Automatic weighing method in material conveying

An automatic weighing and material technology, applied in the direction of continuous material flow weighing equipment, weighing, measuring devices, etc., can solve the problems of slow weighing speed, high labor cost, affecting production efficiency, etc., and achieve the goal of improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the drawings.

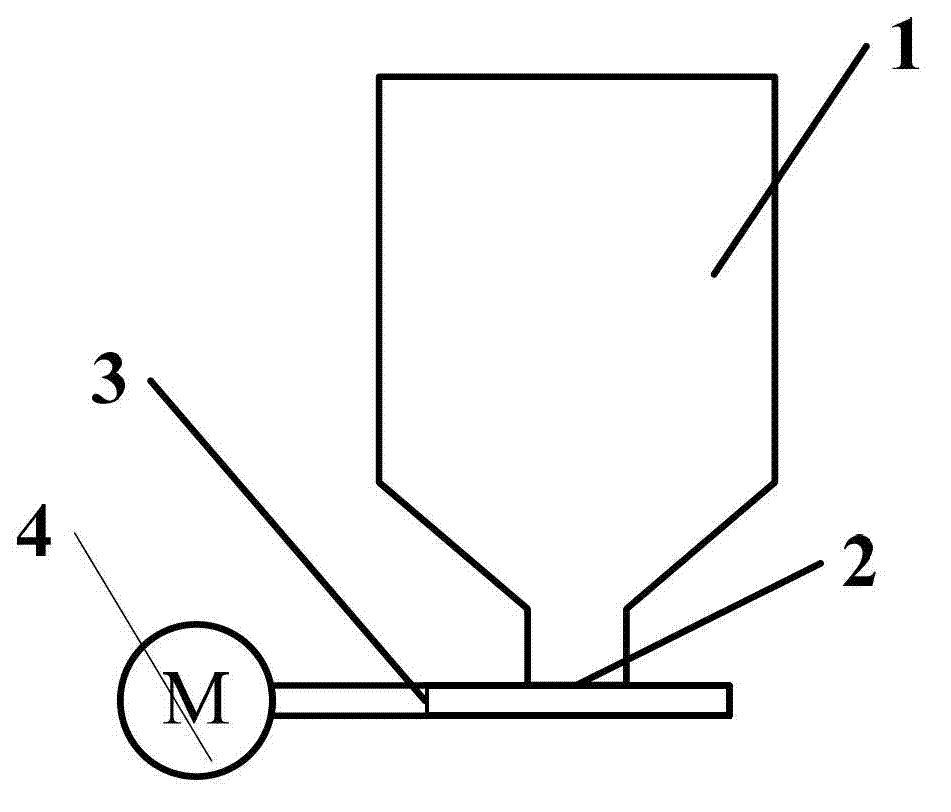

[0011] See figure 1 , The figure shows an automatic weighing method for material transportation, including hopper 1, discharge port 2, baffle 3 and motor 4. Among them, discharge port 2 is below hopper 1, and baffle 3 is installed on the discharge Below port 2, connect to motor 4.

[0012] The discharge port area S is constant, and the material is transported outwards by its own weight g, the speed is fixed at V, the baffle is controlled by the motor, the opening time of the control baffle is t, and the weight of the discharged material is M=g×S×V×t.

[0013] The present invention has been described in detail above in conjunction with the embodiments of the drawings, and those of ordinary skill in the art can make various changes to the present invention based on the above description. Therefore, some details in the embodiments should not constitute a limitation to the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com