Patents

Literature

129results about How to "Realize automatic weighing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Washing machine and method for weighing clothes of washing machine

ActiveCN103225195ARealize accurate automatic weighingRealize automatic weighingOther washing machinesTextiles and paperLaundry washing machineControl engineering

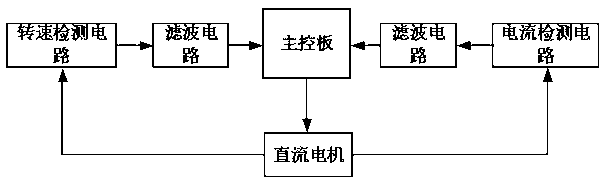

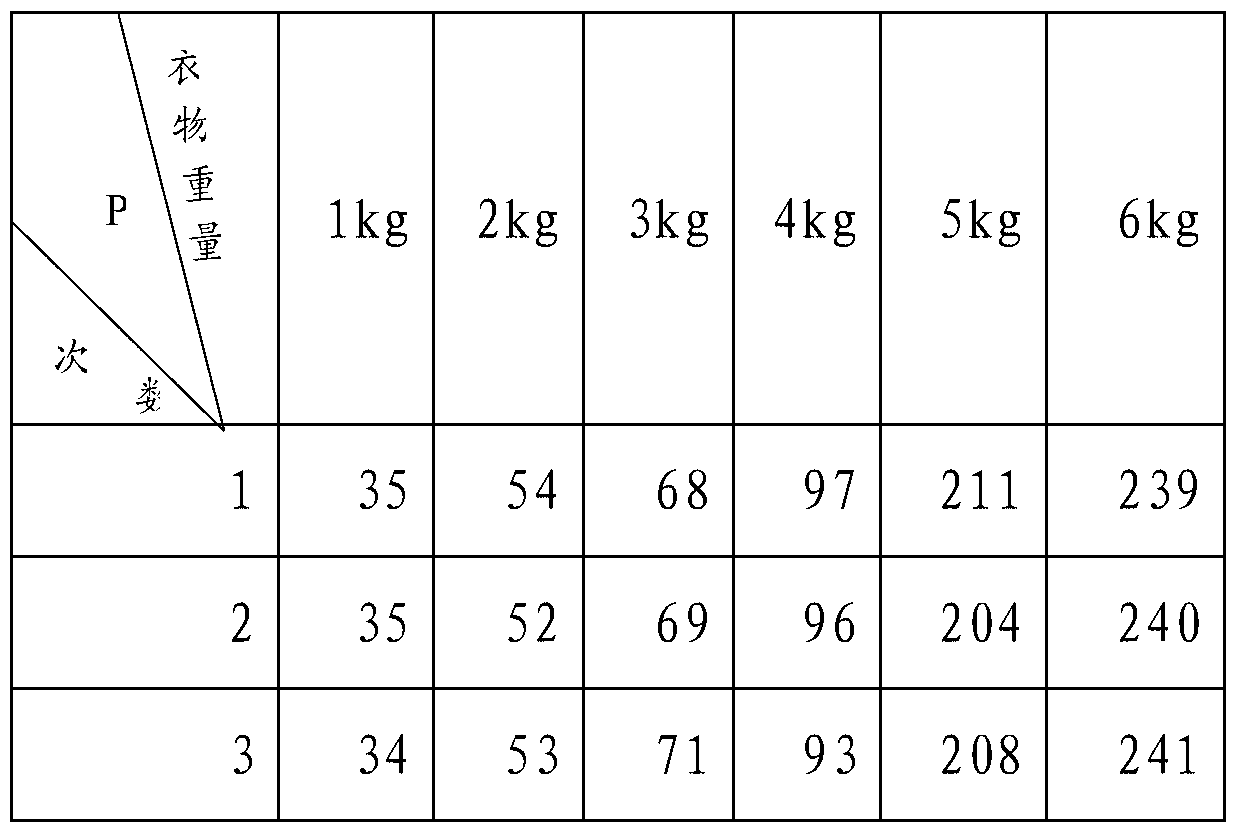

The invention relates to a washing machine and a method for weighing clothes of the washing machine. The method comprises the following steps: controlling the running state of a direct current motor by using a main control panel of the washing machine; calculating the average output power P of the direct current motor according to the armature current which is detected and filtered by a current detection circuit and the actual motor rotating speed which is detected and filtered by a rotating speed detection circuit; and calculating to obtain the weight of clothes, calculating the washing time, the washing dynamics, the using amount of washing water and the water inlet time according to the obtained clothes weight, and washing according to the calculated parameters. The corresponding relationship between the washing machine and the clothes weight is established by calculating the average output power P of the direct current motor, so that the clothes can be weighed more accurately. The invention can realize the function of accurately weighing the clothes and improves the performance of the washing machine.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

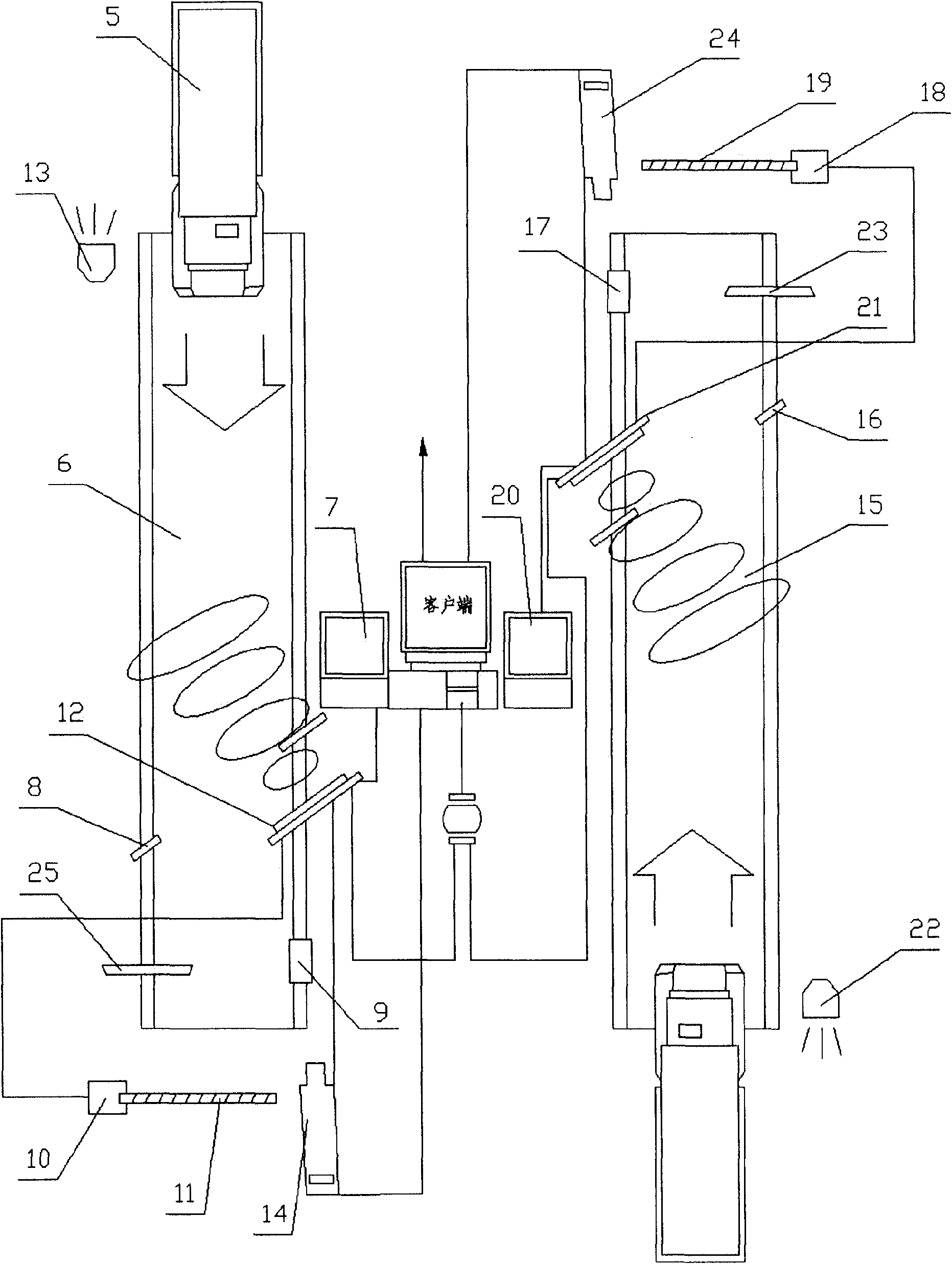

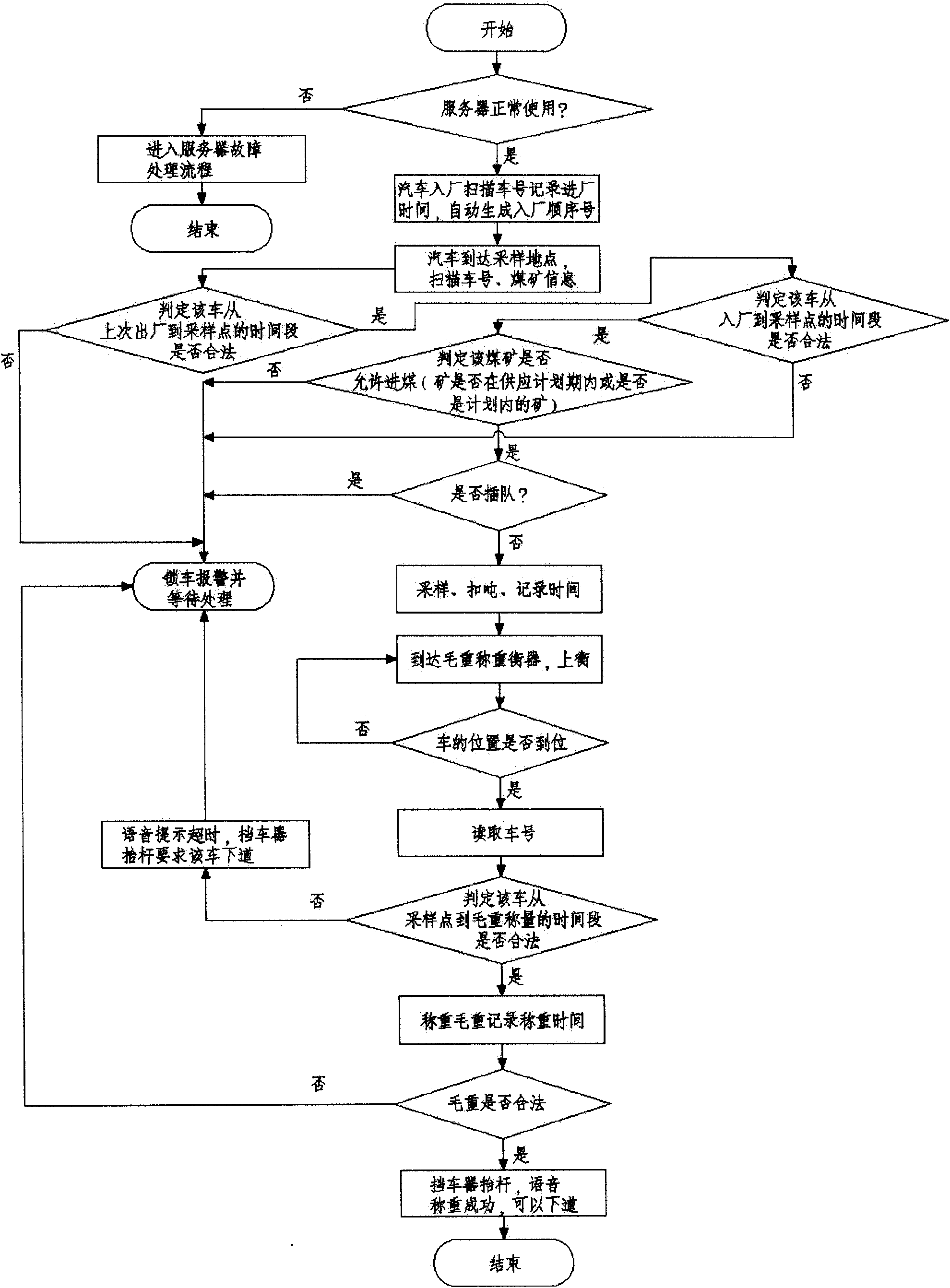

Vehicle entry and exit factory unattended system and method of thermal power plant

InactiveCN101609572AImprove efficiencyRealize automatic weighingWithdrawing sample devicesPreparing sample for investigationEngineeringClient machine

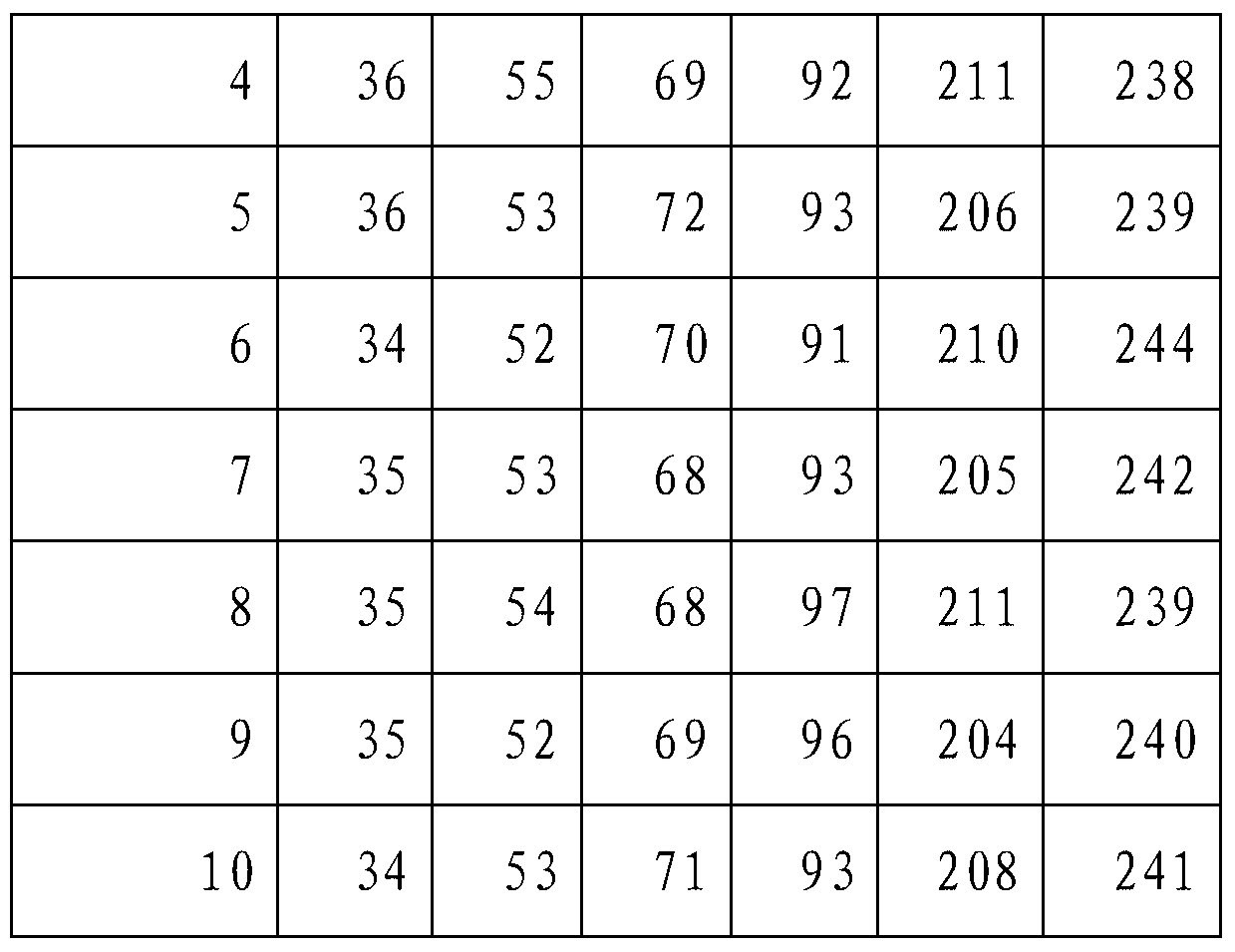

The invention relates to a vehicle entry and exit factory unattended system and a method of a thermal power plant; the unattended system comprises a system control module, an automatic scanning device, a sampling and sample preparing and testing device and a weighing device, and the system control module comprises a server, a client computer and a network office device which are mutually connected through a computer local area network. The adoption of the unattended system can realize the automation of entry factory, sampling, weighing and empty vehicle weighing, effectively save staff cost, greatly improve production efficiency, effectively monitor time periods among various processes of vehicles which enter a factory, effectively solve the chaotic order of entering the factory and greatly improve the efficiency of the vehicles which enter and exit the factory of the thermal power plant.

Owner:王辉 +1

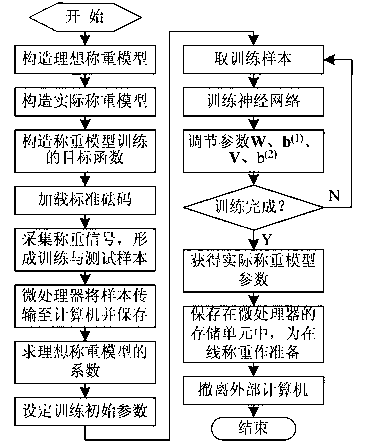

Weighing method applicable to truck scale

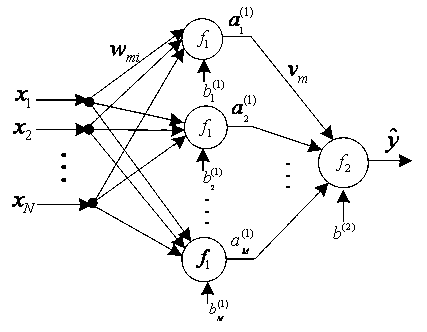

InactiveCN103234610ARealize automatic weighingImprove accuracyBiological neural network modelsSpecial purpose weighing apparatusAlgorithmMathematical model

The invention discloses a weighing method applicable to a truck scale, and the method comprises a weighing sensor, a data acquisition device, a microprocessor and a display which are used, and the following steps that a weighing mathematical model is established, a weighing signal is acquired and on-line weighing is carried out; the step of establishing the weighing mathematical model comprises an ideal weighing model, an actual weighing model and the training methods thereof; the ideal weighing model is a linear function; the actual weighing model is a three-layer BP neural network, wherein a first layer is an input layer, a second layer is a hidden layer and a third layer is an output layer; before on-line weighing, the training of setting sample sizes must be carried out on the ideal weighing model and the actual weighing model; the training is carried out when the microprocessor is connected with an external computer; sample information of set quantity is acquired; the ideal weighing model and a derivative thereof serve as constraint conditions; finally the parameters W, b (1), V and b (2) of the actual weighing model are acquired and saved in the microprocessor; and then the external computer is removed.

