Patents

Literature

858results about How to "Accurate weighing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

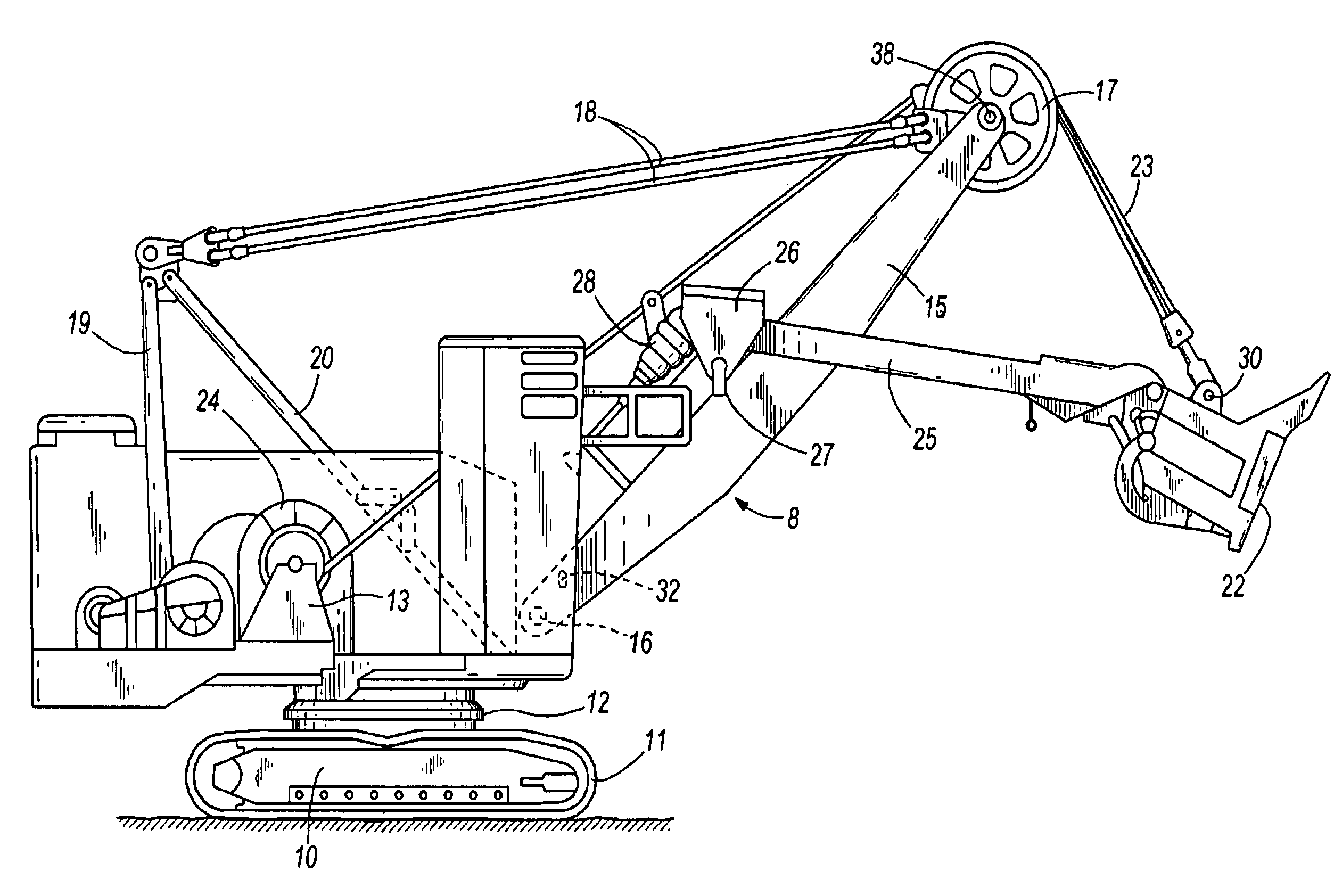

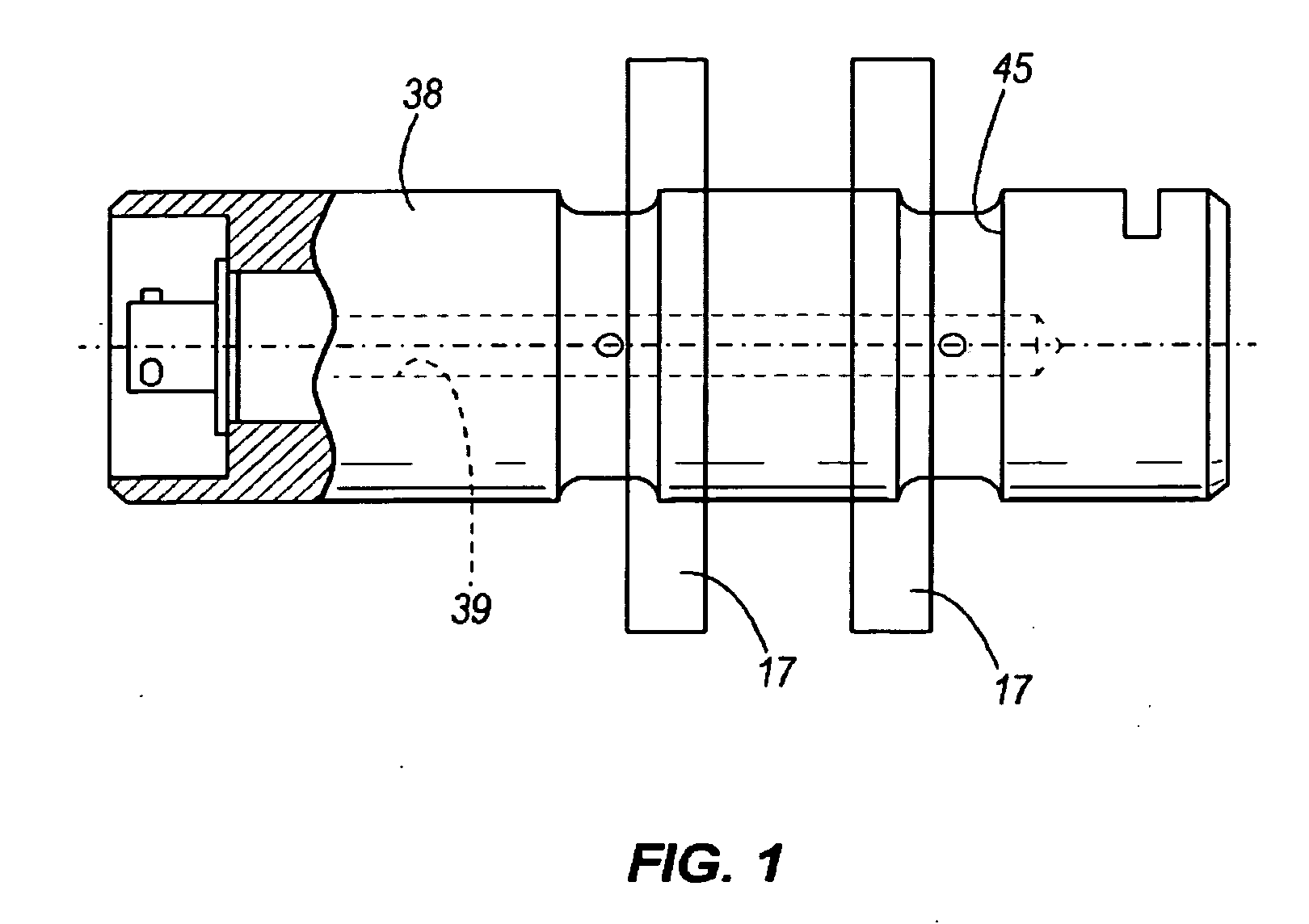

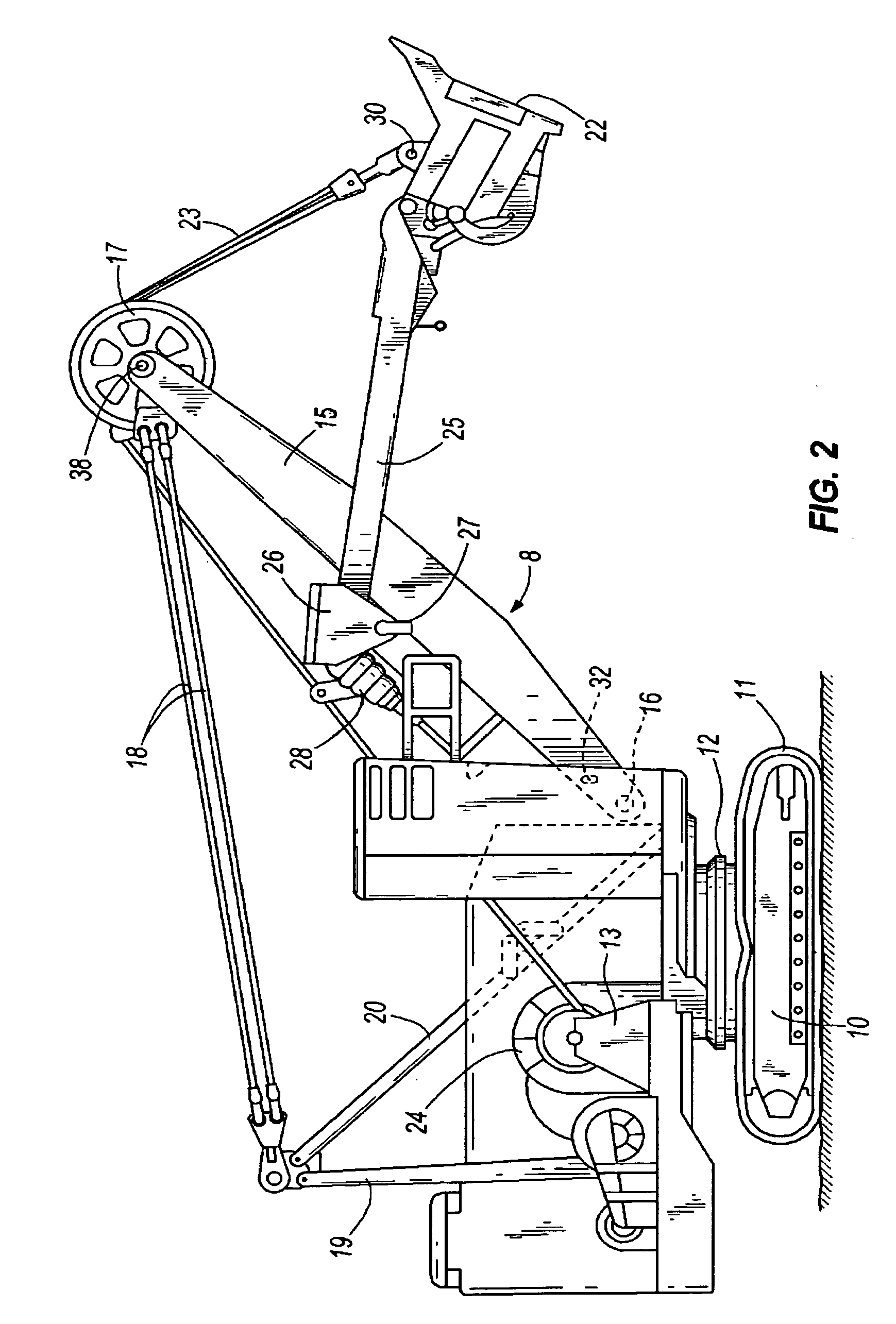

Device for measuring a load at the end of a rope wrapped over a rod

InactiveUS20070266601A1Accurate weight measurementAccurately determine it locationWeighing apparatus using elastically-deformable membersMechanical machines/dredgersStrain gaugePull force

A machine for raising and lowering a load, the machine including a platform, a boom attached at one end to the platform, a rod mounted transverse to the longitudinal axis of the boom on the other end of a boom, the rod having a central bore there through, with at least two strain gauges mounted therein and angled relative to each other, a hoist rope extending over the rod and having an end adapted to be attached to the load, and a mechanism connected to the at least two strain gauges for determining the angle of departure of the hoist rope from the rod and the amount of pull of the load on the hoist rope.

Owner:HARNISCHFEGER TECH

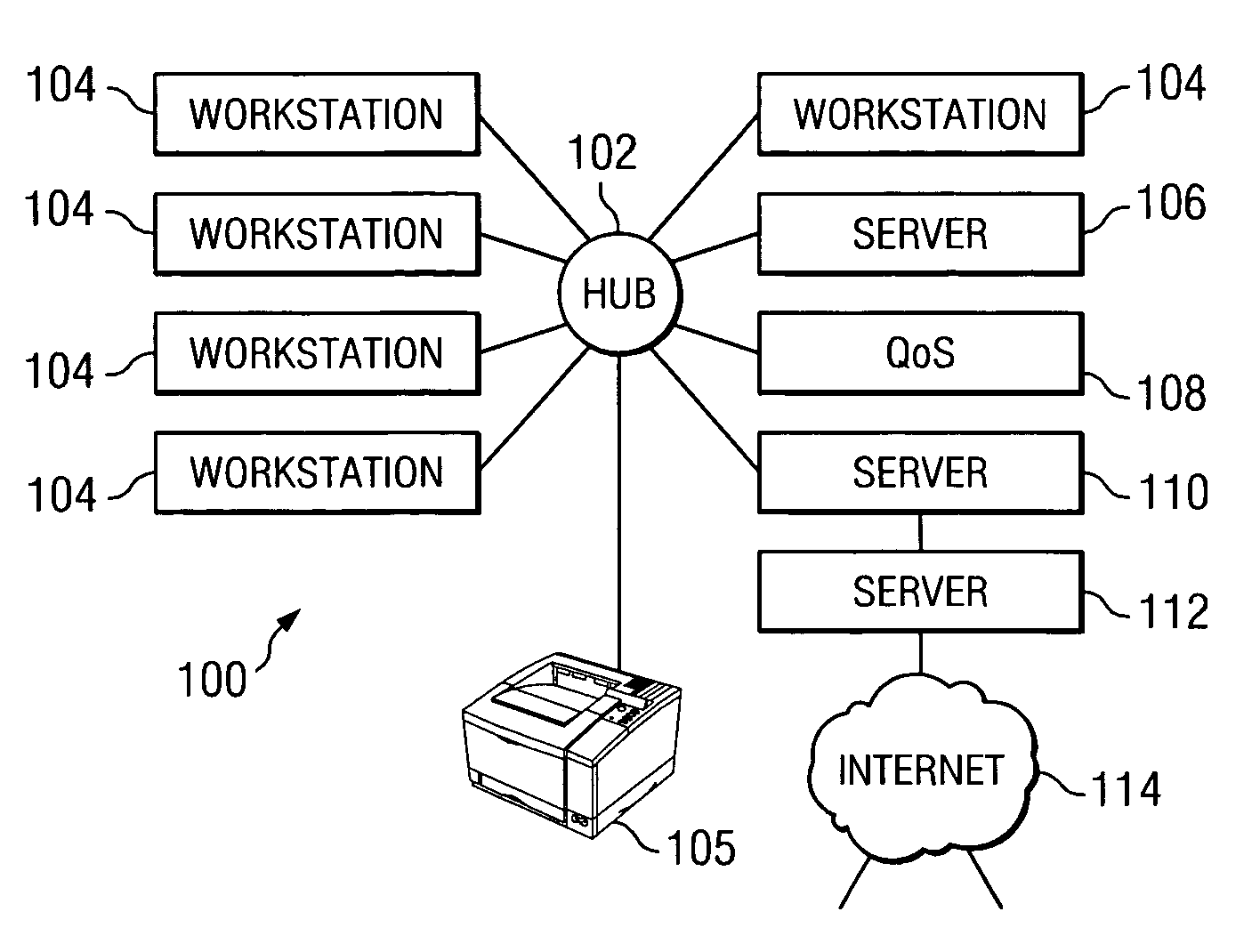

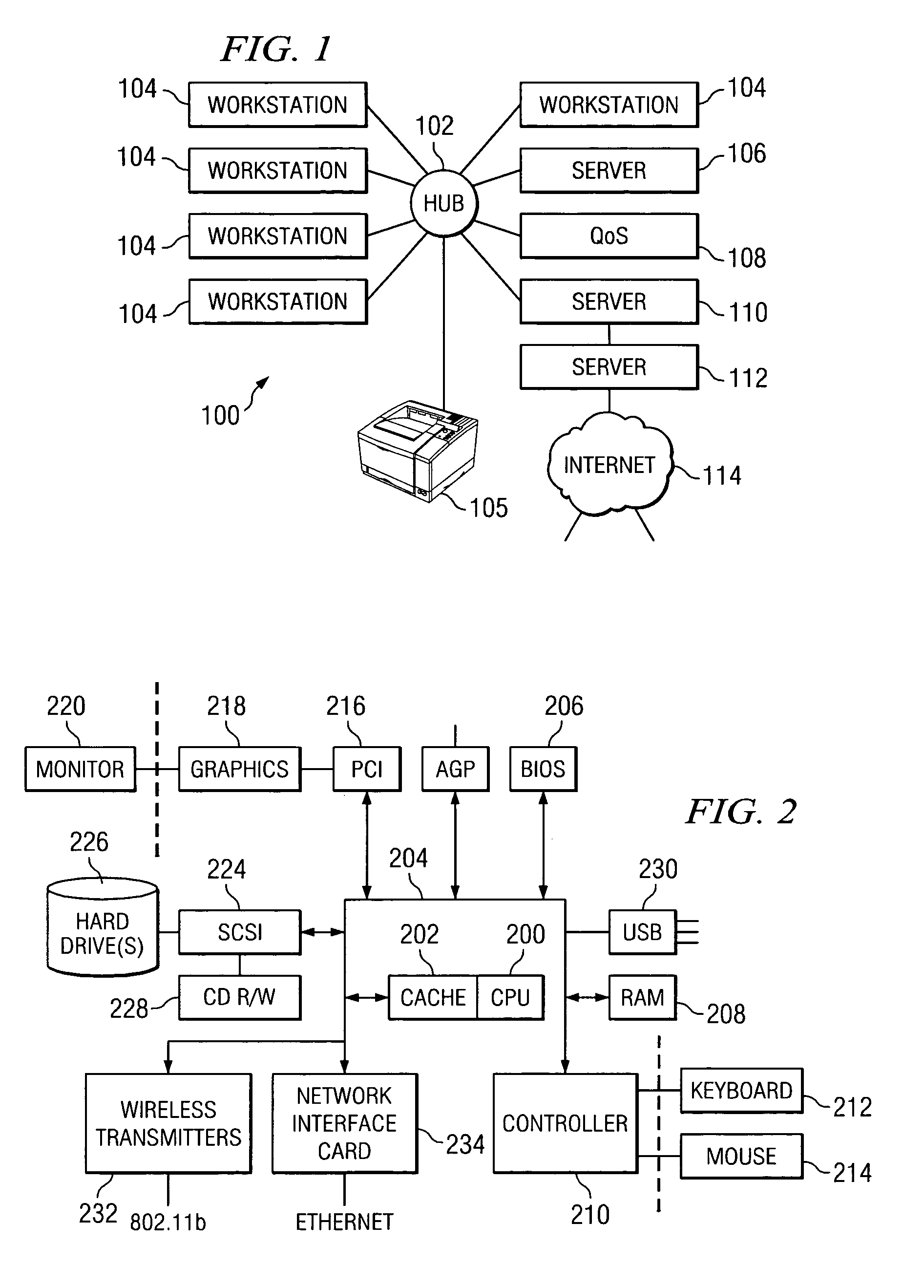

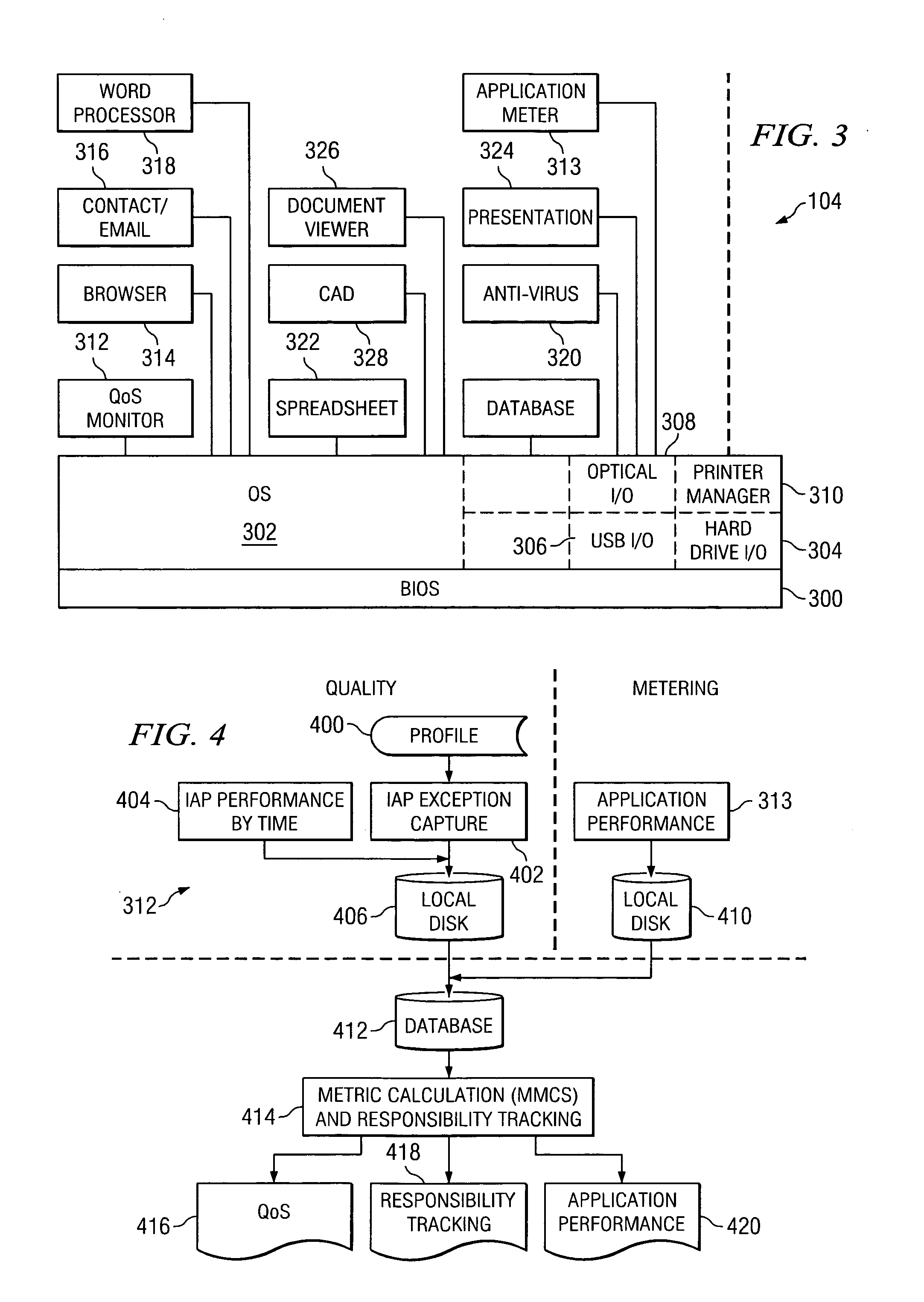

User-centric measurement of quality of service in a computer network

InactiveUS6959265B1Accurate weighingVariation is detectedDigital computer detailsNuclear monitoringInformation accessWorkstation

In a business network environment, each workstation or information access point (IAP) has installed thereon a quality of service (QoS) module to monitor the IAP's performance. The QoS module declares exceptions when it perceives that one or more of a predetermined plurality of functions or conditions of the computer has entered into a state indicative of degraded performance. At the time that an exception is declared, a snapshot is taken of the software applications running on the IAP, the amount of resources that they are using, and presence or absence of the user. As used in calculating a QoS index representative of the operational state of the IAP, exceptions are weighted to take into account the relative importance of these exceptions and the users which they affect. Because the QoS indices are time-normalized, they may be aggregated or compared across the network by an IT administrator.

