Patents

Literature

2006results about "Gas passages" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

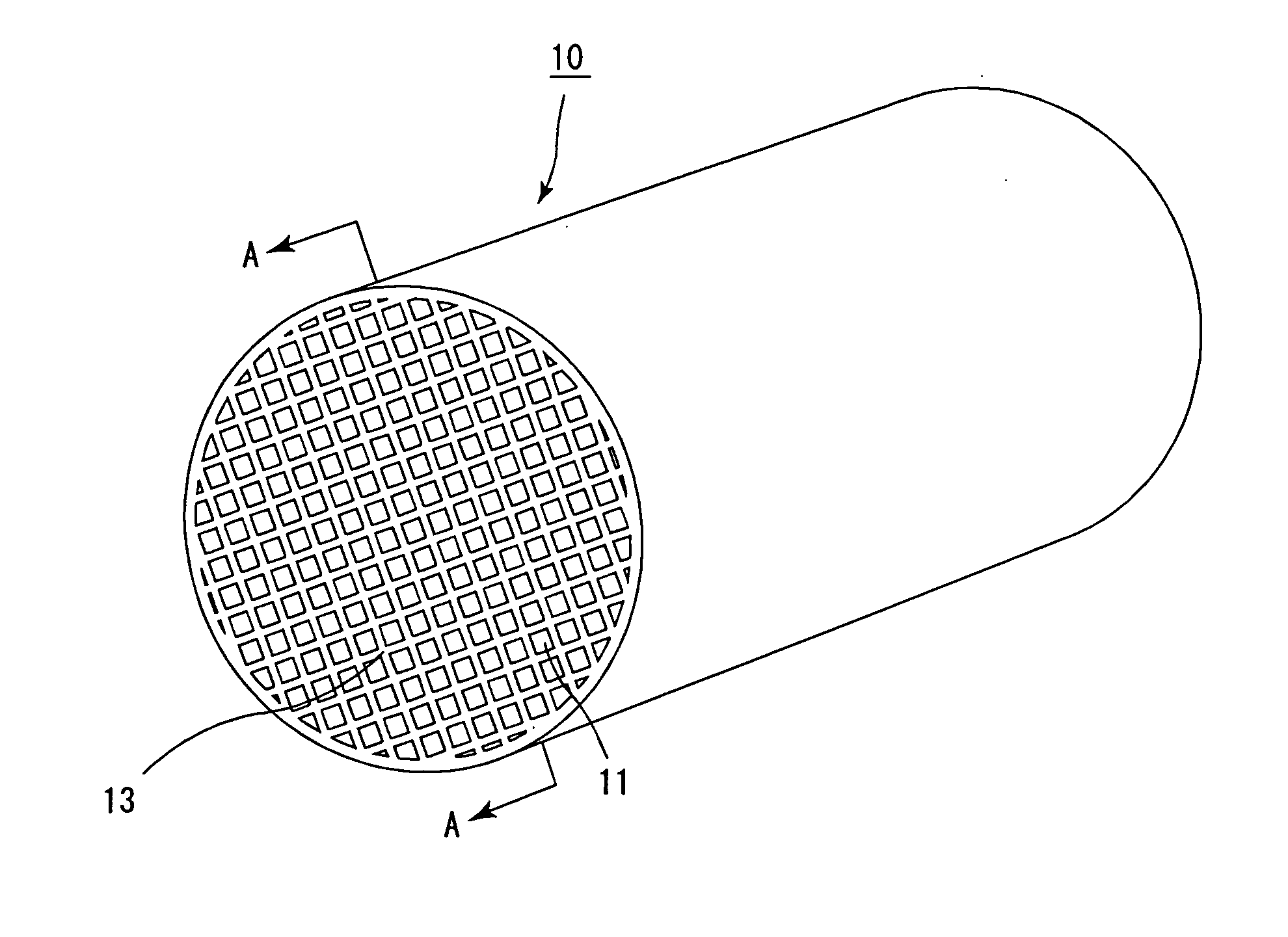

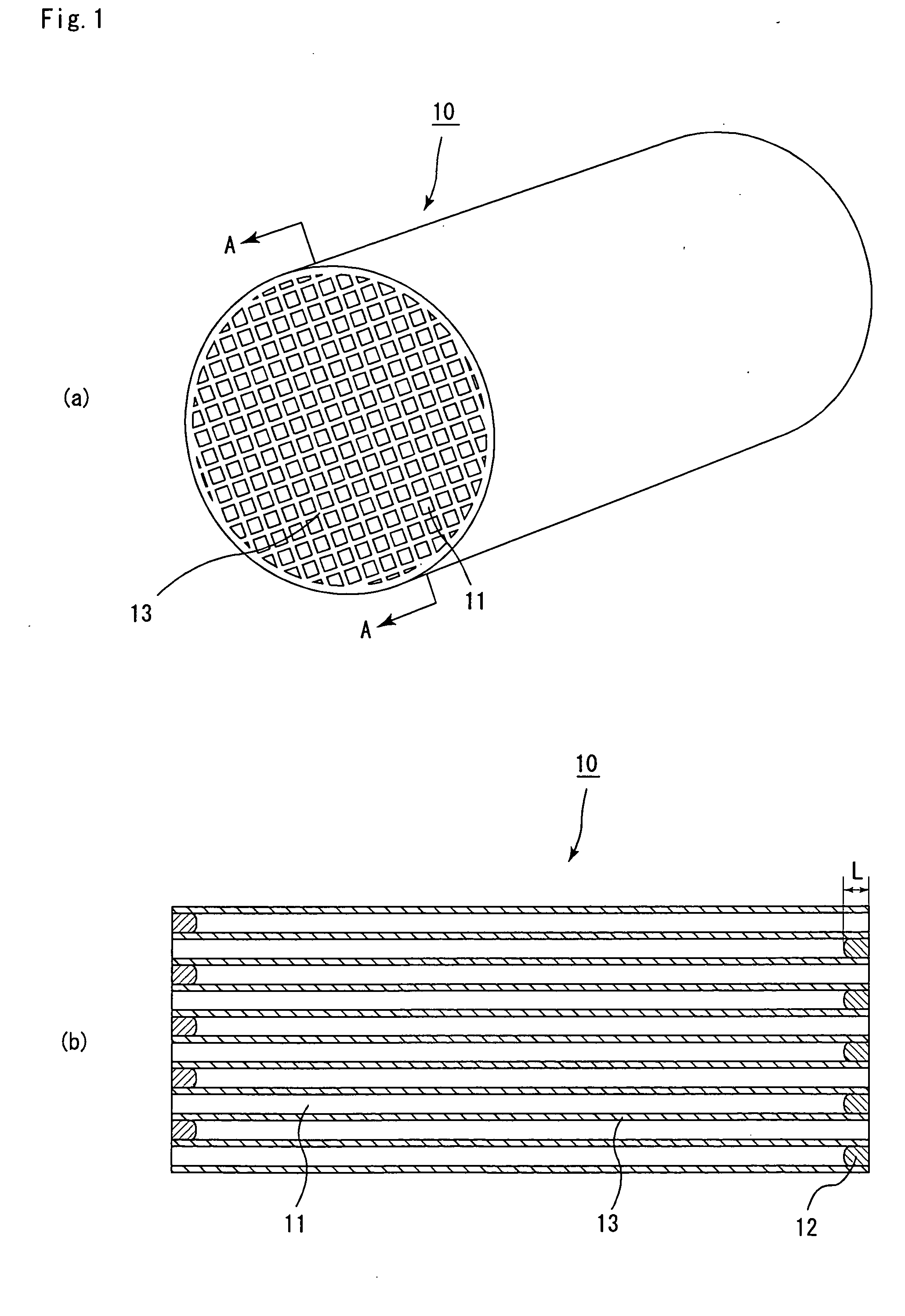

Honeycomb filter for clarifying exhaust gas

ActiveUS20050175514A1Increased durabilityCombination devicesPhysical/chemical process catalystsHoneycombFlexural strength

A honeycomb filter for purifying exhaust gases that is free from occurrence of cracks and coming-off of plugs and is superior in durability upon its use. The honeycomb filter includes a columnar body made of porous ceramics, which has a number of through holes placed in parallel with one another in the length direction with wall portion interposed therebetween, designed so that predetermined of the through holes are filled with plugs at one end of the columnar body, while the through holes not filled with the plugs at the one end are filled with plugs at the other end of the columnar body, and part of or the entire wall portion functions as a plug for collecting particles. A bending strength Fα (MPa) of the honeycomb filter and a length L (mm) of the plug in the length direction of the through hole satisfy the relationship of Fα×L≧30.

Owner:IBIDEN CO LTD

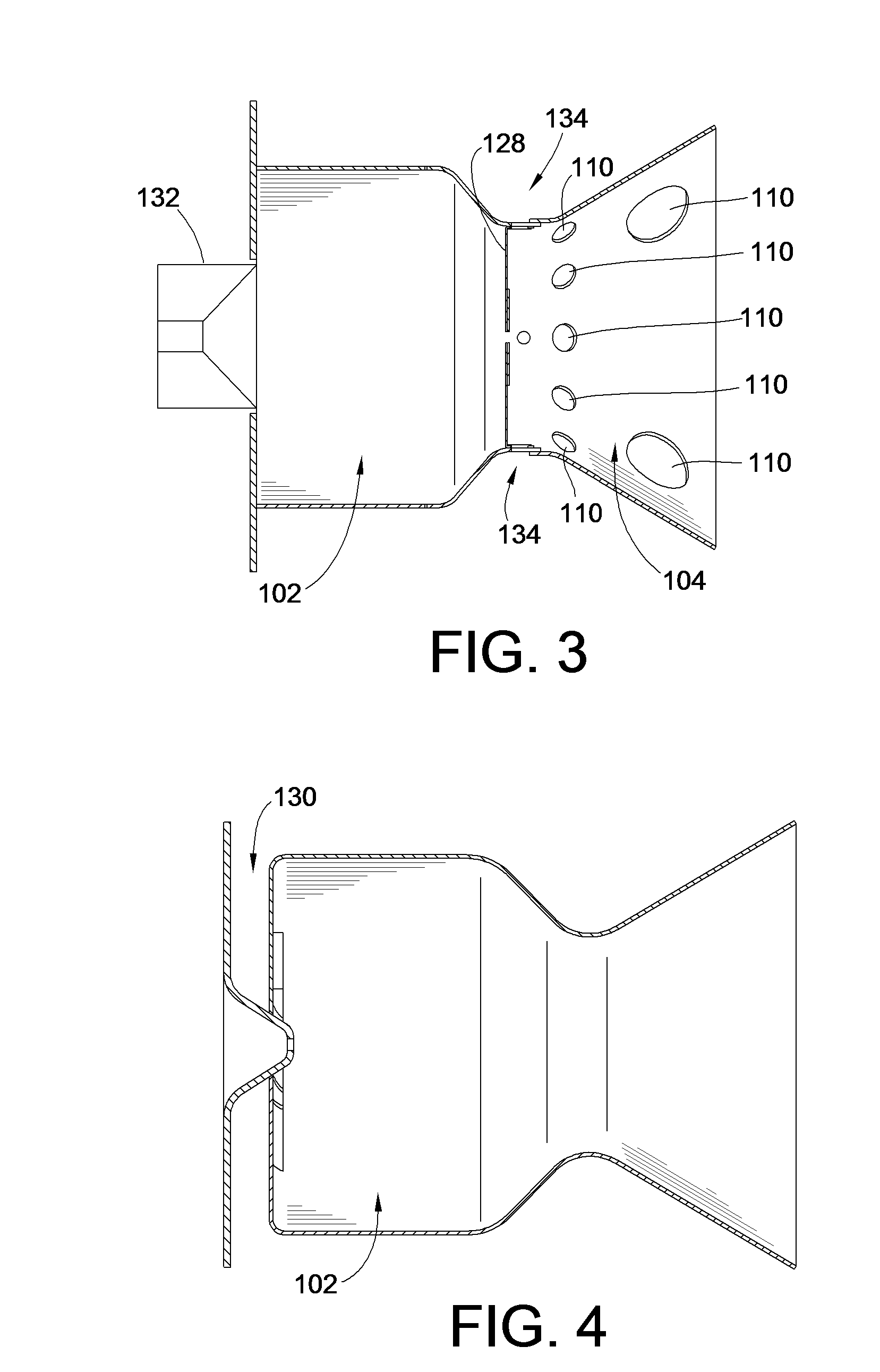

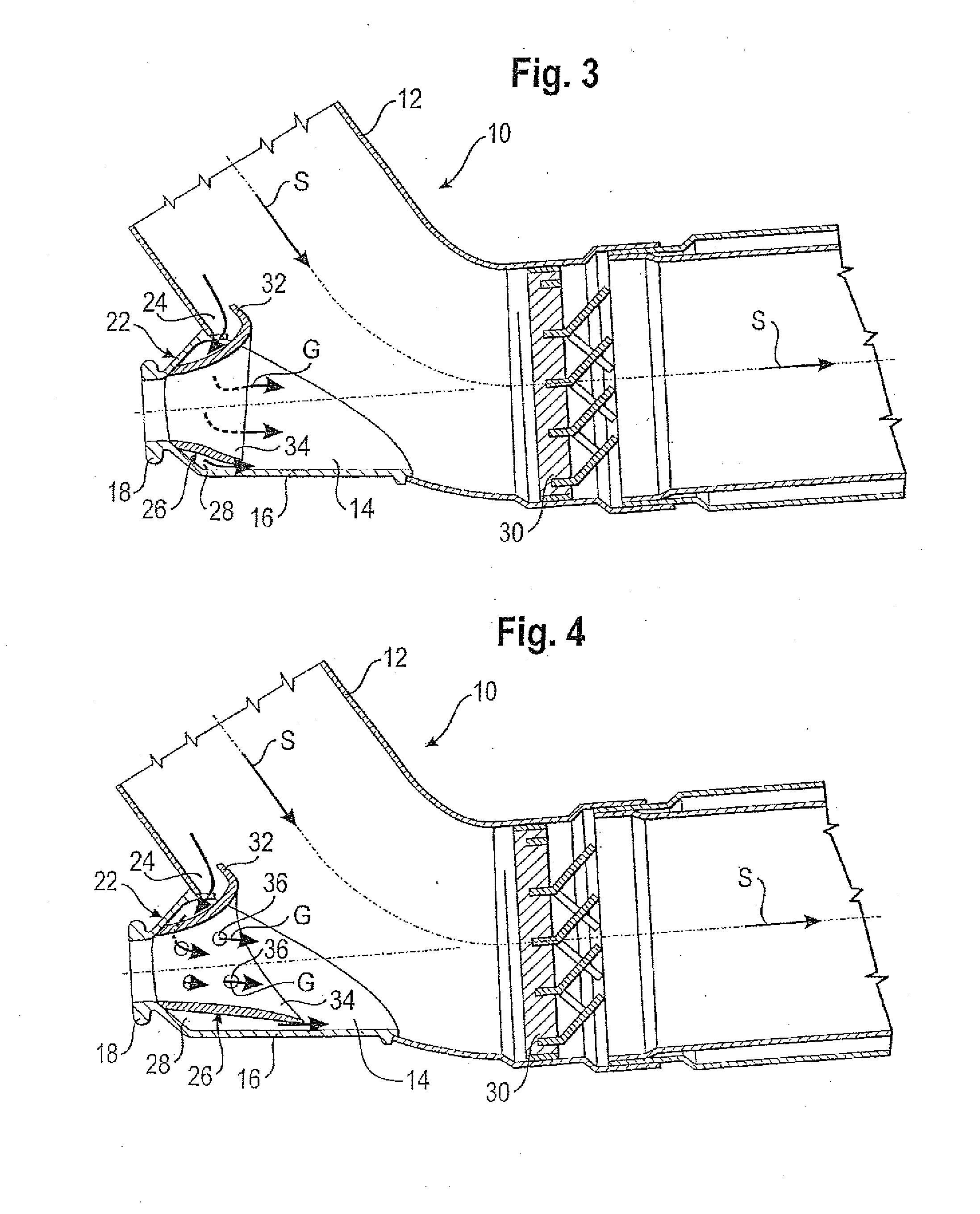

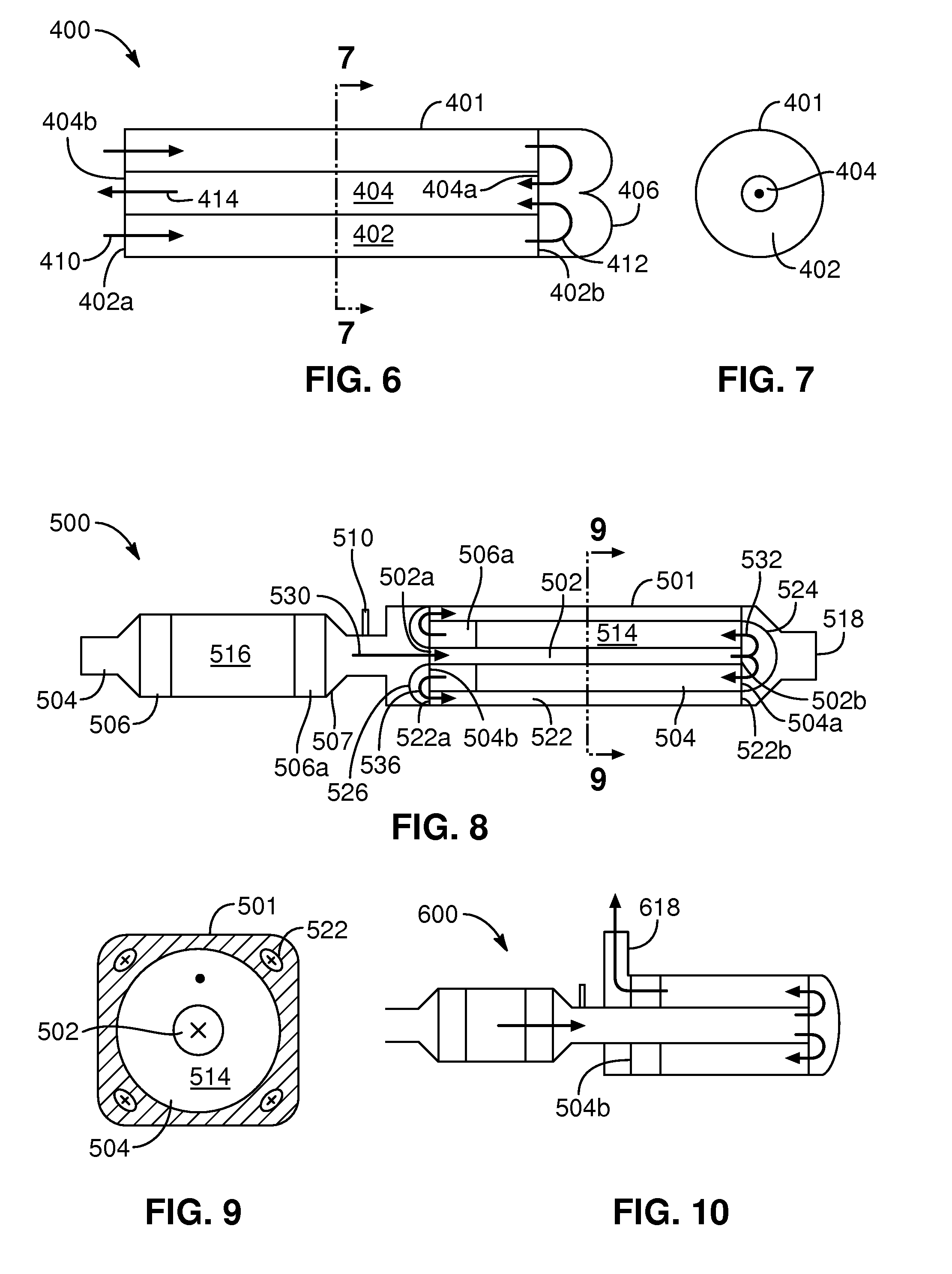

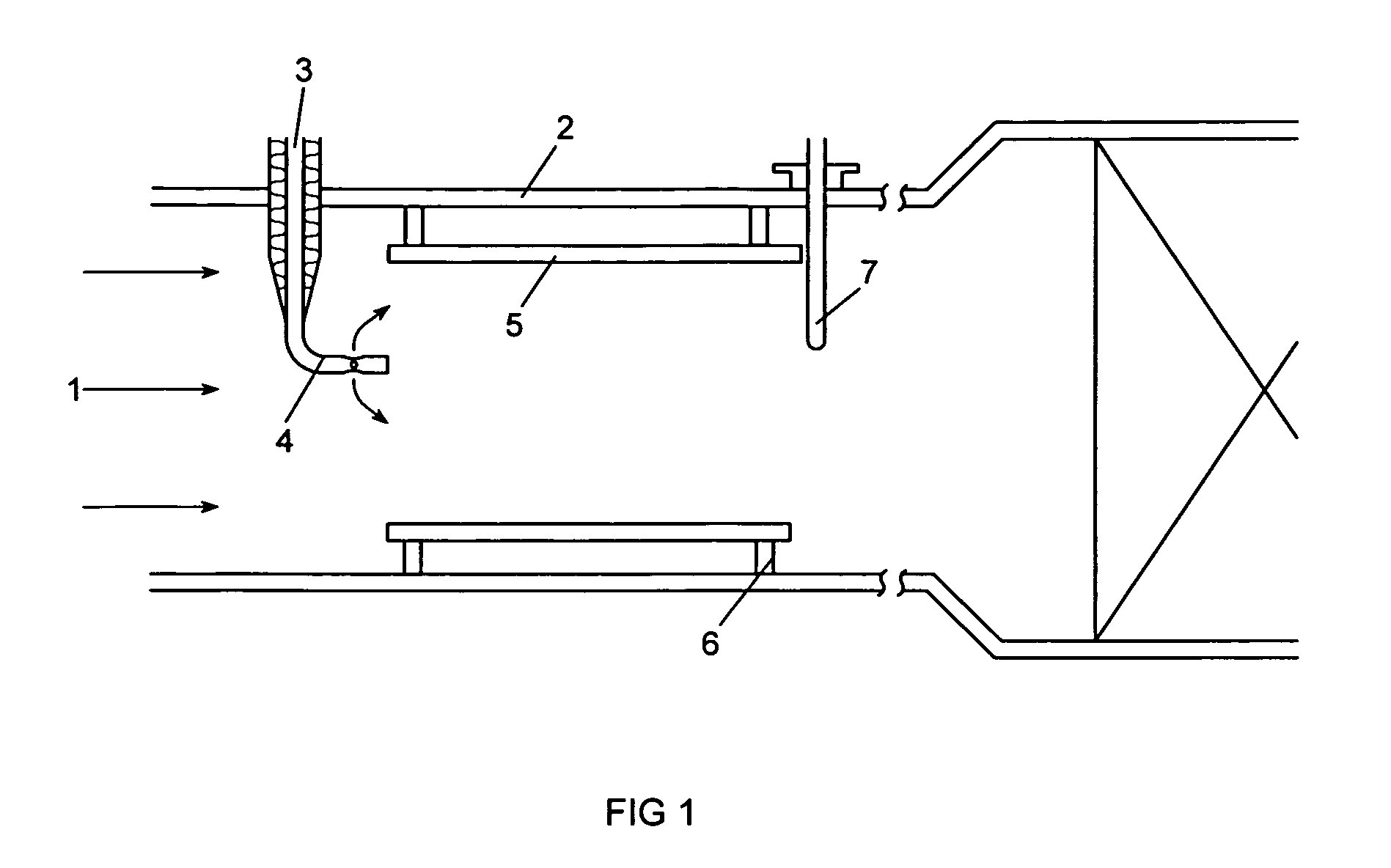

Low Pressure Drop Mixer for Radial Mixing of Internal Combustion Engine Exhaust Flows, Combustor Incorporating Same, and Methods of Mixing

ActiveUS20090255242A1Increase surface areaEnhanced interactionInternal combustion piston enginesFlow mixersCombustion chamberCombustor

An exhaust aftertreatment system is provided. The exhaust aftertreatment system includes a mixing arrangement for mixing flows of exhaust along a flow path. The mixing arrangement radially and angularly rearranges segments of two different portions of flow to mix the different portions of flow. The mixing arrangement initially converts a generally radially stratified temperature profile into an angularly stratified temperature profile to increase surface area between cool segments of exhaust gas and hot segments of exhaust gas. The aftertreatment system may also include a combustion chamber, a combustor housing and a combustor liner. The mixing arrangement is downstream from the combustion chamber to direct radially outward hot gas passing through the combustor liner and to direct radially outer cool gas passing between the liner and the combustor housing radially inward in an interleaving fashion.

Owner:WOODWARD GOVERNOR CO

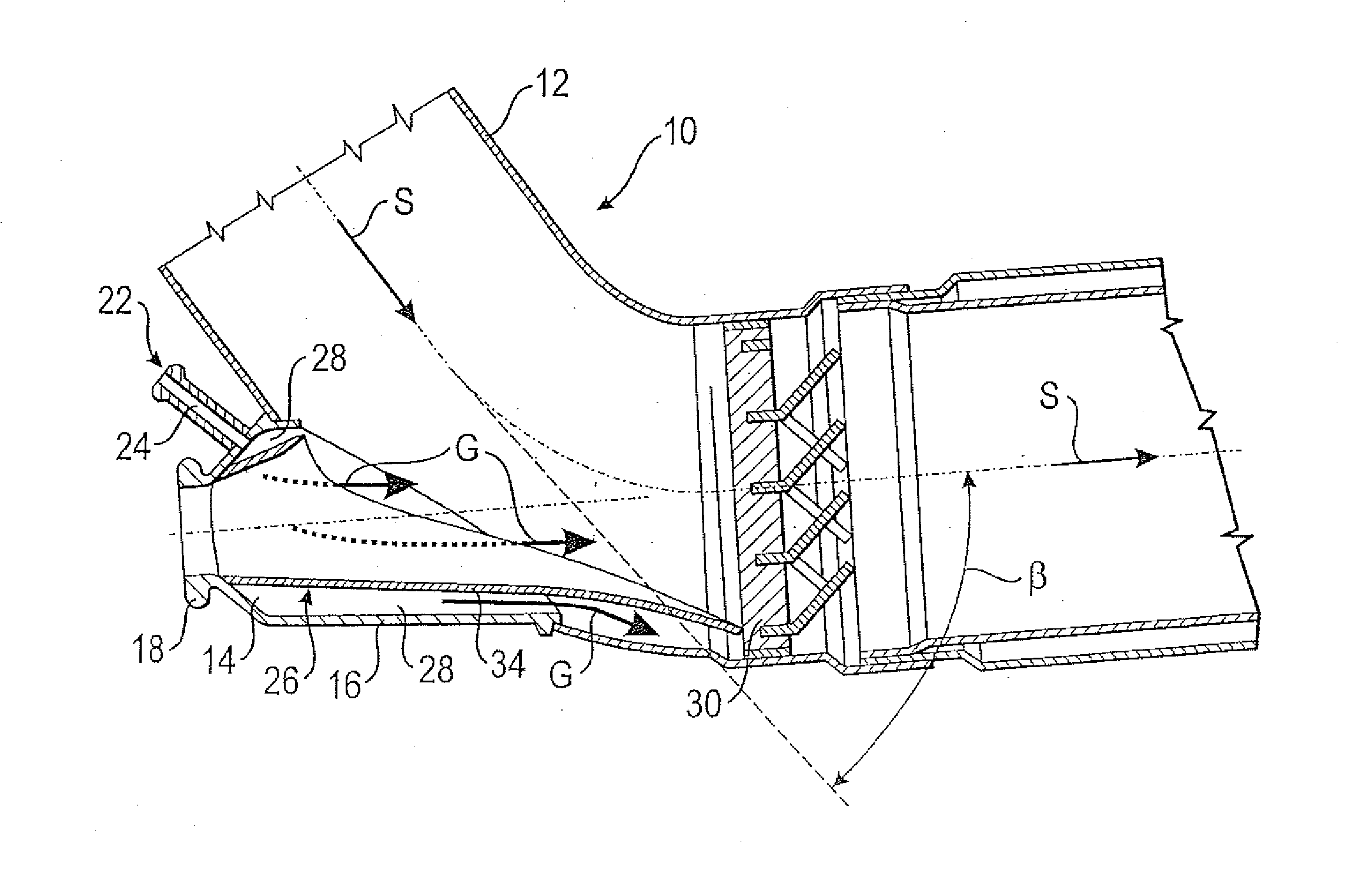

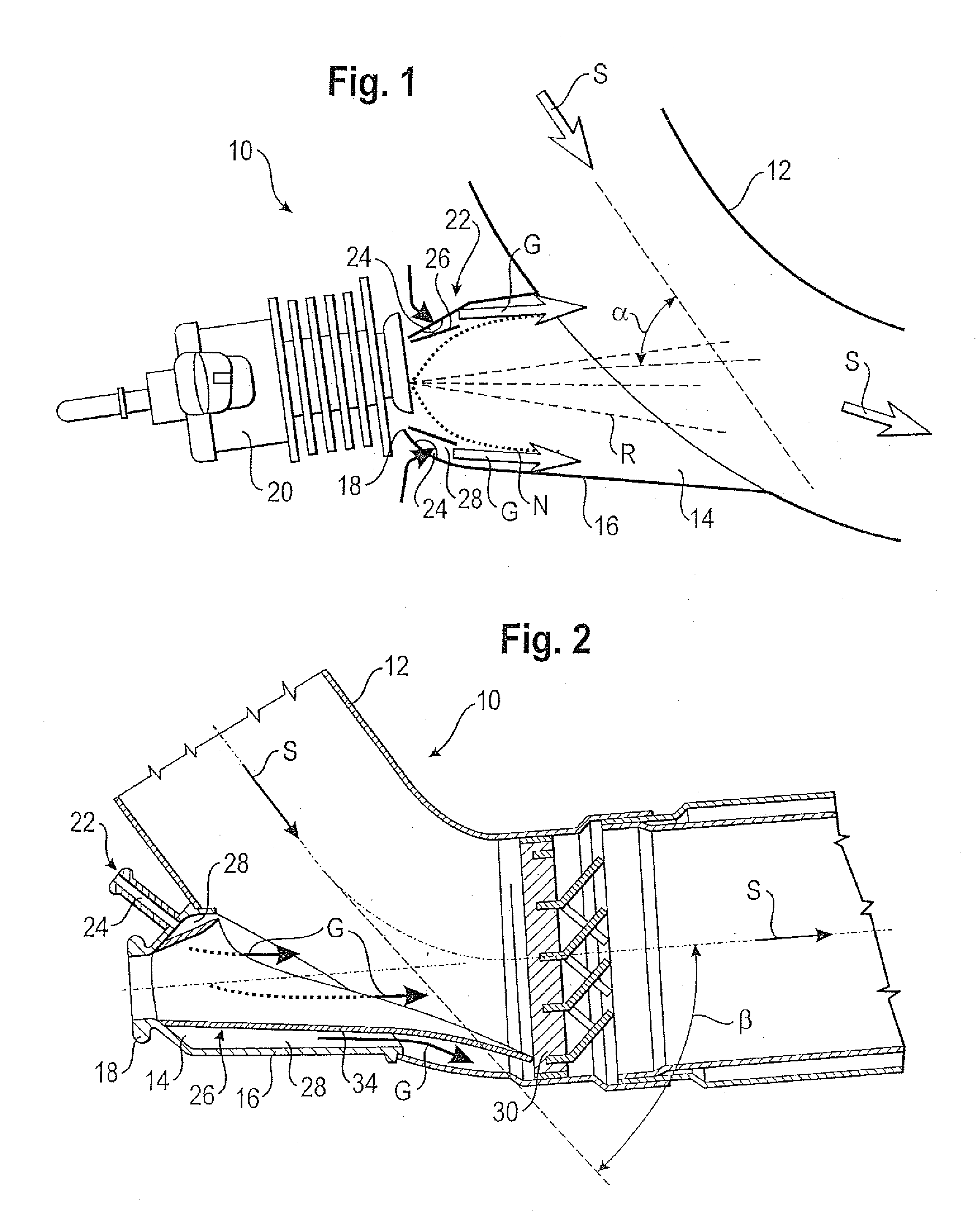

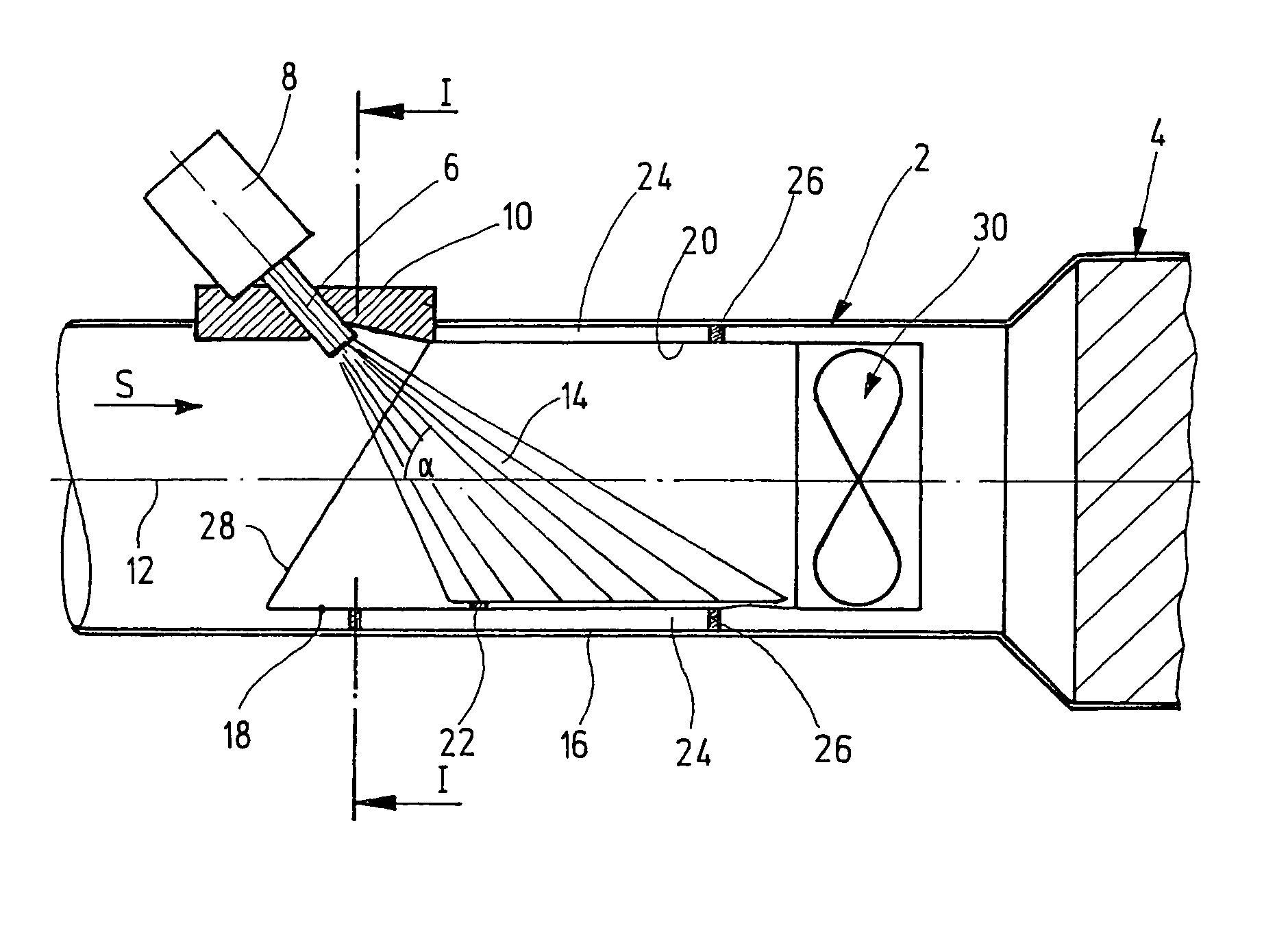

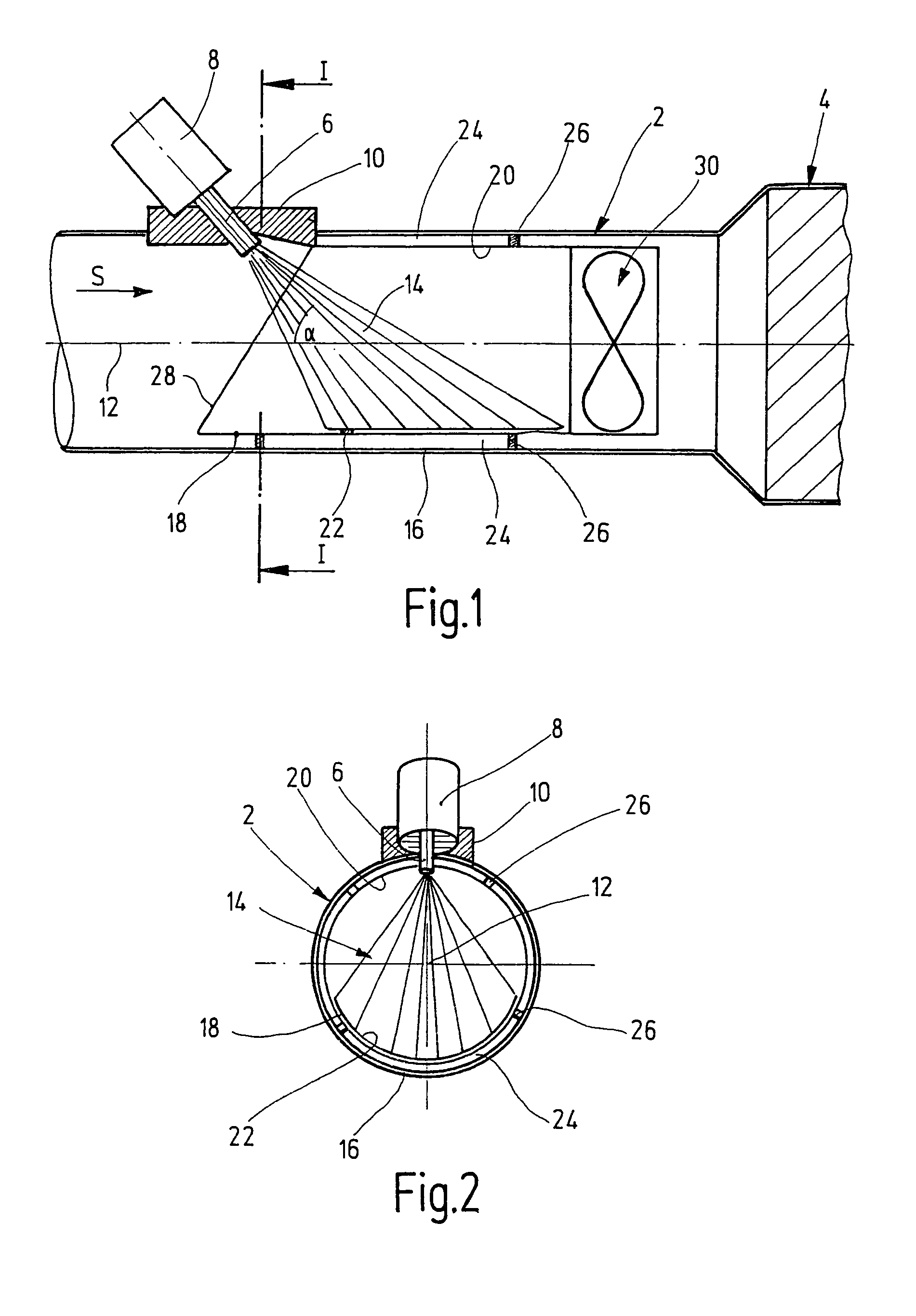

Assembly and Method for Introducing a Reducing Agent into the Exhaust Pipe of an Exhaust System of an Internal Combustion Engine

InactiveUS20100212292A1Avoid depositionWell mixedGas treatmentInternal combustion piston enginesMobile vehicleExternal combustion engine

An assembly and method for introducing a reducing agent into an exhaust pipe of an exhaust system of an internal combustion engine, in particular of a motor vehicle includes a feed connector which opens into the exhaust pipe and has a wall; a feed device for reducing agents which opens into the feed connector; and a device that generates a gas flow which is additional to the reducing agent flow and lines the wall of the feed connector.

