Patents

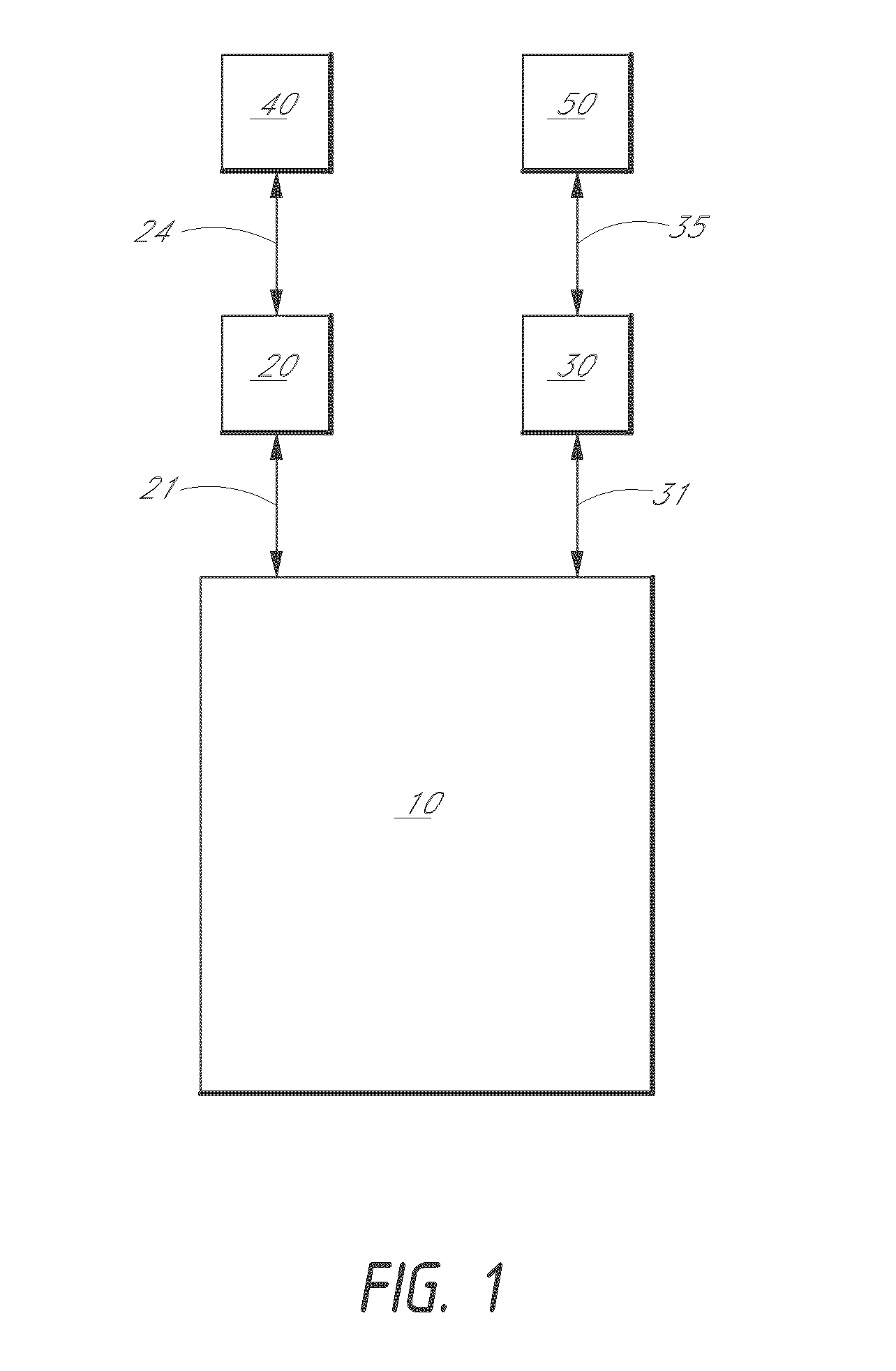

Literature

1367results about How to "Promote withdrawal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

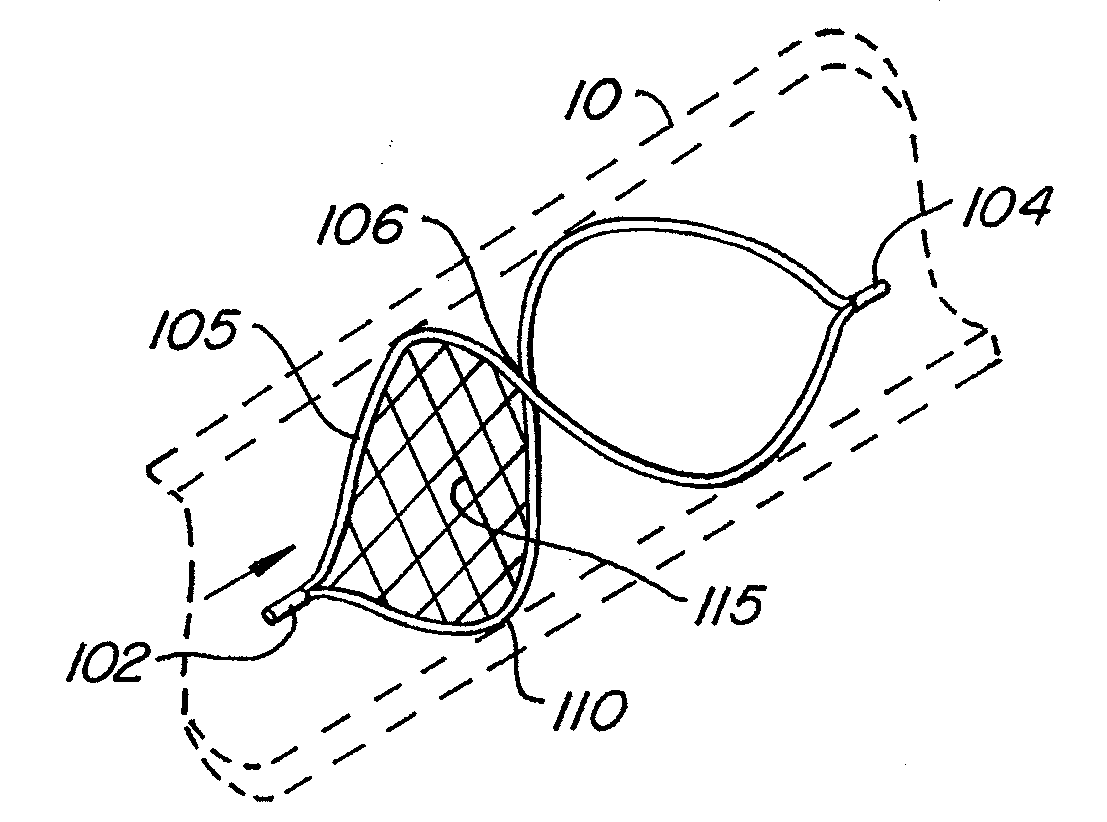

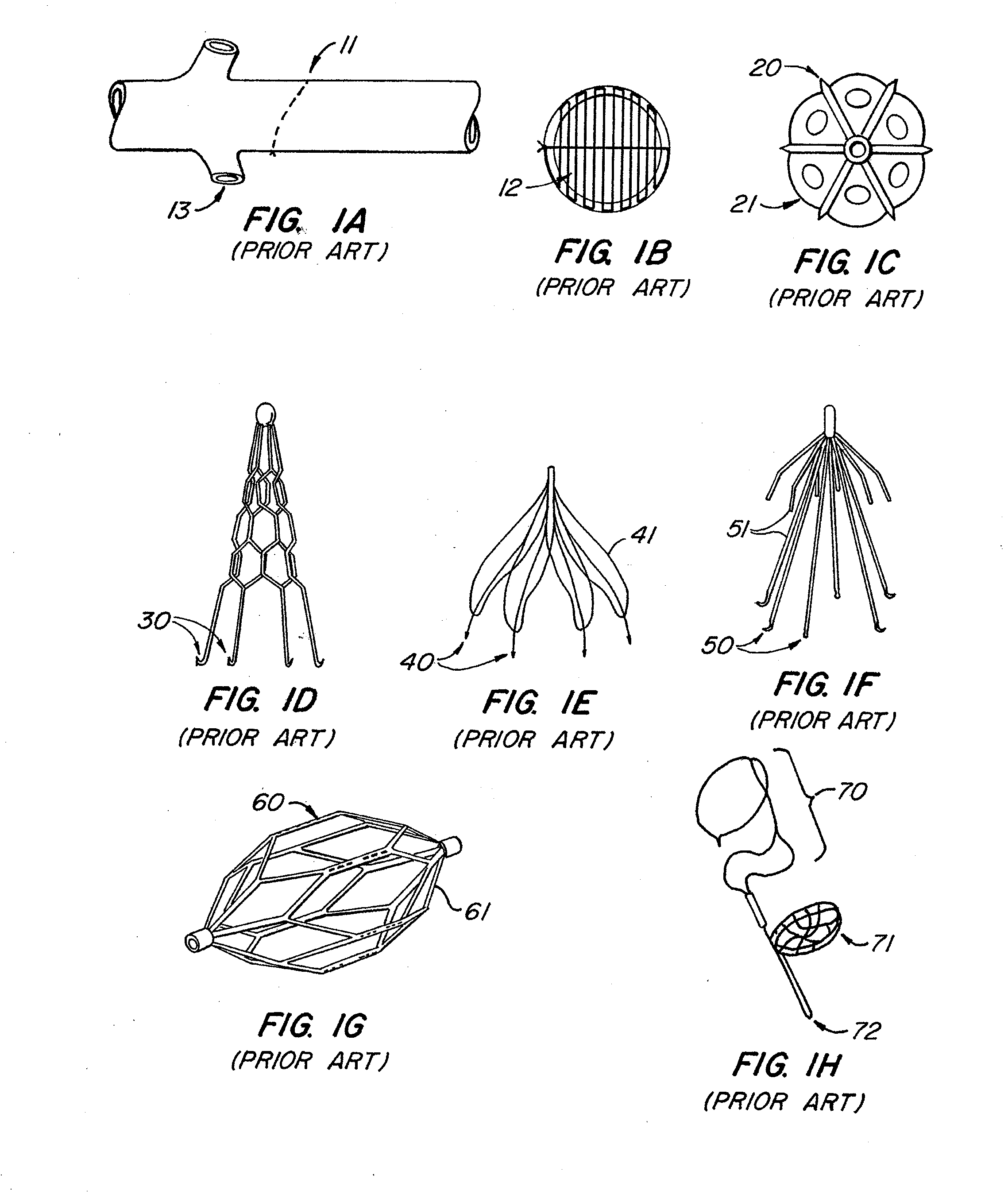

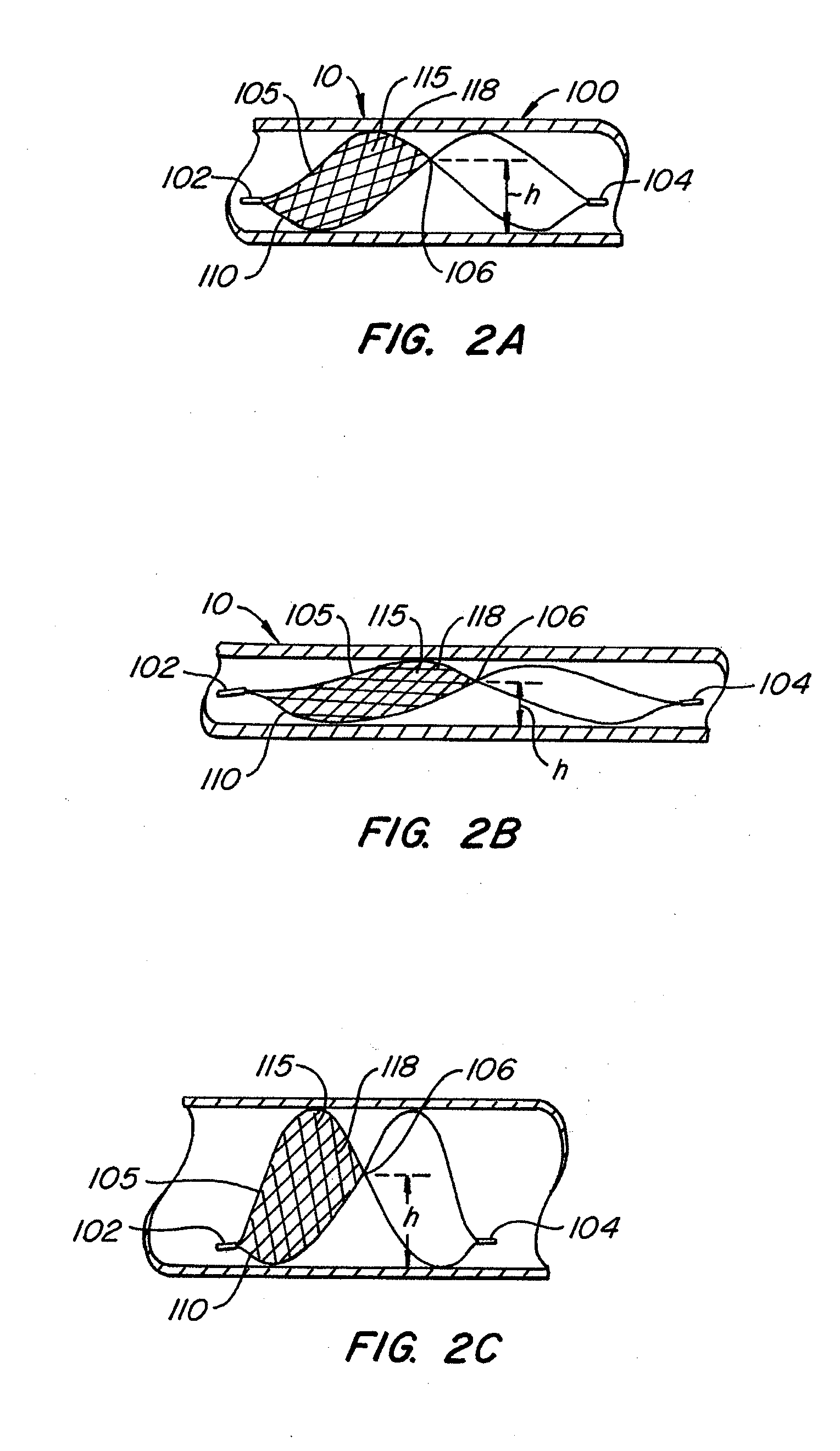

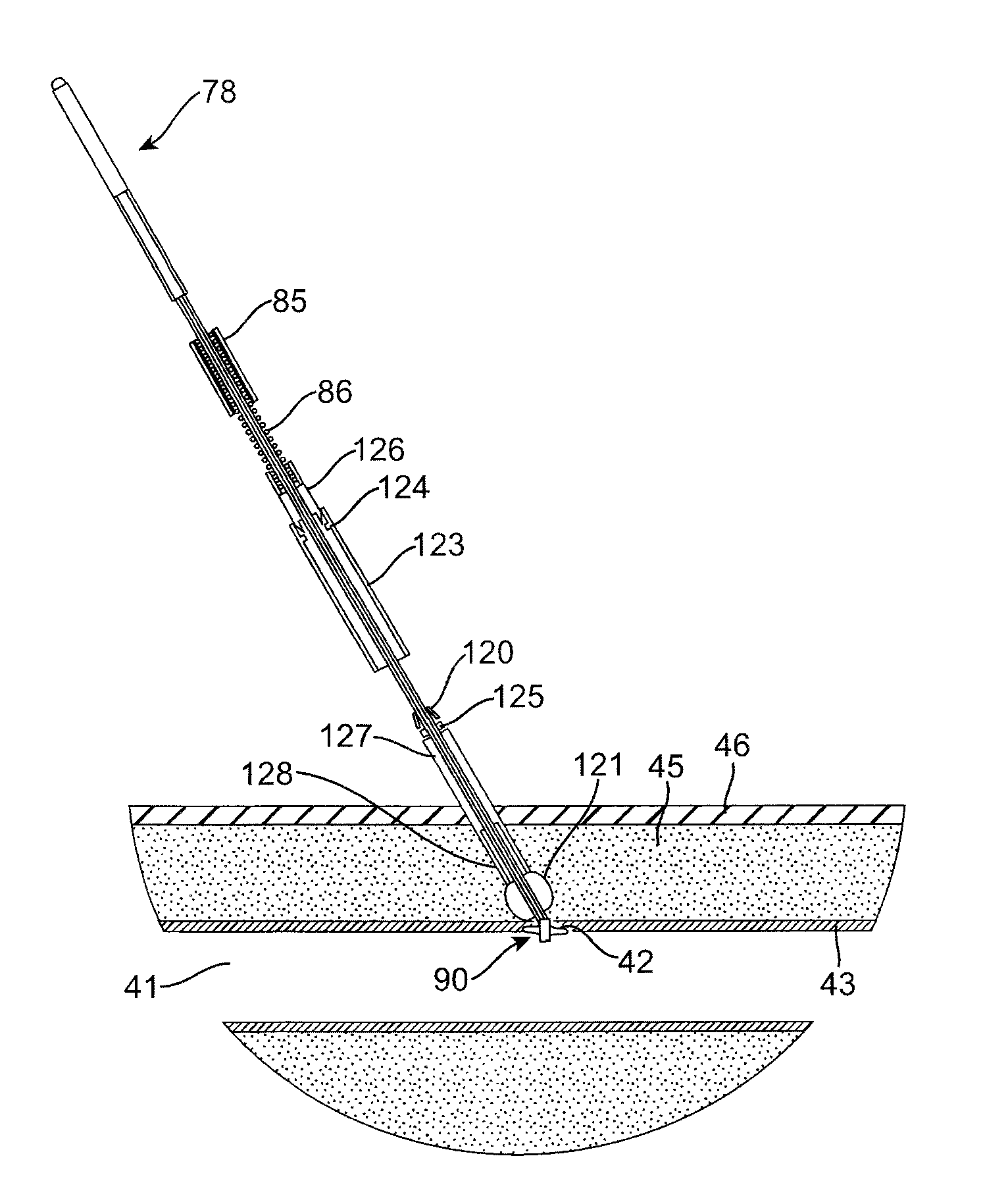

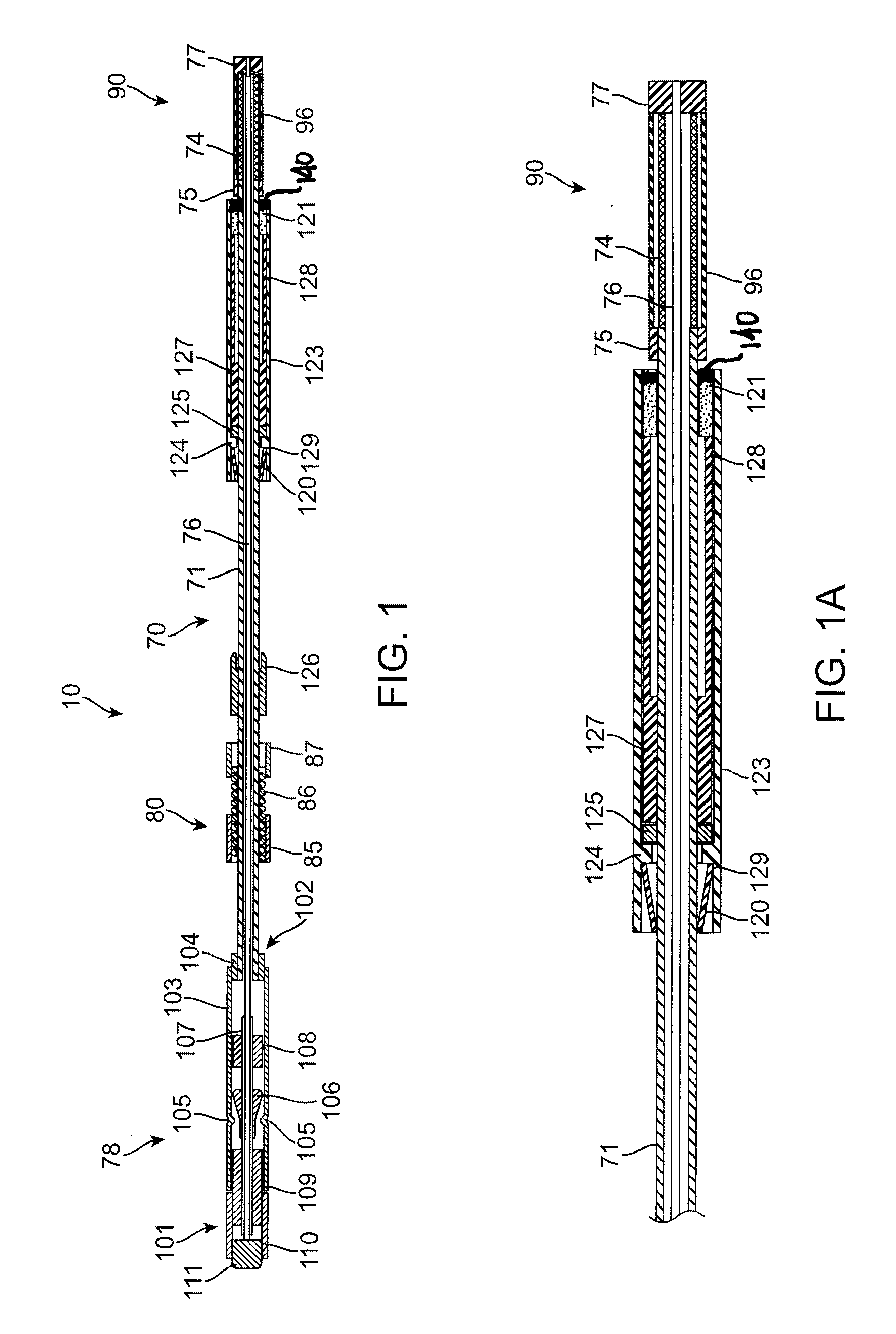

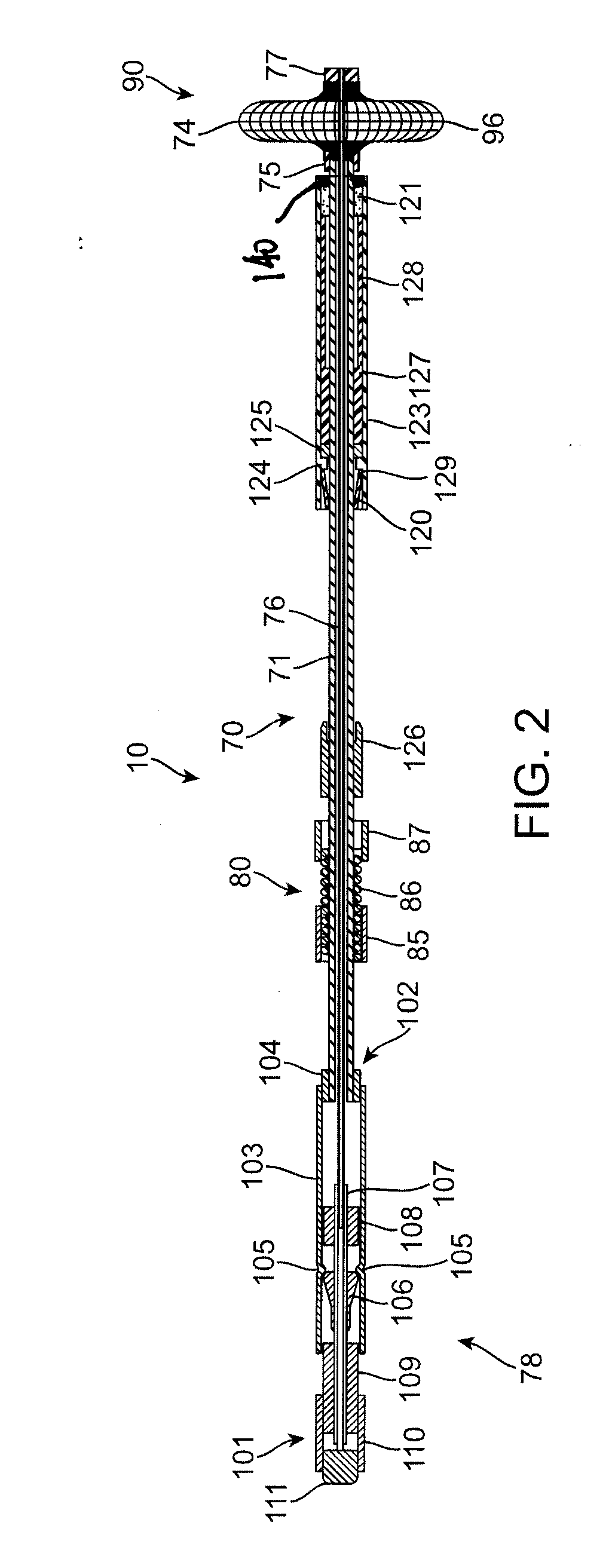

Endoluminal Filter With Fixation

An endoluminal filter including a first support member having a first end and a second end and a second support member attached to the first end of the first support member or the second end of the first support member and forming a crossover with the first support member. The endoluminal filter also includes a material capture structure extending between the first and second support members, the crossover and the first end or the second end of the first support member and at least one tissue anchor on the first support member or the second support member. A method of positioning a filter within a lumen including advancing a sheath containing a filter through the lumen. Next, deploying a portion of the filter from the sheath into the lumen to engage the lumen wall while maintaining substantially all of a material capture structure of the filter within the sheath. Next, deploying the material capture structure of the filter from the sheath to a position across the lumen.