Owner:INTERACT SOFTWARE

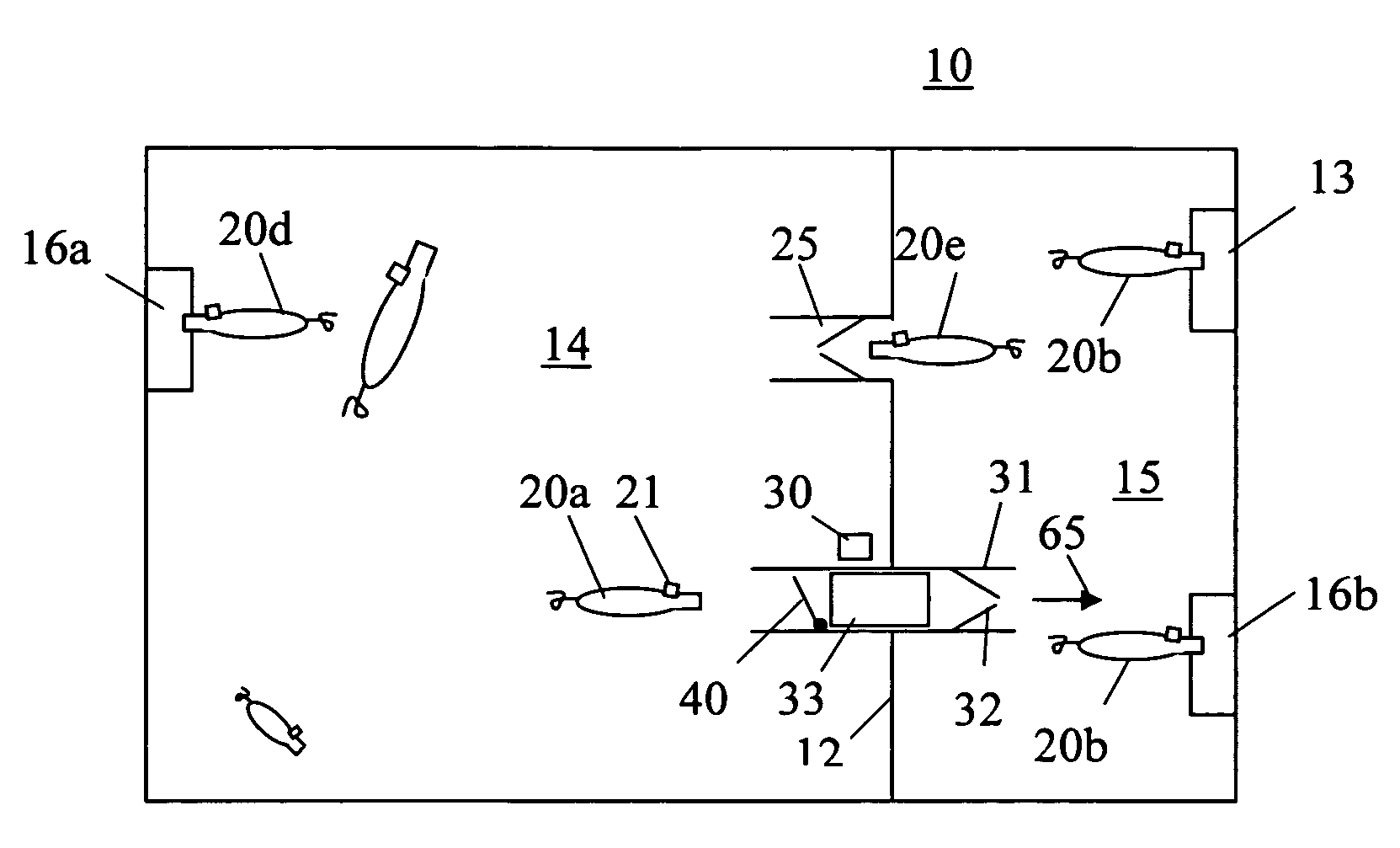

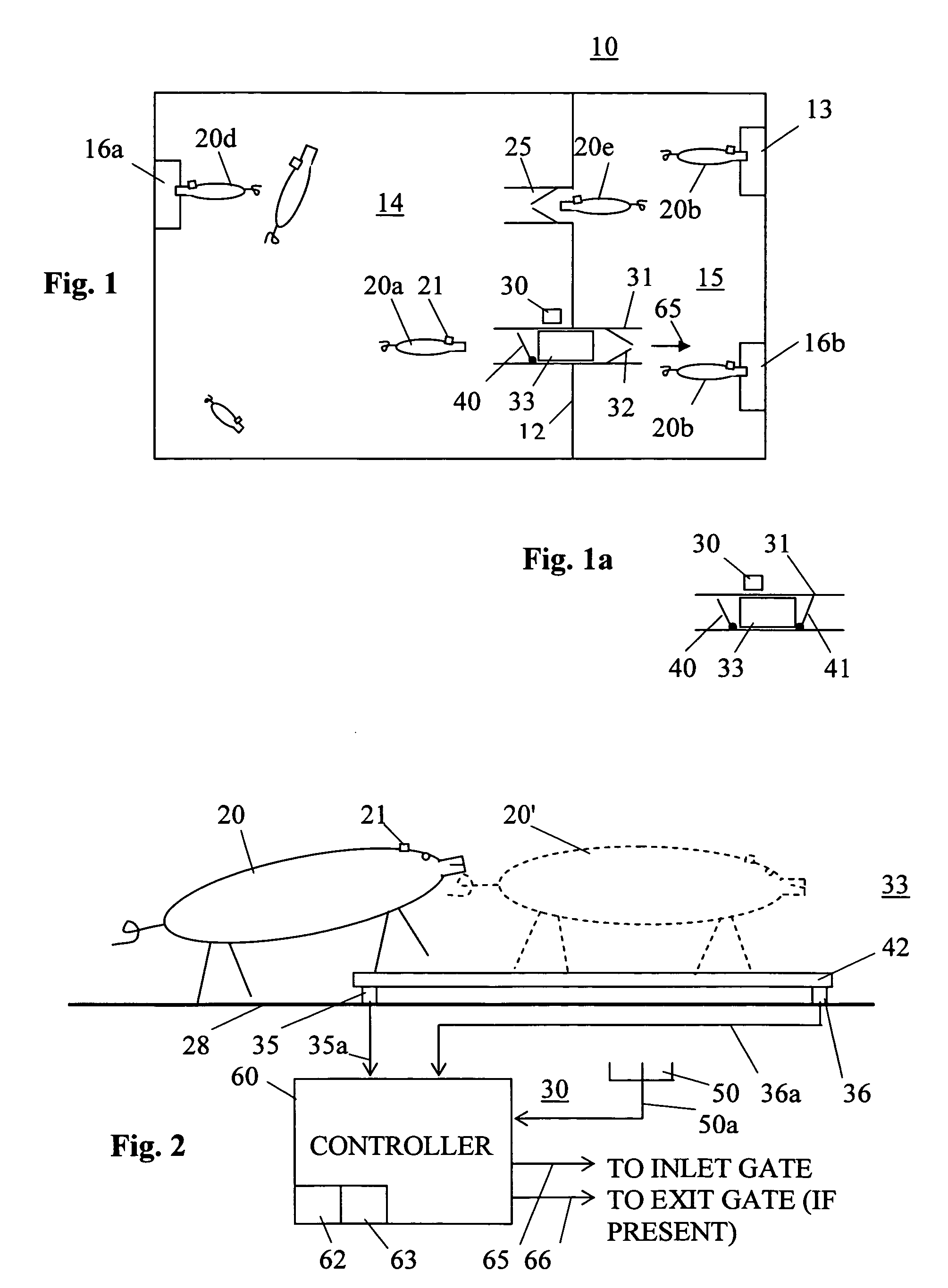

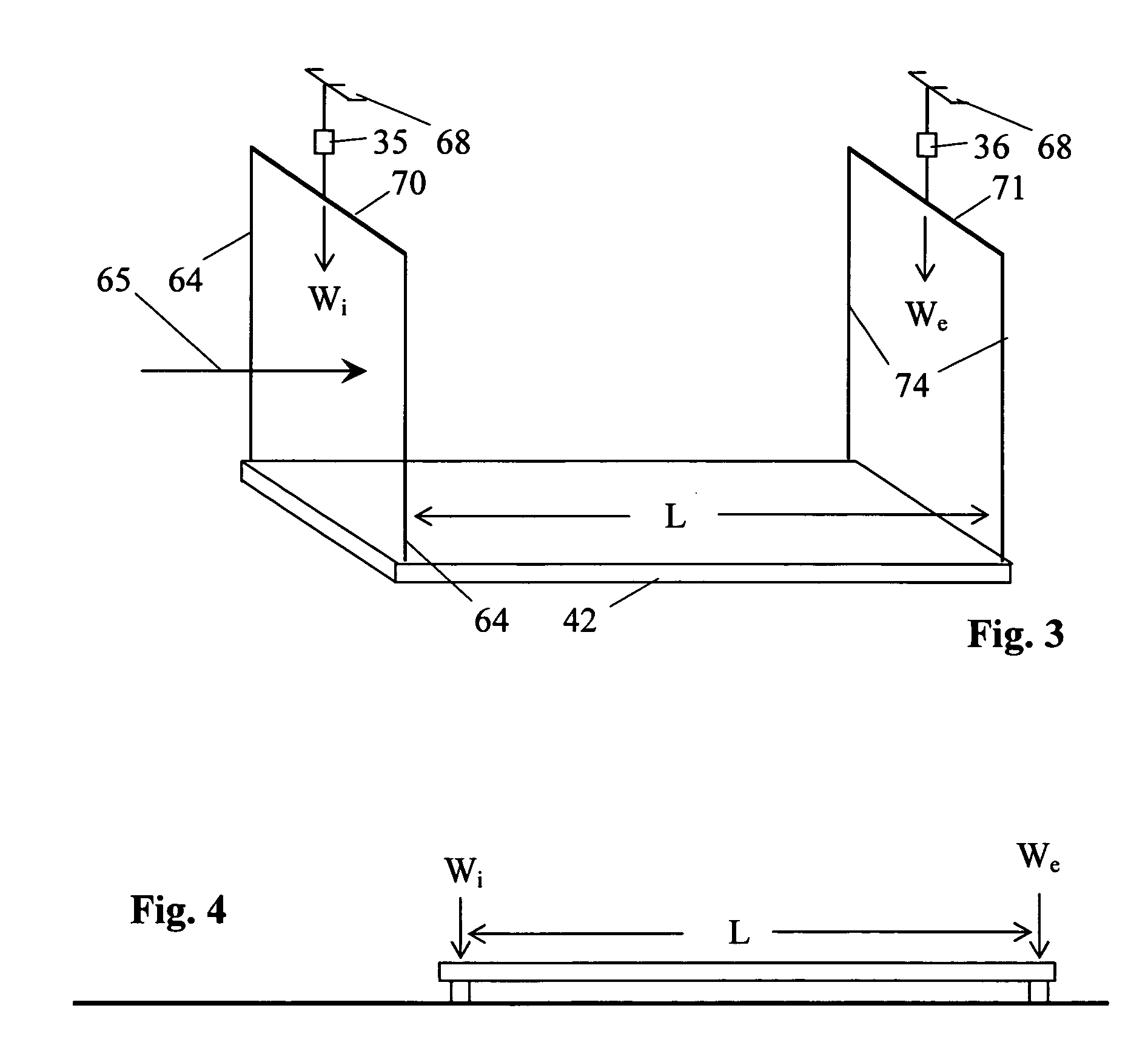

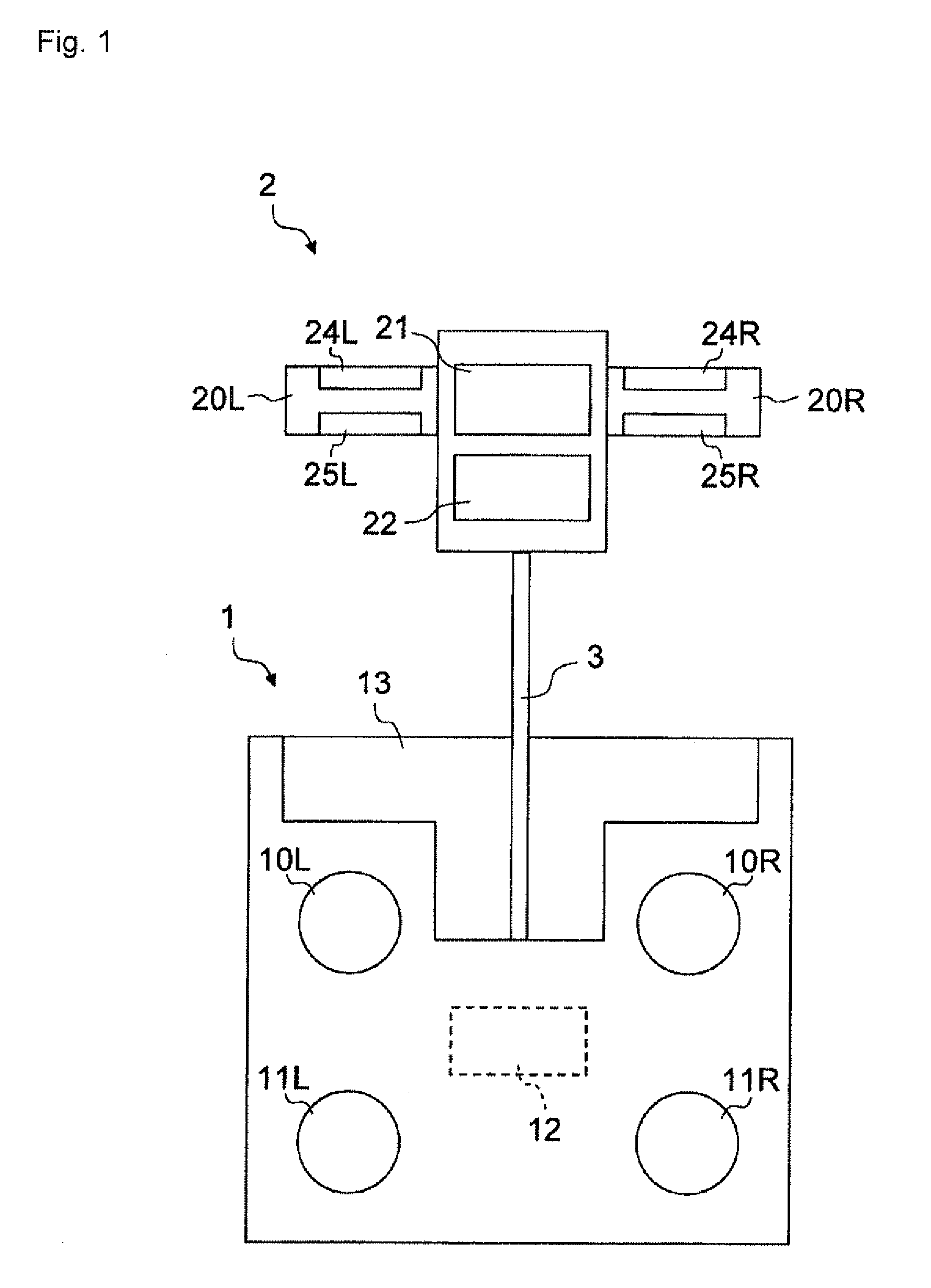

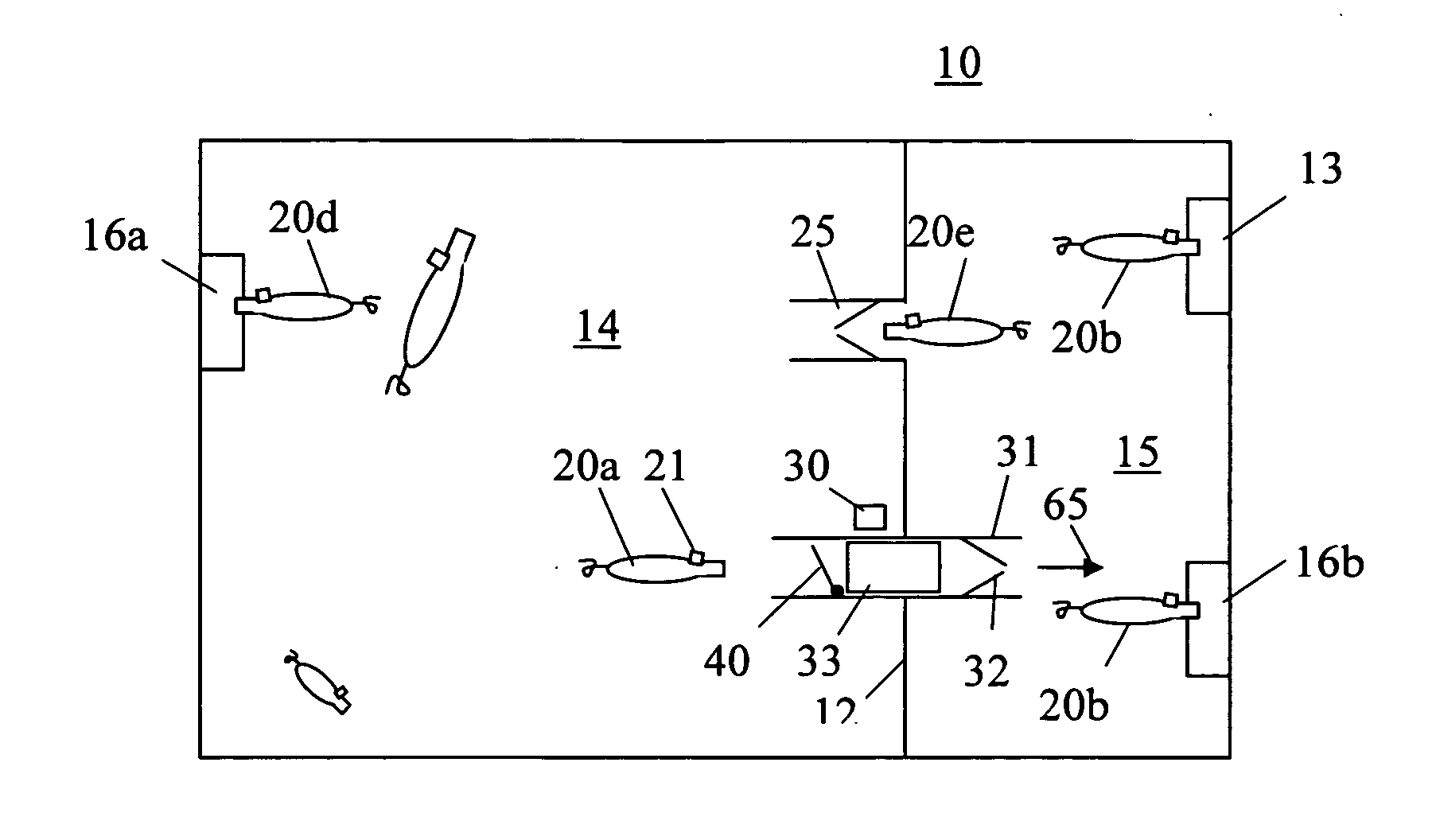

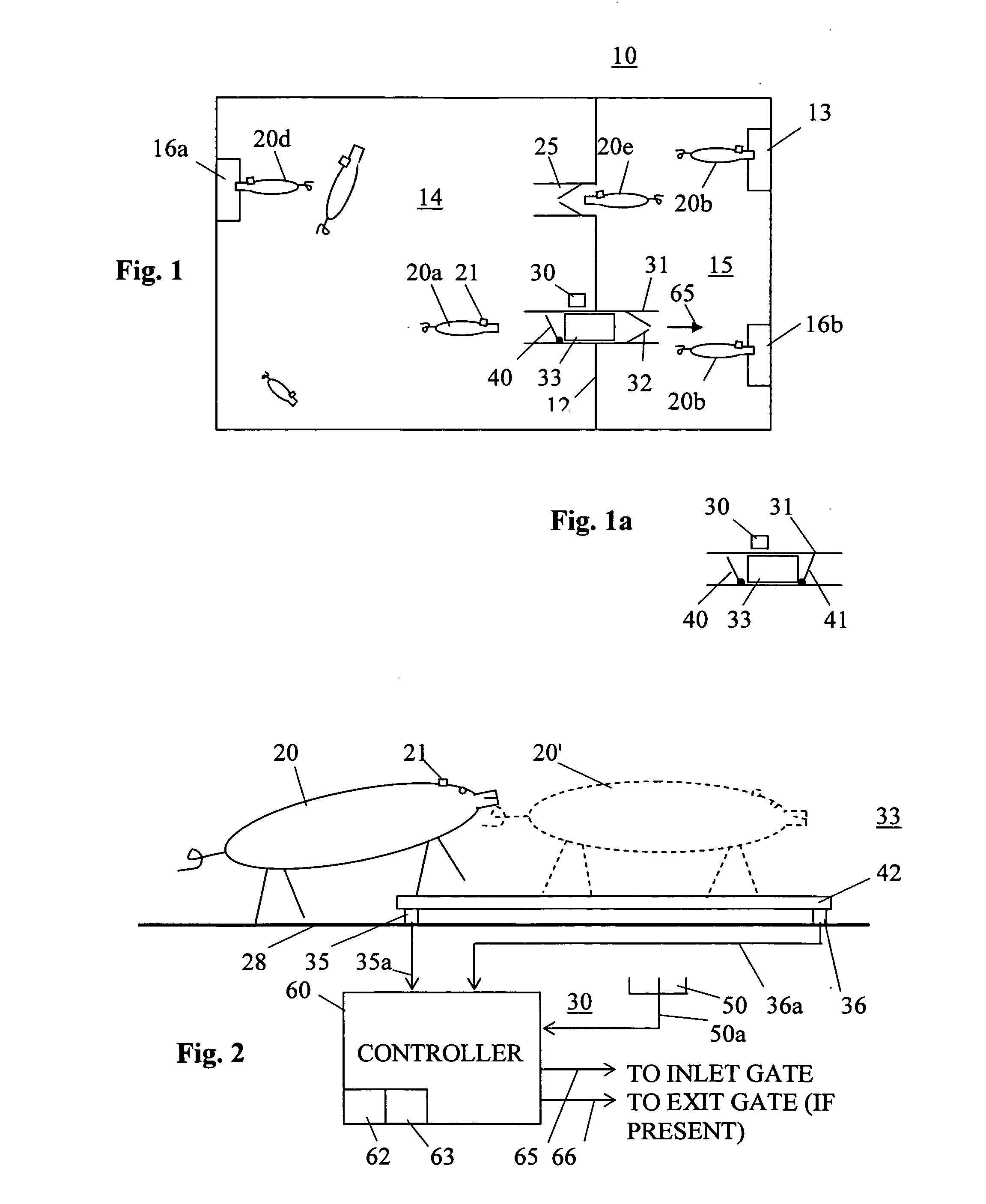

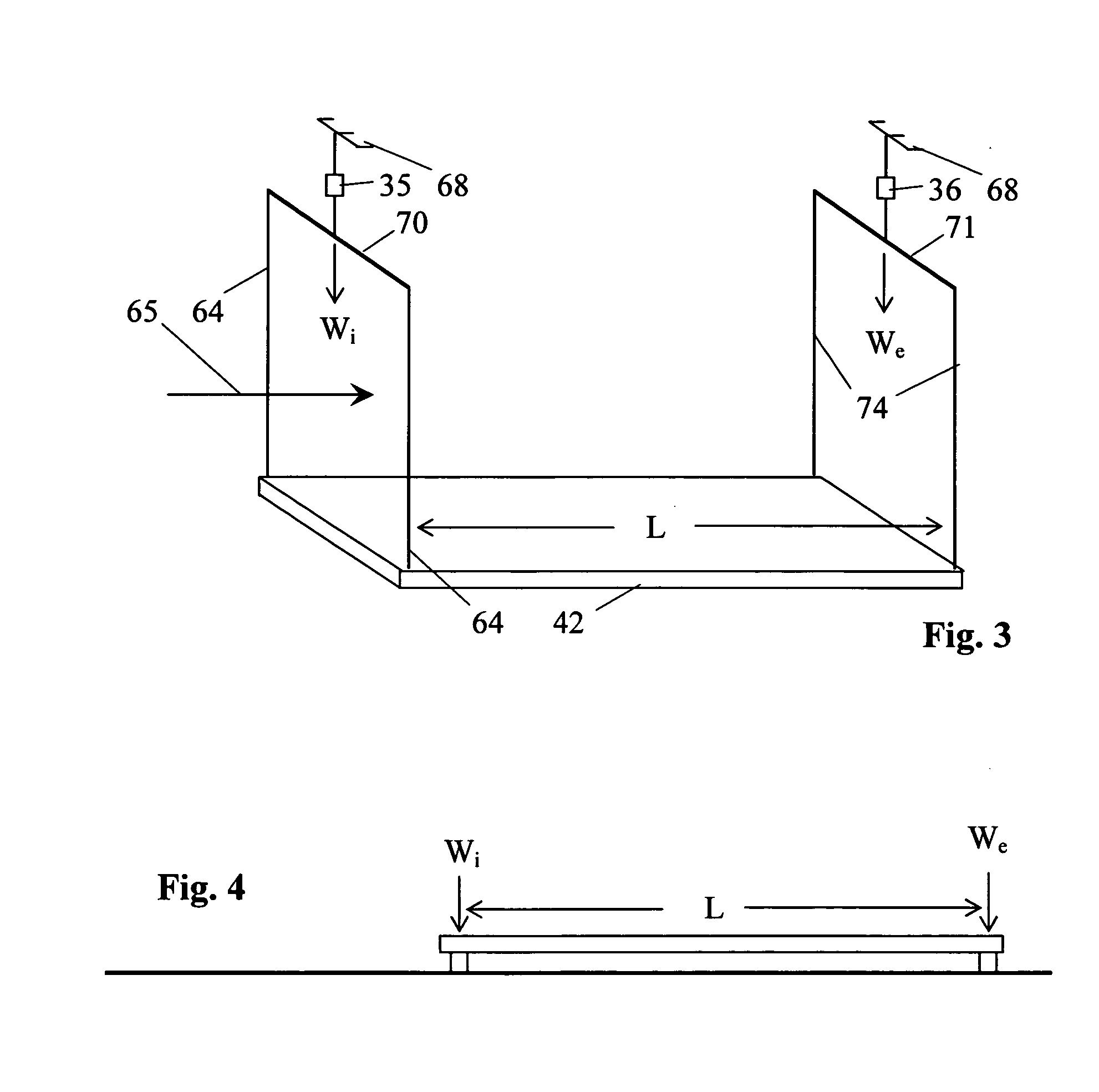

Automatic livestock weighing system

ActiveUS7129423B2Accurate operationAccurate weighingAnimal feeding devicesAnimal housingEngineeringLivestock

A system for weighing a plurality of quadruped animals is for use in a pen confining the animals. The pen has at least first and second segregated spaces with a first one-way chute allowing animal passage from the second space to the first space. A weighing station is located within a passage having an entrance and an exit, and that allows animal passage from the first area to the second area. The weighing station includes a weighing platform within the passage over which an animal must pass when passing from the first to the second space. The weighing platform has inlet and exit scales that support the weighing platform adjacent to inlet and exit ends thereof, and provides inlet and exit weight signals. A controller receives the inlet and exit weight signals and uses them in an iterative process to determine the presence of a single animal on the weighing platform. Once that determination is made, the sum of the inlet and exit weight values is very likely to accurately provide the animal weight. The controller may also use the inlet and exit weight signals to control closing of an inlet gate to bar more than one animal at a time from the weighing platform. An animal sorting system can easily incorporate this weighing system to provide more accurate sorting.

Owner:HERDSTAR

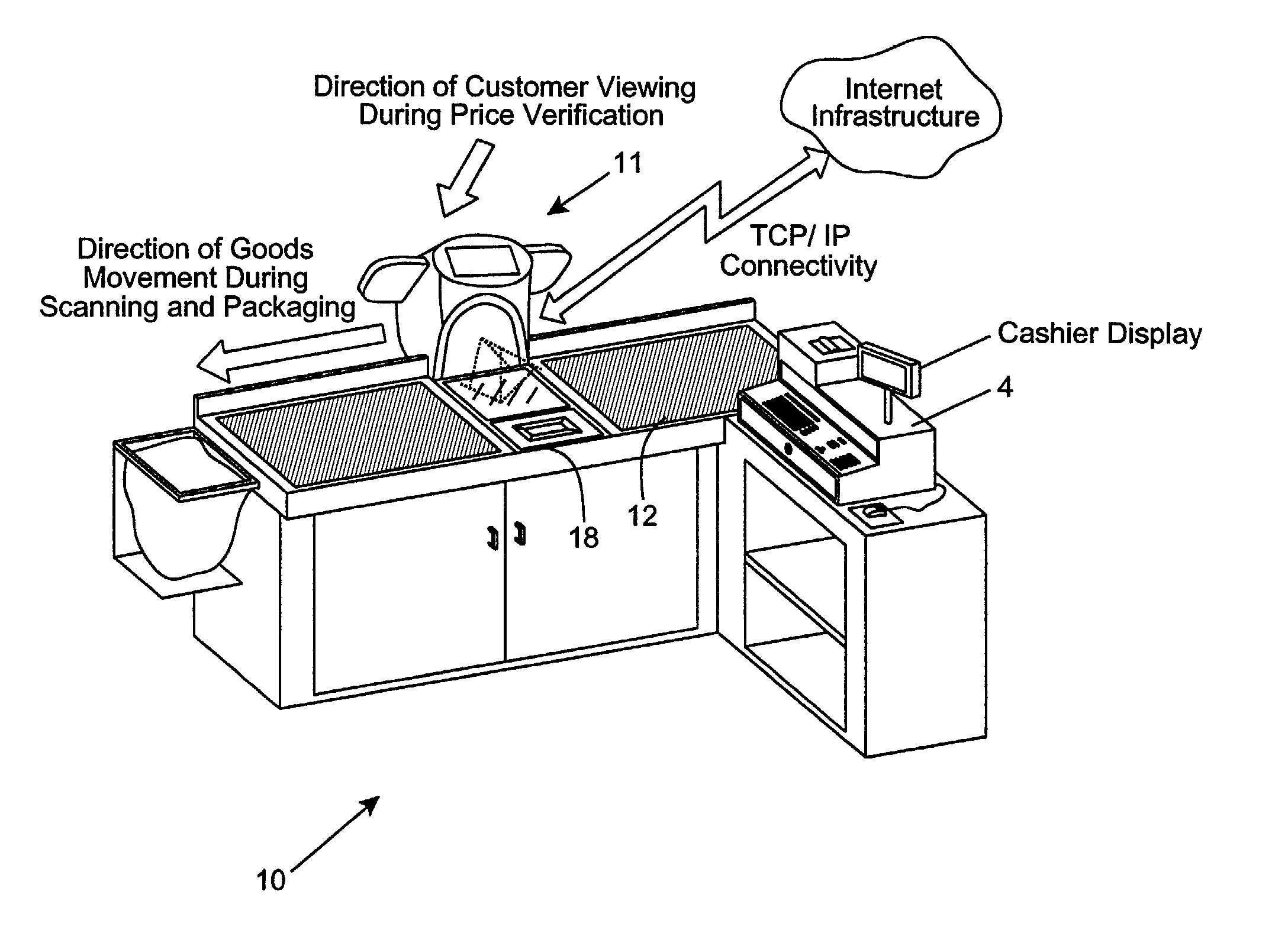

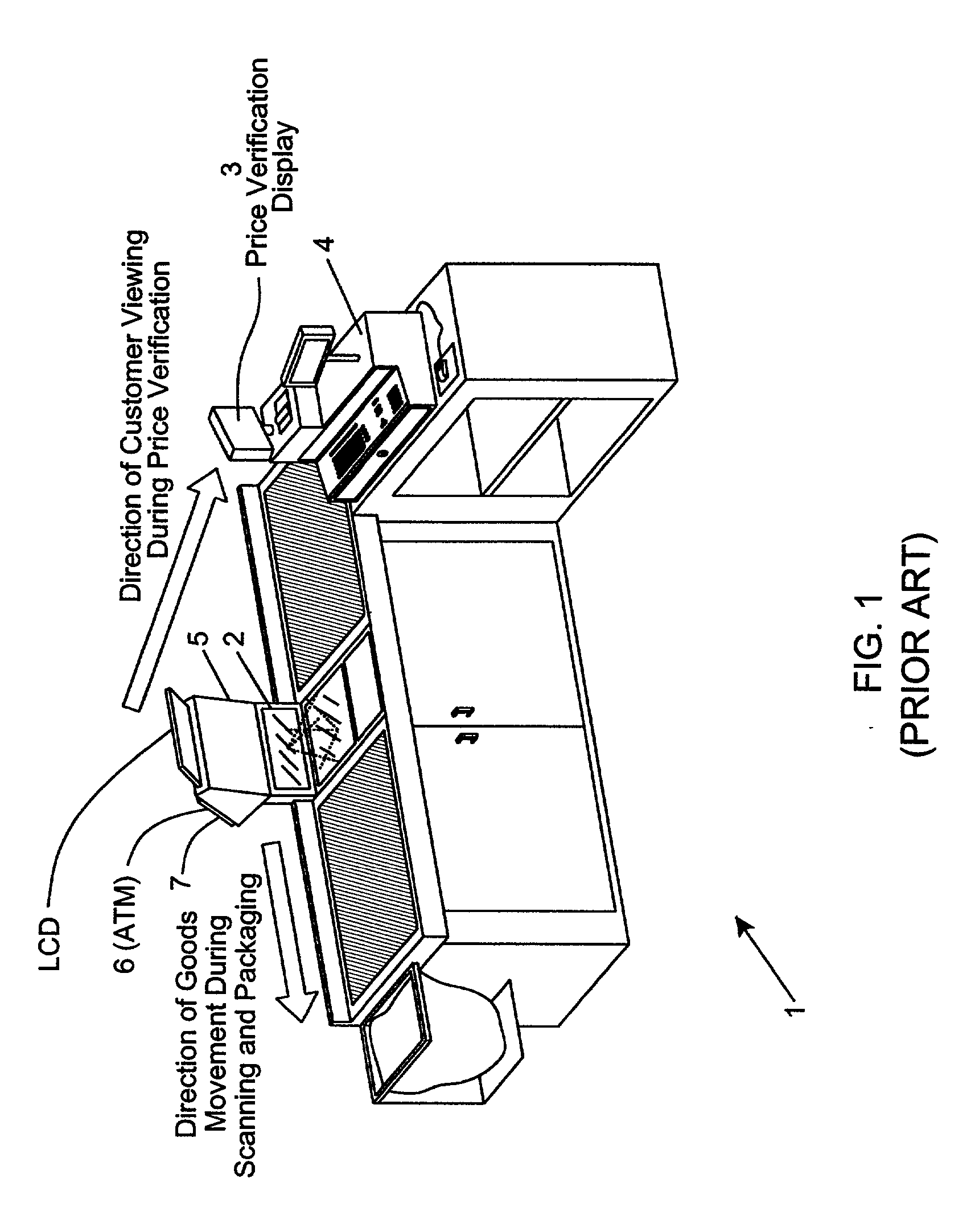

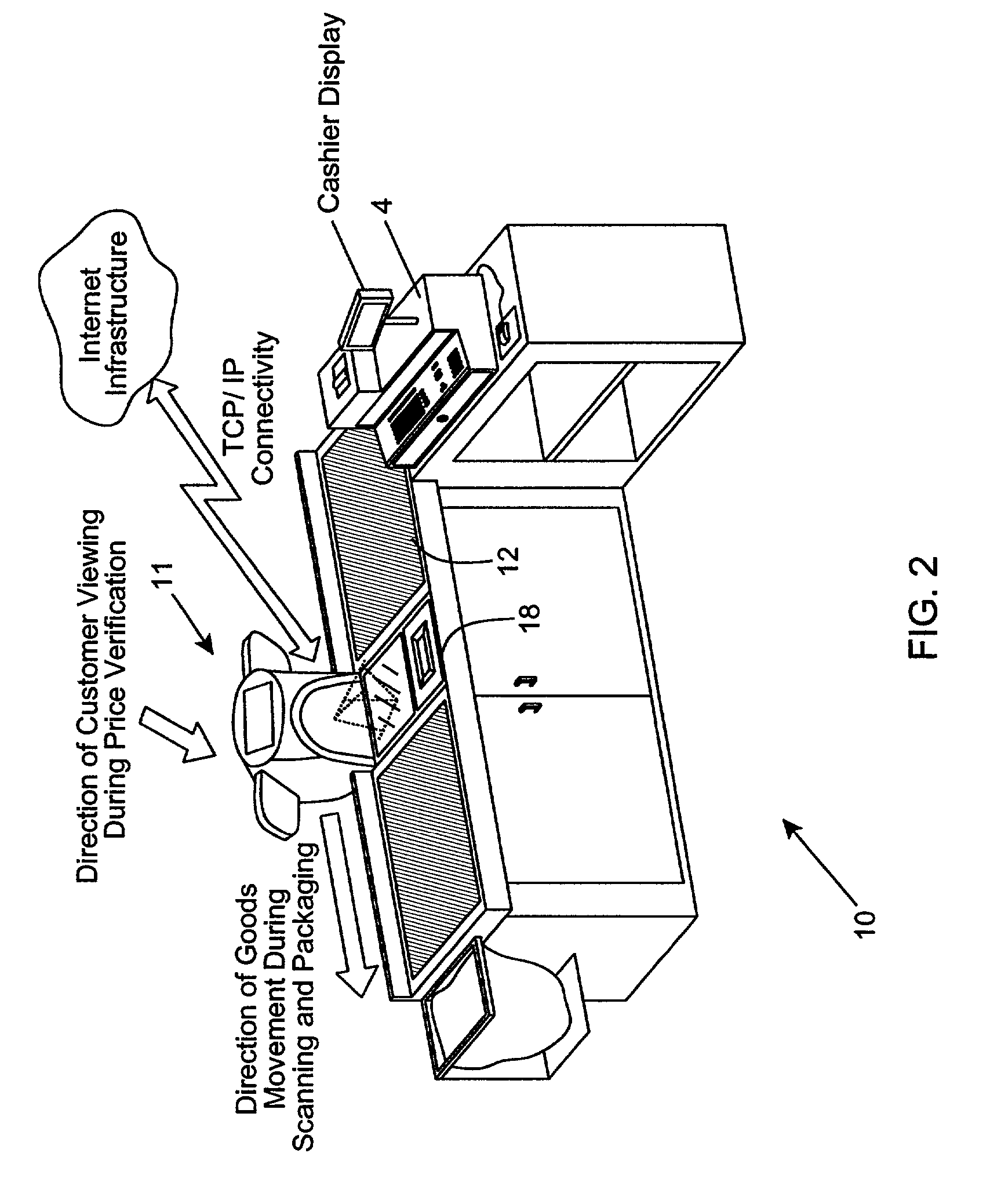

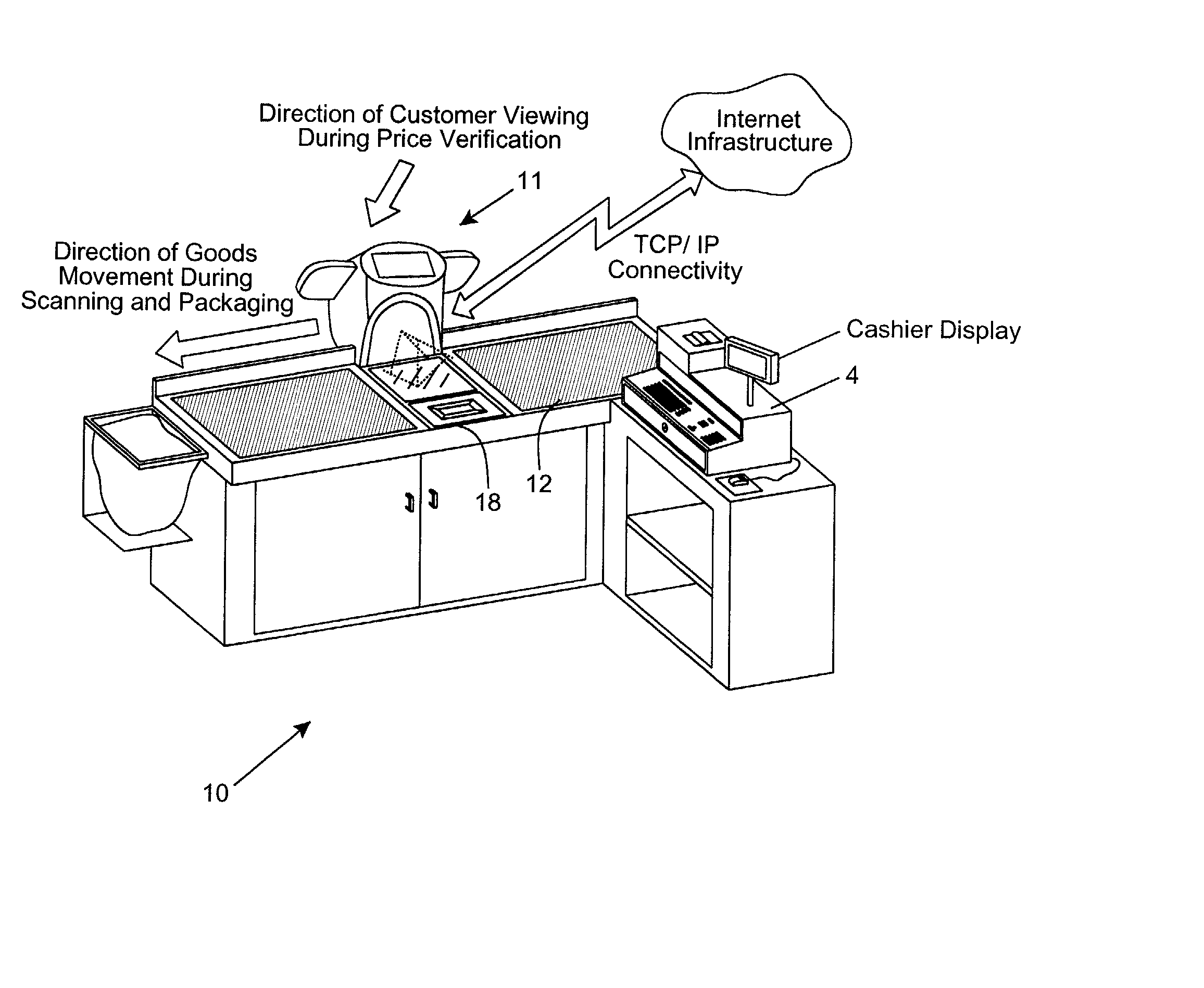

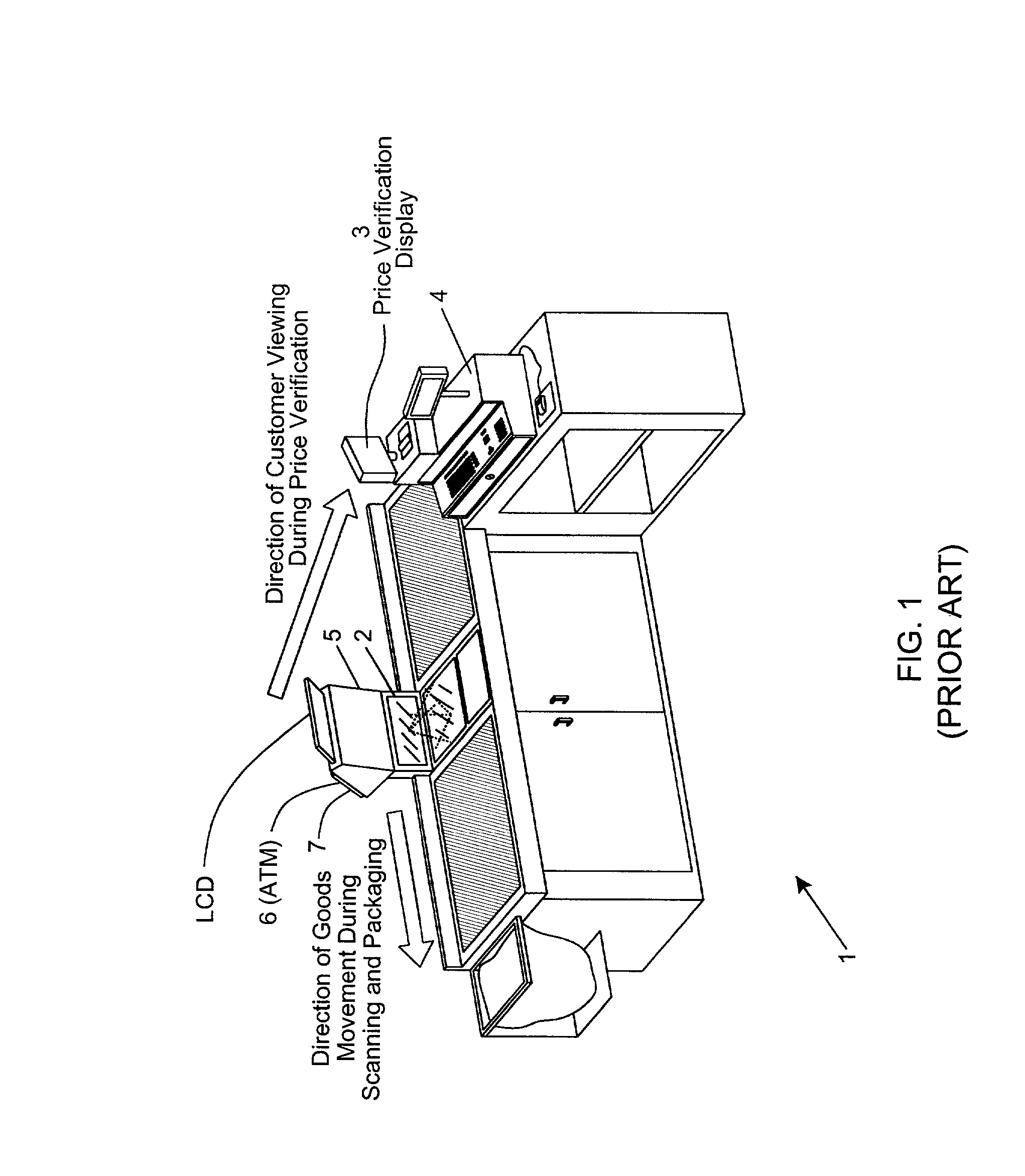

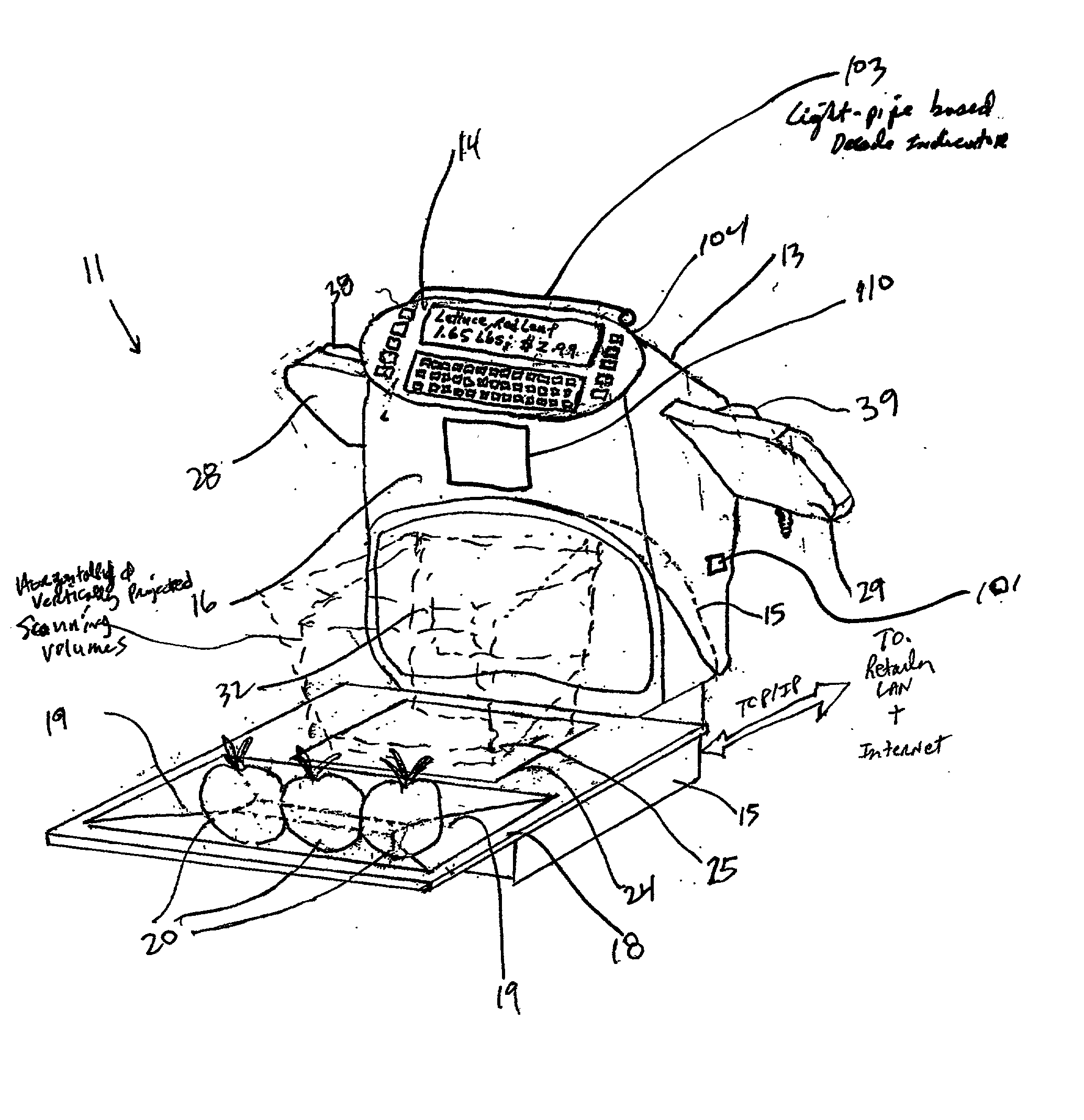

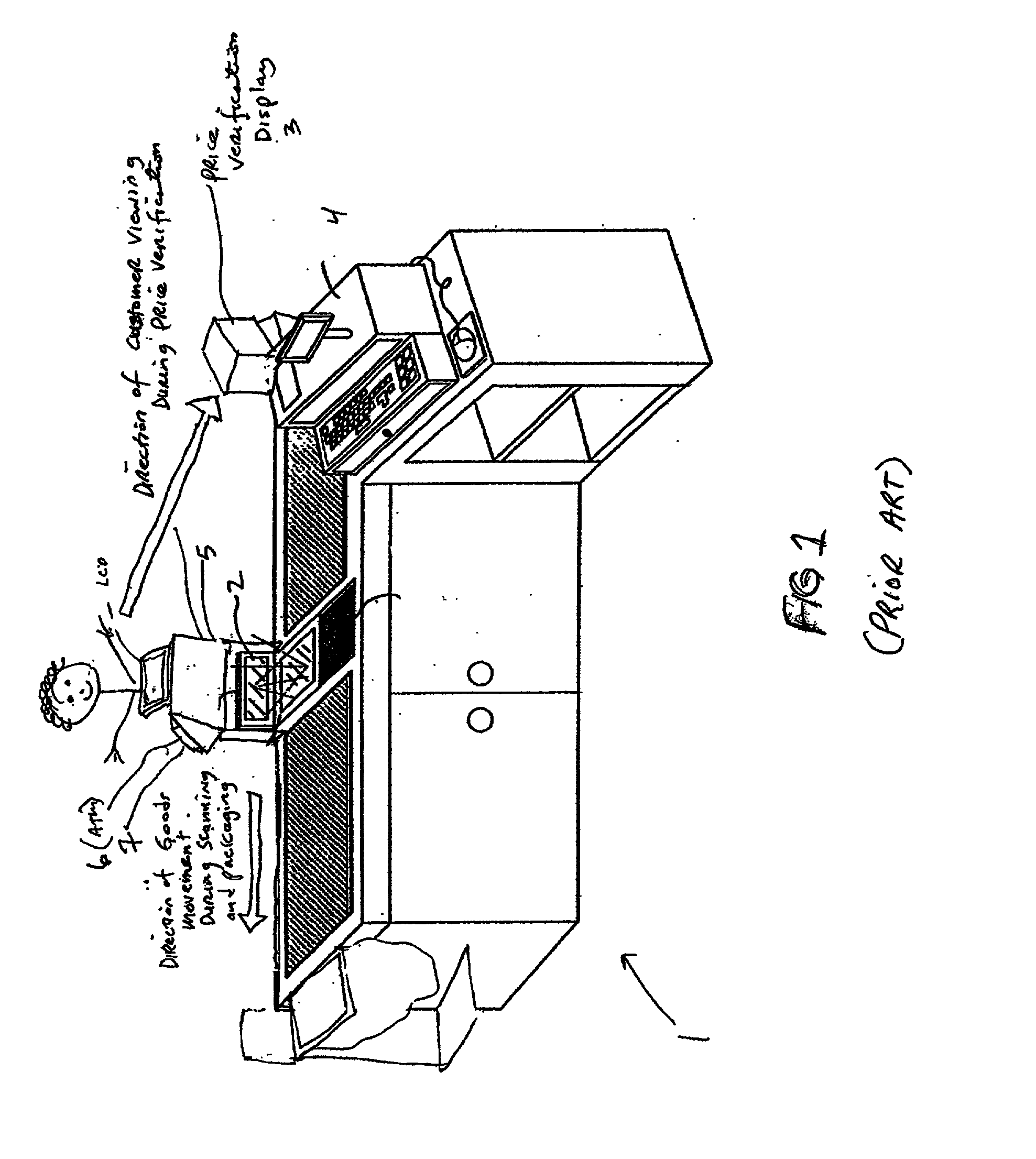

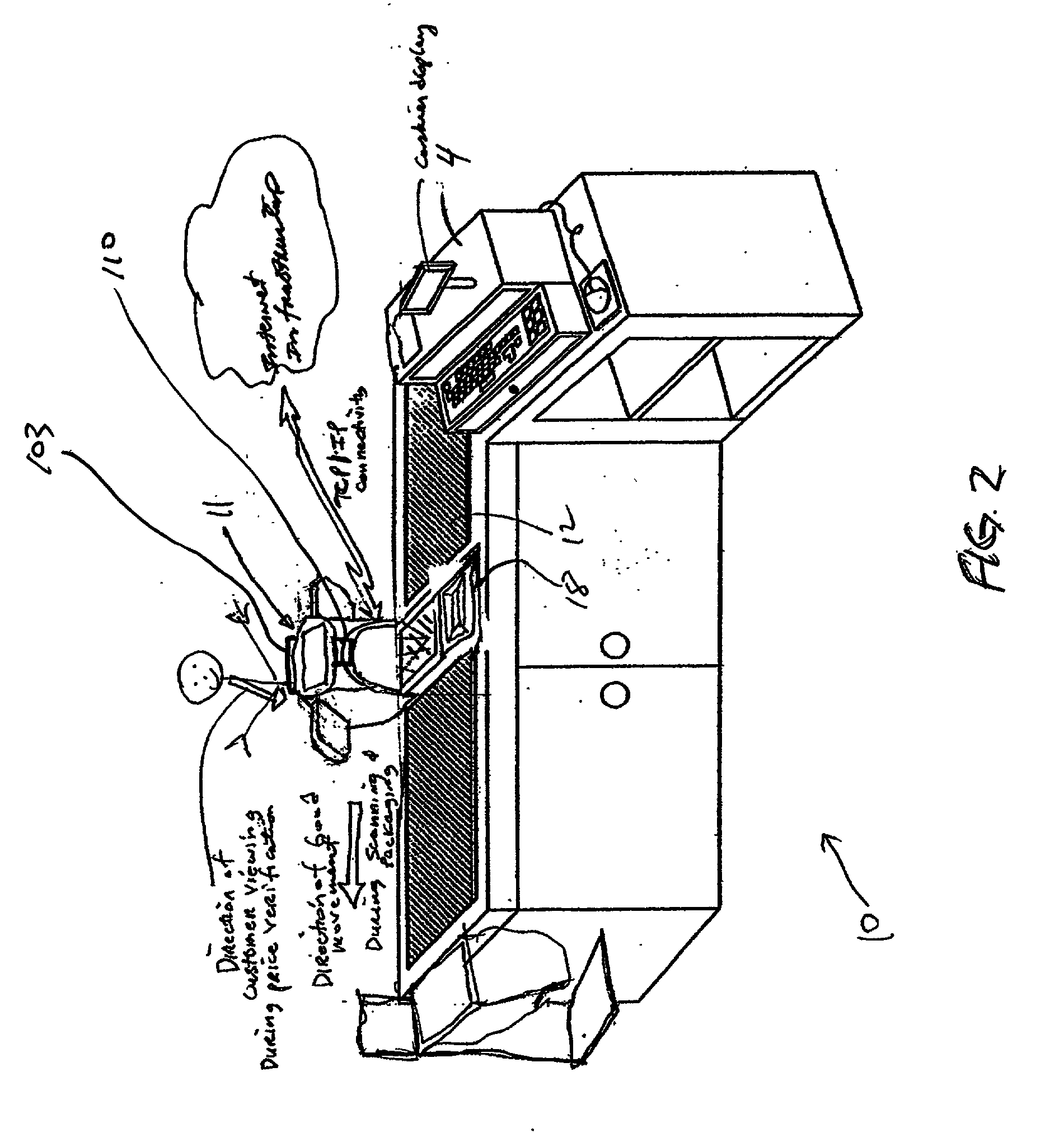

Point-of-sale (POS) station having a based bar code driven cash register system with an integrated internet-enabled customer-kiosk terminal

