Patents

Literature

1509results about "Weighing apparatus with automatic feed/discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

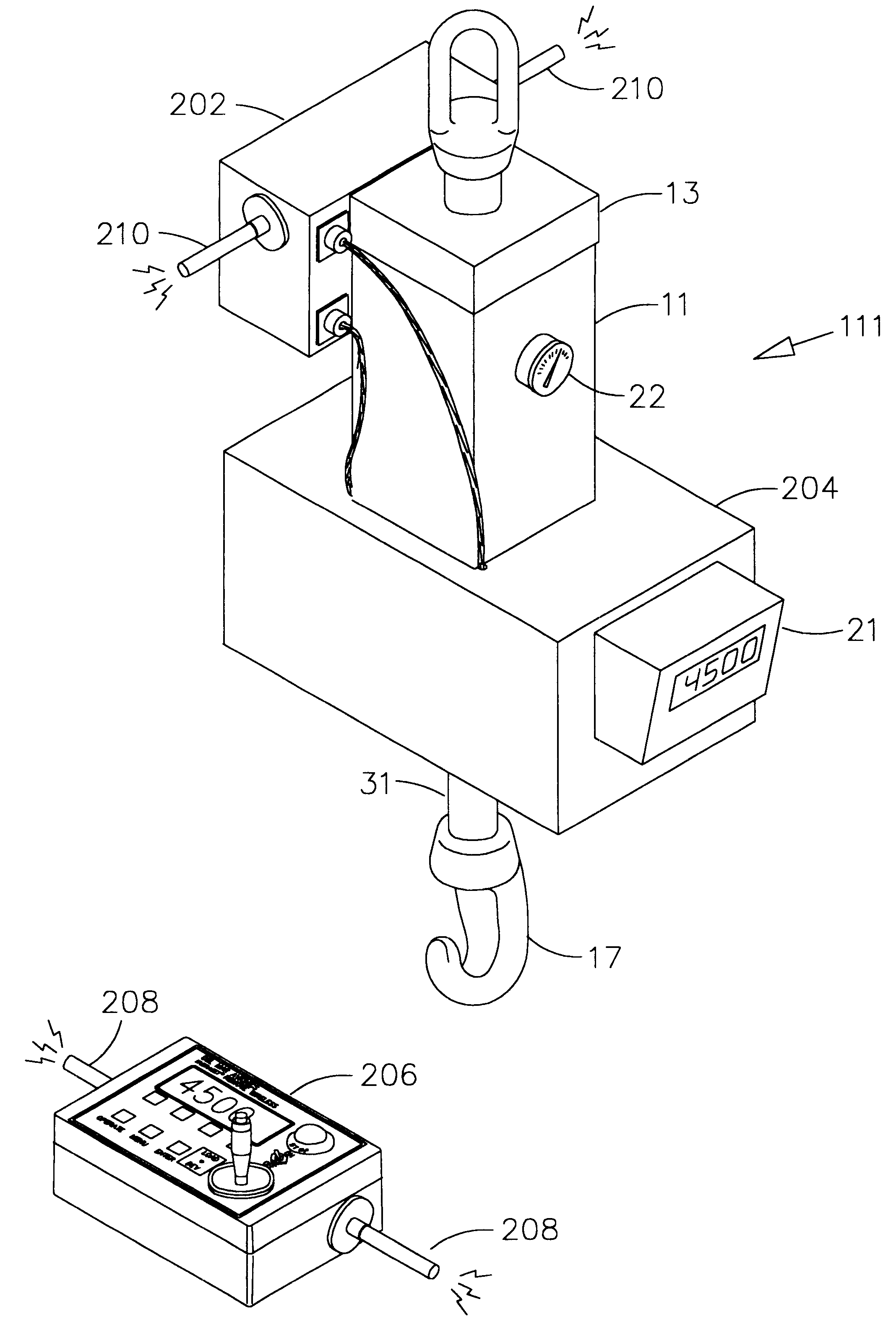

Weighing apparatus having an automatic filter adjusting capability

InactiveUS6271484B1Short response timeShort timeWeighing apparatus using elastically-deformable membersWeighing apparatus testing/calibrationDigital filterAutomatic filtering

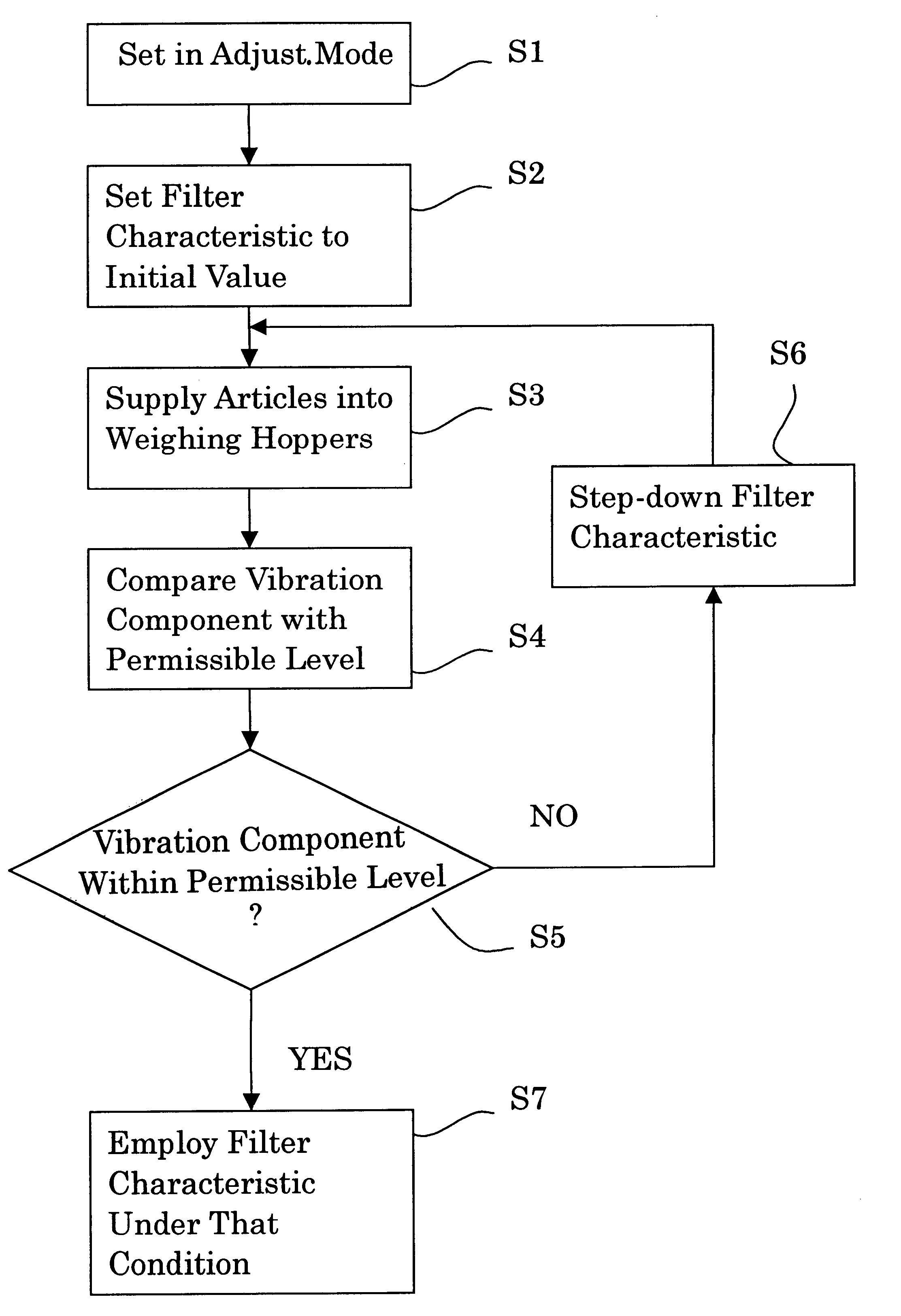

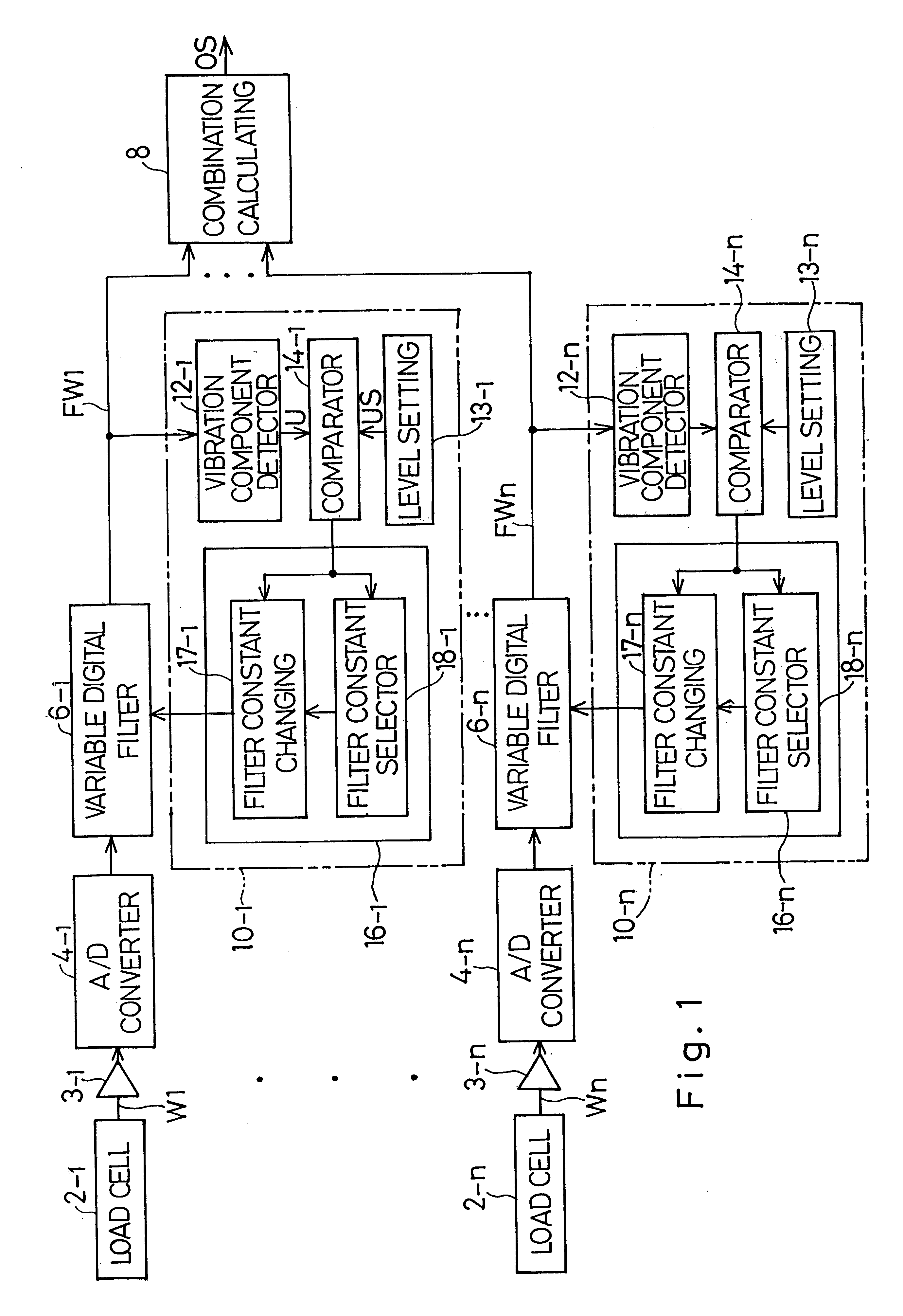

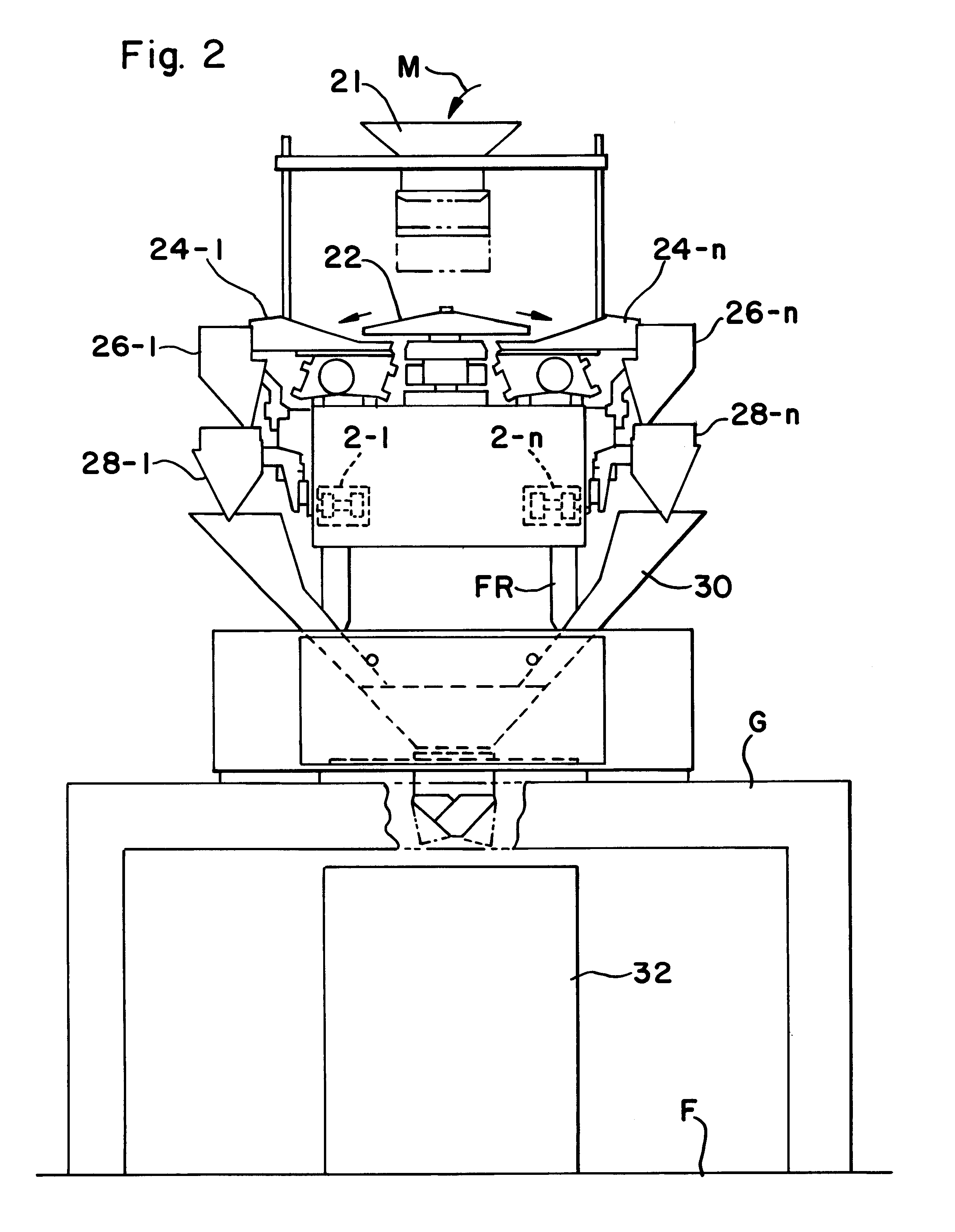

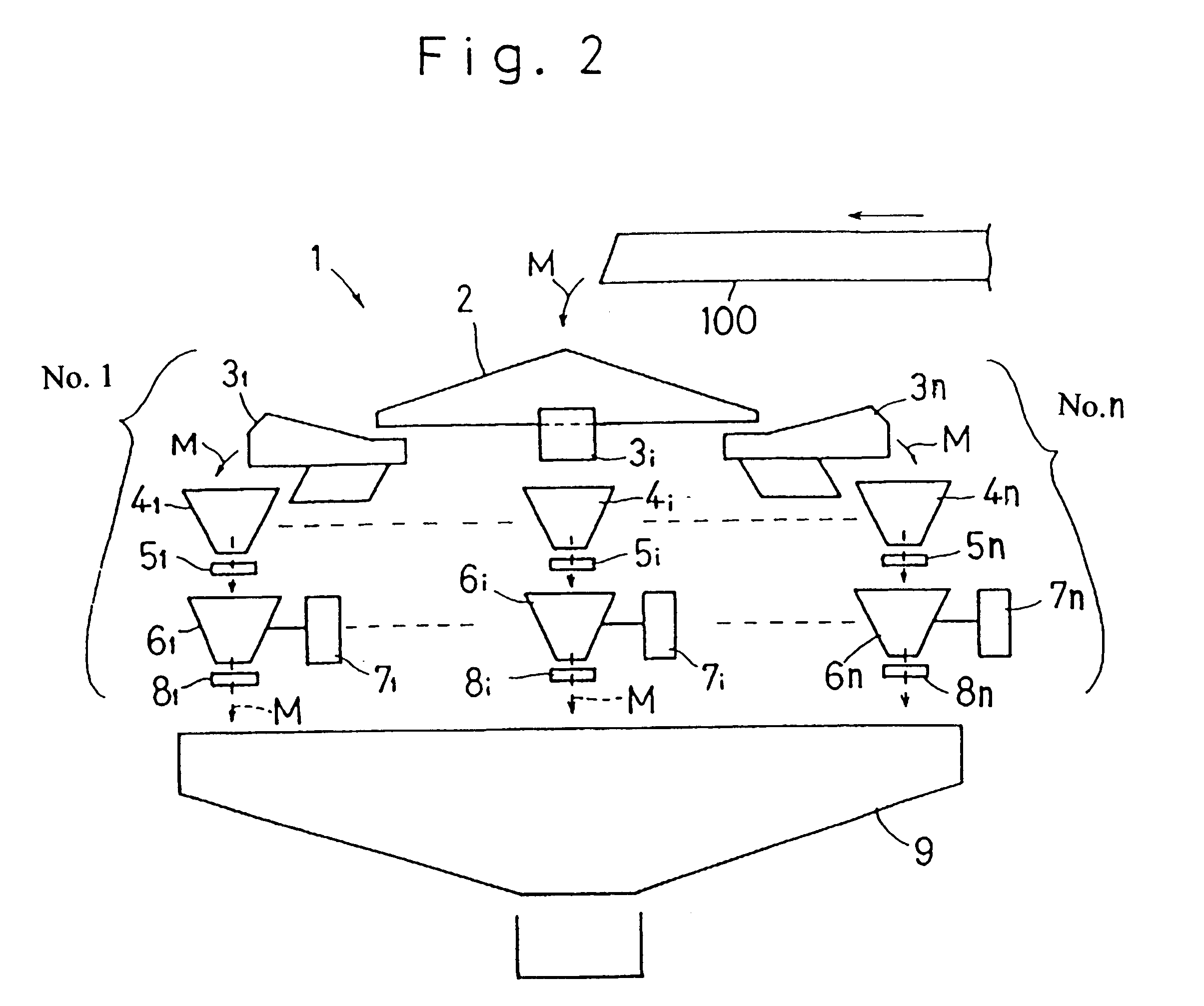

In order to provide a combination weighing apparatus having an automatic filter adjusting capability which is effective to secure a weighing accuracy and also to adjust a filter characteristic of a digital filter having a short response time, the filter characteristic is automatically adjusted, based on a result of comparison of respective vibration components U of filtered weight signals FW1 to FWn with a permissible level US of the vibration components, so that the respective vibration components U of the filtered weight signals FW1 to FWn can attain a value approximating to the permissible level US, but not exceeding the permissible level US. In this way, by damping the vibration components U down to a value within the permissible level US, the weighing accuracy can be secured and, on the other hand, by damping the vibration components U down to a value approximating to the permissible level US, the filter characteristic can be obtained quickly in a short time.

Owner:ISHIDA CO LTD

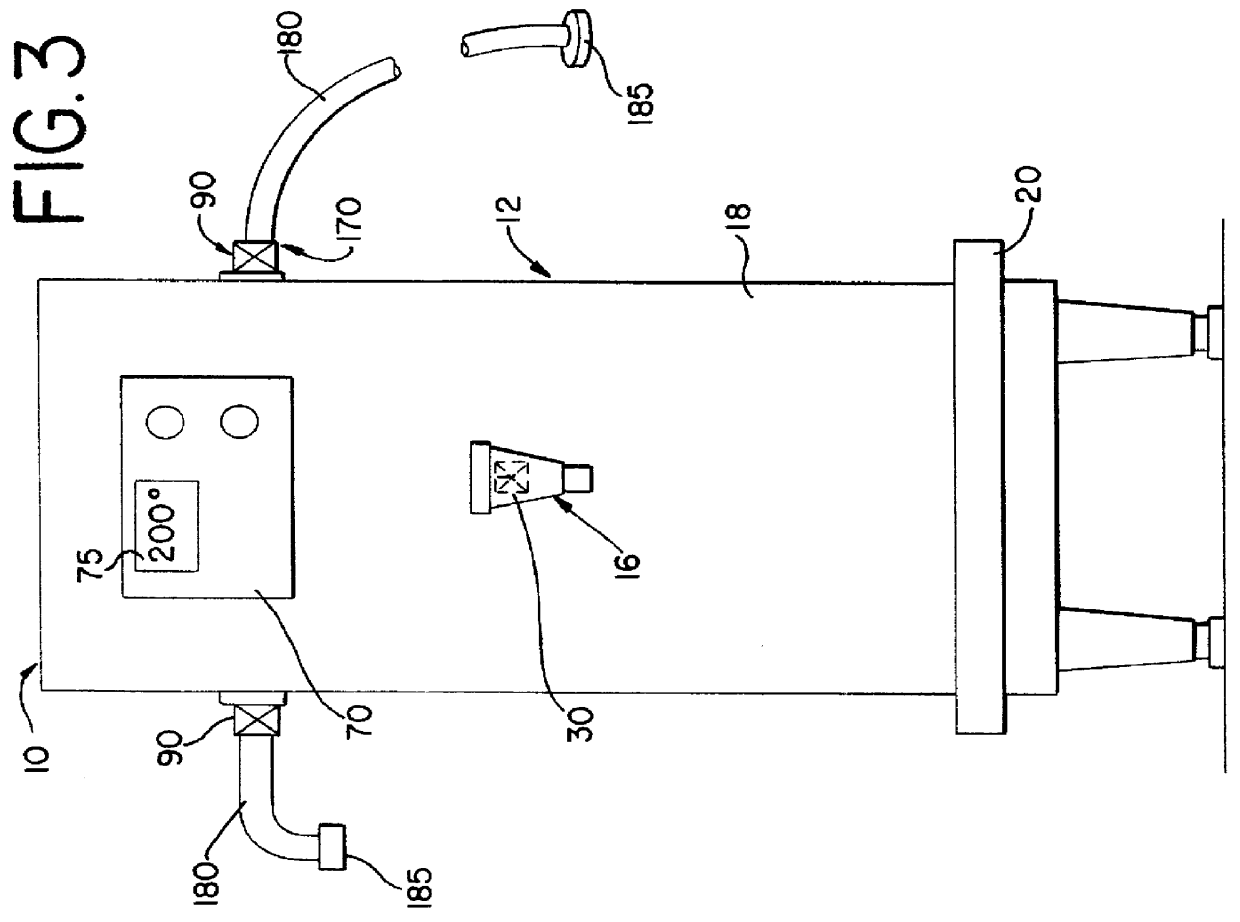

Heated water dispensing system

InactiveUS6164189AAutomatic productionProducing water of a selected temperature quickly and efficientlyBeverage vesselsLiquid transferring devicesControl signalEngineering

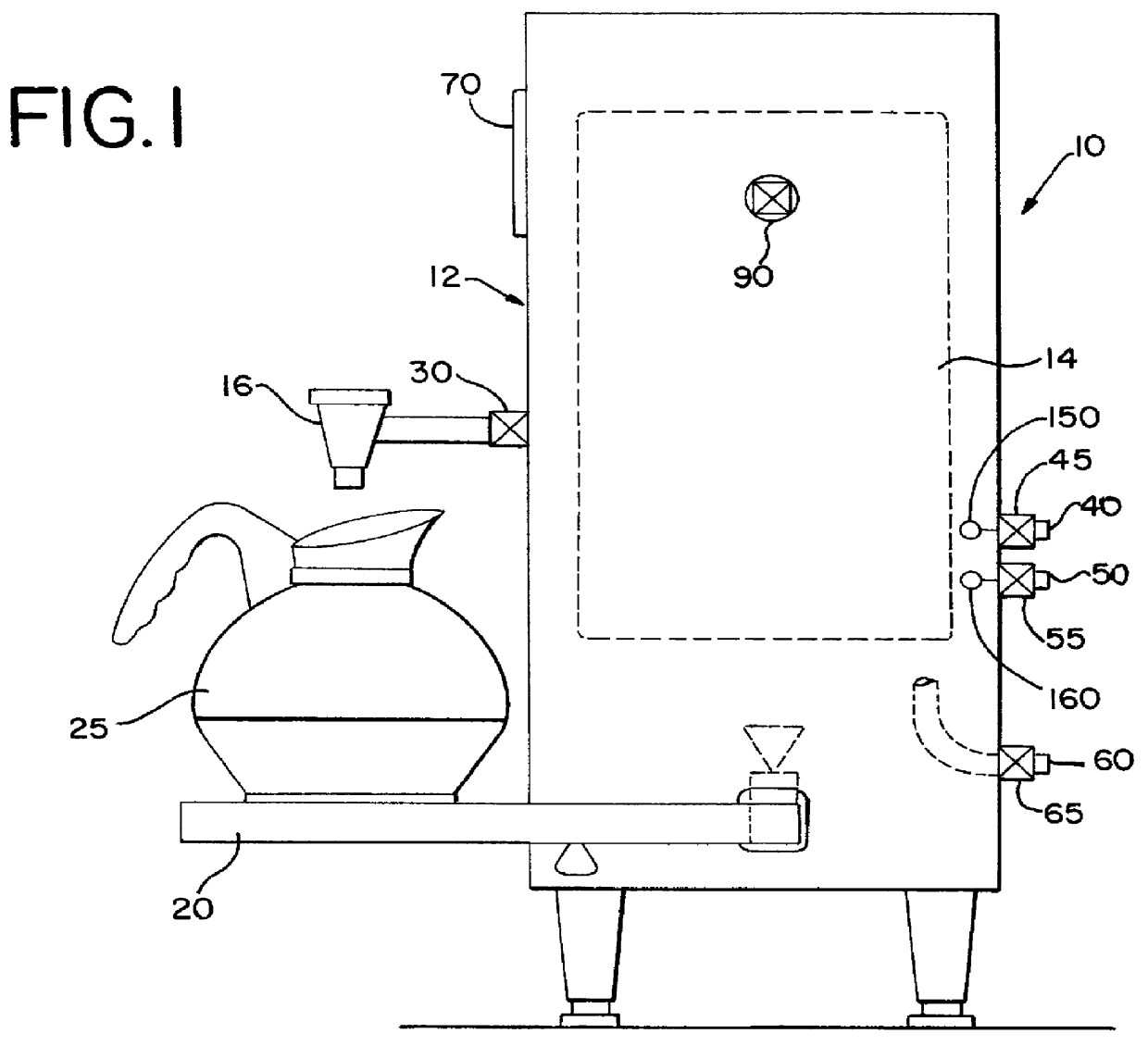

A heated water dispensing apparatus has been described. The heated water dispensing apparatus includes a reservoir for retaining a quantity of water, a selector for selecting a temperature of water and a volume of water to be dispensed, and a controllable dispense valve for automatically dispensing water from the reservoir. The heated water dispensing apparatus also includes a weighing assembly which generates a weight control signal relating to the volume of water dispensed through the dispense valve and at least one device outlet valve for providing heated water to a remote device. The heated water dispensing apparatus also includes a controller. The controller operates the dispense valve in accordance with the weight control signal so that a selected volume of water is automatically and accurately dispensed. The controller also operates the dispense valve to prevent dispensing of water through the dispense valve before water of a selected temperature has been produced. The controller operates the device outlet valve so that a predetermined quantity of water at a predetermined flowrate and a predetermined temperature is dispensed to a selected remote device.

Owner:BUNN O MATIC

Method and apparatus for mass based dispensing

ActiveUS20040245284A1Excessive shock to the scale is prevented during loadingTableware washing/rinsing machine detailsTransportation and packagingDiluentEngineering

A dispenser (200) dispenses an amount of concentrate in a container (204) using a diluent to form a use solution. A dispenser includes a housing (201). A product holder (210) is positioned to support the container (204) with the concentrate in the cavity of the housing. The product holder (210) carried by a scale (240), wherein weight of the concentrate is concerned. A moveable container holder (215) is moveable between a first position and a second position. The container holder is positioned between the housing (201) and the container (204). A cover (216) is operatively connected to the container holder (215) at a connection. A cam surface is adjacent the housing (201). The cover (216) has a cam (216d) for contacting the cam surface (201a), wherein when the cover (216) is moved from a closed position to an open position, the connection moves upward, thereby carrying the container holder (215) and the container (204) which are moved upward lifting the container (204) off of the product holder (210).

Owner:ECOLAB USA INC

Weight-filling method, and a corresponding device

InactiveUS6073667ASuppress mutationAccurate weighingLiquid fillingWeighing apparatus using elastically-deformable membersEngineeringLoad cell

Owner:SERAC GROUP

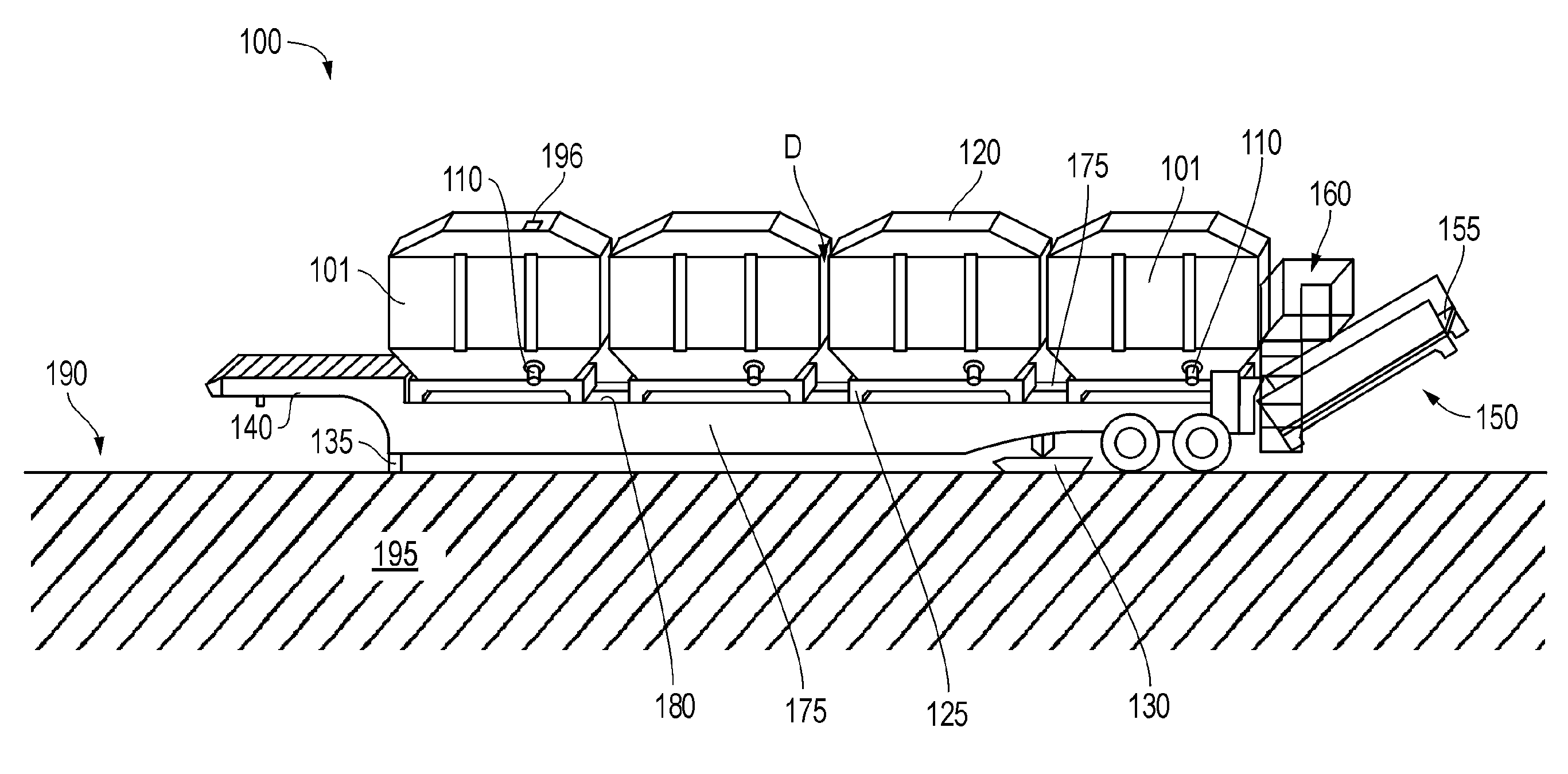

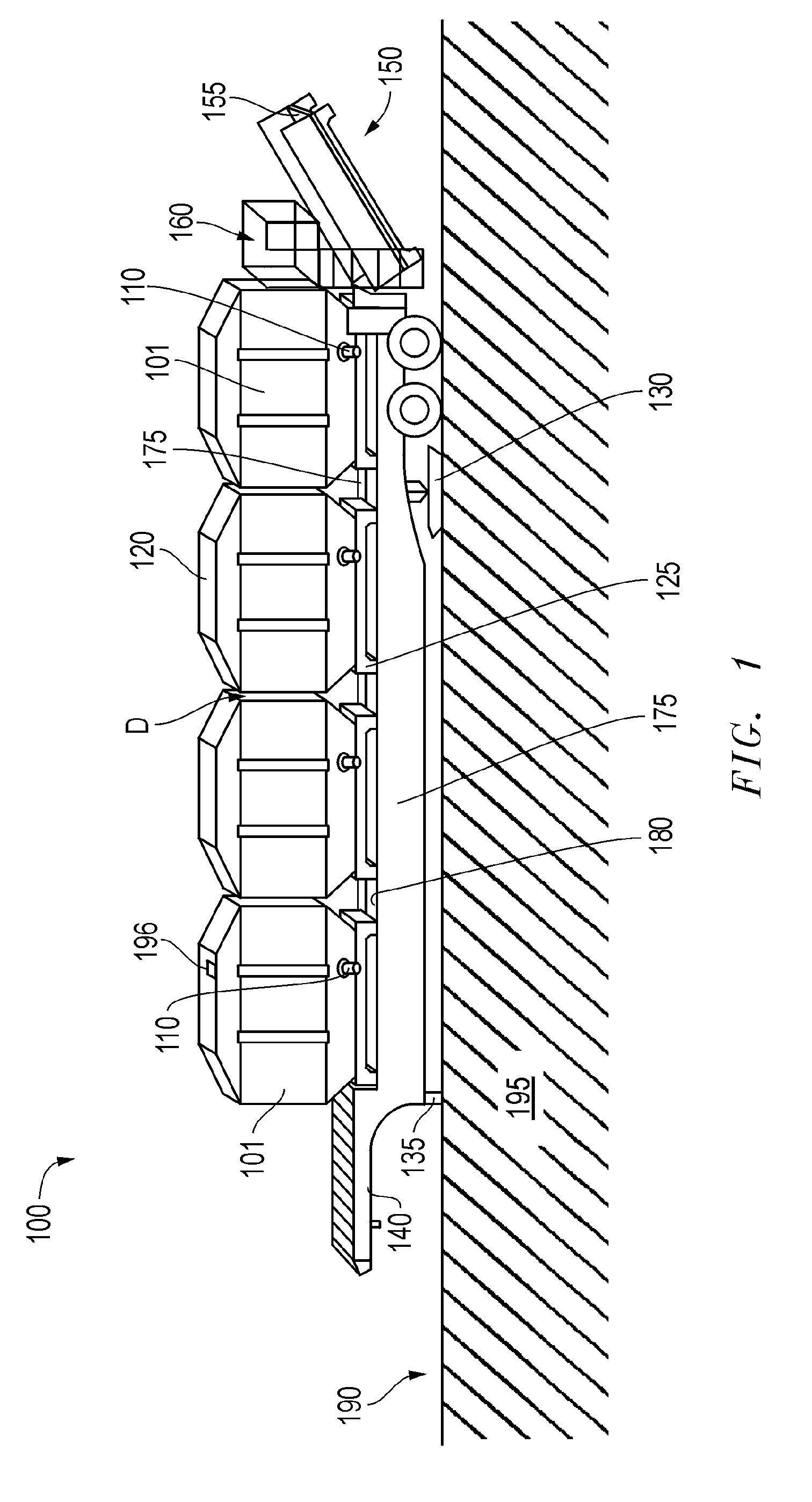

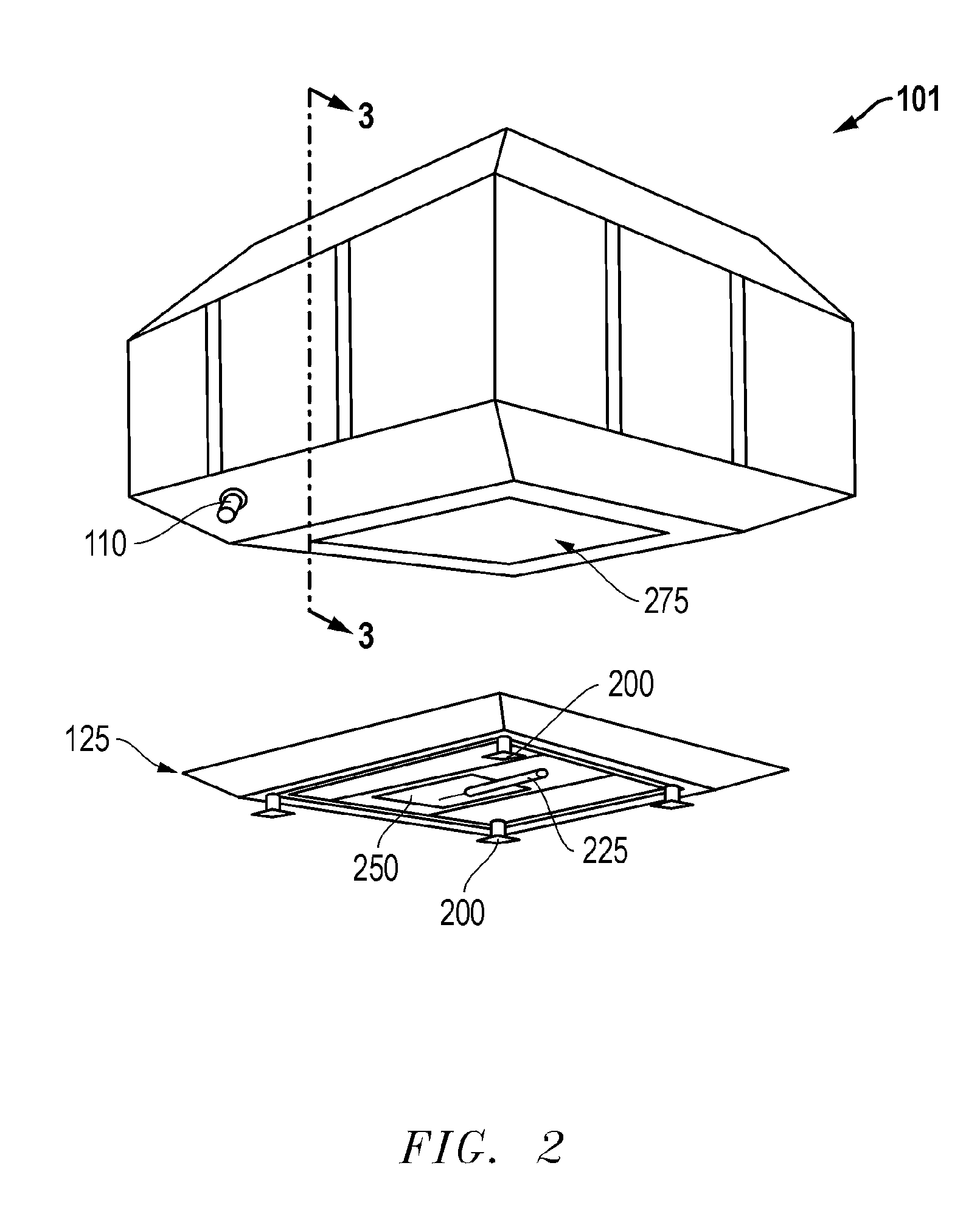

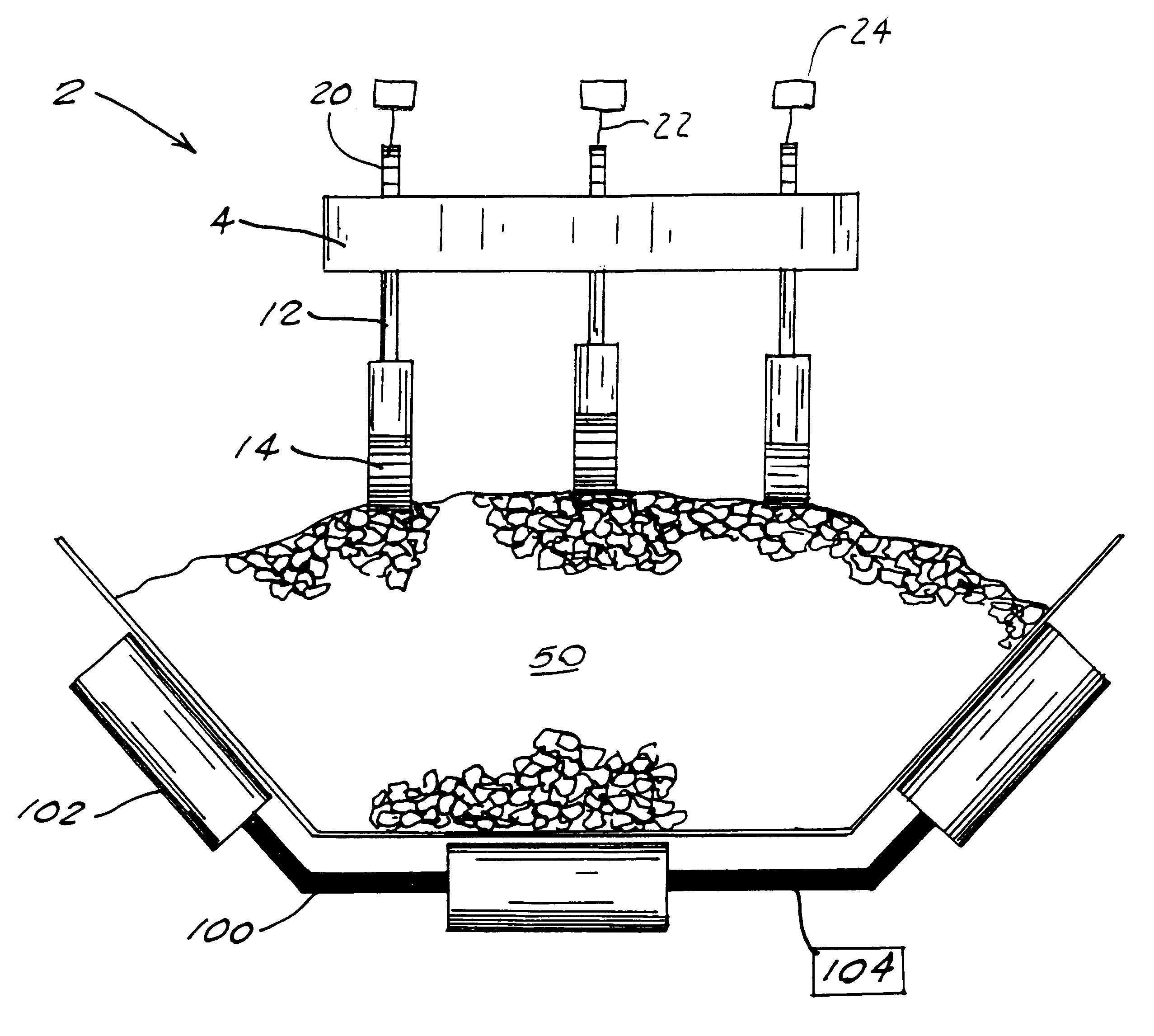

Aggregate delivery unity

ActiveUS20140321950A1Large containersVehicle with removable loadingWireless controlMeasurement device

A delivery unit for providing aggregate to a worksite, such as a wellsite location. The unit may include a mobile chassis for accommodating a plurality of modular containers which in turn house the aggregate. As such, a weight measurement device may be located between each container and the chassis so as to monitor aggregate levels within each container over time. The units may be particularly well suited for monitoring and controlling aggregate delivery during a fracturing operation at an oilfield. The modular containers may be of an interchangeable nature. Furthermore, a preferably wireless control device may be provided for monitoring and directing aggregate delivery from a relatively remote location.