Owner:HUNAN NORMAL UNIVERSITY

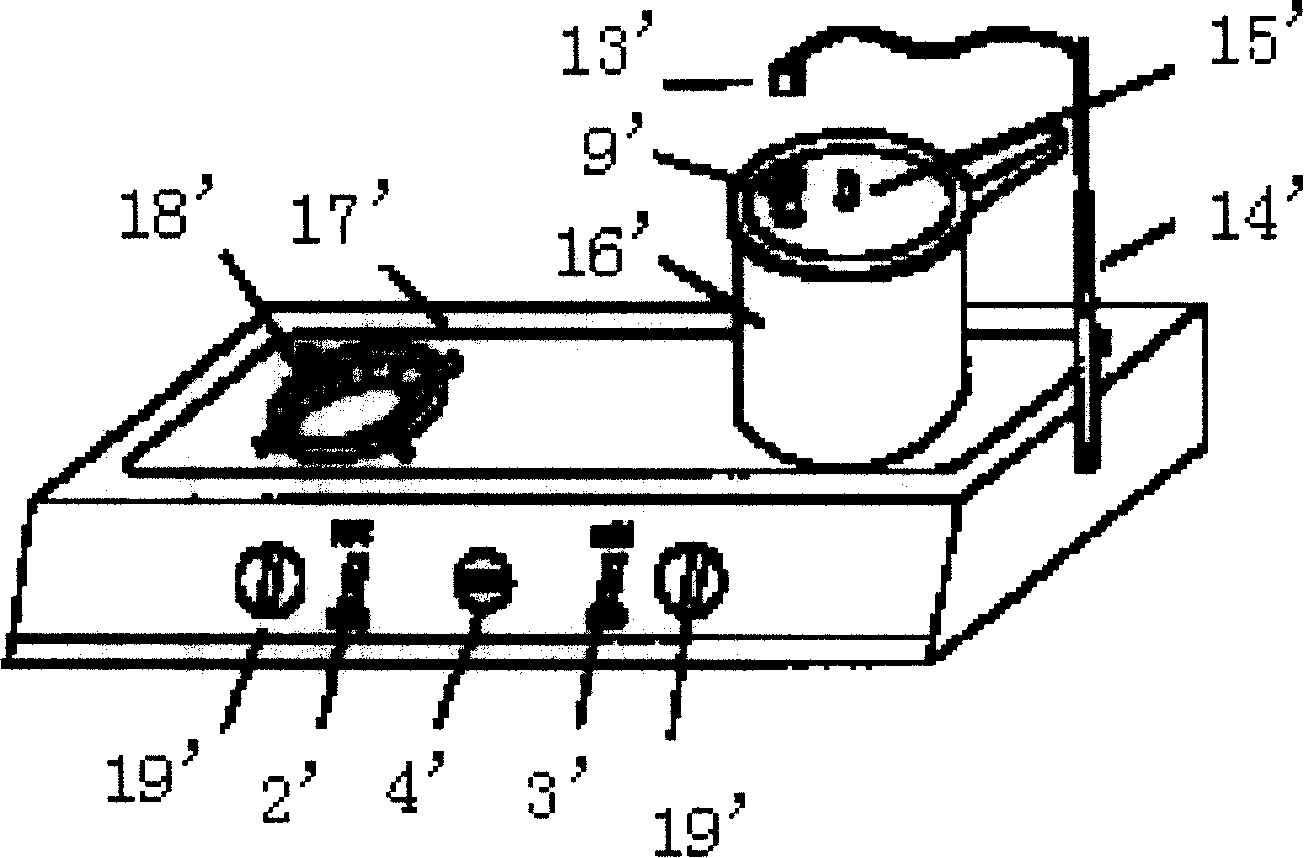

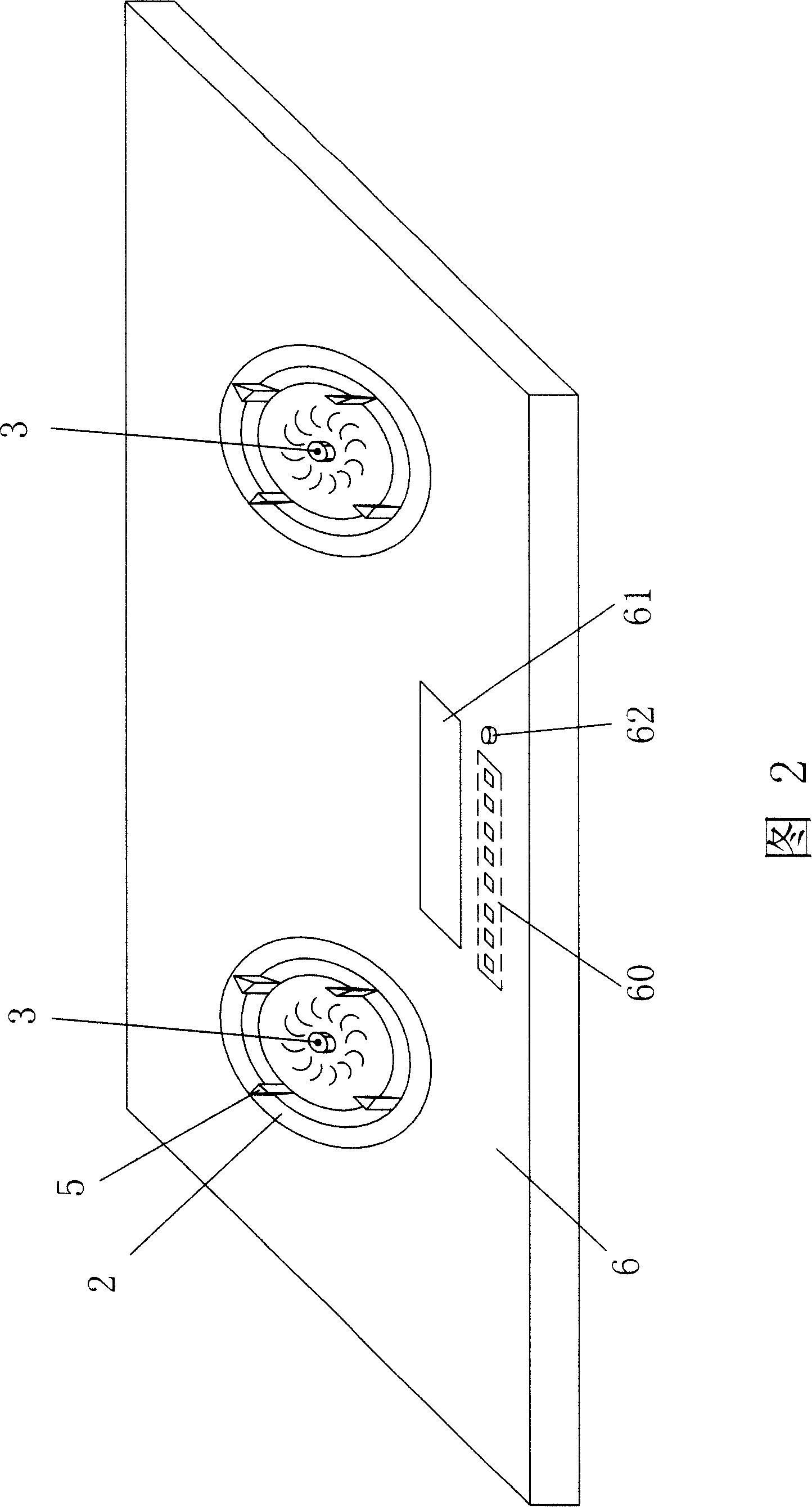

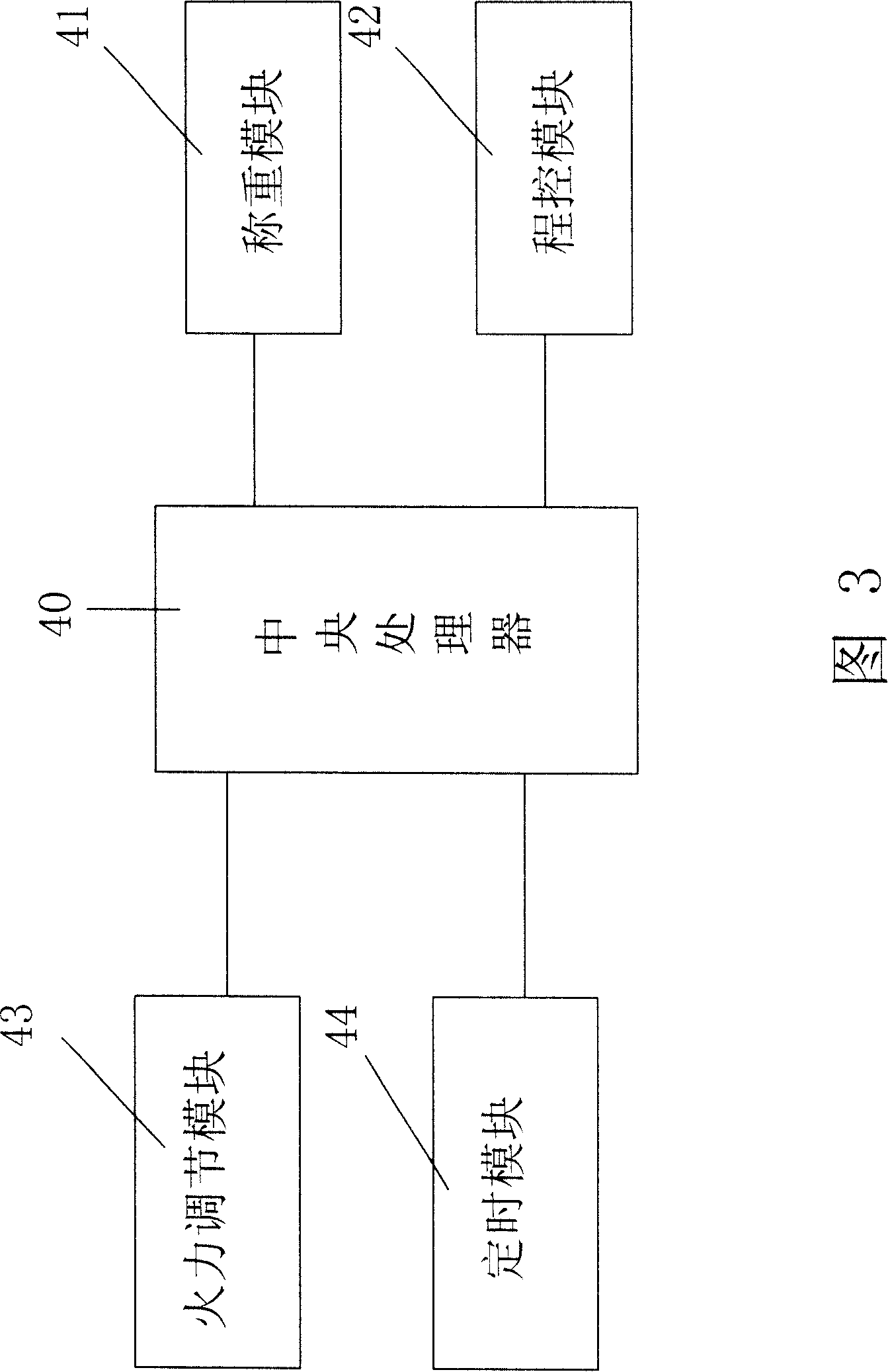

Gas stove with weighing function capable of automatically controlling firepower

ActiveCN101191622ASimple structureAccurate detectionDomestic stoves or rangesCooking fumes removalAutomatic controlCooker

The invention provides a gas cooker which has the function of weighing and can automatically control firepower, wherein, an area which can sense the weight of a heated object on a gas hood is provided with a weight sensor, and an output end of the weight sensor is connected with a control computer panel. The gas hood of the invention has simple structure and accurate detection, senses whether a cooking appliance is put on the gas hood through an electric press switch, a voltage dependent resistor and other weight sensing elements, which are arranged between a pot support and a liquid holding plate of the gas hood, thereby achieving the mode of full electronic control to control fire; a sensed signal is fed back to the computer panel for processing after being processed by the sensing elements, thereby the computer panel can distribute working time according to different weights of cooking appliances, achieves the mode of automatic weighing, and automatically controls heating period.

Owner:QINGDAO HAIER WISDOM KITCHEN APPLIANCE CO LTD +1

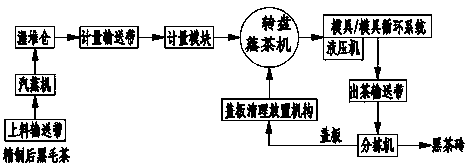

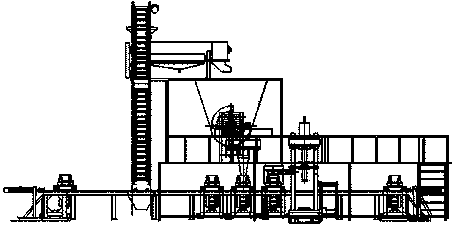

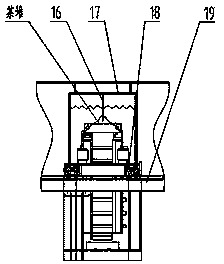

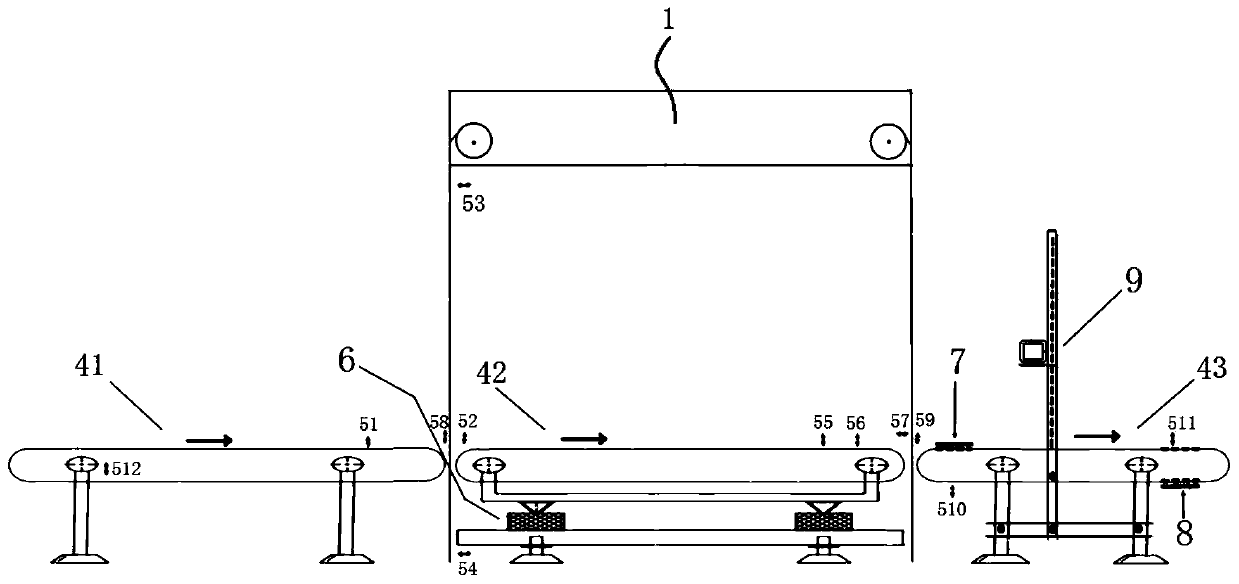

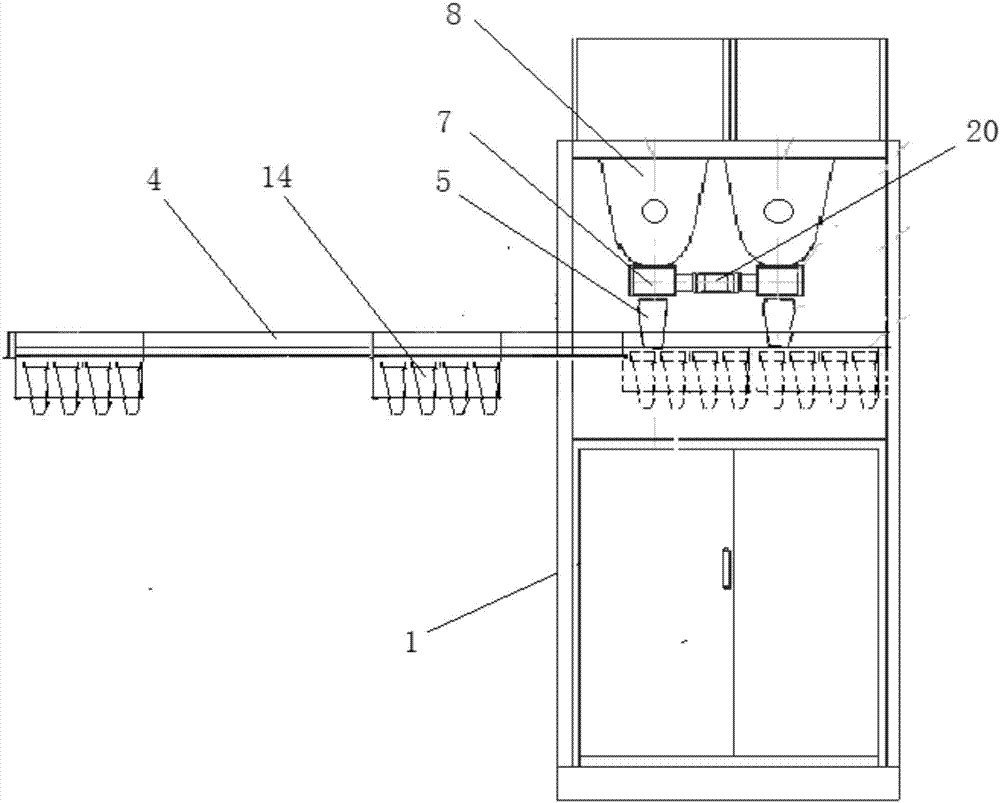

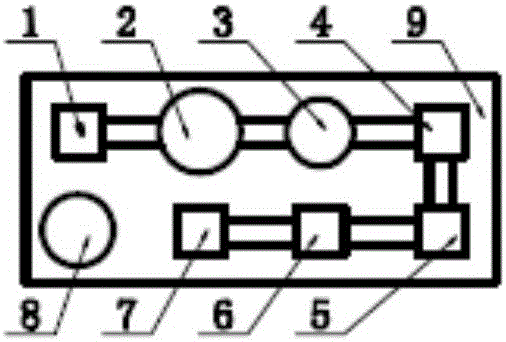

Continuous dark green tea pressing production line

ActiveCN103947776AFully automatedAchieve serializationPre-extraction tea treatmentGreen teasProgrammable logic controller

The invention relates to a continuous dark green tea pressing production line which comprises a loading inclined conveyer (1), a steamer (2), a pile fermentation cabin (3), a metering conveyer belt (4), a metering module (5), a turntable tea evaporator (6), a tea spreading mechanism (11), a cover plate cleaning and placing mechanism (13), a hydraulic machine (7), a die circulating system (8), a tea discharging conveyer belt (9), a die (10) and a sorter (12). The production line is characterized in that three PLC (Programmable Logic Controller) control cabinets and a central control computer are arranged for the production line and are interconnected with each other through the Ethernet, and the production line can be monitored and controlled through the PLC control cabinets or the central control computer, so that the production line can automatically and continuously press refined and screened raw dark green tea.

Owner:CHANGSHA XIANGFENG TEA MACHINERY MFG +1

Novel process for synthesizing bead granular rubber antioxidant

The process of producing granular rubber antioxidant TMQ includes the following steps: feeding aniline, acetone in 1-10 times weight of aniline and hydrochloric acid as catalyst in 0.1-0.5 times weight of aniline into a reaction kettle, reaction at 80-190 deg.c temperature and 200-1200 rpm rotation speed for 2-10 hr to obtain antioxidant TMQ gel with content of 60-90 %; and pelletizing inside a pelletizing pipe at 2-10 MPa to produce granular rubber antioxidant TMQ of 1-10 mm granularity. The granular rubber antioxidant TMQ has high purity and is used for radial ply tire.

Owner:KEMAI CHEM

Intelligent storage channel machine and work method thereof

ActiveCN110227657AFree from external interferenceEfficient shieldingTypewritersSortingControl systemEmbedded system

The invention discloses an intelligent storage channel machine and a work method thereof. The intelligent storage channel machine comprises a conveying device, a sensing device, an RFID scanning channel, a dynamic weighing and scanning device arranged in the RFID scanning channel, a master control system arranged on the RFID scanning channel, a code spraying device and a sorting device, and the code spraying device and the sorting device are arranged on the conveying device. The master control system controls the conveying device, the sensing device, the dynamic weighing and scanning device, the code spraying device and the sorting device to achieve dynamic weighing, RFID scanning, code spraying and sorting of storage goods boxes.

Owner:青岛东哲科技有限公司

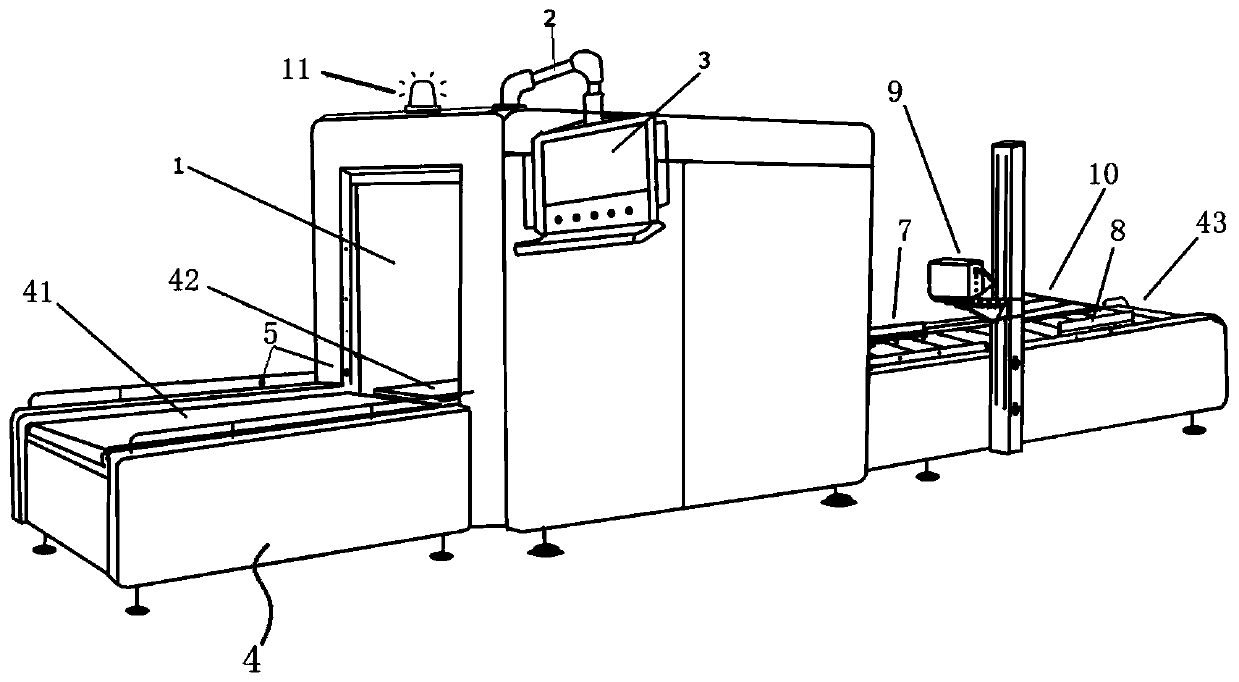

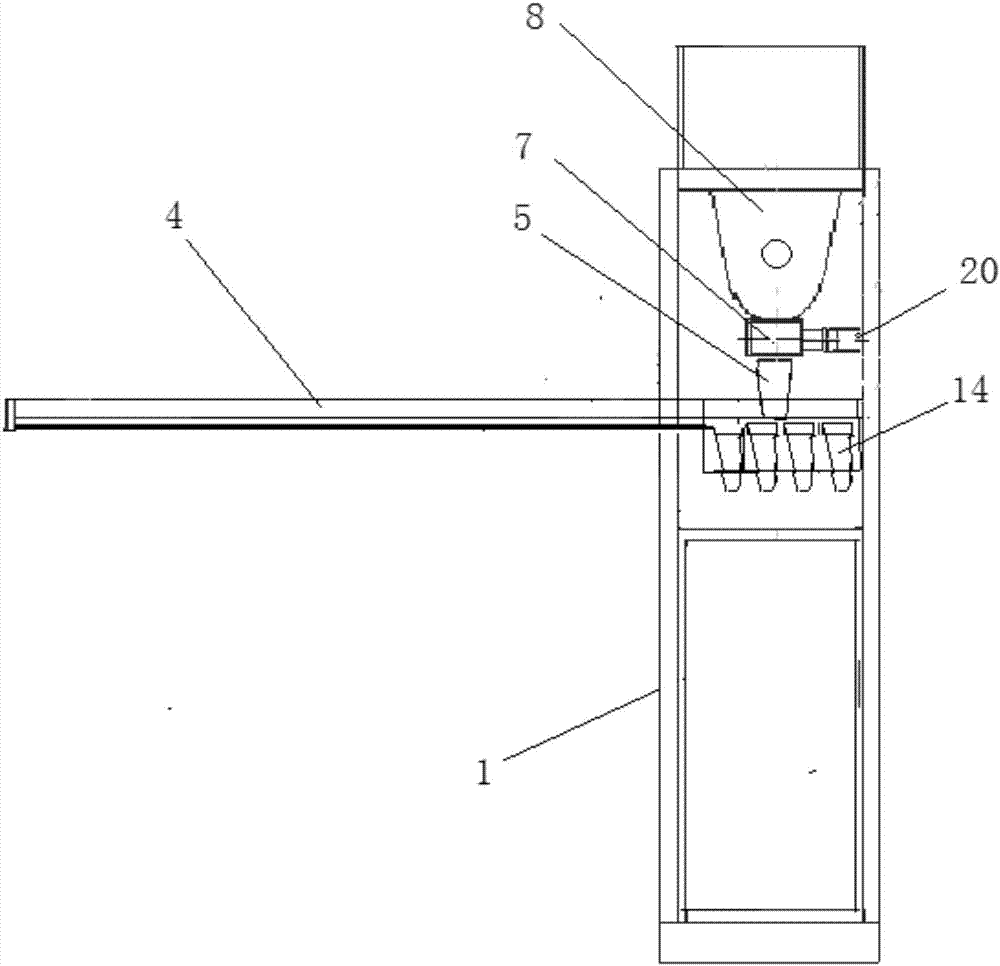

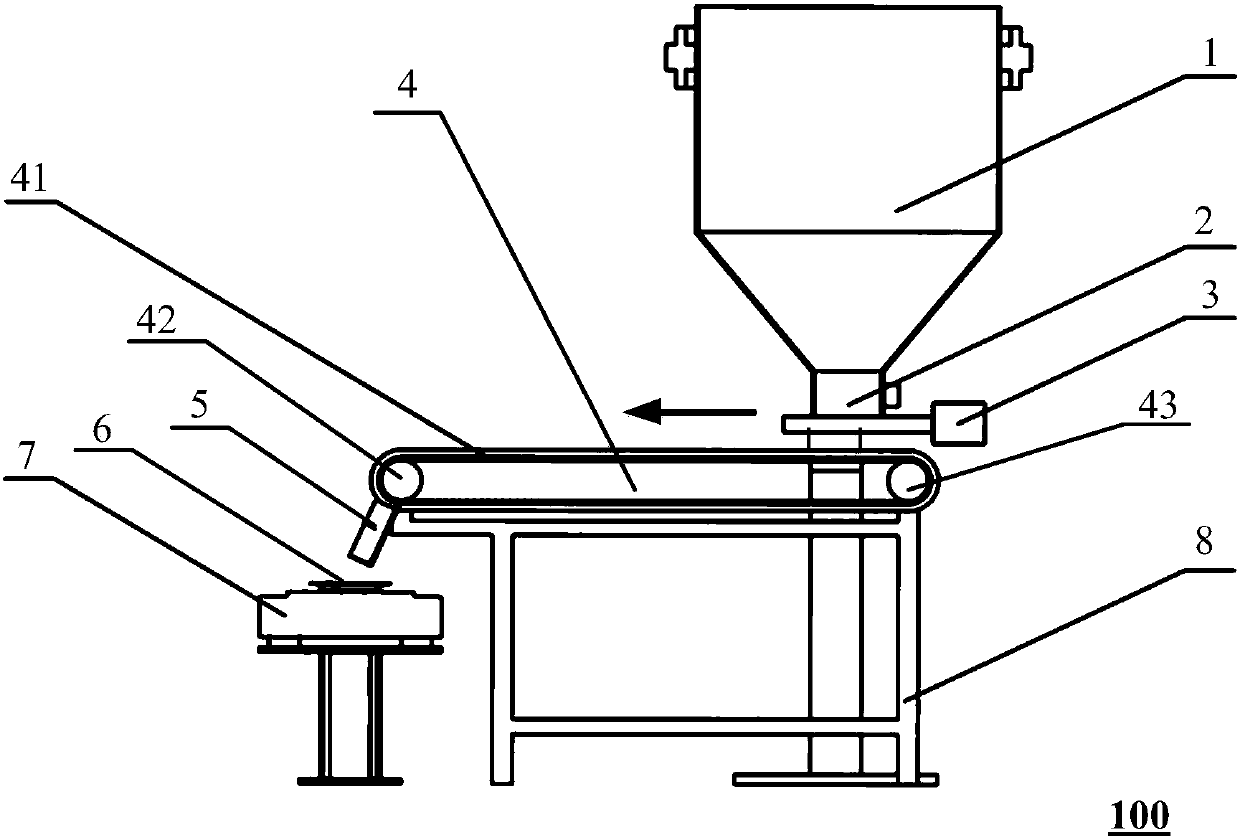

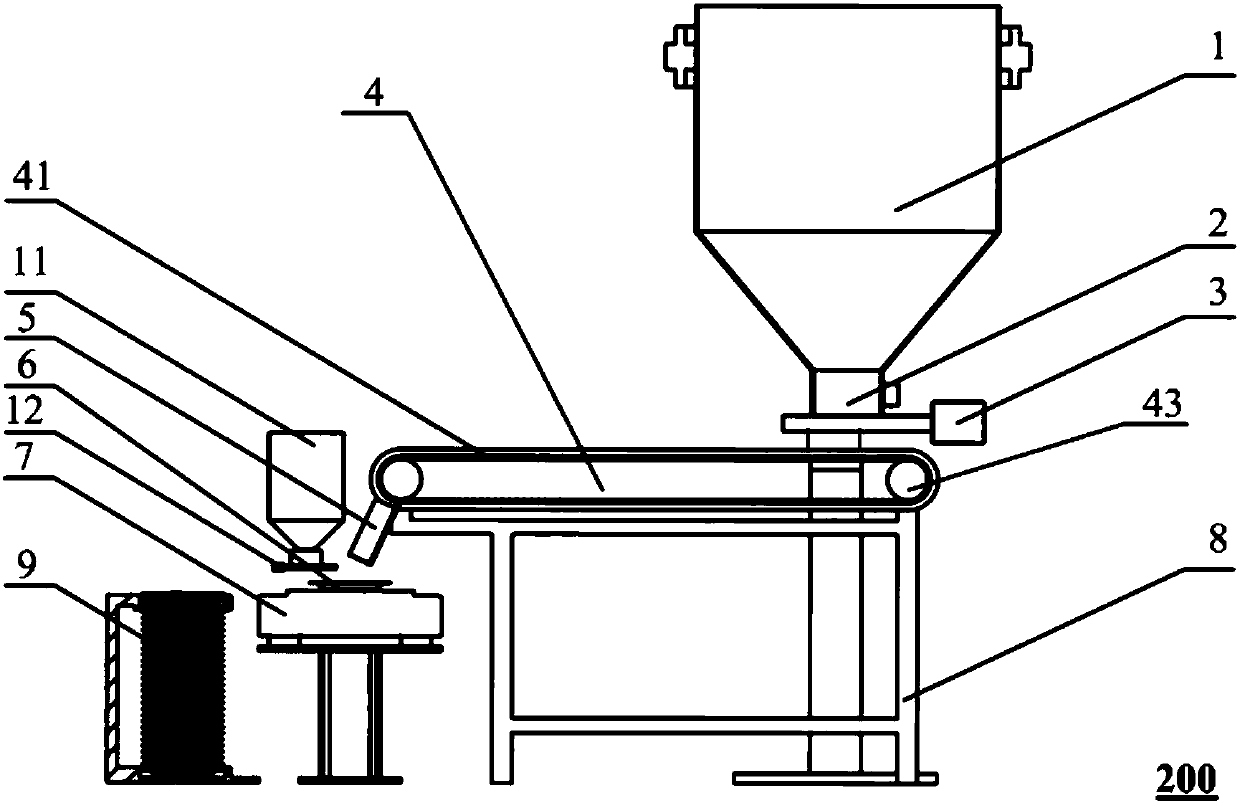

Powder quantitative weighing and die throwing integrated production equipment and work method thereof