Owner:FAURECIA EMISSIONS CONTROL TECH GERMANY

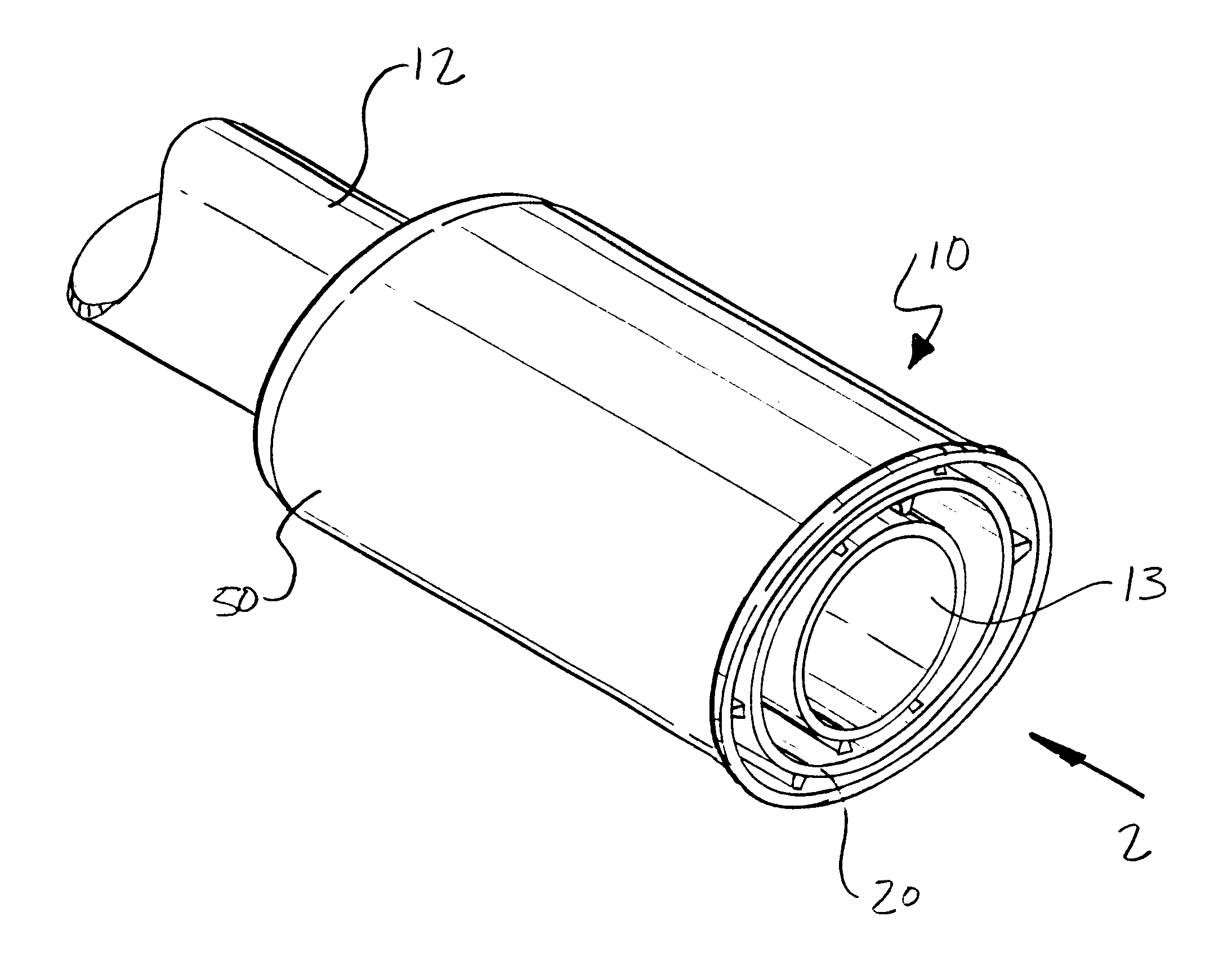

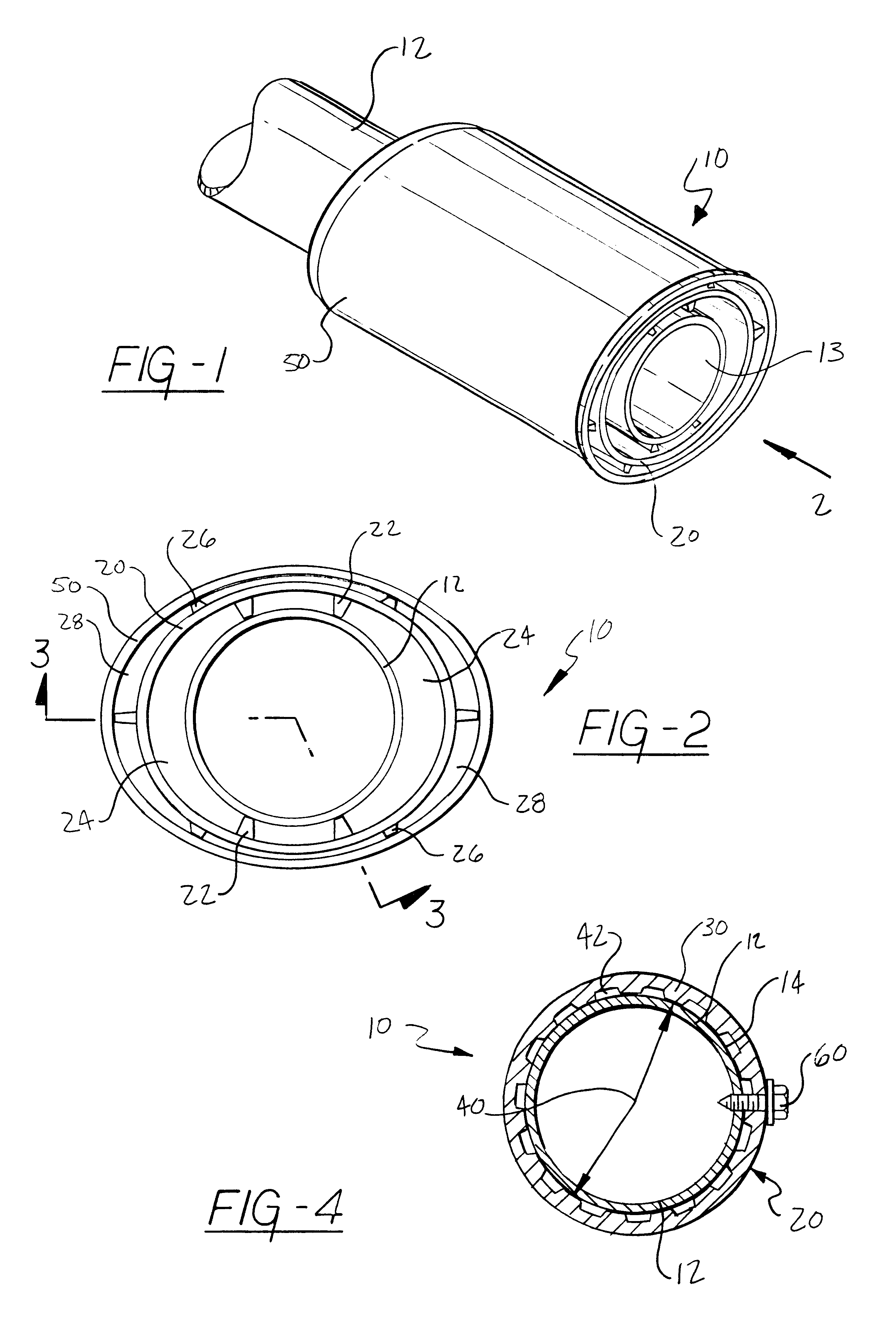

Exhaust tip

InactiveUS7007720B1Severe design restrictionOverall design flexibilityThermal insulationSilencing apparatusEngineeringThermal effect

An exhaust tip for attachment to a tailpipe that includes a thermoset heat shield at least partially surrounding and fastened to the tailpipe, and a thermoplastic decorative cover at least partially surrounding and fastened to the thermoset heat shield. The thermoset heat shield insulates the thermoplastic decorative cover from thermal effects of the tailpipe and spaces the thermoplastic decorative cover a predetermined distance away from the tailpipe.

Owner:LACKS INDUSTRIES INC

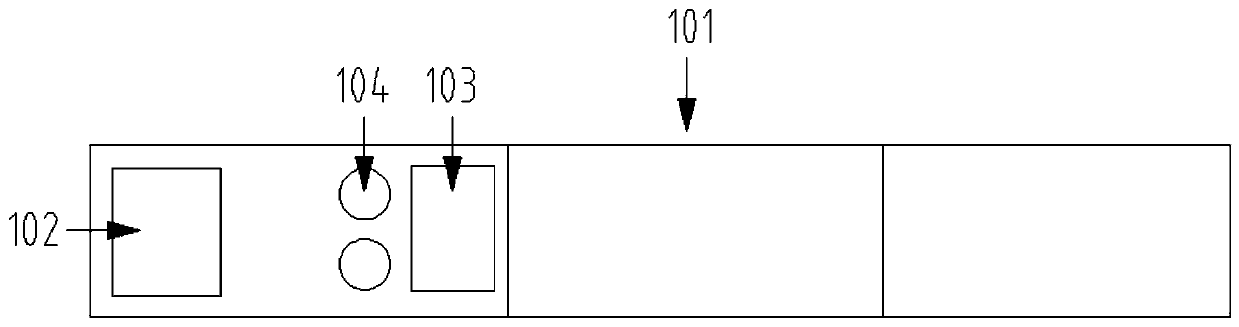

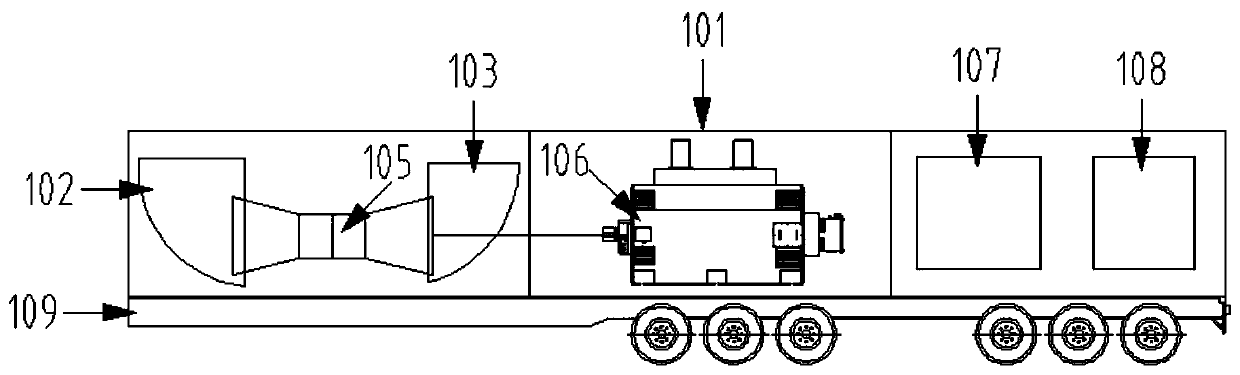

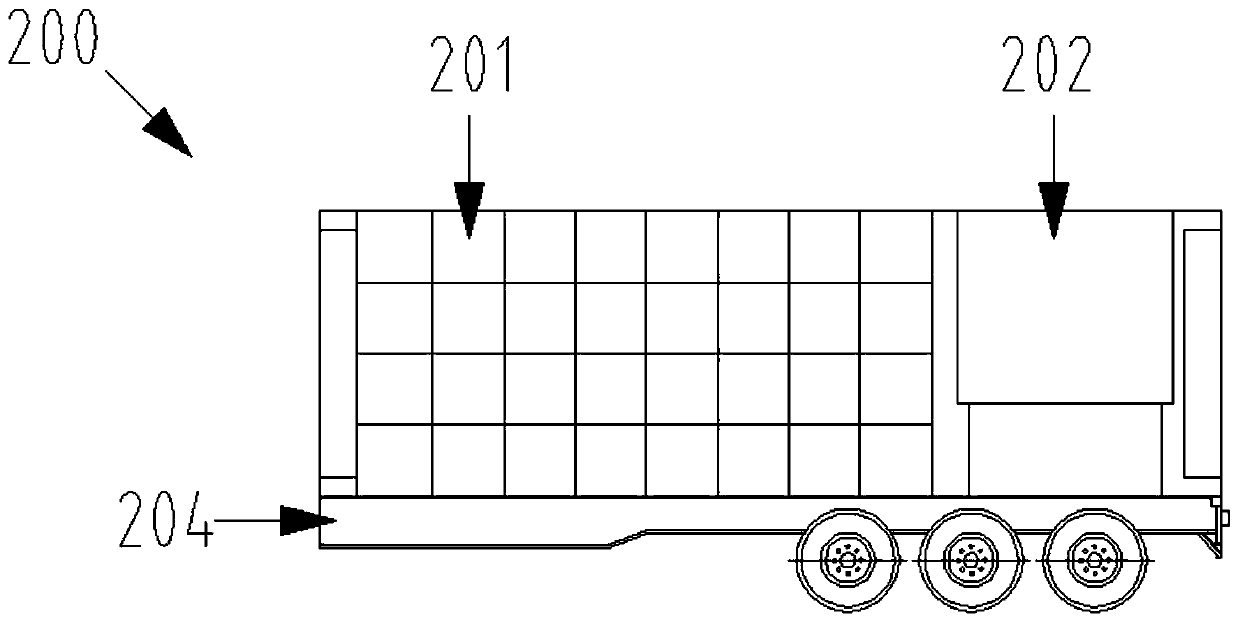

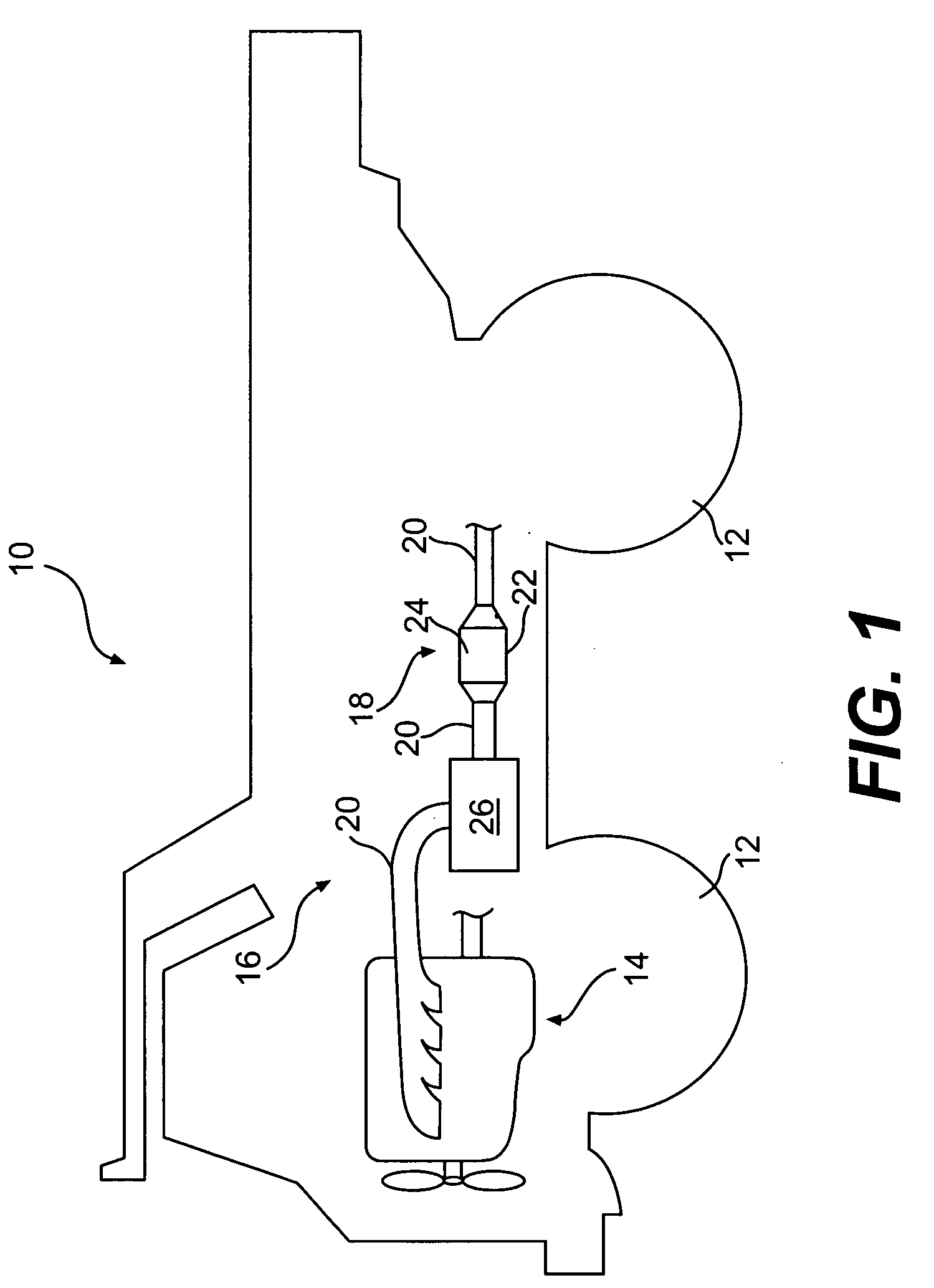

Portable power generation system

PendingCN110145399ASmall footprintSimple designEngine fuctionsSilencing apparatusCombustionPortable power

The invention discloses a portable power generation system. The whole power generation system is divided into two conveyances. A combustion gas turbine, an electric generator, an inlet chamber, an exhaust gas receiver and an auxiliary system are arranged on the first conveyance, and an inlet component and an exhaust pipeline as a whole are arranged on the second conveyance. At least four lifting devices are arranged on the second conveyance and are used for separating the inlet component and the exhaust pipeline from the second conveyance and realizing upward jacking, so that a power-generation transport device can move to the position under the inlet component and the exhaust pipeline. Then, the inlet component and the exhaust pipeline descend by using the lifting devices to butt againstthe inlet chamber and the exhaust gas receiver respectively. The gravity of the inlet component and the exhaust pipeline are utilized to realize the sealing of butting.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

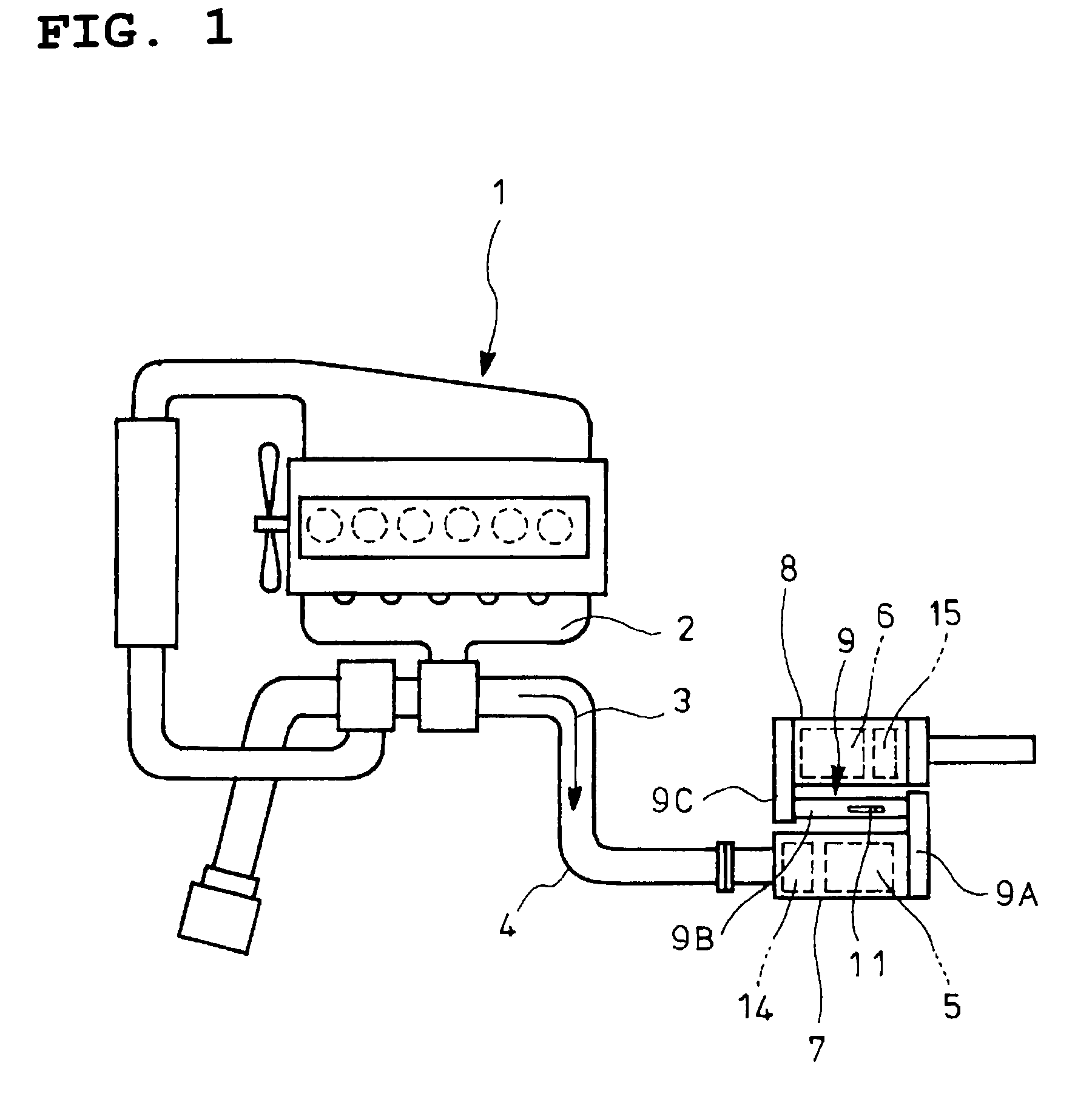

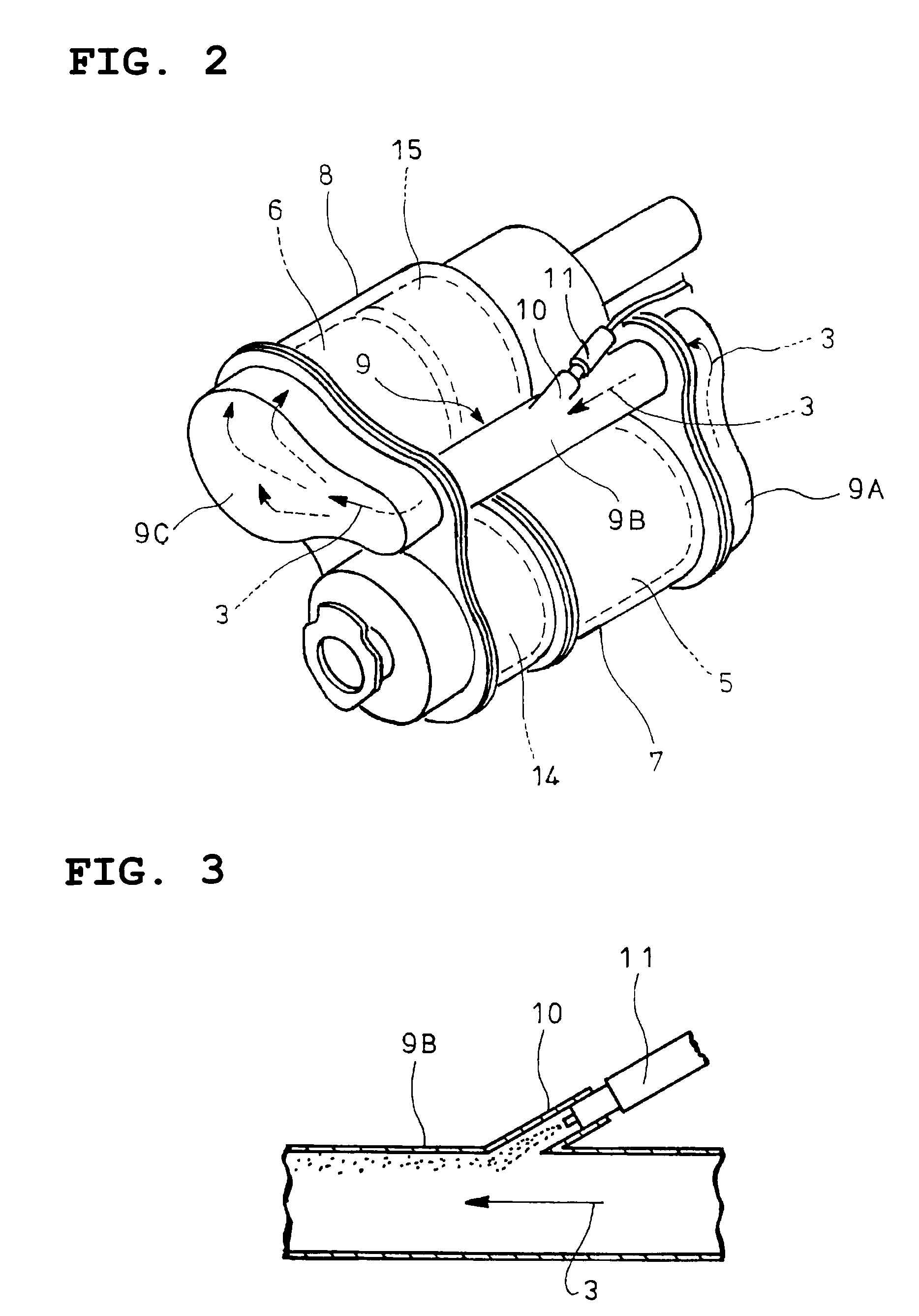

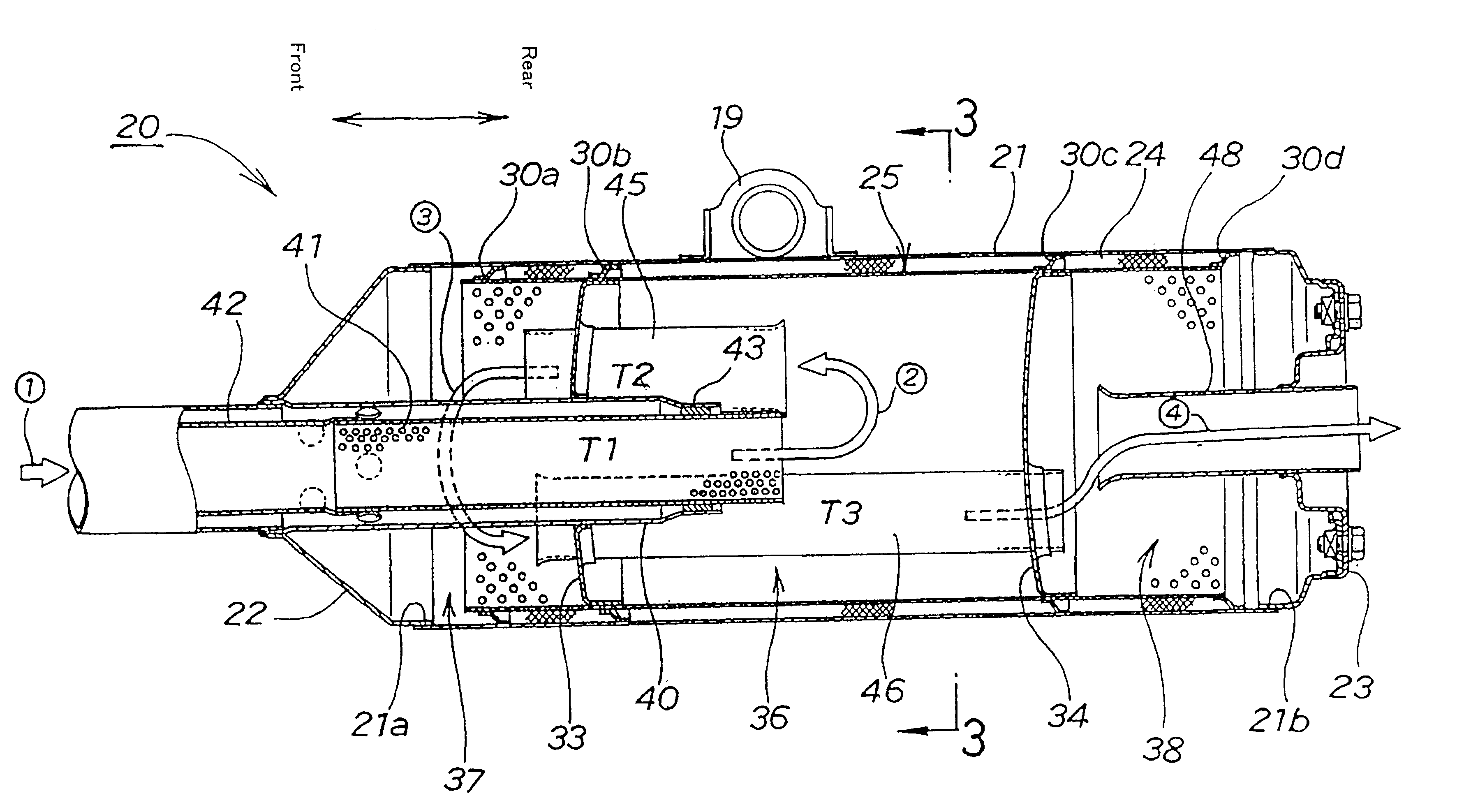

Exhaust emission control device

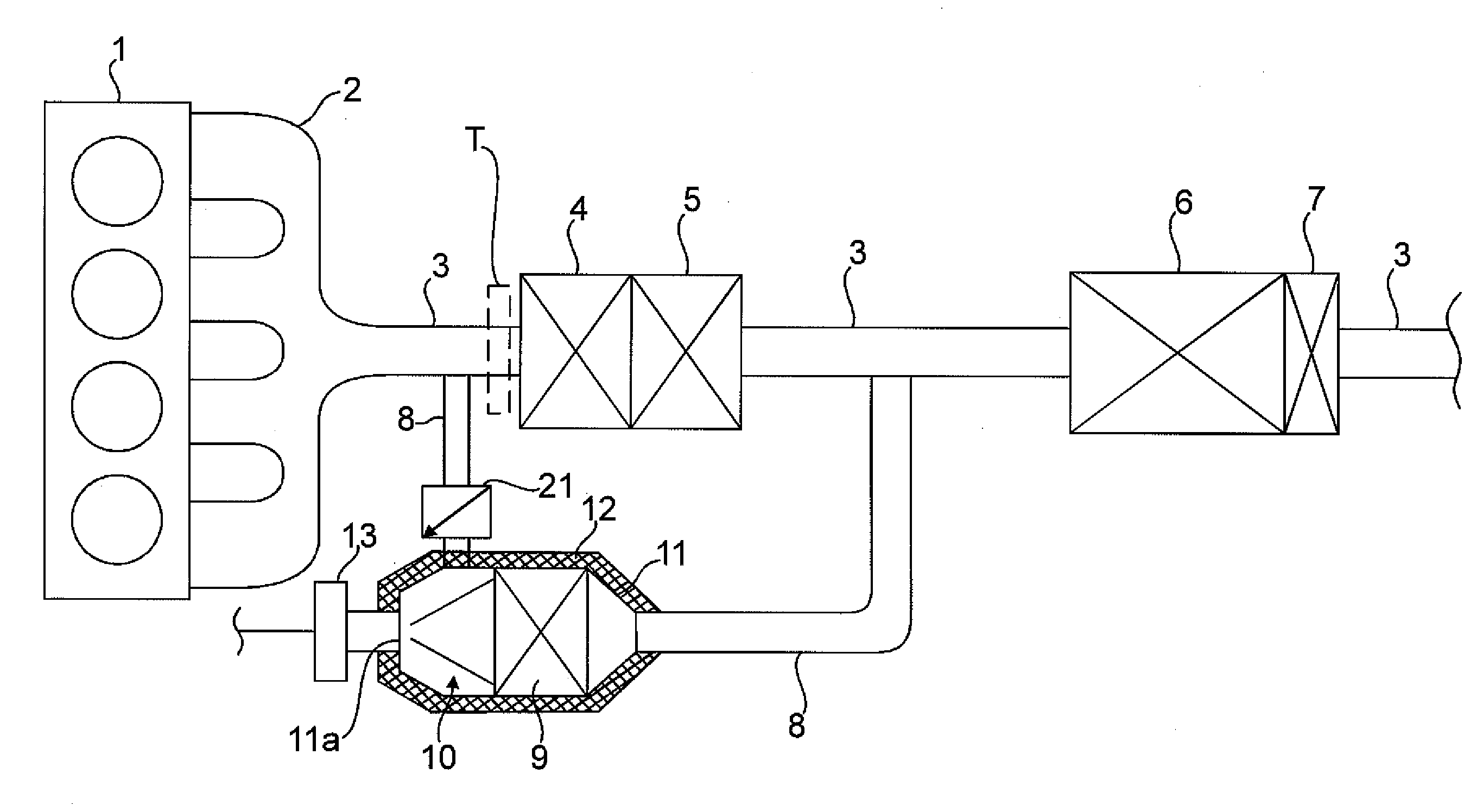

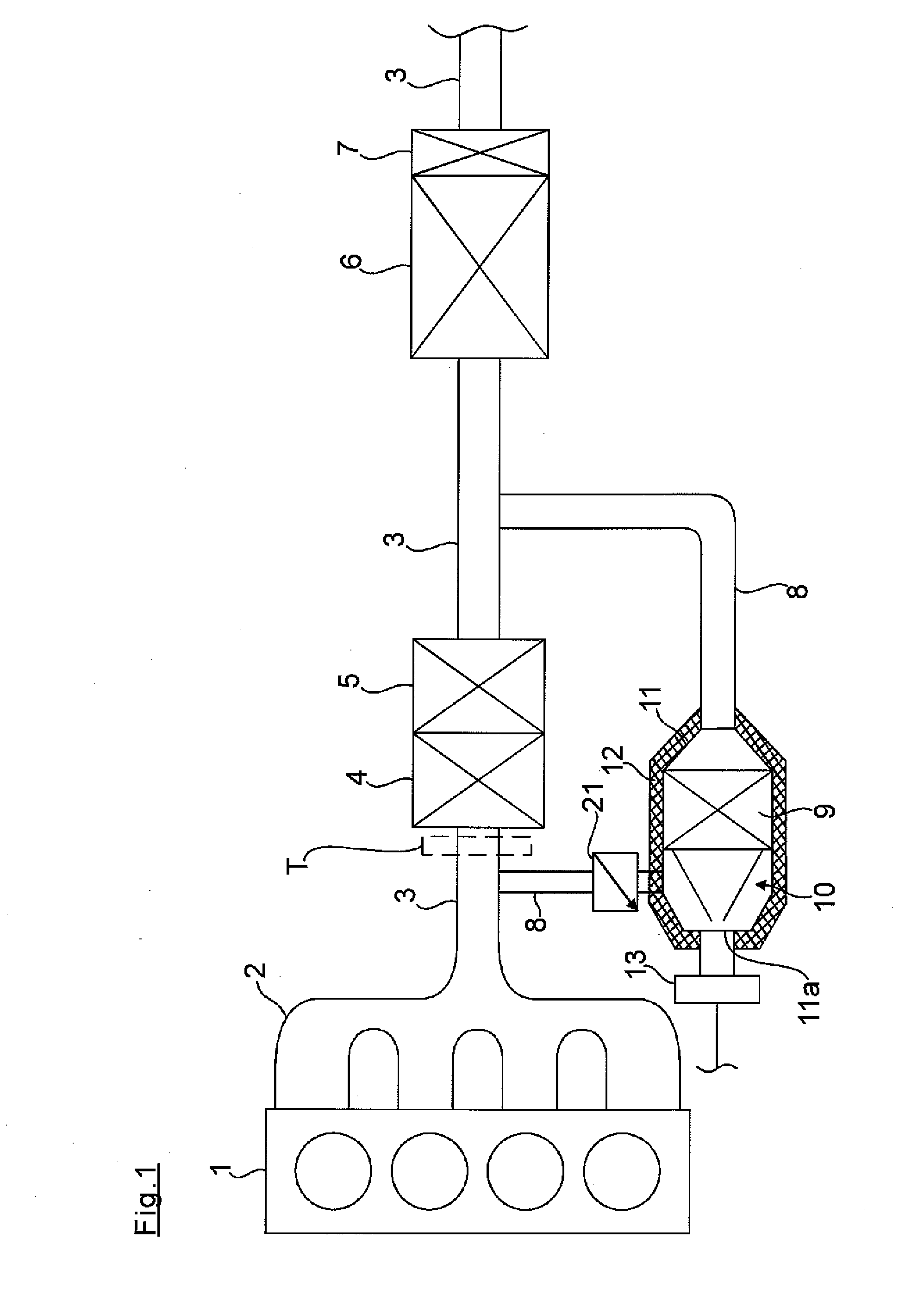

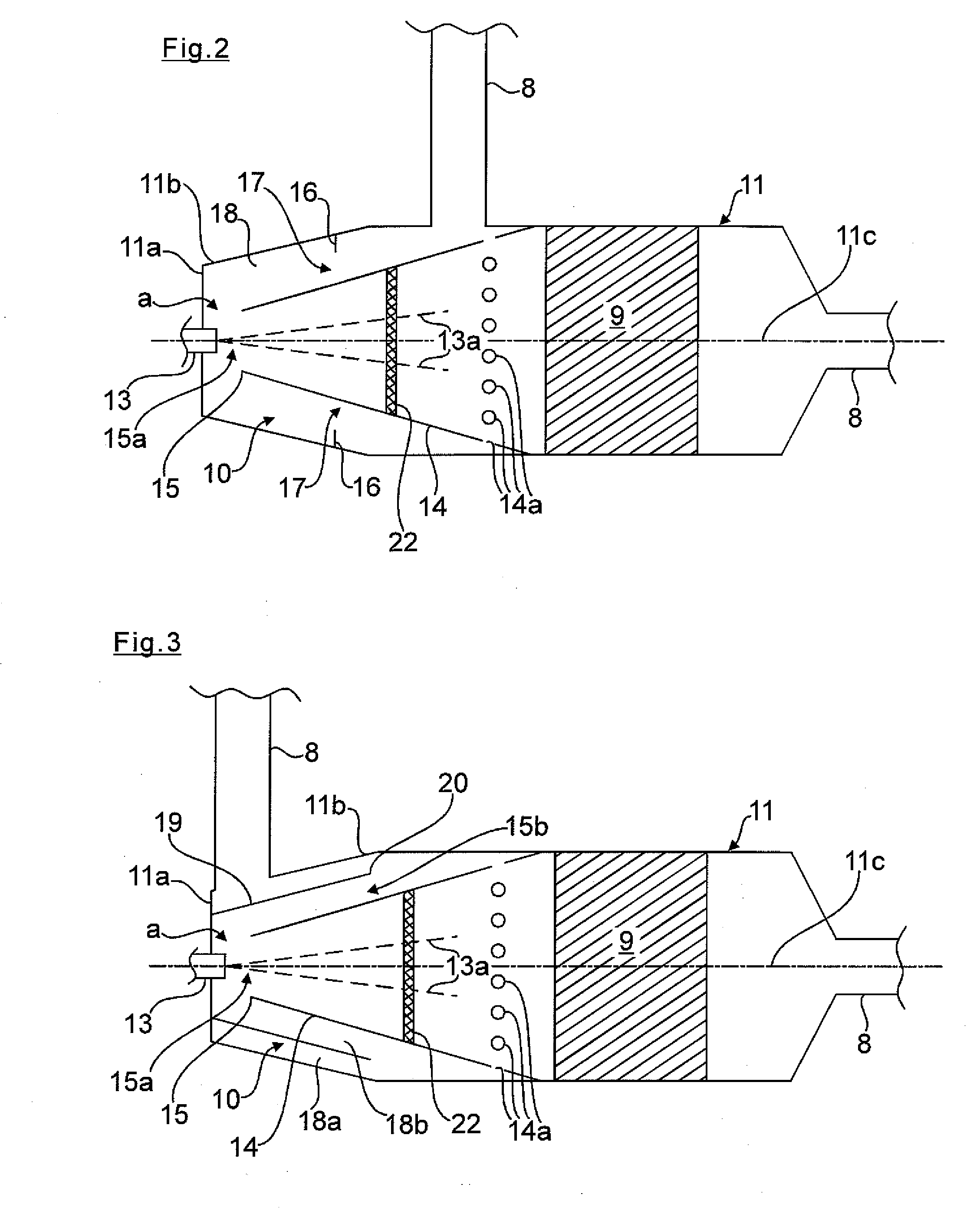

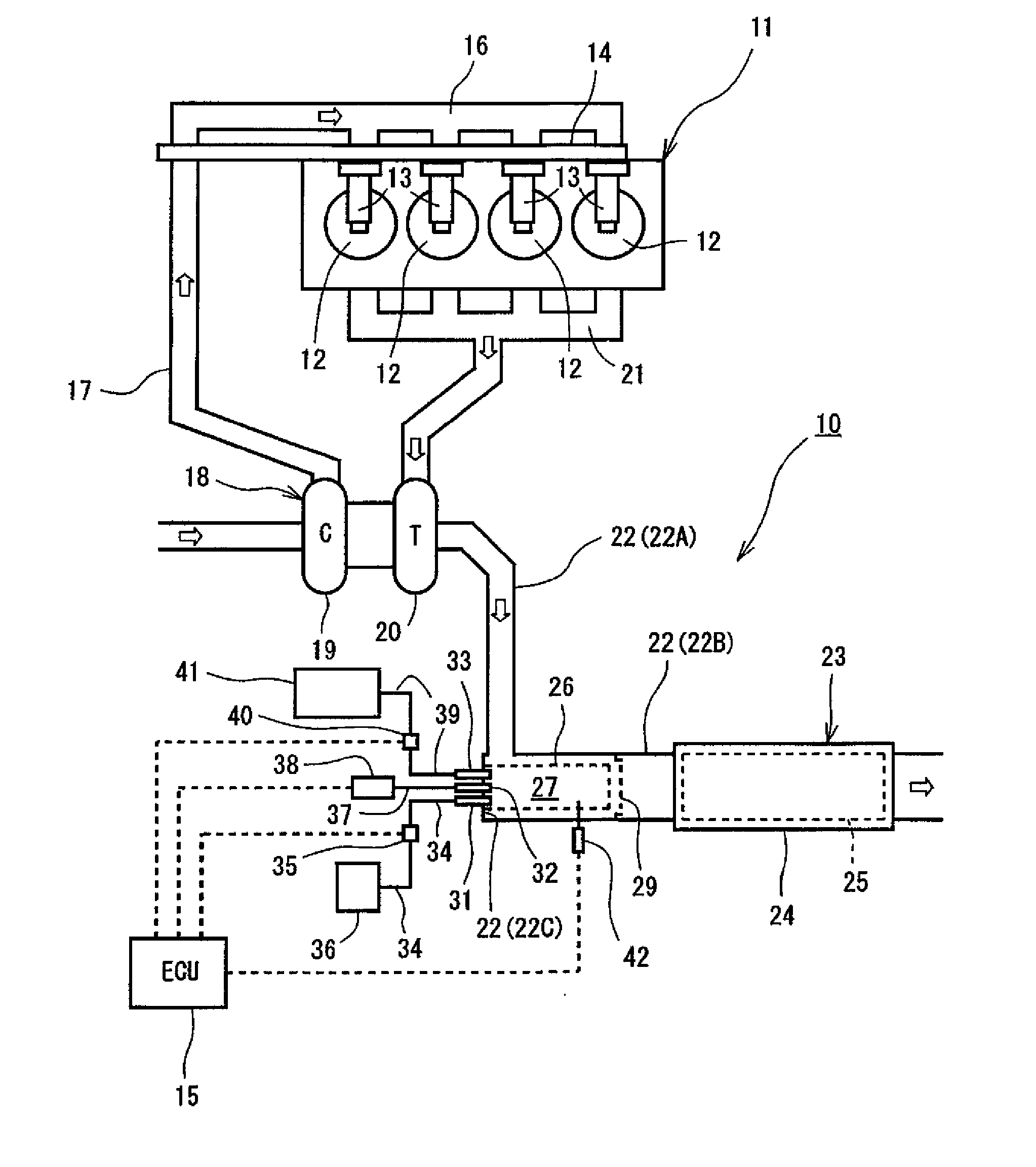

ActiveUS20090313979A1Well mixedIncrease flow rateGas treatmentInternal combustion piston enginesParticulatesEnvironmental engineering

An exhaust emission control device has a particulate filter 5 and a selective reduction catalyst 6 arranged side by side. An S-shaped communication passage 9 is arranged for introduction of exhaust gas 3 from a rear end of the filter 5 to a front end of the adjacent catalyst 6 in a forward fold-back manner and with a urea water addition injector 11 arranged midway of the passage 9. In order to satisfactorily disperse the urea water with enhanced mixing with the exhaust gas 3 even if the flow rate is increased, slits 12 are formed in circumferentially spaced positions on a rear end of a mixing pipe 9B constituting an upstream portion of the communication passage 9 so as to introduce the exhaust gas 3. A downstream end 9a of a gas gathering chamber 9A is connected to the rear end of the mixing pipe 9B such that the slits 12 are encased and the rear end of the mixing pipe 9B is closed.

