Patents

Literature

252results about How to "Small installation space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Comprehensive advanced geological detection system carried on tunnel boring machine

ActiveUS20150233242A1Improve accuracyImprove efficiencySeismic signal processingTunnelsDecision systemComputer module

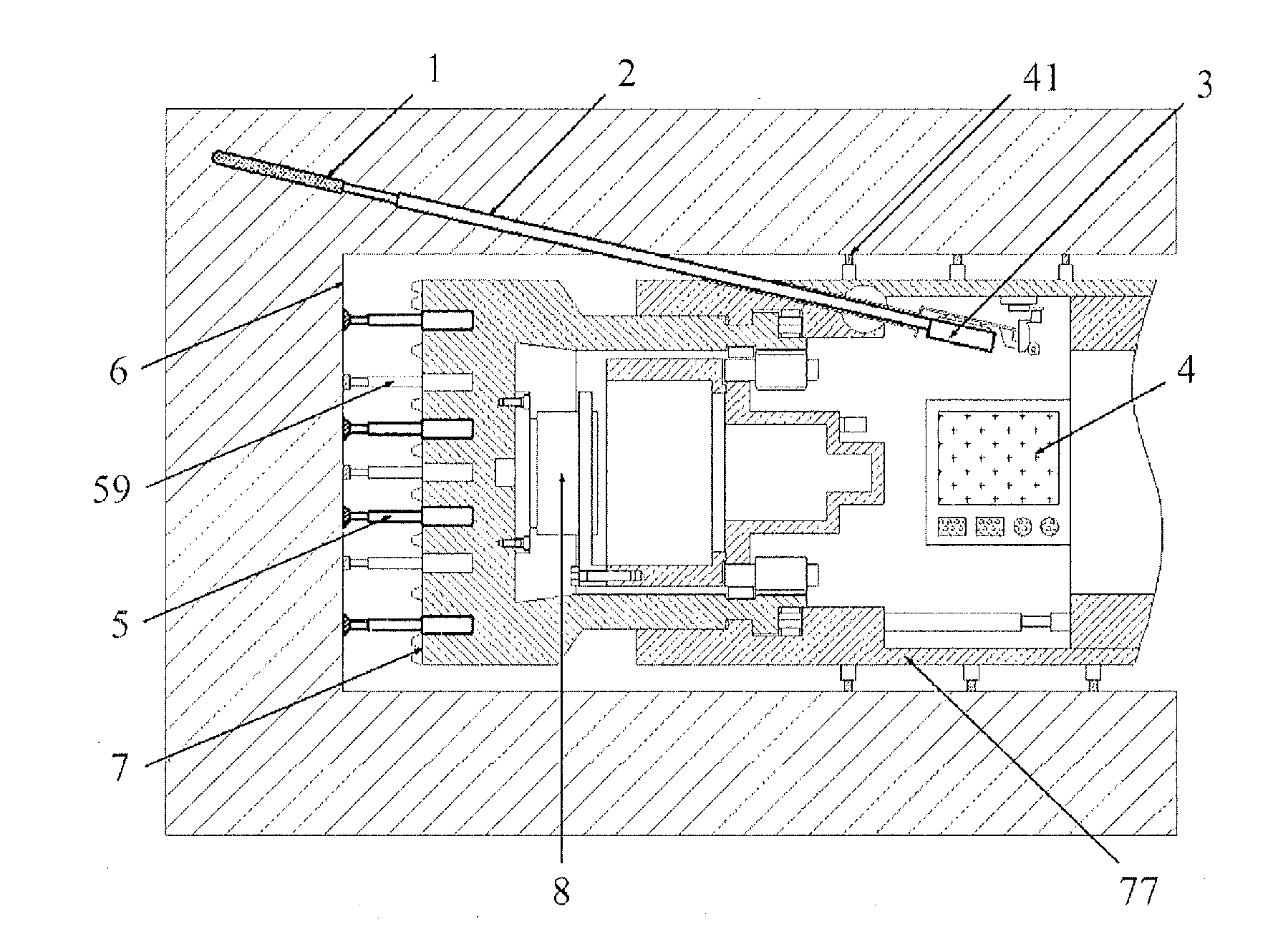

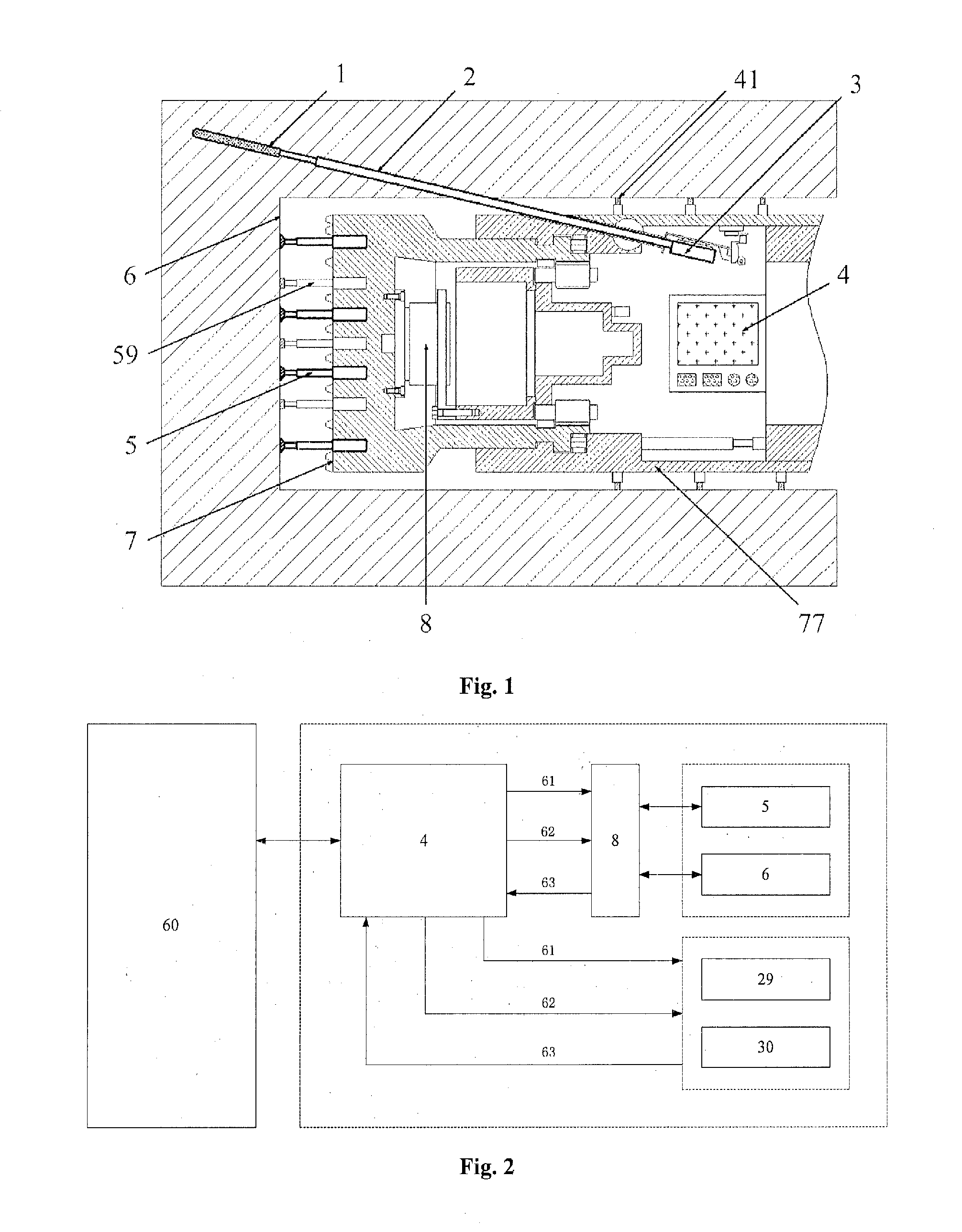

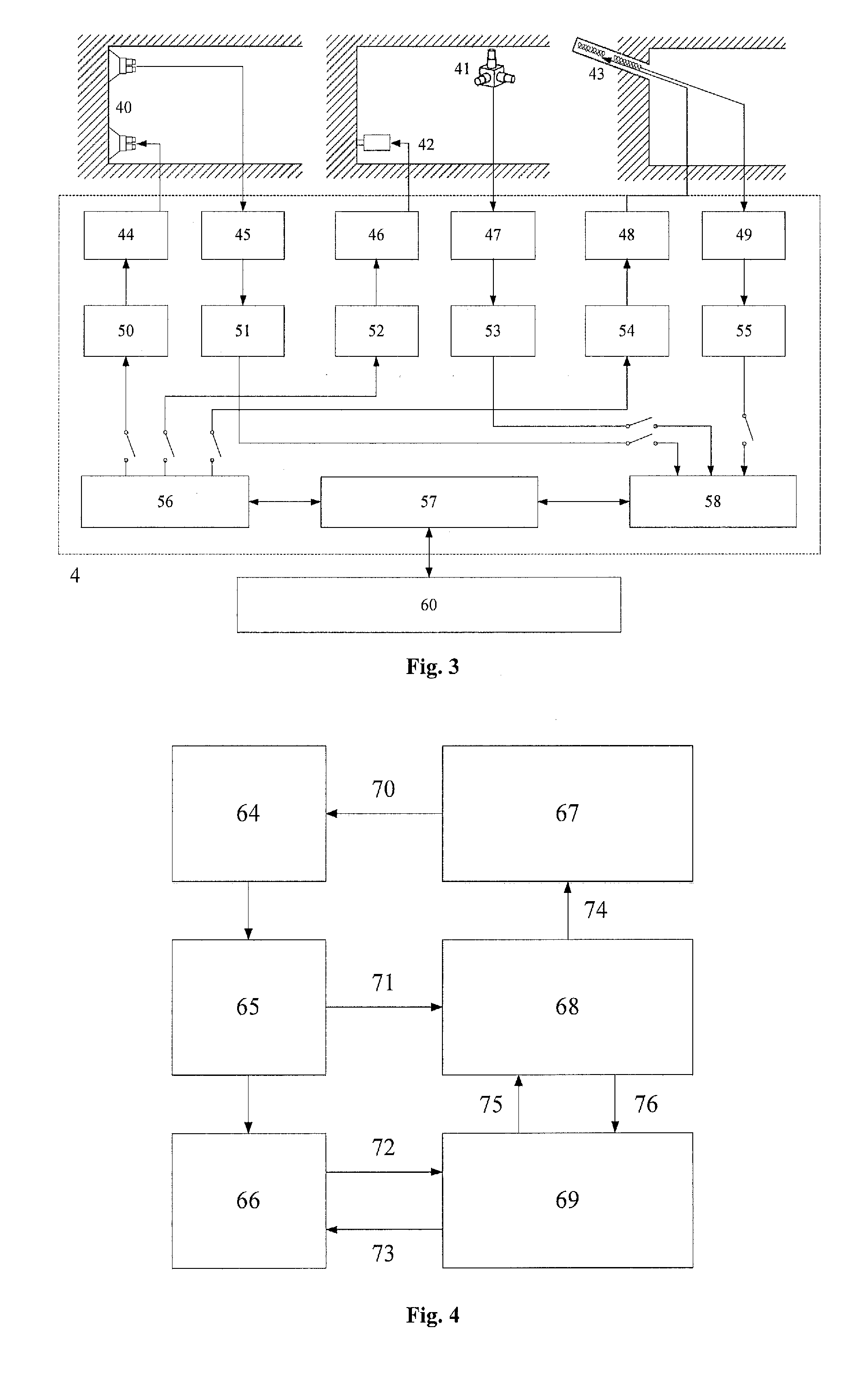

The present invention presents a comprehensive advanced geological detection system carried on a tunnel boring machine. The comprehensive advanced geological detection system includes a multifunctional combination main frame, an induced polarization detection device, a seismic wave detection device, an integrated junction device, a borehole ground penetrating radar detection device and a comprehensive interpretation and decision system; the multifunctional combination main frame includes a time division multiplexing control module, an excitation source control module and a parallel data acquisition module; the excitation source control module outputs trigger signals to the three detection devices respectively, and the three detection devices respectively output measurement data and feedback signals to the time division multiplexing control module through the parallel data acquisition module; and the comprehensive interpretation and decision system supports geological interpretations and decisions through the inversion / migration imaging joint inversion of three detection methods.

Owner:SHANDONG UNIV

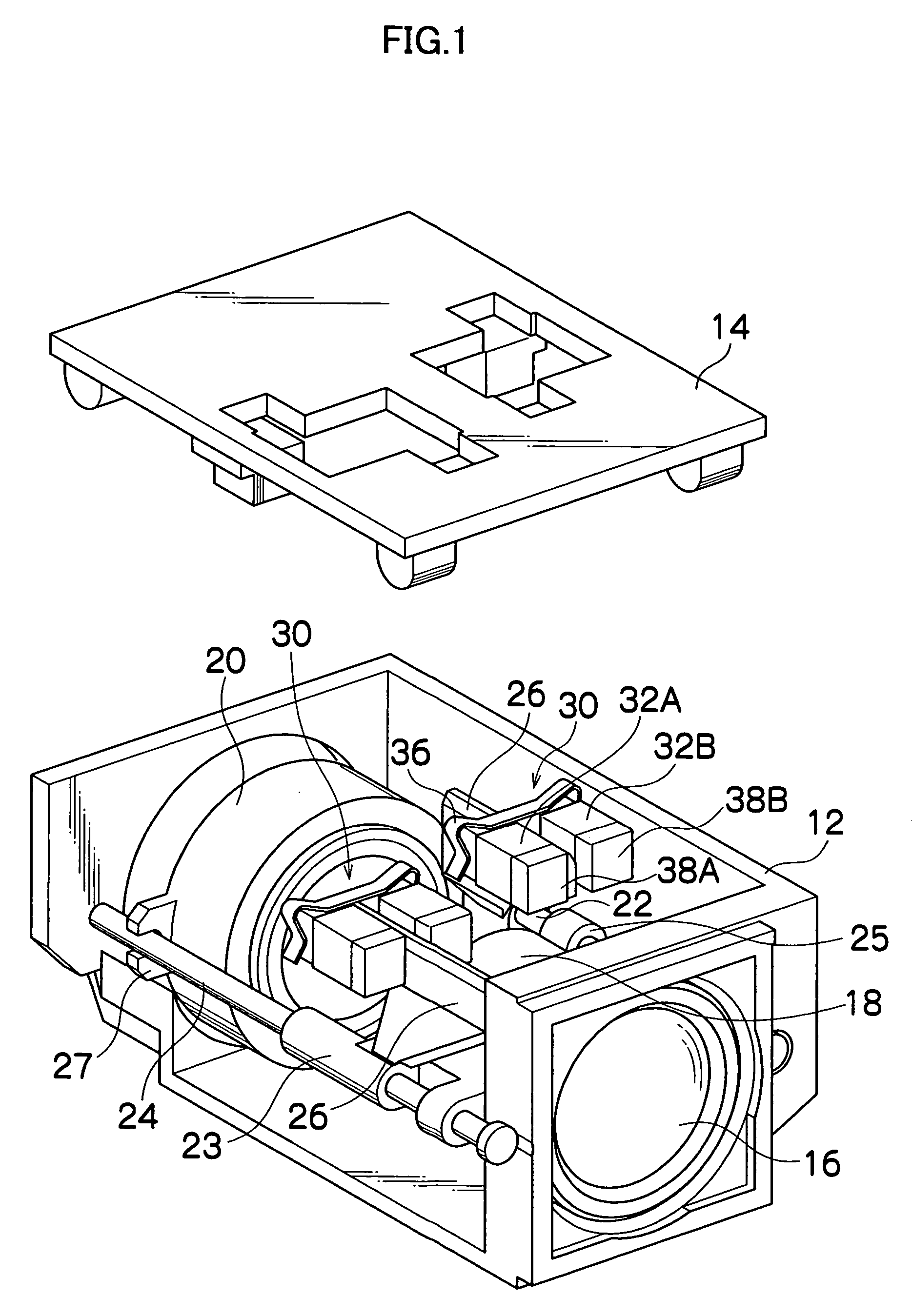

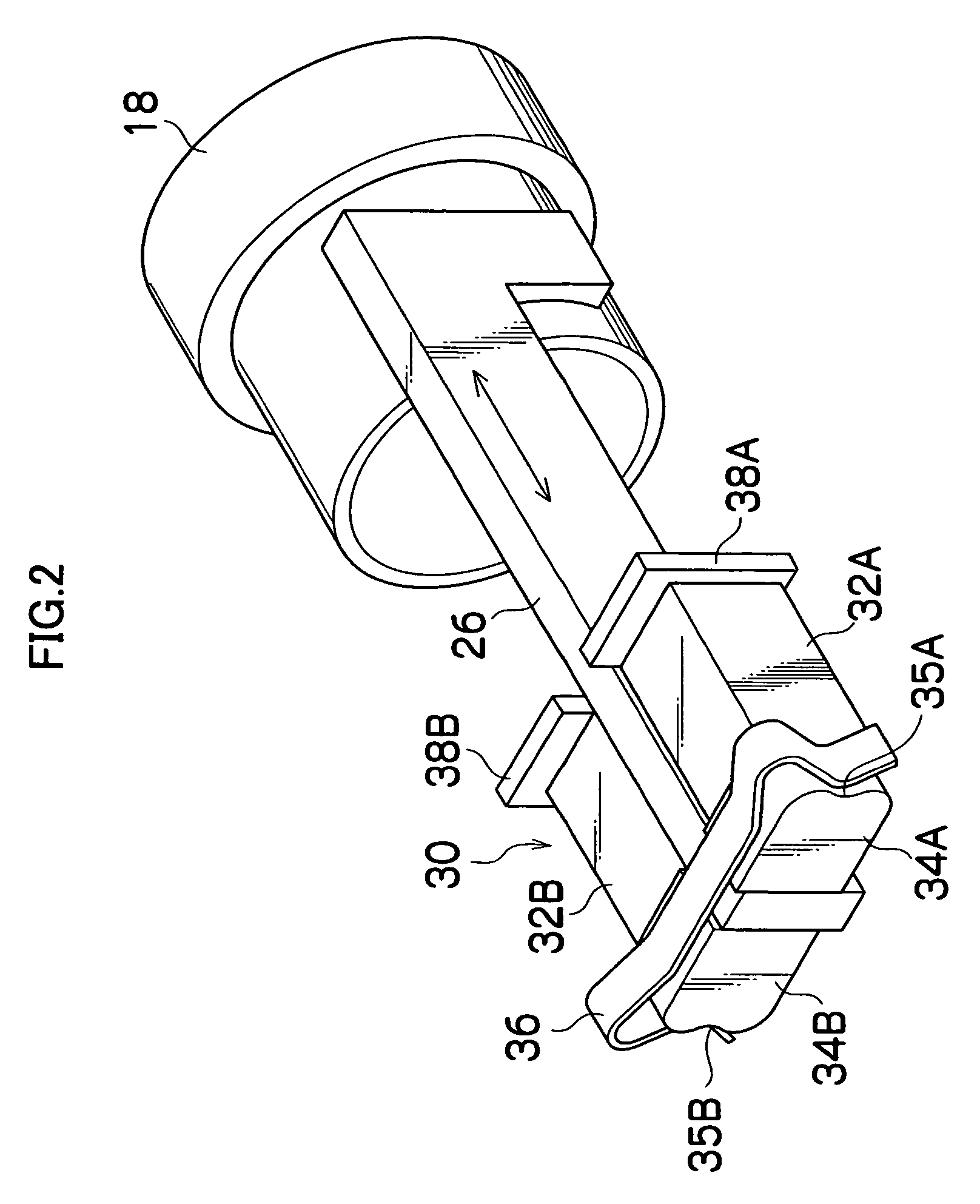

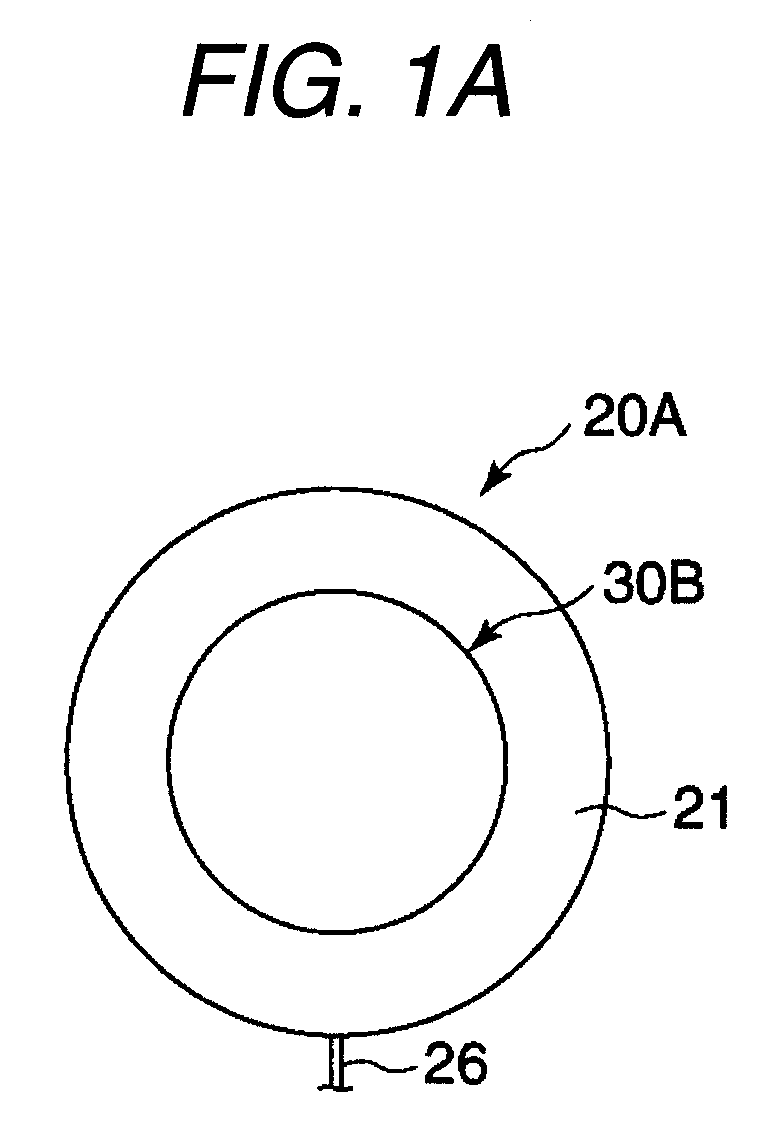

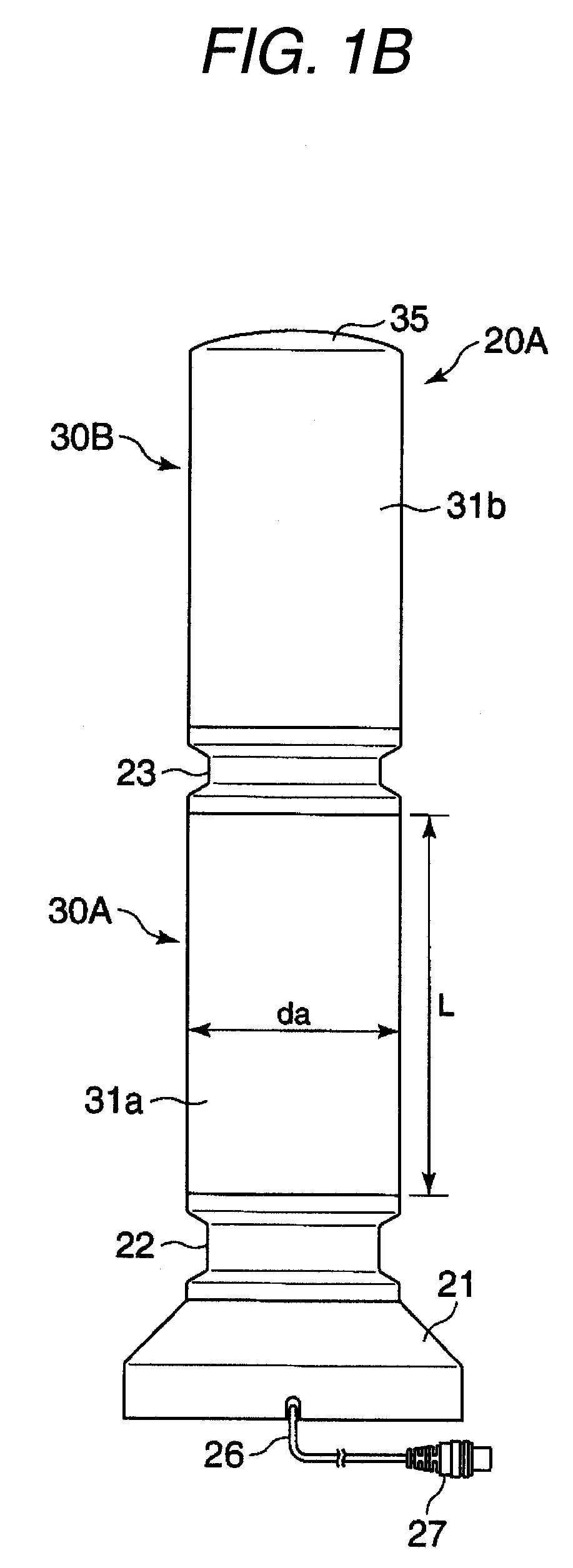

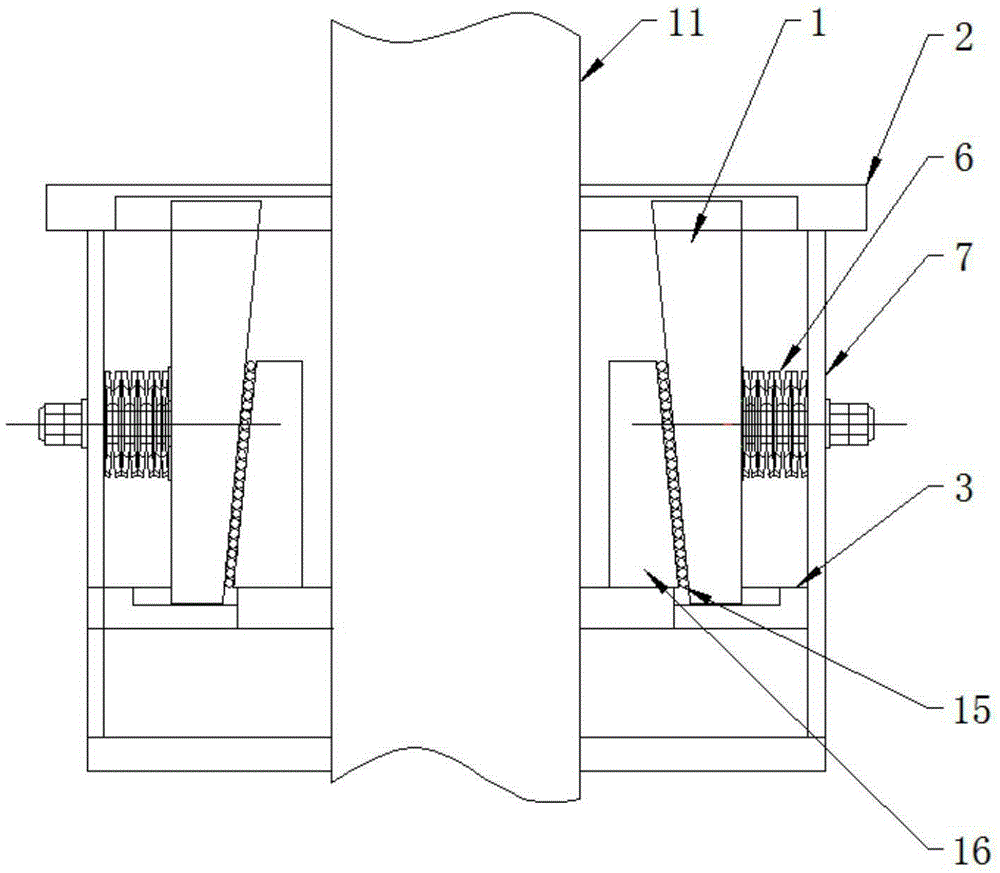

Actuator and its control method and lens device

InactiveUS20050275315A1Small installation spaceMove preciselyPiezoelectric/electrostriction/magnetostriction machinesMountingsOptical axisActuator

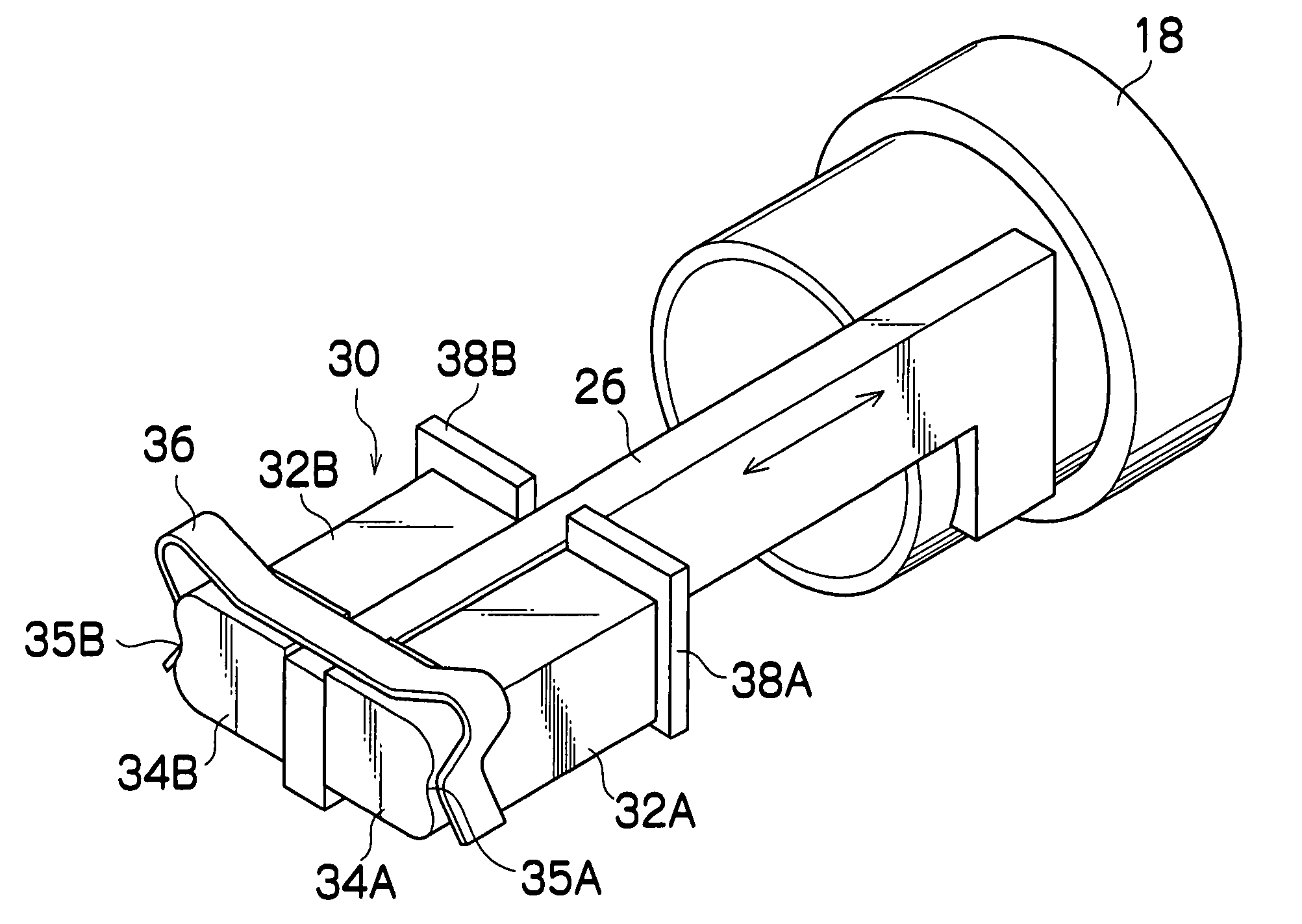

An actuator which drives a lens frame in an optical axis direction is constructed by piezoelectric elements, driving members, and a pressing spring. The piezoelectric elements are placed at opposite sides with a driven plate therebetween, and the driving members are fixed to the respective piezoelectric elements. The driving members are pressed against the driven plate from both sides by the pressing spring.

Owner:FUJI PHOTO OPTICAL CO LTD

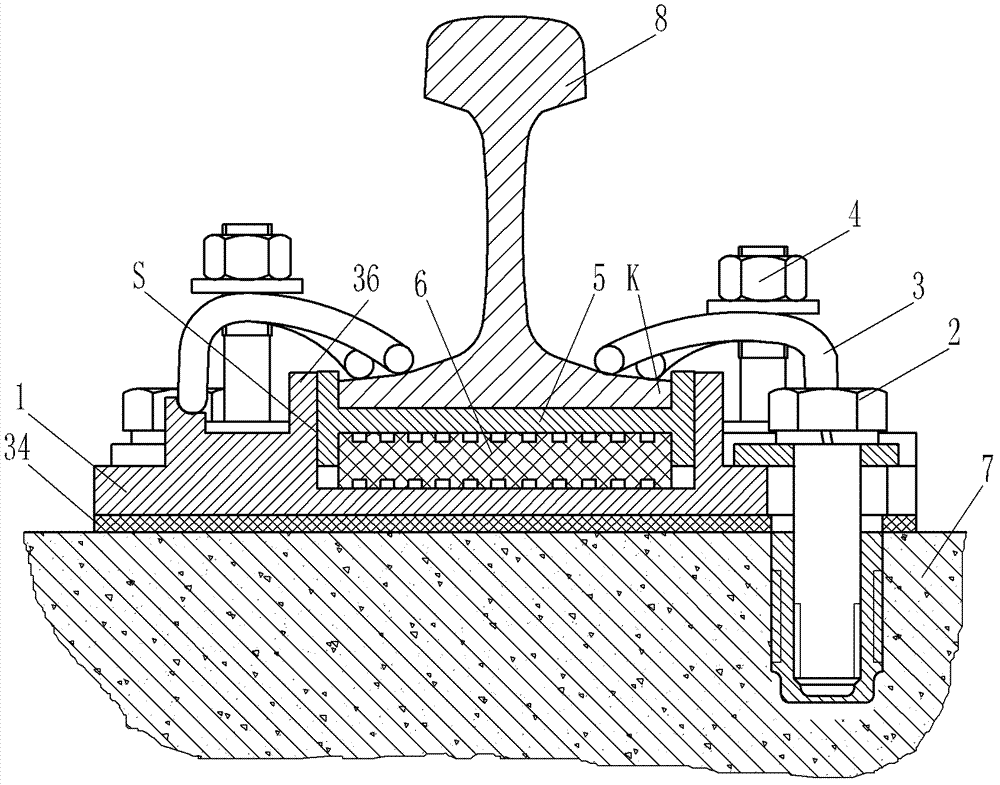

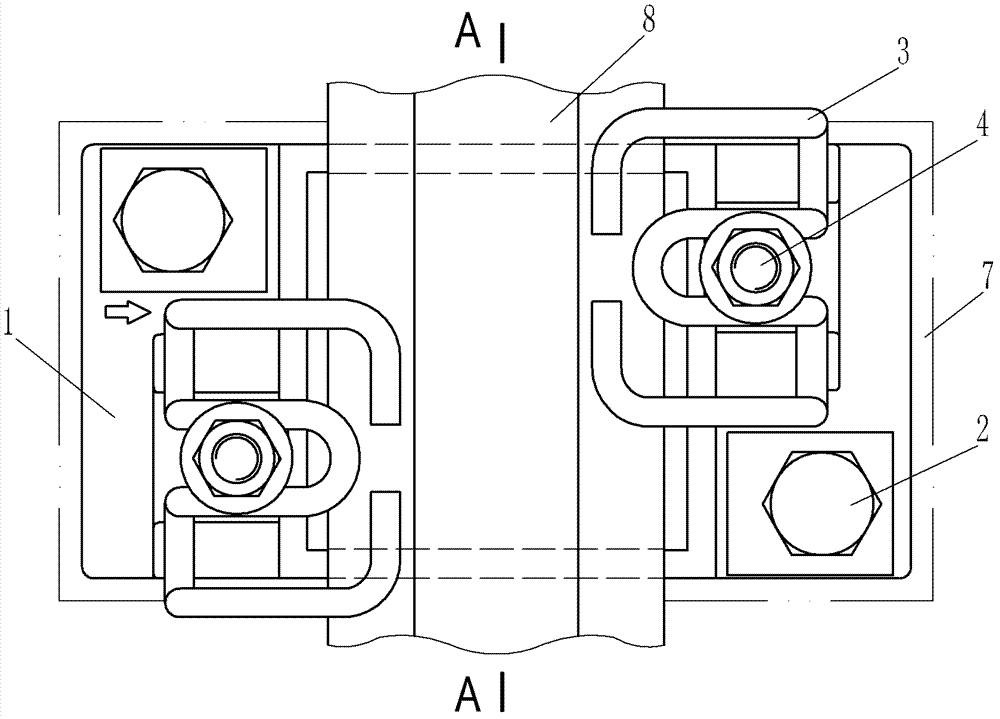

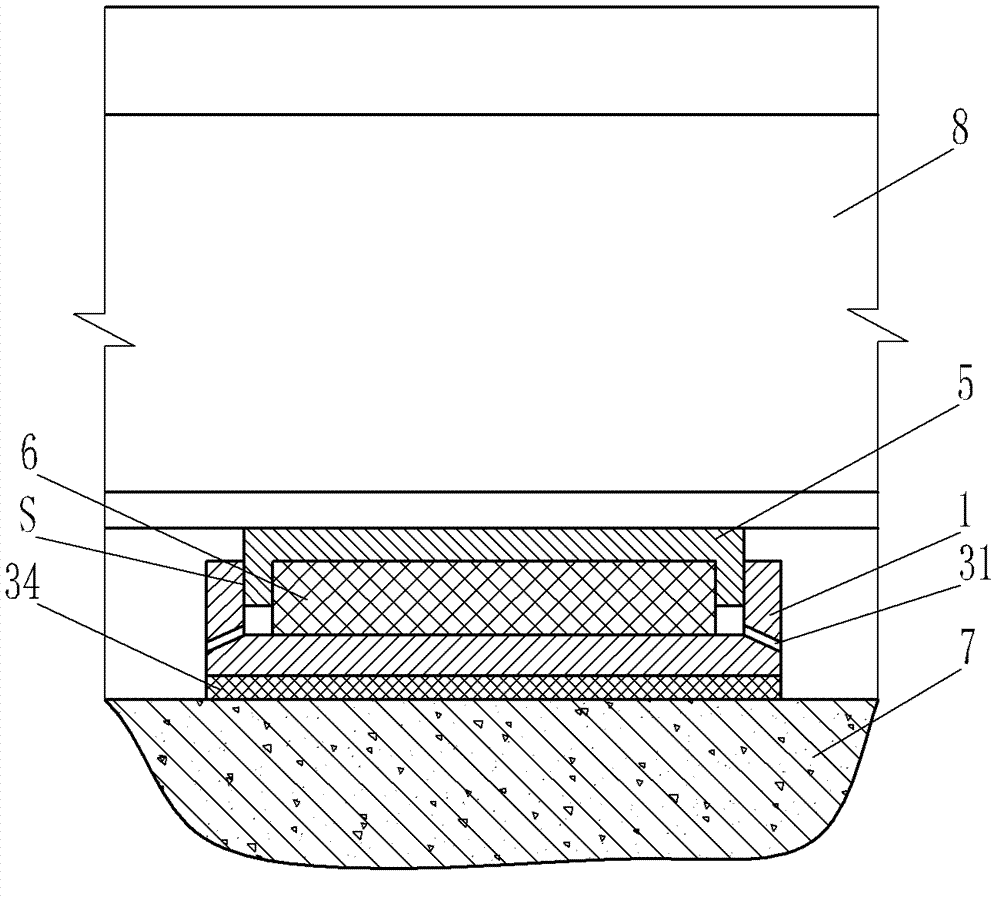

Transverse stiffness-reinforced rail fastener

The invention relates to a transverse stiffness-reinforced rail fastener comprising a base, an anchor bolt, a bar spring and an elastomeric bearing part. The base is fixed on a railway sleeper by the anchor bolt. The transverse stiffness-reinforced rail fastener is characterized by further comprising a guiding element arranged between the base and a steel rail. Interworking guiding surfaces are arranged on the guiding element and the base respectively, the guiding surfaces are all parallel to the steel rail and perpendicularly arranged and the elastomeric bearing part is arranged between the base and the guiding element. The transverse stiffness-reinforced rail fastener can ensure vertical elasticity of the fastener, maintain perfect transverse intensity and effectively prevent the steel rail from occurring deflection and shimmy. The transverse stiffness-reinforced rail fastener can realize effects of reducing vibrate and noise as the traditional rail fastener, can also retard or prevent abrasion of the steel rail so that service life of the steel rail is prolonged greatly. The transverse stiffness-reinforced rail fastener needs small assembling space, is an economic beneficial utility, and is compact in structure, cost effectively and wide in market application prospect.