InactiveUS20030001010A1Accurate weighingFunction is performedTelevision system scanning detailsSoldering apparatusBarcodeCode reading

Novel POS-based bar code symbol reading systems are disclosed having an integrated customer-kiosk terminal. Also disclosed are novel POS-Based Bar Code Reading Cash Register Systems having Integrated Internet-Enabled Customer-Kiosk Terminals.

Owner:SCHMIDT MARK +2

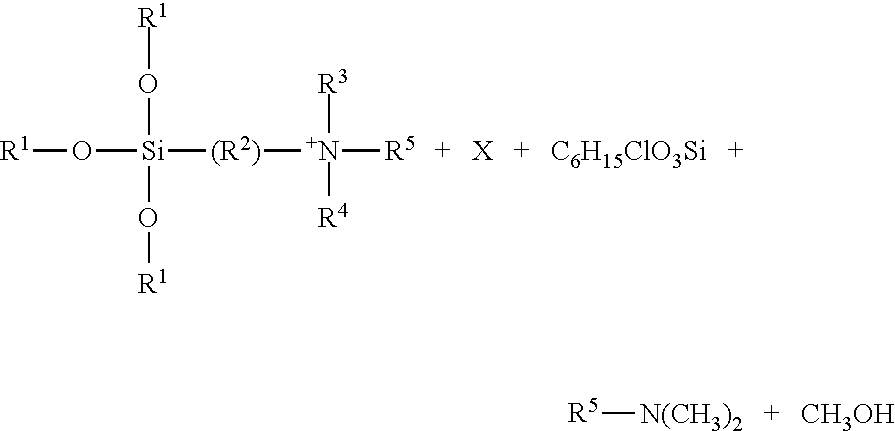

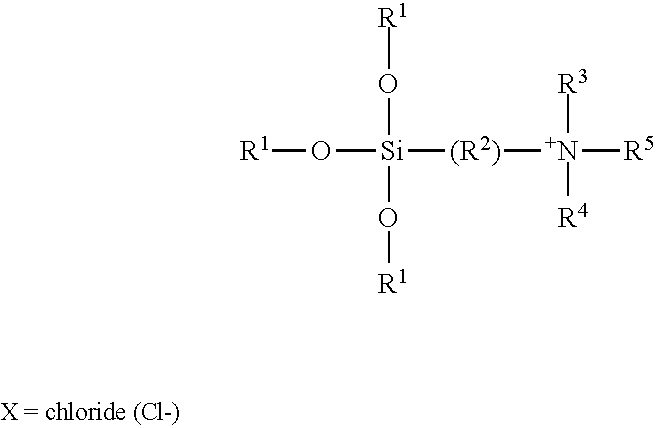

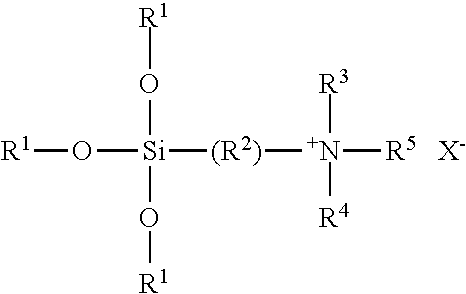

Solvent-Free Organosilane Quaternary Ammonium Compositions, Method of Making and Use

InactiveUS20110271873A1Improve responseStable storageBiocideGroup 4/14 element organic compoundsPersonal careOrganic solvent

Non-flammable, VOC-free organosilane quaternary ammonium compositions are provided in the form of pure or substantially pure water-soluble products that have bactericidal, fungicidal and viricidal activity and which are capable of bonding to various surfaces to form durable hydrophobic coatings. The resulting compositions are free of unreacted chloropropyltrialkoxysilanes, alkylamines and organic solvents that would otherwise provide flammable, corrosive, and / or toxic properties thereby inhibiting their safe and effective use in surface care, personal care and coating products.

Owner:RESOURCE DEV LLC

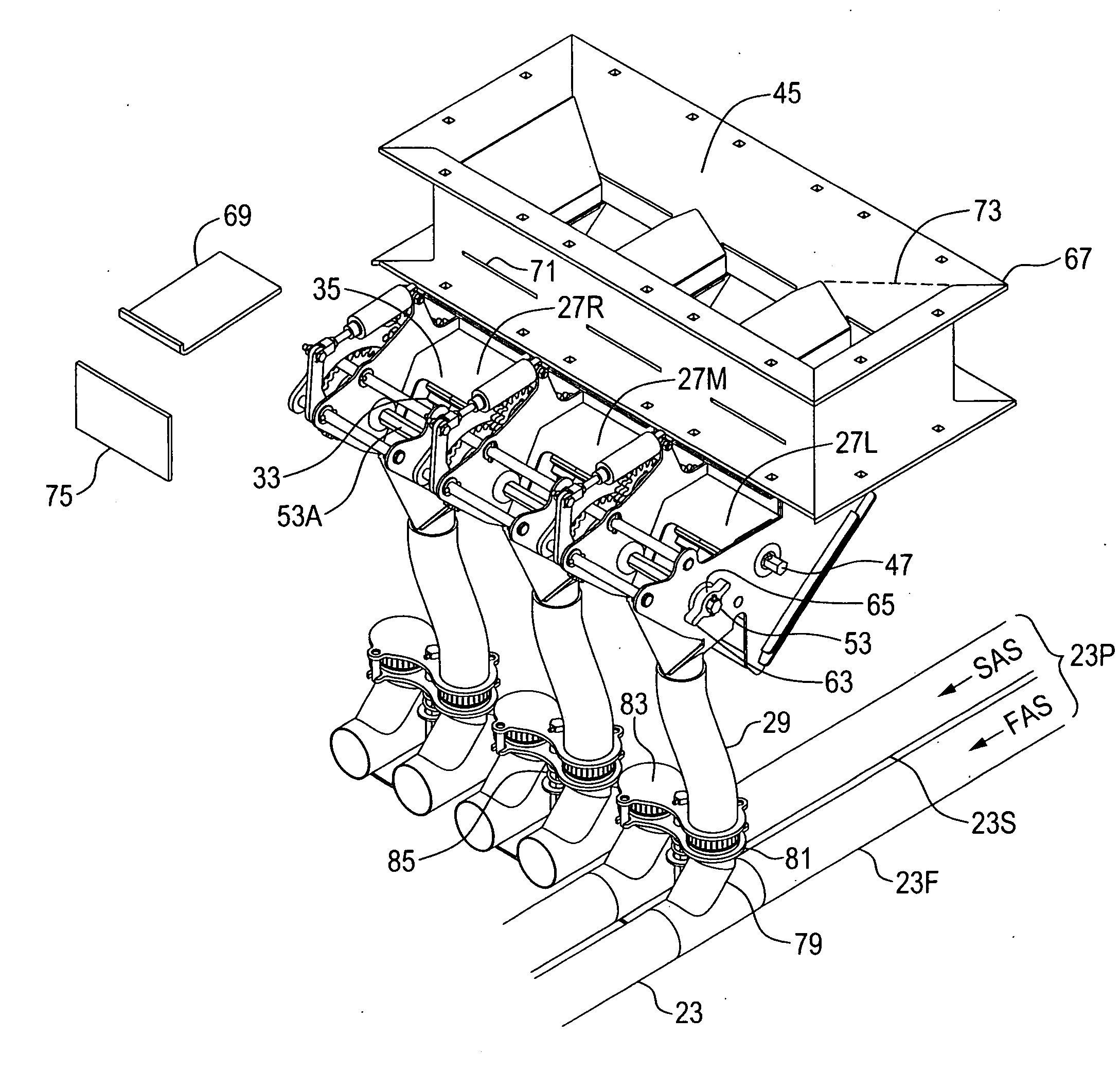

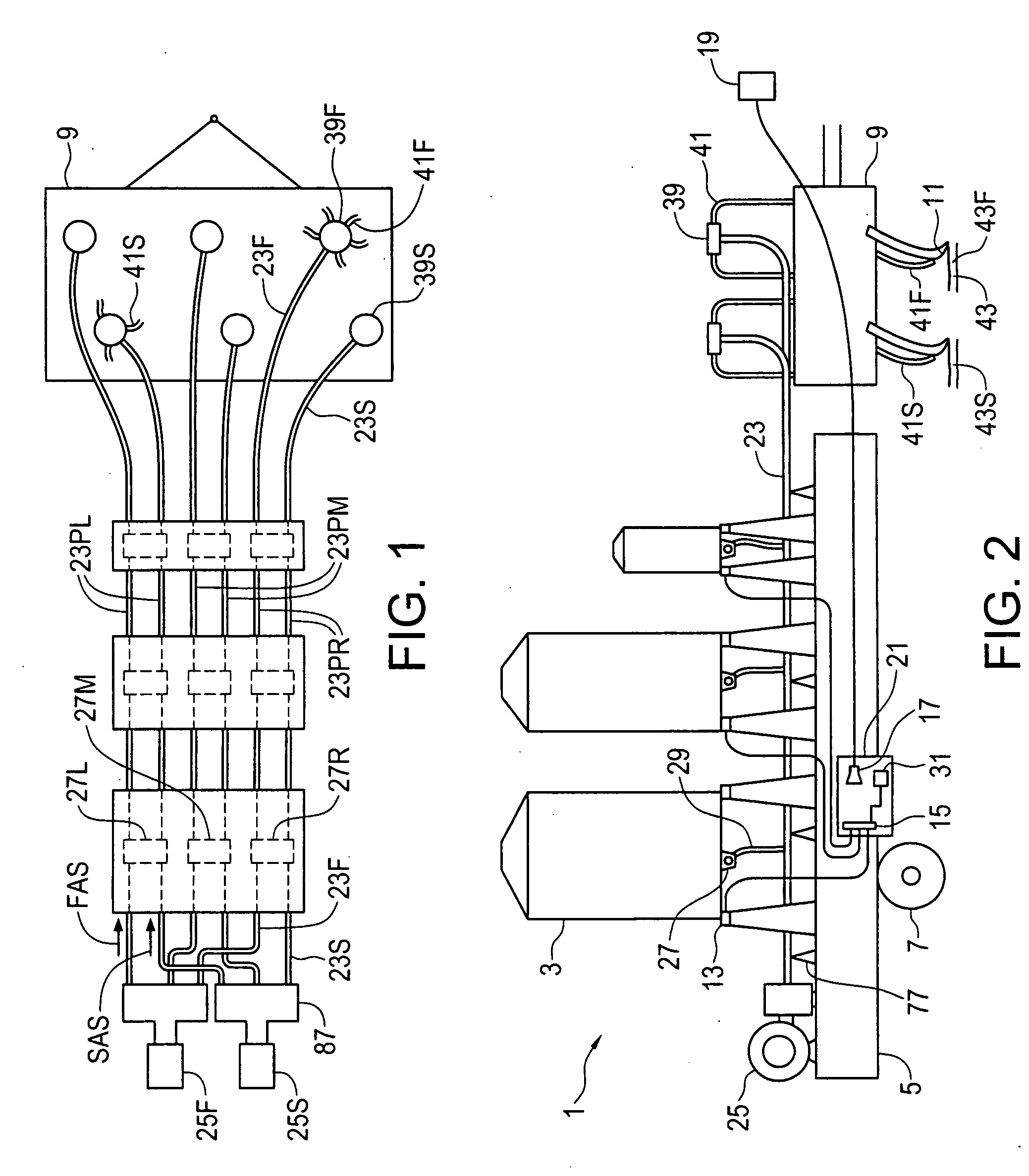

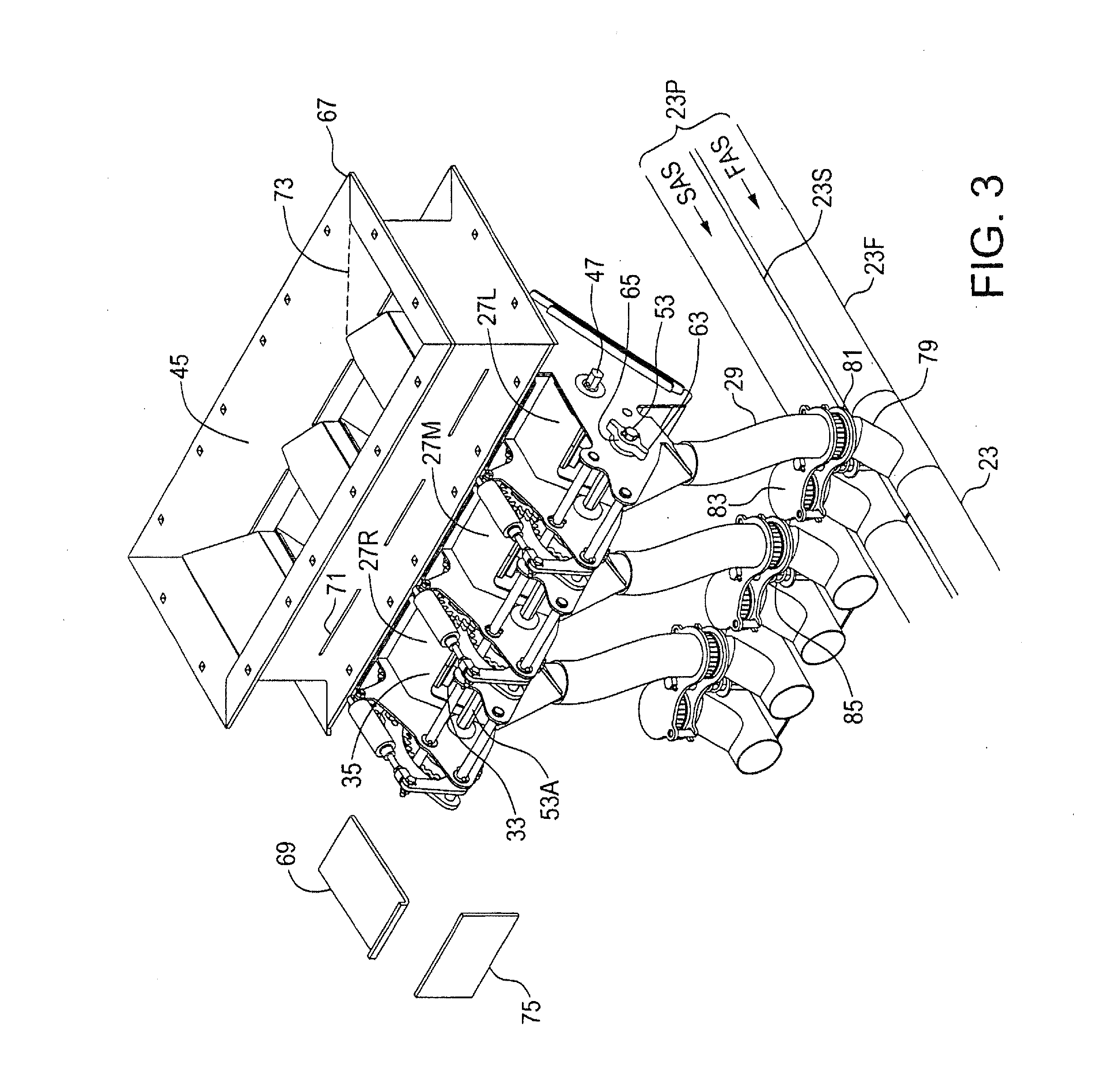

Air seeder tank and distribution apparatus

ActiveUS20120103238A1Different air speedDifferent pressureFertiliser distributersAgriculture and animal husbandary industryInternal pressureMechanical engineering

An air seeder distribution apparatus has seed and fertilizer tanks, and a like plurality of metering devices mounted on each product tank. A manifold set comprises a like plurality of product manifolds and each manifold is separately fed from one metering device on each of the seed and fertilizer tanks. A control selectively starts and stops rotation of the feed roller of each metering device to feed product from either tank, or both tanks to the connected manifold. The weight of each tank can be displayed on a weight indicator. Balancing of the pressure in each supply conduit can be provided. A remote opener exerts downward force on the tank lid to maintain interior pressure.

Owner:SEEDMASTER MFG

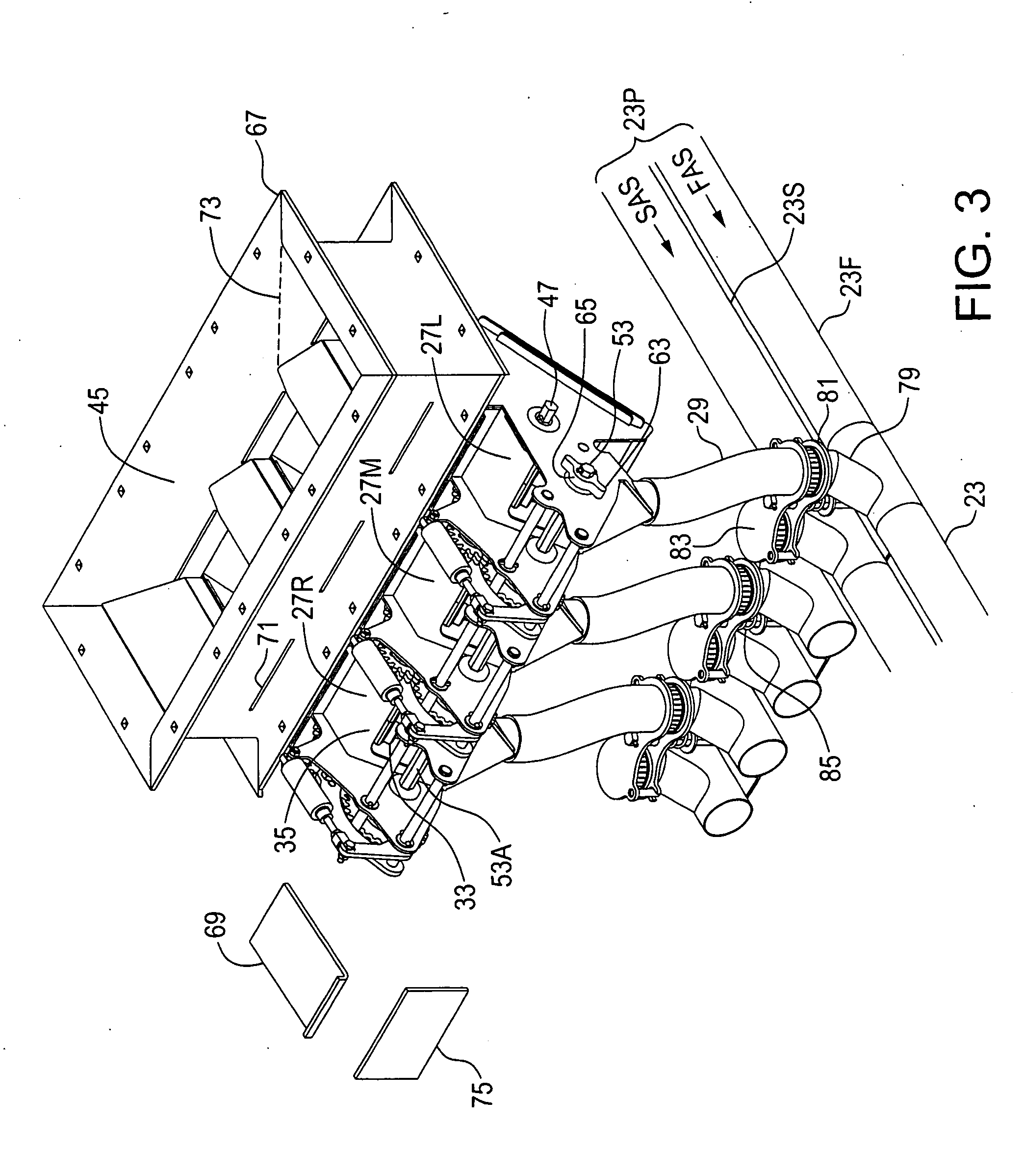

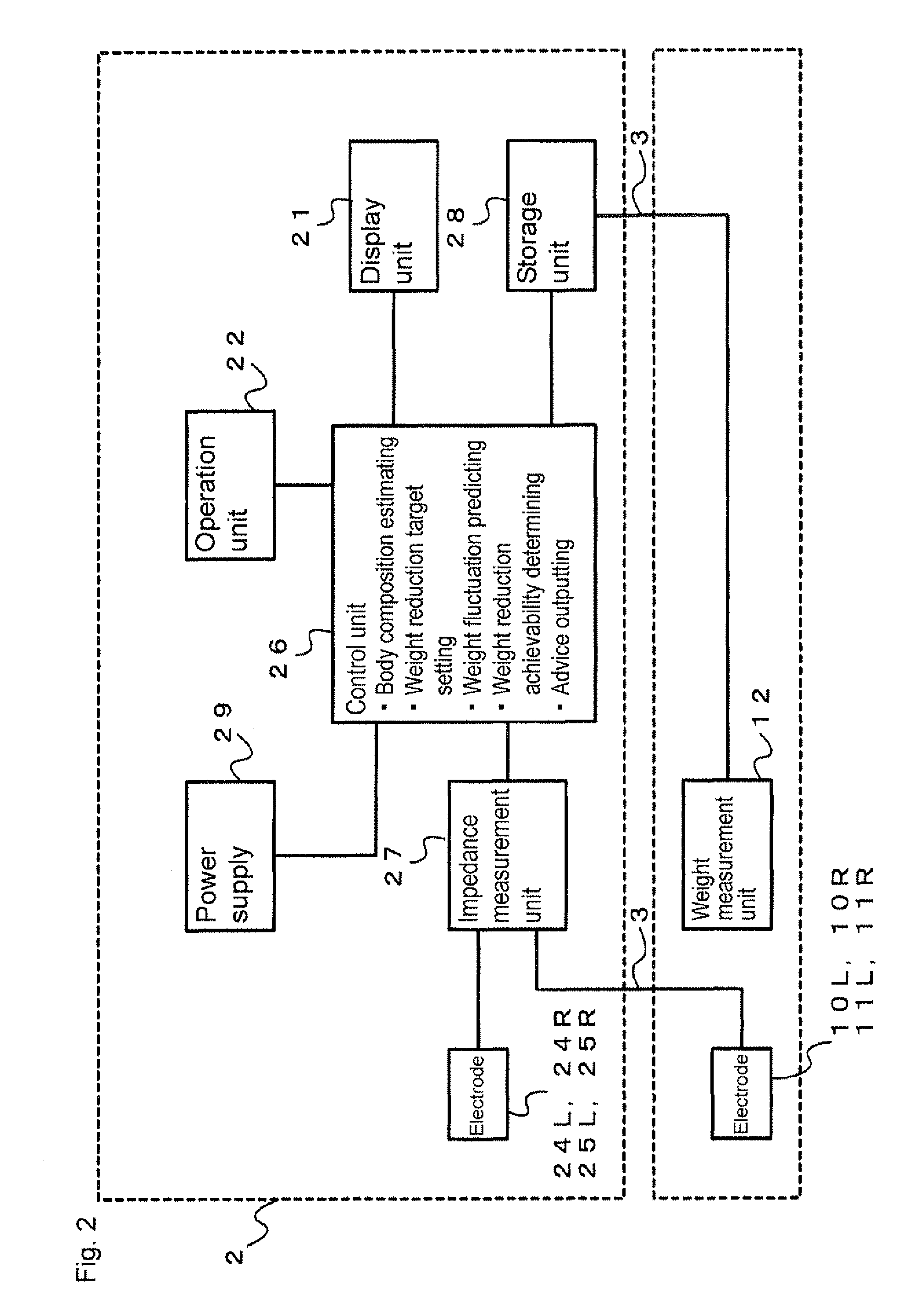

Health management guideline advising device

ActiveUS20110106553A1Accurate weighingAccurate predictionPhysical therapies and activitiesData processing applicationsWeight FluctuationMeasurement device

A health management guideline advising device includes input means for inputting personal information of a measuring subject; measurement means for measuring weight and body impedance of the measuring subject; estimation means for estimating a body composition distribution of the measuring subject from the inputted personal information and the measurement result by the measurement means; storage means for storing the measurement result by the measurement means and an estimation result by the estimation means with a measurement date and time, prediction means for predicting future weight fluctuation from the stored weight and the body composition distribution; and display means for displaying the predicted future weight fluctuation. Furthermore, target setting means for setting a weight reduction target and determination means for determining whether or not the weight reduction target can be achieved based on the prediction result by the prediction means are preferably arranged.

Owner:OMRON HEALTHCARE CO LTD

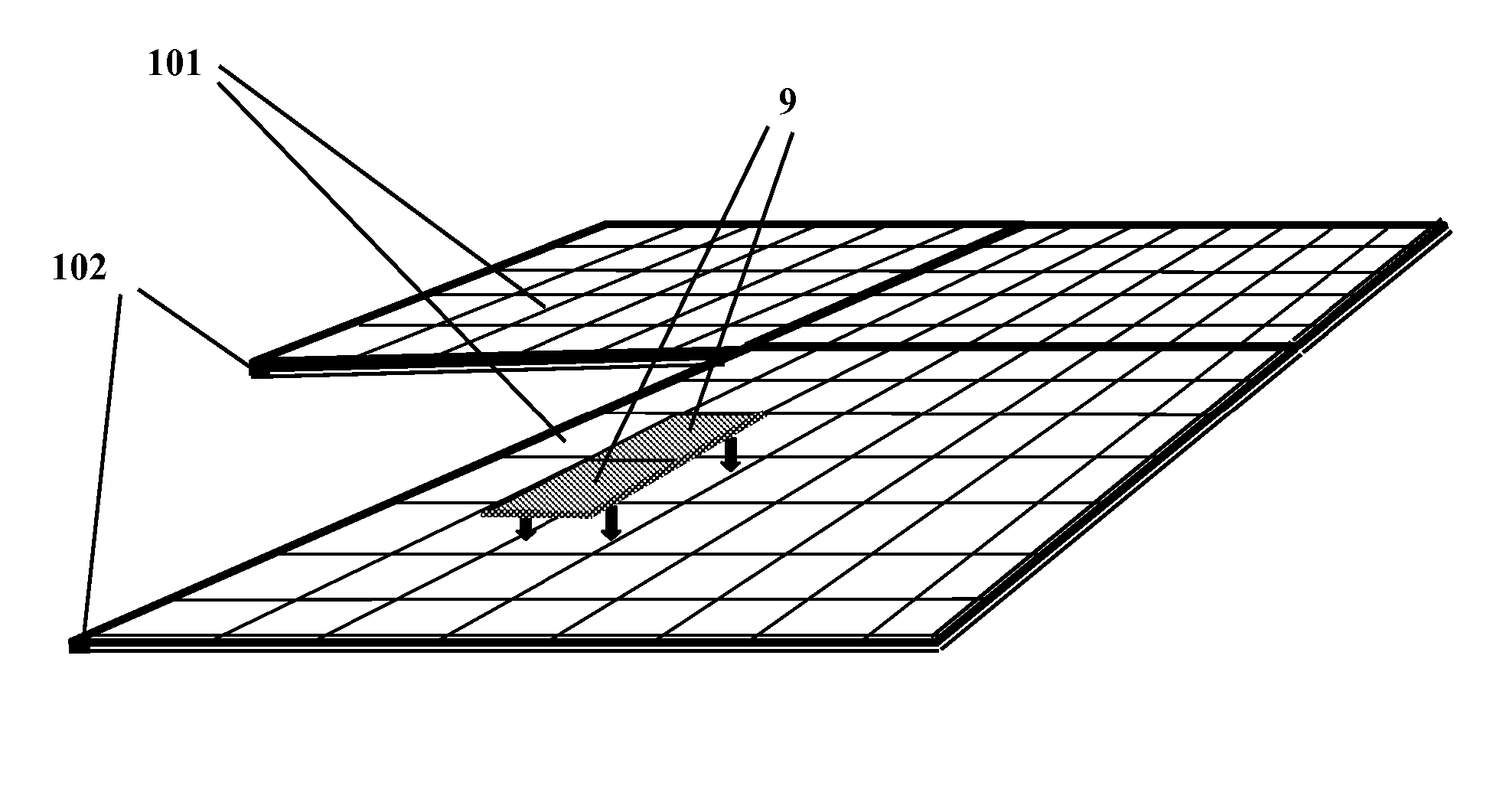

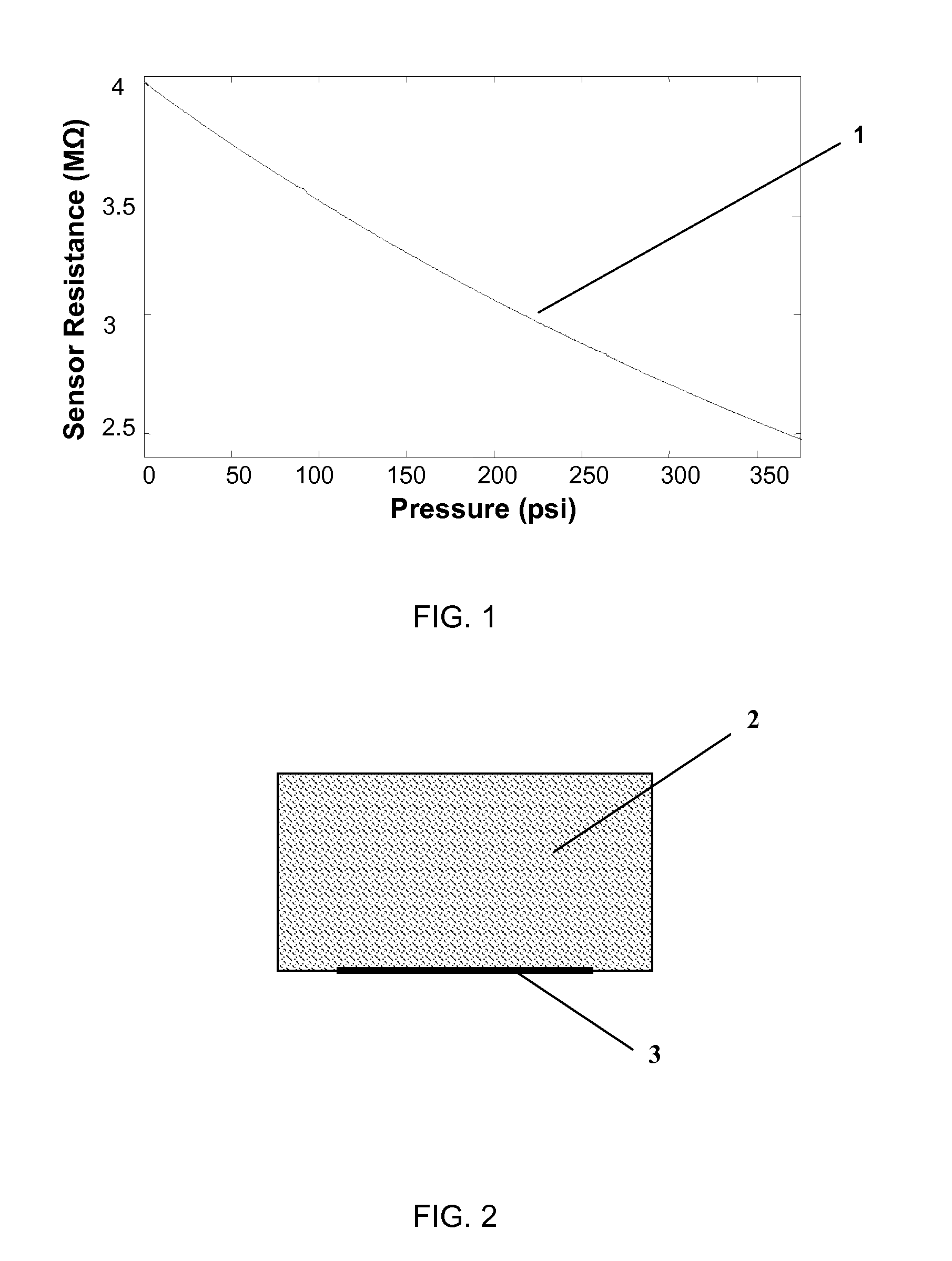

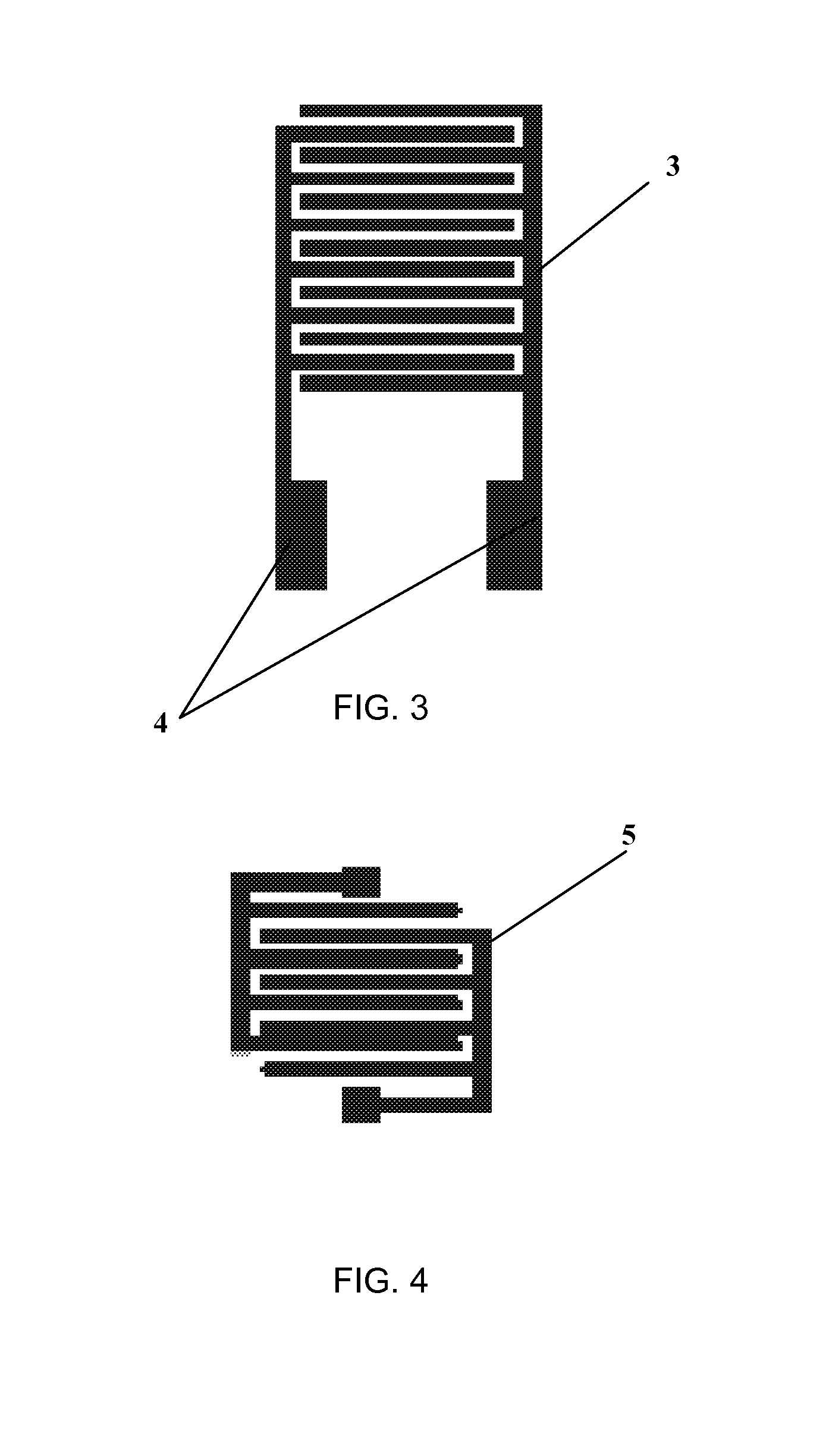

Digital flooring detection system

InactiveUS20070171058A1Reducing sensor resolutionLess finite resolution of location detectionBurglar alarm by pressureElectricityInterdigitated electrode

A flooring system comprising a plurality of electrode pairs in contact with a metaplastic composite material. The metaplastic material is such that it locally conducts electrical current in an area where any load is applied to the metaplastic. An electric potential is applied to one or more interdigitated electrodes located at a face of the metaplastic material in line with applied loads. Larger area coverage can be obtained either by pre-installing a subsurface layer comprising of an array of interdigitated electrodes and their trace line outputs and then covering this layer with a tiling of metaplastic material sheets that is in direct contact with the array of interdigitated electrodes, or, by directly attaching one or more interdigitated electrodes and their output trace lines to an individual sections of metaplastic material and electrically interconnecting their outputs. By applying a sufficient number of interdigitated electrodes and sheets of the metaplastic material and monitoring the electrical current flowing in each interdigitated electrode so placed, it can be determined whether and where loads are being applied to the PCC flooring material and the approximate size and shape of the load.

