Patents

Literature

119results about How to "Accurate stroke control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

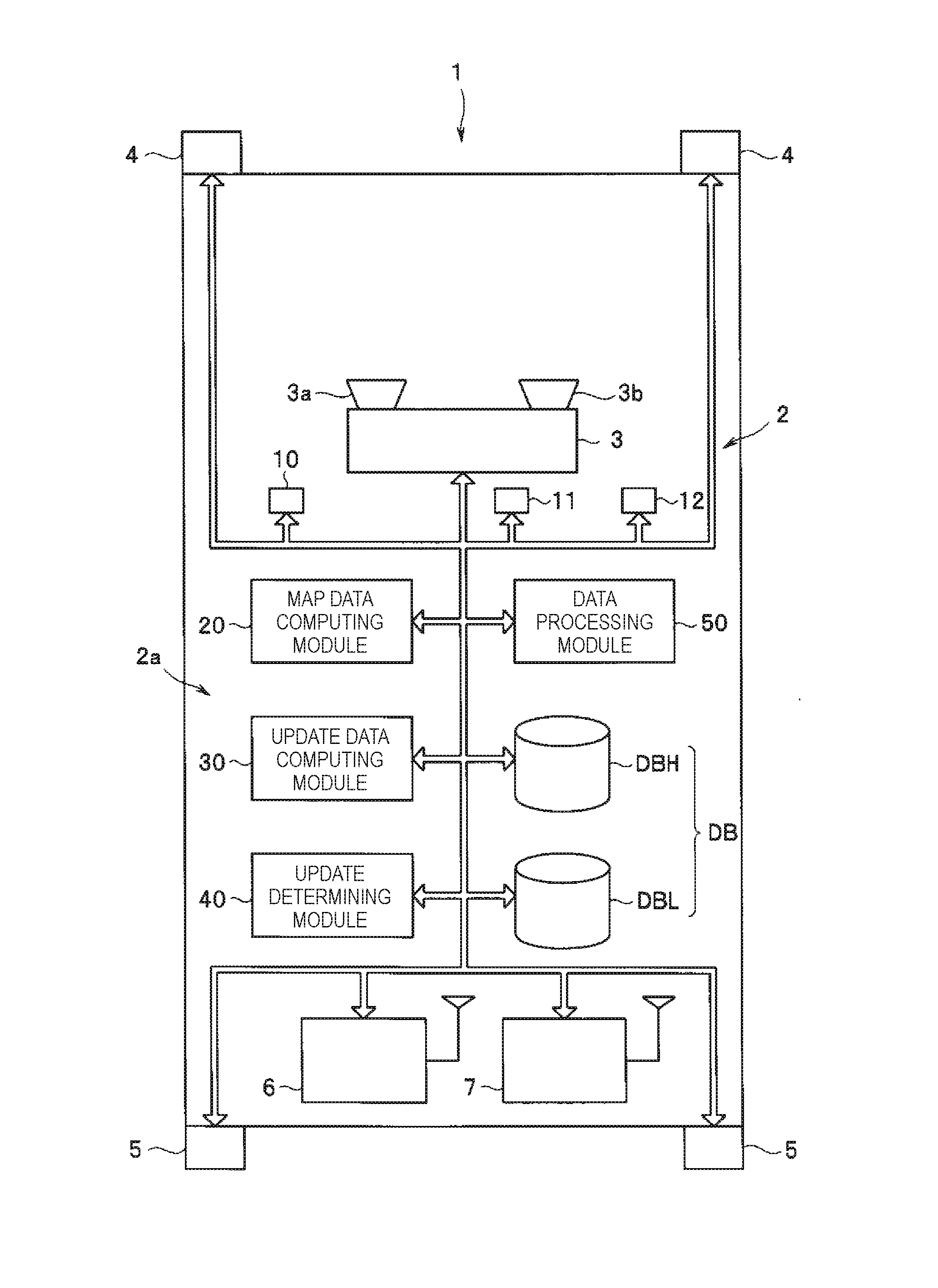

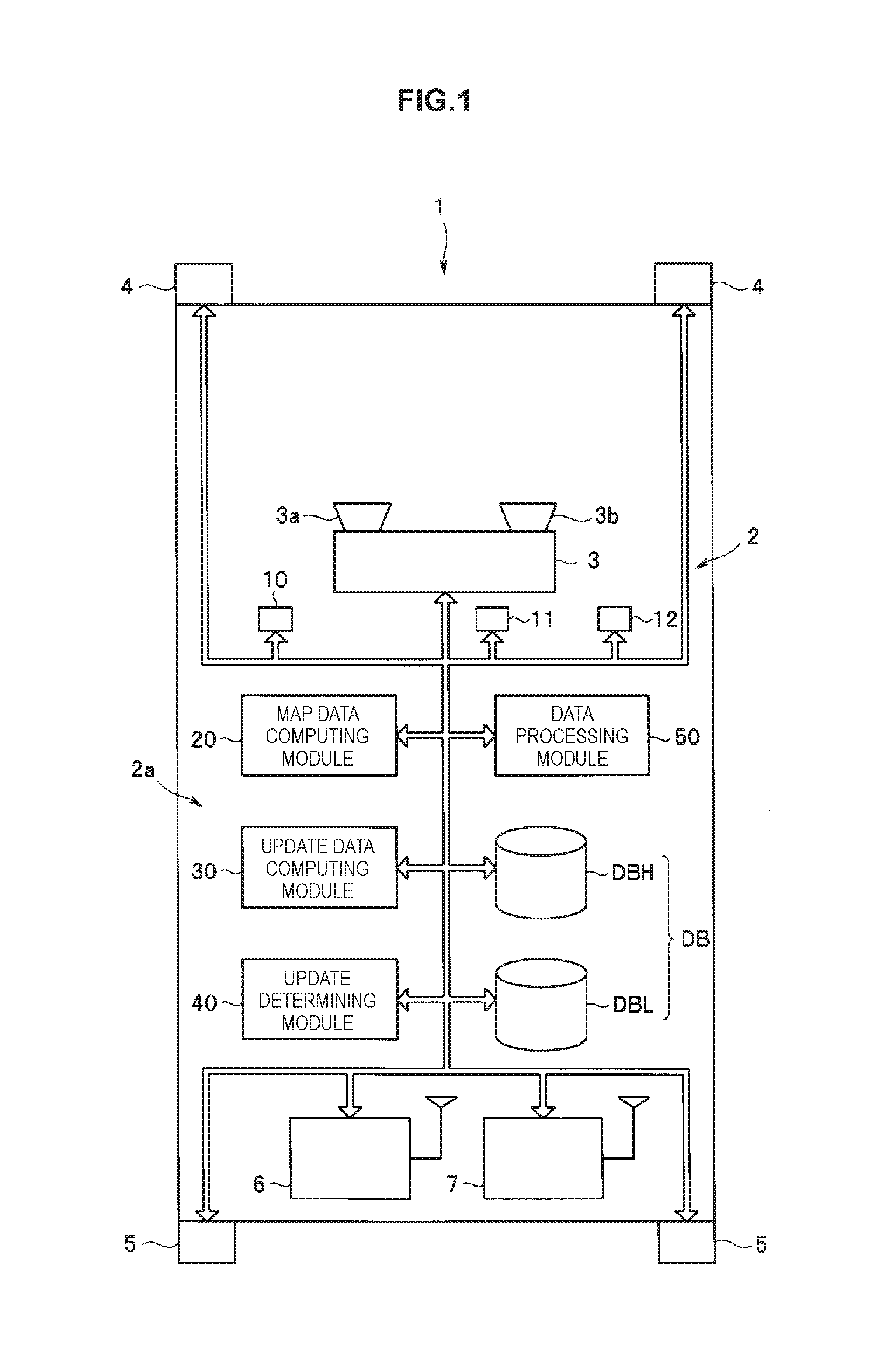

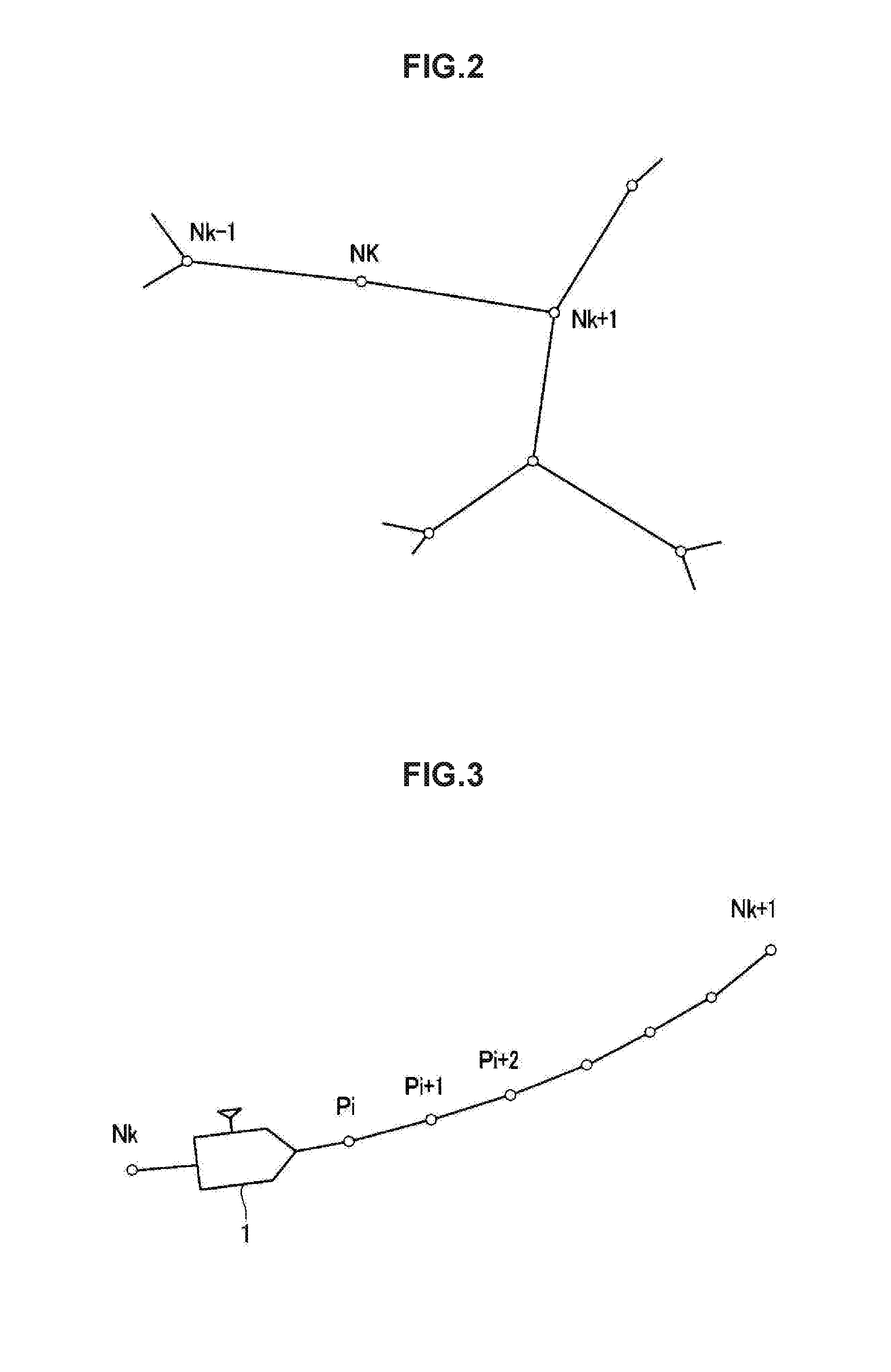

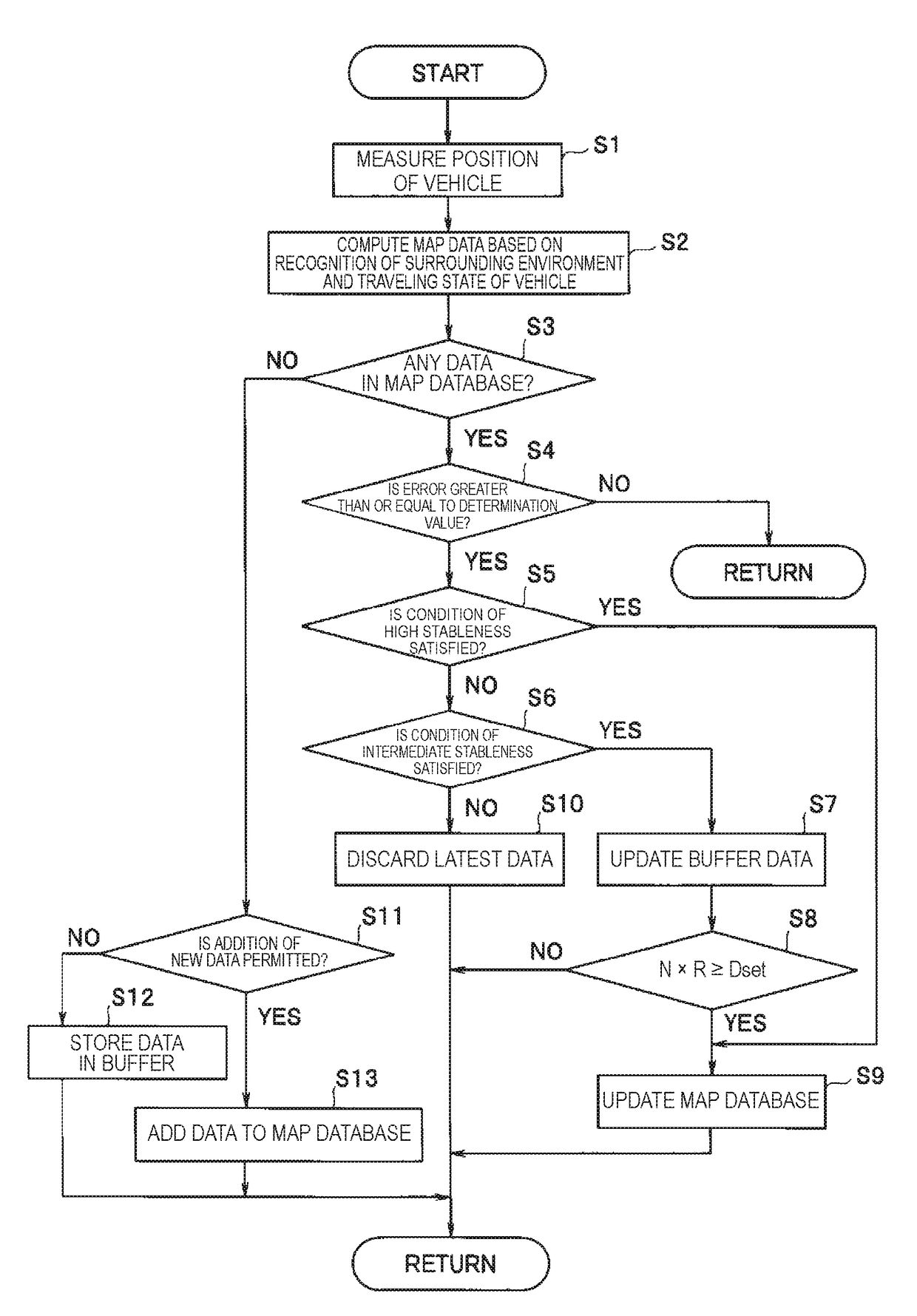

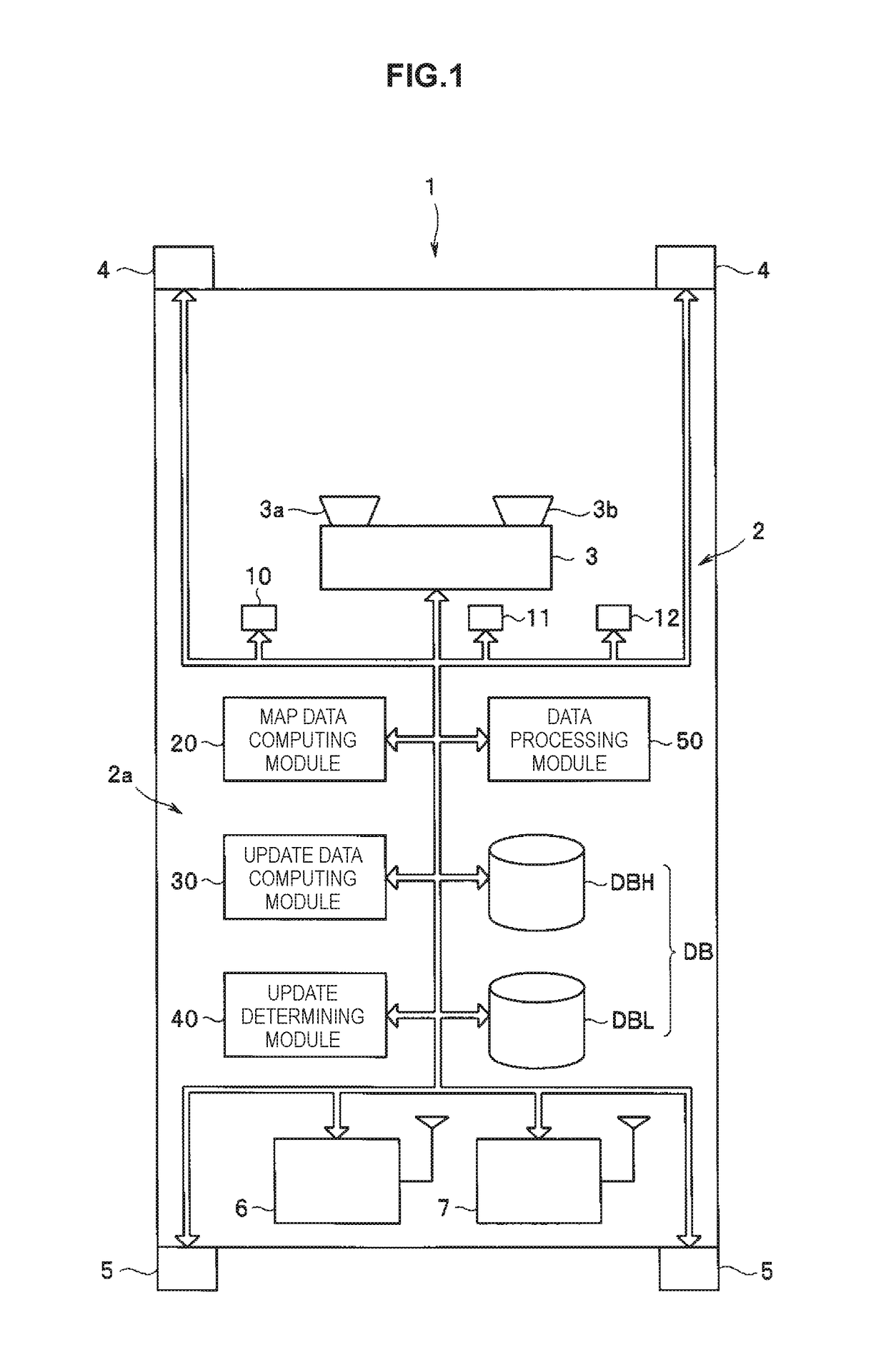

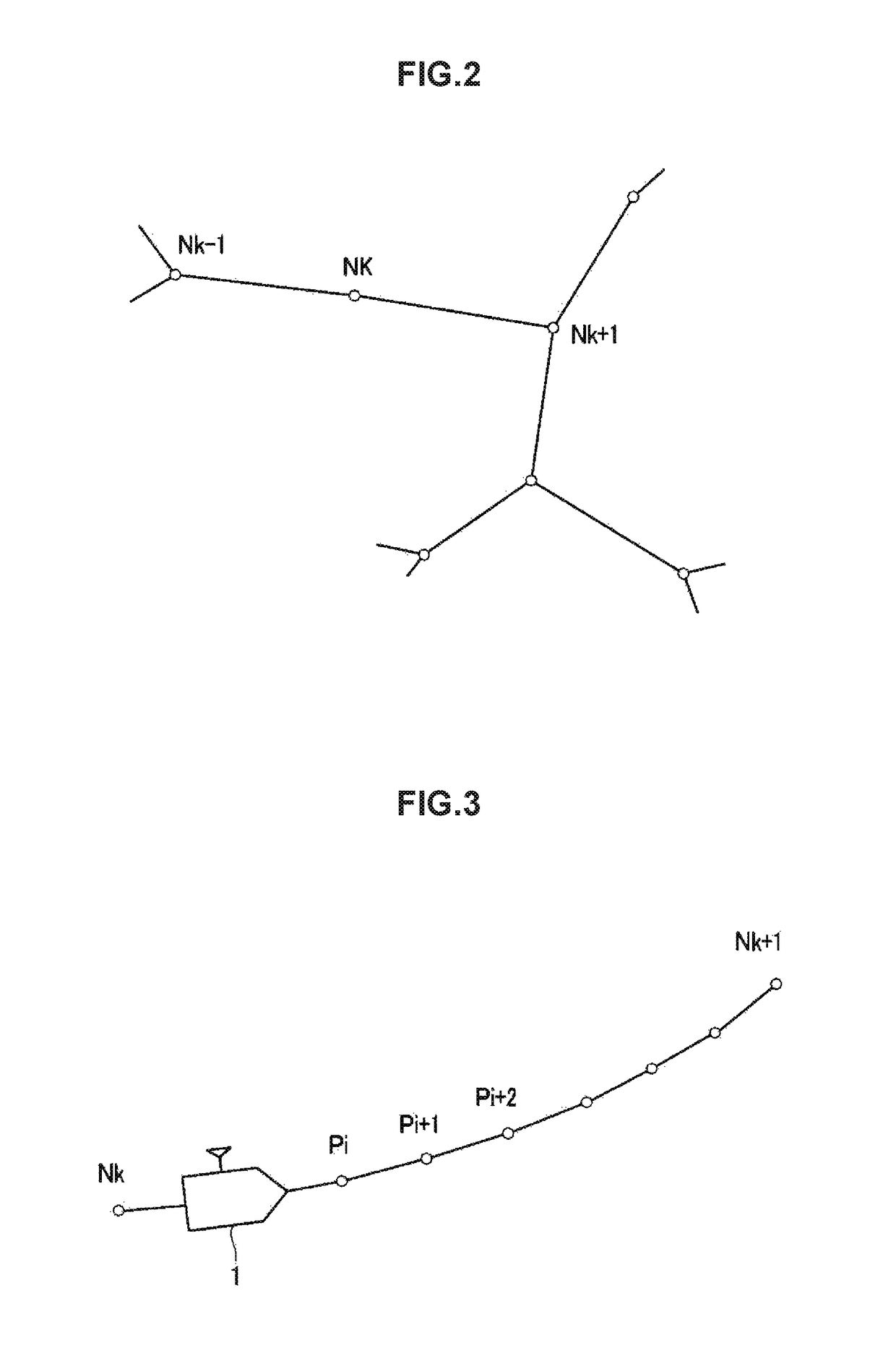

Map data processing device for vehicle

ActiveUS20160259814A1Accurate identificationAccurate stroke controlInstruments for road network navigationGeographical information databasesComputer moduleComputer science

In a map data processing device for a vehicle, a map database has first map data of a road on which the vehicle travels. A map data computing module computes second map data of the road based on a surrounding environment and a traveling state of the vehicle. An update data computing module computes update data for updating the map database, based on a reliability of the second map data. An update determining module then compares the first map data with the update data. When both disagree with each other, the update determining module determines whether to update first map data with the update data, based on a frequency of discrepancy and the reliability. A data processing module executes a processing of updating the map database in accordance with a determination result by the update determining module.

Owner:SUBARU CORP

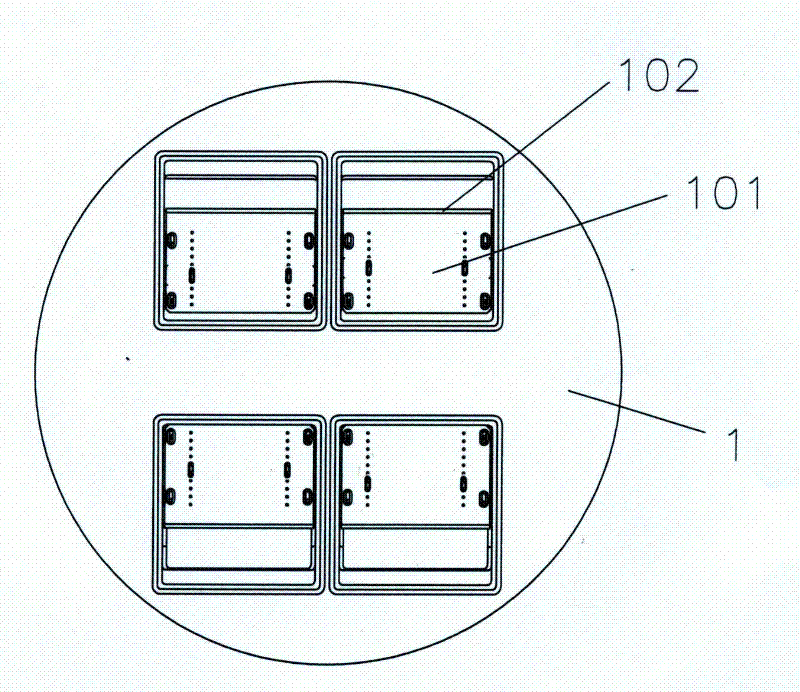

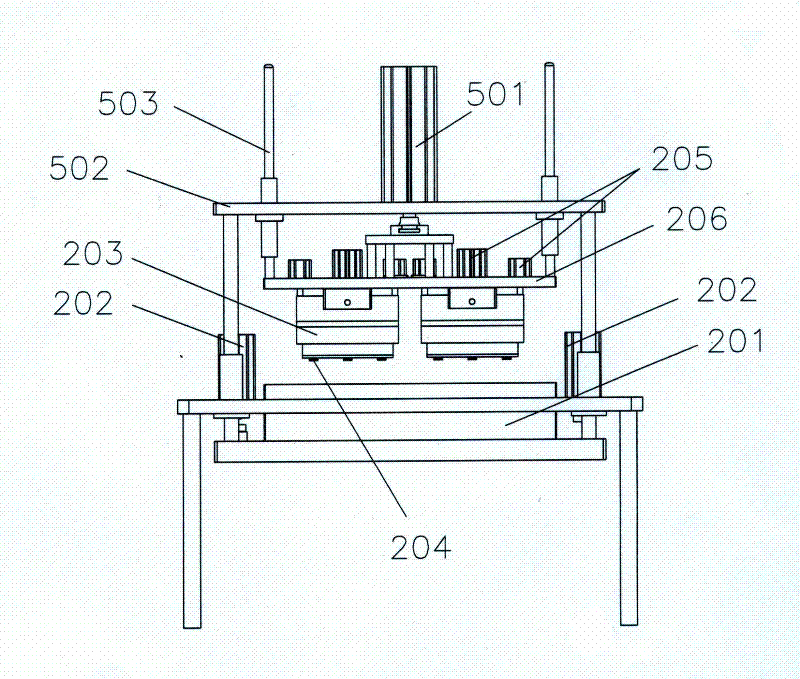

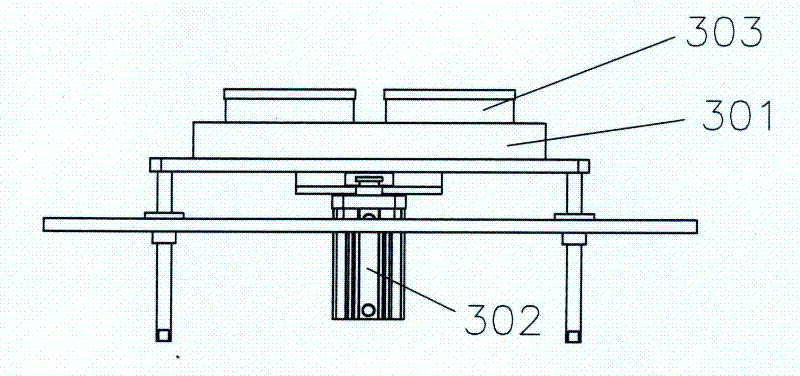

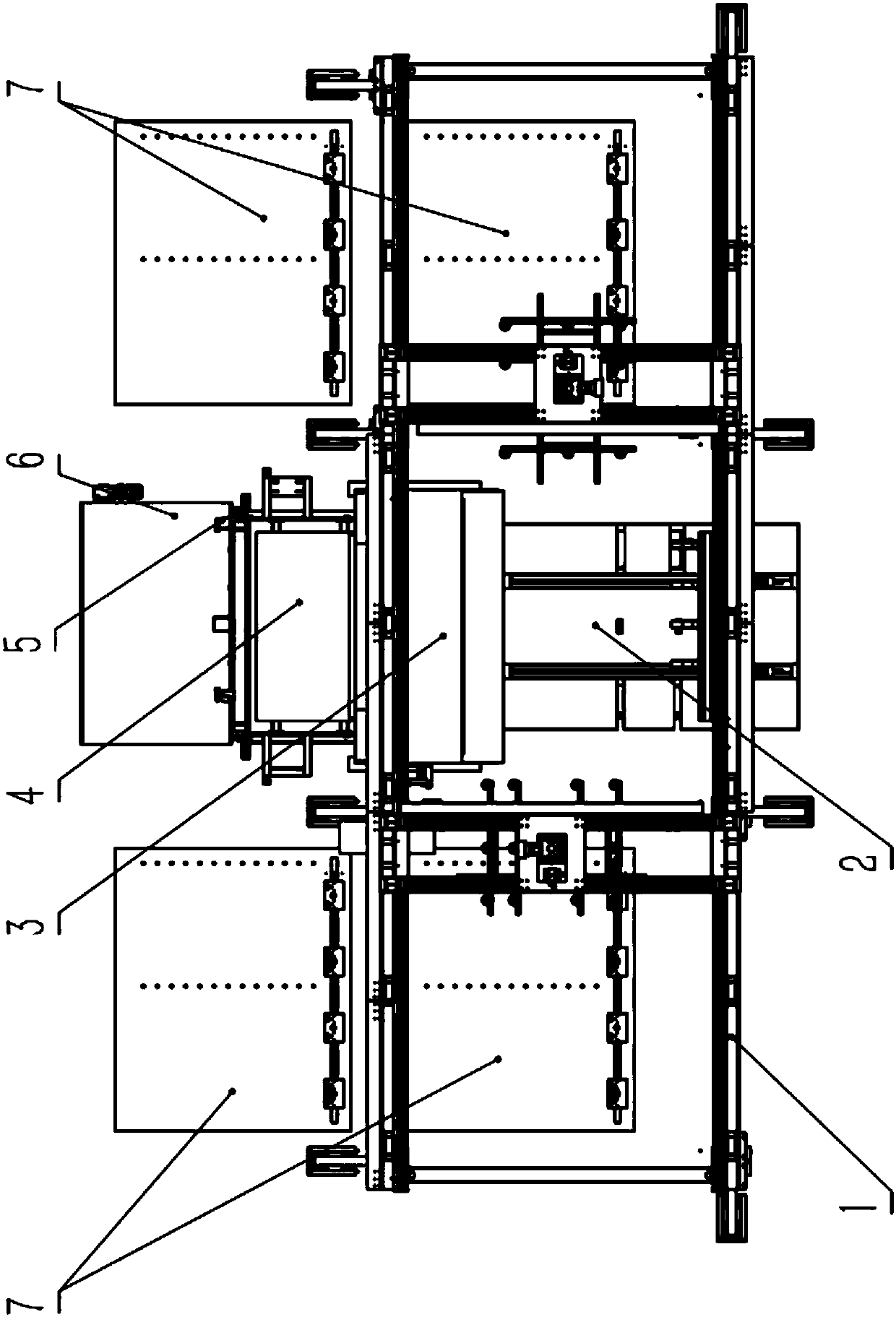

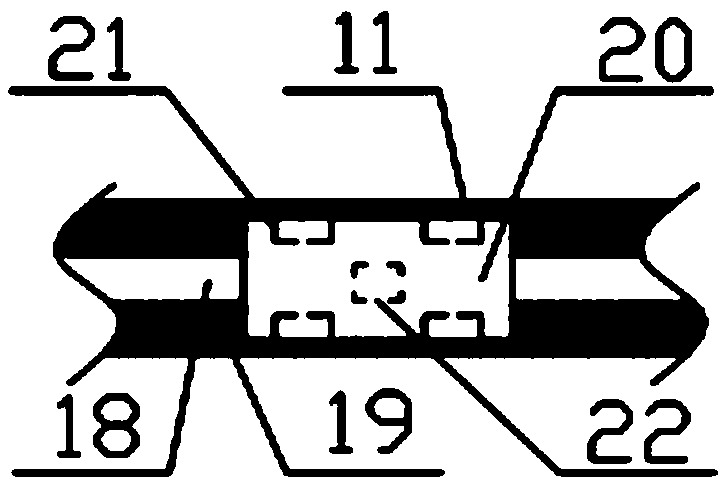

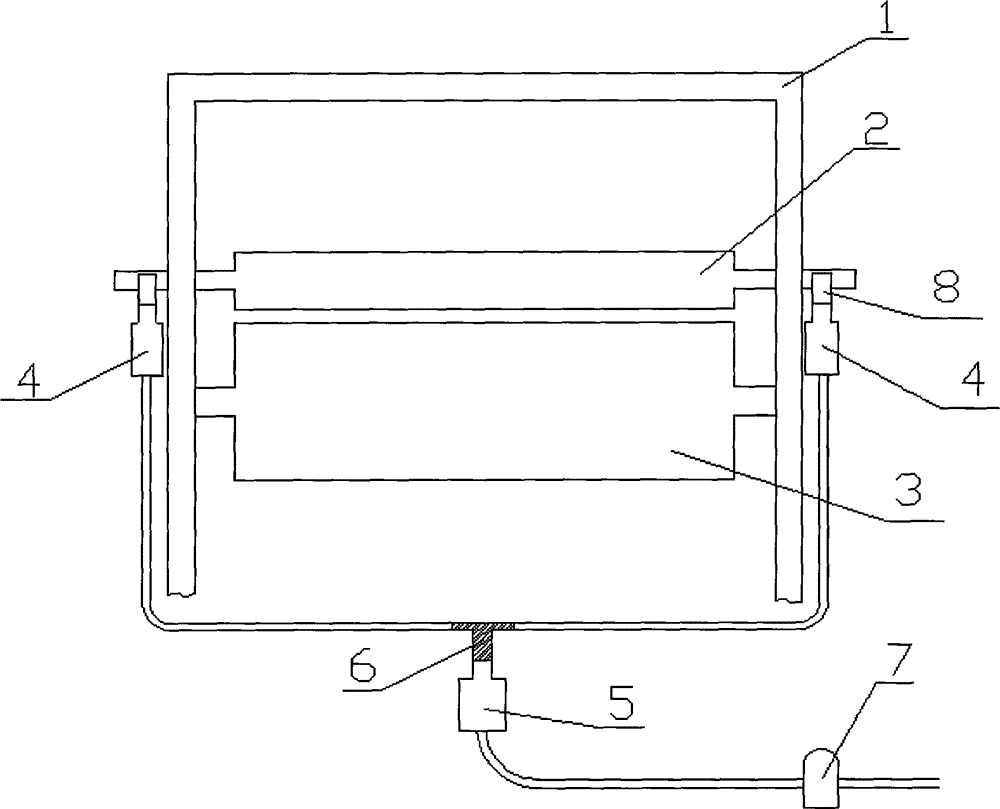

Servo double-surface heating vacuum packaging machine

ActiveCN102201592AQuality is not affectedGuarantee exclusionFinal product manufactureSecondary cells manufactureControl systemEngineering

The invention discloses a servo double-surface heating vacuum packaging machine and belongs to liquid extraction seal secondary forming and packaging equipment of flexible packaged lithium batteries. The servo double-surface heating vacuum packaging machine comprises a double-station turntable feeding device driven by a cam partitioning device, a packaging mechanism with an up-and-down packaging device, and an electric control system, wherein the up-and-down packaging device comprises an upper cavity main body and a lower cavity main body; the opening directions of the upper cavity main body and the lower cavity main body are opposite to each other; the upper cavity main body and the lower cavity main body can clamp the turntable to form a sealed cavity body; a pressing board, an upper sealing head and a bayonet are arranged in the upper cavity main body; a lower sealing head and an aspirating hole are arranged in the lower cavity main body; the aspirating hole is communicated with an external vacuum source; the upper sealing head corresponds to the lower sealing head; and a heating body is arranged inside the servo double-surface heating vacuum packaging machine. The servo double-surface heating vacuum packaging machine has a compact structure and high efficiency; the electric core packaging quality is stable and the cost is low; vacuum liquid extraction can be realized; and pollution of the electrolyte to the equipment can be reduced to minimum.

