Patents

Literature

43results about How to "Improve perfusion quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation and application of two-component self-compacting concrete for slab ballastless track

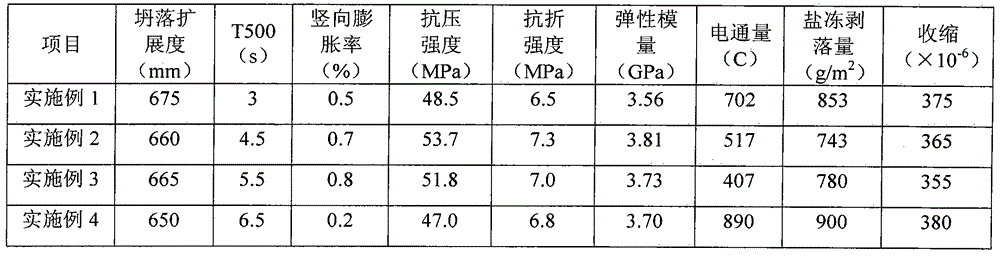

The invention relates to a preparation and an application of two-component self-compacting concrete for a slab ballastless track. The preparation of the two-component self-compacting concrete is characterized in that the two-component self-compacting concrete is formed by mixing a dry mixture with a liquid in the ratio of 1:(0.05-0.15), wherein the dry mixture is formed by mixing components in parts by mass as follows: 100 parts of a bonding component, 0-30 parts of an inert mineral additive, 150-400 parts of fine aggregate, 150-300 parts of coarse aggregate, 0-2.0 parts of a water reducing agent, 5-20 parts of an expansion component, 0-10 parts of a viscosity regulating component, 0-0.5 parts of fiber and the like; and the liquid is formed by mixing components in parts by mass as follows: 100 parts of water, 0-4.0 parts of the water reducing agent, 0-3 parts of the viscosity regulating component and the like. According to the preparation and the application of the two-component self-compacting concrete for the slab ballastless track, the sensibility of the self-compacting concrete can be reduced, loss of the self-compacting concrete is reduced, and environment-friendly construction is realized. The two-component self-compacting concrete is applicable to the slab ballastless track of a high speed railway and is also applicable to the field of bridges, civil buildings, repair and strengthening and the like.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

Methods of thrombolytic organ treatment and repair

InactiveUS20020051779A1Improve survivabilityEffective therapyPeptide/protein ingredientsDead animal preservationStreptokinaseThrombus

The invention teaches methods and compositions for removing thrombi lodged in the microvasculature of an organ. To remove the thrombi, the organ may be perfused, flushed or washed with a suitable perfusion solution to which a sufficient amount of a thrombolytic agent, such as Streptokinase, has been added. The perfusing, flushing or washing process of the organ with the thrombolytic agent will promote thrombolysis on existing thrombi, prevent the formation of new thrombi in the organ, and / or open the vasculature of the organ thereby decreasing vascular resistance and increasing flow. The method of the invention may be practiced using an organ perfusion apparatus that would allow the viability of the organ to be sustained and / or restored upon perfusion with a thrombolytic agent.

Owner:ORGAN RECOVERY SYST

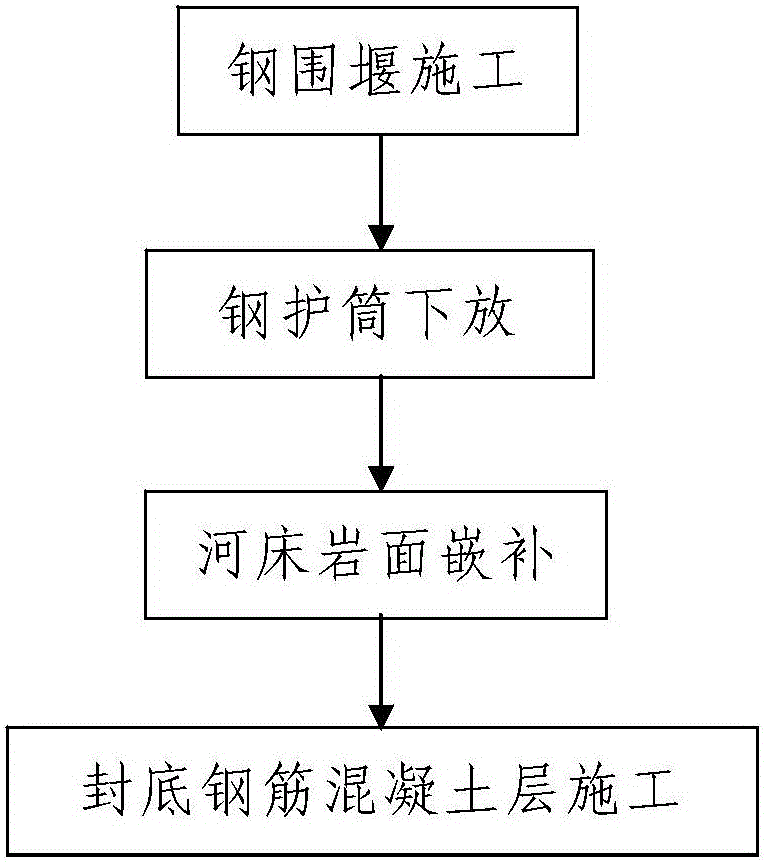

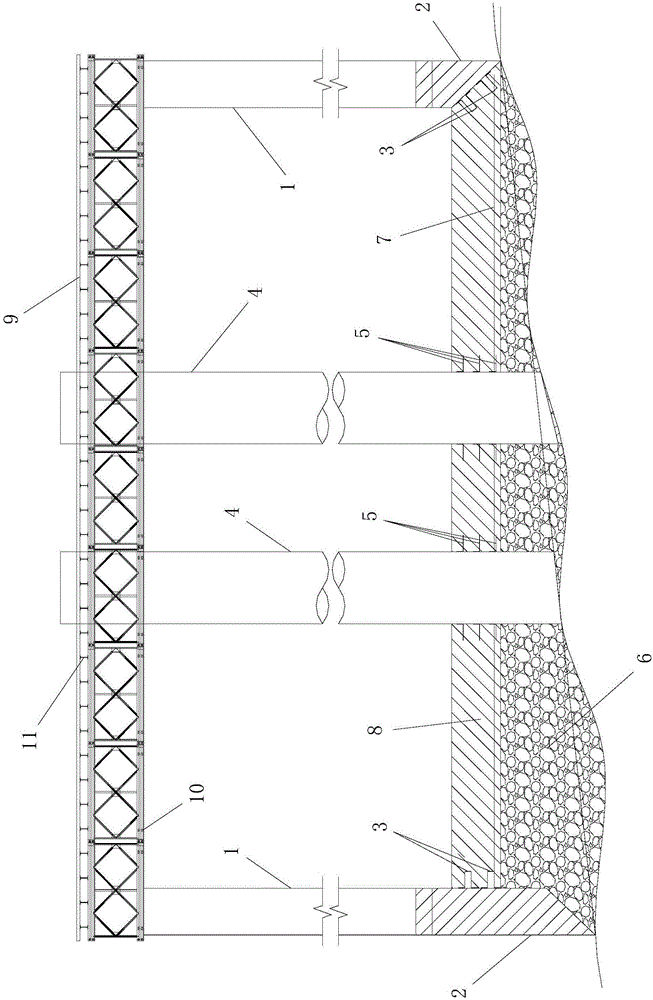

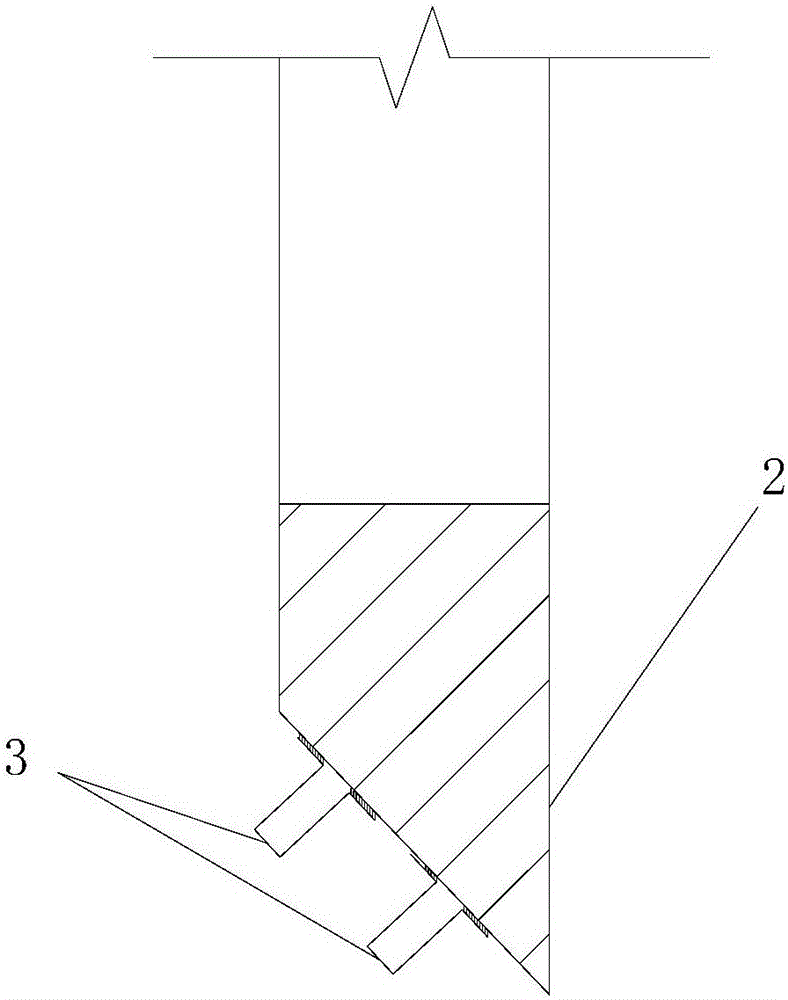

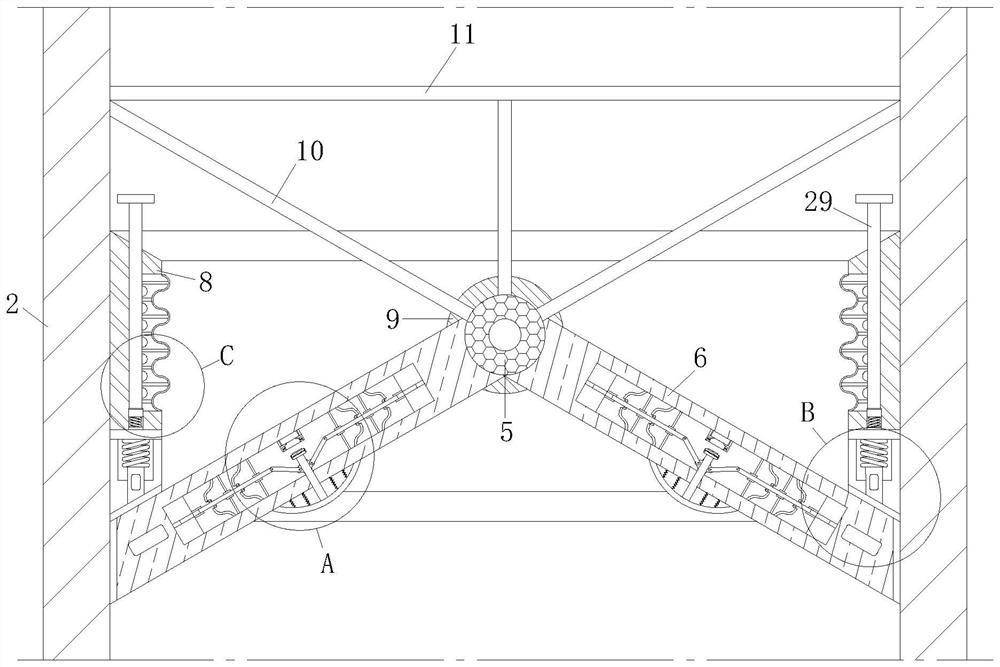

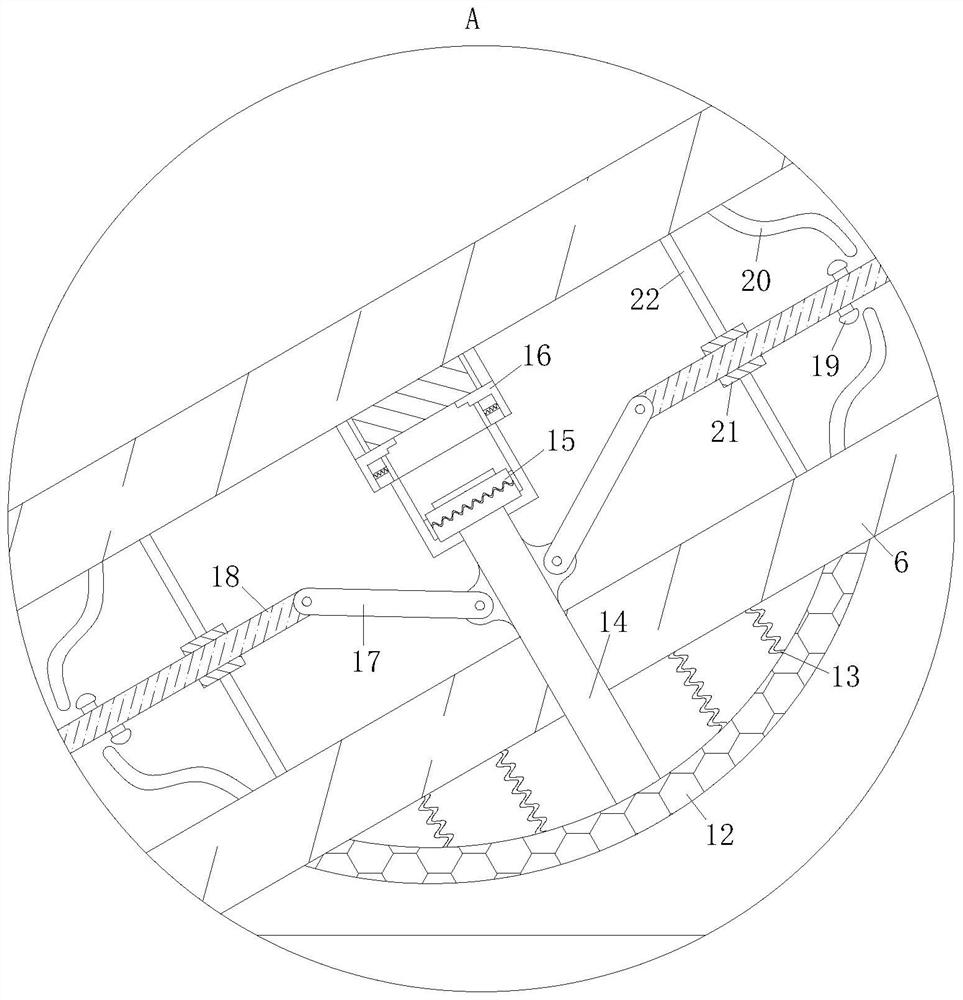

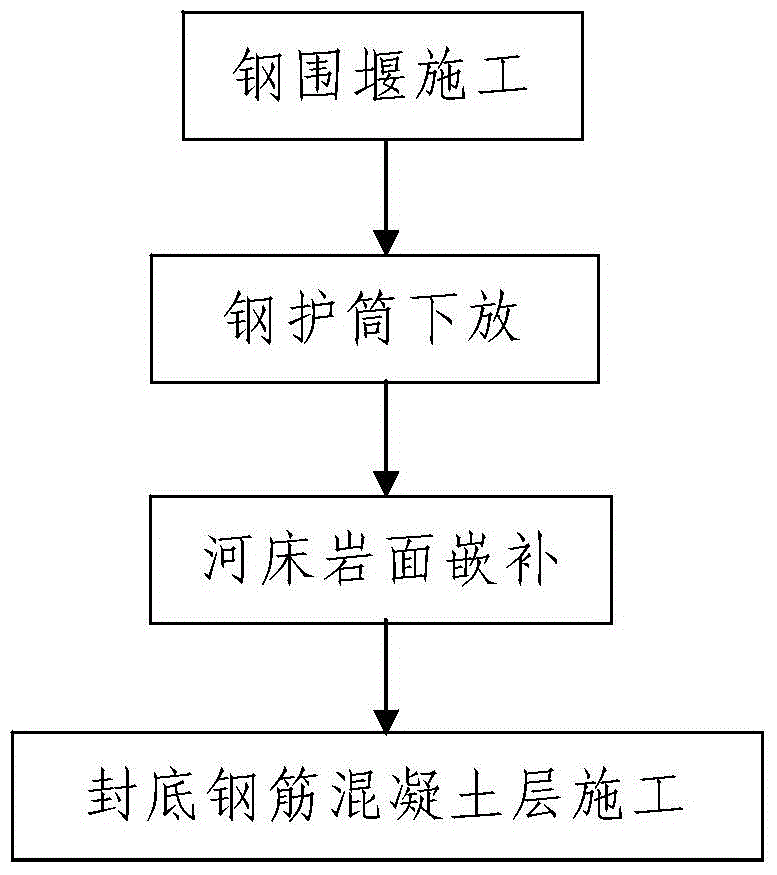

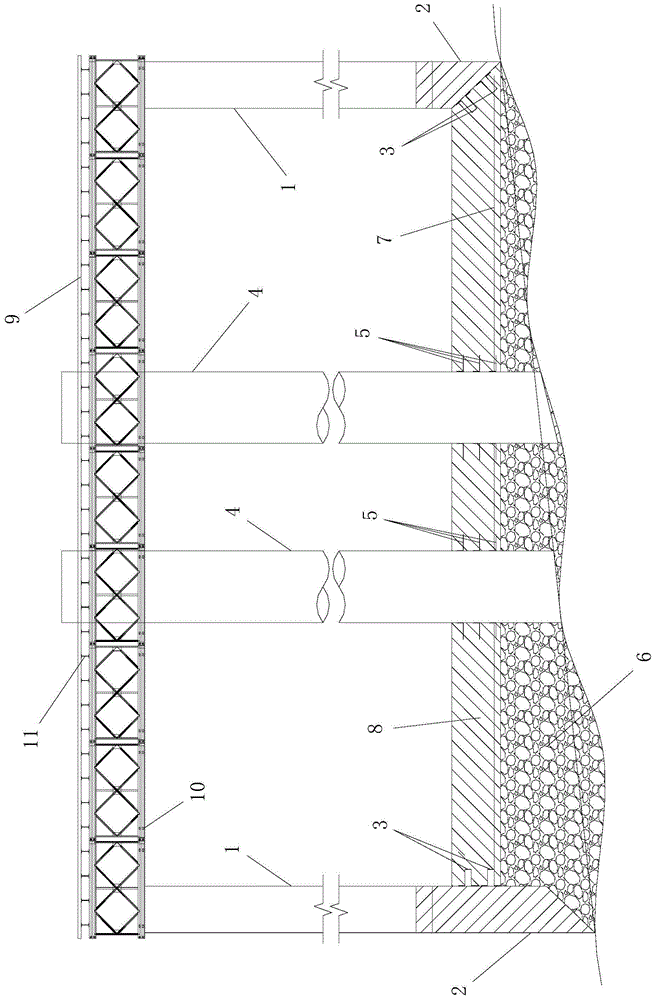

High-low cutting edge double-wall steel cofferdam reinforced concrete once bottom sealing construction method

ActiveCN105064381AThe method steps are simpleReasonable designFoundation testingCaissonsReinforced concreteCofferdam

The invention discloses a high-low cutting edge double-wall steel cofferdam reinforced concrete once bottom sealing construction method which comprises the steps that Step one, steel cofferdam construction is performed: double-wall steel cofferdam sinks to a pre-designed construction position, high-low cutting edges are arranged at the bottom of the double-wall steel cofferdam, inclined surfaces are designed as the bottom surfaces of the cutting edges, and are supported on an inclined bare rock surface, and a plurality of groups of first anchor steel bars are arranged on the cutting edges; Step two, steel casing laying is performed: a steel bar anchor structure is arranged on the outer side wall of the bottom of each steel casing, and comprises a plurality of rows of second anchor steel bars distributed from the top down; Step three, riverbed rock surface patching is performed: a riverbed rock surface is backfilled with a mixture to form a backfilled layer; and Step four, bottom sealing reinforced concrete layer construction is performed: a horizontal steel bar mesh is mounted on the backfilled layer, and concrete is poured into the double-wall steel cofferdam to form a concrete bottom sealing layer. The method is simple in step, reasonable in design, low in construction difficulty, short in construction period and good in using effect, and can effectively solve the various problems in the conventional plain concrete bottom sealing method.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