Owner:LATITUDE BROADBAND

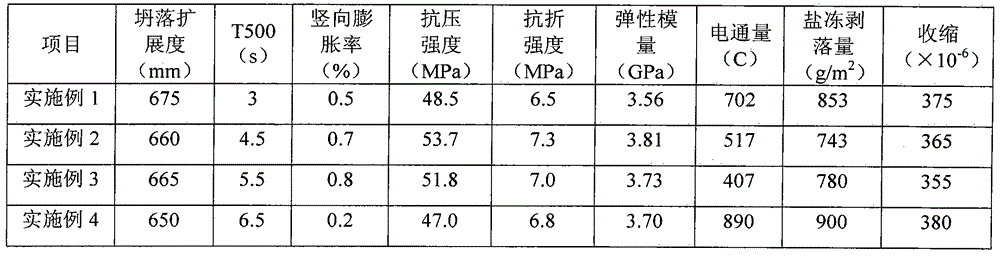

Preparation and application of two-component self-compacting concrete for slab ballastless track

The invention relates to a preparation and an application of two-component self-compacting concrete for a slab ballastless track. The preparation of the two-component self-compacting concrete is characterized in that the two-component self-compacting concrete is formed by mixing a dry mixture with a liquid in the ratio of 1:(0.05-0.15), wherein the dry mixture is formed by mixing components in parts by mass as follows: 100 parts of a bonding component, 0-30 parts of an inert mineral additive, 150-400 parts of fine aggregate, 150-300 parts of coarse aggregate, 0-2.0 parts of a water reducing agent, 5-20 parts of an expansion component, 0-10 parts of a viscosity regulating component, 0-0.5 parts of fiber and the like; and the liquid is formed by mixing components in parts by mass as follows: 100 parts of water, 0-4.0 parts of the water reducing agent, 0-3 parts of the viscosity regulating component and the like. According to the preparation and the application of the two-component self-compacting concrete for the slab ballastless track, the sensibility of the self-compacting concrete can be reduced, loss of the self-compacting concrete is reduced, and environment-friendly construction is realized. The two-component self-compacting concrete is applicable to the slab ballastless track of a high speed railway and is also applicable to the field of bridges, civil buildings, repair and strengthening and the like.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

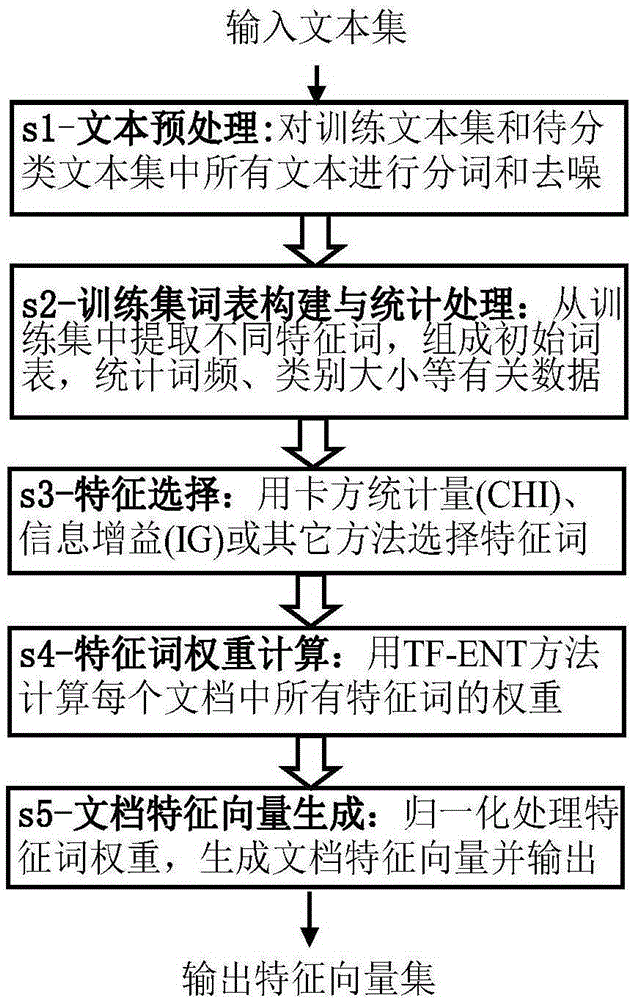

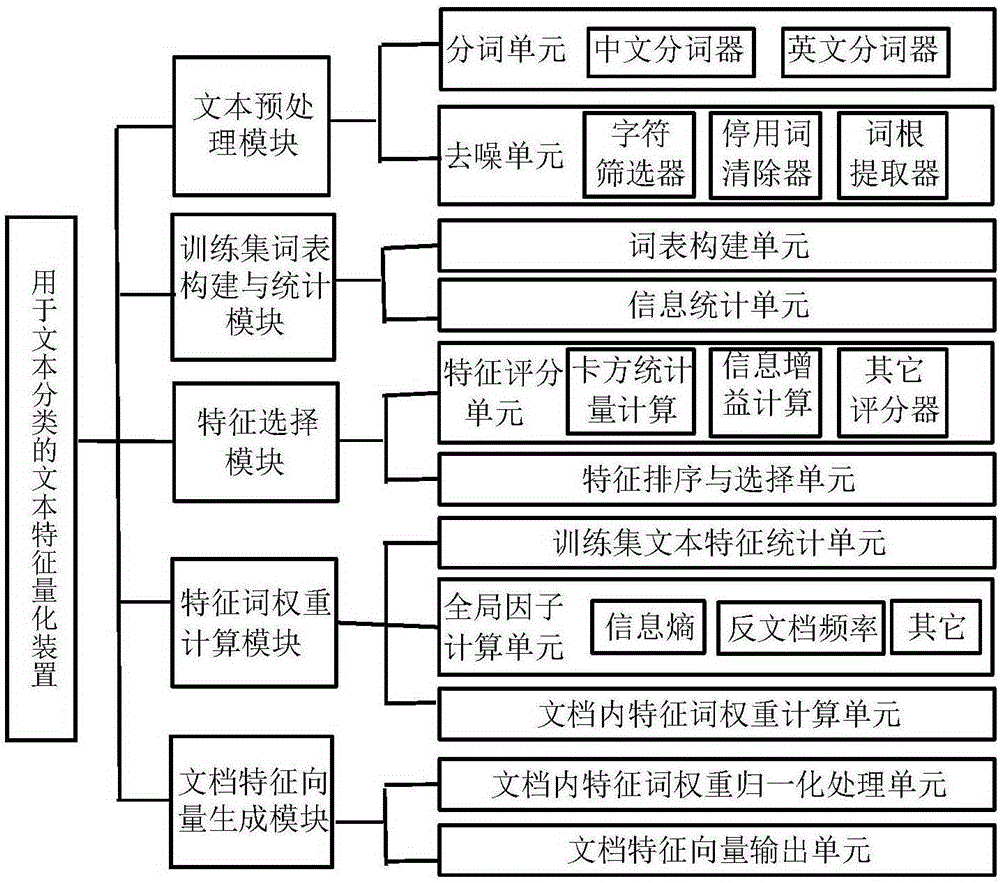

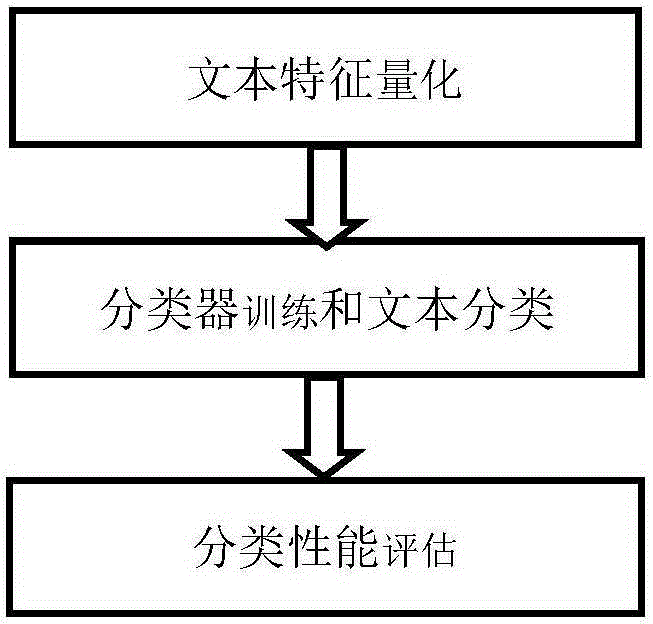

Text feature quantification method based on comentropy, text feature quantification device based on comentropy, text classification method and text classification device

InactiveCN105224695AAvoid estimationAccurate feature quantificationSpecial data processing applicationsText database clustering/classificationFeature vectorText categorization

The invention discloses a text feature quantification method based on comentropy, a text feature quantification device based on comentropy, a text classification method and a text classification device. The text feature quantification method comprises the following steps that: the weight of each feature word in a document is calculated according to the word frequency of feature words in a text document and the comentropy distributed on different text classes; meanwhile, the inter-class distribution entropy of the feature words is calculated in different modes according to the unbalance performance of the scale of each class of a text set; in addition, the inverse document frequency is introduced as required according to the distribution features of each feature word in the text set; local word frequency factors are properly reduced, so that the weight distribution of each feature word in the document is reasonable; and the feature differences of different classes of texts are sufficiently reflected by generated document feature vectors. The text feature quantification device and the text classification device disclosed by the invention have a plurality of options or parameters; and the optimum text classification effect can be achieved through regulation. The text feature quantification method has the advantages that the text classification accuracy is improved, and the performance on different text sets is stable.

Owner:CENT SOUTH UNIV

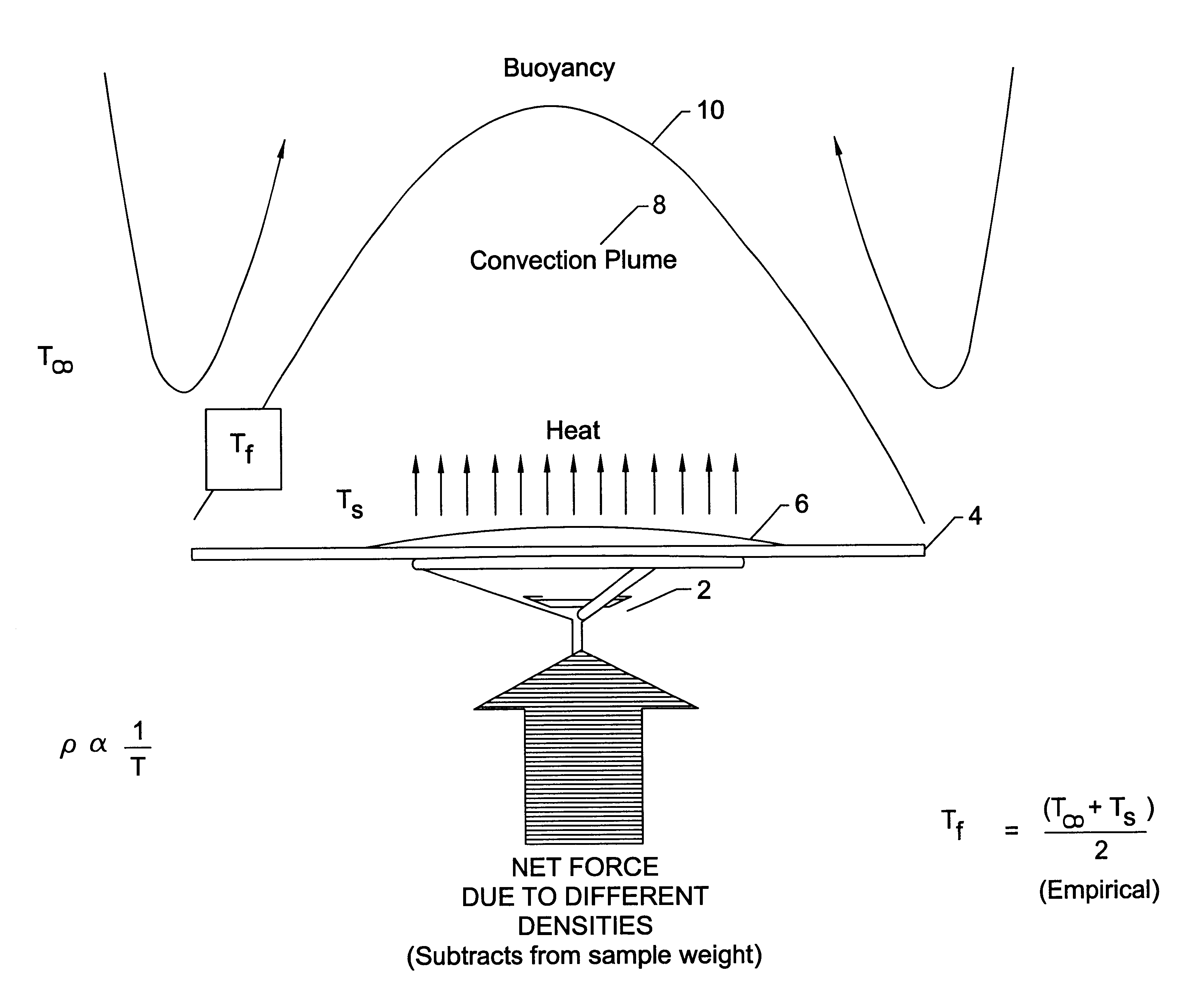

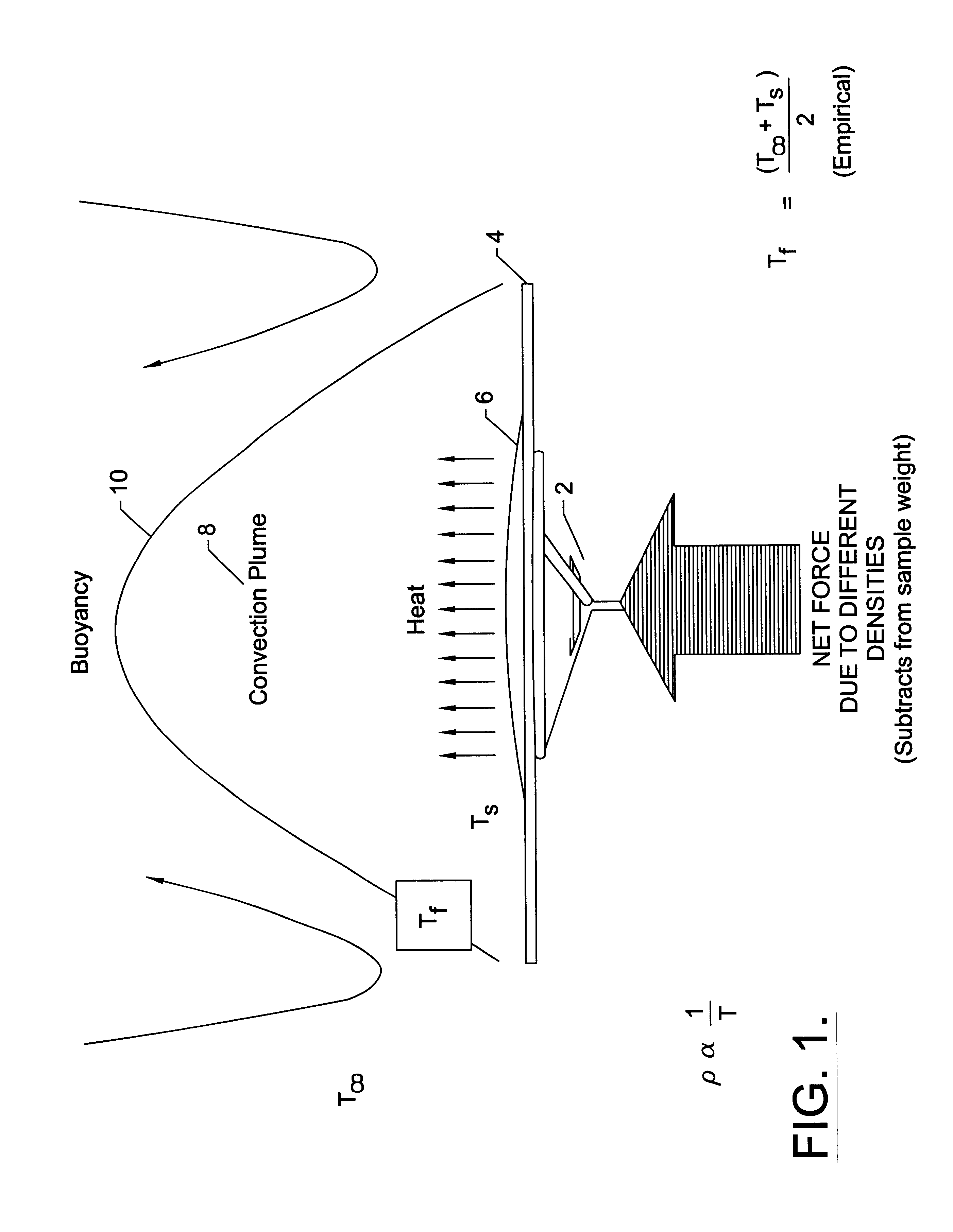

Method for correcting weight measurement errors during microwave heating

InactiveUS6268570B1Accurate sample weight measurementAccurate weighingWeighing apparatus testing/calibrationMaterial moisture contentObservational errorMicrowave

The invention is a method of measuring an apparent weight of a substance, while concurrently measuring a surface temperature of the substance and an ambient air temperature surrounding the substance, then predicting buoyancy forces acting upon the substance based on these temperature measurements. Thereafter, the true weight of the substance can be determined by correcting the apparent weight by the predicted buoyancy forces acting upon the substance.

Owner:CEM CORP

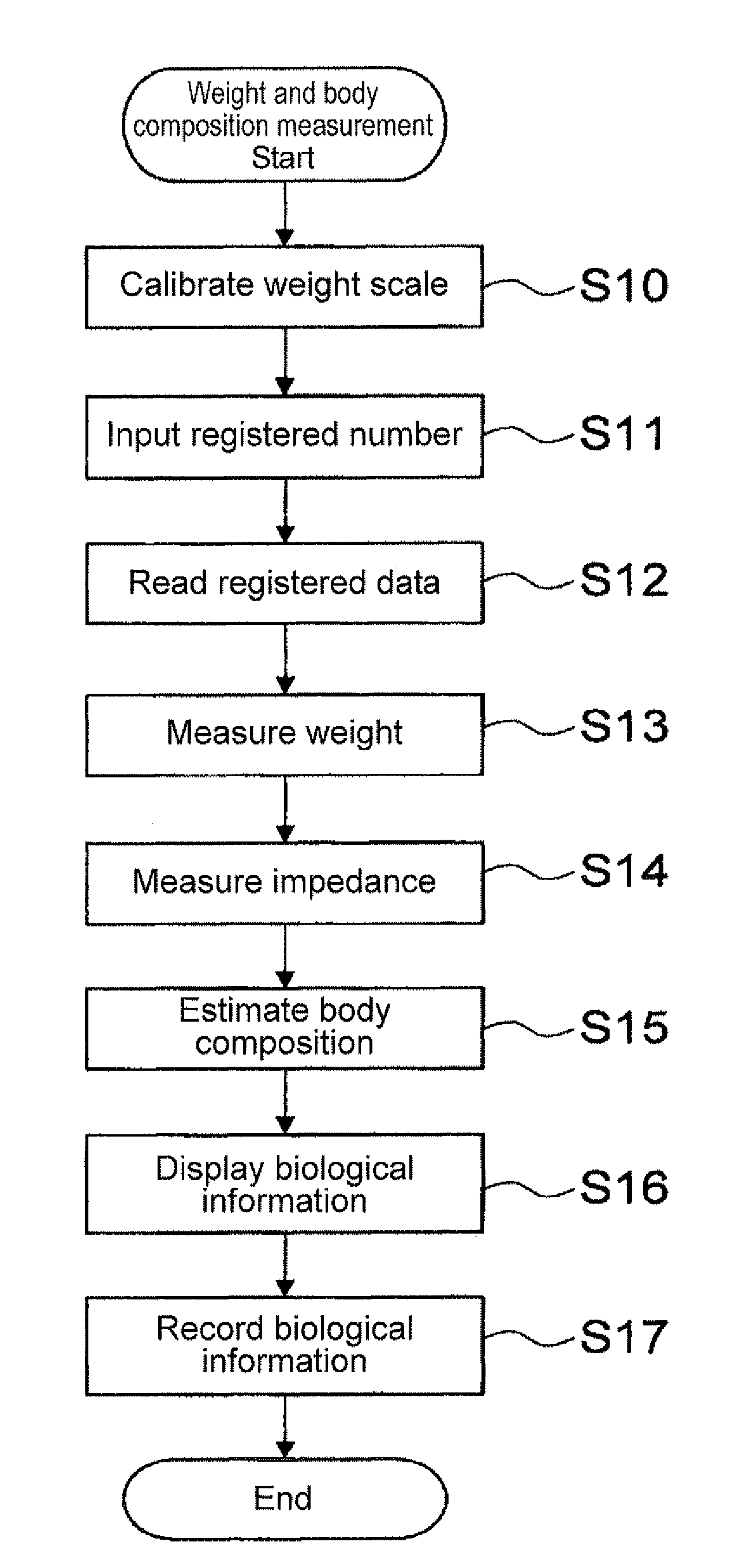

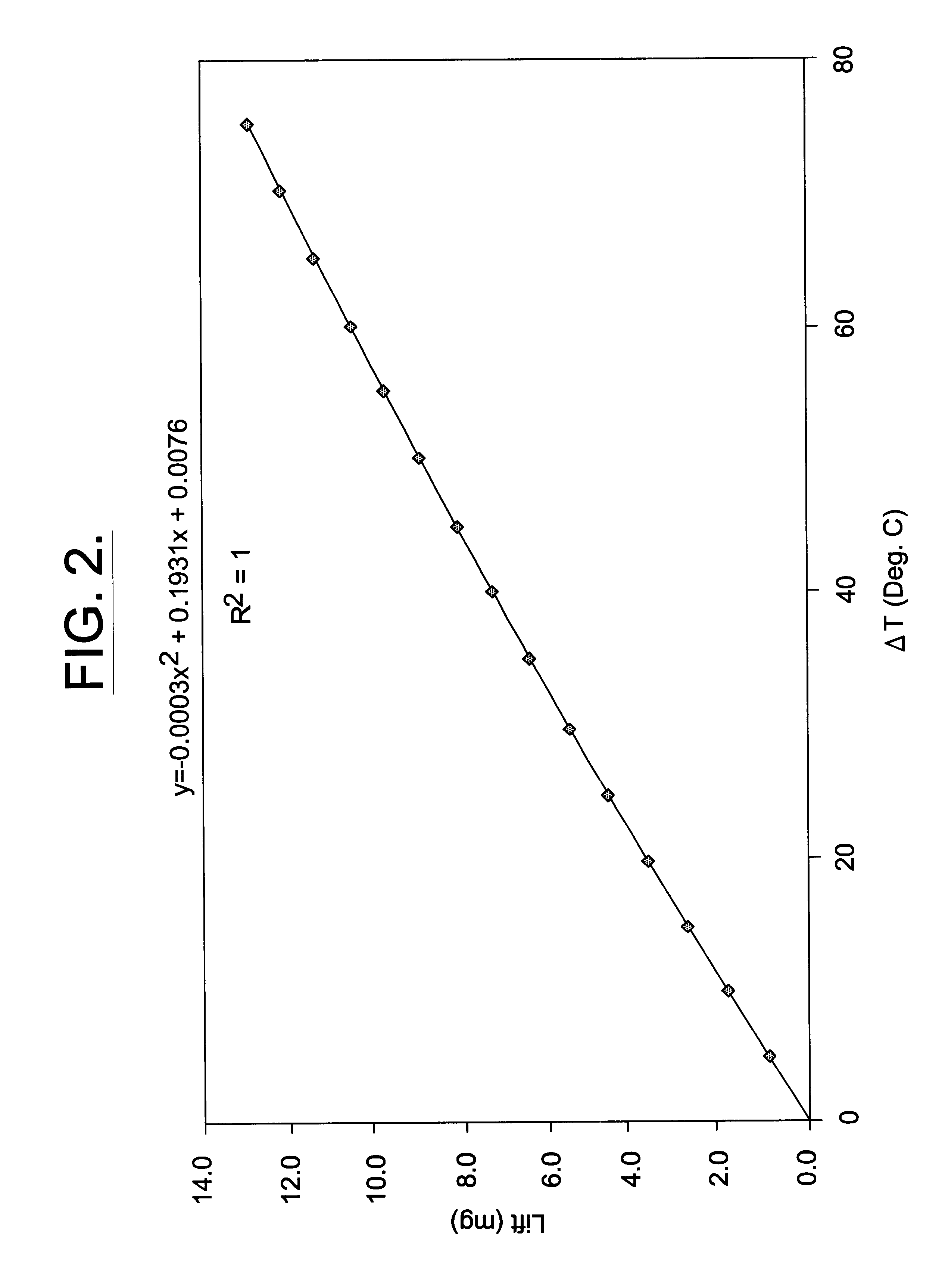

Base apparatus for device holder

ActiveUS7992831B2Accurate weighingAvoid disadvantagesStands/trestlesKitchen equipmentEngineeringMechanical engineering

Owner:FAN EAGLE

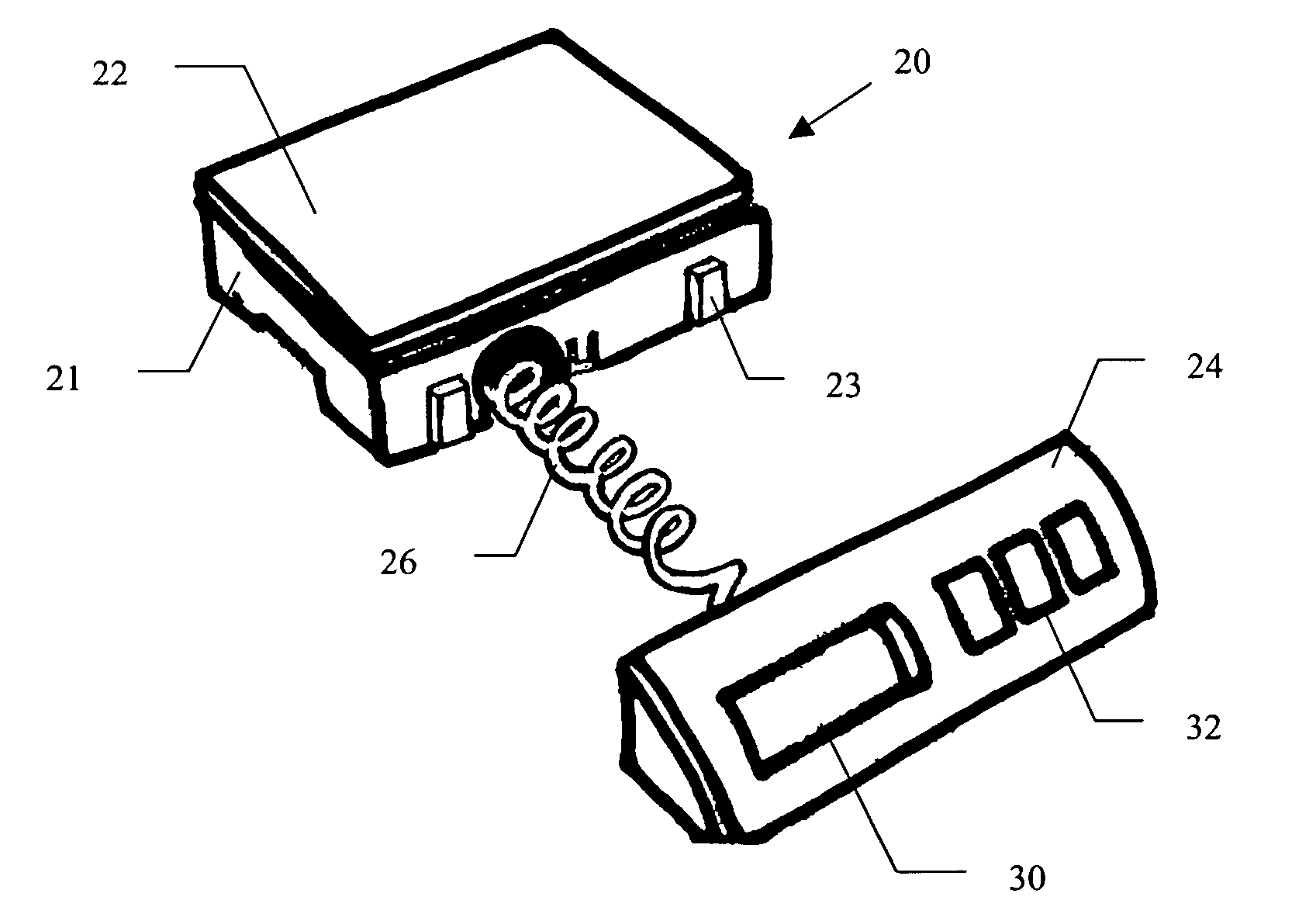

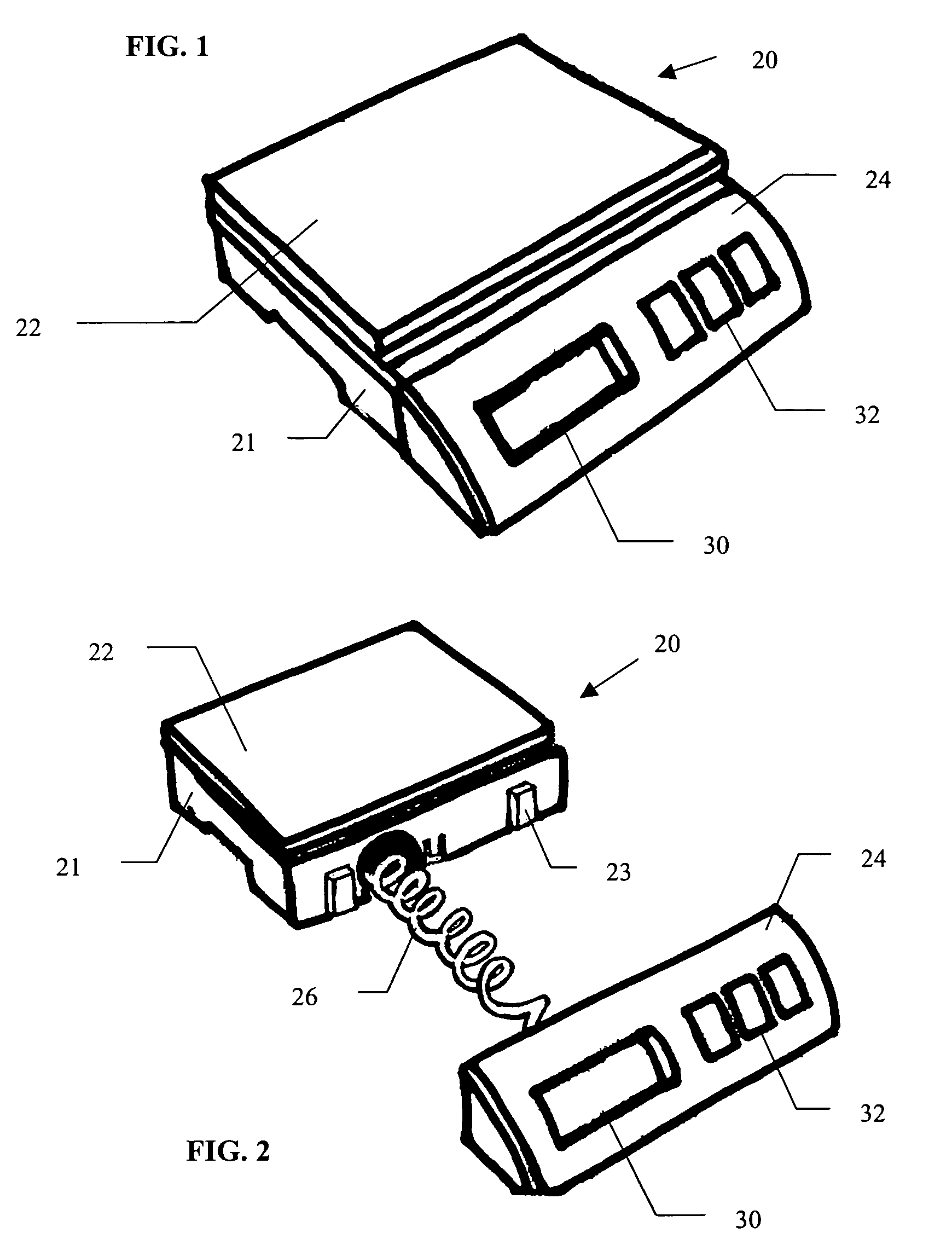

Postal scale with extendable input/output unit

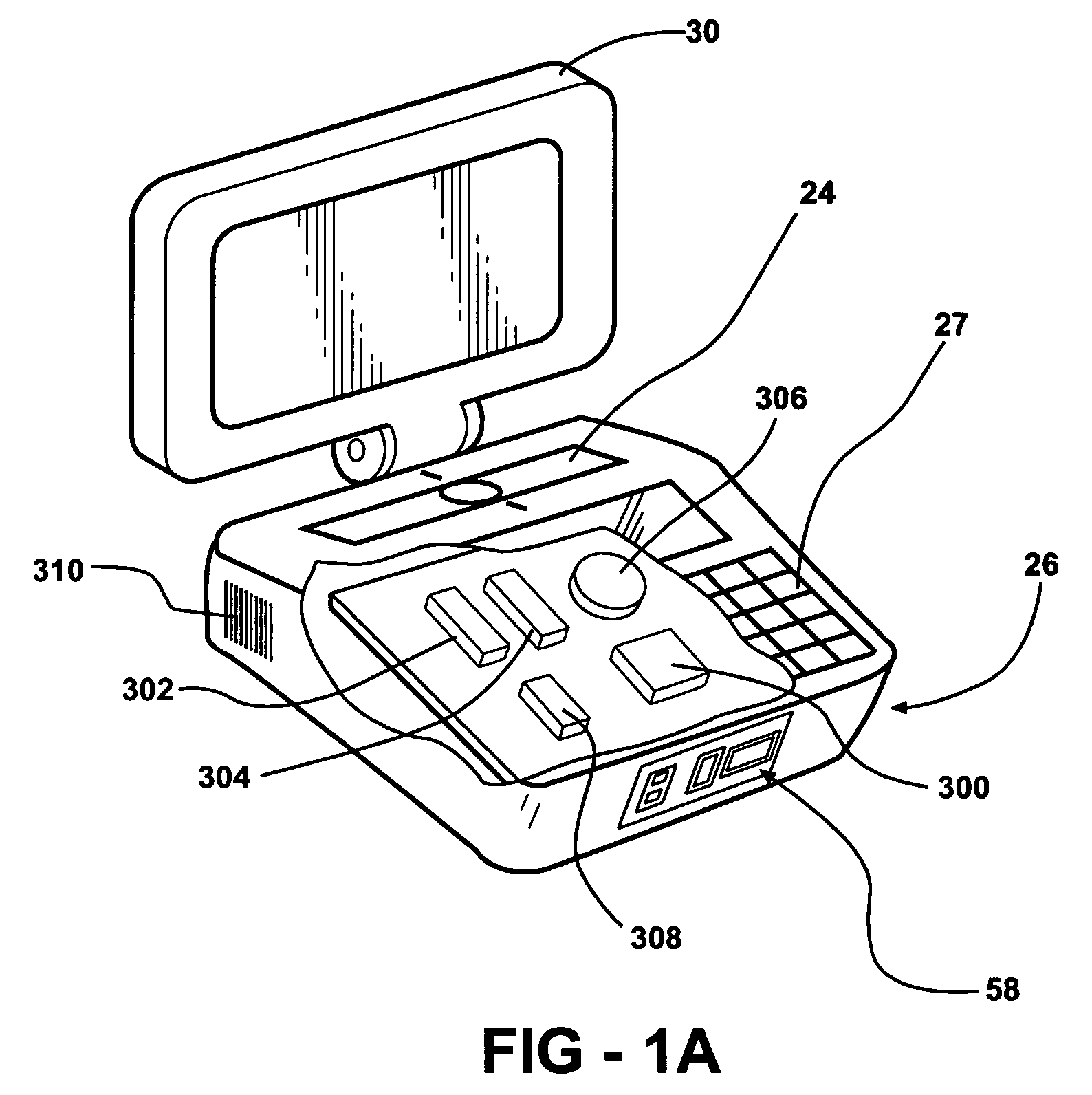

ActiveUS7256357B1Easy to operateAccurate weighingWeighing apparatus detailsSpecial purpose weighing apparatusDisplay deviceEngineering

A postal type scale, such as an electronic scale, capable of weighing a plurality of different size packages is provided. The scale includes a weighing mechanism in its base, a platform for supporting a package thereon in a weighing relationship, and an extendable input / output unit (e.g., weight display and keypad) removeably attached to the scale and extendable therefrom. The input / output unit includes a weight display, such as an LCD display, and an input device such as a keypad or touchscreen or the like. When attached to the scale, weight display and keypad form a compact unitary design. When extended away from the scale, the display and keypad may be located at a position remote from the scale on any plane.