Owner:HINO MOTORS LTD

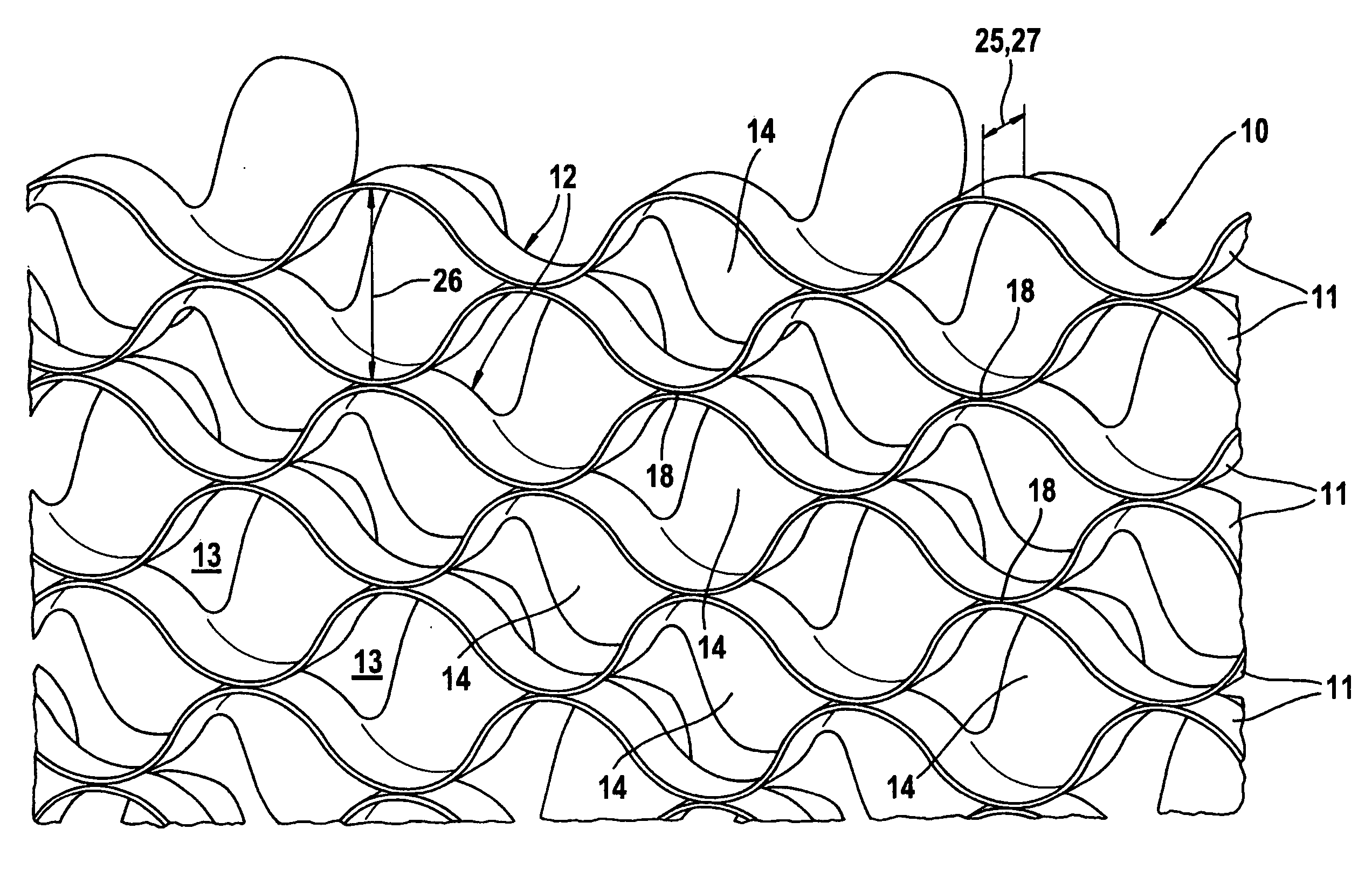

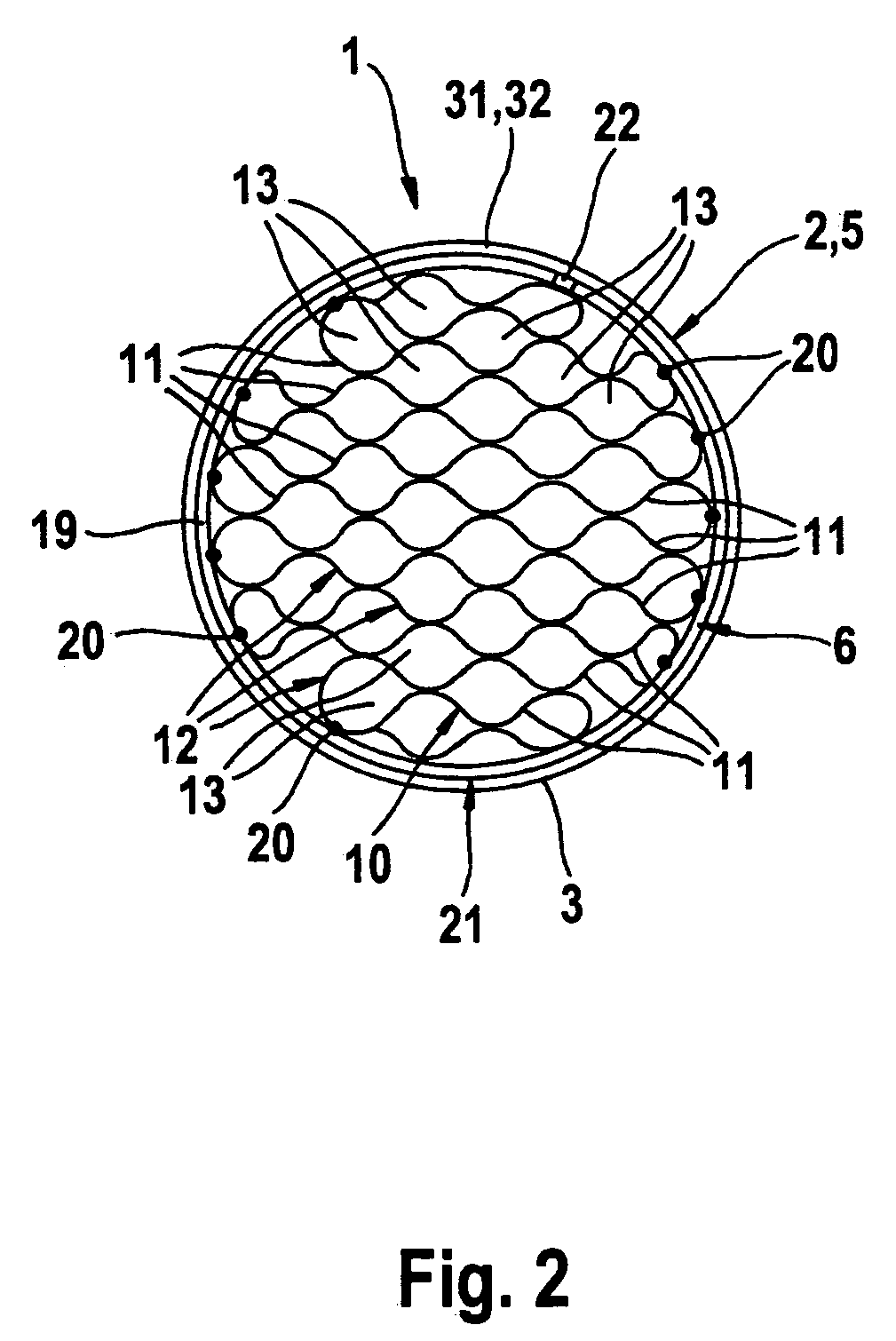

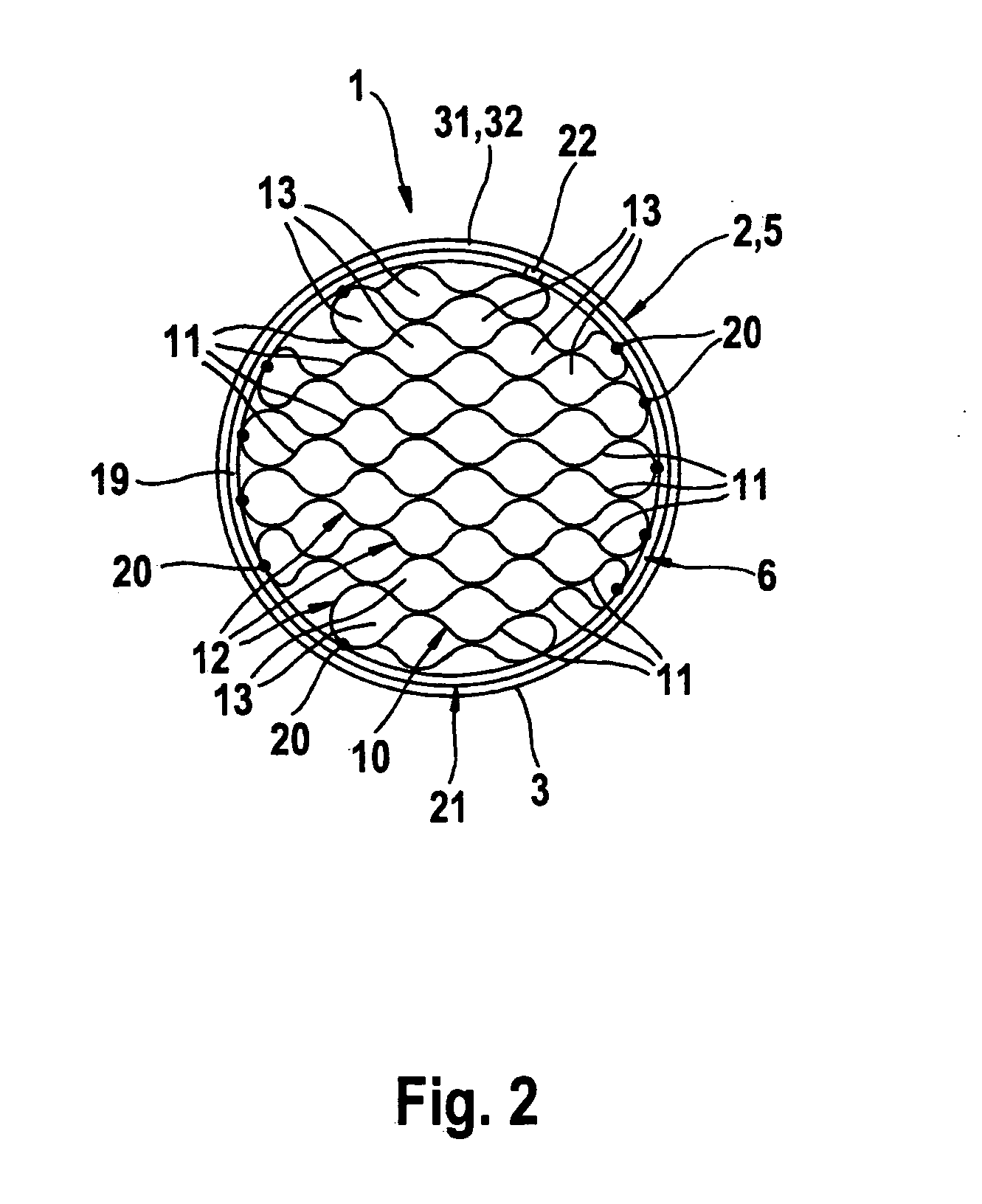

Static mixer and exhaust gas treatment device

InactiveUS7793494B2Design economyIntense mixing effect and vaporization effectInternal combustion piston enginesFlow mixersExhaust fumesEngineering

The invention relates to a static mixer for an exhaust system of an internal combustion engine. The mixer has a wall structure that is arranged across the directional of flow in a pipe and has several layers of a corrugated sheeting material laying across one another in the direction of flow. The cells through which the flow can pass in the direction of flow are provided between the sheeting material of neighboring layers. The sheeting material has baffles for all or several of the cells. The baffles are arranged on the sheeting material so that they are arranged on their outgoing flow side in the case of said cells and extend in the direction of flow and across it.

Owner:EBERSPACHER EXHAUST TECH GMBH & CO KG

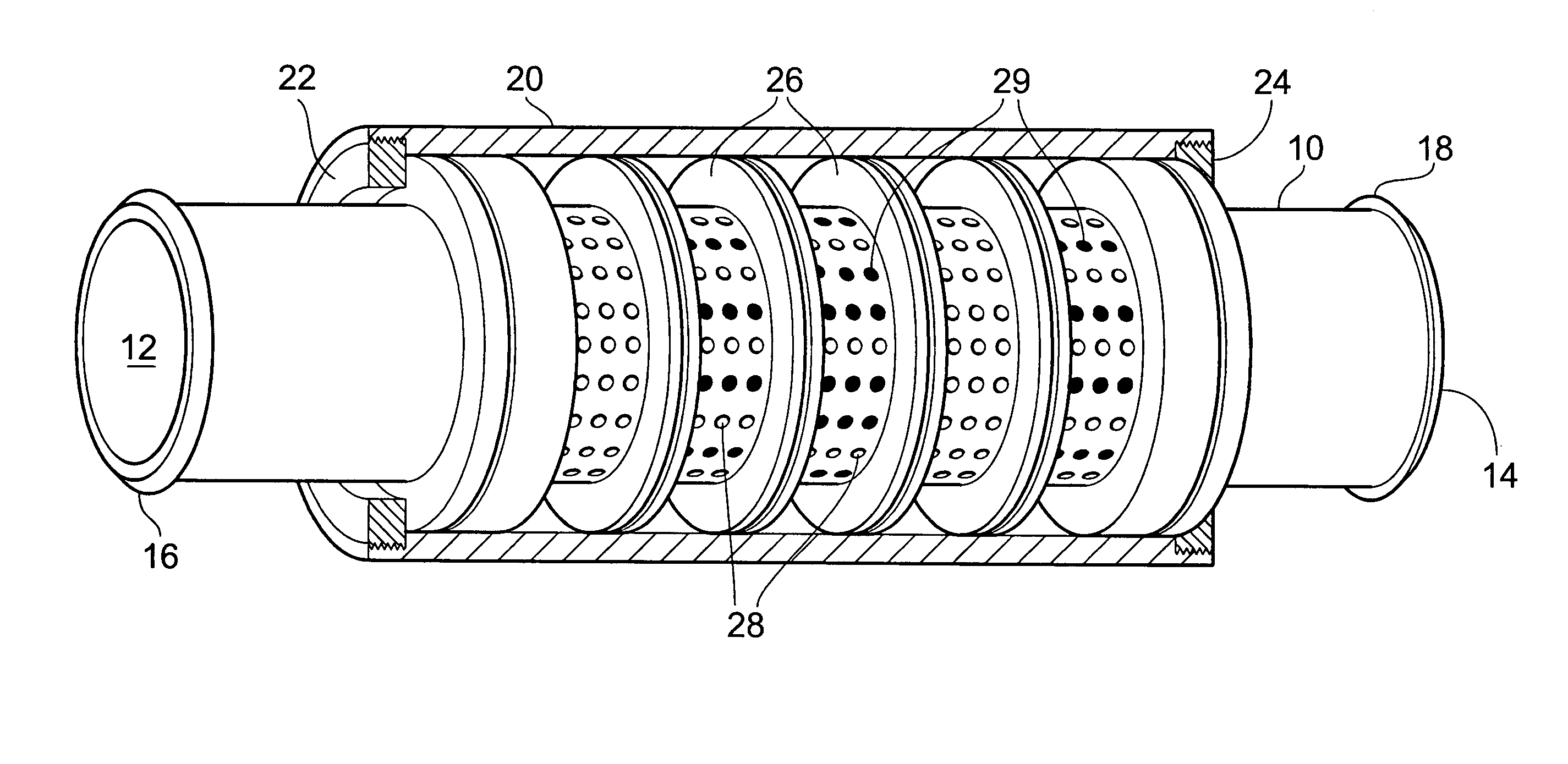

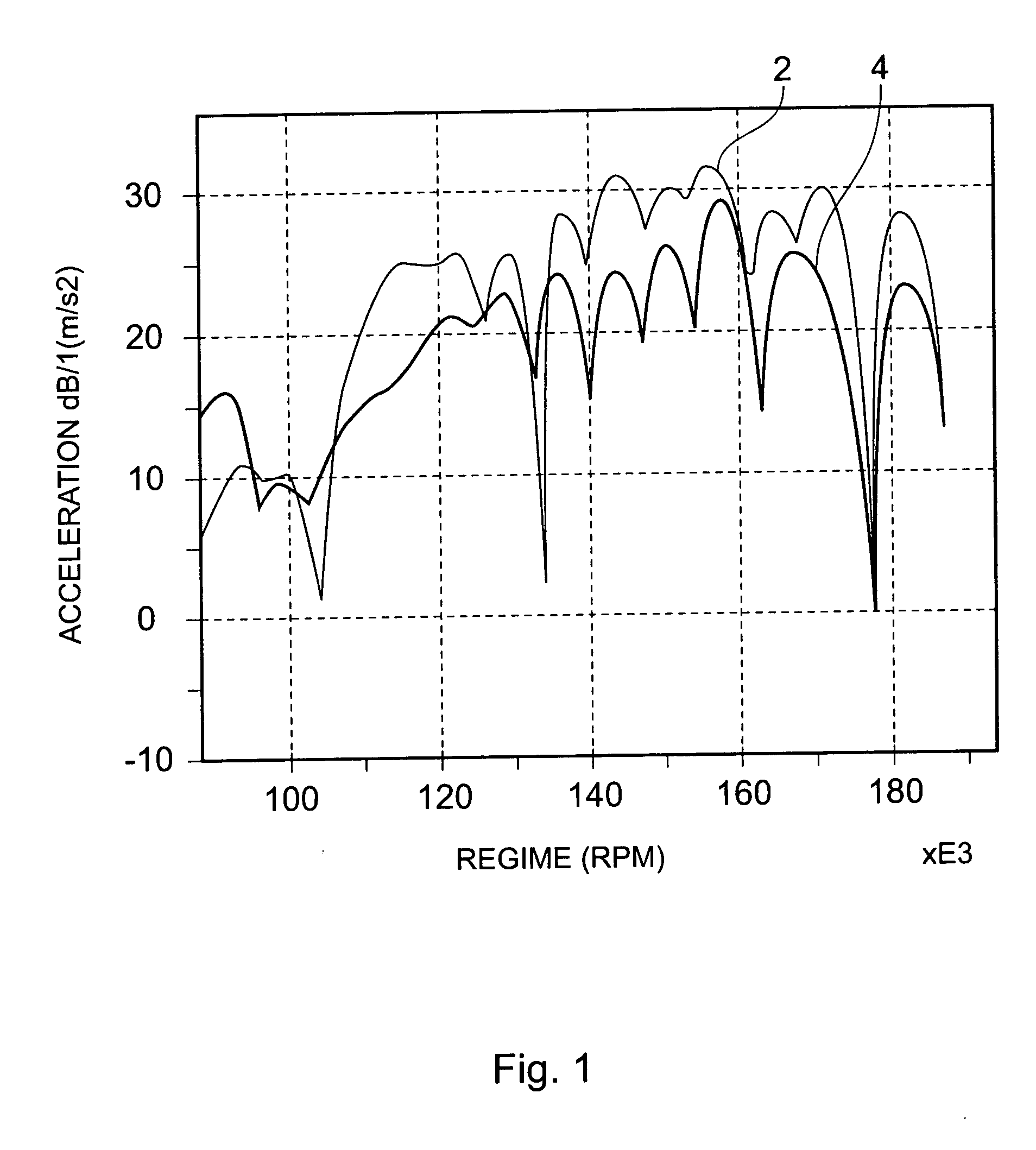

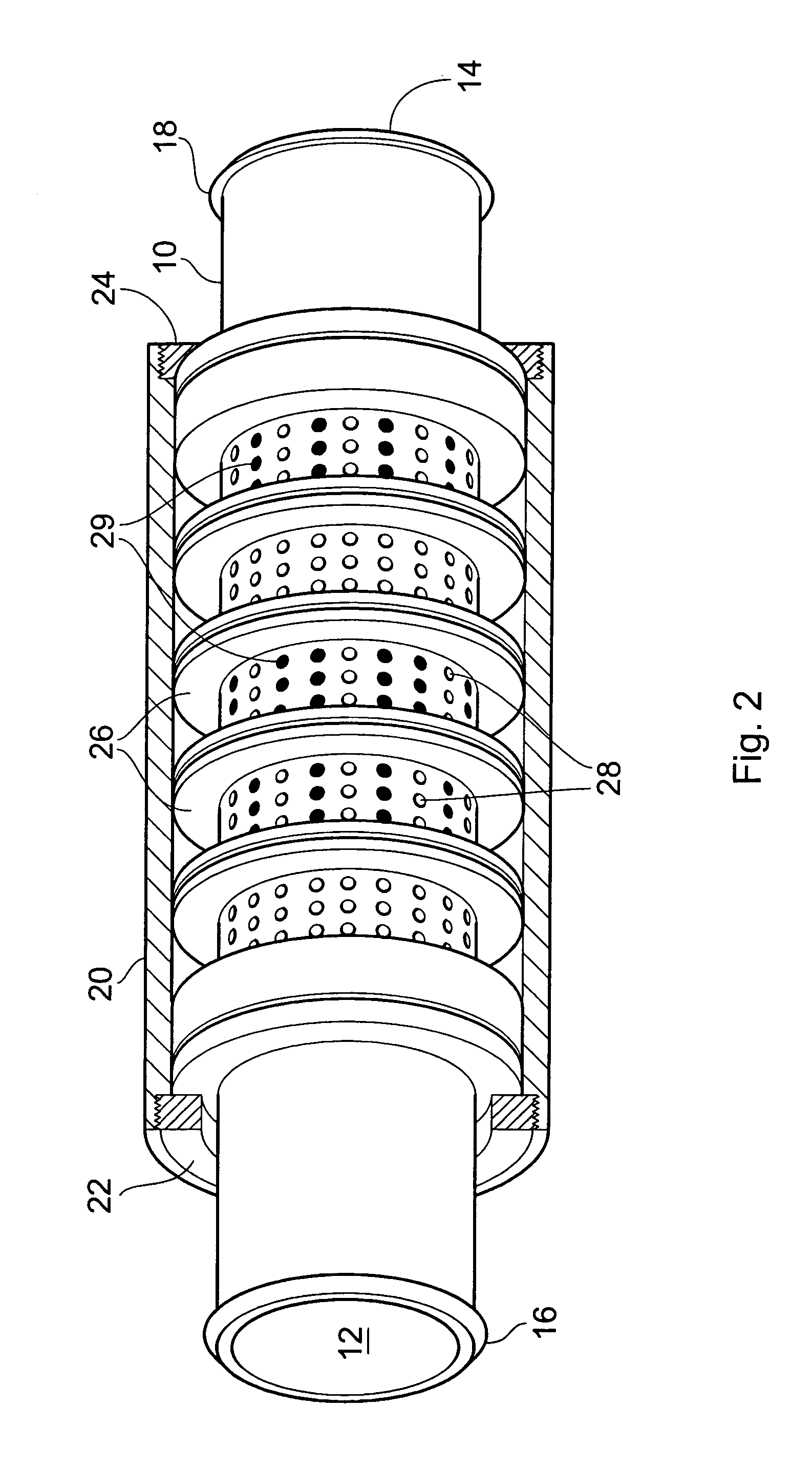

Noise and vibration suppressors

InactiveUS6983820B2Increase dampingSuppress noisePositive displacement pump componentsSilencing apparatusSuppressorModularity

In order to form a noise suppressor in a hose of e.g. a motor vehicle, modular portions are connected in series to define suppression chambers with particular noise suppression characteristics. Those characteristics are due to the volume of each chamber, to the size of the apertures from the chambers to the central duct of the suppressor, and optionally due to spacers which are inserted into at least one aperture of the chambers to alter the effective open area of that aperture. Such spacers may also be used in which the noise suppressor is not modular. Where modular portions are used, it is preferable that each chamber is bounded by parts of two modular portions. A wall of one modular portion may then close the chamber in another modular portion, making the manufacture of the modular portions easier. Also disclosed is the use of a mass acting as a damper, which may be a noise suppressor as previously discussed, within a hose. The mass is connected to the hose by resilient means, e.g. electrometric material.

Owner:CADILLAC RUBBER & PLASTICS

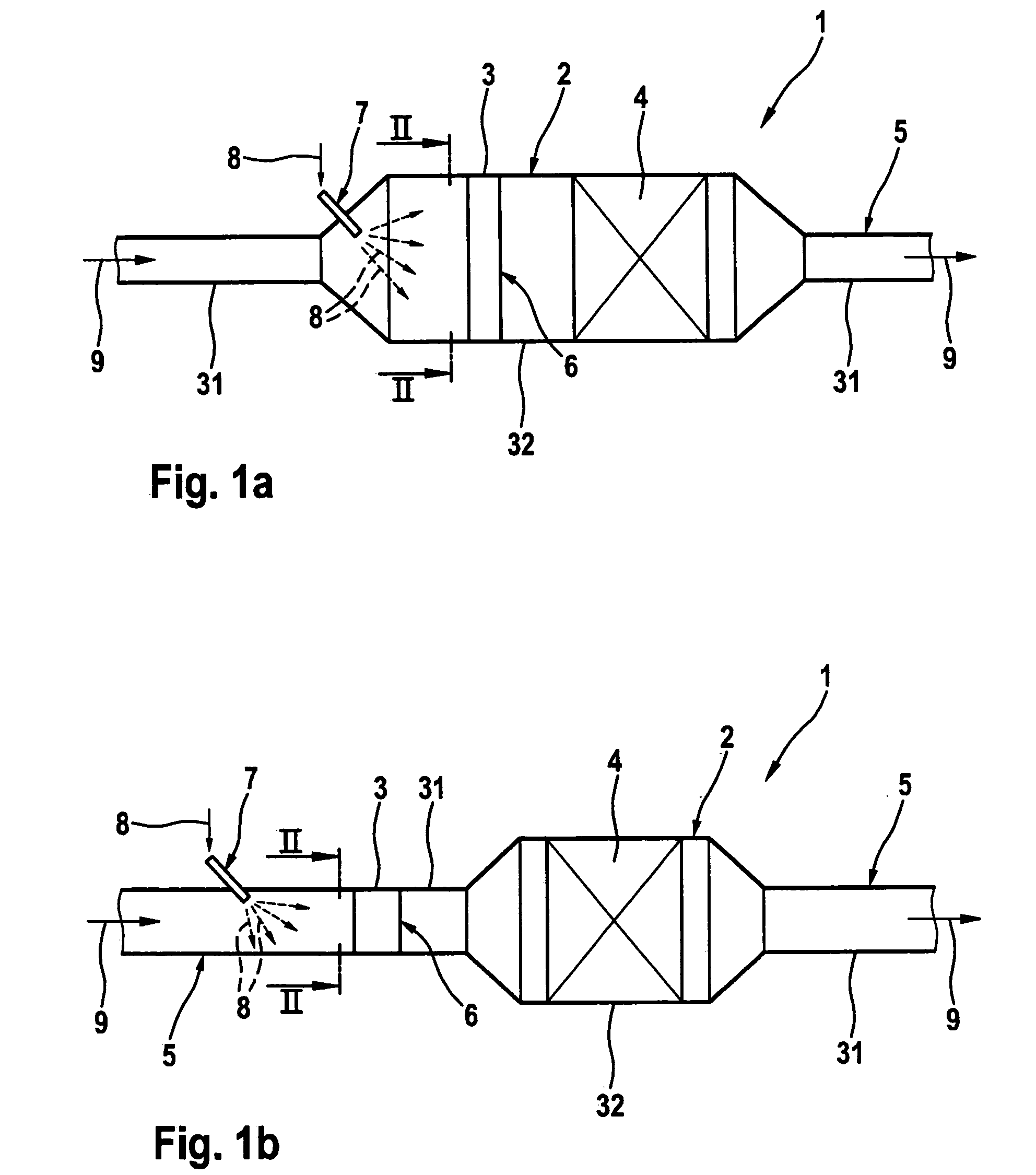

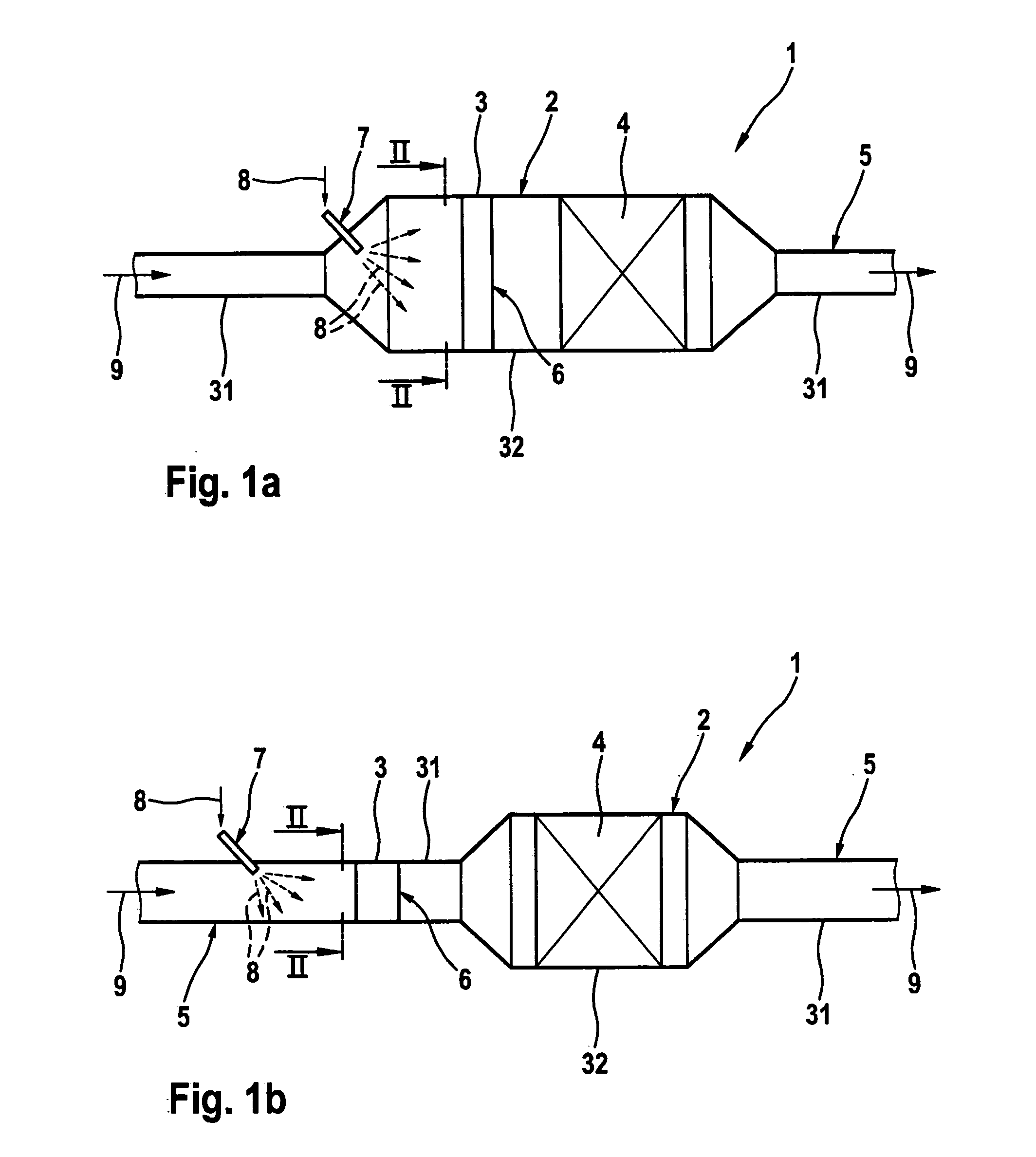

Device for the aftertreatment of exhaust gases of internal combustion engines

ActiveUS20110113759A1Simple and reliable functionSmall installation spaceInternal combustion piston enginesSilencing apparatusDecompositionEnvironmental engineering

A device for the aftertreatment of exhaust gases in an exhaust gas system of internal combustion engines, having at least one reductant decomposition catalyst. Arranged in the exhaust gas flow, and a metering device arranged upstream of the latter in an exhaust gas line for supplying reductant. Preferably at least one other catalyst device is provided downstream of the reductant decomposition catalyst. An inlet section for the exhaust gas having at least one flow deflection area is arranged upstream of the reductant decomposition catalyst and constructed for the exhaust gas to be fed into a housing radially outside an inlet pipe adjoining the reductant decomposition catalyst that encloses the inlet pipe, and is guided in counterflow through a front inlet opening of the inlet pipe to the reductant decomposition catalyst. The reductant is fed into the flow deflection area associated with the inlet opening.

Owner:MAN NUTZFAHRZEUGE AG

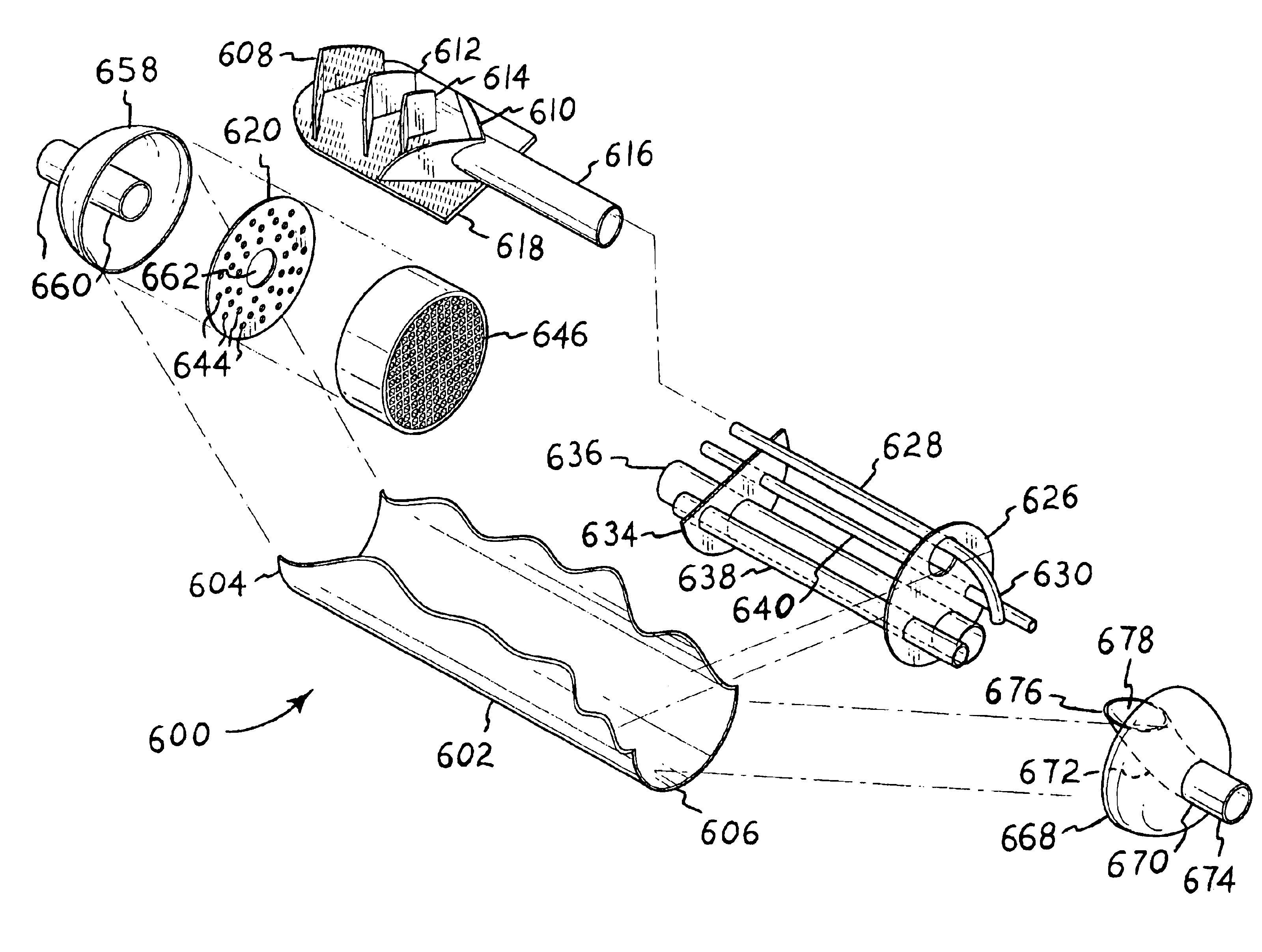

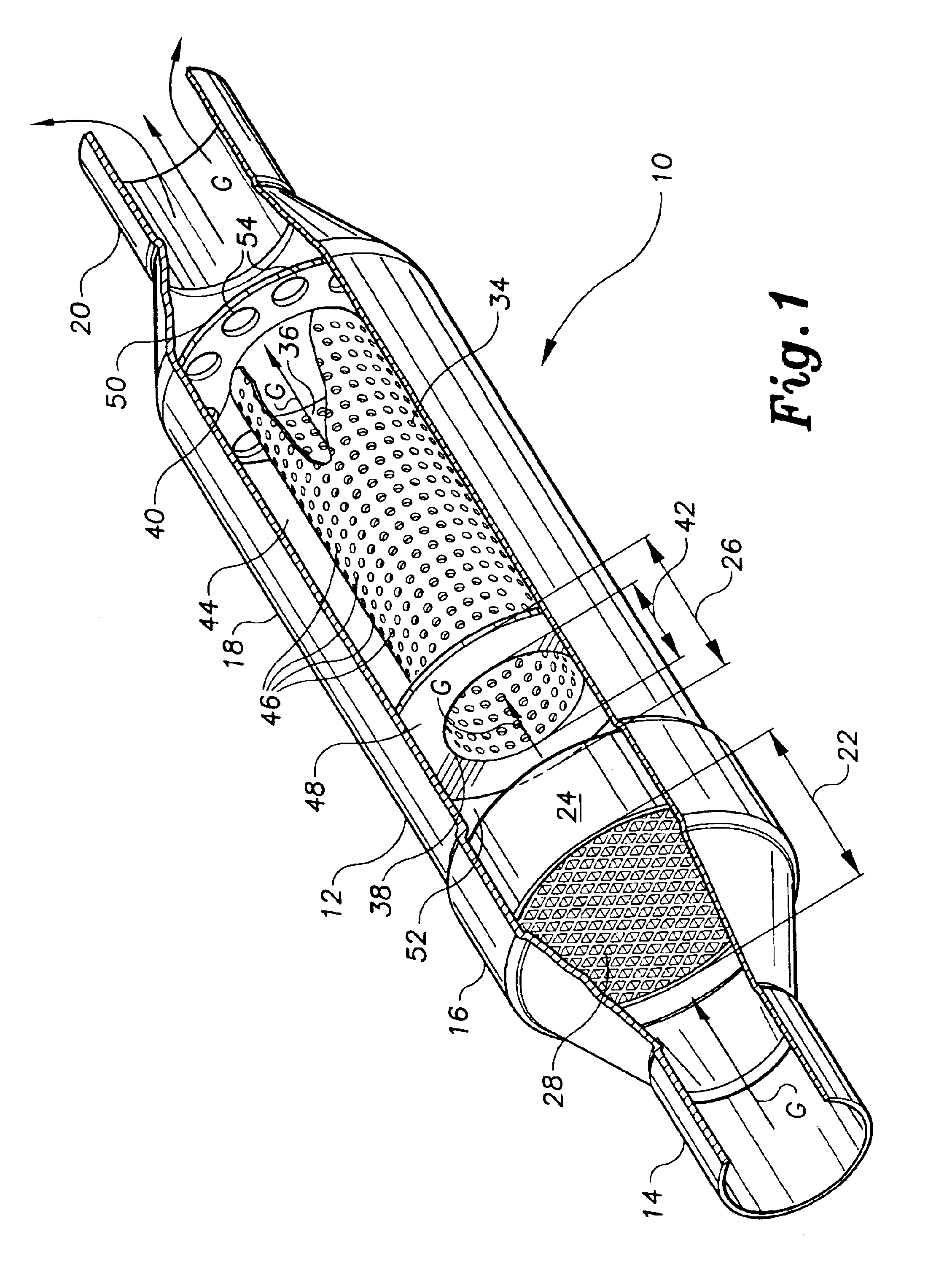

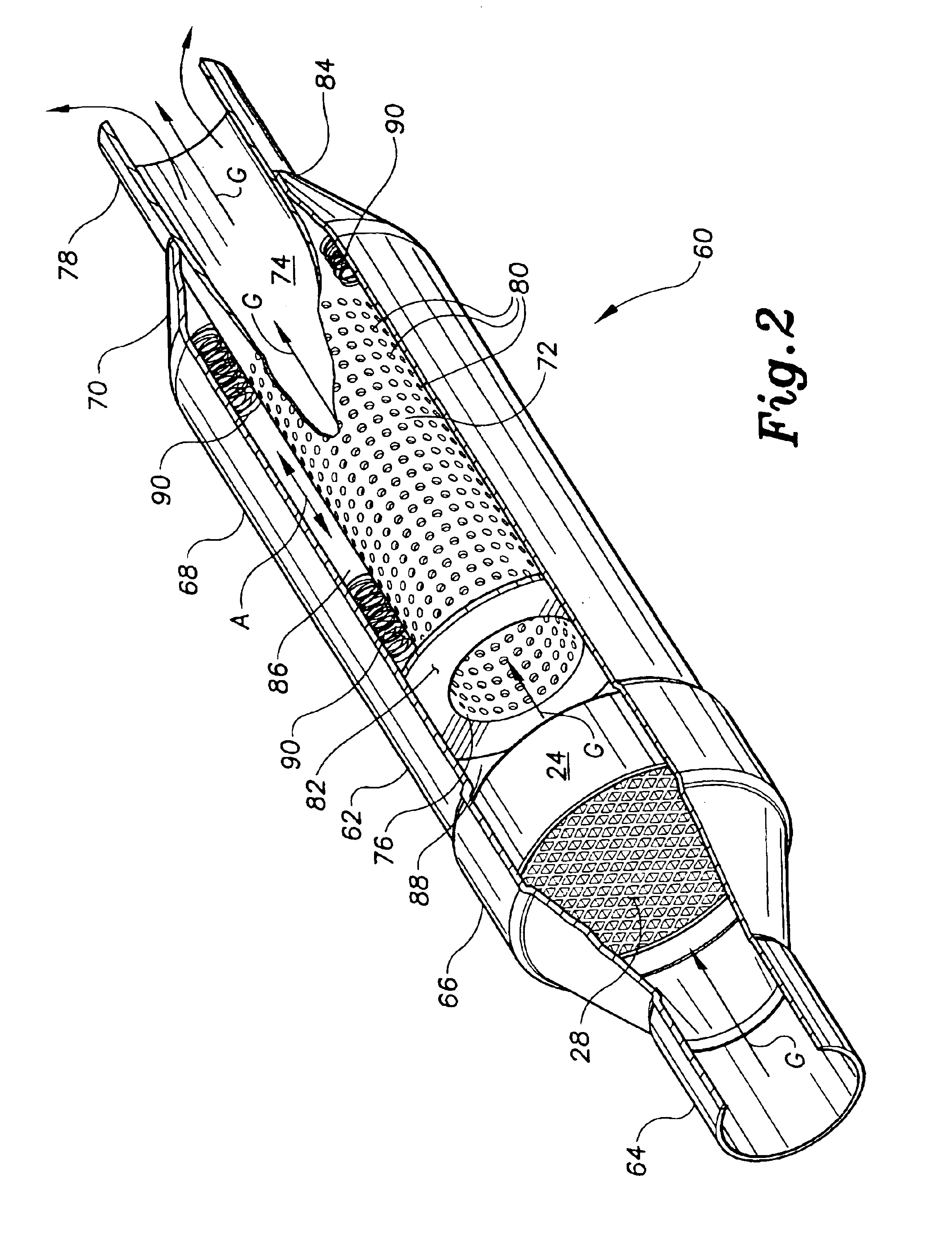

Exhaust sound and emission control systems

InactiveUS6935461B2Enhance emission reductionReduce componentsSilencing apparatusThermometers using physical/chemical changesControl systemDouble wall

The exhaust sound and emission control system is a system for reducing sound and noxious emissions from an automotive exhaust. The system may have an exhaust resonator having one or more catalytic converter elements in combination therewith in a single device. Alternatively, the system may have multiple angularly disposed chambers therein, with a series of V-shaped baffles or guides in one of the chambers, thereby combining resonator and muffler functions in a single device. In another alternative, the system has a series of longitudinal tubes therein, in combination with a series of V-shaped guides or vanes, combining catalytic converter, muffler, and resonator functions in a single device. The various elements of the different embodiments, e.g. catalytic converter element(s), double wall shell, perforated tubes and multiple flow paths, interconnecting crossover tubes, etc., may be combined with one another as practicable.

