Patents

Literature

1221results about "Ultrasonic/sonic/infrasonic wave generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

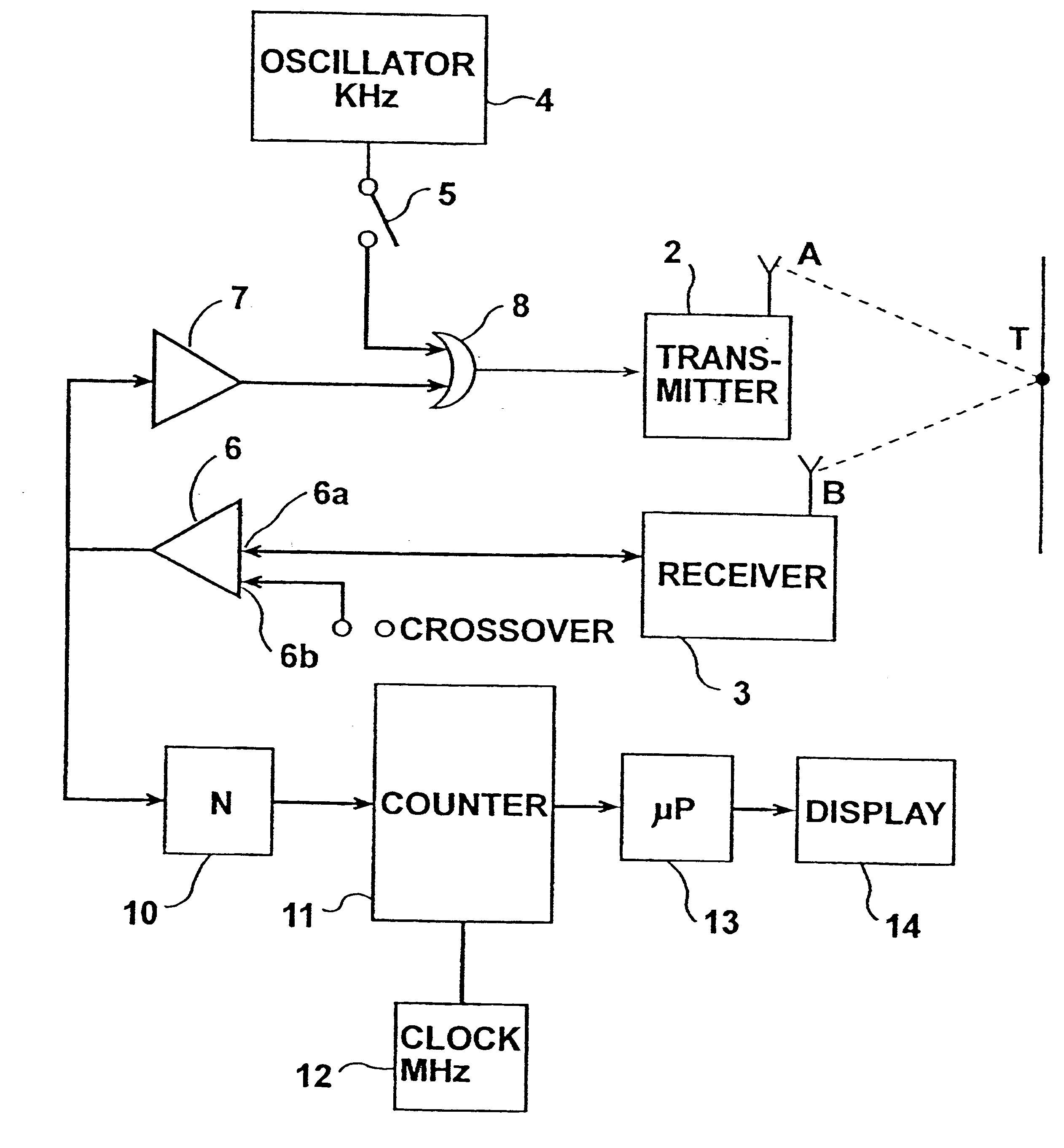

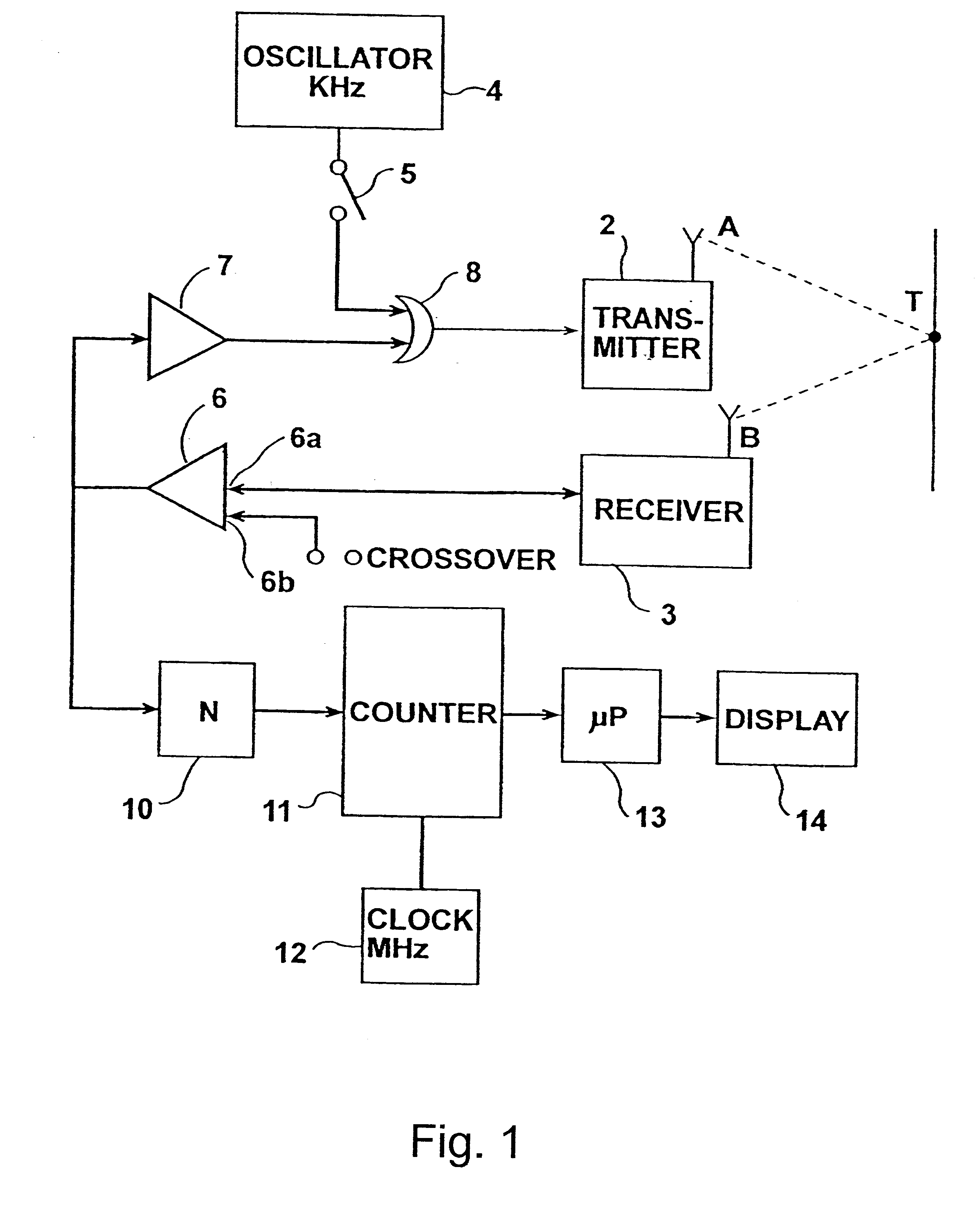

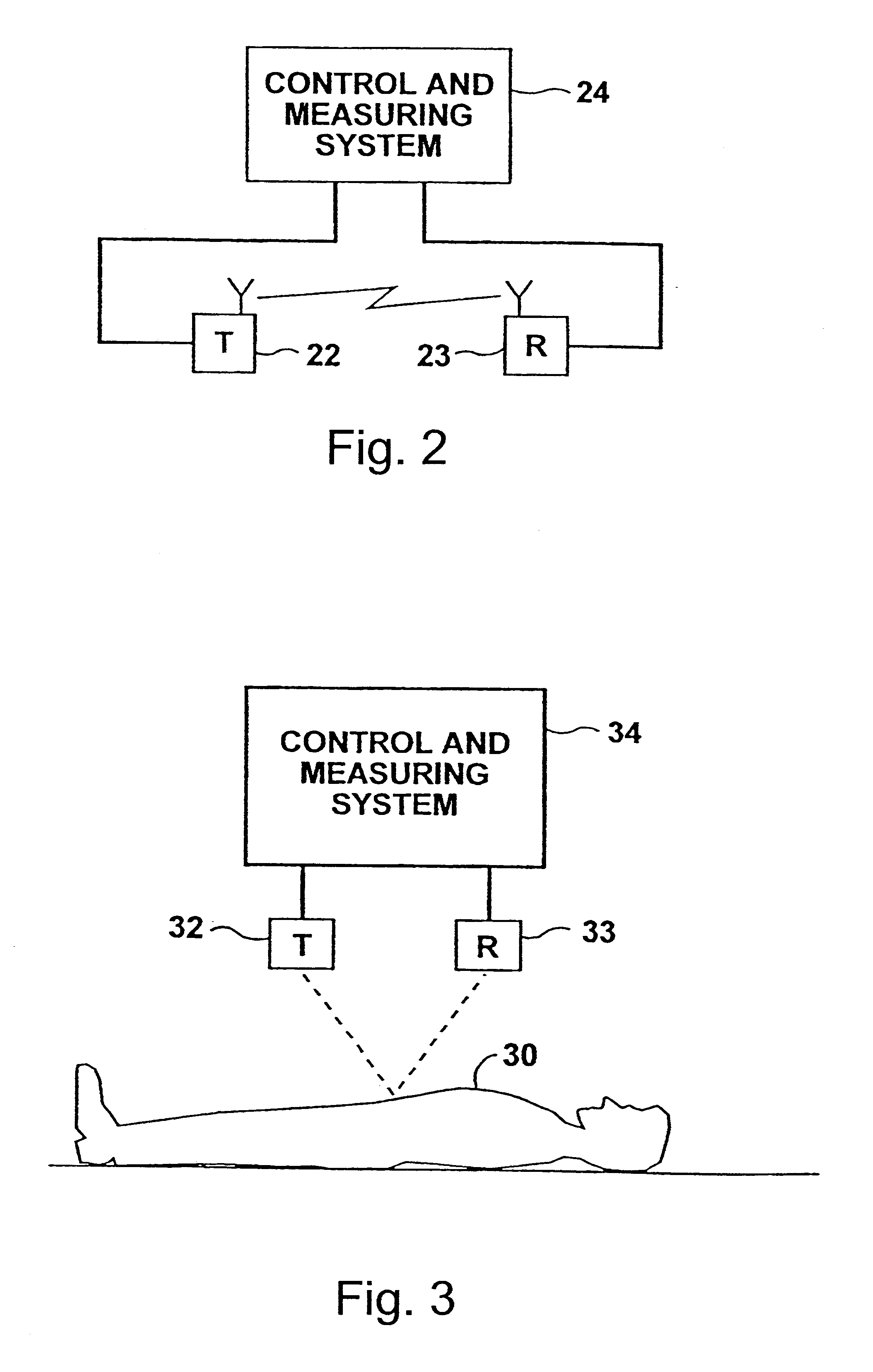

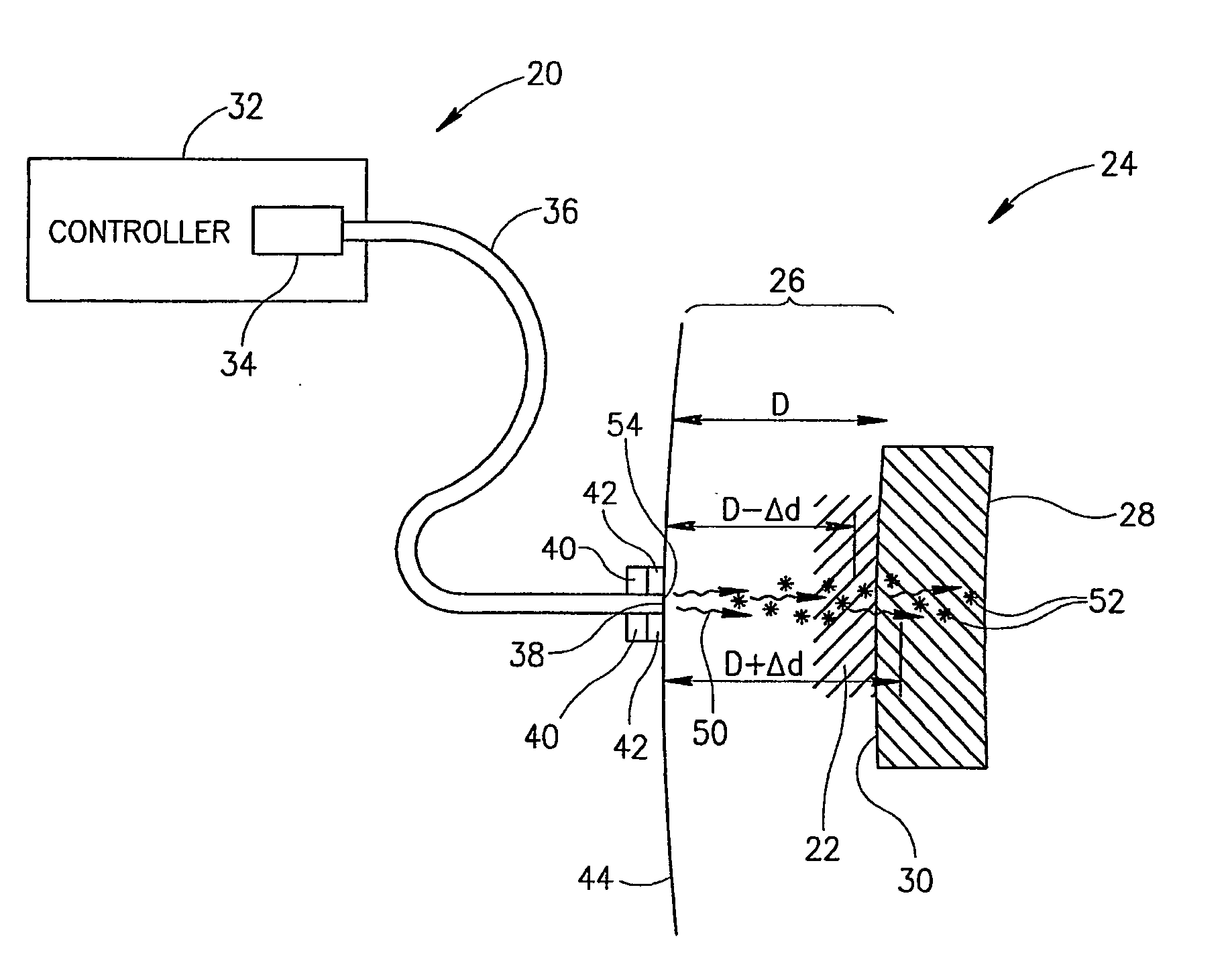

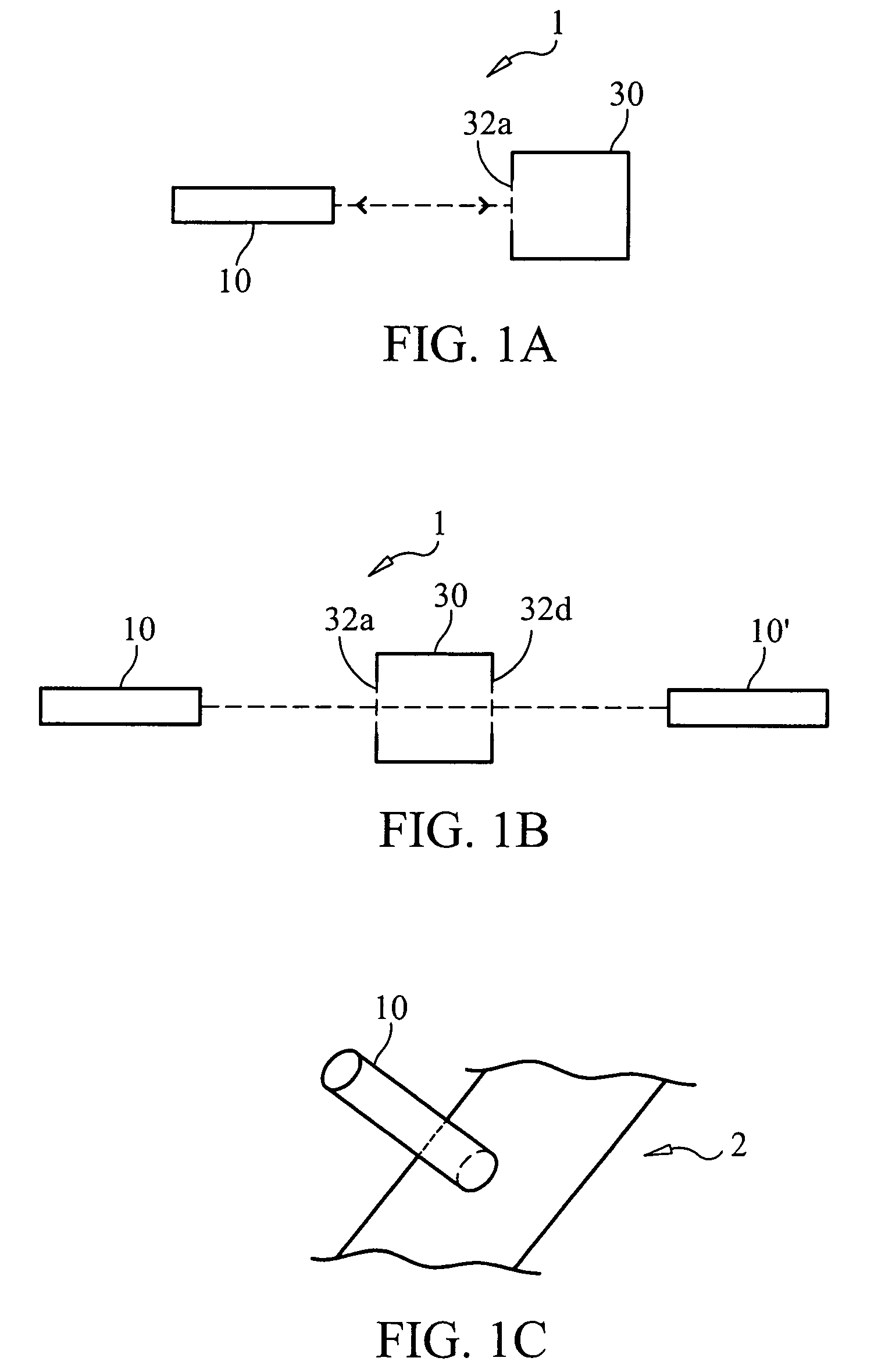

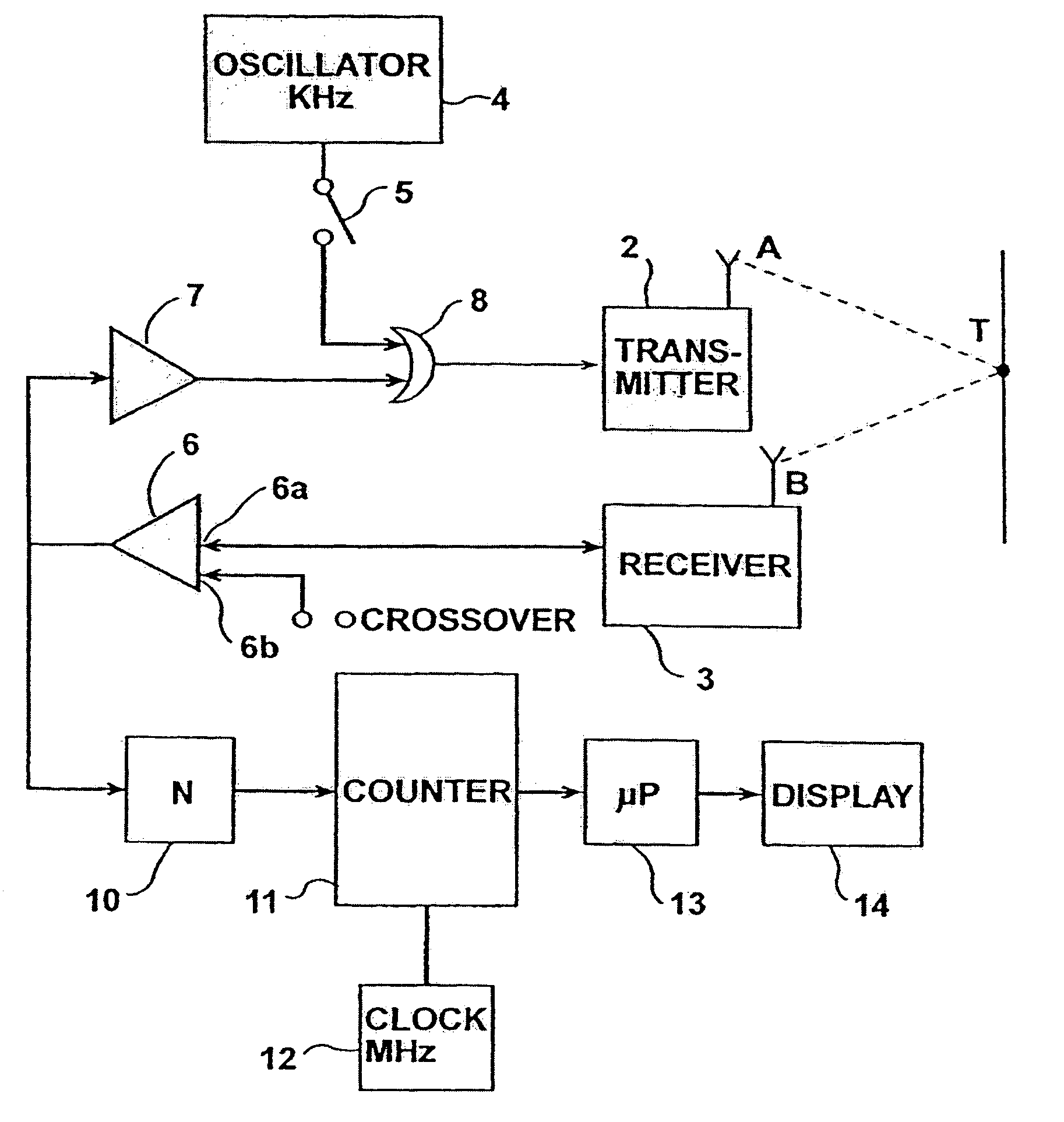

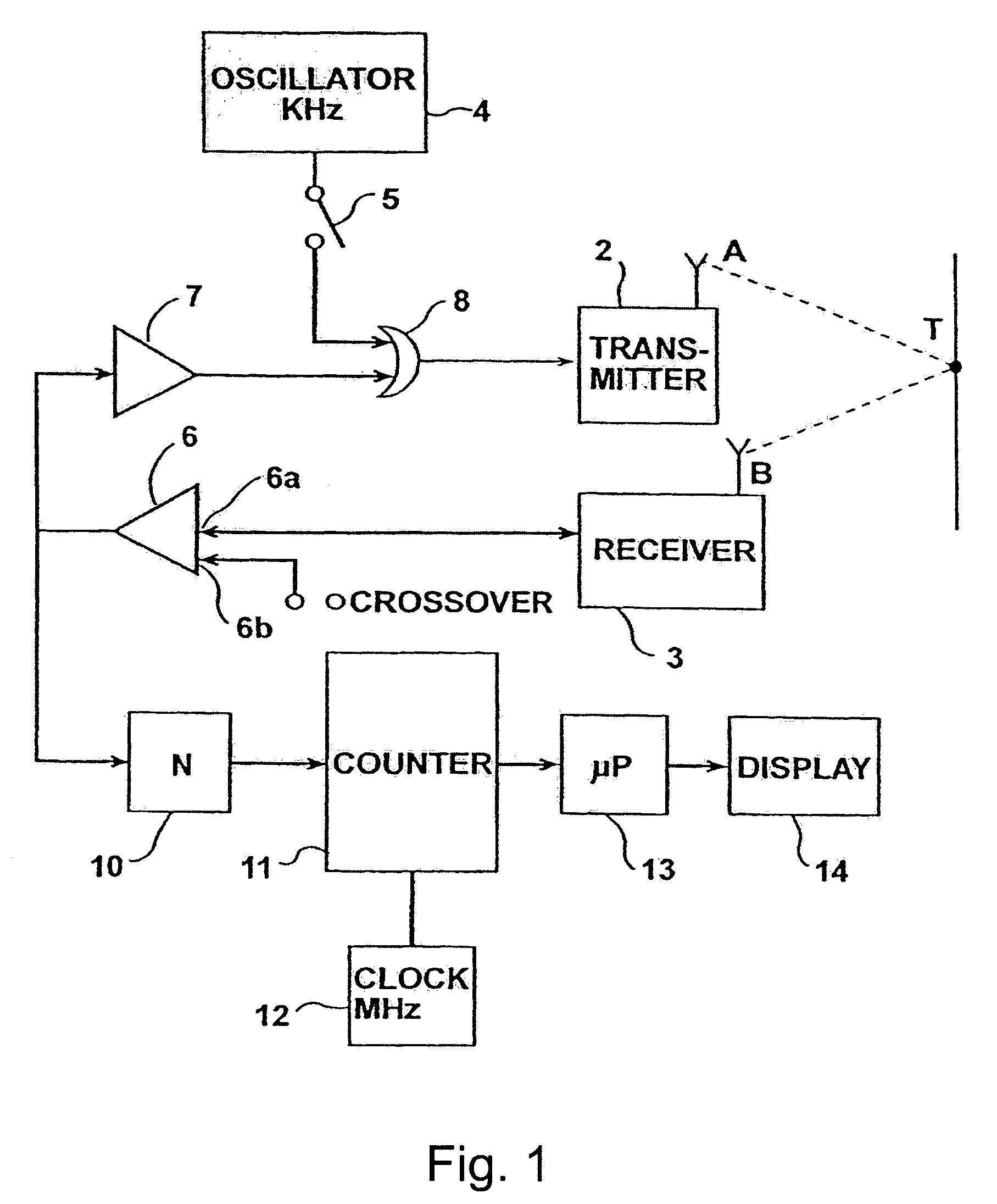

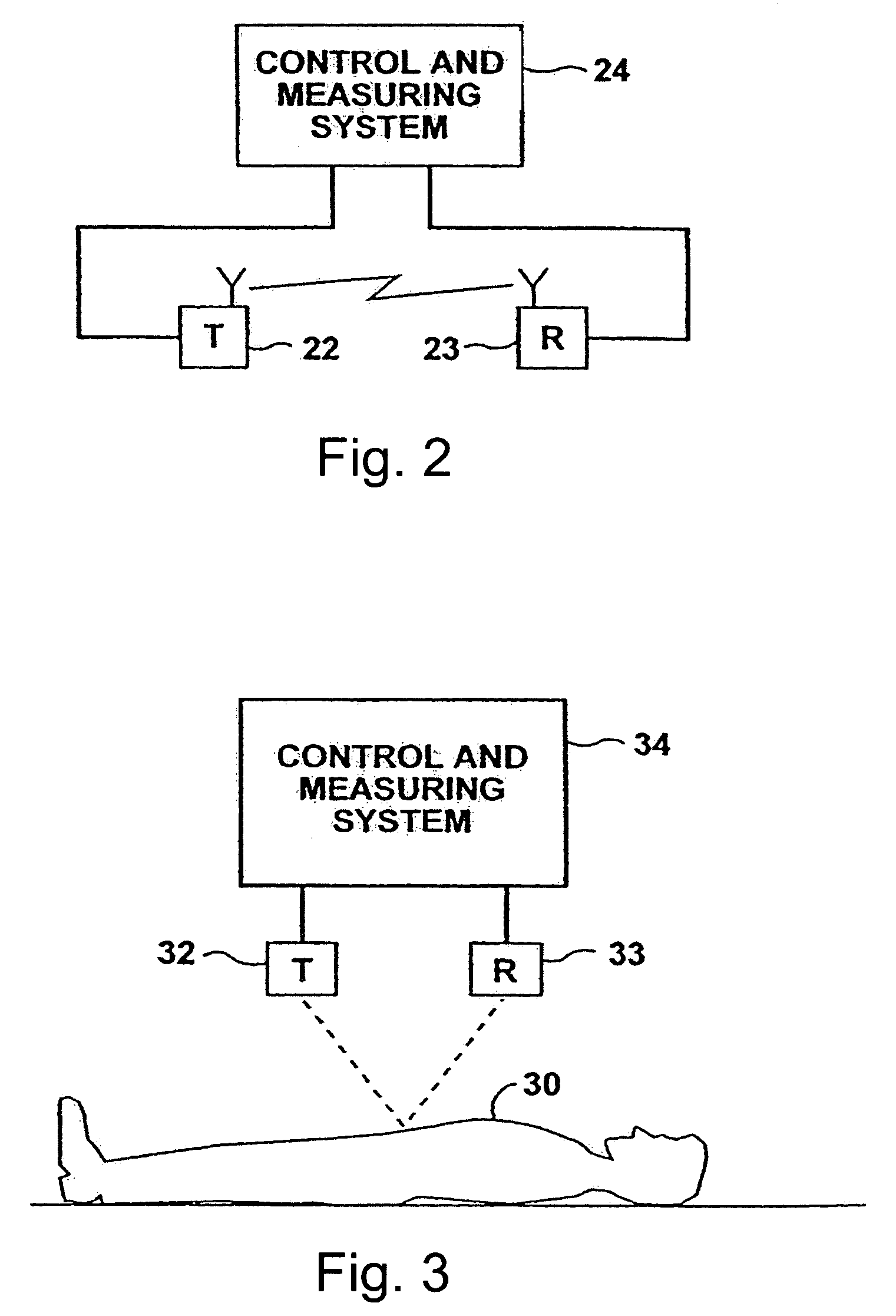

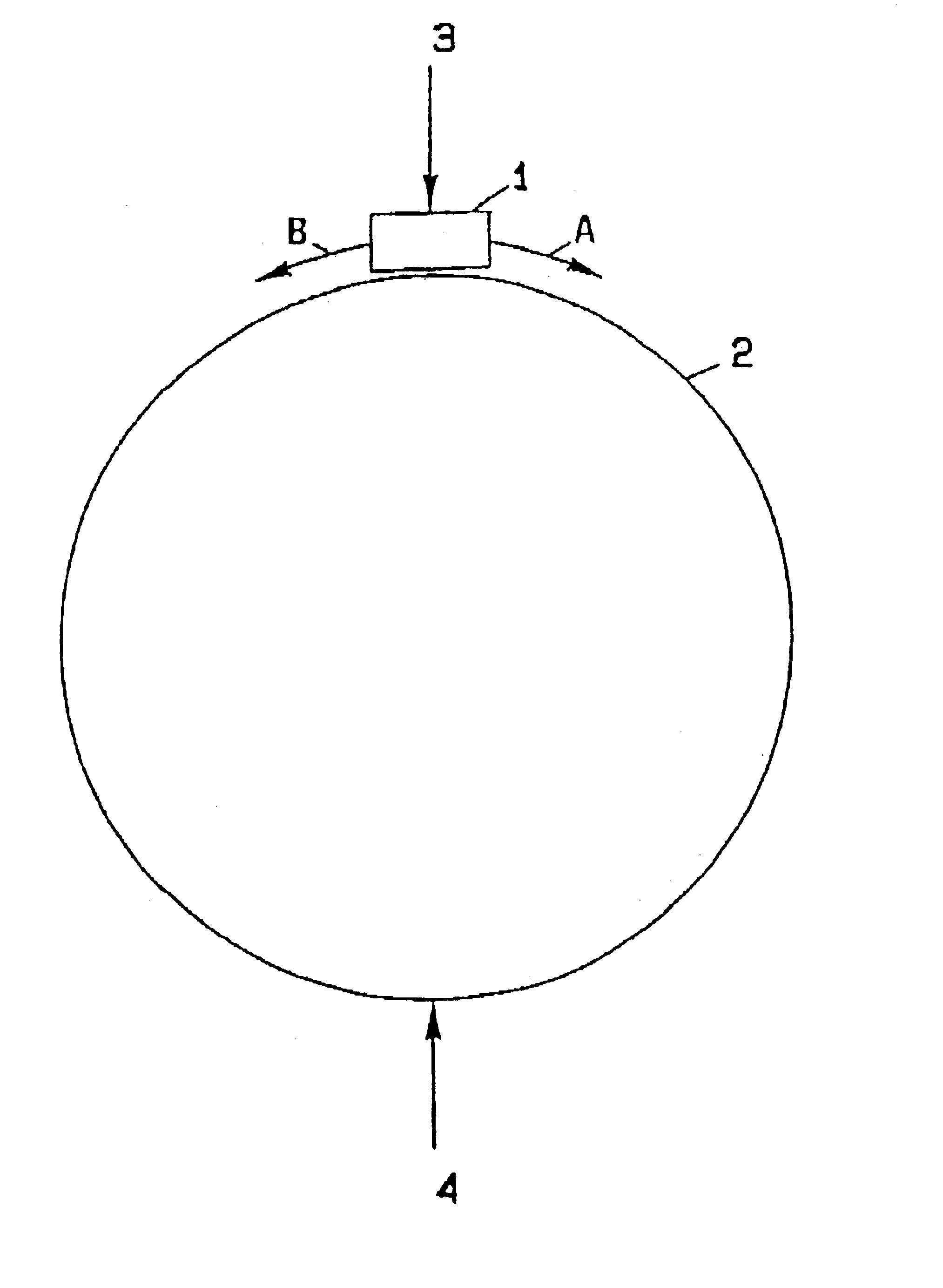

High-precision measuring method and apparatus

InactiveUS6621278B2Low-cost equipmentHigh precisionUltrasonic/sonic/infrasonic diagnosticsAnalysing fluids using sonic/ultrasonic/infrasonic wavesEngineeringFiducial points

A method and apparatus of measuring a predetermined parameter having a known relation to the transit time of movement of an energy wave through a medium, by transmitting from a first location in the medium a cyclically-repeating energy wave; receiving the cyclically-repeating energy wave at a second location in the medium; detecting a predetermined fiducial point in the cyclically-repeating energy wave received at the second location; continuously changing the frequency of transmission of the cyclically-repeating energy wave from the first location to the second location in accordance with the detected fiducial point of each received cyclically-repeating energy wave received at the second location such that the number of waves received at the second location from the first location is a whole integer; and utilizing the change in frequency to produce a measurement of the predetermined parameter.