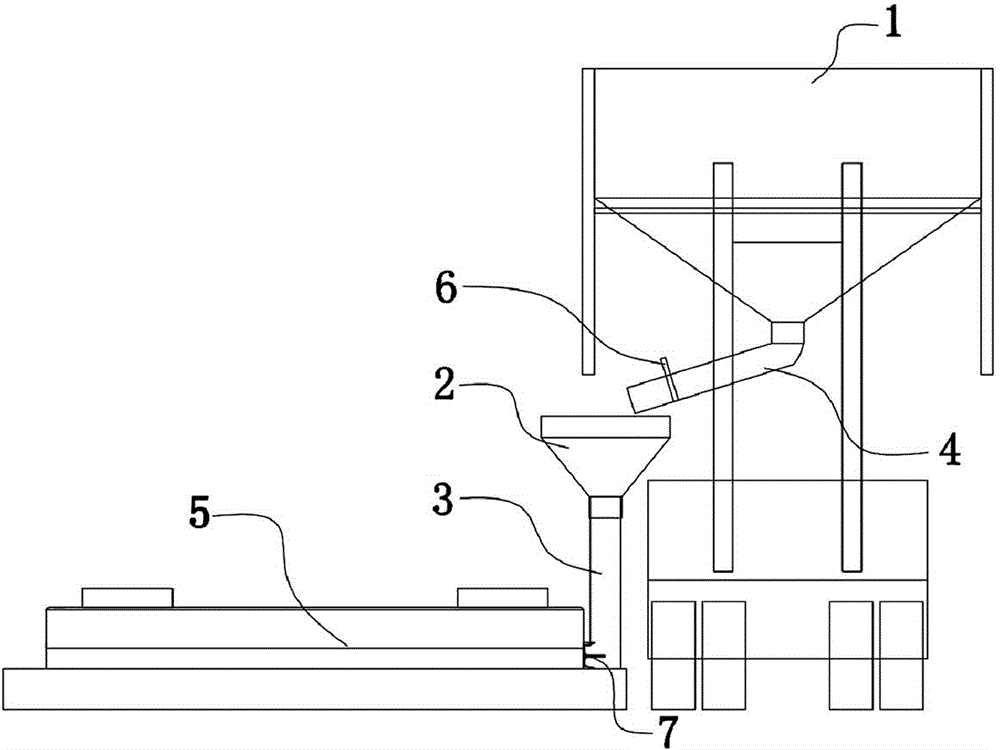

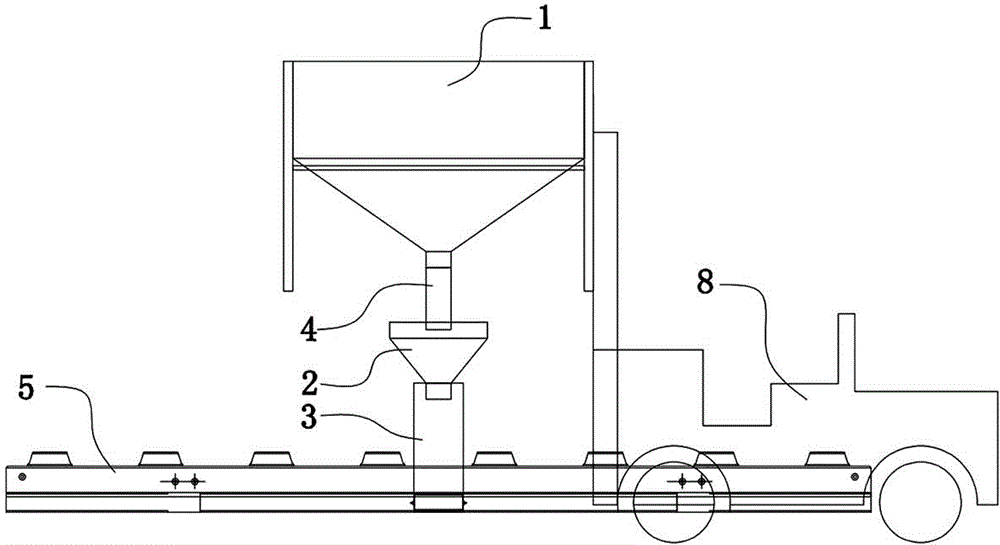

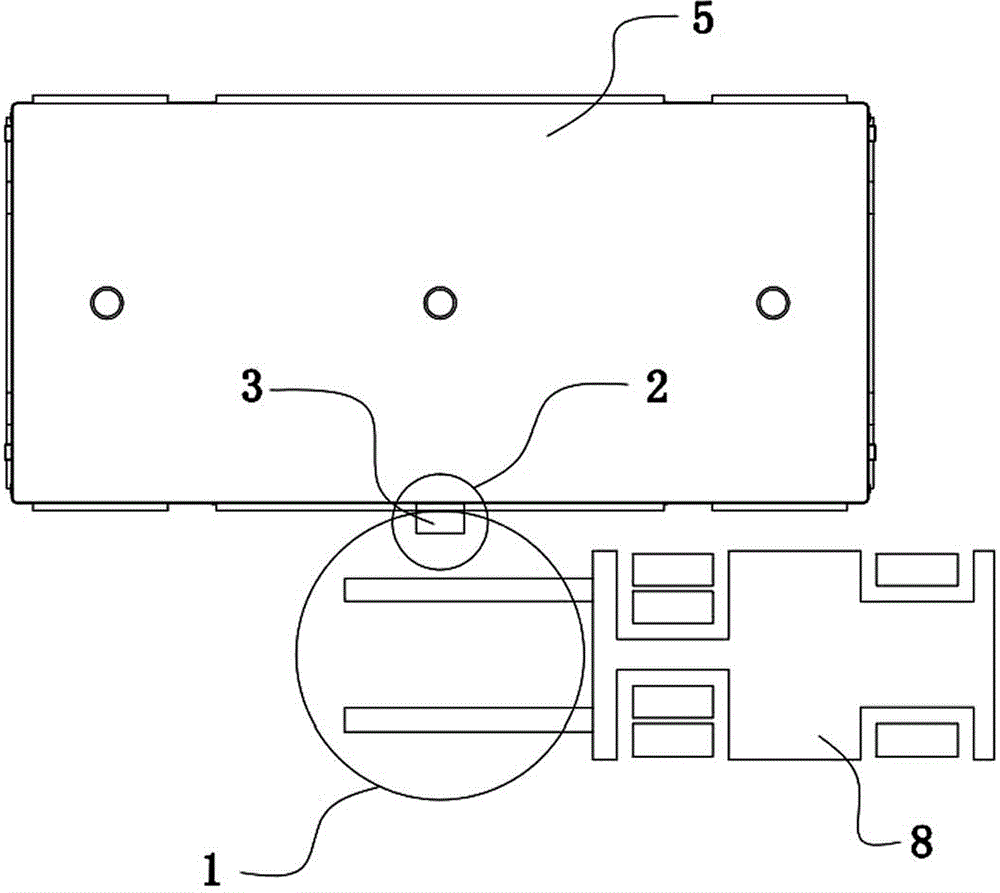

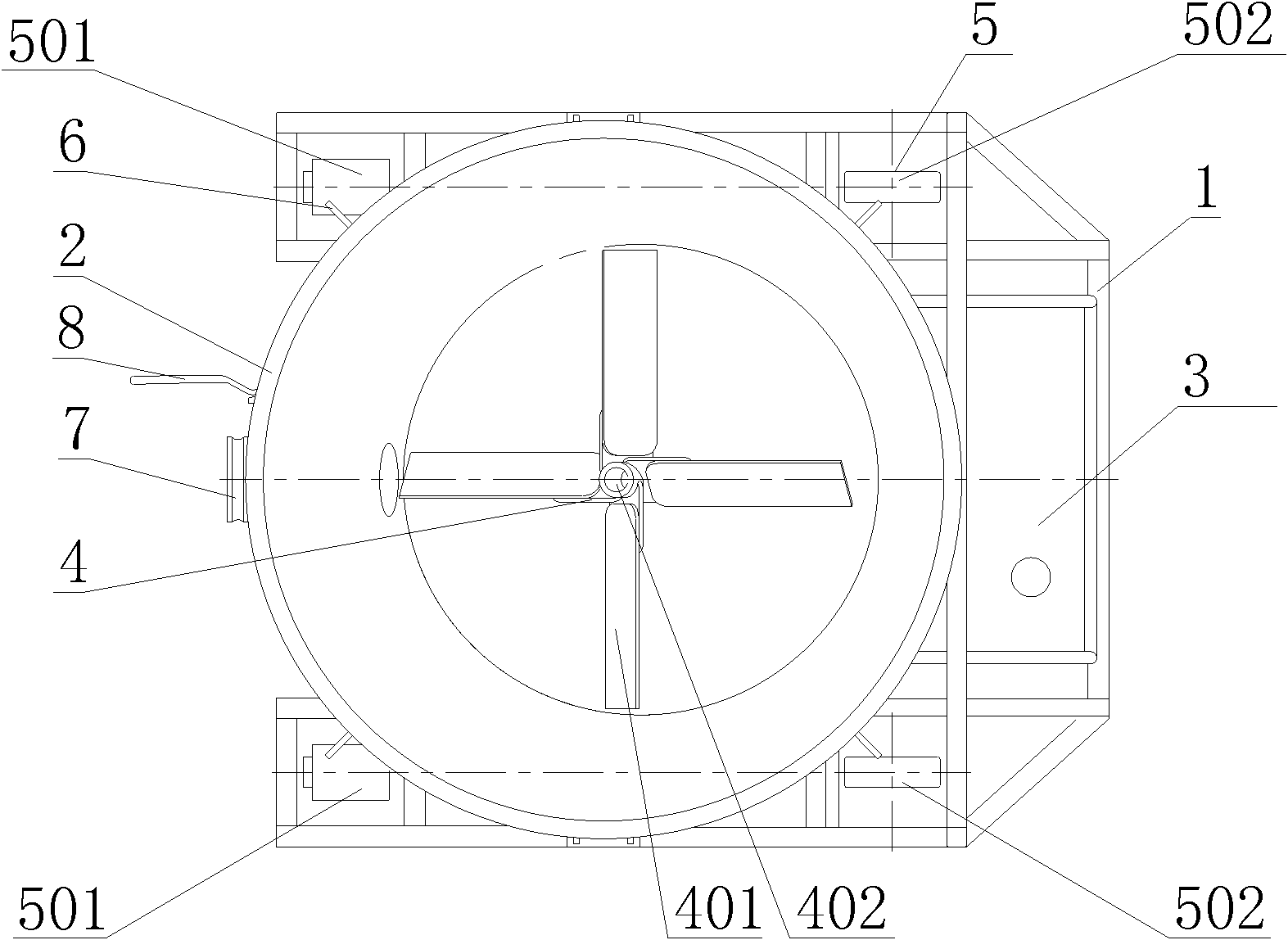

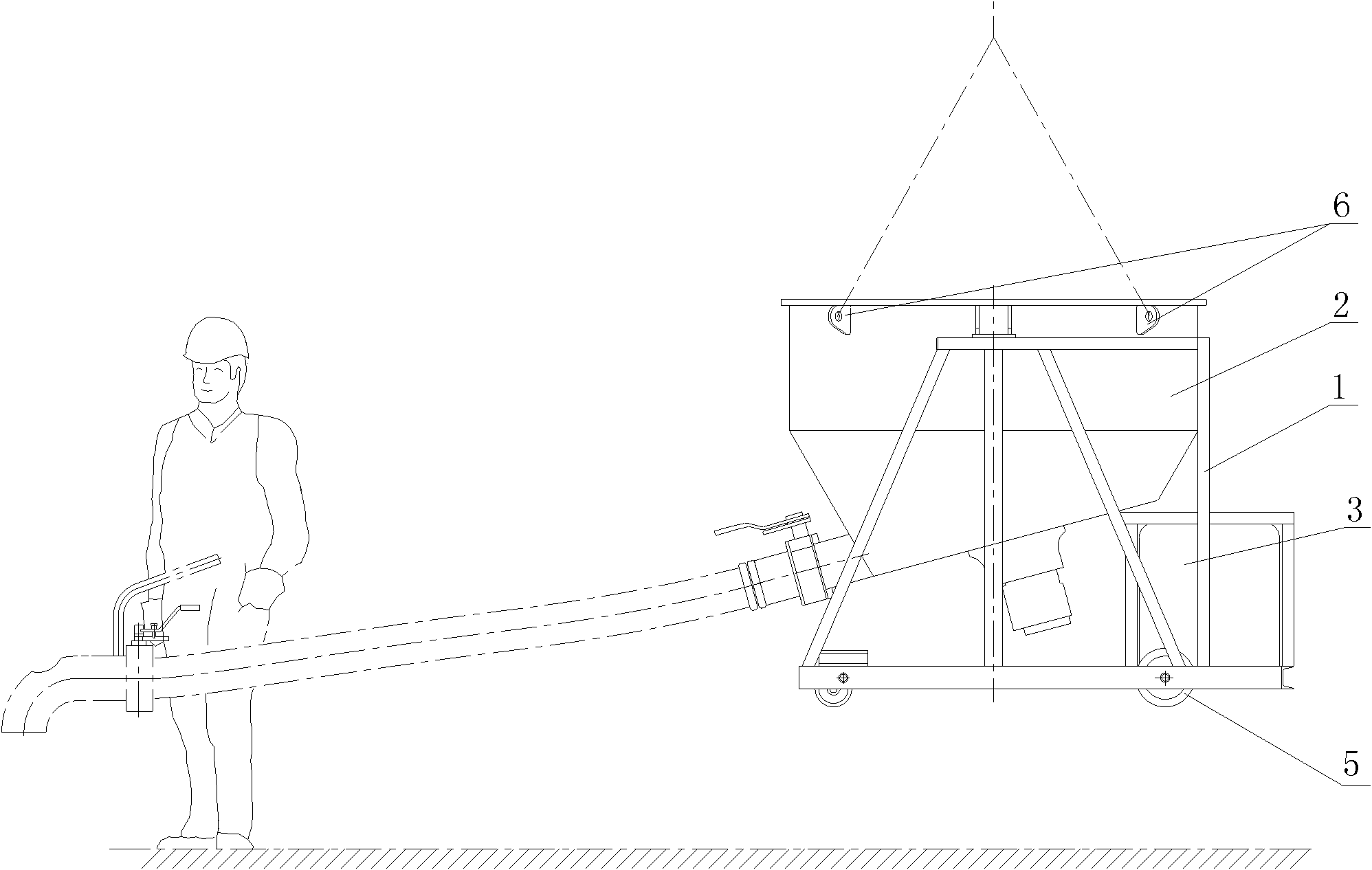

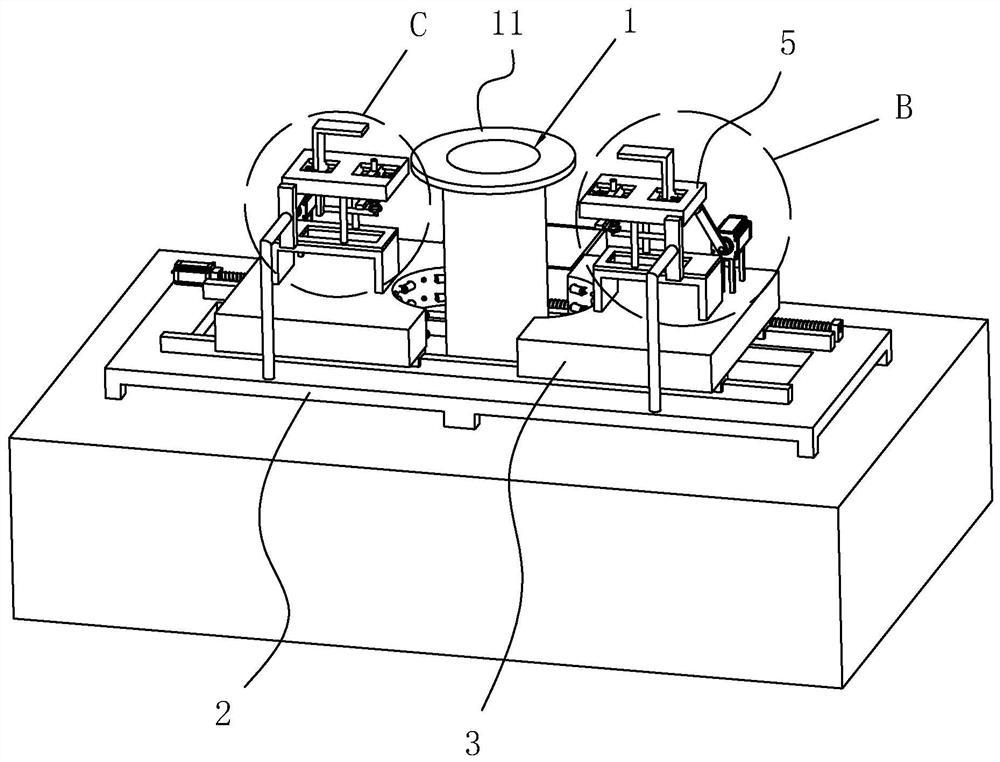

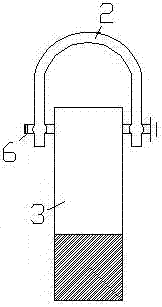

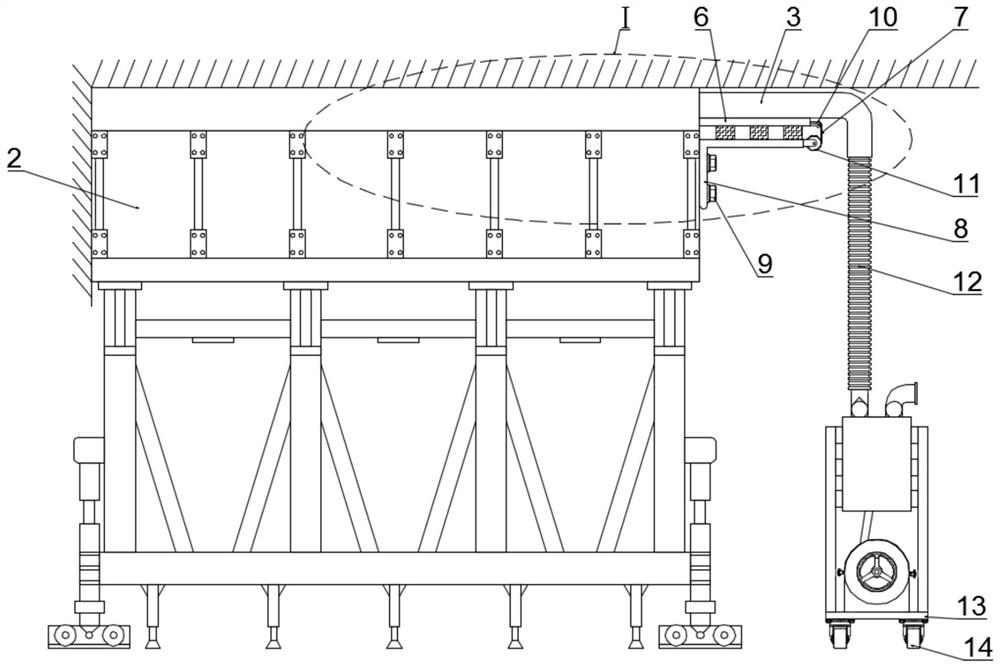

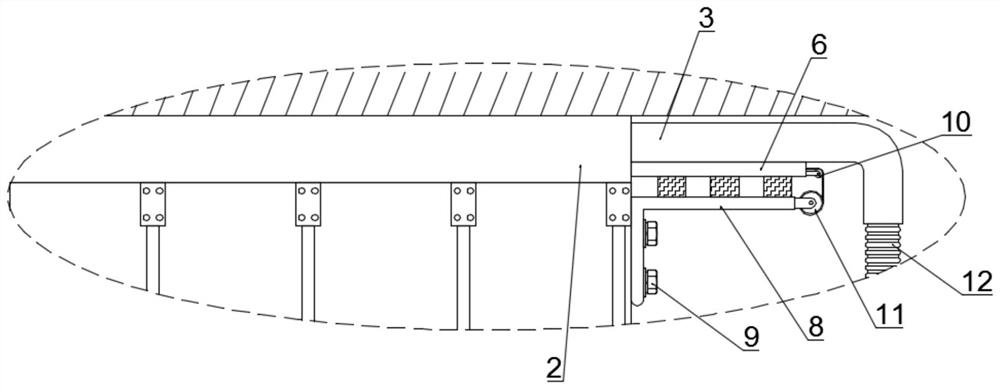

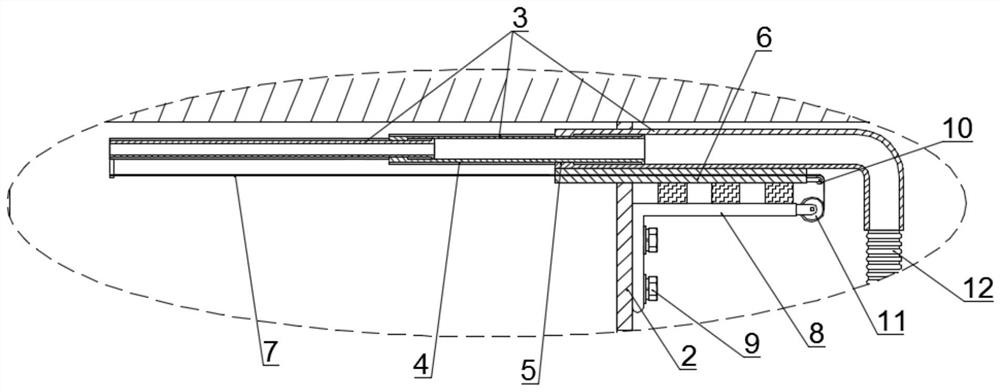

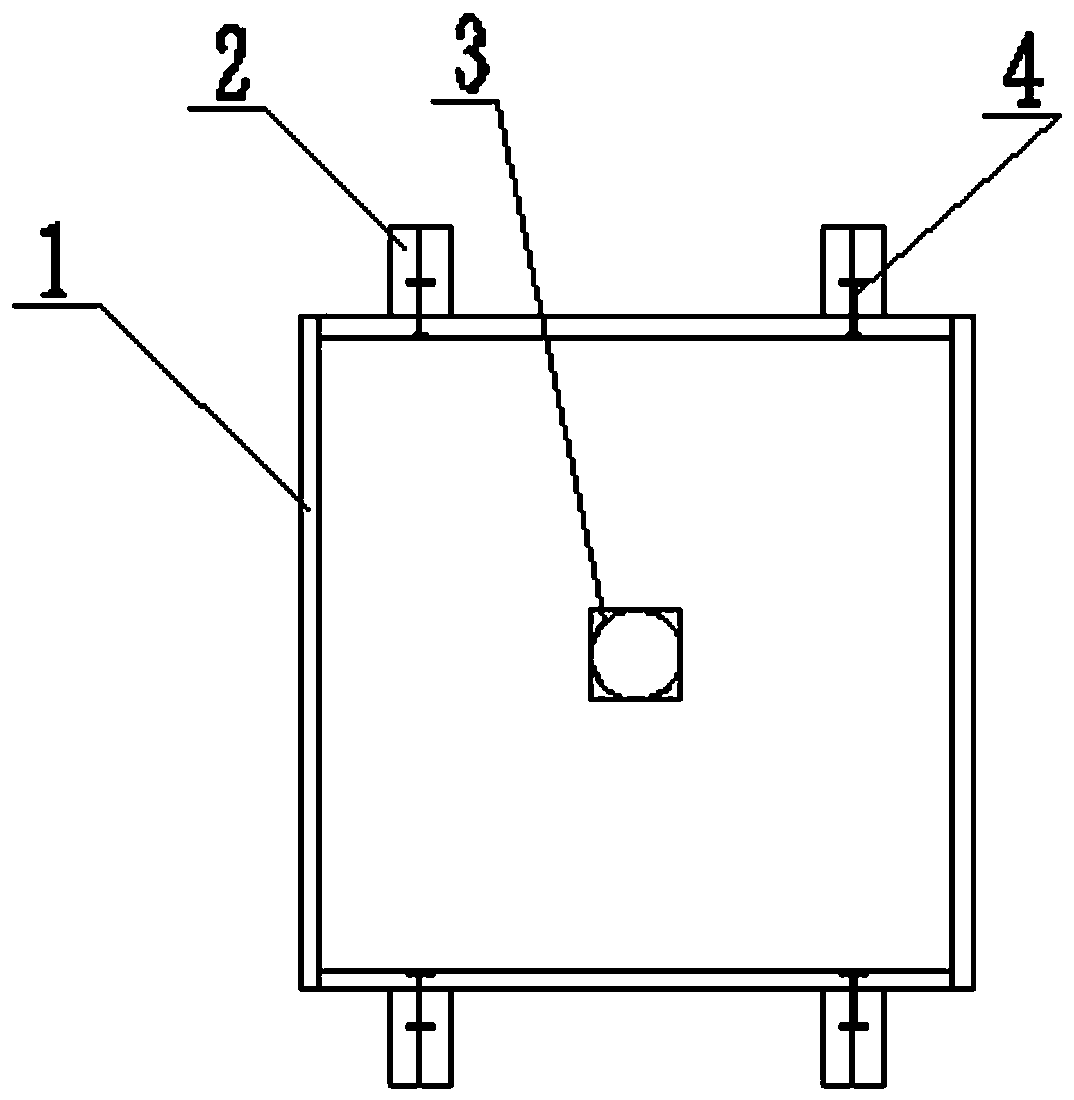

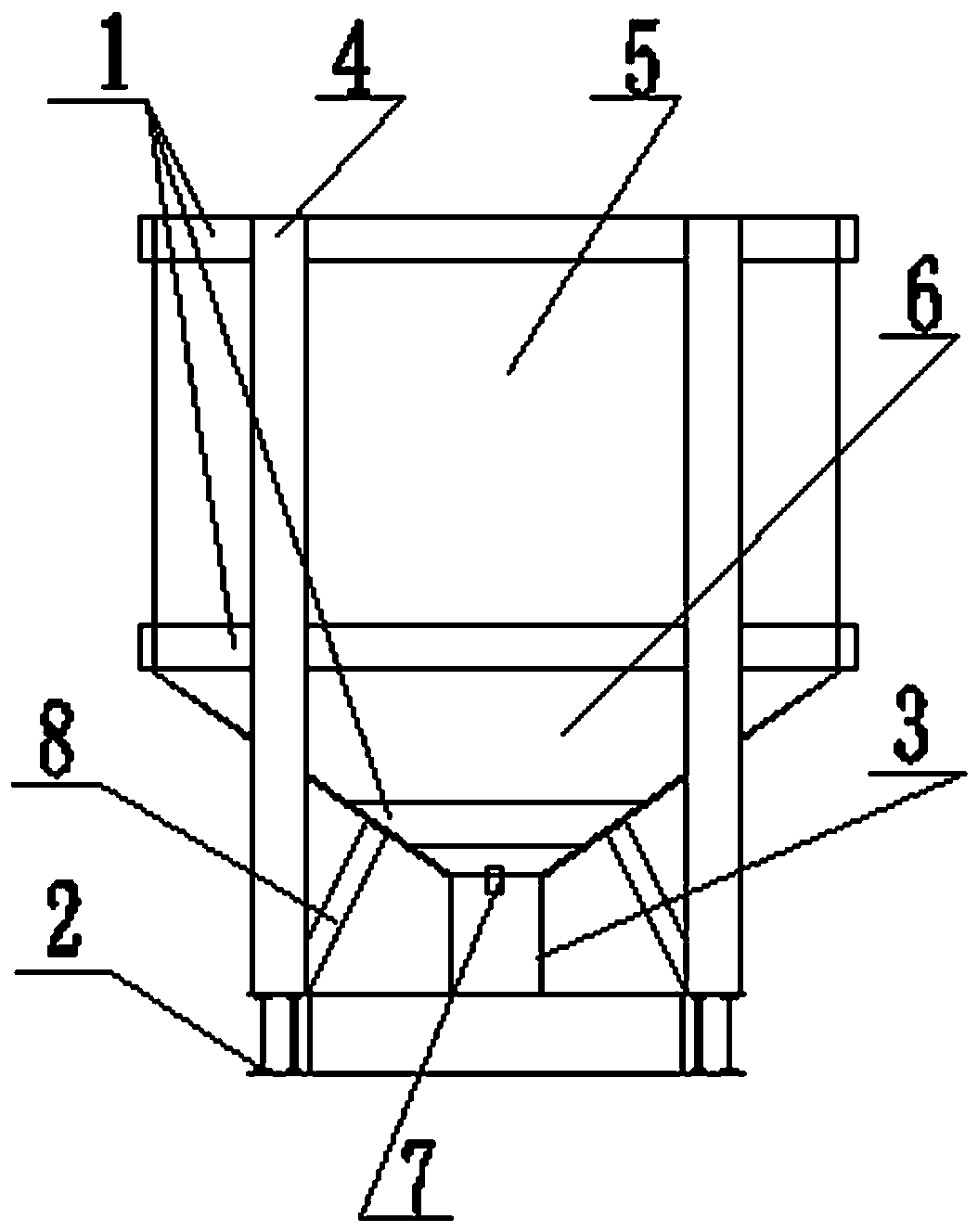

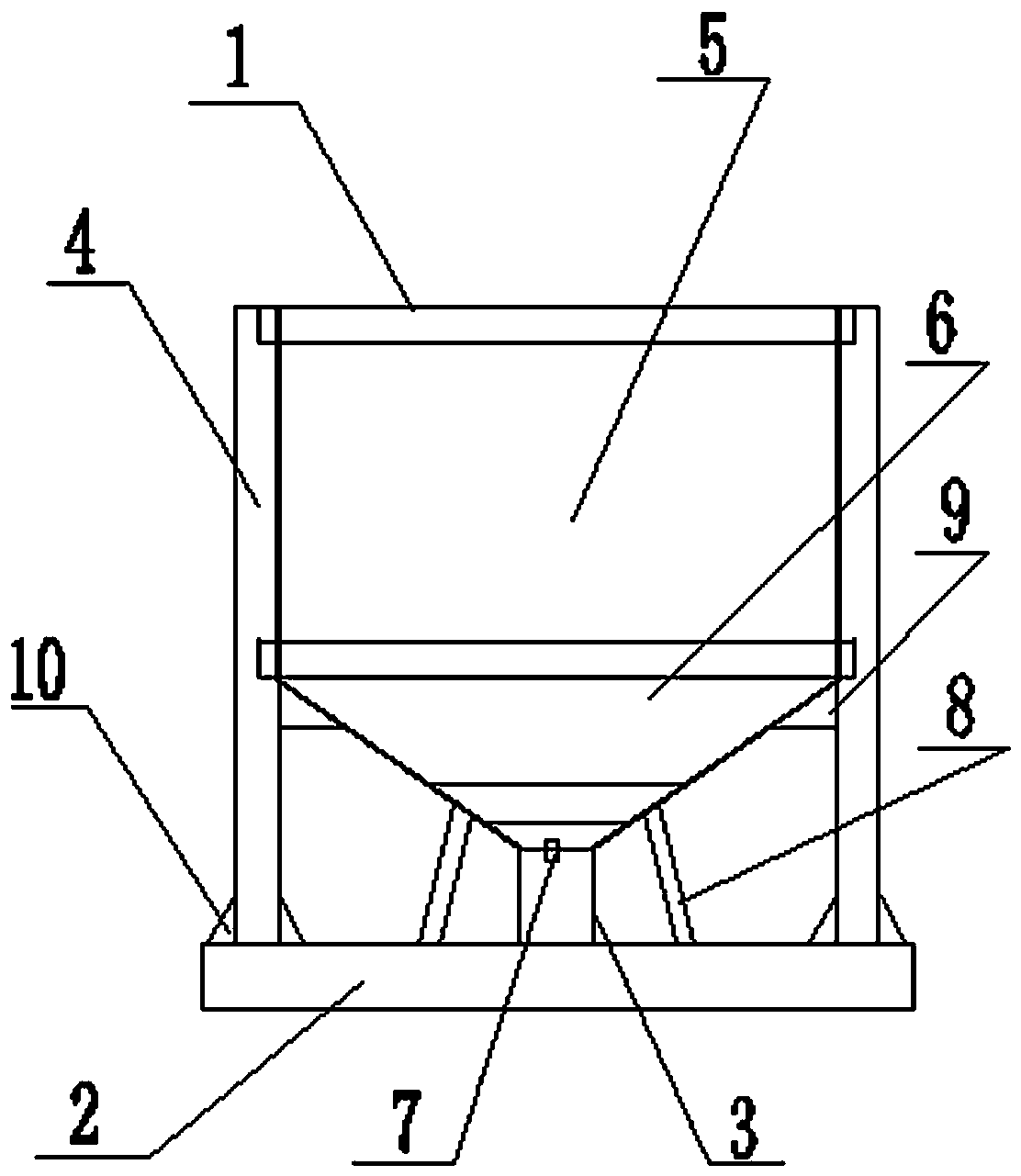

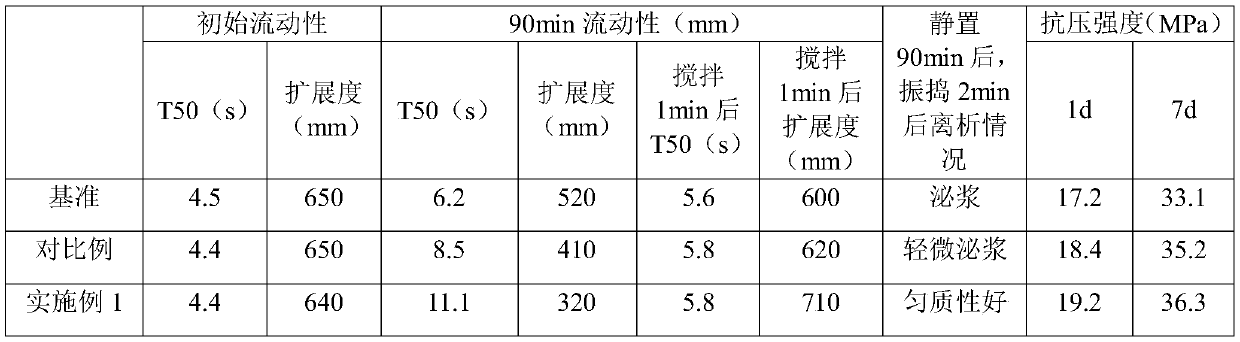

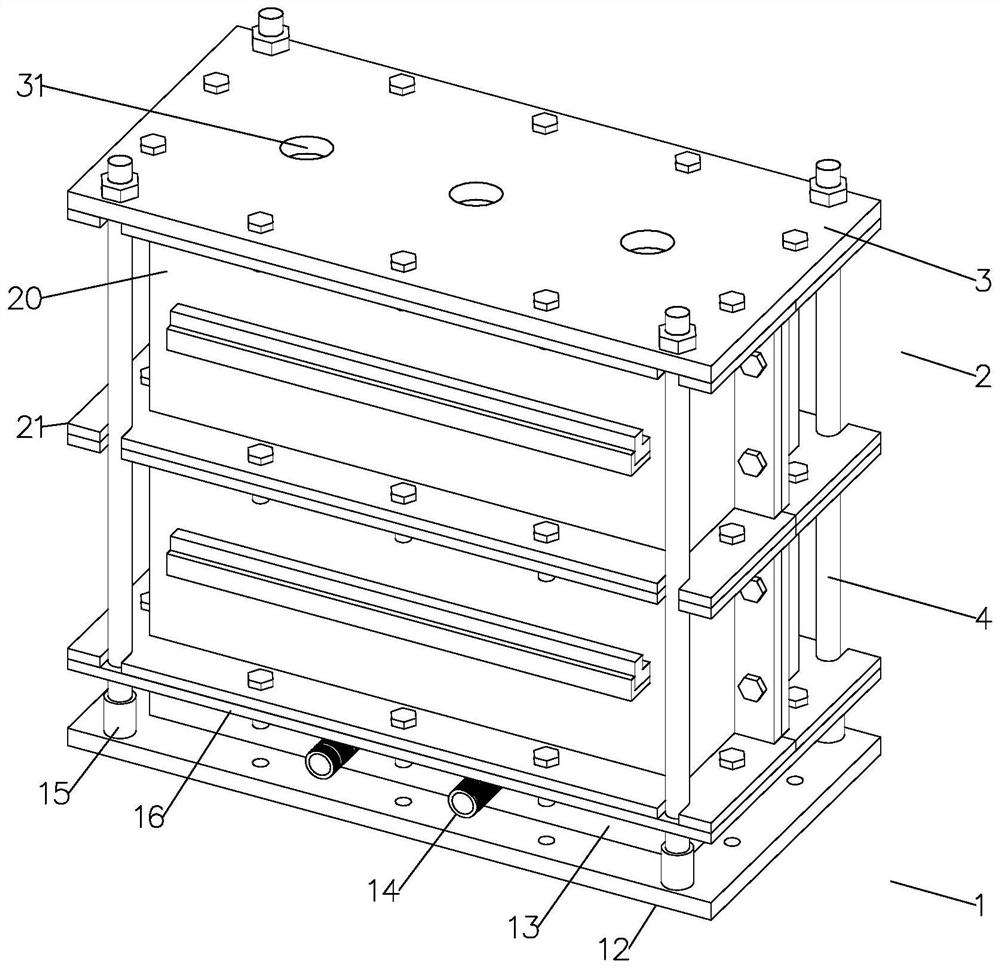

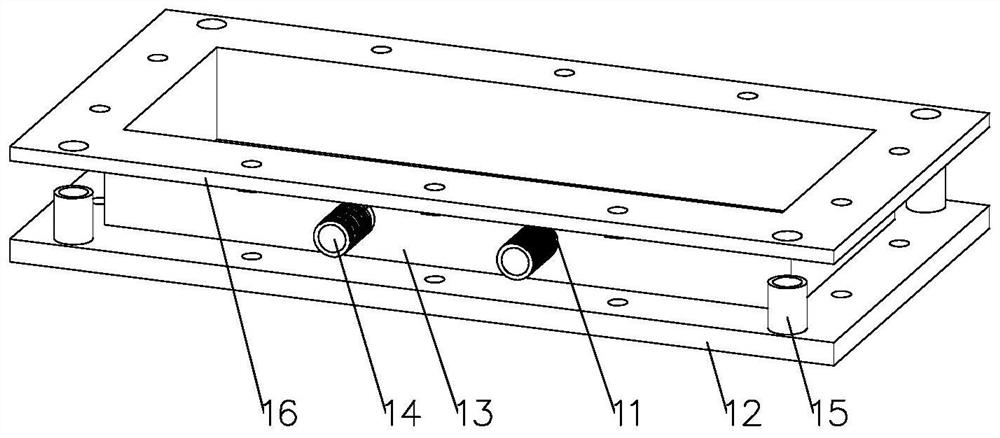

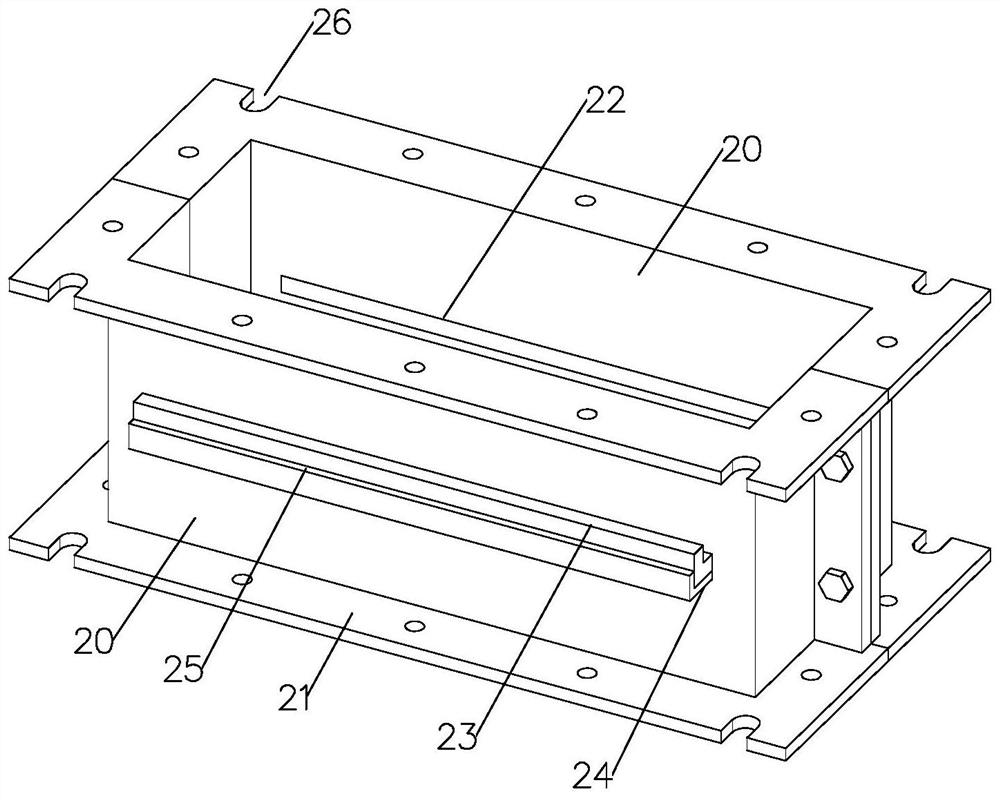

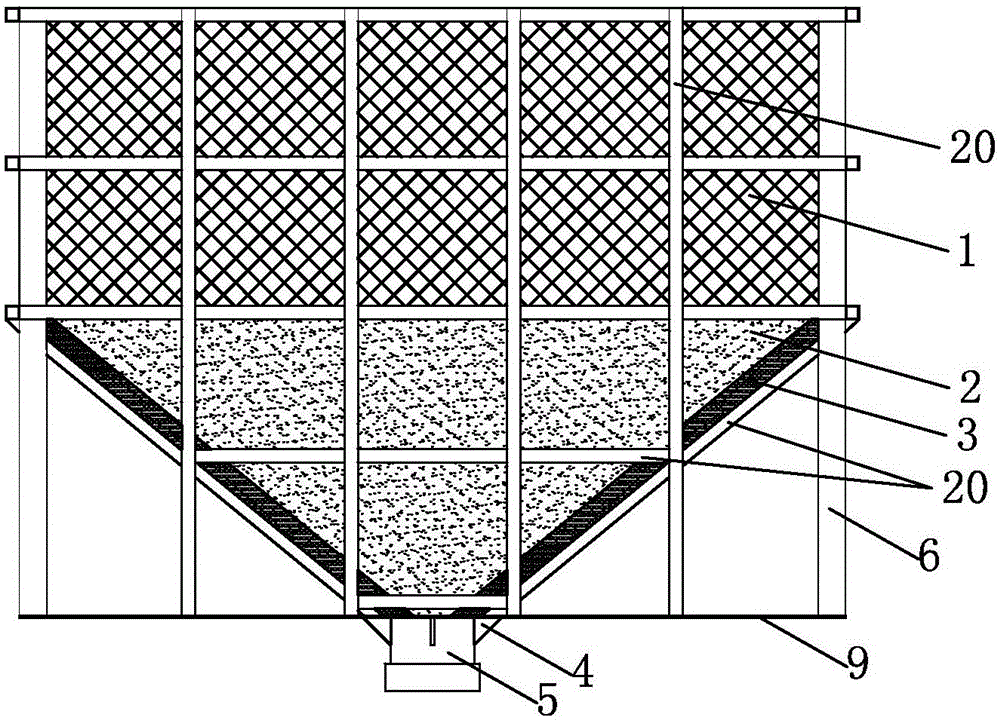

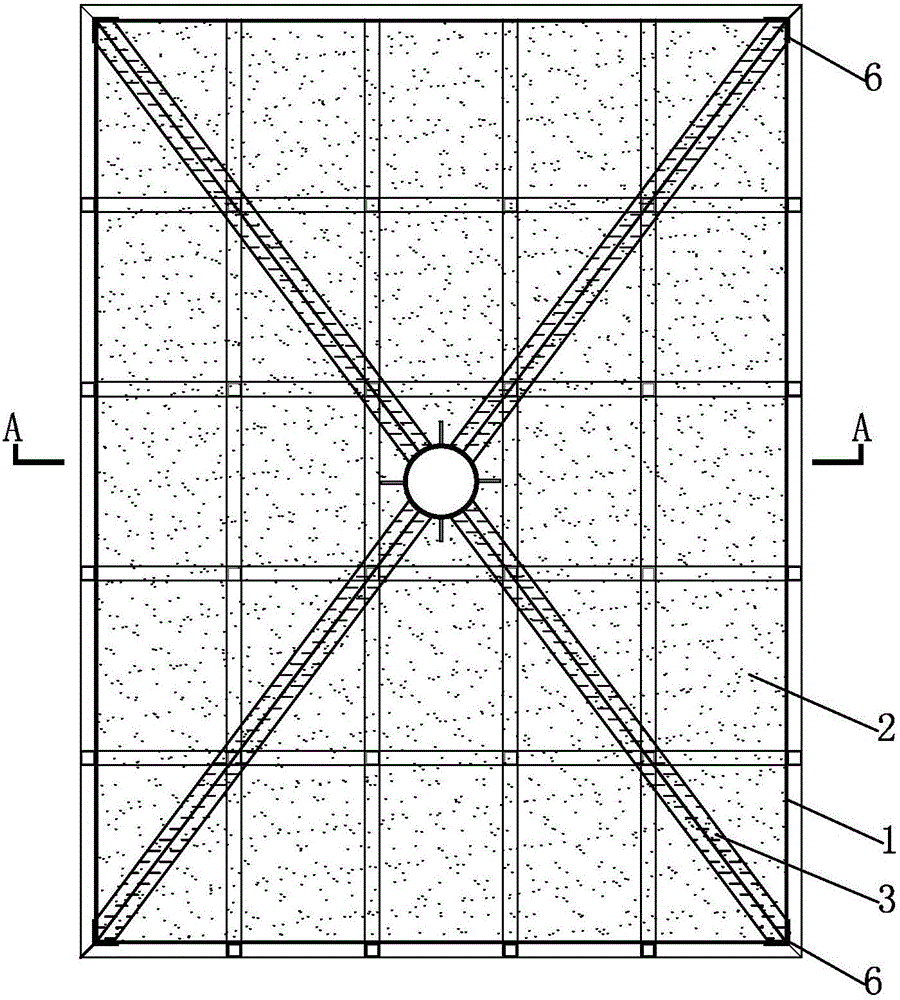

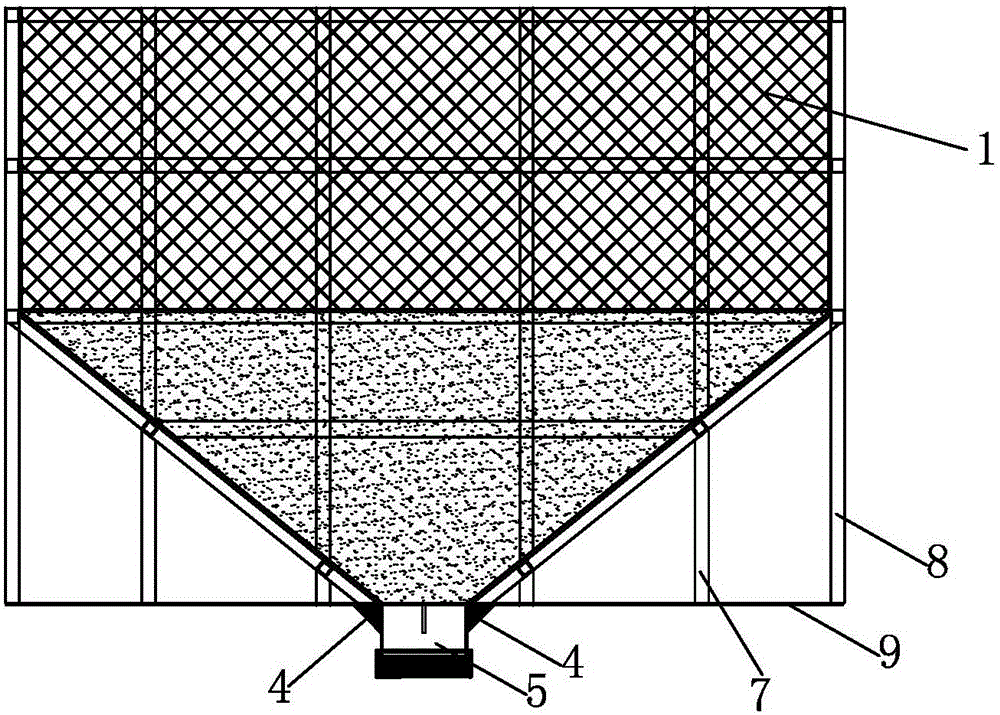

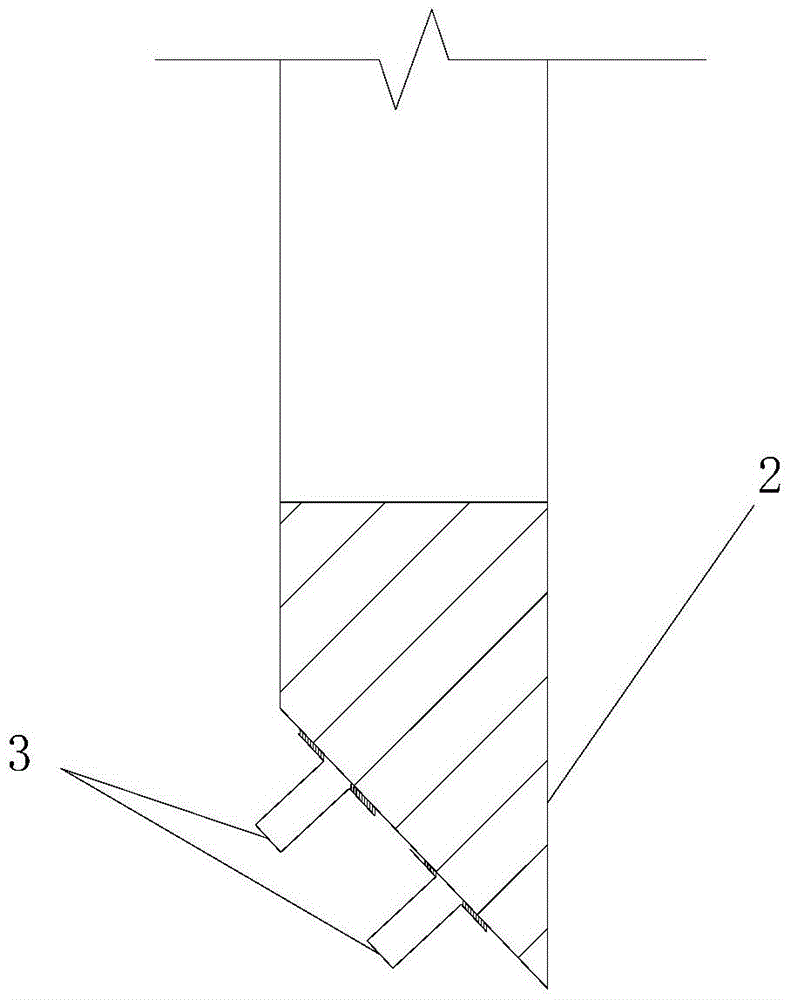

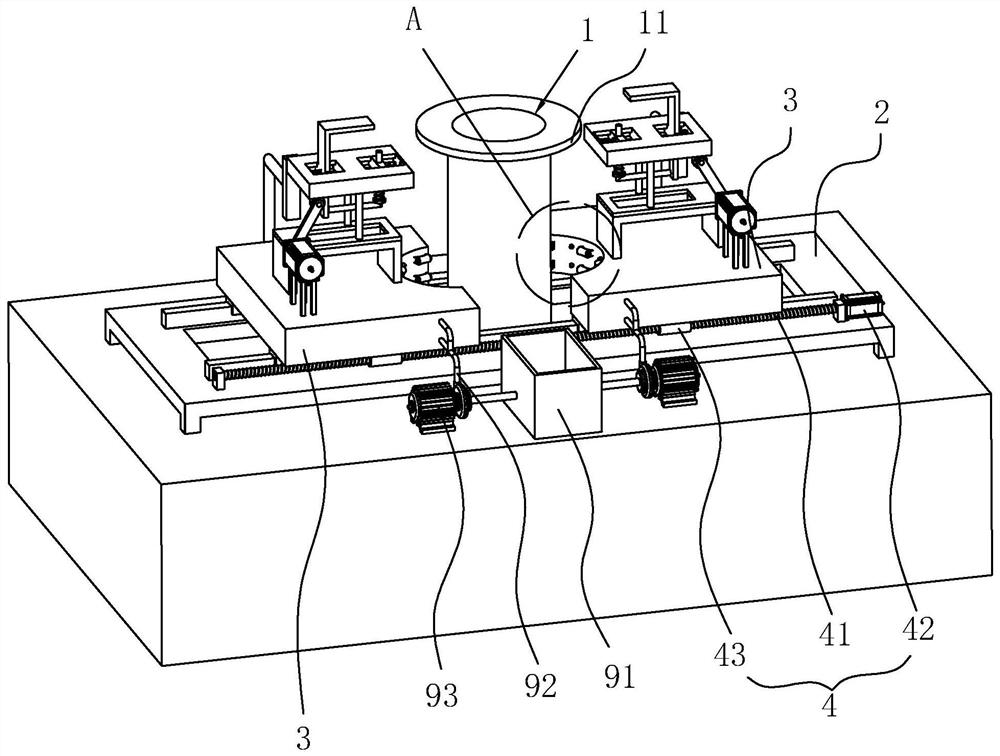

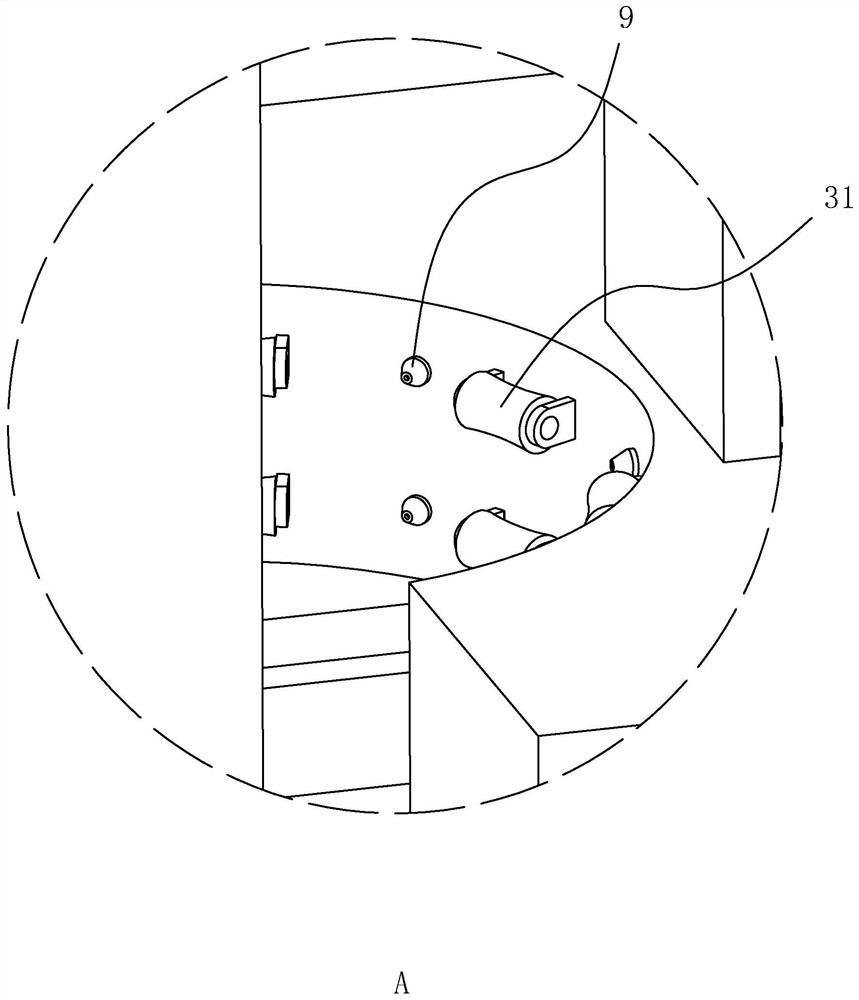

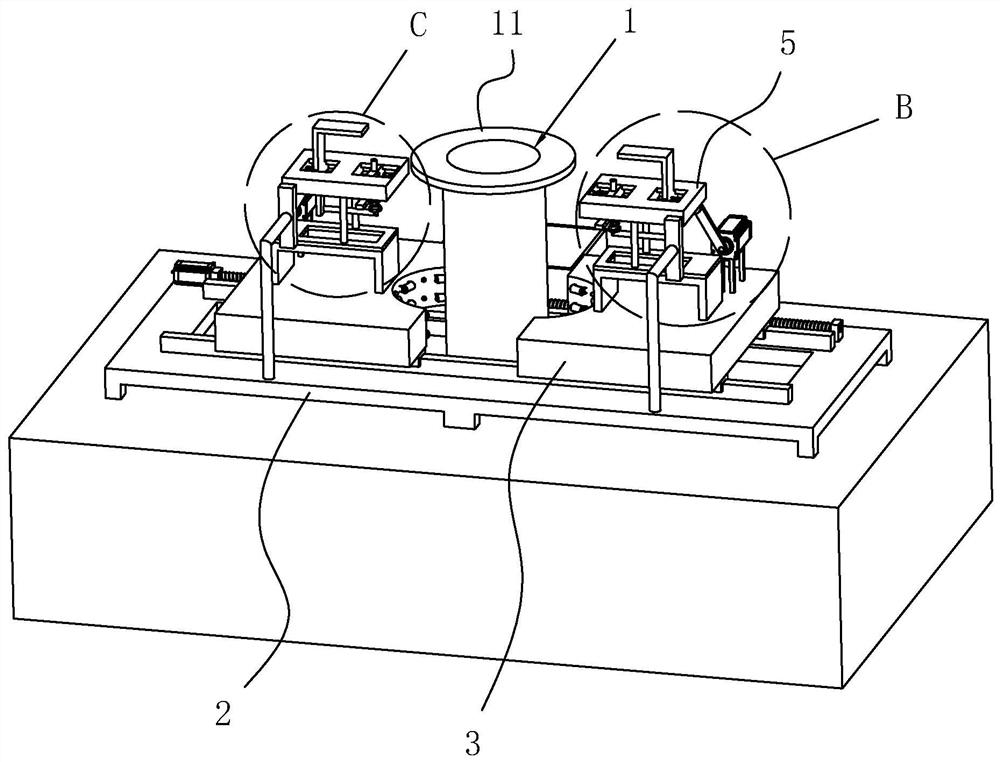

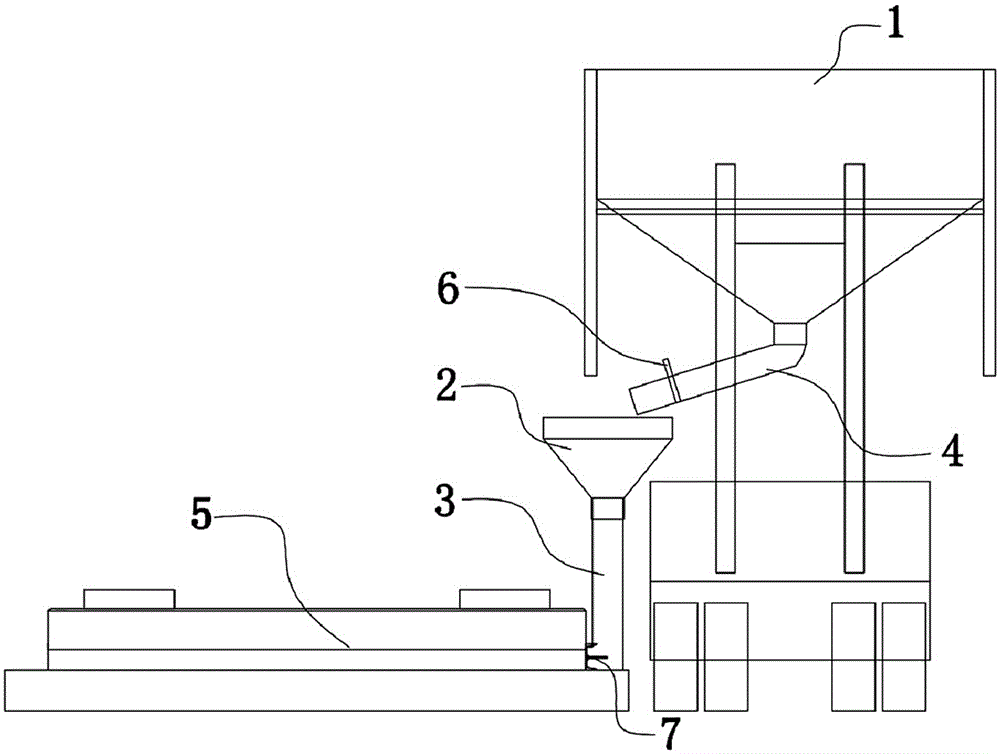

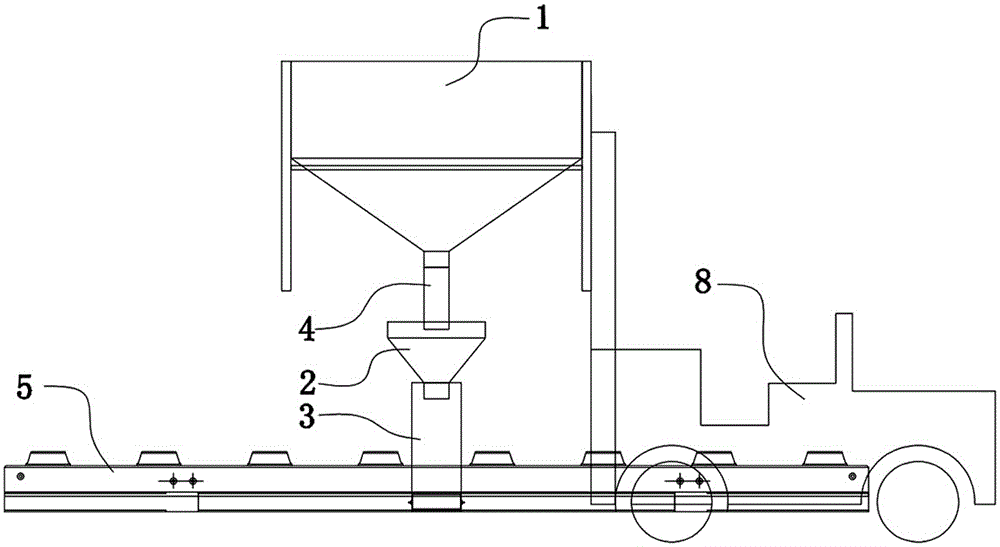

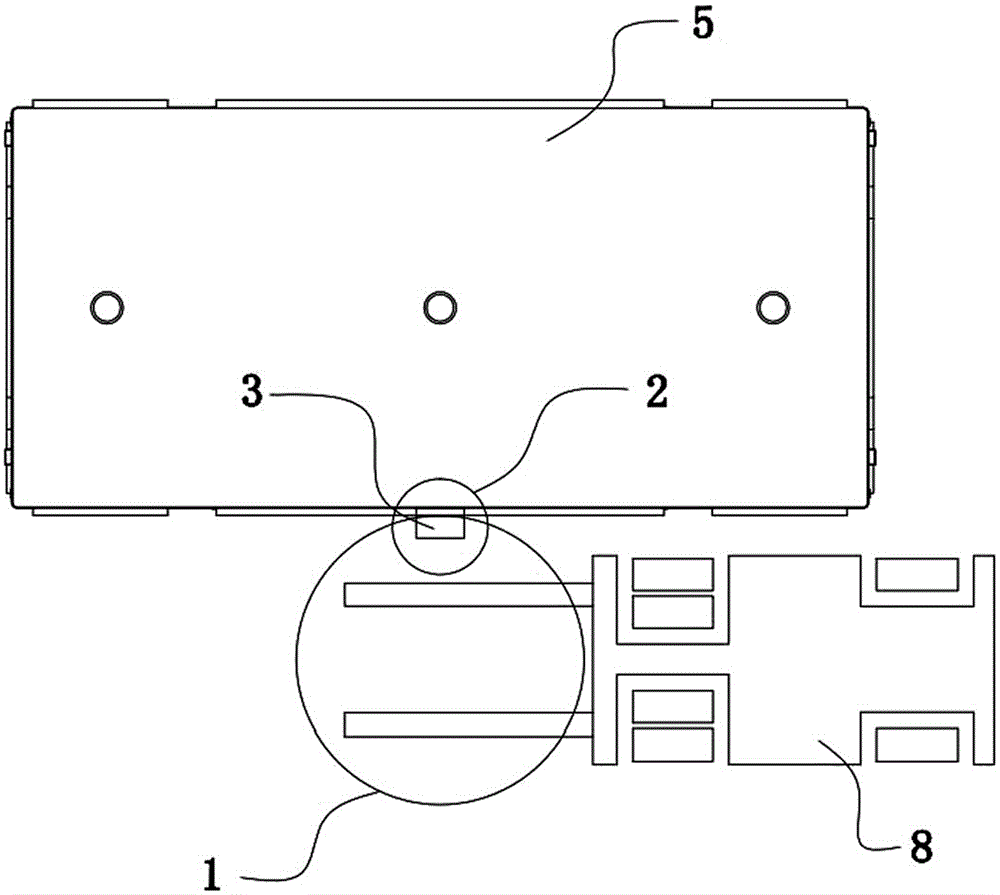

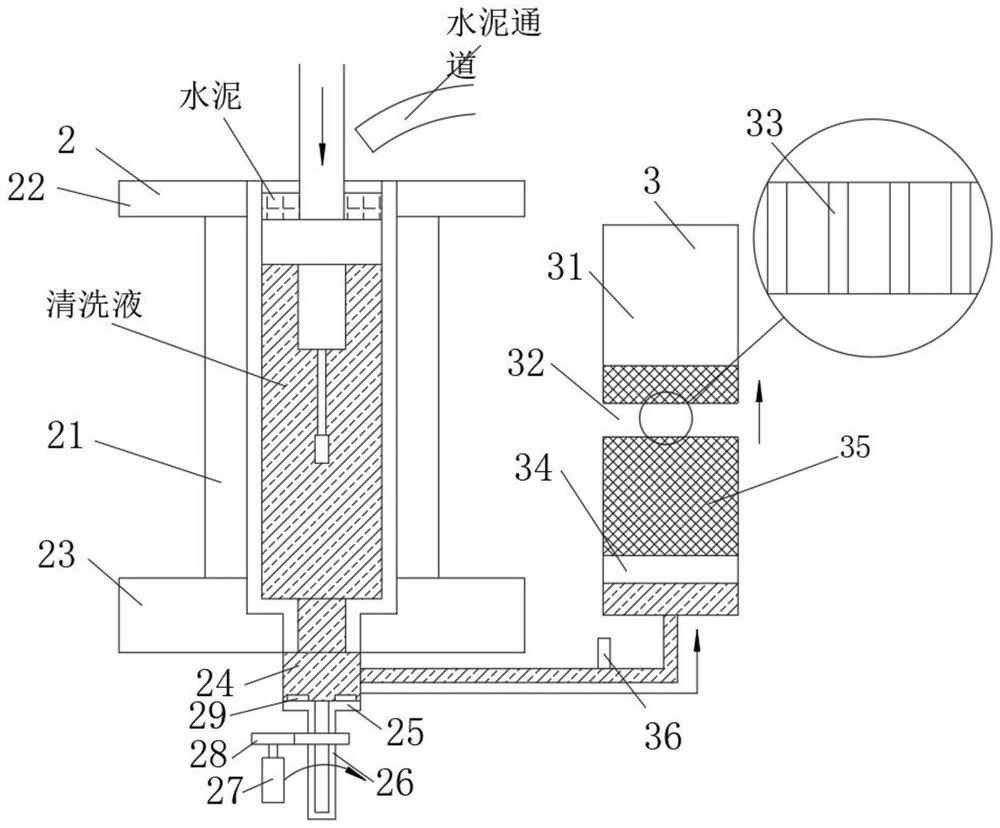

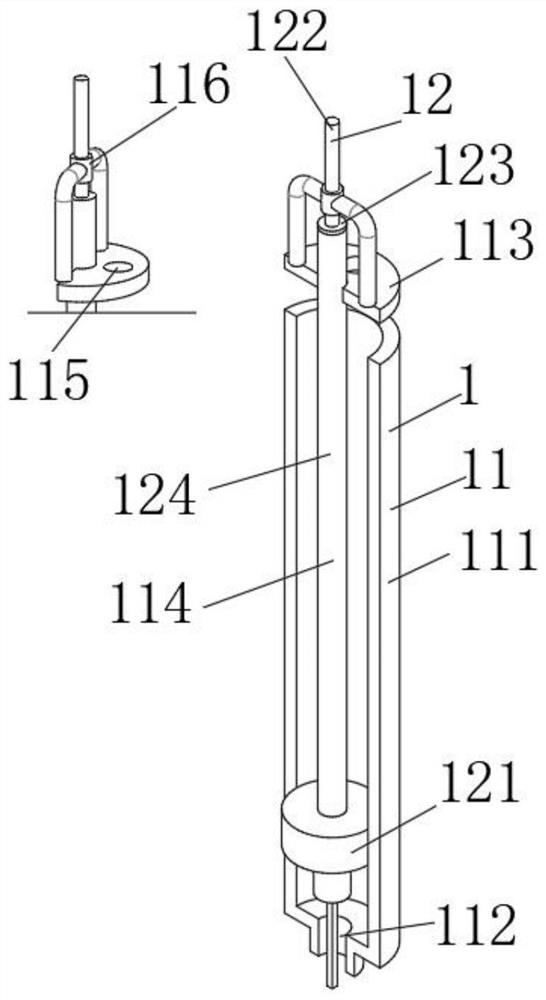

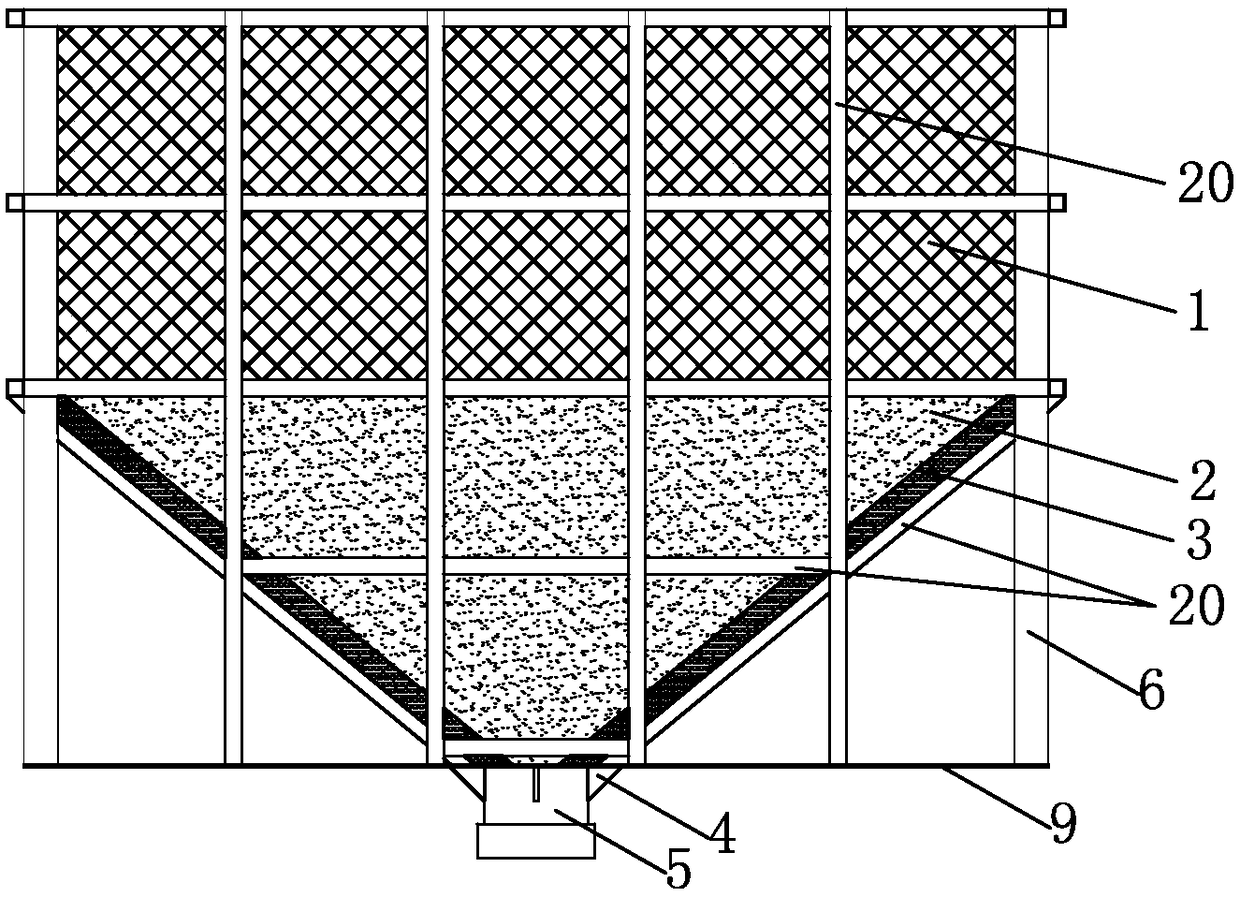

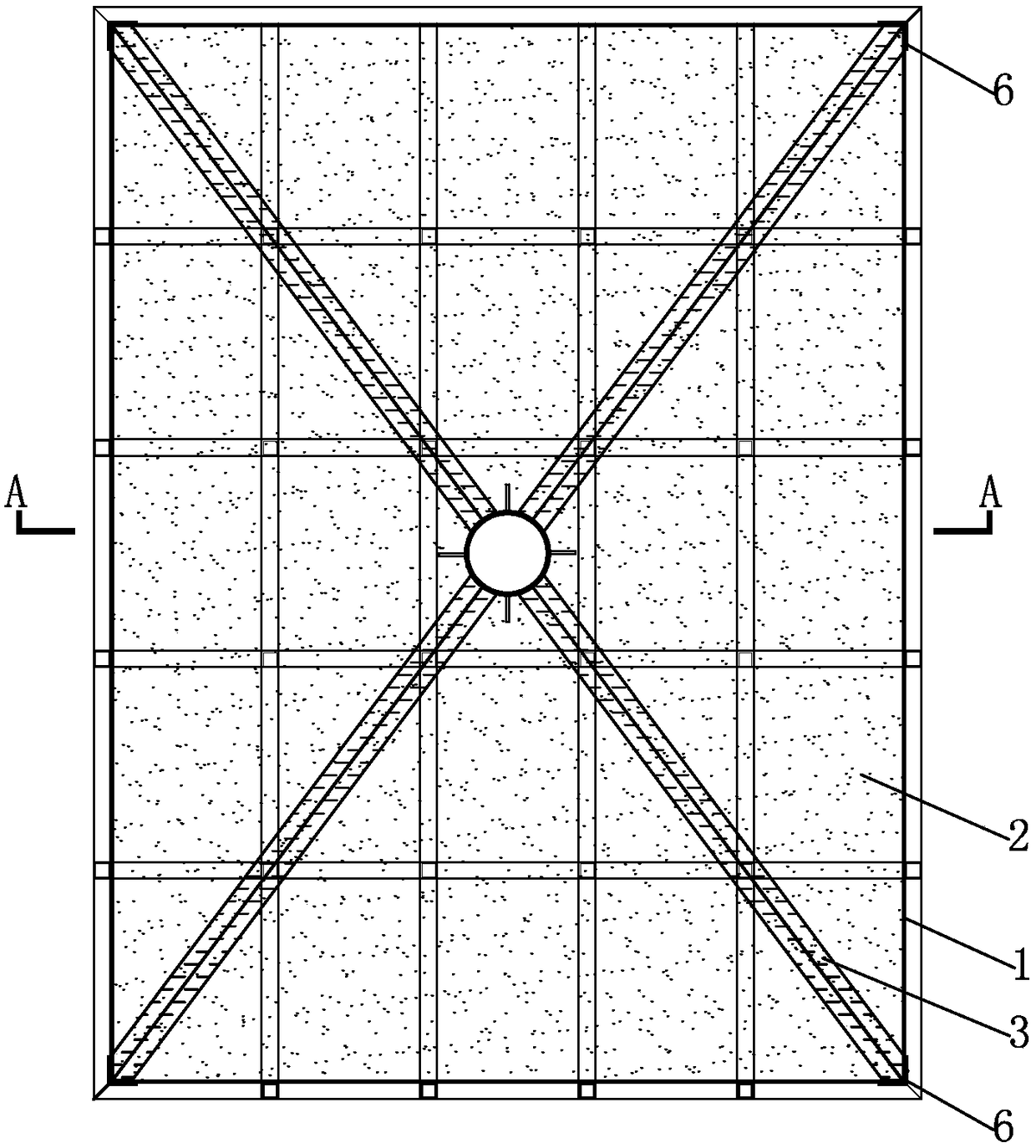

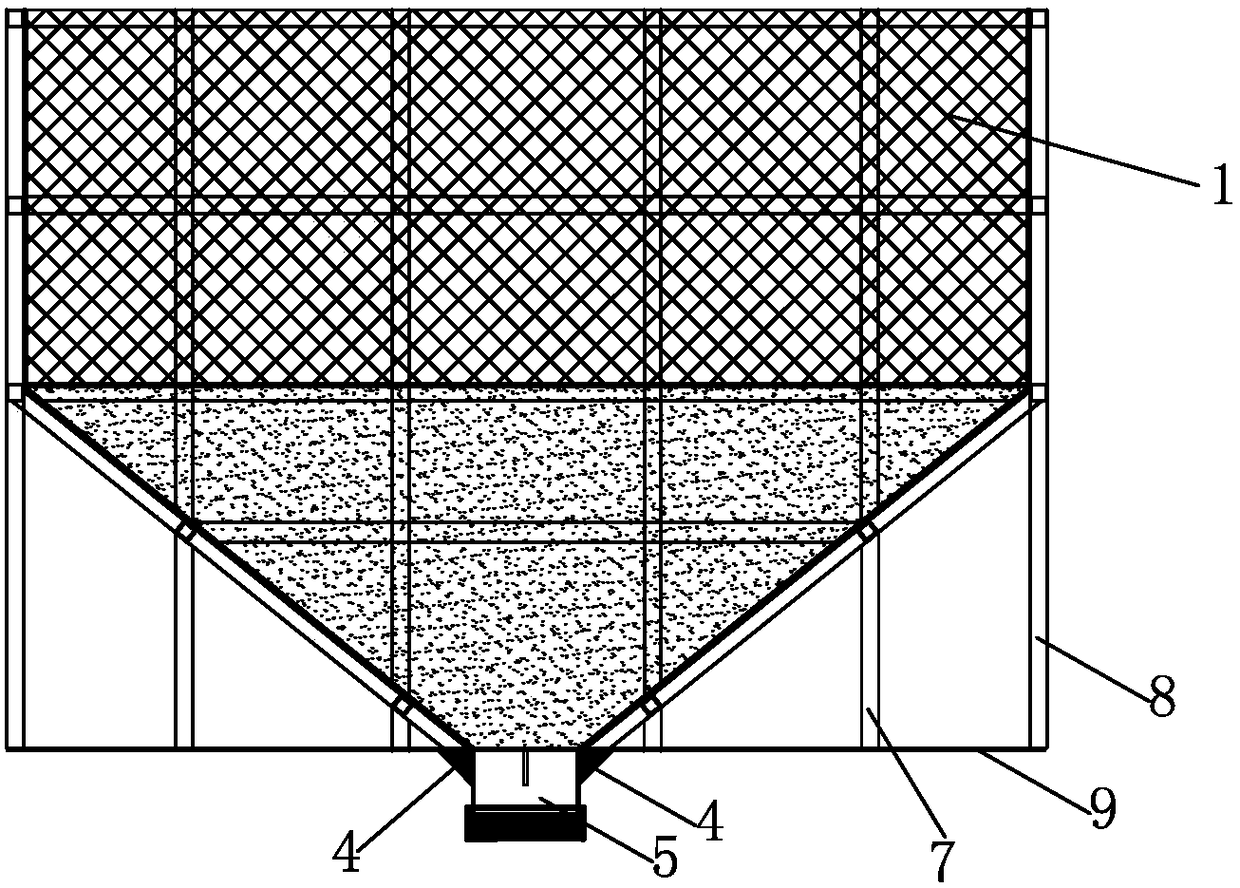

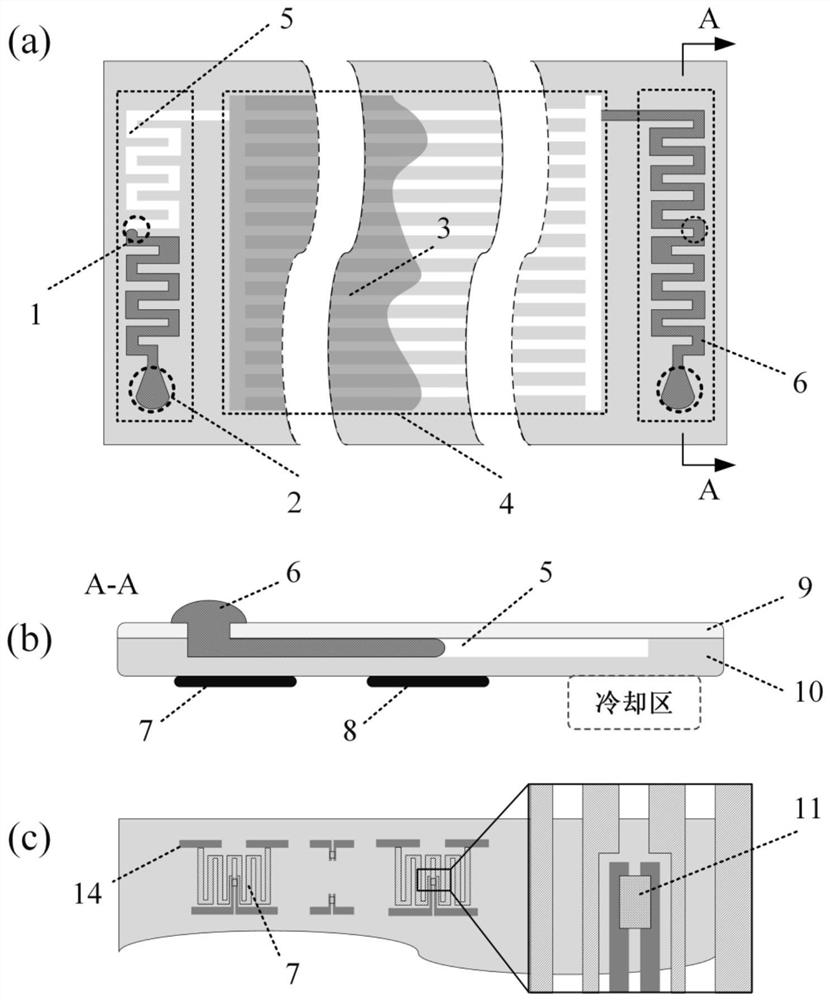

