Assembly and Method for Introducing a Reducing Agent into the Exhaust Pipe of an Exhaust System of an Internal Combustion Engine

a technology of exhaust system and reducing agent, which is applied in the direction of machines/engines, mechanical equipment, membrane technology, etc., can solve the problem of complete blockage of the exhaust pip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

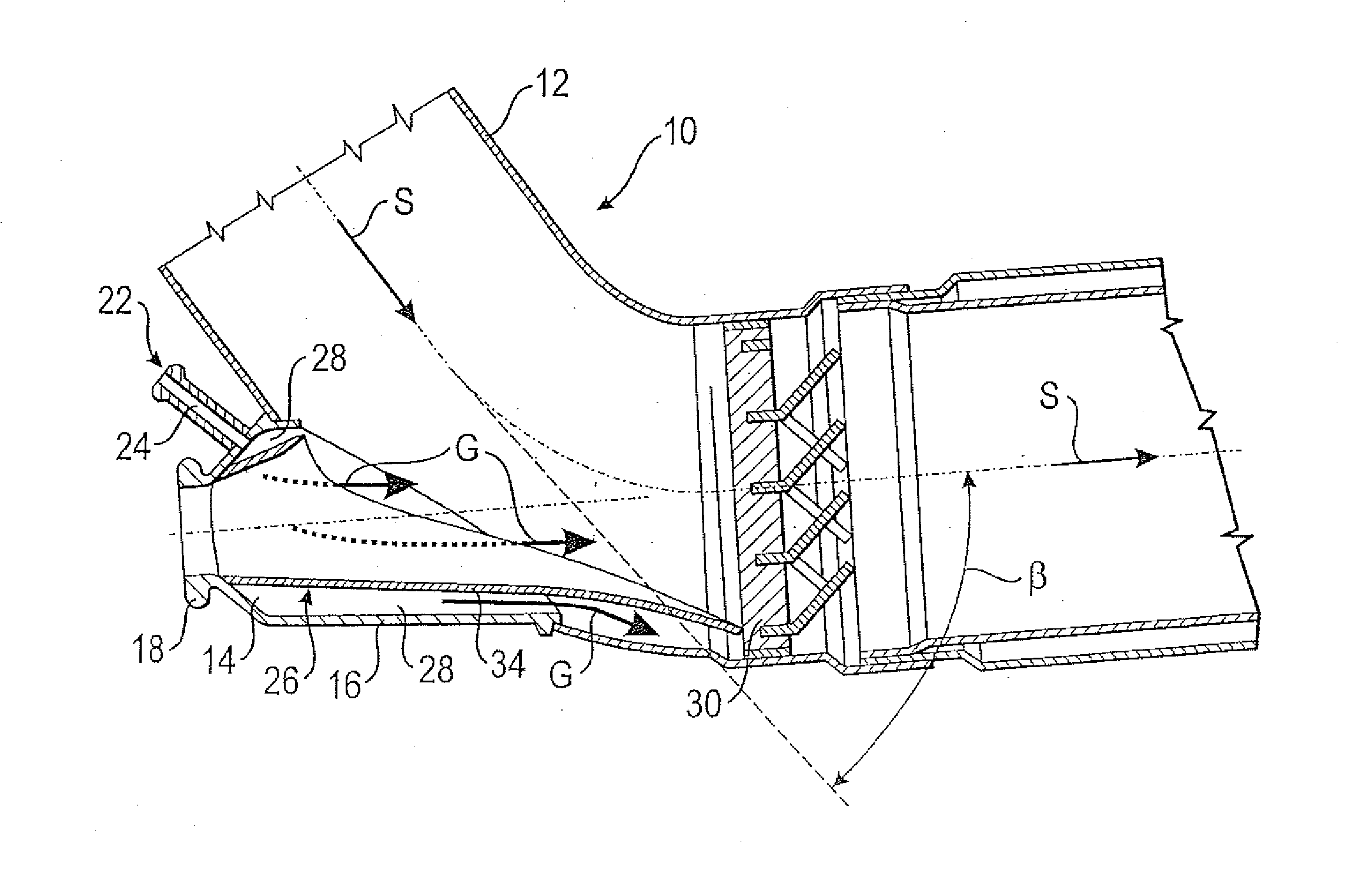

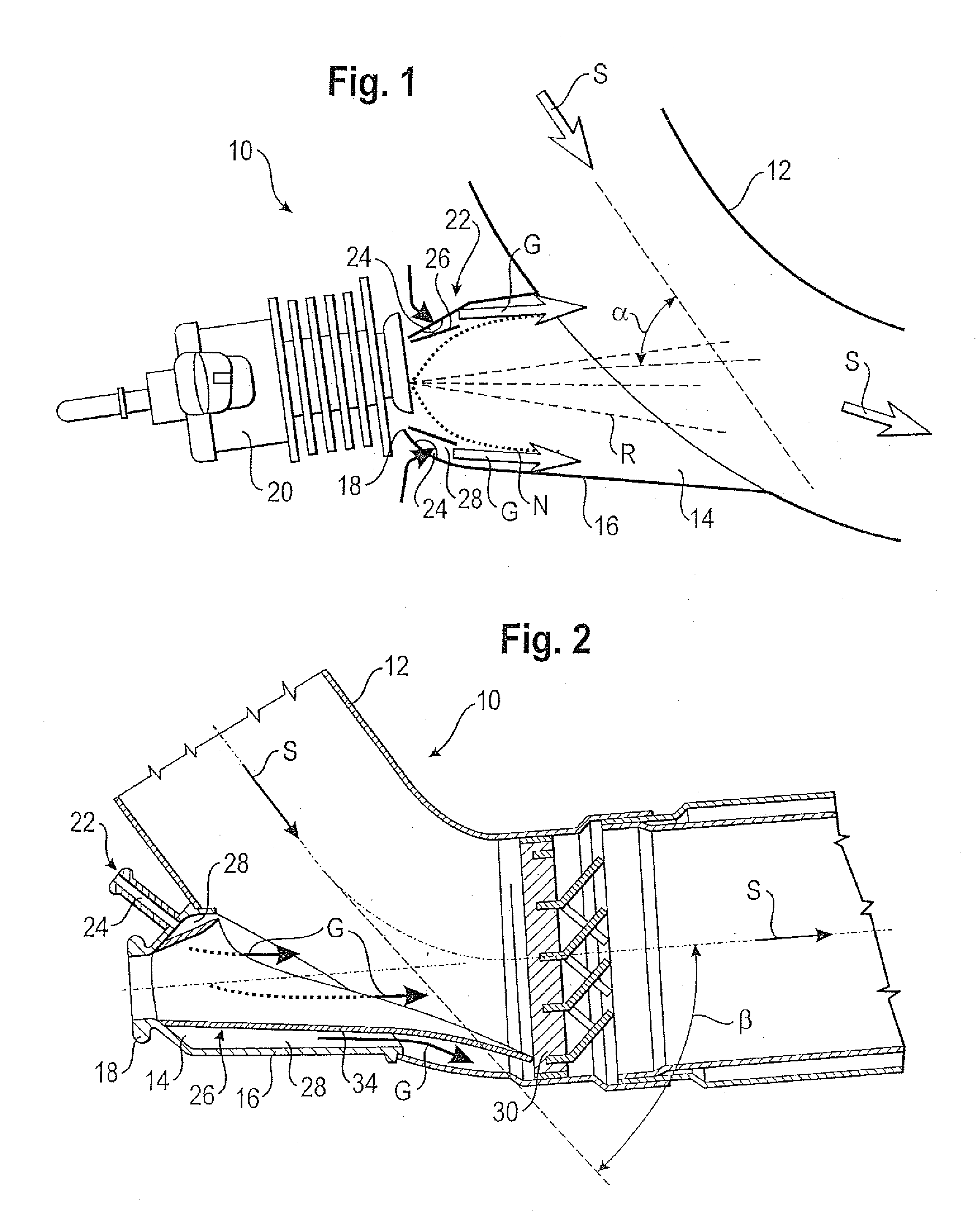

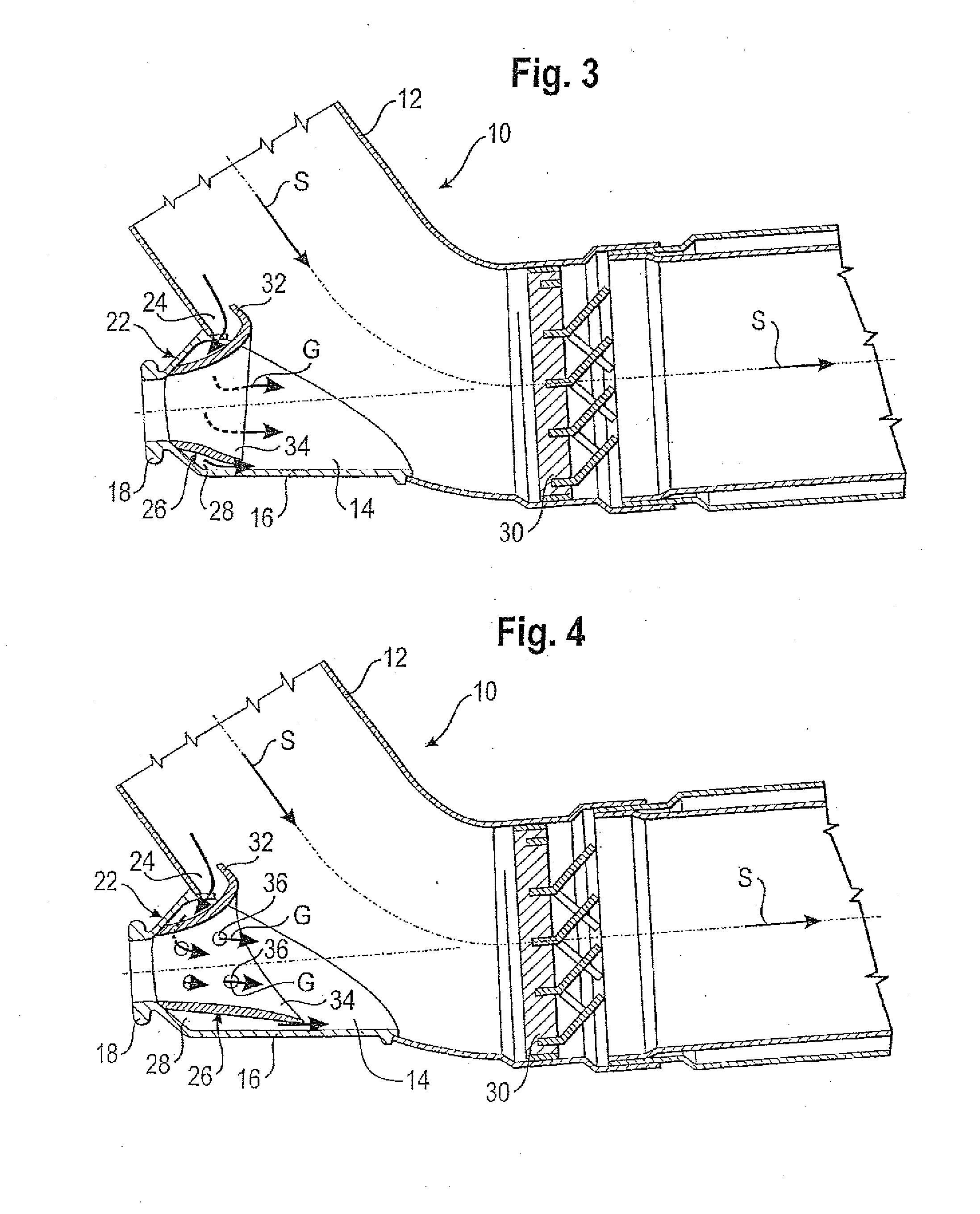

[0038]FIG. 1 schematically shows an assembly 10 that introduces a reducing agent into an exhaust pipe 12 of an exhaust system of an internal combustion engine. In particular, the exhaust system of a motor vehicle is involved. The exhaust gas flow in the exhaust pipe 12 is denoted by S. The assembly 10 includes a feed connector 14 which is of a substantially conical configuration and opens into the exhaust pipe 12, preferably at an angle a of between 20° and 70°, and in the example shown is approximately 55°. An inside wall of the feed connector 14 is identified by reference number 16.

[0039]A feed device 20 for reducing agents is arranged in a mount 18 provided at an end of the feed connector 14 that is opposite to the exhaust pipe 12. The feed device 20 opens into the feed connector 14 and is an injection valve, in this case a low-pressure fuel injection valve. The reducing agent preferably is an aqueous urea solution which is introduced into the exhaust pipe 12 upstream of an SCR c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com