Stable silicon controlled rectifier (SCR) urea injector easy to control

A technology of injectors and urea, applied in the direction of machines/engines, chemical instruments and methods, mechanical equipment, etc., can solve the problems of insufficient electromagnetic force, cost waste, poor spray effect, etc., to reduce danger, slow down wear, Ensure consistency and stability of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

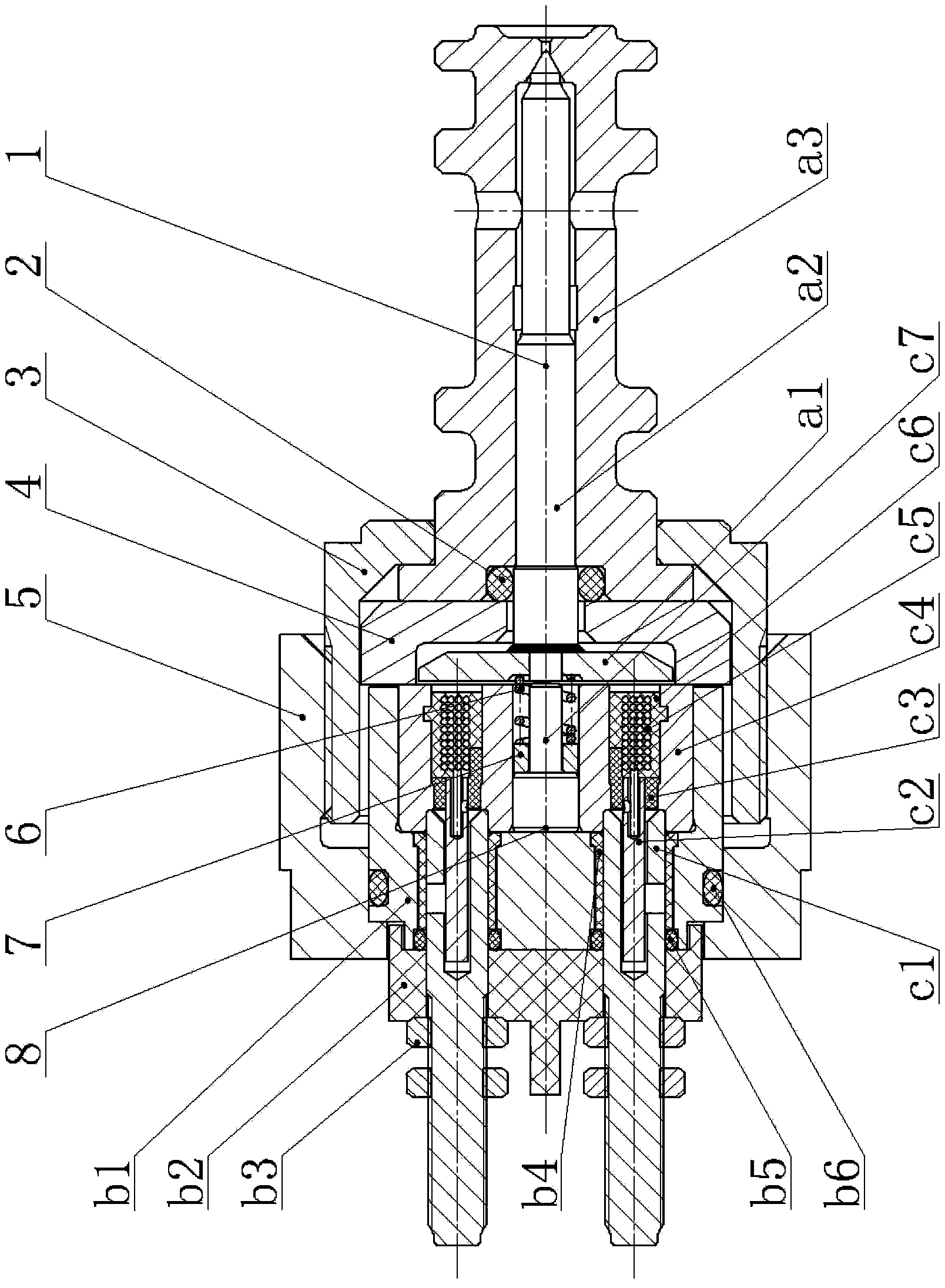

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] Such as figure 1 As shown, the present invention comprises valve seat pair 1, solenoid valve part 8, spacer ring 4, spring 6, spring seat 7, limit pin c7, connecting device, wherein one end of valve seat pair 1 is the injection end, and the other One end is provided with spacer ring 4. One end of the solenoid valve component 8 is a terminal, and the other end is provided with a center hole I, which houses a limit pin c7 and a spring seat 7 and a spring 6 sleeved thereon; the valve seat pair is provided with a spacer One end of the ring 4 is connected with the other end of the solenoid valve part 8 through a connecting device.

