Patents

Literature

40results about How to "Avoid rotational offset" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

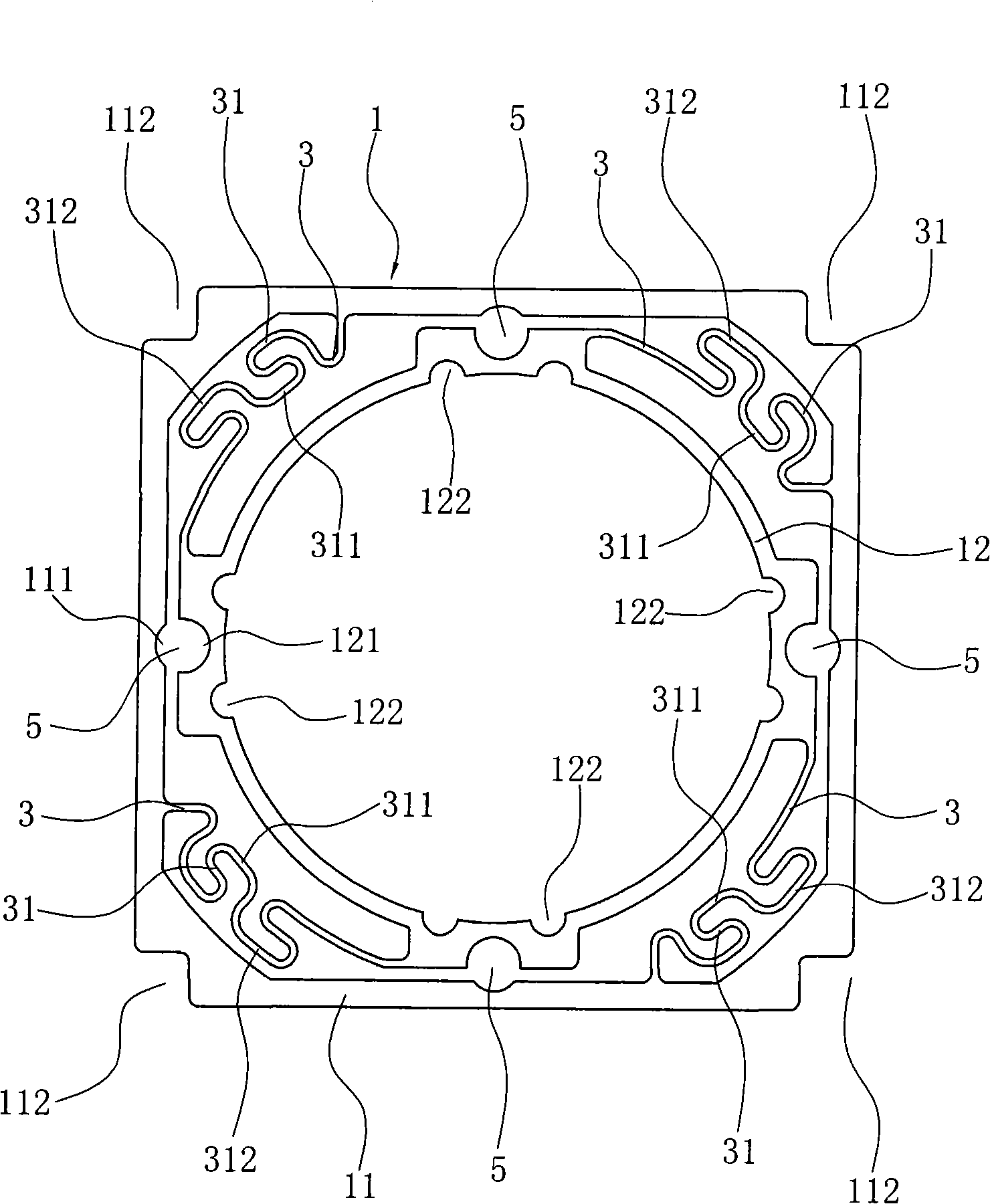

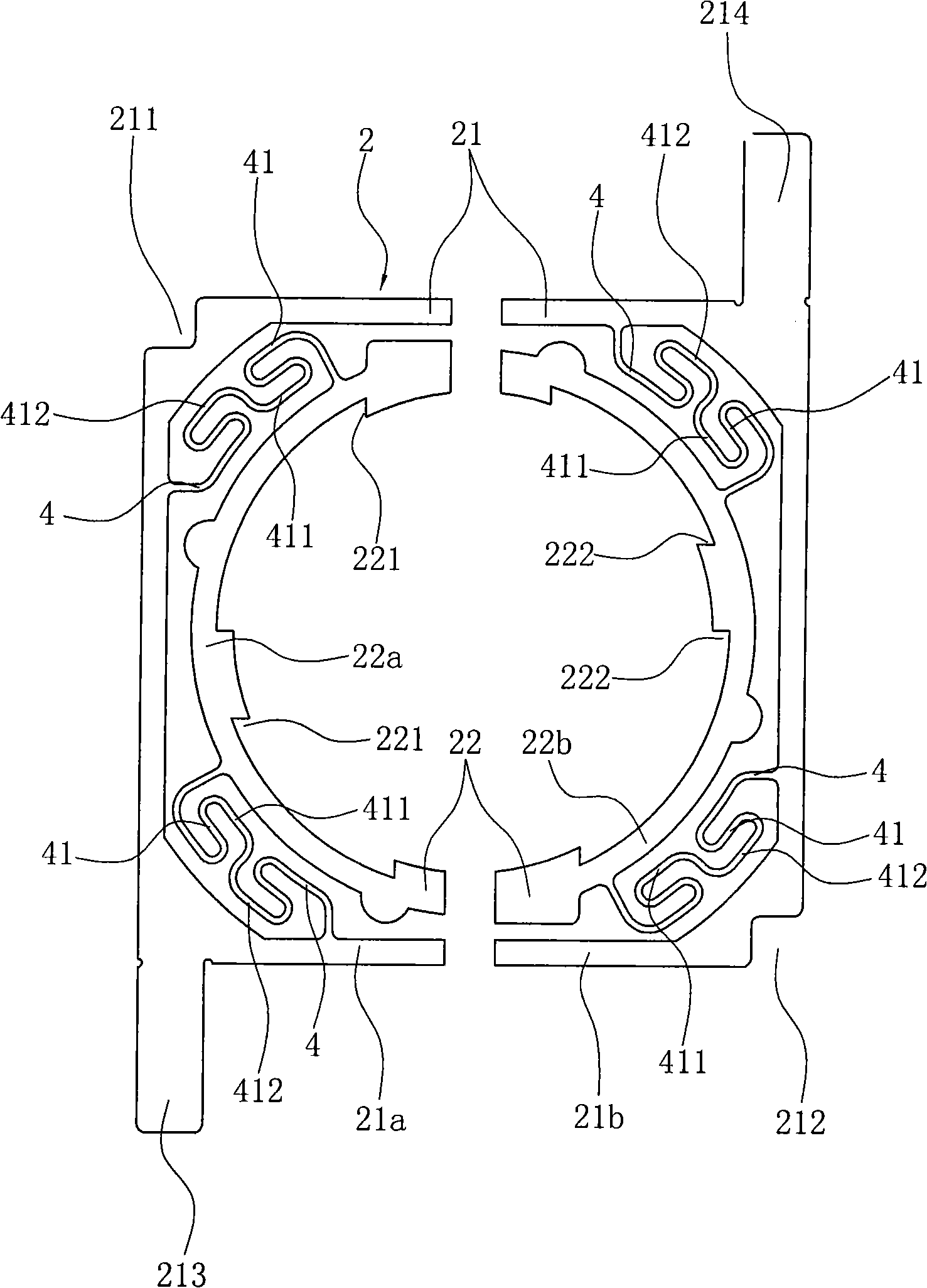

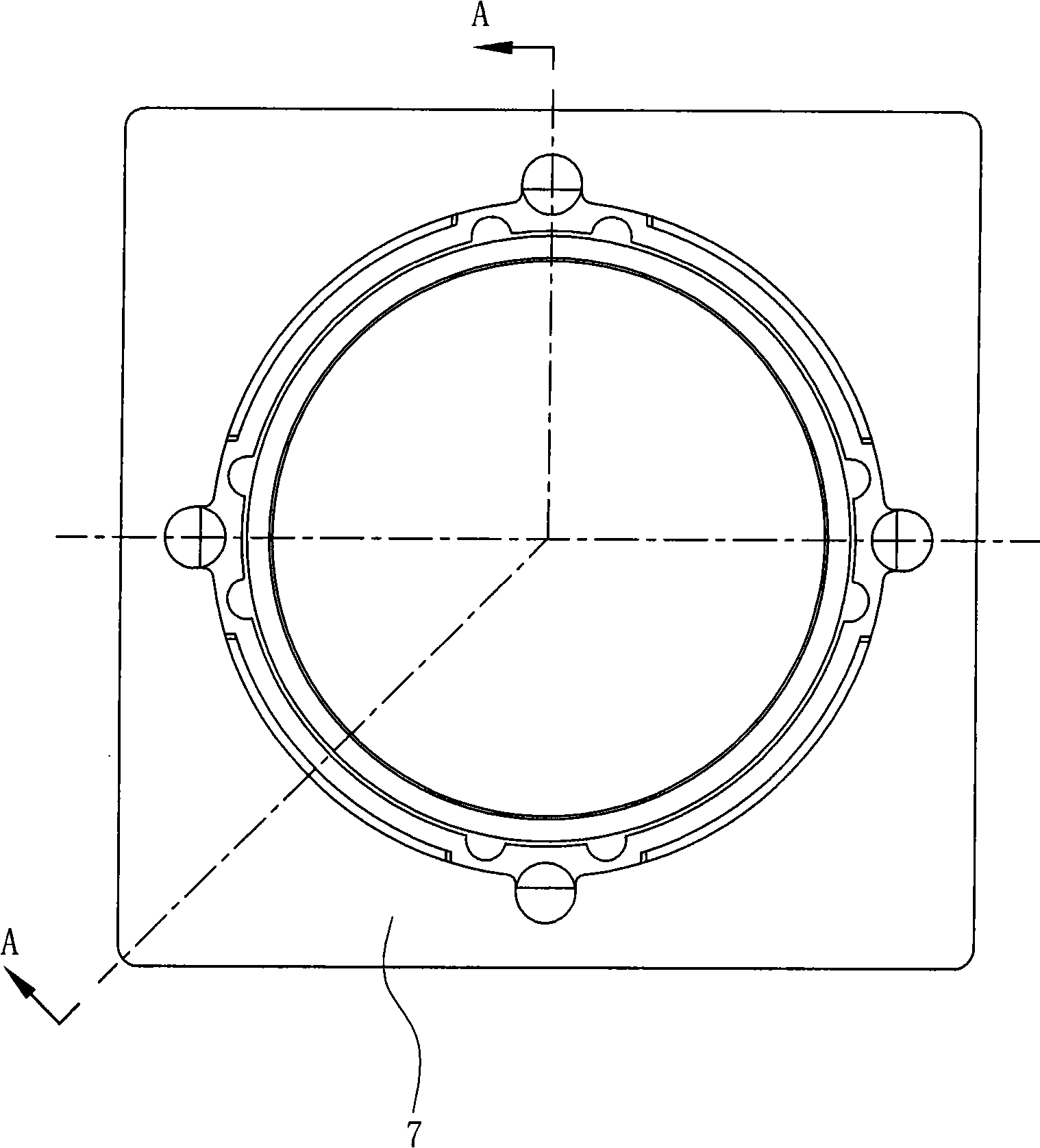

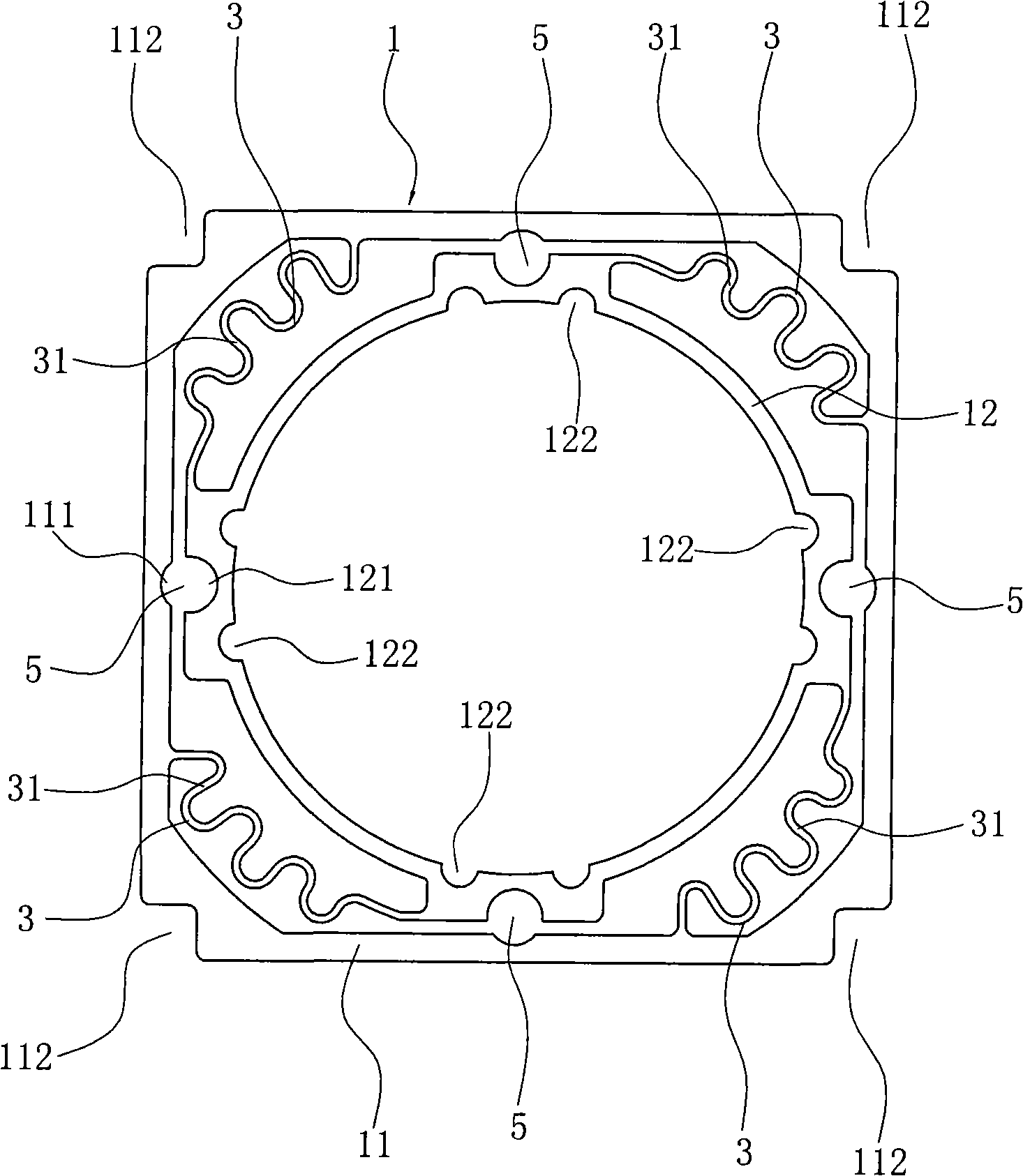

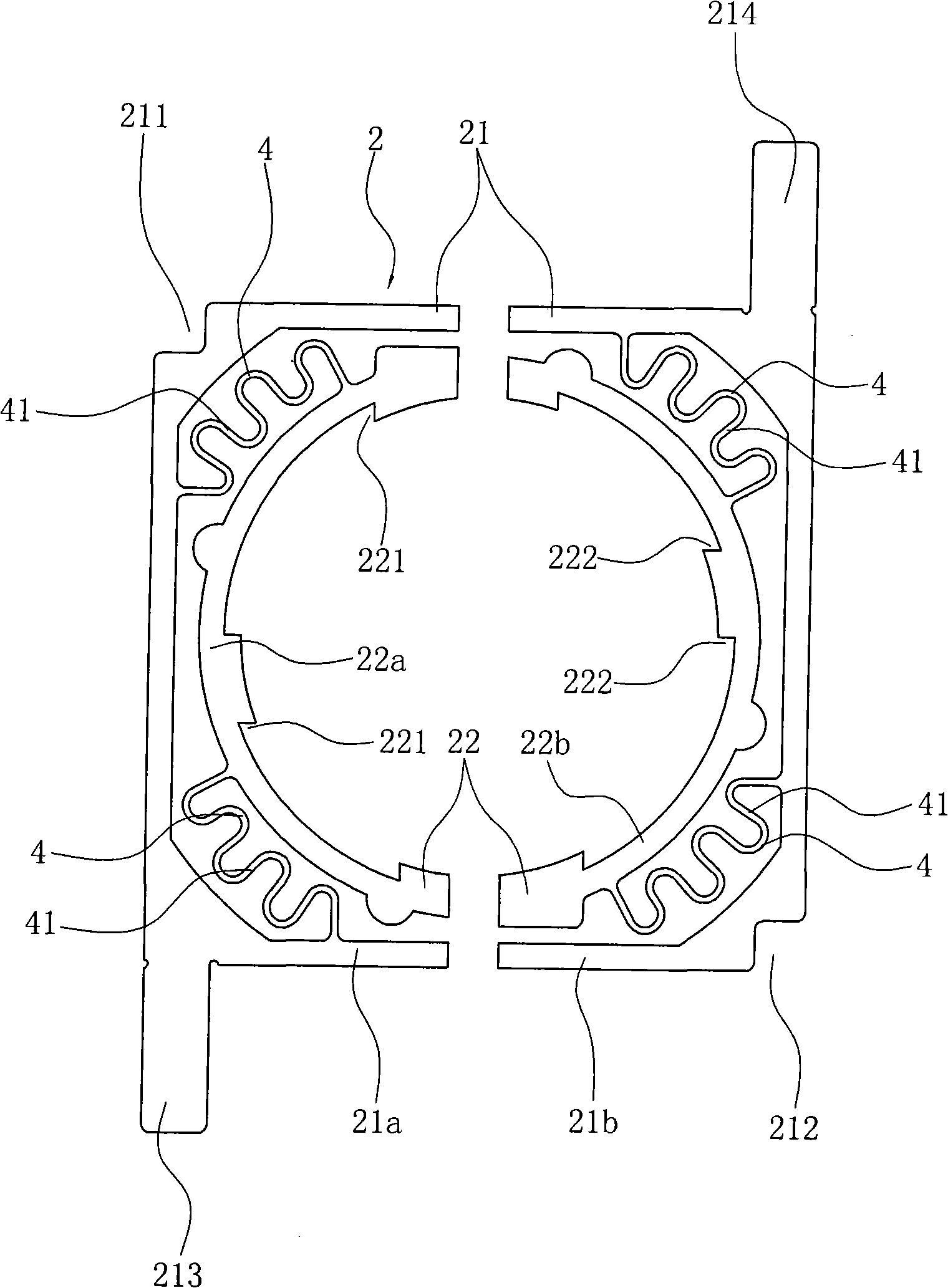

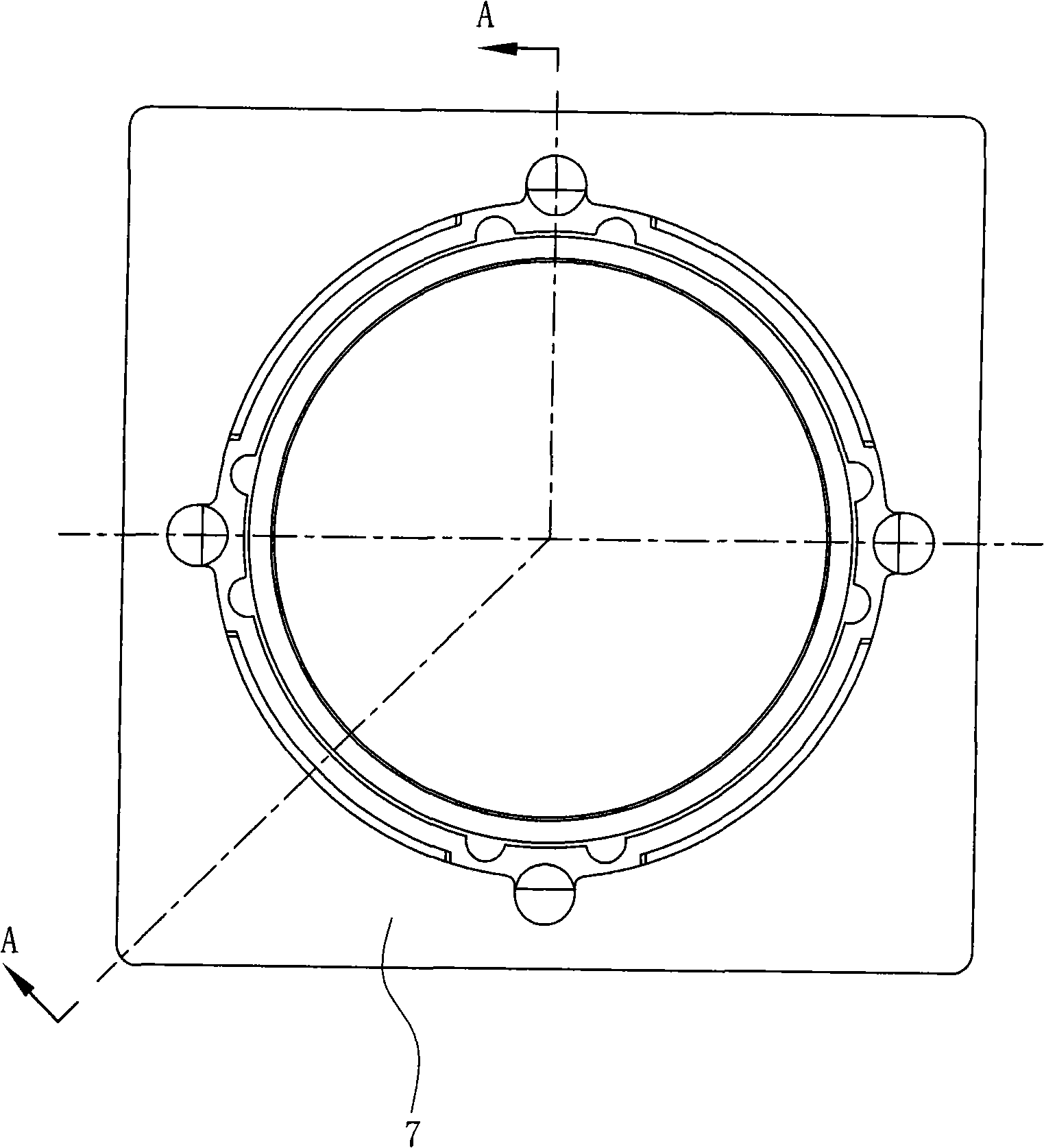

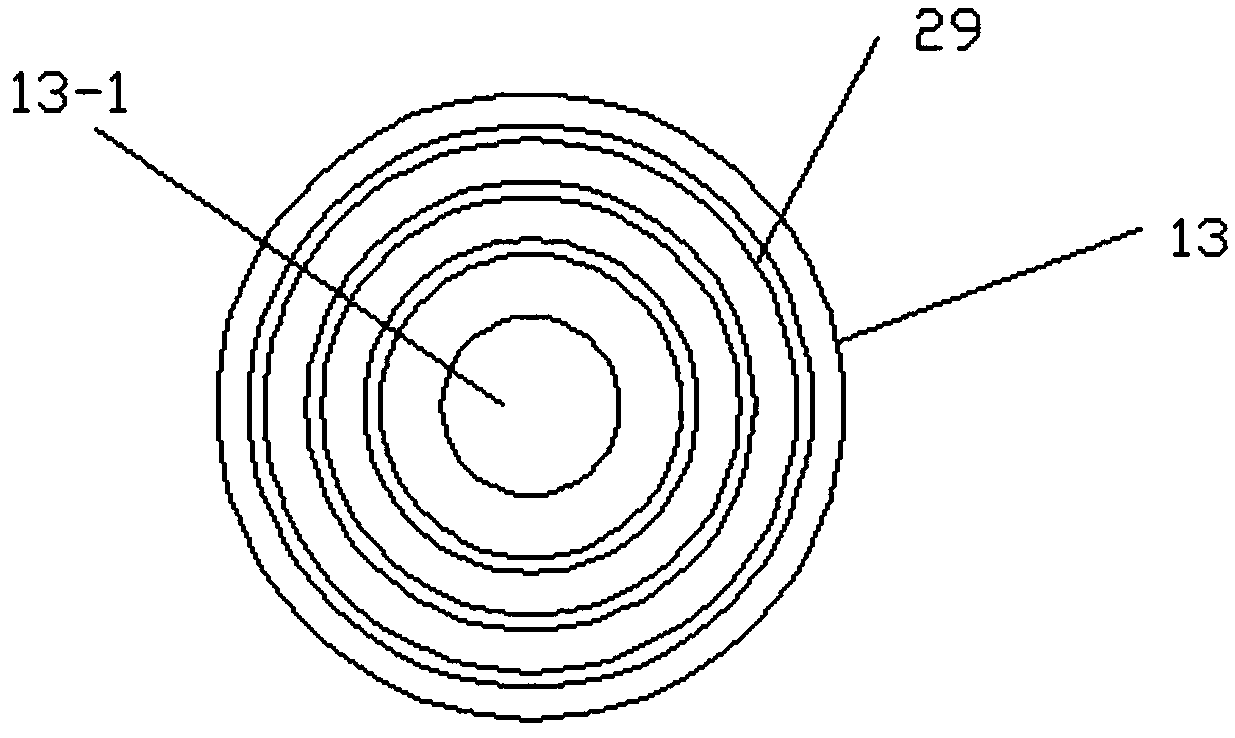

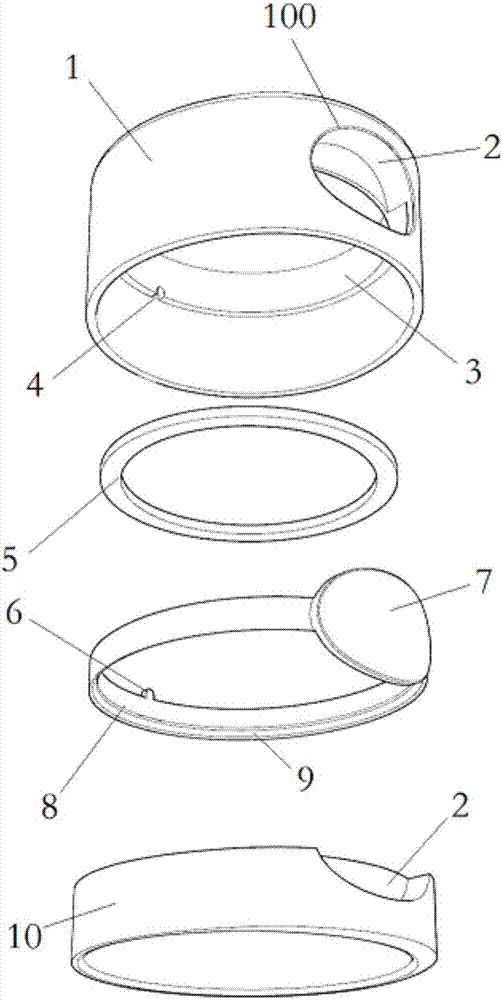

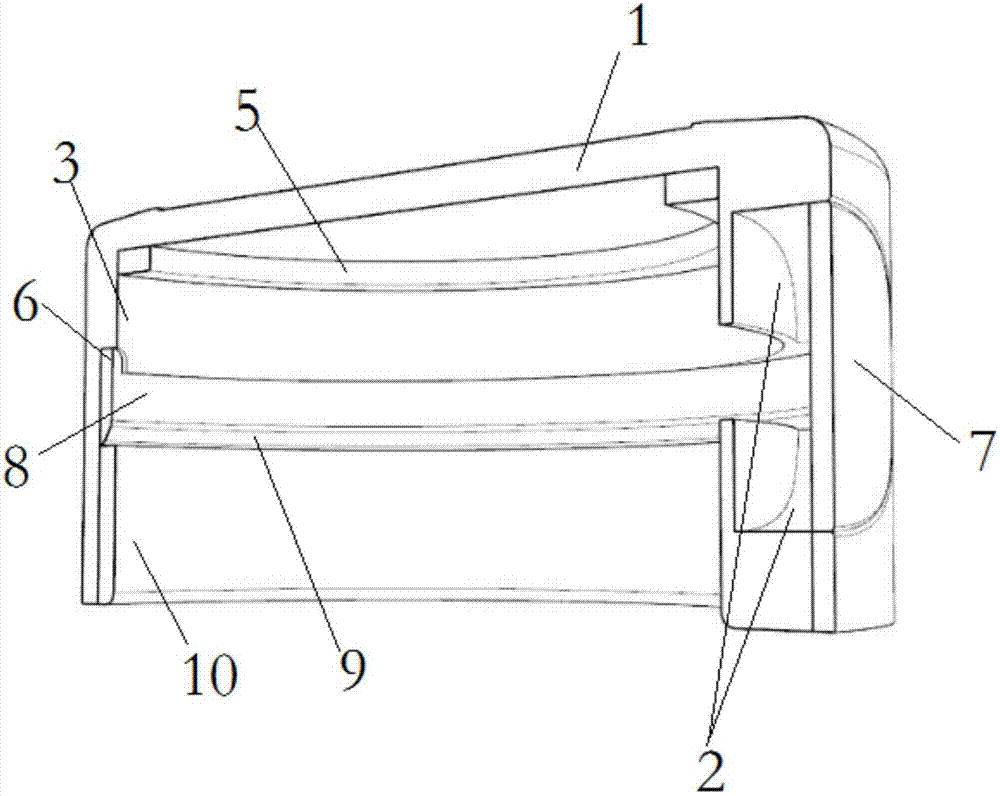

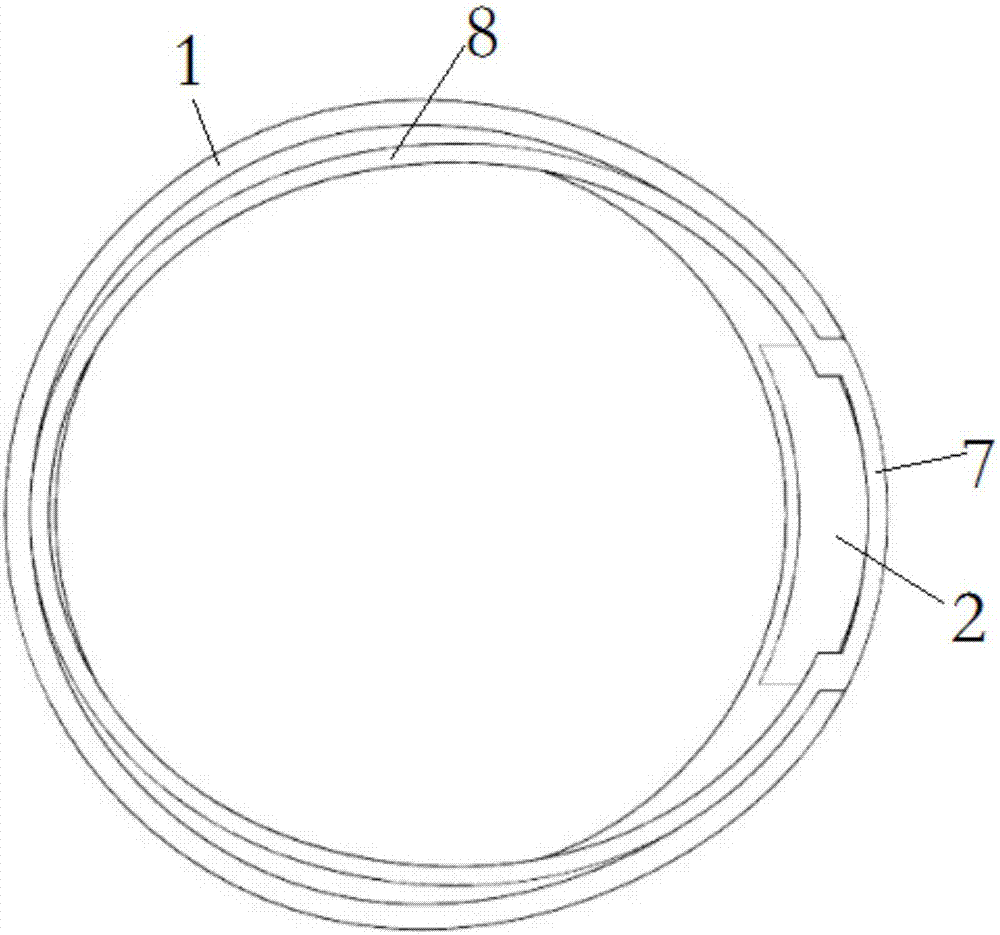

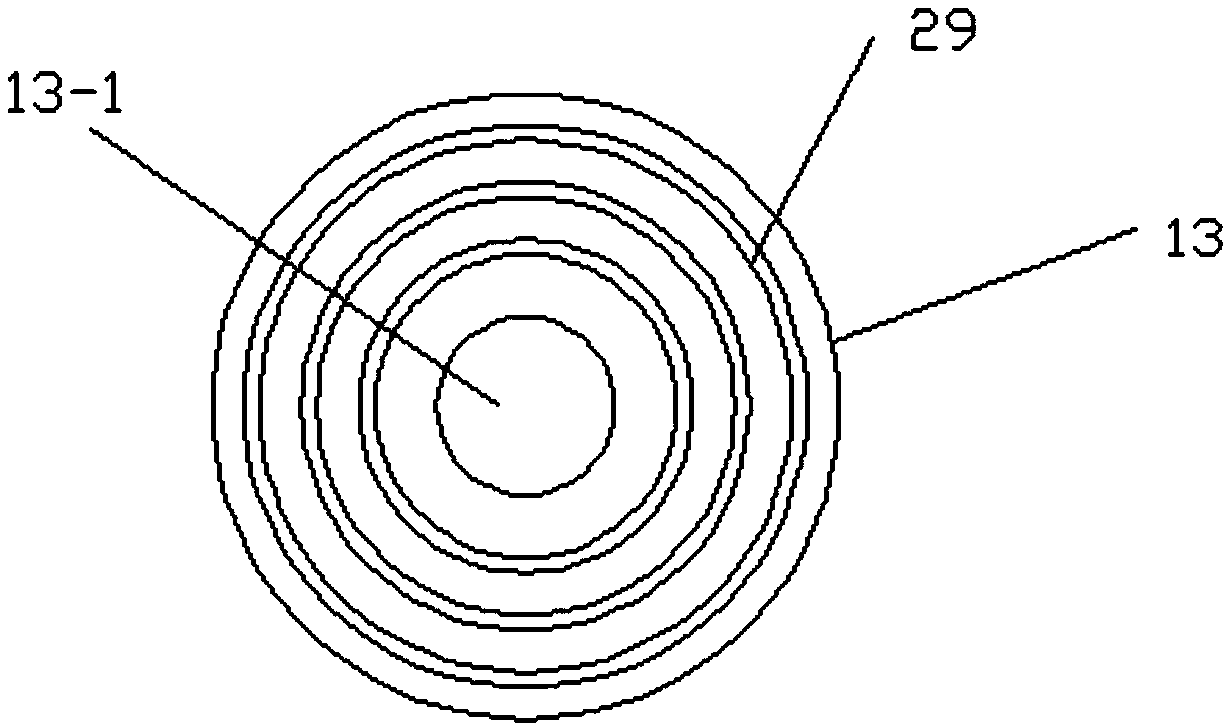

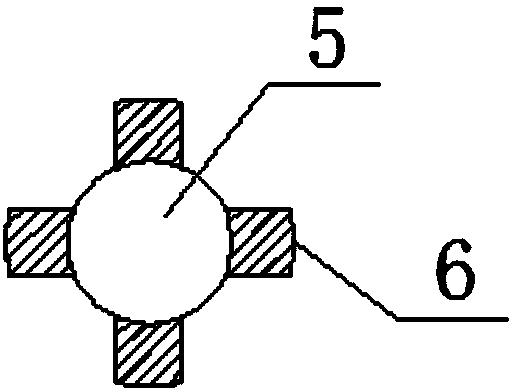

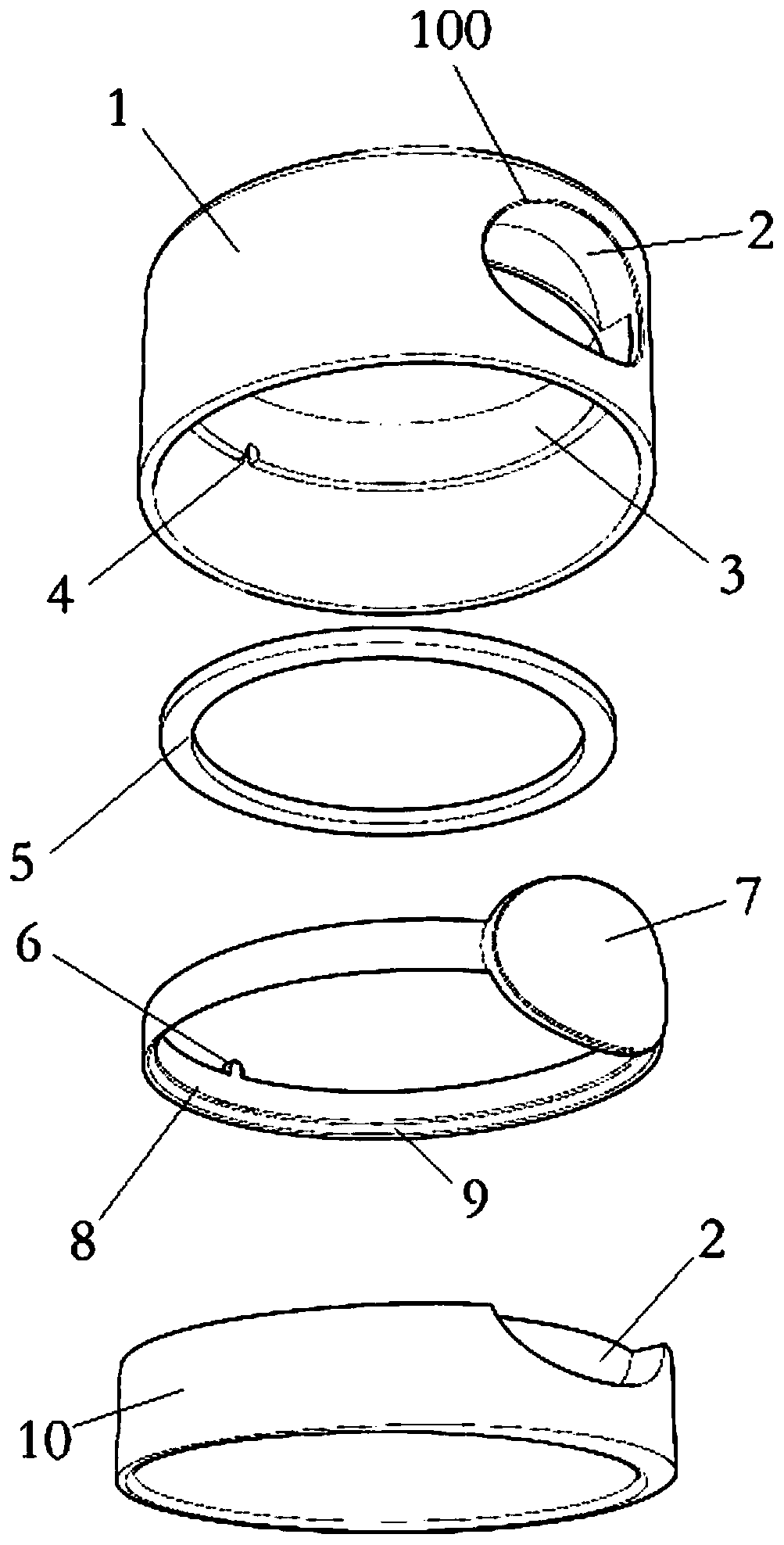

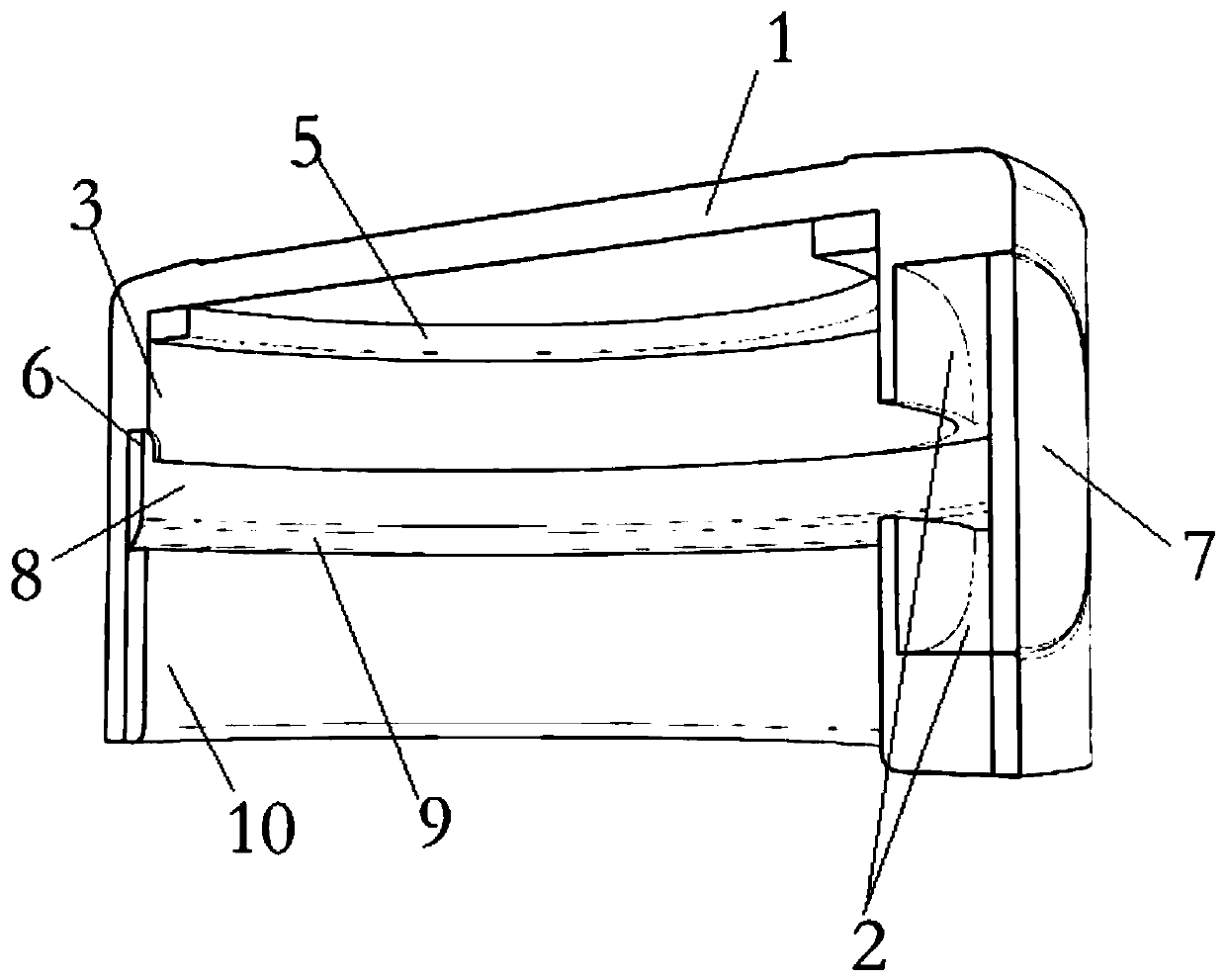

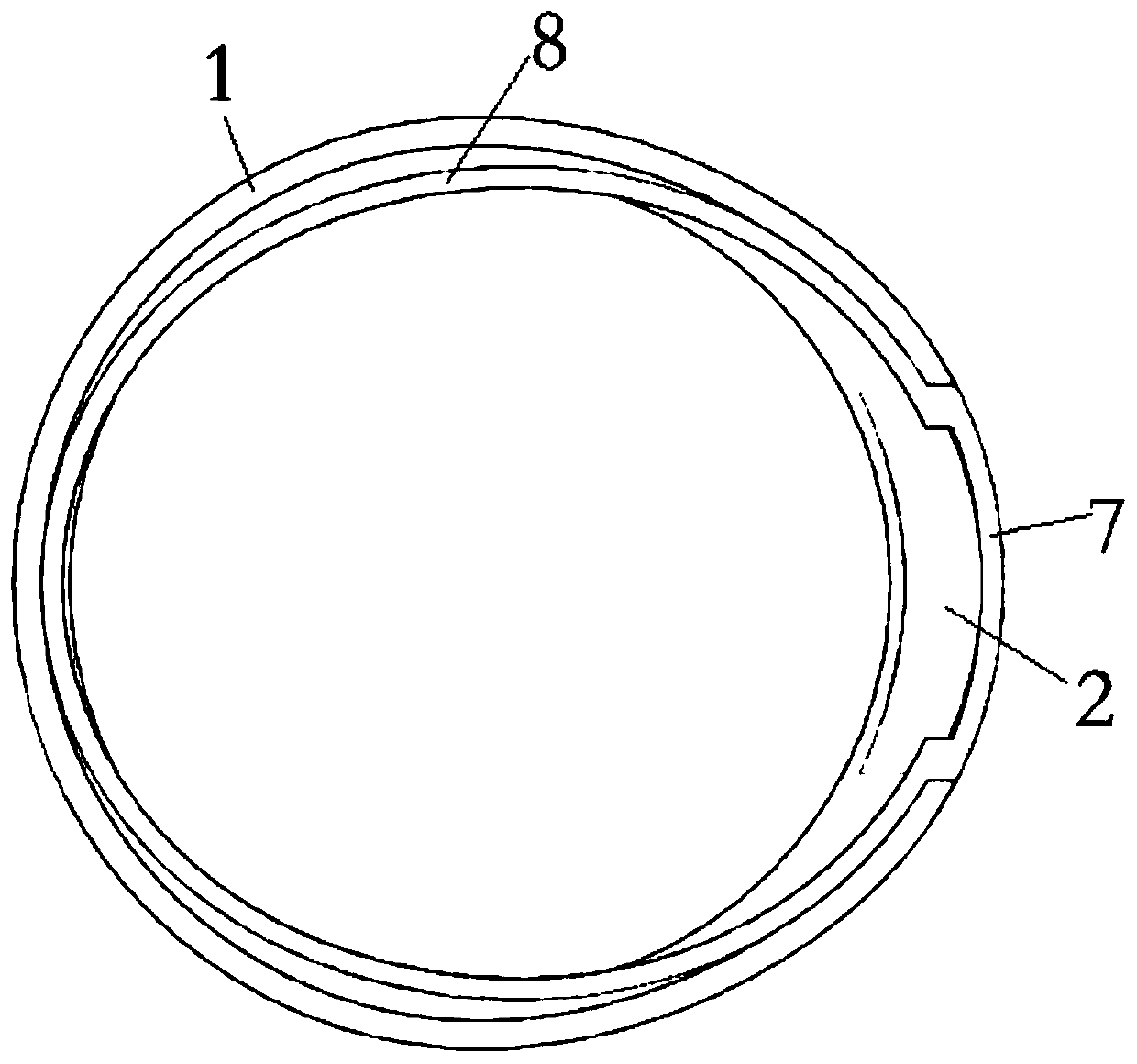

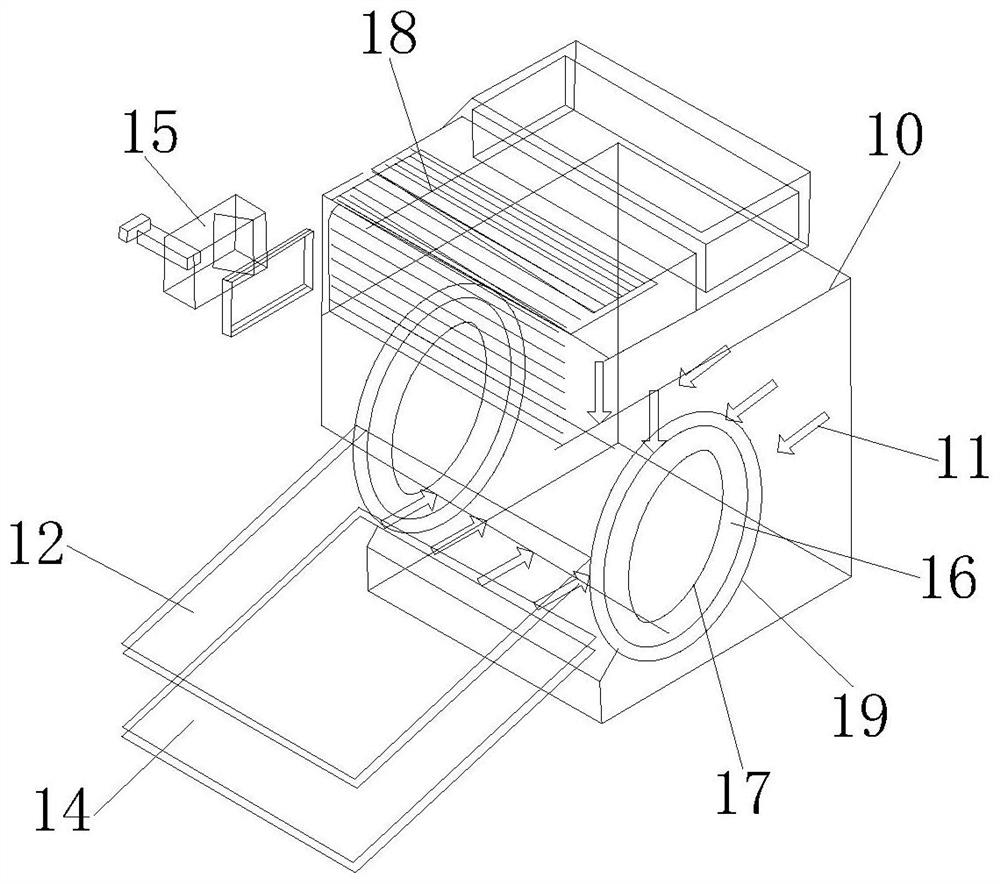

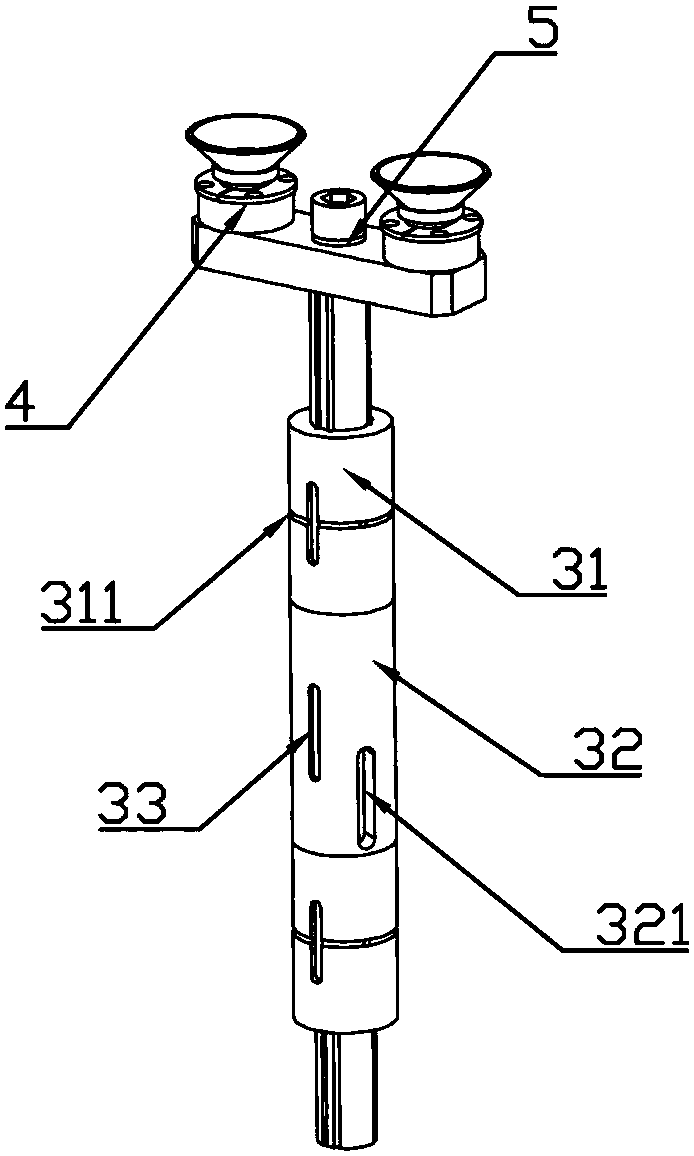

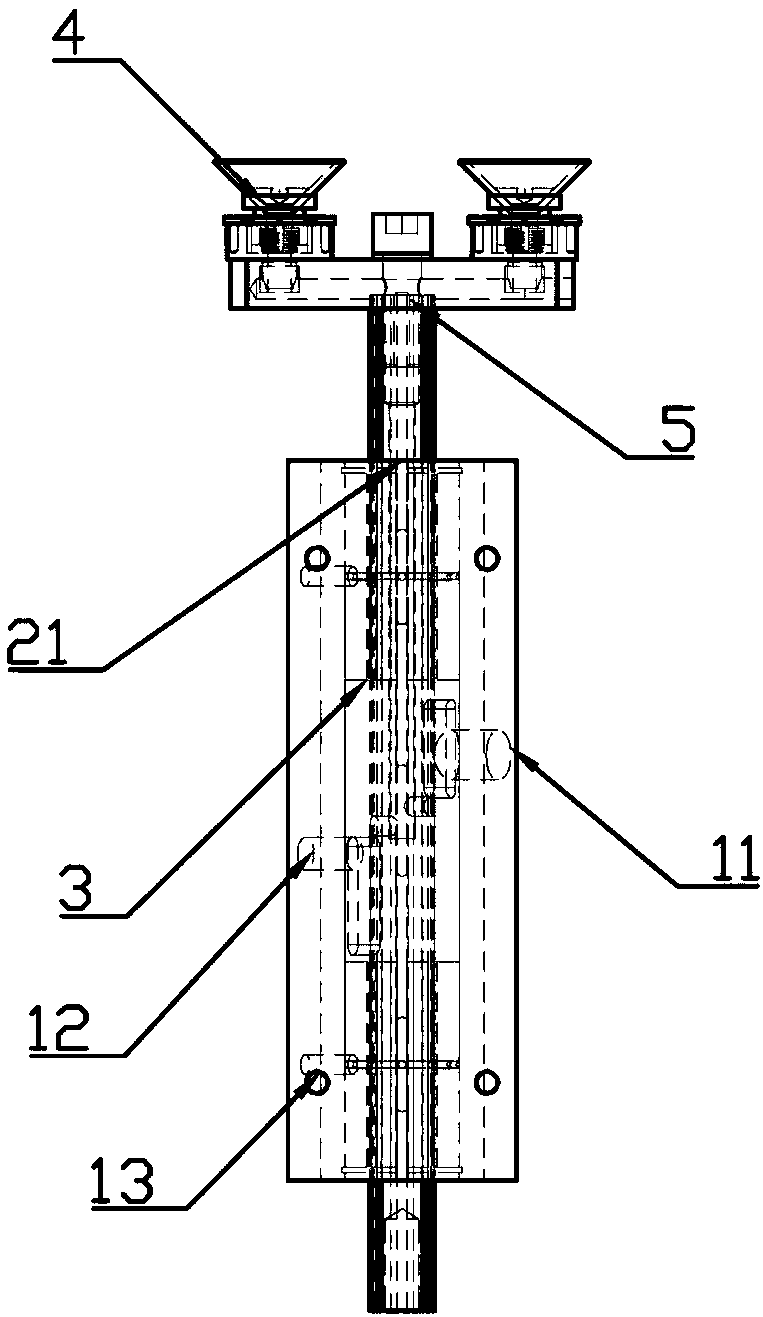

Reed for driving mechanism of camera lens

The invention relates to a reed used on a camera lens drive mechanism; the entire reeds (1,2) are shaped as thin sheets and are composed of annular outer profiles (11,21) and annular inner profiles (12,22) inside the outer profiles; gaps are arranged between the inner walls of the outer profiles and the outer walls of the inner profiles; and at least two alternately arranged connecting spring wires (3,4) are connected between the outer profiles and the inner profiles. The invention is characterized in that the connecting spring wires are arranged in a circumferentially consecutive double-S-shaped coil form; in two adjacent S-shaped parts (31,41), the lower edges (311,411) of the front S-shaped part are connected with the upper edges (312,412) of the back S-shaped part; the outer profiles are square or rectangular, while the inner profiles are circular; and the connecting spring wires are arranged at the corners and edges of the outer profiles. Through the coiling effect of the S-shaped parts, the anti-deformation ability can be improved; the connecting spring wires are provided with good flexibility, and the overall stiffness and impact resistance can be effectively upgraded to ensure good imaging quality of the lens drive structure using the reed.