Owner:QINGDAO CREATE ENVIRONMENT CONTROL TECH +1

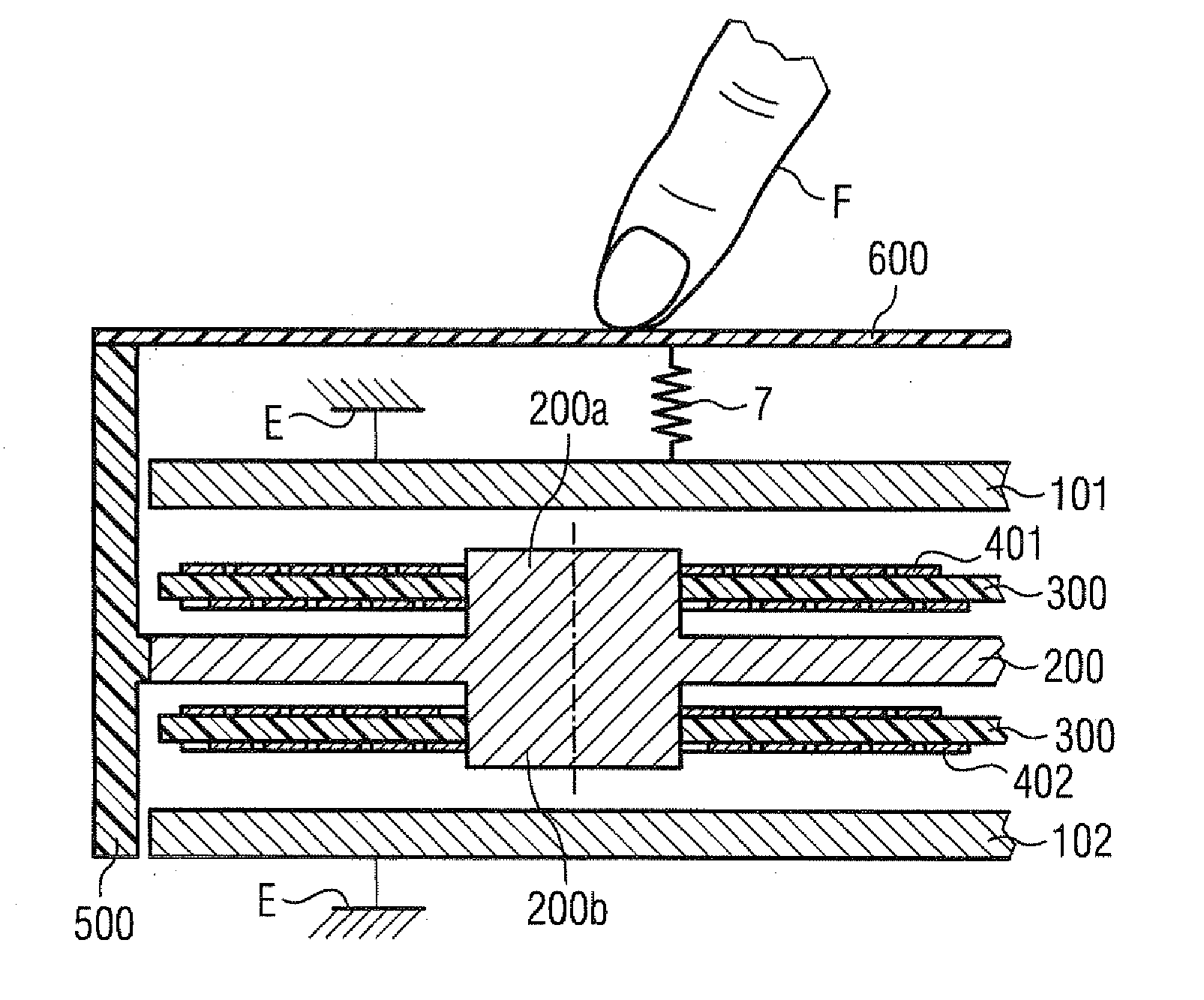

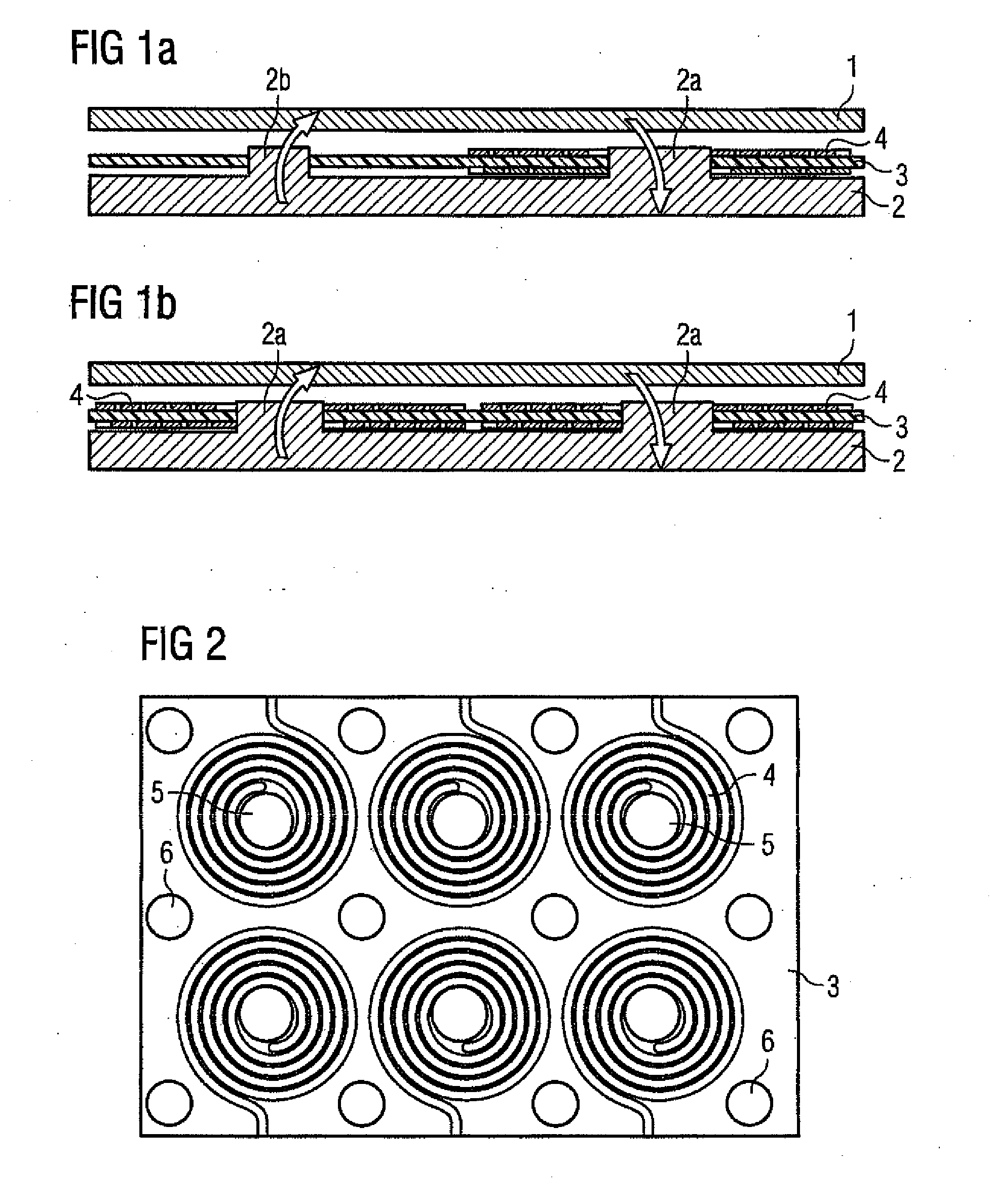

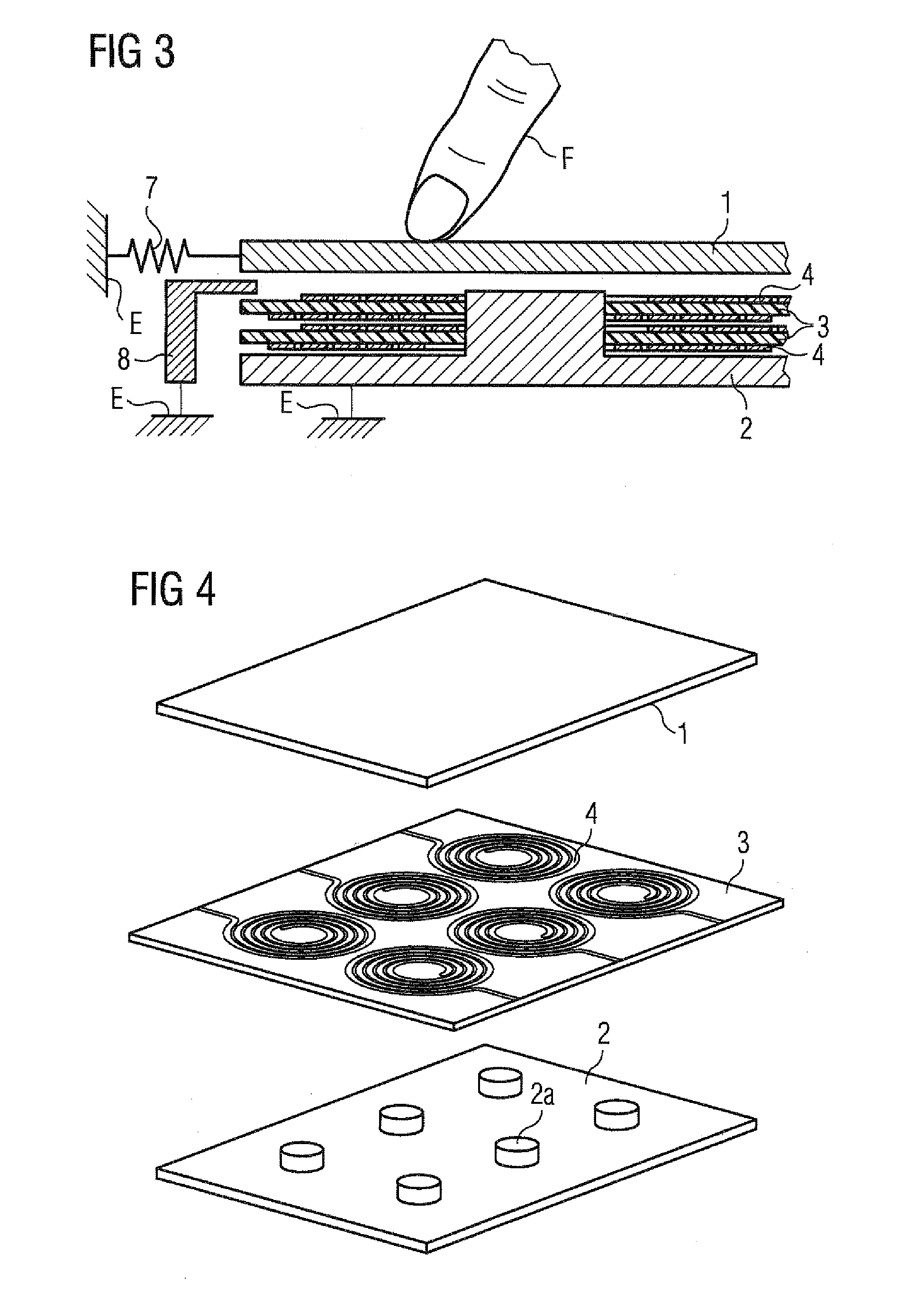

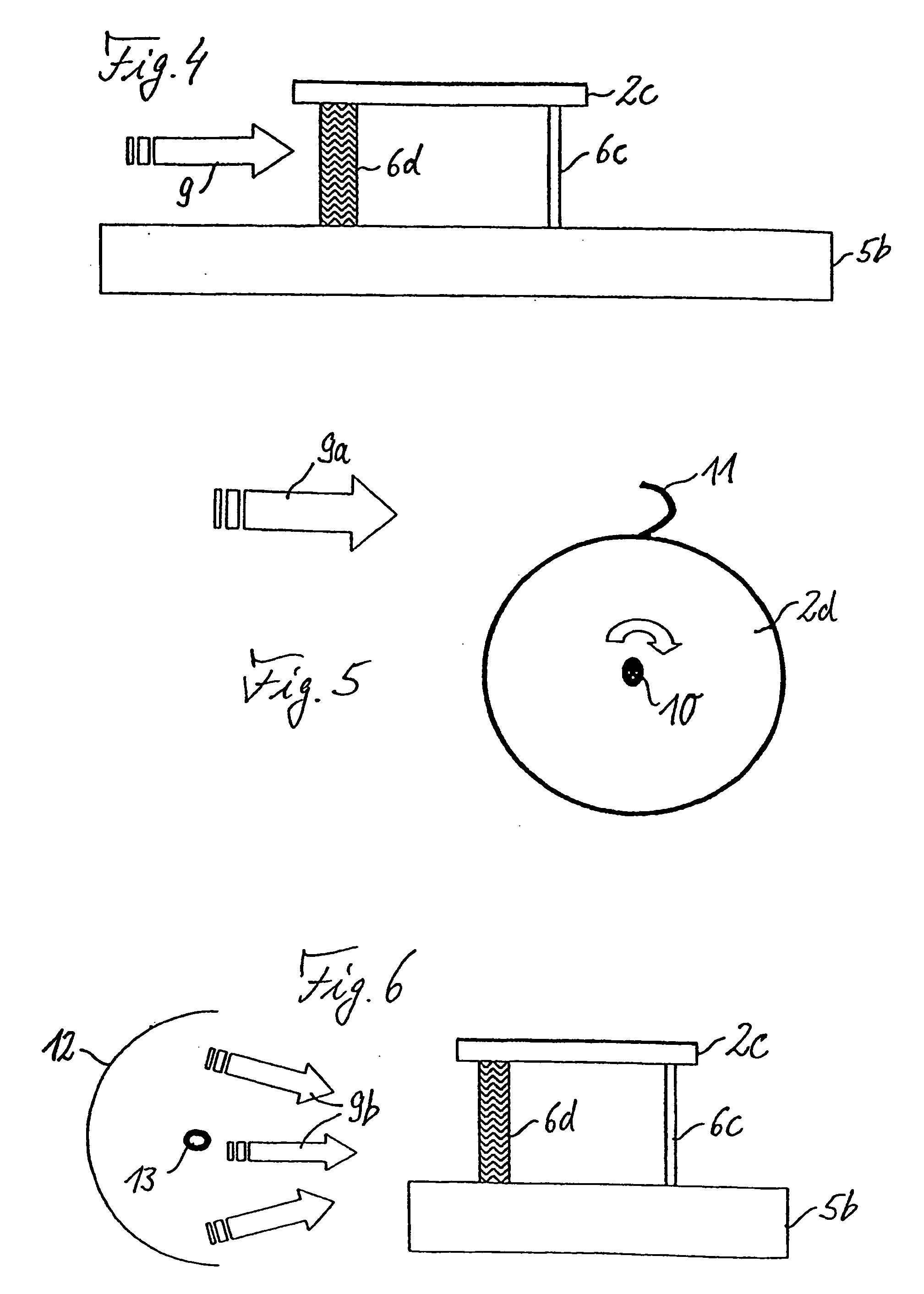

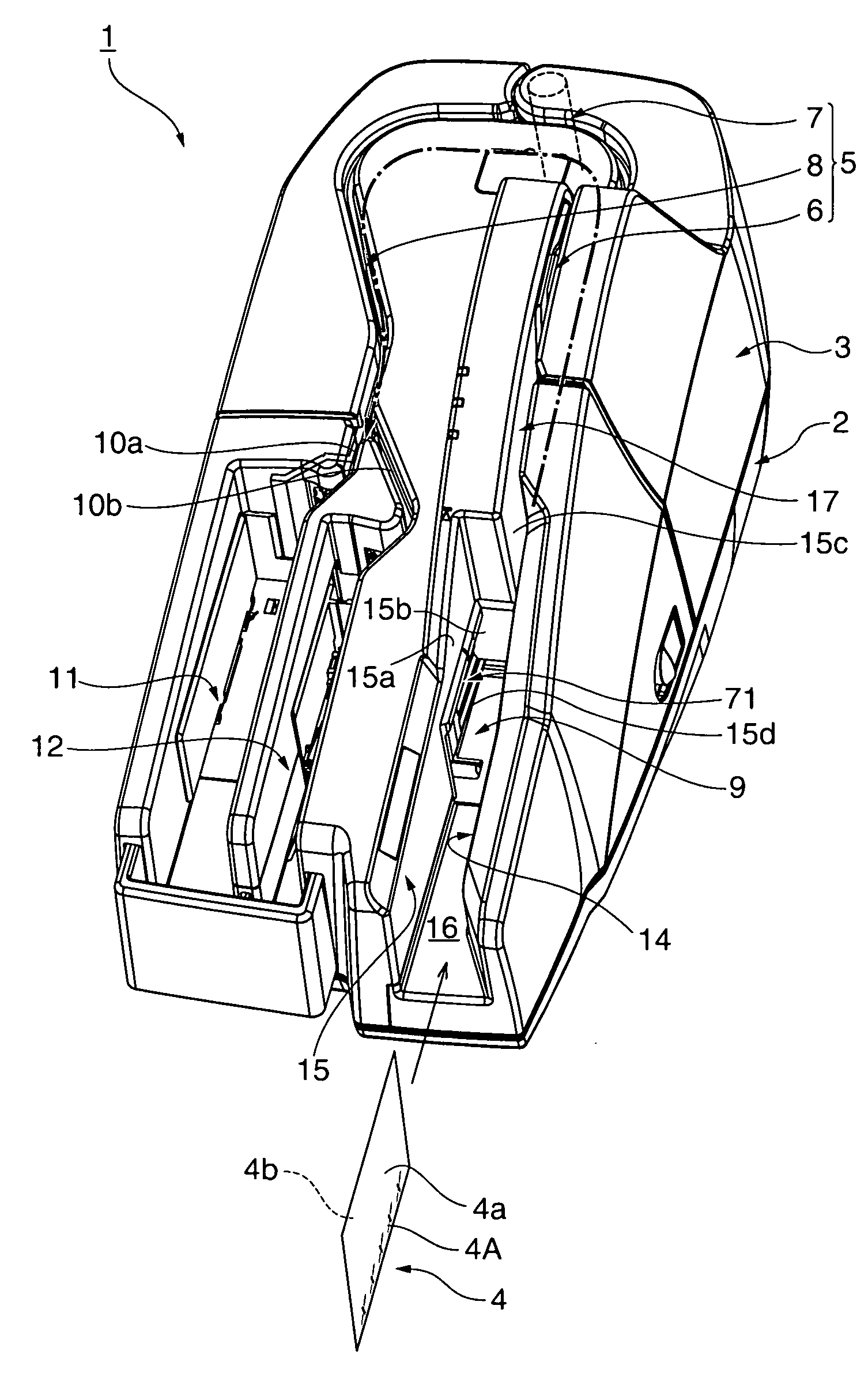

Operating Device

ActiveUS20120306798A1Small installation spaceSimple designRepeater circuitsTactile signalling systemsHaptic sensingElectrical and Electronics engineering

An operating device having an operating element with haptic feedback. The operating element can be actuated by an operator by means of an input member, the operating device includes two ferromagnetic planar components and a flat coil. The largest surfaces of the ferromagnetic planar components are oriented toward each other and the components can be moved relative to each other. The flat coil is disposed between the ferromagnetic components and the ferromagnetic planar components can be moved toward each other by energizing the flat coil. The movement of one of the ferromagnetic planar components can be perceptible to the tactile sense of the operator on the operating element either directly or by a coupling device.

Owner:CONTINENTAL AUTOMOTIVE GMBH

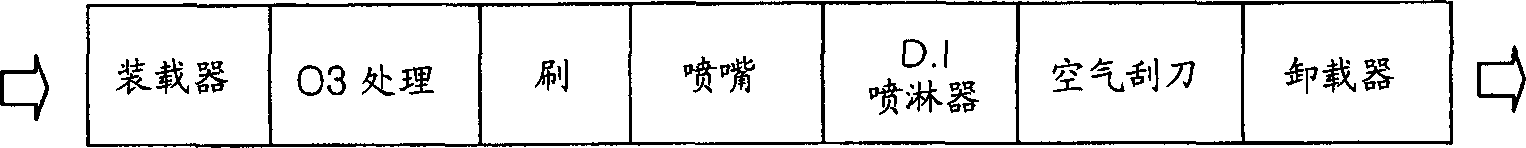

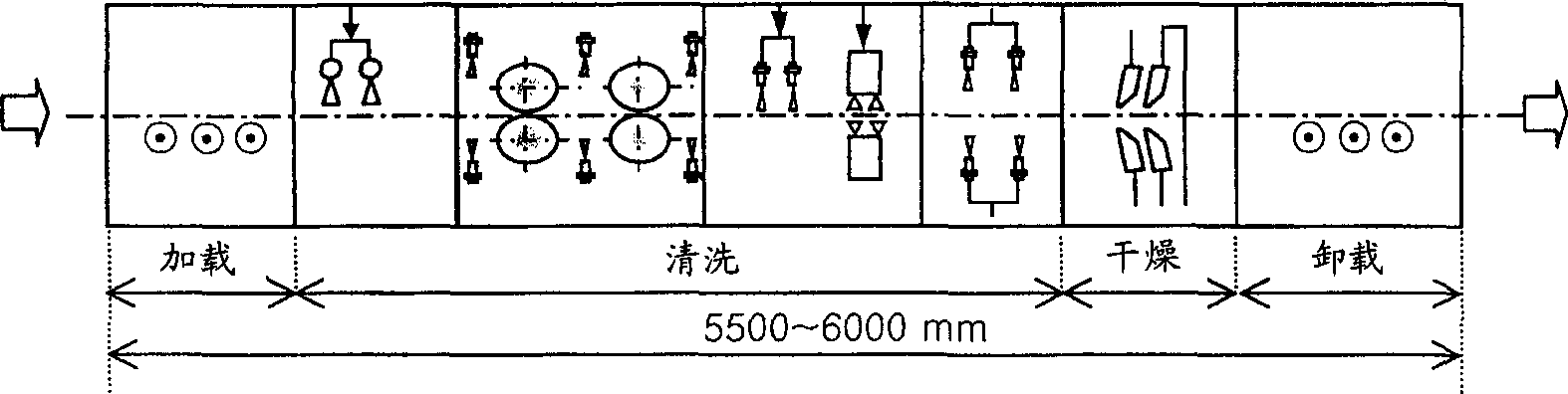

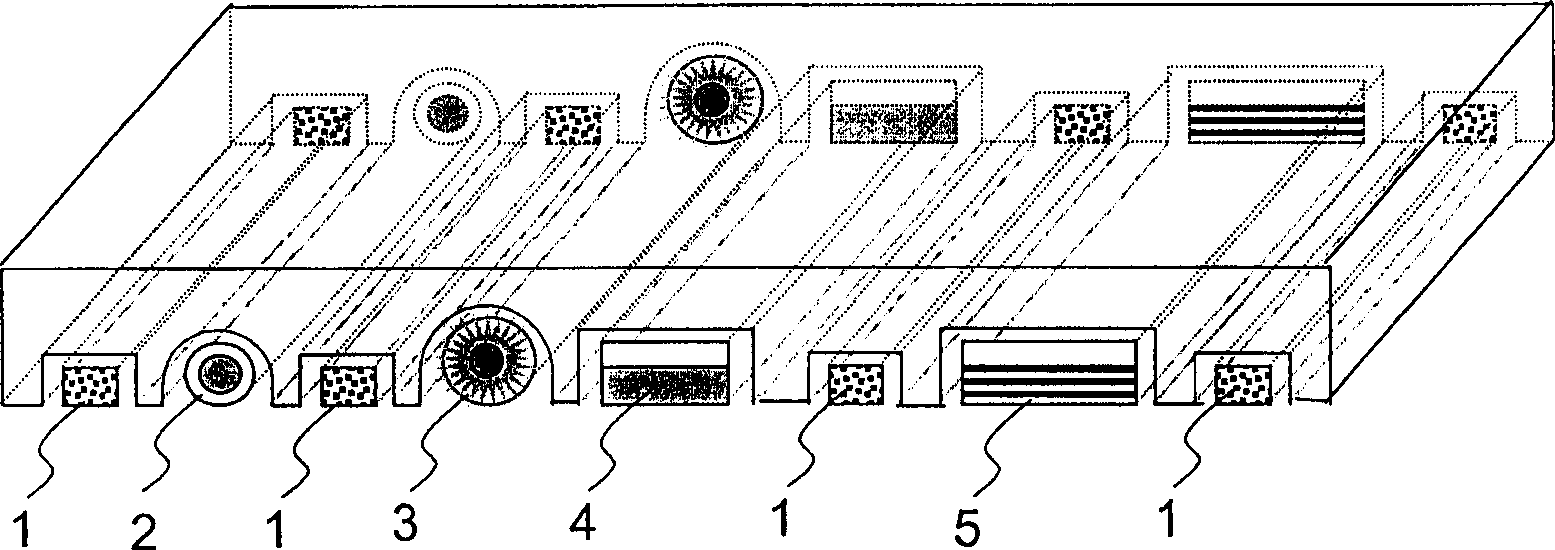

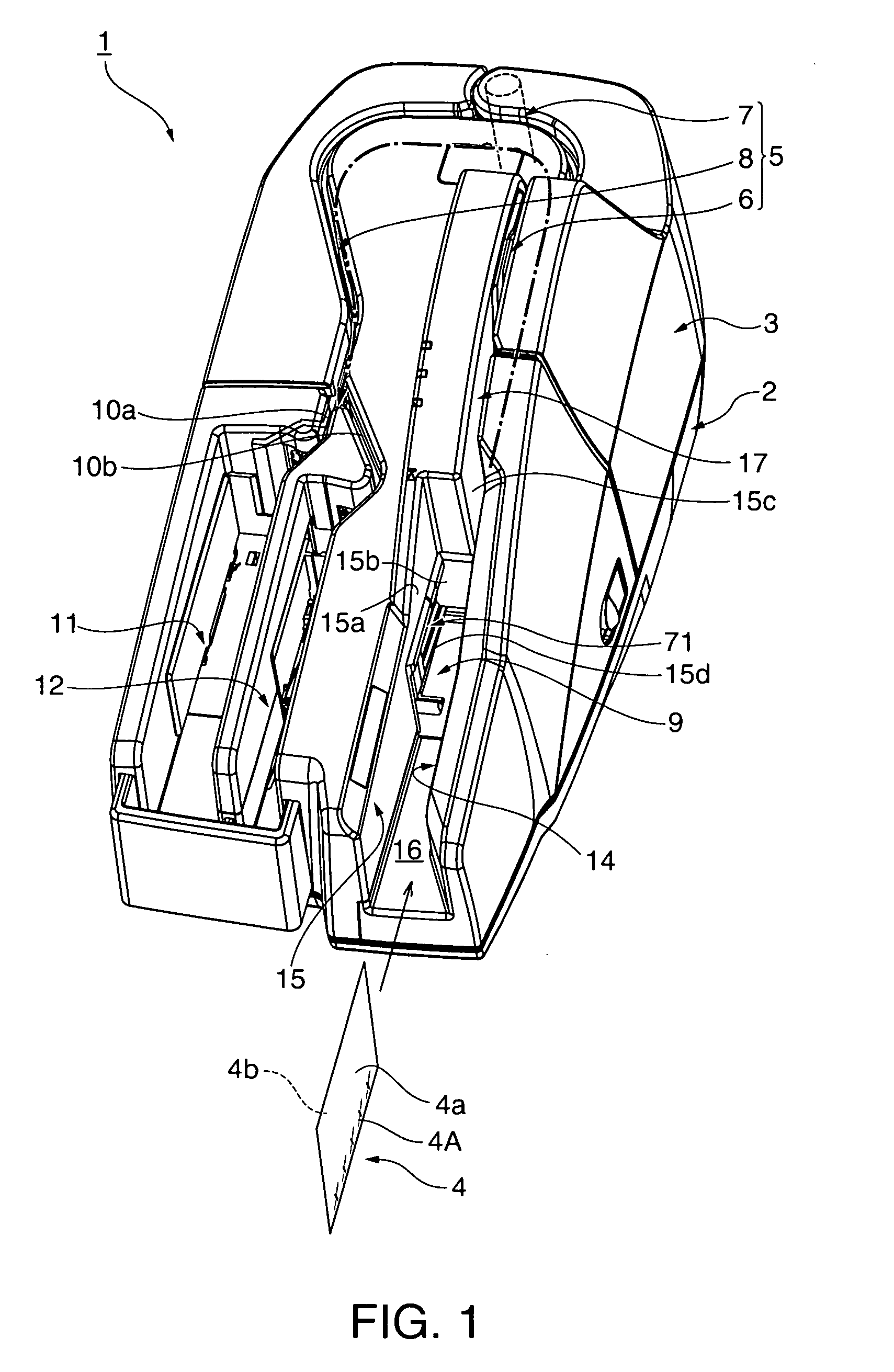

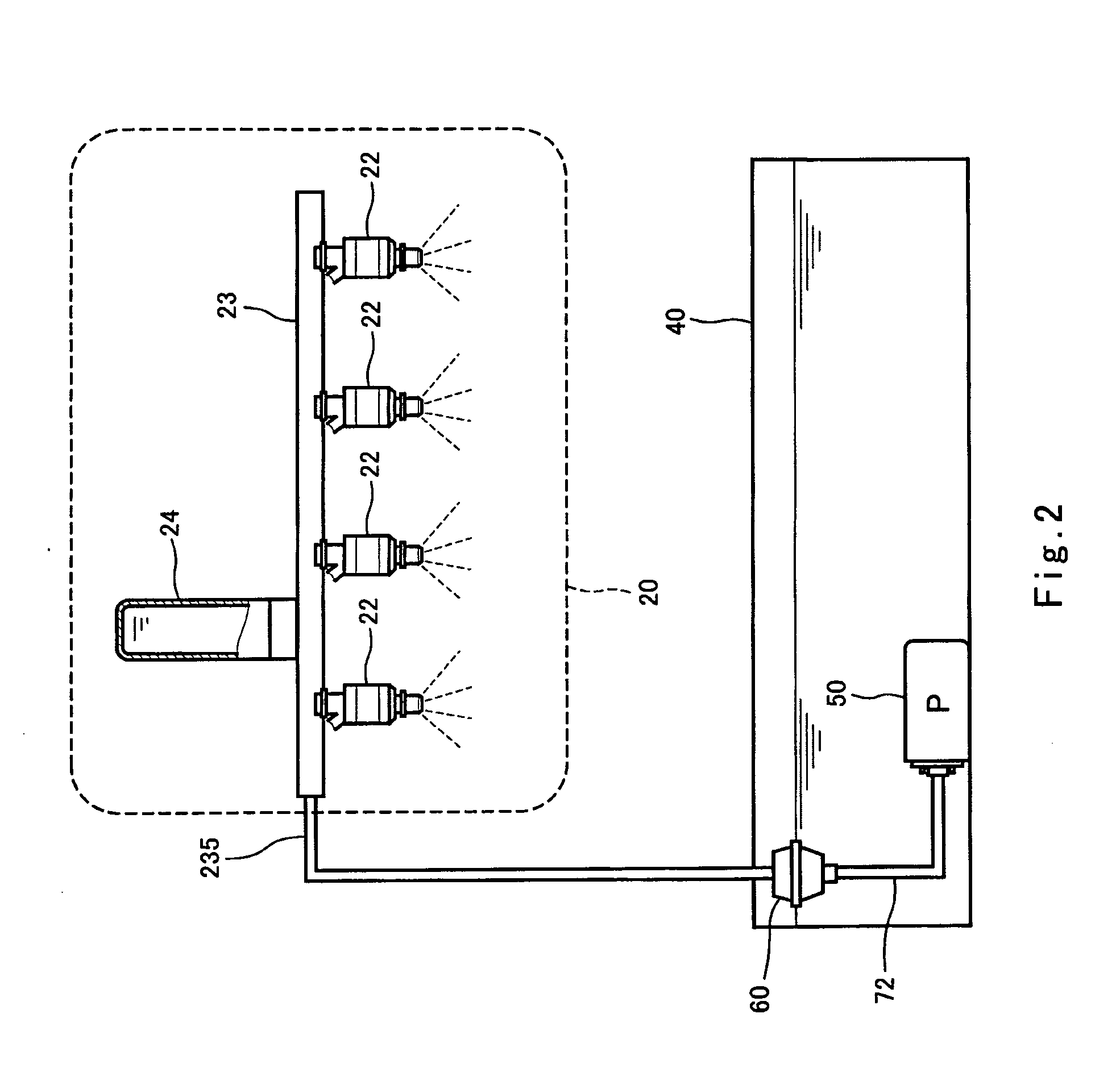

Multi-functional cleaning module and cleaning apparatus using the module

InactiveCN1344590ASmall installation spaceControl FAB SpaceConveyorsSpraying apparatusComputer moduleUltraviolet lights

The multi functional cleaning module comprises a plurality of air curtain, an eximer ultraviolet light irradiating device, a brush, a high-speed shower device, and an air knife, where they are arranged continually on a plan and the glass substrates are inserted continually into them. The cleaning apparatus using the multi functional cleaning module comprises a driving part having a loading and an unloading portions as well as the multi functional cleaning module.