PendingCN107283913ASolve the problems of high labor intensity and low production efficiencyEasy to locateWeighing apparatus with automatic feed/dischargeShaping pressEngineeringMechanical engineering

The invention discloses powder quantitative weighing and die throwing integrated production equipment and a work method thereof. The powder quantitative weighing and die throwing integrated production equipment is composed of feeding mechanisms, storage bins, a charging mechanism, a split charging and weighing mechanism, a conveying mechanism, an unloading mechanism and a controller, all of which are arranged on an equipment frame. Through coordinated cooperation of the multiple feeding mechanisms, the multiple storage bins, the charging mechanism and the split charging and weighing mechanism, all of which are sequentially arranged on the equipment frame, die throwing of two or more kinds of powder raw materials in sequence can be achieved, double-box one-time automatic weighing of each powder can be achieved, and the production efficiency of a pressing machine is improved in a multiplied manner.

Owner:泰安市泰山九鼎称重系统设备有限公司

Caustic soda flake packaging machine

PendingCN110861792AEvenly dispersedAvoid shock dumpingWrapper twisting/gatheringSolid materialIndustrial engineeringManufacturing engineering

The invention discloses a caustic soda flake packaging machine. A feeding and weighing device conducts feeding through a spiral feeding machine, and a weighing barrel receives materials discharged bythe spiral feeding machine and weighs the materials. After grabbing hands grab a packaging bag which is horizontally placed, the packaging bag is rotated to be located at the vertical position. An absorption disc absorbs a bag opening, a bag opening stretching device transversely moves to open the bag opening, and the opened packaging bag is tightly pressed on the weighing barrel in the circumferential direction by a clamping device. A bag supporting platform moves upwards when material filling operation is conducted, the bag supporting platform moves downwards when the material filling operation is accomplished, the bag supporting platform bears the packaging bag all the time in the blanking process, and the phenomenon that due to the fact that the packaging bag suddenly drops, the impactfall happens is avoided. The bag supporting platform can vibrate in the material filling process, and the materials can be evenly dispersed in the packaging bags. The air in the space located above the materials can be pressed out of the packaging bag by an air exhaust transfer device. When a conveying belt drives the packaging bag to arrive at an opening sealing device, the opening sealing device is used for sealing the bag opening of the packaging bag, and the packaging process is accomplished. The automatic weighing, filling and packaging operation of the materials is achieved, the automatic operation is achieved, and the packaging efficiency is improved.

Owner:CHONGQING BOZHANG MECHANO ELECTRONICS EQUIP

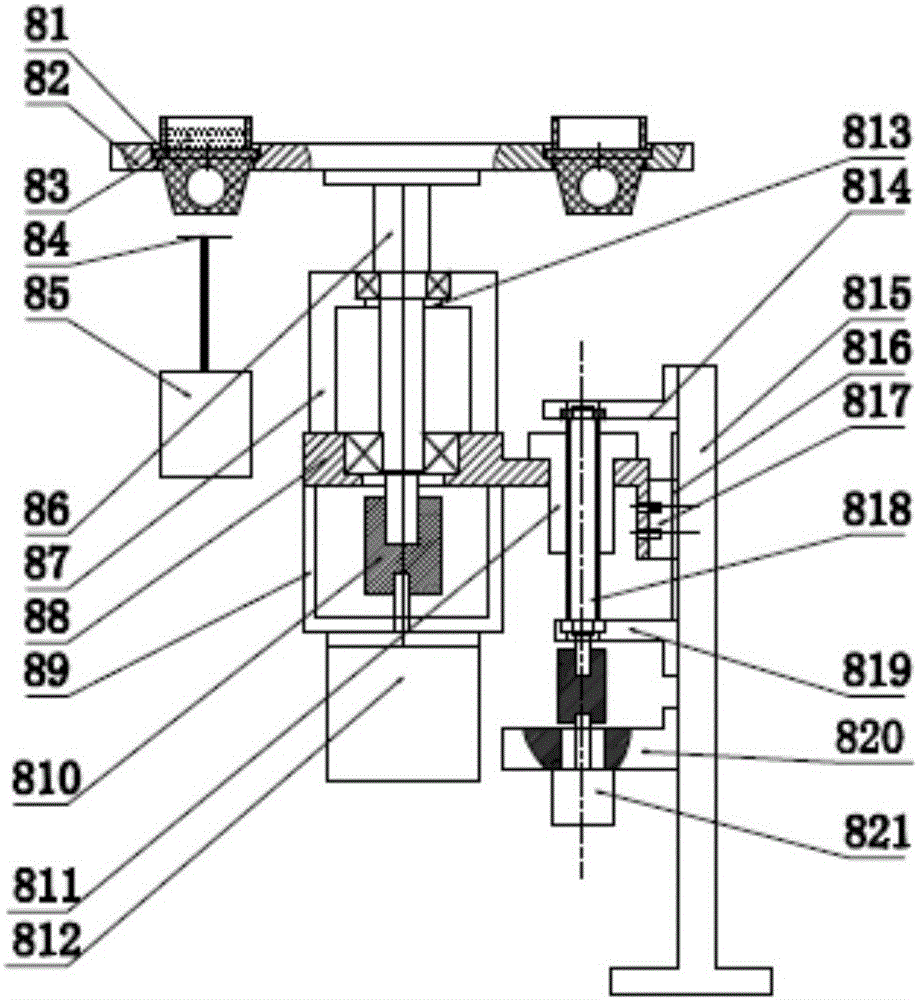

Sulfur detector capable of weighing barium sulfate automatically

The invention discloses an aldrin sulfur detector capable of weighing barium sulfate automatically, and belongs to the field of automatic measuring equipment for sulfur contents in coal. The sulfur detector comprises an aldrin sample manufacturing device, a combustion furnace, a solution stirring device, a first filtering device, a second filtering device, a chloride ion removing device, a filter paper ashing device and a barium sulfate weighing device which are fixed on a bottom plate; the barium sulfate weighing device comprises a weighing plate, a weighing rod, a bearing frame, a rotary motor frame, a rotary motor, a main support, an upper support, a lower support, a lifting motor frame, a ball screw, a guide track, a slider, a rolling nut and a lifting motor; the weighing plate is assembled on the top of a rotating shaft; and the weighing rod is assembled on a digital balance. The aldrin sulfur detector can automatically weigh the barium sulfate without manual operation, and full automation of the aldrin sulfur detector is guaranteed.

Owner:CHANGZHOU UNIV

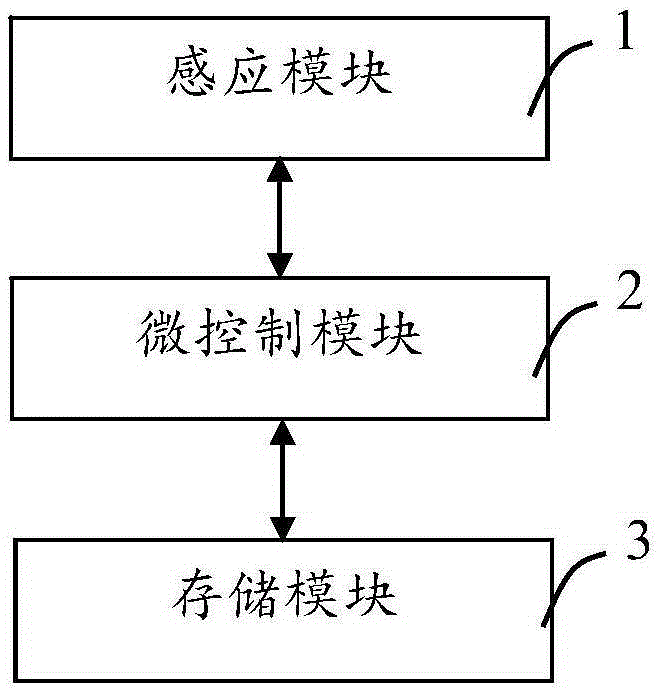

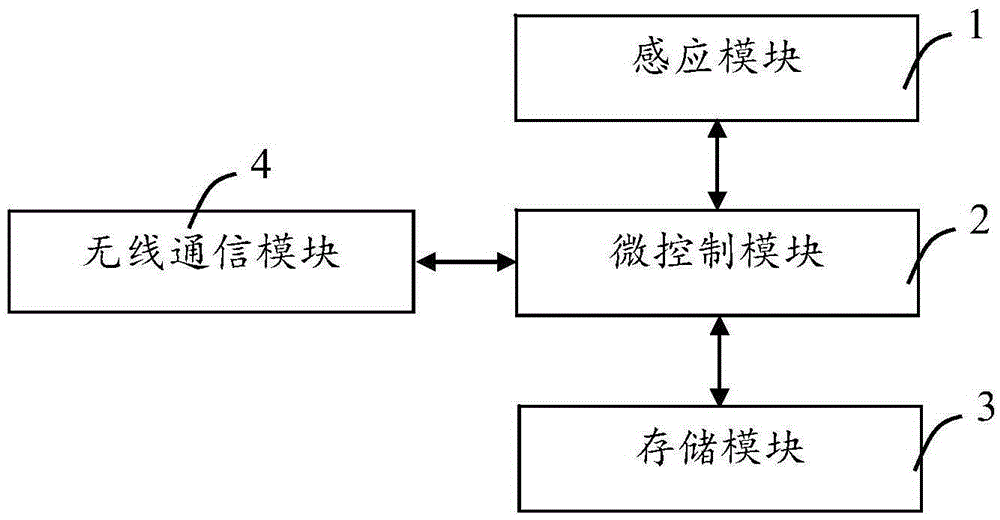

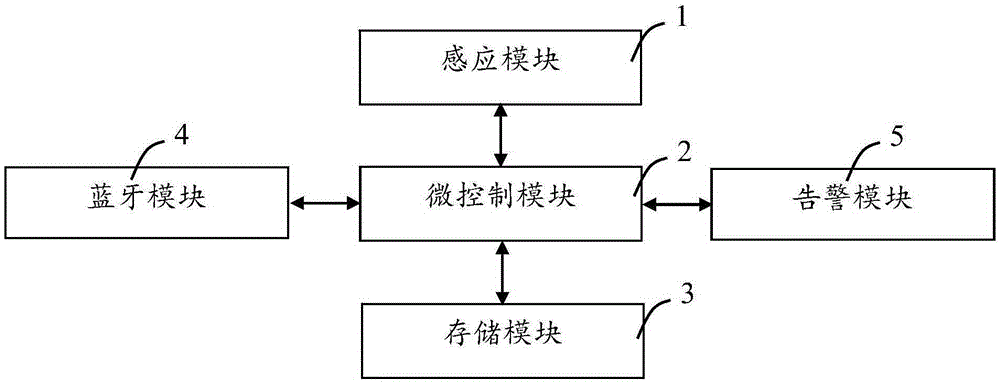

Intelligent system used for luggage case

ActiveCN105242607ARealize vibration monitoringReal-time connectionProgramme controlComputer controlComputer moduleSmart system

The invention discloses an intelligent system used for luggage cases, comprising an induction module, a micro control module and a storage module; the induction module and the storage module are connected to the micro control module; the induction module induction inducts the state information of the luggage case and transmits the luggage case information to the micro control module; the micro control module processes the state information and transmits the processed state information to the storage module for storing; the intelligent system inducts the state information of the luggage case at various moments through the induction module and stores the processed state information in the storage module for the user to visit and check at any time; as a result, no matter whether the luggage case is in the control range of the user, the user can know the state of the luggage case; and, particularly, when the luggage case is damaged, people can get to know whether the luggage case is thrown, dropped or fiercely shaken through state data in the storage module, and the luggage case shaking detection is realized.

Owner:彭德权

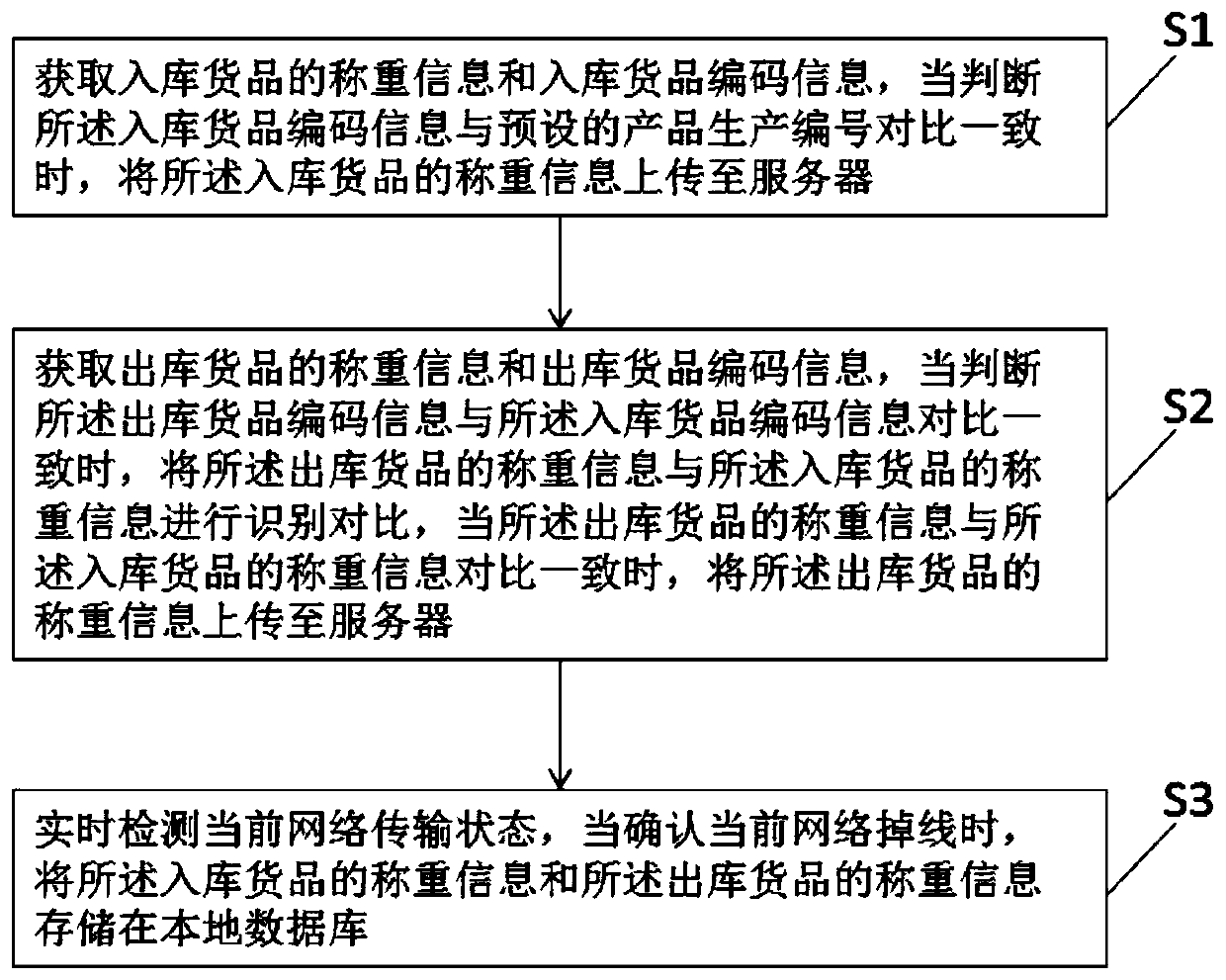

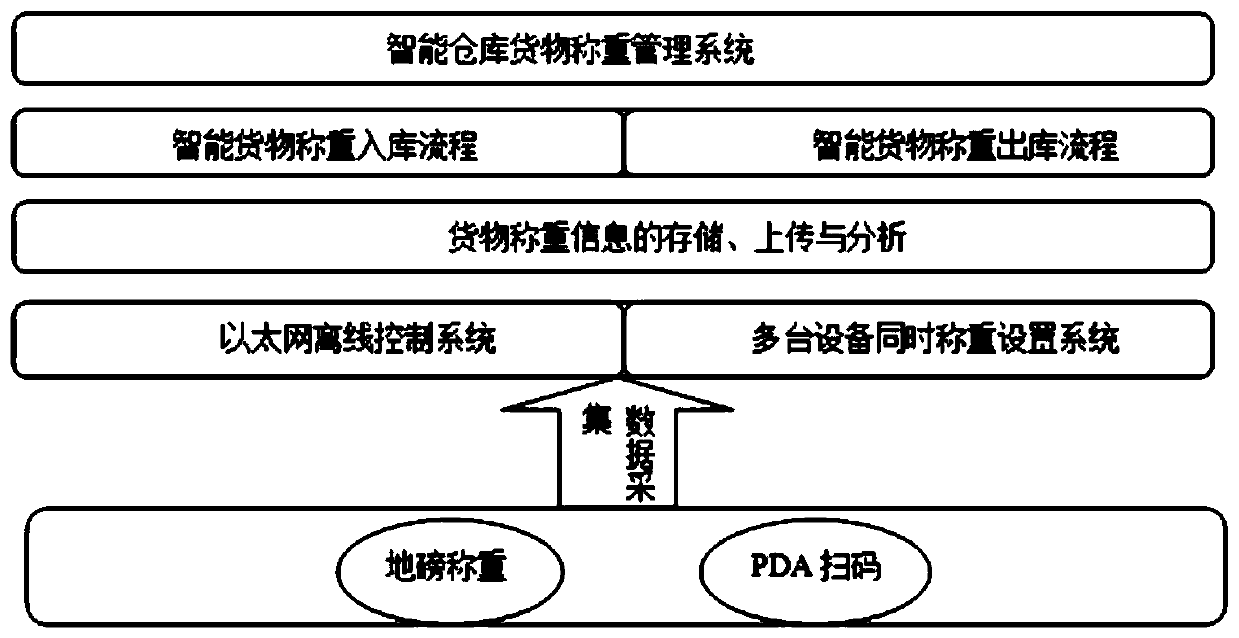

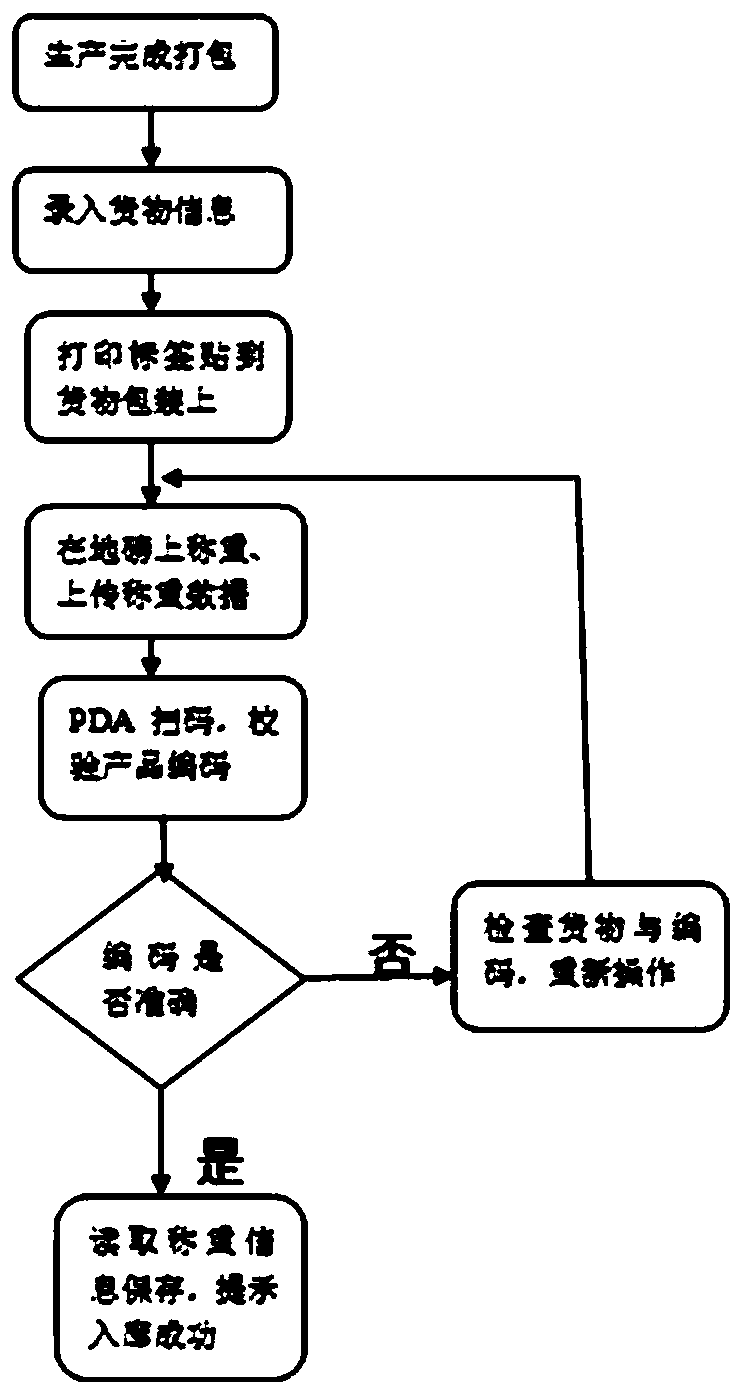

Intelligent logistics warehouse cargo weighing management method and system

InactiveCN110704701ASolution accuracy and low weighing efficiencyReduce stepsOther databases queryingLogisticsData miningInformation storage

The invention discloses an intelligent logistics warehouse cargo weighing management method. The method is used for weighing goods through a weighbridge and comprises: acquiring weighing information and warehousing goods code information of the warehousing goods, and when it is judged that the warehousing goods code information is consistent with a preset product production number, uploading the weighing information of the warehousing goods to a server; obtaining weighing information and warehouse-out goods coding information of warehouse-out goods; when it is judged that the warehouse-out goods code information is consistent with the warehouse-in goods code information through comparison, sending the warehouse-out goods code information to a server; identifying and comparing the weighinginformation of the warehouse-out goods with the weighing information of the warehouse-in goods, and uploading the weighing information of the warehouse-out goods to a server when the weighing information of the warehouse-out goods is consistent with the weighing information of the warehouse-in goods; detecting the current network transmission state in real time, and storing the weighing information of the warehouse-in goods and the weighing information of the warehouse-out goods in a local database when it is confirmed that the current network is offline.