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

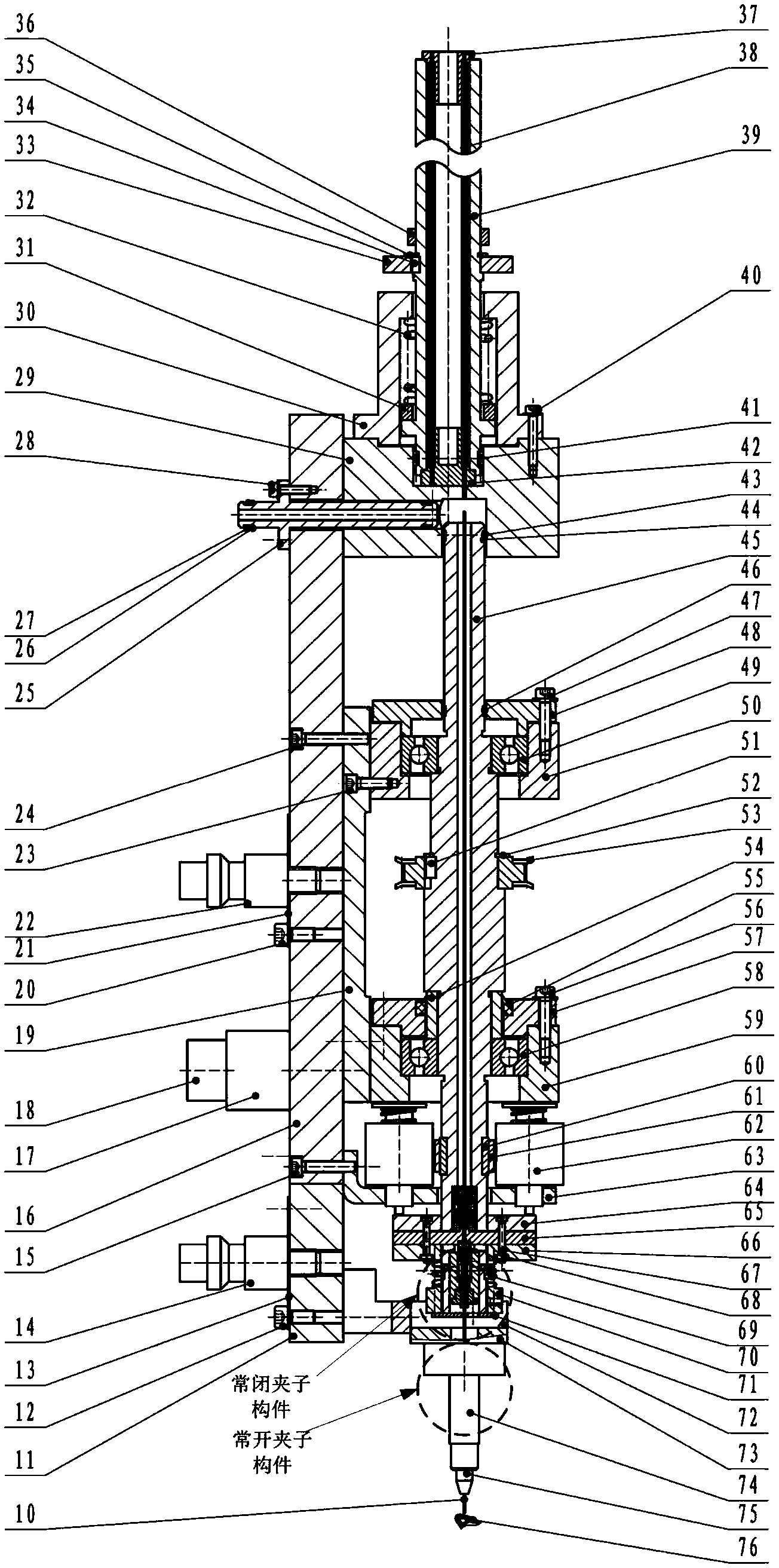

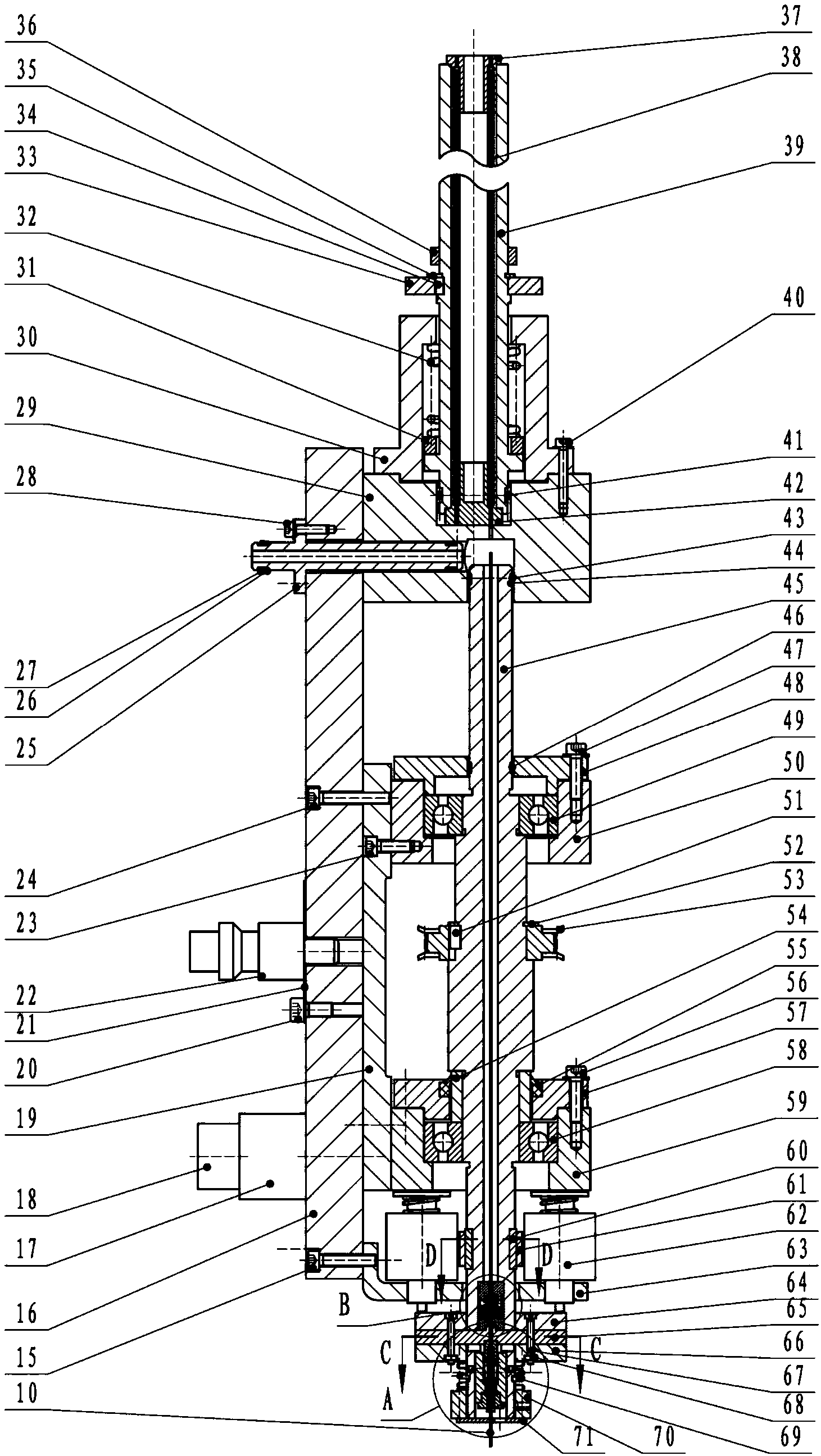

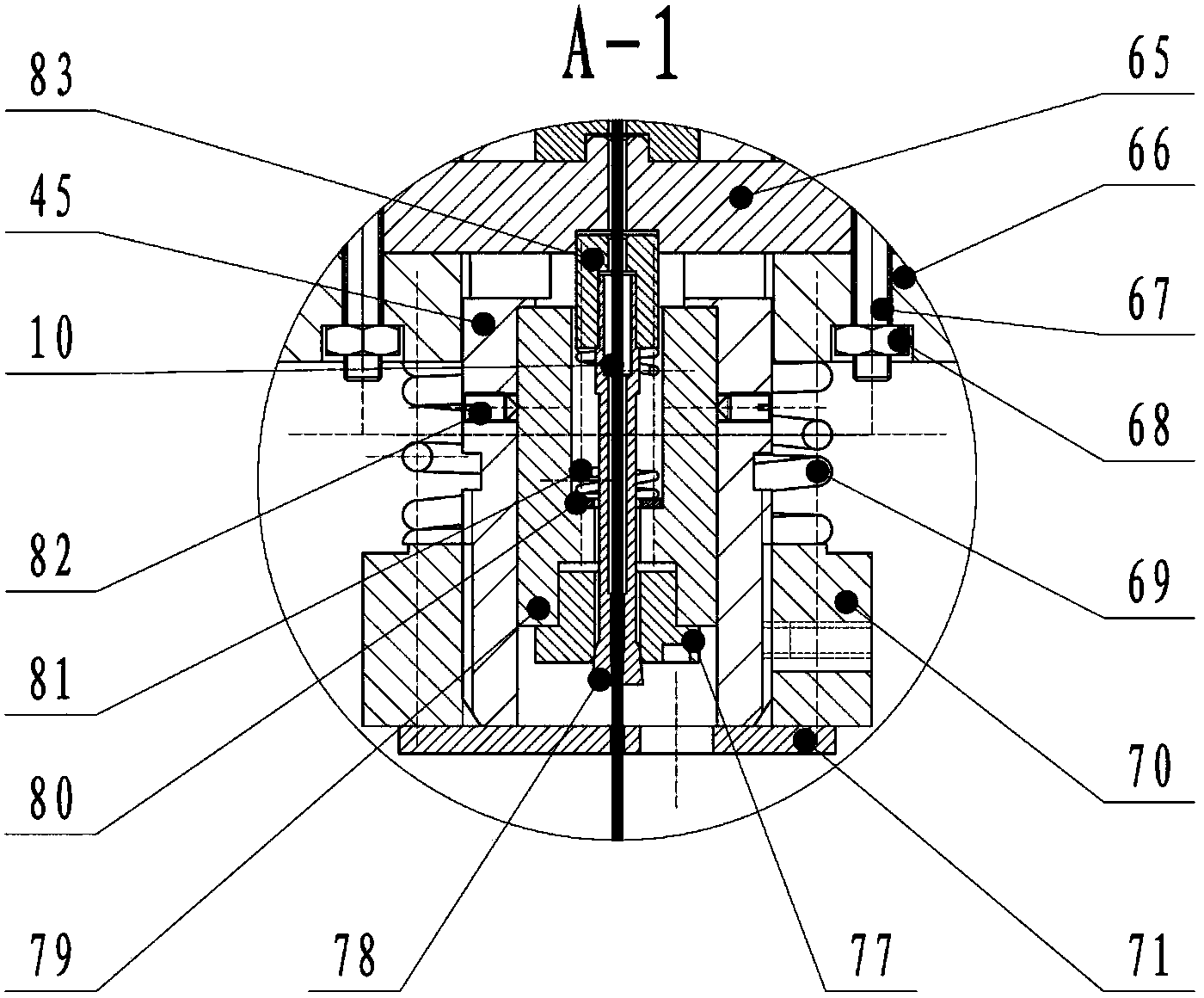

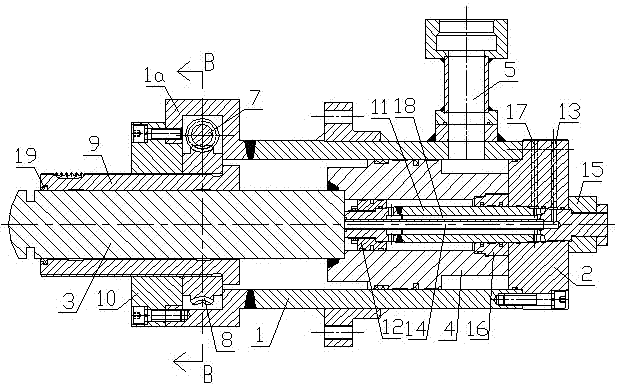

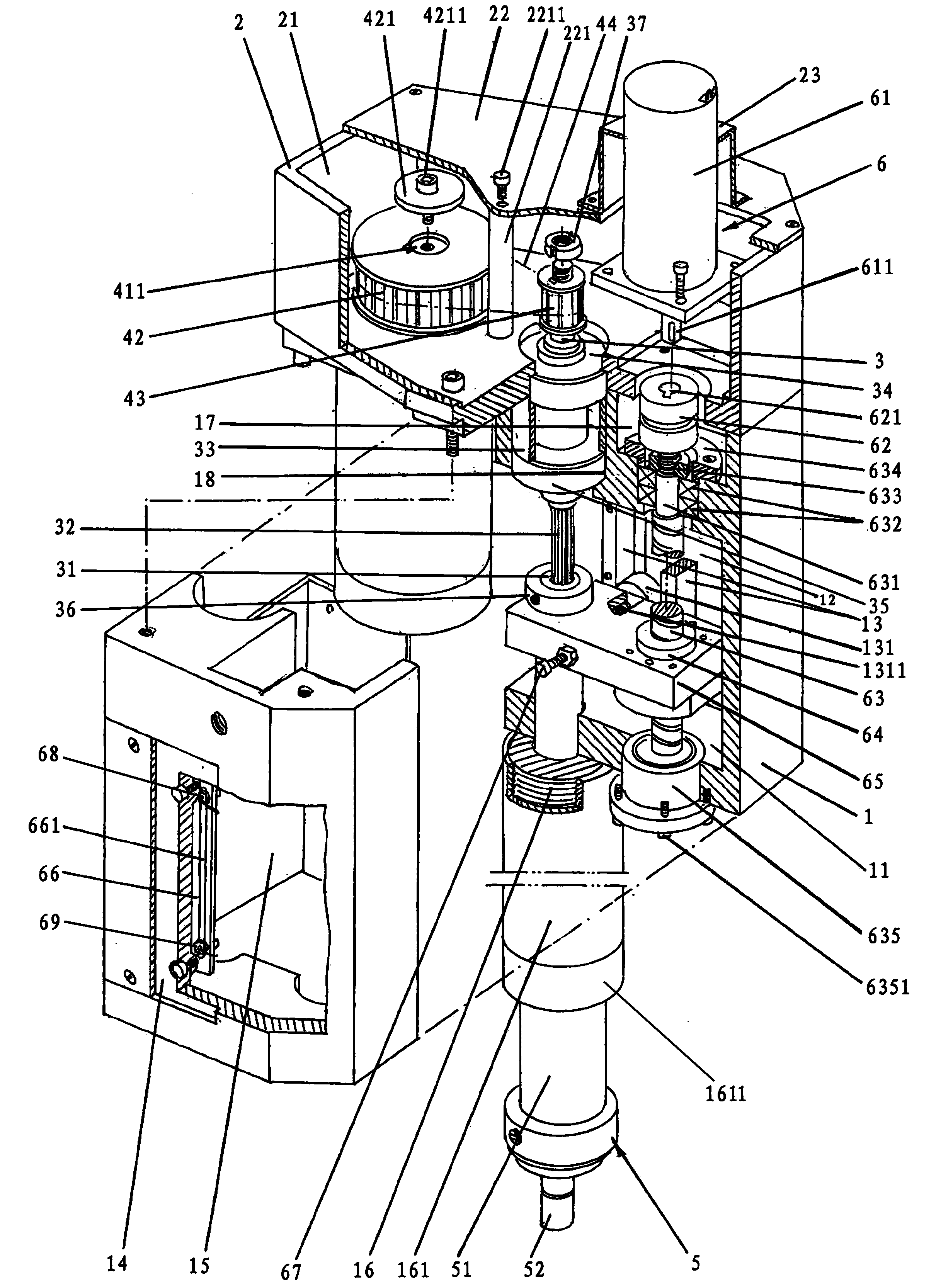

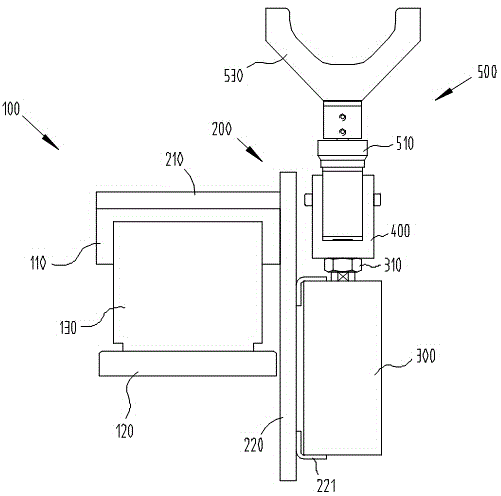

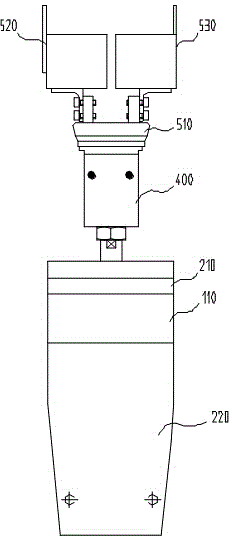

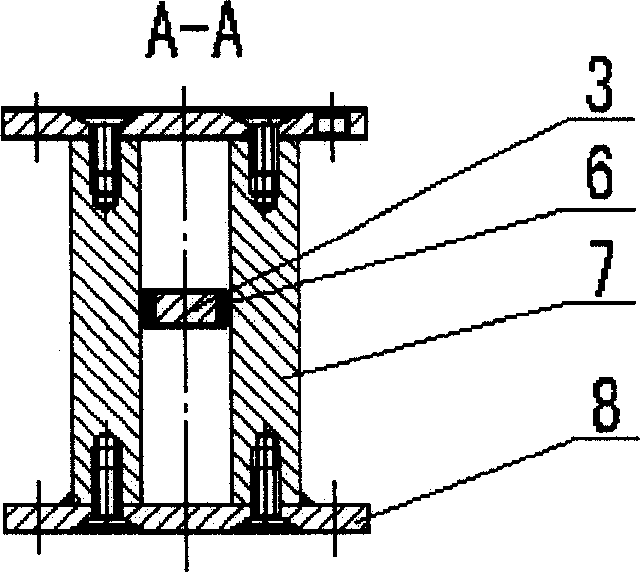

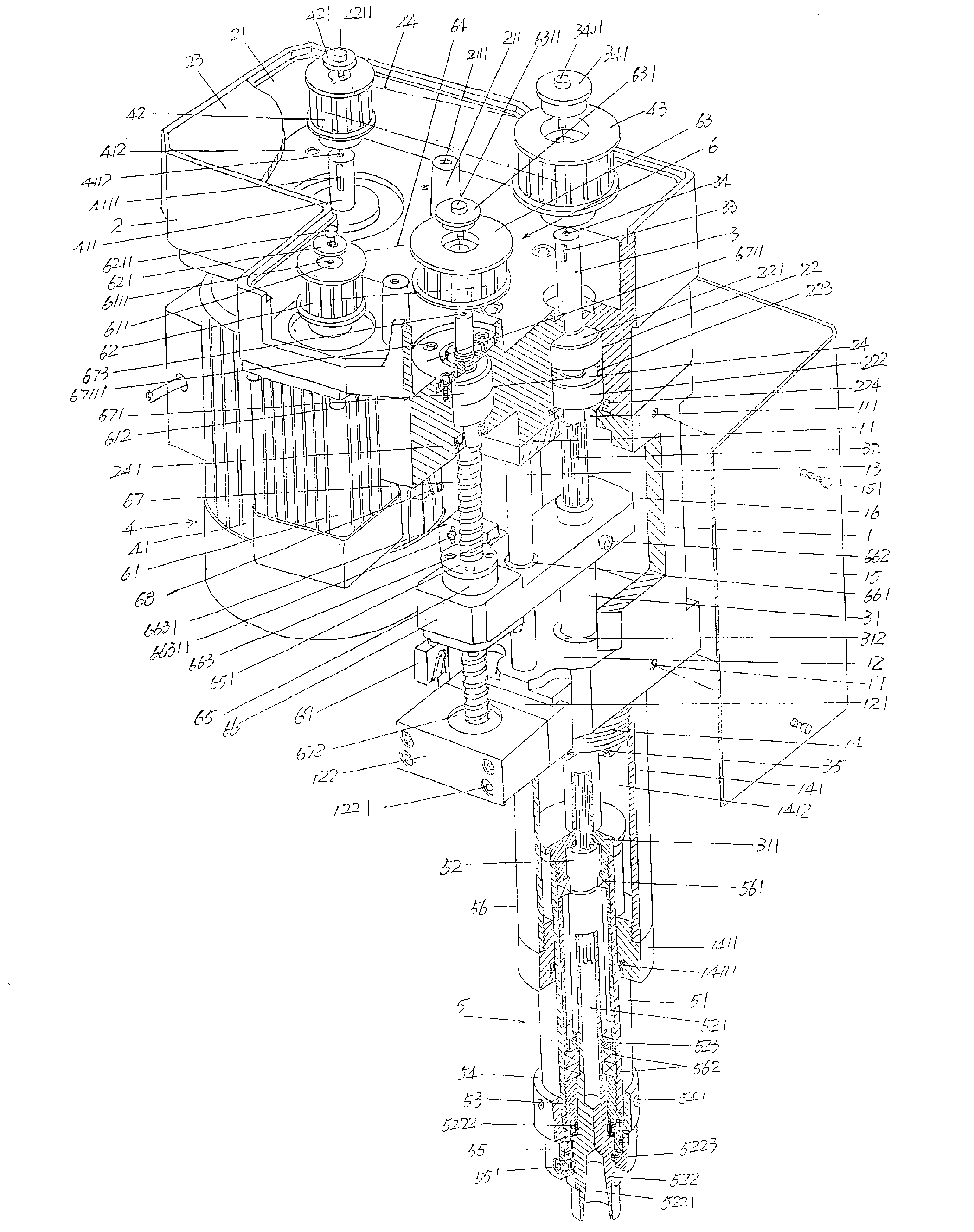

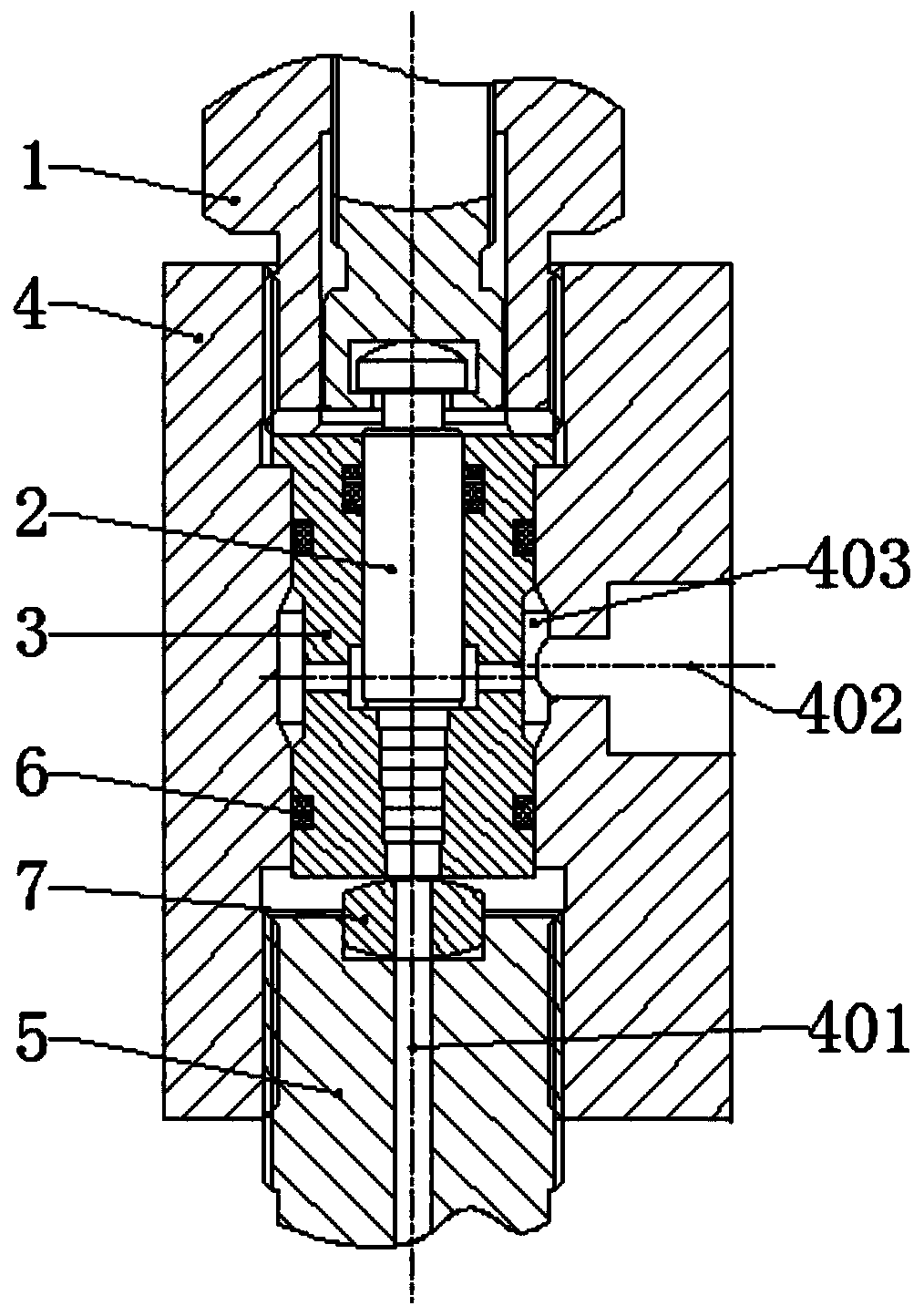

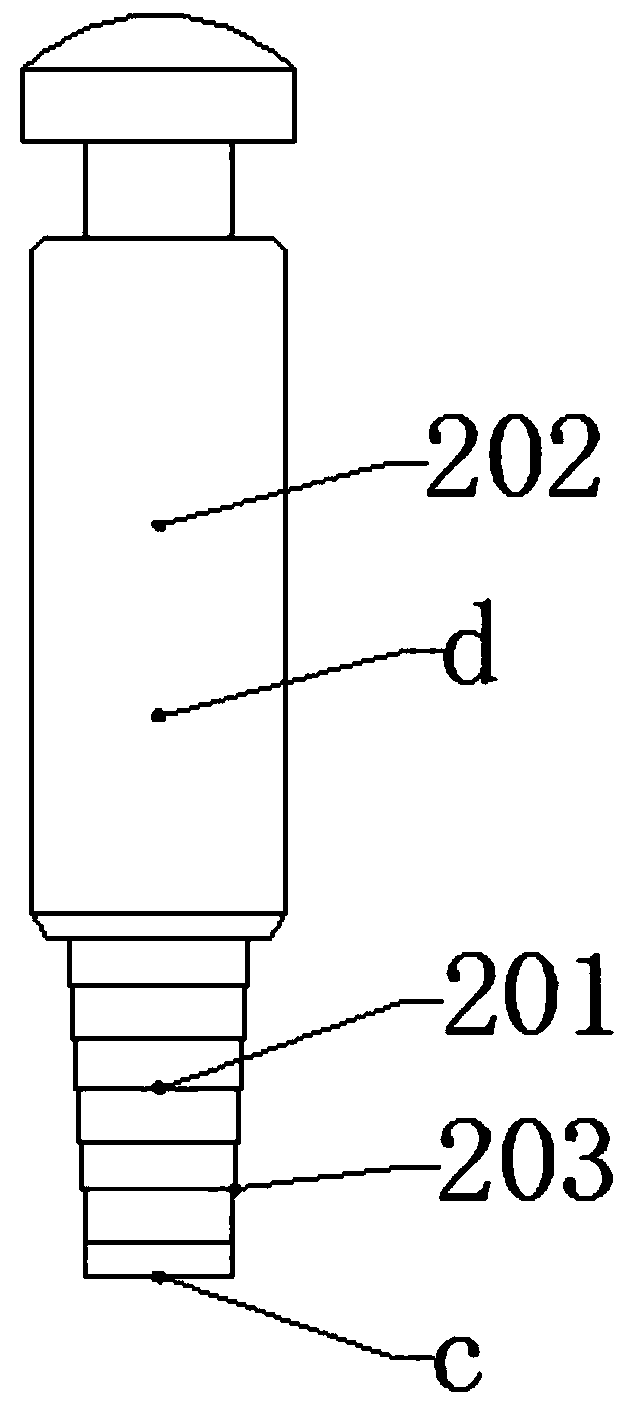

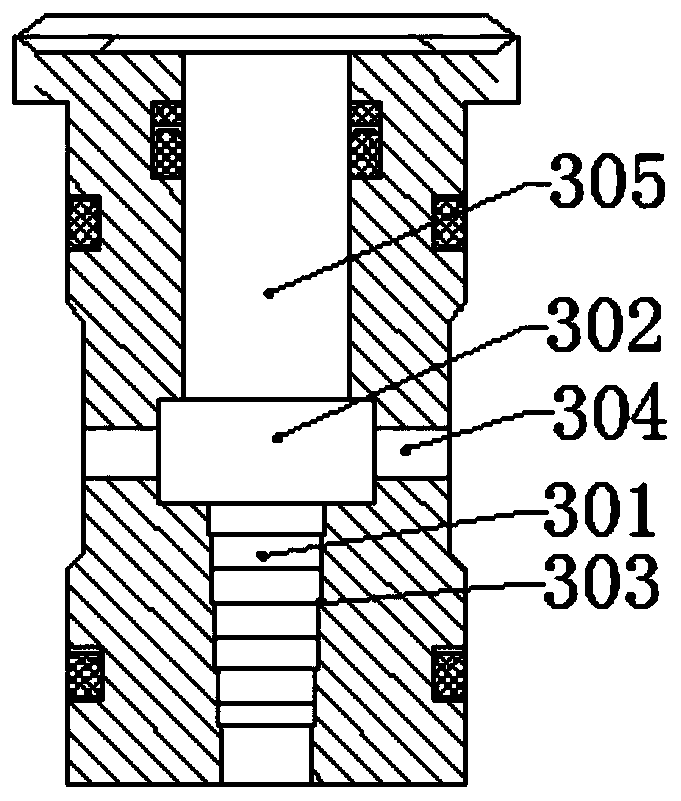

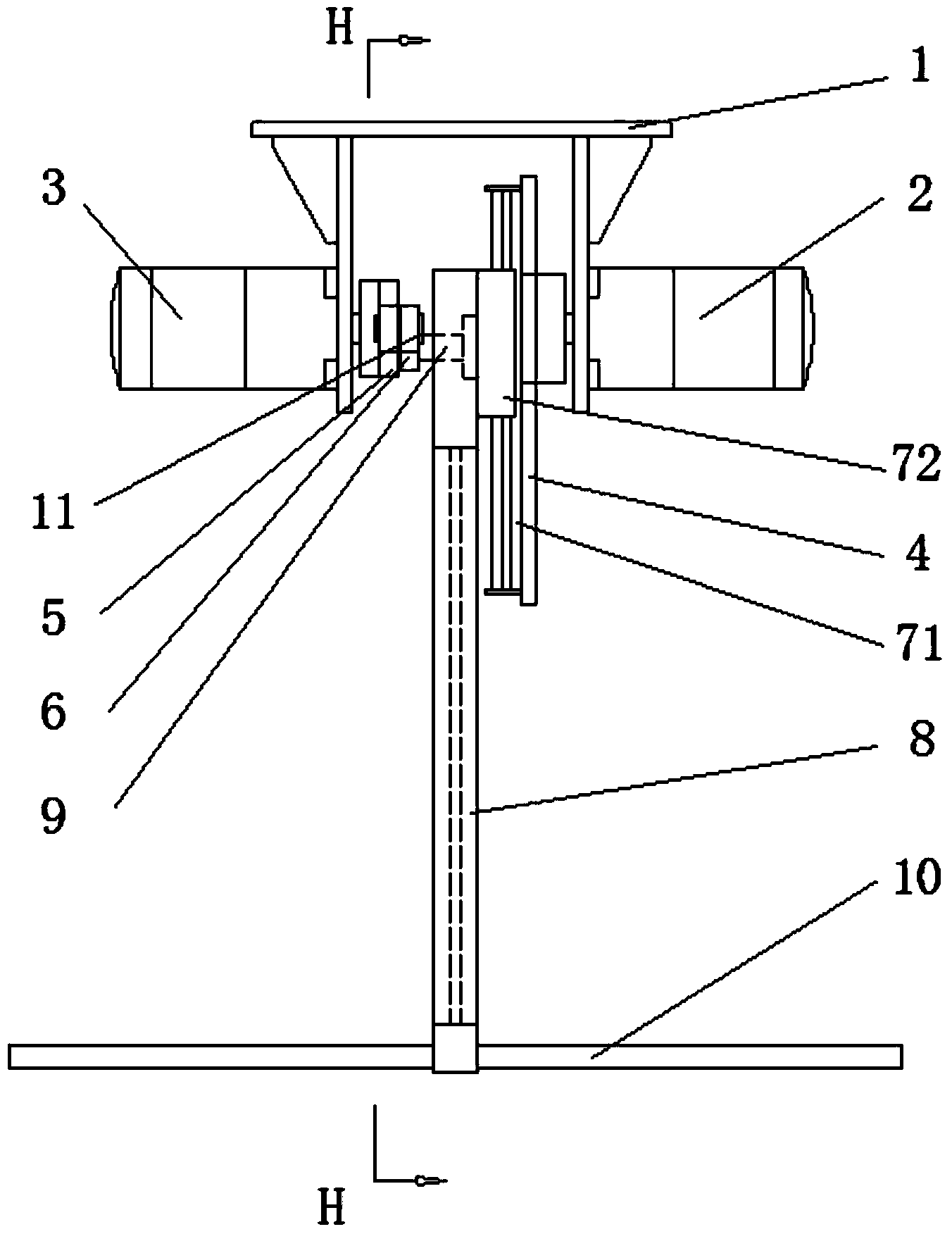

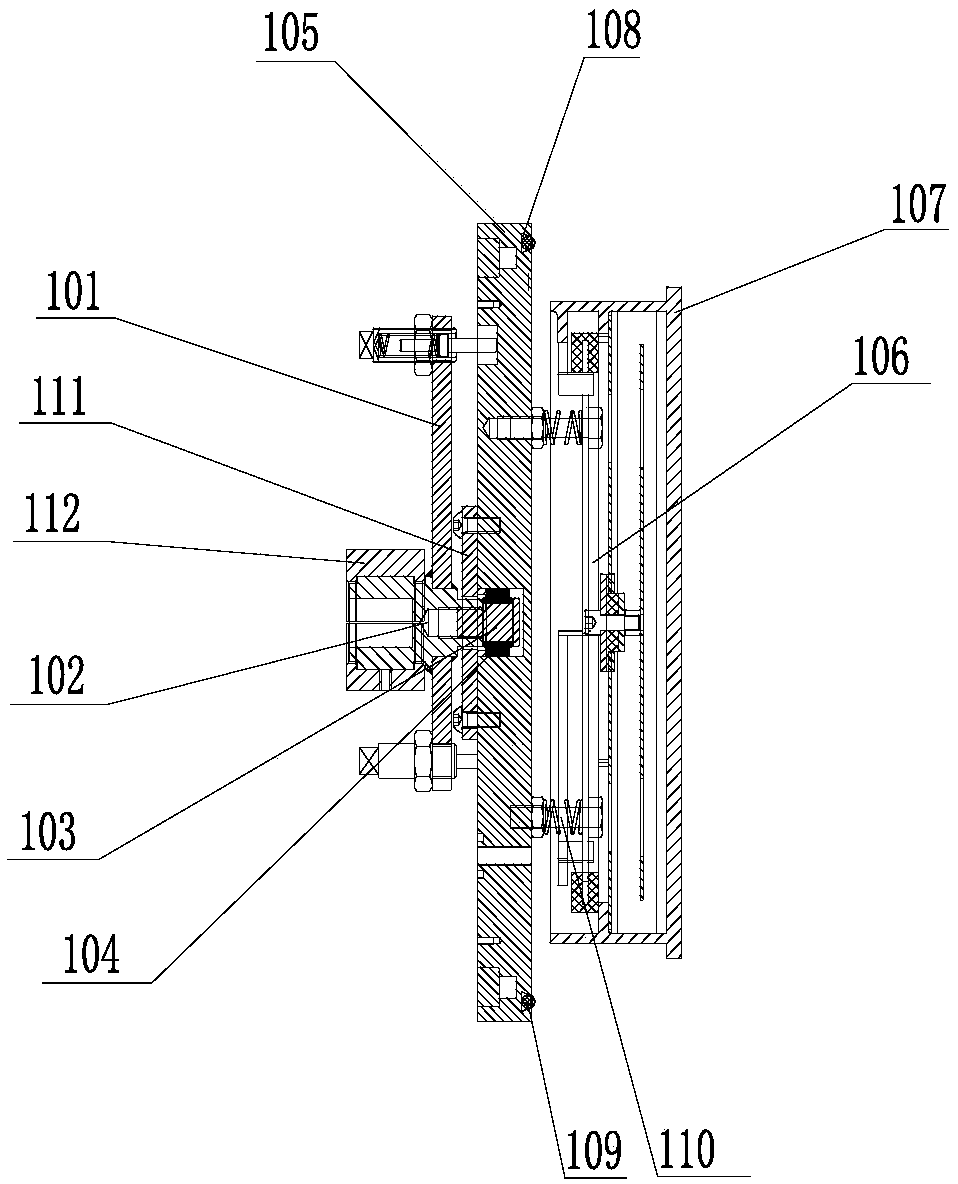

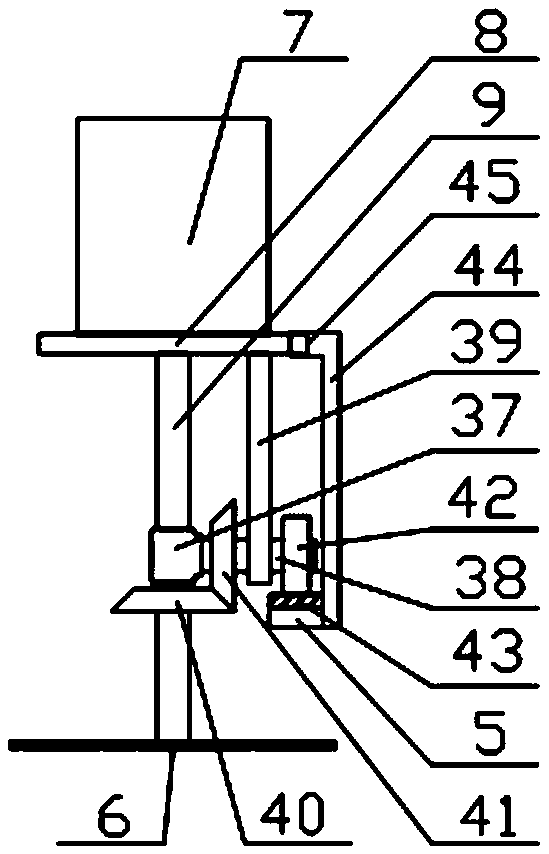

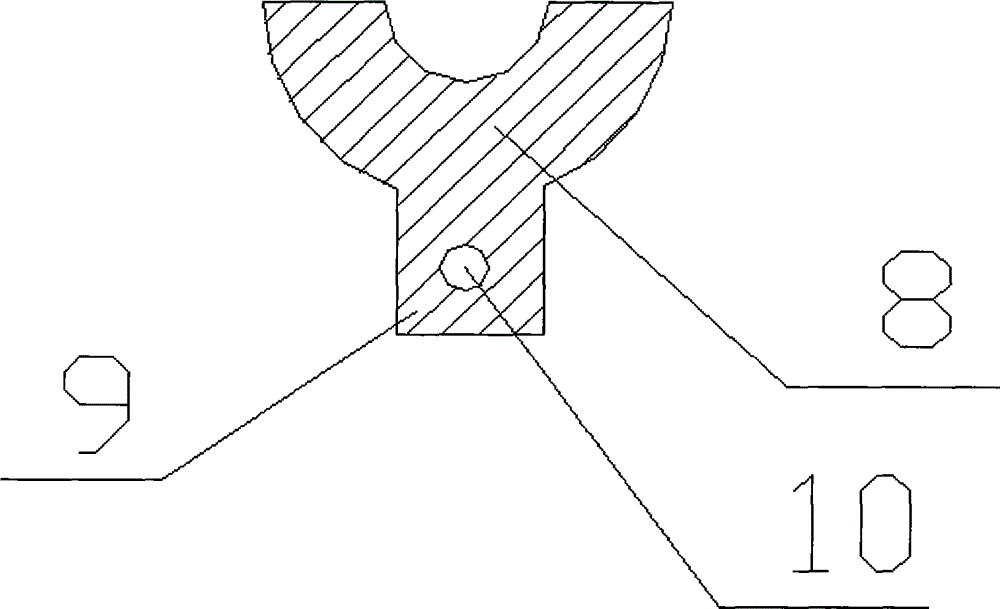

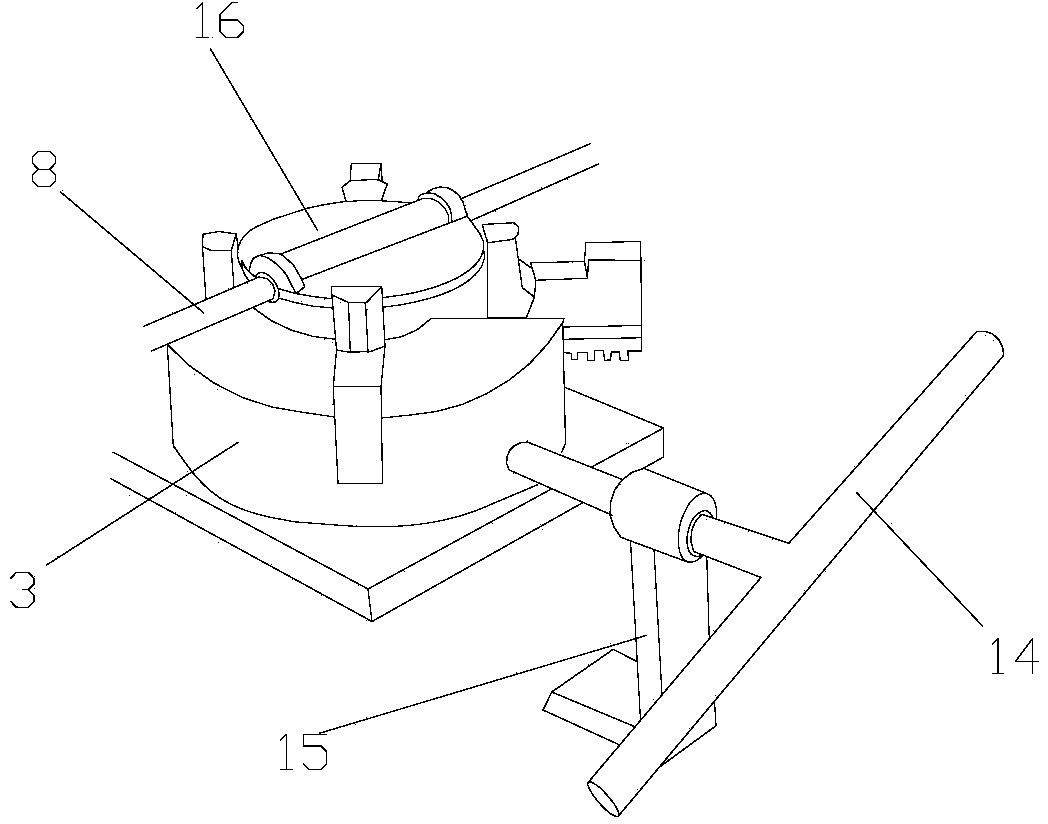

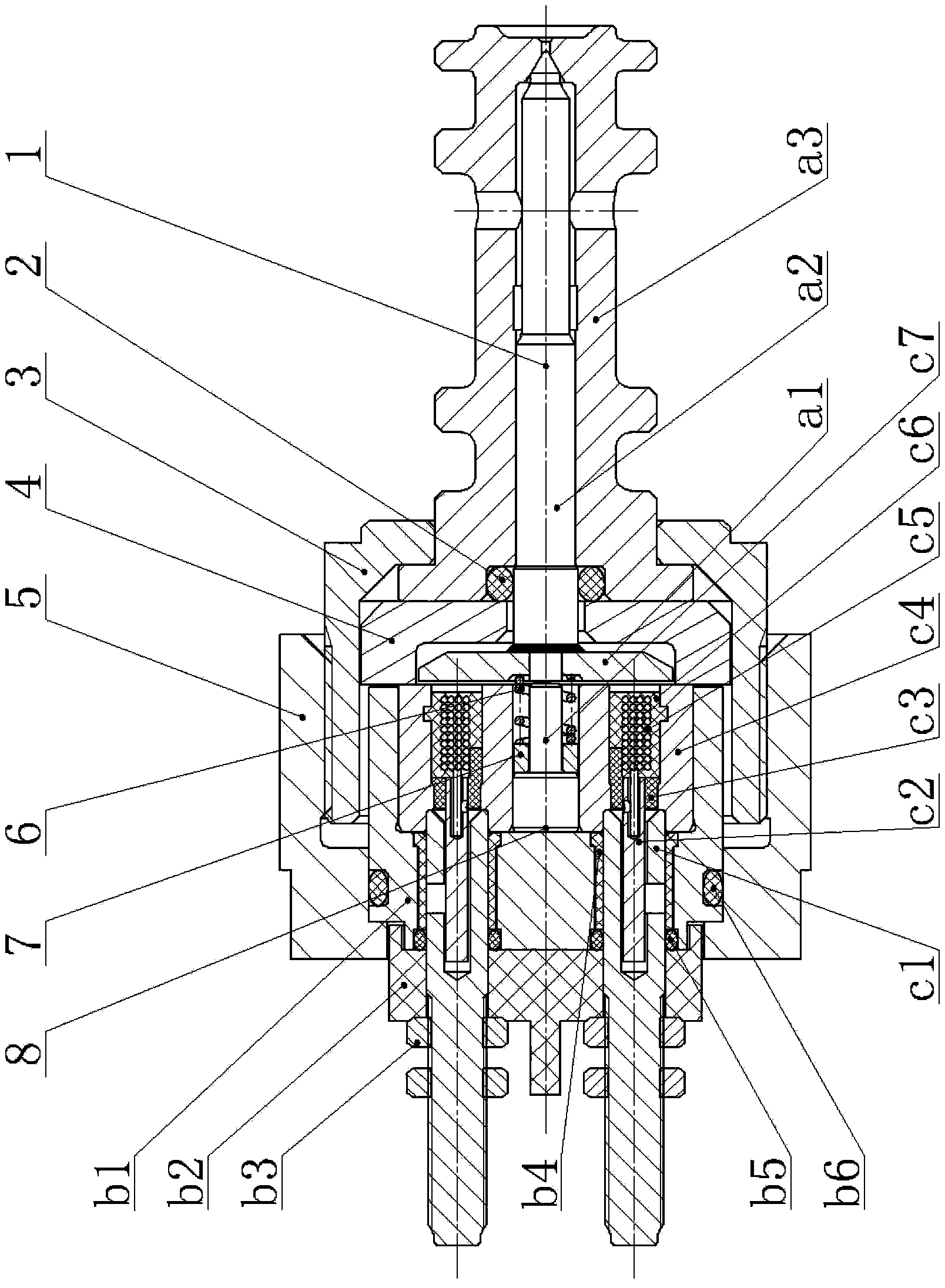

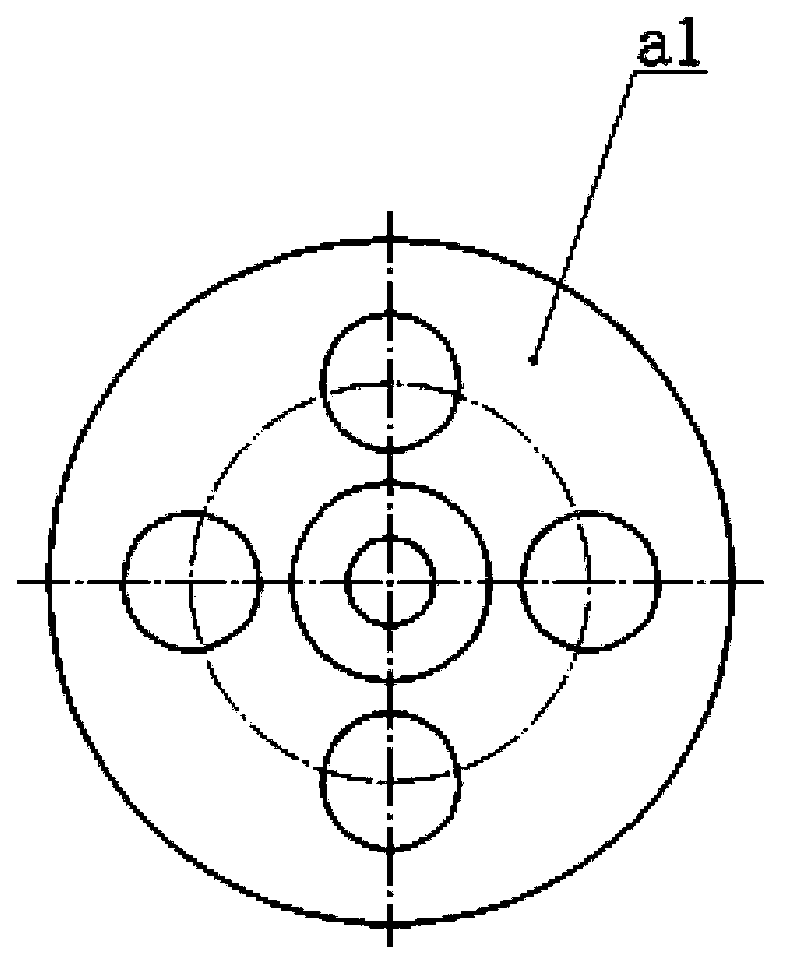

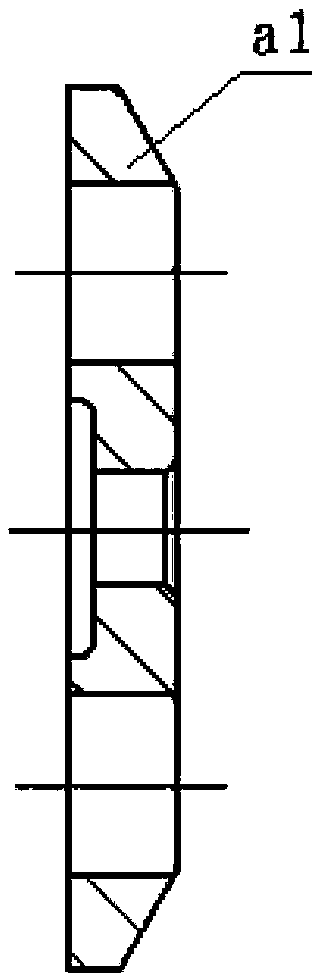

Multi-functional spindle mechanism used for small deep holes electrical discharge machining

InactiveCN103769705AImproved electrode feed stiffness and spindle servo stabilityImproved dimensional accuracy and aspect ratioElectrical-based auxillary apparatusGas turbinesEngineering

The invention discloses a multi-functional spindle mechanism used for the small deep holes electrical discharge machining, belonging to the technical field of micro non-traditional machining. The multi-functional spindle mechanism comprises a rotating spindle mechanism, a transmission mechanism, a normally closed clamp mechanism, a sealing mechanism, an electric brush mechanism, a wire replacing mechanism, a normally opened clamp mechanism, a guide mechanism and a connecting mechanism, wherein the rotating spindle mechanism, the transmission mechanism, the normally closed clamp mechanism, the sealing mechanism, the electric brush mechanism and the wire replacing mechanism are fixedly mounted on an upper mounting plate, and the normally opened clamp mechanism is mounted on a lower mounting plate; the upper mounting plate is connected to the lower mounting plate through the guide mechanism and a degree of freedom of relative movement in the z direction is kept; the upper mounting plate is connected to a z-axis top plate through the connecting mechanism, and the lower mounting plate is connected to a z-axis bottom plate through the connecting mechanism. The mechanism processes the film cooling group holes in the hot components of the aero-engines and the gas turbines, which can realize multiple functions of the forward pushing creep feed, the high precision rotation and the hollow high pressure flushing of the tool electrodes, and the on-line replacement of the electrodes.