Owner:NEXENSE

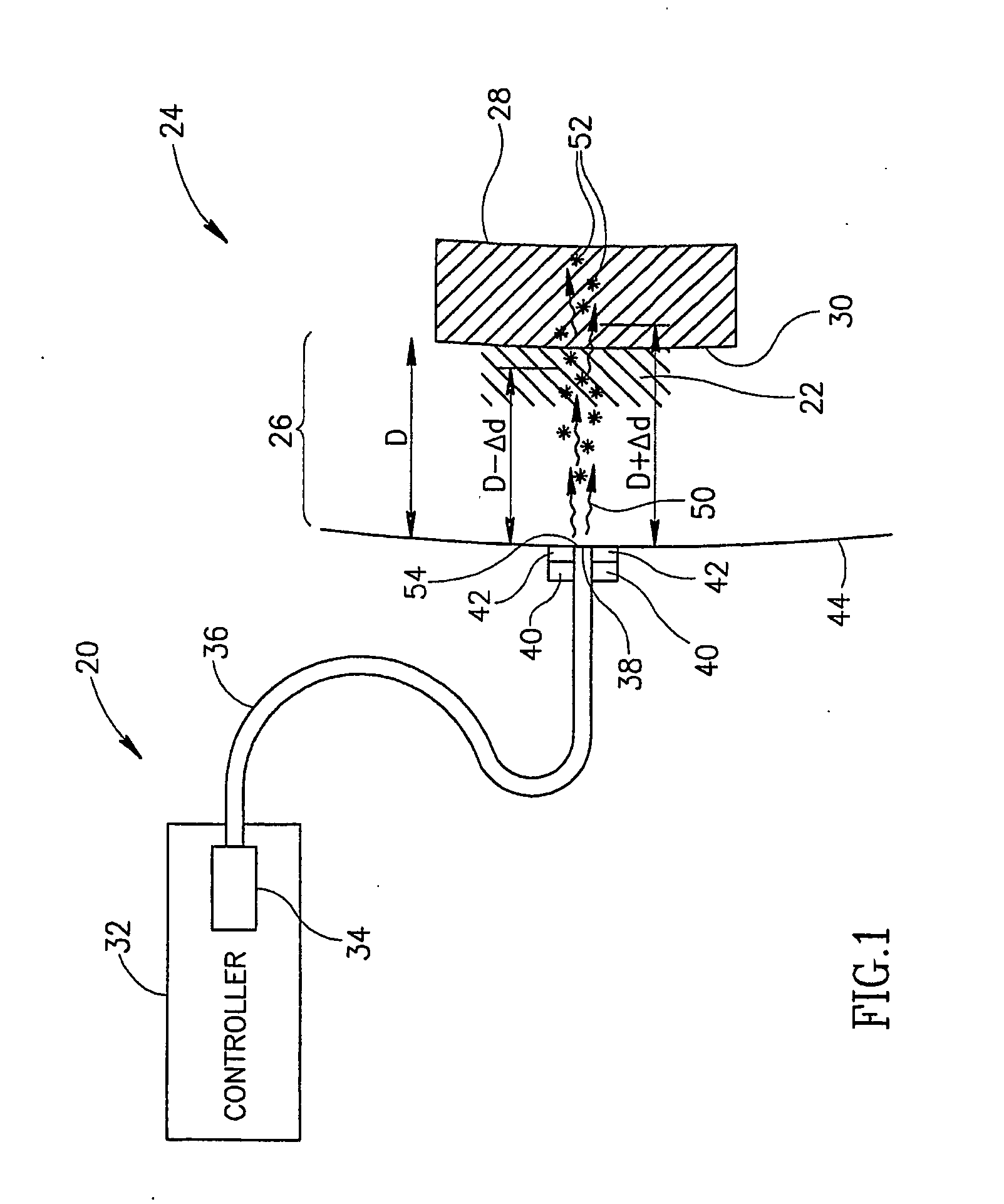

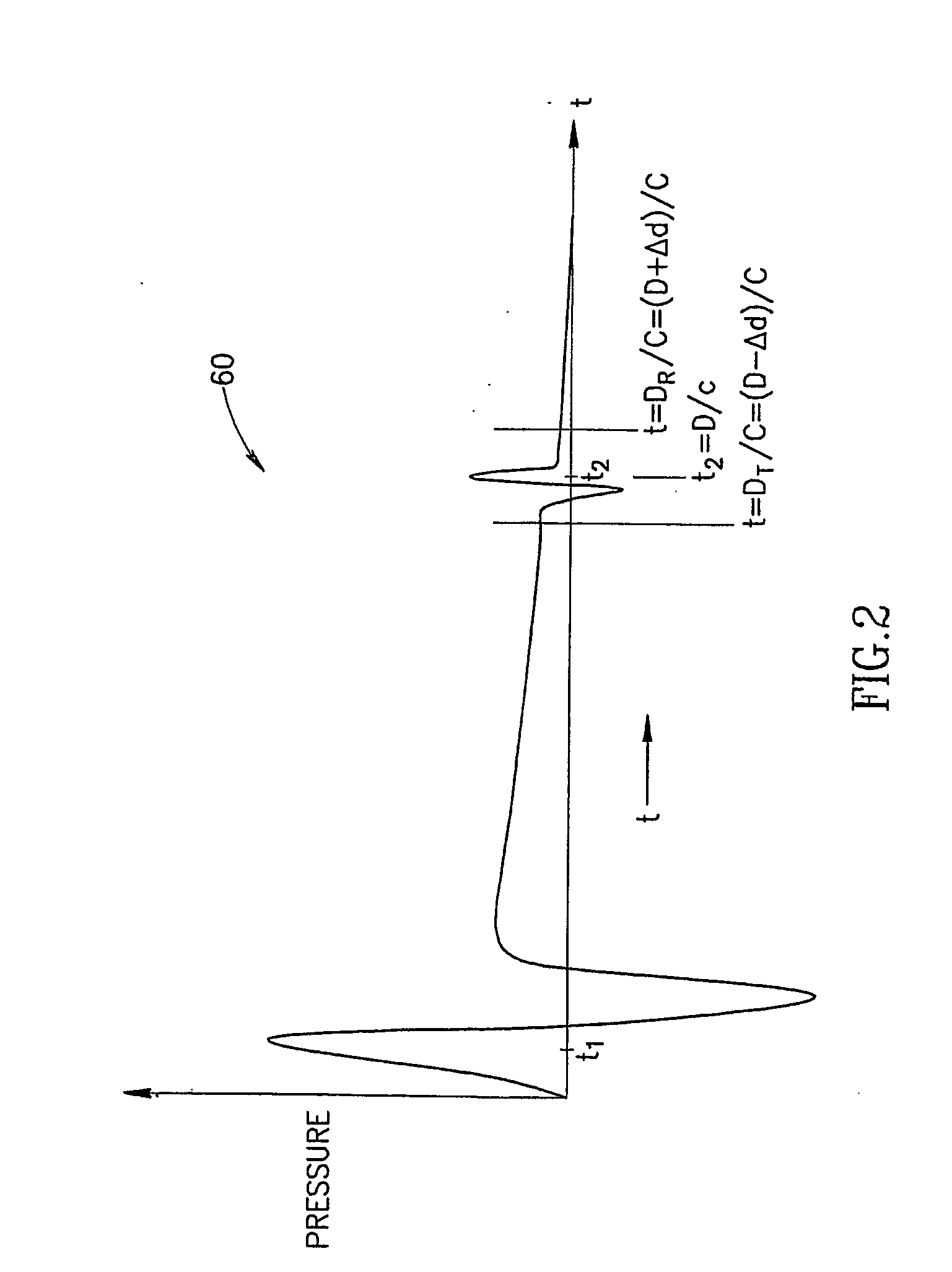

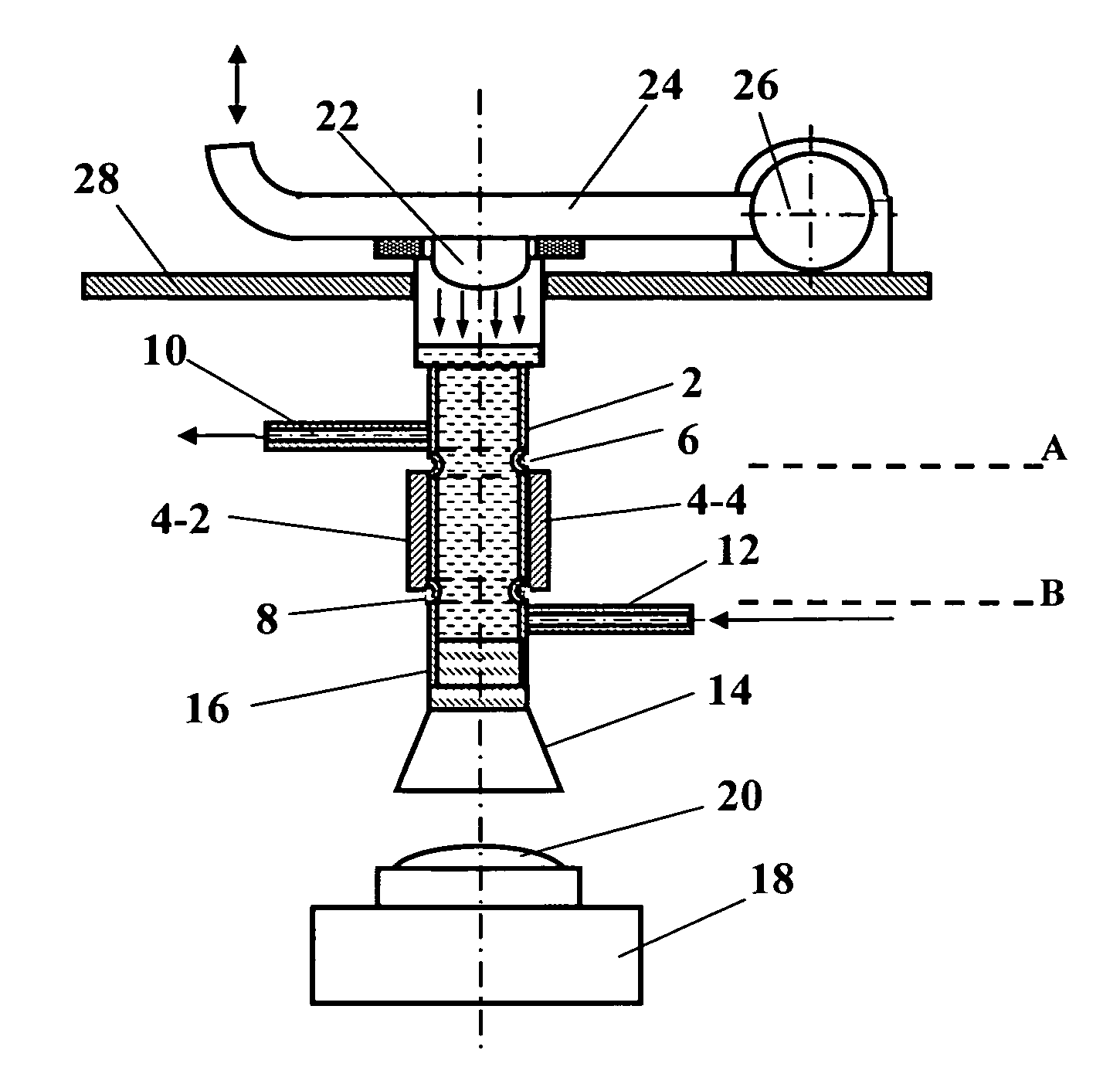

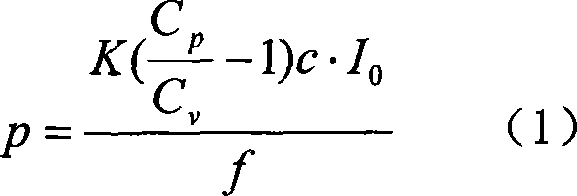

Photoacoustic assay method and apparatus

InactiveUS20060264717A1Ultrasonic/sonic/infrasonic wave generationProcessing detected response signalAnalyteReference Region

A method of assaying an analyte in a body part comprising: illuminating the body part with at least one pulse of light at each of first and second wavelengths that stimulates photoacoustic waves in a first, target, region and a second, reference, region of the body part, wherein the reference region interfaces with the target region and has at least one known optoacoustic property and wherein light at the first wavelength is absorbed by the analyte; sensing pressure in the photoacoustic waves from the target and reference regions stimulated by the light at the first and second wavelengths; and using the sensed pressures and the at least one known optoacoustic property to assay the analyte in the target region.

Owner:GLUCON

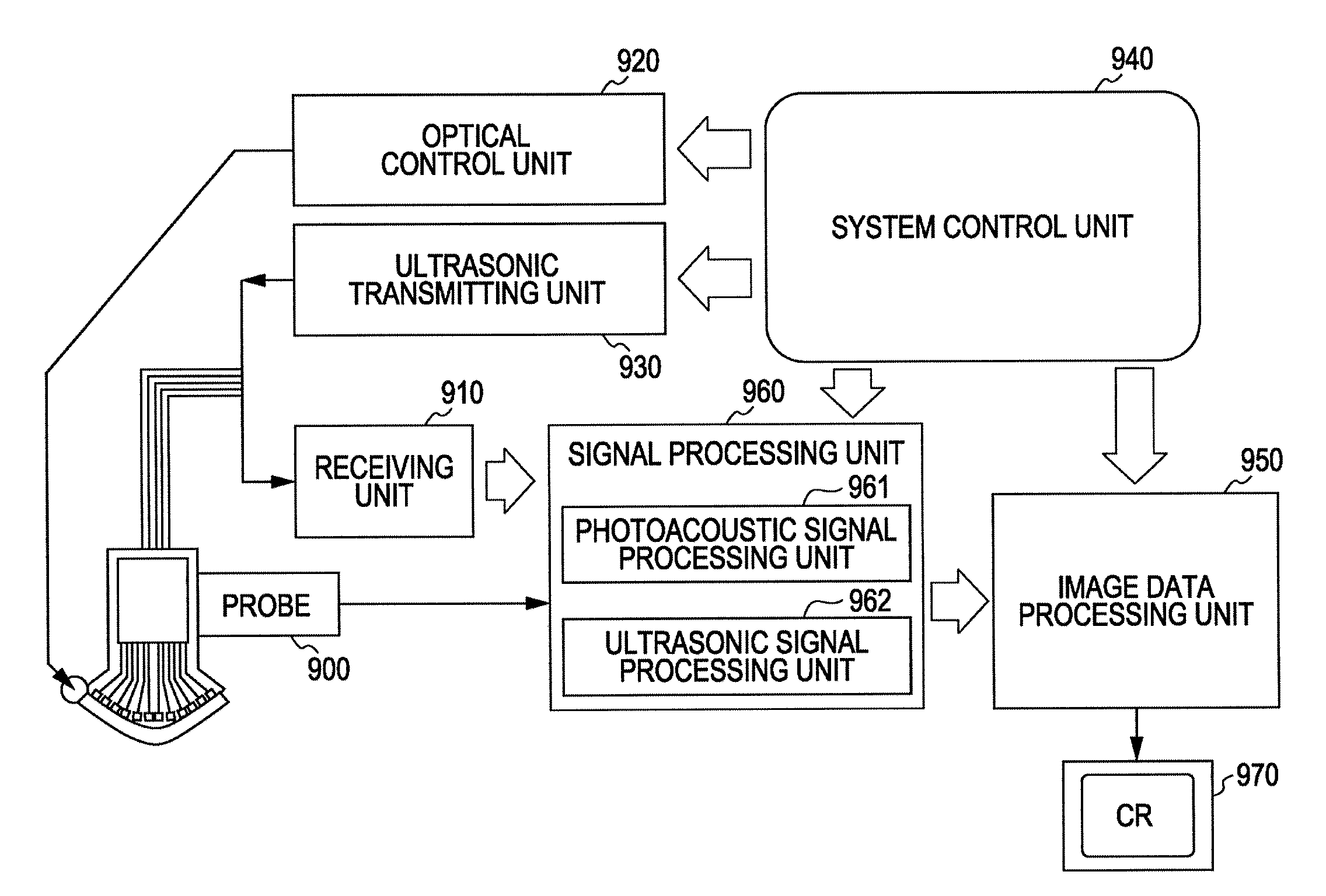

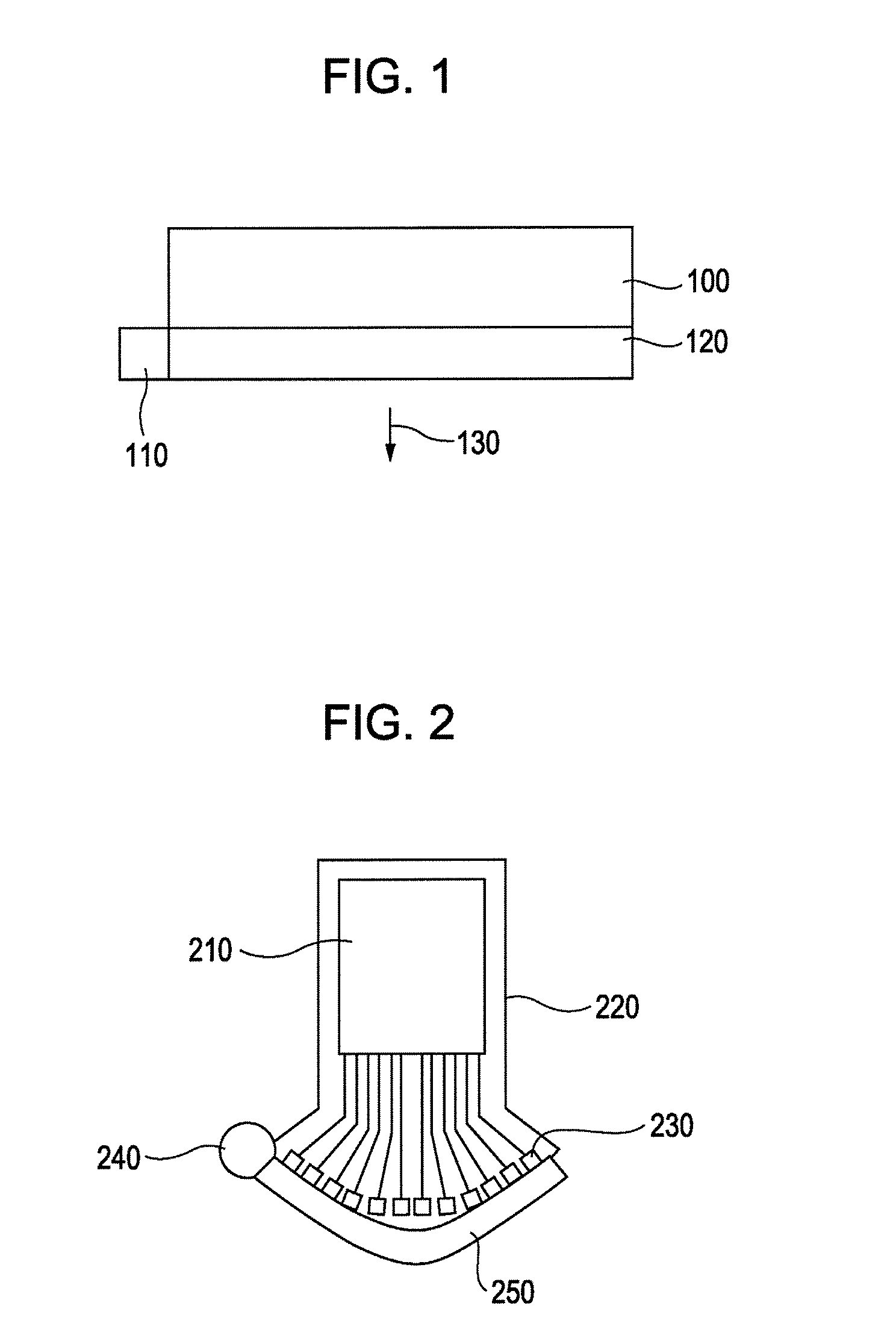

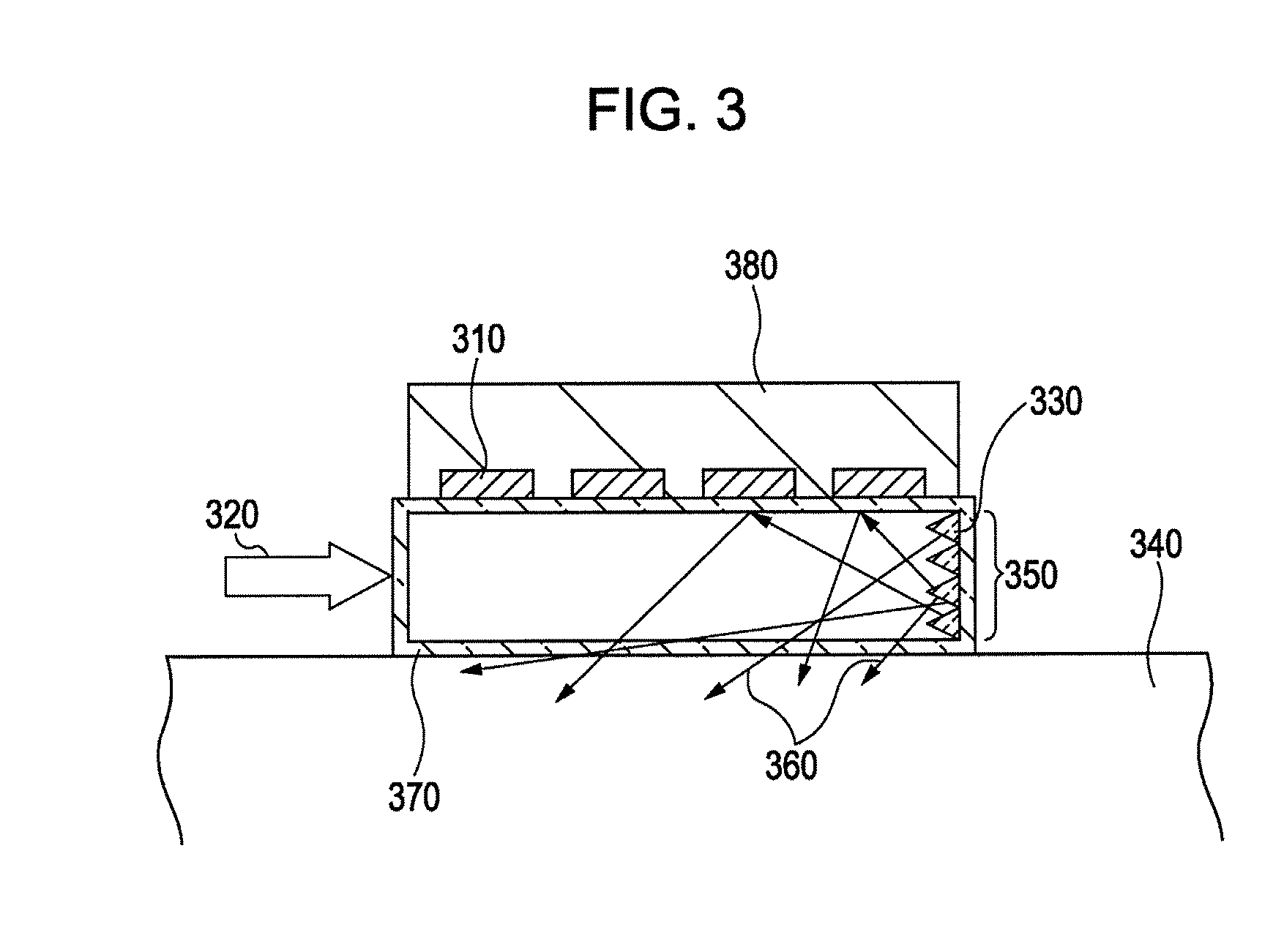

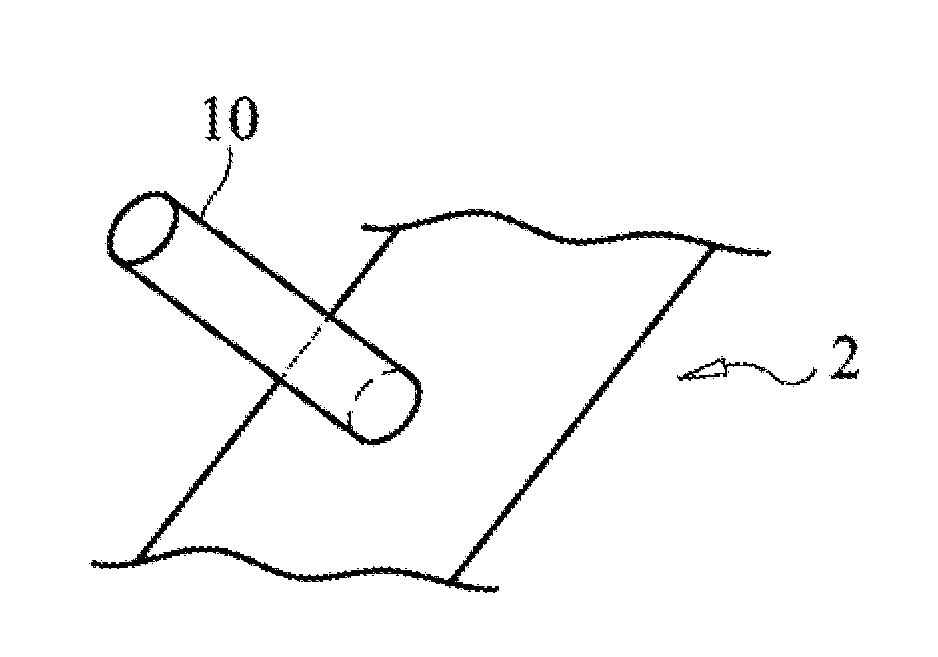

Ultrasonic probe and inspection apparatus equipped with the ultrasonic probe

InactiveUS20090005685A1Easy to takeUltrasonic/sonic/infrasonic diagnosticsDiagnostic signal processingLight guideLight absorber

An ultrasonic probe includes a light irradiating portion configured to radiate light for generating ultrasonic waves from a light absorber, an ultrasonic transducing portion configured to transduce the ultrasonic waves to an electric signal, and a light guide member configured to introduce light from a light source to the light irradiating portion. A light irradiating region of the light irradiating portion is included within an ultrasonic receiving region of the ultrasonic transducing portion.