Owner:广州市微嵌计算机科技有限公司

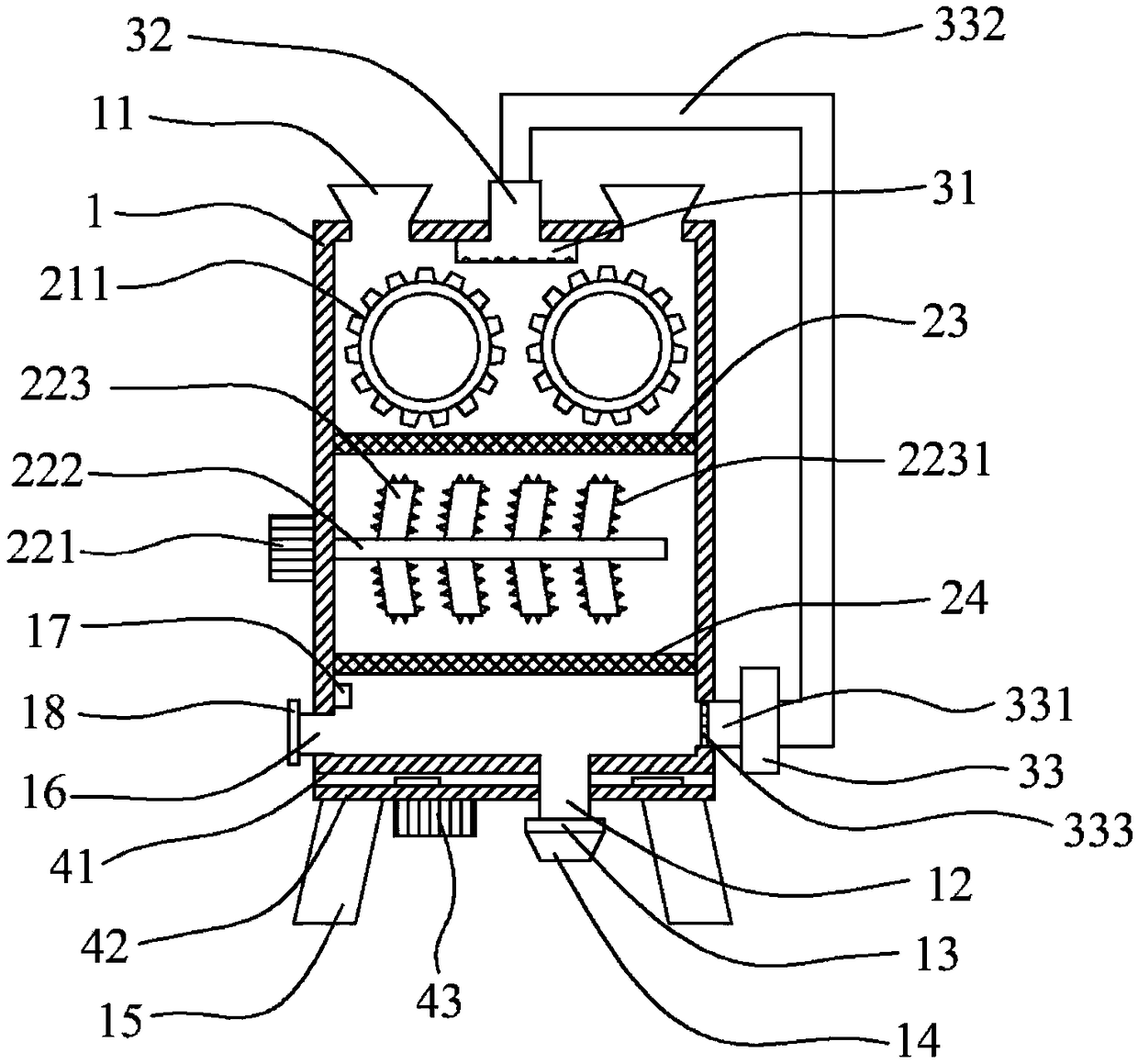

Multifunctional glass crusher

InactiveCN109201273AReduce transportation linksReduce splashCleaning using liquidsGrain treatmentsCrusherGlass manufacturing

The invention discloses a multifunctional glass crusher, and relates to the technical and mechanical field of glass manufacturing. The multifunctional glass crusher solves the problems that glass splash, accidental injury to operators and increased operation cost are prone to causing when waste glass is transported into a glass crusher after being cleaned and dried. The multifunctional glass crusher comprises a cavity, wherein a crushing device, a cleaning device and a drying device are arranged in the cavity; the crushing device comprises a primary crushing device and a secondary crushing device, wherein the primary crushing device is positioned above the secondary crushing device, and a first sieve plate is arranged between the primary crushing device and the secondary crushing device; the cleaning device comprises a spray head arranged on the inner wall of the cavity and a liquid inlet connected to the upper end of the spray head; and the drying device is positioned below the secondary crushing mechanism. The multifunctional glass crusher has the beneficial effects that the waste glass can be cleaned, crushed and dried at the same time, glass transportation links are omitted, glass splashing is reduced, and operation cost is reduced.

Owner:TG ANHUI GLASS

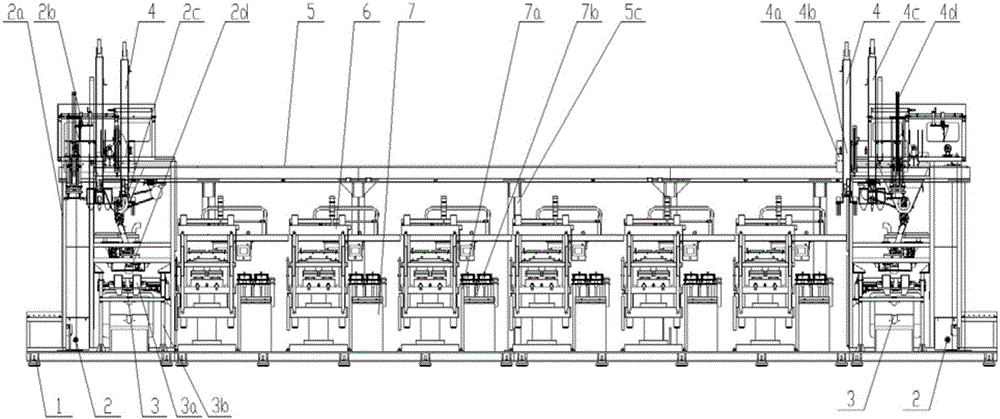

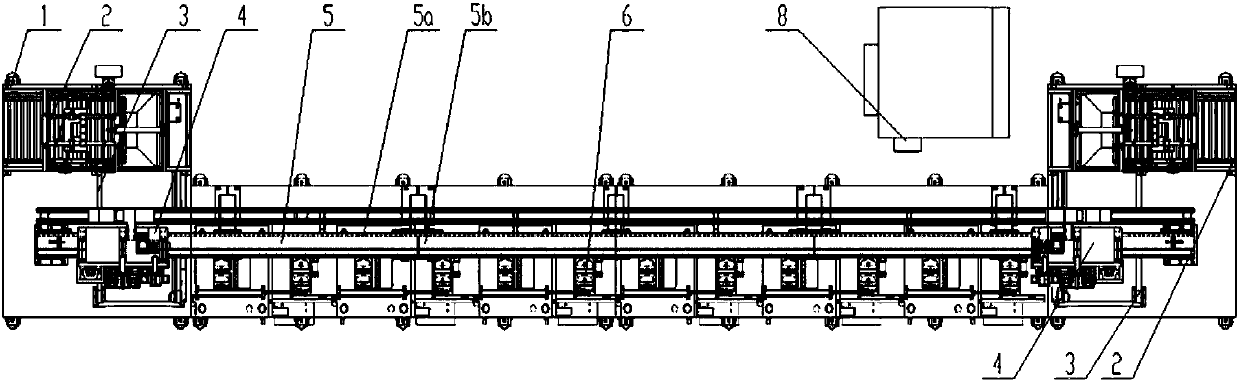

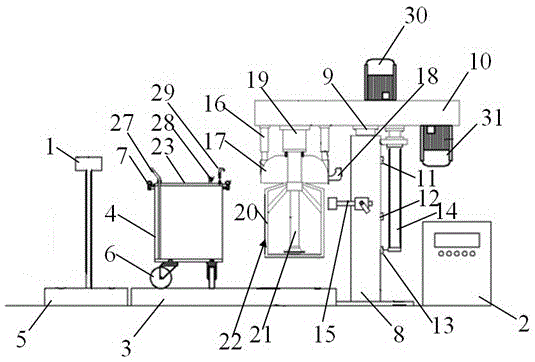

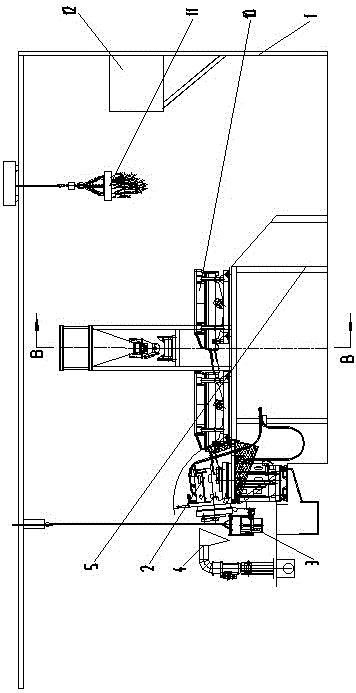

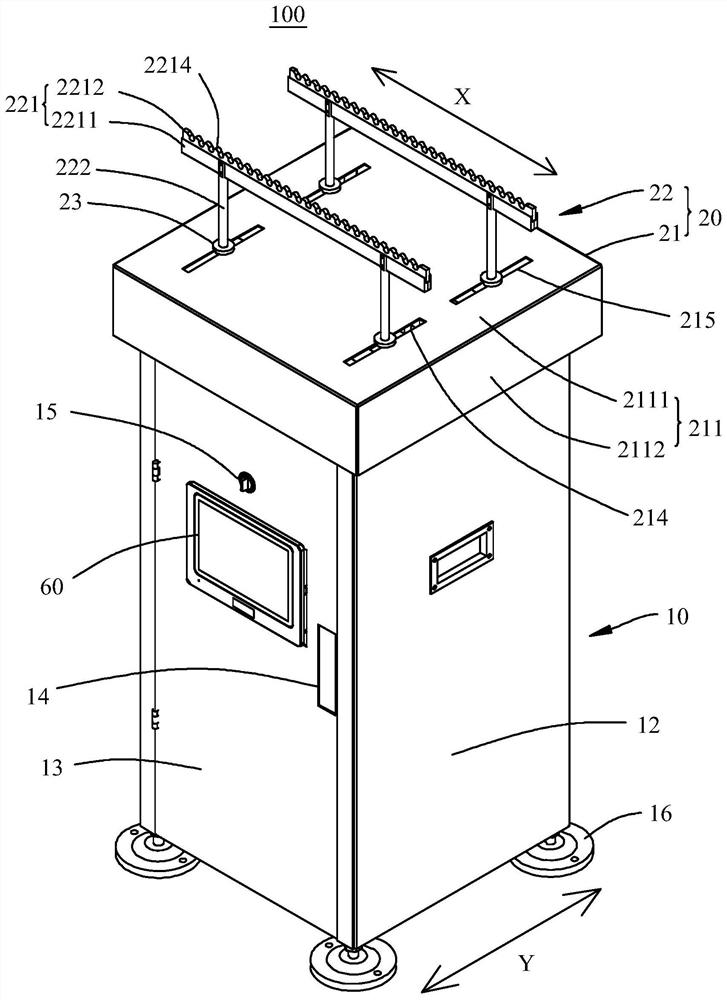

Semi-automatic hot-press molding production line for brake pads for brakes for passenger cars

InactiveCN106553302ARealize automatic feeding processRealize automatic weighingProduction lineMolding machine

The invention belongs to the field of machine manufacturing and particularly relates to a semi-automatic hot-press molding production line for brake pads for brakes for passenger cars. The production line comprises a mounting base (1), two loading, stirring and weighing systems (2), two unloading mechanisms (3), two service robot trolleys (4), a trolley traveling truss (5), six hot-press molding machines (6), six steel back jacking mechanisms (7) and an oil source (8). The production line is mainly used for producing the brake pads for the brakes for the passenger cars, steel backs are required to be placed manually and pressed products are required to be collected manually during operation, and the production line is semi-automatic hot-press molding production equipment.

Owner:XIAN E FLY AVIONICS TECH

Mud content detection device for concrete aggregate

InactiveCN110879186ARealize automatic weighingRealize washingWeighing by removing componentEnvironmental geologyWastewater

The invention discloses a mud content detection device for concrete aggregate, and relates to the field of concrete detection. The mud content detection device comprises a detection box, a detection cylinder is suspended in the detection box, a plurality of leakage holes are uniformly distributed in the lower end surface of the detection cylinder, and a wastewater tank located below the detectioncylinder is arranged on the bottom wall of the detection box; a supporting frame is arranged on the inner wall of the upper end of the detection box, an angle lug located above the supporting frame isarranged on the outer wall of the upper end of the detection cylinder, and a weighing instrument is arranged between the supporting frame and the angle lug; a stirring paddle located in the detectioncylinder is arranged on the top wall of the detection box, a speed reducer used for driving the stirring paddle to rotate is arranged on the upper end face of the detection box, and a feeding hopper,a water injection pipe and a plurality of air pipes which communicate with the detection cylinder are further arranged on the upper end face of the detection box. Compared with the prior art, the detection device has the following advantages and effects that by arranging the high-automation detection device, automatic weighing, washing and drying of aggregate are achieved, manual operation is perfectly replaced, the labor intensity of workers is greatly reduced, and meanwhile the aggregate detection efficiency is improved.

Owner:深圳市龙岗大工业区混凝土有限公司

Production method of spherical high-content rubber antioxidant RD

InactiveCN101580602AHigh content of active ingredientsSolve problems that cannot be applied to radial tiresOrganic chemistrySpherical granuleMass ratio

The invention discloses a production method of a spherical high-content rubber antioxidant RD. The process of the method comprises the following steps: aniline, hydrochloric acid and acetone are added into a reaction kettle under the conditions that the temperature is 80 DEG C to 190 DEG C and the rotating speed is 500 rev / min to 2000 rev / min according to the mass ratios that the mass ratio between the acetone and the aniline is 3-10:1 and the mass ratio between the hydrochloric acid catalyst and the aniline is 1:5-15, the reaction is carried out for 2 to 10 hours, and antioxidant RD gelatin with the content of 60% to 90% is obtained by the reaction; and the antioxidant RD gelatin is fed into a granulation tube with the diameter of 0.2mm to 5mm under the pressure of 0.2MPa to 1MPa, fluid is controlled within the range of smooth flow, disturbance with the frequency of 50Hertz to 500Hertz is applied to the fluid, the fluid ruptures to form uniform droplets, and the droplets are crystallized and solidified in a falling process so as to form the spherical high-content rubber antioxidant RD with uniform granularity. The invention has the advantages that the operation of the new technology is simple, the content of the effective components of the produced antioxidant RD is high, and the problem that the RD can not be applied to radial tire is thoroughly solved as the content of the effective components of the RD is low; and the RD is uniform spherical granules and is not easy to break, no dust pollution exists in the processes of manufacture and use, automatic weighing can be realized, and the RD has favorable fluidity and dispersivity.

