Concrete pumping equipment, serial oil cylinder and stroke self-adaptive tail end compensation method thereof

A technology of connecting oil cylinders and oil cylinders, applied in the direction of fluid pressure actuating devices, etc., can solve the problems of inability to achieve intelligence and trouble.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

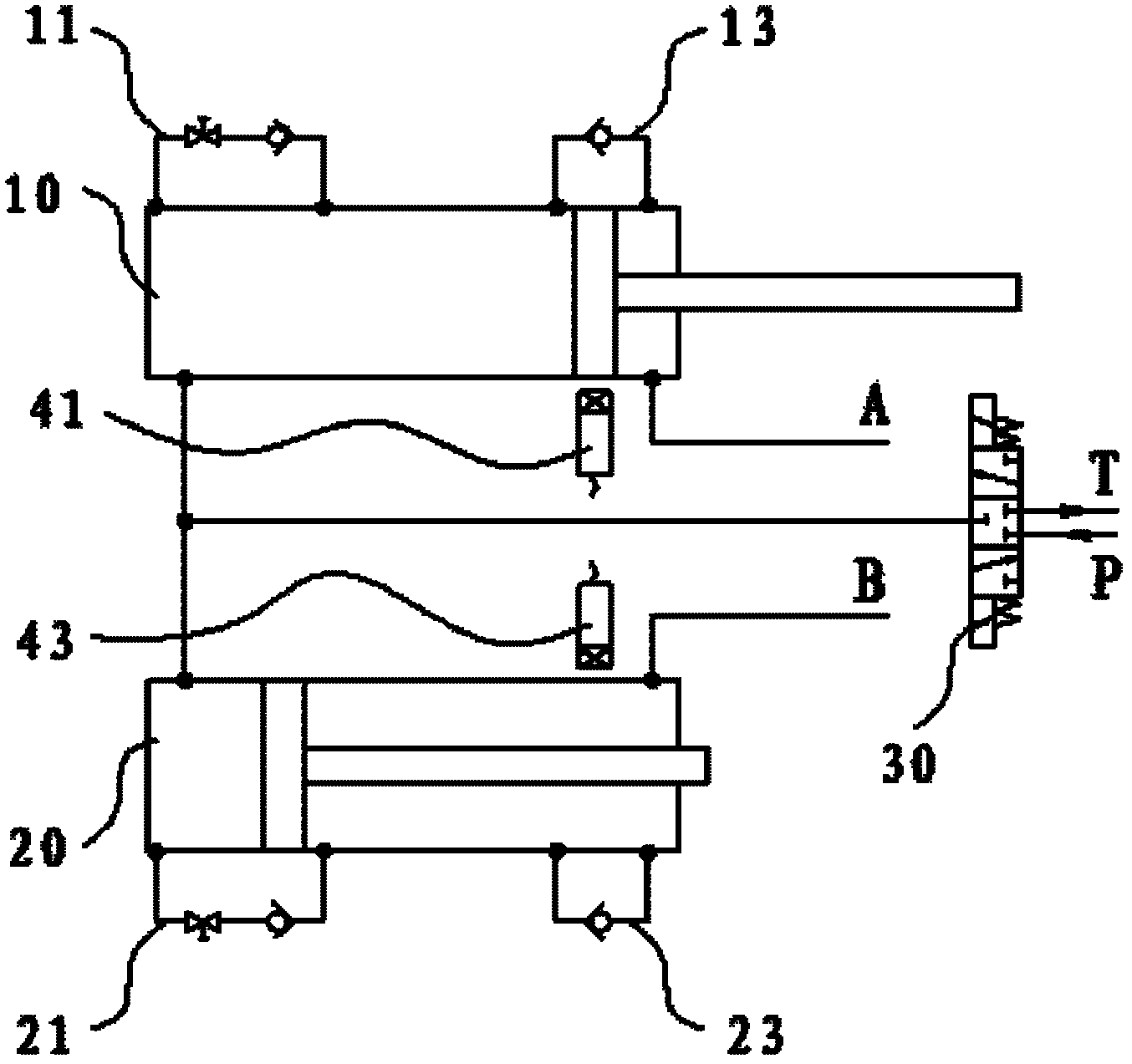

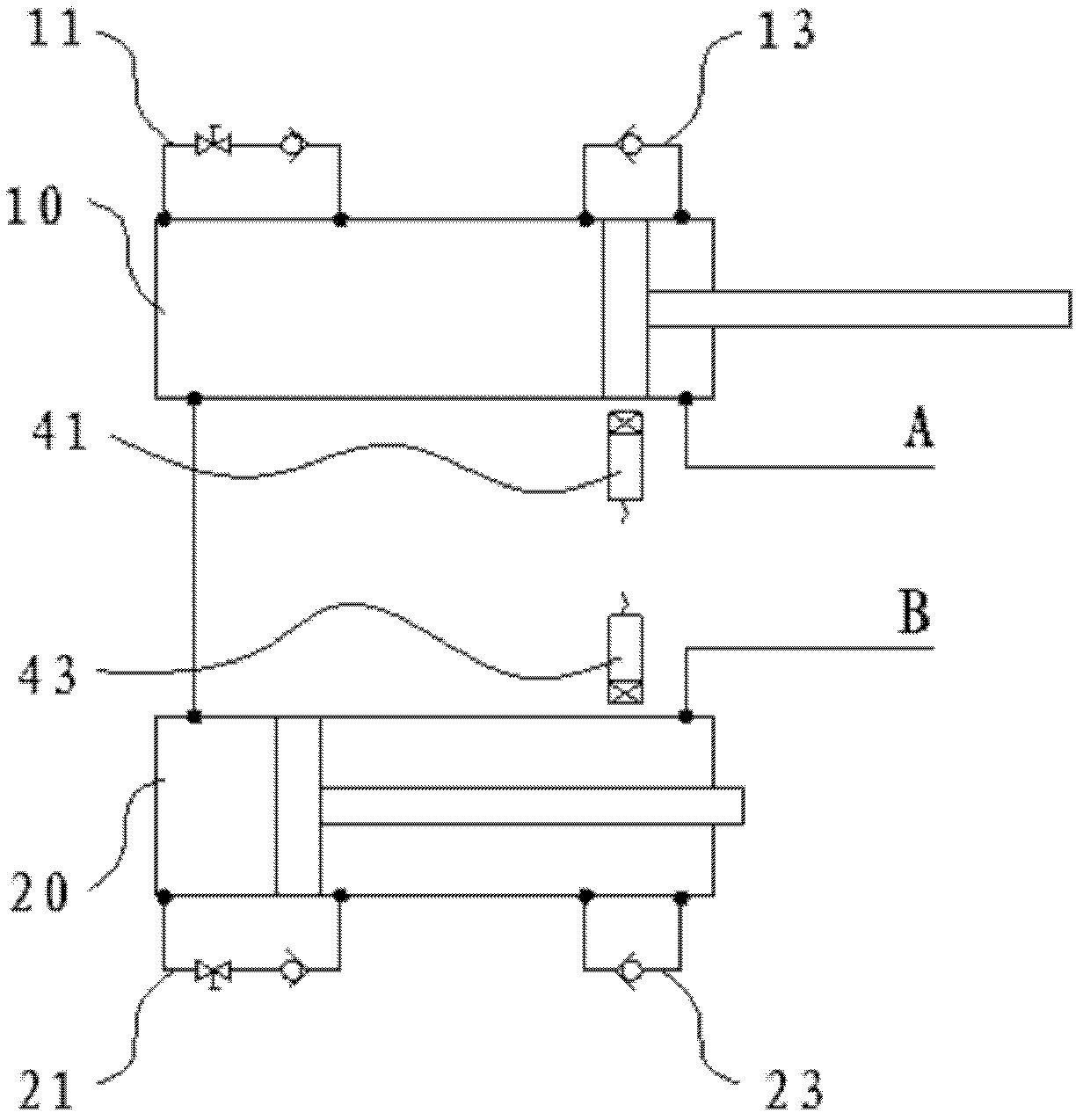