Owner:MAROCCO GREGORY M

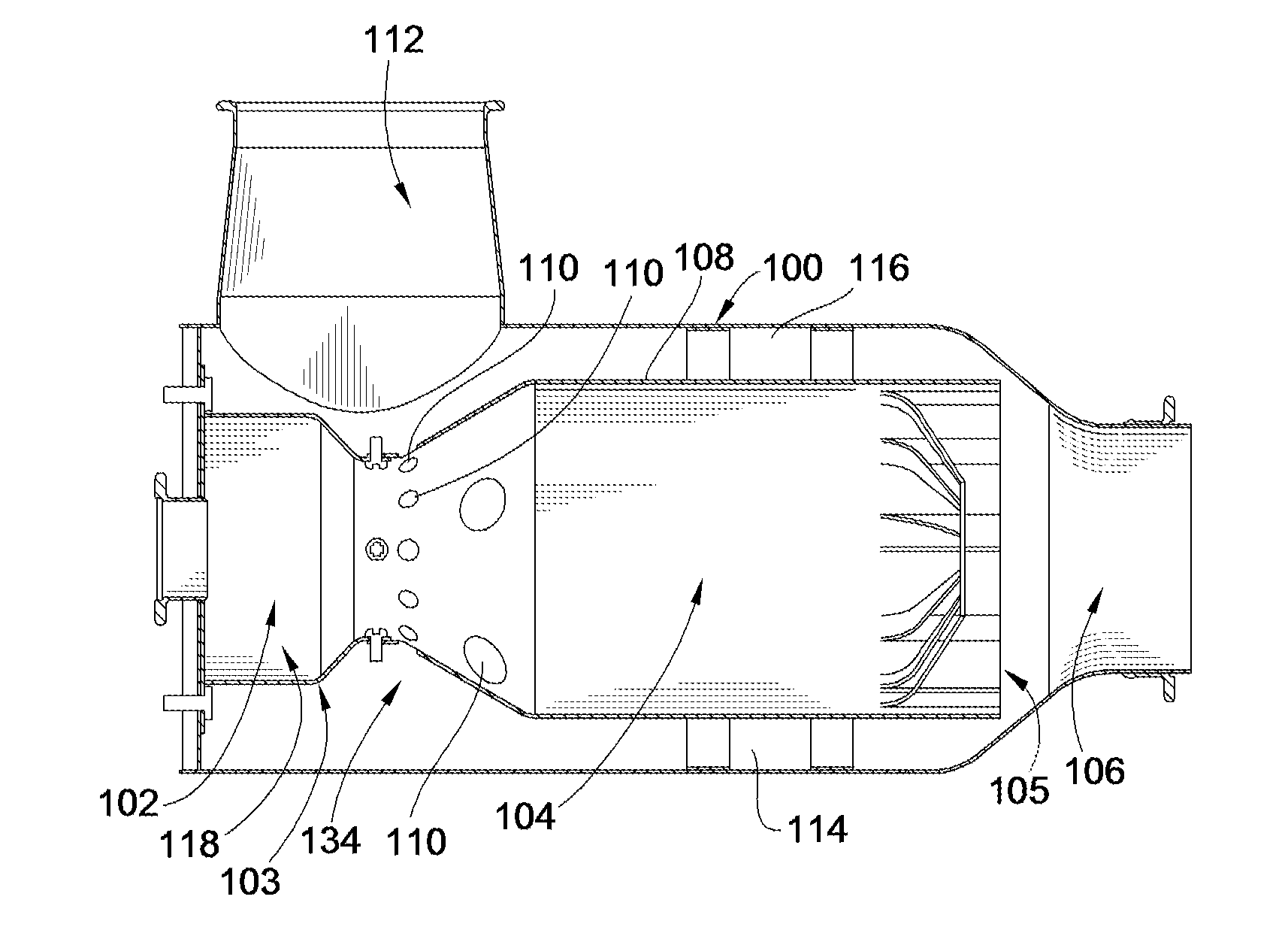

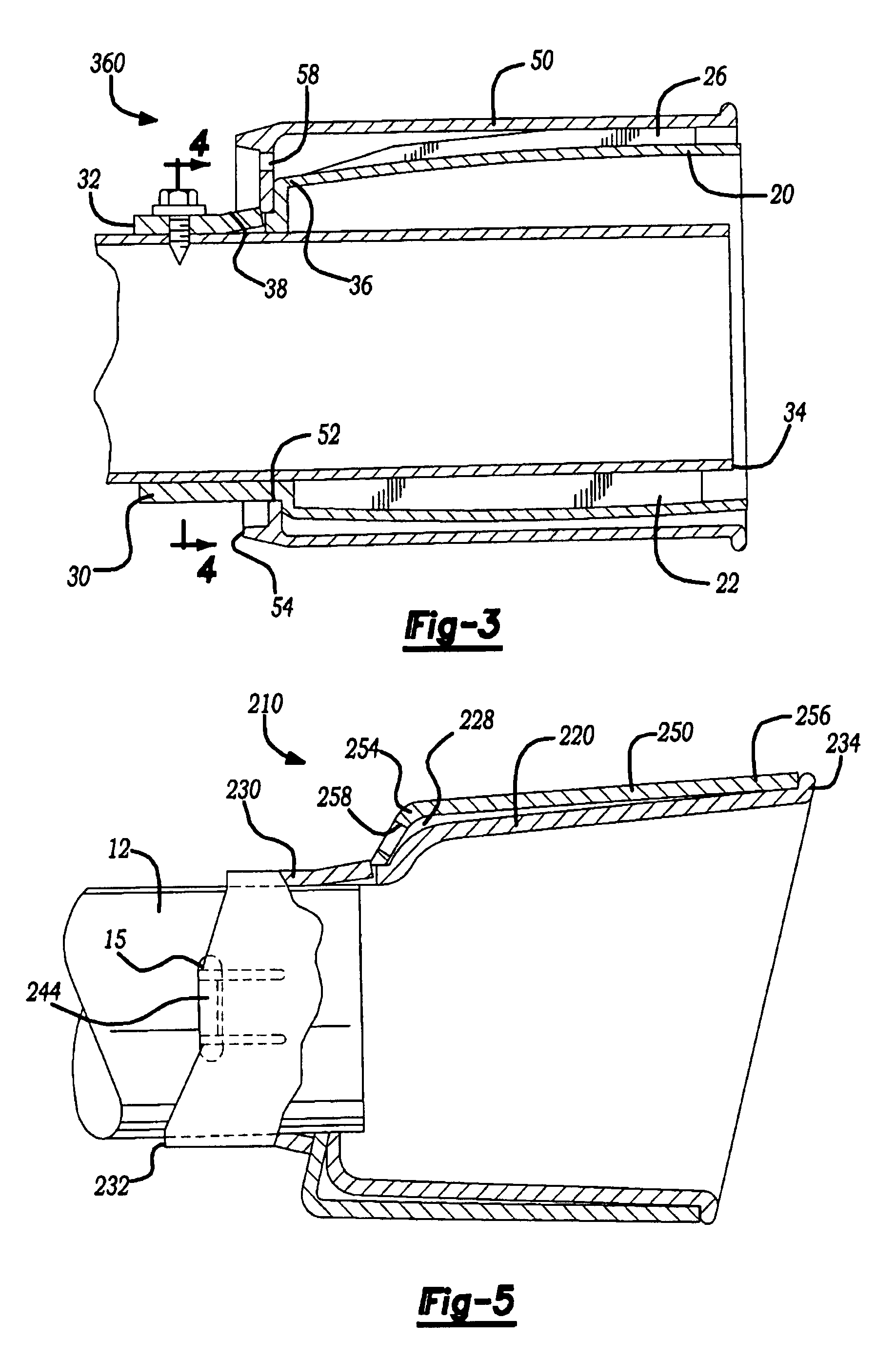

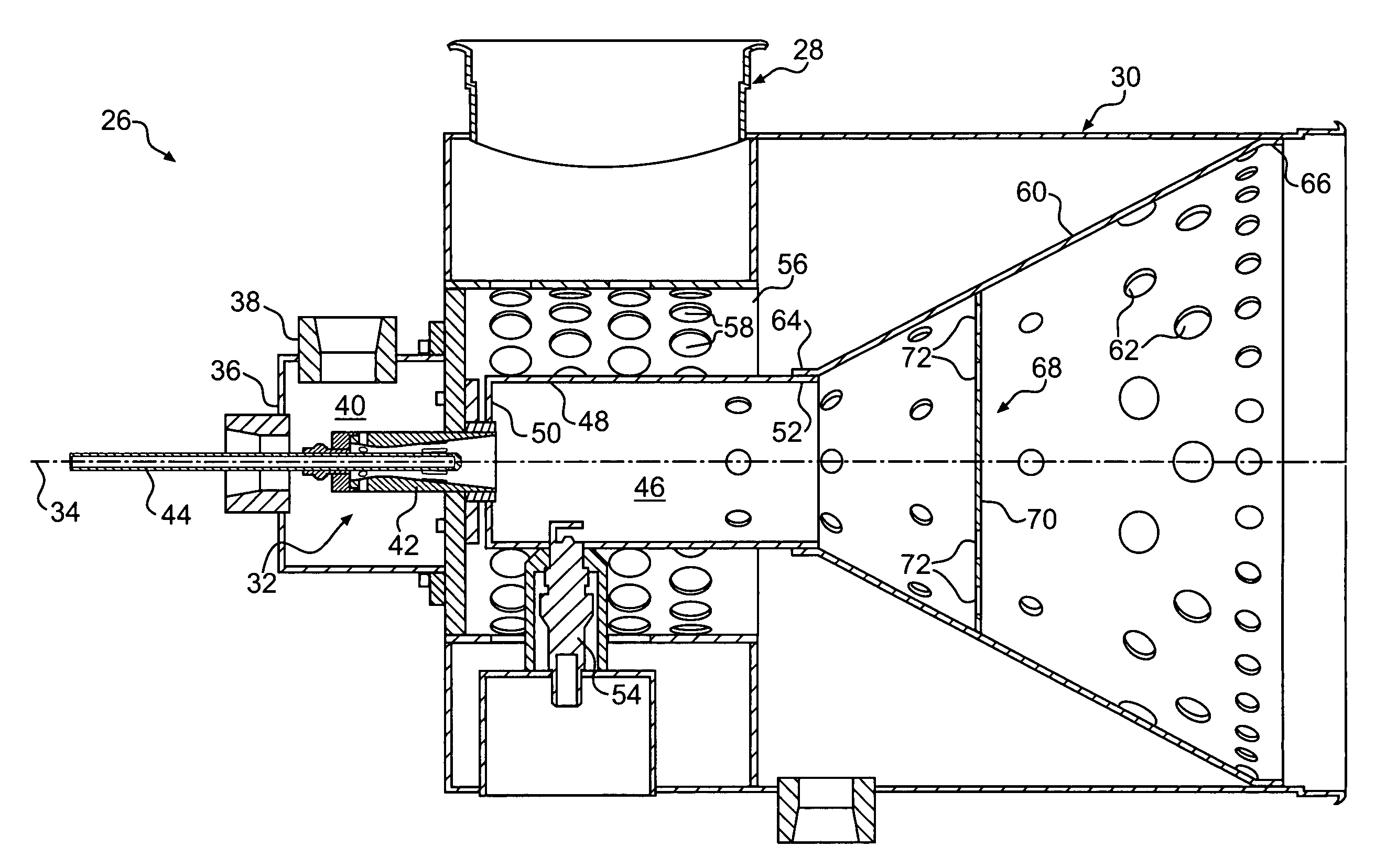

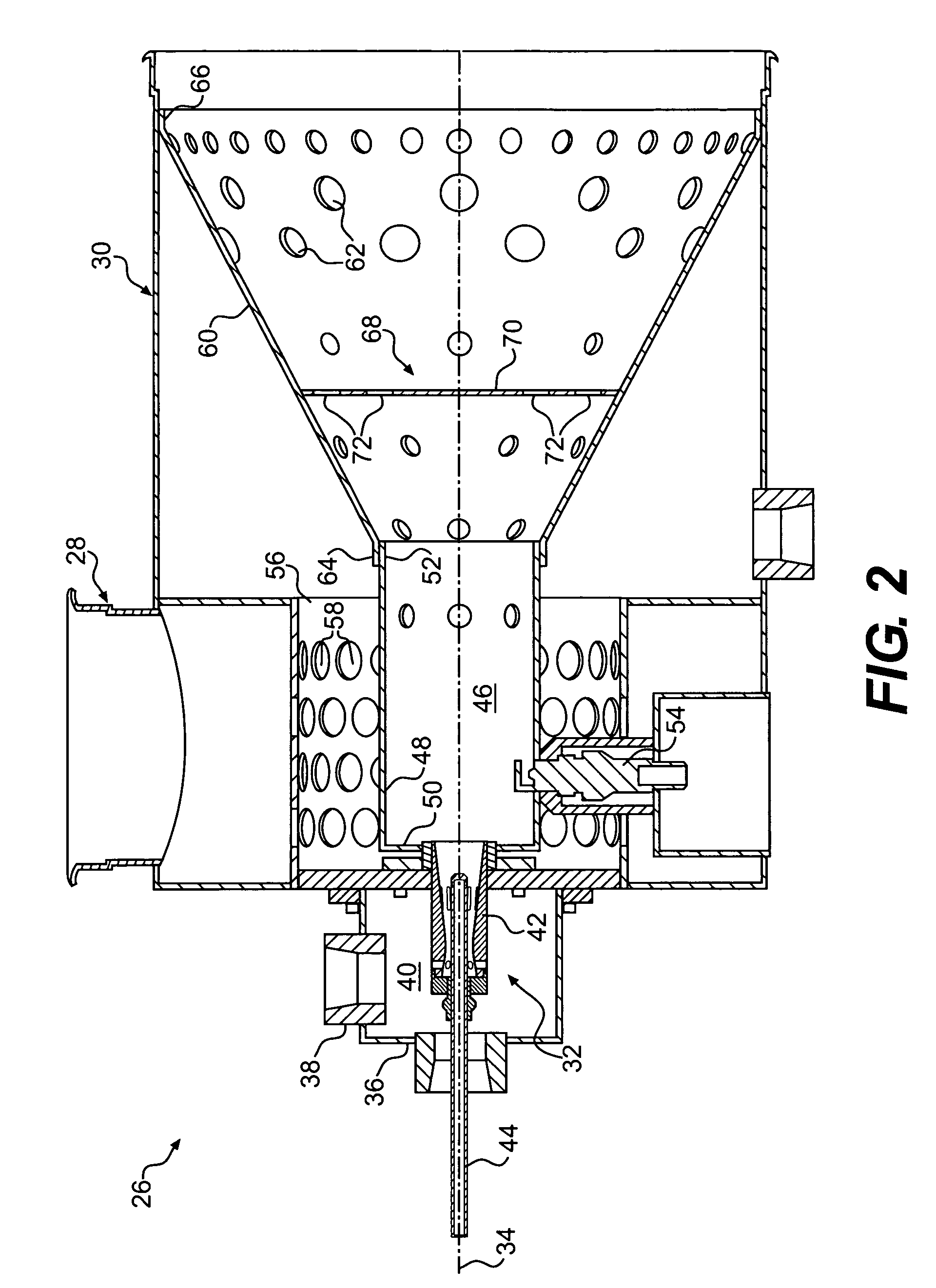

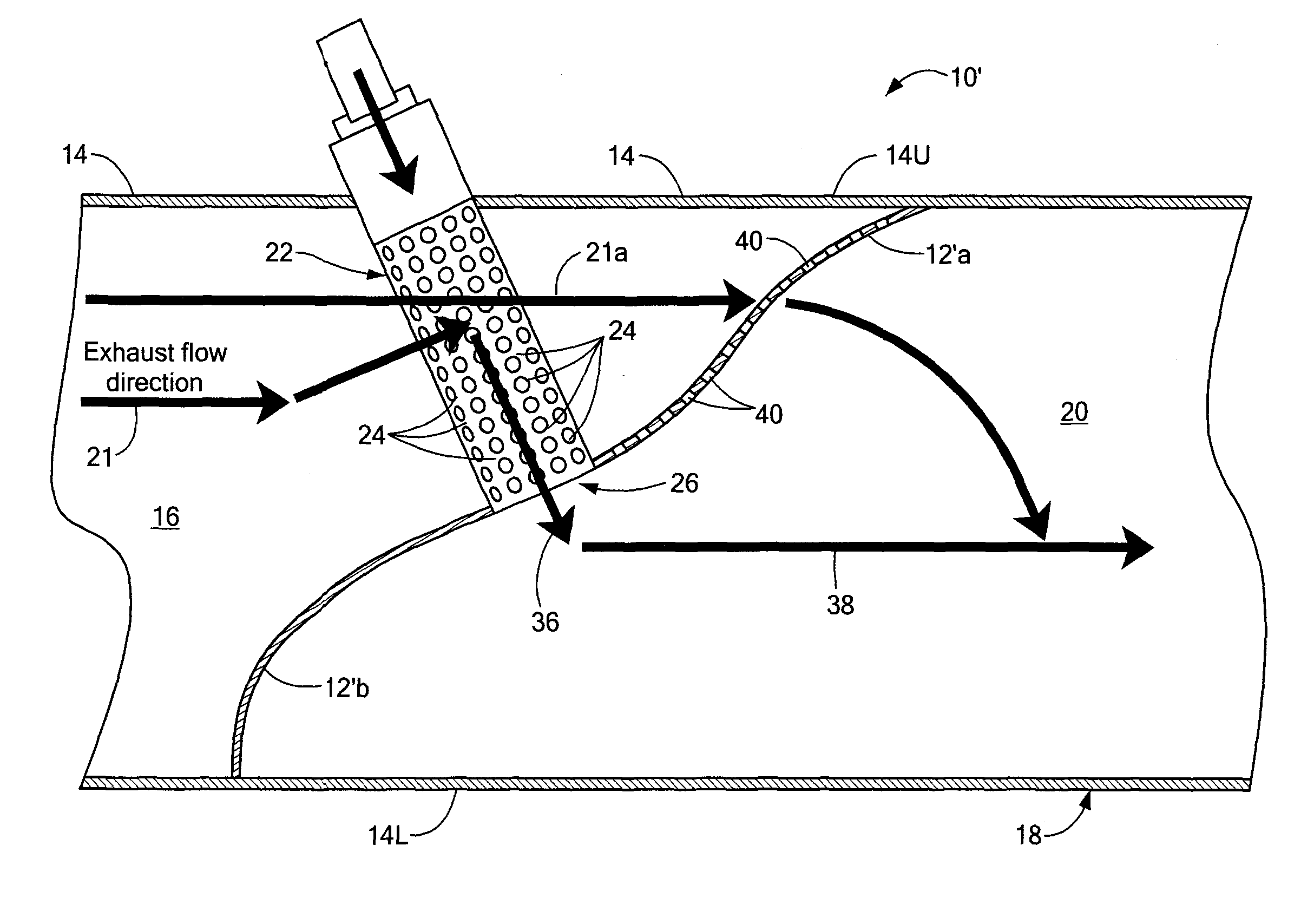

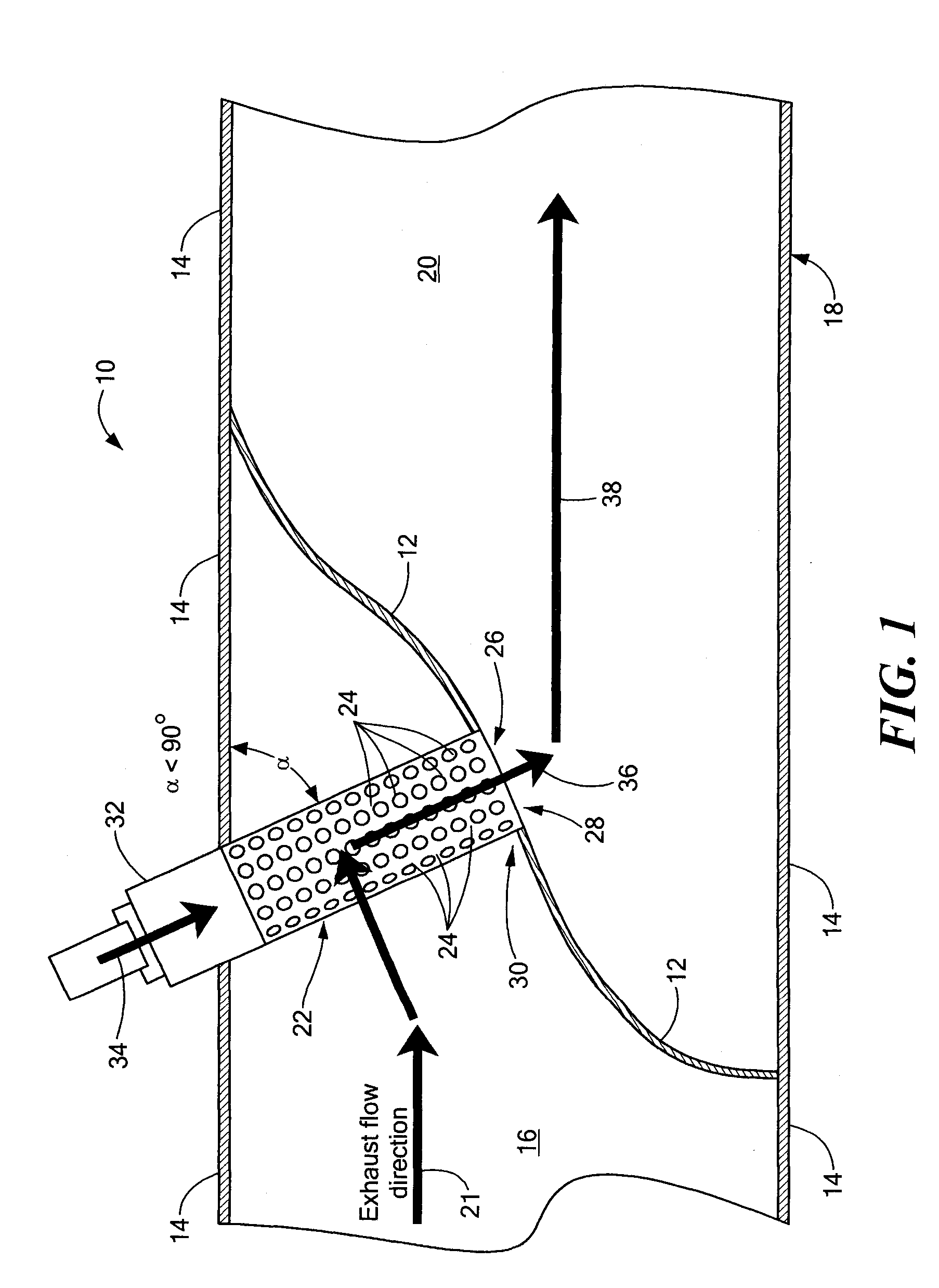

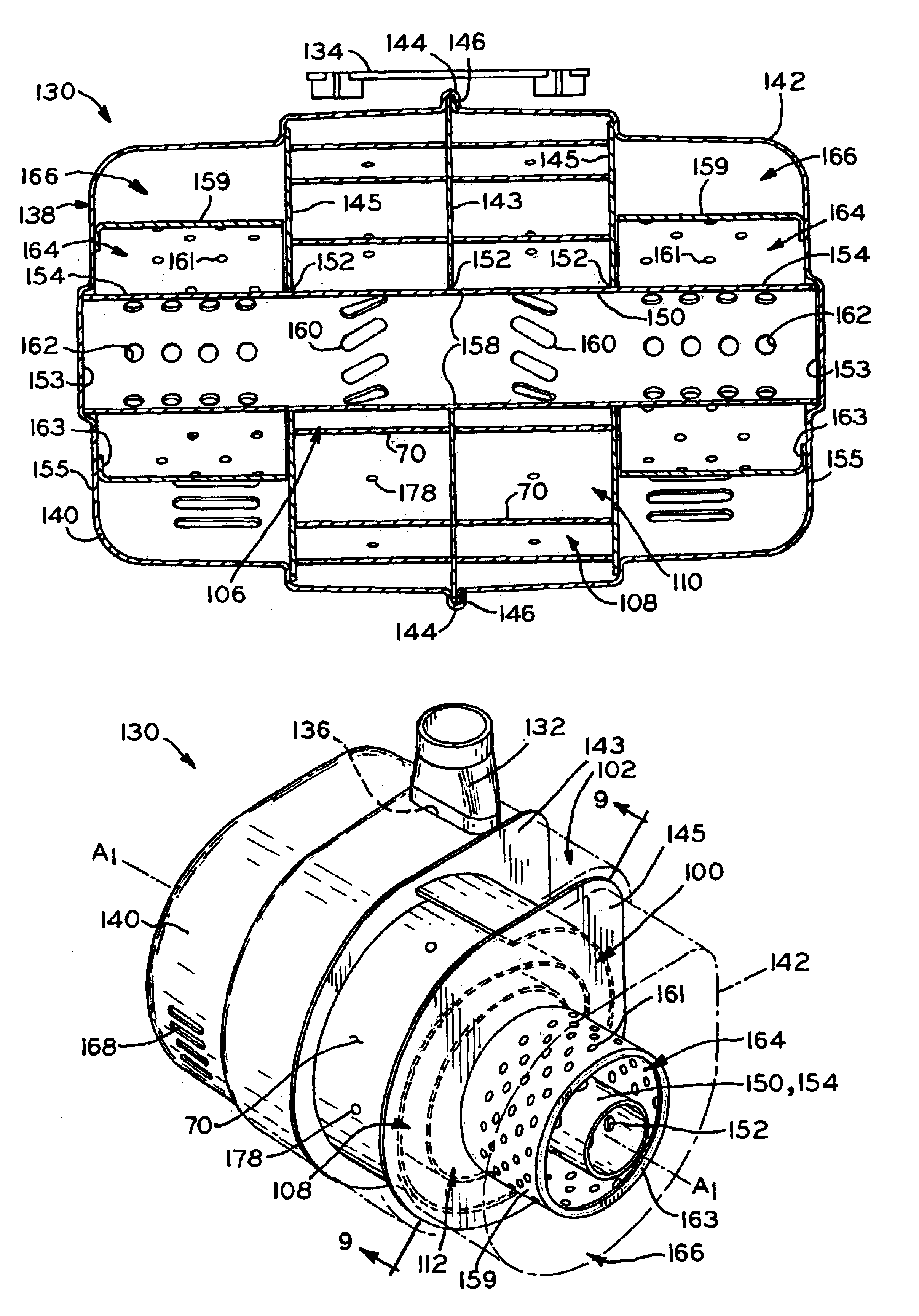

Burner assembly for particulate trap regeneration

InactiveUS20060218902A1Increase temperatureEqually distributedBurnersSilencing apparatusParticulatesCombustion chamber

An exhaust treatment system is provided. The system may include a particulate trap configured to remove one or more types of particulate matter from an exhaust flow, the exhaust flow including at least a portion of a totality of exhaust gases produced by an engine. The system may further include a burner assembly configured to increase a temperature of gases in the exhaust flow at a location upstream from the particulate trap. The burner assembly may include an exhaust inlet oriented in a direction along a first axis and configured to direct the exhaust flow into the burner assembly and an exhaust outlet oriented in a direction along a second axis at an angle relative to the first axis, the exhaust outlet being configured to direct the exhaust flow out of the burner assembly toward the particulate trap. The burner assembly may also include a fuel injector having a longitudinal axis in substantial alignment with the second axis. In addition, the burner assembly may include a cylindrical combustion chamber member defining a combustion chamber, having a longitudinal axis in substantial alignment with the longitudinal axis of the fuel injector, and configured to house a flame that is fueled by the fuel injector within the combustion chamber. The burner assembly may further include an exhaust flow distribution member configured to substantially evenly distribute exhaust about the combustion chamber member and in a heat exchange relation to the combustion chamber member.

Owner:SOLAR TURBINES

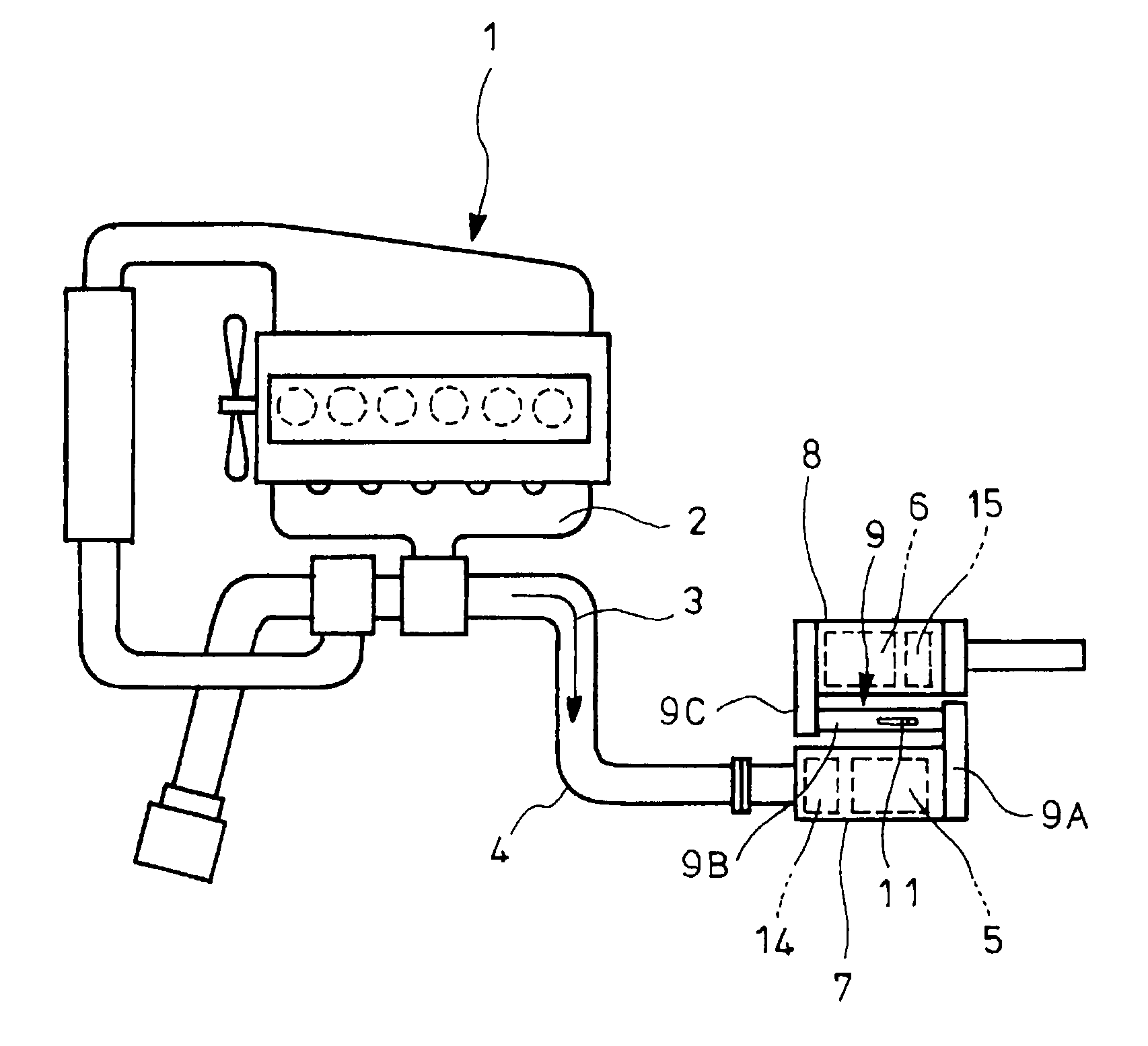

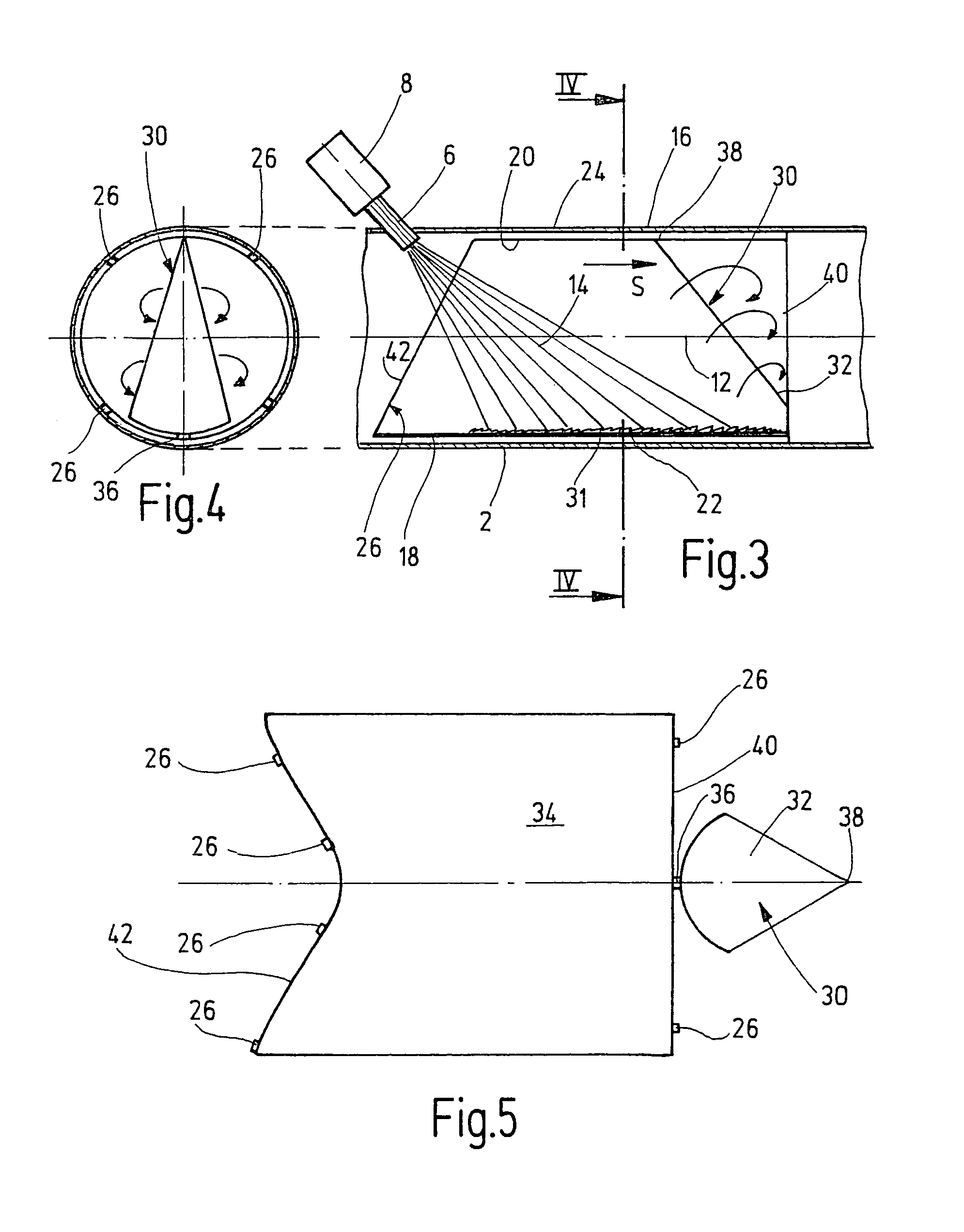

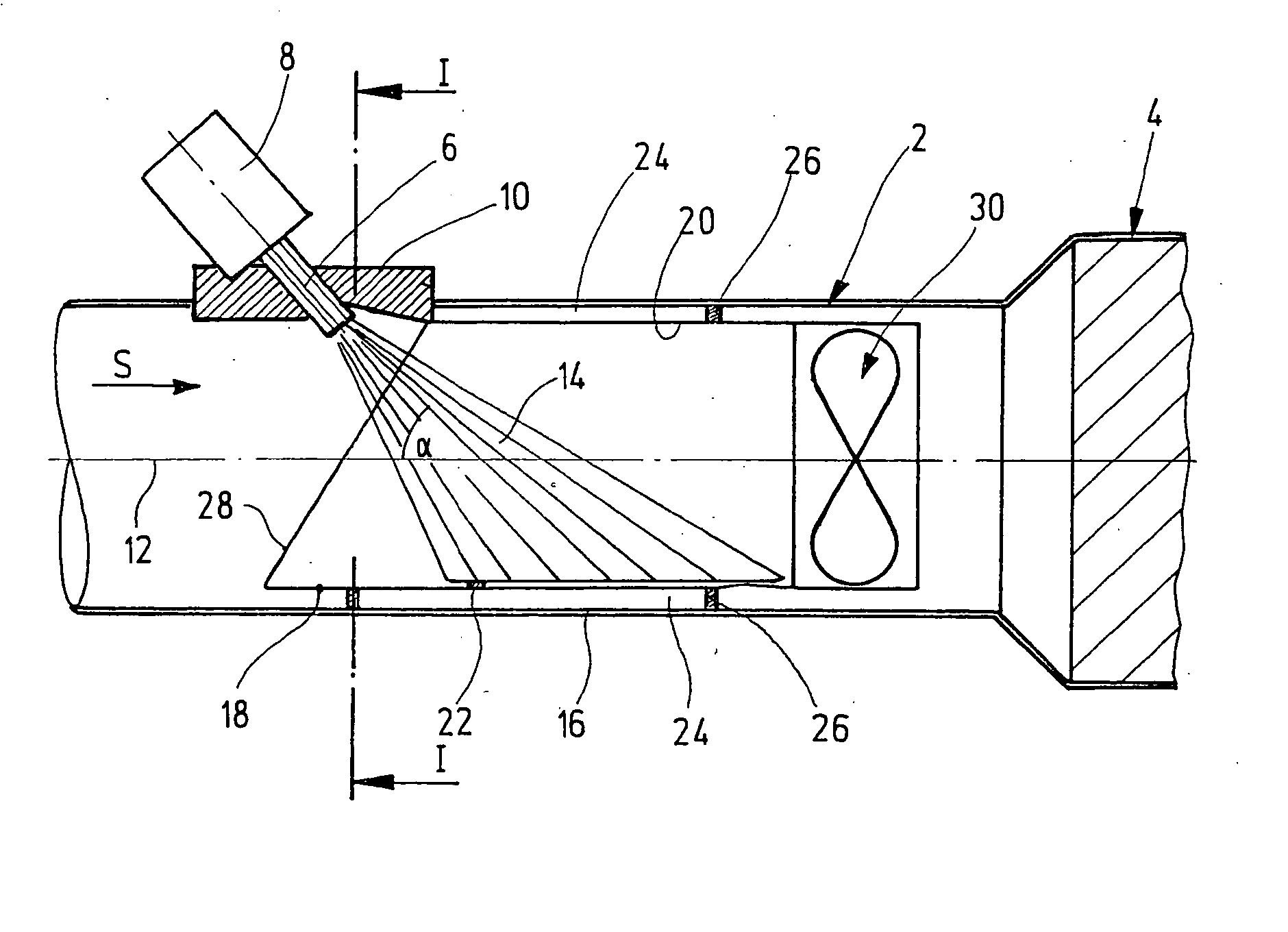

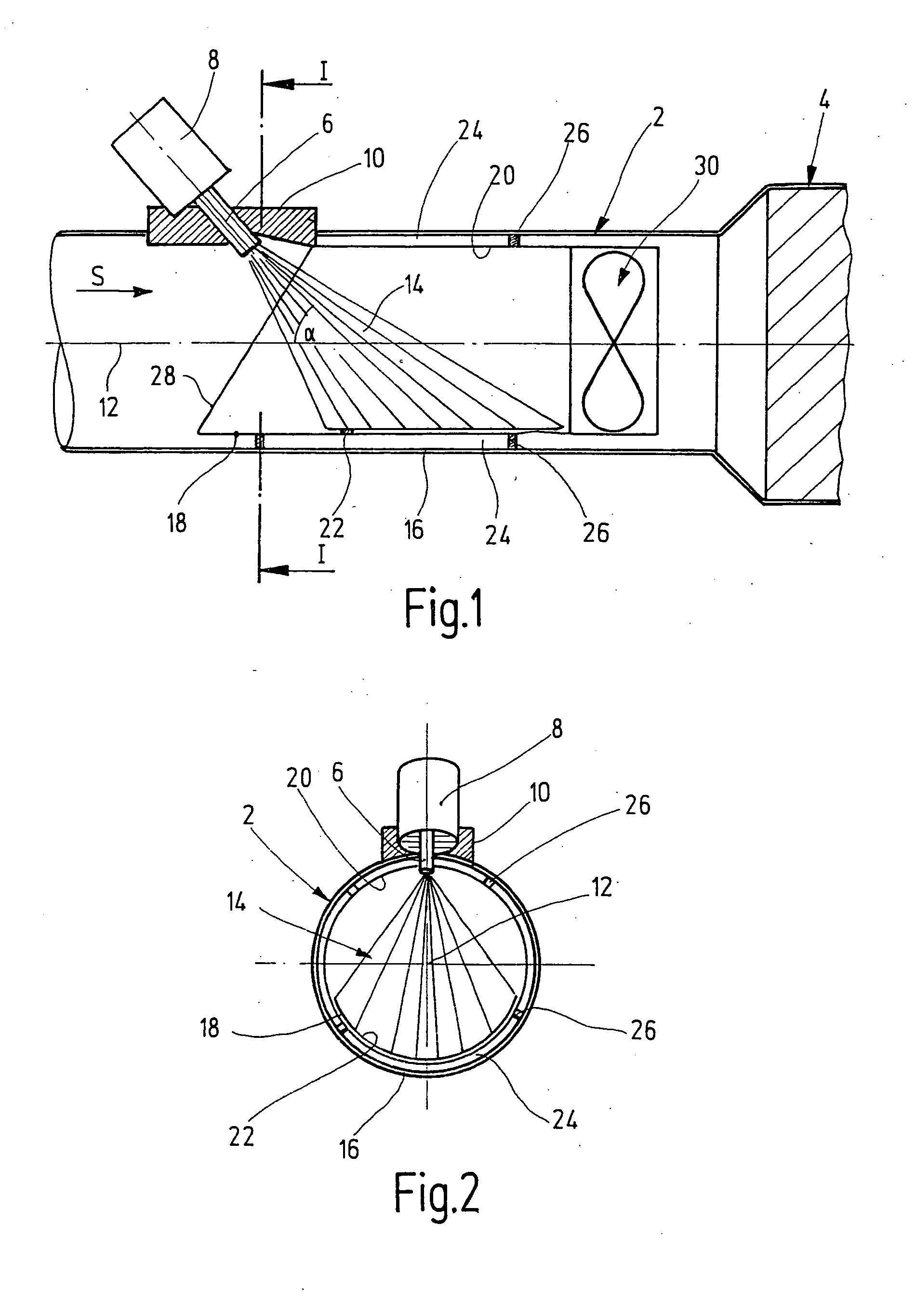

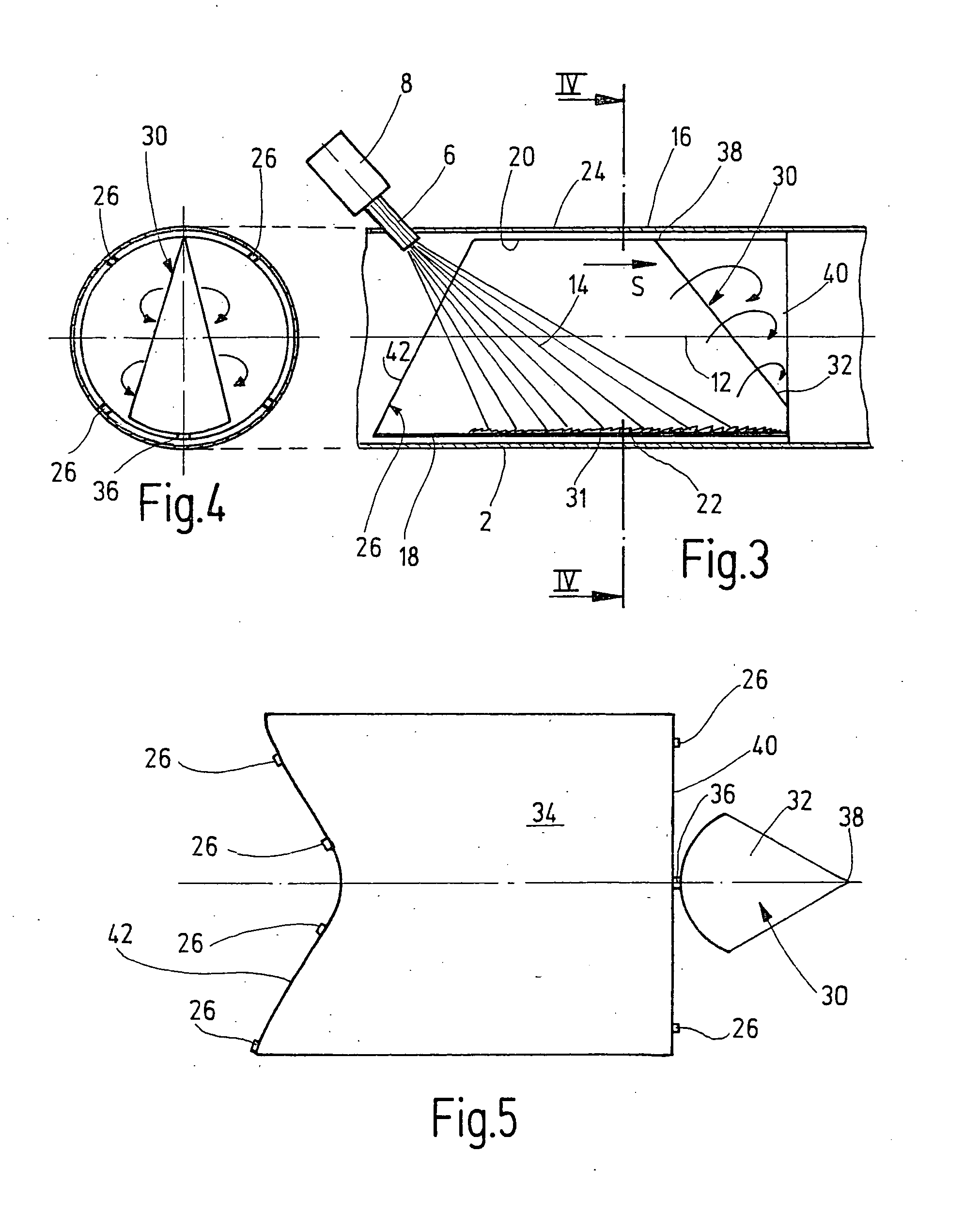

Method and apparatus for posttreatment of an exhaust gas from an internal combustion engine

InactiveUS7448206B2Internal combustion piston enginesFlow mixersExhaust fumesInternal combustion engine

A method of and an apparatus for posttreatment of an exhaust gas from an internal combustion engine, in which a substance to be mixed with the exhaust gas is sprayed in metered quantities into an exhaust gas line through which the exhaust gas flows. The substance is sprayed onto an impact plate disposed inside the exhaust gas line.

