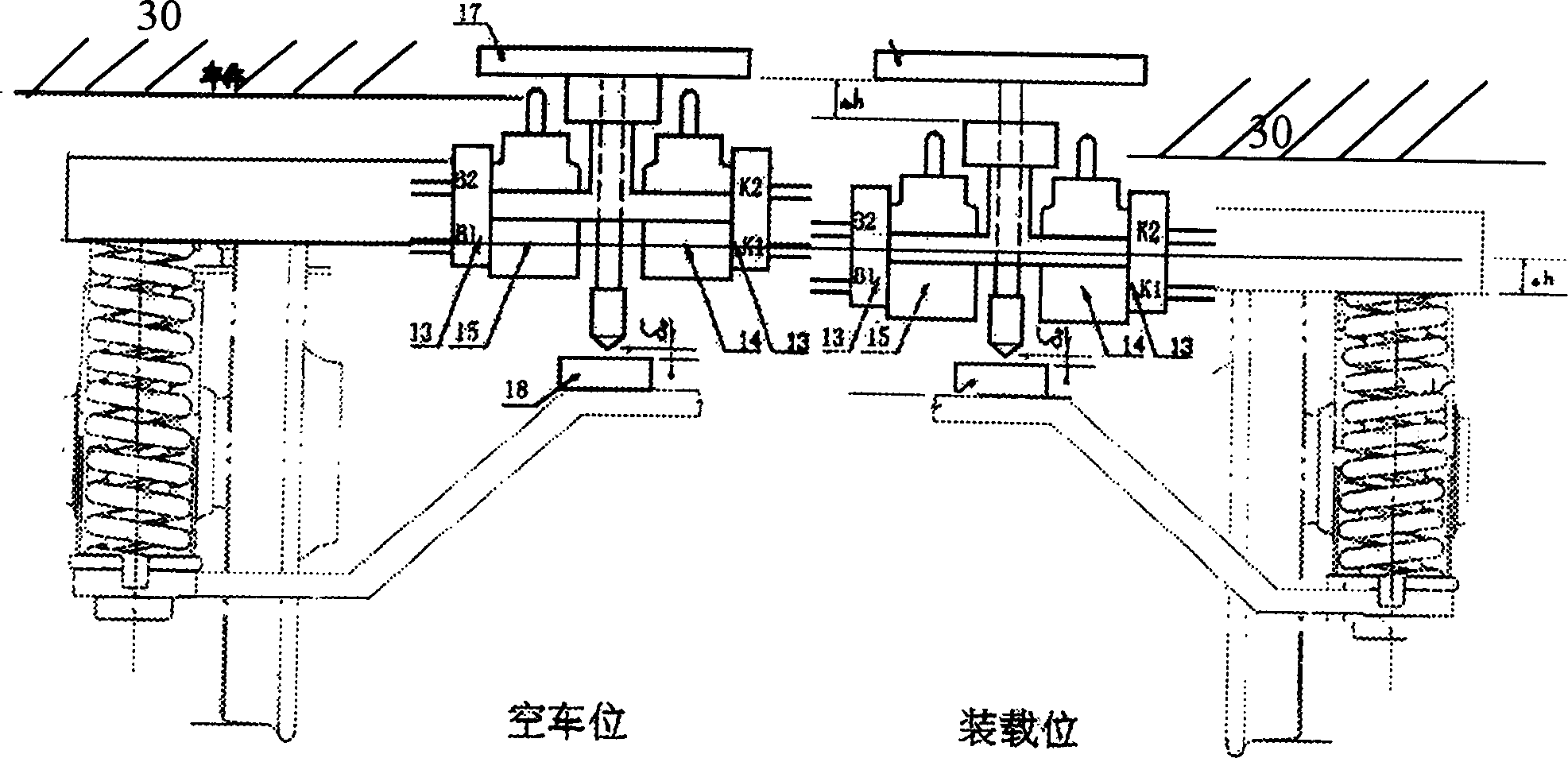

Compensation type stepless adjustment device of empty weight/heavy weight wagon with vibration damping

InactiveCN1843821ABraking rate close to the sameEliminate weighing inaccuraciesRail brake actuationTruckBrake pressure

The invention relates to a compensated step-less bare weight automatic adjuster of truck with damping vibration attenuation, while the former brake system can not reduce the pressure of brake cylinder significantly. The invention uses the control part 14 and the compensate part 15 of sensing valve to assist the adjusting valve 12 to adjust the pressure of brake cylinder and reduce the pressure of wind cylinder. It can step-less adjust the pressure of brake cylinder from bare weight to heavy weight of truck, without changing the former brake system, to significantly reduce the pressure of brake cylinder. The invention comprises a damping spring recover function, a air damping vibration attenuation, and a brake pressure self-locking weight-detecting restrain disc 17, to completely eliminate the effect on detecting weight by vibration when driving, therefore, the working state of restrain disc and sensing valve will all the same when the truck is braked. The invention can effectively reduce the longitudinal impact and avoid accidence.