Owner:TSINGHUA UNIV

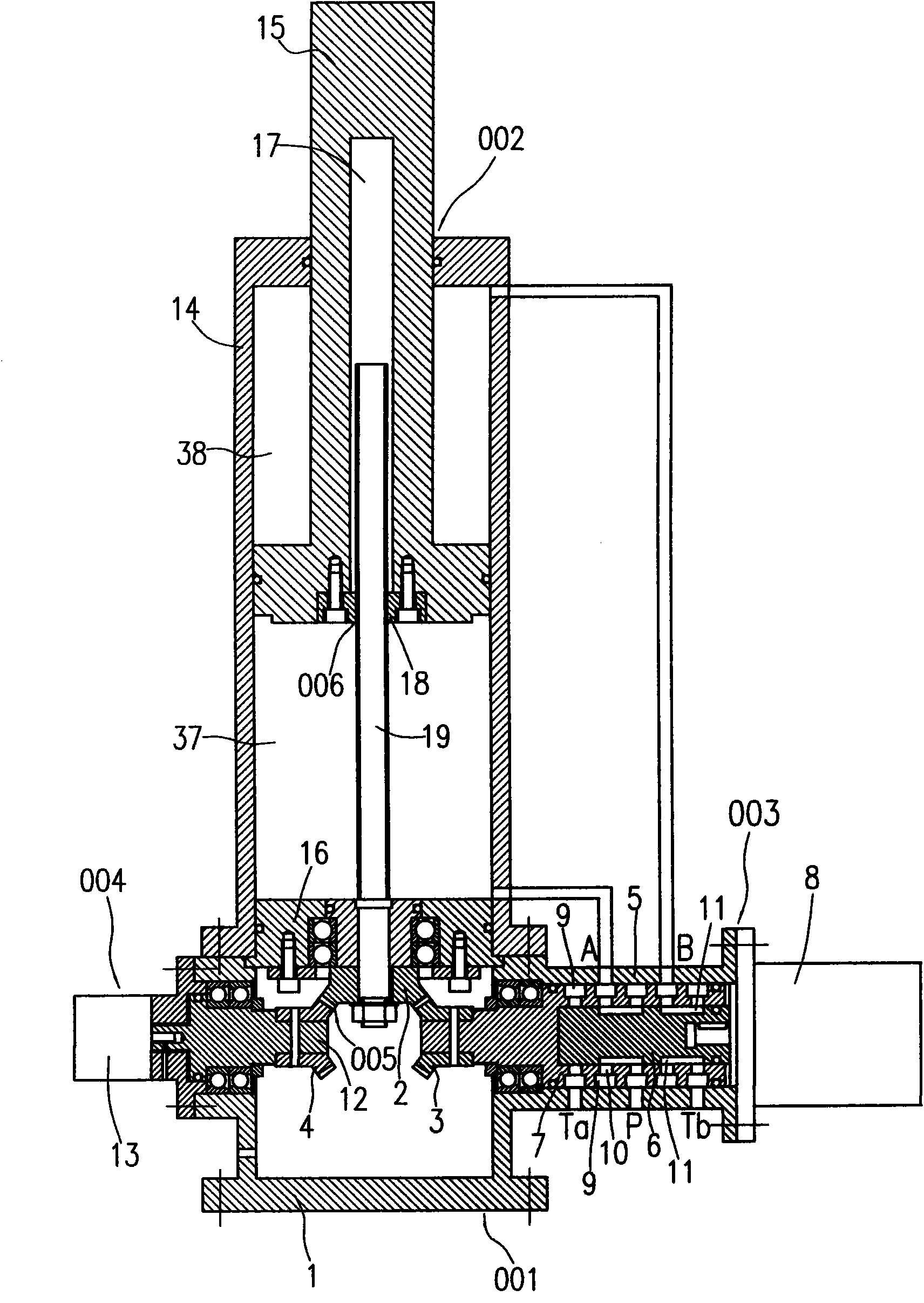

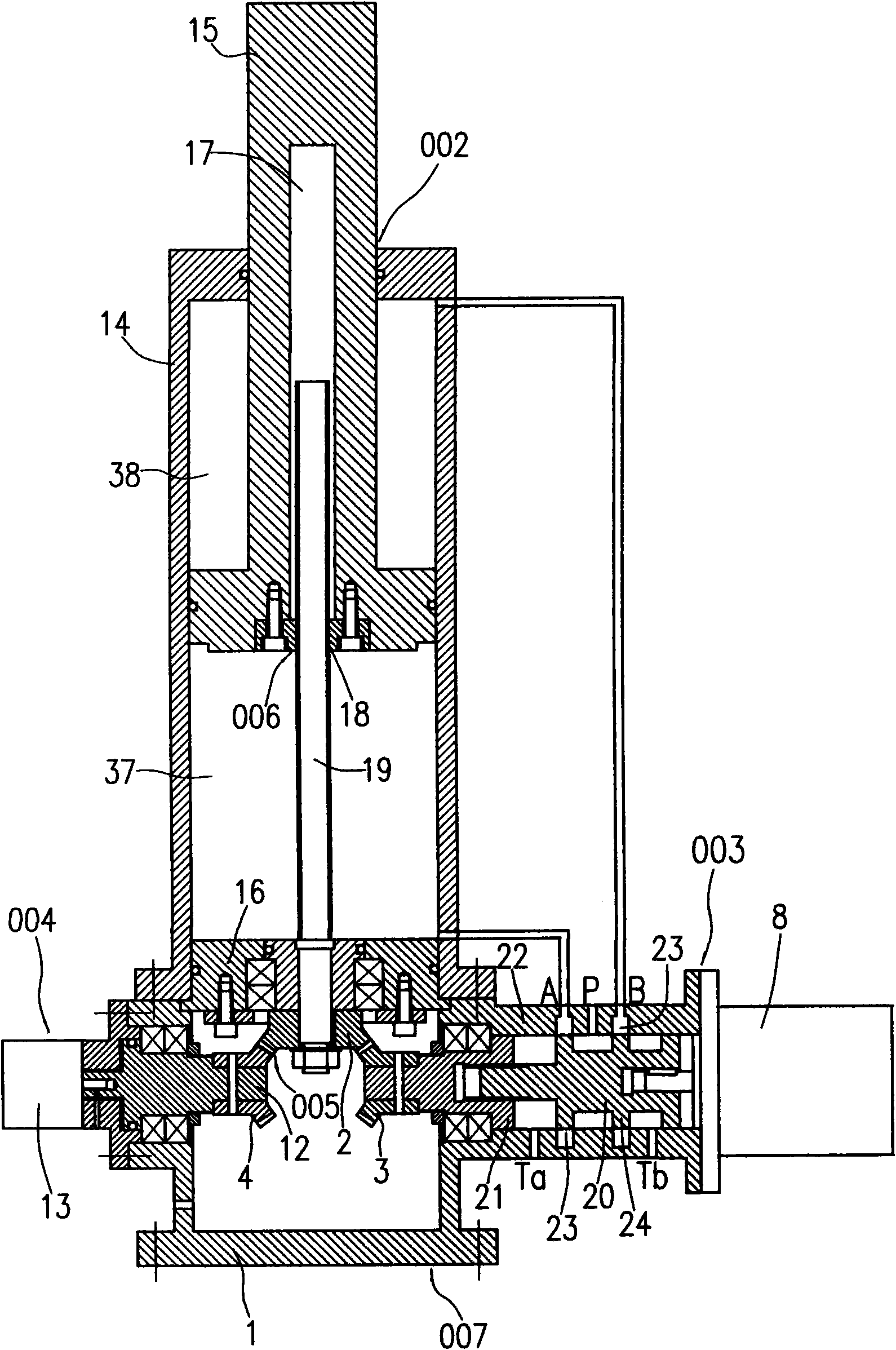

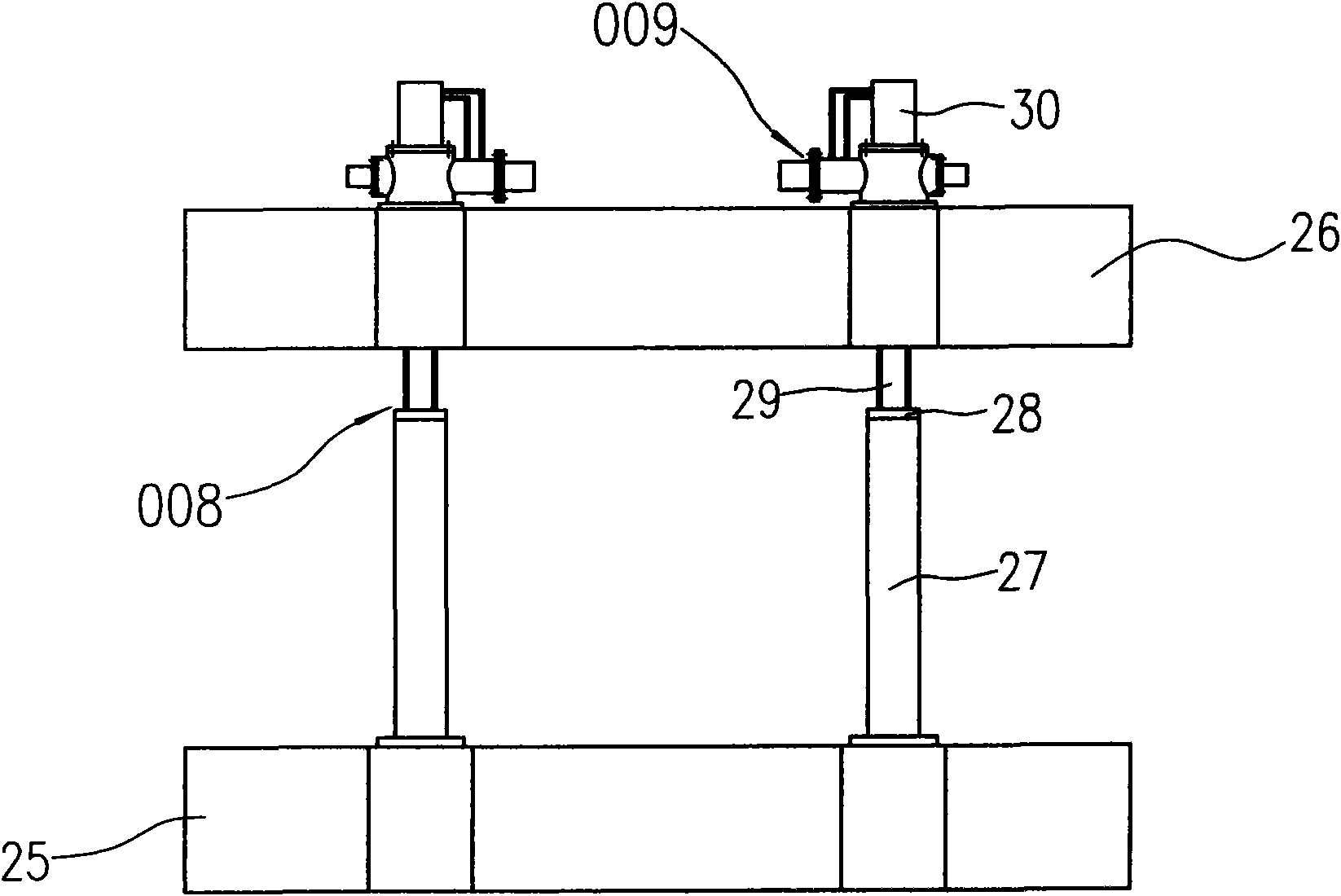

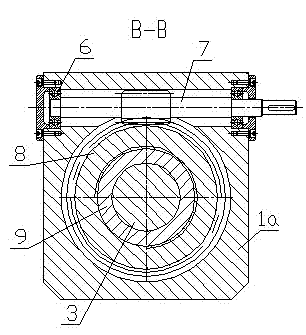

Servo hydraulic transmission mechanism

InactiveCN101839258AAvoid hidden dangers of mechanical failureVersatileServomotor componentsFiltration separationAutomatic controlControl function

Conventional pressure filters generally adopt hydraulic cylinder-driven opening / closing compression mechanisms, and have numerous disadvantages of unreliable multi-cylinder synchronous operation, bad control sensitivity and precision, and the like. The invention proposes an opening / closing compression mechanism driven by a hydraulic cylinder comprising a servo hydraulic valve or by a hydraulic motor in order to realize digital control over position, stroke, speed, pressure and other motion variables and adapt to the work characteristics and need of pressure filters better. The servo hydraulic valve has a hydraulic control valve controlled by a stepping motor, a position sensor and a pressure sensor, and is combined with the hydraulic cylinder or the hydraulic motor as a whole. The mechanism has the advantages of perfect control function, improved sensitivity, precision, work stability and reliability and use convenience. In addition, as a hydraulic system, a motion control system and an electric automatic control system are simplified and less in components, the servo hydraulic transmission mechanism is advanced, reasonable, economical and applicable.

Owner:宋家骏

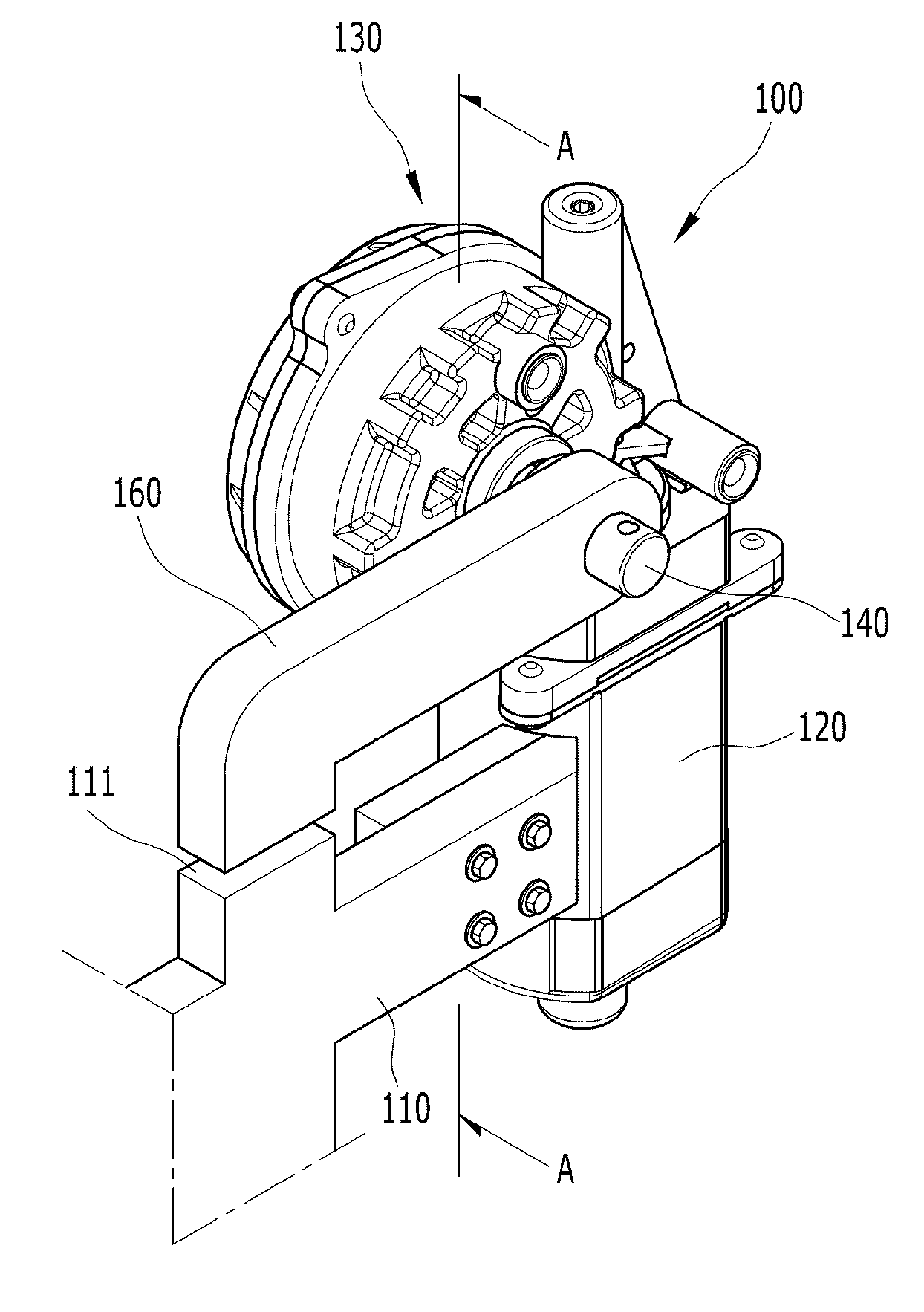

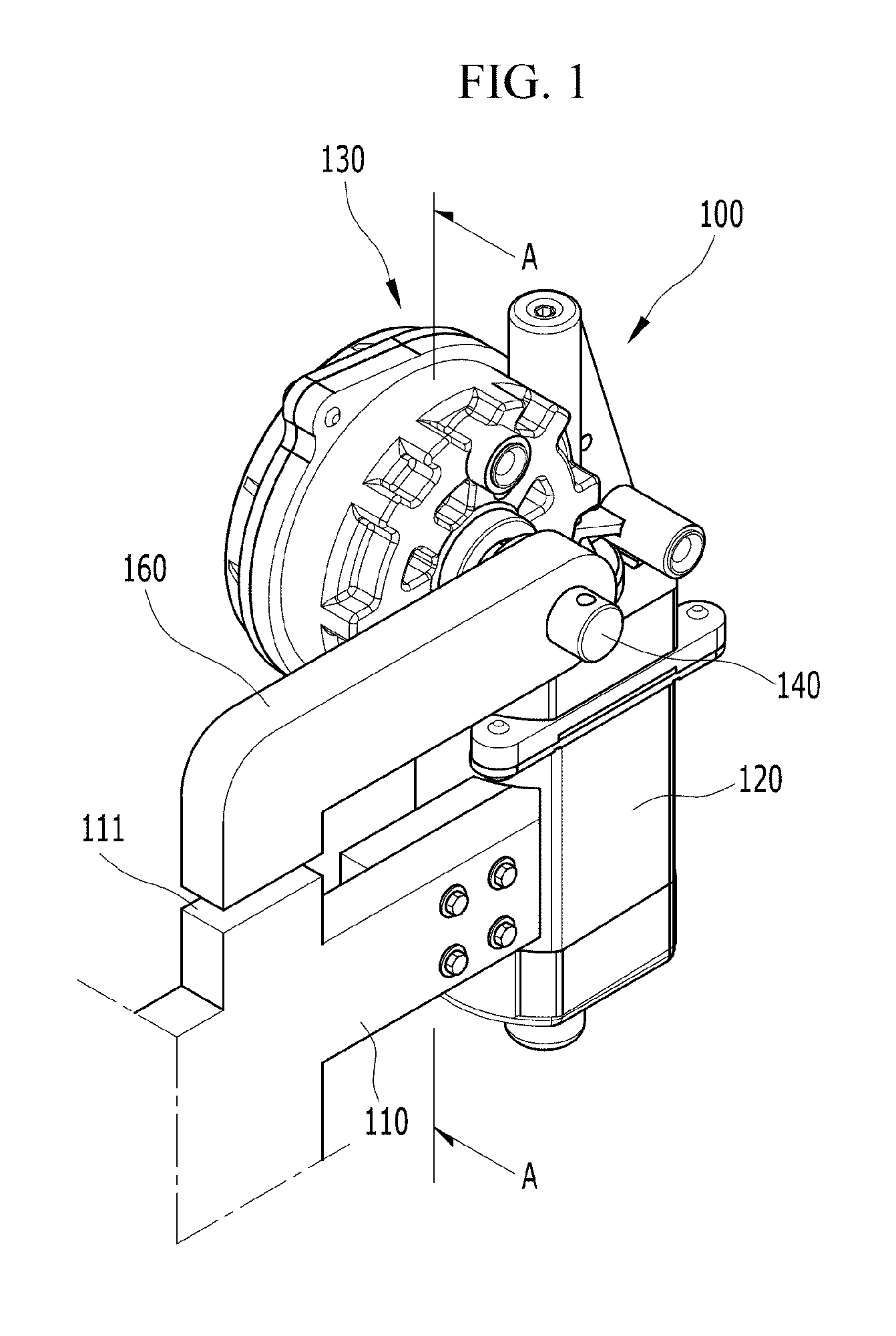

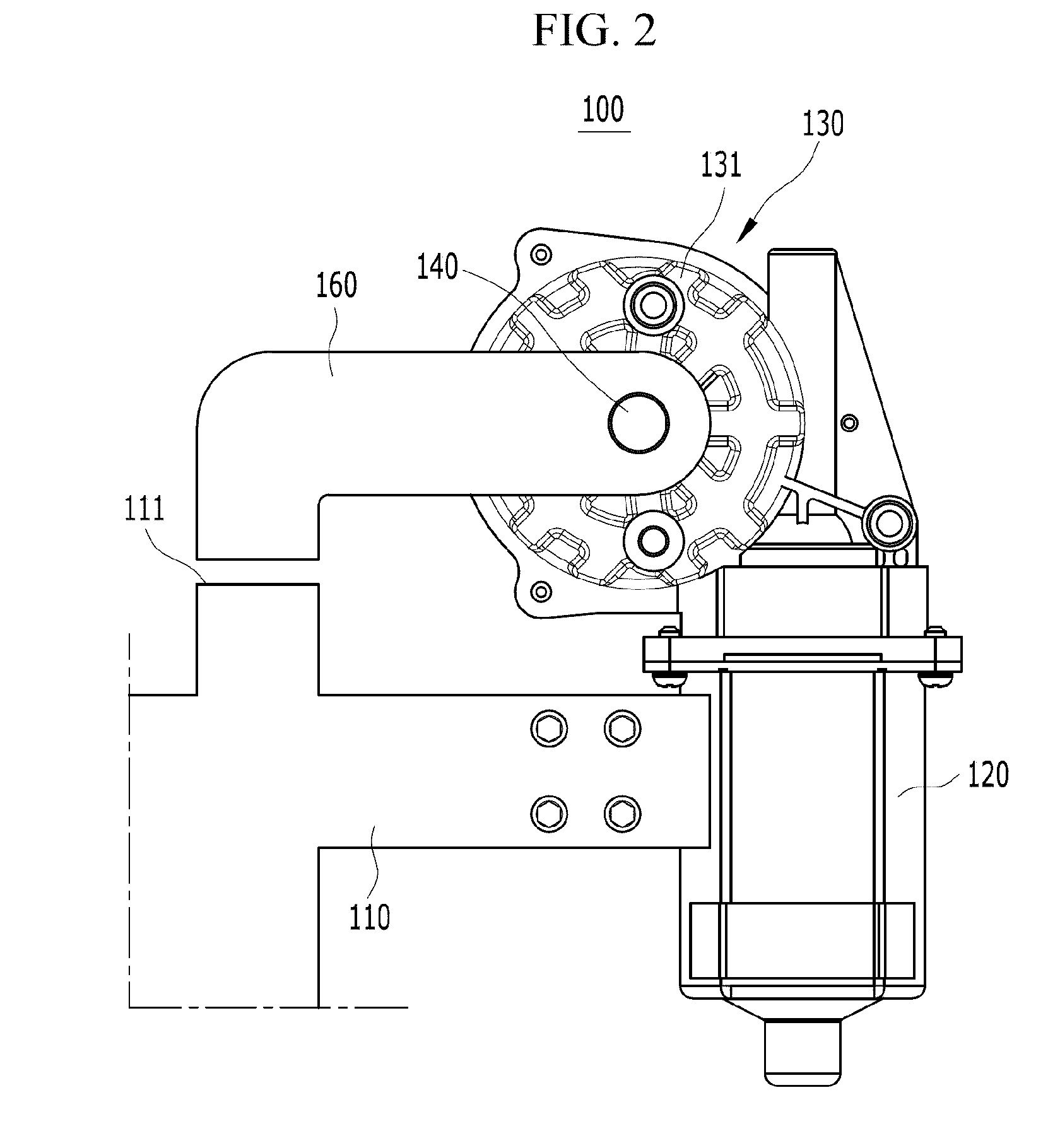

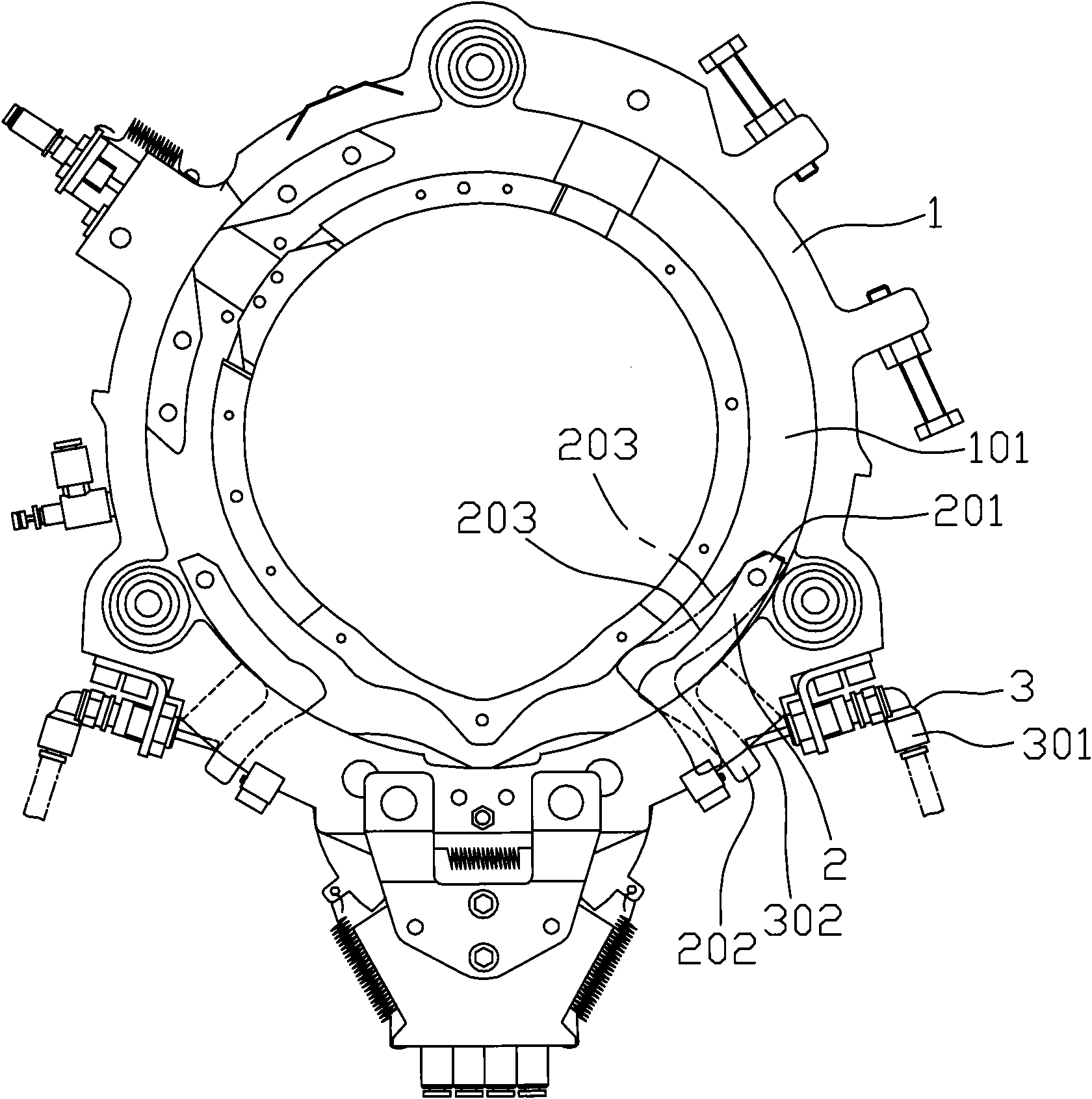

Clamping device

InactiveUS20120146275A1Manufacturing cost be reduceReduce weightVicesClampsElectric machineryDrive motor

Disclosed is a clamping device which reduces the overall size typical clamping devices used for similar operations by implementing a motor as a driving source and maintaining a clamping force applied to a panel constantly through accurate stroke control by incorporating a worm gear. More specifically, the clamping device includes a locator on which a panel is seated and a driving motor incorporated into a portion of the locator. A gear box rotates a rotation rod by receiving a rotational force from the driving motor and a clamper connected with the rotation rod, clamps the panel seated on the locator.

Owner:HYUNDAI MOTOR CO LTD

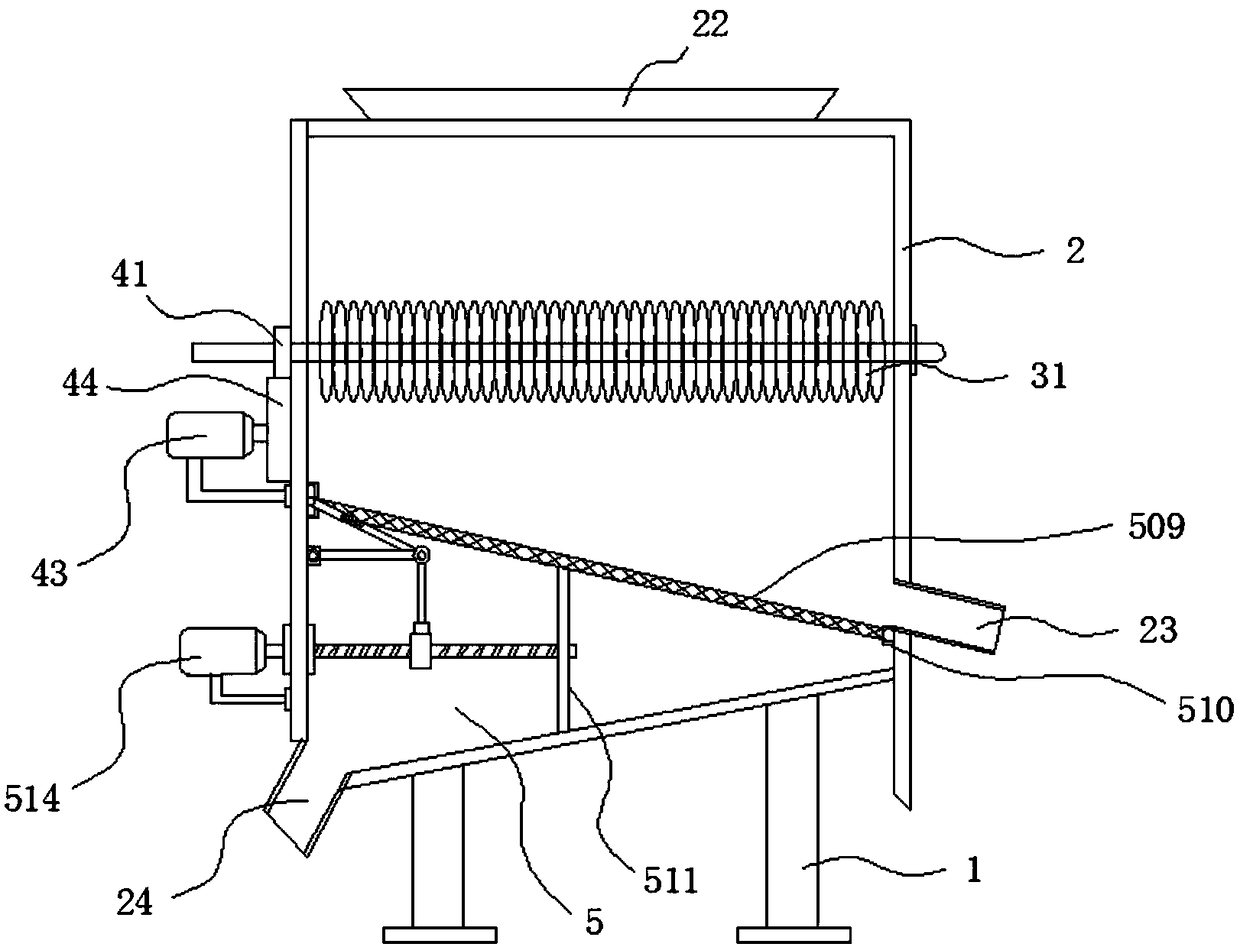

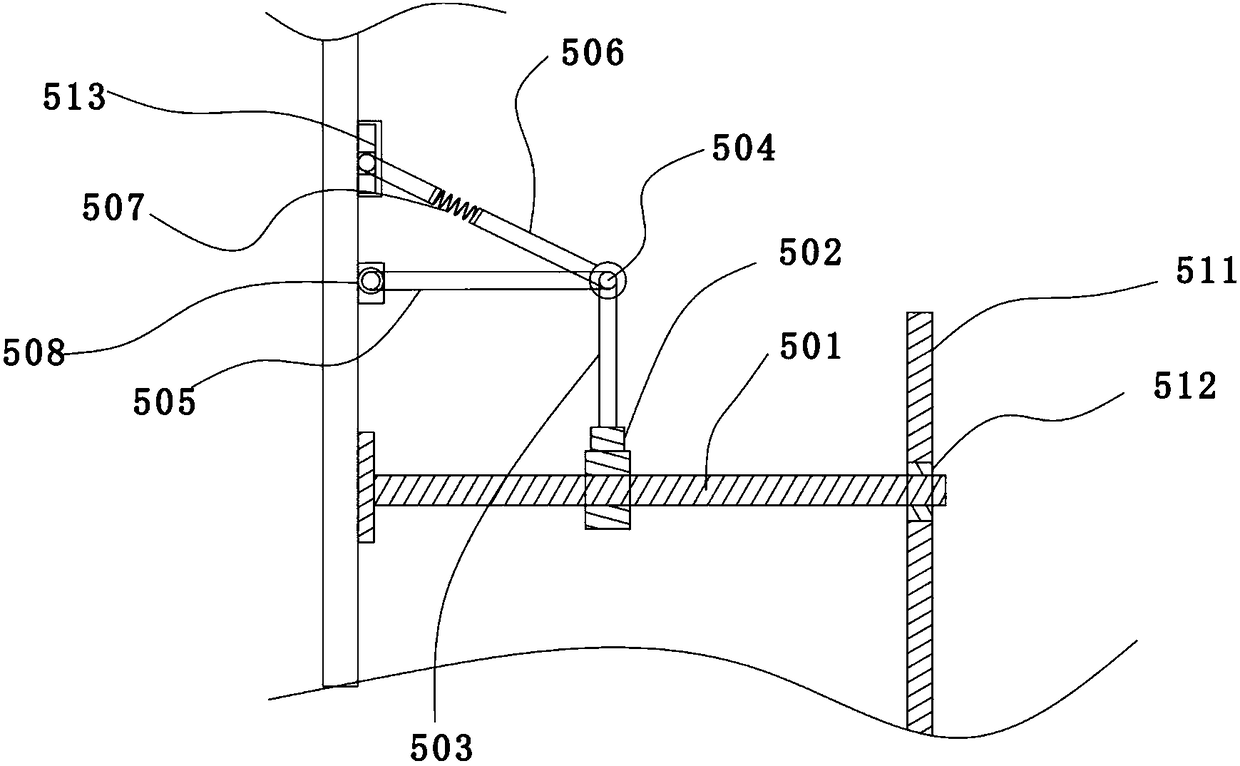

Automobile steel plate fine shearing automatic production device

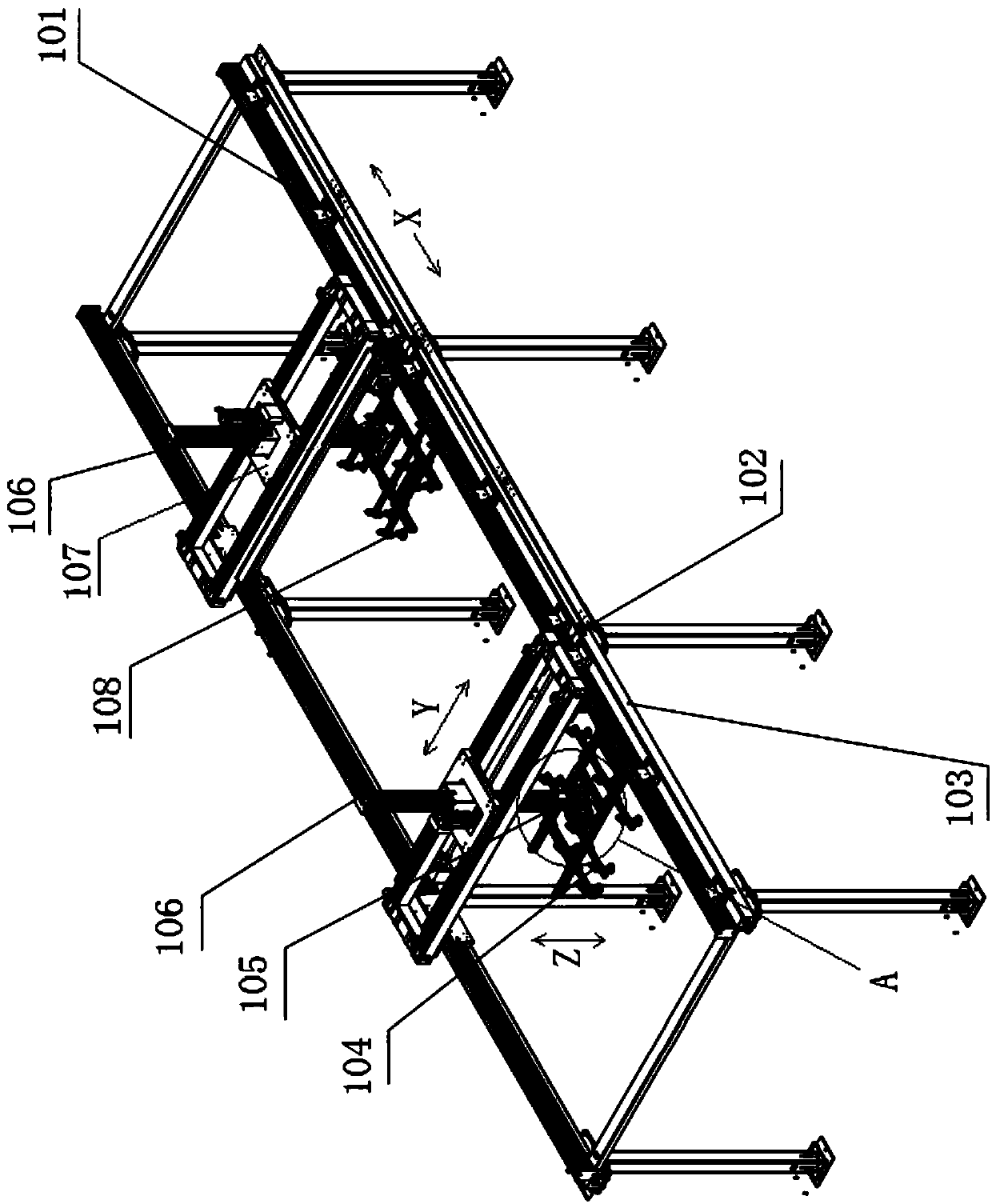

ActiveCN109692992AAchieve cutGuaranteed bevel cutShearing machinesStacking articlesSheet steelDegrees of freedom

