Aqueous polyurethane superfine fiber synthetic leather and preparation method thereof

A water-based polyurethane and microfiber technology, applied in fiber types, fiber treatment, textiles and papermaking, etc., to achieve the effects of reducing investment, eliminating solvent waste, reducing cost and energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

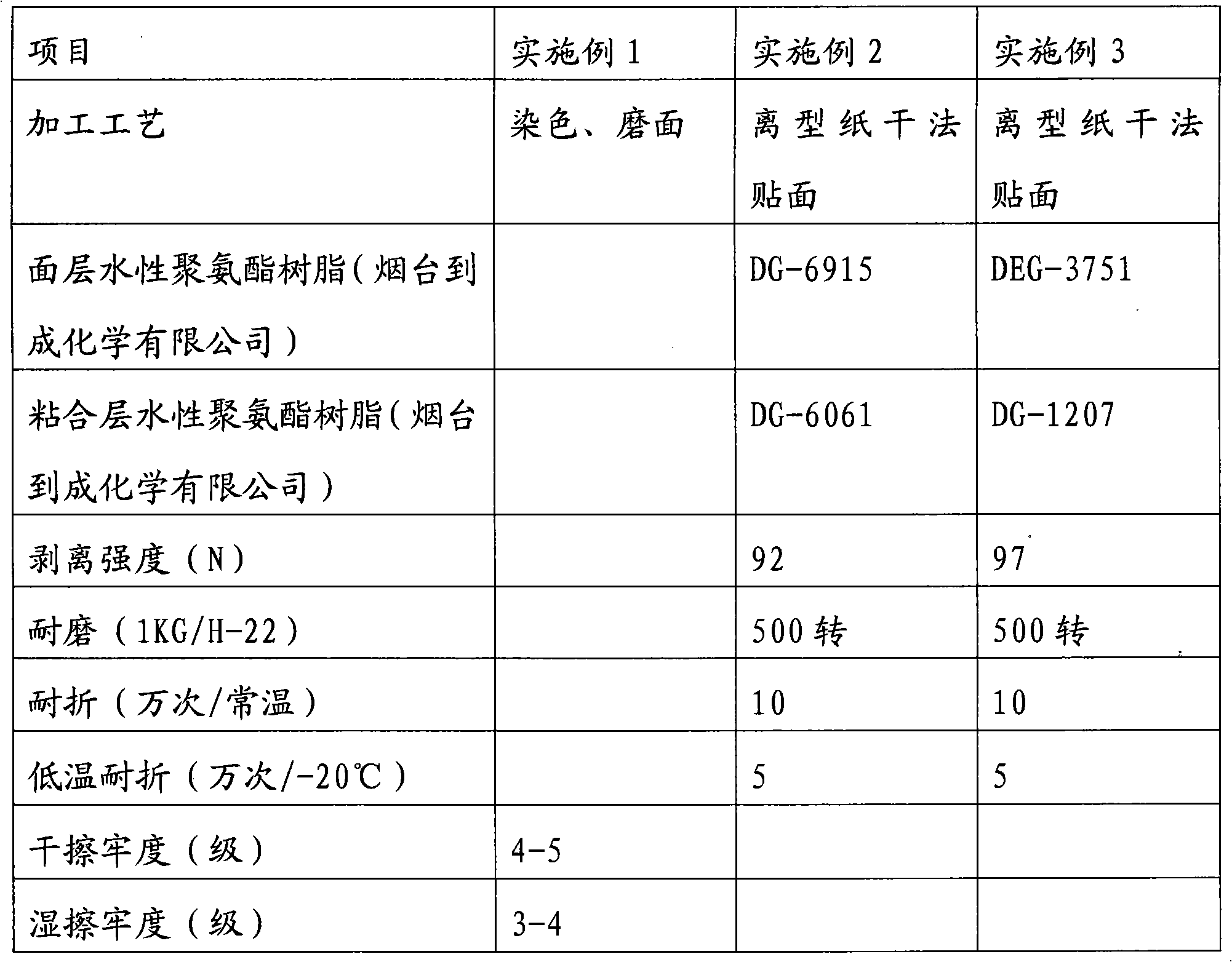

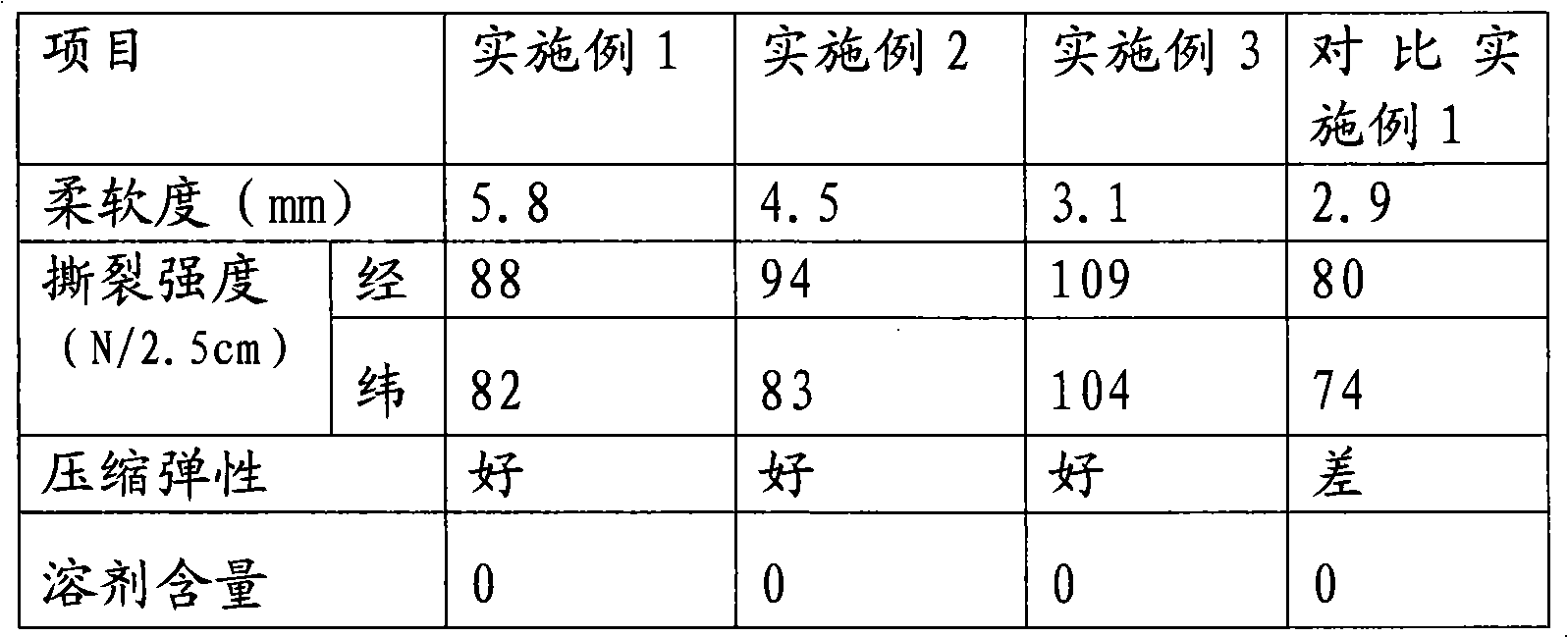

Embodiment 1

[0035] PA / COPET type fixed island non-woven fabric, its unit weight is 240g / m 2 , its apparent density is 0.30g / m 3 ; 100 parts of water-based polyurethane slurry, the water-based polyurethane slurry is DG-3020, and its dry film 100% modulus is 20KG / cm 2 , solid content 20% by weight, its viscosity is 6Pa.s, 3 parts of sodium dodecylbenzenesulfonate, 2 parts of stearic acid amine and 50 parts of water, stir with high-speed mixer, make the density of mixed slurry be 300g / L; impregnate the non-woven fabric with the mixed slurry in the impregnation tank, the impregnation amount is 400-550g / m 2 , to keep 30-60% of the cells; then in the coagulation tank, the pH value is 5, and the temperature is 20 ℃ aqueous coagulation liquid coagulation, washed in the water washing tank, and dried in an infrared drying oven to obtain the base cloth; and then The dried base fabric is subjected to an alkali weight reduction process in a continuous or batch type alkali weight reduction machine. ...

Embodiment 2

[0038] PA / COPET type fixed island non-woven fabric, its unit weight is 300g / m 2 , its apparent density is 0.33g / m 3 ; 100 parts of water-based polyurethane slurry, the water-based polyurethane slurry is DG-3050, and its dry film 100% modulus is 50KG / cm 2 , the solid content is 25% by