Owner:CANON KK

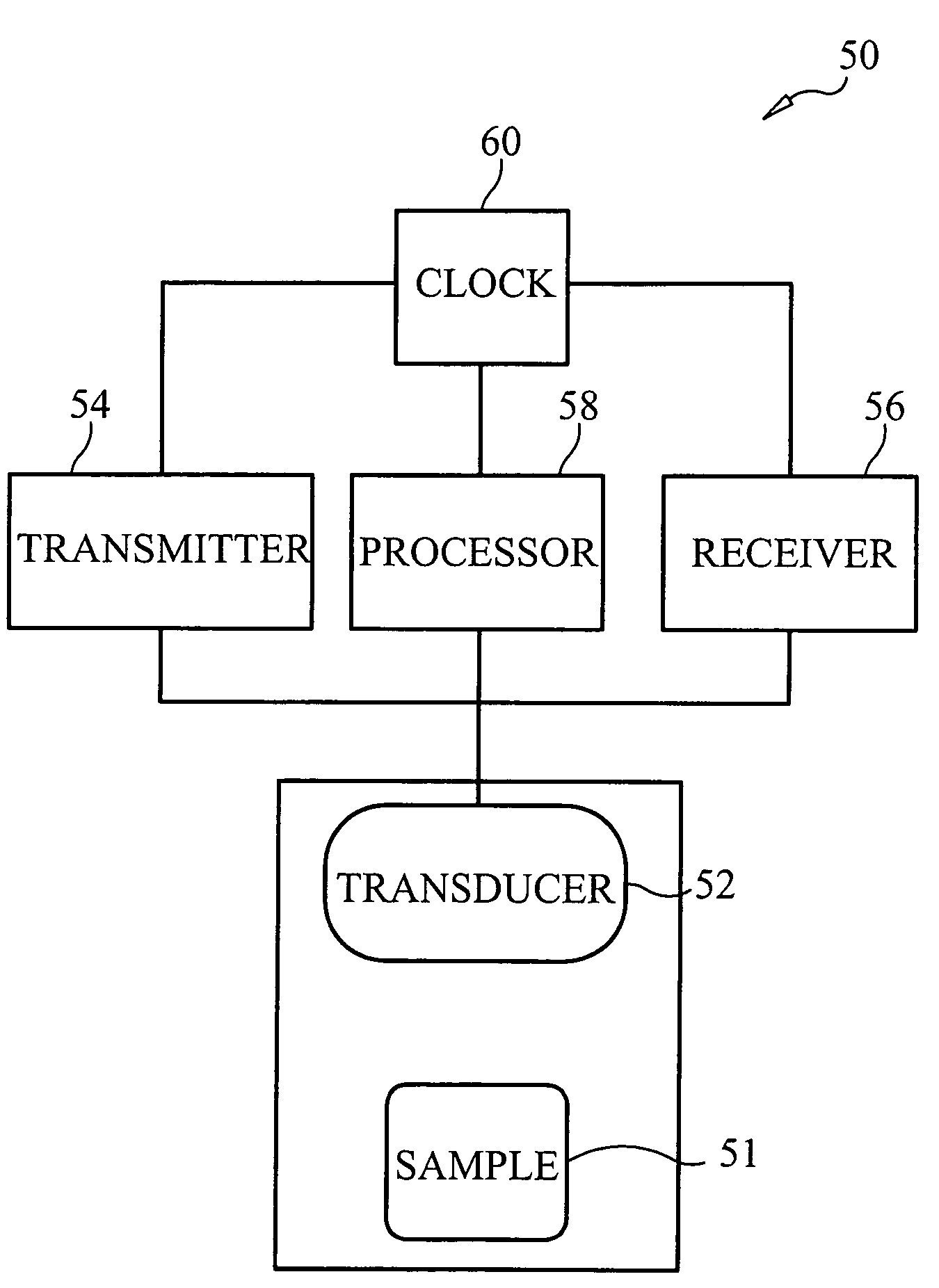

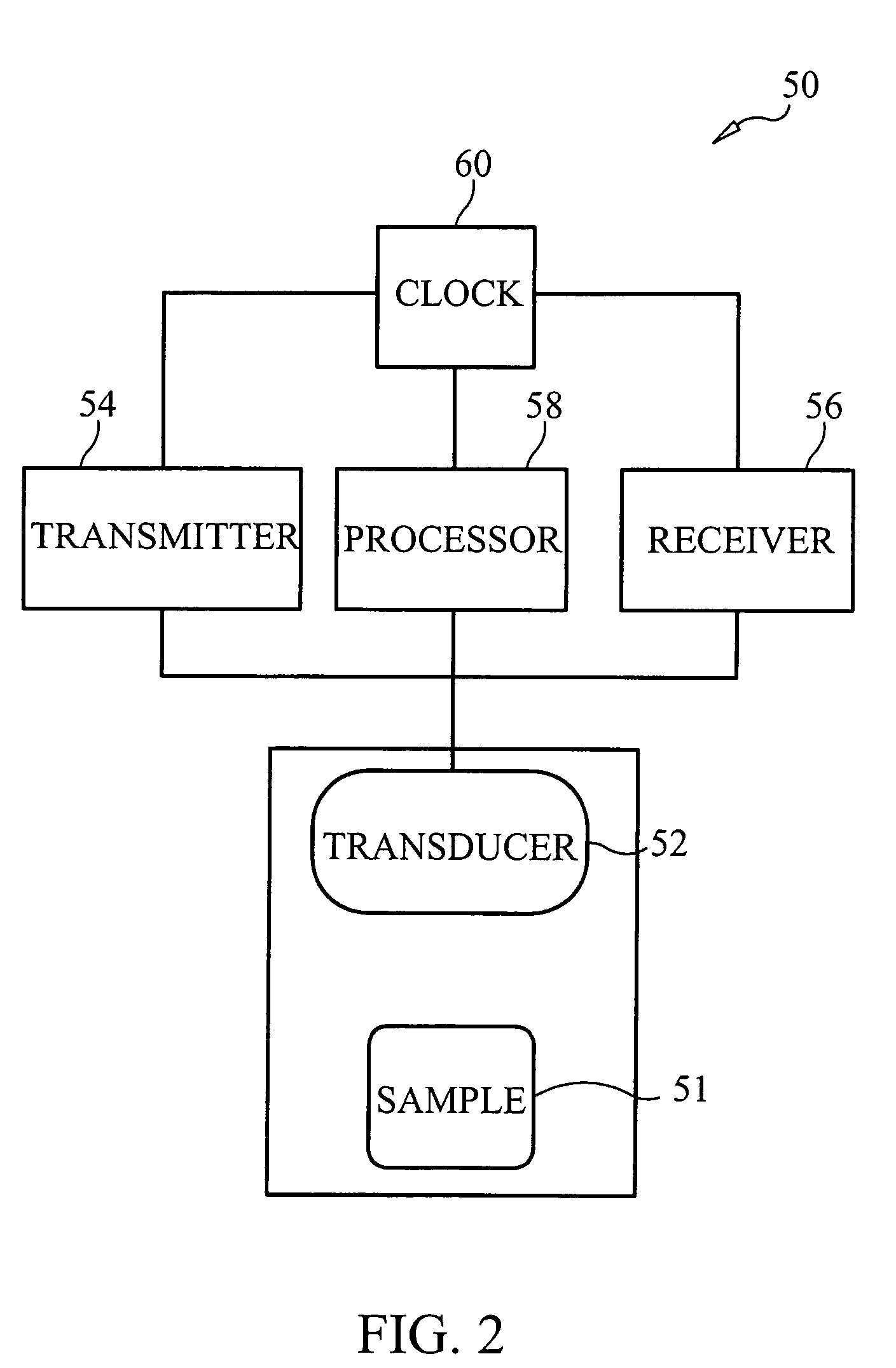

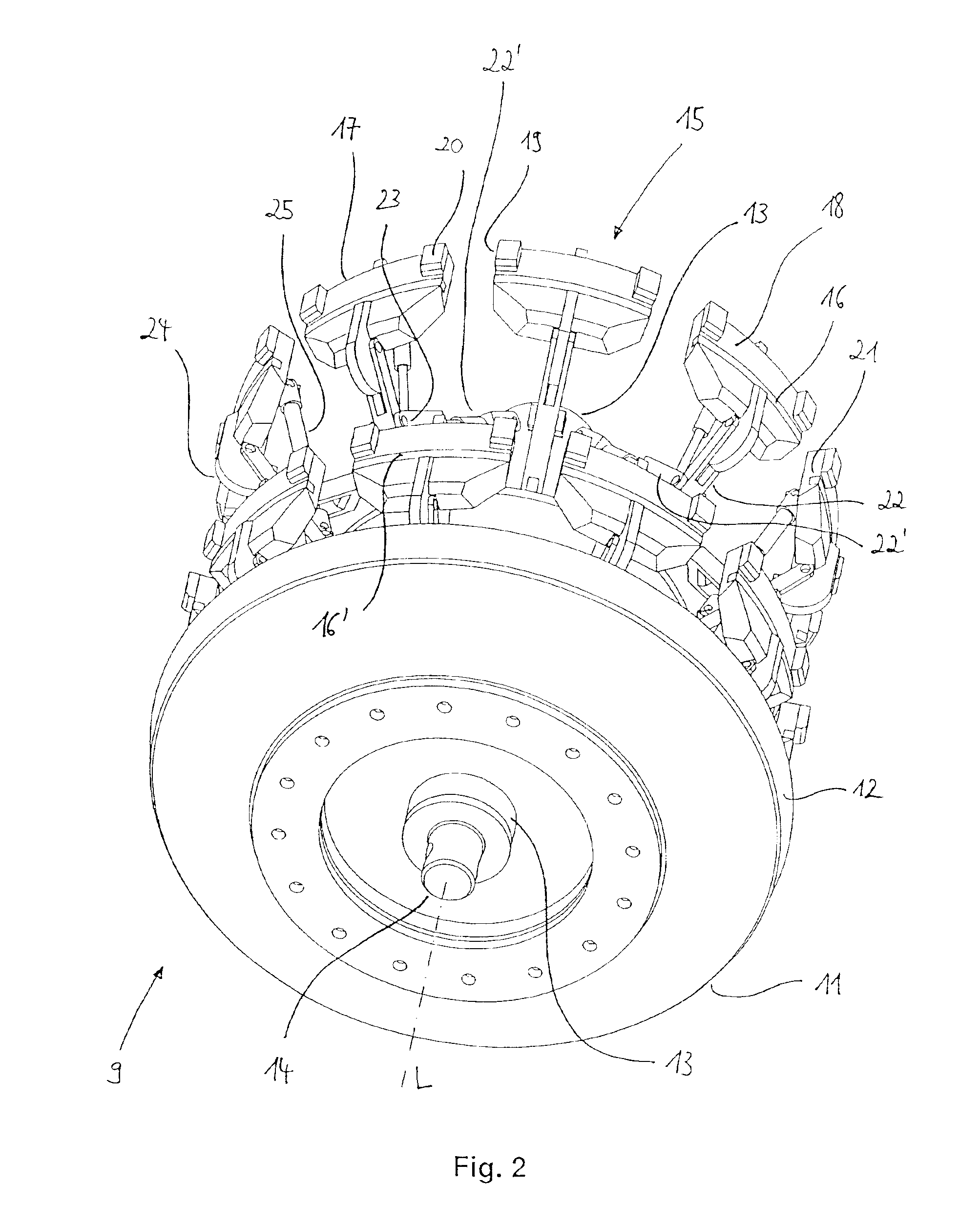

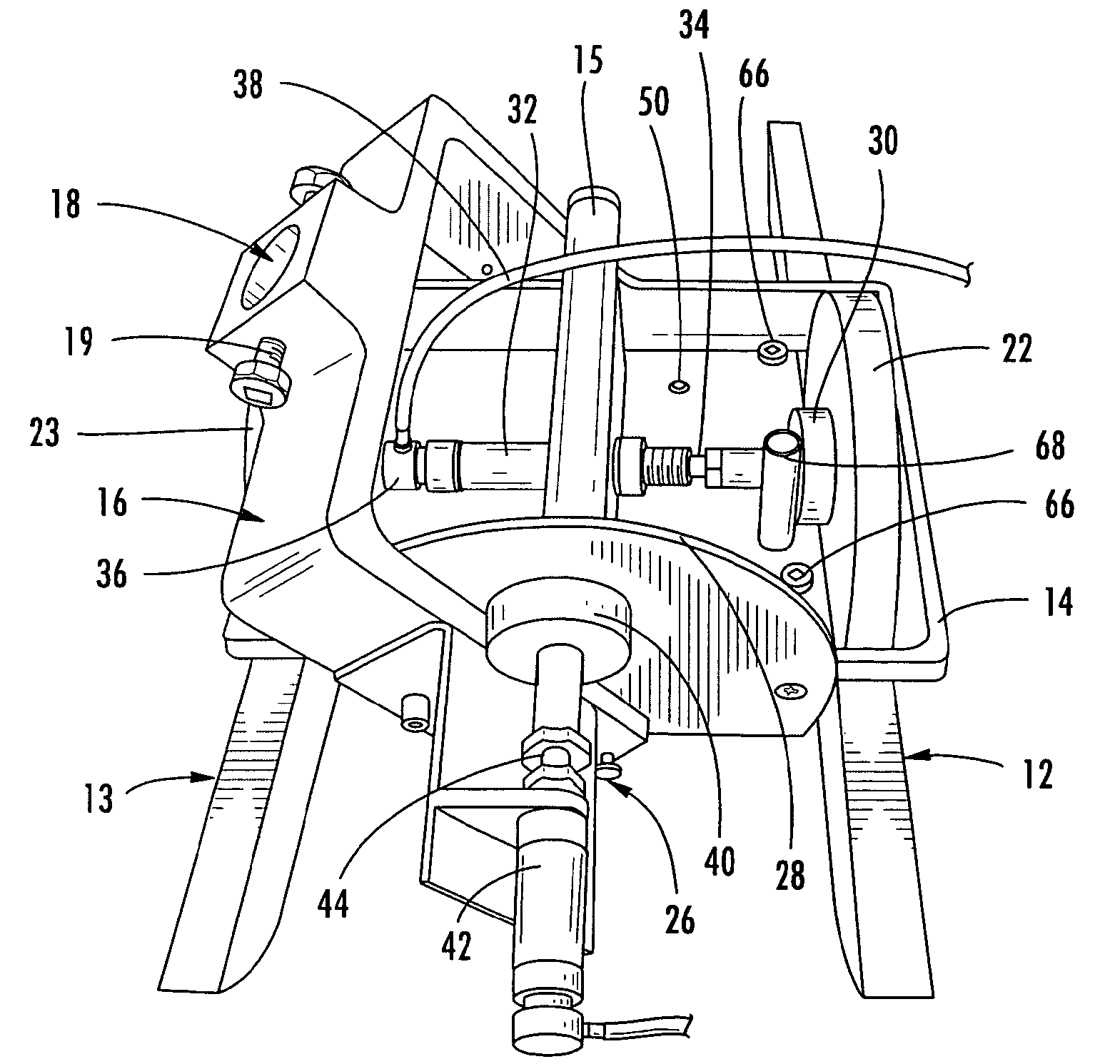

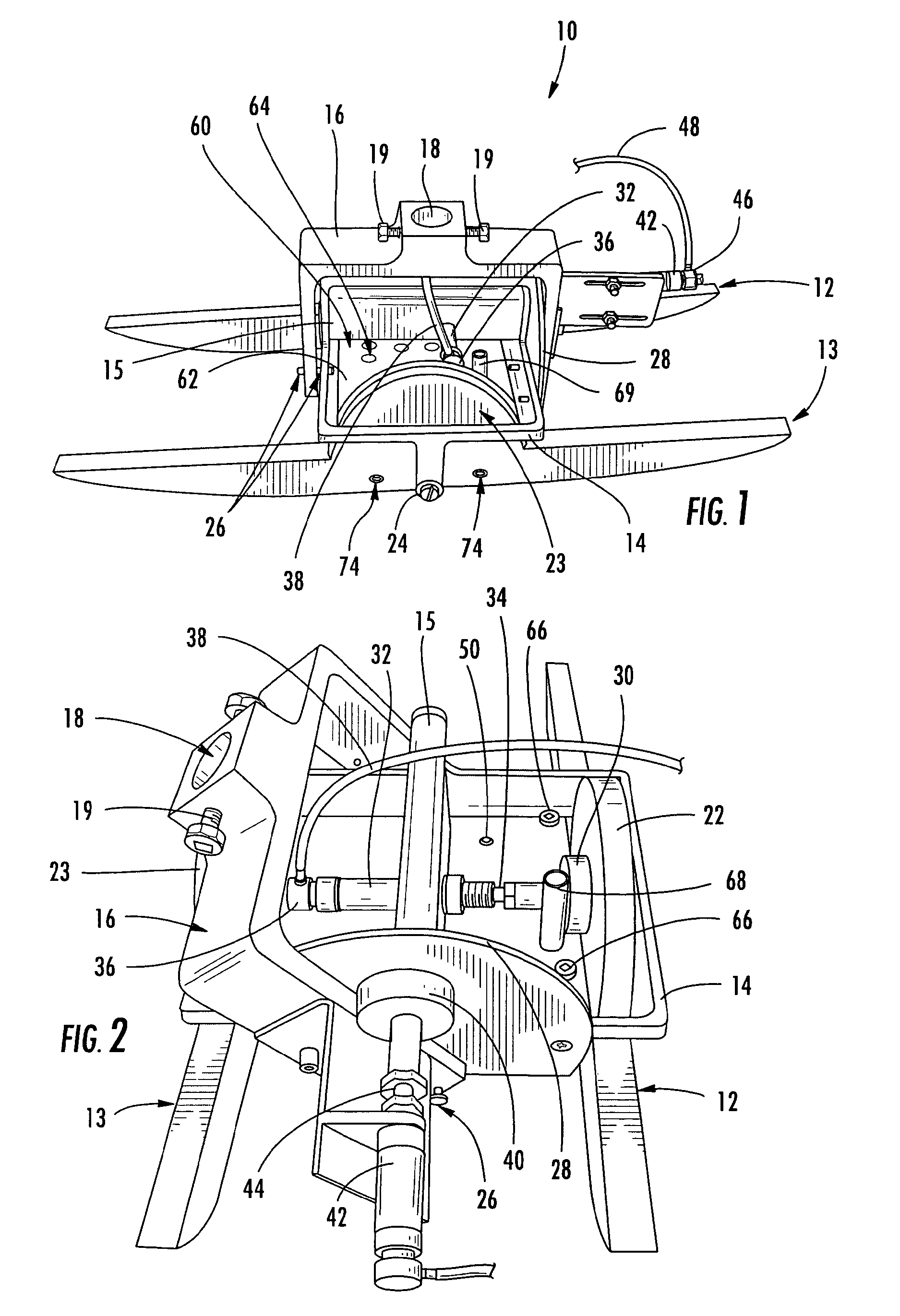

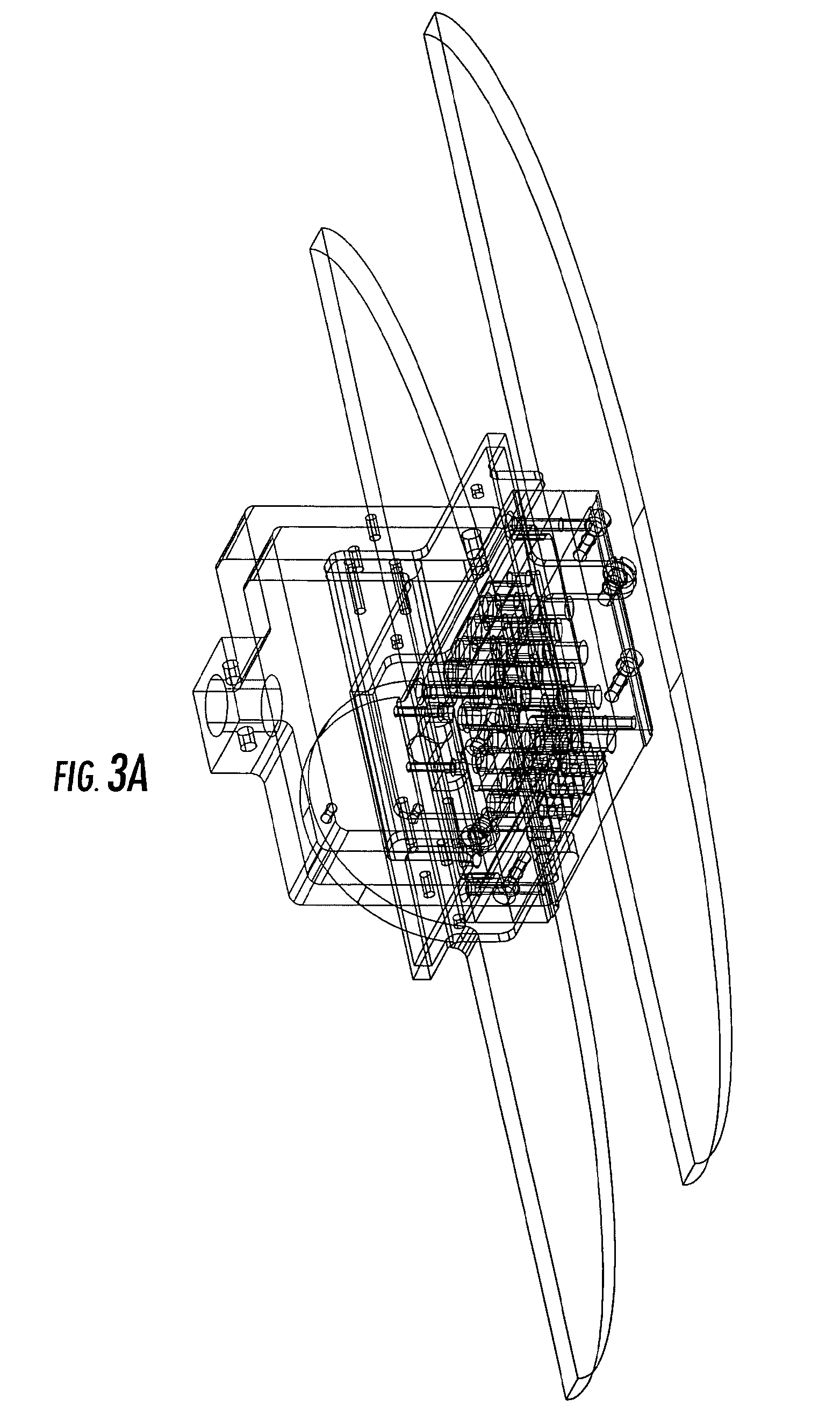

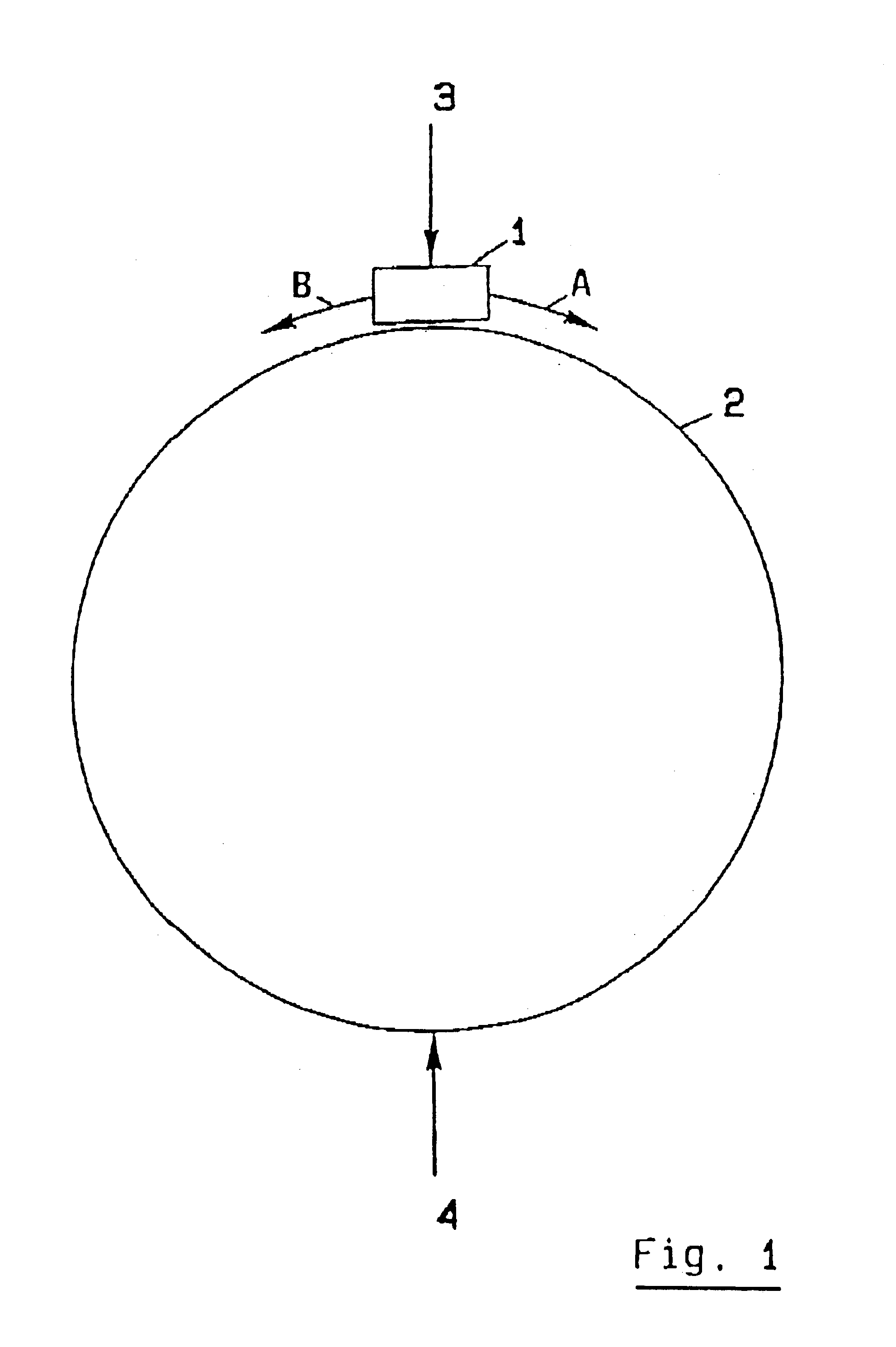

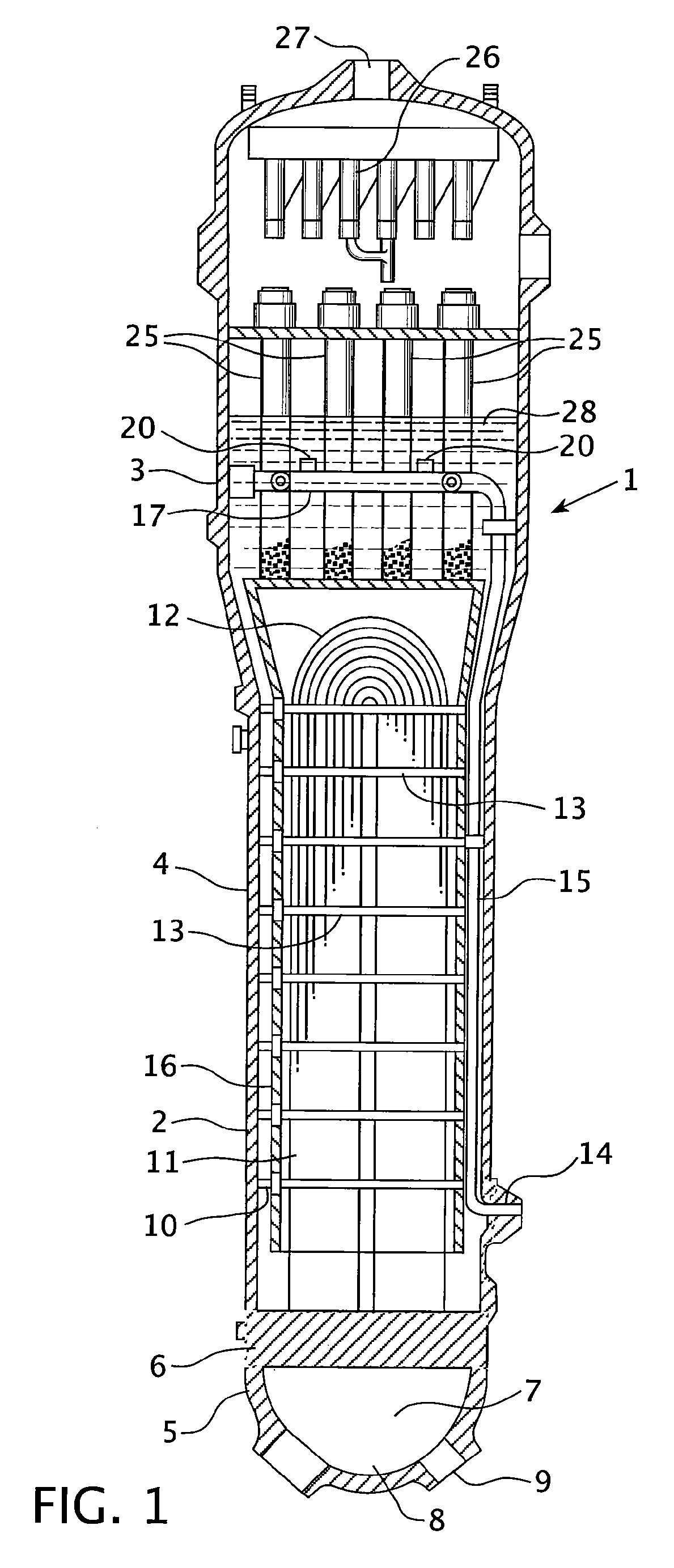

Method of and an apparatus for detecting, identifying and recording the location of defects in a railway rail

InactiveUS6055862AAccurate and repeatable flaw detectionAccurate detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationTransducerEngineering

Method and apparatus for ultrasonic inspection of an object. A tire is mounted for rolling along the surface of the object. It contains a liquid and a transducer assembly. The transducer assembly is positioned in the tire adjacent a portion of the surface of the tire in contact with the object. The liquid and the surface of the tire in contact with the object provide an acoustic bridge between the transducer assembly and the object. An electric signal processing system is connected to the transducer assembly. It generates electric signals which are converted to acoustic signals in the transducer assembly to place acoustic signals in the object. Acoustic signals returned from the object are converted to electric signals by the transducer assembly, and are processed in the electric signal processing system to indicate flaws in the object.

Owner:HERZOG SERVICES

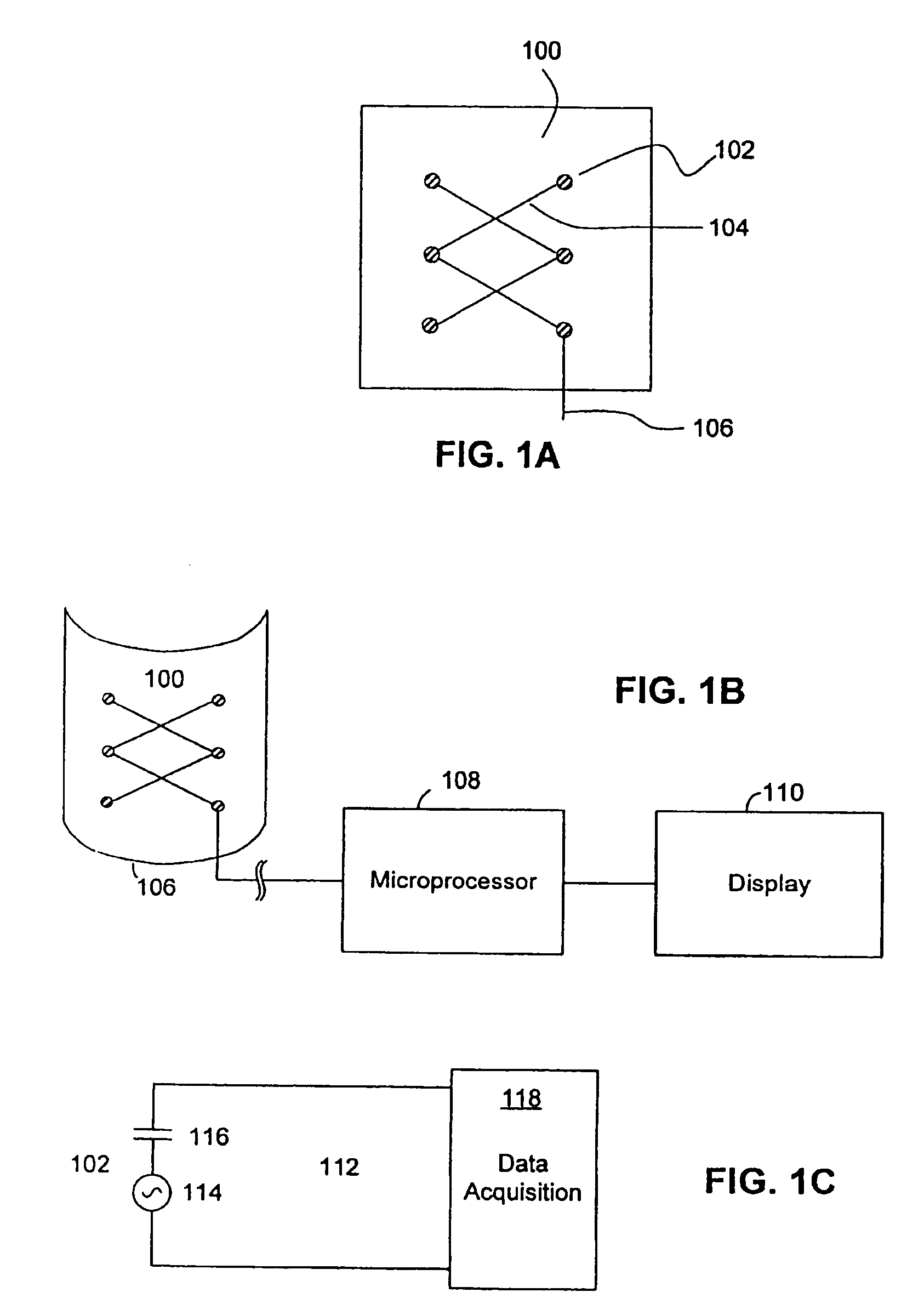

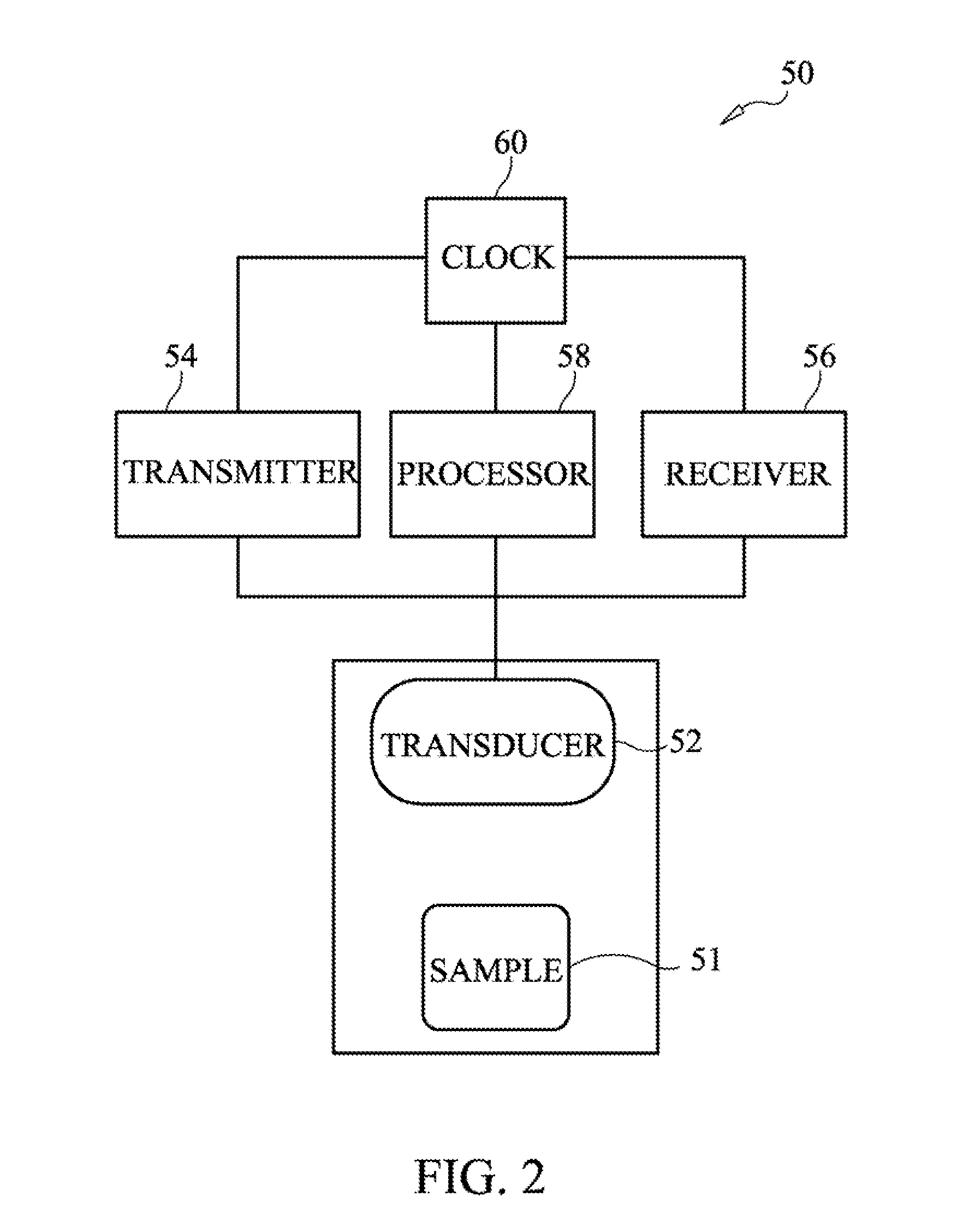

Method and apparatus for characterization of clot formation

ActiveUS20050148899A1Analysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationHigh intensityClot formation

Methods, apparatus and systems for characterizing changes in at least one physical property of soft tissue. A series of acoustic pulses is generated and directed into the soft tissue such that at least one of the pulses is of sufficiently high intensity to induce physical displacement of the tissue. Waves reflected off the tissue, or a flexible member that moves with the tissue, are received and measured to estimate at least one characteristic of the physical displacement induced thereby. Repetition of the generating, receiving and estimating steps provides characterization of the at least one physical property over time. Methods, apparatus and systems for characterizing at least one physical property of blood, by generating a series of acoustic pulses and directing the series of pulses into the blood such that at least one of the pulses is of sufficiently high intensity to induce physical displacement of the blood. Acoustic pulses and / or optical waves reflected from the blood, or a flexible member in contact with the blood that moves with the blood, are received and measured to estimate at least one characteristic of the physical displacement induced thereby.