Owner:NINGBO JCT ELECTRONICS

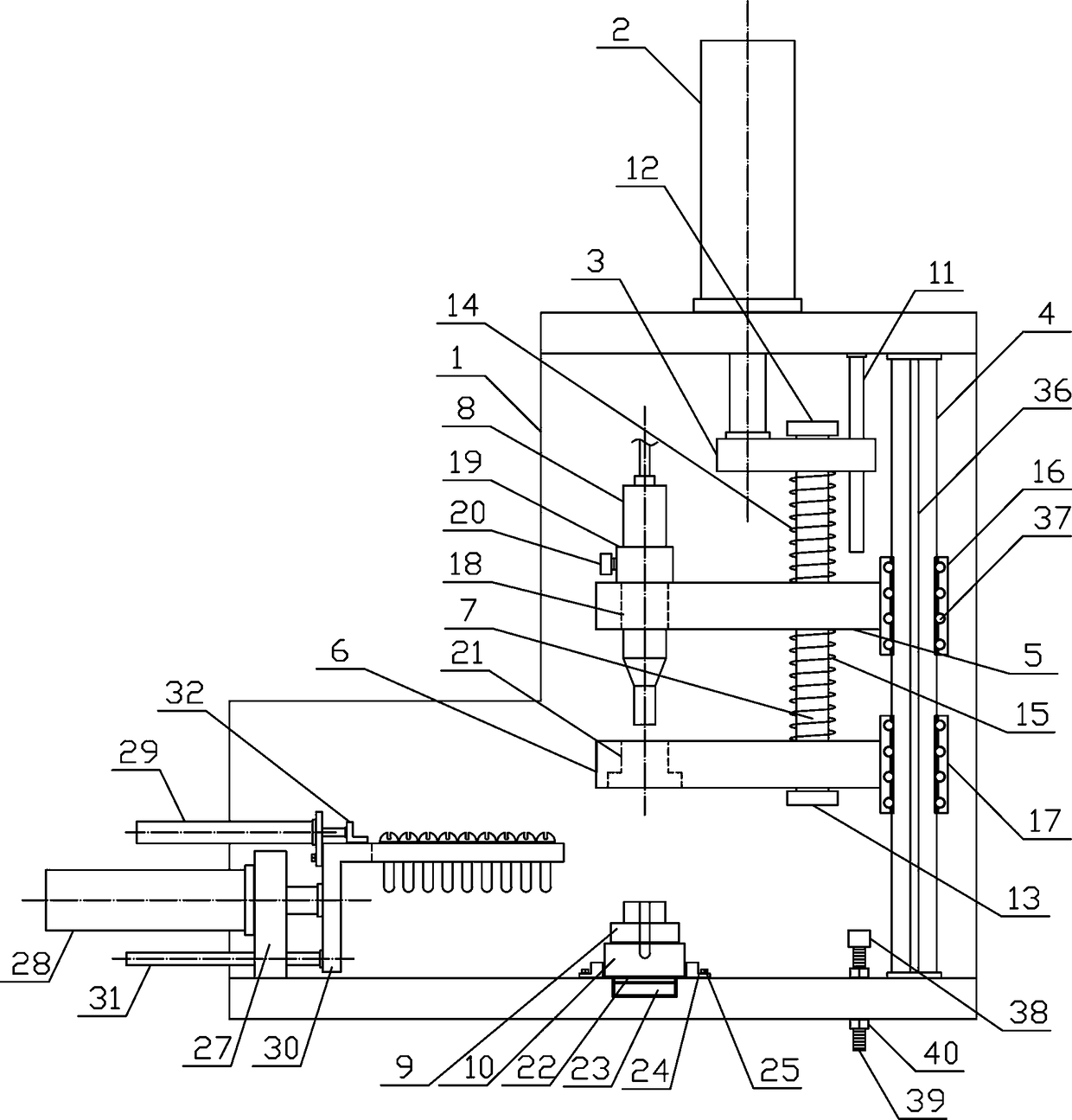

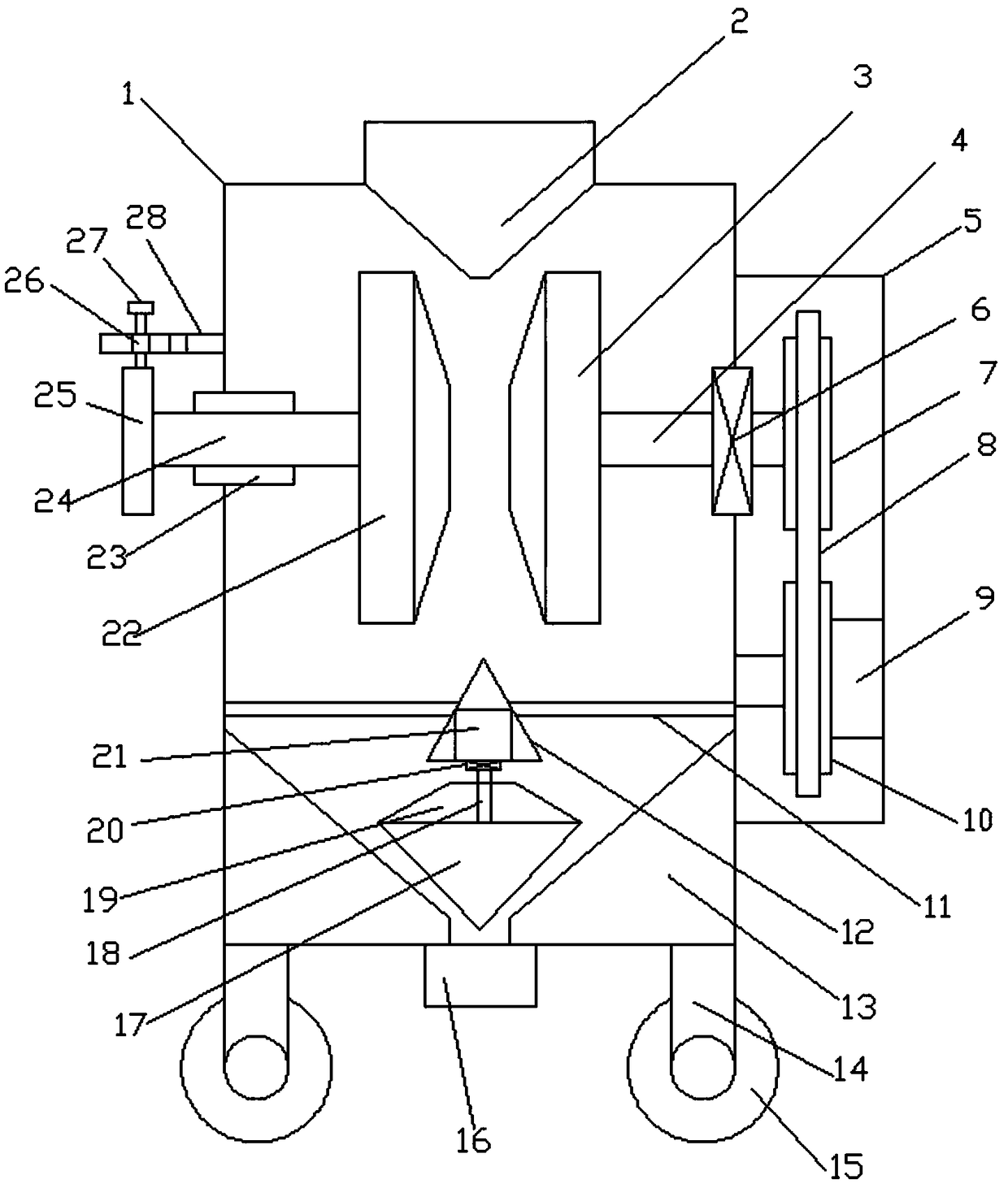

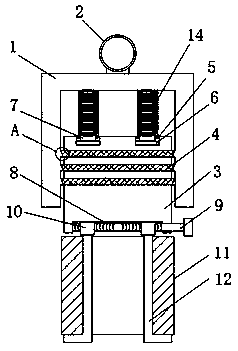

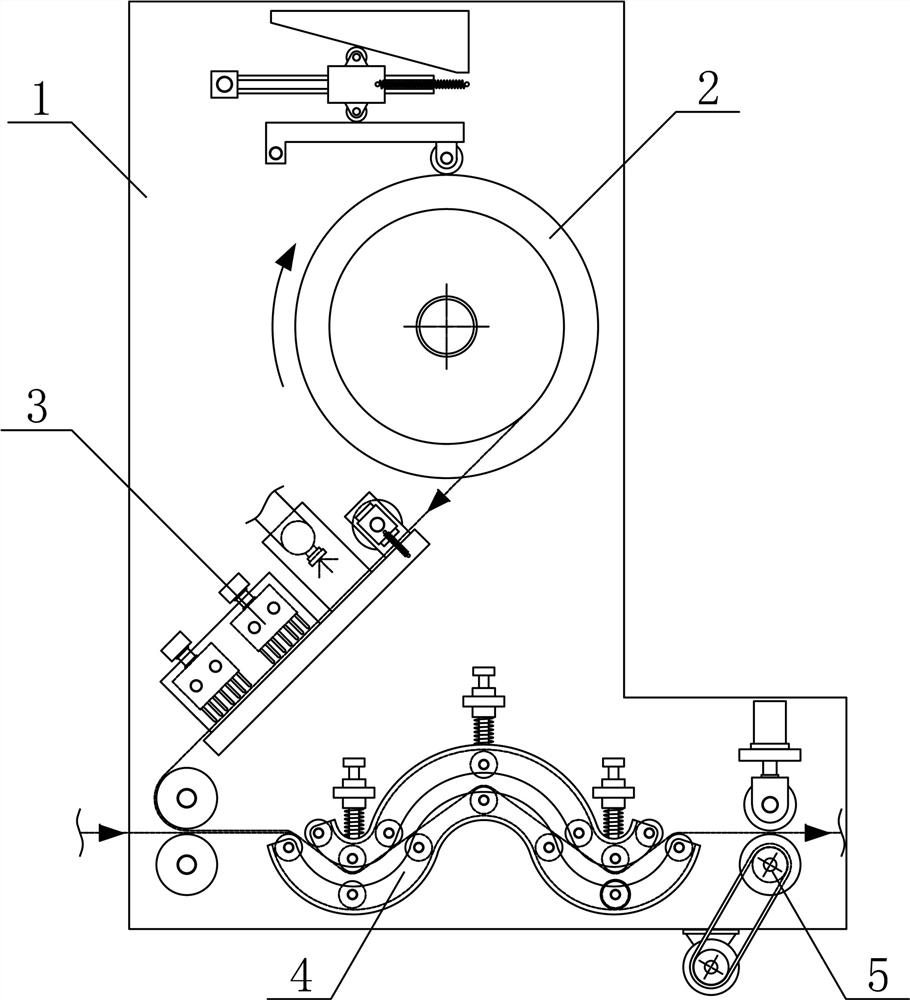

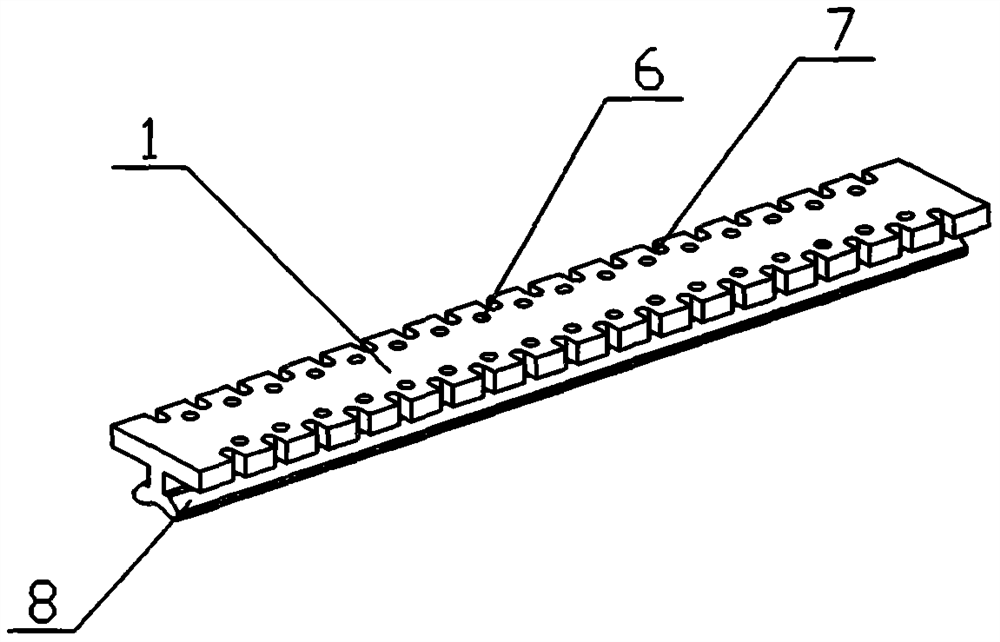

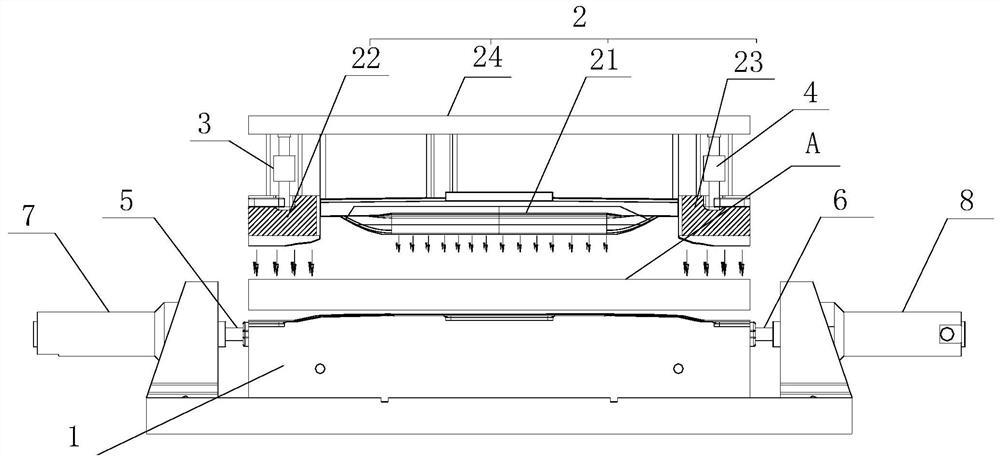

Workpiece assembling mechanism

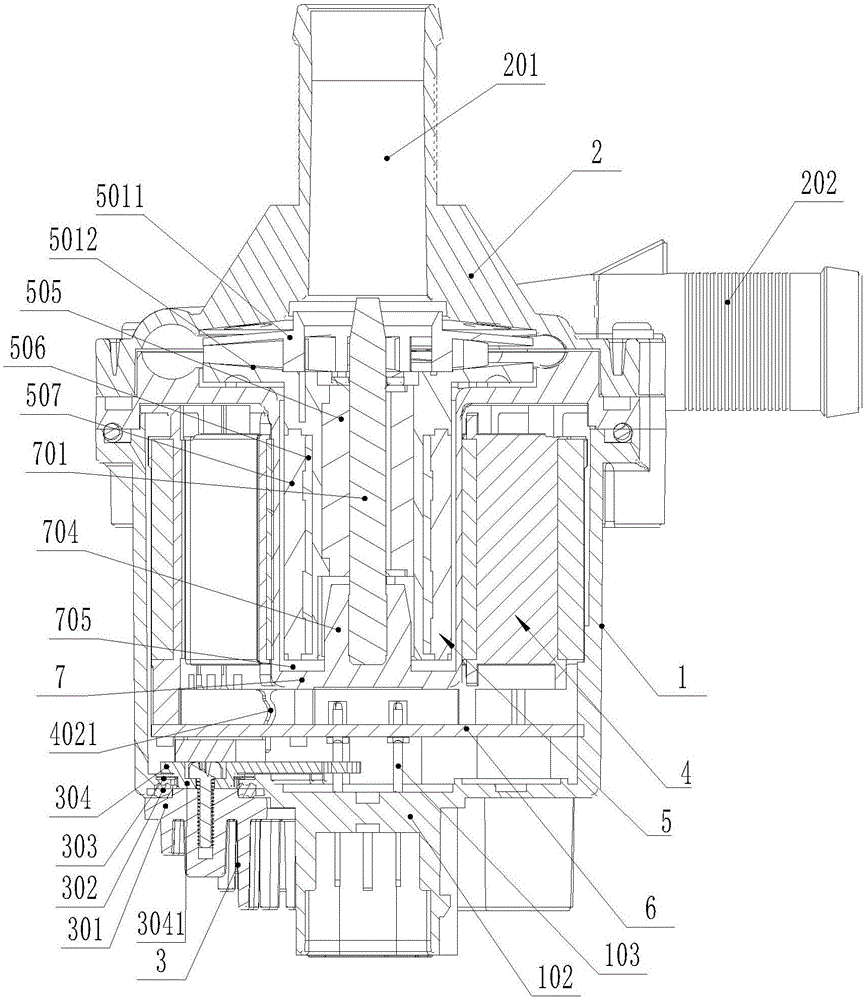

InactiveCN108161383AAssembled preciselyEasy to take outMetal working apparatusEngineeringMechanical equipment

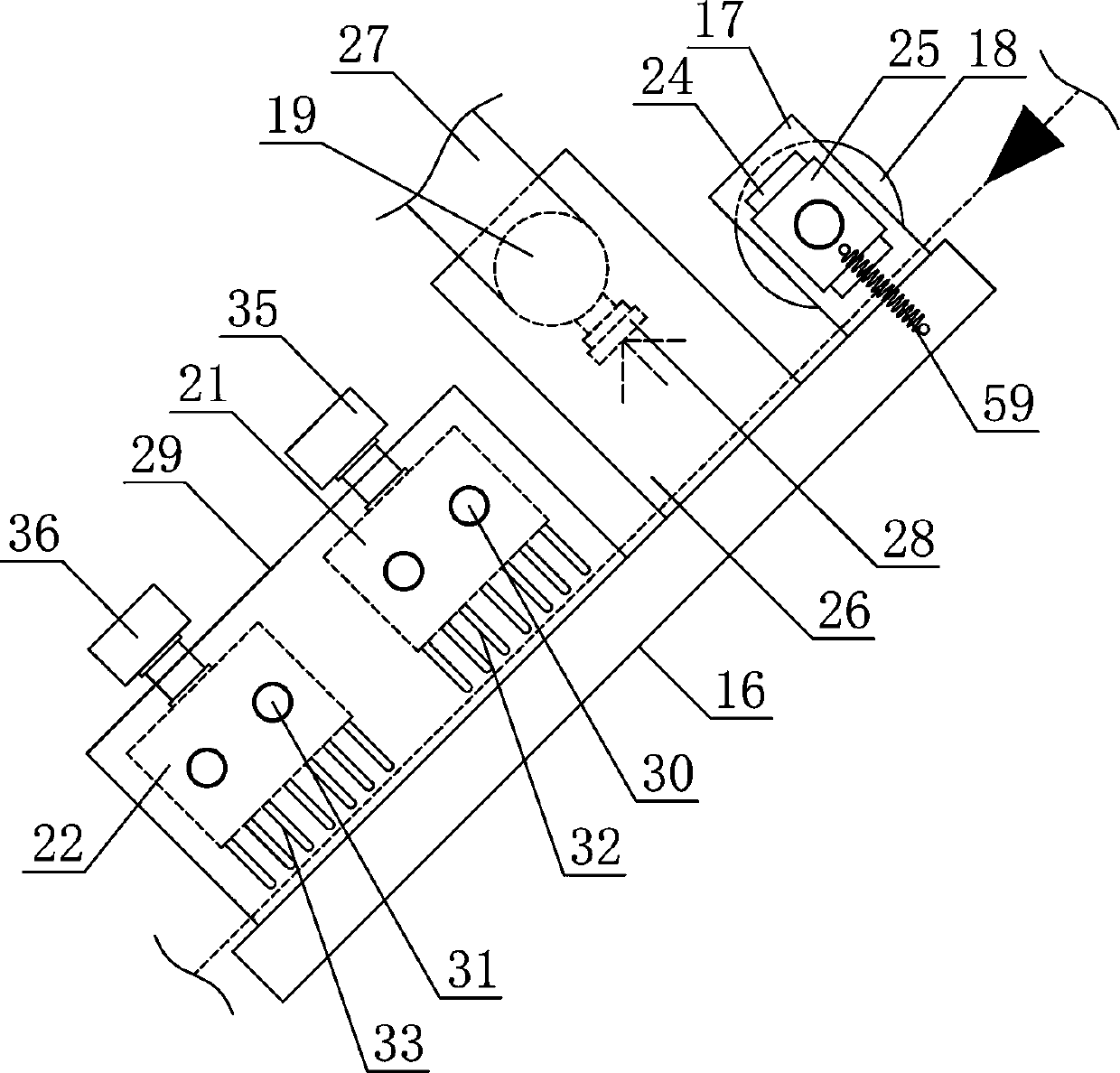

The invention discloses a workpiece assembling mechanism, and belongs to the field of assembly machining mechanical equipment. A screw feeding mechanism is horizontally arranged on one side below a fixed support, a driving guide plate is horizontally arranged on the lower side of an assembling air cylinder, an assembling guide rod is vertically and slidably provided with an assembling support anda pressing support from top to bottom, the lifting guide rod is provided with an assembling sleeve and a pressing sleeve in a sliding mode from top to bottom in the vertical direction, a pressing through hole is vertically formed in one side of the pressing support, an anti-skid rubber layer and a material attracting magnet are horizontally arranged on a fixed support in the middle of the lower side of a lower assembly tool from top to bottom in sequence, limiting clamping plates are symmetrically arranged on the fixed support on the outer side of the lower assembly tool; and the screw feedingmechanism comprises a feeding support, a feeding air cylinder, a nail pushing air cylinder and a screw clamping plate. The mechanism is reasonable in structural design, so that the workpiece can be stably held and fixed efficiently, and the workpiece can be assembled accurately, the automatic feeding of screws can be realized, the automation degree is high, and the requirements of assembly and use are met.

Owner:TONGXIANG SHENGHUI PRECISION MACHINERY

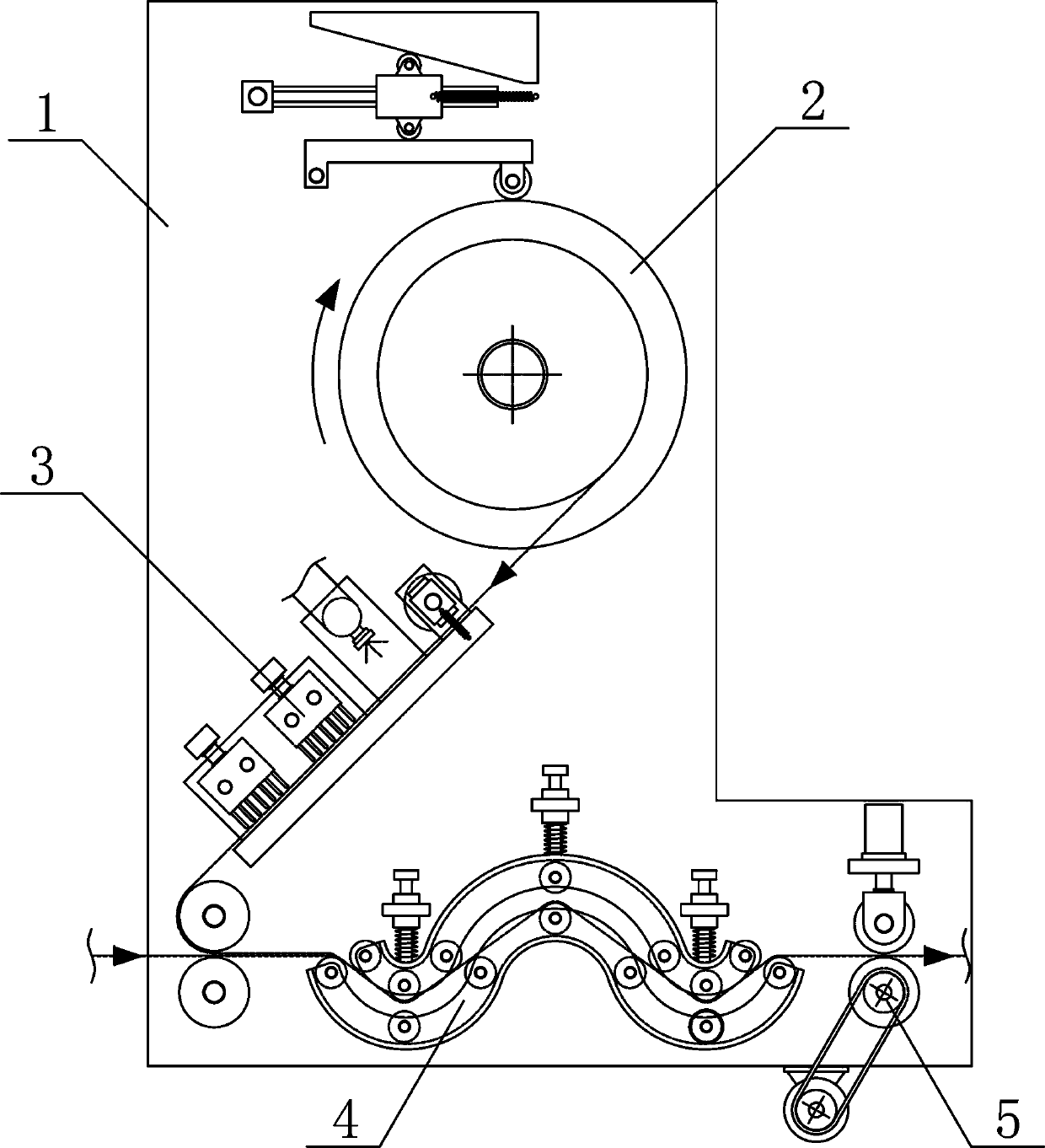

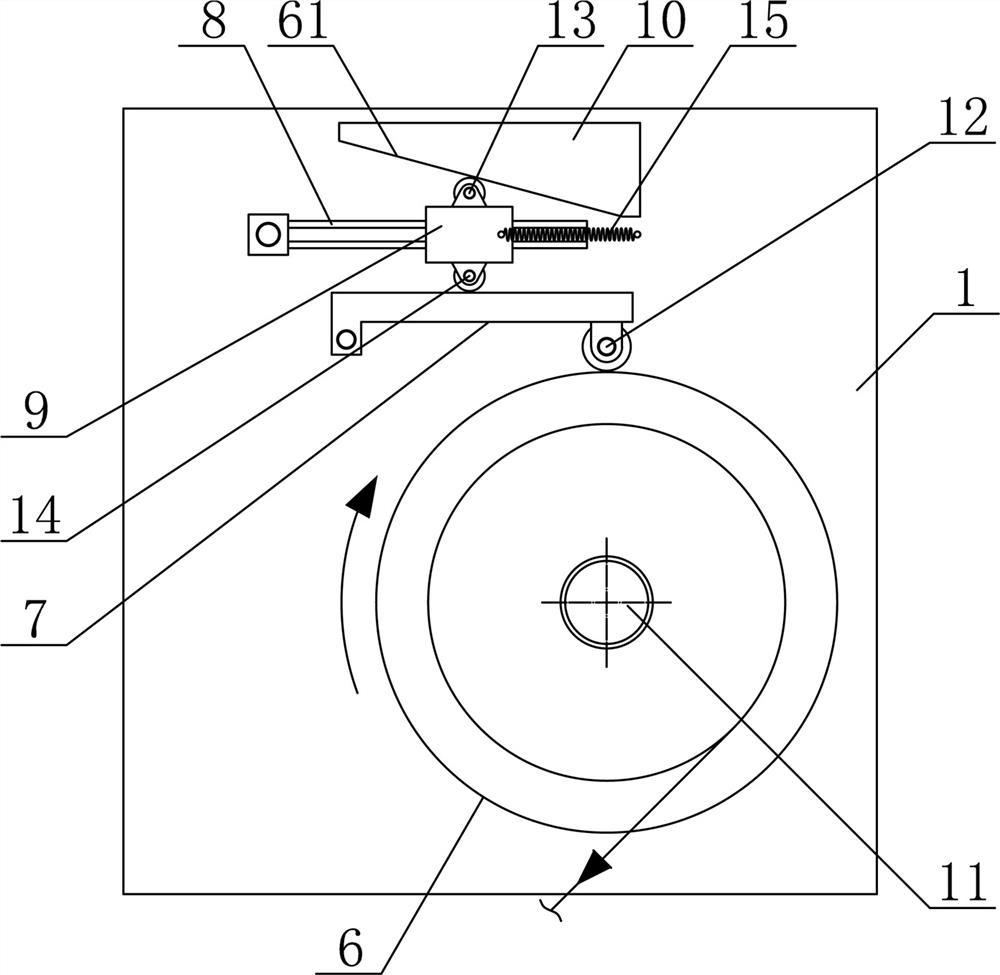

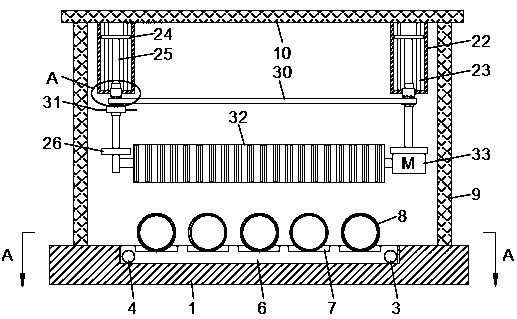

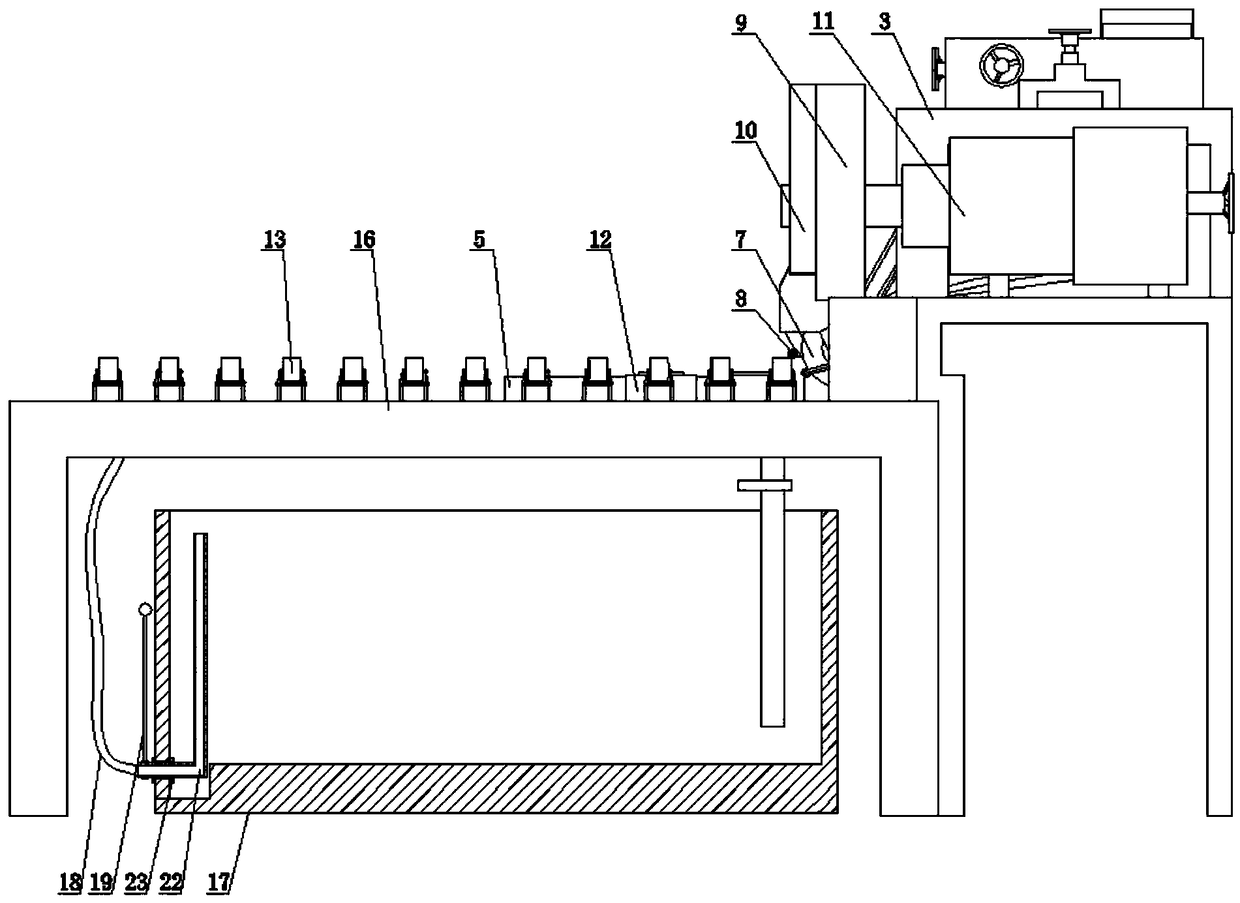

Fabric compounding apparatus

ActiveCN110802909AUnwinding is smooth and orderlyEfficient and smooth coatingSpraying apparatusLaminationElectric machineryMechanical equipment

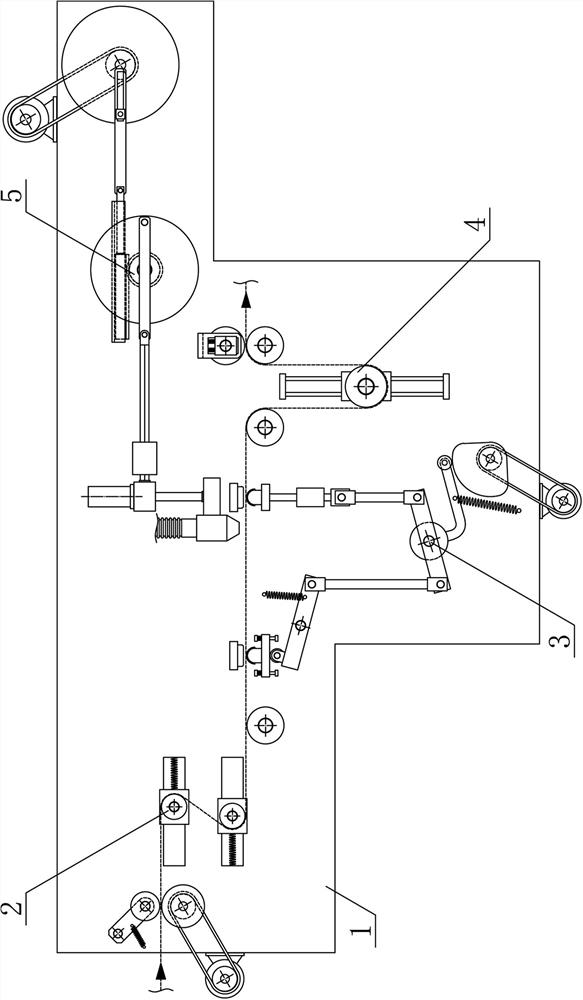

The invention discloses a fabric compounding apparatus, and belongs to the field of textile processing machinery and equipment. In the apparatus, the middle of an unwinding turntable is horizontally and fixedly provided with an unwinding bearing rod, the terminal end of a pressure disc rotation rod at the upper side of the unwinding turntable is vertically and rotationally connected with a dampingrotation wheel, a pressure rod slide block is arranged on a rotation guide rod in a sliding manner, a cloth guide bearing plate is tilted downwards and fixedly arranged on a composite support frame at the lower side of the unwinding bearing rod, a feeding roller is horizontally arranged at the upper side of the cloth guide bearing plate, a plurality of gluing nozzles are arranged at the lower side of a glue spraying guide pipe, an upper material guide roller and a lower material guide roller are arranged in a compression fit manner, an upper pressing support frame and a lower pressing supportframe are arranged on the composite support frame in order from top to bottom, and a cloth pulling motor and a cloth pulling roller are connected by a cloth pulling chain in a transmission manner. The structure design of the apparatus is reasonable, the continuous and smooth compounding of the fabric can be performed rapidly and efficiently during the material transfer process, the efficiency andquality of fabric compounding are improved, the automation degree is high, and the needs of processing and use are met.