Slab ballastless track self-compacting concrete grouting device and method

ActiveCN104153258AFast perfusionImprove perfusion qualityRailway track constructionStructural engineeringSelf-consolidating concrete

The invention discloses a slab ballastless track self-compacting concrete grouting device and method. The slab ballastless track self-compacting concrete grouting device comprises a transfer storage hopper. A grouting hopper is arranged at a discharging port of the transfer storage hopper. The grouting hopper is connected with a grouting opening of a concrete formwork. The grouting hopper comprises a conical barrel and a rectangular hopper body. The conical barrel is arranged on the rectangular hopper body. The rectangular hopper body is connected with a discharging port of the conical barrel. The discharging port of the transfer storage hopper is connected with a discharging pipe. The discharging end of the discharging pipe is arranged above the conical barrel. The rectangular hopper body is arranged on the side portion of the concrete formwork. The side, facing the concrete formwork, of the rectangular hopper body is provided with a discharging port. The grouting port is formed in the side, close to the rectangular hopper body, of the concrete formwork. By the adoption of the slab ballastless track self-compacting concrete grouting device and method, the grouting speed is increased, and the grouting quality is better.

Owner:中建八局检测科技有限公司

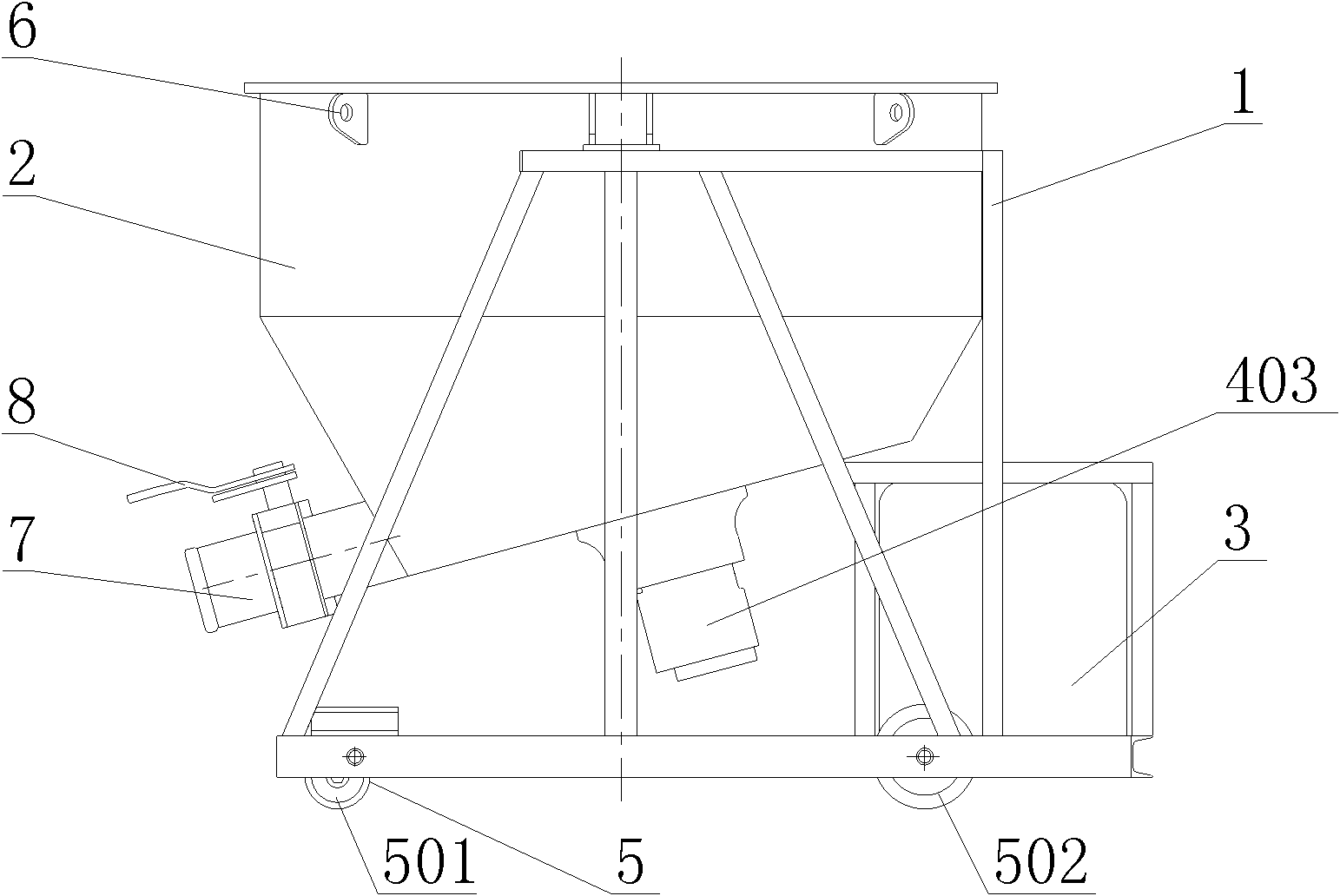

Mortar transfer device

InactiveCN101857144ACompact structureImprove work efficiencyBulk conveyorsBuilding material handlingElectric machineryAgricultural engineering

The invention discloses a mortar transfer device comprising a rack and a hopper fixed on the rack, wherein a self-stirring assembly is arranged in the hopper and comprises a stirring shaft, a stirring blade and a motor, the stirring blade is fixed on the stirring shaft which is connected with the output end of the motor, and the motor is connected with a power supply assembly assembled on the rack. The invention is a mortar transfer device which has simple, compact and beautiful structure, self stirring function, convenient movement, flexible steering, convenient hoisting, low cost and high efficiency and is provided with a power supply.

Owner:SANY HEAVY IND CO LTD (CN)

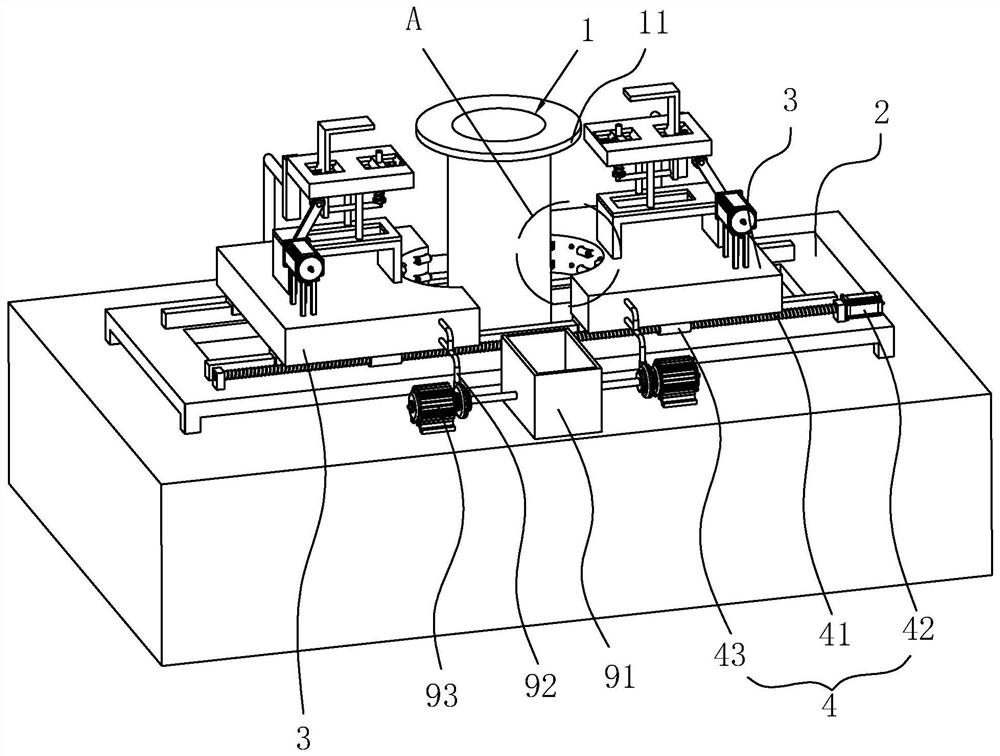

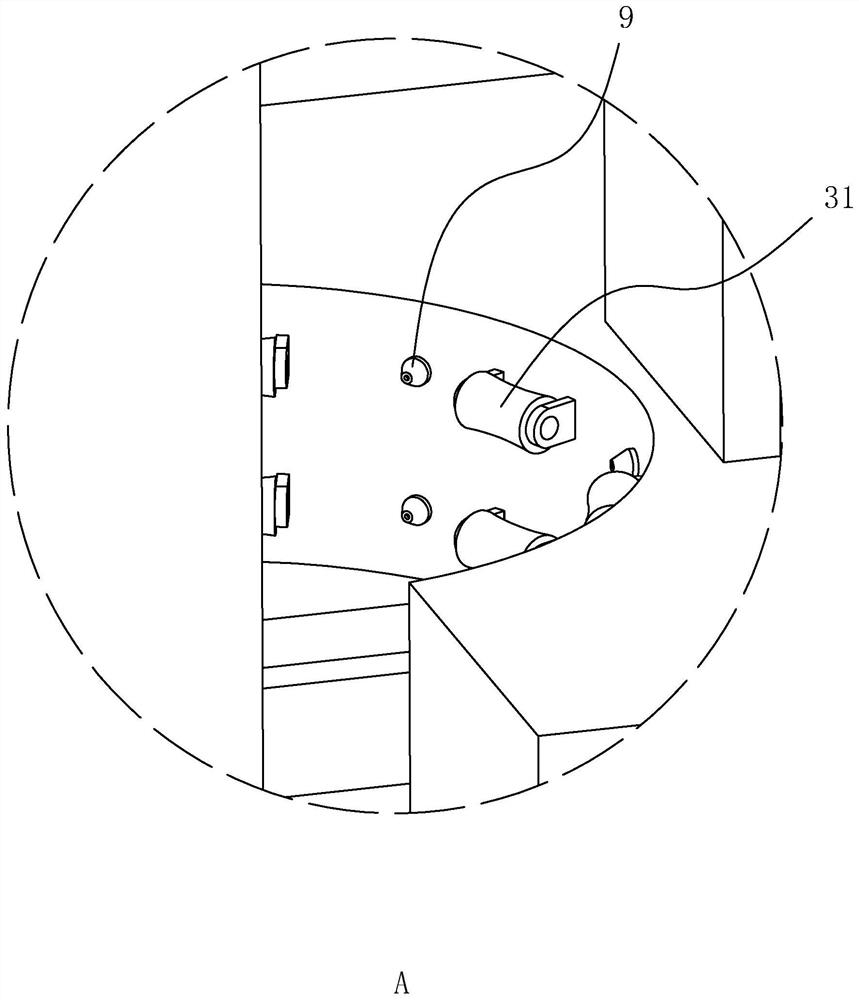

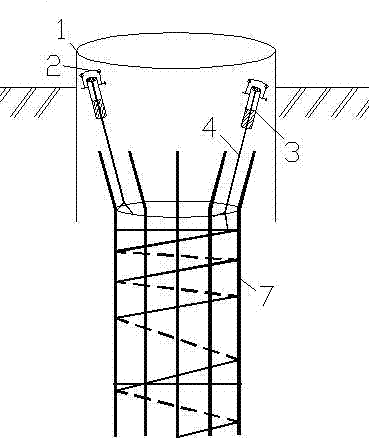

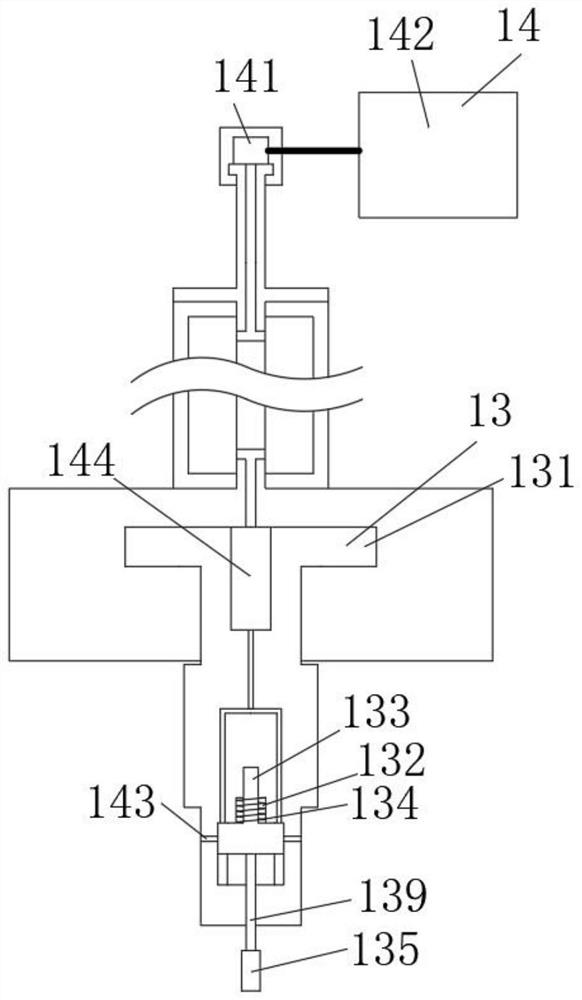

Cast-in-situ bored pile grouting device and construction method thereof

ActiveCN112227375APrevent accumulation and cloggingAvoid problemsBulkheads/pilesArchitectural engineeringLap joint