Owner:HEMOSONICS

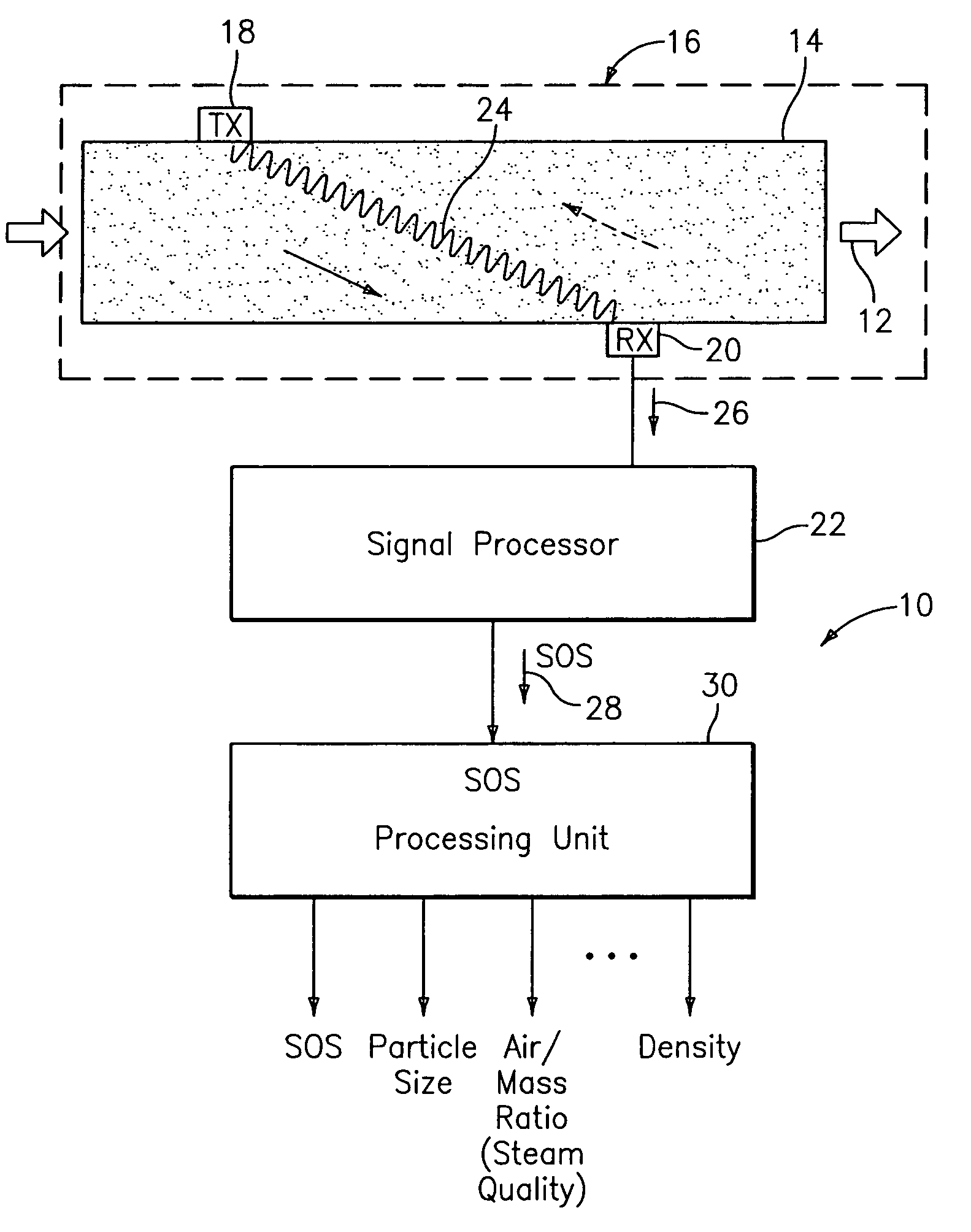

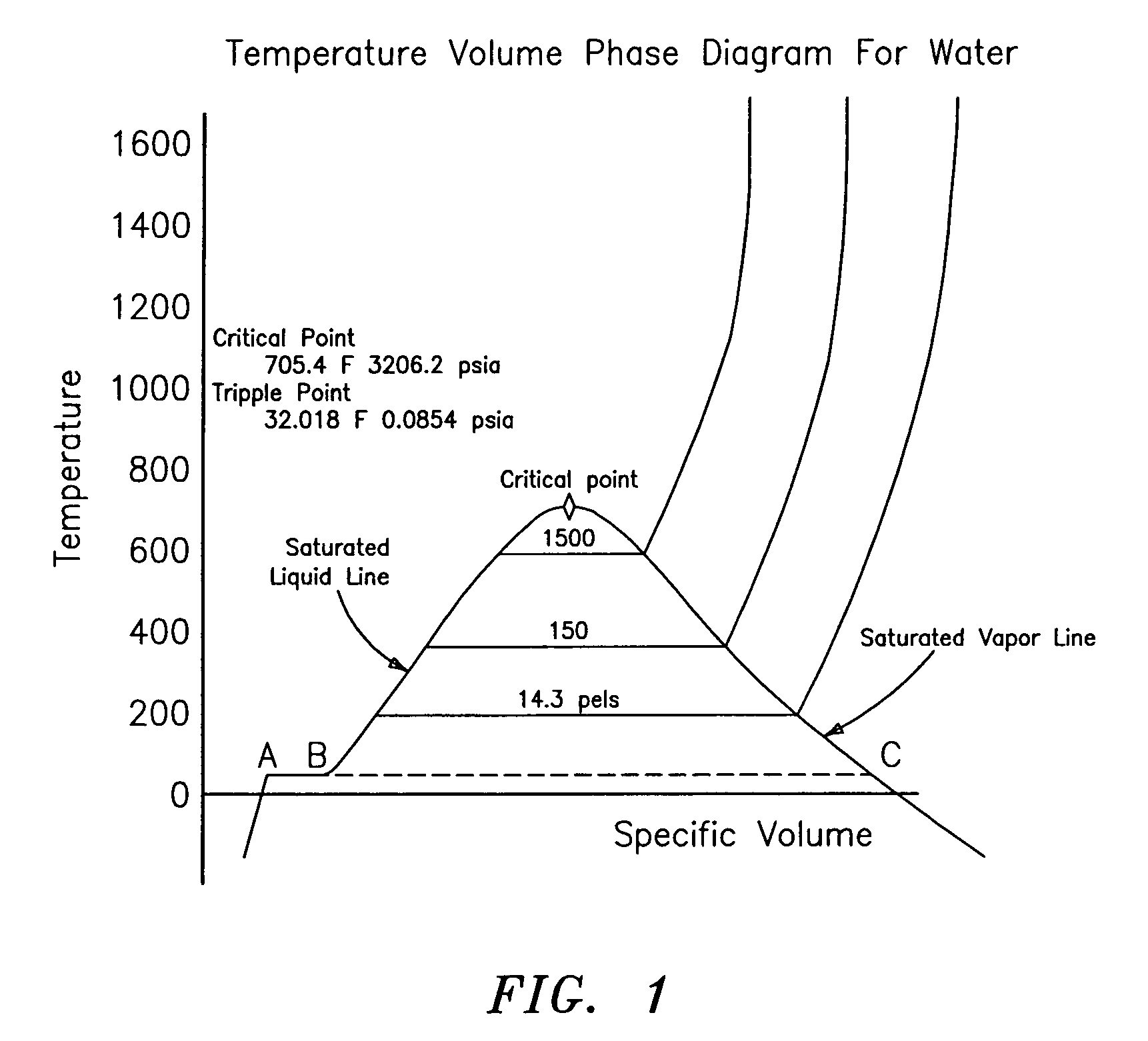

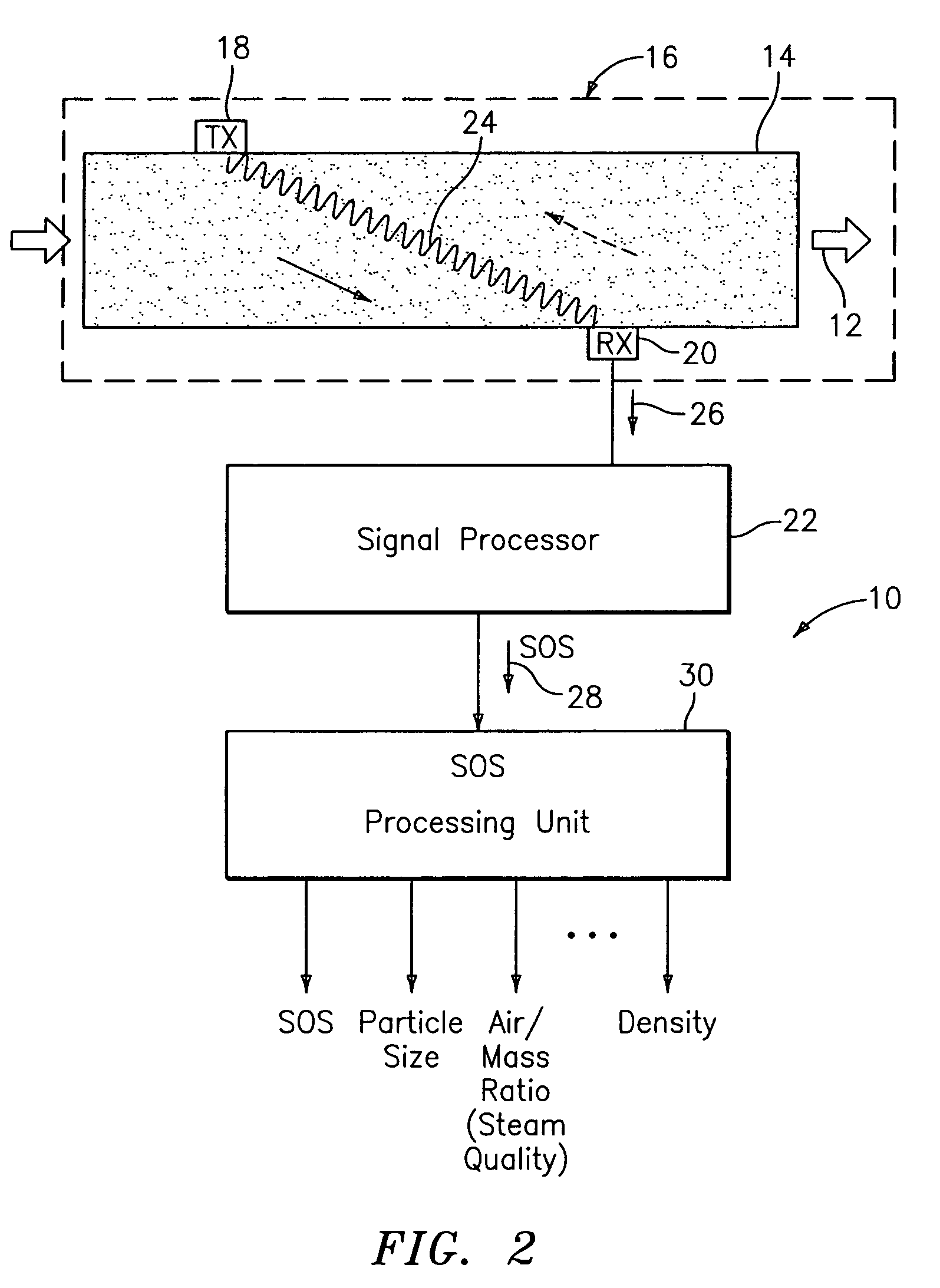

Apparatus for measuring parameters of a flowing multiphase mixture

ActiveUS7096719B2Analysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic sensorMass ratio

An apparatus 10 is provided that measures the speed of sound propagating in a multiphase mixture to determine parameters, such as mixture quality, particle size, vapor / mass ratio, liquid / vapor ratio, mass flow rate, enthalpy and volumetric flow rate of the flow in a pipe or unconfined space, for example, using acoustic and / or dynamic pressures. The apparatus includes a pair of ultrasonic transducers disposed axially along the pipe for measuring the transit time of an ultrasonic signal to propagate from one ultrasonic transducer to the other ultrasonic transducer. A signal process, responsive to said transit time signal, provides a signal representative of the speed of sound of the mixture. An SOS processing unit then provides an output signal indicative of at least one parameter of the mixture flowing through the pipe. The frequency of the ultrasonic signal is sufficiently low to minimize scatter from particle / liquid within the mixture. The frequency based sound speed is determined utilizing a dispersion model to determine the at least one parameter of the fluid flow and / or mixture.

Owner:CIDRA CORP SERVICES

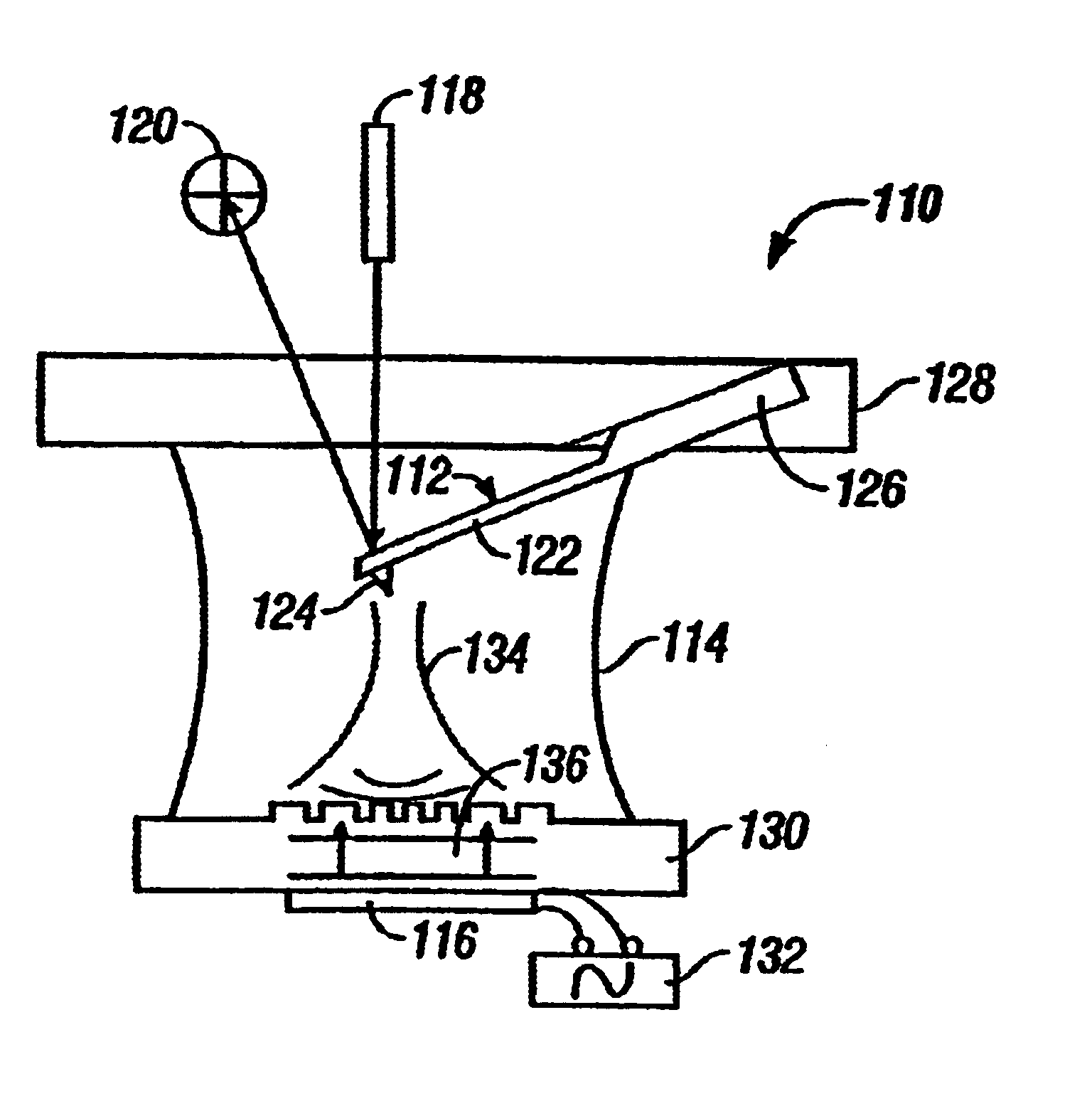

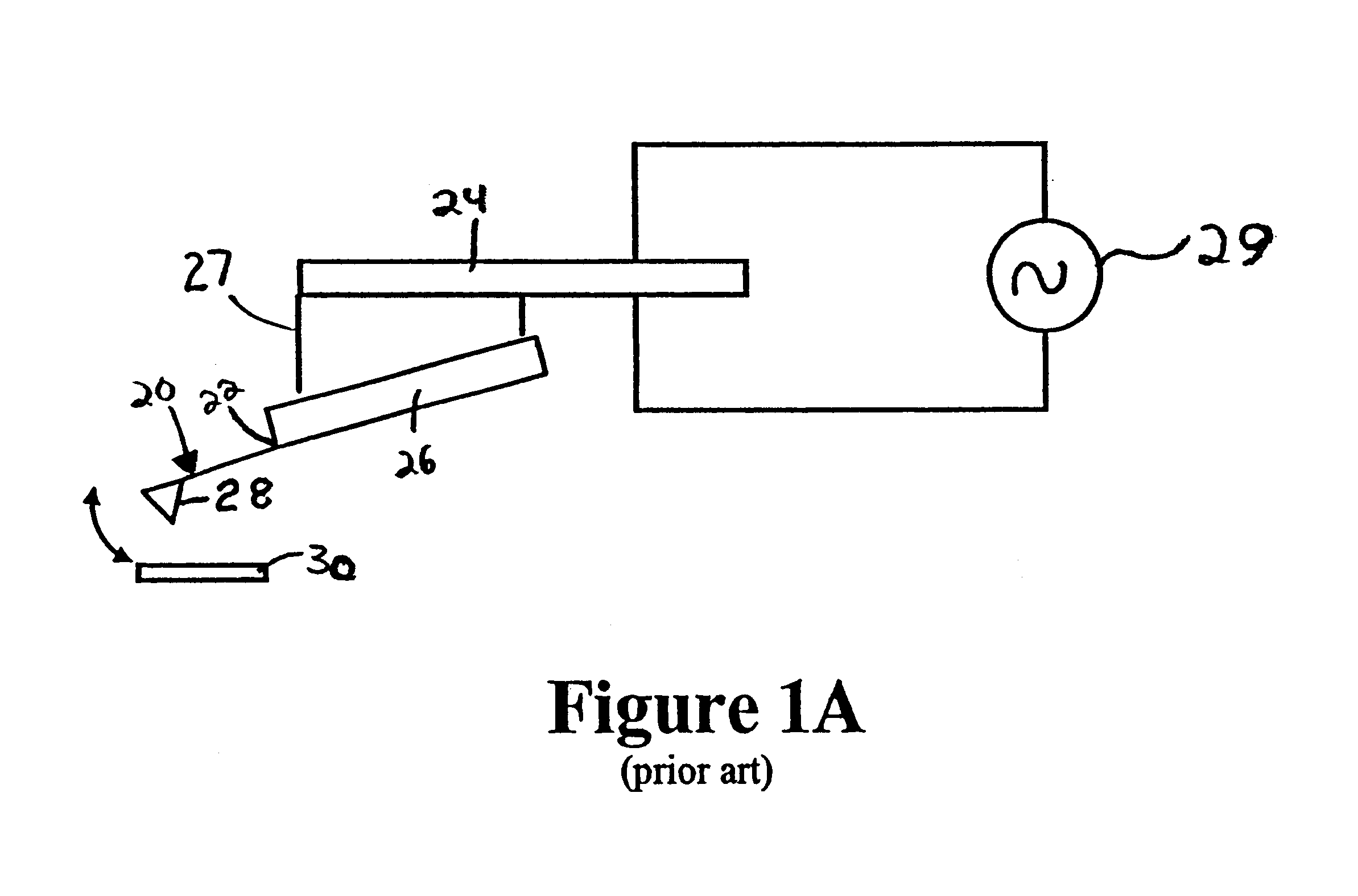

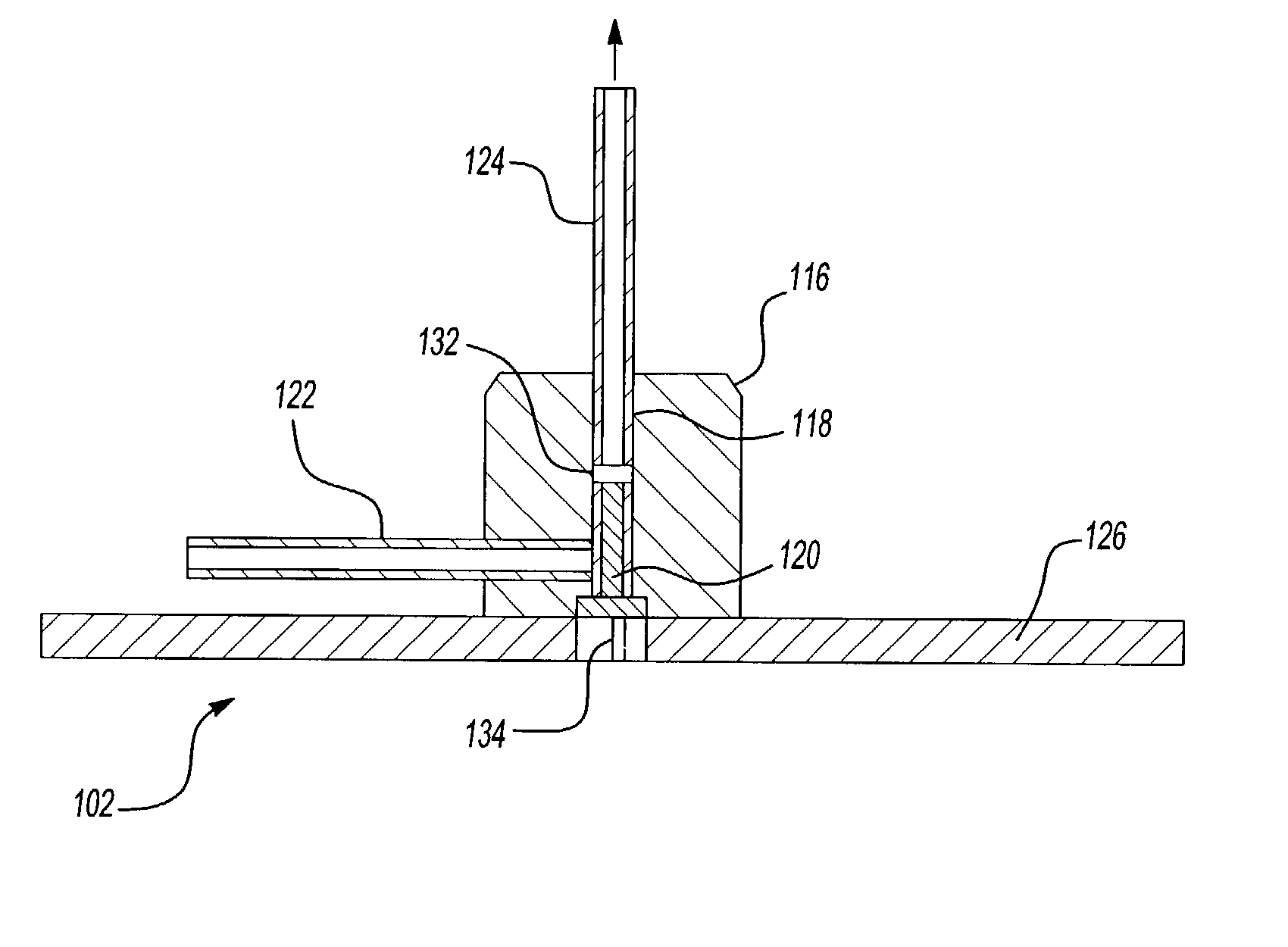

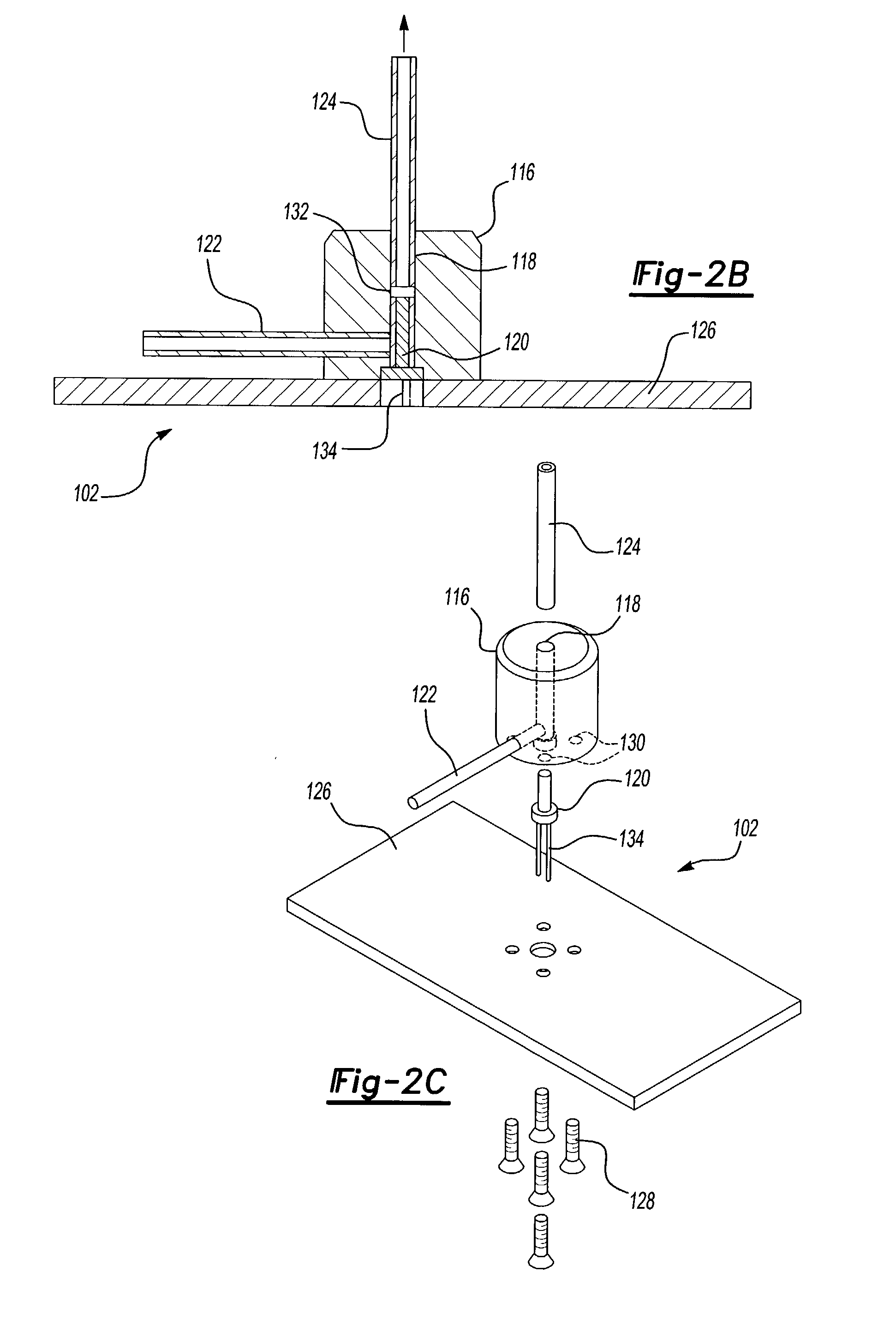

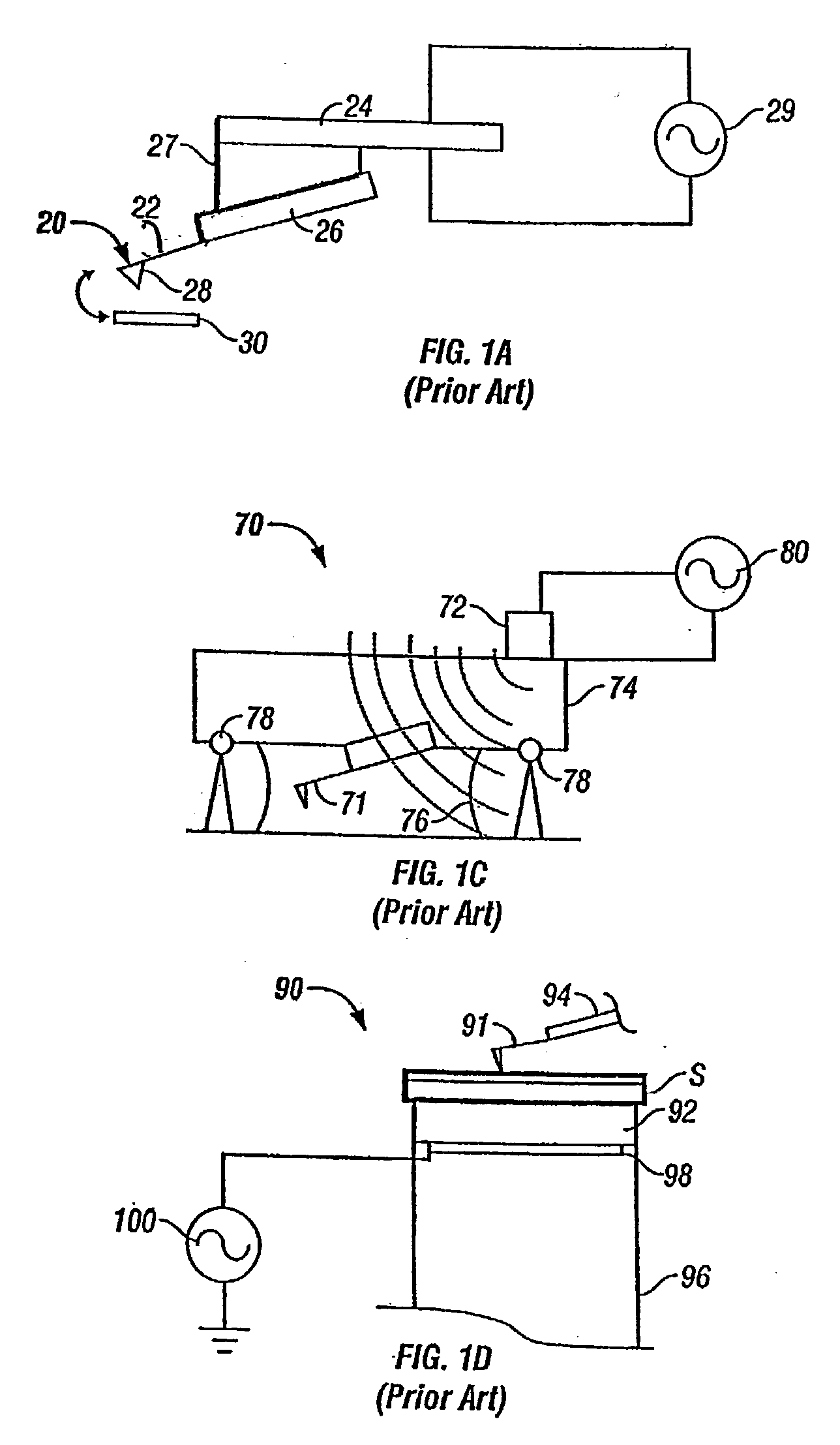

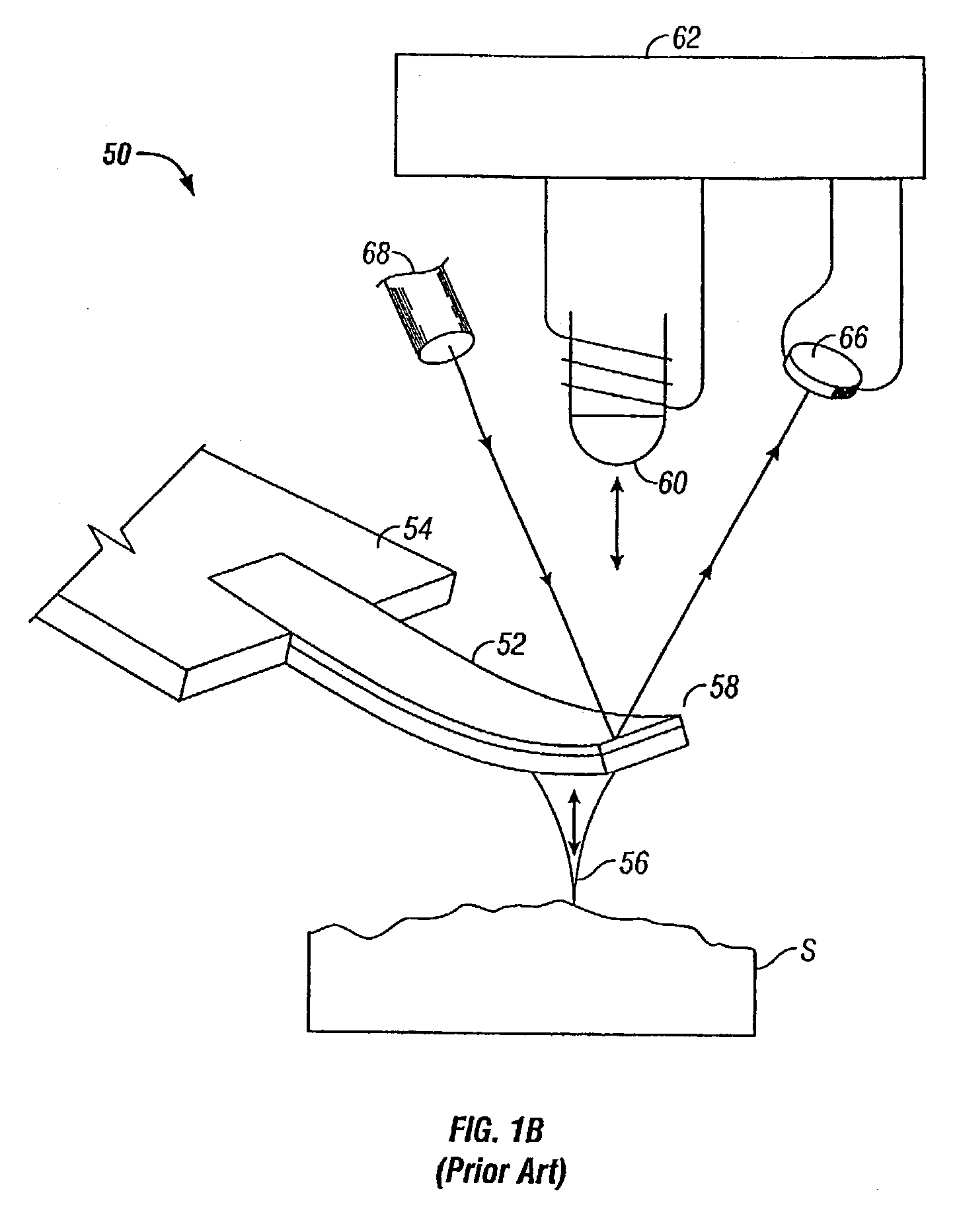

Method and apparatus for the ultrasonic actuation of the cantilever of a probe-based instrument

The cantilever of a probe-based metrology instrument such as an AFM is deflected by directing a beam of ultrasonic energy at the cantilever to apply ultrasonically generated acoustic radiation pressure to the cantilever. The energy is generated by an ultrasonic actuator such as a ZnO transducer driven by a power source such an RF signal generator. The transmitted beam preferably is shaped by focusing, collimation, or the like so that it impinges at least primarily on a region of interest of the cantilever such as the free end. The ultrasonic actuator produces a much better controlled force on the cantilever than can be achieved through the use of a traditional piezoelectric actuator and, accordingly, produces a response free of spurious effects (at least when the cantilever is operating in liquid). It also has a frequency bandwidth in the MHz range.