The invention relates to the field of automobile steel plate processing, and specifically relates to an automobile steel plate fine shearing automatic production device. The device includes a loadingand unloading mechanism, a feeding mechanism, a fine plate-shearing machine, a transmission mechanism, a palletizing mechanism and ground rail electric translation vehicles; the loading and unloadingmechanism includes a support rack body and two sucker driving mechanisms; one sucker driving mechanism is provided with a loading sucker assembly having X, Y and Z degrees of freedom and freedom of rotation, and the other sucker driving mechanism is provided with an unloading sucker assembly having X, Y and Z degrees of freedom; the feeding mechanism is arranged at the middle part on the lower side of the support rack body; the ground rail electric translation vehicles are respectively arranged on the two sides of the feeding mechanism; the feeding mechanism is provided with feeding clamps; aplate is driven to move to the fine plate-shearing machine along the Y direction through the clamping of the feeding clamps; and the side, away from the feeding mechanism, of the fine plate-shearing machine is successively provided with the transmission mechanism and the palletizing mechanism. Thus, various steel plate shearing modes can be realized, and the precision and production efficiency ofautomobile steel plate shearing can be enhanced.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

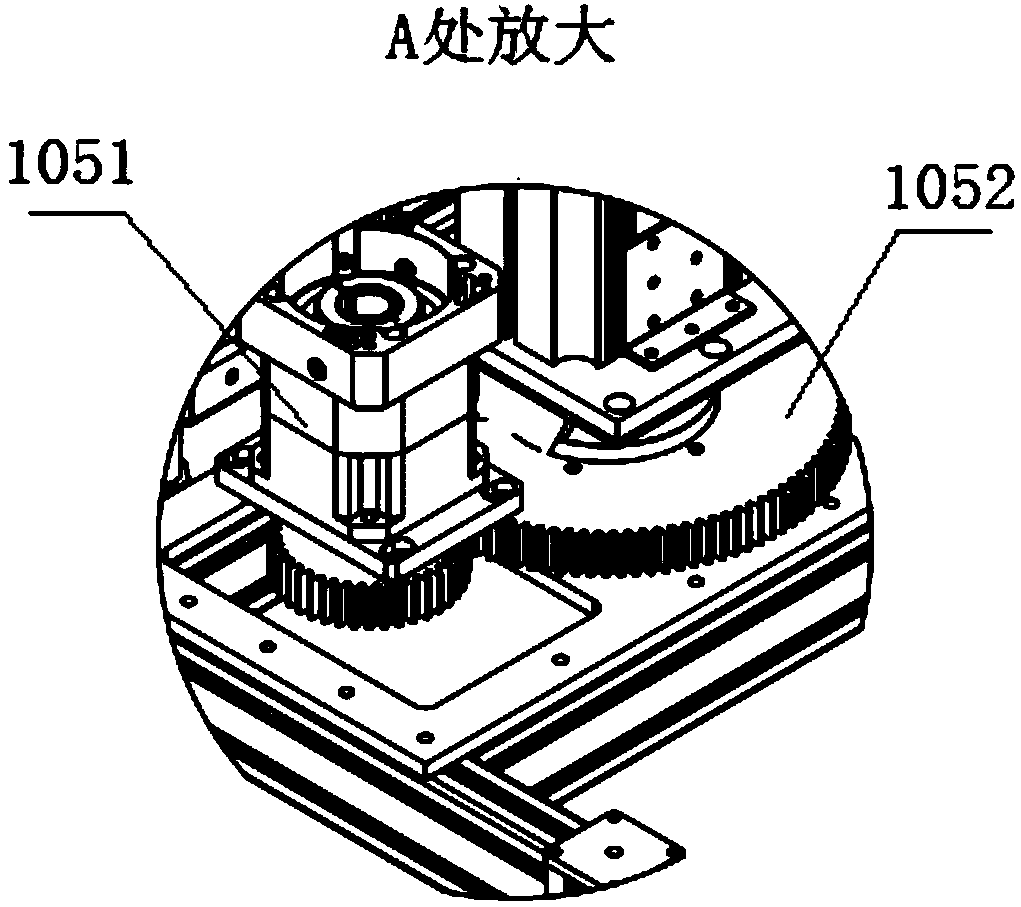

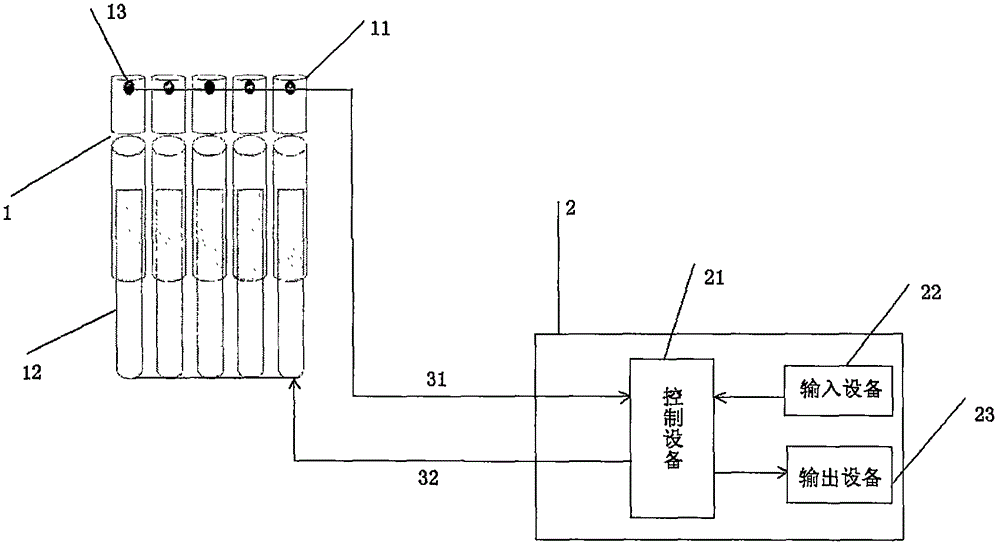

Intelligent bed system for computer control

The invention provides an intelligent bed system for computer control. The system comprises a massage bed, and a computer for control over the massage bed. The intelligent bed system for computer control has following beneficial effects: movable rods that are needed to be moved and strokes thereof are determined by taking into consideration user's related data and selecting massage modes so that personalized massage can be achieved and the best massage effect is obtained; and in the meantime, waste of unnecessary power supplies is avoided by precisely controlling stroke of each movable rod during application.

Owner:张强

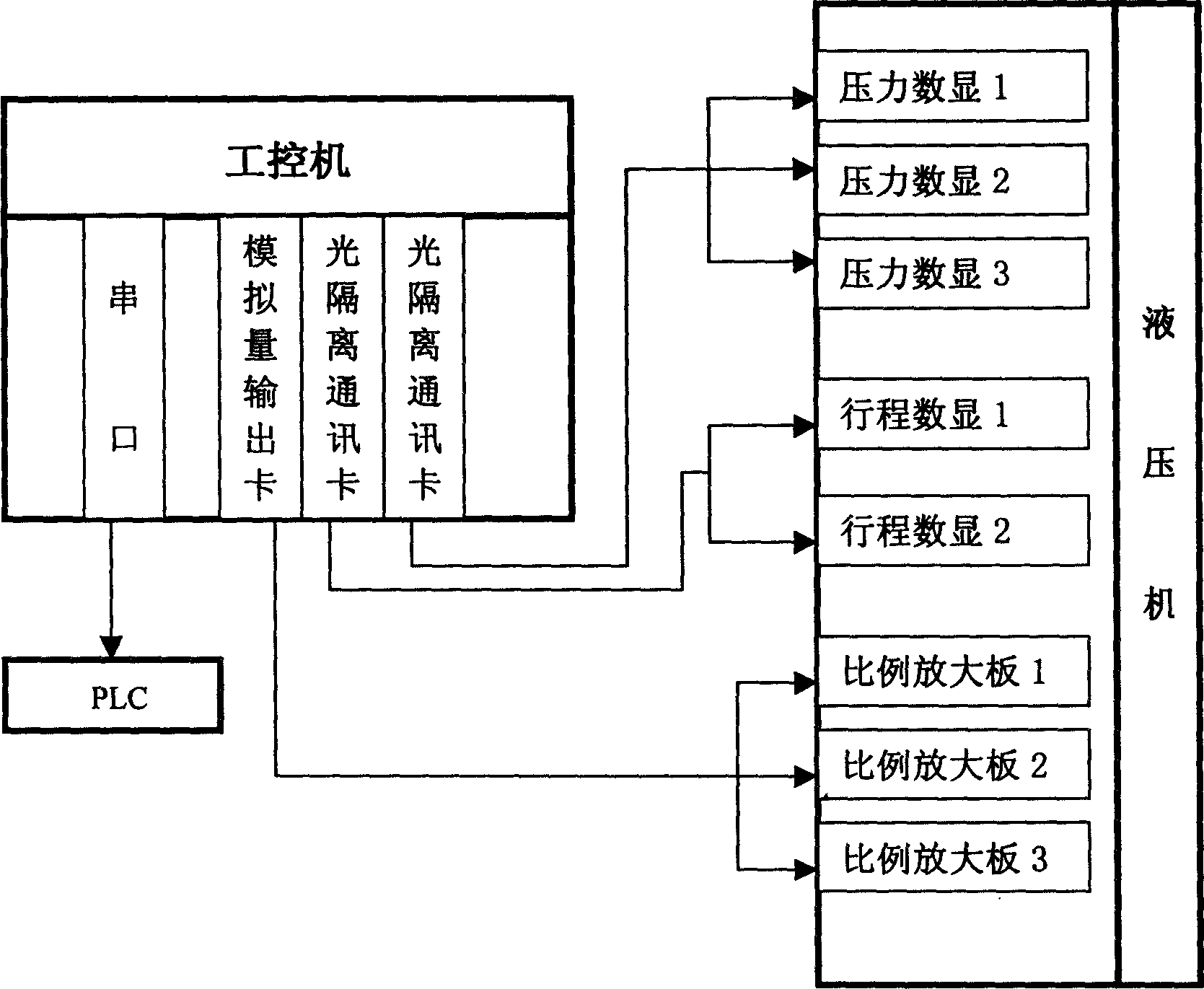

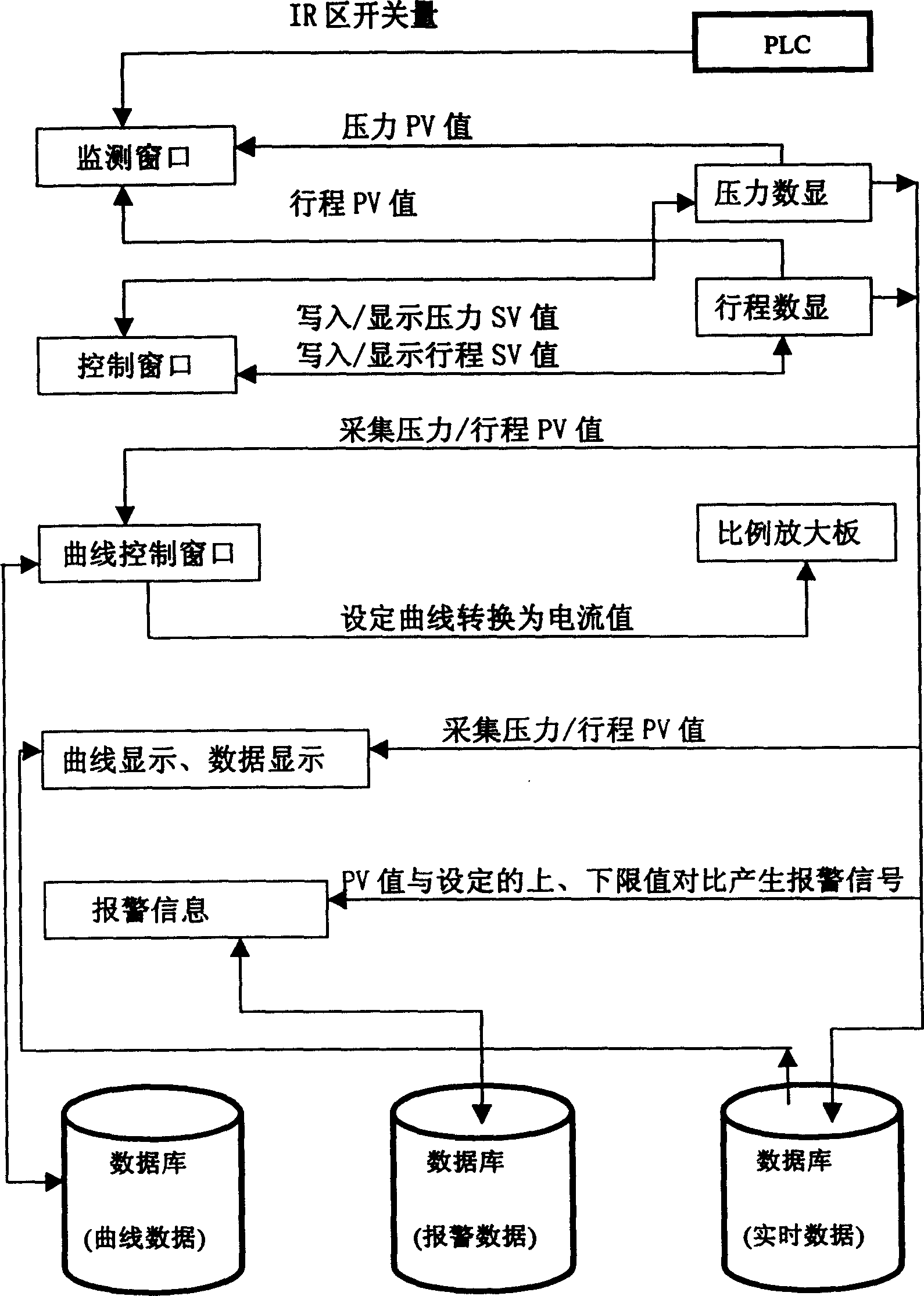

Monitoring system of metal extrusion hydraulic press

InactiveCN1621223APrecise speed controlAccurate stroke controlProgramme control in sequence/logic controllersPressesEngineeringDigital control

The present invention is the monitoring system for metal extruding hydraulic press and belongs to the field of hydraulic machinery technology. The monitoring system consists of industrial control computer, display terminal, controller, hydraulic press sensor and rotary coder. Structurally, the monitoring system features that the industrial control computer is connected with the display terminal and the programmable controller; and that the industrial control computer mainboard is provided with light isolated communication card connected with the digital display of pressure and the digital display of stroke and analog amount output card connected with proportional amplifier board for controlling the proportional variable pump of the hydraulic press. The present invention has stepless digital control of speed, stroke and pressure of hydraulic press, no PLC module and lowered production cost.

Owner:TIANJIN TIANDUAN PRESS CO LTD

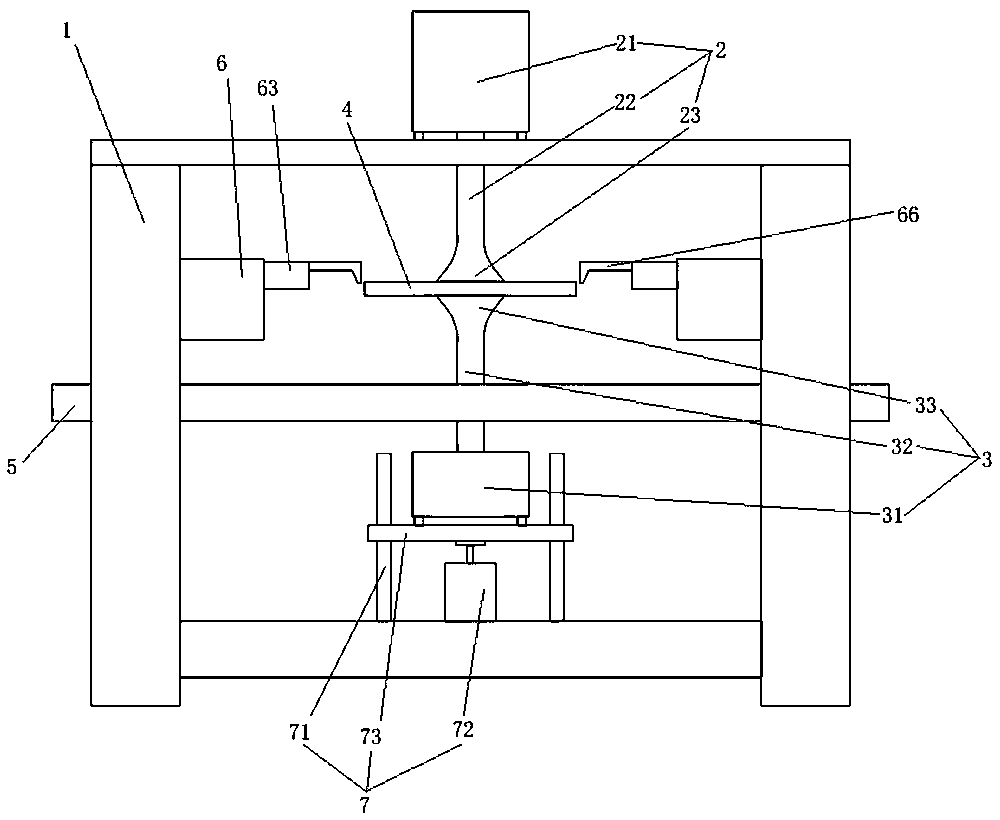

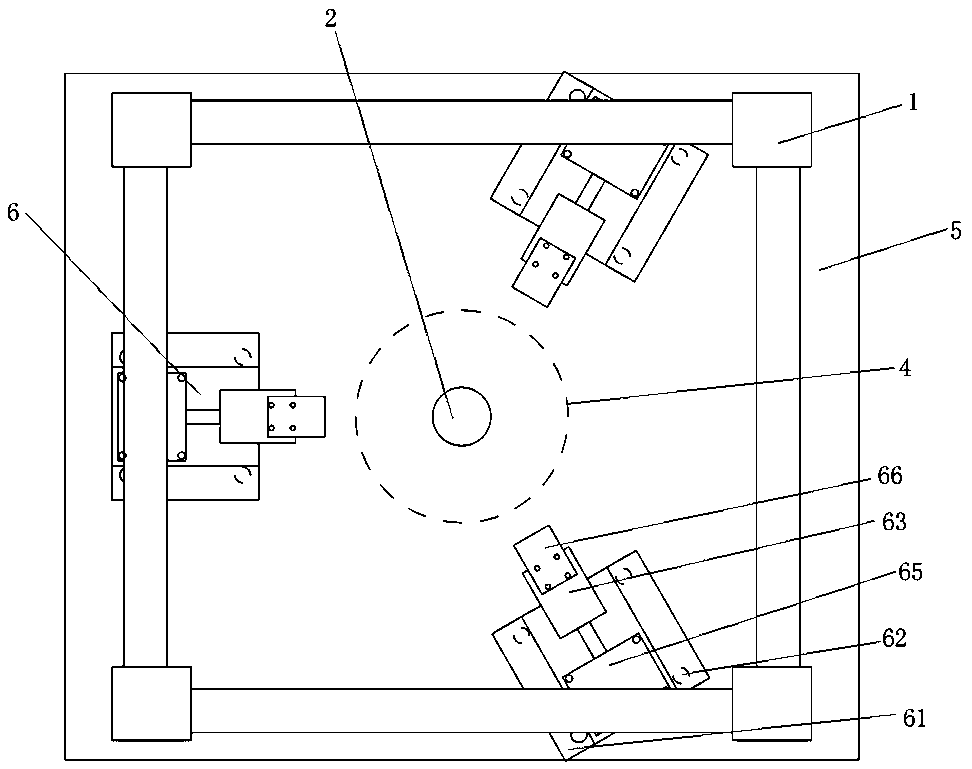

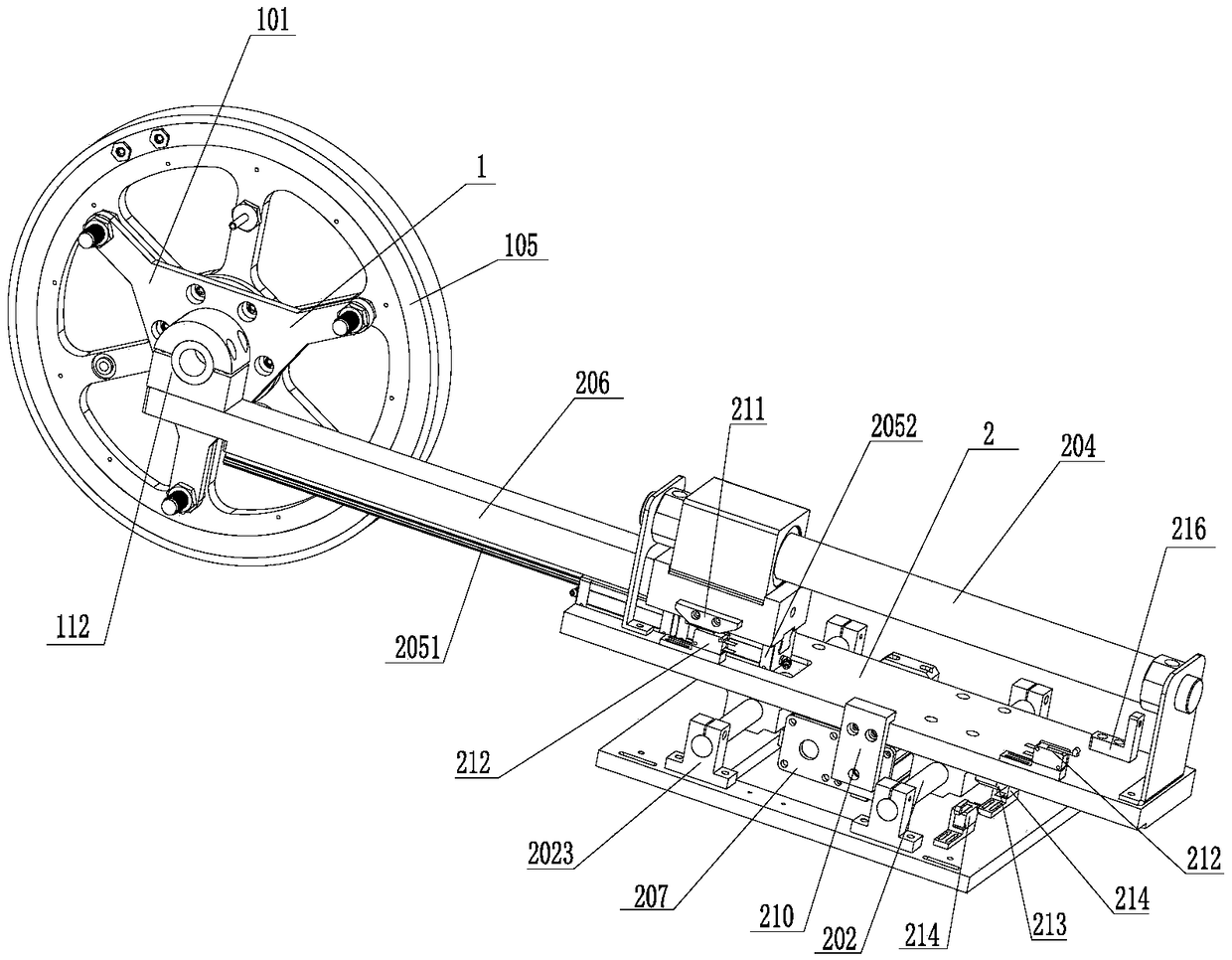

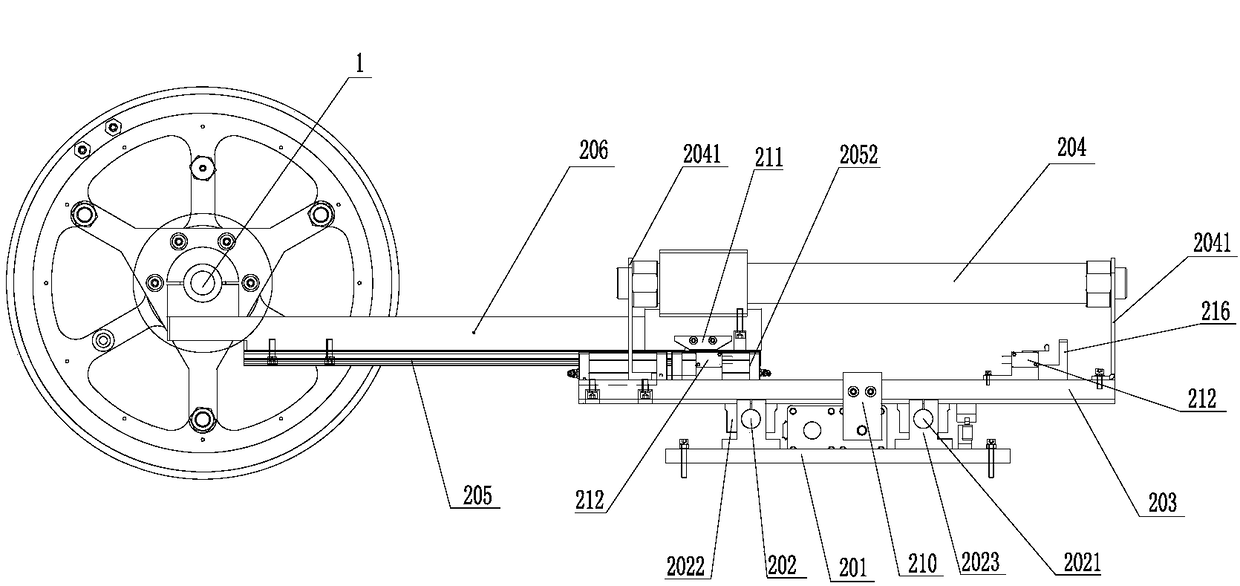

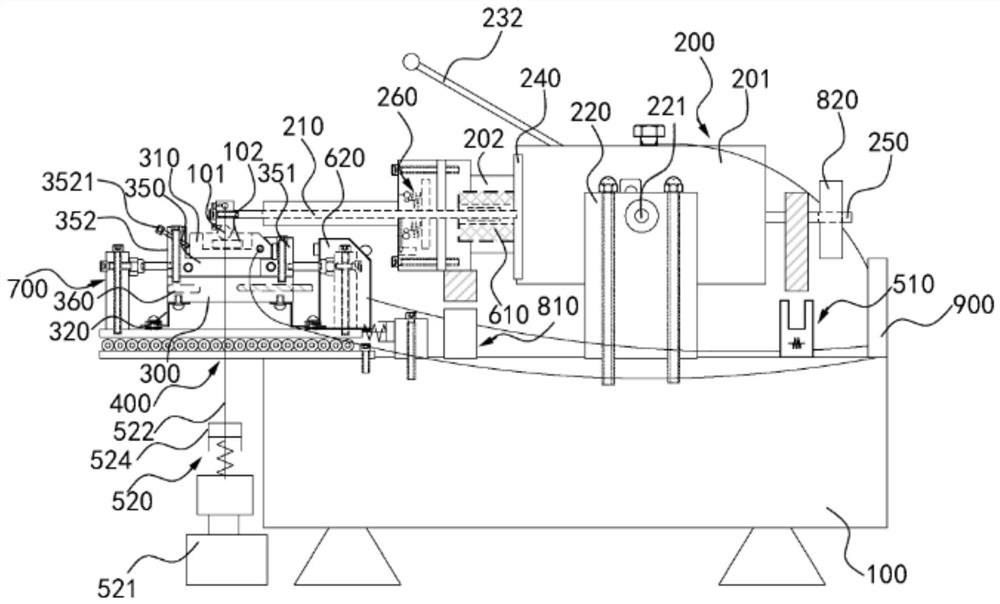

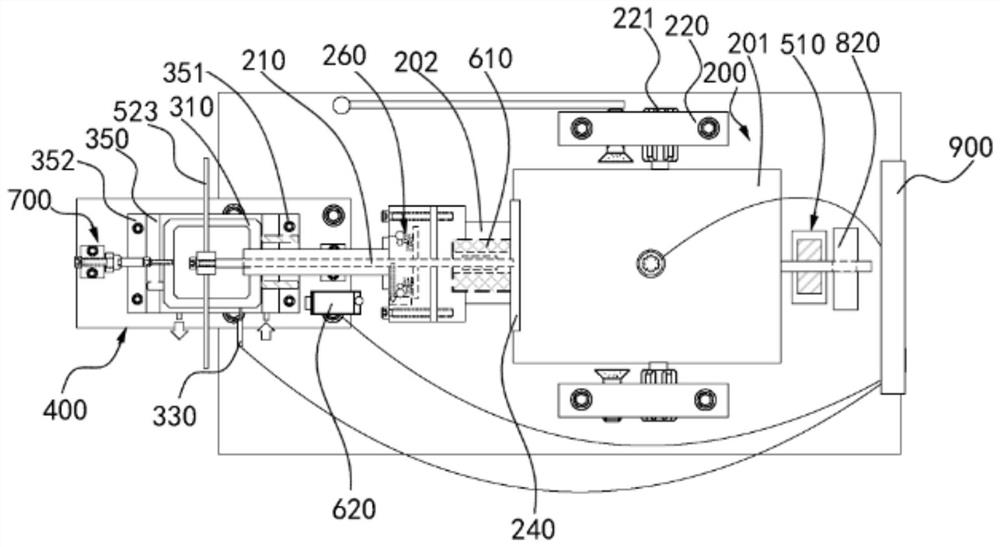

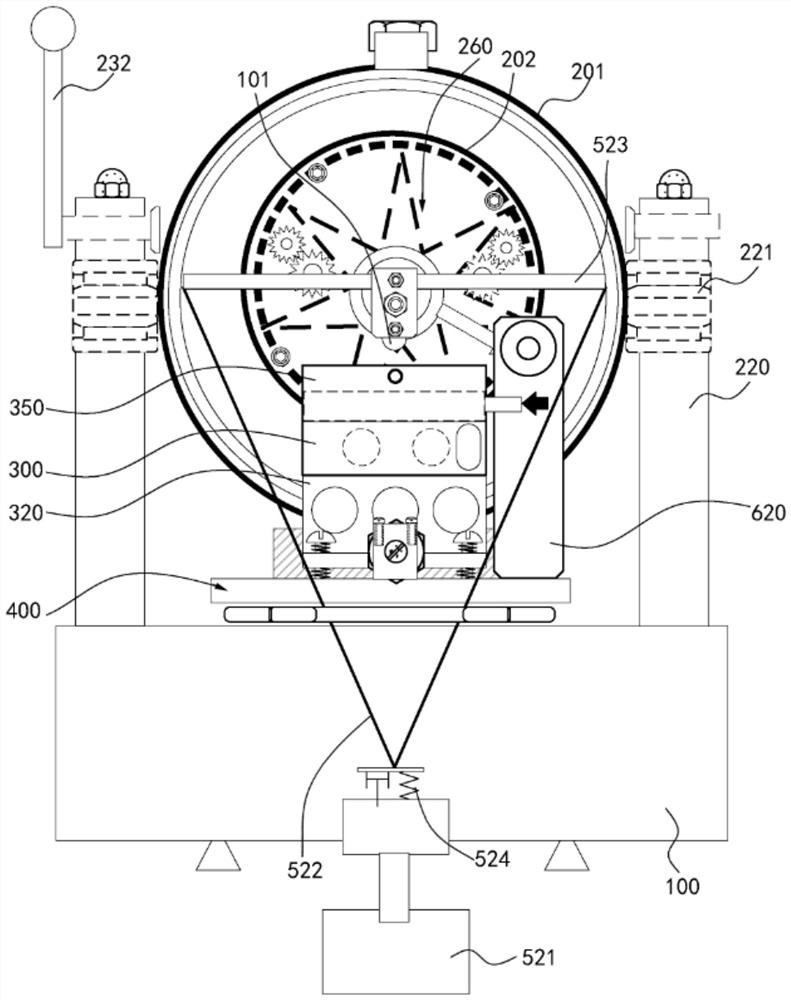

Wheel hub spinning machine

InactiveCN109201836AEliminate structural damageAvoid shakingMetal-working apparatusHydraulic cylinderProduction quality

The invention relates to a wheel hub spinning machine, and relates to the field of wheel hub production equipment. The wheel hub spinning machine comprises a rack, a spindle module and spinning modules. The spindle module comprises a first shaft group and a second shaft group which are arranged on the rack in the longitudinal direction and used for mounting a wheel hub blank, the first shaft group, the second shaft group and the wheel hub blank are coaxial, a horizontal spinning platform is arranged in the middle of the rack, and the three spinning modules are circumferentially distributed around the wheel hub blank axis; and each spinning module comprises a base, a guide rail, a knife rest, a longitudinal hydraulic cylinder and a transverse hydraulic cylinder, wherein the guide rail is vertically arranged above the spinning platform, the base is movably mounted on the guide rail, the knife rest is movably arranged on the base and points to the wheel hub blank, and the longitudinal hydraulic cylinder is longitudinally connected to the base, and the transverse hydraulic cylinder is fixedly connected to the base and connected to the knife rest. Through the wheel hub spinning machine,the upper and lower ends of the wheel hub blank can be synchronously rotated to prevent deformation, diversified processes adapt to different production requirements, meanwhile, the good processing stability is achieved, and the production quality is improved.