Owner:LIBERTY OILFIELD SERVICES LLC

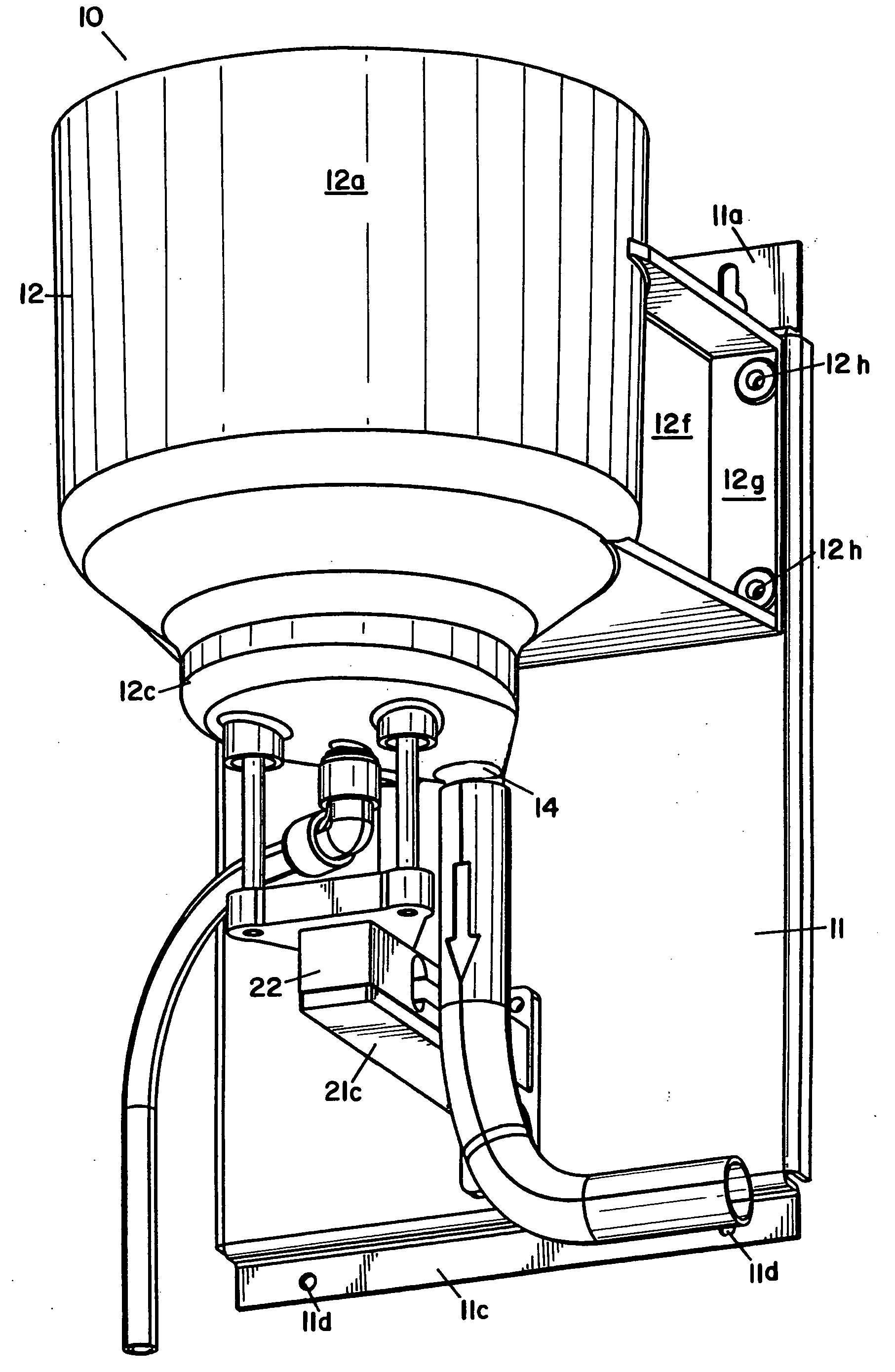

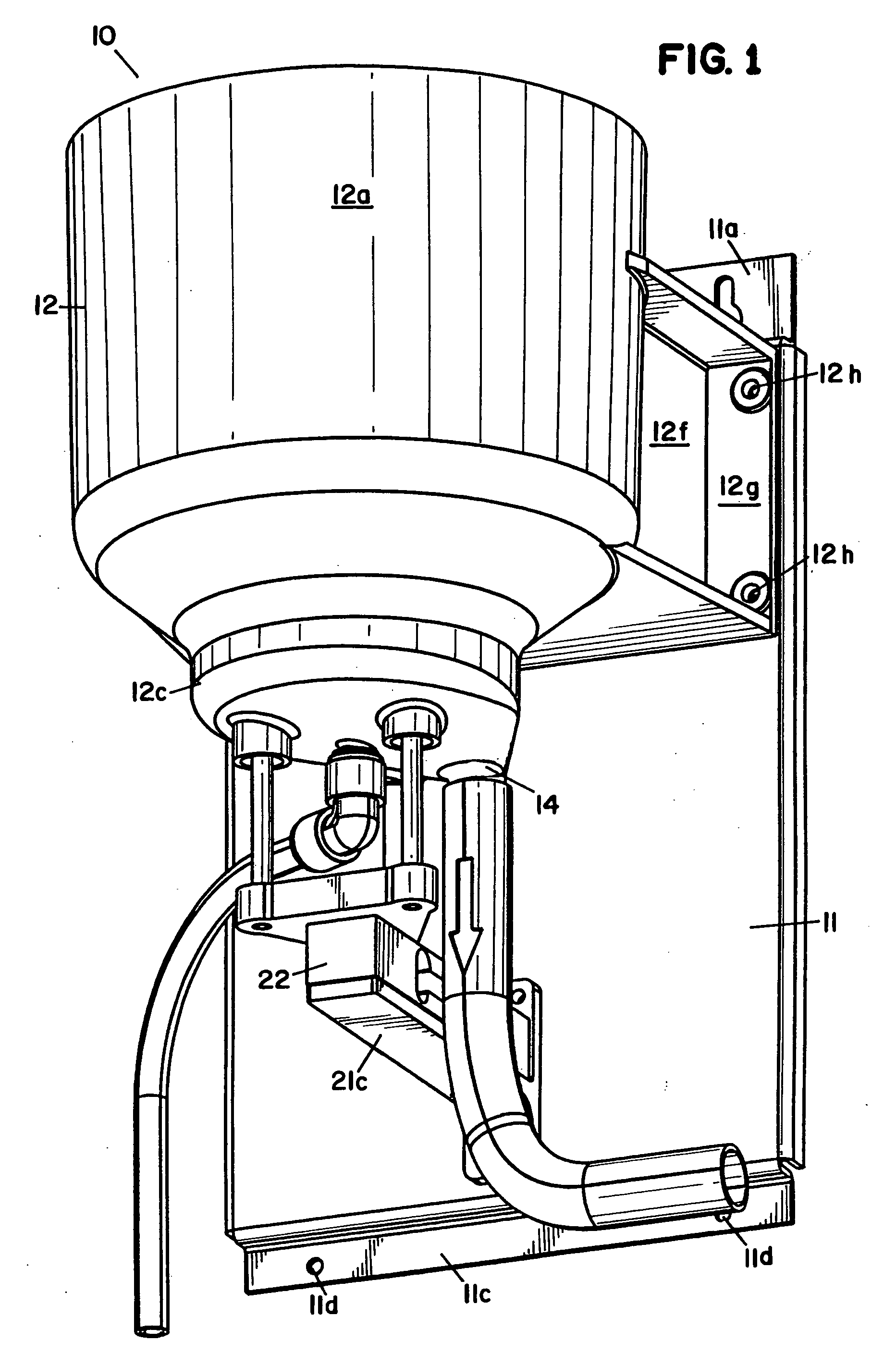

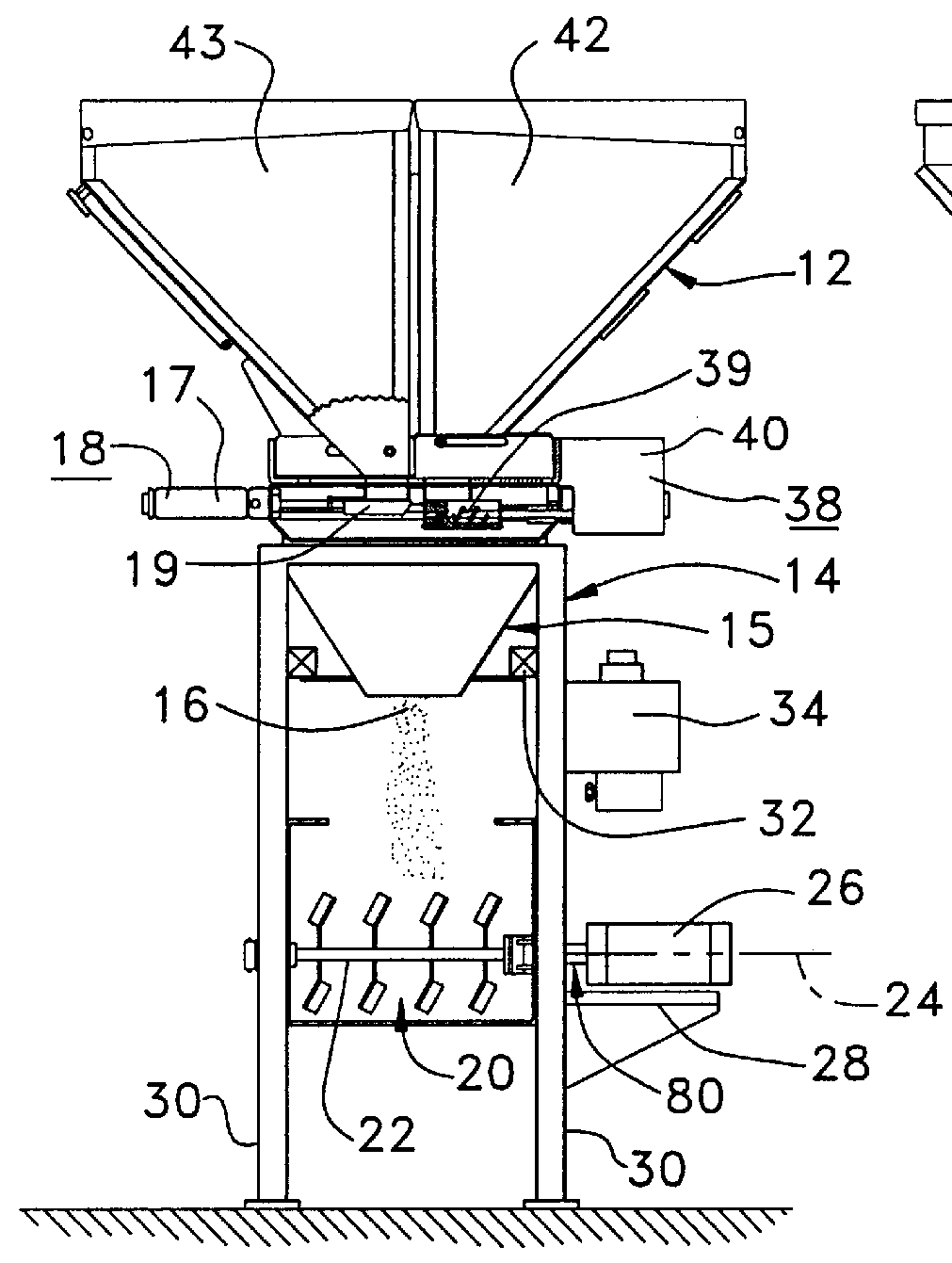

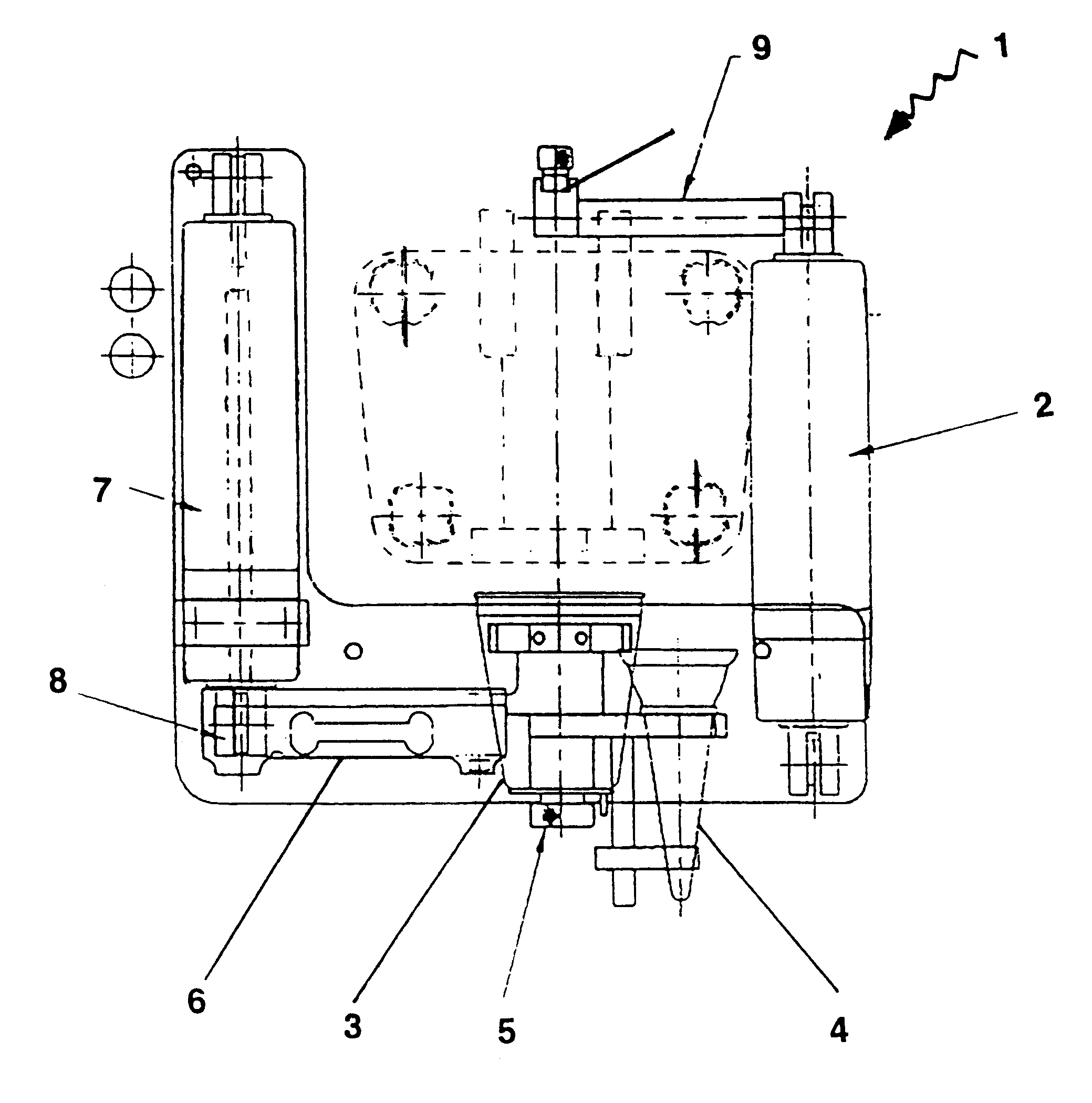

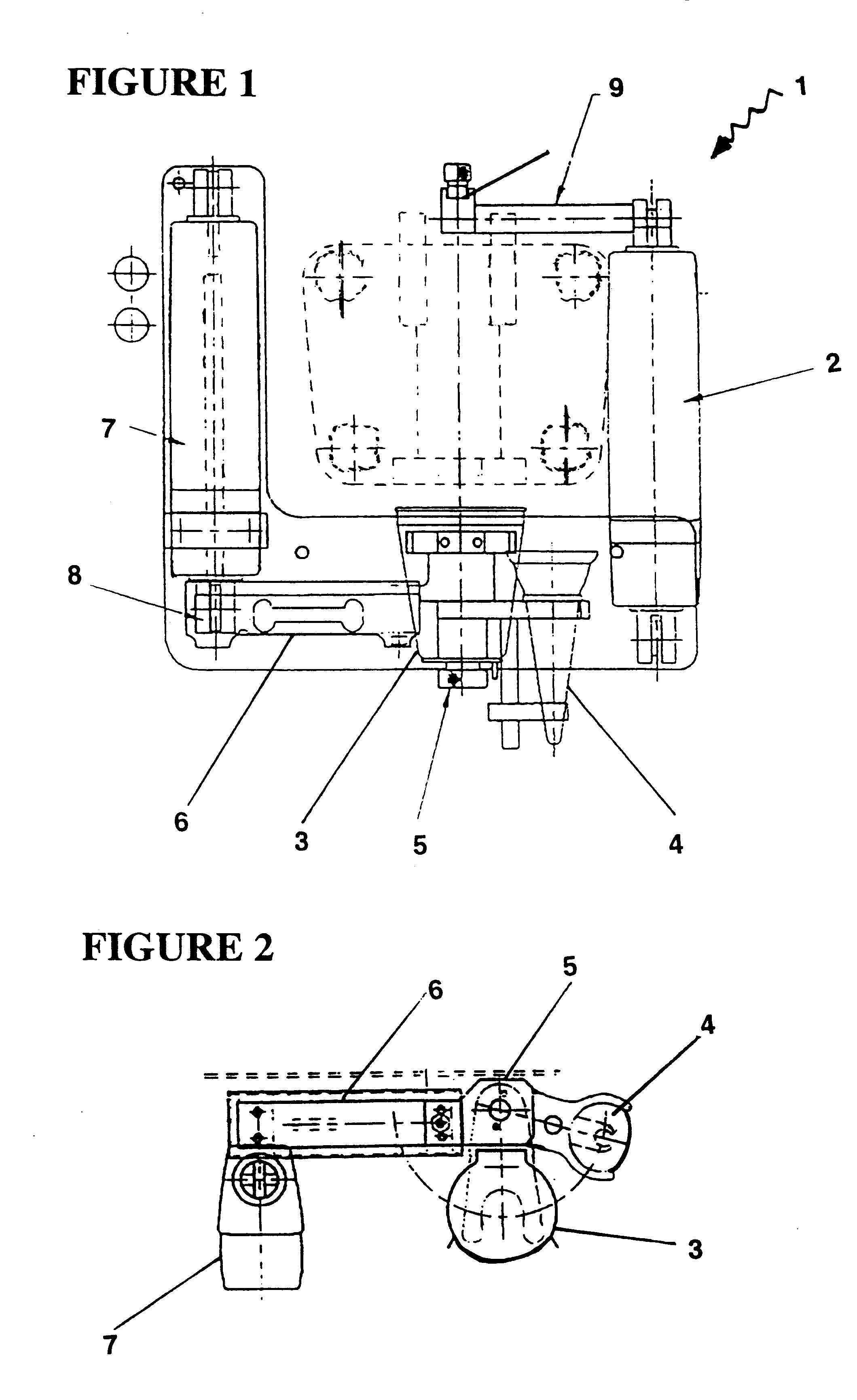

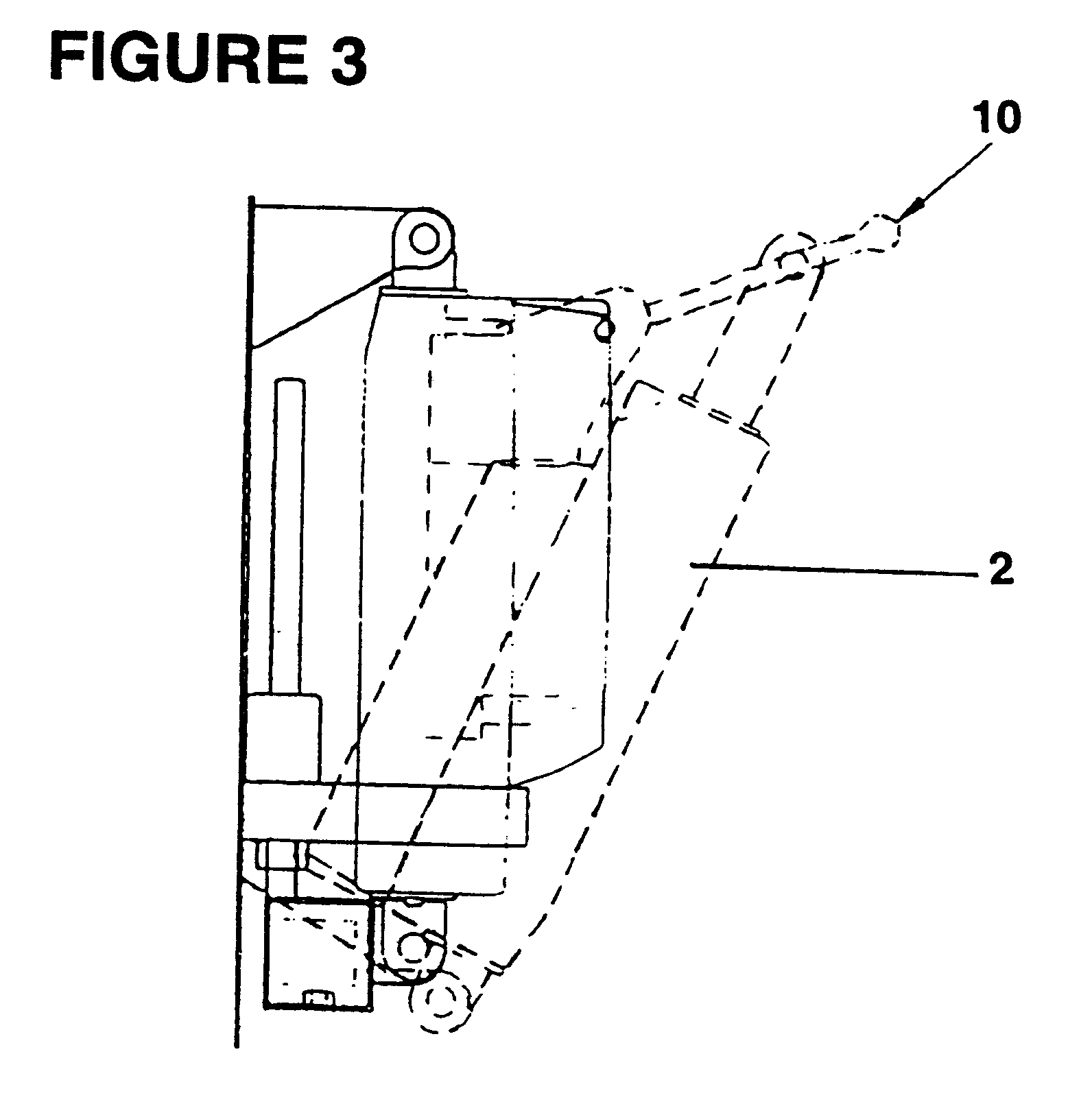

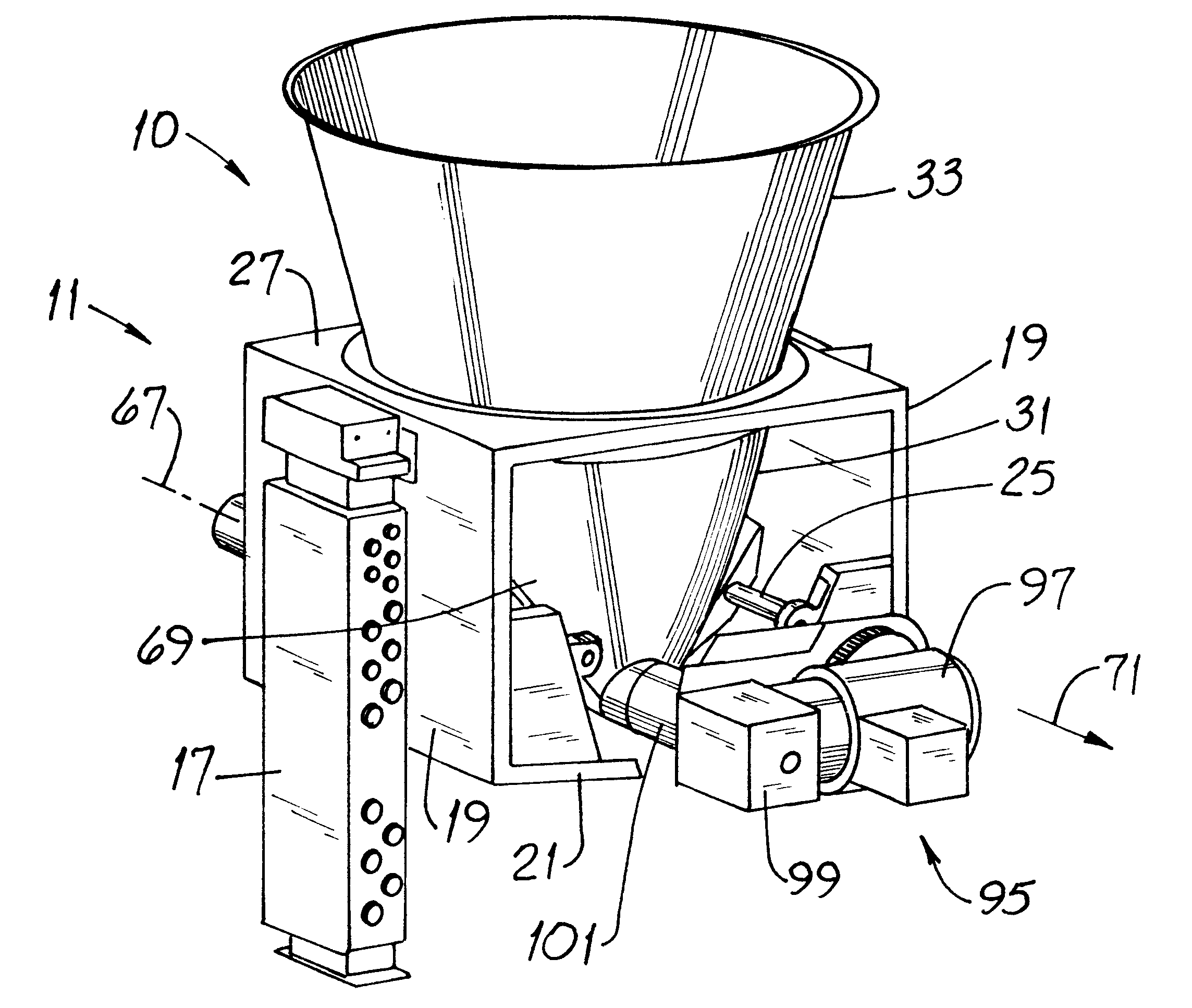

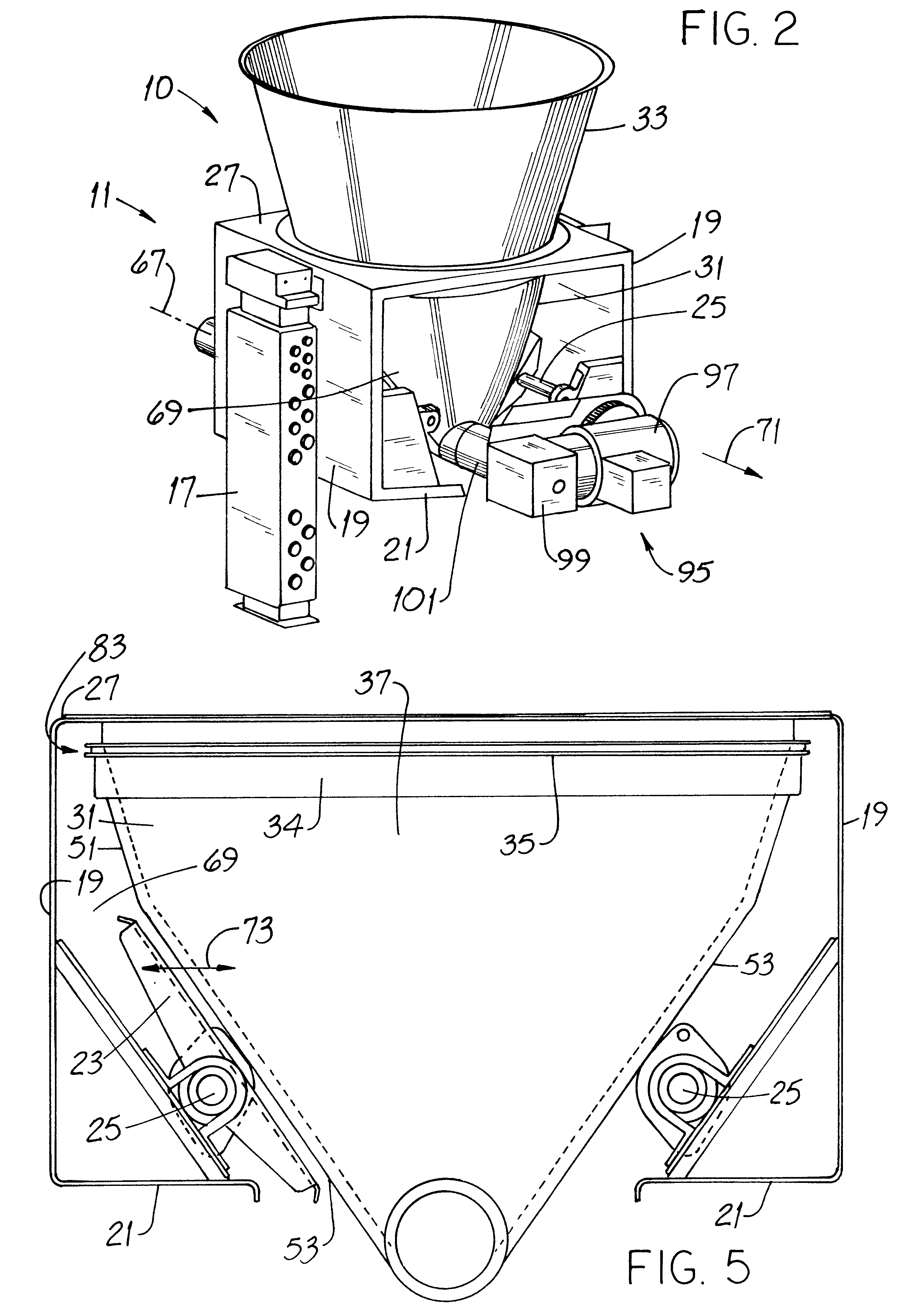

Removable hopper with material shut-off

A gravimetric weigh scale blender having a plurality of hoppers 41, 42 and 43 discharging into a weigh chamber 14. The hoppers are funnel-shaped, each terminating in a discharge opening which permits flow of material from the hopper through a metering device 19 or 38 into a weigh chamber 14. Two of the hoppers are mounted for horizontal sliding displacement in the frame of the blender and a valve is provided at the bottom of each hopper to automatically close the hopper when it is moved horizontally. The valve consists of a shoe 53 slidable on the bottom of the funnel of the hopper to be operated by a saddle 51 on the frame so as to allow flow through the opening when the hopper is in its operating position but is displaced to close the opening when the hopper is moved away from the operating position. An improved metering device is also disclosed which comprises an auger device 70 which includes a trough 71 pivotally mounted under one of the hopper openings for pivotal movement between an operative position adjacent the opening and a clean-out position remote from the opening. An auger is provided in the trough which may be driven at the desired speed to provide a positive metered flow through the trough from the hopper's discharge opening into the weigh chamber.

Owner:MAGUIRE STEPHEN B

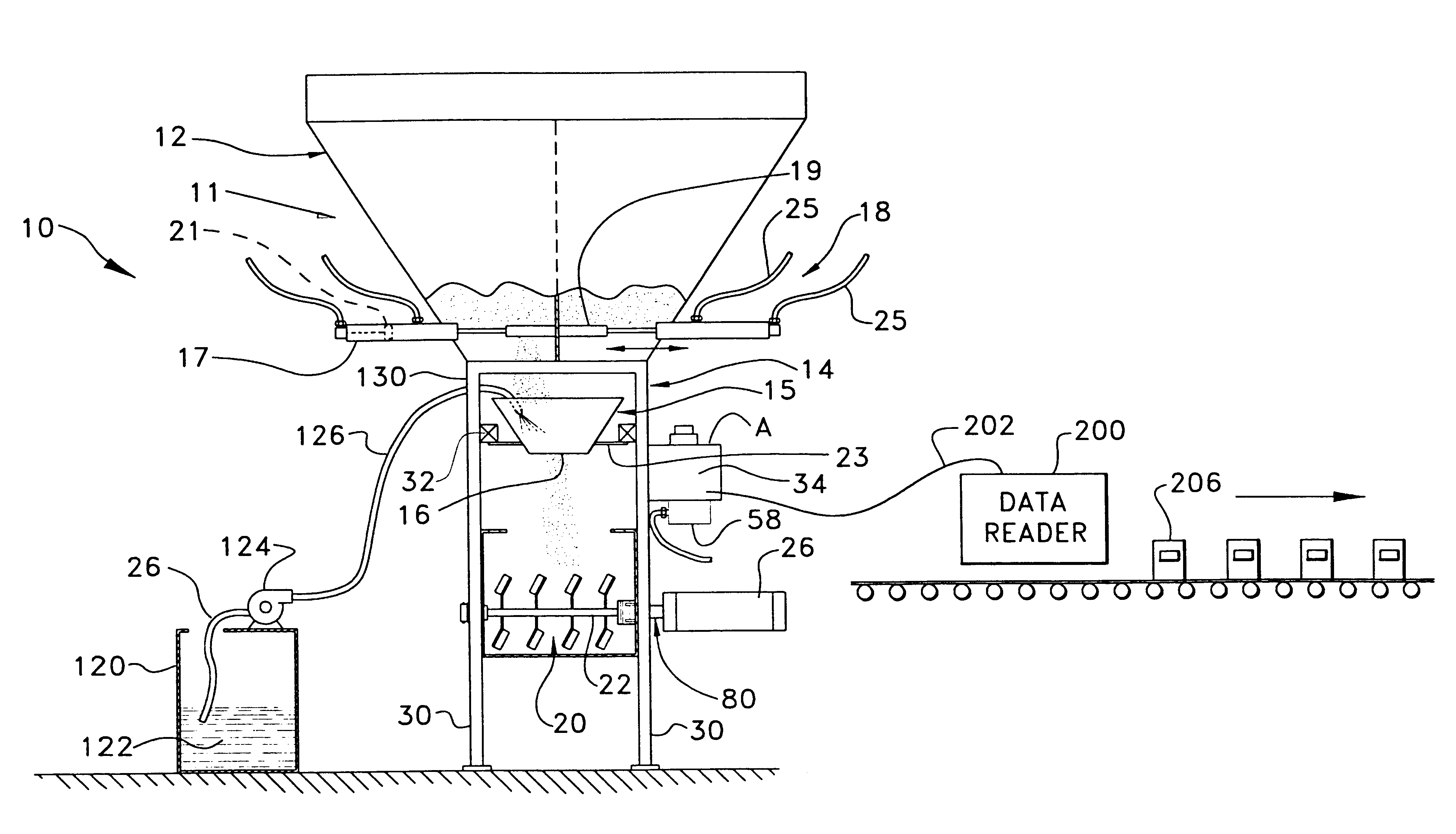

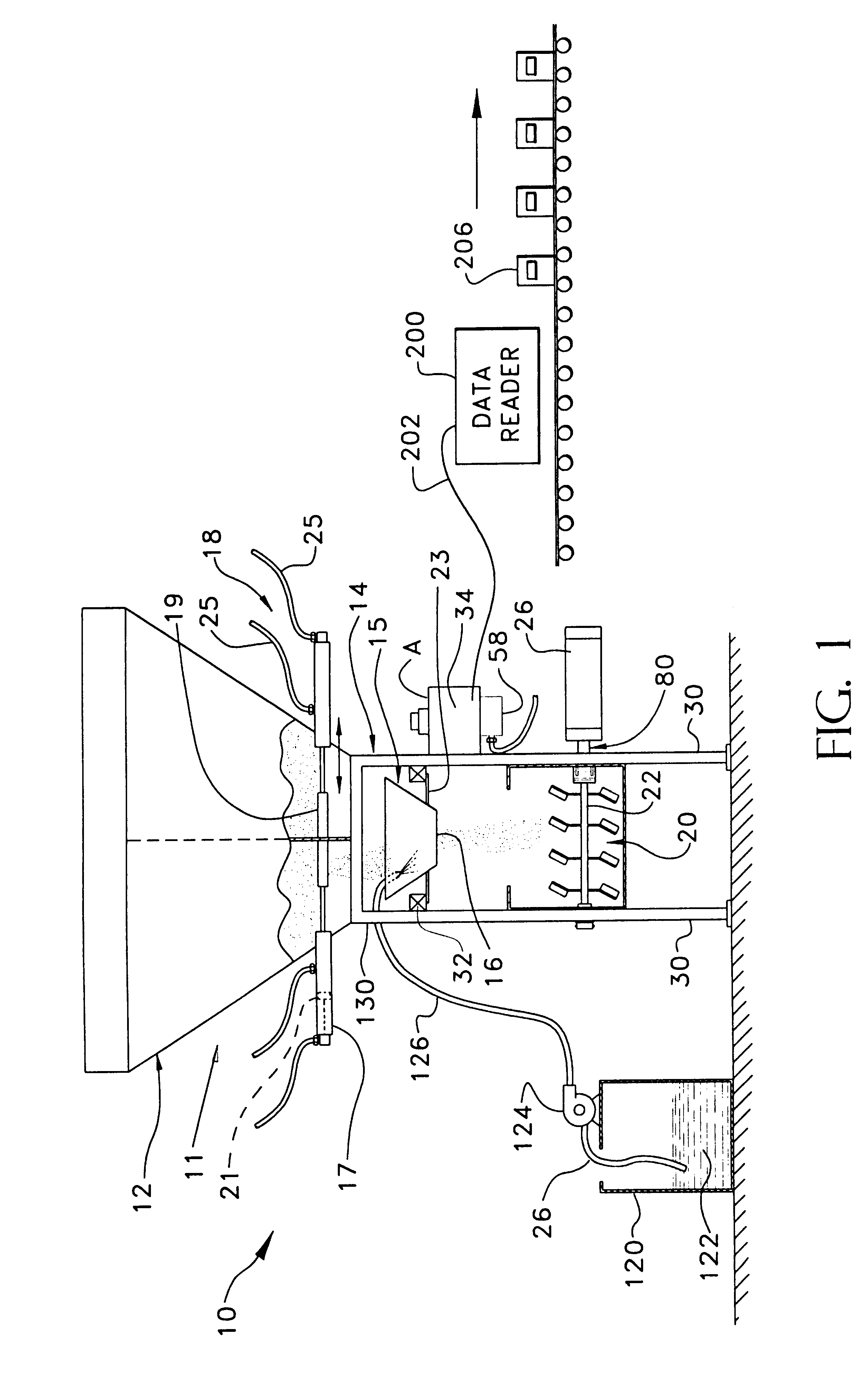

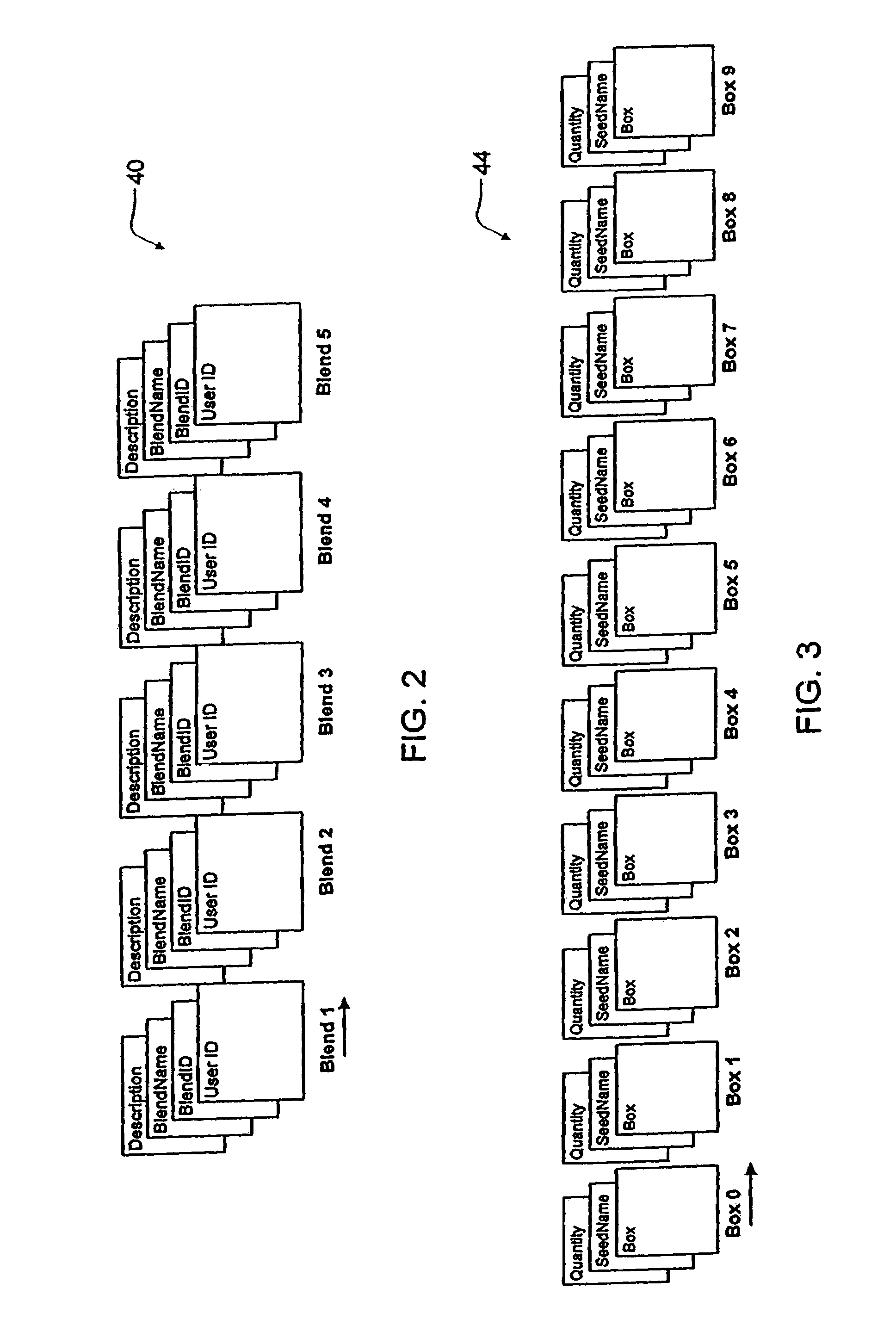

Gravimetric blender with operatively coupled bar code reader

InactiveUS6188936B1Accurate measurementEntered easily and accuratelyDigital data processing detailsRotary stirring mixersBarcodeMicroprocessor

A method for weight blending of granular materials comprises at a remote site generating a command for desired operation of granular material weight blending apparatus; encoding said command into transportable time-stable machine readable tangible storage media; transporting said media to a bar code reader operatively connected to said granular material weight blending apparatus; scanning the tangible media having the command encoded thereon to read the command; and providing the read command as input to a in microprocessor operatively connected to said granular material weight blending apparatus for regulating operation of the same.