Owner:KESSELMAN JOSHUA D

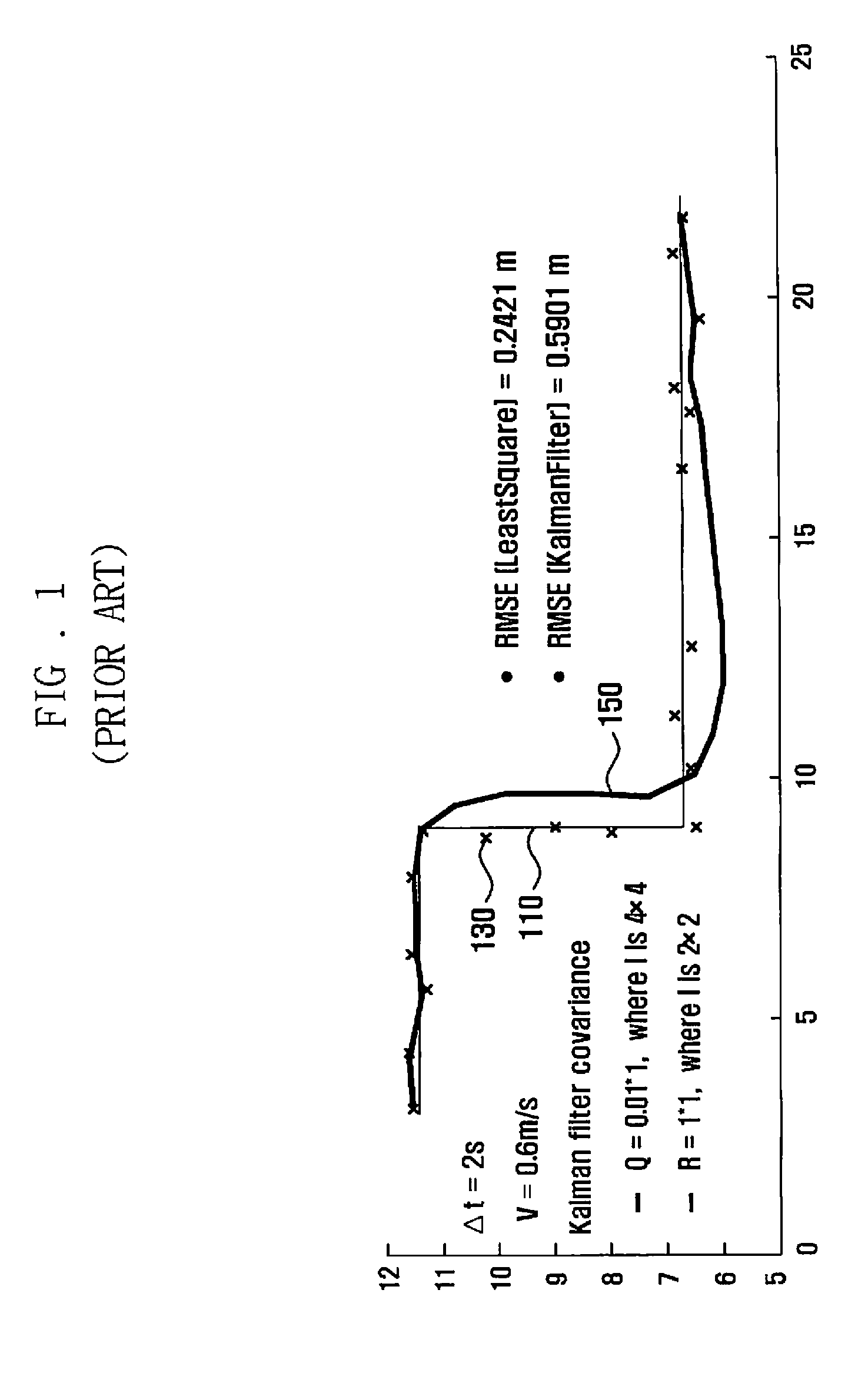

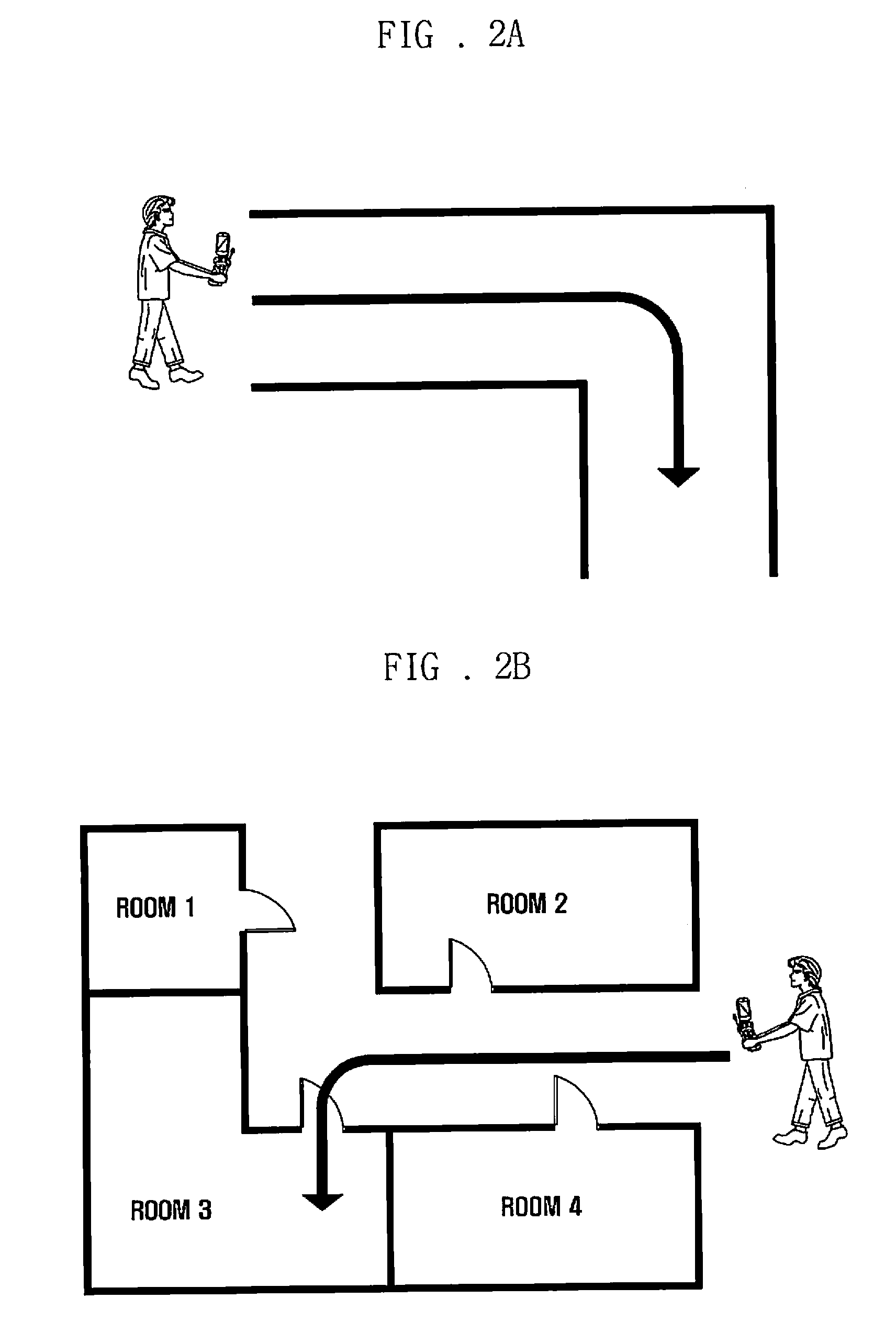

Location measurement method based on predictive filter

ActiveUS20090227266A1Improve measurement accuracyHigh measurement accuracyInstruments for road network navigationDirection finders using radio wavesReal-time computingDevice Sensor

Provided is a location measurement method of a mobile node using a predictive filter is provided for improving the location measurement accuracy of the mobile node. The location measurement method of a mobile node detects change of movement pattern of the mobile node, corrects weights of a location measurement period and a predictive filter depending on the change of movement pattern, and compensates a location of the mobile node using the corrected weights of the location measurement period and predictive filter.

Owner:SAMSUNG ELECTRONICS CO LTD +1

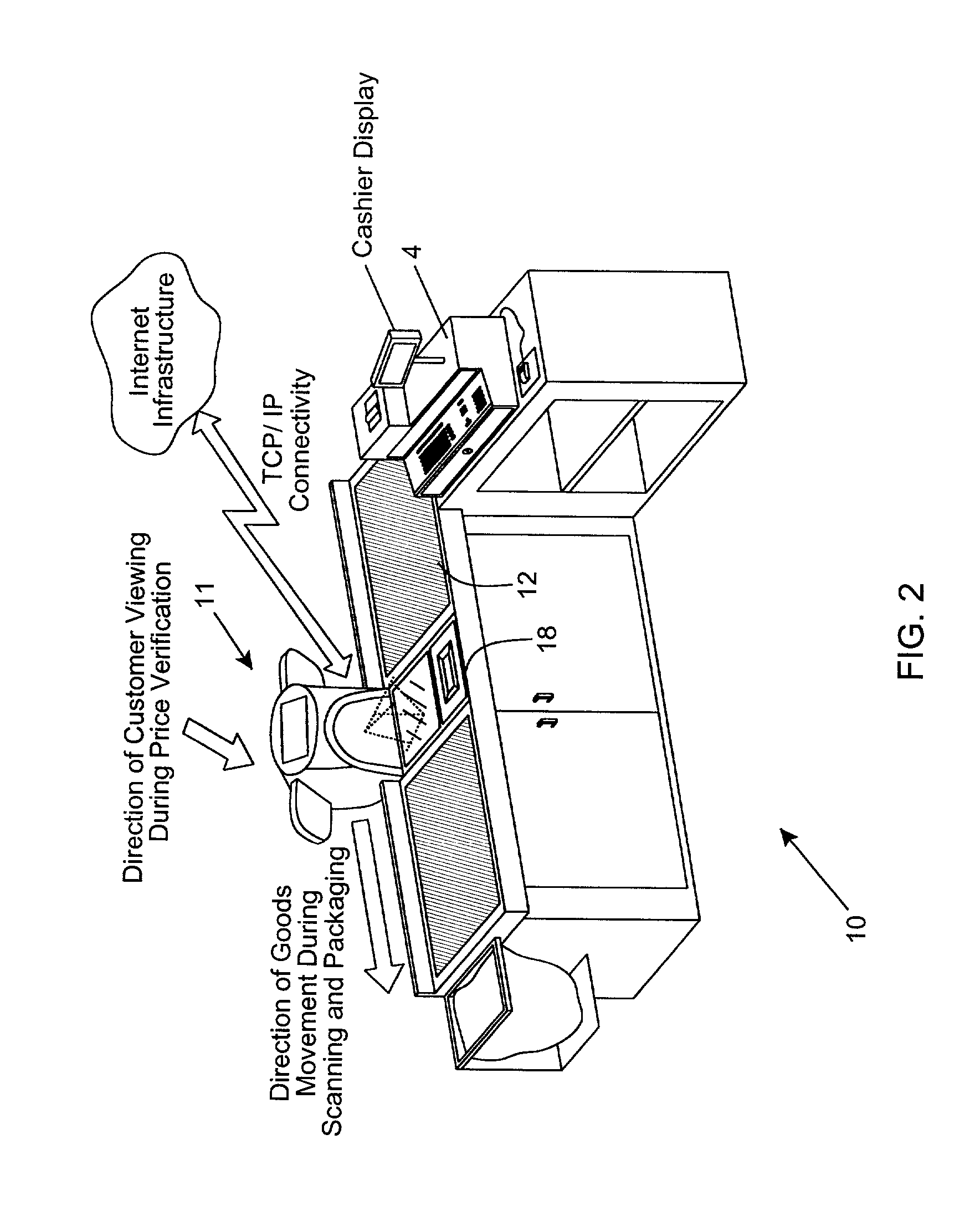

Point of sale (POS) based bar code reading system with integrated internet-enabled customer-kiosk terminal

InactiveUS20030010825A1Accurate weighingFunction is performedTelevision system scanning detailsSoldering apparatusThe InternetBarcode

Novel POS-based bar code symbol reading systems are disclosed having an integrated customer-kiosk terminal. Also disclosed are novel POS-Based Bar Code Reading Cash Register Systems having Integrated Internet-Enabled Customer-Kiosk Terminals.