Owner:GEORGIA TECH RES CORP +1

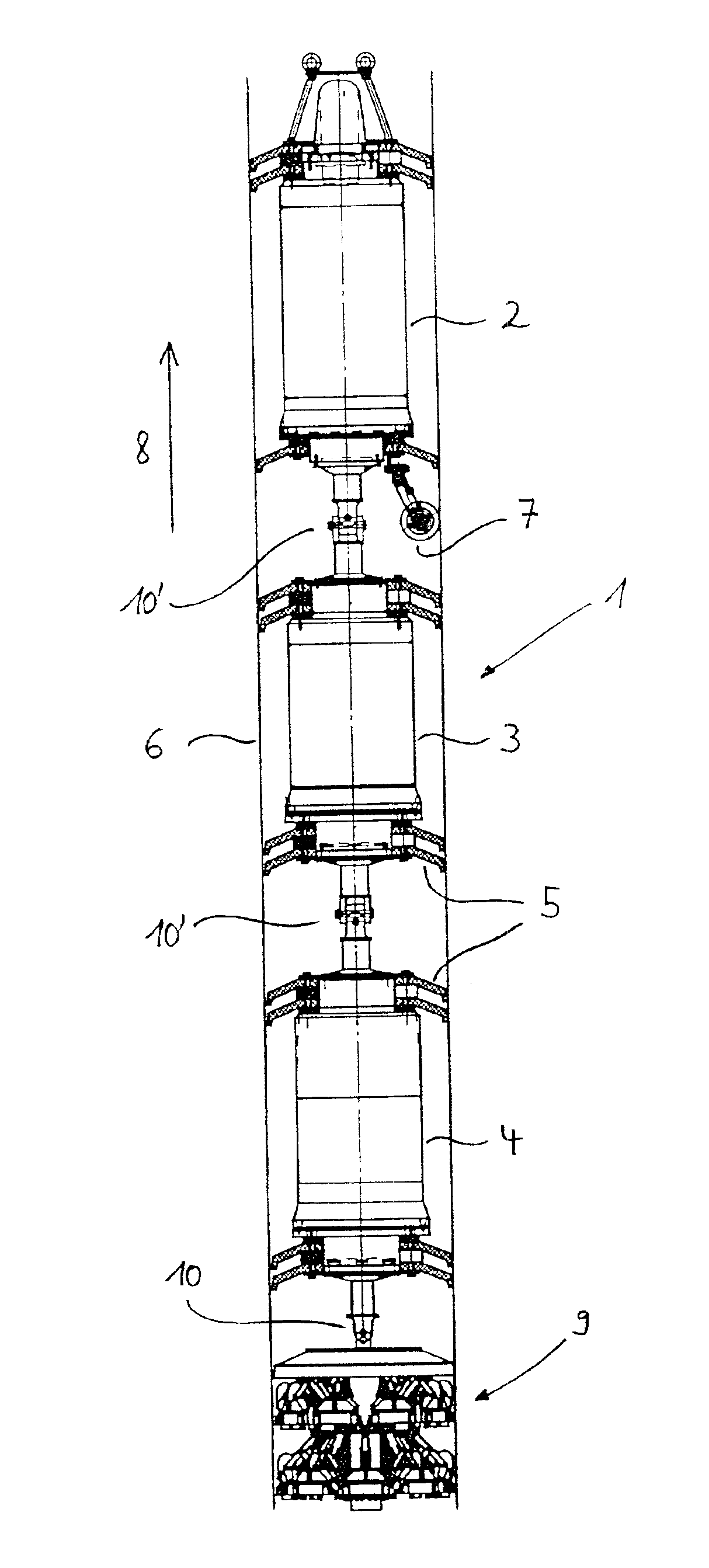

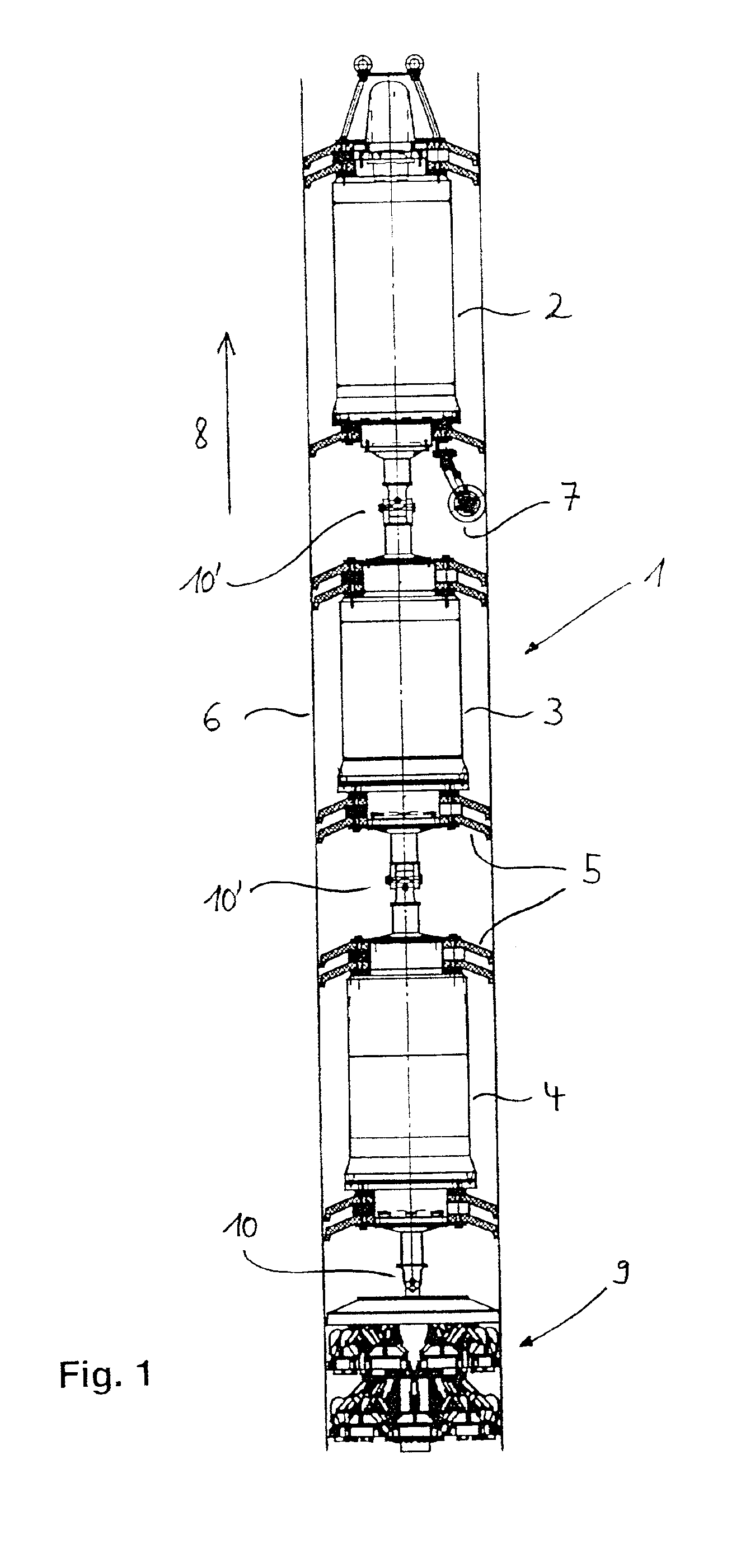

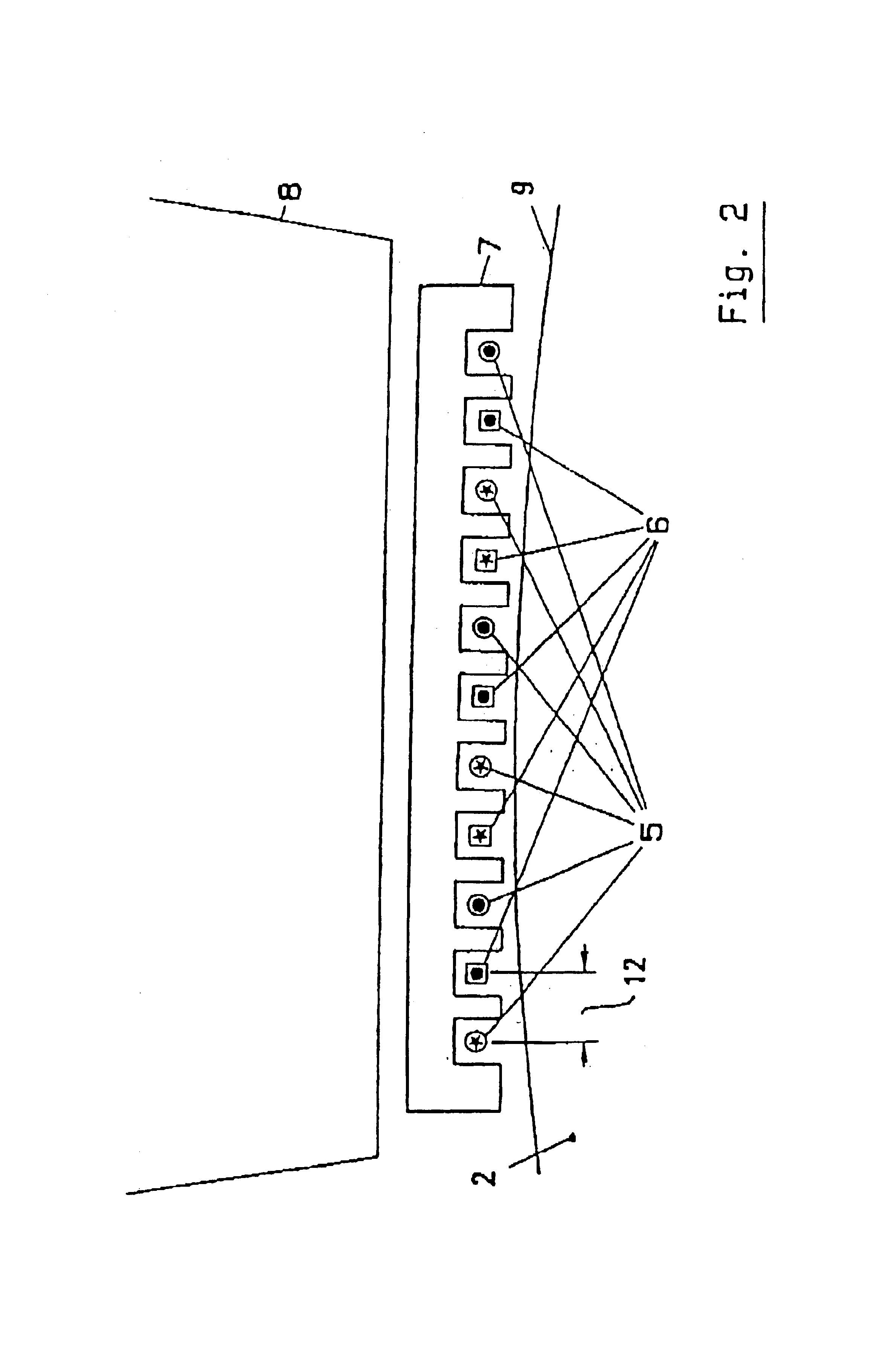

Method and device for inspecting pipelines

InactiveUS6848313B2Avoid bouncingImprove resilientAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationEngineeringBoundary region

The invention concerns a method and a device for inspecting pipelines, in particular for detecting defects in pipelines by means of ultrasound. Towards this end, measuring sensors transmit ultrasound signals during passage through a pipeline. The signals reflected on boundary regions of a pipeline wall, e.g. surfaces or defects, are then measured and evaluated. The invention is characterized in that partial regions of the measuring sensors (virtual sensors) formed of a plurality of neighboring sensor elements irradiate ultrasound signals into the pipe wall at at least one radiation angle which is inclined with respect to the normal to the pipe wall and the signals reflected at boundary regions of the pipe wall are received by same and / or other partial regions of the respective measuring sensors, wherein defects in the pipe wall are determined by evaluation of the acoustical signals reflected by different boundary regions.

Owner:PII PIPETRONIX

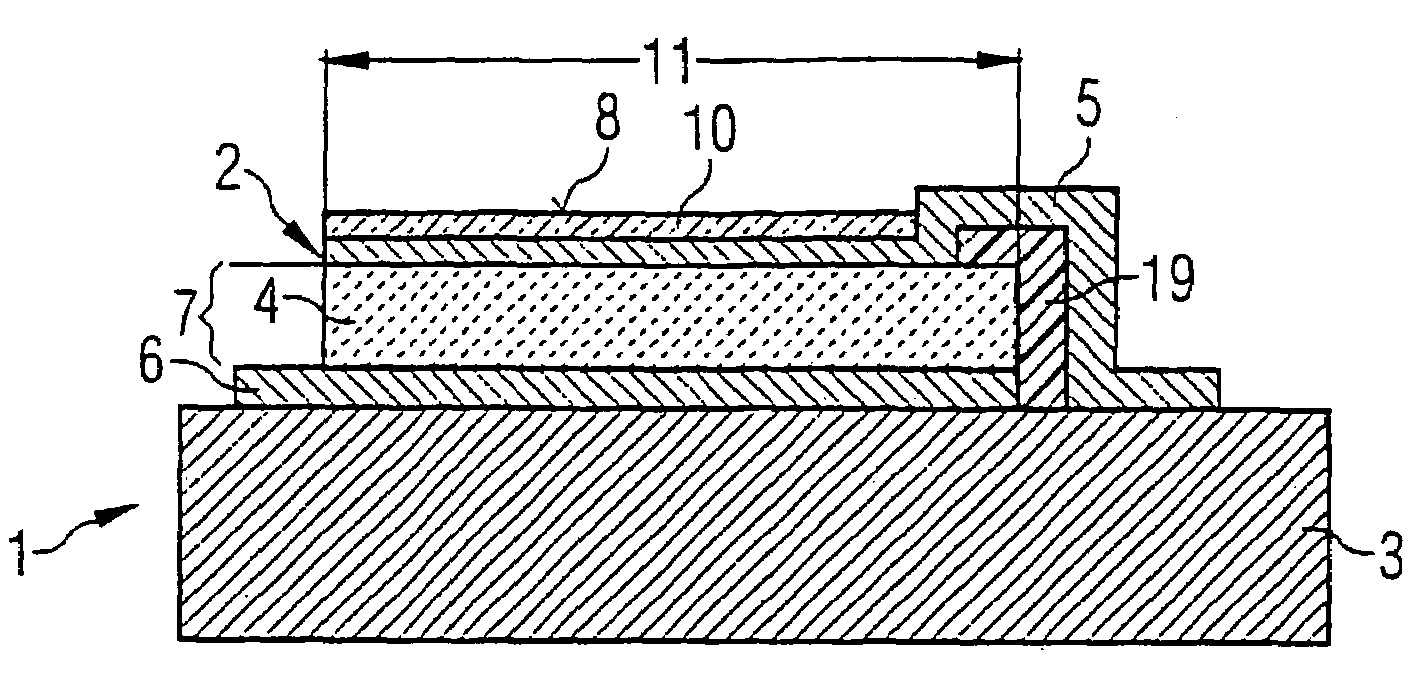

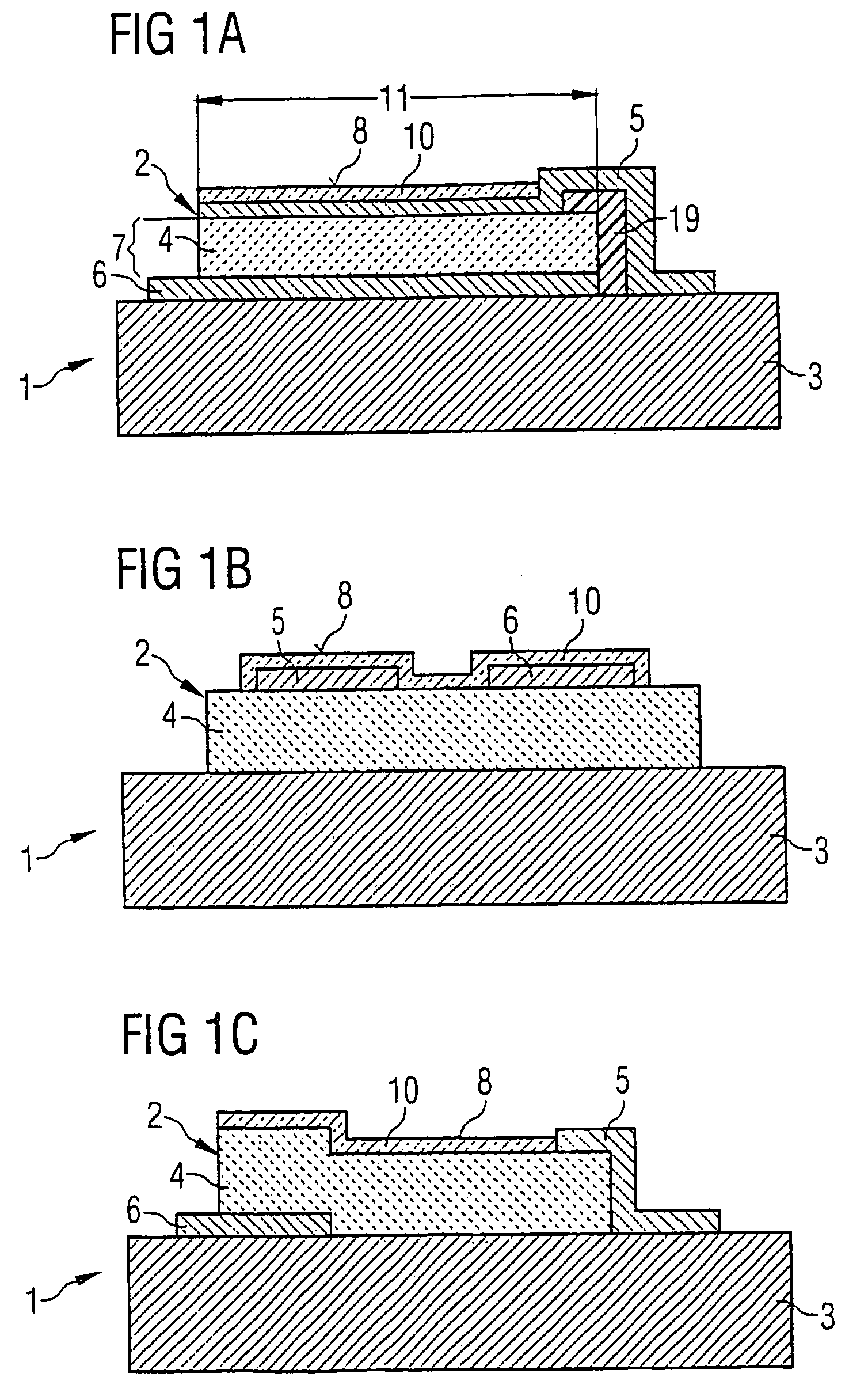

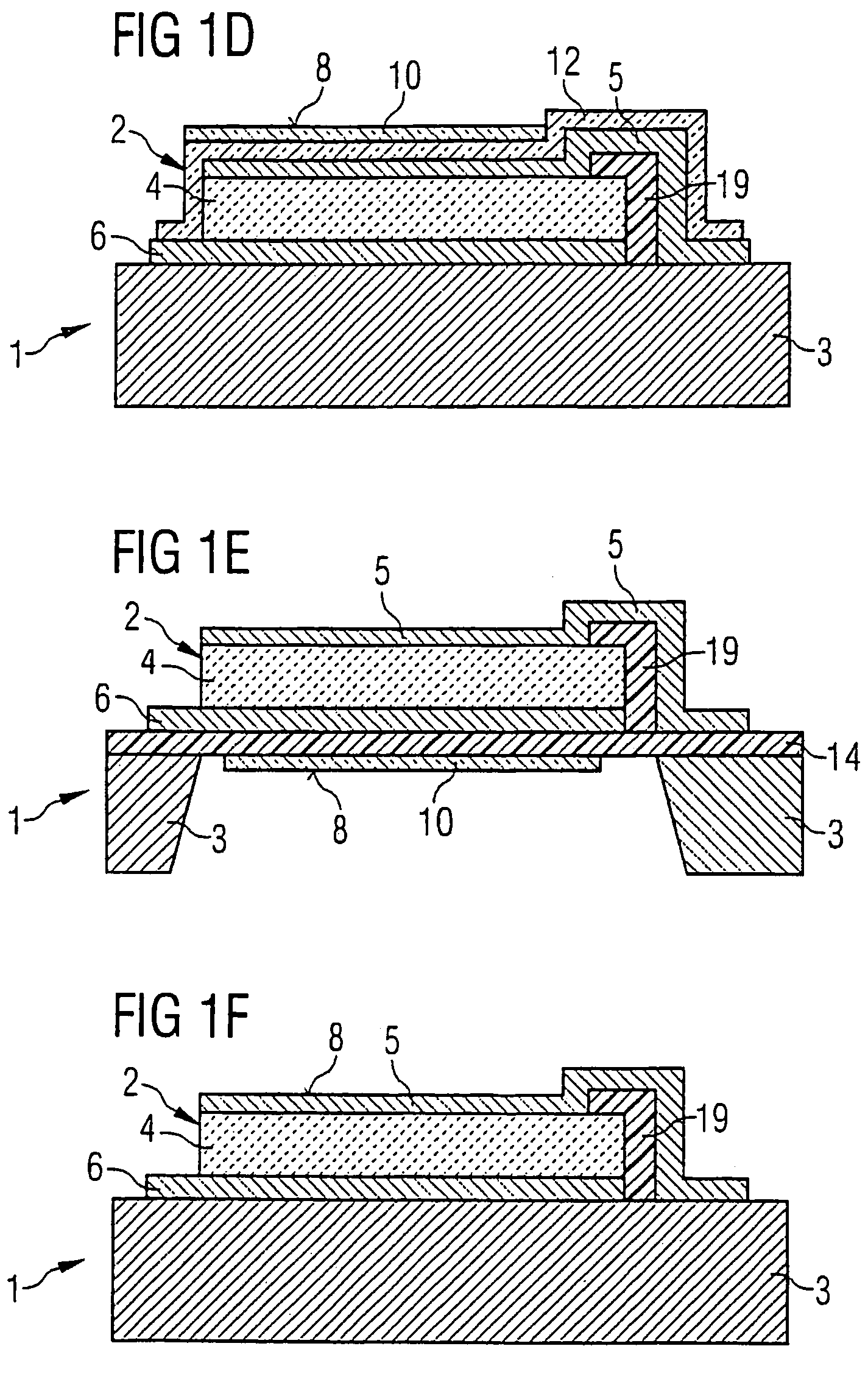

Device and method for detecting a substance of a liquid

ActiveUS7468608B2Eliminates high-frequency lossEliminates interfering inductanceAnalysing fluids using sonic/ultrasonic/infrasonic wavesShaking/oscillating/vibrating mixersResonancePiezo electric

A device for detecting at least one substance of a fluid includes at least one piezo-acoustic resonator with at least one piezo layer, an electrode arranged on the piezo-electric layer, at least one other electrode arranged on the piezo-electric layer and a surface section used for sorption of the substance of the fluid. The piezo-electric layer, the electrodes and the surface section are disposed in such a way that electric control of the electrodes leads to an oscillation of the resonator at a resonance frequency which depends upon the amount of the substance which is sorbed on the surface section. The thickness of the pioelectric layer is in the region of 0.5 to 20 μm and the resonance frequency of the oscillation ranges from 500 MHz to 2 GHz. The device is a mass sensor with a piezo-acoustic high-frequency thin film resonator.

Owner:BIOMENSIO LTD

High-precision measuring method and apparatus

InactiveUS7080554B2Vibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesPhase locked loop circuitTransmission channel

Owner:NEXENSE

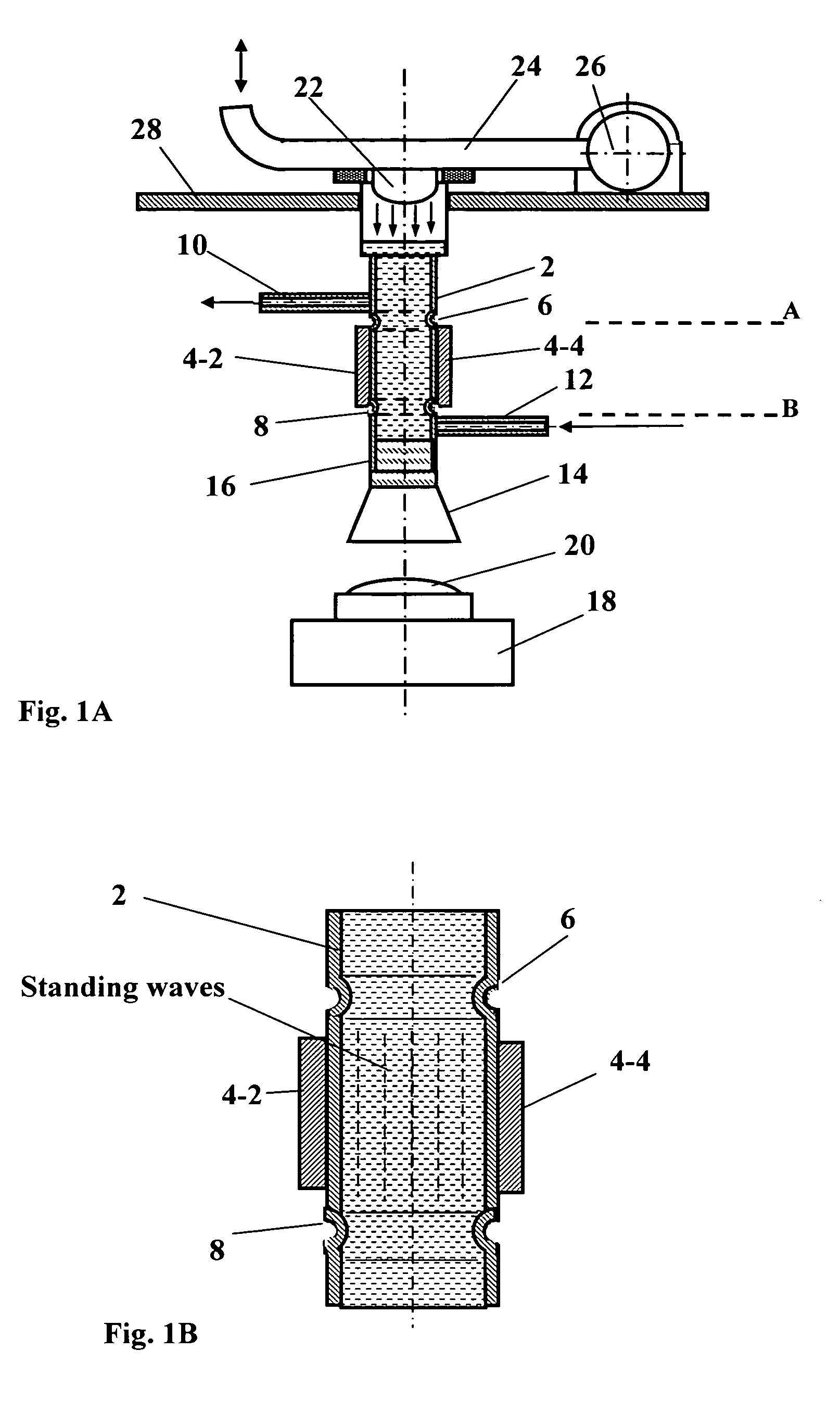

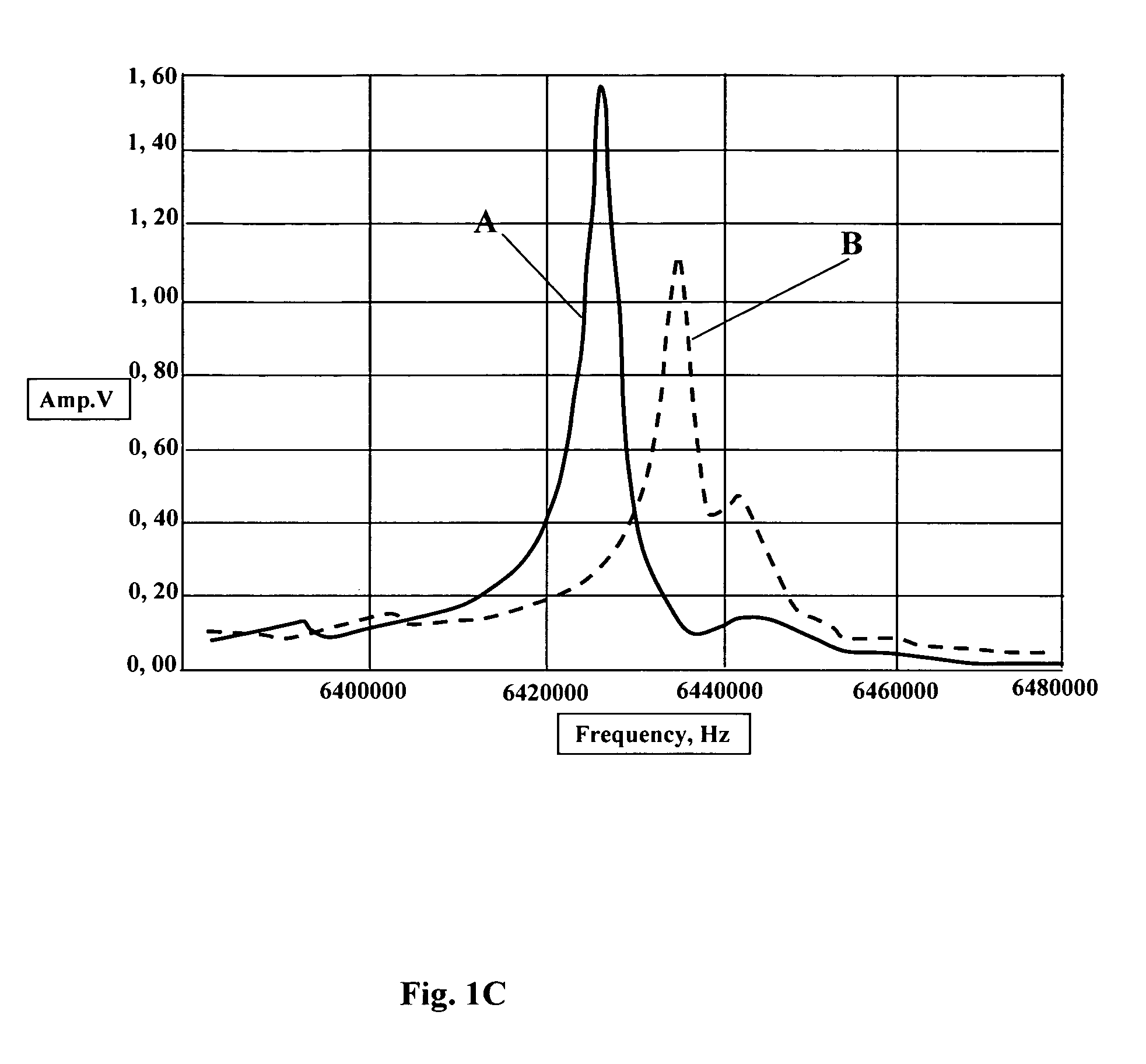

Method and apparatus for determination of the concentration of particles in multi-component fluid systems

InactiveUS20070119239A1Low temperature controlVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesFluid systemLarge particle

A method for determining the concentration of a large particle component in a multi-component system. The method requires first separating and concentrating the large particle component of the system by acoustic means and then measuring an acoustical parameter of the separated large particle component. The invention also provides for an apparatus for determining the concentration of large particles in a multi-component fluid system. The apparatus is comprised of an acoustic standing wave resonator, at least one acoustic standing wave generating source, electronic circuitry for actuating, controlling and processing the acoustic standing wave generating source and means for measuring at least one parameter of the multi-component system after the large particles have been concentrated and aggregated by the generated standing wave(s).