Owner:ROBERT BOSCH GMBH

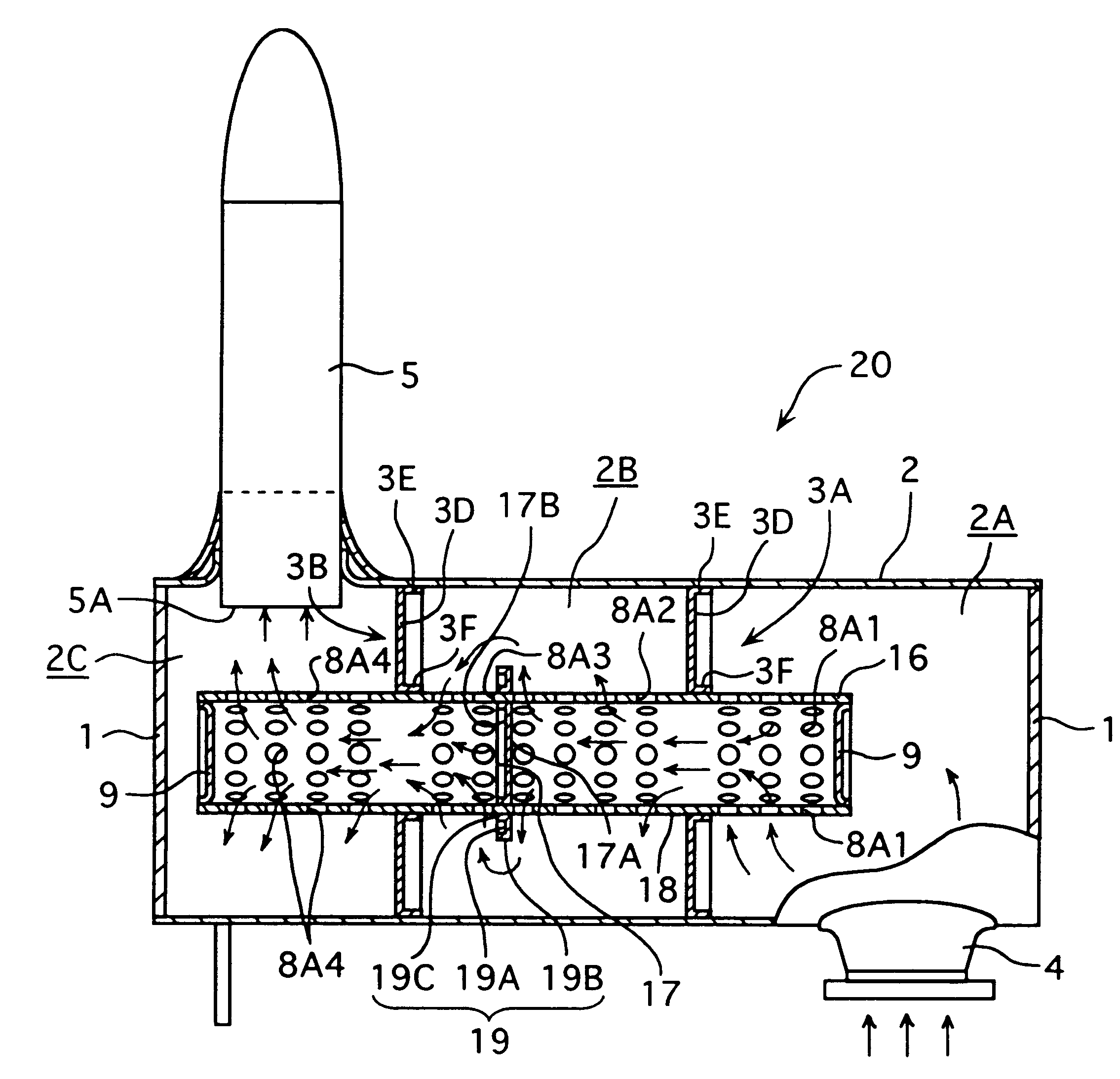

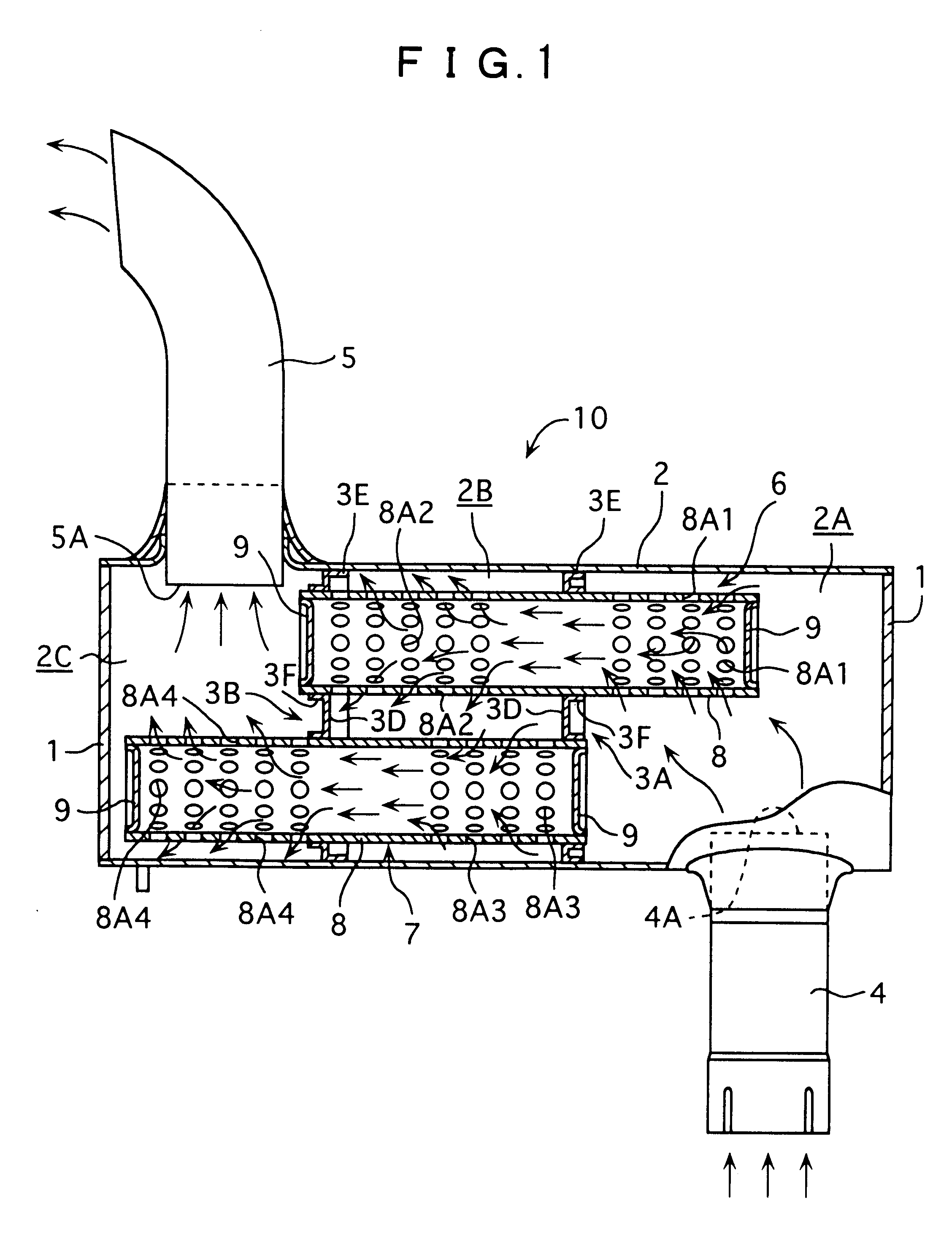

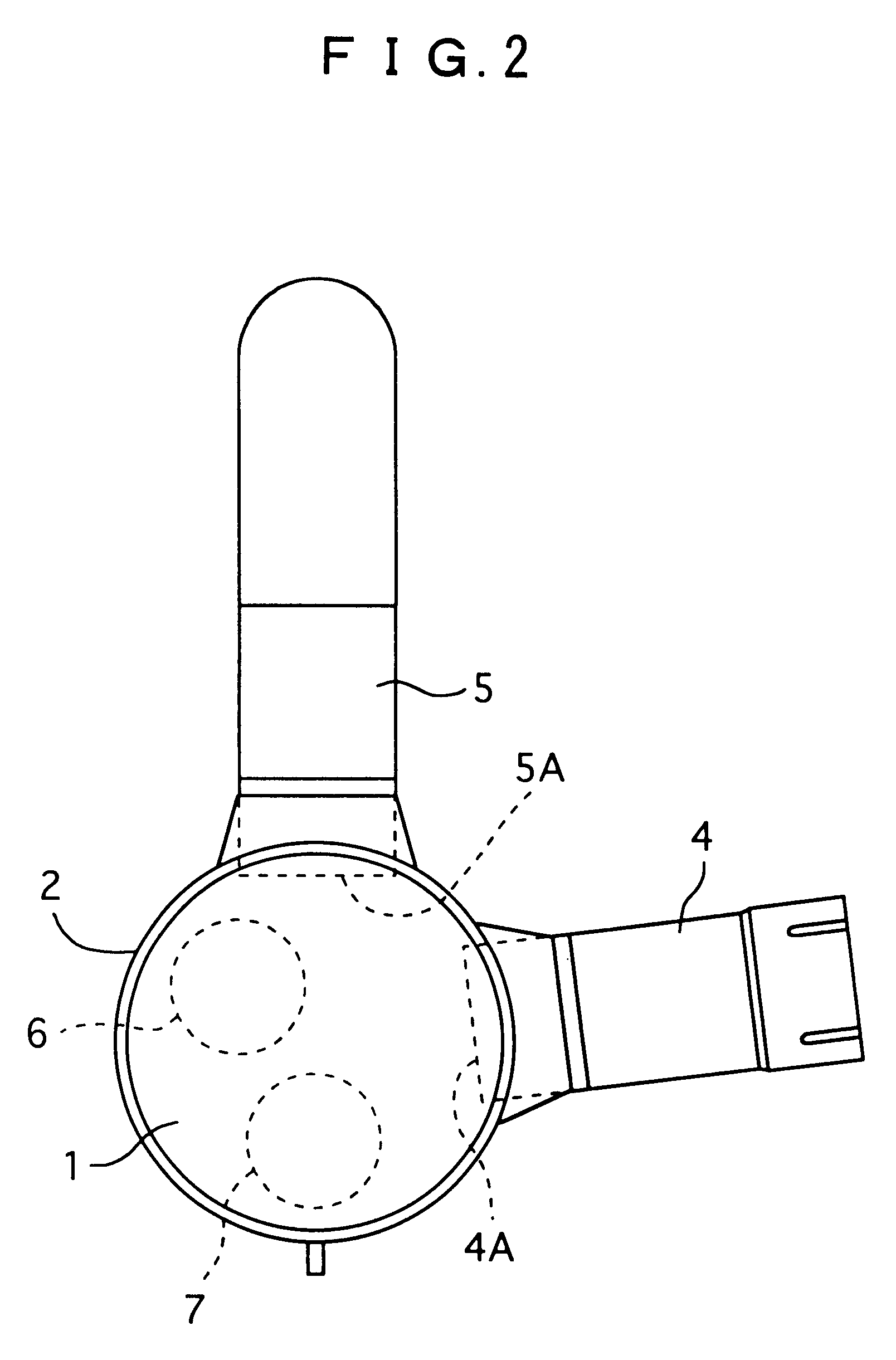

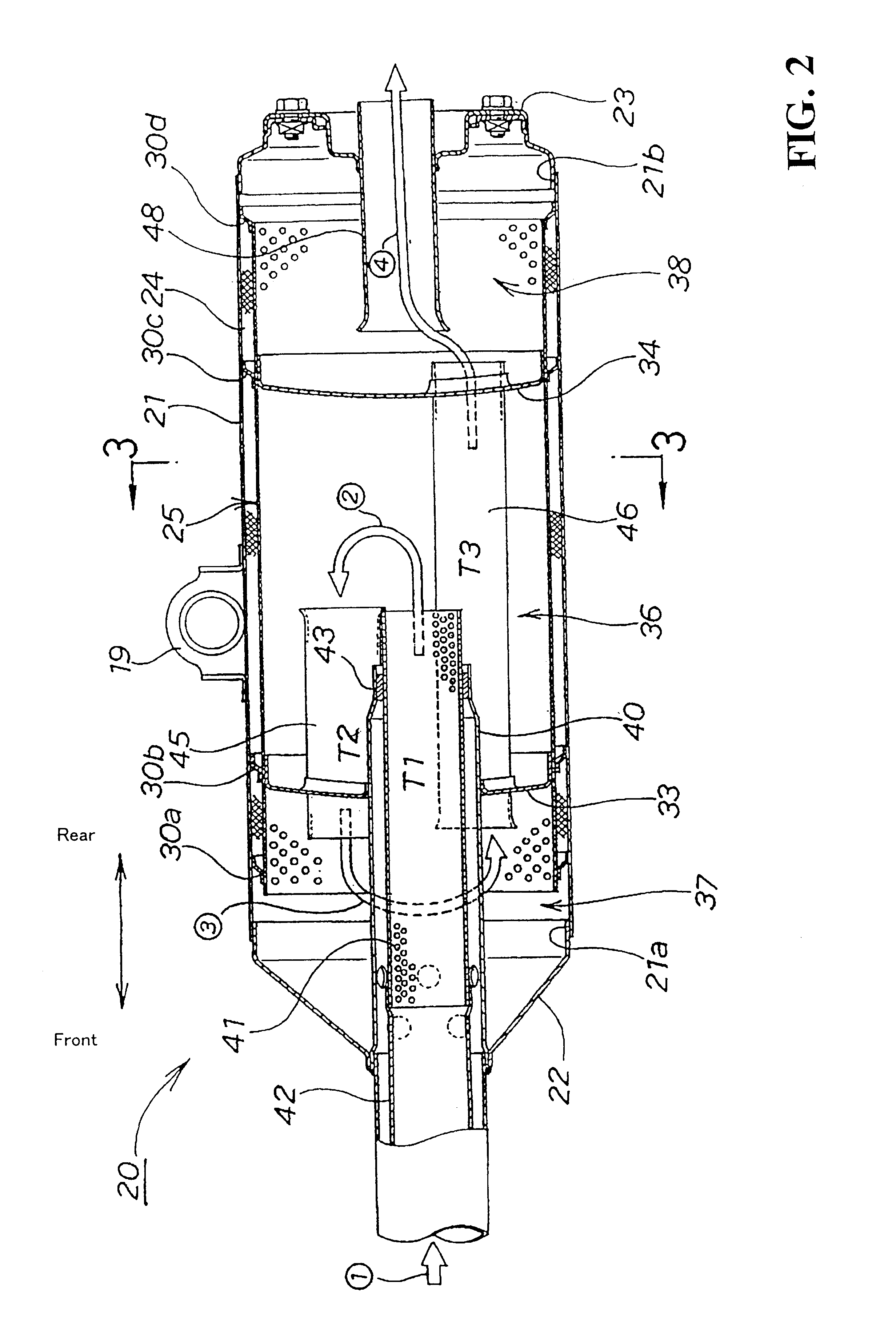

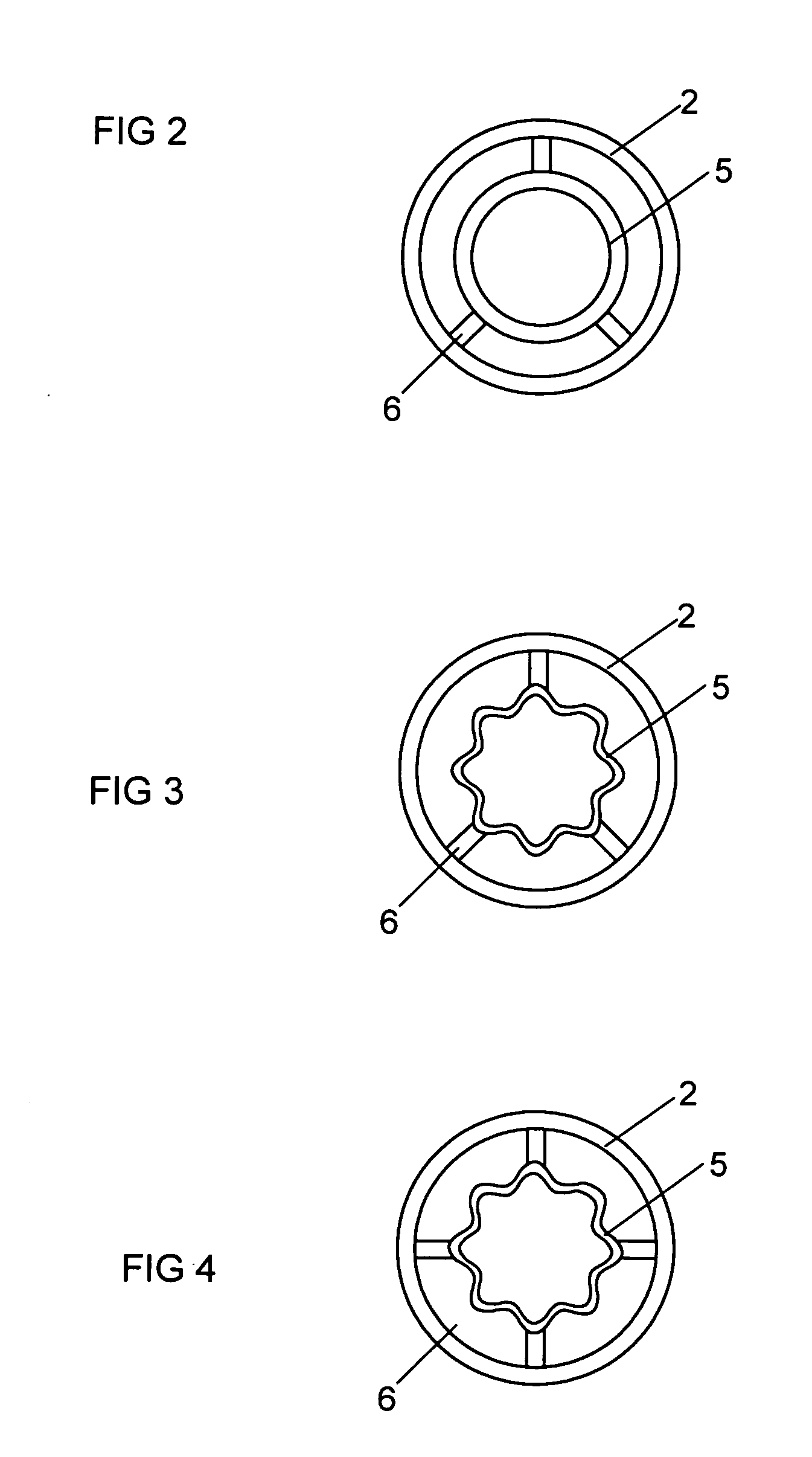

Exhaust silencer and communicating pipe thereof

InactiveUS6241044B1Reduce total pressure lossSufficiently exhaust noiseSilencing apparatusMachines/enginesEngineeringExhaust gas

More than two damping chambers 2A to 2C), a communicating pipe (6) for intercommunicating the damping chambers (2A, 2B) and another communicating pipe (7) for intercommunicating the damping chambers (2B, 2C) are provided. Both ends of the communicating pipes (6, 7) are closed by an end plate (9) and the respective damping chambers (2A to 2C) and inside of the communicating pipes (6, 7) are intercommunicated by communicating holes (8A) on an outer circumference of the communicating pipes (6, 7). Exhaust gas flows from the damping chamber (2A) to communicating holes (8A1), inside of the communicating pipe (6), communicating holes (8A2), the damping chamber (2B), communicating holes (8A3), inside of the communicating pipe (7), communicating holes (8A4), and the damping chamber (2C), thus damping exhaust noise by repeated effective contraction and expansion.

Owner:KOMATSU LTD

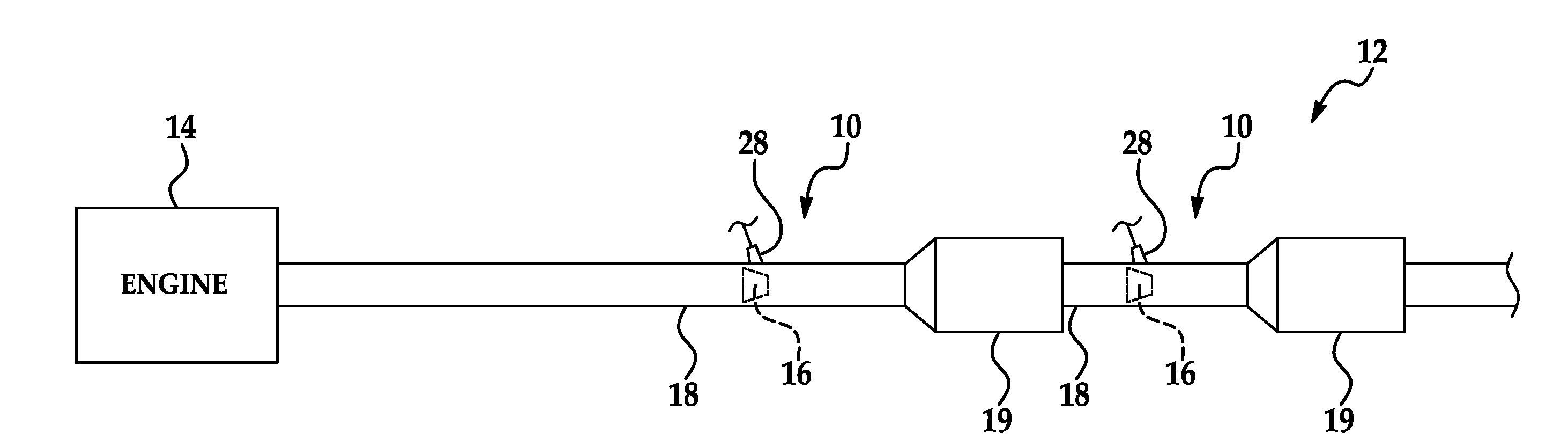

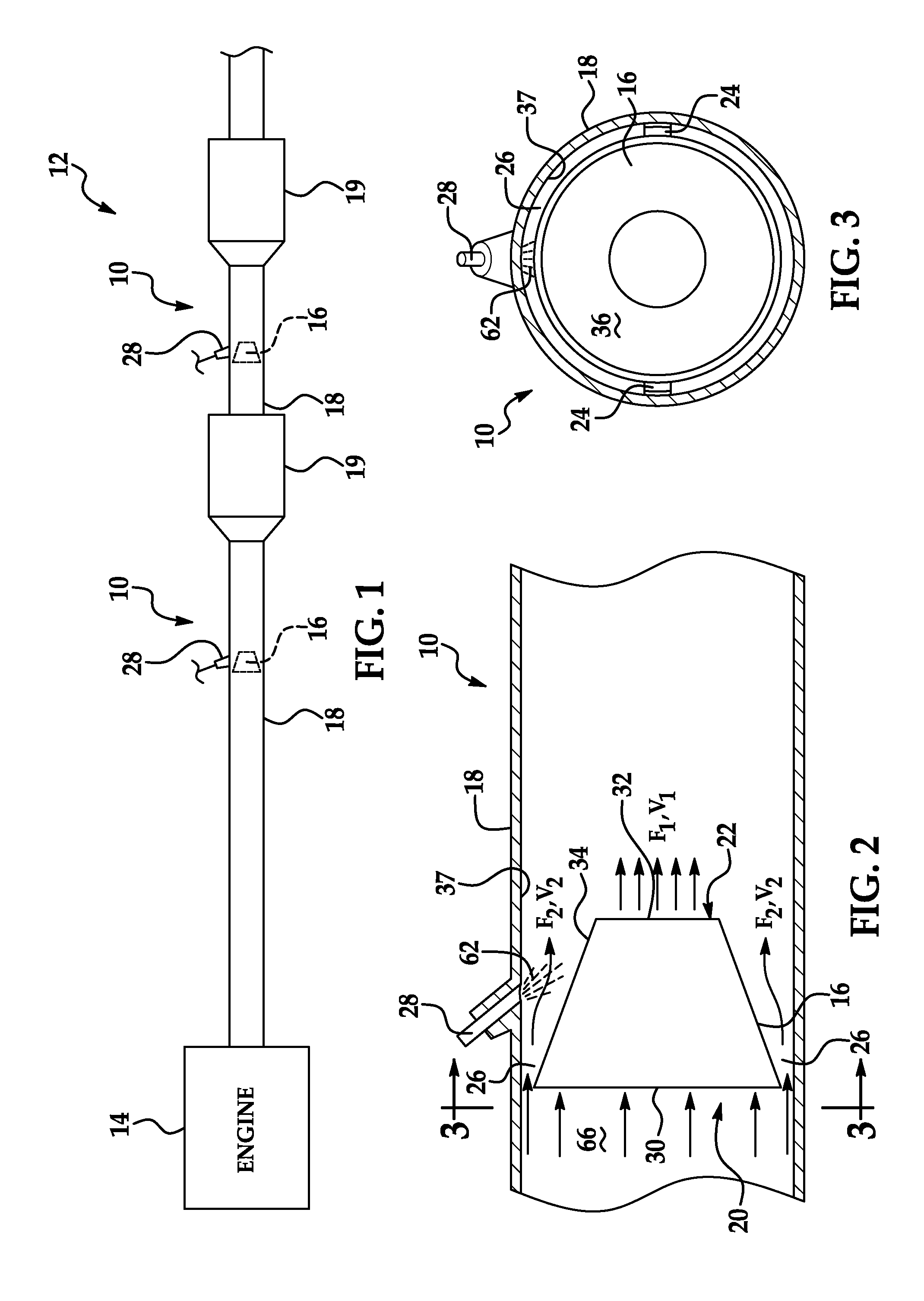

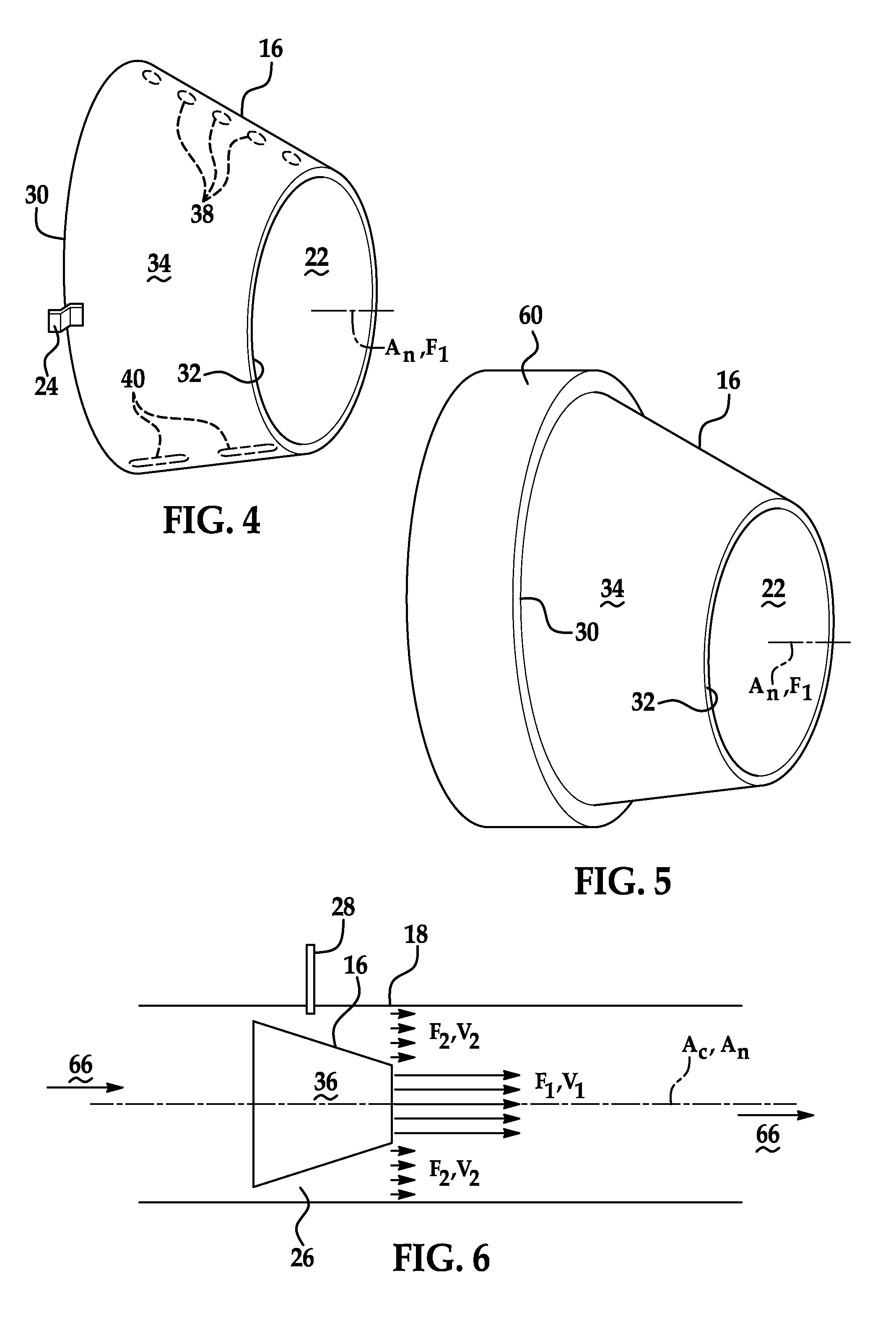

Nozzle Diffuser Mixer

Exemplary embodiments of the present invention are directed towards an apparatus and method for control of fluid flow through a conduit of an exhaust system for an engine, particularly prior to an exhaust treatment device. In one embodiment, a fluid flow control device for receiving and guiding exhaust gas from an engine towards an exhaust gas treatment device is provided. The fluid flow control device includes a nozzle disposed within an exhaust conduit of the engine. The nozzle includes an inlet opening and an outlet opening for forming a first flow path through the nozzle. The nozzle is spaced from the exhaust conduit for forming a second flow path between the nozzle and the exhaust conduit. The fluid flow control device also includes an injector disposed adjacent the nozzle. The injector may be oriented to direct a pressurized fluid to the first or second flow path.

Owner:GM GLOBAL TECH OPERATIONS LLC

Selective catalytic reduction (SCR) catalyst injection systems

ActiveUS8033104B2Speed up the flowPromote atomizationInternal combustion piston enginesSilencing apparatusExhaust fumesExhaust pipe

A Selective Catalytic Reduction (SCR) injection system for mixing reductant with exhaust gasses. The system includes a plate disposed between walls of an entrance portion and an egress section of the exhaust pipe. The plate intercepts exhaust gasses entering the entrance section of the exhaust pipe and directs such exhaust gasses through apertures in a wall of a reductant-introducing conduit. The conduit has an outlet disposed in the egress section of the exhaust pipe. The wherein dimensions of the apertures in the wall and dimensions in the outlet of the conduit being selected to increase the velocity of the exhaust leaving the outlet of the conduit into the egress section of the exhaust pipe relative to the velocity of the exhaust gases in the entrance section.

Owner:FORD GLOBAL TECH LLC

Method and apparatus for posttreatment of an exhaust gas from an internal combustion engine

InactiveUS20070163241A1Internal combustion piston enginesFlow mixersExhaust fumesInternal combustion engine

A method of and an apparatus for posttreatment of an exhaust gas from an internal combustion engine, in which a substance to be mixed with the exhaust gas is sprayed in metered quantities into an exhaust gas line through which the exhaust gas flows. The substance is sprayed onto an impact plate disposed inside the exhaust gas line.