Owner:SCHMIDT MARK +2

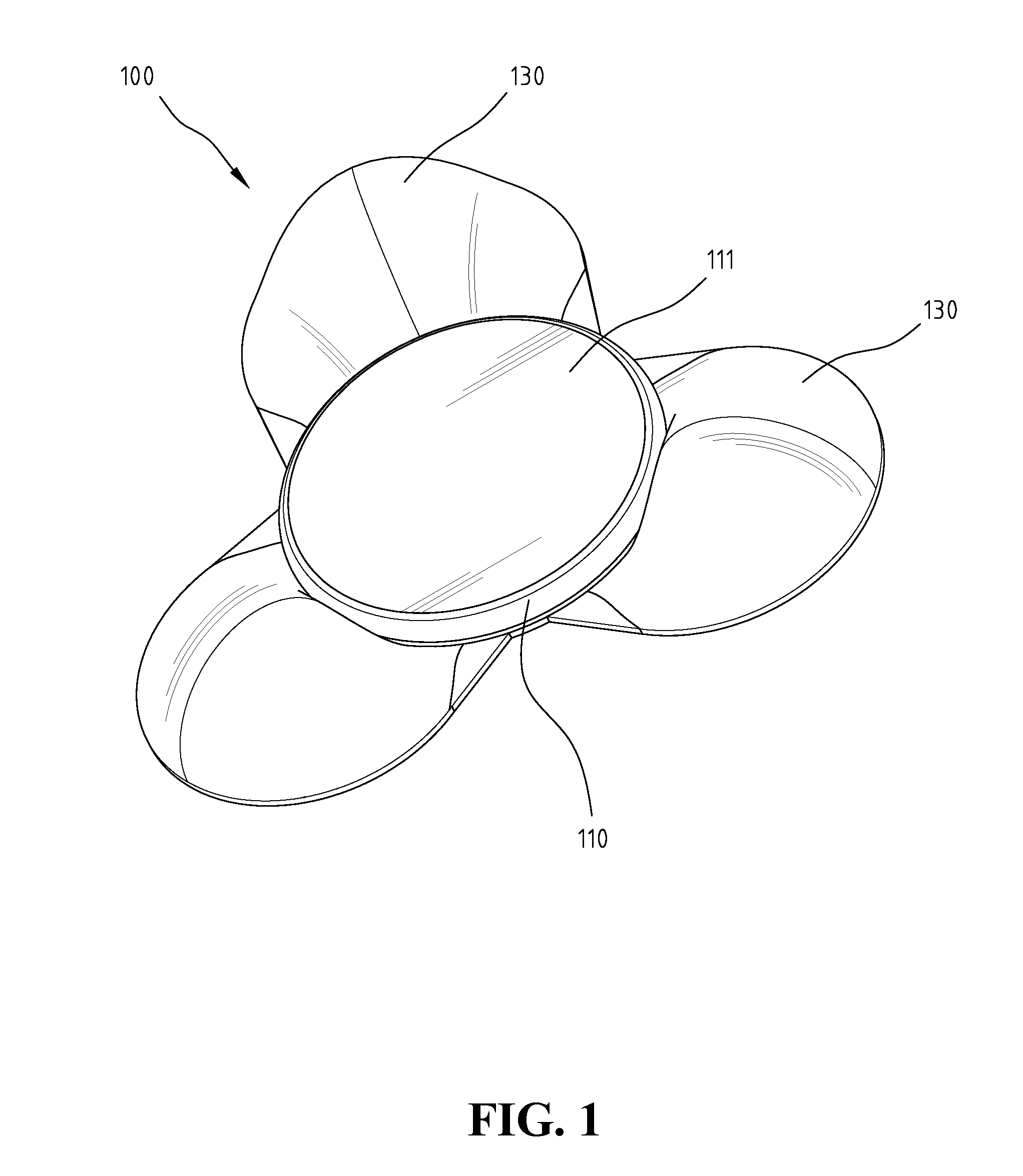

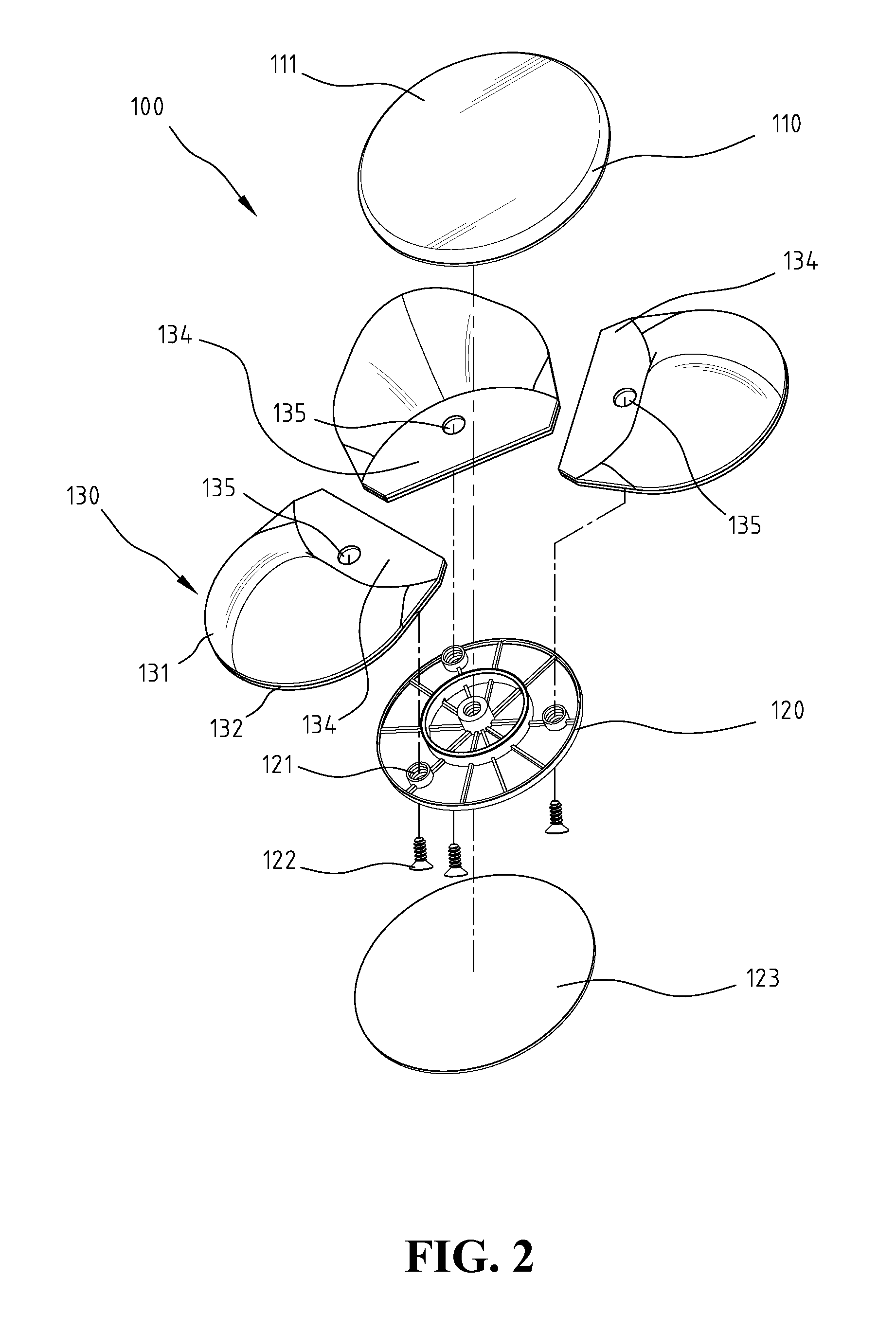

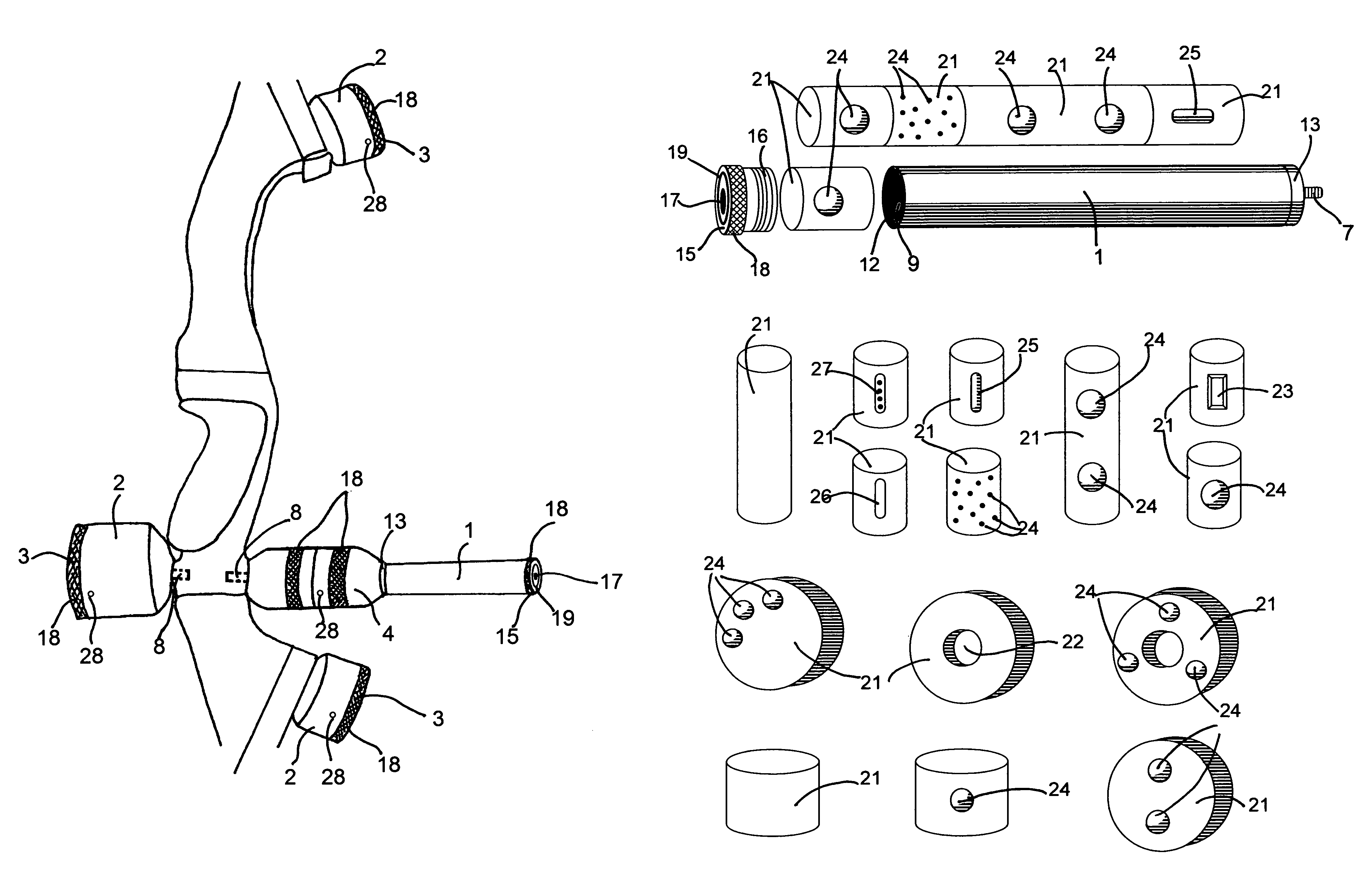

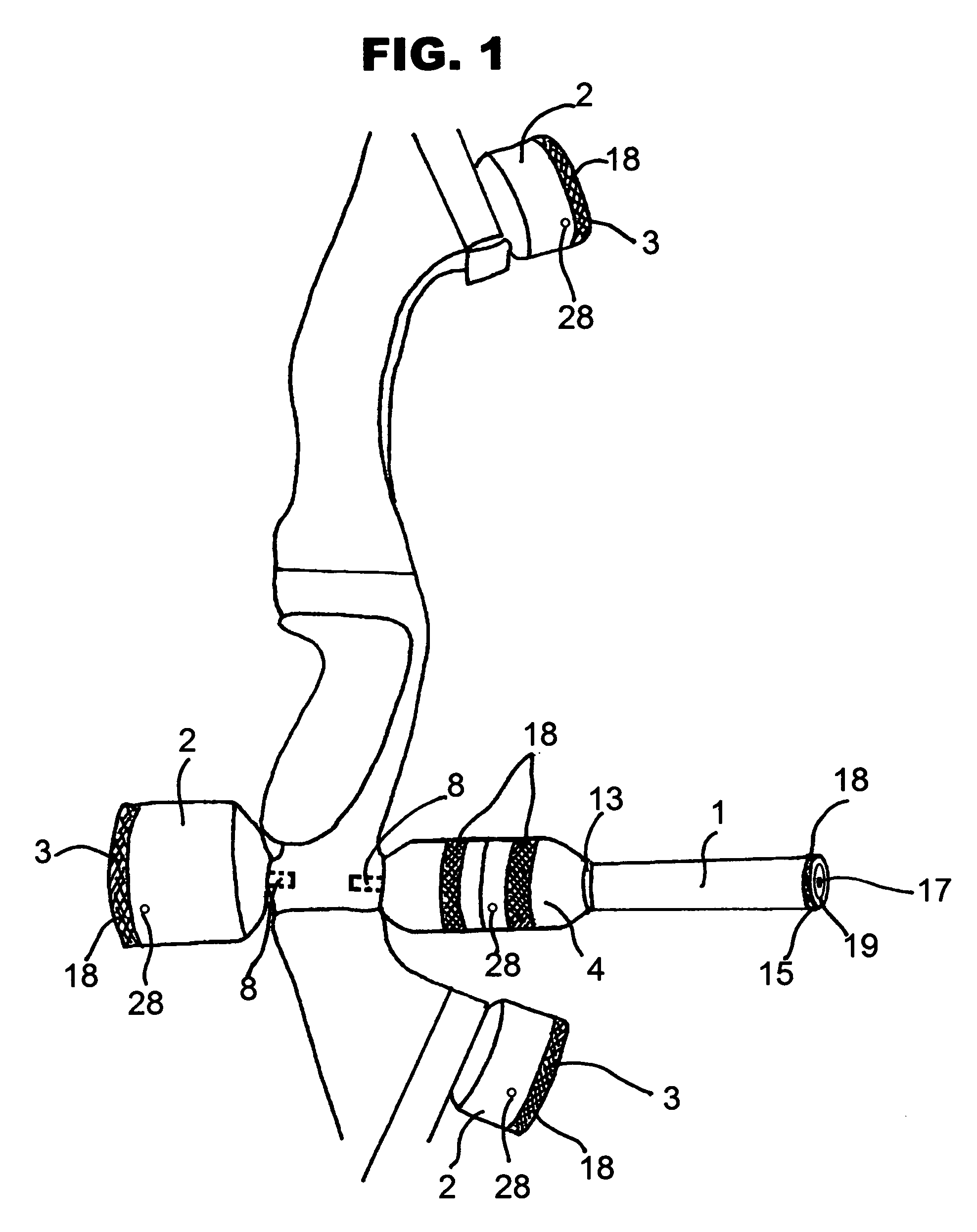

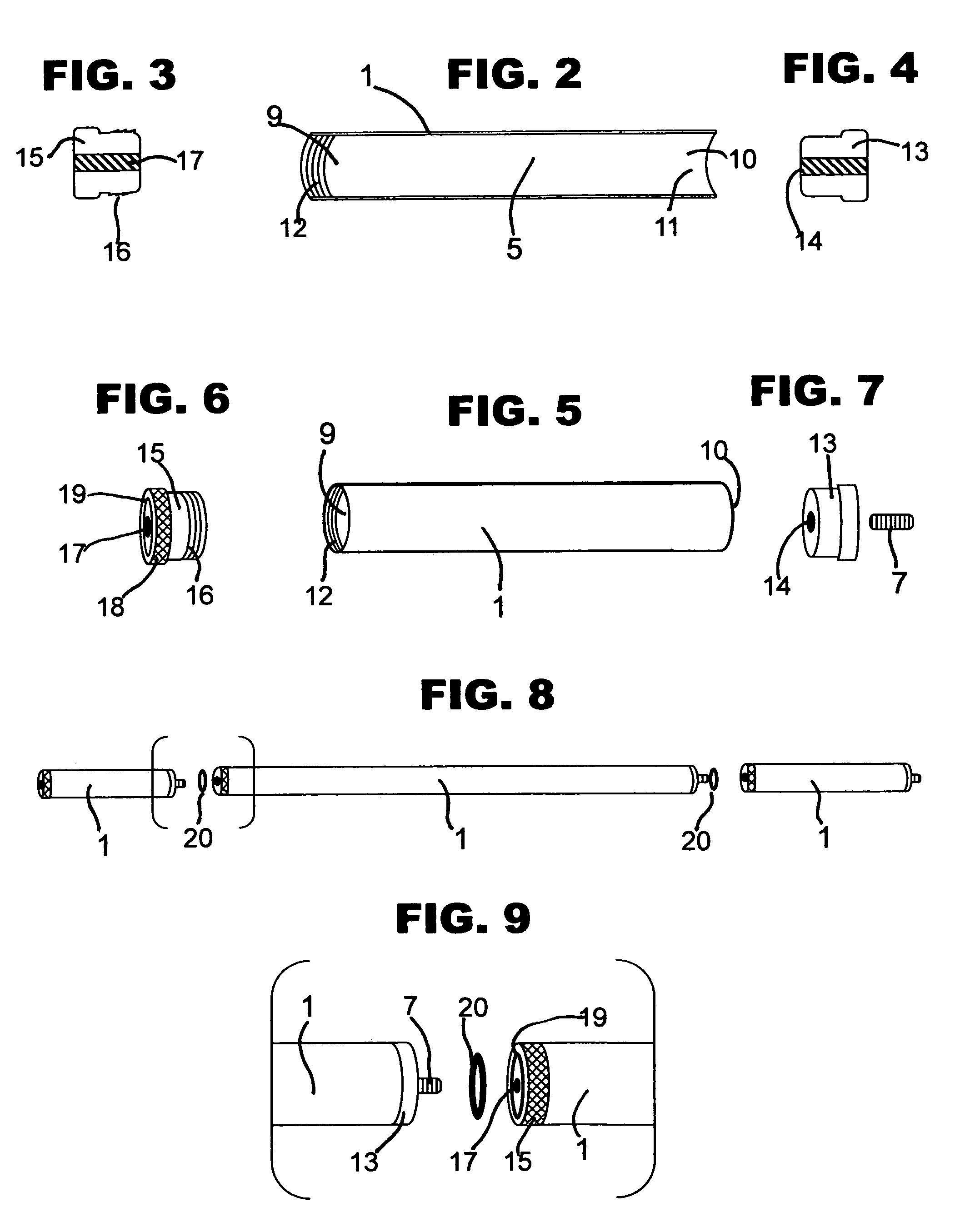

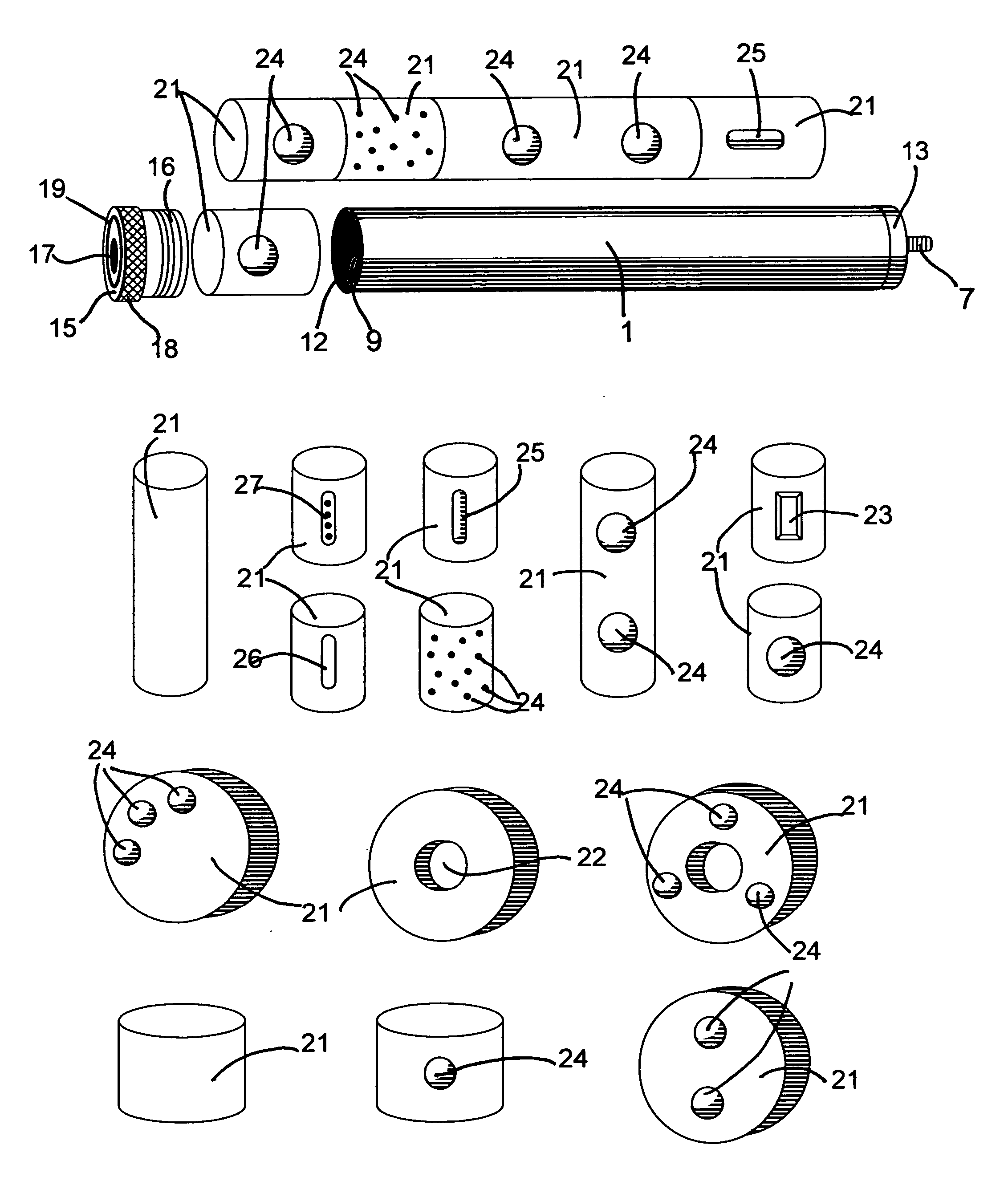

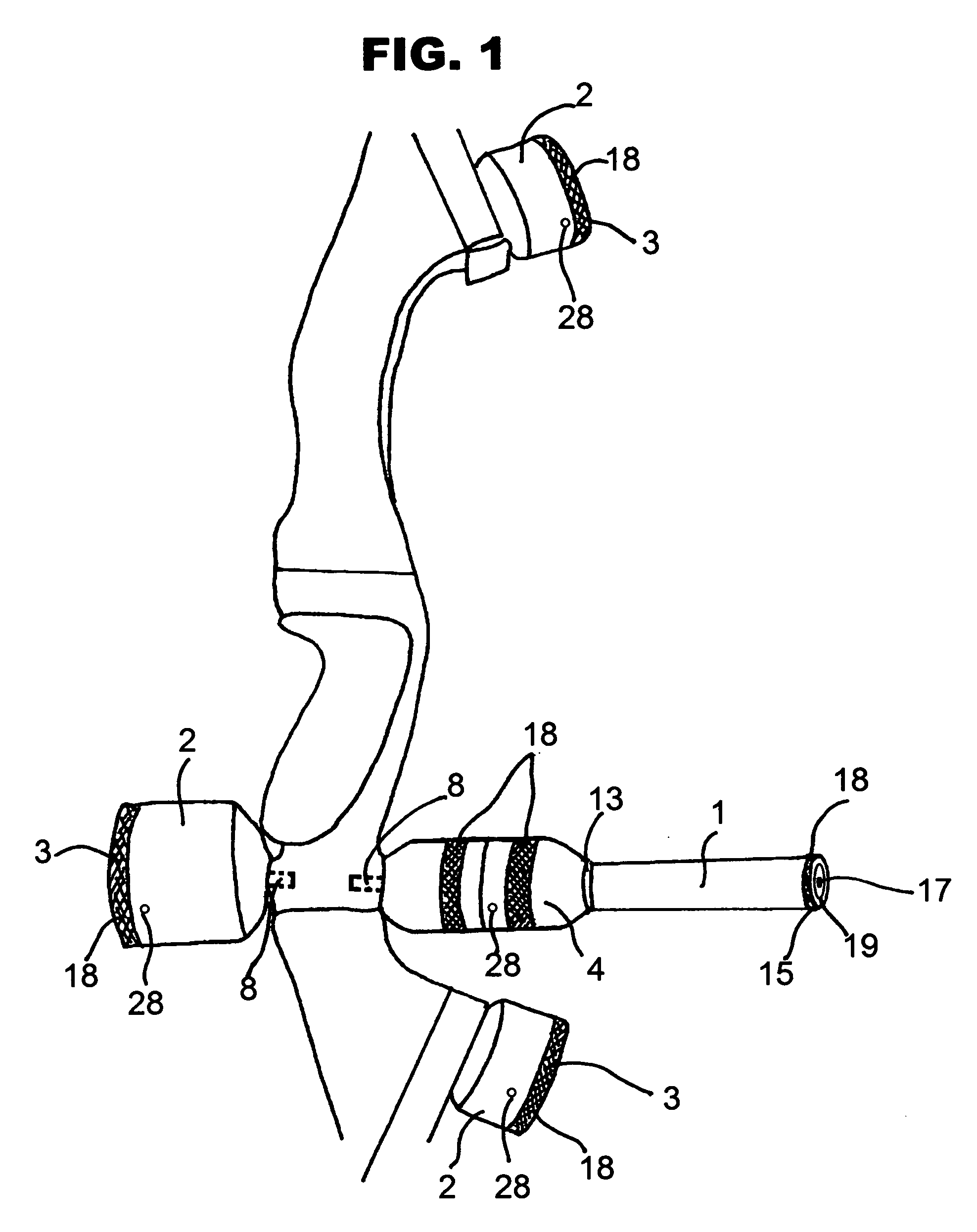

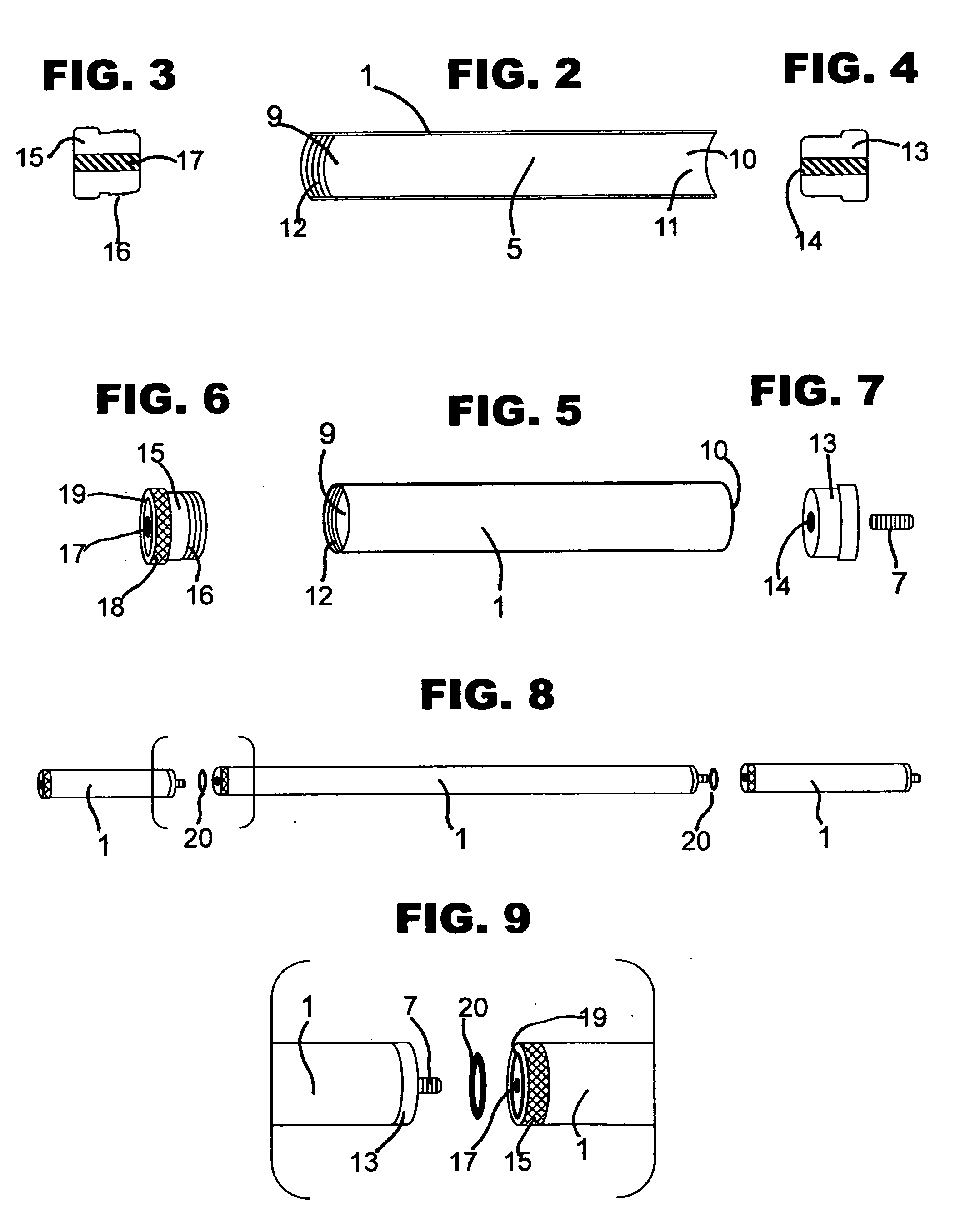

Stabilizer and vibration/noise dampening device that attaches to an archery bow

A stabilizer for balancing / leveling an archery bow, dampening vibration and reducing the noise of releasing the arrow. The stabilizer housing can be easily opened and re-closed securely by the user, who can remove, replace, and change the contents, which includes extra elastomer modules of varying weight to get the exact desired weight, side-to-side and / or front-to-back balance, and / or vibration and sound dampening effect. The contents consist of removable soft, dense elastomer modular units, some with, some with no molded weights inside, which could be steel, lead shot, ball bearings, weight rods, fluid-filled capsules, or any combination of these, that absorb vibration and sound. One or more of these stabilizer units can also be securely placed in a position not normally available, because of the limitations and configuration of most archery stabilizers and / or bow handle / risers. For instance, they can be affixed to the limb bolts and / or the back of the bow handle riser.

Owner:PELLERITE BERNARD M

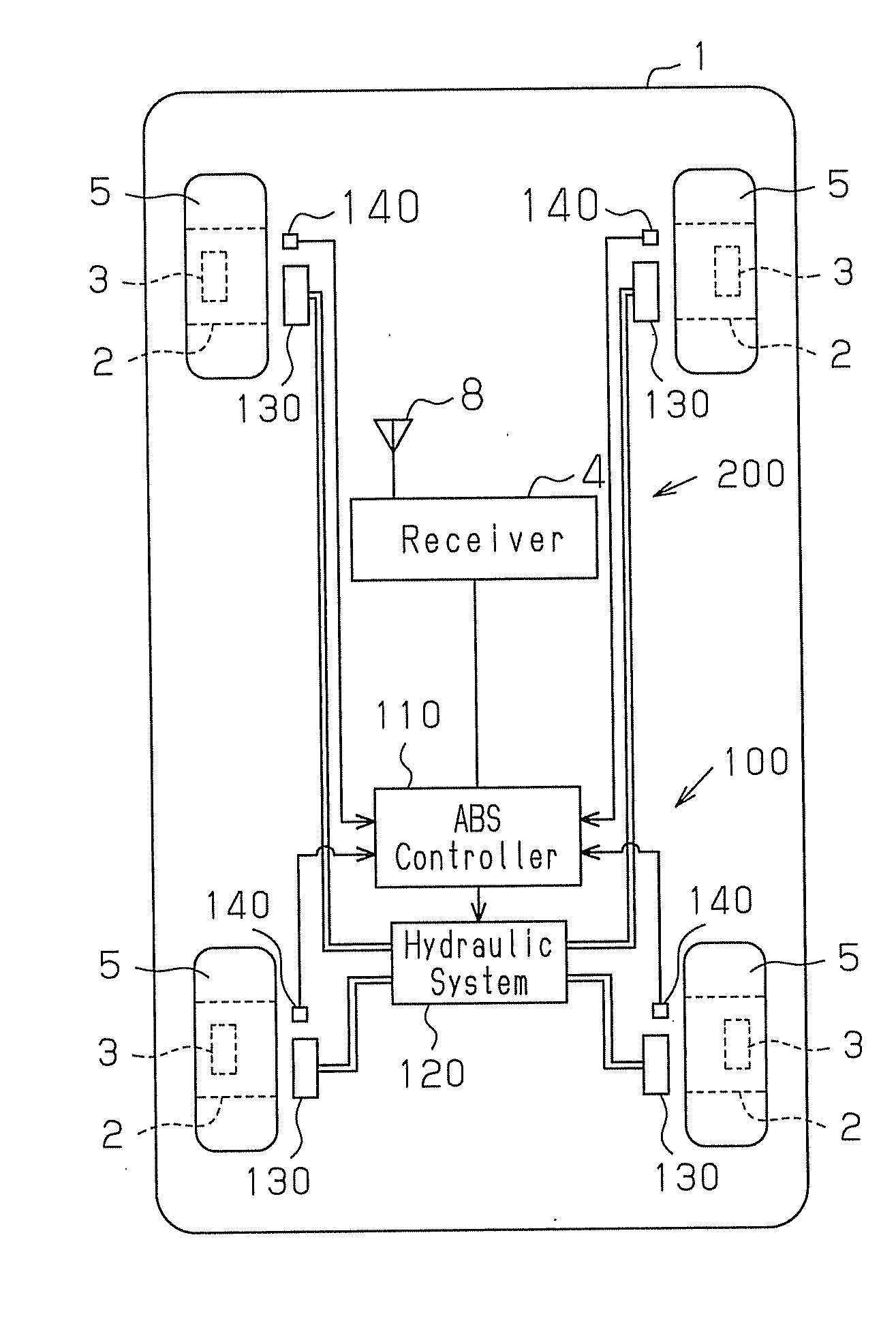

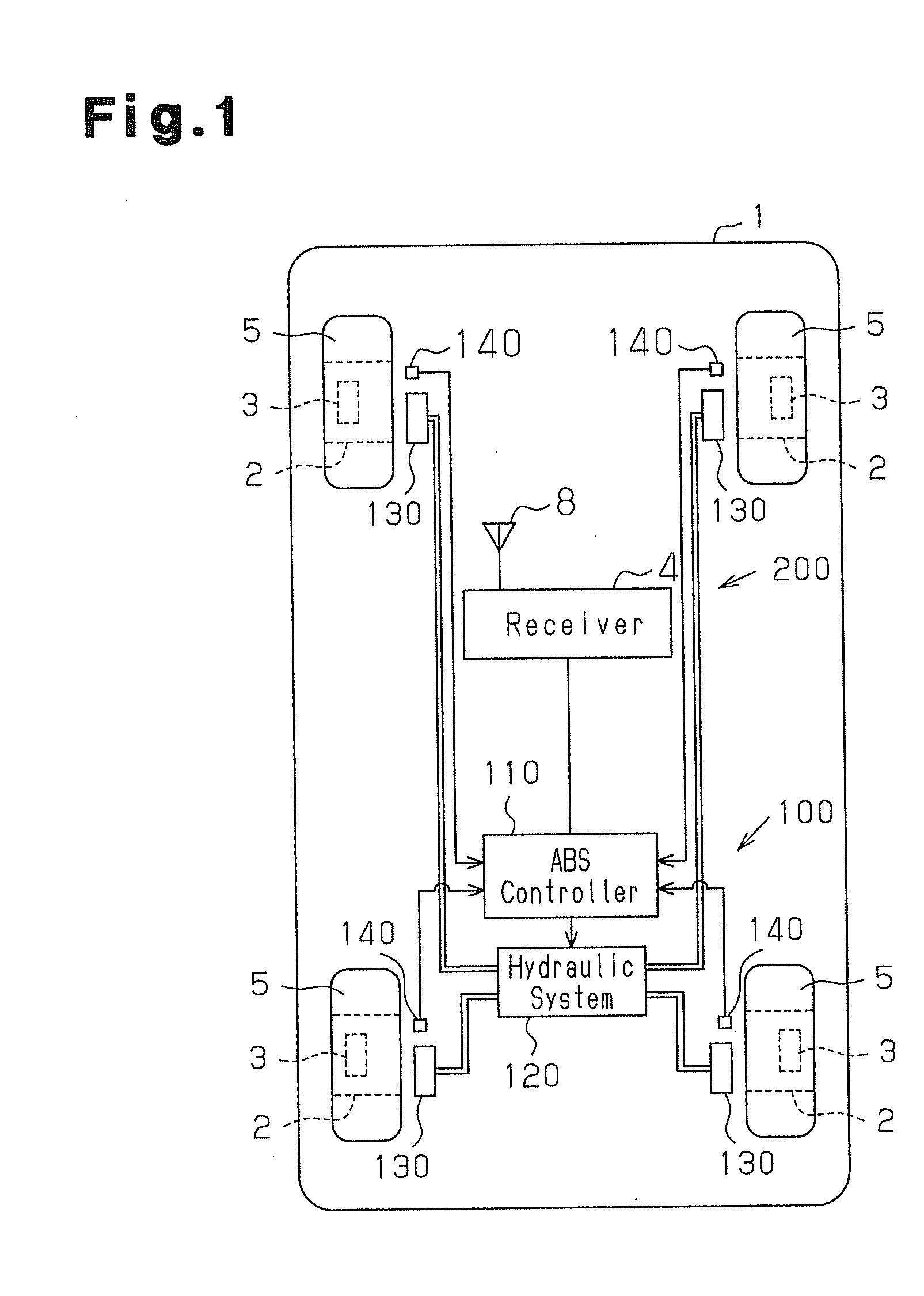

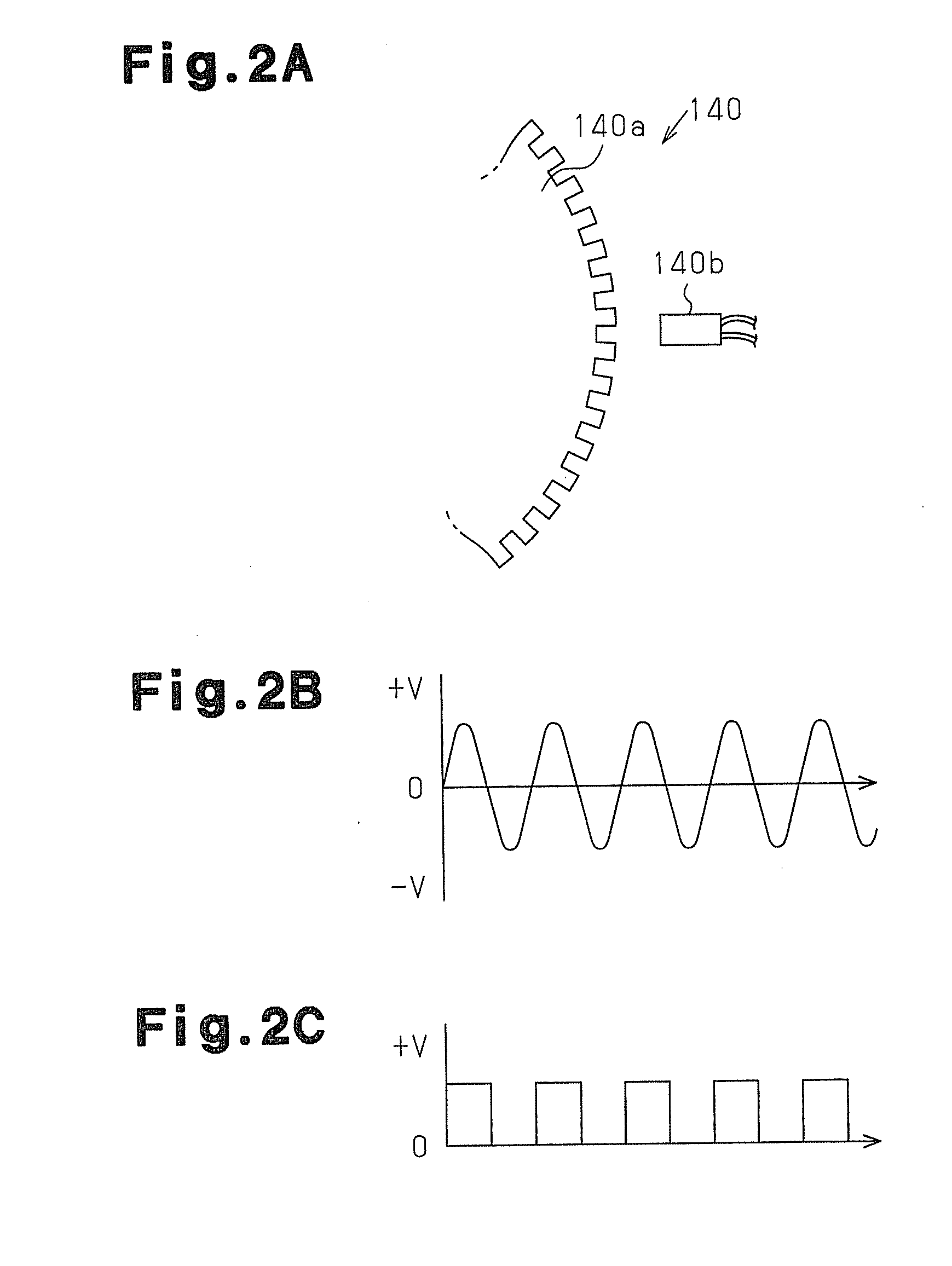

Vehicle load weight detecting apparatus

ActiveUS20100180677A1Simple structureCostDigital data processing detailsAutomatic initiationsAtmospheric pressureRotation sensor

A vehicle includes an ABS, which controls braking force on wheels, and a tire condition monitoring apparatus, which detects the internal air pressure of tires. The dynamic rolling radius of the tires is computed based on signals from rotation sensor units of the ABS. The weight of a load carried by the vehicle is computed based on the dynamic rolling radius of the tires and the internal air pressure of the tires detected by the tire condition monitoring apparatus. When computing the load weight, a load weight determination map, which previously sets the relationship among the internal air pressure of the tires, the dynamic rolling radius of the tires, and the weight of the load carried by the vehicle, is used.

Owner:PACIFIC INDUSTRIAL CO LTD

Point of sale (POS) based bar code reading systems having light-pipe based bar code read indication subsystems integrated therein

InactiveUS20030205620A1Accurate weighingFunction is performedCash registersSensing by electromagnetic radiationProgramming languageLight pipe

Novel POS-based bar code symbol reading systems are disclosed having an integrated customer-kiosk terminal. Also disclosed are novel POS-Based Bar Code Reading Cash Register Systems having Integrated Internet-Enabled Customer-Kiosk Terminals.

Owner:METROLOGIC INSTR

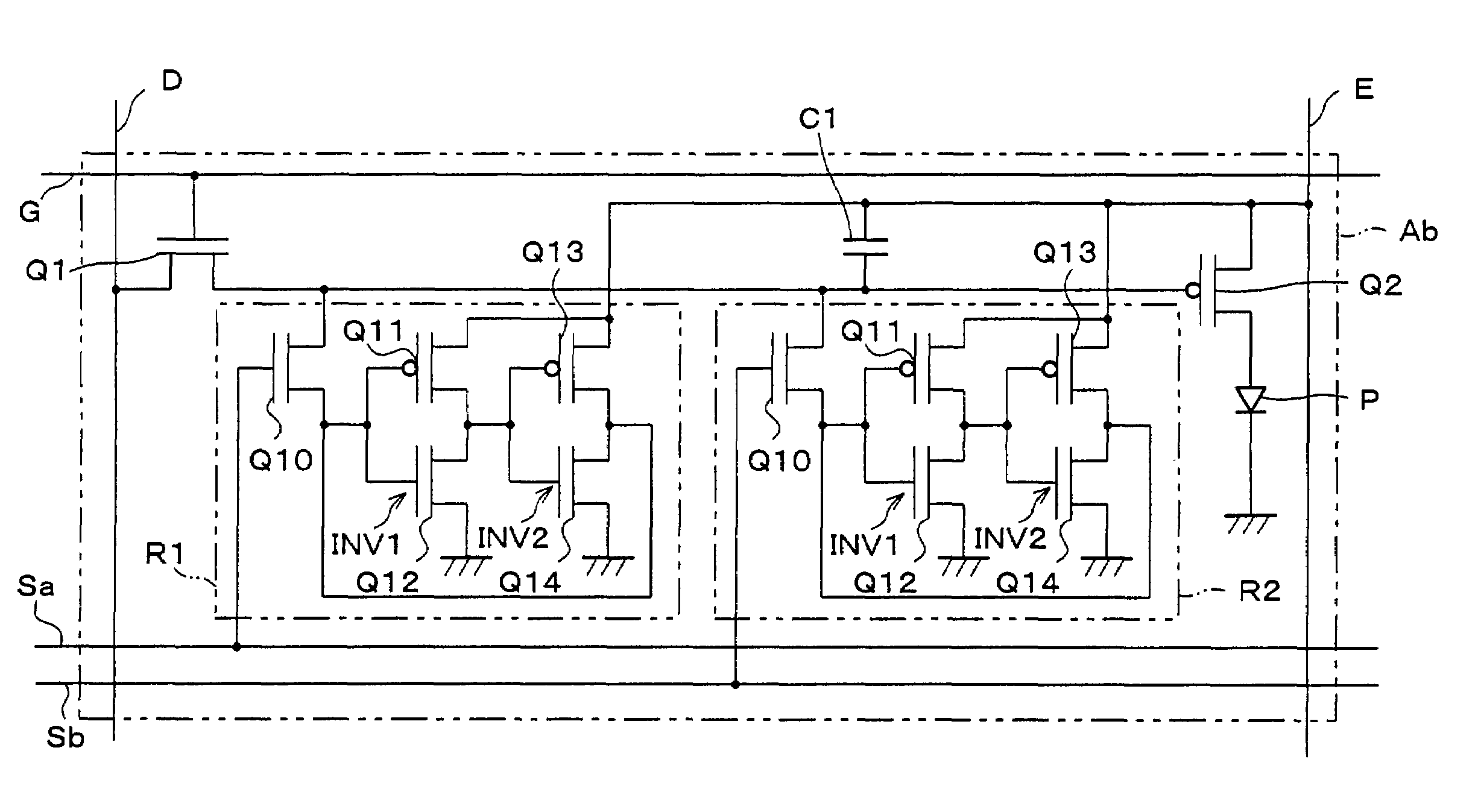

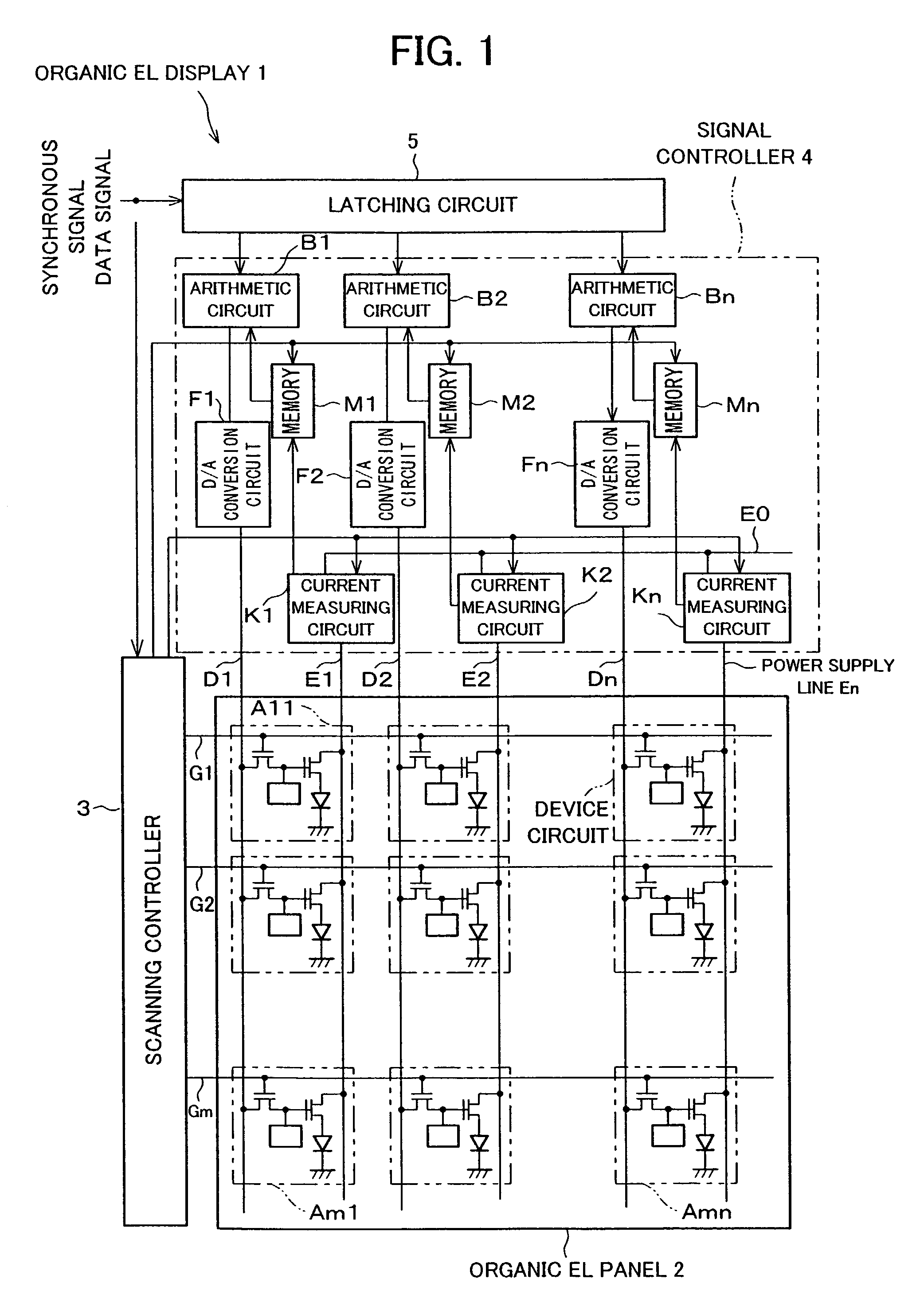

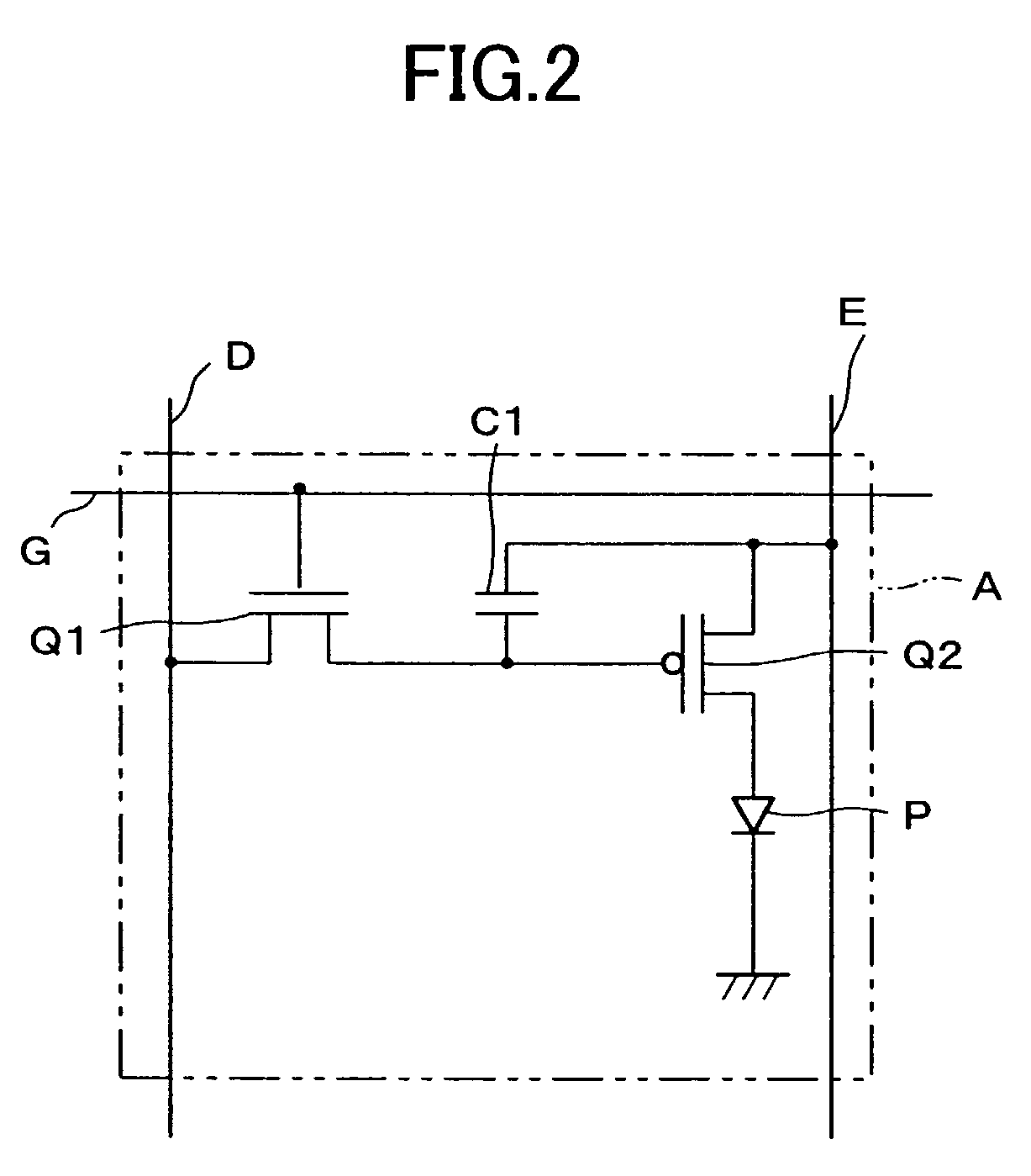

Display apparatus and display method

InactiveUS7009590B2Efficient detectionLarge numerical apertureCathode-ray tube indicatorsInput/output processes for data processingComputer scienceCapacitor

A display apparatus conducting time-division gradation display is provided with: a capacitor for keeping a signal level captured by a first TFT; at least one pixel memory, for keeping the signal level captured by the first TFT; a second TFT matched with the corresponding pixel memory; and a bit selecting line for selectively-driving the second TFT, wherein, when a scanning signal line is selected, the first TFT sets the display signal level is set in the capacitor via the first TFT and the second TFT is selectively driven so that the display signal level is set in the at least one pixel memory, whereas the TFT is selectively driven so that a display signal level which has been displayed is switched to the display signal level supplied from the at least one pixel memory.

Owner:SHARP KK

Stabilizer and vibration/noise dampening device that attaches to an archery bow

The contents of stabilizers for archery bows in the past have been a non-removable material that is permanently sealed inside the stabilizer housing unit by the manufacturer. Most stabilizers are made from tubular aluminum or other lightweight materials. The inside contents of the tubular stabilizers vary, such as fluid, granular steel, granular rubber, lead or solid elastomer, none of which can be moved around, altered or removed or added to by the archer. A unique feature of this device is that the housing of the stabilizer can be easily opened and re-closed securely by the archer, enabling the archer to remove, replace, adjust, change, add to or subtract from the contents, in order to get the exact desired weight, balance and / or vibration and sound dampening effect. An additional unique feature of this design is that the contents can consist of weighted material inside removable soft elastomer modular units of various sizes and / or mass weights. The weighted material can be made of steel or lead shot, ball bearings, weight rods, capsules filled with fluid, or fluid plus weighted pellets, or any combination of these weighted materials. Any or all of these can be suspended and / or sealed or molded inside the soft elastomer modules. This weighted material and / or fluid suspended in the elastomer absorbs vibration and sound, and the vibration and sound then is dissipated and absorbed further by the elastomer, then by the stabilizer housing itself. The archer can use different sized and / or weighted sections or internal modules, packets, that fit and / or stack snugly inside the housing of the stabilizer. The archer can change them easily, at will, to get the desired weight, balance and / or amount of vibration and sound dampening. The size and weight of these removable internal vibration dampening modules are only limited by the inside volume of the hollow chamber of the stabilizer housing that attaches to the bow. Another unique feature of this design is that two or more stabilizer housing of the same or varying sizes and shapes can be joined together, with or without an O-ring compressed between the stabilizer housings, to make one longer modular stabilizer with adjustable internal variable weight components. Also, a system of offset brackets and / or V-bars can be used to secure one or more of these stabilizer units in a position not normally available because of the limitations and configuration of a particular archery bow handle / riser.

Owner:PELLERITE BERNARD M

Honeycombed porous ceramic having high thermal conductivity and ultralow expansion coefficient

ActiveCN103145439AGood coating effectImprove mechanical propertiesCeramicwareCeramic moldingCrystal orientation

A honeycombed porous ceramic having a high thermal conductivity and an ultralow expansion coefficient relates to the technical field of the silicate industry. The ceramic having a low even negative thermal expansion coefficient and a high thermal conductivity is obtained through treating a rare earth mixture, potassium phosphotungstate, zirconium oxide and amorphous quartz particles as a sintering aid, and expansion coefficient and thermal conductivity adjustment agents, and the ceramic has a high-orientation sheet iolite structure and has a good catalyst coating performance and good mechanical strengths; and ethylene oxide having different molecular weights are adopted as a ceramic molding binder, rapeseed oil or peanut oil is treated as a primary molding lubrication agent, a paste goes through a high-pressure extruder orientation extruding channel, a crystal orientation carding die and a honeycombed porous die to obtain a green body having high-orientation arranged crystals, and a special sintering curve is adopted to obtain the ceramic. The above whole ceramic preparation process flow and the above formula are economic, stable and environmentally-friendly.

