Patents

Literature

2070 results about "Concrete pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

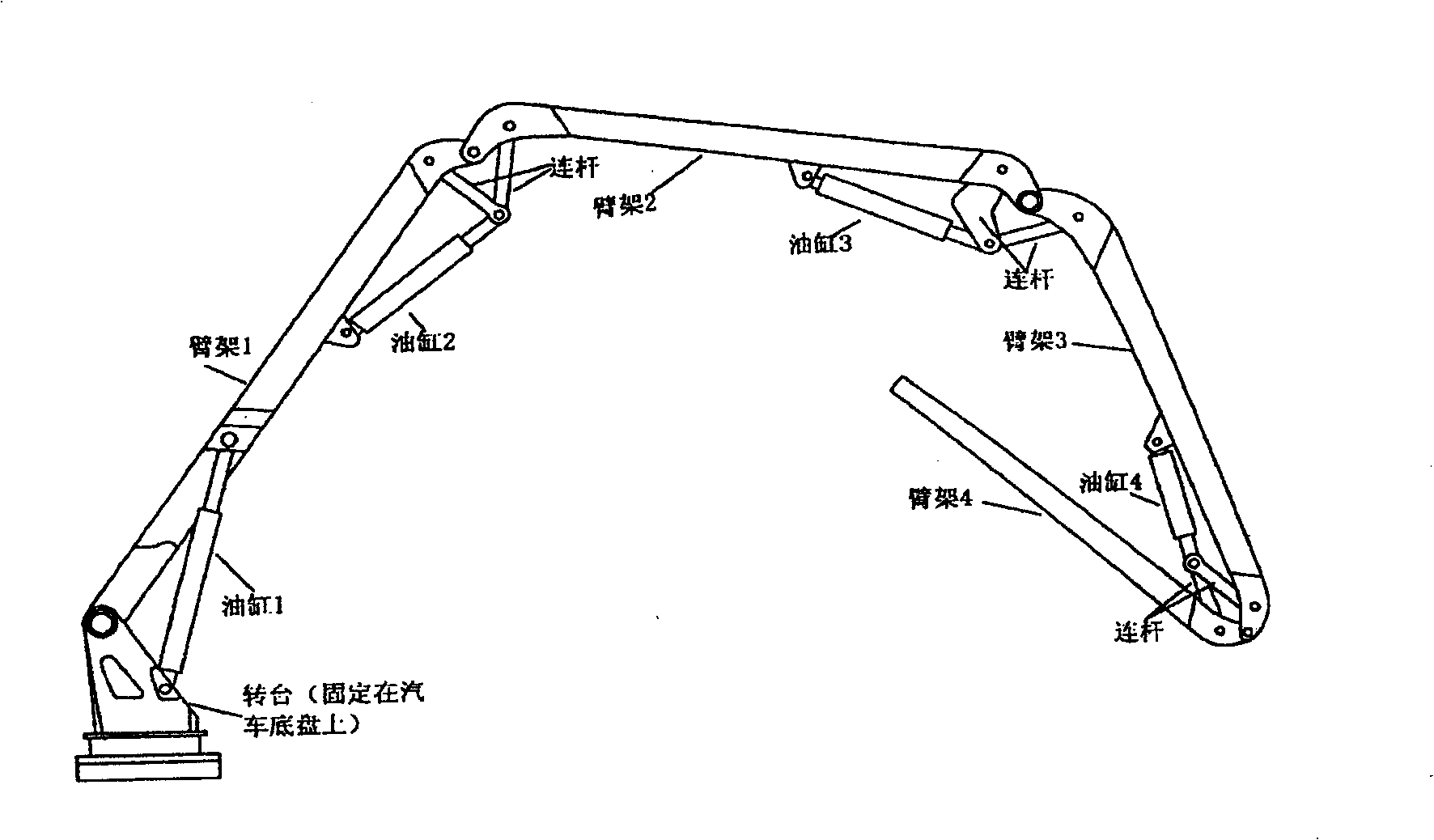

A concrete pump is a machine used for transferring liquid concrete by pumping. There are two types of concrete pumps. The first type of concrete pump is attached to a truck or longer units are on semi-trailers. It is known as a boom concrete pump because it uses a remote-controlled articulating robotic arm (called a boom) to place concrete accurately. Boom pumps are used on most of the larger construction projects as they are capable of pumping at very high volumes and because of the labour saving nature of the placing boom. They are a revolutionary alternative to line-concrete pumps.

Concrete pump truck intelligent arm support control system and control method thereof

InactiveCN101525944AGuaranteed accuracyGuaranteed reasonablenessBuilding material handlingLocation detectionControl system

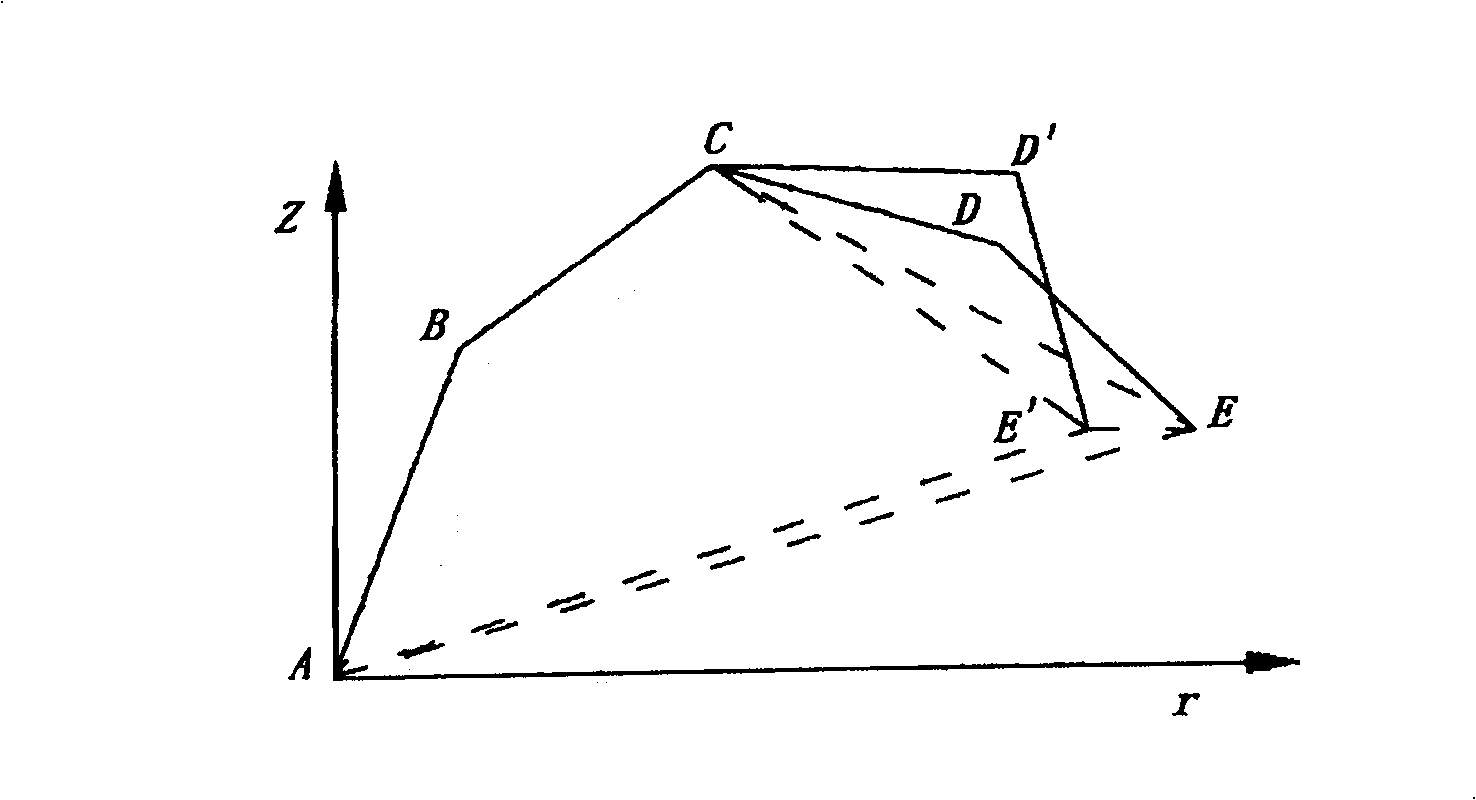

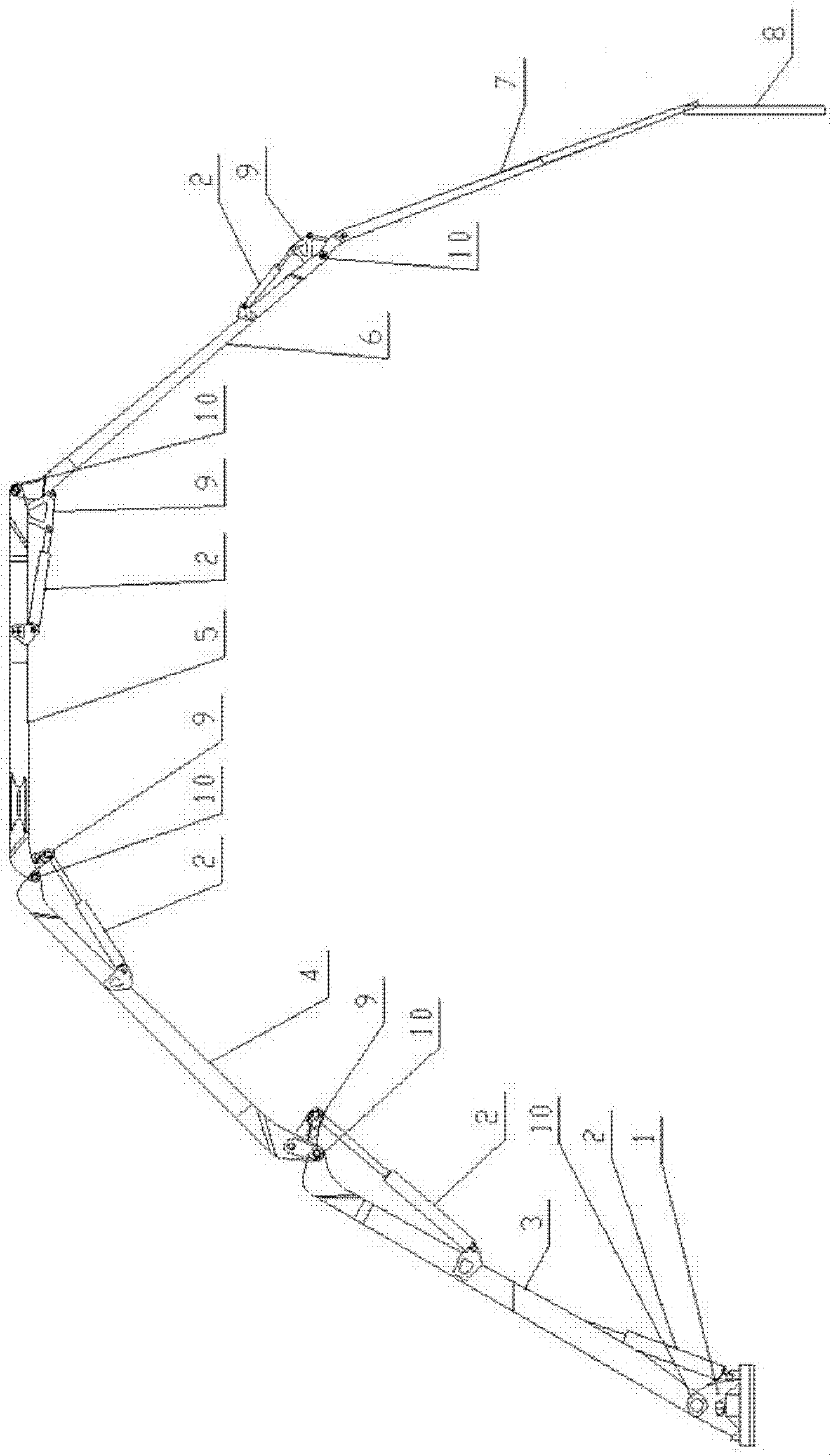

The invention provides a concrete pump truck intelligent arm support control system and a control method thereof. The control system comprises an arm support, a controller, an operating device and an actuator. The control system is characterized in that the control system also comprises an arm support detecting device which is used for detecting the spatial location of each segment of the arm support and transmitting detected spatial location signals of each segment of the arm support to the controller. The control method comprises: the construction of an arm support coordinate system; the detection of the current arm support position; the control of the actions of the arm support. In the concrete pump truck intelligent arm support control system, an operator is not required to manually regulate the position the gyratory angle of each segment of the arm support, the pouring accuracy and the operational reasonability are guaranteed, and the construction efficiency and the whole service life of the truck are improved greatly; within the stress impact allowable range and on the basis of the consideration of the concrete fluidity, coordinated actions of a plurality of segments of the arm support are realized; simultaneously, during the controlling process, extreme conditions and unreasonable operations of the movements of a plurality of the segments of the arm support are limited, the labor intensity and the experience requirement of the operator are alleviated greatly, and influences of unreasonable operations on the arm support structure and the service life of a hydraulic system are avoided.

Owner:BEIJING EASYSOLUTION ELECTRONICS

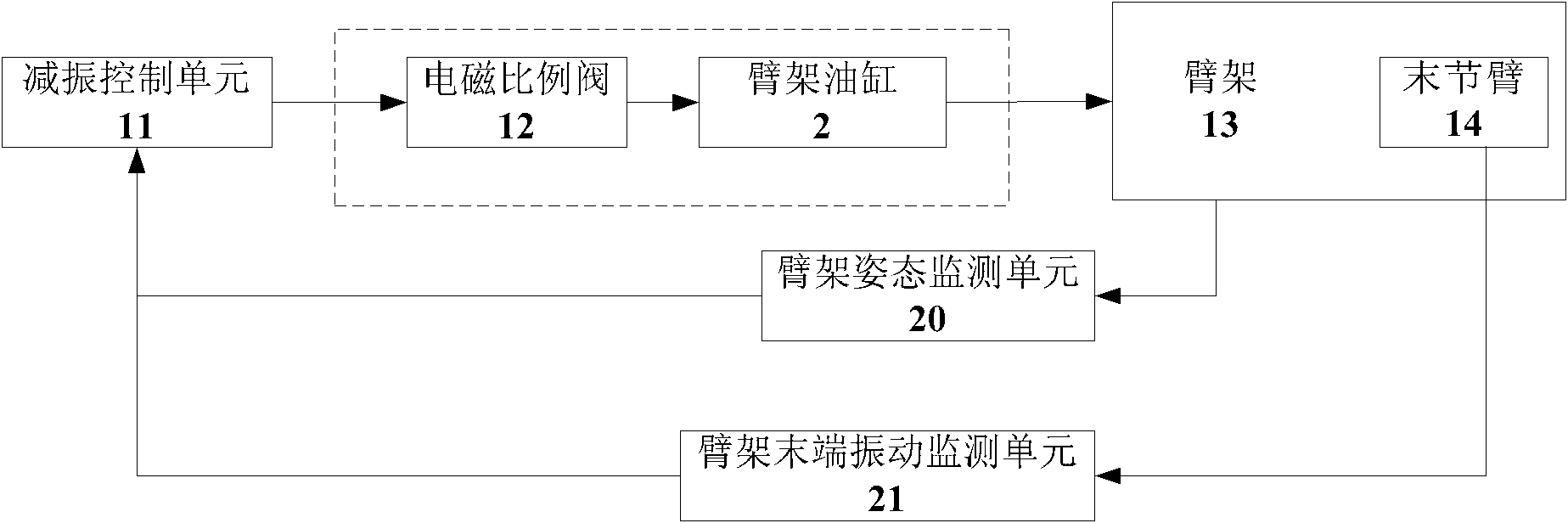

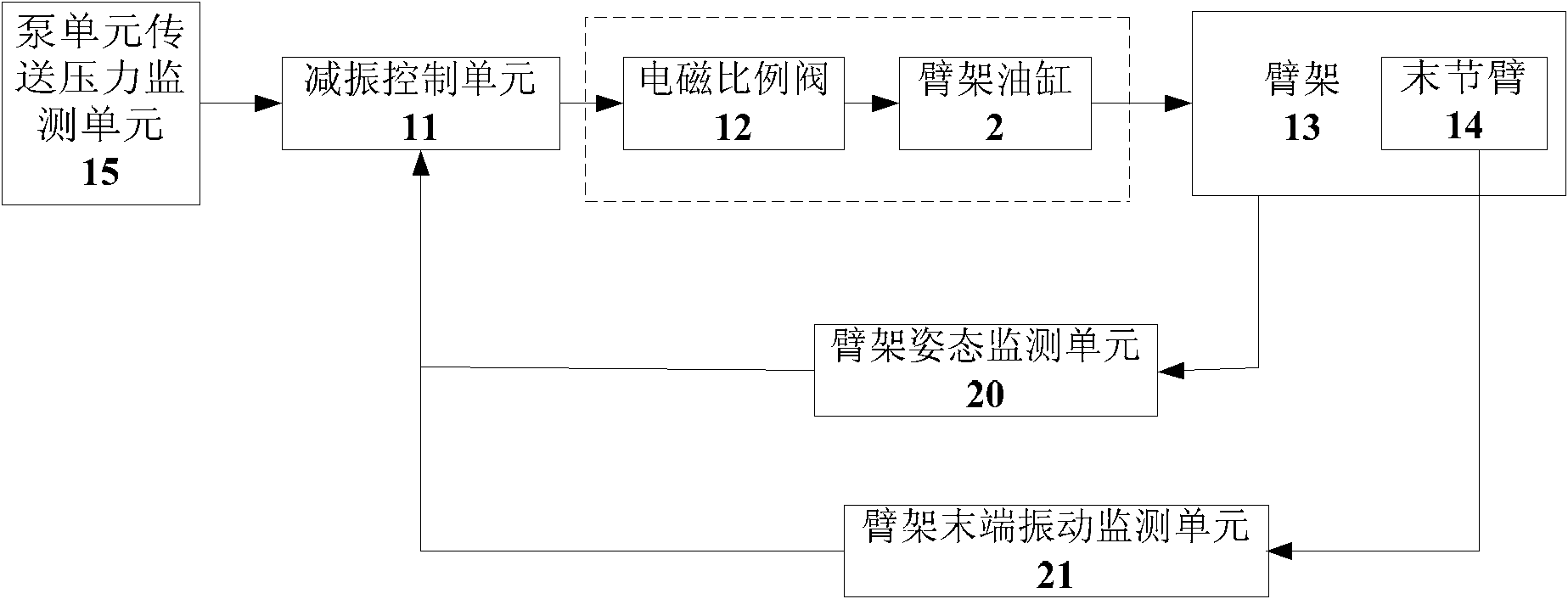

Concrete pump truck, damping device and method for concrete pump truck arm support

ActiveCN102071809ASimple structureGood vibration reduction effectPump controlPumpsVibration amplitudeControl signal

The invention provides a concrete pump truck, a damping device and a damping method for a concrete pump trunk arm support. The damping device of the concrete pump trunk arm support comprises a damping control unit, an arm support tail end vibration monitoring unit and an arm support posture monitoring unit, wherein the damping control unit is connected with an electromagnetic proportional value connected with an arm support cylinder; the arm support tail end vibration monitoring unit monitors amplitude parameters of a tail arm of the arm support and transmits amplitude parameter signals to the damping control unit; and the arm support posture monitoring unit monitors angle parameters of the arm support and transmits angle parameter signals to the damping control unit. The concrete pump truck also comprises the damping device of the concrete pump truck arm support. The damping method for the concrete pump truck arm support comprises the following steps of: monitoring operation parameters of a concrete pump and the arm support; generating control signals according to monitoring parameters; and outputting an electromagnetic proportional valve control current according to the control signals to control a piston position of the arm support cylinder, wherein the monitoring parameters of the arm support comprise the vibration amplitude parameters of the tail arm of the arm support and the angle parameters of the arm support.

Owner:ZOOMLION HEAVY IND CO LTD

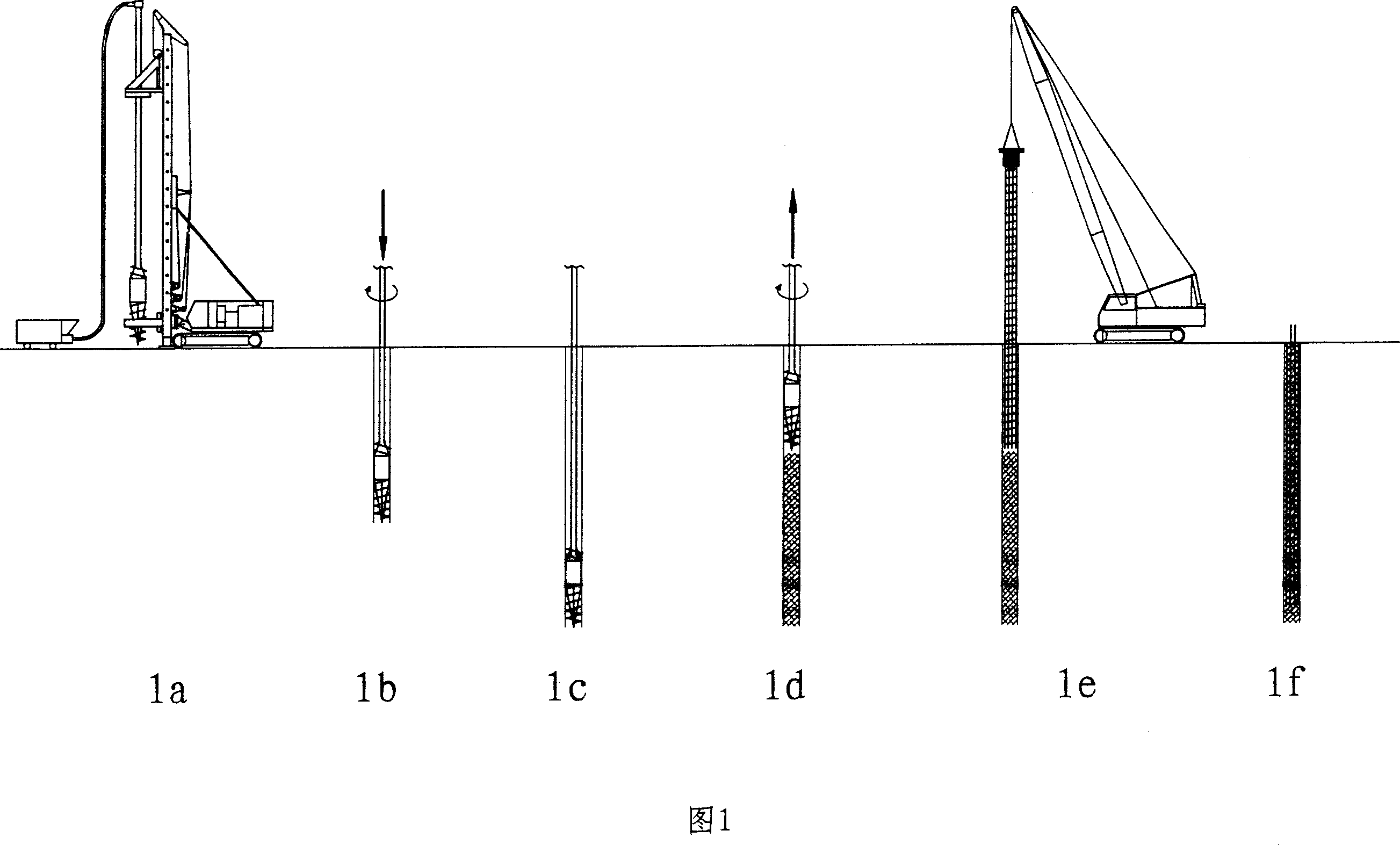

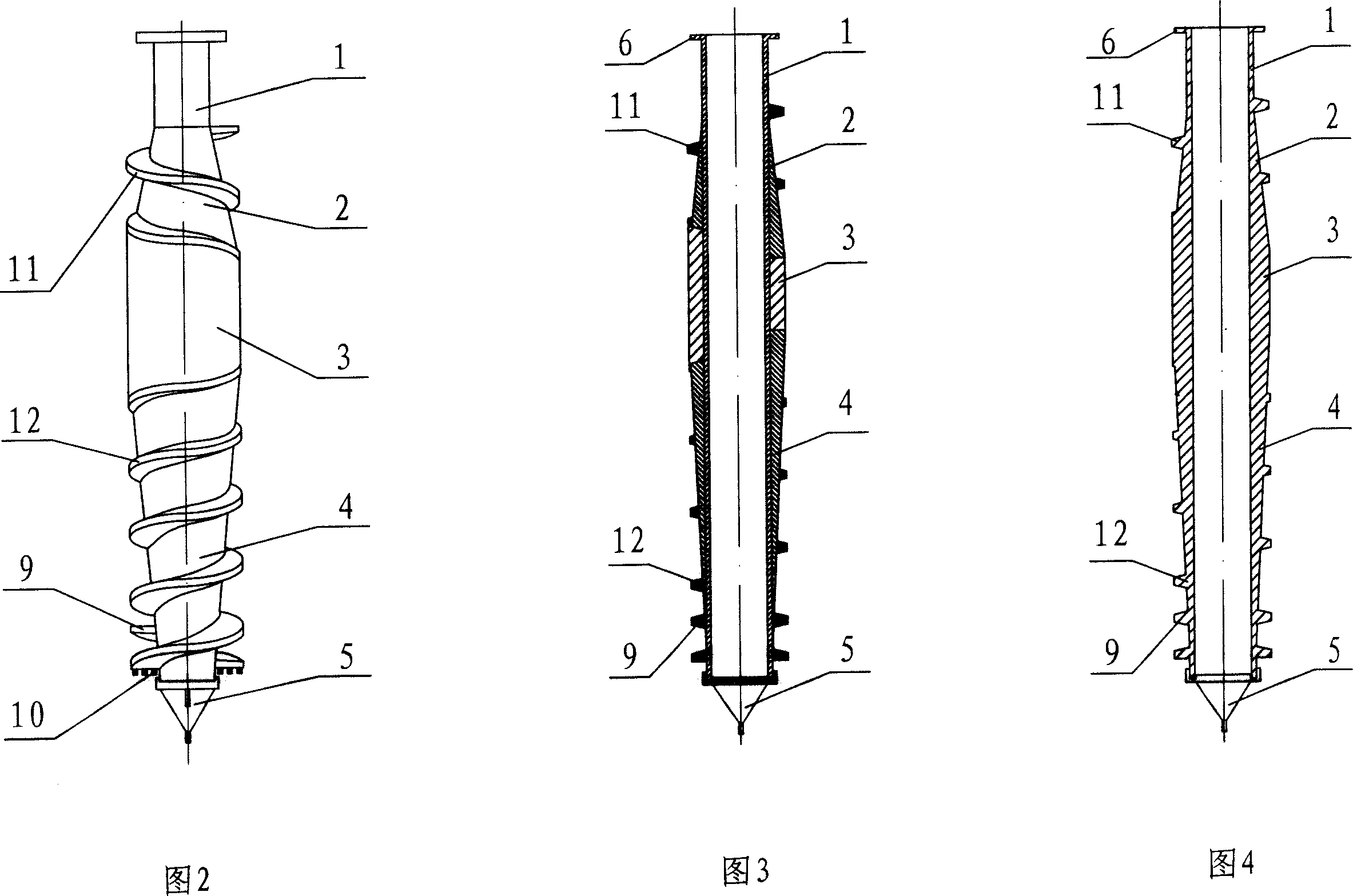

Bidirectional helix extruding-enlarging pile construction method and bidirectional helix closed extruding-enlarging aiguille

ActiveCN101012649AIncrease resistanceImprove bearing capacityDrill bitsBulkheads/pilesConcrete pumpEnergy consumption

The invention relates to a construction method for bidirectional spiral expand pile and the bidirectional spiral closed expand bit. The construction method comprises drilling and expanding bore by the bidirectional spiral closed expand bit; pushing soil, which is obtained in drilling and expanding bore downwards, into the side wall of pile bore; the bidirectional spiral closed expand bit rotating upwards to drill and expand the bore again; pushing soil, which is obtained in drilling, expanding and lifting upwards, into the side wall of pile bore; starting the concrete pump to press the pile material into the pile bore while the bit is lifted. The bidirectional spiral closed expand bit comprises a connecting bar. At the lower of the connecting bar spiral expand body, closed expand body and dynamic sealing expand body are assembled on the connecting bar in the same axial line in turn from the bottom to the top or they are machined on the connecting bar together. The invention is provided with high loading capacity, small sedimentation quantity, better quality, low cost and smaller energy consumption so on.

Owner:CHINA JINGYE ENG

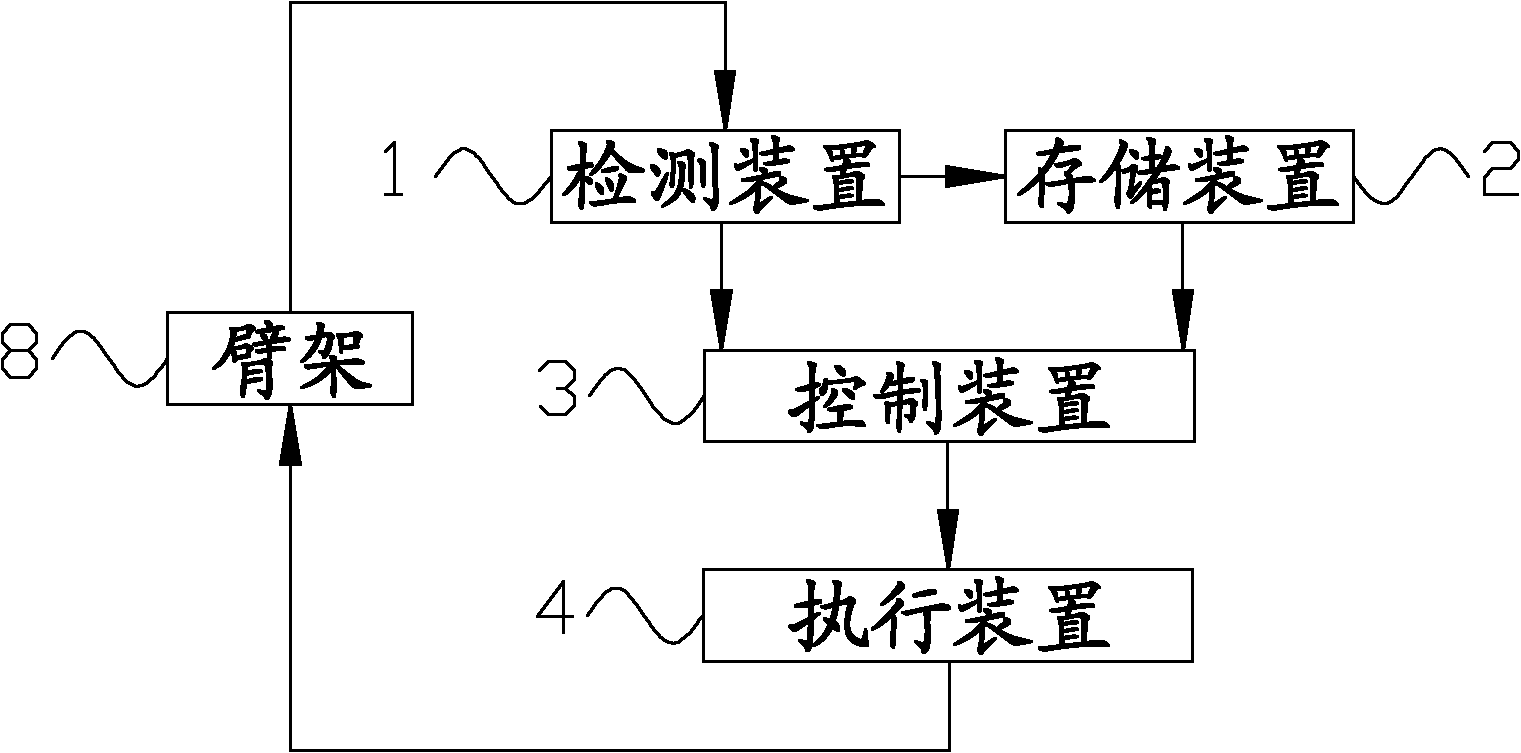

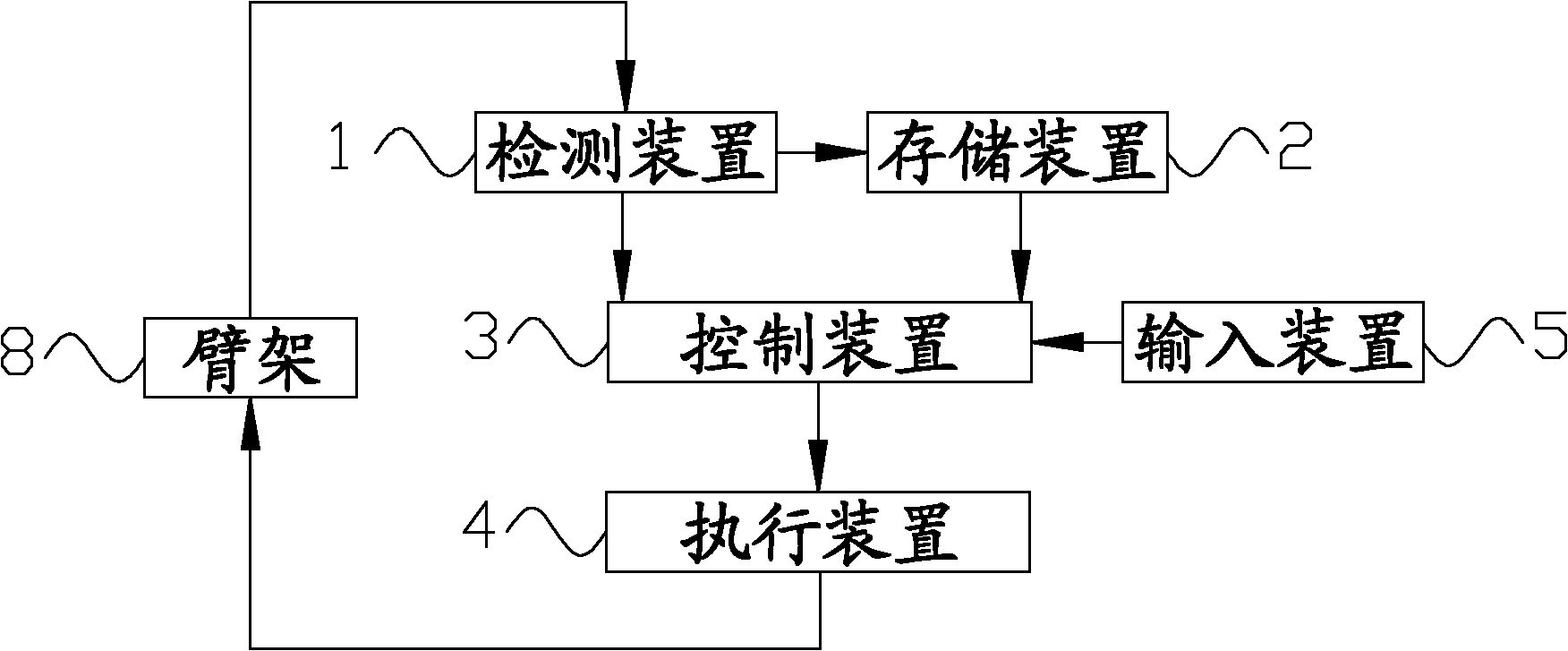

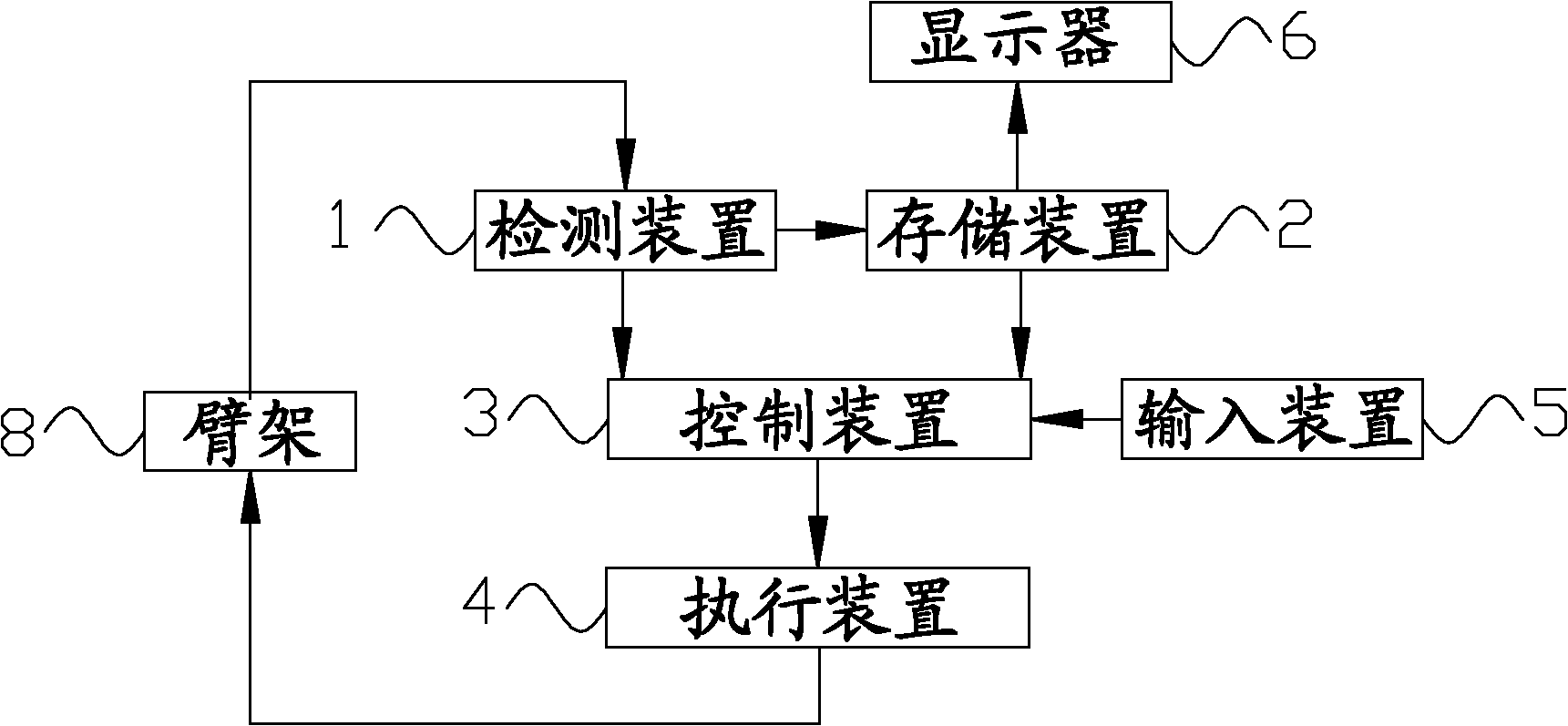

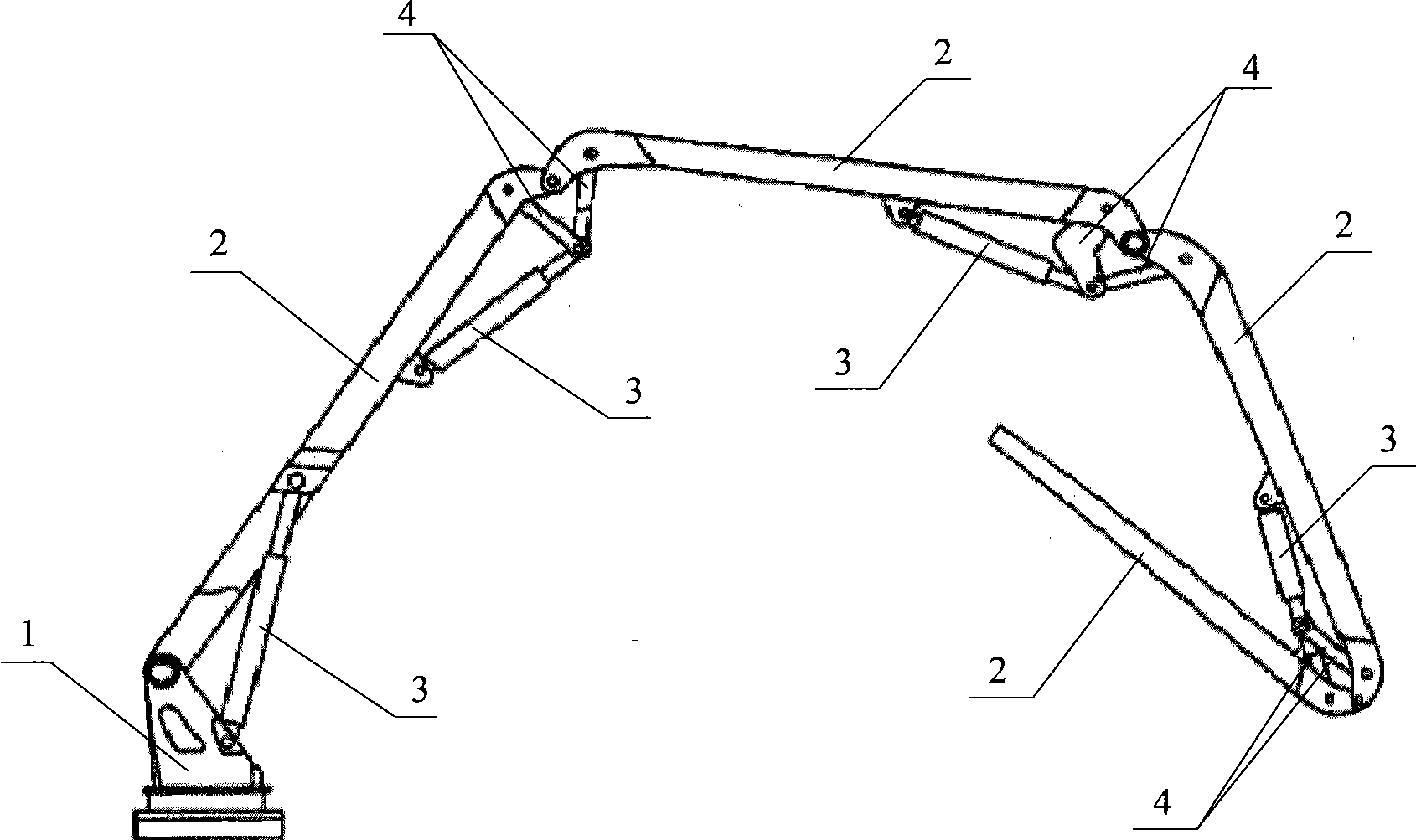

Concrete pumping equipment and arm support state control system thereof

ActiveCN102108790AEasy to controlAchieve vibrationElectric programme controlPumpsControl systemTime delays