Owner:ROBERT BOSCH GMBH

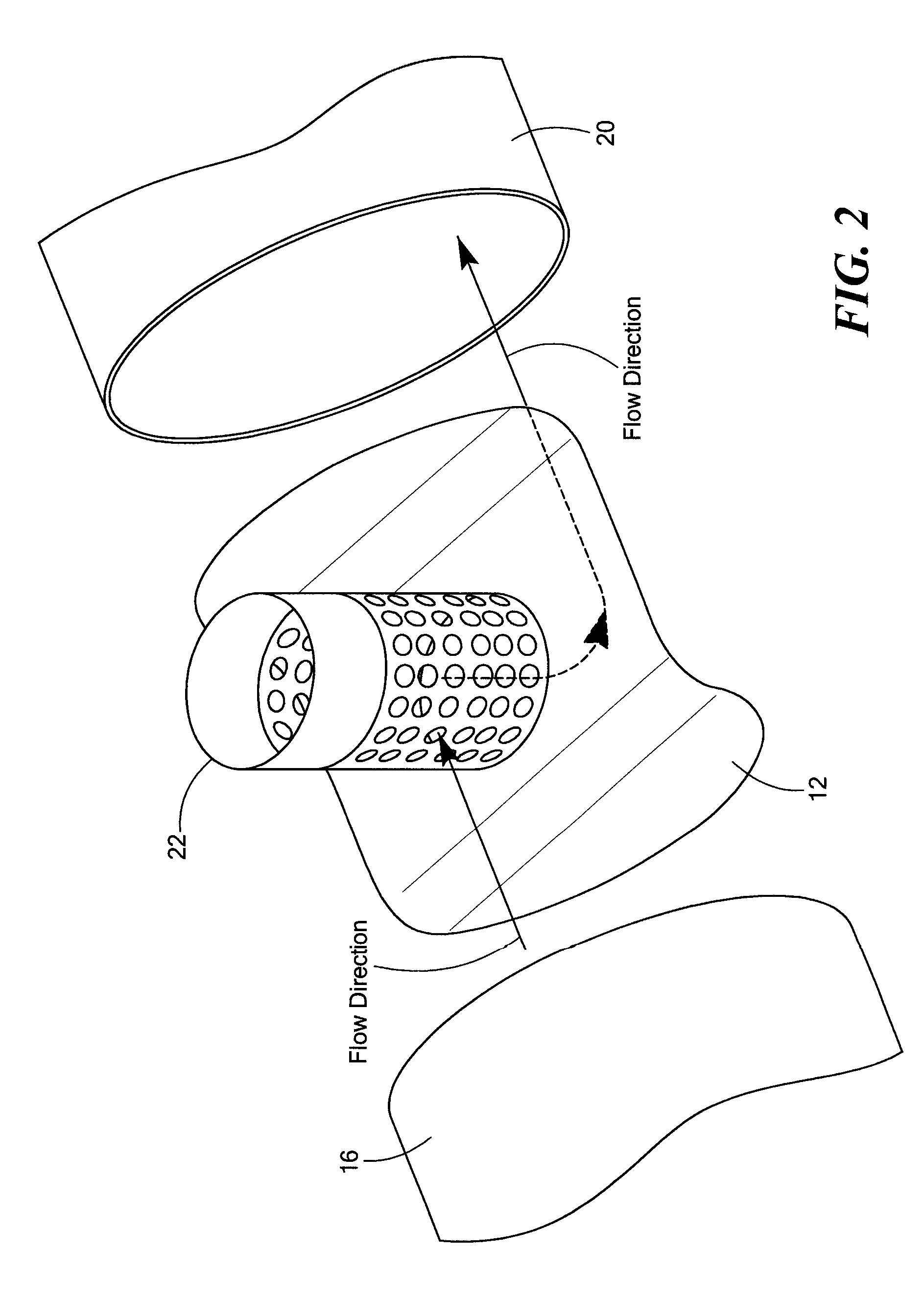

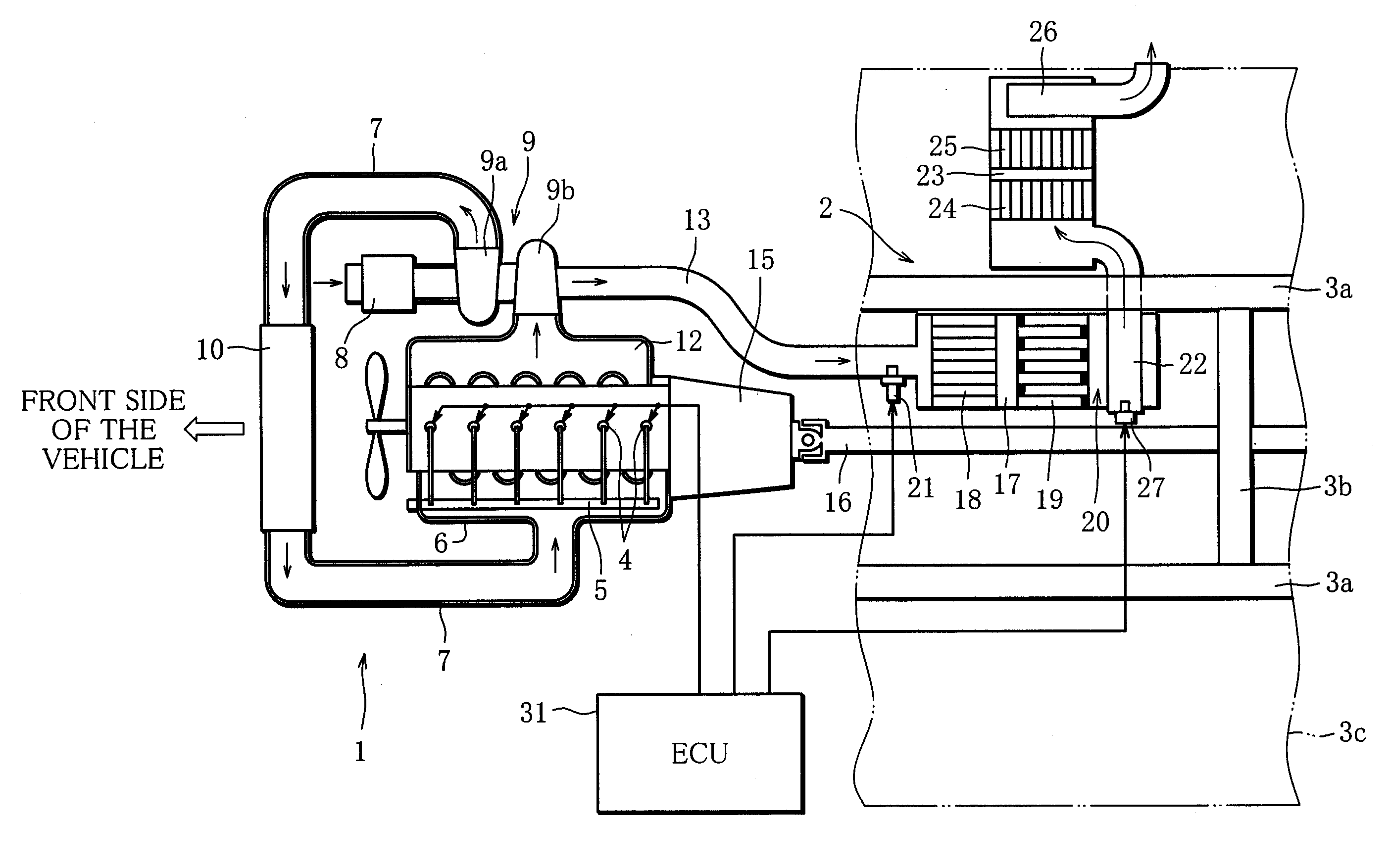

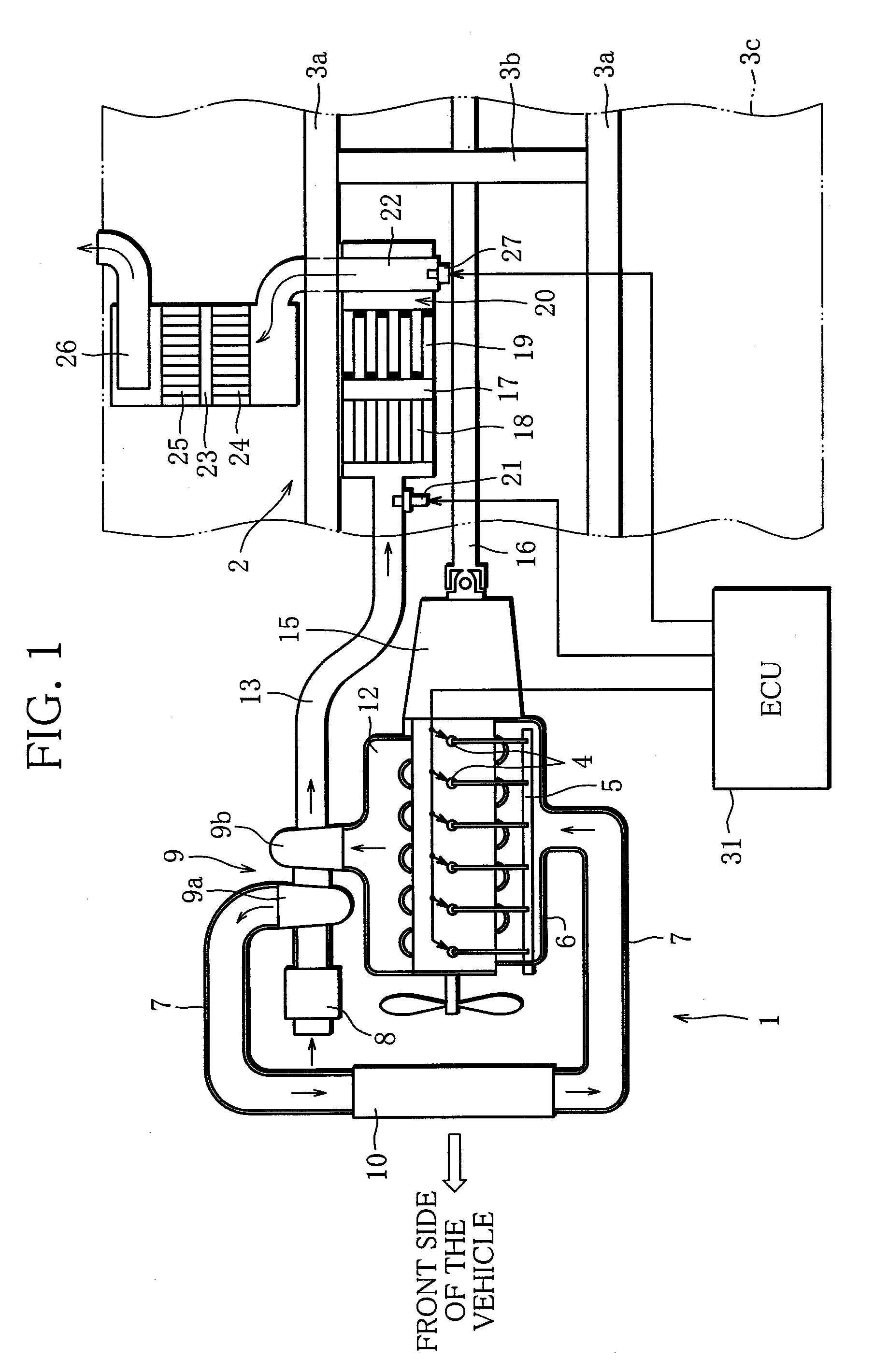

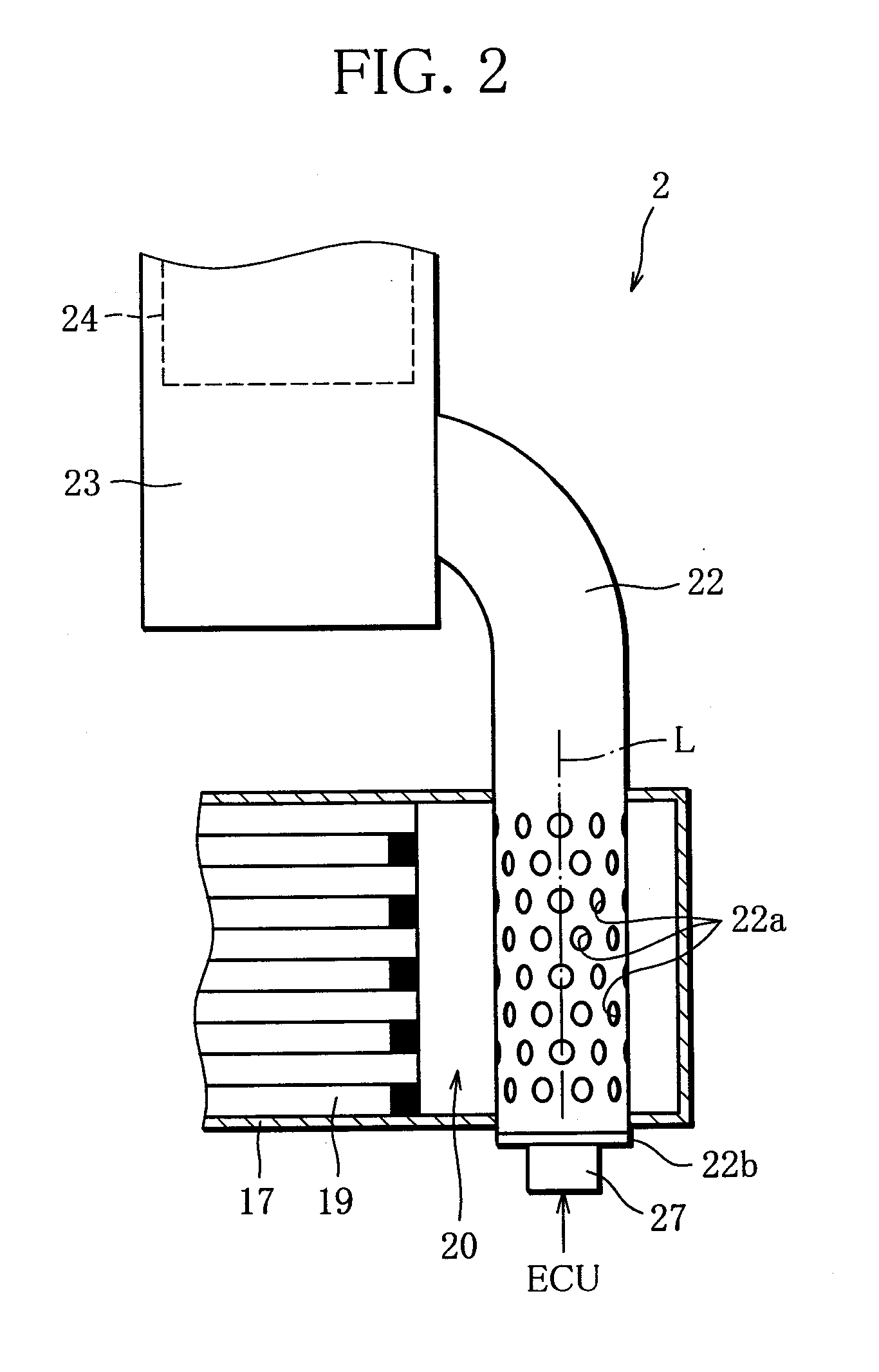

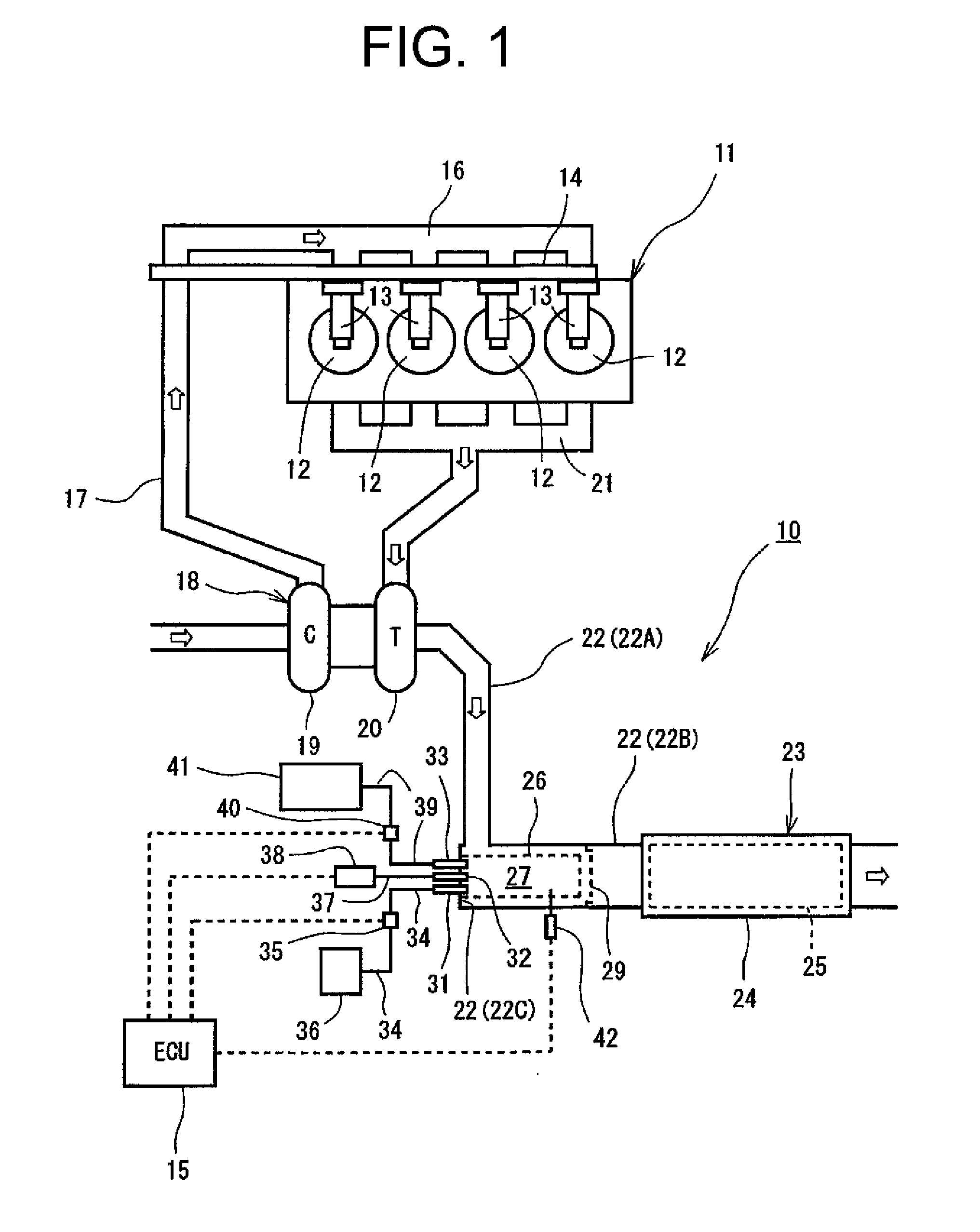

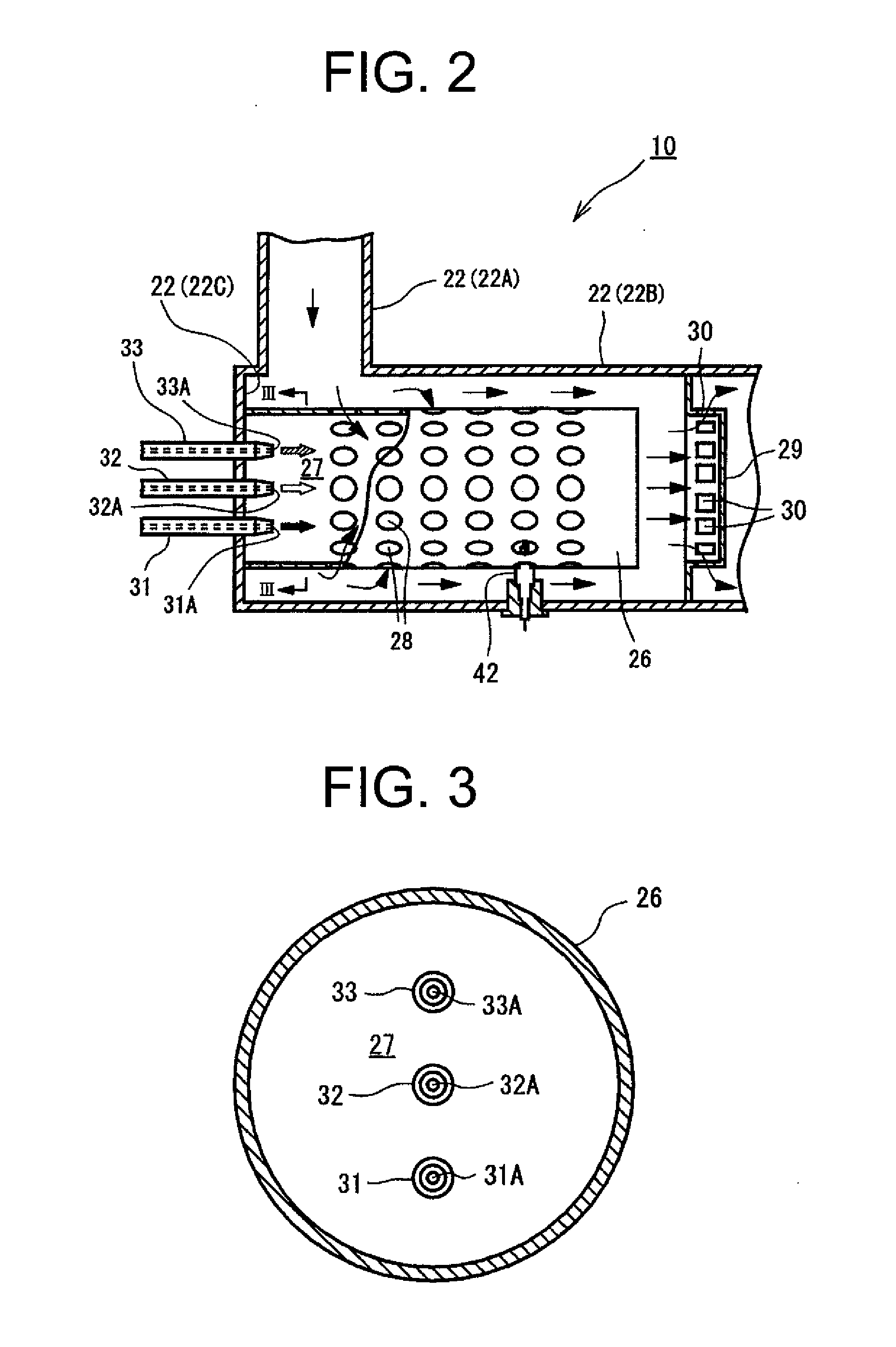

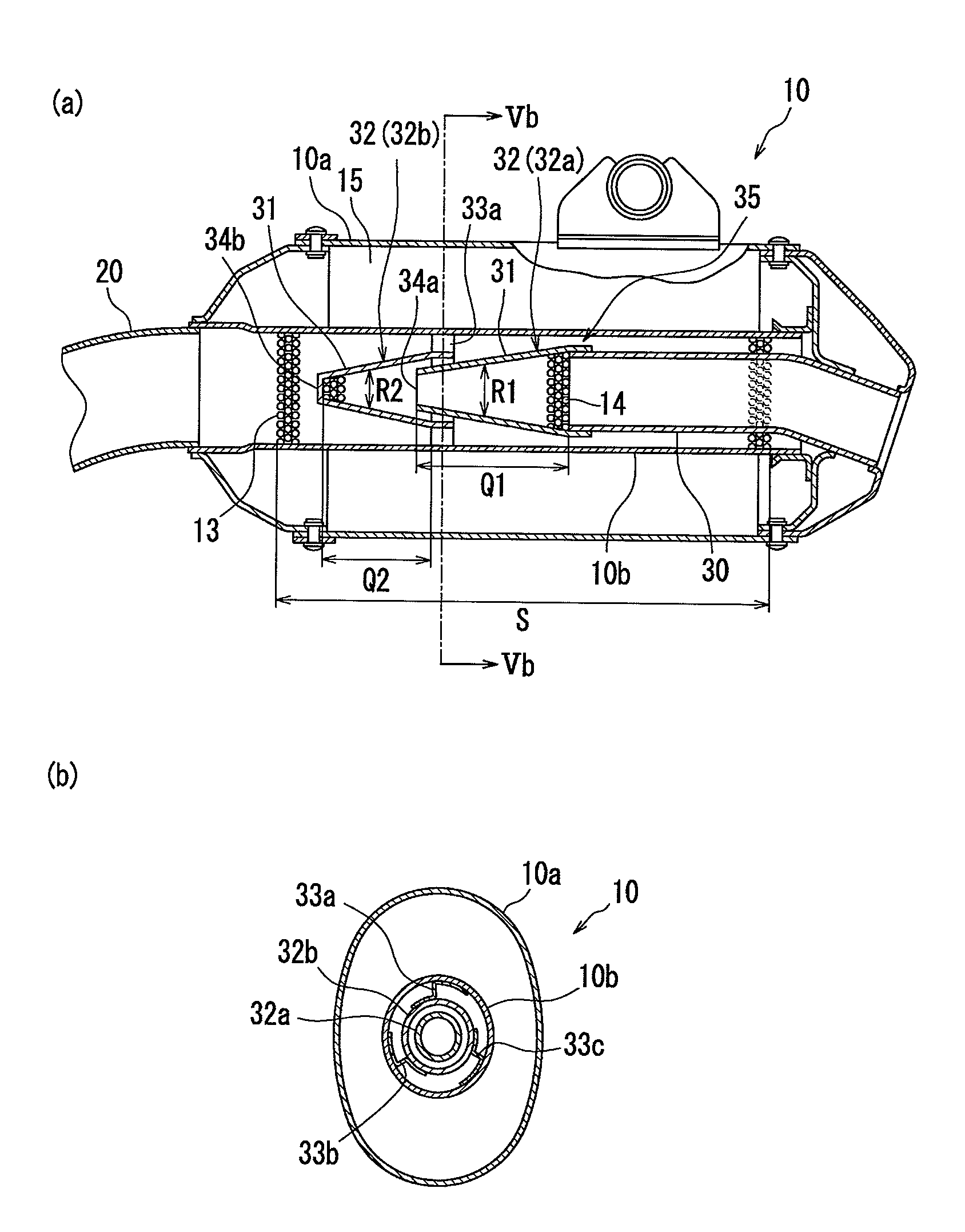

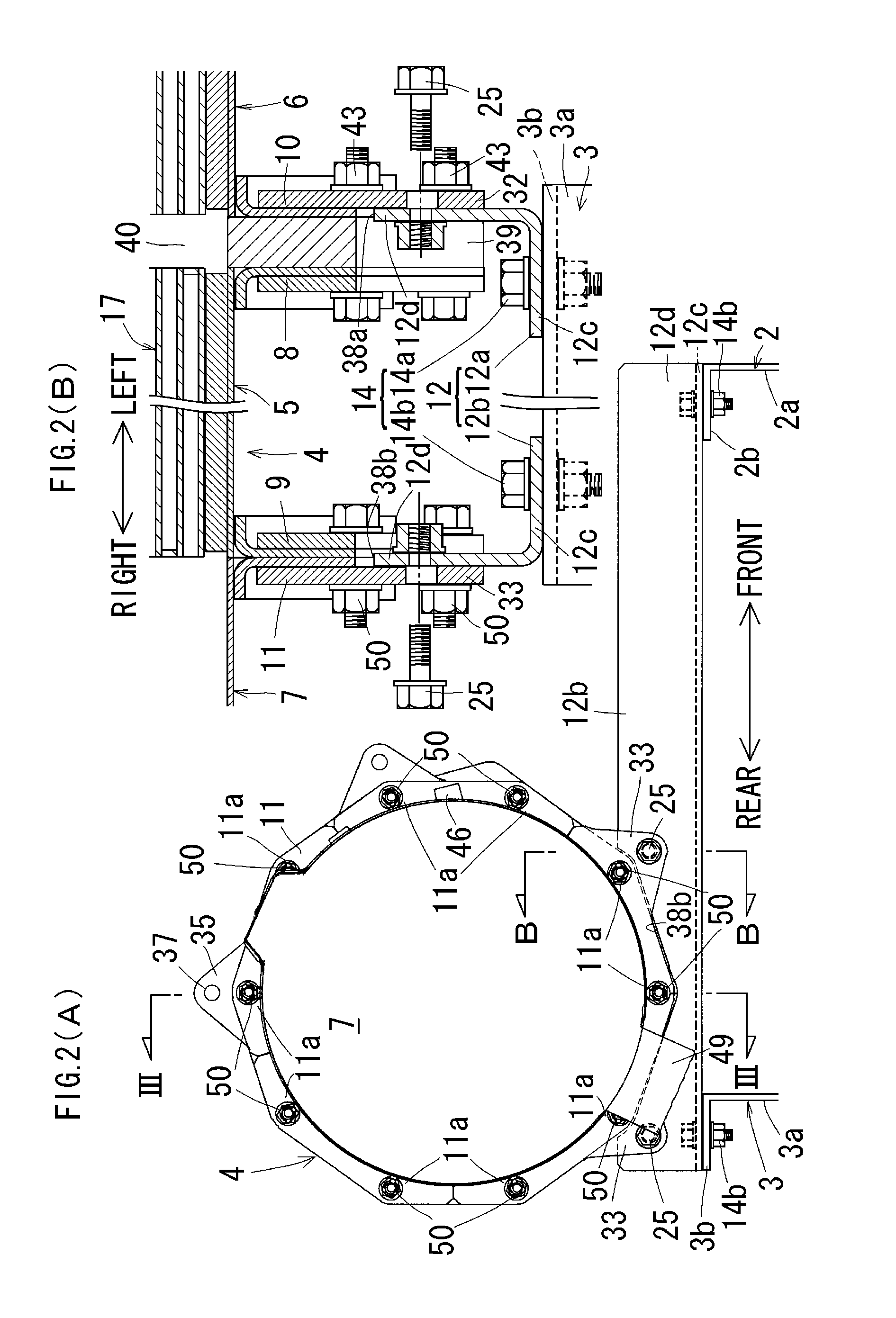

Exhaust purification apparatus for an engine

InactiveUS20100107612A1Suppresses distributionGood exhaust purification functionInternal combustion piston enginesDispersed particle separationExhaust fumesEngineering

An exhaust purification apparatus for an engine has a first casing (17) that is interposed in an exhaust path (13); a second casing (23) that is set downstream of the first casing (17) and contains an exhaust purification device (24); a connecting pipe (22, 41, 51) that connects the first casing and the second casing (23) to each other and includes an insertion portion that is inserted in the first casing (17); and an injection nozzle (27, 52) that has a tip end inserted in the connecting pipe (22, 41, 51) and injects an auxiliary agent from the tip end. The insertion portion of the connecting pipe (22, 41, 51) is provided with a plurality of through-holes (22a, 41a, 41b, 51a) connecting the inside and the outside of the connecting pipe (22, 41, 51), so that the exhaust gas contained in the first casing (17) is introduced into the connecting pipe (22, 41, 51) through the through-holes and guided towards the second casing (23).

Owner:MITSUBISHI FUSO TRUCK AND BUS CORPORATION

Exhaust gas treatment system

InactiveUS20110061374A1Internal combustion piston enginesSilencing apparatusInjection portExhaust fumes

An exhaust gas treatment system includes an exhaust passage through which exhaust gas from an internal combustion engine is allowed to flow, a selective catalytic reduction catalyst provided in the exhaust passage, a mixing chamber provided upstream of the selective catalytic reduction catalyst in the exhaust passage as viewed in the direction of exhaust gas flow, a fuel injection valve for injection of fuel, an air injection valve for injection of air, and a urea water injection valve for injection of urea water. The fuel injection valve, the air injection valve and the urea water injection valve each has an injection port directed to the mixing chamber.

Owner:TOYOTA IND CORP

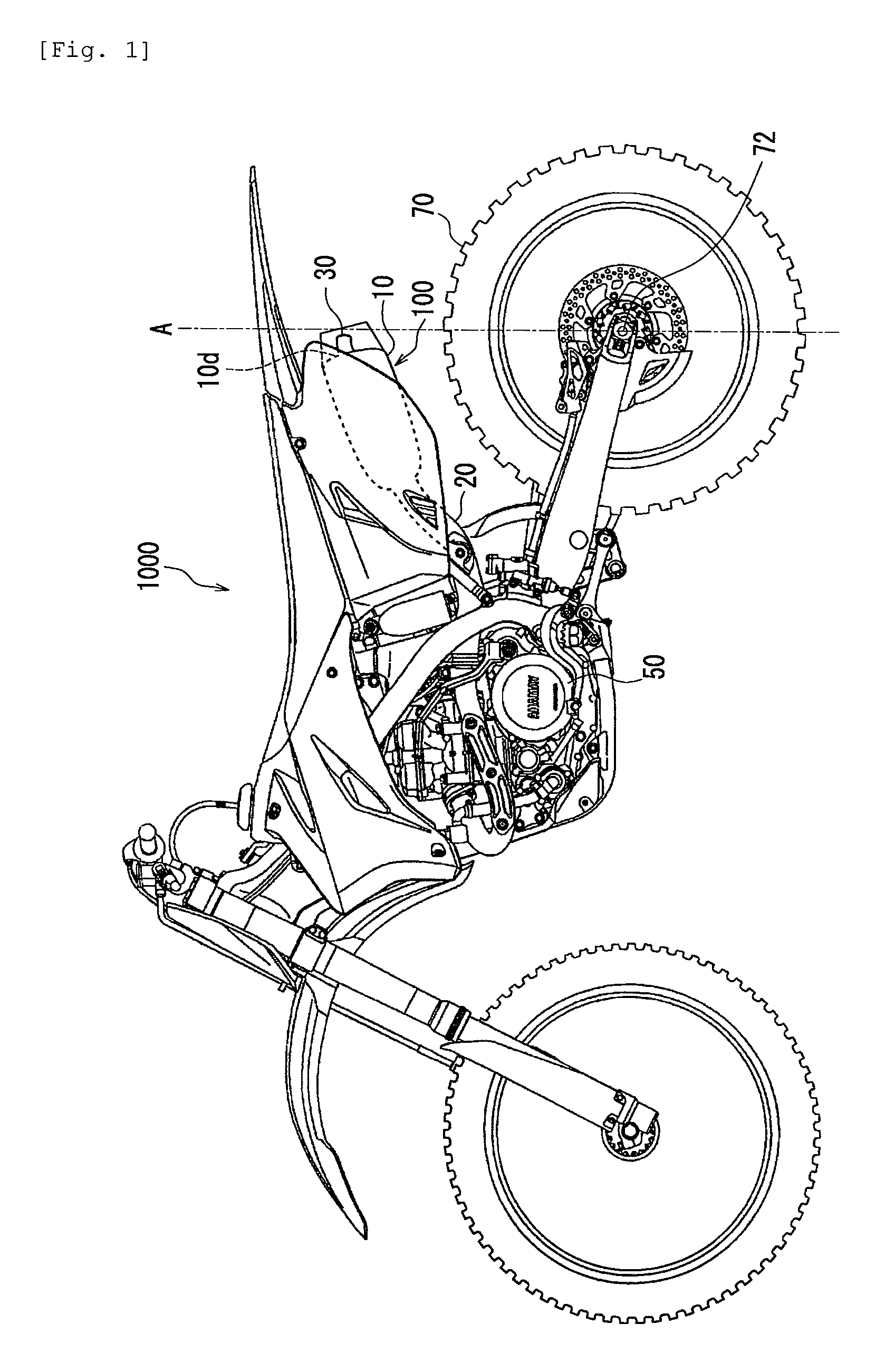

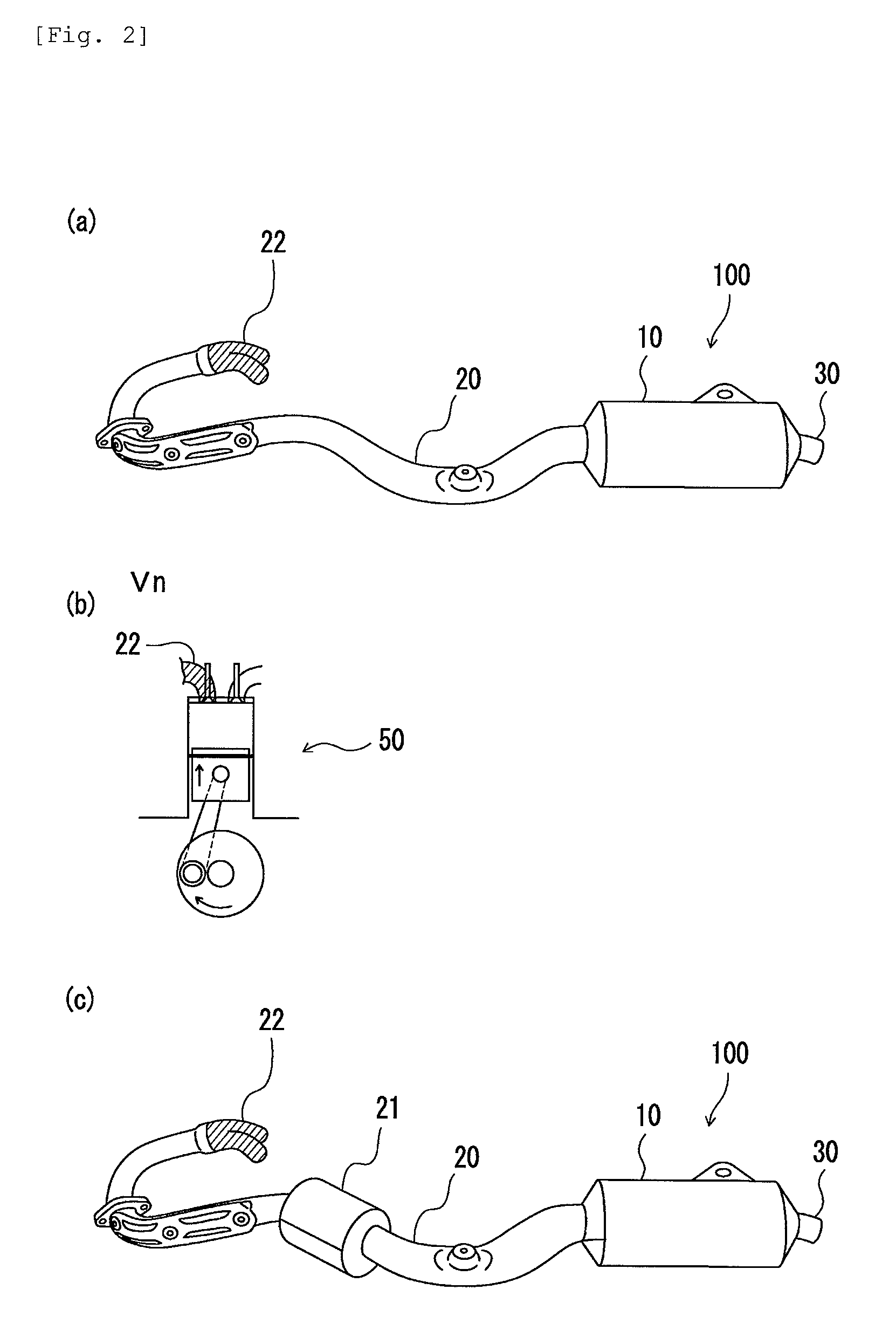

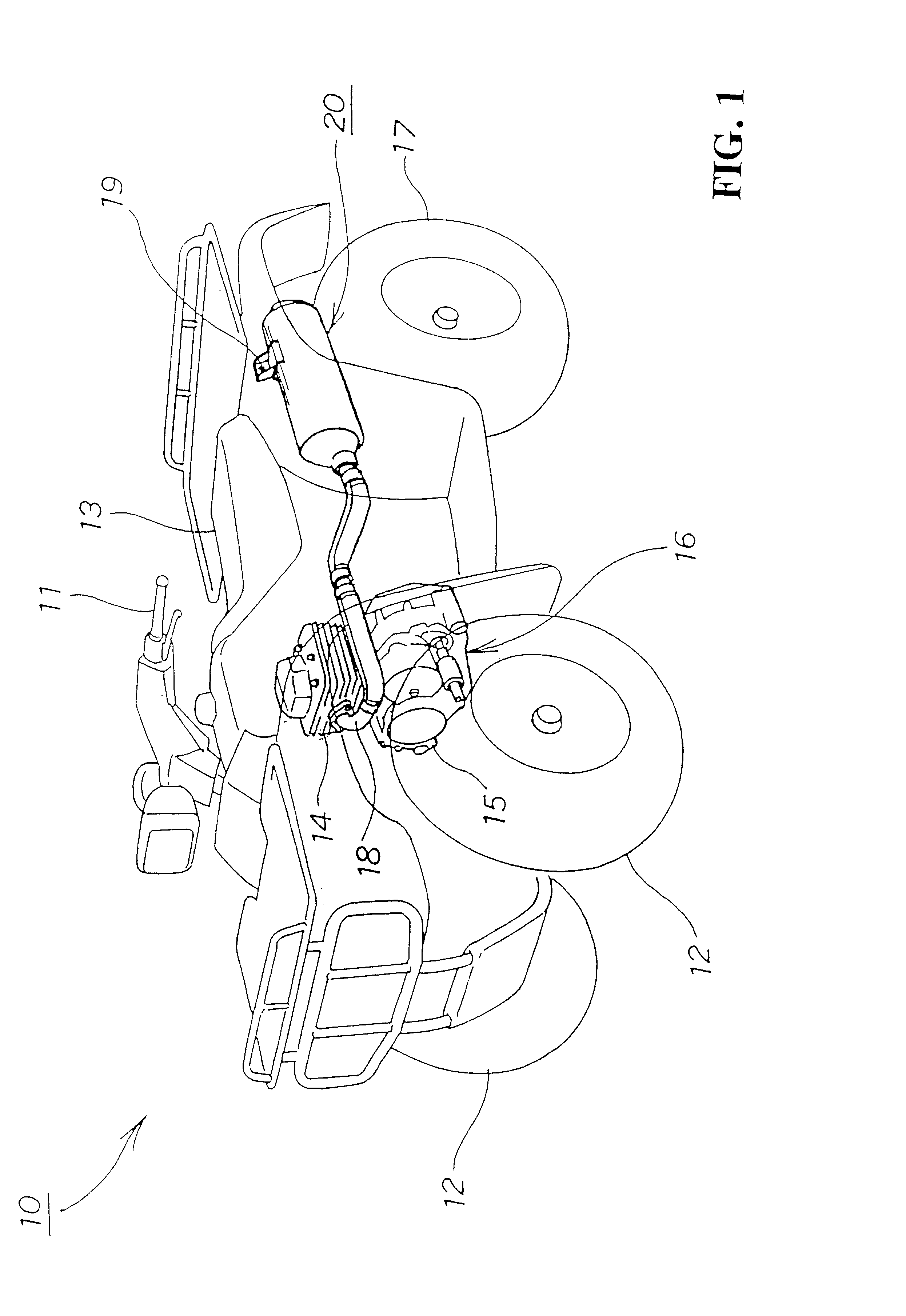

Vehicle exhaust system

InactiveUS7766123B2Improve featuresAbsorb noiseSilencing apparatusMachines/enginesMiniaturizationEngineering

An exhaust system for a vehicle, such as a motorcycle or other straddle-type vehicle, that achieves miniaturization while providing advantageous noise reduction characteristics. The exhaust system is associated with an engine of a vehicle and includes an exhaust pipe connected to the engine and a silencer. A conical member is positioned within the silencer and includes an upstream end and a downstream end. At least a portion of a side wall of the conical member includes a plurality of through-holes. The conical member is oriented such that a radial dimension of the conical member increases in a direction from the upstream end to the downstream end.

Owner:YAMAHA MOTOR CO LTD

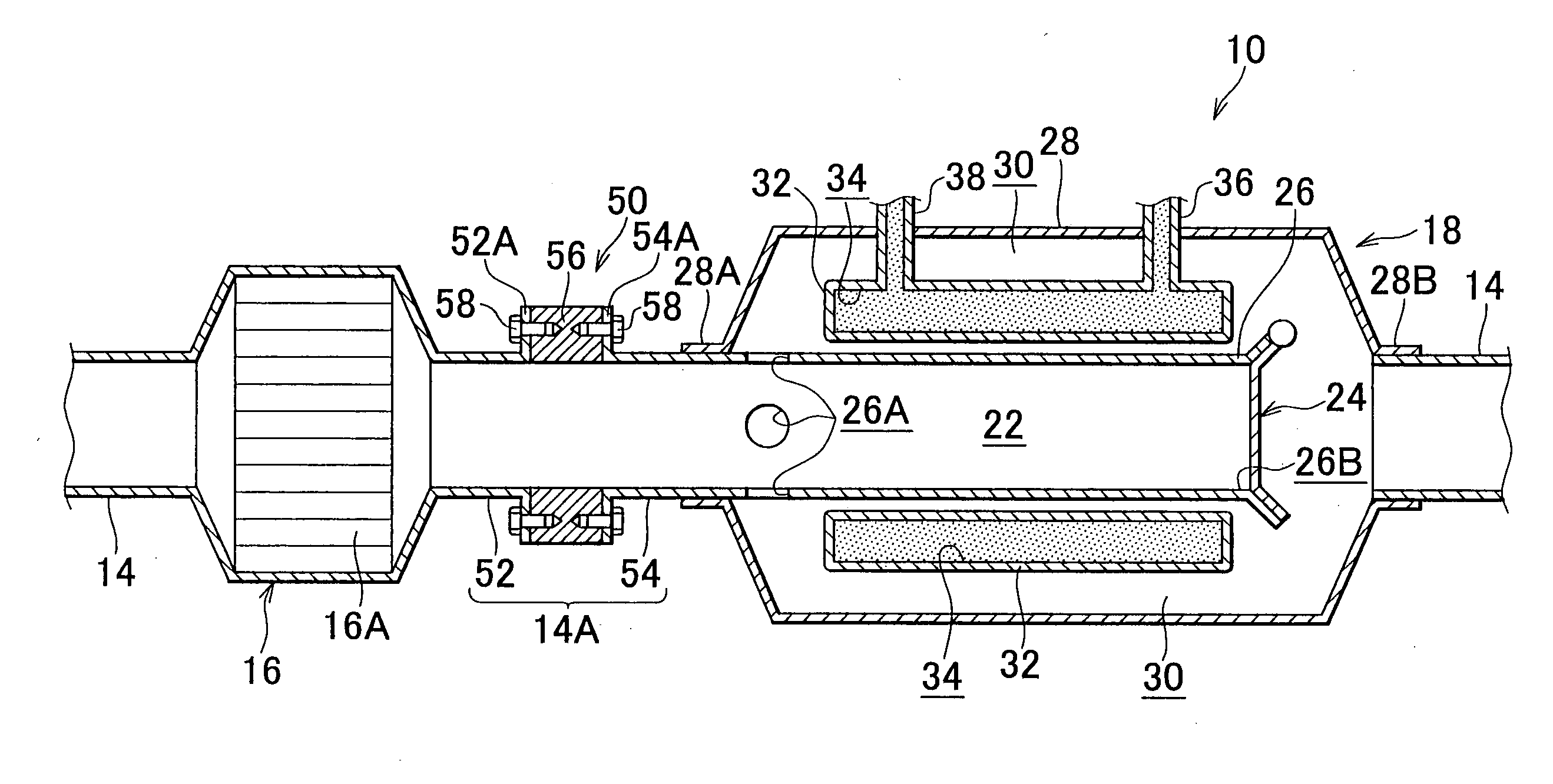

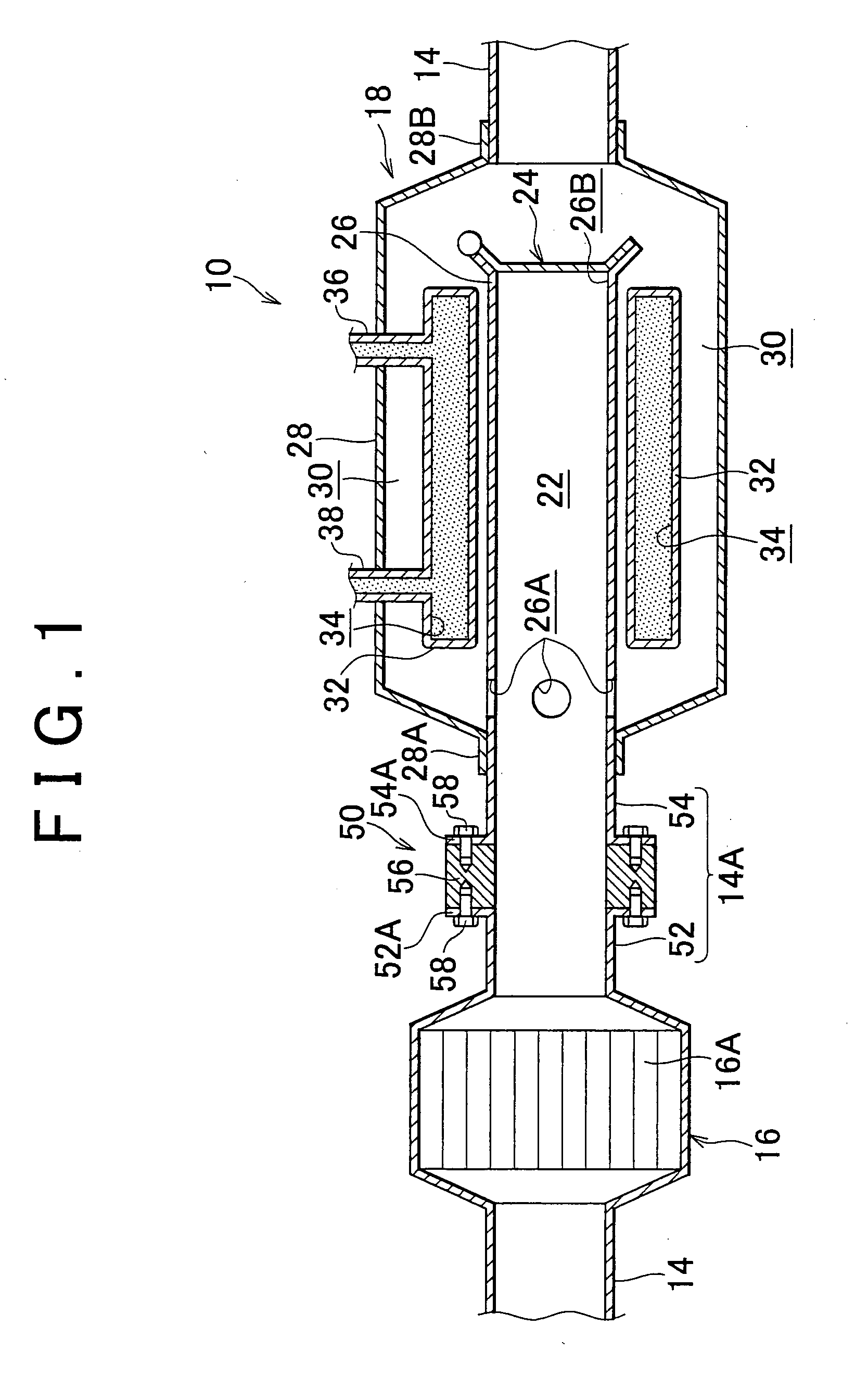

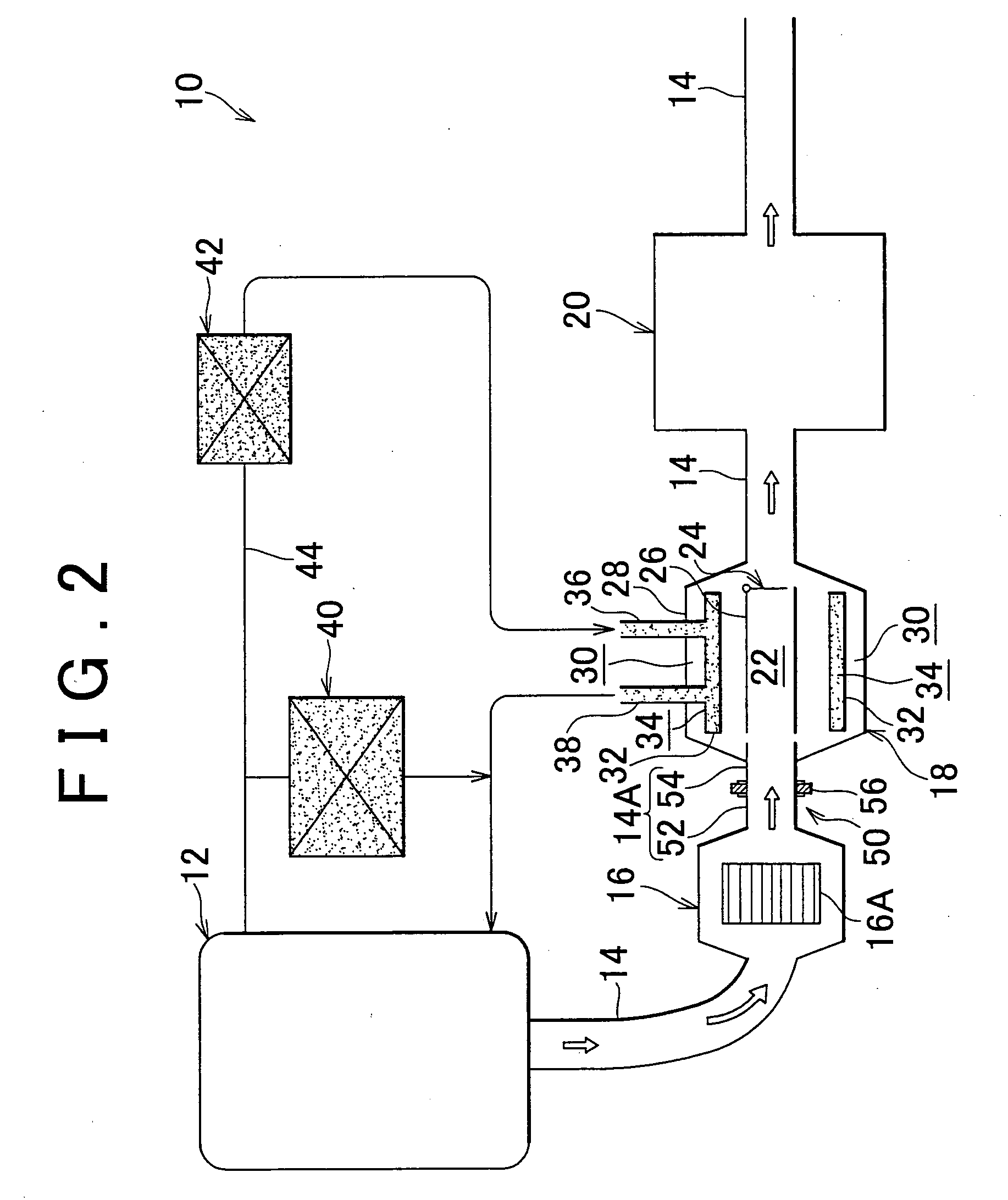

Exhaust heat recovery system

InactiveUS20100043413A1Combination devicesInternal combustion piston enginesEngineeringExhaust heat recovery system

An exhaust heat recovery system (10) includes: an exhaust heat exchanger (18) that is communicated with a catalytic converter (16) through an exhaust gas pipe (14A), and that recovers exhaust heat into a coolant; and heat transfer restriction means (50) provided between the catalytic converter (16) and the exhaust heat exchanger (18). The heat transfer restriction means (50) includes a heat insulator (56) disposed between a first exhaust gas pipe (52) and a second exhaust gas pipe (54) that constitute the exhaust gas pipe (14A), and. restrains a released heat from the catalytic converter (16) from reaching the exhaust heat exchanger (18).