Owner:MAGUIRE PROD

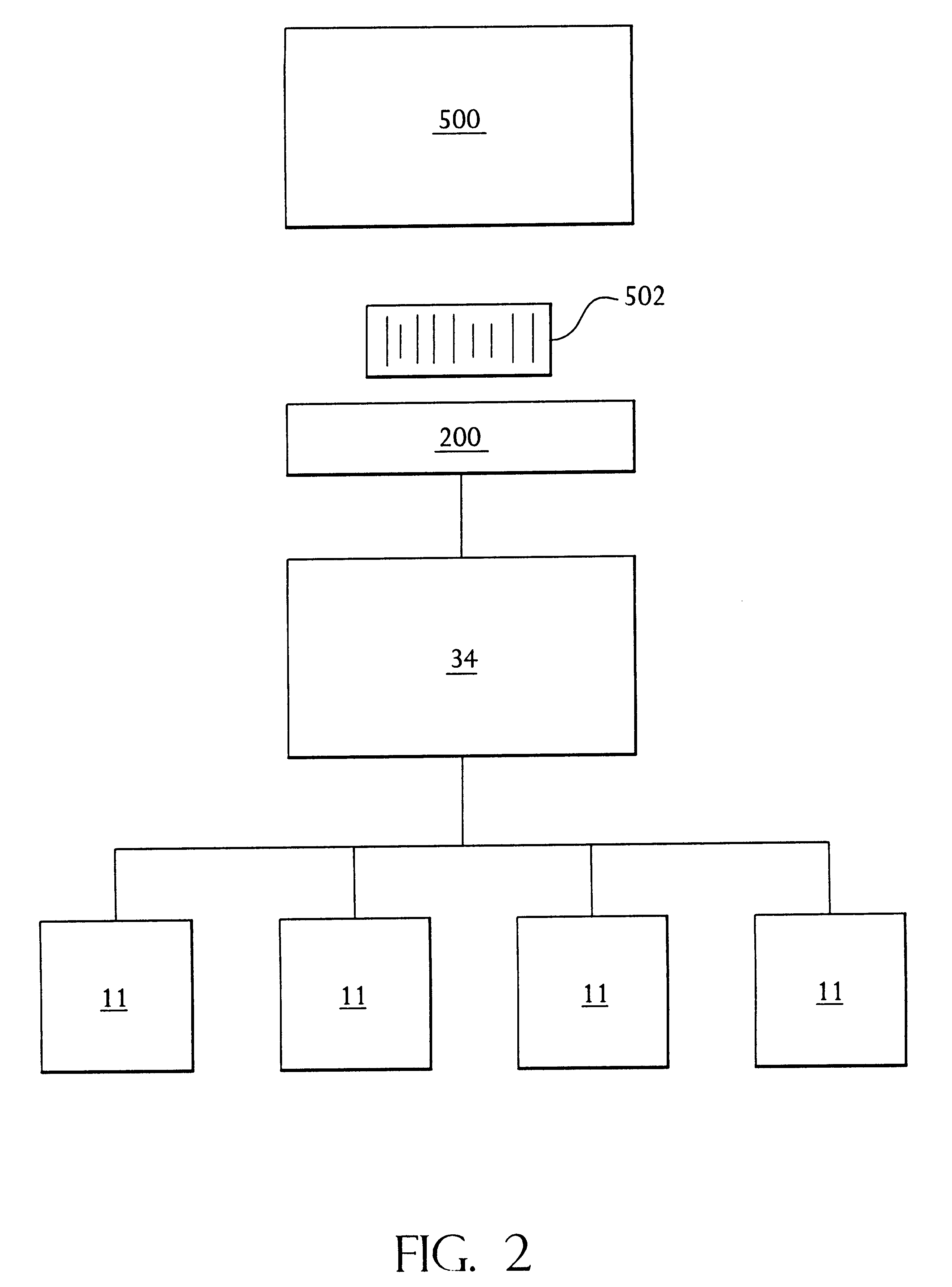

System and method for dispensing bulk products

A dispensing system and method is used to dispense a bulk product or to mix and to dispense bulk products on site and to price the products according to the quantity and distribution thereof. The dispensing system preferably provides automated merchandising by providing up-to-date product information and by allowing customers to select and purchase one or more bulk products. The dispensing system can be located indoors or outdoors and is preferably designed for self-service and cash less transactions.

Owner:MAZUR GREGORY

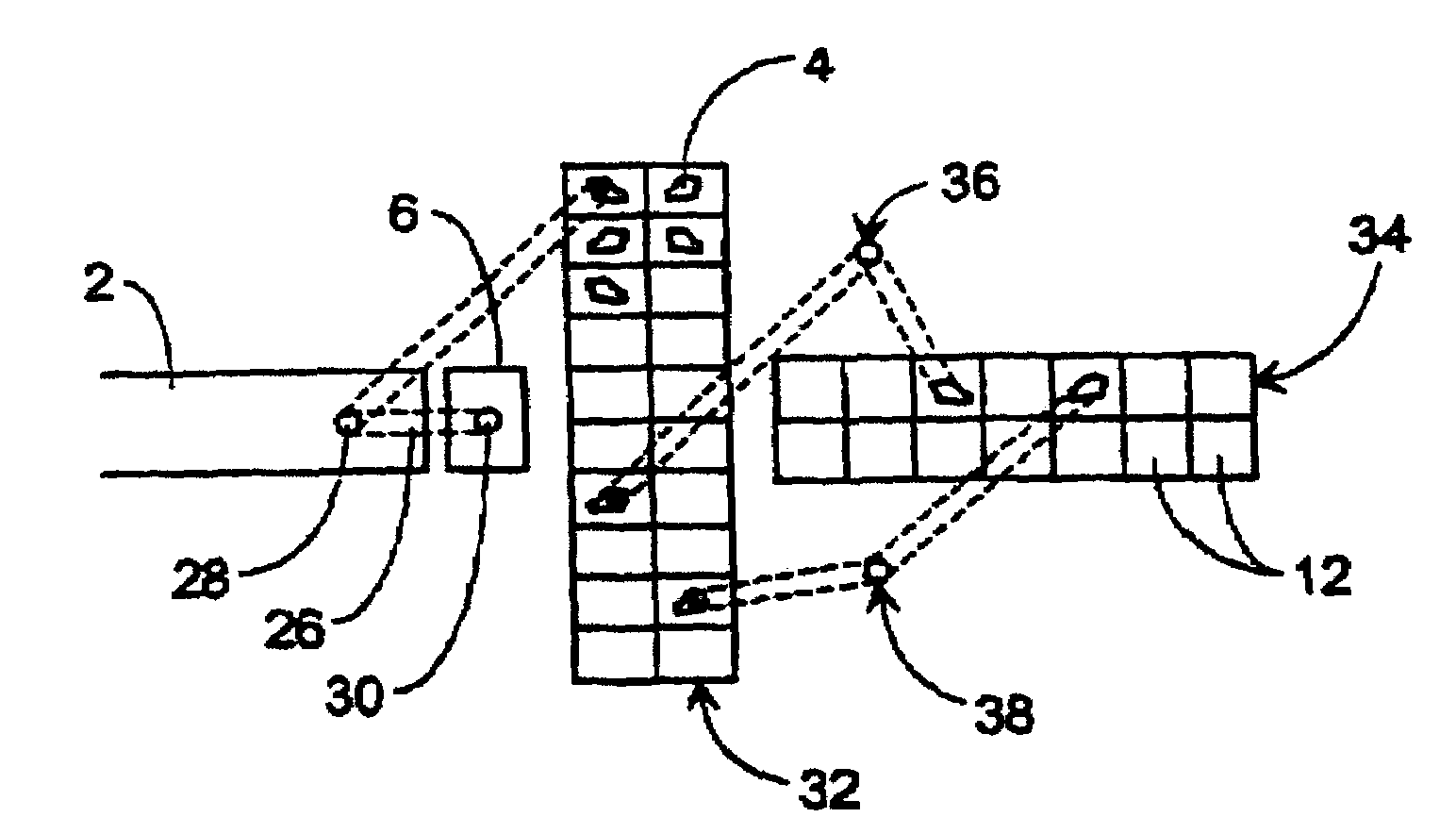

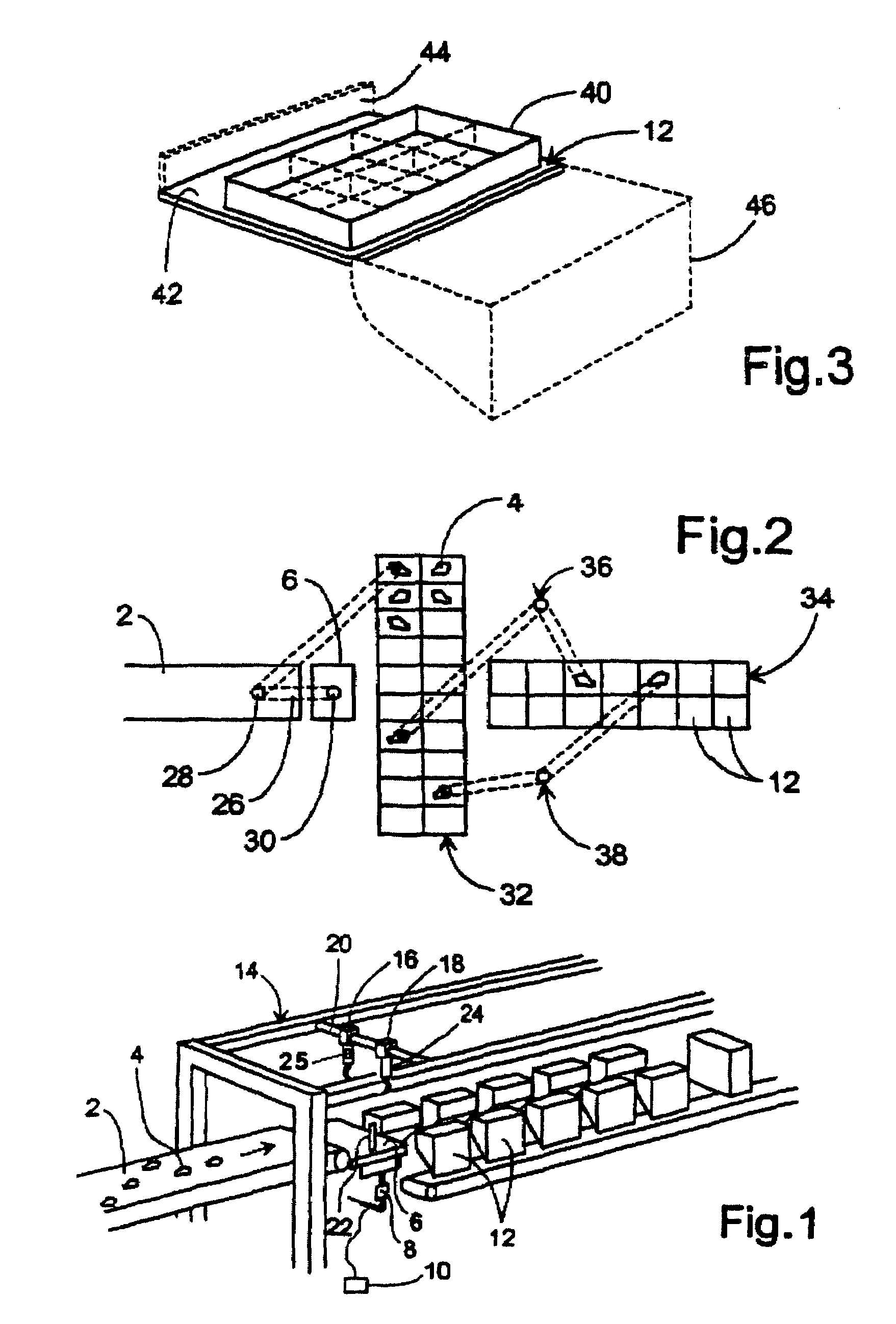

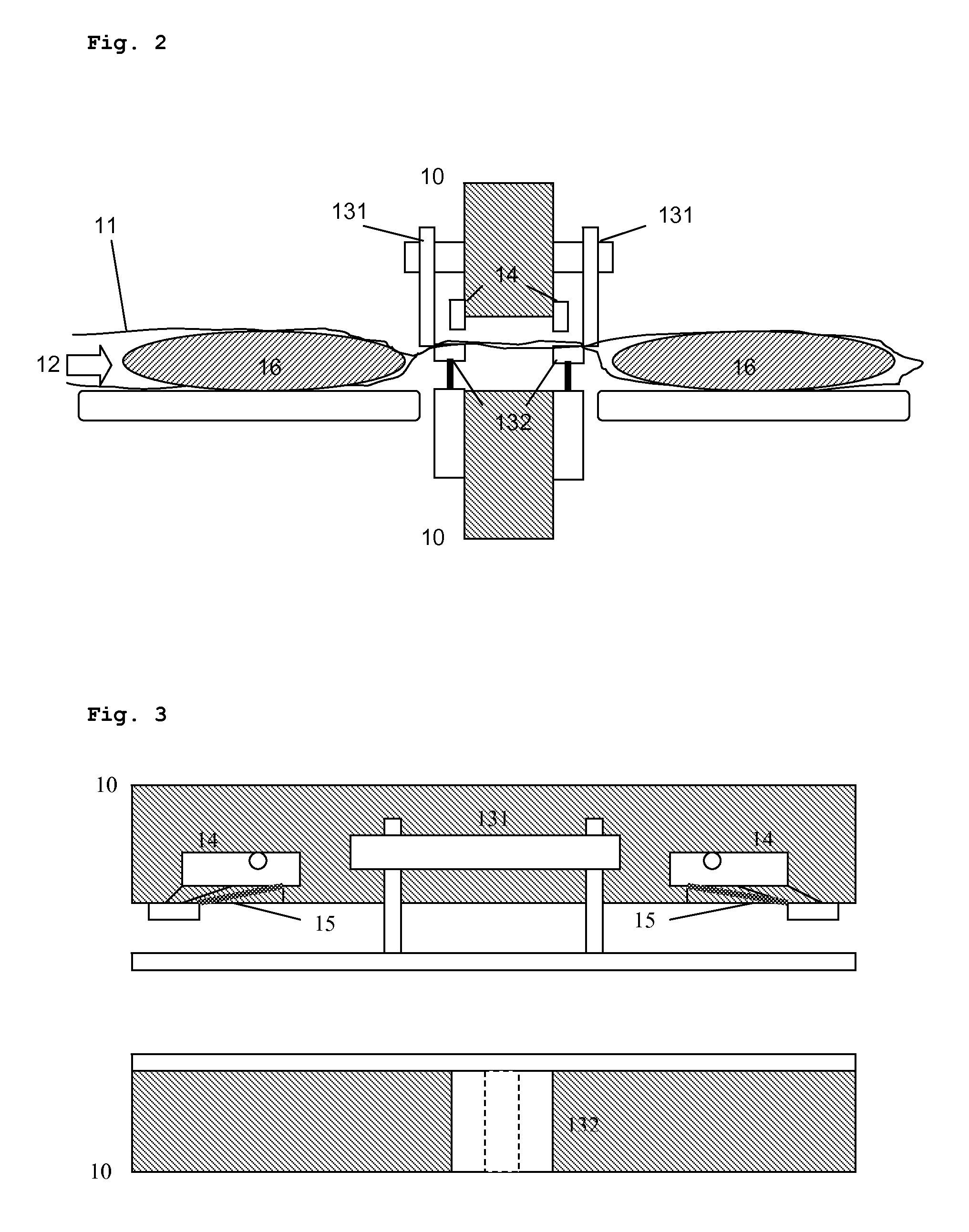

Grader apparatus

InactiveUS7258237B2Weighing apparatus with automatic feed/dischargeSortingIndustrial engineeringInstrumentation

A method for weighing and portioning items utilizing a robot device. The robot device includes a grip, e.g., a suction cup, to remove an item from a delivery station to a receiving area for placement into a particular batch. The method involves placing the items at delivery station according their weight and the weight of items already moved to a receiving area, selecting the items for a batch from the combination of items available for movement to the batch, and selective batching of the items in weight-determined and, optionally, type-determined groups.

Owner:SCANVAEGT INT AS

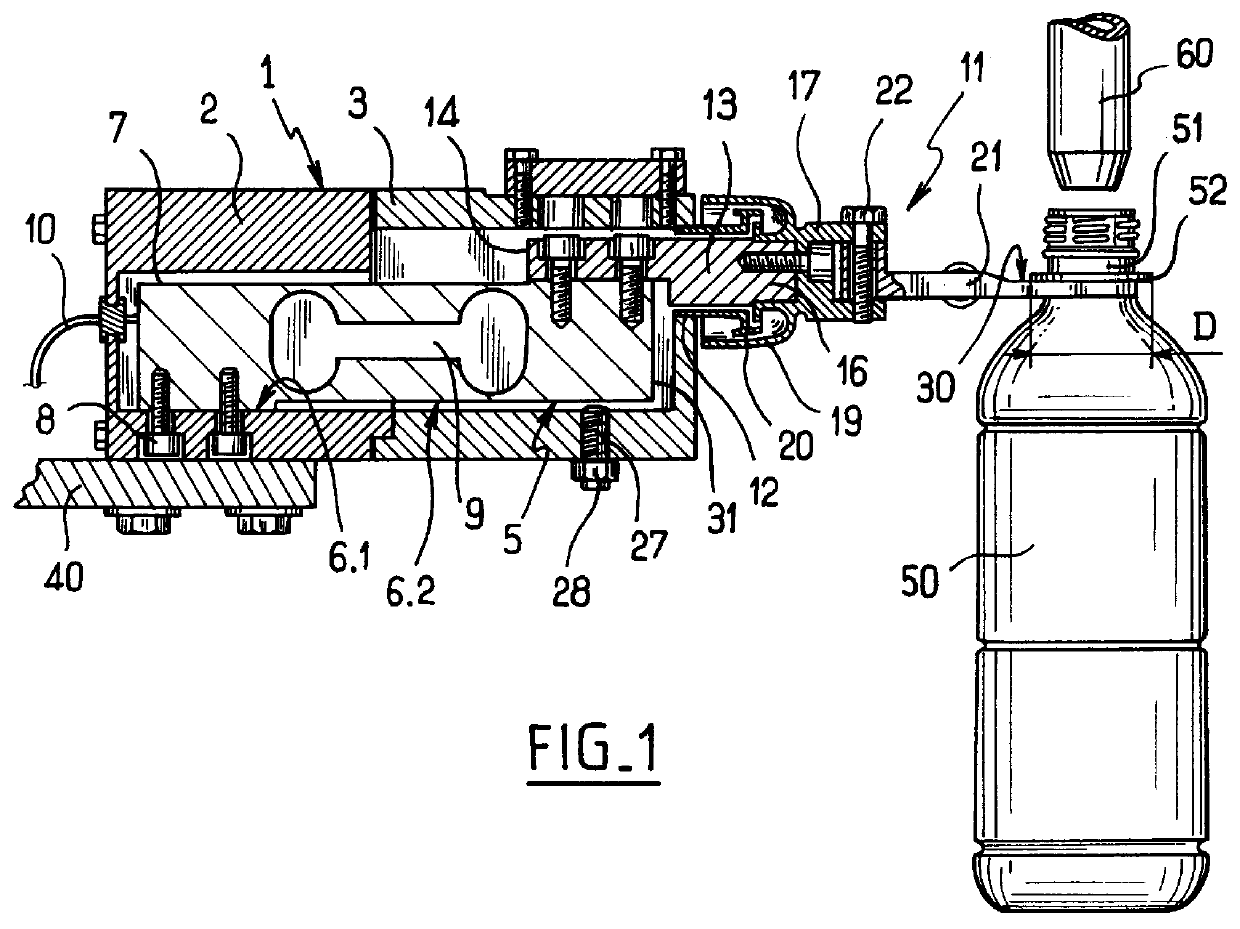

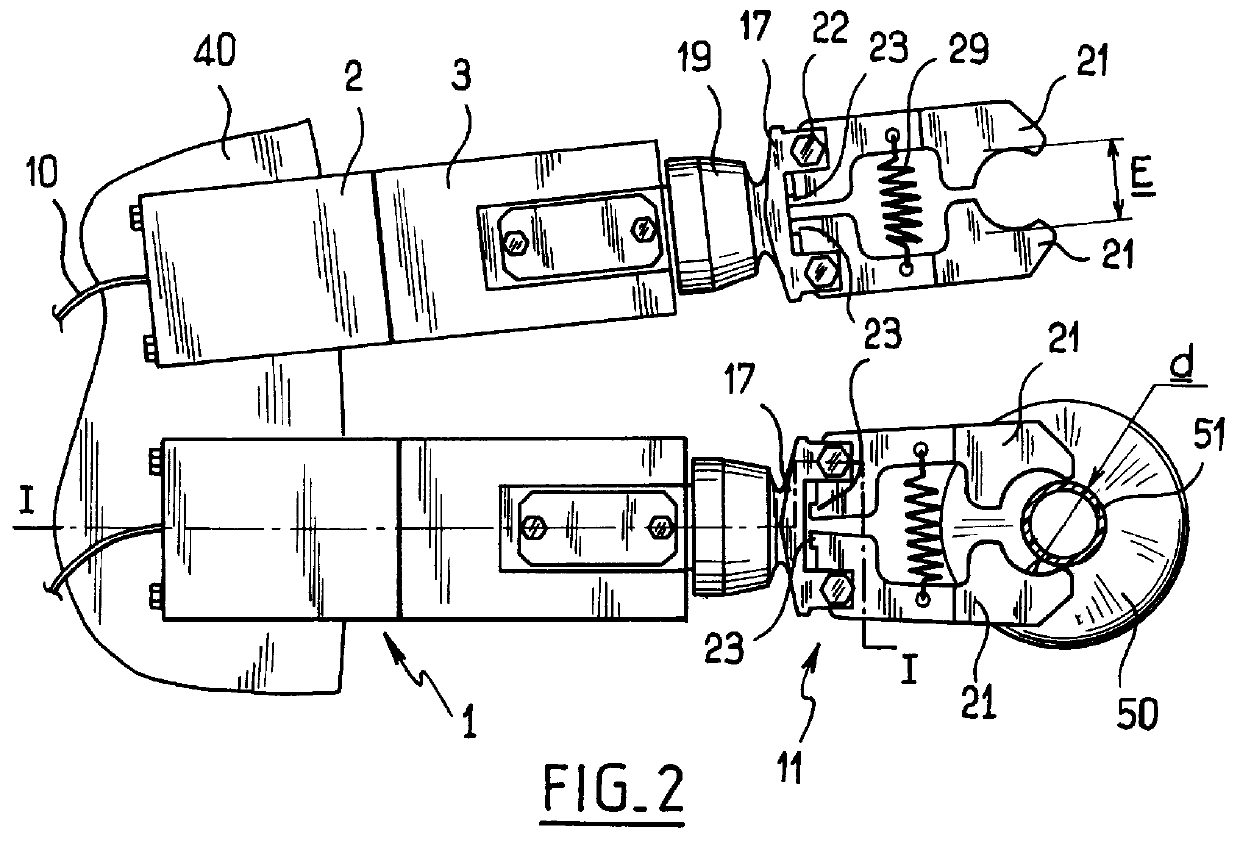

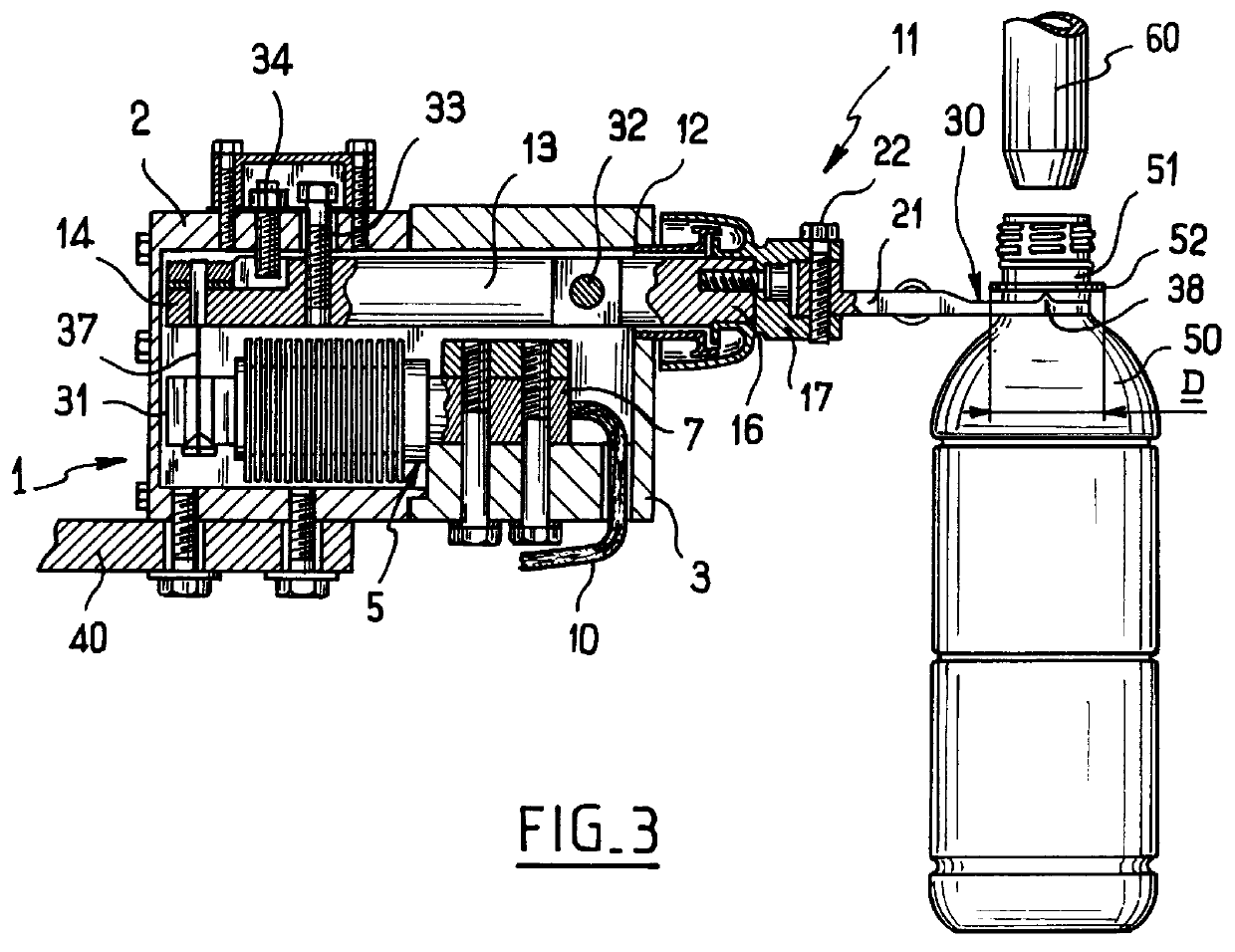

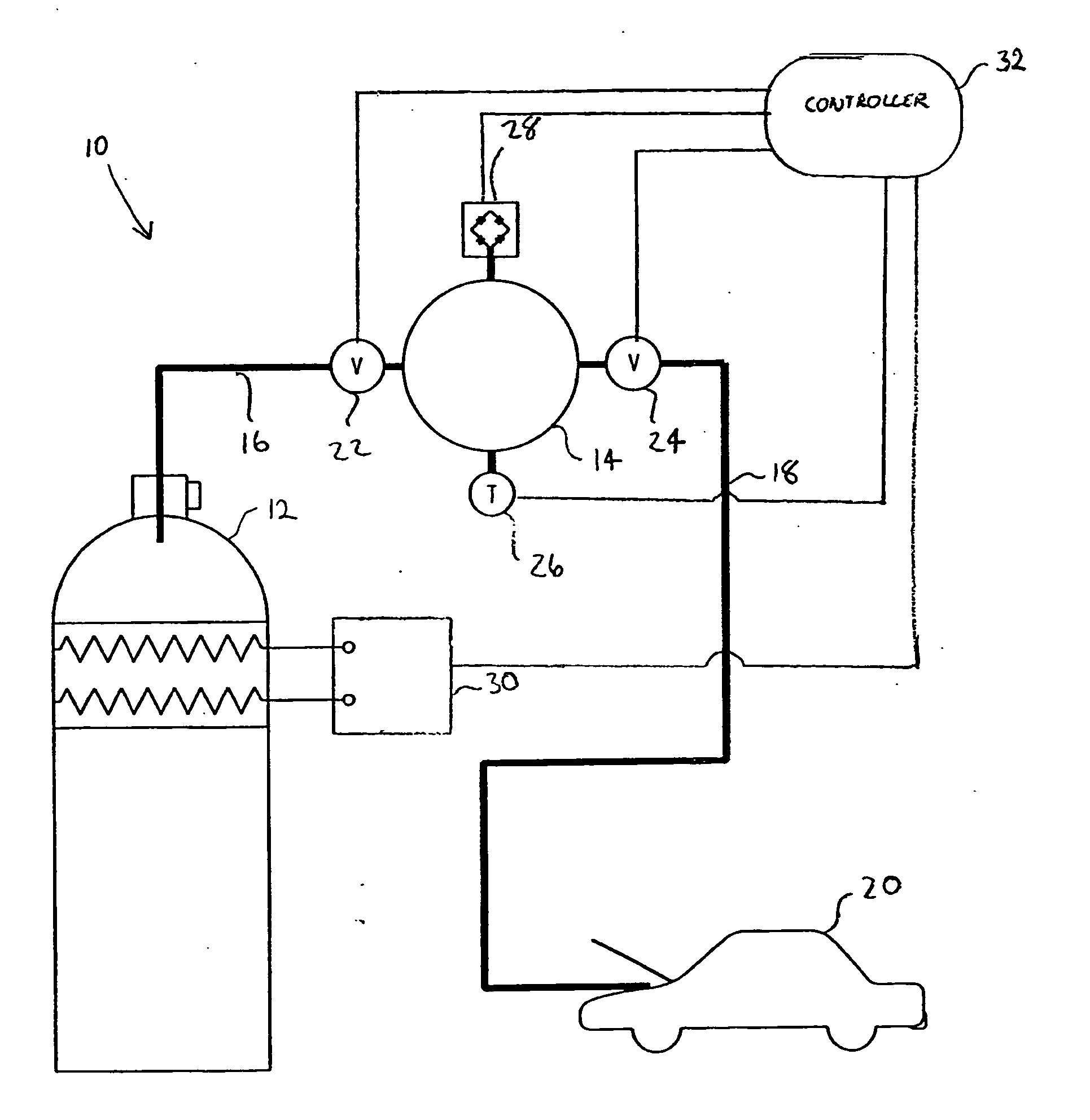

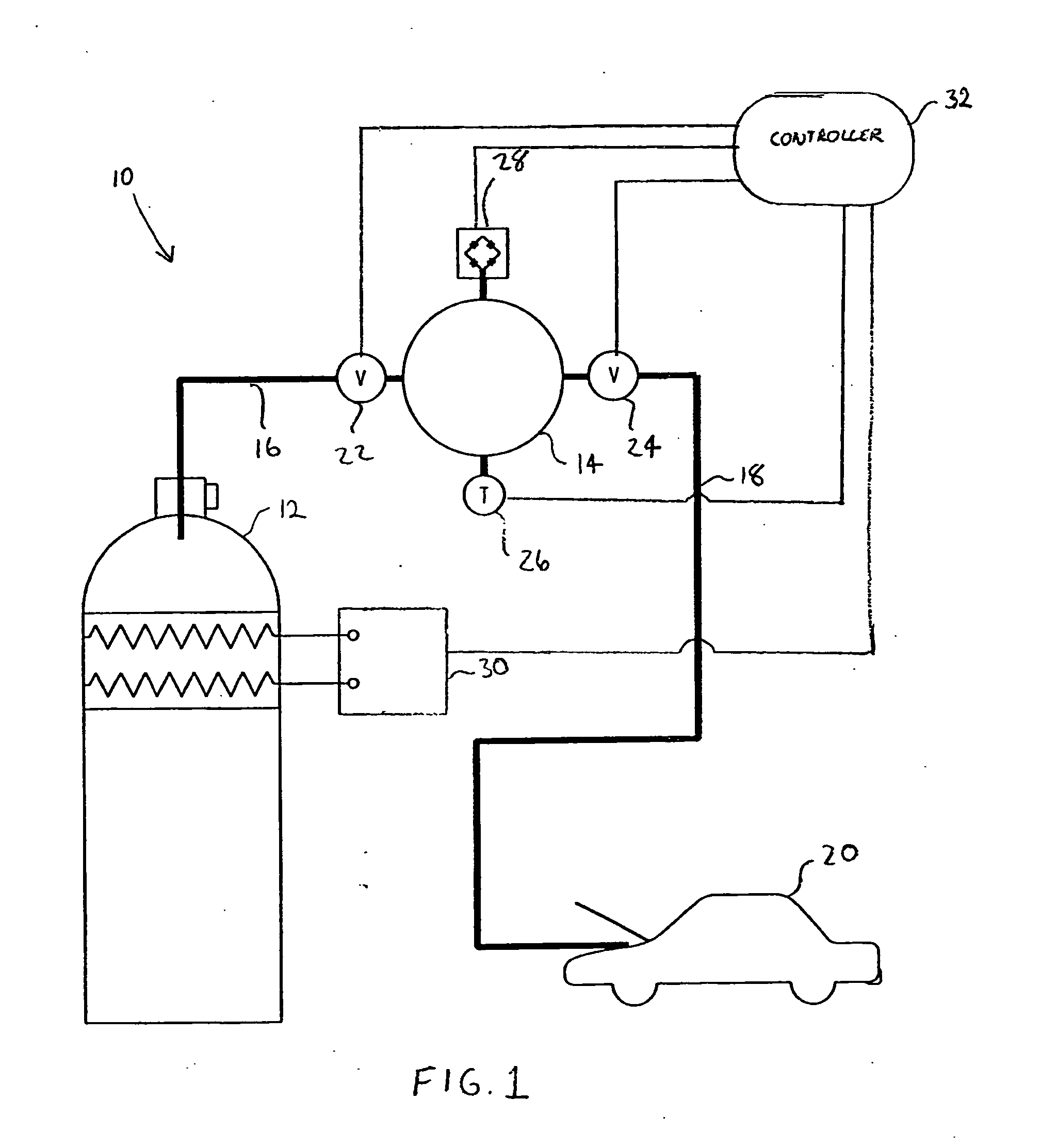

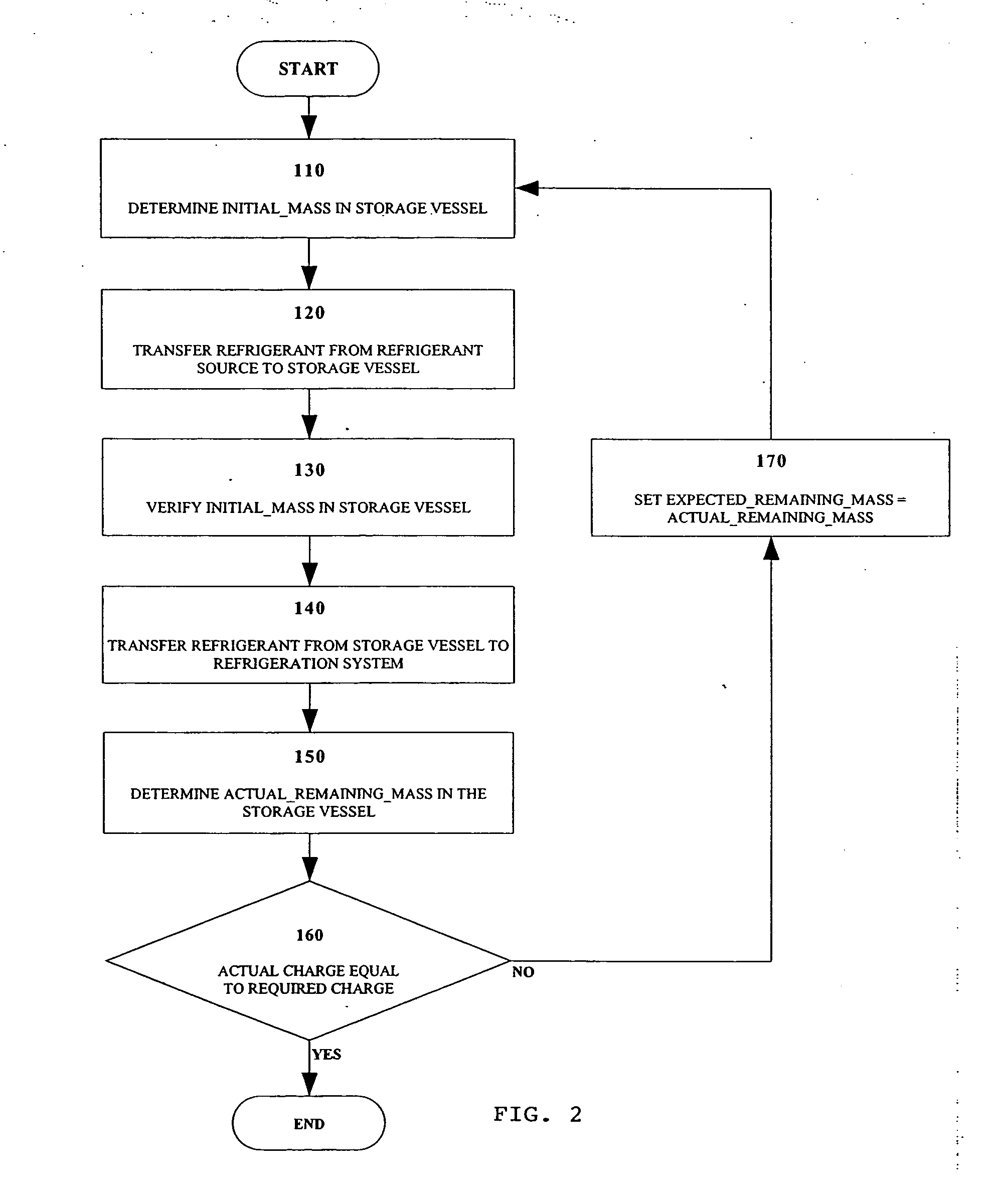

System for refrigerant charging with constant volume tank

ActiveUS20060010898A1Increase temperatureContainer filling methodsVehicle heating/cooling devicesLine tubingInput control

A refrigerant charging system for charging a refrigeration system with refrigerant includes a refrigerant source, a storage vessel, input and output lines, and a device for detecting mass of refrigerant within the storage vessel. The input line fluidly connects the refrigerant source to the storage vessel, and the output line extends from the storage vessel and is adapted to connect to the refrigeration system. The system also includes an input control valve disposed between the storage vessel and the refrigerant source, and an output control valve disposed between the storage vessel and the refrigeration system. A heater is connected to the refrigerant source for raising the temperature of refrigerant within the refrigerant source. A method of charging a refrigeration system is also disclosed. The system and method are useful to charging the refrigerant system of an automotive vehicle, among others.