The invention relates to a cast-in-situ bored pile grouting device and a construction method thereof. The cast-in-situ bored pile grouting device comprises a rack arranged at an orifice of a foundation pile, two sliding seats symmetrically sliding in the radial direction of the orifice on the rack, guide rollers rotationally arranged on the side walls, close to the orifice, of the sliding seats, and a driving device for driving the two sliding seats to synchronously and reversely slide are arranged on the rack; the cast-in-situ bored pile grouting device further comprises lap-joint lugs whichare fixedly connected to the outer walls of the two ends of a pipe section, a lap-joint table is arranged on the sliding seats in a lifting mode in the vertical direction, and a lifting device used for driving the lap-joint table to ascend and descend in a reciprocating mode is arranged on the sliding seats; and when concrete is poured, the spliced pipe section is inserted into the orifice, the two sliding seats are driven to synchronously get close to each other and clamp a grouting pipe, the guide rollers play a role in guiding and correcting the grouting pipe, then the lap-joint lugs on thegrouting pipe are in lap joint with the lap-joint table, then the lap-joint table is driven to ascend and descend up and down in a reciprocating mode, and smooth flowing of the concrete in the grouting pipe is guaranteed. The cast-in-situ bored pile grouting device and the construction method thereof have the effects of improving the quality of the foundation pile and saving manpower.