Owner:殷璐

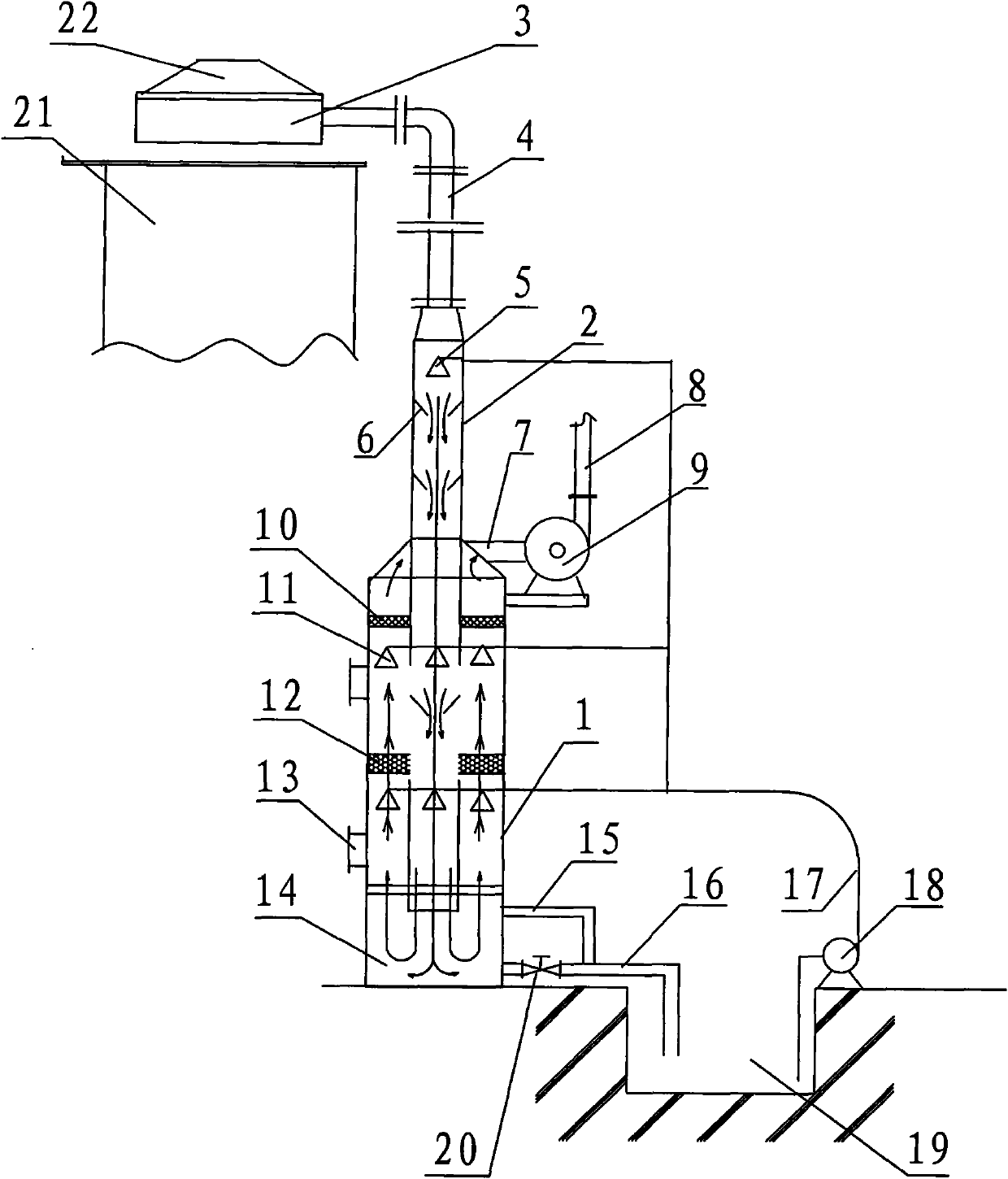

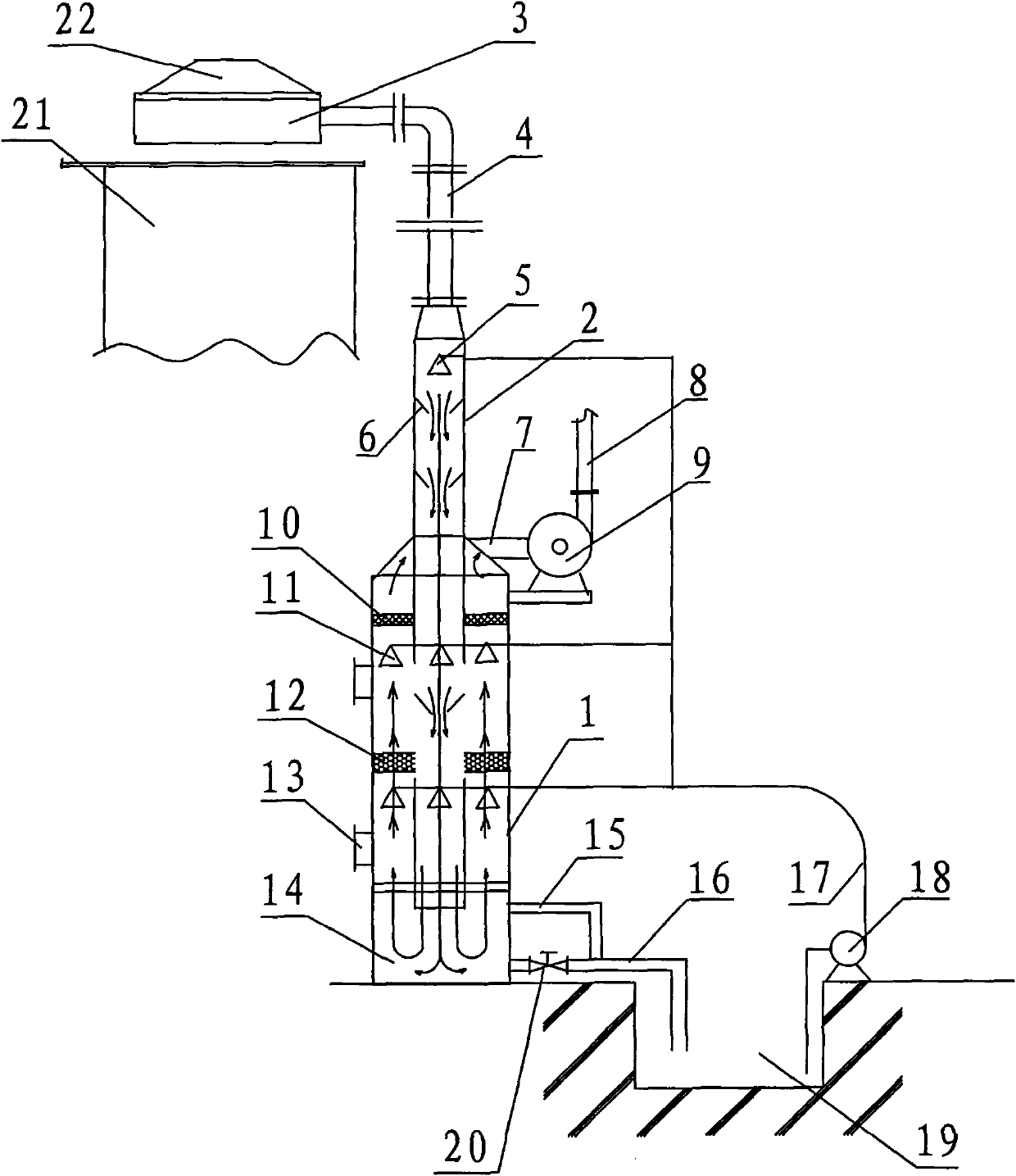

Dust removal and desulphurization device of roasting kiln

InactiveCN102019130AFully contactedComplete contact hydrationUsing liquid separation agentSlagFlue gas

TThe invention discloses a dust removal and desulphurization device of a roasting kiln, which comprises a flue gas dust removal tower, a desulphurization tower, a circulating neutralizing tank, an overflow pipe, a slag discharge pipe, an air blower, a high-pressure circulating pump and an annular dust hood, wherein the upper part of the desulphurization tower is provided with a fresh air discharge outlet, and the lower part of the desulphurization tower is provided with an impact bathing tank; the inner upper part of the flue gas dust removal tower is provided with a central spray header, and the inside of the tower is provided with a plurality of obconical liquid collecting boards; the flue gas dust removal tower is sheathed into the desulphurization tower; the upper and lower parts of a space between the inner wall of the desulphurization tower and the outer wall of the flue gas dust removal tower are respectively provided with a gas-liquid separator and a packing layer, and peripheral spray headers are arranged below the gas-liquid separator and the packing layer; the impact bathing tank is provided with the slag discharge pipe and the overflow pipe, the slag discharge pipe is connected with the circulating neutralizing tank, and the overflow pipe is connected with the slag discharge pipe; the air blower is connected with the fresh air discharge outlet, the water inlet of the high-pressure circulating pump is connected with the circulating neutralizing tank, and the water outlet of the high-pressure circulating pump is respectively connected with the central spray header and the peripheral spray headers by water pipes; and the annular dust hood is arranged at the top of the roasting kiln, and is connected to the top of the flue gas dust removal tower through a flue gas inlet pipe.