Owner:TONGXIANG YUESHUN WRAP KNITTING

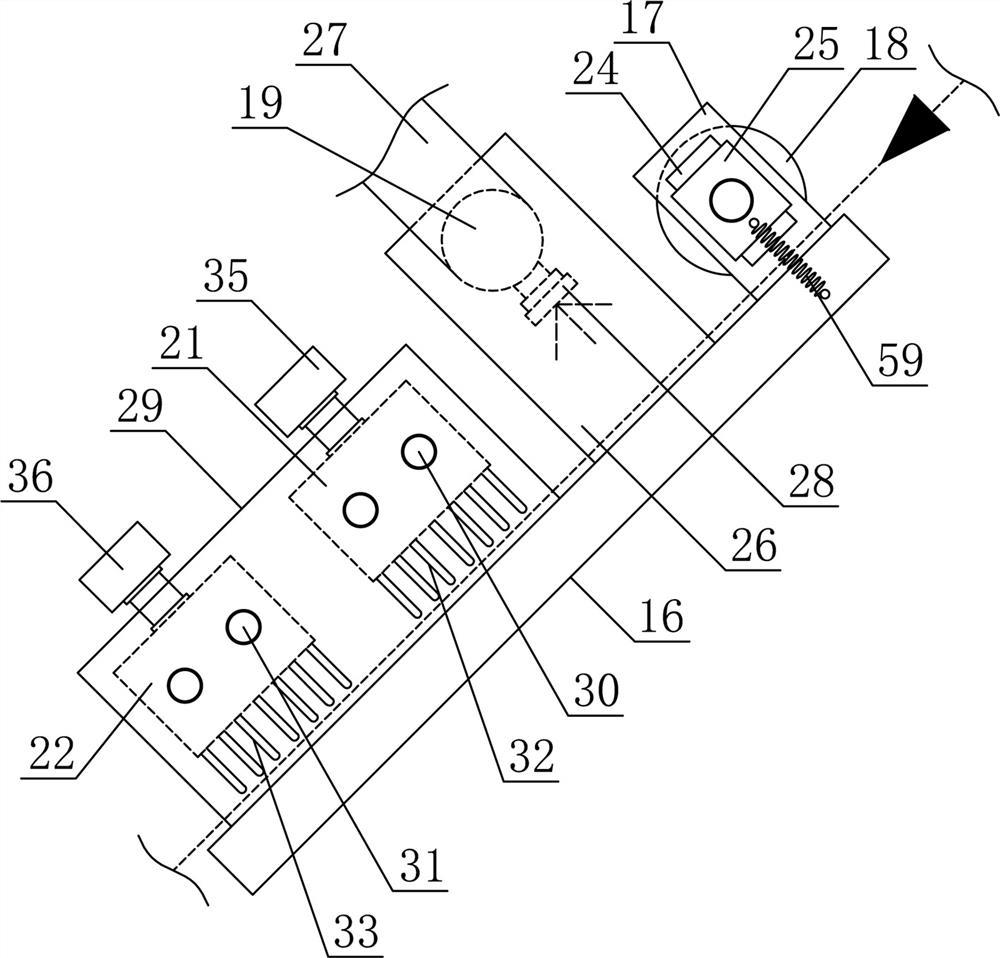

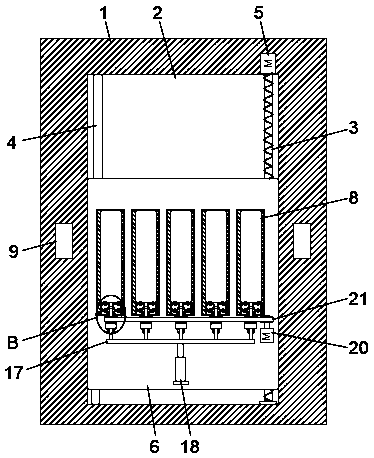

Conveying and impurity suction device for melt-blown cloth production

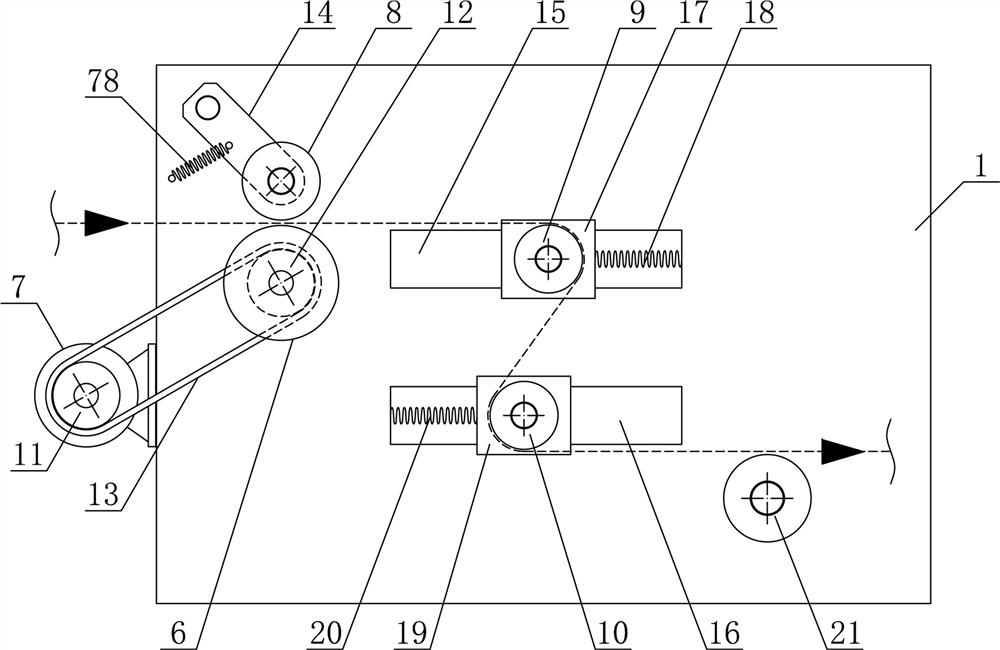

ActiveCN111826920ASmooth and smooth pressing and fixingPress and fix evenlyMechanical cleaningPressure cleaningEngineeringMechanical engineering

The invention discloses a conveying and impurity suction device for melt-blown cloth production, and belongs to the field of melt-blown cloth production equipment. A melt-blown cloth pressing rotary roller is arranged on the upper side of a cloth feeding and conveying rotary roller, a front material guide rotating roller and a rear material guide rotating roller are rotationally connected to a cloth conveying machining bracket in sequence, a front positioning cloth pressing plate is fixedly arranged on the upper side of a front lifting guide plate, a rear positioning cloth pressing plate is fixedly arranged on the upper side of a rear lifting guide plate, a cloth discharging and conveying rotary roller is rotationally connected to the cloth conveying machining bracket on one side of the rear material guide rotating roller, a lifting material guide rotating roller is rotationally connected to a lifting reciprocating guide plate, a reciprocating impurity suction material pipe is arrangedbetween the front positioning cloth pressing plate and the rear positioning cloth pressing plate, and an impurity suction connecting hose is arranged in the middle of the upper side of the reciprocating impurity suction material pipe in a communicating mode. The conveying and impurity suction device for melt-blown cloth production is reasonable in structural design, melt-blown cloth can be pressed and fixed intermittently, efficiently and stably in the conveying process, then the melt-blown cloth can be subjected to segmented impurity suction machining conveniently and smoothly, the automation degree of melt-blown cloth production and machining is improved, and the requirements of production and use are met.

Owner:桐乡市中瑞环保科技有限公司

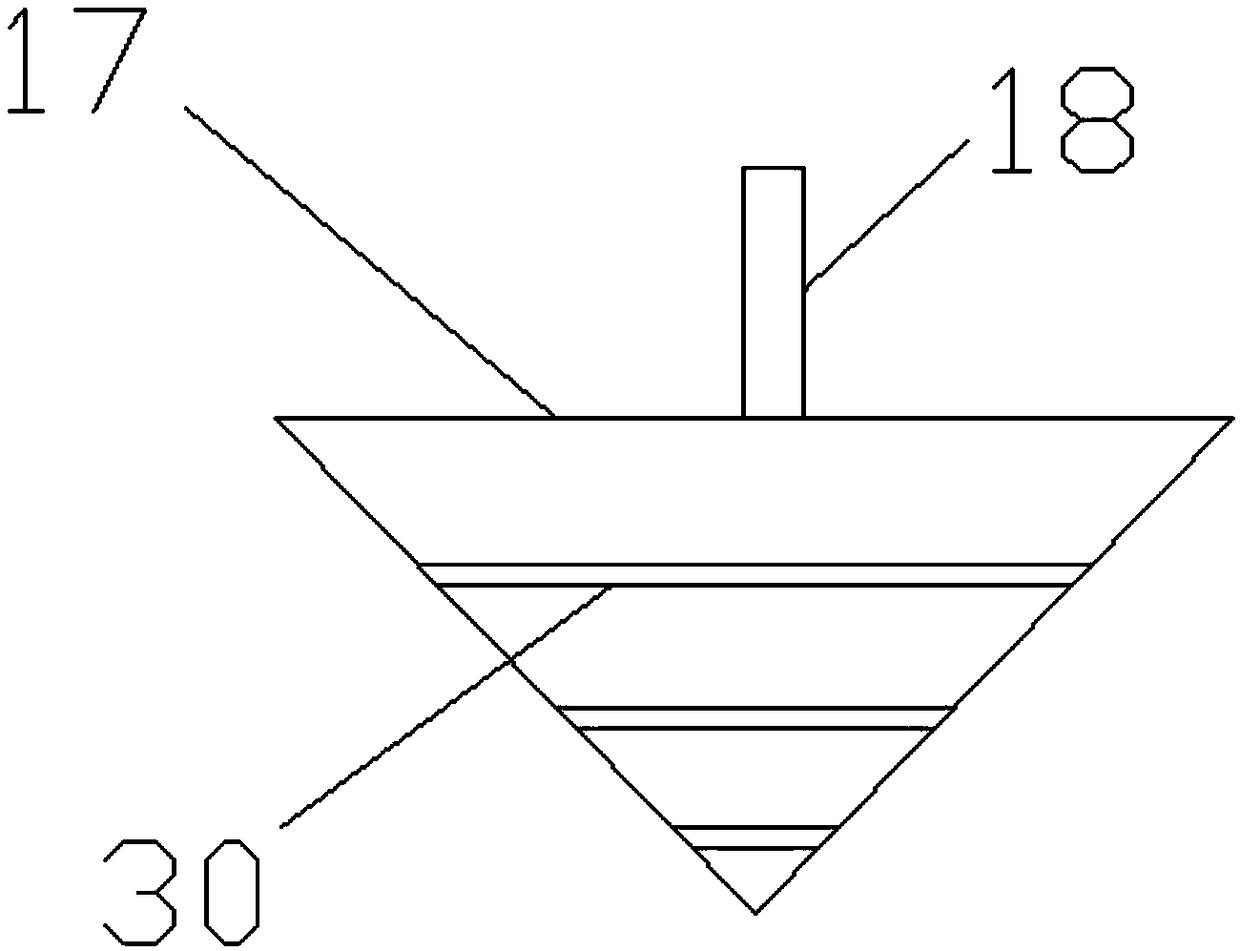

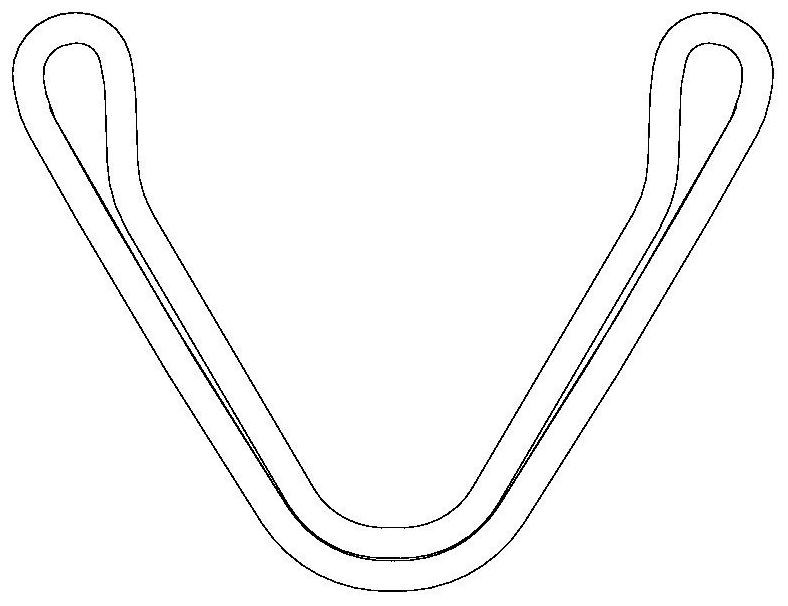

Reed for camera lens drive mechanism

The invention relates to reeds for a camera lens drive mechanism, the reeds (1, 2) are shaped like flakes as a whole and consist of annular outer profiles (11, 21) and annular inner profiles which are positioned in the outer profiles (11, 21), spacing intervals are provided between the inner walls of the outer profiles and the outer walls of the inner profiles, the outer profiles and the inner profiles are connected by at least two connection reed threads (3, 4) which are arranged at intervals, and the connection reed threads (3, 4) are coiled and arranged along a circumferential continuous shape of U. The outer profiles are square or rectangular, the inner profiles are circular, and the connection reed threads are arranged at the side angels in the outer profiles. The connection reed threads can improve the anti-deformation capacity through the U-shaped coiling role, and the connection reed threads further have good elastic effect and can effectively improve overall stiffness and impact resistance performance, thereby ensuring the good imaging quality of the lens drive mechanism which uses the reeds.

Owner:NINGBO JCT ELECTRONICS

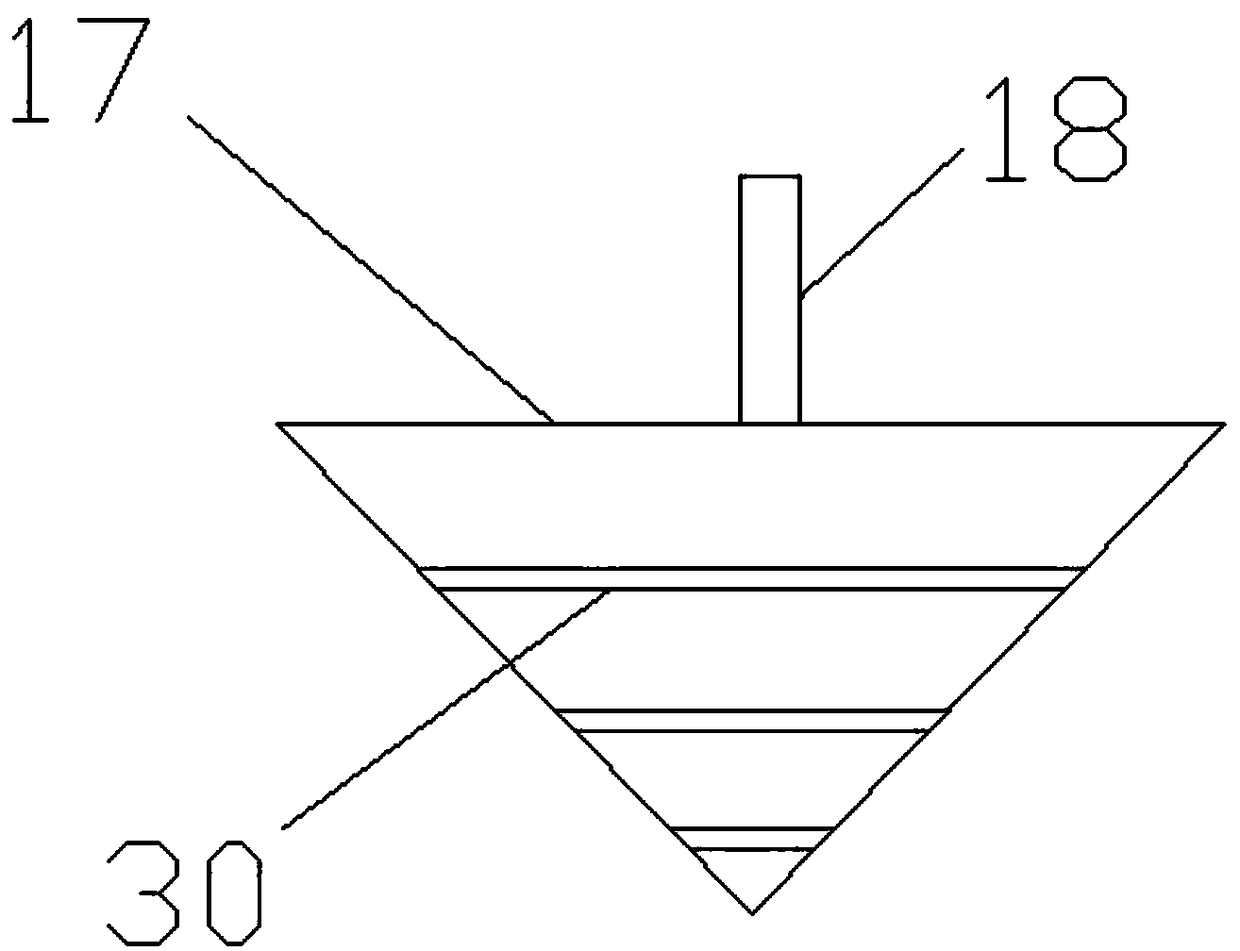

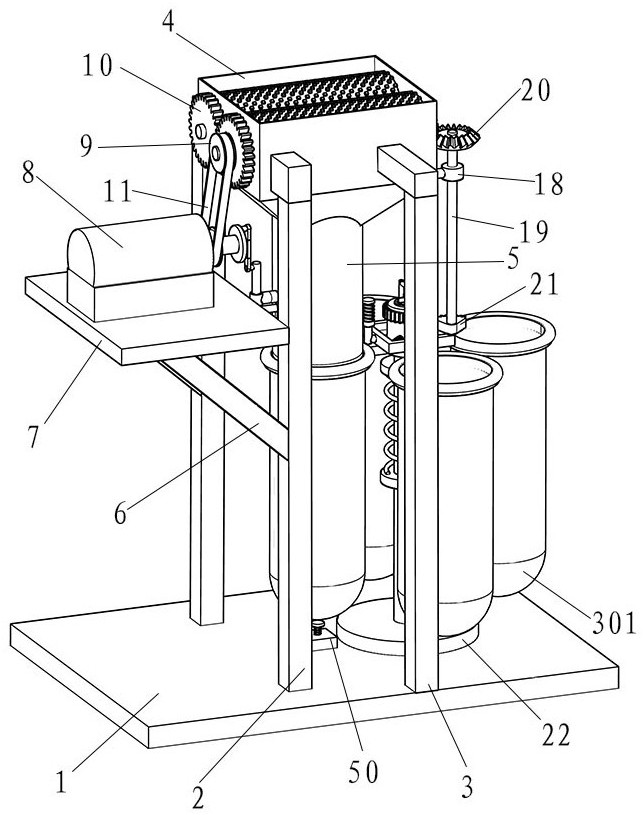

Medicinal material multistage grinding device for biological pharmacy and biopharmaceutical system

InactiveCN109092438ACleverly structuredReasonable arrangementCocoaGrain treatmentsPharmacyEngineering

The invention discloses a medicinal material multistage grinding device for biological pharmacy. The medicinal material multistage grinding device for biological pharmacy comprises a shell; a feed hopper is arranged on the top of the shell; a fixed grinding disc and a movable grinding disc are arranged at the positions, corresponding to the lower portion of the feed hopper, of the shell and are arranged below the feed hopper in a bilateral symmetry mode; the movable grinding disc is installed on a first bearing in a sleeving mode through a transverse rotating shaft, and the first bearing is arranged at the corresponding position of the right side wall of the interior of the shell; a first cabin is arranged on the right side of the shell; the right end of the transverse rotating shaft extends into the first cabin; a transverse rotating shaft drive mechanism is arranged in the first cabin; the fixed grinding disc is fixed to the left side wall of the shell through a fixing mechanism; a grinding base is arranged at the bottom of the interior of the shell; and a conical groove is formed in the grinding base. The medicinal material multistage grinding device for biological pharmacy is ingenious in structure setting and reasonable in layout, multistage grinding is achieved, and the medicinal material grinding efficiency and effect are achieved.

Owner:SHENGSHIYAOLAN SHENZHEN TECH CO LTD

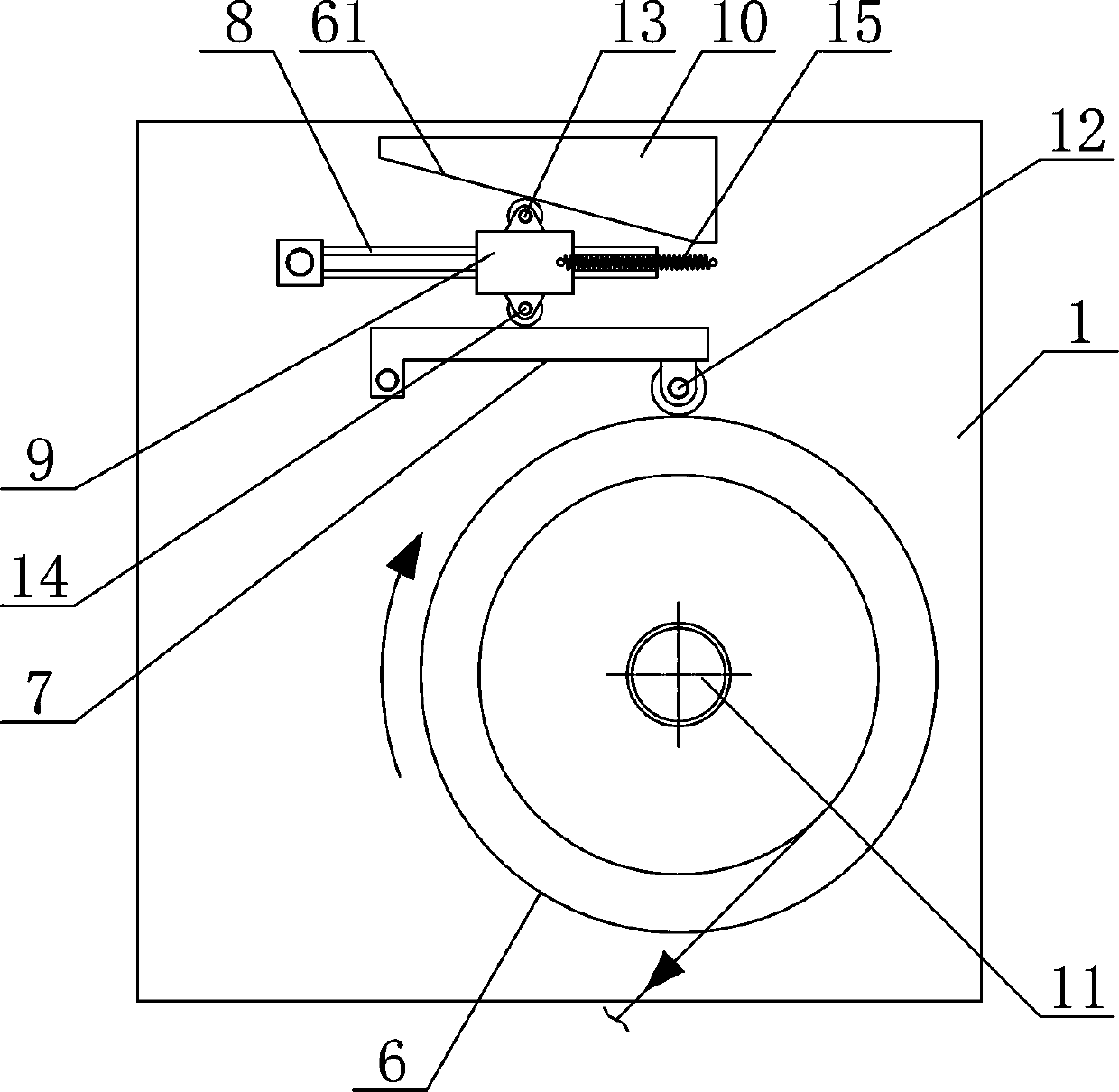

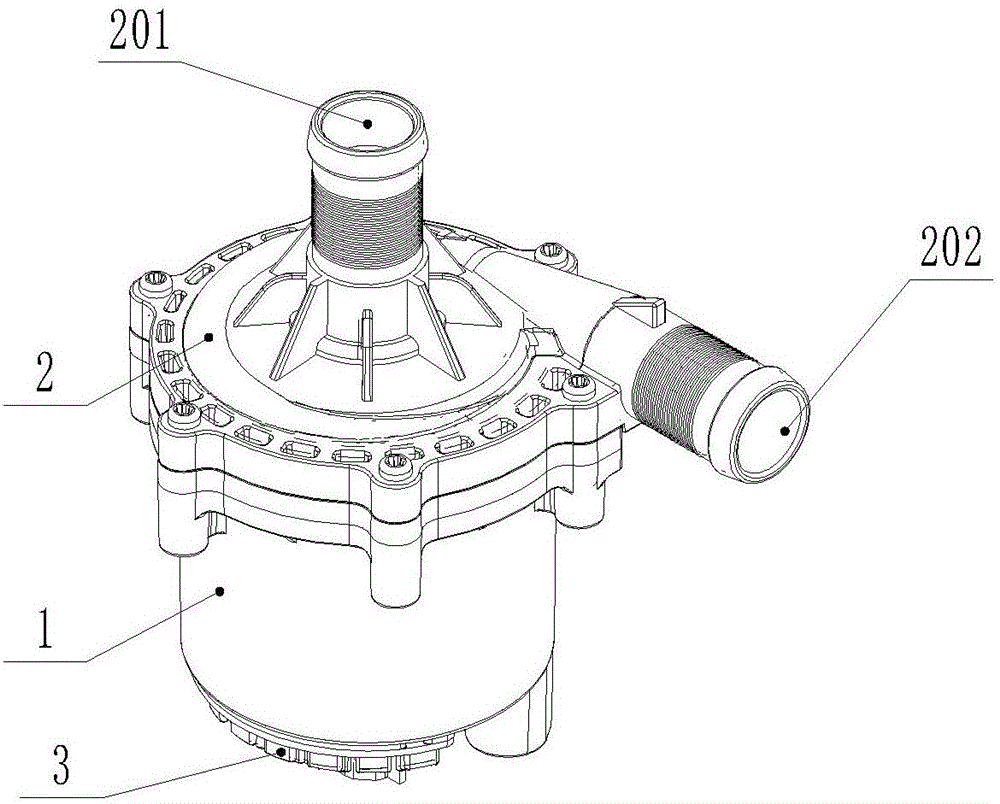

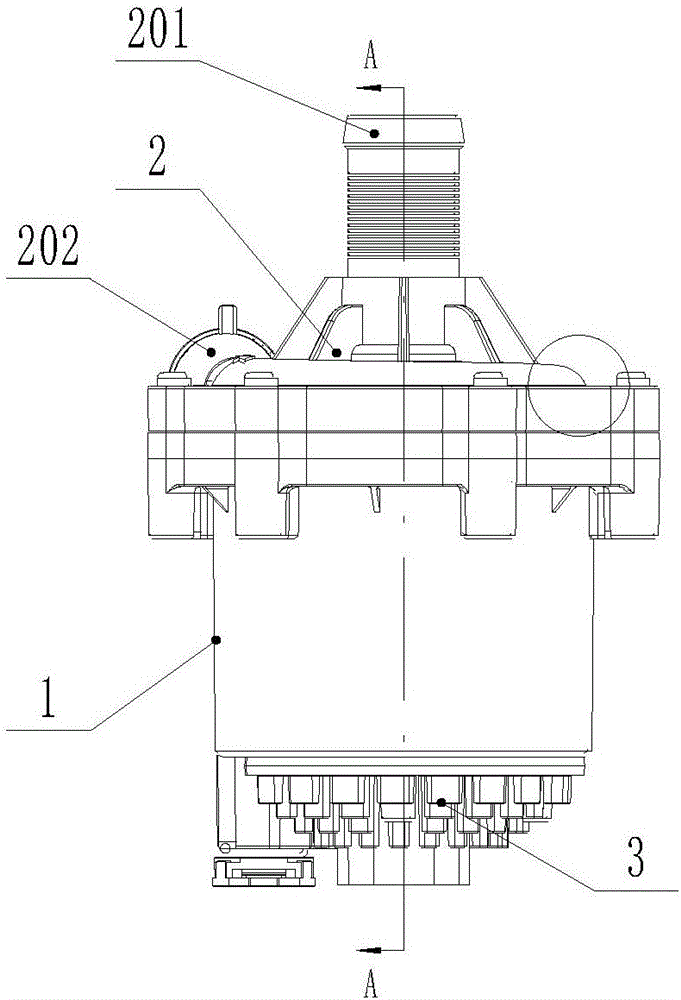

Brushless electronic water pump

PendingCN106640681ASmooth rotationLow rotational resistancePump componentsMechanical energy handlingImpellerHeat conducting

The invention discloses a brushless electronic water pump. The brushless electronic water pump comprises a shell body, an isolating sleeve and an upper cover which can be detachably fixed. The isolating sleeve divides the shell body and the upper cover into an installing chamber and a fluid chamber. A stator assembly and a PCB are fixed into the installing chamber. A rotor assembly is installed in the fluid chamber in a rotating manner. The upper cover is provided with a water inlet and a water outlet. The rotor assembly comprises an impeller and a connecting drum. A wear-resisting lubricating insert is fixedly inserted into an inner hole of the connecting drum. A center hole is formed in the wear-resisting lubricating insert. A magnet yoke drum is fixedly installed outside the connecting drum concentrically in a sleeving manner. A magnet ring drum is fixedly installed outside the magnet yoke drum concentrically in a sleeving manner. The isolating sleeve is provided with a locating center shaft which is inserted into the center hole. The shell body is provided with a heat dissipating device connected with the PCB in a heat-conducting manner. According to the brushless electronic water pump, a bearing does not need to be arranged on a rotor, no water inlet space is occupied, the reliability of the brushless electronic water pump is improved, and the service life of the brushless electronic water pump is prolonged.