Owner:CRUX BIOMEDICAL

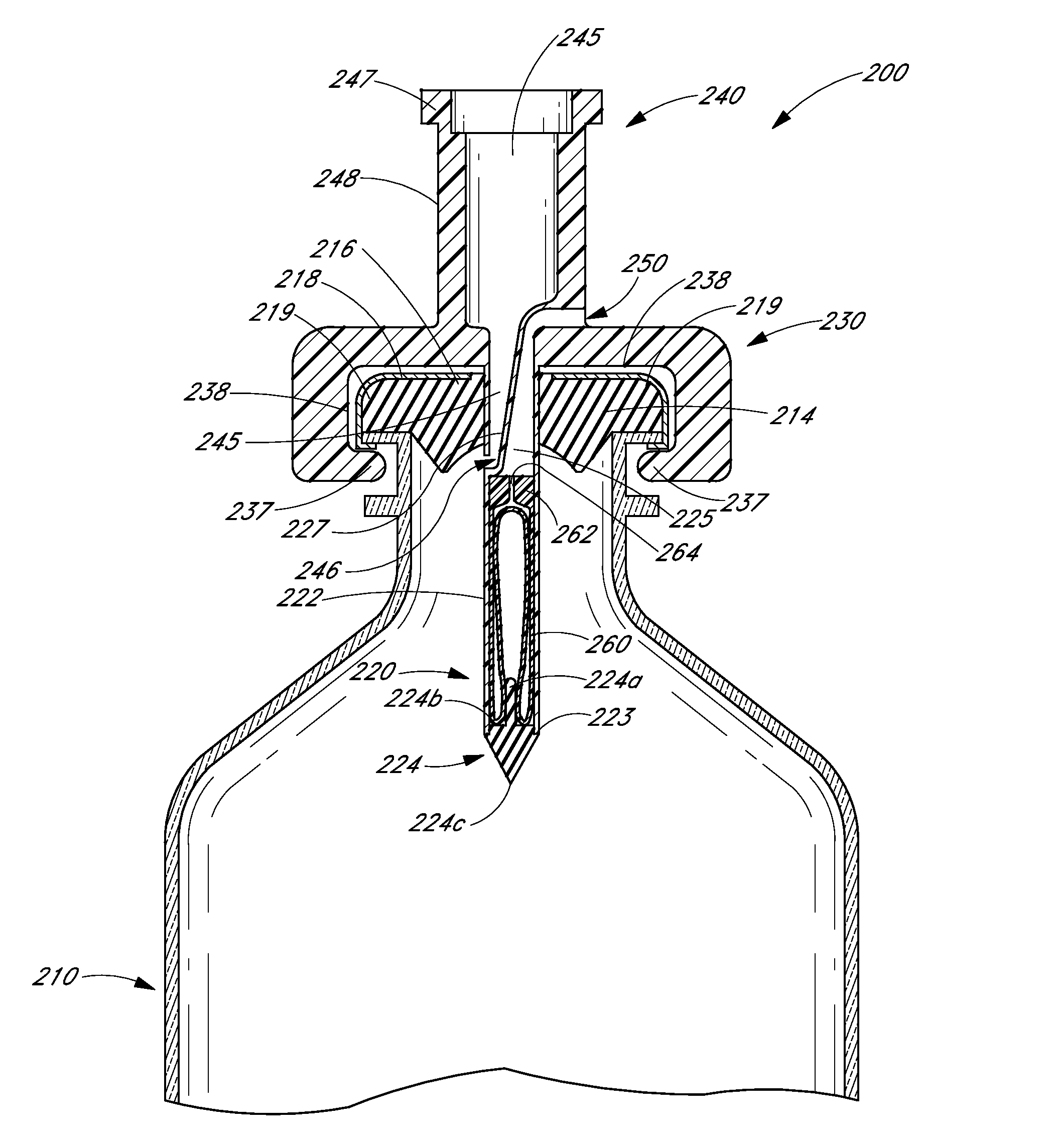

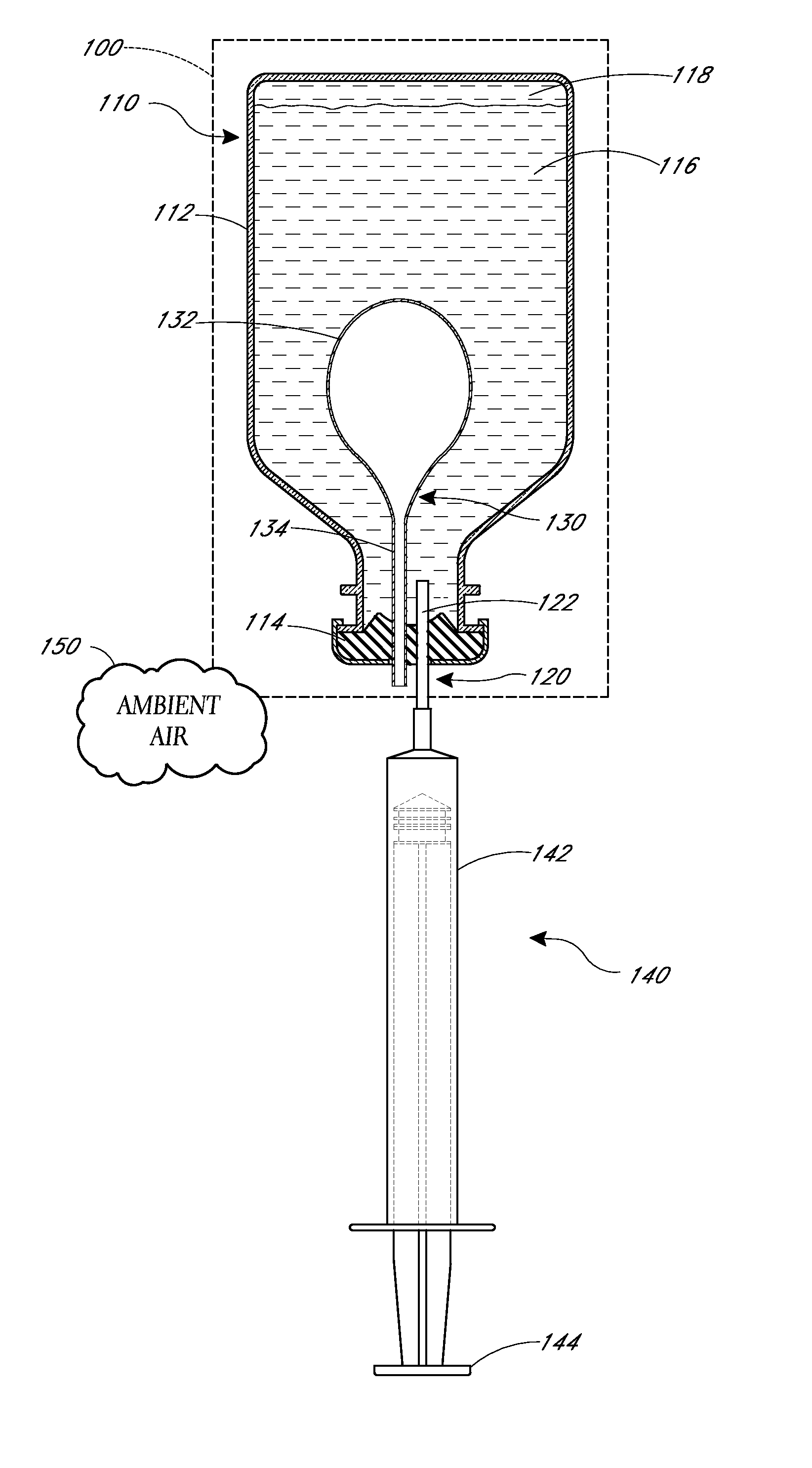

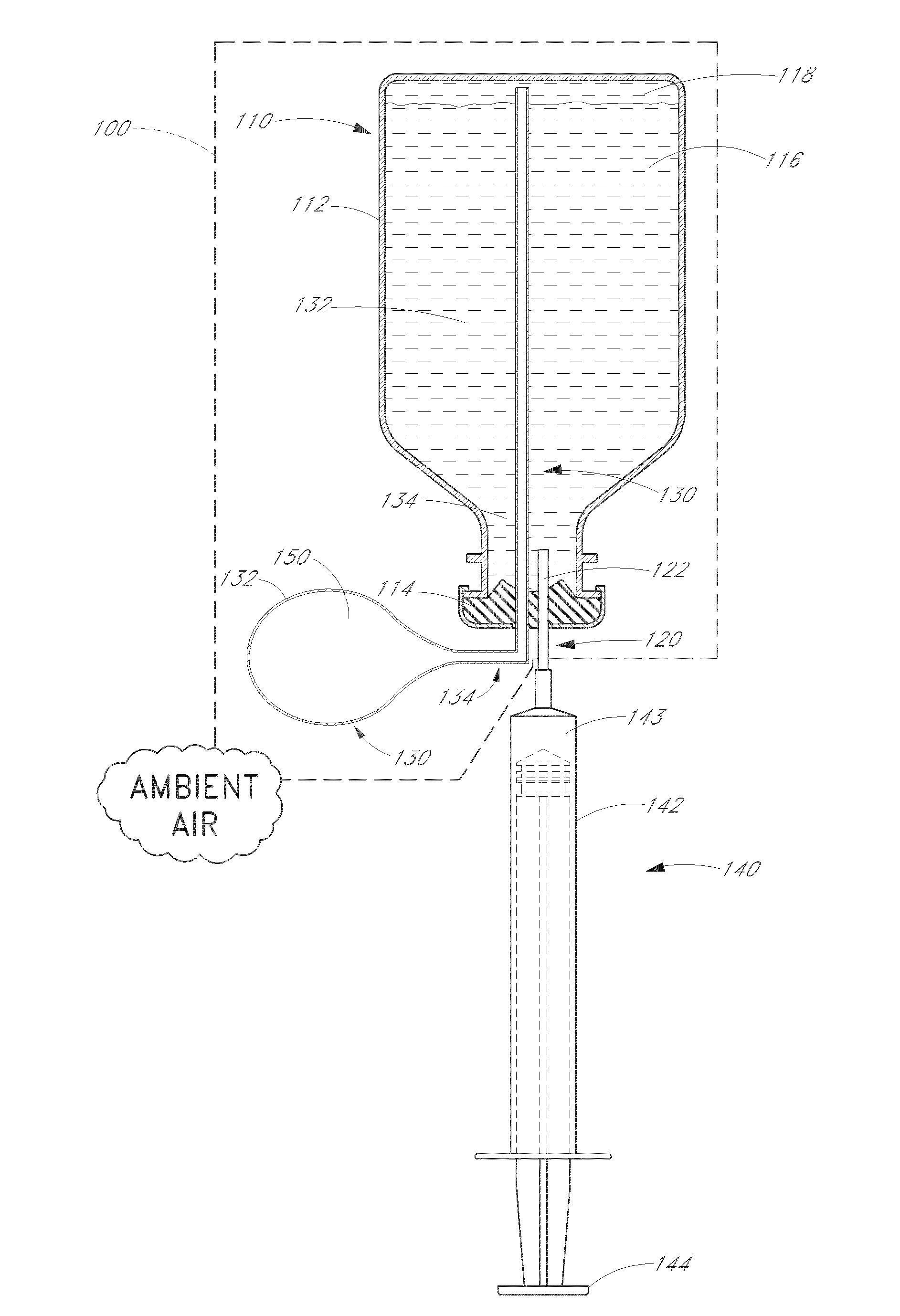

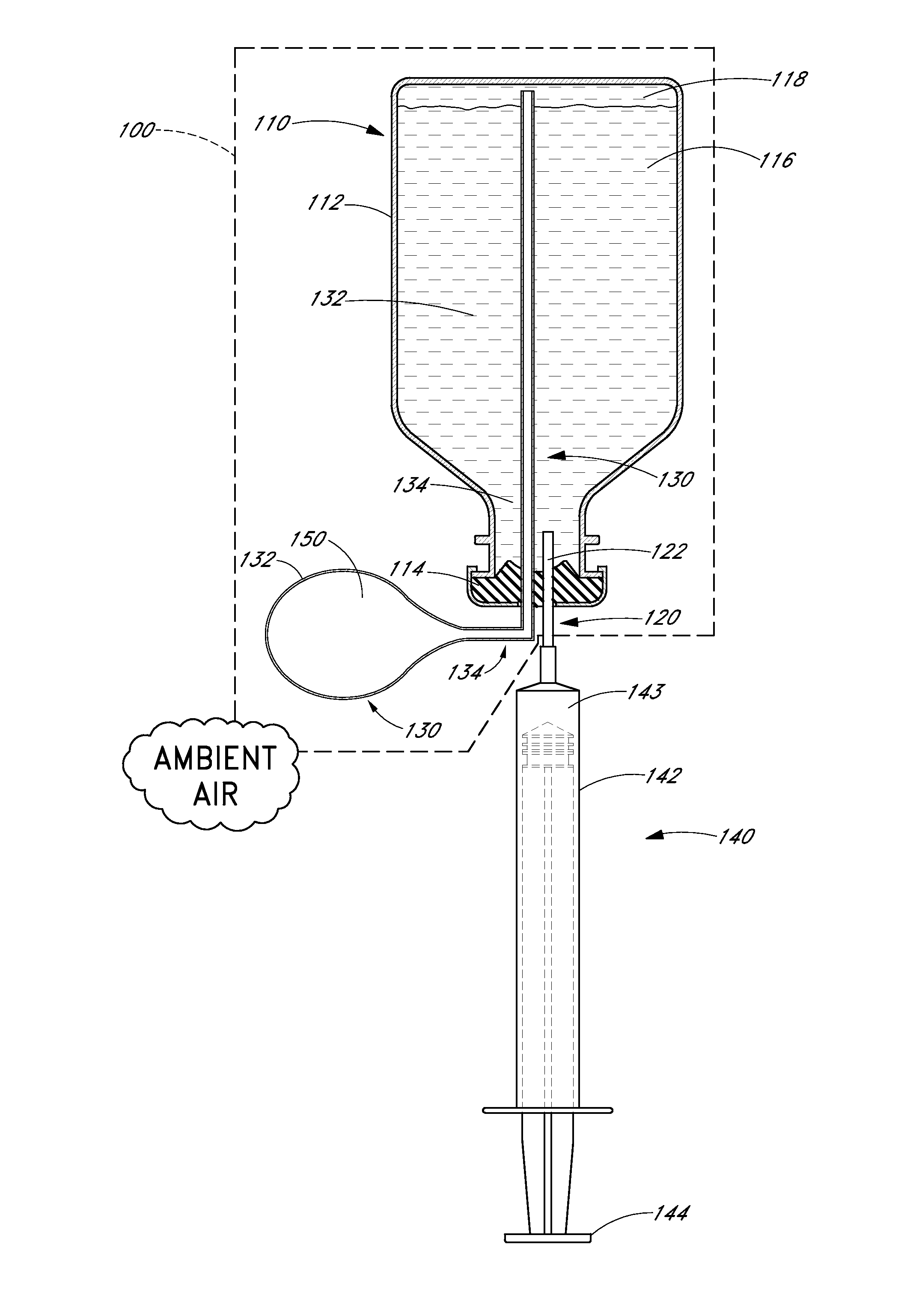

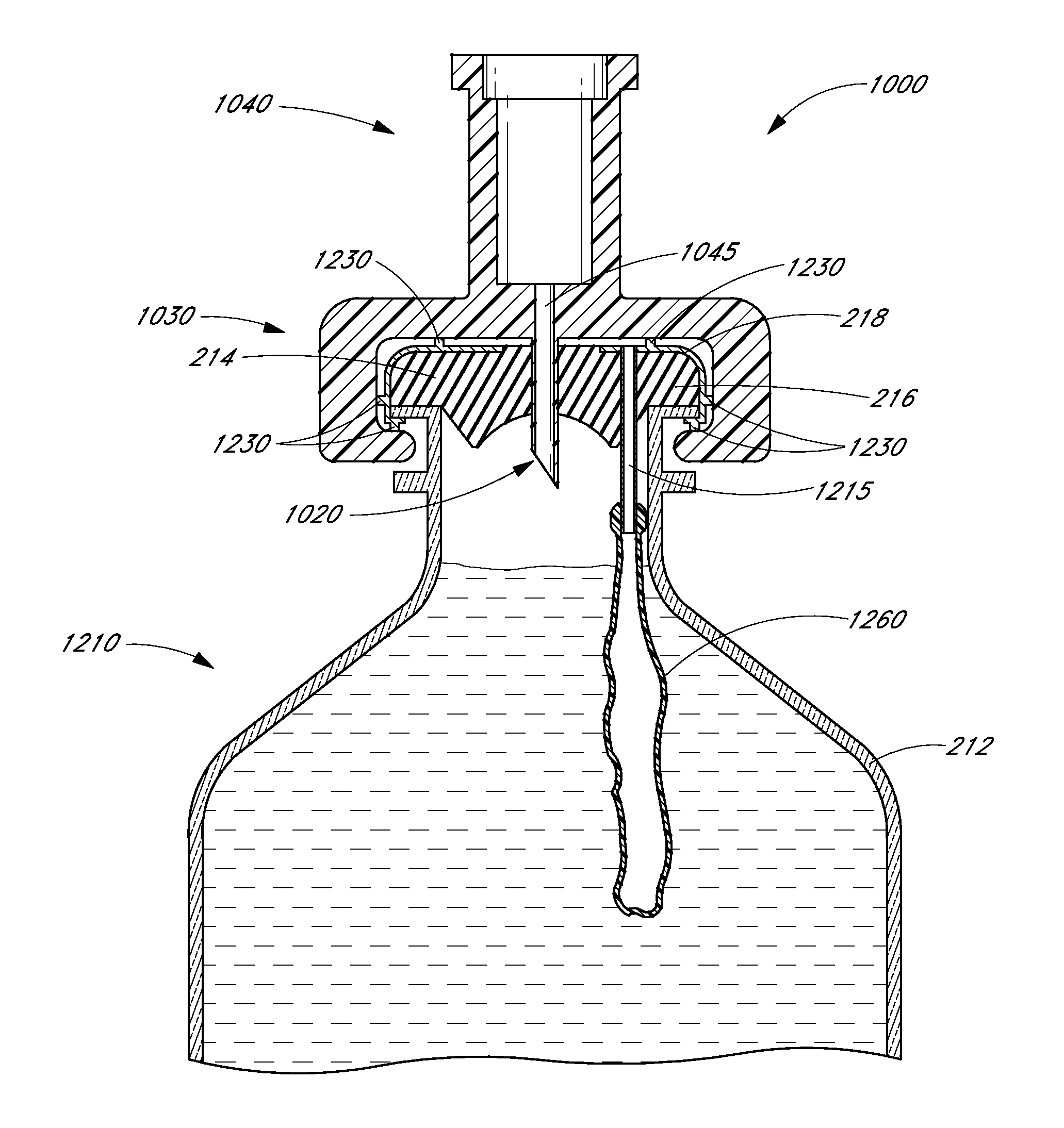

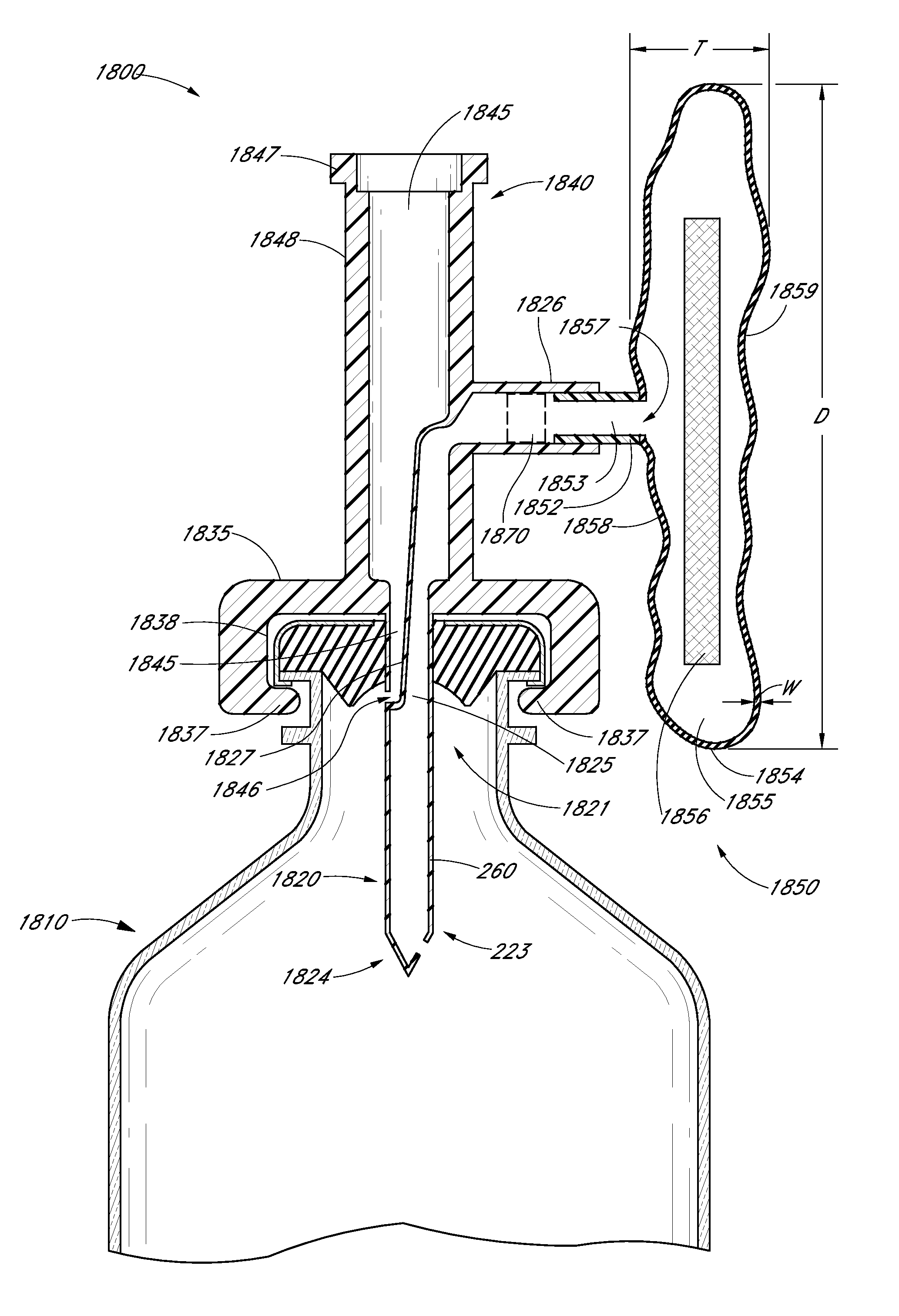

Anti-reflux vial adaptors

ActiveUS20100049157A1Regulating pressurePromote withdrawalJet injection syringesDiagnosticsReflux valveEngineering

In certain embodiments, a vial adaptor comprises a housing member, a connector configured to couple the adaptor with a vial, and an extractor channel formed in the housing member. The extractor channel is configured to facilitate withdrawal of fluid from the vial when the adaptor is coupled to the vial. In some embodiments, an anti-reflux valve is positioned within the extractor channel. The anti-reflux valve can be configured to impede or obstruct fluid returning to a fluid source after withdrawal of the fluid from the fluid source.

Owner:ICU MEDICAL INC

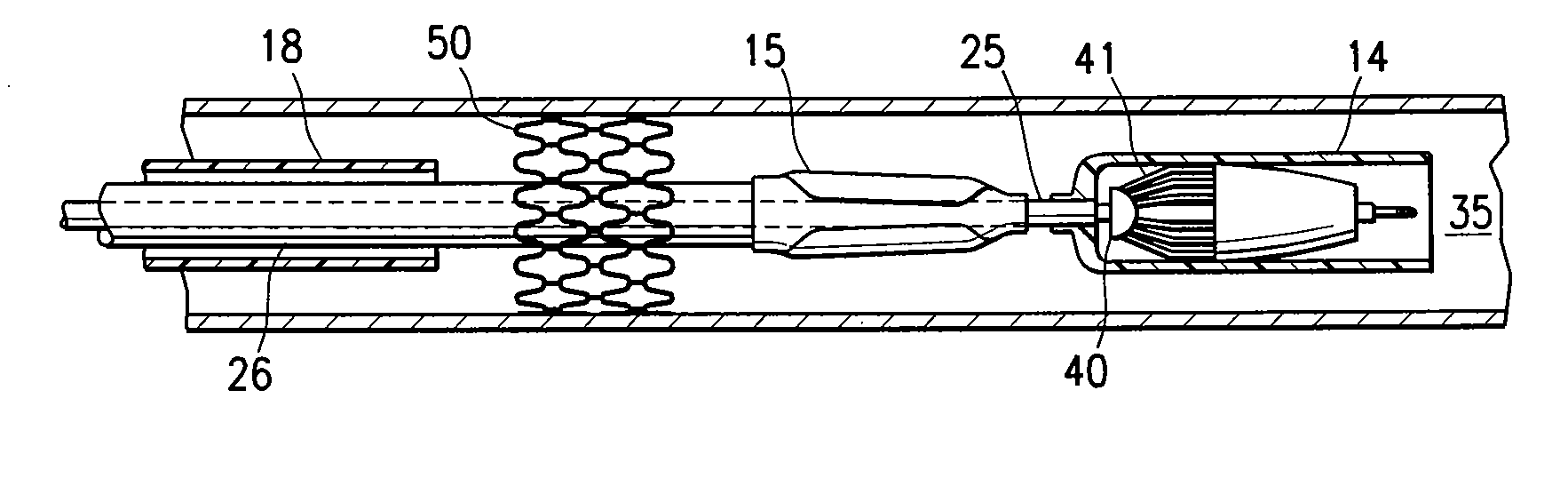

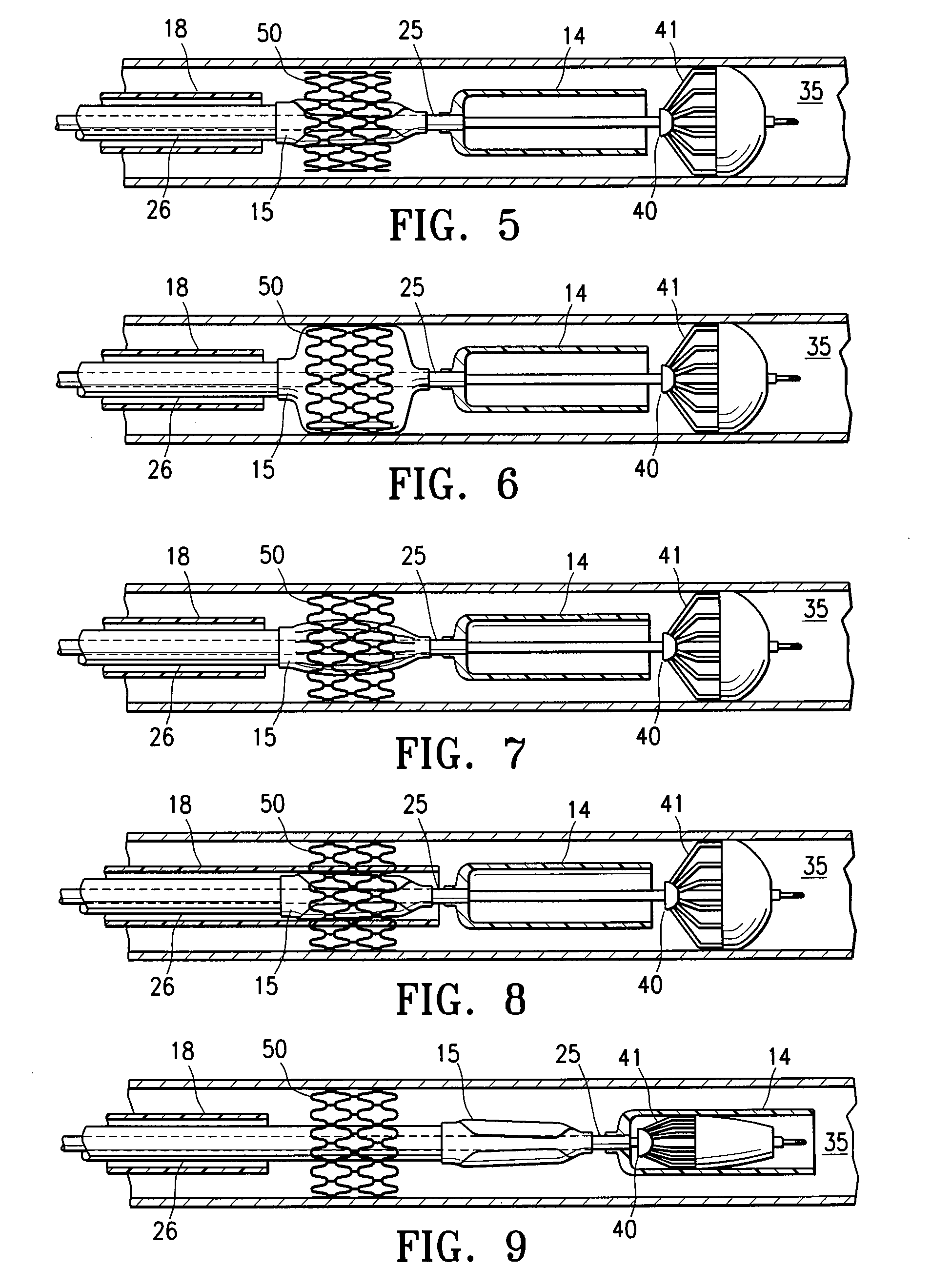

Balloon catheter having a regrooming sheath and method for collapsing an expanded medical device

InactiveUS20080140003A1Low profileFacilitate maneuveringStentsBalloon catheterEmbolic Protection DevicesMedicine

A method of using a balloon catheter to perform a medical procedure at a treatment site in a patient's body lumen and to recover an expanded device, such as an embolic protection device, which is adjacent to the treatment site in the body lumen. The inflated balloon is deflated and regroomed to a low profile configuration in the body lumen, and the balloon catheter is advanced distally from the treatment site to collapse the expanded device (e.g., embolic protection filter) within the balloon catheter. The balloon catheter has a recovery distal tip for collapsing an expanded device, and has a regrooming sheath member configured to slidably receive the deflated balloon therein to regroom the balloon.

Owner:ABBOTT CARDIOVASCULAR

Anti-reflux vial adaptors

ActiveUS8409164B2Promote withdrawalReduce riskJet injection syringesDiagnosticsReflux valveEngineering

In certain embodiments, a vial adaptor comprises a housing member, a connector configured to couple the adaptor with a vial, and an extractor channel formed in the housing member. The extractor channel is configured to facilitate withdrawal of fluid from the vial when the adaptor is coupled to the vial. In some embodiments, an anti-reflux valve is positioned within the extractor channel. The anti-reflux valve can be configured to impede or obstruct fluid returning to a fluid source after withdrawal of the fluid from the fluid source.

Owner:ICU MEDICAL INC

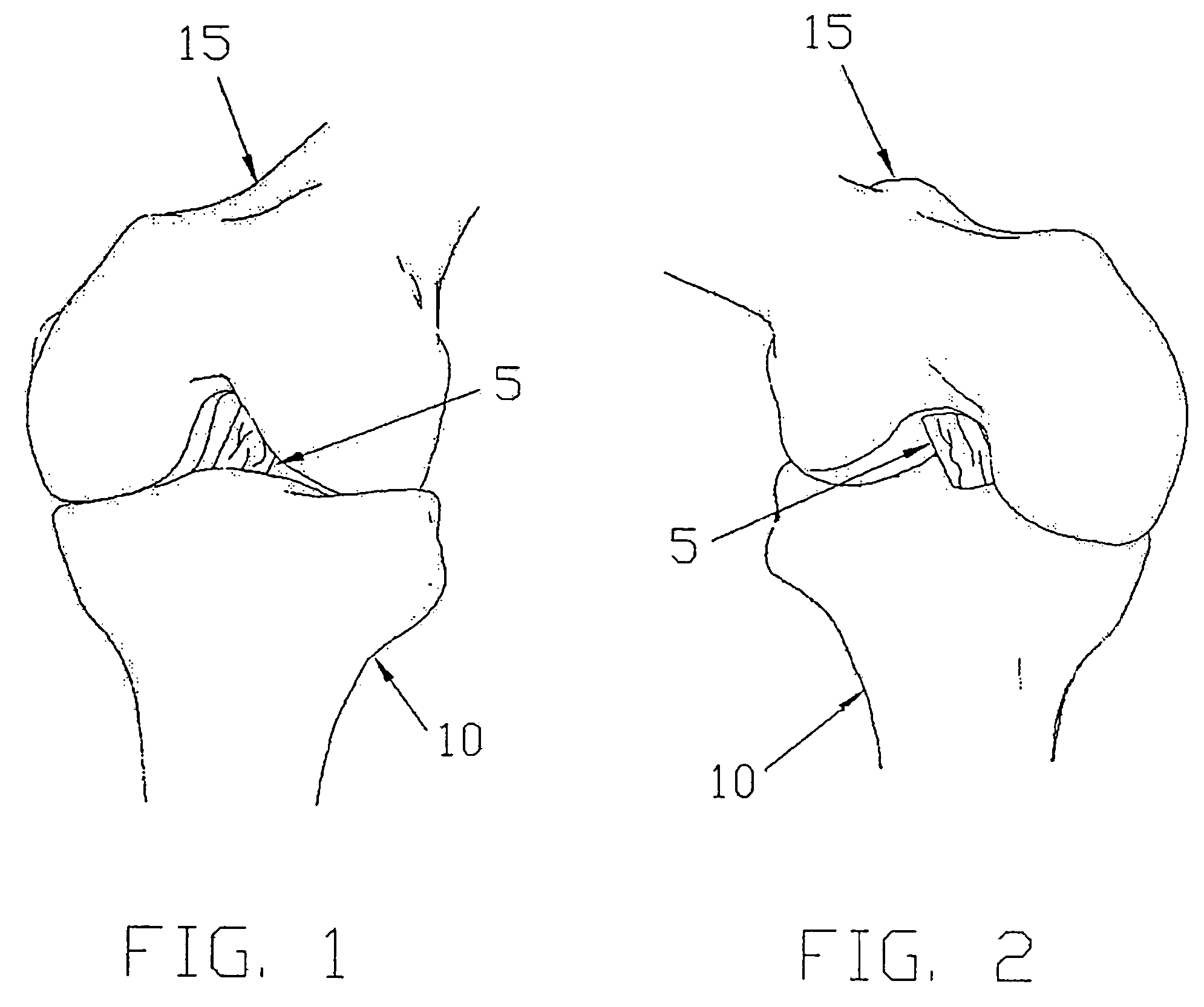

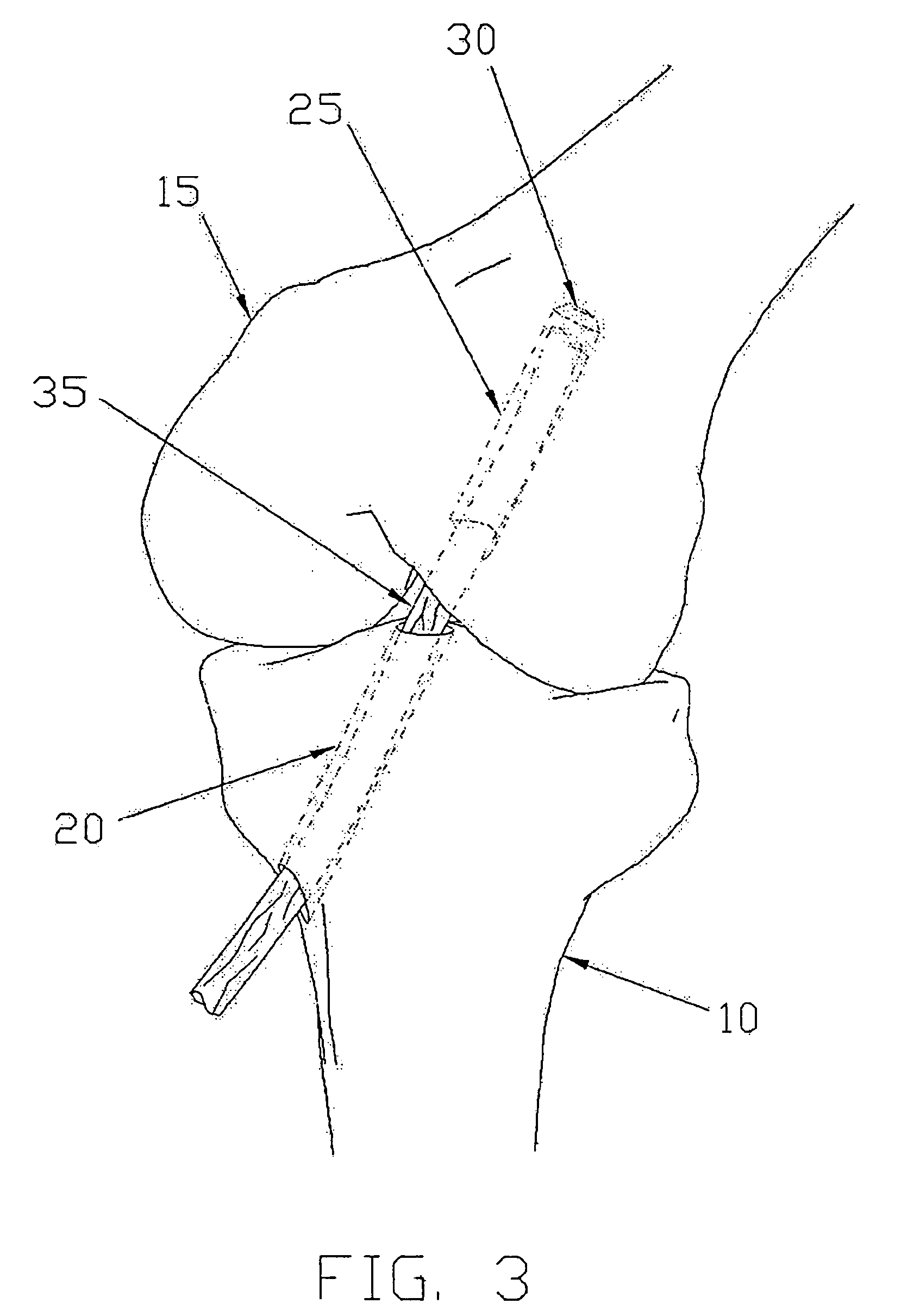

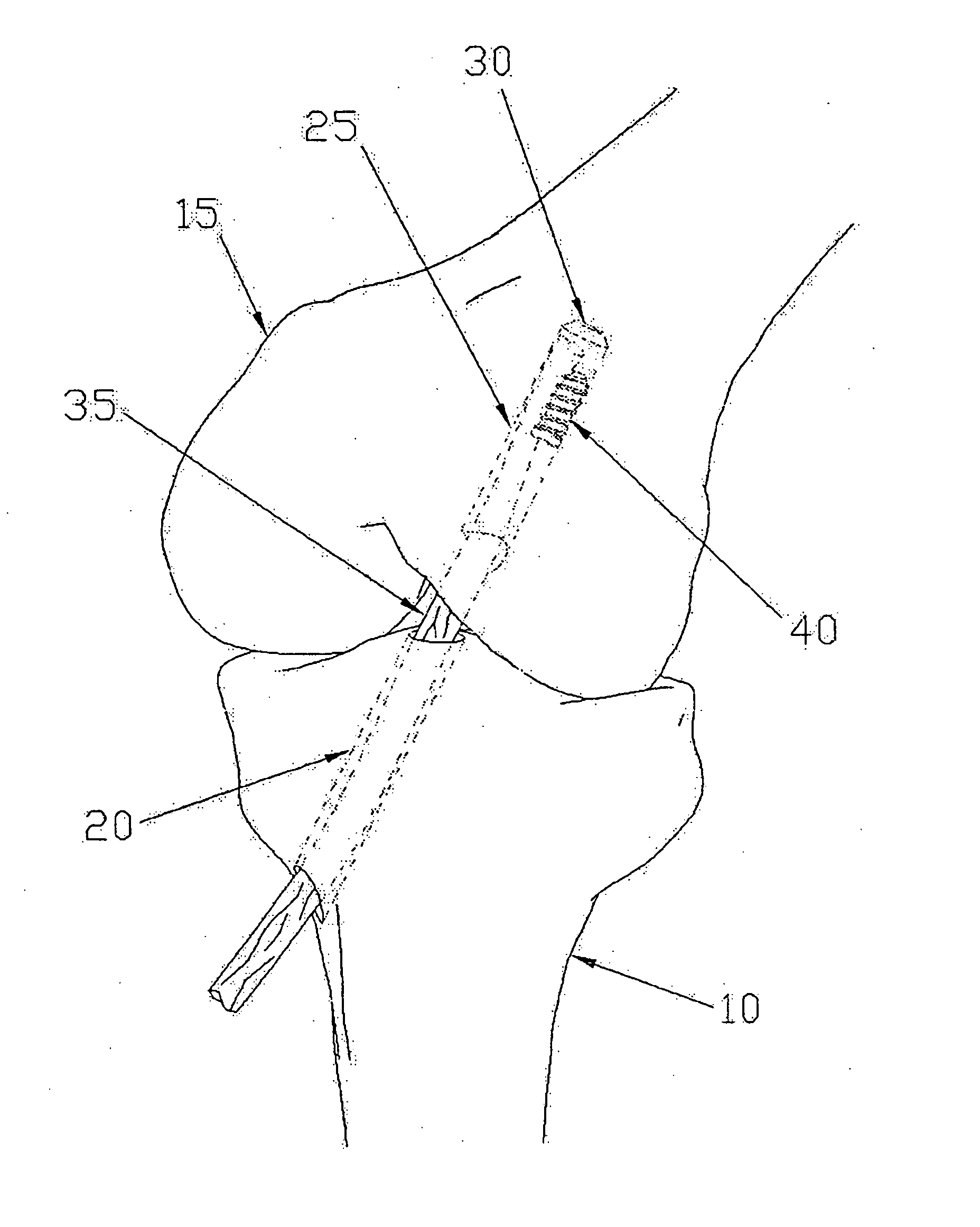

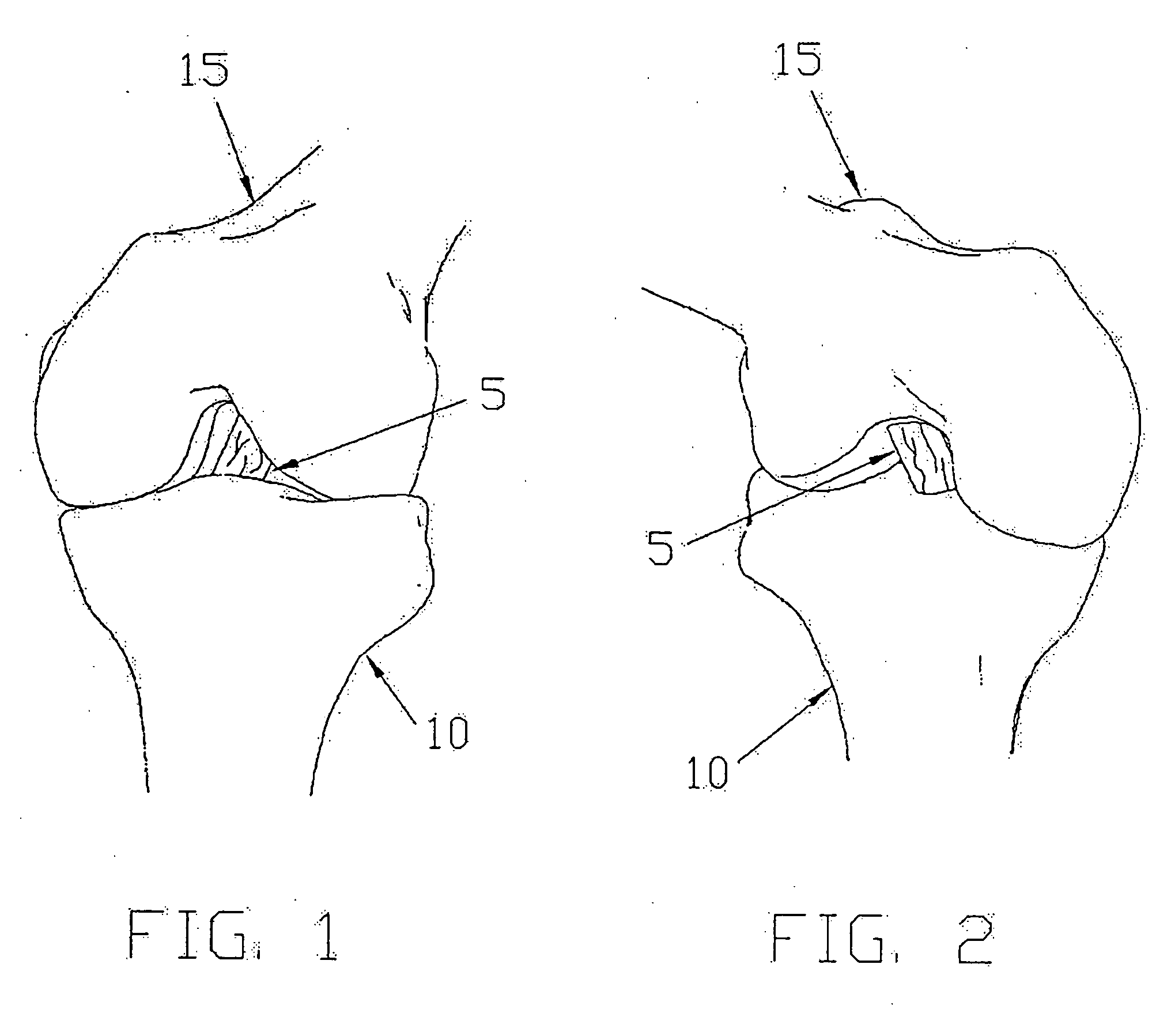

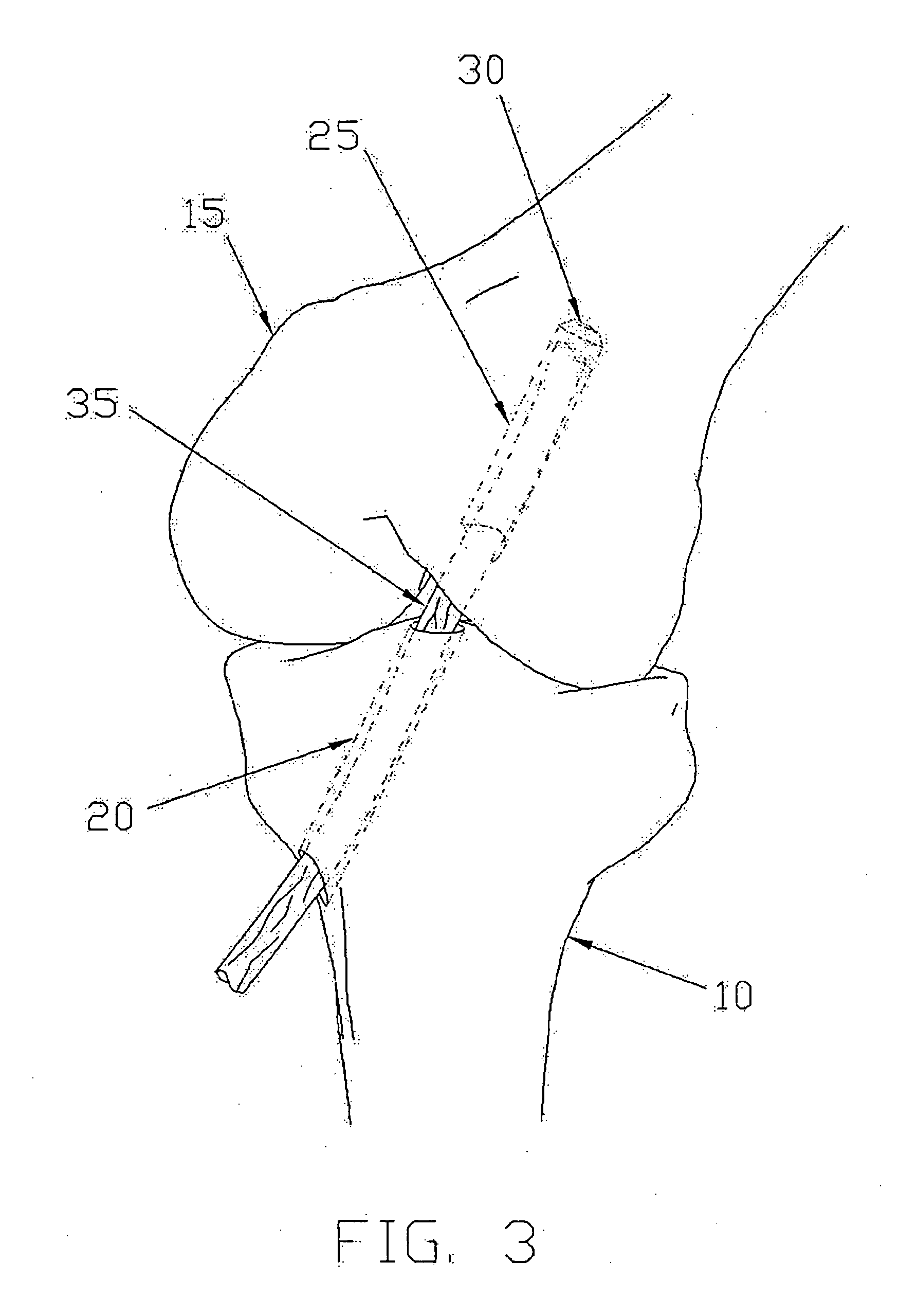

Apparatus and method for reconstructing a ligament

InactiveUS7520898B2Promote withdrawalAid removalSuture equipmentsDiagnosticsBone tunnelSurgical site