Owner:SPX CORP

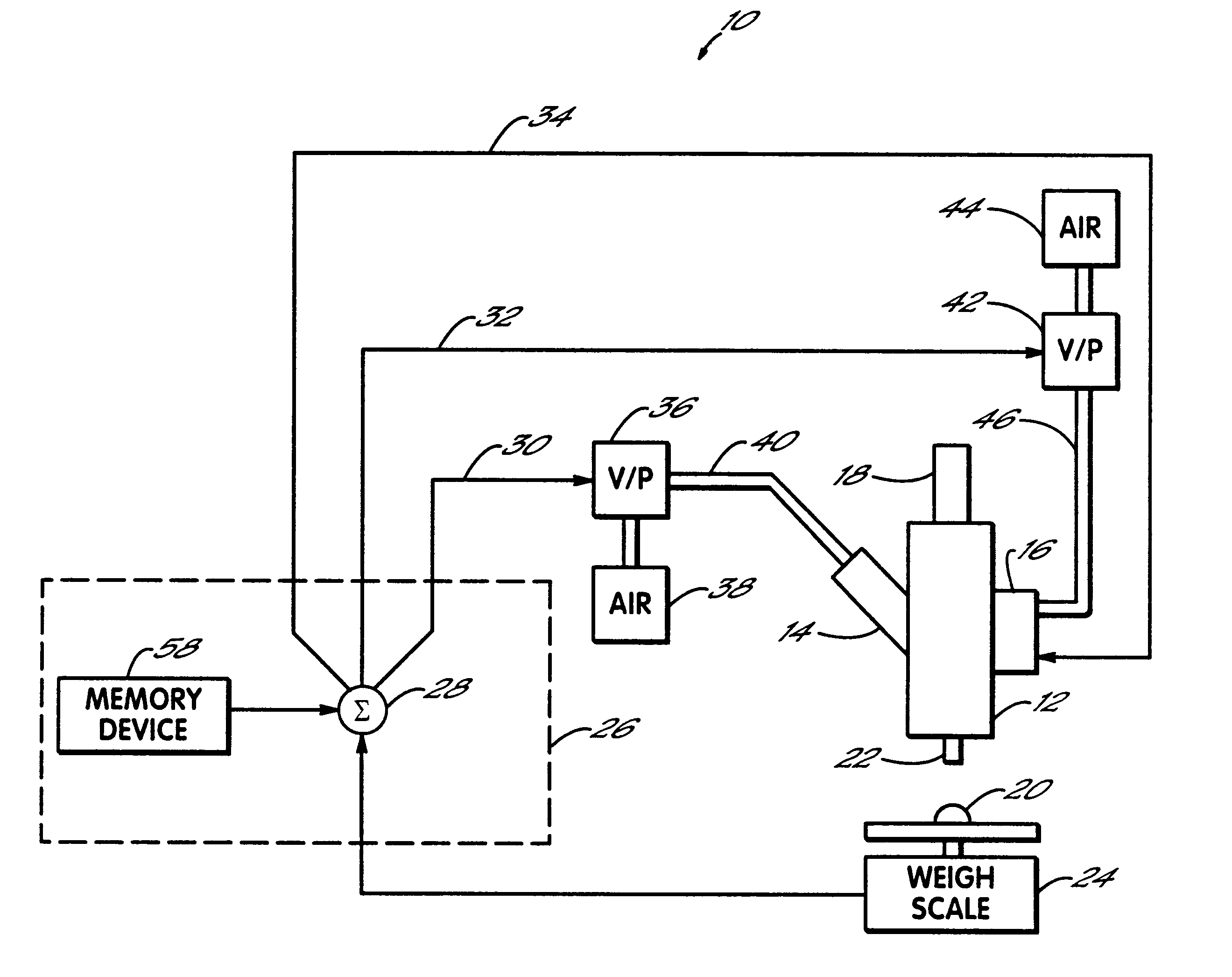

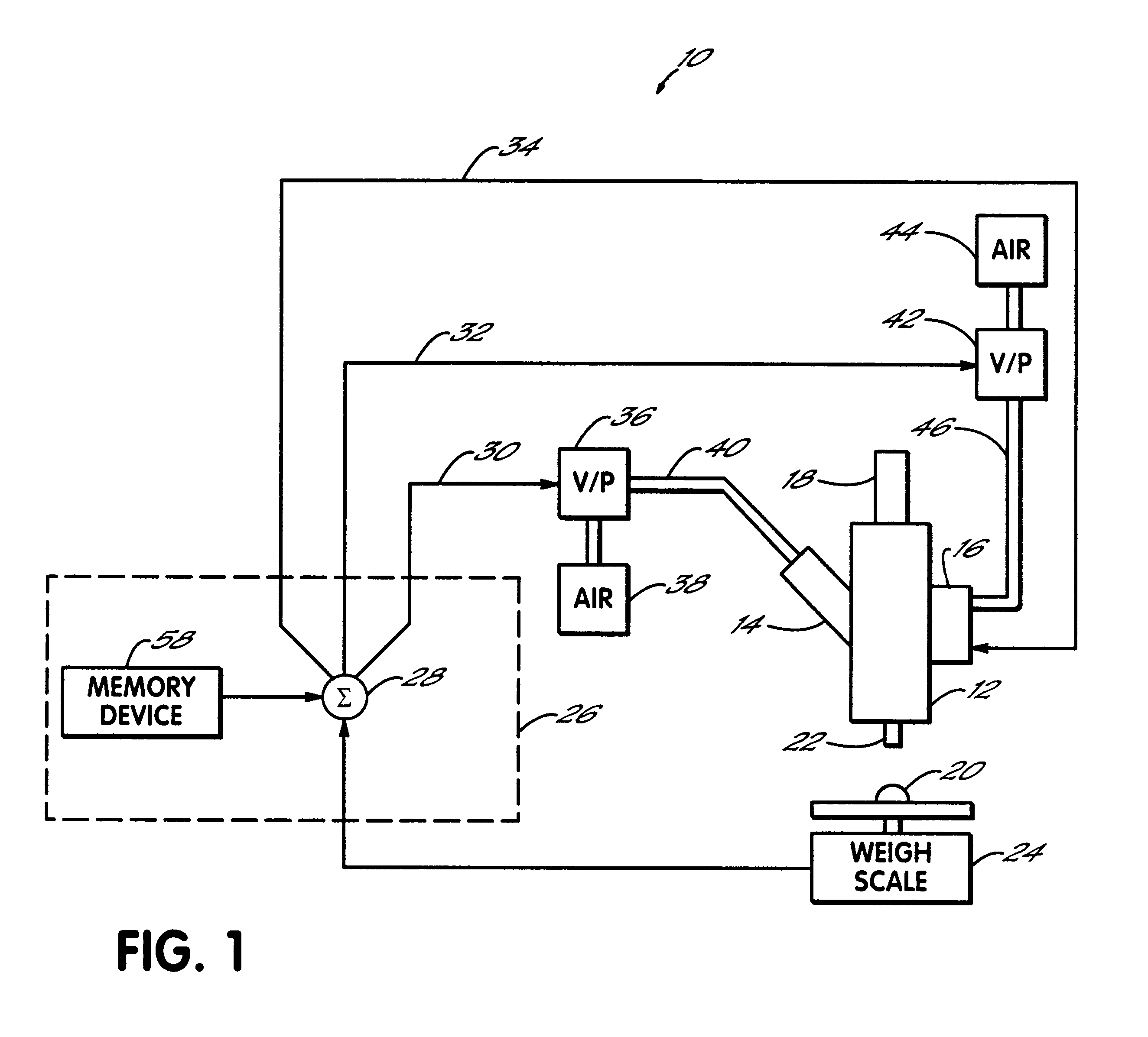

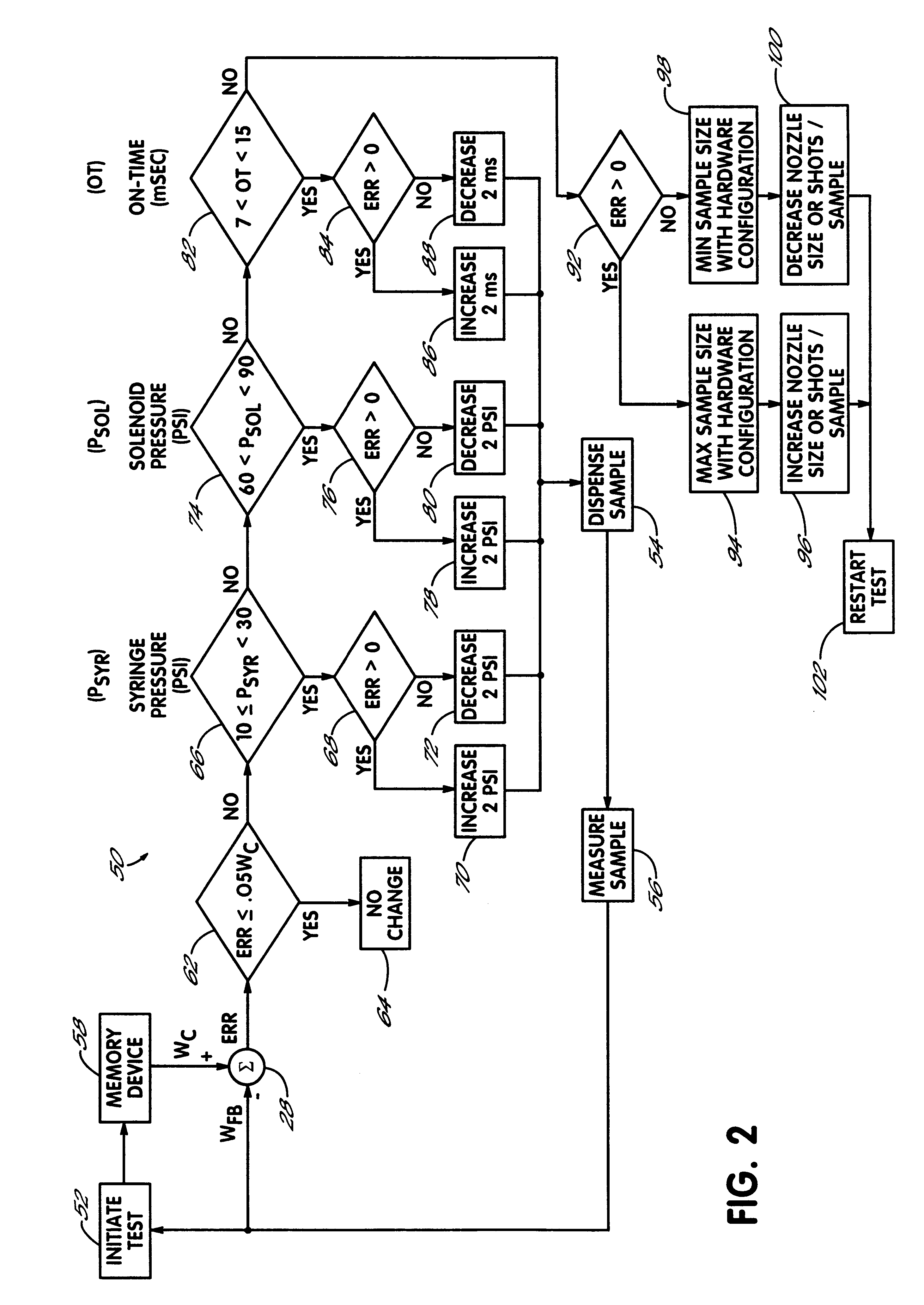

Viscous material dispensing system and method with feedback control

InactiveUS6173864B1Allocation is accuratePretreated surfacesLiquid transferring devicesFeedback controllerFeedback control

A system for accurately dispensing controlled amounts of viscous material. The system includes a pressurized supply of the viscous material, a dispenser connected with the pressurized supply and a feedback control for ensuring that a discrete dispensed amount corresponds closely to the desired dispensed amount for a particular application. The different methods of feedback control include changing pressure of the pressurized supply after measuring a dispensed amount and comparing the dispensed amount with a stored value representing the desired amount. Another manner of feedback control includes changing an air operating pressure associated with the dispenser. A third type of feedback control includes adjusting the duration that the dispenser is maintained on to dispense the viscous material. Each of these types of feedback control are preferably used in succession, as necessary, to ensure that the desired amount of viscous material is discharged from the dispenser. Methods of controlling an amount of viscous material discharged from a dispenser further include using one or more of the feedback controls described above.

Owner:NORDSON CORP

Apparatus and methods for storing and dispensing solid material

InactiveUS7614429B2Easy to fillEasy to emptyLarge containersLaboratory glasswaresGate valveControl unit

The invention is directed to a dispensing unit suitable to precisely dispense material in powdery and / or granular form. The dispensing device comprises an gate valve opening sealingly closed by a blend. A control unit, which is interconnected to a scaling device, controls the opening of the gate valve opening by the position of the blend. The precise amount of the material is adjusted in relation to the signal of the scaling device.

Owner:FREESLATE

Methods and apparatus for mixing powdered samples

Method for preparing a mixed powder sample by mixing two or more different powders comprising transferring a quantity of a first powder to a mixing vessel and transferring a quantity of a second powder to the mixing vessel to form a powder bed in the mixing vessel comprising the first and second powders. The quantities of the powders are selected so the mixed sample has a predetermined ratio of first powder to second powder. The powder bed is fluidized to mix the powders and produce a mixed sample. The mixed sample weighs about 5 grams or less. The invention also includes apparatus for preparing mixed powder samples by mixing two or more different powders.

Owner:FREESLATE

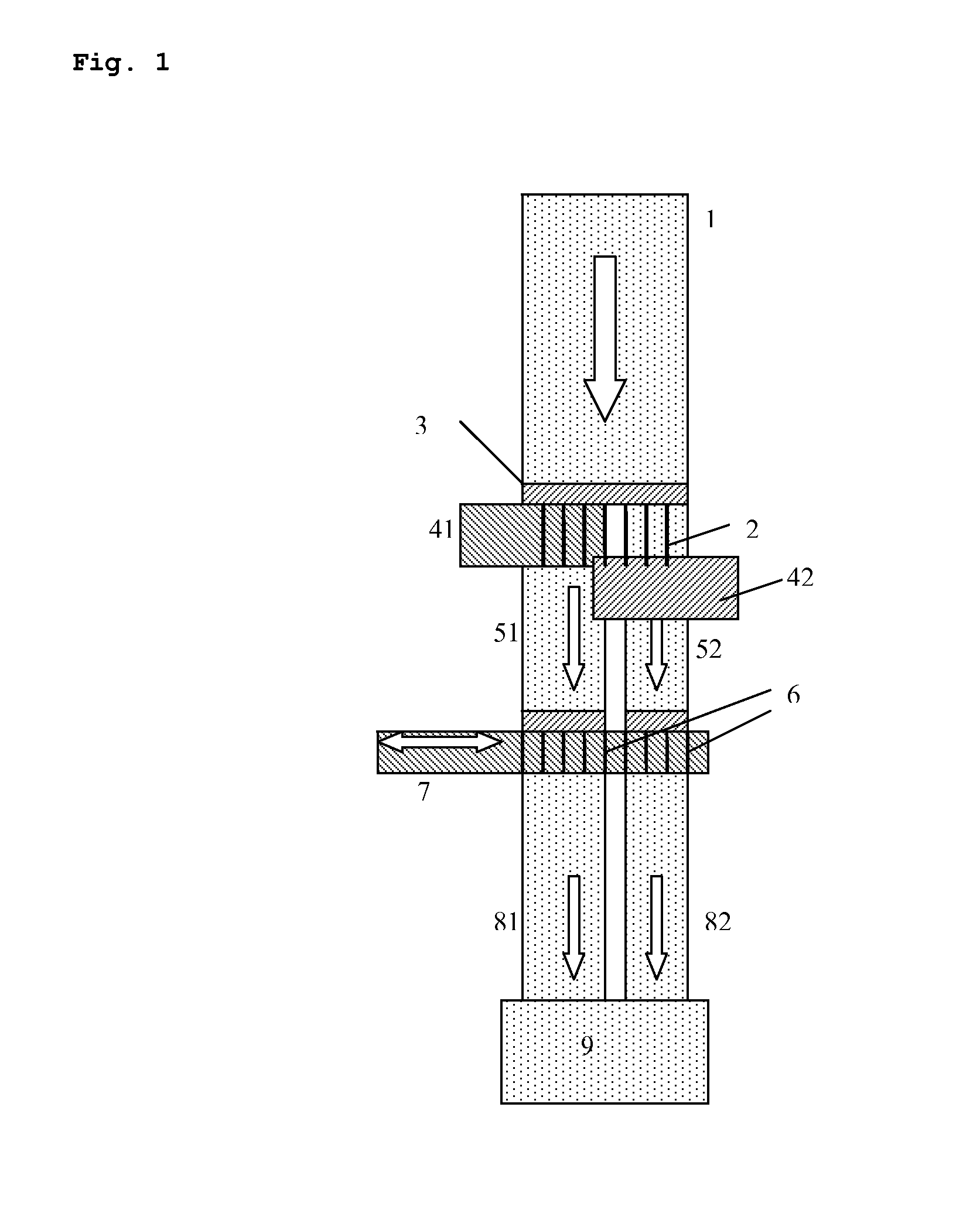

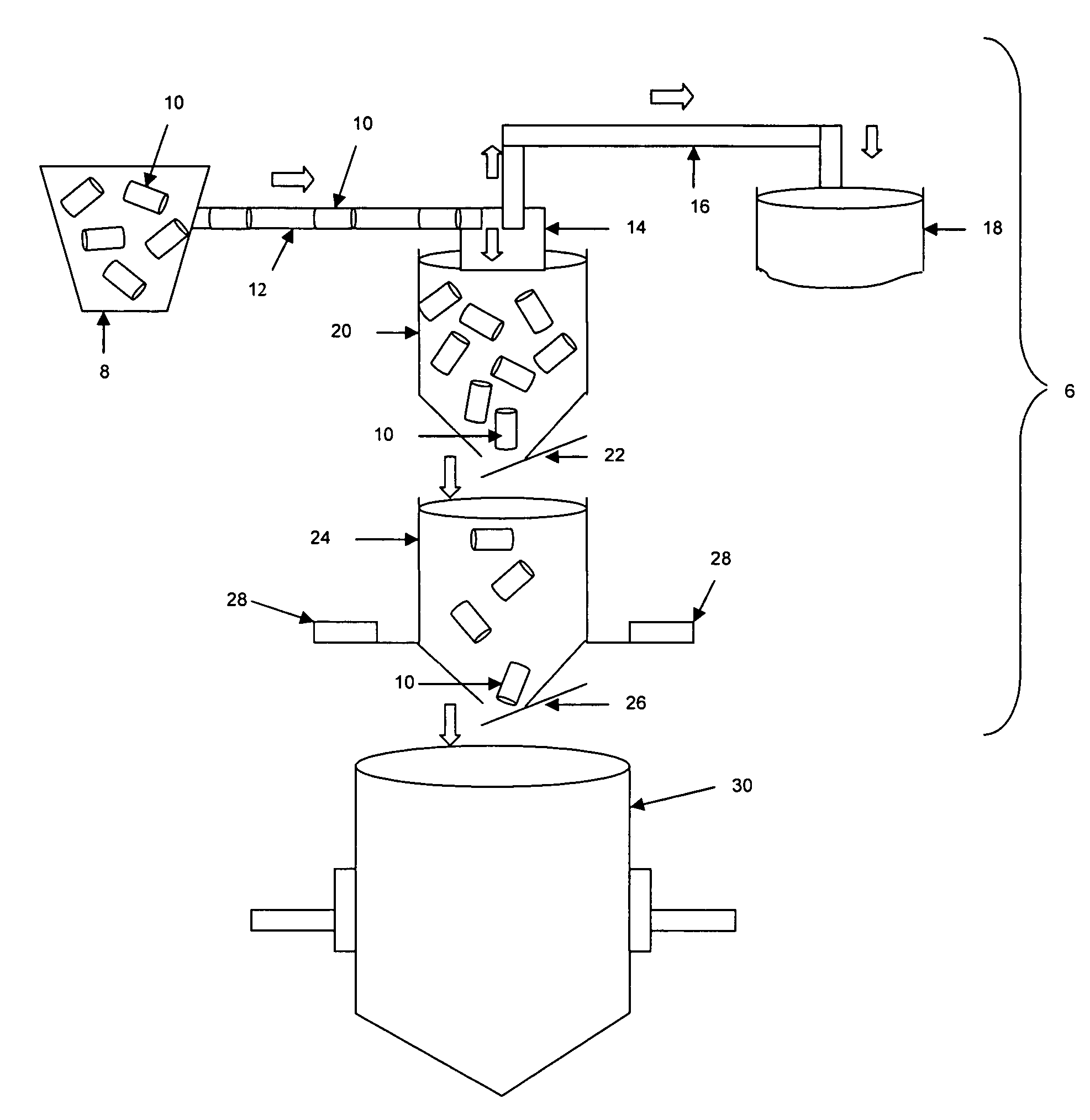

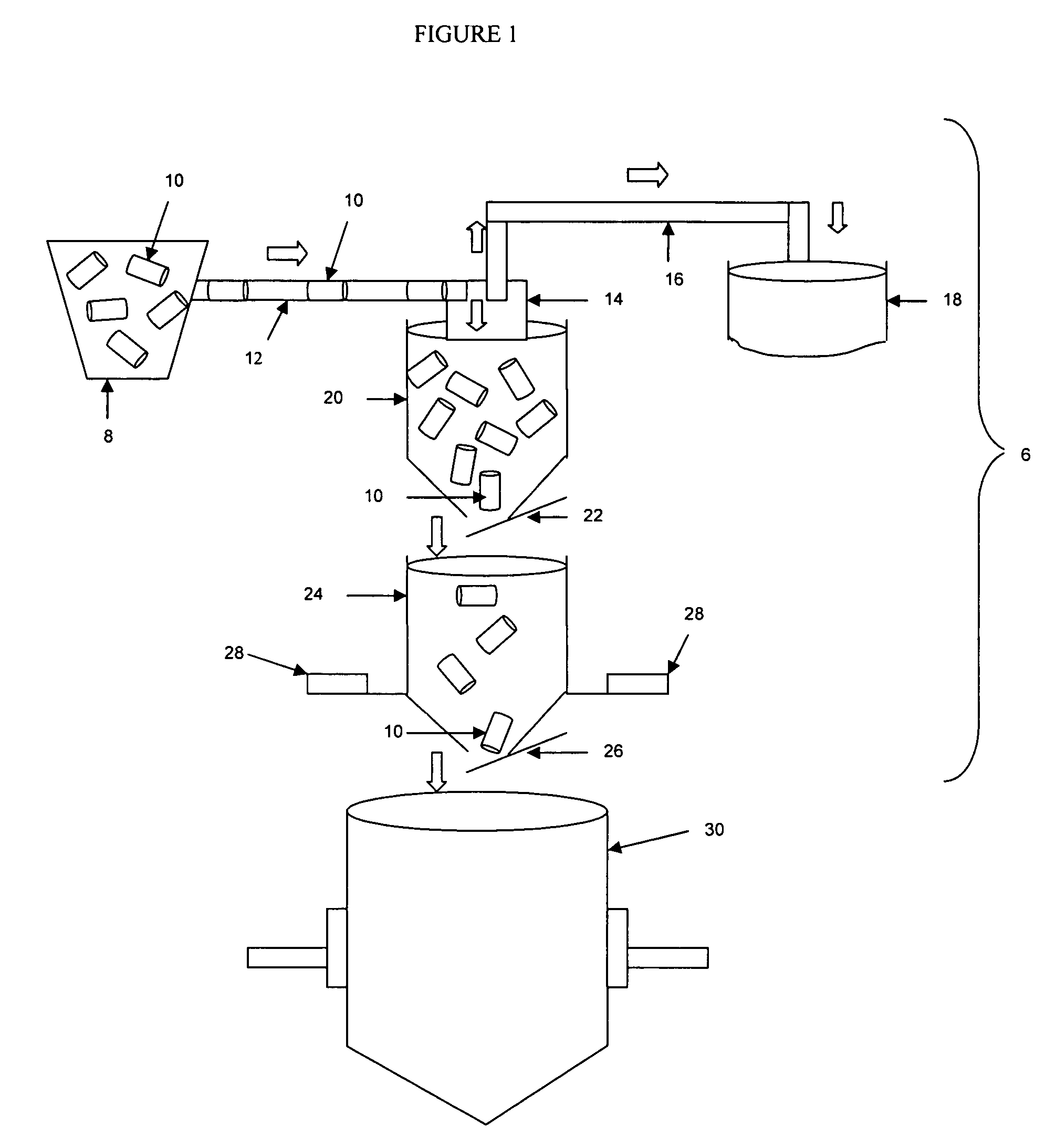

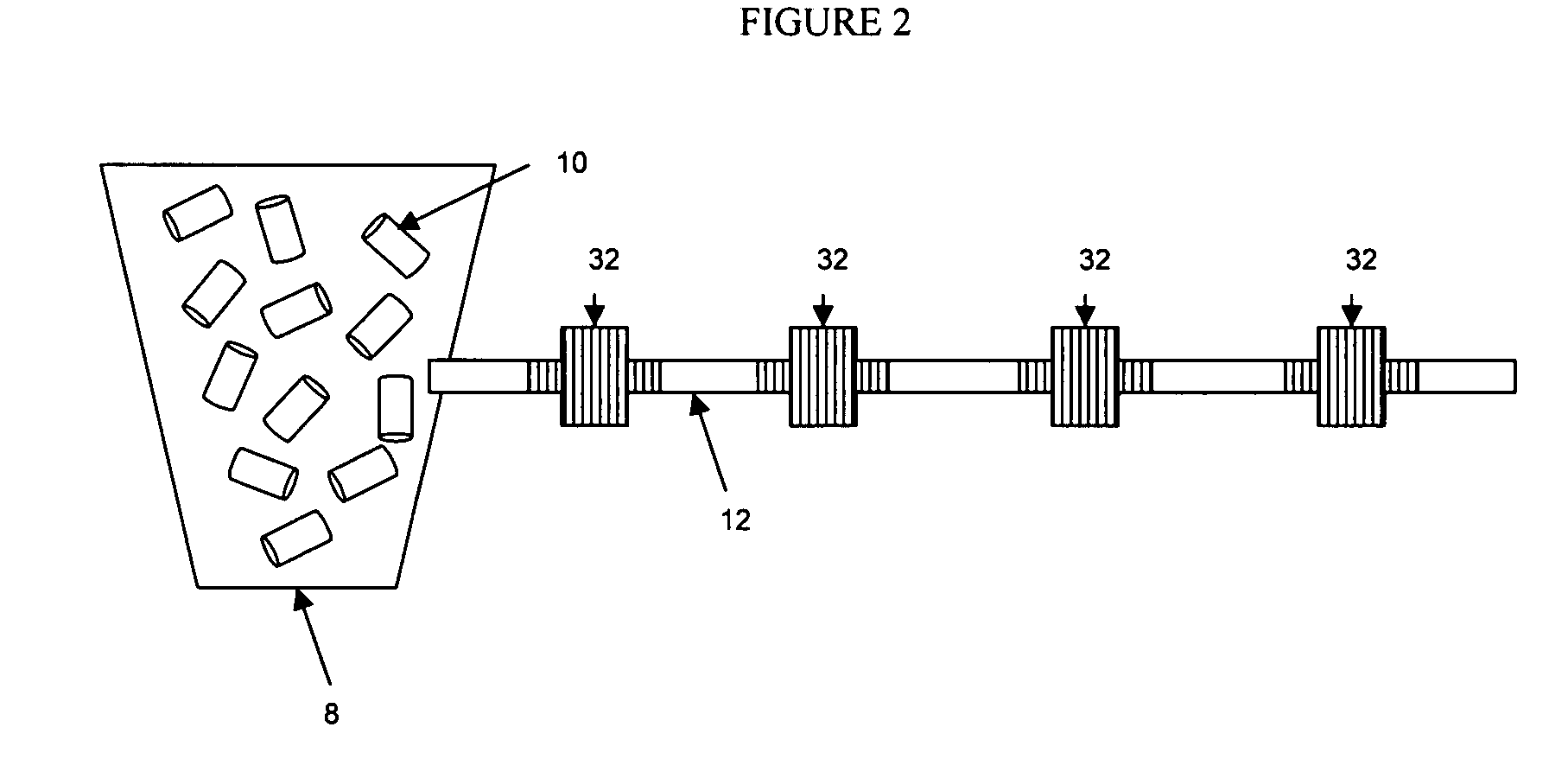

Method and device for dosing and packaging polysilicon chunks and dosing and packaging unit

ActiveUS20120198793A1Low costAccurate doseWrapper twisting/gatheringSolid materialHard metalProcess engineering

Disclosed is a method for dosing and packaging polysilicon chunks, wherein a product flow of polysilicon chunks is transported via a feed channel, separated by at least one screen into coarse and fine chunks, weighed and dosed to a target weight by a dosing balance, discharged via a discharge channel and transported to a packaging unit where a first plastic bag is filled with the polysilicon chunks and sealed, the plastic bag containing polysilicon chunks being packaged with a further plastic bag which is formed by a shaper and subsequently welded, wherein the at least one screen and the dosing balance at least partially include a hard metal on their surfaces and the shaper for forming the plastic bag includes a wear-resistant coating. Also disclosed are a dosing unit, a packaging unit and a device for dosing and packaging polysilicon chunks, which contains a dosing unit and a packaging unit.

Owner:WACKER CHEM GMBH

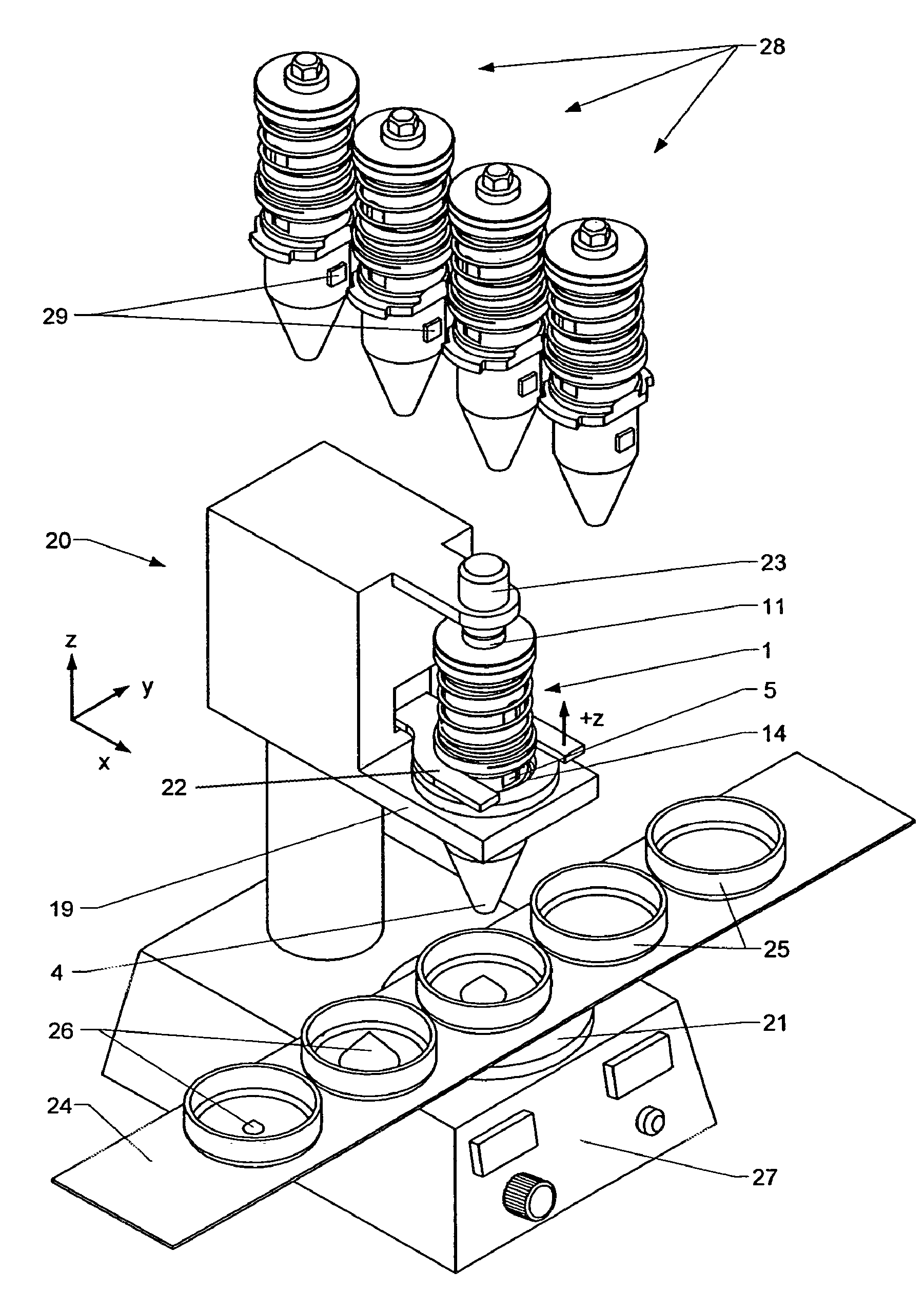

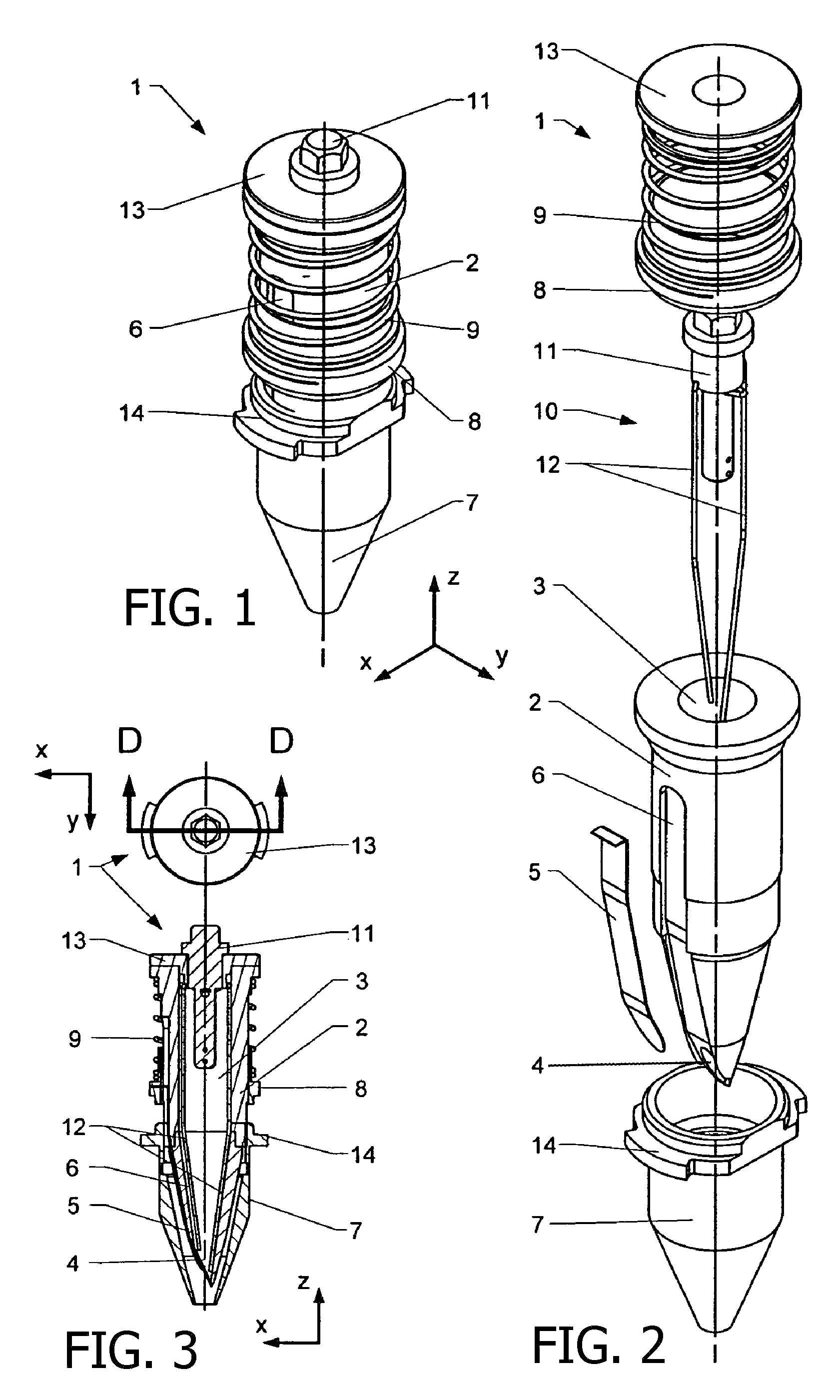

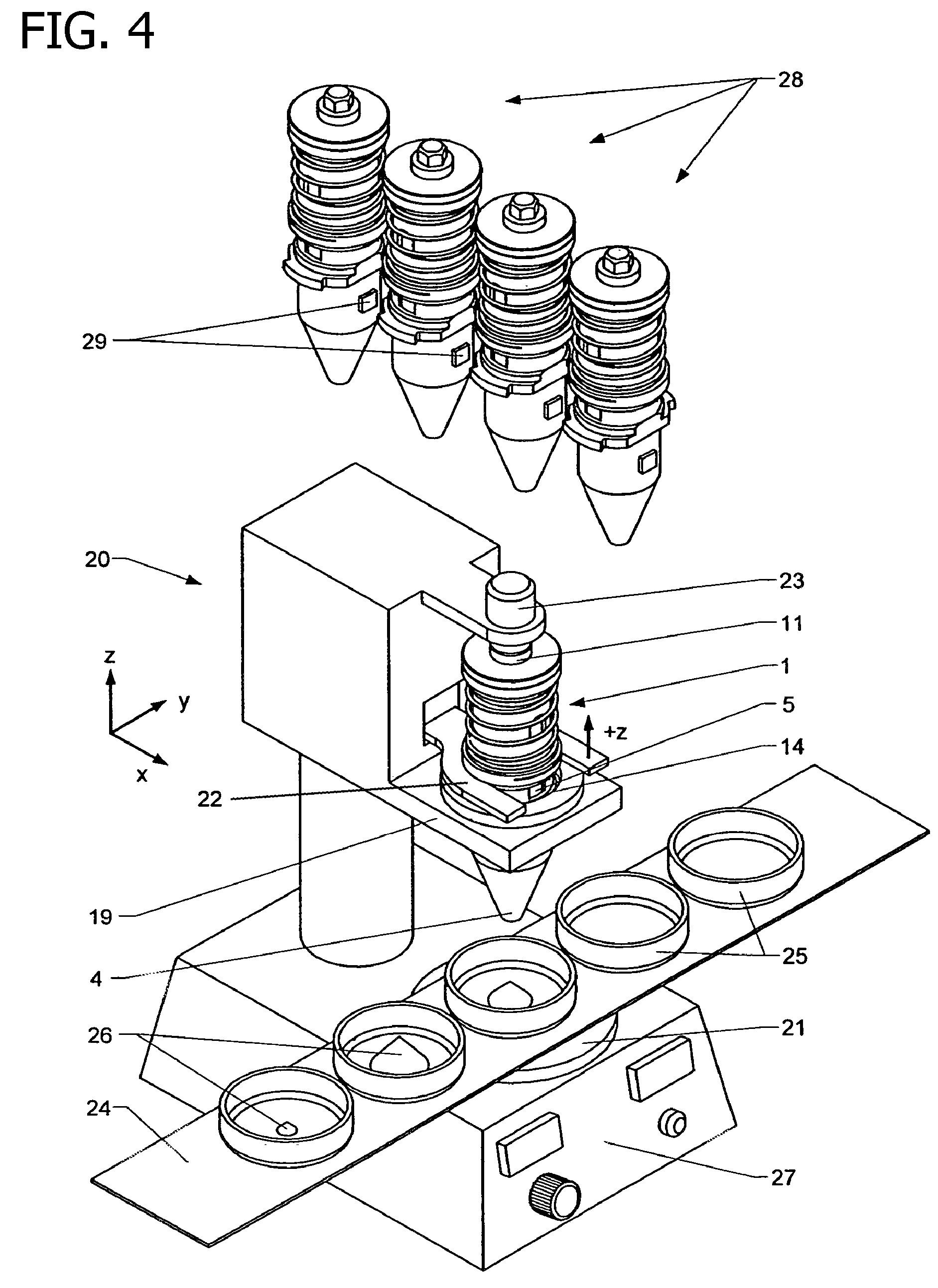

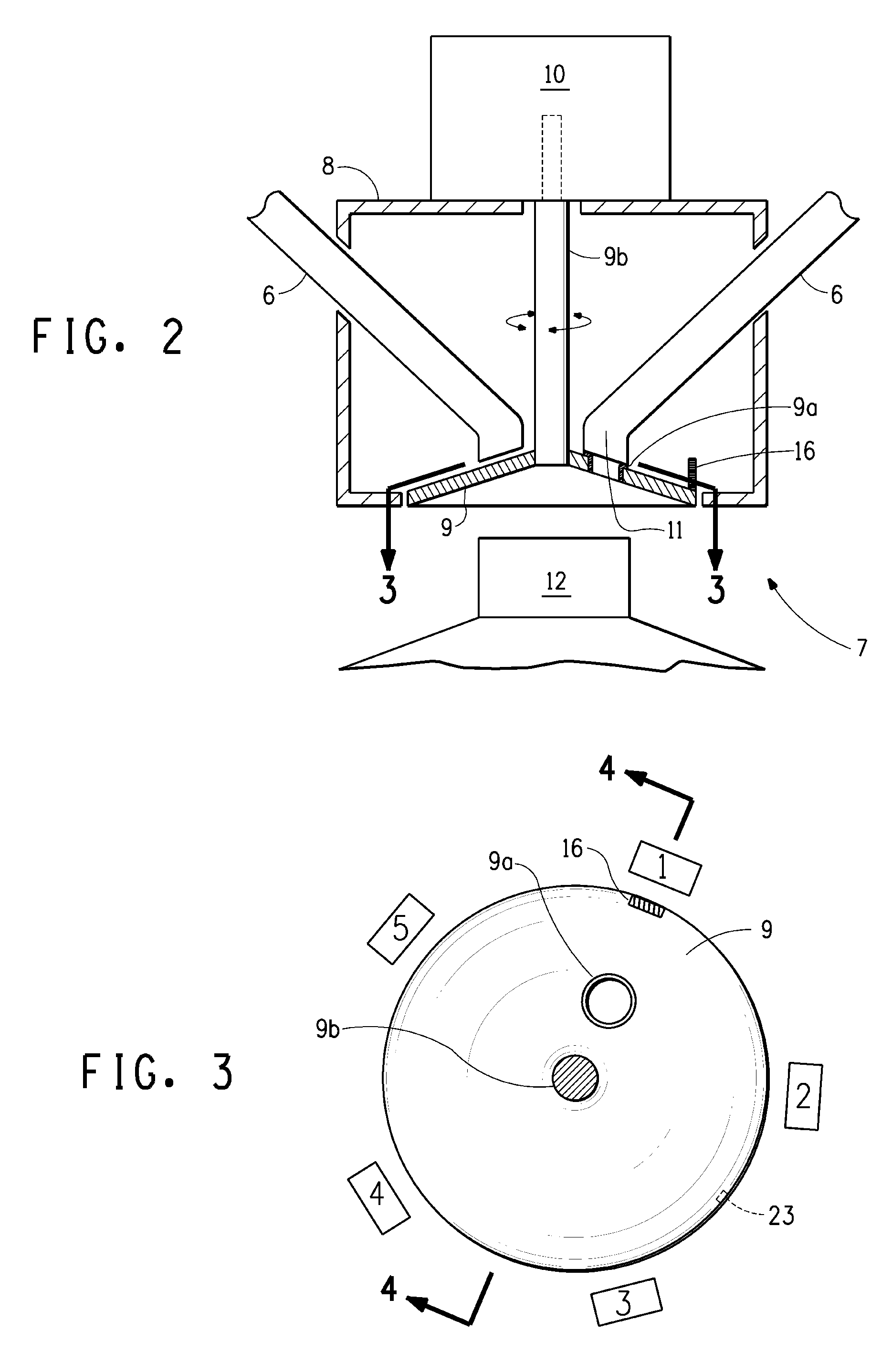

Method and apparatus for mass based dispensing

ActiveUS20040226961A1Tableware washing/rinsing machine detailsTransportation and packagingEngineeringProcess engineering

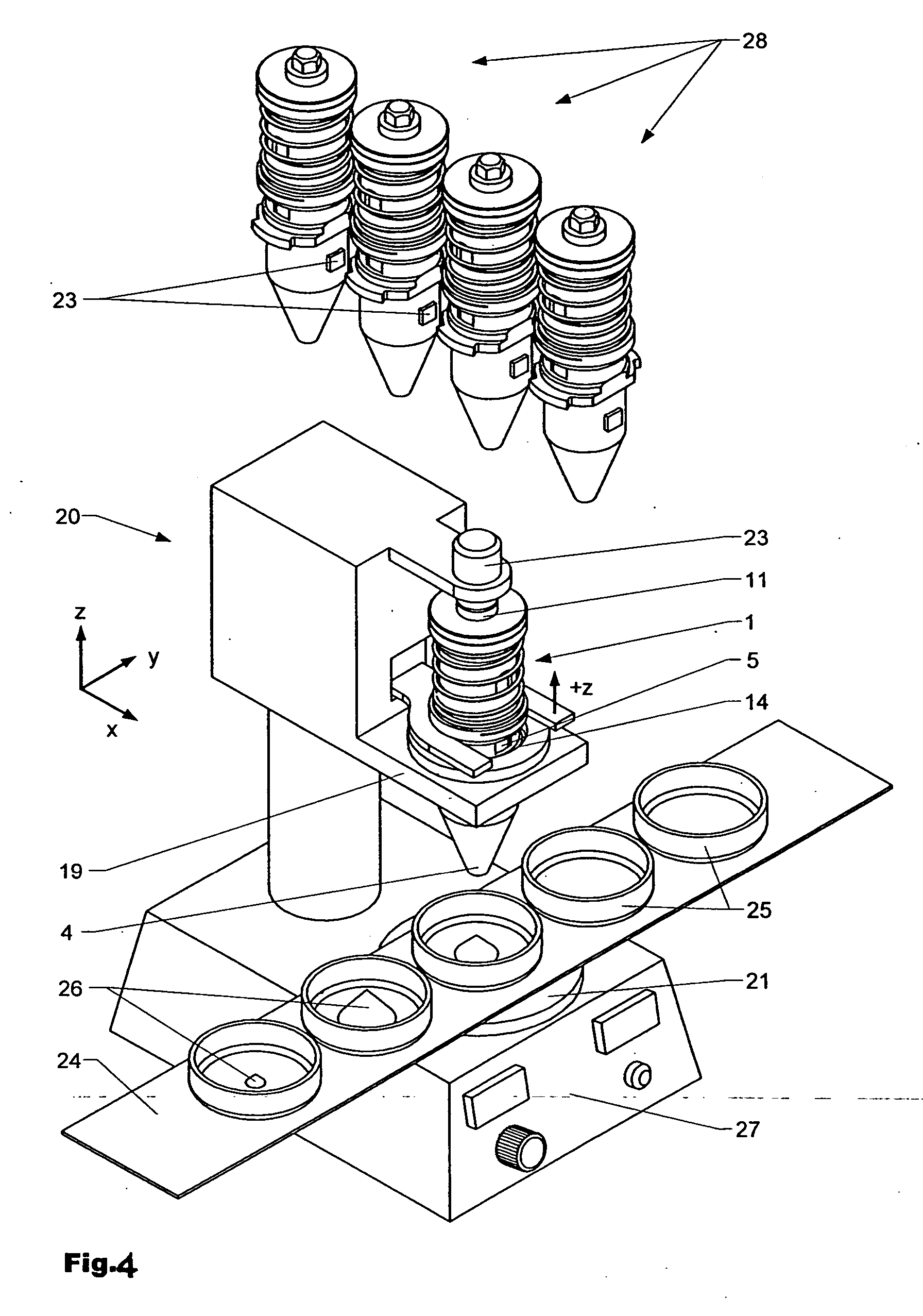

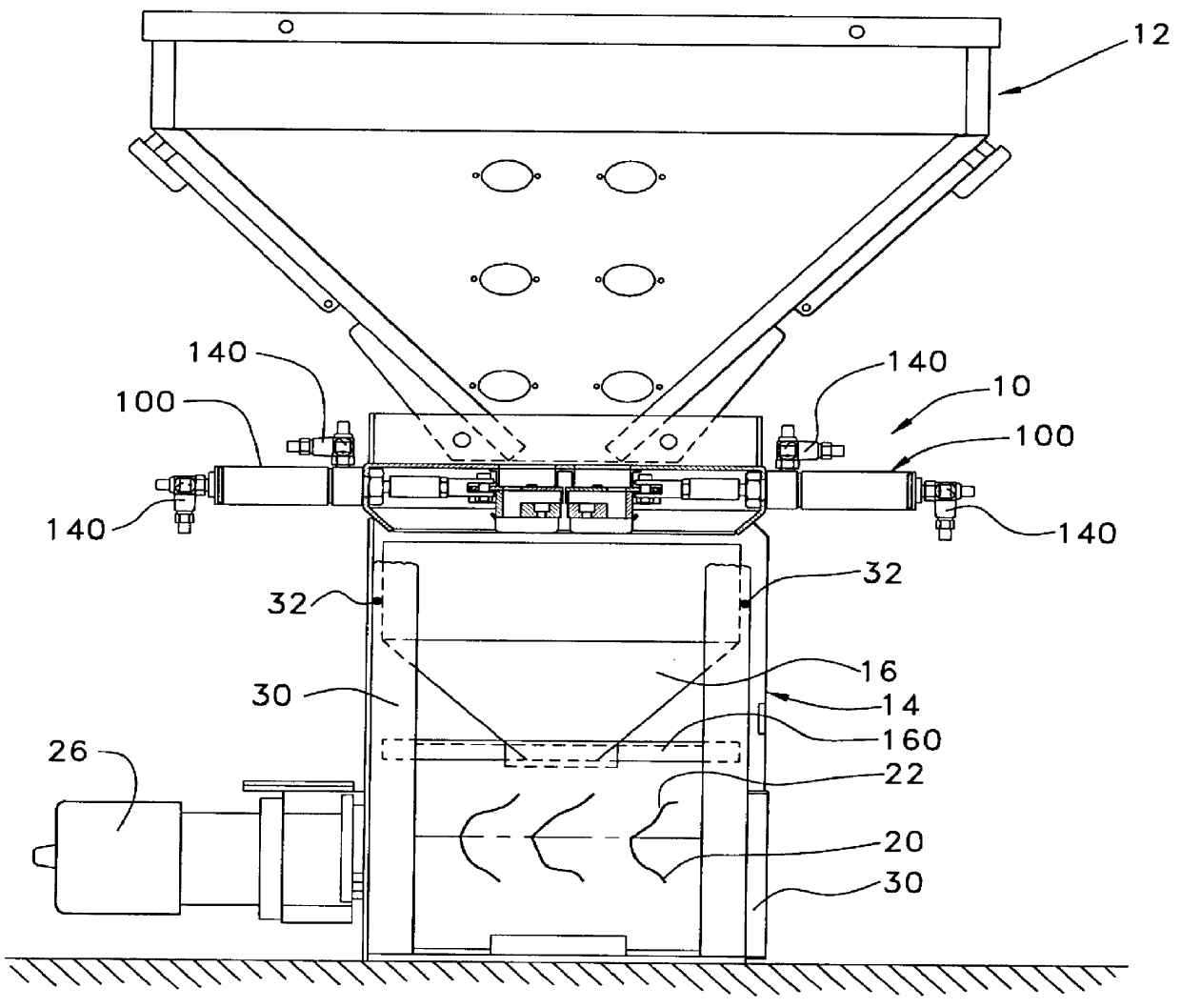

A method and apparatus for dispensing of a product based on weight as a load cell (22) which supports a structure holding the product (20a) to be dispensed. The weight of the product (20a) that is dispensed is determined by use of a controller (23).

