Concrete pouring machine for tunnel secondary lining vault

A concrete and pouring machine technology, applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of cumbersome construction personnel, affect the pouring efficiency, and increase the labor intensity of construction personnel, so as to improve construction efficiency, improve pouring quality, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

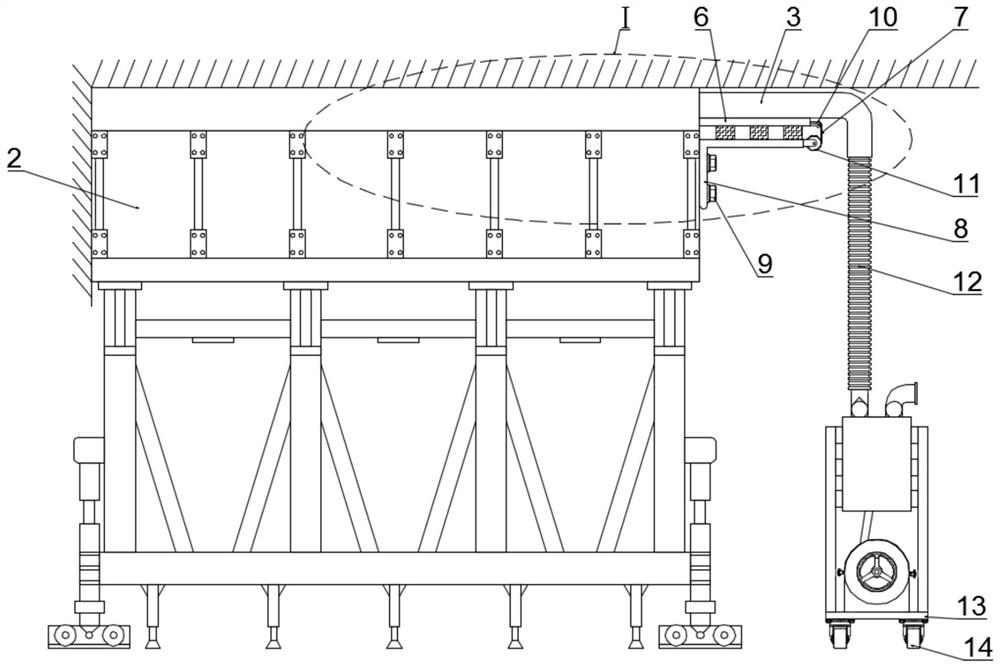

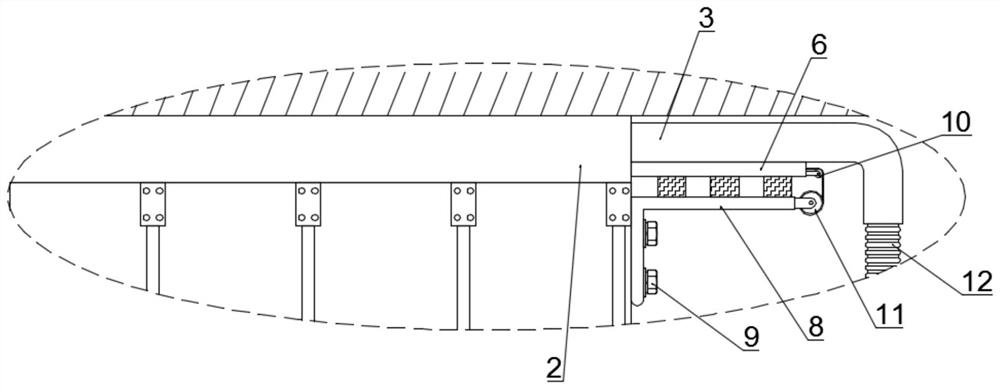

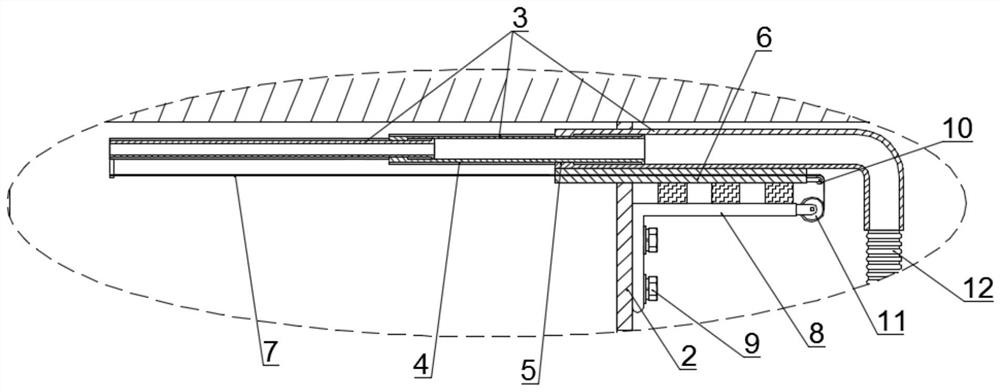

[0029] Such as Figure 1-3 As shown, a concrete pouring machine for the second lining vault of the tunnel includes a telescopic tube that can be inserted into the vault formwork 2, and a hollow sleeve 6 is fixedly connected to the surface of the telescopic tube. When the telescopic tube is inserted into When entering the vault formwork 2, the hollow sleeve 6 is then inserted into the vault formwork 2, and the telescopic tube is composed of at least two mutually socketed pipe bodies 3, which run through the section of the vault formwork 2 side wall. The body 3 is connected to the discharge end of the concrete conveying device through the hose 12, and the pipe body 3 at the farthest end in the vault formwork 2 is connected with a steel wire rope 7, and the steel wire rope 7 extends through the hollow sleeve 6 to The outside of the vault template 2, a support platform assembly is detachably installed on the outer surface of the vault form 2, and a storage wheel 11 for accommodati...

Embodiment 2

[0036] Such as Figure 1-3 As shown, a concrete pouring machine for the second lining vault of the tunnel includes a telescopic tube that can be inserted into the vault formwork 2, and a hollow sleeve 6 is fixedly connected to the surface of the telescopic tube. When the telescopic tube is inserted into When entering the vault formwork 2, the hollow sleeve 6 is then inserted into the vault formwork 2, and the telescopic tube is composed of at least two mutually socketed pipe bodies 3, which run through the section of the vault formwork 2 side wall. The body 3 is connected to the discharge end of the concrete conveying device through the hose 12, and the pipe body 3 at the farthest end in the vault formwork 2 is connected with a steel wire rope 7, and the steel wire rope 7 extends through the hollow sleeve 6 to The outside of the vault template 2, a support platform assembly is detachably installed on the outer surface of the vault form 2, and a storage wheel 11 for accommodati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com