A graft ligament is looped through a graft hole in a graft ligament support block, and the graft ligament support block is mounted to an installation tool. Then the installation tool is used to advance the graft ligament support block into a bone tunnel, with the two free ends of the looped graft ligament extending back out the bone tunnel. Next, a transverse tunnel is formed in the host bone, with the transverse tunnel being aligned with a transverse fixation pin hole in the graft ligament support block. Then the graft ligament support block is secured in place by pinning the graft ligament support block within the tunnel, i.e., by advancing a transverse fixation pin along the transverse tunnel and into the transverse fixation pin hole in the graft ligament support block. Then the installation tool is detached from the graft ligament support block and withdrawn from the surgical site.

Owner:ENTERPRISES HLDG INC

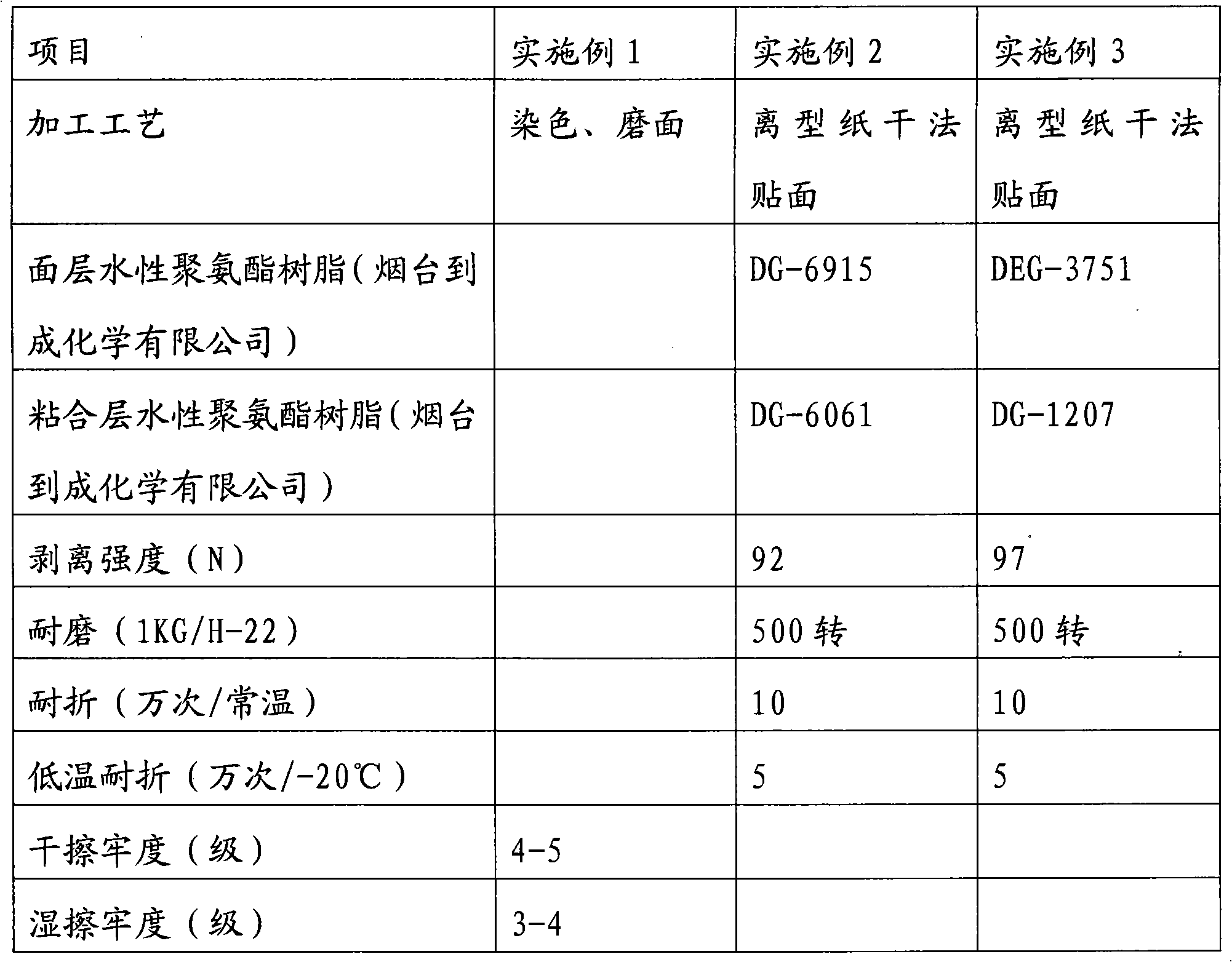

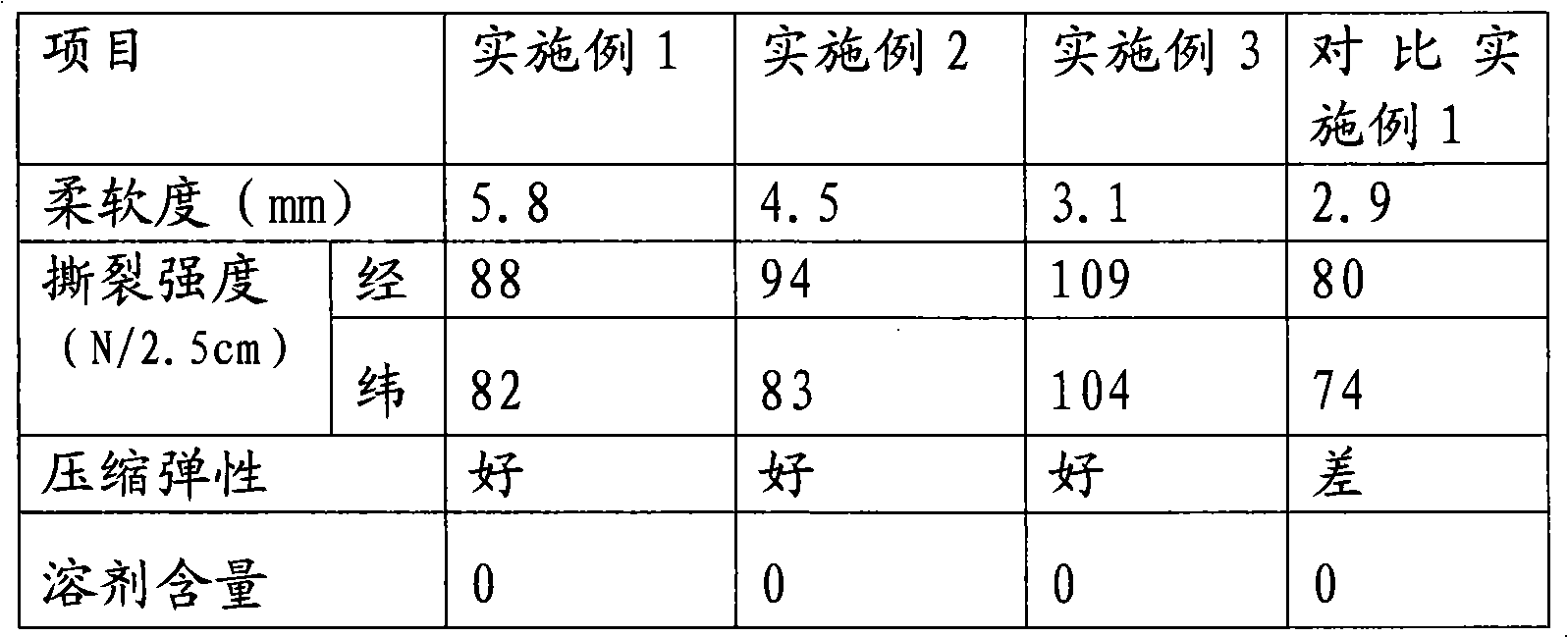

Aqueous polyurethane superfine fiber synthetic leather and preparation method thereof

The invention relates to aqueous polyurethane superfine fiber synthetic leather and a preparation method thereof. The preparation method comprises the following steps of: firstly, adding the following components according to parts by weight, i.e. 2-5 parts of foaming agents, 50-200 parts of water, 2-3 parts of foam stabilizers and 0-3 parts of waterborne colorants, into 100 parts of aqueous anionic polyurethane dipping sizing agents, and stirring the components and the sizing agents uniformly at high speed by using a blender so as to prepare a sizing agent; secondly, dipping non-woven fabricsin the sizing agent, scrapping the surface of the fabrics and keeping partial cells; thirdly, solidifying aqueous polyurethane on the dipped non-woven fabrics through aqueous coagulating liquid so asto form cells; fourthly, carrying out water scrubbing after aqueous polyurethane resin is completely solidified, and drying the aqueous polyurethane resin by an infrared drying oven so as to obtain base cloth; fifthly, treating the dried base cloth through an alkali reducing process; sixthly, treating the base cloth treated through the alkali reducing process through an postprocessing process; and seventhly, preparing the obtained base cloth into the synthetic leather. The aqueous polyurethane superfine fiber synthetic leather is prepared by the method.