Owner:JIANGSU LANGXIN ELECTRIC

One-key opened bottle cap

The invention relates to a one-key opened bottle cap. The one-key opened bottle cap comprises a bottle opening and a bottle cover. The one-key opened bottle cap also comprises a positioning ring, a fixing ring and an elliptical elastic snap ring. The positioning ring and the fixing ring are successively arranged from top to bottom in the bottle cap, an interdeep is reserved between the positioning ring and the fixing ring, two ends of a long shaft of the elastic snap ring are located in the interdeep, a pressing sheet is arranged at one of the two ends of the long shaft of the elastic snap ring, a cavity for accommodating the pressing sheet is formed in a position of the positioning ring and the fixing ring corresponding to the pressing sheet, the pressing sheet can shift along the radial direction of the bottle cap in the cavity, and a port communicating with the cavity is formed in a position, corresponding to the cavity, of the side wall of the bottle cap; a slot is formed in a position, corresponding to the elastic snap ring, on the side wall surrounding the bottle opening, two ends of a short shaft of the elastic snap ring are located in the slot to lock connection between the bottle cap and the bottle opening, and the elastic snap ring is separated from the slot and enters the interdeep while the pressing sheet is pressed to stretch, so that connection between the bottle cap and the bottle opening is unlocked. The one-key opened bottle cap provided by the invention is simple in structure and simple and labor-saving in operation, and is safe and convenient to uncap.

Owner:CLOWN FISH SHANGHAI IND CO LTD

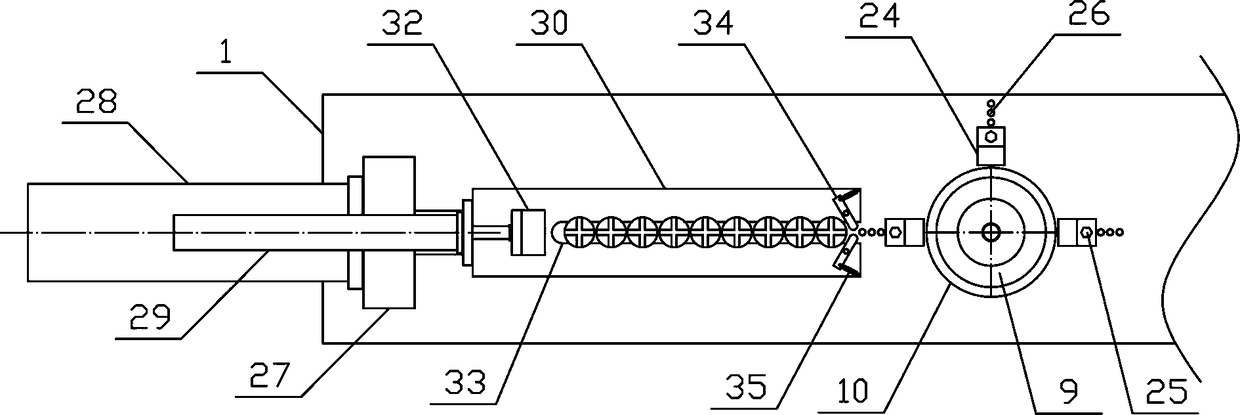

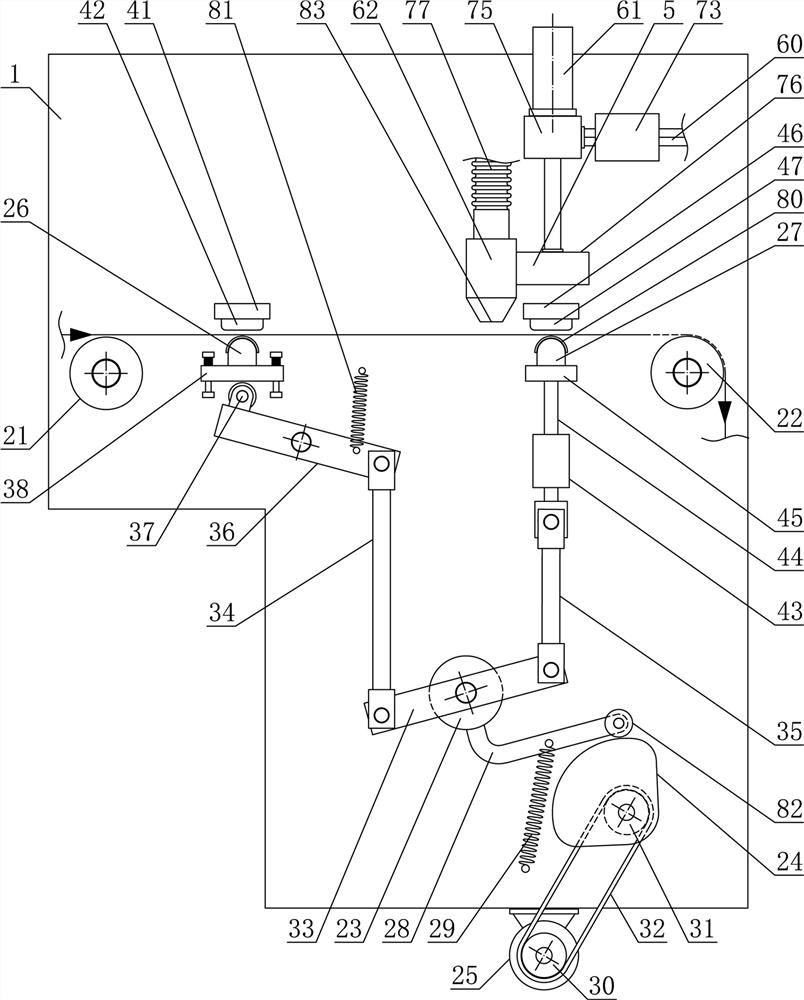

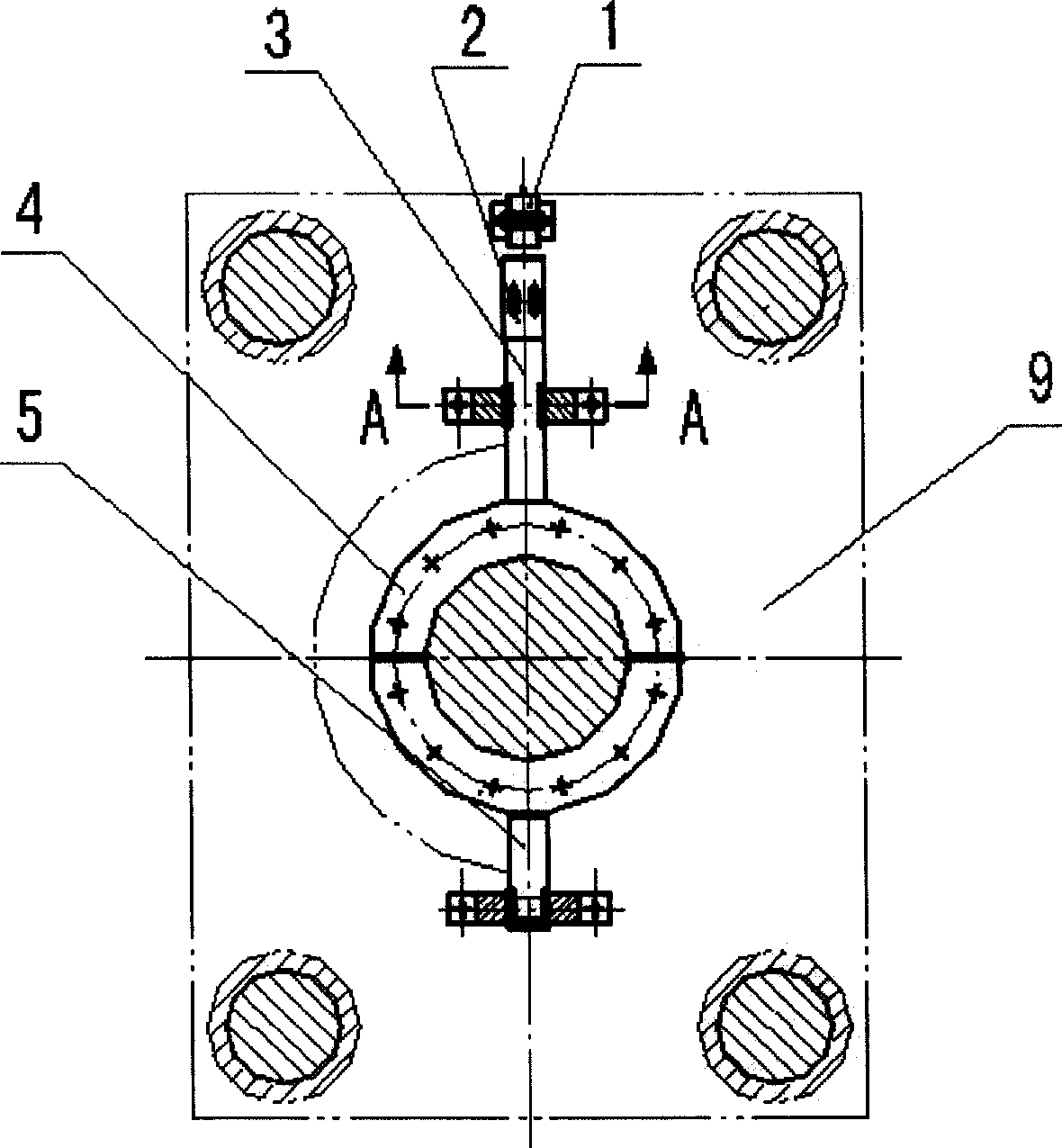

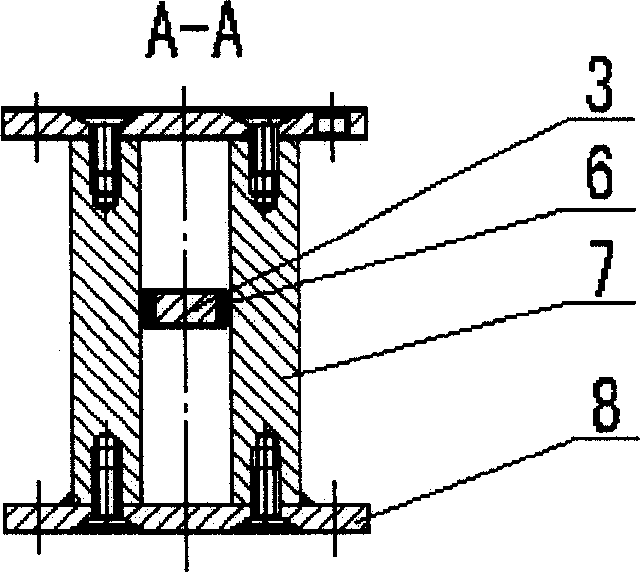

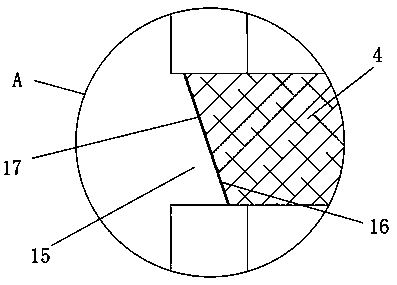

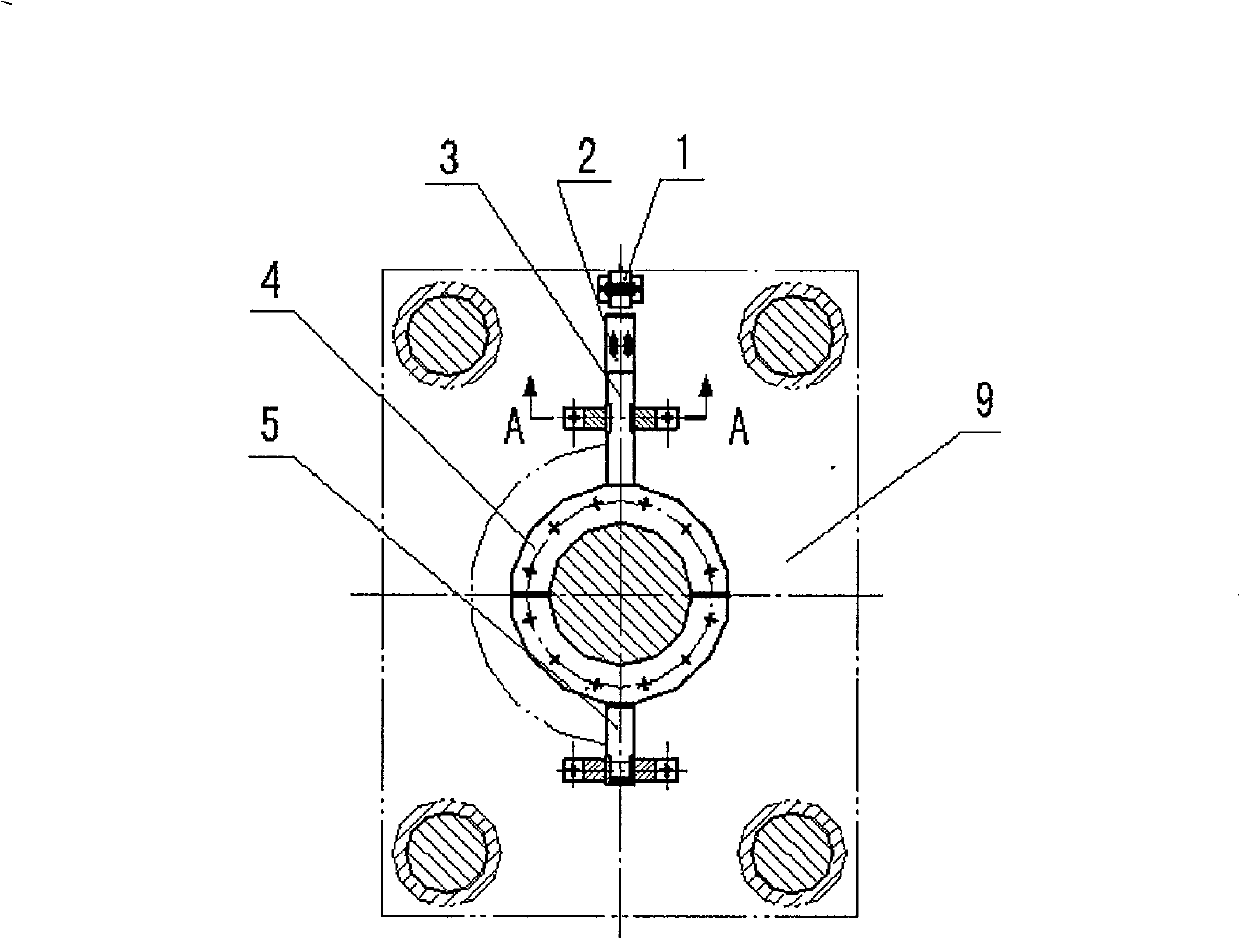

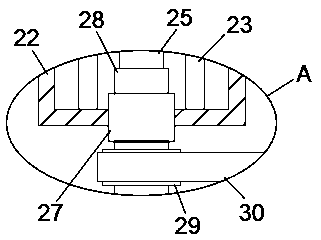

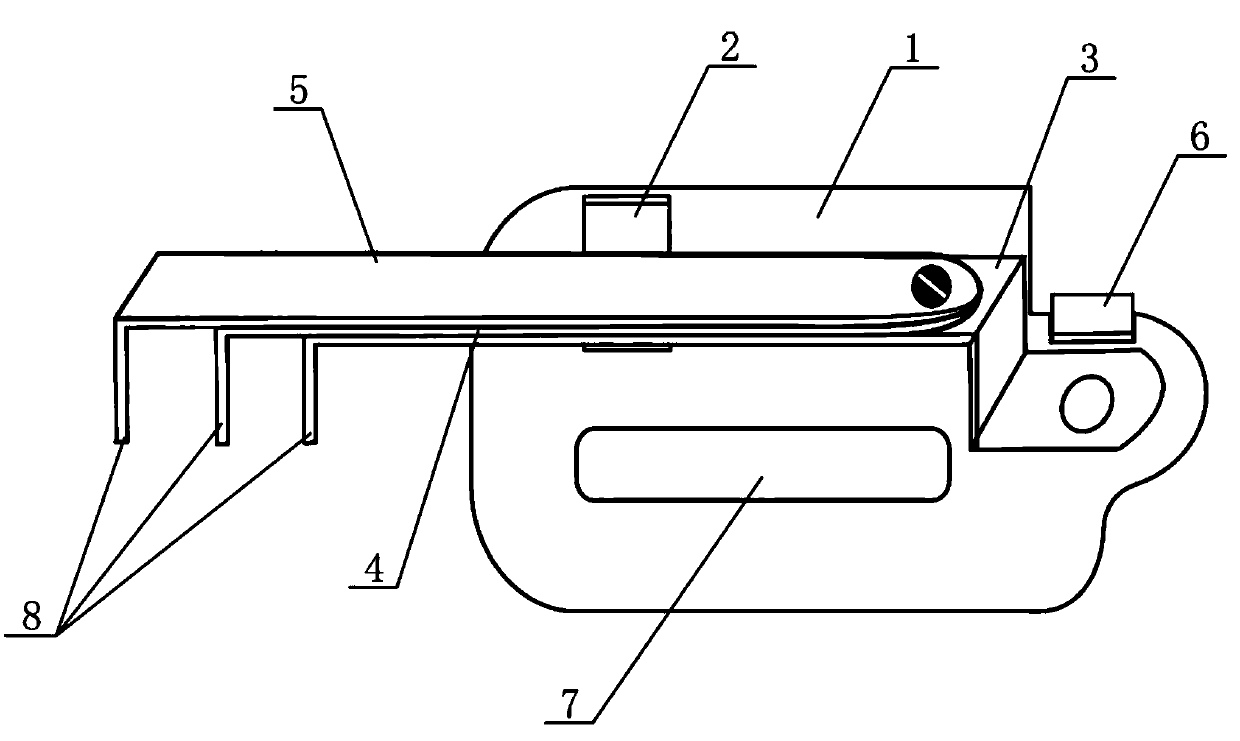

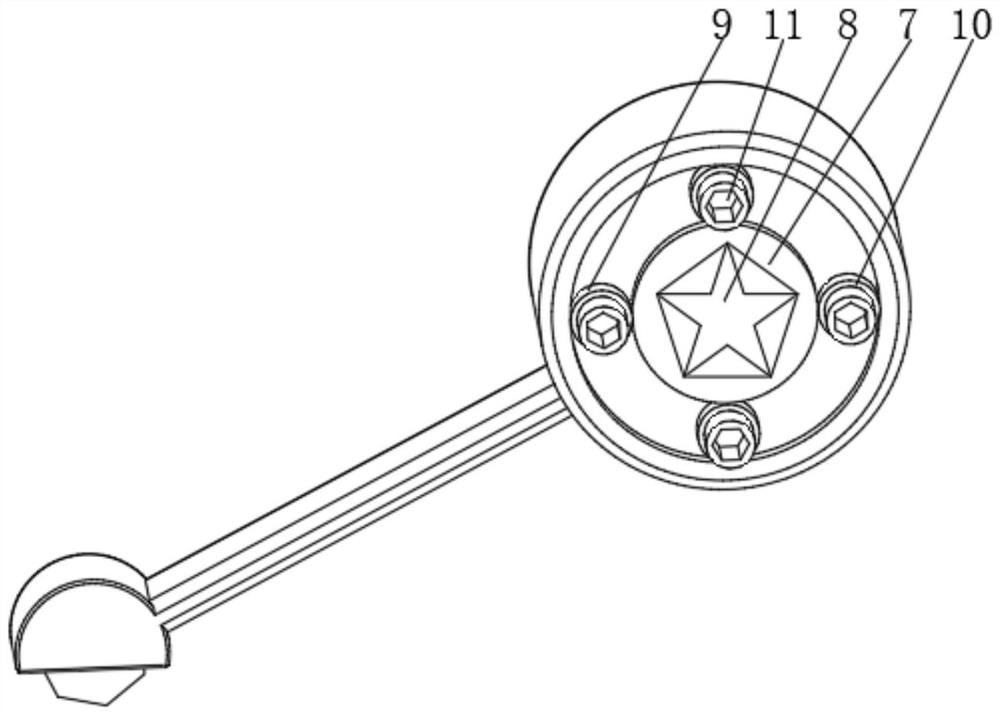

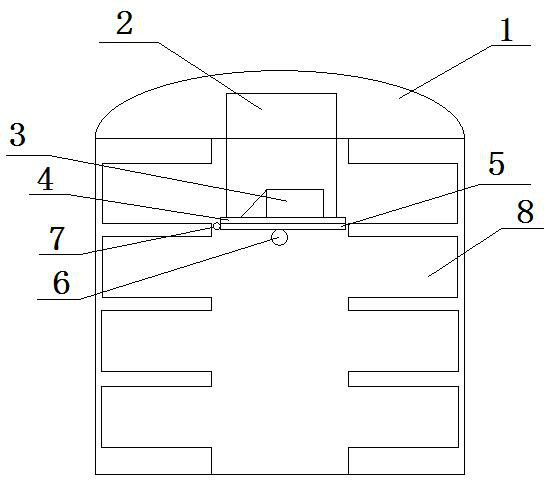

Stroke control device

ActiveCN1883932AAvoid rotational offsetGuaranteed normal operationMetal working apparatusPressesEngineeringPiston rod

The invention discloses a breaking cylinder travel controller of a breaking machine for electrolytic aluminium anode assembling, whose structure is characterized in that an approach switch (1) connects with a fixing plate (9), a flange (4) connects with a top surface of a breaking cylinder piston rod, a torsional arm (3) and a torsional arm (5) connects with the two sides of the flange (4), the torsional arm (3) connects with an induction plate (2), the torsional arm (3) and the torsional arm (5) are disposed in a guide rail (7), the guide rail (7) connects with a connection plate (8), the connection plate (8) connects with a fixed plate (9), wherein the induction plate (2) is provided with a long round hole, and the torsional arm (3) connects with the induction plate through the long round hole and a bolt, the flange (4) connects with the top surface of the breaking cylinder piston rod by bolts, and inlayed strips (6) are disposed on the torsional arm (3) and the torsional arm (5), the guide rail (7) connects with the connection plate (8) by sunk screws. If the breaking cylinder piston rod wants to deflect when moving, it will be restricted by the guide rail (7).

Owner:GUIYANG AL-MG DESIGN & RES INST

Efficient multi-level rice grinding device

InactiveCN108654747ACleverly structuredReasonable arrangementCocoaGrain treatmentsEngineeringMechanical engineering

The invention discloses an efficient multi-level rice grinding device. The efficient multi-level rice grinding device comprises a shell. A feeding hopper is arranged on the top of the shell. Corresponding to the lower portion of the feeding hopper, the shell is provided with a fixed grinding disc and a movable grinding disc. The fixed grinding disc and the movable grinding disc are arranged alongthe lower portion of the feeding hopper in a left-right symmetry manner. The movable grinding disc sleeves a first bearing through a transverse rotation shaft, wherein the first bearing is arranged atthe corresponding position of the right side wall in the shell. A first machine bin is arranged on the right side of the shell, the right end of the transverse rotation shaft stretches into the firstmachine bin, a transverse rotation shaft drive mechanism is arranged in the first machine bin, the fixed grinding disc is fixed to the left side wall of the shell through a fixing mechanism, a grinding base is arranged at the bottom in the shell, and the grinding base is provided with a conical groove. The efficient multi-level rice grinding device is provided and is ingenious in structure arrangement and reasonable in arrangement. According to the efficient multi-level rice grinding device, multi-level grinding is achieved, and the rice grinding efficiency and the grinding effect are improved.