Owner:TOYOTA JIDOSHA KK

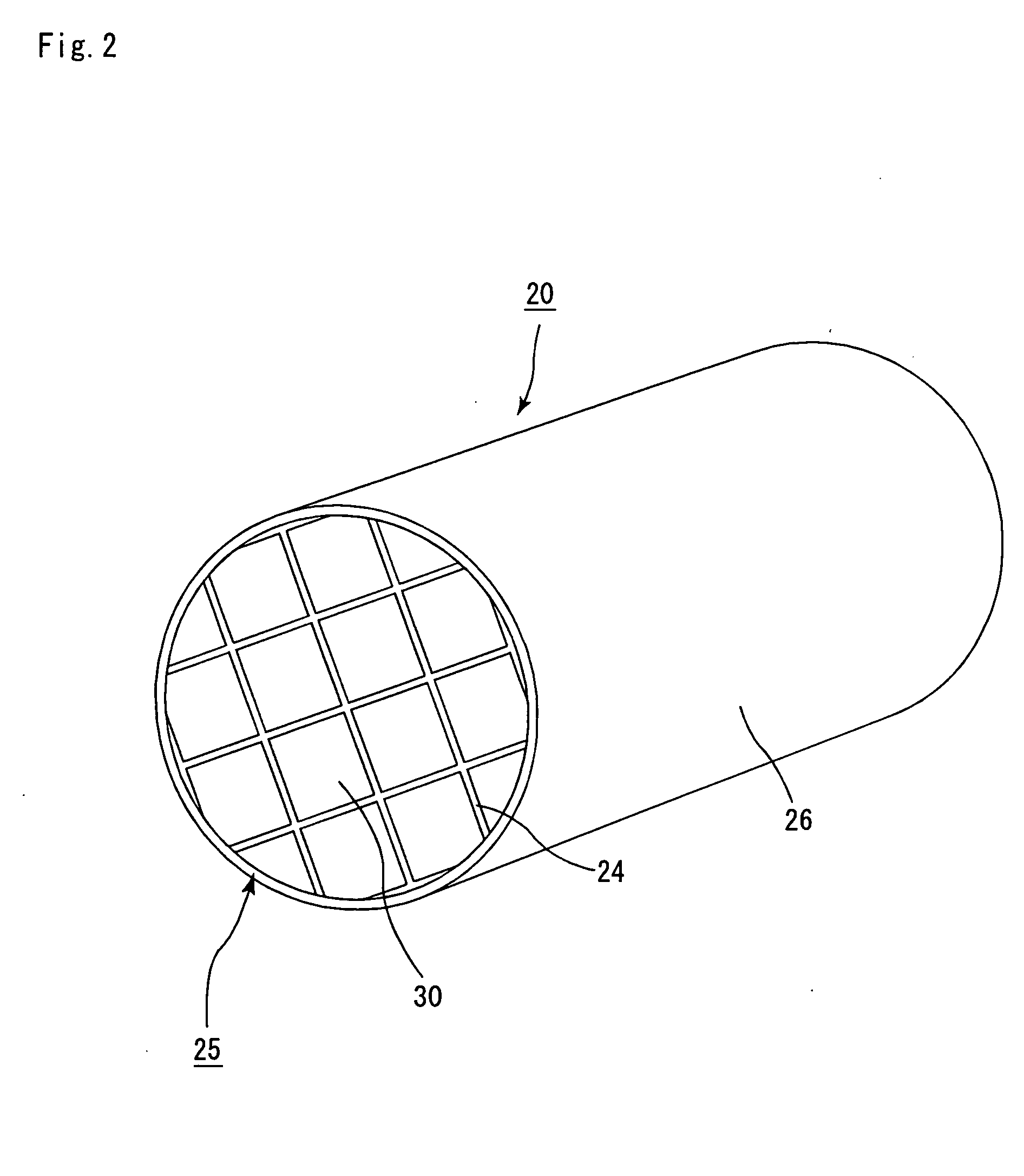

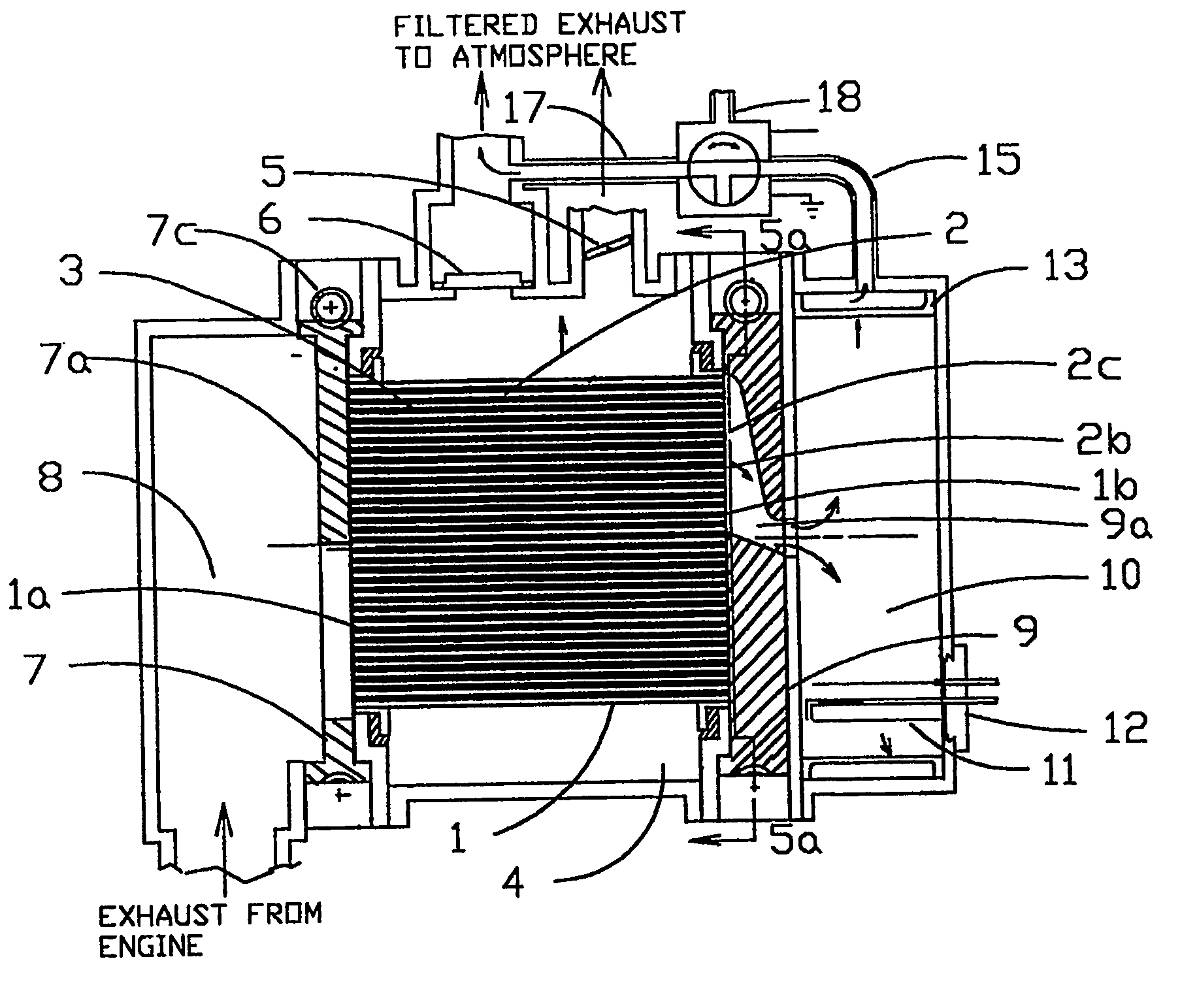

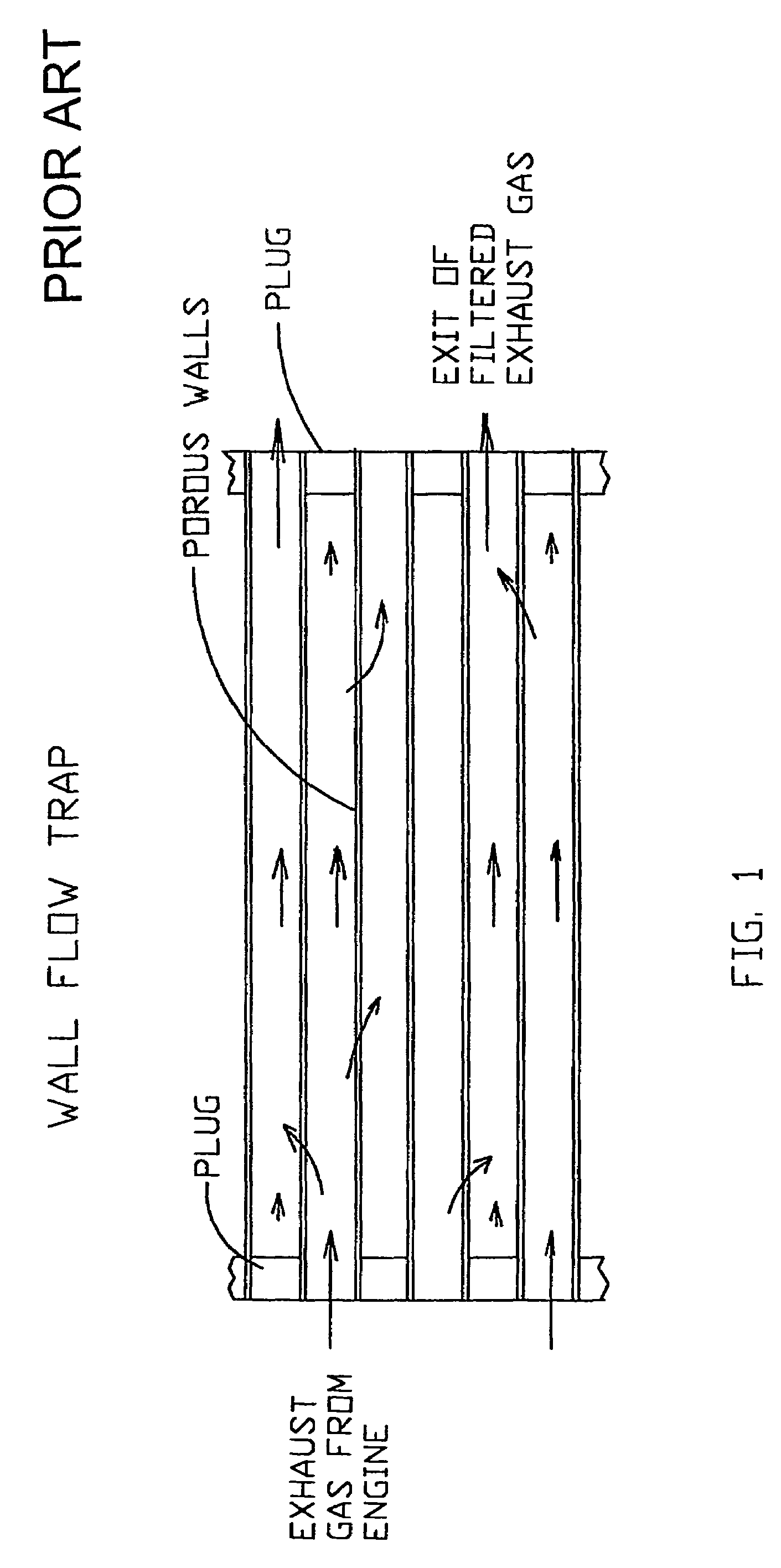

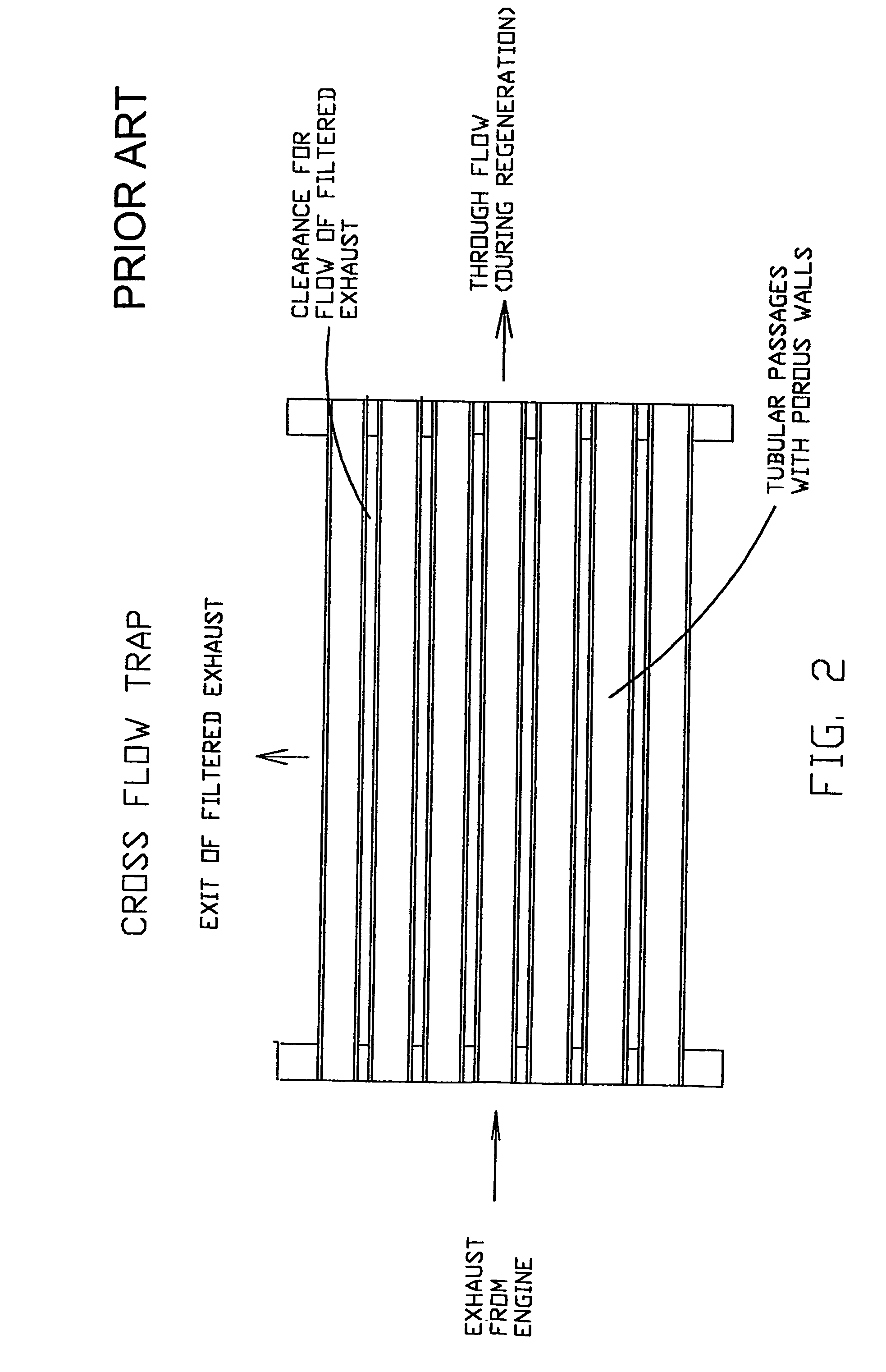

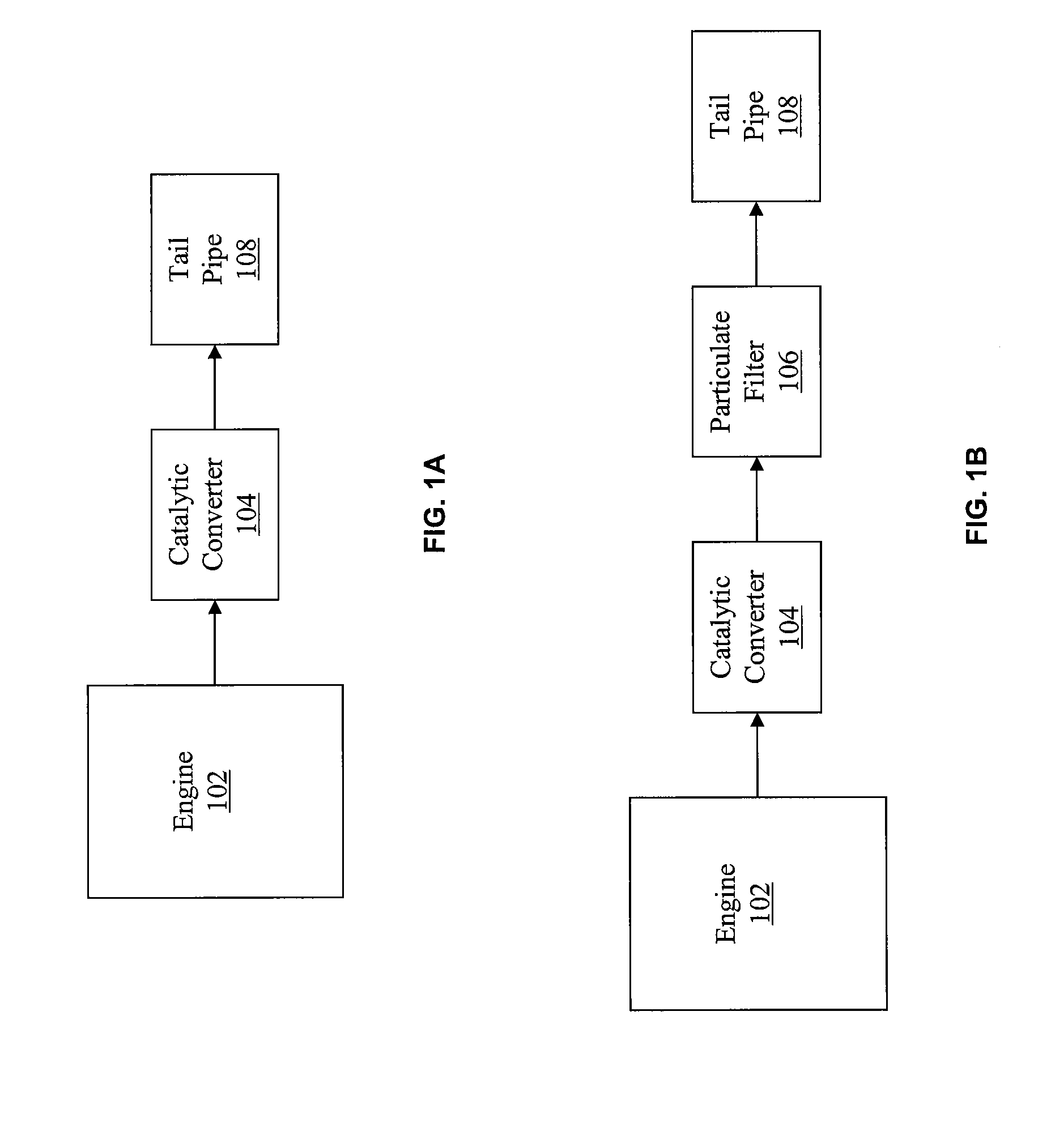

Apparatus and method for filtering particulate and reducing NOx emissions

InactiveUS6989045B2Increase engine fuel consumptionIncrease in weight of filterCombination devicesLiquid degasificationParticulatesProcess engineering

An apparatus and method for filtering particulate from an internal combustion engine by use of monolithic particulate trap systems having porous walls (2c, 24c). The porous walls (2c, 24c) filter the particulate. The filtered particulate on inner surfaces of the porous walls is periodically removed or regenerated via back flow of previously filtered exhaust gas. The back flow is caused by creating a pressure difference across the porous walls. The back flow of the previously filtered exhaust gas is simultaneously or sequentially coupled with high velocity through flow of exhaust gas in the channels. In addition, the particulate trap system can be an adsorber-catalyst particulate trap system for filtering particulate and reducing NOx via an adsorber-catalyst trap systems to achieve the EPA 2007 standards.

Owner:ILLINOIS VALLEY HLDG

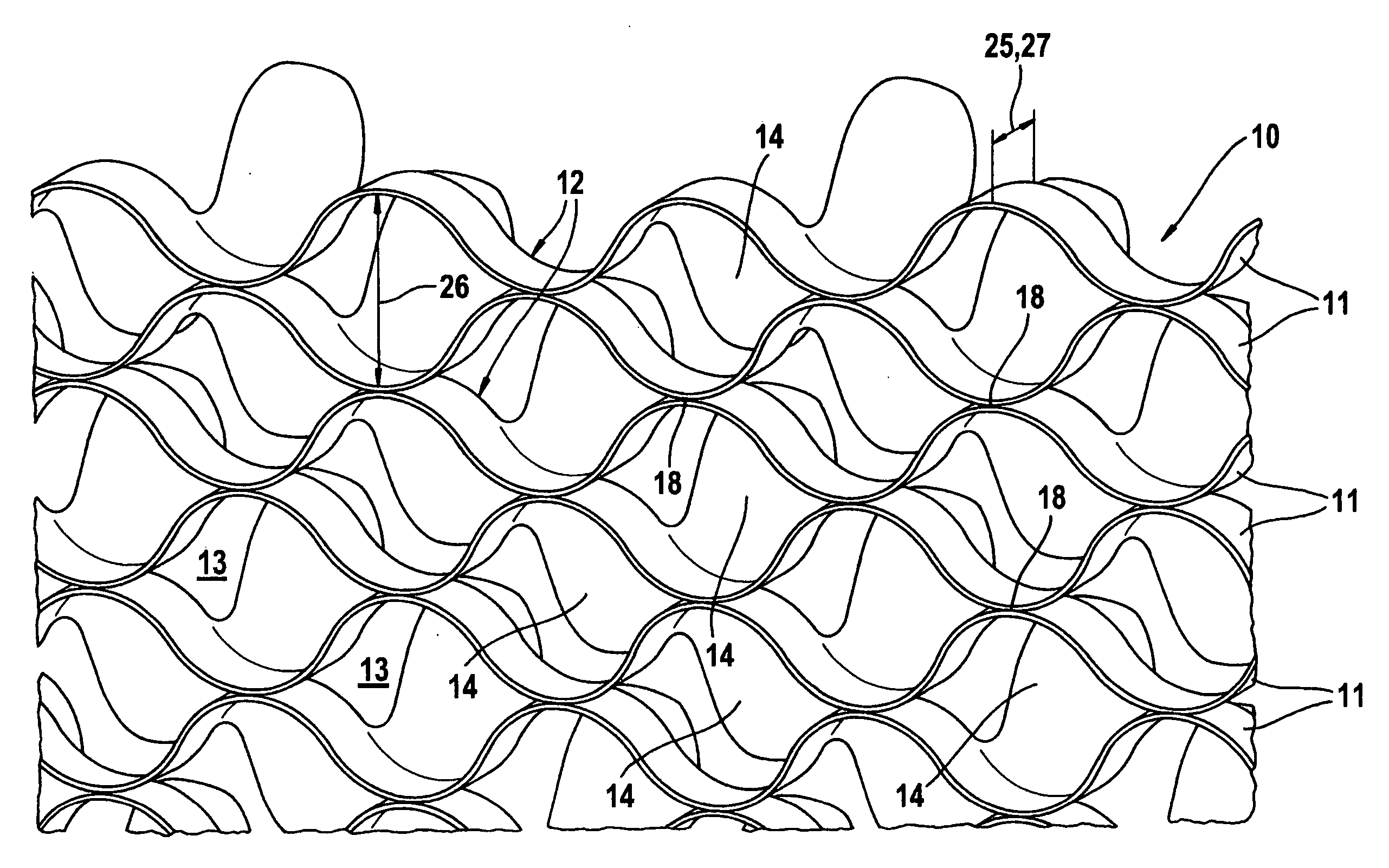

Static mixer and exhaust gas treatment device

InactiveUS20070204751A1Design economyIntense mixing effect and vaporization effectInternal combustion piston enginesFlow mixersExhaust fumesEngineering

The invention relates to a static mixer for an exhaust system of an internal combustion engine. The mixer has a wall structure that is arranged across the directional of flow in a pipe and has several layers of a corrugated sheeting material laying across one another in the direction of flow. The cells through which the flow can pass in the direction of flow are provided between the sheeting material of neighboring layers. The sheeting material has baffles for all or several of the cells. The baffles are arranged on the sheeting material so that they are arranged on their outgoing flow side in the case of said cells and extend in the direction of flow and across it.

Owner:EBERSPACHER EXHAUST TECH GMBH & CO KG

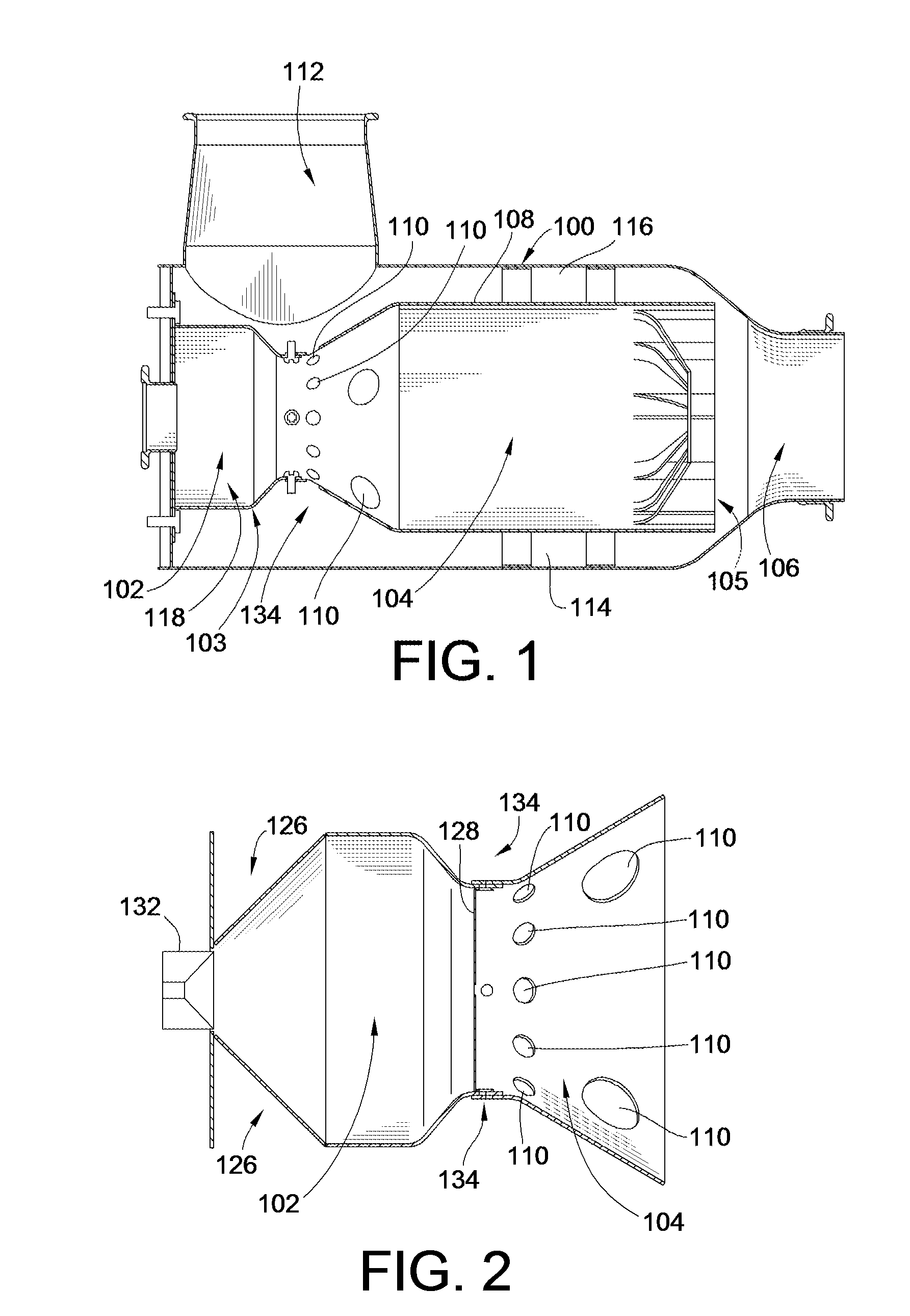

Exhaust treatment packaging apparatus, system, and method

An exhaust treatment packaging apparatus, system, and method includes an elongate exhaust gas passage comprising an inlet for the entrance of flowing exhaust gases and an outlet for the exit of the gases. A catalytic device comprising an inlet and an outlet completely or partially overlaps the passage to reduce the length required for the system. The passage outlet is disposed adjacent the catalytic device inlet, and a flow connector connects the passage outlet to the catalytic device inlet. A particulate filter or other treatment device may be substituted for or added to the catalytic device. A doser disposed upstream of the passage doses an additive which evaporates, mixes, or otherwise undergoes change in the passage before reaching the catalytic device.

Owner:CUMMINS FILTRATION IP INC

Muffler structure

To provide a muffler structure capable of lowering muffler cost. A muffler structure is provided in which a sound absorbing material is laid on the inside surface of an outer tube. The sound absorbing material is retained by an inner tube made of a metal that is punched with a plurality of holes. The inner tube is divided into a plurality of expansion chambers. Exhaust gas from an engine is led into the fiat expansion chamber by an inlet pipe. The exhaust gas is discharged out after being supplied to the second and third expansion chambers in succession through the connecting pipes. In the muffler structure, the inner tube is made of an approximately flat metal that is punched with a plurality of holes by bending the metal into circular form until its opposite edges are butted to each other, and is fitted in the outer tube, with the butt portions not jointed, so that the butt portions will come behind the connecting pipe when viewed from the inlet pipe side.

Owner:HONDA MOTOR CO LTD

Exhaust gas treatment system

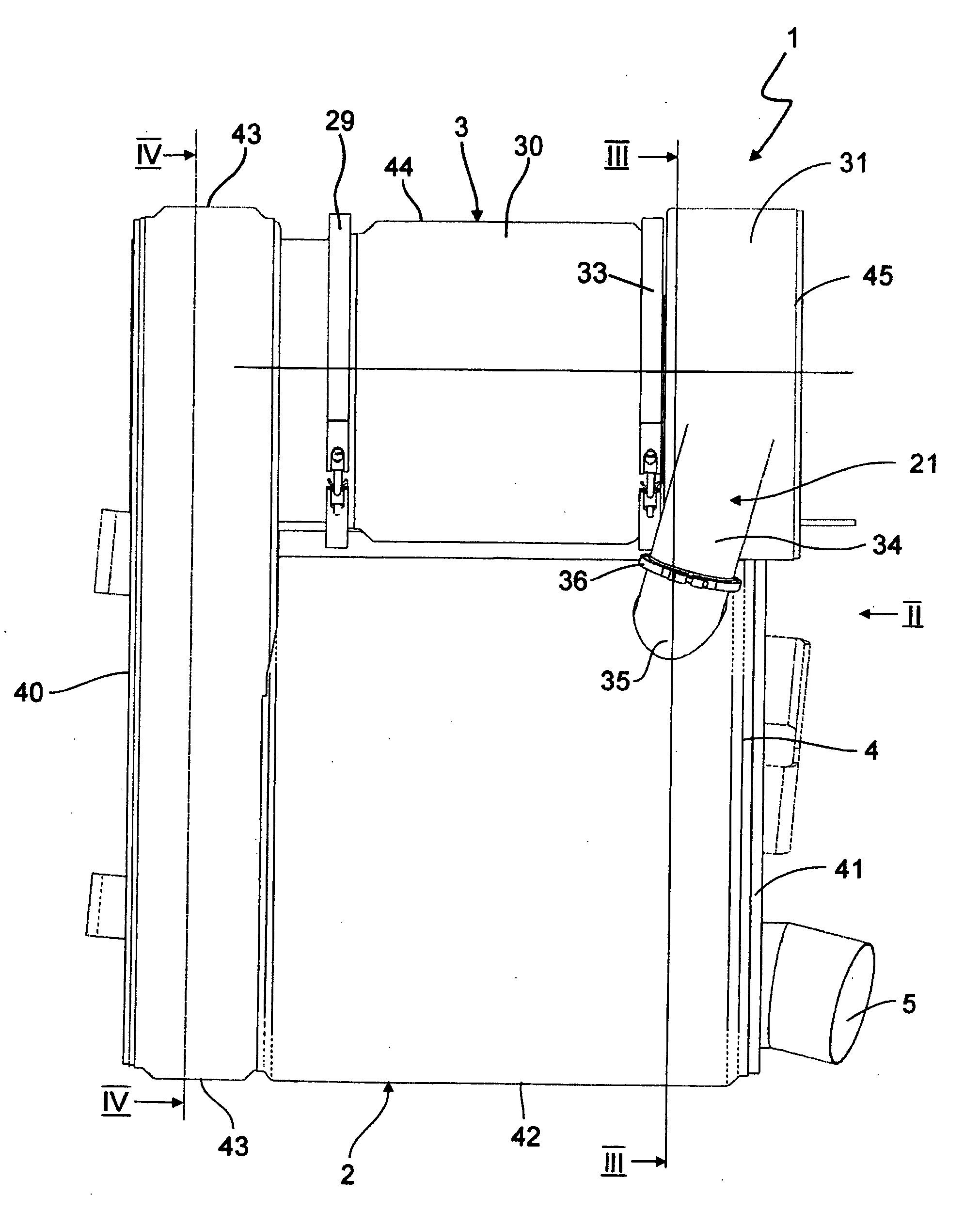

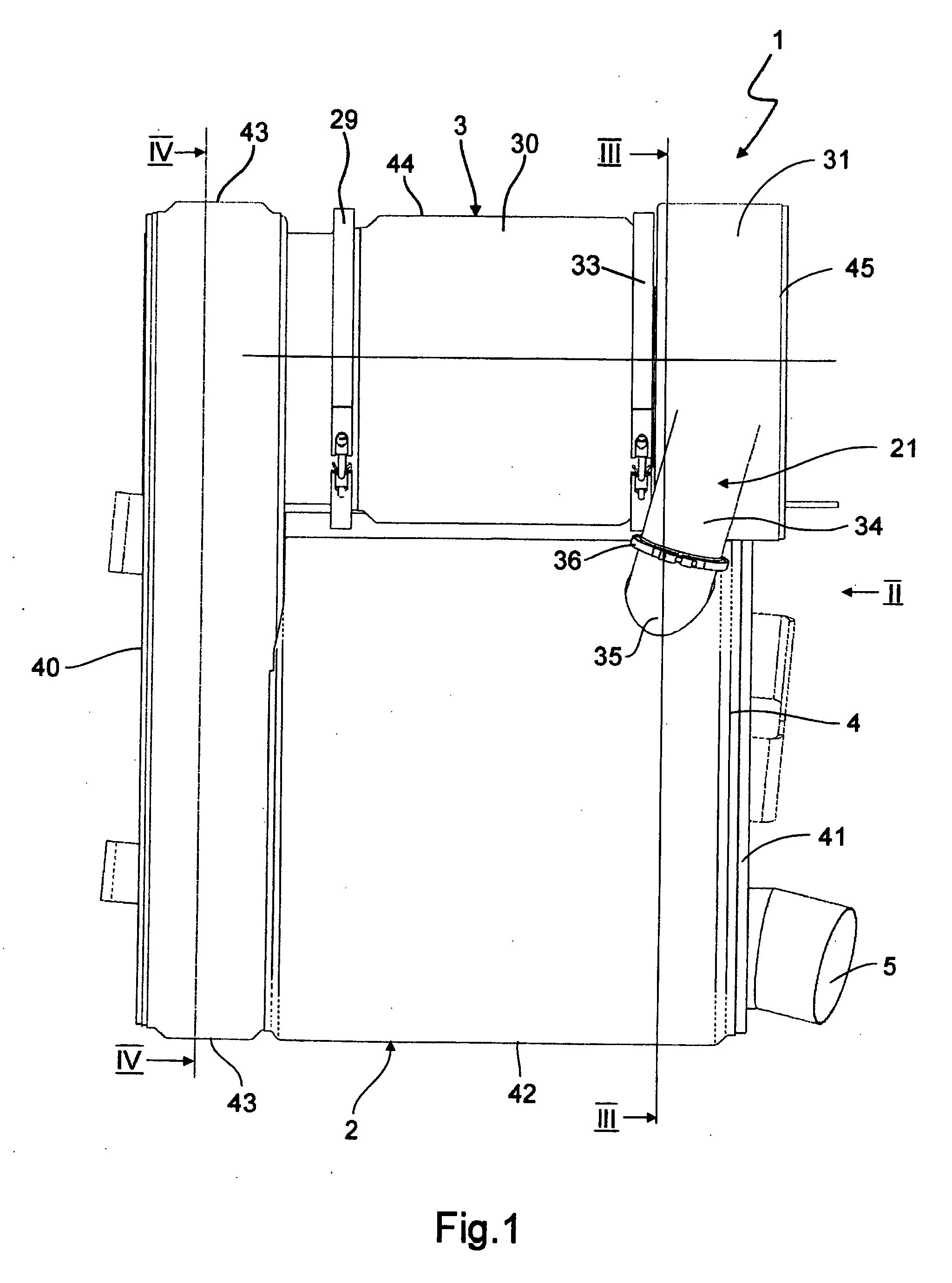

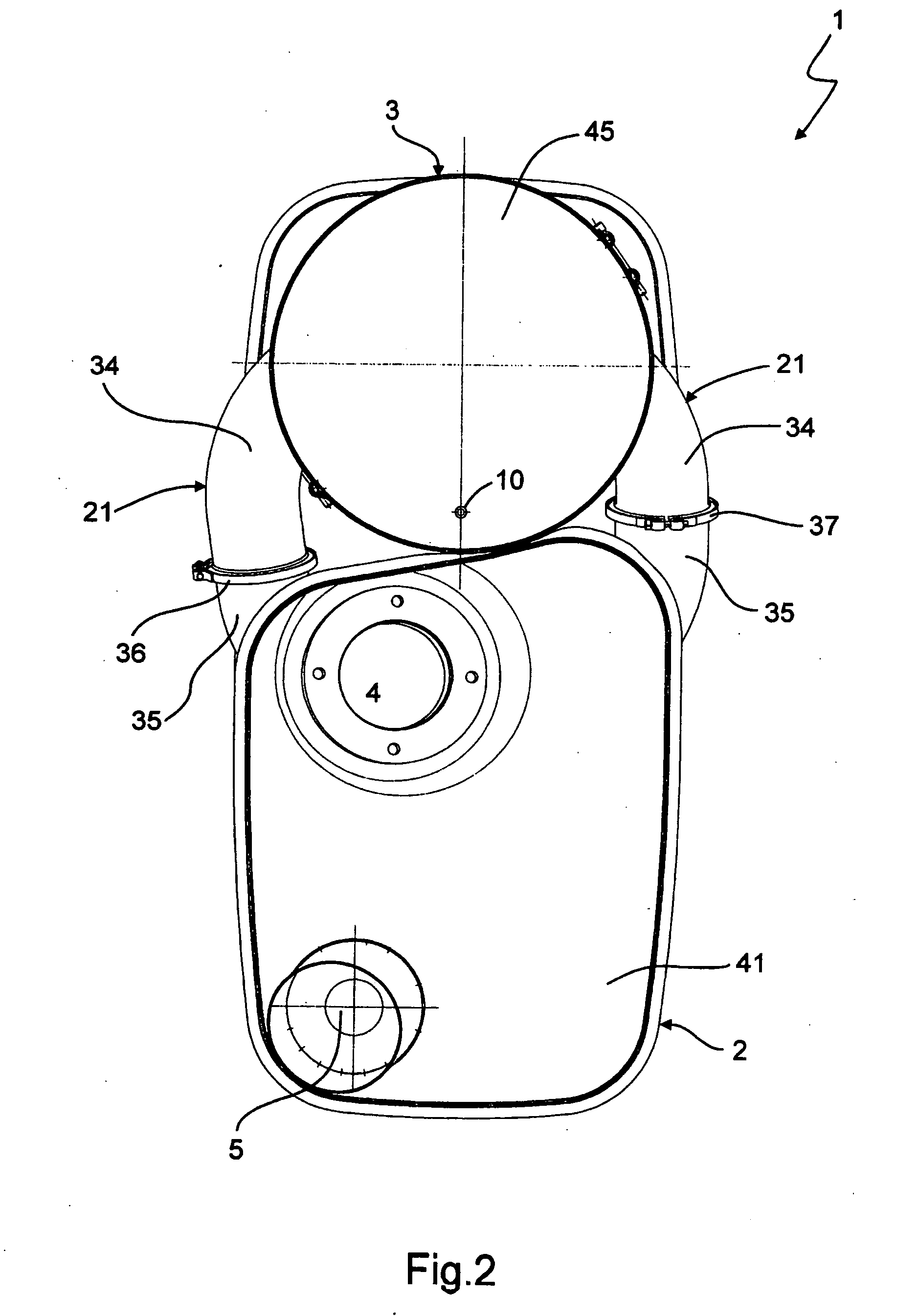

ActiveUS20060156712A1Easy maintenanceCompact designCombination devicesInternal combustion piston enginesExhaust fumesEngineering

The present invention relates to an exhaust gas treatment system for an exhaust system of an internal combustion engine, and comprises a basic housing and an add-on housing mounted thereon so it is at least partially detachable. The basic housing contains at least one inlet pipe which can be connected to the exhaust system and leads into the basic housing, at least one outlet pipe which can be connected to the exhaust system and leads out of the basic housing, at least one SCR catalyst and at least one oxidizing catalytic converter. The add-on housing contains at least one particle separation device and at least one reducing agent feed mechanism.

