Patents

Literature

9951results about "Exhaust treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyzed SCR filter and emission treatment system

ActiveUS7229597B2Reduce the temperaturePromote regenerationCombination devicesLiquid degasification with auxillary substancesNitrogen oxideSoot

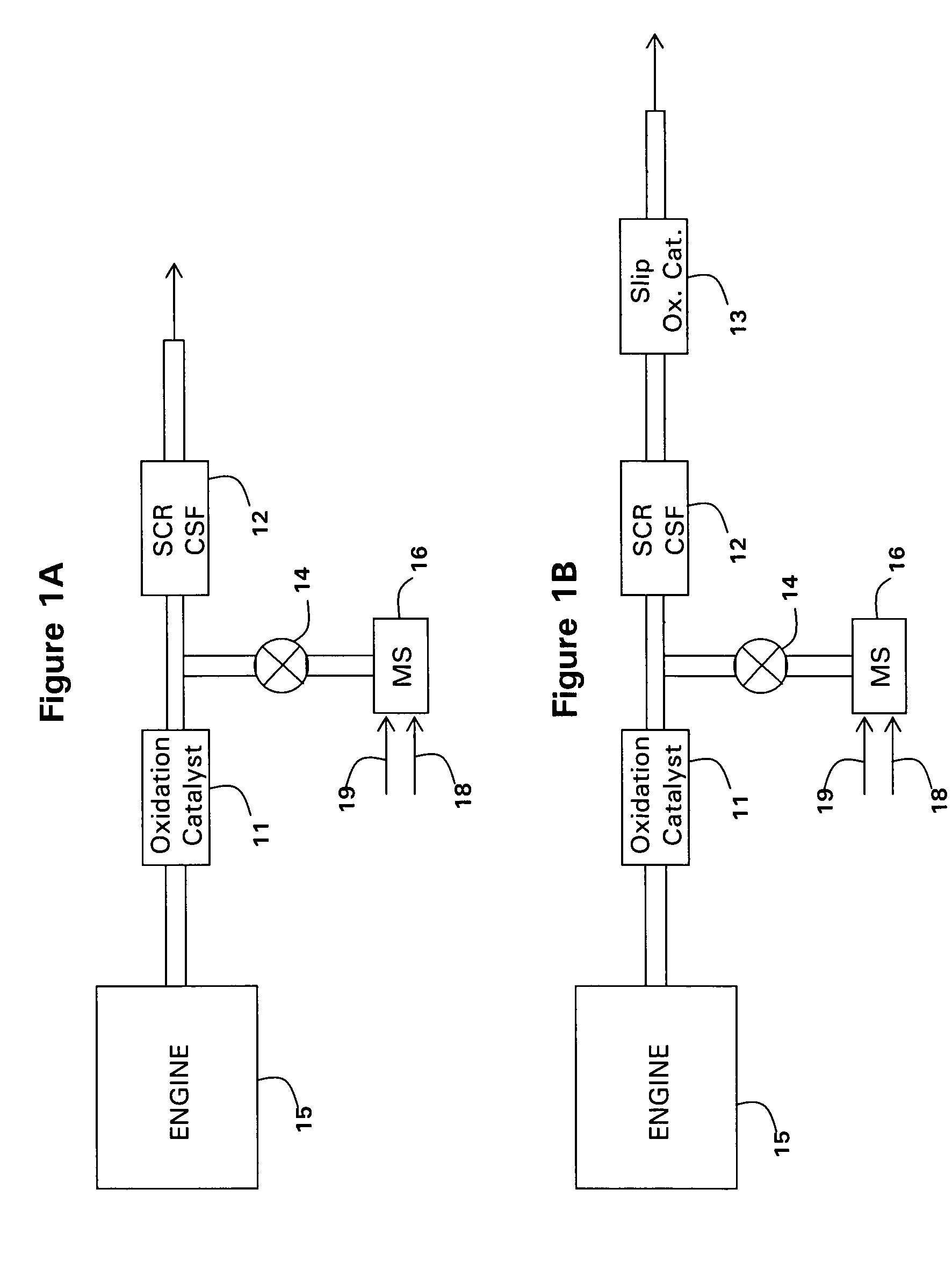

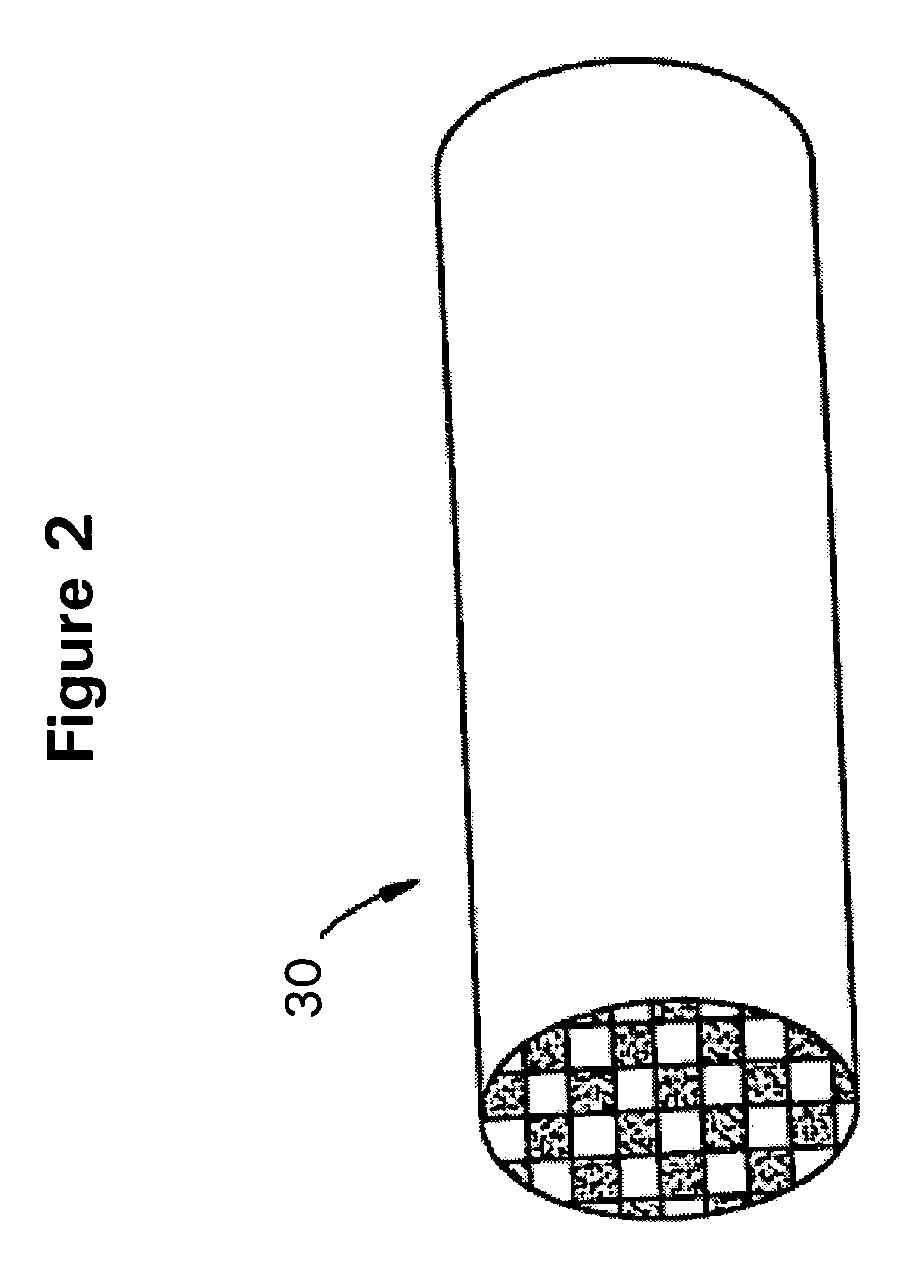

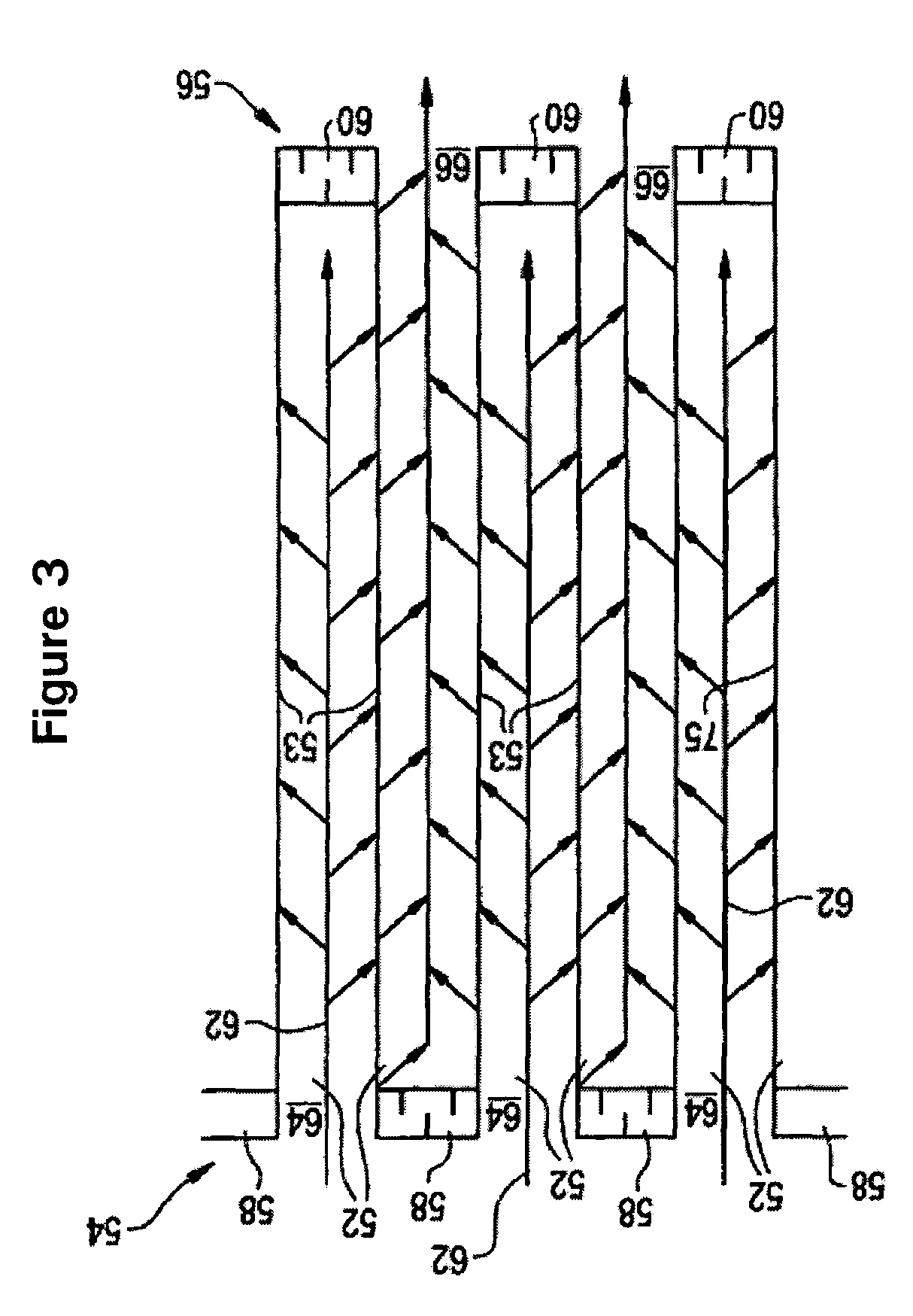

Provided is an emission treatment system and method for simultaneously remediating the nitrogen oxides (NOx), particulate matter, and gaseous hydrocarbons present in diesel engine exhaust streams. The emission treatment system has an oxidation catalyst upstream of a soot filter coated with a material effective in the Selective Catalytic Reduction (SCR) of NOx by a reductant, e.g., ammonia. Also provided is a method for disposing an SCR catalyst composition on a wall flow monolith that provides adequate catalyst loading, but does not result in unsuitable back pressures in the exhaust.

Owner:BASF CORP

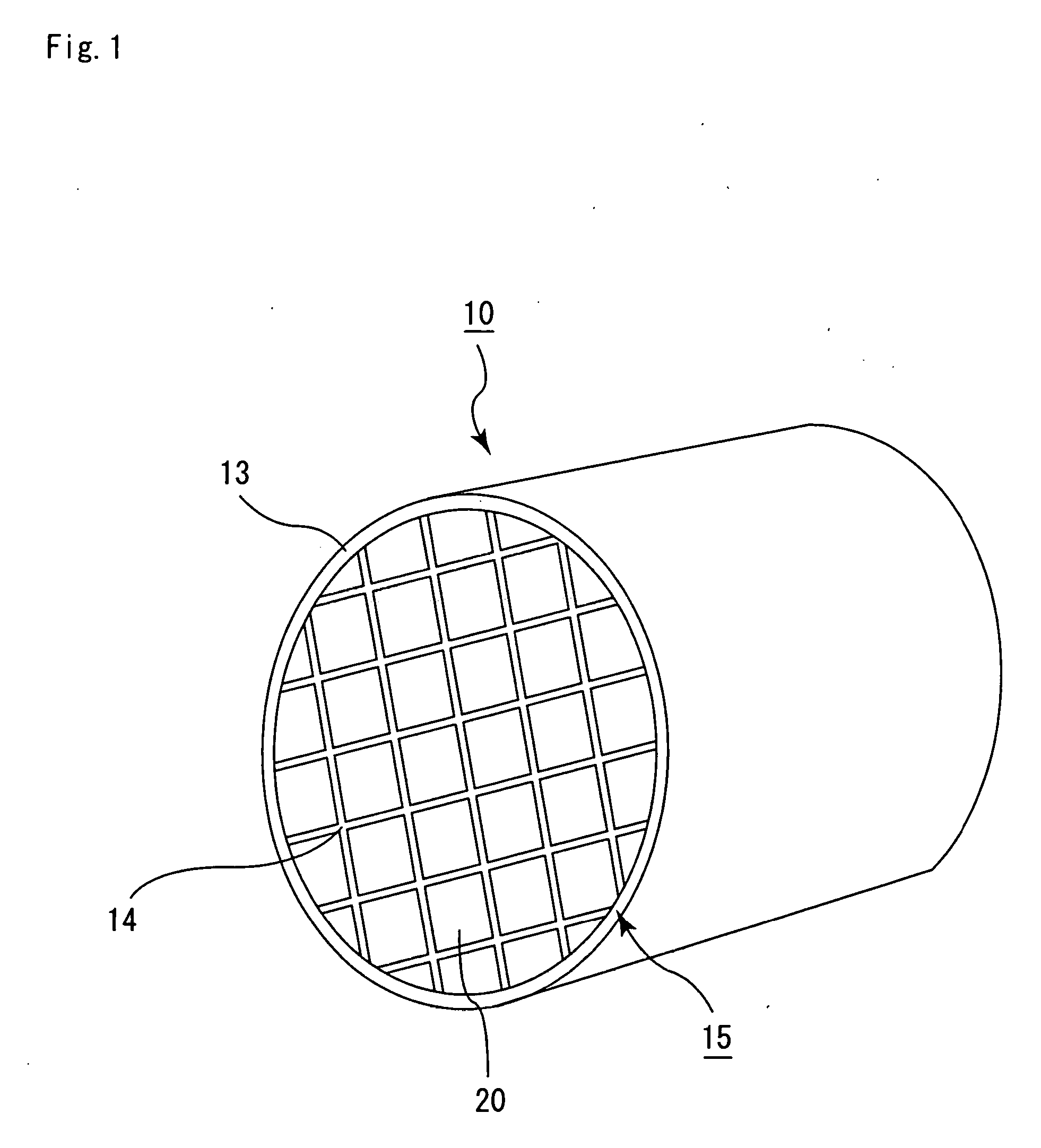

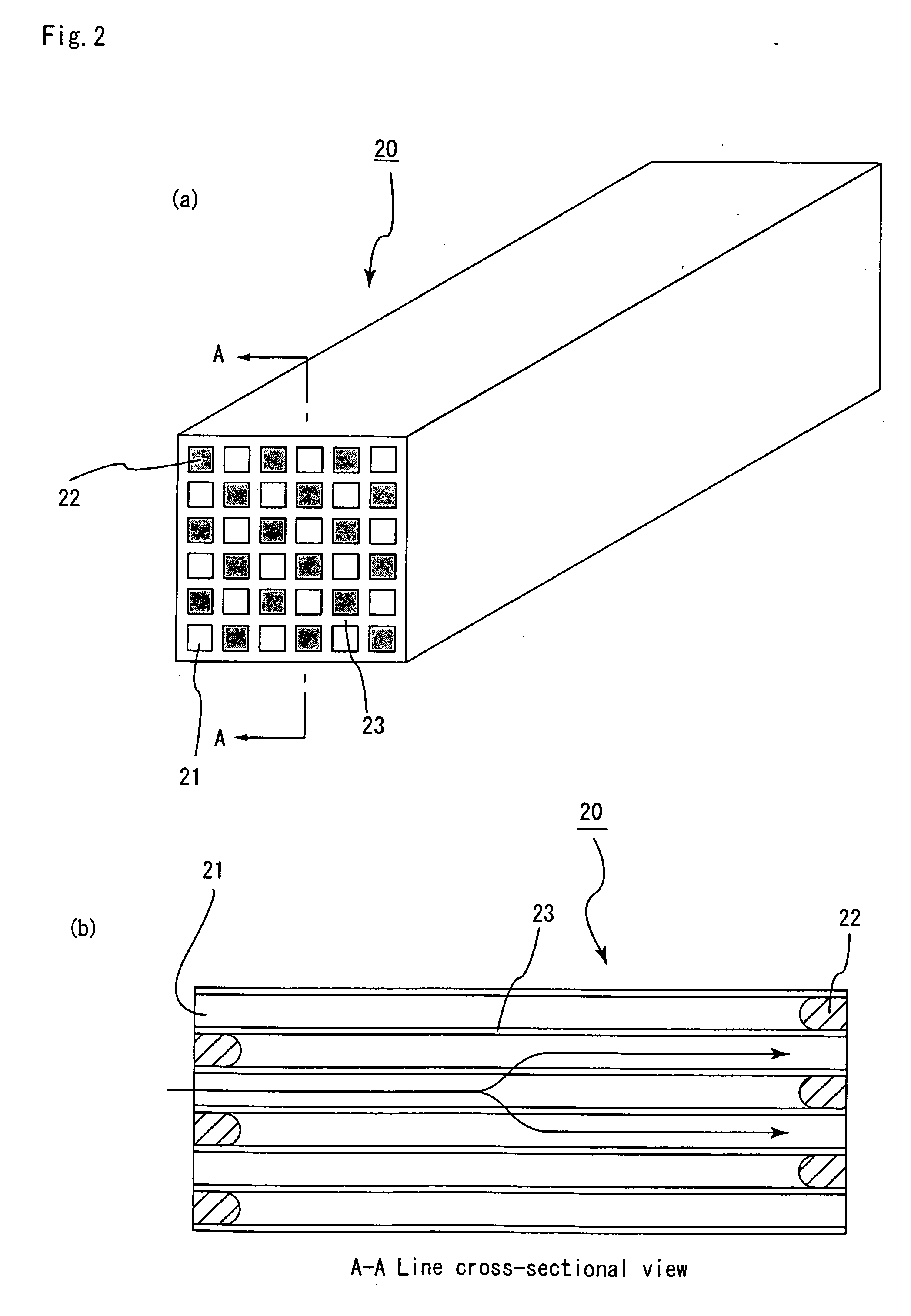

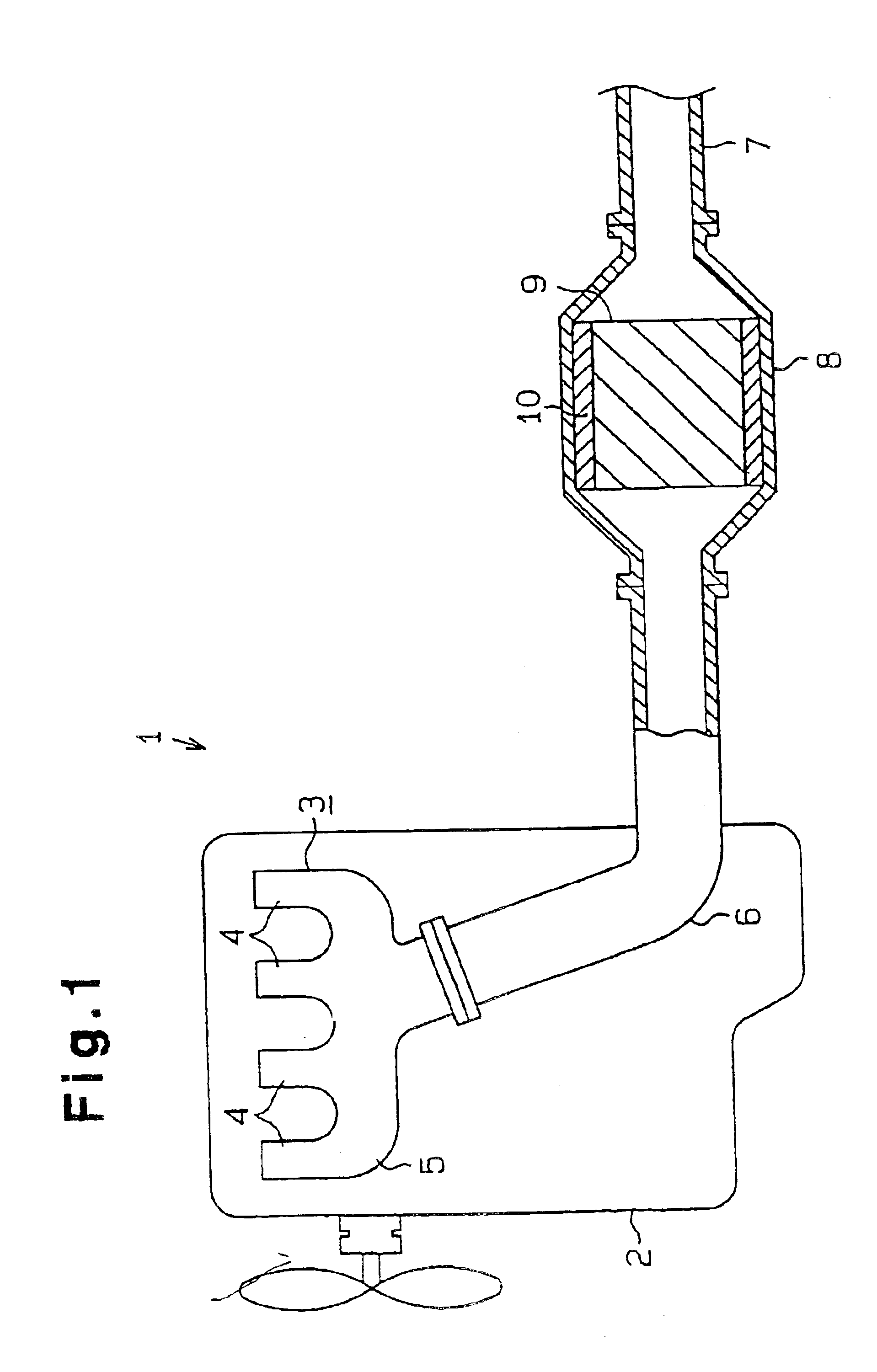

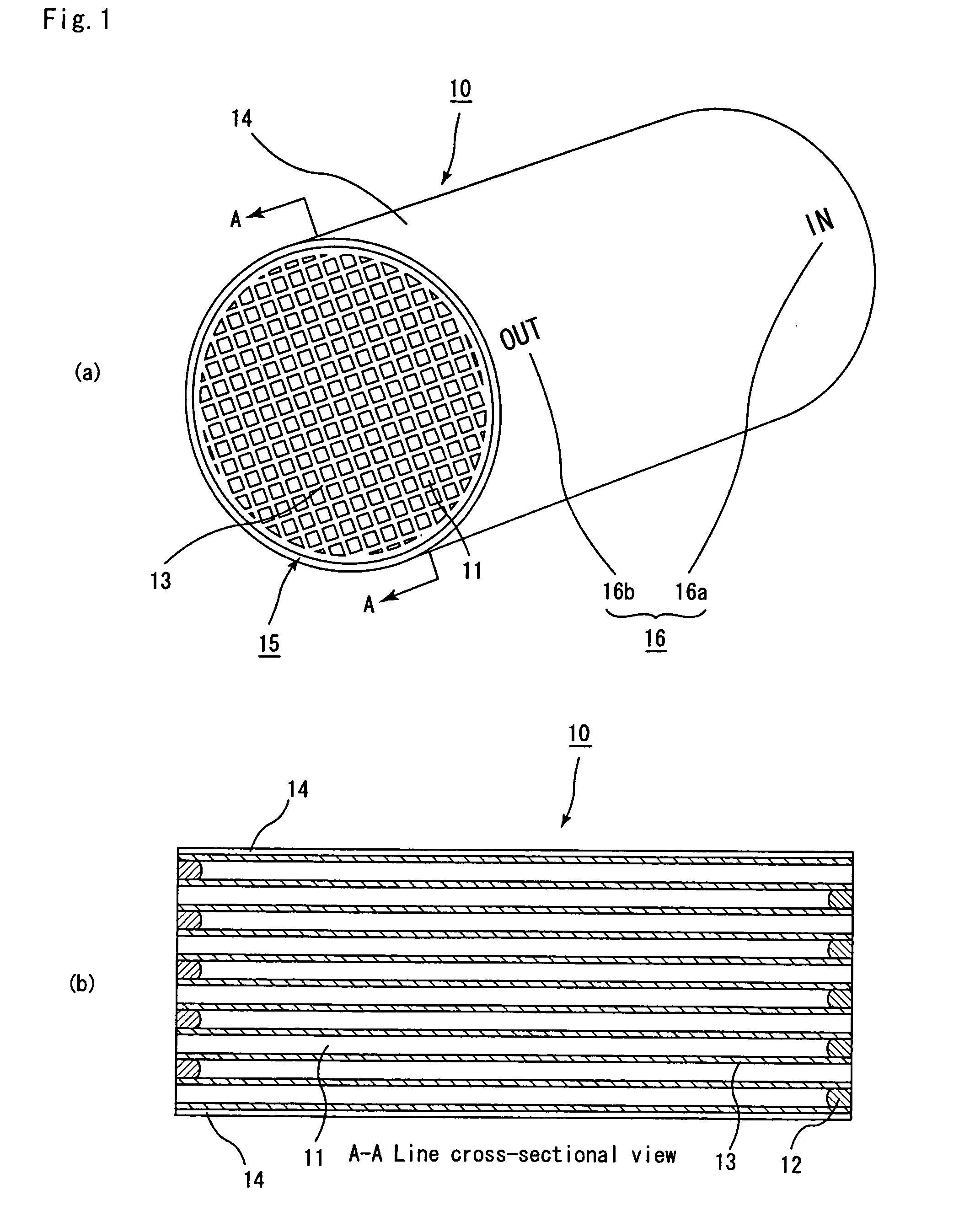

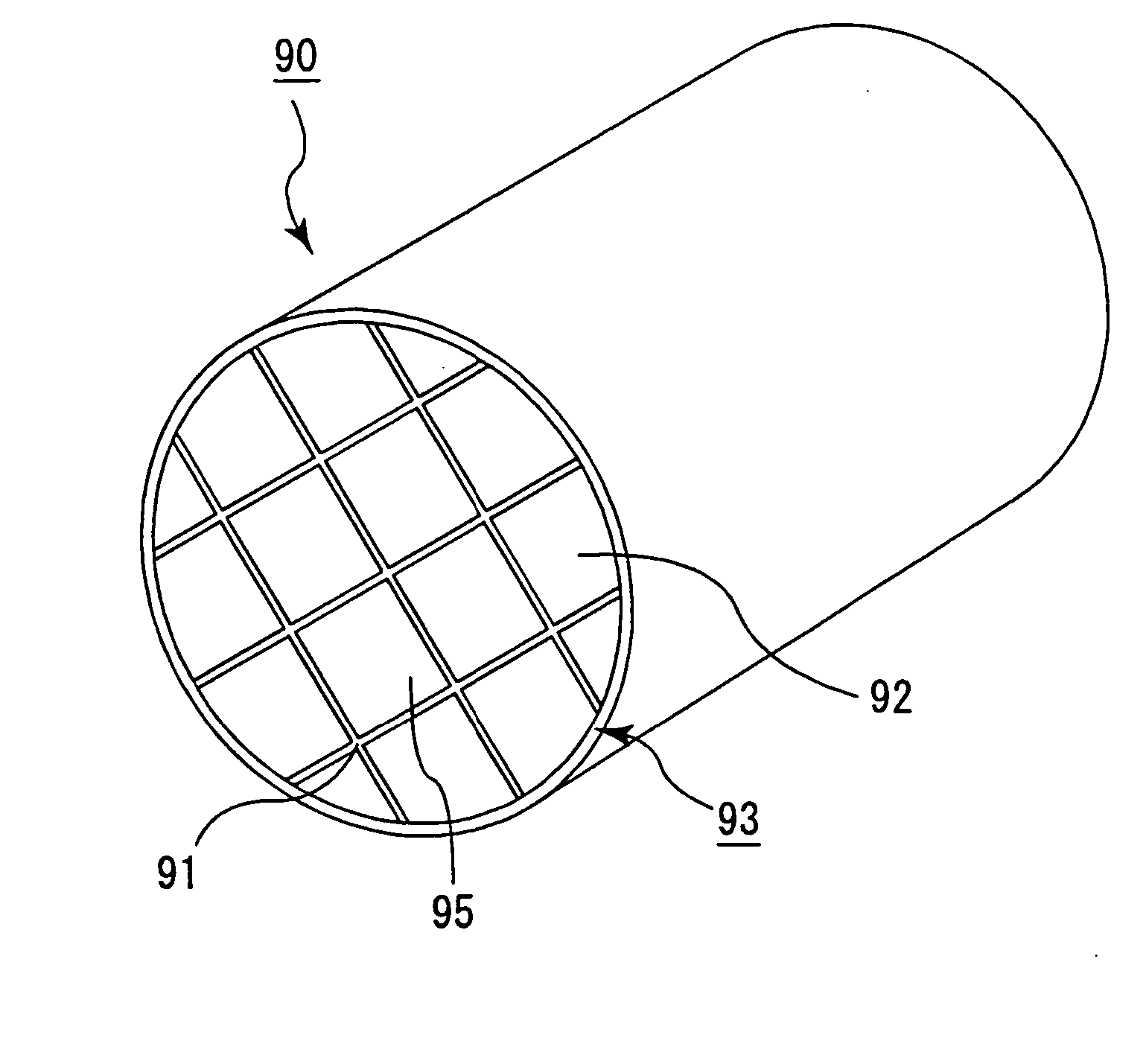

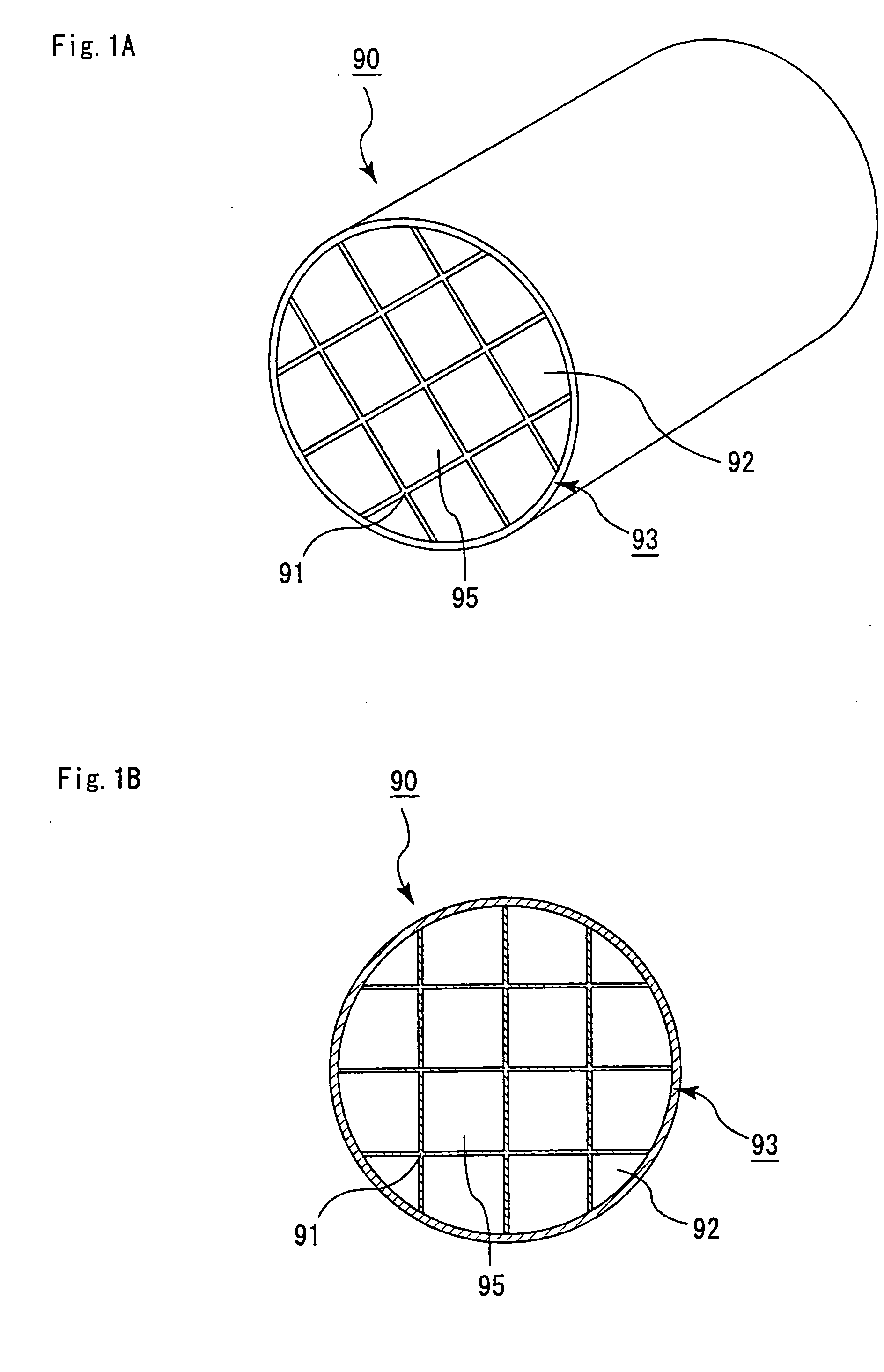

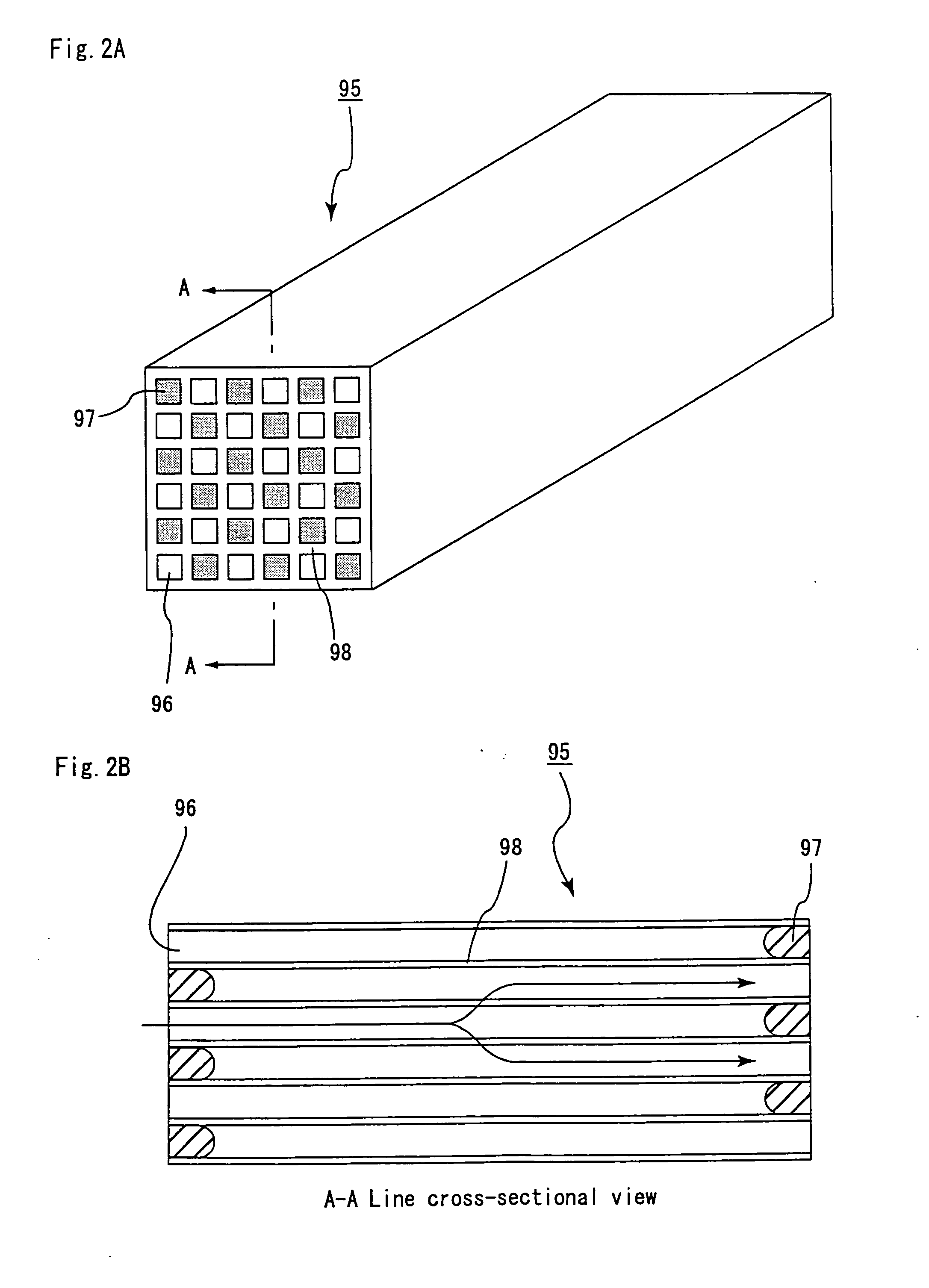

Honeycomb filter for exhaust gas decontamination, adhesive, coating material and process for producing honeycomb filter for exhaust gas decontamination

ActiveUS20050109023A1Reduce thermal stressAlleviating generated thermal stressCombination devicesDispersed particle filtrationParticulatesAdhesive

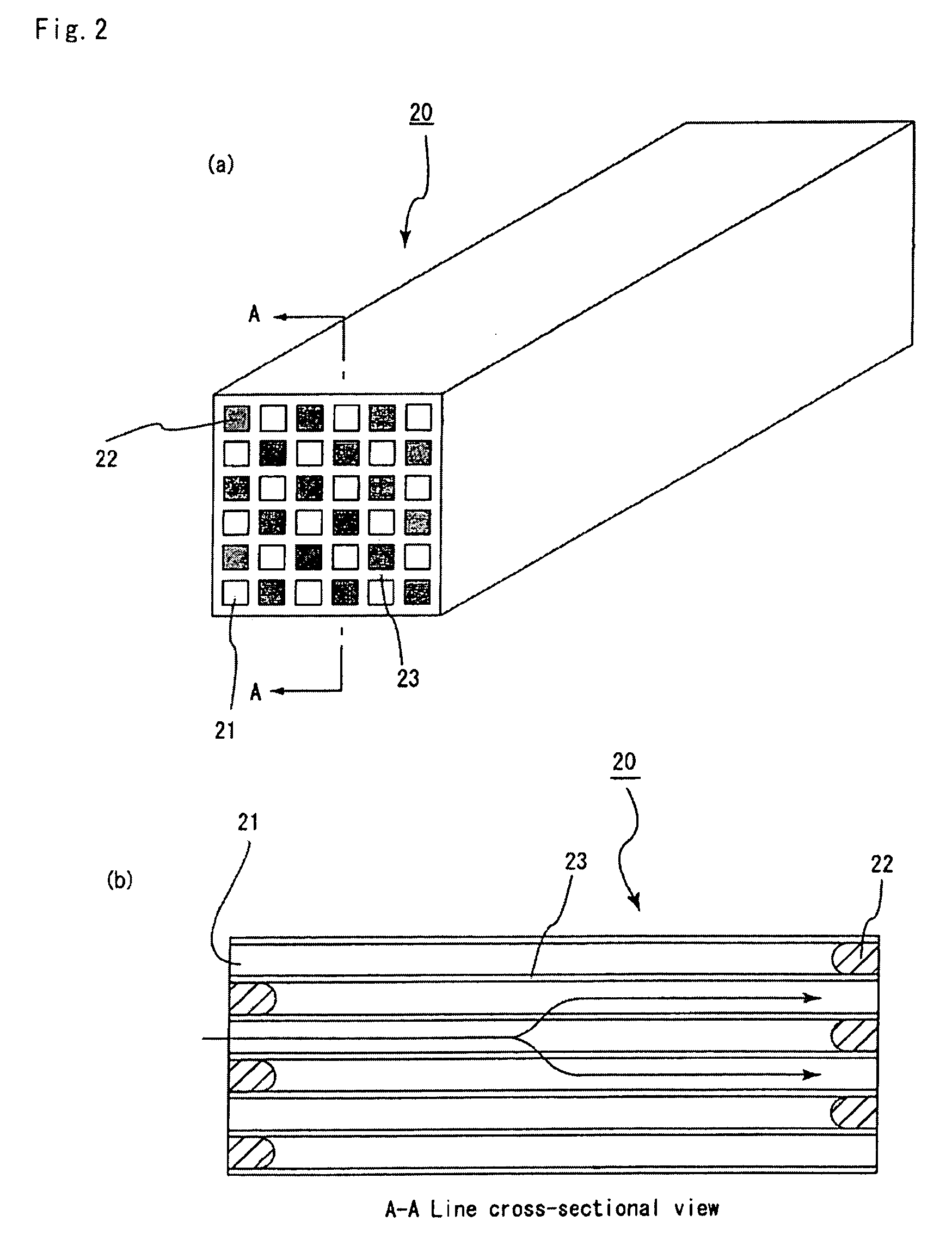

An object of the present invention is to provide a honeycomb filter for purifying exhaust gases which makes it possible to alleviate a thermal stress generated due to occurrence of a local temperature change and which is less likely to generate cracks and superior in strength and durability, an adhesive that has a low thermal capacity and is capable of alleviating the thermal stress, a coating material that has a low thermal capacity with a superior heat insulating property and is capable of alleviating the thermal stress, and a manufacturing method of the honeycomb filter for purifying exhaust gases that can improve precision in the outside dimension, and reduce damages in the manufacturing processes. The present invention relates to a honeycomb filter for purifying exhaust gases, having a structure in that a plurality of column-shaped porous ceramic members, each having a number of through holes that are placed side by side in the length direction with partition wall interposed therebetween, are combined with one another through adhesive layers so that the partition wall that separate the through holes are allowed to function as a filter for collecting particulates, and in this structure, the thermal expansion coefficient αL of the adhesive layer and the thermal expansion coefficient αF of the porous ceramic member are designed to have the following relationship: 0.01<|αL−αF| / αF<1.0.