Owner:蔡王钲

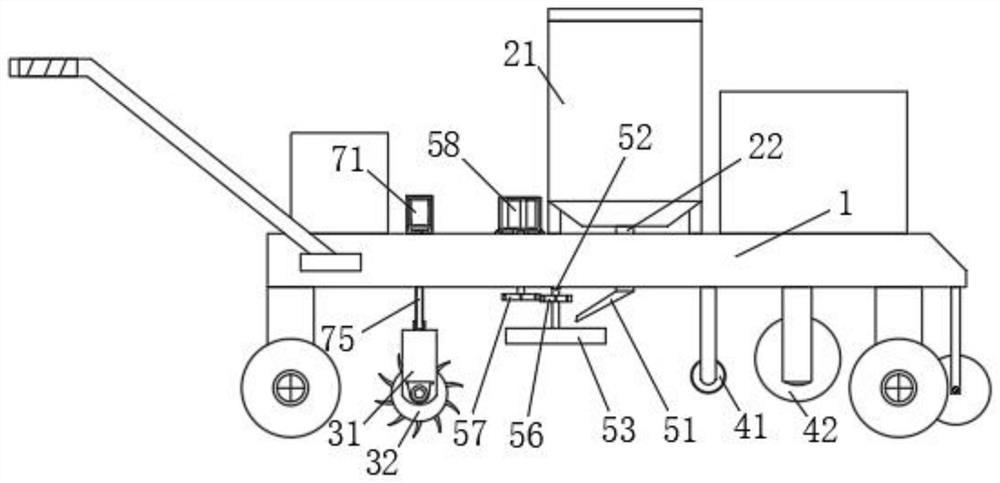

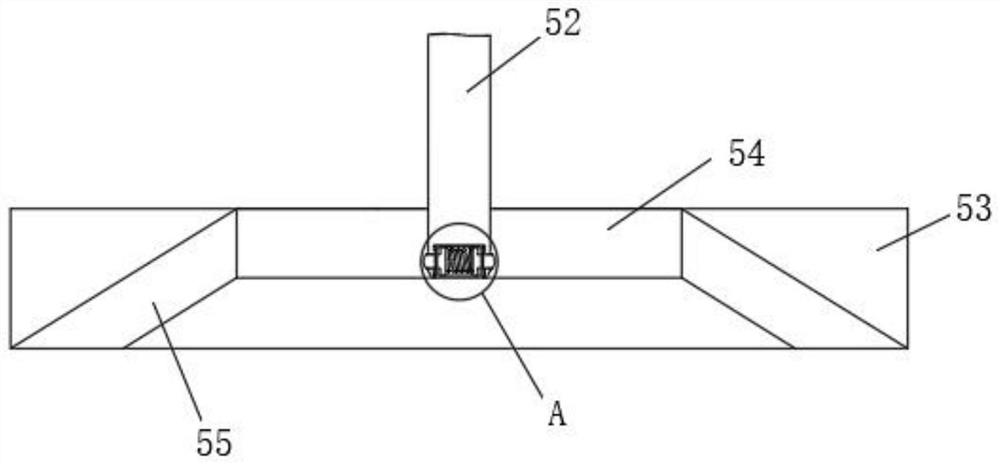

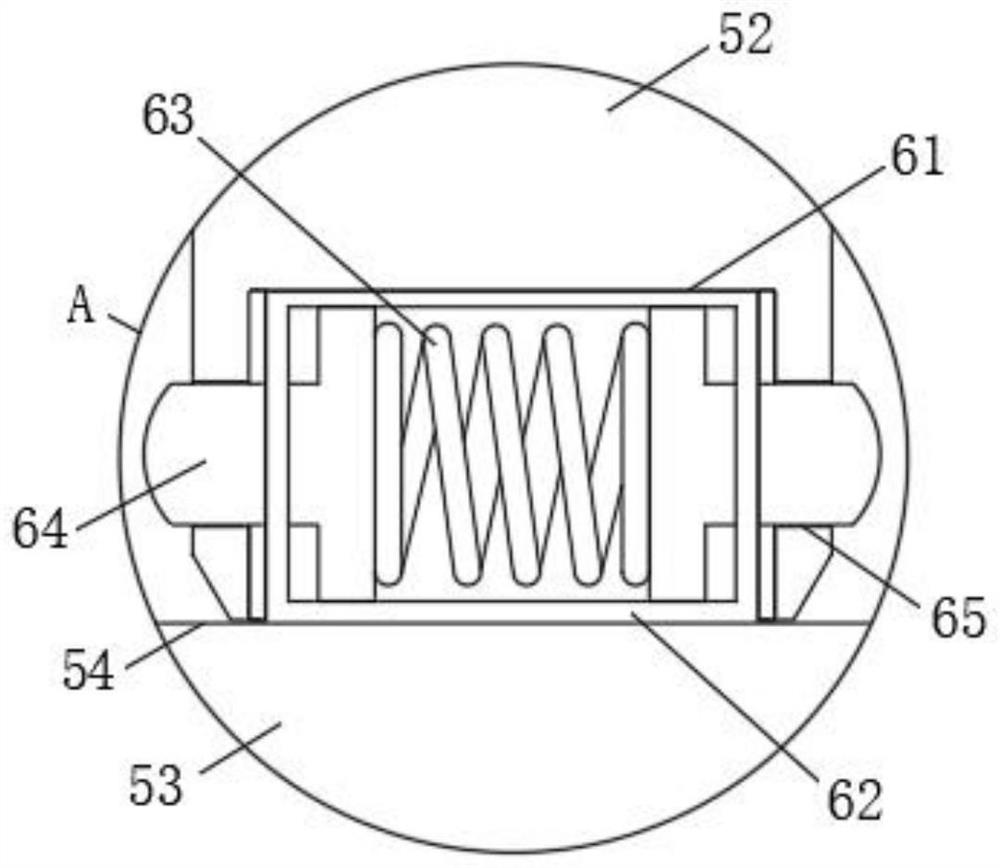

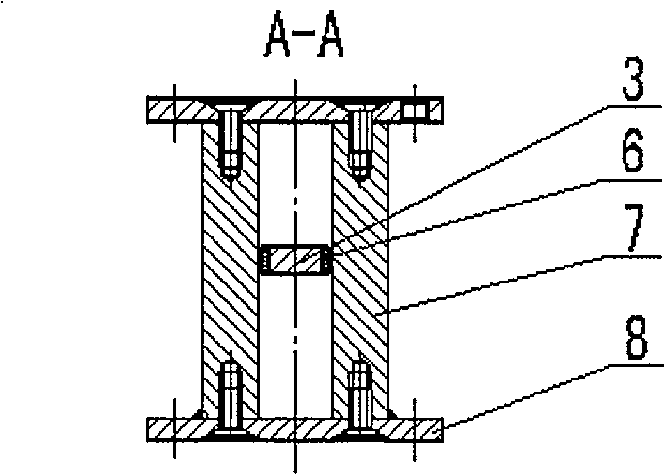

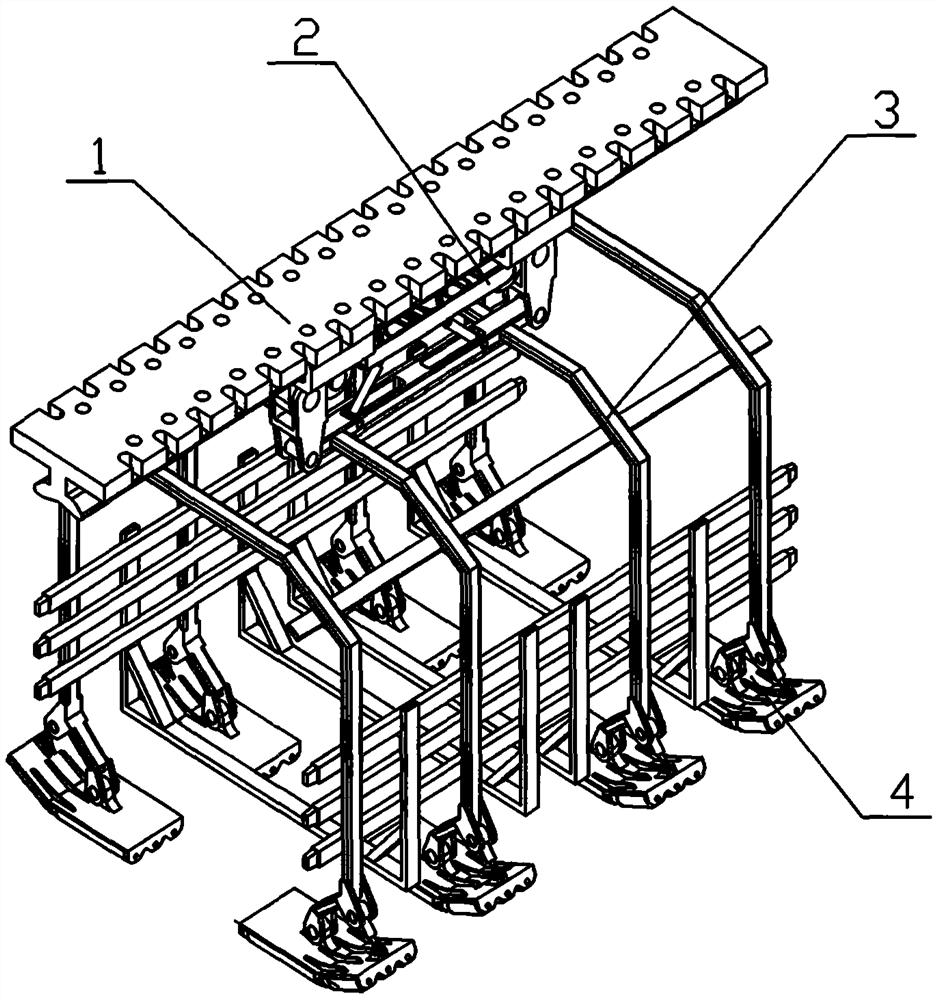

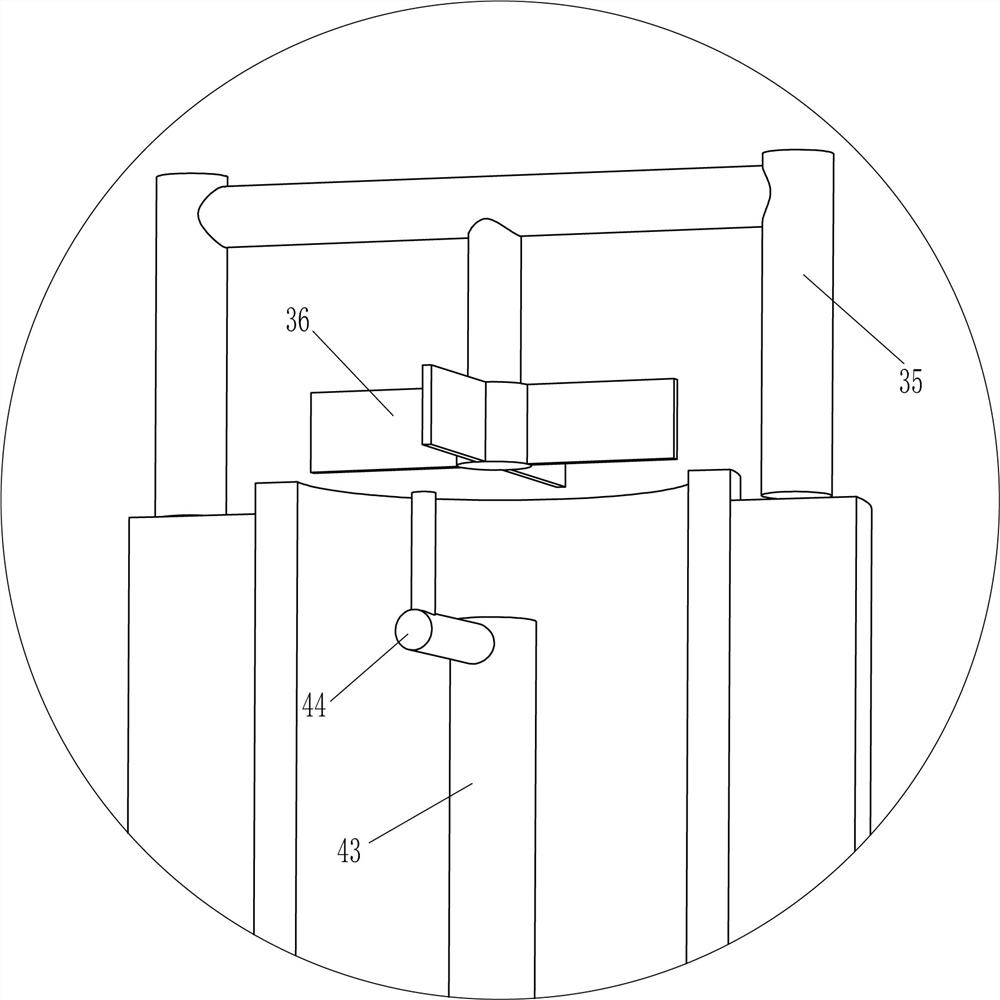

Device and method for sowing whole-plant silage corn in dam area

PendingCN114402725AEvenly distributedAvoid accumulationSpadesFertilising methodsSeederAgricultural engineering

The invention belongs to the technical field of corn seeding, and discloses an on-dam region whole-plant silage corn seeding device which comprises a frame, the seeding mechanism comprises a feed box and a discharge pipe which are fixed on the frame, and the discharge pipe is mounted on the feed box; the ridging mechanism comprises a fixing frame and a ridging roller, and the ridging roller is rotationally installed on the fixing frame; the film laminating mechanism comprises a film hanging roller and a film pressing roller, and the film hanging roller and the film pressing roller are both mounted on the frame; according to the silage corn seed sowing device, through cooperation of the structures such as the material guiding pipe, the rotating rod, the rotating disc and the material discharging groove, the rotating disc can rotate and receive silage corn seeds, so that the silage corn seeds are evenly scattered to the periphery through the material discharging groove, the silage corn seeds can be evenly distributed when being sown, and the silage corn seed sowing efficiency is improved. Accumulation and concentration of silage corn seeds are prevented, and the seeding effect is greatly improved.

Owner:CANGZHOU ACAD OF AGRI & FORESTRY SCI +1

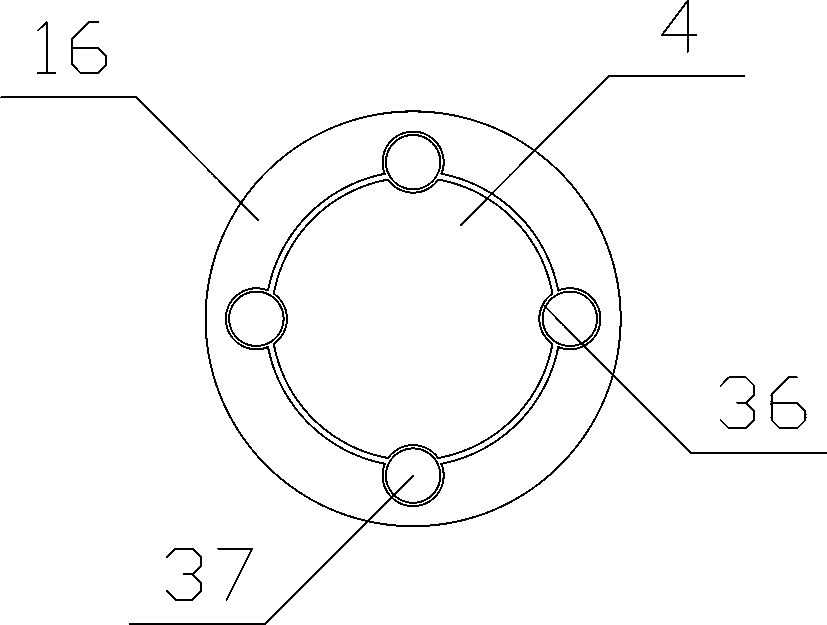

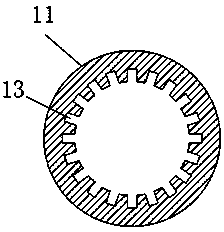

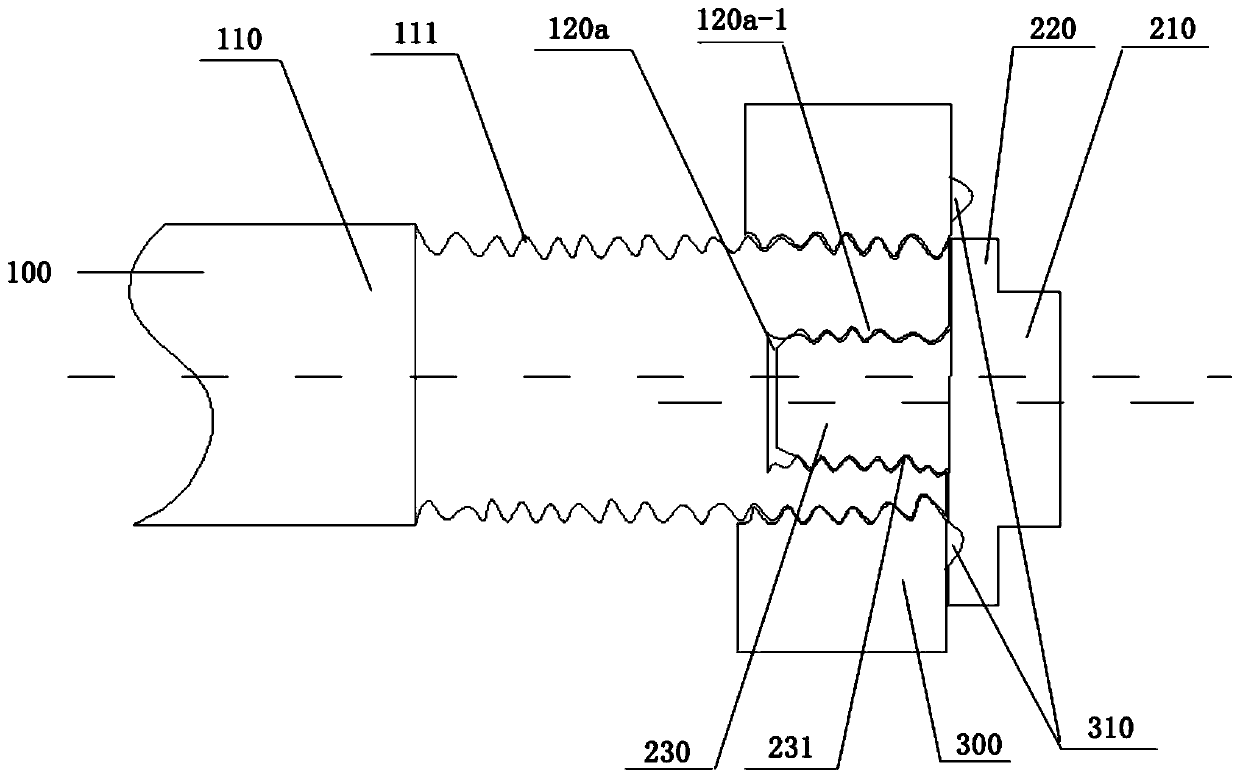

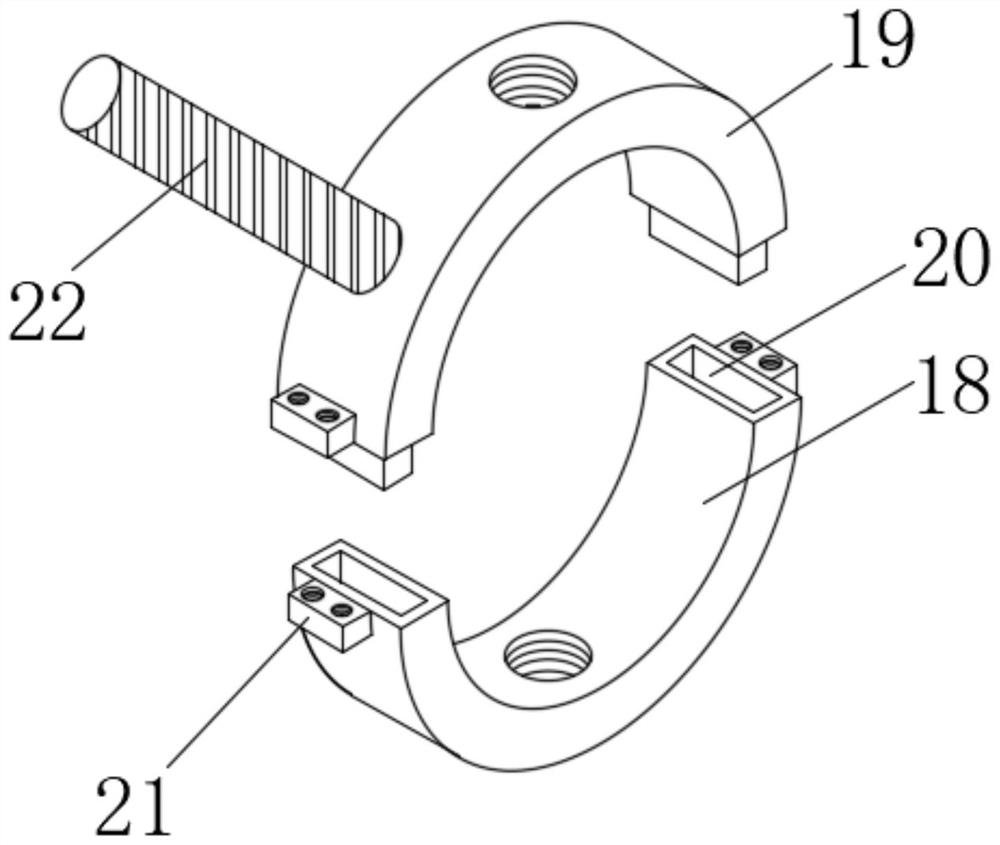

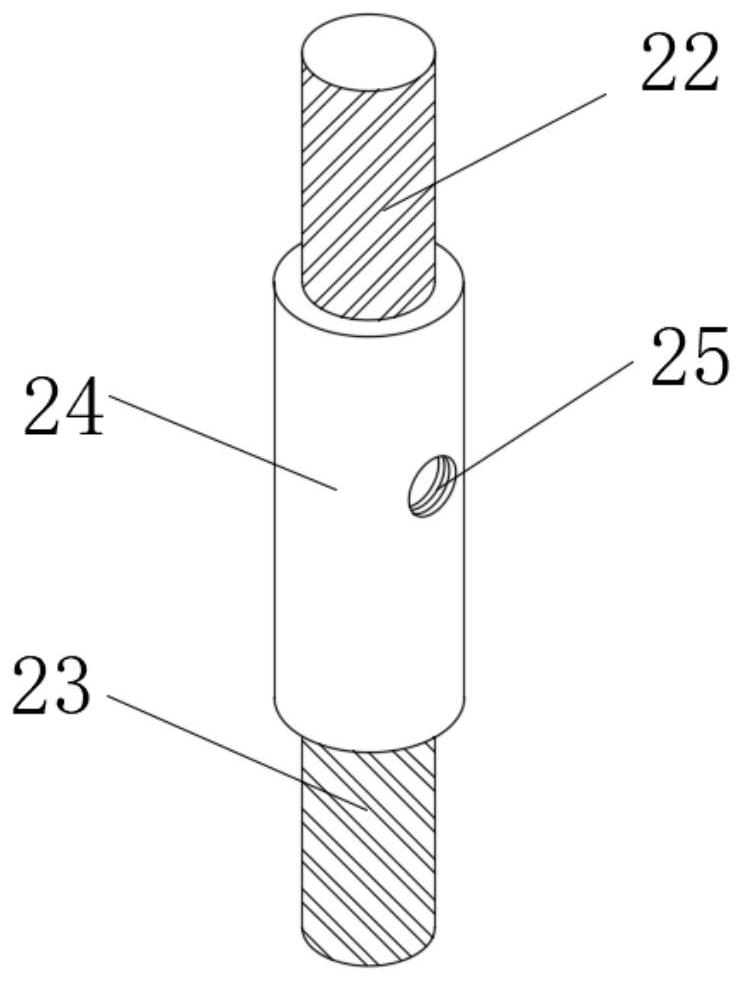

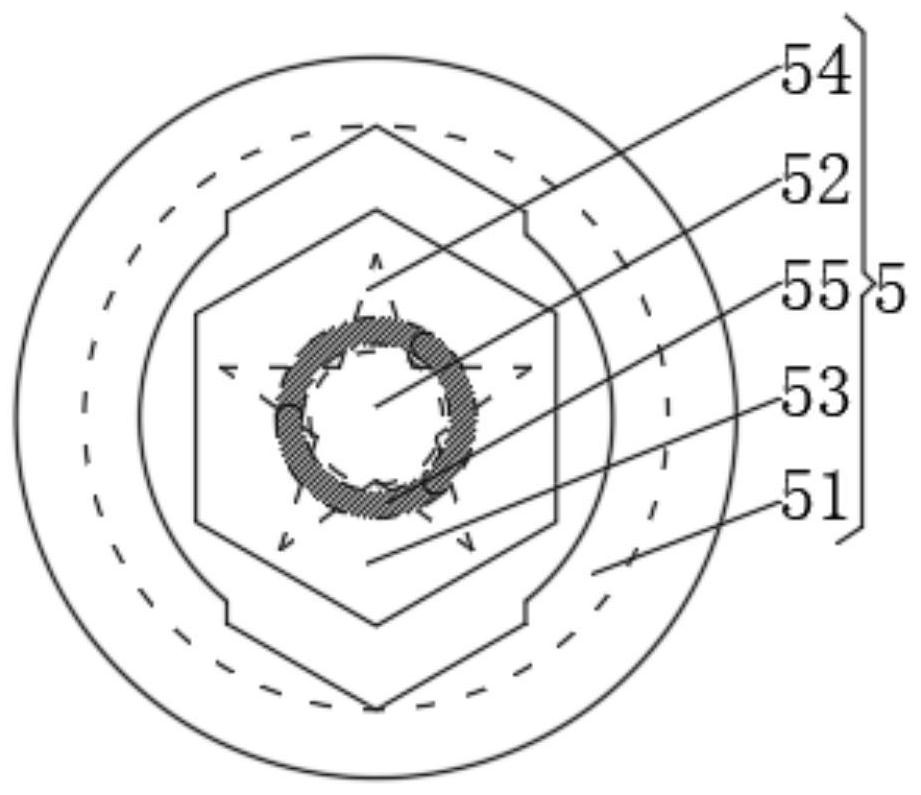

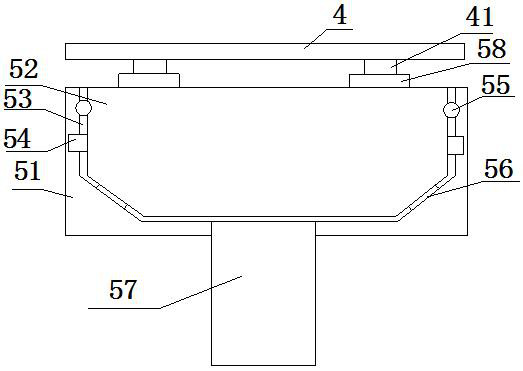

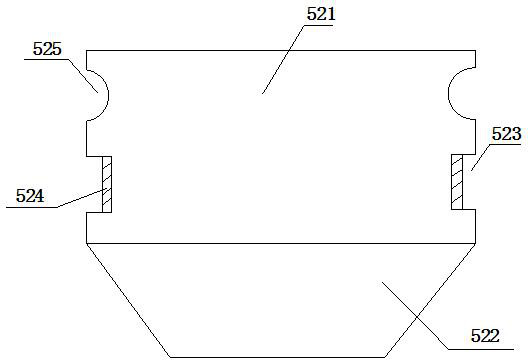

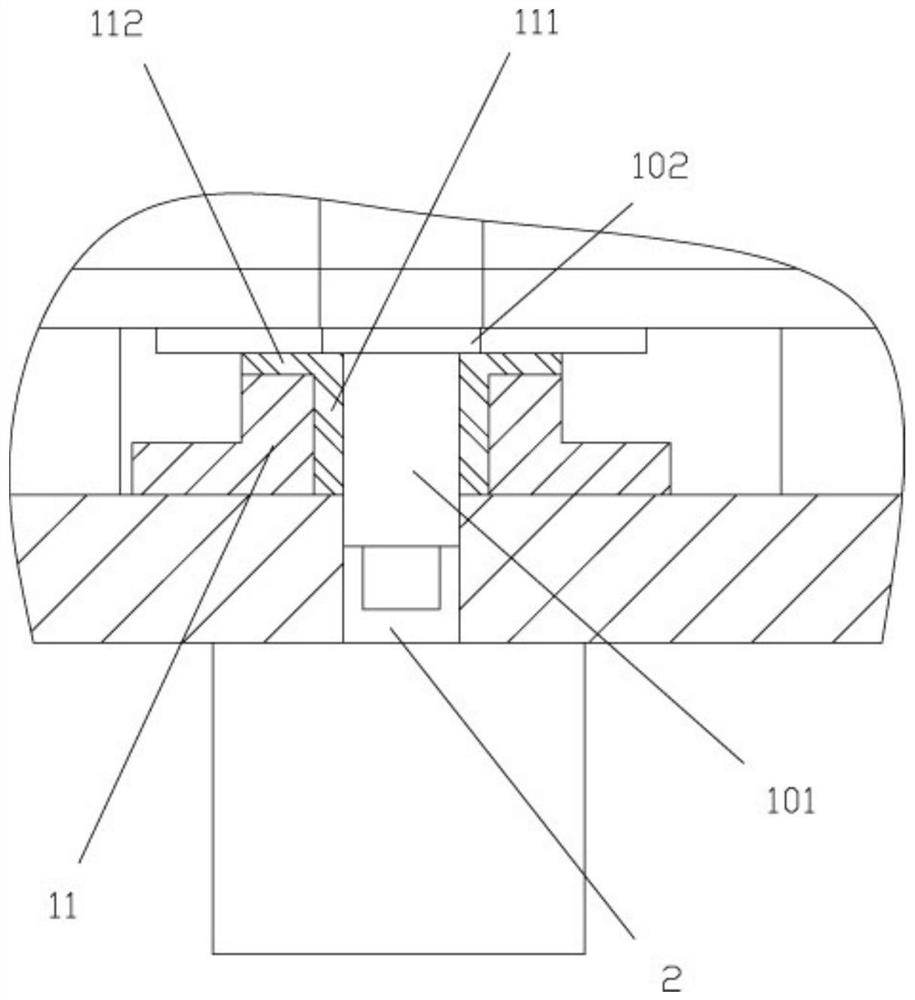

Stator core paint dipping lifting tool

InactiveCN109510416AAvoid rotational offsetImprove securityManufacturing dynamo-electric machinesLoad-engaging elementsEngineeringThreaded rod

The invention discloses a stator core paint dipping lifting tool. The stator core paint dipping lifting tool comprises a lifting sleeve and a lifting block; the lifting sleeve is fixedly connected with a lifting ring; the lifting sleeve is connected with the lifting block through a connecting mechanism; the inner wall of the lifting sleeve is symmetrically and fixedly connected with buffer springs; one end of each buffer spring, which is far away from the inner wall of the lifting sleeve, is fixedly connected with the upper side of the lifting block; the lifting block is provided with a plurality of annular elastic ribs at equal intervals; the inner wall of the lifting sleeve is provided with a plurality of protruding ribs at equal intervals; a groove is formed at the bottom side of the lifting block; a threaded rod is rotatably connected in the groove; and the threaded rod is provided with a stator core through a placement mechanism. According to the stator core paint dipping liftingtool of the invention, primary buffer protection is realized by means of an elastic force generated by the elongation of the two buffer springs; an end surface B starts to press an end surface A, andthe end surface B deviates from the end surface A by a certain distance, so that the annular elastic ribs are elastically deformed, and therefore, secondary buffer protection can be realized; and therefore, the safety of an entire lifting process can be ensured.

Owner:山东迈易特传动有限公司

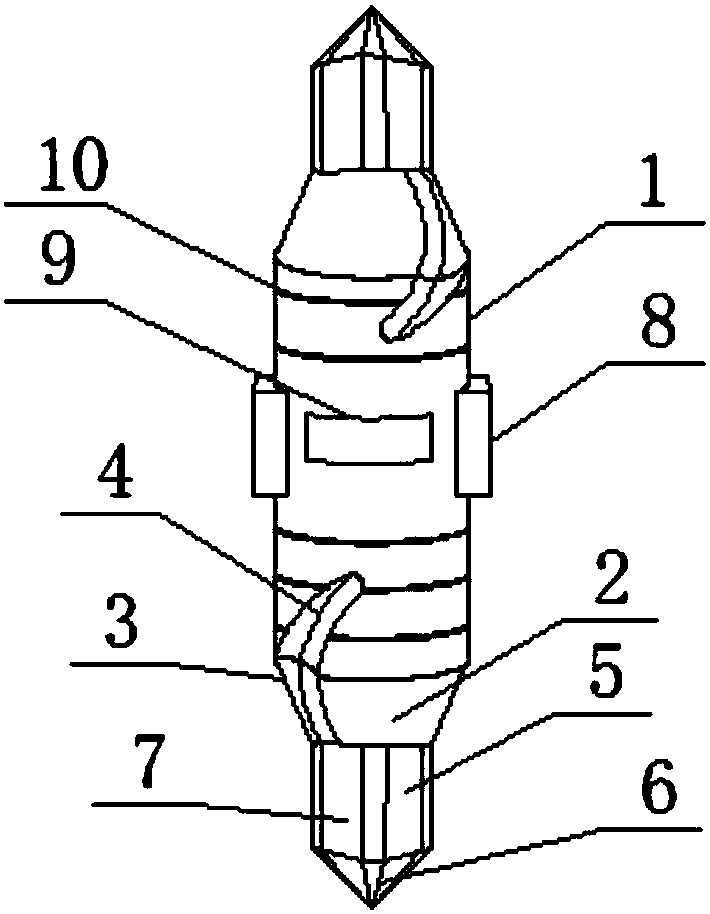

Integral hard alloy A-shaped center drill

InactiveCN107737977AAvoid rotational offsetEasy to understand the processing depthTransportation and packagingWorkpiecesCarbideAlloy

The invention discloses an integral hard alloy A-shaped center drill. The integral hard alloy A-shaped center drill comprises a drill handle, a drill bit, an oblique tool bit, an oblique groove, a center column, a straight tool bit, a straight groove, a clamping block, an identification board and identification rings. The main drill handle is provided with the identification rings, the identification rings are uniformly distributed at intervals, the identification rings correspond to different depth identification, the identification rings are circumferentially arranged, the identification rings can also control the depth in the rotation process of the center drill, the precision of a thread machining process is improved, the drill handle is provided with the symmetric clamping blocks, theclamping blocks can fix the drill handle, the rotating deflection of the drill handle in the application process is avoided, the drill bit is provided with the oblique tool bit, a large-area materialcan be cut and milled, the cross symmetric straight tool bit is arranged on the center column, the connection strength of a center cone can be improved, while the boring speed is increased, the sufficient strength and wear resistance can also be ensured, and the service life of the center drill is prolonged.