Owner:任建利

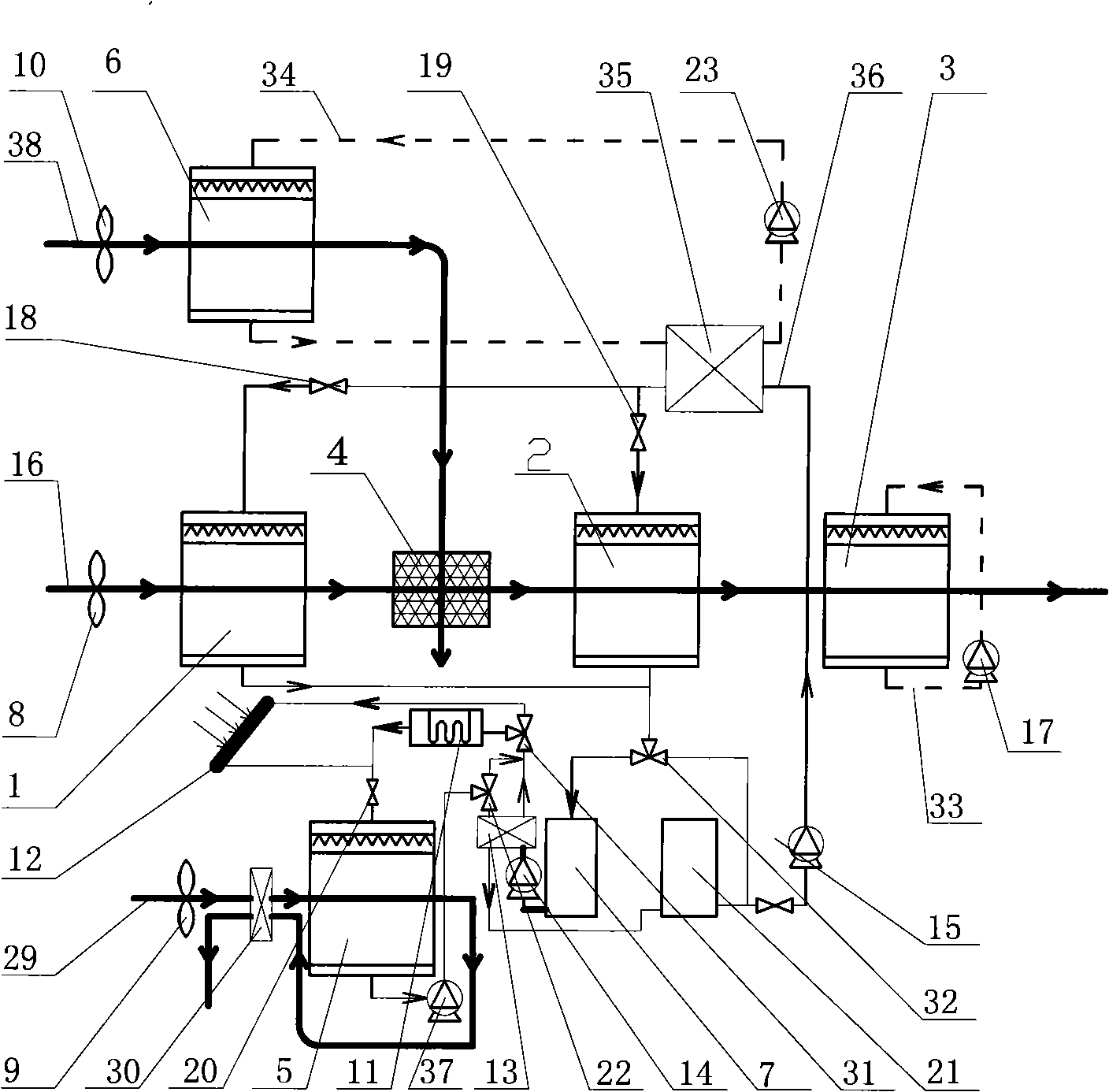

Solar energy driving compaction type two-stage parallel connection liquid dehumidifying air conditioner

InactiveCN101270899AImprove energy storage capacityLess wearing partsSolar heat devicesAir conditioning systemsEvaporative coolerEvaporation

A compact-type liquid dehumidification air conditioner in two-stage parallel connection which is driven by the solar energy comprises a two-stage dehumidification module, a regeneration module, a first evaporation cooling device, a cross flow heat exchanger and a second evaporation cooling device. The two-stage dehumidification module, the cross flow heat exchanger and two evaporation cooling devices constitute the upper layer of the solar compact type of liquid dehumidification air conditioner in two-stage parallel connection; the regeneration module constitutes the lower layer of the liquid dehumidification air conditioner. The modules are connected through the liquid pipeline or the air duct. Compared with the traditional liquid dehumidification air conditioner, the layered design of the air conditioner saves the space greatly; the parallel arrangement of the dehumidification module is convenient for the regulation of the gas and liquid flow ratio of each level; the operation with big concentration difference is in favor of the complete exertion of the liquid dehumidification capability, which realizes the energy storage and saving purpose. Therefore the compact-type liquid dehumidification air conditioner in two-stage parallel connection which is driven by the solar energy improves the deterioration of the dehumidification effect due to the gas liquid mixing heat during the dehumidification process.