Owner:ECOLAB USA INC

Portioning of flowable products

InactiveUS6213174B1Reduce deliveryMinimize inaccuracySolid materialLiquid materialTarget weightEngineering

This invention is directed to methods, procedures and apparatus for controlling the portioning of flowable materials, particularly soft serve frozen confections, though also including other flowable products. Such other products may include soups, beverages such as milk shakes, soft drinks, and alcoholic beverages such as beers, and so forth.Typically a method for controlling the delivery of a portion of a flowable substance includes the steps of:i) Delivering the flowable substance in a stream; andii) Noting the time for the delivery of a portion of a targeted amount; andiii) Determining the weight of the portion, andiv) Using this information to influence the delivery of further substance to meet a pre-determined target value.A preferred method is characterized by both the weight of the flowable substance being delivered and the time for the delivery of same being repeatedly or continuously assessed to achieve delivery of a pre-determined target weight or volume.

Owner:BLUE BOX INT

Powder dispenser modules and powder dispensing methods

InactiveUS20070131707A1Facilitates regulatory approvalImprove compactnessBarrels/casks fillingMovable measuring chambersTransport systemControl system

Powder dispensing and sensing apparatus and methods are provided. The powder dispensing and sensing apparatus includes a tray support structure to receive a cartridge tray holding cartridges, a powder dispenser assembly including powder dispenser modules to dispense powder into respective cartridges of a batch of cartridges in the cartridge tray, a powder transport system to deliver powder to the powder dispenser modules, a sensor module including sensor cells to sense respective fill states, such as the weights, of each of the cartridges in the batch of cartridges, and a control system to control the powder dispenser modules in response to the respective sensed fill states of each of the cartridges of the batch of cartridges.

Owner:MANNKIND CORP

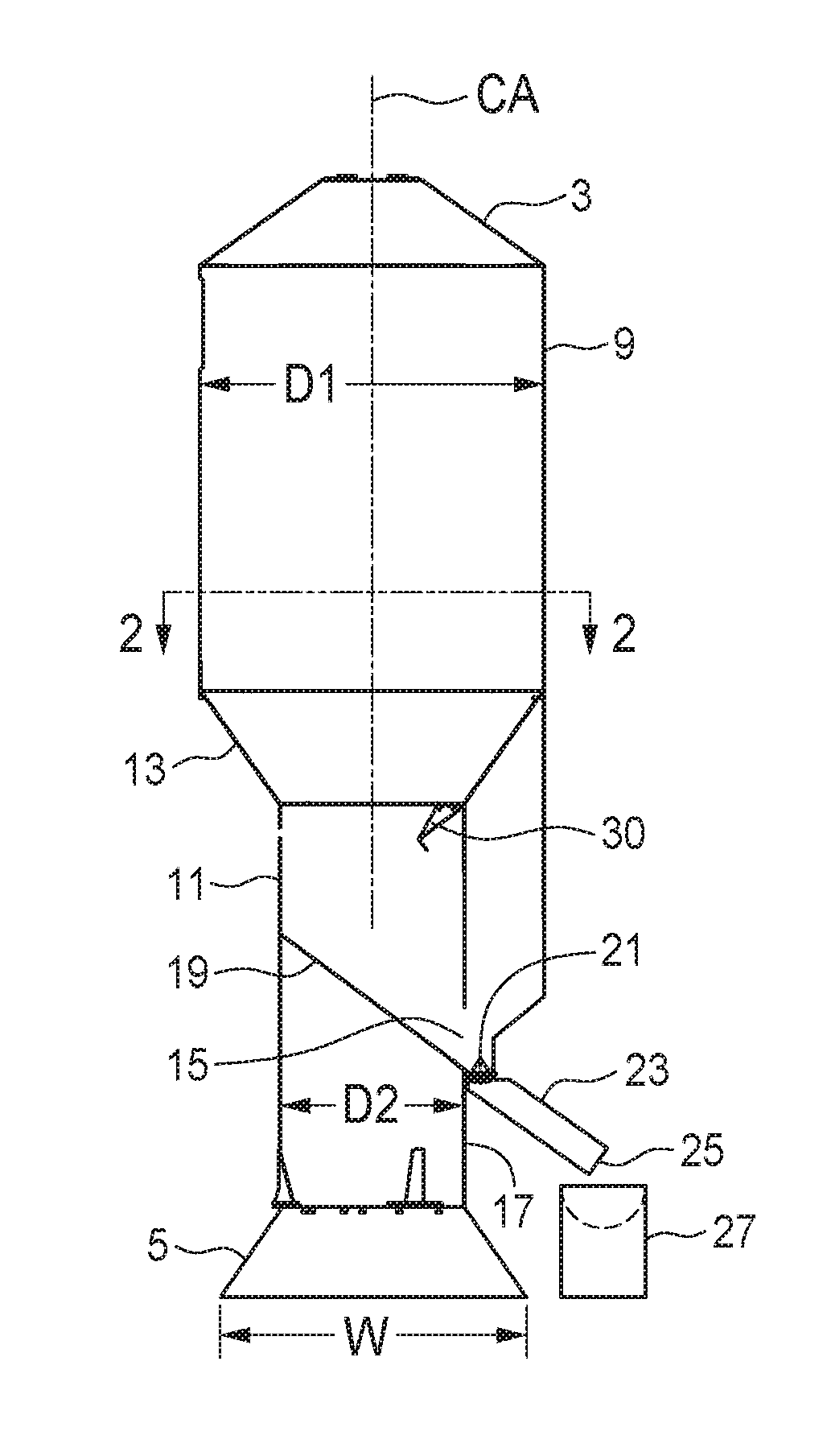

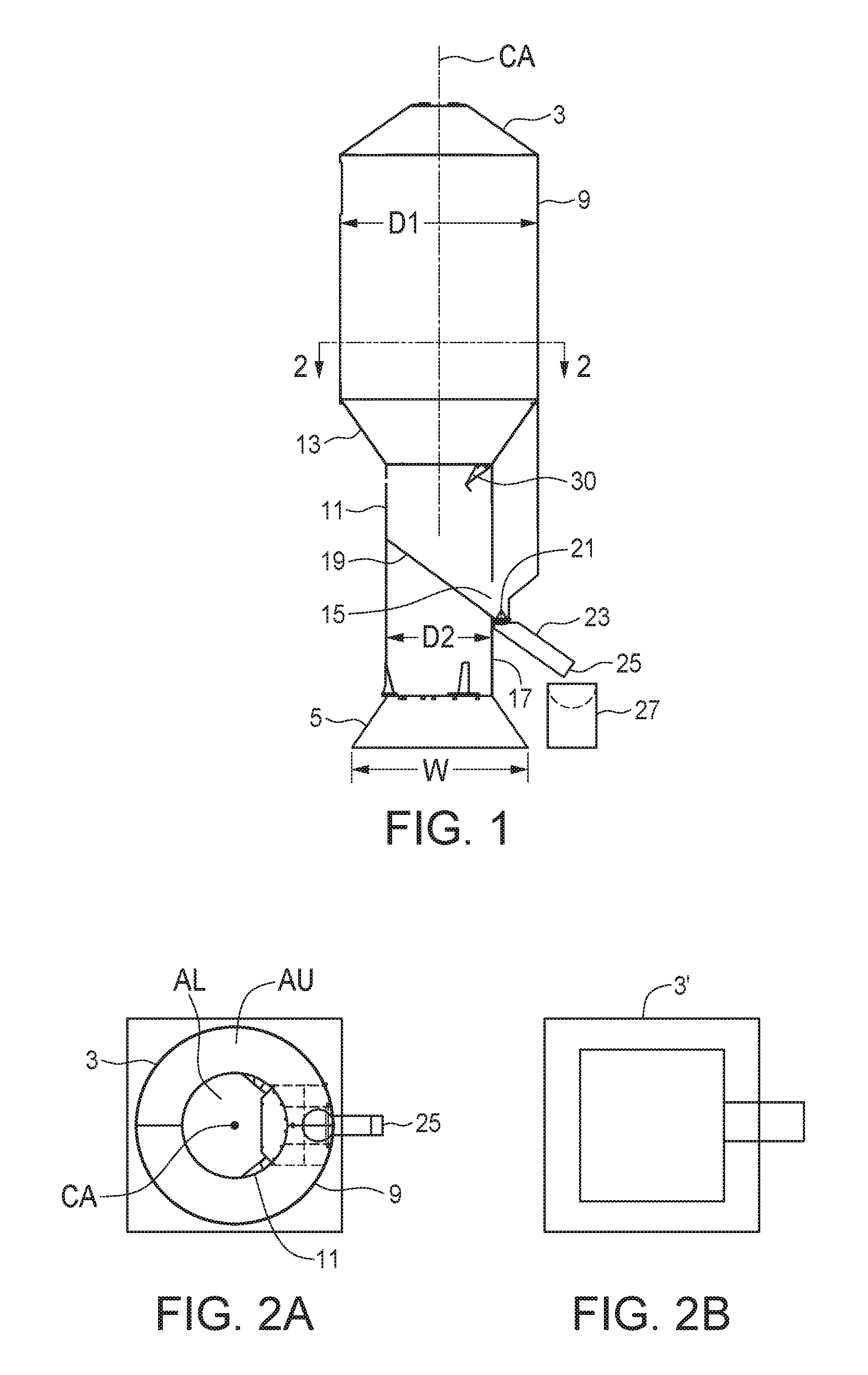

Vertically oriented transportable container with improved stability

ActiveUS20160185522A1Avoiding structural issueIncreased leewayLarge containersVehicle to carry long loadsEngineeringMechanical engineering

A transportable container apparatus includes an elongate container having a central axis and a base attached to a bottom end of the container. The container and base are substantially symmetrical about the central axis and the container is oriented substantially vertically with the base resting on a ground surface when in a working position. The container having an upper container section with upper walls substantially parallel to the central axis and a lower container section with lower walls substantially parallel to the central axis. The upper container section includes a sloping hopper at a bottom thereof to direct granular material into the lower container section. A floor of the container is sloped toward an outlet port defined in a ported wall of the lower container section such that granular material stored in the container slides down the floor to the outlet port.

Owner:QUICKTHREE TECH LLC

Apparatus and method for storing and dispensing material, especially in micro quantities and in combination with limited starting amounts

InactiveUS20070006942A1Improve accuracyMaximum flexibilityLarge containersLaboratory glasswaresGate valveControl unit

The invention is directed to a dispensing unit suitable to precisely dispense material in powdery and / or granular form. The dispensing device comprises an gate valve opening sealingly closed by a blend. A control unit, which is interconnected to a scaling device, controls the opening of the gate valve opening by the position of the blend. The precise amount of the material is adjusted in relation to the signal of the scaling device.

Owner:FREESLATE

System and method for dispensing bulk products

InactiveUS20070255450A1Lighting and heating apparatusVolume/mass flow measurementEngineeringSelf-service

A dispensing system and method is used to dispense a bulk product or to mix and to dispense bulk products on site and to price the products according to the quantity and distribution thereof. The dispensing system preferably provides automated merchandising by providing up-to-date product information and by allowing customers to select and purchase one or more bulk products. The dispensing system can be located indoors or outdoors and is preferably designed for self-service and cash less transactions.