Owner:ANHUI STRONG AUTO PARTS

Cylinder mechanism with adjustable stroke

InactiveCN102979779AReasonable structureEasy to adjustFluid-pressure actuatorsEngineeringMechanical engineering

The invention provides a cylinder mechanism with an adjustable stroke. The cylinder mechanism with the adjustable stroke comprises a cylinder body, a piston and a piston rod. The cylinder body is provided with a baffle plate. The piston rod penetrates through the baffle plate and is provided with a polyurethane buffering ring in a sleeved mode. The piston rod is provided with a fixing stud in a rotating mode. The fixing stud is provided with an adjusting buffing ring and a locknut in a rotating mode, wherein the locknut is locked with the adjusting buffing ring. By adjusting the position of the adjusting buffer ring on the fixing stud, the distance for which the other end of the piston rod of the cylinder is extended is controlled and stroke control of the cylinder is achieved. The cylinder mechanism with the adjustable stroke is convenient to adjust and accurate in the stroke control, capable of ensuring that a double-rod cylinder is converted into the cylinder mechanism with the adjustable stroke for use and being applied to a plurality of specific occasions.

Owner:苏州尚原工业技术有限公司

Stroke adjustable oil cylinder

InactiveCN102927079AAccurate stroke controlEasy to processFluid-pressure actuatorsCylinder headCylinder block

The invention discloses a stroke adjustable oil cylinder which comprises a cylinder body, a cylinder head, a piston rod, a piston which is connected with the piston rod, and a rodless cavity oil opening. The stroke adjustable oil cylinder is characterized in that an installing seat is fixedly connected at the front end of the cylinder body, a worm and a worm gear which is meshed with the worm are arranged in the installing seat through bearings, a stroke positioning sleeve is arranged on the piston rod in sliding mode, the worm gear is connected with the stroke positioning sleeve through threads, the stroke positioning sleeve is arranged on the inner sides of the installing seat and the cylinder body, and a worm gear positioning sleeve is fixedly connected at the front end of the installing seat. The stroke adjustable oil cylinder has the advantages of being convenient to machine, and high in percent of pass. Meanwhile, a stroke is convenient and accurate to control, a stroke control part is not contacted with oil liquid, tightness is good, and leakage phenomenon is little.

Owner:泸州华西机械有限责任公司

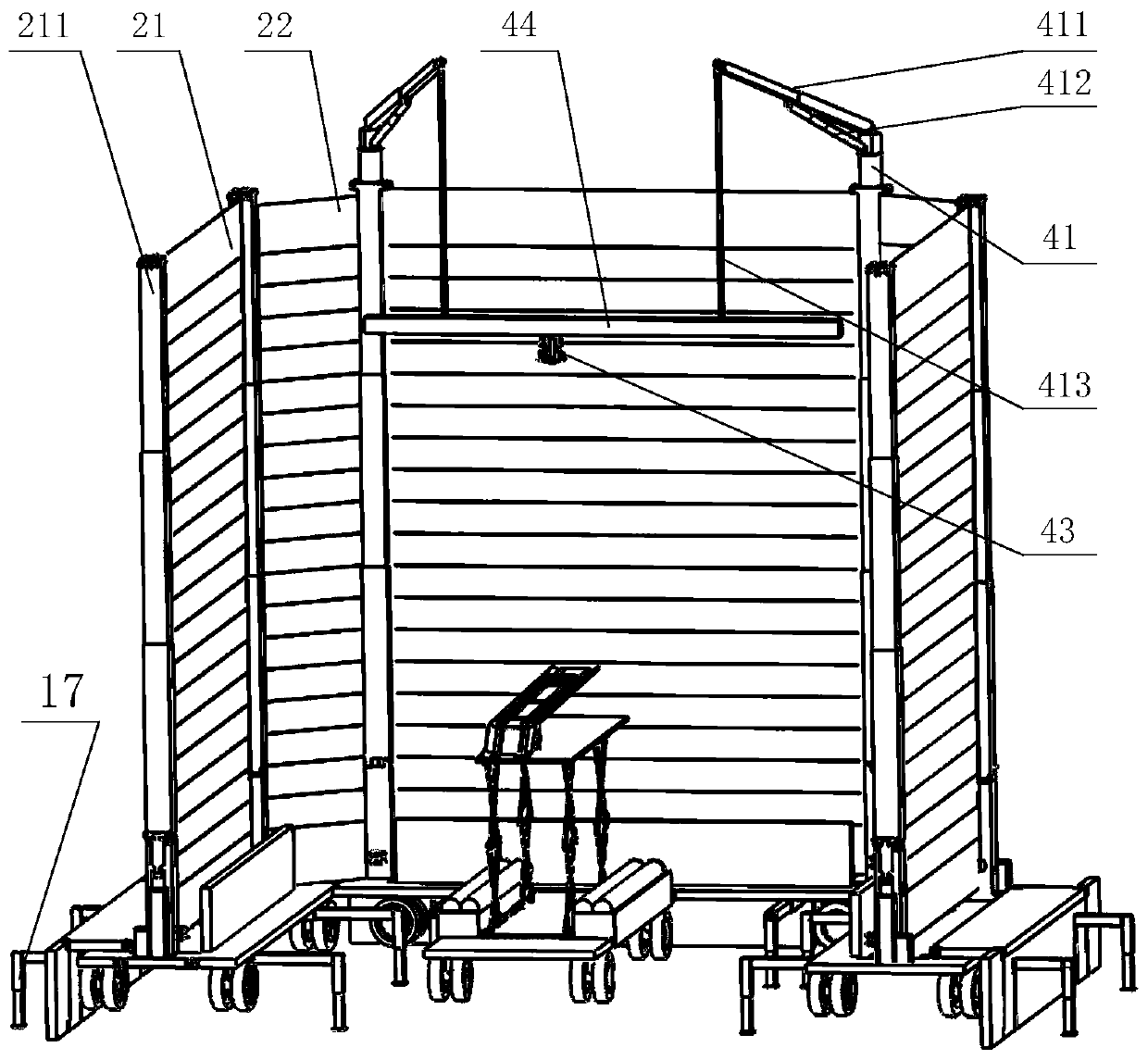

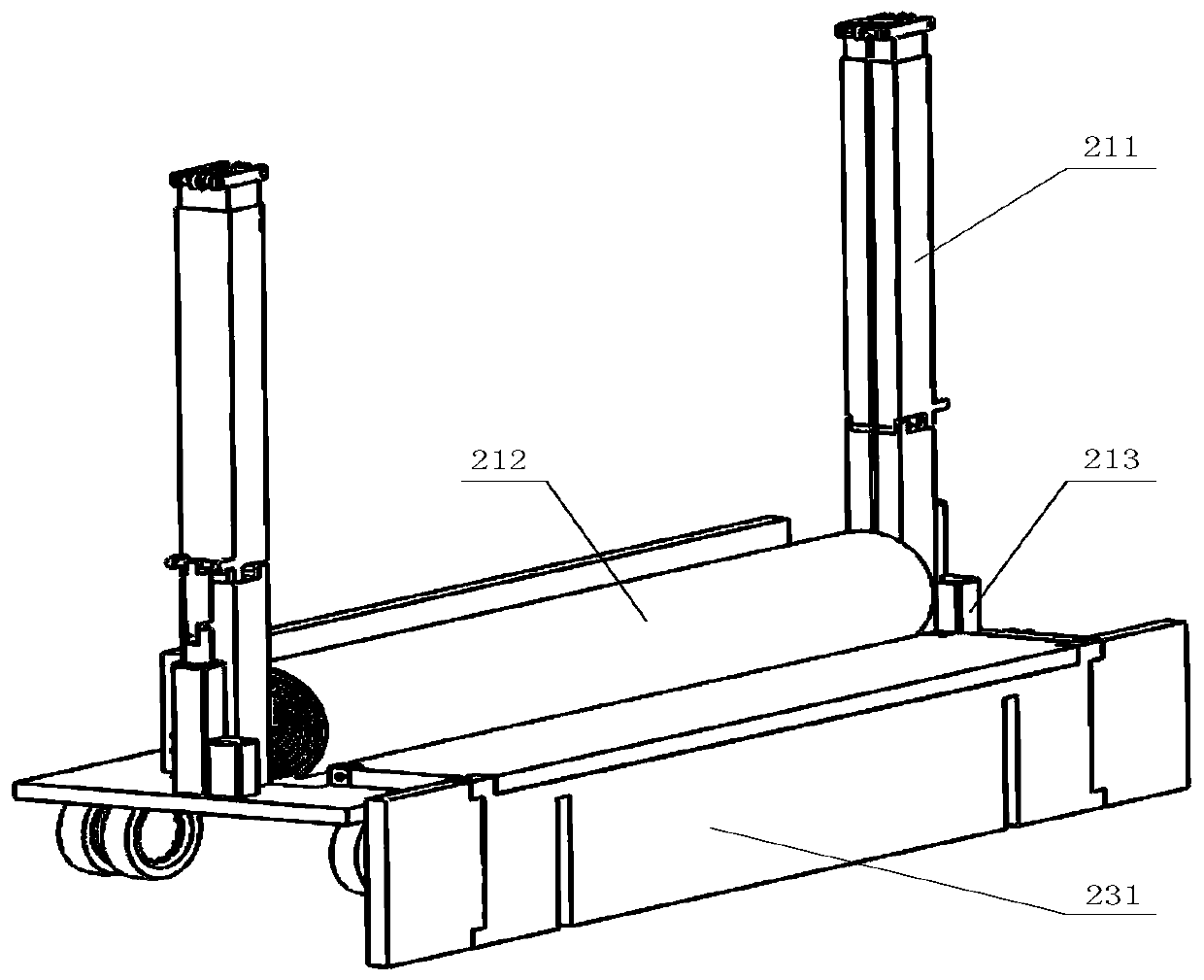

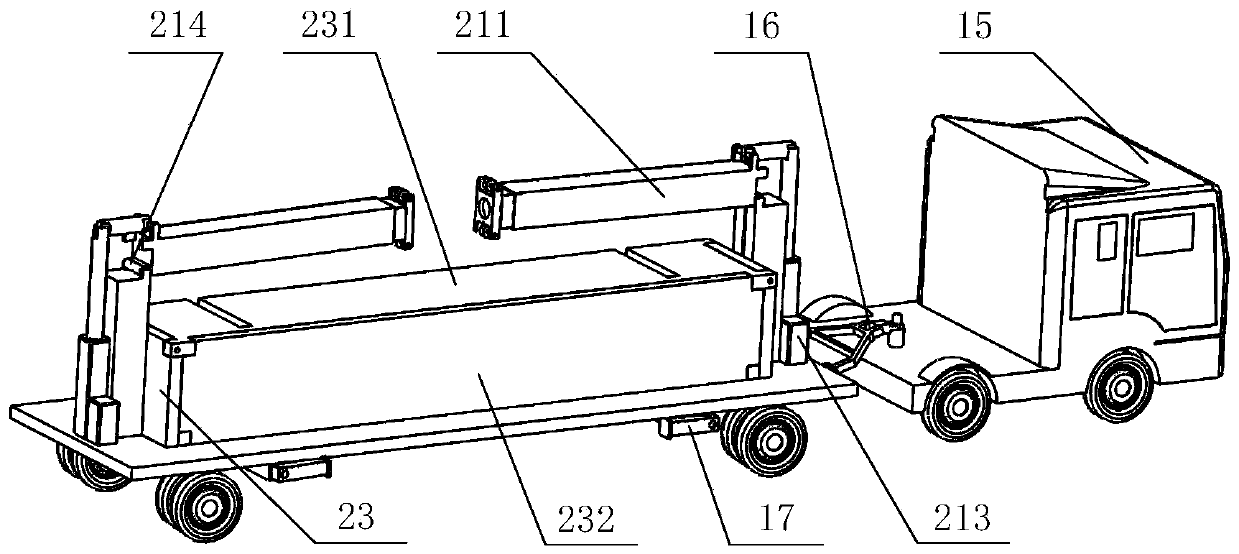

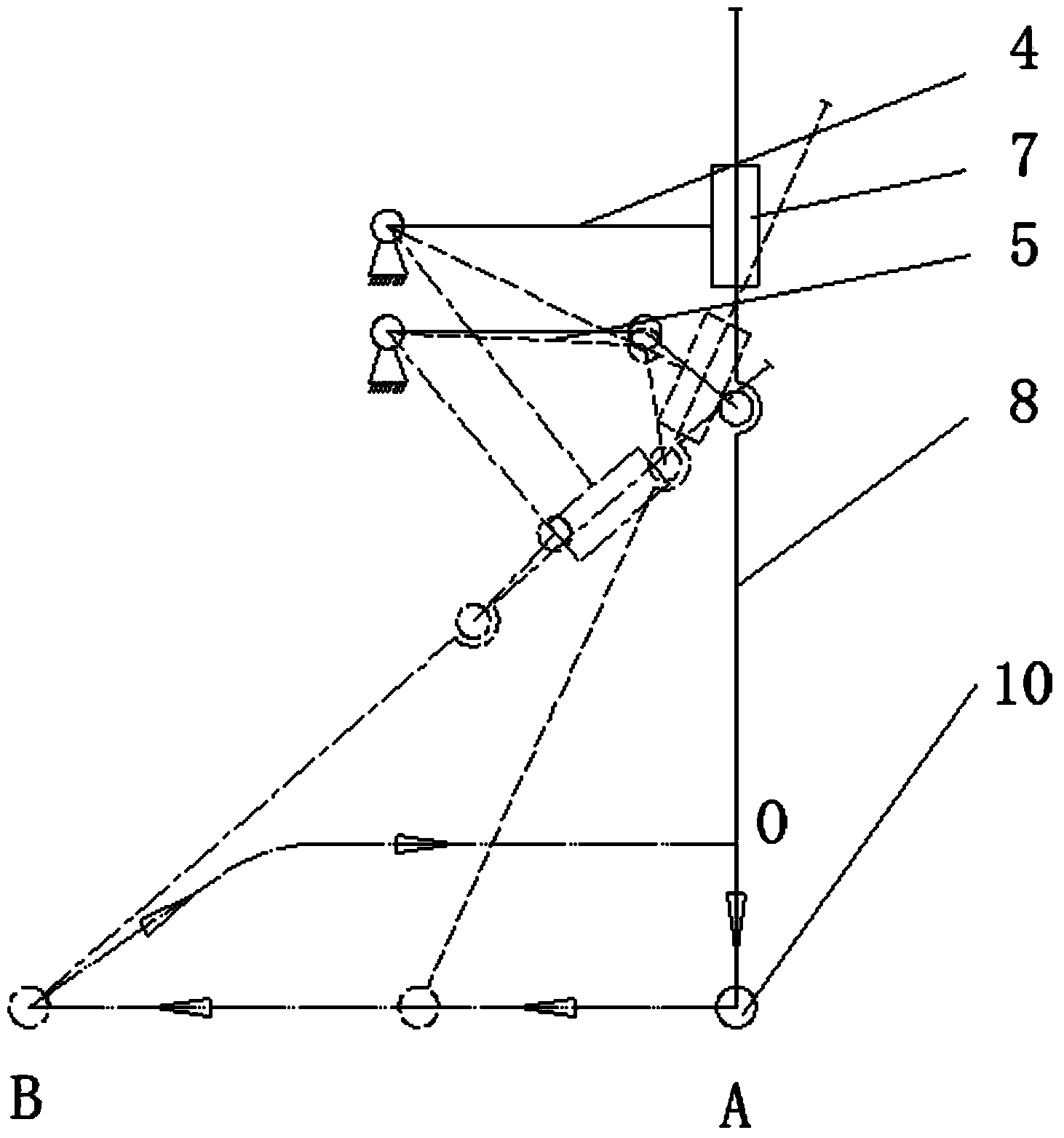

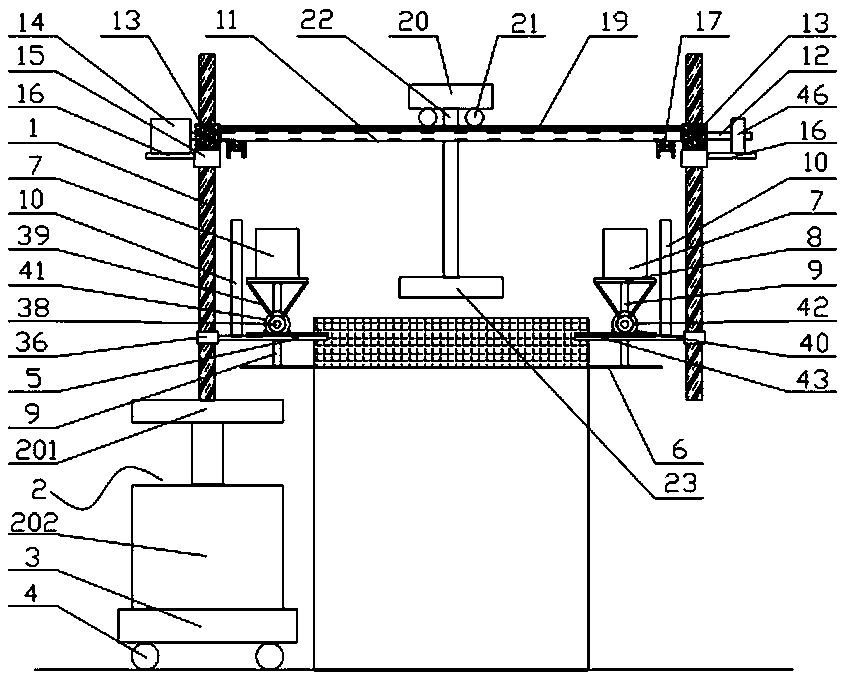

High-altitude balloon maneuverable and rapid release system

ActiveCN110481753AQuick releaseSave human effortItem transportation vehiclesBalloon aircraftsHigh-altitude balloonModularity

The invention provides a high-altitude balloon maneuverable and rapid release system. The system comprises a carrying subsystem, a windproof subsystem, an release subsystem and an inflation hoisting subsystem, adopts the modular design, can realize the functions of rapid mounting, dismounting, unfolding, folding, transition transportation and the like. When the system is in a transportation state,all the devices are folded, and the system can be dragged to a road directly by a tractor for transition transportation. The system can create a weak wind or windless safety environment for inflatingand release the balloons in an unfolded state, and can perform overall translation, steering and in-situ rotation. The system is compact in structure, high in maneuverability, high in deployment efficiency and environmental adaptability, can reduce the influence of the meteorological and environmental factors on the balloon release, and can greatly improve the release capacity of the high-altitude balloons. The system has the all-weather rapid maneuvering capacity, the on-site rapid building windproof capacity and the automatic releasing capacity, and can rapidly transit and release the high-altitude balloons.

Owner:中国人民解放军63660部队

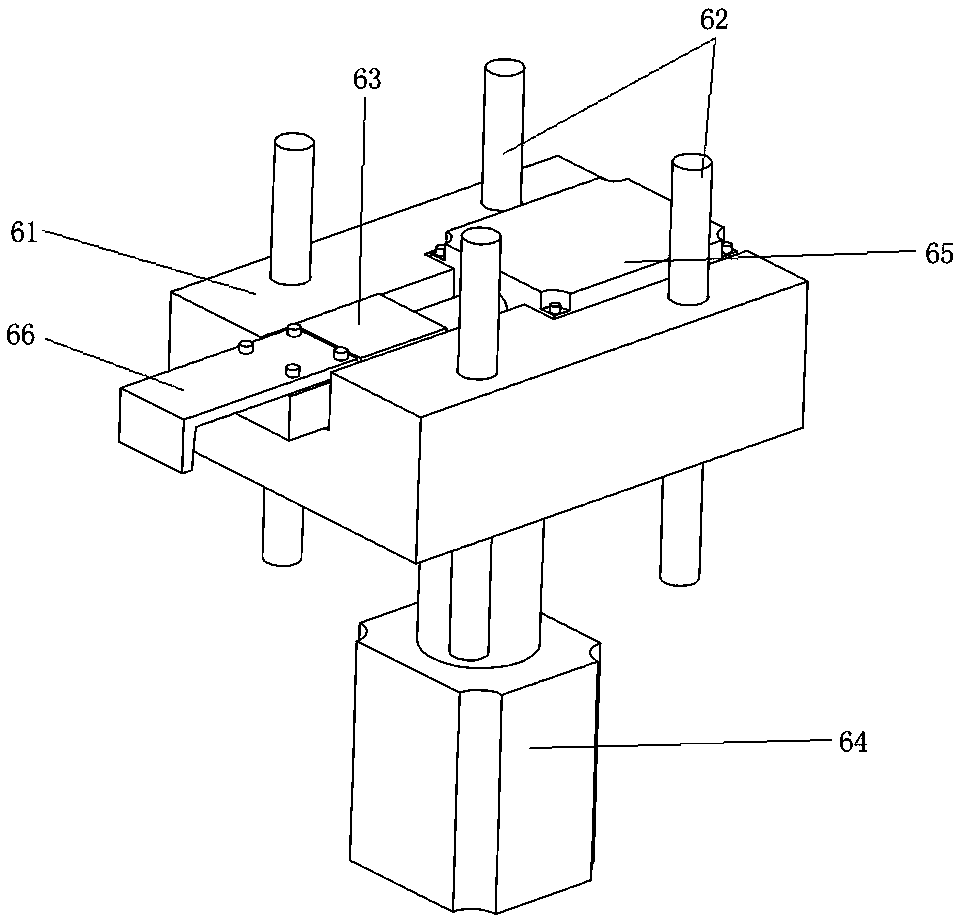

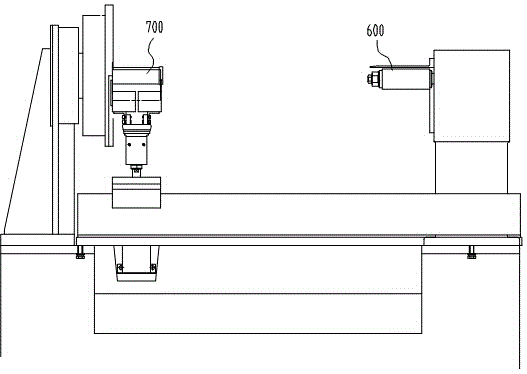

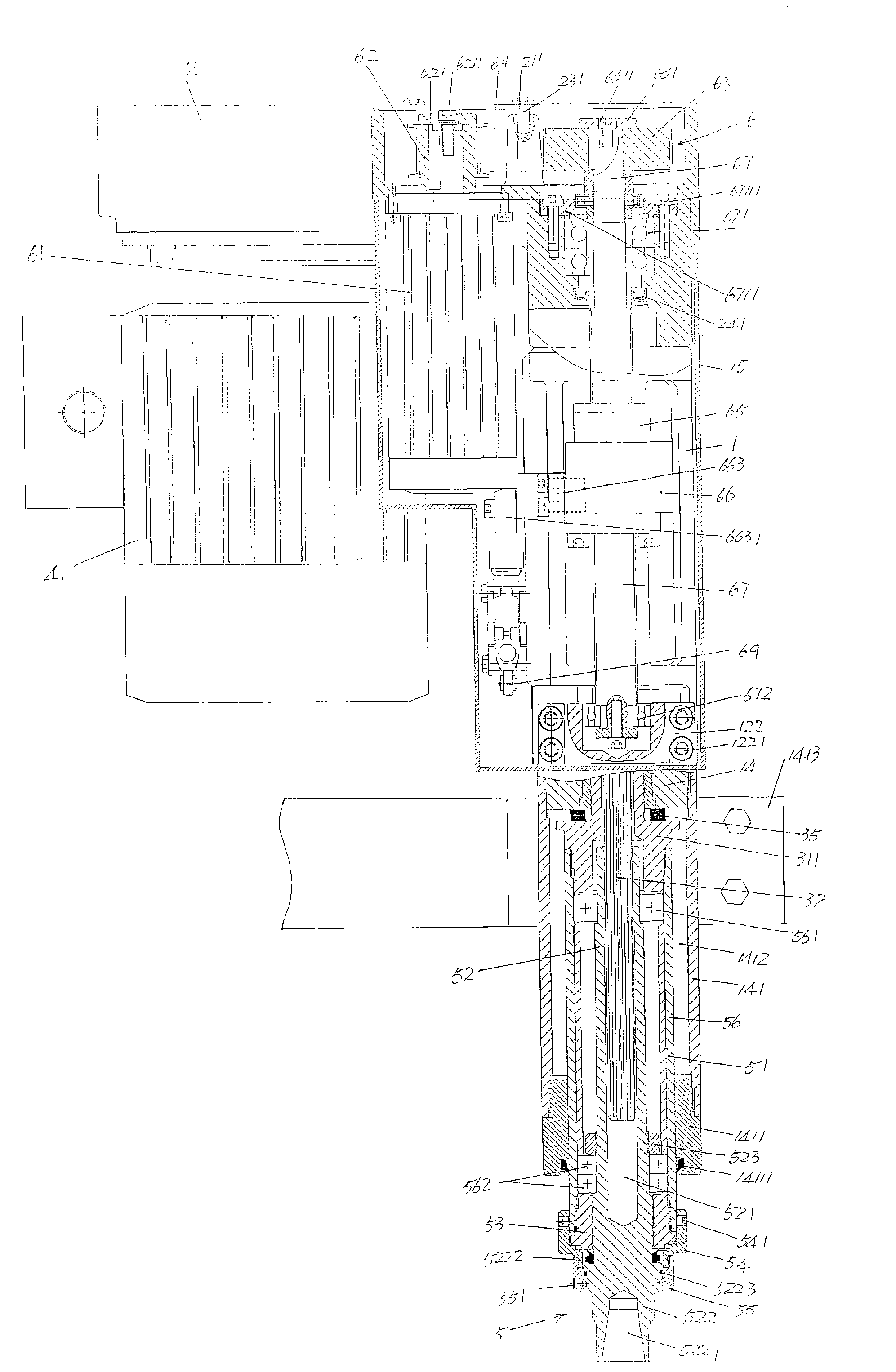

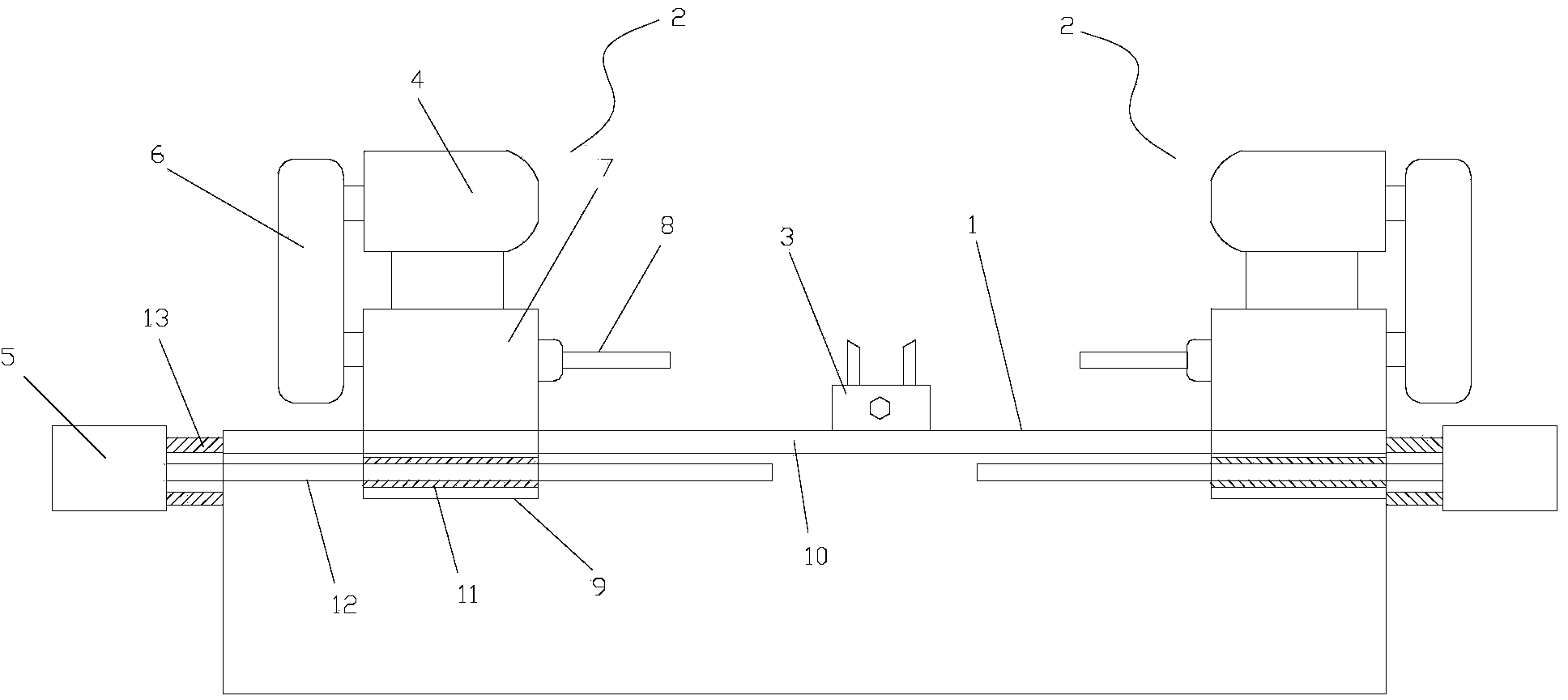

High-speed precise double servo feed drilling power head

InactiveCN103878415AImprove straightnessAccurate stroke controlDriving apparatusBoring/drilling componentsAutomatic controlBall screw

The invention provides a high-speed precise double servo feed drilling power head, and belongs to the technical field of drilling tools. The power head comprises a transmission case fixing base, a transmission case, a spline shaft, a spline shaft driving mechanism, a workpiece drilling mechanism and a servo feed control mechanism, and is characterized in that the spline shaft driving mechanism comprises a first servo motor, a large synchronous pulley, a small synchronous pulley and a transmission belt; the servo feed control mechanism comprises a second servo motor, a coupler, a ball screw, a lead screw nut, a sliding block, a stroke contactor, a driver adjustment plate, a first stroke limiting sensor and a second stroke limiting sensor; guide rails are arranged on wallboards of the transmission case fixing base, and an idler wheel is installed on the side face of the sliding block and is located between the two guide rails. Under the circumstance that no mechanical part is replaced, the rotating speed of a main shaft can be adjusted at will so that the requirement that different hole diameters correspond to different cutting speeds can be met; efficiency is high, the size is small, and the requirements for high-speed and high-precision machining of small hole diameters can be met; it is guaranteed that the main shaft has good straightness and good rigidity; the automated control effect is good.