Owner:DMS CO LTD +1

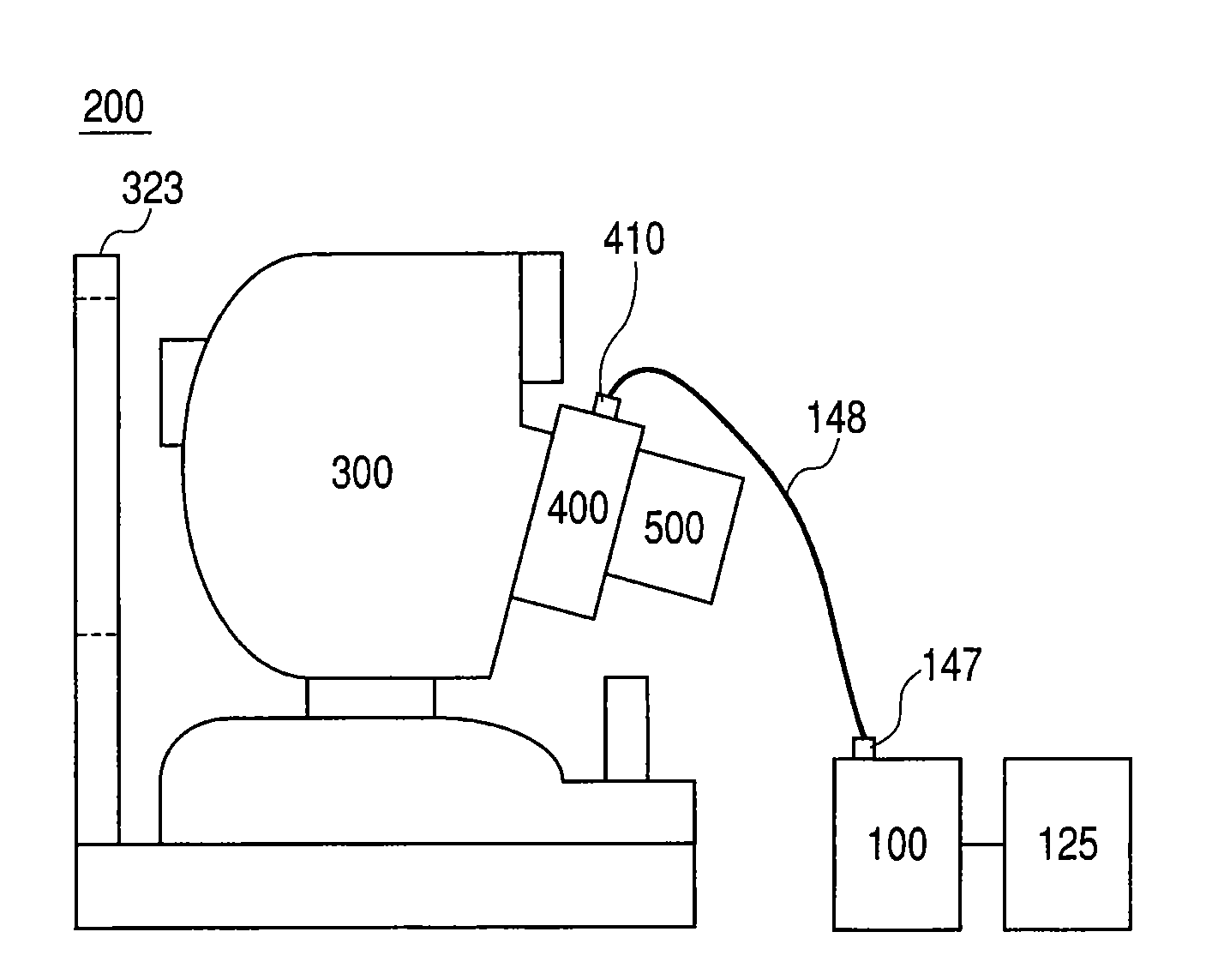

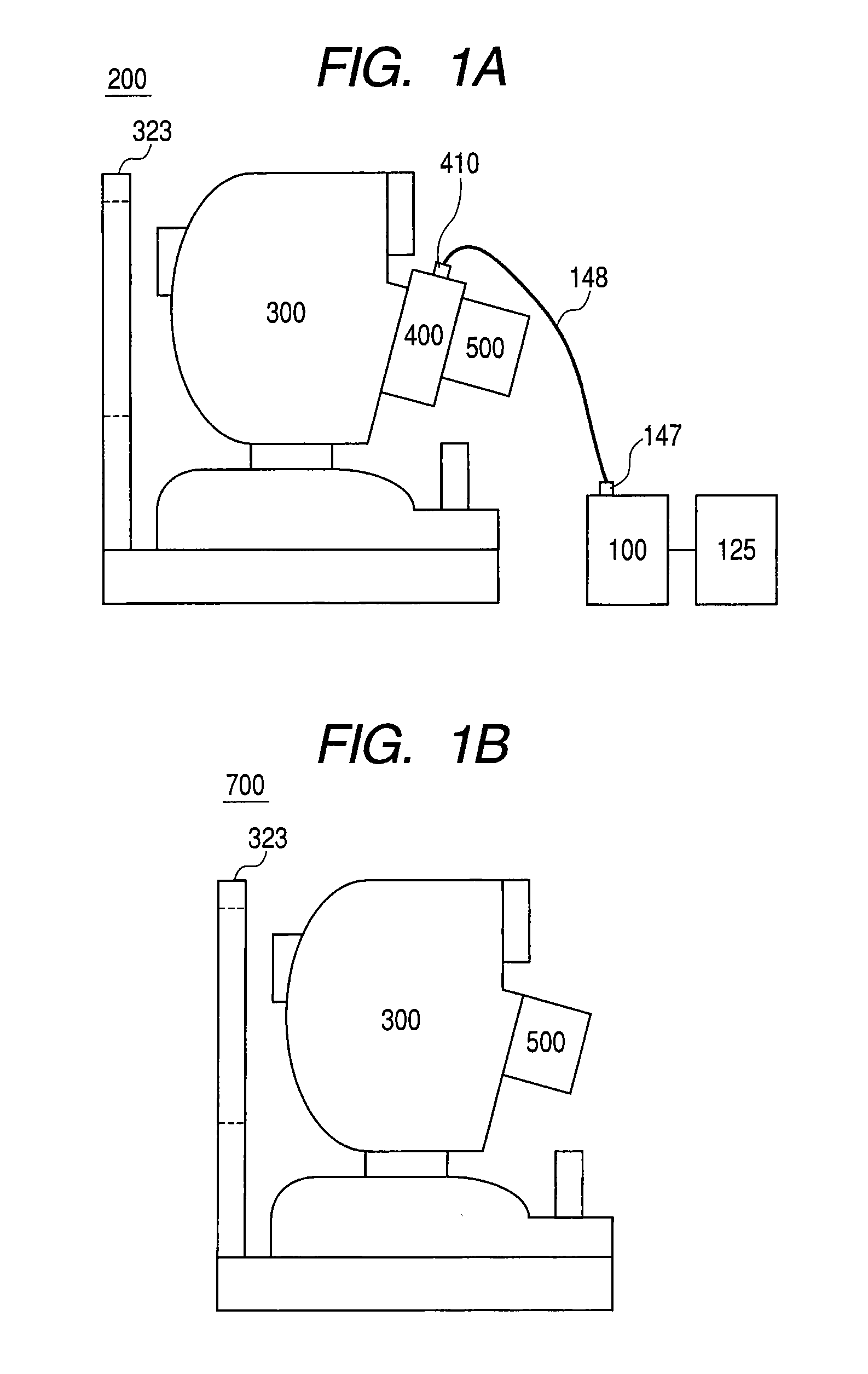

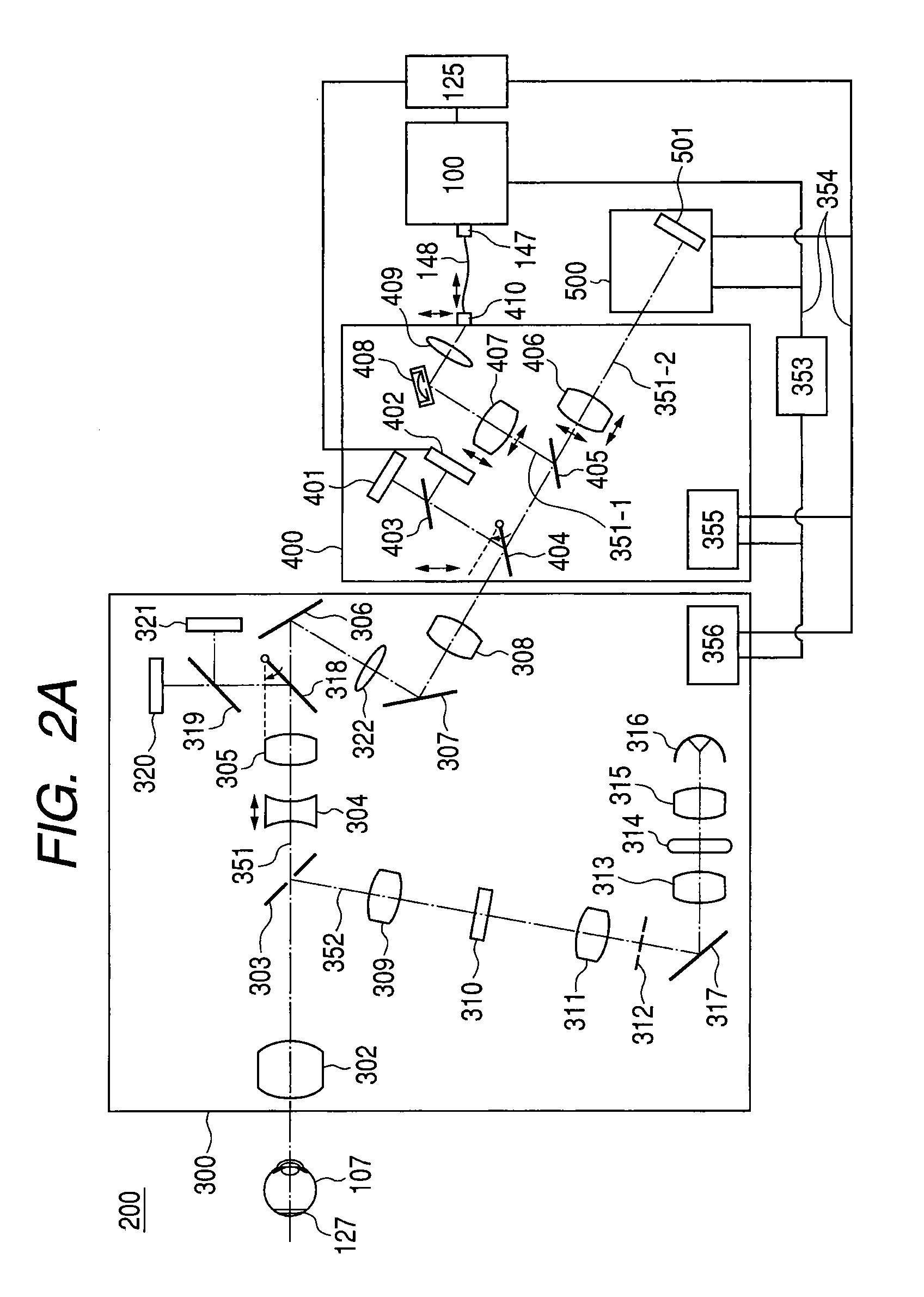

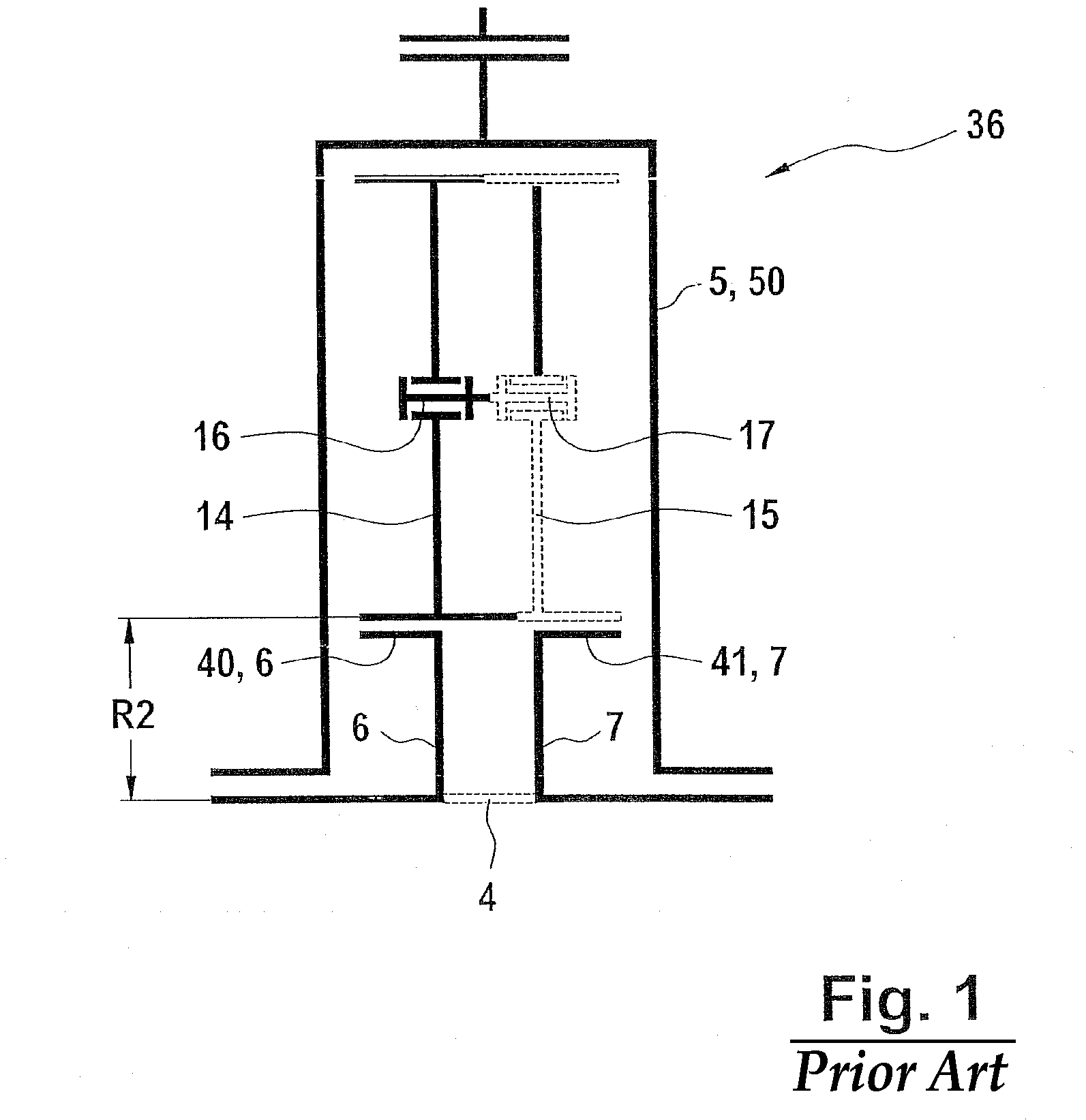

Connection adapter, optical tomographic imaging apparatus, program for executing imaging method and memory device for the program

InactiveUS20100103374A1Small installation spaceOptimize and adjust the structureOthalmoscopesFundus cameraLight guide

Provided is a connection adapter that is capable of constituting an optical tomographic imaging apparatus having a small installation space and high use efficiency. A connection adapter is disposed between the fundus camera main body portion and a camera portion to be attached to the fundus camera main body portion for imaging a surface image of a fundus as an object in an optical tomographic imaging apparatus, and connects them in a detachable manner. The connection adapter includes: a first light guide unit for guiding tomographic image measuring beams guided from the fundus camera main body portion for imaging the tomographic image to a tomographic imaging portion; and a second light guide unit for guiding fundus image measuring beams guided from the fundus camera main body portion for imaging the surface image of the fundus to the camera portion.

Owner:CANON KK

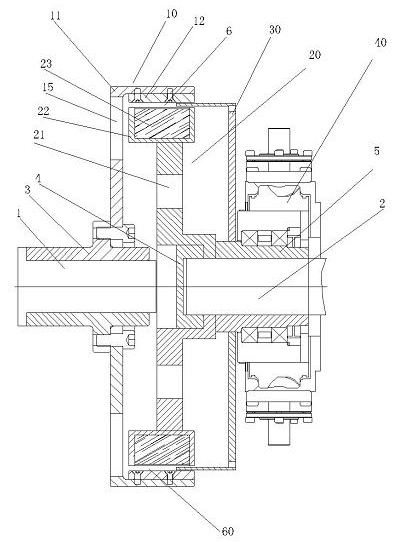

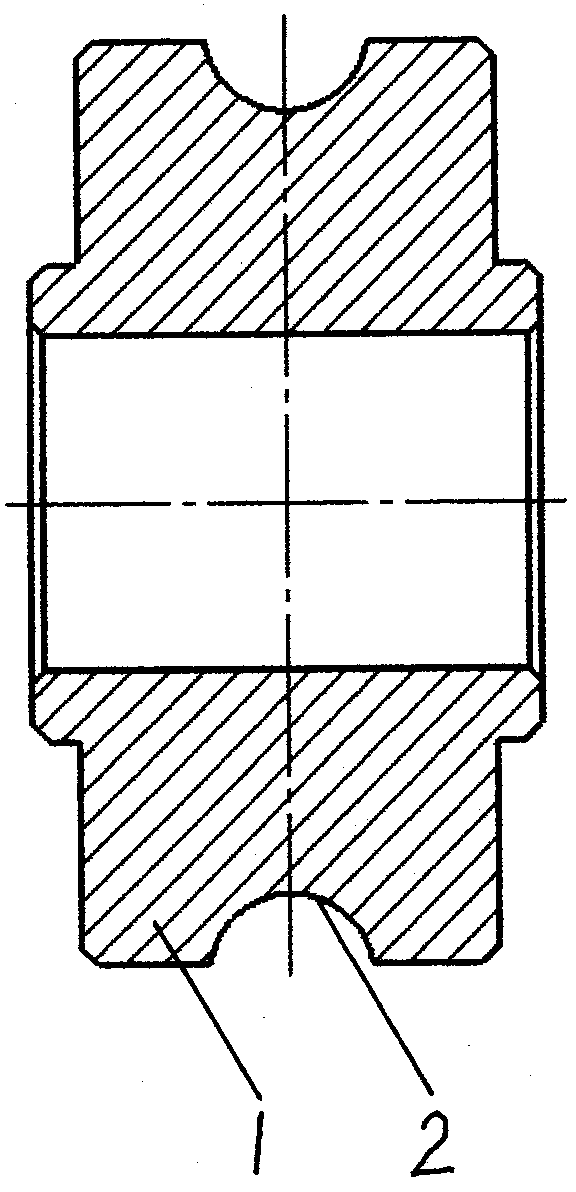

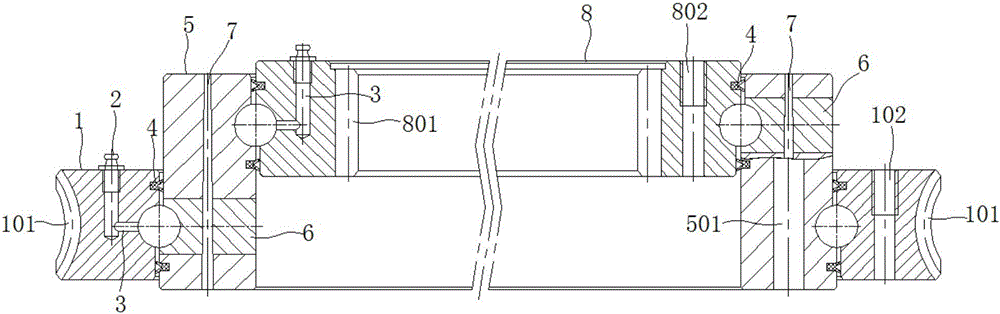

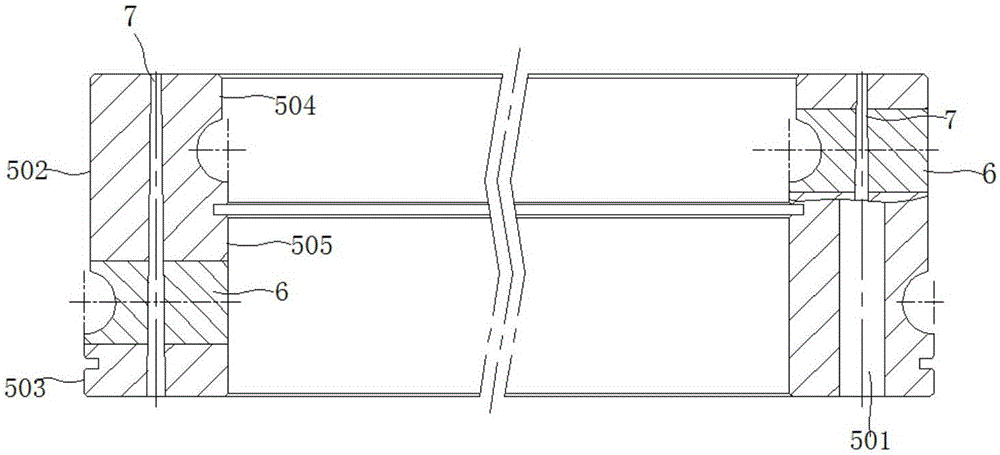

Permanent magnet coupling speed regulator

InactiveCN102035351AImprove operational reliabilitySimple structureAsynchronous induction clutches/brakesPermanent-magnet clutches/brakesPermanent magnet rotorLoad torque

The invention discloses a permanent magnet coupling speed regulator. The speed regulator comprises a cylindrical conductor rotor, a cylindrical magnetic isolation housing, a cylindrical permanent magnet rotor and a regulator, wherein the cylindrical magnetic isolation housing is positioned between the cylindrical conductor rotor and the cylindrical permanent magnet rotor; gaps are reserved between the cylindrical magnetic isolation housing and the cylindrical conductor rotor and between the cylindrical magnetic isolation housing and the cylindrical permanent magnet rotor; the cylindrical conductor rotor and the cylindrical permanent magnet rotor independently rotate around rotation axes of the cylindrical conductor rotor and the cylindrical permanent magnet rotor respectively and the axial positions are not changed; and under the action of the regulator, the cylindrical magnetic isolation housing slides along the axial direction, so that the area of an acting magnetic field between the cylindrical permanent magnet rotor and the cylindrical conductor rotor is changed; therefore, load torque and rotation speed are changed.

Owner:南京艾凌节能技术有限公司

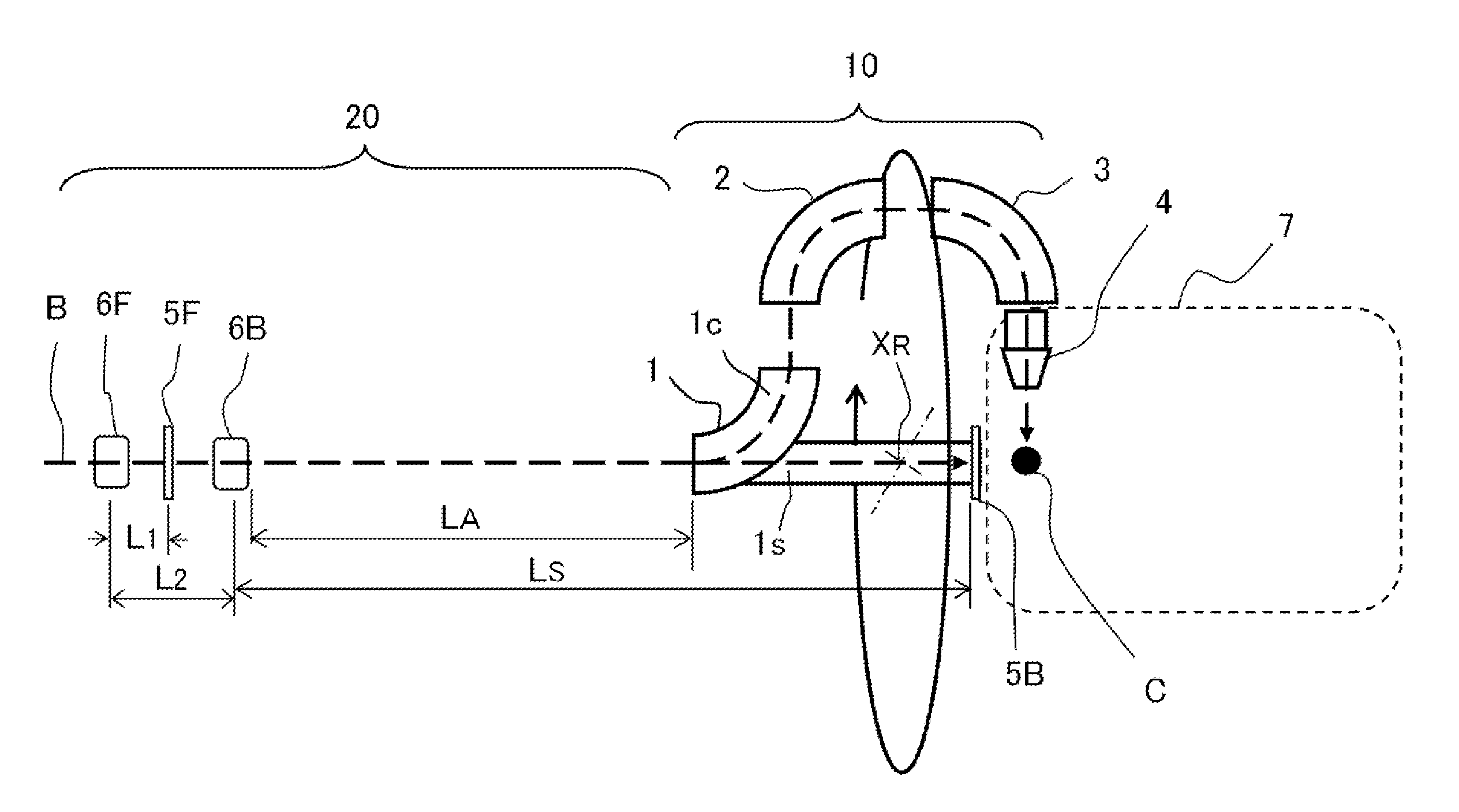

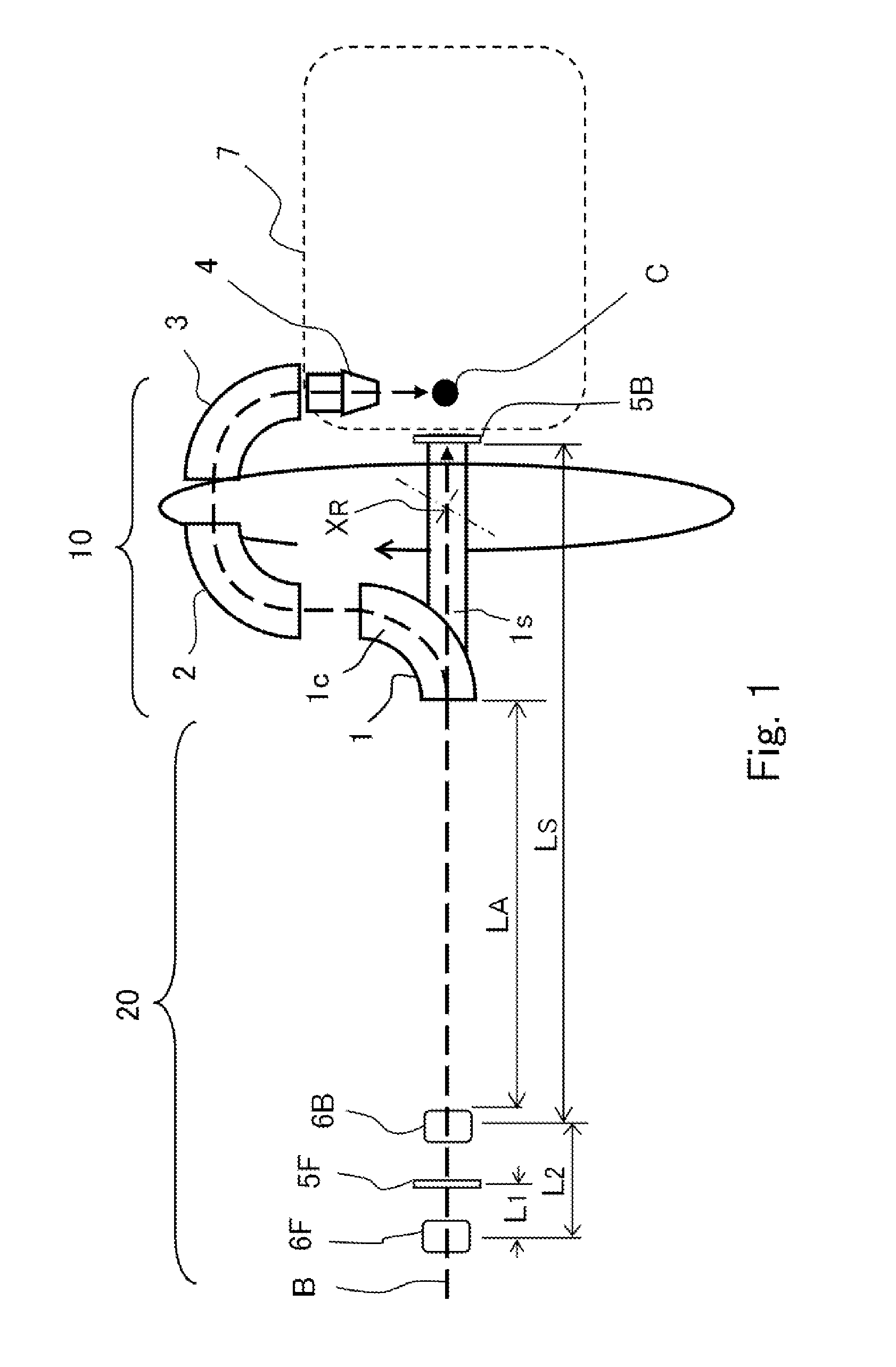

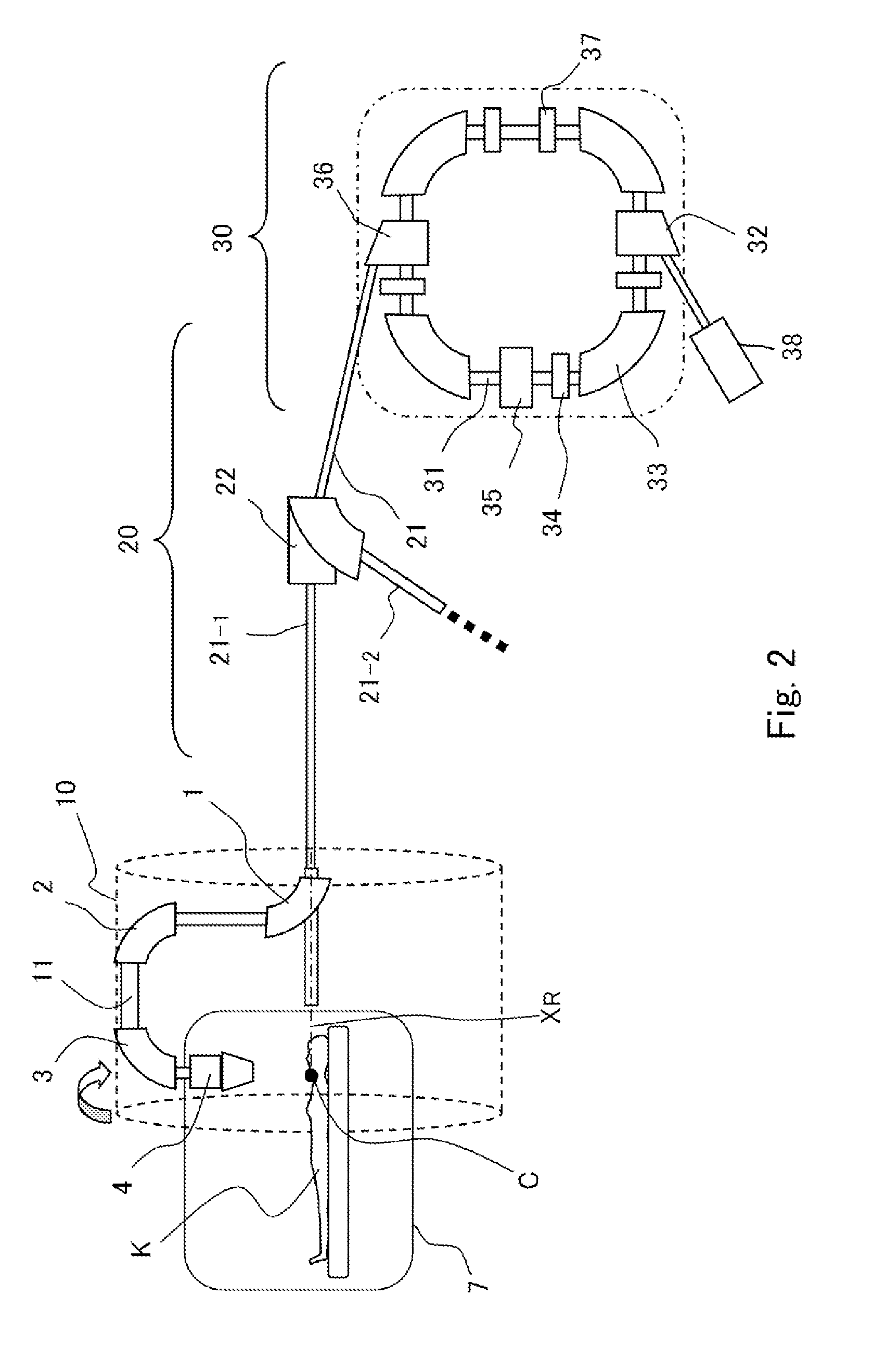

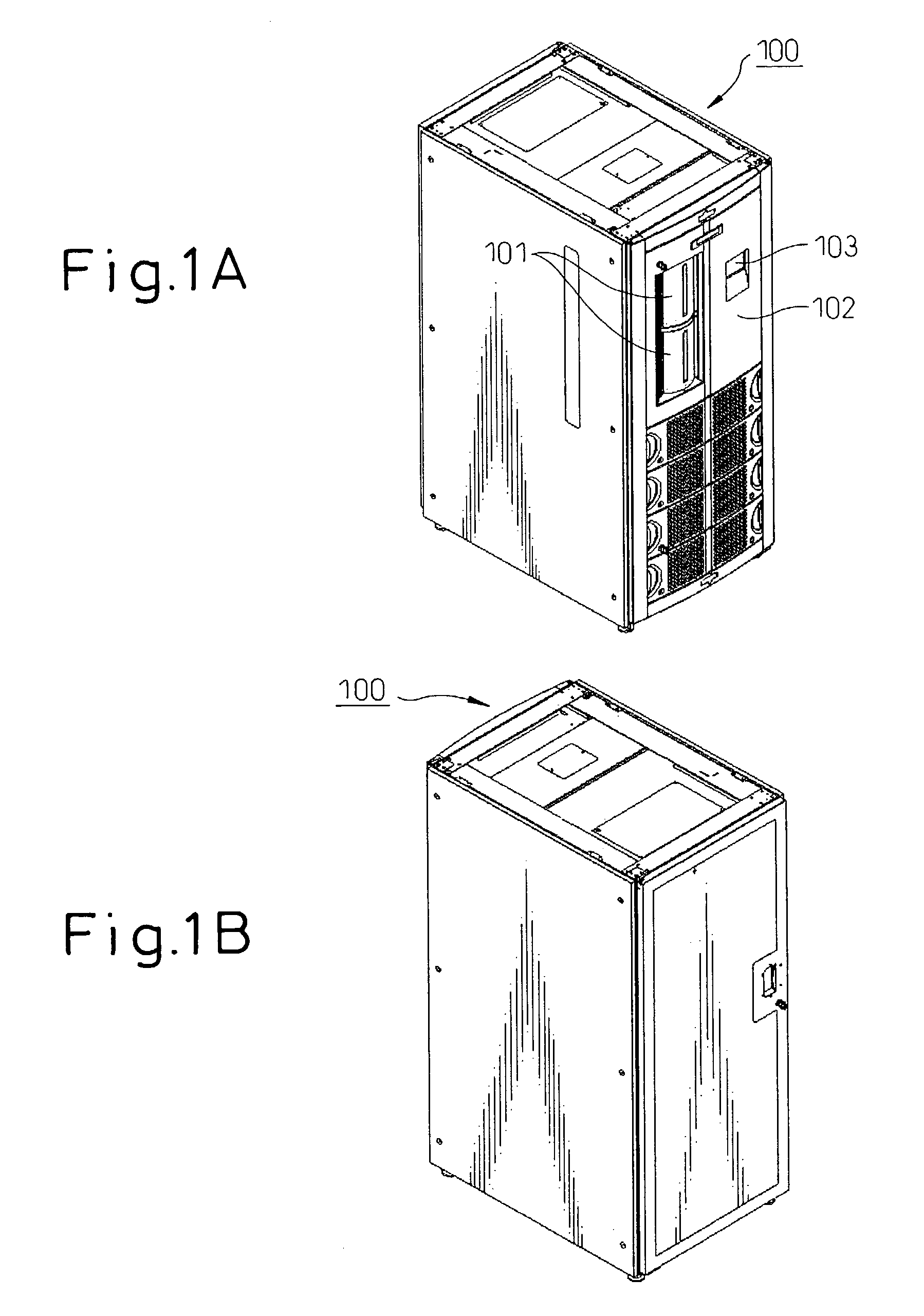

Particle therapy apparatus

InactiveUS20150328483A1Small installation spaceAccurate and appropriate doseAcceleratorsX-ray/gamma-ray/particle-irradiation therapyRotary stageParticle beam

A particle therapy apparatus has a rotating gantry configured in such a way that an irradiation device is rotated around a rotation axis and a particle beam is irradiated onto an irradiation subject; the rotating gantry is provided with an entrance-side deflection electromagnet having a deflection path for radially deflecting the particle beam supplied along the rotation axis so as to guide the particle beam to the irradiation device and a straight path that is switchable with the deflection path and is for making the supplied particle beam travel in a straight manner; there are provided trajectory correcting devices having two position sensors that are arranged along the rotation axis so as to flank the entrance-side deflection electromagnet.