Owner:飞帆集团有限公司

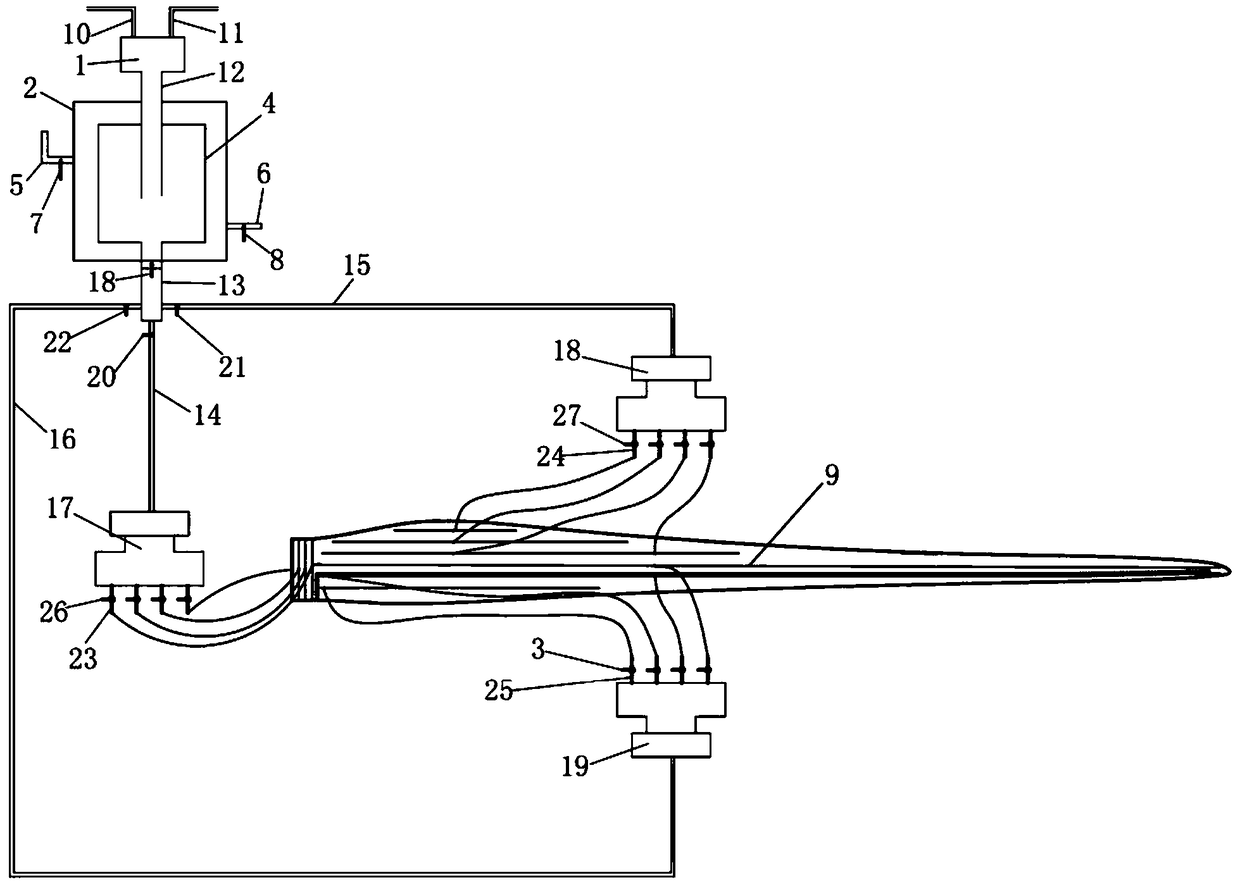

Integrated perfusion assembly line for wind turbine blade and perfusion process thereof

ActiveCN108790216ALow costReduce labor costsFinal product manufactureDomestic articlesTurbine bladeControl engineering

The invention discloses an integrated perfusion assembly line for a wind turbine blade and a perfusion process thereof. The integrated perfusion assembly line comprises a resin mixing room, a resin mixing and defoaming all-in-one box and a perfusion storage room, wherein an ultrasonic room is formed in the resin mixing and defoaming all-in-one box; the outer wall of the resin mixing and defoamingall-in-one box has a heating or cooling function and is equipped with a bleeder pipe with a gas vent valve and a suction pipe with a suction port valve; the suction pipe can be externally connected with a vacuum pump; a resin component A feed pipe and a resin component B feed pipe are mounted on the resin mixing room; the resin mixing room communicates with the ultrasonic room through a resin drainage pipe; the ultrasonic room is connected to at least one perfusion storage room through a resin feeding pipe and a resin conveying pipeline which are mutually connected; a feeding pipe valve is mounted on the resin feeding pipe; a conveying pipeline valve is mounted on the resin conveying pipeline; a discharge pipe is mounted on the perfusion storage room; a discharge control valve is mounted on the discharge pipe; and the discharge pipe is connected to a product vacuum system. The integrated perfusion assembly line performs mixing and defoaming simultaneously, and adopts an integrated perfusion technology to guarantee favorable perfusion quality.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

Method for manufacturing low-disturbance melt-resistant frozen soil foundation of transmission tower

InactiveCN102733408AImprove perfusion qualityShorten the lengthFoundation engineeringMachine toolTransmission tower

The invention relates to a method for manufacturing a low-disturbance melt-resistant frozen soil foundation of a transmission tower. The method comprises the following steps of: drilling a pile position by utilizing low disturbance, reaming the bottom end of the pile hole, placing a steel reinforcement cage and filling concrete to construct a foundation. The method provided by the invention is mature and is easy to operate by utilizing the low disturbance for drilling the pile hole, reaming and filling the concrete to form a pile; an emptying machine tool is simple; the steps of the method can be simultaneously carried out according to the requirements of a construction schedule in groups; a plurality of pile holes are synchronously constructed so that the construction period is shorted, the foundation is convenient to clean, soft soil at the bottom of the pile holes can be clearly cleaned, the construction quality is reliable, and the walls and the bottoms of the pile holes are convenient to check; a quality situation of soil at the bottoms of the pile holes can be checked, the diameter and the depth of the pile can change along with a bearing force situation, and the pile end can be enlarged manually so that the large bearing force can be obtained, the requirement on one pile with one column is met, the length of a construction line is shortened, and the construction cost and the construction period are remarkably reduced; and in addition, when each section of concrete is filled in the pile body, the concrete can be immediately tamped and the filling quality of the concrete is good.

Owner:XINJIANG ELECTRIC POWER DESIGN INST

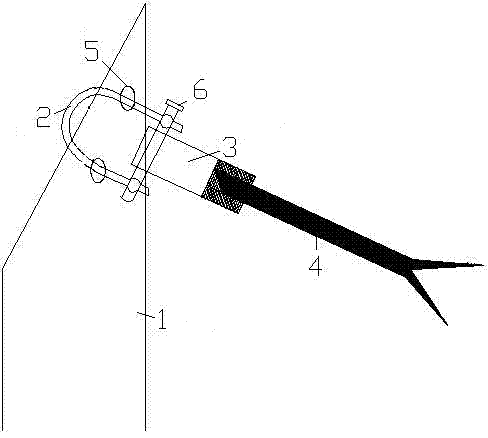

Anti-floating method and device for bored concrete pile reinforcement cage

The invention relates to an anti-floating method and device for a bored concrete pile reinforcement cage. The anti-floating method is characterized in that the technological process is as follows: before starting to drill a hole, taking the center of a pile position as the center of a circle, confirming the position of a steel pile casing on the soil according to the radius of the steel pile casing of the anti-floating device of the bored concrete pile reinforcement cage, after placing the steel pile casing, applying pressure for embedding the steel pile casing into the soil, and then starting to drill the hole; after forming the hole in a bored concrete pile, placing the reinforcement cage into the hole; penetrating a U-shaped lock catch into the reserved hole in the steel pile casing; using a bolt to connect the U-shaped lock catch with a connecting loop bar; inserting the tail part of a fork rod into the connecting loop bar; clamping the head of the fork rod on a top hoop of the reinforcement cage, and then starting to pour concrete; when the concrete is about to be poured to the pile top position, detaching the bolt on the U-shaped lock catch; taking down the connecting loop bar, the steel fork rod and the U-shaped lock catch; continuing pouring the concrete to the designed elevation, and pulling out the steel pile casing. According to the anti-floating method and device provided by the invention, the floating of the reinforcement cage while pouring the concrete can be effectively avoided.

Owner:HUBEI CENT SOUTH EXPLORATION & FOUND ENG

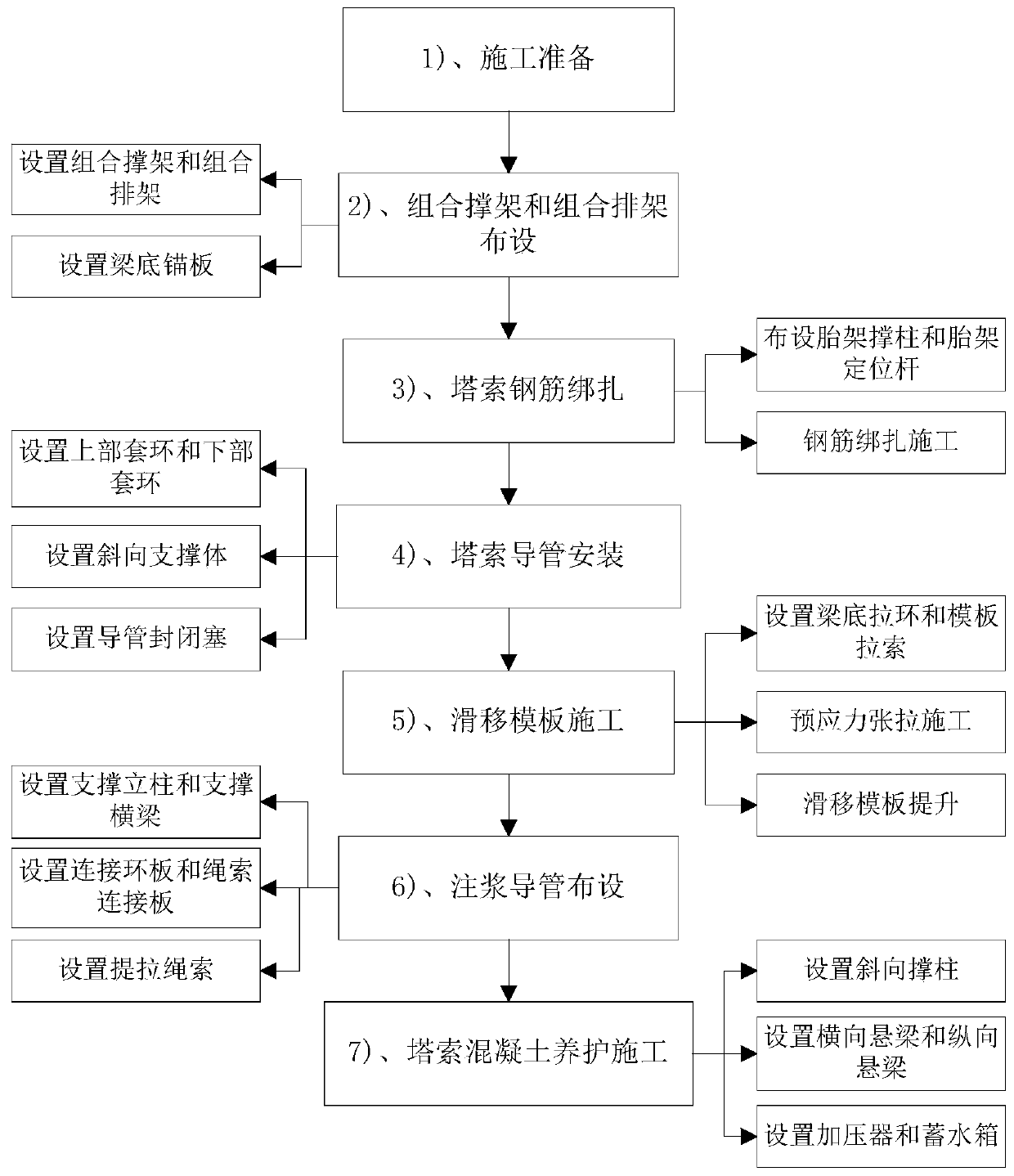

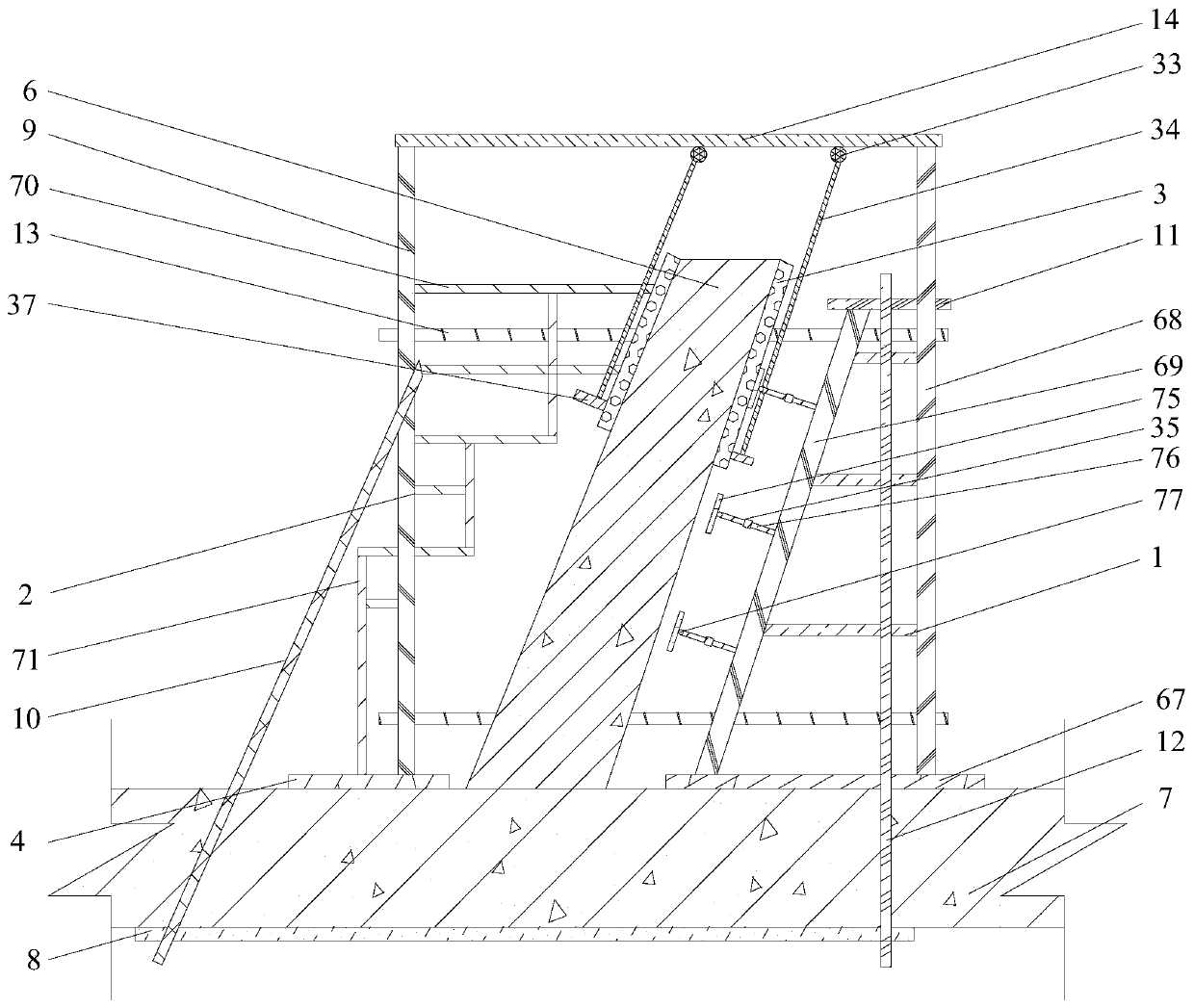

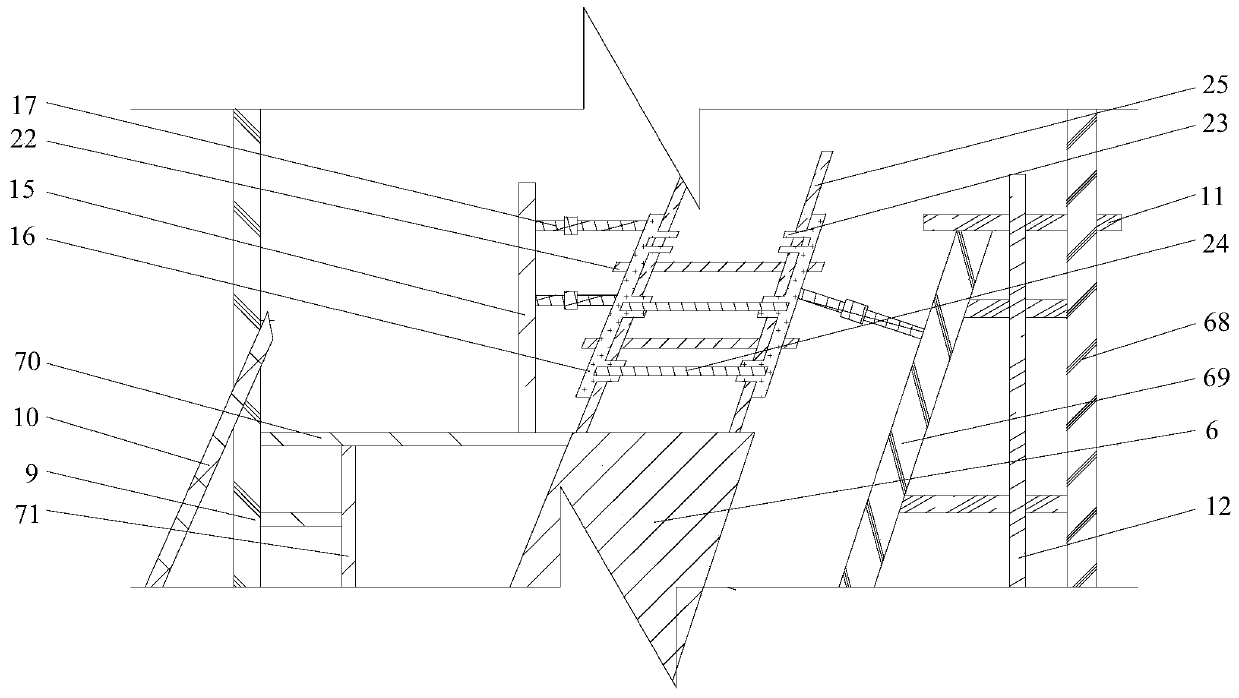

Construction method of inclined cable tower construction structure system

The invention relates to a construction method of an inclined cable tower construction structure system, which comprises the following steps of: 1) construction preparation; 2) arrangement of a combined support frame and a combined grid frame; 3) binding of cable tower steel bars; 4) installation of a tower cable guide pipe; 5) construction of a sliding moulding plate; 6) arrangement of a groutingguide pipe; and 7) concrete maintenance construction of the cable tower. The construction method of the inclined cable tower construction structure system has the advantages that arrangement efficiency of the combined support frame and the combined grid frame can be improved, integrity of the structure can be enhanced, and supporting quality of the sliding moulding plate can be effectively improved; positioning of the cable tower steel bars is accurate, connection is convenient, binding construction quality of longitudinal steel bars and transverse stirrups can be effectively improved, and on-site construction difficulty is reduced; and on-site arrangement of the concrete grouting guide pipe is convenient, an inclination angle of the grouting guide pipe can be dynamically adjusted according to an inclination condition of the cable tower, on-site positioning difficulty is reduced, and concrete pouring quality is improved.

Owner:ANHUI HIGHWAY BRIDGE ENG CO LTD

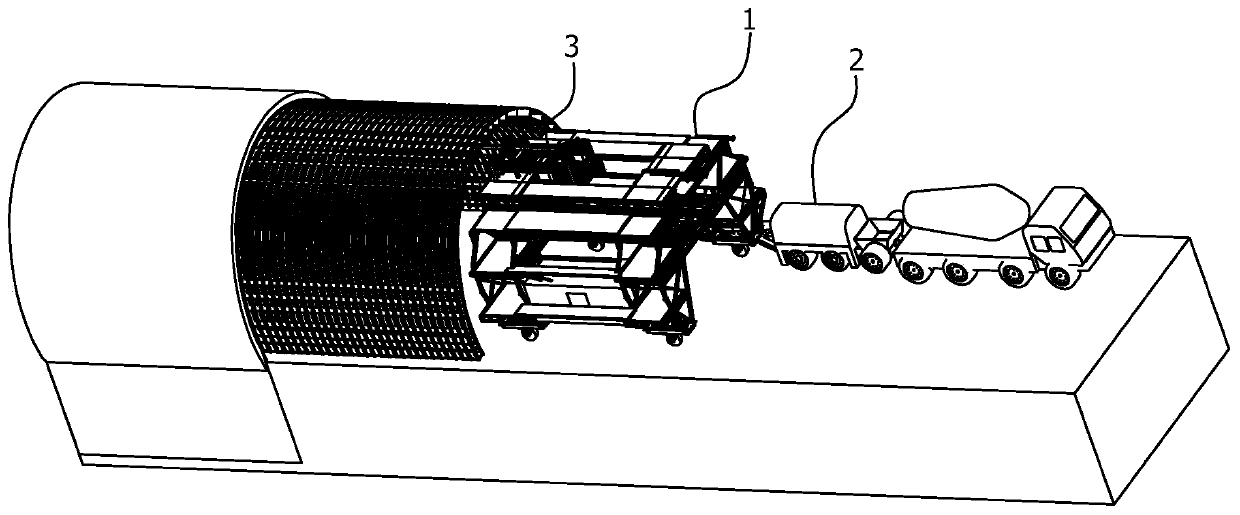

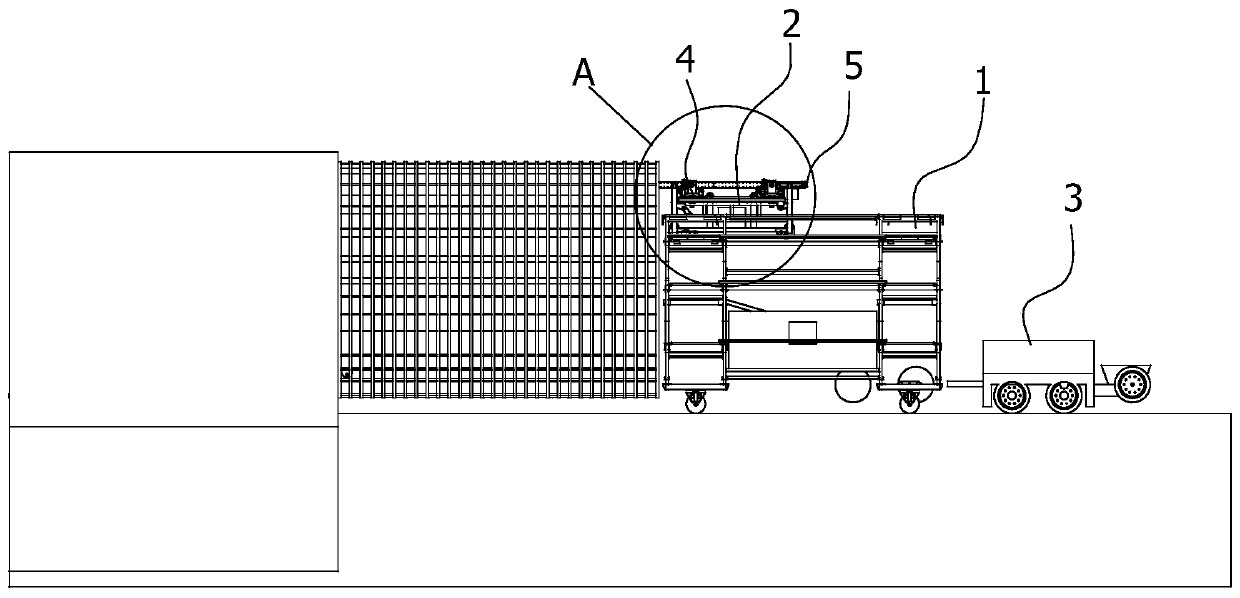

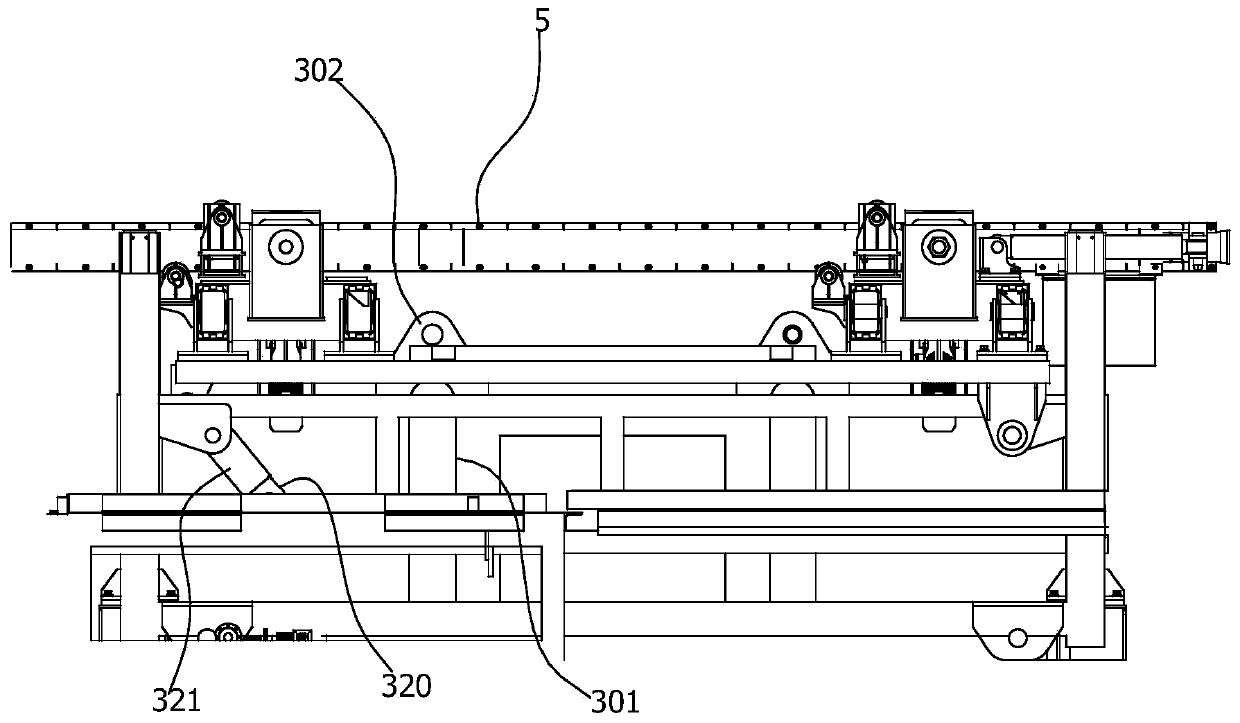

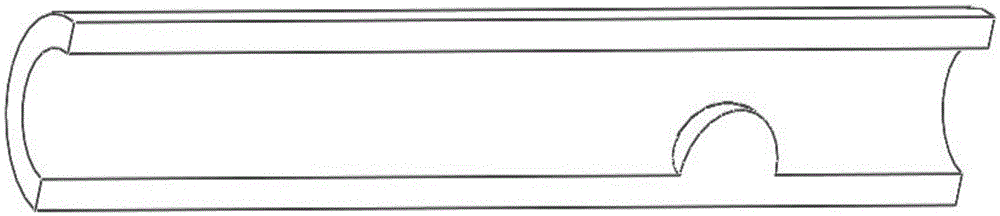

Tunnel second liner concrete longitudinal dispersion grouting device and construction method thereof