Owner:安徽中鼎美达环保科技有限公司

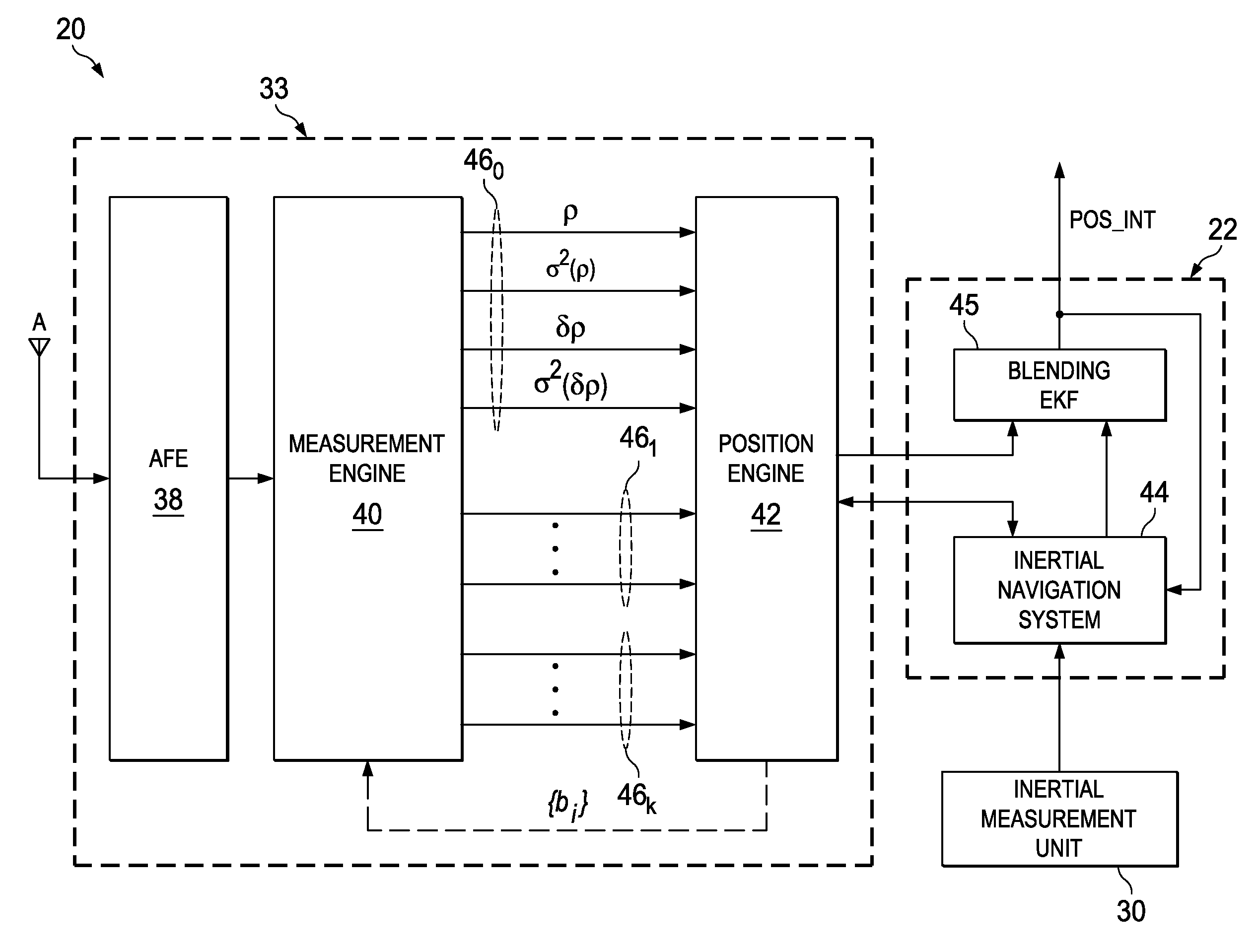

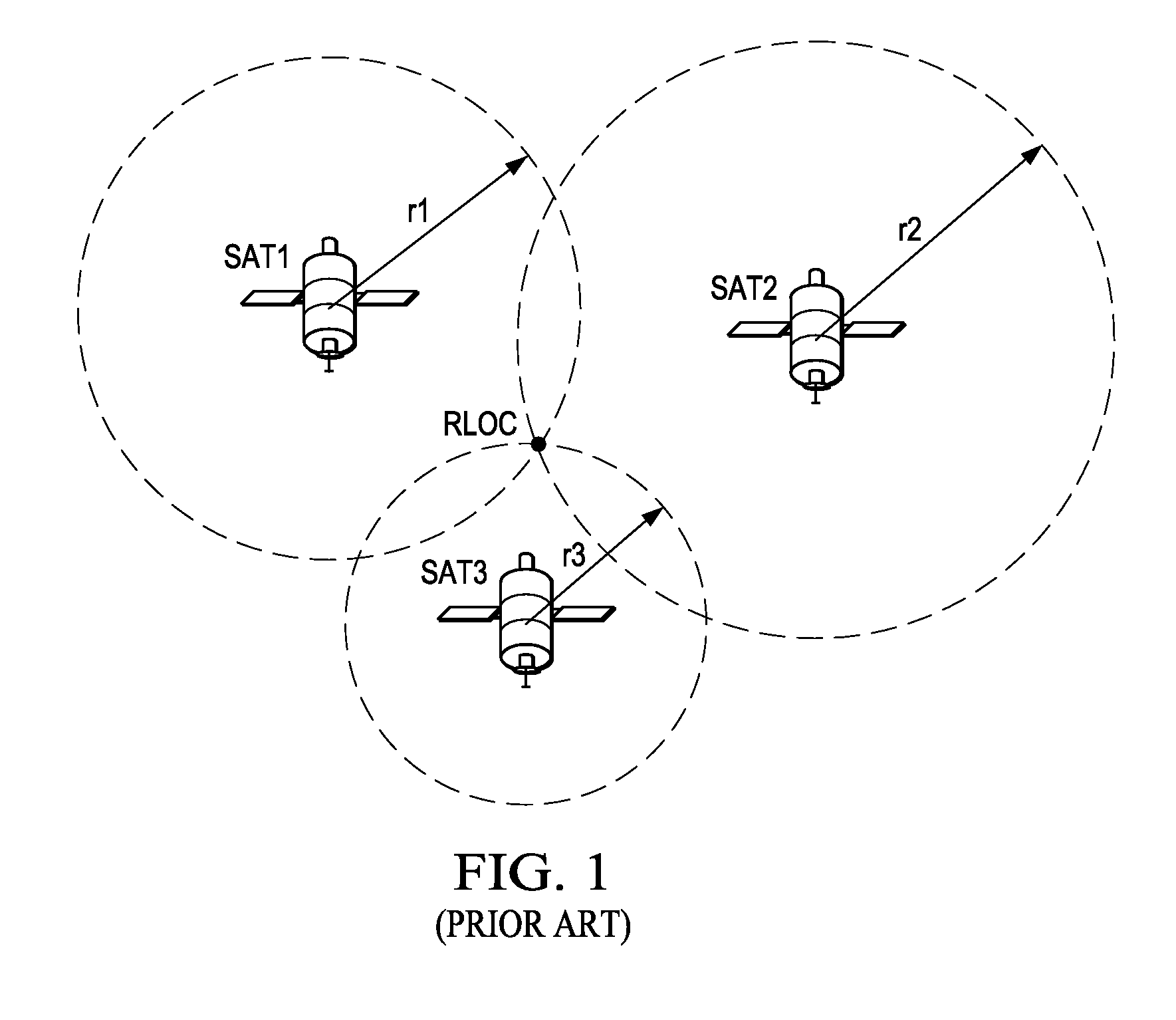

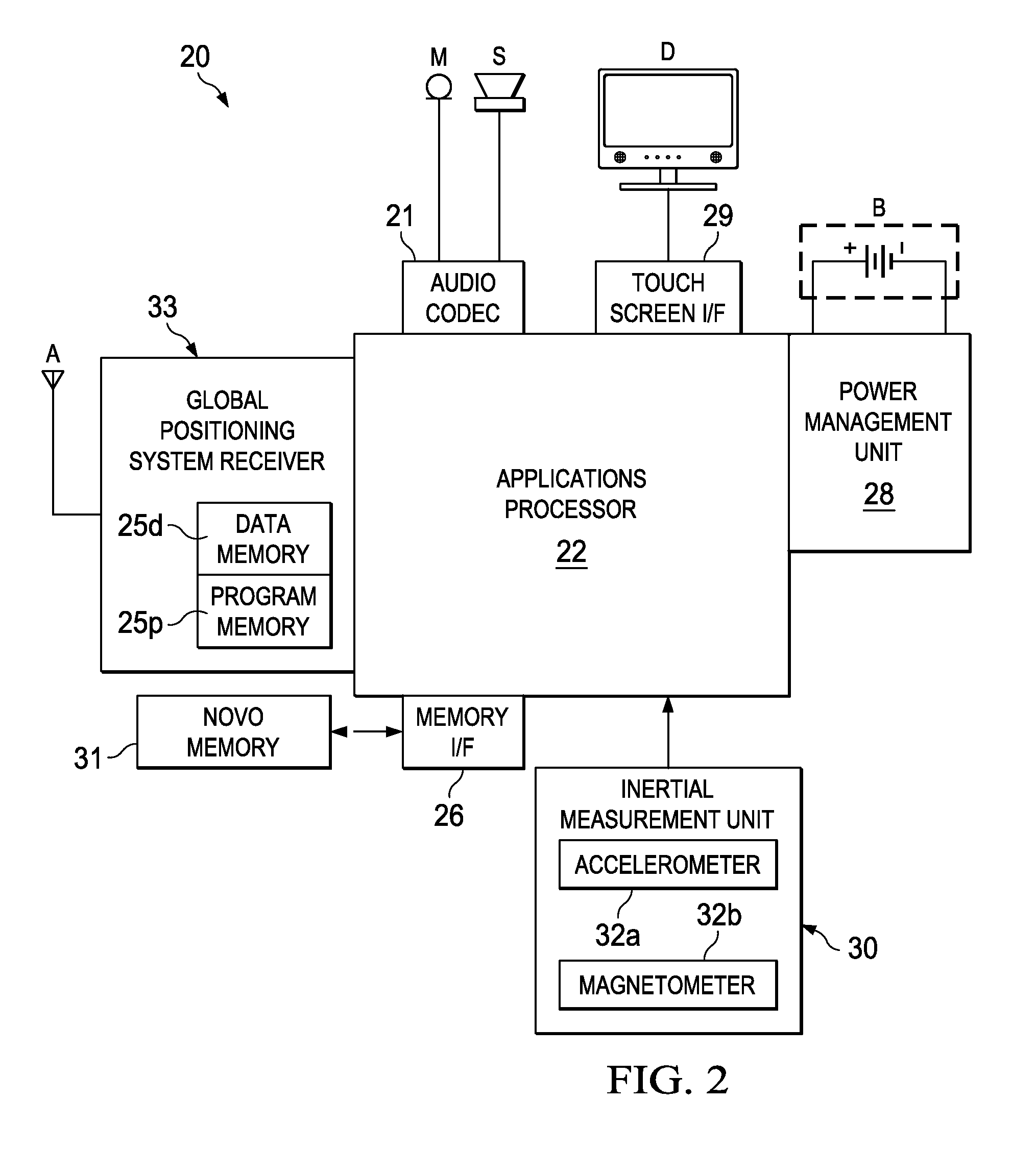

Position and Velocity Uncertainty Metrics in GNSS Receivers

ActiveUS20110156954A1Accurate estimateAccurate weighingSatellite radio beaconingNavigation systemNavigation function

A GNSS navigation system and navigation method for determining user position, user velocity, and improved uncertainty metrics for position and velocity. A measurement engine in an applications processor of the system determines pseudorange and delta range values over each time period for each received satellite signal, and also determines measurement noise variances for both pseudorange and delta range for the individual signals. The satellite-specific pseudorange and delta range measurement variances are used to determine the position and velocity uncertainties by a position engine, either by way of a least-squares linearization or by way of an enhanced Kalman filter. The uncertainties may be communicated to the system user, or used in generating an integrated position and velocity result from both the GNSS navigation function and an inertial navigation system result.

Owner:TEXAS INSTR INC

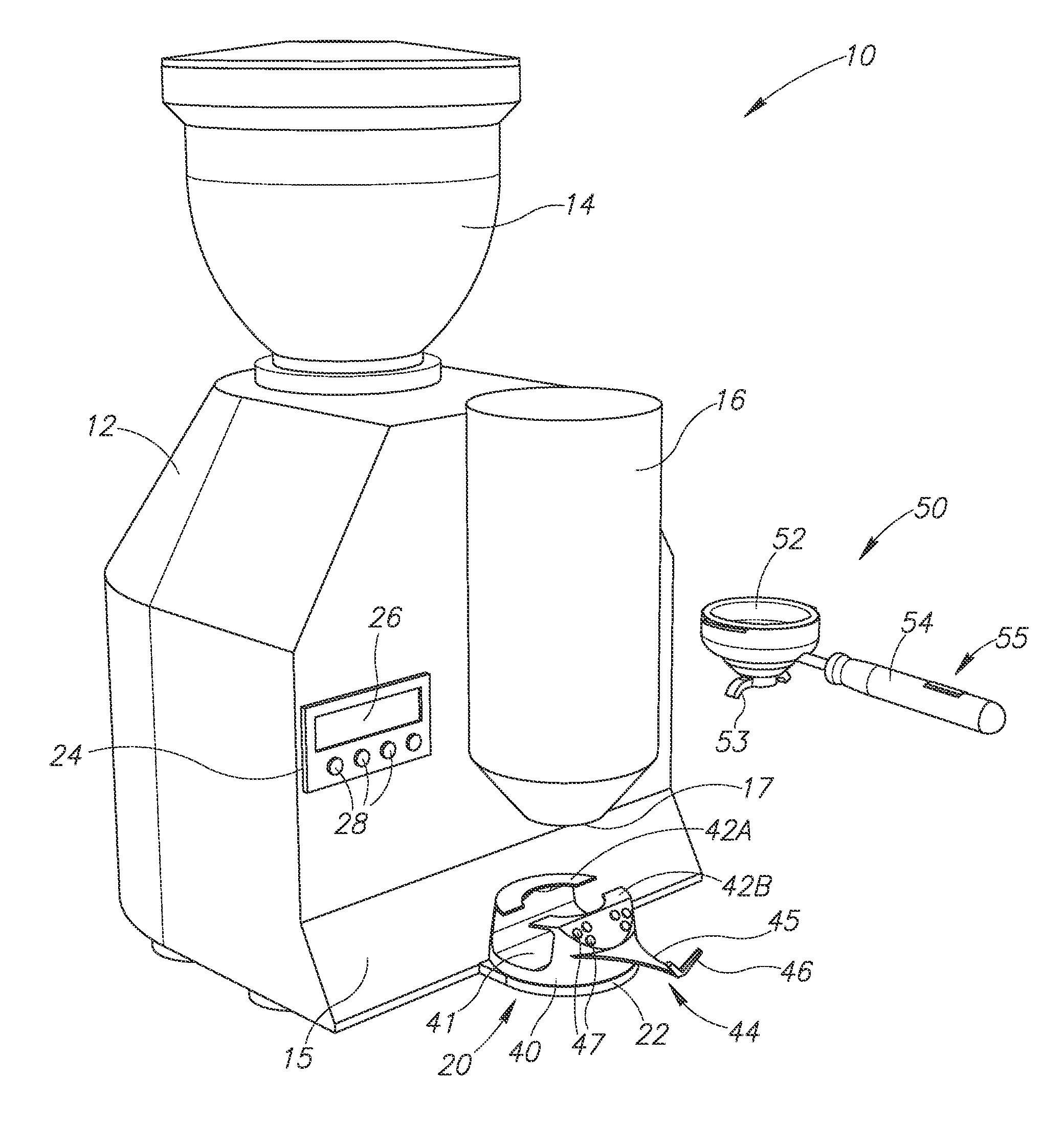

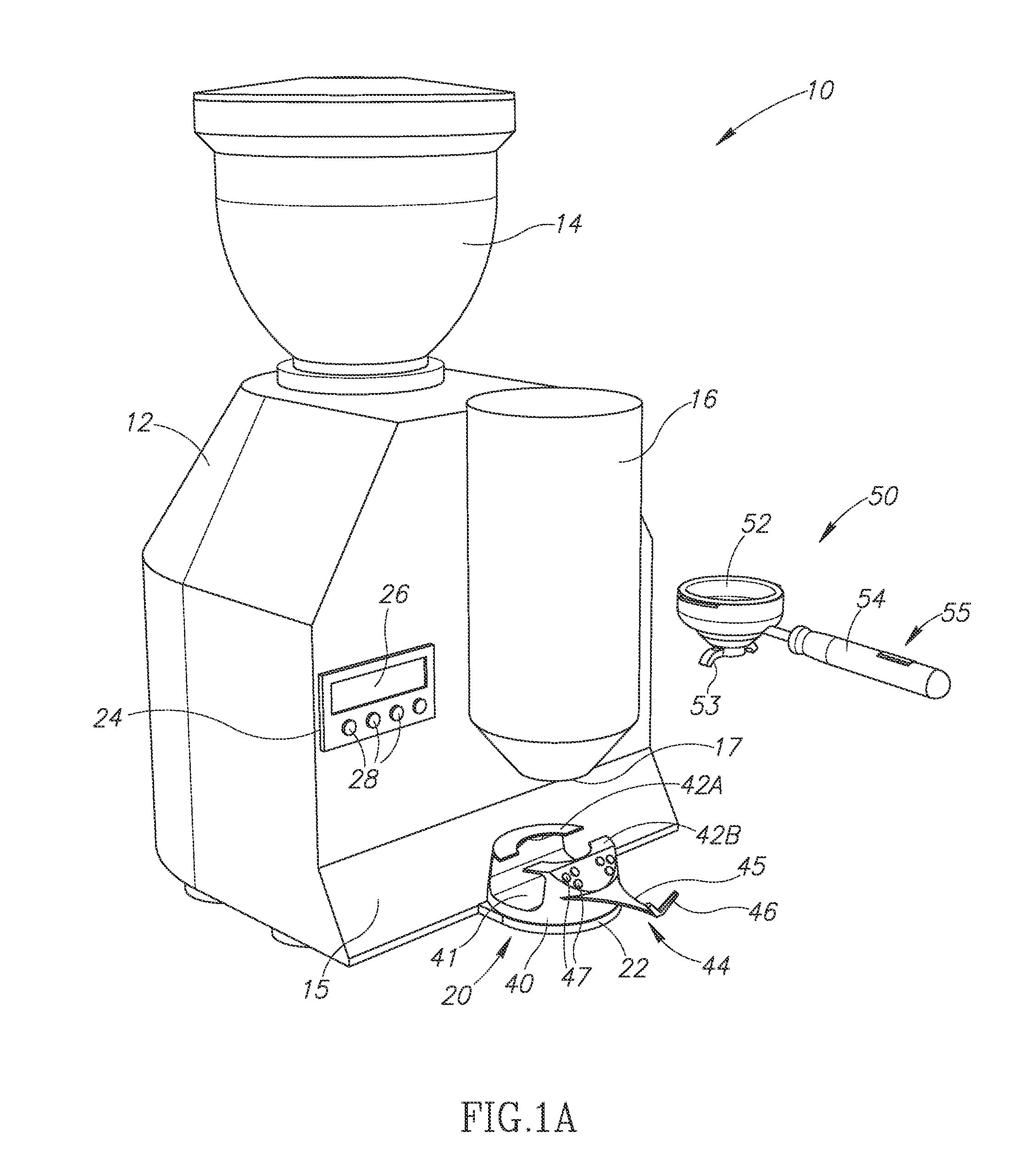

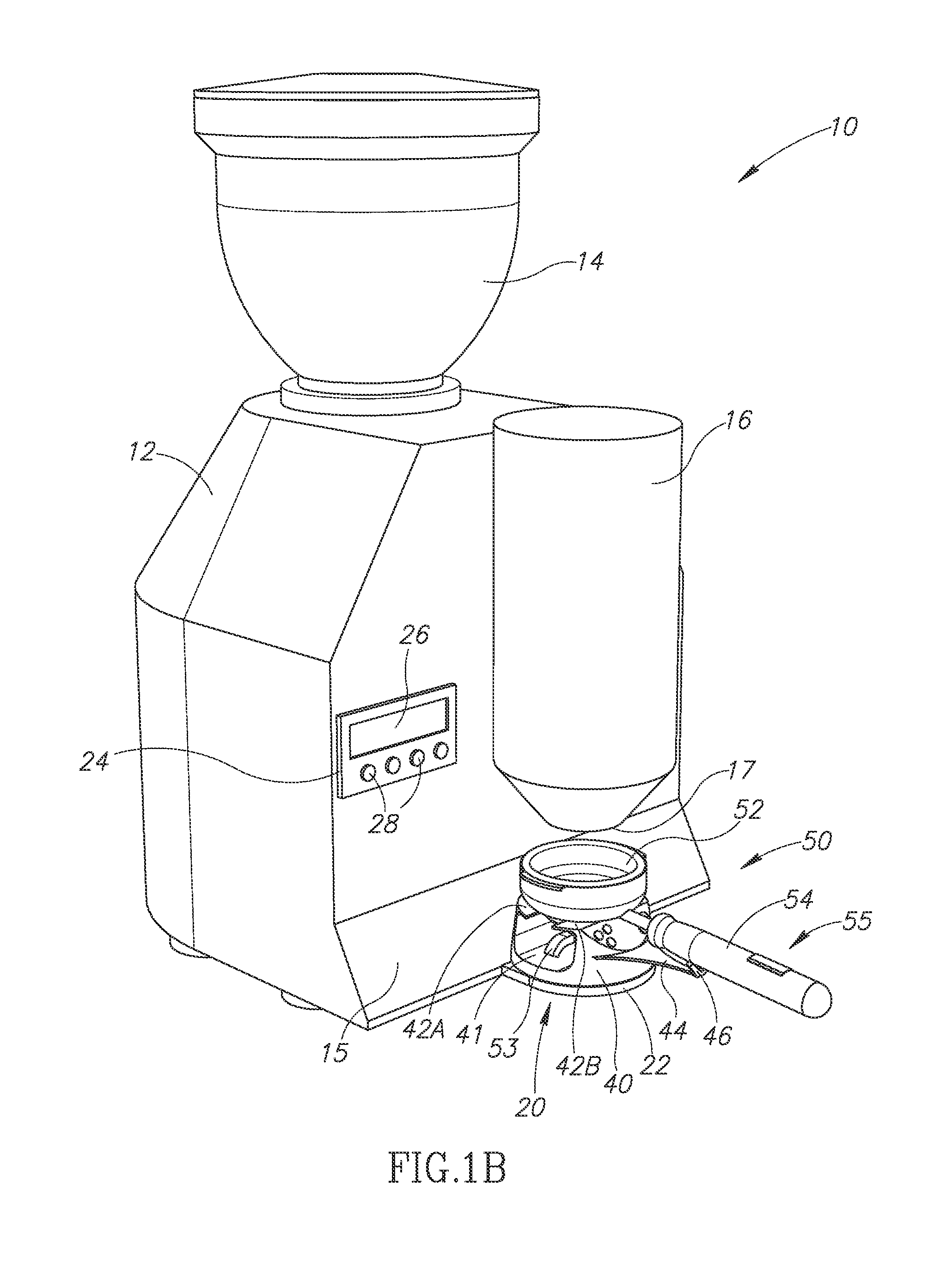

Apparatus for measurement of coffee

InactiveUS20140123857A1Accurate weighingCoffee millsSpice millsMeasurement deviceMechanical engineering

A coffee grinding apparatus (10) and related methods for precisely measuring the weight of ground coffee to be used for preparing espresso shots and espresso-based beverages. The coffee grinding apparatus (10) includes a coffee grinding mechanism (30) that is operative to grind whole coffee beans into ground coffee. The coffee grinding mechanism (30) also includes a portafilter platform (40) positioned directly below an output portion (16) of the coffee grinding apparatus (10). The portafilter platform (40) is coupled to a weight measurement device (20) so the net weight of the ground coffee in a basket (52) of a portafilter (50) resting on the portafilter platform may be measured. The coffee grinding apparatus (10) may be configured to automatically stop the coffee grinding mechanism (30) when a desired weight of ground coffee has been dispensed into the basket (52) so that a precise weight of coffee may be dispensed.

Owner:MAZZER LUIGI

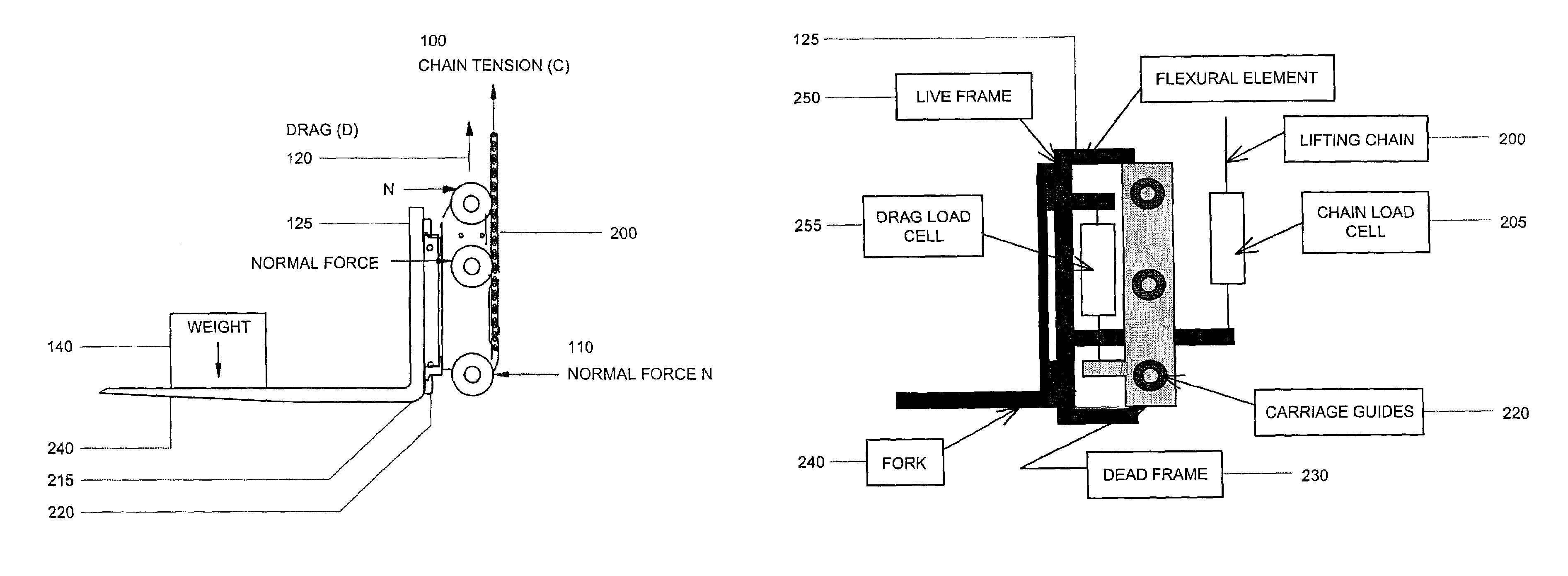

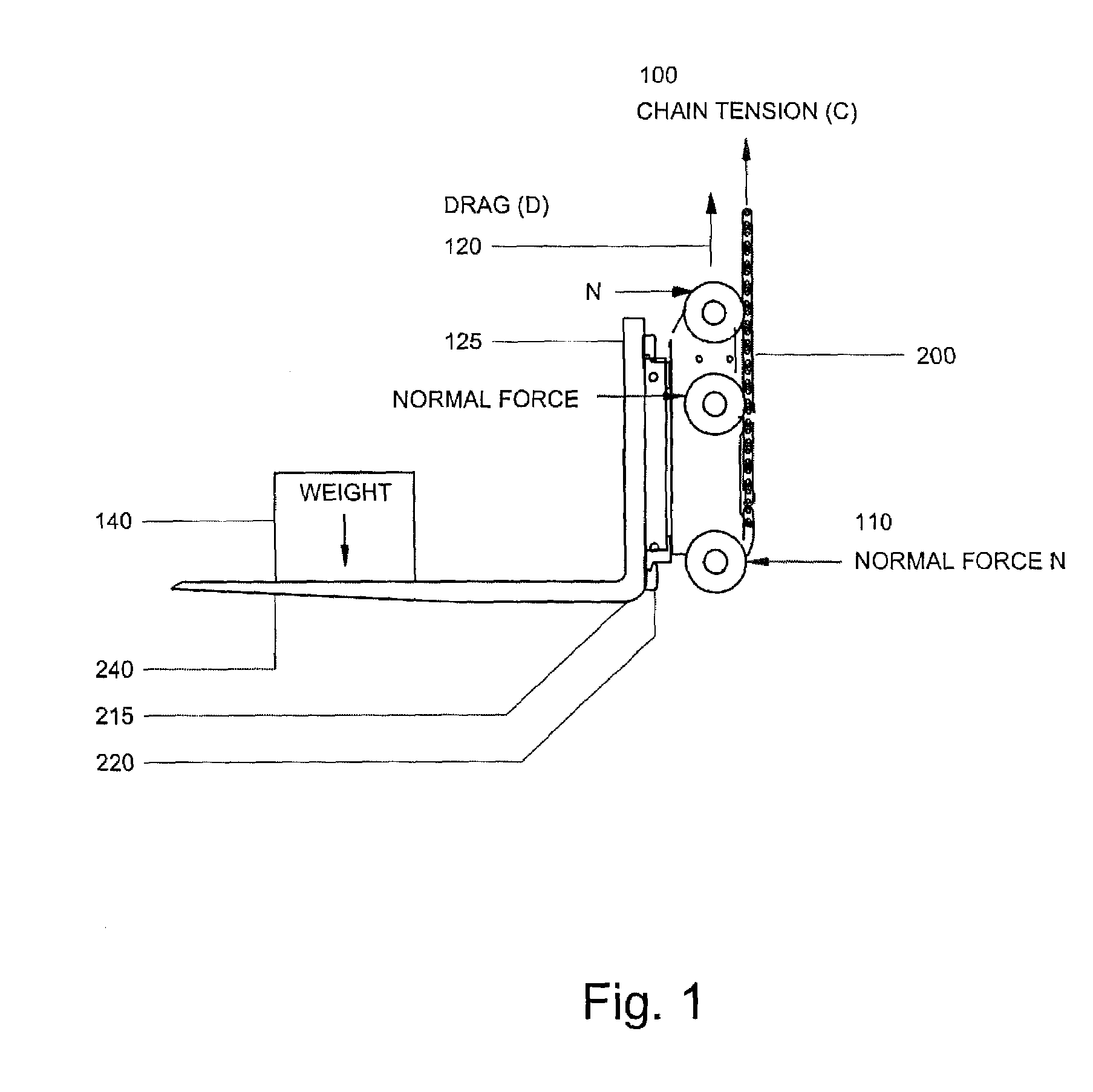

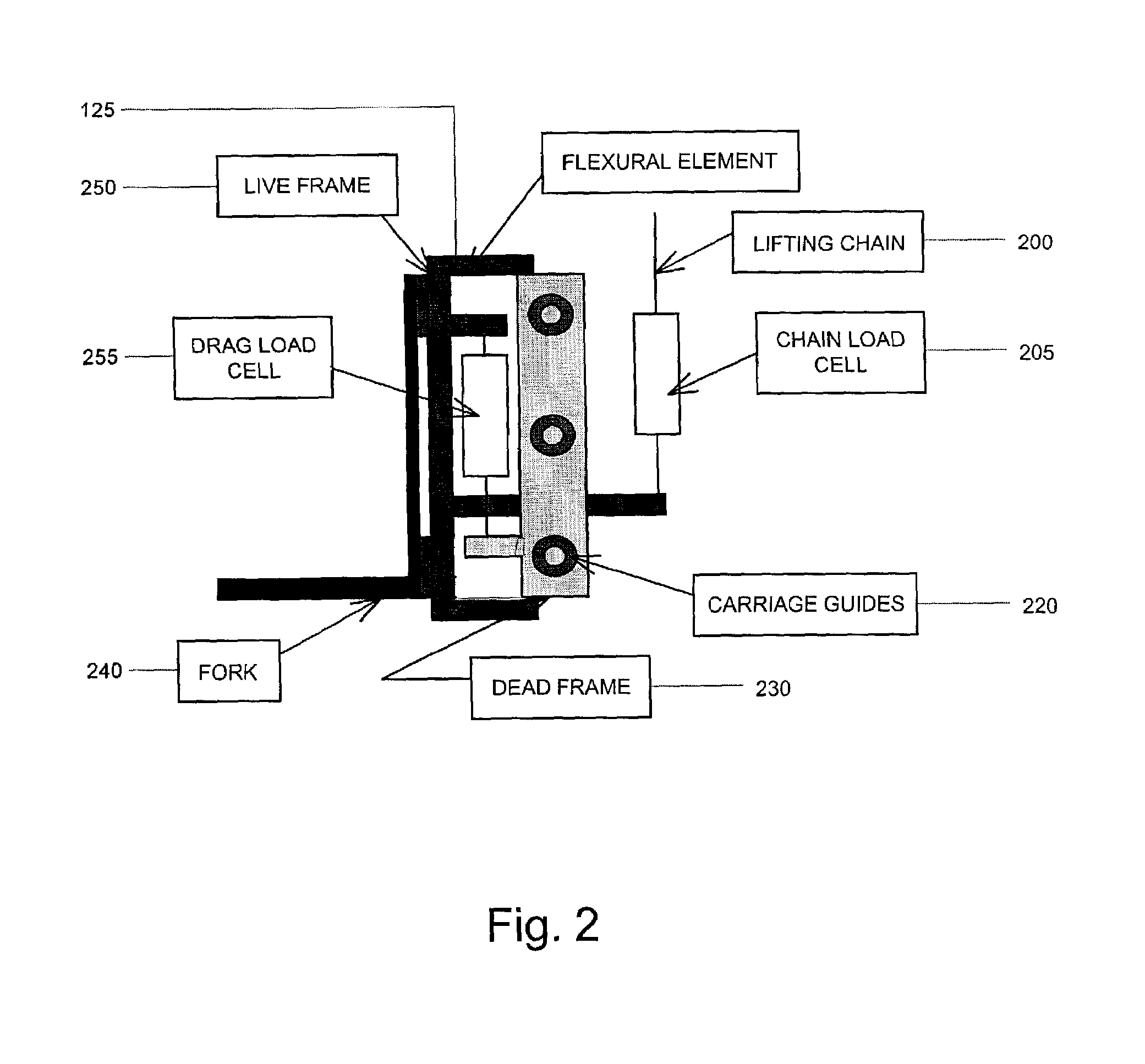

Apparatus and method for weighting objects on a fork lift truck

ActiveUS7026557B2Eliminate errorsMore accurate weighing deviceAnalogue computers for trafficDigital computer detailsEngineeringCarriage

This invention relates to an improved apparatus for measuring the weight of an object being carried by a fork lift truck. Accurate weight is obtained by combining the measurements of the tension load(s) exerted by the chain(s) used to lift and support the fork carrying carriage with a measurement of the vertical forces imposed on the carriage by the mast through the carriage guides that are used to contain carriage movement within the mast and support the moment created by the object being weighed. The weight thusly determined can be easily calibrated for both pitch and roll mast angles. The apparatus can be integrated into the mast system of the fork truck without significantly affecting the fork truck's load carrying capacity. Specifically, the scale apparatus does not increase the overturning moment created by the weight of the object as compared with that of the standard non-instrumented carriage.

Owner:METTLER TOLEDO INC

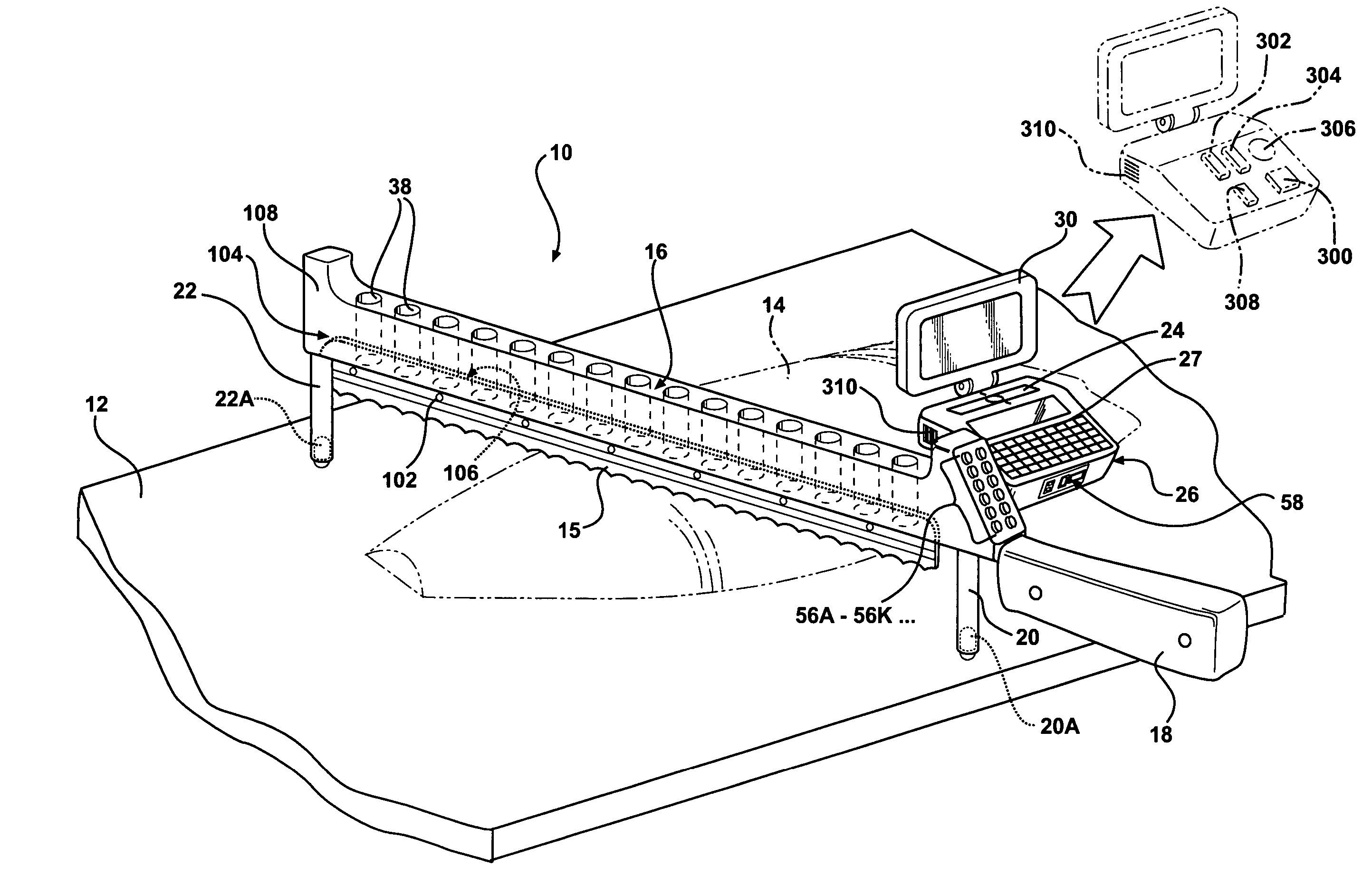

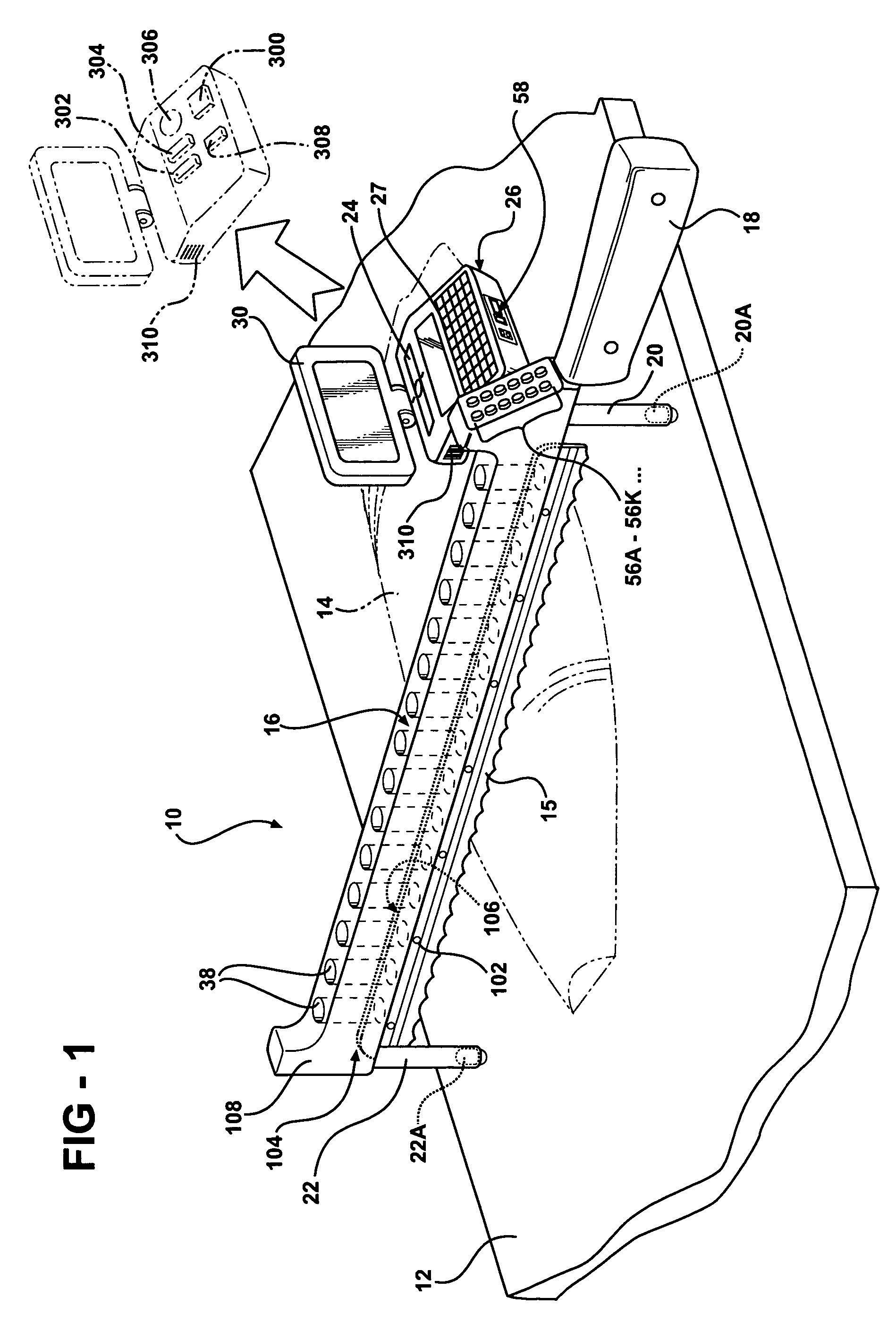

Apparatus and method for displaying numeric values corresponding to the volume of segments of an irregularly shaped item

ActiveUS7158915B2Low costFast and accurate determinationMeat holding apparatusFeeler-pin gaugesNumeric ValueWeight value

An apparatus and method for displaying the weight or cost of segments of an irregularly shaped item involves passing a sensor bar supported above a supporting surface over the item lying on the surface. A compact hand-held embodiment of the sensor bar enables the operator to move the sensor bar in various linear or non-linear motions over the item surface as the sensor bar moves laterally across the item surface while the sensor bar support posts remain in constant contact with the supporting surface. The sensor bar contains one or more sensors which generate signals corresponding to the height of the item as the sensor bar traverses the item. At the same time, a displacement detector arrangement generates signals corresponding to displacement of the sensor bar relative to the support surface. These signals are processed in a signal processor to determine the volume of an uncut segment of the item lying behind the sensor bar at successive positions. Each of these cumulative volume determinations may be continuously converted into numeric weight values based on the density factor for the particular type of item, whereby numeric weight and cost values (based on weight) are continuously displayed as the sensor bar is stroked over the item, thus enabling the operator to accommodate an on-looking consumer's specific requests as per the particular portion desired based on the physical appearance, weight, and cost of an item before the item is cut.