Owner:KEMAI CHEM

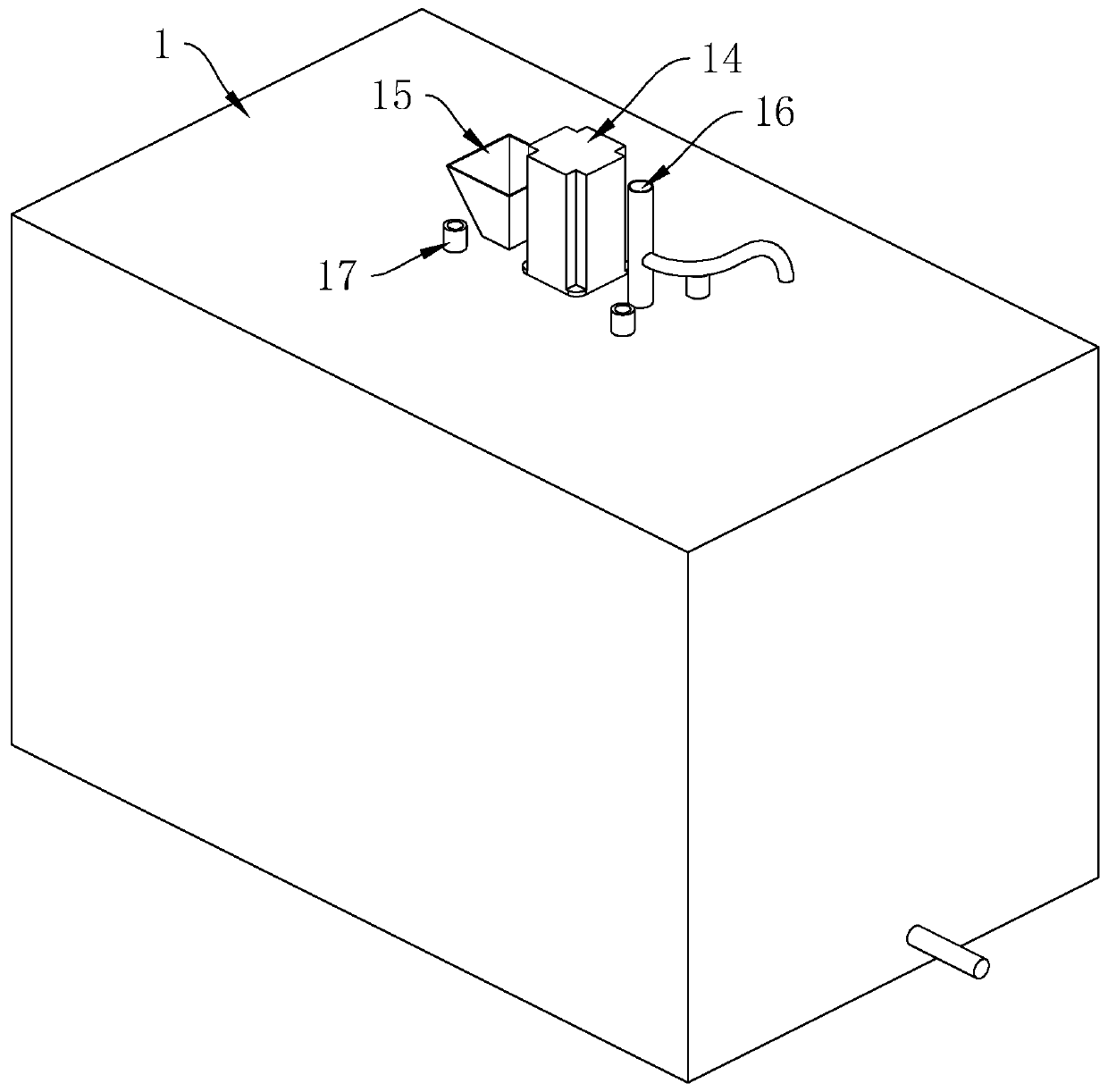

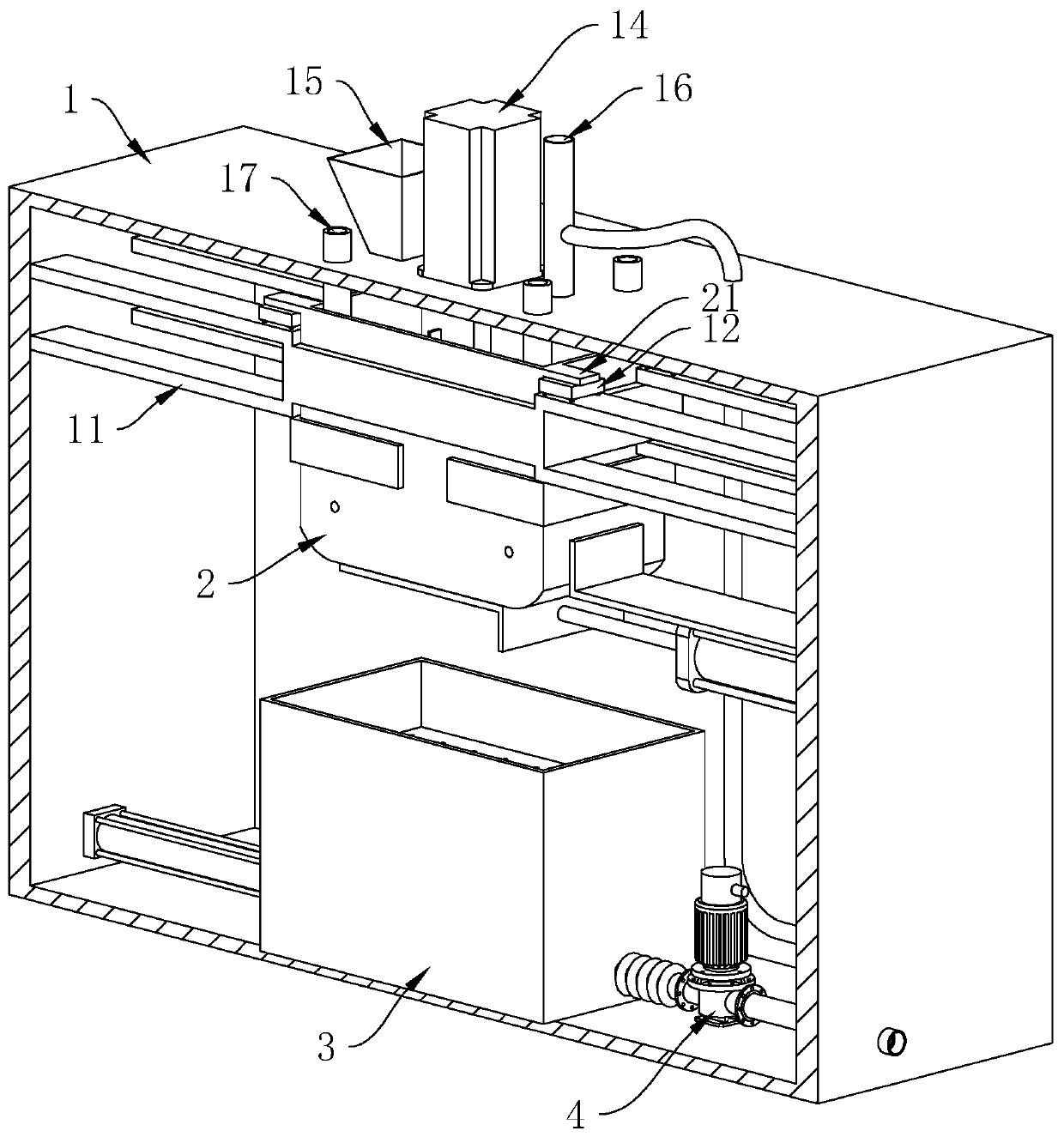

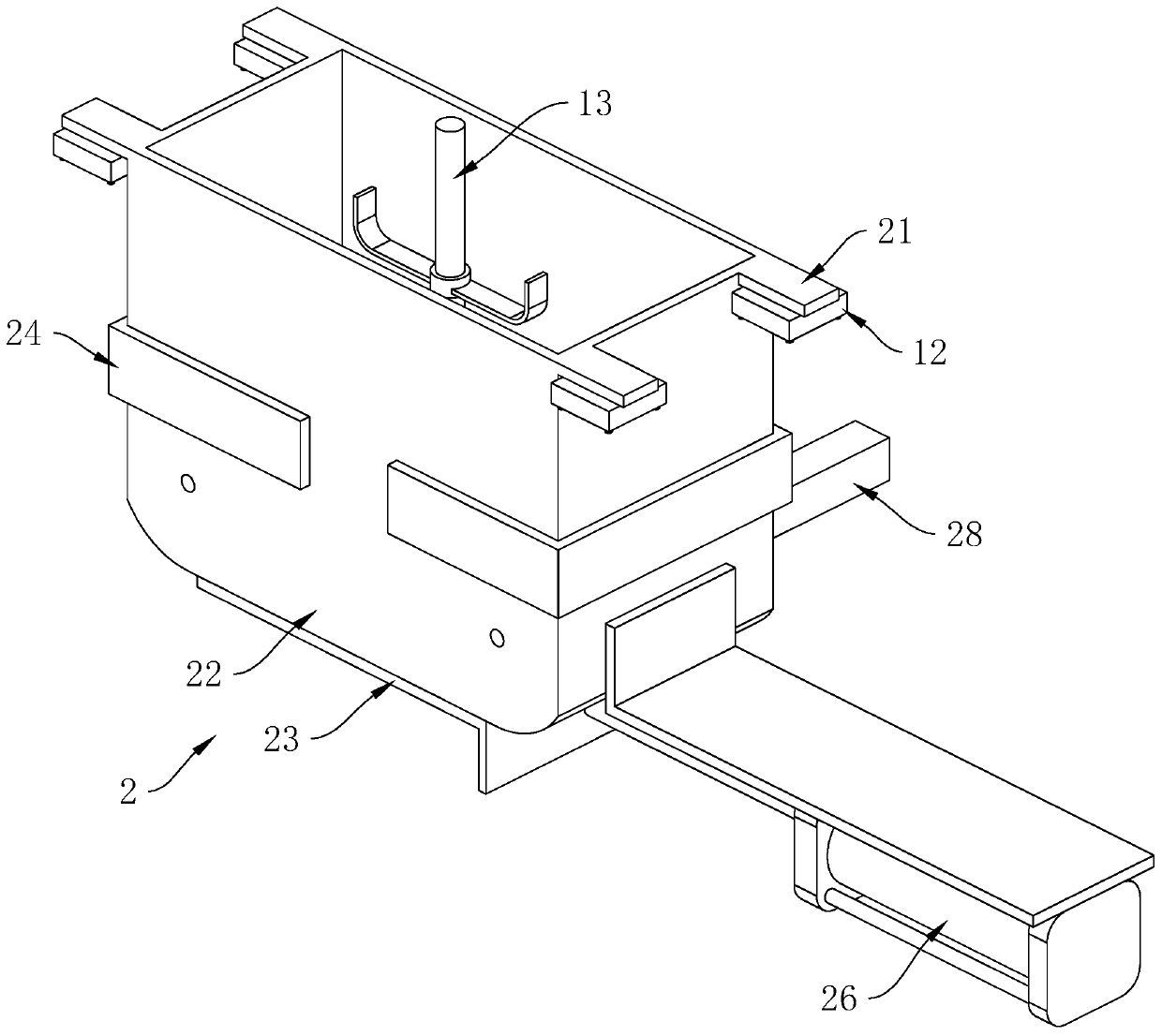

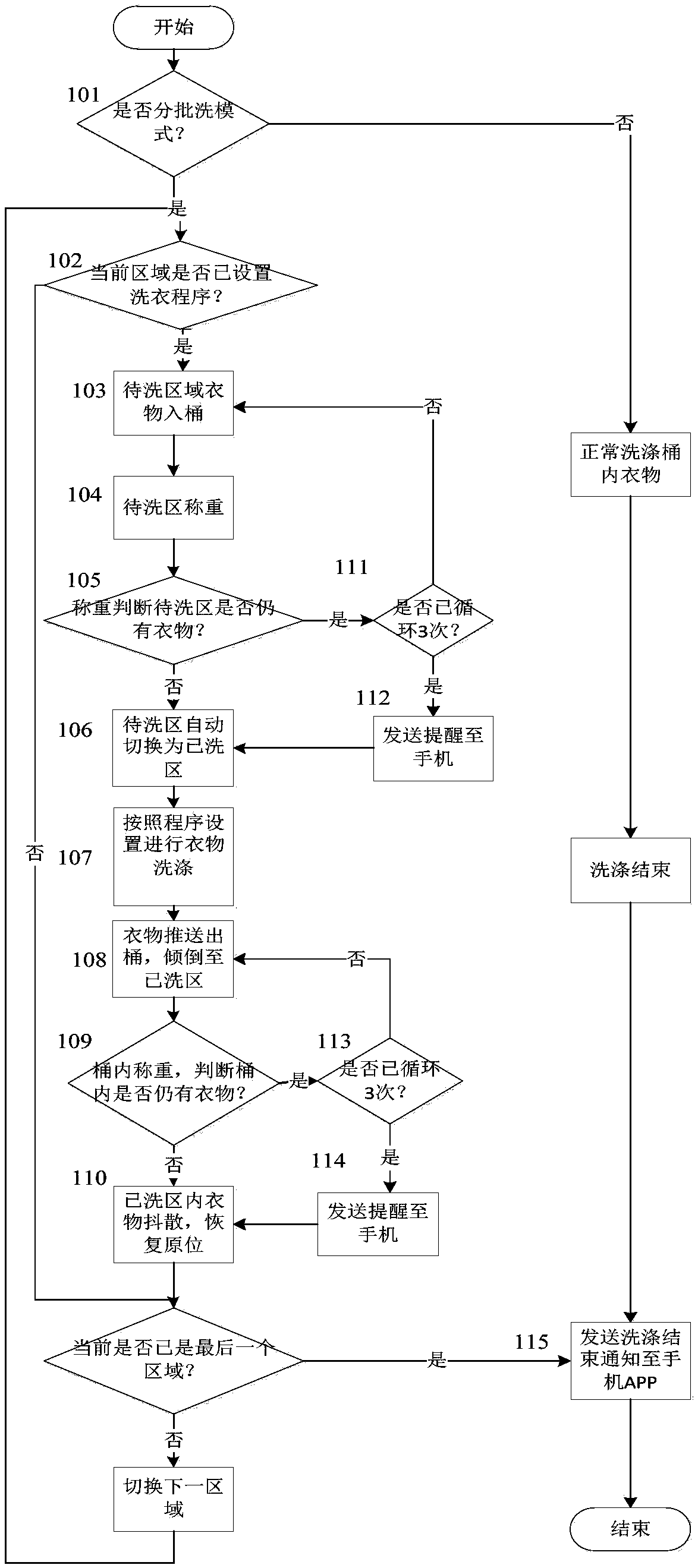

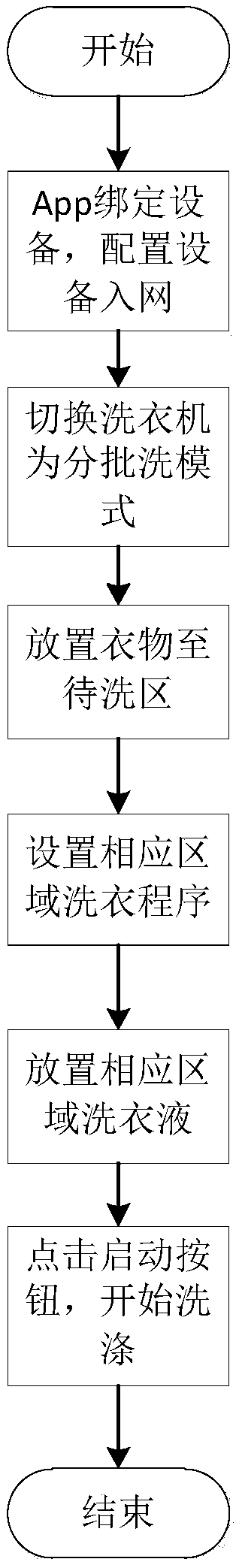

Washing machine and batch washing control method and system thereof

ActiveCN108625099ARealize automatic weighingOther washing machinesControl devices for washing apparatusProcess engineeringLaundry

The invention provides a washing machine and a batch washing control method and system thereof. The method includes the steps of judging whether or not a laundry program is set for a current to-be-washed area; if yes, controlling the current to-be-washed area to move from an initial position to a putting position, controlling laundry in the current to-be-washed area to be put into a barrel of thewashing machine, sensing the weight of the laundry in the current to-be-washed area through a to-be-washed area weighing unit, automatically starting washing of the laundry when a sensing result indicates that there is no laundry in the current to-be-washed area, and identifying the current to-be-washed area as a currently washed area; if the laundry program corresponding to the currently washed area is completed, conducting controlling to dump the laundry to the currently washed area, sensing the weight of the laundry through the weighing unit in the barrel, identifying a next to-be-washed area as the current to-be-washed area when a sensing result indicates that there is no laundry in the inner barrel of the washing machine, and continuing a batch washing control process until all to-be-washed areas are traversed. The batch washing process can be automatically performed.