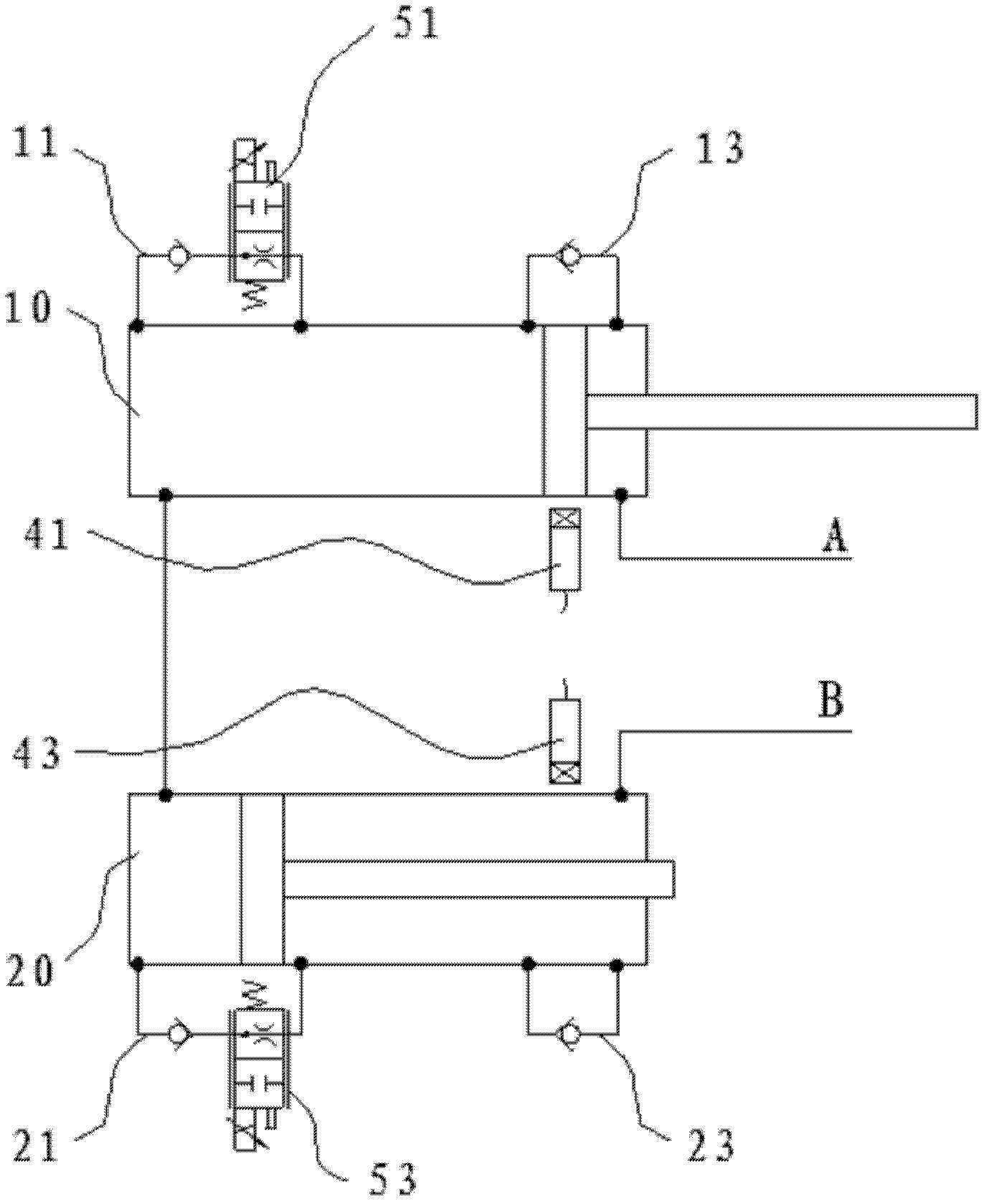

[0037] The present invention cancels the external stroke compensation device in the prior art, replaces the cut-off valve in the U-shaped pipe with an electric proportional throttle valve, and controls the opening of the valve port of the electric proportional throttle valve according to the stroke feedback signal of the oil cylinder, thereby controlling The oil volume that enters or leaks out of the connecting chamber achieves the purpose of precisely controlling the stroke of the oil cylinder.

[0038] "U-shaped pipe" is a technical term in this field, which is different from the commonly understood "U-shaped pipe". It refers to the compensation of the stroke end of the two series cylinders and the replacement of the oil in the communication chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com