Owner:MAZUR GREGORY

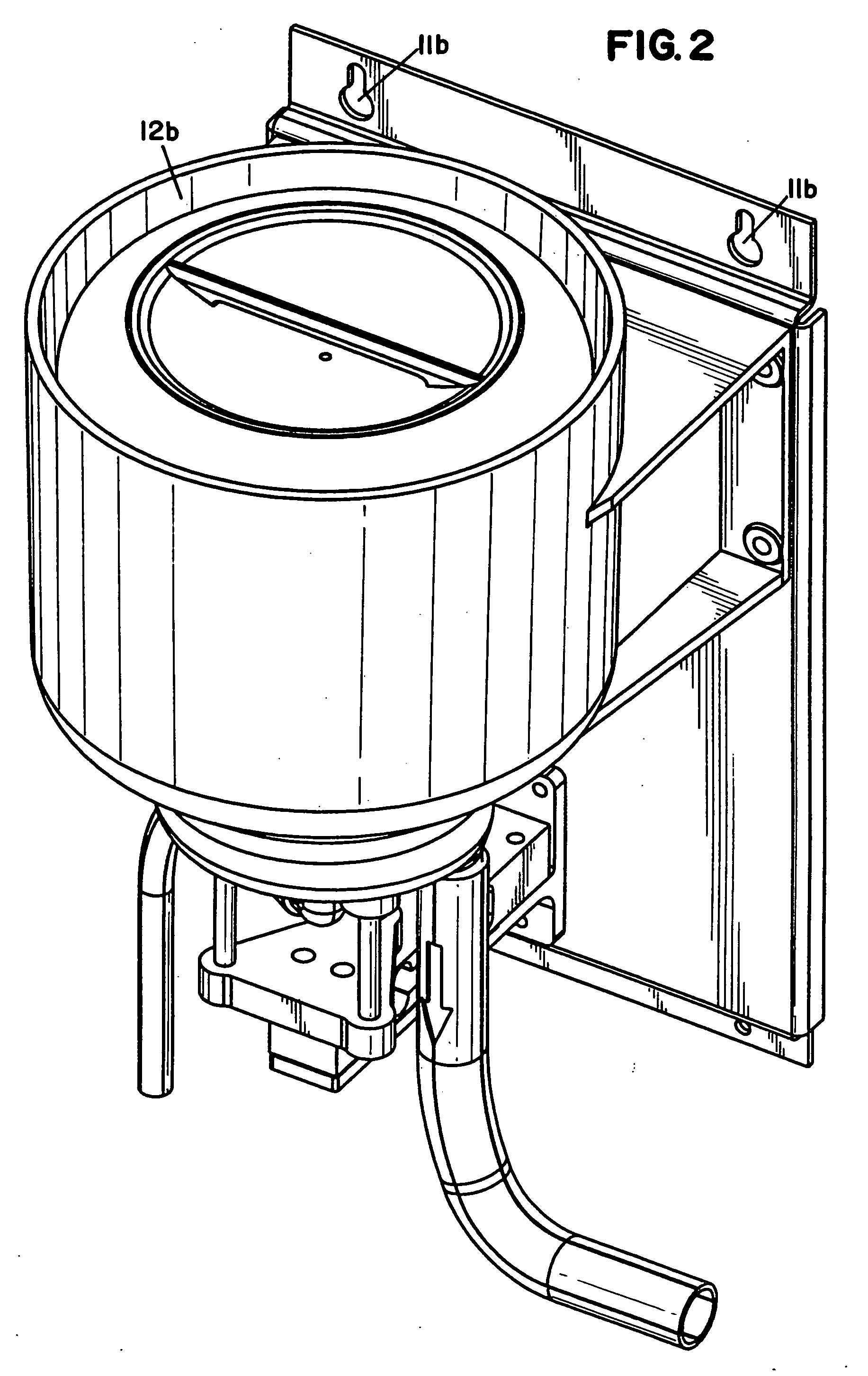

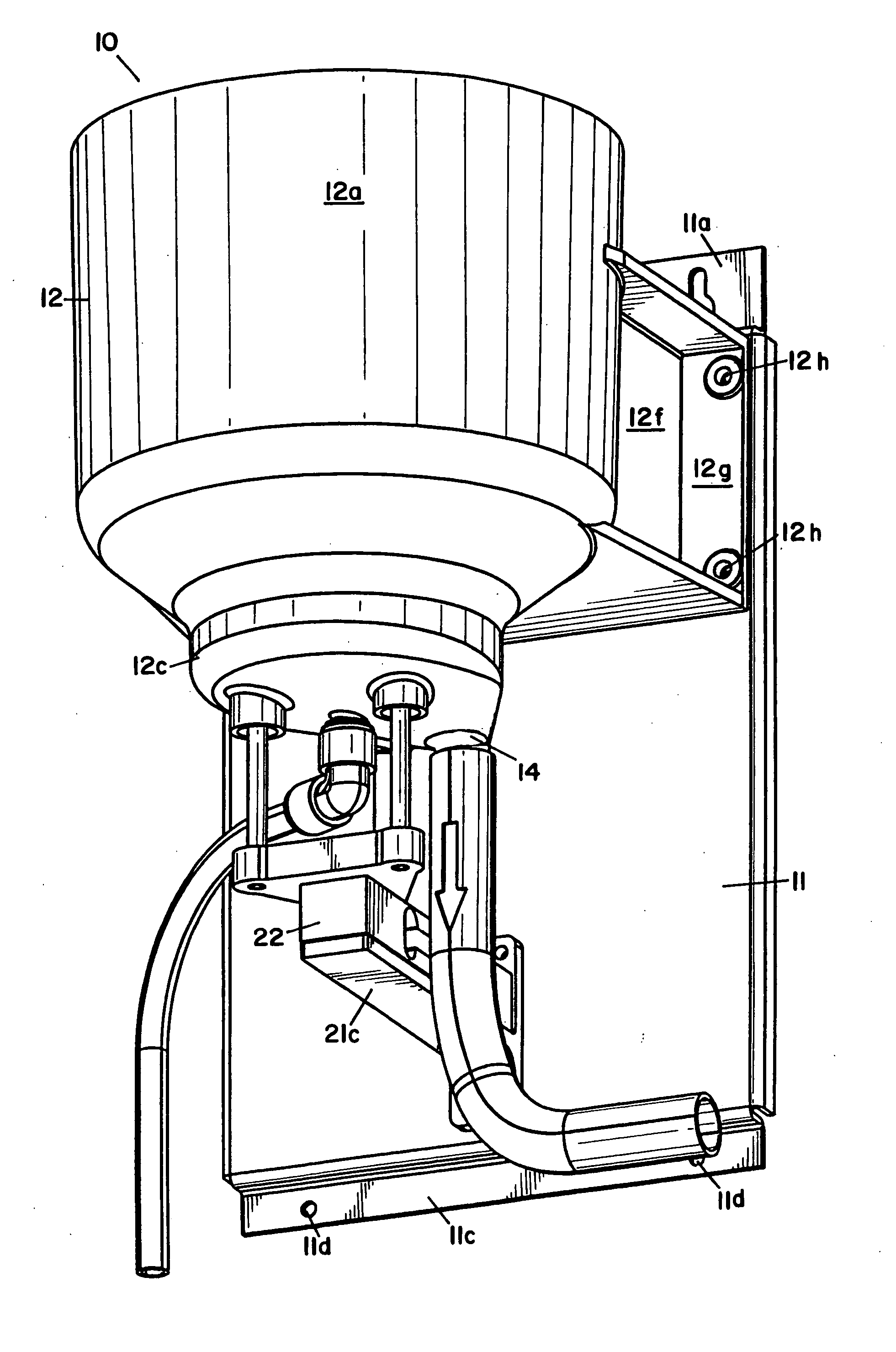

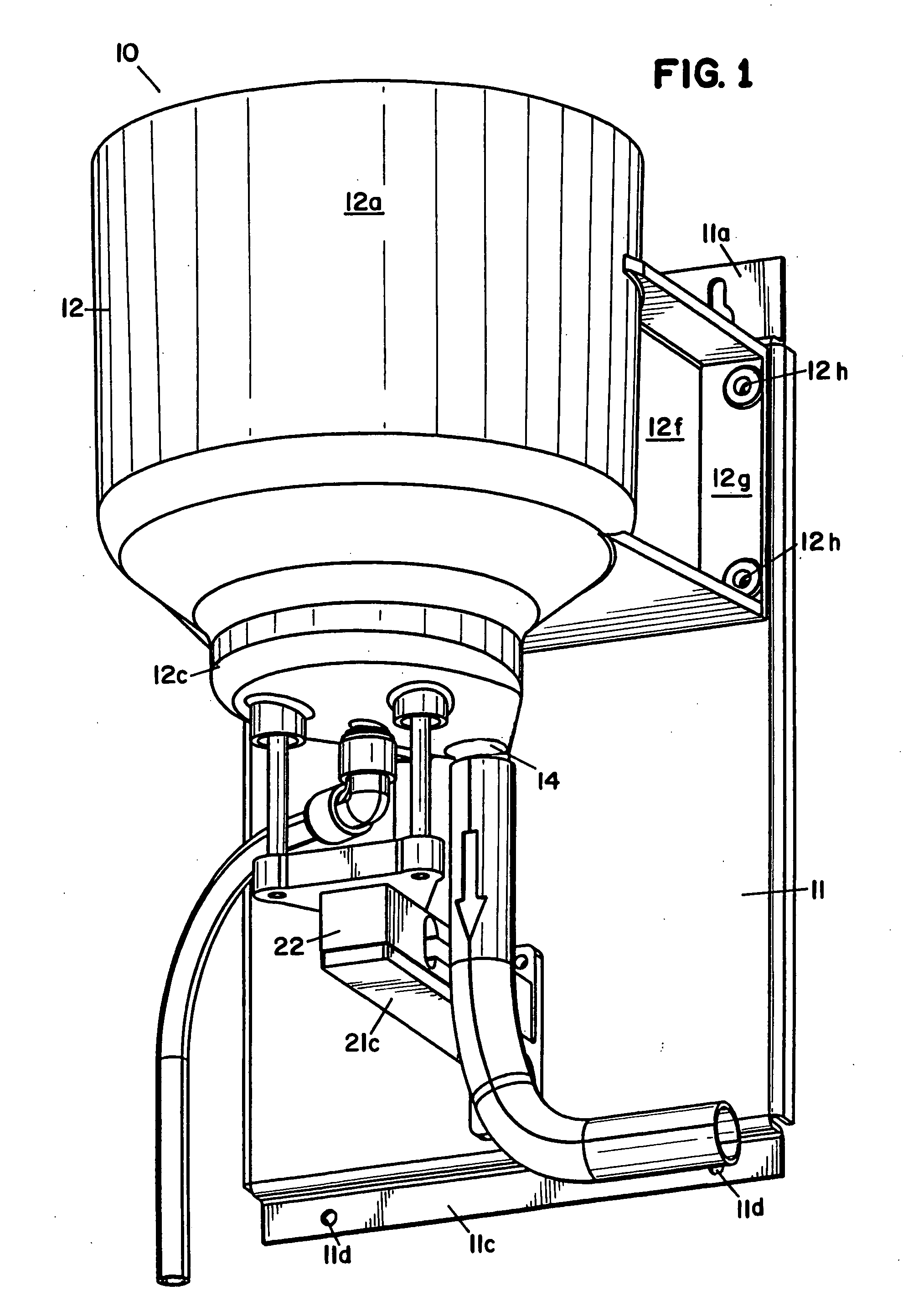

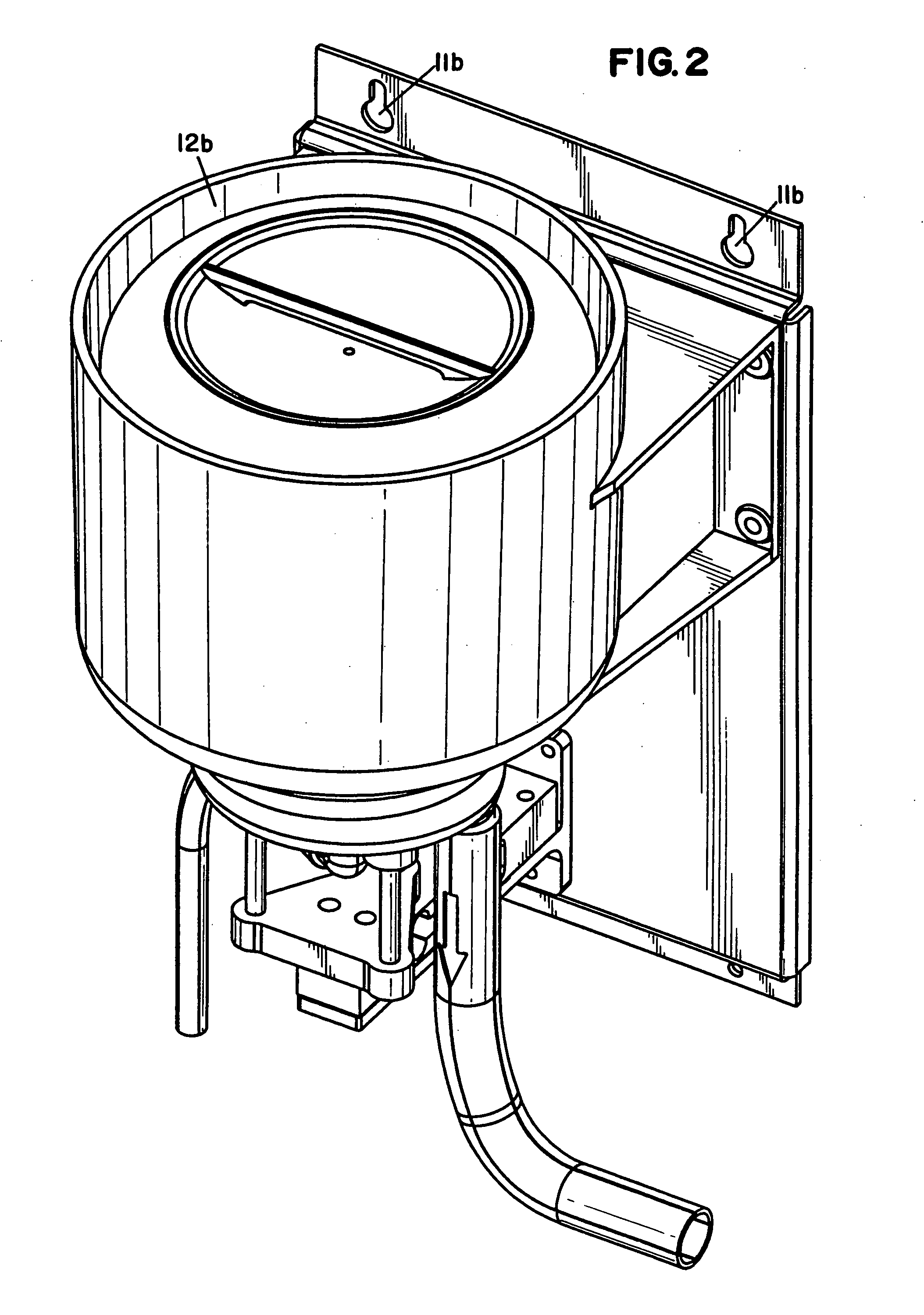

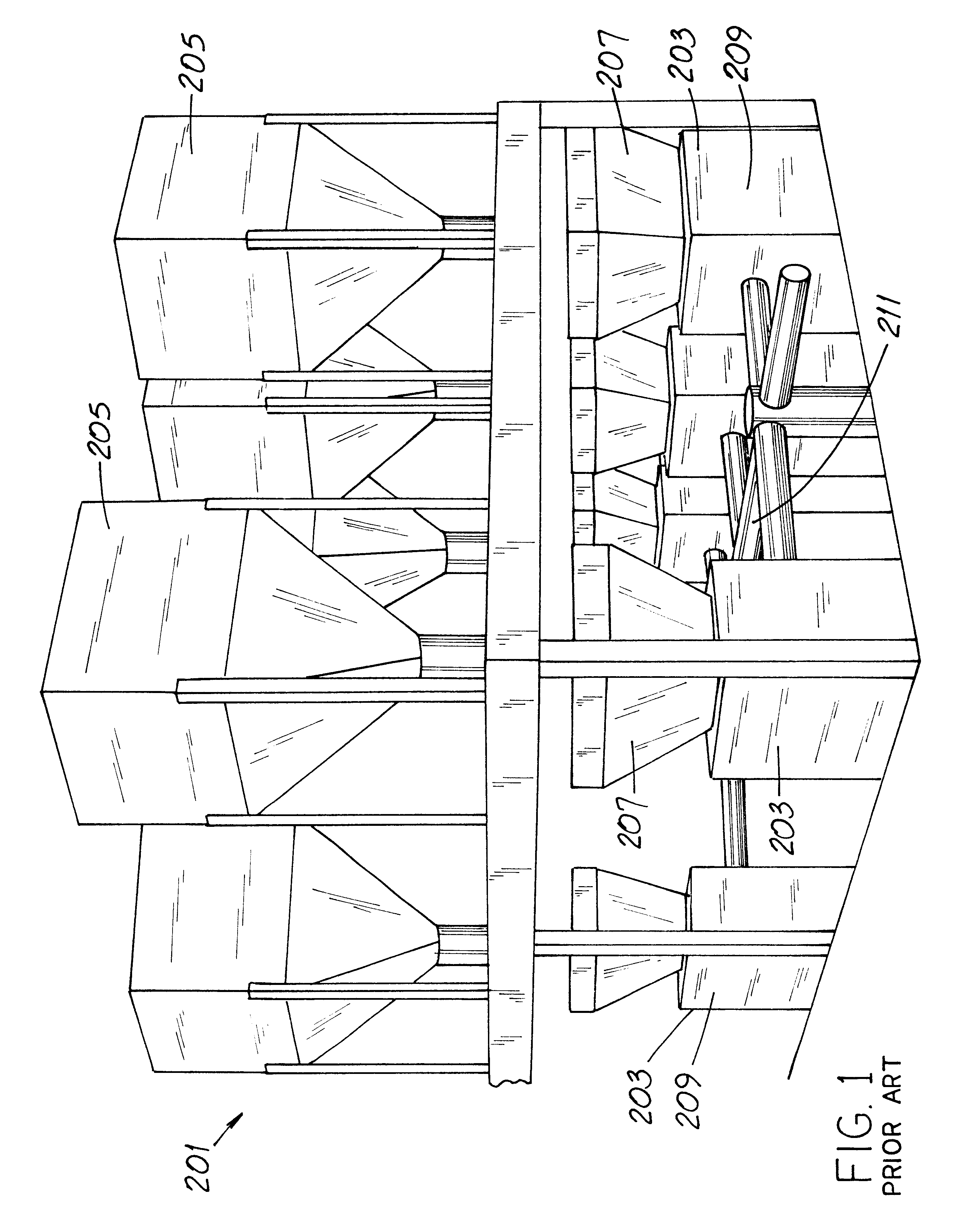

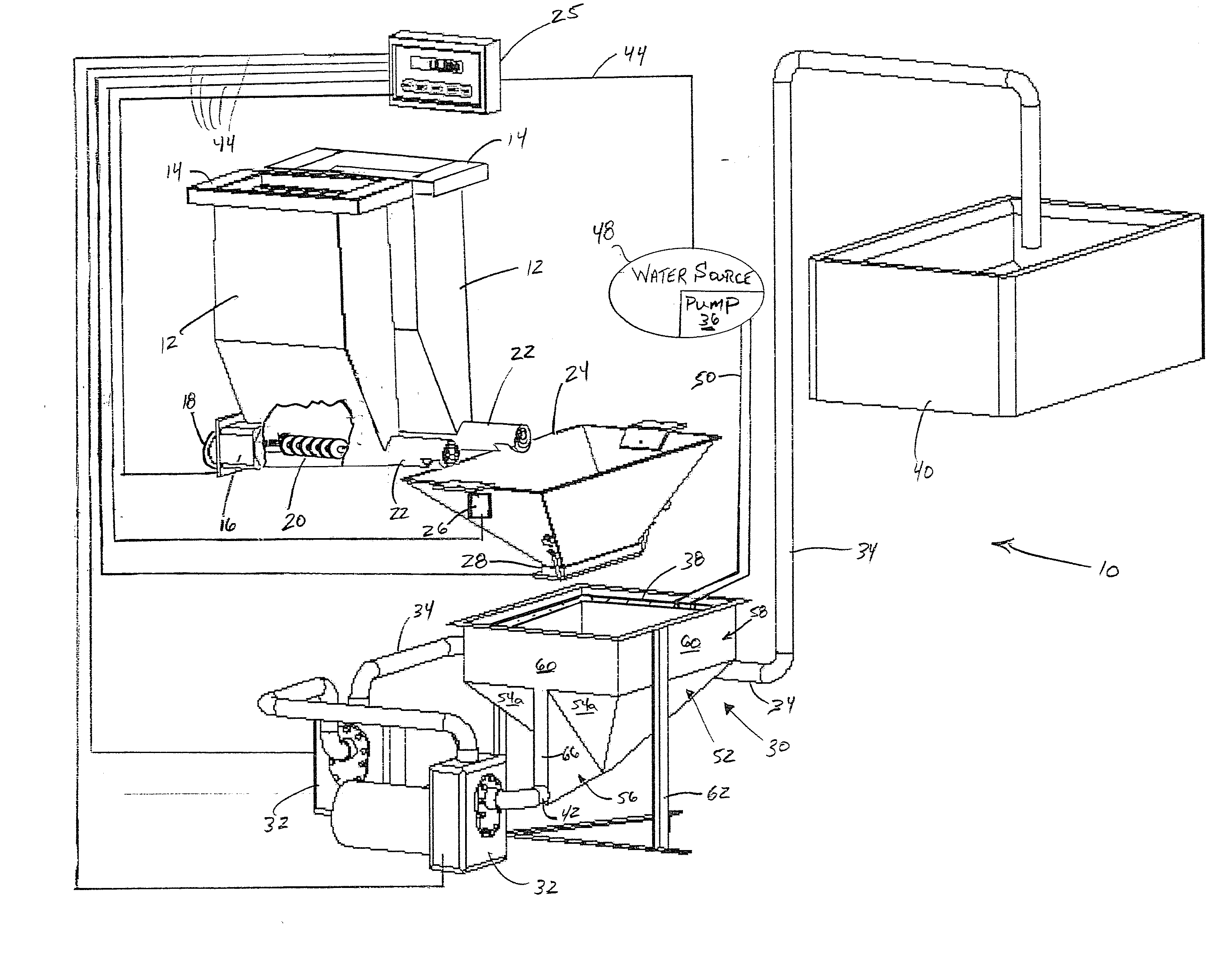

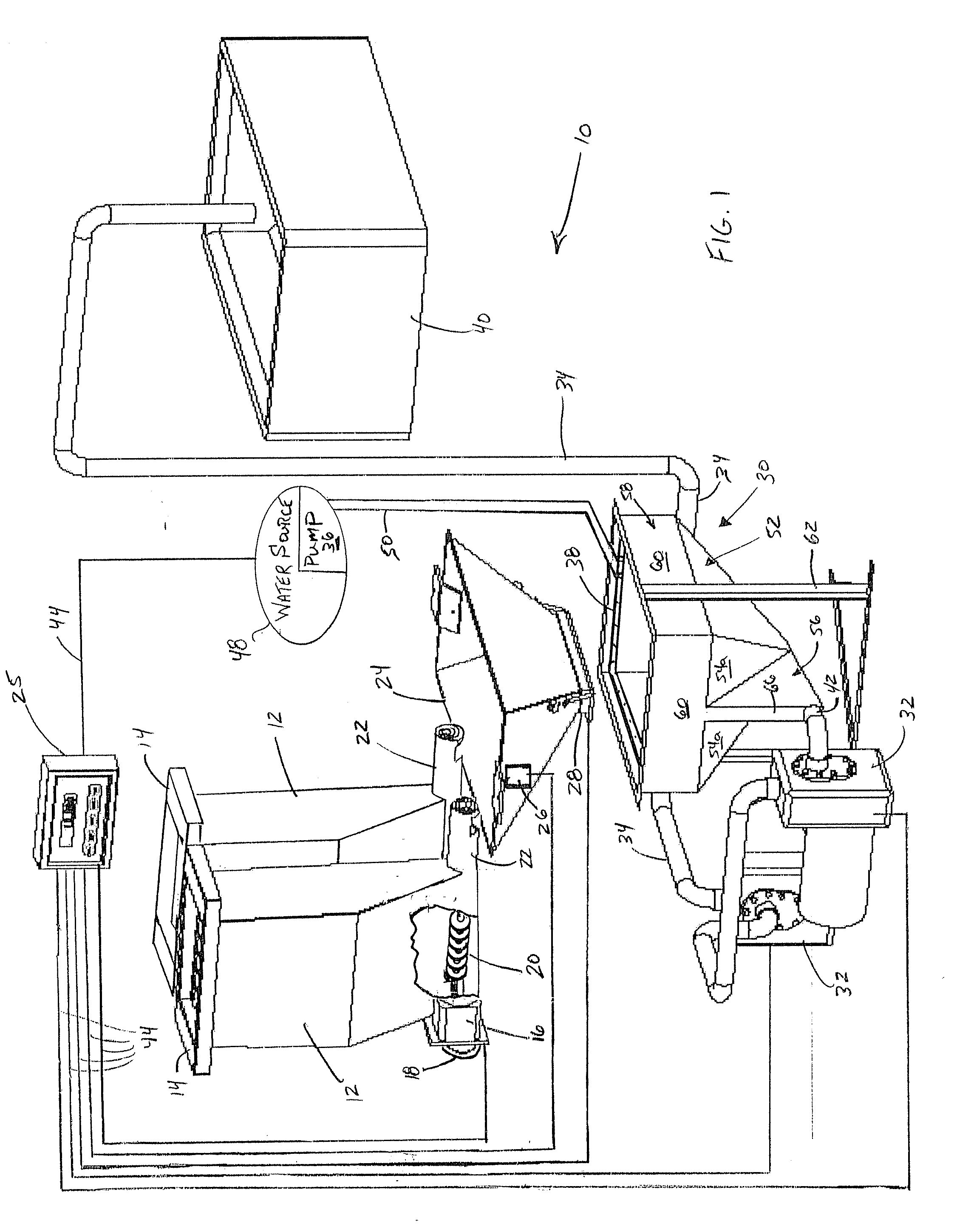

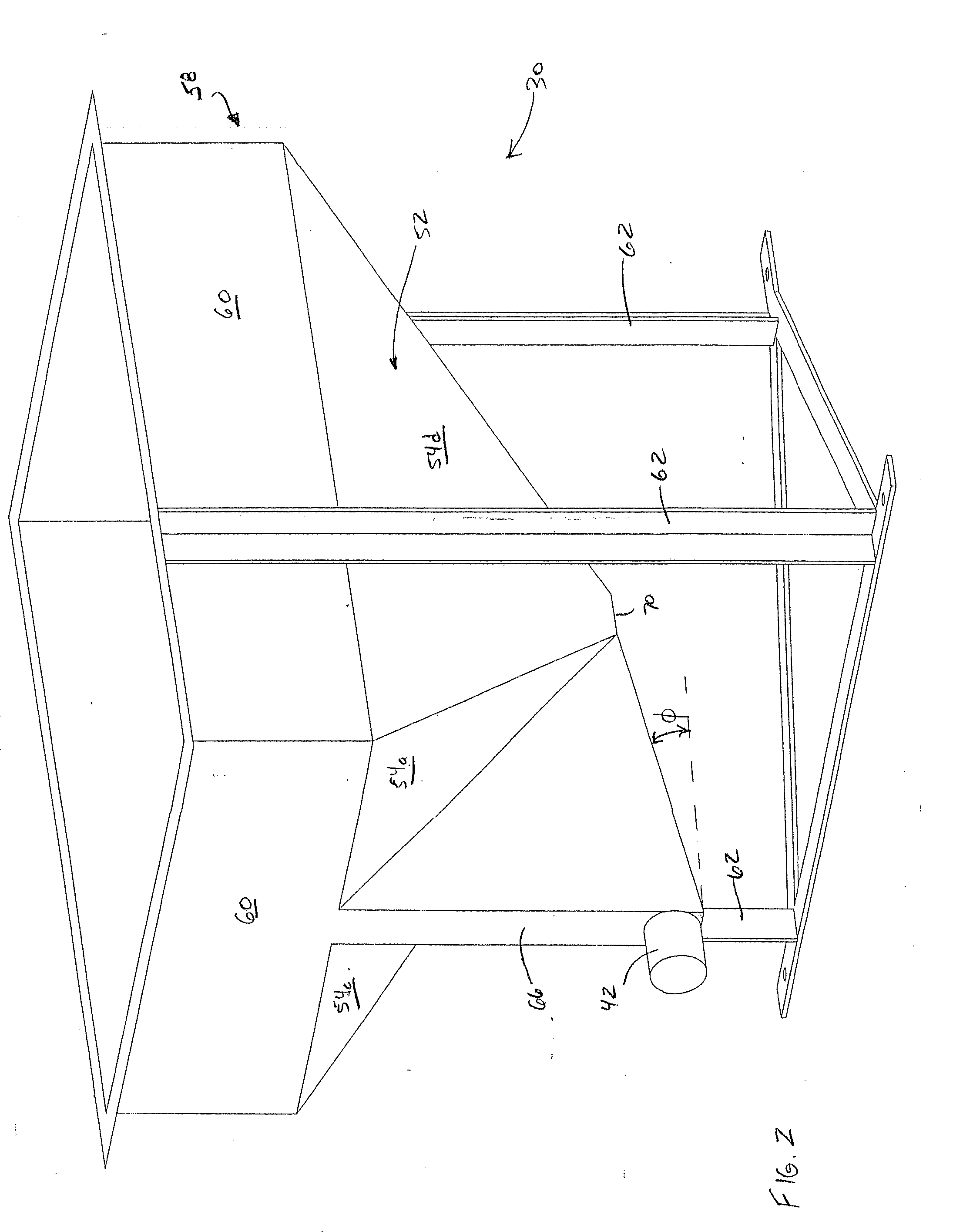

Gravity flow sludge load-out system

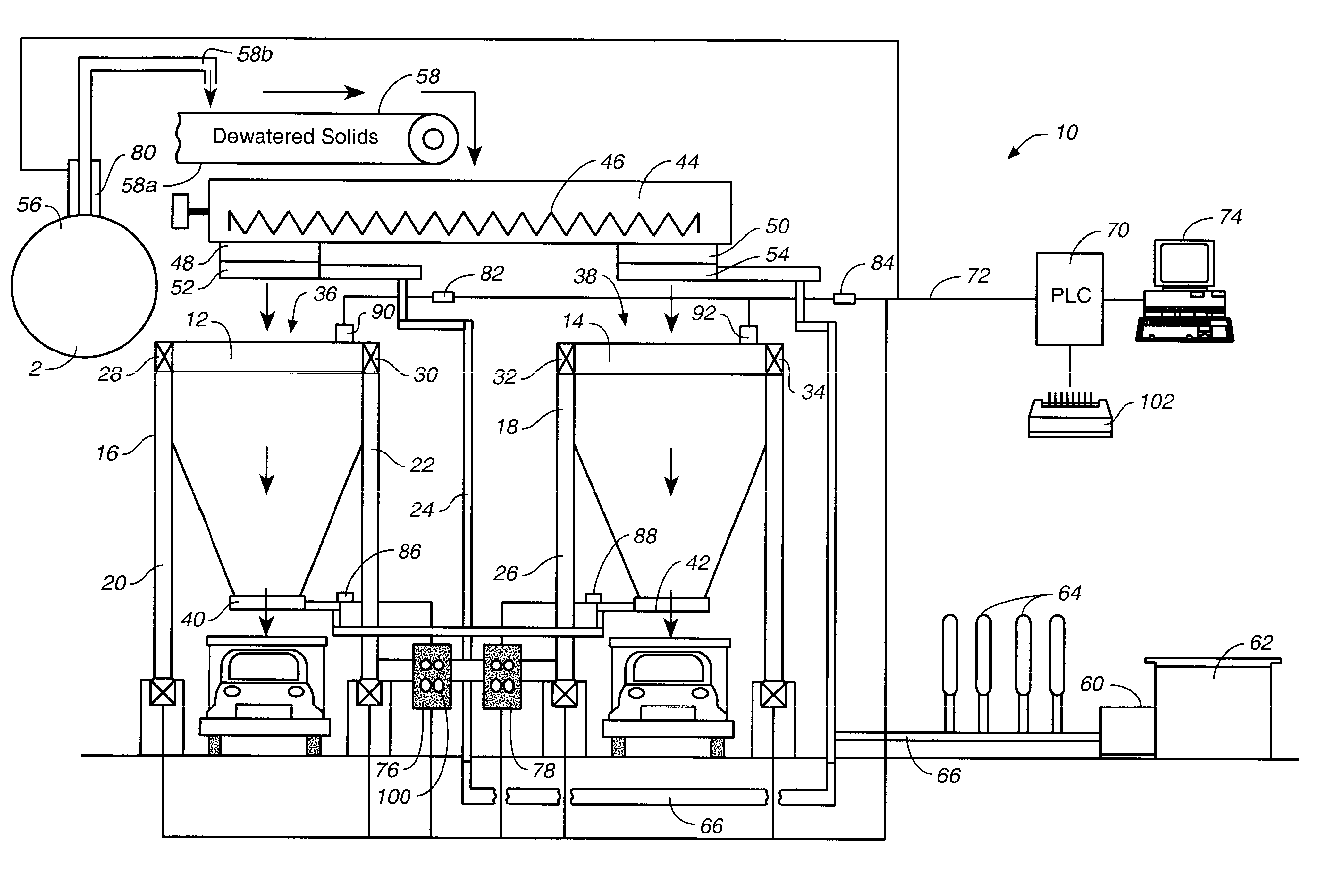

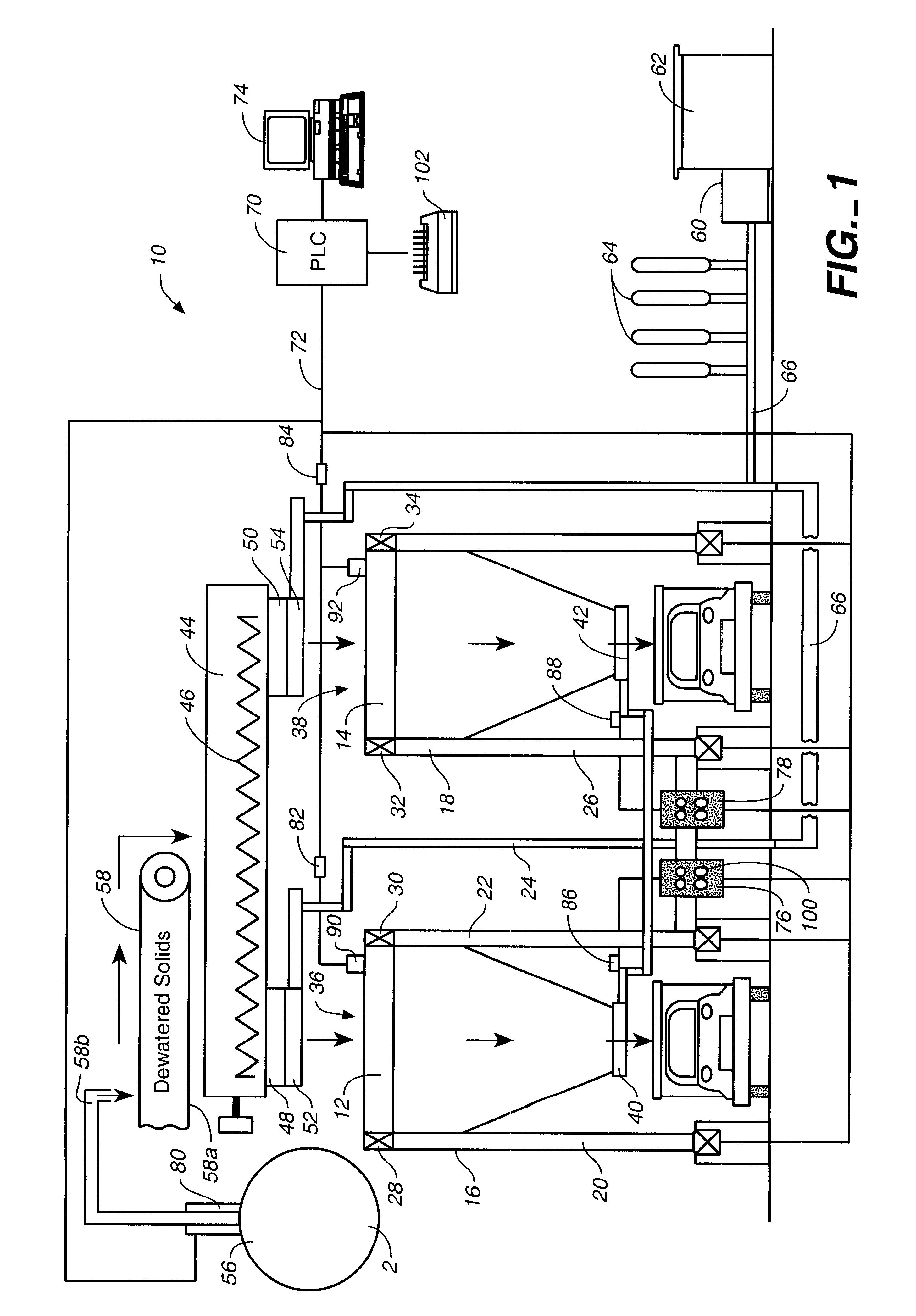

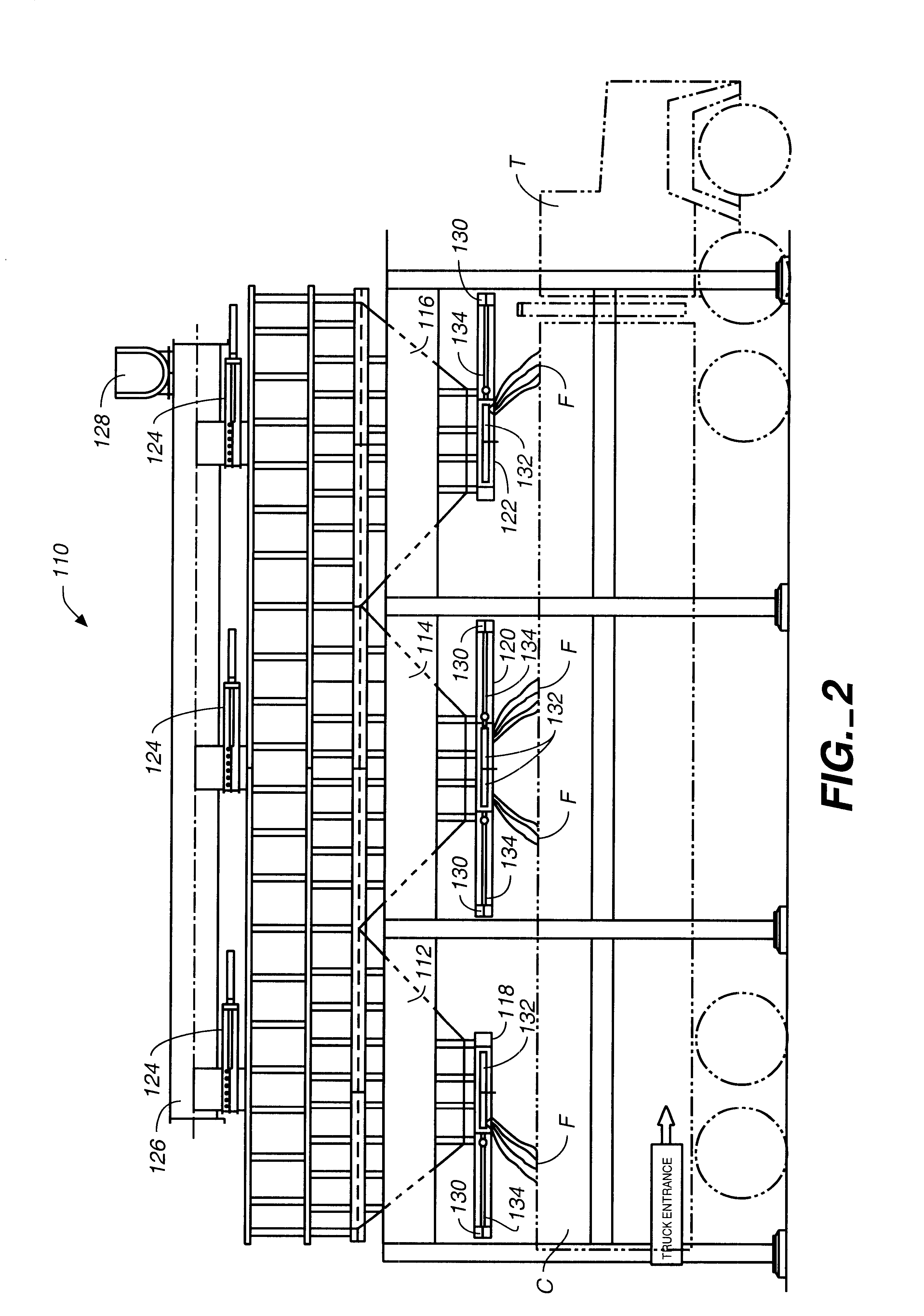

InactiveUS6447674B1Rapidly and accurately loading-out large volumeSettling tanks feed/dischargeCentrifugal force sediment separationWastewaterGravity flow

A gravity flow sludge load-out system for rapid and accurate loading-out of large volumes of treated biosolids from a wastewater dewatering plant, said system includes a plurality of hoppers 12, 14 supported by a main structure 16 having a plurality of vertical support members 20, each resting on a load cell 28, a sludge inlet at the tip of each hopper, and hydraulically controlled metering gates 40 at the bottom. A PLC 70 controls delivery of sludge from a dewatering facility, including e.g. a dewatering centrifuge 56, into the hoppers and then controls load-out of the sludge to a container truck by providing real-time monitoring of net sludge load-out and tight control of metering gates.

Owner:RDP TECH

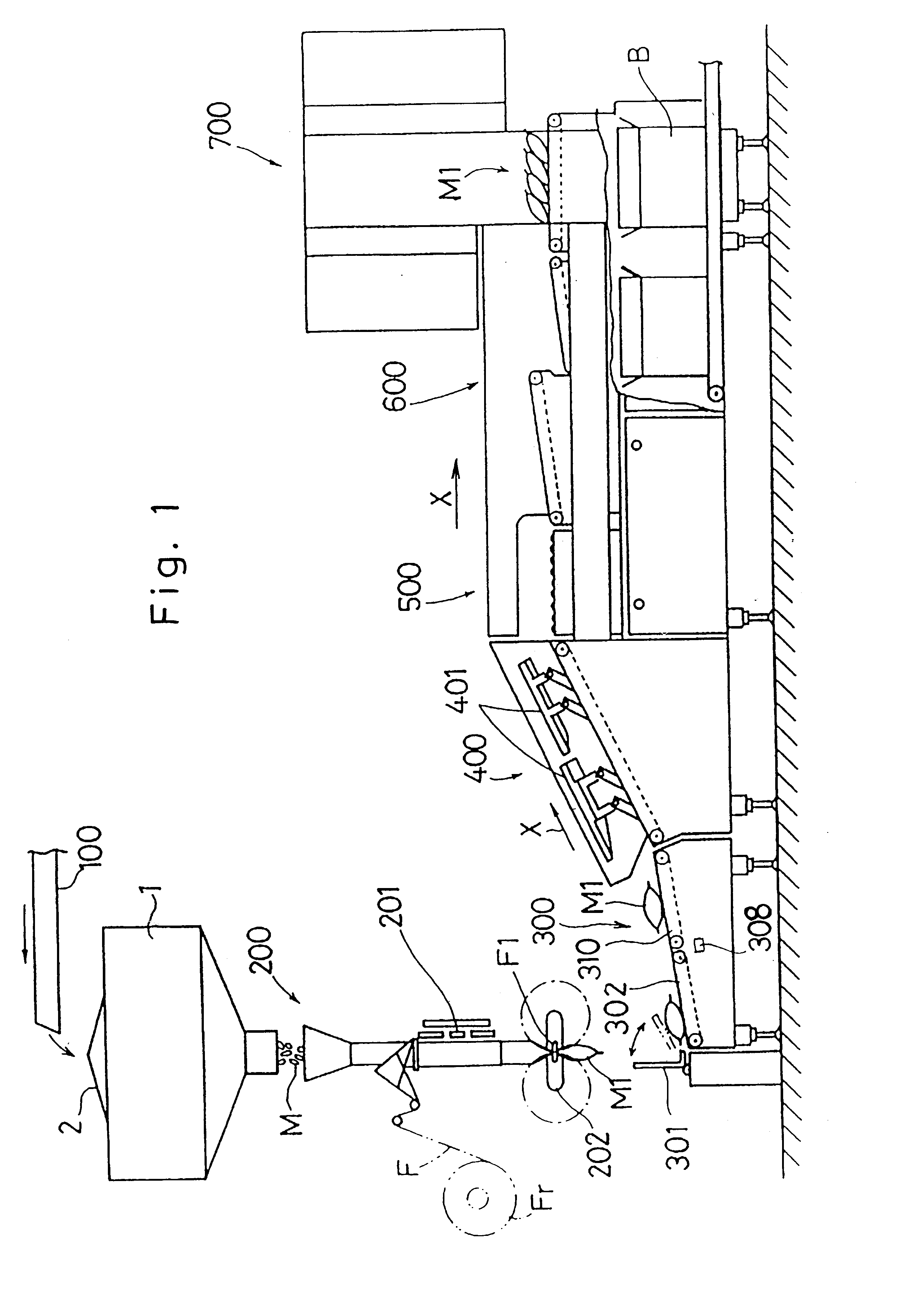

Unitized fibrous construct dispensing system

InactiveUS7228990B2Without affecting structural integrityAssist with stability of systemMixing operation control apparatusLiquid transferring devicesFiberBiomedical engineering

The present invention is directed to a method and system for transporting and dispensing fibers into an aggregate mix, and more specifically, to a method and system for transporting and dispensing unitized fibrous constructs into a mix without affecting the structural integrity of the unitized construct. The dispensing system will transport and dispense unitized fibrous constructs intact into a cementitious mixture.

Owner:FABPRO ORIENTED POLYMERS L L C

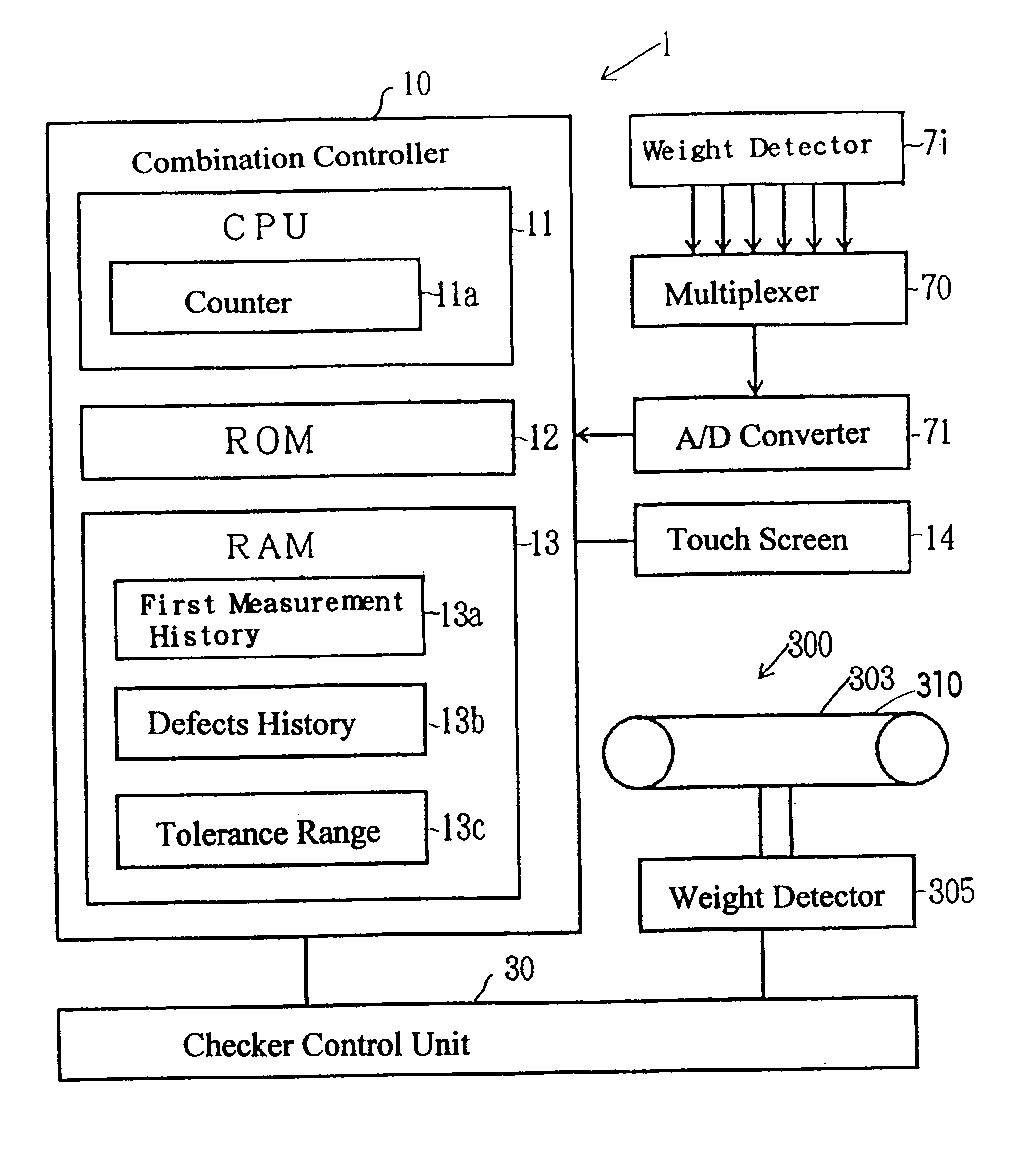

Weighing, packaging and inspecting system

InactiveUS6373001B1Weighing apparatus testing/calibrationWeighing indication devicesDisplay devicePost discharge

There is provided an abnormal device determining means (CPU 51) which reads a tendency of displacement between the combination calculated weight Wc of the contents M and the post-discharge Ws measured value of the same contents M measured after such contents M have been bagged and which, based on the tendency of displacement so read, determines which one of the combination calculated value Wc and the post-discharge measured value Ws is abnormal, and a display device (54) for displaying a result of the determination. Thus, since based on the displacement tendency of the combination calculated value Wc and the post-discharge measured value Ws, which one of the combination calculated value Wc and the post-discharge measured value Ws is abnormal is determined, it can readily and easily grasped which one of the combination weighing apparatus (1) and the weight checker (300) suffers from a trouble.

Owner:ISHIDA CO LTD

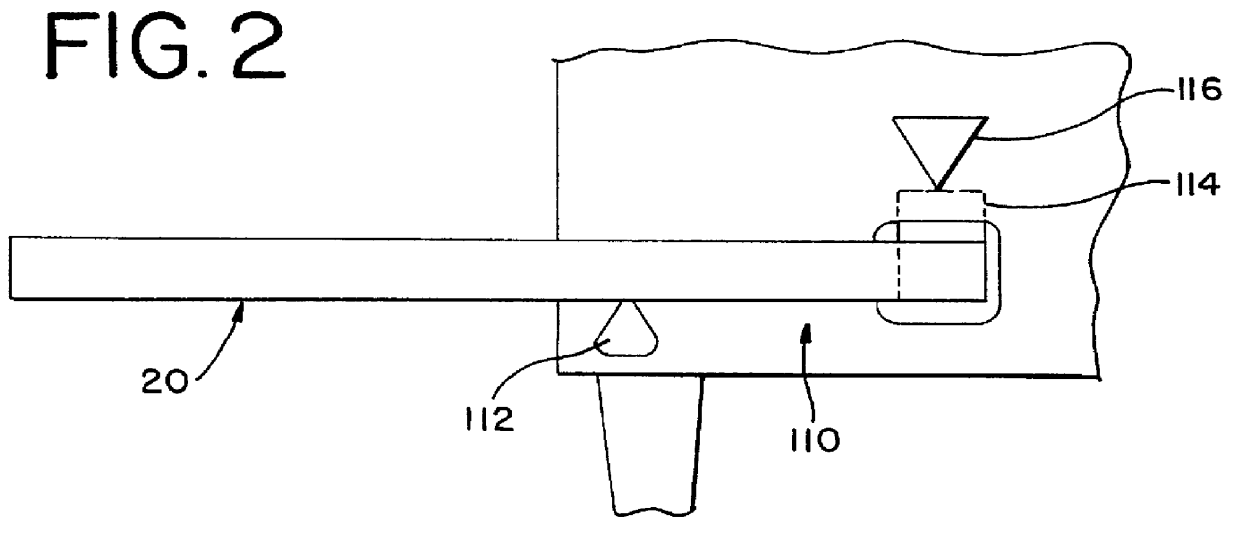

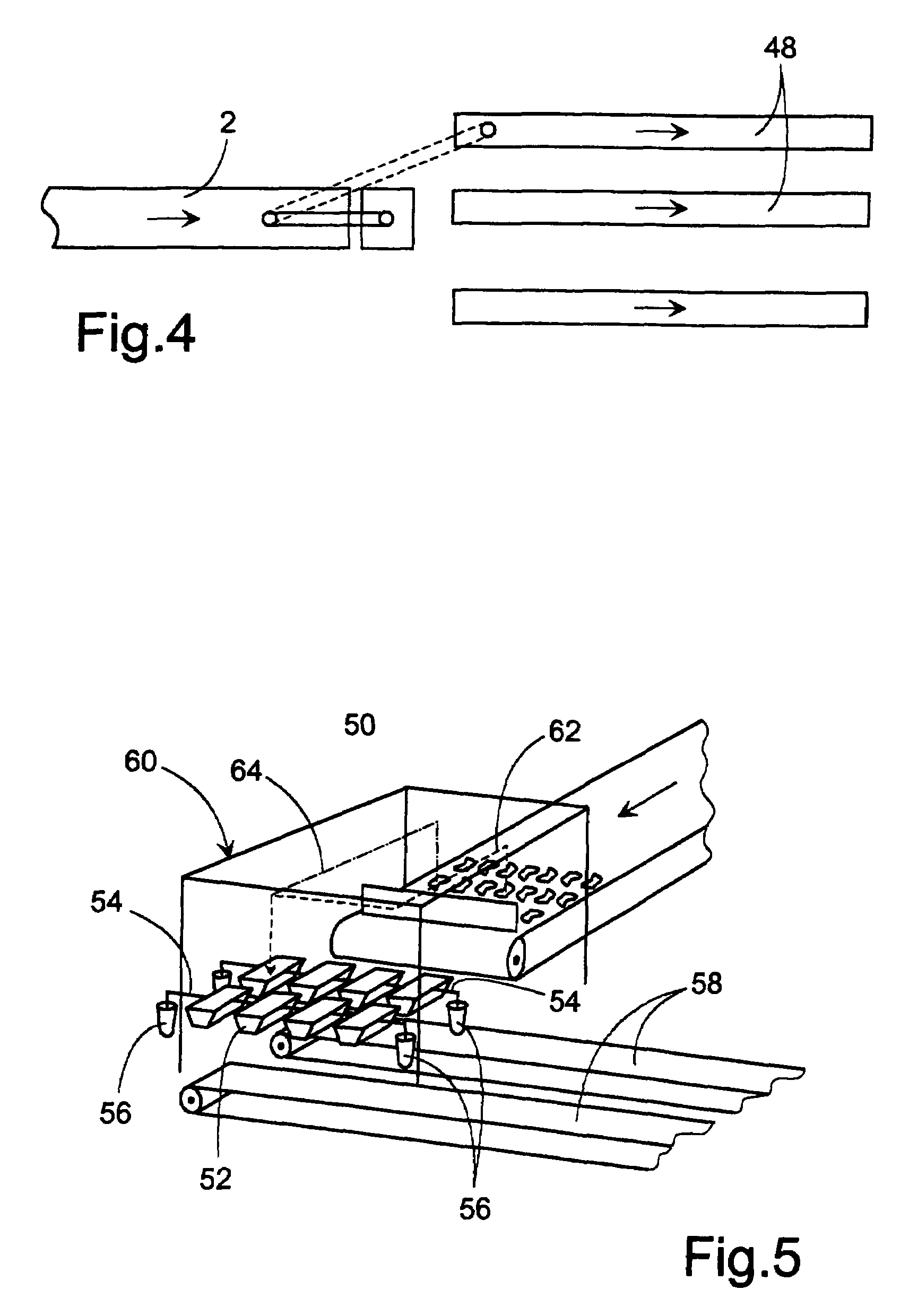

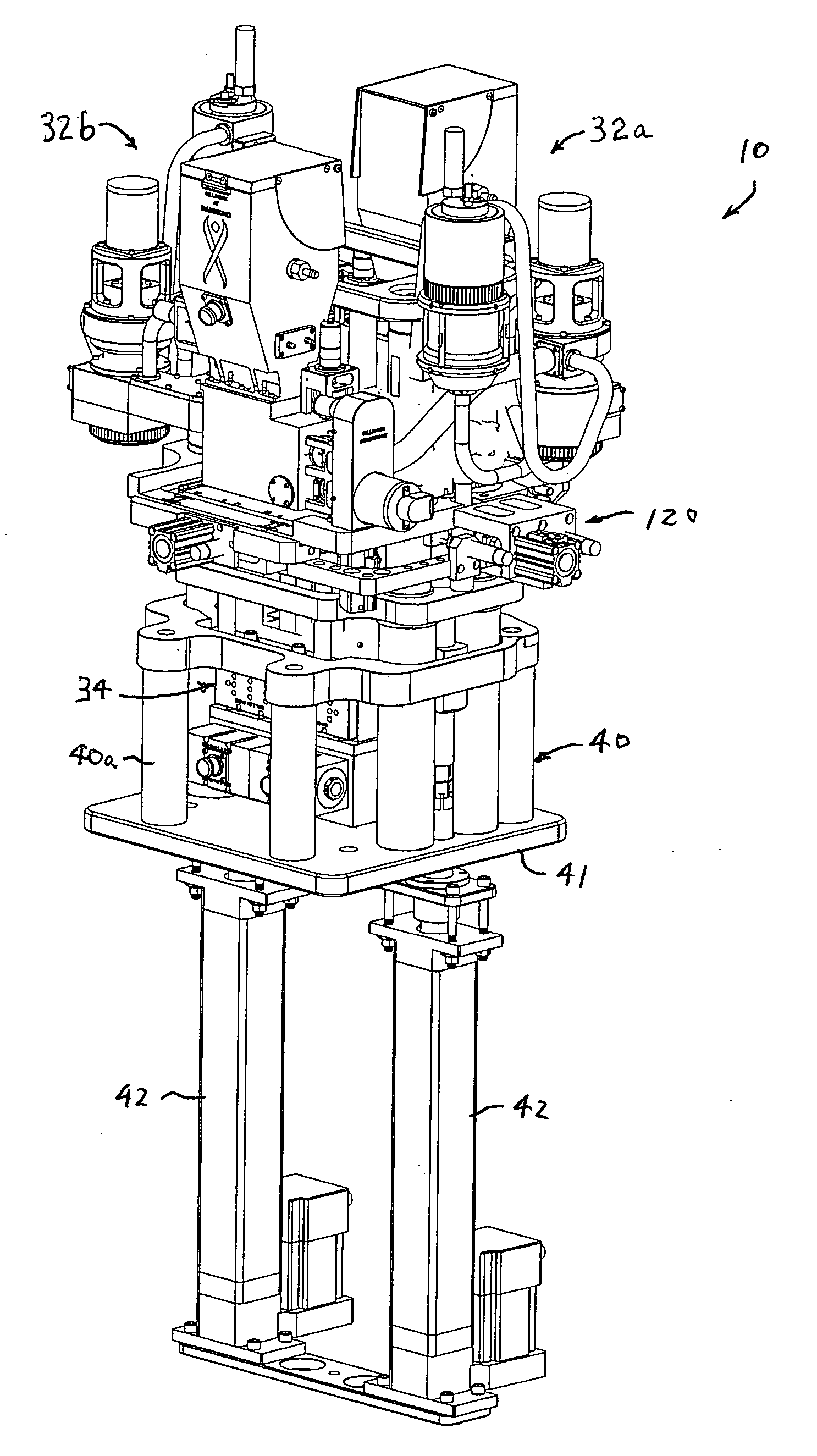

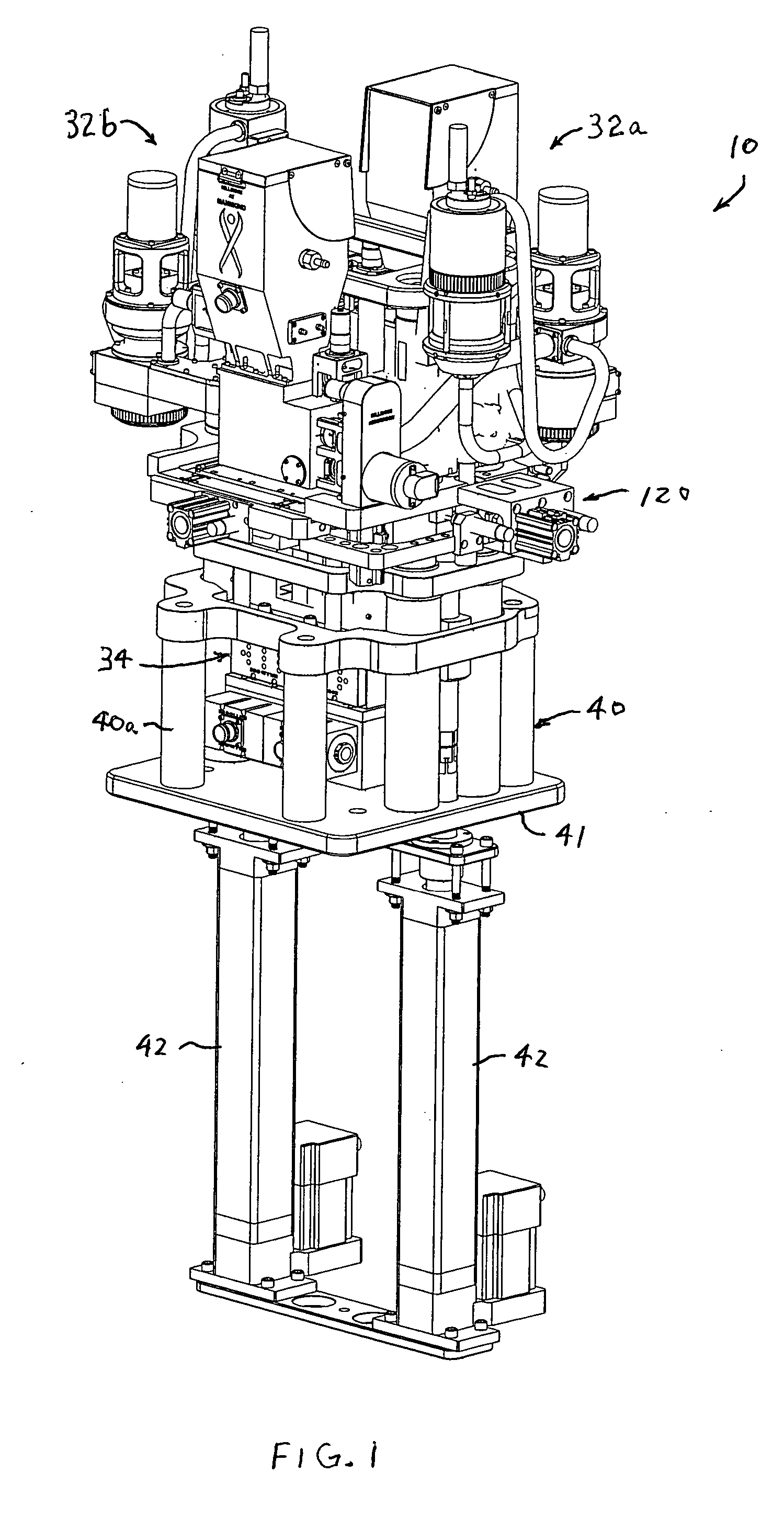

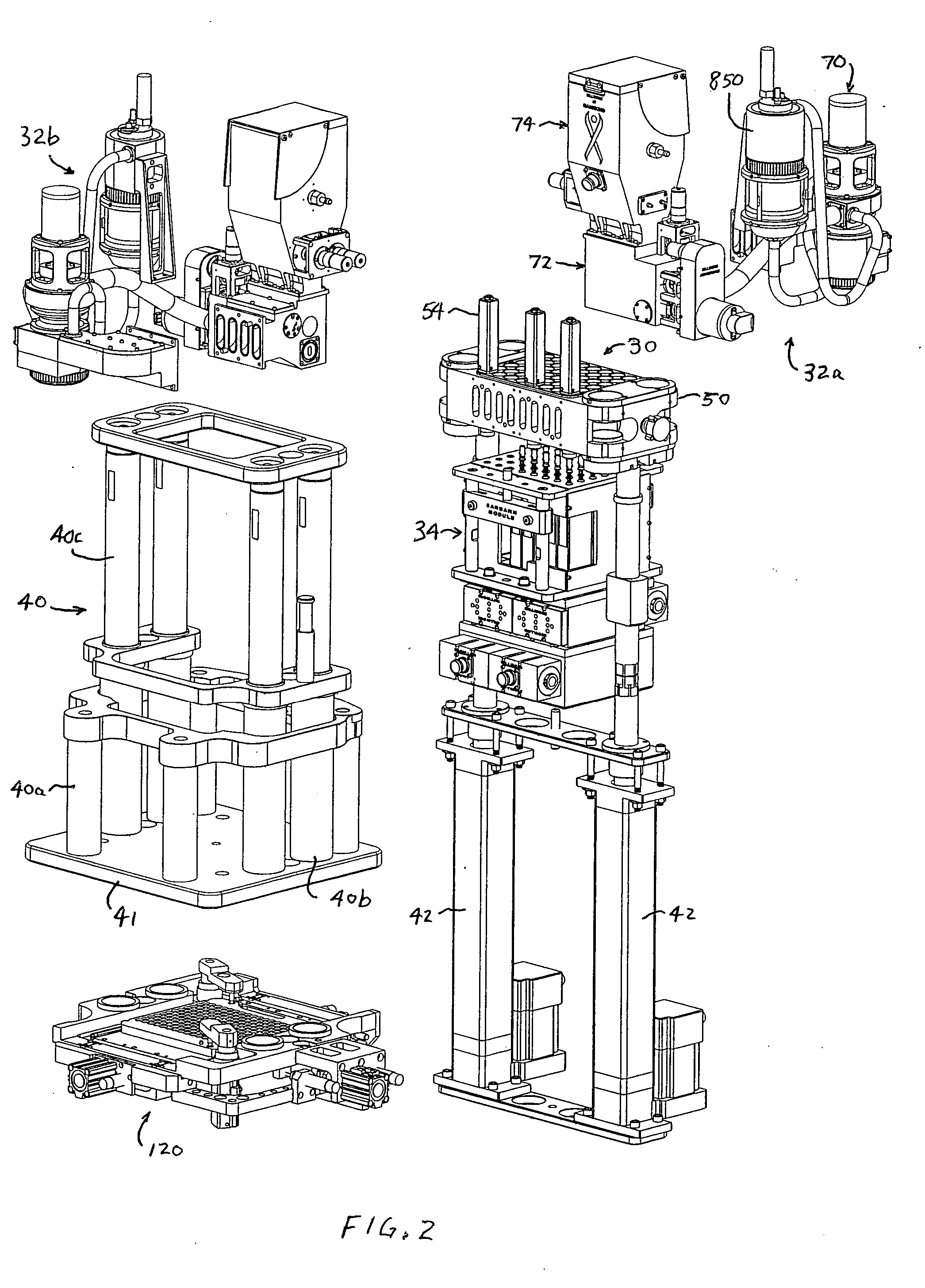

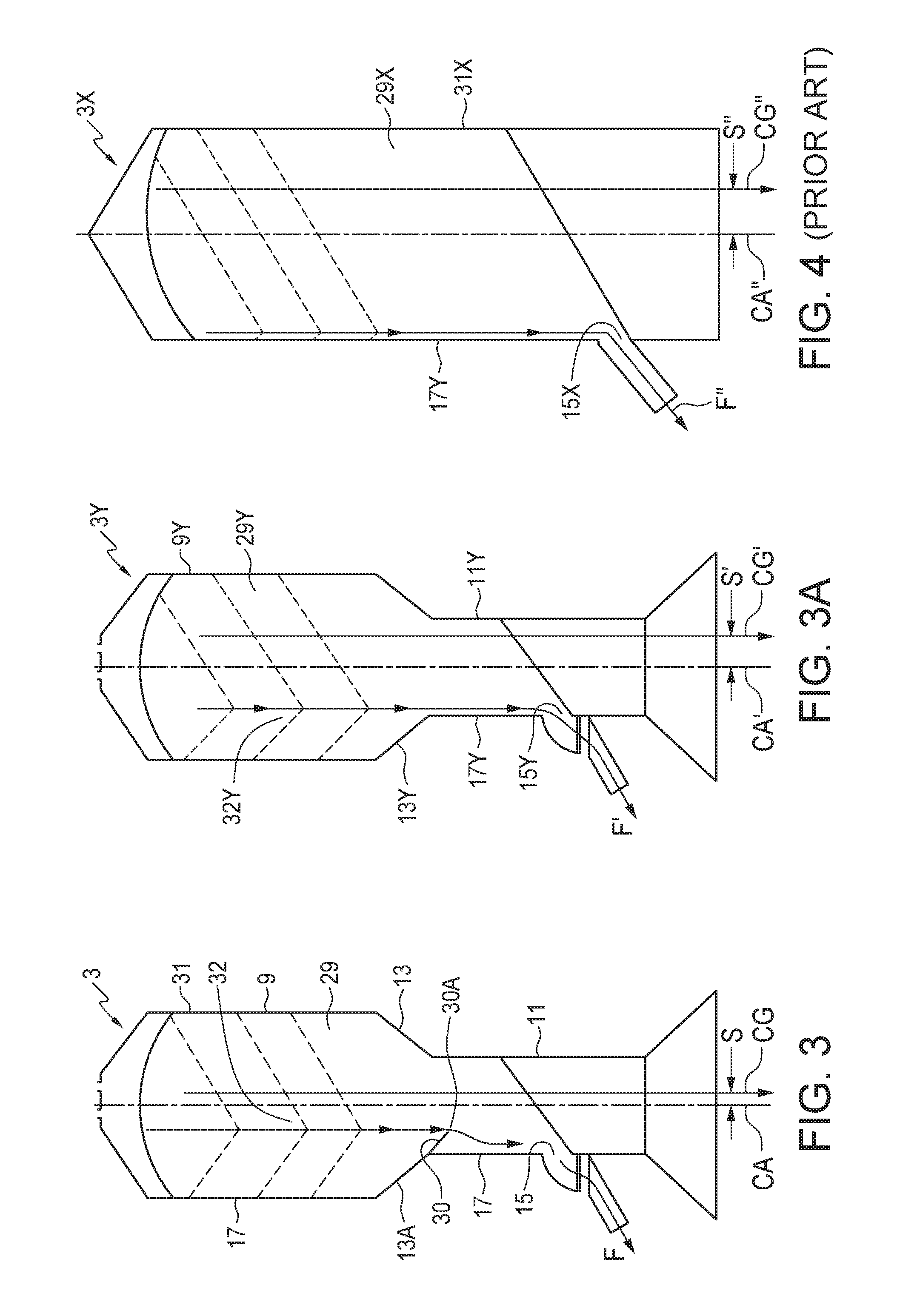

Apparatus and method for gravimetric blending with horizontal material feed

InactiveUS6111206AMovable measuring chambersLiquid transferring devicesReciprocating motionEngineering

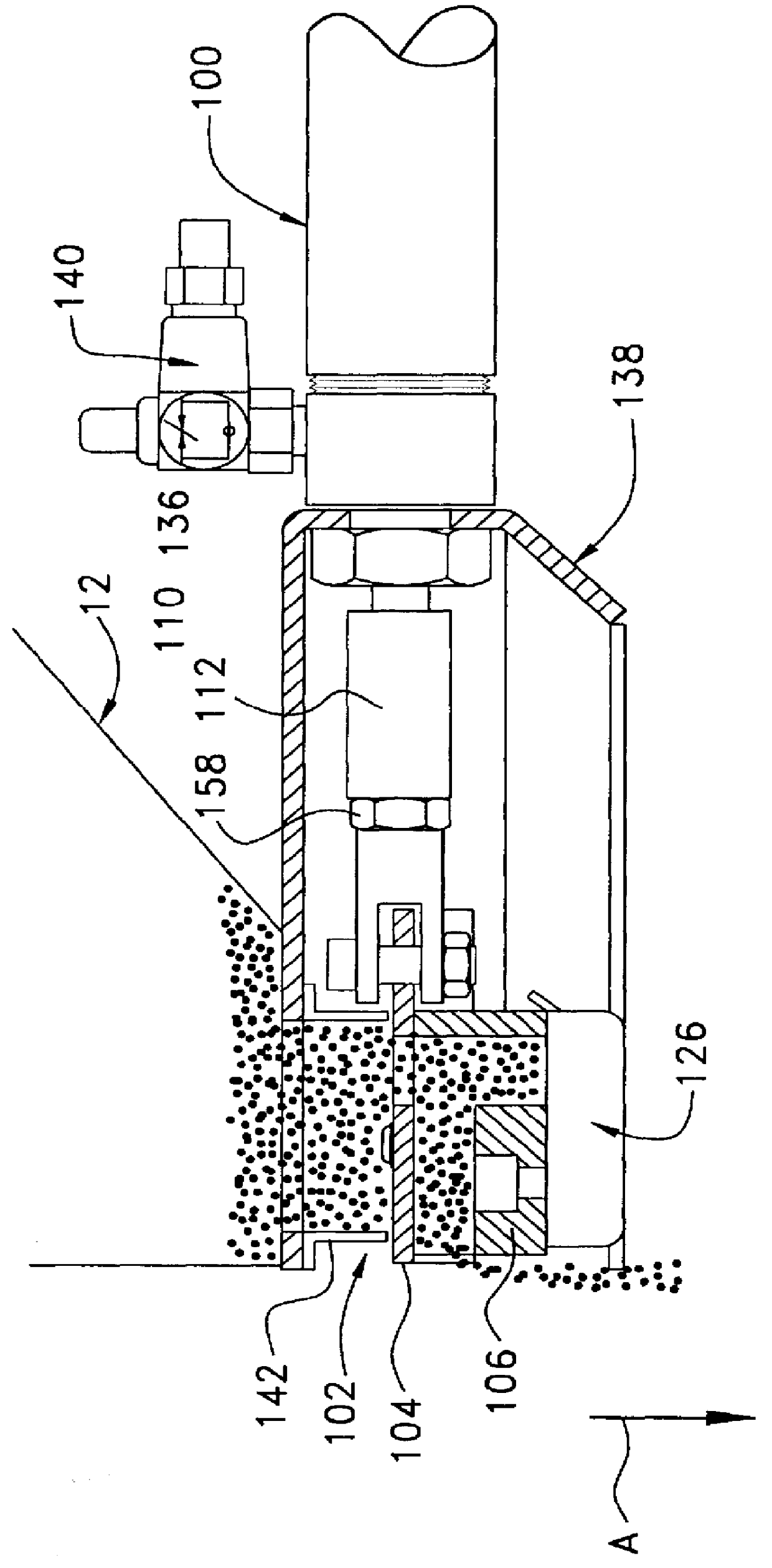

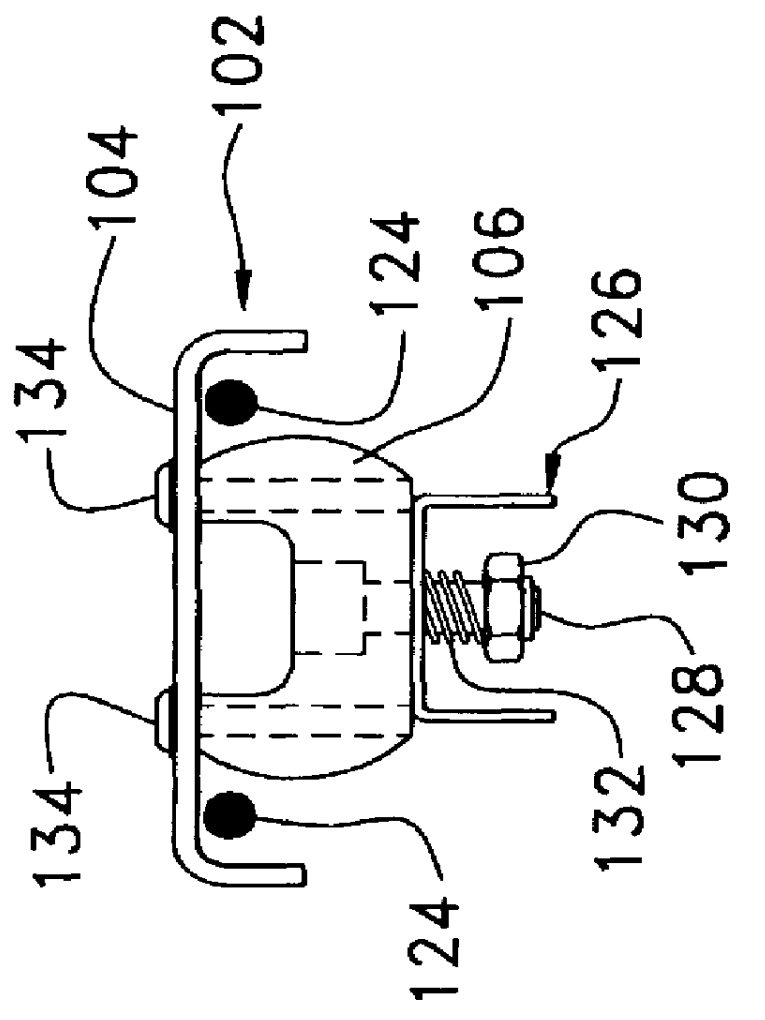

A method and apparatus of supplying material from a storage hopper (12) to a weighing hopper (16) where the material is fed at a controllable rate by a sliding plate member (104) that acts as a shutter for the storage hopper (12), which includes an aperture (154) for receiving material gravity fed from the storage hopper (12). As the plate (104) is reciprocated horizontally at a preselected frequency, material is conveyed at a controlled rate from the storage hopper (12) to the weighing hopper (16).