Owner:IBIDEN CO LTD

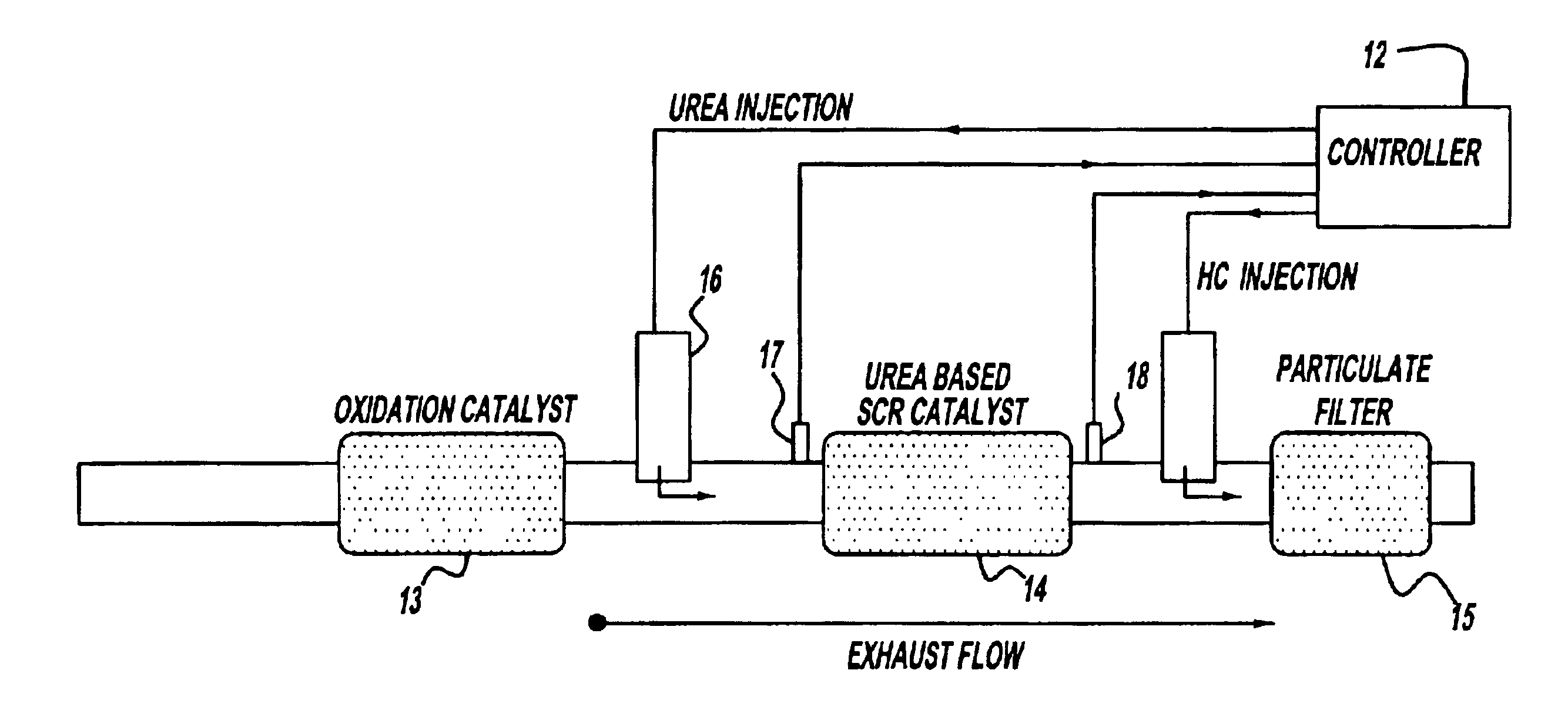

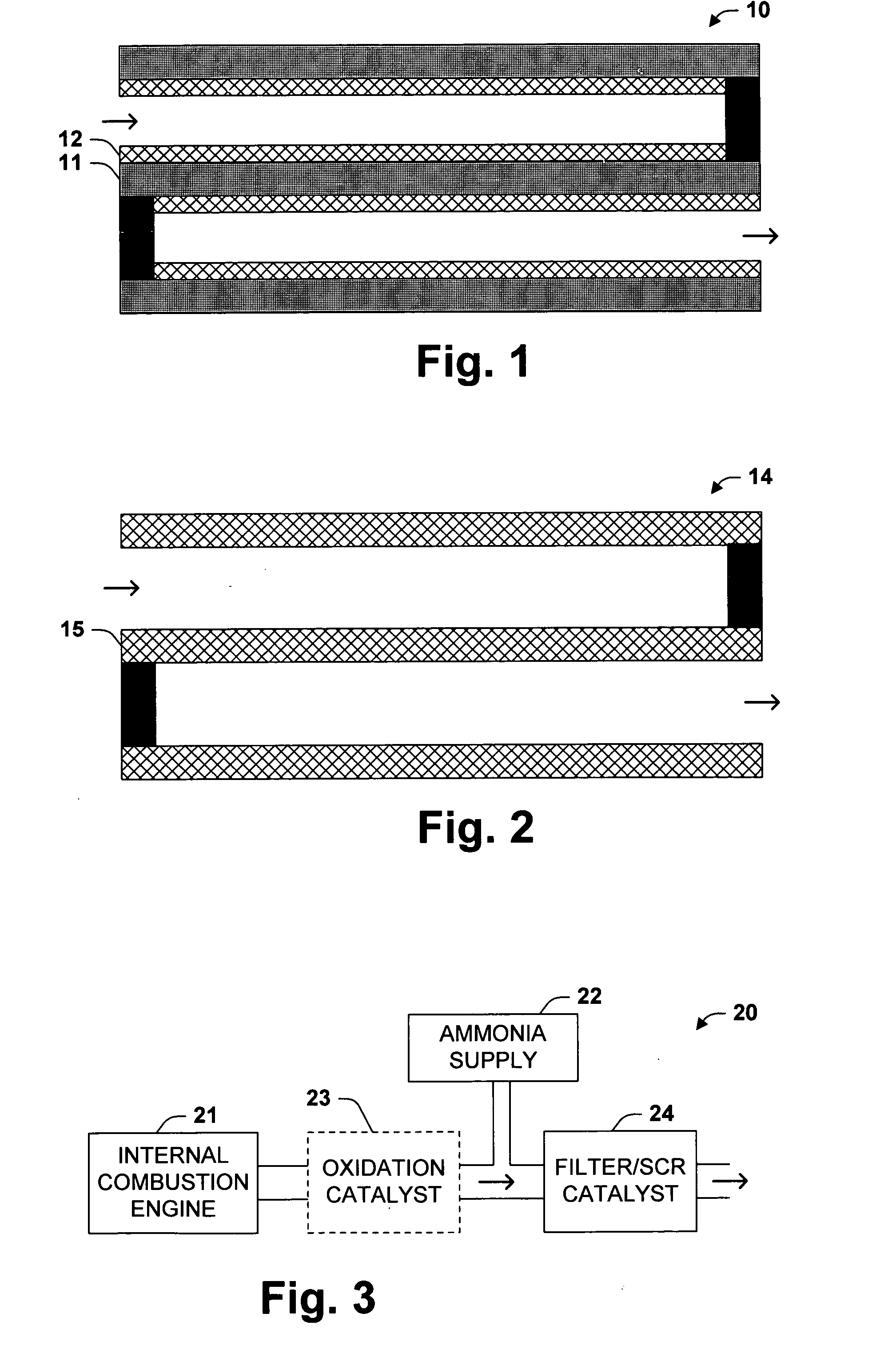

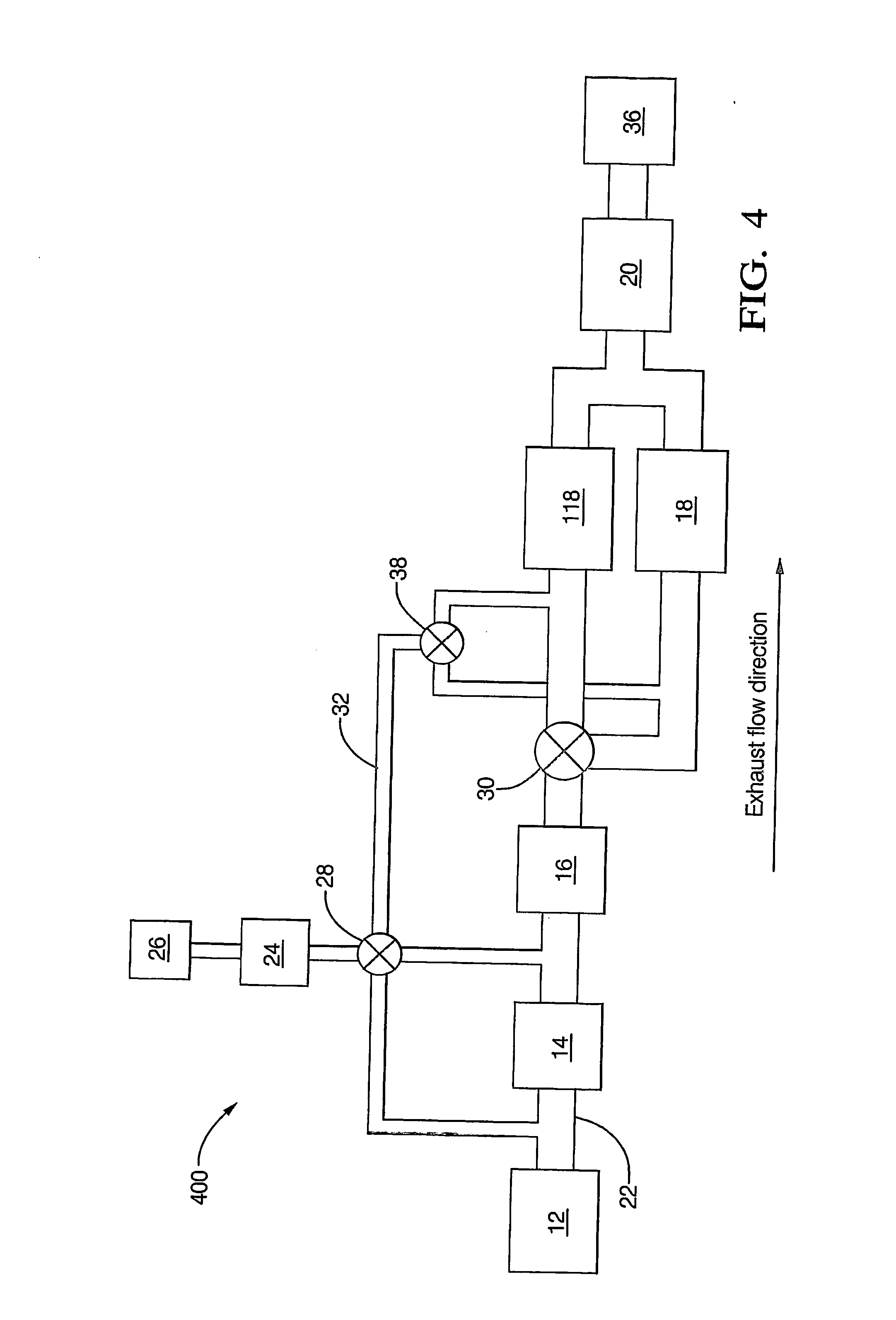

Exhaust gas aftertreatment systems

InactiveUS6928806B2Improve NOx conversion efficiencyHigh operating temperatureElectrical controlInternal combustion piston enginesExhaust fumesSystem configuration

A system for effective NOx and particulate matter control in a diesel or other lean burn internal combustion engine is presented. The system includes a urea-based SCR catalyst having an oxidation catalyst coupled upstream of it and a particulate filter coupled downstream of the SCR catalyst. This system configuration results in improved NOx conversion due to fast SCR catalyst warm-up and higher operating temperatures. Additionally, placing the particulate filter last in this system configuration reduces tailpipe ammonia emissions as well as prevents any thermal damage to the SCR catalyst due to the particulate filter regeneration.

Owner:FORD GLOBAL TECH LLC

Apparatus, method, and system for concentrating adsorbable pollutants and abatement thereof

InactiveUS6105365ALess fuelLow oxygenGas treatmentInternal combustion piston enginesCombustionExhaust fumes

Owner:ENGELHARD CORP

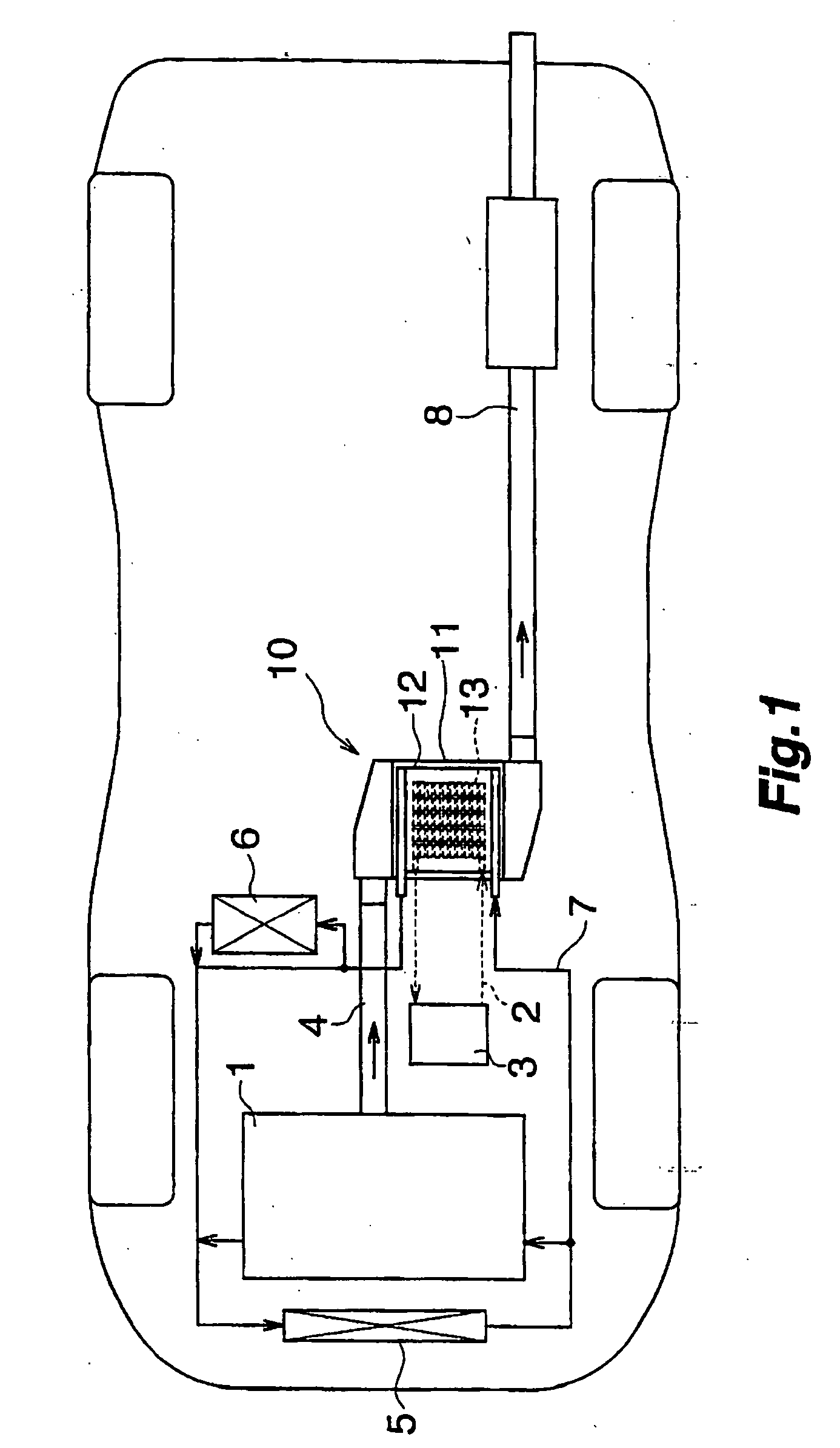

Waste heat recovery system and thermoelectric conversion system

InactiveUS20060157102A1Increase powerImprove efficiencyInternal combustion piston enginesThermoelectric device with peltier/seeback effectWaste heat recovery unitFuel cells

A waste heat recover system includes a mechanism for supplying power by use of a thermoelectric conversion unit, and a mechanism for utilizing heat released from the thermoelectric conversion unit. Heat released from the thermoelectric conversion unit is utilized for, for example, heating, defrosting, defogging, temperature keeping of fuel, temperature keeping of an internal combustion engine, and temperature keeping of a fuel cell. The waste heat recovery system is equipped in, for example, cars, incinerators, fuel cells, and industrial machinery.