Owner:MITSUBISHI ELECTRIC CORP

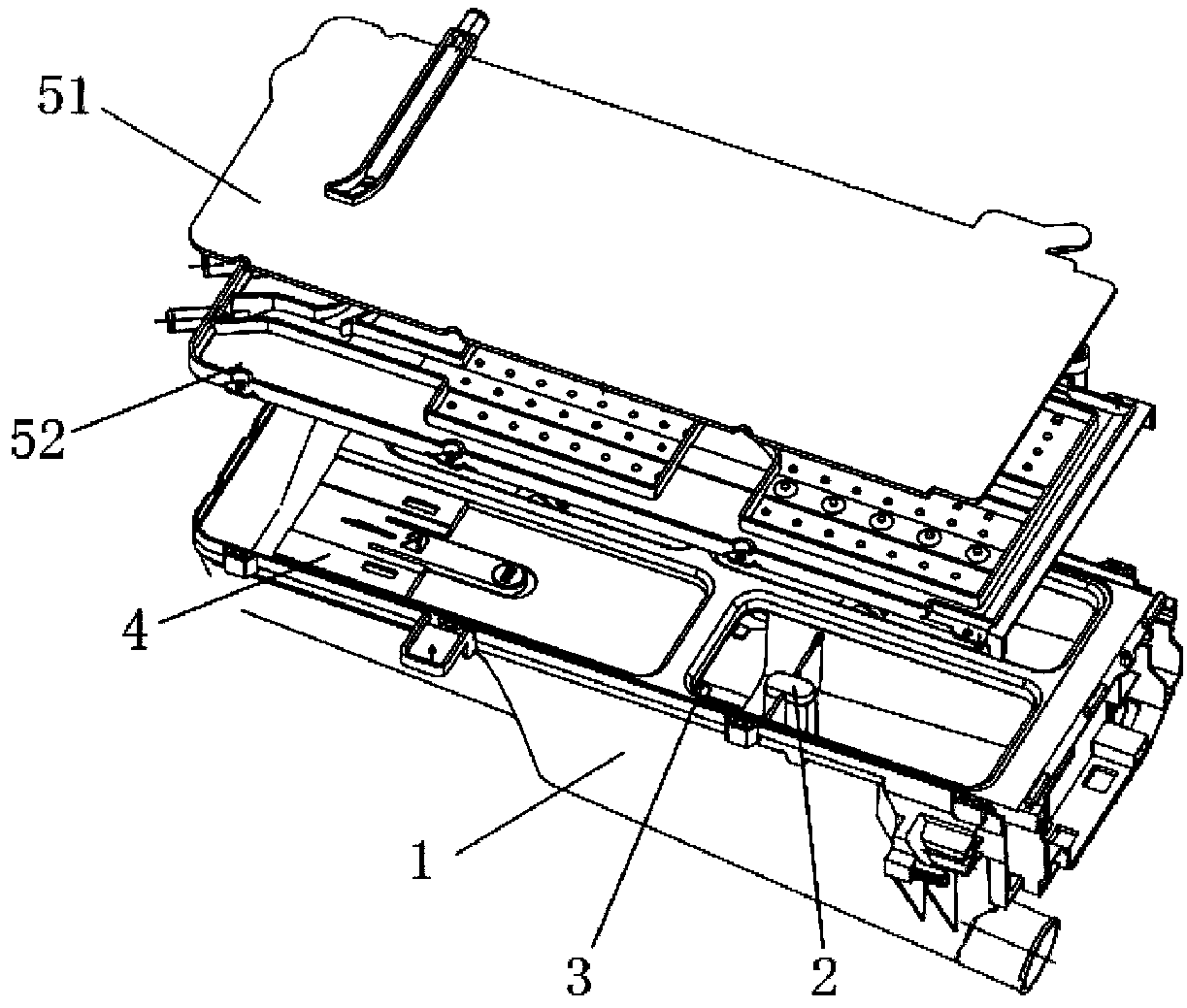

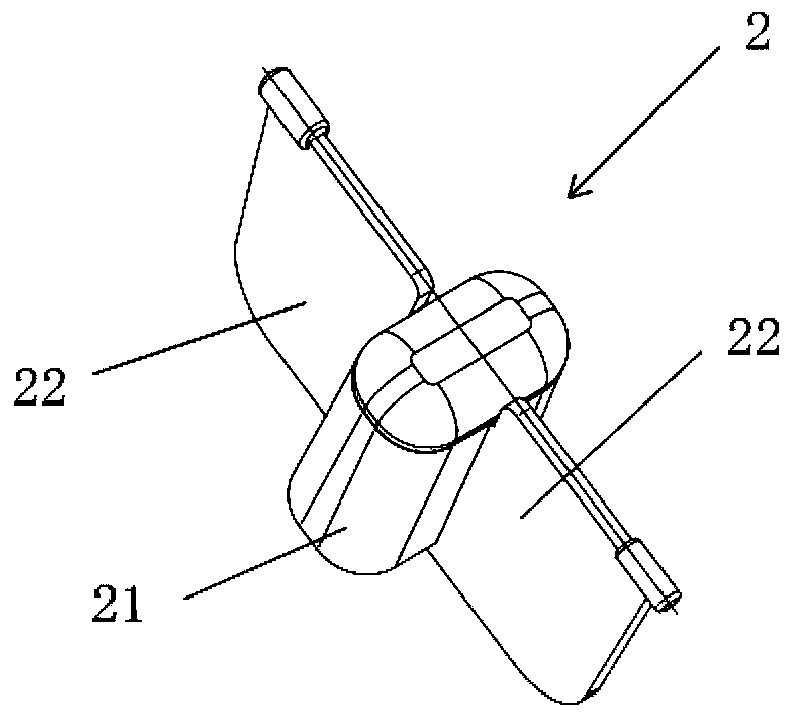

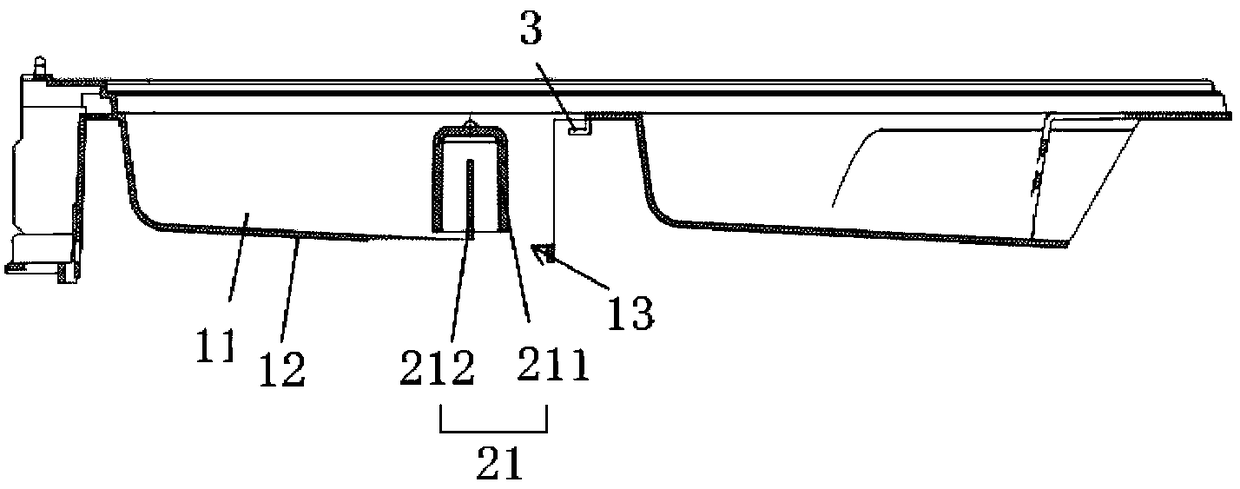

Detergent box and washing machine with same

ActiveCN109183360AReduce volumeSimple structureOther washing machinesTextiles and paperSiphonLaundry washing machine

The invention relates to the field of washing machines, and discloses a detergent box. The detergent box includes an additive box having an adding chamber. The detergent box further includes a siphonstructure and a limit plate. The siphon structure is rotationally arranged in the adding chamber, and can divide the adding chamber into two chambers. When liquid detergent is put in, the two chamberscan be connected by the siphon structure. When solid detergent is put in, the limit plate supports the siphon structure and makes the two chambers fully connected. According to the detergent box provided by the invention, liquid detergent and solid detergent can be put in via the same adding chamber. Compared with the prior art in which different forms of detergents are put in via different adding chambers, the size of the detergent box is reduced, less installation space is occupied, the processing cost is lowered, and the structure of the detergent box is simplified. The invention further provides a washing machine including the detergent box. Different forms of detergents can be added via one adding chamber. The detergent box has the advantages of small size and low processing cost.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

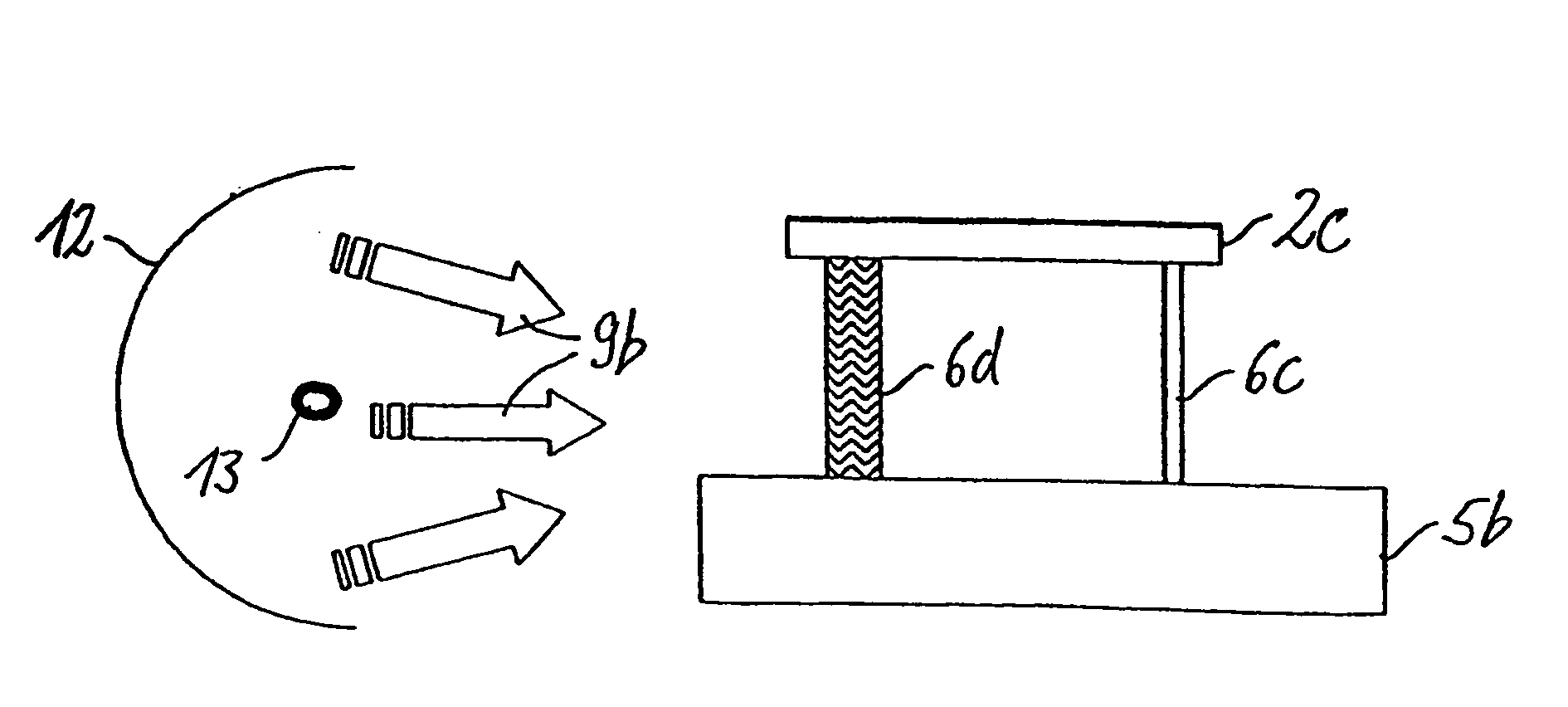

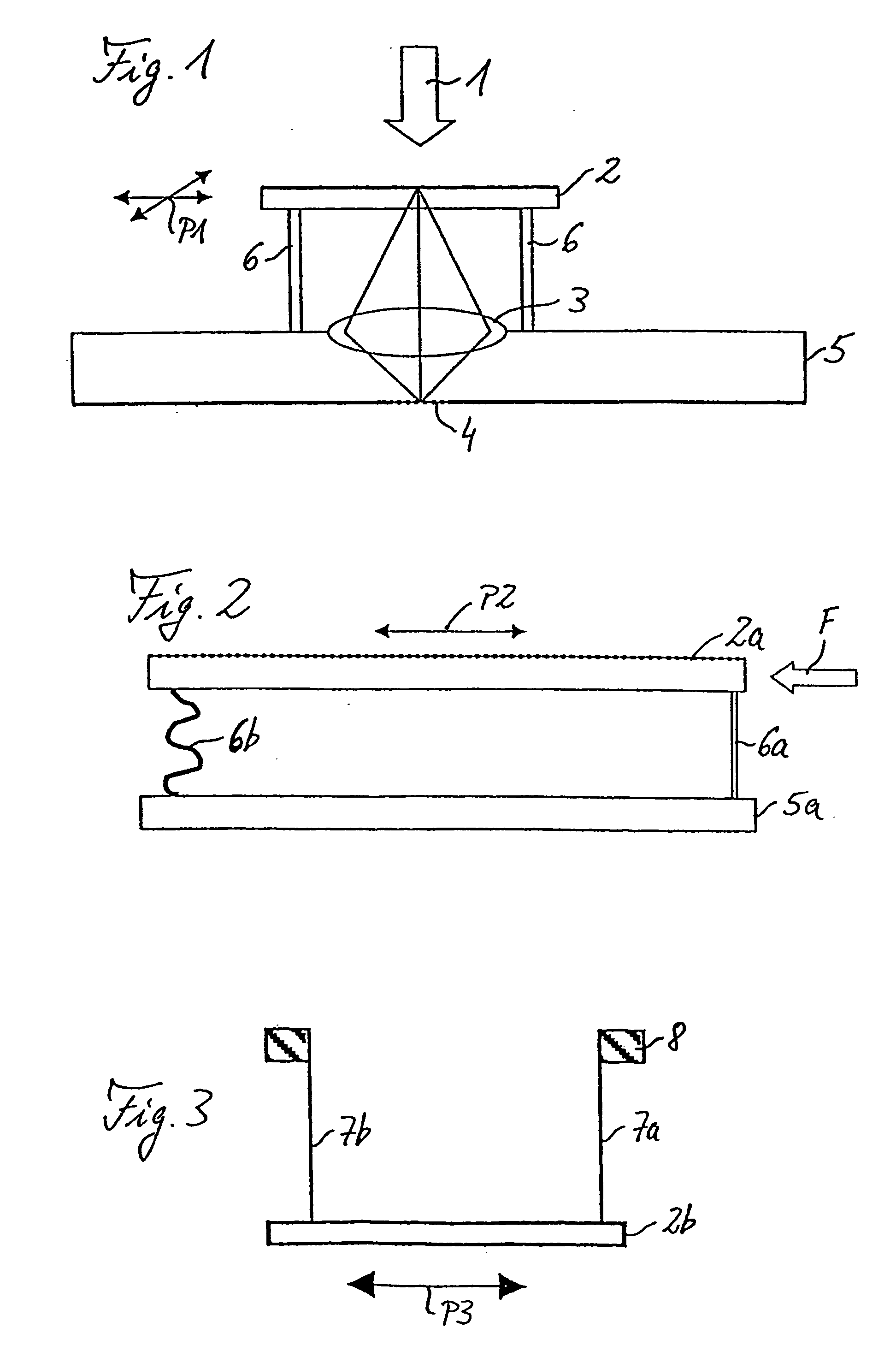

Illuminating system having a diffuser element

InactiveUS20050002102A1Reduce spendingSmall installation spaceDiffusing elementsPhotomechanical exposure apparatusWavefrontLight beam

An illuminating system having a diffuser element (2) that is introduced into an illuminating beam path (1) and is arranged movably, in particular for oscillatory movement. Such system has applicability, for example, in microlithography projection exposure machines and associated wavefront measurement interferometers.

Owner:CARL ZEISS SMT GMBH

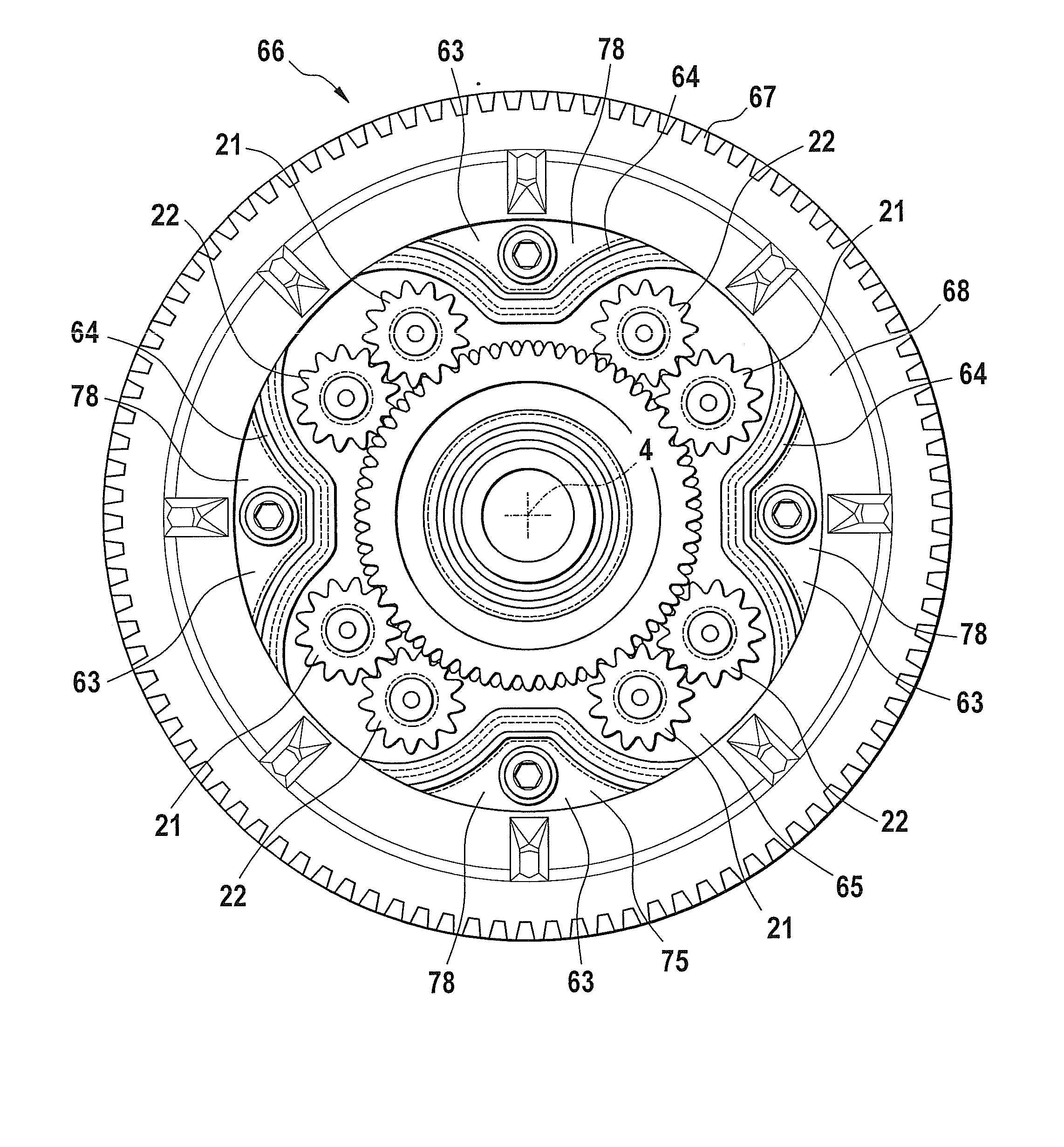

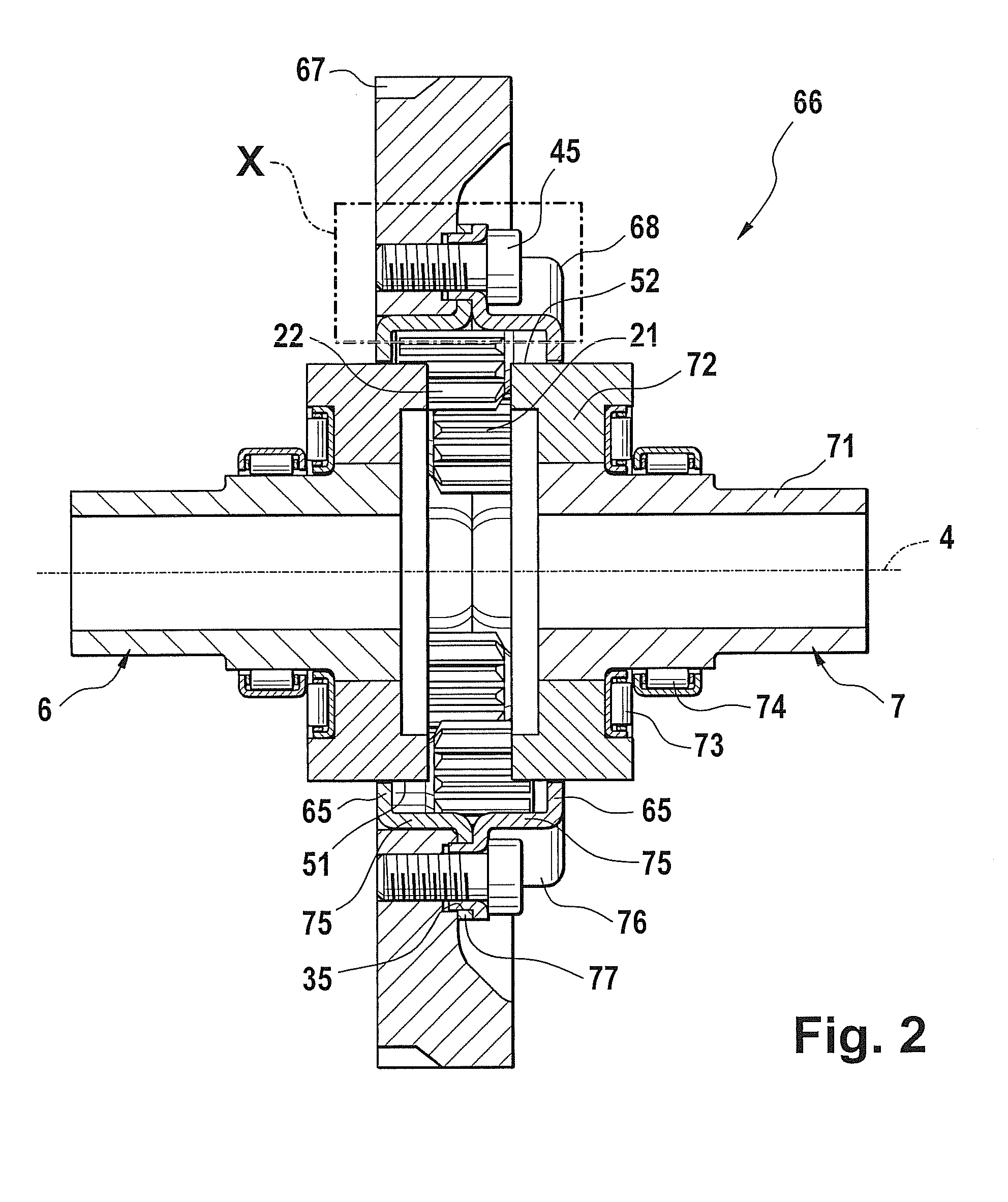

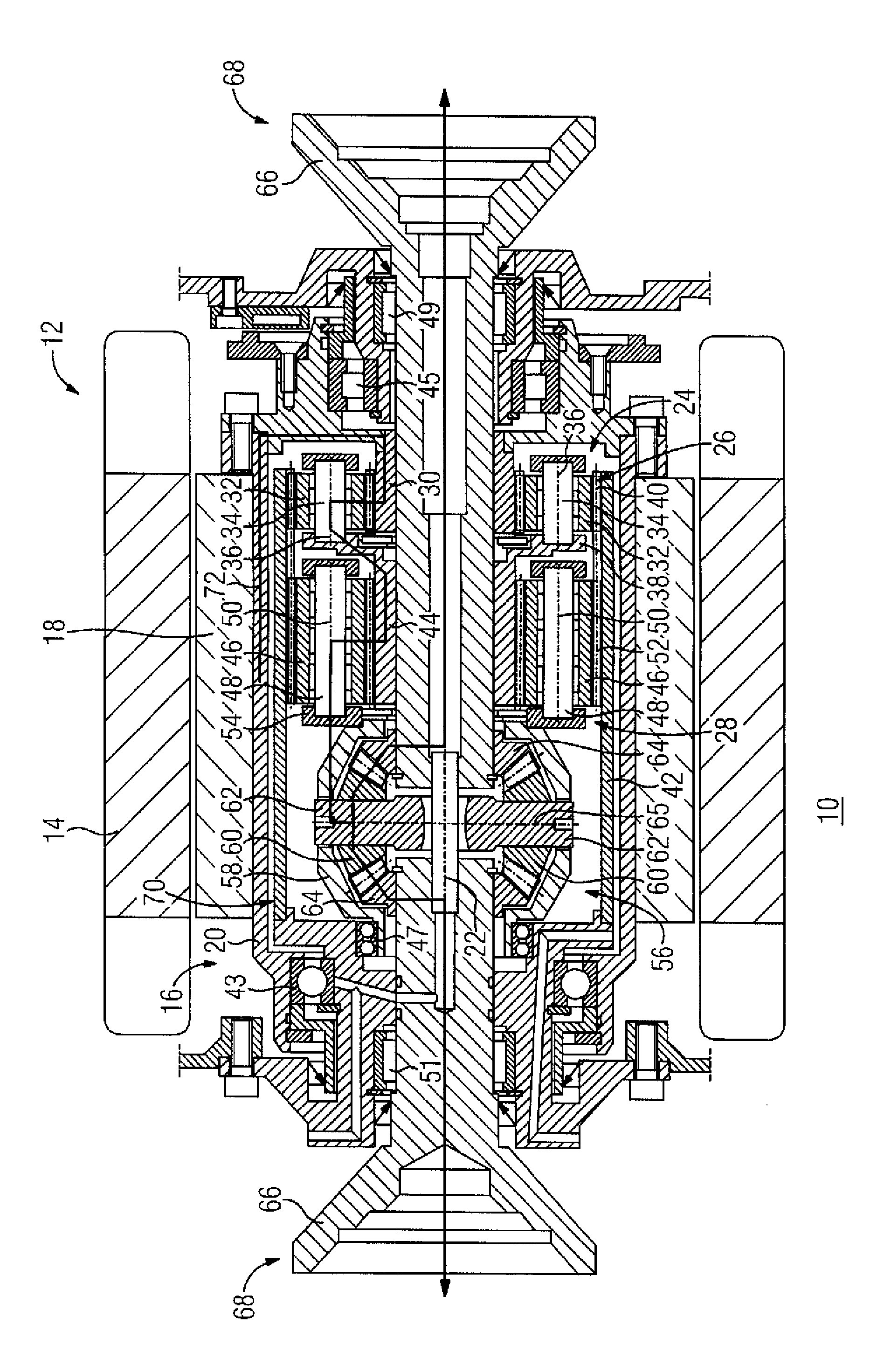

Spur gear differential

InactiveUS20110045934A1Transmitting high torqueSmall installation spaceDifferential gearingsRotational axisDrive wheel

The invention relates to a spur gear differential (66) comprising a housing (68) that is embodied as a sum wheel (50) and that rotates around a longitudinal rotational axis (4), at least three planet gears (21, 22) disposed on the periphery at a distance in relation to each other around the rotational axis (4), and a drive wheel (67) at the housing (68), withthe housing (68) comprised of at least two housing sections (75) fixed to each other,each of the planet gears (21, 22) mounted longitudinally on both sides in the housing sections (75),at least one of the housing sections (75) formed in the shape of a pot, with the housing section (75) formed from a pot (76) having a base (65) arranged on the front side of the housing, a wall starting from the base (65) and extending around the rotational axis (4)

Owner:SCHAEFFLER TECH AG & CO KG

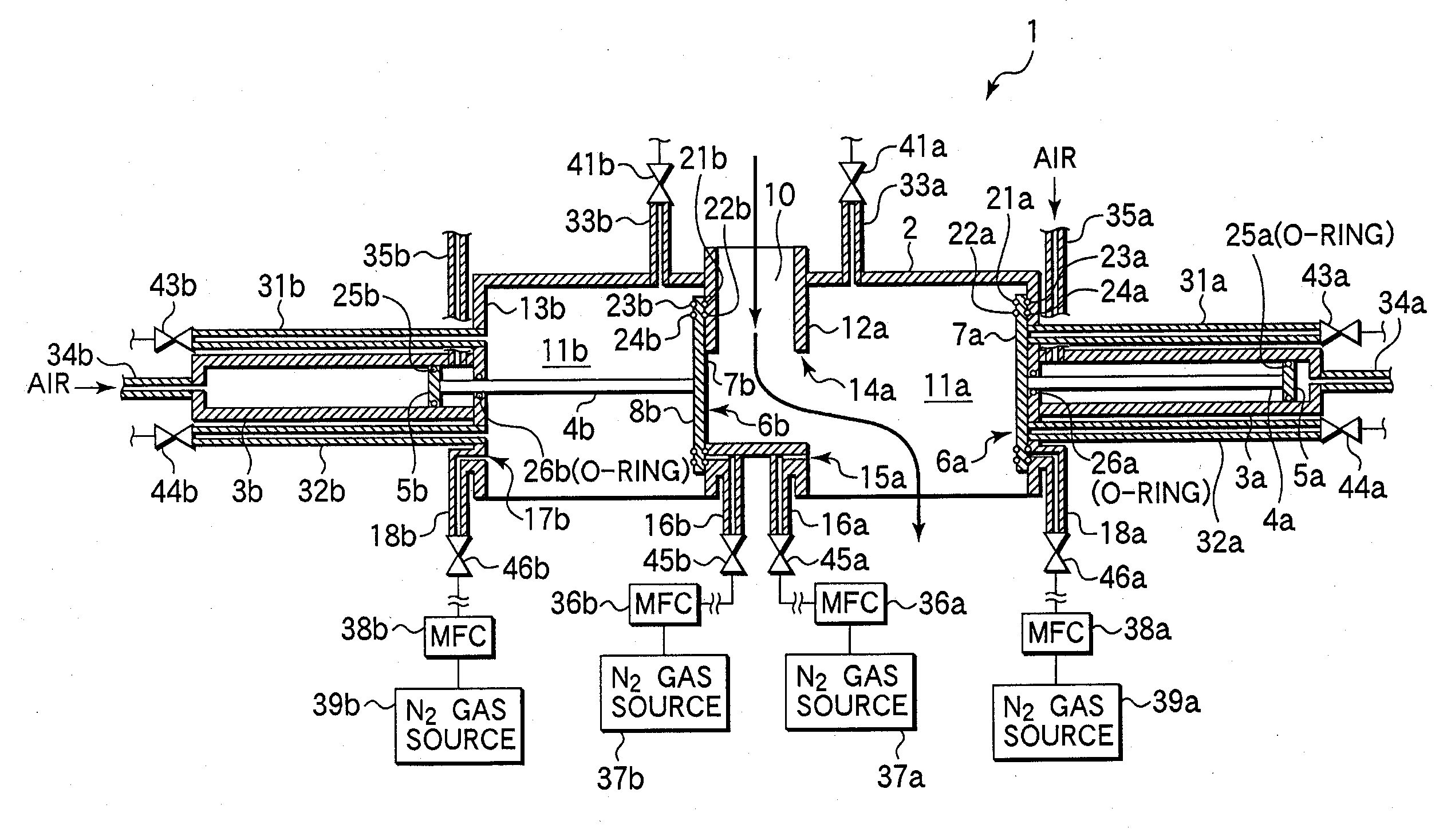

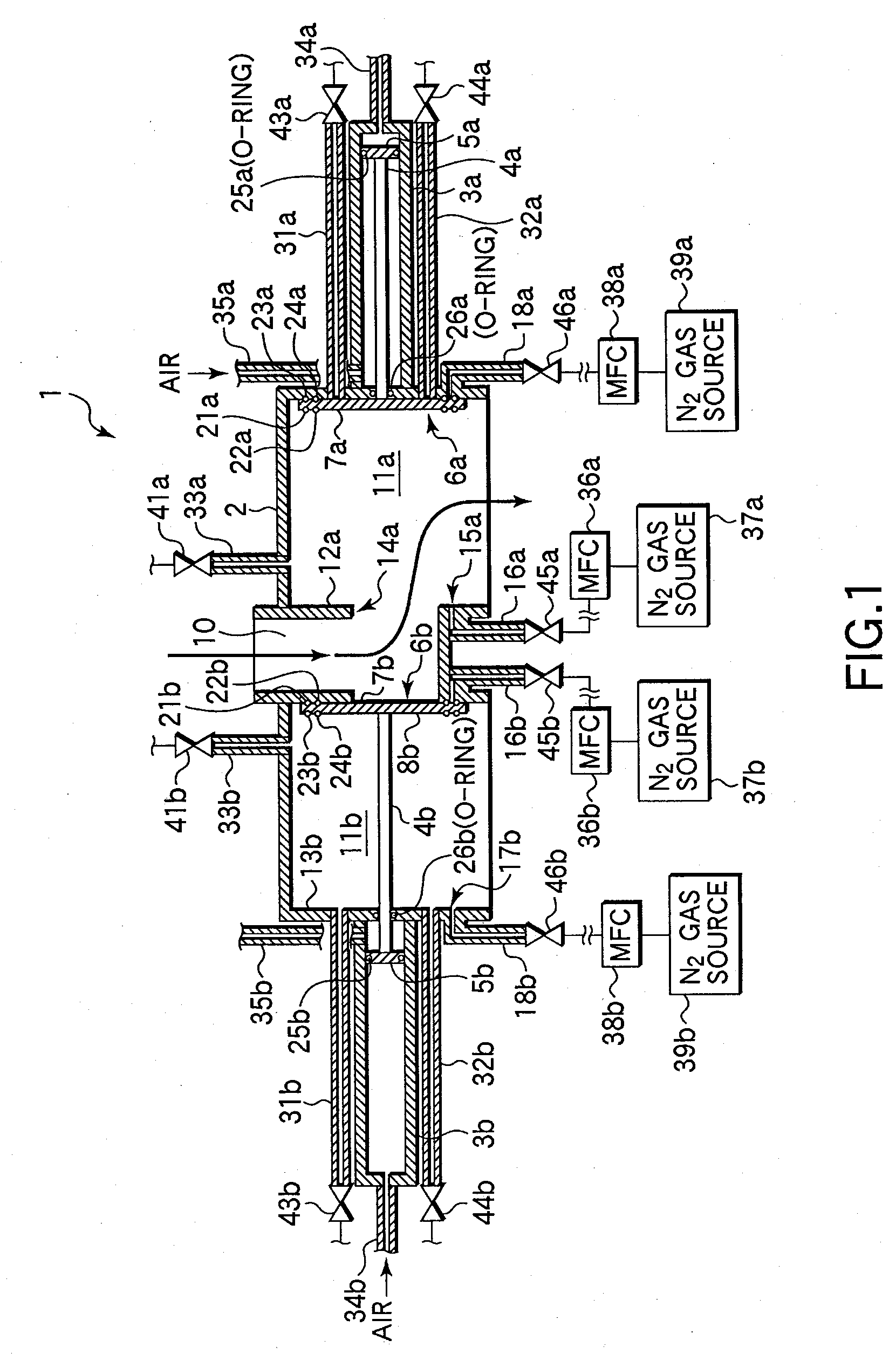

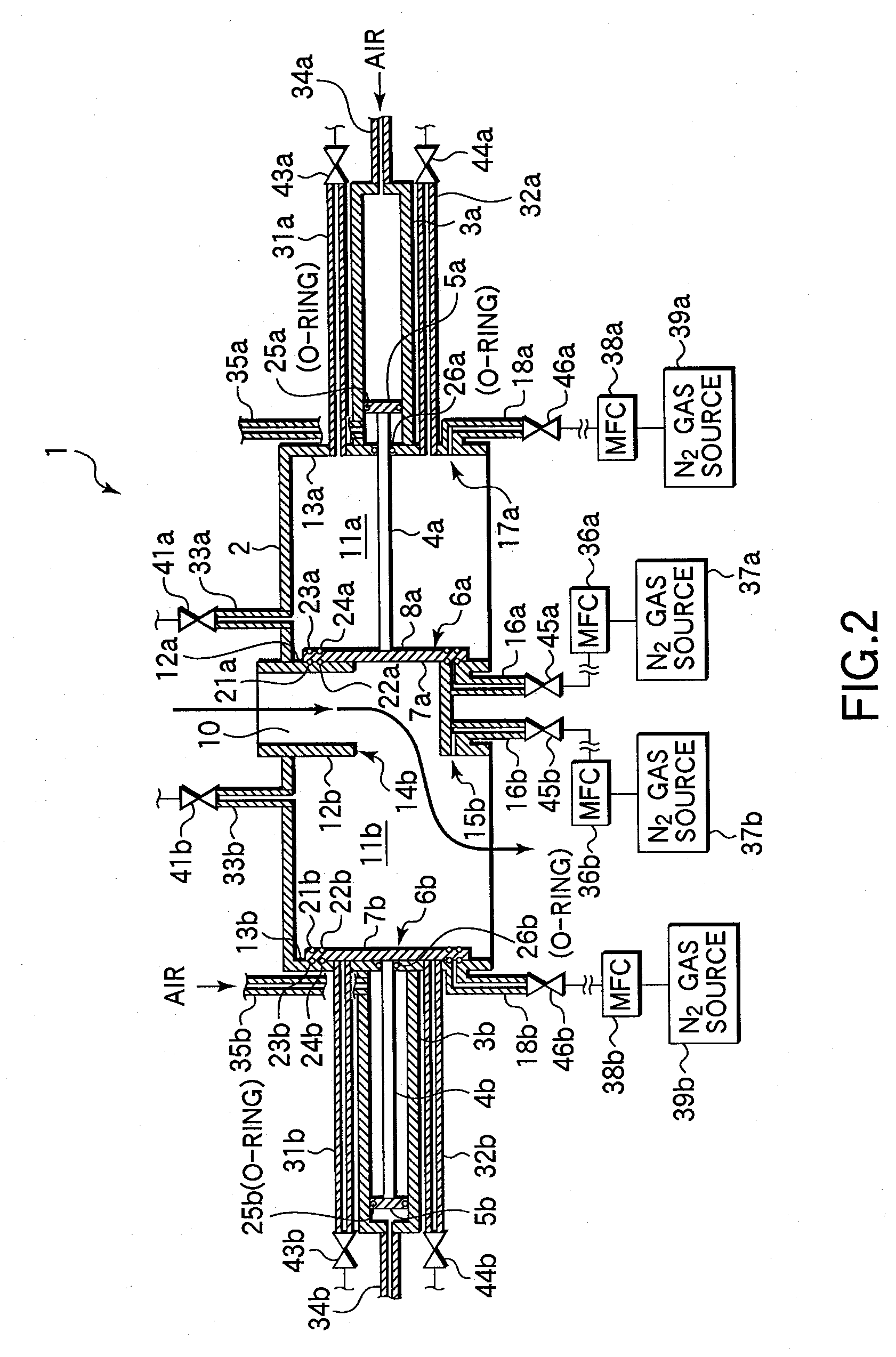

Valve element, valve, selector valve, and trap device

InactiveUS20090114296A1Wide range of applicationsSimple structurePlug valvesValve members for heating/coolingFluid supplyEngineering