Owner:SHANGHAI JIAO TONG UNIV

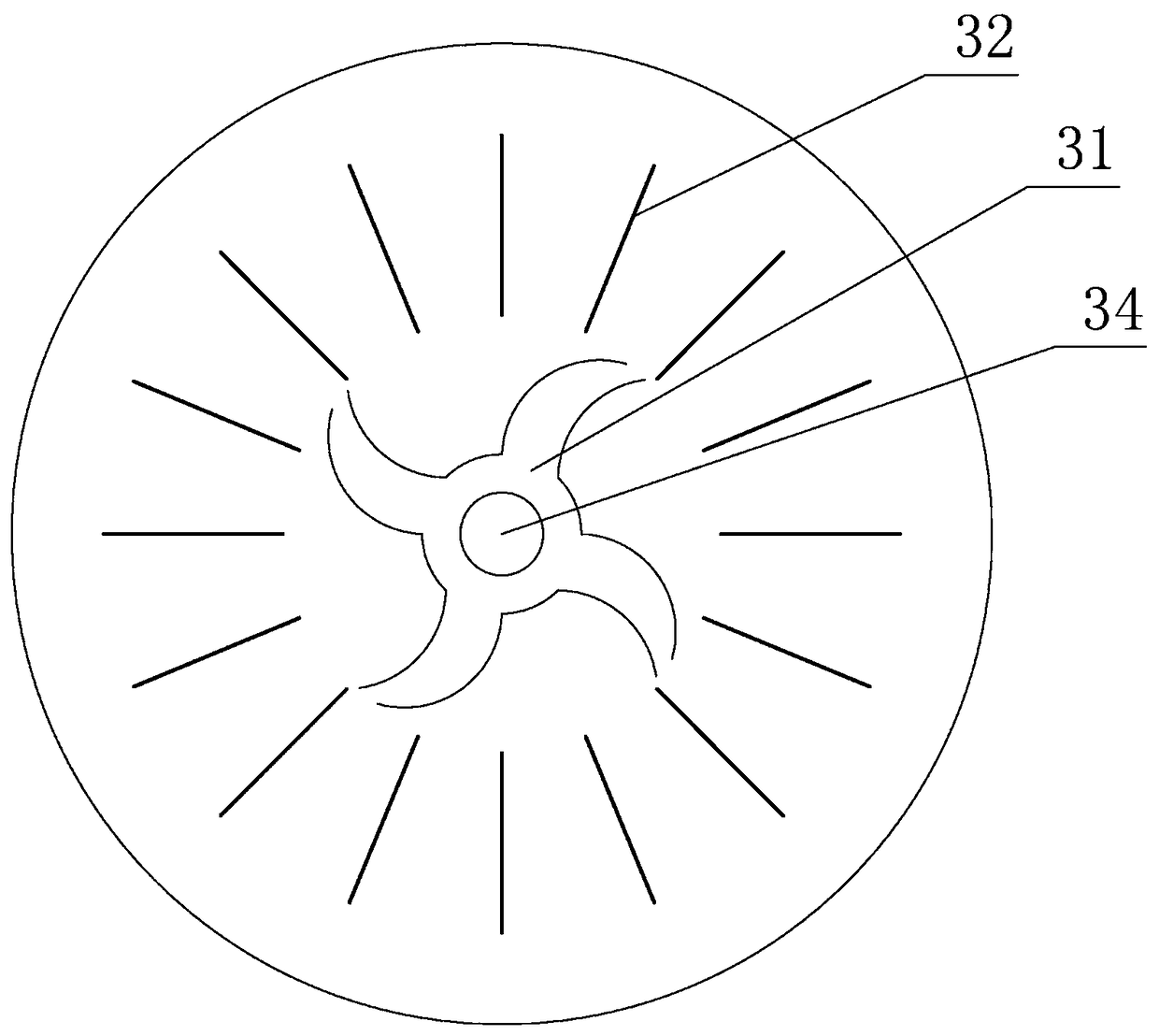

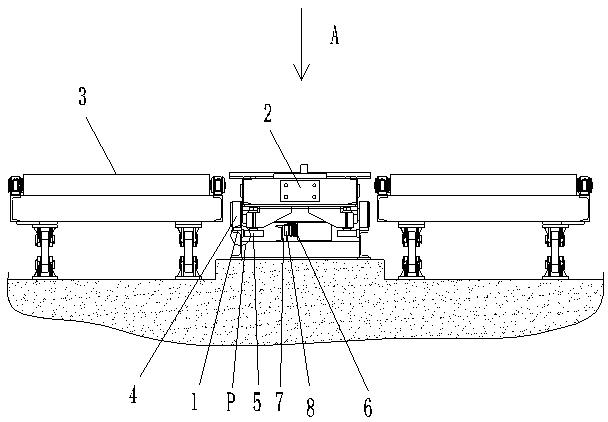

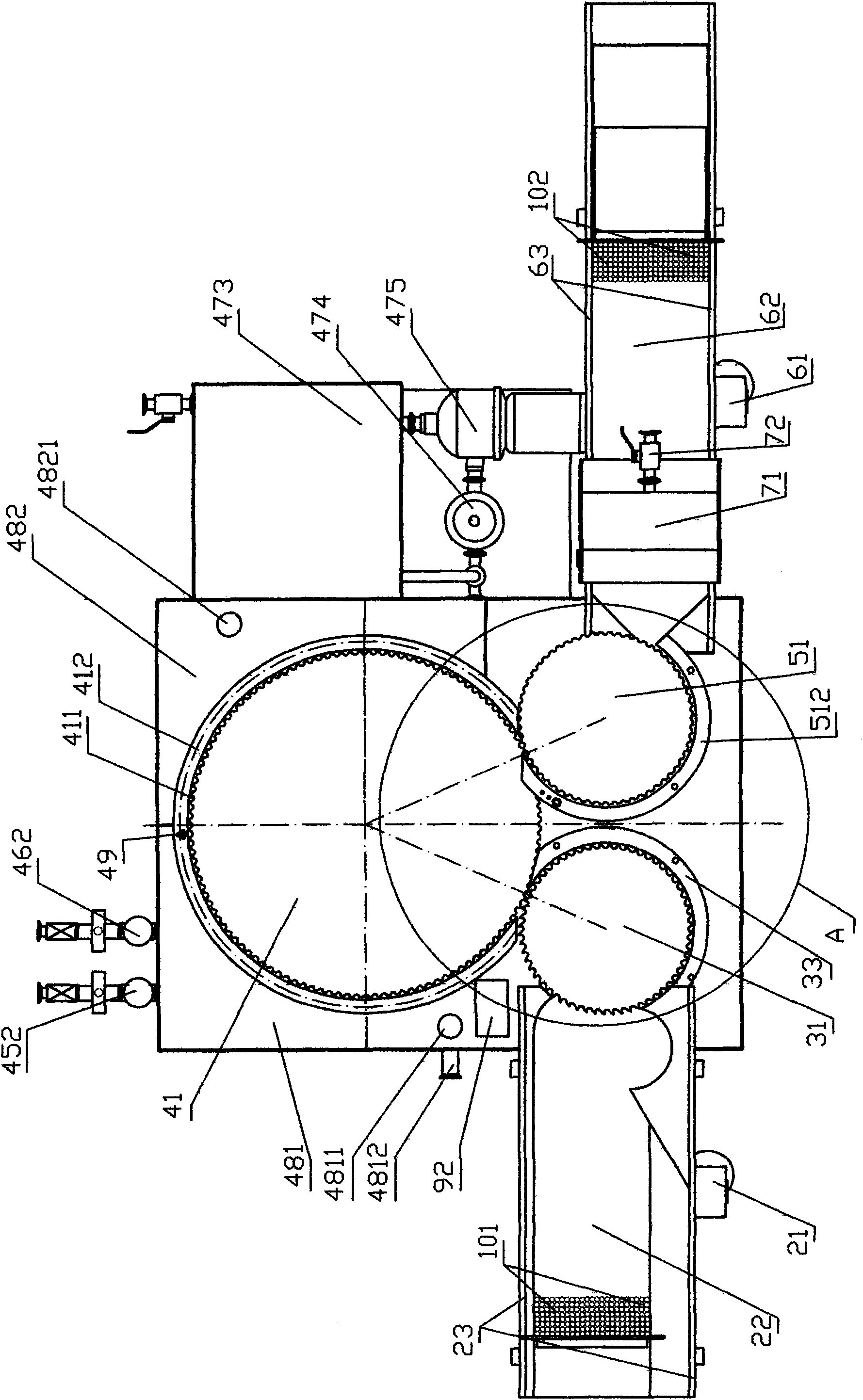

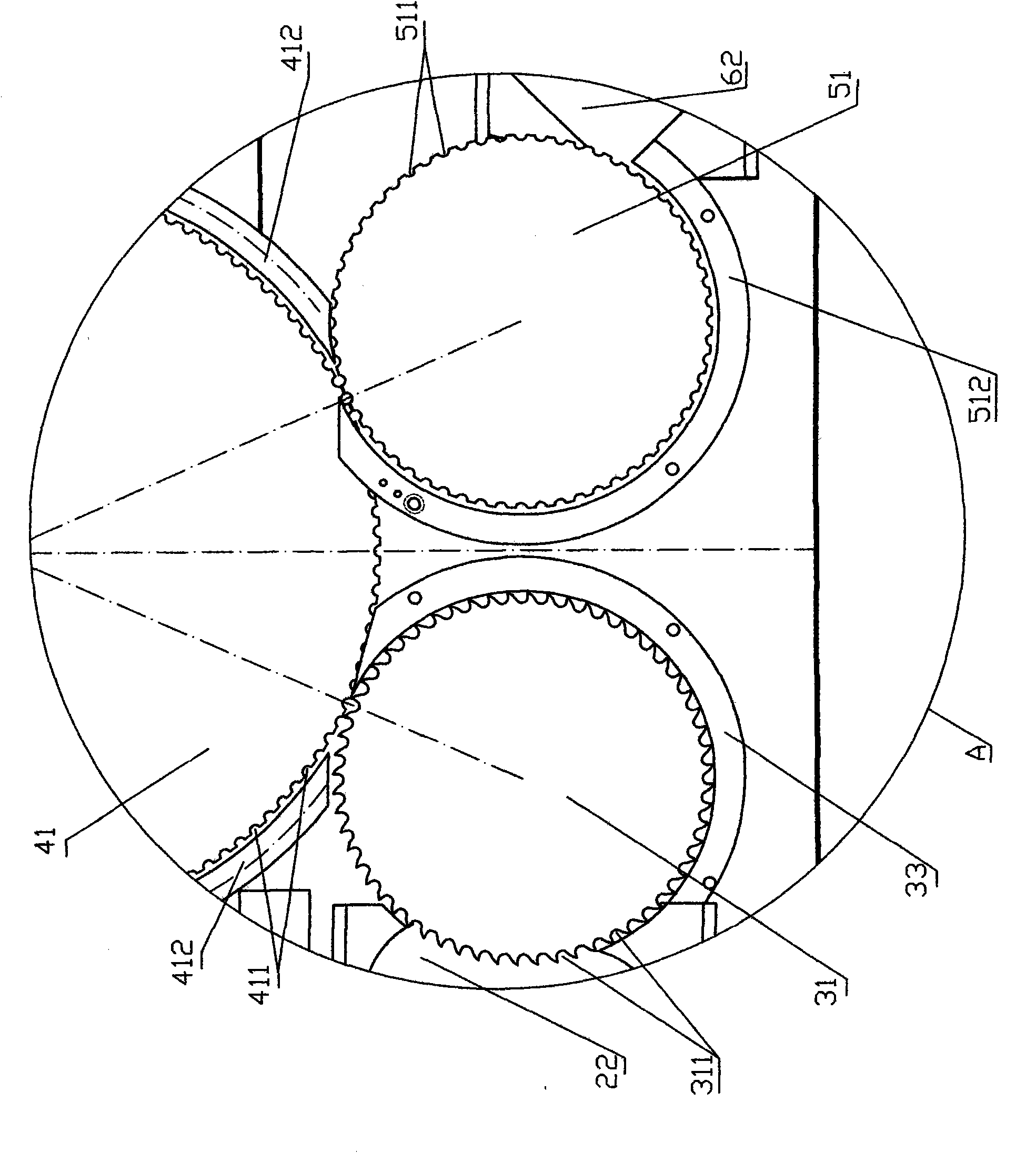

Cone-disc type waste concrete regenerated coarse aggregate mortar stripping device

ActiveCN109012867AWeaken protruding cornersReduce mud contentCocoaGrain treatmentsMetallurgyConstruction aggregate

The invention discloses a cone-disc type waste concrete regenerated coarse aggregate mortar stripping device. The cone-disc type waste concrete regenerated coarse aggregate mortar stripping device comprises a base, a material collection bin and a cone-disc type grinding disc, wherein the cone-disc type grinding disc is composed of an upper grinding disc and a lower grinding disc, the grinding surface of the lower grinding disc is of a convex cone type, the grinding surface of the upper grinding disc is of a concave cone type, and the grinding surface of the upper grinding disc is in fit with that of the lower grinding disc; the base is provided with a plurality of reverse-hook-shaped supports, the disc surface of the upper grinding disc is correspondingly provided with position-limiting holes, and reverse hooks of all the reverse-hook-shaped supports penetrate into the corresponding position-limiting holes to restrict the upper grinding disc to be only capable of sliding up and down; ahydraulic force transmitting device is arranged between the upper grinding disc and all the reverse-hook-shaped supports, and ascending and descending of the upper grinding disc are controlled through stretching and contracting adjustment of the hydraulic force transmitting device; and the center of the upper grinding disc is provided with a material inlet, the material inlet penetrates out of the top of the material collection bin, and the lower portion of the material collection bin is provided with a