Owner:SHOWA DENKO KK

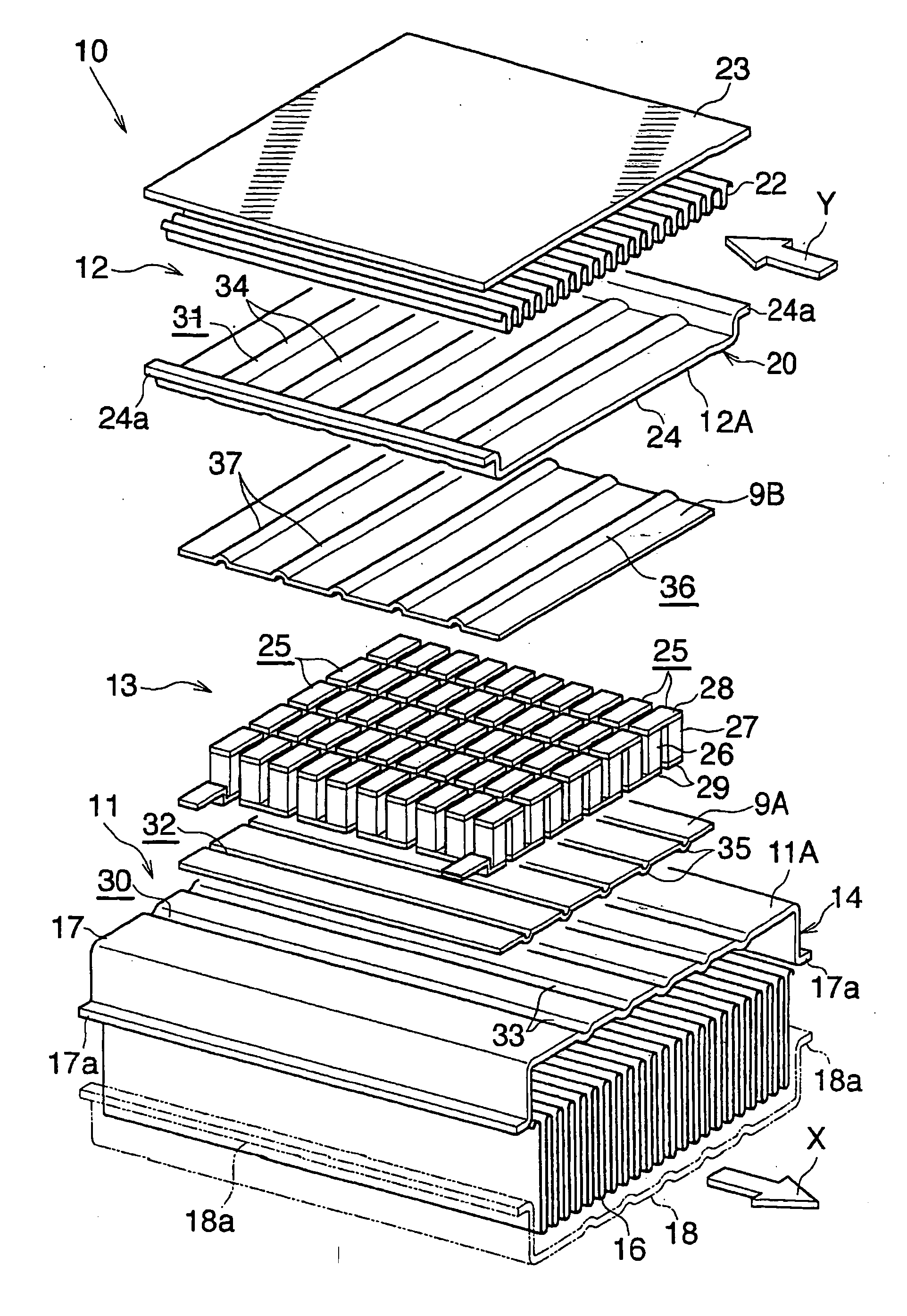

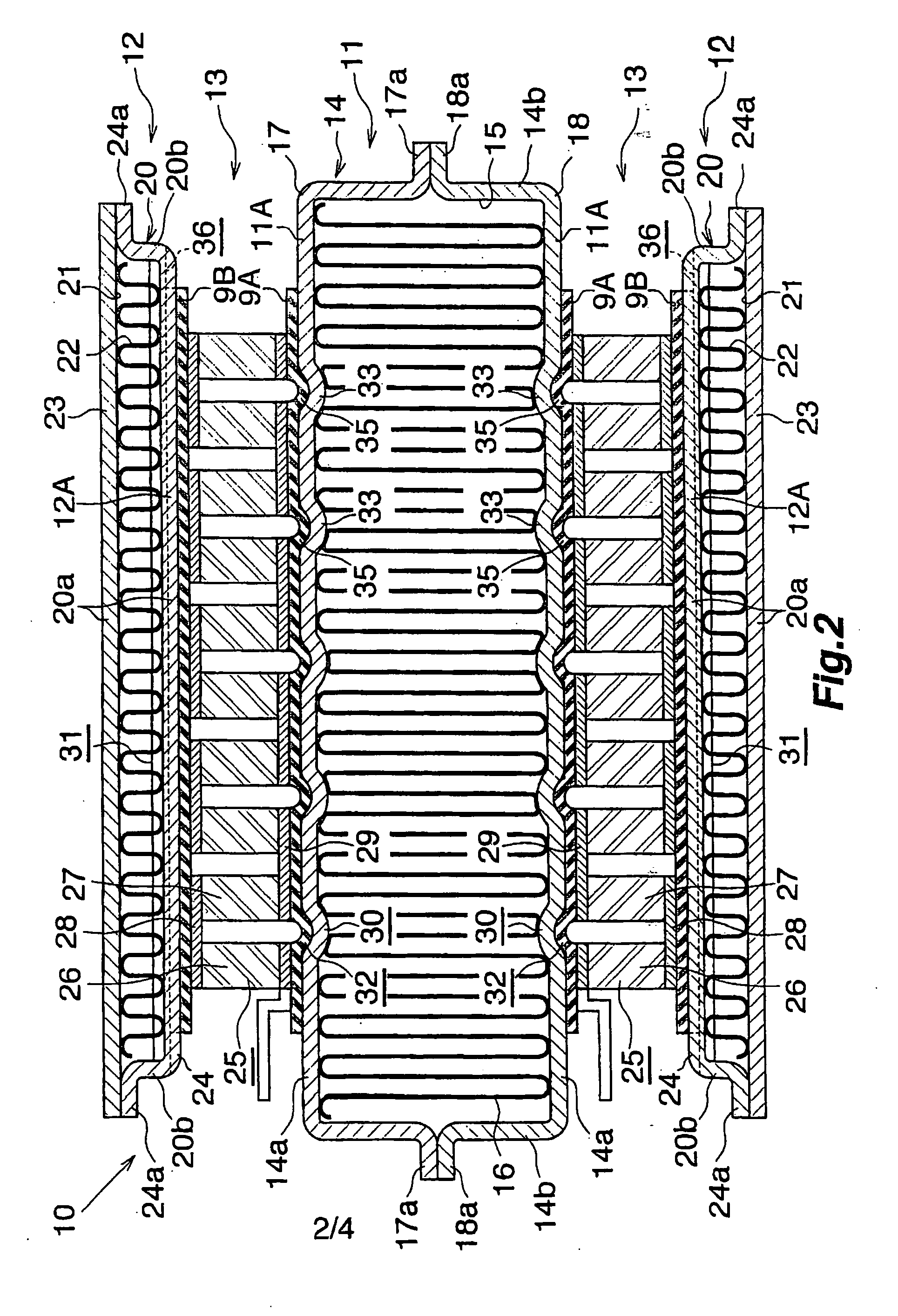

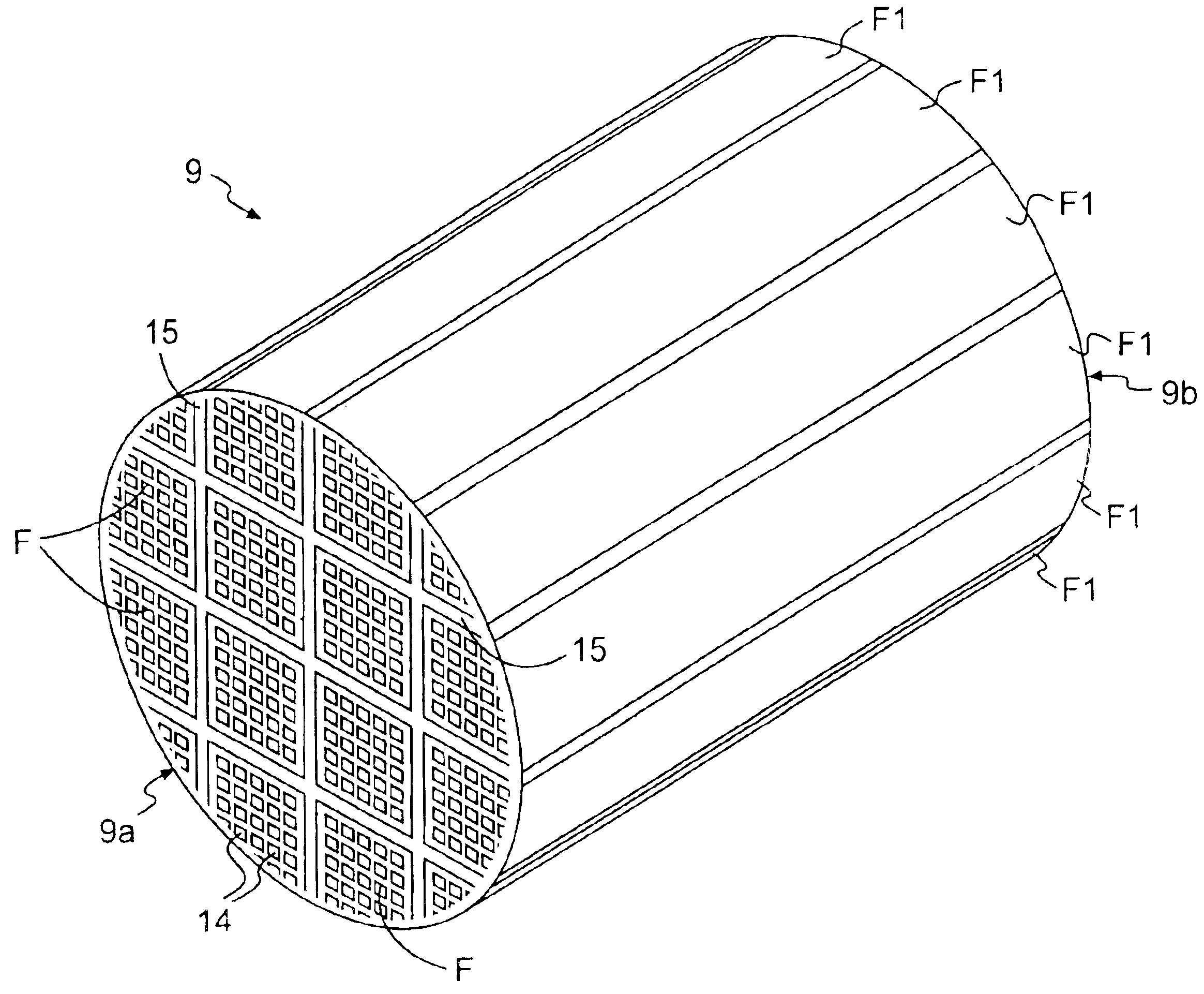

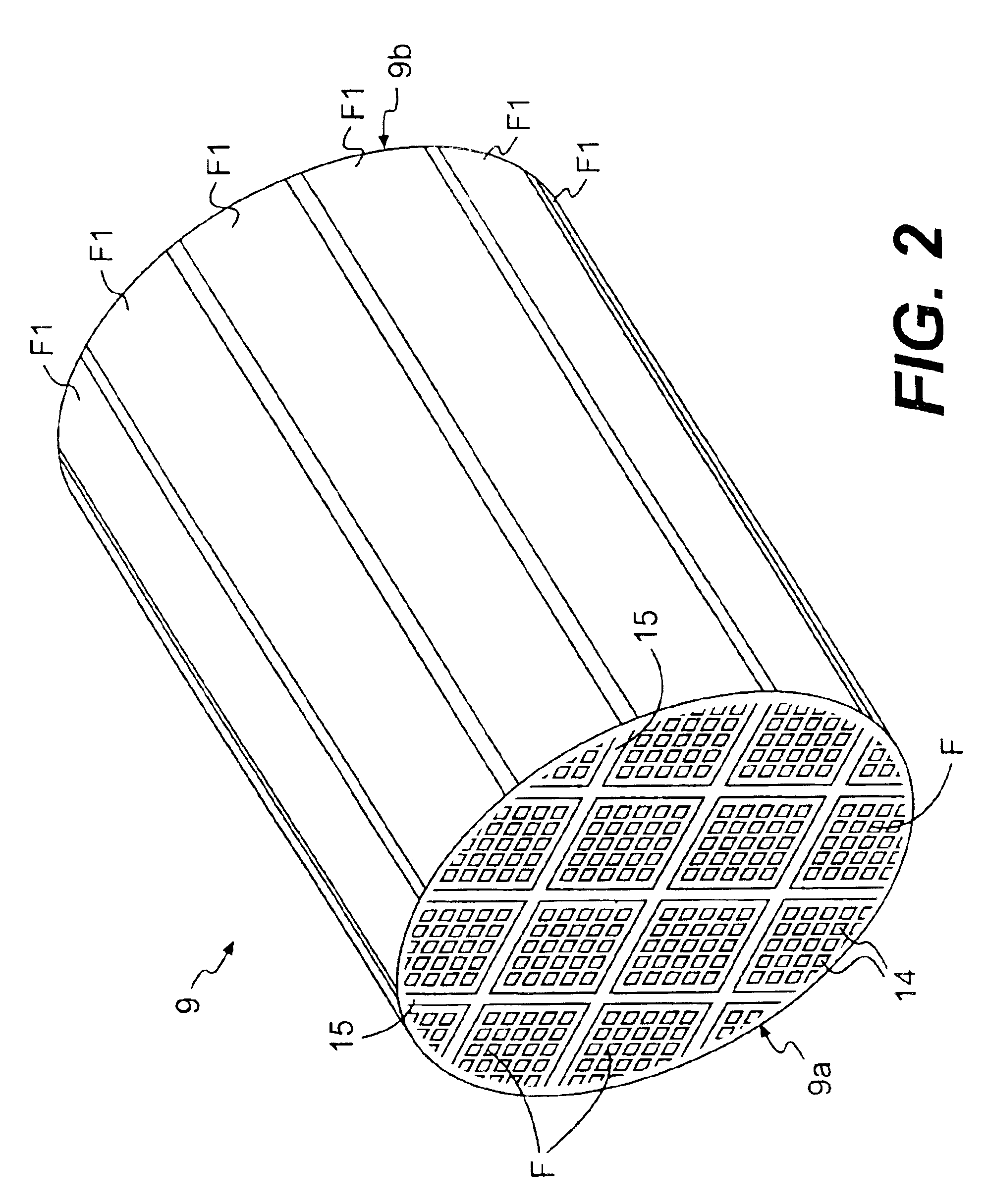

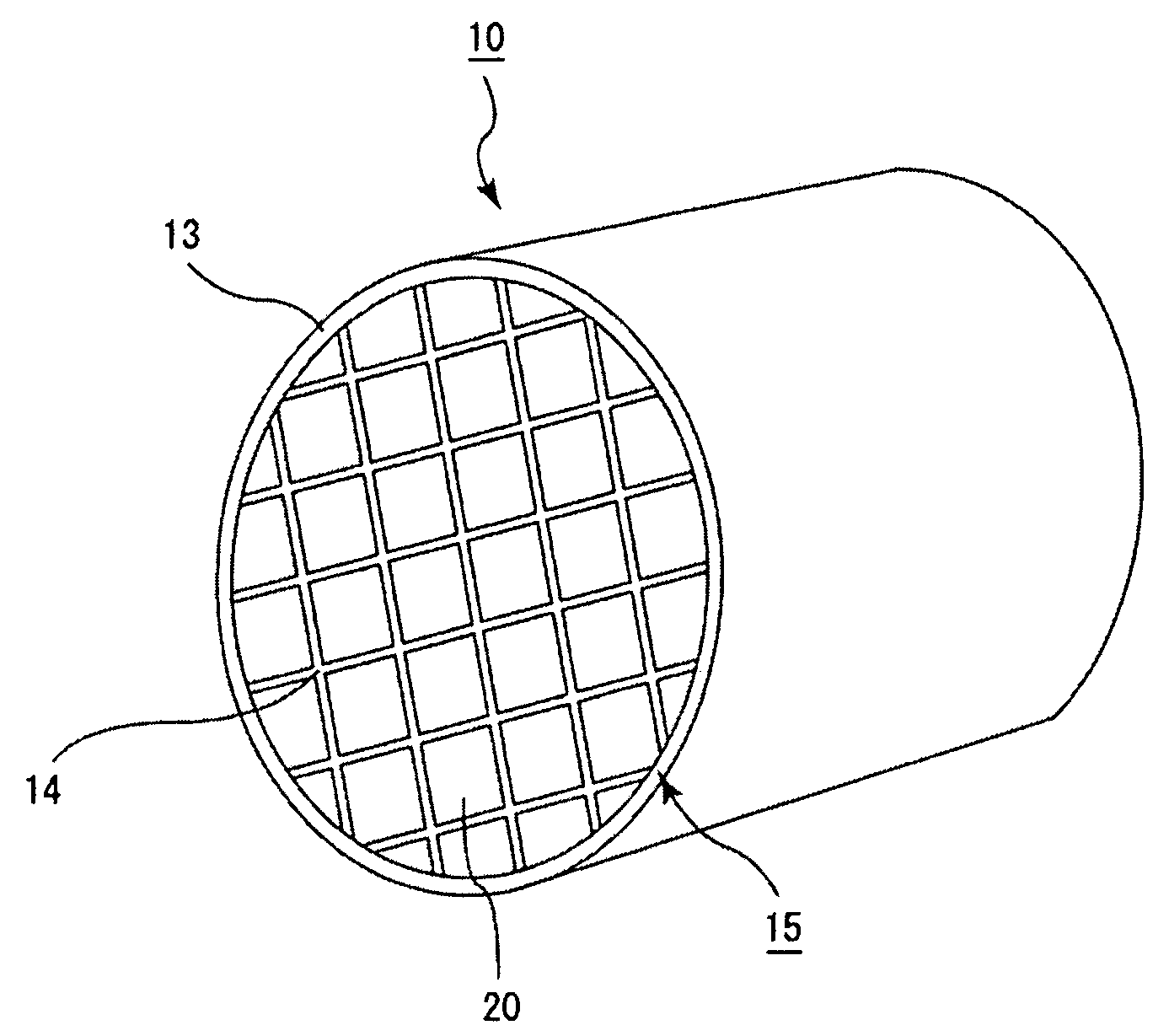

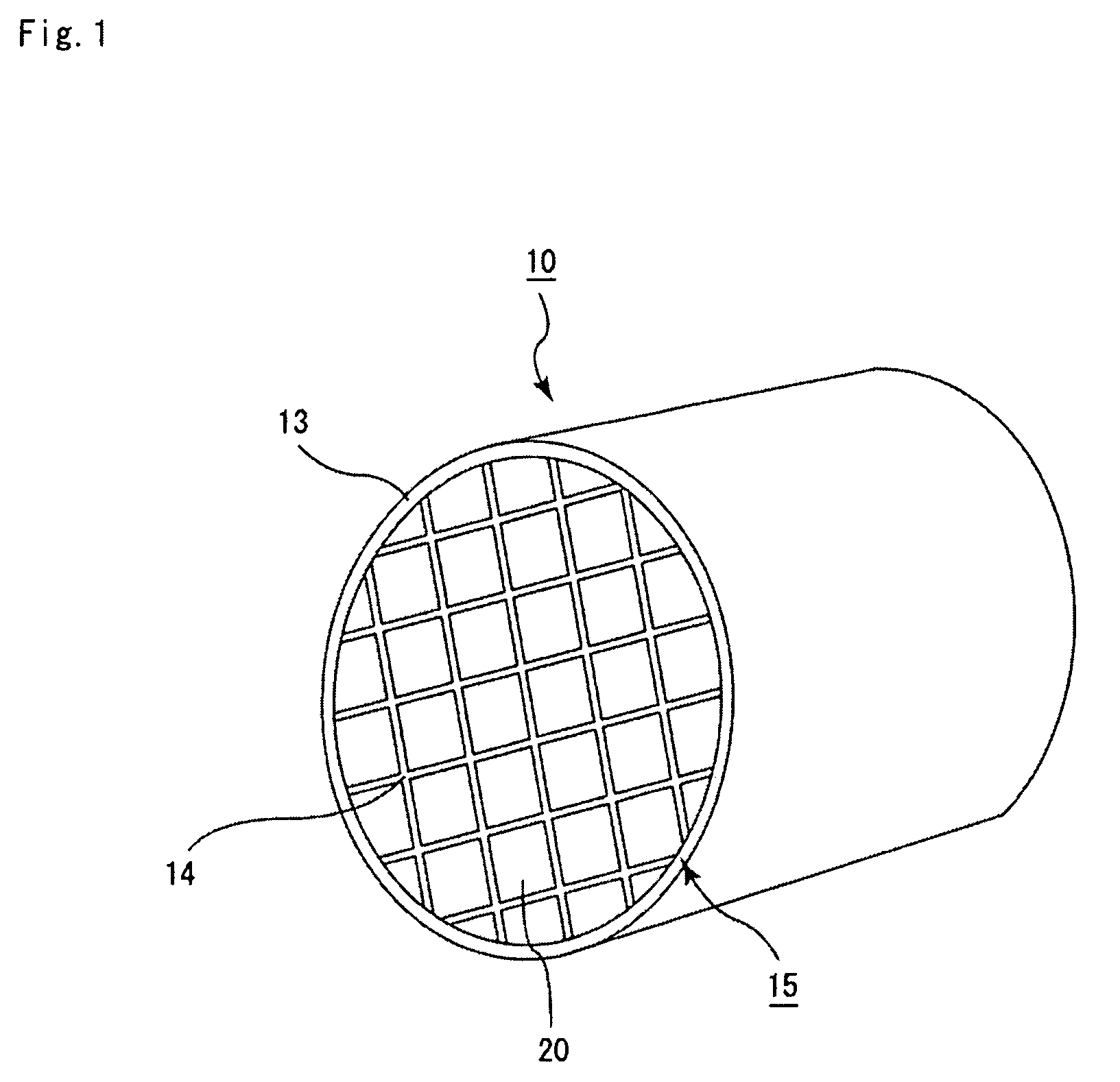

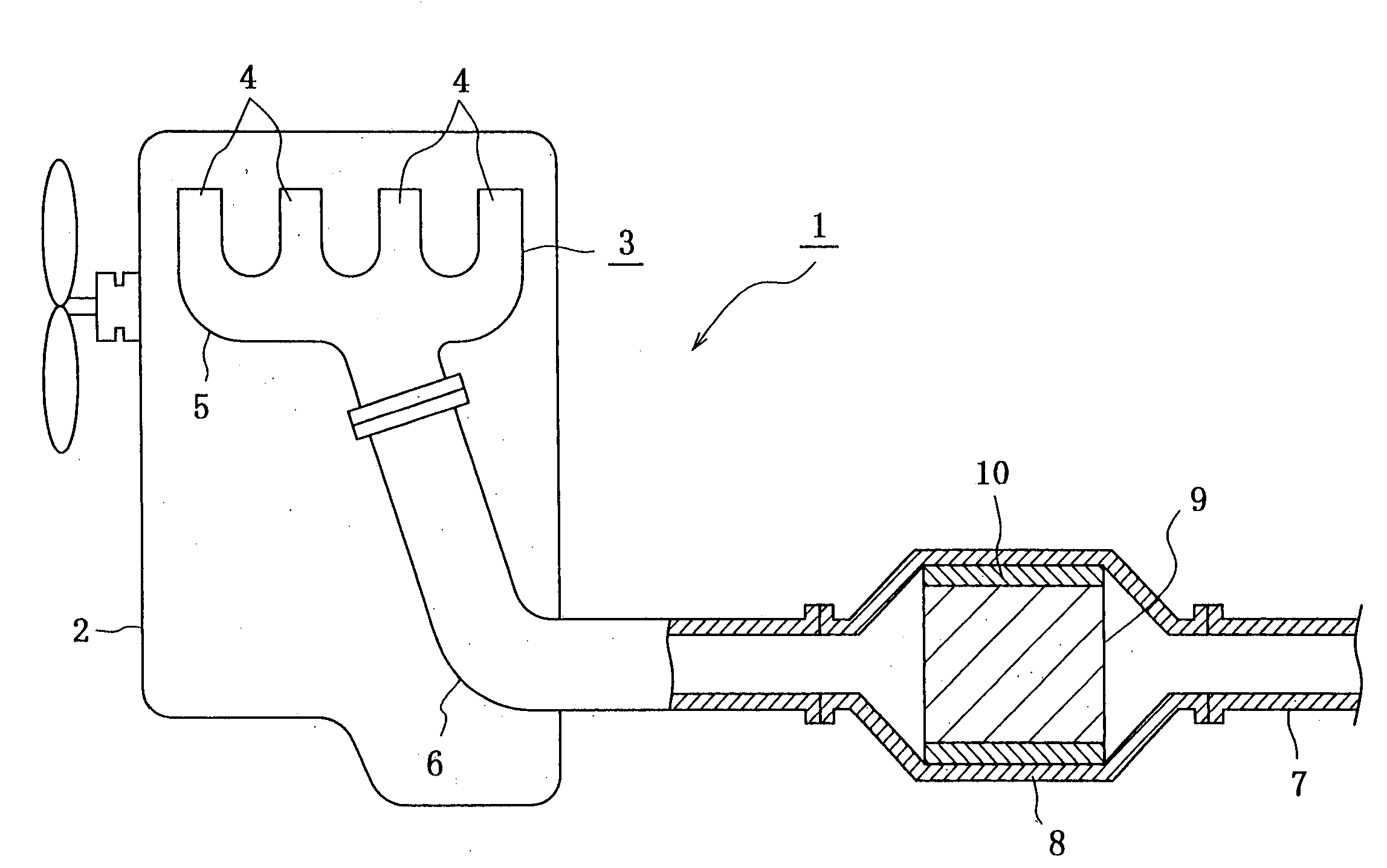

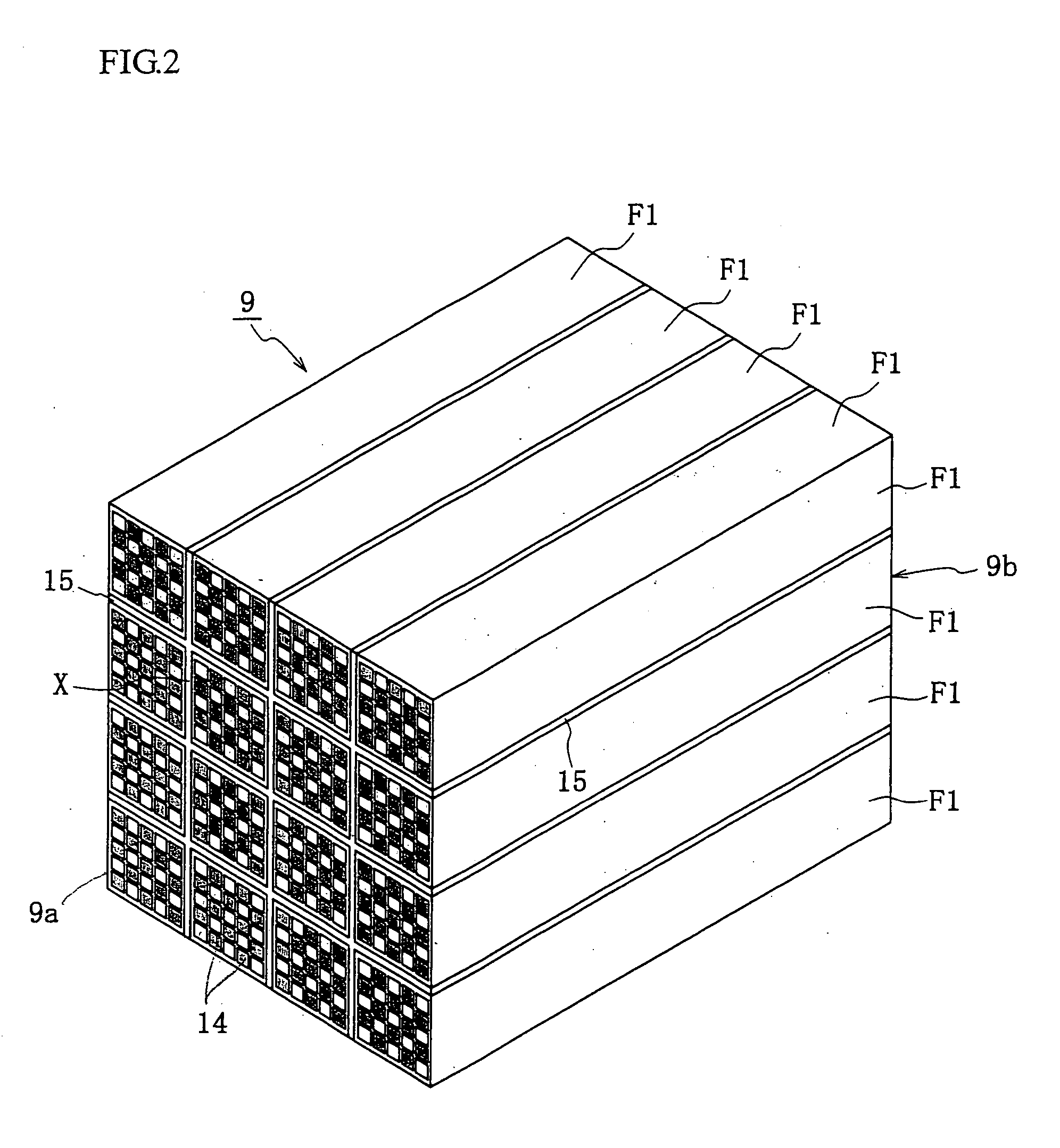

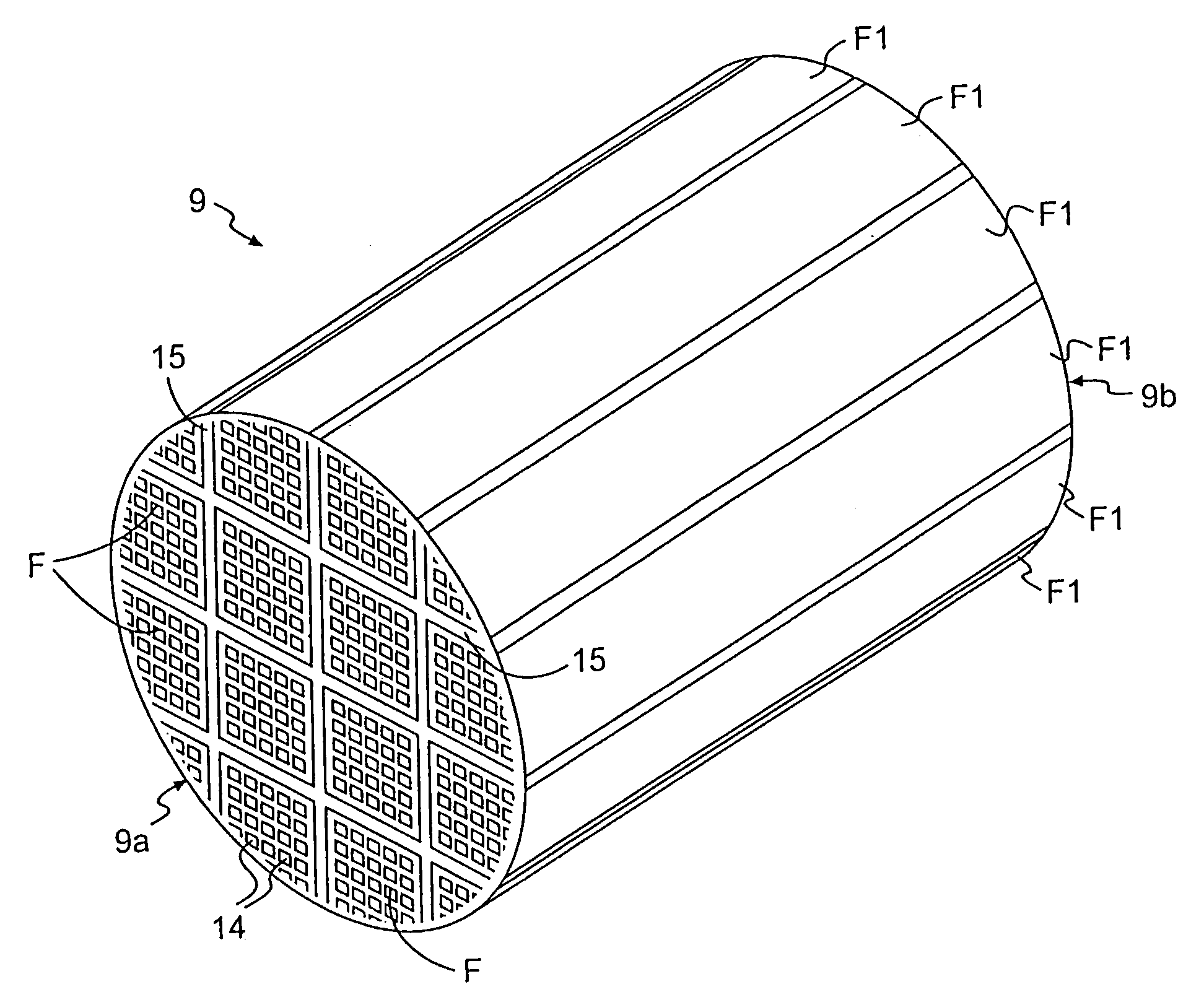

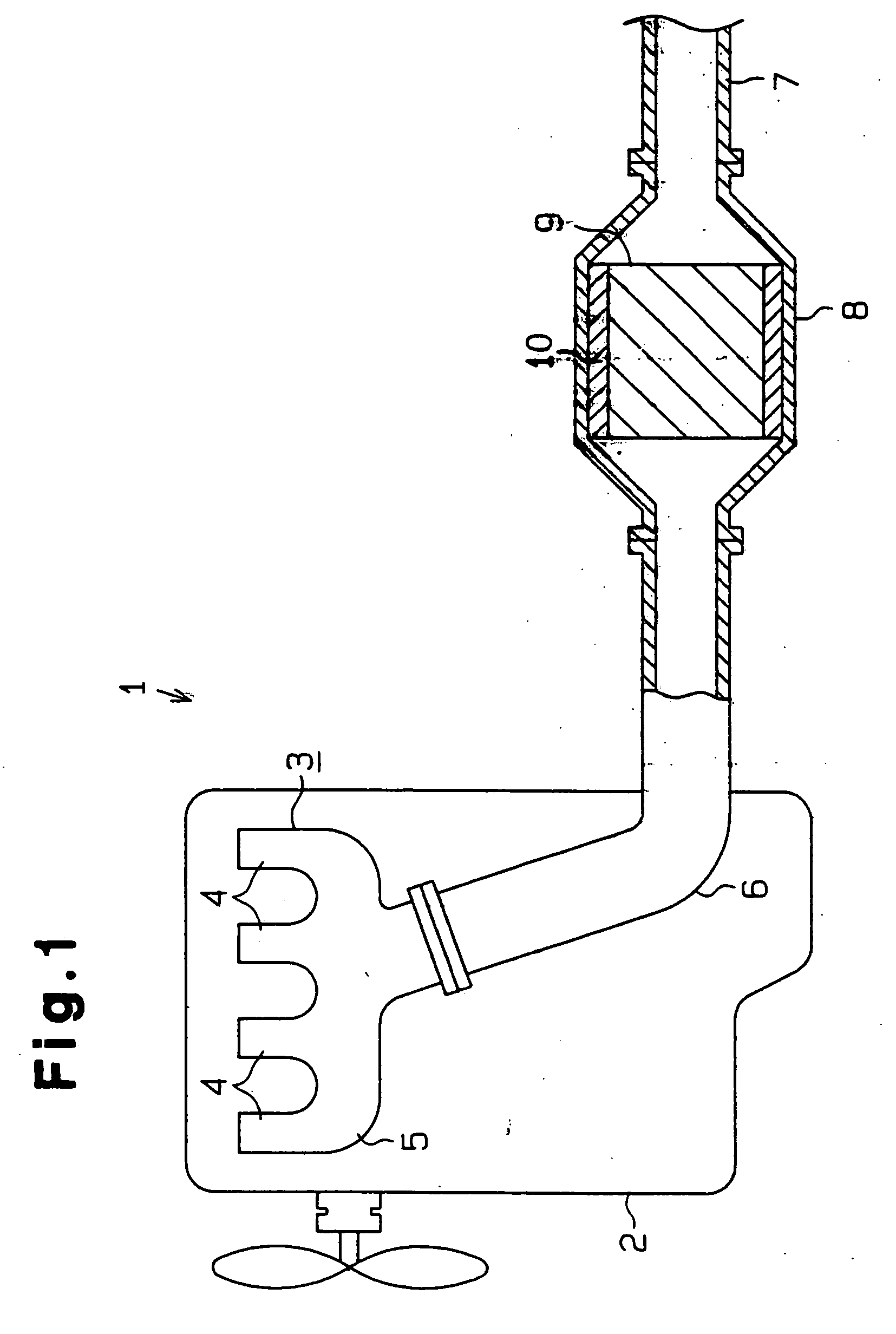

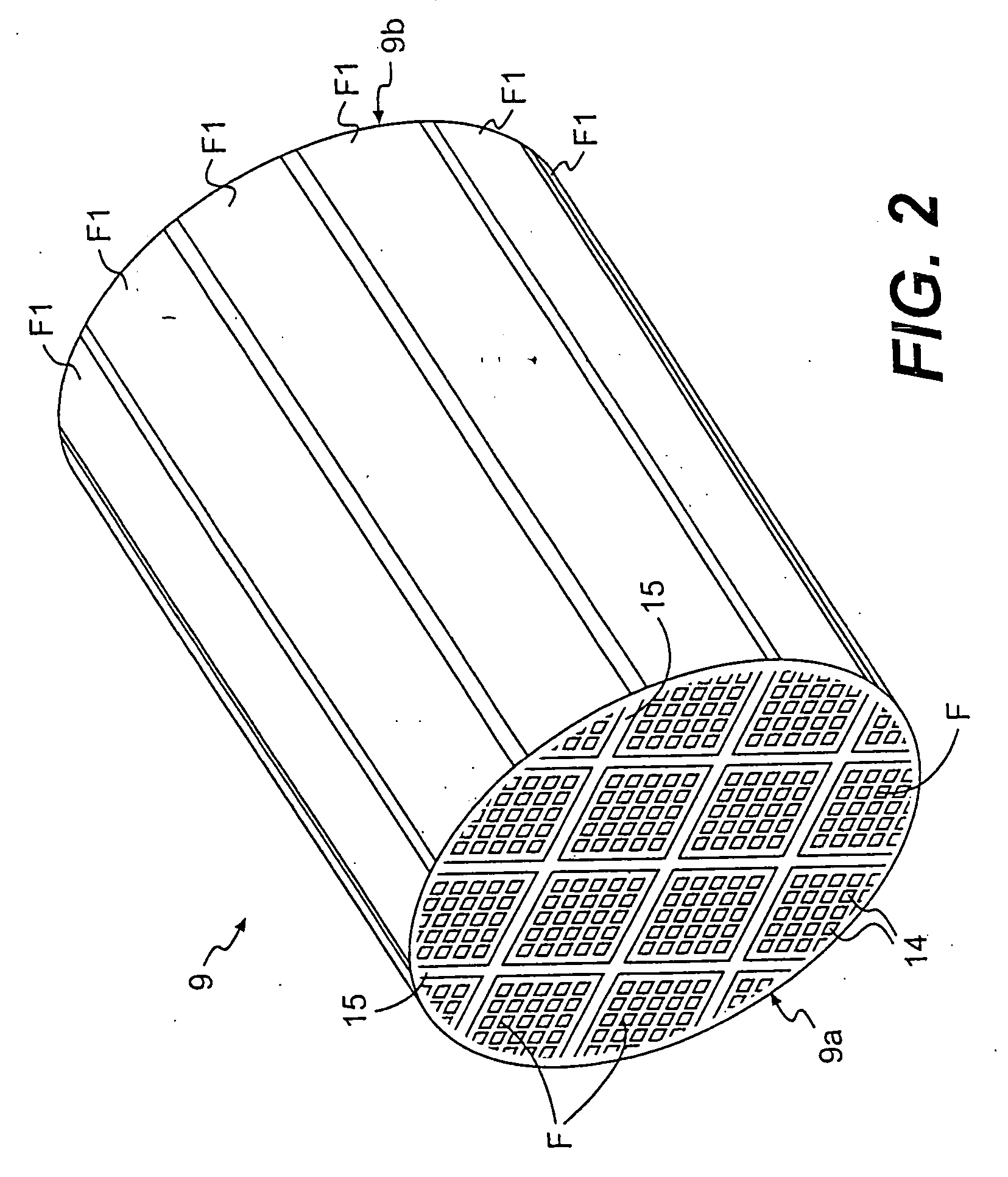

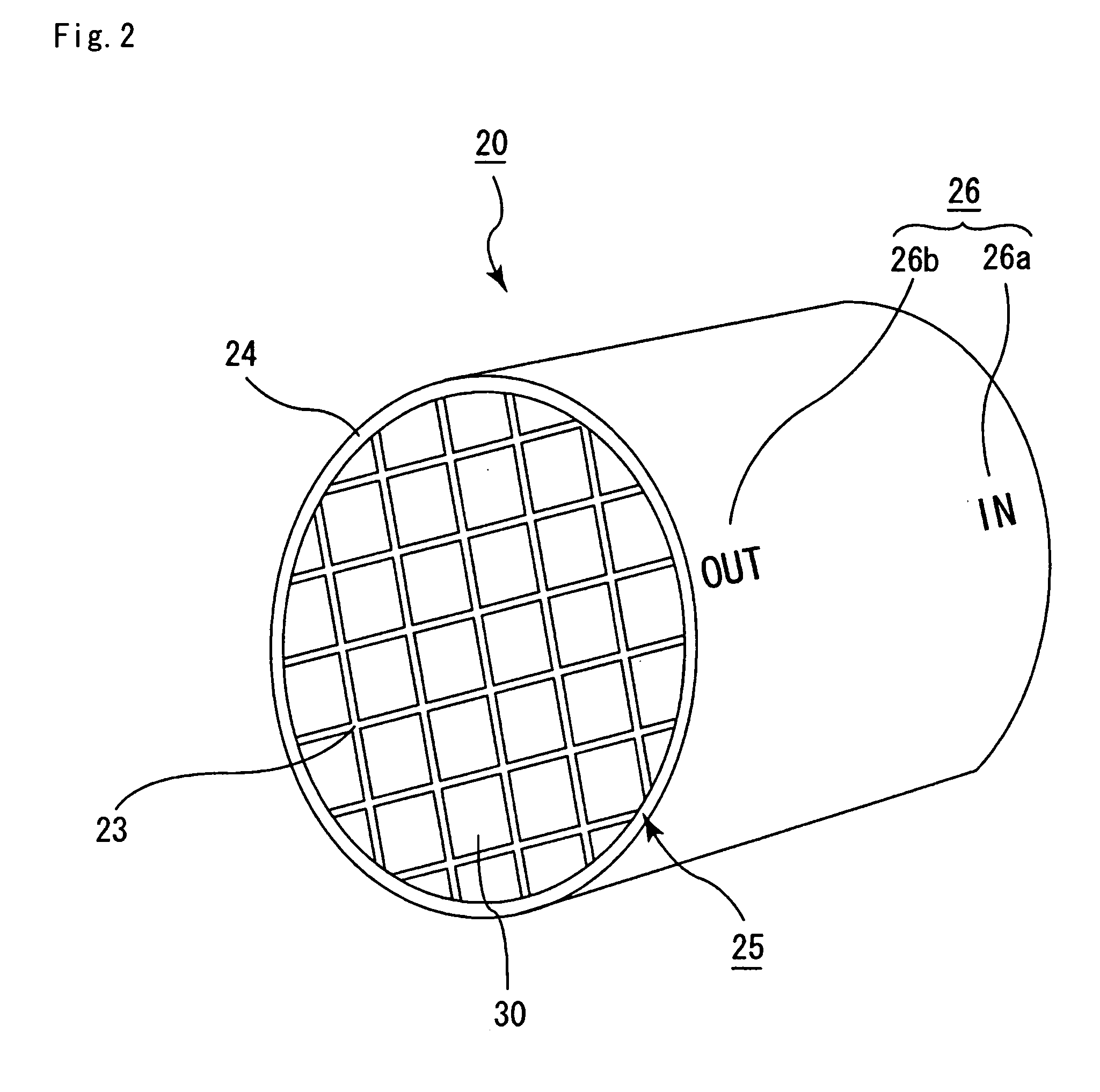

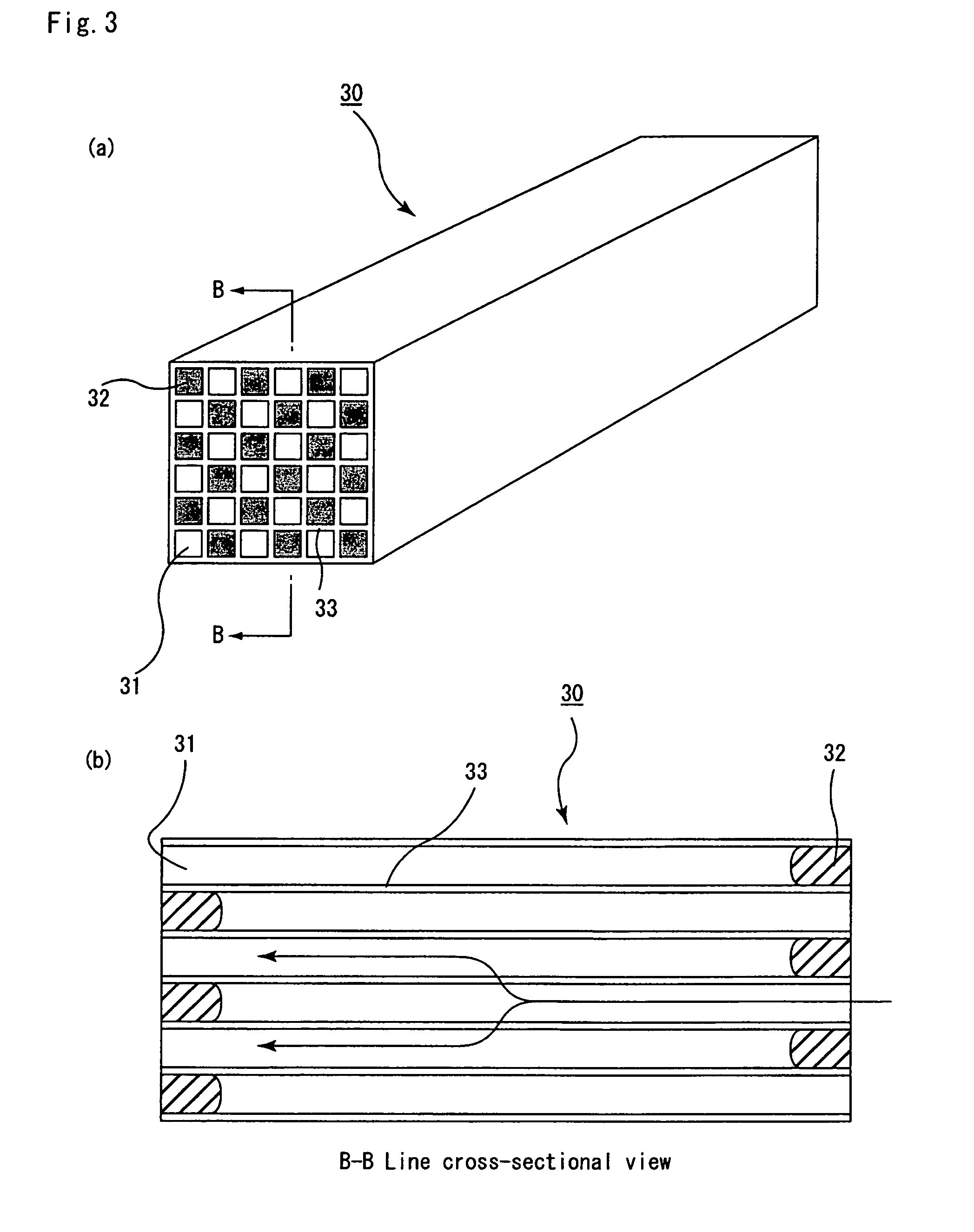

Honeycomb filter and ceramic filter assembly

A ceramic filter assembly having improved exhaust gas processing efficiency. The ceramic filter assembly (9) is produced by adhering with a ceramic seal layer (15) outer surfaces of a plurality of filters (F1), each of which is formed from a sintered porous ceramic body. The seal layer (15) has a thickness of 0.3 mm to 3 mm and a thermal conductance of 0.1 W / mK to 10 W / mk.

Owner:IBIDEN CO LTD

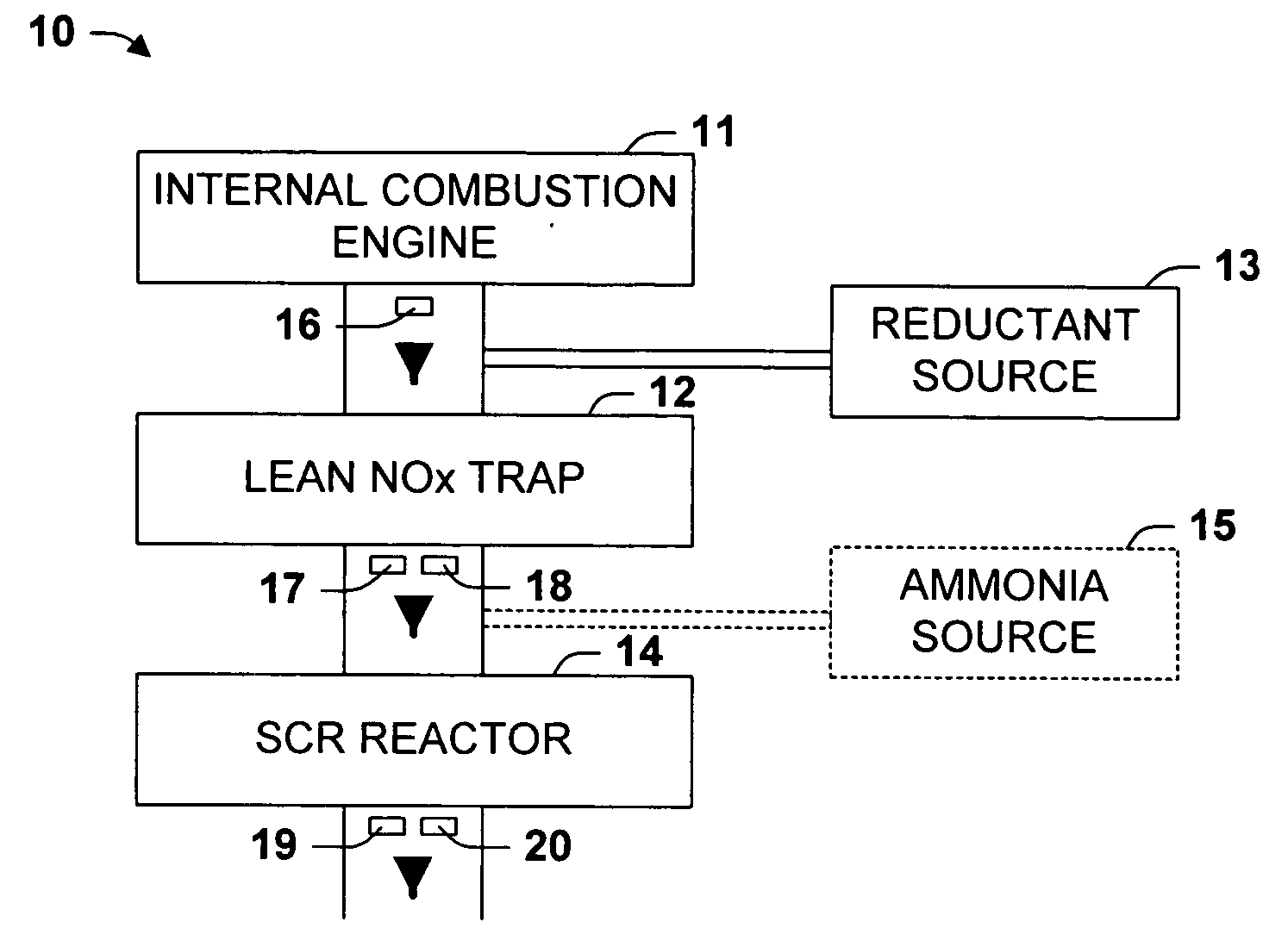

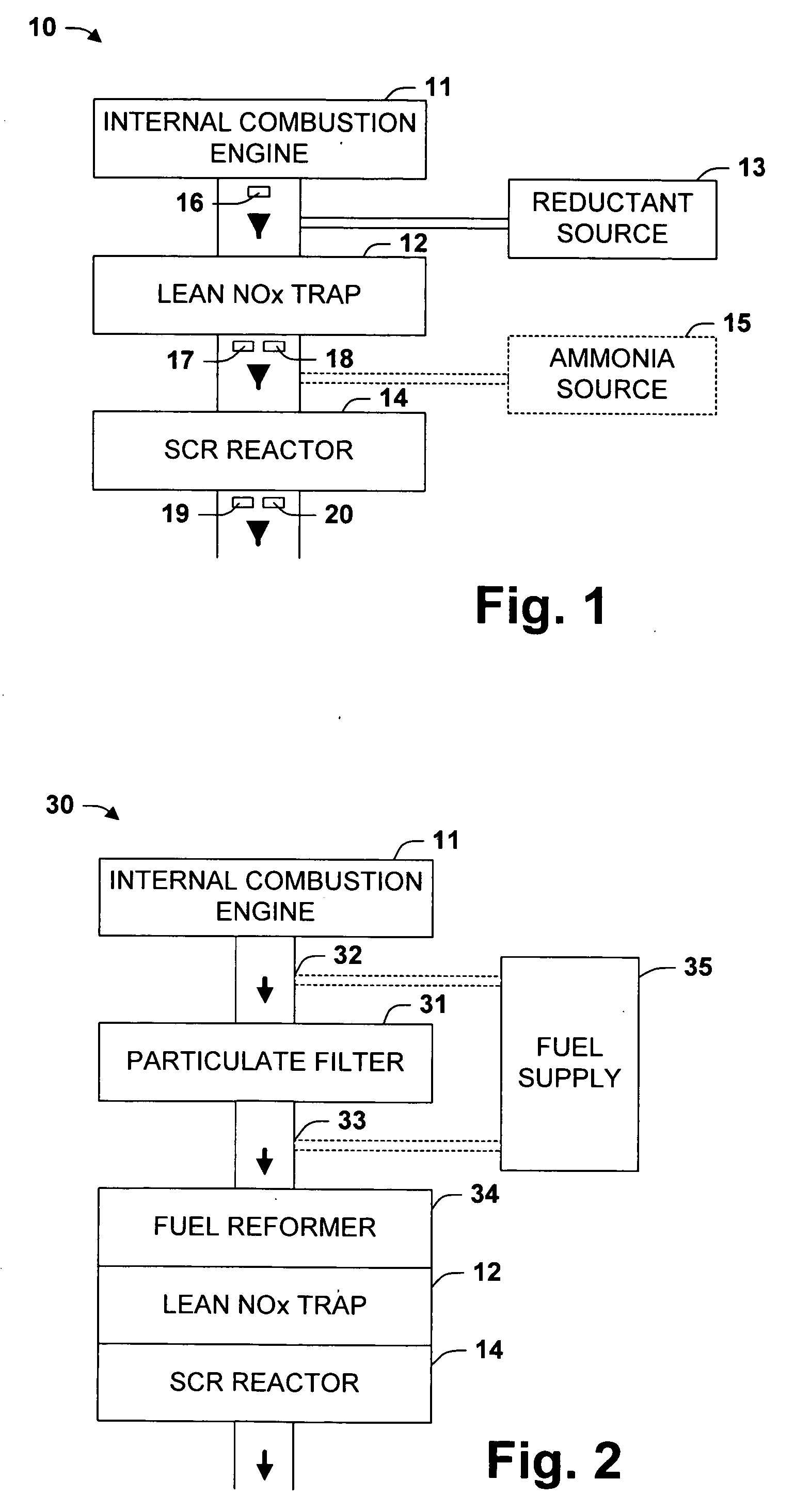

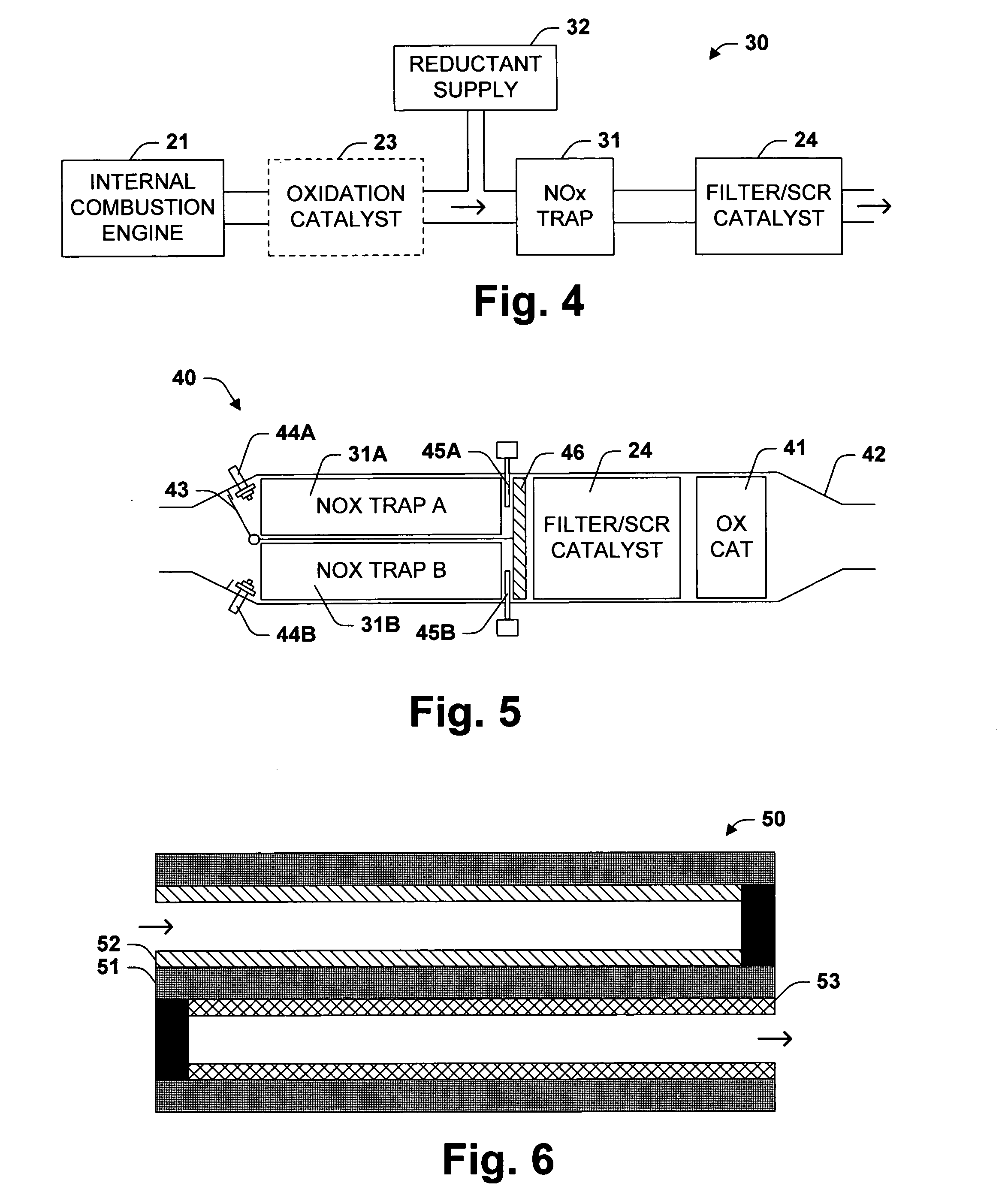

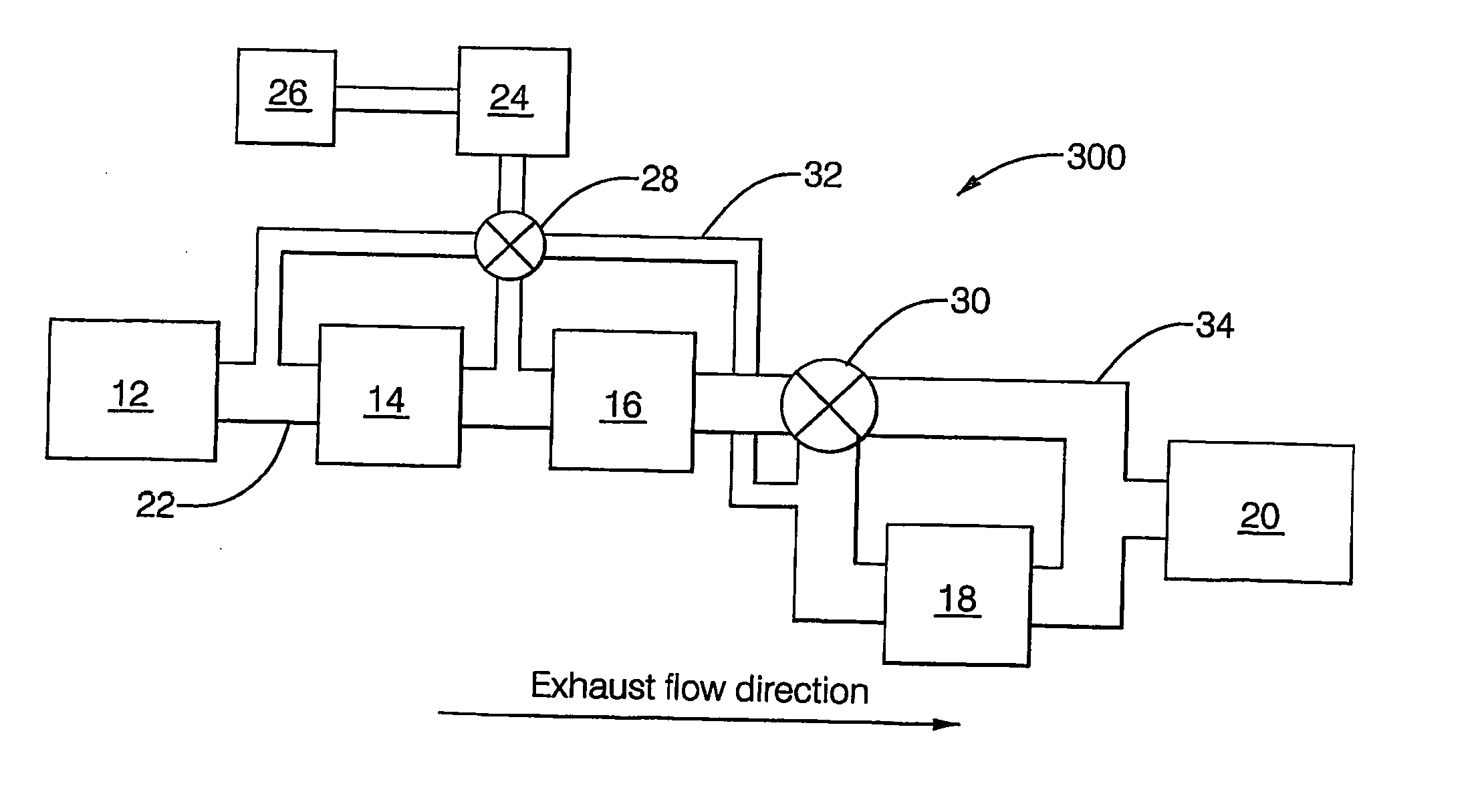

Hybrid catalyst system for exhaust emissions reduction

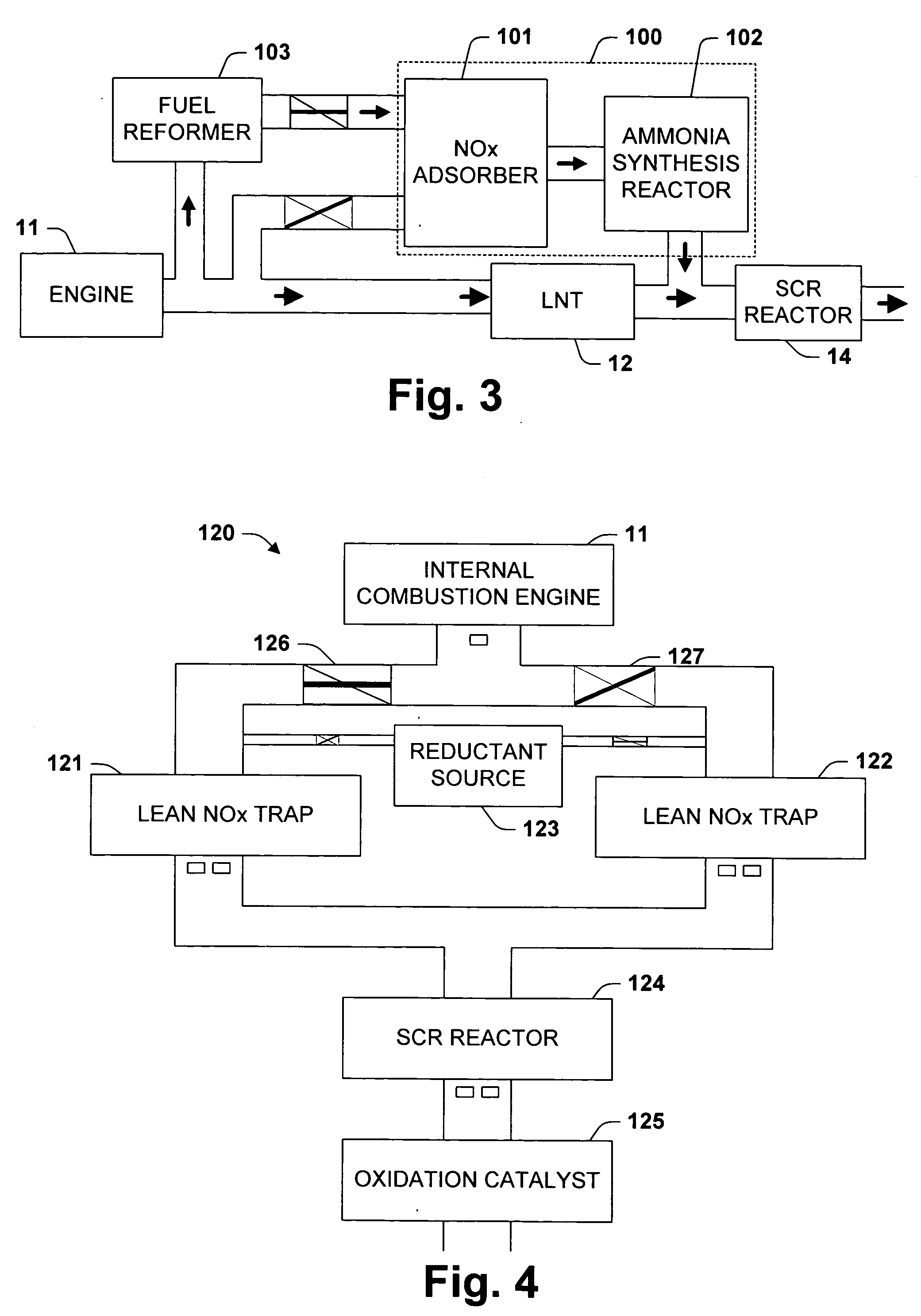

InactiveUS20060010857A1Improve efficiencySpeed up the conversion processHydrogenGas treatmentExhaust fumesEngineering

One aspect of the invention relates an exhaust treatment system having an SCR reactor following a NOx adsorber. Syn gas is used to regenerate the NOx adsorber. Another aspect relates to an LNT / SCR provided with an ammonia source separate from the LNT. A further aspect relates to a system comprising first and second LNTs and one or more SCRs downstream of the LNTs. A still further aspect relates to a device comprising first and second NOx adsorbers contained in a single housing. Another aspect relates to coating a surface of a moving part in an exhaust system with an oxidation catalyst to mitigate fouling. Additional aspects of the invention relate to strategies for controlling one or more of the time to initiate a regeneration cycle, the time to terminate a regeneration cycle, and the reductant injection rate during regeneration of LNT / SCR exhaust treatment systems.