Owner:TOKYO ELECTRON LTD

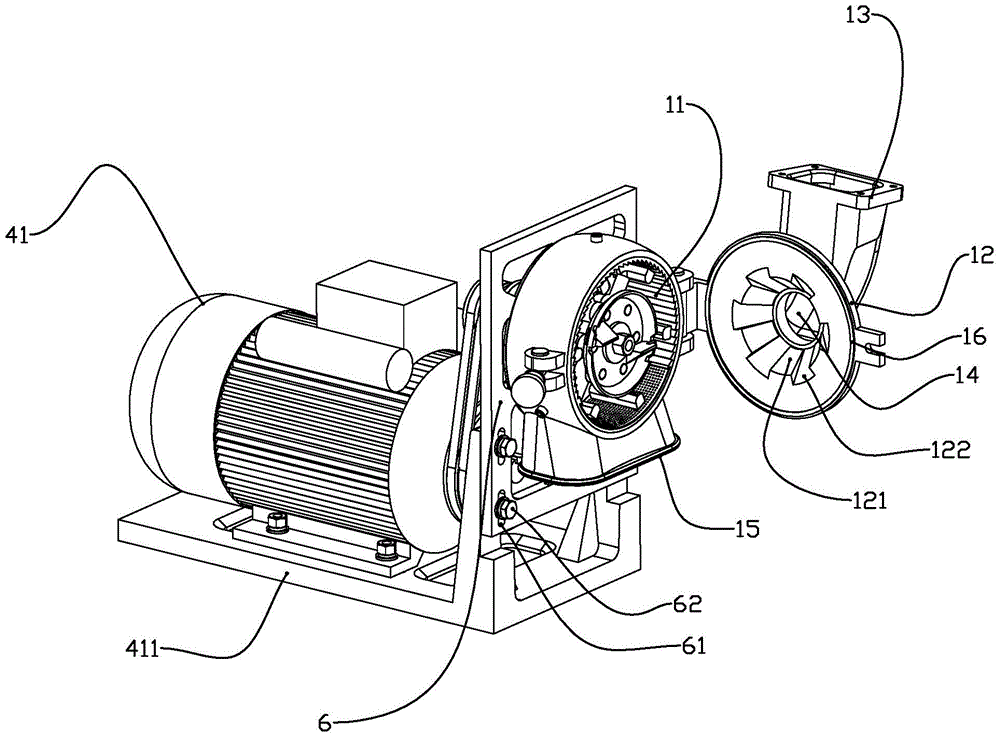

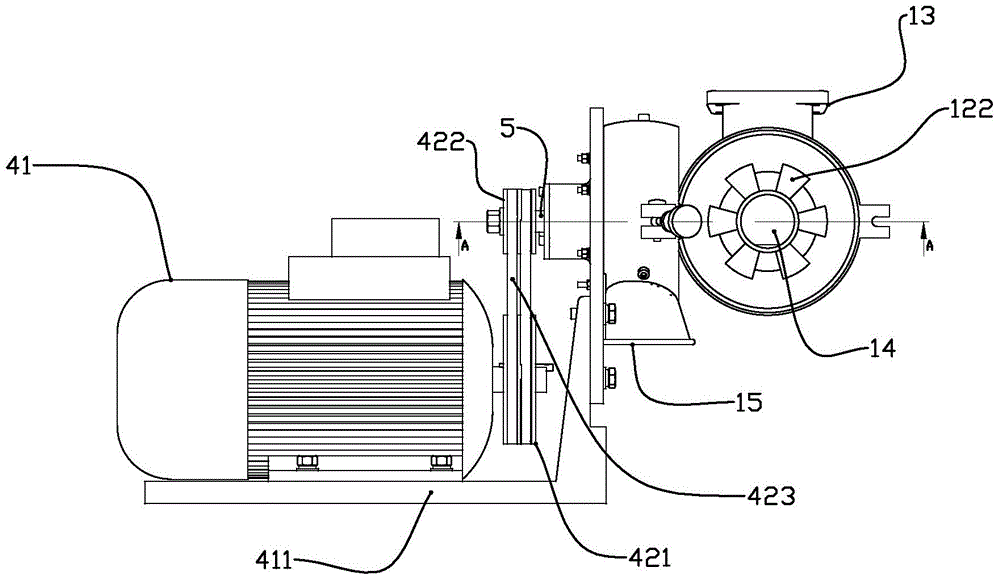

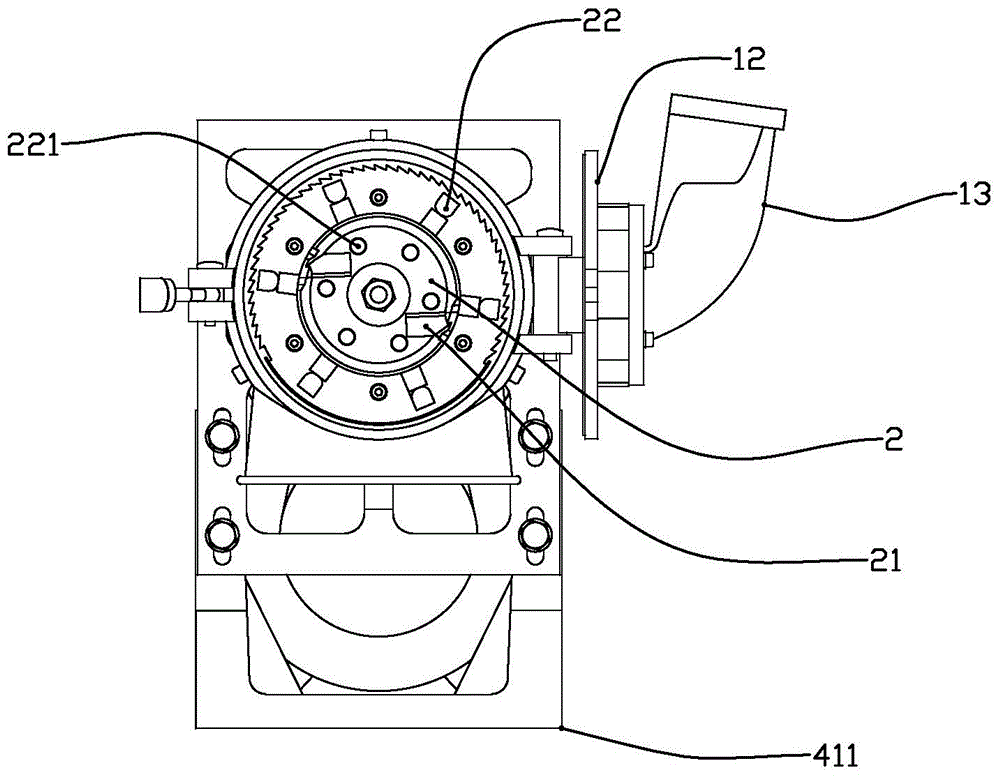

Grading crushing machine

InactiveCN104959189AImprove refinementEfficient crushing effectGrain treatmentsEngineeringRaw material

The invention discloses a grading crushing machine. The grading crushing machine comprises a feeding opening, a discharging opening as well as a crushing cavity, a crushing assembly and a power device of a sieve screen, wherein the crushing assembly comprises a turntable with a hammerhead, the turntable is installed in the crushing cavity, the turntable is provided with crushing teeth, the crushing cavity is provided with crushing grooves matched with the crushing teeth, the crushing grooves are arranged along the radial end surface of the side inner wall, the hammerhead is arranged on the outer circumferential surface of the turntable, furthermore, an inlet of the crushing groove is communicated with the feeding opening, an outlet of the crushing groove extends to the outer circumferential surface of the turntable, furthermore, an inner gear ring is embedded on the inner wall of the crushing cavity, the inner gear ring is provided with a crushing gear bar, a grinding cavity is formed between the crushing gear bar and the hammerhead, materials are primarily ground by virtue of the crushing teeth and then conveyed to the hammerhead by virtue of the crushing grooves, the materials are further refined by virtue of the hamming of the hammerhead and then ground by the grinding cavity, so the raw materials are broken level by level, the refining of the raw material particles can be accelerated, so that the operation efficiency can be improved; multilevel crushing can be realized in one crushing cavity, the crushing effect is good, the size is small, and the occupied space is small.

Owner:WENZHOU DINGLI MEDICAL APP & INSTR

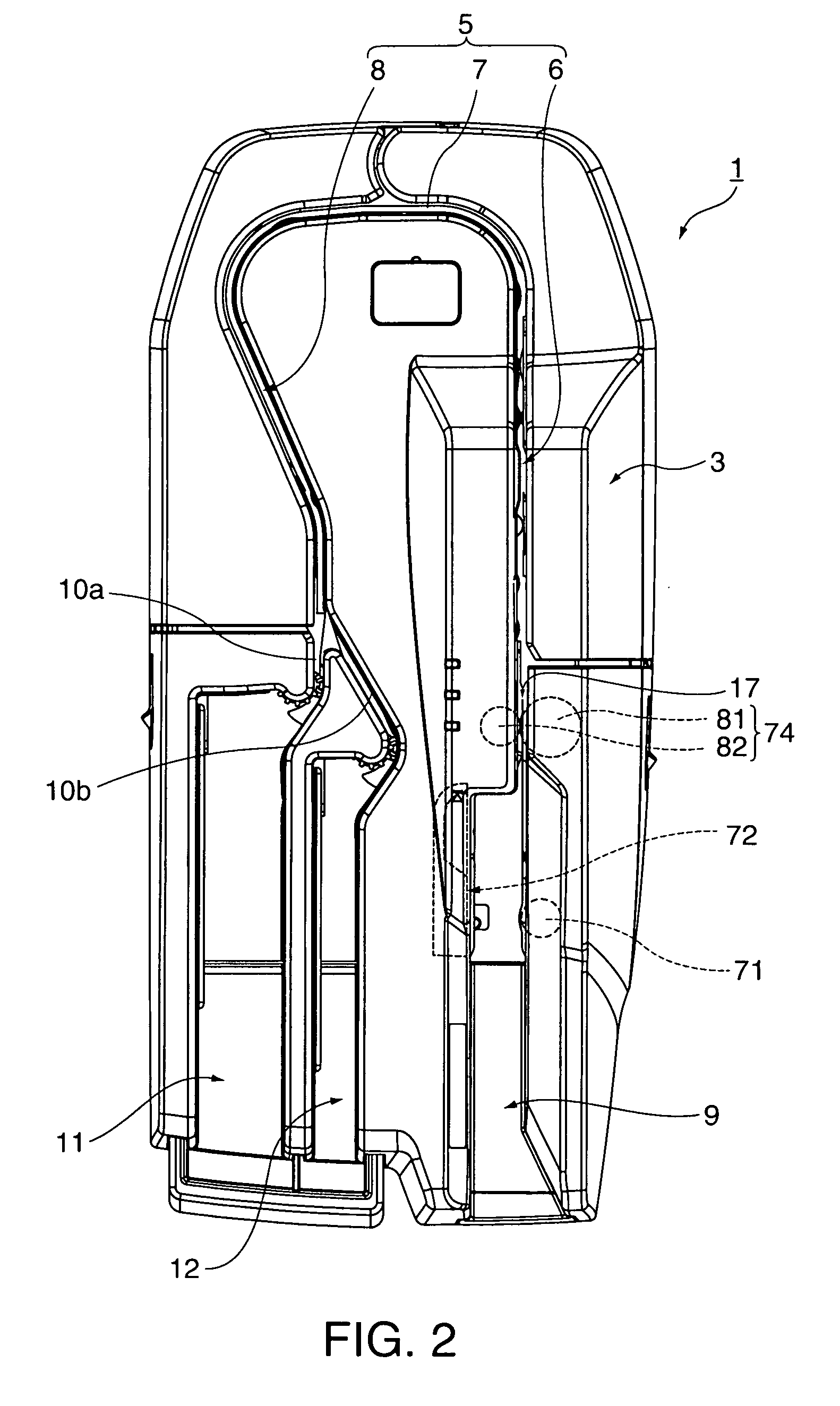

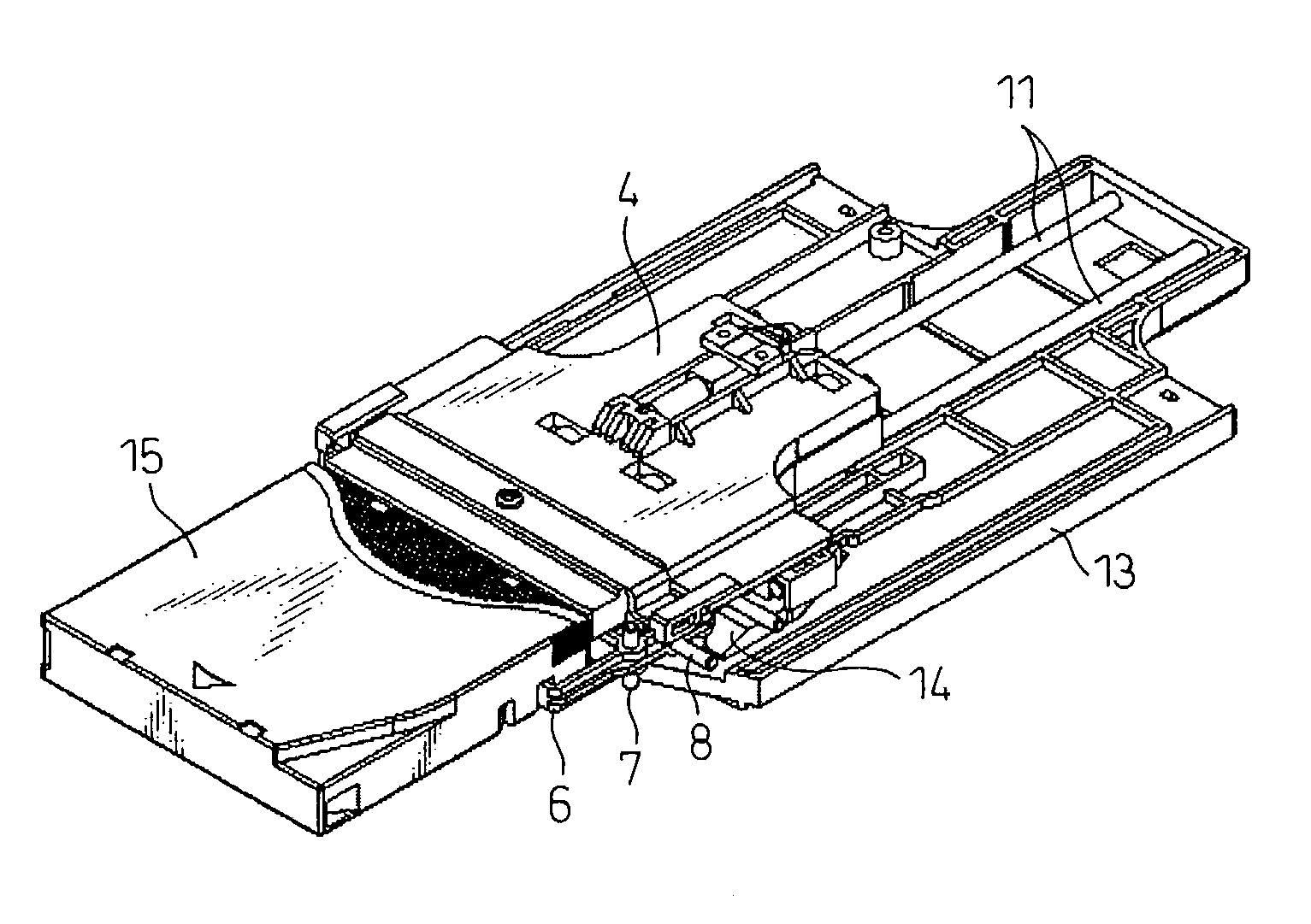

Media separating and feeding device and media processing device

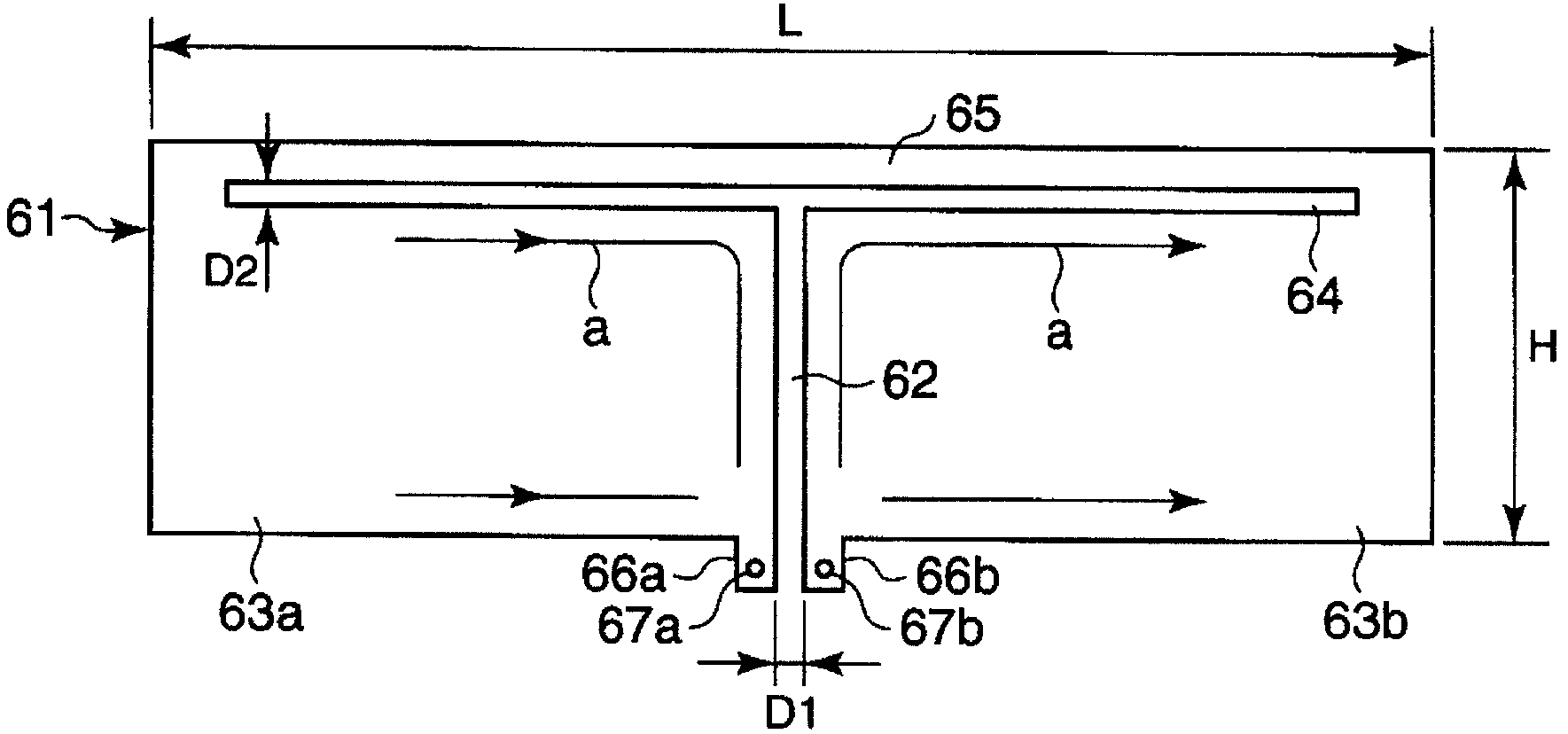

ActiveUS20090014943A1Small and low cost drive mechanismSmall installation spaceArticle feedersArticle separationDrive motorEngineering

A mechanism enables efficiently reducing the size of a check feeding device for separating and feeding checks one at a time. The check separating and feeding mechanism 13 uses a single drive motor 85 to drive the feed roller 71, pressure member 72, and separation roller 81. When the drive motor 85 turns in a second direction, torque is transferred through a second one-way clutch mechanism 88f to both rollers 71 and 81, and the check 4 separating and feeding operation begins. When the drive motor 85 turns in this direction, the first one-way clutch mechanism 88e disengages the drive motor 85 from the drive power transfer path to the pressure member 72, and a tension spring 99 pulls the pressure member 72 in the direction pressing the checks 4 to the feed roller 71. When the drive motor 85 turns in an opposite first direction, the torque of the drive motor 85 returns the pressure member 72 to the standby position, drive power is not transferred to the rollers 71 and 81, and the rollers do not turn.

Owner:SEIKO EPSON CORP

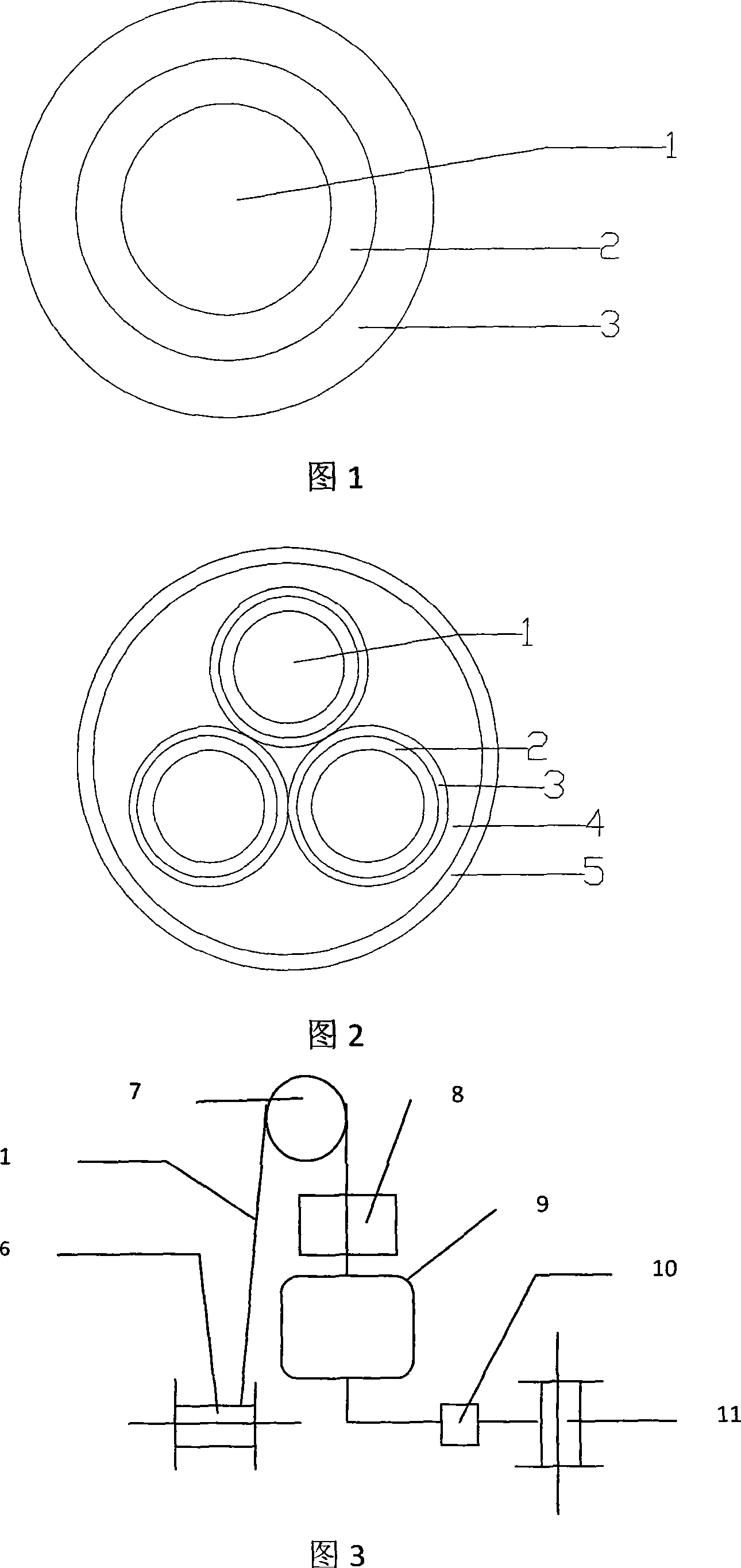

Process for manufacturing shielding soft cable with two-core semicircular conductor for communication power supply

InactiveCN102314972AImprove roundnessSmall outer diameterPower cables with screens/conductive layersCable/conductor manufactureElectrical conductorInsulation layer

The invention discloses a process for manufacturing a shielding soft cable with a two-core semicircular conductor for a communication power supply. The process mainly comprises a process for manufacturing the semicircular conductors of two core wires, a process for manufacturing the two core wires and a process for cabling, namely a braided wire consists of single wires; a plurality of braided wires form the conductor; the conductor sequentially enters a first frame-type strander and a die for re-stranding; the die behind the first frame-type strander is a circular die; the dies behind the subsequent frame-type stranders are semicircular pinch roller dies consisting of upper pinch rollers and lower pinch rollers; the conductor is gradually formed into a semicircular conductor in the process of passing through the semicircular pinch roller dies; by passing through the last frame-type strander and the semicircular pinch roller die, the semicircular conductor is formed and wrapped with a layer of binding strip so as to be fixed; insulation layers are squeezed outside the two semicircular conductors respectively so as to form the core wires; a die core and a die sleeve of a squeezing die are semicircular; planes of the two core wires are stranded relatively; the two core wires are cabled by pre-stranding; and a wrapping layer, a shielding layer and an outer sheath are wrapped outside the stranded core wires. The process is advanced and practical and is low in investment. The shielding soft cable with the two-core semicircular conductor for the communication power supply manufactured by using the process has high roundness, smaller outer diameter, high heat dissipation performance and low manufacturing cost and occupies a small space.

Owner:JIANGSU HENGTONG POWER CABLE

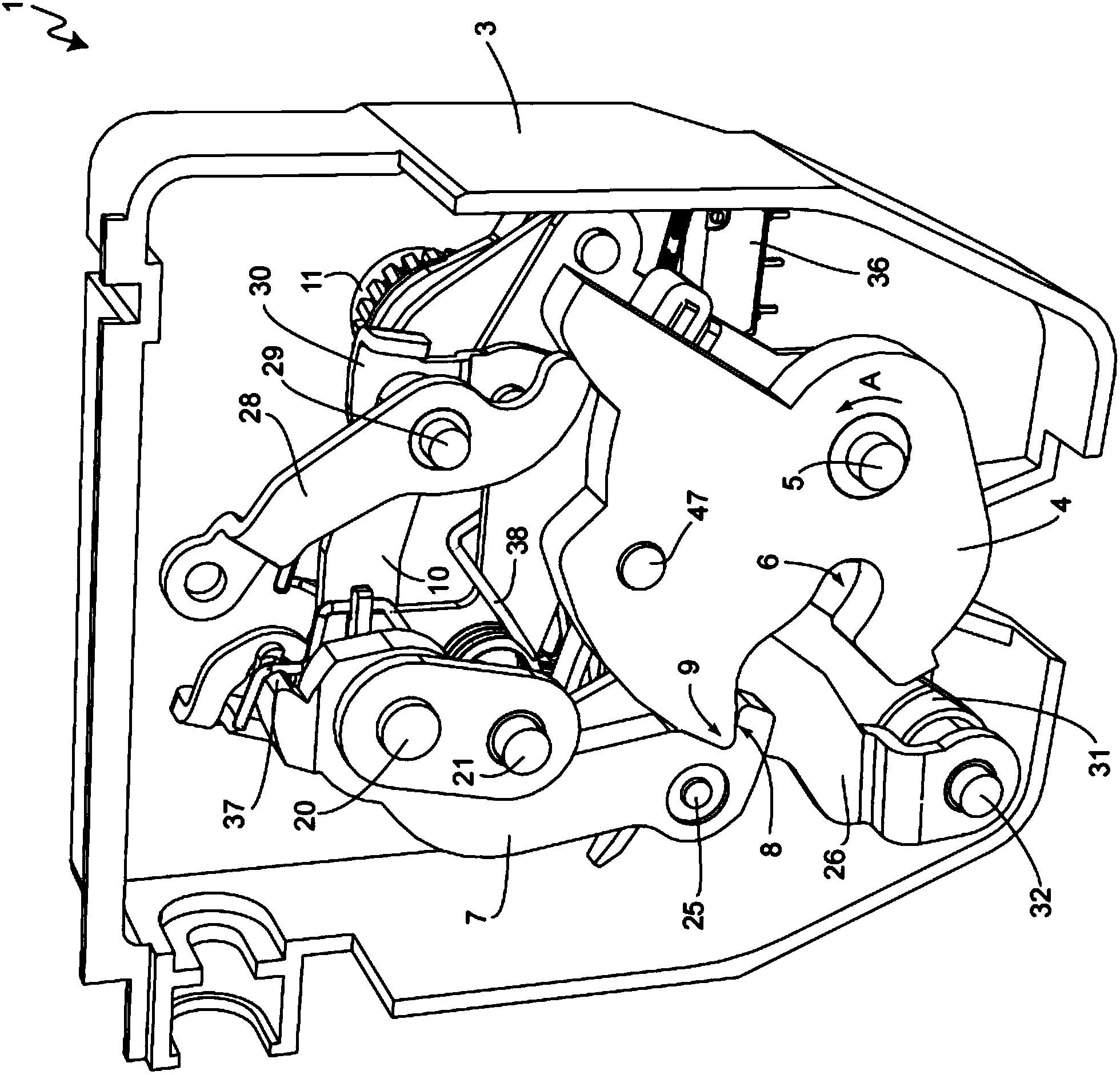

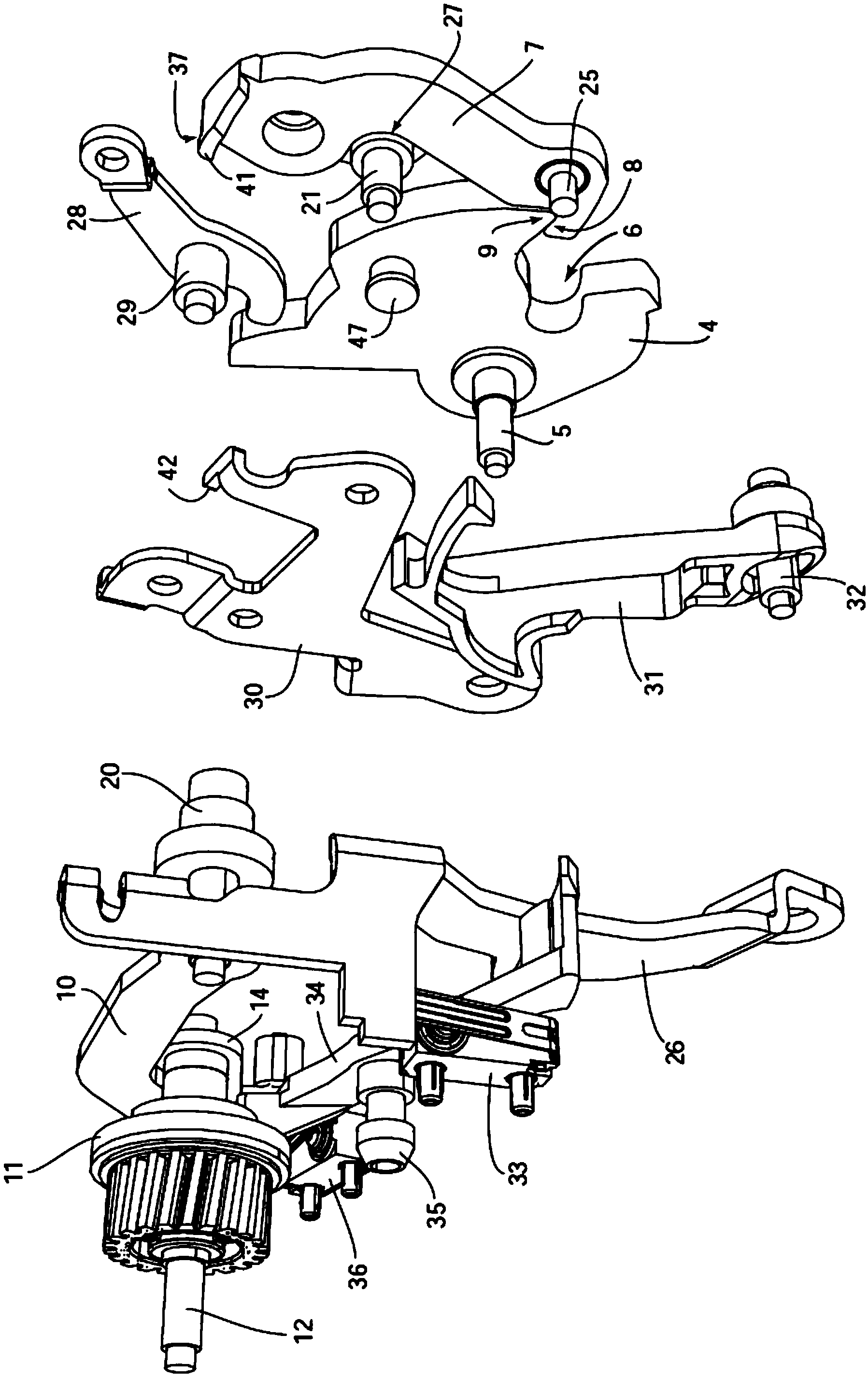

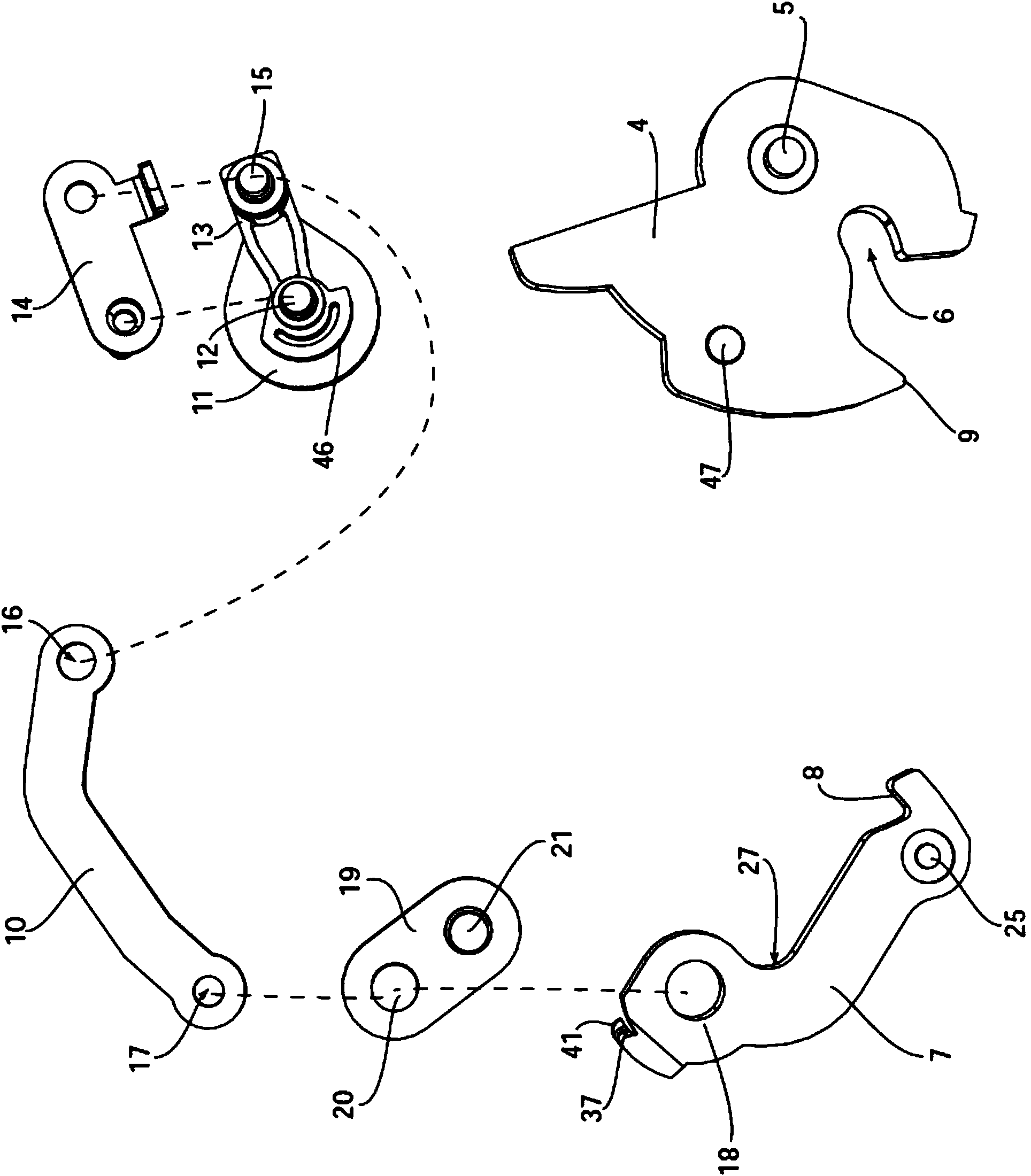

Motor vehicle door lock

ActiveCN104169510ASave installation spaceSmall installation spaceNoise-prevention/anti-rattling lockingNon-mechanical controlsCouplingElectric machine

The invention relates to a motor vehicle door lock (1), comprising a rotary latch (4) that in a locking position encompasses a locking element (2) and that is pre-tensioned in the direction of an open position releasing the locking element (2), a pawl (7) that, in an engagement position with the rotary latch (4), is engaged in such a manner that the rotary latch (4) is inhibited from moving in the direction of the open position, and a drive element (11), by means of which a coupling section (18) of the pawl is coupled in terms of movement and which moves the pawl (7) between an engagement position and a release position in which the pawl (7) is not engaged with the rotary latch (4), so that the rotary latch (4) can move in the direction of the open position. The invention aims at creating a solution by means of which a reliably working motor vehicle door lock having a compact design is provided both in a simple manner in terms of design and cost-effectively, said motor vehicle door lock being able to make do with a motor operating on a low energy level. This is achieved in that force is applied to the pawl (7) only in the engagement position thereof and the force application holds the pawl (7) in engagement with the rotary latch (4).