material outlet. The cone-disc type waste concrete regenerated coarse aggregate mortar stripping device is simple in structure, the aggregate mortar stripping effect is good, and the original particle size of coarse aggregate can be maintained to make the performance of the coarse aggregate be close to natural aggregate, so that the workability, strength and durability of freshly-mixed waste concrete are improved.

Owner:CHINA UNIV OF MINING & TECH

High-efficiency circuit board welding robot with flue gas purification function

ActiveCN108526641AHigh degree of automationImprove welding efficiencyCombination devicesGas treatmentFlue gasEngineering

The invention relates to a high-efficiency circuit board welding robot with a flue gas purification function. The high-efficiency circuit board welding robot comprises a housing, a base, a feeding mechanism and a welding mechanism, and further comprises a transfer mechanism, a purification mechanism and a center control mechanism, wherein the transfer mechanism comprises a transfer machine, a rotating shaft, a lifting assembly, a fixing assembly and two torsion springs; the fixing assembly comprises a drive unit, a second gear, two lead screws, two moving rods, two limiting blocks and two bearing blocks; the purification mechanism comprises an extraction hood, an air pump, a first breather pipe, a water tank, an exhaust port, an adapter and at least two second breather pipes. According tothe high-efficiency circuit board welding robot with the flue gas purification function, due to the transfer mechanism, the time of manually replacing the circuit board by an operator is shortened, and the welding efficiency of the welding robot is improved; due to the purification mechanism, harmful gases produced in the welding process of the welding robot can be purified, and the influences ofthe harmful gases on health of workers are reduced.