Owner:INT ENGINE INTPROP CO LLC

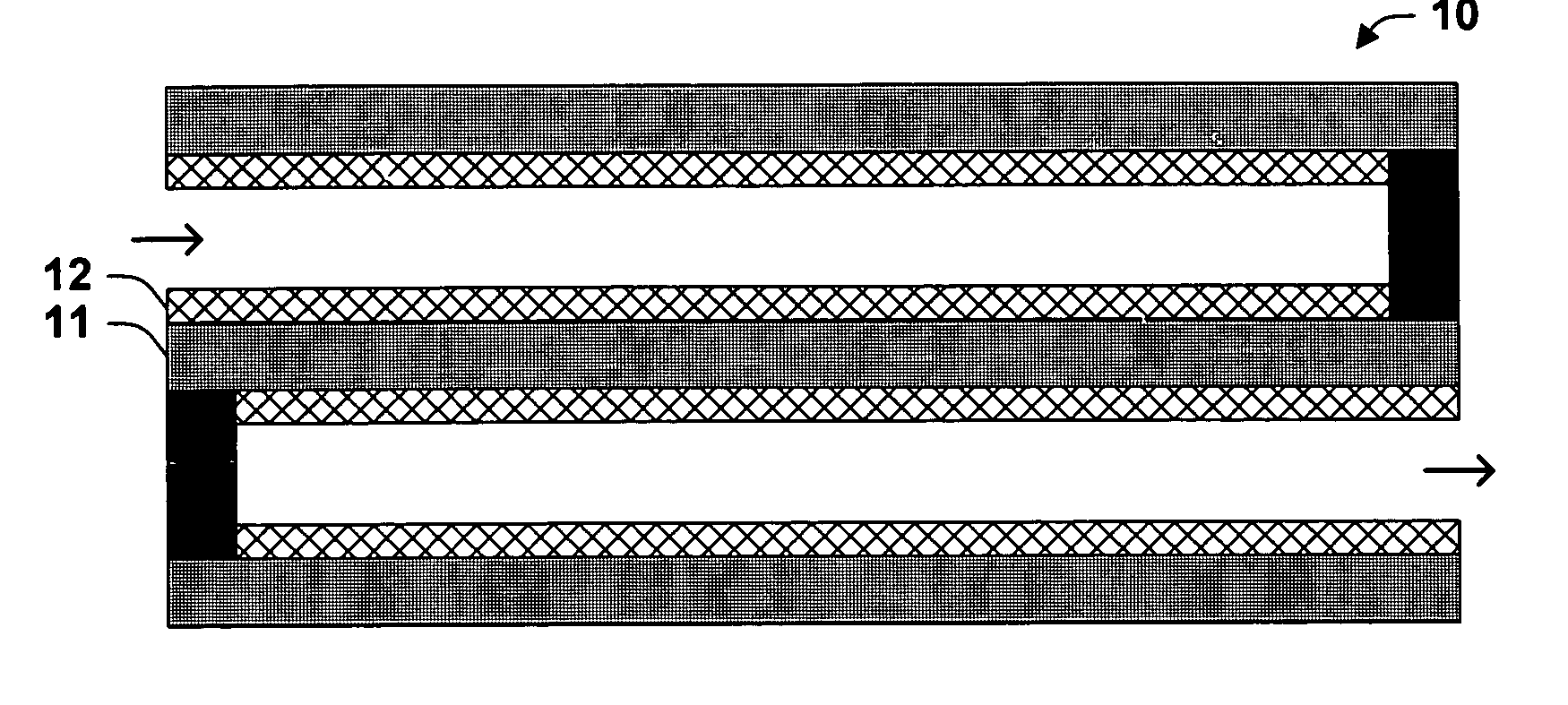

Compact diesel engine exhaust treatment system

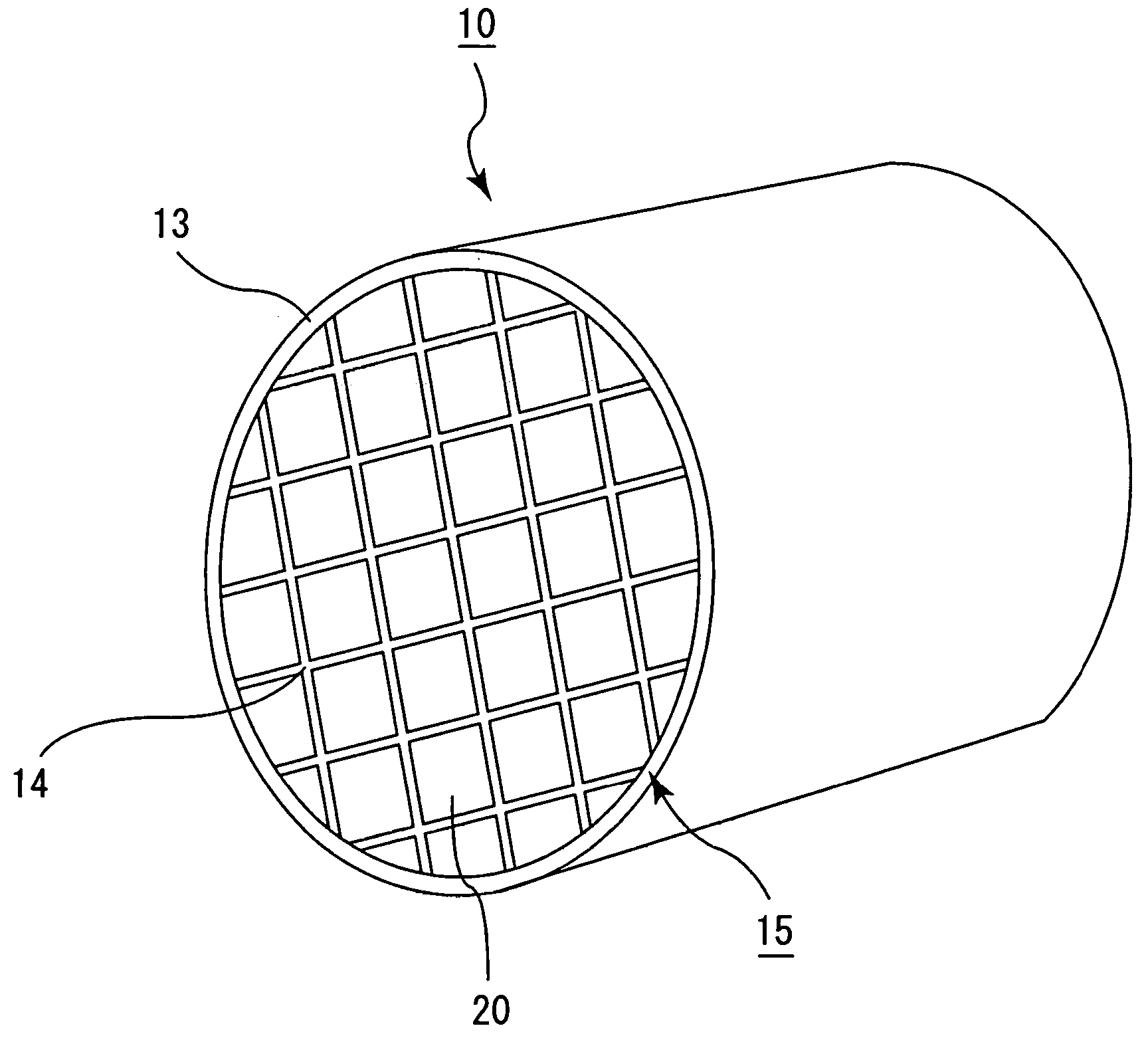

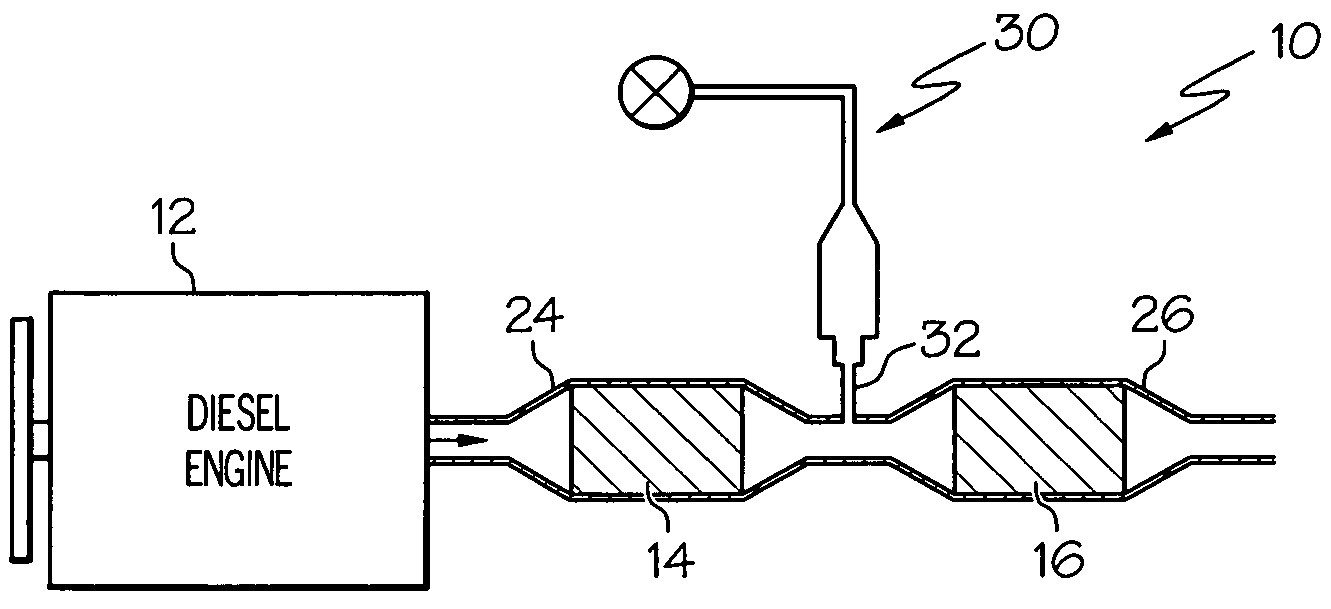

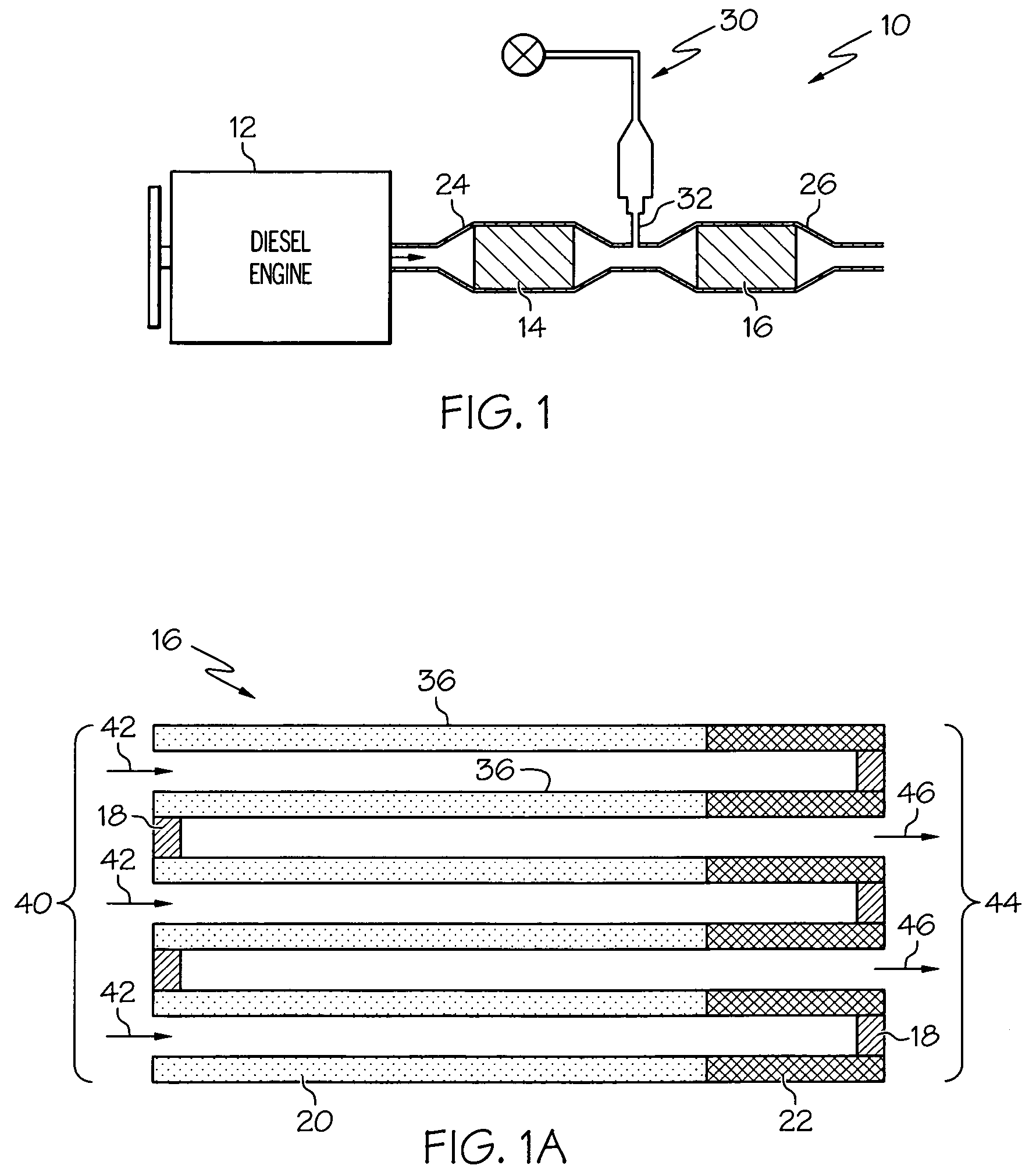

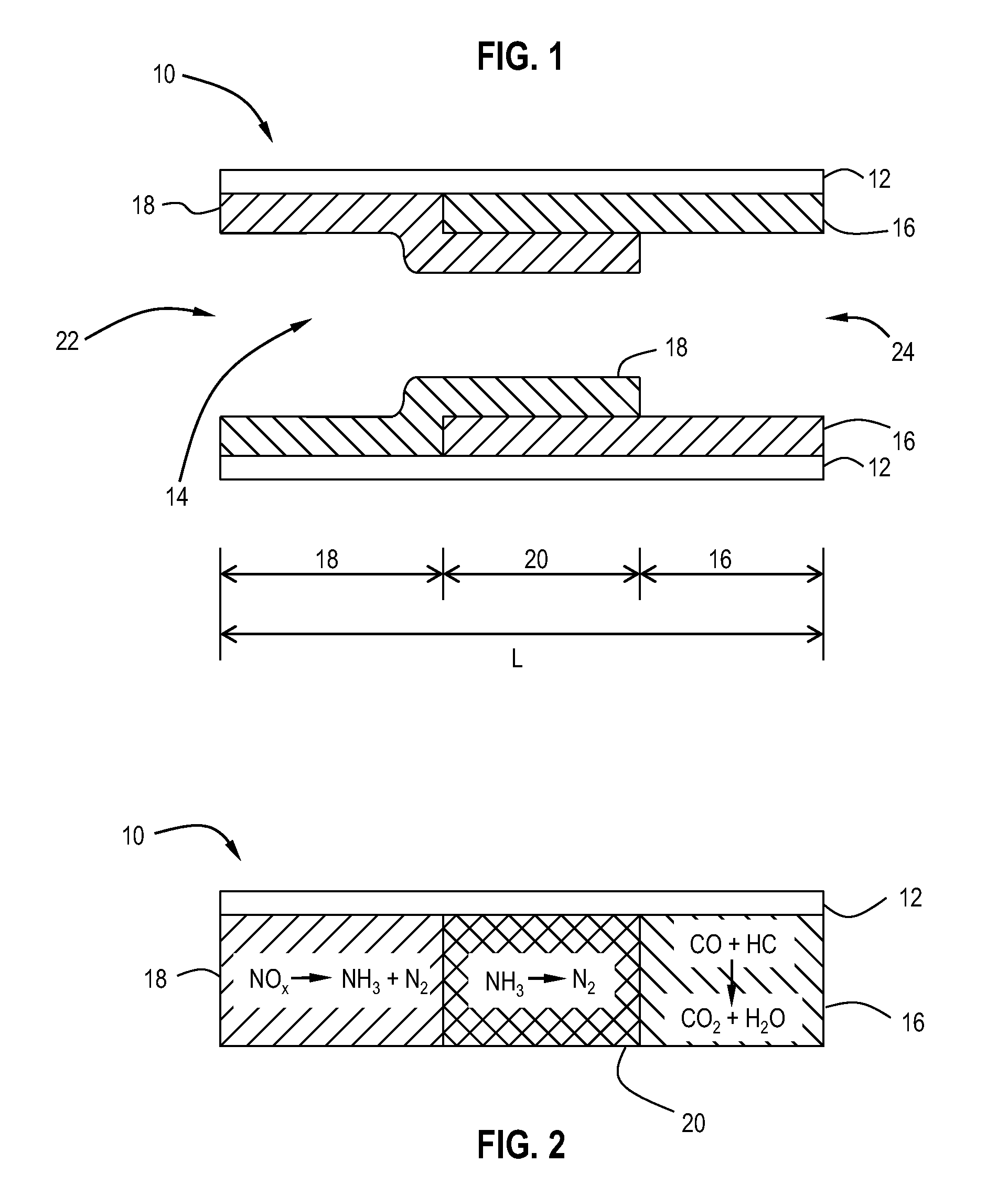

ActiveUS20100175372A1Compact efficient in removingMinimal backpressureGas treatmentInternal combustion piston enginesExhaust fumesDiesel particulate filter

A diesel engine exhaust treatment system and method is provided which utilizes a diesel particulate filter positioned in the exhaust gas stream of a vehicle which includes an SCR catalyst, an ammonia oxidation catalyst, and / or a diesel oxidation catalyst. The system is capable of performing multiple functions including converting NOx to N2, converting HC and CO to H2O and CO2, trapping particulates, and minimizing ammonia emissions. The system is more compact and efficient than prior systems utilizing separate catalyst units, and minimizes backpressure while maximizing catalyst performance.

Owner:FORD GLOBAL TECH LLC

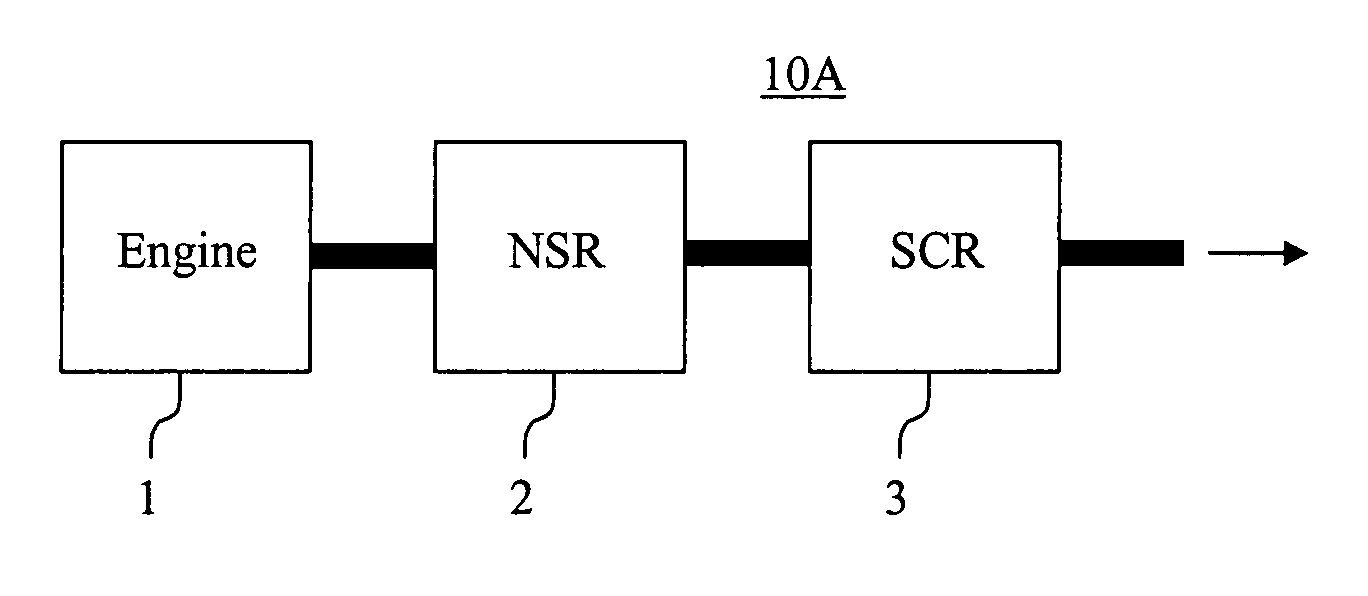

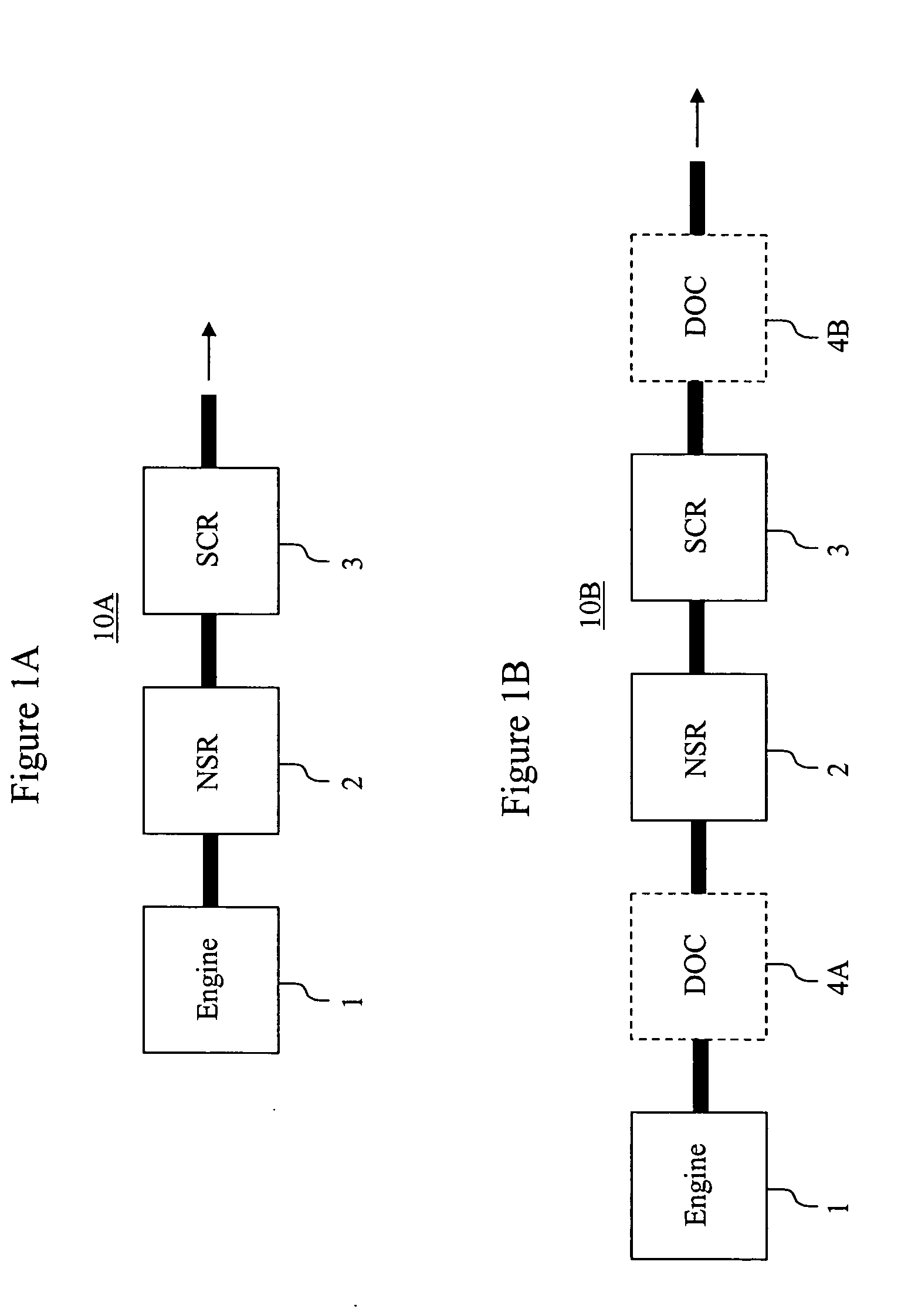

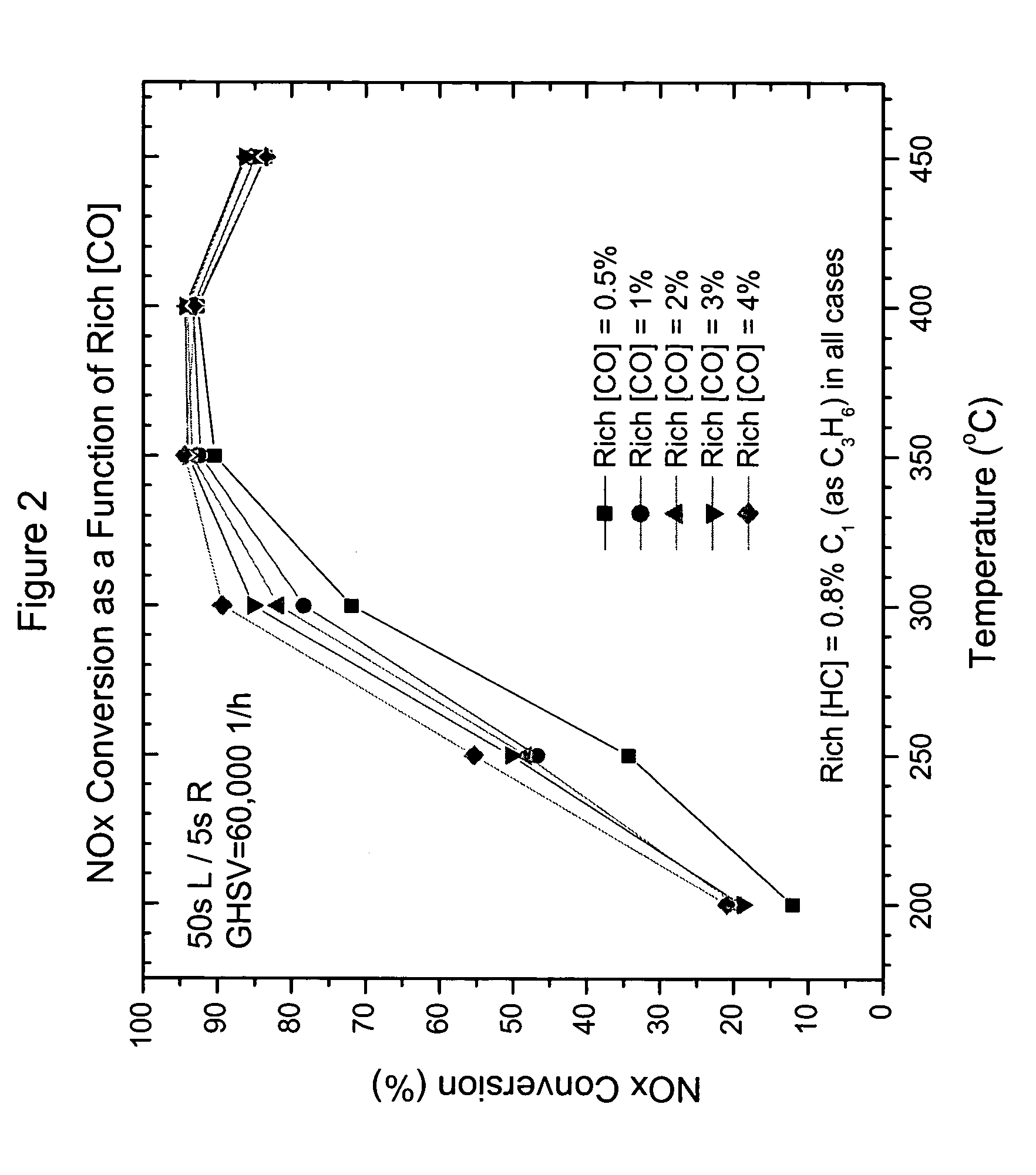

Emissions treatment system with NSR and SCR catalysts

ActiveUS20050129601A1Small sizeReduce amount particulate matterGas treatmentNitrogen compoundsSorbentGasoline

Provided is an emissions treatment system for an exhaust stream, having a NOx storage reduction (NSR) catalyst with a NOx sorbent at a concentration of at least 0.1 g / in3 and a platinum group metal component dispersed on a refractory metal oxide support; and, an SCR catalyst disposed downstream of the NSR catalyst. The emissions treatment system is advantageously used for the treatment of exhaust streams from diesel engines and lean burn gasoline engines.