Owner:HUF HULSBECK & FURST GMBH & CO KG

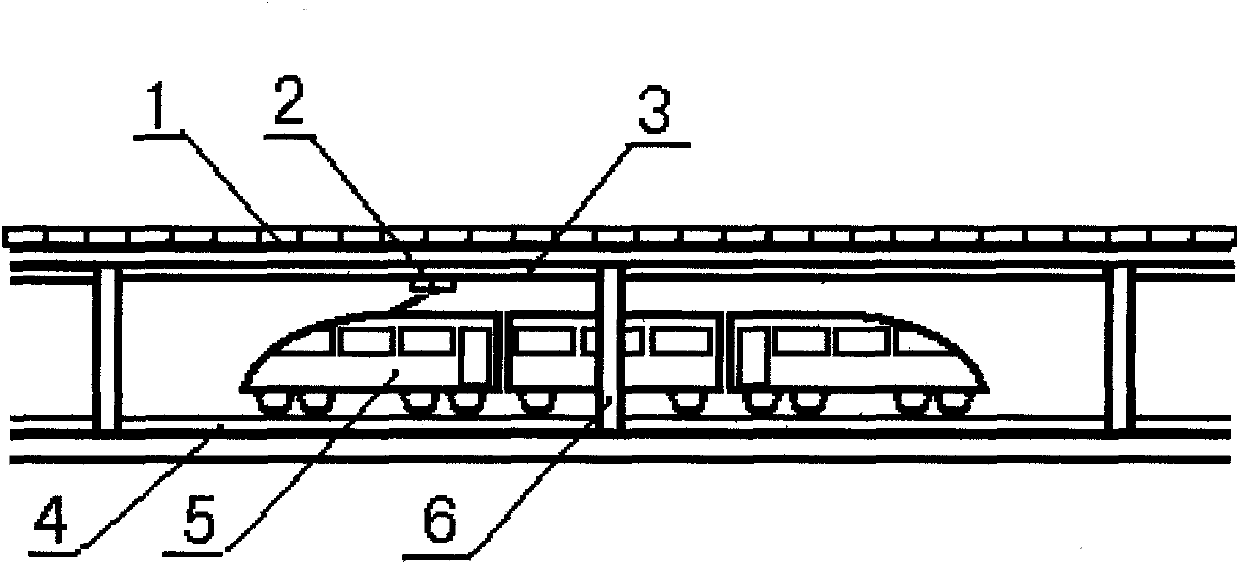

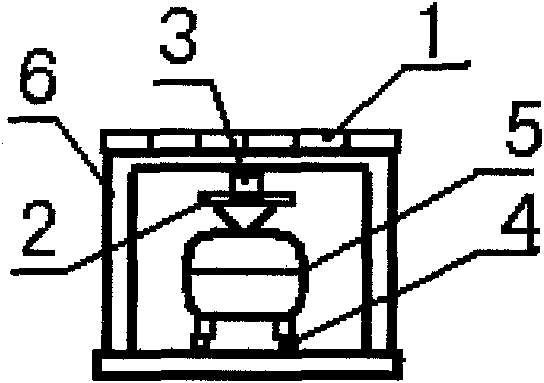

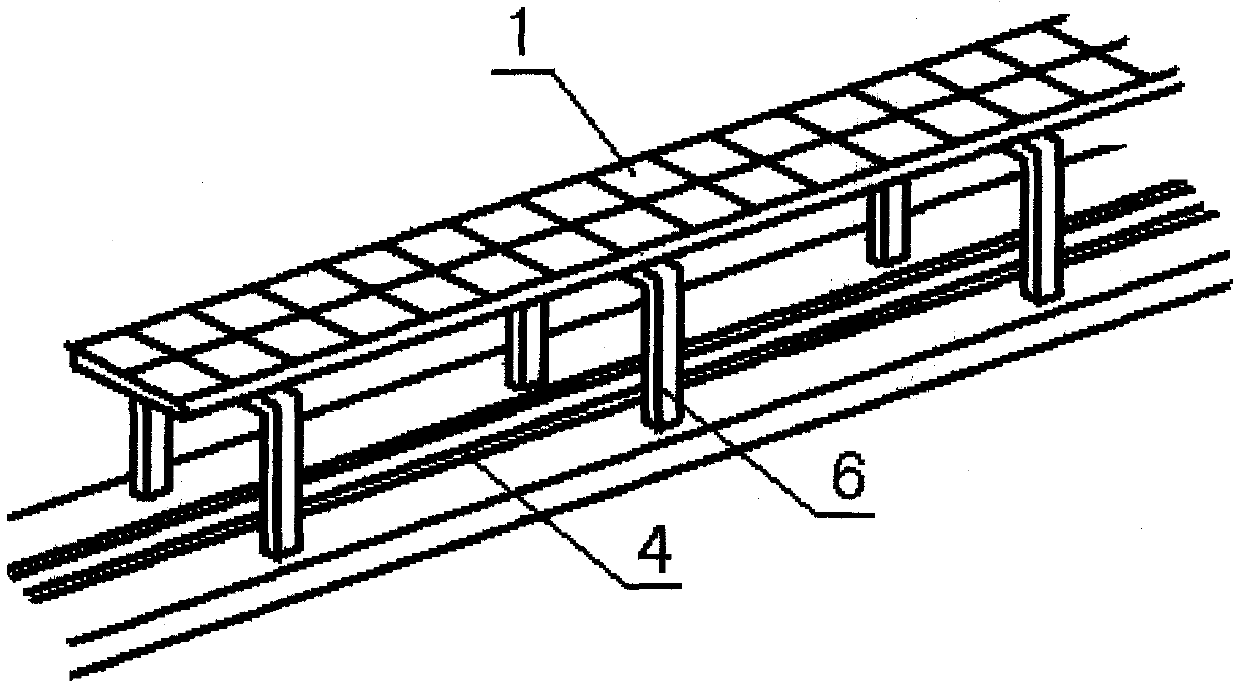

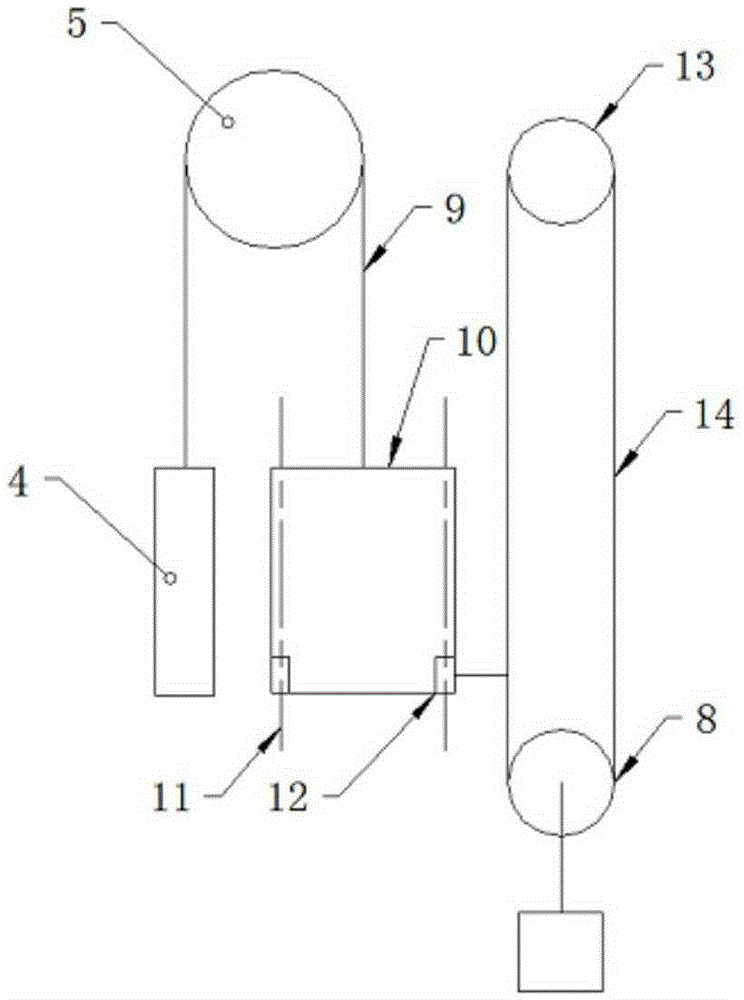

Rail transportation system powered by solar energy

InactiveCN101774355ASave resourcesSmall installation spacePower railsVehicular energy storageElectric machineryDriving range

The invention relates to a rail transportation system powered by solar energy, which consists of a solar panel, an installation rack, supply rails, rails for the running of vehicles and rail vehicles or road vehicles which are provided with collectors and are driven by motors. The rail transportation system is characterized in that the solar panel and the supply rails are arranged above the rails or on both sides of the rails through the installation rack; the vehicles run on lines are contacted with the supply rails through the collectors to provide electrical power for the vehicle-mounted motors to drive the vehicles; and the rail transportation system can meet the requirement of the running of the vehicles on high-speed rails of over 300 kilometers. A solar interval power-supply system consists of a plurality of continuous disconnected and independent power-supply intervals, can provide the electric power for the rail vehicles and automobiles which are provided with the collectors and are driven by the motors, and overcomes the defects of large installation space of storage cells, and excessive increment of dead weight and short driving range of pure electric automobiles, so that the pure electric automobiles and dual-mode vehicles can be widely applied on a large scale; and in addition, when automobiles with light-weight steel wheels are run on steel rail lines, energy can be saved by 40 to 70 percent, and thus the solar interval power-supply system can save the energy and protect environment.

Owner:HEFEI BOPU HIGH TECH

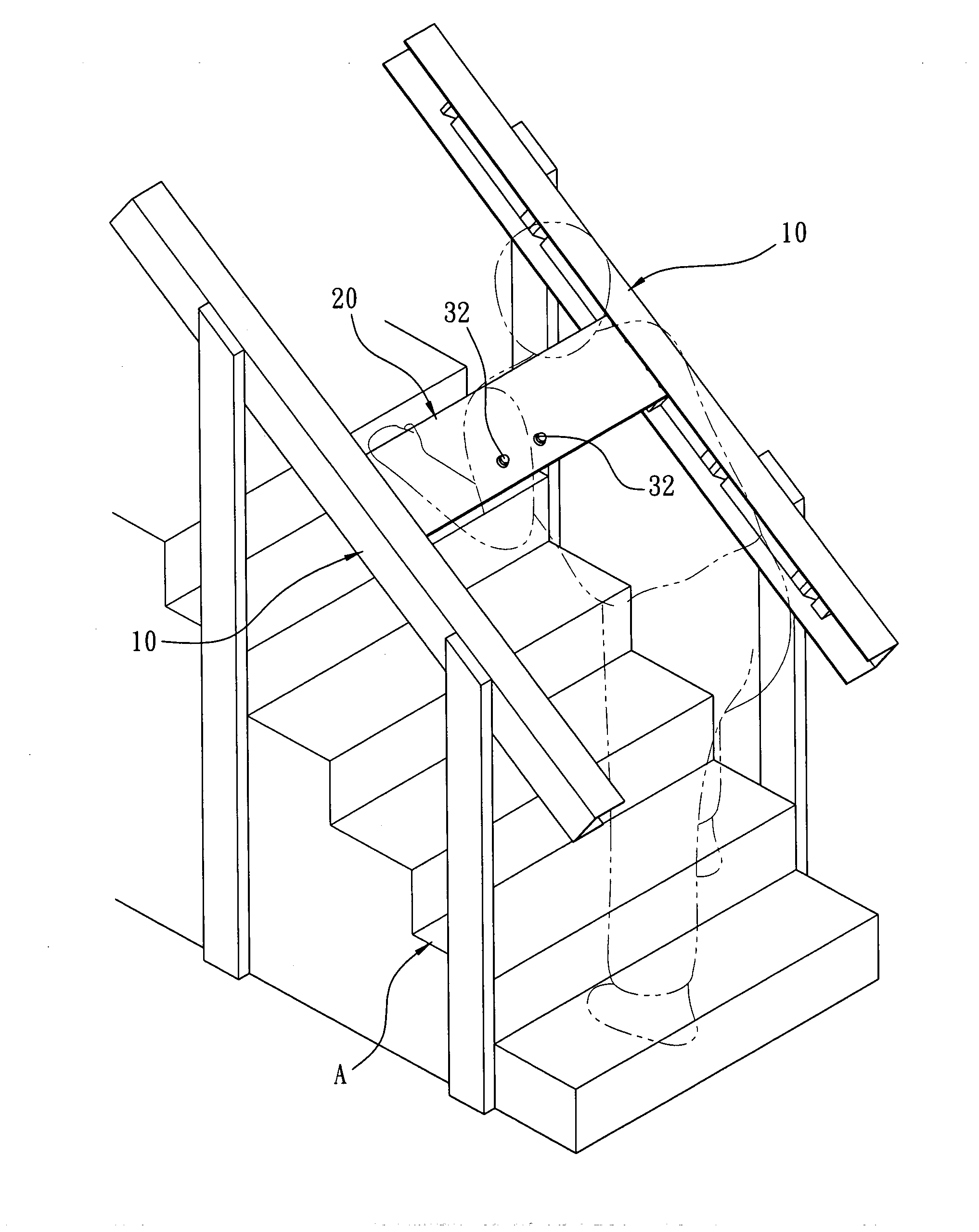

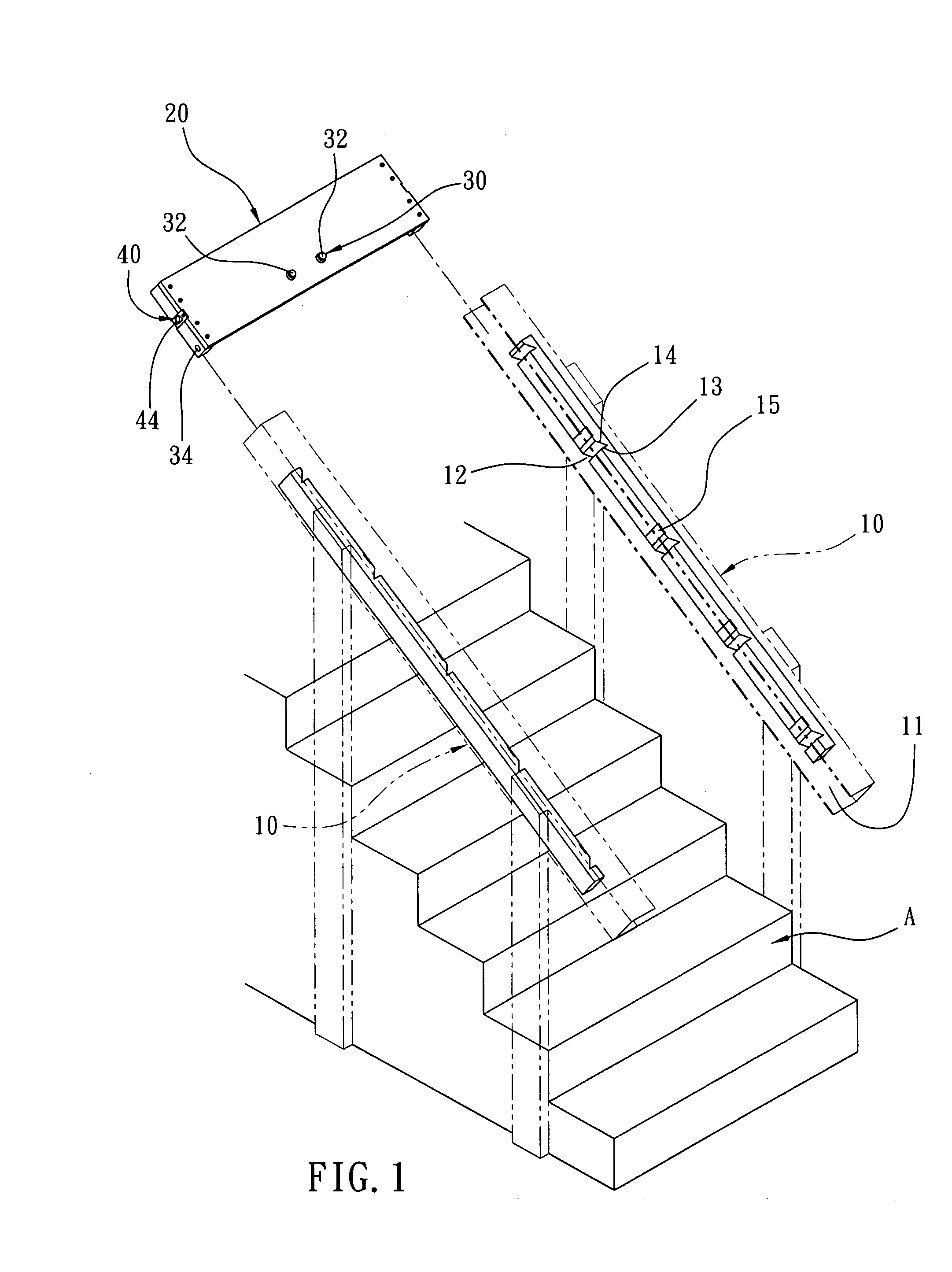

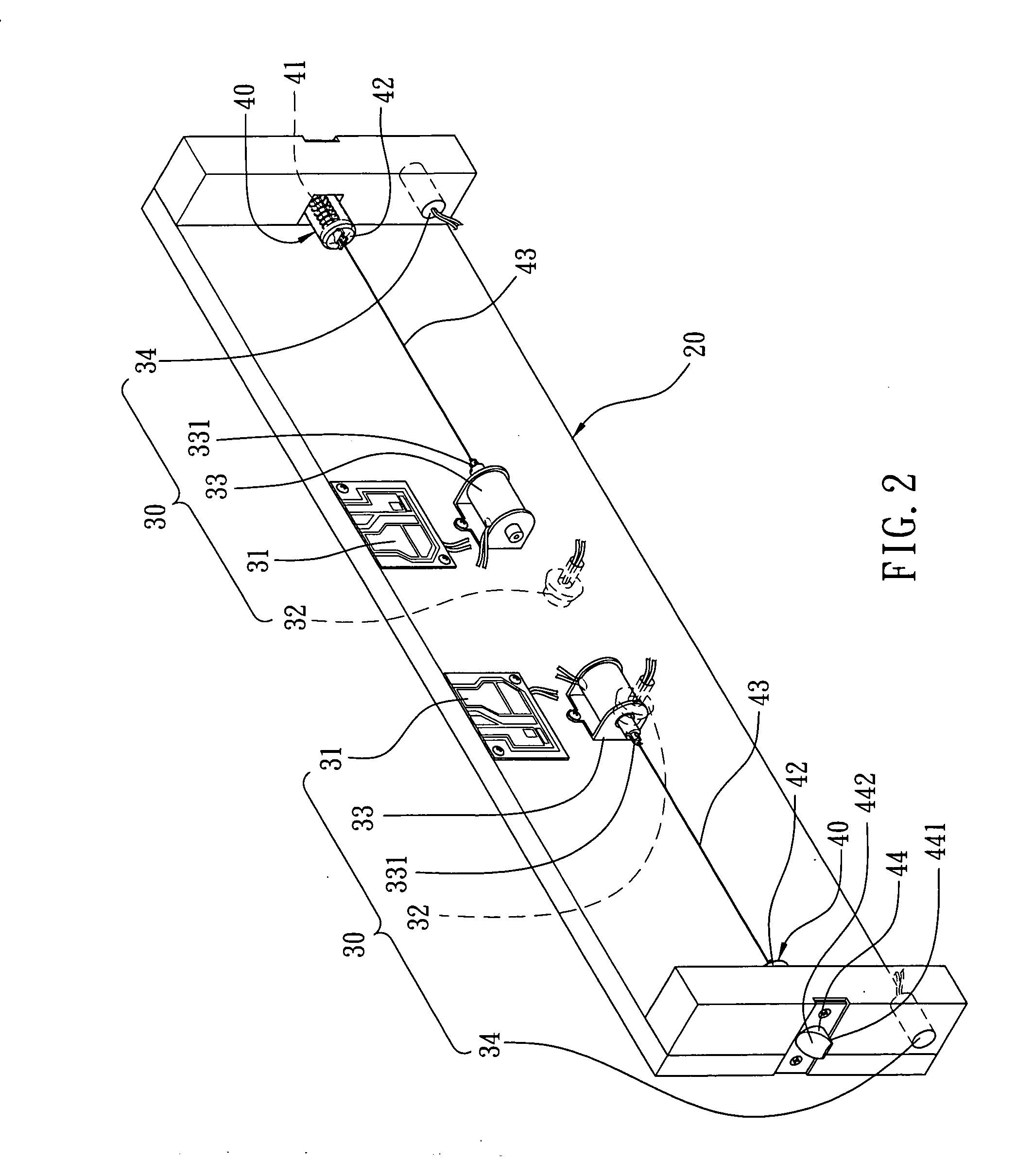

Stair Climbing Aid

InactiveUS20080264722A1Affordable for any familySmall installation spaceWalking sticksScaffold connectionsEngineeringPositioning system

A stair climbing aid comprises two slide rails, an assist member, a control mechanism and two positioning assemblies. The slide rails and the assist member are assembled to handrails at both sides of the stairs. The control mechanism is disposed on the assist member to be controlled by the user. The positioning assemblies are disposed at both sides of the assist member, each positioning assembly is provided with an engaging portion to be engaged in the respective positioning portions of the slide rail. Thereby, an anti-slide effect is produced, so as to prevent the user from falling down the stairs and to help the user move from step to step safely.

Owner:NAN KAI COLLEGE

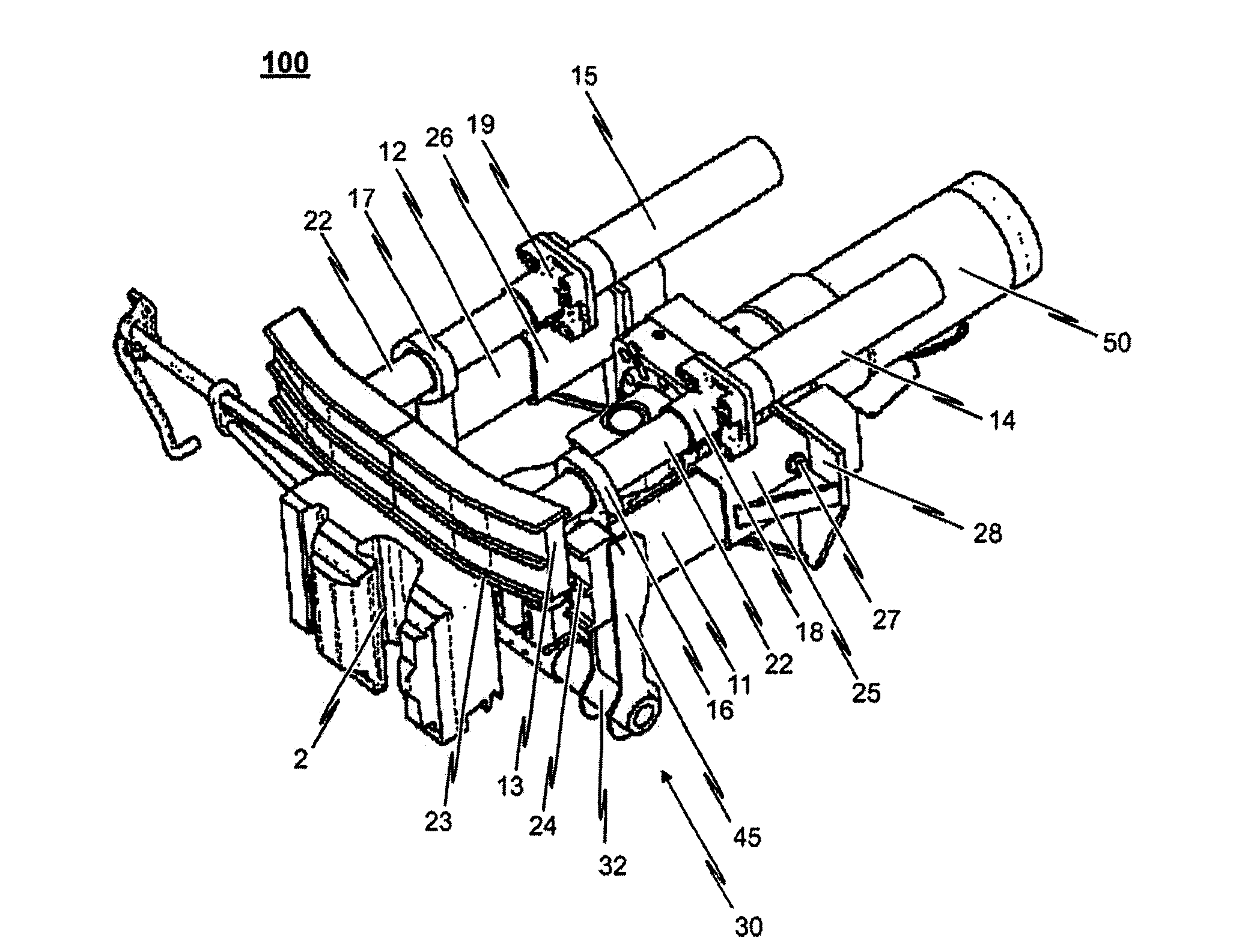

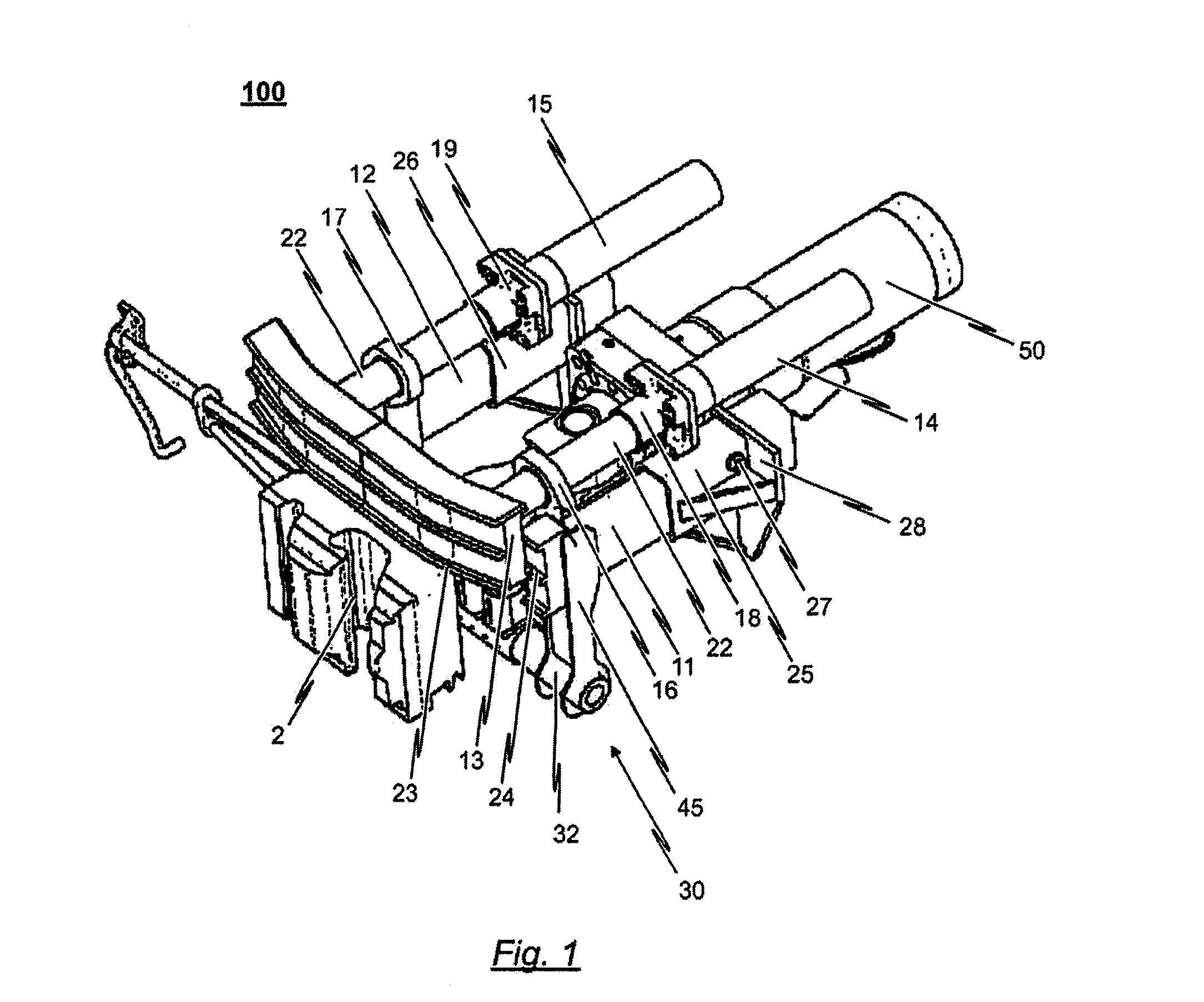

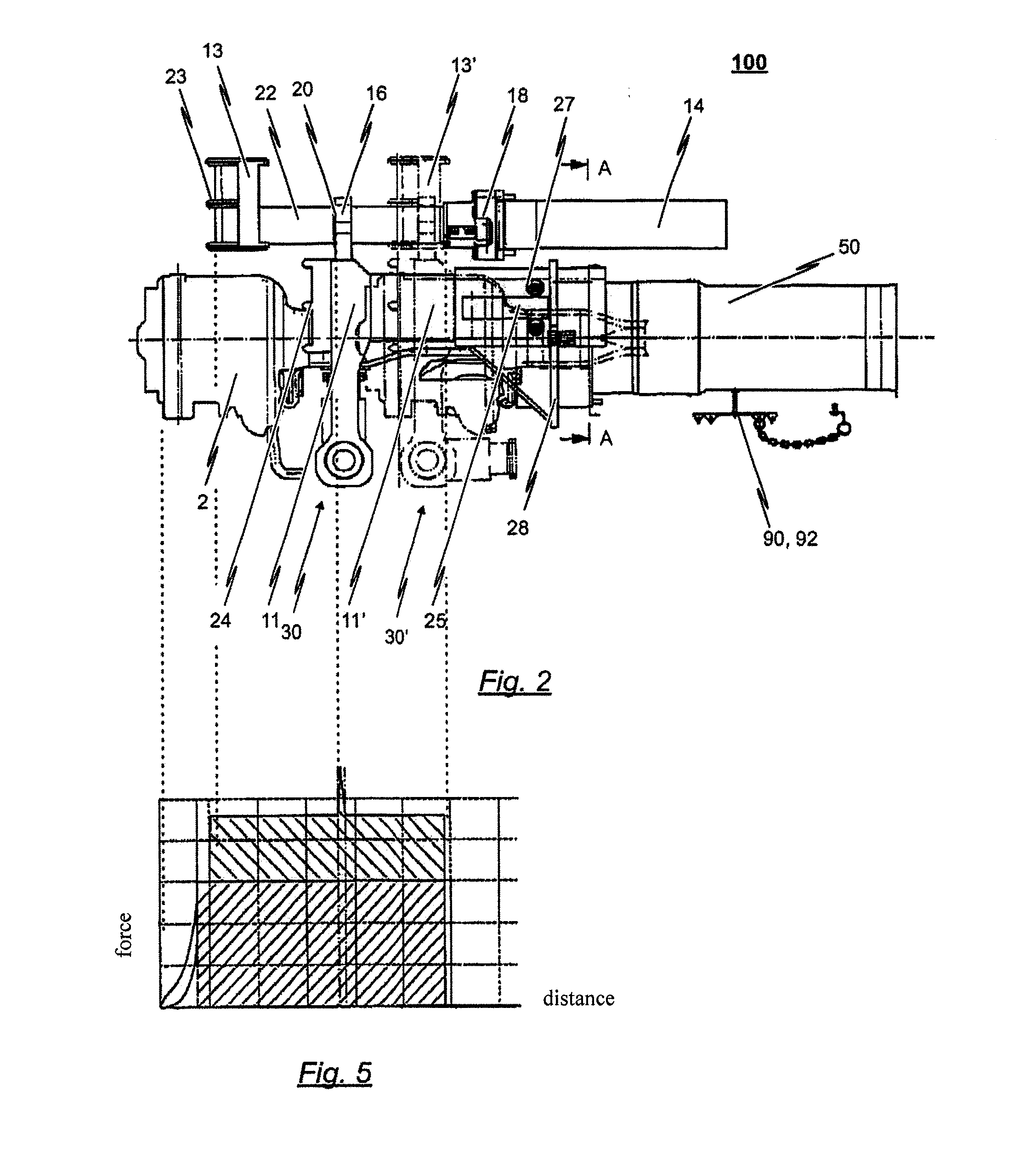

Coupling arrangement for the front of a tracked vehicle

ActiveUS20130126458A1Improve energy consumptionSmall installation spaceBufferDraw-gearCouplingClassical mechanics

A coupling arrangement for the front of a tracked vehicle is disclosed, comprising a central buffer coupling having a gladhand, a coupling shaft supporting the gladhand and a bearing, via which the coupling shaft can be joined with the undercarriage of the vehicle pivotable in a horizontal and / or vertical direction. An energy consuming device allocated to the central buffer coupling having at least one energy consuming element with a destructive design is provided. To ensure maximum energy consumption in a crash with a course of events definable in advance, the coupling arrangement additionally comprises a supporting structure with two longitudinal beams arranged on the sides of the central buffer coupling and a crossbeam joined with the two longitudinal beams, said crossbeam beam being arranged above the central buffer coupling such that a vertical deflection of the coupling shaft relative to the undercarriage of the vehicle is limited by the crossbeam.