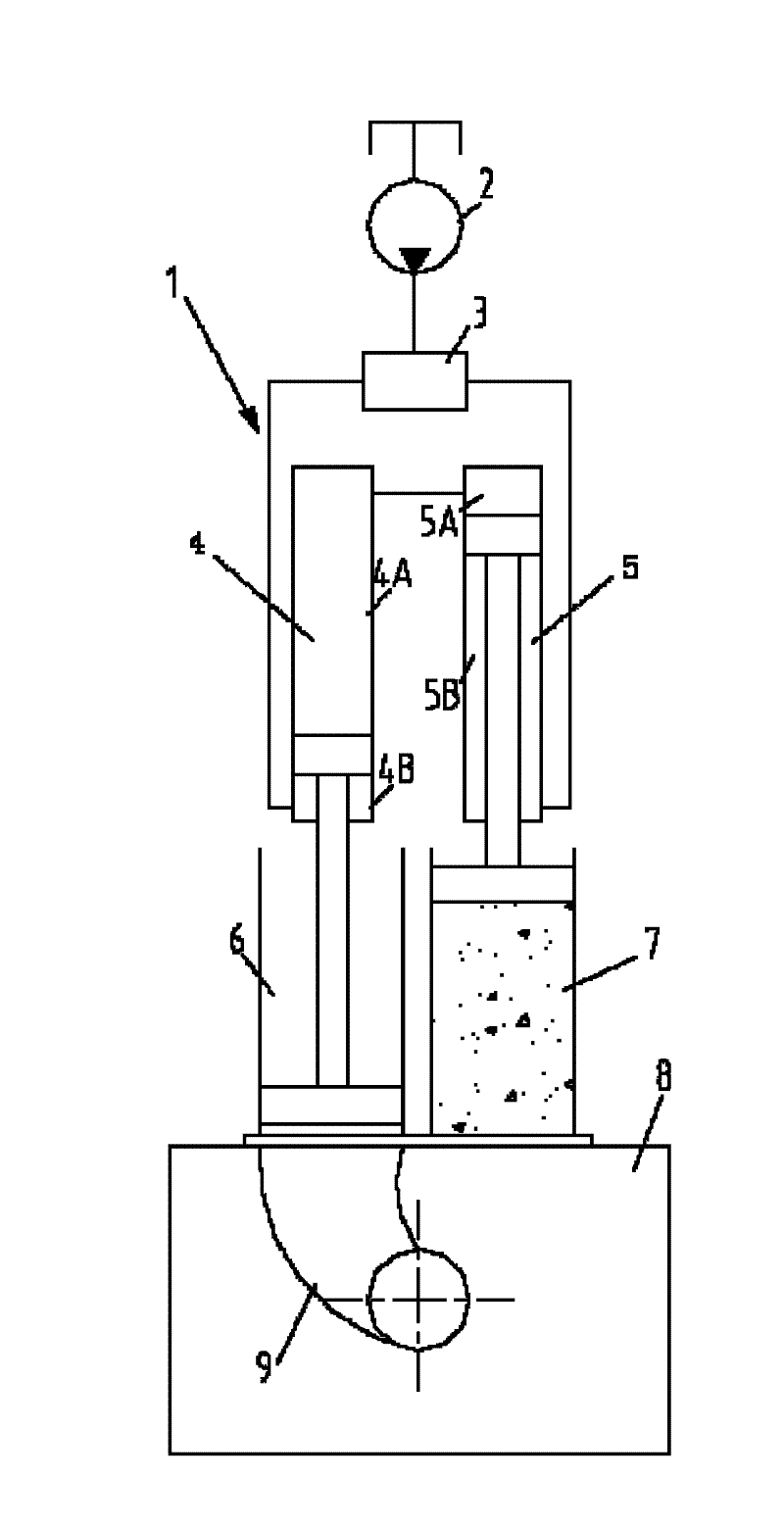

The invention discloses an arm support state control system, which comprises a detection device (1), a storage device (2), a control device (3) and an actuating device (4), wherein the detection device (1) is used for detecting the position state and vibration state of an arm support (8) of concrete pumping equipment to obtain a position state signal and a vibration signal; the storage device (2) is used for storing the vibration signal to obtain the periodical vibration signal of the arm support (8); the control device (3) is used for receiving the position state signal, the vibration signal and the periodical vibration signal and obtaining a control instruction according to a preset arm support vibration range, a preset advanced regulation time and a preset control policy; and the actuating device (4) is used for changing the state according to the control instruction and controlling the arm support (8) to act the preset arm support vibration range. The arm support state control system provided by the invention can avoid control error caused by time delay in the detection process of the detection device and the actuating process of the actuating device, absorb vibration in time and improve the operation convenience of the arm support. The invention also discloses concrete pumping equipment.

Owner:SANY AUTOMOBILE MFG CO LTD

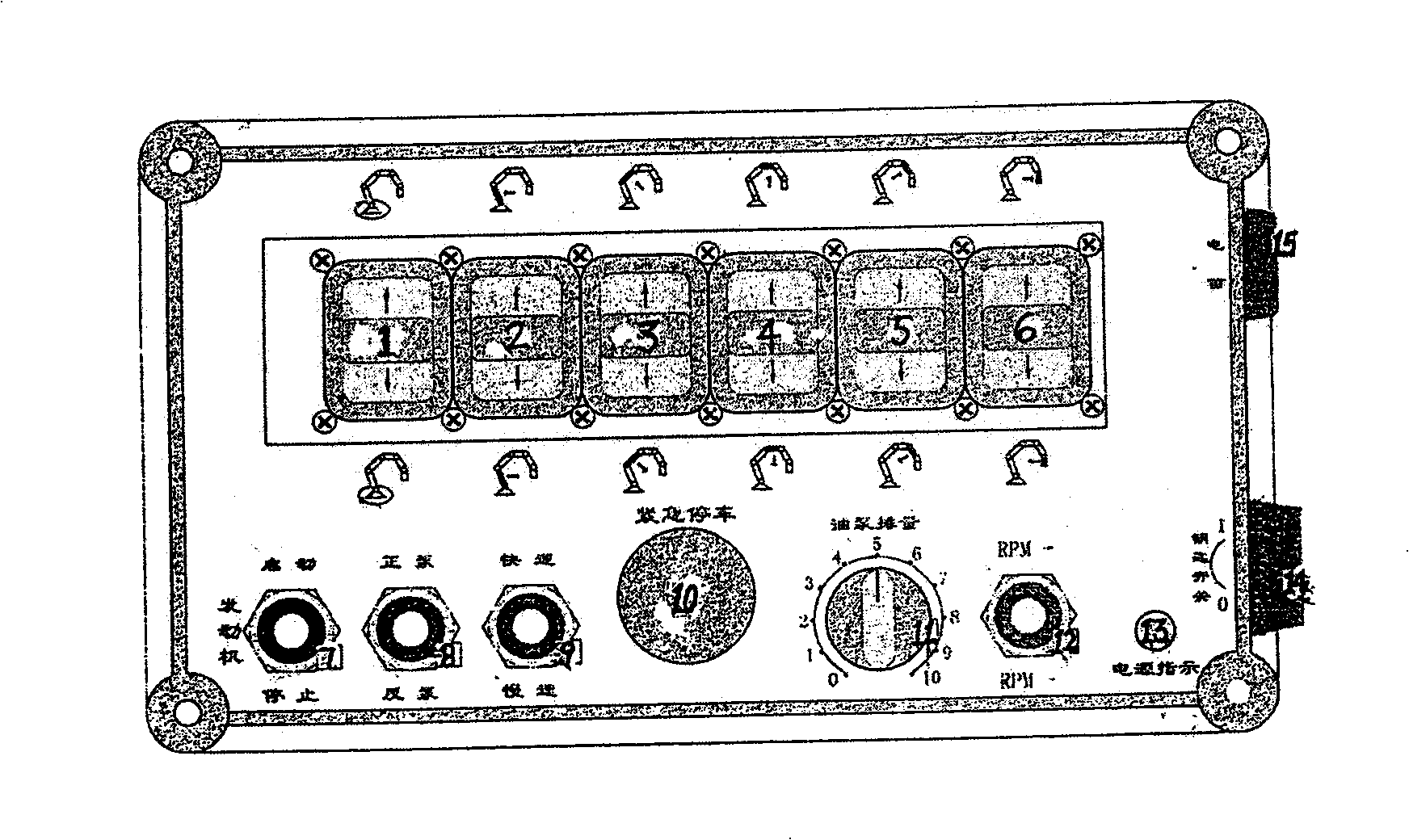

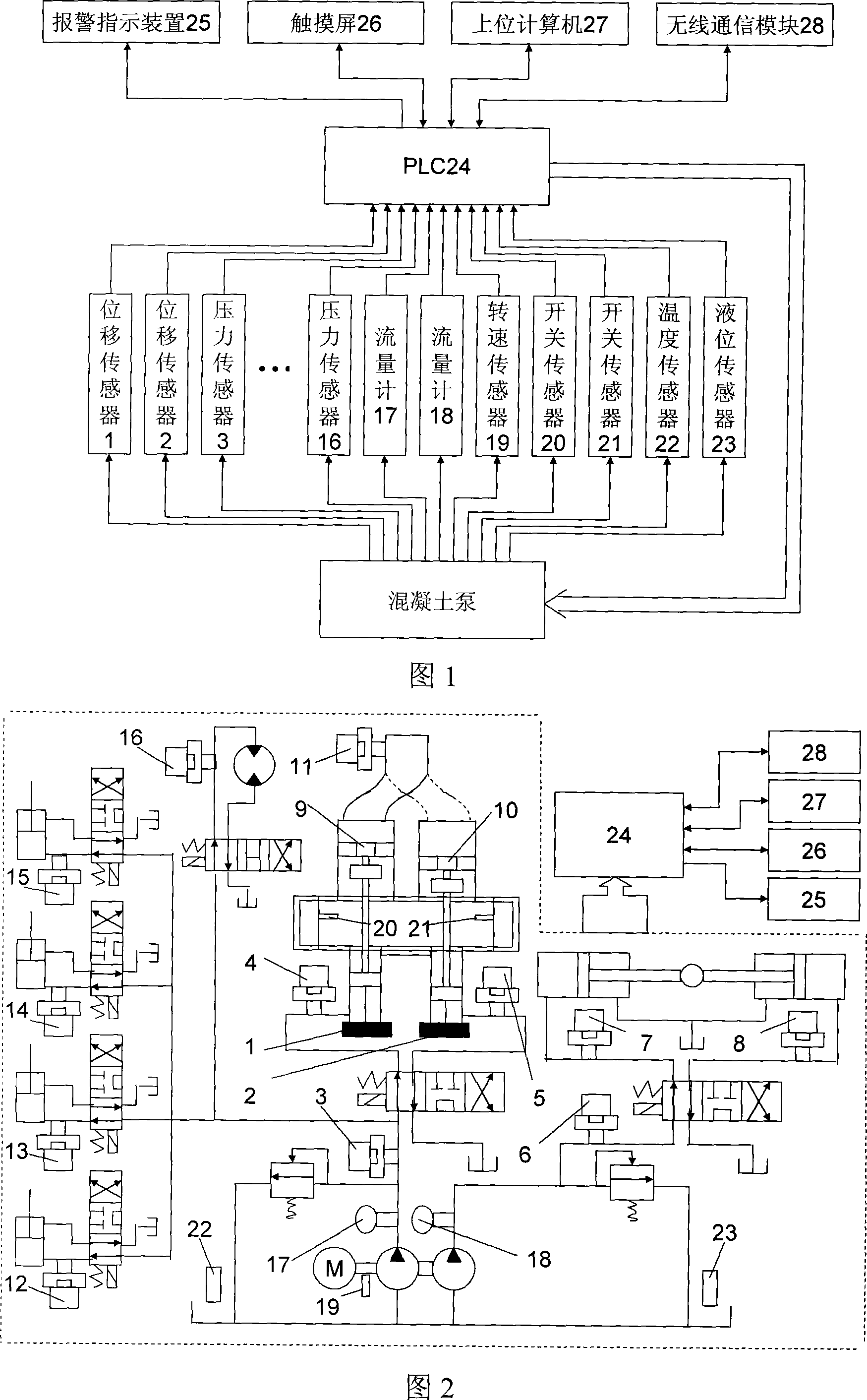

Concrete pump intelligent monitoring and control system

InactiveCN101178061AImprove performanceRealize intelligencePump controlBuilding material handlingElectric machineControl system

The invention discloses a concrete pump intelligent monitoring and control system. A magnetic telescopic displacement sensor is respectively arranged on the piston rod of the main cylinder of a concrete pump; pressure sensors are respectively arranged on a main pump hydraulic system, a concrete pump main cylinder, a swing hydraulic system, a swing cylinder, a concrete conveying cylinder piston, a concrete pump outlet, a concrete pump supporting leg hydraulic system, and a mixed hydraulic system; the outlet of the main cylinder and the outlet of an auxiliary pump are respectively provided with flowmeters; a rotation speed sensor is arranged on a motor mainshaft; a switch sensor is respectively arranged at the position of a concrete water tank; a temperature sensor and a liquid level sensor are arranged at the position of a concrete pump oil tank; all parts are respectively connected with the concrete pump and a PLC; the PLC is respectively connected with an alarm indicator device, a contact screen, an upper bit computer, and a wireless communication module. The invention can implement timely, online and remote state monitoring, malfunction diagnosing and intelligent control, so as to improve the integration performance of the concrete pump.

Owner:ZHEJIANG UNIV

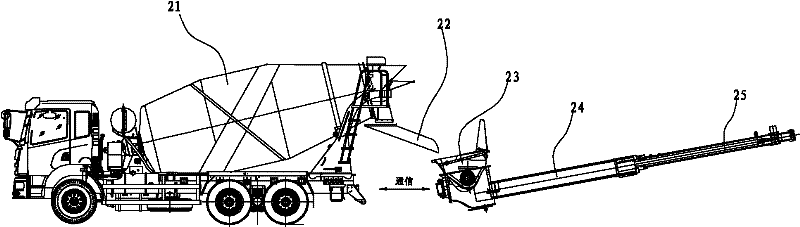

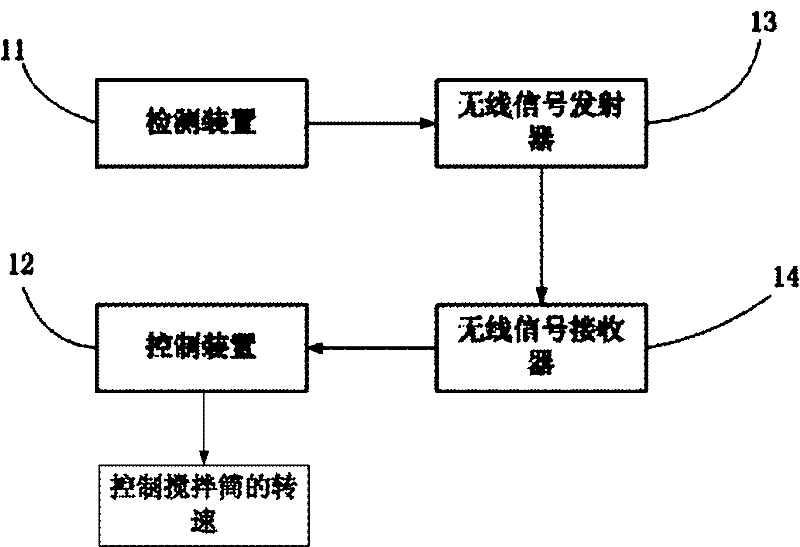

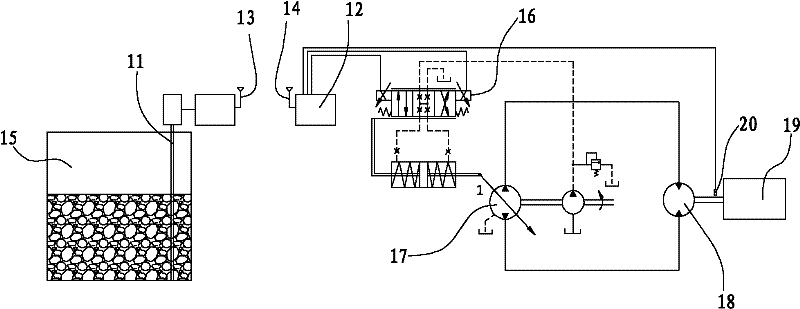

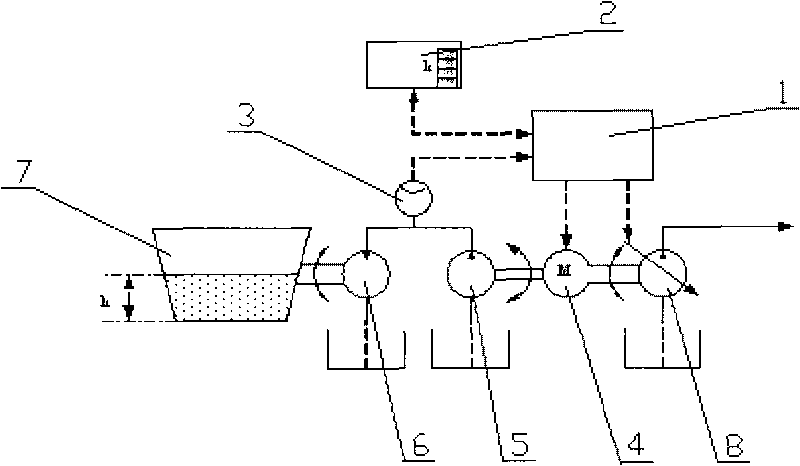

Collaborative operation system and method, concrete pumping apparatus and agitating truck

InactiveCN102230336AImprove construction efficiencySave personnel costsBuilding material handlingCement mixing apparatusConcrete pumpBuilding construction

The invention relates to a collaborative operation system and method, a concrete pumping apparatus and an agitating truck. A detection device in the collaborative operation system detects concrete level information and / or concrete remain information in a hopper; and a control device receives a detection signal and controls the discharge speed of the agitating truck according to a prestored control strategy, so that the concrete in the hopper can not overflow or be pumped emptily, or the level of the concrete in the hopper is maintained to a certain level, thereby implementing collaborative operation between the pumping truck and the agitating truck. By using the invention, the pumping truck and the agitating truck can implement collaborative operation at the concrete construction site, and one operator can be saved. The invention also provides a pumping apparatus provided with the detection device and an agitating truck provided with the control device, so that the pumping apparatus and the agitating truck have the conditions for collaborative operation. Besides, the invention also provides a collaborative operation method, according to which the collaborative operation between the agitating truck and the pumping equipment apparatus can be controlled.

Owner:SANY HEAVY IND CO LTD (CN)

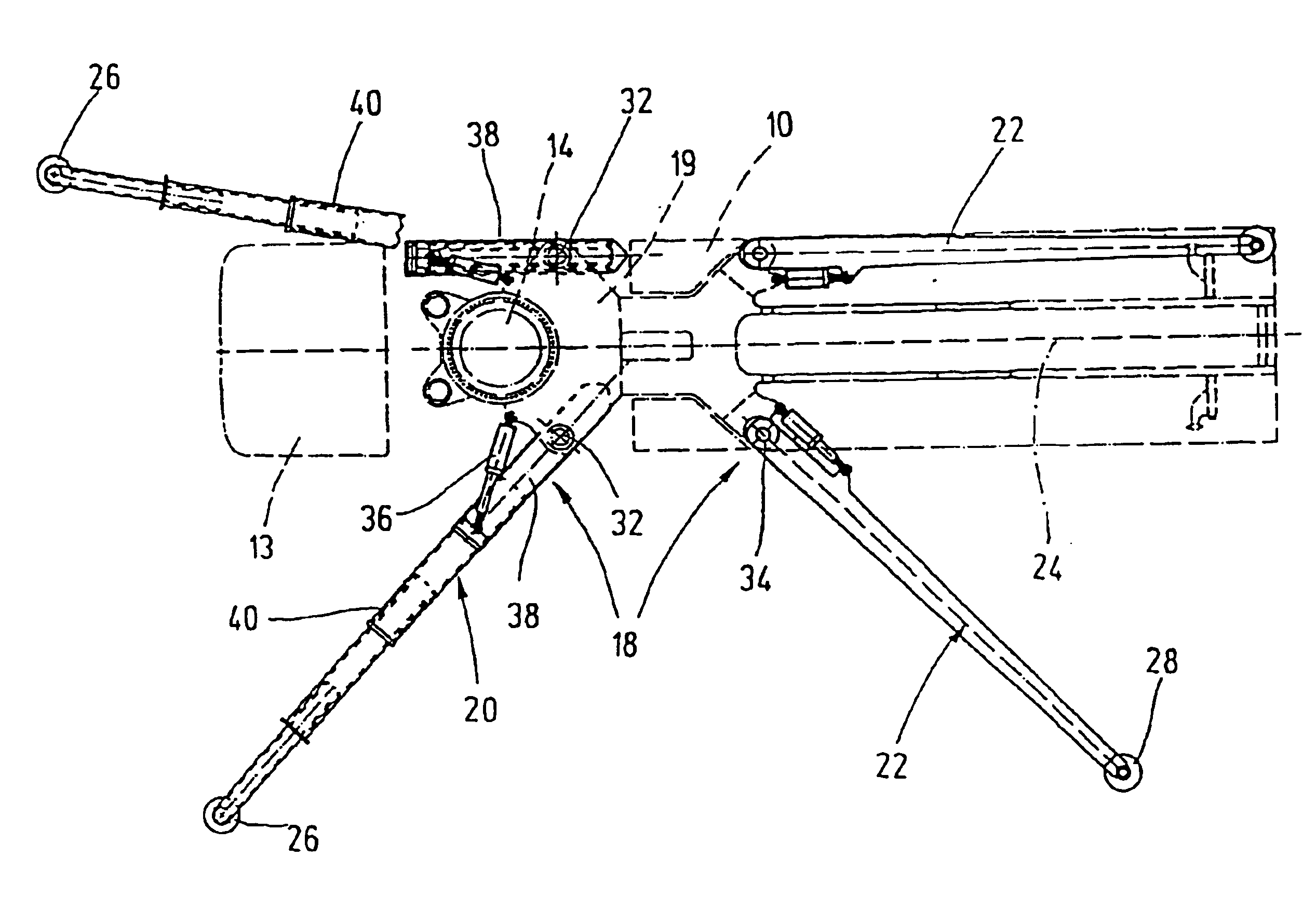

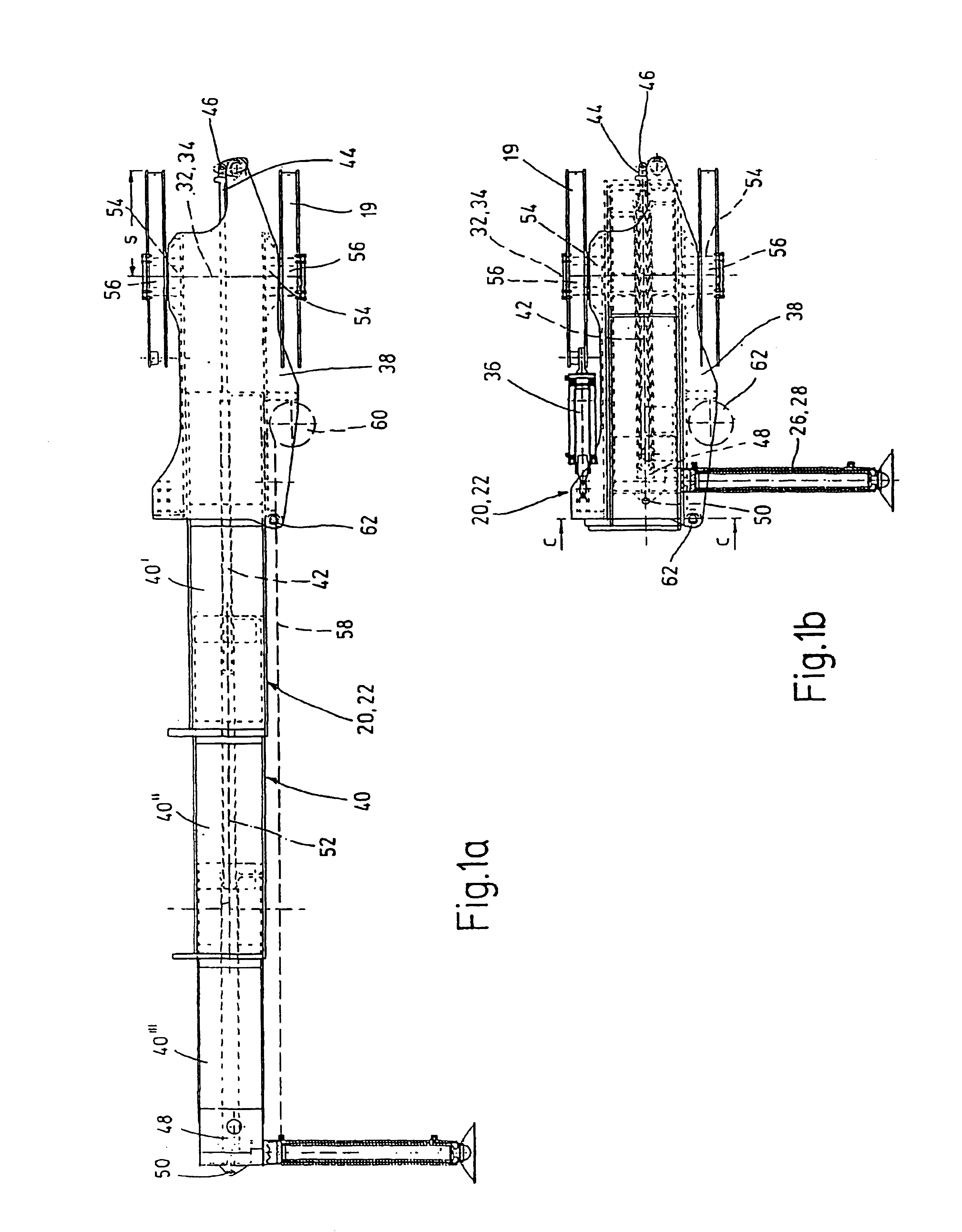

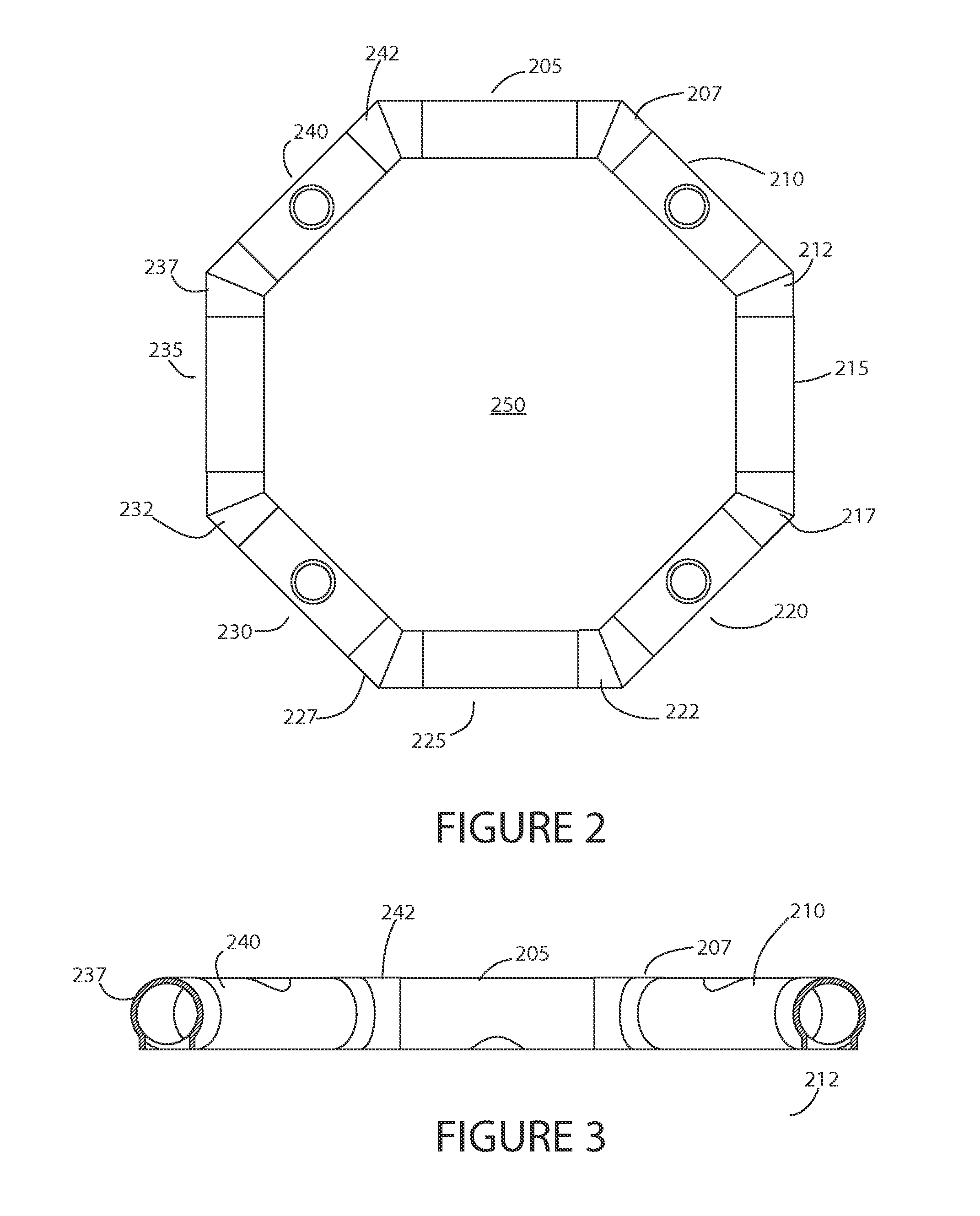

Support struts for mobile working machines and mobile concrete pump with said support struts

InactiveUS6840540B2Improvement of support strut stance stabilityReduce frictionVehicle fittings for liftingVehicle cleaning apparatusHydraulic cylinderAxial distance

A support strut for mobile working machines, especially for mobile concrete pumps. The support strut (20) has a strut body (38) that can be pivoted around a vertical pivoting axis (32) on a chassis (10), a telescopic part (40), a dual-acting hydraulic cylinder (42) (38) and the telescopic part (40), in addition to a foot part (26) that. Both ends of the telescopic hydraulic cylinder (42) are fixed on fixing points (46, 50) in the area of the opposite ends of the body of the strut (39 / 8) and the telescopic part (40). The vertical pivoting axis (32) is defined by a divided bearing or journal location arranged at an axial distance (S) from the inboard fixing point (46) in the direction of the foot part on the body of the boom (38), said location being positioned in such a way that it transects the displacement axis (52) of the hydraulic cylinder (42) transversely.