Owner:BASF CATALYSTS LLC

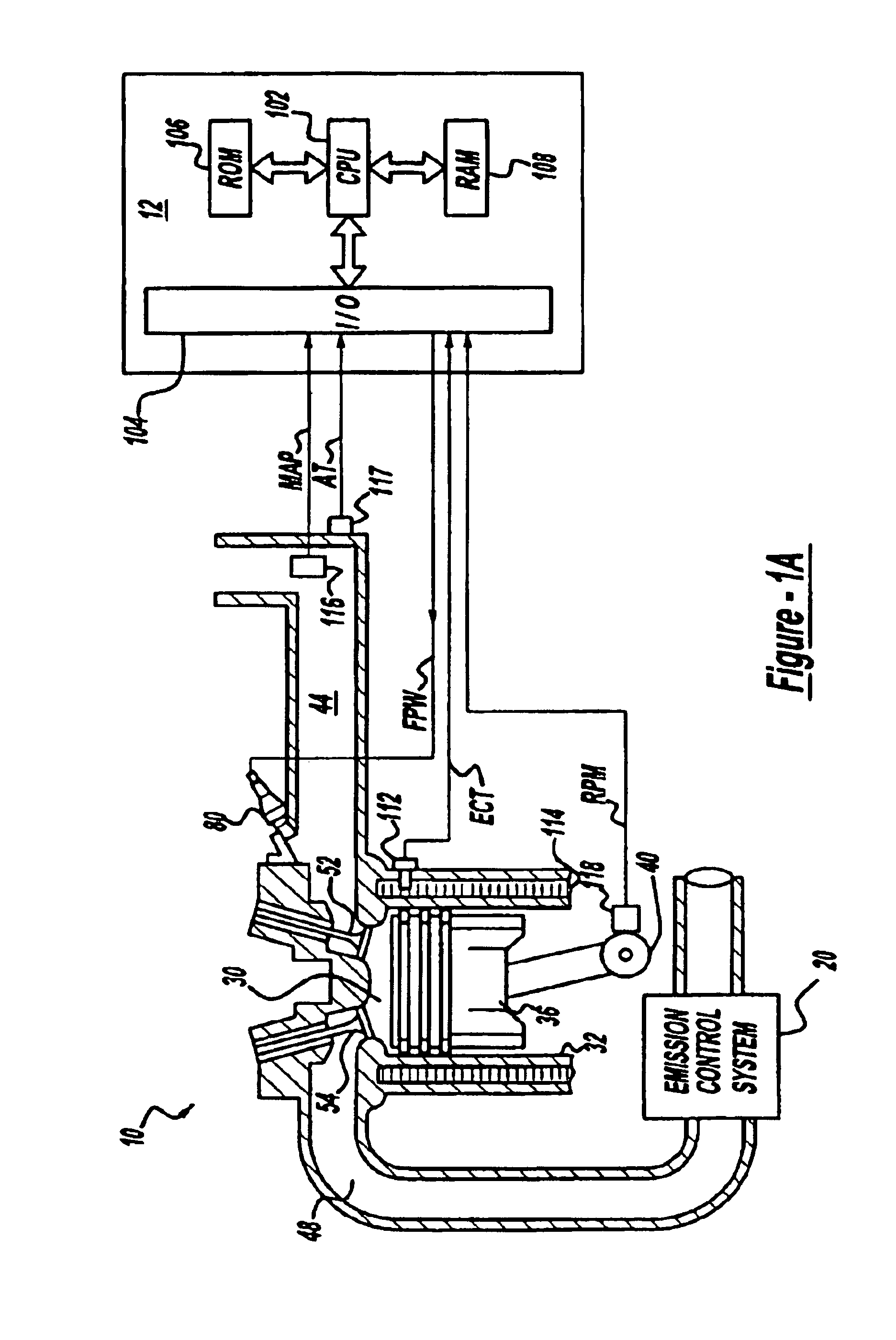

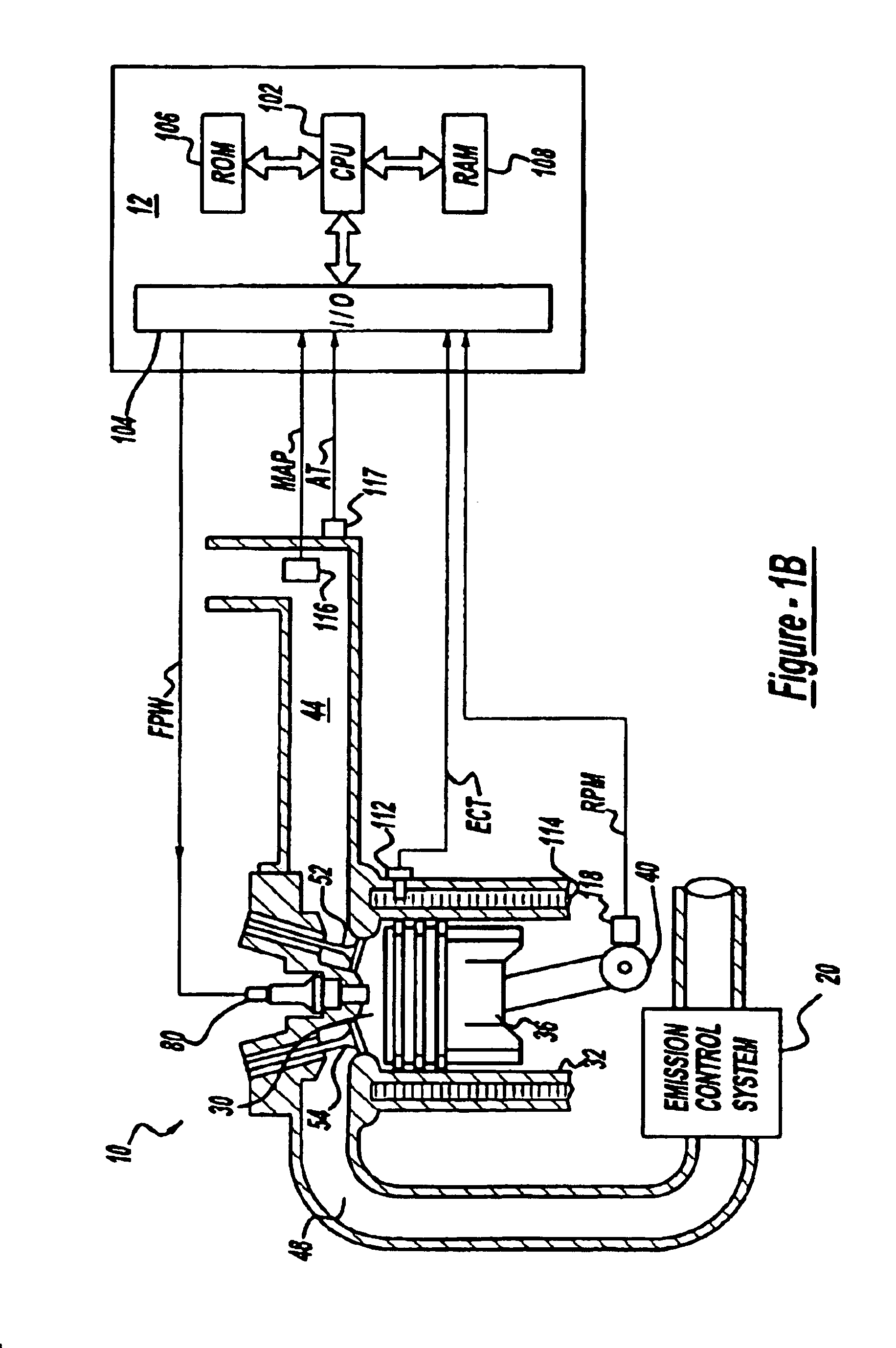

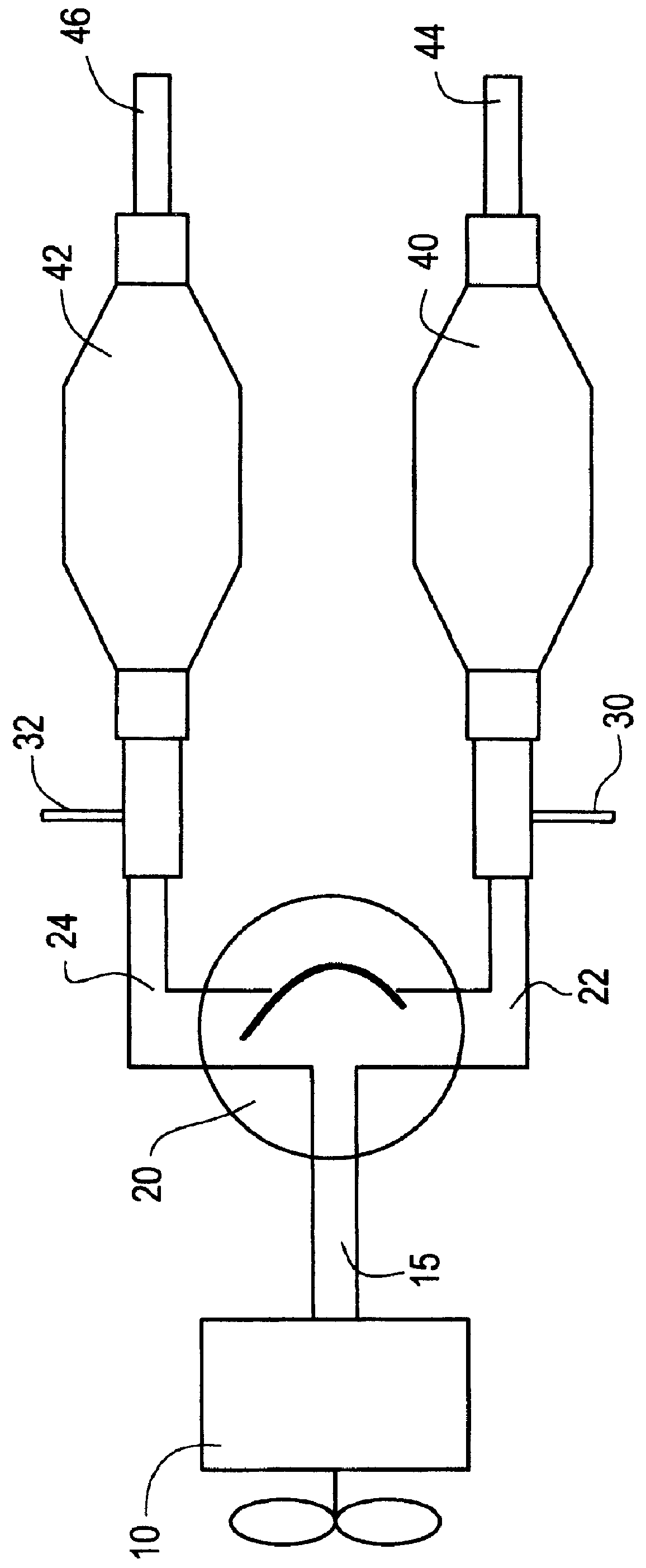

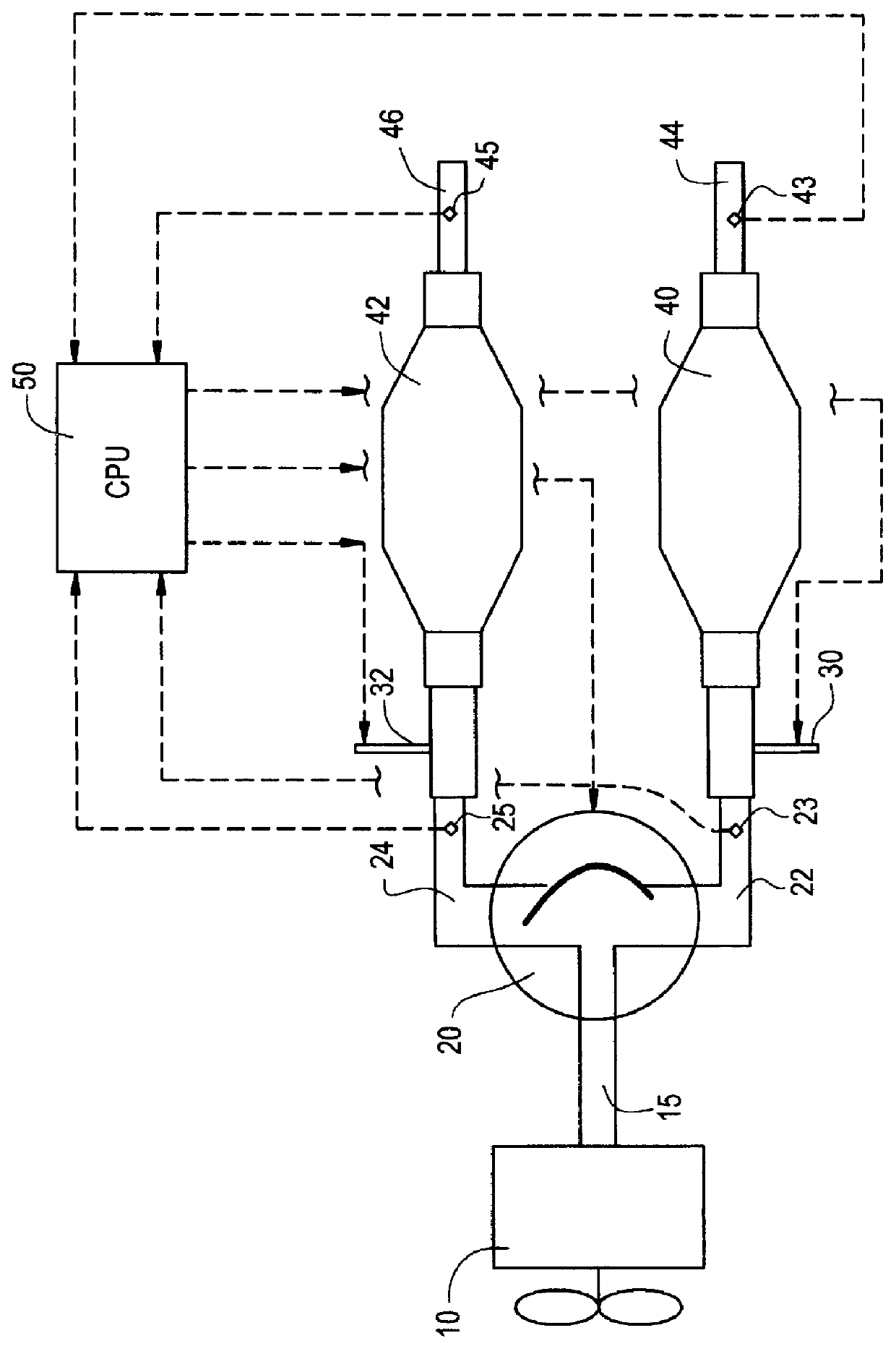

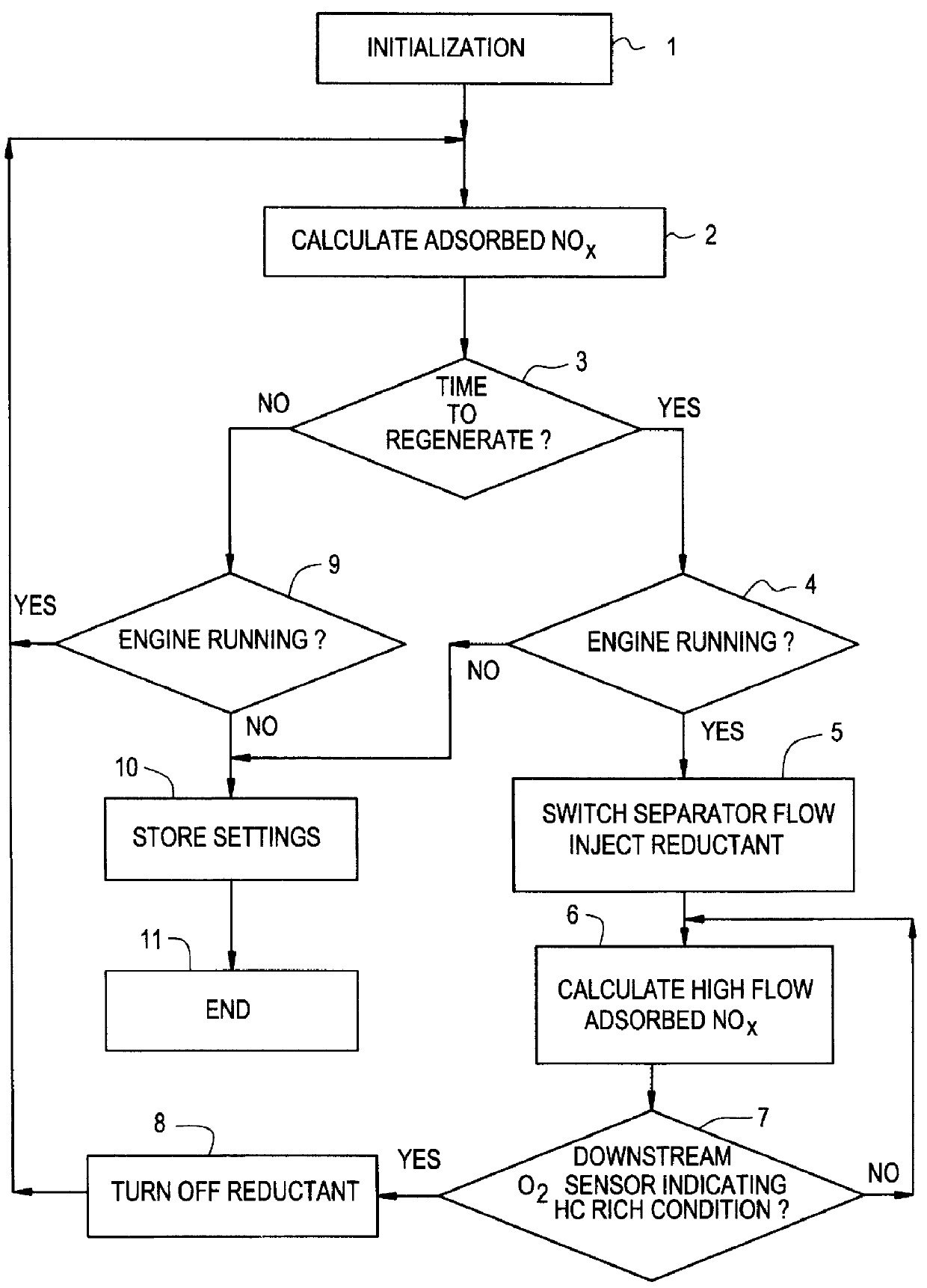

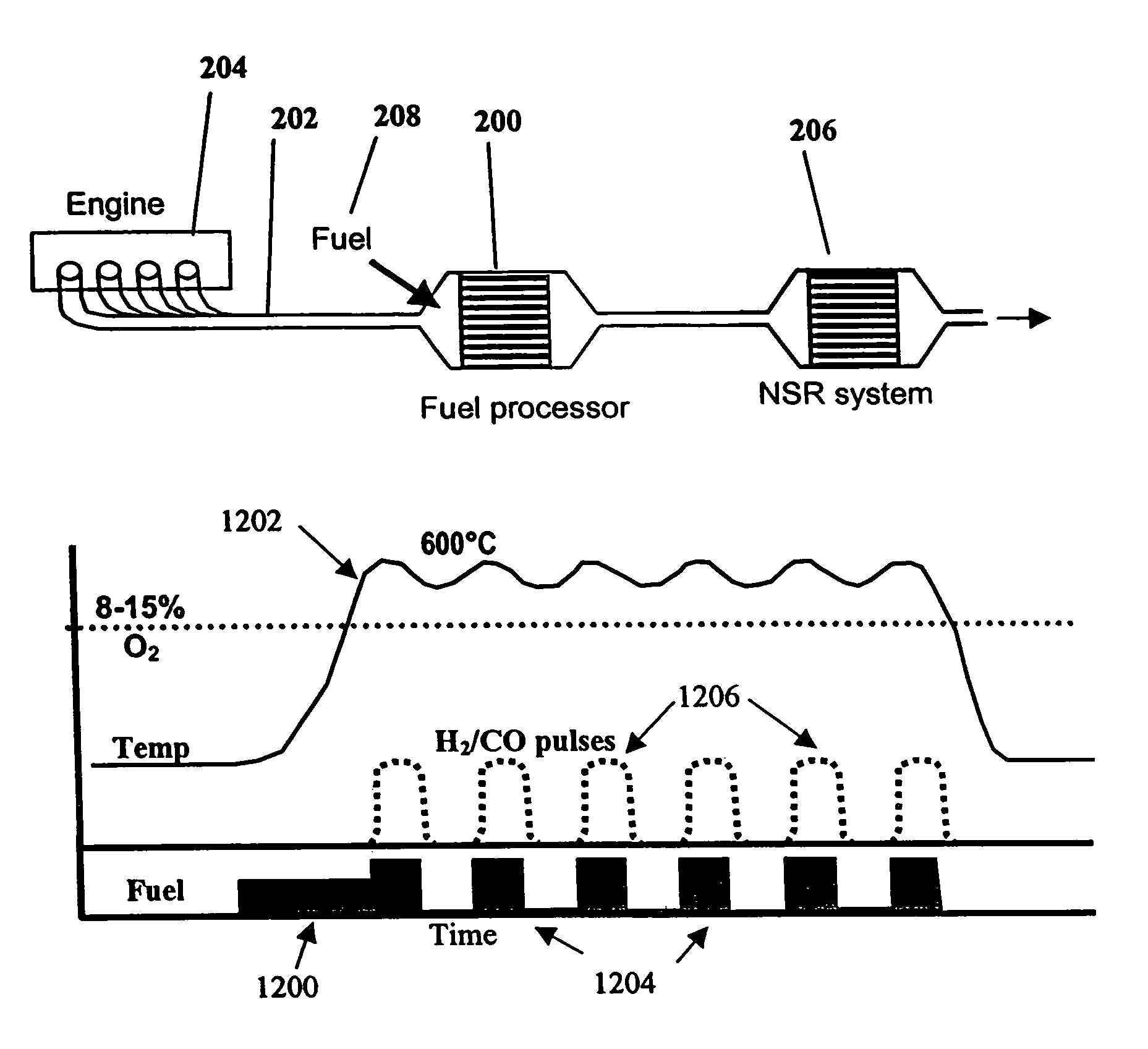

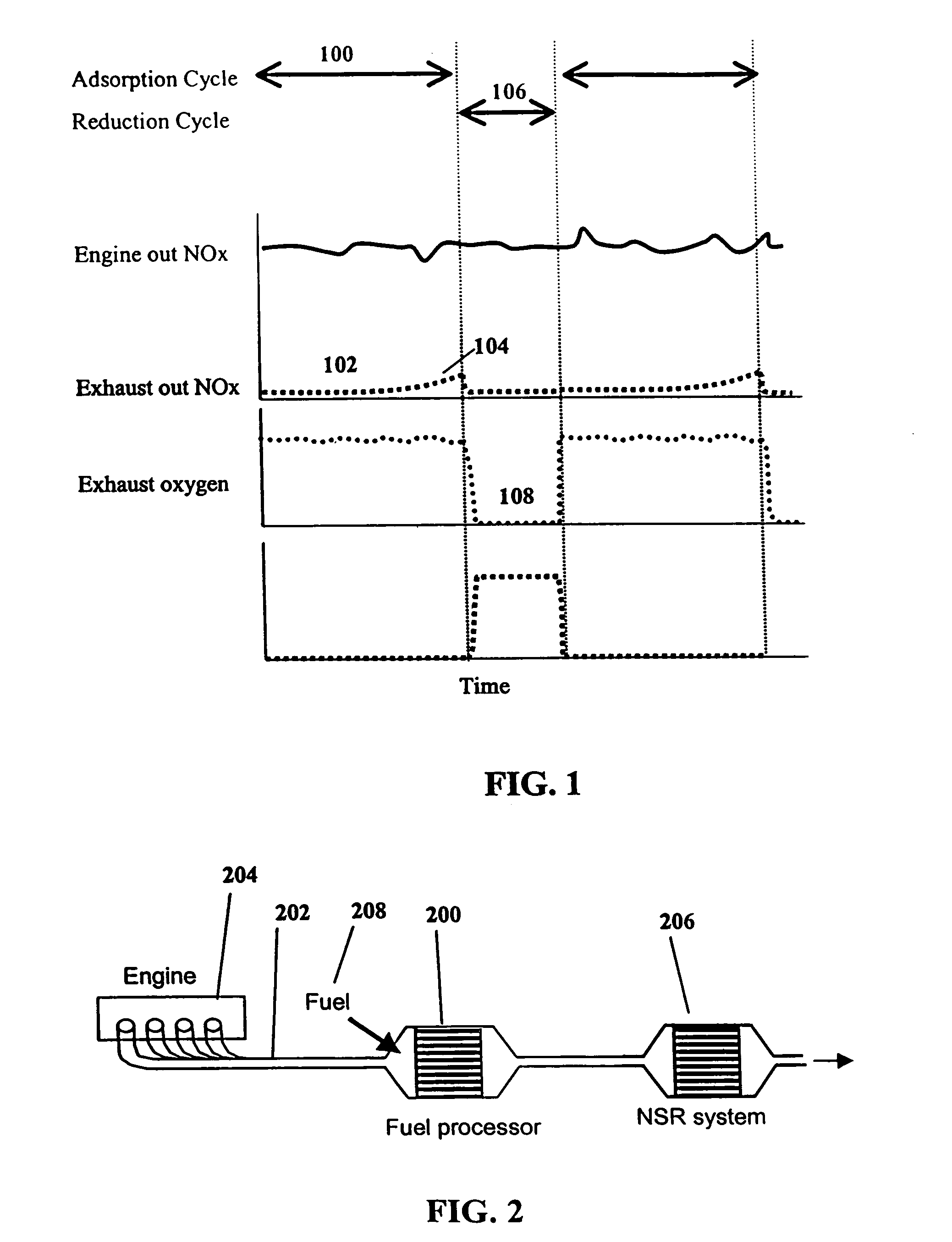

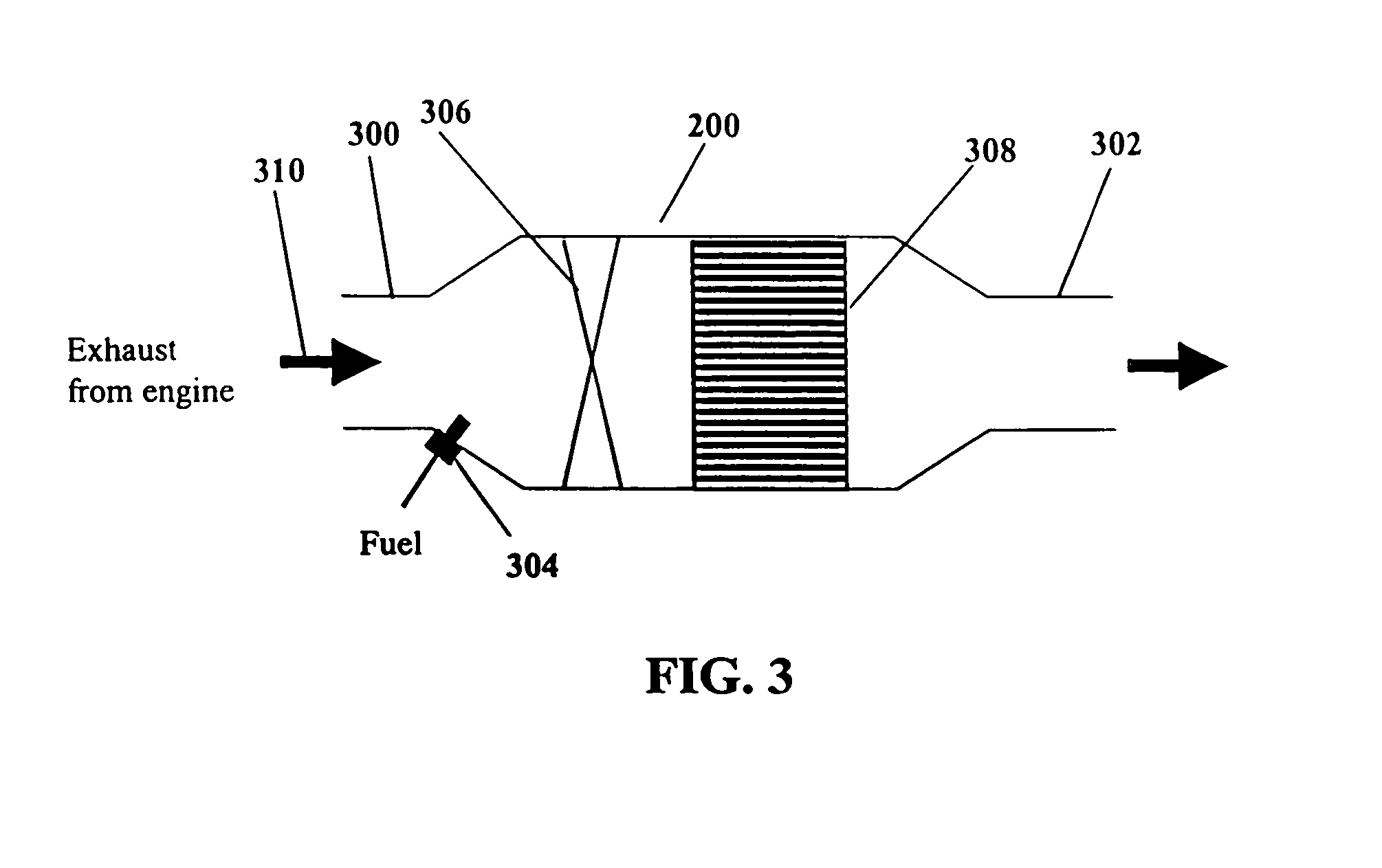

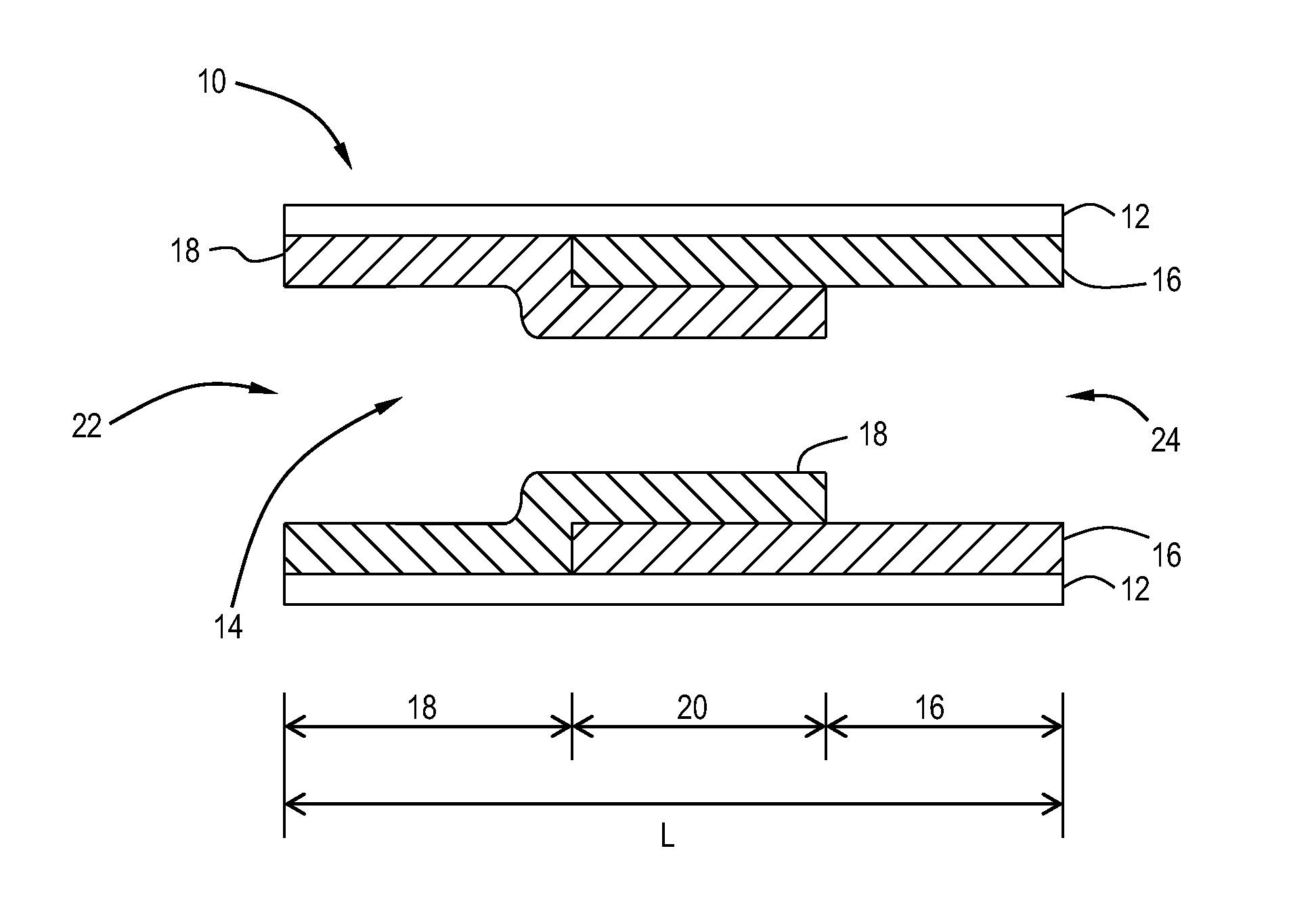

System and methods for improved emission control of internal combustion engines using pulsed fuel flow

InactiveUS7082753B2Save oilReducing greenhouse gas emissionExhaust apparatusCombustion enginesPartial oxidationExternal combustion engine

The present invention provides systems and methods to improve the performance and emission control of internal combustion engines equipped with nitrogen oxides storage-reduction (“NSR”) emission control systems. The system generally includes a NSR catalyst, a fuel processor located upstream of the NSR catalyst, and at least one fuel injection port. The fuel processor converts a fuel into a reducing gas mixture comprising CO and H2. The reducing gas mixture is then fed into the NSR catalyst, where it regenerates the NSR adsorbent, reduces the NOx to nitrogen, and optionally periodically desulfates the NSR catalyst. The fuel processor generally includes one or more catalysts, which facilitate reactions such as combustion, partial oxidation, and / or reforming and help consume excess oxygen present in an engine exhaust stream. The methods of the present invention provide for NSR catalyst adsorbent regeneration using pulsed fuel flow. Control strategies are also provided.

Owner:INT ENGINE INTPROP CO LLC

Integrated SCR and AMOX Catalyst Systems

Catalysts and catalytic articles for treating exhaust gas streams are described. In one or more embodiments, a catalyst system includes a first zone to abate nitrogen oxides by selective catalytic reduction, a second zone to oxidize ammonia and a third zone to oxidize carbon monoxide and hydrocarbons. Methods for treating the exhaust gas stream are also provided. Methods of making and using such catalysts and catalytic articles are also described.

Owner:BASF CORP

Integrated NOx and PM reduction devices for the treatment of emissions from internal combustion engines

InactiveUS20060179825A1Reduce volumeReduce expensesNitrous oxide captureGas treatmentEnvironmental engineeringDiesel particulate filter

One concept of the inventors relates to a system and method in which a particulate filter comprises at least about 40% by weight of an NOx adsorbant. The filter can be used as both an NOx trap and a particulate filter. By constructing the filter elements using a substantial amount of NOx adsorbant, a large volume of NOx adsorbant can be incorporated into the particulate filter, which substantially reduces the volume and expense of an exhaust system that includes both a catalytic diesel particulate filter and an NOx trap having a large quantity of NOx adsorbant. In a preferred embodiment, the filter also oxidizes NO to NO2. In another preferred embodiment, an SCR catalyst is position downstream of the filter elements.

Owner:EATON CORP

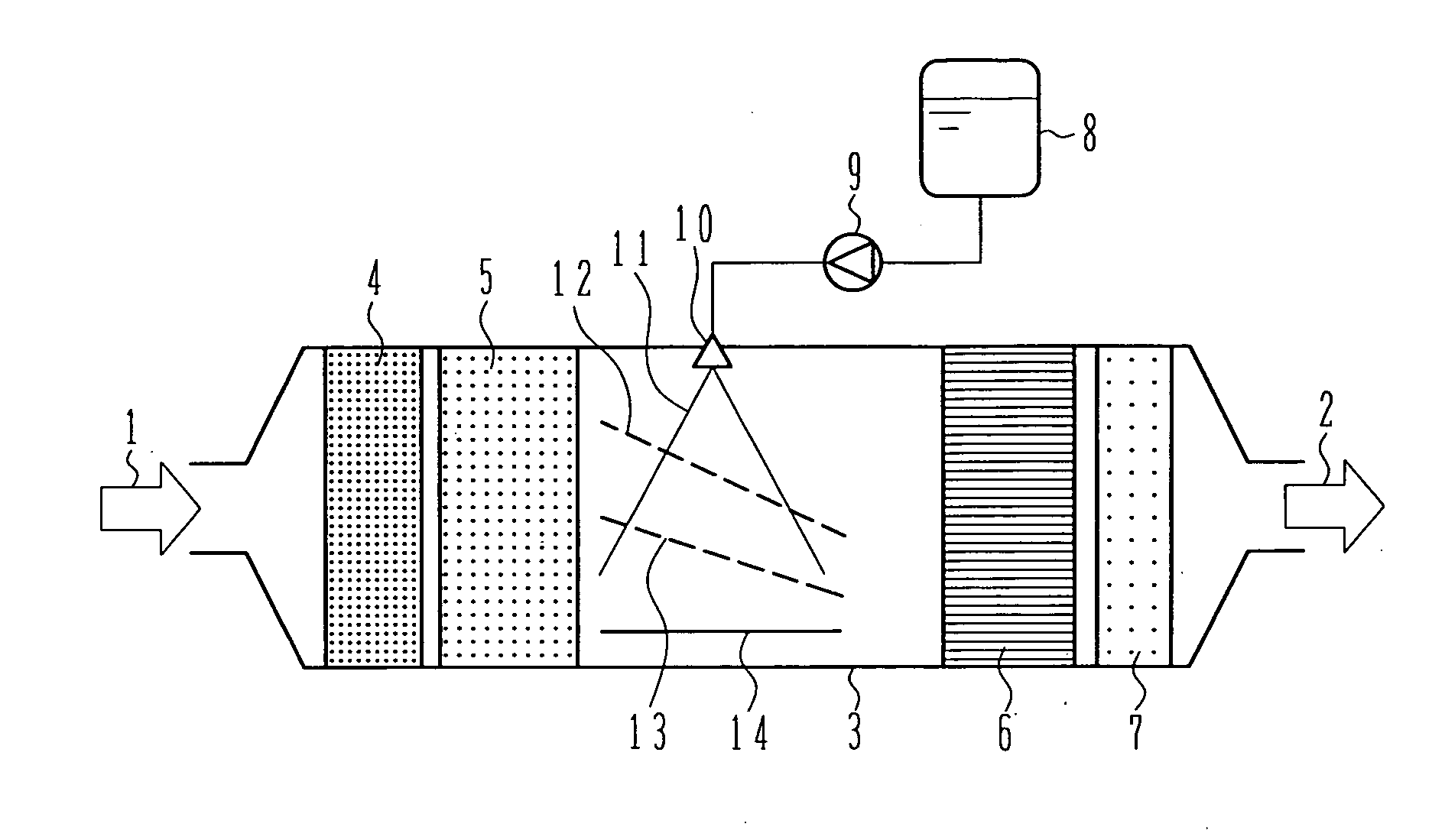

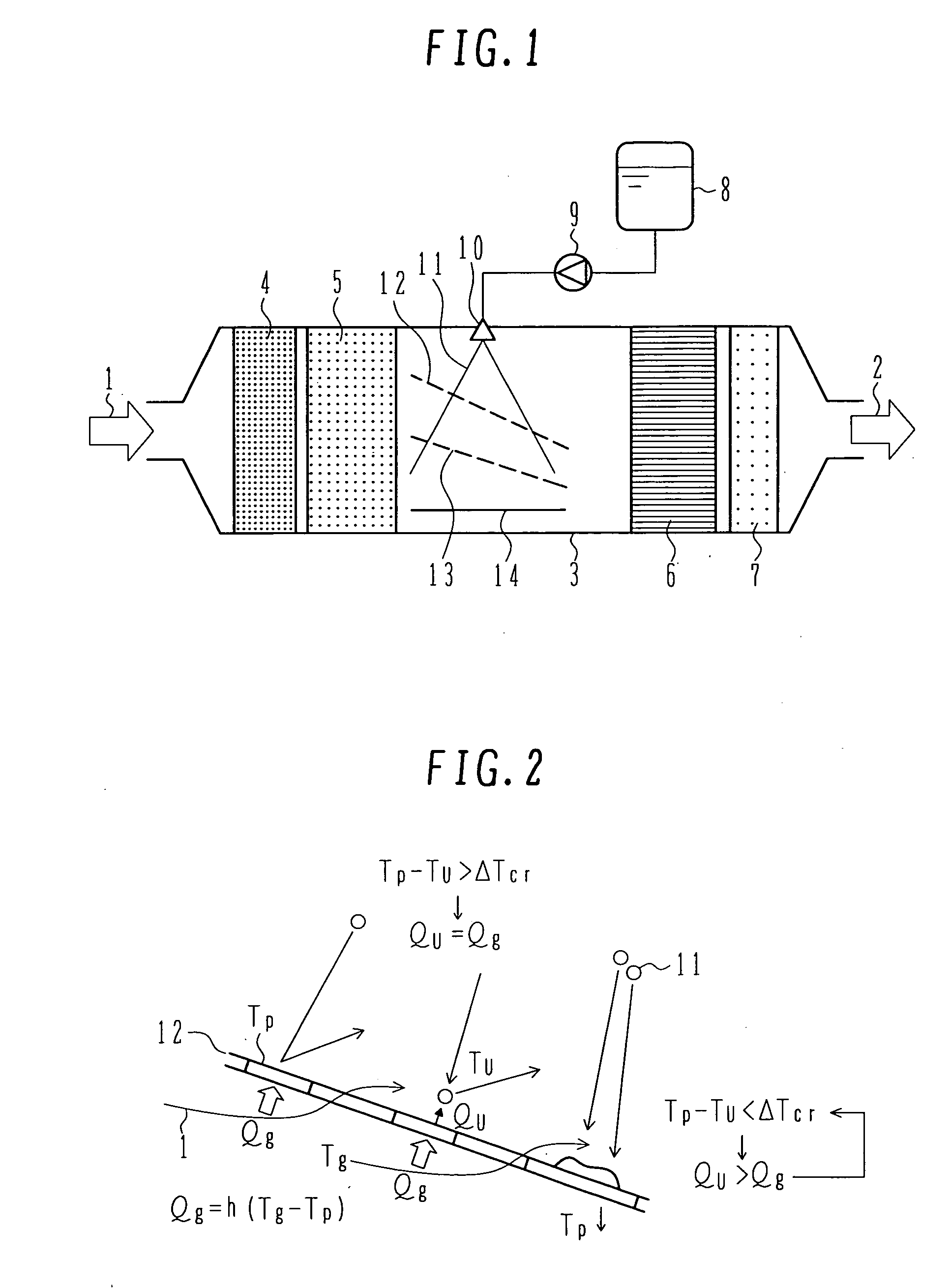

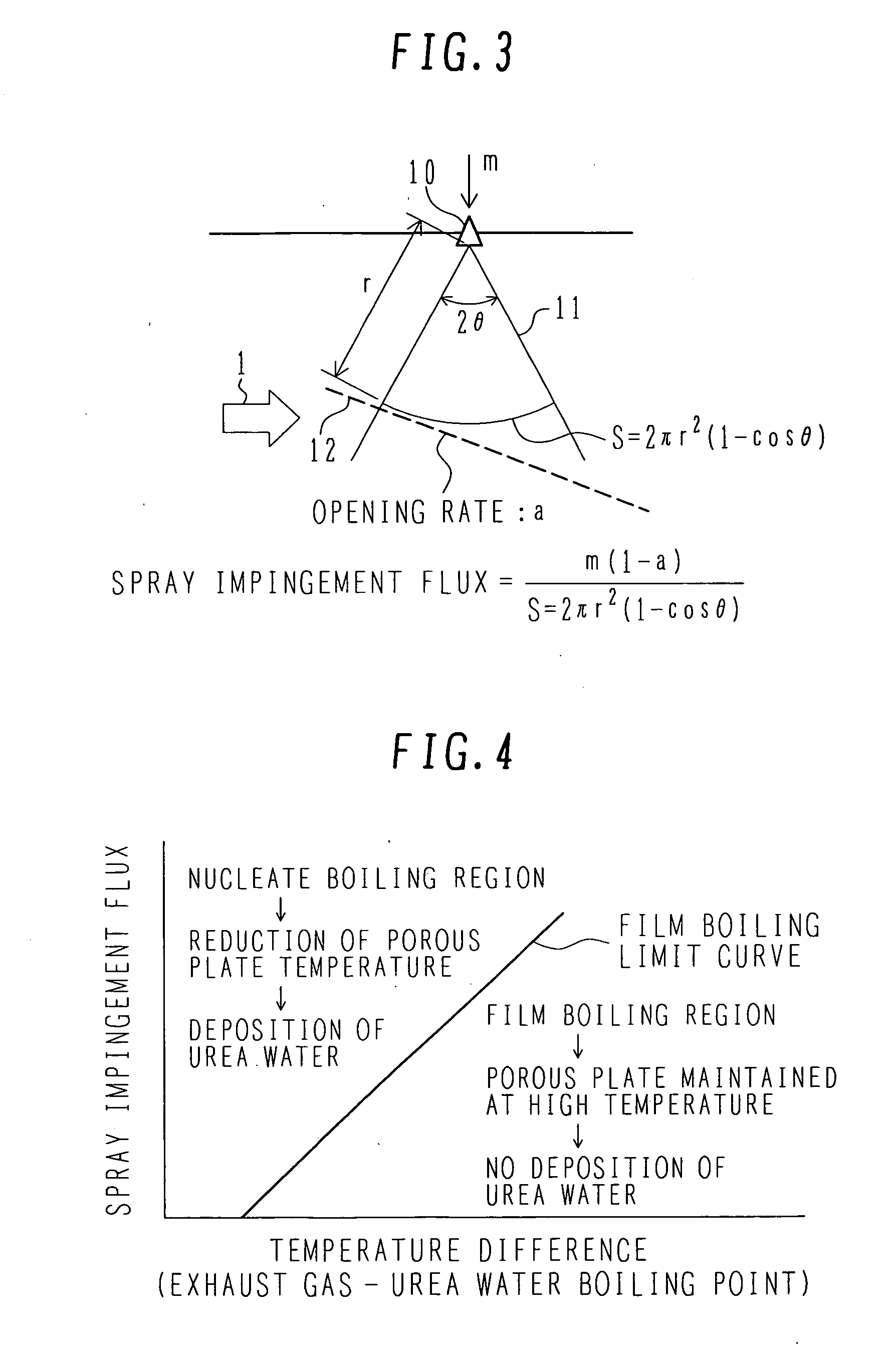

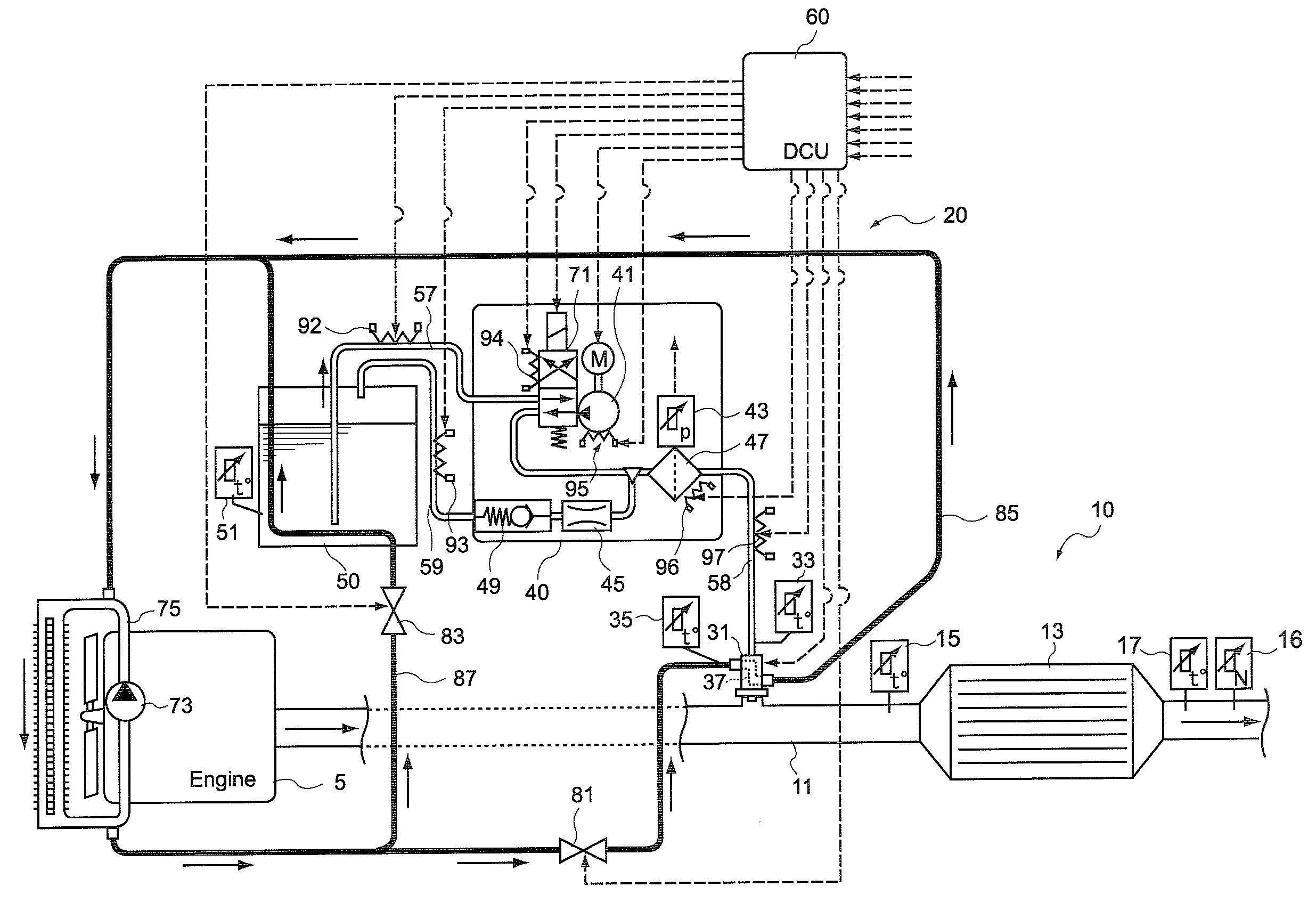

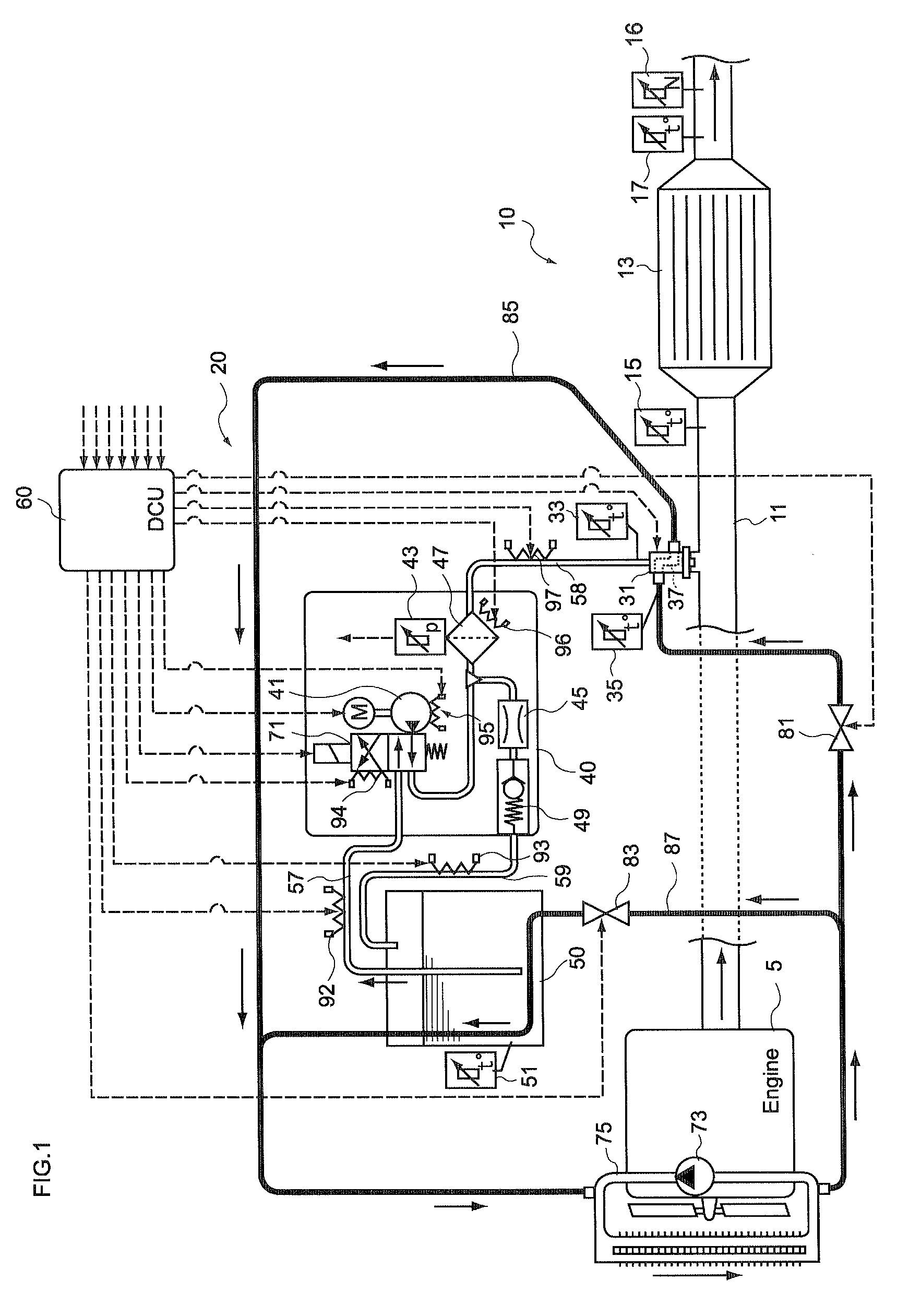

Exhaust aftertreatment system using urea water

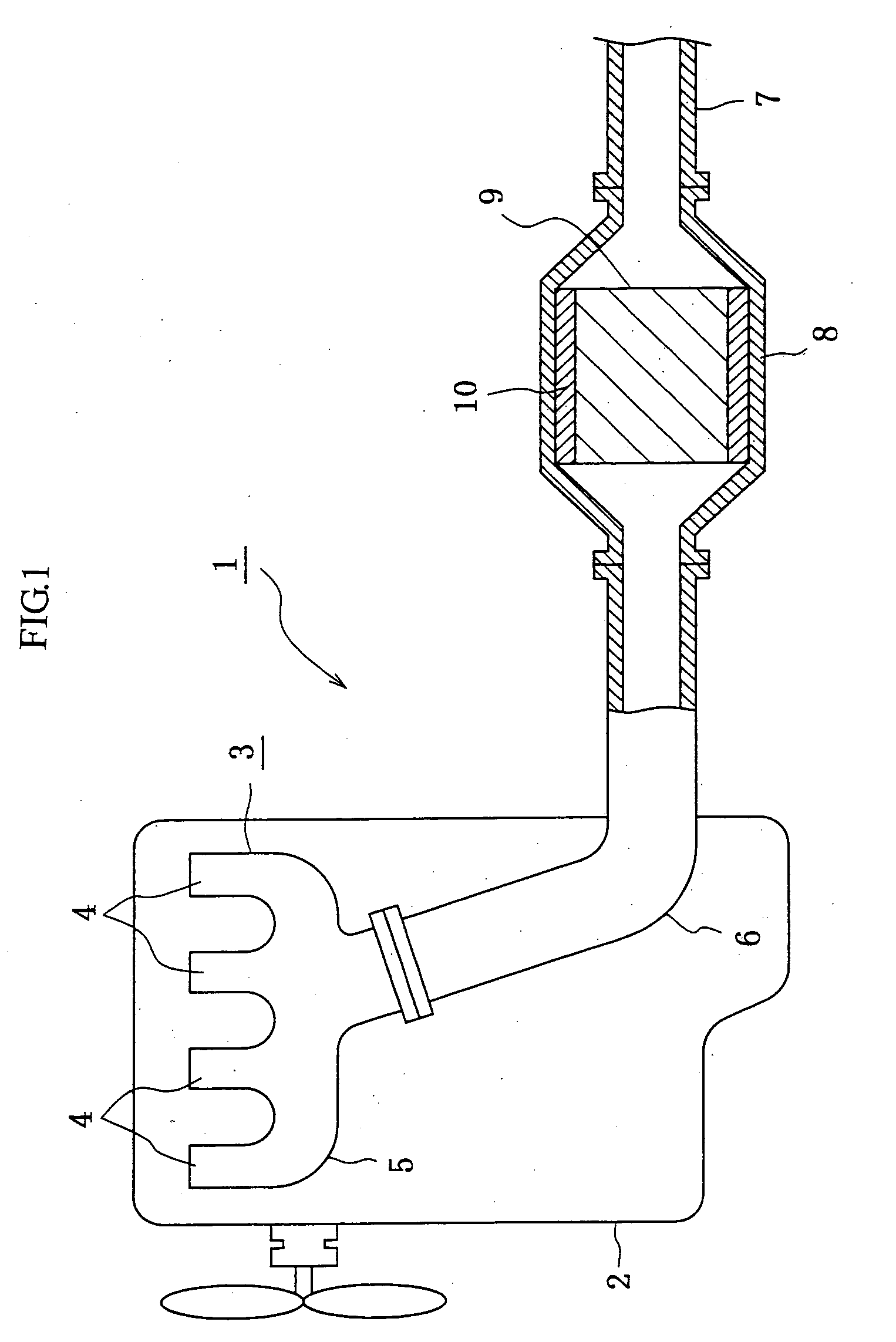

InactiveUS20070036694A1Avoid depositionReduced responseCombination devicesInternal combustion piston enginesHandling systemMultiple stages

An exhaust aftertreatment system comprises an injector for injecting urea water into an exhaust duct, and a denitration catalyst disposed downstream of the injector with respect to a flow of exhaust gas. The exhaust aftertreatment system reduces nitrogen oxides in the exhaust gas by the denitration catalyst while using ammonia produced from the urea water injected from the injector. The urea water is injected along a direction of the flow of the exhaust gas within the exhaust duct, and a porous plate is disposed in multiple stages in a space of the exhaust duct such that droplets of the injected urea water impinge against the porous plate before reaching a wall surface of the exhaust duct. A surface of the porous plate subjected to the impingement of the droplets is arranged to face downstream with respect to the flow of the exhaust gas. Deposition of the urea water is prevented by causing film boiling when the droplets impinge against the porous plate, and the urea water reflected by the porous plate is uniformly dispersed into the exhaust gas. Thus, the urea water is uniformly dispersed into the exhaust gas without increasing a pressure loss of the exhaust gas. The urea water is prevented from depositing on the wall surface and producing a precipitate in the form of a solid.