Owner:HUADA CHEM GRP CO LTD

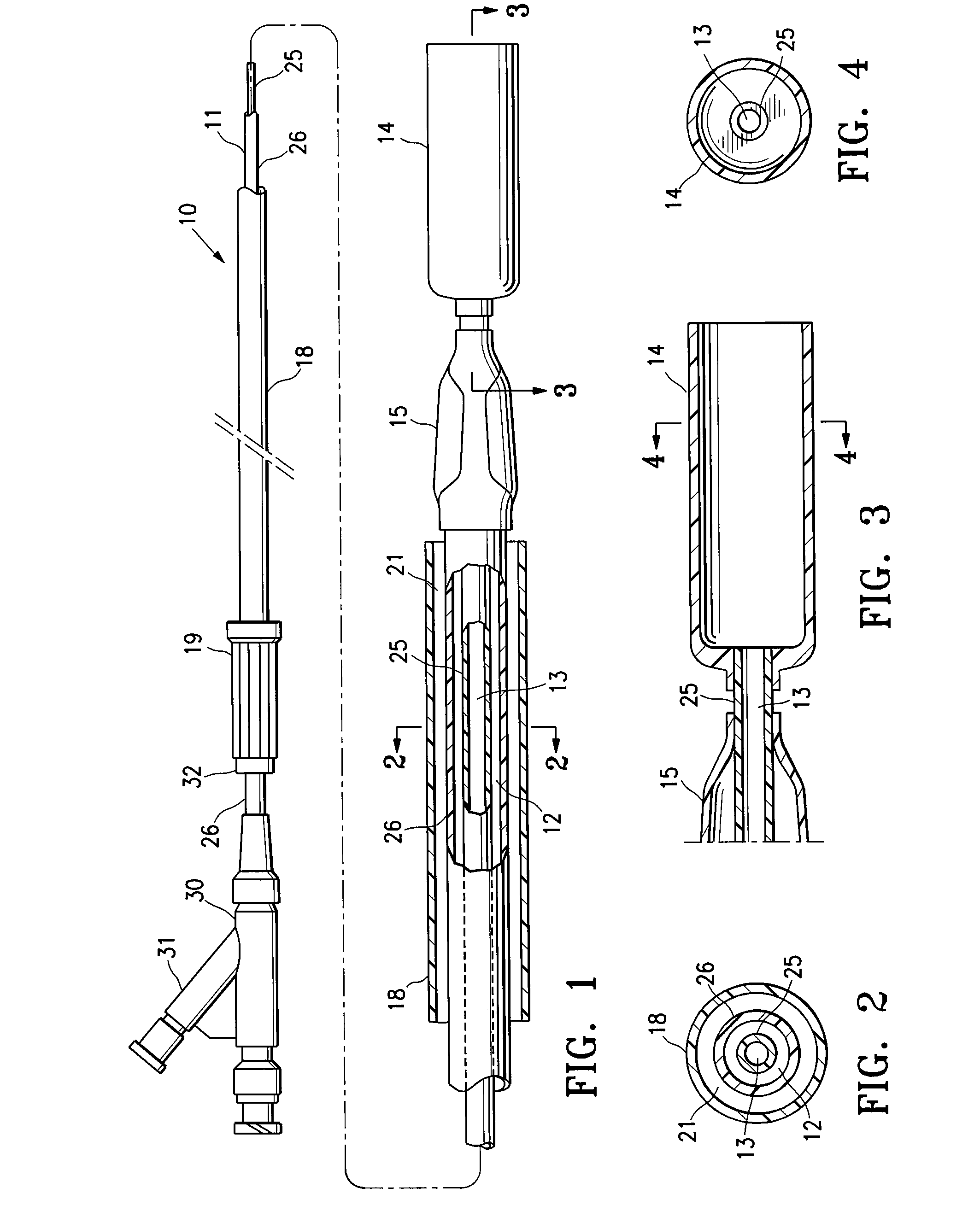

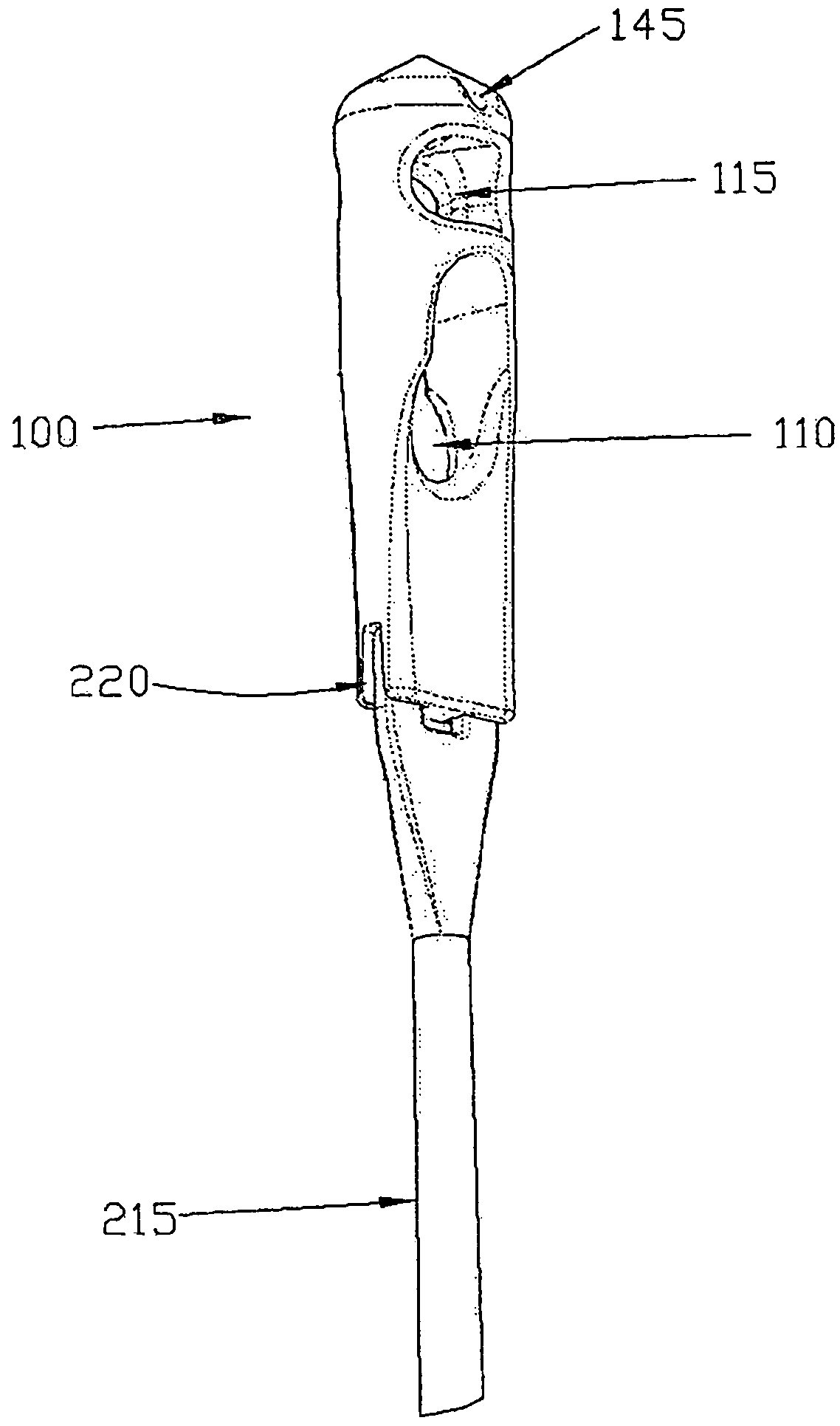

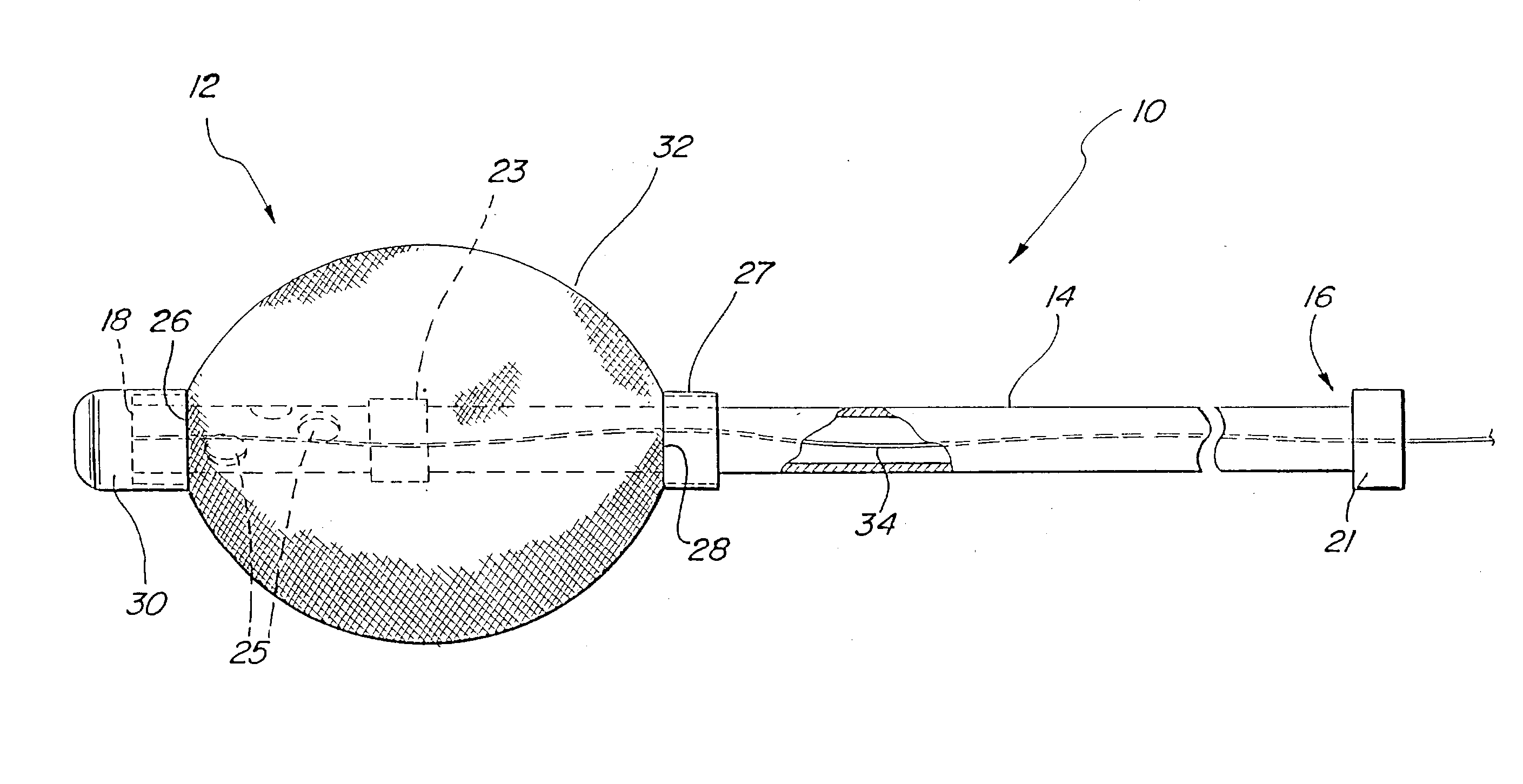

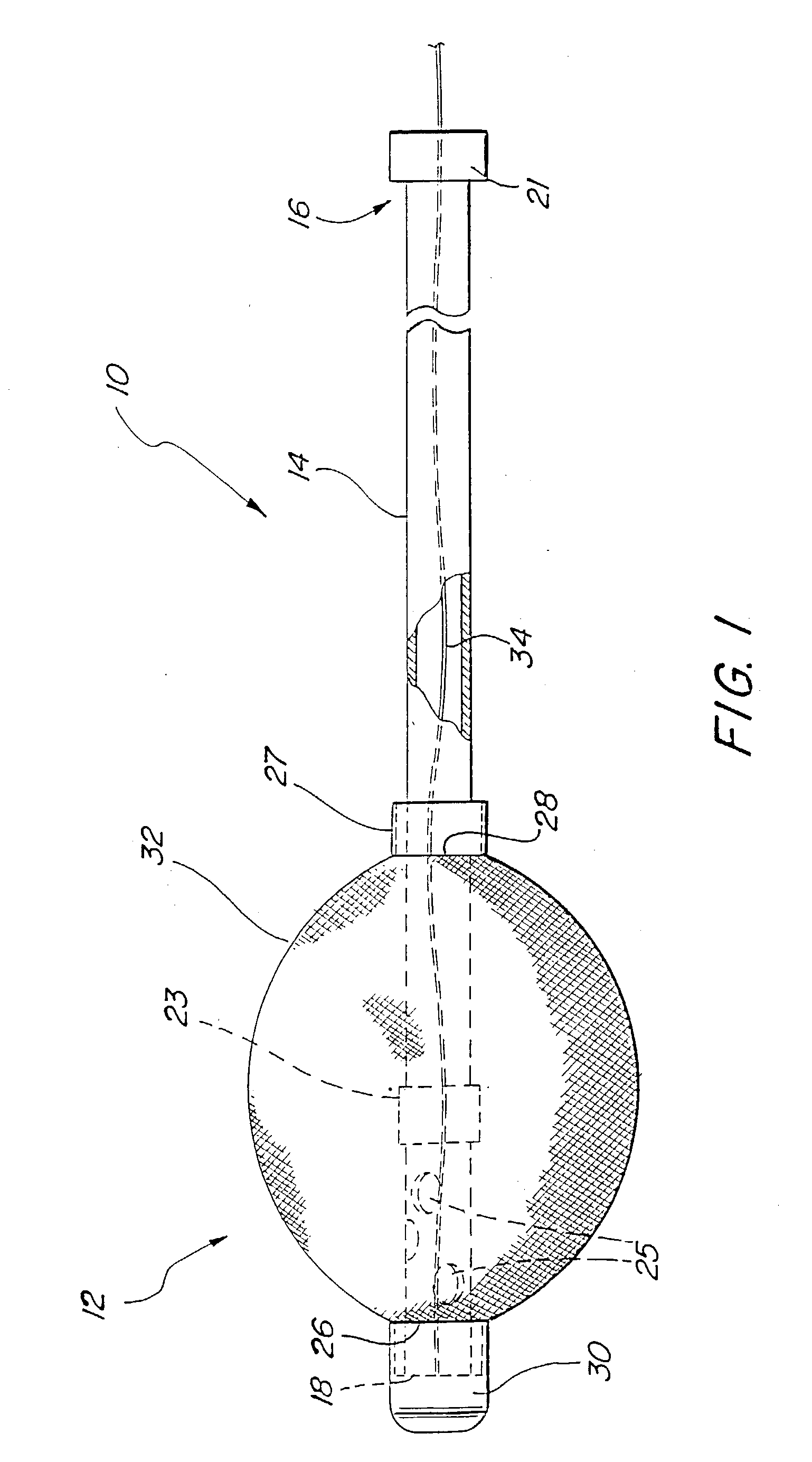

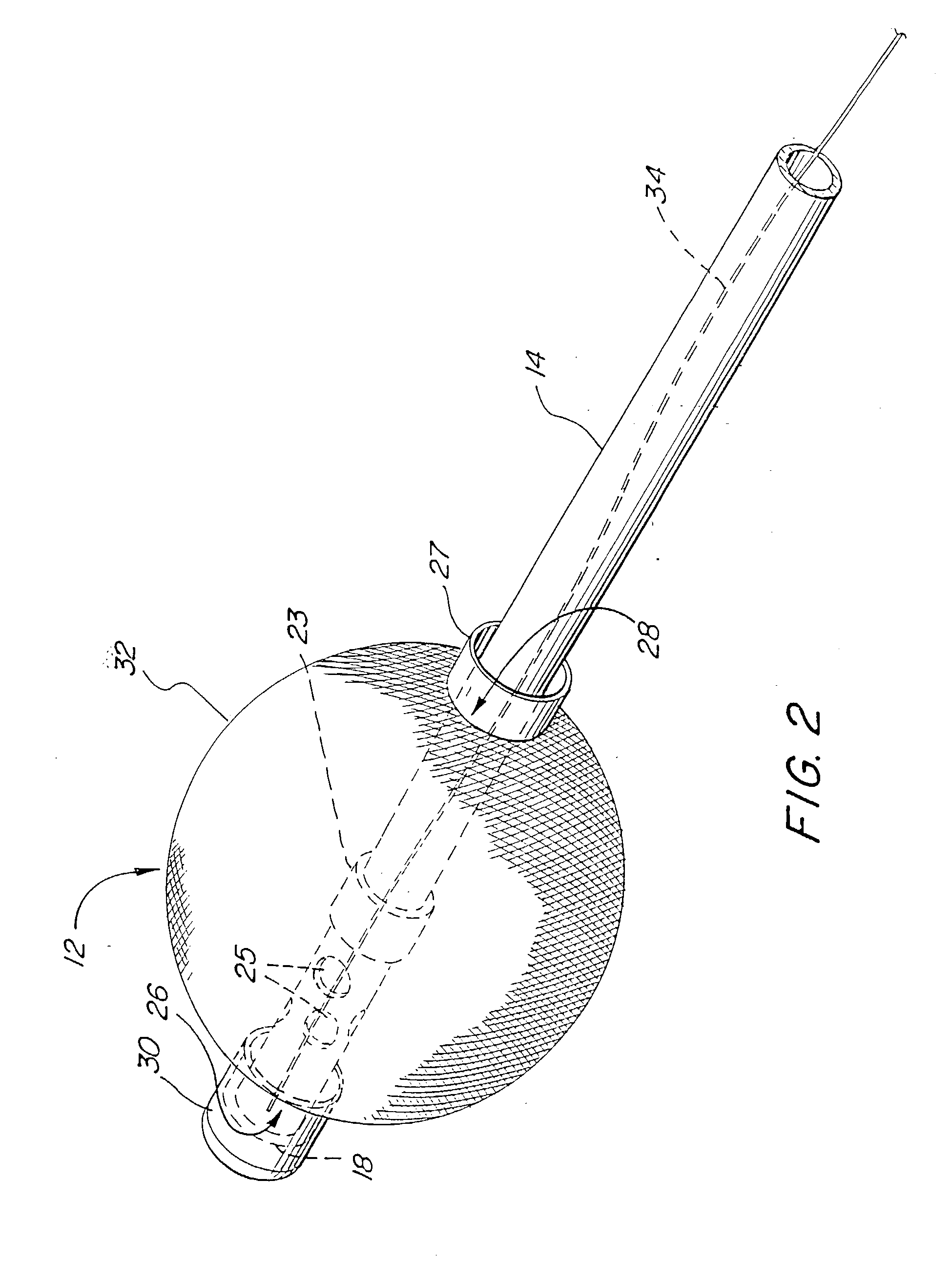

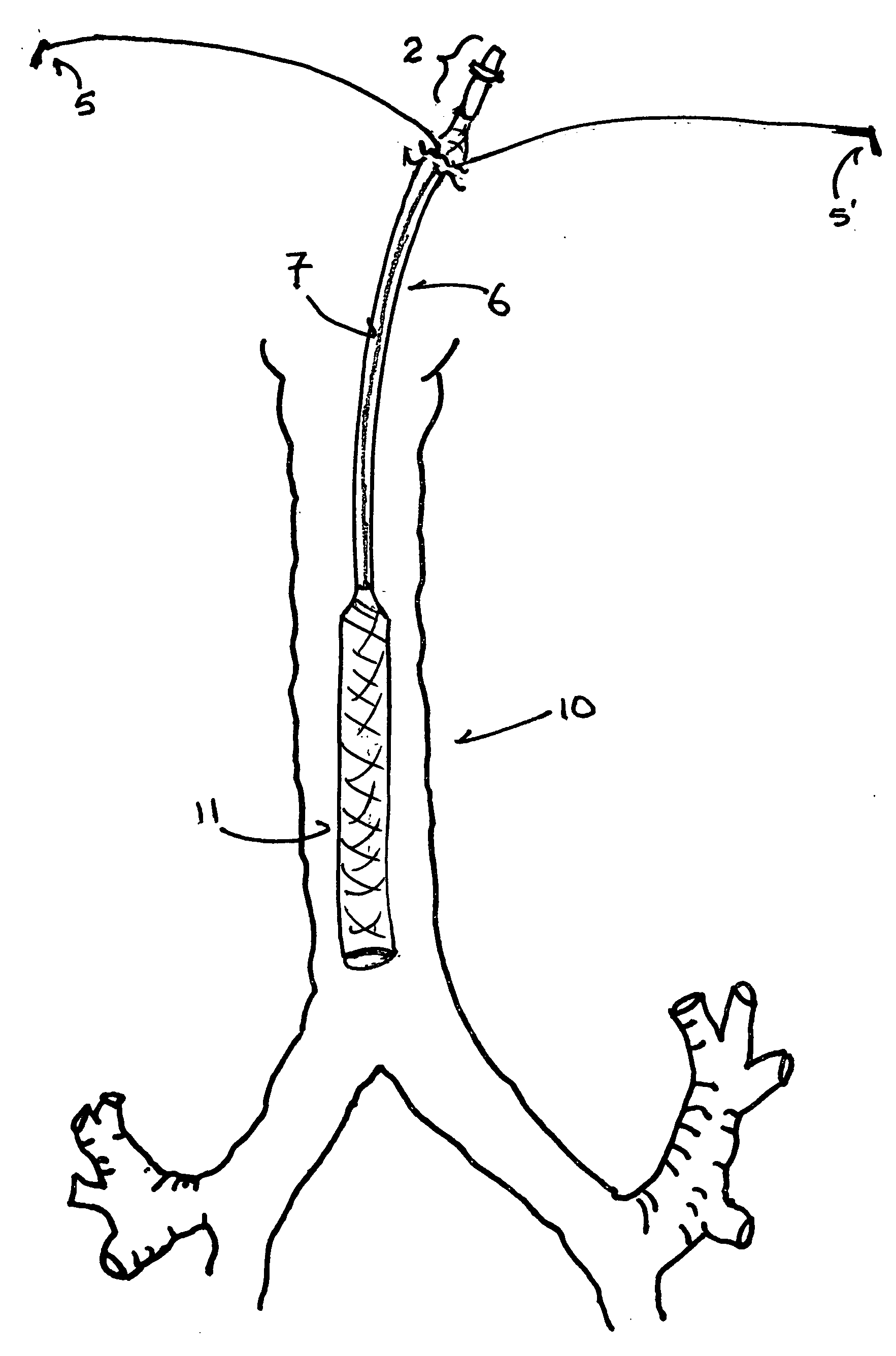

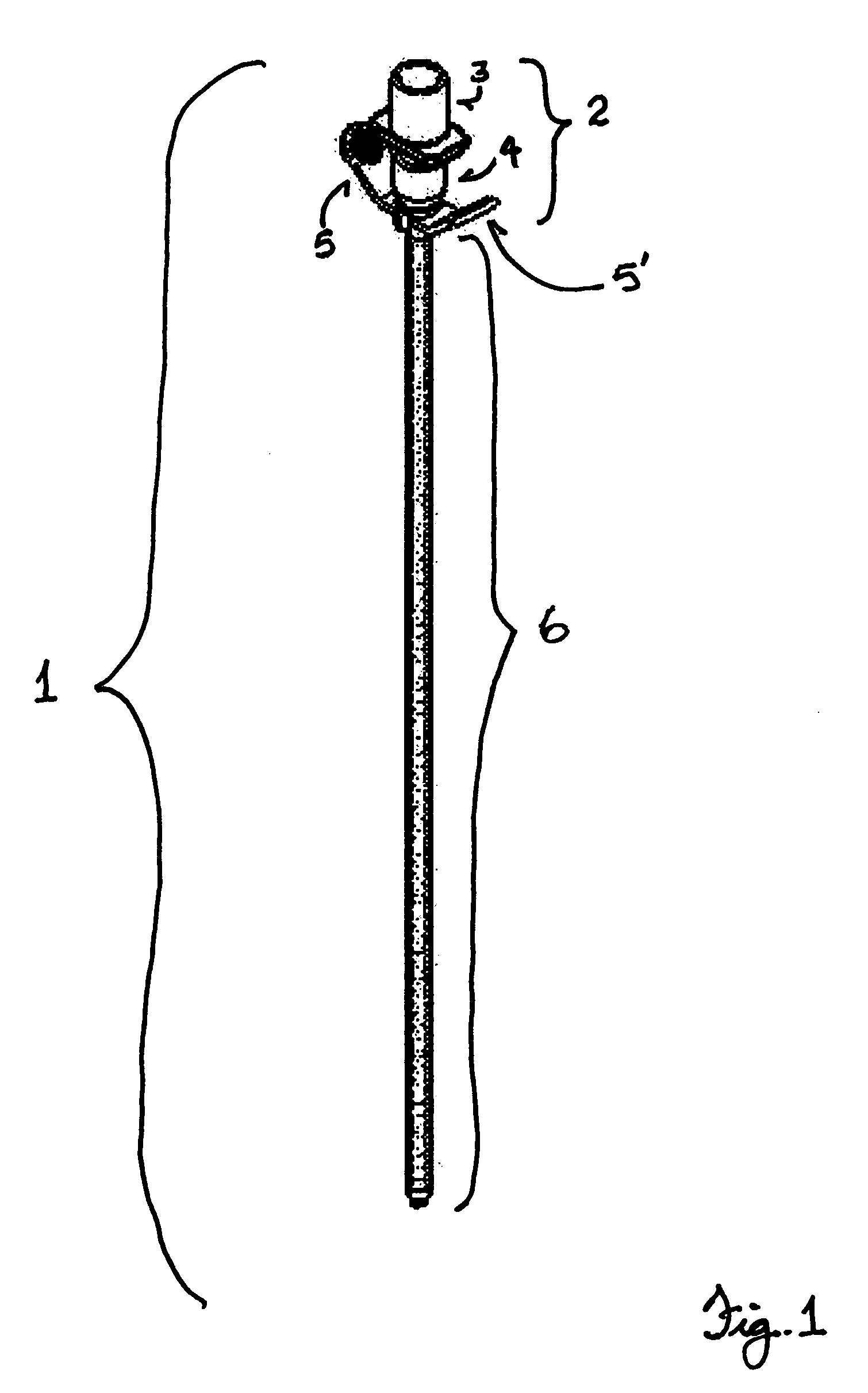

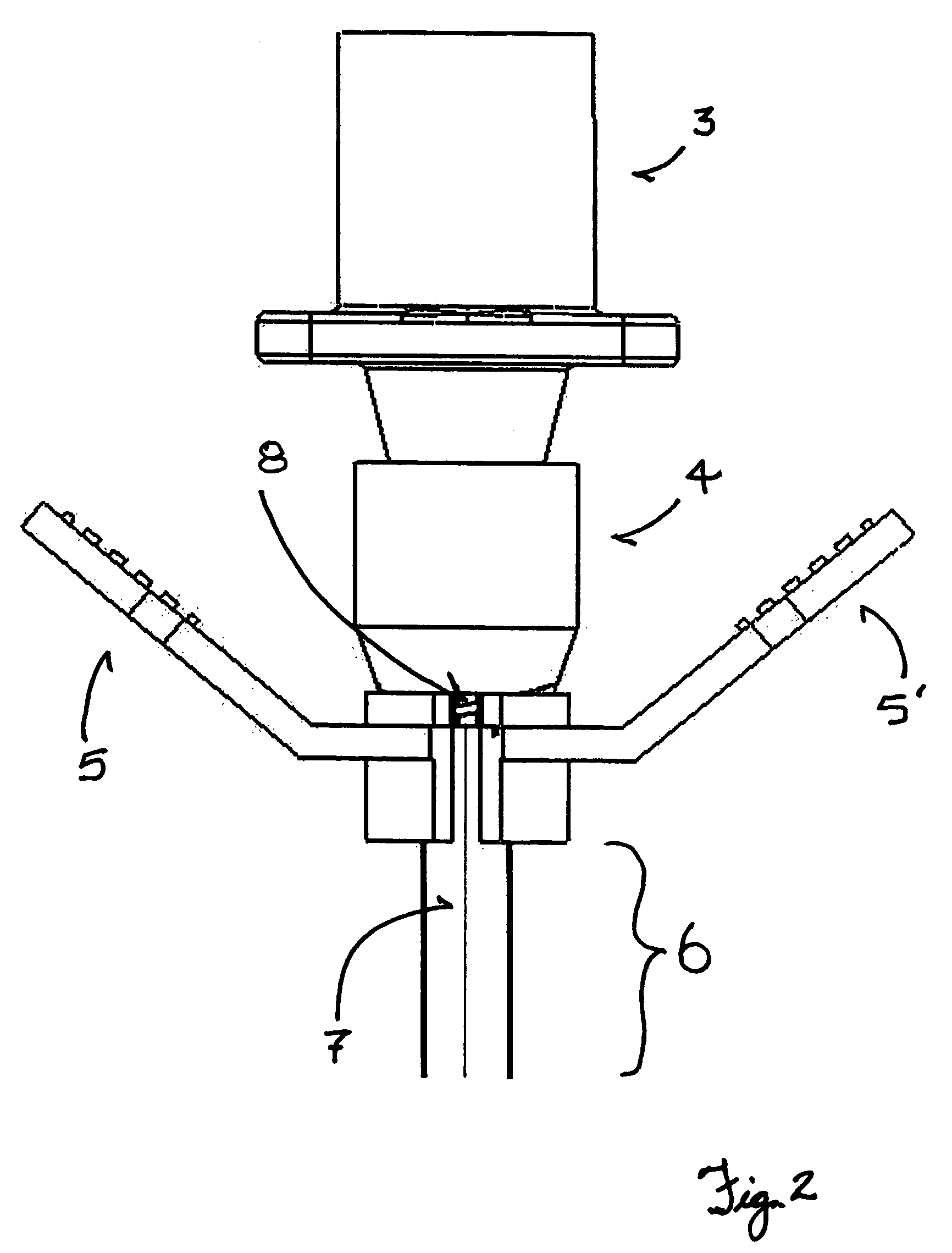

Self-deploying catheter assembly

InactiveUS20030167069A1Low-profile characteristicPromote withdrawalStentsBalloon catheterDrainage tubesTension member

A catheter having an elongate drainage tube with a proximal end and a distal end, is adapted to extend through a body conduit and into a body cavity. An anchor disposed the distal end of the tube is disposed in the body cavity and is adapted to be moved from an insertion position to a withdrawal position. The anchor in the insertion position has a low profile when the tube is moved distally and in the withdrawal position has a low profile when the tube is moved proximally. The first end of the anchor is attached to the tube, and a tension member is provided to extend distally of the tube to releasably hold the second end of the anchor in a fixed relationship with the tube. In an associated method, this tension member is severed to release the second end of the anchor from the tube and permit withdrawal of the tube and the anchor in a low-profile state.

Owner:APPL MEDICAL RESOURCES CORP

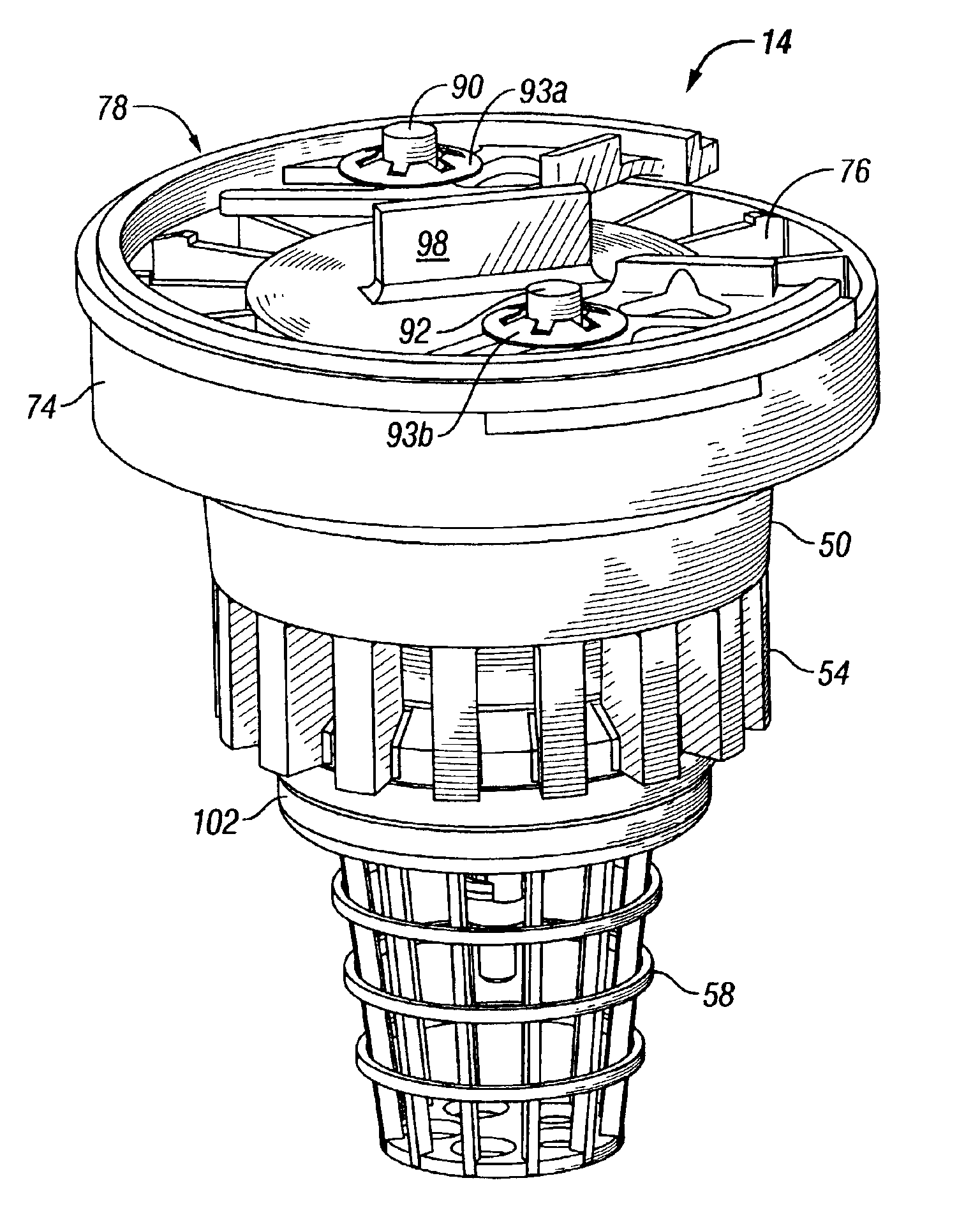

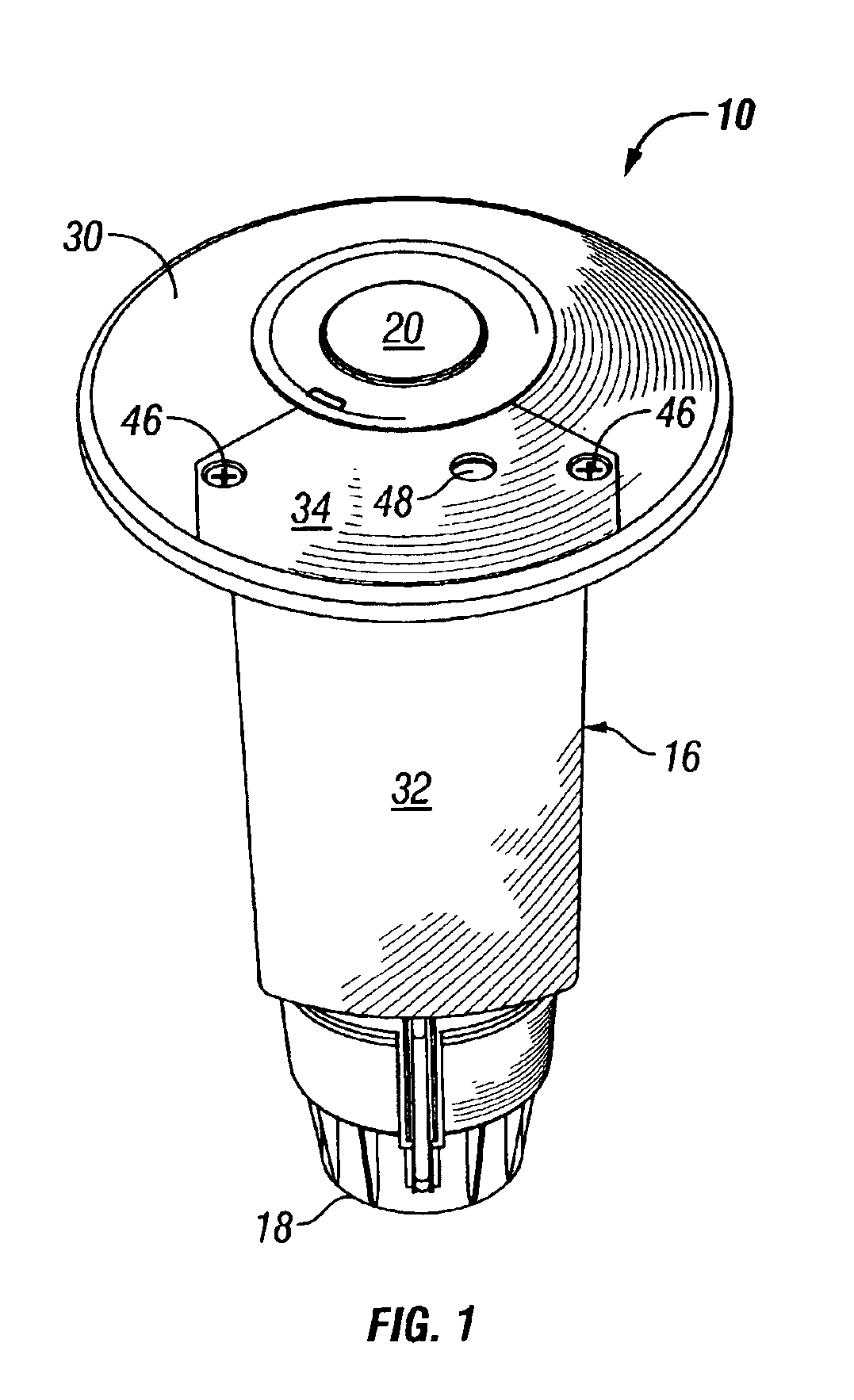

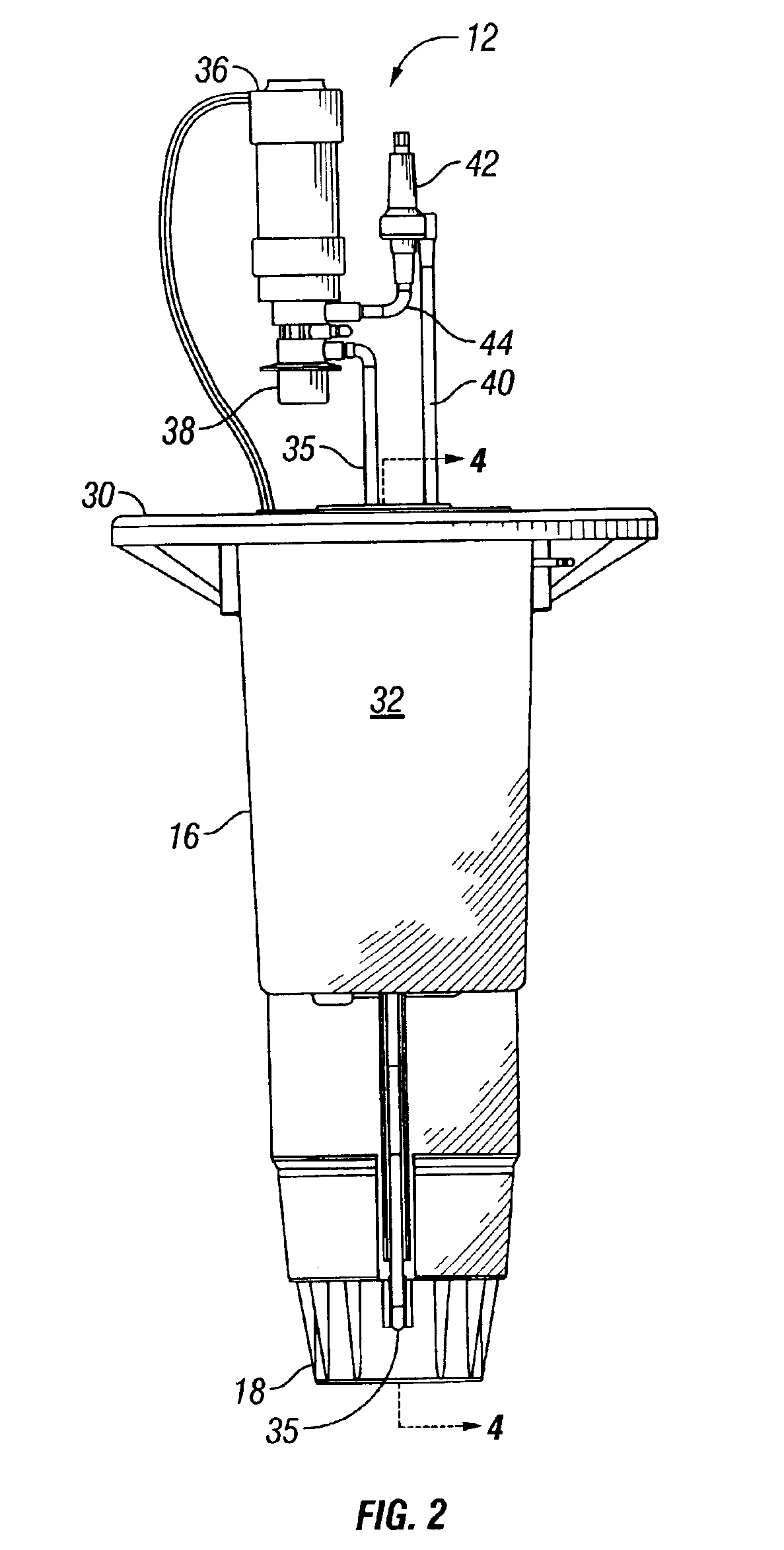

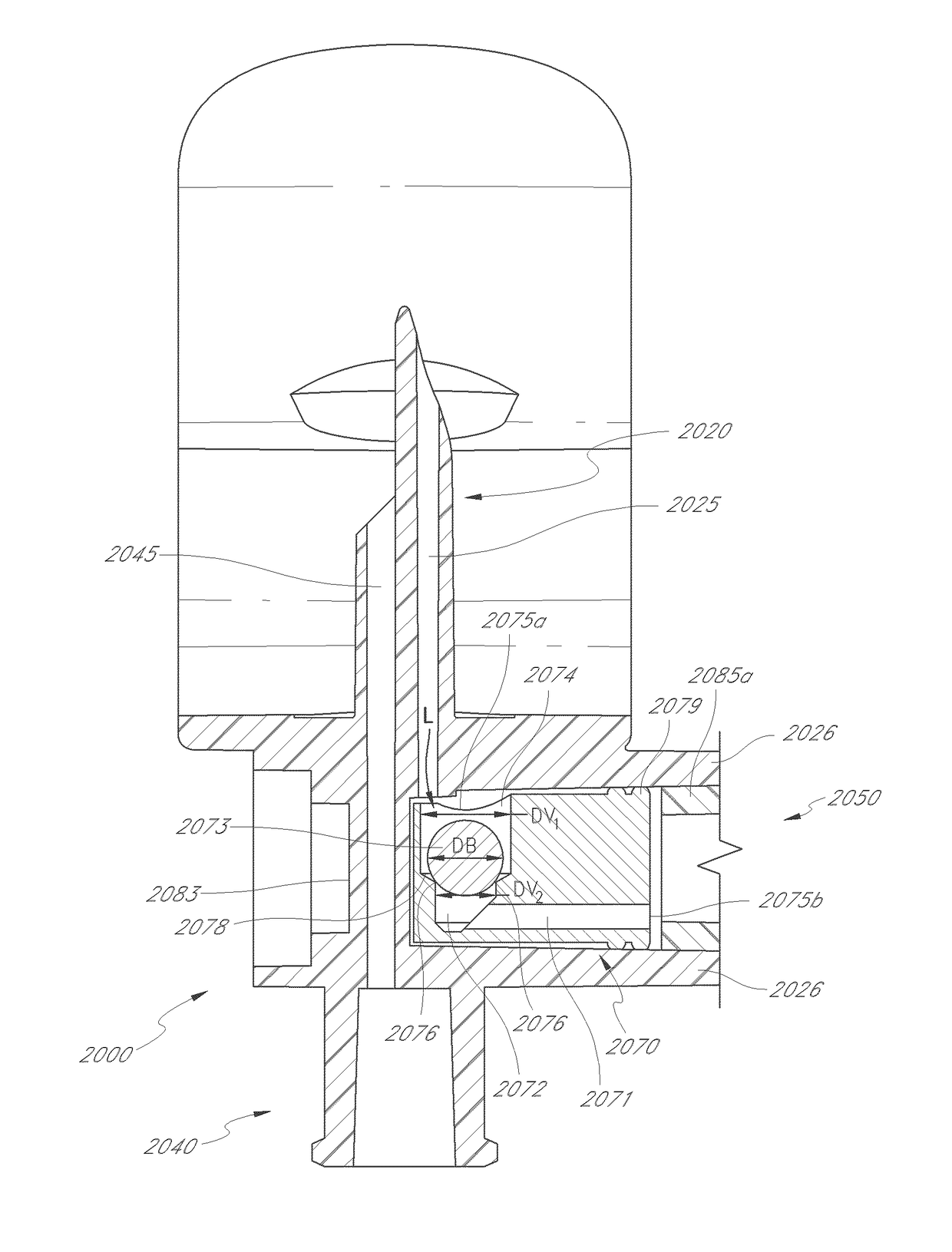

Self-camming snap ring for pop-up sprinkler with top serviceable diaphragm valve module

InactiveUS6854664B2Promote repairEasy to replaceCandle holdersLighting support devicesValve actuatorWater flow

A diaphragm valve module is mounted in the lower end of the outer housing of a pop-up rotor type sprinkler for controlling the flow of water through an inlet in response to actuation of a valve actuator component. A resilient deformable semi-circular snap ring is mounted on top of the module and has a pair of opposing peripheral annular portions. Upon removal of the sprinkler riser, the snap ring can be disengaged from an annular groove formed in the interior wall of the outer housing by manually squeezing the annular portions together. This permits removal of the module for repair or replacement. The annular portions of the snap ring are formed with angled slots that receive projections that extend from the cover of the module to produce a camming movement that uniformly retracts the snap ring out of the annular groove to more readily permit removal of the module.

Owner:HUNTER INDUSTRIES

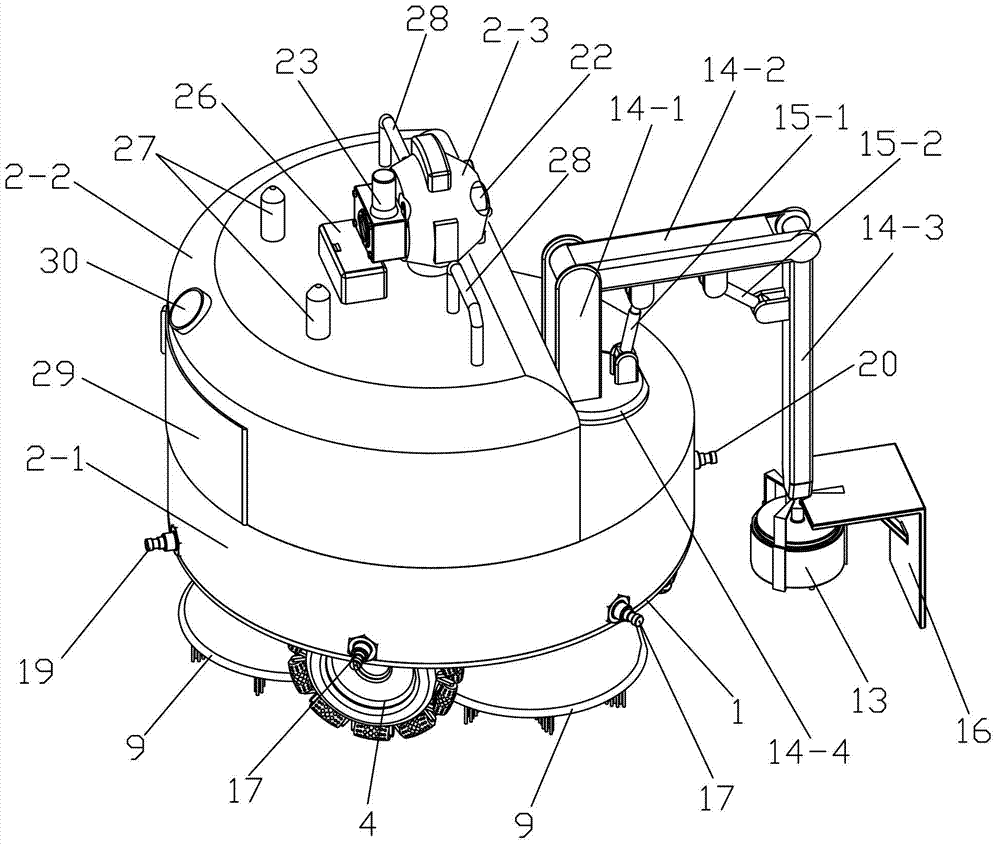

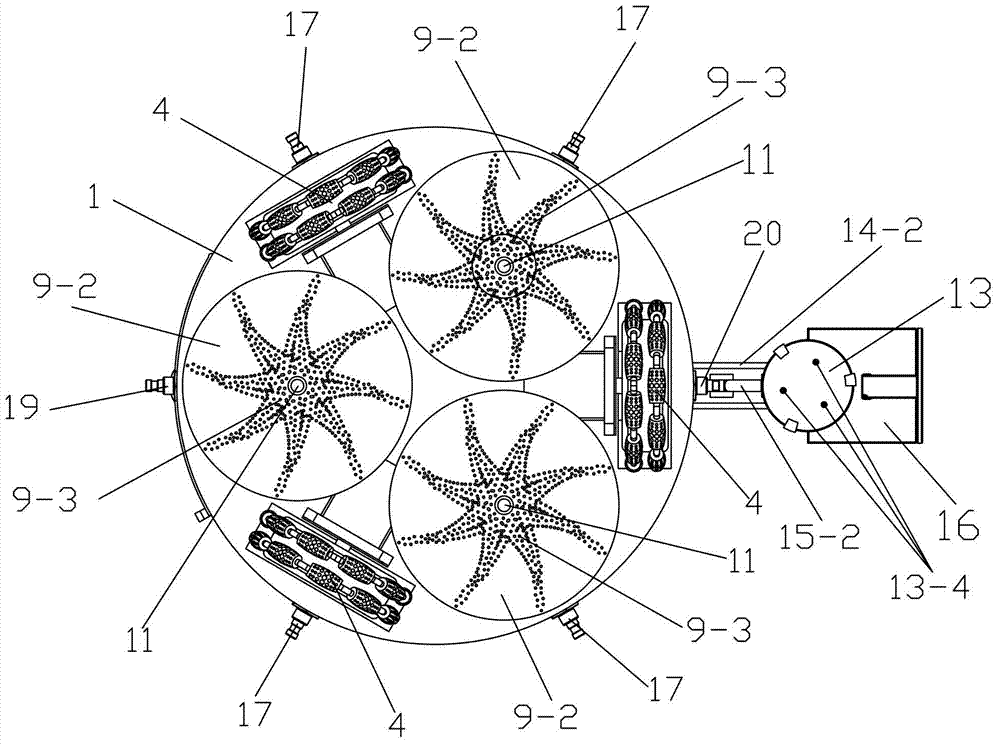

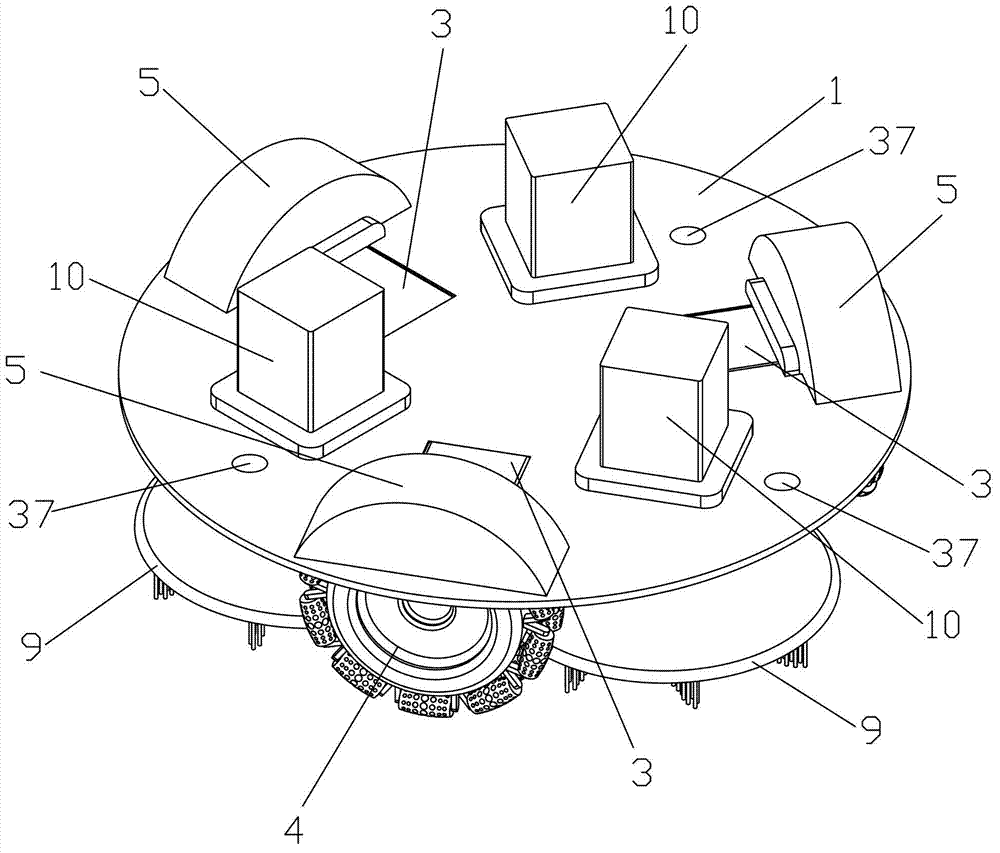

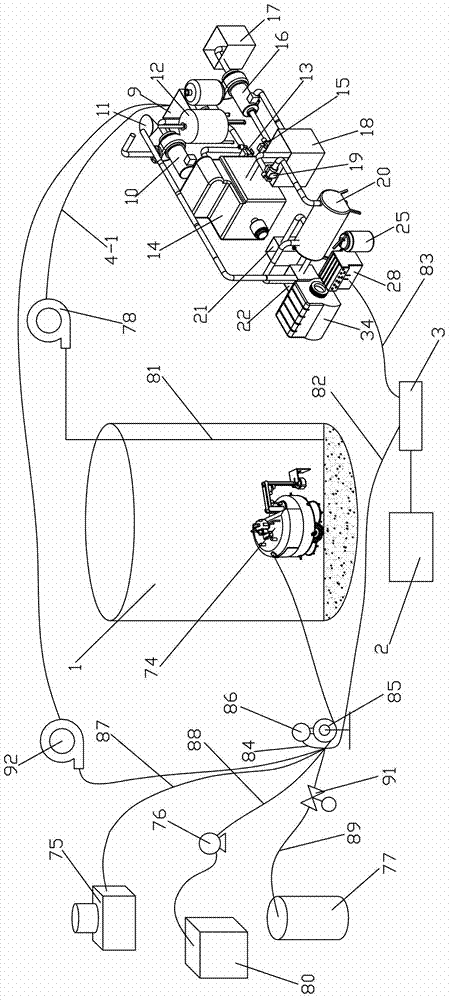

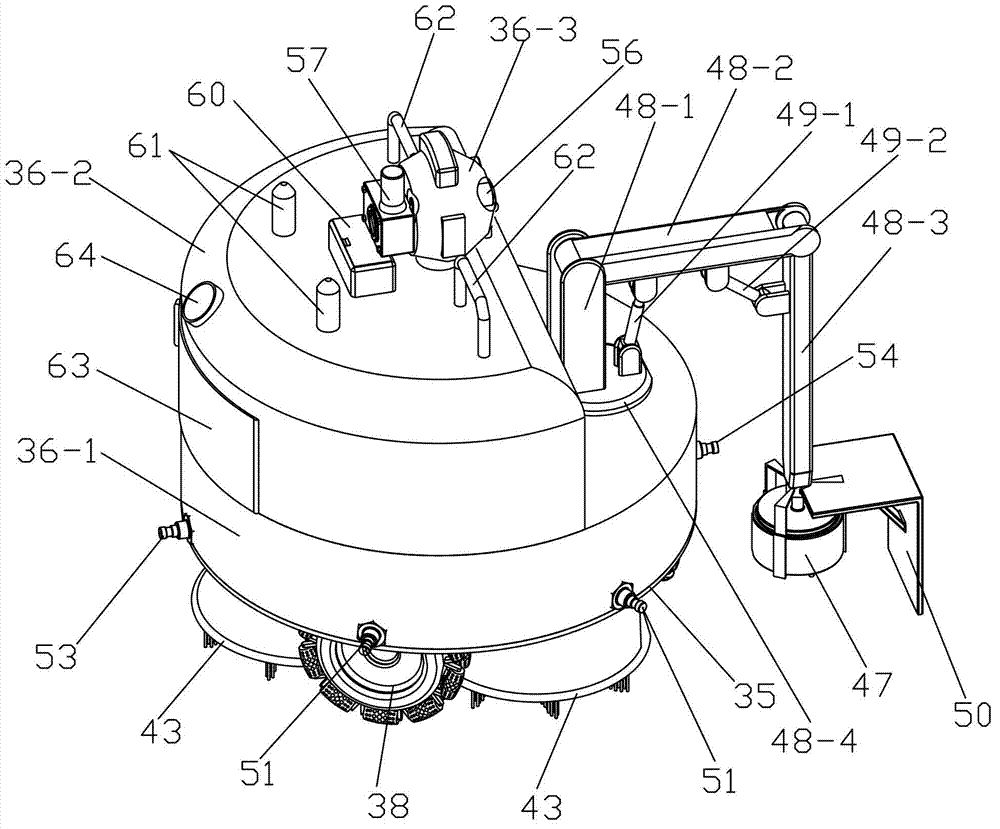

Oil tank cleaning robot

InactiveCN102764750ARealize all-round cleaningCompact structureHollow article cleaningDrive wheelUltrasonic sensor

The invention discloses an oil tank cleaning robot. The robot comprises a robot body, a walking unit, a cleaning unit, a control unit, a sensing communication unit and a power supply unit, wherein the robot body comprises a base plate, a lower casing and an upper casing, the walking unit comprises three driving wheels and three driving wheel hydraulic motors, the cleaning unit comprises a cleaning device and a self-excitation pulse device, the cleaning device comprises three cleaning disk brushes and three cleaning disk brush hydraulic motors, the self-excitation pulse device comprises a pulse device hydraulic motor, a retractable beam assembly and a self-excitation oscillating pulse nozzle, the control unit is composed of a remote control portion and a robot body control portion, and the sensing communication unit comprises a pressure sensor, a temperature sensor, an infrared sensor, an ultrasonic sensor, a horizontal attitude sensor, a turbidity sensor, a camera and an oil-gas concentration monitor. The robot is novel in design, high in intelligent degree, high in working reliability, good in safety performance, energy-saving, environment-friendly, high in practicability, high in popularization and application value and capable of achieving omni-directional cleaning.