Owner:SUZHOU DESIMIER SMART TECH CO LTD

Shock absorber for drilling tool in oil-gas drilling

ActiveCN102031938AAvoid fatigue failureGreat vibration reductionDrilling rodsDrilling casingsUpper jointWell drilling

The invention discloses a shock absorber for a drilling tool in oil-gas drilling. The shock absorber comprises a mandrel, wherein a spline and a fixed piston are arranged on the mandrel; a spline outer cylinder is arranged on the spline, and the spline outer cylinder and the spline form an axial sliding pair; a plurality of damping channels are axially formed between the spline and the spline outer cylinder; the lower end of the spline outer cylinder is connected with a lower outer cylinder, and the upper end of the spline outer cylinder is sequentially connected with an upper outer cylinder,an upper seal joint and an upper joint; the spline outer cylinder and the upper outer cylinder, the upper seal joint and the lower outer cylinder, the fixed piston respectively form an upper annular cavity and a lower annular cavity at the periphery of the mandrel, and the two cavities are communicated through the damping channels; an oil injection nozzle and a gas injection nozzle are respectively formed on the spline outer cylinder and the upper seal joint in the radial direction; the oil injection nozzle is communicated with the damping channels; the gas injection nozzle is communicated with the upper annular cavity through a gas injection annular channel; and a movable piston is arranged in the upper annular cavity. The shock absorber for the drilling tool in the oil-gas drilling integrates liquid, damping and gas shock absorption so as to avoid the fatigue failure of the drilling tool, and has the characteristics of high shock absorption performance, long service life, low manufacturing cost, simple structure, a few quick-wear parts, convenience of maintenance and the like.

Owner:CHINA PETROLEUM & CHEM CORP

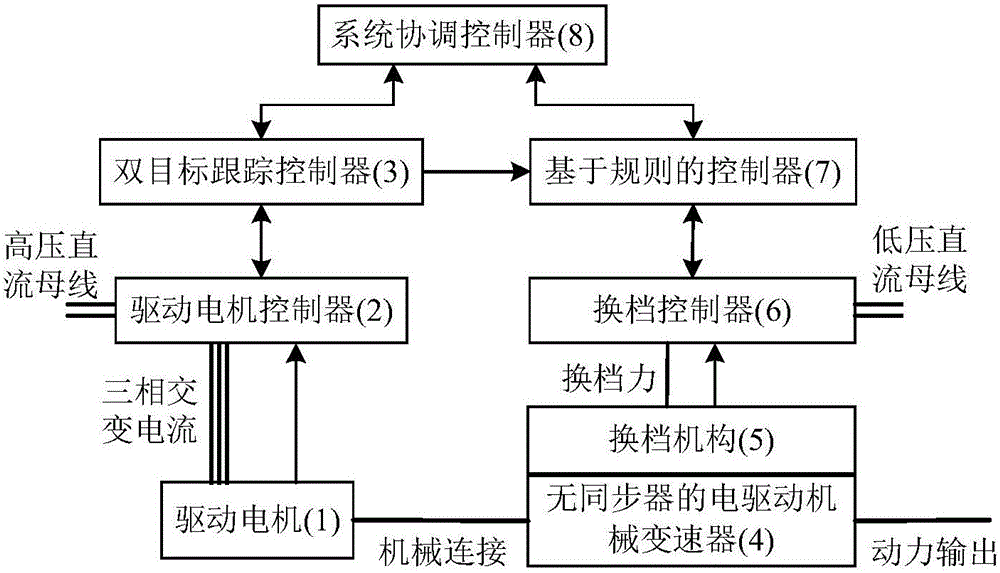

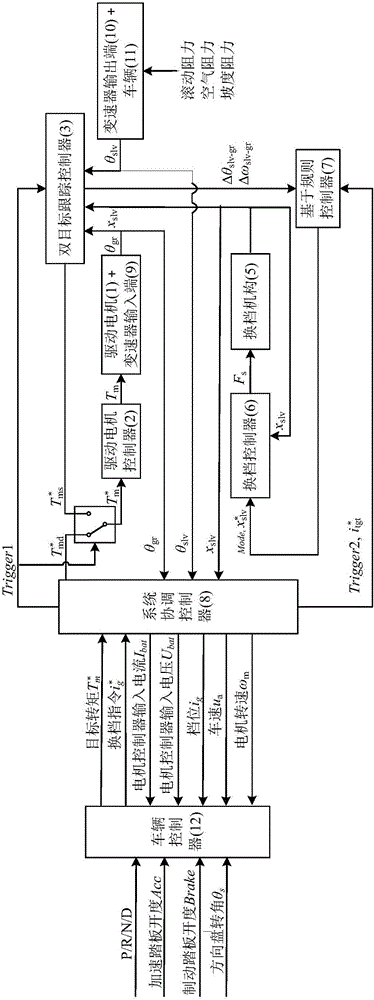

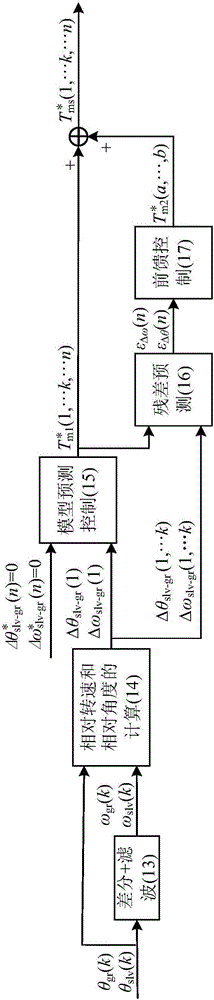

Impact-free gear shift control method and system for electrically driven mechanical transmission without synchronizer

The invention relates to an impact-free gear shift control method and system for an electrically driven mechanical transmission without a synchronizer. The electrically driven mechanical transmission is provided with no synchronizer; a drive motor and the electrically driven mechanical transmission are directly coupled, and a clutch between the drive motor and the electrically driven mechanical transmission is omitted. An automobile controller determines the target gear and sends a gear shift instruction to a system coordinating controller; the system coordinating controller coordinates the working sequence and working mode of a dual target tracking controller and a rule-based controller, so that the drive motor and the electrically driven mechanical transmission are in coordinated fit to achieve gear shift; and by accurately controlling a motor rotor, a target joint gear ring accurately tracks rotation of a joint sleeve in the joint process, the requirements for zero rotation speed difference and zero rotation corner difference are met, and impact-free gear shift control is achieved. The method and system can eliminate collision between the joint sleeve and the joint gear ring in the joint process, then gear shift impact is restrained, and the power failure duration is shortened.