Owner:PUTZMEISTER ENG

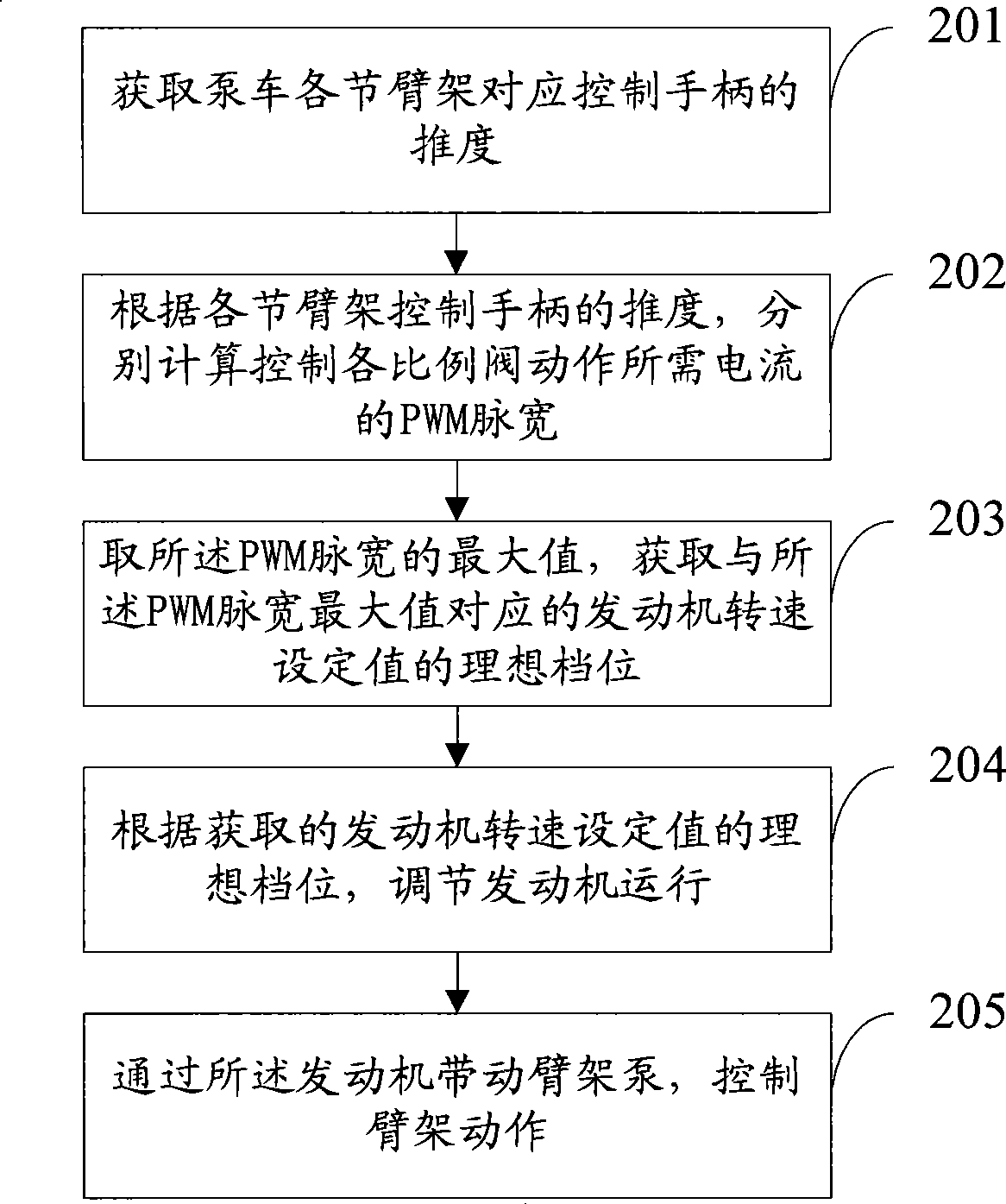

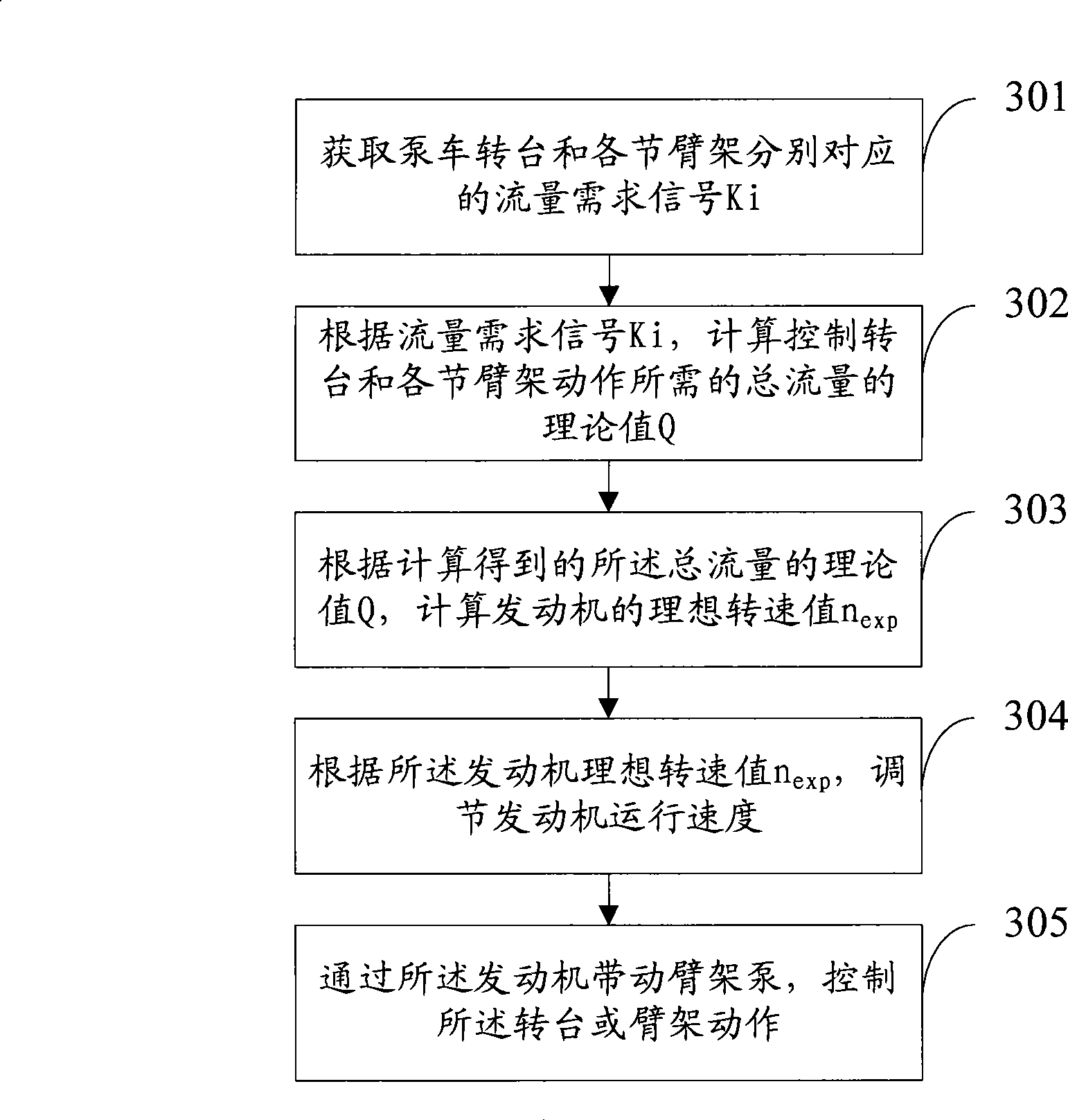

Control method, apparatus and system for concrete pump vehicle

InactiveCN101487343ARealize energy-saving controlAvoid wastingEngine controllersMachines/enginesControl theoryConcrete pump

The invention provides a control method of a concrete pump truck. The control method comprises the following steps: flow demand signals corresponding to a rotating floor and each arm support respectively are obtained; a theoretical value of total flow needed for controlling the movements of the rotating floor and each arm frame is calculated according to the flow demand signals; an ideal value of rotating speed of an engine is calculated according to the theoretical value of the total flow obtained by calculation; the operating speed of the engine is adjusted according to the ideal value of the rotating speed obtained by calculation; and an arm support pump is driven by the engine to control the movements of the rotating floor and each arm support. The invention further provides control equipment and a system of the concrete pump truck. By using the control method, the equipment and the system, the energy-saving control of the arm supports of the pump truck can be realized.

Owner:SANY HEAVY IND CO LTD (CN)

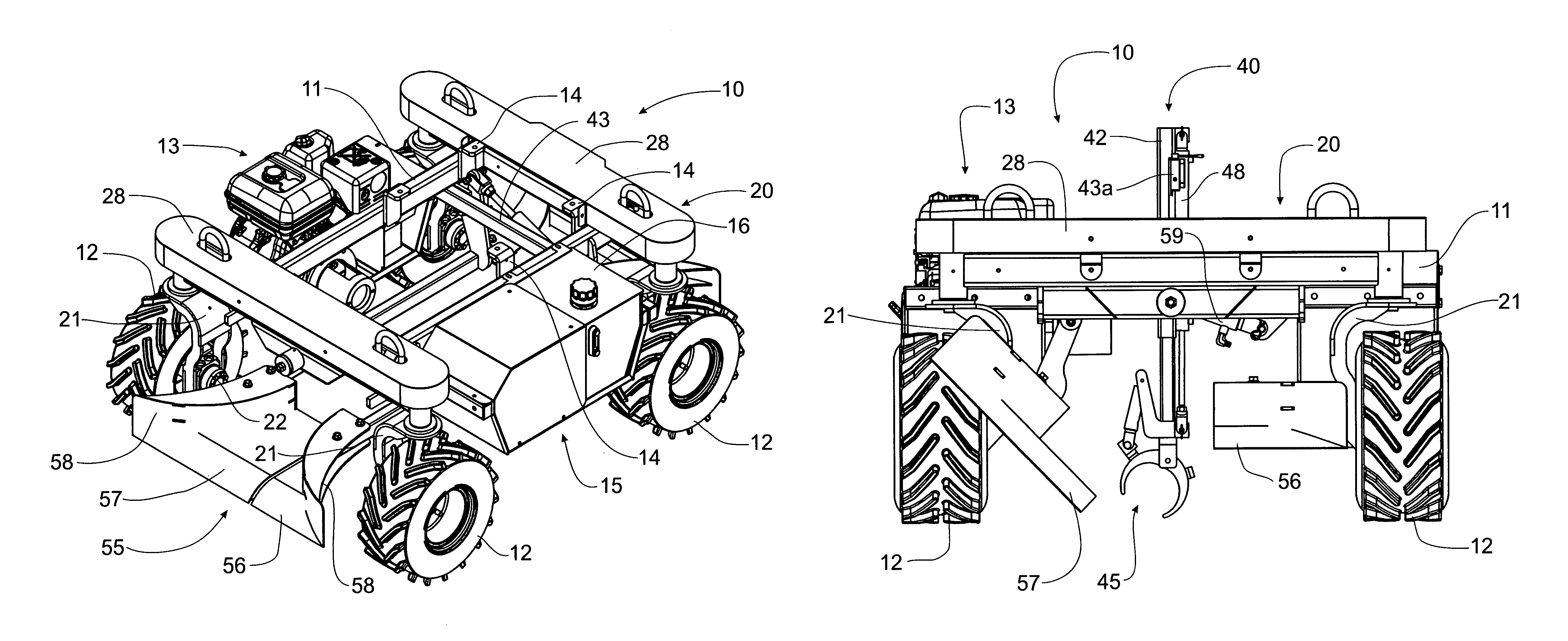

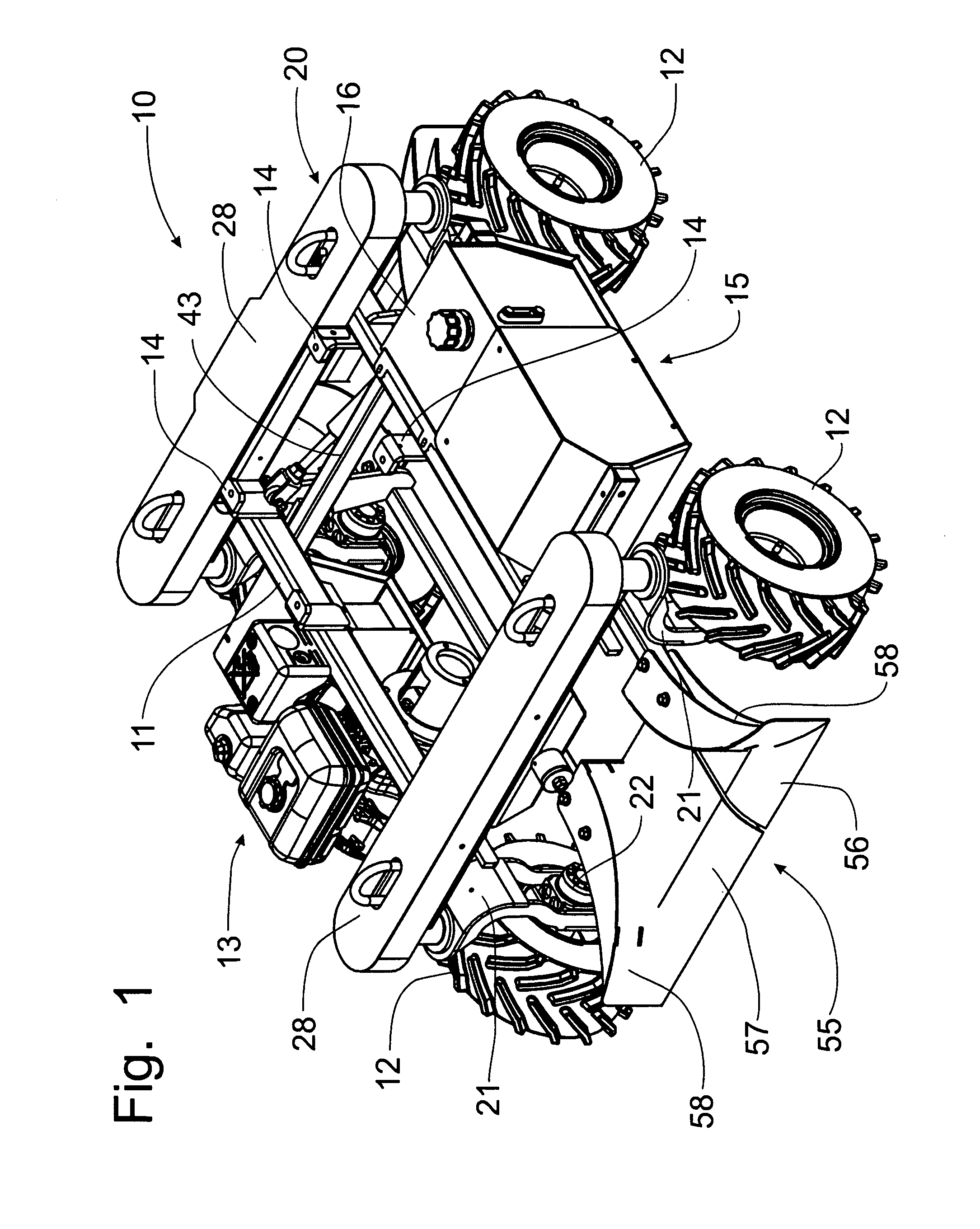

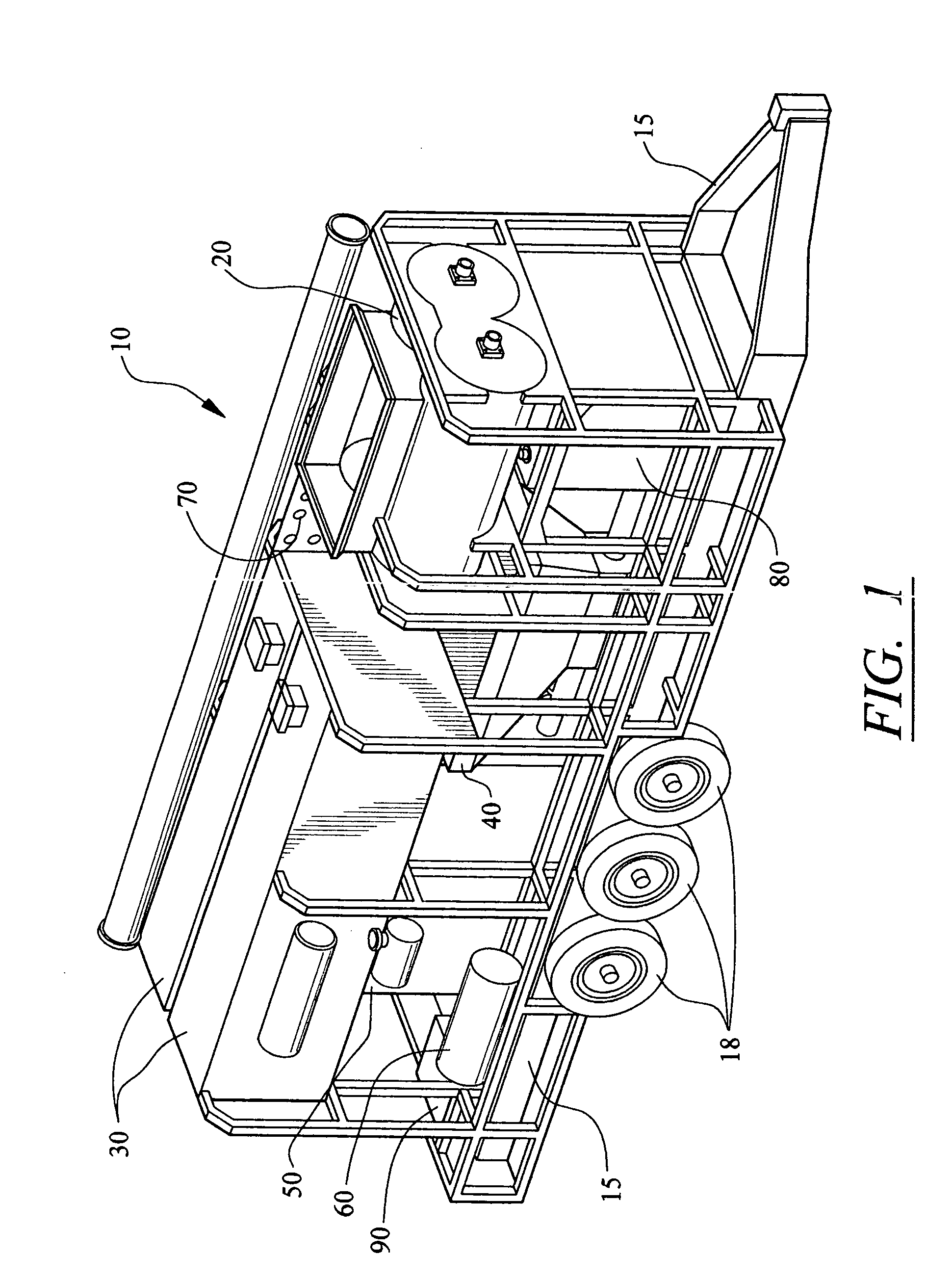

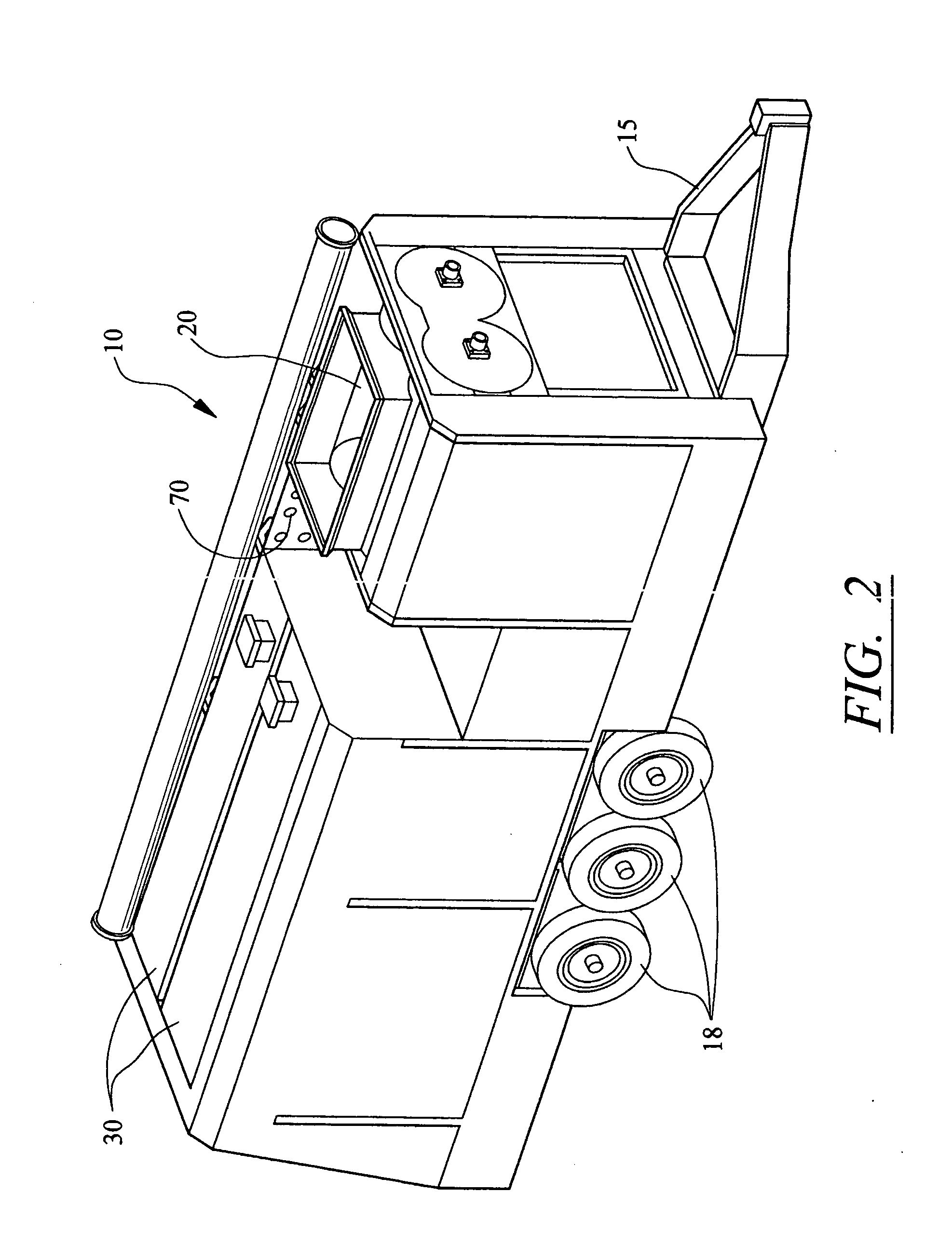

Apparatus for moving concrete pump hoses

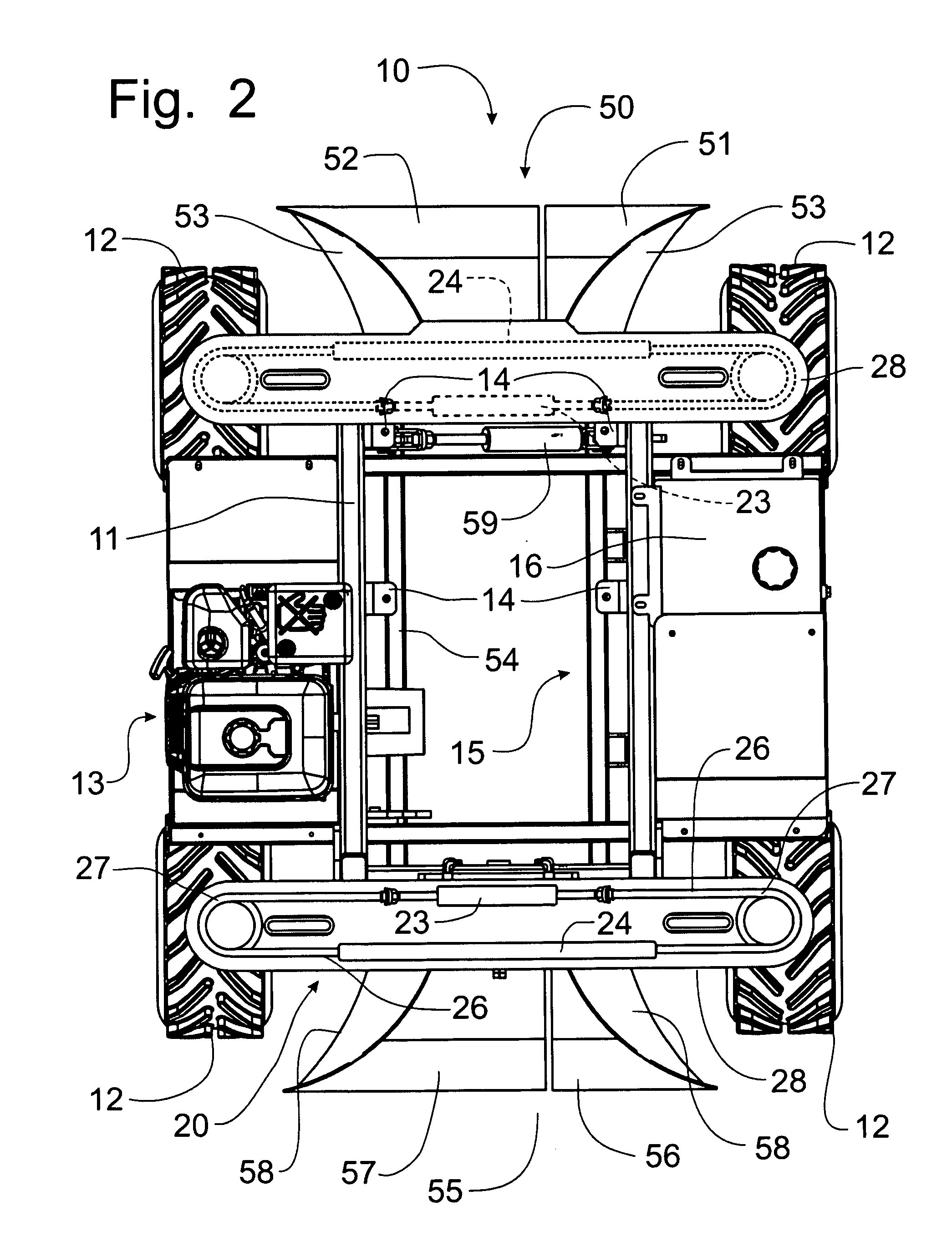

ActiveUS8312957B1Improve mobilityReliable constructionSteering linkagesFluid steeringVehicle frameEngineering

A mobile apparatus moves a concrete pump hose over a base surface and has a wheeled frame in which the wheels are pivotable about a generally vertical pivot axis between a longitudinal orientation and a transverse orientation. Each of the front pair of wheels and the rear pair of wheels are coupled to a steering mechanism to permit independent pivotal movement of the respective pairs of wheels to provide four wheel steer of the frame. The hose is supported by front and rear horn members above the base surface and below the frame. An intermediate grappling apparatus engages the hose to affect elevation thereof onto the horn members. The horn members are split between a fixed portion and a pivotally movable portion that pivots away from the fixed portion to permit the hose to be elevated above the horn members. A boom apparatus can substitute for the grappling apparatus.

Owner:SOMERO ENTERPRISES INC

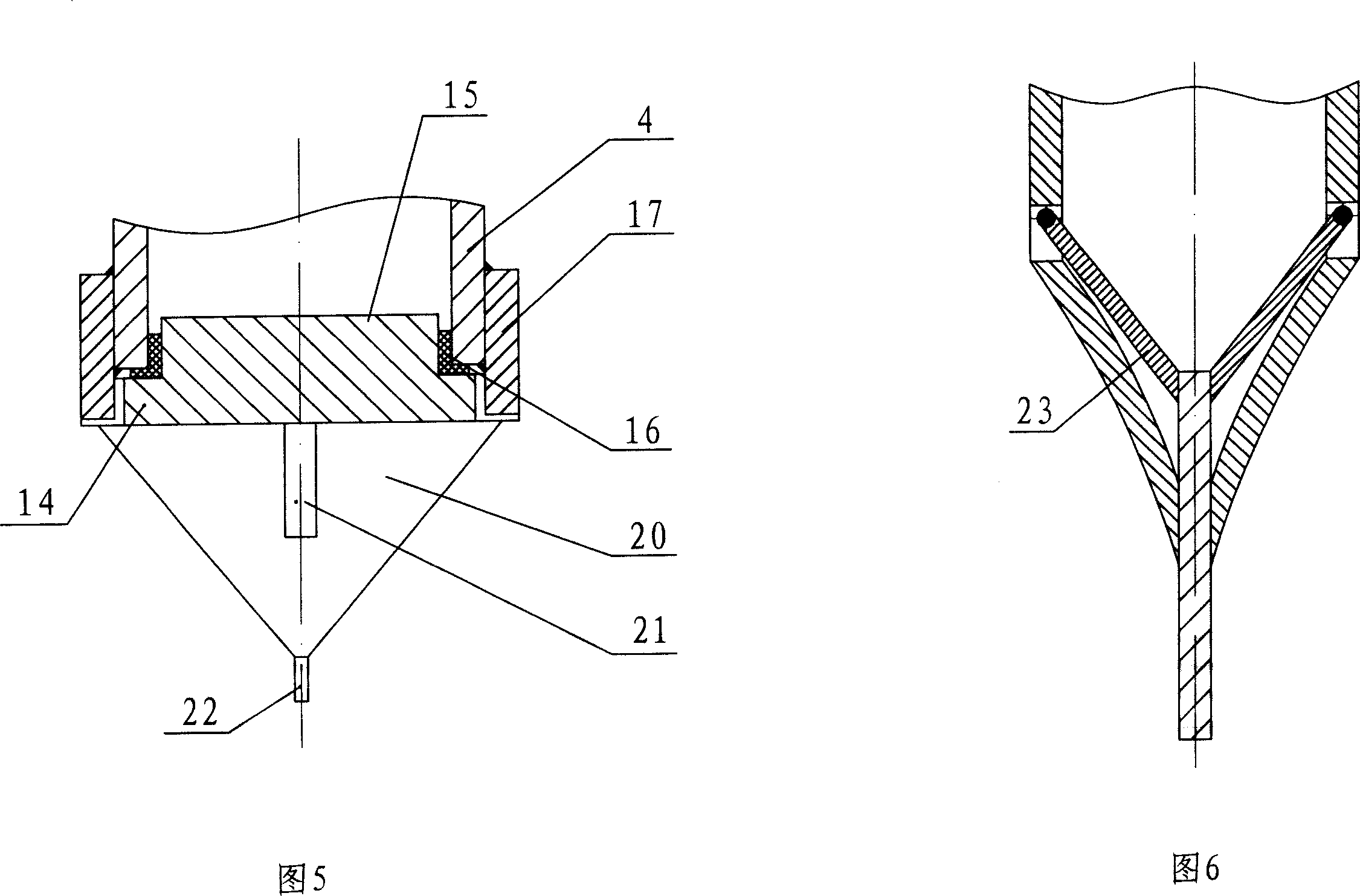

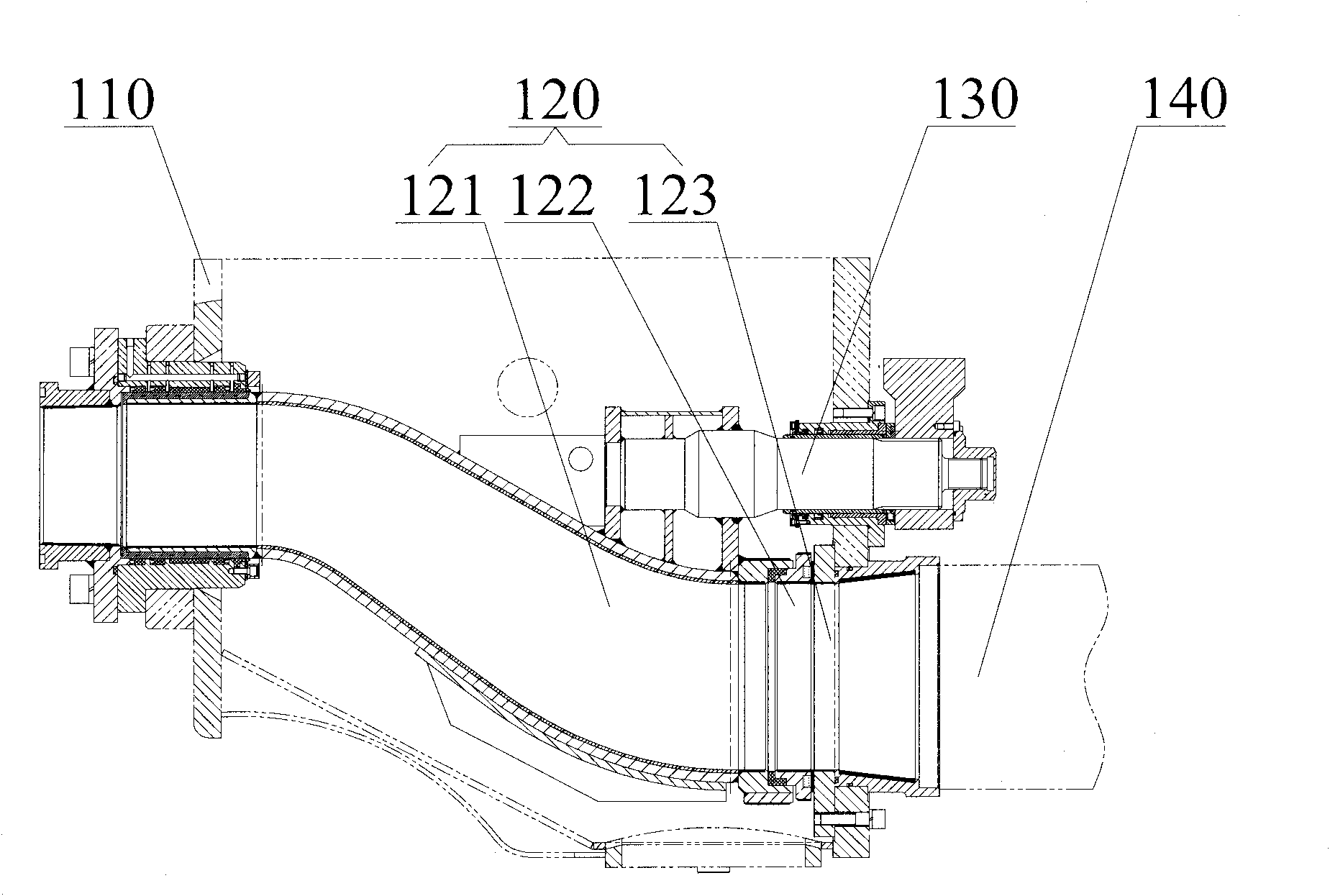

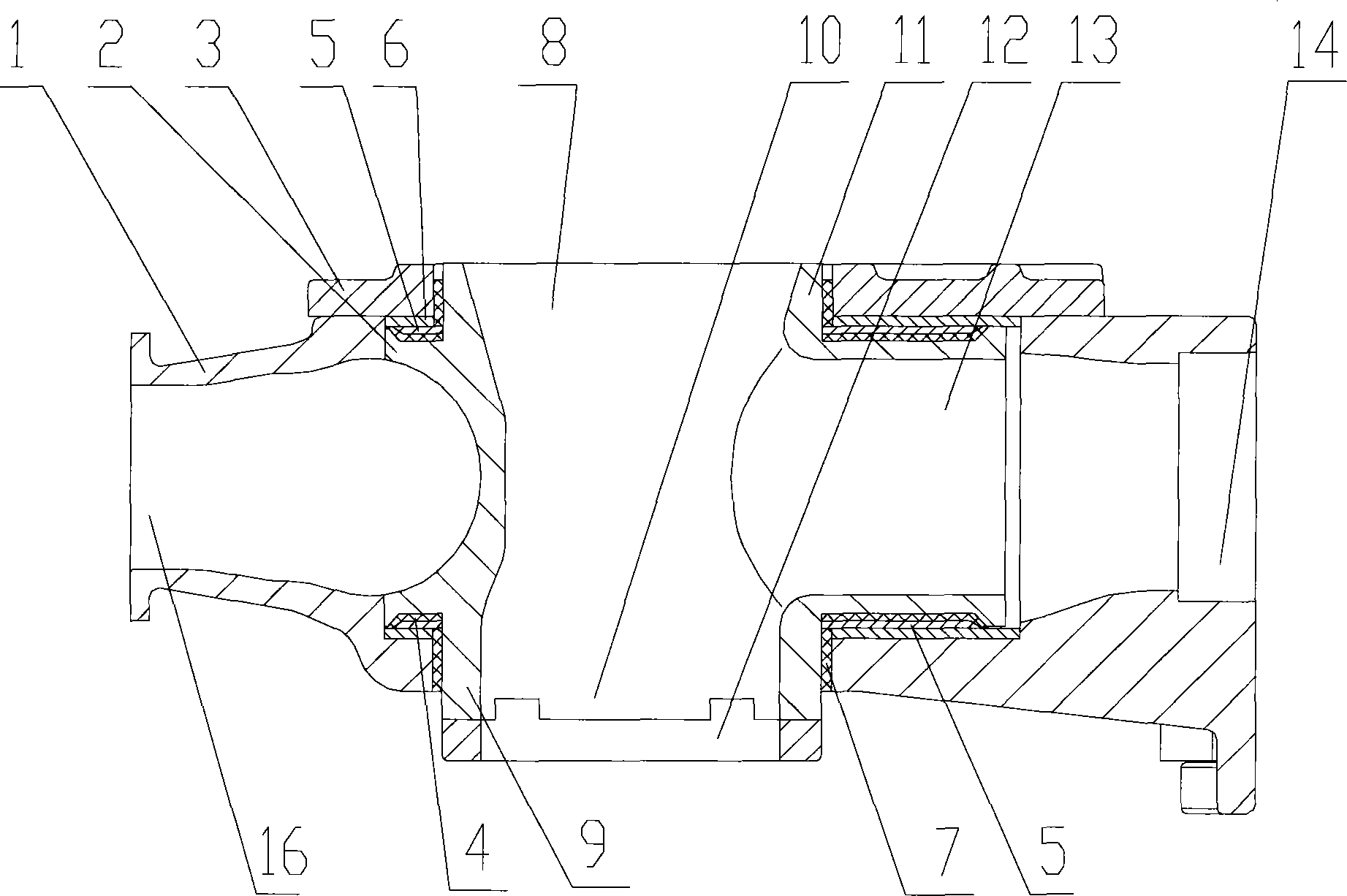

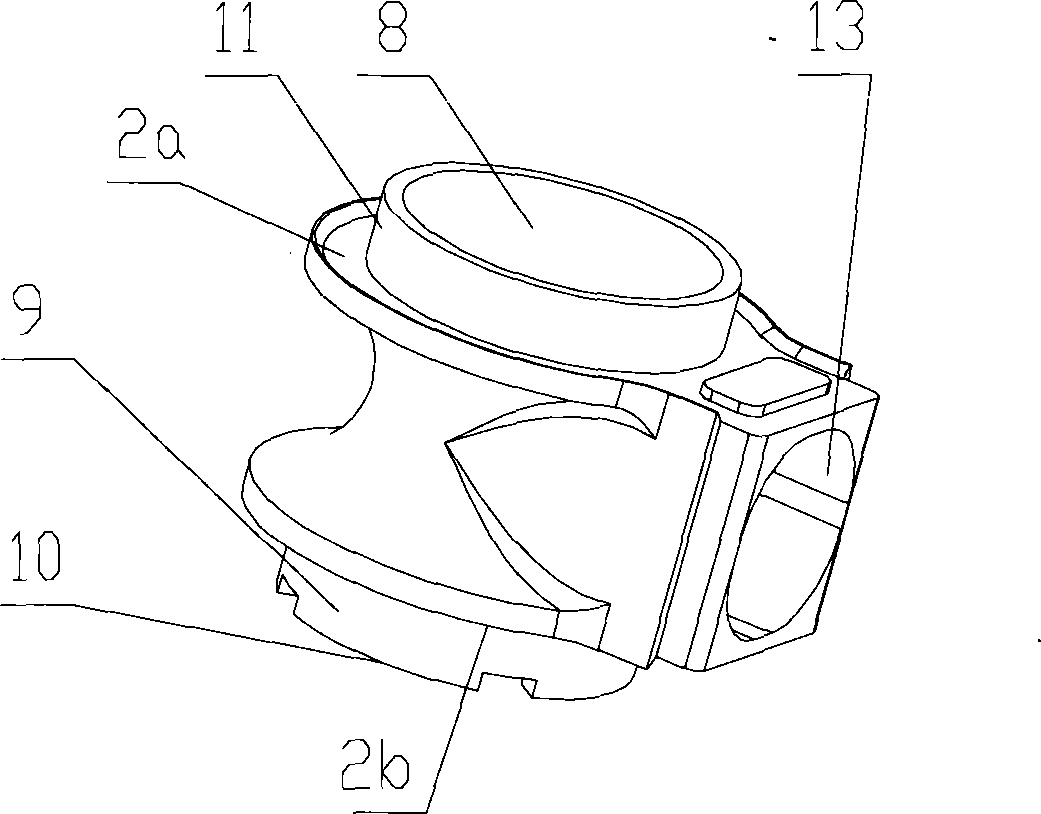

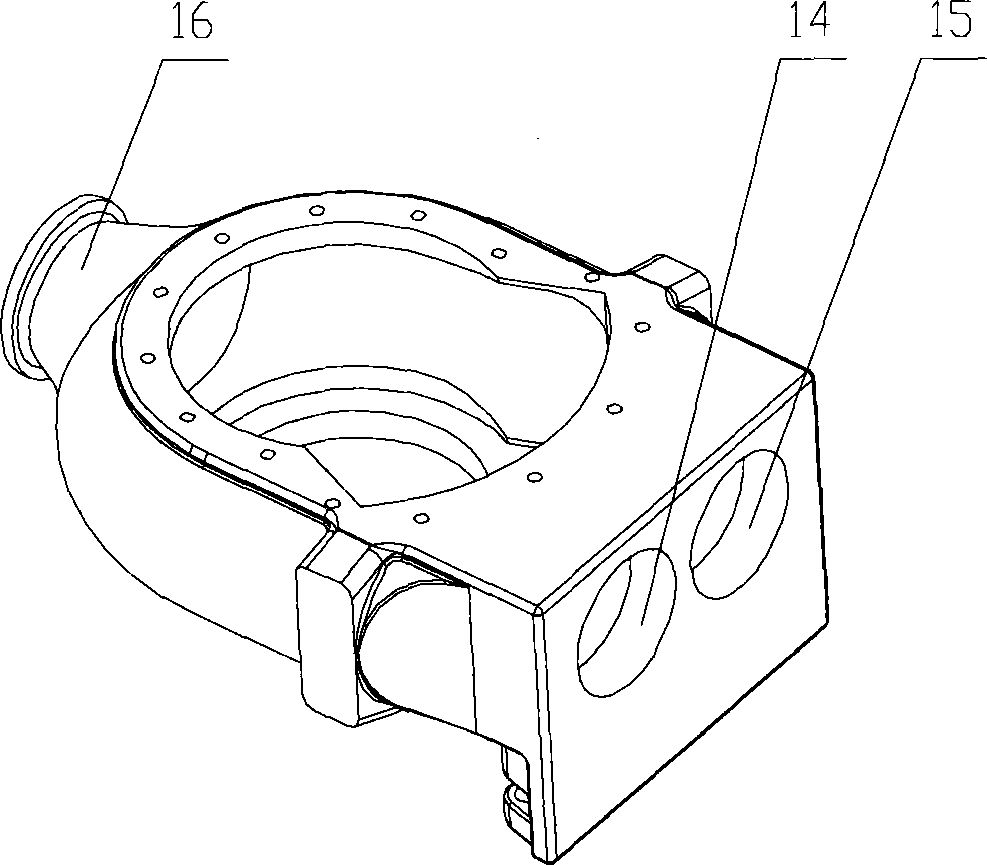

Distributing valve for concrete pump, concrete pump, control method thereof and concrete pump truck

InactiveCN101787973AReduce wear rateImprove suction performancePositive displacement pump componentsPump controlSlurryHigh pressure

The invention discloses a distributing valve for a concrete pump, the concrete pump, a control method thereof and a concrete pump truck. The distributing valve for the concrete pump comprises a valve body and a wear-resisting plate. The valve body comprises a first suction pipe and a first pumping pipe, wherein the back end of the first suction pipe is communicated with an outlet of a hopper so as to communicate the hopper and a delivery cylinder, and the back end of the first pumping pipe is rotatably connected with a delivery pipe of the concrete pump so as to communicate the delivery cylinder and the delivery pipe. The valve body can be switched between a first state and a second state under the driving of a drive mechanism, in the first state, concrete slurry is sucked into the delivery cylinder through the first suction pipe, and in the second state, the delivery cylinder pumps over the concrete slurry through the first pumping pipe. Because of the distributing valve with the structure, the concrete pump can thoroughly employ the self-flowing capacity of the concrete slurry in order to increase the suction performance of the concrete pump. The distributing valve has higher pressure bearing capacity, and the concrete pump can ensure that the concrete slurry has higher pressure through the delivery cylinder, thereby meeting the needs of high-pressure pumps to pump over the concrete slurry.

