Permanent magnet coupling speed regulator

A technology of permanent magnetic coupling and governor, applied in permanent magnetic clutches/brakes, electric brakes/clutches, asynchronous inductive clutches/brakes, etc., can solve the problems of high cost and achieve low cost, simple structure, shortened shaft effect on size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

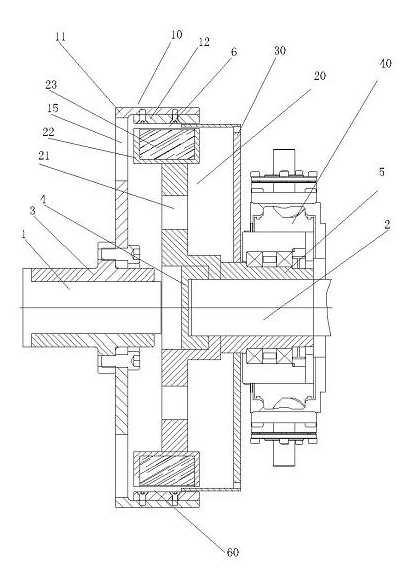

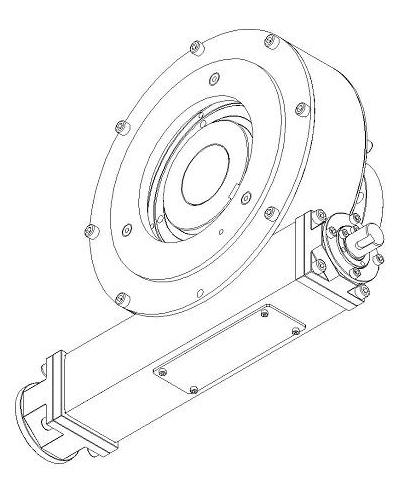

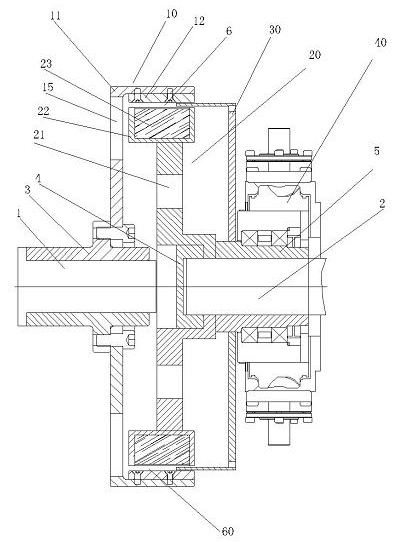

[0016] Refer to attached Figure 1~2 :

[0017] The input shaft 1 and the output shaft 2 are coaxial, and the cylindrical conductor rotor 10 is installed on the input shaft 1 through the flange 3 . The cylindrical conductor rotor body 11 is equipped with a cylindrical conductor piece 12 made of non-magnetic conductive material, and the bottom of the cylindrical conductor rotor body 11 is provided with a ventilation hole 15 .

[0018] The cylindrical permanent magnet rotor 20 is installed on the output shaft 2 through the clamping sleeve 4 , the vent hole 21 is provided at the web, and the permanent magnet seat 22 is set on the outer ring.

[0019] The cylindrical permanent magnet rotor 20 is installed in the cylindrical conductor rotor 10 separated by an air gap 60 therebetween.

[0020] The cylindrical magnetic isolation cover 30 is installed on the output shaft 2 through the moving sleeve 5, and is located between the cylindrical conductor rotor 10 and the cylindrical perm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com