Owner:TSINGHUA UNIV

Novel overspeed petective slide valve

ActiveCN1749584ALess wearing partsSolution to short lifeFluid-pressure actuator safetySpool valvePetroleum engineering

Owner:HANGZHOU HOLLYSYS AUTOMATION

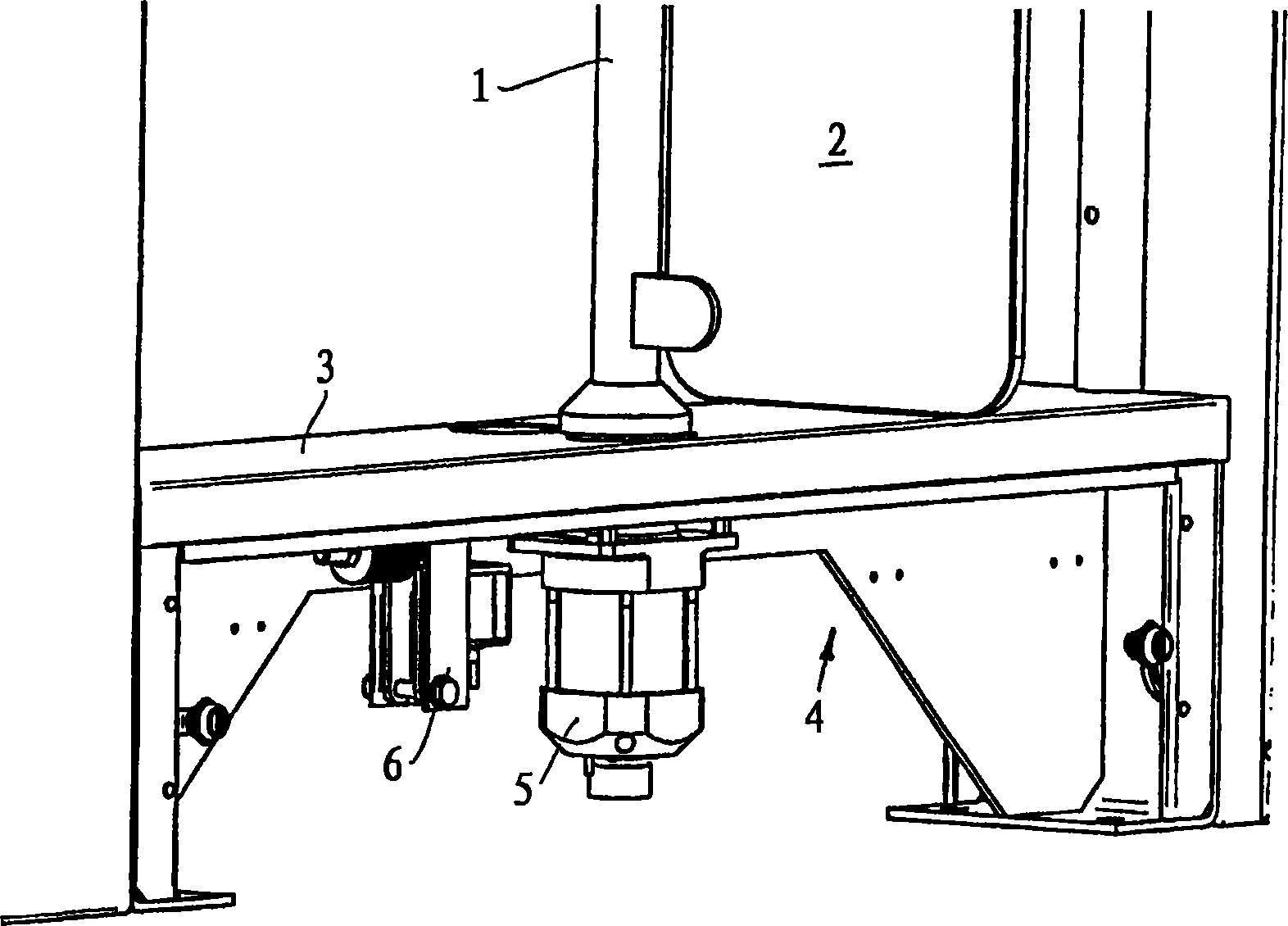

Feeding conveyer for machining of large workpiece

The invention discloses a feeding conveyer for the machining of a large workpiece, which comprises a track and a driving vehicle, wherein the driving vehicle is used for bearing and driving the workpiece to move along the track and is arranged on the track by moving to and fro along the track. The feeding conveyer for the machining of the large workpiece has no relative sliding between the workpiece and the driving vehicle and can not cause damage to the surface of the workpiece by conveying the workpiece through the driving vehicle moving along the track, and also has a high feeding precision and a simple structure, has no complex transmission mechanism, has a few vulnerable components, a low failure rate during running and a low manufacturing cost and is convenient to maintain; non-powered roll tables on two sides of the driving vehicle make the workpiece be more stable in the running process and overcome the defect of inconsistent linear speed of live rollers on a powered roll table; the non-powered roll tables and the workpiece have no relative sliding therebetween, so no damage on the workpiece can be caused; the positive pressure between the workpiece and the driving vehicle, and between the workpiece and the roll tables can be regulated by regulating the height of the non-powered roll tables, so that the driving vehicle can work under the optimal working condition, the sliding of the workpiece is avoided and the stable feeding is ensured.