Owner:PUREM GMBH

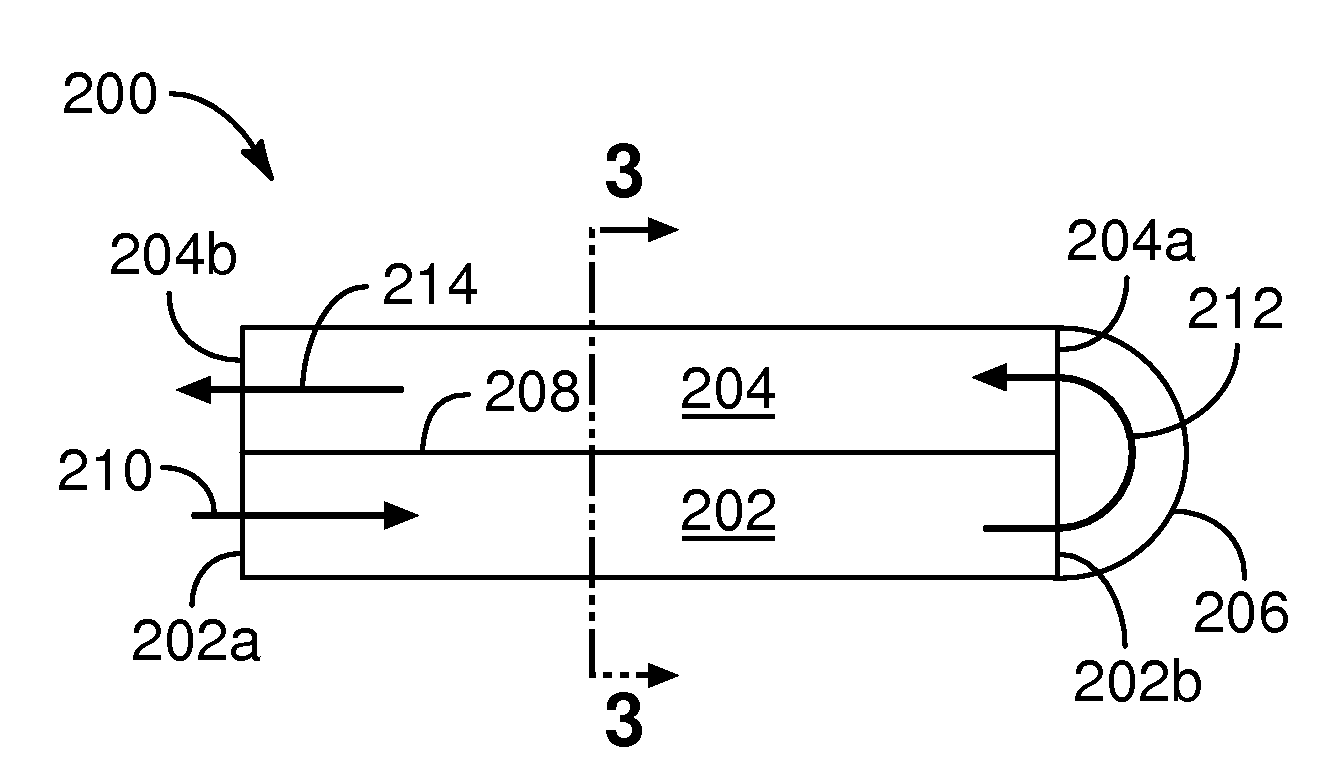

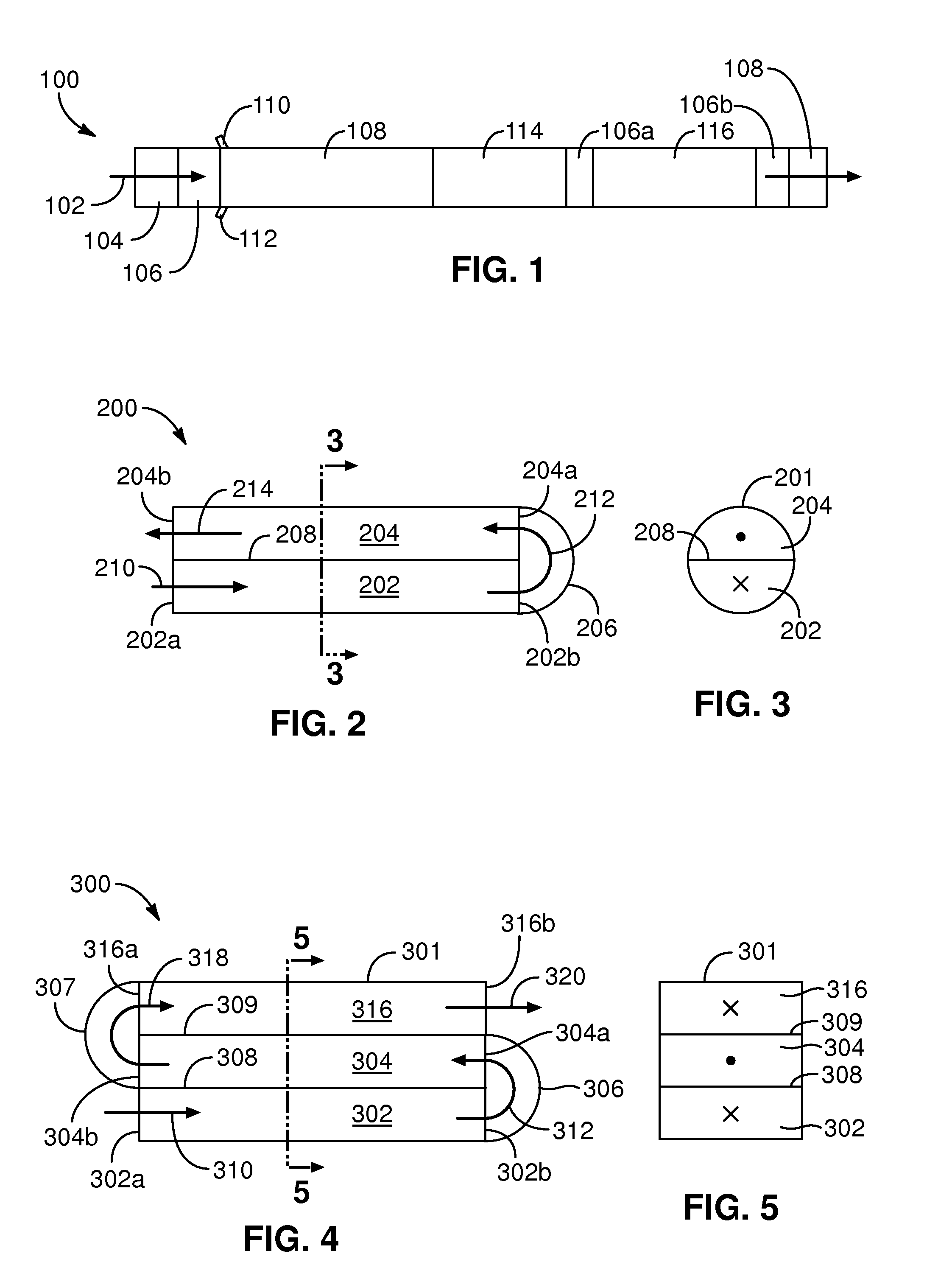

Method and system for injection of a solution into a gas stream

ActiveUS20060275192A1Reduce contentNitrogen compoundsInternal combustion piston enginesCylindrical channelInterior space

The invention provides a method and a system for injection of a solution of a compound into a gas at elevated temperature, evaporating the solution and decomposing the compound in the gas at the elevated temperature, comprising injecting the solution into an injection channel being provided into at least a portion of an outer channel and being surrounded by and spaced apart from the outer channel, passing the gas along space between inner wall of the outer channel and outer wall of the injection channel and along inner space of the injection channel, evaporating the solution in and on inner wall of the injection channel and decomposing the compound in and on the inner wall of the injection channel and in the gas. The solution can be an aqueous solution comprising urea or ammonia, the gas is an exhaust gas from combustion and the injection channel typically is a cylindrical channel concentrically installed in the outer channel.

Owner:UMICORE AG & CO KG

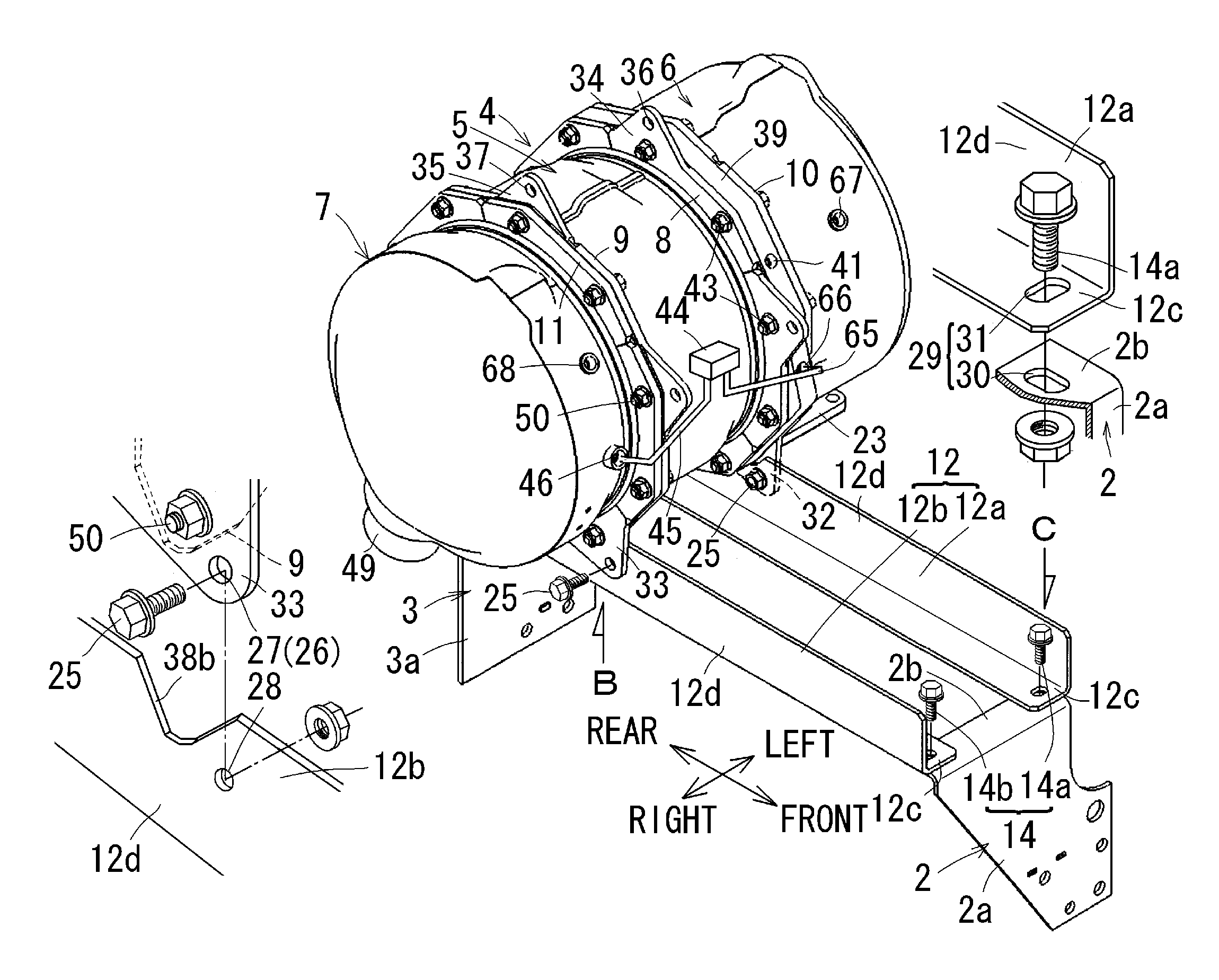

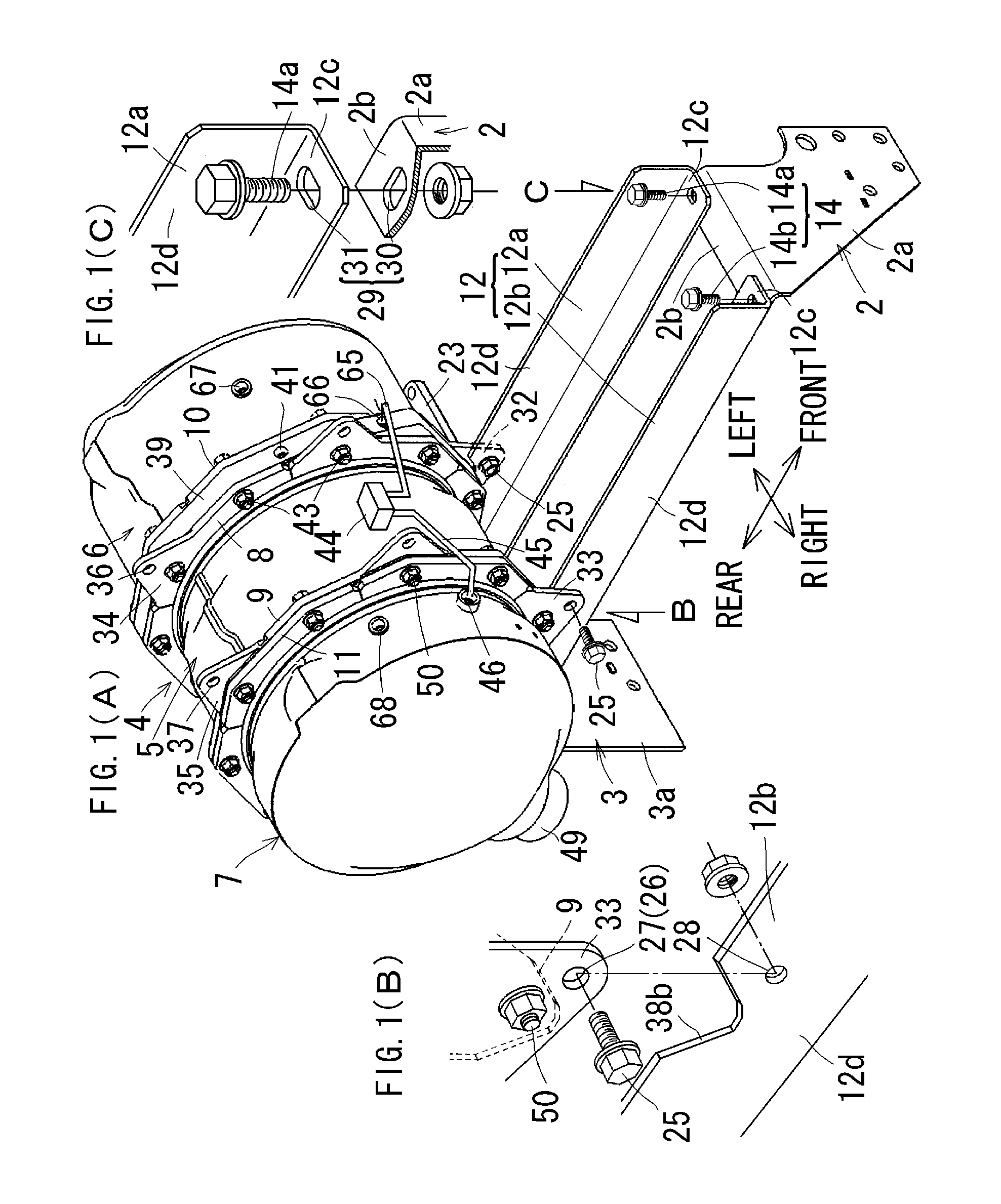

Engine with exhaust gas treatment apparatus

ActiveUS20110167808A1Improve rigidityReduce load appliedInternal combustion piston enginesSilencing apparatusExhaust pipeFlange

An object of the present invention is to provide an engine having an exhaust gas treatment apparatus attached thereto, wherein an exhaust pipe 13 can be prevented from being damaged by a vibration of the engine body 1. To achieve the object, in the engine having the exhaust gas treatment apparatus attached thereto in which an exhaust gas treatment apparatus 4 is supported by an engine body 1 and the engine body 1 and the exhaust gas treatment apparatus 4 communicate with each other through an exhaust pipe 13, the casing of the exhaust gas treatment apparatus consists of a plurality of casing units 5, 6, and 7 separable from each other, connection flanges 8, 9, 10, and 11 are disposed in respective end portions of the casing units 5, 6, and 7, the casing units 5, 6, and 7 are coupled together by a connection of the connection flanges 8, 9, 10, and 11, and the exhaust gas treatment apparatus 4 is supported by the engine body 1 through the connection flanges 8, 9, 10, and 11.

Owner:KUBOTA LTD

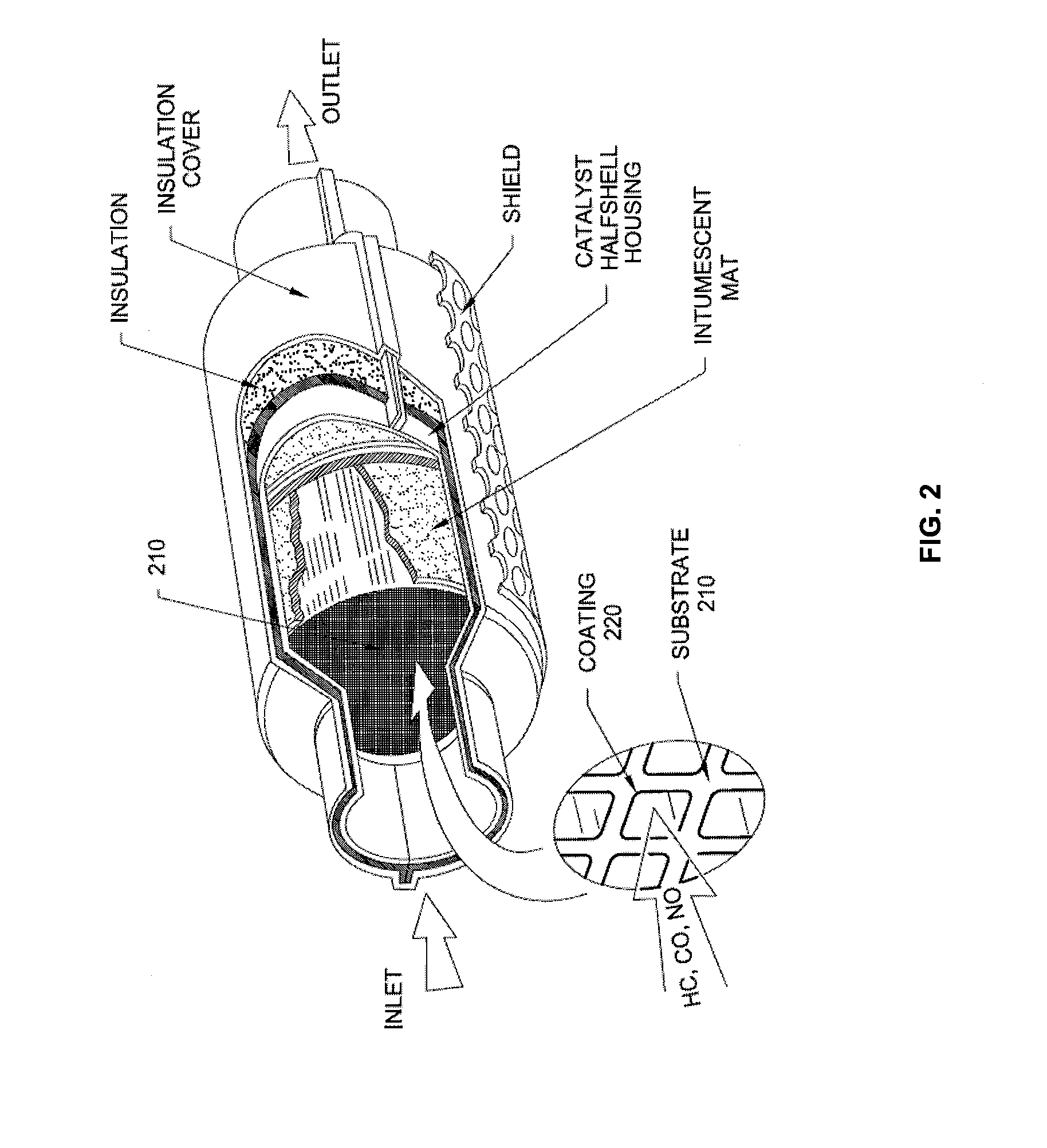

Engine exhaust catalysts containing palladium-gold

InactiveUS8258070B2Improved CO and HC reduction performanceImprove low temperature performanceMolecular sieve catalystsInternal combustion piston enginesMetal catalystPalladium

An emission control catalyst that exhibits improved CO and HC reduction performance includes supported precious group metal catalysts that are coated onto different layers of the substrate for the emission control catalyst. Zeolites of one or more types are added to the emission control catalyst as a hydrocarbon absorbing component to boost the low temperature performance of the emission control catalyst. Y zeolite is used by itself or mixed with other zeolites to enhance hydrocarbon storage at low temperatures.

Owner:WGCH TECH LIMITED WORLD GOLD COUNCIL

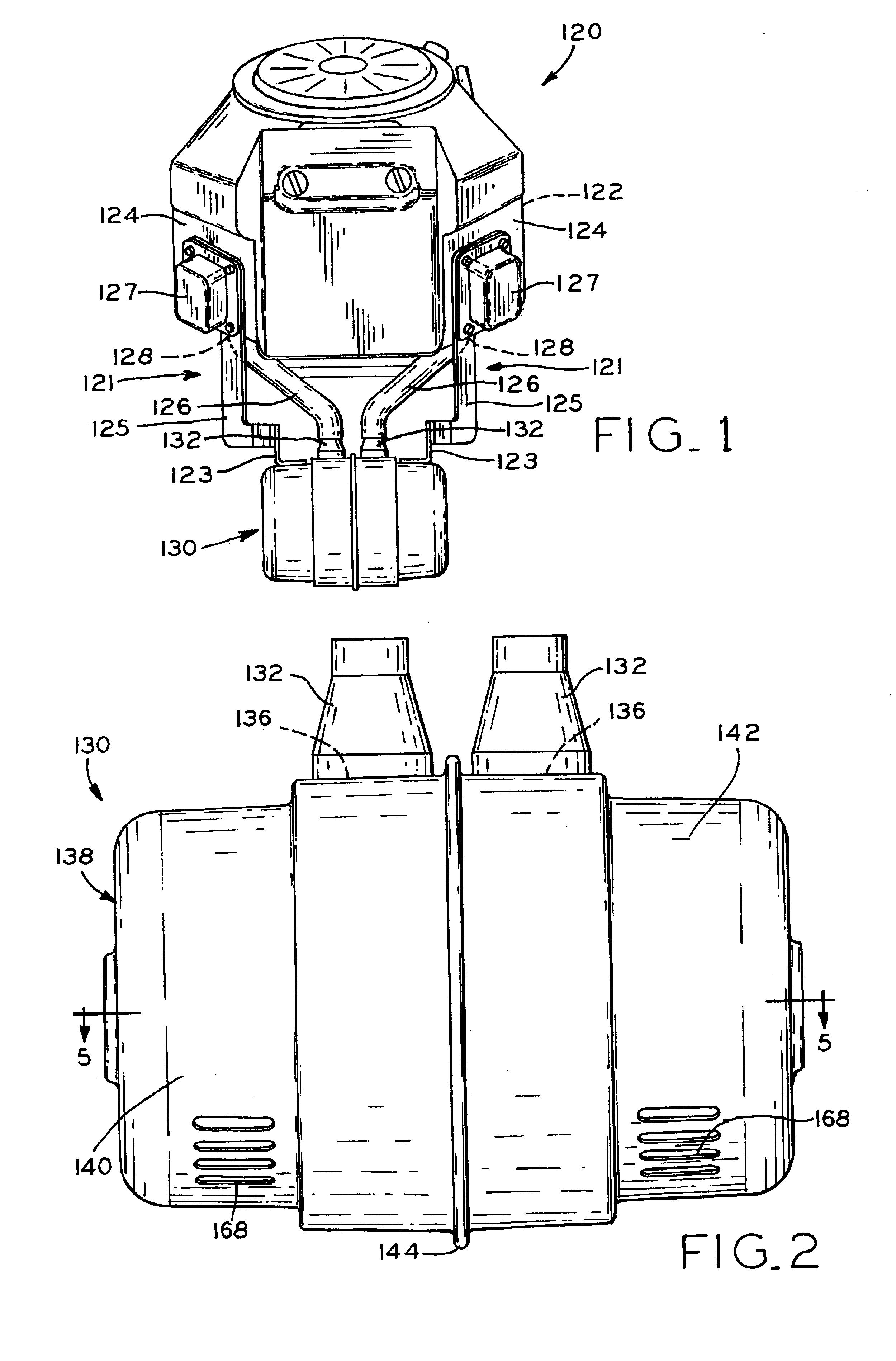

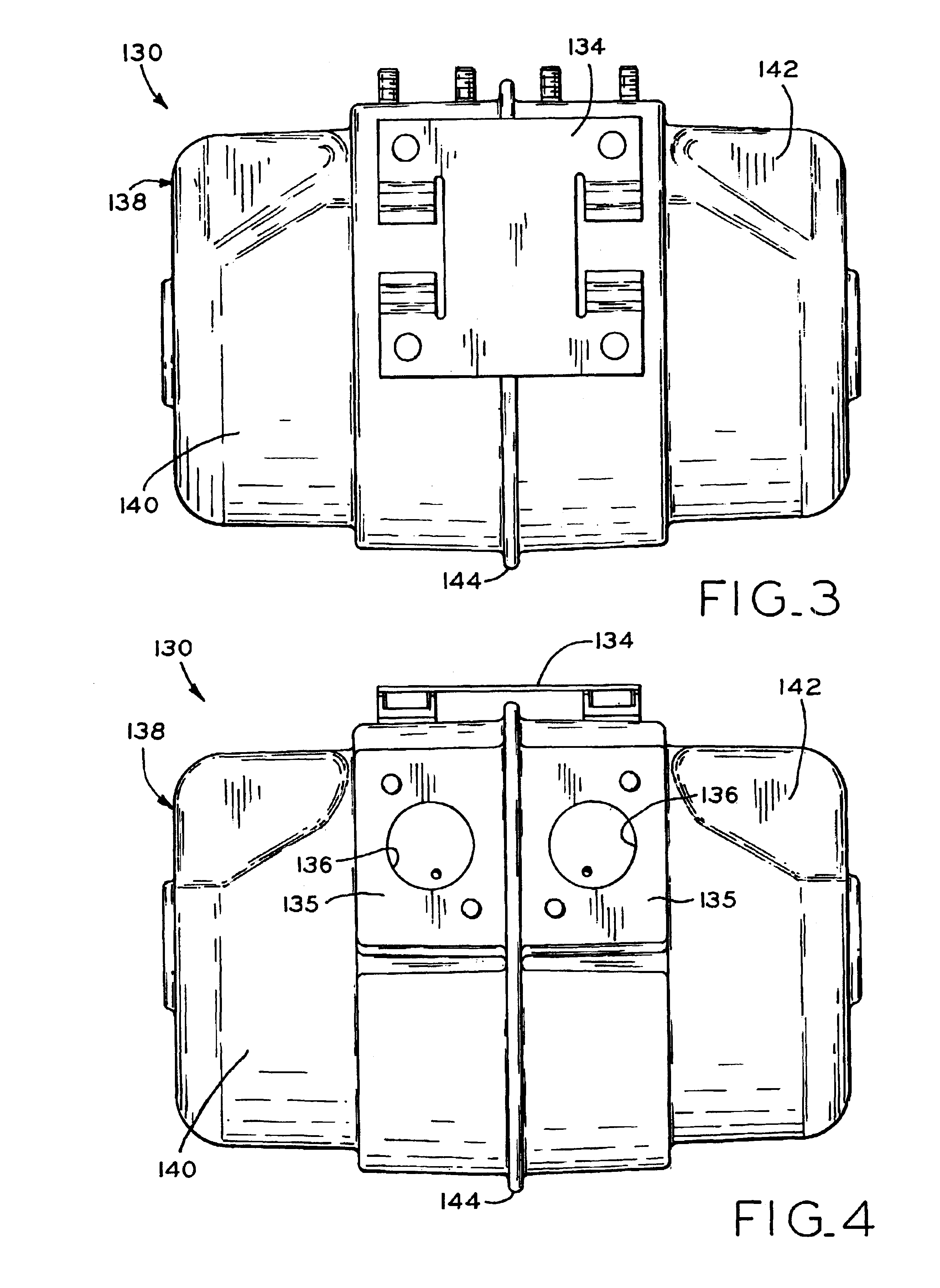

Tuned exhaust system for small engines

InactiveUS6959782B2Reduced overall size and profileImprove engine performanceCombustion enginesSilencing apparatusExhaust fumesPulp and paper industry

A tuned exhaust system for small two cylinder engines, the exhaust system including a pair of exhaust passage through which exhaust gasses pass. The exhaust passages are dimensioned to providing a tuning effect to the exhaust gasses for enhanced engine performance. The exhaust passages are not straight and elongated, but rather are sprialed, scrolled, coiled, or otherwise folded upon themselves at least twice. In this manner, the exhaust passages may be housed at least in part within a muffler having a significantly reduced overall size or profile, such that the muffler may be used in small engines.

Owner:TECUMSEH POWER

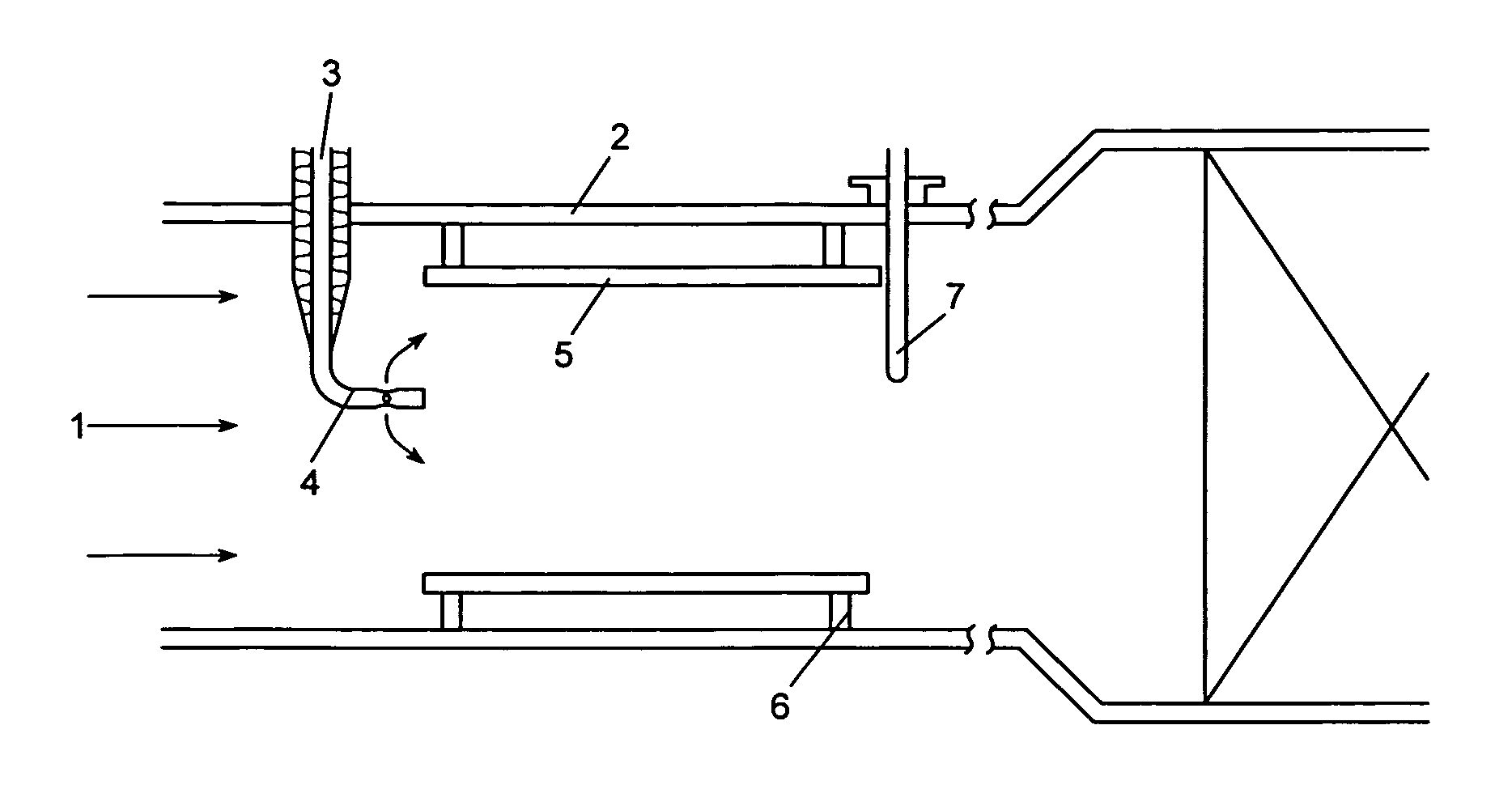

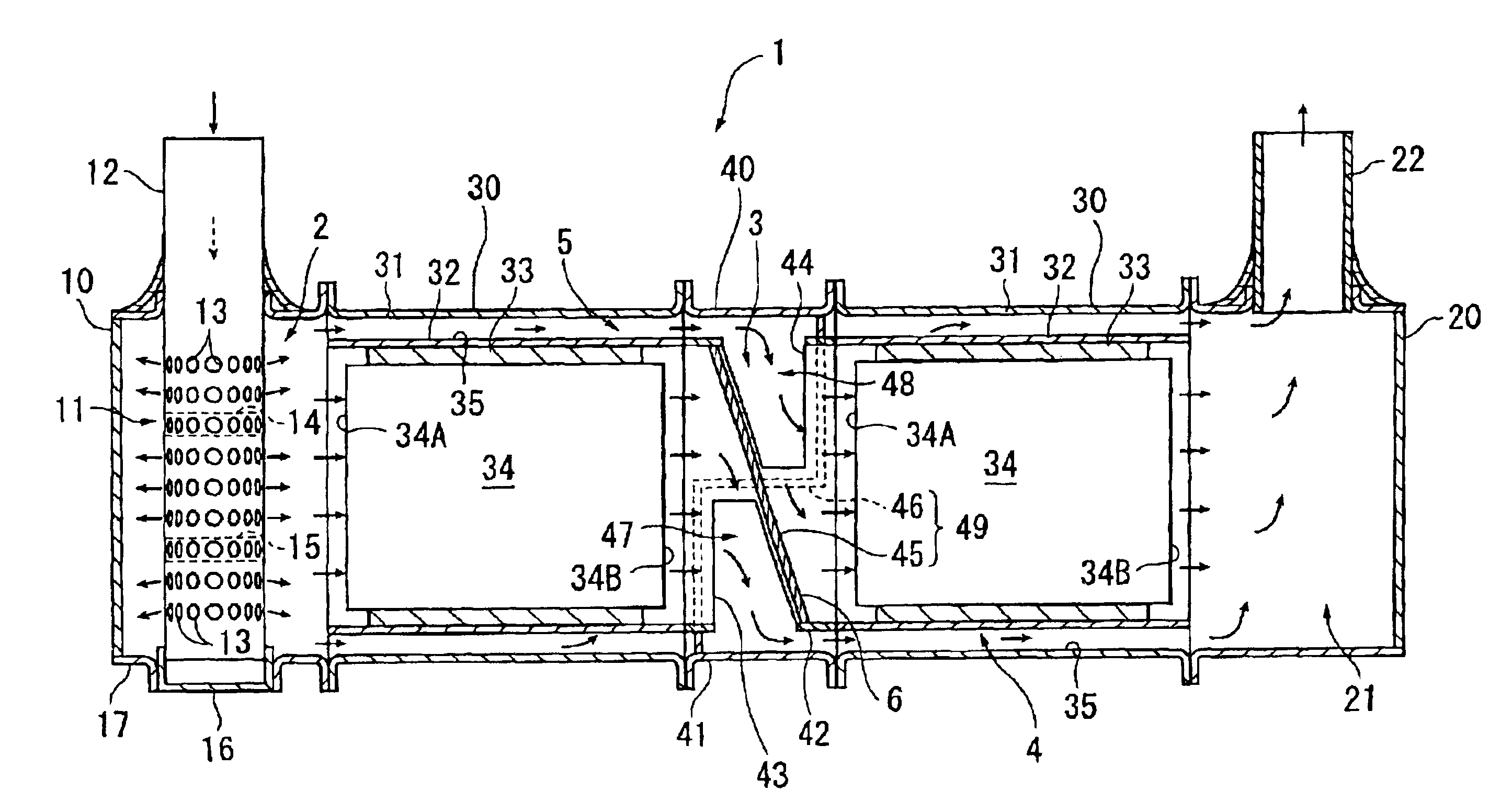

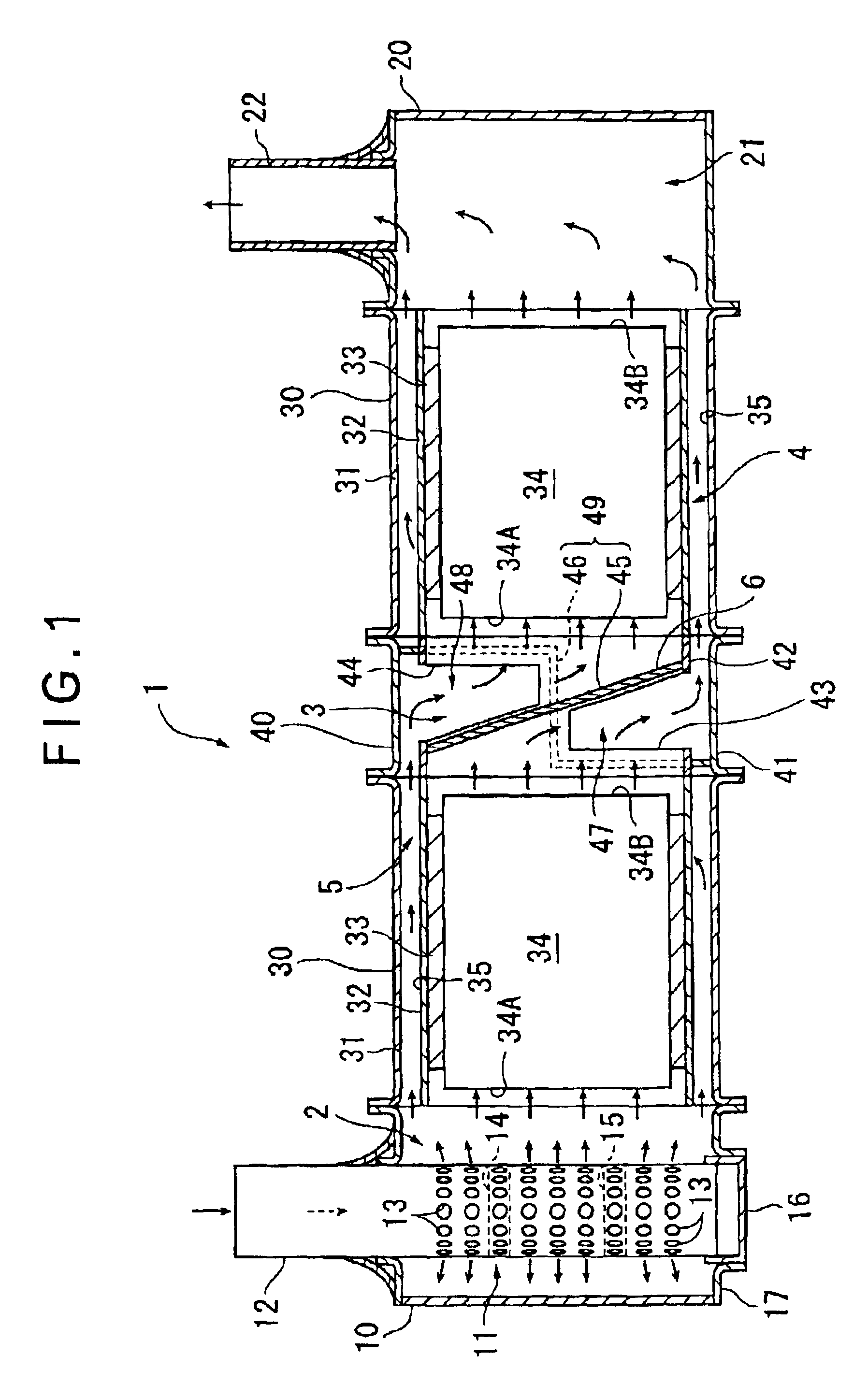

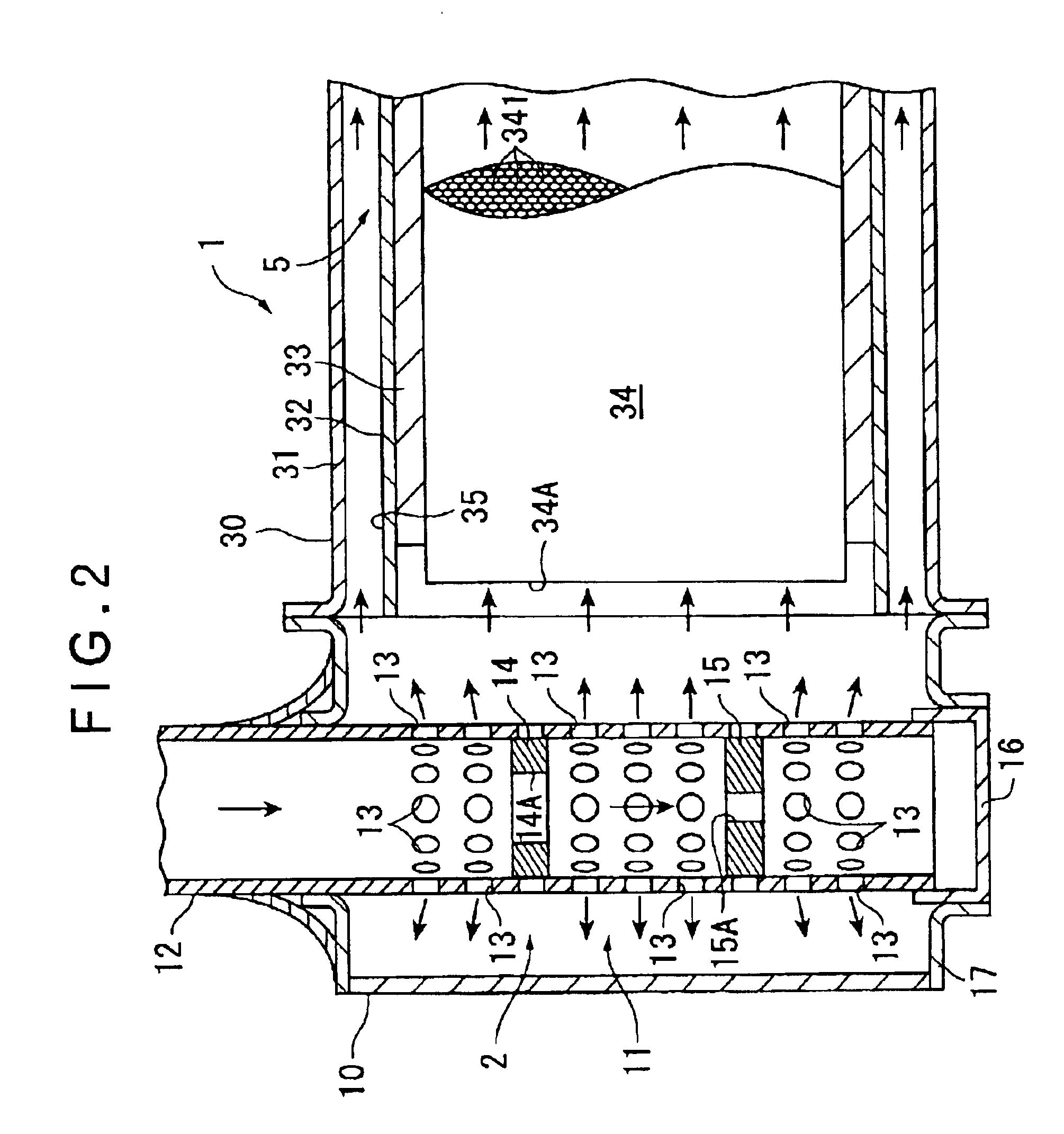

Exhaust gas purifying system for internal combustion engine

InactiveUS6767378B2Function increaseSmall spacingCombination devicesAuxillary pretreatmentExternal combustion engineExhaust fumes

In an exhaust gas purifying system 1, a pair of carriers 34 is arranged in series along the flow direction of exhaust gas. Approximately a half of the exhaust gas passing through a first distribution flow path 4 flows in the upstream-side carrier 34, and the remaining half of the exhaust gas passing through a second distribution flow path 5 flows in the downstream-side carrier 34. Therefore, the capacity of the whole of the paired carriers 34 can be substantially doubled as in the case where the carriers 34 are arranged in parallel, so that the function as the exhaust gas purifying system 1 can be improved.

Owner:KOMATSU LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com