Owner:NANOALERT ISRAEL

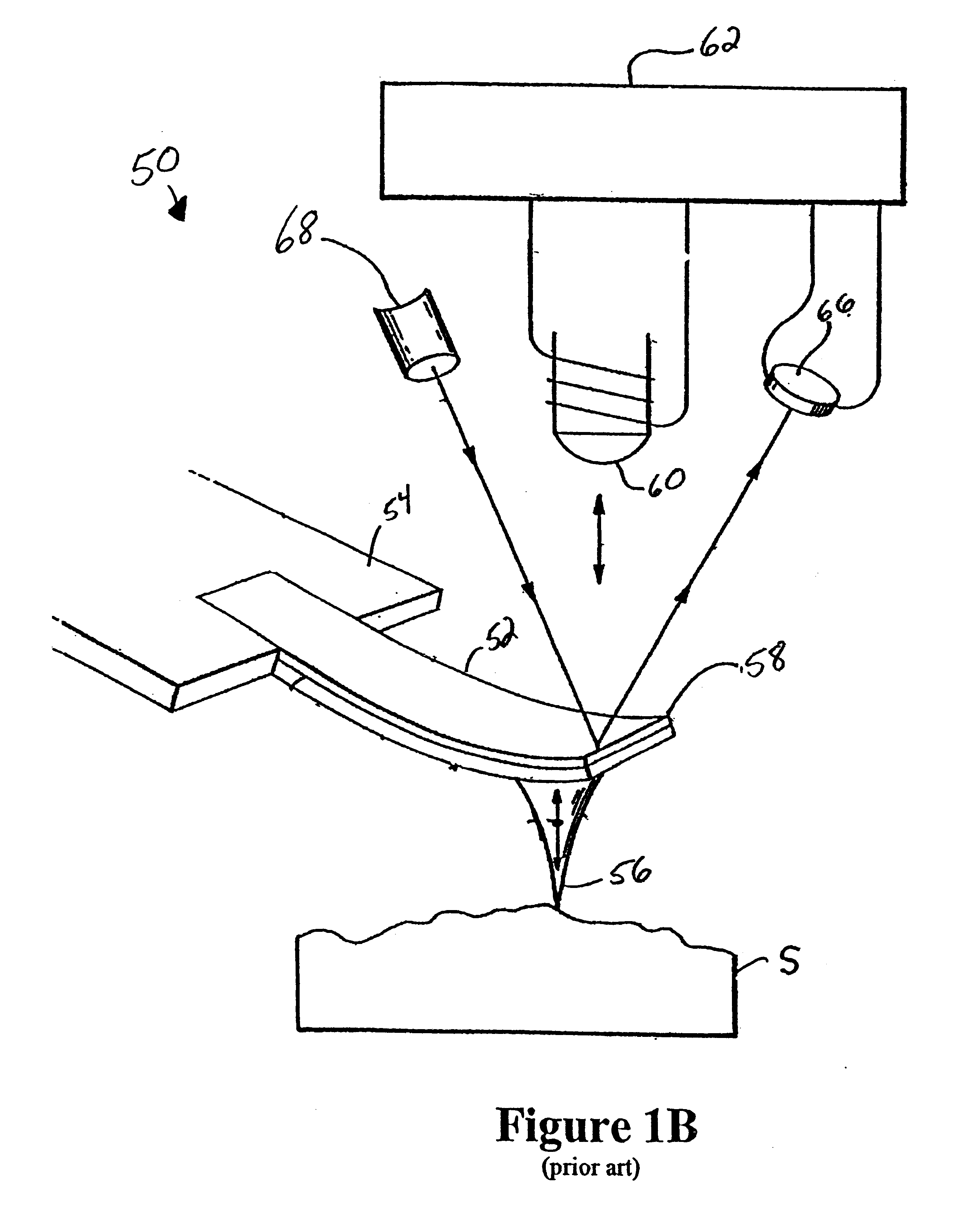

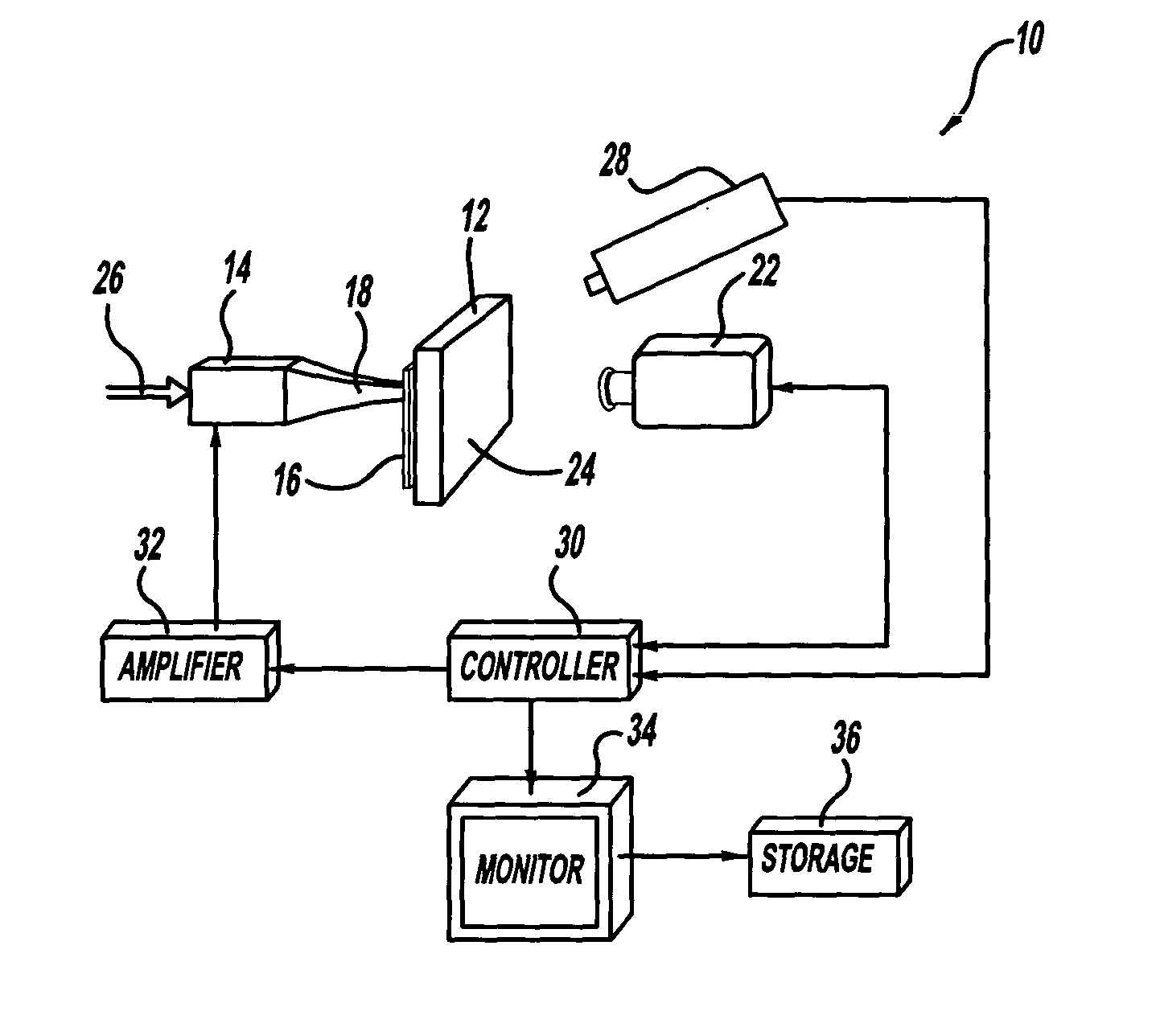

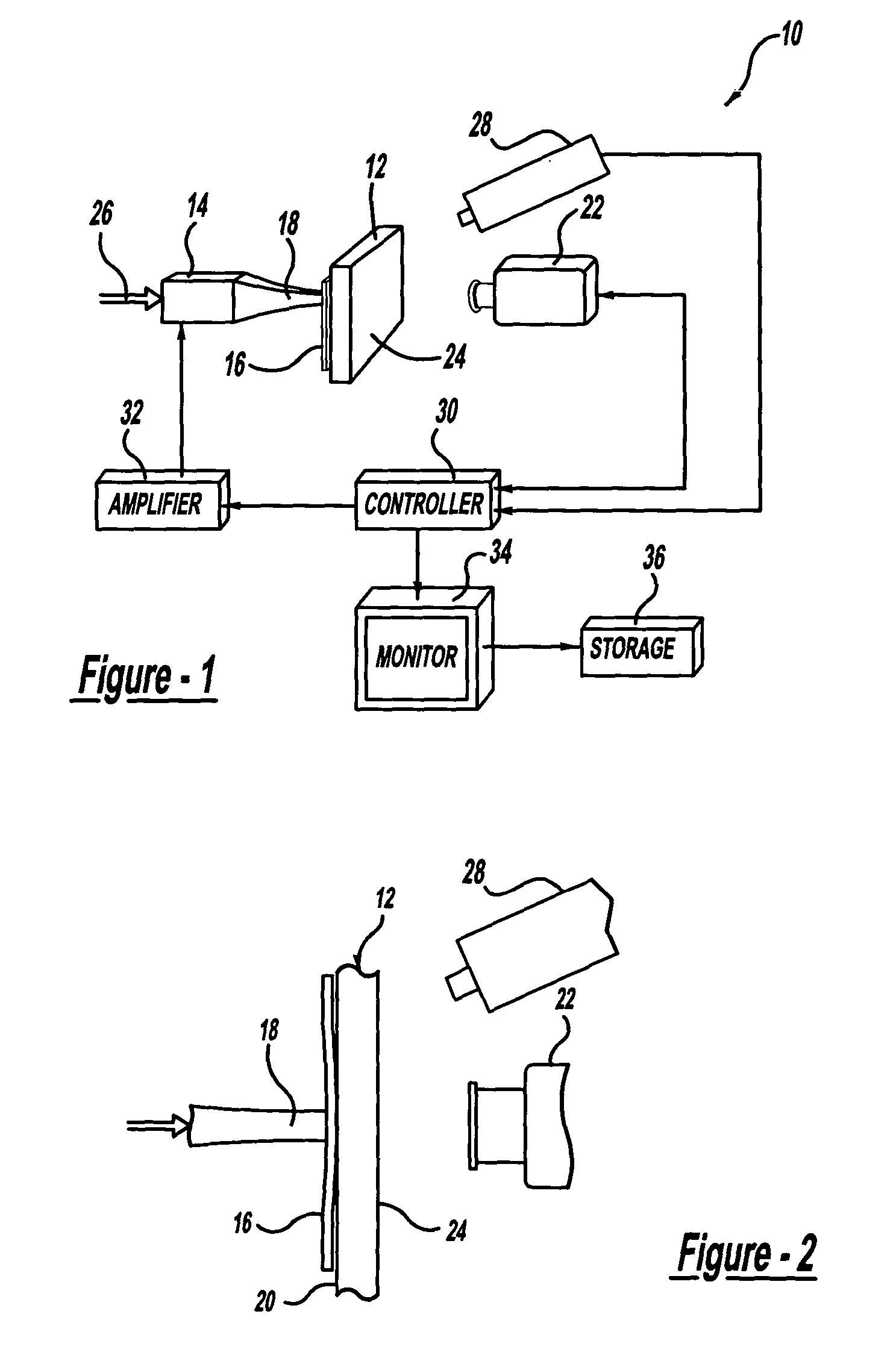

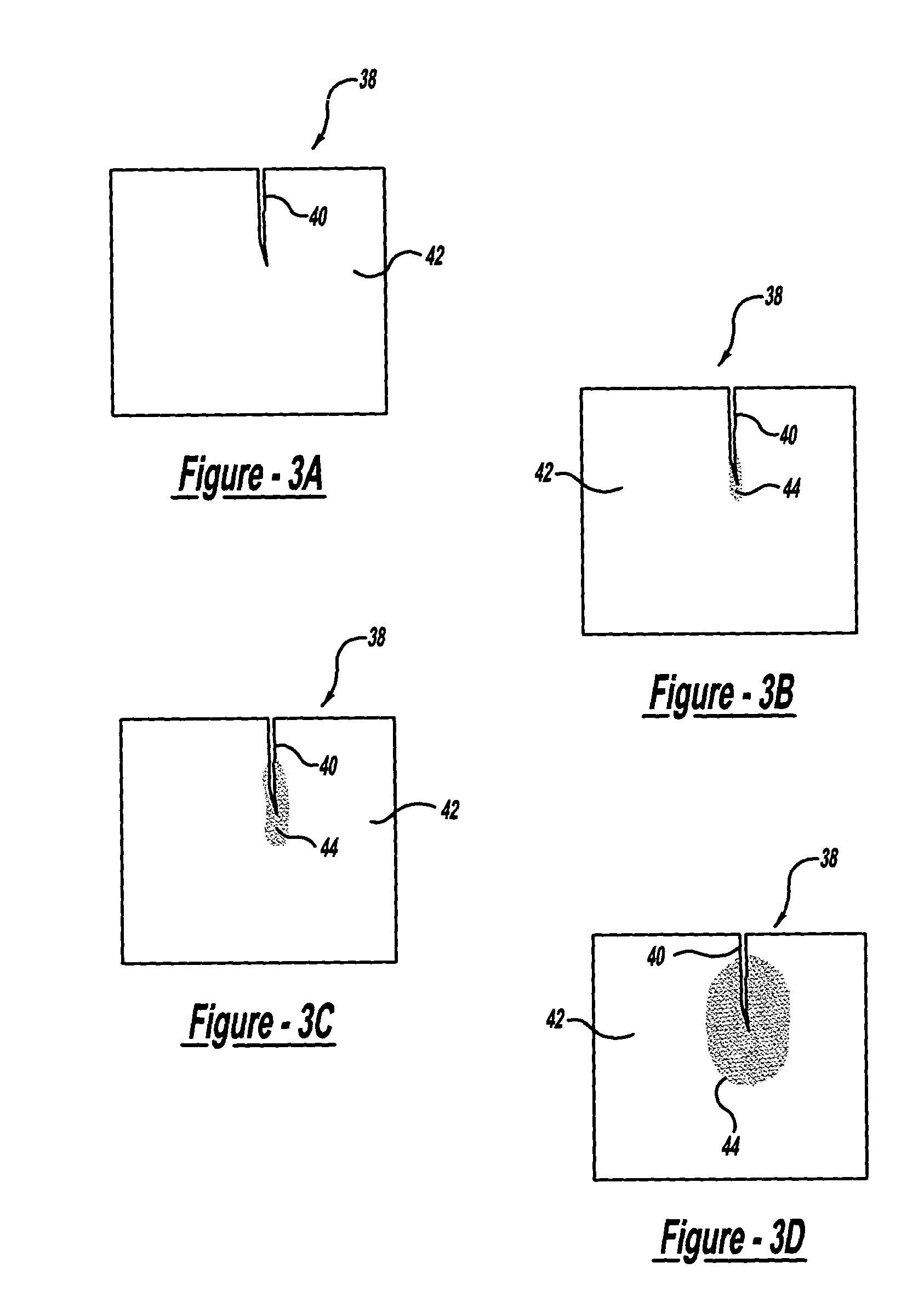

System and method for multiple mode flexible excitation and acoustic chaos in sonic infrared imaging

ActiveUS20040089812A1Analysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationThermal energyCamera image

A defect detection system for thermally imaging a structure that has been energized by a sound energy. The system includes a transducer that couples a sound signal into the structure, where the sound signal causes defects in the structure to heat up. In one embodiment, the sound signal has one or more frequencies that are at or near an eigen-mode of the structure. In another embodiment, an on-linear coupling material is positioned between the transducer and the structure to couple the sound energy from the transducer to the structure. A predetermined force is applied to the transducer and a pulse duration and a pulse frequency of the sound signal are selected so that the sound energy induces acoustic chaos in the structure, thus generating increased thermal energy. A thermal imaging camera images the structure when it is heated by the sound signal.

Owner:WAYNE STATE UNIV +1

Flow detectors having mechanical oscillators, and use thereof in flow characterization systems

ActiveUS20030000291A1Ability to useNormalize signalAnalysing fluids using sonic/ultrasonic/infrasonic wavesComponent separationTuning forkEngineering

An improved system, device and method for characterizing a fluid sample that includes injecting a fluid sample into a mobile phase of a flow characterization system, and detecting a property of the fluid sample or of a component thereof with a flow detector comprising a mechanical resonator, preferably one that is operated at a frequency less than about 1 MHz, such as a tuning fork resonator.

Owner:MEAS FRANCE

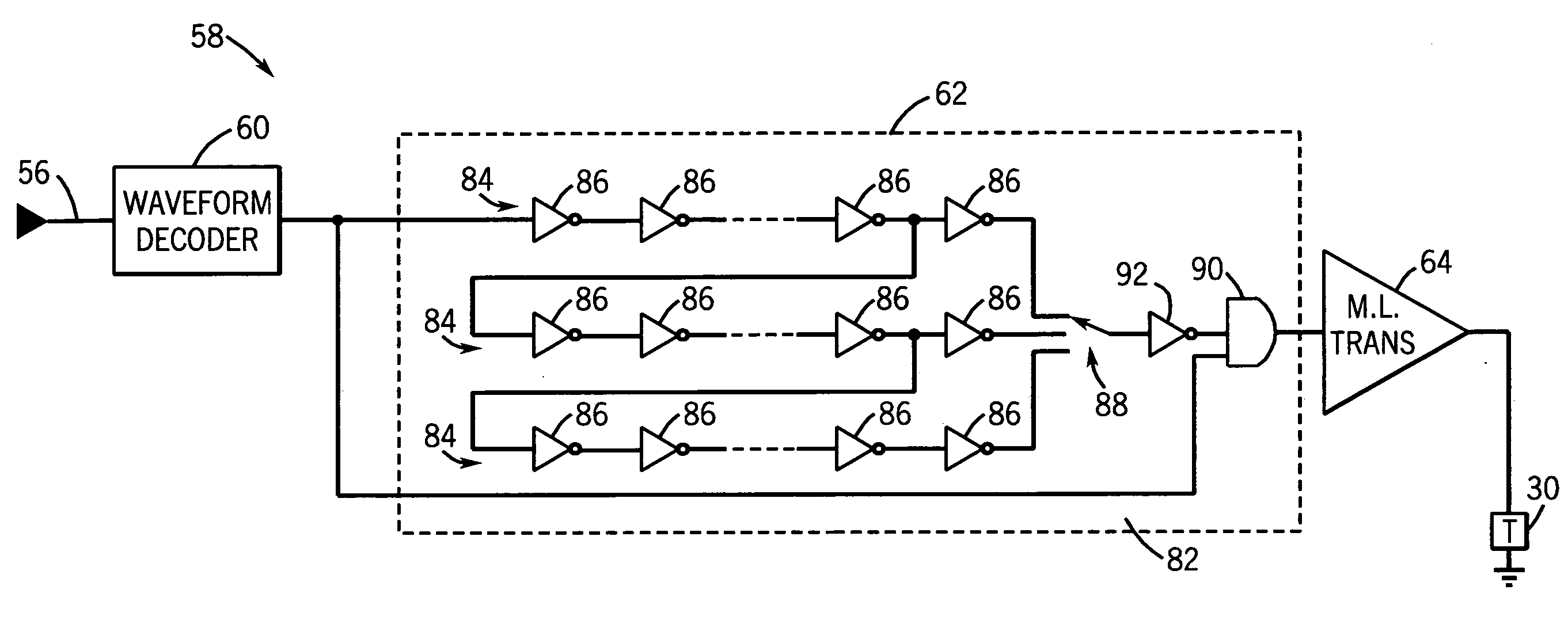

Reconfigurable array with multi-level transmitters

ActiveUS20080264171A1Minimal expenditure of powerSmall footprintUltrasonic/sonic/infrasonic diagnosticsAnalysing solids using sonic/ultrasonic/infrasonic wavesAcoustic energyEngineering

An imaging probe having multi-level transmitter cells. The imaging probe includes a plurality of acoustical sub-elements for transmitting and receiving acoustic energy for imaging. Each of the multi-level transmitter cells is arranged along a respective transmitter cell path between a switching matrix and one of the acoustical sub-elements. The multi-level transmitter cells in the probe are capable of producing signals having multiple voltage levels.

Owner:GENERAL ELECTRIC CO

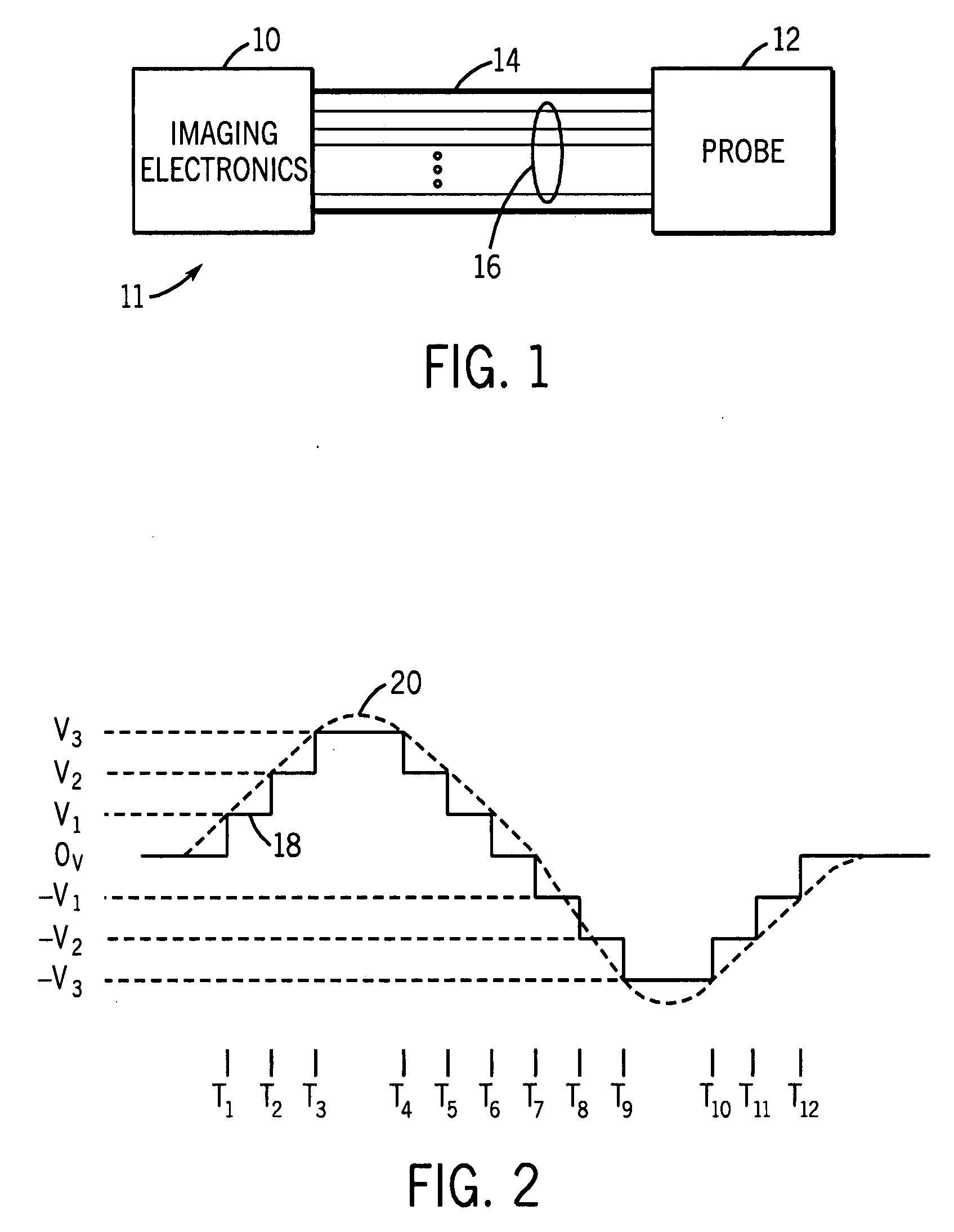

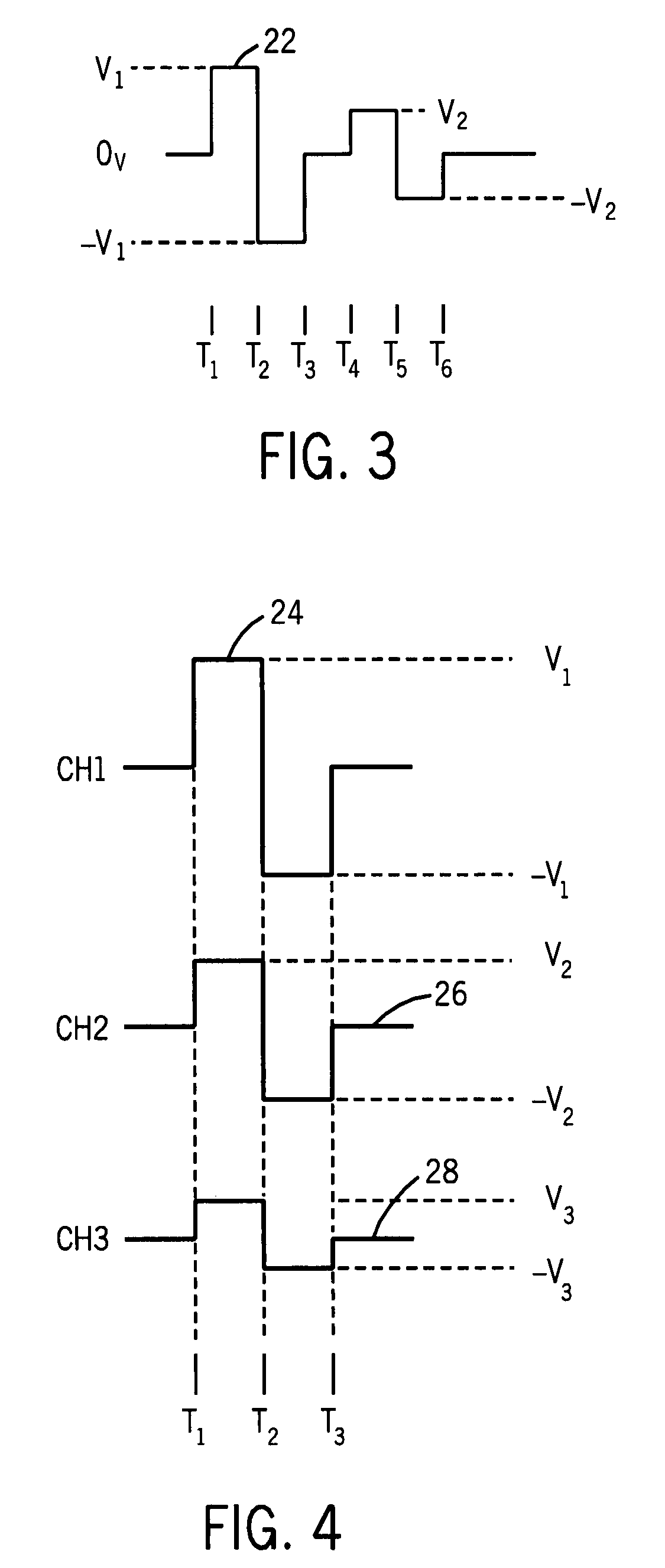

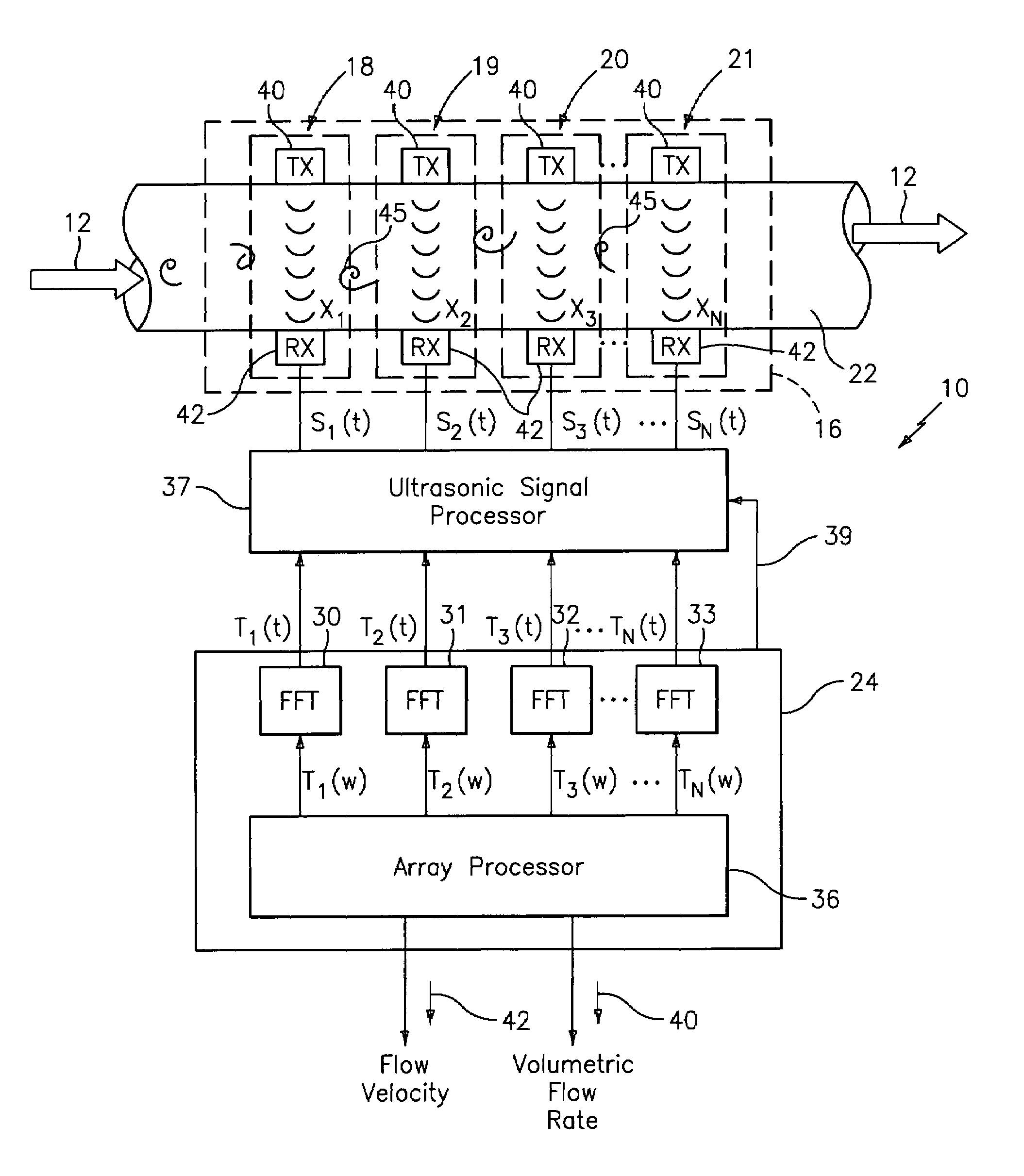

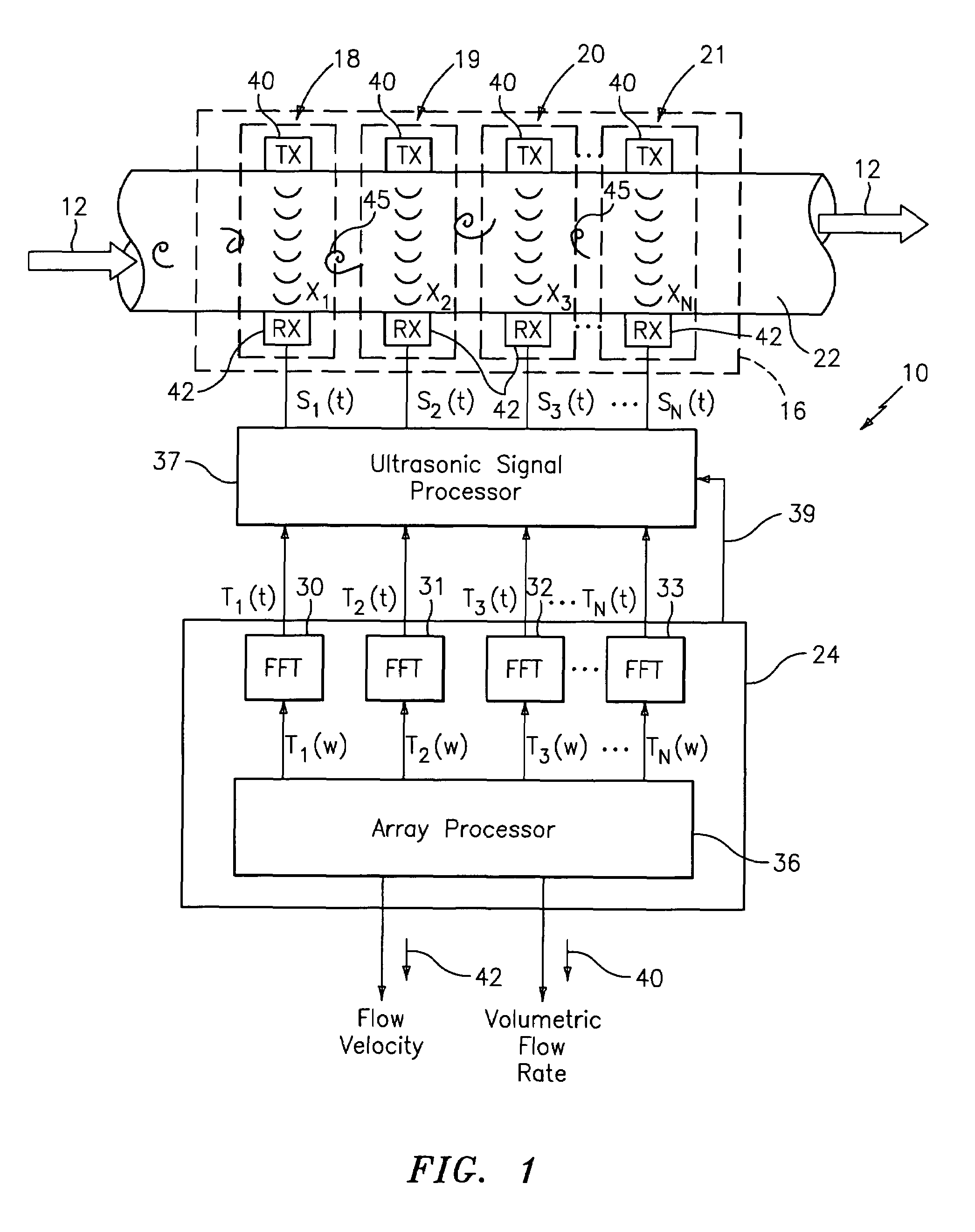

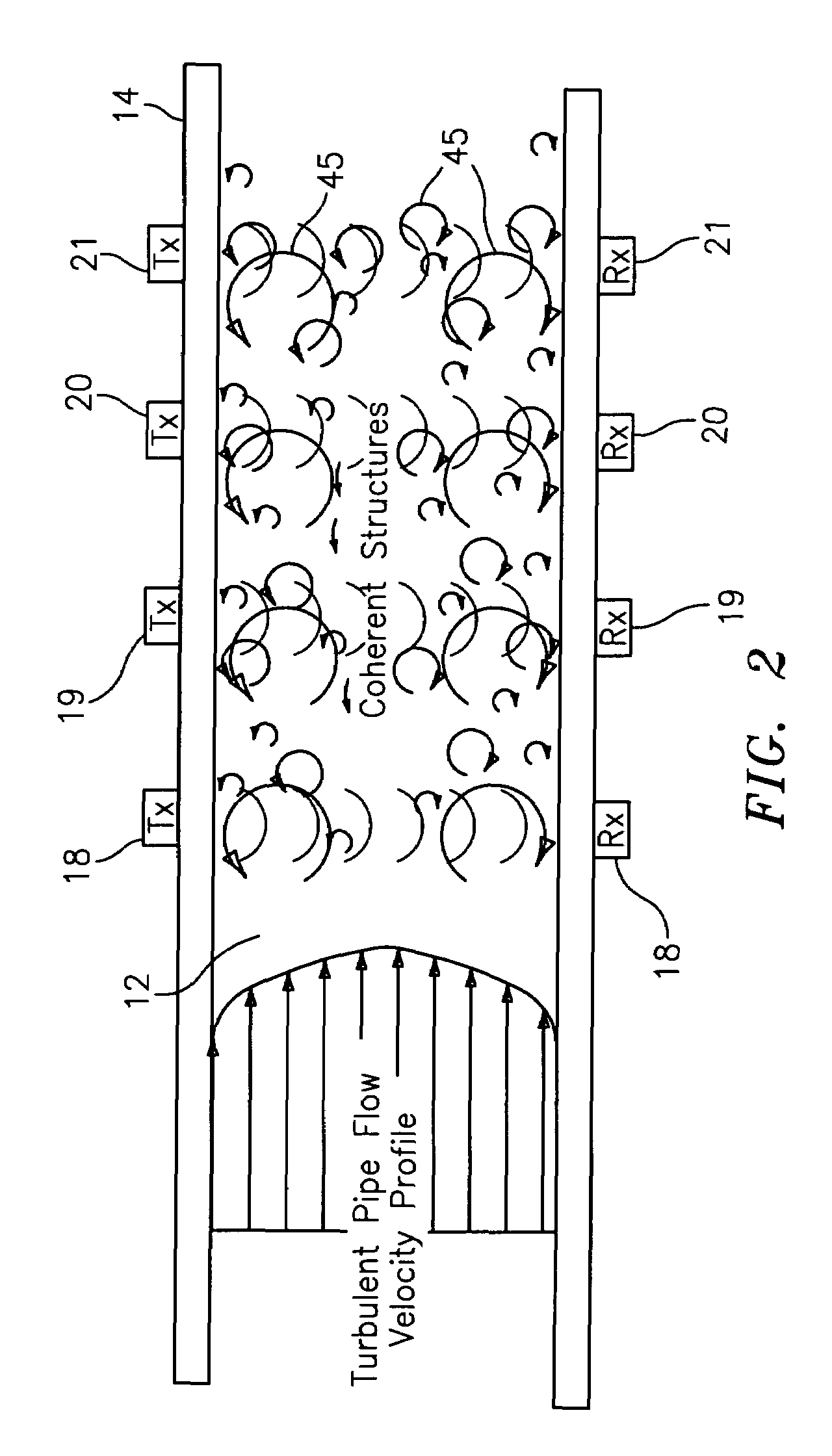

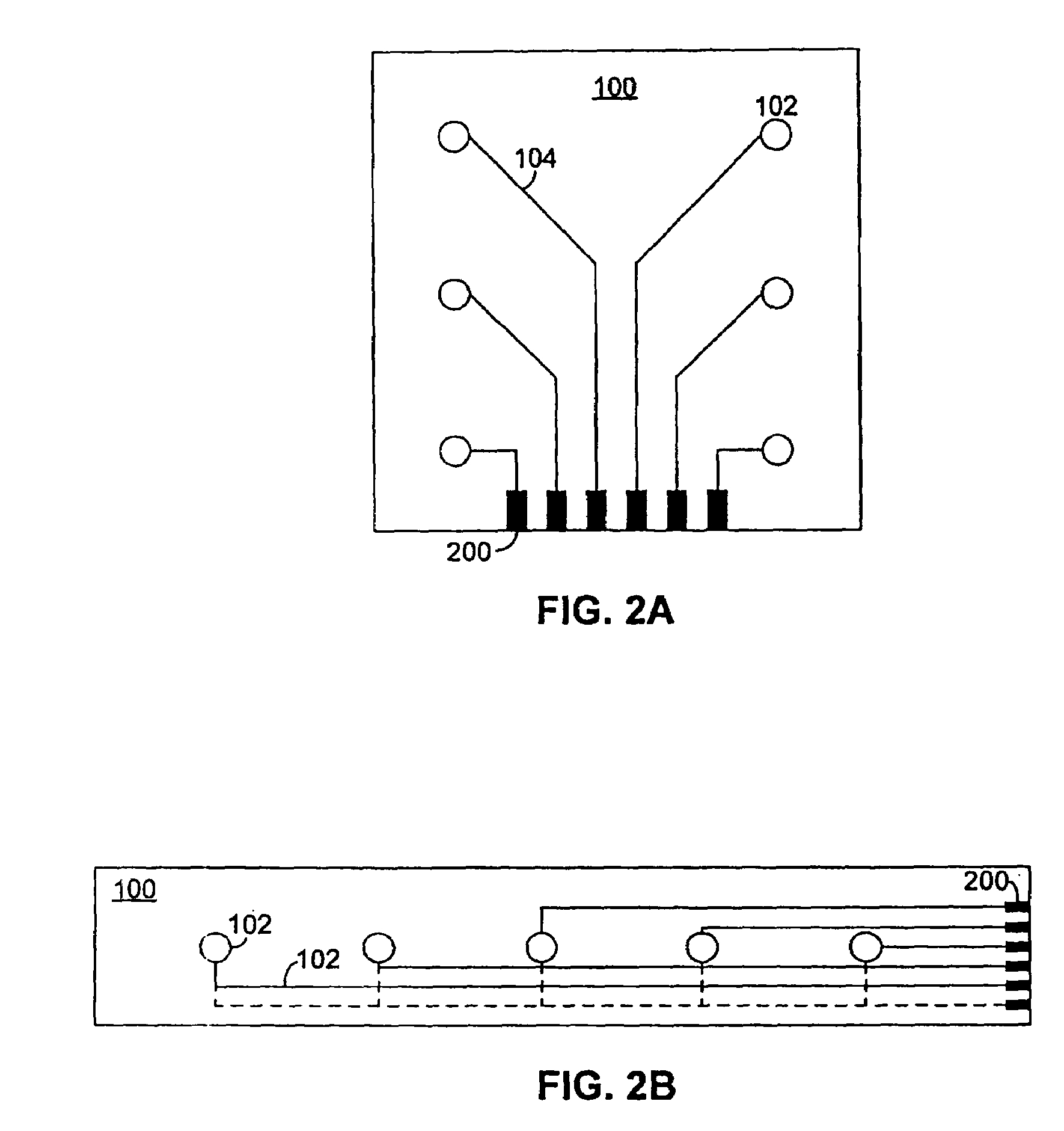

Apparatus and method using an array of ultrasonic sensors for determining the velocity of a fluid within a pipe

ActiveUS7389187B2LiquidityUltrasonic/sonic/infrasonic wave generationVolume/mass flow measurementSonificationPropagation time

An apparatus and method for measuring the flow velocity of a fluid flowing through a pipe that includes an array of at least two ultrasonic sensor units (with as many as 16 sensor units) disposed at predetermined locations along the pipe. Each sensor unit includes an ultrasonic transmitter and an ultrasonic receiver. Each sensor unit provides a respective signal indicative of a parameter of the transit time or amplitude of the ultrasonic signal propagating between each respective ultrasonic transmitter and ultrasonic receiver. A signal processor defines a convective ridge in the k-ω plane in response to the ultrasonic signals using an adaptive beamforming algorithm, such as Capon and Music. The signal processor further determines the slope of at least a portion of the convective ridge to determine the flow velocity of the fluid.