Owner:周利坤

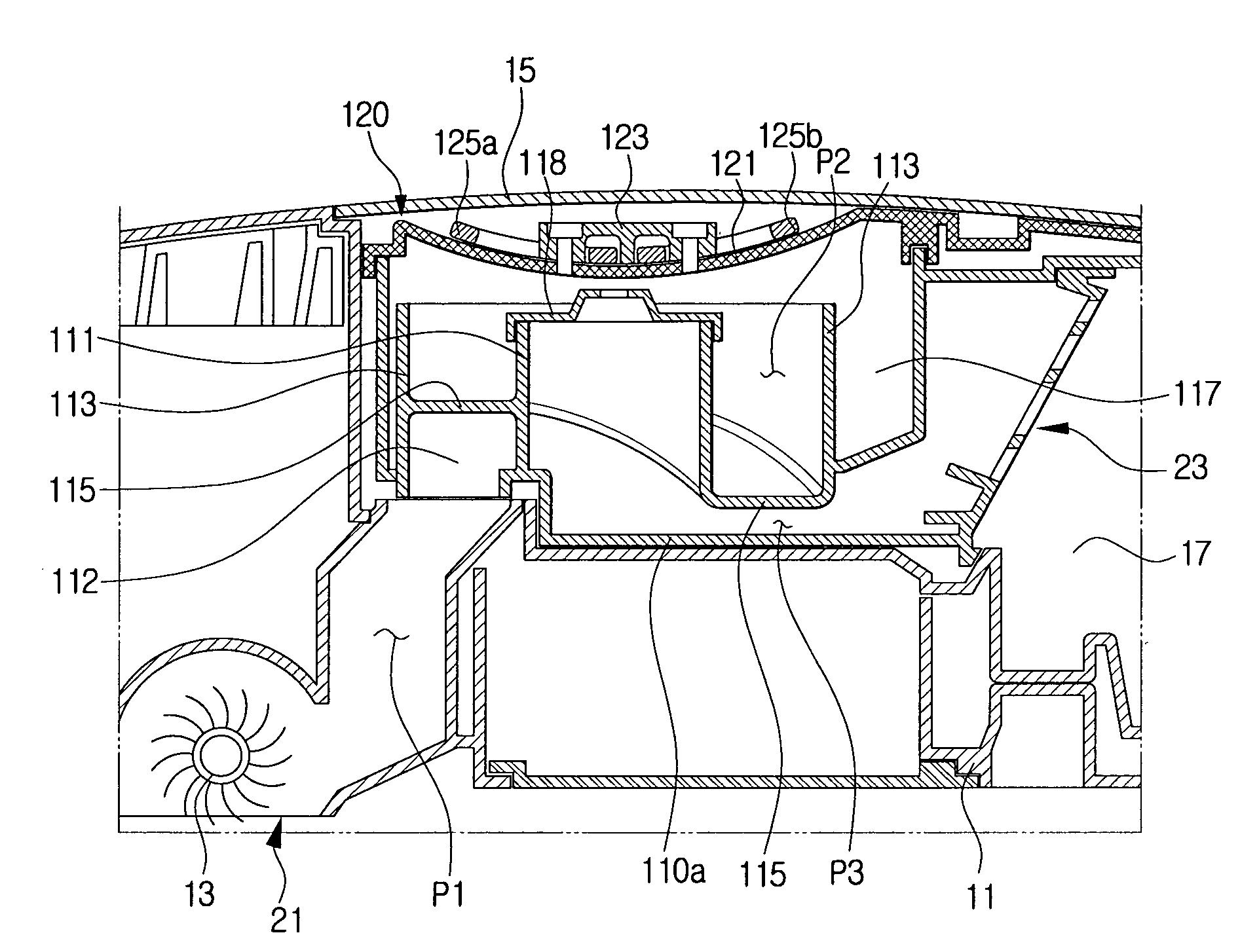

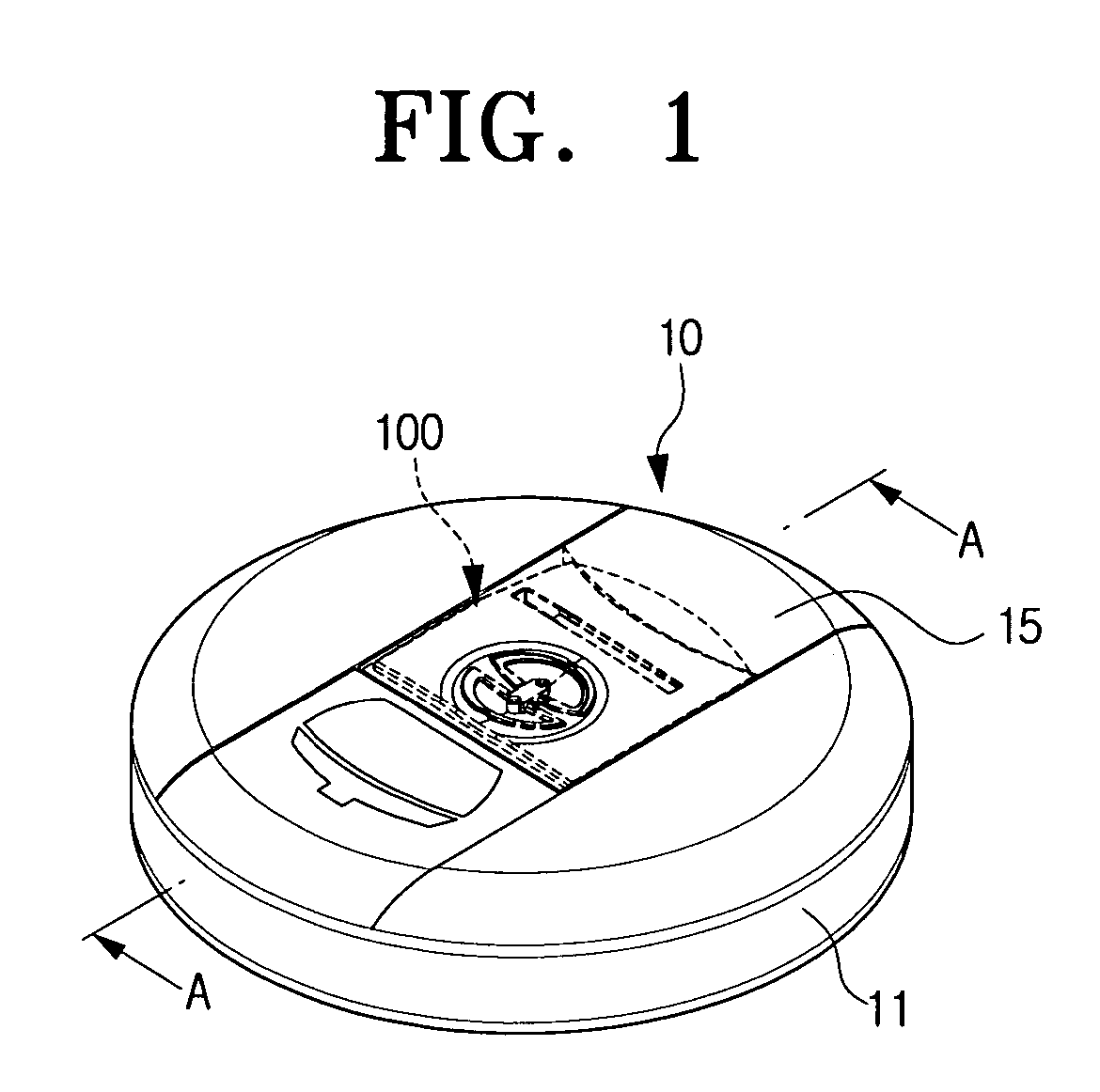

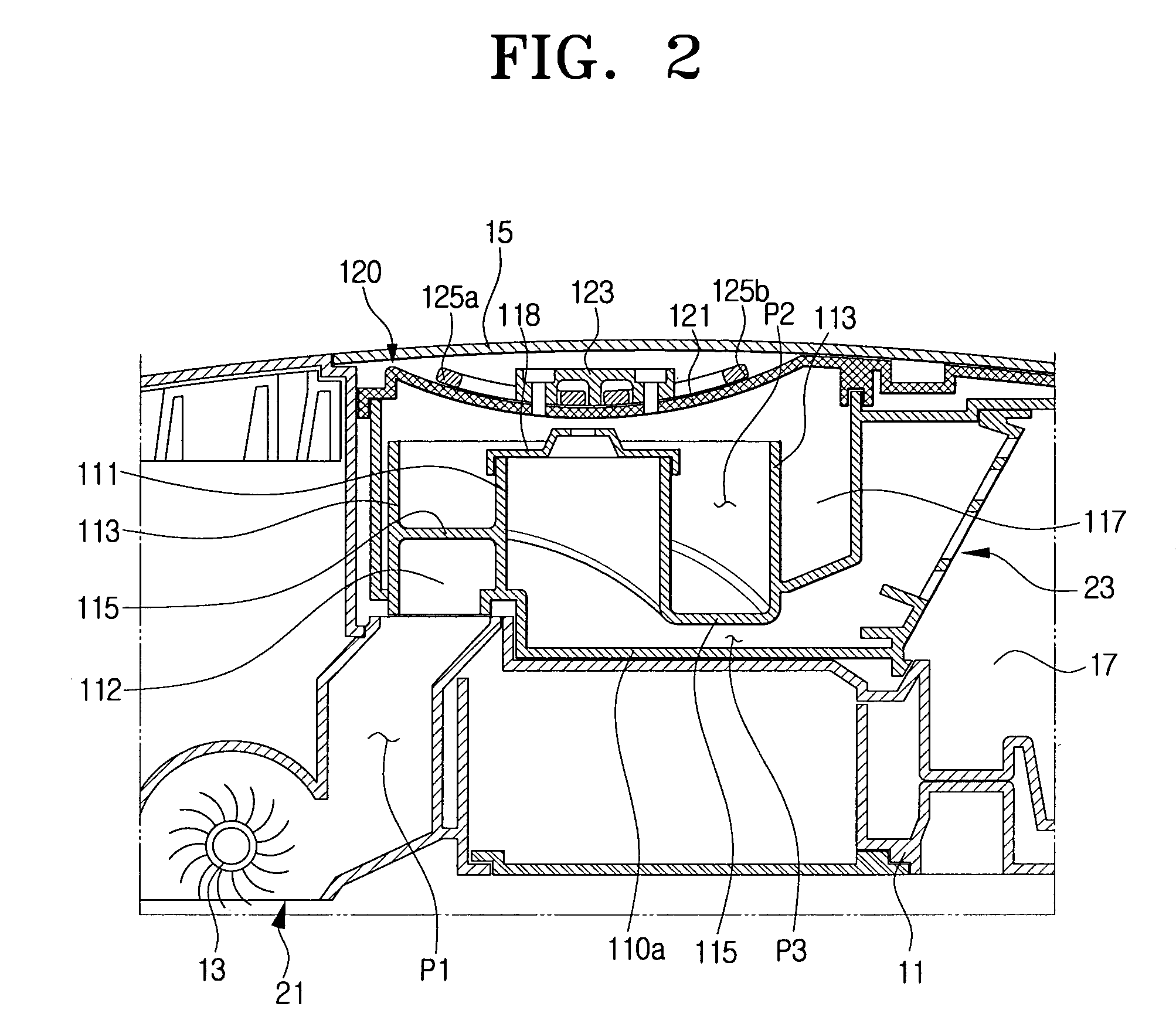

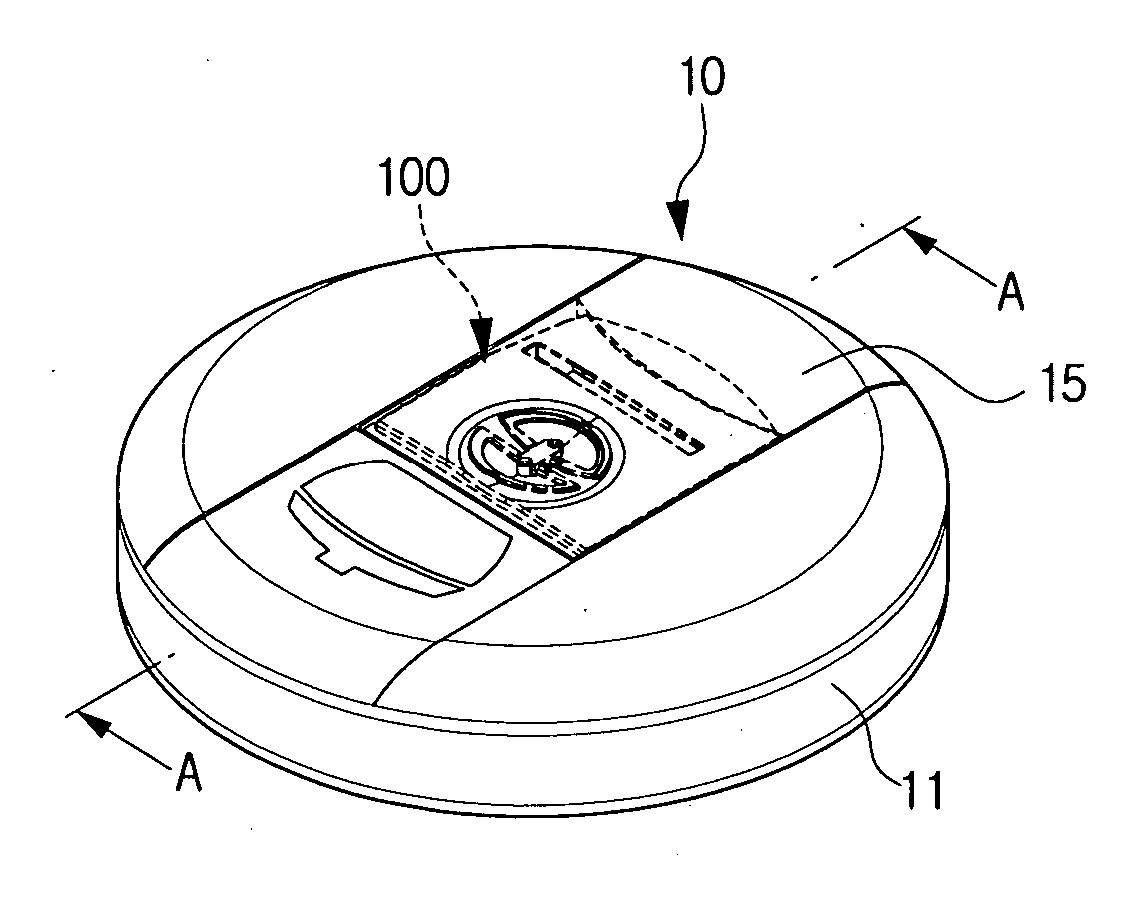

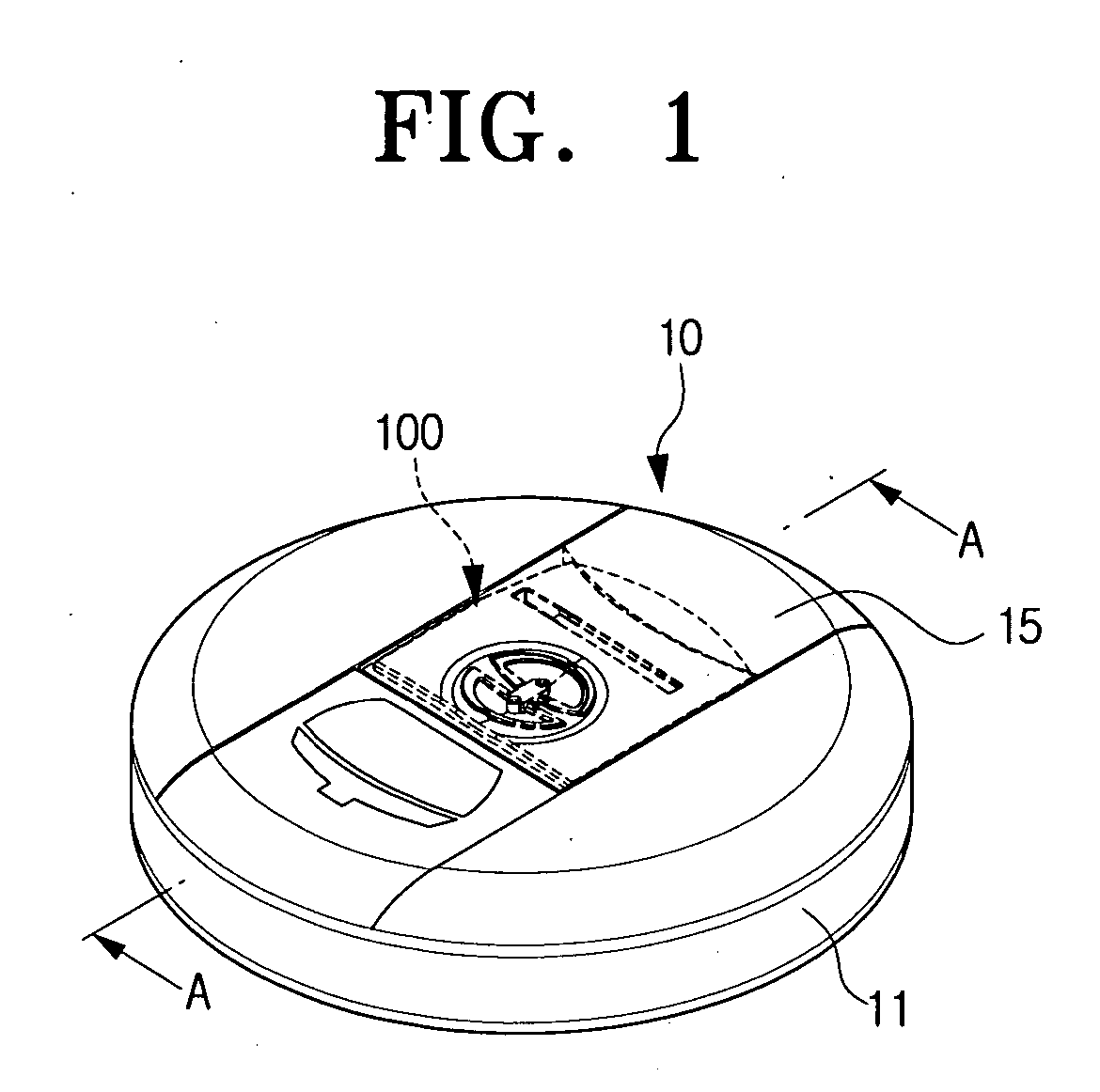

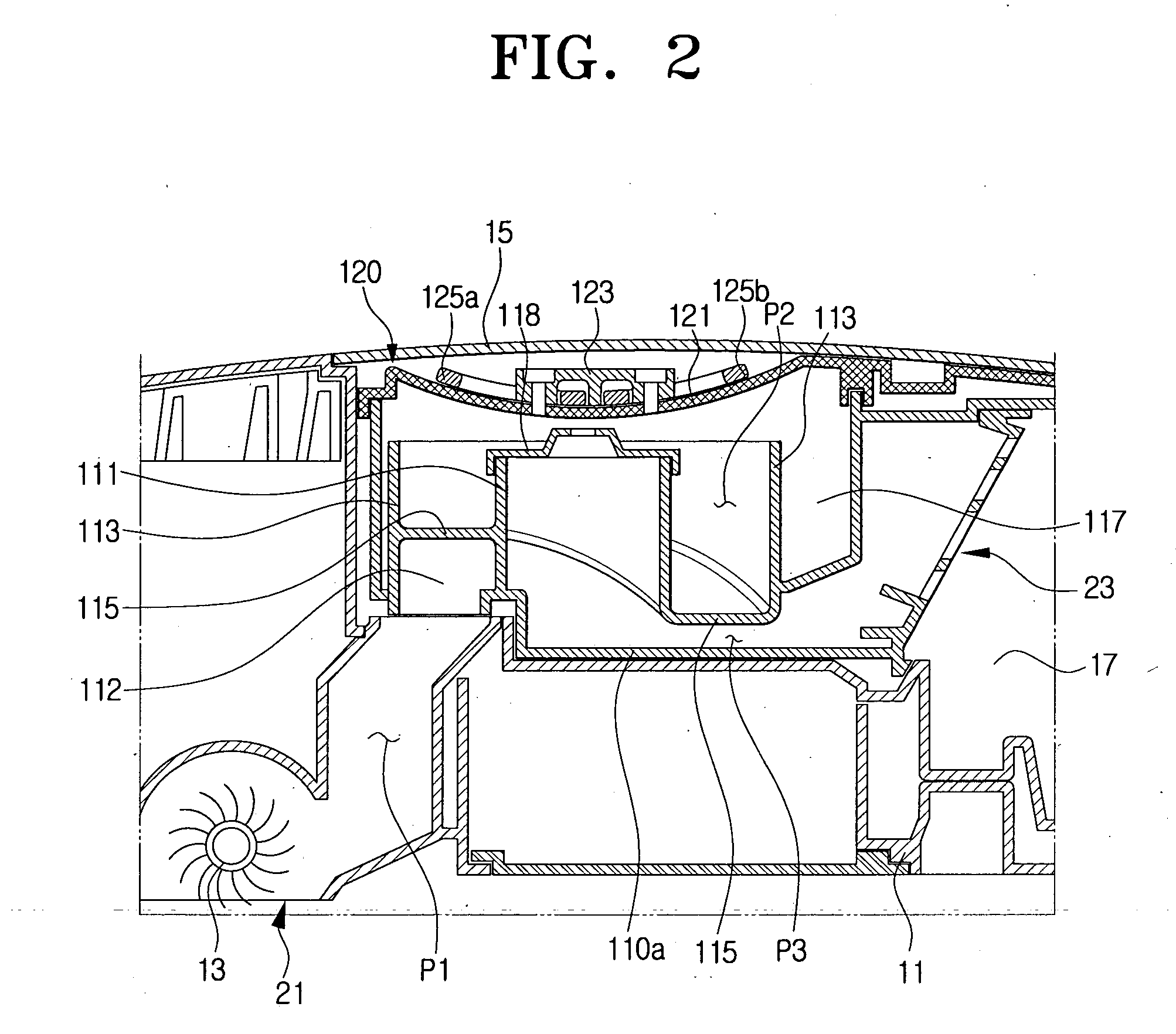

Compact robot vacuum cleaner

ActiveUS7749294B2Small sizeReduce the overall heightCleaning filter meansCombination devicesEngineeringCentrifugal force

A robot cleaner that has a dust collection unit with a cyclone part generating an ascending rotary air current from the dust-laden air being drawn in through a lower part thereof, separating the dust from the air using a centrifugal force, and discharging the dust-separated air to the lower part through a center part, and a collection part surrounding the cyclone part to receive the dust being centrifugally separated.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

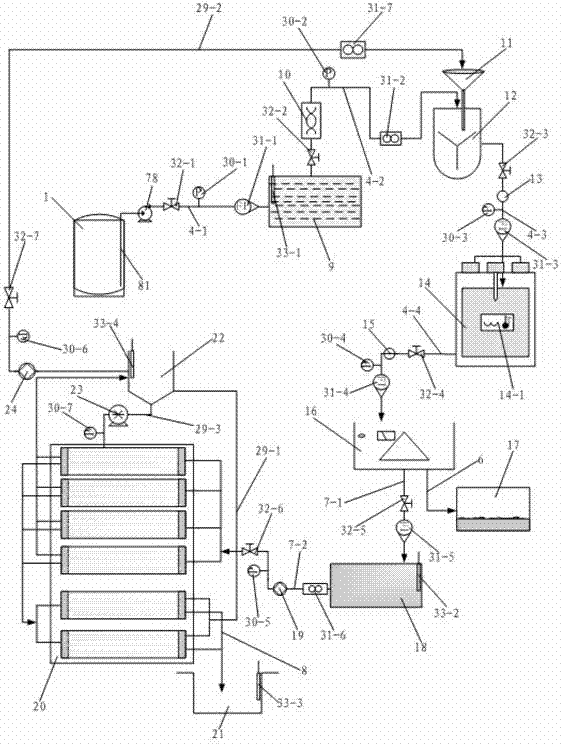

Oil sludge cleaning and processing system for oil tank

InactiveCN102825040ARealize all-round cleaningCompact structureSludge treatmentHollow article cleaningUltrafiltrationResource utilization

The invention discloses an oil sludge cleaning and processing system for an oil tank. The oil sludge cleaning and processing system comprises a cleaning system, an oil sludge processing system and an integrated control system, wherein the cleaning system comprises a cleaning robot, an electric hydraulic pump, a water pump, an inert gas storage tank and a screw pump; the cleaning robot comprises a machine body, a traveling unit, a cleaning unit, a robot cleaning control unit, a sensing and communication unit and a robot power supply unit; the oil sludge processing system comprises an oil sludge processing device, an oil sludge processing control system and an oil sludge processing power supply device; the oil sludge processing device comprises a stirring machine, an ultrasonic emulsion breaking device, a centrifuge and an ultrafiltration system, as well as an oil sludge storage pool, a sludge pool, a centrifugal liquid storage tank, a concentration tank and a filtrate pool; a funnel is arranged on the stirring machine; and the integrated control system comprises an integrated control computer and a communication circuit module. The oil sludge cleaning and processing system disclosed by the invention has the advantages of reasonable design and high degree of intelligentization, and can realize comprehensive cleaning of the oil tank, good safety, fast oil sludge processing speed and resource utilization of oil sludge, and further reduce environmental pollution and waste of resources.

Owner:周利坤

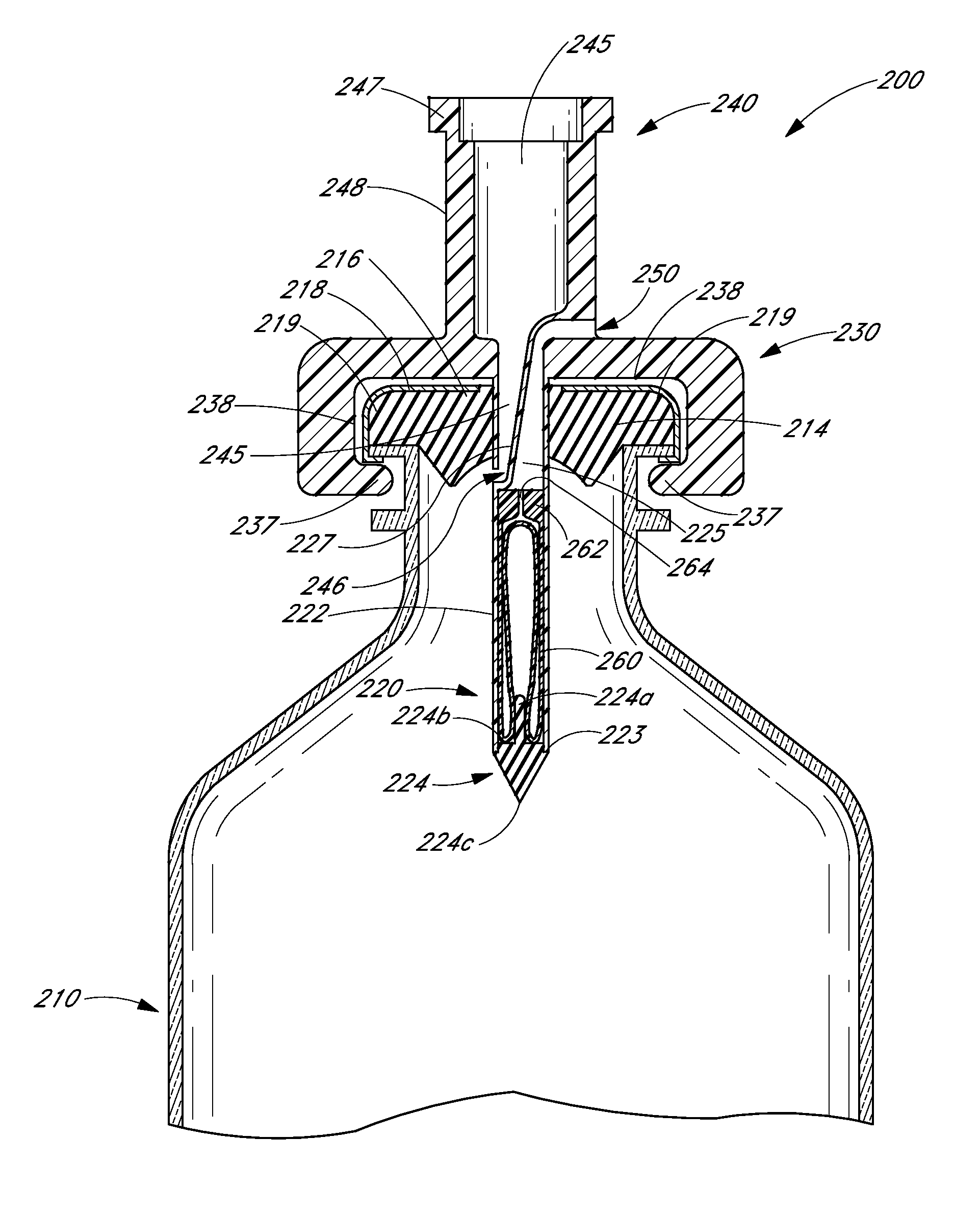

Pressure-regulating vial adaptors and methods

In certain embodiments, a vial adaptor comprises a housing member, a connector configured to couple the adaptor with a vial, a regulator channel, and an extractor channel formed in the housing member. The extractor channel is configured to facilitate withdrawal of fluid from the vial when the adaptor is coupled to the vial. The regulator channel is configured to facilitate flow of a regulating fluid to compensate for changes in volume of a medical fluid in the vial. In some embodiments, an expansion member is disposed on the housing member and is configured to expand and contract in accordance with changes in the volume of a medical fluid in the vial.

Owner:ICU MEDICAL INC

Pressure-regulating vial adaptors

ActiveUS20150000787A1Promote withdrawalEasy to movePharmaceutical containersMedical packagingEngineeringVial

In certain embodiments, a vial adaptor comprises a housing configured to couple the adaptor with a vial, an access channel, a regulator channel, and a regulator assembly. The access channel is configured to facilitate withdrawal of fluid from the vial when the adaptor is coupled to the vial. The regulator channel is configured to facilitate a flow of a regulating fluid from the regulator assembly to compensate for changes in volume of a medical fluid in the vial. The regulator assembly can include a valve configured to transition between a closed configuration and an opened configuration.

Owner:ICU MEDICAL INC

Pressure-regulating vial adaptors

ActiveUS20150297461A1Promote withdrawalEasy to moveLiquid fillingPharmaceutical containersEngineeringVial

In certain embodiments, a vial adaptor comprises a housing configured to couple the adaptor with a vial, an access channel, a regulator channel, and a regulator assembly. The access channel is configured to facilitate withdrawal of fluid from the vial when the adaptor is coupled to the vial. The regulator channel is configured to facilitate a flow of a regulating fluid from the regulator assembly to compensate for changes in volume of a medical fluid in the vial. In some embodiments, the regulator assembly includes a flexible member configured to expand and contract in accordance with changes in the volume of the medical fluid in the vial. In some embodiments, the flexible member is substantially free to expand and contract. In some embodiments, the flexible member is not partly or completely located in a rigid enclosure.

Owner:ICU MEDICAL INC

Catheter with sealed hydratable hemostatic occlusion element

InactiveUS20130060279A1Promote withdrawalPrevent proximal retractionSurgical veterinaryWound clampsHemostaticsVascular wall

Apparatus for sealing a vascular wall penetration disposed at the end of the tissue tract comprises a shaft, an optional occlusion element, a hydratable hemostatic implant, and a protective sleeve. The apparatus is deployed through the tissue tract with the occlusion element optionally occluding the vascular wall penetration and inhibiting backbleeding therethrough. The hydratable hemostatic implant, which will typically be a biodegradable polymer such as collagen carrying an anti-proliferative agent or coagulation promoter, will then be deployed from the sealing apparatus by retracting the protective sleeve and left in place to enhance closure of the vascular wall penetration with minimum scarring. The hydratable implant will be protected from premature hydration and swelling by a soluble plug covering the implant's distal end prior to sleeve retraction.