Owner:三一西北重工有限公司

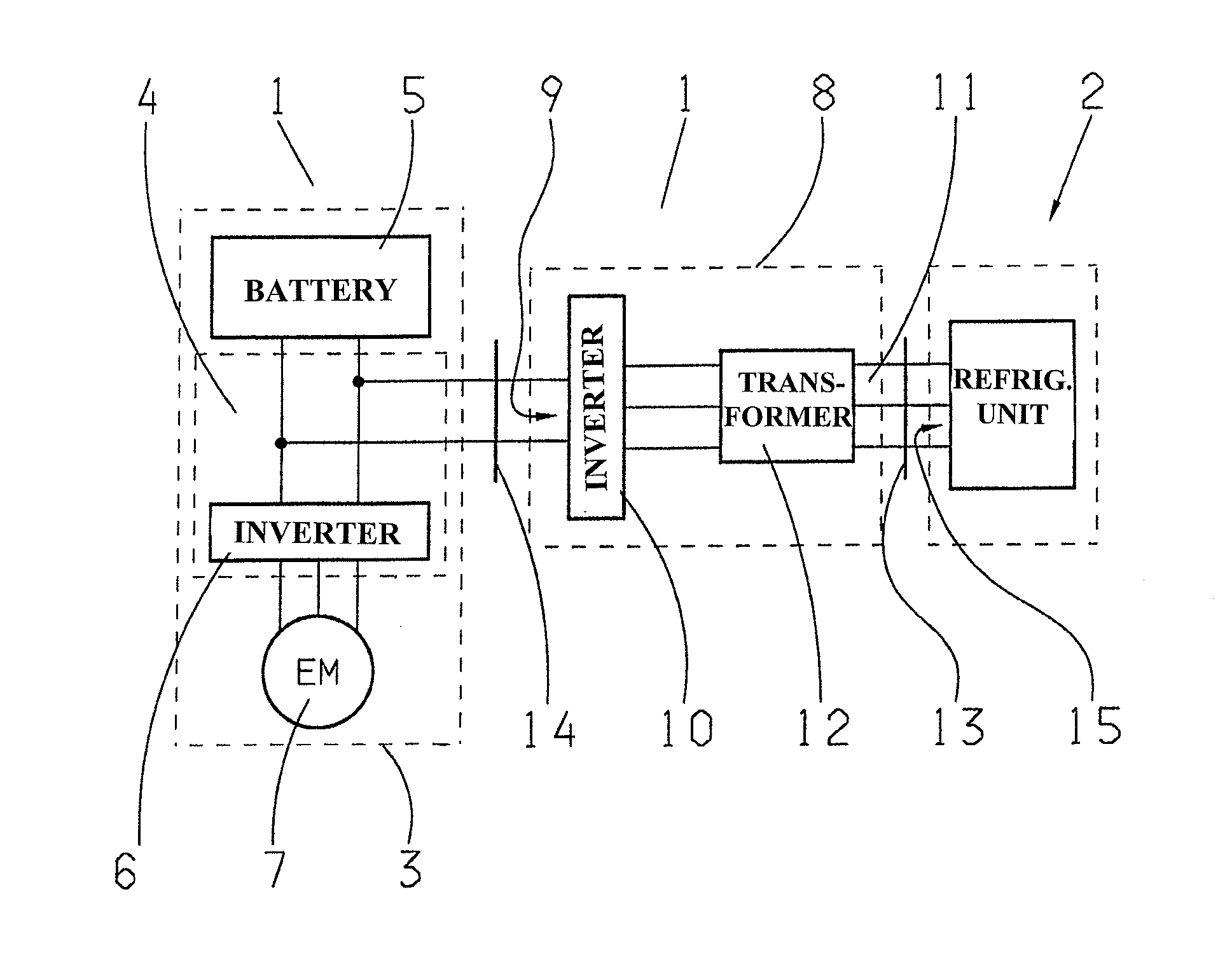

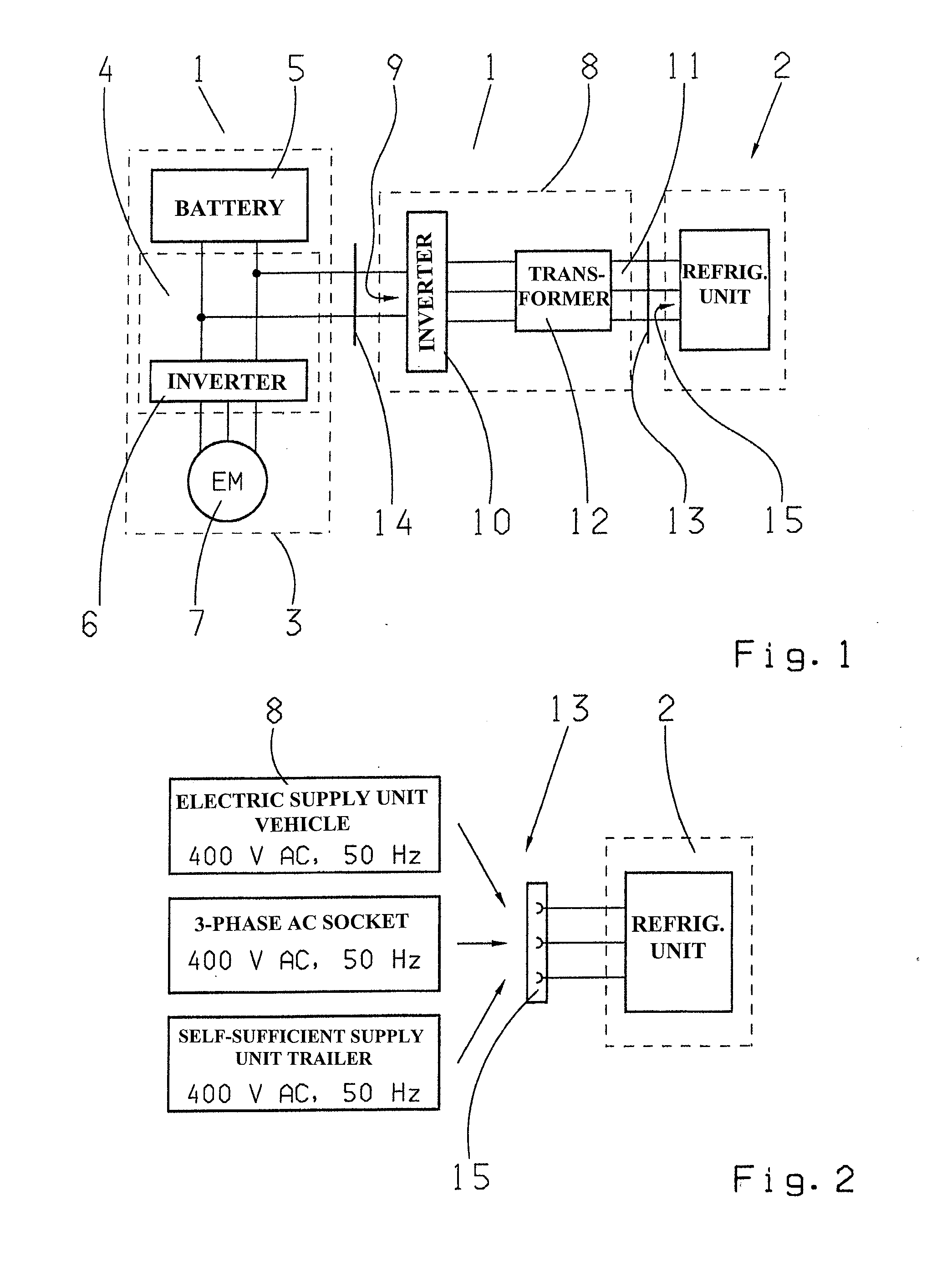

Power supply device and unit

A power supply device for a unit that is to be supplied with electrical energy and typically arranged on a commercial vehicle trailer, for example. The power supply device comprises an electro-hybrid drive system for a commercial vehicle and a supply unit which is designed to convert a direct voltage, from a high-voltage system of the electro-hybrid drive system, into a three-phase alternating voltage. The supply unit comprises an output which transmit the three-phase alternating voltage for supplying power to the unit. The output is designed to form a standardized interface together with the unit. In addition, the unit which can be connected to the power supply device is one of a refrigerator unit, a concrete mixer, a concrete pump or a shredder.

Owner:ZF FRIEDRICHSHAFEN AG

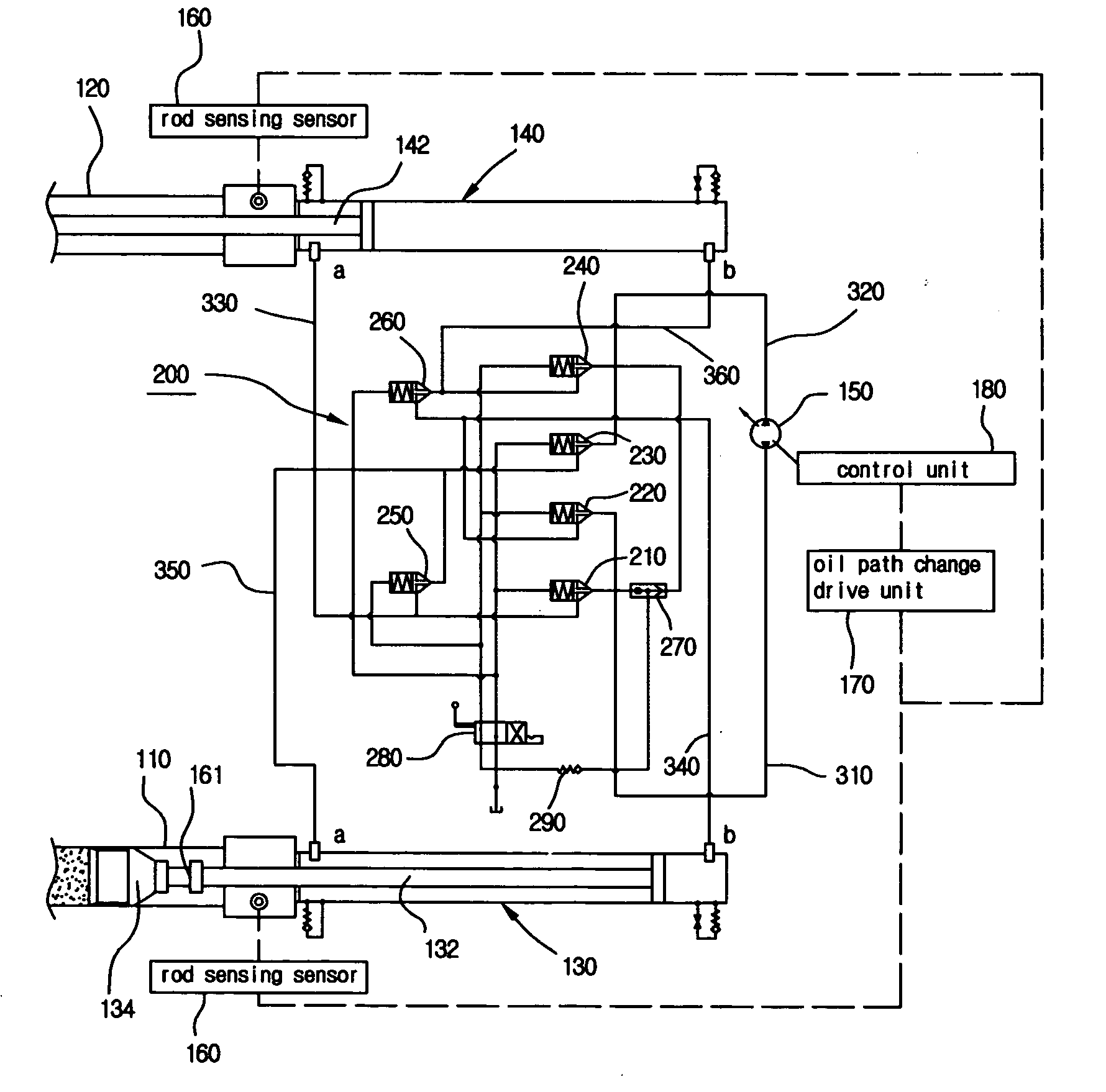

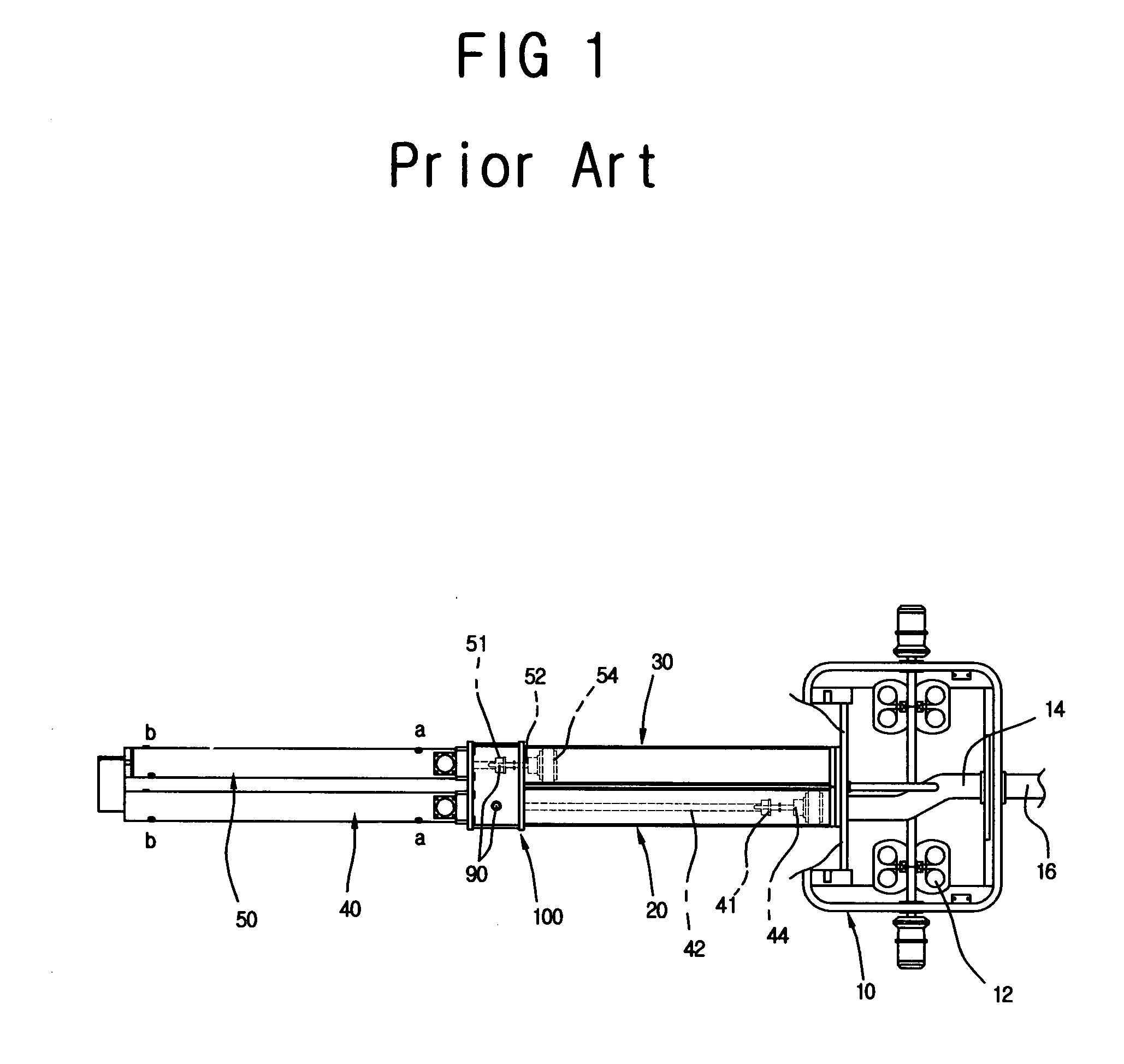

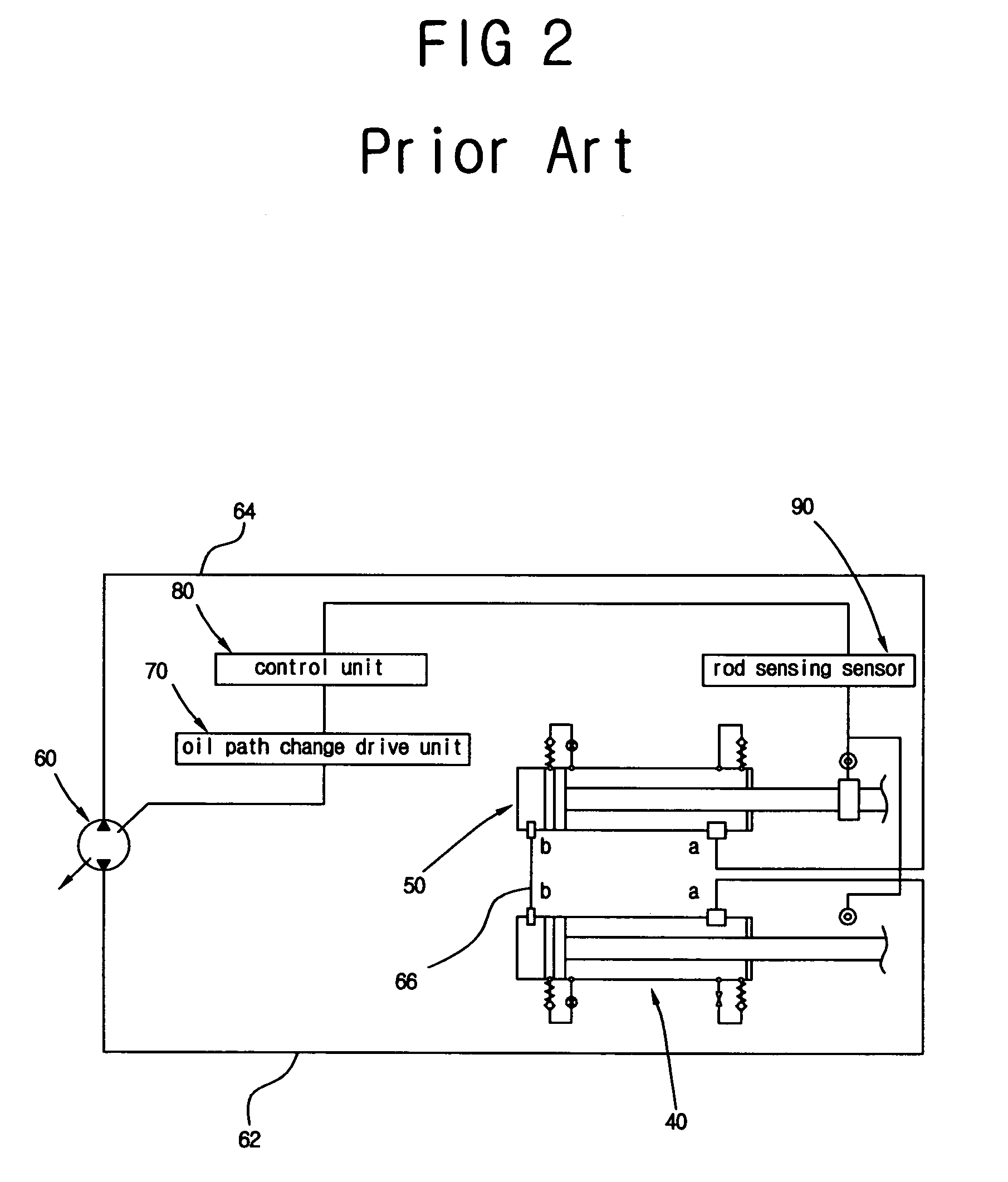

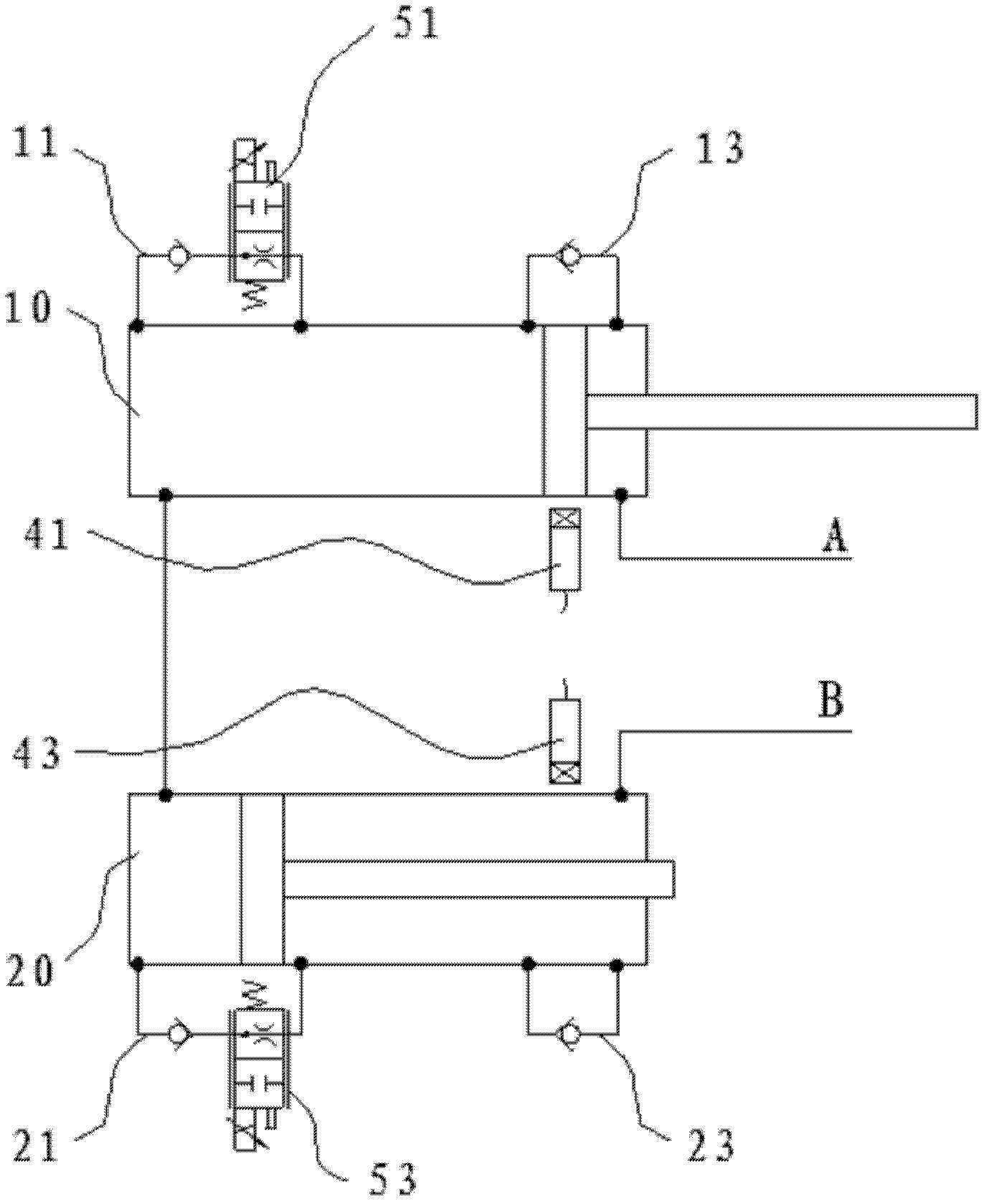

Concrete-mortar transfer system of concrete pump car

InactiveUS20050232069A1Low costEasy to operateServomotor componentsServomotorsReverse currentTransfer system

The present invention relates to a concrete transfer system of a concrete pump car which comprises a pair of concrete input tubes mounted in union to a pair of communication holes punched to the inside surface of a hopper, first and second drive cylinders mounted on the same lines of the concrete input tubes for sucking and transferring the concrete by forward and backward movements of pressure pistons mounted to rod ends, an oil pressure pump for supplying the fluid to the first and second drive cylinders, a rod sensing sensor for sensing the movement of the rods of the first and second drive cylinders, a control unit for performing a predetermined control operation by receiving the sensing signal of the rod sensing sensor, an oil path change drive unit for supplying selectively the fluid with the first and second drive cylinders according to the control signal of the control unit, the concrete transfer system of the concrete pump car comprising: a first logic valve to sixth logic valves, a reverse current preventive device, and a high / low pressure selection valve.

Owner:DNS

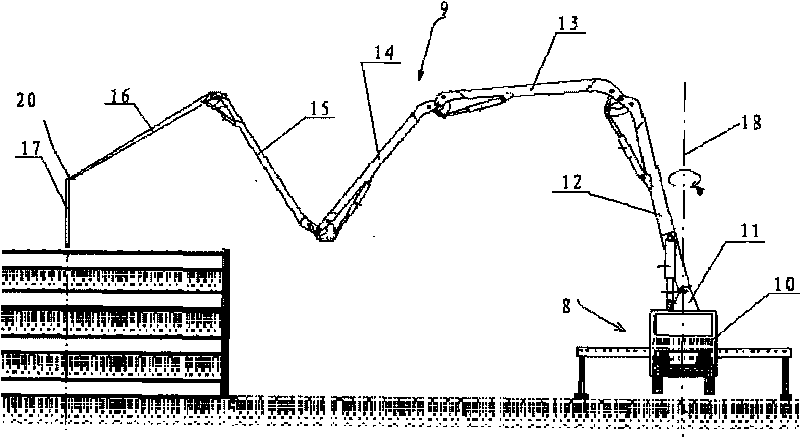

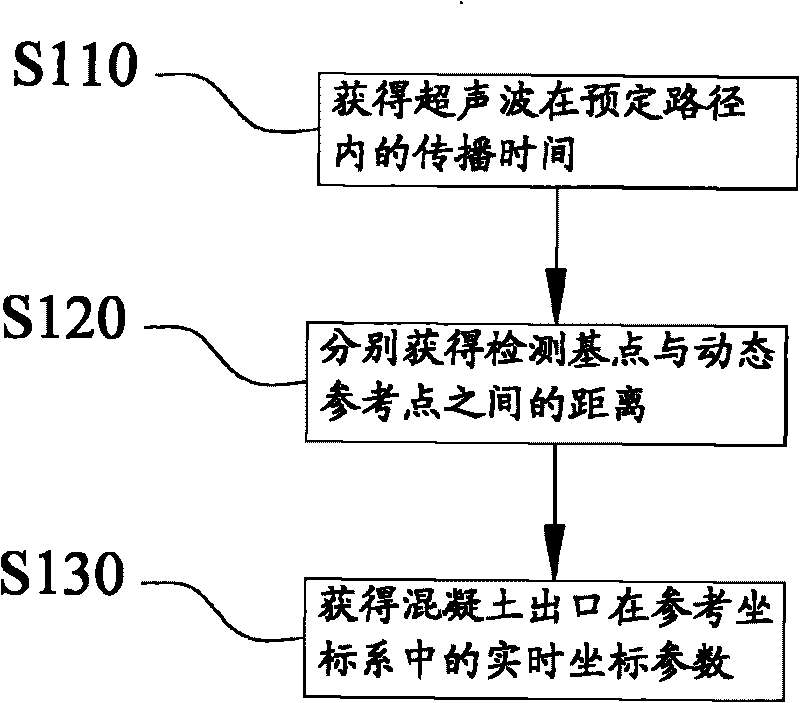

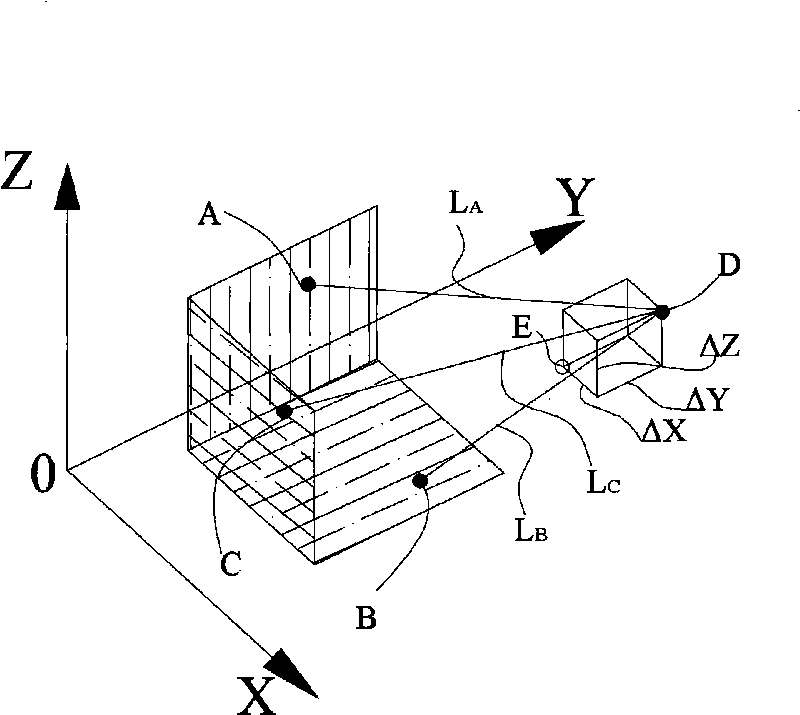

Device and method for detecting position of concrete pump truck and concrete pump truck

InactiveCN101718861AImprove accuracyImprove reliabilityPosition fixationBuilding material handlingInformation controlLocation detection

The invention discloses a device and a method for detecting the position of a concrete pump truck and the concrete pump truck. The device for detecting the position of the concrete pump truck comprises a processor, a timer, a dynamic sensor and a fixed point sensor, wherein the ultrasonic wave sending and reception can be carried out between the dynamic sensor and the fixed point sensor; the timer can obtain the transmission time of the ultrasonic wave in a predetermined path according to the time of transmitting the ultrasonic wave and the time of receiving the ultrasonic wave, and the predetermined path is determined according to the position relation between the dynamic sensor and the fixed point sensor; the processor acquires the real-time coordinate parameters, real-time moving direction and real-time moving speed of a concrete outlet in a reference coordinate system according to a predetermined strategy. In the disclosed concrete pump truck, an intelligent control system can control the moving direction of the moving speed of the tail end of an information control arm support according to the information obtained by the processor so as to locate the tail end of the arm support at a preset position and ensure successful casting operation.

Owner:SANY HEAVY IND CO LTD (CN)

Concrete pumping agent as well as preparation method and application thereof

The invention relates to the field of building materials and in particular relates to a concrete pumping agent as well as a preparation method and an application thereof. The concrete pumping agent comprises the following components in parts by weight: 15-35 parts of polycarboxylate-type water reducing agent, 0.1-0.6 part of defoaming agent, 1-3 parts of rheological agent, 1-5 parts of retarder, 0.03-0.2 part of air entraining agent and 56.2-82.87 parts of water, wherein solid content of the polycarboxylate-type water reducing agent is 40%. By adopting the concrete pumping agent, the problems that concrete prepared by a common concrete pumping agent is rough in surface and many air holes, voids and pits are formed can be effectively solved, and a good effect on formation of a clear water and mirror surface effect of bare concrete is realized.