Owner:MAGUIRE STEPHEN B

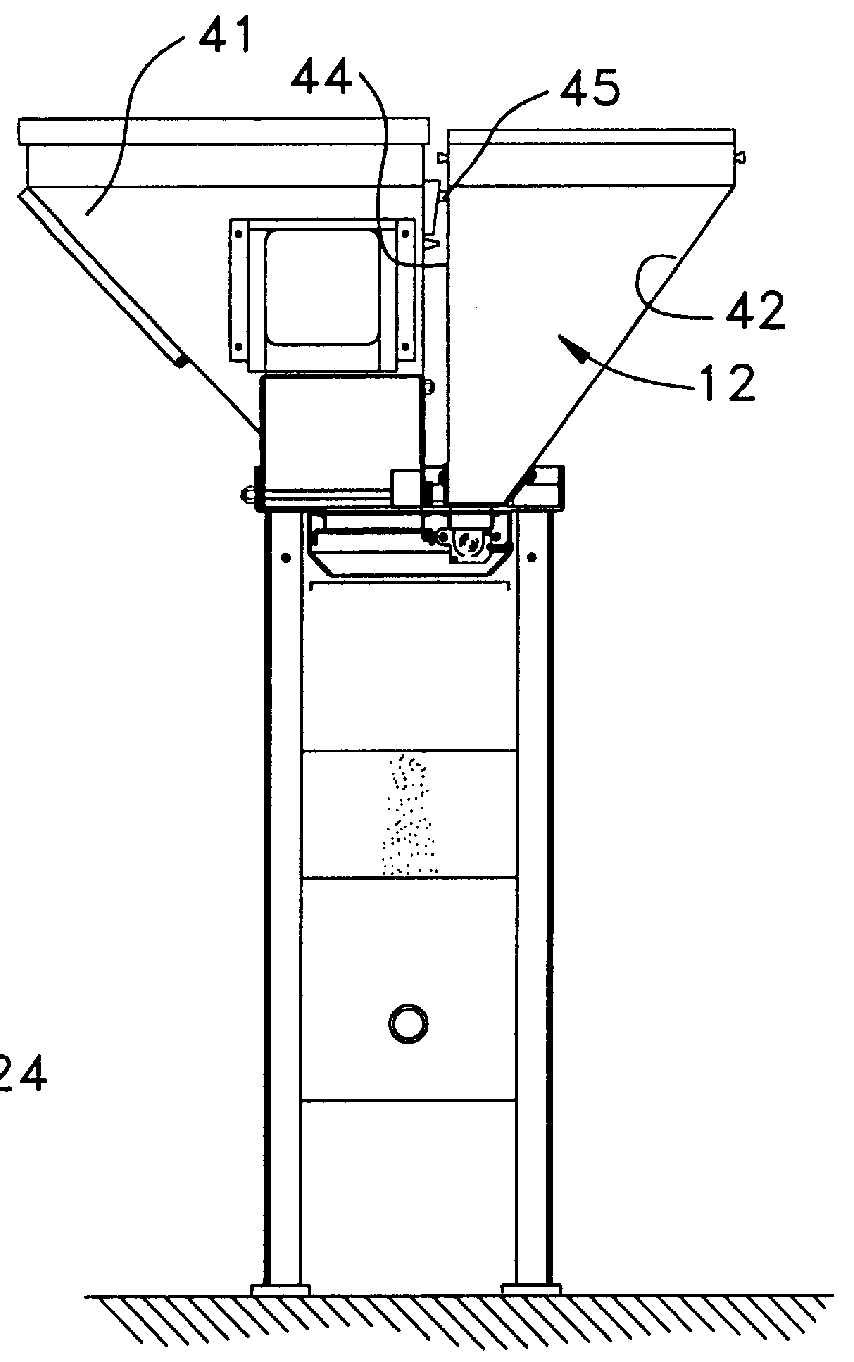

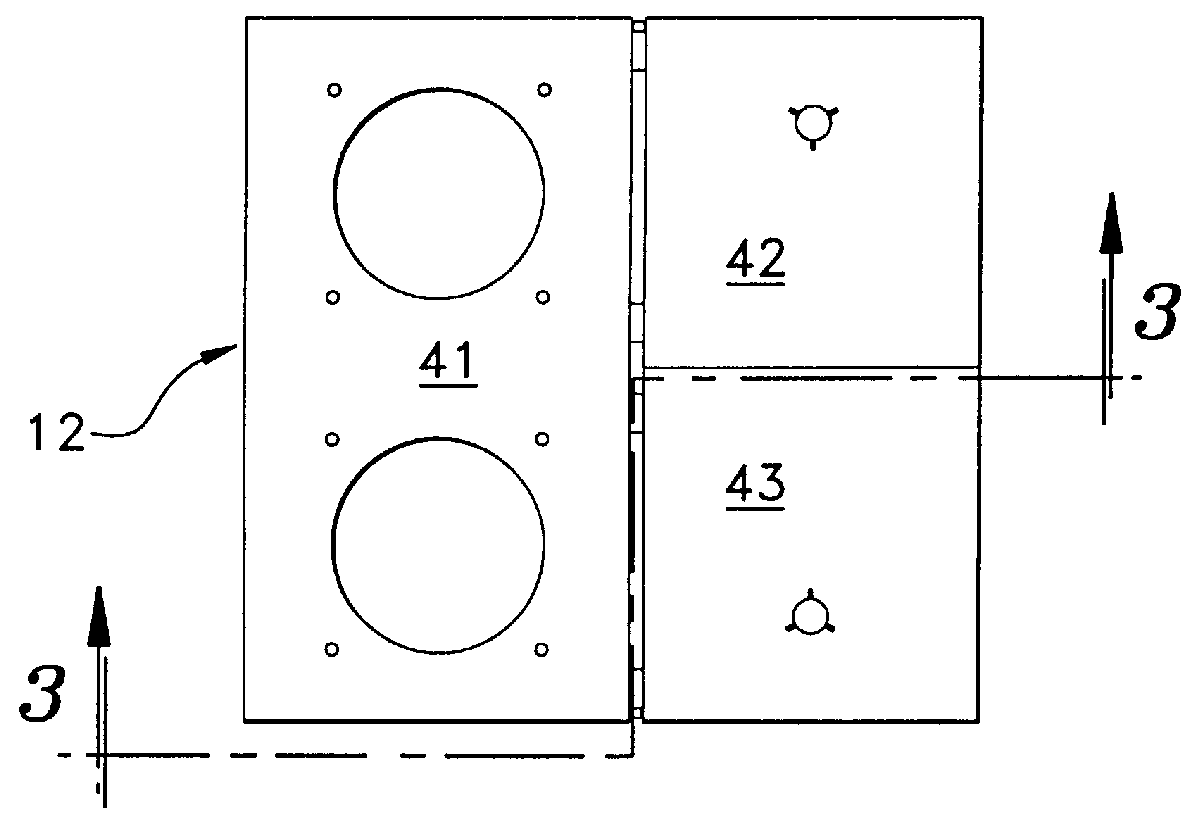

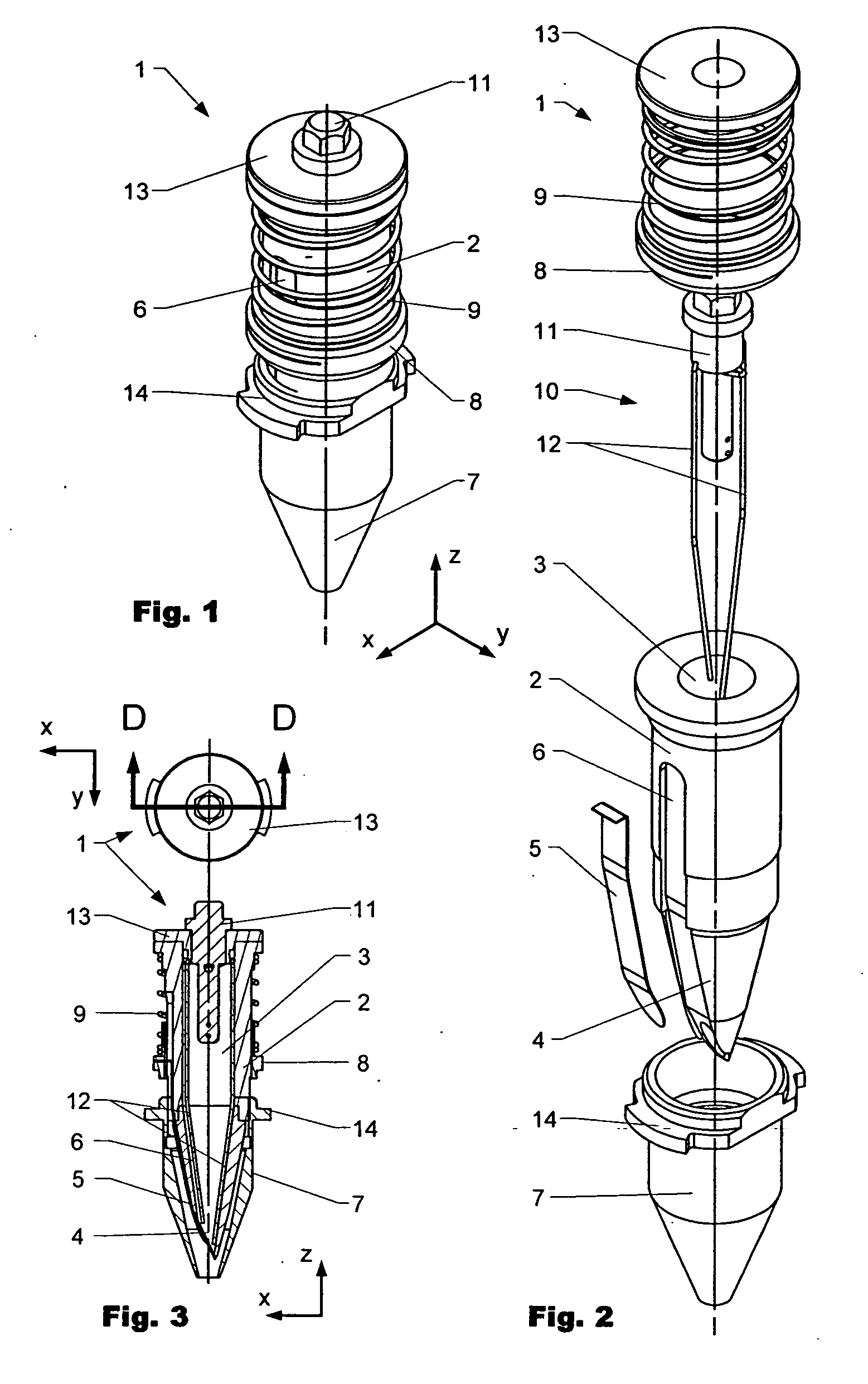

Bulk-solid metering system with laterally removable feed hopper

InactiveUS6568567B2Simplifies certain aspectHigh trafficMovable measuring chambersLarge containersEngineeringFlange

A bulk-solid metering system has a support structure. A feed hopper is mounted with respect to the structure and has an upper edge. In the improvement, the structure includes an upper member and the upper edge is below such upper member. The structure defines a lateral opening sized and shaped to permit the feed hopper to be withdrawn laterally through the opening. The feed hopper includes a spout extending therefrom. In a highly preferred embodiment, the lateral opening is positioned to permit withdrawal of the feed hopper in a direction away from the spout. The feed hopper is configured to promote very good mass flow as well as to permit agitation in that, in one embodiment, it has a body made of flexible material. There is a hopper upper flange and the spout is spaced below such flange. The body has a first cross-sectional shape, e.g., circular, adjacent to the upper flange and has a second cross-sectional shape, e.g., ellipse-like, intermediate the upper flange and the spout.

Owner:SCHENCK PROCESS LLC

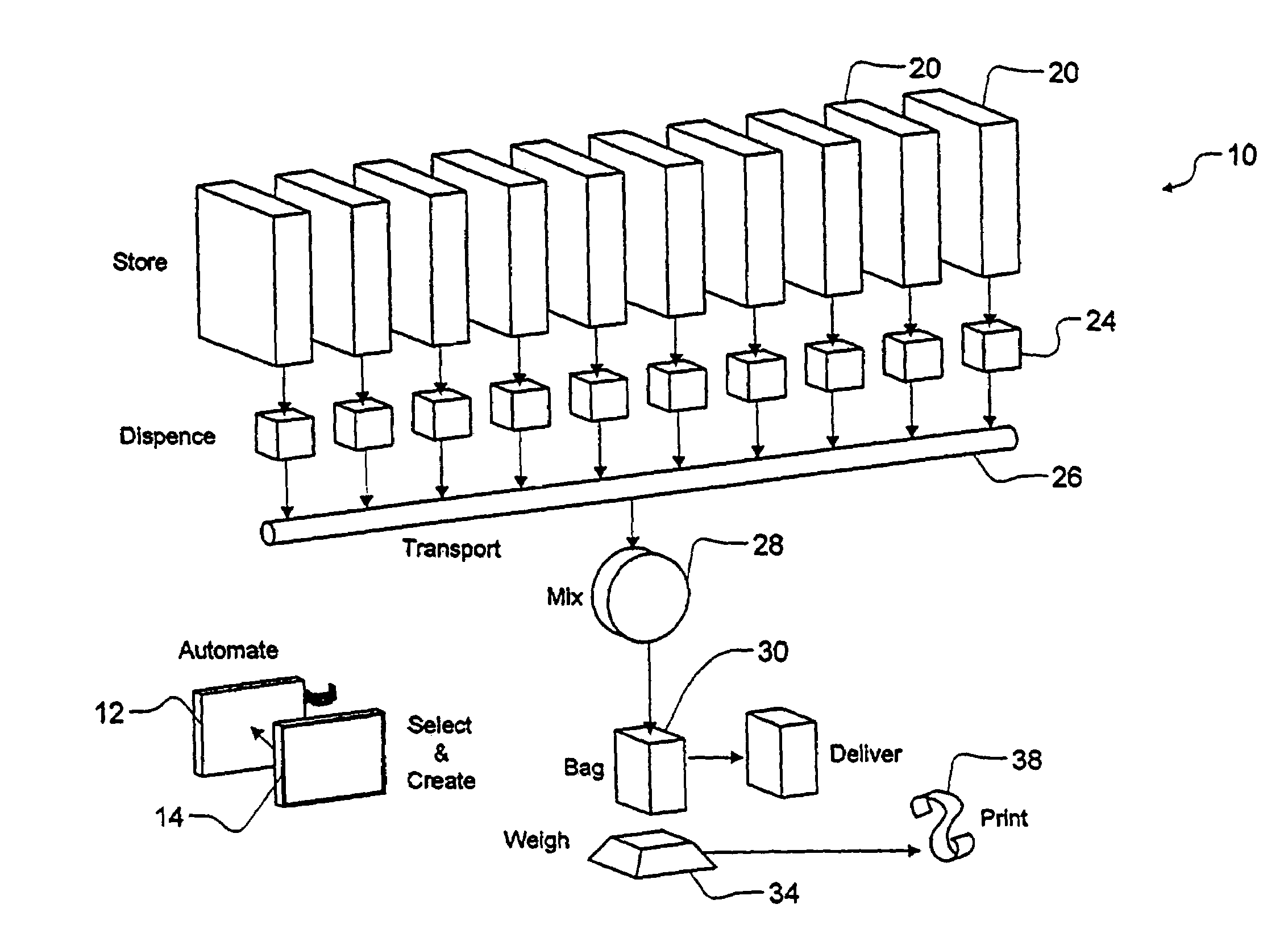

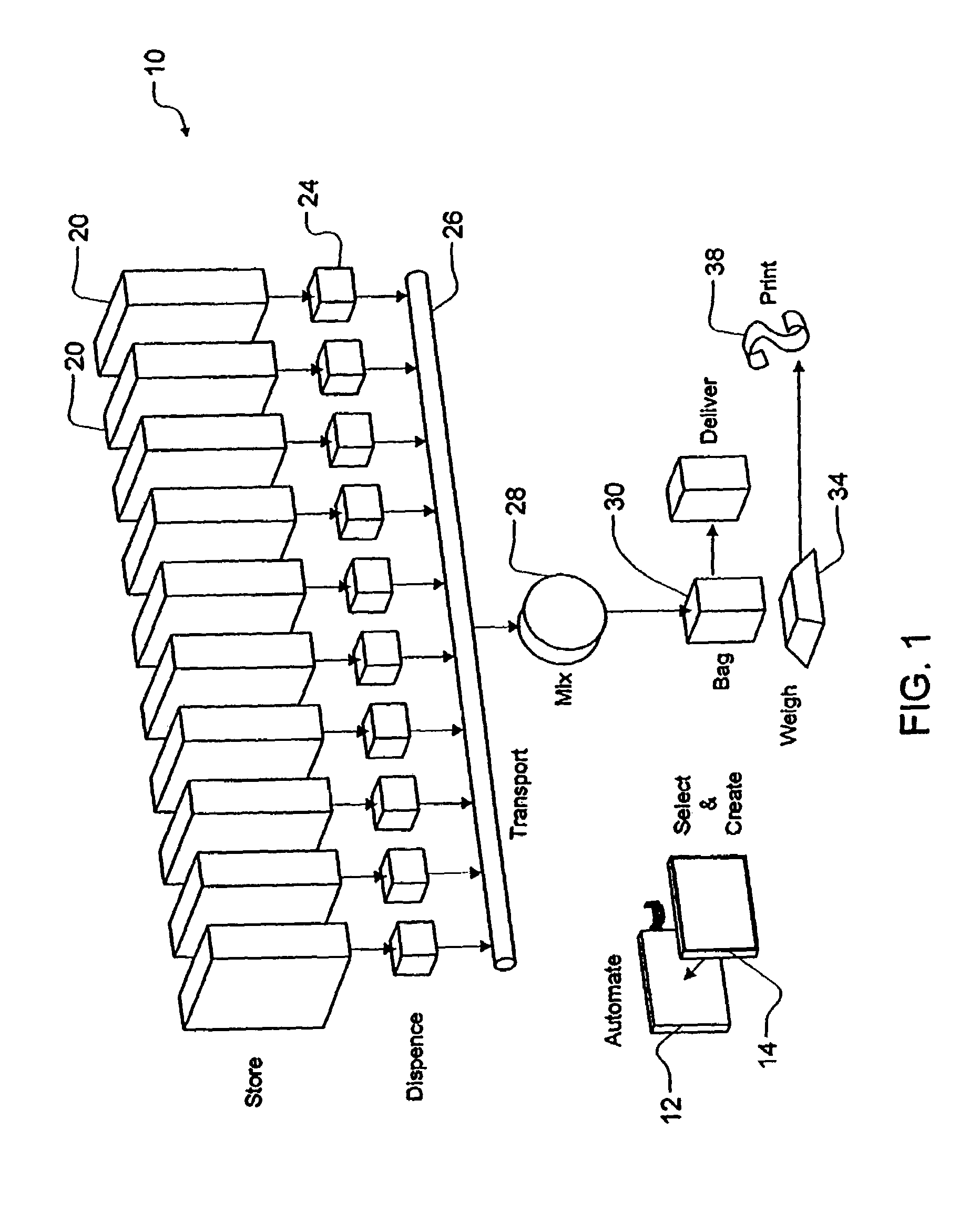

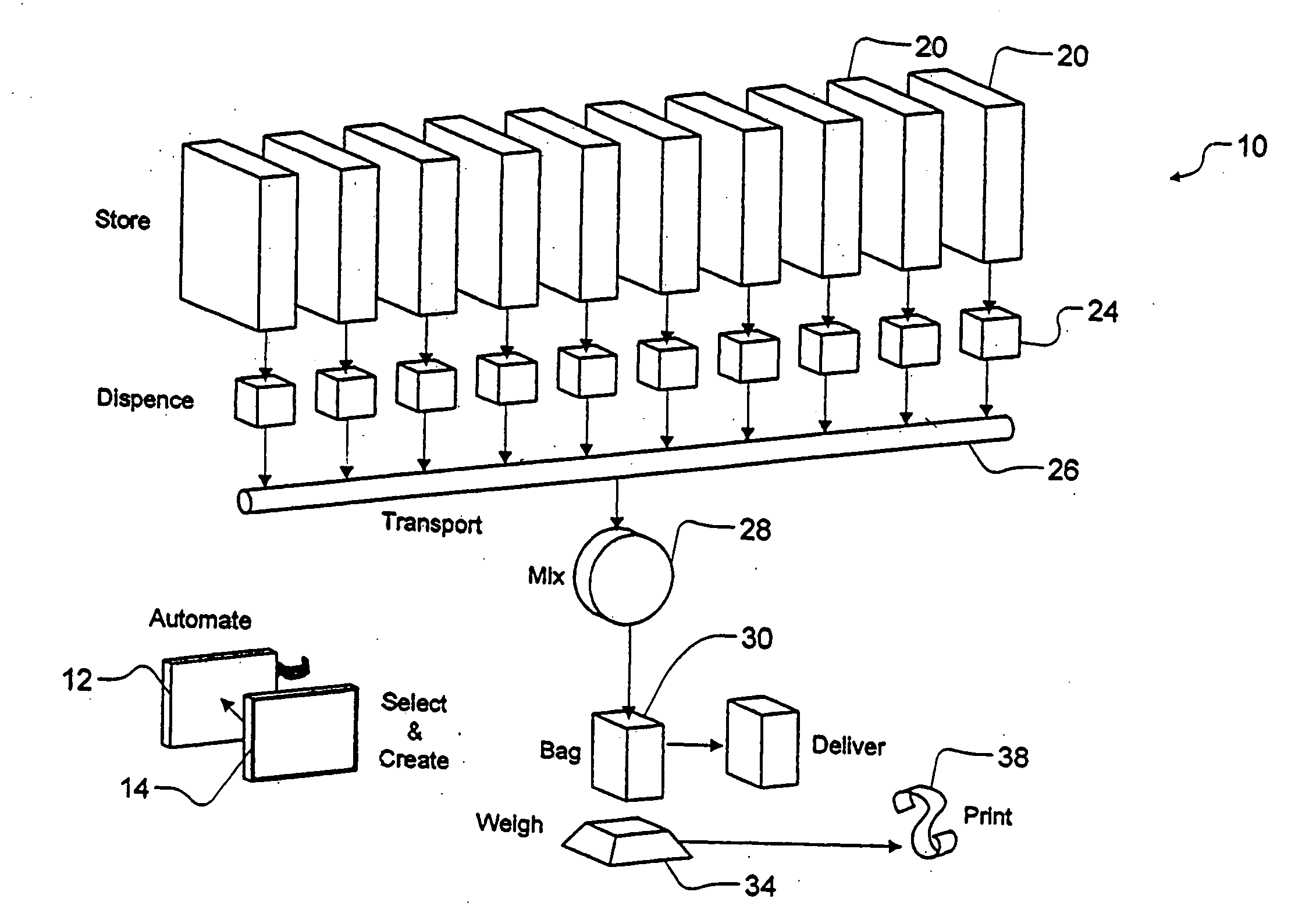

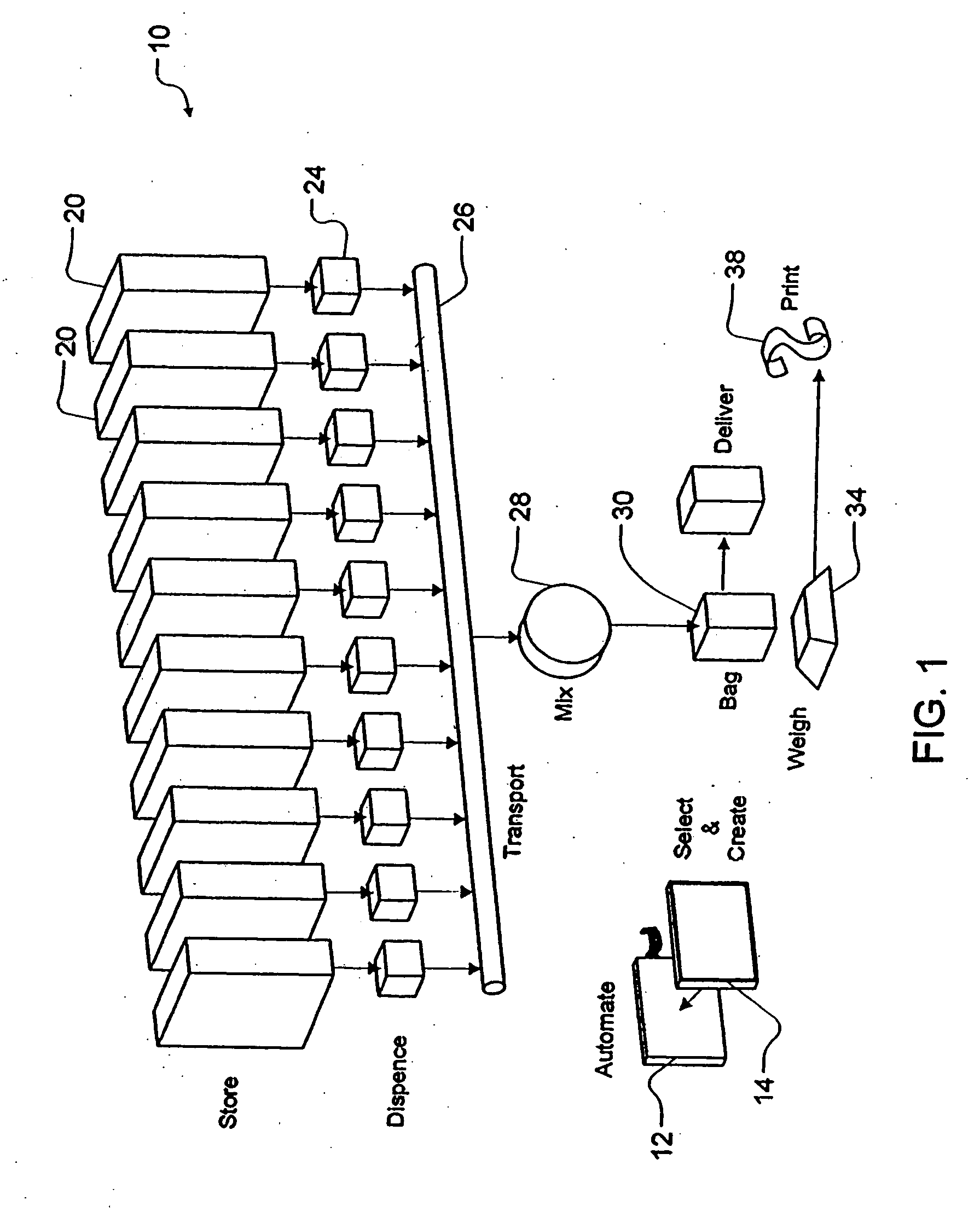

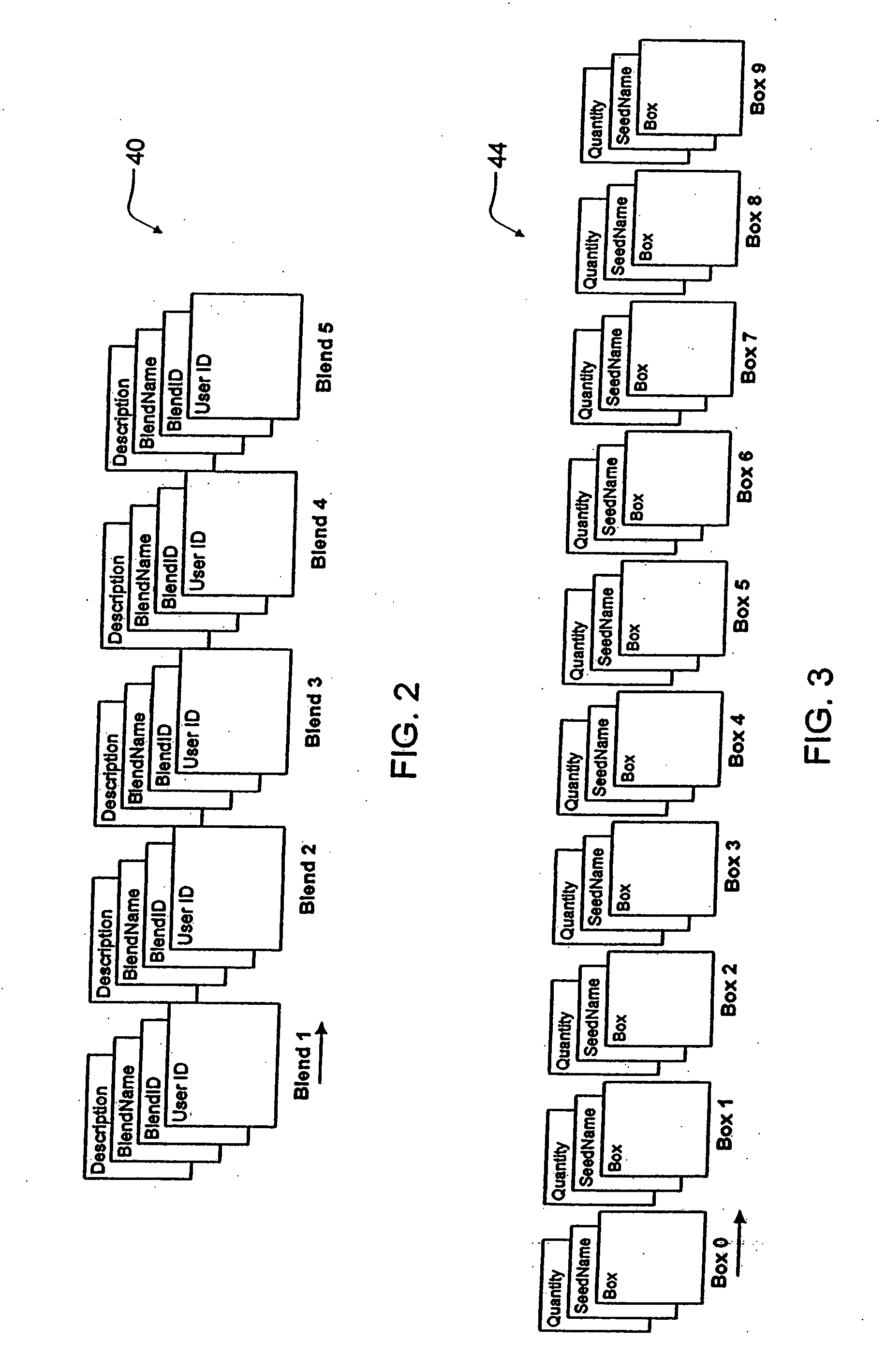

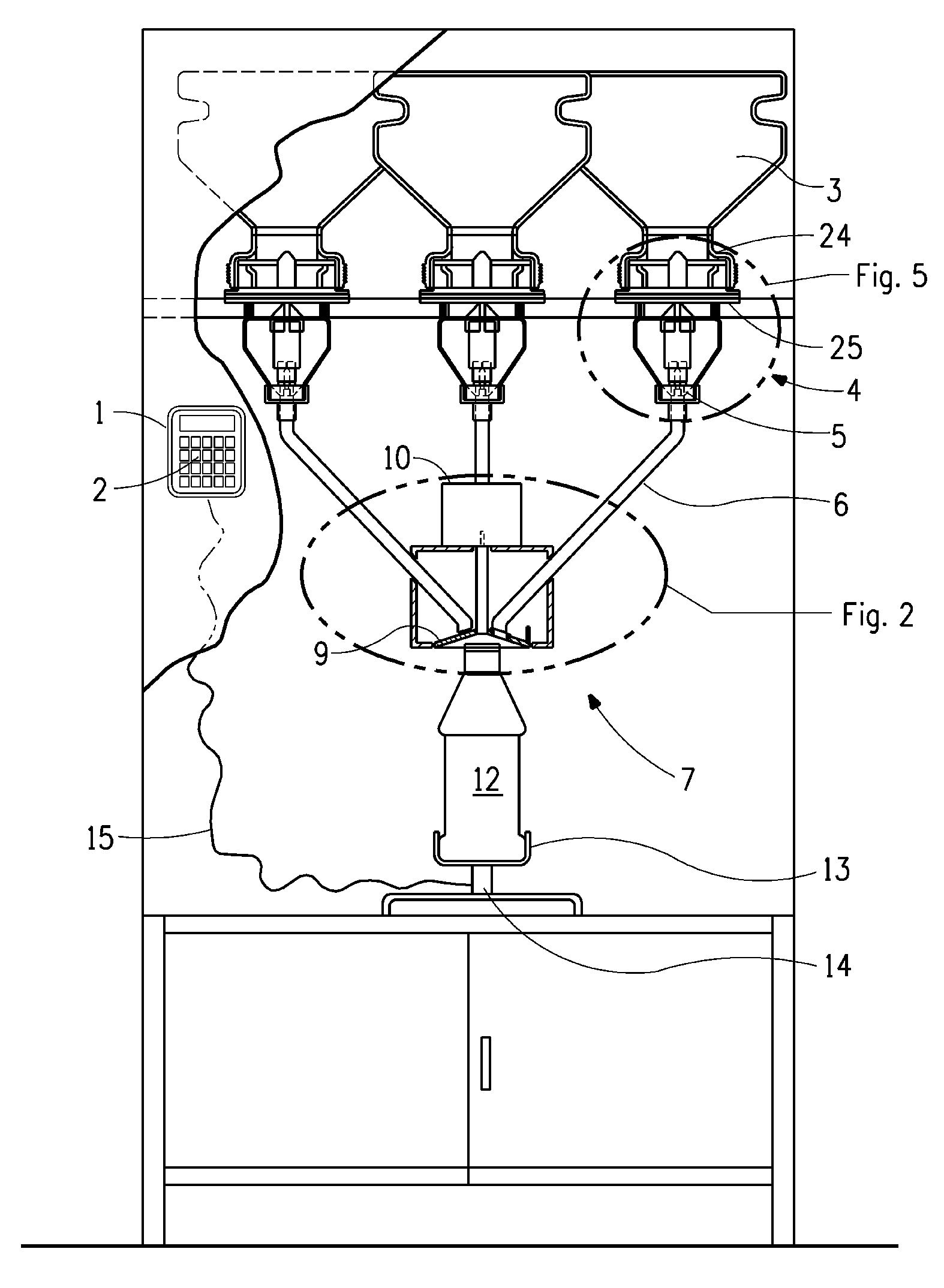

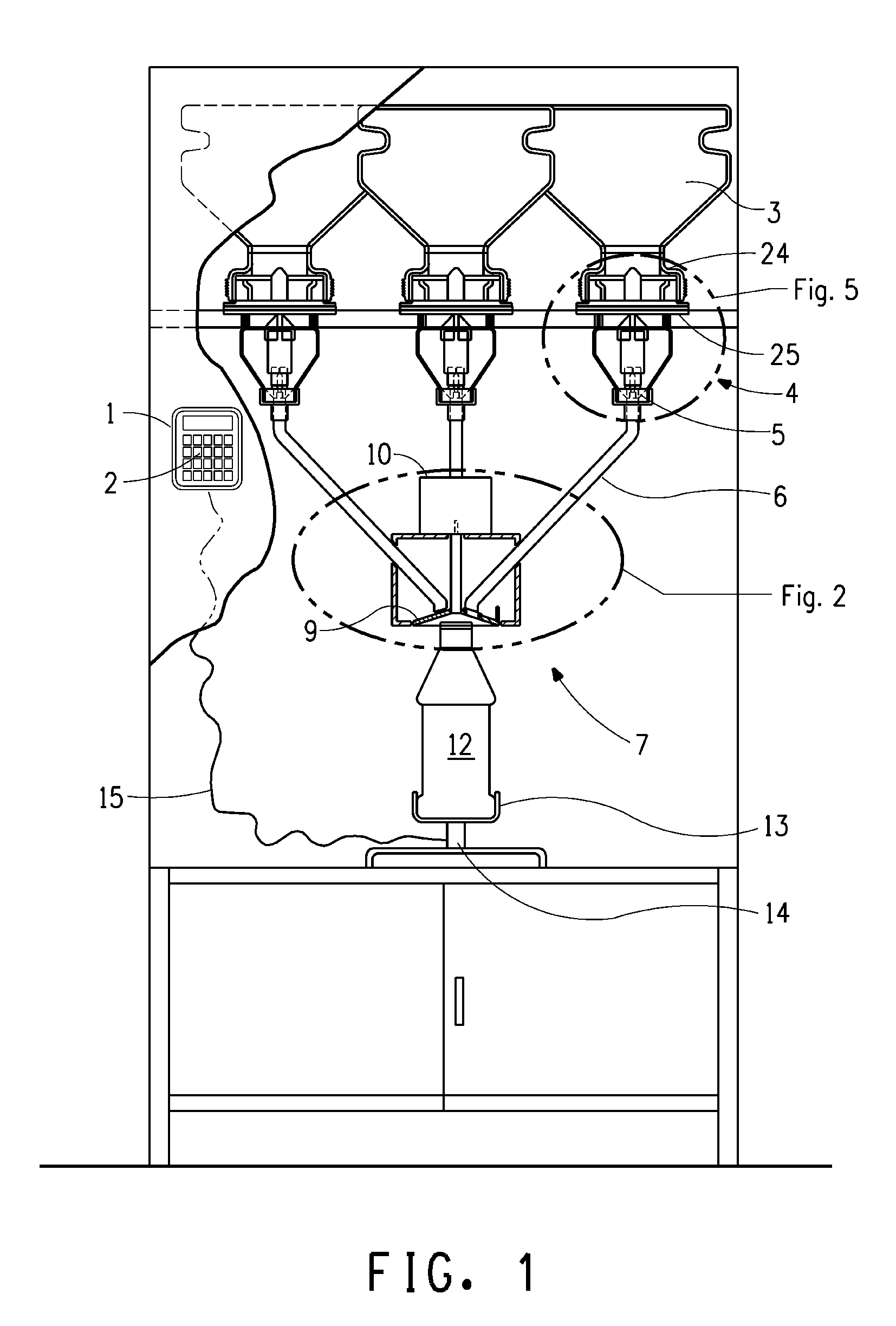

Multi-product dispensing system for granular materials

A dispensing system for granular materials, in particular agricultural products, capable of dispensing multiple products that comprises a control means for entering a product formula, hoppers that contain material for formulating the product each having a dispensing means controlled by the control means, material is fed from each hopper through a tube and fed into a housing having a rotatable structure that allows the material to be dispensed into a receptacle connected to a weighing means and weighed and feedback means connected to the weighing means and to the control means feeds weight information to the control means which adjusts the dispensing of the material from each of the hoppers as necessary to accurately formulate a product.