Owner:EXPRO METERS

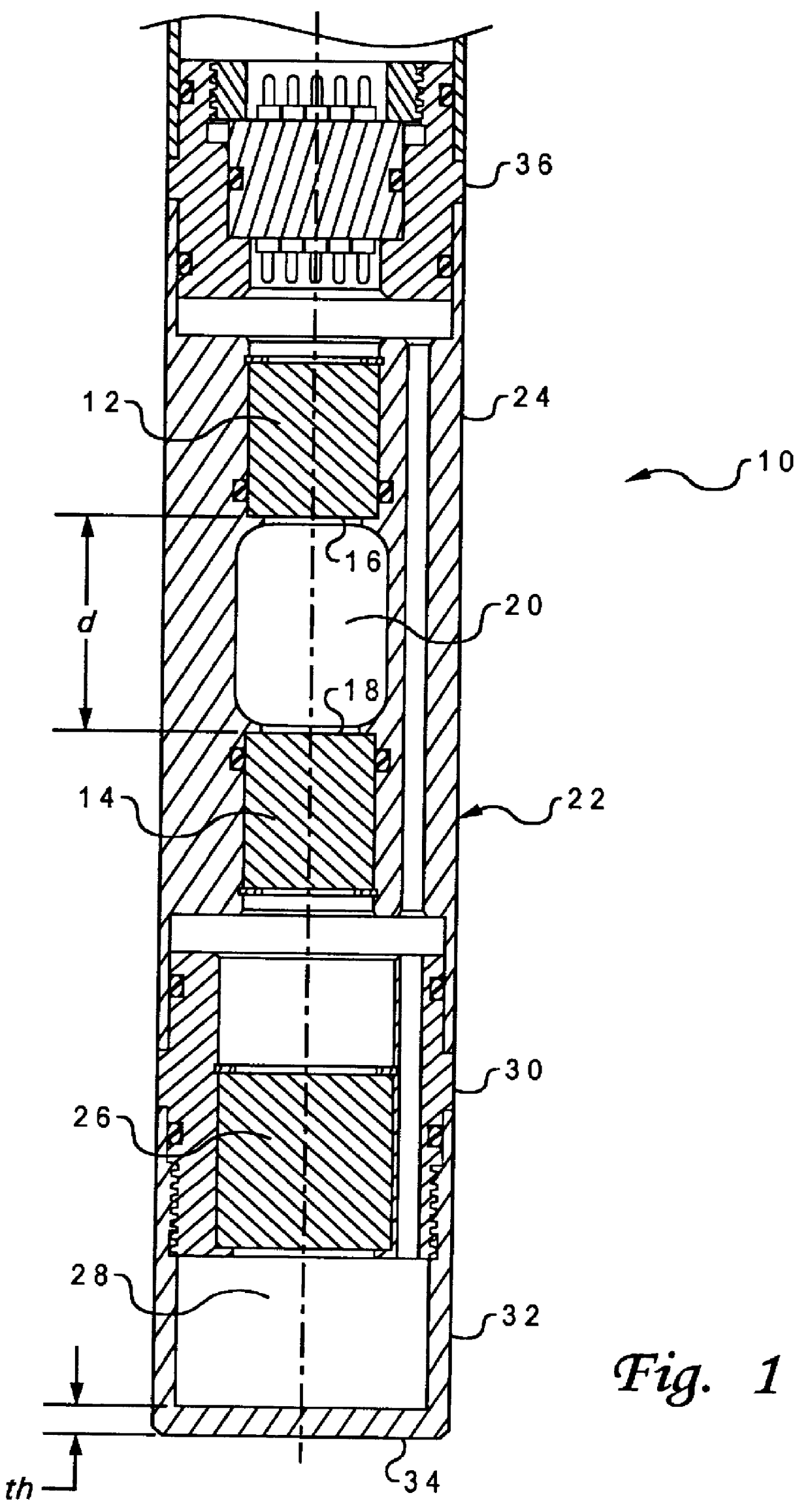

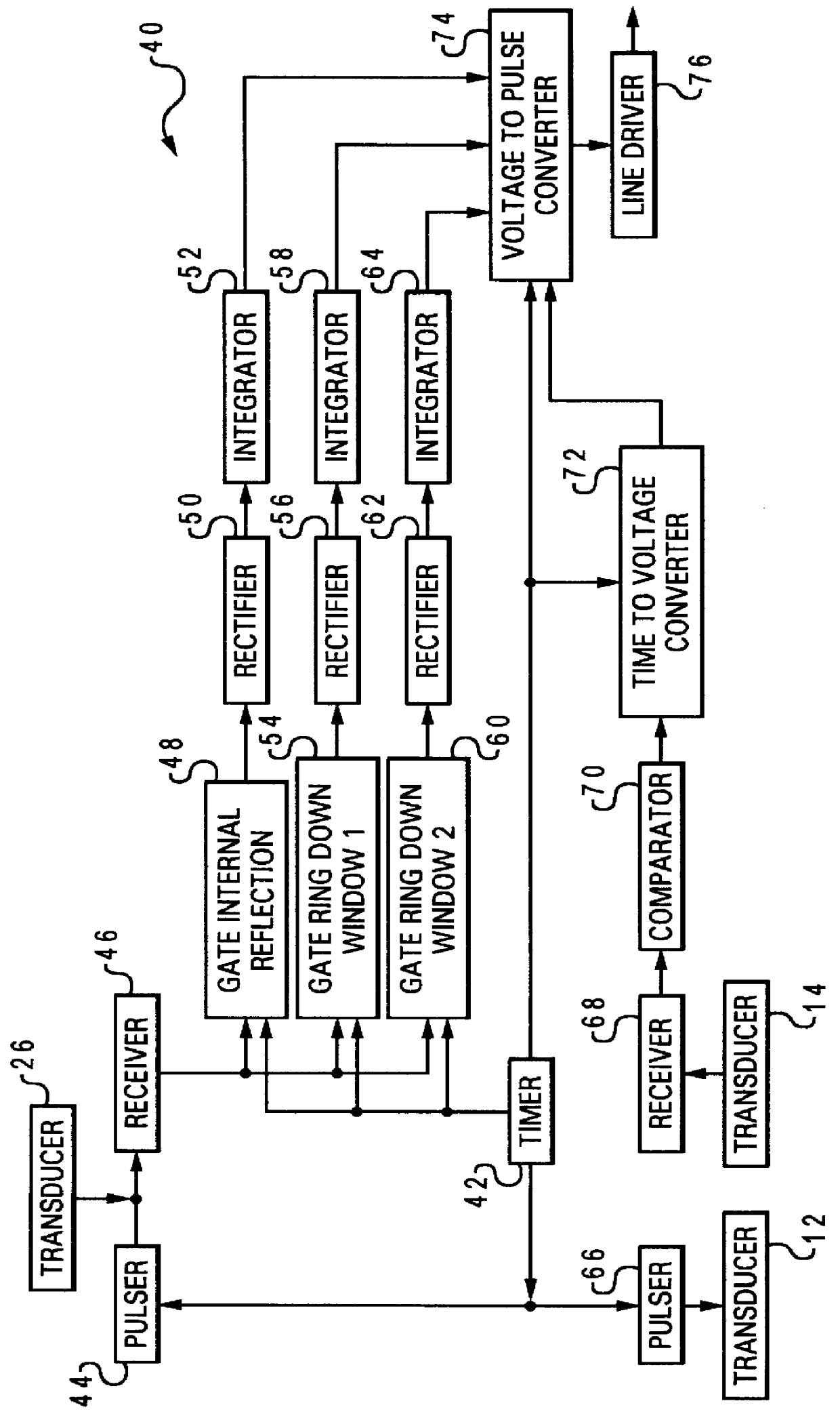

Method and apparatus for acoustic logging of fluid density and wet cement plugs in boreholes

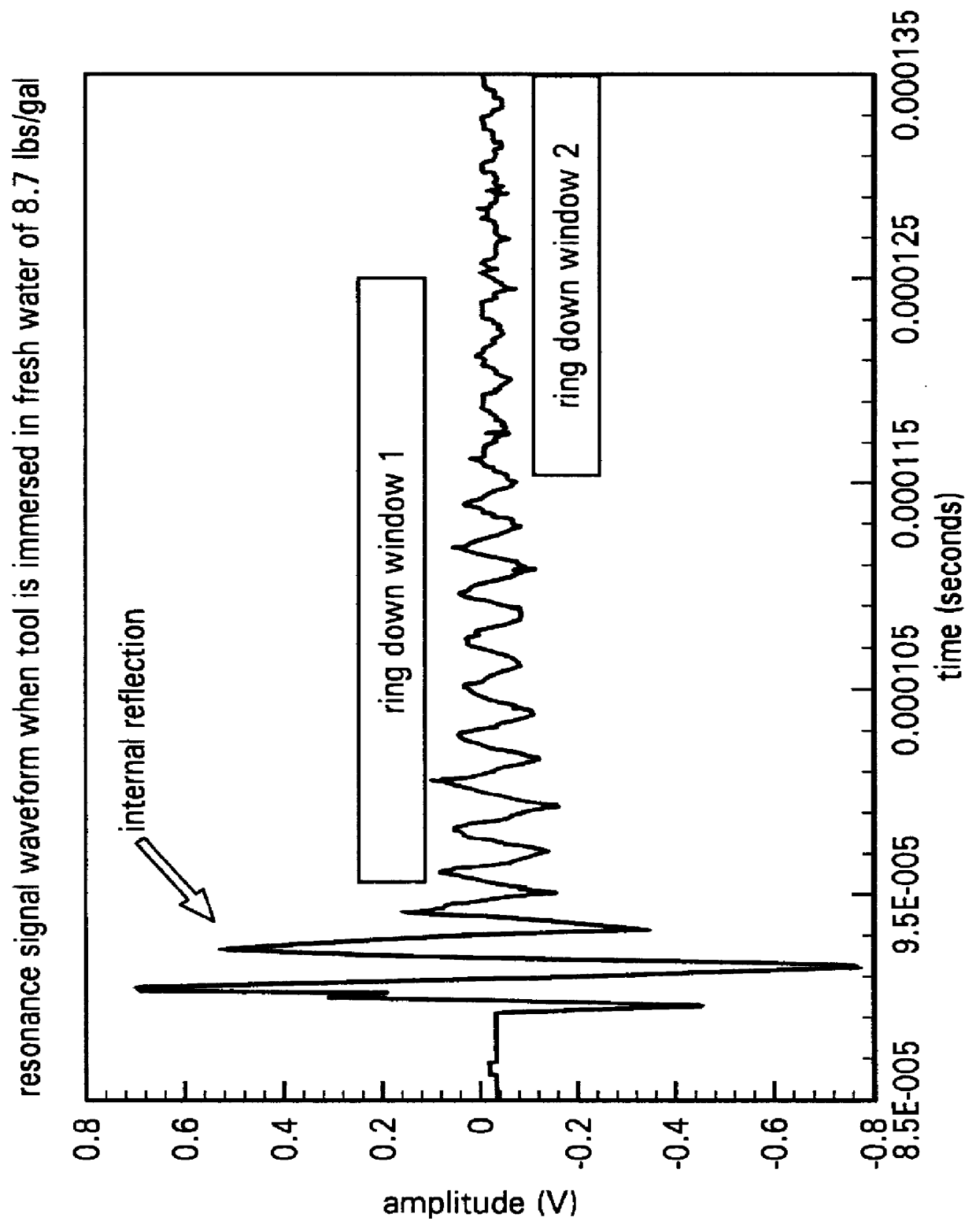

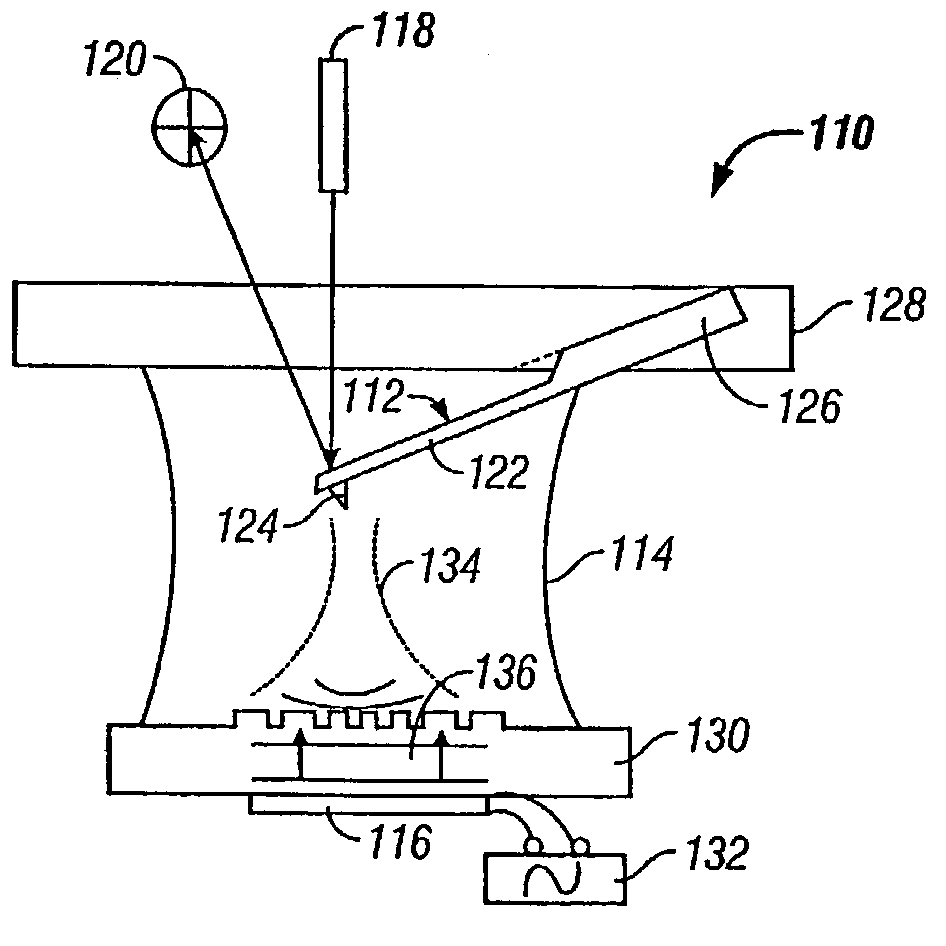

A method of determining the acoustic impedance of a fluid in a borehole, by gating a reflected acoustic signal into a plurality of time slots, and comparing received energies of the signal for the time slots to obtain a value indicative of the acoustic impedance of the fluid. The value may be normalized to yield the acoustic impedance of the fluid using the acoustic impedance of, e.g., water as a calibration point. The comparison is performed by comparing a ratio of an integration of a first ring down time slot and a second ring down time slot, to an integration of an internal reflection time slot. The acoustic pulse may be generated using a transducer immersed in an intermediate fluid contained within a chamber defined in part by a plate in contact with the borehole fluid and having a thickness such that a mechanical resonance frequency of the plate in a thickness mode is substantially equal to a resonance frequency of the transducer. The sonic velocity of the fluid is also measured and, when combined with the acoustic impedance, is used to determine the fluid density.

Owner:WEATHERFORD CANADA PARTNERSHIP +1

Method and apparatus for the actuation of the cantilever of a probe-based instrument

InactiveUS20040020279A1NanotechAnalysing solids using sonic/ultrasonic/infrasonic wavesResonanceCarrier signal

An electromagnetic drive causes a cantilever of a probe-based instrument to deform flexurally by transmitting a high frequency AC signal through an electromagnetic actuator located in the vicinity of the cantilever. The AC signal preferably is an RF carrier signal having a frequency that is substantially higher than the resonant frequency of the cantilever. The carrier signal may, if desired, be modulated with a lower frequency modulation signal to induce the cantilever to oscillate, preferably at resonance. Alternatively, the carrier signal may be transmitted to the electromagnetic actuator without being modulated in order to deflect the cantilever quasi-statically. Cantilever response can then be monitored either directly in response to the imposition of the electromagnetically induced deformation of the cantilever in response to probe / sample interaction to obtain measurements regarding characteristics of the sample, the environment, and / or the cantilever.

Owner:GEORGIA TECH RES CORP

Multiple-frequency ultrasonic test probe, inspection system, and inspection method

ActiveUS20070227250A1Improve efficiencyIncrease speedAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationCatheterMultiple frequency

Owner:THE BOEING CO

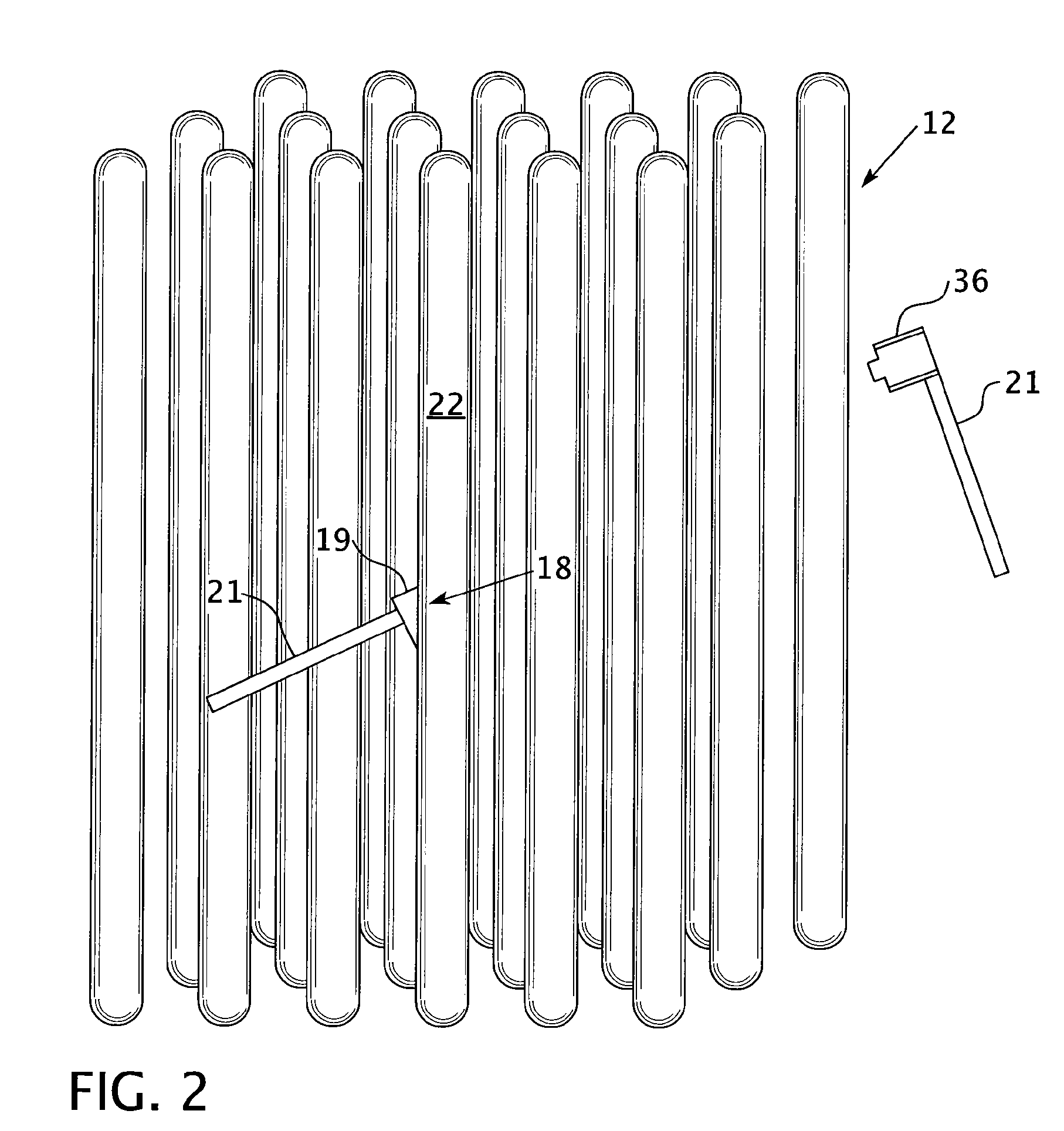

Method of detecting discontinuities on elongated workpieces

InactiveUS6843131B2Complex structureDetection securityAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationUltrasonic testingEngineering

In a method of detecting discontinuities on elongated workpieces, in particular tubes and bars, using ultrasonic testing system, a test object is positioned in relationship to a test head of the testing system, with the test object and the test head being moveable to one another. Signals from the test head are transmitted to an evaluation unit, where they are digitized and evaluated. The digitized signals of a test shot of a length position X are compared with digitized signals of a test shot of a length position X+ΔX, wherein ΔX is a multiple of a shot distance, and the difference is evaluated.

Owner:MANNESMANN ROHRENWERKE

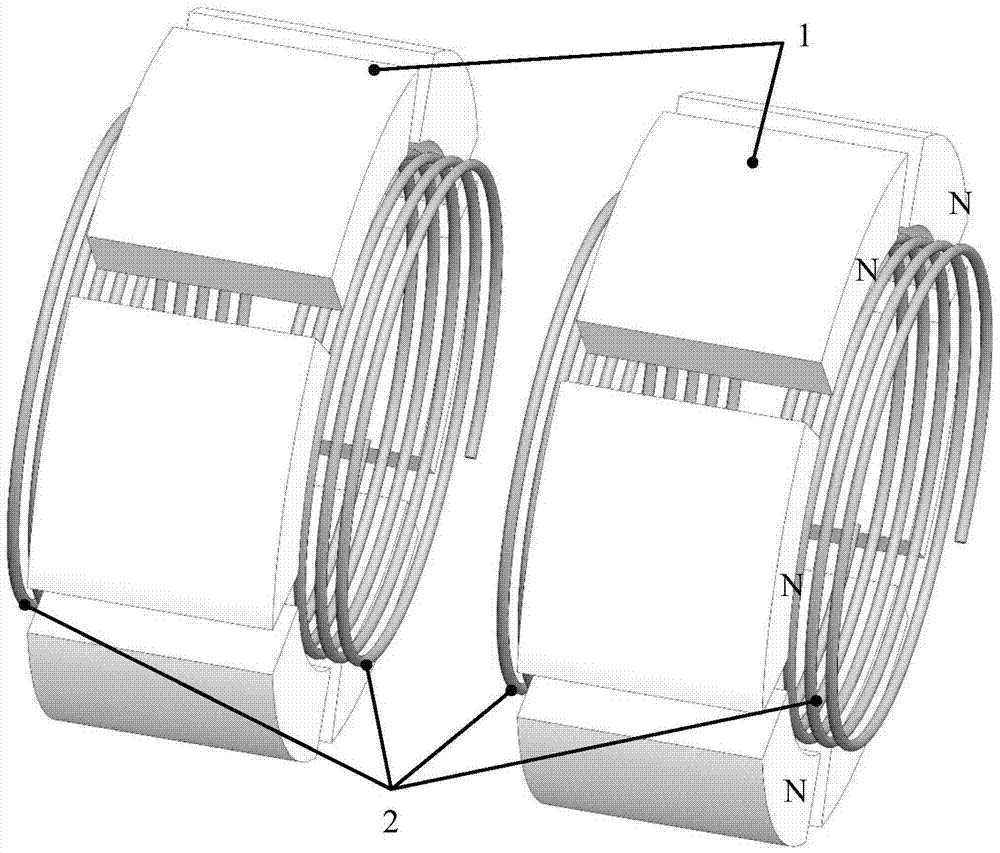

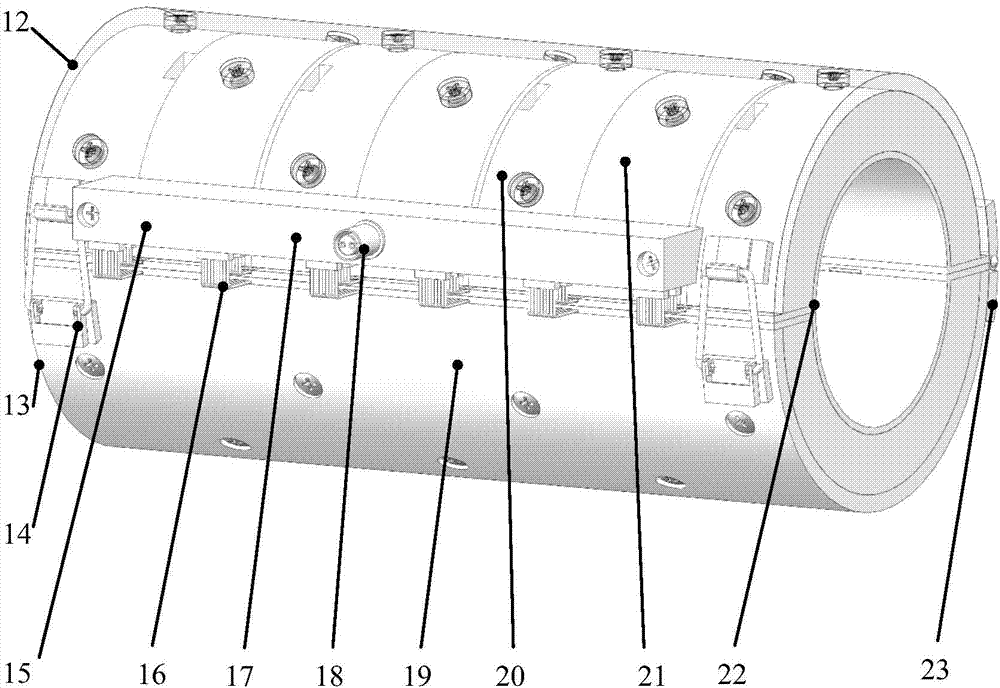

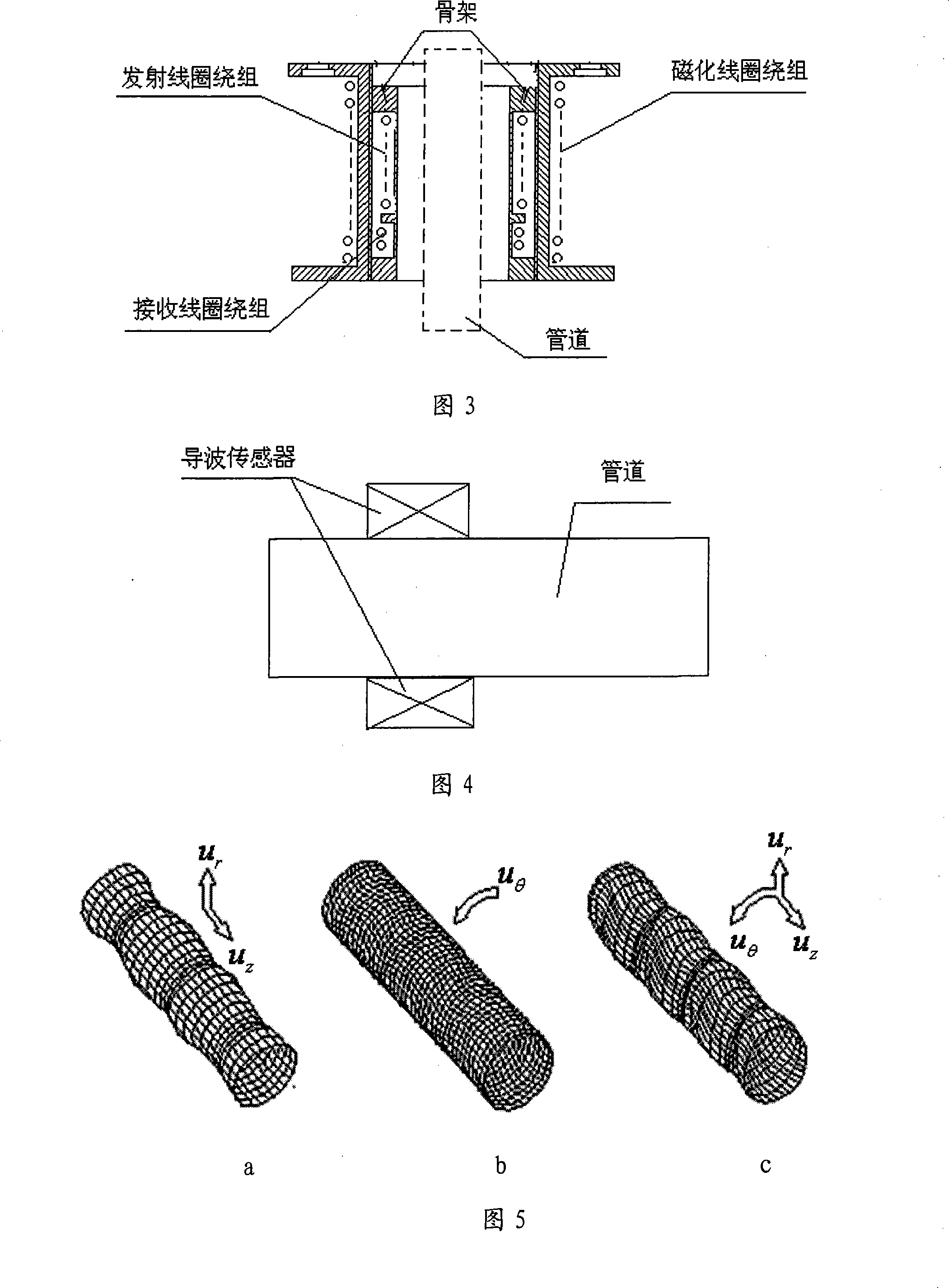

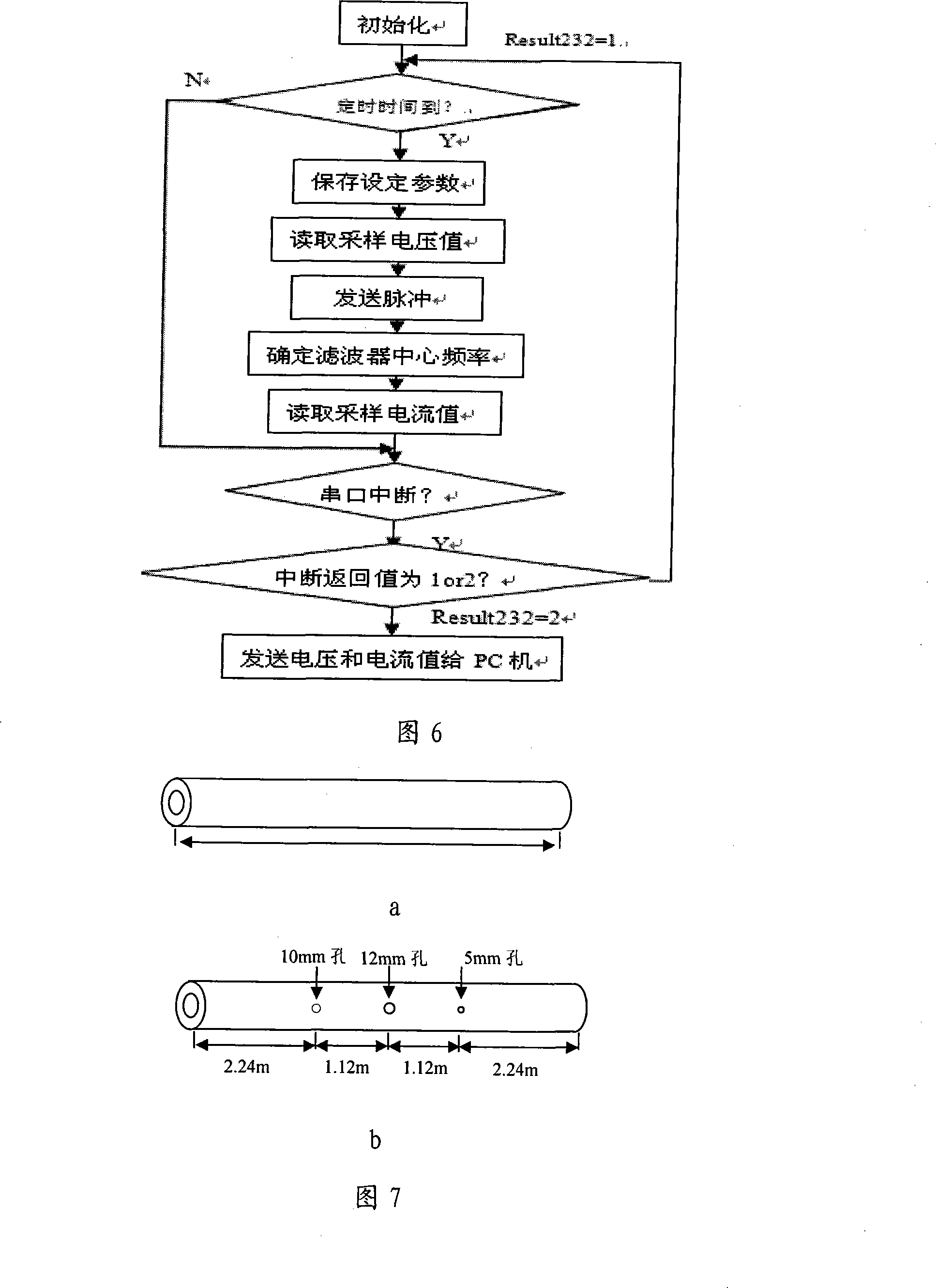

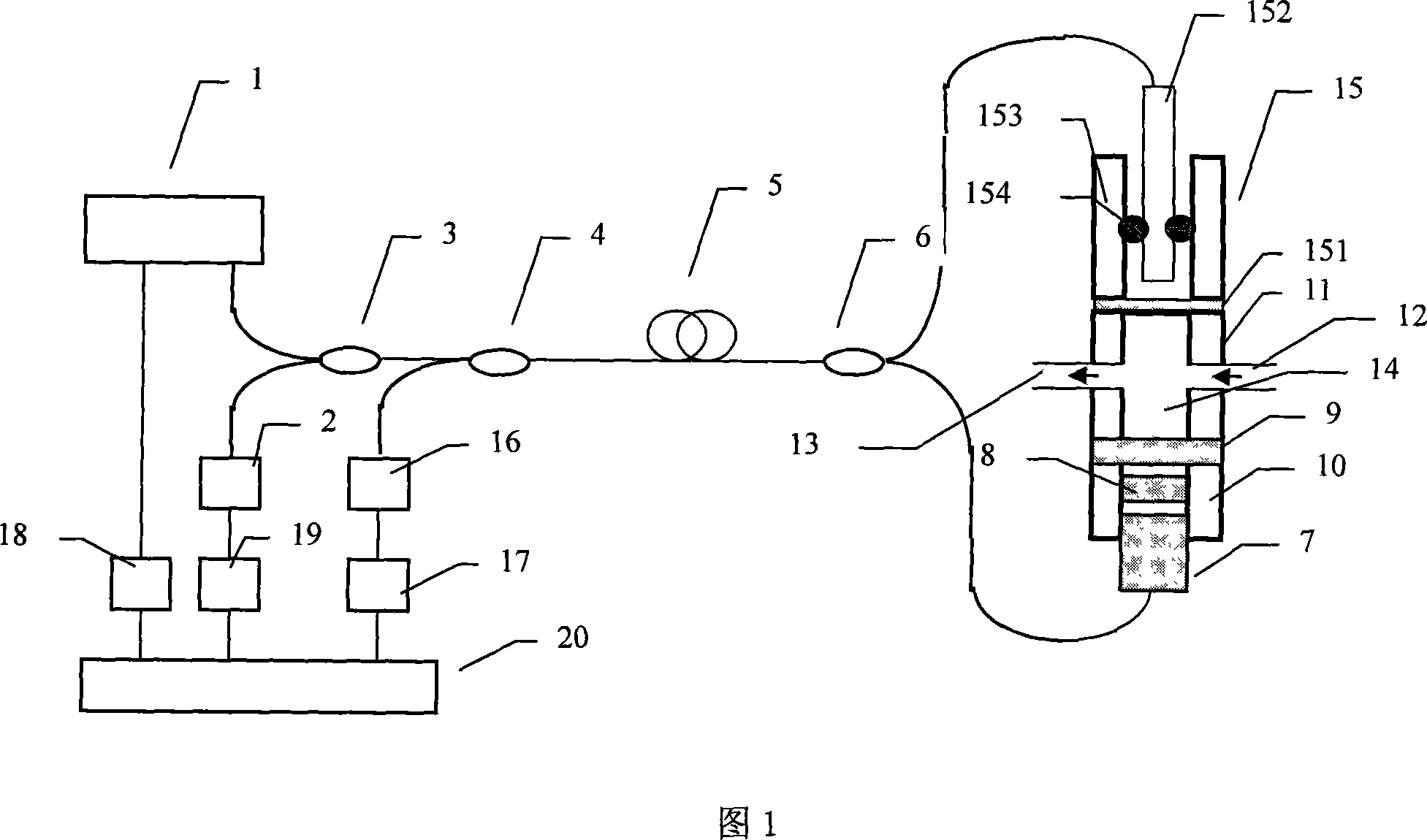

Pipeline defect detection method and device based on electromagnetic ultrasonic longitudinal guided waves

InactiveCN104122330AReduce in quantityReduce complexityAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationMagnetAcoustics

The invention discloses a pipeline defect detection method based on electromagnetic ultrasonic longitudinal guided waves. The method comprises the following steps: arranging a plurality of annular magnets coaxial with a pipeline, so as to generate a radial static magnetic field on the surface of the pipeline; coaxially sleeving two sides of each annular magnet array with solenoid coils, so as to generate circumferential inducing vortex in the to-be-detected pipeline; and stimulating longitudinal-mode guided waves under the combined action of the circumferential inducing vortex and the radial static magnetic field, wherein when encountering a defect, the longitudinal-mode guided waves are reflected, and reflection echoes cause change of sensing voltage of a sensing coil when passing through a sensing coil, so as to judge that whether the defect exists in the pipeline or not. The invention further discloses a detection device and a sensor for detecting the pipeline by virtue of the device and the method. According to the method, the radial magnetic fields at the edges of the magnet arrays are adequately utilized, and the uniform radial magnetic field does not need to be generated, so that the complexity of the sensor is reduced; meanwhile, a single longitudinal-mode guided wave signal can be obtained, so that the defect signal analysis difficulty is reduced, and the detection process is rapid and efficient.