Owner:WARGON KENNETH

Liquid-injecting method of battery and liquid-injecting production line thereof

InactiveCN101635343AAccurate weighingImprove work efficiencyCell component detailsWeight valueEngineering

The invention discloses a liquid-injecting method of a battery and a liquid-injecting production line thereof. The method comprises the following steps of: a) putting an electric core which is not injected with liquid on a front weighing device to weigh, and memorizing the weight value of the electric core which is not injected with the liquid in a control module; b) putting the electric core which is not injected with the liquid in a tray, and putting the tray on the liquid-injecting production line; c) injecting the liquid to the eclectic core by the liquid-injecting device at the tray which is put with the electric core, and vacuuming the electric core by a vacuuming device; and d) putting the electric core which is injected with the liquid on a back weighing device to weigh, and memorizing the obtained weight value of the electric core which is injected with the liquid in the control module; and e) comparing the weight value of the electric core which is not injected with the liquid with the weight value of the electric core which is injected with the liquid by the control module, if the different value exceeds a set value, supplying the liquid to the electric core. Each of the trays is provided with the plurality of electric cores. The invention is provide with the control module for memorizing and comparing the weight value of the electric core before and after liquid injection, has exact weighing and high automation degree, and improves the work efficiency of the production line.

Owner:GEESUN AUTOMATION TECH

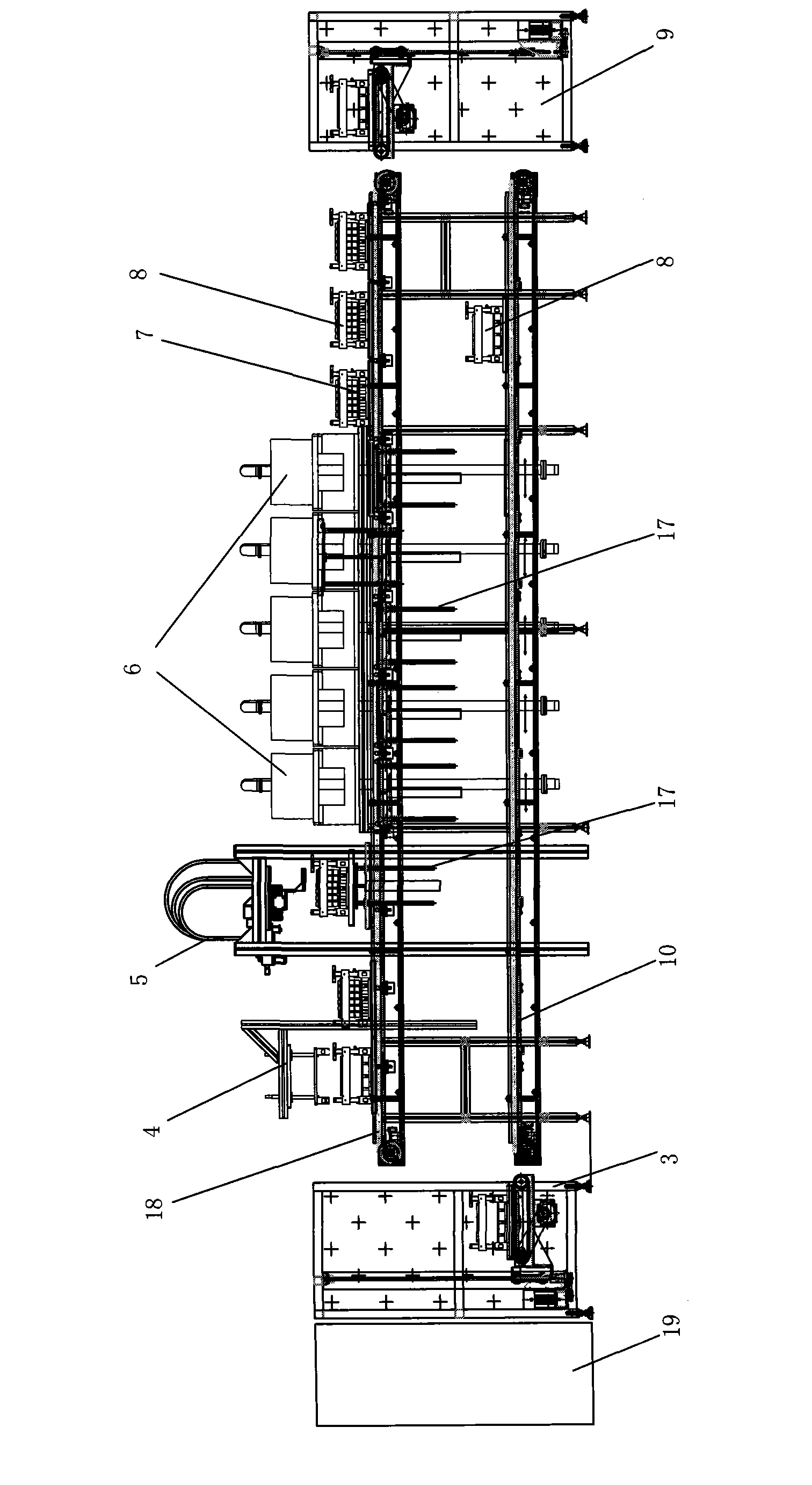

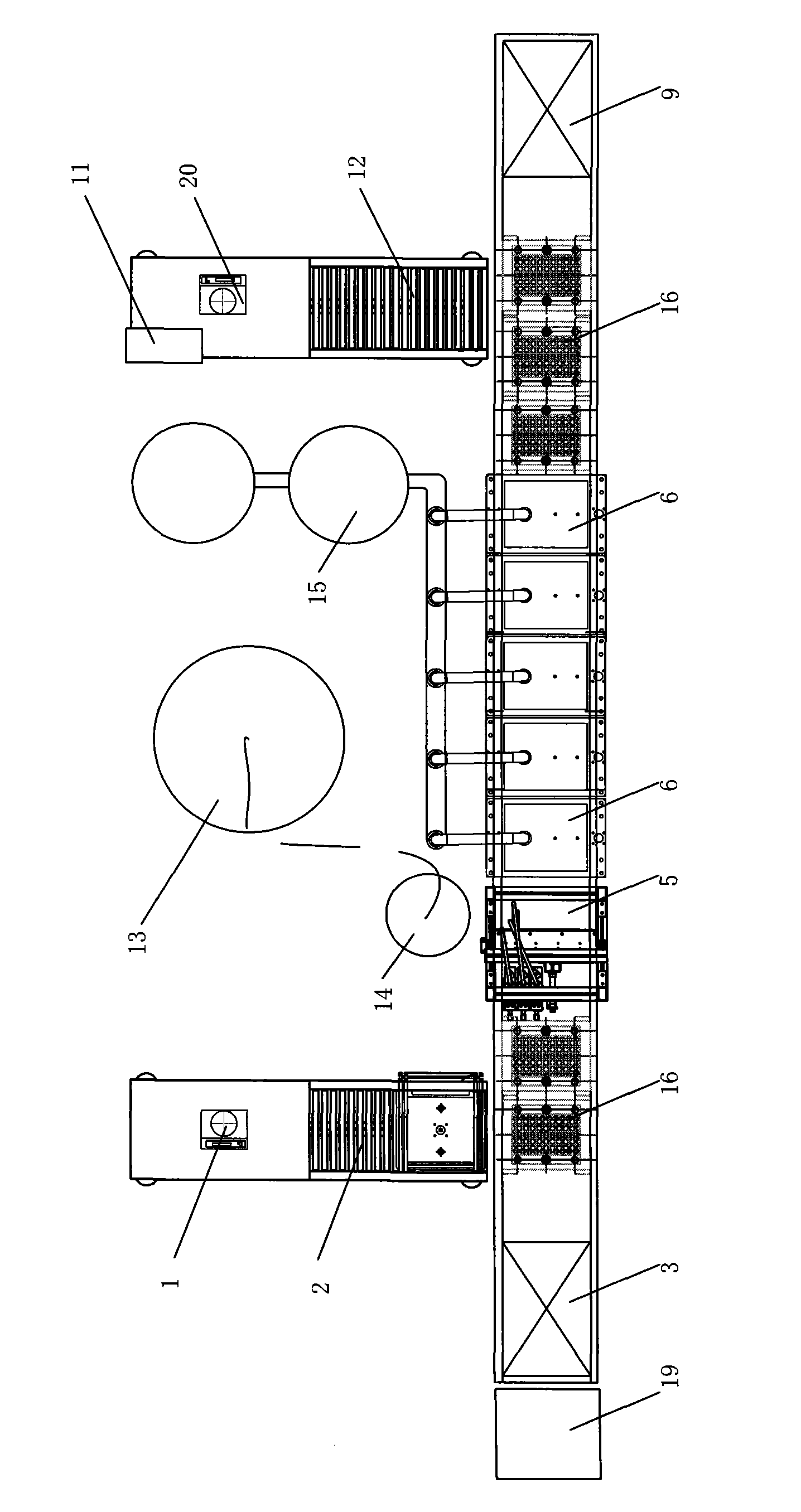

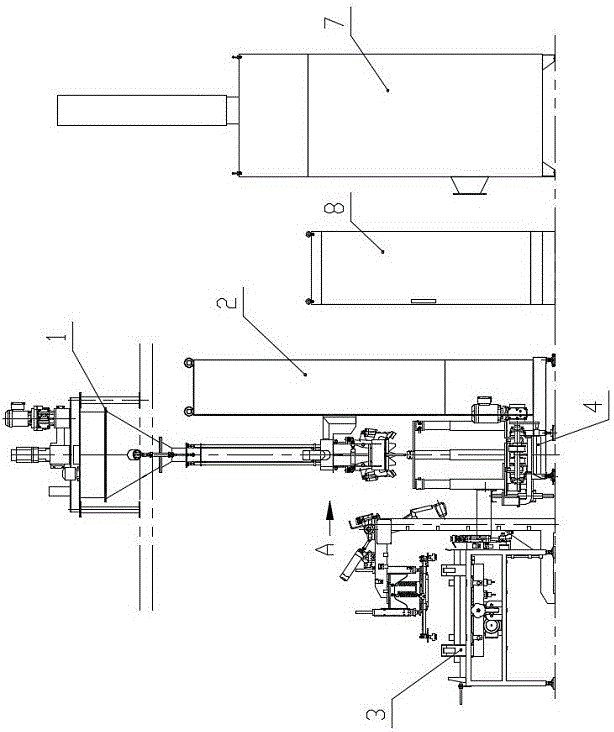

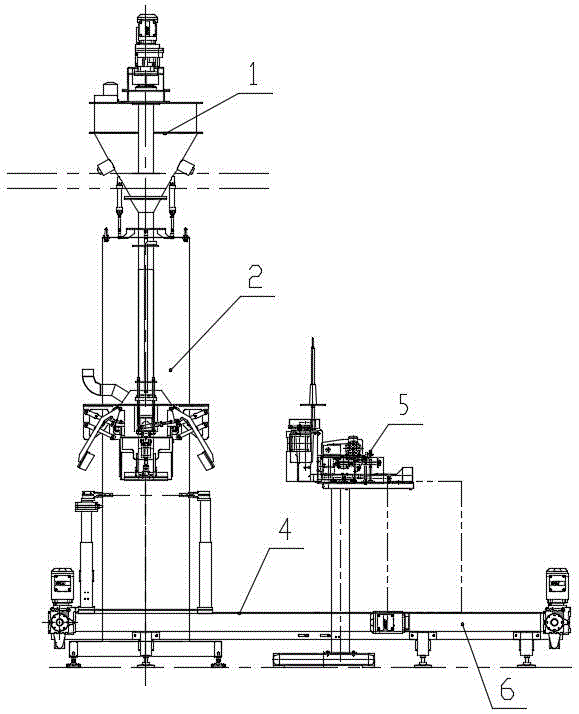

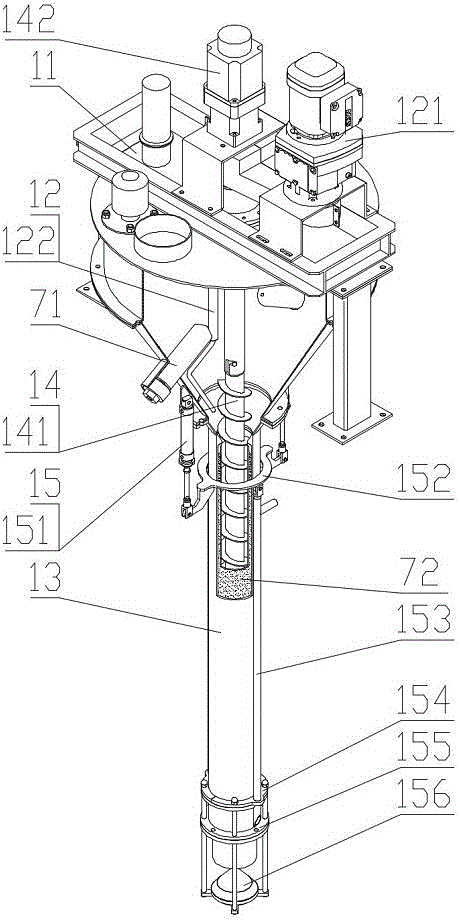

Full-automatic powder packaging system

The invention discloses a full-automatic powder packaging system. The full-automatic powder packaging system comprises a screw filling device (1), a lifting bag clamping and weighing device (2), an automatic bagging device (3), a clamping, transferring and conveying device (4), a bag sewing device (5), a finished product transfer device (6), a powder recycling device (7) and an electronic control device (8). The lifting bag clamping and weighing device comprises a weighing mechanism (24) and a duckbill bag clamping mechanism (25) which can ascend and descend synchronously. A discharging cylinder (13) is sleeved with the duckbill bag clamping mechanism. The duckbill bag clamping mechanism clamps a packaging bag and ascends before filling operation so that a movable material door (156) can be located at the bottom in the packaging bag, the duckbill bag clamping mechanism gradually descends synchronous with ascending of the material level in the filling operation process, and the weighting mechanism conducts weighing at the same time. By the adoption of the full-automatic powder packaging system, powder materials can be weighed precisely, packaging bags are sealed and conveyed, and the full-automatic powder packaging system is especially suitable for premise metering and automatic packaging of extremely fine powder materials.

Owner:SAIMO ELECTRIC

Automatic livestock weighing system

ActiveUS20050006153A1Accurate weighingAccurate operationAnimal housingWeighing apparatus for materials with special property/formAnimal scienceDraft animals

A system for weighing a plurality of quadruped animals is for use in a pen confining the animals. The pen has at least first and second segregated spaces with a first one-way chute allowing animal passage from the second space to the first space. A weighing station is located within a passage having an entrance and an exit, and that allows animal passage from the first area to the second area. The weighing station includes a weighing platform within the passage over which an animal must pass when passing from the first to the second space. The weighing platform has inlet and exit scales that support the weighing platform adjacent to inlet and exit ends thereof, and provides inlet and exit weight signals. A controller receives the inlet and exit weight signals and uses them in an iterative process to determine the presence of a single animal on the weighing platform. Once that determination is made, the sum of the inlet and exit weight values is very likely to accurately provide the animal weight. The controller may also use the inlet and exit weight signals to control closing of an inlet gate to bar more than one animal at a time from the weighing platform. An animal sorting system can easily incorporate this weighing system to provide more accurate sorting.

Owner:HERDSTAR

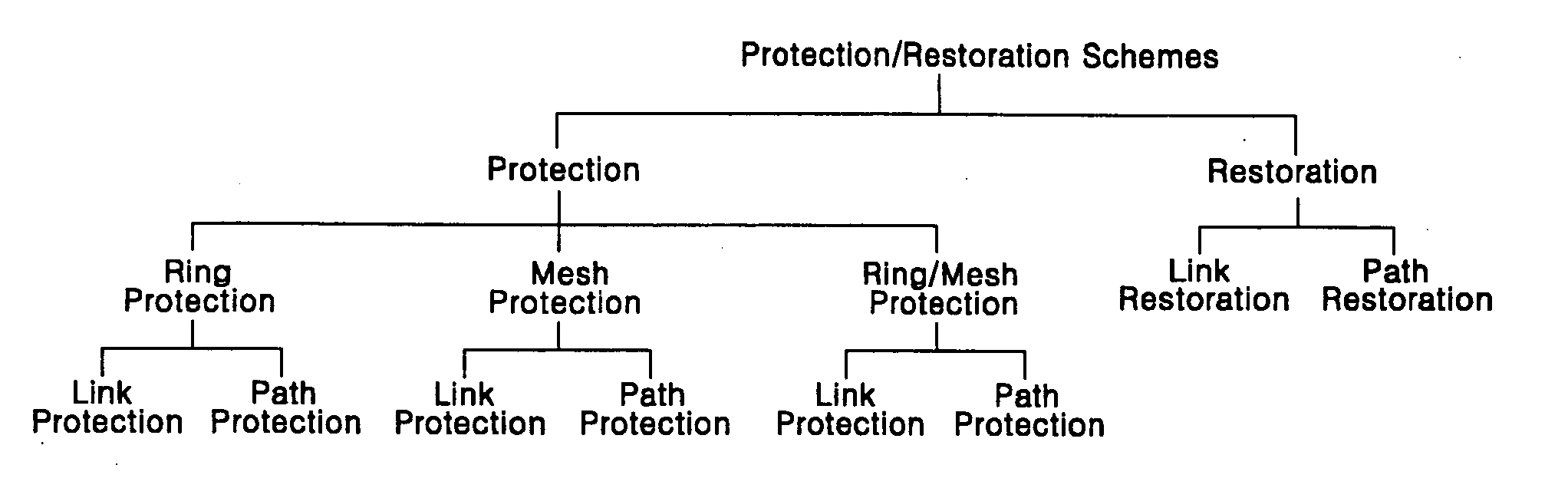

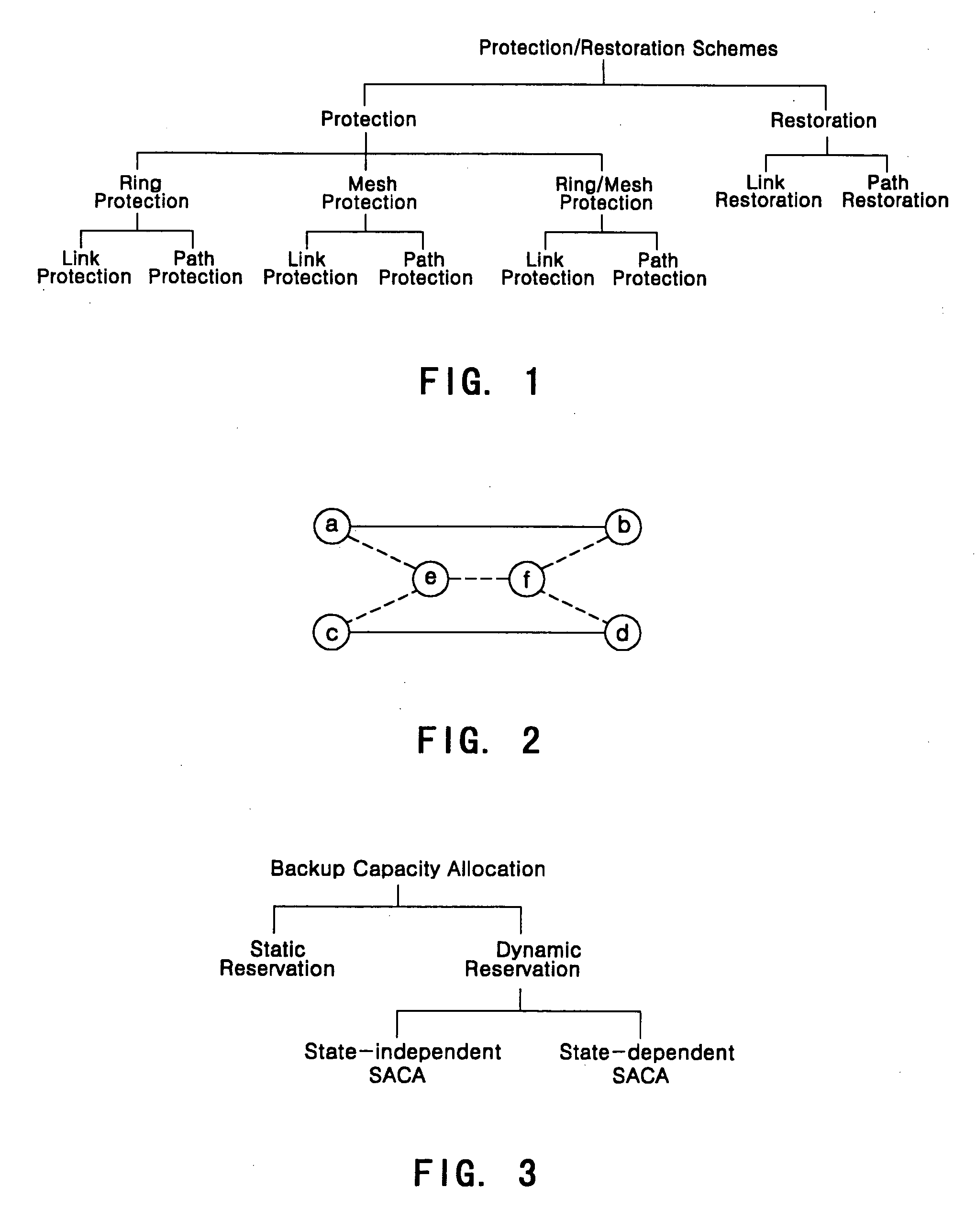

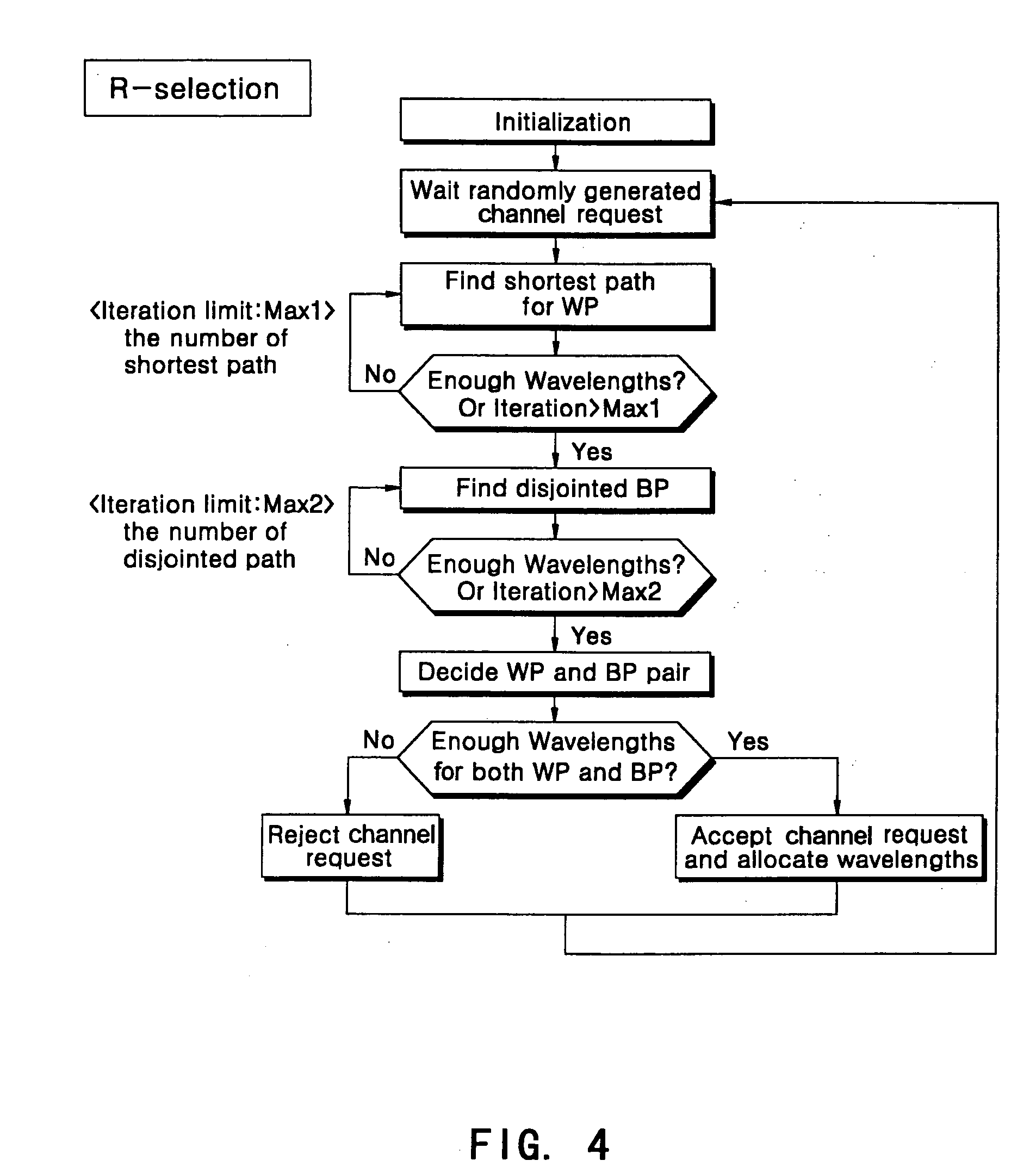

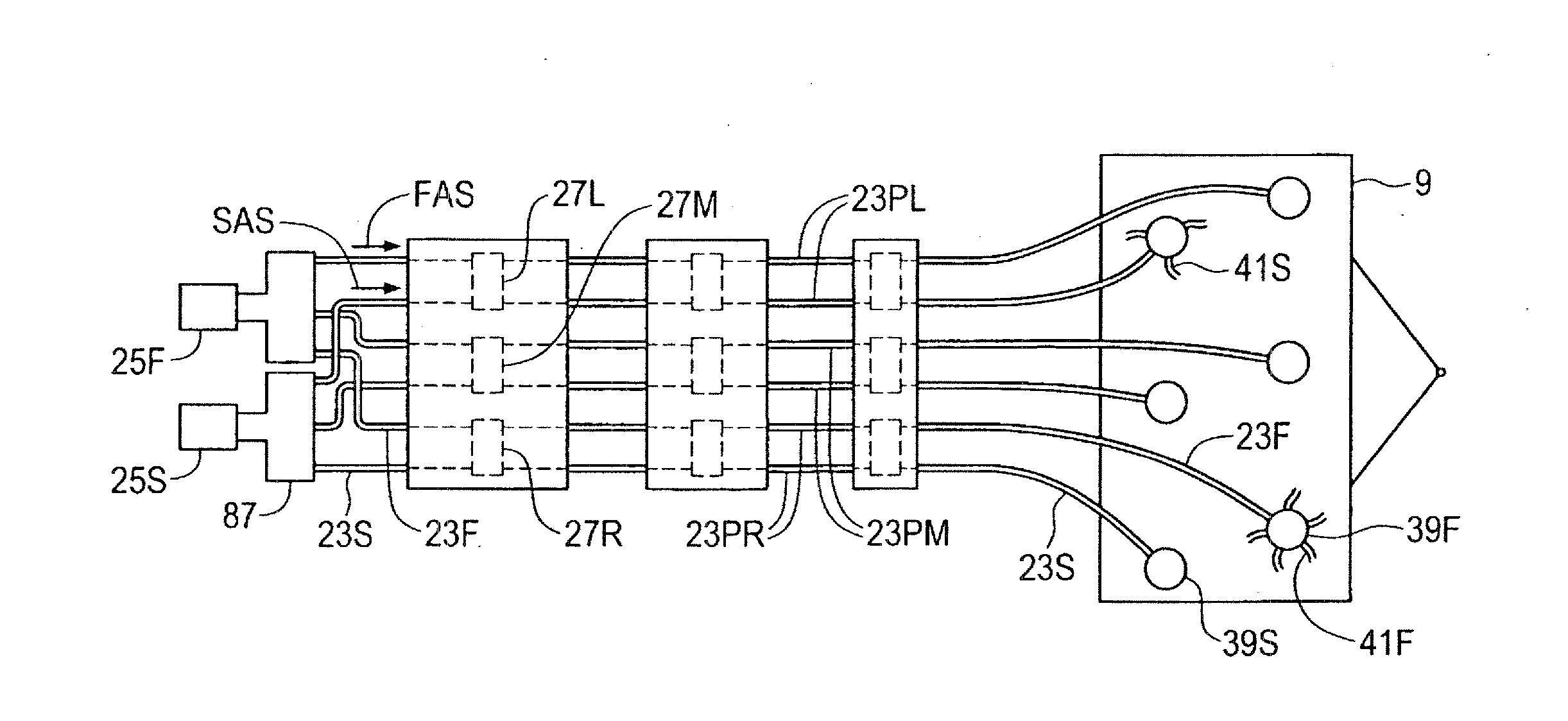

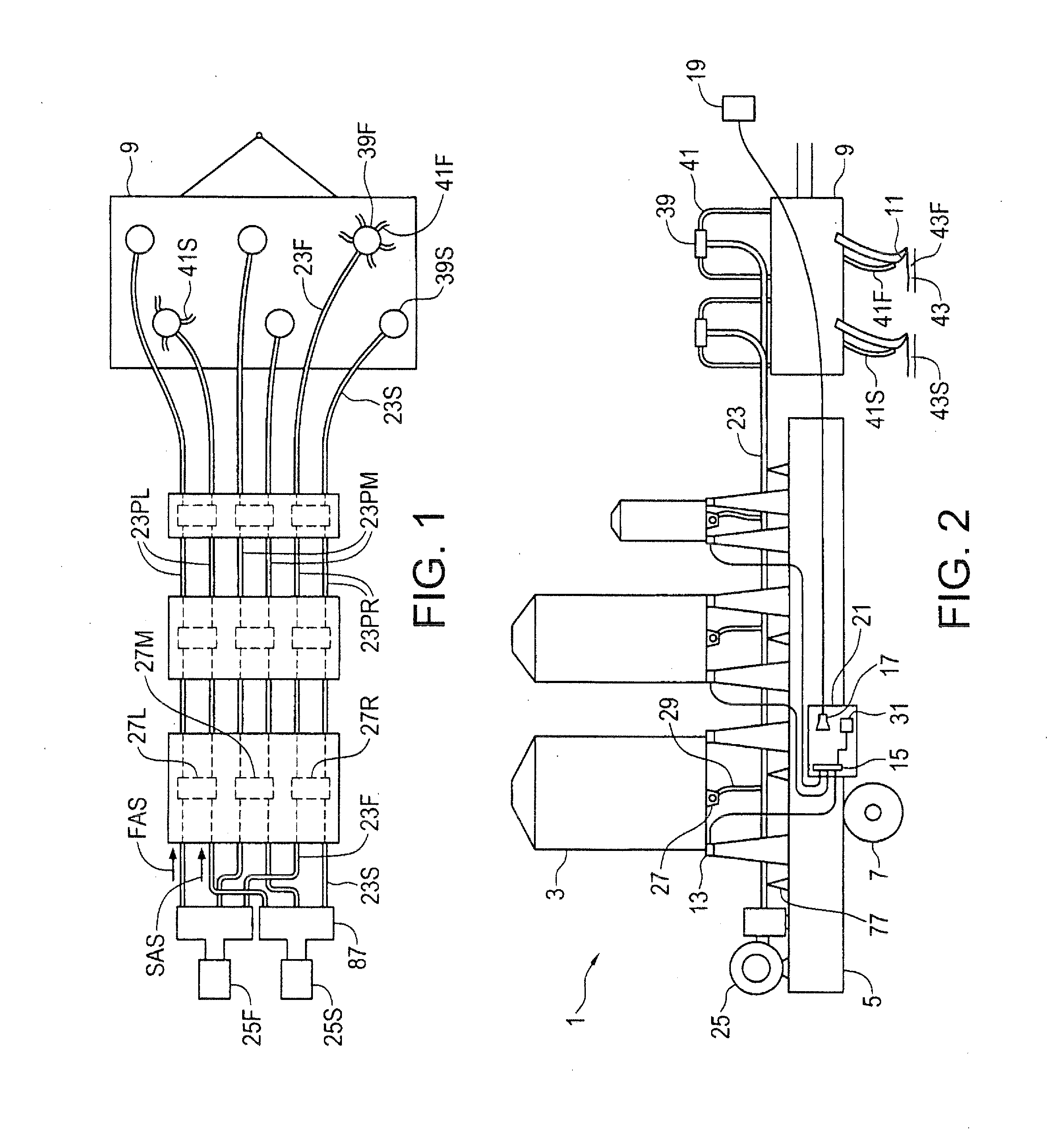

Highly utilizable protection mechanism for WDM mesh network

InactiveUS20050071484A1Optimization mechanismImprove performanceLaser detailsError preventionTraffic volumeProper weights

In this application, the invention is a novel heuristic mechanism of working path and backup path reservation for highly utilizable WDM mesh networks, which we call dynamic-network adapted cost selection (DAC-selection) mechanism. One of its characteristics is simple traffic distribution mechanism, and the performance of DAC-selection mechanism is superior to that of Random selection (R-selection) and Advanced Combined Min-cost selection (ACM-selection) mechanism. DAC-selection mechanism provides simple cost function by assigning proper weights to each component of the cost function and the total cost is obtained by just summing up the individual cost. Therefore, it is possible to select a best pair of working path and backup path which consumes least wavelength for reservation.

Owner:ICU RES & INDAL COOPERATION GROUP

Air seeder tank and distribution apparatus

ActiveUS20140216315A1Different pressureDifferent speedFertiliser distributersAgriculture and animal husbandary industryInternal pressureMechanical engineering

An air seeder distribution apparatus has seed and fertilizer tanks, and a like plurality of metering devices mounted on each product tank. A manifold set comprises a like plurality of product manifolds and each manifold is separately fed from one metering device on each of the seed and fertilizer tanks. A control selectively starts and stops rotation of the feed roller of each metering device to feed product from either tank, or both tanks to the connected manifold. The weight of each tank can be displayed on a weight indicator. Balancing of the pressure in each supply conduit can be provided. A remote opener exerts downward force on the tank lid to maintain interior pressure.

Owner:SEEDMASTER MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com