Owner:VOITH PATENT GMBH

Fireproof cable and its making method

ActiveCN101236801AImprove fire resistanceHigh temperature resistanceInsulated cablesInsulated conductorsFiberElectrical conductor

The invention relates to an improvement for a fire-resistant cable. The invention is characterized in that: an outer refractory insulating layer of a conductor is high temperature extruded siliceous compounds with a thickness of 0.05 to 1.0 millimeter, and an outer protective layer is a refractory fiber braid ply. Compared with the prior fire-resistant cable, the fire-resistant cable can be produced with long length; the production process is simple; the outside diameter of the cable is small; the occupied space of laying is small; the twisting property is moderate; recovery and separation of waste cables are easy, and recovery materials can be recycled and are pollution-free; refractory insulating raw material resources are numerous and the cost of the refractory insulating raw material resources is low, thereby the cost of fire-proof insulation of the cable can be reduced and is respectively reduced by 70 percent, 40 percent and 50 percent compared with mineral insulation, mica insulation and silicon rubber insulation; the waterproof, oil proof and radioresistant performances are superior to the prior fire-resistant cable; the refractoriness and the thermotolerant level are high; the fire-resistant cable can be operated under the environment of 1000 DEG C over a long period of time; the bend radius is 20 times or so of the cable diameter. At least one intermediate layer of the silicon refractory insulating layer is made of silicon dioxide, and an inner layer and an outer layer on both sides are made of silicon compounds different from the silicon dioxide or silicon dioxide with different crystalline structures, thereby light signals can be also transmitted and then the fire-resistant cable simultaneously has the function of photocommunication.

Owner:FAR EAST CABLE +2

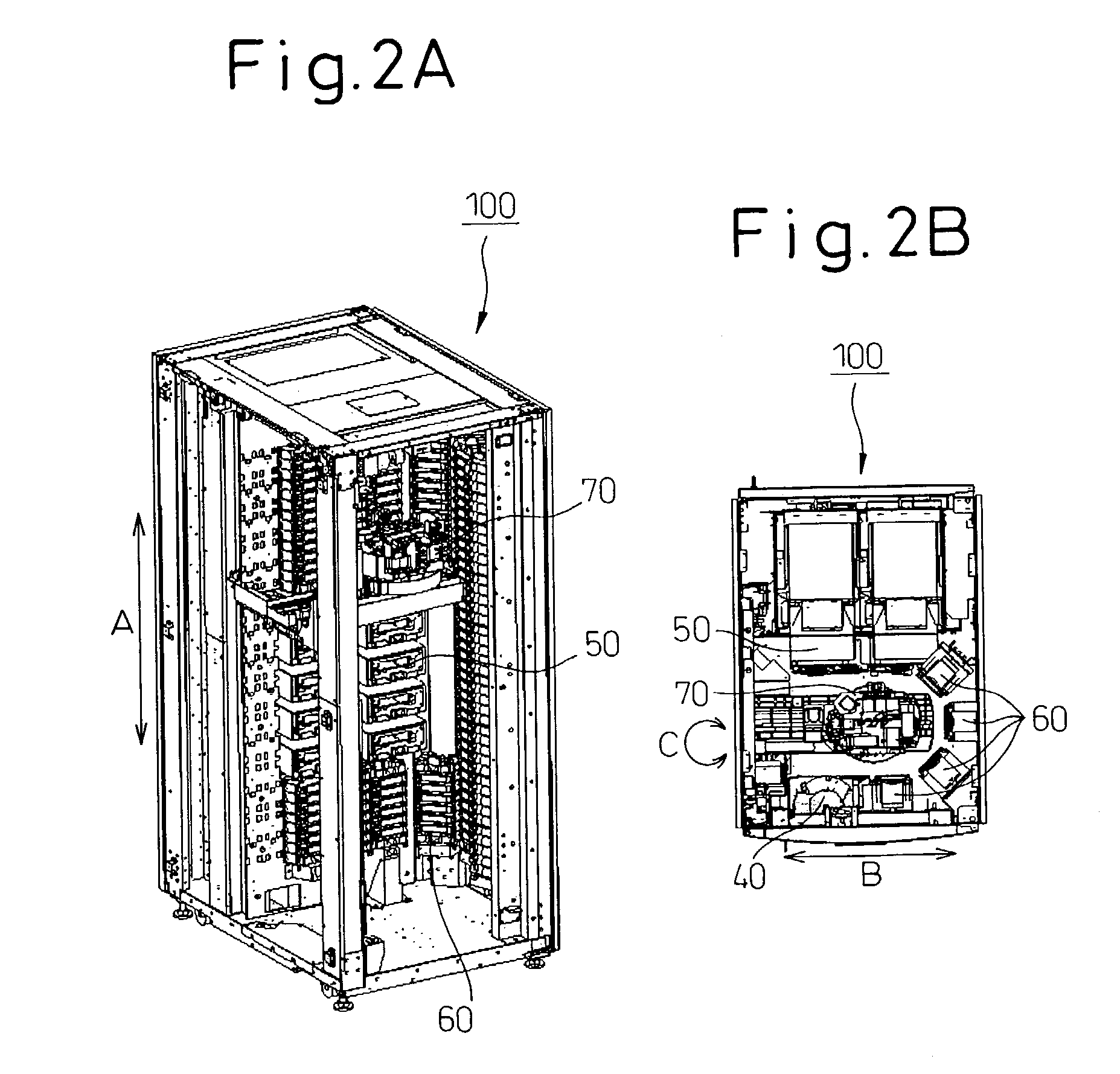

Robot hand for transferring an article in a housing, and a library apparatus equipped with the robot hand for transferring and article stored in a rack

InactiveUS7016144B2Small installation spaceEasy constructionRecord information storageAutomatic cassette changing arrangementsEngineeringReciprocating motion

A robot hand that does not depend on cartridge types wherein high reliability can be ensured and the size and cost can be reduced with a simple construction. In a library apparatus including a recording and reproducing device for cartridge type media and cartridge accommodating racks, a robot hand is configured to include a hand mechanism including hooks for holding the cartridge and actuators for performing to and fro movement and opening and closing movement of the hooks, and a mounter for pushing the cartridge when the cartridge is inserted into the recording and reproducing device by the hand mechanism, wherein the to and fro movement and the opening and closing movement of the robot hand and the pushing movement of the mounter is performed by one motor. The cartridge is grasped / released efficiently by the movement of the hooks, the actuators and the mounter.

Owner:FUJITSU LTD

Brake system for a vehicle and method for operating a brake system for a vehicle

InactiveUS20120091788A1Easy to coverFree travel distanceRotary clutchesTelemotorsInternal pressureActuator

A brake system for a vehicle includes: a brake activation element; an input piston displaceable by at least a predefined minimum actuator travel distance when the brake activation element is operated; an output piston to which a driver braking force is transmittable from the brake activation element via the displaced input piston such that an internal pressure in a piston-cylinder unit of the brake system is increased; a first brake booster; and a spring device which, when the brake activation element is operated for an actuator travel distance which is less than the minimum actuator travel distance, is deformed in such a way that transmission of the driver braking force to the output piston is prevented.

Owner:ROBERT BOSCH GMBH

Antenna

InactiveUS20090121957A1Easy to set upThe degree of freedom becomes largerProtective material radiating elementsRadiating element housingsRadiating elementMetal

A plate-shaped radiating element of a shape having at least three planes is formed by bending a metal plate having a substantially rectangular shape. A first slit is provided from a lower edge of the plate-shaped radiating element up to a portion in the vicinity of an upper edge of the plate-shaped radiating element while passing through a center point of the plate-shaped radiating element, and forms plate-shaped dipole elements on both sides thereof. A second slit is provided parallel to the upper edge of the plate-shaped radiating element and forms a folded element on an upper side thereof. Feeding points are provided on both sides of the first slit at the lower edge of the plate-shaped radiating element.

Owner:YAGI ANTENNA

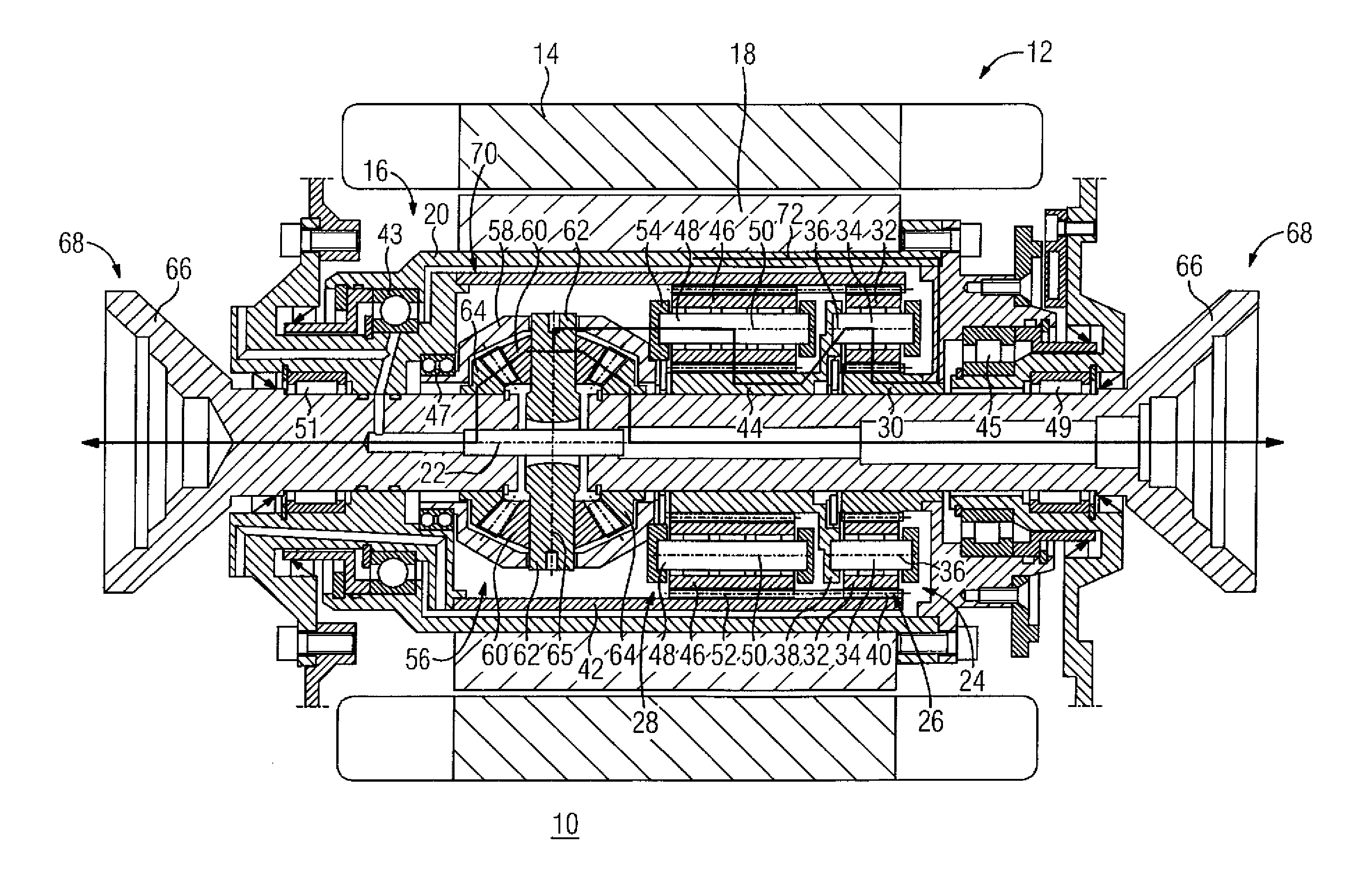

Drive device for a motor vehicle

InactiveUS20130274050A1Small space requirementEffective and efficient conversion of torqueElectric propulsion mountingToothed gearingsElectric machineMotorized vehicle

A drive device for a vehicle includes at least one electric machine having at least one rotor element which is configured to delimit an installation area in a radial direction. Disposed, at least partly, in the installation area, is at least one transmission device which is configured to be driven by the electric machine via the rotor element.

Owner:SIEMENS AG

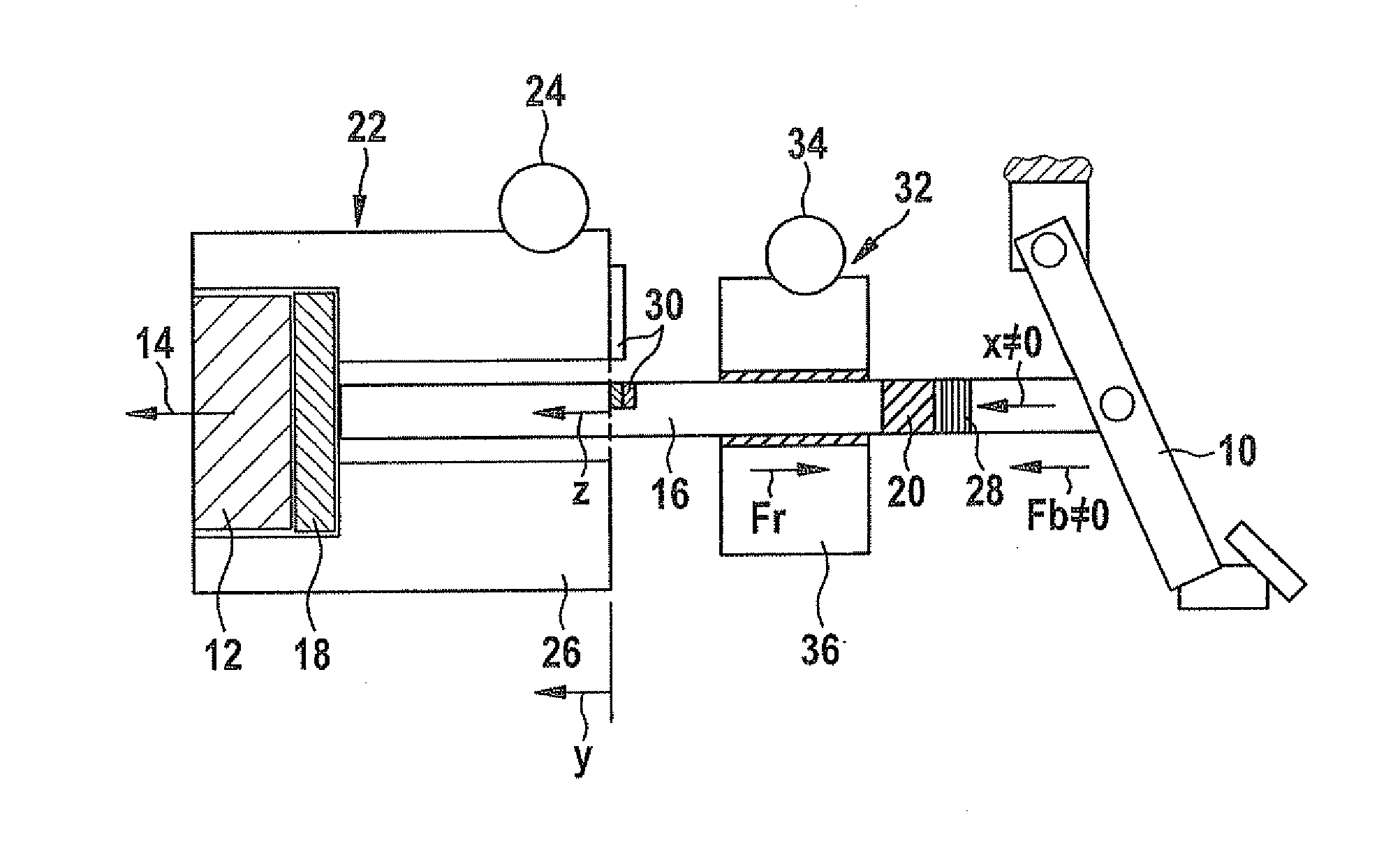

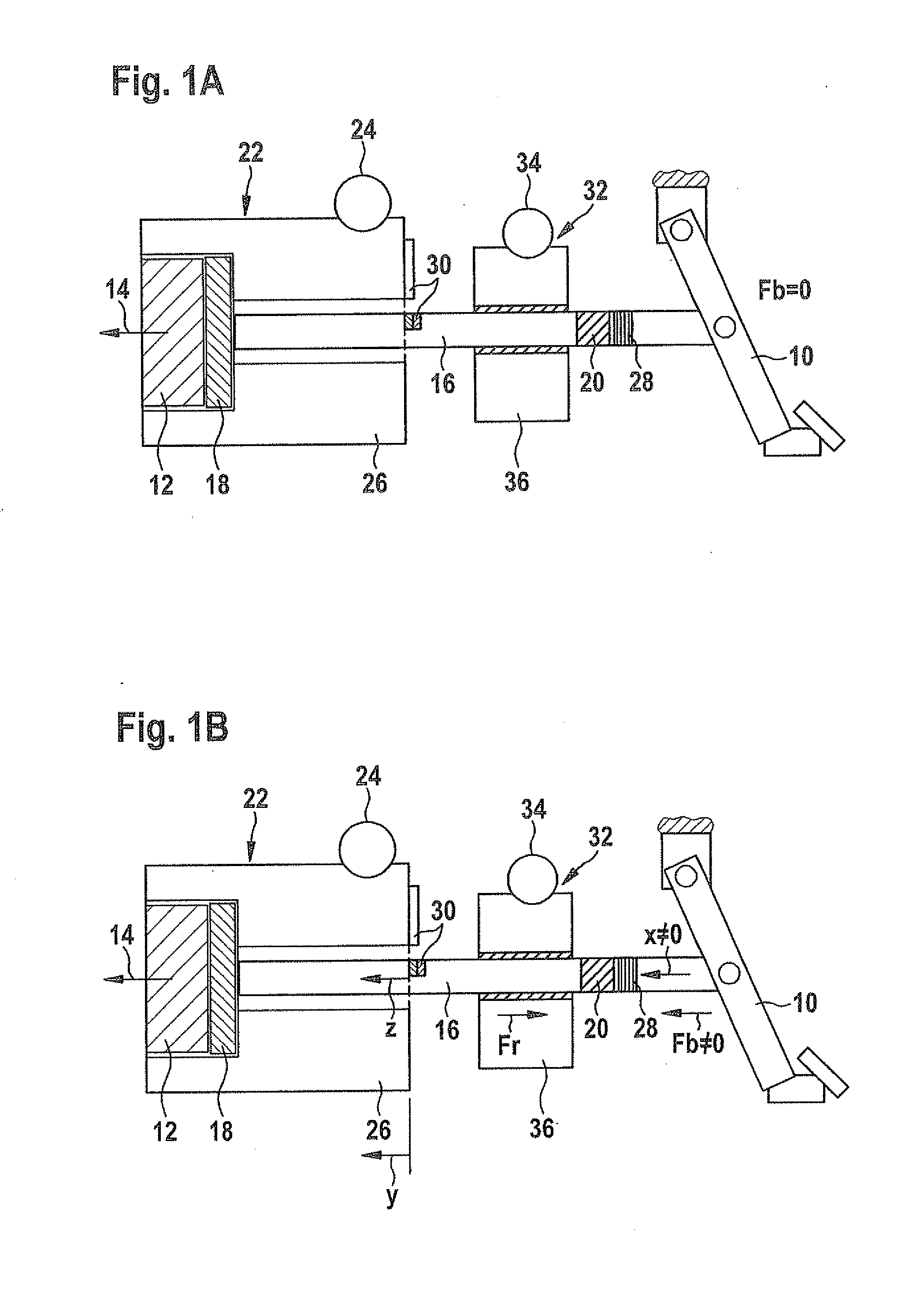

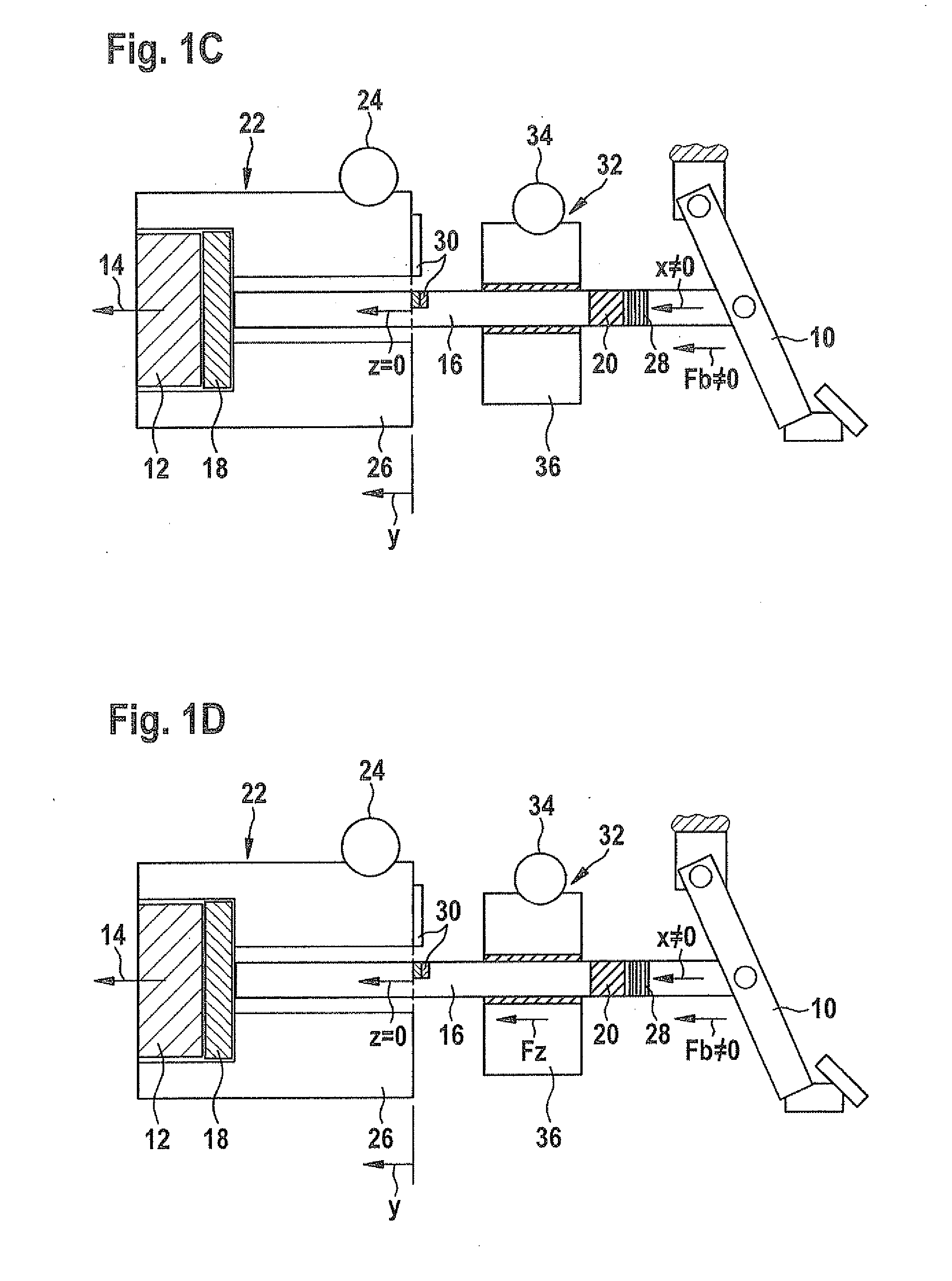

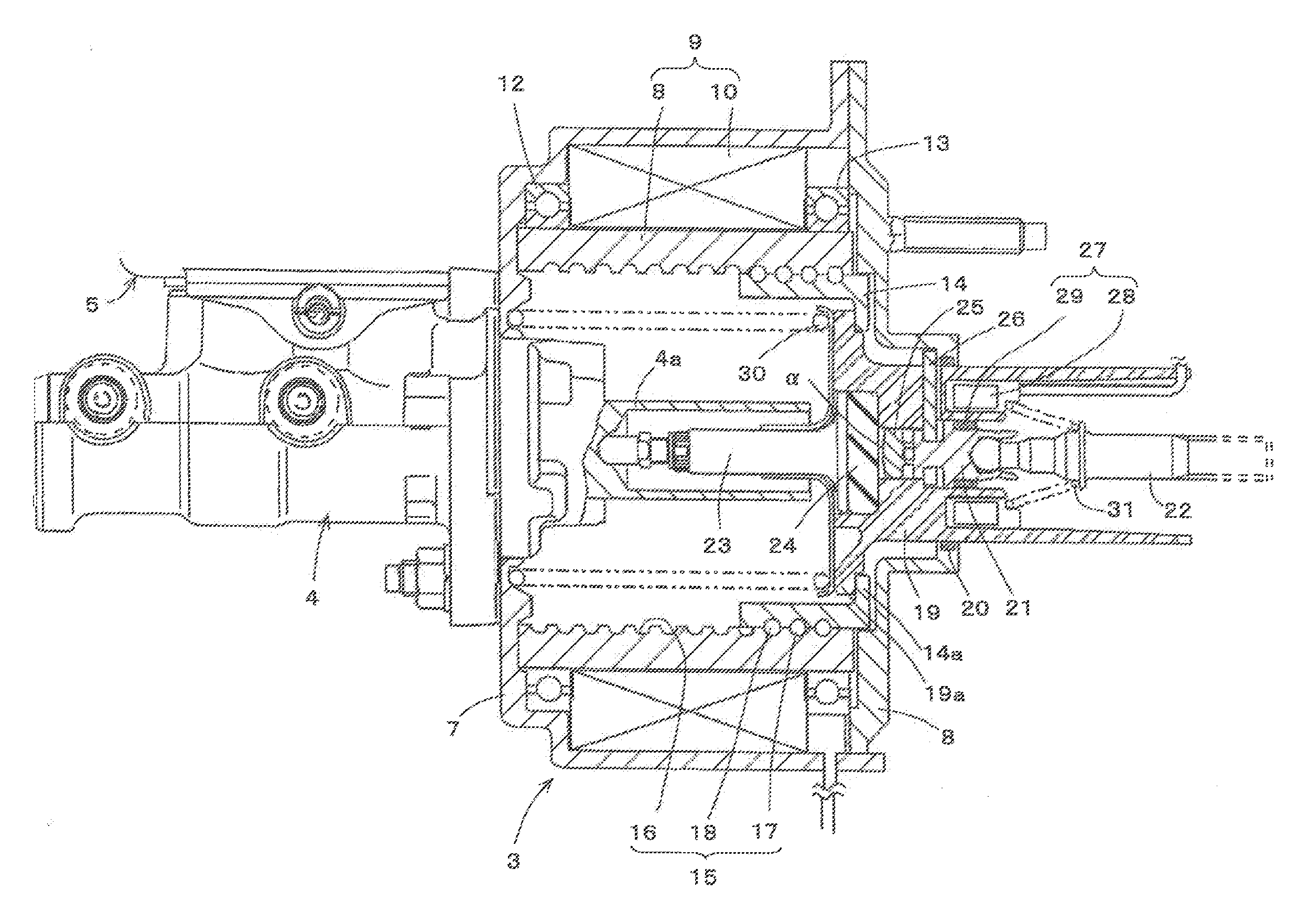

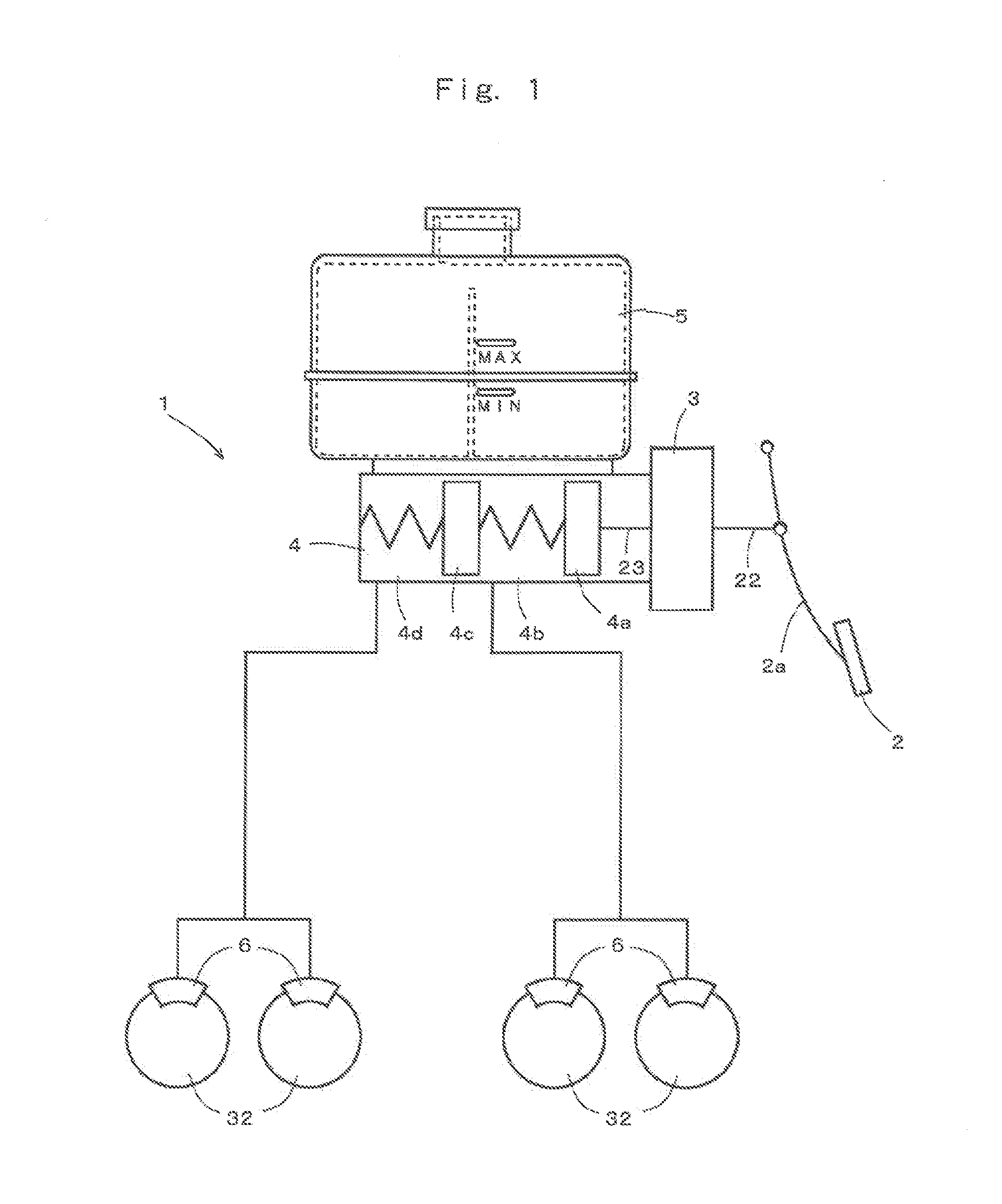

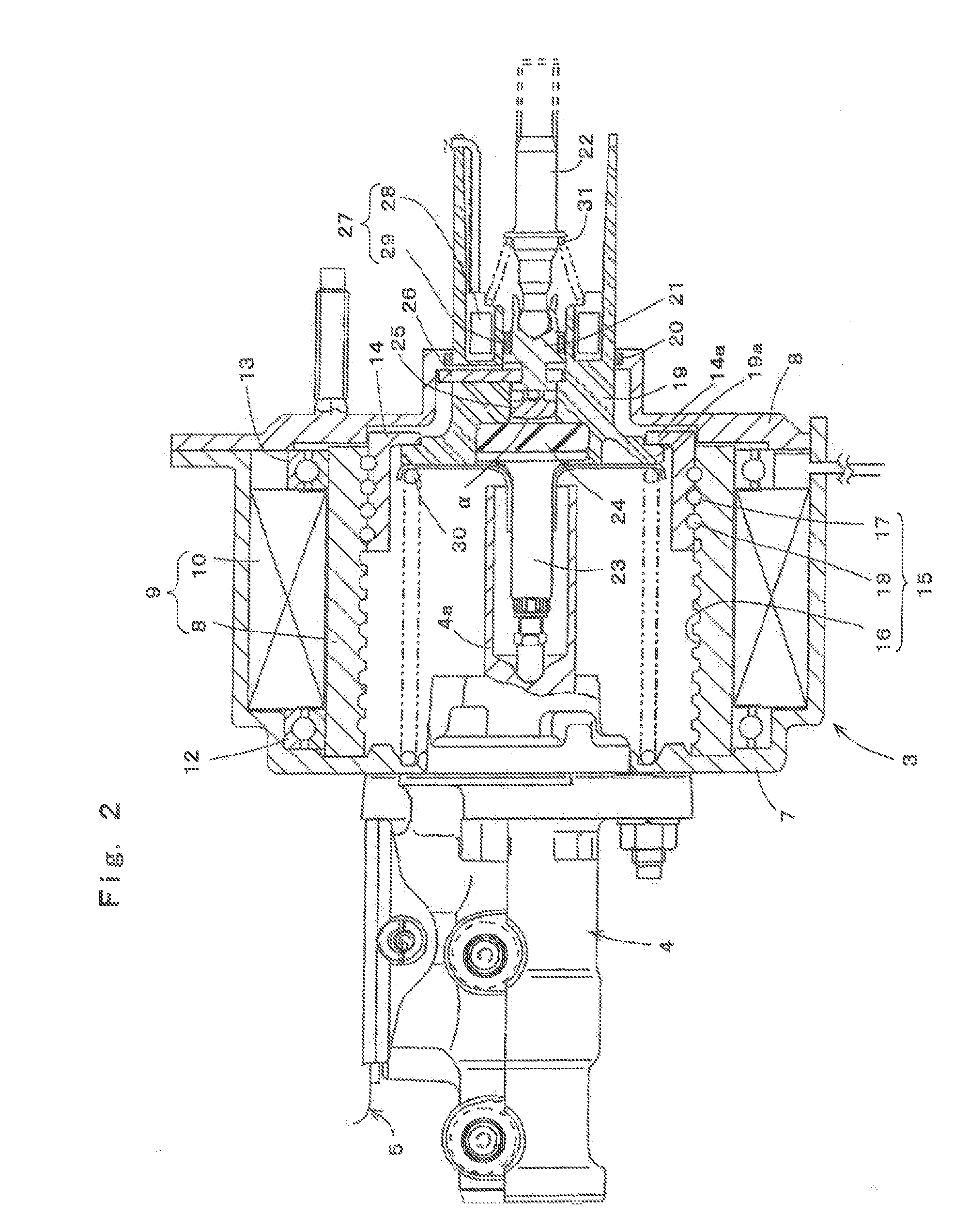

Electric booster and brake device using the same

InactiveUS20120324882A1Reduce in quantityReduction in torque resistanceBraking action transmissionRotary clutchesHysteresisPiston

[Problem] To provide an electric booster that can mechanically exhibit a jump-in characteristic and hysteresis characteristic without relying on control software.[Means for Resolution] An electric booster 3 includes an electric motor 9; a power piston 14 that receives impelling force generated by rotation of the electric motor 9; a power piston support member 19 that supports the power piston 14; an input shaft 22; an input receiving member 21 that receives input from the input shaft 22 and that is provided so as to be relatively moveable with respect to the power piston support member 19; an output shaft 23; reaction disc 24, formed from a viscoelastic material, that receives reaction force from the output shaft 23; and a spacing member 25 that is connected to the input receiving member 21 and that is disposed with a predetermined gap α between it and the reaction disc 24.