Owner:CHINA 19TH METALLURGICAL CORP +1

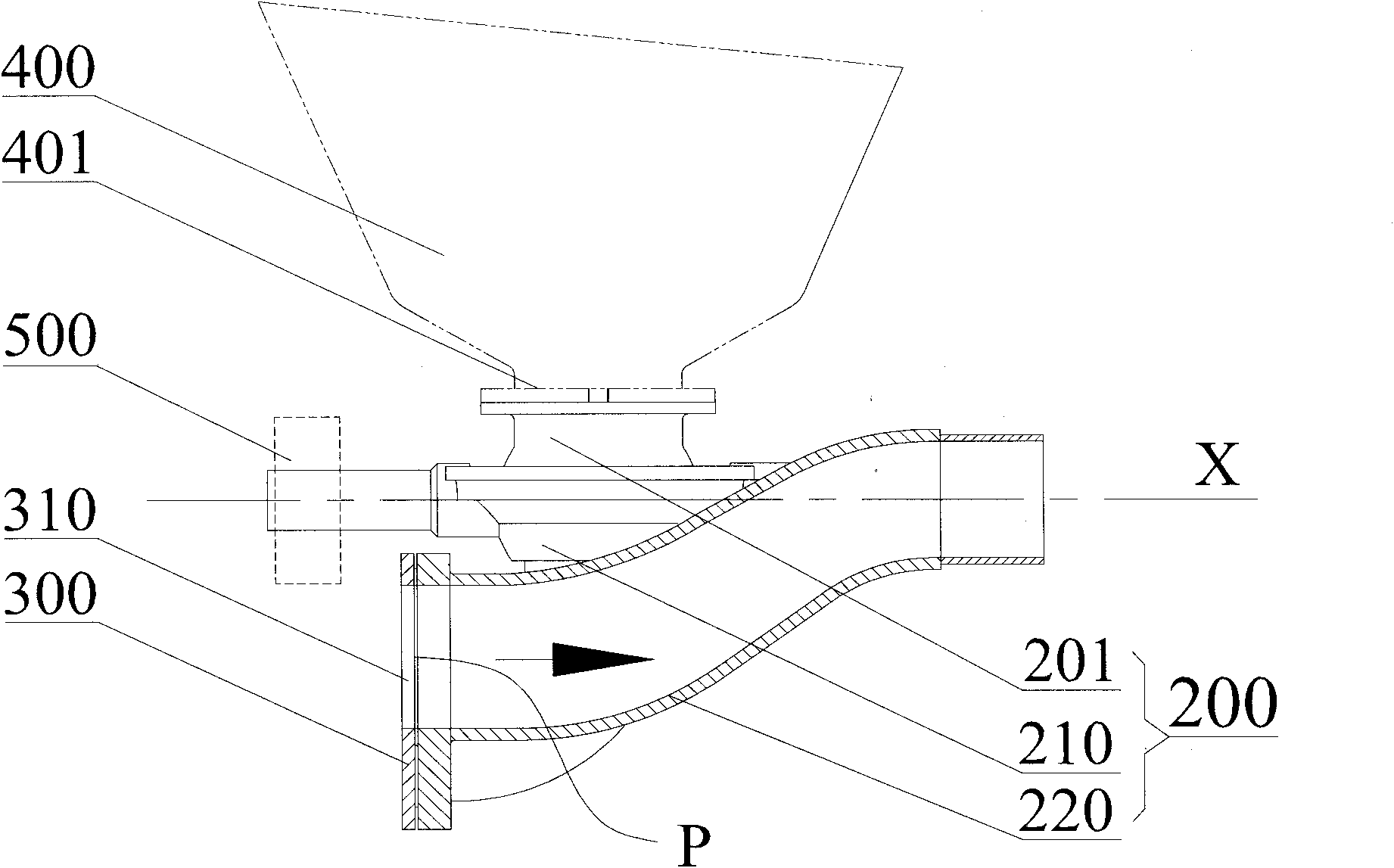

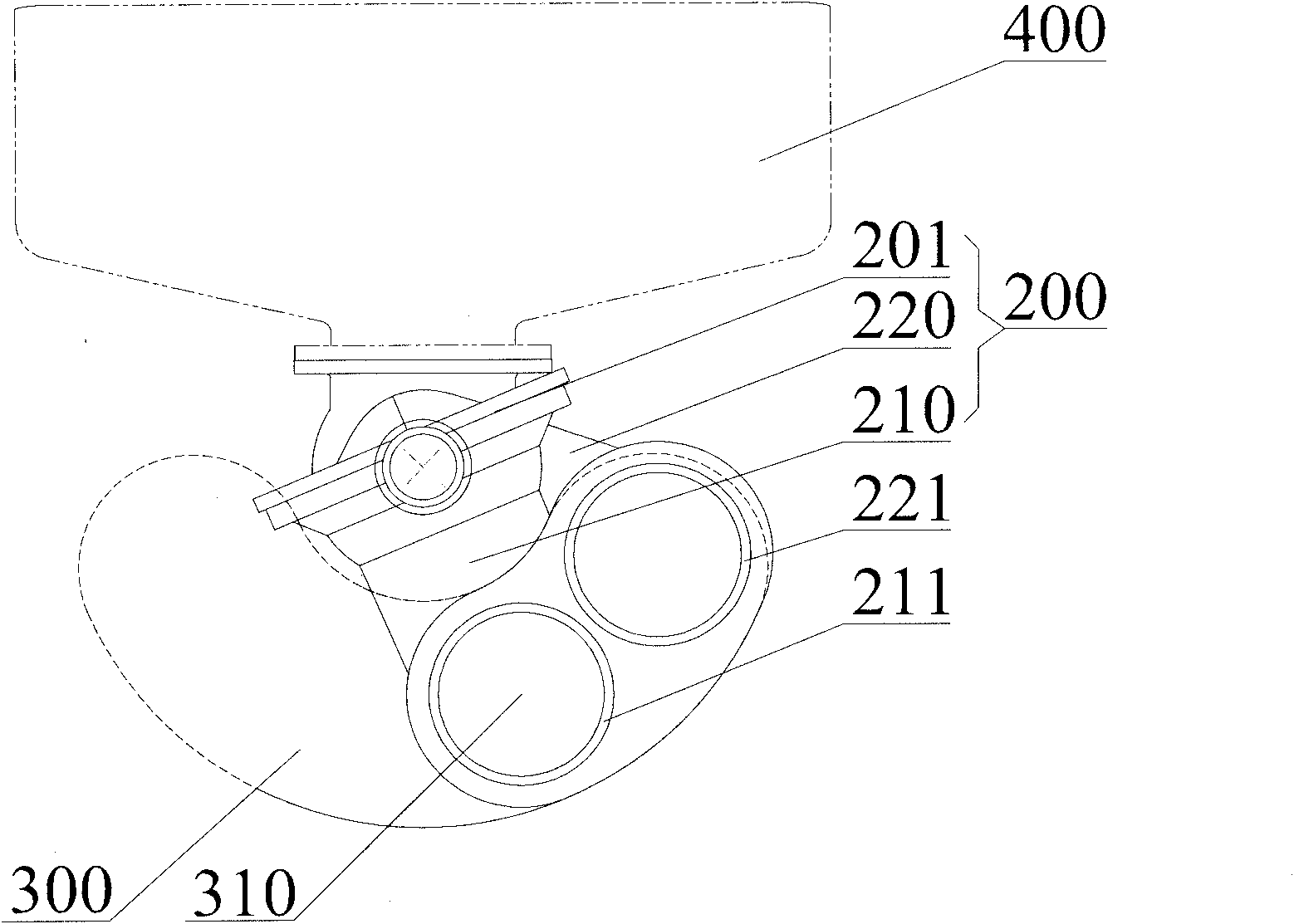

Concrete distributing valve and concrete pumping mechanism

InactiveCN101245866AImprove suction performancePositive displacement pump componentsMultiple way valvesConcrete pumpMechanical engineering

Owner:SANY AUTOMOBILE MFG CO LTD

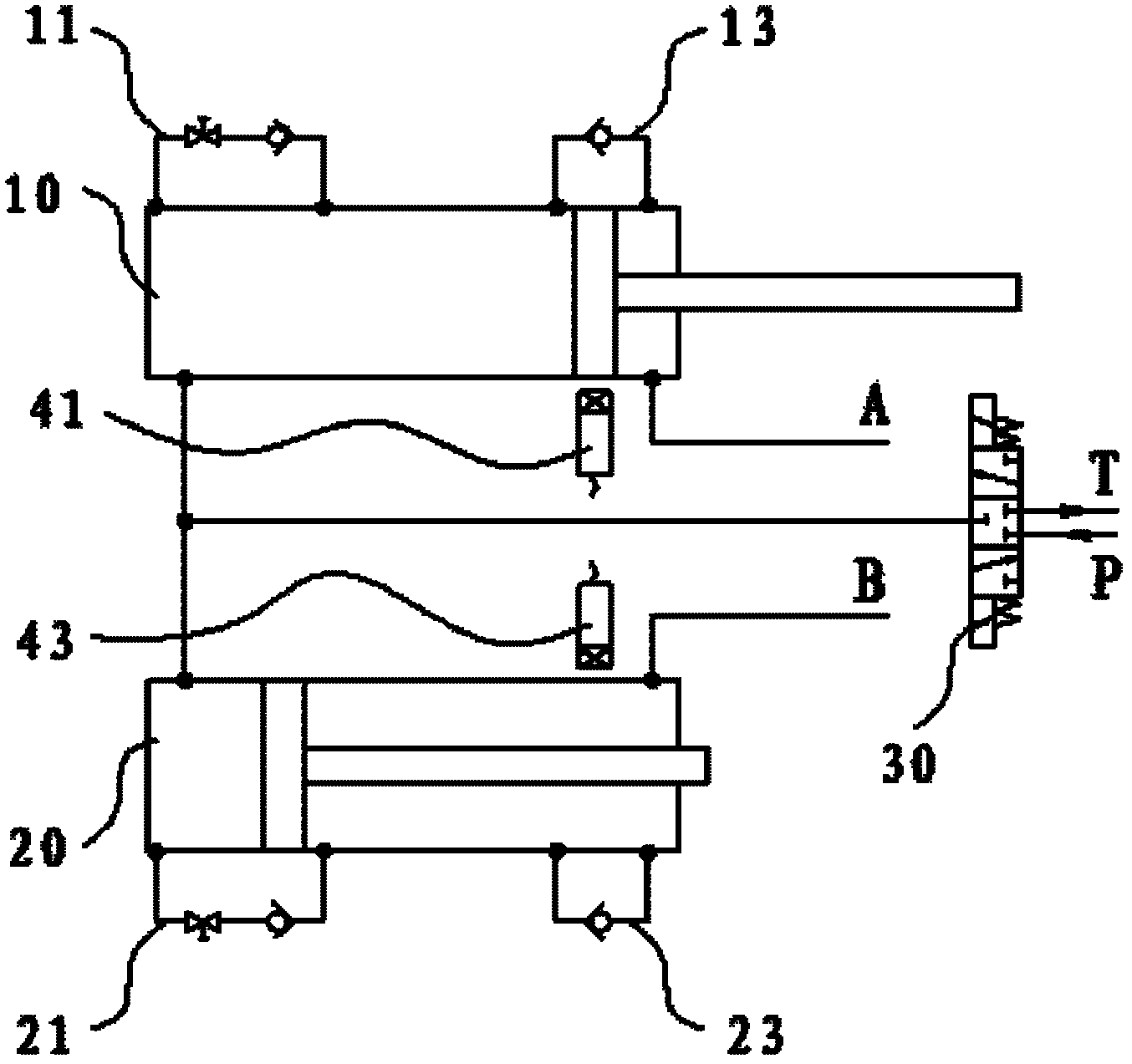

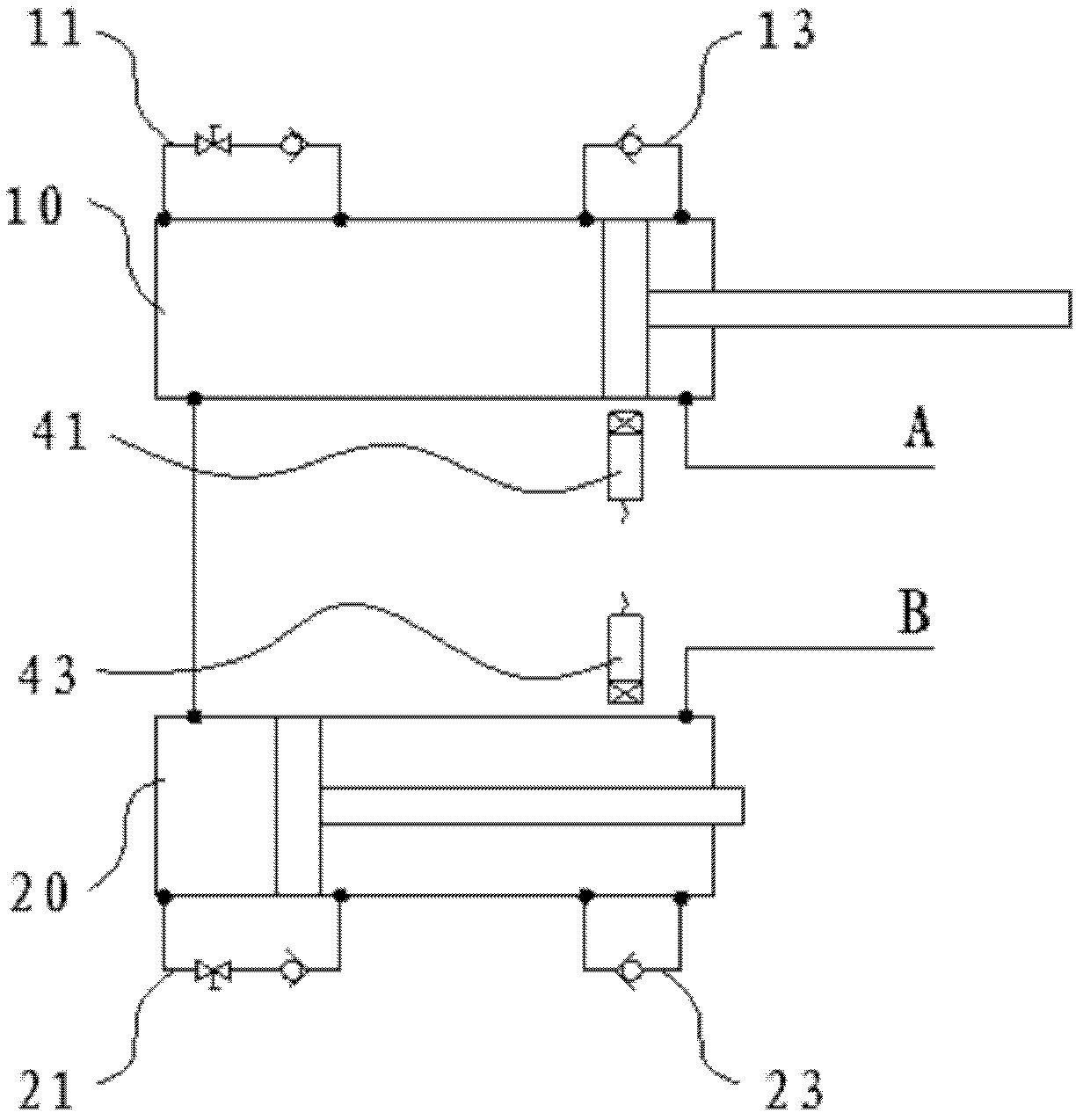

Concrete pumping equipment, serial oil cylinder and stroke self-adaptive tail end compensation method thereof

The invention discloses concrete pumping equipment, a serial oil cylinder and a stroke self-adaptive tail end compensation method thereof; the compensation method comprises the steps that: electric proportional throttle valves are respectively arranged on at least one of a first U-shaped pipe and a second U-shaped pipe and at least one of a third U-shaped pipe and a fourth U-shaped pipe; whether the liquid oil volume of a communicating cavity of the serial oil cylinder is in a balanced state is detected, if the volume is not in the balanced state, the opening of the valve ports of the electric proportional throttle valves is controlled, so that oil is supplemented into or relieved from the communicating cavity, and the liquid oil volume of the communicating cavity is in the balanced state. In the invention, because the electric proportional throttle valves are arranged on the U-shaped pipes and the opening of the valve ports of the electric proportional throttle valves is controlled, so that the volume of the liquid oil which enters or is relieved from the communicating cavity is controlled, and the purpose of precisely controlling the stroke of the oil cylinder is achieved.

Owner:ZOOMLION HEAVY IND CO LTD

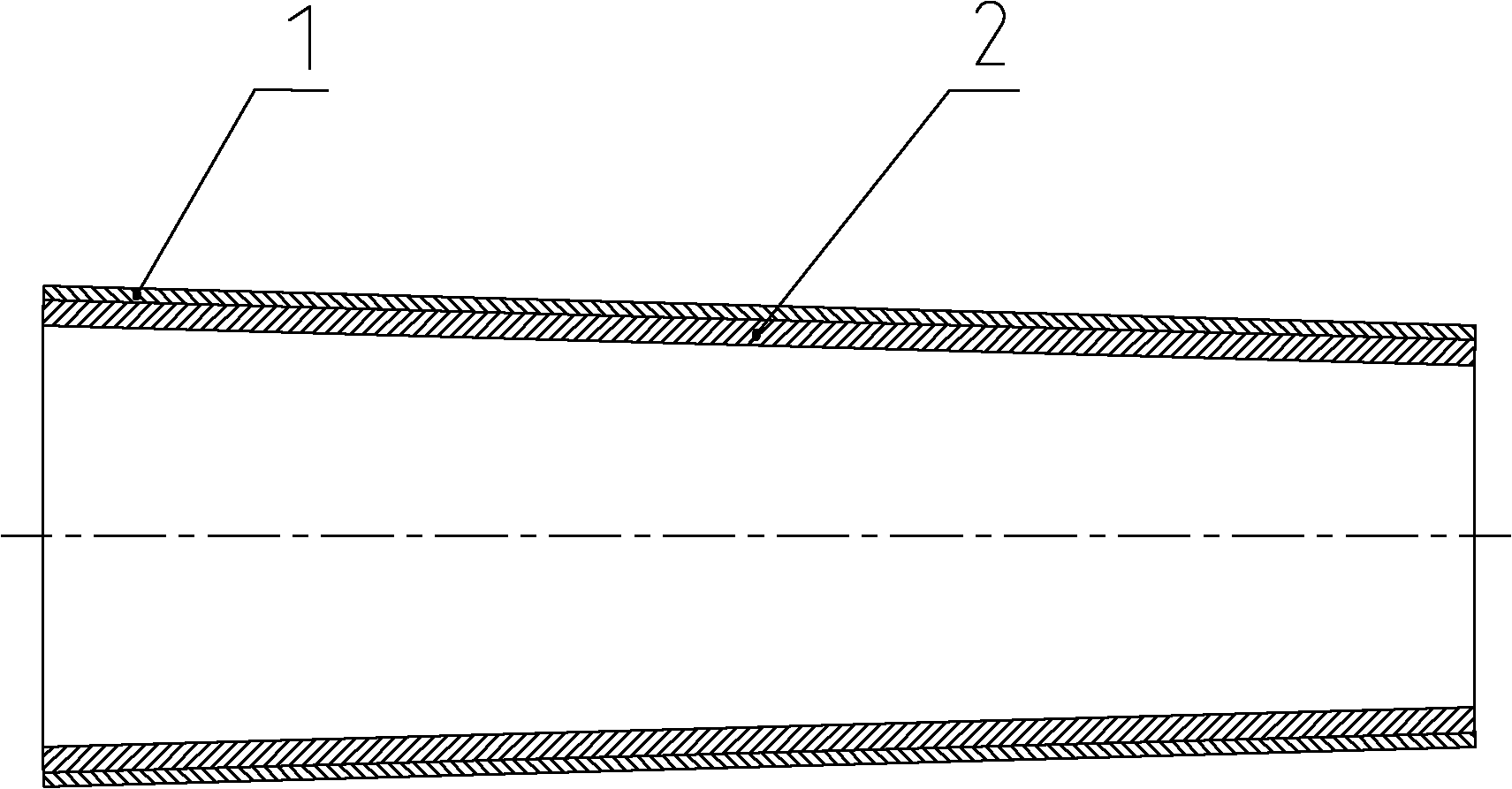

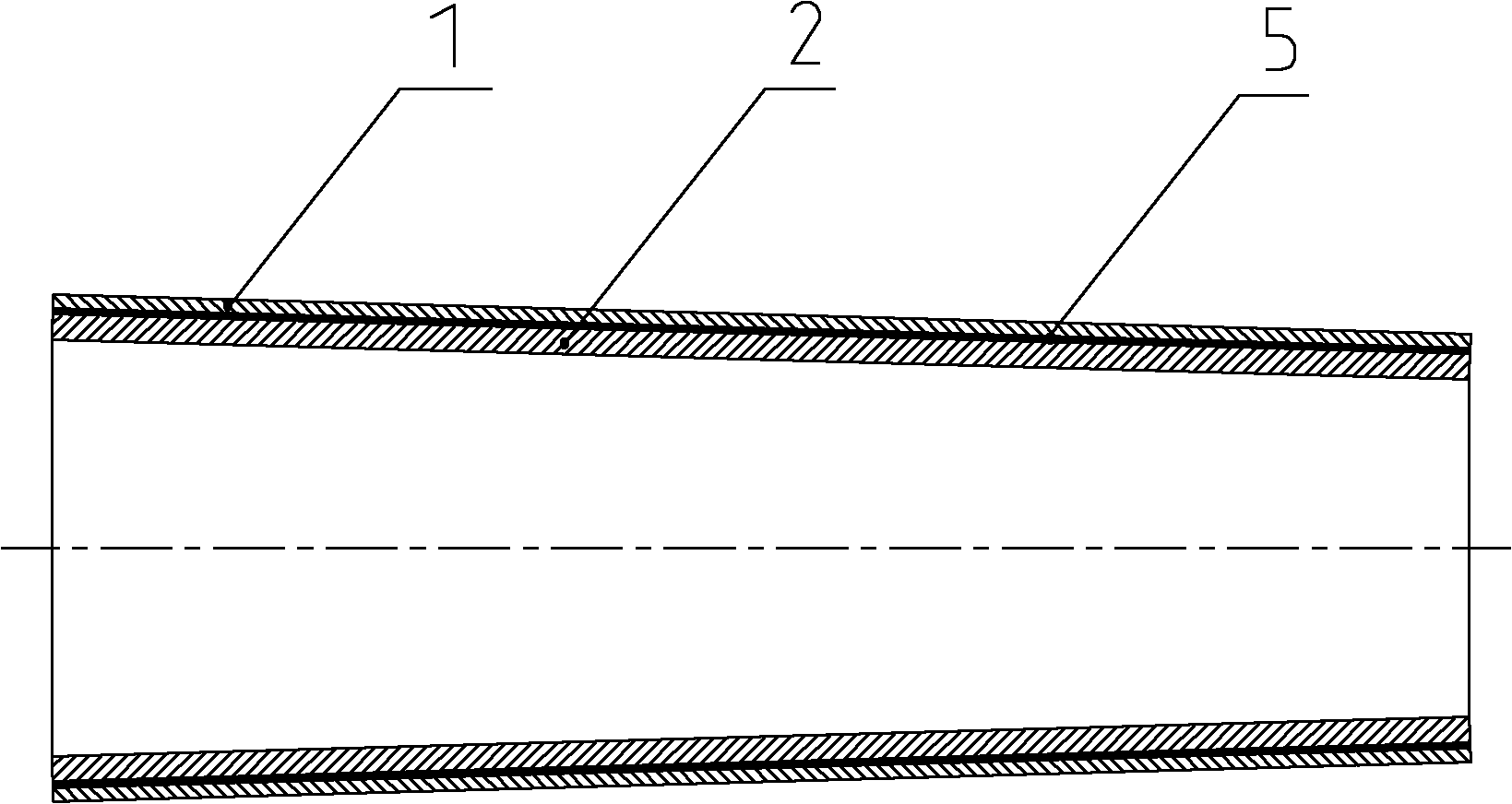

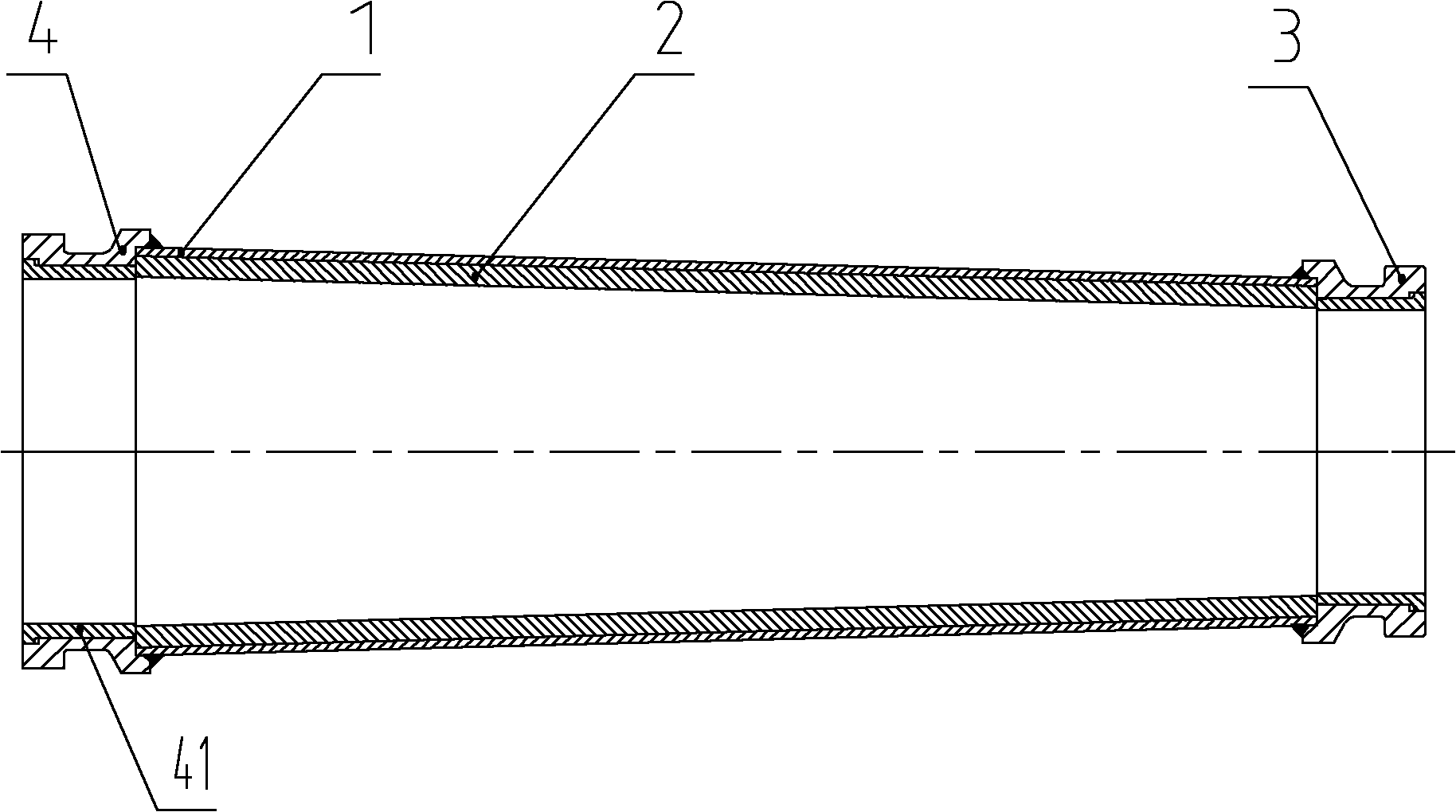

Taper pipe for concrete pumping device and manufacturing method thereof

InactiveCN102128312AImprove hardenabilityHigh hardnessBulk conveyorsRigid pipesMetallic materialsShock resistance

The invention relates to a taper pipe for a concrete pumping device. The taper pipe comprises an inner pipe and an outer pipe which are made from different metal materials, the rigidity of the inner pipe is higher than that of the outer pipe; and the toughness of the outer pipe is higher than that of the inner pipe; materials can be used for the inner pipe comprise medium and high carbon low-alloy steel, wear-resisting cast steel, wear-resisting cast iron and tool steel; and the materials of the outer pipe can be common carbon steel and low-carbon alloy steel. The invention also relates to a method for manufacturing the taper pipe. A double-layer composite taper pipe provided by the invention has the advantages that the wall thickness design of a thin large end and a thick small end conrresponds with the design principle of equal service life; the raw materials are saved; the inner pipe has high through quenching capability, smooth surface, and high rigidity and good wear resistance; the outer pipe has low rigidity, good toughness and high capability of shock resistance, and can protect the inner pipe well; and simultaneously the comprehensive requirement on the abrasion resistance and toughness of the taper pipe for the pumping device is satisfied.

Owner:SANY HEAVY IND CO LTD (CN)

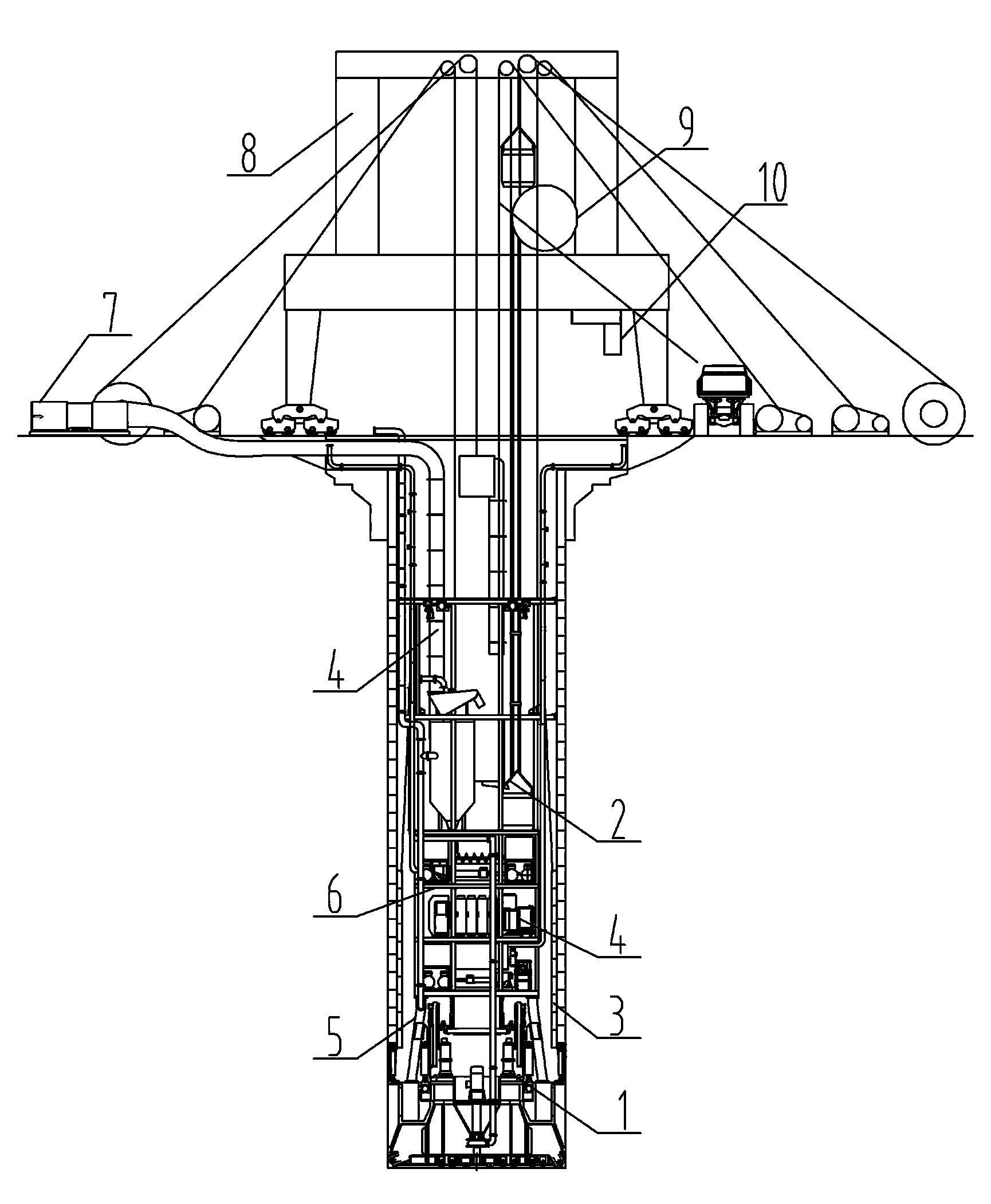

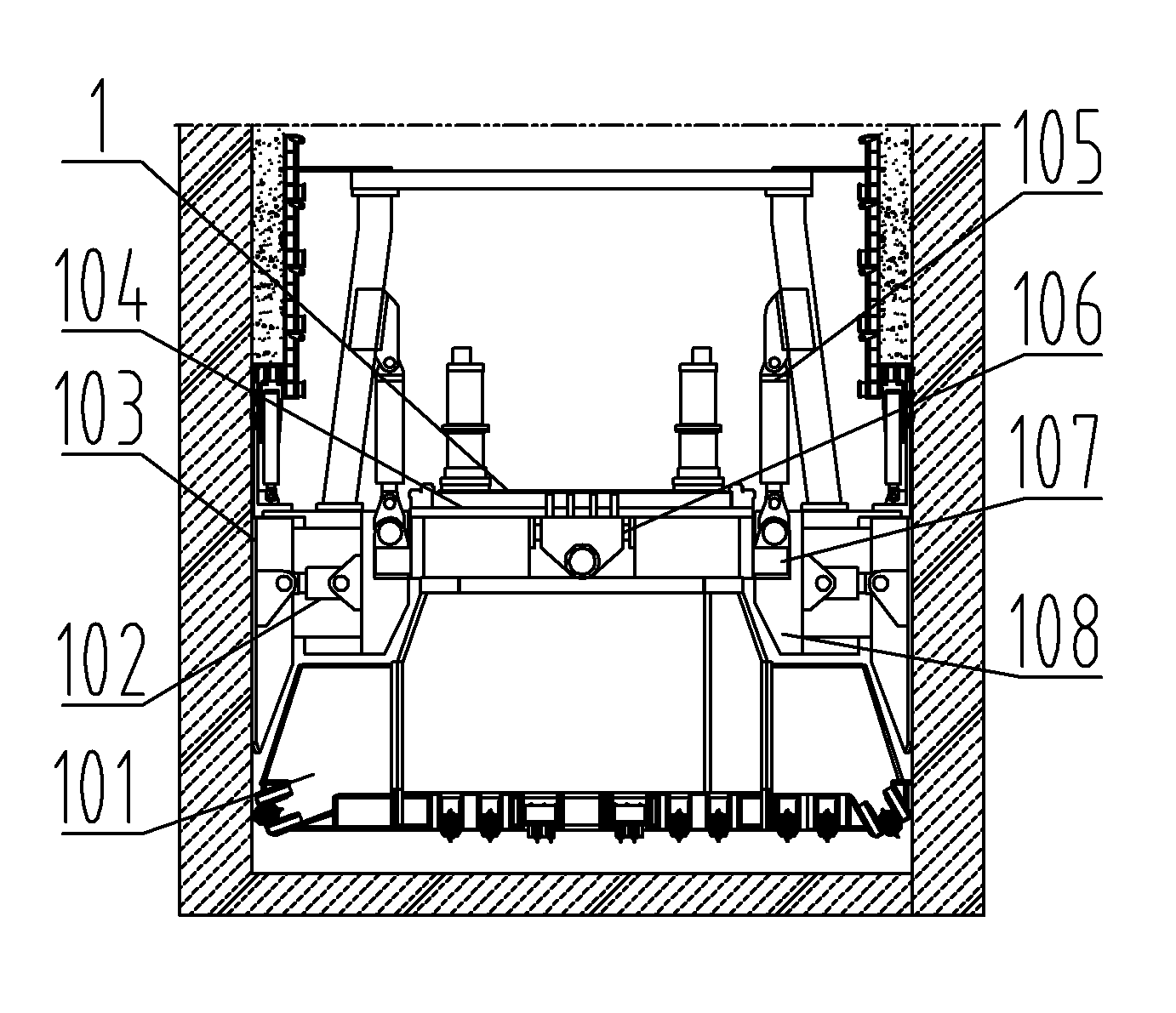

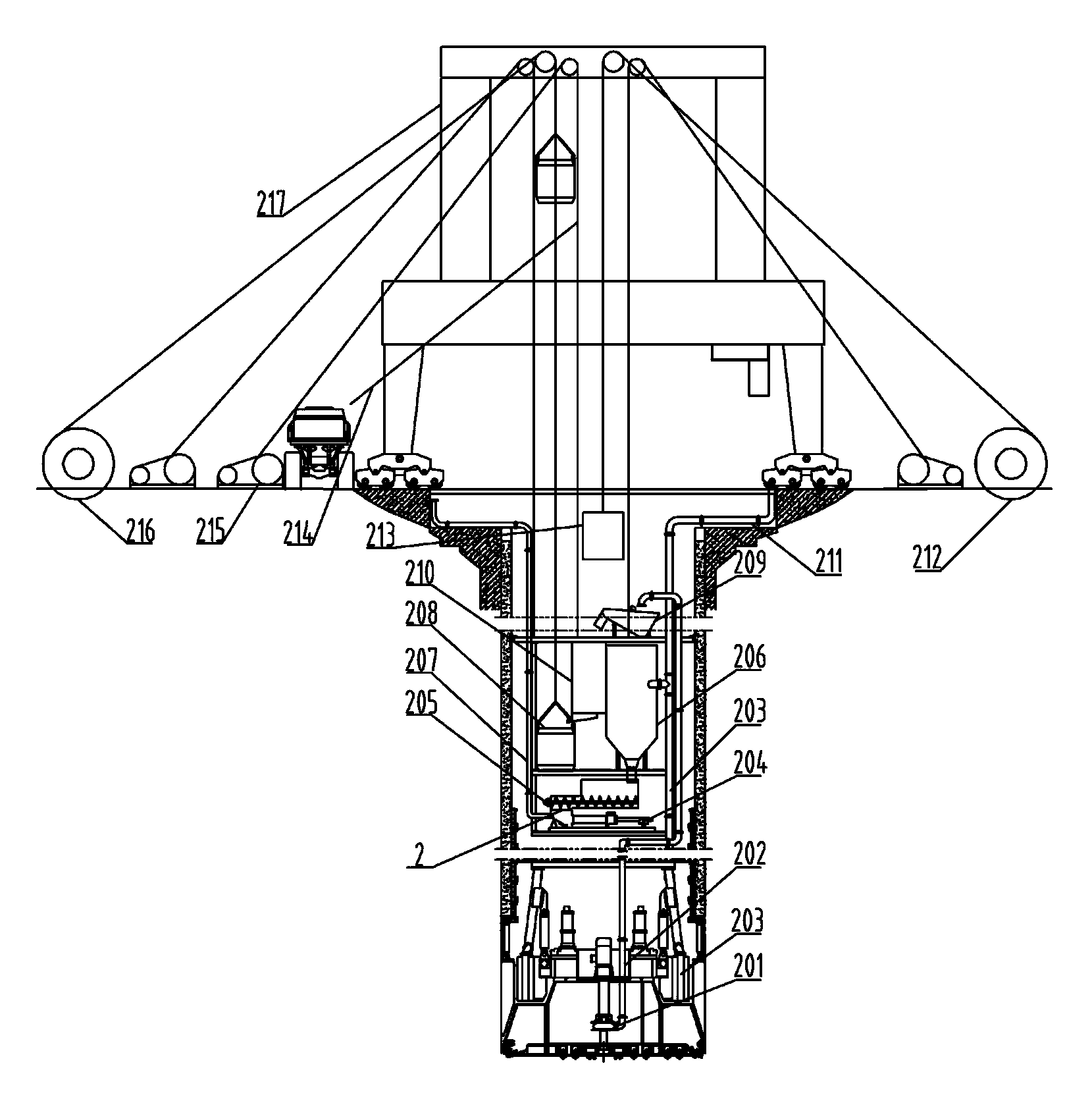

Full-fracture-surface vertical shaft drilling machine

ActiveCN103670420AEfficient constructionImprove construction efficiencyShaft sinkingShaft liningSlagControl engineering

