Compensation type stepless adjustment device of empty weight/heavy weight wagon with vibration damping

An adjustment device and compensation technology, applied in transportation and packaging, railway car body parts, railway braking systems, etc., can solve the problems that the air pressure of the brake cylinder cannot be adjusted separately, and cannot solve the deviation and limitation, so as to achieve braking The rate is close to the same, the effect of eliminating inaccurate weight measurement and reducing wheel rubbing accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

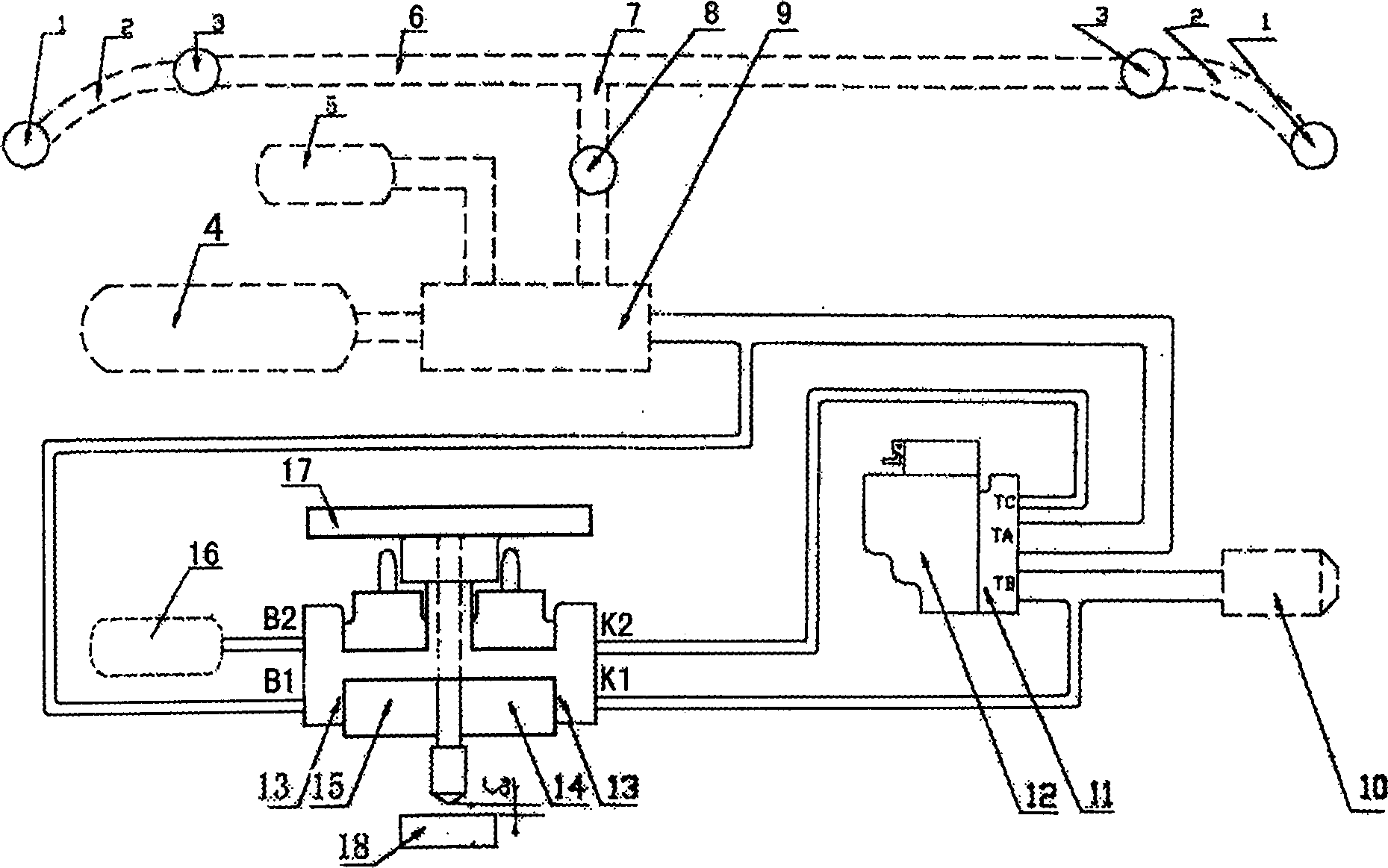

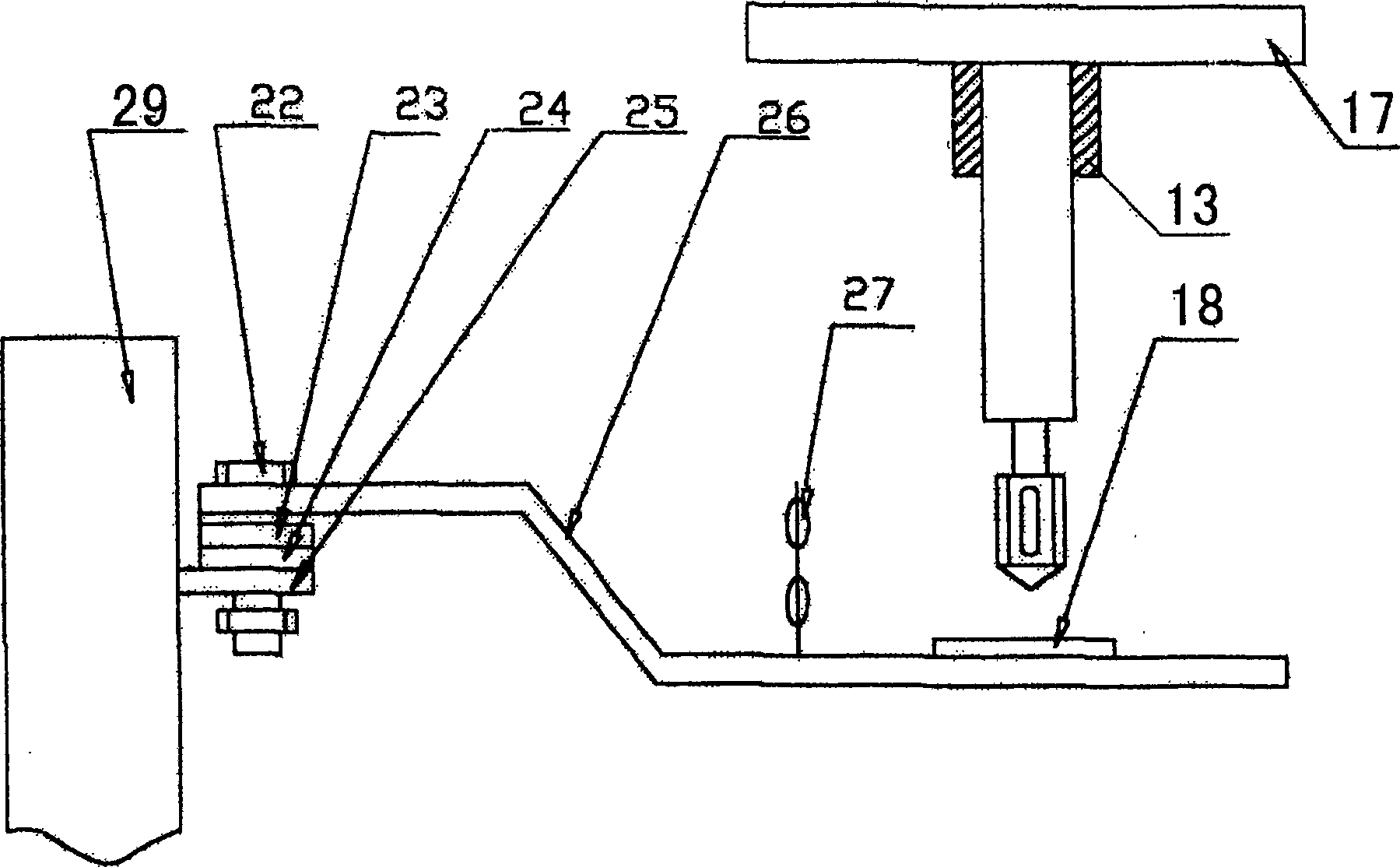

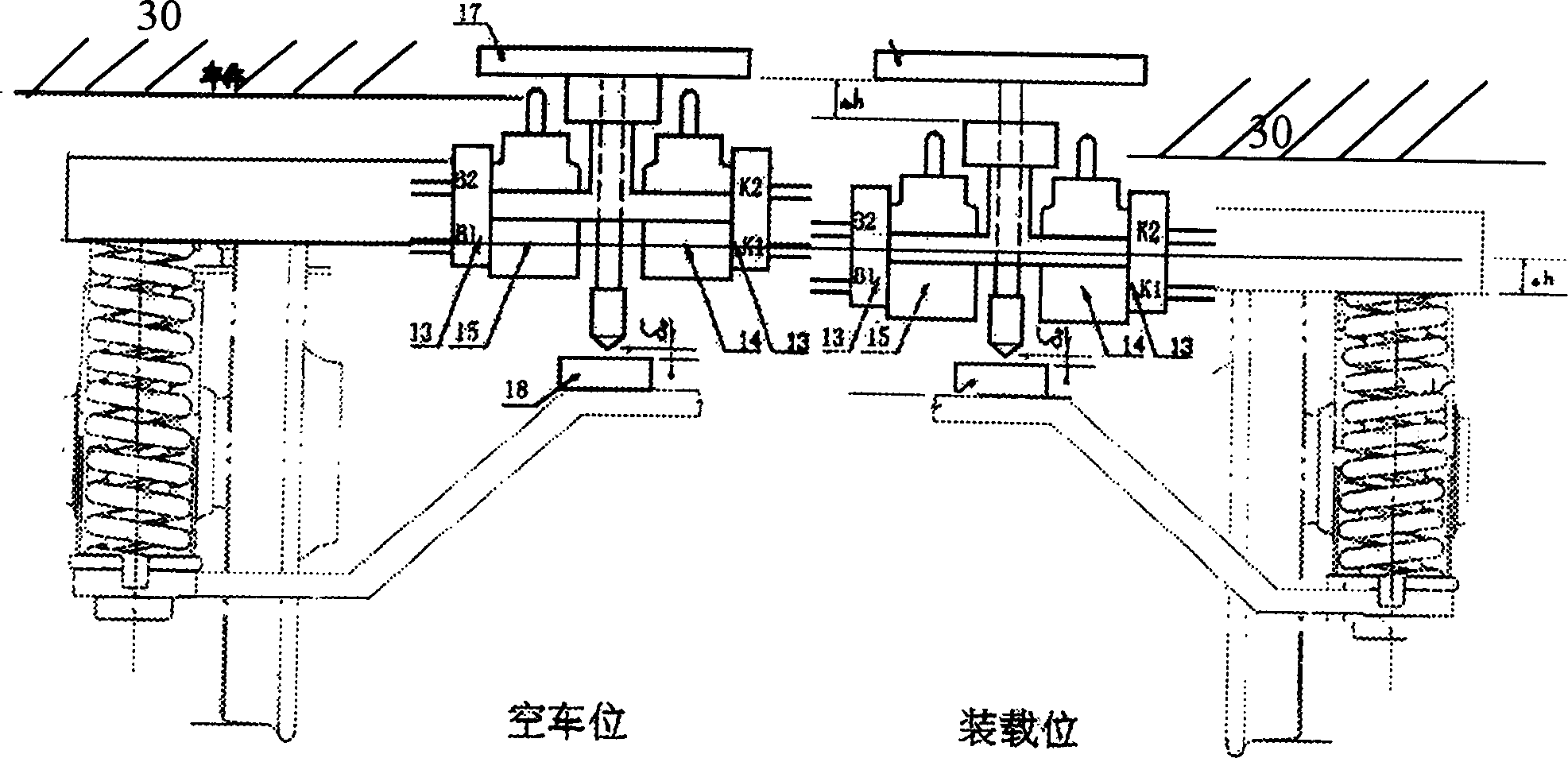

[0026] Compensated truck stepless automatic adjustment device system for empty and heavy trucks with damping and vibration reduction, see attached figure 1 . Dotted line part among the figure is the equipment of former two pressure brake systems. Its composition mainly contains secondary air cylinder 4, brake cylinder 10, step-down air cylinder 16, brake control valve 9, and train pipe 6, and they all needn't refit. This device has only six parts: adjusting valve 12, valve seat suppressing disc support 13, sensing valve control part 14, sensing valve compensating part 15, damping and damping suppressing disc 17 and touch plate 18. Wherein the control part 14 and the compensating part 15 of the sensing valve are integrated and installed on the valve seat bracket 13 . Seat support and suppression disc support are made of precision casting as a whole. The pipeline connection mode is divided into two ways by the brake hole outlet of the brake control valve 9 (referring to the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com