Owner:BOSCH CORP

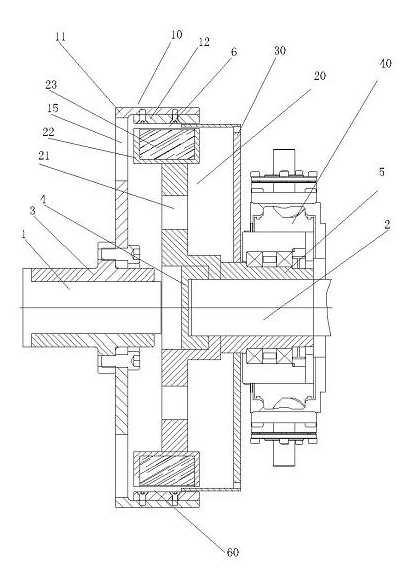

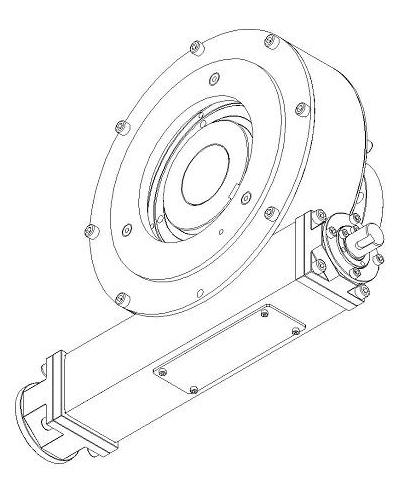

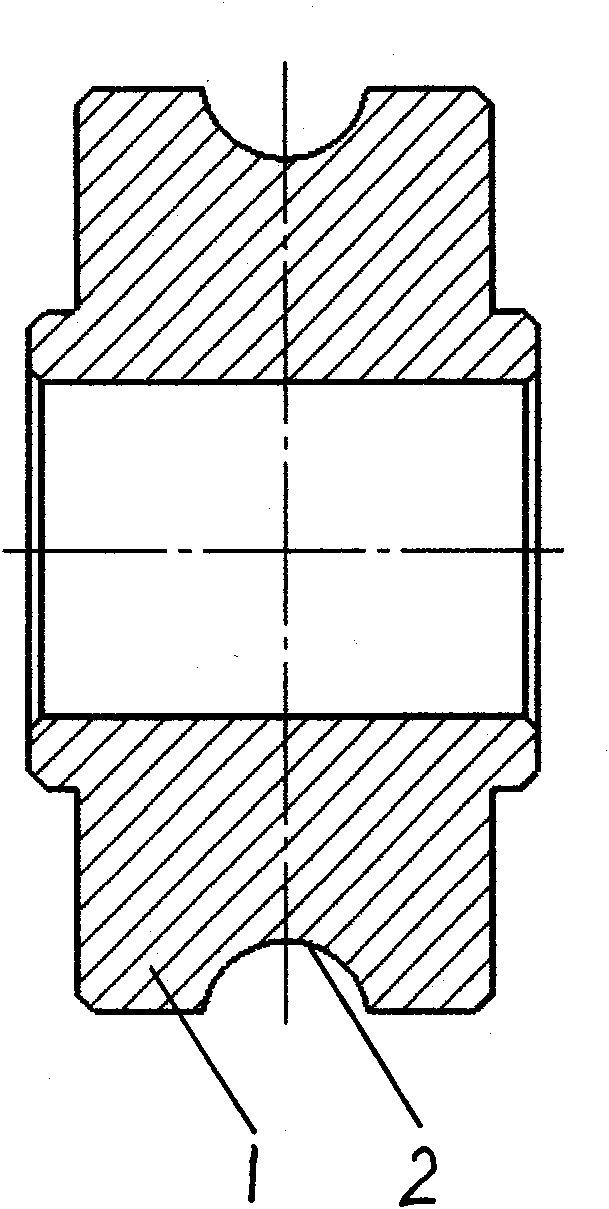

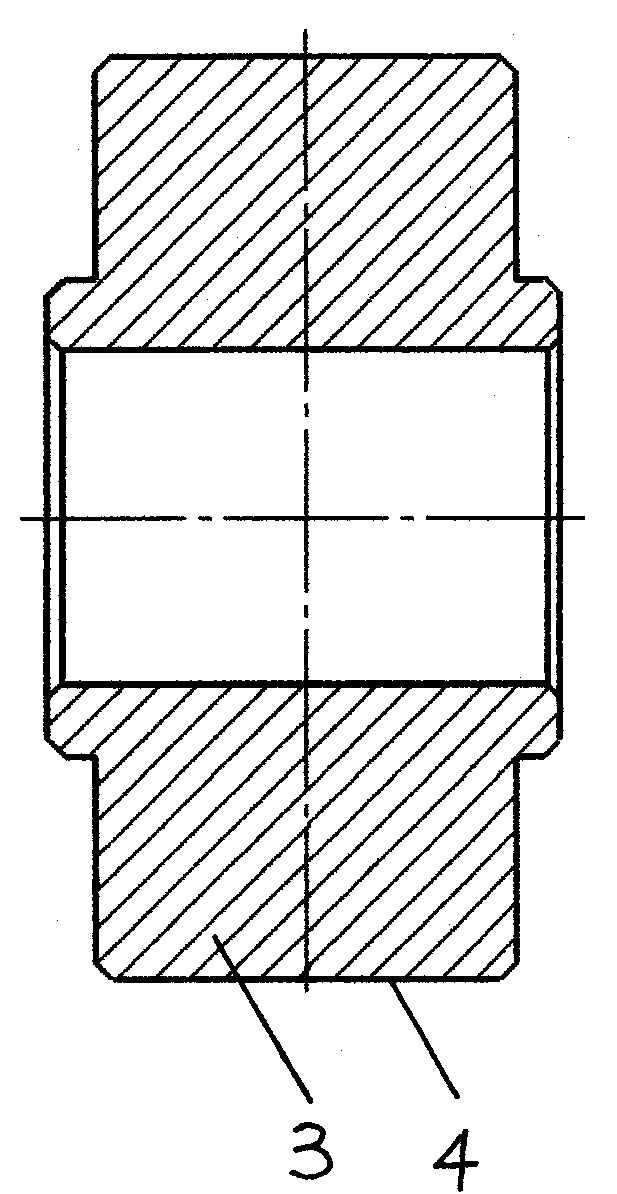

Machining method of worm gear type pivoting support

The invention discloses a machining method of a worm gear type pivoting support and belongs to the technical field of pivoting support machining. The machining method of an outer ring of the worm gear type pivoting support comprises the steps of rough turning, half finish turning, heat treatment, finish turning, hobbing, scribing, drilling and lathe grinding. The machining method of a middle ring of the worm gear type pivoting support comprises the steps of rough turning, boring and drilling, half finish turning, heat treatment, finish turning, scribing, drilling and lathe grinding. The machining method of an inner ring of the worm gear type pivoting support comprises the steps of rough turning, half finish turning, finish turning I, gear shaping, heat treatment, finish turning II, scribing, drilling and lathe grinding. The pivoting support machined through the machining method can meet the requirements of entertainment machinery, light industry machinery, filling machinery and the like for bidirectional rotational motion and bear large turning torque, the abrasion resistance of gear teeth is remarkably improved, installation between a sealing ring and the pivoting support is firmer, the sealing ring and the pivoting support are not prone to falling off, and the service life of the worm gear type pivoting support is greatly prolonged.

Owner:马鞍山市安耐特回转支承有限公司

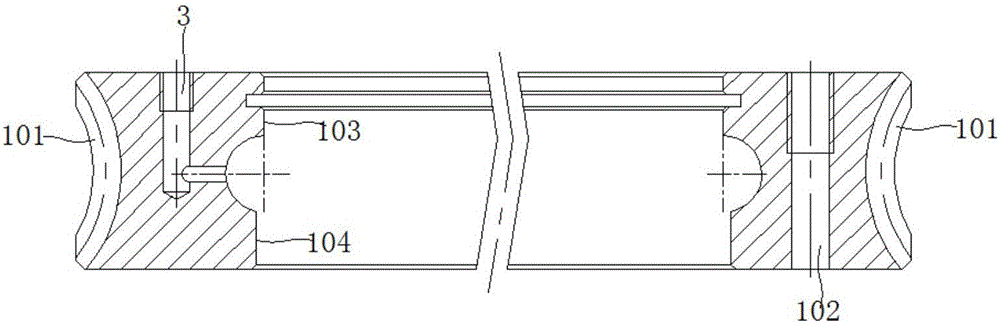

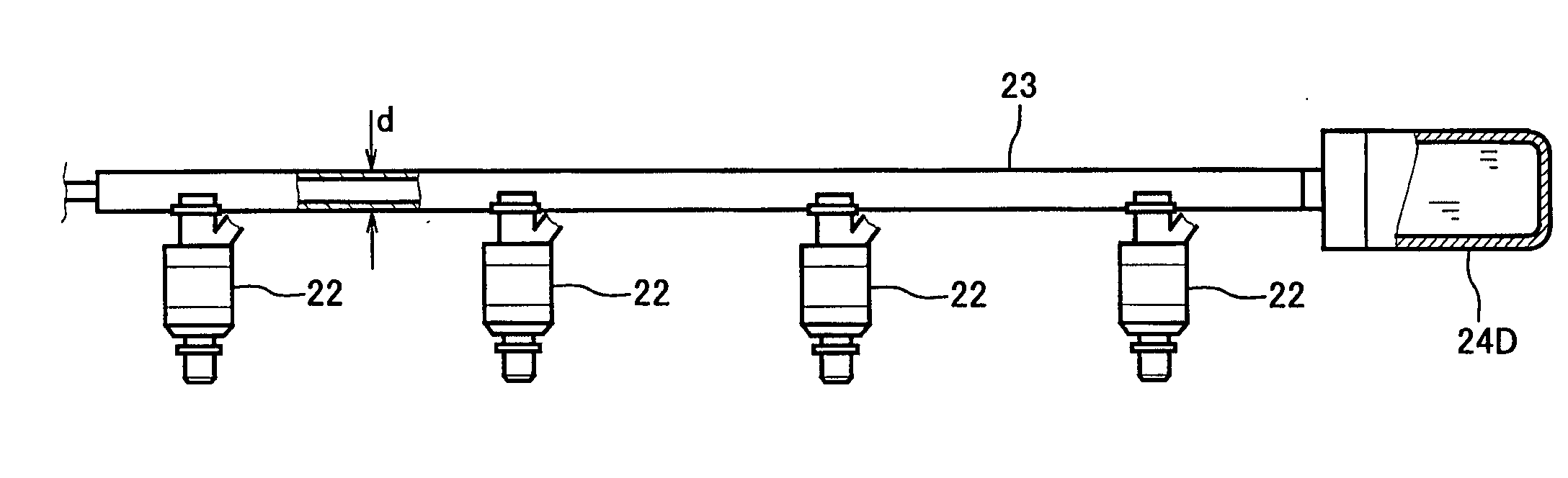

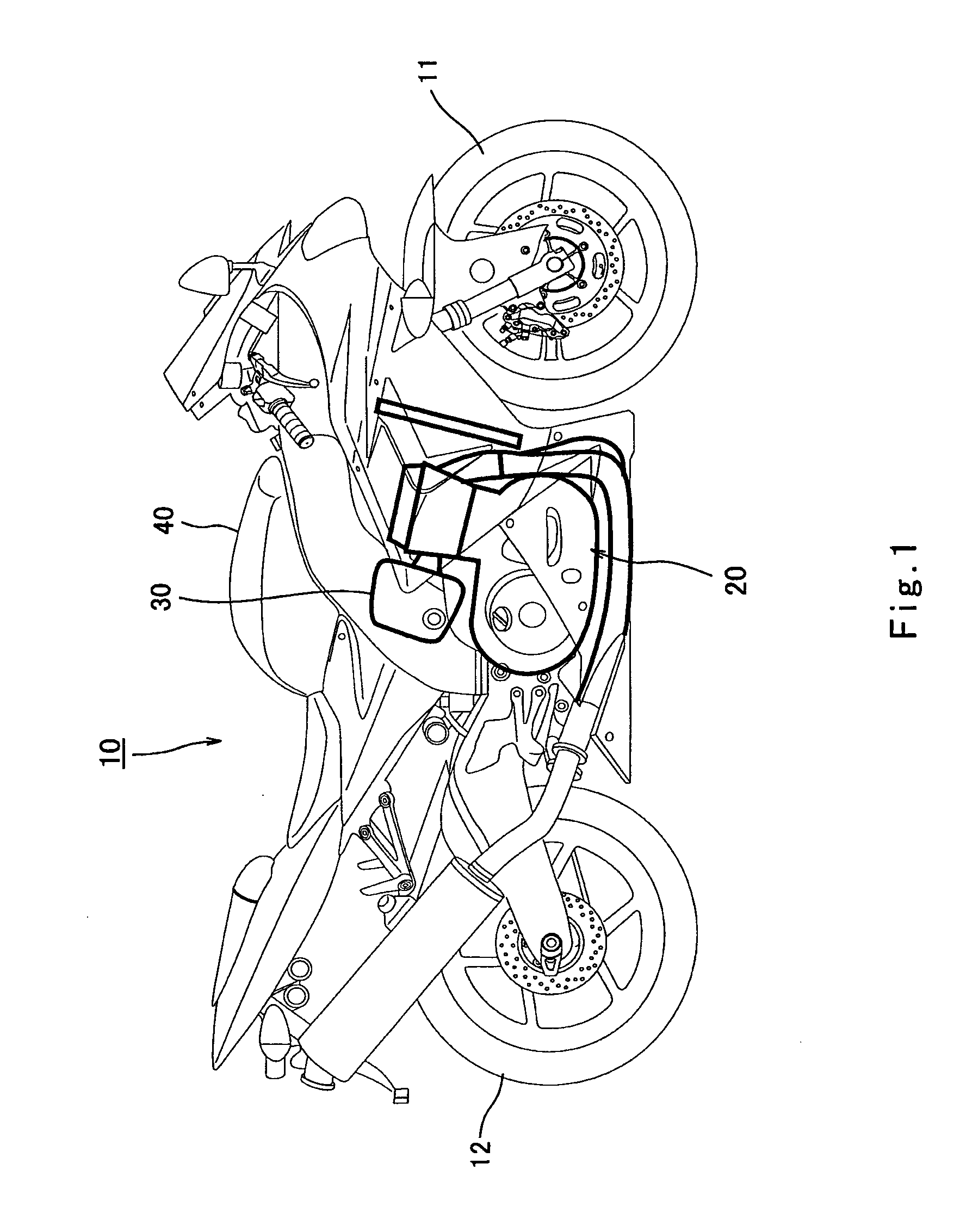

Engine for a vehicle and vehicle equipped with an engine

InactiveUS20080178846A1Reduce air volumeLower the volumeLow-pressure fuel injectionMachines/enginesInterior spaceCombustion

An engine for a vehicle, which is configured to enable a combustion stroke to occur in a plurality of cylinders substantially simultaneously, comprises a fuel pipe coupled to a fuel supply source for storing a fuel, a plurality of fuel injectors which are attached to the fuel pipe to respectively correspond to the plurality of cylinders and are configured to inject the fuel to their associated cylinders, and a damper chamber which is provided at the fuel pipe and has an inner space connected to an inner space of the fuel pipe.

Owner:KAWASAKI HEAVY IND LTD

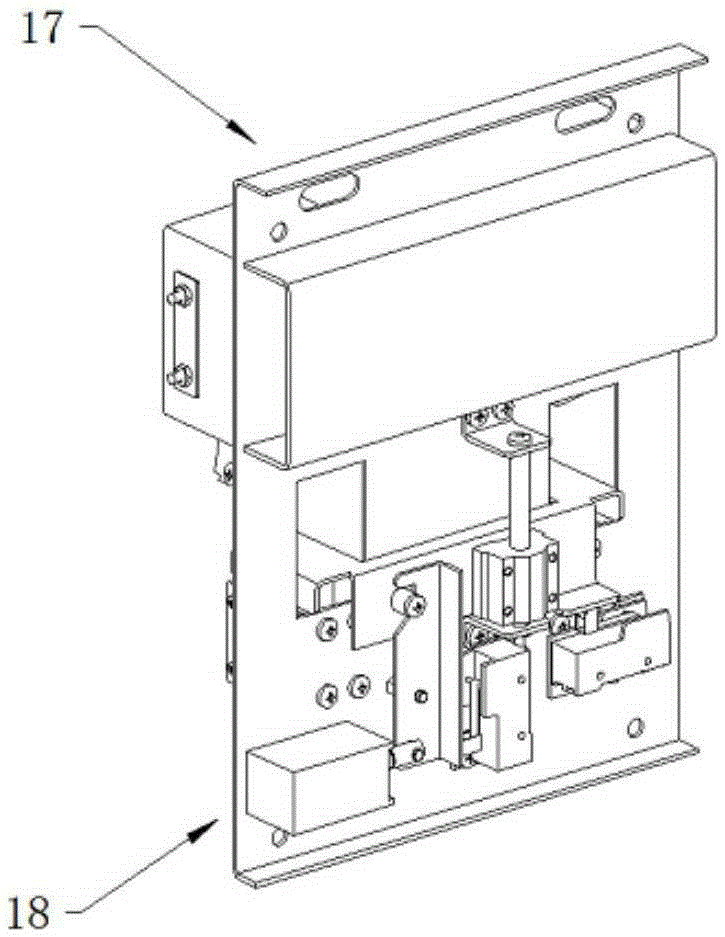

Electric control falling-preventing system, carrying platform system and control method of electric control falling-preventing system

ActiveCN105329737ASmall installation spaceEasy to installElevatorsLocking mechanismElectrical control

The invention provides an electric control falling-preventing system, a carrying platform system and a control method of the electric control falling-preventing system. The electric control falling-preventing system comprises a triggering electromagnet (300), a brake part triggering rod (32), a triggering spring (34) and a locking mechanism. The triggering electromagnet (300) enables the position of the brake part triggering rod (32) to be changed between a triggering position and a non-triggering position through switching between an adsorption state and a releasing state. Through electric control and the function of triggering emergent braking in a mechanical manner, compared with a traditional braking system, the electric control falling-preventing system has the beneficial effects that needed installation space is small, installation is easy and convenient, and good safety is achieved. The braking function is finally achieved through the spring, a wedge is not operated directly in an electrical manner, and the triggering manner is a mechanical triggering manner.

Owner:上海和蕴机电科技有限公司

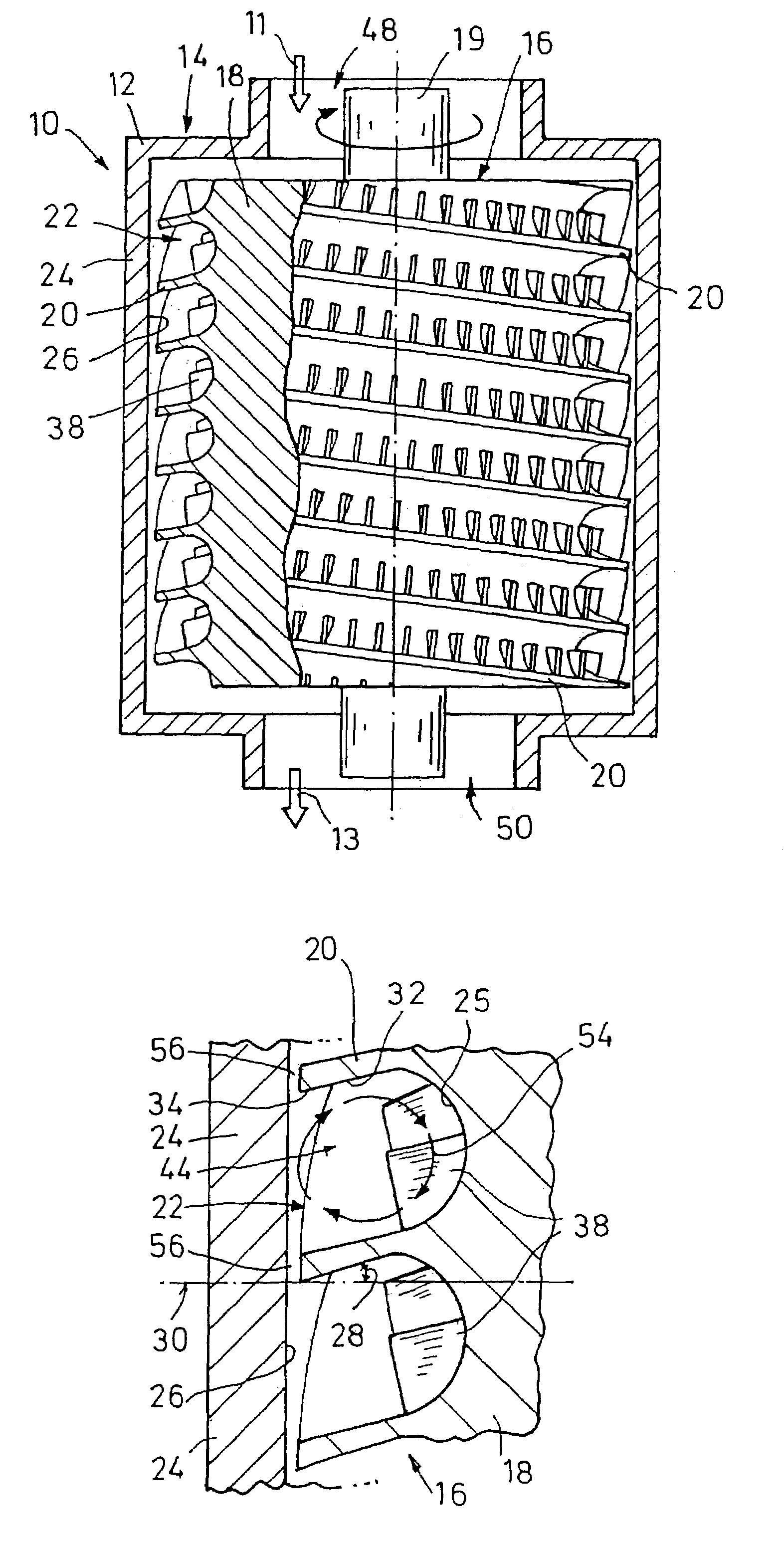

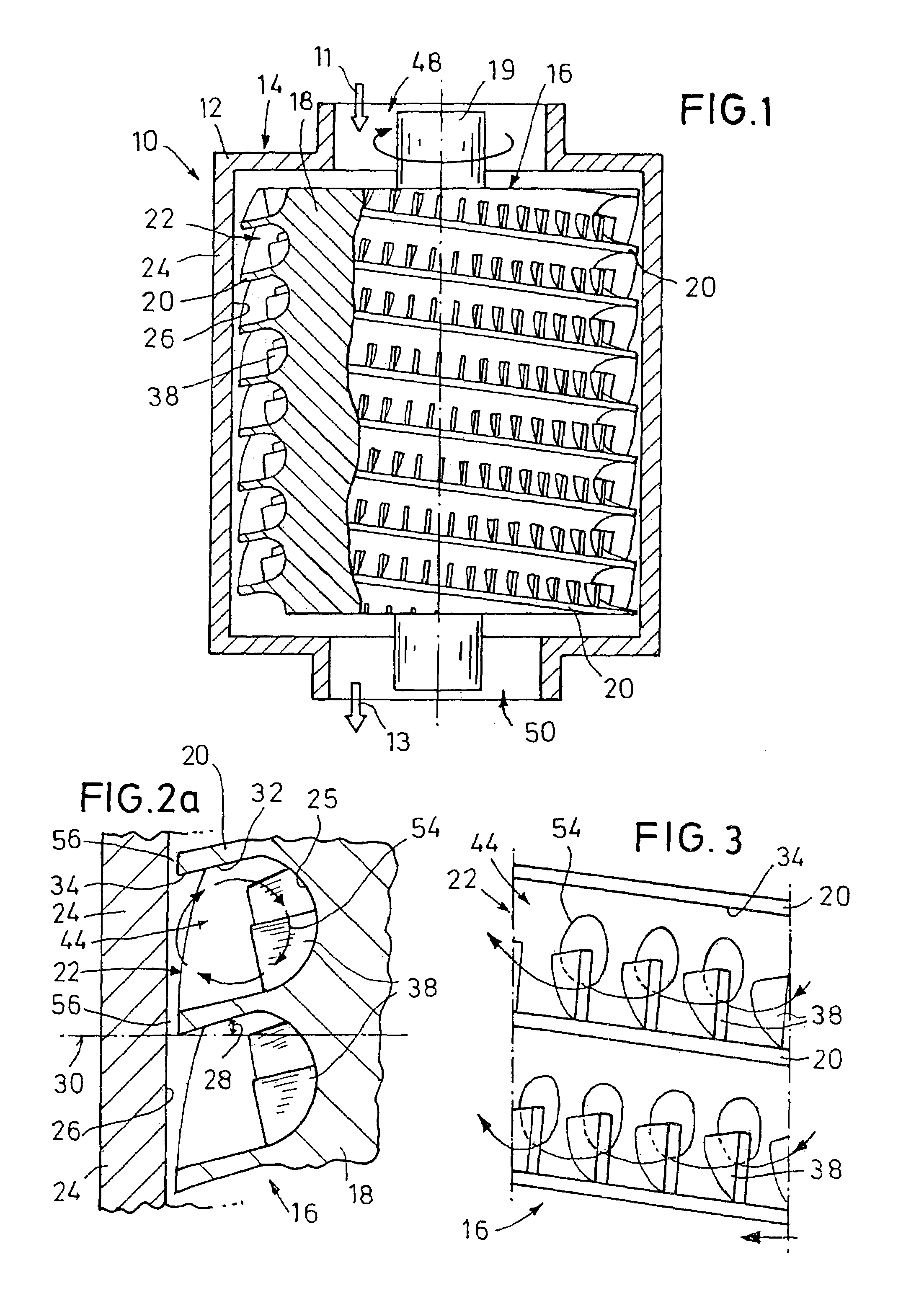

Pump embodied as a side channel pump

InactiveUS7090460B2Easy to compressReduce noisePropellersCircumferential flow pumpsConductor CoilVacuum pump

A side channel pump, preferably a vacuum pump, includes a driven rotor (16) and a fixed stator (14). The rotor (16) and the stator (14) define a pump channel circulating in a peripheral direction. Blades are fixed onto the rotor, protruding into the cross-section of the pump channel. The pump channel also includes a blade-free side channel (44). The pump channel (22) containing the side channel (44) extends in a helical manner around the rotor (16). The pump channel is advantageously not limited to the length of a winding but can have the length of substantially any number of uninterrupted windings. As a result, a high suction performance and a high compression ratio in the pump can be obtained.

Owner:LEYBOLD VAKUUM GMBH

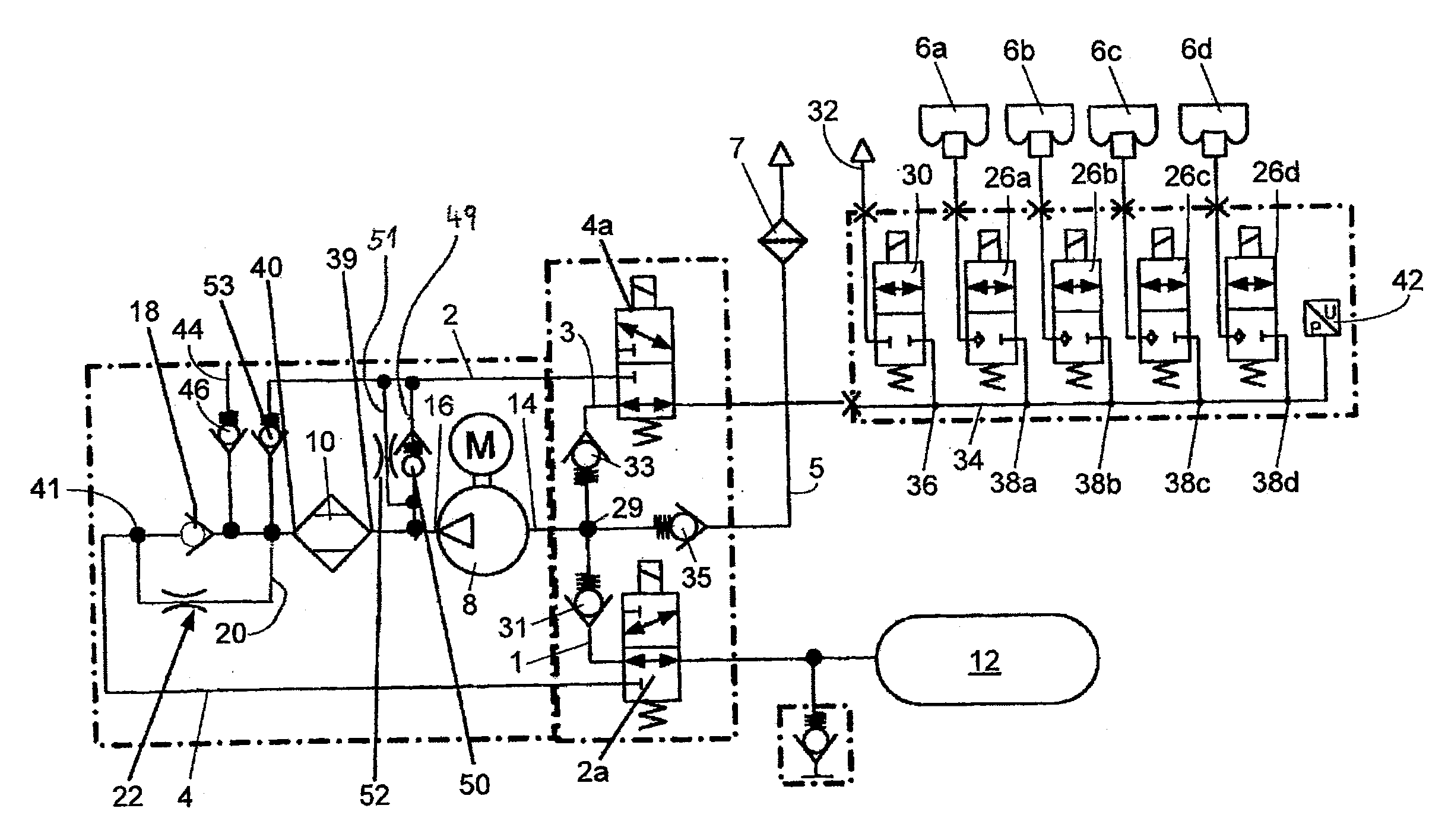

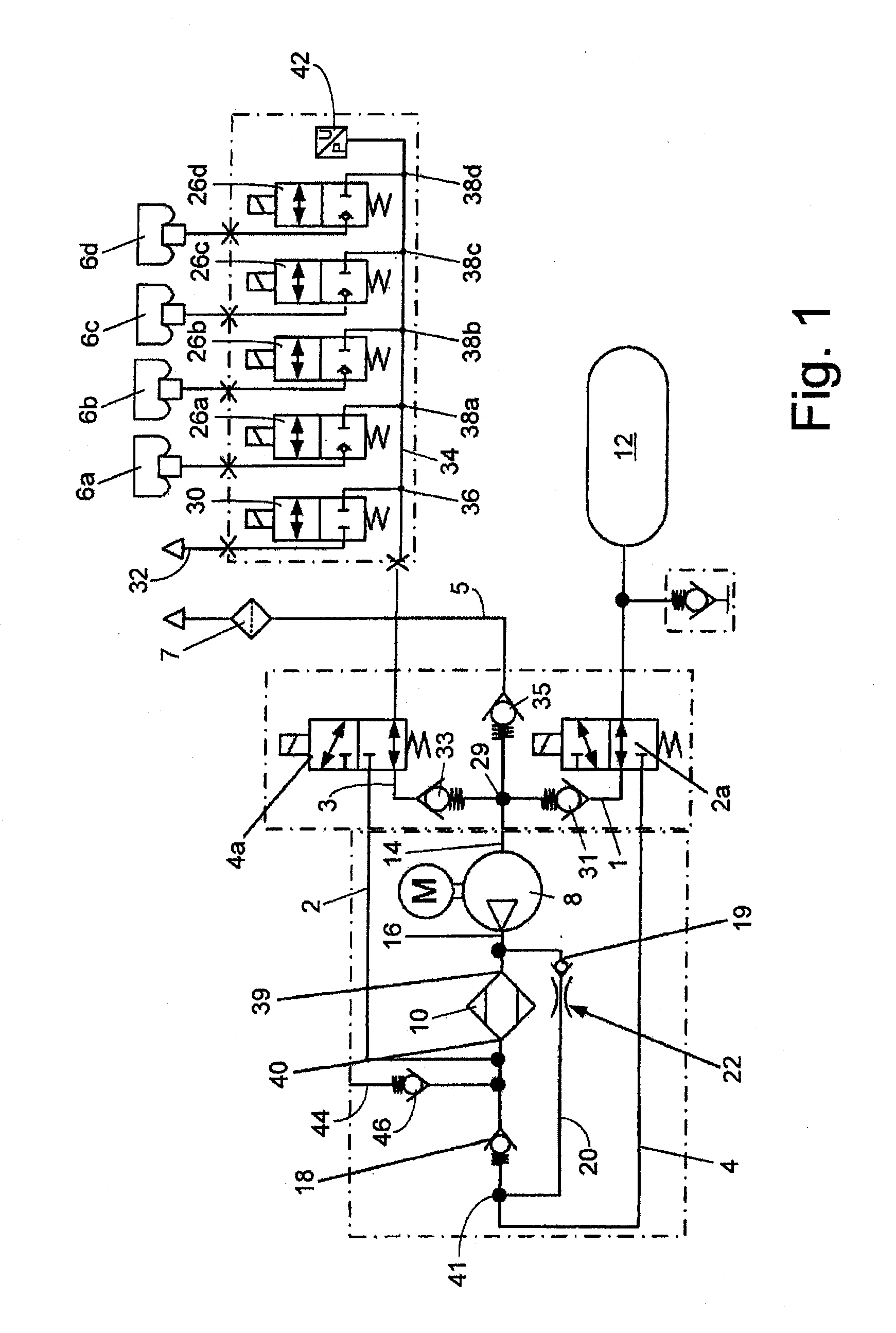

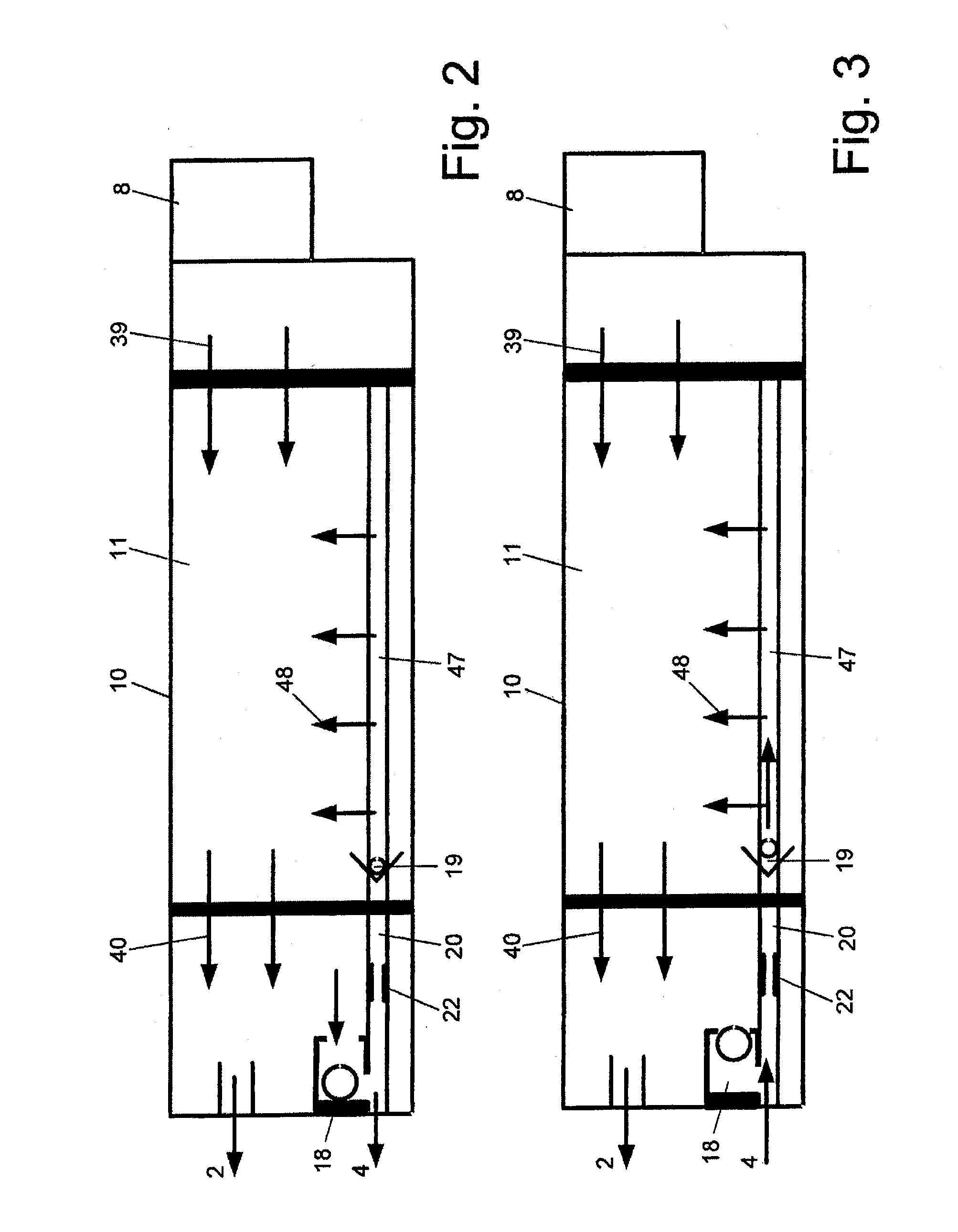

Closed ride control system for vehicles

InactiveUS20110316248A1Simple structureSmall installation spaceVehicle cleaning apparatusLoading/unloading vehicle arrangmentControl systemAir dryer

A closed ride control system for vehicles by which a vehicle body is suspended with respect to at least one vehicle axle and which includes the following components: pressure medium chambers which are connected via branches to a pressure medium line, a compressor, an air dryer which is arranged in a pressure medium line, a pressure medium reservoir which is connected via the compressor to the pressure medium chambers, and a non-return valve arranged in the pressure medium line between an outlet of the air dryer and the directional valve in order to connect the outlet of the air dryer to the pressure medium reservoir.

Owner:CONTINENTAL TEVES AG & CO OHG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com