Owner:HITACHI HIGH-TECH CORP +2

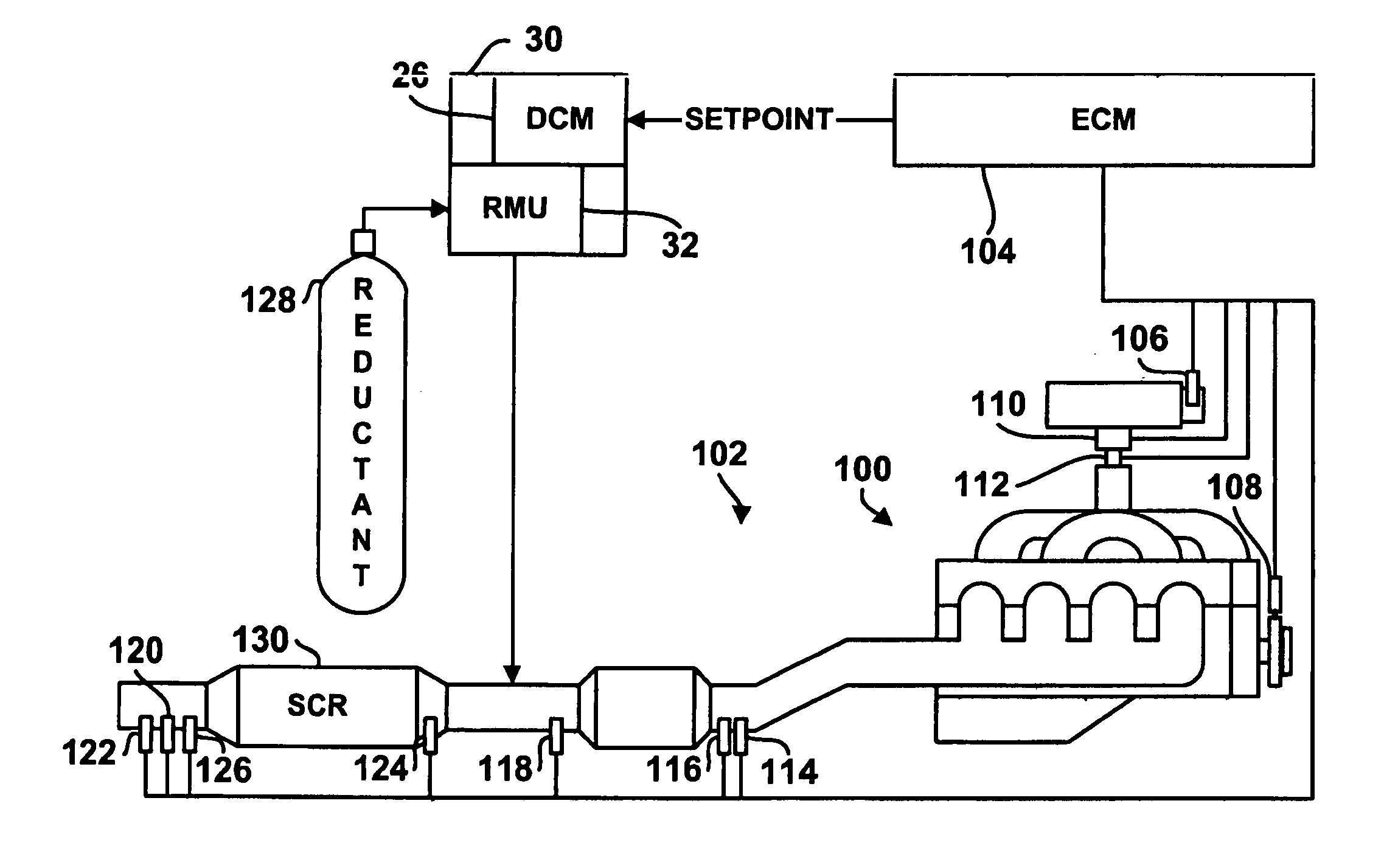

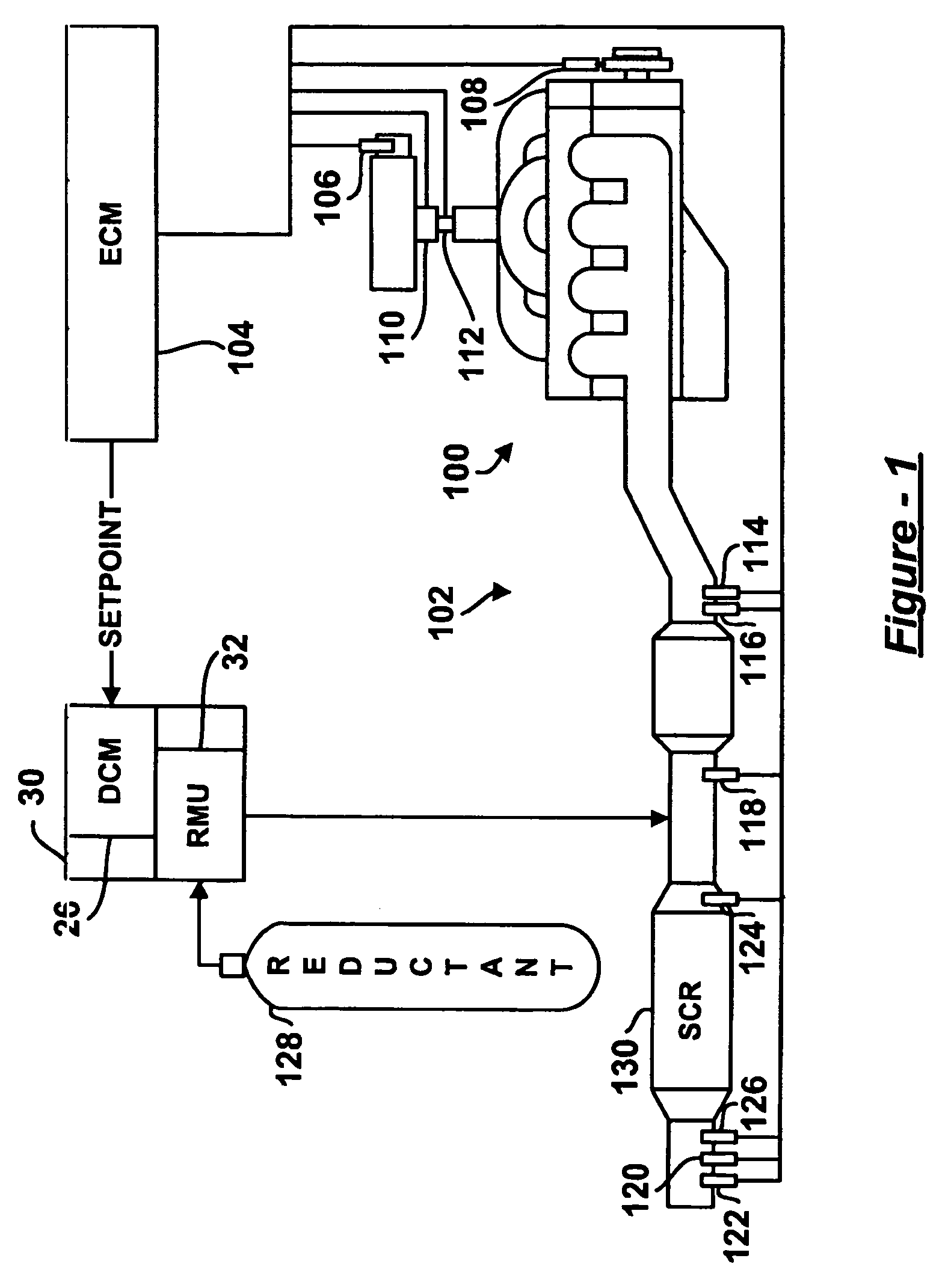

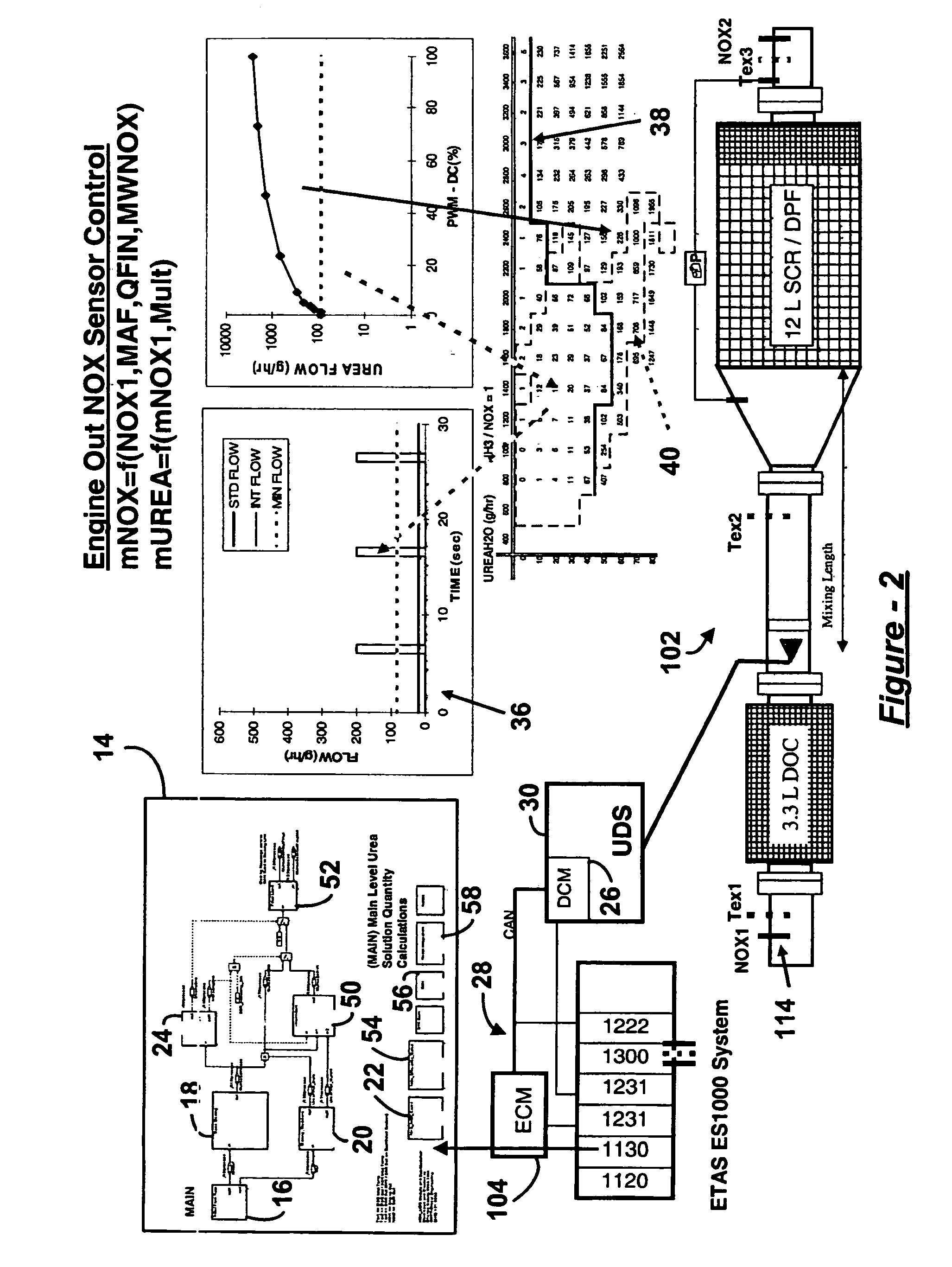

System for controlling the urea supply to SCR catalysts

A reductant dosing control system, for use in a Selective Catalytic Reduction (SCR) system of a motor vehicle includes an input receiving a NOx feedback signal from an NOx sensor provided to the SCR system. A base dosing module calculates a required quantity of reductant to inject in front of a SCR catalyst of the SCR system based on the NOx feedback signal. The SCR catalyst has ammonia storage properties. An output signals a reductant metering mechanism to periodically or continuously inject excess reductant based on the required quantity of reductant.