PendingCN110118094AImprove flow and dispersion conditionsGuaranteed flow and dispersion conditionsUnderground chambersTunnel liningSlurryGun barrel

The invention discloses a tunnel second liner concrete longitudinal dispersion grouting device and a construction method thereof. The tunnel second liner concrete longitudinal dispersion grouting device includes a travelling trolley, a grout transportation mechanism connected with the travelling trolley and a longitudinal displacement grouting mechanism arranged on the travelling trolley; the longitudinal displacement grouting mechanism includes a longitudinal displacement dolly, a clamping regulation assembly located on the longitudinal displacement dolly and a grouting spray pipe connected to the clamping regulation assembly, and a grouting gun barrel is connected with the grout transportation mechanism. According to the tunnel second liner concrete longitudinal dispersion grouting device, a retrusive concrete continuous transportation and grouting mode is adopted to conduct continuous retreating for grouting; by matching transportation pressure of a concrete pump, a spillover diffusion effect and a gravity field in the grout transportation mechanism, dispersed and continuous grouting is conducted on the front end and the two sides, the tunnel second liner concrete longitudinal dispersion grouting device is reliable in structure and convenient to construct, the grouting quality of a tunnel second liner can be greatly improved, the grouting thickness of a second liner is ensured, and tunnel structure with the even tunnel thickness is formed.

Owner:成都睿智达科技有限公司 +1

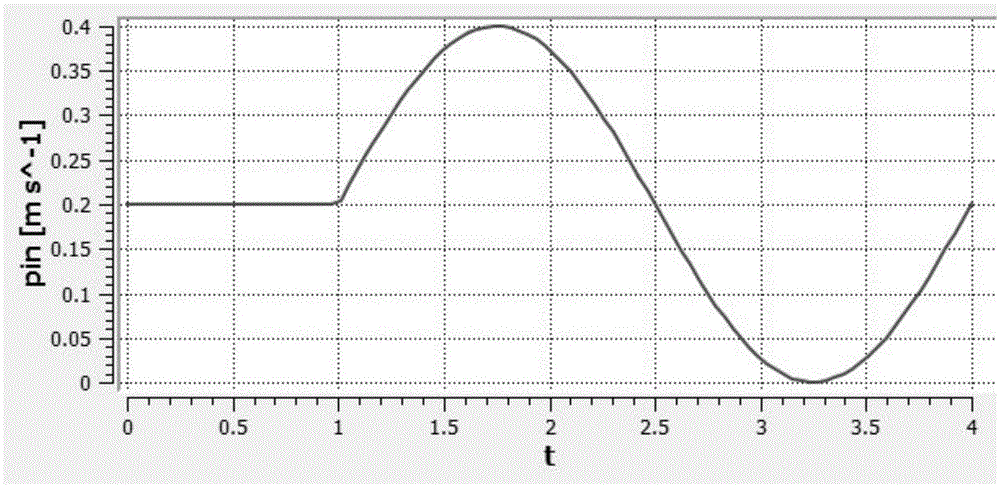

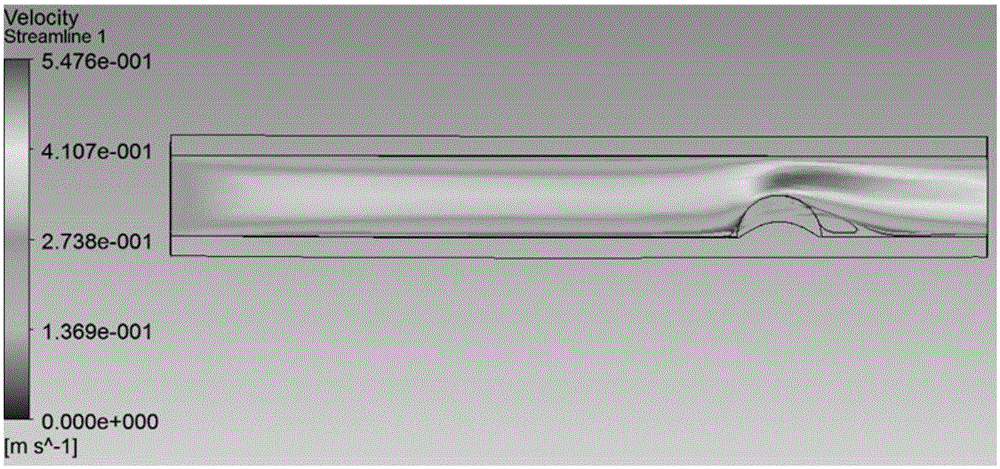

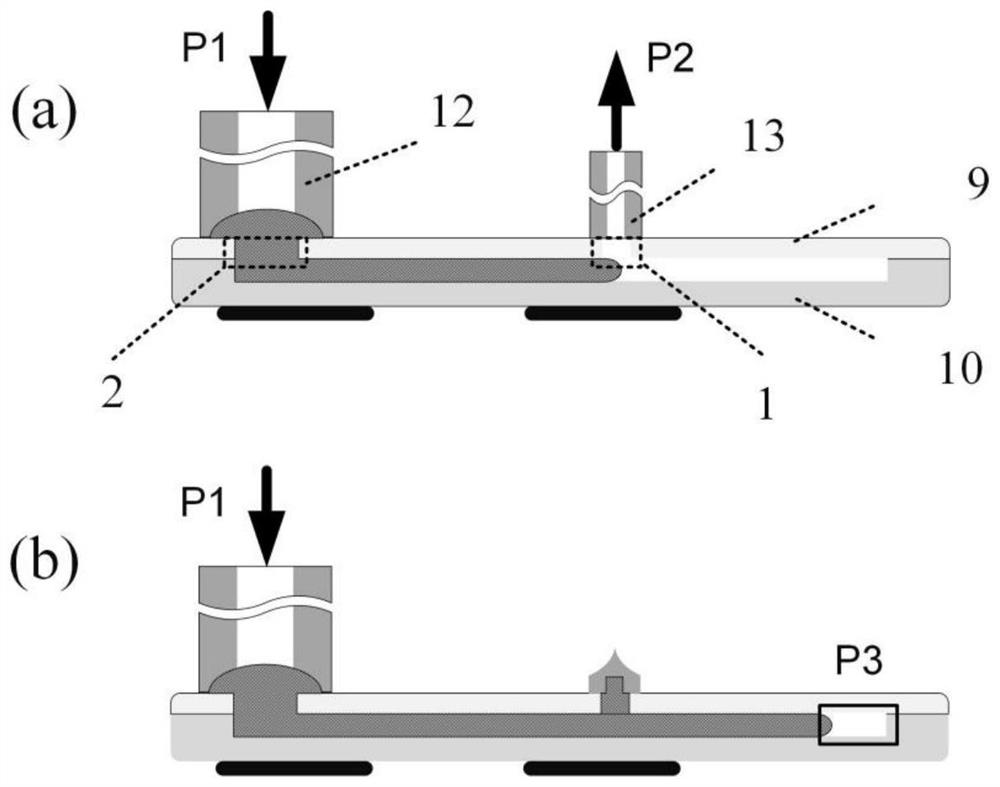

1/3 time intermittent single pulsating flow perfusion method capable of reducing foreign matters deposited on vascular wall

InactiveCN105561425AImprove perfusion qualityReduce turbulenceInfusion devicesForeign matterPulsatile flow

The invention provides a 1 / 3 time intermittent single pulsating flow perfusion method capable of reducing foreign matters deposited on the vascular wall. According to the method, pulsation and constant flow are combined, wherein the ratio of the pulsation perfusion time to the constant flow perfusion time within the single cycle is 3 to 1, and the pulsating flow enters the blood vessel in a periodic flow state for carrying out perfusion. The method comprises the following steps: (1) measuring the weight of the foreign matters in the blood vessel; (2) determining the surface intensity of pressure needed for impacting the foreign matters according to the obtained foreign matters, thus obtaining the perfusion speed; and (3) introducing the 1 / 3 time intermittent single pulsating flow into the blood vessel, observing the kinetic phenomenon of the blood vessel generated during the perfusion process through a medical means, and determining kinetic parameters of the blood vessel for evaluating the blood vessel perfusion quality according to the medical data. Finally, according the comparison of the two kinetic parameters of the blood vessel, the perfusion quality of blood vessel perfusion adopting the 1 / 3 time intermittent single pulsating flow is analyzed, thus the blood vessel perfusion is table, and meanwhile, the condition that the foreign matters are deposited on vascular wall is well improved, and the cleanness of the vascular wall is effectively improved.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Concrete pouring machine for tunnel secondary lining vault

InactiveCN112392511AEvenly filledEasy to operateUnderground chambersTunnel liningArchitectural engineeringElectric machinery

The invention provides a concrete pouring machine for a tunnel secondary lining vault, and relates to the technical field of tunnel construction. The concrete pouring machine comprises a telescopic pipe capable of being inserted into a vault formwork, and a hollow sleeve is fixedly connected to the surface of the telescopic pipe. When the telescopic pipe is inserted into the vault formwork, the hollow sleeve is inserted into the vault formwork in a following mode, the telescopic pipe is composed of at least two sections of pipe bodies which are connected in a sleeve mode, and the section, penetrating through the side wall of the vault formwork, of the pipe body is communicated with the discharging end of a concrete conveying device through a hose. Due to the fact that the positions of discharging ports of the pipe bodies can be controlled only by controlling starting of a first motor, the vault formwork can be more evenly filled with concrete discharged by the pipe bodies, and comparedwith the situation in the prior art that a spliced concrete conveying pipe needs to be frequently detached to change the pouring position of the concrete, operation is more convenient. The construction efficiency is further improved.

Owner:ZHENGZHOU YUNQI IND EQUIP TECH CO LTD

A grouting method for underwater large-diameter bored piles in corrosion geology

ActiveCN106245628BUniform and stable deliveryGuaranteed perfusion qualityBulkheads/pilesTank truckEngineering

The invention discloses a grouting method for a corrosion geological underwater large-diameter drilled pile. The grouting method comprises the following steps of: (1) hole opening; (2) drilling to form the hole; (3) hole cleaning; (4) steel reinforcement cage placement, (5) guide tube lowering; (6) first batch concrete grouting, namely hoisting a large hopper, which is connected to the guide tube, onto a guide tube platform; arranging 2-4 concrete tank trucks and 2-4 ground pumps on the shore, wherein pump lines of the ground pumps are connected to the large hopper by means of a temporary floating bridge; the concrete tank trucks deliver concrete to the ground pumps, and the ground pumps pump concrete into the large hopper; after the large hopper is full of concrete, a ball is pulled out; and 2-4 ground pumps are employed to feed concrete at the same time; and (7) subsequent concrete grouting, namely after the completion of first batch concrete grouting, replacing the large hopper by a small hopper having the capacity of 2-5 m3 for grouting to a designed elevation. By means of the grouting method for a corrosion geological underwater large-diameter drilled pile, the construction difficulties of the corrosion geological condition and a wide river channel can be overcome, and the quality of the drilled pile can be improved so as to ensure the stability of the main tower of a bridge.

Owner:SHANGHAI CIVIL ENG GRP FIFTH +1

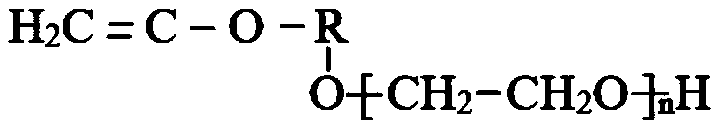

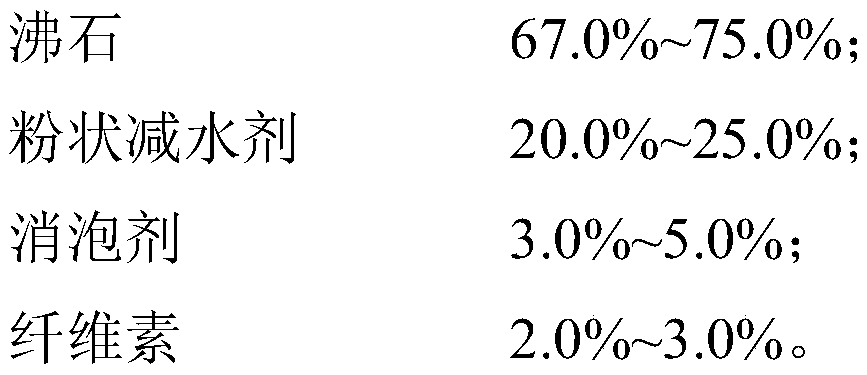

Efficient thixotropic agent for tunnel lining concrete and preparation method of efficient thixotropic agent

InactiveCN111533483AIncreased static yield stressImprove stabilityComposite materialDefoaming Agents

The invention provides an efficient thixotropic agent for tunnel lining concrete and a preparation method of the efficient thixotropic agent. The efficient thixotropic agent is prepared from the following raw materials in parts by mass: 10-20 parts of a long-acting dispersing agent, 20-60 parts of water, 0.5-2.5 parts of a thickening agent, 0.4-1 part of sulfate, 0.4-1 part of carbonate, 0.6-1.2 parts of a defoaming agent and 4-8 parts of nano powder. The efficient thixotropic agent is excellent in thixotropic effect and high in thixotropic effect retention capacity, stirred concrete is good in flowing property, the setting time of the concrete is not affected, the segregation problem caused by large-altitude-difference free falling, long-term vibration and the like can be effectively solved, and the pouring efficiency and the construction quality of tunnel lining concrete are guaranteed.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

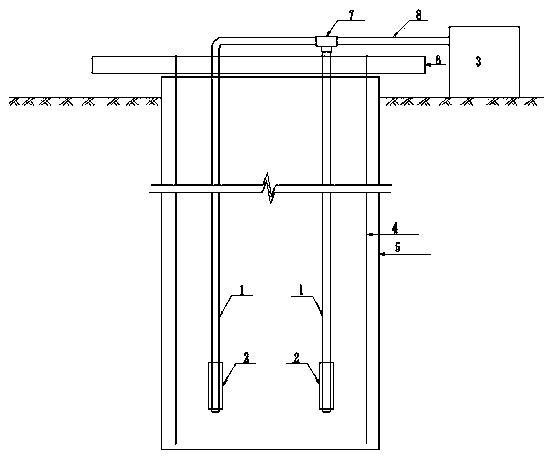

Drilled-pile mud pneumatic anti-settling circulatory system and application method thereof

ActiveCN103711119AAddress issues that impact qualityImprove perfusion qualityBulkheads/pilesAir compressorRebar

The invention relates to a drilled-pile mud pneumatic anti-settling circulatory system and an application method thereof. The drilled-pile mud pneumatic anti-settling circulatory system is structurally characterized in that an air compressor is mounted on a construction platform, a tee-joint connector is connected with a main air supply pipeline formed by a holed high-pressure air duct, a high-pressure ventilation steel tube, two to three high-pressure ventilation hoses and high-pressure air hose counterweights are arranged in a drill hole, the high-pressure ventilation steel tube and a steel reinforcement cage are fixed on the construction platform, the high-pressure ventilation steel tube is connected with the tee-joint connector, the main air supply pipeline and the air compressor, the spacing between the high-pressure ventilation flexible tubes and the hole wall is not less than 50cm, the spacing between the high-pressure ventilation flexible tubes and the hole bottom is kept between 40cm to 50cm. The drilled-pile mud pneumatic anti-settling circulatory system has the advantages that the problem that pile foundation concrete quality is affected due to the fact that part of the particles of mud sink to the hole bottom because of gravity under the stationary state of the mud is solved; the drilled-pile mud pneumatic anti-settling circulatory system is small in system investment, simple to operate and capable of greatly improving pile foundation concrete pouring quality.

Owner:THE FOURTH ENG CO LTD OF CHINA ZHONGTIEMAJOR BRIDGE ENG GRP +1

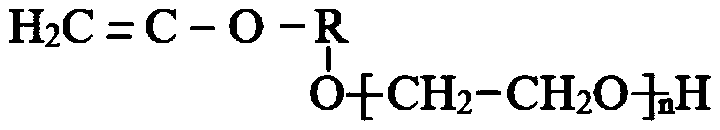

Preparation and application of dry powder mortar for self-compacting concrete of slab ballastless track

The invention relates to preparation and application of dry-mixed mortar for plate-type ballastless track self-compacting concrete. The dry-mixed mortar is prepared by mixing cement, a mineral additive, fine aggregate, a water-reducing and collapse-preventing component, an expanding component, a viscosity adjusting component and fiber according to a certain ratio, wherein 100 parts of cement, 50-120 parts of the mineral additive, 150-400 parts of the fine aggregate, 0.2-3 parts of the water-reducing and collapse-preventing component, 5-20 parts of the expanding component, 1-10 parts of the viscosity adjusting component and 0-0.5 part of the fiber are included. The invention further provides preparation and application of the dry-mixed mortar. The dry-mixed mortar is prepared by a high-speed mixer in a factory; the dry-mixed mortar is transported by a bulk truck or by an automobile in a bagged way; the dry-mixed mortar, coarse aggregate and water are weighed on a construction site in parts by weight and uniformly stirred for use. According to the technical scheme, the sensitivity of the self-compacting concrete to quality fluctuation of the raw materials can be greatly reduced and the loss of the self-compacting concrete can be significantly reduced; the dry-mixed mortar is suitable for a plate-type ballastless track of a high-speed railway, and can also be applied to bridges, civil buildings and the repairing and strengthening field.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

Plate removal detection method for detecting self-compacting concrete pouring of ballastless track

InactiveCN105067799AFully reflect the hardening resultsPerfusion process familiarization and improvementMaterial testing goodsTrackwayArchitectural engineering

A plate removal detection method for detecting self-compacting concrete pouring of a ballastless track comprises steps as follows: firstly, a track plate is separated from a self-compacting concrete layer through a tool after pouring and initial setting of self-compacting concrete; next, the track plate is hoisted by hoisting equipment in 24 hours and then slowly put on a plate storage pedestal of a testing bench; finally, the self-compacting concrete layer is checked carefully after the track plate is hoisted away, whether bleeding, unsaturated pouring, bubbling, layering and cracking phenomena occur to the self-compacting concrete layer is checked, recorded and analyzed, and the plate-removal detection of self-compacting concrete pouring is finished. The pouring quality of the self-compacting concrete is detected visually and directly, the hardening result of the self-compacting concrete can be reflected comprehensively, the construction technology is learnt about well and improved, and the construction quality is improved.