The invention belongs to the technical field of mineral product machinery and discloses a full-fracture-surface vertical shaft drilling machine which comprises a device main girder, device platforms, a head frame, a tunneling system, a personnel and material conveying system, a shaft wall supporting and protecting system, a guaranteeing system and a manipulating chamber. The tunneling system is installed at the front end of the device main girder, the device platforms are installed at the rear end of the device main girder, the head frame is arranged on a shaft mouth, the manipulating chamber is arranged on the head frame, the personnel and material conveying system and the guaranteeing system are installed on the rear portion of the tunneling system, the shaft wall supporting and protecting system is arranged on the rear portion of the tunneling system and the periphery of the tunneling system, the personnel and material conveying system comprises a hoister, a first-level separation station, a slag storage cabin, a second-level separation station, a feeding mechanism and a conveying pump, the shaft wall supporting and protecting system comprises an auxiliary crane, a hoister, an underground concrete mixing tank, a concrete pump and an anchoring system, and the auxiliary crane, the hoister, the underground concrete mixing tank, the concrete pump and the anchoring system are installed on the device platforms respectively. The full-fracture-surface vertical shaft drilling machine solves the construction problems of large-scale vertical shafts such as coal mines, complete equipment of automation, mechanization and integration of the functions of shaft tunneling, slag tapping, supporting, protection, water discharging, ventilation and the like, the construction efficiency is improved, the construction cost is reduced, the construction safety is improved, and the application range is wide.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

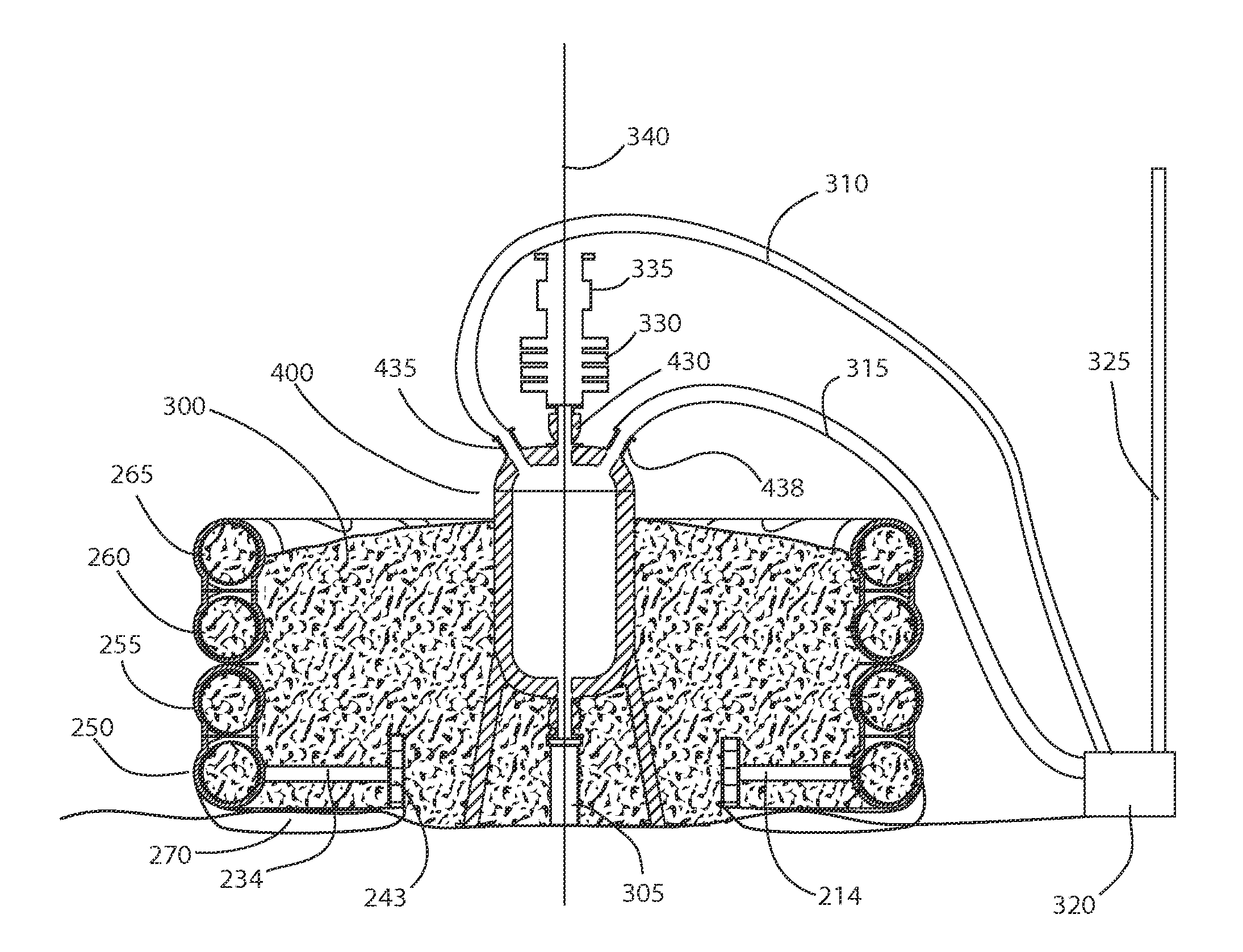

Method and system for confining and salvaging oil and methane leakage from offshore locations and extraction operations

A method of, and system for, collecting and controlling hydrocarbons leaking from offshore sea bottom environments entail providing a concrete containment barrier and catenary gasket around the leak source, pumping concrete onto the catenary gasket, opening ports and valves in a containment vessel while it is positioned over the leak source, at least partially embedding the containment vessel in the pumped concrete, closing the ports and valves to capture leaking fluids, and communicating the fluids to the surface for further processing. The modular containment barrier may be placed around an existing or potential well site, or an operating well, abandoned well or sea bottom fissure to facilitate implementation of the method in the event of a leak.

Owner:BREY ARDEN L

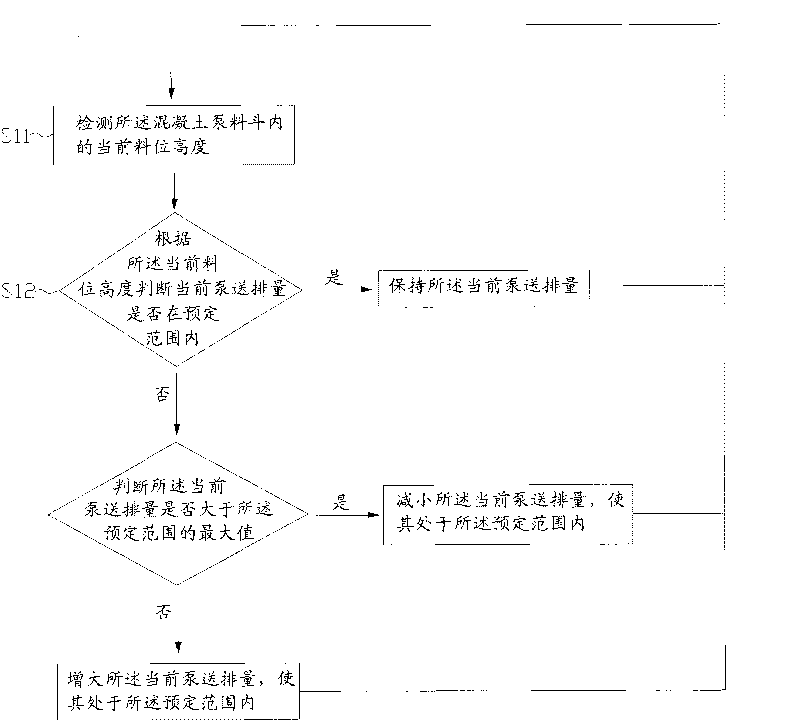

Pump displacement control system, pump displacement control method and concrete pump

ActiveCN101725517AAvoid wastingReal-time adjustment of pumping displacementPump controlPumpsControl systemDisplacement control

Owner:SANY AUTOMOBILE MFG CO LTD

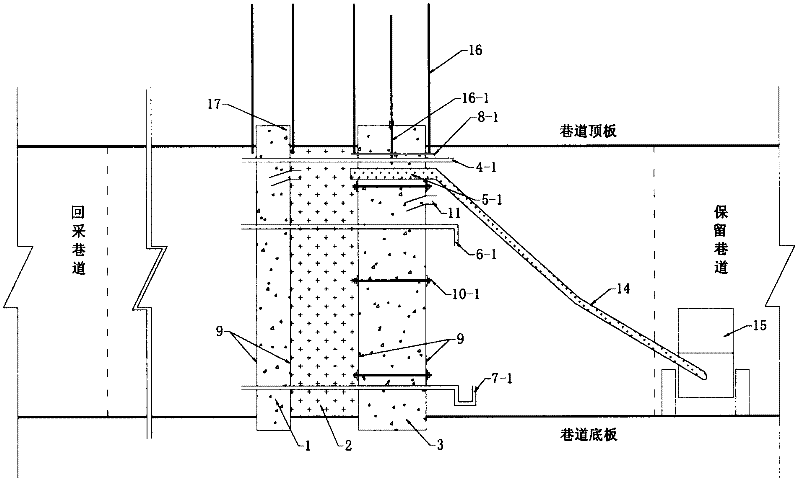

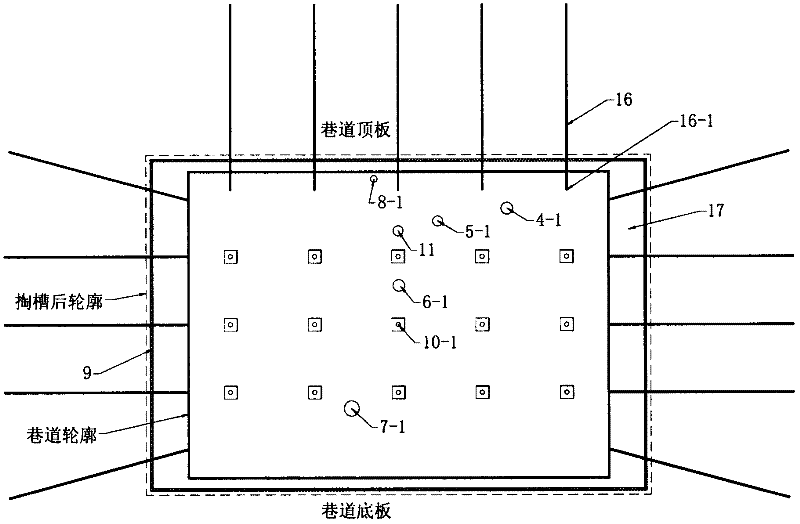

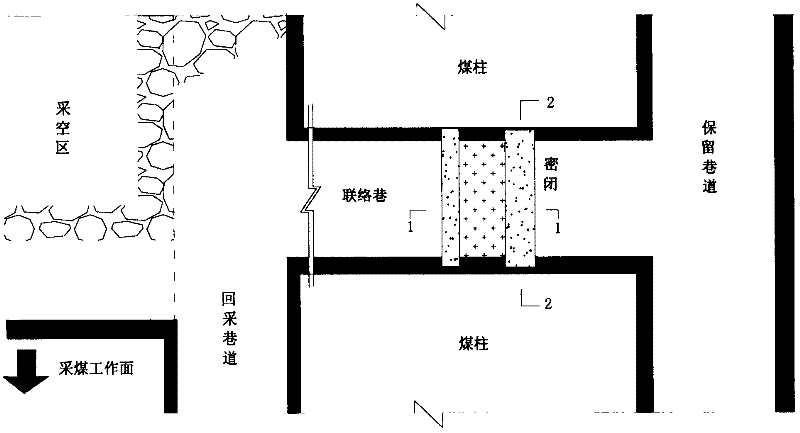

Construction method for pouring airtight partition wall between recovered roadway and reserved roadway

The invention discloses a construction method for pouring an airtight partition wall between a recovered roadway and a reserved roadway. The airtight partition wall is formed by an inner concrete single wall, an outer concrete single wall and a middle loess concrete wall; and the airtight structure is provided with three layers of walls: the inner side and the outer side are respectively provided with the airtight single wall which is formed in a way that a concrete pump pours concrete into a fiber flexible template, and the loess concrete wall filled by loess-based materials is arranged between the two single walls. The flexible templates are made in advance according to design requirements; a slot is drilled on a preset airtight surrounding rock connecting the roadways; anchor rods are constructed in the slot; after the flexible templates are hung onto the slot through a single hydraulic prop or the anchor rods, the concrete is successively poured into the inner side flexible template and the outer side flexible template by a concrete conveying pipe and a pouring opening through the concrete pump to form the inner single wall and the outer single wall; and after the inner single wall and the outer single wall are poured completely, the loess is poured between the inner single wall and the outer single wall to form the concrete airtight wall. The structure is safe and reliable, the construction cost is low, the construction speed is fast, the labor intensity is low, and the requirements of mine production with high production and high efficiency are met.

Owner:XIAN UNIV OF SCI & TECH +1

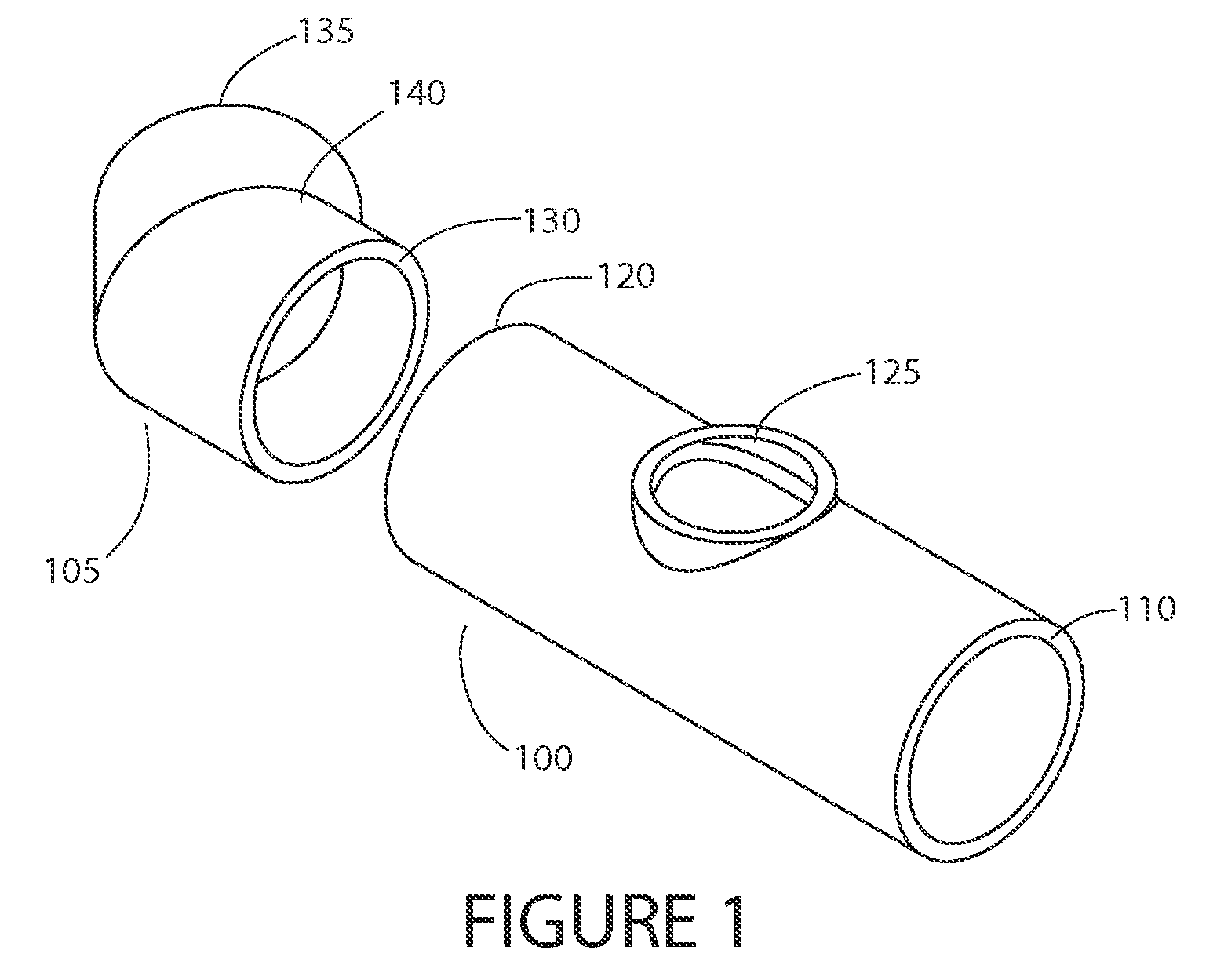

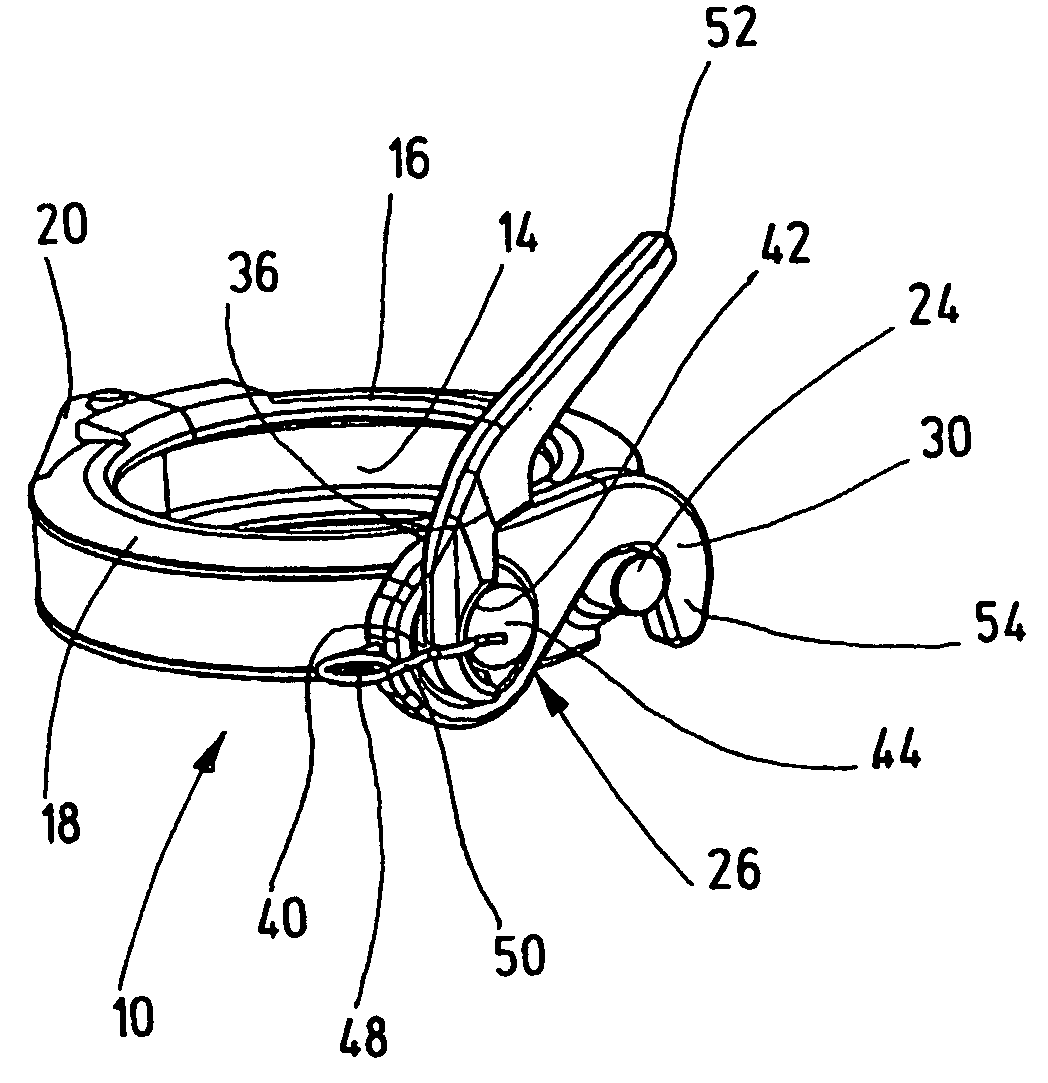

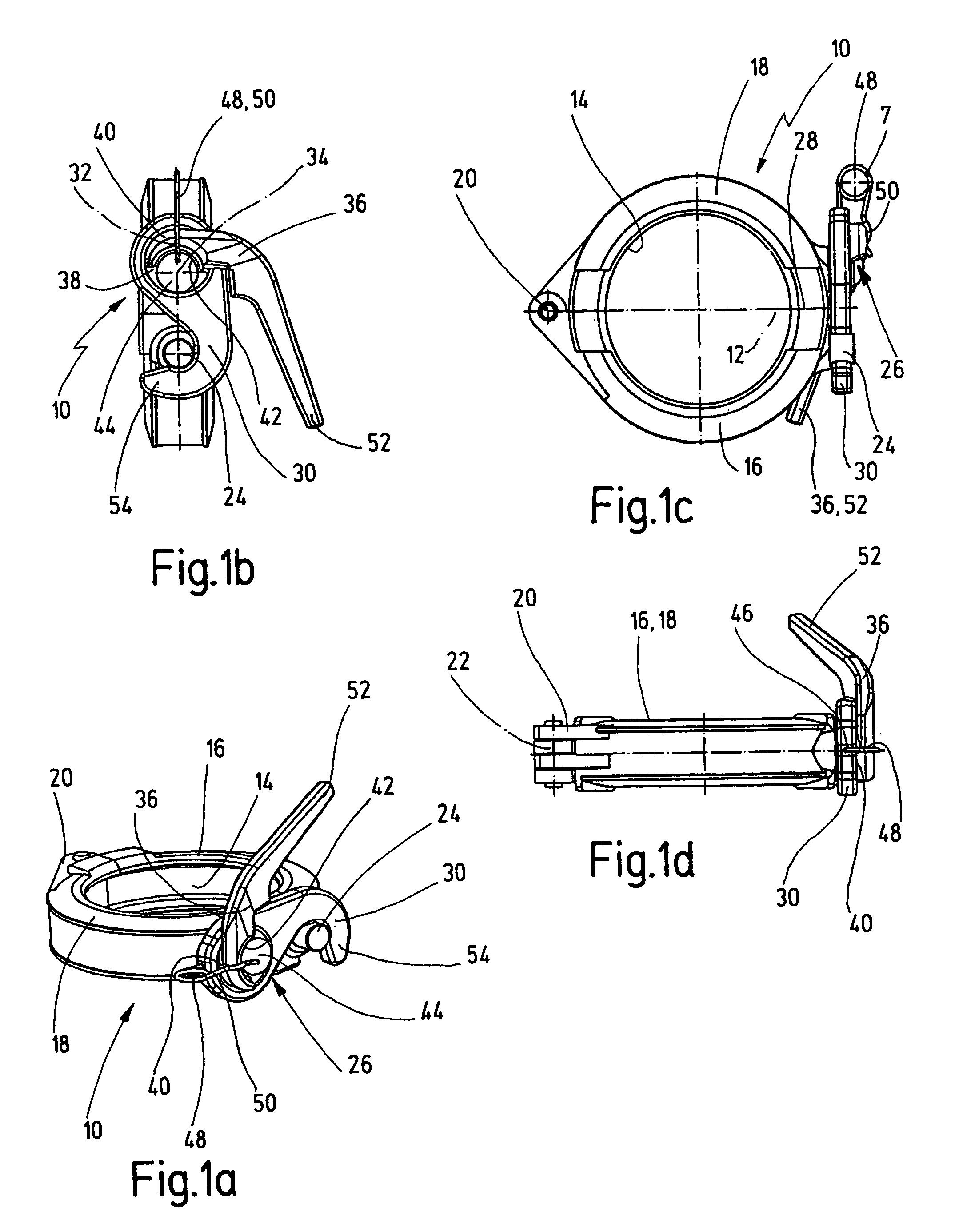

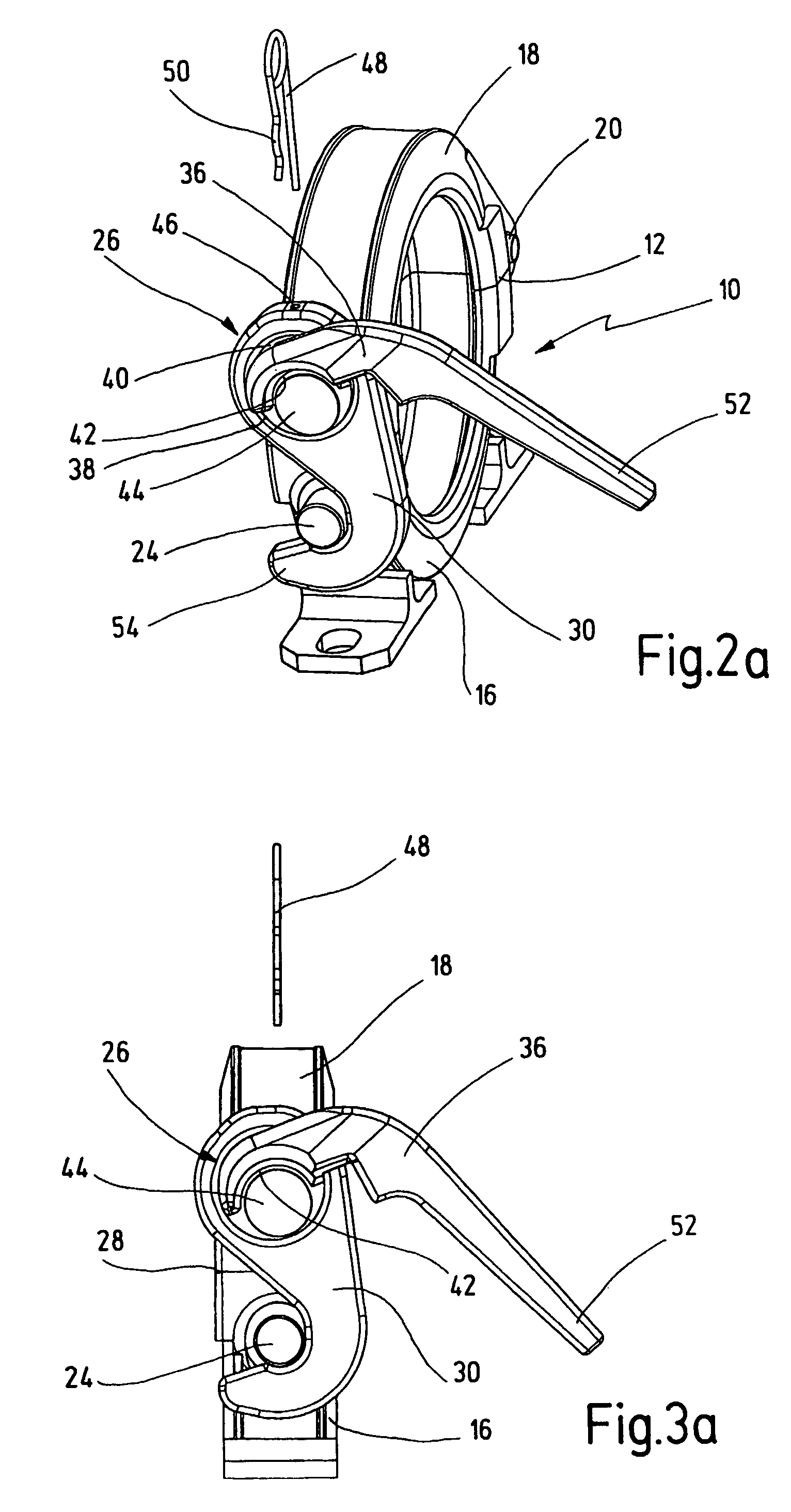

Clamp coupling for pipes

The invention concerns a clamp coupling for coupling pairs of pipes. Such clamp couplings are used, for example, for coupling concrete conduits from concrete pumps. This clamp coupling (10) comprises two clamp shells (16, 18) which, in the coupling state, define a circular opening (14) for the passage-through of the pipes. The coupling shells can be pivoted relative to each other via a pivot linkage (20) at their one end, and have a locking mechanism (26) provided at their other end. In order to be able to fasten the clamp coupling (10) even in confined spaces, the locking mechanism (26) comprises a locking hook (30) which, in the closed state, positively grasps a latch pin (24) provided on the other coupling clamp (16), and pulls the clamp shells (16, 18) towards each other at their point of separation (28) opposite the linkage (20). During the opening process, the locking hook (30) can be lifted from the latch pin (24) and pivoted out of its engaged position about a pivoting axis (32) which is perpendicular to the linkage axis (22). The locking mechanism (26) also comprises a clamping lever (36) which can be pivoted relative to the coupling clamp about a lever axis (34) which is perpendicular to the linkage axis. The clamping lever is also operatively associated with the locking hook (30).

Owner:PUTZMEISTER CONCRETE PUMPS GMBH

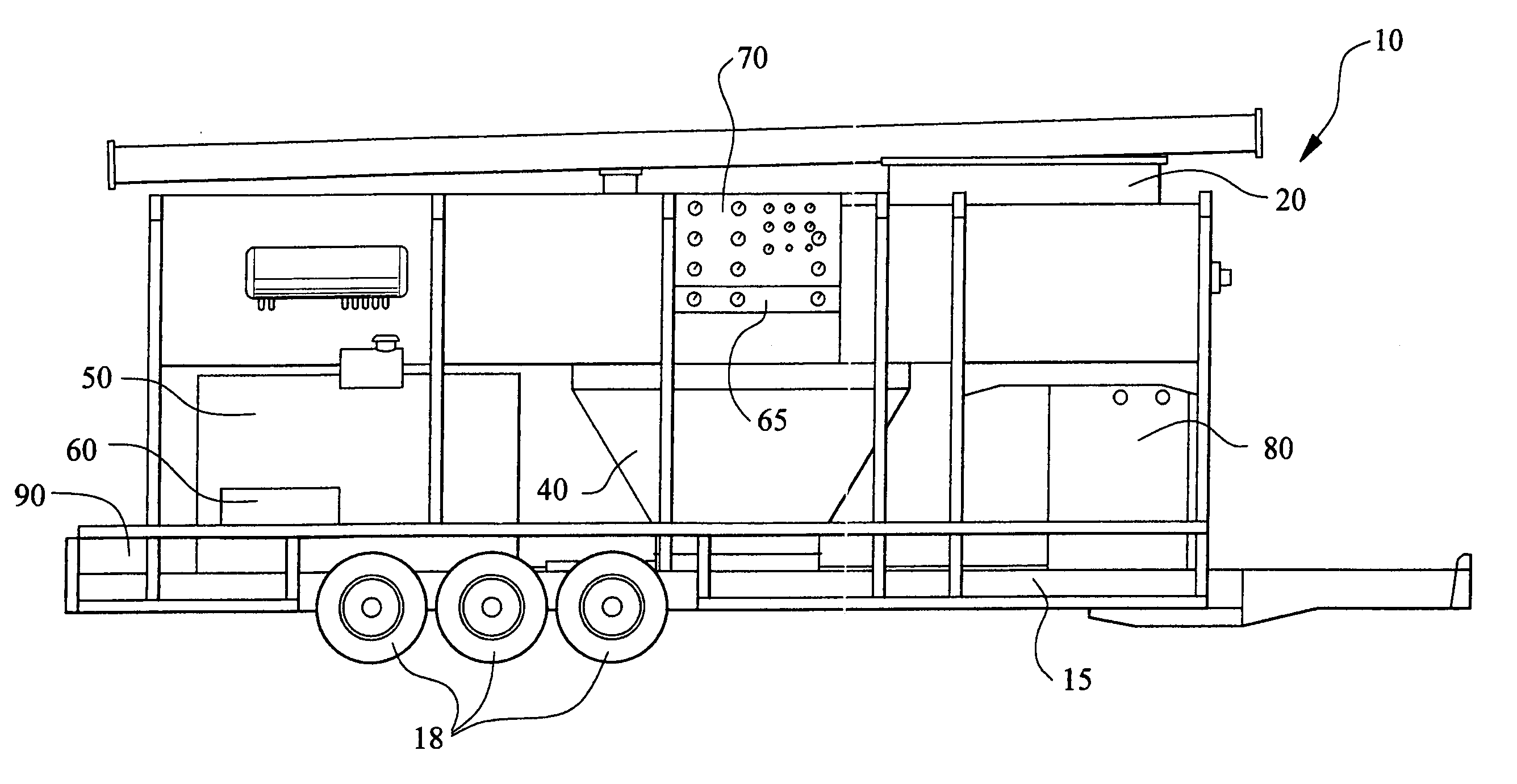

Lightweight concrete mixer

InactiveUS20050195681A1Discharging apparatusMixing operation control apparatusFoaming agentHydraulic pump

An apparatus for on-site manufacturing of lightweight concrete used for insulation in roof decks and roof systems of building structures. The apparatus is supported on a transportable trailer frame and includes a mixer, one or more tanks for holding water and chemical products, such as foaming agents, and a concrete pump. The chemical agents and water are forced through a foam generating carburetor with pressurized air to produce a foam product. Concrete and the foam product are combined in the mixer, in accordance with a predetermined mixture ratio, and released into the concrete pump for forced discharge from the apparatus and application to a roof structure. An internal combustion engine drives hydraulic pumps which operate several components of the apparatus. Controls are provided for operating the several components, functions and operations of the apparatus.