Owner:FMC CORP

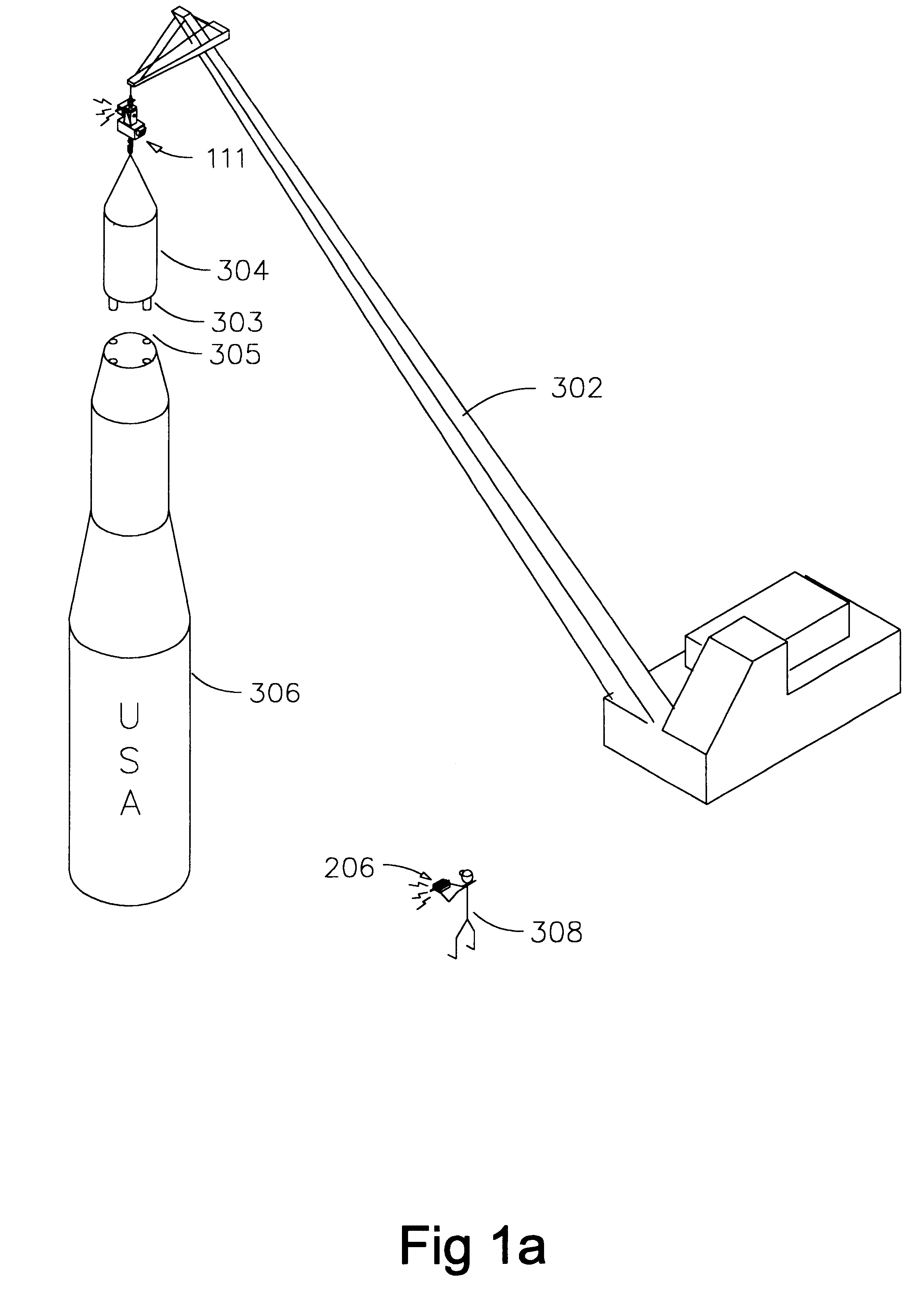

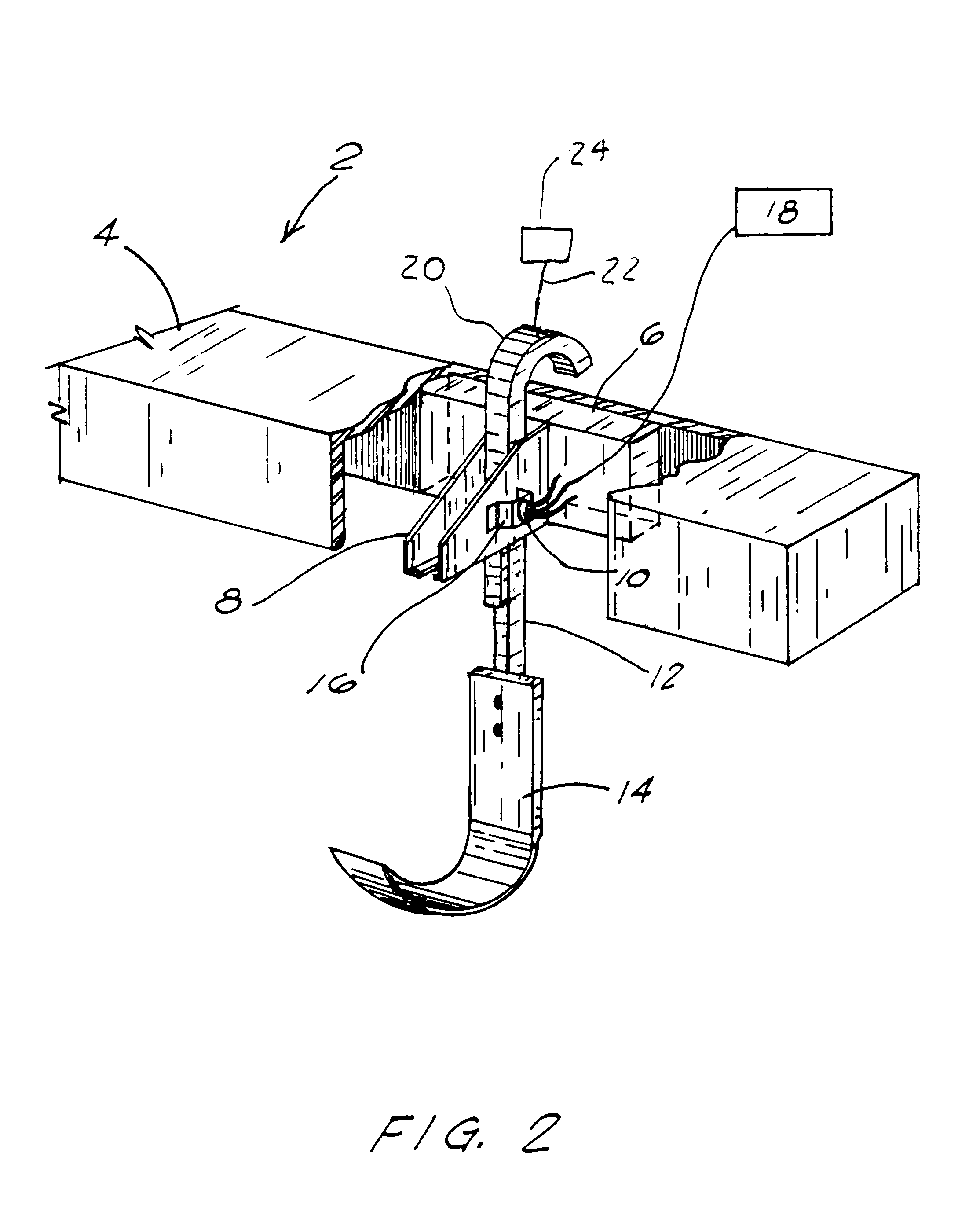

Remote operation auxiliary hoist control and precision load positioner

InactiveUS6474922B2Weighing apparatus with automatic feed/dischargeLoading/unloadingTransceiverRadio frequency

An electromechanical, remotely operated Auxiliary Hoist Control and Precision Load Positioner system and device is disclosed utilizing a Radio Frequency Hand Controller transceiver Unit distal to a Radio Frequency Hoist Controller Transceiver Unit for raising and lowering a large, heavy, bulky, fragile, or expensive piece of equipment by very gradual means to avoid hang ups that might otherwise destroy or seriously damage the equipment.

Owner:DEL MAR AVIONICS

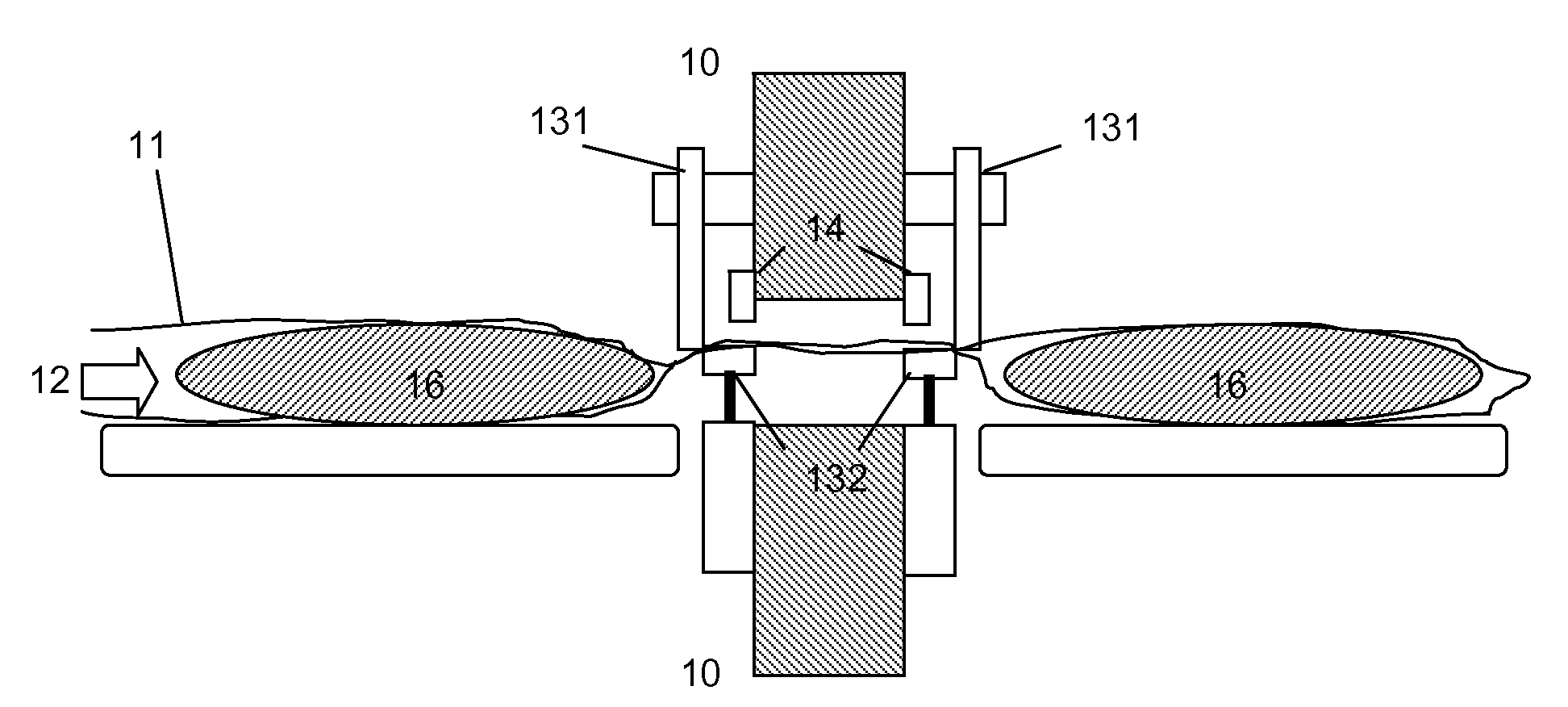

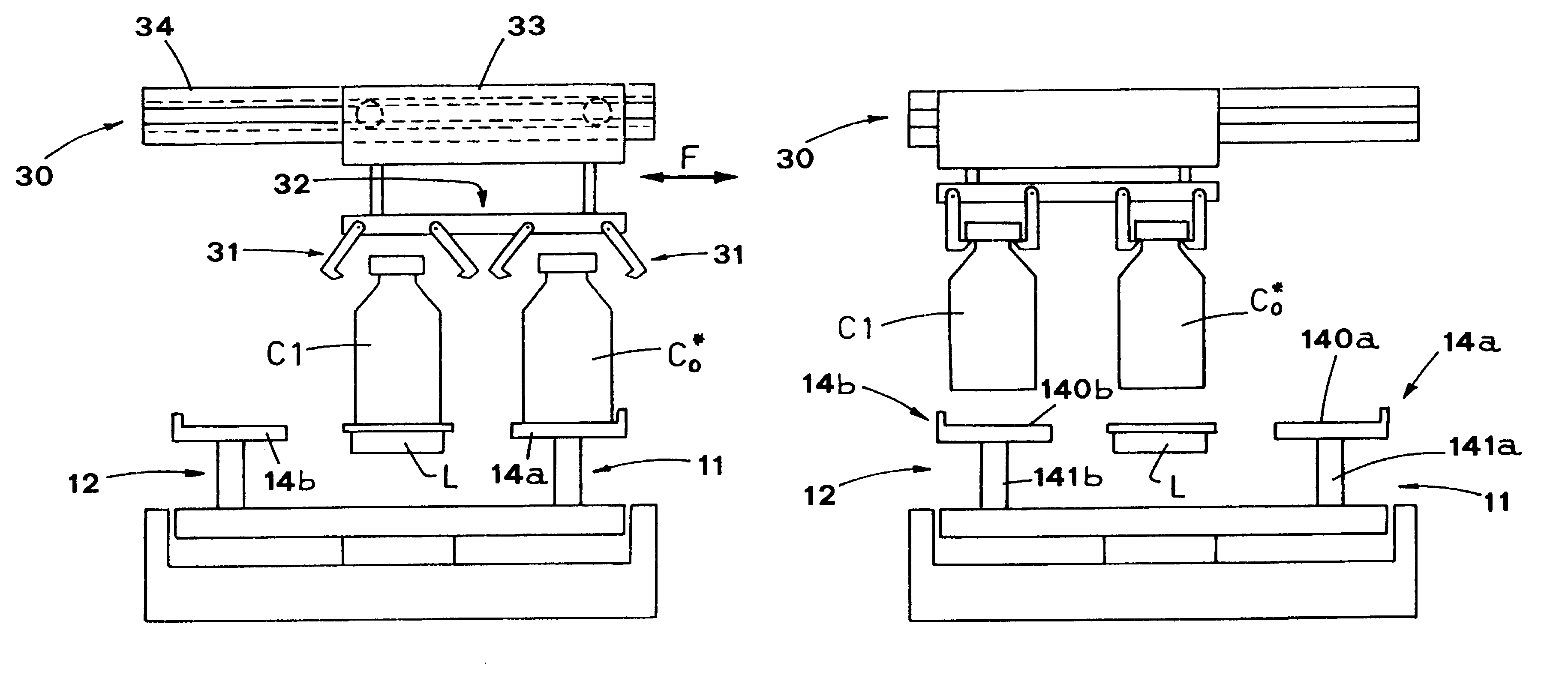

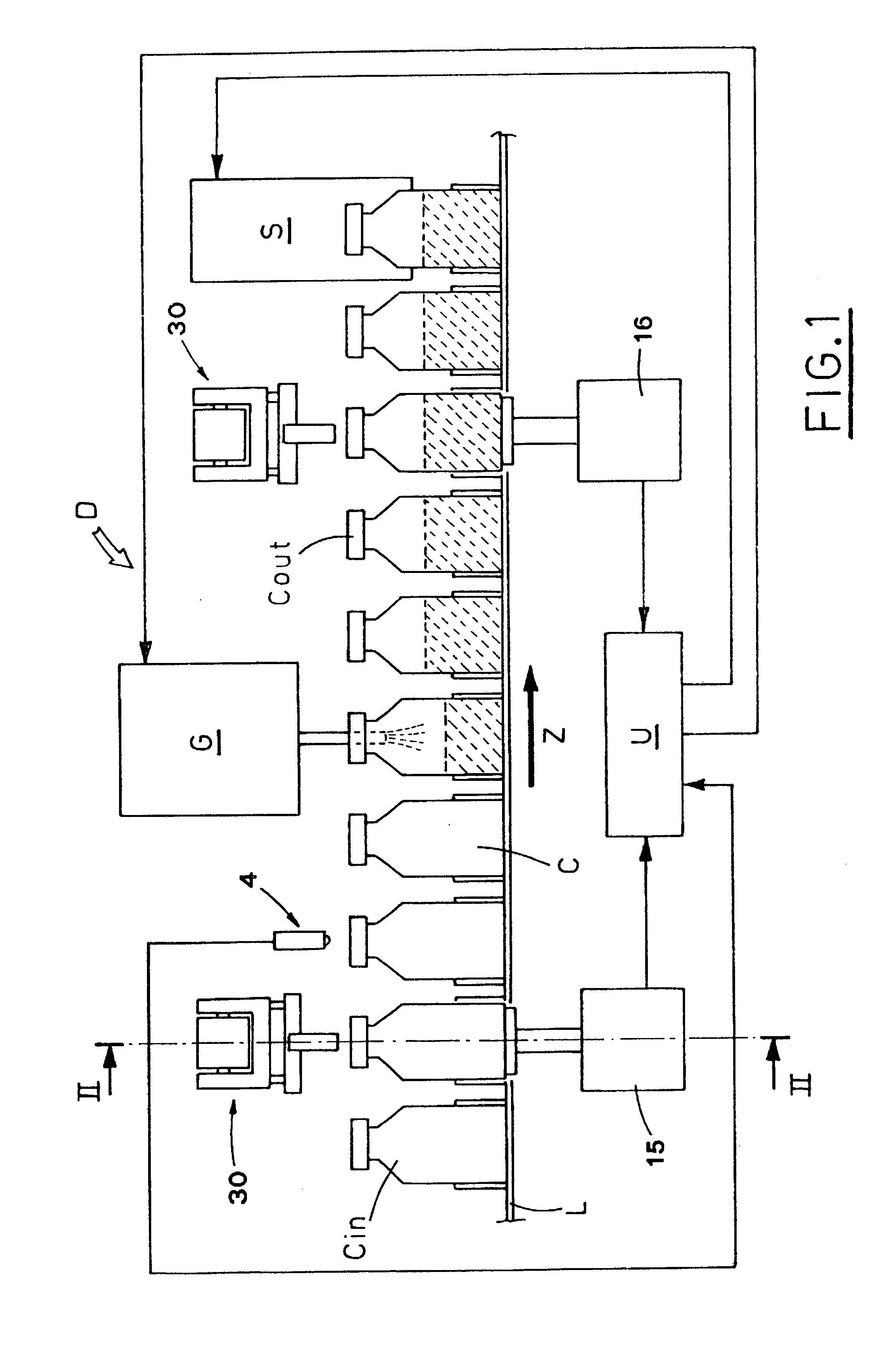

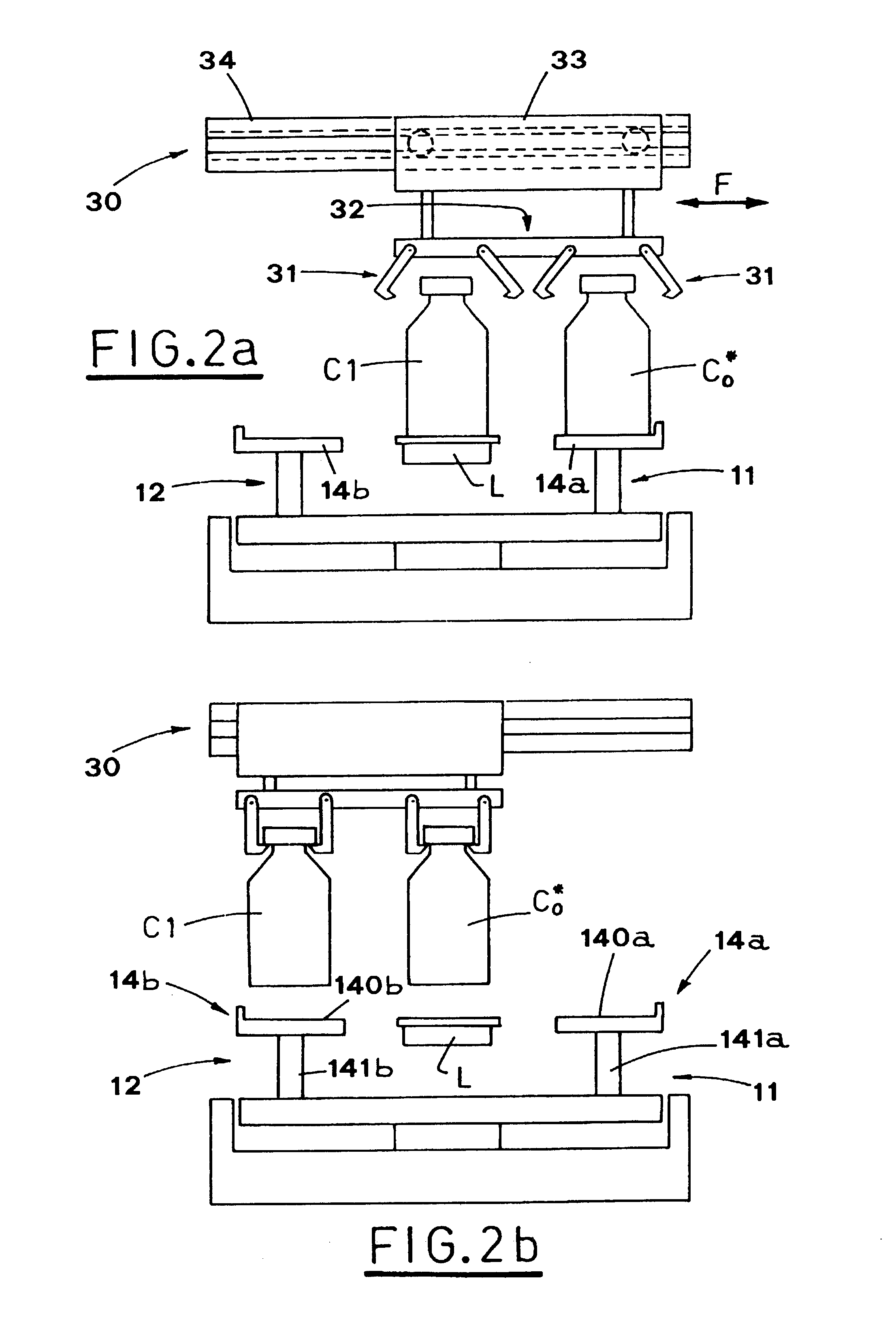

Distributor unit

InactiveUS6800818B2Precise and effectiveAvoid problemsLiquid fillingPackaging automatic controlTransfer line

A distributor unit (D) includes a stepwise moving conveying line (L) for conveying containers (C) through one filling unit (G), where the containers (C) are filled with a predetermined filling liquid or powder substance. In a weighing station (15,16), associated to the conveying line (L), two weighing groups (11,12) are situated on opposite sides of the conveying line (L) and have one weighing area (14a,14b) for weighing a container (C). One transfer group (30) is associated to the weighing station (15,16) and moves crosswise to the conveying line (L). The transfer group (30) transfers containers (Ci) to be weighed from the conveying line (L) to the weighing area (14b) of one of the weighing groups (12), and transfers at the same time an already weighed containers (C*i-1) from the area (14a) of the other weighing group (11) to the conveying line (L).

Owner:IMA IND MASCH AUTOMATICHE SPA

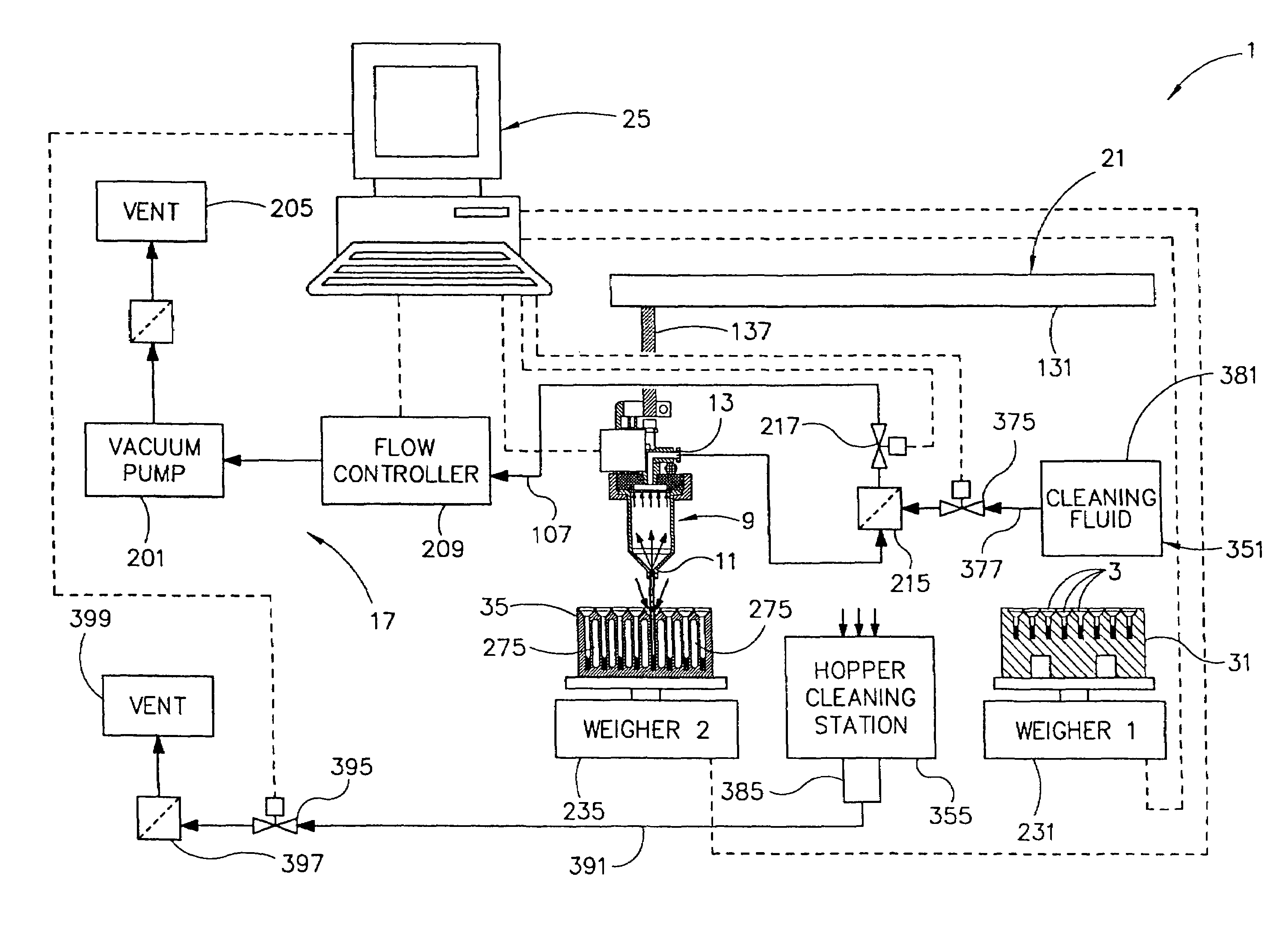

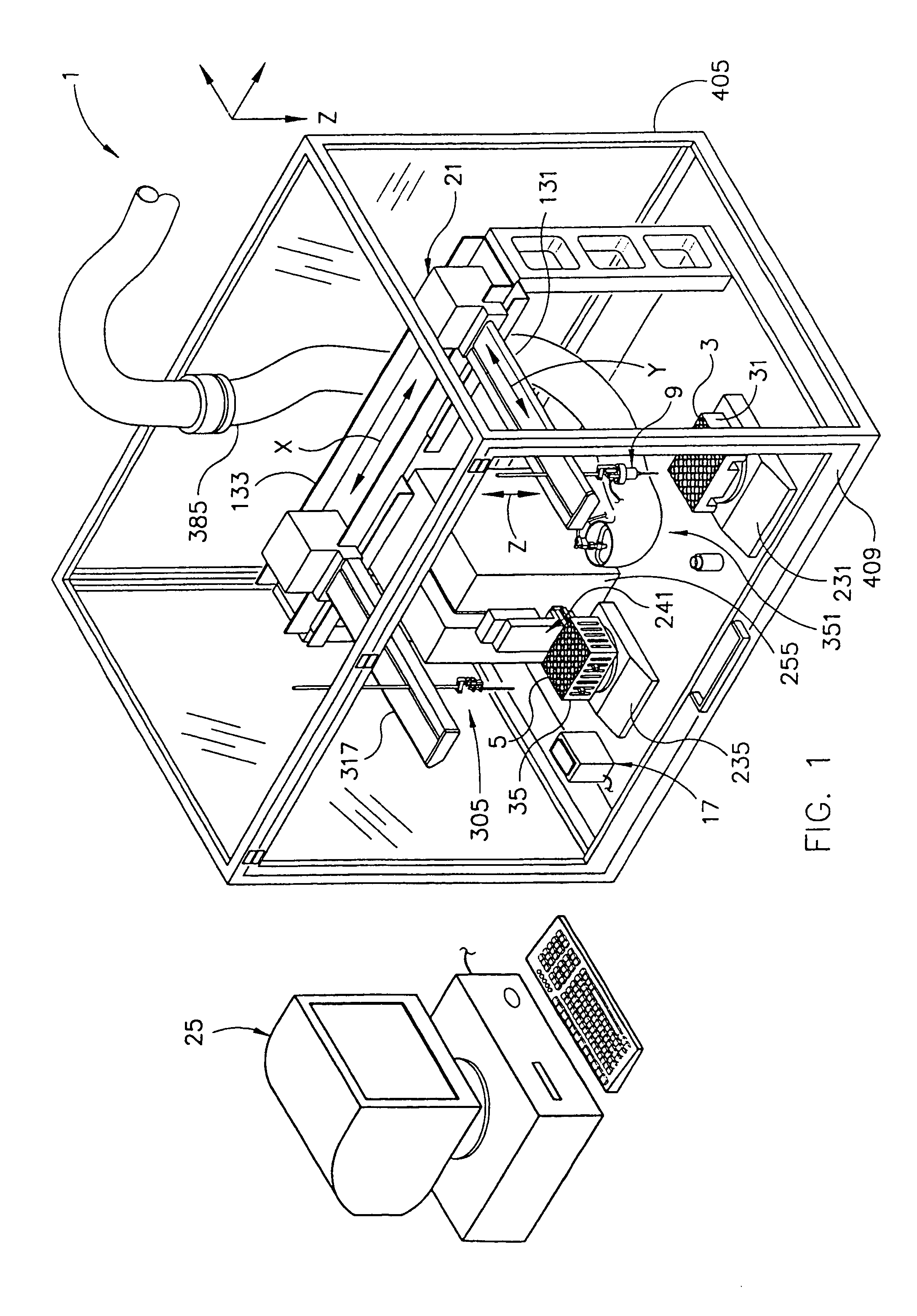

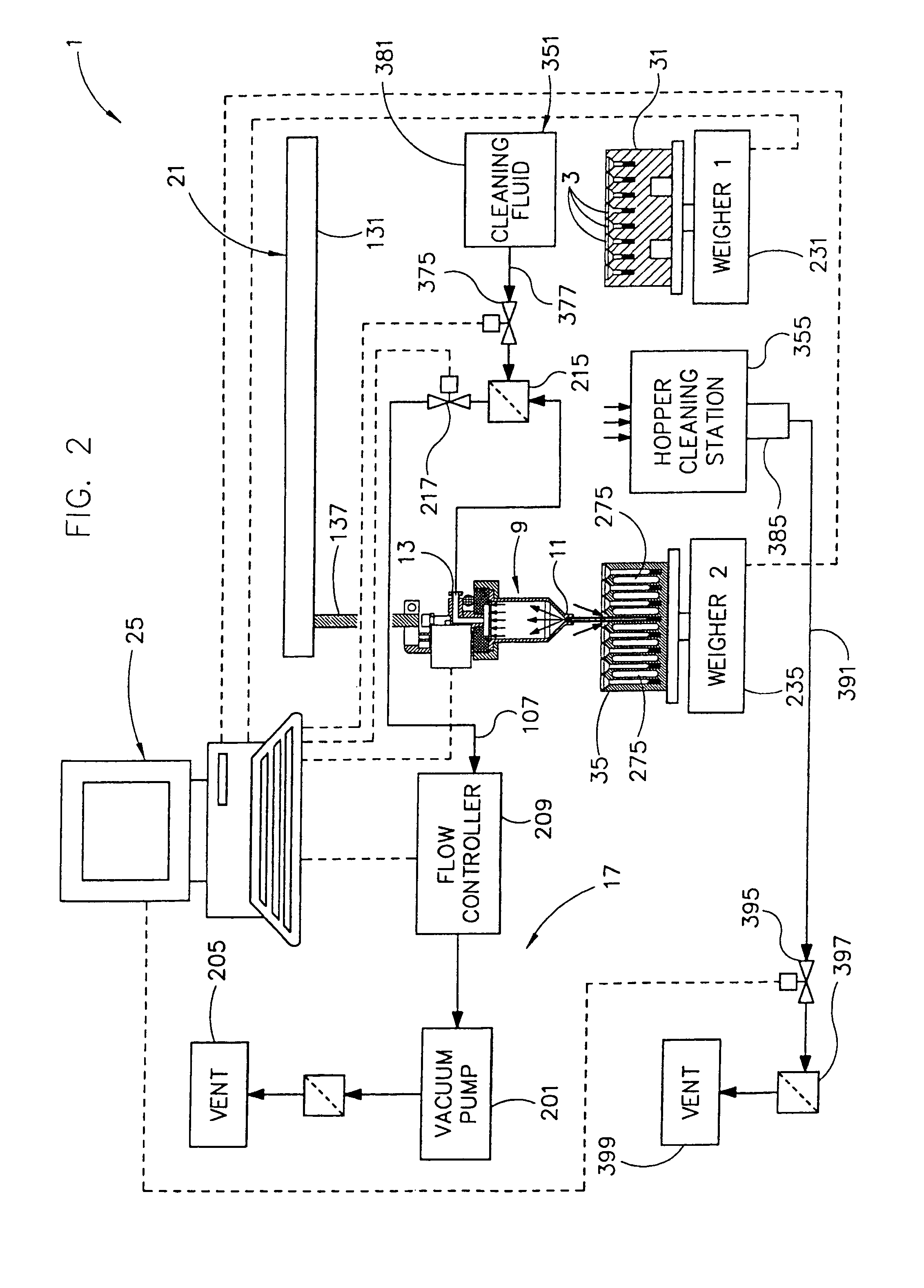

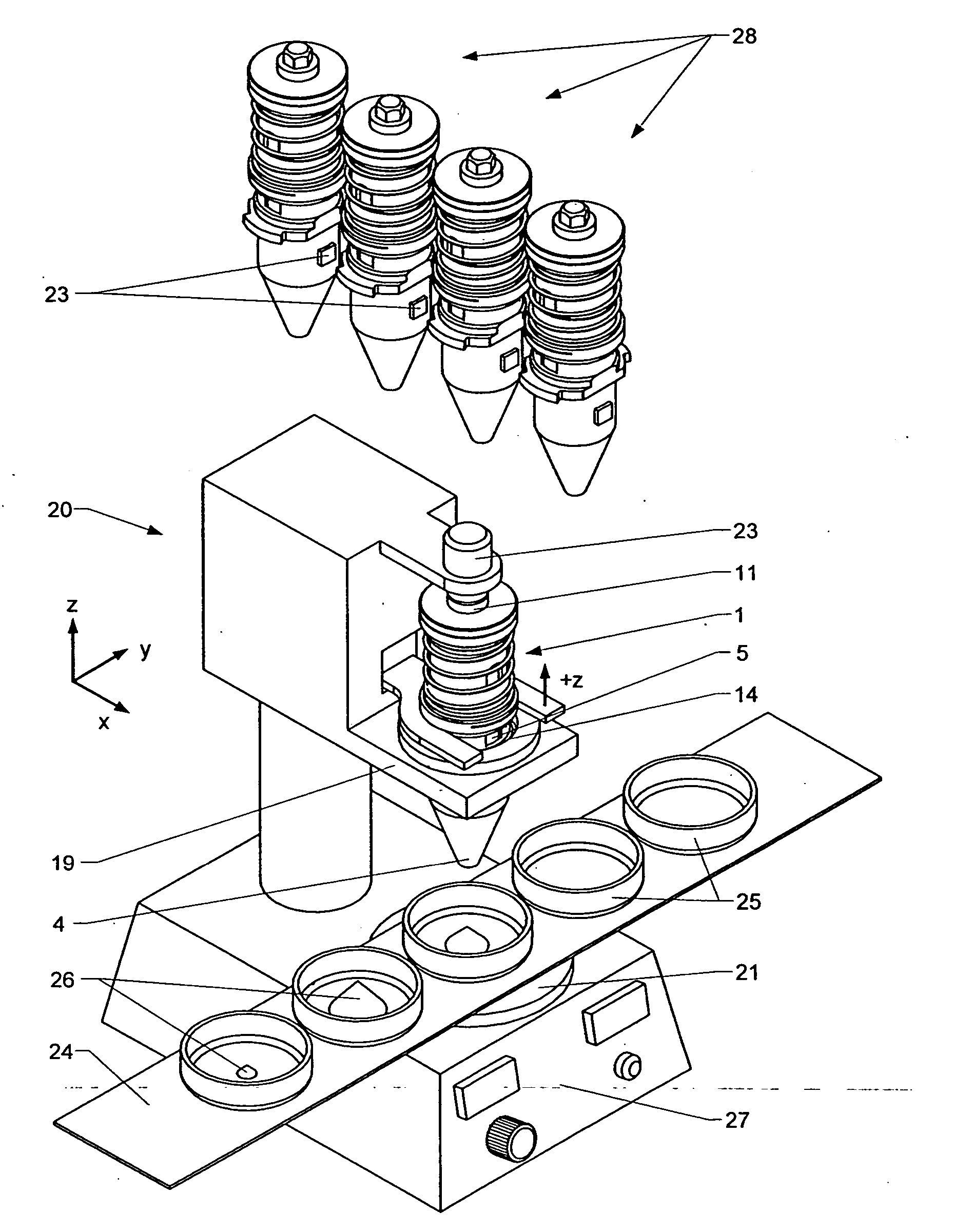

Method and Apparatus for Administering Micro-Ingredient Feed Additives to Animal Feed Rations

ActiveUS20070145068A1Opening closed containersBottle/container closureAdditive ingredientControl system

A method and apparatus are provided for administering micro-ingredient feed additives to animal feed rations. The apparatus may be referred to as a system which includes a number of discrete components which cooperate together to ultimately deliver micro-ingredients to a desired location, such as a feed mixer containing a feed ration. Structure is provided for storing, measuring, dispensing, and conveying the micro-ingredients. Measuring of the micro-ingredients may be achieved by loss in weight, gain in weight, or volumetric metering methods. Transport by a liquid carrier such as water may be achieved by providing one or a plurality of conveyance pumps connected to a transport line. The system is operated by a control unit which controls components of the system to achieve delivery of specified amounts and types of micro-ingredients to the feed ration.

Owner:ANIMAL HEALTH INT

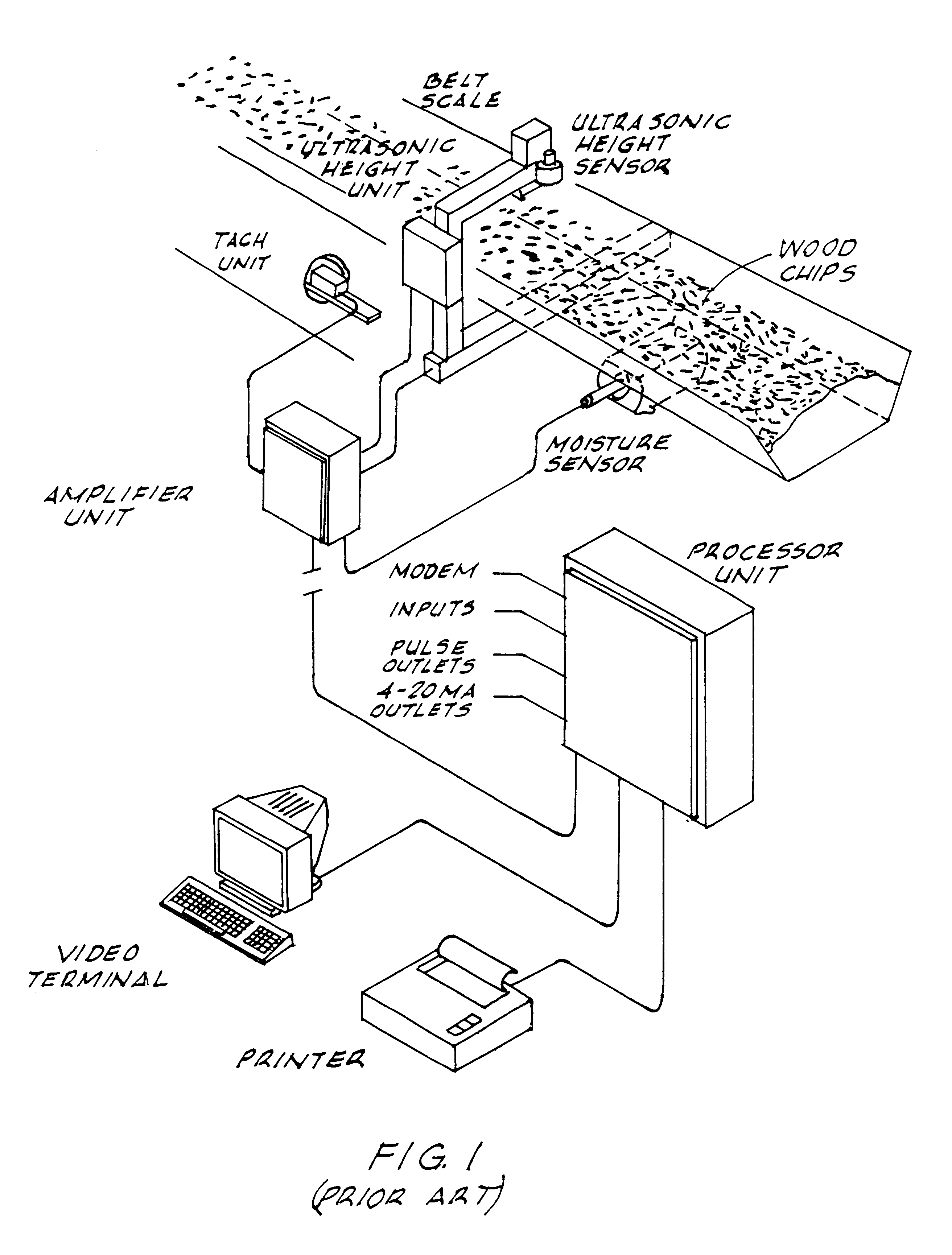

Height measurement apparatus for determining the volume/density of wood chips on a conveyor

InactiveUS6211470B1Volume/density can be accuratelyEase of assemblyControl devices for conveyorsLiquid transferring devicesMeasurement deviceEngineering

This invention relates to a height measurement apparatus for determining volume / density of wood chips on a conveyor. Such structures of this type, generally, employ the use of contacts that ride on top of the pile of wood chips in order to more accurately measure the volume and density of the wood chips.

Owner:MEADWESTVACO CORP

Popular searches

Oscillations damping for weighing Electrical measurements Testing/calibration of speed/acceleration/shock measurement devices Special data processing applications Special purpose weighing apparatus Weighing apparatus for materials with special property/form Water heaters Liquid dispensing Solid sorbent liquid separation Liquid displacement

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com