Owner:QINGDAO HAIER TECH

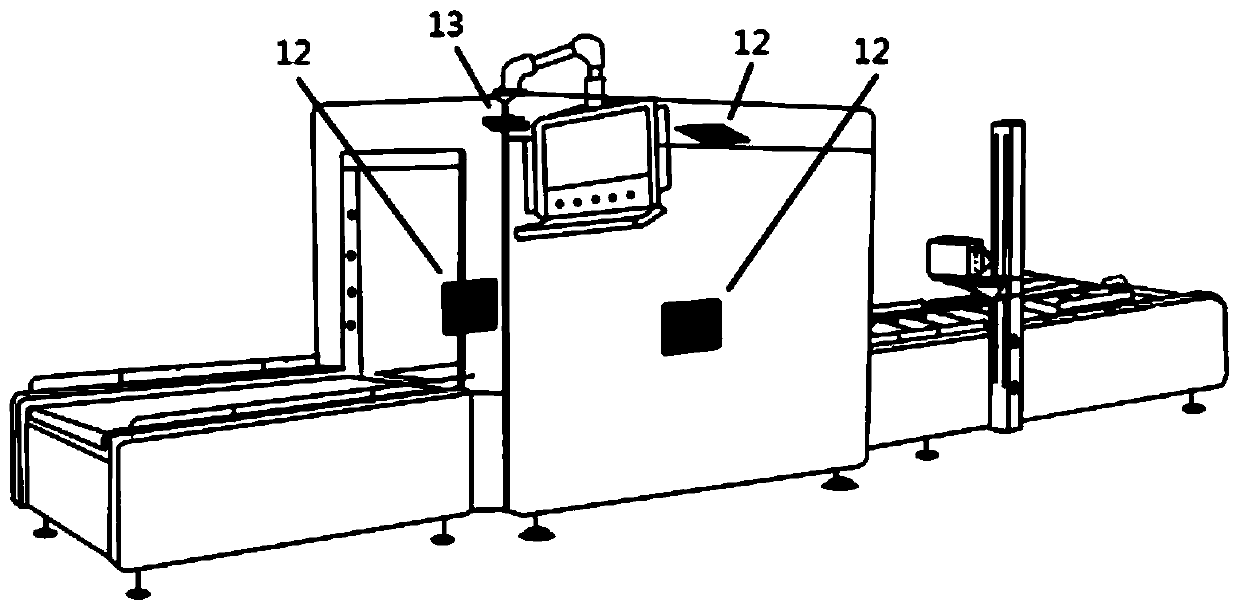

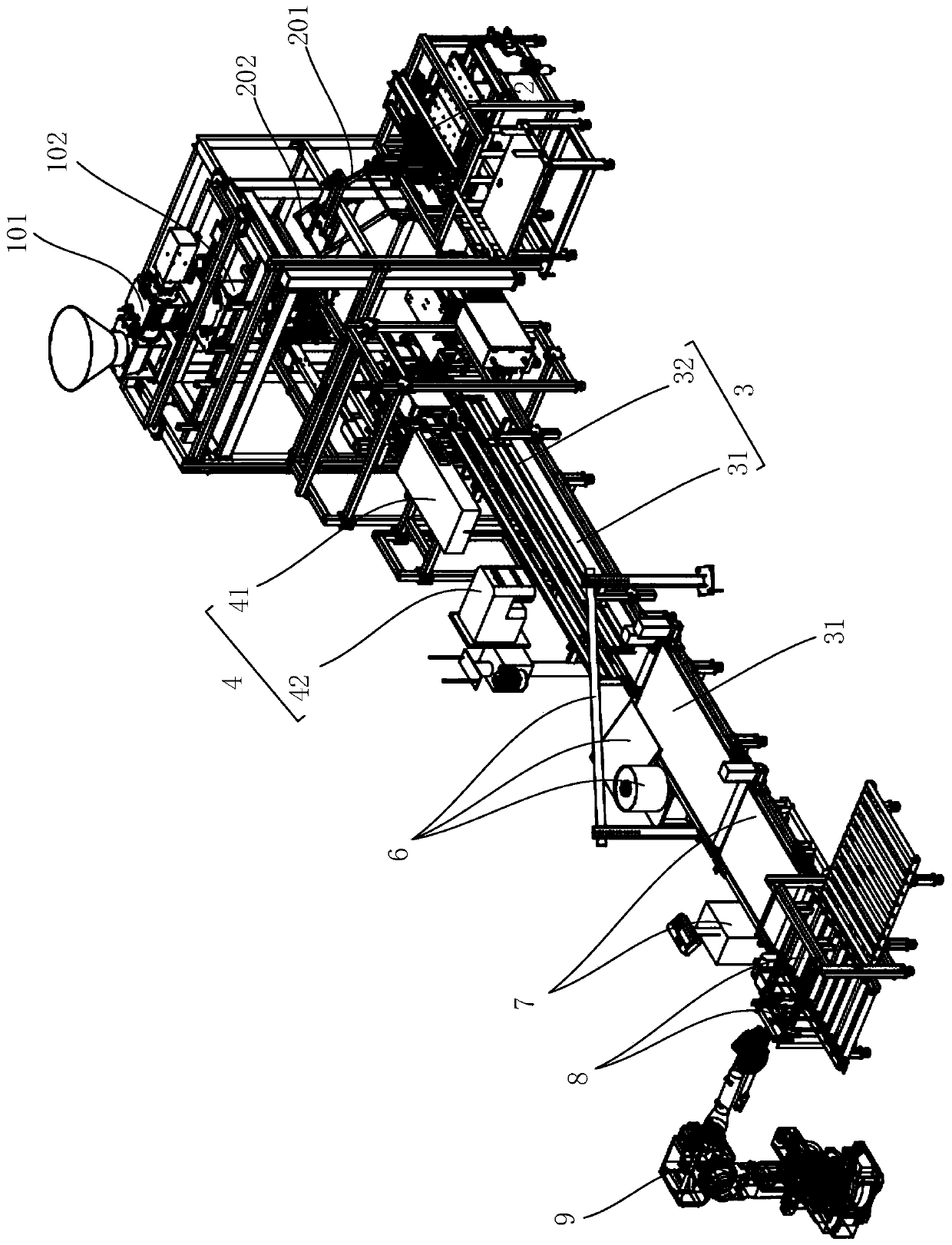

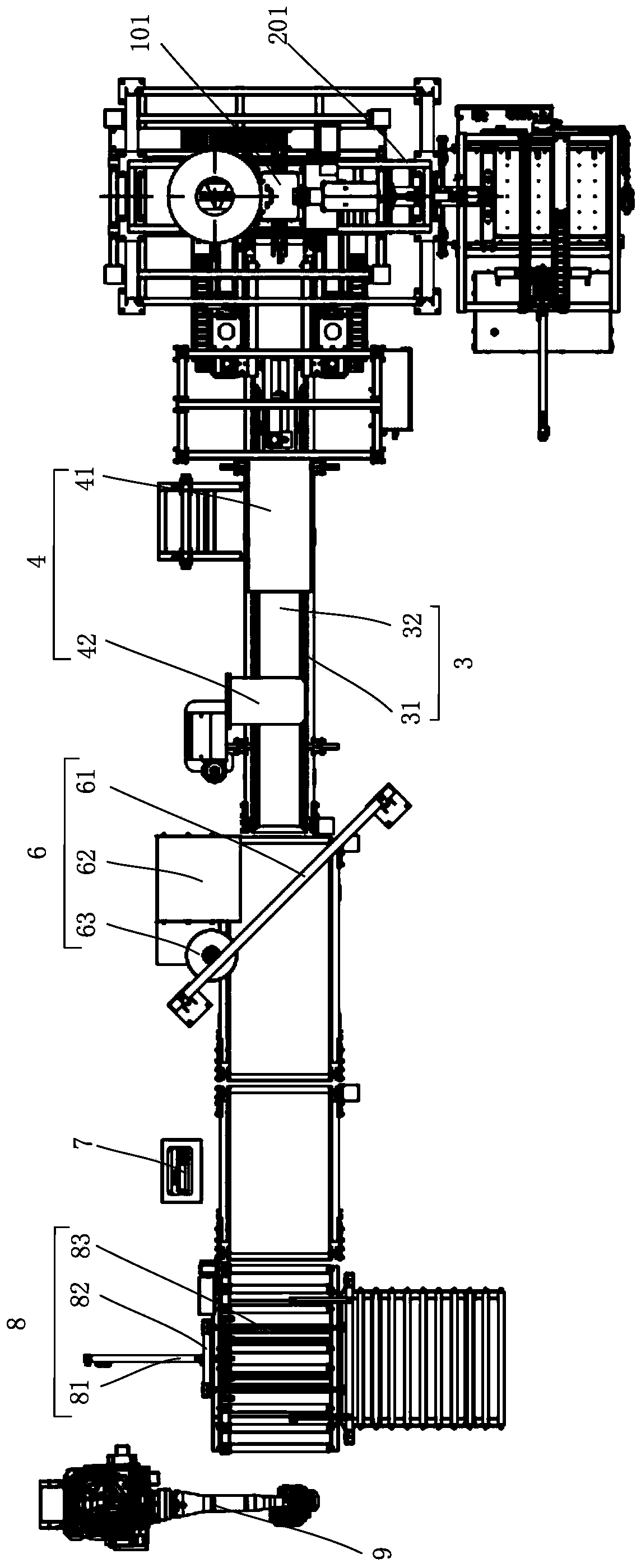

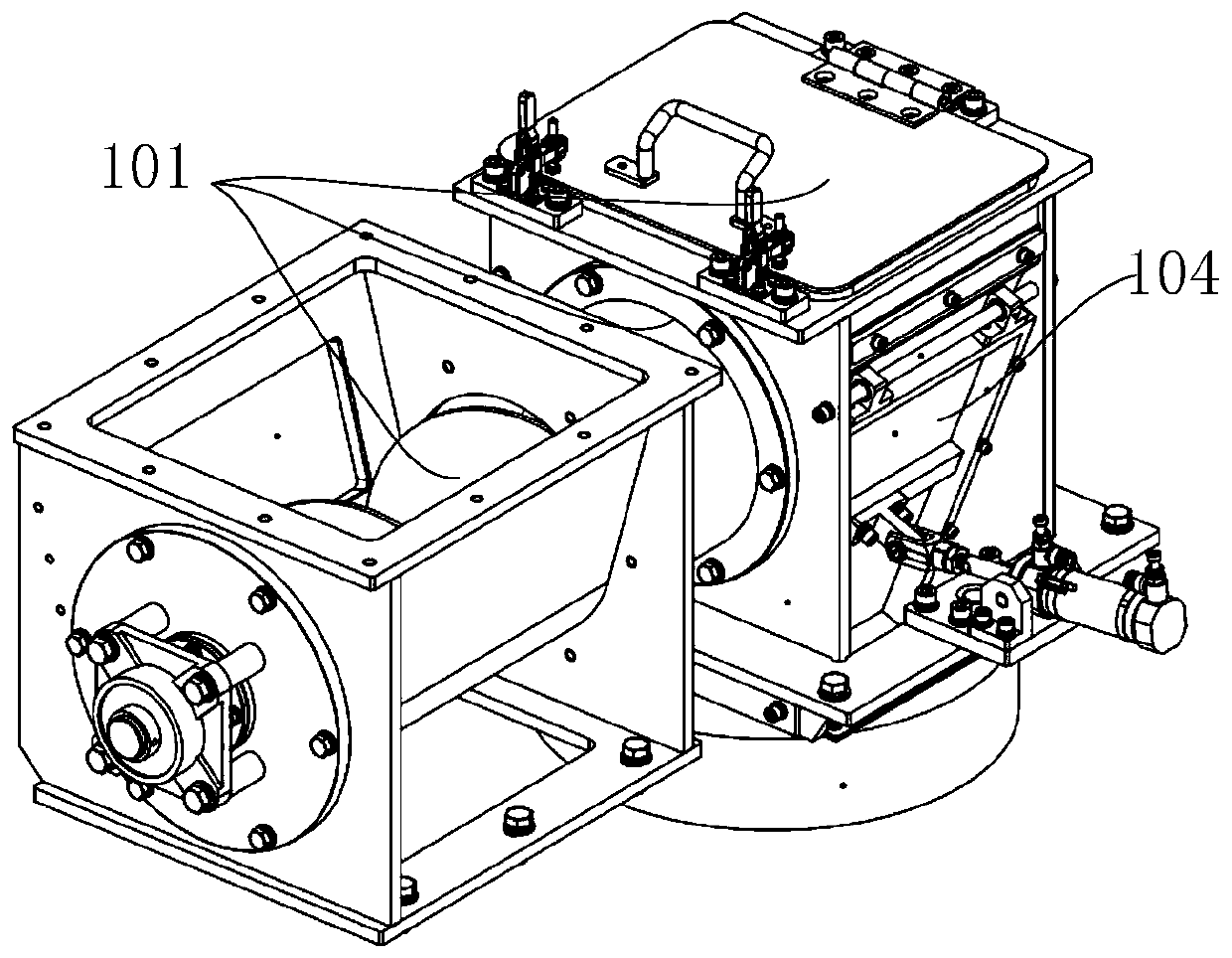

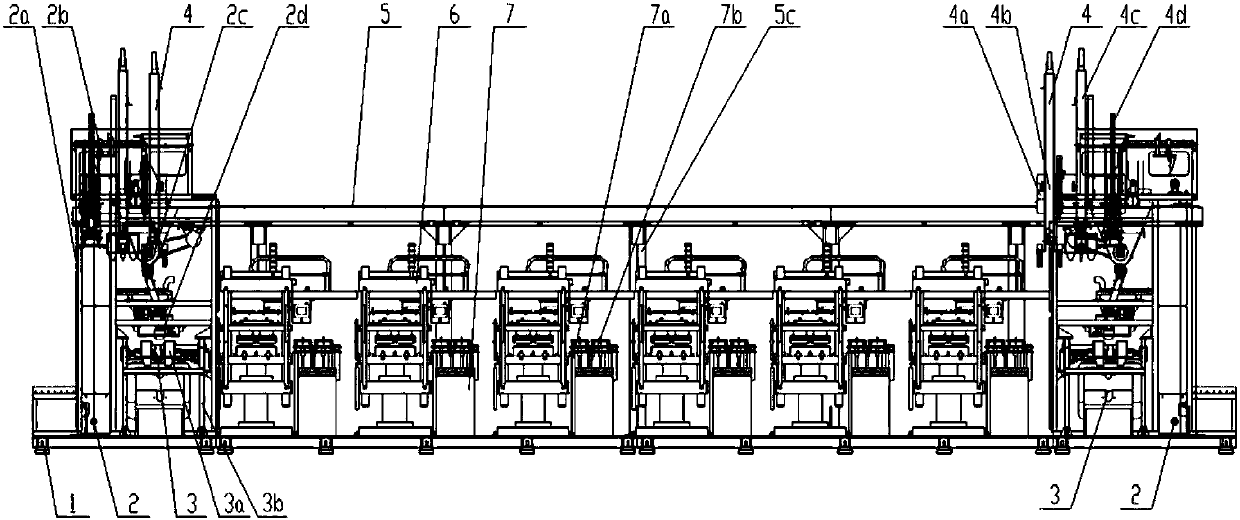

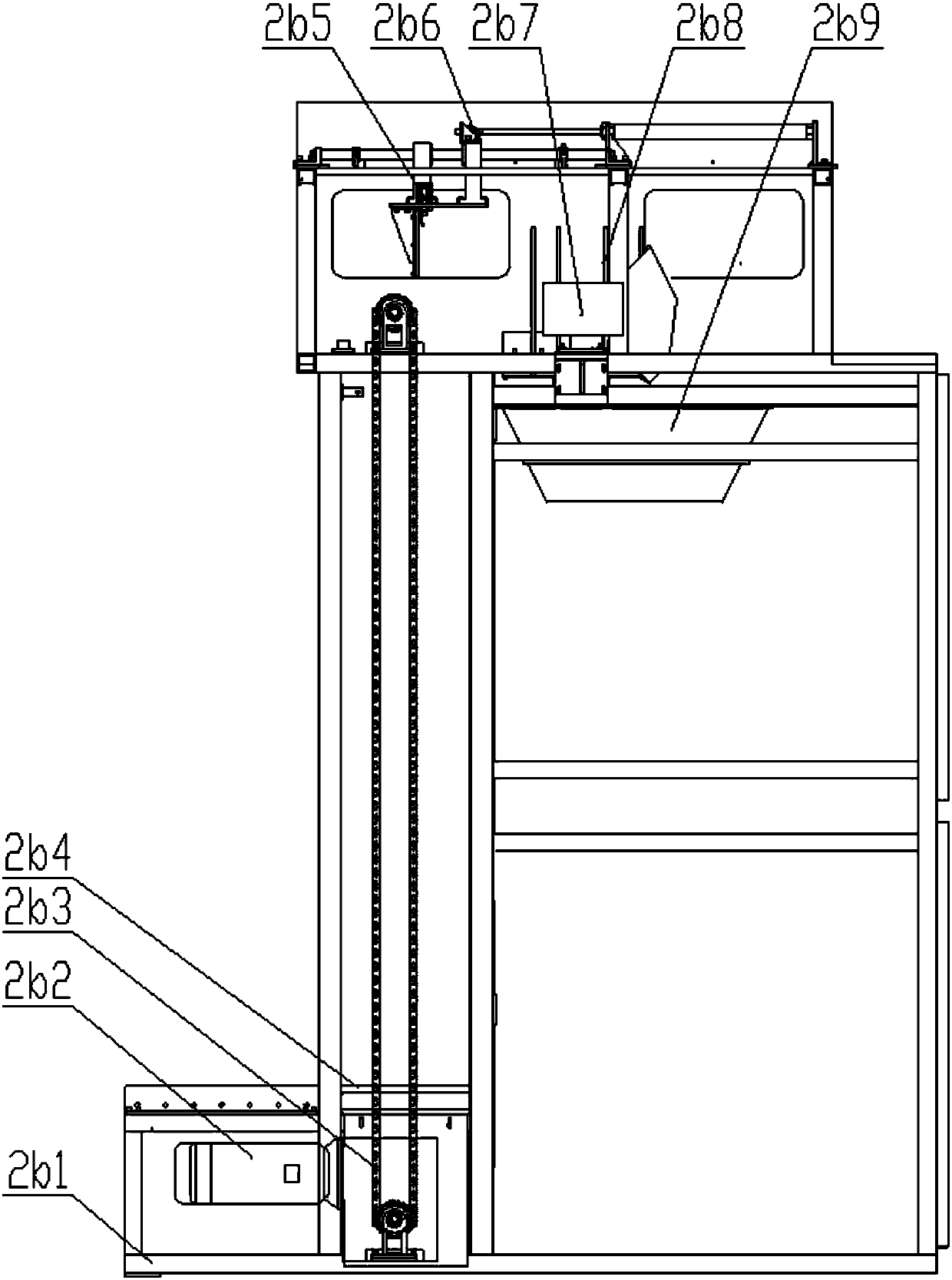

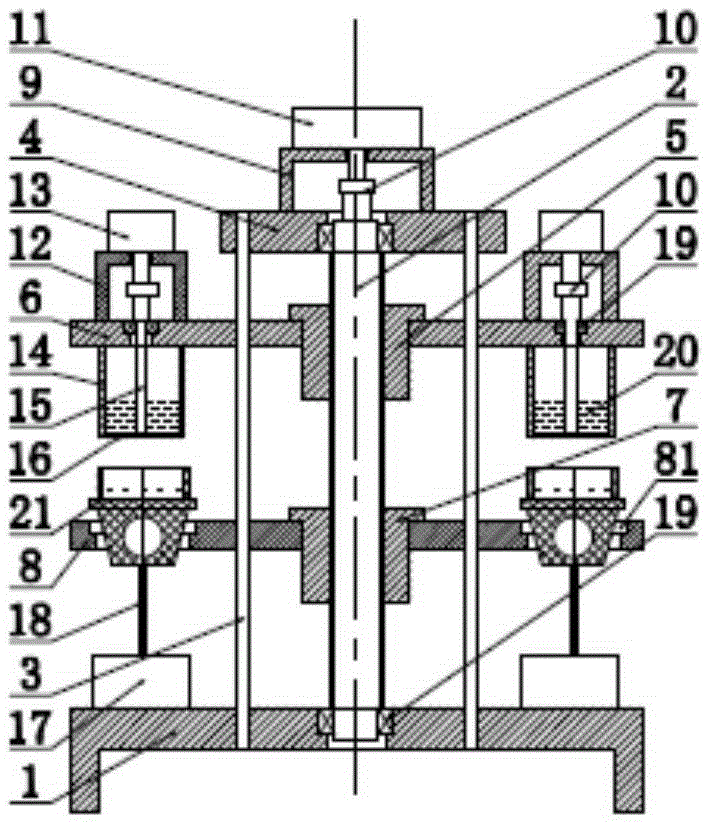

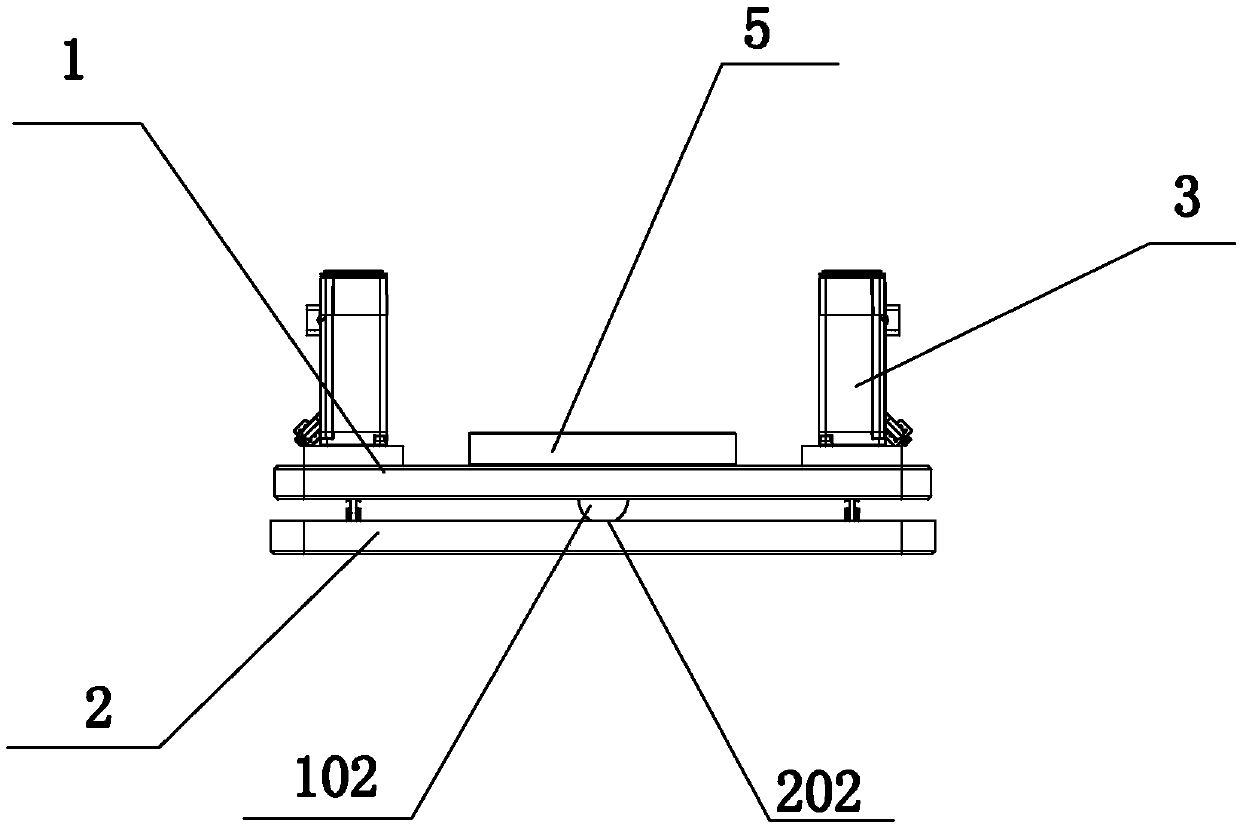

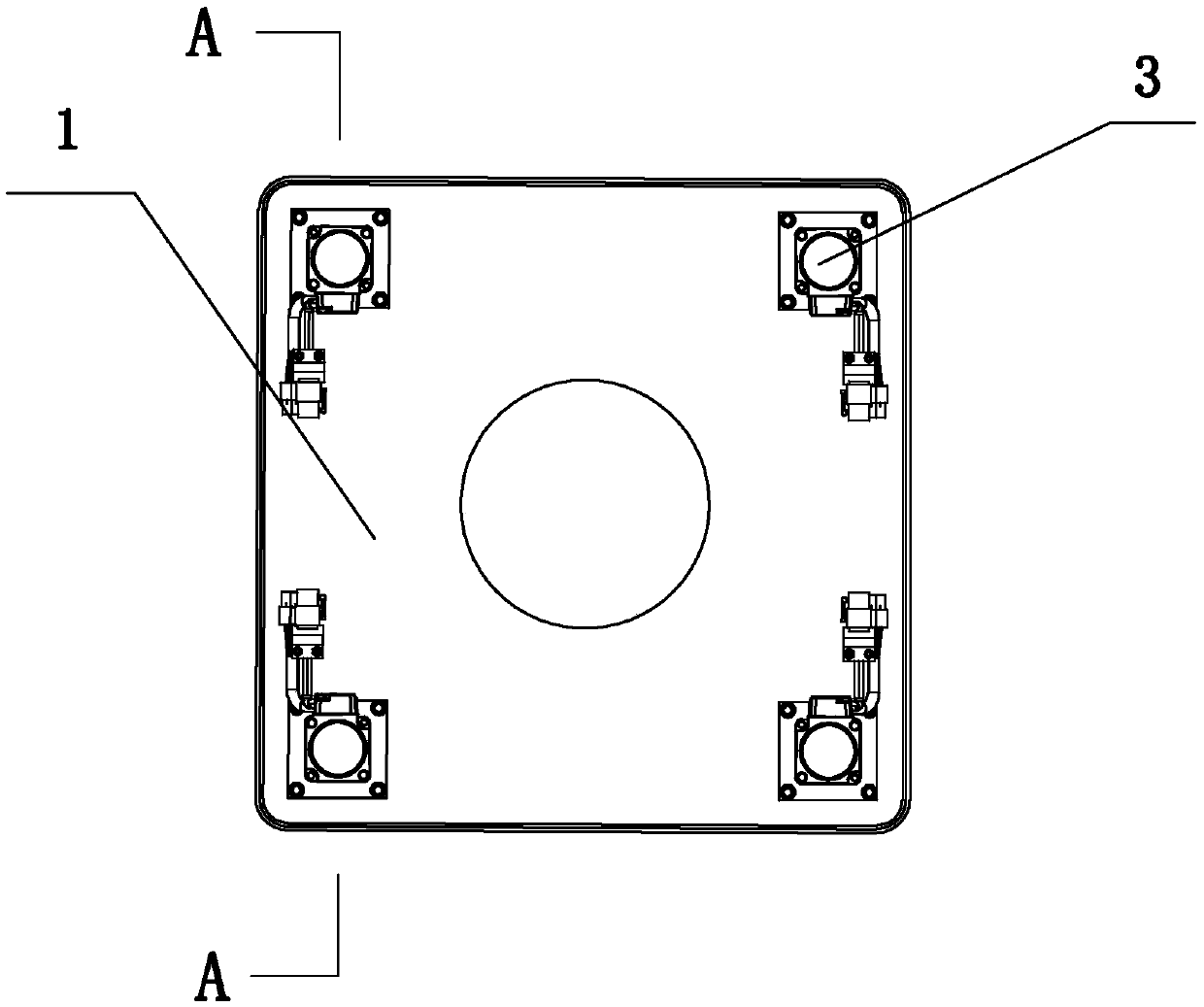

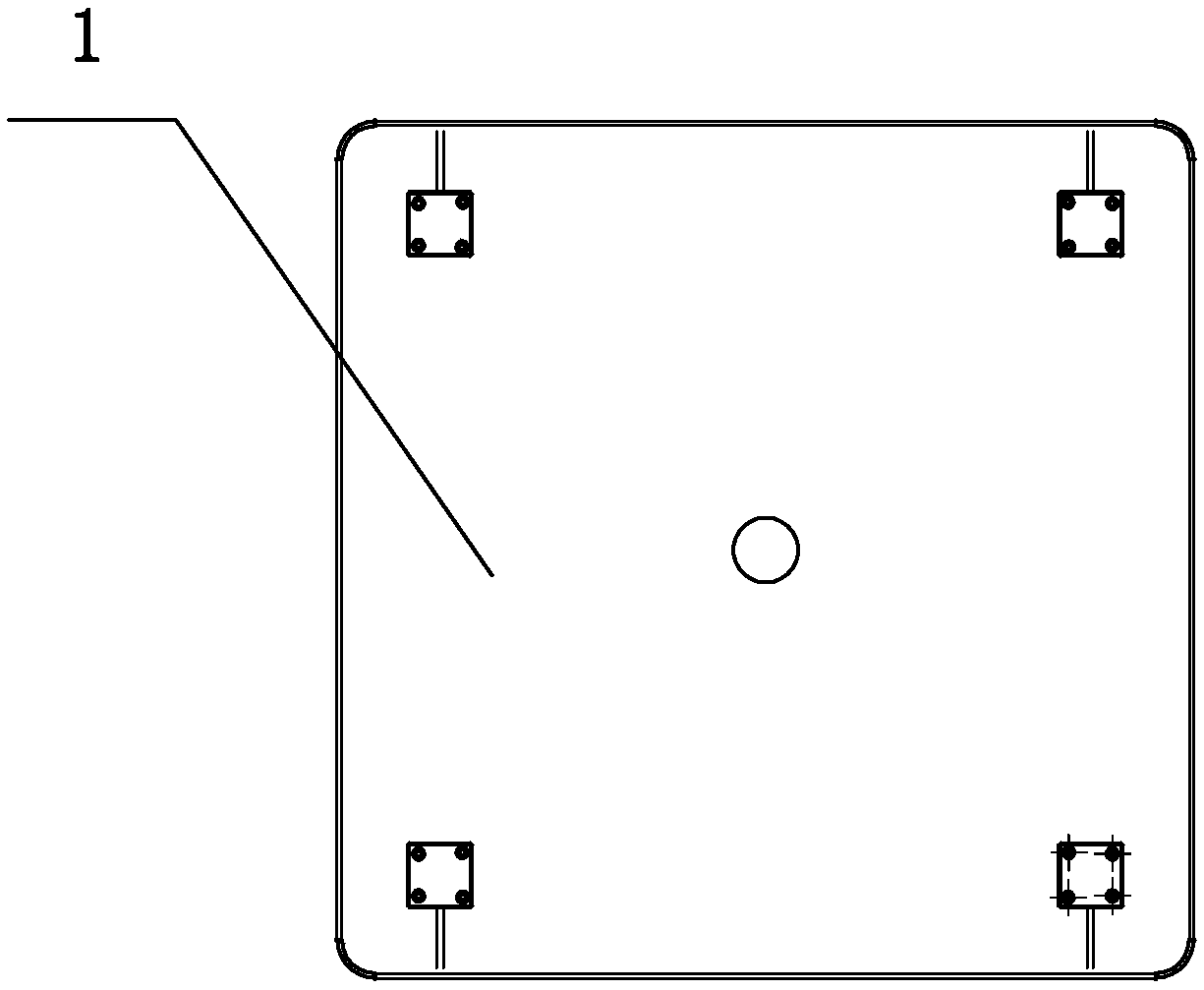

Brake pad hot press molding semi-automatic production line of passenger car brake

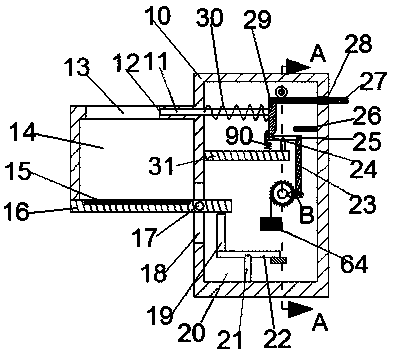

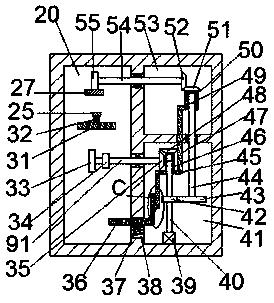

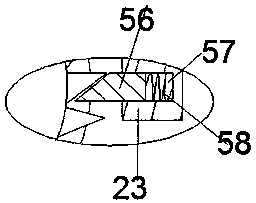

ActiveCN107756706ARealize automatic feeding processRealize automatic weighingProduction lineMolding machine

The invention belongs to the field of mechanical manufacturing, and in particular, relates to a brake pad hot press molding semi-automatic production line of a passenger car brake. The brake pad hot press molding semi-automatic production line of the passenger car brake comprises a mounting base [1], two sets of loading, stirring and weighing systems [2], two sets of transfer mechanisms [3], two sets of service robot cars [4], a car walking truss [5], six hot press molding machines [6], six sets of steel back jacking mechanisms [7] and an oil source [8]. The brake pad hot press molding semi-automatic production line of the passenger car brake is mainly used for producing a brake pad of the passenger car brake; during operating, steel backs are manually placed, and pressed products are manually taken; and the brake pad hot press molding semi-automatic production line of the passenger car brake is semi-automatic hot press molding production equipment.

Owner:XIAN E FLY AVIONICS TECH

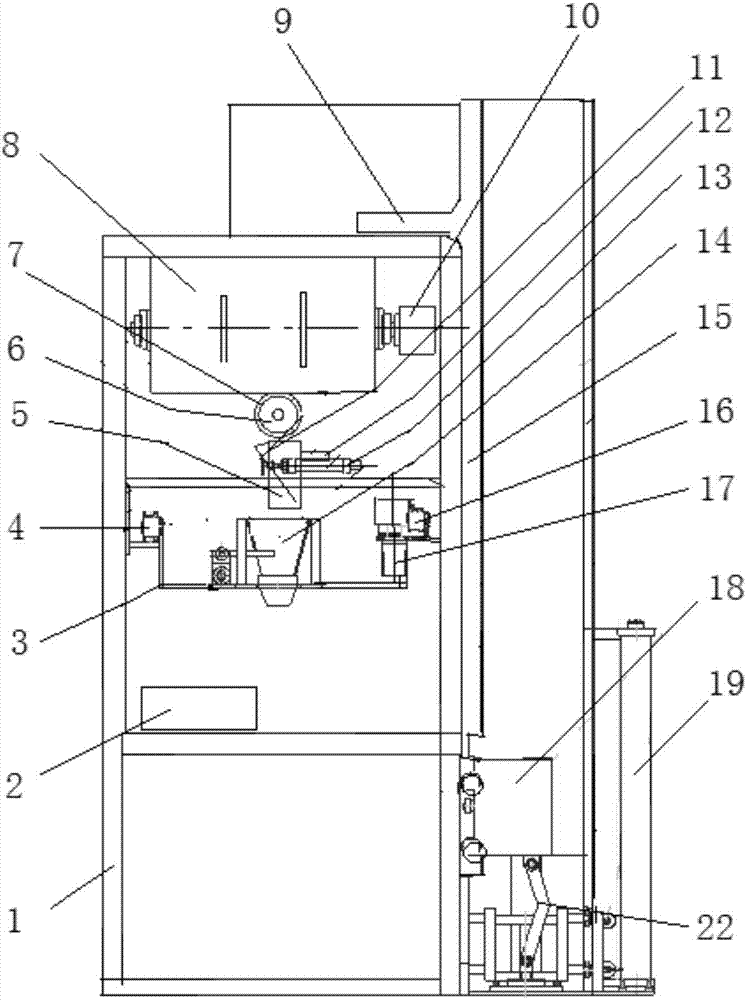

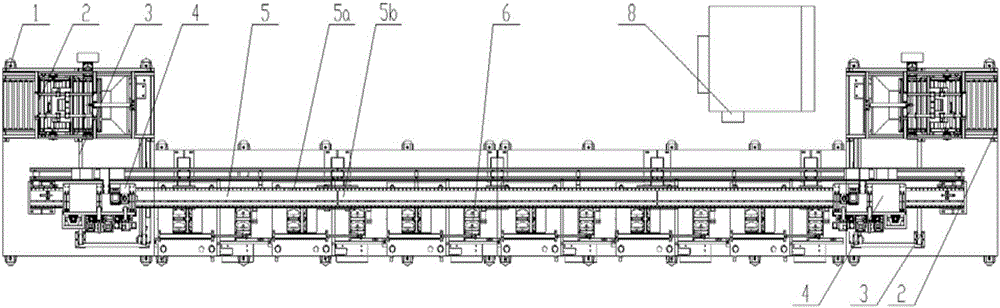

Quick quantitative weighing device and system comprising same

PendingCN109516234AContinuous uniform outputRealize automatic weighingConveyorsWeighing apparatus for continuous material flowEngineeringTransfer mechanism

The invention provides a quick quantitative weighing device and a system comprising the same. The quick quantitative weighing device comprises a first stock bin, a first stirring device, a first sending mechanism, a transferring mechanism, a falling plate and a weighing module; the first stock bin is used for storing to-be-weighed powder; the first stirring device is located at a discharging opening of the first stock bin; the first sending mechanism is located below the discharging opening of the first stock bin and used for continuously and evenly outputting the powder which is evenly stirred by the first stirring device, and the output powder falls onto a transfer belt; the transferring mechanism comprises the transfer belt; the falling plate is located at the end of the transferring mechanism and used for delivering the powder on the transfer belt onto a tray, and the tray is located on the weighing module; and the weighing module is used for weighing the powder on the tray. The labor cost can be lowered, and the weighing efficiency is improved.

Owner:KEDA INDUSTRIAL GROUP CO LTD

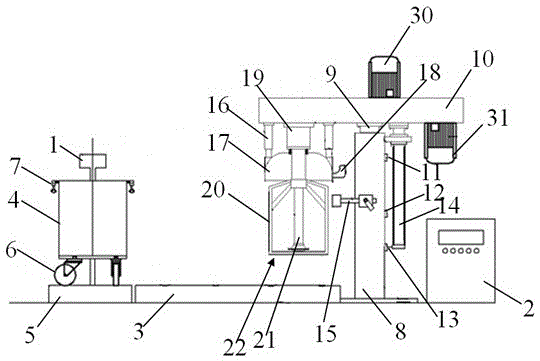

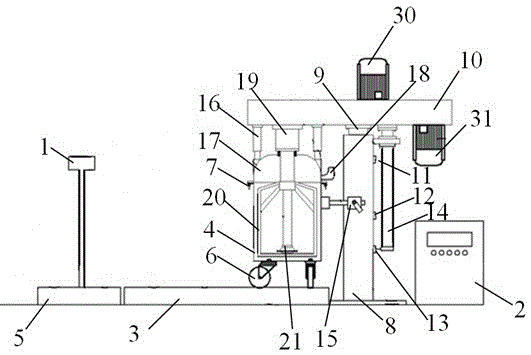

Automatic glue preparation device

ActiveCN105056815AIncrease the amount of preparationRealize automatic weighingRotating receptacle mixersTransportation and packagingDisplay deviceEngineering

The invention discloses an automatic glue preparation device, which includes a weighing system, a stirring system, a subpackaging system and a mixing barrel. The weighing system comprises an electronic balance and a display connected by a signal line. The stirring system comprises a working platform and a support column, an upper displacement restrictor, a middle displacement restrictor and a lower displacement restrictor are installed on the right side wall of the support column from top to bottom, a barrel body fixation frame is mounted at the middle part of the left side wall, and an air cylinder is mounted above the support column. A mobile platform is mounted above the air cylinder, the upper end of a fixation rod is fixed to the lower undersurface of the mobile platform, two groups of mobile rods are fixed on a barrel cover, and the upper ends of the mobile rods are fixed to fixed to the lower undersurface of the mobile platform, the barrel cover is communicated with the ventilation port of a ventilation system, one ends of stirring blades and a stirring frame are all fixed to the lower undersurface of the mobile platform, and the other ends all pass through the barrel cover. The subpackaging system consists of a material splitting barrel cover and a pneumatic pump set. The automatic glue preparation device provided by the invention realizes the functions of automatic weighing, mixing and subpackaging of glue solution, and guarantees mixing uniformity and consistency.