Owner:SUGINO CHANGSHU CO LTD

Automatic piston ring fetching and handling device

InactiveCN104354057AAccurate stroke controlEasy to operateGrinding feedersMetal working apparatusVertical planePiston ring

The invention provides an automatic piston ring fetching and handling device. The automatic piston ring fetching and handling device comprises a linear sliding table, wherein a horizontal sliding block is arranged on the linear sliding table, an air cylinder mounting plate is fixedly arranged on the horizontal sliding block, a lifting air cylinder is vertically arranged on the air cylinder mounting plate, and the tail end of a piston rod of the lifting air cylinder is connected with parallel pneumatic jaw assemblies used for clamping piston rings. The automatic piston ring fetching and handling device the ascending and descending actions in a vertical plane are realized through the lifting air cylinder, the horizontal loosening and clamping actions are realized through the parallel jaw assemblies, the reciprocating linear motion in the horizontal plane is realized through the linear sliding table and the control stroke is accurate; the parallel pneumatic jaw assemblies clamp a plurality of piston rings and then horizontally handle the piston rings, the postures of the piston rings are guaranteed not to be changed during handling, the operation is facilitated, the processing efficiency is high, and the time and labor are saved.

Owner:安庆安帝技益精机有限公司

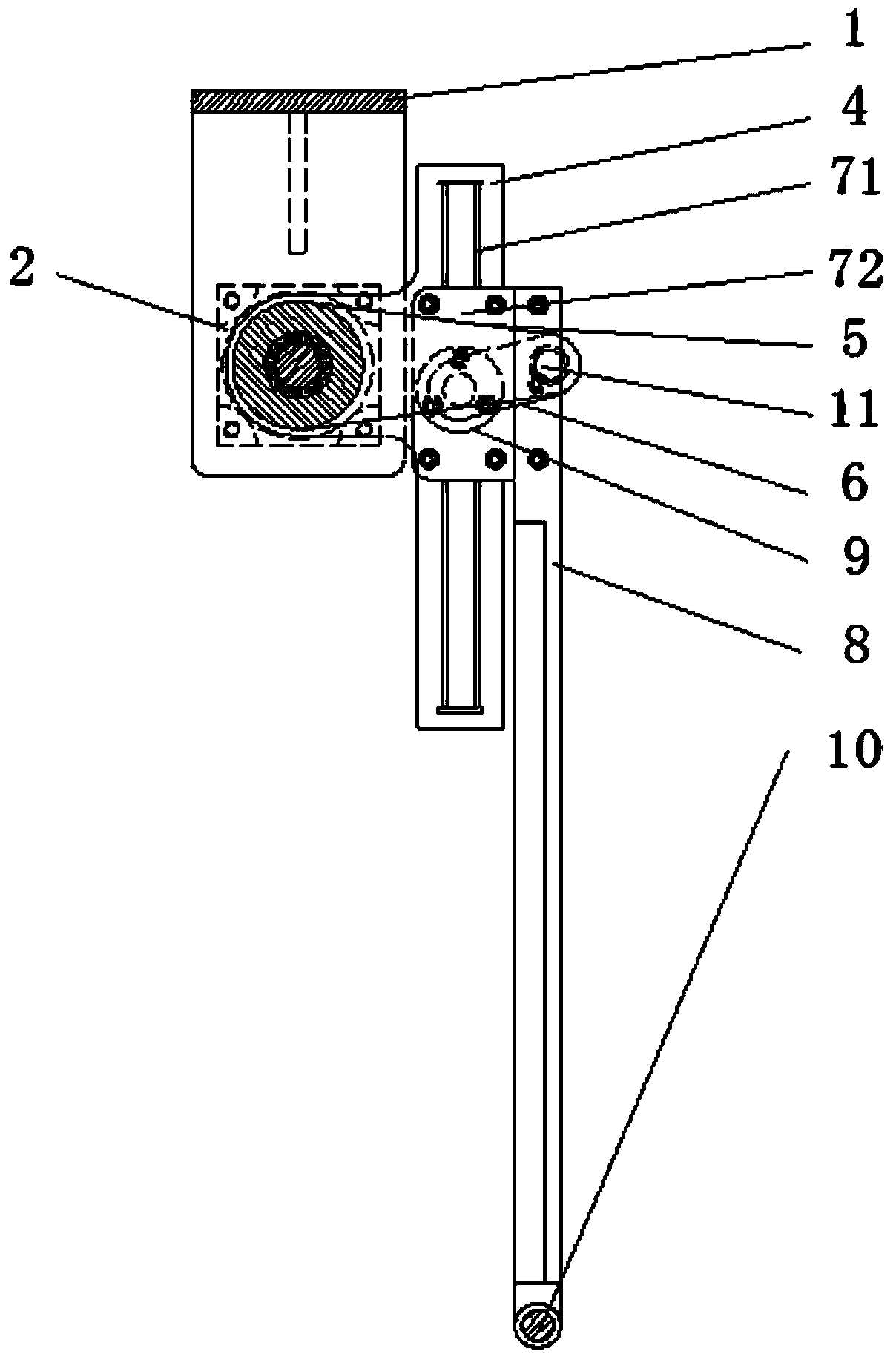

Stroke control device

ActiveCN1883932AAvoid rotational offsetGuaranteed normal operationMetal working apparatusPressesEngineeringPiston rod

The invention discloses a breaking cylinder travel controller of a breaking machine for electrolytic aluminium anode assembling, whose structure is characterized in that an approach switch (1) connects with a fixing plate (9), a flange (4) connects with a top surface of a breaking cylinder piston rod, a torsional arm (3) and a torsional arm (5) connects with the two sides of the flange (4), the torsional arm (3) connects with an induction plate (2), the torsional arm (3) and the torsional arm (5) are disposed in a guide rail (7), the guide rail (7) connects with a connection plate (8), the connection plate (8) connects with a fixed plate (9), wherein the induction plate (2) is provided with a long round hole, and the torsional arm (3) connects with the induction plate through the long round hole and a bolt, the flange (4) connects with the top surface of the breaking cylinder piston rod by bolts, and inlayed strips (6) are disposed on the torsional arm (3) and the torsional arm (5), the guide rail (7) connects with the connection plate (8) by sunk screws. If the breaking cylinder piston rod wants to deflect when moving, it will be restricted by the guide rail (7).

Owner:GUIYANG AL-MG DESIGN & RES INST

Map data processing device for vehicle

ActiveUS9990375B2Accurate identificationAccurate stroke controlInstruments for road network navigationGeographical information databasesComputer scienceData processing

In a map data processing device for a vehicle, a map database has first map data of a road on which the vehicle travels. A map data computing module computes second map data of the road based on a surrounding environment and a traveling state of the vehicle. An update data computing module computes update data for updating the map database, based on a reliability of the second map data. An update determining module then compares the first map data with the update data. When both disagree with each other, the update determining module determines whether to update first map data with the update data, based on a frequency of discrepancy and the reliability. A data processing module executes a processing of updating the map database in accordance with a determination result by the update determining module.

Owner:SUBARU CORP

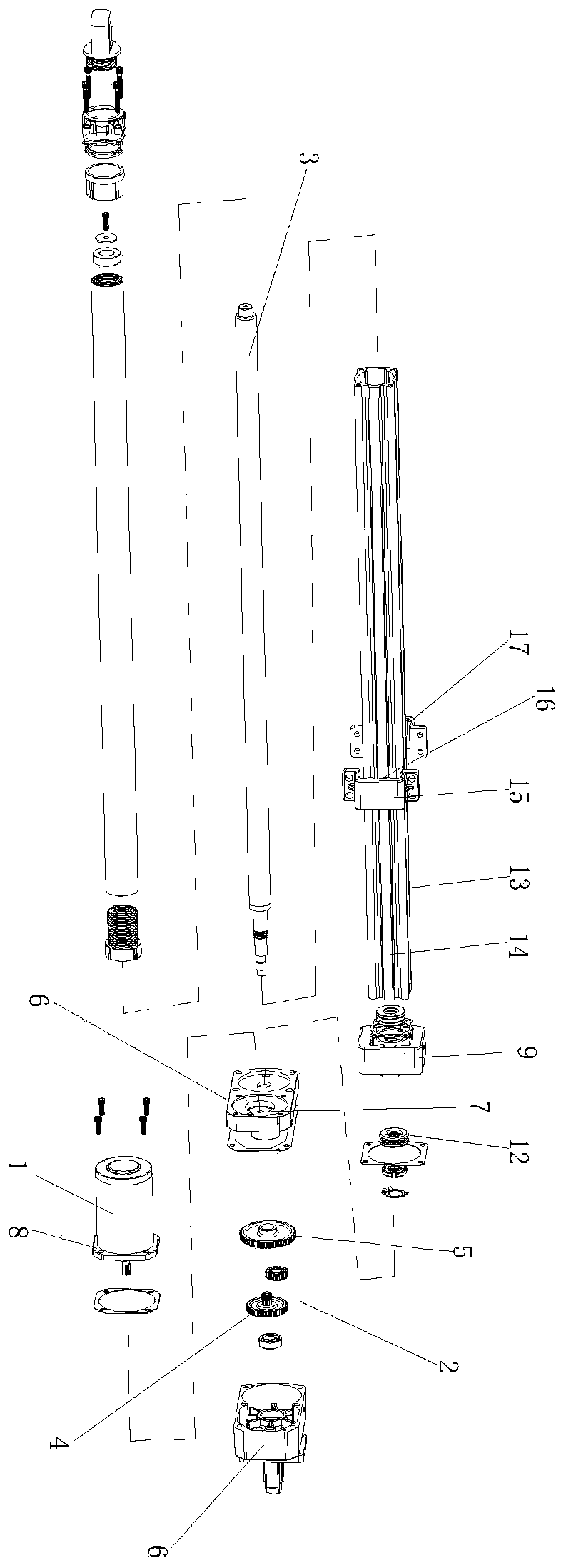

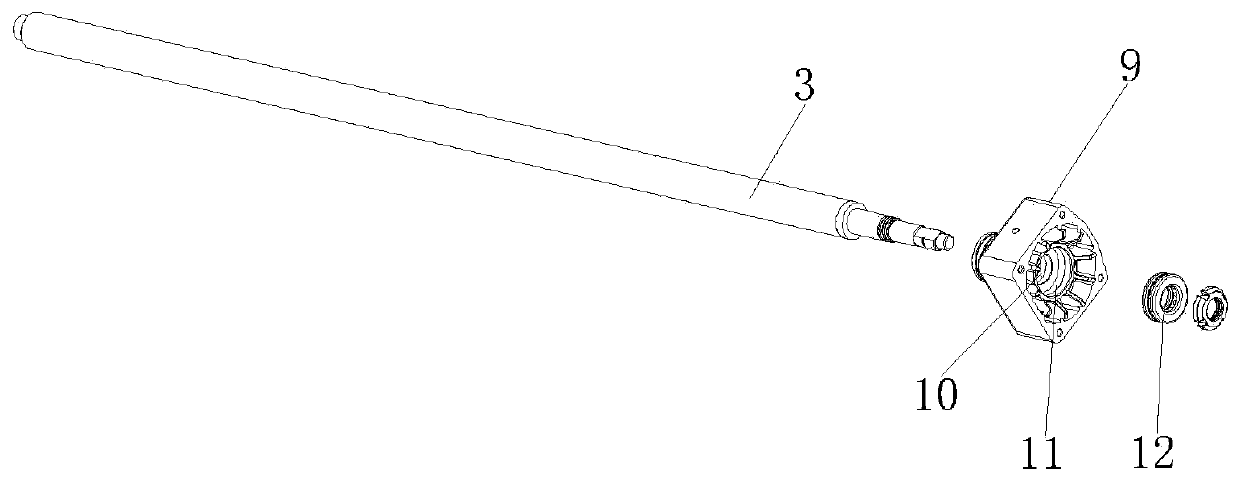

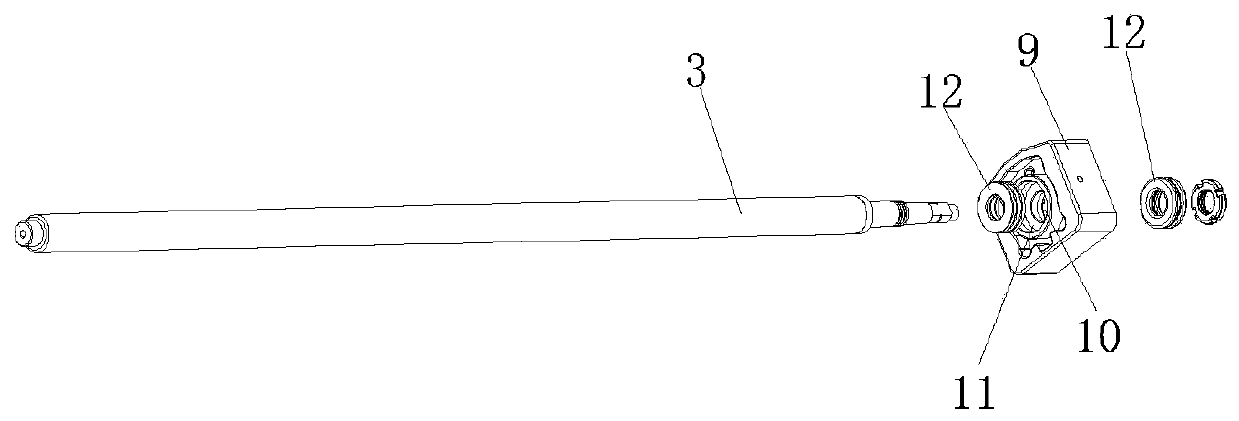

Electric push rod

PendingCN109756066AEasy to maintainEasy to replaceStructural associationMechanical energy handlingEngineeringWheel speed sensor

The invention discloses an electric push rod. The electric push rod comprises a DC motor, a transmission mechanism and a push rod, wherein the transmission mechanism comprises a main gear in axis connection with the DC motor and a transmission gear connected with the push rod, a plurality of wheel speed sensors are uniformly arranged on the transmission gear at interval, a signal receiver is arranged below the transmission gear, the signal receiver is connected with a controller, the controller controls and is connected with the DC motor, and the wheel speed sensors, the signal receiver and the controller coordinate with each other so as to control the DC motor and further control rotation turns and rotation angle of the transmission gear, thereby enabling the push rod to produce accurateaxial movement stroke. The wheel speed sensors and the signal receiver coordinate so as to calculate rotation turns of the transmission gear, when the transmission gear rotates to the desired turns, the controller controls the DC motor to start or stop.

Owner:浙江百缔传动科技有限公司

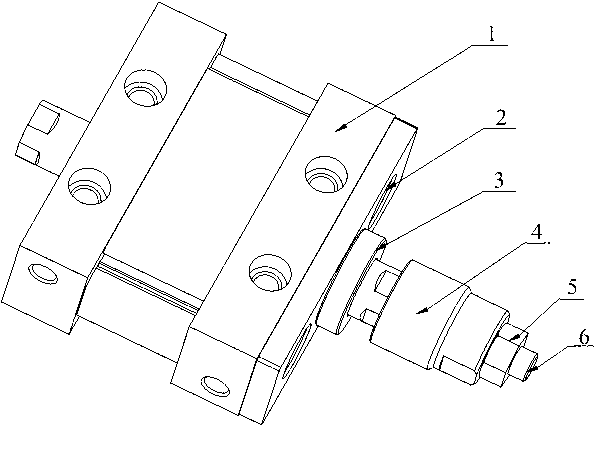

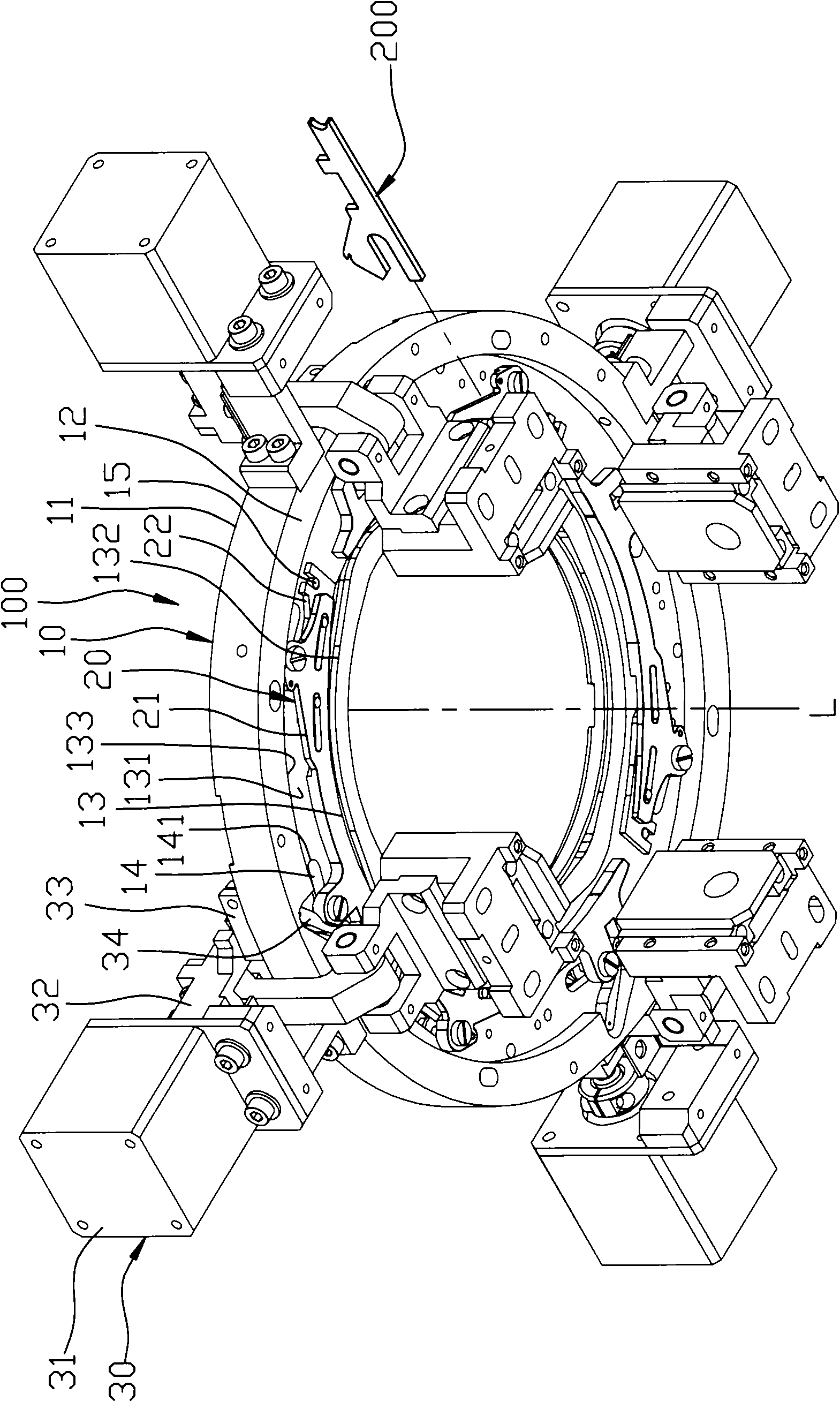

Servo-feed drilling power head structure

ActiveCN103317159AEnsure drilling qualityProtection of drilling toolsBoring/drilling componentsBoring/drilling machinesAutomatic controlCompressed air

The invention discloses a servo-feed drilling power head structure, and belongs to the technical field of drilling tools. The servo-feed drilling power head structure comprises a transmission box fixing seat, a transmission box, a spline shaft, a spline shaft driving mechanism and a workpiece drilling mechanism, and is characterized by further comprising a servo-feed control mechanism, and the servo-feed control mechanism is used for driving the workpiece drilling mechanism to move upwards or downwards, is arranged on the transmission box and is connected with the workpiece drilling mechanism. The servo-feed drilling power head structure has the advantages that an auxiliary facility for providing compressed air is omitted, the workpiece drilling quality can be guaranteed, and a drilling tool can be effectively protected; the servo-feed drilling power head structure is low in noise, so that an environment of a work place can be obviously improved; manual troublesome adjustment is omitted; an excellent automatic control effect can be realized.

Owner:SUGINO CHANGSHU CO LTD

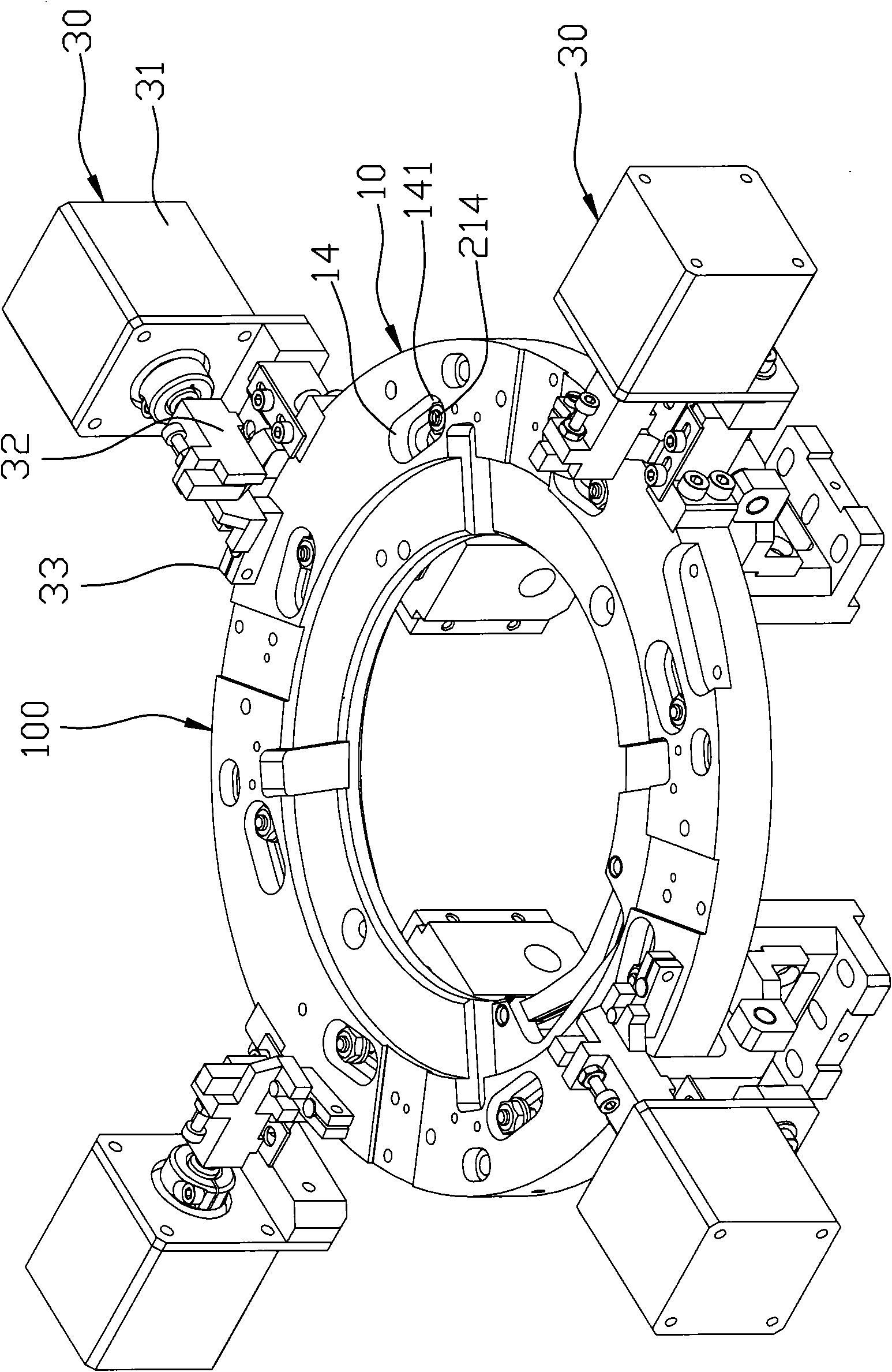

Sinker control device of sock knitting machine

The invention relates to a sinker control device of a sock knitting machine. The sinker control device comprises a sinker cover, a plurality of control units arranged on the sinker cover and a plurality of drive units arranged on the sinker cover and used for linking the control units, wherein the sinker cover is provided with an annular groove and a plurality of guide slot sets; and each controlunit is provided with a first control piece and a second control piece, the first control piece is provided with two guide pins inserted in the guide slot sets and two guide parts, and the second control piece is provided with two sliding guide parts mutually sleeved with the guide parts. The first control pieces are respectively driven by utilizing the drive units to displace along the annular direction, therefore a gap between the control units and the annular groove can be changed, and the purposes of accurately controlling the stroke of the pieces and improving the quality of knitted socks are reached.

Owner:赵国超

Multistage clearance throttling pressure adjusting valve

PendingCN110360324AAvoid concentrated impactExtended service lifeLift valveValve housingsPressure rangeFluid pressure

The invention discloses a multistage clearance throttling pressure adjusting valve and relates to the technical field of fluid pressure control. The multistage clearance throttling pressure adjustingvalve comprises a valve body, a valve seat connected in the valve body in a sealed manner, a valve element contained in the valve seat and a push rod driving the valve element to move in the longitudinal direction of a valve seat runner. The valve seat is provided with at least three flange step limiting radial gradual change cavities arranged in the longitudinal direction of the valve seat, the valve element is provided with at least three flange step limiting radial change parts arranged in the axial direction of the valve element, and the radial gradual change cavities are matched with theradial gradual change parts. A buffering face is formed on the axial end face of a flange step in the medium flowing direction of the runner. By means of the multistage clearance throttling pressure adjusting valve, the regularly changing zigzag runner is formed by the radial gradual change parts arranged on the valve element and the radial gradual change cavities formed in the valve seat. The buffering purpose is achieved through the classified axial end faces of the radial gradual change parts, pressure is reduced stably stage by stage damage to the valve element and the valve seat is small,the service life of the valve is prolonged effectively, machining is easy, and the applicable pressure range is large.

Owner:四川杰特机器有限公司

Transition pushing hand device of packaging machine

ActiveCN103449120ACompact structureSmall space sizeConveyorsPackagingControl theoryPackaging machine

The invention discloses a transition pushing hand device of a packaging machine. The transition pushing hand device comprises a fixing base, a first servo motor and a second servo motor, wherein the first servo motor and the second servo motor are oppositely and fixedly arranging on the fixing base; a swing base is arranged on an output shaft of the first servo motor and is connected with a pushing hand handle and a rotating shaft through a linear slide rail; a swing arm is arranged on an output shaft of the second servo motor; the tail end of the swing arm is hinged to the rotating shaft through a connecting rod; the first servo motor and the second servo motor control the pushing hand handle together. The transition pushing hand device is simple and compact in structure. Compared with a rail pushing hand device, the transition pushing hand device has the advantages that the space size is saved, circulating work is realized, and the requirement of high-speed work is met by the transition pushing hand device but not by a simple linear reciprocating pushing hand device.