weight, and its viscosity is 10Pa.s, 5 parts of sulfonated ammonium succinate foaming agents, 3 parts of foam stabilizer stearic acid amines and 100 parts of water, and the high-speed mixer stirs evenly to make the mixed slurry The density is 500g / L; in the impregnation tank, impregnate the non-woven fabric with the mixed slurry, and the impregnation amount is 600-660g / m 2, to keep 30-60% of the cells; then in the coagulation tank, the pH value is 4, the temperature is 25 ℃ water-based coagulation liquid coagulation, washed in the water washing tank, and dried in an infrared drying oven to obtain the base cloth; and then The dried base fabric is subjected to an alkali reduction process in a cont...

Embodiment 3

[0041] PA / COPET type fixed island non-woven fabric, its unit weight is 400g / m 2 , its apparent density is 0.35 / m 3 ; 100 parts of water-based polyurethane slurry, the dry film of DG-3100 slurry 100% tensile strength is 100KG / cm 2 , solid content is 30% by weight, and its viscosity is 16Pa.s, adds 4 parts of foaming agents of sodium sulfosuccinate, 2 parts of foam stabilizer ammonium stearates, 150 parts of water and 3 parts of water-based colorants (Shanghai Si Lianhei G-55), stir evenly with a high-speed mixer, so that the density of the mixed slurry is 550g / L; impregnate the non-woven fabric with the mixed slurry, and the impregnation amount is 950-1000g / m 2 , and then in the coagulation tank, the pH value is 3, and the temperature is 30 ° C. The water-based coagulation liquid is solidified, washed in the water washing tank, and dried in an infrared drying oven to obtain a base cloth; then the dried base cloth is continuously or intermittently Alkali reduction process in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com