Owner:常州蓝丁格尔工具有限公司

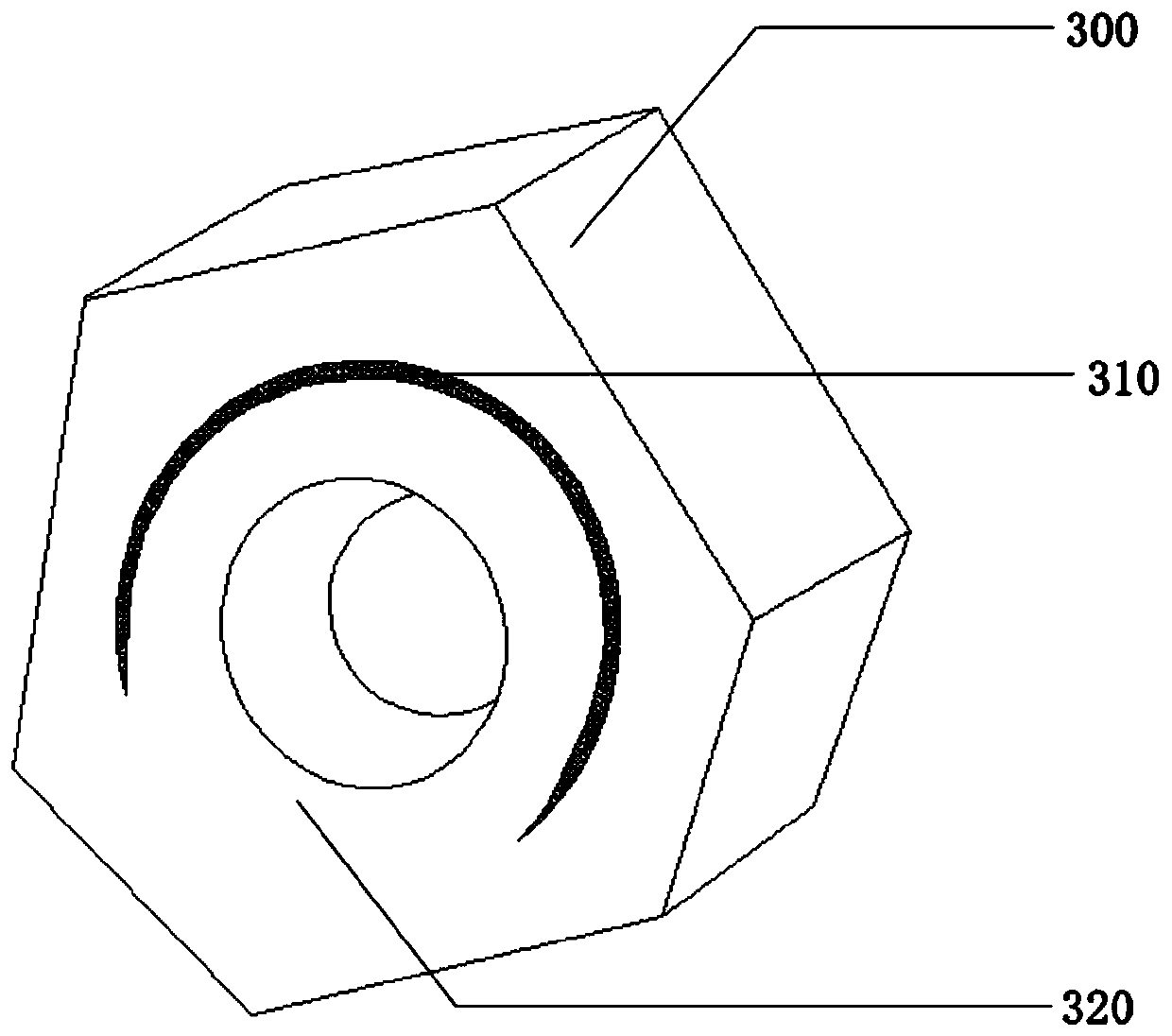

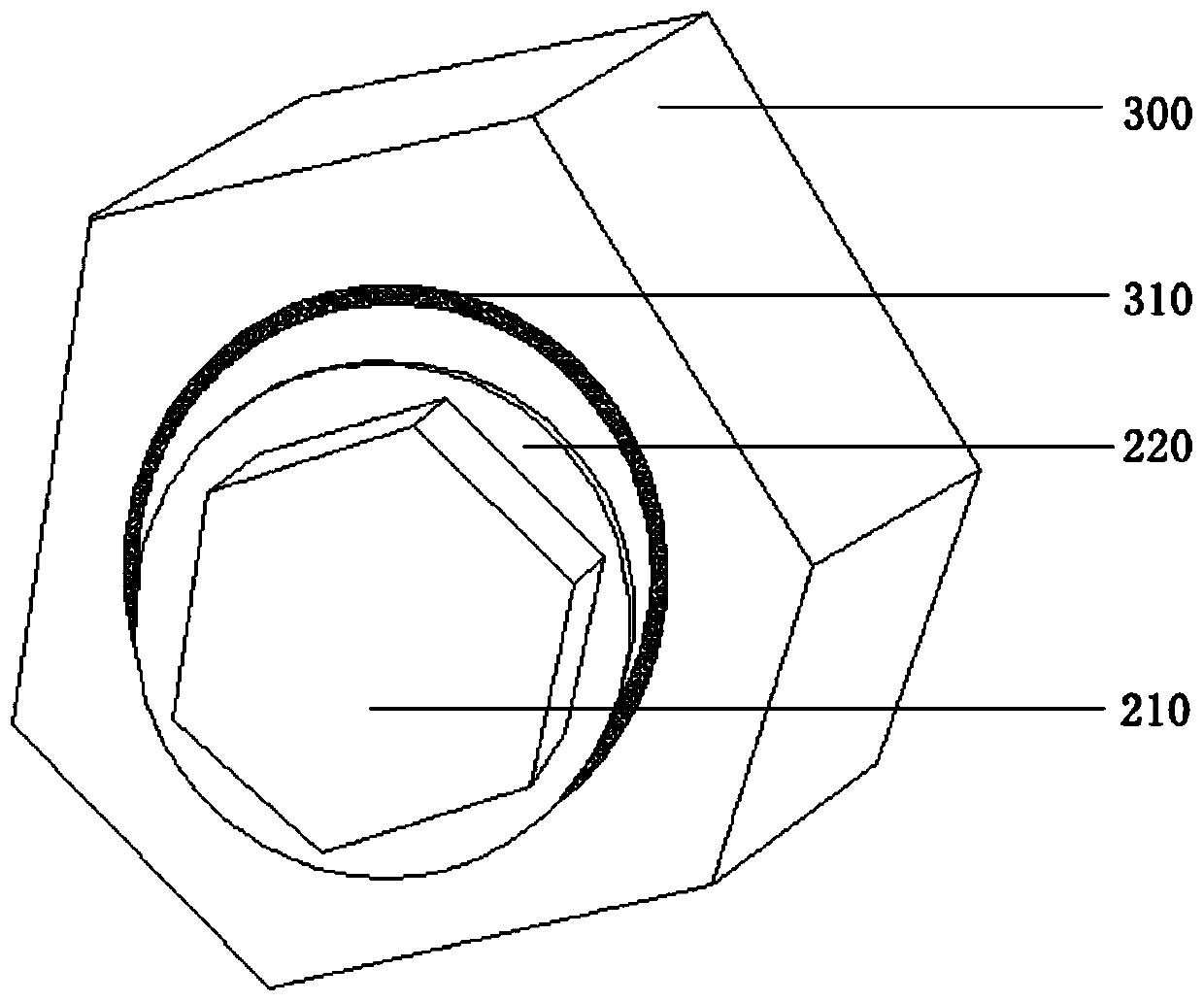

Anti-loose connection pair

The invention discloses an anti-loose connection pair which comprises an eccentric bolt, a retaining piece and a locking piece, wherein the eccentric bolt comprises a screw part, an inner nut or an extending bolt being in threaded matched with the locking piece is arranged at one end of the screw part, and the inner nut or the extending bolt is not in the same straight line with the axis of the screw part; the retaining piece is arranged on the screw part in a sleeving mode, and a raised part is arranged on the side, facing the locking piece, of the retaining piece; a C-shaped bayonet is formed in the raised part; and the locking piece is abutted against the retaining piece and is stuck into the C-shaped bayonet. When a machine with the connection pair is in the state of high-frequency vibration, the connection pair is more reliable and stable for locking due to the existence of multiple functions.

Owner:贾贤杰

A one-button open bottle cap

The invention relates to a one-button open bottle cap, which includes a bottle mouth and a bottle cap, and also includes a positioning ring, a fixing ring and an oval elastic snap ring. The positioning ring and the fixing ring are sequentially arranged in the bottle cap from top to bottom. There is a gap between the positioning ring and the fixed ring, and the two ends of the long axis of the elastic snap ring are located in the gap, and one of the two ends of the long axis of the elastic snap ring is provided with a pressing piece, and the corresponding pressing pieces of the positioning ring and the fixing ring There is a chamber for accommodating the pressing piece at the position, and the pressing piece can be displaced radially along the bottle cap in the chamber. The side wall of the bottle cap corresponding to the position of the chamber is provided with a port connecting the chamber; the side wall surrounding the bottle mouth There is a slot on the top corresponding to the position of the elastic snap ring, and the two ends of the short axis of the elastic snap ring are located in the slot to lock the connection between the bottle cap and the bottle mouth, and can break away from the slot and enter the space when the pressing piece is pressed and opened. slot, thereby unlocking the connection between the cap and the mouth of the bottle. The invention has the advantages of simple structure, convenient and labor-saving operation, and safe and fast opening of the cover.

Owner:CLOWN FISH SHANGHAI IND CO LTD

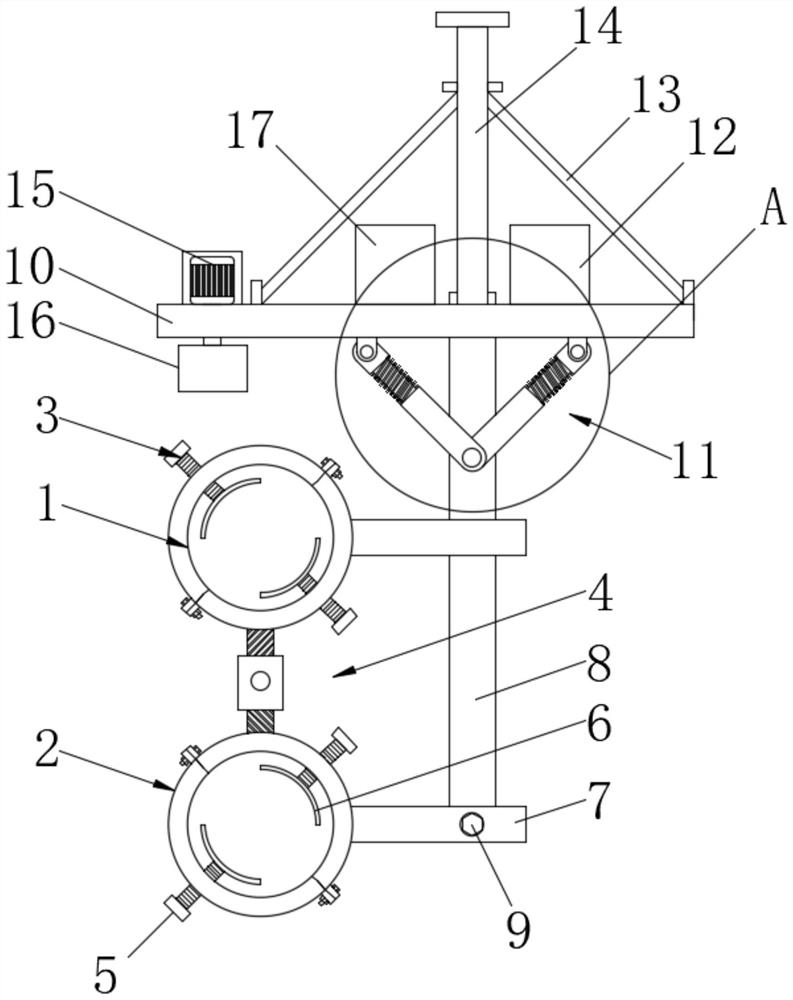

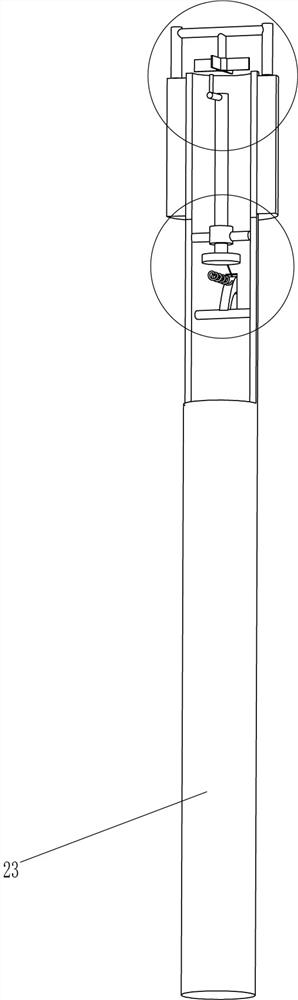

A video monitoring fixture based on deep water cage

ActiveCN112161160BGuaranteed stabilityAvoid rotational offsetTelevision system detailsColor television detailsVideo monitoringStructural engineering

The invention discloses a video surveillance fixing device based on a deep water cage, comprising a first fixing ring, a second fixing ring and a connecting mechanism connecting the two, the first fixing ring and the second fixing ring are related to the connecting mechanism Mirror image setting, two sets of symmetrically arranged clamping mechanisms are installed in the first fixed ring and the second fixed ring, and horizontally arranged side struts are welded on the same side of the first fixed ring and the second fixed ring. A set of vertical rods are inserted and fixed on the side of the side strut away from the first fixing ring and the second fixing ring, and a group of supporting top plates are welded at the top of the vertical rods. The video surveillance fixing device based on the deep water net cage can not only ensure the stability of the fixed support when fixing the overall structure, avoid the rotation and deviation of the single fixing ring on the enclosure pipe, but also adjust the first fixing ring and the second fixing ring. The distance between the two fixing rings makes it more convenient and quick when installing the enclosure pipes on the tops of different deep-water net cages.

Owner:四川富美建利科技有限公司

Double-hot-wind three-dimensional non-woven fabric pattern forming device

PendingCN111996671AEnhanced stereo renderingAvoid rotational offsetPattern makingNon-woven fabricsEngineeringNonwoven fabric

The invention provides a double-hot-wind three-dimensional non-woven fabric pattern forming device which comprises a hot wind forming machine. Hot air exists around an inner cavity of the hot wind forming machine. A B carded cotton upper layer web is connected to the top of the left side of the hot wind forming machine in a transmission manner. Three-dimensional pattern non-woven fabric is connected to the bottom of the hot wind forming machine in a transmission manner. An A carded cotton lower layer web is connected to the bottom of the left side of the hot wind forming machine in a transmission manner. A circulating windmill is connected to the back face of the hot wind forming machine in a bolting manner. According to the device, by means of cooperation among the hot wind forming machine, the hot air, the B carded cotton upper layer web, the three-dimensional pattern non-woven fabric, the A carded cotton lower layer web, the circulating windmill, a three-dimensional pattern hot windmachine forming net, a hot wind inner drum, a heater and a concentric outer circle barrel, the B carded cotton upper layer web and the A carded cotton lower layer web are fully heated and bonded, theaerology principle is utilized, heat is generated through hot air penetrating to enable the non-woven fabric to be bonded, and the non-woven fabric shows patterns formed in a three-dimensional manneron the hot wind forming net.

Owner:萧 进华 +1

A fabric compounding device

ActiveCN110802909BUnwinding is smooth and orderlyEfficient and smooth coatingSpraying apparatusLaminationElectric machineryConductive materials

The invention discloses a fabric compounding device, which belongs to the field of textile processing machinery and equipment. The middle part of the unwinding turntable of the invention is horizontally and fixedly provided with an unwinding supporting rod, the end of the pressure plate rotating rod on the upper side of the unwinding turntable is vertically rotated and connected with a damping runner, and a pressing rod slider is slidably arranged on the rotating guide rod, and the guide The cloth supporting plate is fixedly arranged on the composite support under the unwinding support rod at an angle downward, the feeding roller is horizontally arranged on the upper side of the cloth guiding supporting plate, and the lower side of the glue spraying pipe is provided with a plurality of glue nozzles, and the upper guide The rotary roller and the lower guide roller are pressed and fitted with each other. The upper pressing bracket and the lower pressing bracket are arranged on the composite bracket in turn from top to bottom. The cloth pulling motor and the cloth rotating roller are connected by a cloth chain transmission. . The invention has a reasonable structural design, can quickly and efficiently process fabrics in a continuous and stable compound process in the material transfer process, improves the efficiency and quality of fabric compounding, and has a high degree of automation to meet the needs of processing and use.

Owner:TONGXIANG YUESHUN WRAP KNITTING

Stroke control device

ActiveCN100515748CAvoid rotational offsetGuaranteed normal operationMetal working apparatusPressesAluminum anodeEngineering

The invention discloses a press release machine stroke control device for an electrolytic aluminum anode assembly. The top surface is connected, the first torque arm (3) and the second torque arm (5) are connected on both sides of the flange (4), the first torque arm (3) is connected with the induction plate (2), the first torque arm (3) ) and the second torsion arm (5) in the guide rail (7), the guide rail (7) is connected with the connecting plate (8), and the connecting plate (8) is connected with the fixed plate (9). Among them, there is an oblong hole on the induction plate (2), the first torsion arm (3) is connected with the induction plate (2) through the oblong hole and bolts, and the flange (4) is connected with the top surface of the piston rod of the pressure release cylinder by bolts. Connect, on the first torsion arm (3) and the second torsion arm (5) there is the inlay (6), and the guide rail (7) is connected with the connecting plate (8) with countersunk screws. When the piston rod of the press-off cylinder intends to deflect during motion, it is limited by the guide rail (7).

Owner:GUIYANG AL-MG DESIGN & RES INST

A track-type underground mechanical and electrical equipment transportation device

ActiveCN110939480BImprove stabilityReduce contact frictionEarth drilling and miningUnderground transportStructural engineeringControl theory

Owner:安阳市主焦煤业有限责任公司

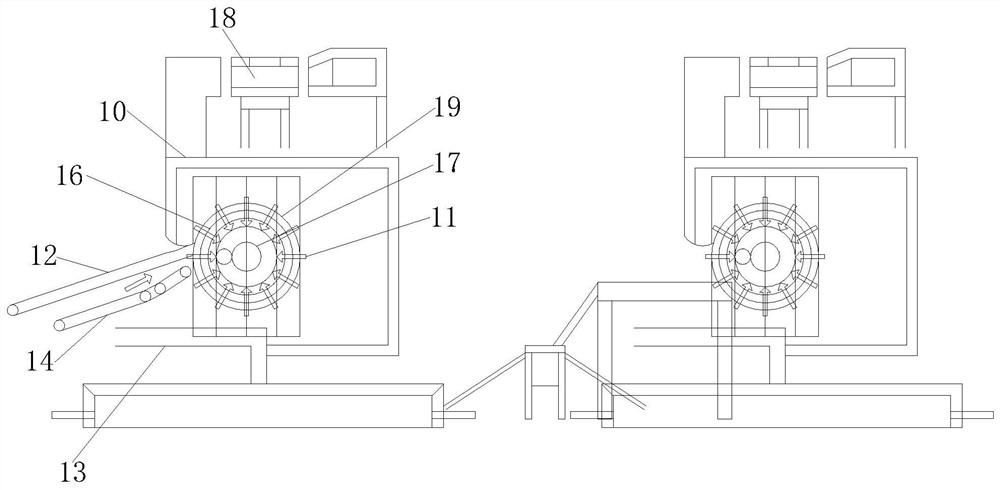

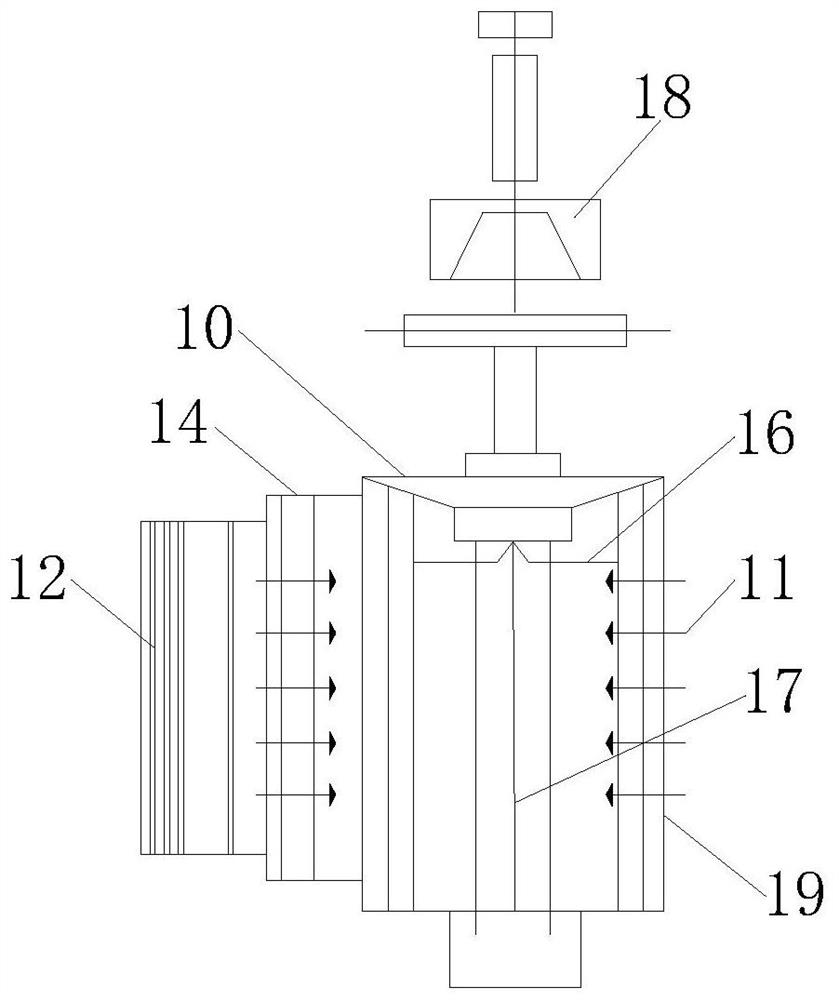

A wire drawing processing device for the outer surface of stainless steel pipe

ActiveCN109318083BAvoid rotational offsetEasy to processGrinding carriagesGrinding drivesElectric machinerySS - Stainless steel

The invention discloses a wire drawing processing device for the outer surfaces of stainless steel pipes. The wire drawing processing device comprises a base. A sliding chute is formed in the upper end of the base. A threaded rod and a first limiting rod are arranged in parallel in the sliding chute. A first motor is fixedly arranged on the inner wall of the sliding chute, and one end of the threaded rod is fixedly connected with an output rod of the first motor. The threaded rod and the first limiting rod are provided with a sliding plate in a penetrating mode. A plurality of placing groovesare formed in the upper surface of the sliding plate at equal intervals. A limiting adjusting mechanism matched with the plurality of stainless steel pipes during use is arranged on the surface of thesliding plate. Two supporting columns are symmetrically and fixedly connected to the two ends of the upper surface of the base. By means of the wire drawing processing device, the plurality of stainless steel pipes can be subjected to wire drawing processing at the same time, so that the working efficiency is high; the positions of all the stainless steel pipes can be adjusted conveniently at thesame time, so that all-round wire drawing processing of round surfaces of the stainless steel round pipes can be carried out; and the rotation deviation of stainless steel round pipes can be effectively prevented during wire drawing processing of the stainless steel round pipes, so that the processing effect is better.

Owner:博斯特机械制造新沂有限公司

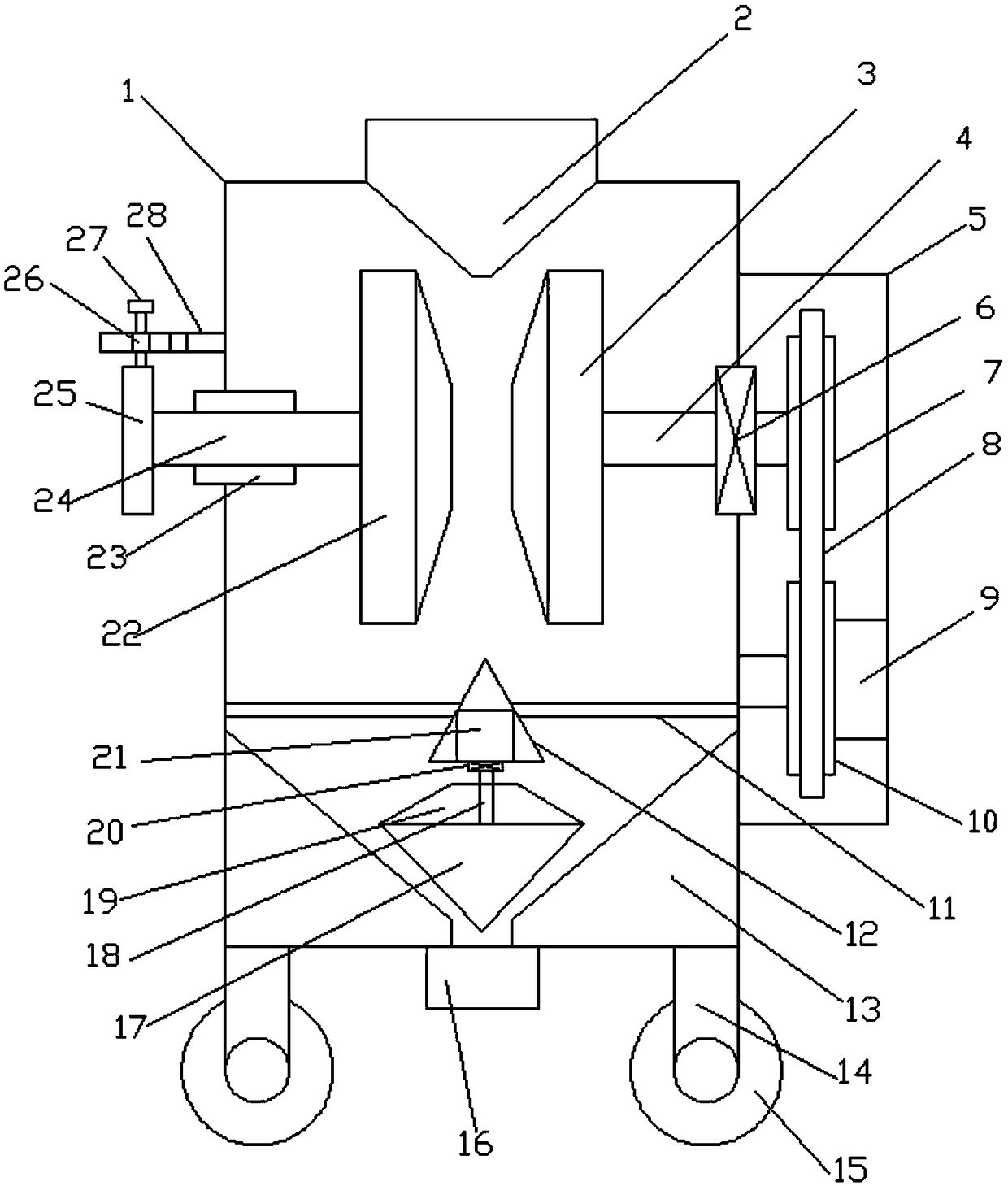

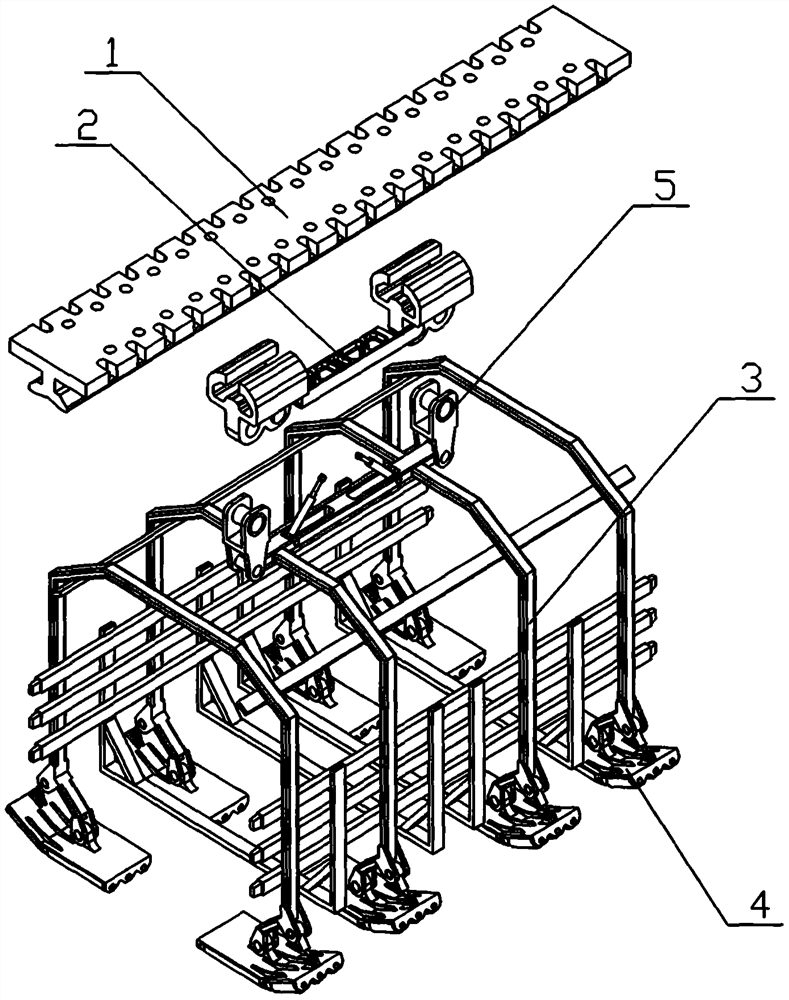

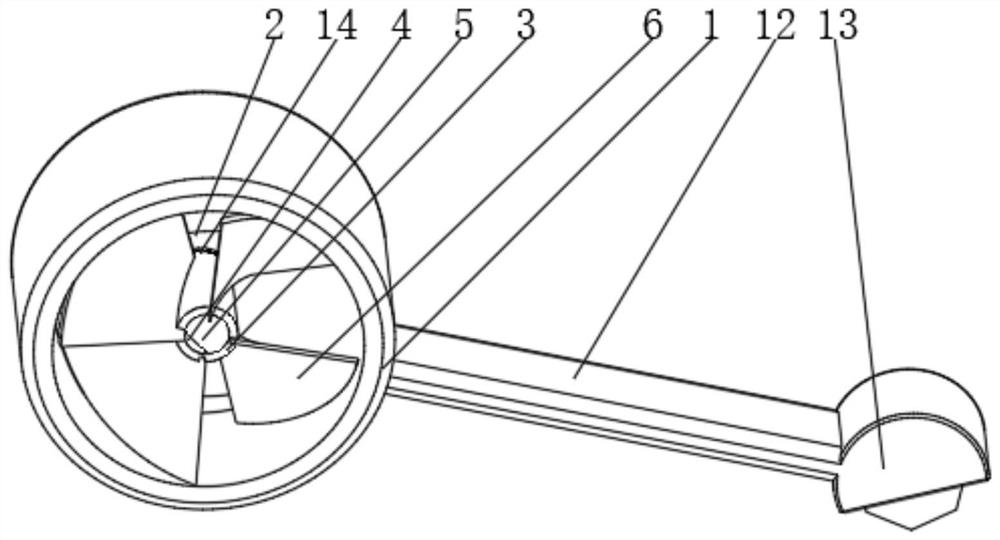

A segmented preforming method for torsion beams

ActiveCN109807252BAvoid rotational offsetShaping toolsMetal-working feeding devicesMechanical engineeringPhysics

The invention discloses a segmented torsion beam preforming method, which comprises the following steps: S1, raw material selection; S2, adopting split preforming equipment to press the selected pipe to form a predetermined shape, and the split preforming equipment includes A lower mold and an upper mold, the upper mold includes a middle insert and a first insert and a second insert relatively arranged at both ends of the middle insert; the specific pressing steps are as follows: S21, placing the selected pipe on the lower mold and make one end of the pipe under the first insert, and the other end under the second insert; S22, push the upper die to move toward the lower die to press the pipe placed on the lower die, and press During the forming process, the first insert and the second insert in the upper mold are brought into contact with the pipe in advance to pre-compress the two ends of the pipe; S23, after pressing and forming, push the upper mold to reset. The invention can effectively ensure that the "V"-shaped R-angle shape is uniformly distributed on the left and right in the processed product.