Owner:CARDIVA MEDICAL

Anti-reflux vial adaptors

In certain embodiments, a vial adaptor comprises a housing member, a connector configured to couple the adaptor with a vial, and an extractor channel formed in the housing member. The extractor channel is configured to facilitate withdrawal of fluid from the vial when the adaptor is coupled to the vial. In some embodiments, an anti-reflux valve is positioned within the extractor channel. The anti-reflux valve can be configured to impede or obstruct fluid returning to a fluid source after withdrawal of the fluid from the fluid source.

Owner:ICU MEDICAL INC

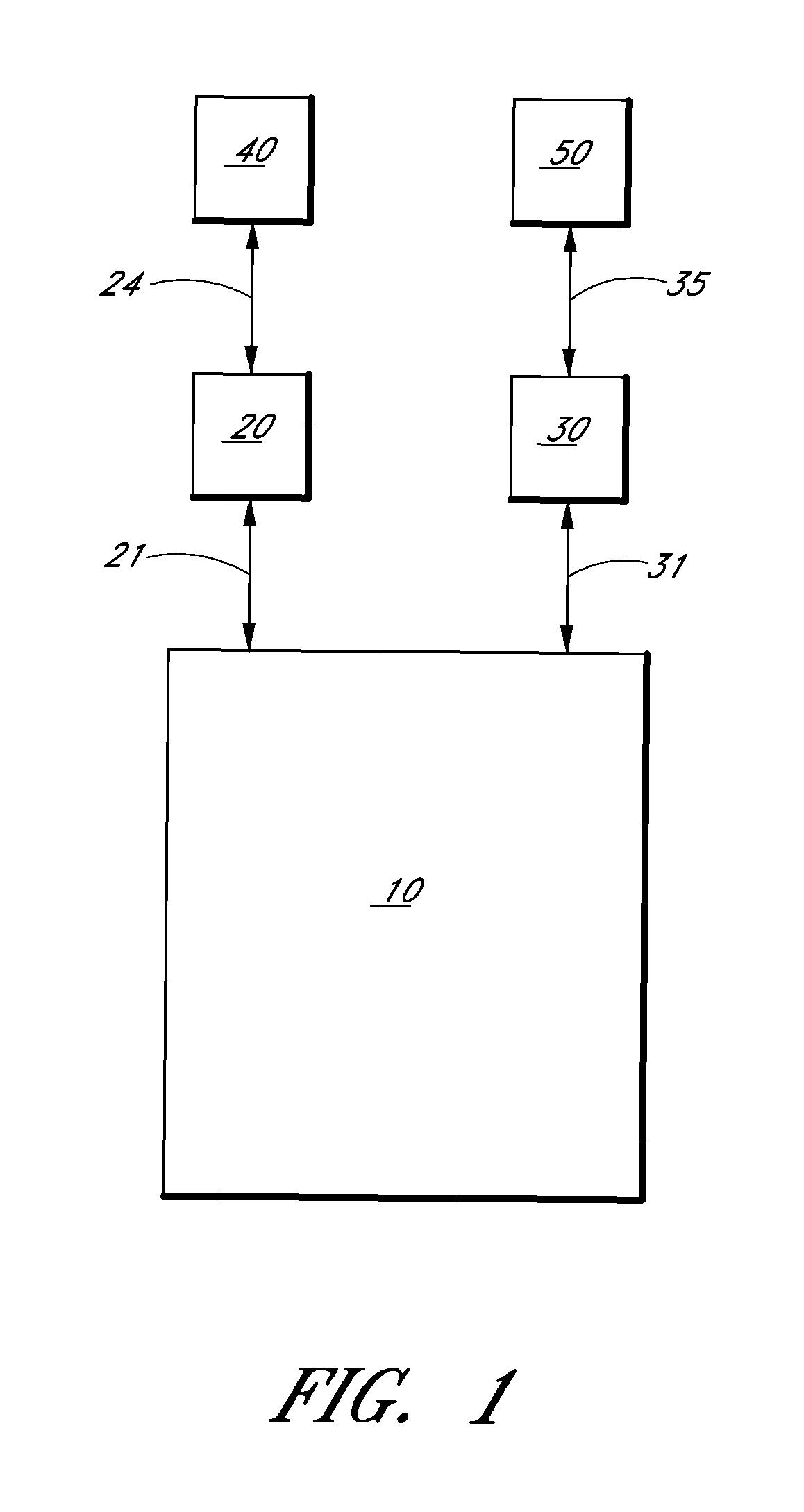

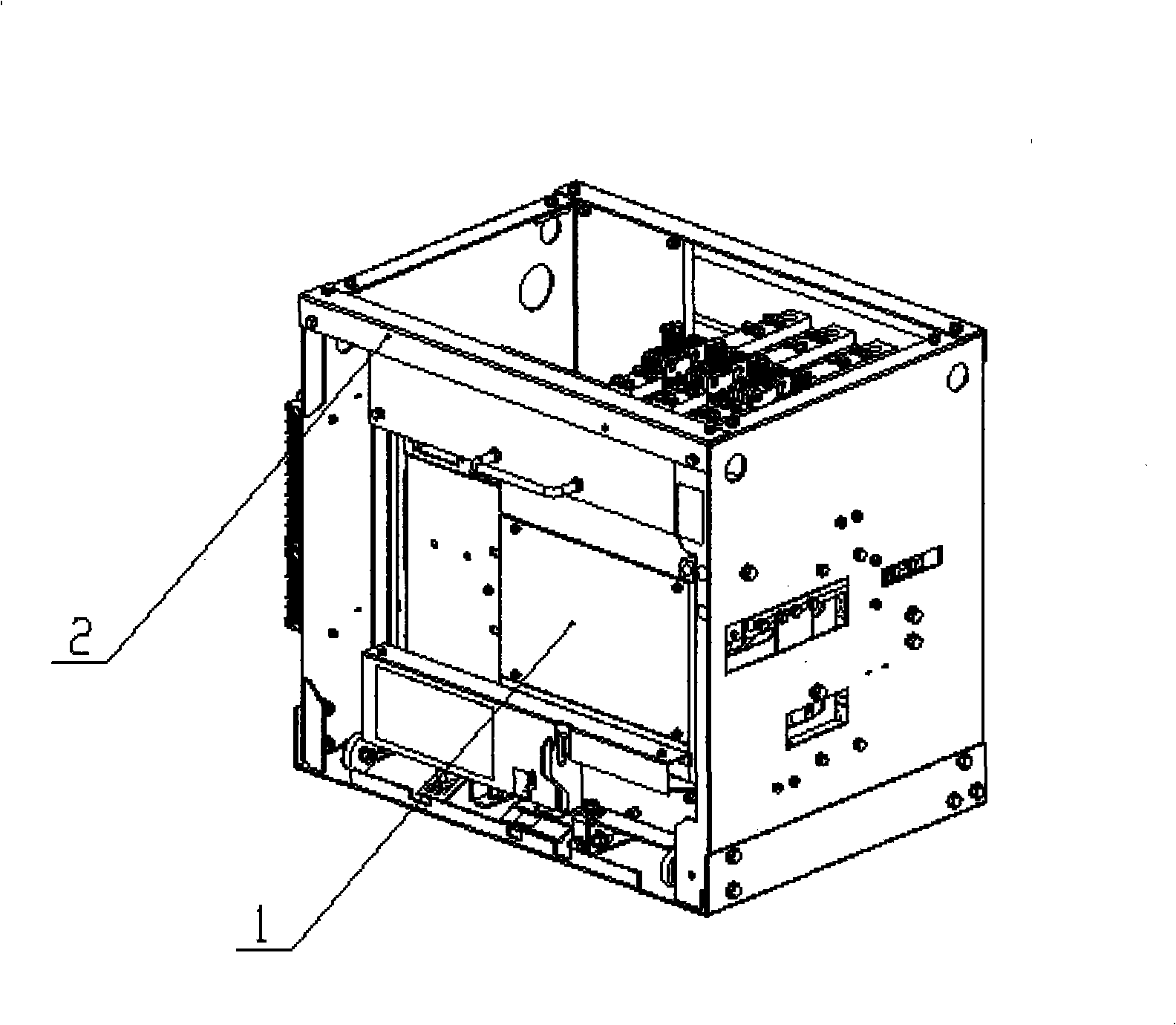

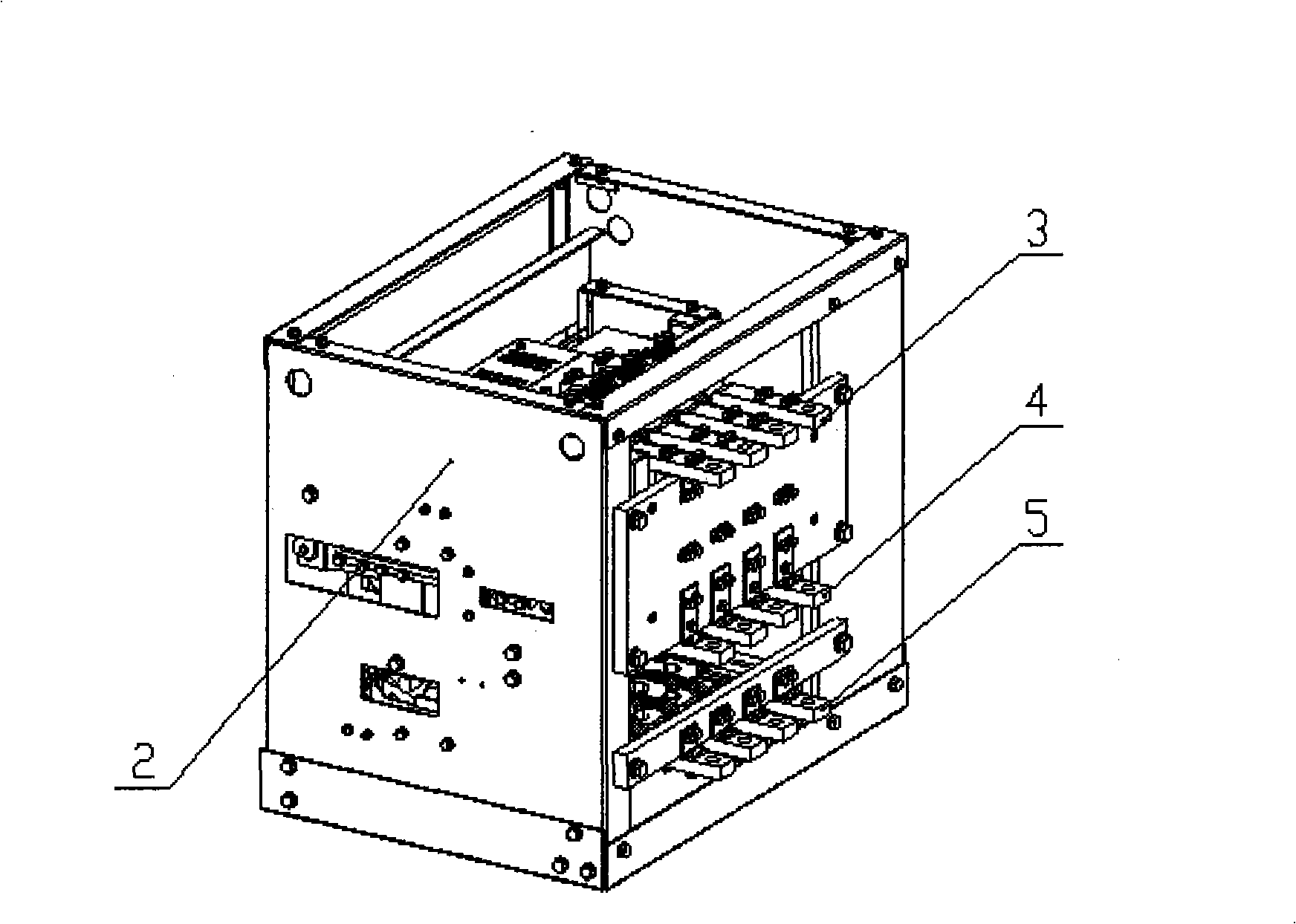

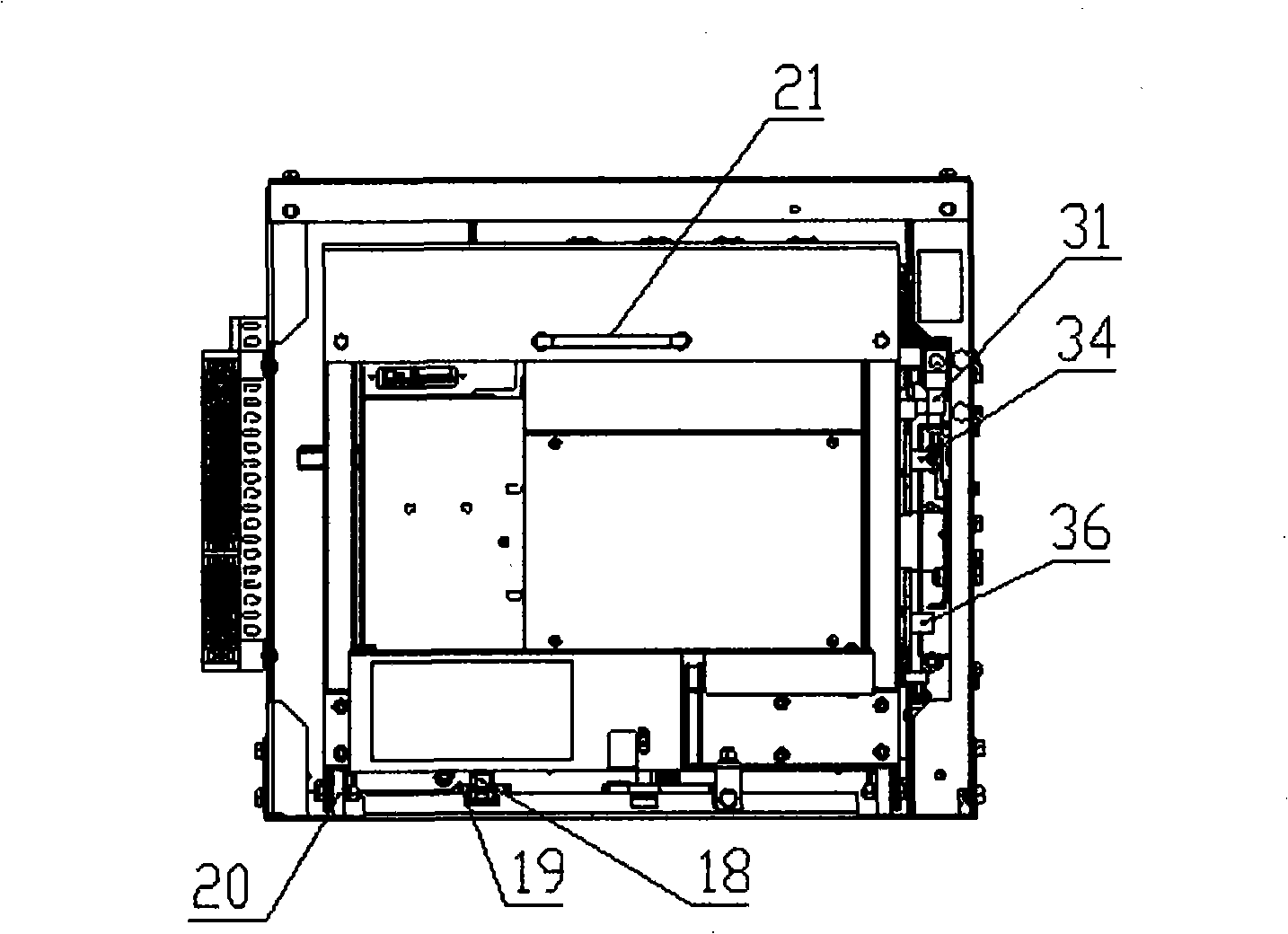

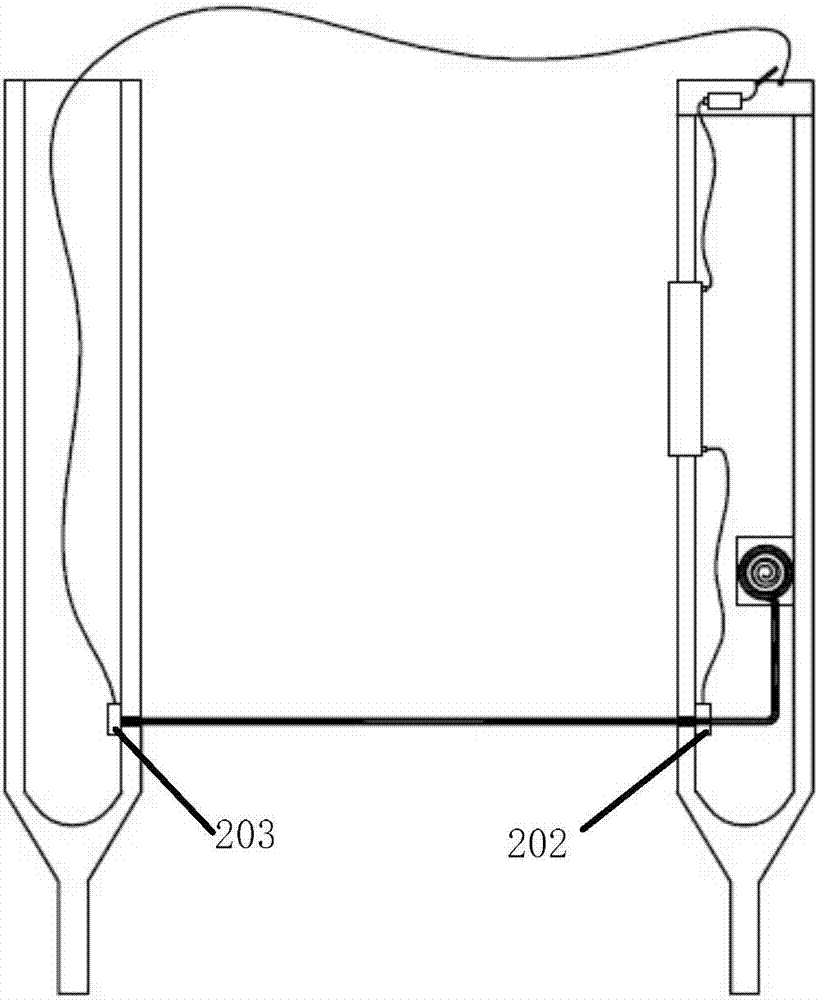

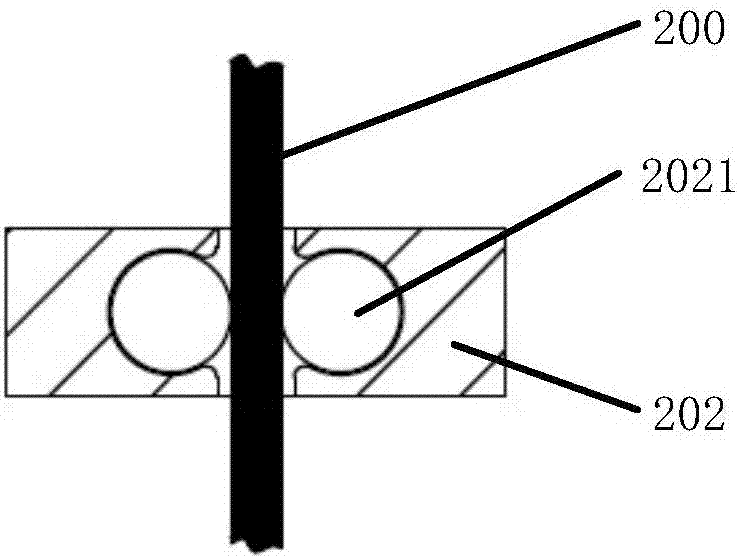

Extraction type automatic change-over electric appliance with by-path

InactiveCN101350505APromote withdrawalEasy maintenanceSwitchgear detailsSelf lockingContinuous operation

The invention relates to a draw-out automatic changeover switch provided with a shunt circuit. Prior automatic switchover switch needs repair and replacement during changeover, therefore, the operation is very inconvenient. The invention comprises a main-body switch, rollers, guide rails, locating pins, a shunt-circuit frame and a power supply connecting terminal A, a power supply connecting terminal B, a load connecting terminal, a shunt-circuit contact self-locking mechanism, a shunt-circuit moving contact, a shunt-circuit static contact, a shunt-circuit draw-out interlocking mechanism fixed on the frame. The switch mainly has the functions of draw-out and shunt circuit. When the main-body switch needs repair or replacement, the shunt circuit is switched on, the power is supplied to the load by a normal power supply, the main-body switch is drawn out to be repaired or replaced outside the power supply circuit; after repair, the main-body is pushed into the frame, the shunt-circuit switch is switched off, and the switch main-body is integrated into the system for continuous operation. Such process does not influence normal power supply to the load, and the repair and replacement become more convenient and rapid.

Owner:深圳市泰永科技有限公司

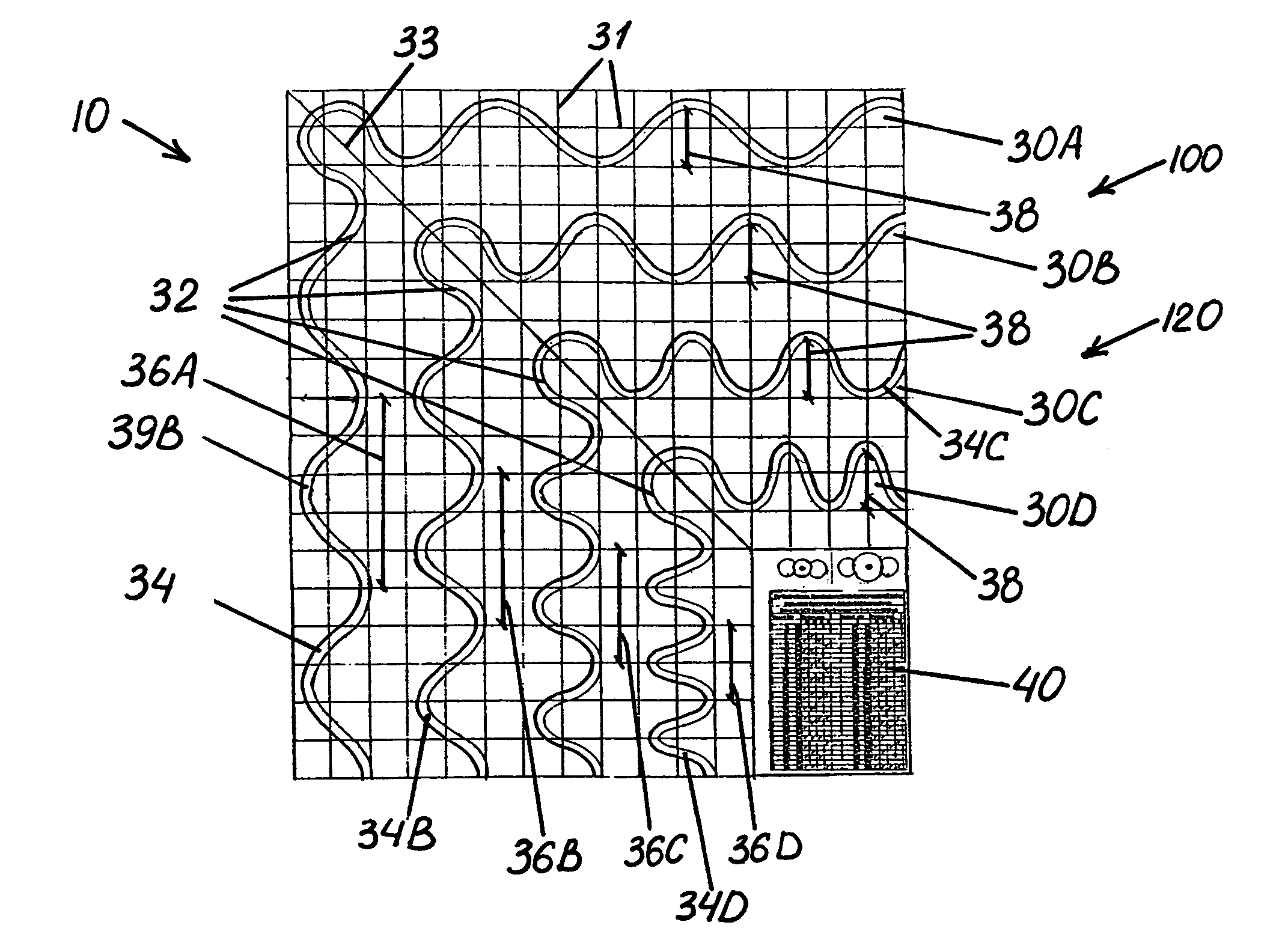

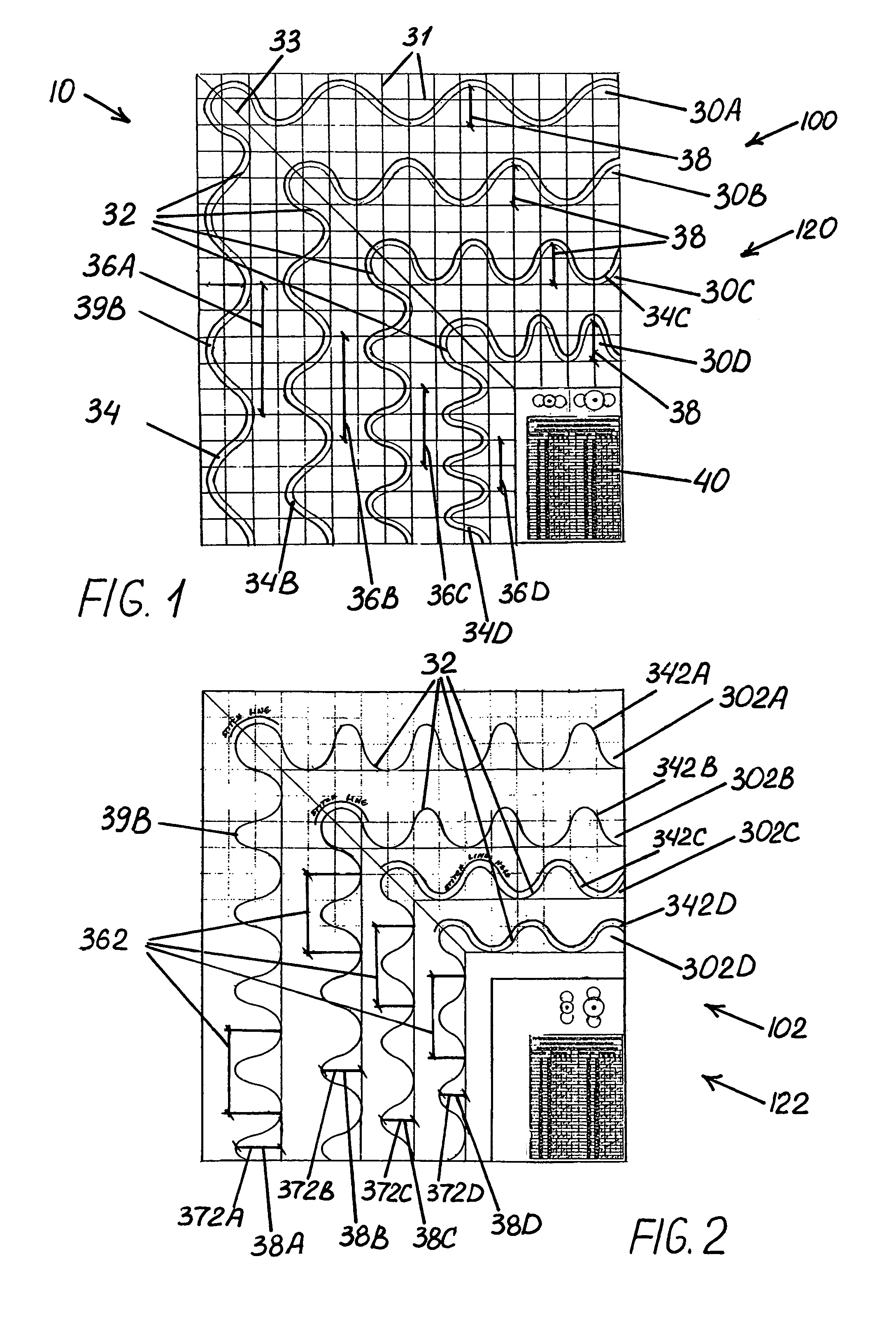

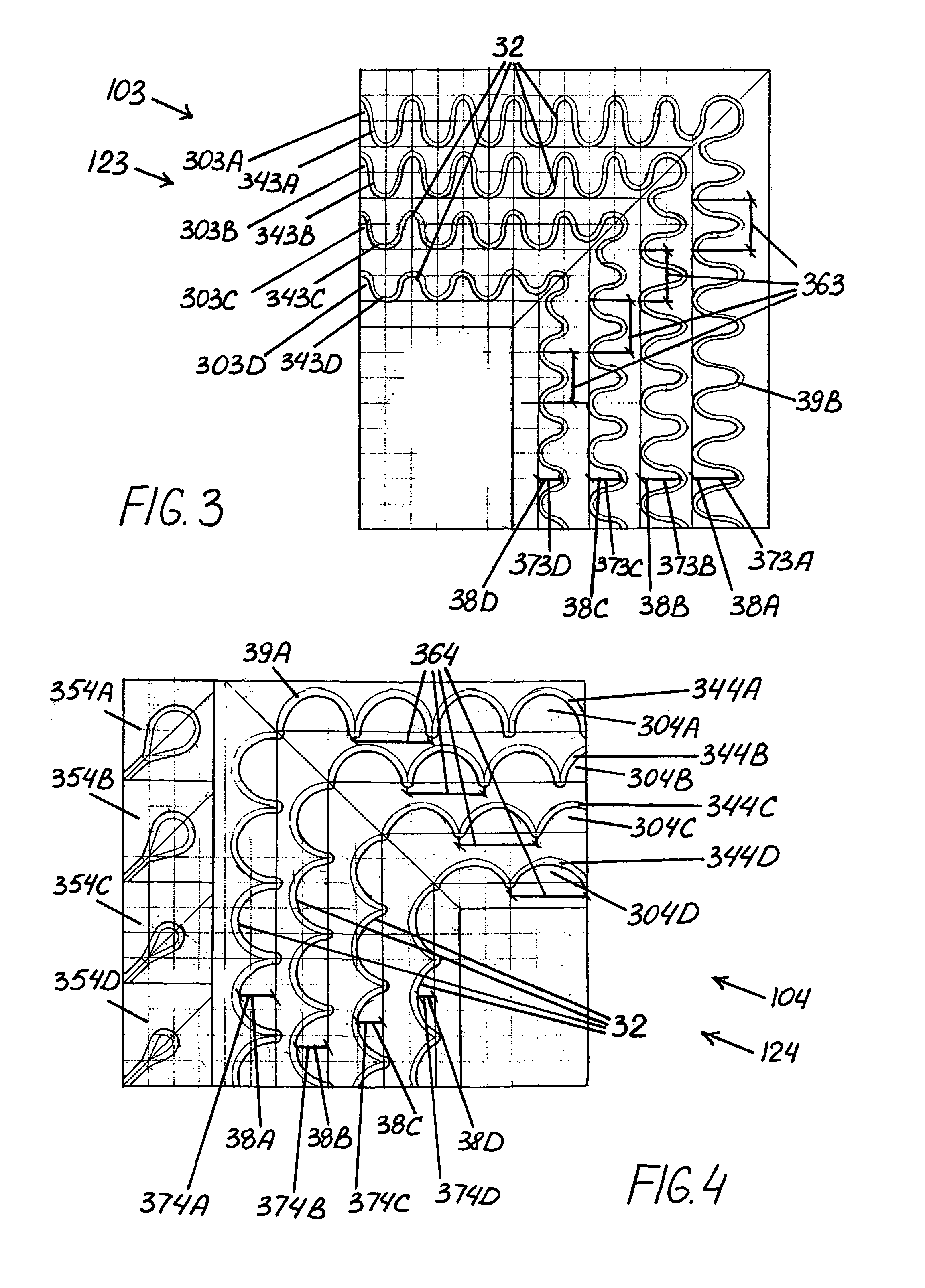

Quilting template system

InactiveUS7383640B2Improve organizationFacilitate quilting the craft-workLiquid surface applicatorsWriting aidsRepeat patternEngineering

Owner:BARRY PATRICIA C

Pressure-regulating vial adaptors

ActiveUS20140238532A1Promote withdrawalEasy to movePharmaceutical containersMedical packagingEngineeringVial

In certain embodiments, a vial adaptor comprises a housing configured to couple the adaptor with a vial, an access channel, a regulator channel, and a regulator assembly. The access channel is configured to facilitate withdrawal of fluid from the vial when the adaptor is coupled to the vial. The regulator channel is configured to facilitate a flow of a regulating fluid from the regulator assembly to compensate for changes in volume of a medical fluid in the vial. In some embodiments, the regulator assembly includes a flexible member configured to expand and contract in accordance with changes in the volume of the medical fluid in the vial. In some embodiments, the flexible member is substantially free to expand and contract. In some embodiments, the flexible member is not partly or completely located in a rigid enclosure.

Owner:ICU MEDICAL INC

Pressure-regulating vial adaptors

ActiveUS9610217B2Promote withdrawalEasy to movePharmaceutical containersMedical packagingEngineeringVALVE PORT

In certain embodiments, a vial adaptor comprises a housing configured to couple the adaptor with a vial, an access channel, a regulator channel, and a regulator assembly. The access channel is configured to facilitate withdrawal of fluid from the vial when the adaptor is coupled to the vial. The regulator channel is configured to facilitate a flow of a regulating fluid from the regulator assembly to compensate for changes in volume of a medical fluid in the vial. The regulator assembly can include a valve configured to transition between a closed configuration and an opened configuration.

