Rapid vacuum switching mechanism

A conversion mechanism and vacuum technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of poor stability of the suction process, slow suction speed, short service life of the cylinder, etc., to improve production efficiency and product quality, reduce Human and material resources, the effect of improving conversion speed and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a further understanding of the purpose, features and functions of the present invention, preferred embodiments are hereby given and described in detail in conjunction with the drawings as follows:

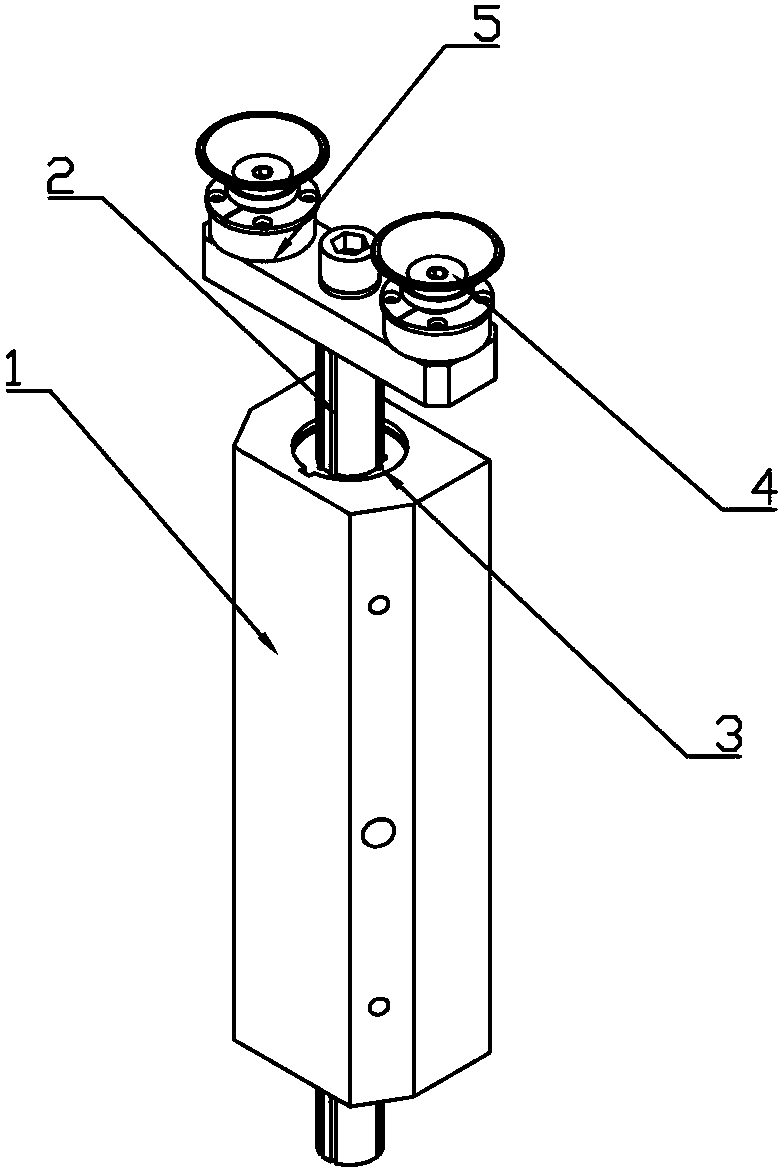

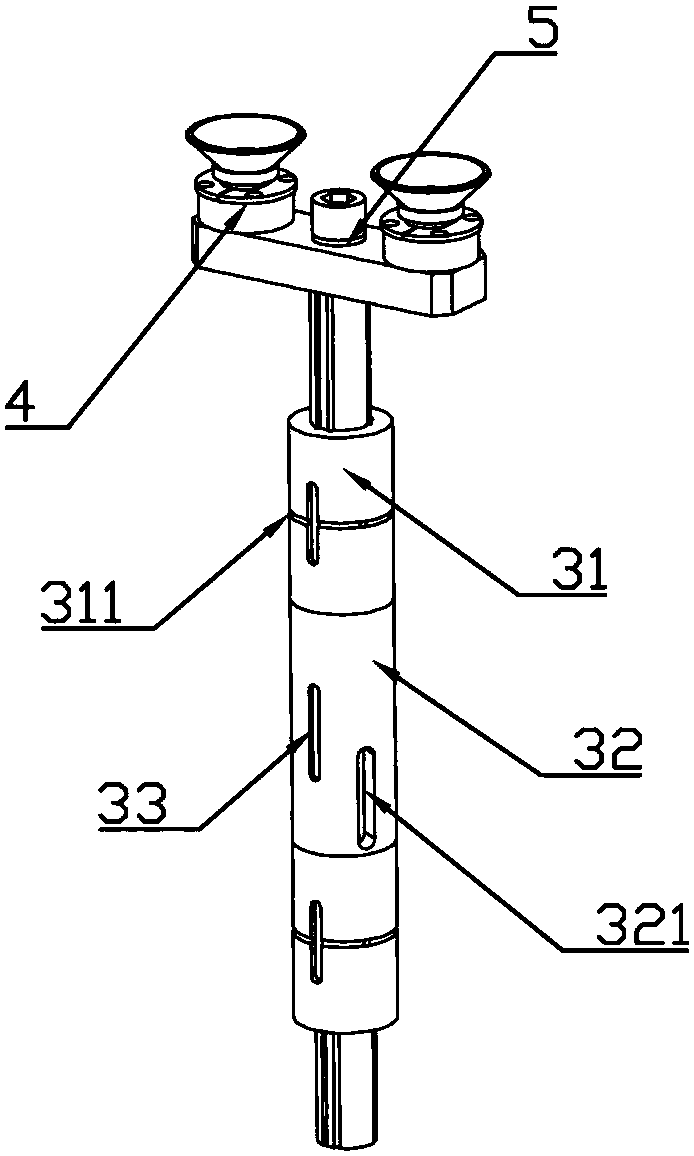

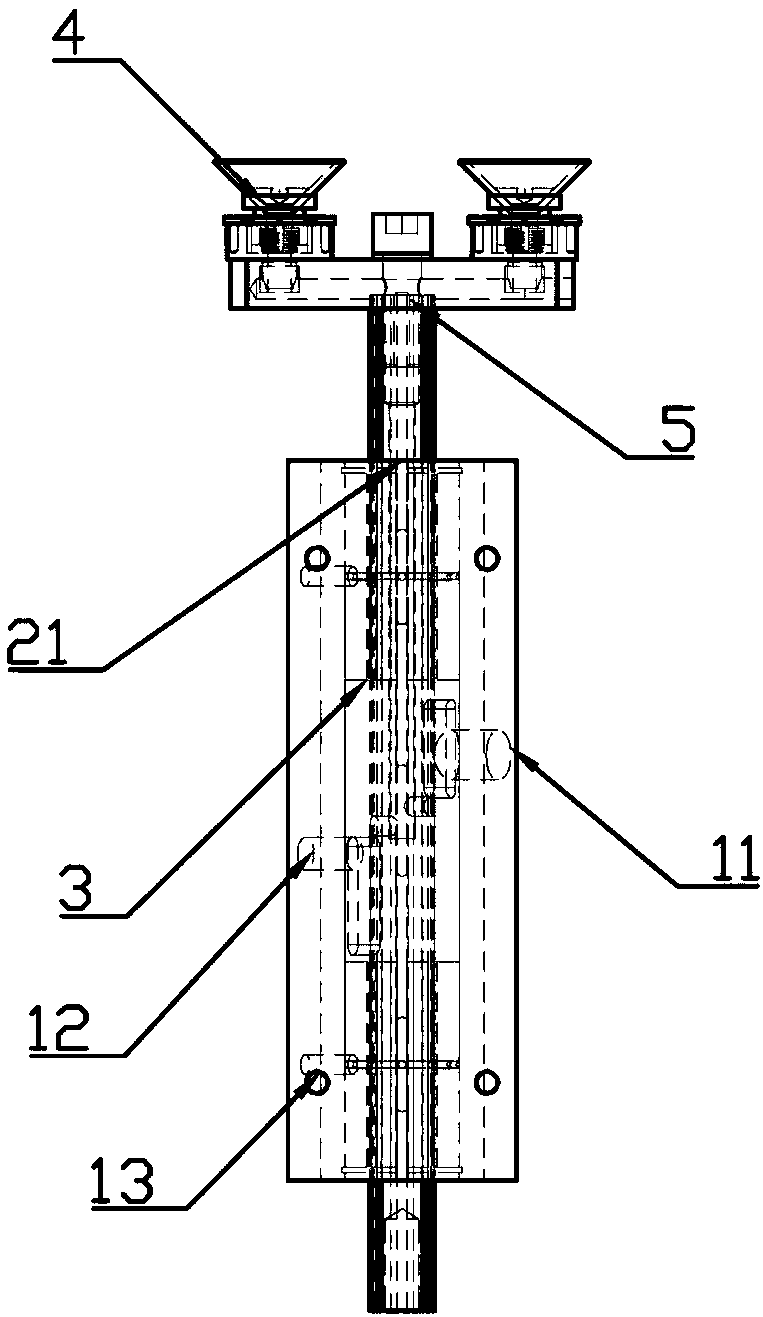

[0021] Figures 1~5 As shown, it is a schematic structural diagram of a preferred embodiment of the present invention. The present invention is a rapid vacuum conversion mechanism, which mainly includes: a guide sleeve seat 1, a guide shaft 2, a guide bearing sleeve 3, a suction cup buffer 4 and a suction cup connection. Rod 5, the guide bearing sleeve 3 is arranged in the guide sleeve seat 1, the guide shaft 2 runs through the guide bearing sleeve 3, the guide shaft 2 drives the guide bearing sleeve 3 to move along the inside of the guide sleeve seat 1, and the top of the guide shaft 2 is connected For the suction cup connecting rod 5, the suction cup buffer 4 is installed on the bottom of the suction cup connecting rod 5, and the guide sleeve seat 1 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com