Owner:GM GLOBAL TECH OPERATIONS LLC

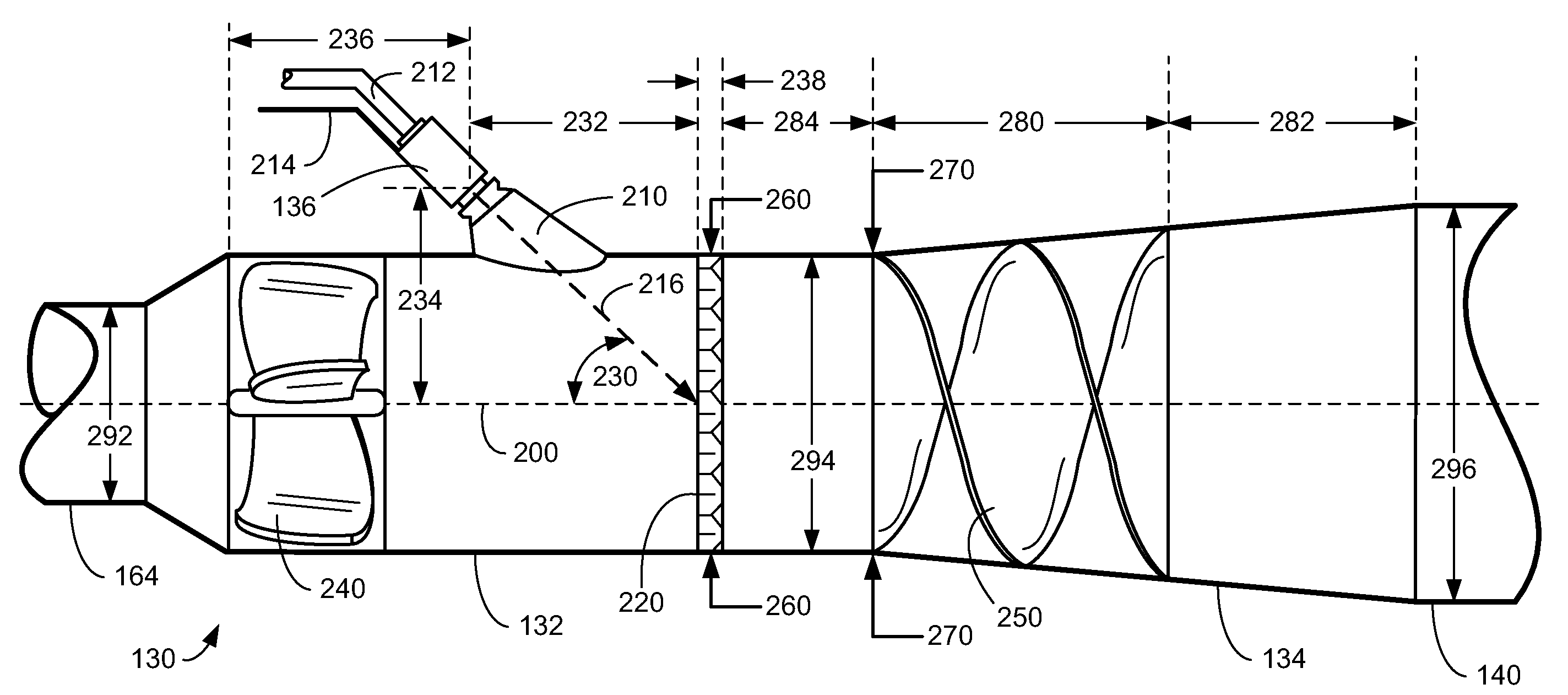

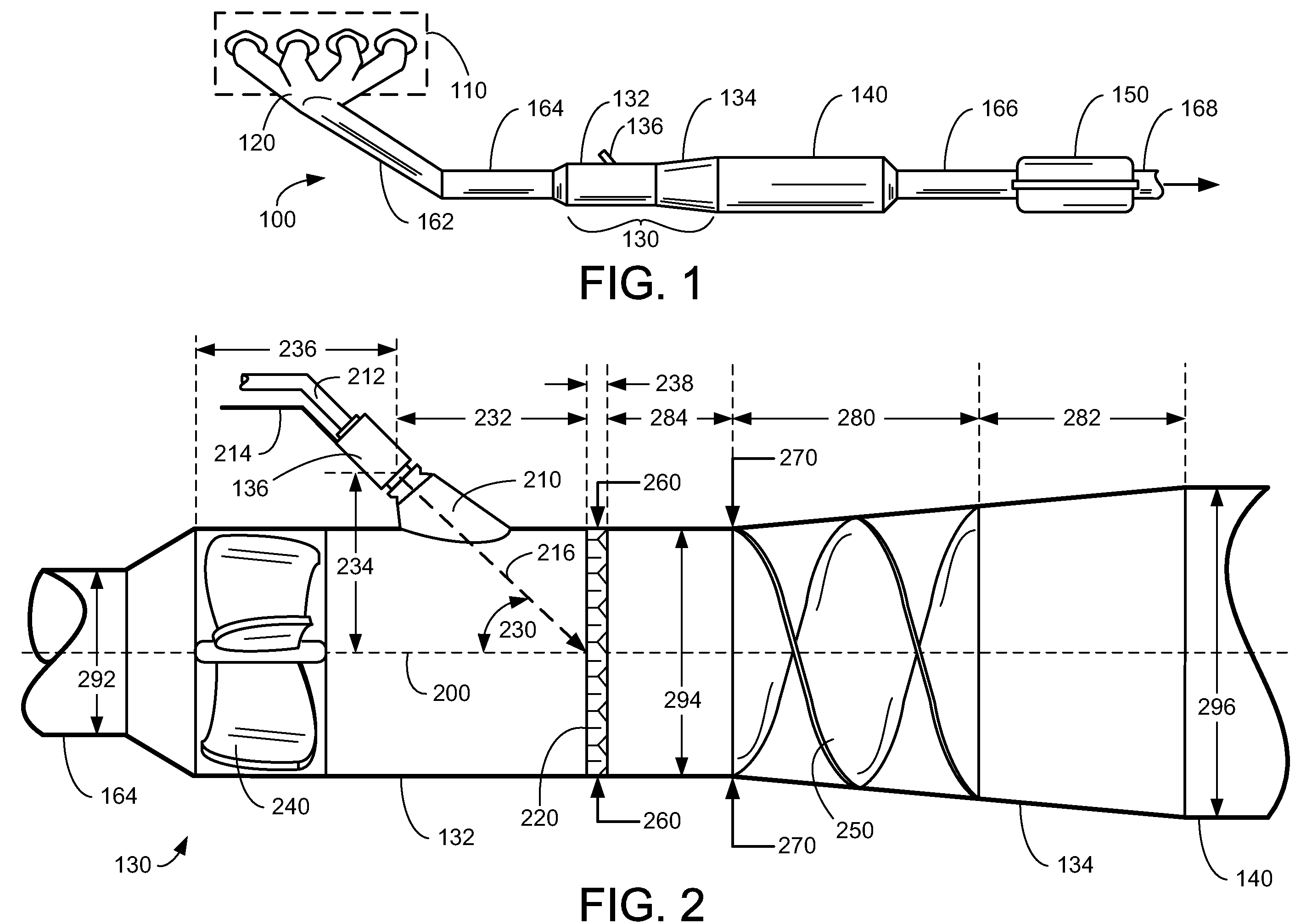

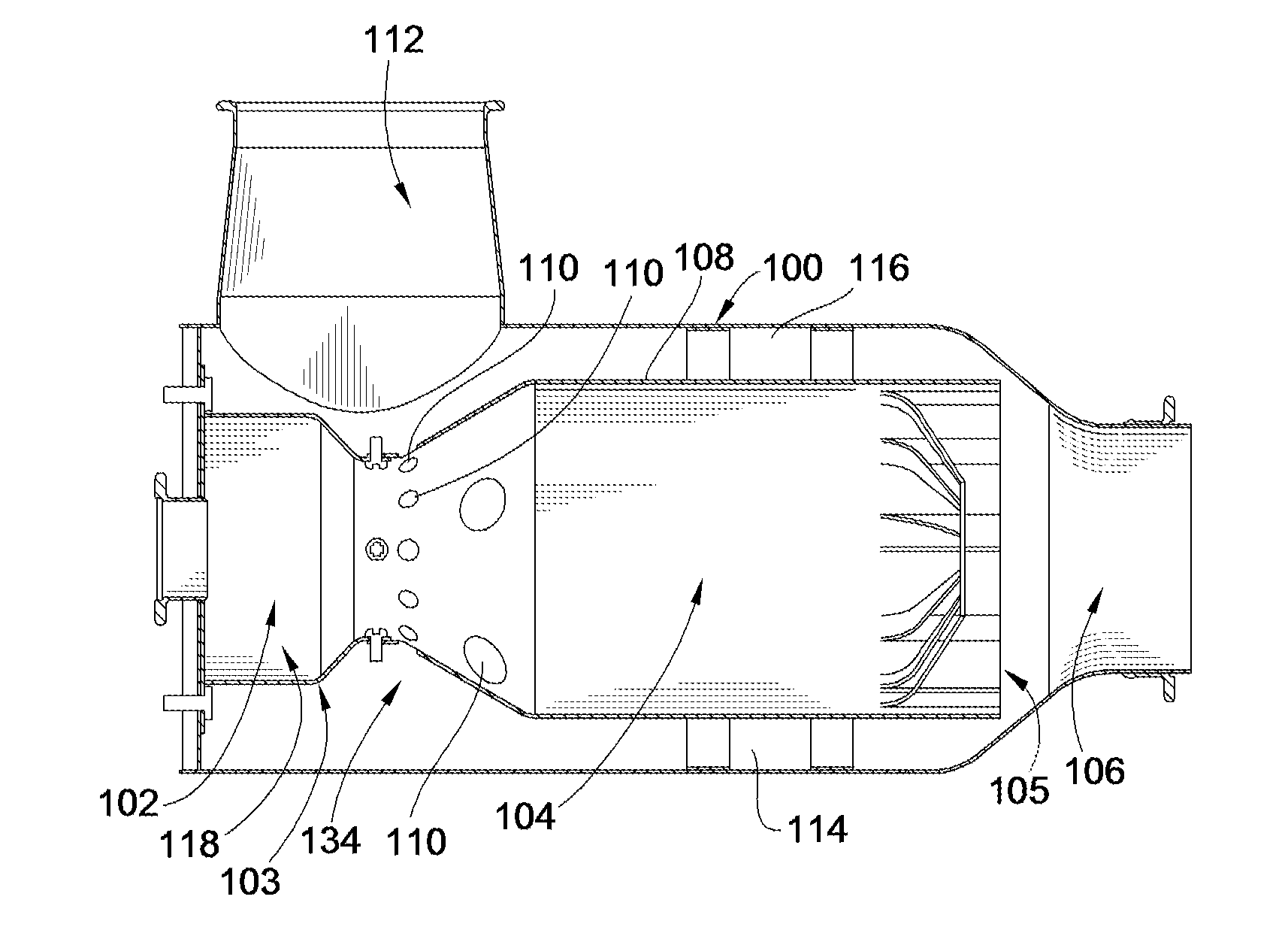

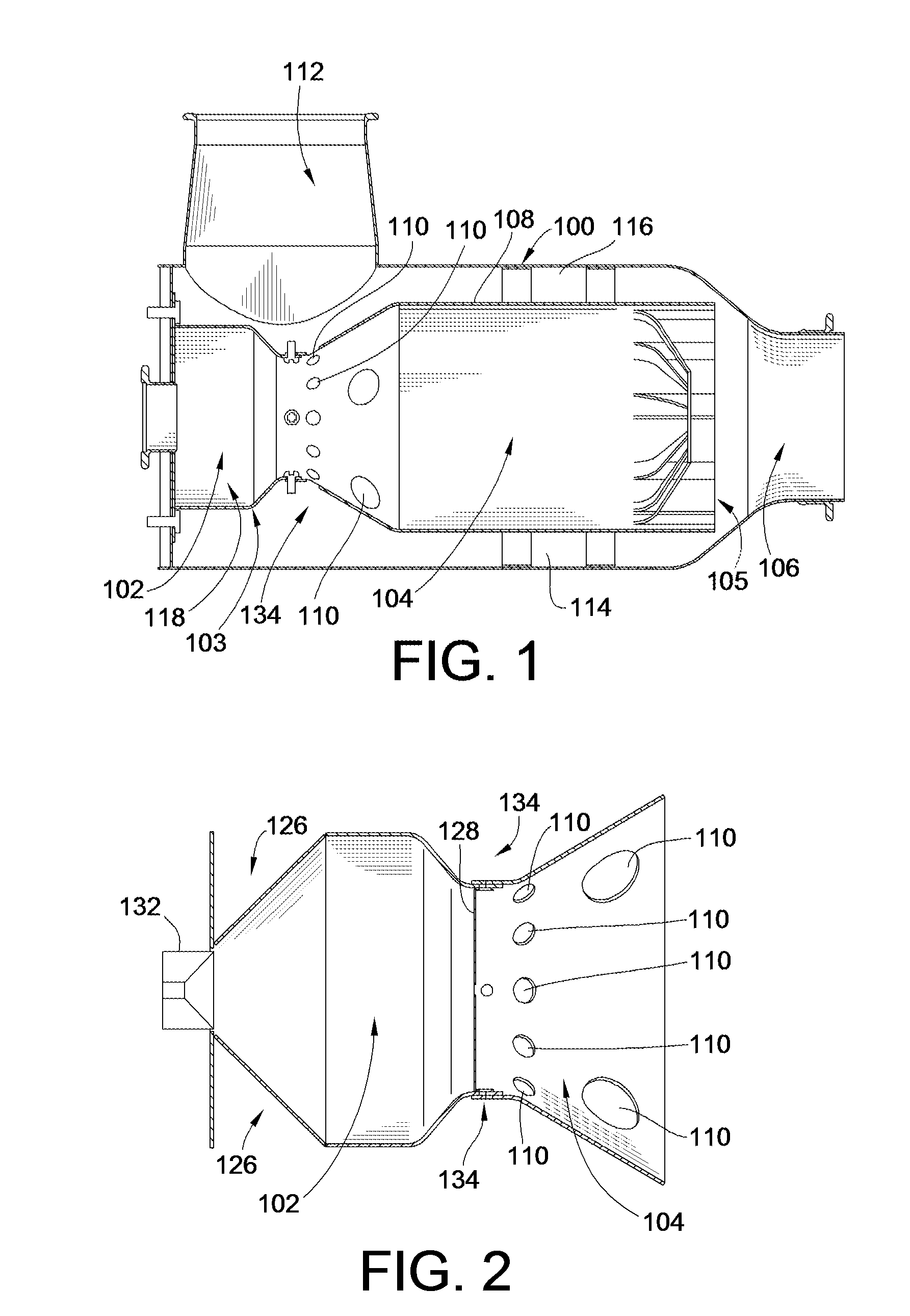

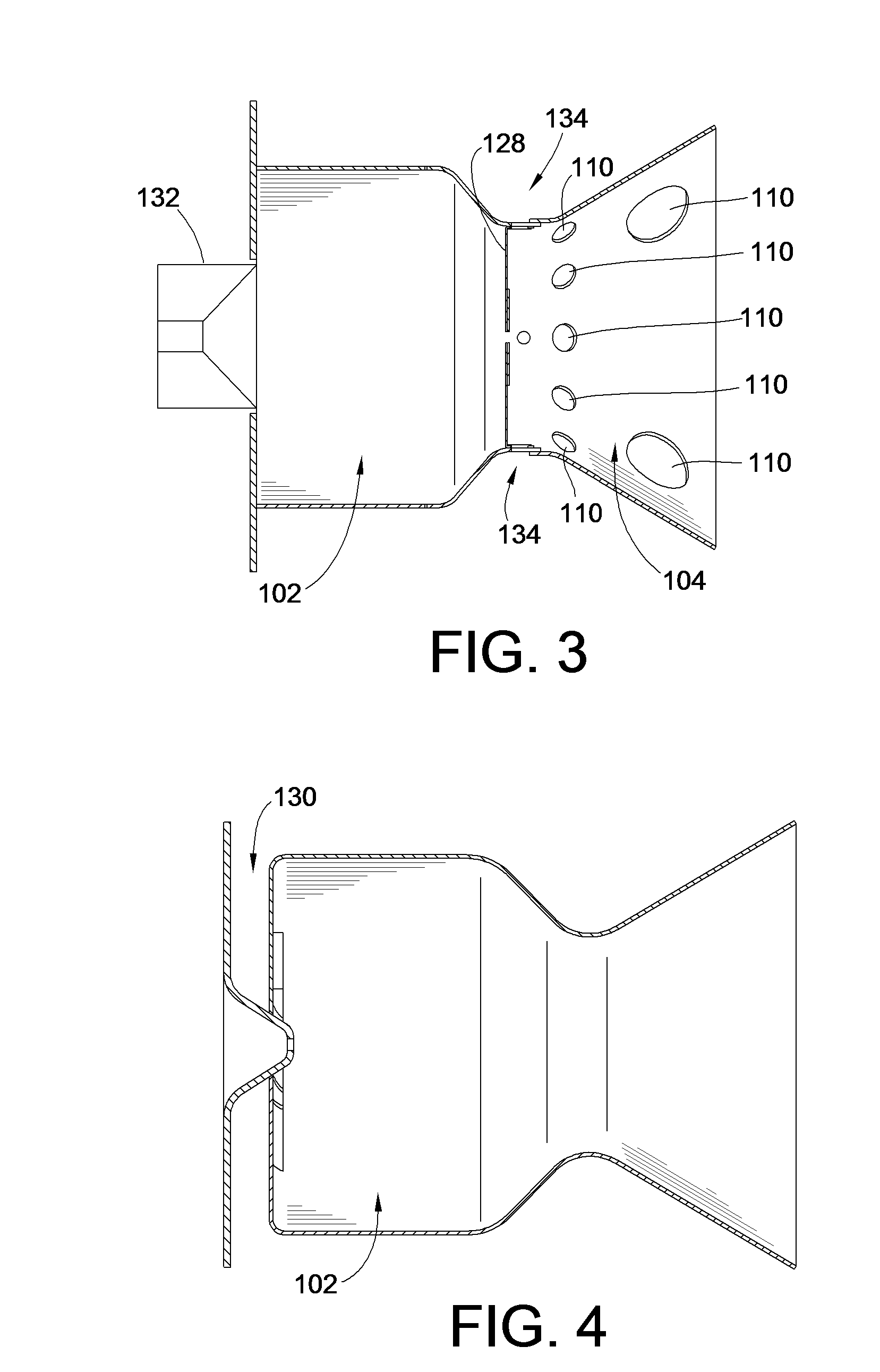

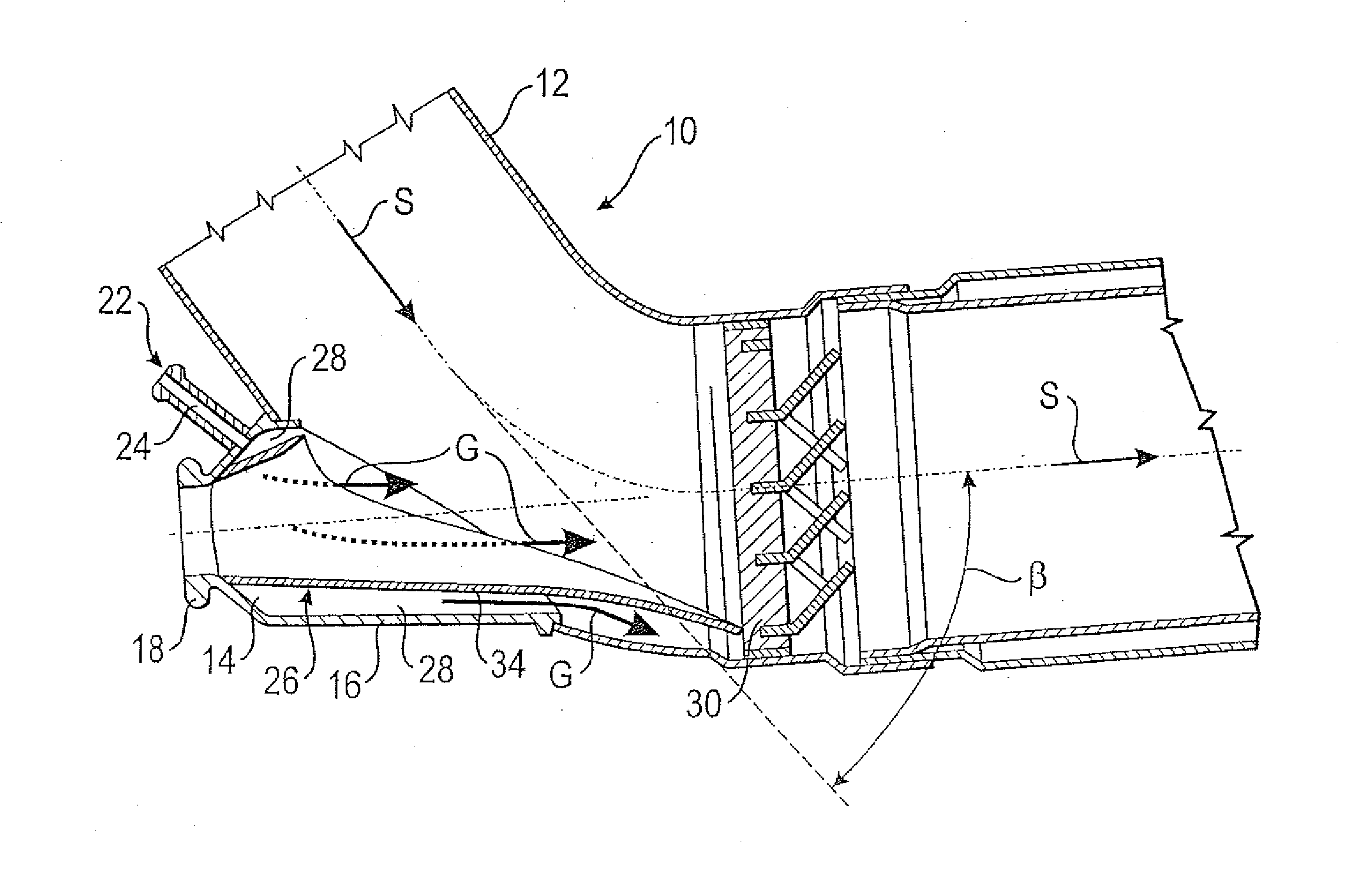

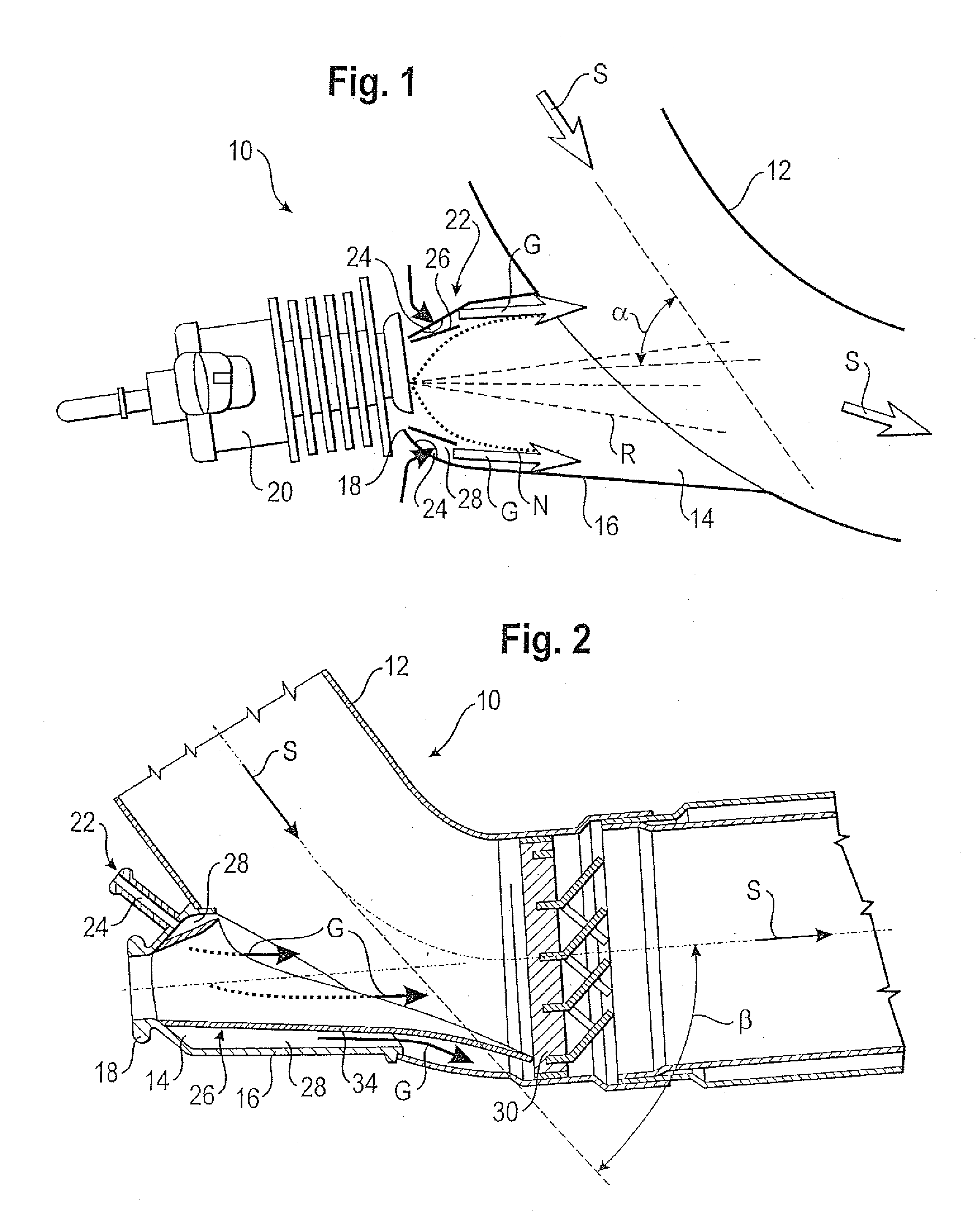

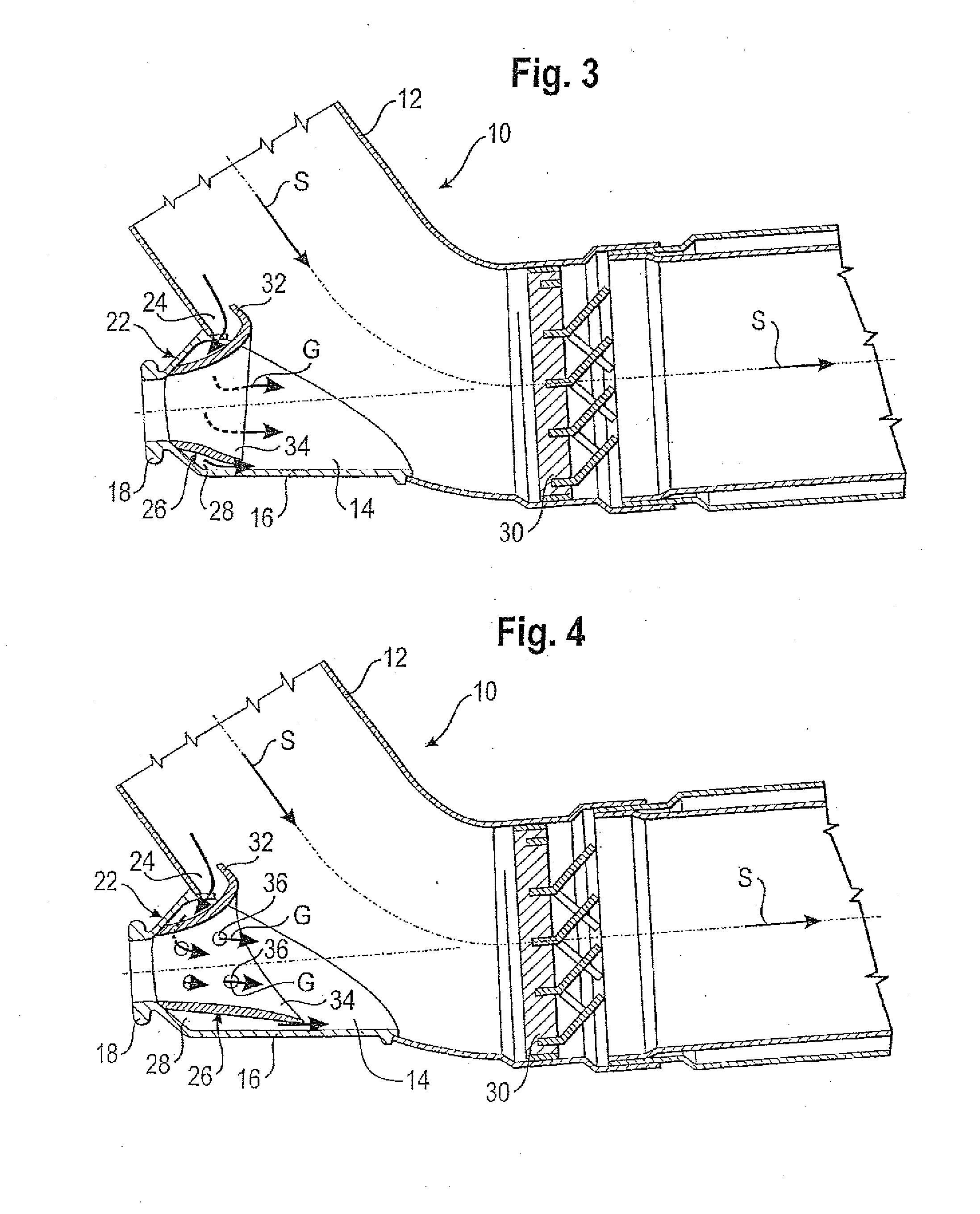

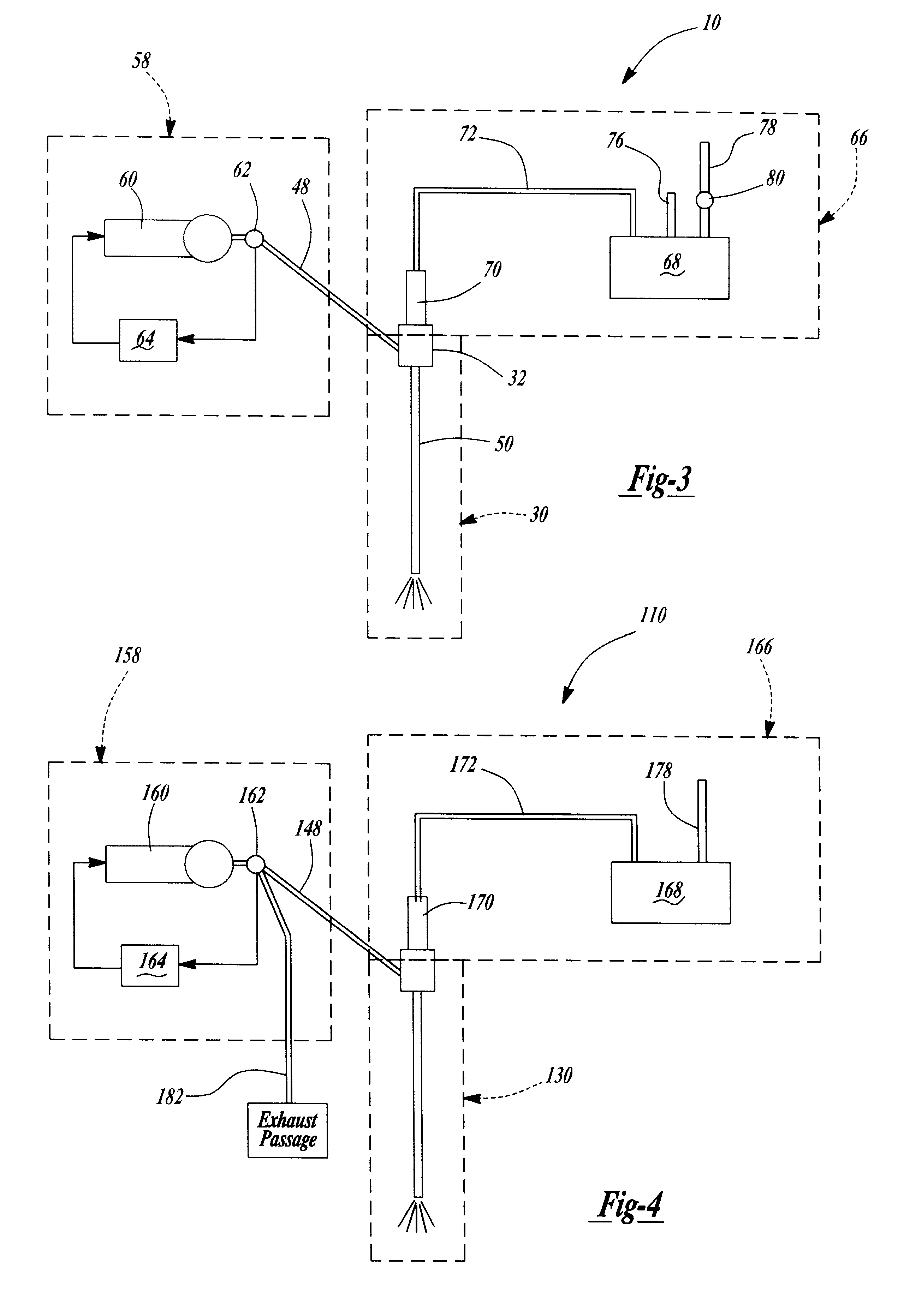

Approach for Delivering a Liquid Reductant into an Exhaust Flow of a Fuel Burning Engine

ActiveUS20090019843A1Extended driving distanceReduction in injector costInternal combustion piston enginesFlow mixersExhaust fumesInternal combustion engine

An exhaust system for an internal combustion engine for a vehicle is provided. The system comprises an exhaust passage for transporting exhaust gases from the engine; an injector coupled to a wall of the exhaust passage, said injector including an injection axis that is angled relative to a longitudinal axis of a mixing region of the exhaust passage; and a first mixing device arranged within the exhaust passage downstream of the injector within the mixing region, said first mixing device including a plurality of flaps, wherein said plurality of flaps are inclined relative to the longitudinal axis; a second mixing device arranged within the exhaust passage downstream of the first mixing device; wherein the injection axis of the injector intersects the first mixing device.

Owner:FORD GLOBAL TECH LLC

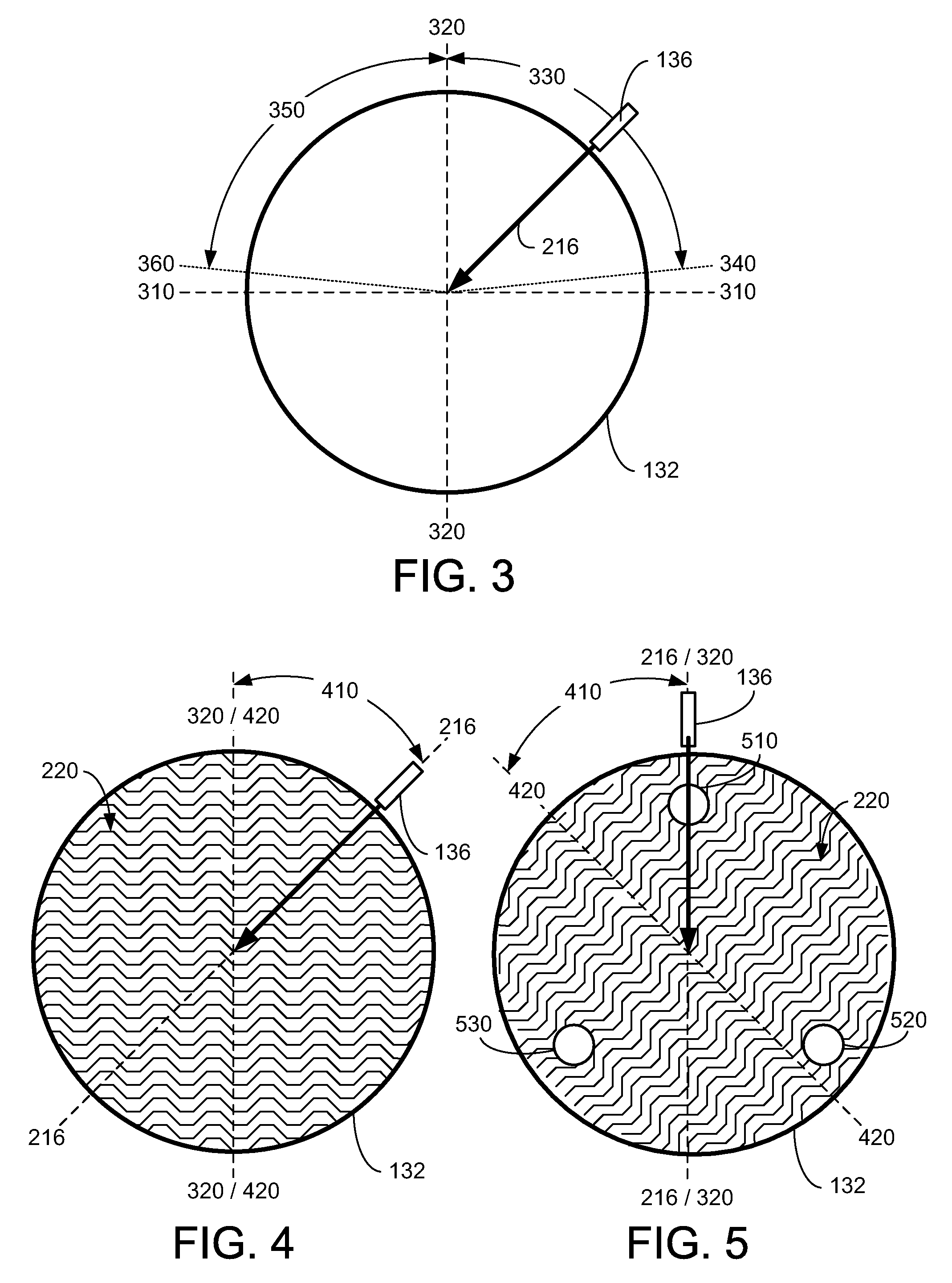

Low Pressure Drop Mixer for Radial Mixing of Internal Combustion Engine Exhaust Flows, Combustor Incorporating Same, and Methods of Mixing

ActiveUS20090255242A1Increase surface areaEnhanced interactionInternal combustion piston enginesFlow mixersCombustion chamberCombustor

An exhaust aftertreatment system is provided. The exhaust aftertreatment system includes a mixing arrangement for mixing flows of exhaust along a flow path. The mixing arrangement radially and angularly rearranges segments of two different portions of flow to mix the different portions of flow. The mixing arrangement initially converts a generally radially stratified temperature profile into an angularly stratified temperature profile to increase surface area between cool segments of exhaust gas and hot segments of exhaust gas. The aftertreatment system may also include a combustion chamber, a combustor housing and a combustor liner. The mixing arrangement is downstream from the combustion chamber to direct radially outward hot gas passing through the combustor liner and to direct radially outer cool gas passing between the liner and the combustor housing radially inward in an interleaving fashion.

Owner:WOODWARD GOVERNOR CO

Honeycomb filter for purifying exhaust gases, adhesive, coating material, and manufacturing method of honeycomb filter for purifying exhaust gases

InactiveUS20080241015A1Increased durabilityHigh strengthCombination devicesPhysical/chemical process catalystsParticulatesAdhesive

Owner:IBIDEN CO LTD

Ceramic filter and exhaust gas decontamination unit

ActiveUS20050102987A1Improve filtering efficiencyExtended service lifeCombination devicesInternal combustion piston enginesMetallurgyActive component

It is to provide a filter for an exhaust gas having a high thermal conductivity irrespective of a relatively high porosity or showing characteristics that the whole of the filter containing a high refractive index substance or pigment is easily warmed but hardly cooled while making low the thermal conductivity of the filter as a whole. This filter is provided with a catalyst coat layer formed by carrying a catalyst active component on a surface of a porous ceramic carrier, in which a porosity of the porous ceramic carrier is 40-80% and a substance or a pigment indicating a thermal conductivity as the filter of 3-60 W / mk or having a large refractive index at a thermal conductivity of 0.3-3 W / mk.

Owner:IBIDEN CO LTD

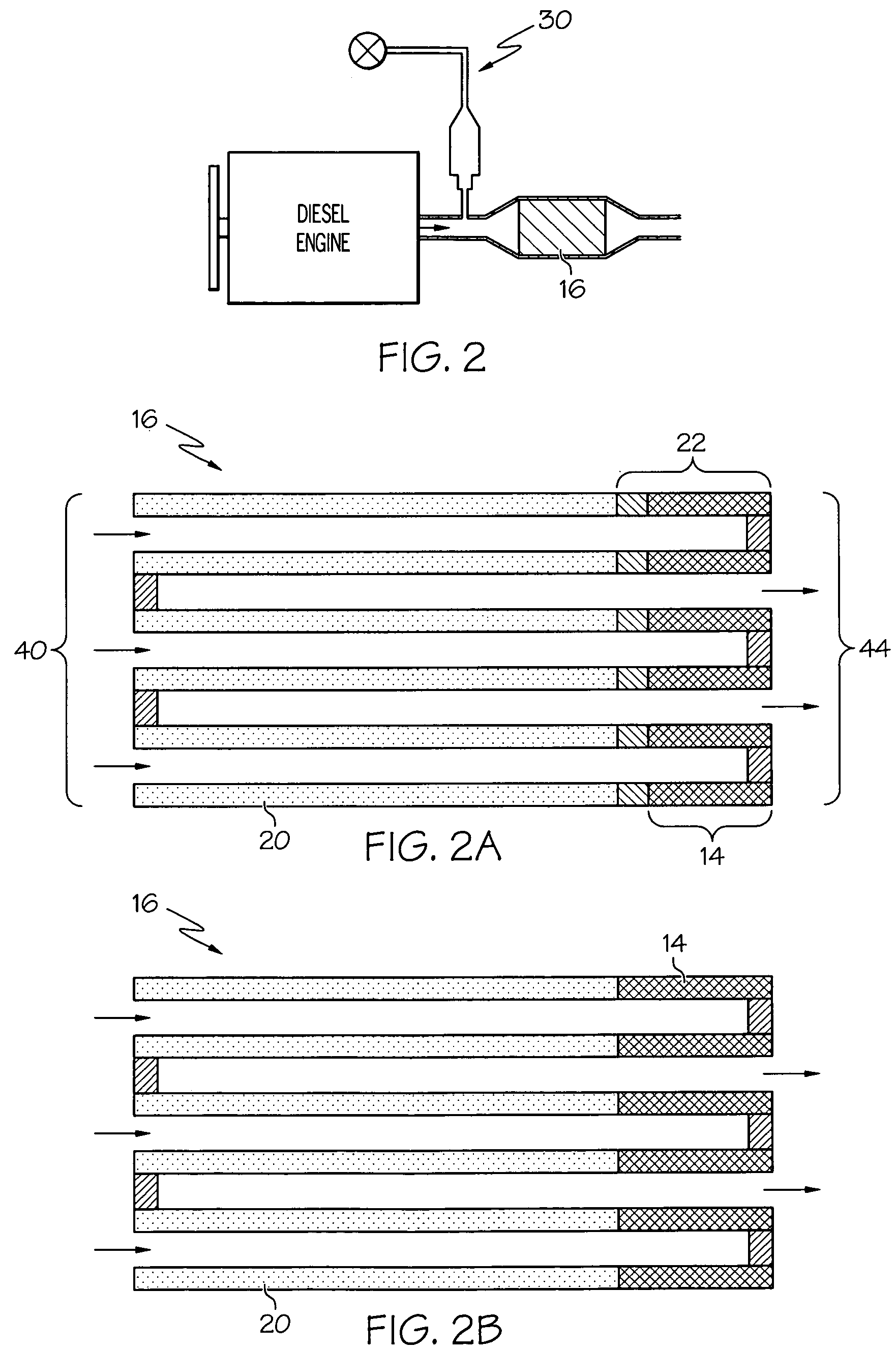

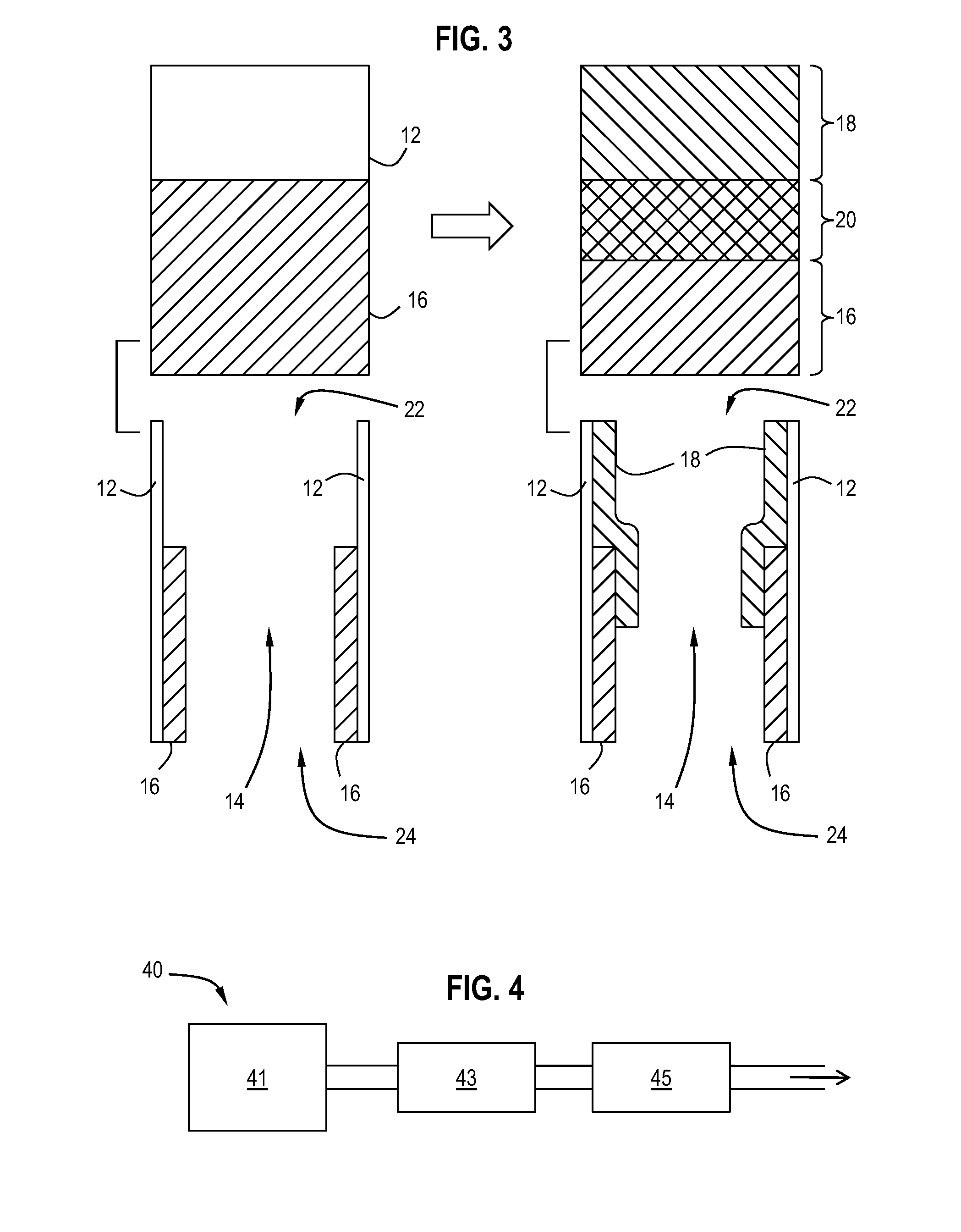

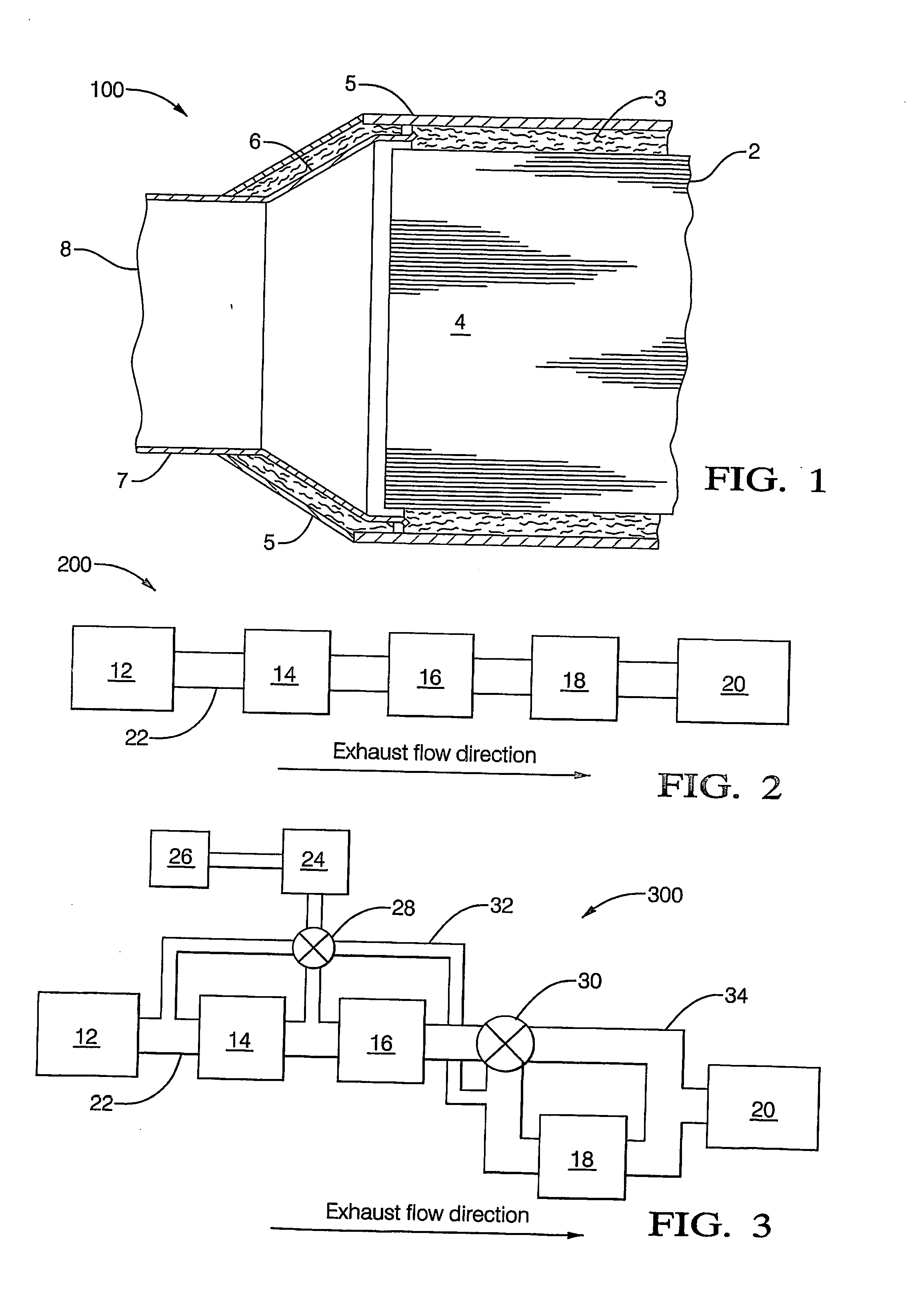

System and method of nox abatement

InactiveUS20060213187A1Internal combustion piston enginesExhaust apparatusHydrogenProcess engineering

A NOx abatement system comprising: a first NOx adsorber (18) capable of being disposed in-line and downstream of and in fluid communication with an engine (12); a selective catalytic reduction catalyst (20) disposed in-line and downstream of and in direct fluid communication with the first NOx adsorber (18), wherein the selective catalytic reduction catalyst (20) is capable of storing ammonia; and an off-line reformer (24) disposed in selective communication with and upstream of the first NOx adsorber (18) and the selective catalytic reduction catalyst (20), wherein the reformer (24) is capable of producing a reformate comprising primarily hydrogen and carbon monoxide.

Owner:DELPHI TECH INC

Honeycomb filter and ceramic filter assembly

InactiveUS20060021310A1Internal combustion piston enginesDispersed particle filtrationMetallurgyHoneycomb

A ceramic filter assembly having improved exhaust gas processing efficiency. The ceramic filter assembly (9) is produced by adhering with a ceramic seal layer (15) outer surfaces of a plurality of filters (F1), each of which is formed from a sintered porous ceramic body. The seal layer (15) has a thickness of 0.3 mm to 3 mm and a thermal conductance of 0.1 W / mK to 10 W / mk.

Owner:IBIDEN CO LTD

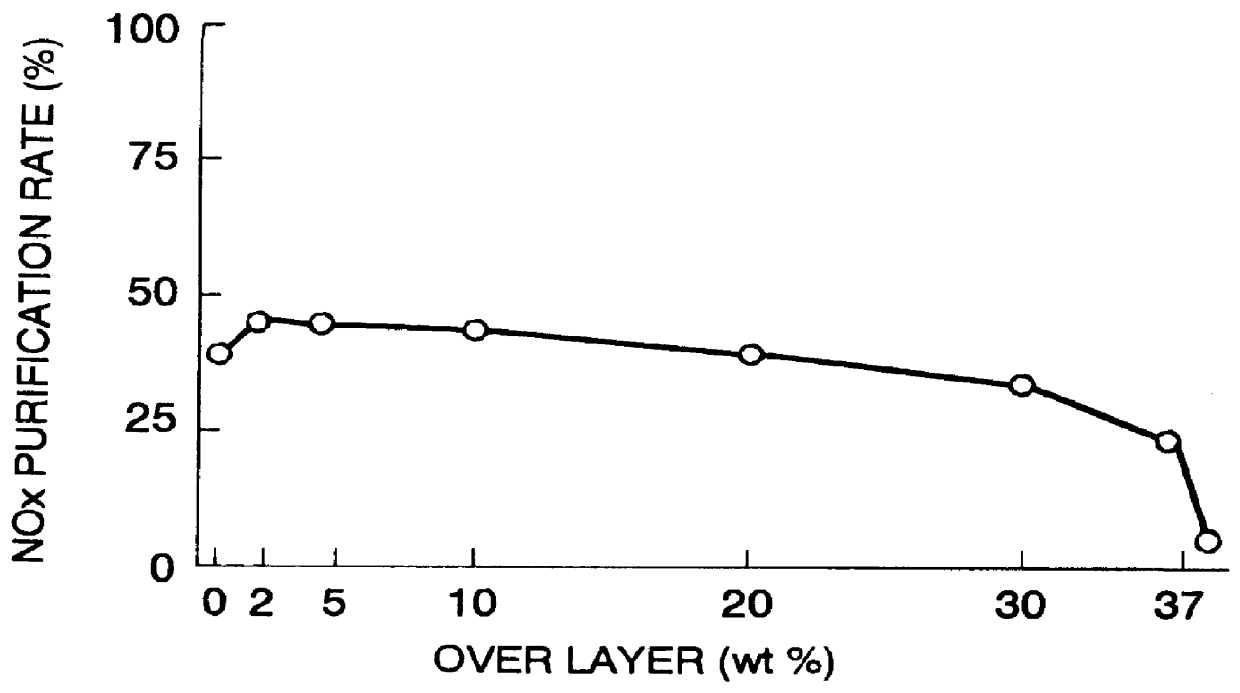

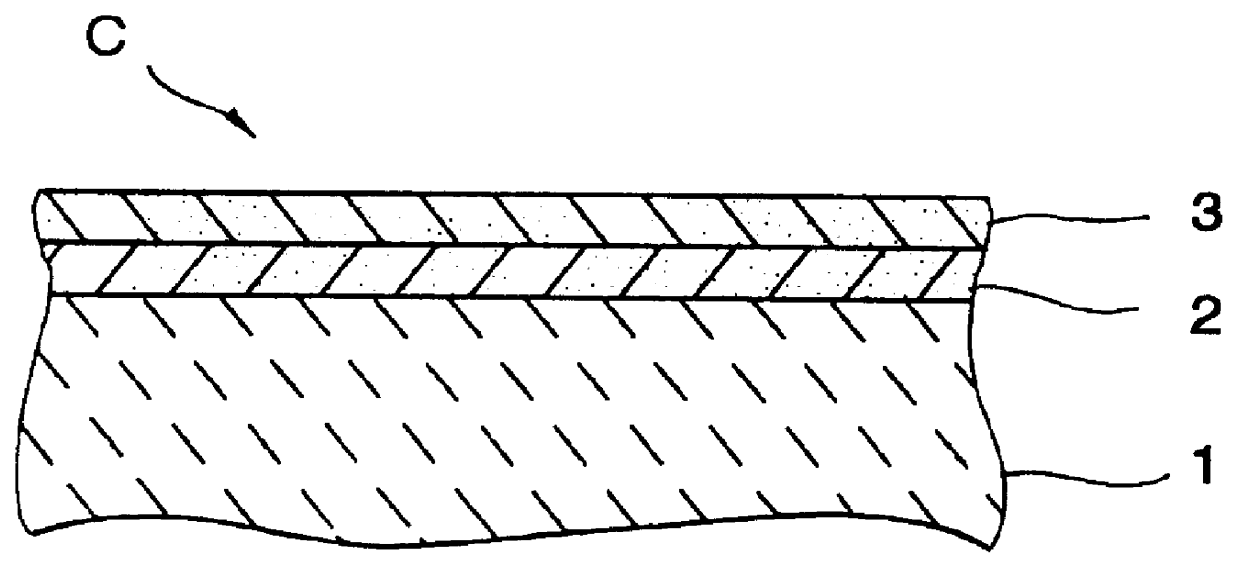

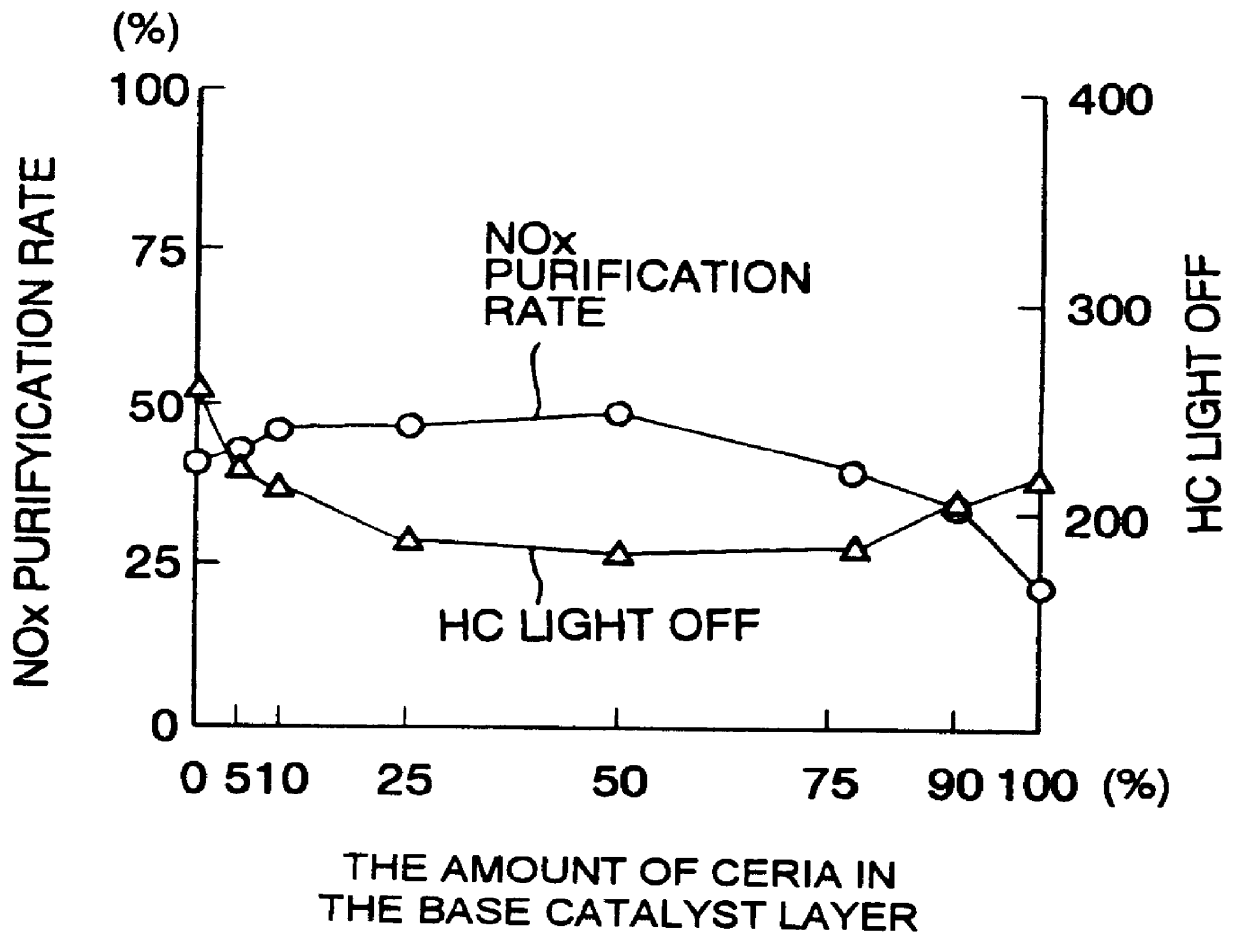

Catalyst for purifying exhaust gas

InactiveUS6066587AImprove responseImprove purification effectMolecular sieve catalystsInternal combustion piston enginesPlatinumPartial oxidation

A catalyst has a base catalyst layer containing platinum and barium as precious metal supported by alumina and an over catalyst layer containing platinum and rhodium as precious metal supported by zeolitr. The platinum and rhodium in the over catalyst layer activate NOx and HC so as to make them more reactive in terms of energy, and the barium in the base catalyst layer makes the platinum be more dispersive in the base catalyst layer. Under the existence of dispersive platinum, NOx in exhaust gas is decomposed and purified by reaction with reactive NO2 and partially oxidized HC generated in the over catalyst layer.

Owner:MAZDA MOTOR CORP

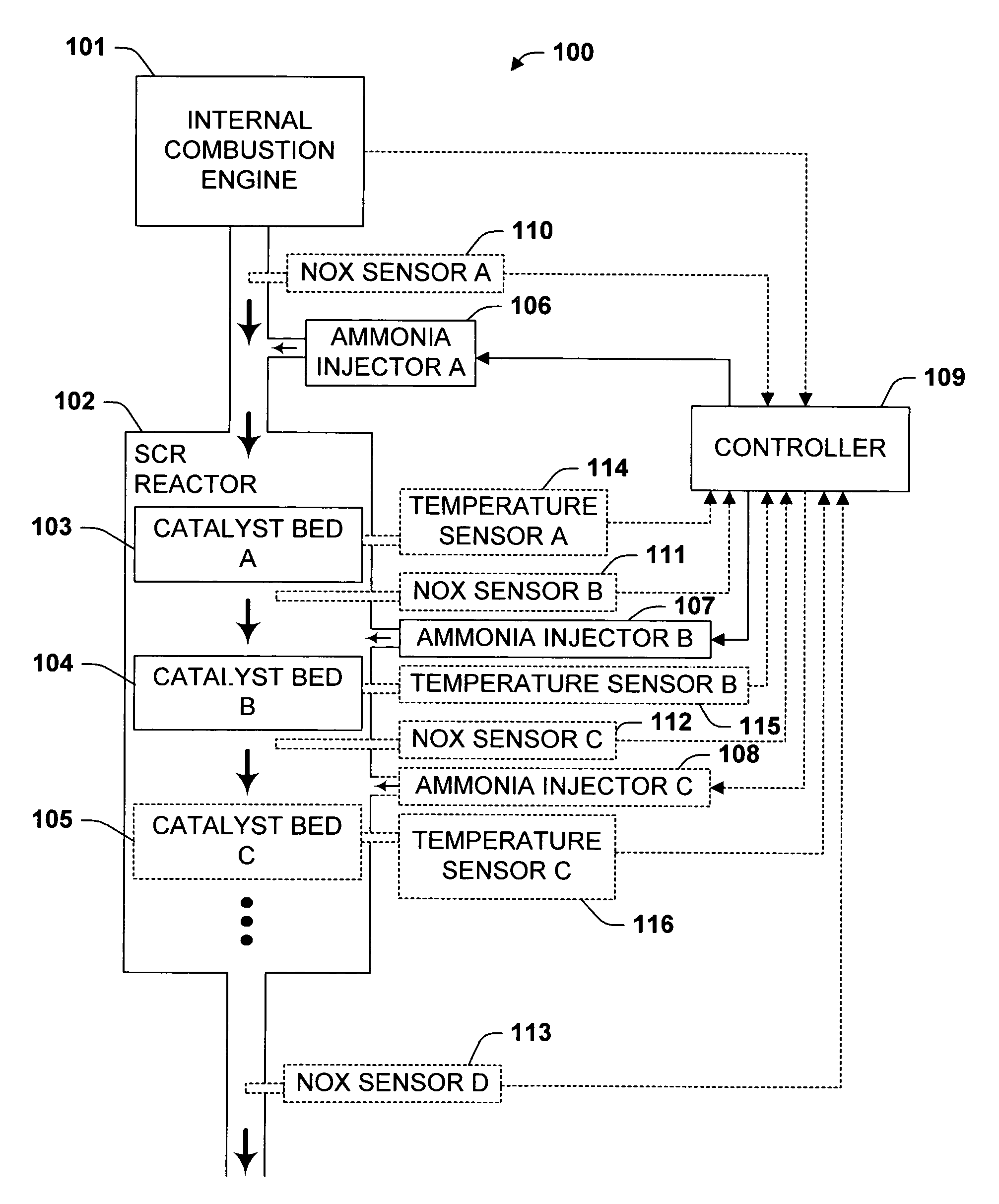

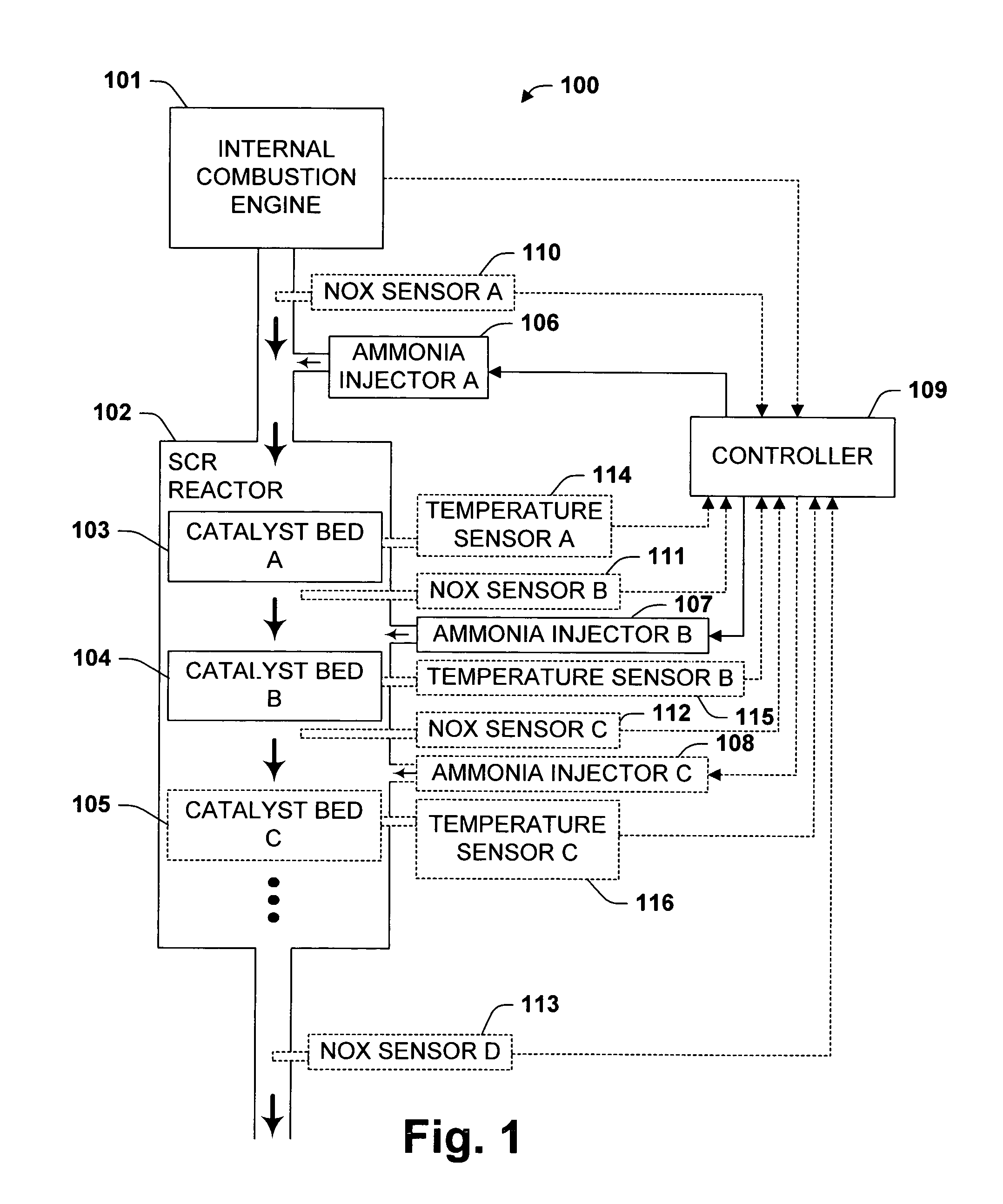

Multistage reductant injection strategy for slipless, high efficiency selective catalytic reduction

InactiveUS6996975B2Reduce riskReduce controlInternal combustion piston enginesExhaust apparatusInjection portAmmonia

One aspect of the invention relates to an exhaust treatment apparatus having an NOx reduction system comprising first and second catalyst beds in series with associated first and second ammonia injectors. The first catalyst bed with its associated ammonia injector preferably targets removing only about 80 to about 95% percent of the NOx in the vehicle exhaust. The second catalyst bed with its associated injector preferably target removing about 70 to about 100% of the remaining NOx. Staging the reduction system in this manner improves control over NOx reduction and reduces the risk of ammonia slip. Other aspects of the invention relate to methods of treating vehicle exhaust to remove NOx and an SCR reactor comprising a housing having an entrance port, an exit port, and an ammonia injection port, wherein the injection port is configured to inject ammonia in between SCR catalyst beds contained in the housing.

