Static mixer for mixing urea aqueous solution and engine exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

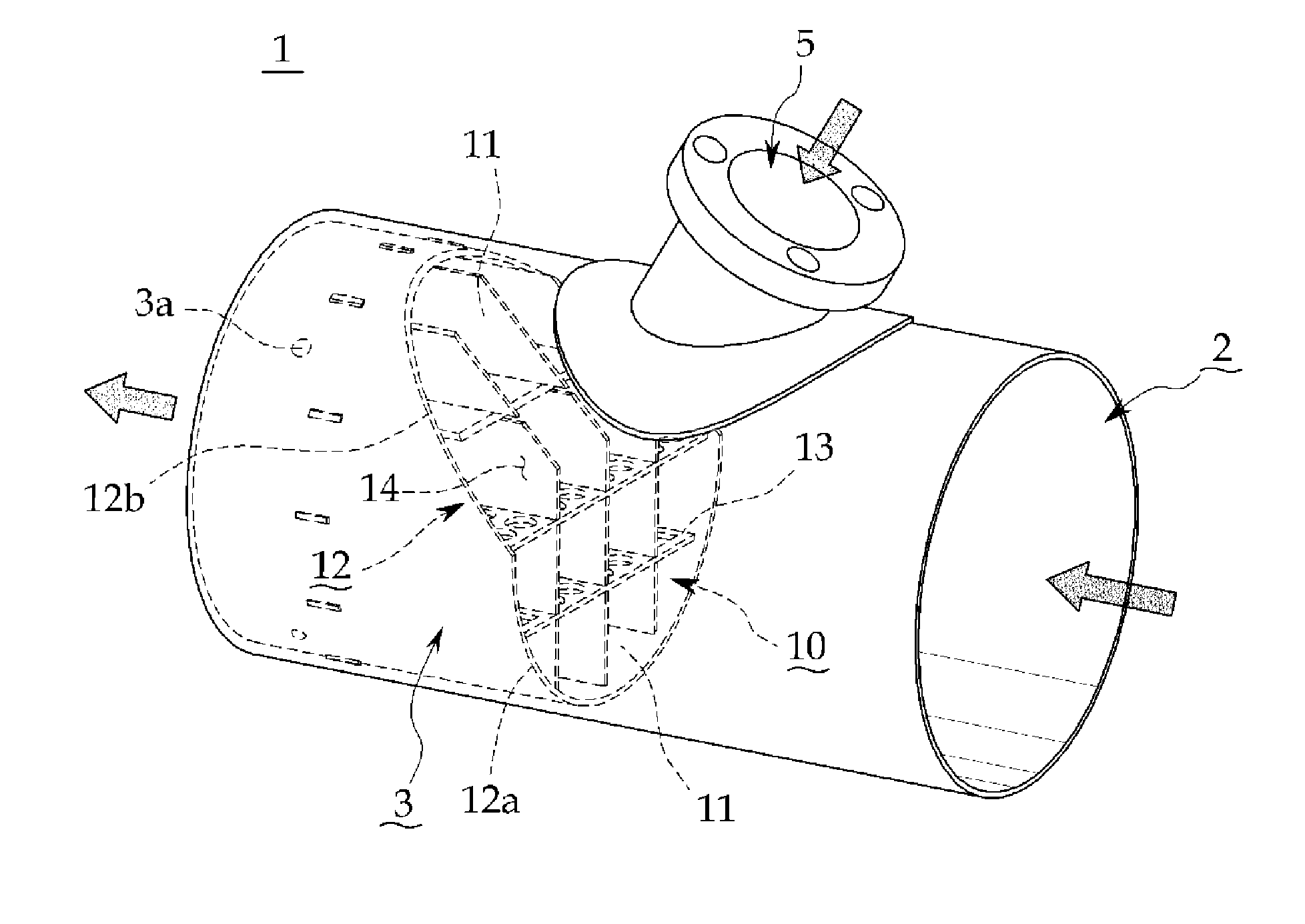

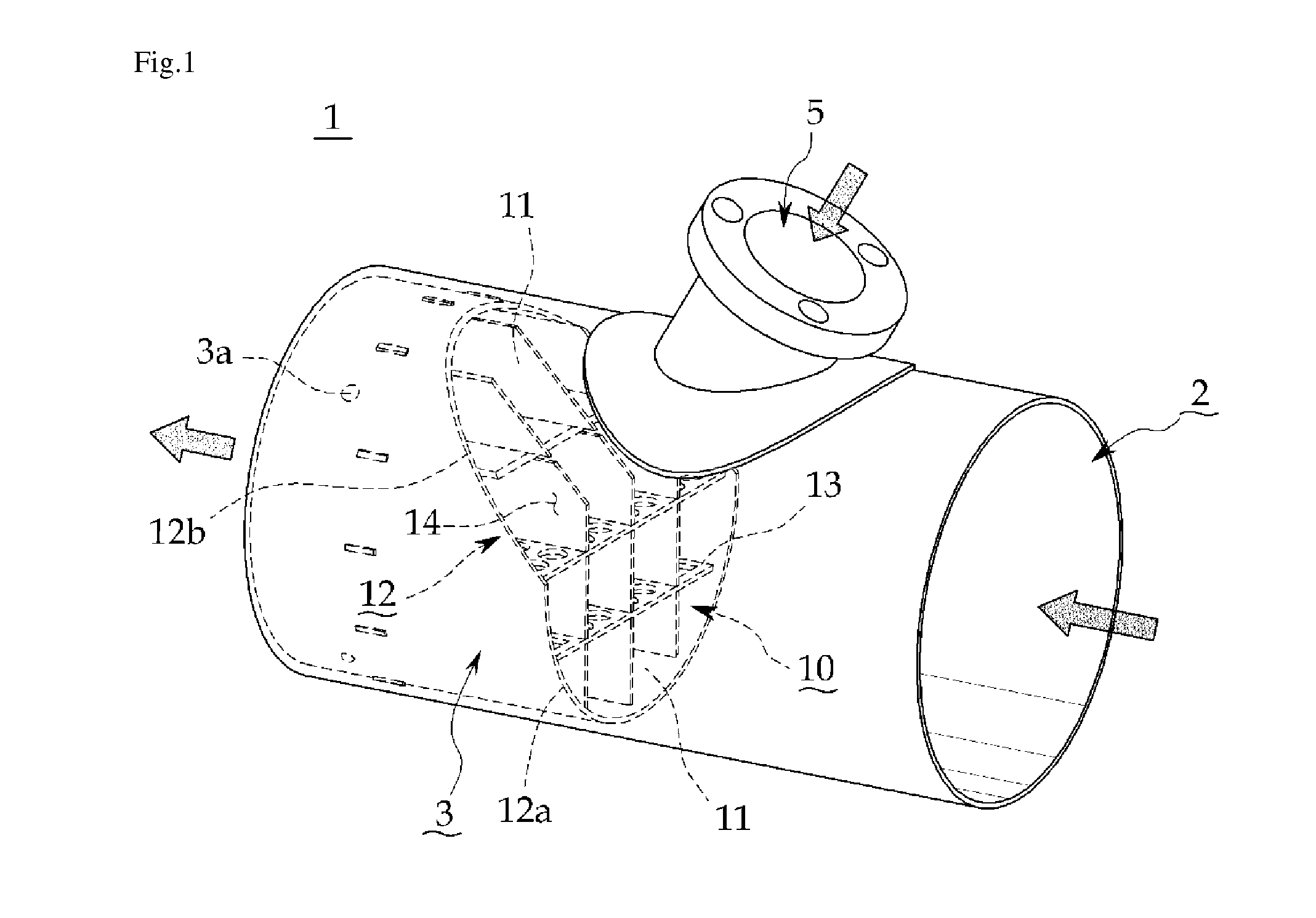

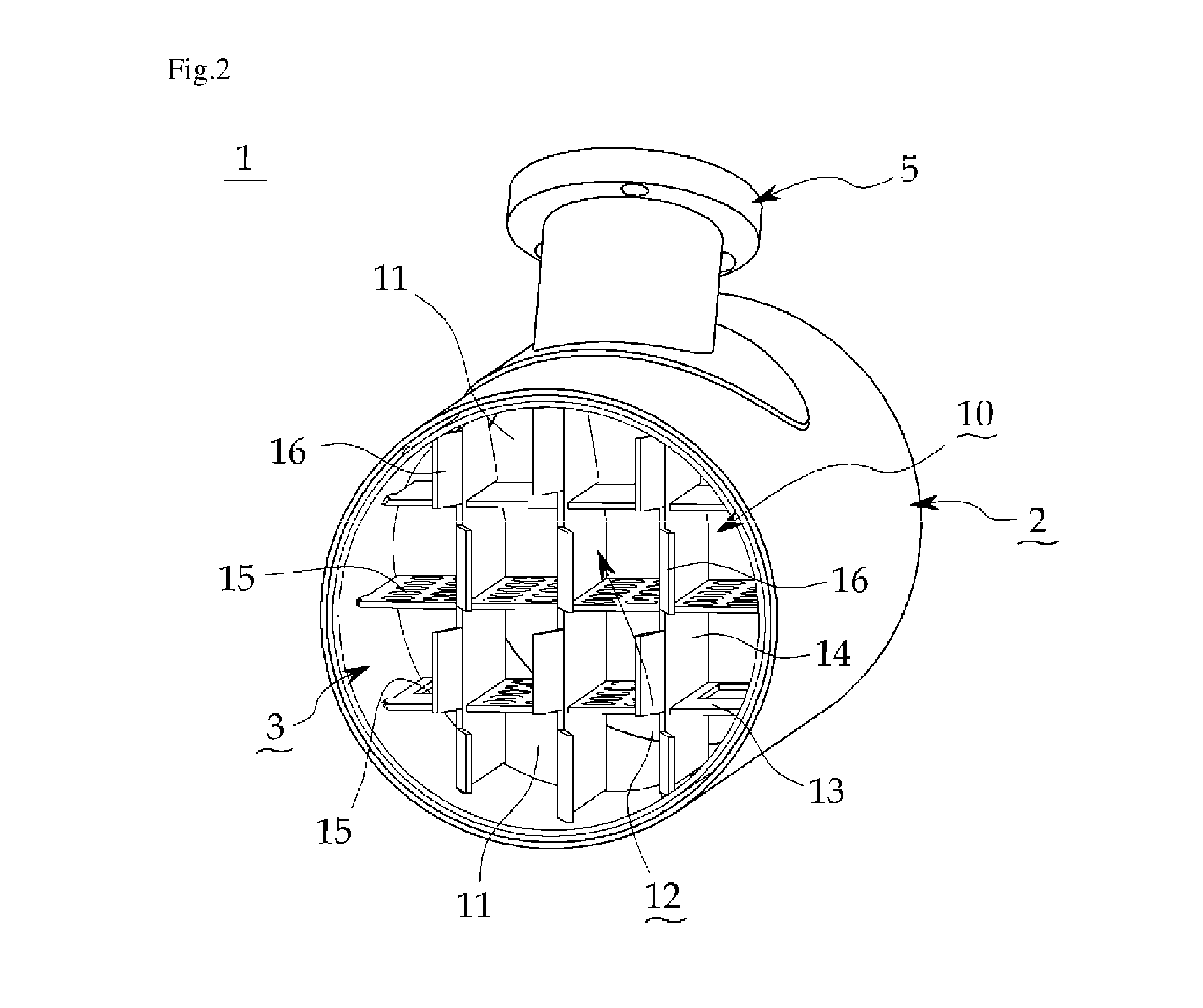

[0034]Hereinafter, an exemplary embodiment of a static mixer for mixing a urea solution and engine exhaust gas according to the present disclosure will be described with reference to FIGS. 1 to 4.

[0035]First, a term “static mixer” is an expression widely used in a corresponding business field and is a counterpart concept to a dynamic mixer, and means a mixer (or a mixing device) for finely and evenly mixing exhaust gas and a urea solution without a dynamic motion.

[0036]Further, in a description of the present disclosure, two terms of “a plurality of” and “multiple” are discriminatingly used. The term of “a plurality of” is used so as to emphasize a case in which a technical meaning is significant when the number of corresponding constituent elements is two or more, and the term of “multiple” is used so as to represent a case in which there are simply a lot of corresponding constituent elements.

[0037]The static mixer 1 of the present disclosure includes, as illustrated in FIGS. 1 to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com