Owner:中国原子能工业有限公司

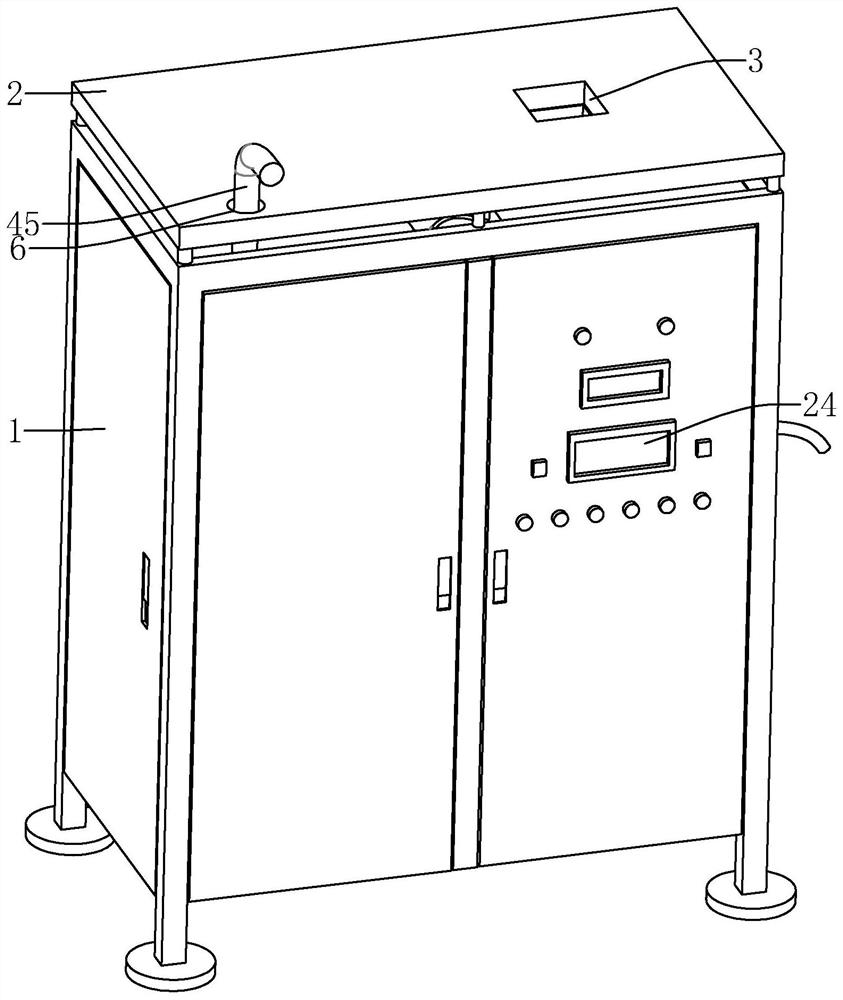

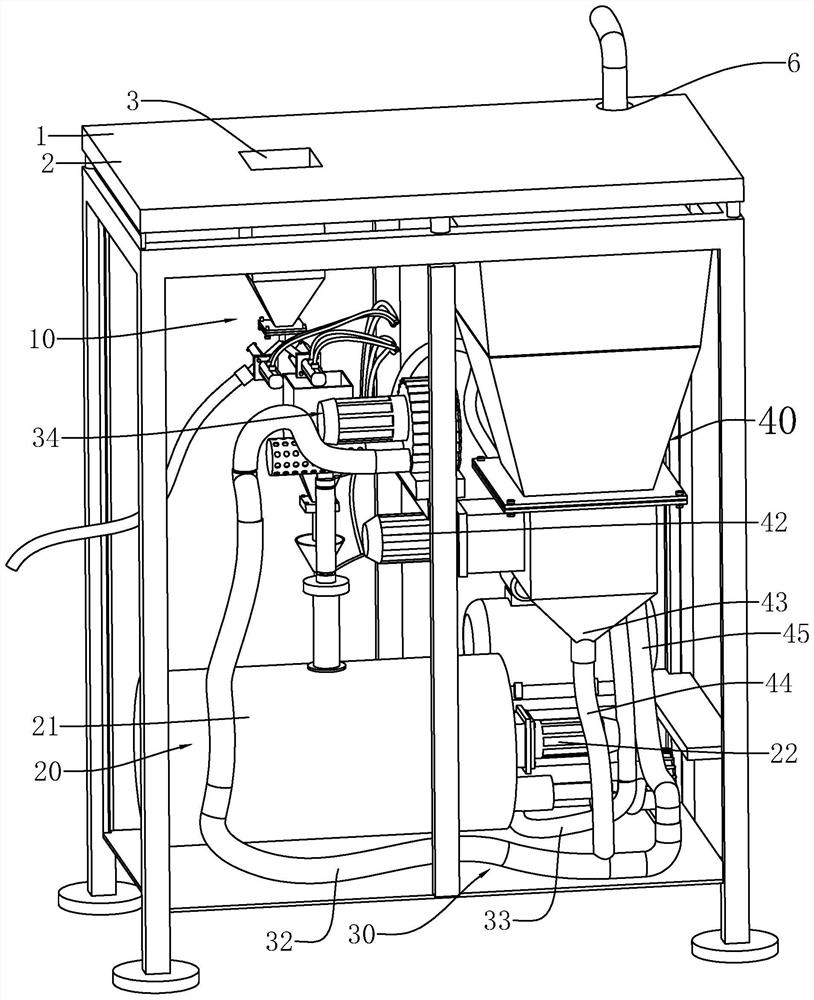

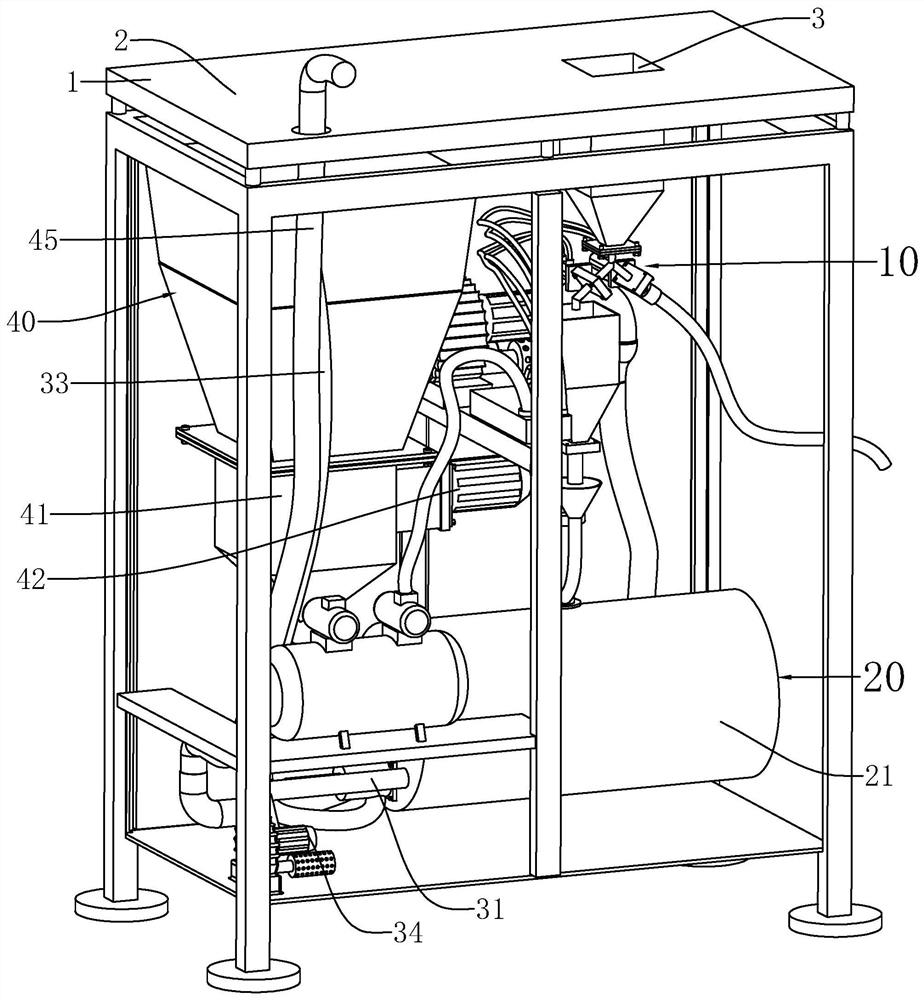

Pre-foaming machine for lost foam casting and working method thereof

PendingCN112828243AImprove automationEasy to useFoundry moulding apparatusProcess engineeringManufacturing engineering

The invention relates to a pre-foaming machine for lost foam casting and a working method thereof. The pre-foaming machine comprises a machine shell, a feeding assembly, a heating assembly, a conveying pipeline and a crushing assembly. The pre-foaming machine is reasonable in structural arrangement, the overall size is reduced, and integrated work of material heating, foaming and discharging is achieved; and through reasonable pipeline arrangement, foamed materials can be crushed very easily and conveyed to the exterior of the device through the pipeline, labor force is reduced, and the working efficiency is improved.

Owner:河北代氏科技有限公司

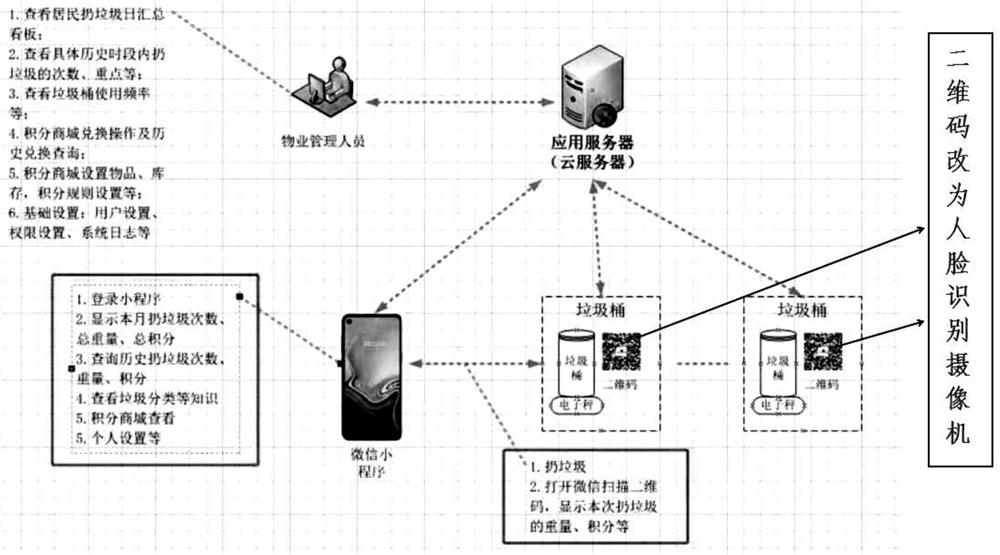

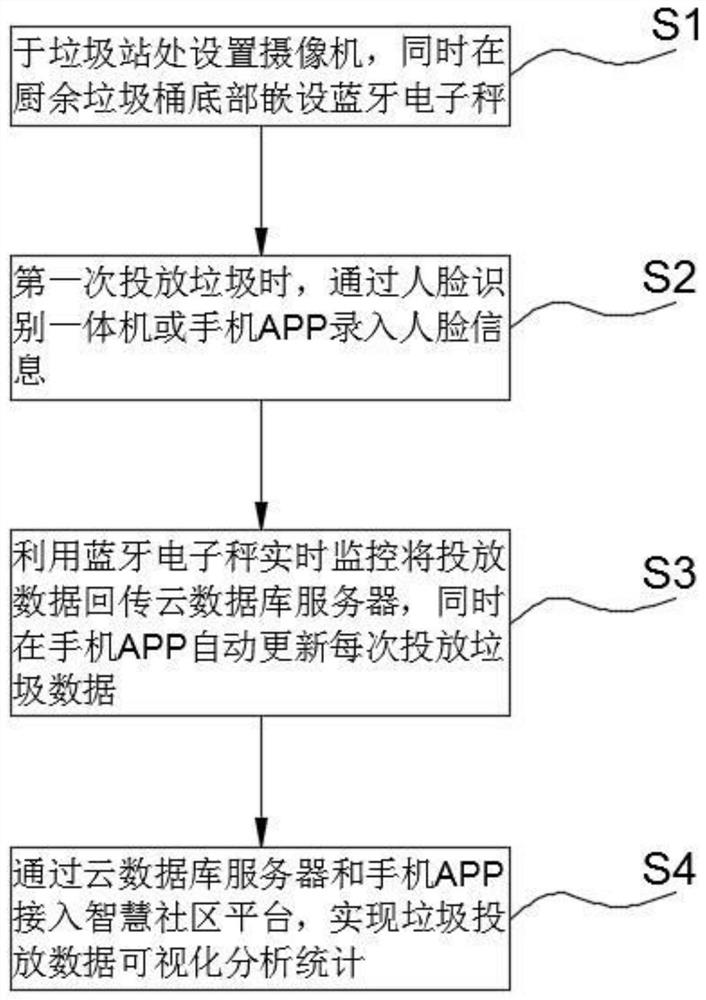

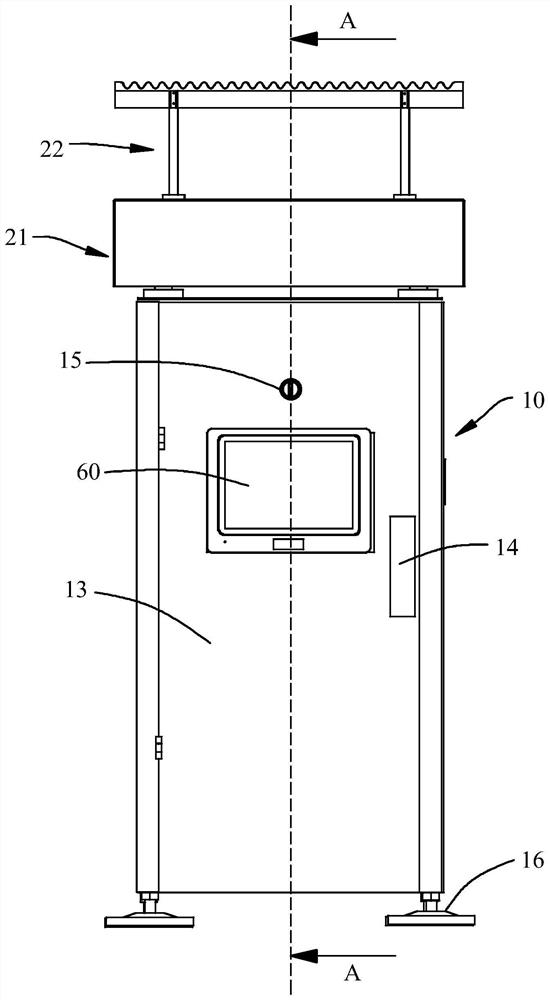

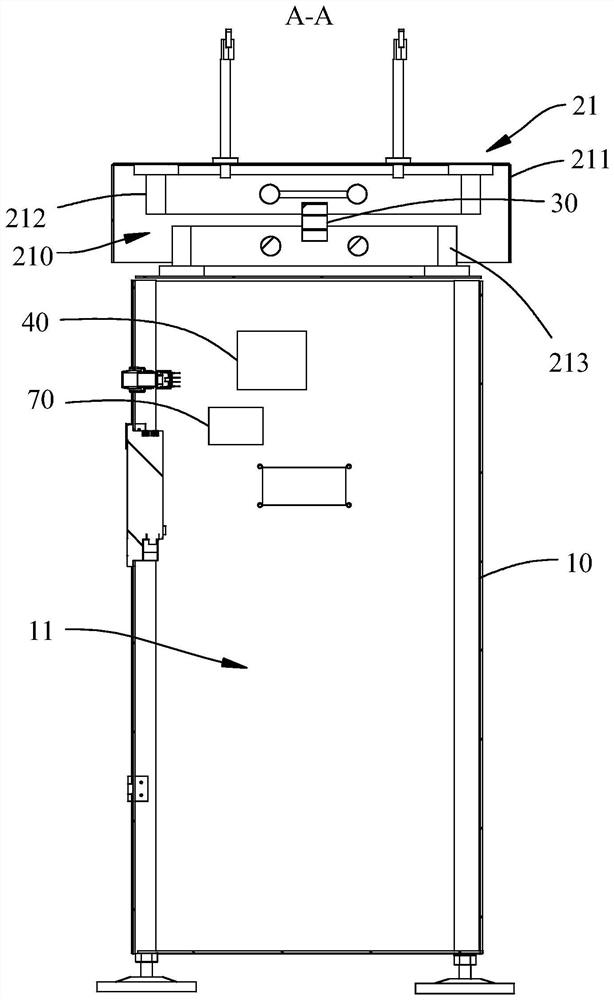

Automatic weighing system and method for garbage classification

InactiveCN112607263ARealize personalized applicationRealize intelligent identificationDatabase distribution/replicationCharacter and pattern recognitionInformatizationPersonalization

The invention relates to the technical field of garbage classification, in particular to an automatic weighing system and method for garbage classification. The automatic weighing system is provided with a face recognition all-in-one machine, face input is carried out or face information is input in a mobile phone App during the first-time throwing, a Bluetooth electronic scale is embedded in the bottom of a kitchen garbage can, throwing data are transmitted back to a cloud database server in real time through a data gateway, the mobile phone App automatically updates garbage throwing data each time, and the cloud database server and the mobile phone App are both connected to an intelligent community platform to achieve data visualization analysis and statistics. According to the automatic weighing system and method, the functions of intelligent personnel identification, automatic kitchen garbage weighing, real-time bucket fullness reminding and visual management analysis are realized; and kitchen garbage dumping situations can be accessed into wechat applets in real time, personalized application of the information is achieved, the kitchen garbage dumping situations of all garbage stations are stored and processed in real time through a cloud platform, background visual big data analysis is achieved, and the community kitchen garbage classification management informatization level and benefits are improved.

Owner:北京天华新瑞科技有限公司

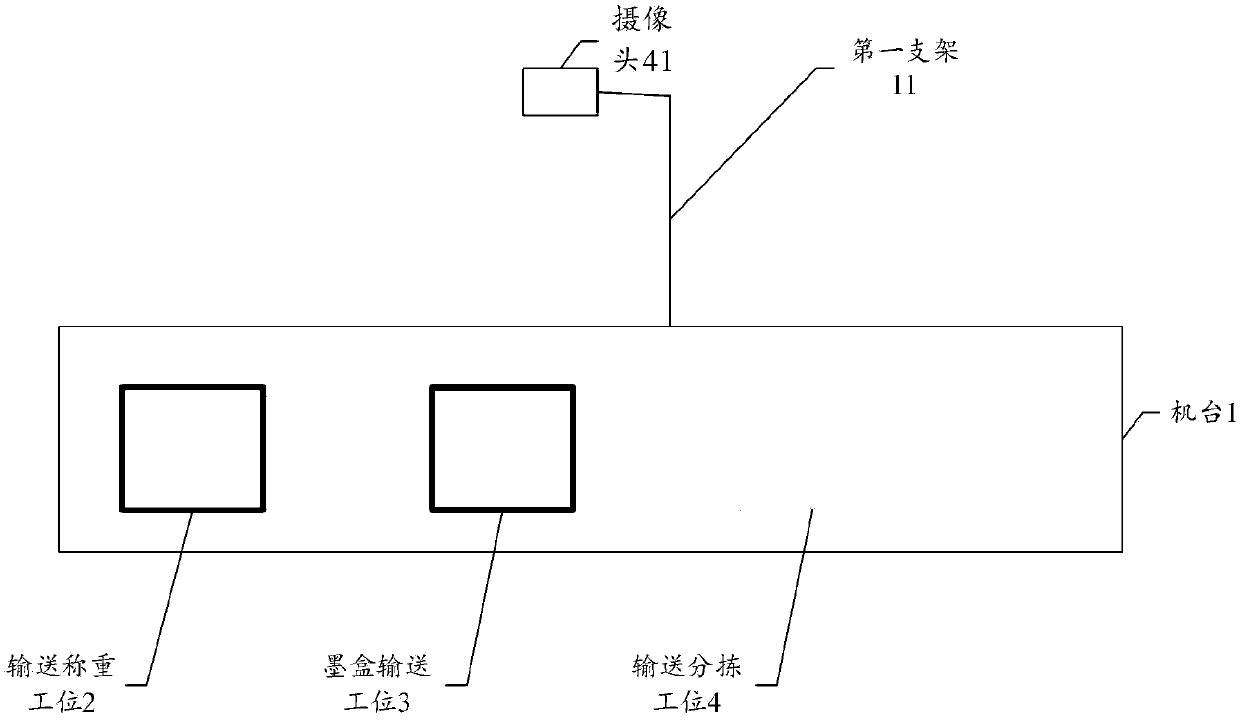

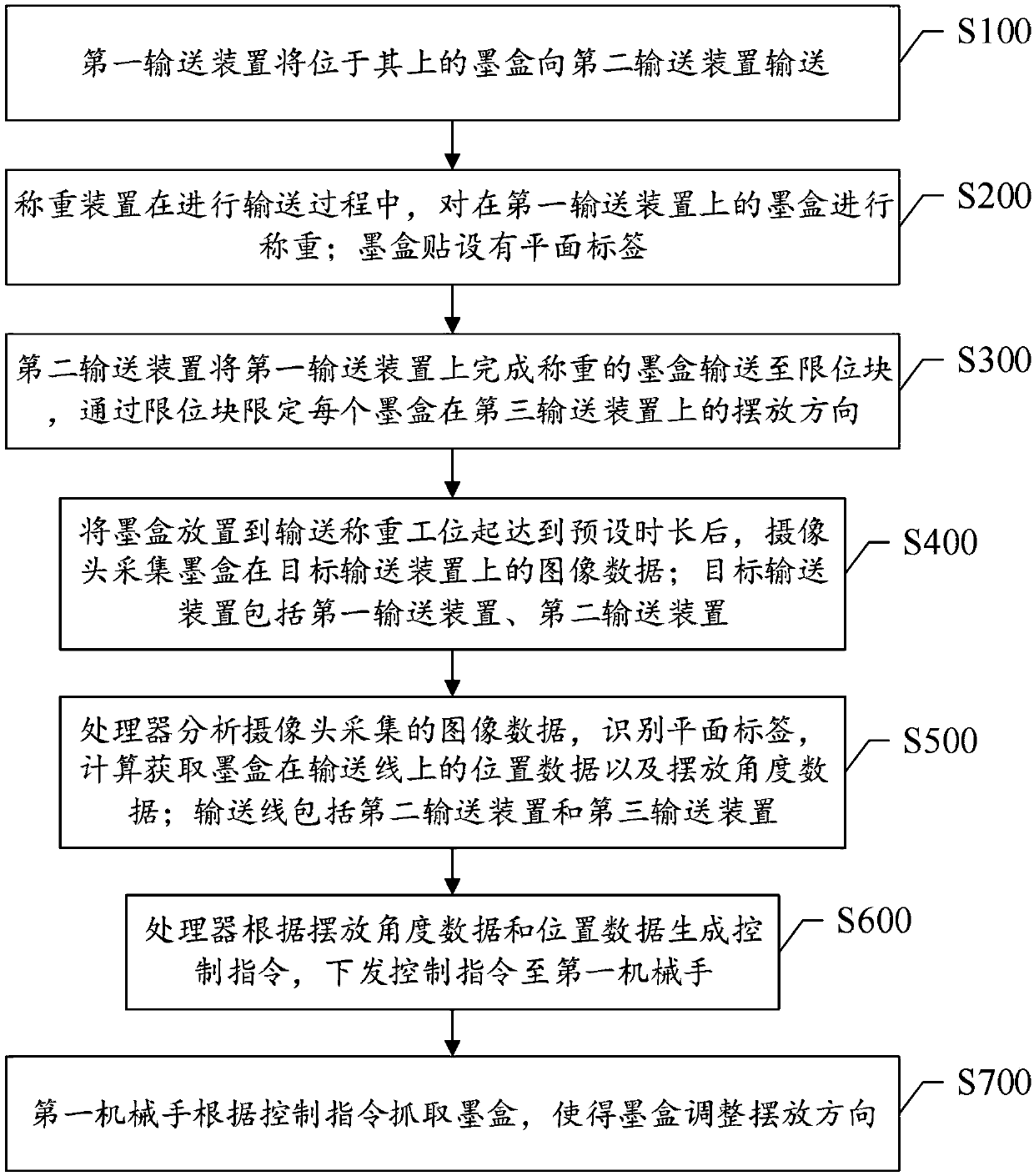

Weighing, positioning and sorting control method and weighing and sorting machine for ink box

InactiveCN109663744AAutomatically adjust the conveying directionRealize automatic weighingSortingManipulatorControl engineering

The invention provides a weighing, positioning and sorting control method and a weighing and sorting machine for an ink box. The weighing and sorting machine comprises a processor and a machine platform; the machine platform is sequentially provided with a conveying and weighing station, an ink box conveying station and a conveying and sorting station; the machine platform further comprises a first bracket, a camera and a first manipulator which is matched with the position of a limiting block; the first bracket is positioned in front of the limiting block; the processor is connected with thefirst manipulator and the camera; the conveying and weighing station comprises a first conveying device and a weighing device which is used for weighing the ink box which is positioned on the first conveying device; the ink box conveying station comprises a second conveying device; the second conveying device is used for conveying the ink box which is weighed on the first conveying device to the conveying and sorting station; the conveying and sorting station comprises a third conveying device and a limiting block which is positioned at the input end of the third conveying device; and the limiting block is used for limiting the arrangement direction of each ink box on the third conveying device. The weighing and sorting machine realizes automatic weighing, reduces the probability of missing weighing, realizes regulation of the conveying direction of the ink box and improves the sorting and packaging efficiency and accuracy.