Owner:EATON CORP

Honeycomb structure body

InactiveUS20060073970A1Distinguish clearlyInternal combustion piston enginesDispersed particle filtrationExternal combustion engineEngineering

An object of the present invention is to provide a honeycomb structural body which is inserted, for use, into a pipe forming an exhaust passage of an internal combustion engine, and makes it possible to clearly distinguish an exhaust gas flow-in side and an exhaust gas flow-out side. The present invention is directed to a columnar honeycomb structural body comprising porous ceramics each including a number of through holes that are placed in parallel with one another in the length direction with a wall portion interposed therebetween, wherein information regarding the honeycomb structural body is displayed on a circumferential surface and / or an end face thereof.

Owner:IBIDEN CO LTD

Honeycomb structural body, manufacturing method of the honeycomb structural body, and exhaust gas purifying device

ActiveUS20050229565A1High strengthIncreased durabilityCombination devicesCatalyst protectionLeast squaresHoneycomb structure

A honeycomb structural body comprising: a pillar-shaped ceramic block and a sealing material provided on an outer peripheral portion of said ceramic block, each of them having irregularities formed on an outer peripheral face wherein: when a least square curve is determined by a least square method on the basis of points constituting the contour of a cross-section, a center-of-gravity is defined as c1, a distance between a minimum concentric circumscribed curve having c1 and the center-of-gravity c1 is defined as D1, a distance between a maximum concentric inscribed curve having c1 and the center-of-gravity c1 is defined as D2, and the following inequality is satisfied: about 0.3 mm≦(D1−D2); same definition is applied to said ceramic block, a center-of-gravity thereof is defined as c2, a distance between a minimum concentric circumscribed curve having c2 and the center-of-gravity c2 is defined as D3, a distance between a maximum concentric inscribed curve having c2 and the center-of-gravity c2 is defined as D4, and the following inequality is satisfied: about 0.5 mm≦(D3−D4)≦about 7.0 mm.

Owner:IBIDEN CO LTD

Assembly and Method for Introducing a Reducing Agent into the Exhaust Pipe of an Exhaust System of an Internal Combustion Engine

InactiveUS20100212292A1Avoid depositionWell mixedGas treatmentInternal combustion piston enginesMobile vehicleExternal combustion engine

An assembly and method for introducing a reducing agent into an exhaust pipe of an exhaust system of an internal combustion engine, in particular of a motor vehicle includes a feed connector which opens into the exhaust pipe and has a wall; a feed device for reducing agents which opens into the feed connector; and a device that generates a gas flow which is additional to the reducing agent flow and lines the wall of the feed connector.

Owner:FAURECIA EMISSIONS CONTROL TECH GERMANY

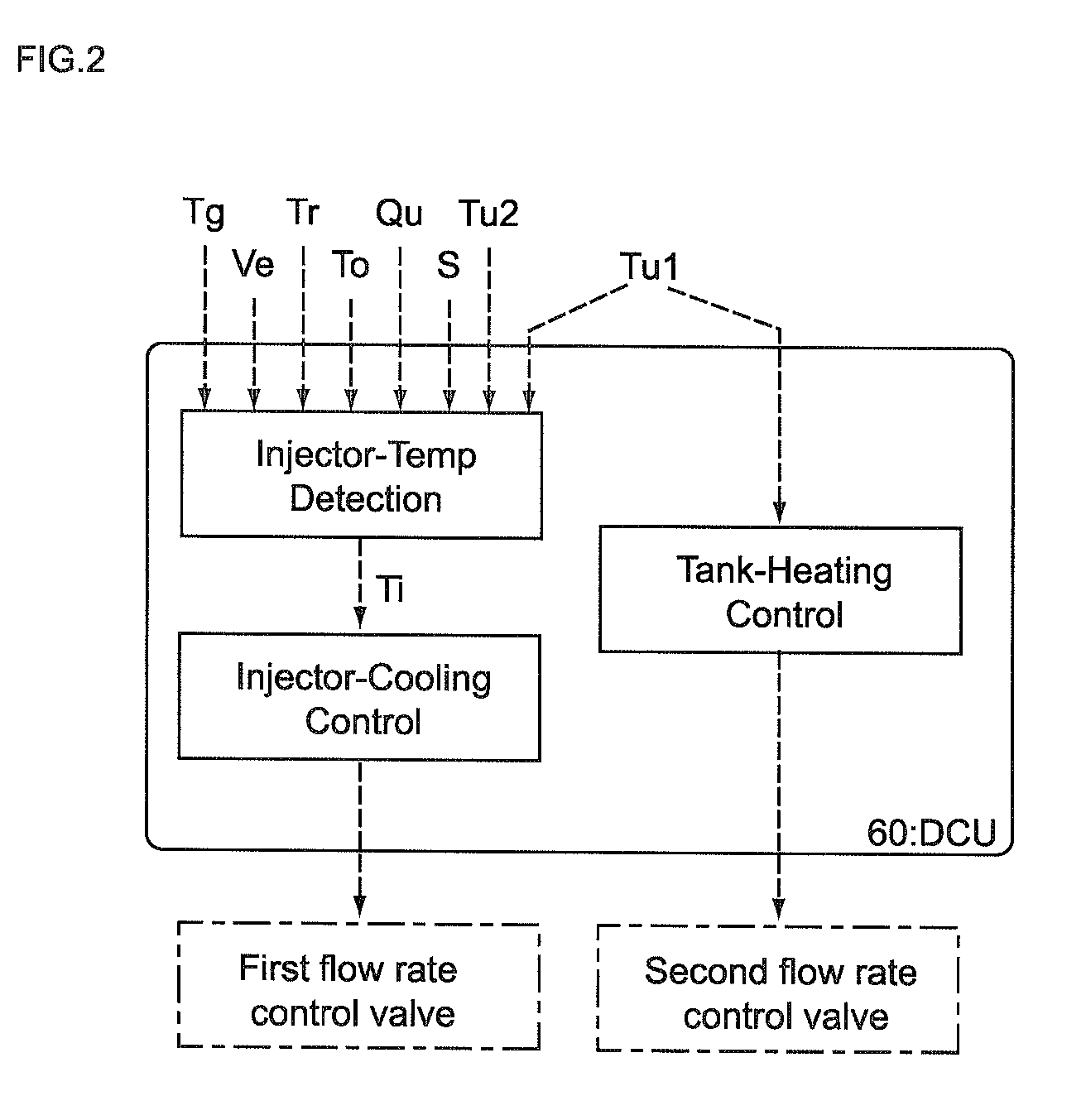

Control unit and control method for reductant supply device

InactiveUS20100242439A1Prevent overcoolingImprove cooling effectLiquid coolingInternal combustion piston enginesEngineeringWater circulation

There are provided a reductant supply device and a control method for the reductant supply device, which can prevent heat damage of a reductant injection valve, and also prevent crystallization of urea solution due to excessive cooling of the solution reductant.The reductant supply device which is used in an exhaust gas purification device that injects and supplies, as a reductant, a urea solution to an exhaust gas upstream side of a reduction catalyst disposed in an exhaust gas passage of an internal combustion engine, and that reduces and purifies nitrogen oxides contained in exhaust gas using the reduction catalyst, the reductant supply device having a reductant injection valve that is fixed to an exhaust pipe on the exhaust gas upstream side of the reduction catalyst, includes: a cooling water circulation passage that circulates at least part of cooling water of the internal combustion engine to cool the reductant injection valve; flow rate control means for adjusting a flow rate of cooling water flowing through the cooling water circulation passage; temperature detection means for detecting a temperature of the reductant injection valve; and control means for controlling the flow rate control means based on the temperature of the reductant injection valve.

Owner:BOSCH CORP

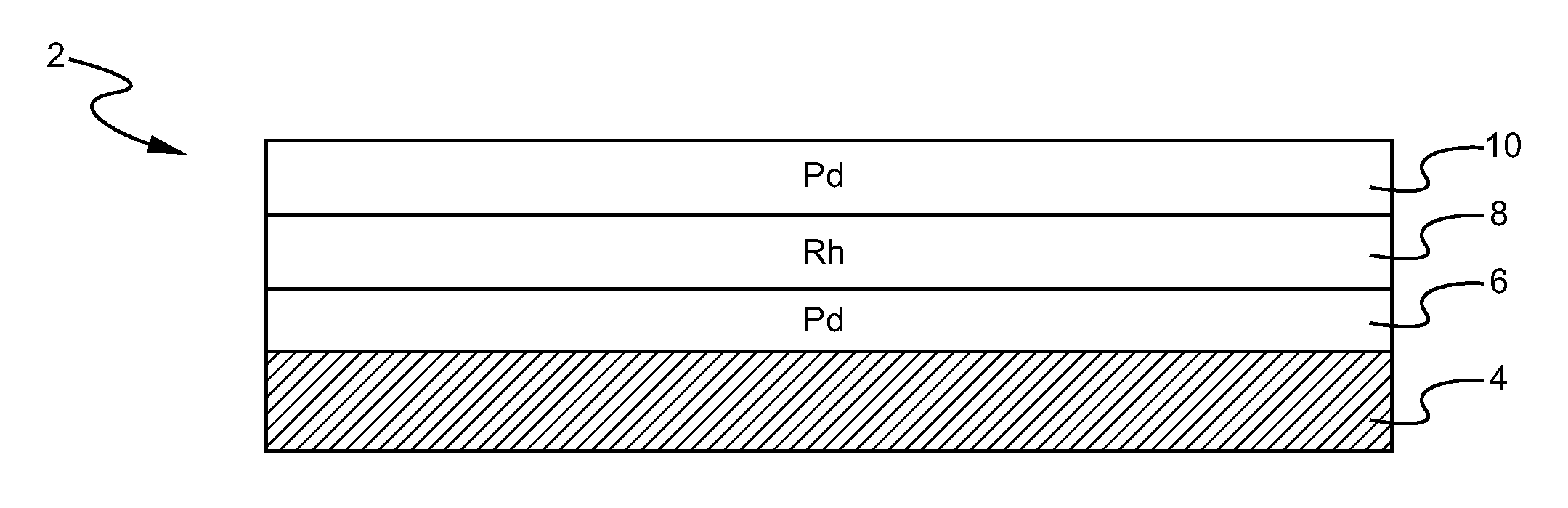

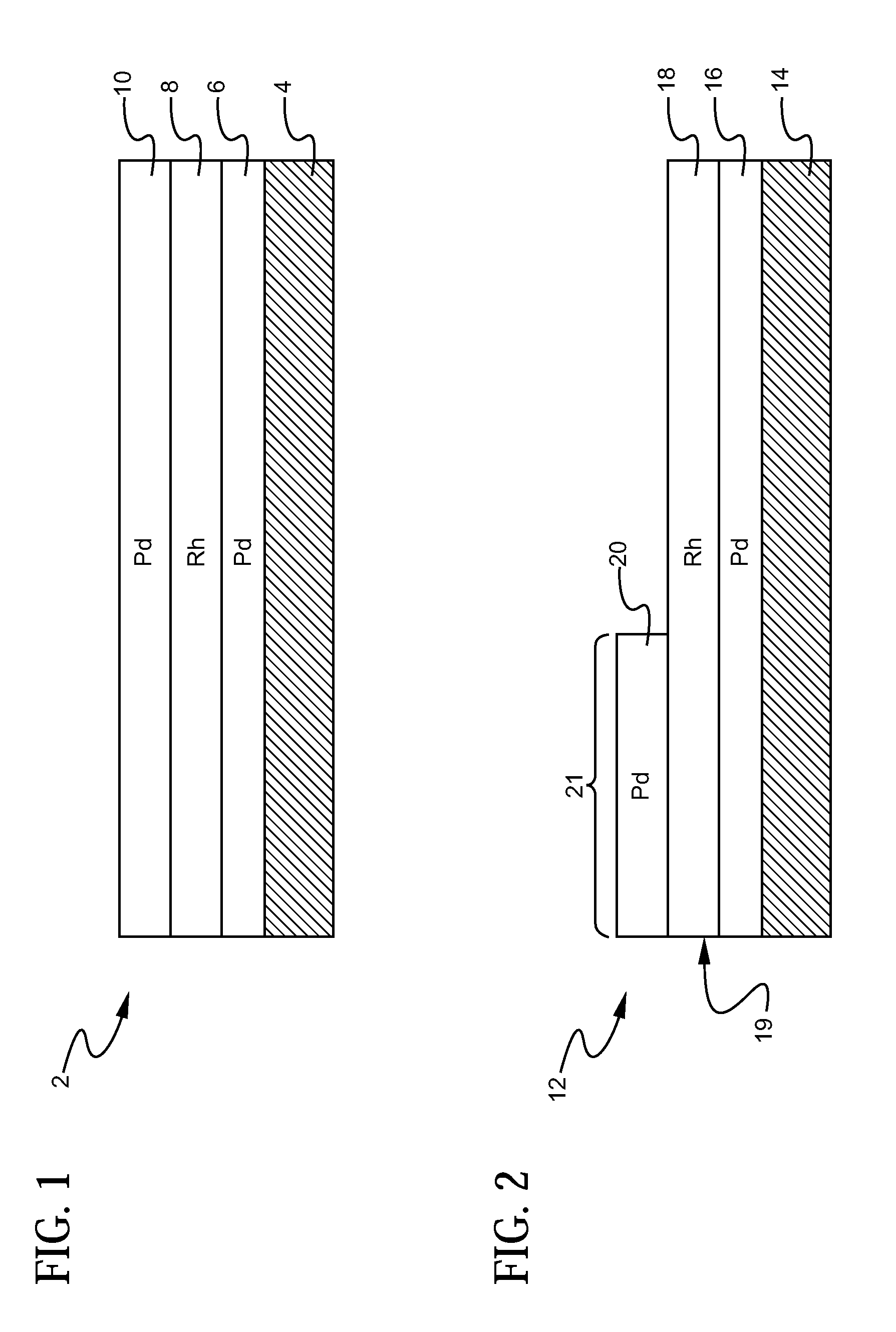

Layered catalyst composite

A layered, three-way conversion catalyst having the capability of simultaneously catalyzing the oxidation of hydrocarbons and carbon monoxide and the reduction of nitrogen oxides is disclosed. In one or more embodiments, the catalyst comprises three layers in conjunction with a carrier: a first layer deposited on the carrier and comprising palladium deposited on a refractory metal oxide and an oxygen storage component; a second layer deposited on the first layer and comprising rhodium deposited on a refractory metal oxide and an oxygen storage component; and a third layer deposited on the second layer and comprising palladium deposited on a refractory metal oxide.

Owner:BASF CATALYSTS LLC

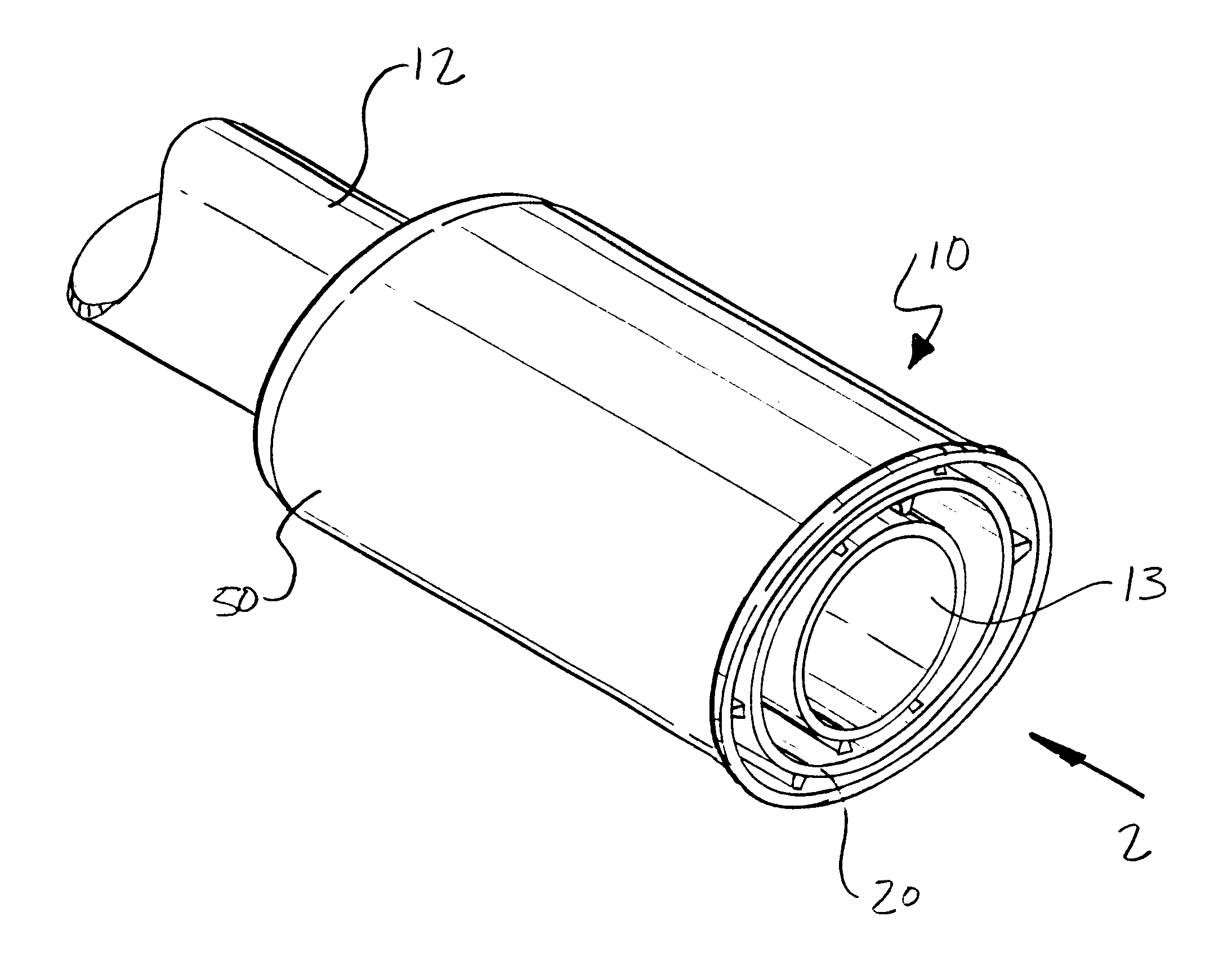

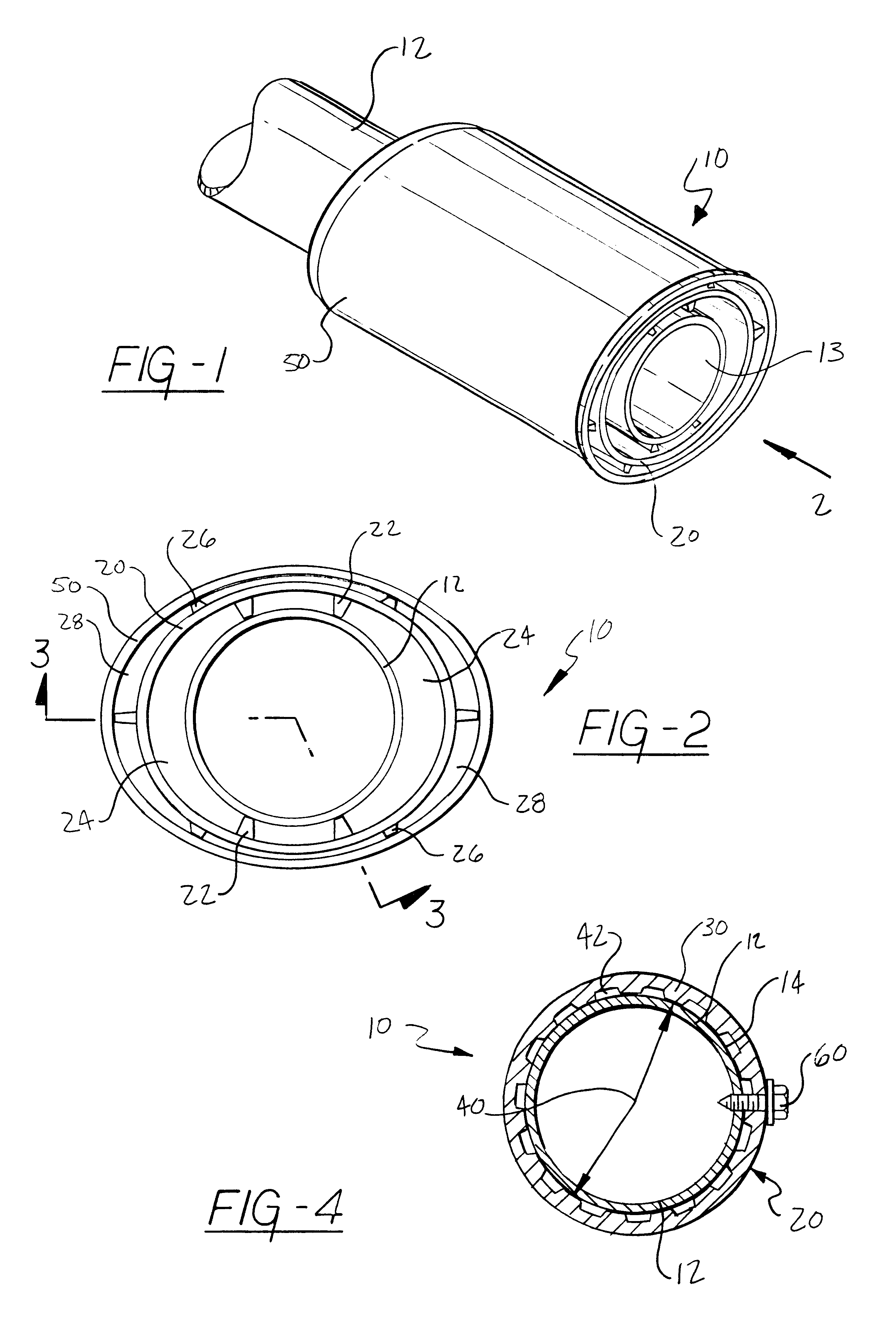

Exhaust tip

InactiveUS7007720B1Severe design restrictionOverall design flexibilityThermal insulationSilencing apparatusEngineeringThermal effect

An exhaust tip for attachment to a tailpipe that includes a thermoset heat shield at least partially surrounding and fastened to the tailpipe, and a thermoplastic decorative cover at least partially surrounding and fastened to the thermoset heat shield. The thermoset heat shield insulates the thermoplastic decorative cover from thermal effects of the tailpipe and spaces the thermoplastic decorative cover a predetermined distance away from the tailpipe.

Owner:LACKS INDUSTRIES INC

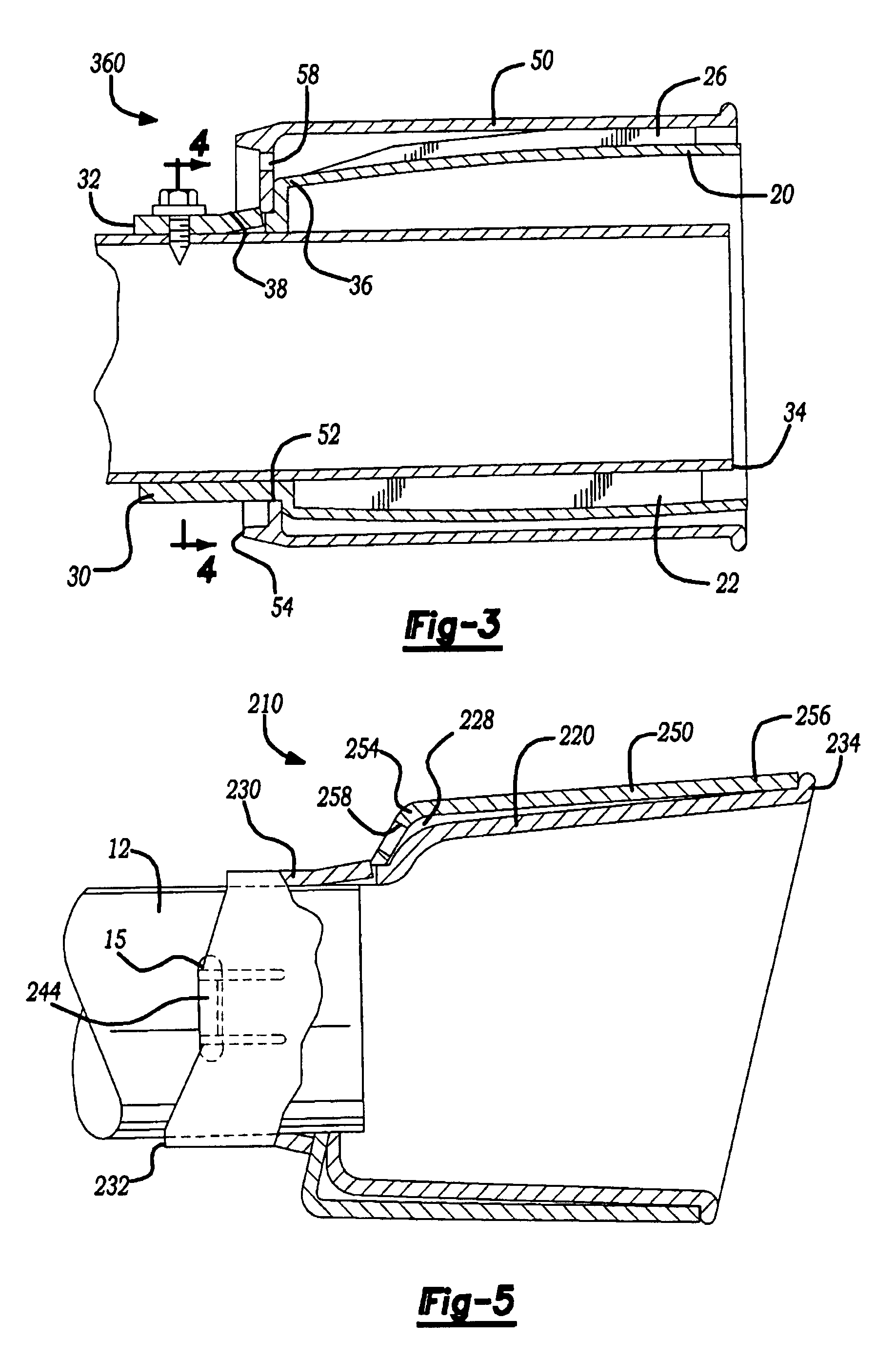

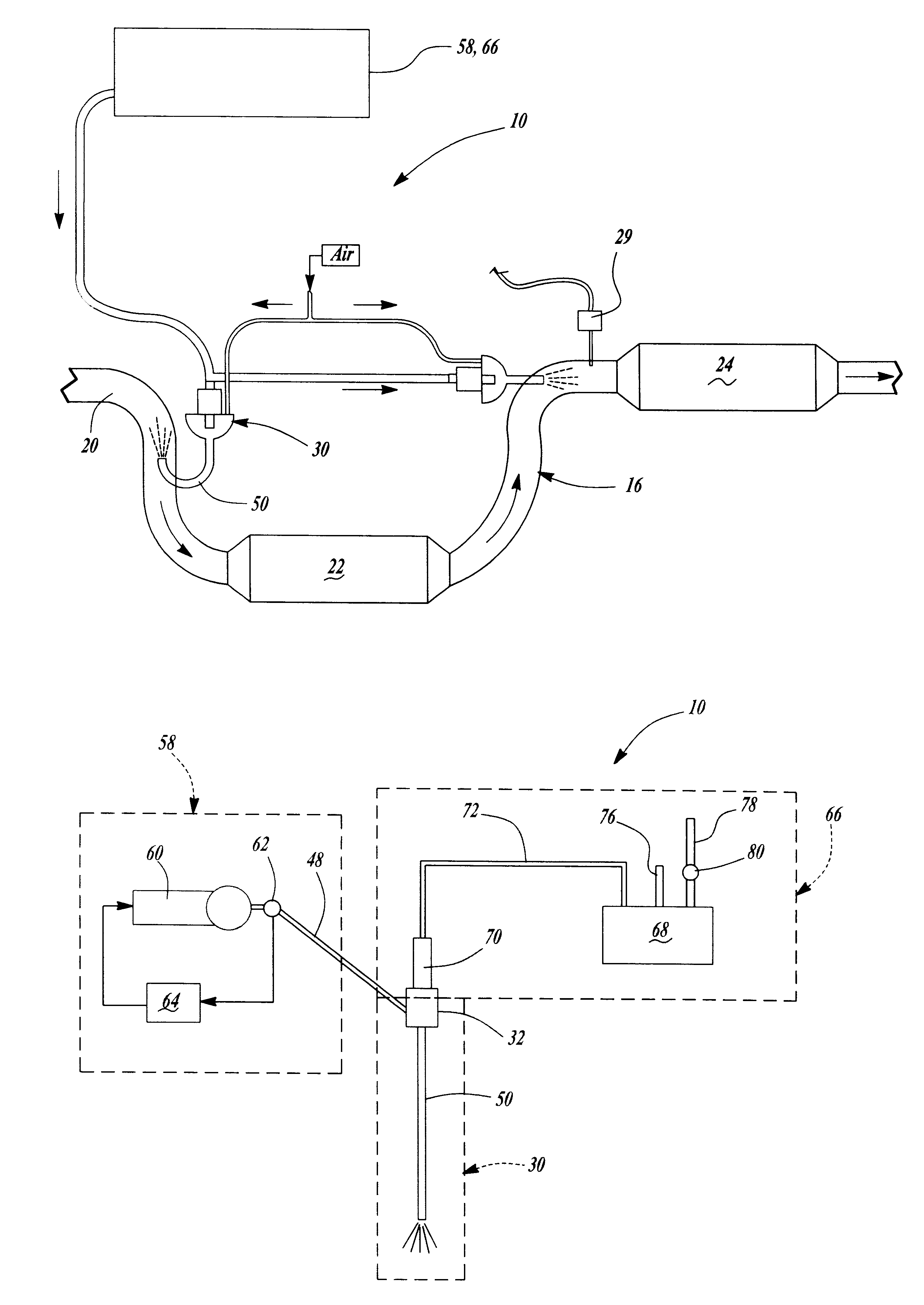

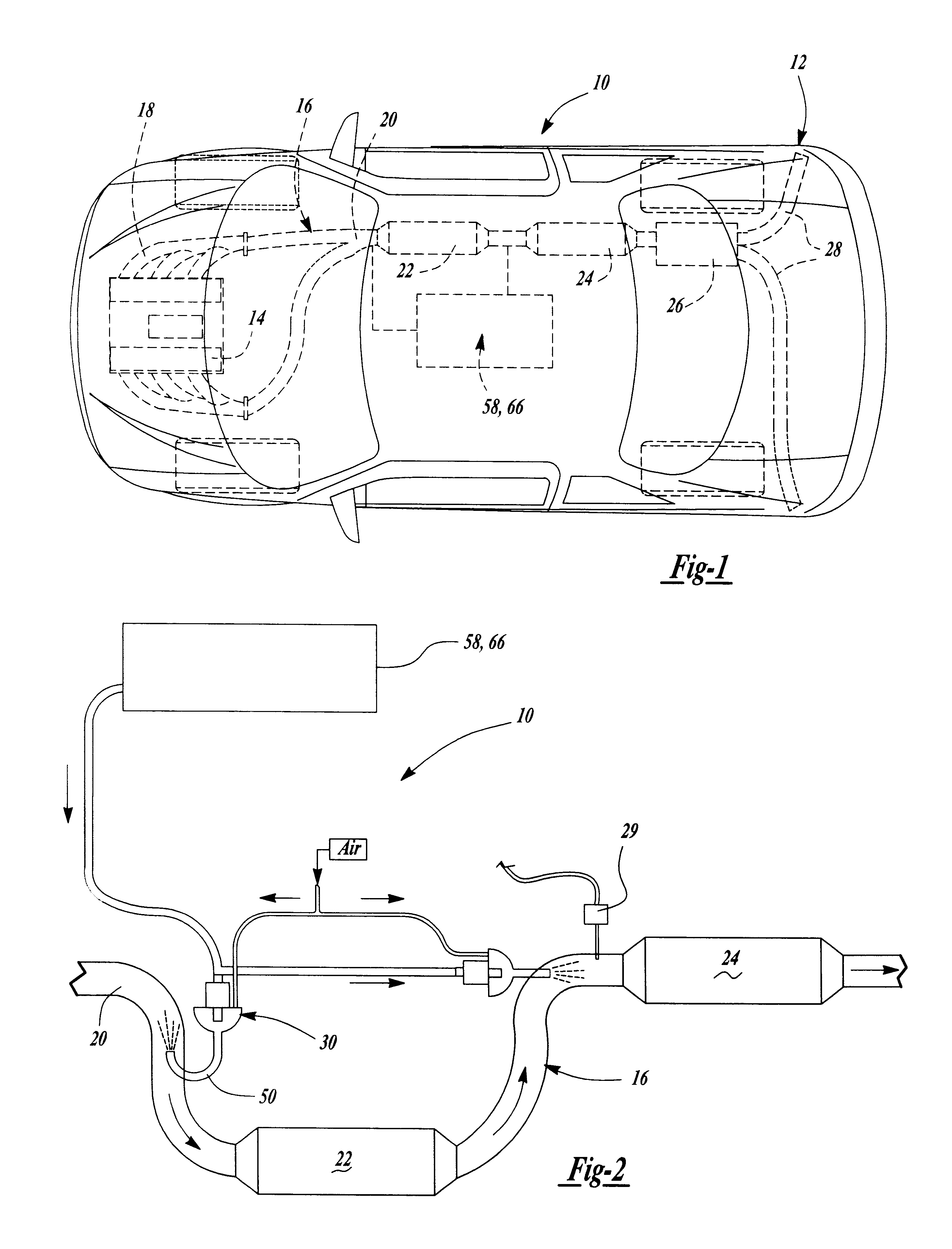

On-board reductant delivery system

An on-board reductant delivery system for a motor vehicle includes a mixer / nozzle system for connection to an exhaust system of a motor vehicle. The on-board reductant delivery system also includes a fluid metering system connected to the mixer / nozzle system for metering reductants to the mixer / nozzle system. The on-board reductant delivery system further includes an air supply system connected to the mixer / nozzle system for delivering pressurized air to the mixer / nozzle system. The mixer / nozzle system mixes the reductants and pressurized air and sprays the mixture in the exhaust system of the motor vehicle to reduce NOx.

Owner:FORD GLOBAL TECH LLC

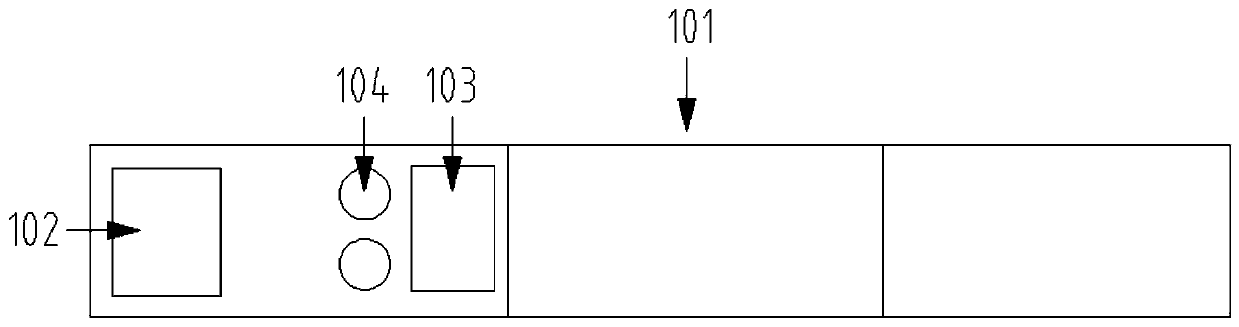

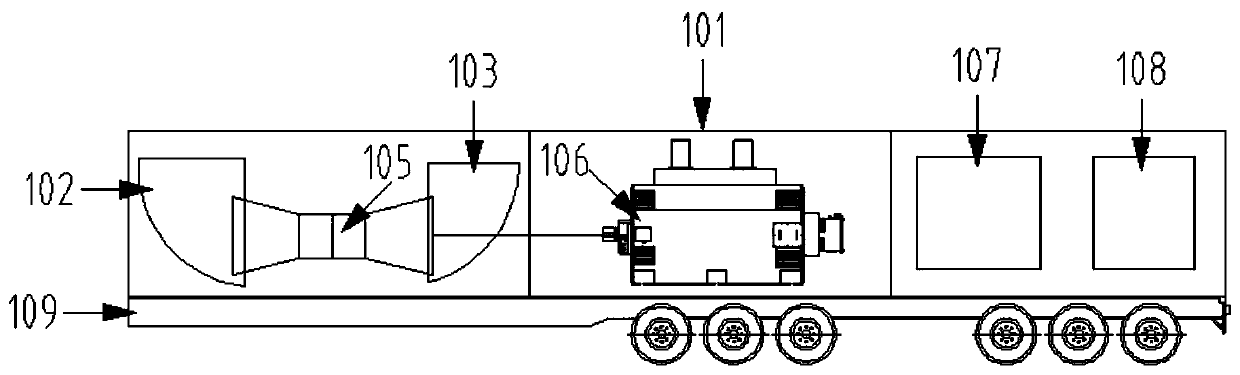

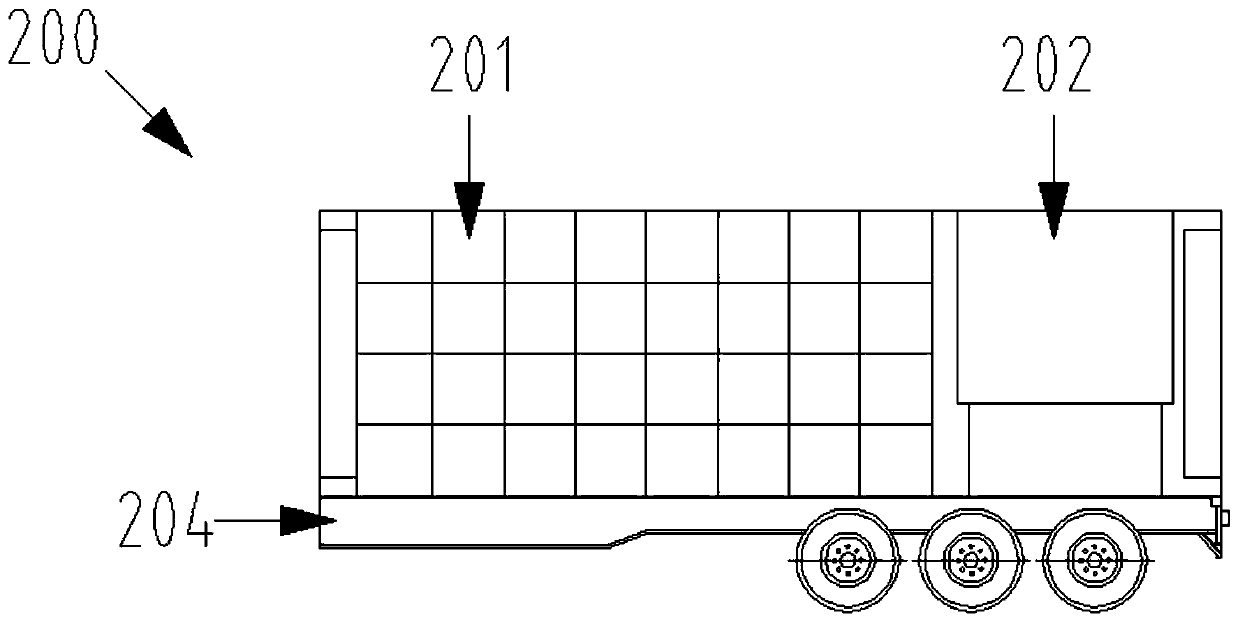

Portable power generation system

PendingCN110145399ASmall footprintSimple designEngine fuctionsSilencing apparatusCombustionPortable power

The invention discloses a portable power generation system. The whole power generation system is divided into two conveyances. A combustion gas turbine, an electric generator, an inlet chamber, an exhaust gas receiver and an auxiliary system are arranged on the first conveyance, and an inlet component and an exhaust pipeline as a whole are arranged on the second conveyance. At least four lifting devices are arranged on the second conveyance and are used for separating the inlet component and the exhaust pipeline from the second conveyance and realizing upward jacking, so that a power-generation transport device can move to the position under the inlet component and the exhaust pipeline. Then, the inlet component and the exhaust pipeline descend by using the lifting devices to butt againstthe inlet chamber and the exhaust gas receiver respectively. The gravity of the inlet component and the exhaust pipeline are utilized to realize the sealing of butting.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com