Owner:NO 4 ENG CO LTD OF CHINA RAILWAY 11 BUREAU GRP +1

Pouring mold and pouring process for light-weight aggregate concrete PC component

PendingCN112476730AEvenly distributedImprove perfusion qualityMouldsArchitectural engineeringStructural engineering

Owner:ZHEJIANG HUA LIN CONSTR GRP

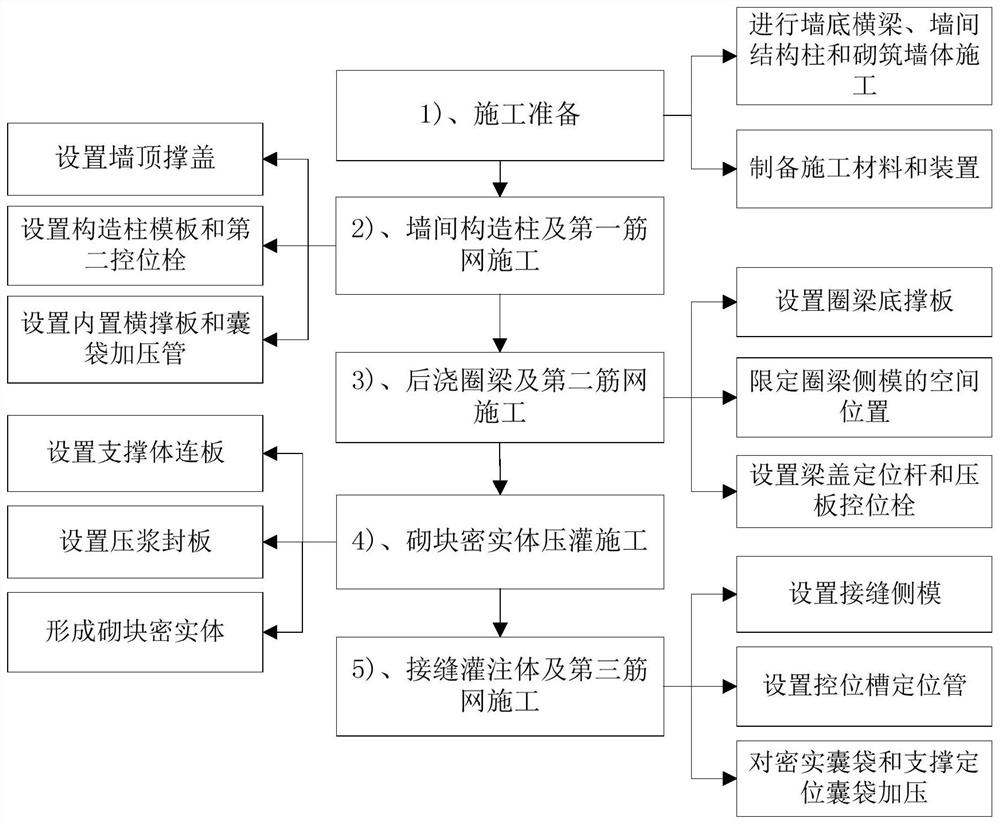

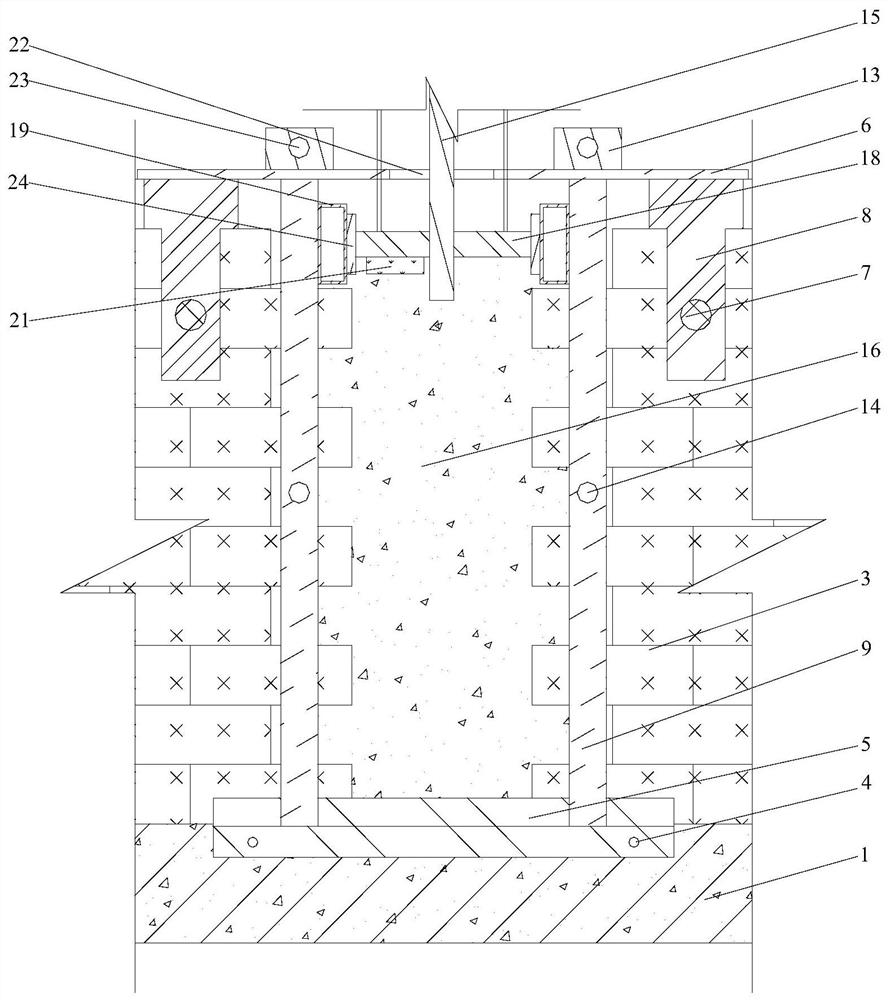

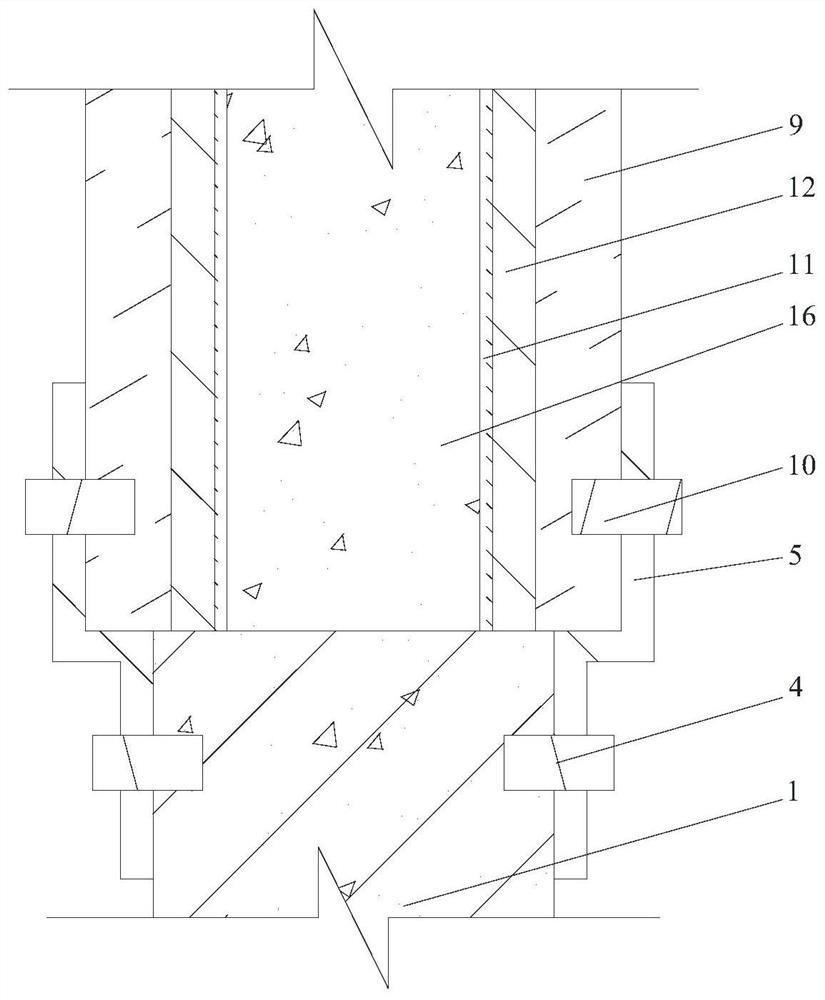

Frame shear wall column and masonry filler wall connecting structure and construction method

ActiveCN112609841AReduce difficultyReduce the impactWallsBuilding material handlingJoint (building)Quoin

The invention relates to a frame shear wall column and masonry filler wall connecting structure and a construction method. A wall top supporting cover is arranged at the top end of a masonry wall; a guide side plate, a first position control bolt and a second position control bolt are used for controlling the position of a constructional column formwork; a side supporting bag and a pressure test body are used for controlling the pouring quality of a constructional column; a beam formwork position correcting bolt and an opposite-pull anchor bar are used for limiting a ring beam side formwork; a wall top connecting bar and a wall top connecting groove are arranged at the top of the masonry wall; the quality of a post-poured ring beam is improved through a beam top pressing plate; grouting sealing plates are arranged on the two sides of the post-poured ring beam in a supported mode respectively; an external grouting pipe is used for grouting a gap of the masonry wall to form a building block dense body; a joint side formwork at the joint of the inter-wall structural column and the masonry wall is in a broken line shape; the joint pouring quality is controlled through a dense bag; a first rib net and the constructional column formwork are synchronously arranged; a second rib net and the ring beam side formwork are synchronously arranged; and a third rib net and the joint side formwork are synchronously arranged. According to the invention, the formwork supporting difficulty can be reduced, the concrete pouring quality can be improved, and the performance of the connecting structure can be improved.

Owner:四川尧顺建设集团有限公司

Double-guide-pipe underwater concrete grouting method for ultra-large diameter pressure bearing pile

ActiveCN106545016AReduce capacityReduce structural strengthFoundation engineeringLarge capacityWellhead

The invention discloses a double-guide-pipe underwater concrete grouting method for an ultra-large diameter pressure bearing pile. The method is characterized by comprising the following steps that a, one type of underwater self-compacting concrete is researched and developed, the slump of the underwater self-compacting concrete is 280 mm, the extended degree is 750 mm, the gradual loss of two hours is zero, and the initial setting time reaches 10 h+ / -2 h; b, a type of large-volume concrete hopper is designed, an oblique panel is correspondingly arranged at the lower end of each vertical panel of the large-volume concrete hopper, and a discharging port is formed by the lower ends of the four oblique panels; c, a well mouth rack is arranged at the position of a pile opening, and two guide pipes are arranged on the well mouth rack side by side; d, the underwater self-compacting concrete is prepared in a concrete mixing plant, and the prepared underwater self-compacting concrete is transported to a construction site; and e, the conveyed underwater self-compacting concrete is poured in two large-volume concrete hoppers. By means of the method, ultra-large-diameter pressure bearing pile concrete grouting can be well finished, and the grouting quality is high.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

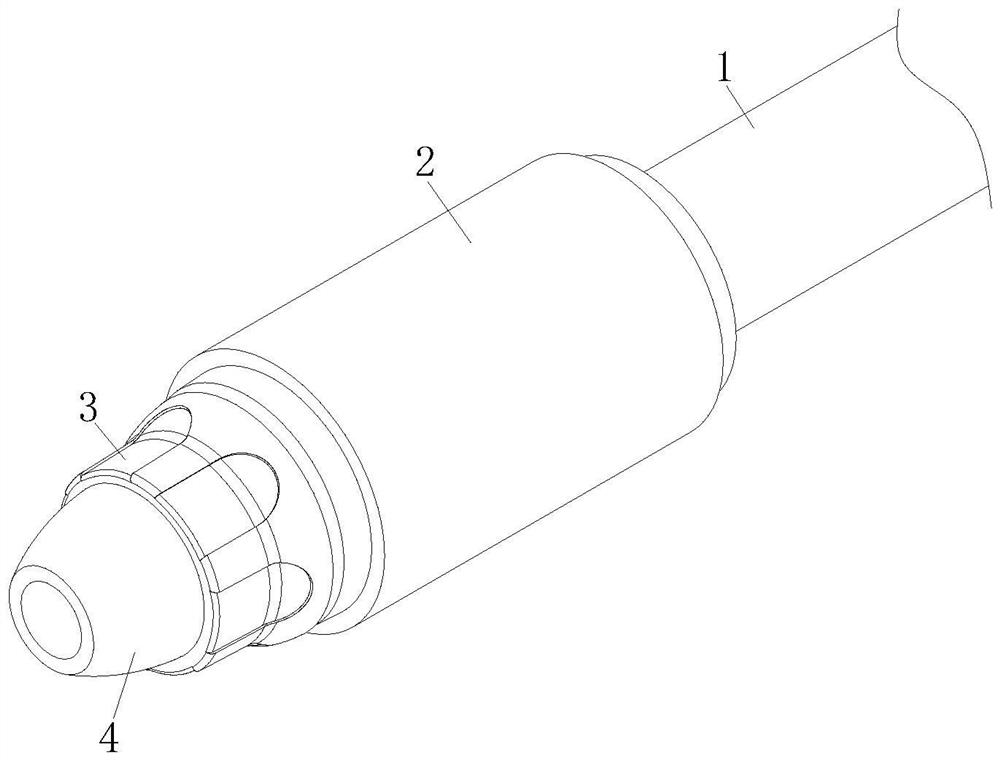

Underwater grouting equipment for large-volume cavity

ActiveCN114541405APrevent backflowGrouting smoothlyHydro energy generationFoundation engineeringMarine engineeringStructural engineering

The invention discloses underwater grouting equipment for a large-volume cavity. The device comprises a grouting pipe, the grouting pipe is connected with a non-return shell, the non-return shell is connected with a connecting ring, and the connecting ring is connected with a spray head; a supporting pin is fixedly arranged in the non-return shell, the outer portion of the supporting pin is hinged to the head end of a partition plate through a torsional spring, and the tail end of the partition plate is movably connected with the inner wall of the non-return shell. The two partition plates are arranged to be used in cooperation with the torsional spring, the two partition plates are folded during grouting so as to be separated from the non-return shell, slurry can be poured smoothly, when slurry flows back, the partition plates make contact with the non-return shell to seal the non-return shell, and therefore the slurry is prevented from flowing back, and the grouting efficiency is improved. Therefore, the effects of preventing the slurry from flowing back and improving the pouring quality are achieved.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

One-time back-sealing construction method of reinforced concrete with double-walled steel cofferdam with high and low blade feet

ActiveCN105064381BThe method steps are simpleReasonable designFoundation testingCaissonsReinforced concreteDouble wall

The invention discloses a one-time back-sealing construction method for reinforced concrete with double-wall steel cofferdams with high and low blade feet, comprising steps: 1. Construction of steel cofferdams: sinking the double-wall steel cofferdams to a pre-designed construction position; double-wall steel cofferdams There is a blade foot at the bottom of the weir, and the blade foot is a high and low blade foot; the bottom surface of the blade foot is an inclined surface and it is supported on the inclined bare rock surface; there are multiple sets of first anchoring steel bars on the blade foot; 2. The lowering of the steel casing: The outer wall of the bottom of each steel casing is provided with a reinforcement anchorage structure, and the reinforcement anchorage structure includes multiple rows of second anchorage reinforcement arranged from top to bottom; 3. Embedding of the rock surface of the river bed: backfilling with mixture and forming a backfill layer; Fourth, the construction of the reinforced concrete layer of the bottom cover: first install the horizontal steel mesh above the backfill layer, and then pour concrete into it to form a concrete bottom seal. The method of the invention has simple steps, reasonable design, low construction difficulty, short construction period and good application effect, and can effectively solve various problems existing in the existing plain concrete bottom sealing method.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

A grouting device for bored pile and its construction method

ActiveCN112227375BSpeed up the flowQuality improvementBulkheads/pilesArchitectural engineeringStructural engineering

Owner:飞帆集团有限公司

Self-compacting concrete pouring device and pouring method for slab ballastless track slab

ActiveCN104153258BFast perfusionImprove perfusion qualityRailway track constructionStructural engineeringSelf-consolidating concrete

The invention discloses a slab ballastless track self-compacting concrete grouting device and method. The slab ballastless track self-compacting concrete grouting device comprises a transfer storage hopper. A grouting hopper is arranged at a discharging port of the transfer storage hopper. The grouting hopper is connected with a grouting opening of a concrete formwork. The grouting hopper comprises a conical barrel and a rectangular hopper body. The conical barrel is arranged on the rectangular hopper body. The rectangular hopper body is connected with a discharging port of the conical barrel. The discharging port of the transfer storage hopper is connected with a discharging pipe. The discharging end of the discharging pipe is arranged above the conical barrel. The rectangular hopper body is arranged on the side portion of the concrete formwork. The side, facing the concrete formwork, of the rectangular hopper body is provided with a discharging port. The grouting port is formed in the side, close to the rectangular hopper body, of the concrete formwork. By the adoption of the slab ballastless track self-compacting concrete grouting device and method, the grouting speed is increased, and the grouting quality is better.

Owner:中建八局检测科技有限公司

Equipment and method for inserting bars into concrete piles

ActiveCN112223525BFew stepsFast manufacturingMouldsShaping reinforcementsArchitectural engineeringStructural engineering

The invention discloses a reinforcement inserting equipment and method for a concrete pile, comprising a pipe body, a fixing hole is arranged at the bottom of the pipe body, a pipe cover is installed at the upper end of the pipe body, and an elastic capsule hole is arranged in the middle of the pipe cover , one side of the elastic capsule hole is provided with a cement port, the upper side of the elastic capsule hole is provided with a clamp, the mold in the pipe includes a bottom plate, and a support rod is installed on the upper side of the bottom plate, and the upper side of the support rod is provided There is a baffle plate, an elastic bag is installed between the baffle plate and the bottom plate, a rotating device is installed in the inner mold of the pipe, a pile core hole adjustment device is installed in the inner mold of the pipe, and the equipment also includes rib insertion equipment, A liquid storage device is installed on one side of the bar inserting equipment. The present invention has the characteristics of automatic cleaning of molds, less waste of cement and high production efficiency of concrete piles.

Owner:盐城市双强管桩有限公司

Double-pipe underwater concrete pouring method for super-large-diameter pressure-bearing piles

ActiveCN106545016BReduce structural strengthMeet the requirements of large quantitiesFoundation engineeringUnderwaterLarge capacity

The invention discloses a double-guide-pipe underwater concrete grouting method for an ultra-large diameter pressure bearing pile. The method is characterized by comprising the following steps that a, one type of underwater self-compacting concrete is researched and developed, the slump of the underwater self-compacting concrete is 280 mm, the extended degree is 750 mm, the gradual loss of two hours is zero, and the initial setting time reaches 10 h+ / -2 h; b, a type of large-volume concrete hopper is designed, an oblique panel is correspondingly arranged at the lower end of each vertical panel of the large-volume concrete hopper, and a discharging port is formed by the lower ends of the four oblique panels; c, a well mouth rack is arranged at the position of a pile opening, and two guide pipes are arranged on the well mouth rack side by side; d, the underwater self-compacting concrete is prepared in a concrete mixing plant, and the prepared underwater self-compacting concrete is transported to a construction site; and e, the conveyed underwater self-compacting concrete is poured in two large-volume concrete hoppers. By means of the method, ultra-large-diameter pressure bearing pile concrete grouting can be well finished, and the grouting quality is high.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

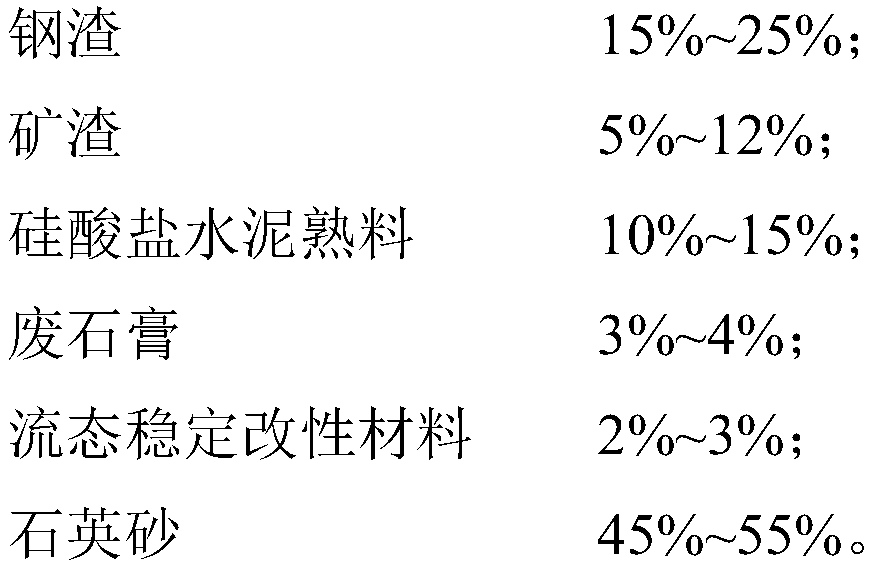

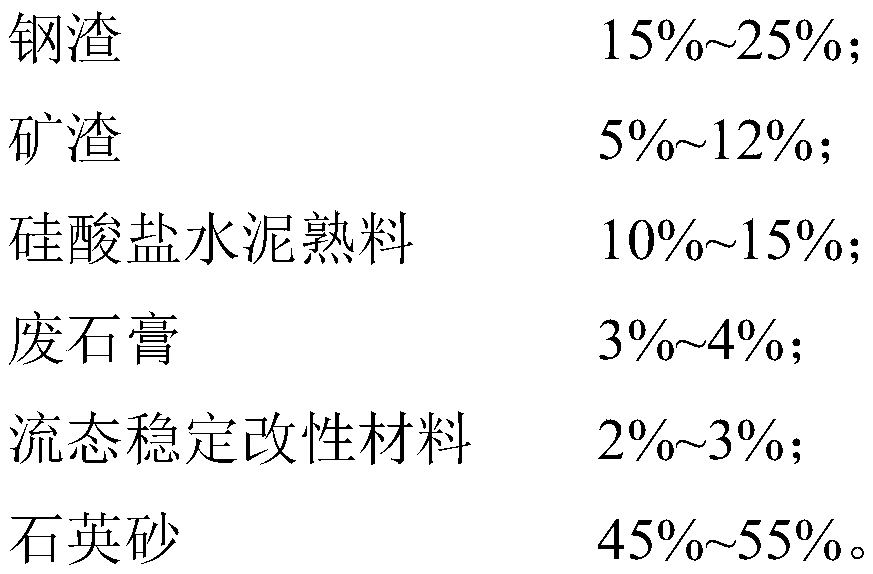

Moisture-proof expansive grouting mortar as well as preparation method and application thereof in construction of prefabricated stairs with adjustable stepping height

The invention mainly aims to provide moisture-proof expansive grouting mortar as well as a preparation method and an application thereof in construction of prefabricated stairs with adjustable stepping height. The pouring mortar comprises the components by the mass percentage: 15% to 25% of steel slag, 5% to 12% of mineral slag, 10% to 15% of Portland cement clinker, 3% to 4% of waste gypsum, 2% to 3% of a flow state stable modified material and 45% to 55% of quartz sand. The preparation method comprises the steps: weighing the raw materials according to the proportion, and uniformly mixing toobtain a dry-mixed composition; and adding water, stirring and grouting. The technical problem to be solved is to enable the grouting mortar to have stable high fluidity and filling property, so thatthe grouting mortar can establish effective expansion to compensate volume shrinkage, crack resistance, early strength and rapid hardening under the condition of no watering maintenance, and thus theconstruction progress is accelerated; and the grouting mortar is particularly suitable for field installation of prefabricated stairs with adjustable step height.

Owner:CHINA BUILDING MATERIALS ACAD

Encapsulation method for silicon-based flat micro heat pipe

PendingCN113023666AFacilitating Integrated Manufacturing ApplicationsImprove the level of potting technologyDecorative surface effectsChemical vapor deposition coatingPhysicsSilicon based

The invention discloses a filling and sealing method for a silicon-based flat micro heat pipe, which can be applied to integrated manufacturing of micro heat pipes and belongs to the field of working medium filling and packaging of heat pipes. Aiming at the problems that a traditional heat pipe filling and sealing method is not suitable for a silicon-based flat plate micro heat pipe and nodes are easy to form after common sealing operation of the silicon-based flat plate micro heat pipe at present, the invention provides a light, thin, flat and miniaturized filling and sealing method which can effectively and accurately realize integrated operation of filling and sealing of a working medium. The integrated manufacturing application of the silicon-based micro heat pipe in the field of electronic devices is promoted, and the glass and the silicon substrate are treated by using the cold processing characteristic of femtosecond laser, and then the hole filling is performed by using gold, so that the stability during the injection of low-melting-point alloy and working medium and the exhaust of air is improved, and the sealing effect is further improved.

Owner:TAIYUAN UNIV OF TECH

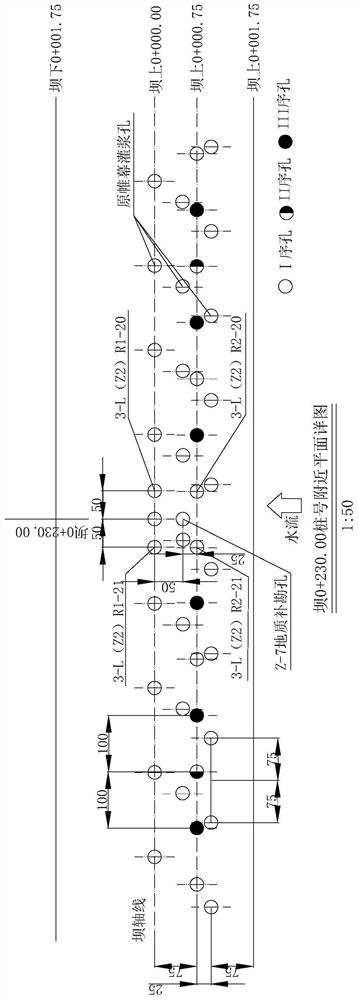

A kind of silica sol grouting material construction technology

ActiveCN112095551BGuaranteed filling qualityImprove perfusion qualityBarrages/weirsFoundation engineeringPermeation groutingCivil engineering

This application relates to the construction process of silica sol, an environmental protection material, and discloses a construction process of silica sol grouting material, which adopts a top-down segmental grouting method, including a silica sol double-liquid grouting step; the silica sol double-liquid grouting step includes the following three steps Stage: The first stage: pour slow grout into the grouting hole, and squeeze out the water in the grouting hole; the second stage: use the designed grouting pressure of 2.0-2.5MPa to pour slow grout to realize the permeable grouting of the crack; the third stage: when The slow grout injection rate reaches 6-8L / min, replace the slow grout with fast grout, control the fast grout injection rate within 15L / min, increase the design grouting pressure to 2.5-3.0MPa; After 200L, close the pulp with pressure to make the fast pulp gel. The fast grout quickly gels to close the micro-cracks, and the slow grout is blocked in the micro-cracks to prevent the ungelled slow grout from being squeezed out of the cracks after the grouting is stopped, thereby improving the grouting effect.

Owner:SINOHYDRO FOUND ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com