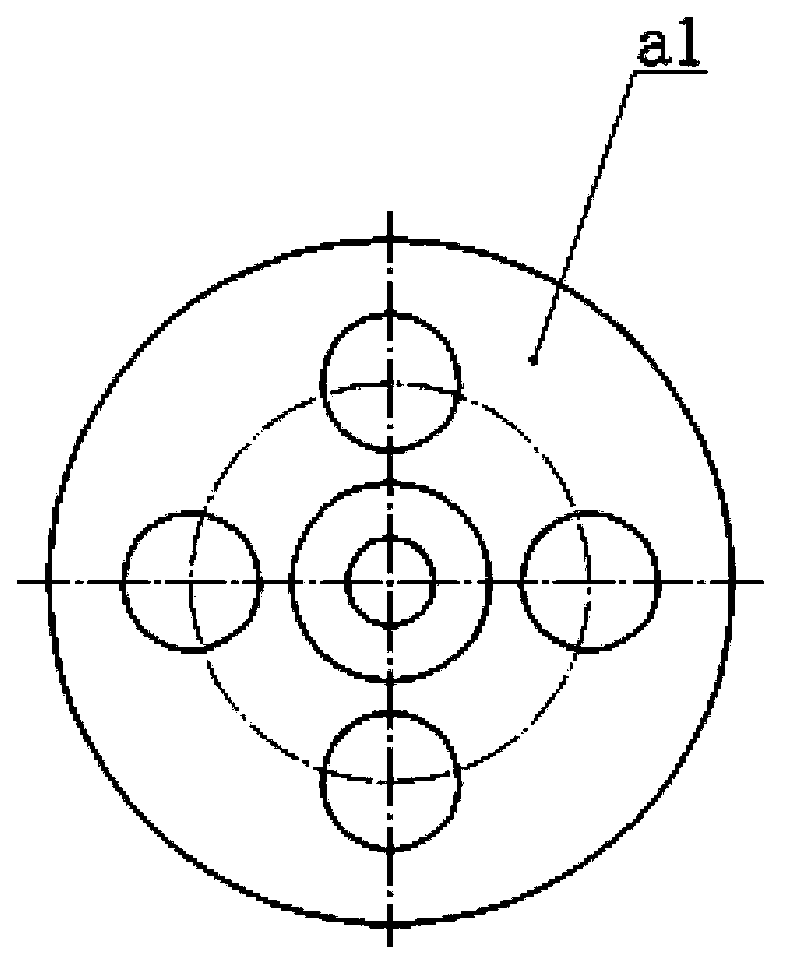

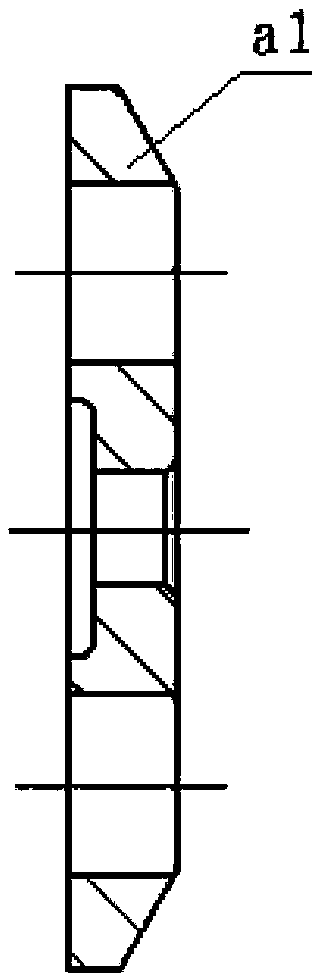

[0026] The valve seat couple 1 includes a sliding fit valve seat a3 and a valve core assembly, the valve core assembly includes a valve core a2 and an armature a1, wherein the valve core a2 is a stepped shaft structure with a conical su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com