Owner:ICU MEDICAL INC

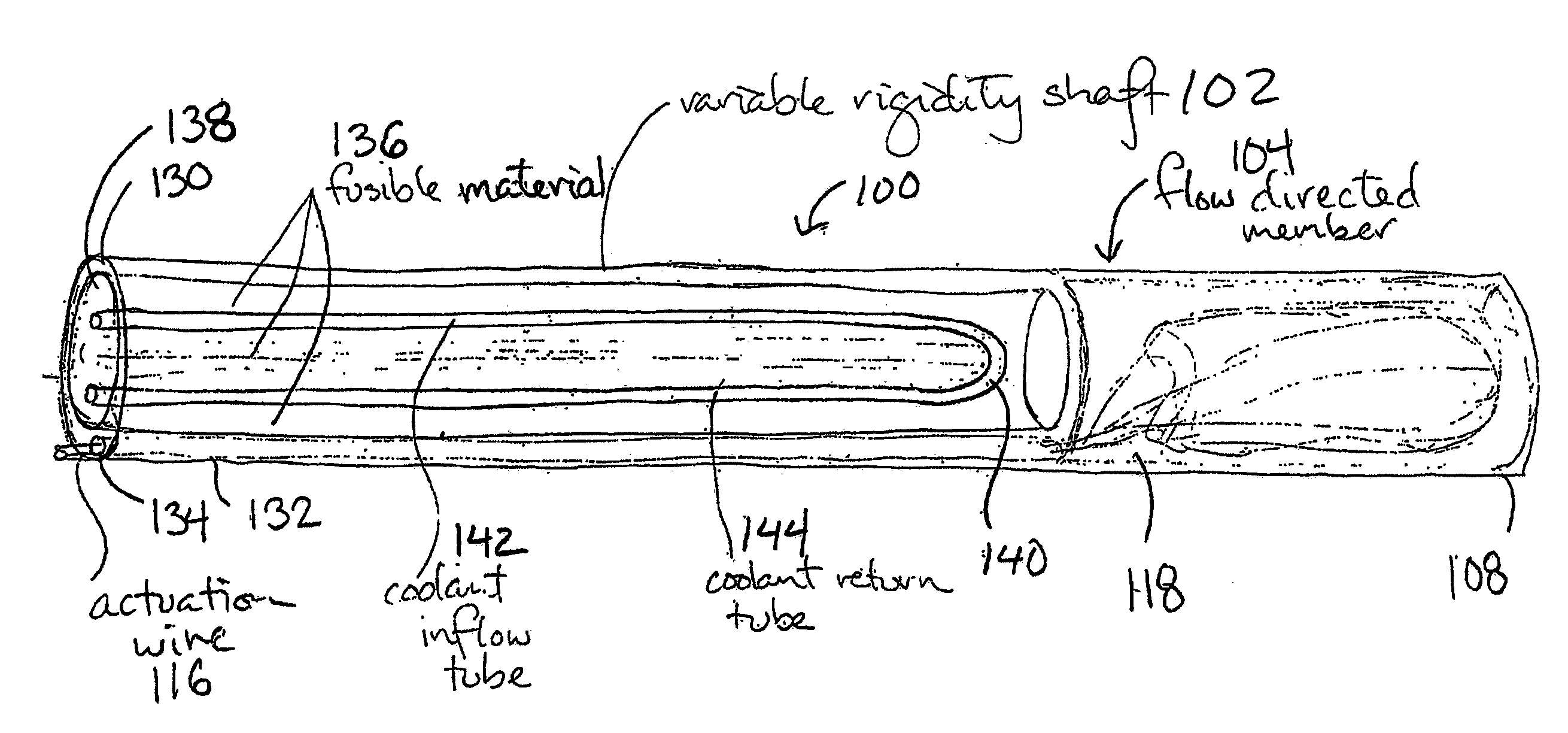

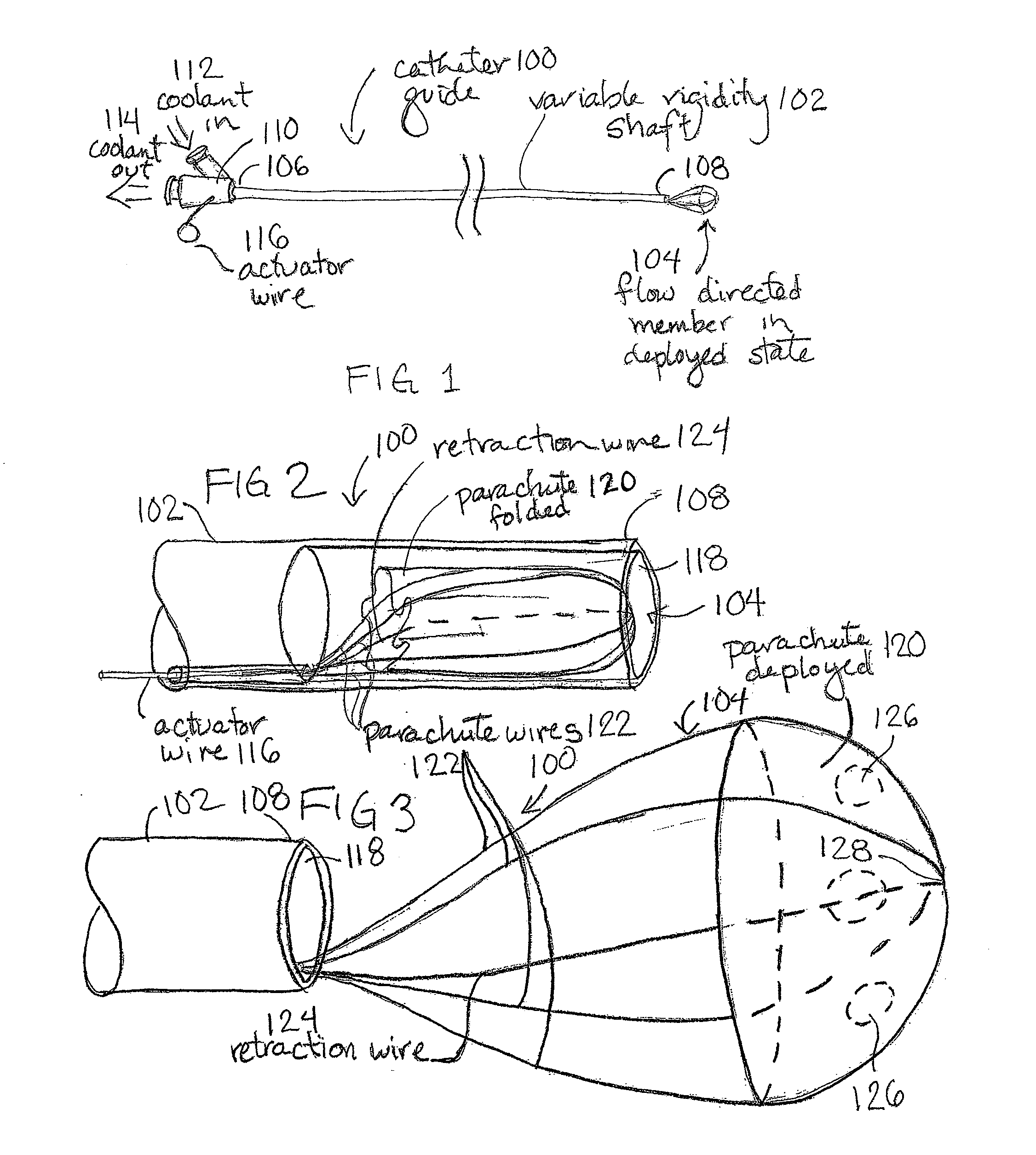

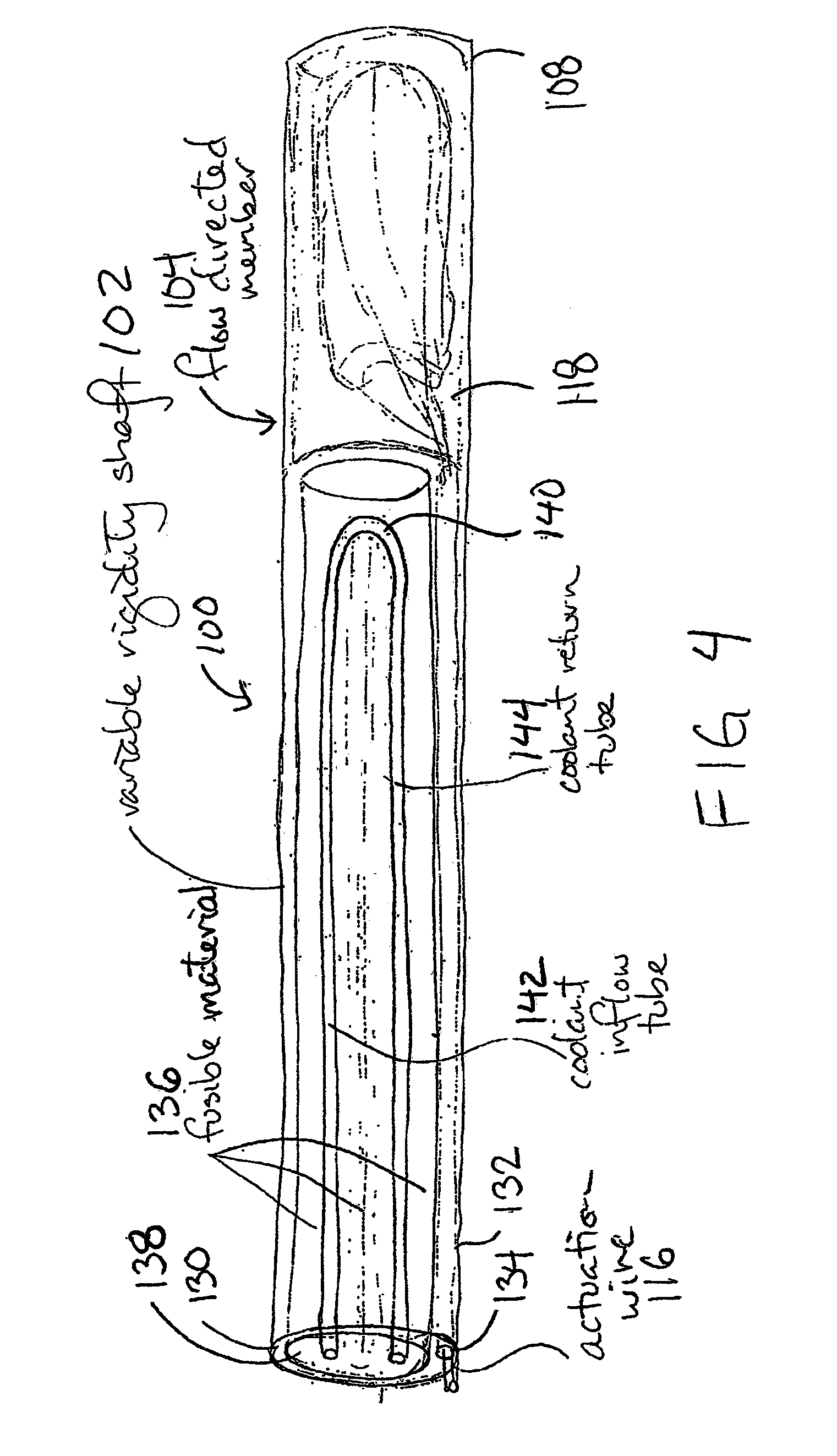

Flow-directed catheter guide with variable rigidity shaft

InactiveUS20100010441A1Promote withdrawalAvoid traumaGuide wiresMedical devicesGuide tubeBlood vessel

A flow-directed catheter guide includes a selectively deployable flow-directed member and a variable rigidity shaft. The variable rigidity shaft can be selectively changed between a flexible state and a rigid state. The flow-directed member can be deployed to direct the distal end of the catheter guide downstream following the blood flow in the vessel.

Owner:VASCULAR PATHWAYS

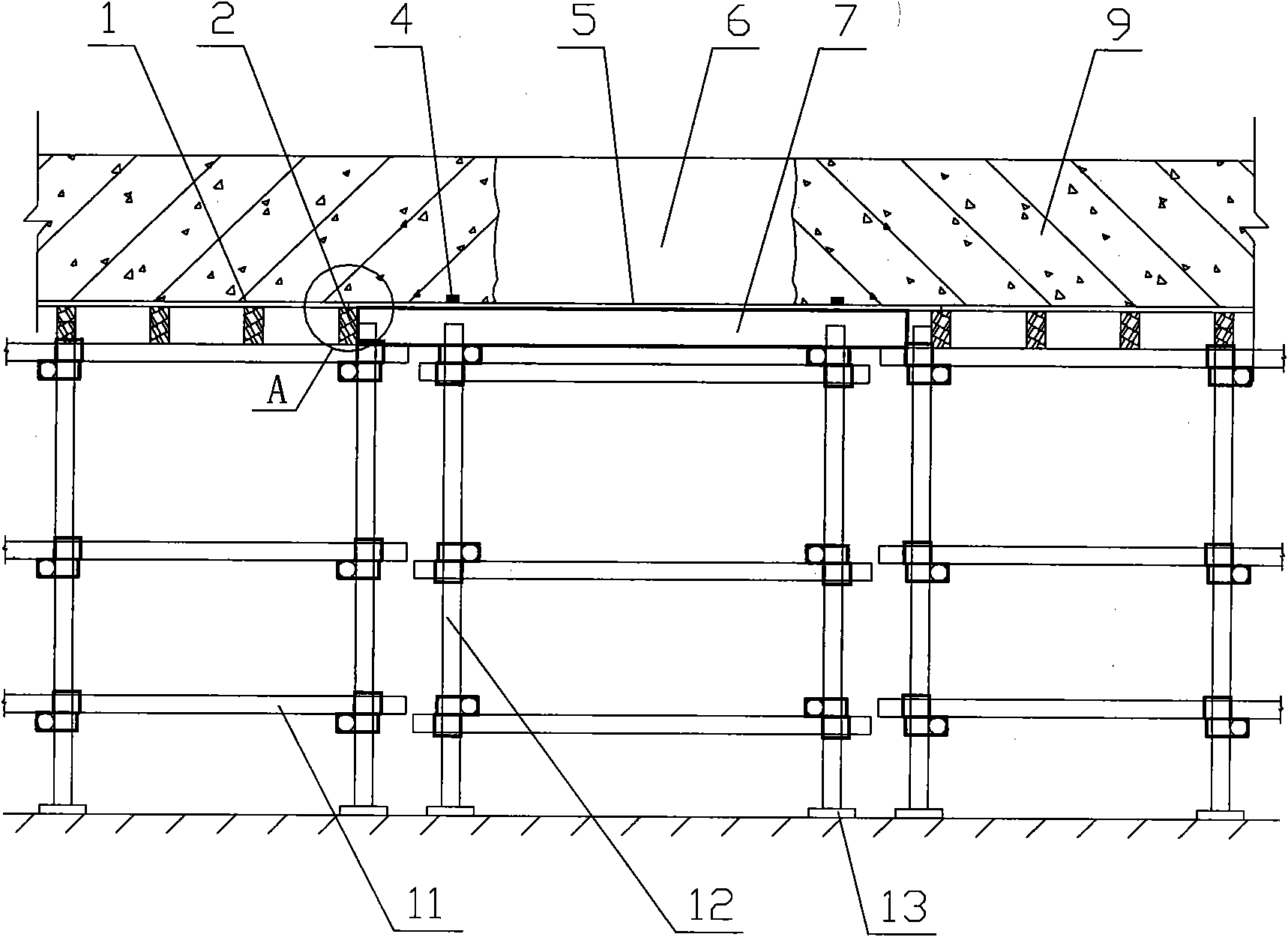

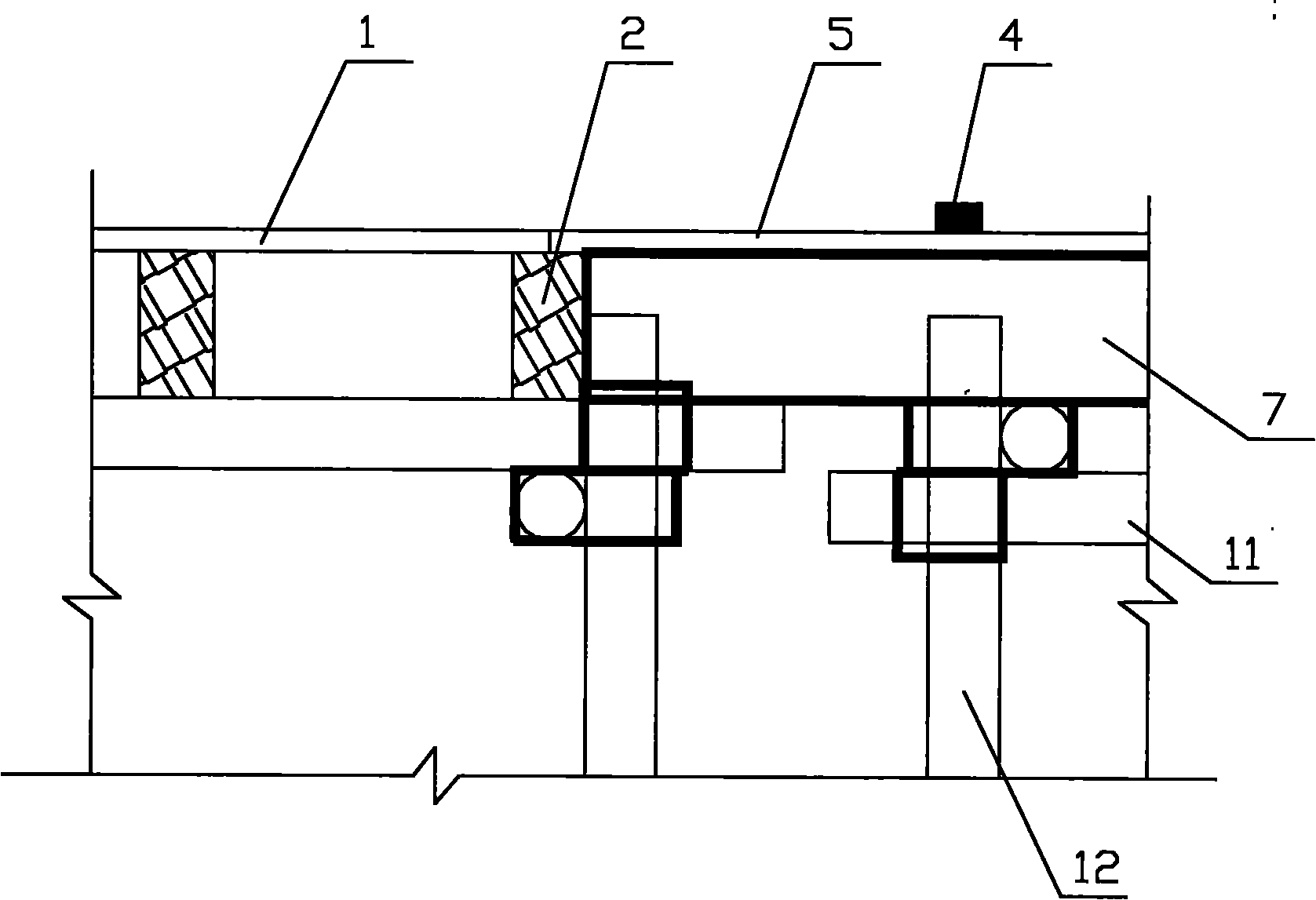

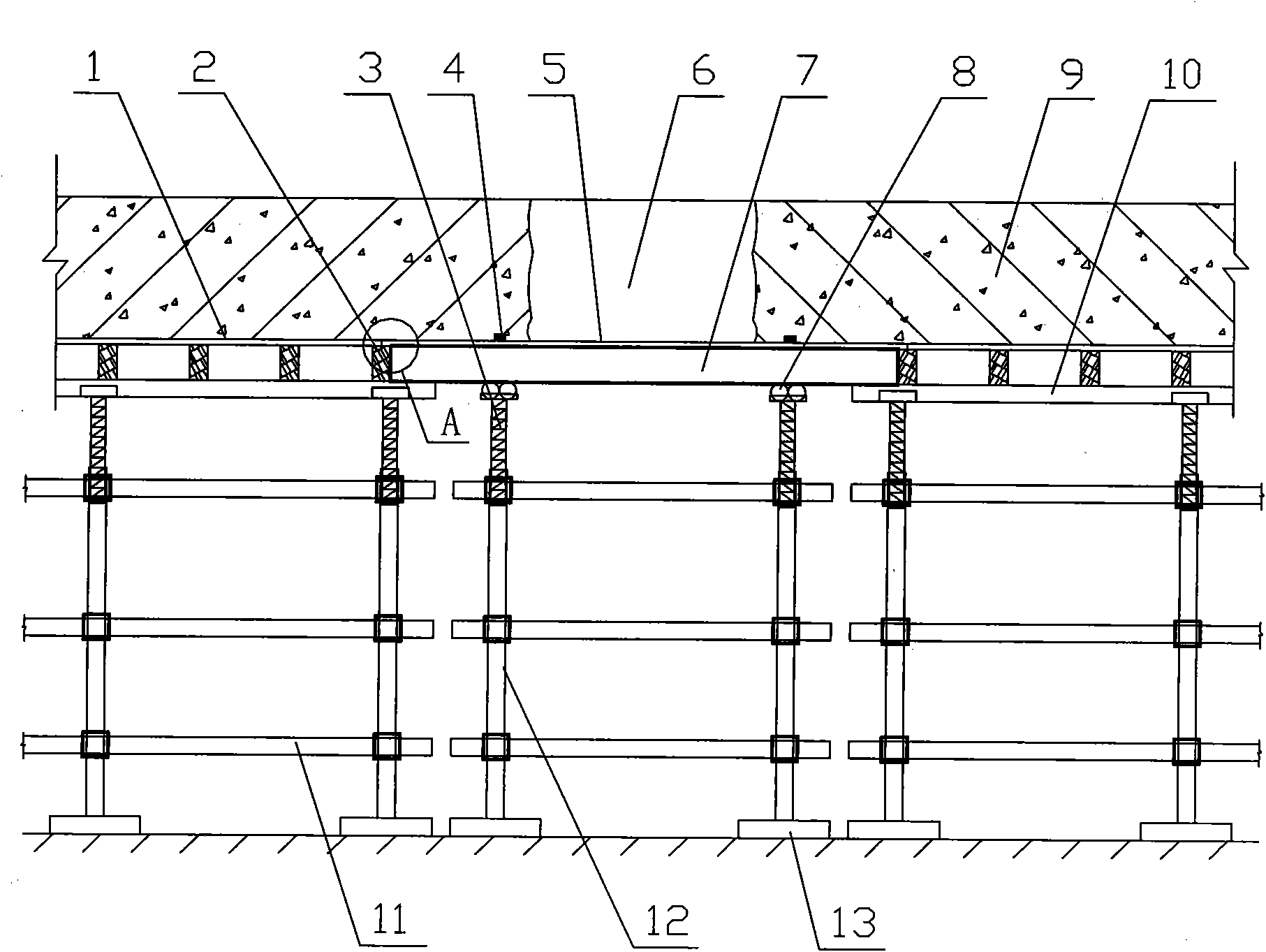

Method for constructing beam plate supporting system having post-cast strip

InactiveCN101871262AEnsure structural safetyEasy to cleanForms/shuttering/falseworksSupporting systemButt joint

The invention discloses a method for constructing a beam plate supporting system having a post-cast strip. The method comprises the following steps: 1) setting up an upright rod and a horizontal rod and forming a supporting bracket, wherein the supporting bracket at the position of the post-cast strip is an independent system, 2) laying a longitudinal secondary keel on the supporting brackets at two sides of the post-cast strip and laying a lateral secondary keel on the supporting bracket at the position of the post-cast strip, and 3) arranging a template at the position of the post-cast strip on the lateral secondary keel, arranging the templates at two sides of the post-cast strip on the longitudinal secondary keel, tightly butt jointing the template at the position of the post-cast strip with the adjacent templates at two sides, and arranging the longitudinal secondary keel under the joint. The post-cast strip of the invention adopts the independent supporting system. After the brackets are arranged, no reconstruction is needed, so the reconstruction for the brackets is avoided and the human labor and materials are saved. The independent supporting system is maintained at the position of the post-cast strip all the time so as to ensure the safety of the post-cast strip.

Owner:ZHONGTIAN CONSTR GROUP

Compact robot vacuum cleaner

ActiveUS20070137153A1Small sizeReduce the overall heightCleaning filter meansCombination devicesAir separationCentrifugal force

A robot cleaner that has a dust collection unit with a cyclone part generating an ascending rotary air current from the dust-laden air being drawn in through a lower part thereof, separating the dust from the air using a centrifugal force, and discharging the dust-separated air to the lower part through a center part, and a collection part surrounding the cyclone part to receive the dust being centrifugally separated.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Shape-memory port-access tube

InactiveUS20060253197A1Promote withdrawalReduce the overall diameterBronchoscopesTracheal tubesEndotracheal intubationEndoscopic surgery

The NaPier tube is a self-expanding port-access tube for insertion into body passages. A NaPier tube is typically used with an endoscope disposed within the lumen of an unactivated tube to enable visual navigation to place the tube in a passage. A NaPier tube comprises a shape-memory element, wall material, and a removable sheath. A tear-away, removable sheath maintains the shape-memory element in a compressed state. Upon placement of the distal end of a NaPier tube in the target location in a passage, the sheath is ruptured and removed through the port and the shape-memory element expands to its memorized geometries. Embodiments of the NaPier tube are adapted by length and memorized dimensions for endotracheal intubation and for port-access procedures, such as endoscopic surgery.

Owner:NAPIER BRADFORD

Apparatus and method for reconstructing a ligament

InactiveUS20050071004A1Promote withdrawalAid removalSuture equipmentsDiagnosticsBone tunnelSurgical site

A graft ligament is looped through a graft hole in a graft ligament support block, and the graft ligament support block is mounted to an installation tool. Then the installation tool is used to advance the graft ligament support block into a bone tunnel, with the two free ends of the looped graft ligament extending back out the bone tunnel. Next, a transverse tunnel is formed in the host bone, with the transverse tunnel being aligned with a transverse fixation pin hole in the graft ligament support block. Then the graft ligament support block is secured in place by pinning the graft ligament support block within the tunnel, i.e., by advancing a transverse fixation pin along the transverse tunnel and into the transverse fixation pin hole in the graft ligament support block. Then the installation tool is detached from the graft ligament support block and withdrawn from the surgical site.

Owner:ENTERPRISES HLDG INC

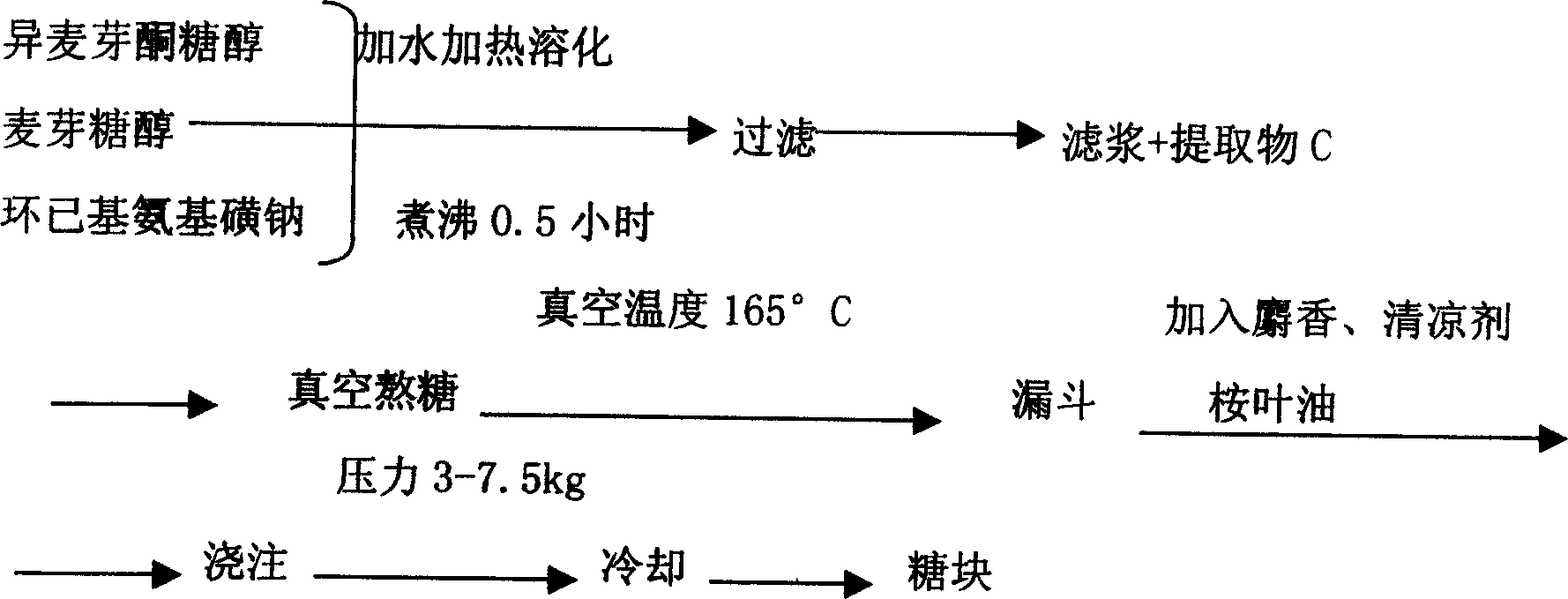

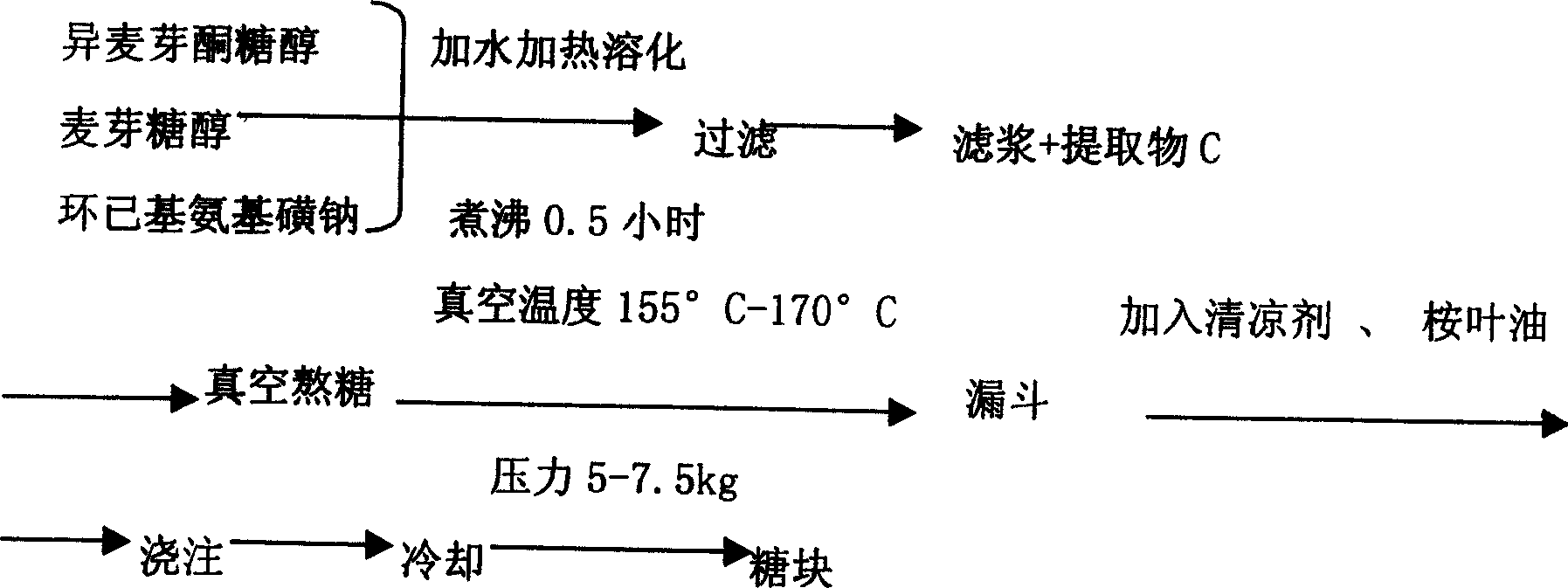

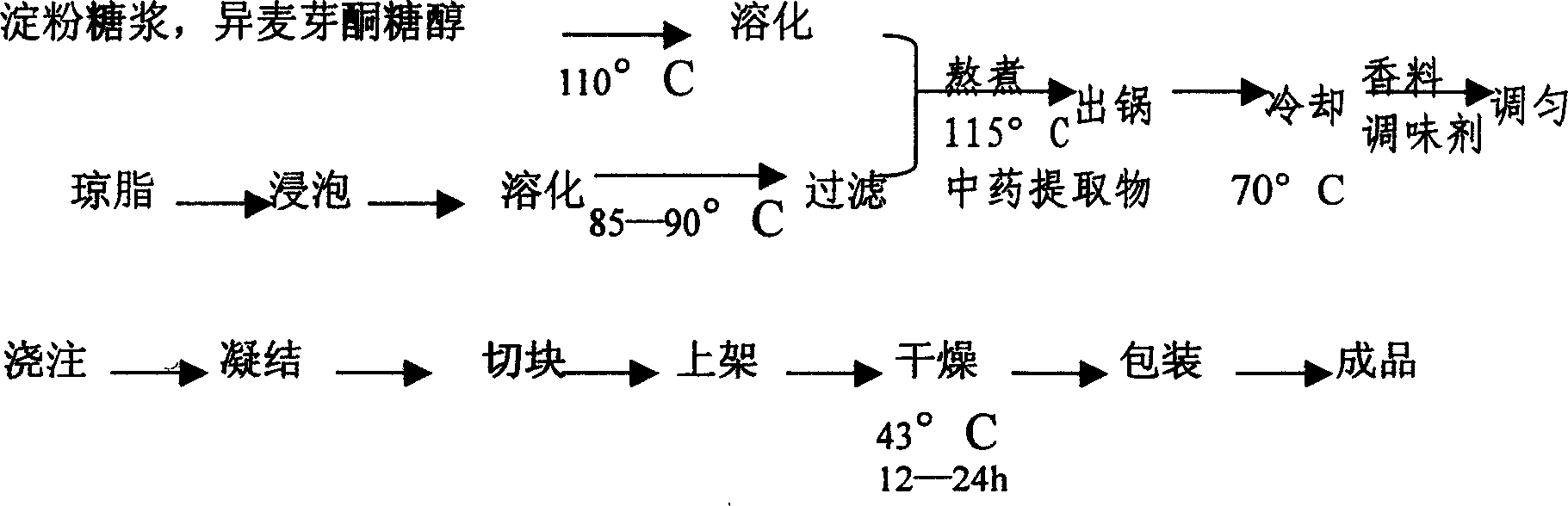

Solid prepn. with functions of clearing and moistening throat, and its prodn. technique

InactiveCN1513381AImprove thermal stabilityPromote withdrawalUnknown materialsRespiratory disorderThroatIsomalt