Owner:CONCRECEL USA

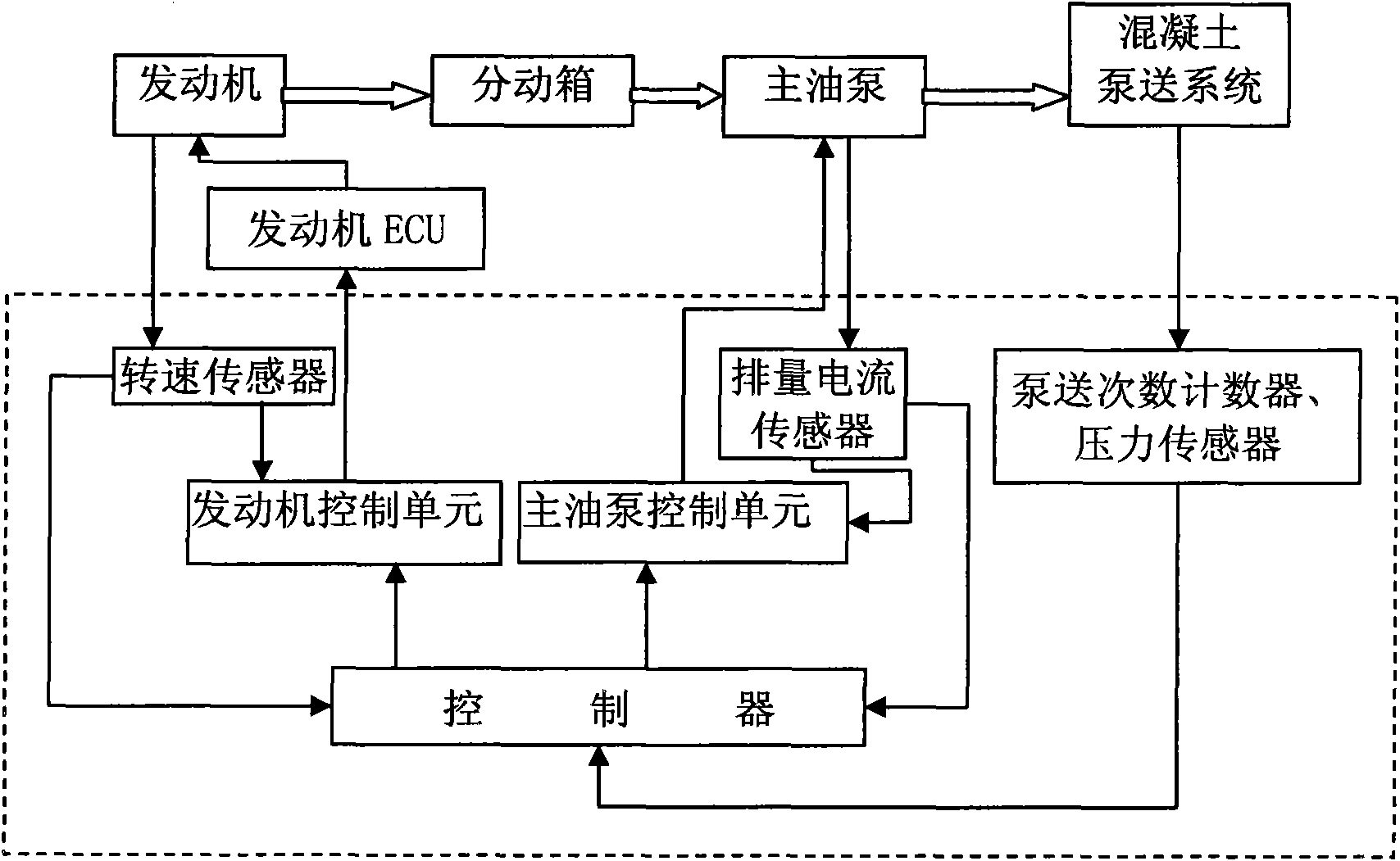

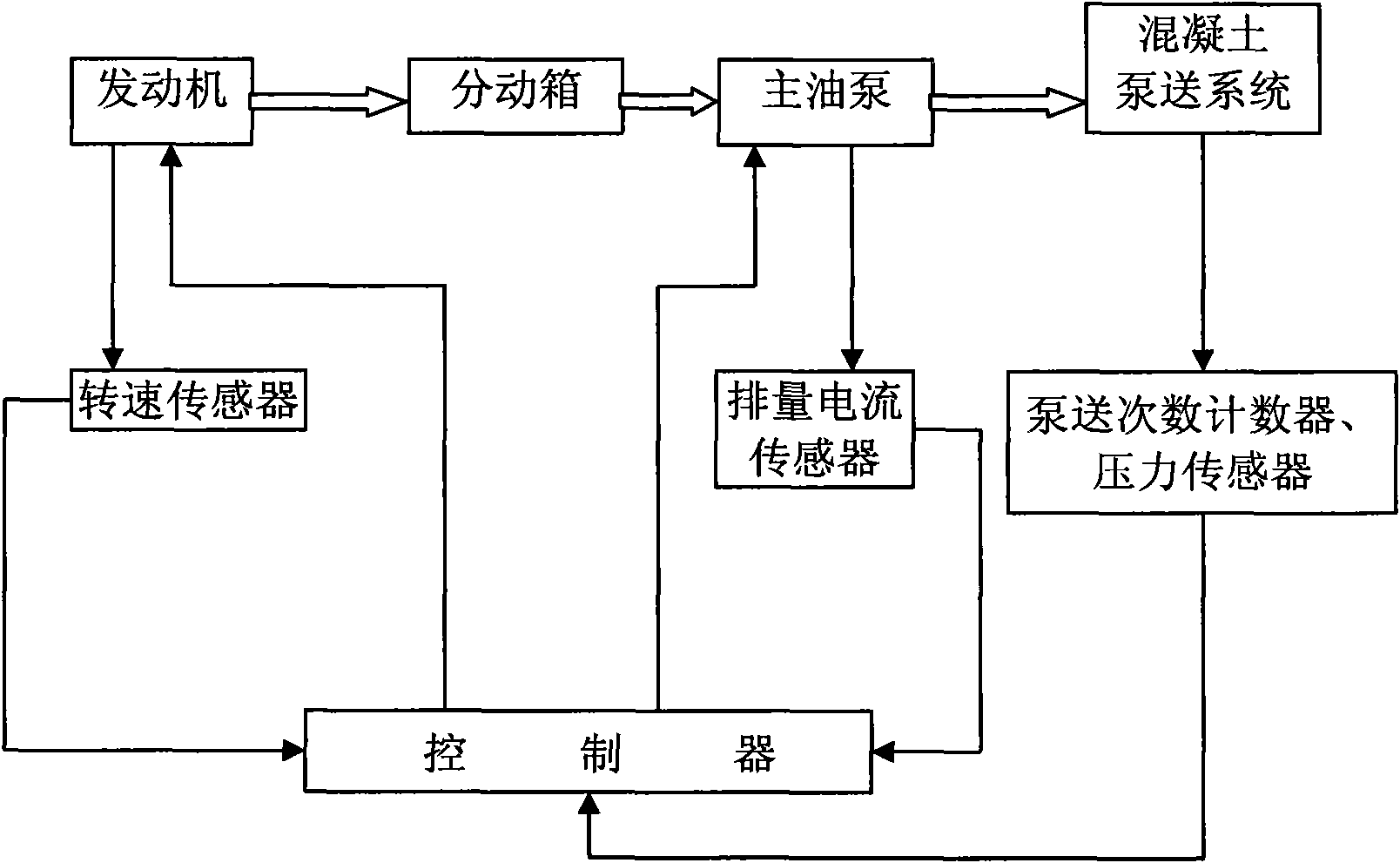

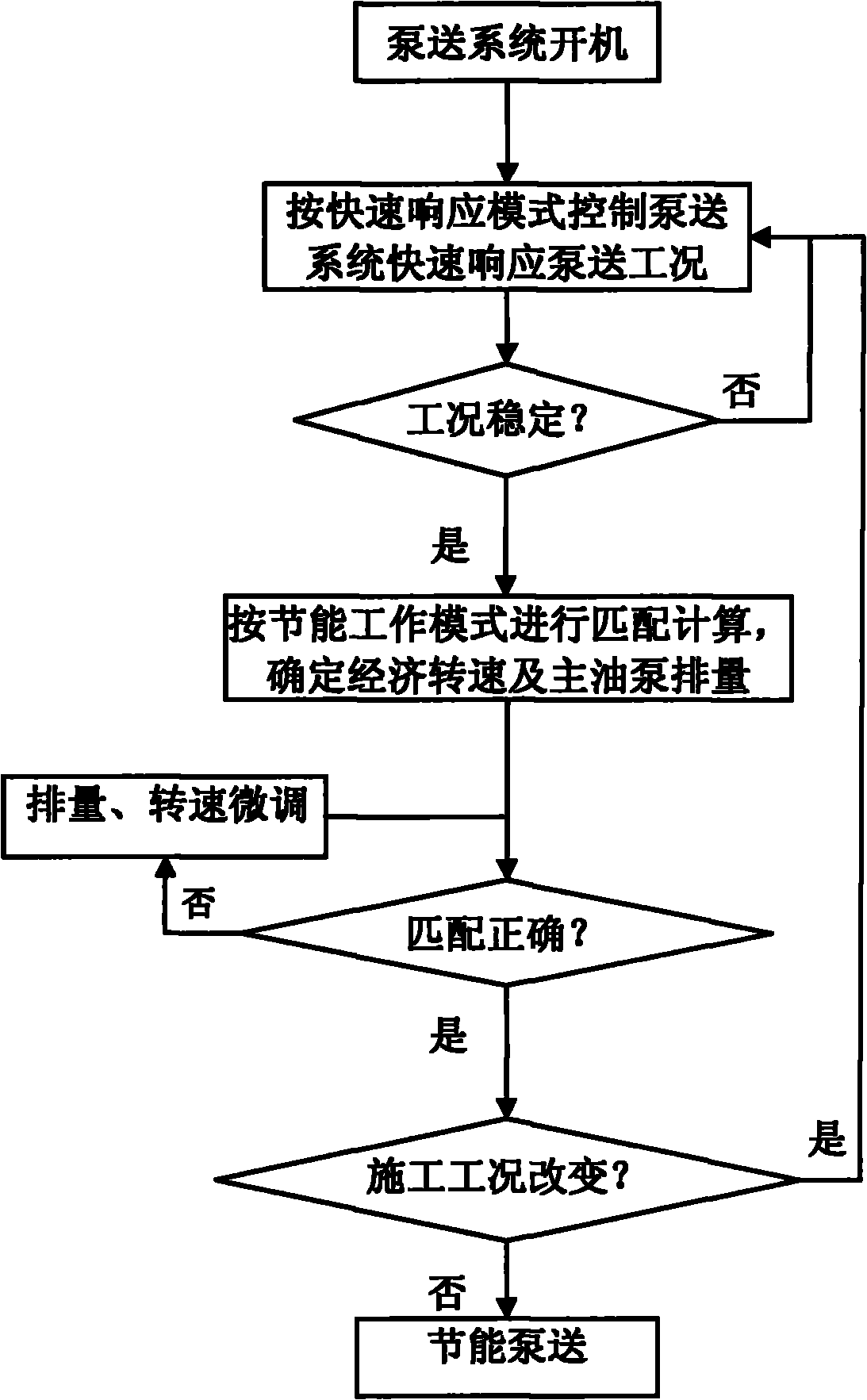

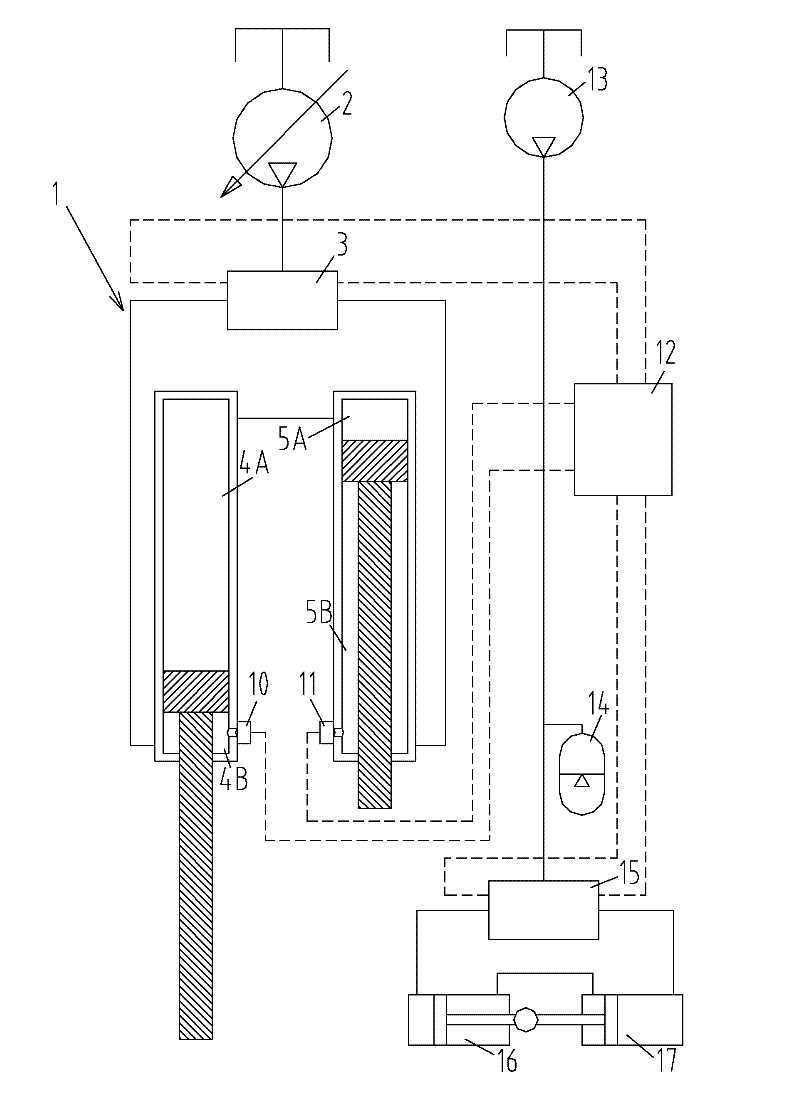

Concrete pump and pumping control device and pumping control method thereof

InactiveCN102312827AQuick responseReduce energy consumptionPump controlPumpsWork unitDisplacement control

The invention discloses a concrete pump and a pumping control device and a pumping control method thereof. The pumping control device is used for pumping control of an engine of the concrete pump, a main oil pump and a pumping system, and comprises a plurality of sensors, a controller, a quick response unit and an energy-saving working unit, wherein the plurality of sensors are used for acquiring revolving speed, displacement, pumping times and pressure signals; the controller is used for judging whether the pumping working condition is stable, if so, performing revolving speed and displacement control on the output of the energy-saving working unit, otherwise, performing revolving speed and displacement control on the output of the quick response unit; the quick response unit is used for outputting revolving speed signals and displacement signals capable of allowing the pumping system to quickly respond the pumping working condition requirement; and the energy-saving working unit is used for calculating the power required for meeting the pumping working condition requirement and calculating and outputting the economic revolving speed and the corresponding displacement of the main oil pump according to an optimal fuel consumption curve. By using the device and the method, the energy consumption is greatly saved on the premise of meeting the construction requirement, and the service life of the pumping system of a pump truck can be prolonged.

Owner:CIMC VEHICLES (GROUP) CO LTD +1

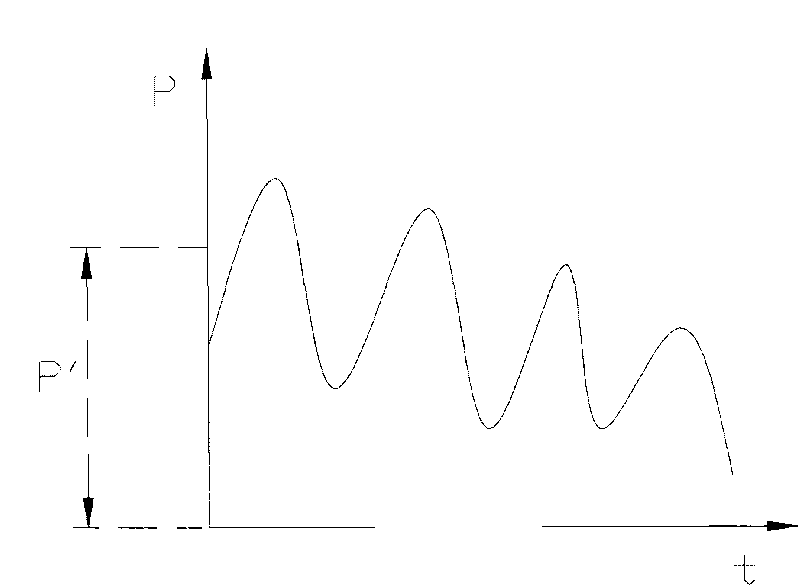

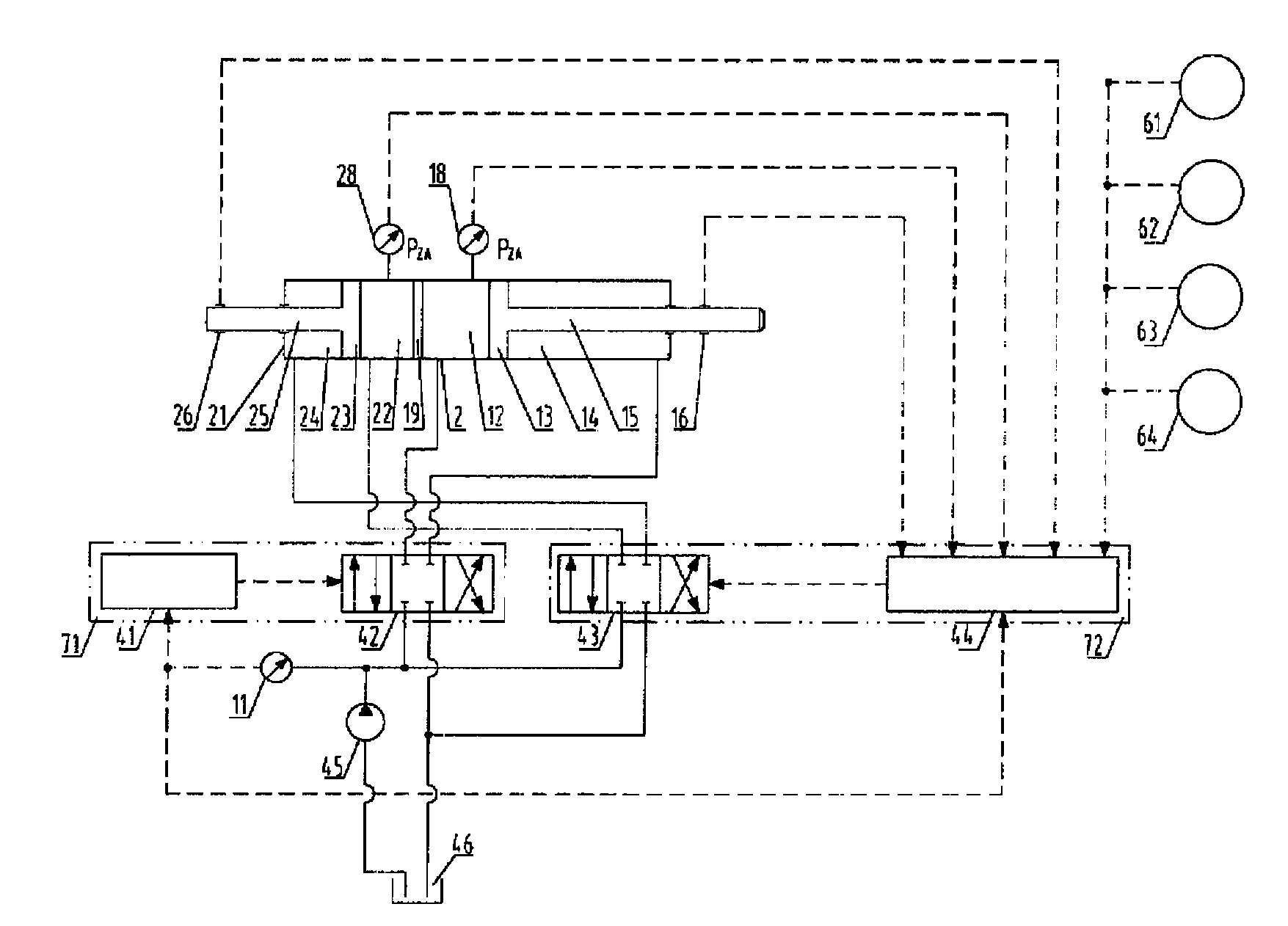

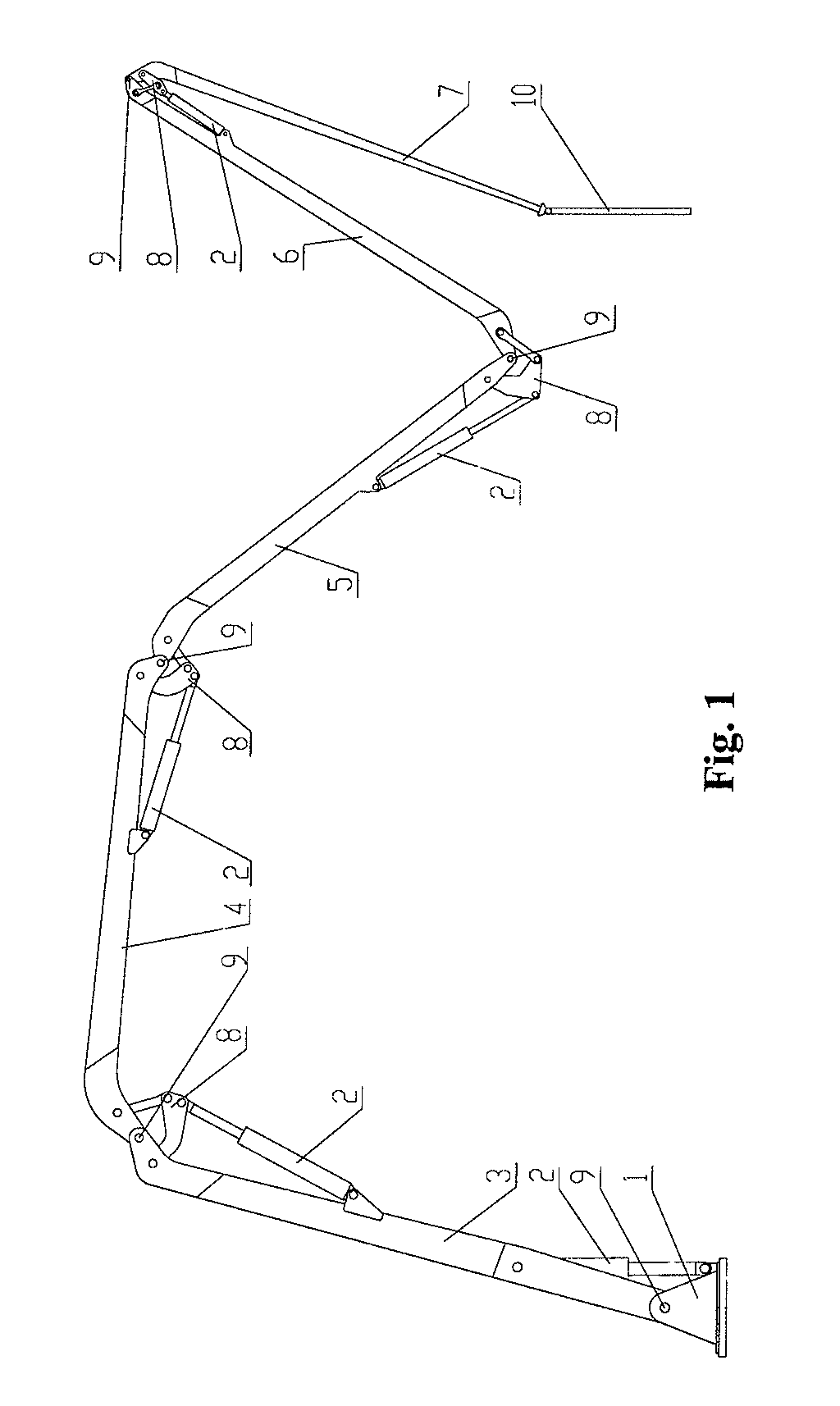

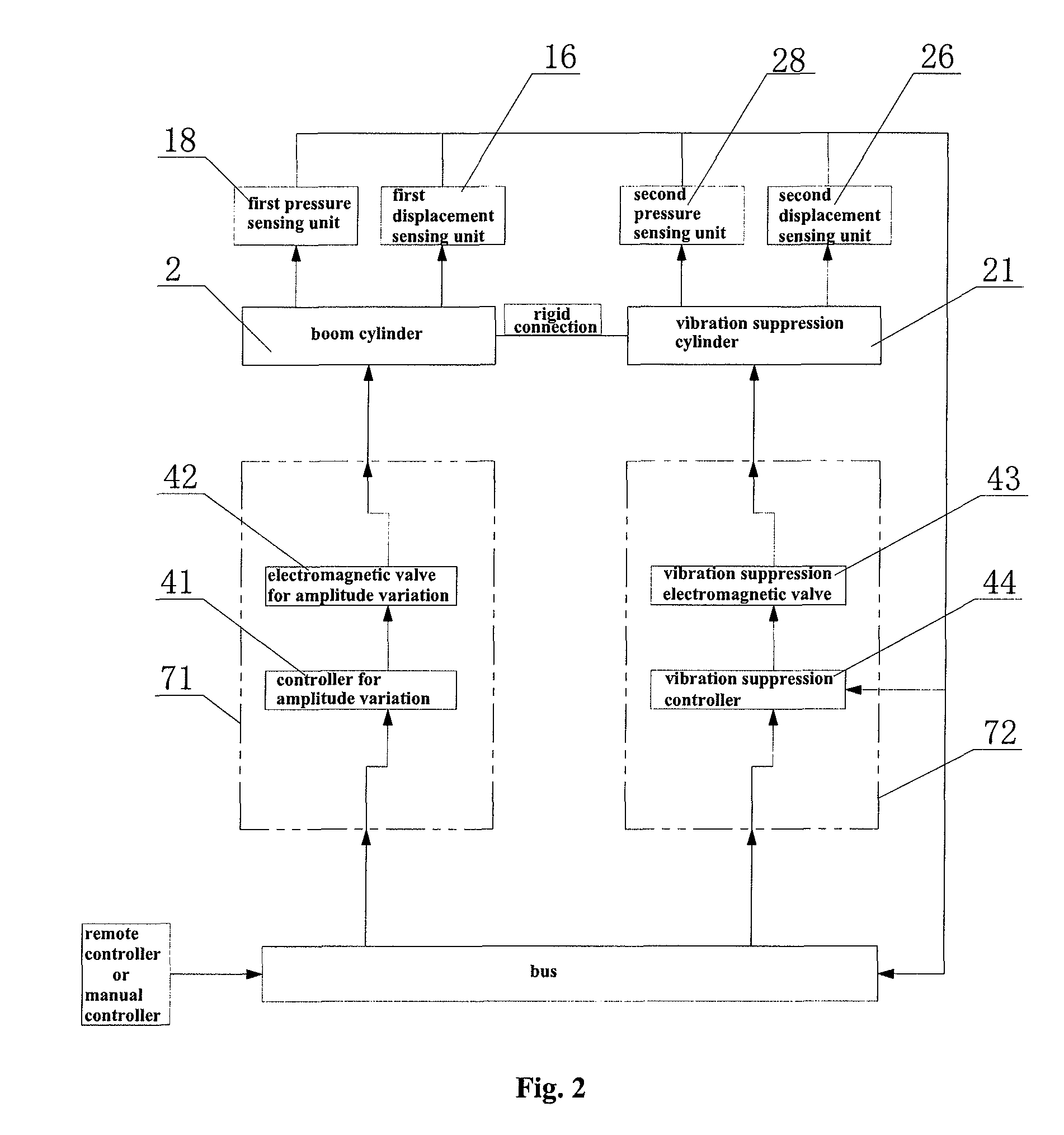

Method and device for suppressing vibration of boom of concrete pump truck

InactiveUS8037682B2Simple structureEasy to operateServomotor componentsTemperatue controlVibration amplitudePhase difference

The present invention discloses a method and device for suppressing vibration of boom of concrete pump truck, in which the boom cylinder is connected with the vibration suppression cylinder; the information about hydraulic pressure in the boom cylinder and / or about changing of concrete pumping direction is monitored by a pressure sensing unit in real time; the monitored information about hydraulic pressure and / or about changing of concrete pumping direction is transmitted to the control unit for vibration suppression cylinder; the control unit for vibration suppression cylinder analyzes and processes the monitored information and adjusts the volumes of the rod side chamber and the non-rod side chamber in the vibration suppression cylinder such that the vibration suppression cylinder may generate a pulsed vibration and the pulsed vibration at the end of the boom is less than or equal to the vibration amplitude caused by the intermittent concrete supply at the end of the boom in amplitude, with a phase difference of 180° between the two vibrations. The vibration suppression method and device for boom of concrete pump truck according to the present invention may be simply configured, easily implemented and operated to effectively suppress the boom vibration.

Owner:SANY HEAVY IND CO LTD (CN)

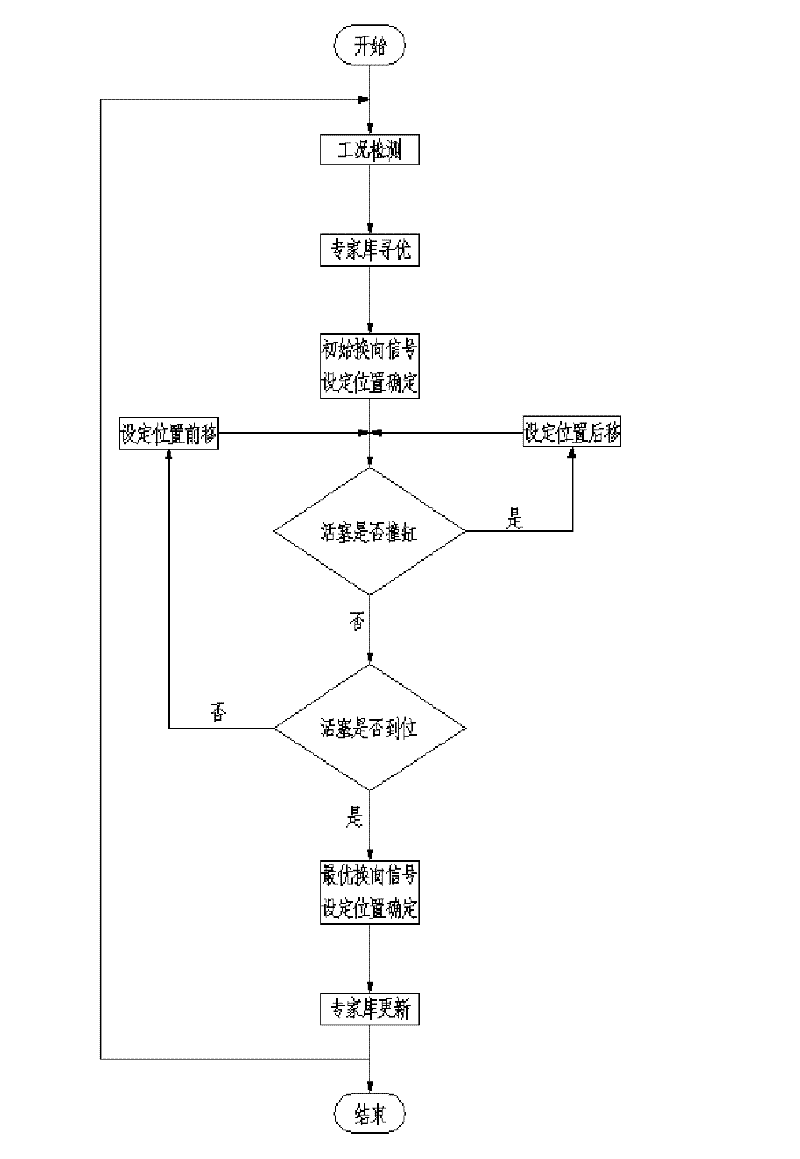

Concrete pumping equipment and reversing control method for pumping oil cylinder of same

The invention provides concrete pumping equipment and a reversing control method for a pumping oil cylinder of the same. The reversing control method comprises the following steps of: acquiring operating condition parameters of the oil cylinder in real time, and determining a current operating condition according to the operating condition parameters so as to determine a corresponding reversing position of the oil cylinder according to the current operating condition; and detecting a piston position of the oil cylinder in real time and controlling the reversing of the oil cylinder when the piston position of the oil cylinder reaches the reversing position. By the reversing control method for the pumping oil cylinder of the concrete pumping equipment, the actual operating condition can be determined according to the detected operating condition parameters, so the reversing position, corresponding to the actual operating condition, of the oil cylinder is determined, and the reversing ofthe oil cylinder is controlled according to the actual operating condition; therefore, optimal stroke of the oil cylinder under any operating conditions of a concrete pump can be ensured, the pumpingefficiency is the highest.