Owner:BAOLONG ANHUI AUTO PARTS

Multifunctional movable sewing edge retaining device

InactiveCN102677407BAvoid rotational offsetGuaranteed stabilityWork-feeding meansEngineeringMechanical engineering

The invention discloses a multifunctional movable sewing edge retaining device, which belongs to a sewing auxiliary device for clothing production, and comprises a base plate and a plurality of edge retaining blocks, wherein an extending section is arranged downwards at the tail end of each edge retaining block, the edge retaining blocks are fixed on the base plate, a fixing device is also arranged on the base plate, the start ends of the edge retaining blocks are mutually overlapped and fixed, and gaps are kept between the extending sections of the tail ends of the edge retaining blocks; and a first baffle is fixed on any one edge retaining block, and the first baffle is arranged in any position between the start end and the tail end of the edge retaining block for preventing the positions of other edge retaining blocks except the edge retaining block from offsetting. The multifunctional movable sewing edge retaining device disclosed by the invention has a simple structure, the volume of the device can be discretionarily set according to a sewing device matched with the device, and the device is suitable for industrial production and is easy to popularize.

Owner:JIHUA 3536 PROFESSIONAL CLOTHING

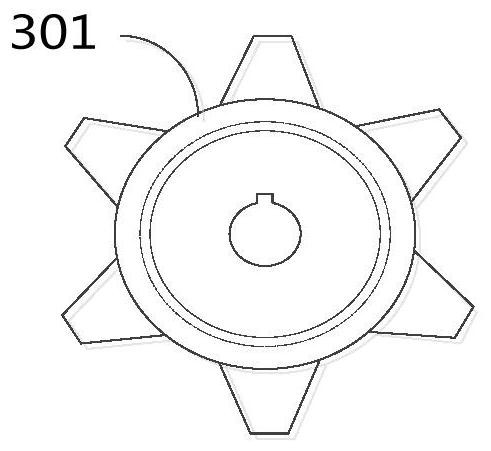

Vehicle-mounted plug-in of self-rescue wrench in automobile mire area

InactiveCN111824079AReduce impactProtect yourselfVehicle fittings for liftingVehicle cleaning apparatusIn vehicleGear wheel

The invention discloses a vehicle-mounted plug-in of a self-rescue wrench for an automobile mire area, which comprises a shell.A center shaft is fixedly connected to the middle of the front face of arotating disc. A pressing type adsorption structure is arranged in an inner cavity of the center hole. Curved fan blades are fixedly connected to the outer surface of the center shaft; the side, awayfrom the rotating disc, of the center gear is fixedly connected with a multi-angle limiting mechanism; and the outer surface of the center gear is in engaged transmission with a star wheel; the side,away from the rotating disc, of the star wheel is fixedly connected with a magnetic connecting end; the middle of the outer surface of the shell is fixedly connected with a protective connecting rod;and the end, away from the shell, of the protective connecting rod is fixedly connected with a directional wheel. According to the vehicle-mounted plug-in of a self-rescue wrench for an automobile mire area disclosed in the invention, which relates to the technical field of vehicle-mounted plug-ins, effective buffering is achieved through magnetic force, impact force in the using process of the equipment is reduced, the safety of the equipment is protected, effective adsorption, positioning and installation are conducted through magnetism, disassembly and assembly are convenient, the equipmentcan be suitable for self rescue in various environments, and the safety of a vehicle is protected.

Owner:余付宁

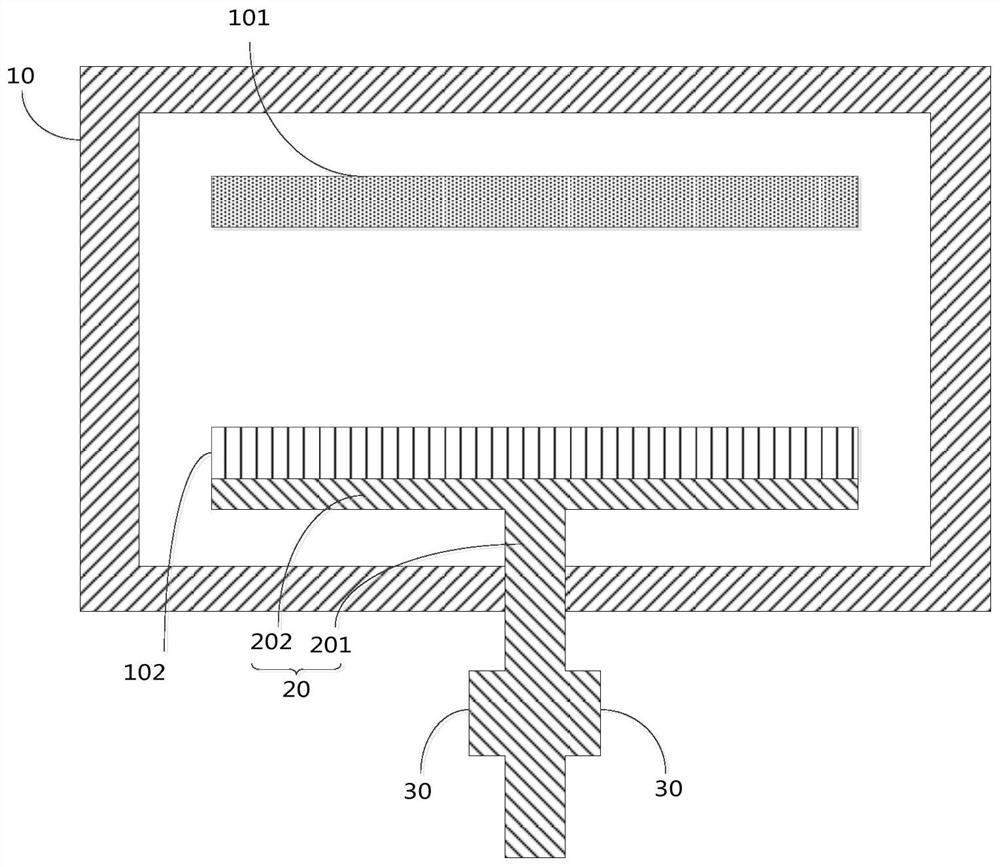

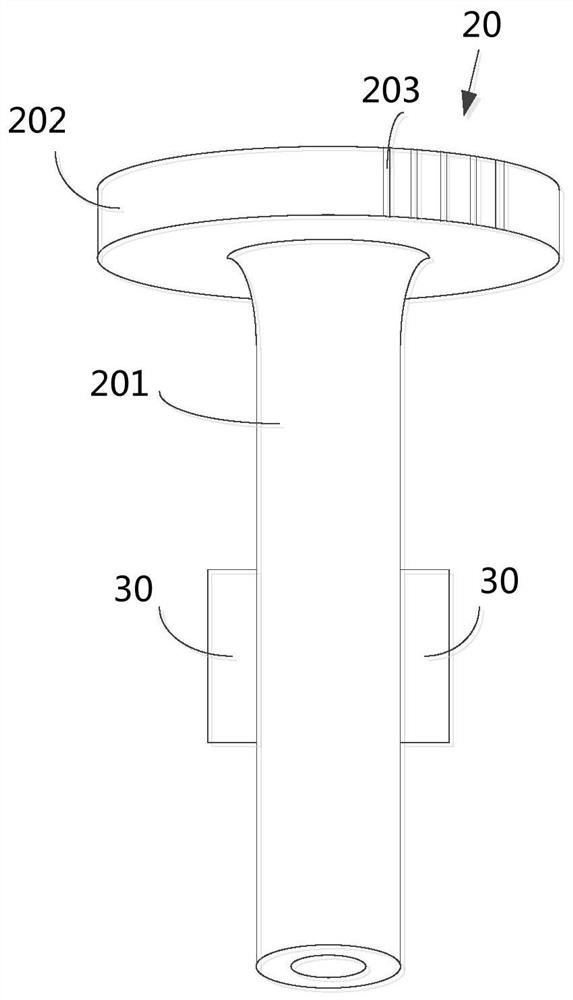

A chemical vapor deposition device

ActiveCN108342715BAvoid rotational offsetShorten the production cycleChemical vapor deposition coatingEngineeringChemical vapor deposition

The invention provides a chemical vapor deposition device. The device comprises a reaction chamber, an upper polar plate, a lower polar plate and a transmission device; the upper polar plate and the lower polar plate are oppositely arranged; and the transmission device comprises a main body part and a supporting part arranged above the main body part, the transmission device is arranged below thelower polar plate, an adjusting part is arranged on the transmission device, the adjusting part is used for adjusting the position of the lower polar plate to prevent the position of the lower polar plate from rotating and shifting. The adjusting part is arranged on the transmission device, in the actual production process, the adjusting part can directly adjust the position of the lower polar plate so as to achieve the purpose of preventing the position of the lower polar plate from rotating and shifting, in addition, during adjustment, cooling is not needed, and the reaction chamber does notneed to be opened, so that the production cycle is shortened, and the production efficiency is improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

An automatic bagging device for blow molding waste crushing

ActiveCN111301776BSave human effortShorten the timeSolid materialPackaging automatic controlBlow moldingProcess engineering

The invention relates to an automatic bagging device, in particular to an automatic bagging device for blow molding waste crushing. The technical problem to be solved is to provide an automatic bagging device for crushing blow molded parts waste that does not require people to hold the bag all the time, can easily change the bag, and can save manpower and time. An automatic bagging device for blow molding waste crushing, including a bottom plate, a first bracket, a second bracket, etc.; both sides of the top of the bottom plate are fixedly connected with the first bracket and the second bracket. The present invention can press down the bag full of waste materials through the pressing assembly, and the rotating assembly can remove the bag full of waste materials and replace it with a new bag at the same time, so that people do not need to hold the bag for filling, thus saving manpower and labor. time, and the bag can be easily changed without spreading the waste all over the place; through the setting of the bell, it can remind people when the waste is full.

Owner:义乌市丹航科技有限公司

an underground garage

ActiveCN111411808BRotation offset does not affectGuaranteed smoothnessParkingsRotational axisAutomobile platform

The invention discloses an underground garage, which comprises a cylindrical garage main body. A lifting mechanism is fixed on the top of the cylindrical garage main body. The lifting mechanism includes a rotating platform. A rotating motor is fixed in the center of the bottom surface of the rotating platform. The motor, the top surface of the rotating platform is crimped with a car platform, and cars are placed on the top surface of the car platform. The main body of the cylindrical garage is provided with several parking garages. A ball, two locking devices, and two round table rotating parts, the cylindrical supporting device is sleeved with a rotating device, there is a gap between the cylindrical supporting device and the rotating device, the bottom of the rotating device is fixed with a rotating shaft, and the rotating platform drives the rotating shaft Rotation, the rotation device is fixed with a number of rollers, the rollers are crimped with the slide rail, and the horizontal transmission motor drives the rollers. The invention can improve the deficiencies of the prior art and improve the running stability.

Owner:合肥速纳工程设计有限公司

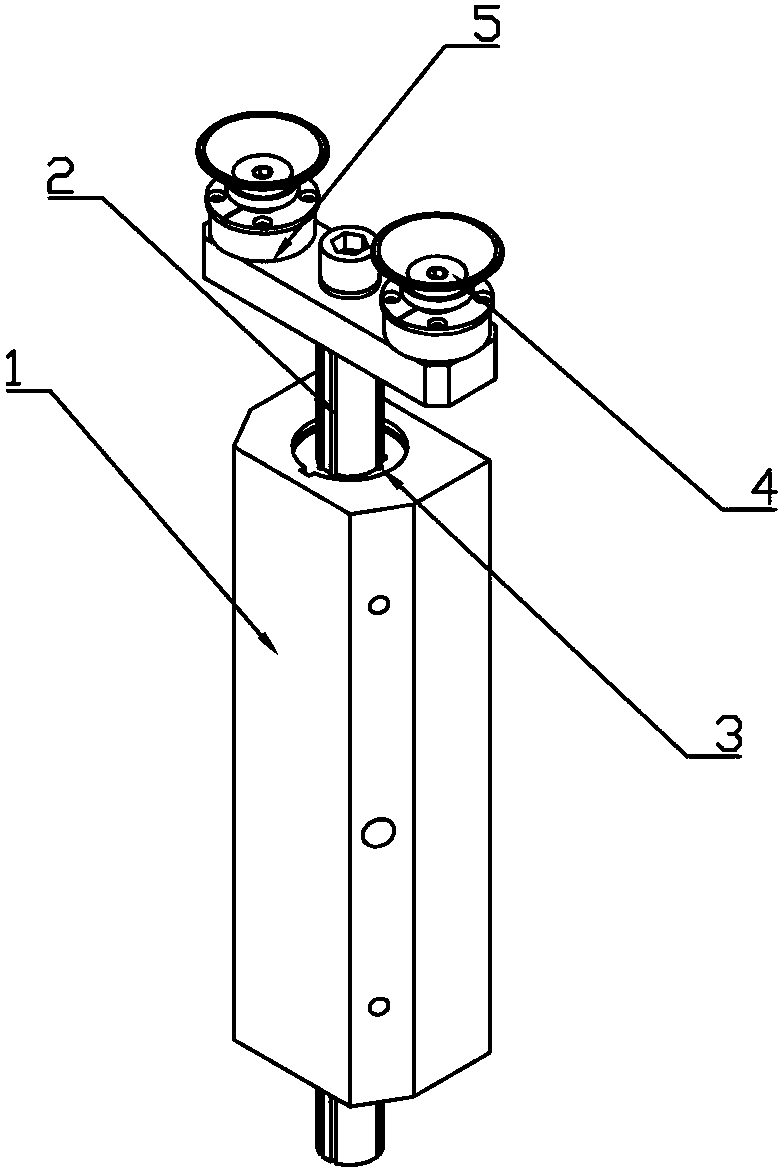

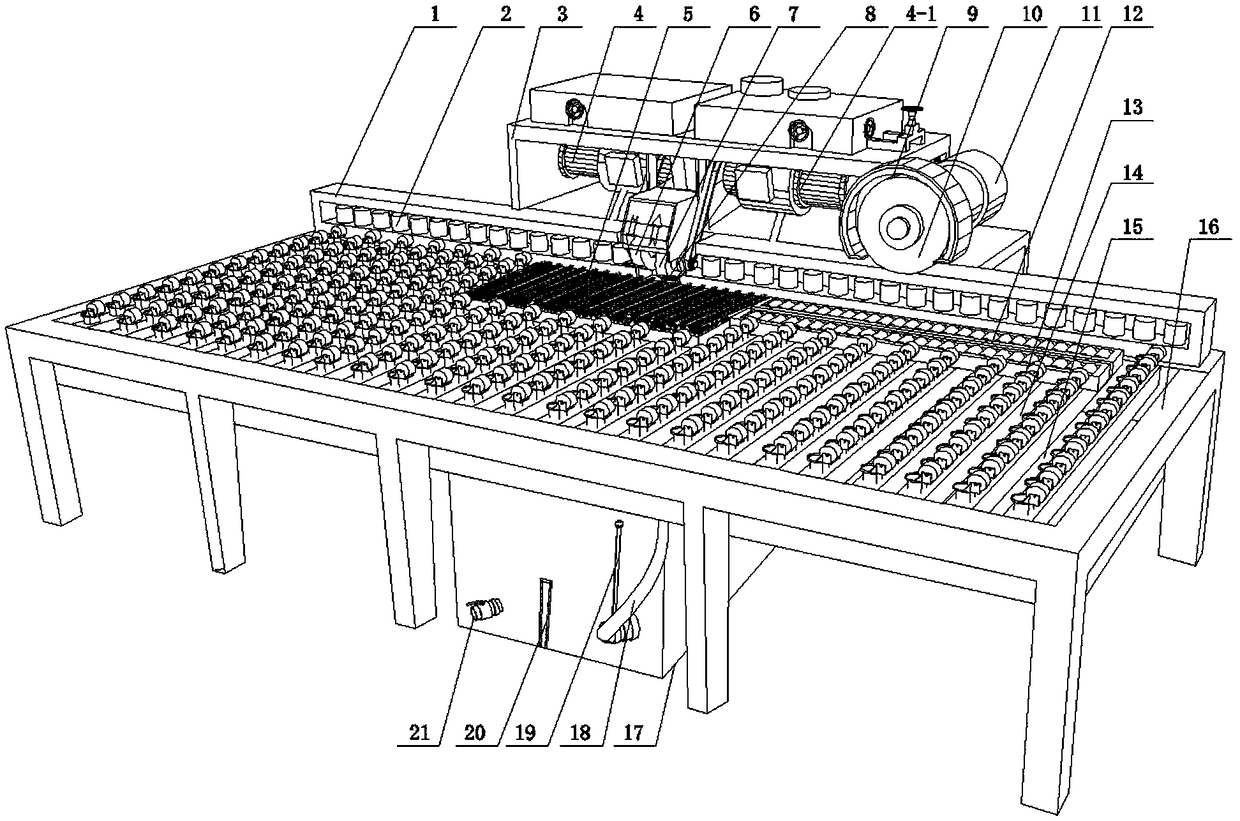

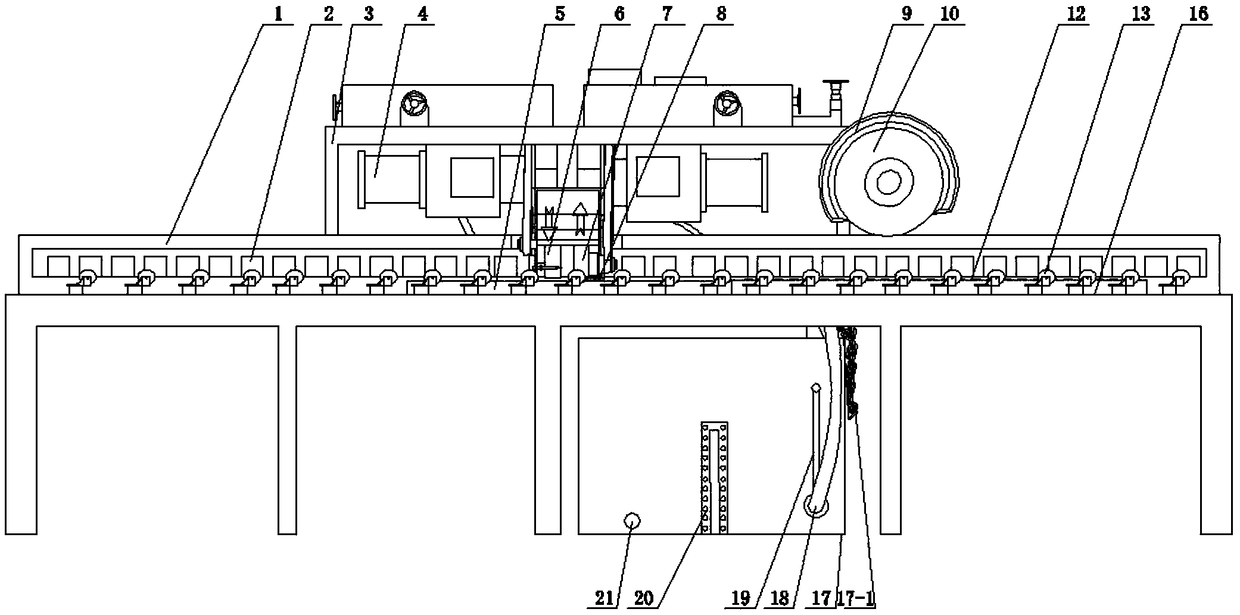

Rapid vacuum switching mechanism

The invention relates to the field of mechanical automation equipment, in particular to a rapid vacuum switching mechanism. A guiding bearing sleeve is arranged in a guiding sleeve seat. A guiding shaft penetrates the guiding bearing sleeve and draws the guiding bearing sleeve to shift along the interior of the guiding sleeve seat. The top of the guiding shaft is connected to a suction disc connecting rod. Suction disc buffer parts are mounted at the bottom of the suction disc connecting rod. The guiding sleeve seat is provided with an air inlet and an air drafting hole. The air inlet and theair drafting hole are formed in the guiding bearing sleeve in a through manner and communicate with the suction disc buffer parts through an inner pipe of the guiding shaft. The rapid vacuum switchingmechanism has the beneficial effects that mechanical type design is adopted for the vacuum switching mechanism so that materials can be rapidly sucked and break away through the suction disc buffer parts; compared with a traditional control air pump, the switching speed of the rapid vacuum switching mechanism is increased, and the automation degree of the rapid vacuum switching mechanism is raised; and thus, manpower and material resources of a manufacturer are reduced, and production efficiency and product quality of the rapid vacuum switching mechanism are greatly improved.

Owner:汕头市信力制罐设备有限公司

Adjustable filtering, impurity removing and edge polishing device on tempered glass production line

PendingCN108972223ASimple structureSimple and efficient operationEdge grinding machinesGrinding/polishing safety devicesSlagScrap

The invention relates to an adjustable filtering, impurity removing and edge polishing device on a tempered glass production line. The device comprises a polishing platform, a polishing mechanism, a water flushing mechanism and a precipitating and liquid drainage mechanism. The polishing mechanism is mounted on one side of the polishing platform, and the water flushing mechanism is mounted on oneside of a polishing wheel of the polishing mechanism. The precipitating and liquid drainage mechanism is arranged on the lower portion of a platform frame of the polishing platform and connected withthe water flushing mechanism through a water pipe with a pump. Glass is pushed from one side of the polishing platform to a polishing head to be polished, and the water flushing mechanism carries outwater flushing on the edges of the glass. Glass powder slag flows into a temporary storage pond of the polishing platform along with water flow of the water flushing mechanism, and finally waste wateris subjected to precipitating and filtering treatment through the precipitating and liquid drainage mechanism. According to the adjustable filtering, impurity removing and edge polishing device, by means of an adjustable filtering water outlet manner, water supplied to the water flushing mechanism each time is clear, the impurity content is small, and the service life of a water gun of the waterflushing mechanism is protected. Waste is easy to recycle, cleaning and replacing are easy, and meanwhile the polishing efficiency is greatly improved.

Owner:鹏凯(天津)玻璃有限公司

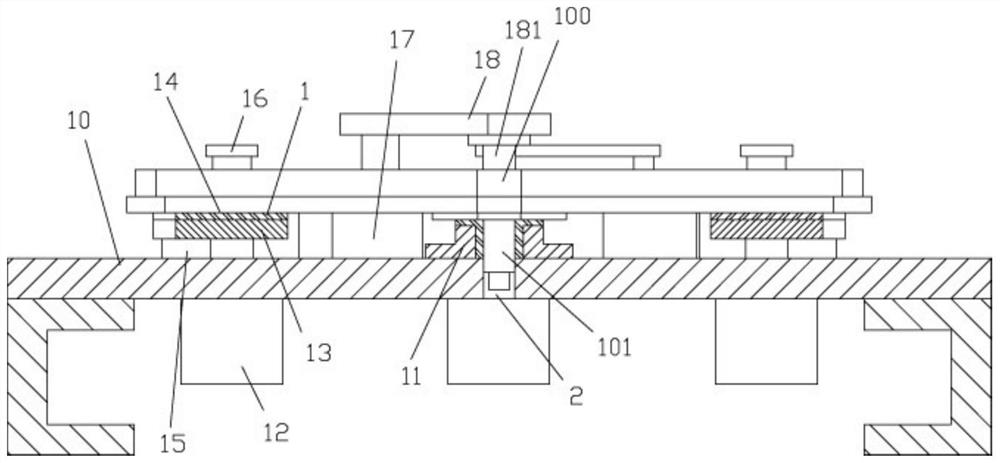

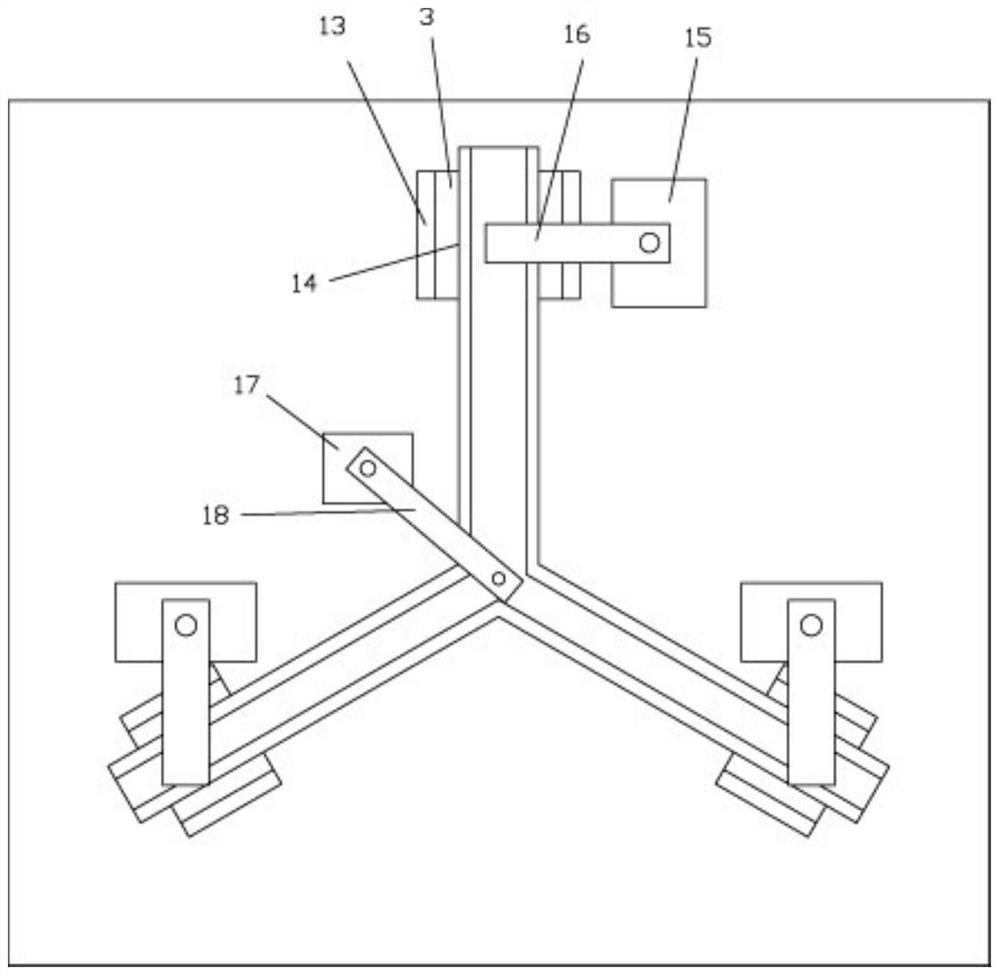

Novel clamping mechanism for washing machine tripod machining

InactiveCN111940590ARotation does not produceStable clampingMetal-working feeding devicesPositioning devicesLaundry washing machineEngineering

The invention discloses a novel clamping mechanism for washing machine tripod machining. The novel clamping mechanism comprises a fixing table plate, wherein a middle shaft containing sleeve body is fixed to the top surface of the middle of the fixing table plate, and a connecting shaft formed on the bottom surface of the middle of a tripod to be machined is inserted into the middle shaft containing sleeve body in a sleeved mode; and bottom pressing air cylinders are fixed to the bottom surface, located below the ends of three connecting supporting rods of the tripod to be machined, of the fixing table plate, push rods of the bottom pressing air cylinders penetrate through the top surface of the fixing table plate and are fixedly provided with lower pressing blocks, inserting grooves are formed in the middles of the top surfaces of the lower pressing blocks, and the connecting supporting rods of the tripod to be machined are inserted into the corresponding inserting grooves in a sleeved mode and are pressed against the bottom surfaces of the inserting grooves. According to the novel clamping mechanism, it can be ensured that the tripod to be machined is firmly clamped and cannot rotate, and the follow-up machining effect is ensured.

Owner:台州路桥城歌机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com