Owner:ANQING HENG CHANG MACHINERY

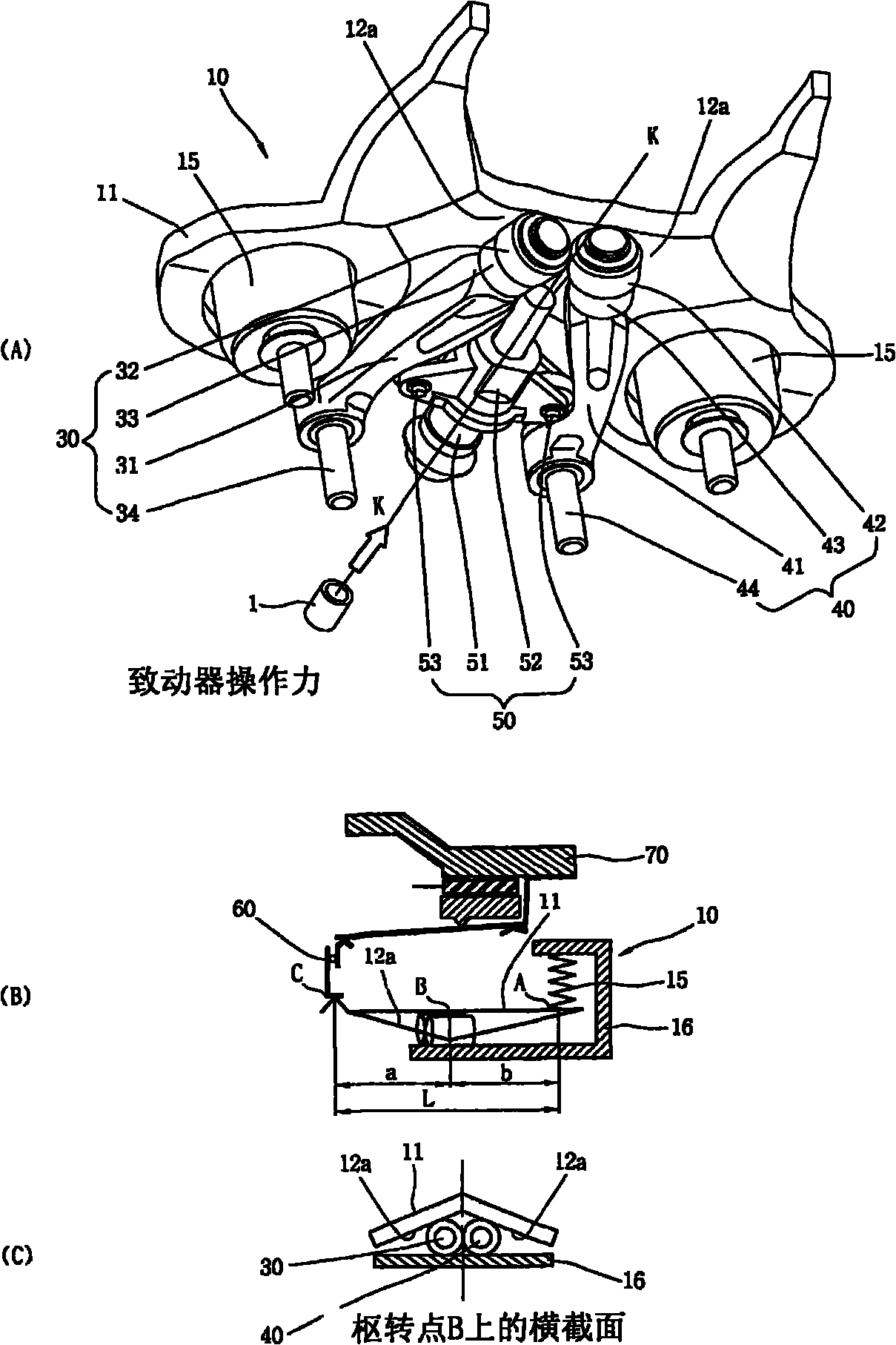

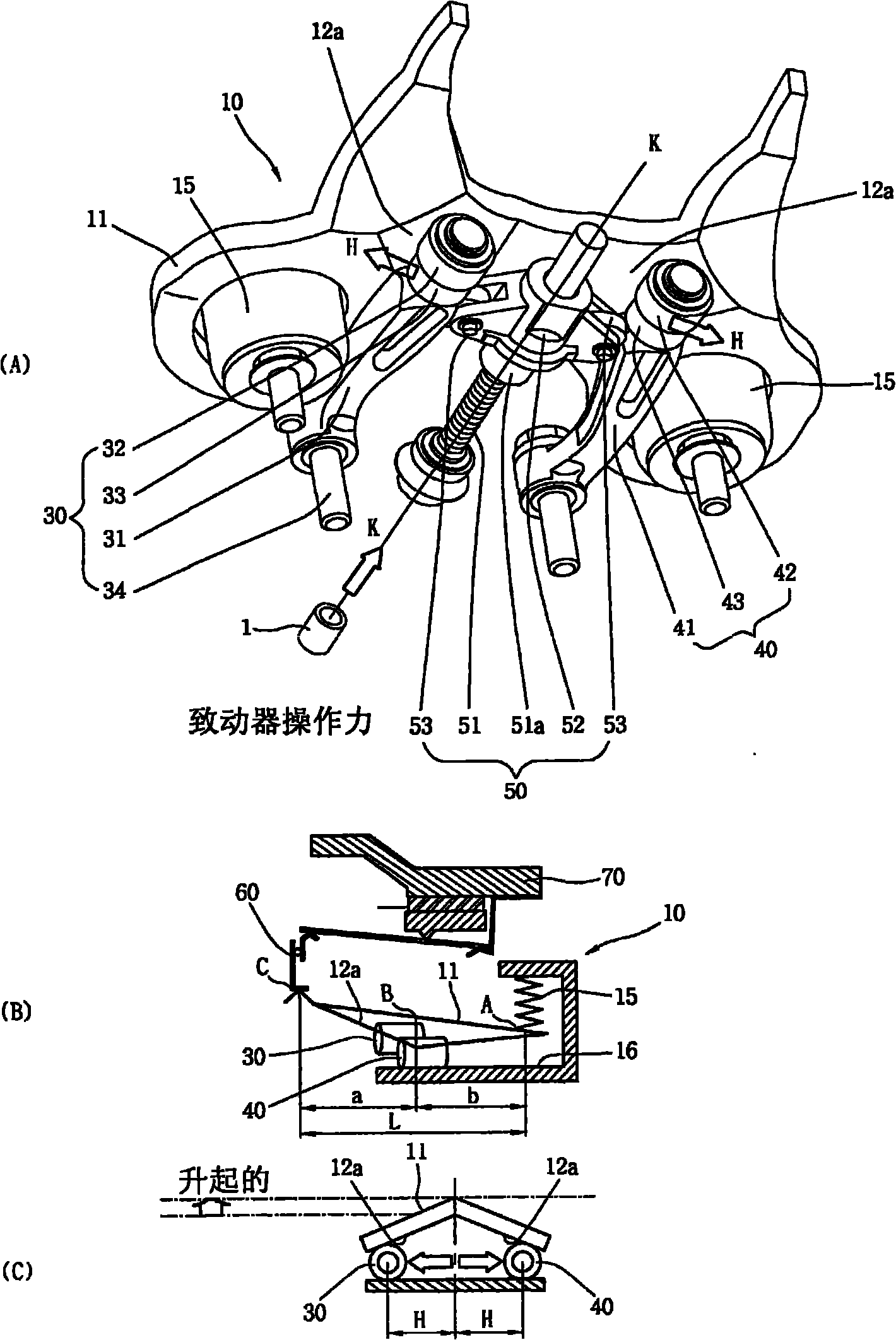

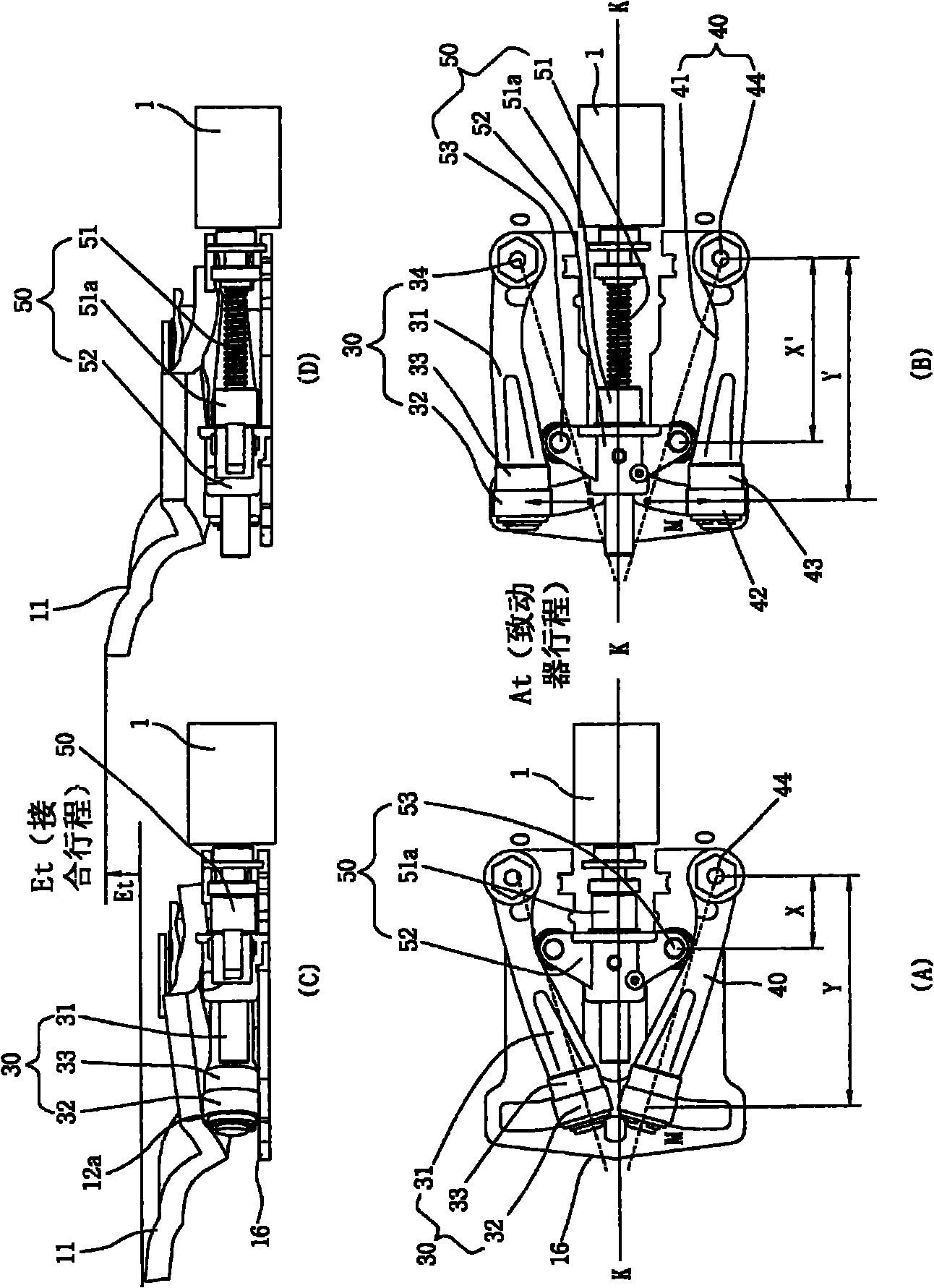

Clutch Driving Device

InactiveCN102252044APrecise stroke controlMinimize movement distanceMechanical actuated clutchesEngineeringActuator

A clutch driving device includes a pair of first and second roller wing arms horizontally moving to both sides by moving body moving forward / backward on an axial center line of an actuator and a roller inclined cam surface defining a move path of a pivot is formed such that first and second roller wing arms horizontally move to both sides from the axial center line of actuator, on the surface of a lever generating a stroke at a release bearing. Therefore, the lever can be lifted above a clutch engagement gap where a sufficient stroke is generated at the release bearing engaging a clutch, such that it is possible to achieve sufficient performance even if the output of actuator is reduced by the amount of energy consumption which is relative reduced.

Owner:HYUNDAI MOTOR CO LTD

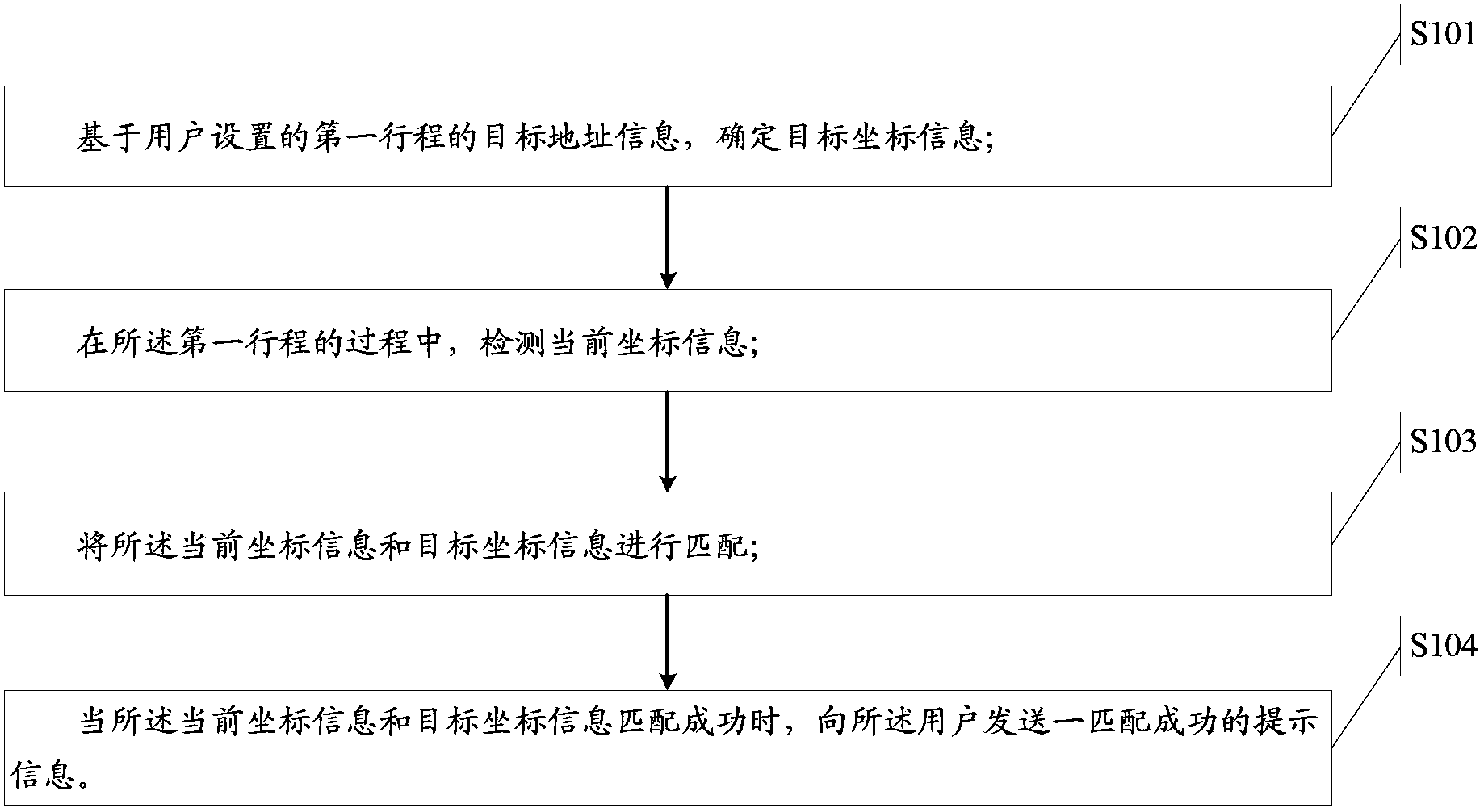

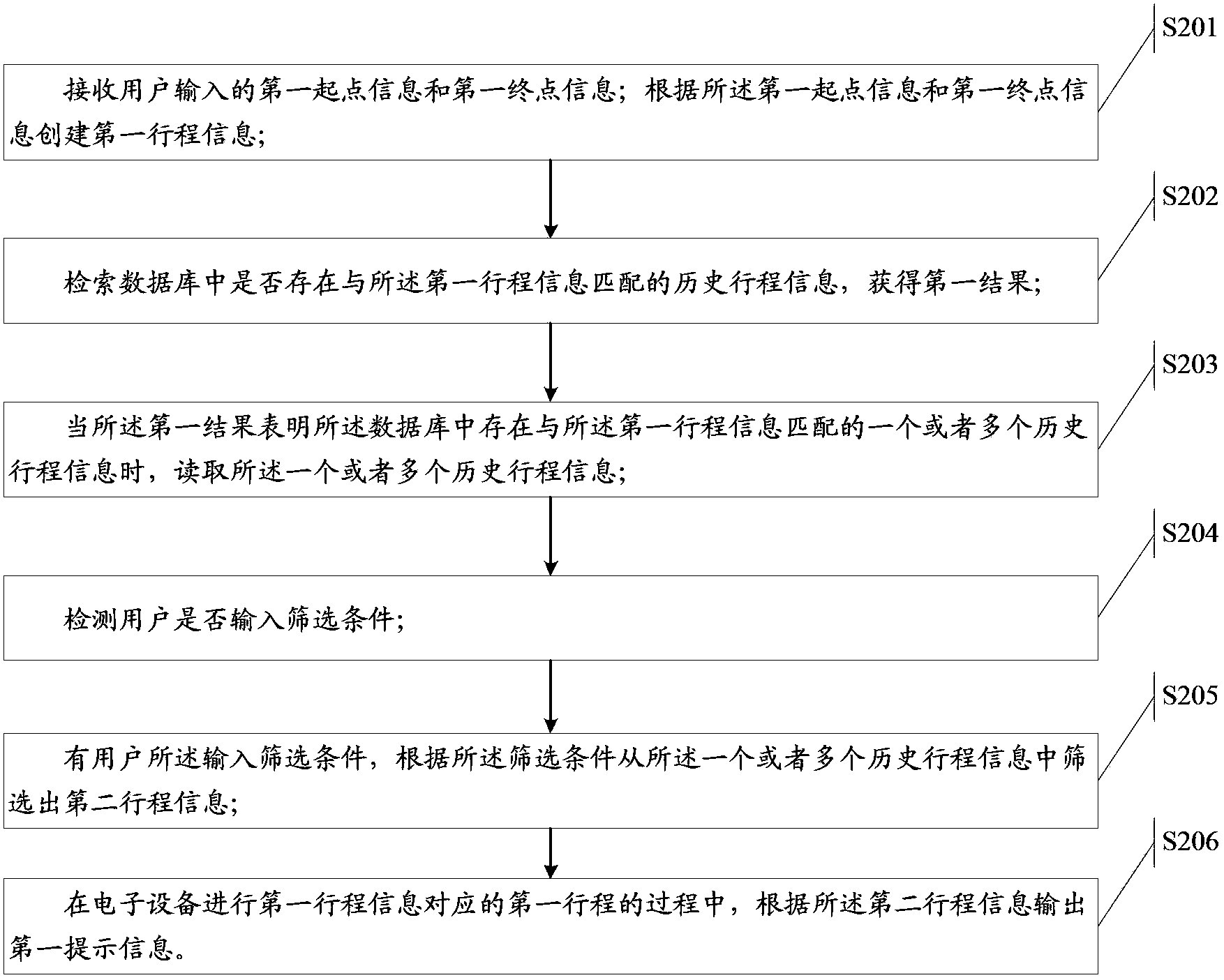

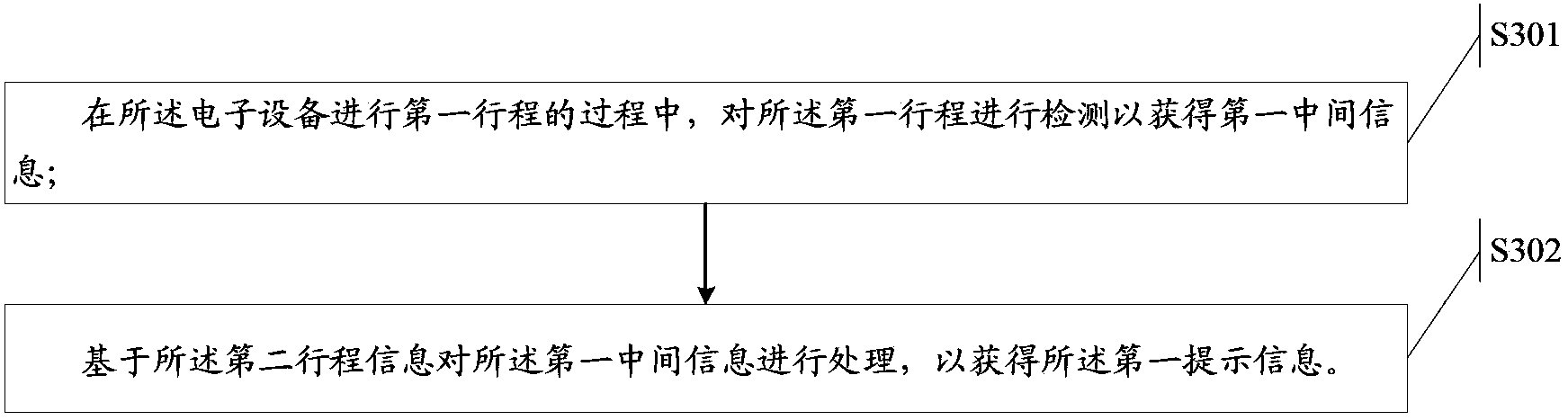

Method for processing information and electronic device

InactiveCN103544162AEffective predictionEasy to controlSpecial data processing applicationsMetadata based other databases retrievalUser inputData mining

The invention discloses a method for processing information and an electronic device. The method for processing the information comprises the steps that first starting point information and first end point information which are input by a user are received; first travel information is established according to the first starting point information and the first end point information; whether historical travel information matched with the first travel information exists in a database or not is retrieved, so that a first result is obtained; when the first result shows that one or more pieces of historical travel information matched with the first travel information exists in the database, the historical travel information is read; whether screening conditions are input by the user or not is detected; if the screening conditions input by the user exist, second travel information is screened from the historical travel information according to the screening conditions; in the process that a first travel corresponding to the first travel information is conducted by the electronic device, first prompt information is output according to the second travel information.

Owner:LENOVO (BEIJING) LTD

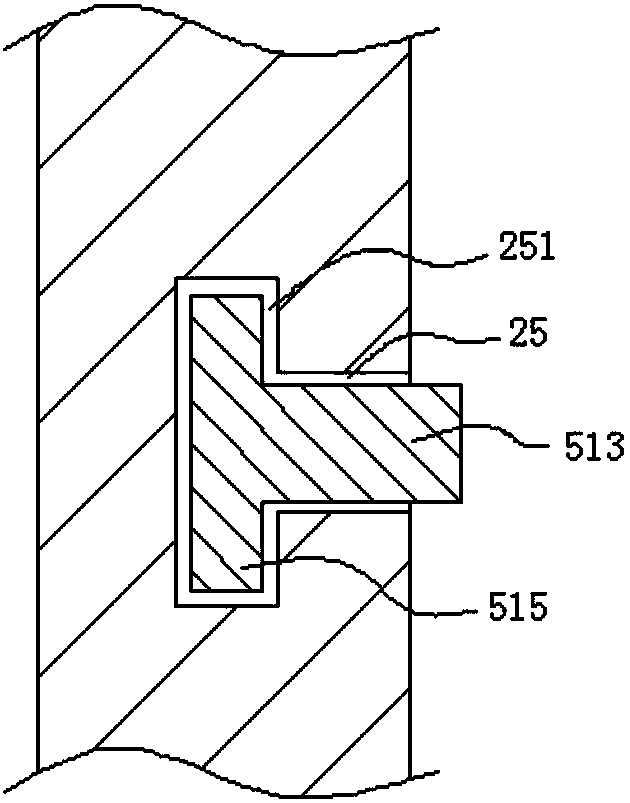

Furnace door body structure for diffusion furnace

PendingCN109373763ASimple structureAchieve sealingFurnace componentsFinal product manufactureSemiconductorQuartz

The invention relates to the technical field of semiconductor processing equipment, in particular to a furnace door body structure for a diffusion furnace. The furnace door body structure comprises afurnace door body and a furnace door driving mechanism. The furnace door body comprises a door supporting plate, a furnace door supporting shaft, a limiting rotary shaft, a radial knuckle bearing, analuminum door, a connecting plate and a quartz door. The furnace door driving mechanism comprises a bottom plate, two sliding bar assemblies, a supporting plate, a rodless cylinder, a sliding rail assembly, a furnace door connecting rod, a first cylinder, a second cylinder, a first cylinder connecting block, a second cylinder connecting block, a first limiting block, two first limiting switches, asecond limiting block and two second limiting switches. The furnace door structure body structure provided by the invention is simple in structure and good in sealing performance. The furnace door driving mechanism is smaller in occupied space and accurate in travel control. When the diffusion furnace adopts the furnace door body structure, the sealing performance of the furnace door body can meet the process requirements. The furnace door body as a whole does not need to be integrated with a boat feeding mechanism and is convenient to install and maintain, and the production efficiency is greatly improved.

Owner:无锡松煜科技有限公司

Snow removal device for electrical equipment

ActiveCN108539597AGuarantee job stabilityAvoid damageSubstation/switching arrangement casingsCleaning using toolsSurface layerProtection mechanism

The invention discloses a snow removal device for electrical equipment, and belongs to the field of electrical equipment maintenance devices. The snow removal device comprises a supporting lifting mechanism, a limiting protection mechanism, a moving mechanism and an ice and snow removal mechanism, wherein the limiting protection mechanism comprises a limiting rod and a rotary cutting disc; the rotary cutting disc can be driven to rotate and horizontally move; the ice and snow removal mechanism mainly comprises a spacing roller, a dislocation roller and a scraper roller; an ice shaving knives are distributed on the spacing roller and the dislocation roller; an ice scraping knife is arranged on the scraper roller; the distance between the bottom of each roller and the rotary cutting disc isequal to that between the bottom of a limiting sleeve and the top of a limiting rod; the rollers and the limiting sleeve move synchronously; collecting holes penetrating through corresponding knife bodies and communicated with corresponding rollers are formed in the ice shaving knives and the ice scraping knife; and a suction ventilator communicated with a corresponding roller is mounted at one end of each roller. The snow removal device is accurate in mechanism travel control, can prevent the surface layer of the electrical equipment from being damaged, is high in ice and snow removal efficiency and good in effect, and can further prevent snow water from permeating the electrical equipment after ice and water are molten.

Owner:李慧

Construction crushing device

ActiveCN108246405AIncrease speedReduce damage rateSievingFeeding-stuffEngineeringEnergy conservation

The invention provides a construction crushing device. The construction crushing device comprises a supporting frame, a box arranged on the supporting frame, a first crushing part, a second crushing part, a driving component and a screen plate, wherein the first crushing part and the second crushing part are rotatably arranged in the box; the driving component is used for driving the two crushingparts to rotate; the screen plate is arranged below the crushing parts. The driving part comprises a driving part arranged on the first crushing part, a driven part arranged on the second crushing part and matched with the driving part in a driving mode and a power part used for driving the first crushing part to rotate. When the power part drives the first crushing part to rotate, the second crushing part and the first crushing part rotate in opposite directions. Through cooperation of the driving part and the driven part, the construction crushing device can drive the two crushing parts through a power source. Electric energy consumption and input of the power source are reduced. Energy conservation and environmental protection are achieved. The project input cost is effectively reduced.

Owner:NINGBO CONSTR GRP

Double-sided gumming machine

InactiveCN105983505AAccurate stroke controlGuaranteed accuracyLiquid surface applicatorsCoatingsControl valvesControl theory

The invention provides a double-sided gumming machine which comprises a rack, a glue evening-up roll, a glue spreader, two operating cylinders, a master control cylinder, a three-way unit and a hand control valve; the glue evening-up roll and the glue spreader are arranged in the rack and are parallel to each other; piston rods of the two operating cylinders are respectively movably connected with two ends of the glue evening-up roll; the master control cylinder is located in the middle of the bottom of the rack, the piston rod of the master control cylinder is inserted into a tube leg of the three-way unit and clings to the inner wall of the tube leg, the other two tube legs of the three-way unit are respectively connected with air inlets of the two operating cylinders by air pipes with equal length; and an adjustable valve is arranged at the front end of the air inlet of the master control cylinder. The double-sided gumming machine has the benefits of changing direct manual control on lifting of the glue evening-up roll in a conventional double-sided gumming machine into cylinder adjusting control, thus saving labor; and meanwhile, the adjusting valve can accurately control the stroke of the operating cylinders, thus ensuring the precision of a clearance between the glue evening-up roll and the glue spreader, reducing the defective percentage of gluing of corrugated paper, and saving production cost.

Owner:TIANJIN YINGTANSHENG PAPER PROD

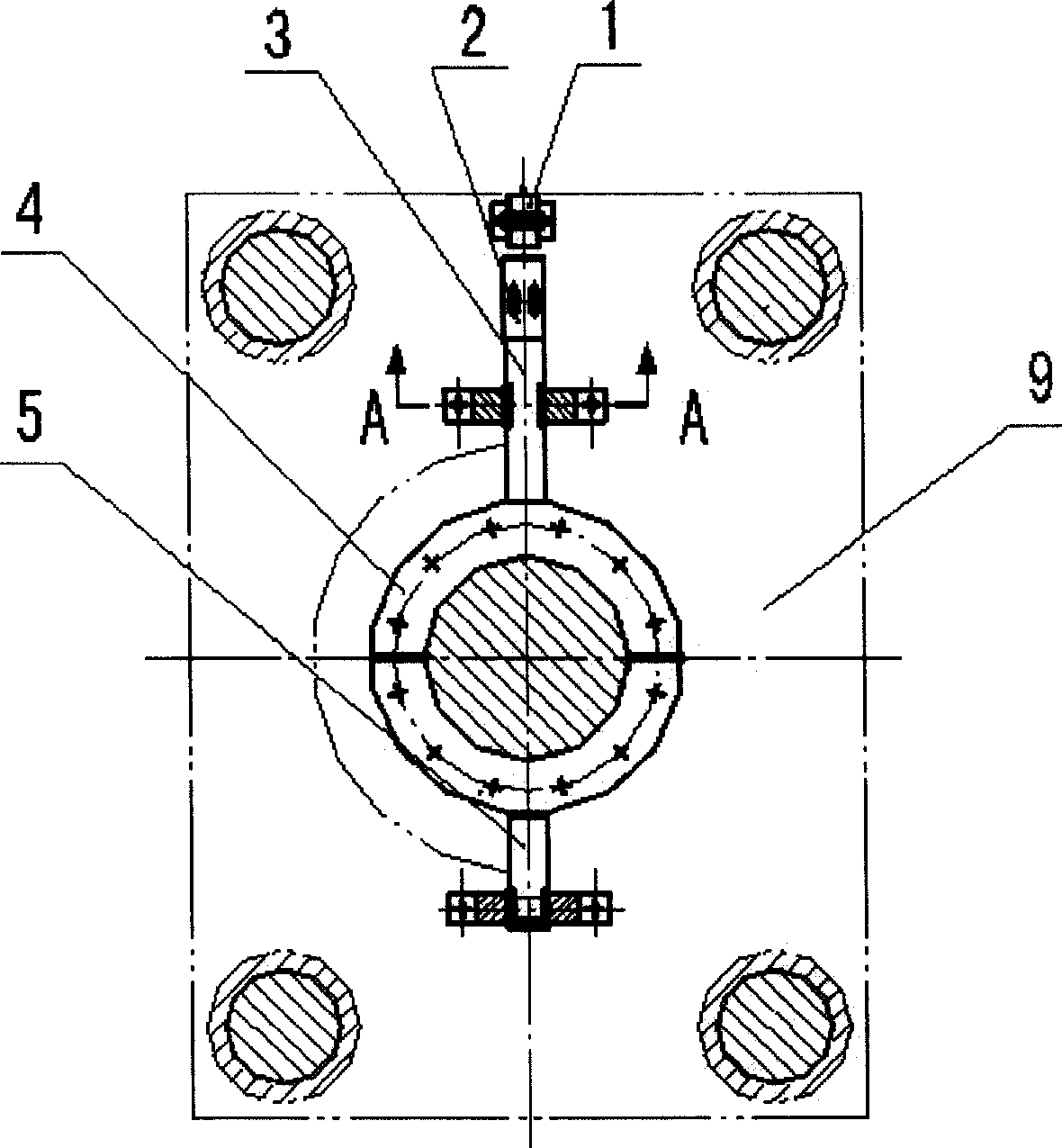

Valve plate valve opening trimming device

InactiveCN104259536AAccurate stroke controlImprove work efficiencyMilling equipment detailsLeft directionMilling cutter

The invention belongs to the technical field of the manufacturing of a valve, and in particular relates to a valve plate valve opening trimming device. The valve plate valve opening trimming device comprises a worktable, two trimming mechanisms and a tightening mechanism, wherein the trimming mechanisms and the tightening mechanism are respectively fixed on the worktable, the two trimming mechanisms are respectively fixed on the worktable, the tightening mechanism is arranged between the two trimming mechanisms, each trimming mechanism mainly consists of a first motor, a second motor, a transmission case, a reduction box and milling cutters, the first motor is arranged on the upper part of the reduction box, the output end of the first motor is connected with the input end of the reduction box through the transmission case, a slide plate is fixedly arranged on the bottom of the reduction box, the slide plate is in sliding fit with a slide rail which is fixed on the worktable, the bottom of the slide plate is provided with a lead screw sleeve, and the lead screw sleeve is matched with a lead screw. The two milling cutters can be used for simultaneously shaping a left hole and a right hole of a valve plate in the left direction and the right direction, the milling cutters can be replaced only by releasing a triangular chuck after the shaping, and the working efficiency is greatly improved.

Owner:TIANJIN AORUITE VALVE

Friction wear test system

PendingCN112730125AGood repeatabilityHigh friction measurement accuracyMaterial testing goodsInvestigating abrasion/wear resistanceControl systemEngineering

A frictional wear test system is provided by the invention, and comprises a base, a vibration exciter, a stroke push rod, a heating table, an oil box, a loading mechanism, a first displacement sensor, a force measuring mechanism, a vibration isolation supporting plate, a second displacement sensor and a control system. The vibration isolation supporting plate is arranged on the base in a floating mode, and the heating table is arranged on the vibration isolation supporting plate through an elastic support. The second displacement sensor is arranged on the vibration isolation supporting plate and configured to measure second displacement generated between the stroke push rod and the vibration isolation supporting plate. The control system is electrically connected to the first displacement sensor, the second displacement sensor and the vibration exciter, and the control system is configured to calculate feedback values of the stroke and the frequency of the stroke push rod according to the first displacement and the second displacement and compare and analyze the feedback values with preset values so as to control the vibration exciter to output the preset stroke and the preset frequency.

Owner:CHINA PETROLEUM & CHEM CORP +1

Stable silicon controlled rectifier (SCR) urea injector easy to control

ActiveCN103775175AGuaranteed stable workEnsure consistencyInternal combustion piston enginesExhaust apparatusSilicon-controlled rectifierEngineering

The invention relates to a diesel engine exhaust post processing device, in particular to a stable silicon controlled rectifier (SCR) urea injector easy to control. The injector comprises a valve seat couple, an electromagnetic valve part, a spacer ring, a spring, a spring seat, a limit pin and a connection device. The valve seat couple comprises a valve seat and a valve core assembly which are in sliding fit. The valve core assembly comprises a valve core and an armature. One end of the valve core is inserted into a middle hole of the valve seat, and the other end stretches out of the valve seat to be connected with the armature. The spacer ring is sleeved on the valve core and located between the armature and the valve seat, one end of the spacer ring is in abutting connection with the end face of the valve seat, a countersink is formed in the other end face, and the armature is contained in the countersink. One end of the electromagnetic valve part is a wiring end, a center hole I is formed in the other end in the axial direction, the limit pin and the spring seat and the spring which are sleeved on the limit pin are contained in the center hole I, and the limit pin is higher than the end face of the electromagnetic valve part. One end of the valve seat couple with the armature is connected with the other end of the electromagnetic valve part through the connection device, and the other end of the spacer ring is in abutting connection with the other end face of the electromagnetic valve couple. The urea injector is sufficient in electromagnetic force and good in spraying effect and saves cost.

Owner:钧风电控科技泰州有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com