Owner:ZOOMLION HEAVY IND CO LTD

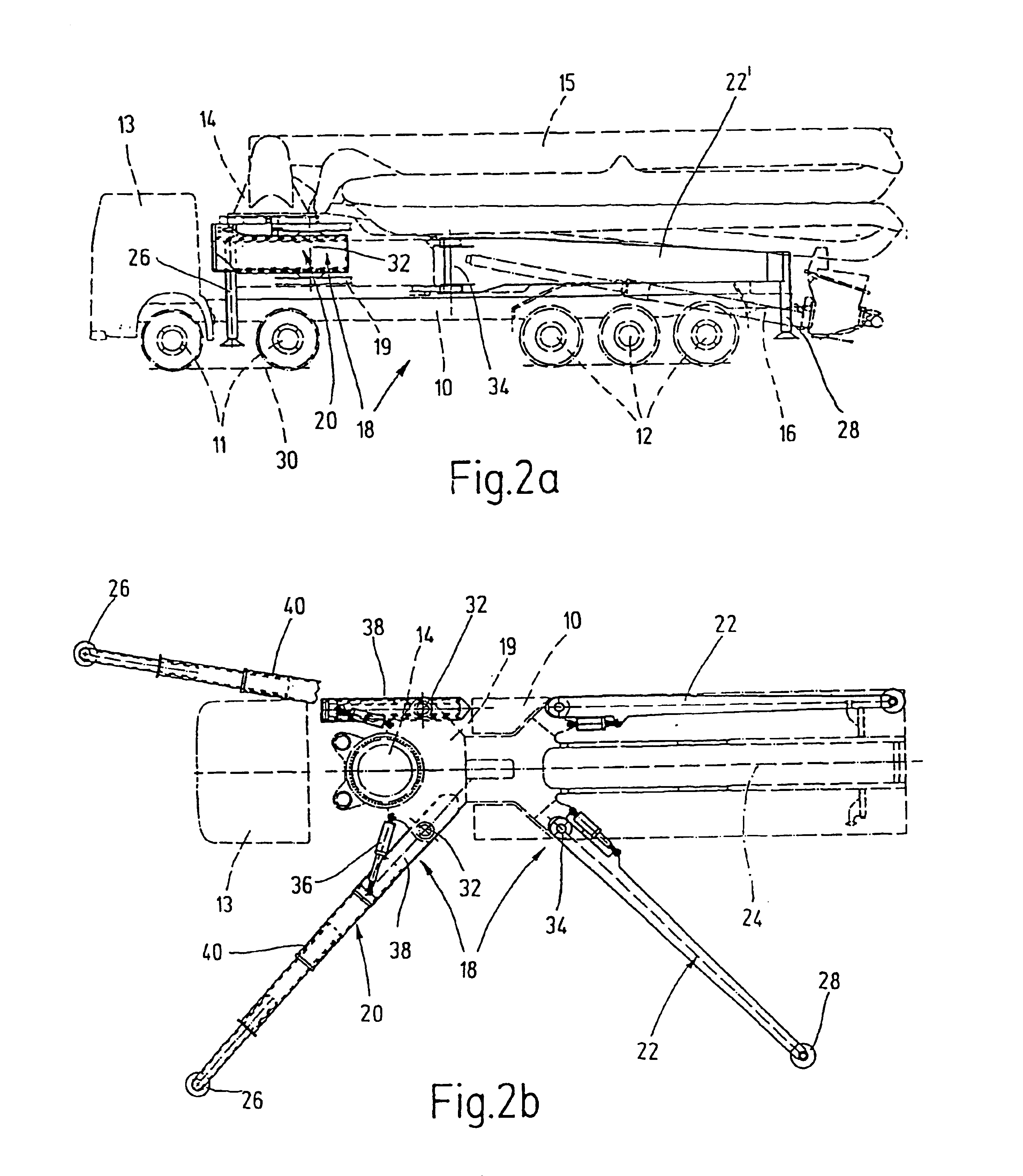

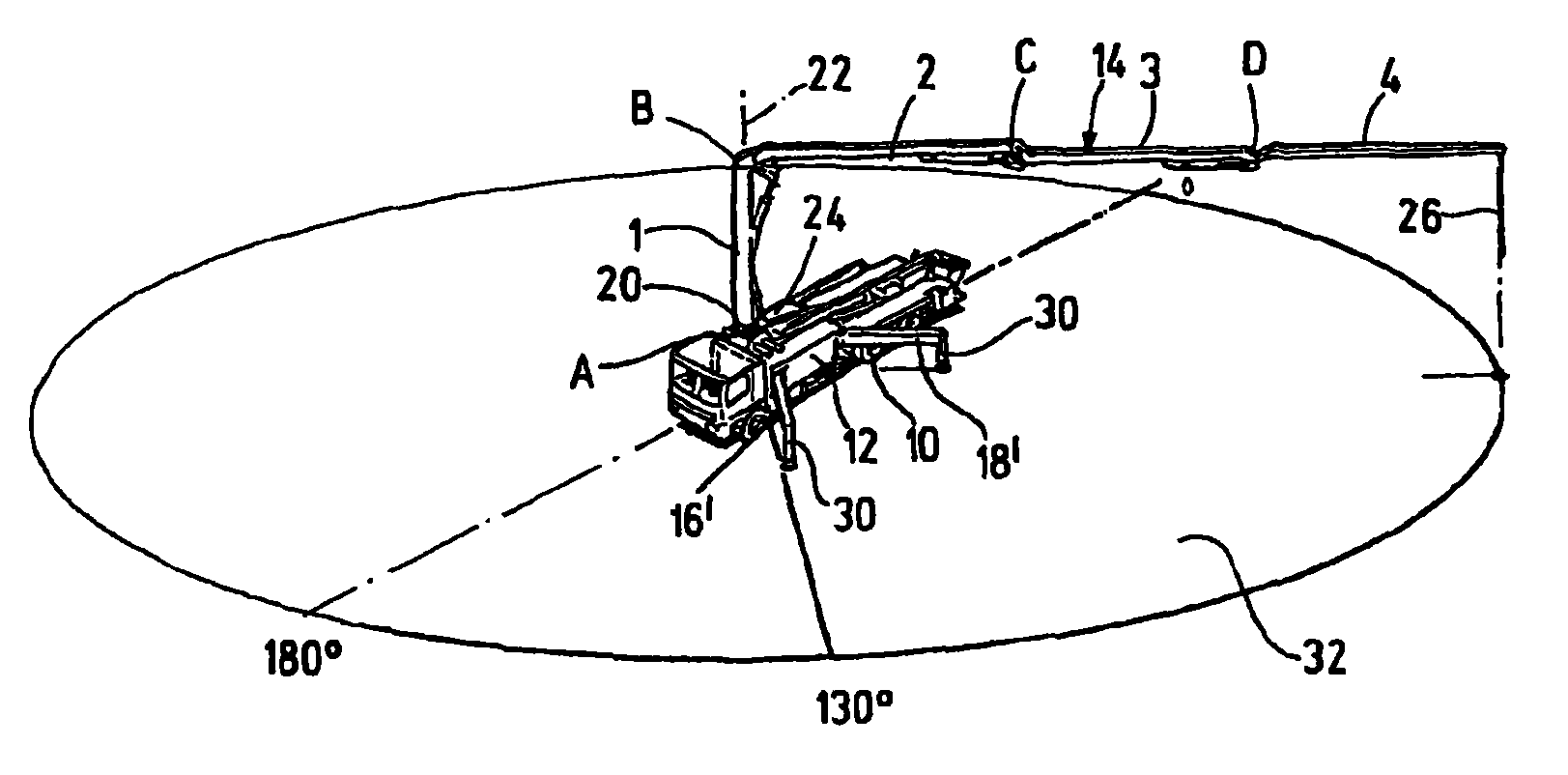

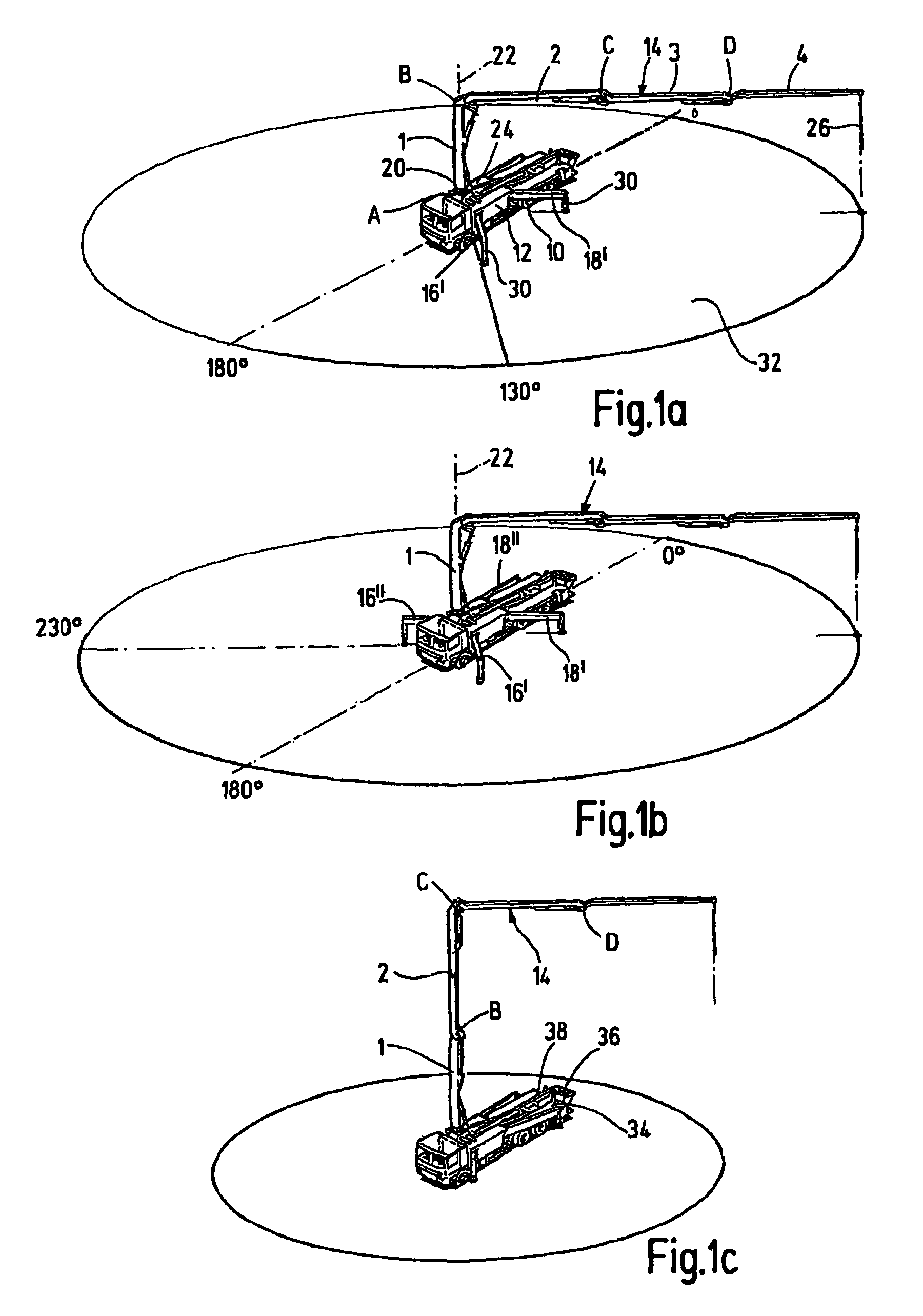

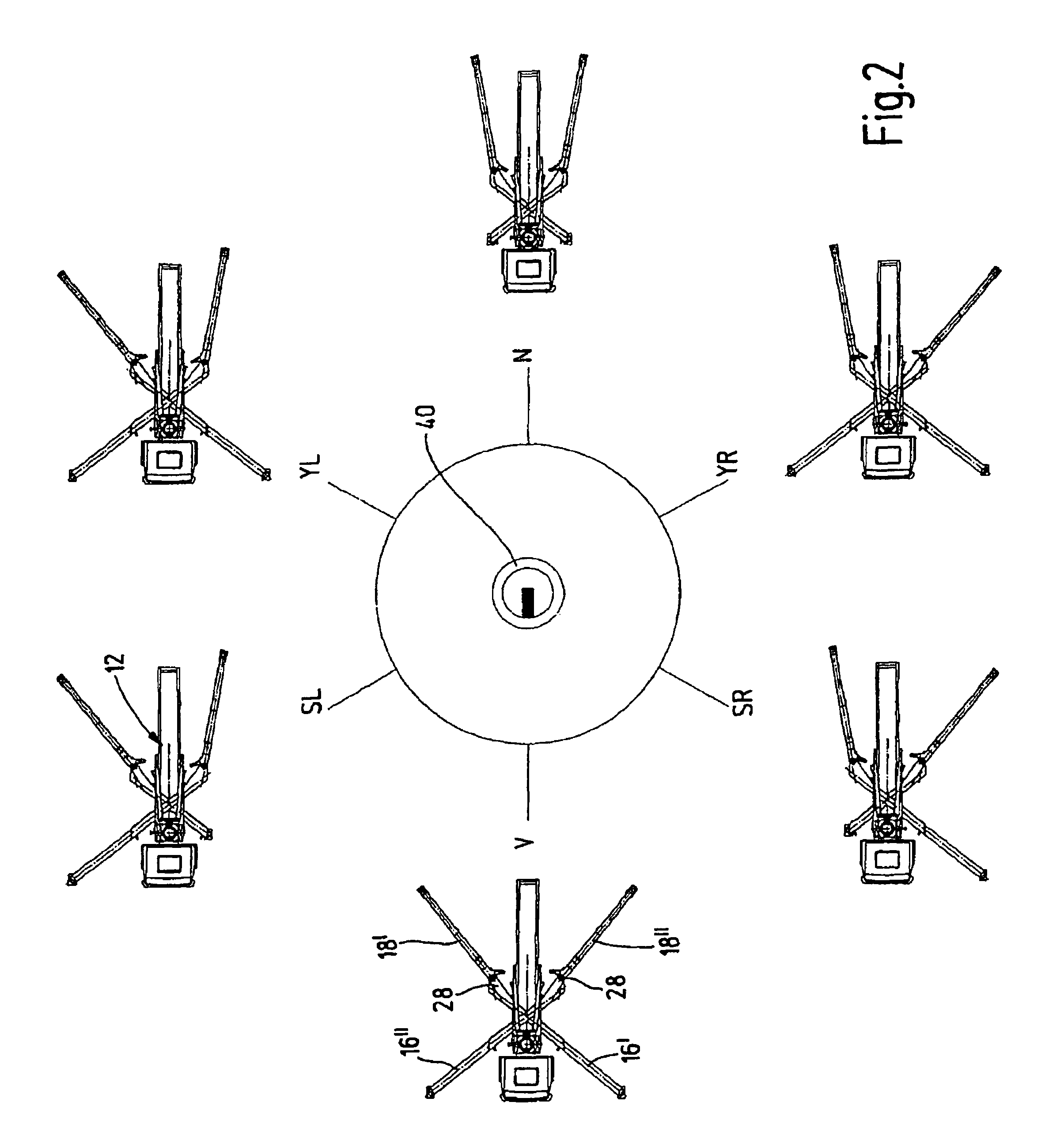

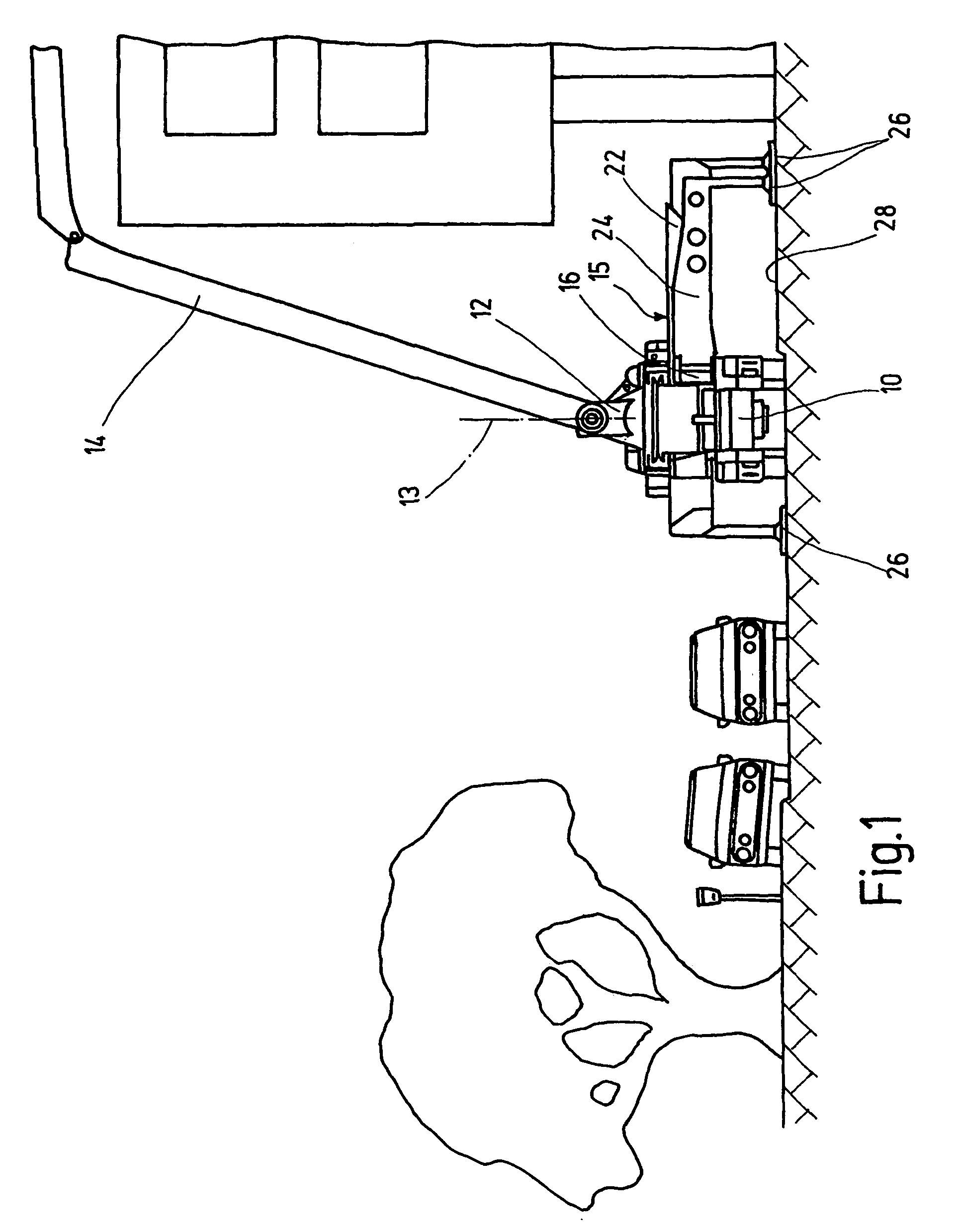

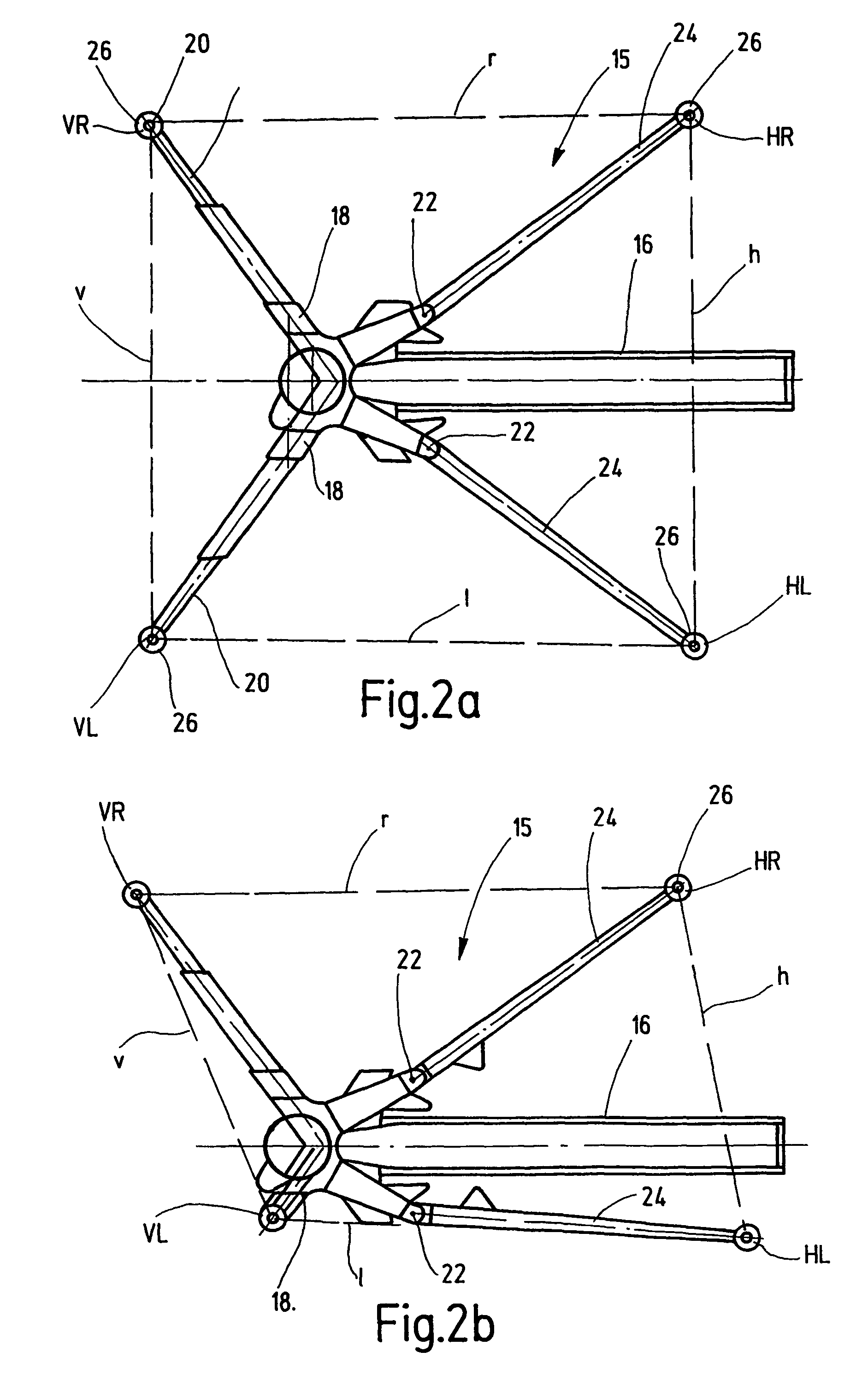

Mobile concrete pump having an articulated mast

InactiveUS7909059B2Expand the scope of workLower center of gravityPositive displacement pump componentsServomotor componentsAngular rotationEngineering

The invention relates to an automatic concrete pump with an articulated mast (14) serving as a support for a supply line and with two forward and two backward support extensions (16′,16″,18′,18″) which can be supported on a base platform (32) and which can be lowered from a driving position into a support position, each with a telescopic support leg (30). According to the invention, each support extension comprises one inner support position near to the chassis, and at least one outer support position away from the chassis, which can be freely selected by forming defined support configurations (V,SL,SR,YL,YR,N) for the four support extensions. Further, a control device for the movement of the mast arm is provided which comprises a software program corresponding to the selected support configuration, which program limits the pivot angle of the first bending arm (1) about its bending axis (A) and an associated range of angular rotation of the rotatable head (24) about the vertical axis (22), according to the specification of the selected support configuration.

Owner:PUTZMEISTER ENG

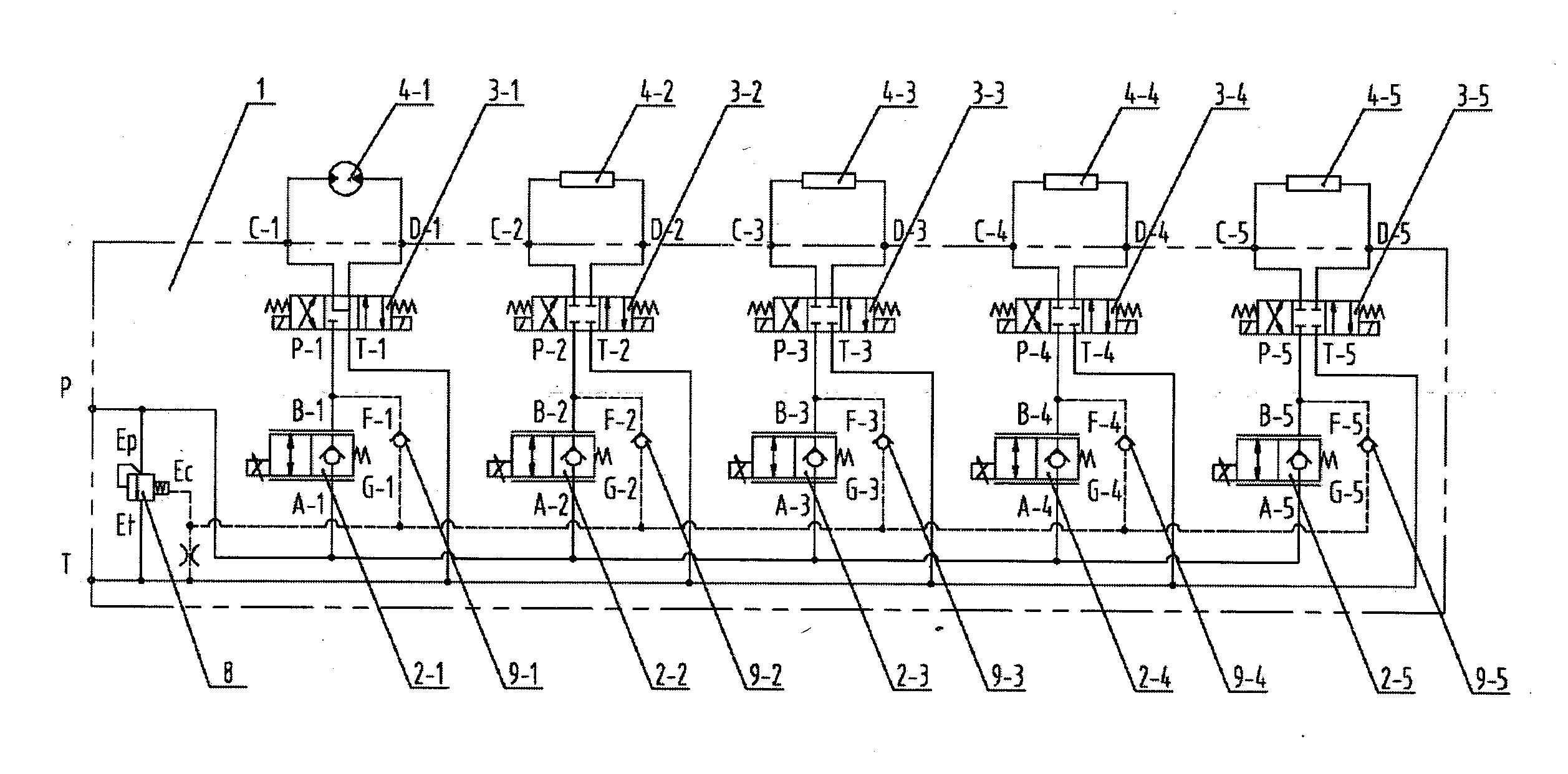

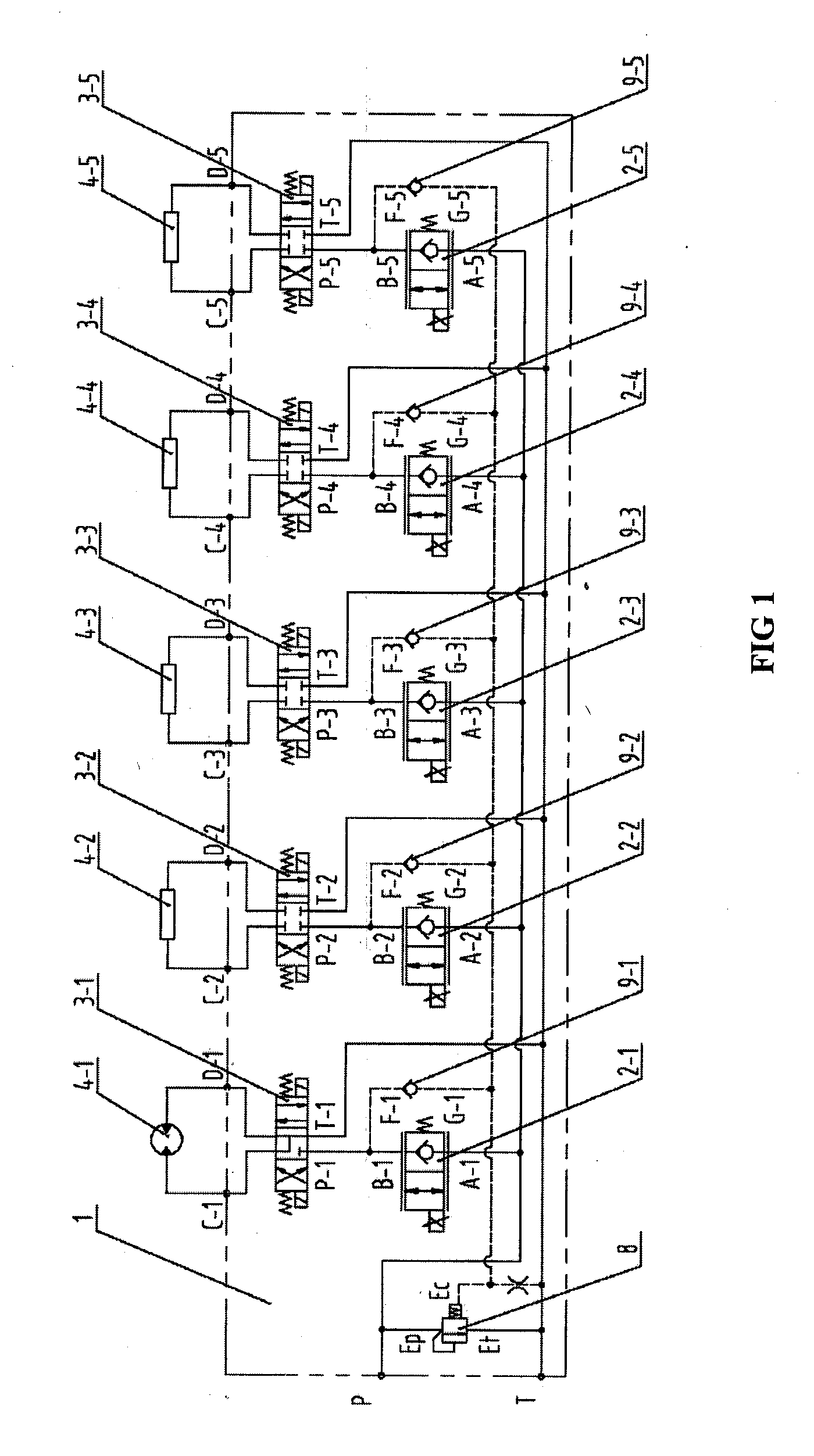

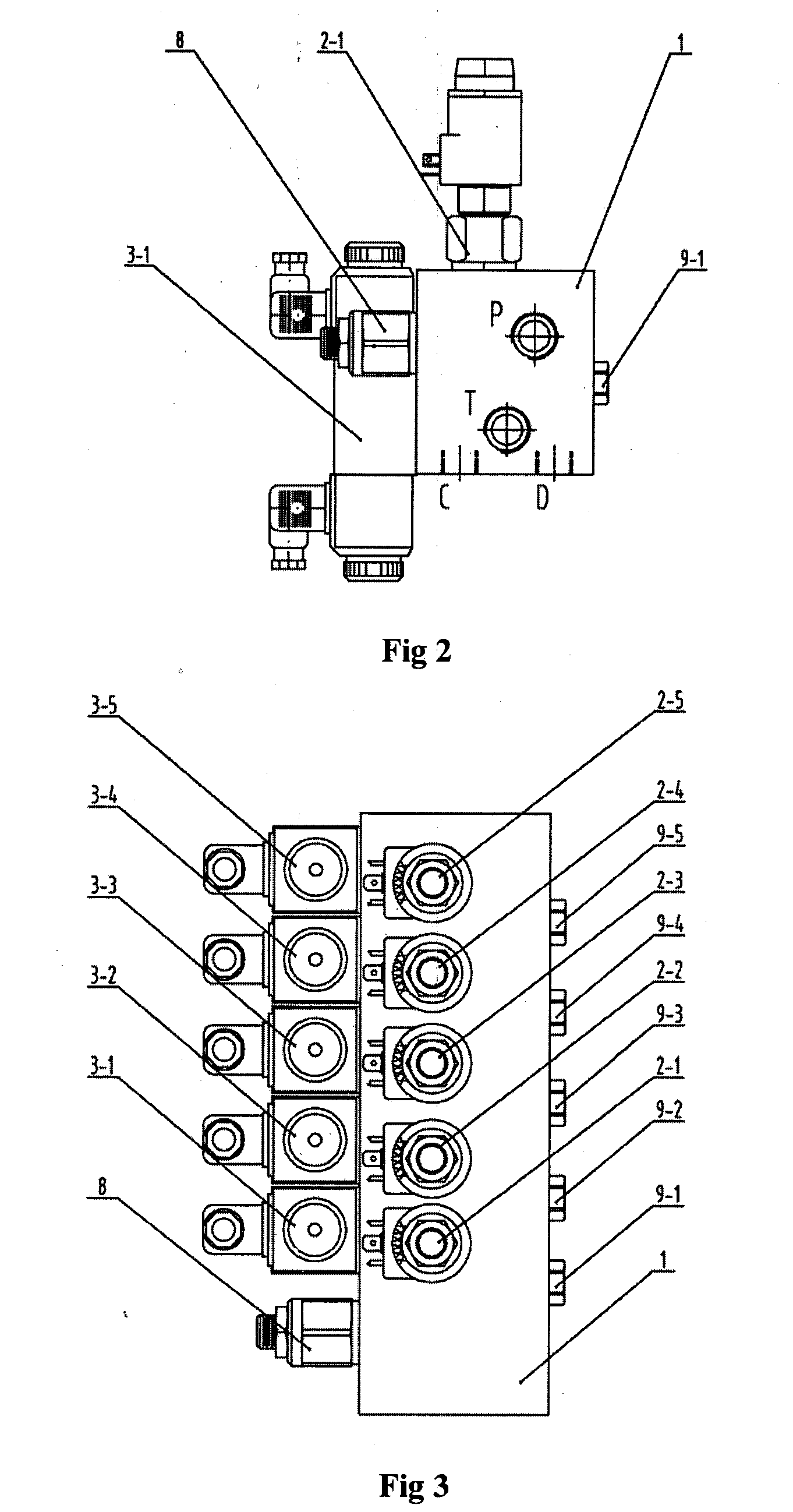

Multi-way valve, hydraulic device and concrete pump vehicle

InactiveUS20120224983A1Weaken energyDecrease productivityOperating means/releasing devices for valvesFluid couplingsProduction rateHydraulic equipment

A multi-way valve includes a plurality of parallel combination valves for controlling corresponding actuators (4-1-4-5). Each combination valve comprises proportional throttle valves (2-1-2-5) and reversing valves (3-1-3-5). An oil inlet of the proportional throttle valve is communicated with a main oil inlet (P), and an oil outlet of the proportional throttle valve is communicated with an oil inlet of the reversing valve. An oil outlet of the reversing valve is communicated with the main oil return port (T). Wherein, each combination valve further comprises a one-way control valve (9-1-9-5, 10-1-10-5) for obtaining the load pressure of corresponding actuator. One side of the one-way control valve is communicated with a pipeline between the proportional throttle valve and the actuator. The multi-way valve further includes a control element (8) which receives the load pressure fed back by each one-way control valve and responds to the load pressure to control the supply of hydraulic oil for the actuators. The multi-way valve has the load-sensitive function, thereby reducing energy loss and system heat productivity. A hydraulic equipment and a concrete pump vehicle corresponding to the multi-way valve are also provided.

Owner:HUNAN SANY INTELLIGENT CONTROL EQUIP +1

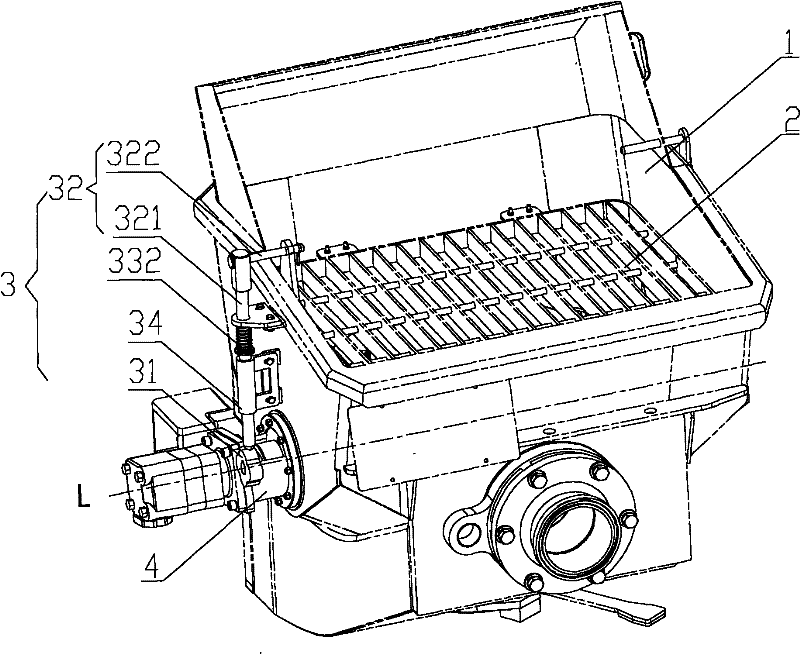

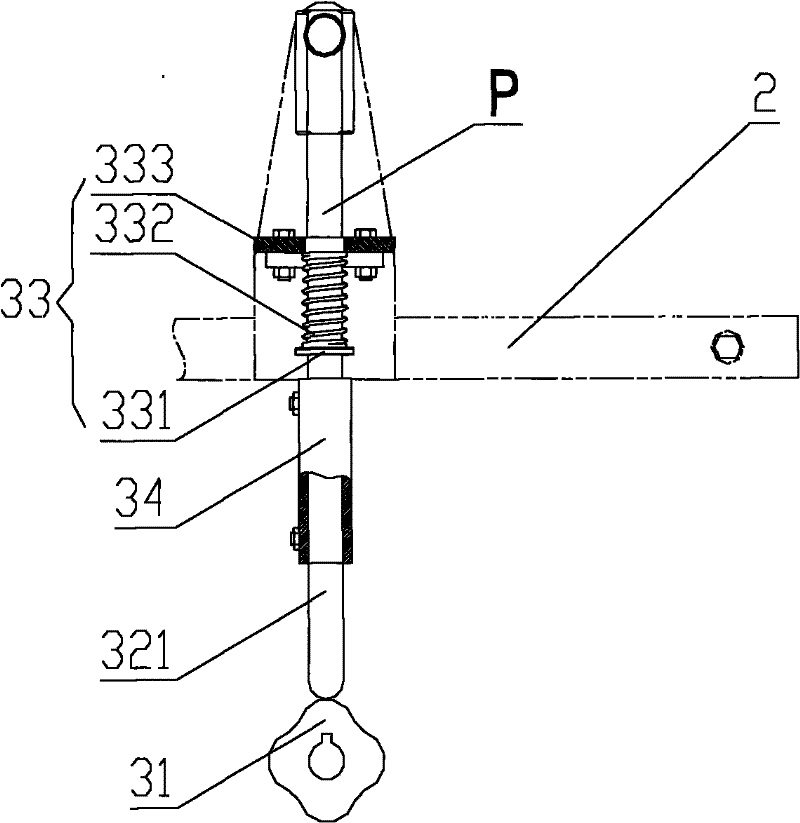

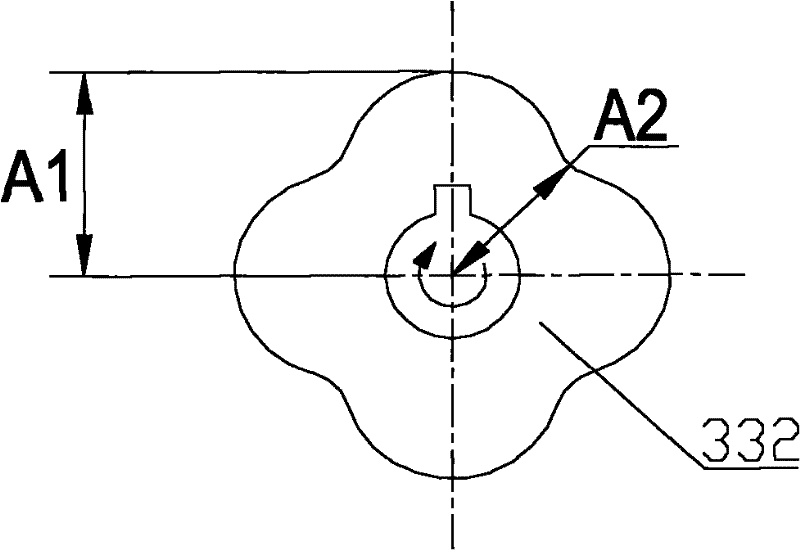

Concrete pump

ActiveCN102192122AEasy accessReduce the amount of accumulationPumpsPositive-displacement liquid enginesDrive wheelReciprocating motion

The invention discloses a concrete pump, which comprises a concrete stirring device, a hopper (1), a fence (2) arranged in the hopper (1), and a vibrating device (3) used for driving the fence (2), wherein the vibrating device (3) comprises a vibrating arm (32) and a driving wheel (31) for driving the vibrating arm (32) to perform reciprocating movement; the driving wheel (31) is a cam and is fixedly connected with a stirring shaft (4) of the concrete stirring device; and the vibrating arm (32) is fixedly connected with the fence (2). The concrete pump solves the problem of easy concrete accumulation on the fence to ensure that concrete can enter the hopper quickly and is pumped smoothly, and the working efficiency and the reliability of the concrete pump are improved.

Owner:XUZHOU XCMG CONSTR MACHINERY CO LTD BUILDING MACHINERY

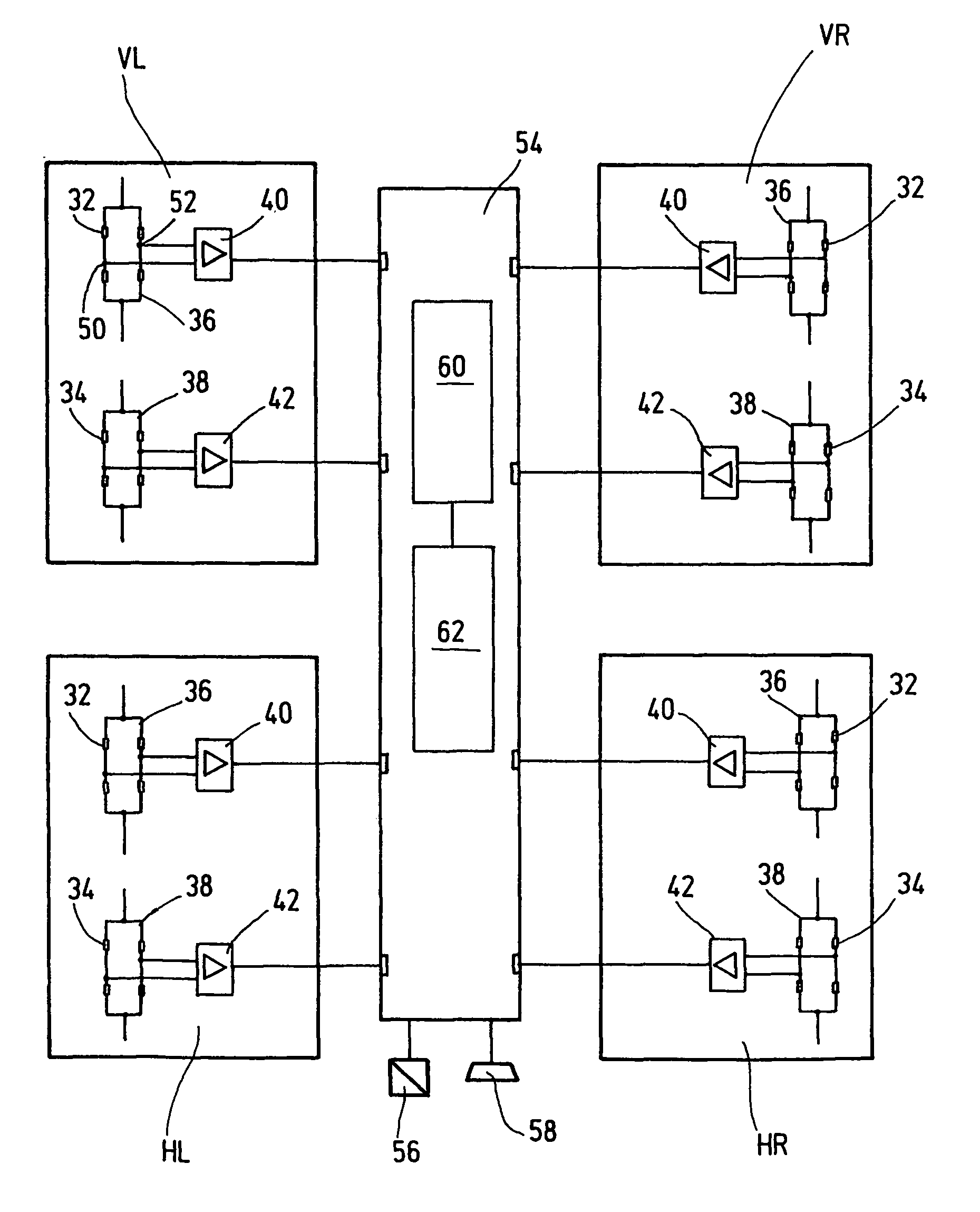

Mobile working machine provided with stability monitoring

InactiveUS7012540B2Improve stance safety monitoringWithout tip stabilityAnalogue computers for vehiclesAnalogue computers for trafficElectricityMeasurement device

The invention relates to a mobile working machine, particularly a mobile concrete pump, comprising a device for monitoring the stability thereof when in operation. The working machine comprises a chassis (10), which contains a supporting structure with two front and two rear support struts (20). The support struts can be extended out of a transporting position and into at least one supporting position and each can be supported on a surface (28) by a telescopic supporting jack or foot (26). The working machine additionally comprises a working boom (14), which can be extended out of a transporting position and into working positions that project beyond the chassis, which can rotate about a vertical axis that is fixed with regard to the chassis, and which is preferably provided in the form of a concrete distributing boom. Measuring devices for determining the respective supporting load are arranged in the area of the supporting foot and their output signals are sent to a stability monitoring device. According to the invention, at least one force sensor (32, 34) is arranged in each supporting jack and is connected in an electrical measuring circuit (36, 38) for outputting a supporting load dependent measurement signal. The monitoring device comprises an evaluation electronic unit (54) which, in predetermined sampling cycles, can be subjected to supporting load measured values and, for their comparison, can be subjected to at least one predetermined stability-determining threshold value.

Owner:PUTZMEISTER ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com