Owner:SPEED INFOTECH (BEIHAI) COMPANY LIMITED

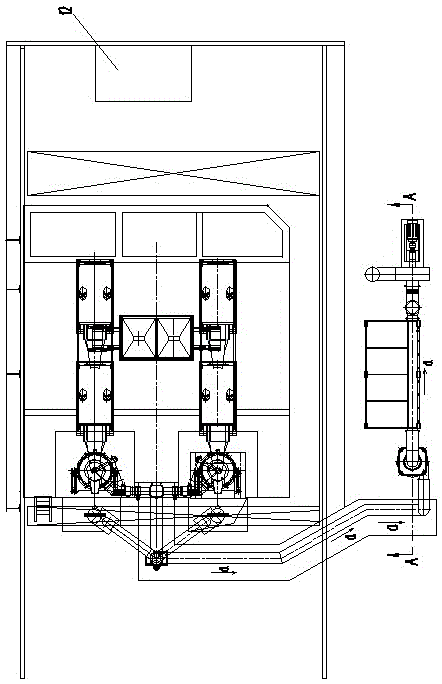

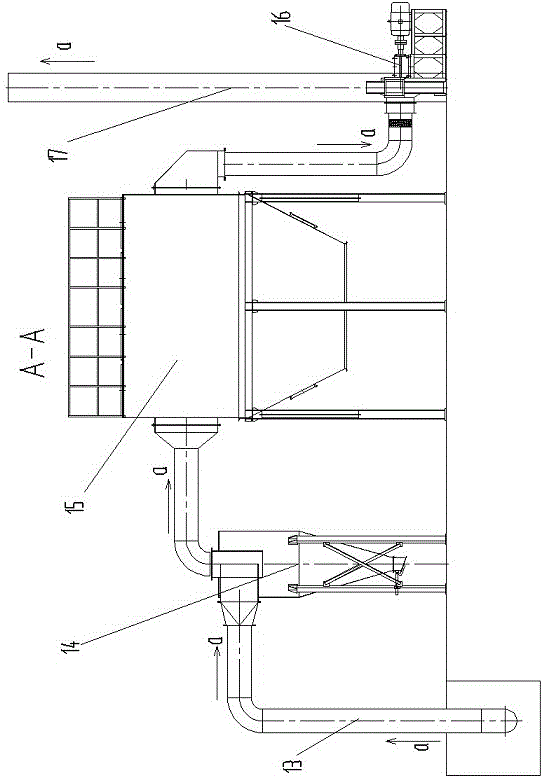

Automatic material feeding and blending, smoke prevention, dust control and emission reduction integrated system for electric furnace

ActiveCN105066709AIngredients with low error rateImprove batching accuracyCharge manipulationWaste heat treatmentIntegrated systemsEngineering

An automatic material feeding and blending, smoke prevention, dust control and emission reduction integrated system for an electric furnace is characterized by comprising a machine frame, the electric furnace installed on a lower platform of the machine frame, a balling bag which is close to the front side of the electric furnace and hung on a top platform of the machine frame, a balling smoke and dust trapping system next to the balling bag, a blending rack located on the back side of the electric furnace and installed on the lower platform of the machine frame, an alloy preparing overhead bin installed on the top of the blending rack, an electromagnetic vibrating feeder installed below the alloy preparing overhead bin, an alloy weighing hopper hung on the alloy preparing overhead bin, a bidirectional belt conveyer located below the alloy weighing hopper and installed on the blending rack, an electric furnace vibrating feeding trolley placed on the lower platform of the machine frame, a movable furnace rear automatic iron preparing device hung on the top platform of the machine frame, and a central integrated control system installed on the machine frame. The system is high in automation degree, capable of achieving smoke and dust removal, energy saving and emission reduction, relieving the labor intensity of staff and improving production efficiency, and capable of being widely applied to electric furnace smelting systems.

Owner:青岛中智达环保熔炼设备有限公司

Material transportation monitoring method and system and storage medium

ActiveCN113422927AMatch weightAvoid loadCharacter and pattern recognitionClosed circuit television systemsDriver/operatorMaterial transport

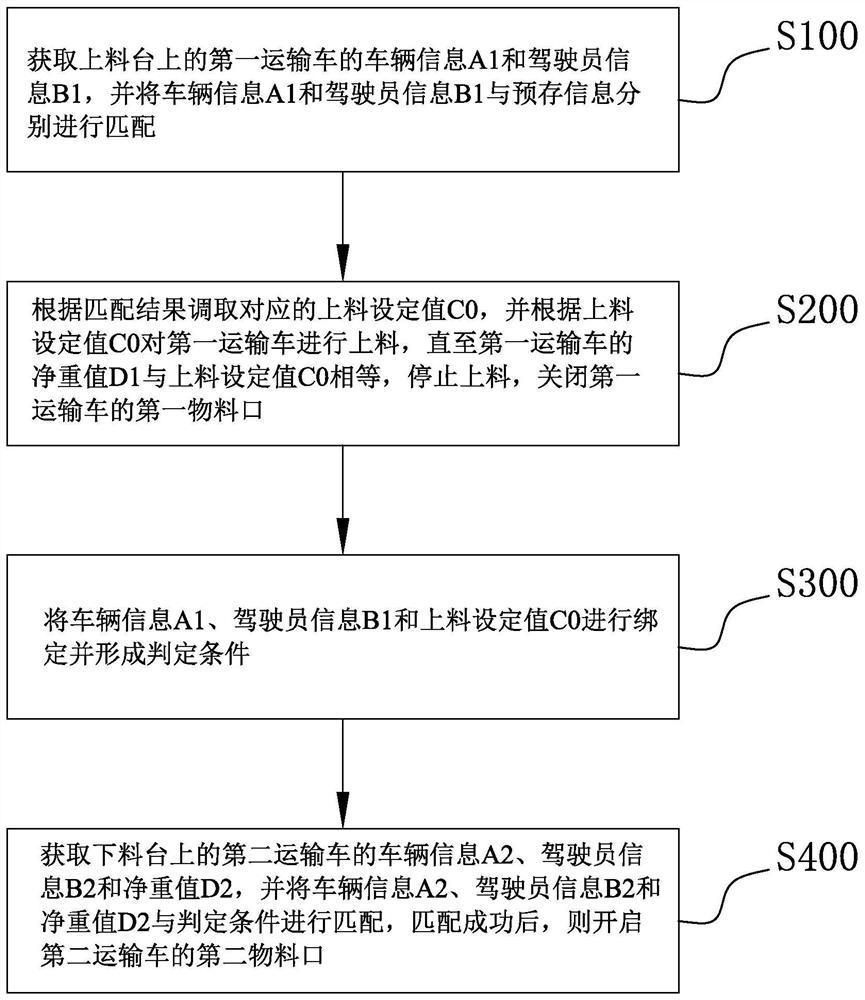

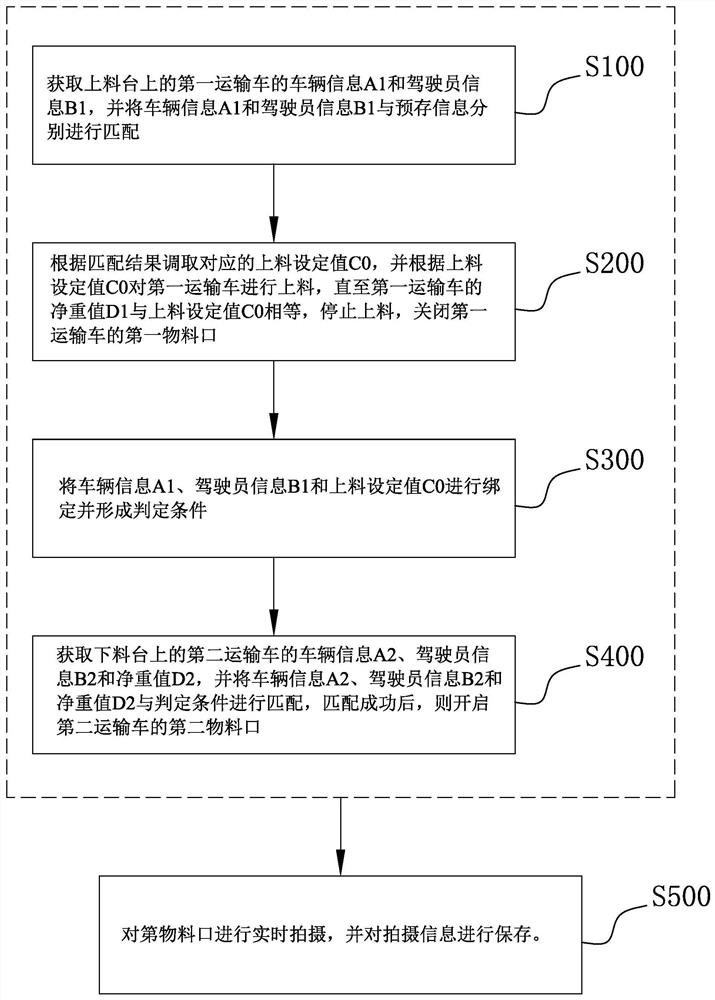

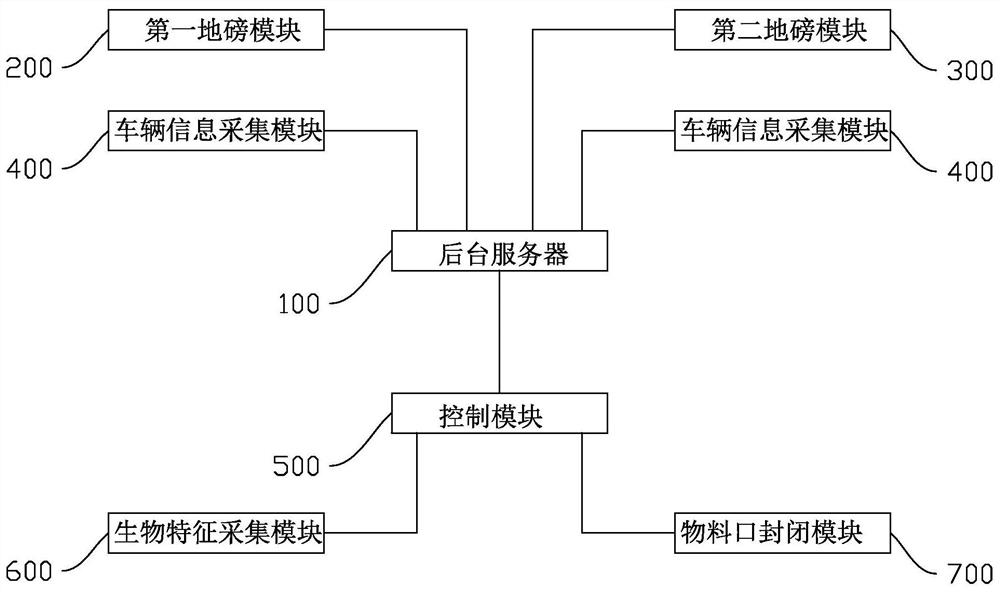

The invention relates to the technical field of material transportation, and discloses a material transportation monitoring method and system and a storage medium, which can realize the monitoring of a whole material transportation process. The method comprises the following steps: acquiring and matching vehicle information A1 and driver information B1 of a first transport vehicle on a feeding table; conducting feeding according to a feeding set value C0 until the net weight value D1 is equal to the feeding set value C0, and then stopping feeding and closing a first material opening; binding the vehicle information A1, the driver information B1 and the feeding set value C0 and forming a judgment condition; acquiring vehicle information A2, driver information B2 and the net weight value D2 of a second transport vehicle on a discharging table, matching the same with the judgment condition, and after matching succeeds, opening a second material opening of the second transport vehicle. According to the invention, the conditions of overload and stealing or replacing of the materials can be effectively prevented, and the reliability and the safety in the material transportation process are effectively improved.

Owner:珠海爱必途科技有限公司

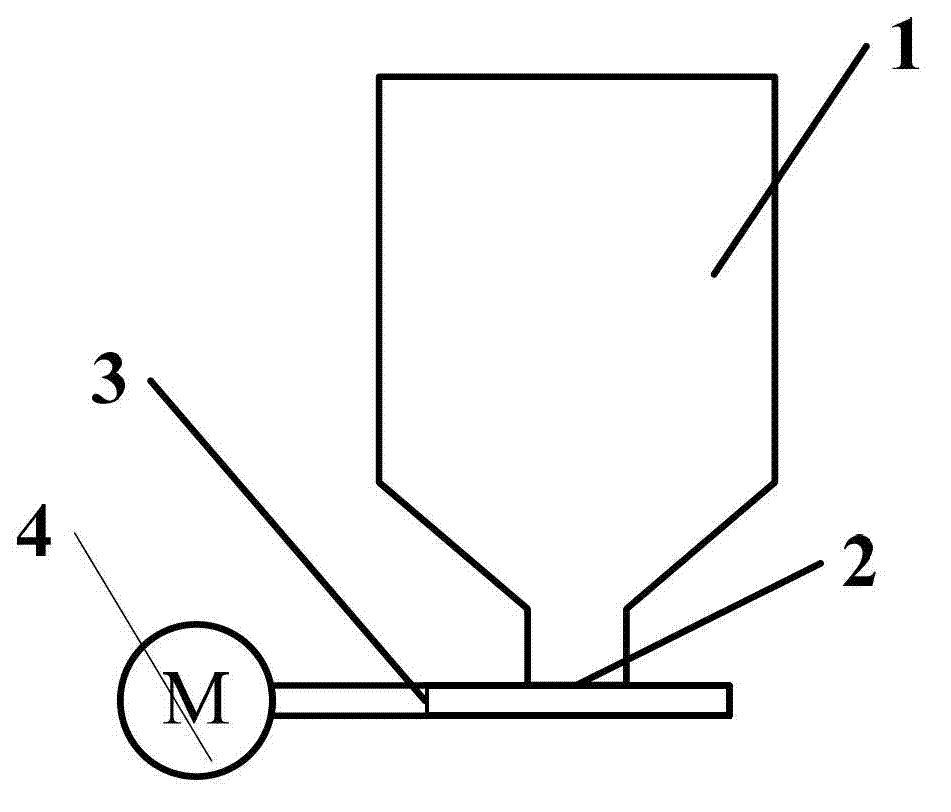

Automatic weighing method in material conveying

InactiveCN102967352ARealize automatic weighingIncrease productivityWeighing apparatus for continuous material flowEngineeringAutomatic testing

The invention discloses an automatic weighing method in material conveying. The automatic weighing method is implemented by a hopper, a discharge hole, a baffle plate and a motor, wherein the discharge hole is formed below the hopper; materials are conveyed out through the discharge hole due to the self weight of the materials; the baffle plate is installed at the discharge hole; the shielding and opening states of the baffle plate are controlled by the motor; as the materials are conveyed at a certain speed, the weight of the materials is reckoned according to the opening time of the baffle plate. The automatic weighing method can be used for realizing the automatic weighing of the conveyed materials in an automation production process so as to improve production efficiency.

Owner:KUNSHAN BEIJI PHOTOELECTRON SCI & TECH

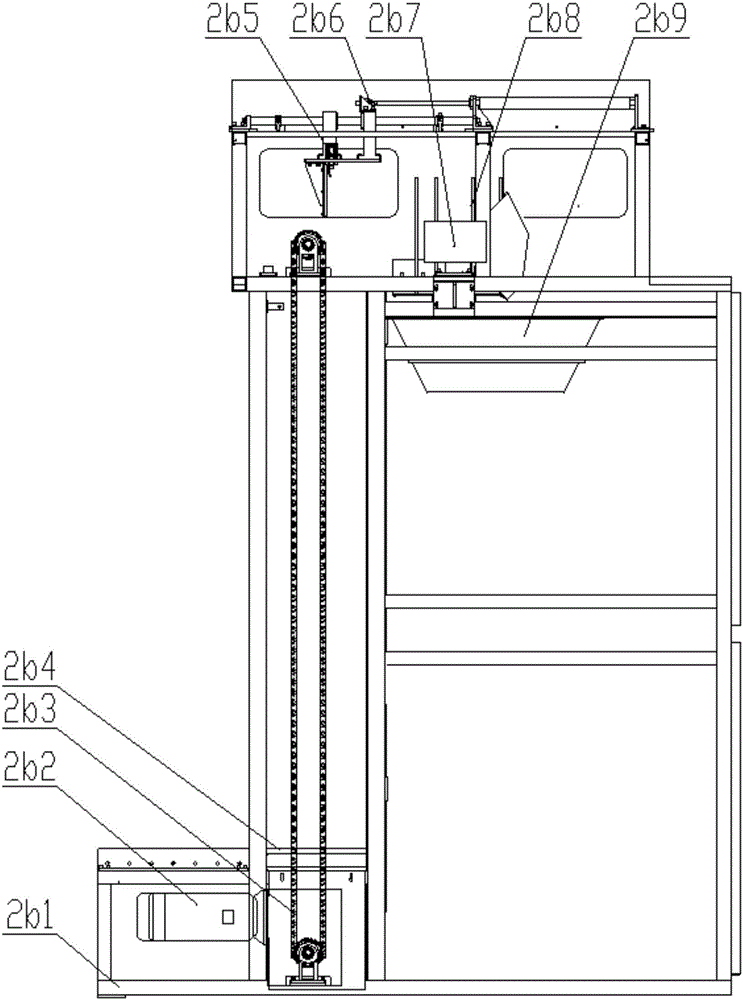

Parallel preparation equipment of Airy coal sample

InactiveCN105300780AImprove production efficiencyAccurately weigh the massPreparing sample for investigationCircular discBiochemical engineering

The invention discloses parallel preparation equipment of an Airy coal sample, and relates to the field of equipment for analyzing the sulfur content in a soft coal combustible substance. The parallel preparation equipment comprises a stander, a positioning plate, a screw rod arranged between the stander and the positioning plate, a guide rod parallel to the screw rod, n balances arranged on the stander, weighing rods arranged on the balances, a first rolling nut and a second rolling nut which are arranged on the screw rod from top to bottom, a first lifting disk and a second lifting disk which are respectively arranged on the two rolling nuts, a lifting motor arranged on the positioning plate through a U-shaped frame, and n groups of sprinkling modules arranged on the first lifting disk, wherein the sprinkling modules can automatically open or close a valve, thus realizing sprinkling of aldrin. The parallel preparation equipment is parallel preparation equipment of an Airy coal sample, which is compact in structure, artificial participation-free and smaller in error, and can prepare a plurality of Airy experiment samples by one step.

Owner:CHANGZHOU UNIV

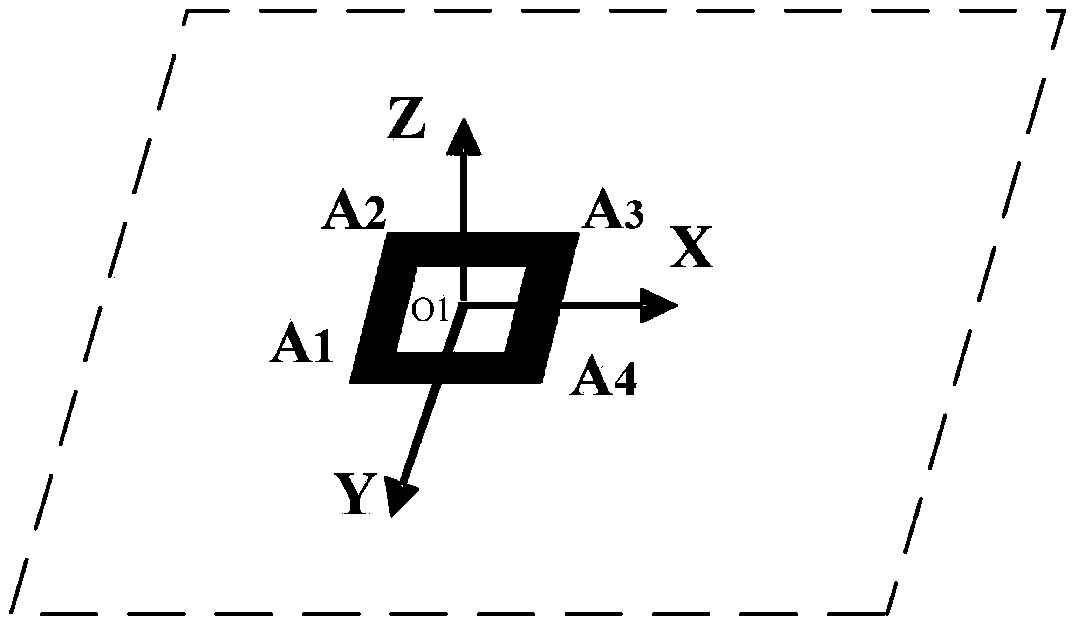

Auto-correcting planar gravity balancing mechanism for welding robot

PendingCN109249424AEvenly distributed gravityEvenly distributedManipulatorDecision controlUniversal joint

The invention belongs to the technical field of auto-correcting planar gravity balancing mechanisms and relates to an auto-correcting planar gravity balancing mechanism for a welding robot. The auto-correcting planar gravity balancing mechanism comprises balance plate A, balance plate B, four floating mechanism units, and a central decision control module PLC (programmable logic controller) system; the balance plate A and the balance plate B are arranged in parallel with the former above the latter; each floating mechanism unit includes a servo motor, connection screws, a universal joint device, a sensor connection block, a high-precision anti-impact pressure sensor and a balance bearing plate, wherein the connection screws, the universal joint device and the sensor connection block form one floating mechanism, and the high-precision ant-impact pressure sensor is disposed in a lower end hole of mounting hole B. The auto-correcting planar gravity balancing mechanism has the advantages that a tool plane bears force evenly and welding effect is optimal.

Owner:宁波亿荣自动化科技有限公司

Weighing device for intelligent manufacturing

InactiveCN111272267AEasy to controlSimple organizationWeighing apparatus using elastically-deformable membersWeighing apparatus detailsControl engineeringProcess engineering

The invention discloses a weighing device for intelligent manufacturing. The weighing device comprises a machine body and a power cavity formed in the machine body, a power device is arranged in the power cavity; a transmission cavity is formed in the machine body; a transmission device is arranged in the transmission cavity; a weighing cavity is formed in the machine body; a weighing device is arranged in the weighing cavity; a control cavity is formed in the machine body, and a control device is arranged in the control cavity; the device is simple in mechanism and easy and convenient to use,automatic weighing is achieved through application of a pressure sensor and mechanical transmission control, accurate control over feeding is achieved, and the problems that manual operation is low in efficiency and consumes manpower are solved.

Owner:温州新兰智能科技有限公司

Online weighing device

PendingCN112577577ARealize automatic weighingReduce labor costsWeighing apparatus with automatic feed/dischargeSortingControl engineeringProcess engineering

The invention relates to an online weighing device, and belongs to the technical field of weighing systems. The online weighing device is applied to weighing of injection-molded products and comprisesa body, a supporting mechanism, a weighing sensor and a controller. The supporting mechanism is used for supporting a to-be-detected product and is arranged above the body; the weighing sensor is connected with the supporting mechanism and is used for weighing the weight of the to-be-detected product supported by the supporting mechanism and generating a weight signal; the controller is located in the body and electrically connected with the weighing sensor, and the controller is used for generating weight data according to the weight signal of the weighing sensor and storing the weight data.The on-line weighing device can realize automatic weighing of the product, save labor cost and improve production efficiency.

Owner:HASCO VISION TECHNOLOGY CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com