Owner:JIANGZHONG PHARMA

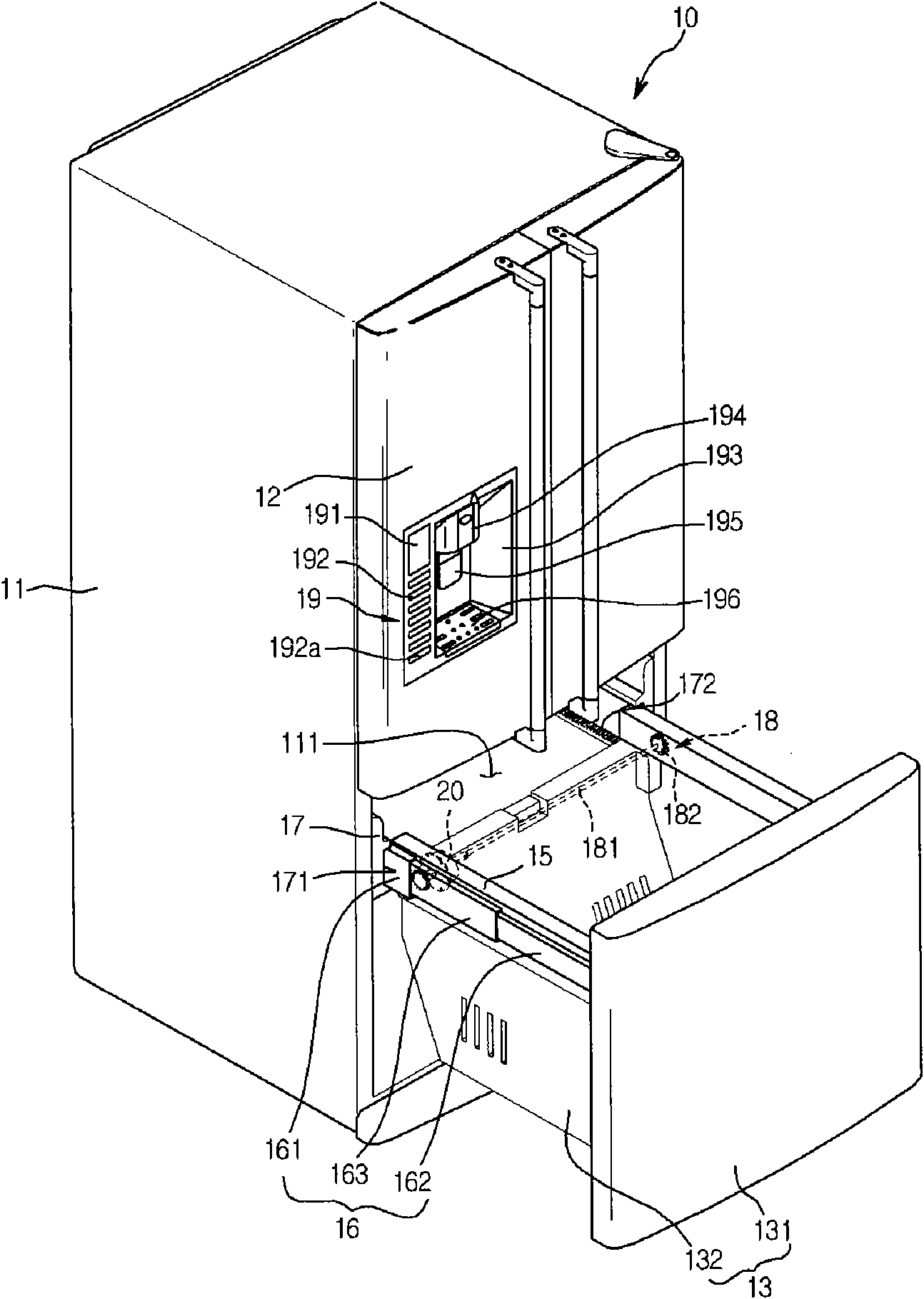

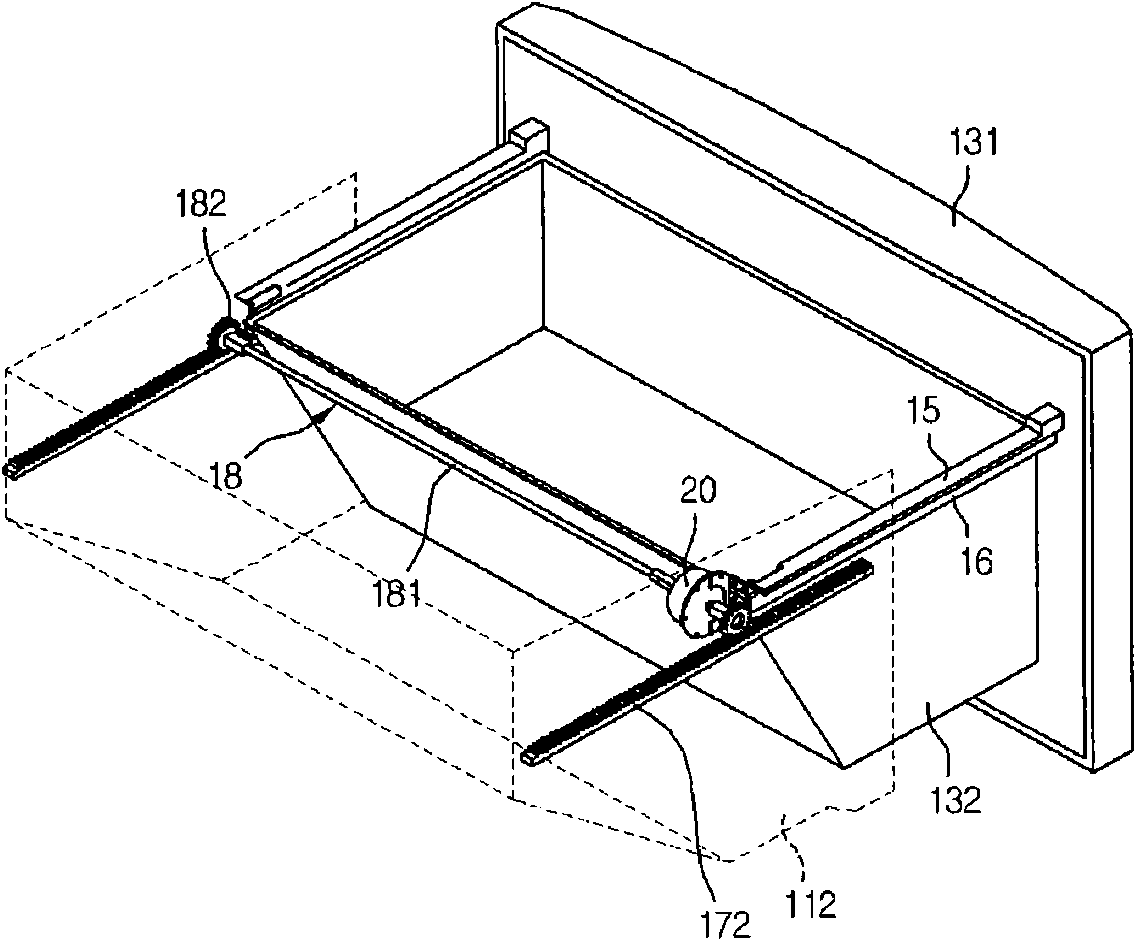

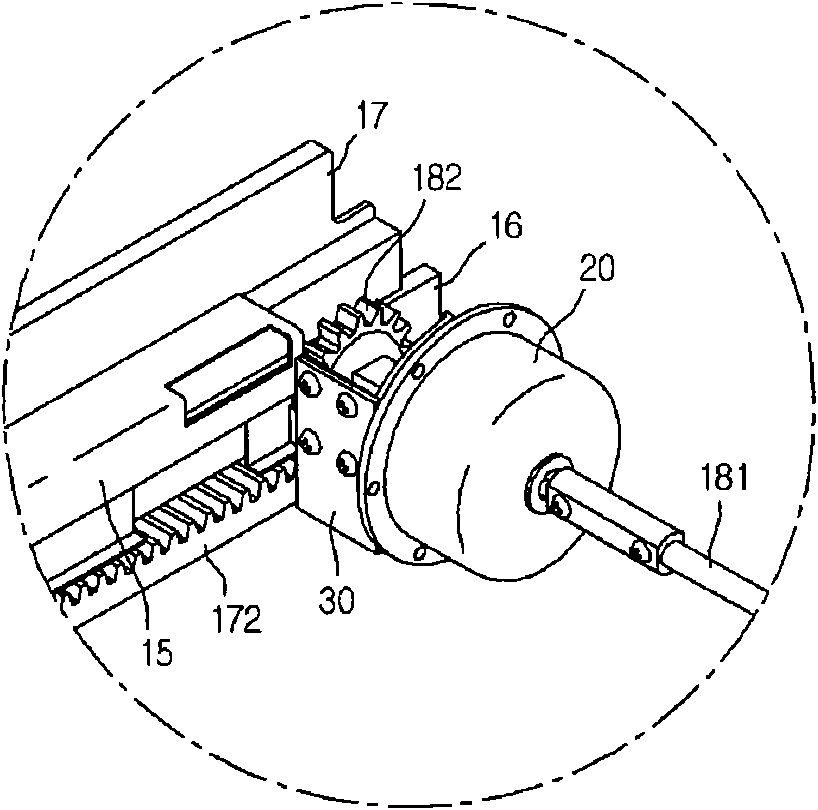

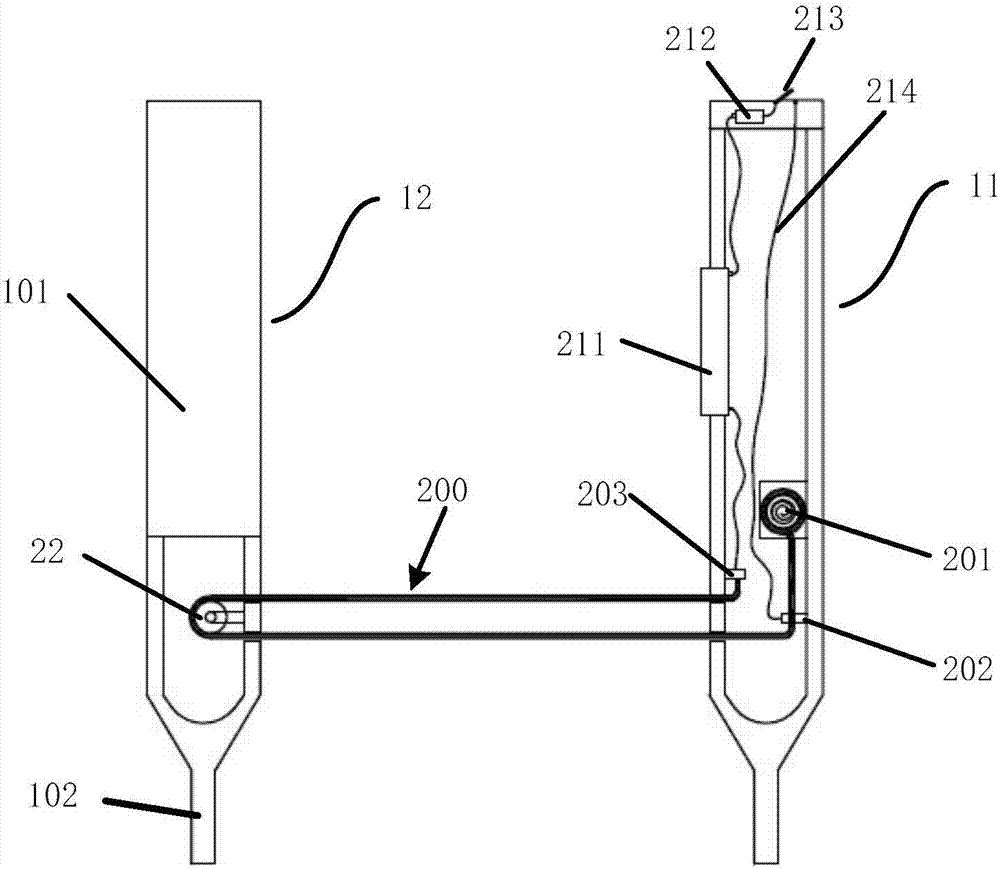

System and method for driving a drawer in a refrigerator

InactiveCN101981396APromote withdrawalImprove ease of useLighting and heating apparatusSupportEngineeringMechanical engineering

The present disclosure relates to a system and method for driving a drawer of a refrigerator. In a system and method for driving a drawer of a refrigerator according to present embodiments, the drawer is always withdrawn or inserted at a preset speed regardless of the weight of food stored inside the storage box, thus increasing reliability of the drawer driving system.

Owner:LG ELECTRONICS INC

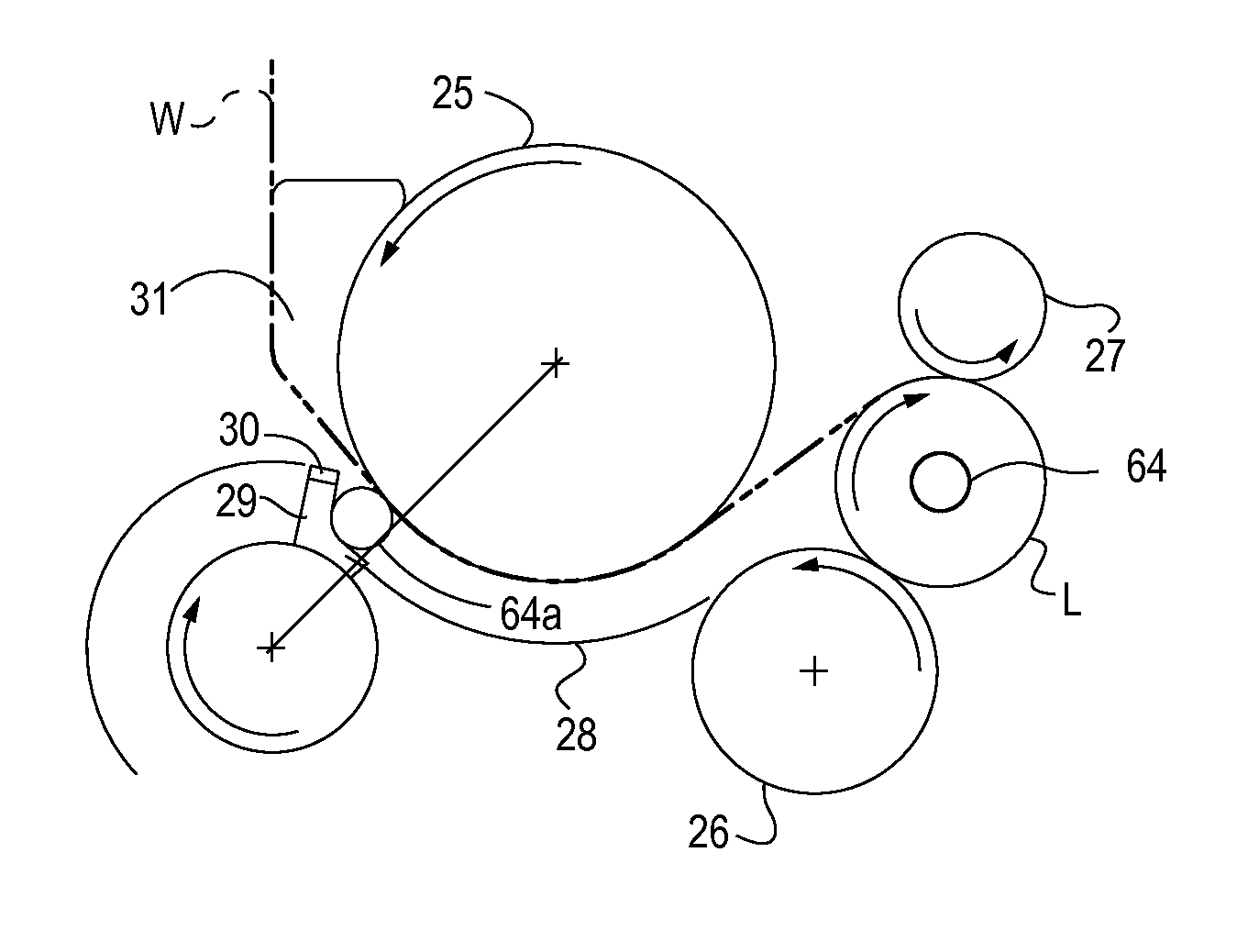

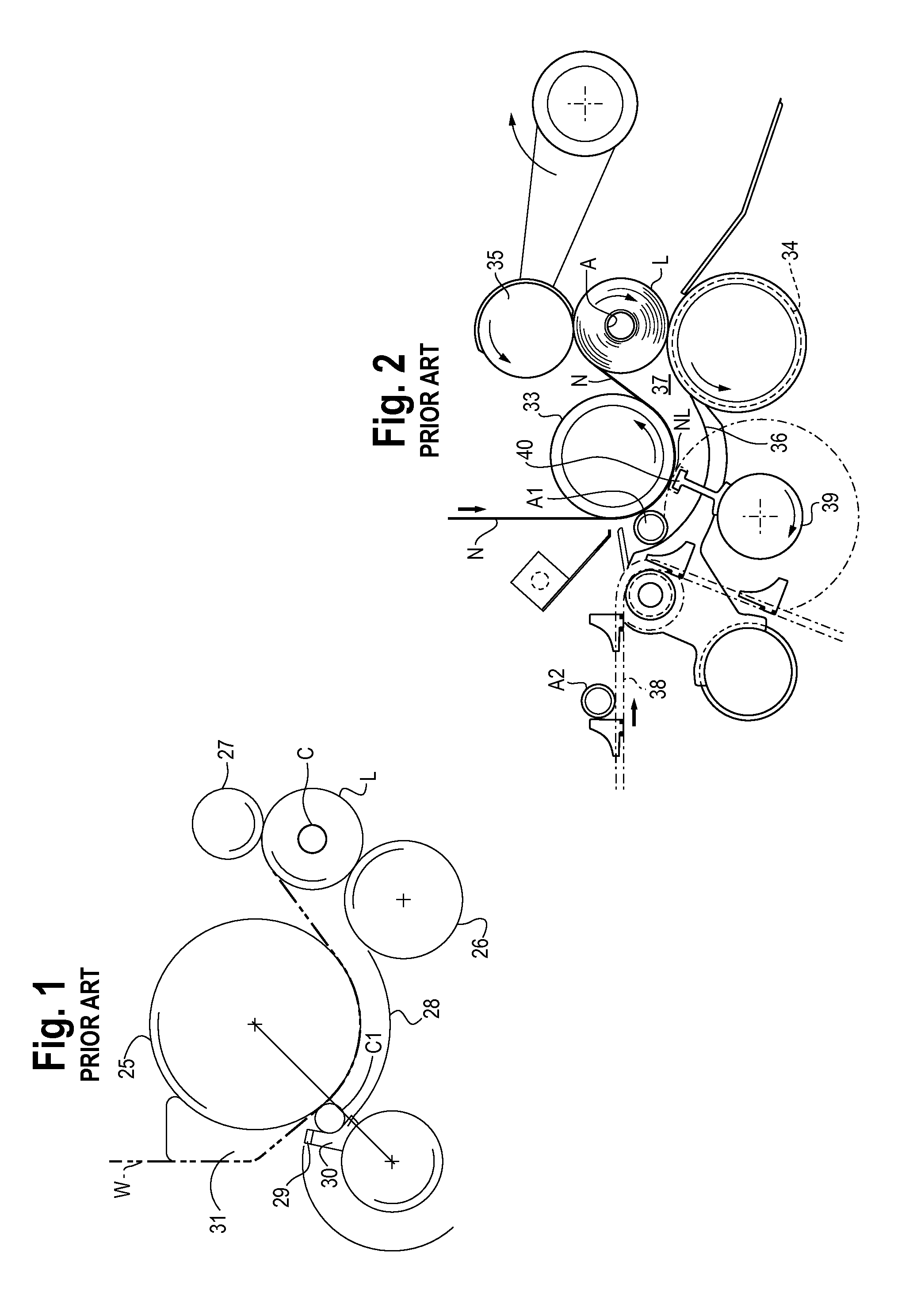

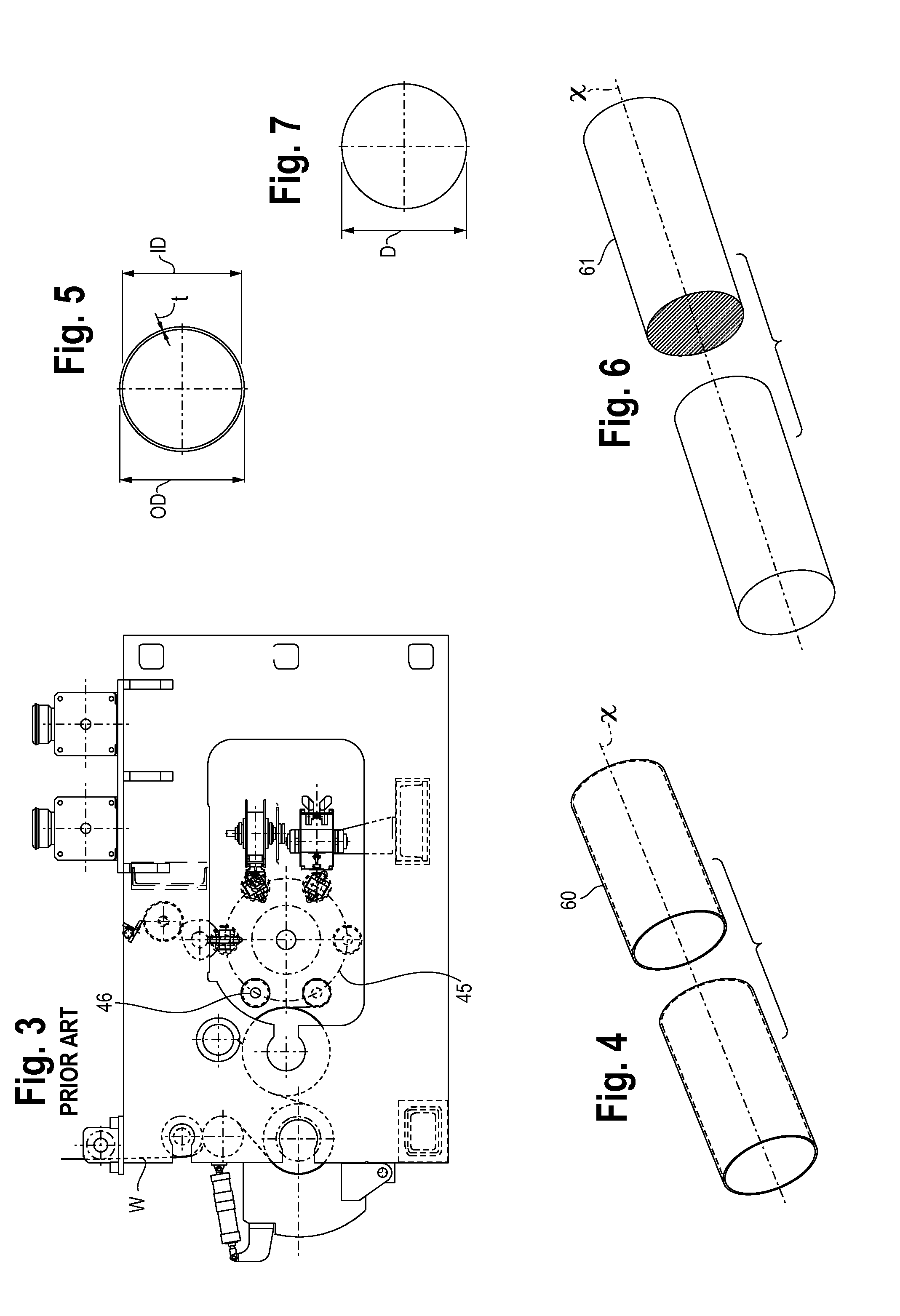

Method and apparatus for producing coreless rolls of paper

ActiveUS20140084102A1Easy and clean mandrel extractionIncrease speedFilament handlingWebs handlingActuatorEngineering

Owner:PAPER CONVERTING MASCH CO INC

Vertebra support ranging device

PendingCN107374752AAvoid measurement errorsEasy to pull outDiagnosticsSurgeryVertebraResistance wire

The invention provides a vertebra support ranging device which comprises probing rods and a resistance wire. Each probing rod comprises a rod body and a probe, wherein the rod bodies are prepared from an insulation material, and the resistance wire and the probes are separated by the rod bodies. The probing rods comprise the first probing rod and the second probing rod. The resistance wire is arranged between the first probing rod and the second probing rod in a penetrating mode. By means of the principle of a slide rheostat, the distance between vertebra supports is measured; meanwhile, by means of an electronic display screen, the distance value can be directly read easily and conveniently.

Owner:SECOND AFFILIATED HOSPITAL SECOND MILITARY MEDICAL UNIV

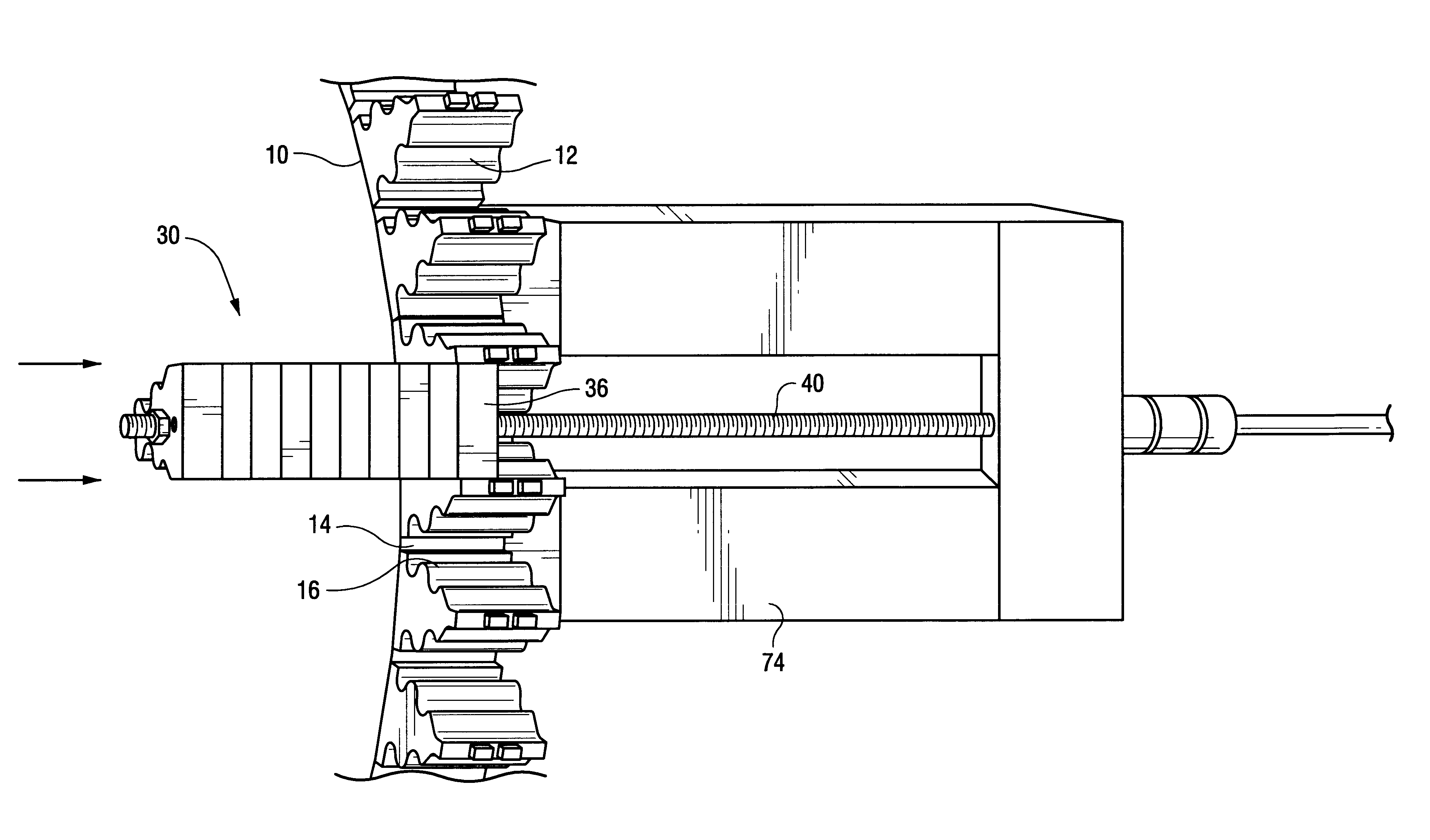

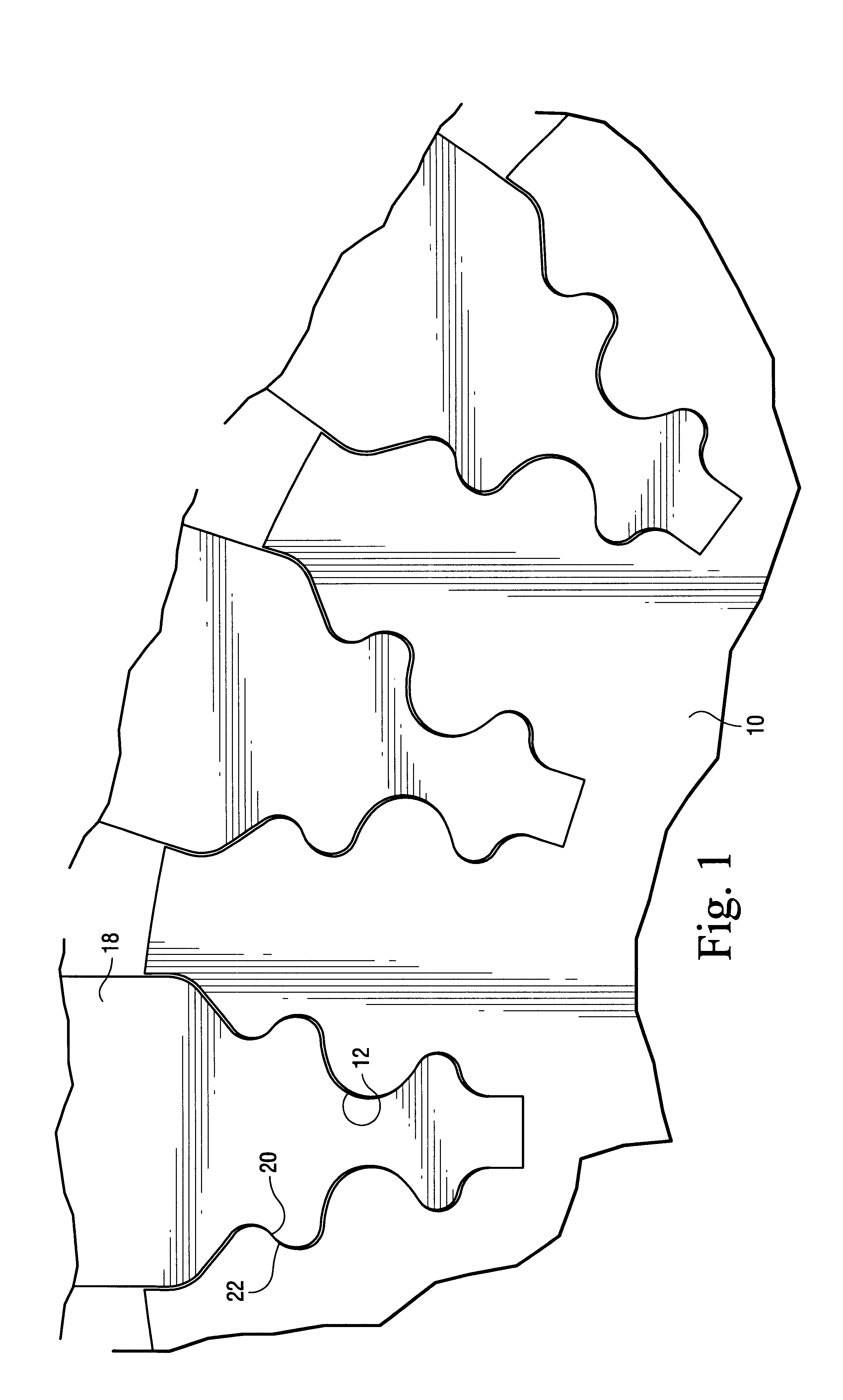

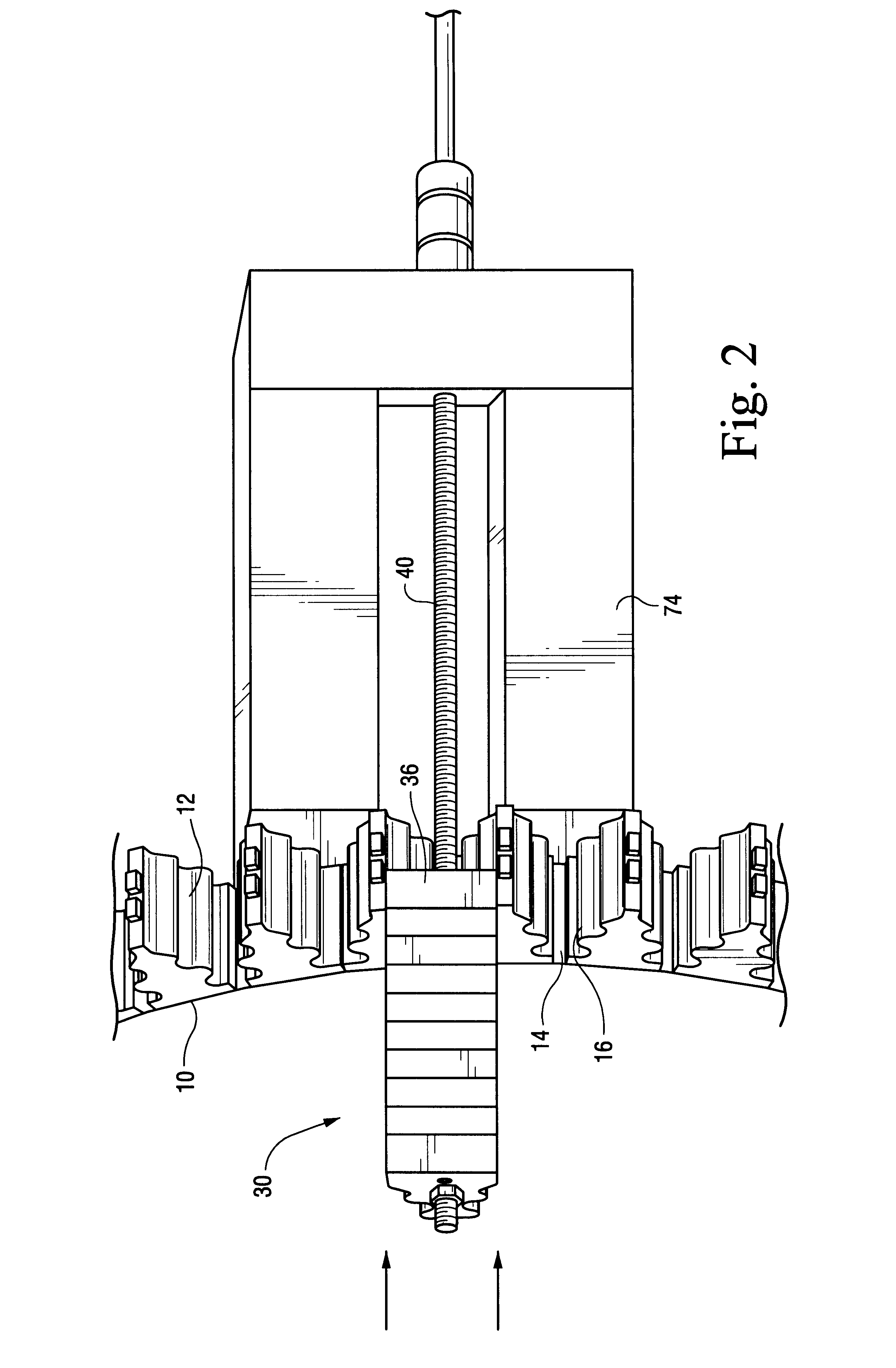

Multi-part dovetail repair broach assembly and methods of use

InactiveUS6676336B2Easy to importInexpensive to fabricateRectilinear broachBroaching toolsImpellerTurbine wheel

The broach assembly includes alternate spacers and cutters arranged in a sub-assembly having a lead at a leading end and a lag at a trailing end. The cutters have side margins in excess of the margins of the spacers for cutting material from the dovetail slots of the turbine wheel as the broach assembly passes through the slots. The bottom or apices of each spacer and cutter are tapered to form a continuously tapered surface along the bottom of the broach assembly. Upon passing the broach assembly through the slot, the assembly is progressively displaced in a radial outward direction to progressively cut the active dovetail slot surfaces. Shims may be disposed in the bottom of the slot to further displace the broach assembly radially outwardly in multiple passes.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com