Owner:CHONGQING UNIV

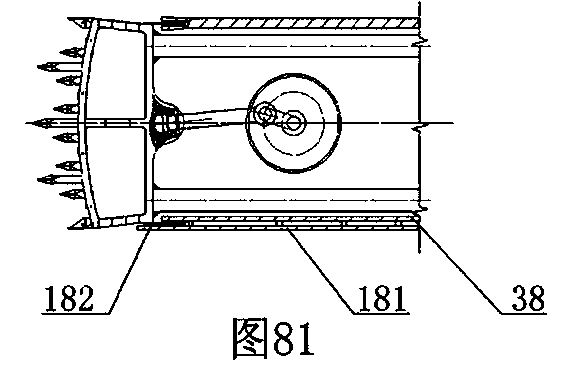

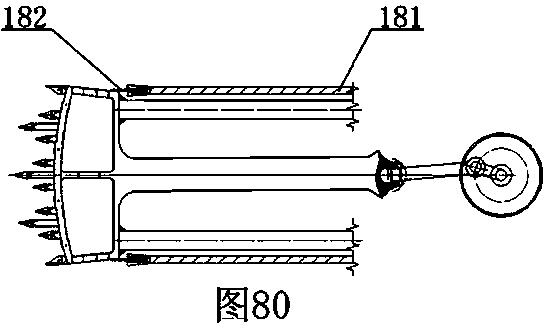

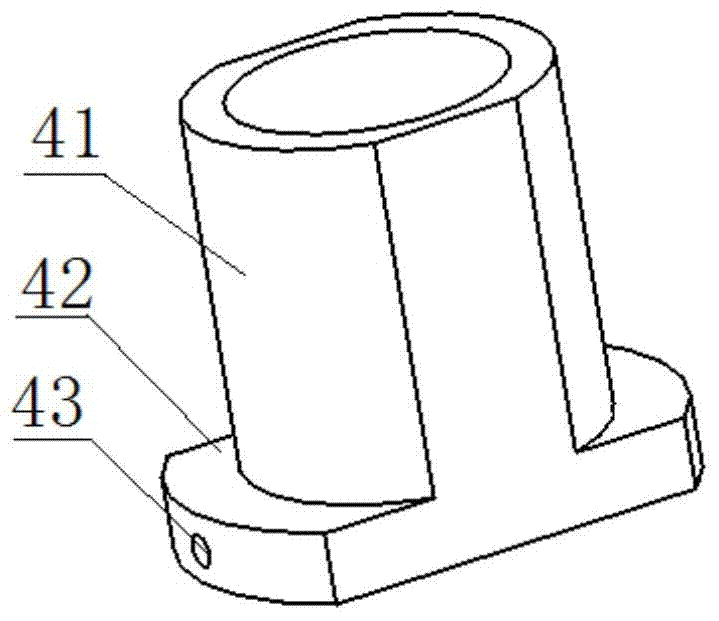

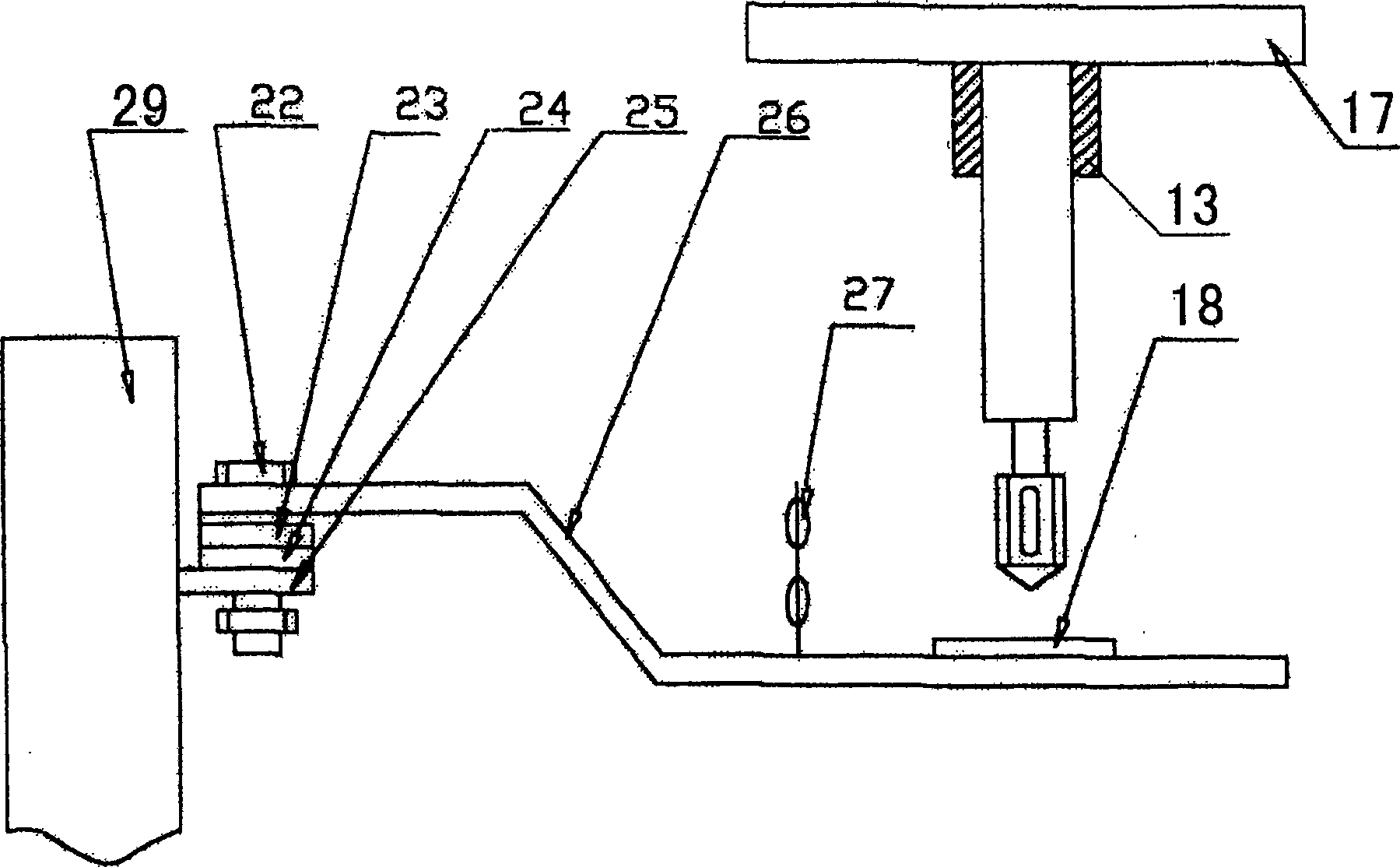

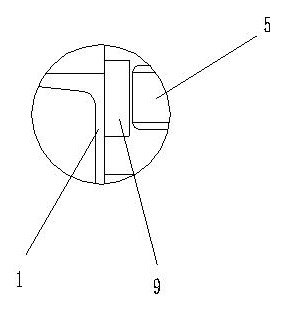

Washing and liquid coating machine for test tube

InactiveCN102114454AEasy to recycleQuality improvementLiquid surface applicatorsHollow article cleaningBlood Collection TubeCoating system

The invention discloses a washing and liquid coating machine for a test tube, which comprises a machine frame (1), a tube transferring mechanism, a tube inlet mechanism, a washing and liquid coating mechanism, a tube outlet mechanism, a tube delivery mechanism, a power transmission mechanism and an operating control system, wherein, a plurality of tube clamping ports (311) are formed on the periphery of a tube inlet disc (31) of the tube inlet mechanism; the washing and liquid coating mechanism comprises a washing and coating station disc (41), a washing and coating station disc shaft (42), a swinging disc (43), a swinging disc shaft sleeve (44), a water spray system, a gas ejecting system and a liquid coating system; a plurality of the tube clamping ports (411) are formed on the periphery of the washing and coating station disc (41); a plurality of the tube clamping ports (511) are formed on the periphery of a tube outlet disc (51) of the tube outlet mechanism; and the power transmission mechanism comprises a main motor (81), a main transmission shaft (82), a swinging disc lifting mechanism, a swinging disc tracking mechanism and a tube disc transmission mechanism. The washing and liquid coating machine is mainly used for washing and oiling a blood collection tube.

Owner:衡阳鑫山机械设备制造有限公司

Freezing and drying integrated vacuum freezing and drying machine

InactiveCN106679353ARaise the suction temperatureShorten drying timeDrying solid materials without heatCompression machines with non-reversible cycleRefrigeration compressorEvaporation

The invention relates to a drying device, in particular to a freezing and drying integrated vacuum freezing and drying machine. The machine comprises a freezing and drying evaporation bin, a freezing evaporation plate arranged in the freezing and drying evaporation bin, a water catching bin, a refrigeration compressor unit, a vacuum pump and an electrical control cabinet, wherein the refrigeration compressor unit is composed of a refrigeration compressor, an oil separator, a condenser and a liquid storage device. The freezing and drying integrated vacuum freezing and drying machine is characterized in that the part between the closed freezing and drying evaporation bin and the closed water catching bin is partitioned through two parallel partition plates, a closed cavity is formed between the two parallel partition plates, a ventilation hole is formed in the lower end of the partition plate on one side of the freezing and drying evaporation bin, and a ventilation hole is formed in the upper end of the water catching bin partition plate on one side of the water catching bin. The refrigeration compressor is connected with the freezing and drying evaporation bin and the water catching bin through a pipeline, and the vacuum pump is connected with the bottom of the water catching bin. The technical scheme has the beneficial effects that the equipment configuration and structure are more reasonable, the equipment running efficiency is high, and the service life is long. The production cost and the using cost of the equipment can be reduced by about 10%-20% compared with current vacuum freezing and drying equipment.

Owner:YINCHUAN LIZHIXIN INTPROP ADVISORY SERVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com