Owner:HUAZHONG UNIV OF SCI & TECH

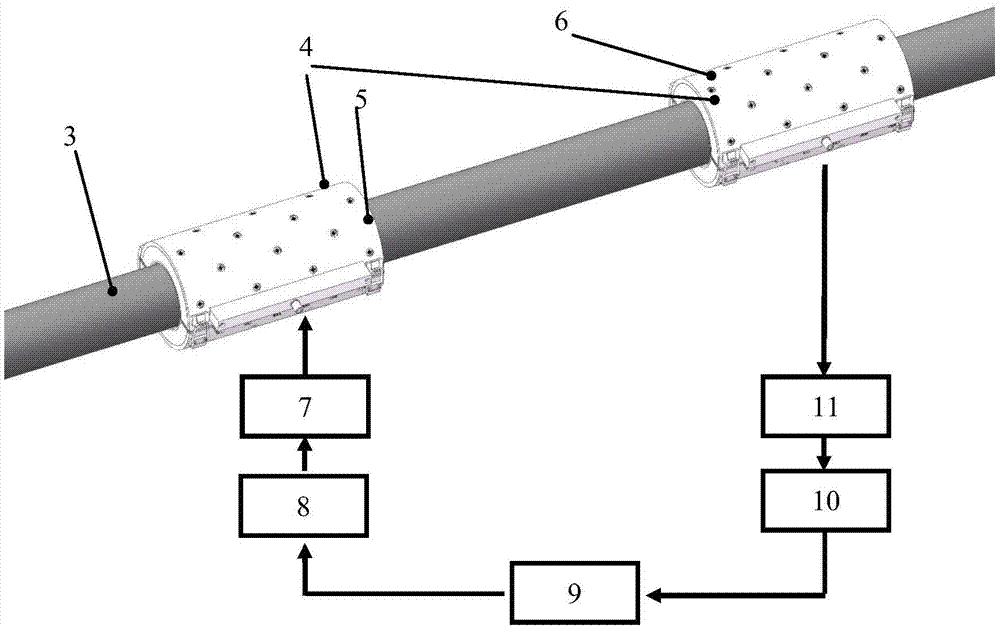

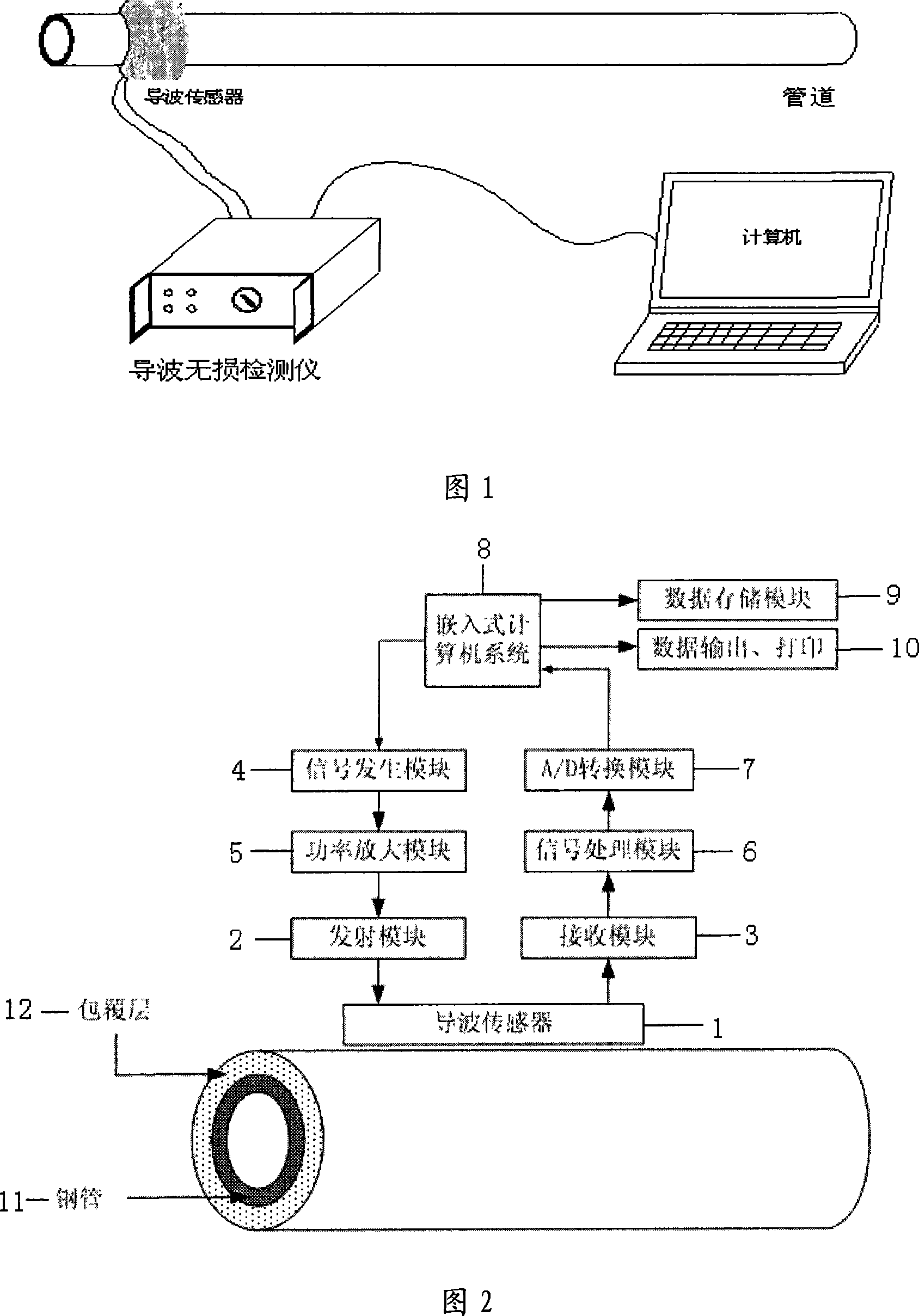

Fast checking method for pipe defect and nondestructive testing apparatus

InactiveCN101173911AQuick scanImprove detection efficiencyUltrasonic/sonic/infrasonic wave generationNon destructiveComputerized system

The invention relates to a fast scanning method of pipeline drawbacks and a non-destructive detection device, which is more particularly suitable for fast scanning and non-destructive detection of drawbacks of the pipelines with insulation. The invention is composed of a guided wave sensor, a transmitting module, a receiving module, a signal generating module, a power amplifying module, a signal processing module, an A / D conversion module and an built-in computer system. The invention is suitable for comprehensive detection of drawbacks of pipelines with different diameters, detection of long distance pipelines, and detection of pipelines in inaccessible places. The invention has the advantages of fast and large-scale detection ability without contact, high efficiency; overcoming a plurality of limitations of the conventional non-destructive detection method; overcoming the restriction conditions of oil pollution, fouling, bending or heat insulation protective layer, judging and locating the drawbacks of the pipelines, reducing the maintenance range, avoiding unnecessary disassembly and replacement, reducing the intensity of artificial detection, and saving the human and material resource. In addition, the invention can achieve on-line monitoring, and evaluate the health condition of the element or predicts the service life of the element.

Owner:NAVAL UNIV OF ENG PLA

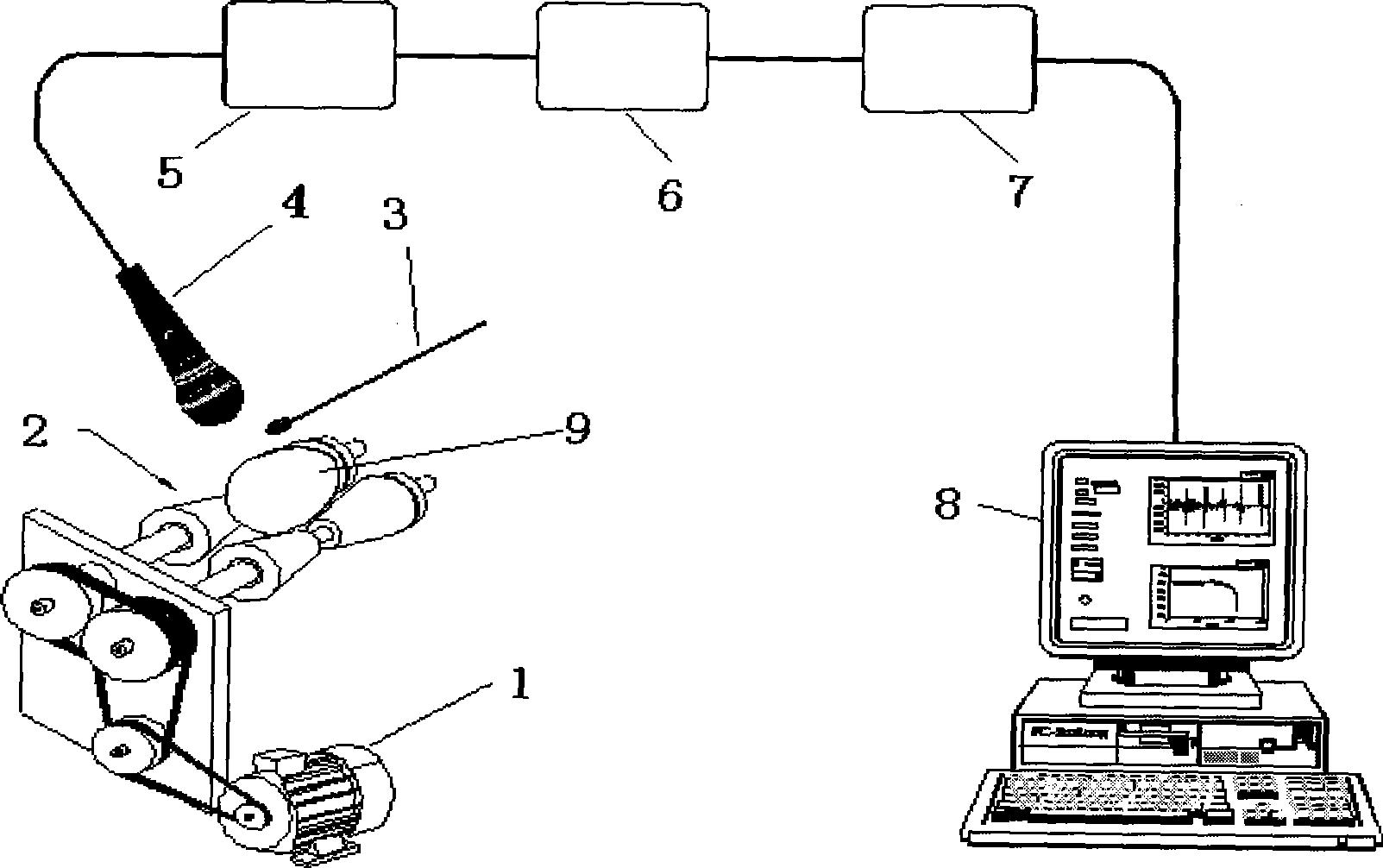

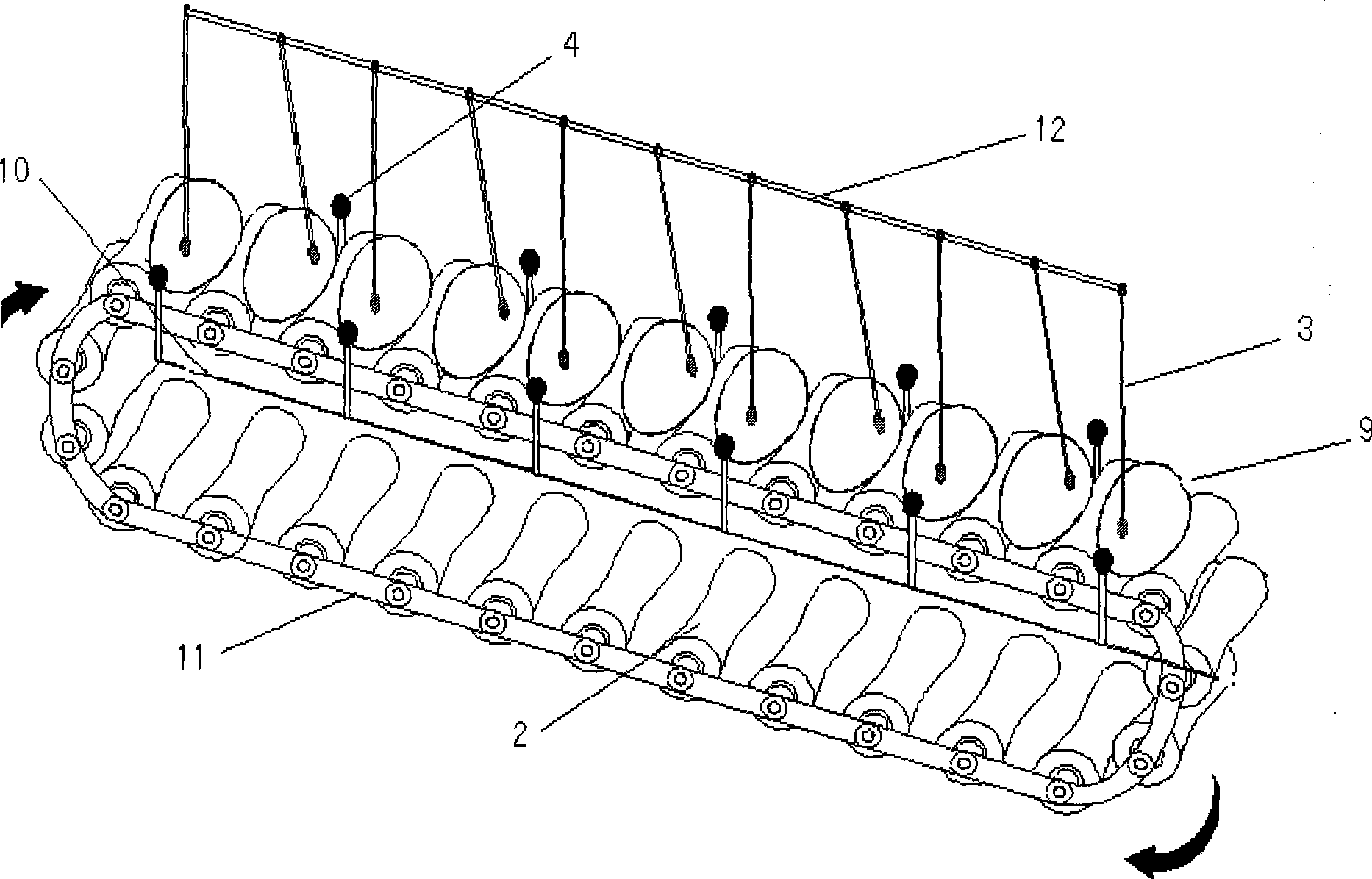

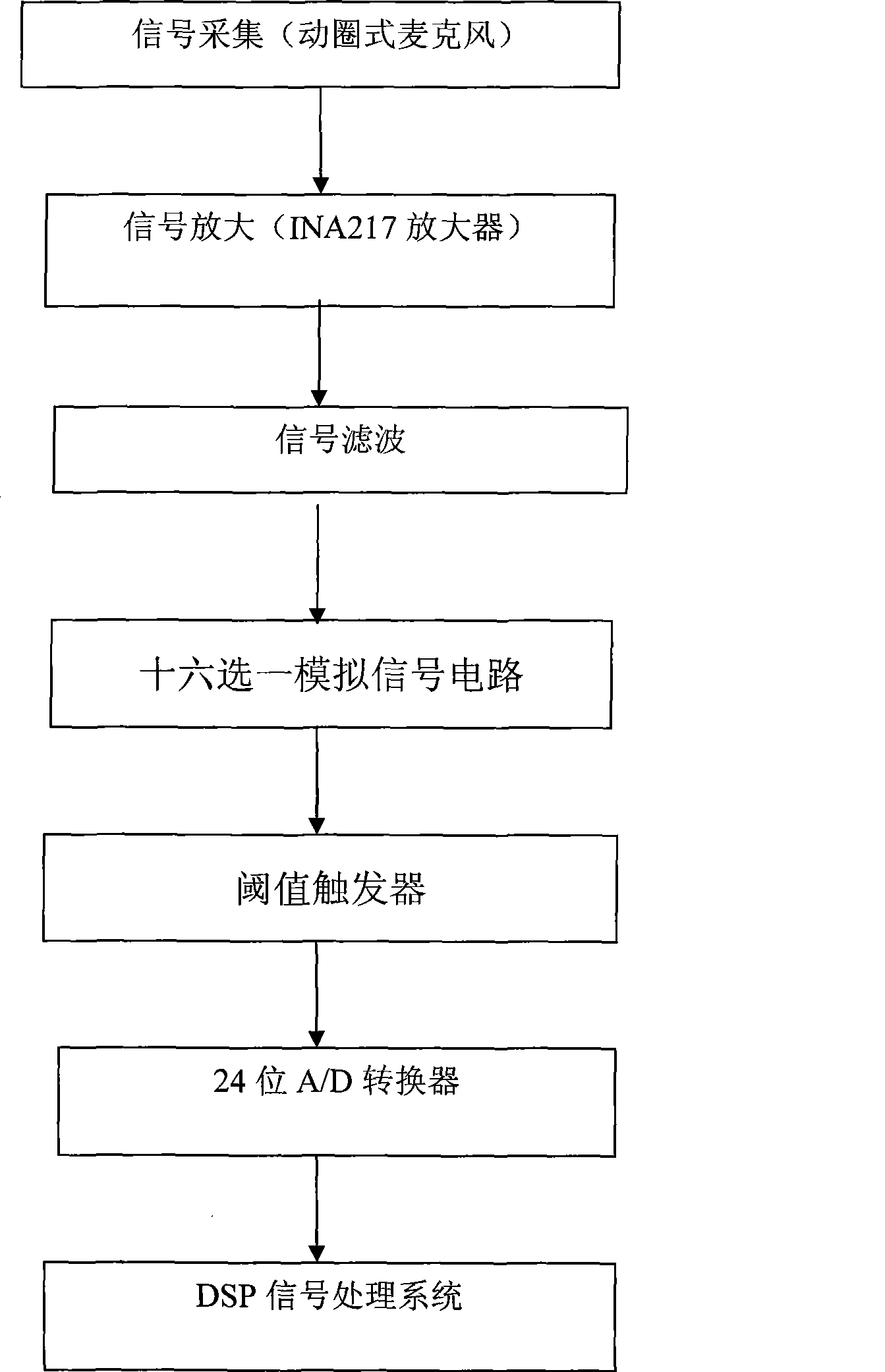

Fowl egg crack rapid on-line nondestructive detection device and method based on acoustic characteristic

InactiveCN101413928AQuality assuranceRealize automated detectionTesting eggsUltrasonic/sonic/infrasonic wave generationFowlAudio power amplifier

The invention discloses a device used for quick online nondestructive detection on cracks of poultry eggs on the basis of acoustic characteristic and a method thereof; the poultry egg is arranged on a supporting idler wheel; a stepping motor is connected with the supporting idler wheel and drives the supporting idler wheel; a microphone which is arranged beside the poultry egg is sequentially connected with a computer by a signal amplifier, a filter and an A / D converter; when the poultry egg rolls on a chain, different parts of the poultry egg are mechanically knocked at multi-point by a knocking rod; sound signals collected by the microphone are amplified by the signal amplifier, filtrated by the filter and converted by the A / D converter and subsequently input to the computer, thus comprehensively judging the cracking situation of the poultry eggs. The device and the method can adapt to poultry eggs with different types and different sizes, realize the classification and automatic detection of the poultry eggs during the production processing and circulation process, and can be popularized and applied to the nondestructive detection on the hardness and the maturity of agricultural products such as fruits, vegetables, and the like.

Owner:JIANGSU UNIV

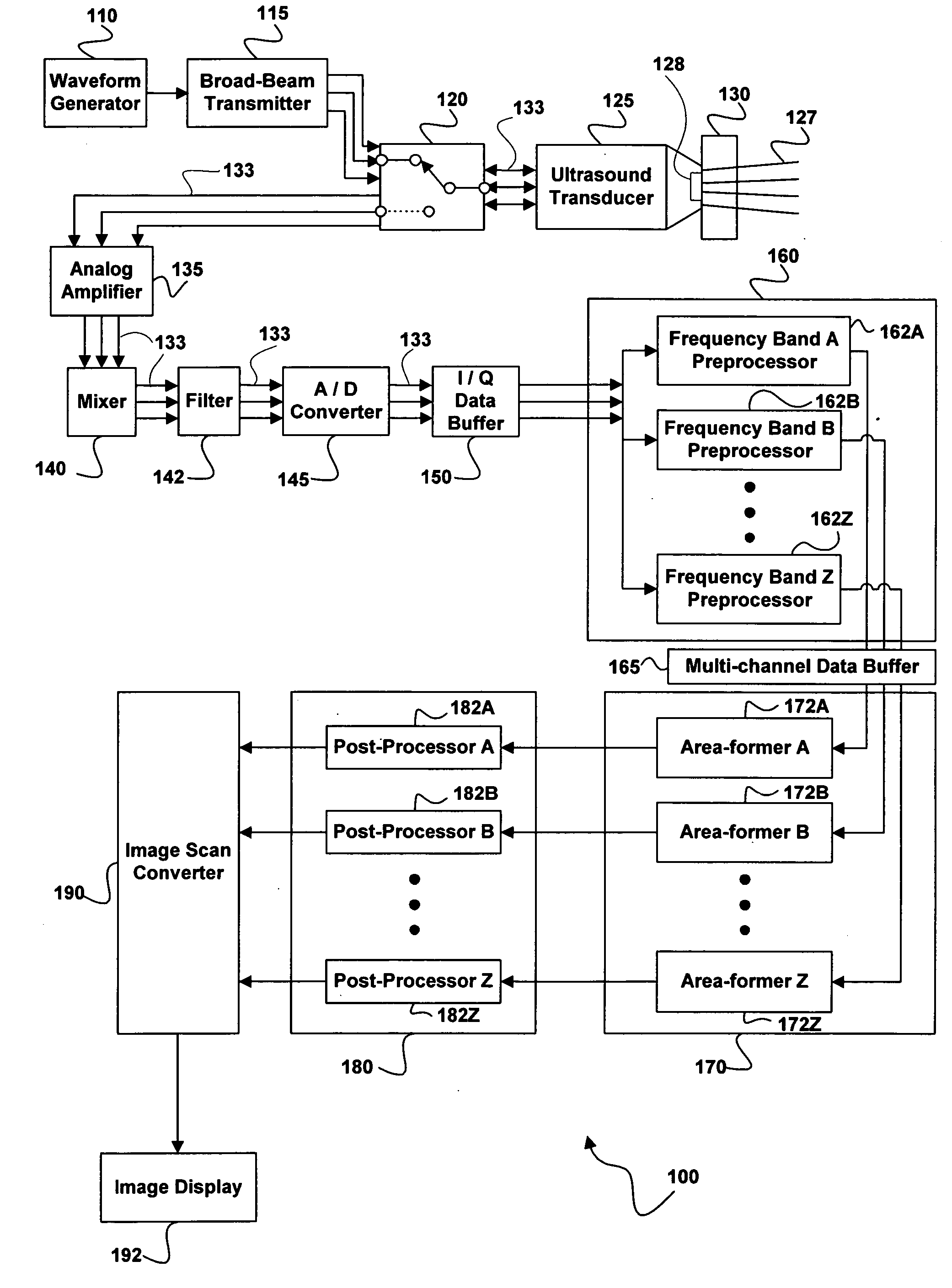

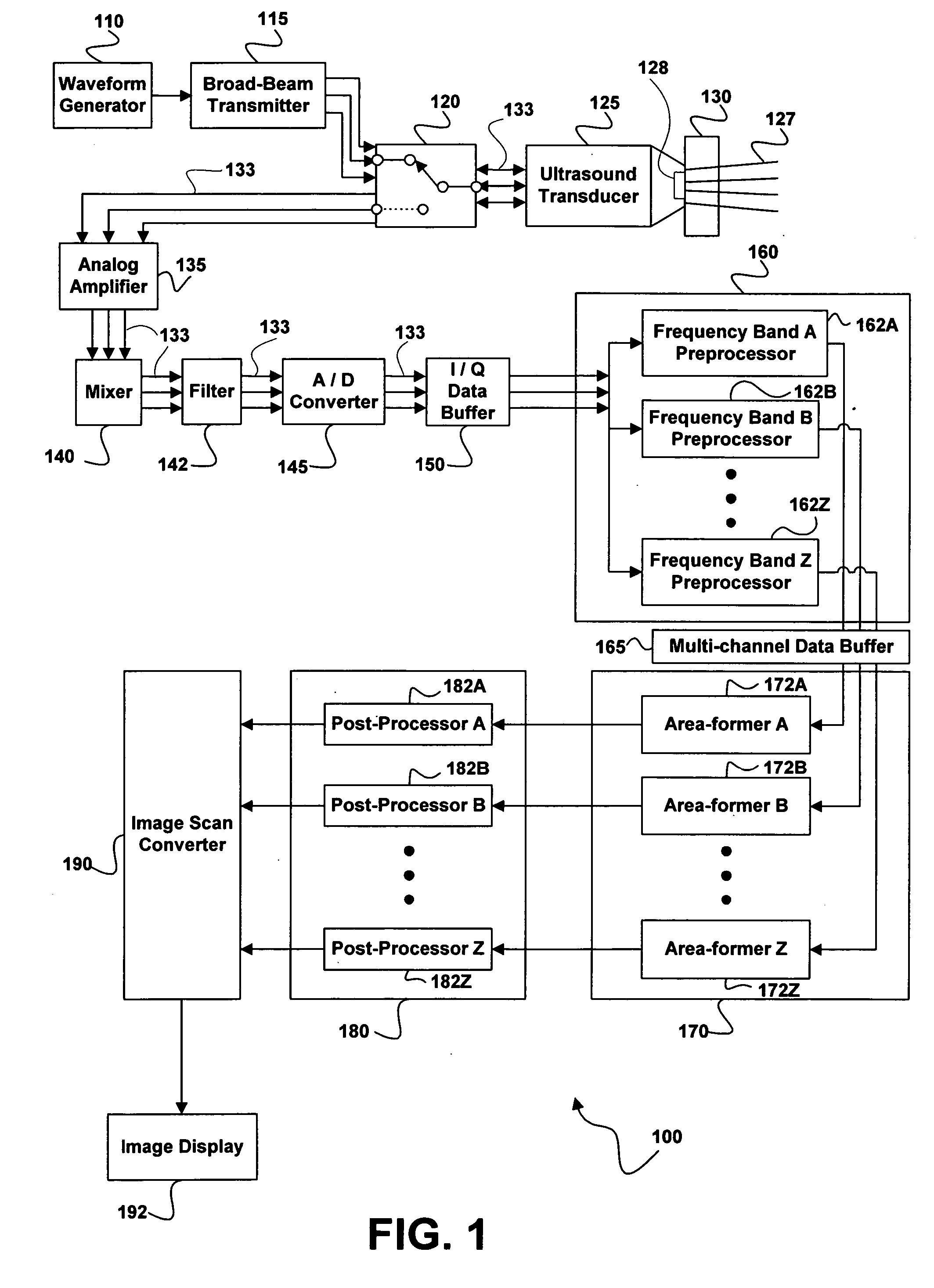

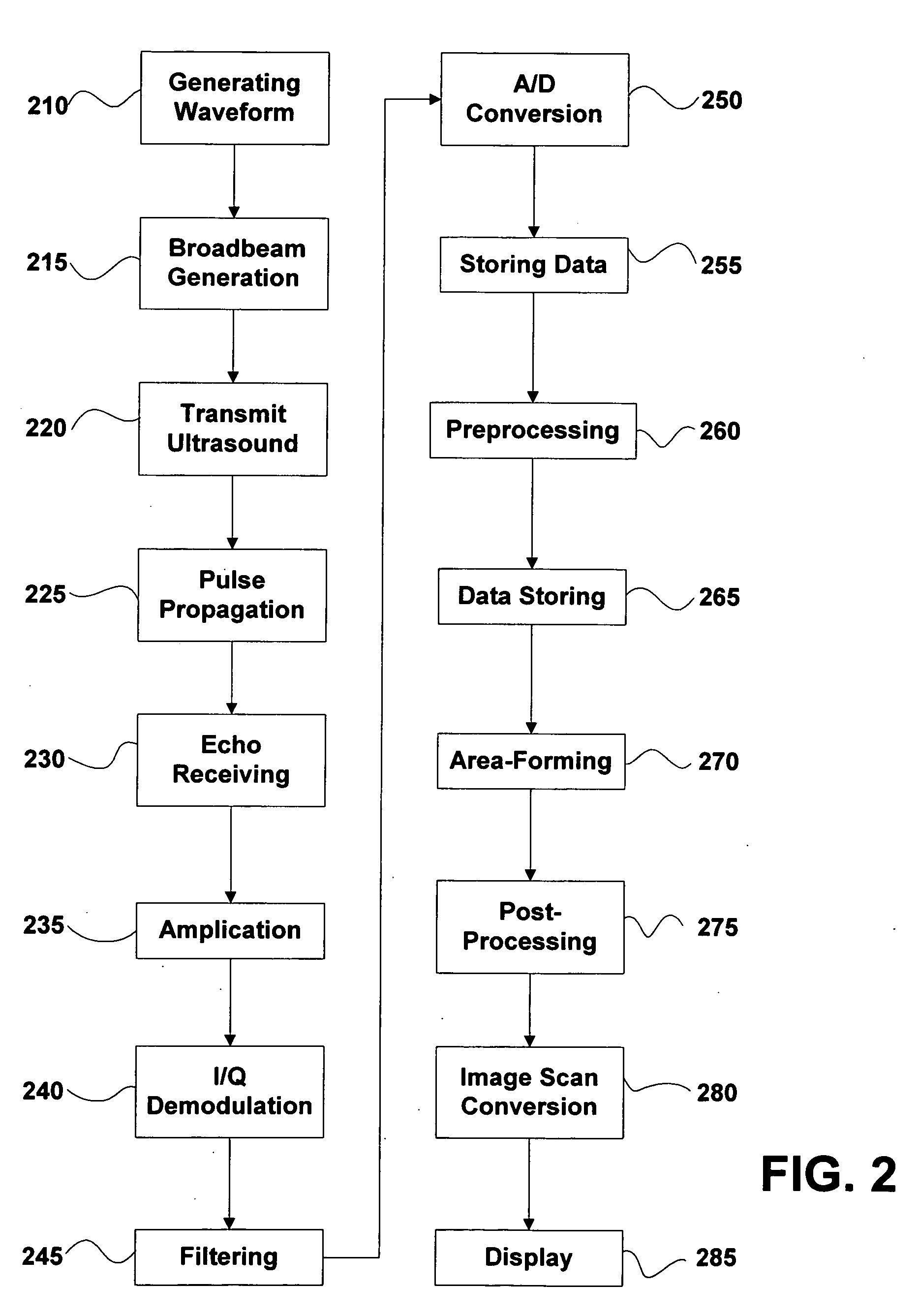

Ultrasound system for generating a single set of ultrasound pulse firings

InactiveUS20050131294A1Ultrasonic/sonic/infrasonic diagnosticsAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasound imagingMulti band

An ultrasound imaging system configured to simultaneously acquire and process multi-mode and multi-band echo information from a single set of pulse firings is provided. Raw ultrasound signals are digitized and stored in an I / Q data buffer. The stored data are then parallel preprocessed as a function of frequency band or alternative encoding. Parallel preprocessing optionally includes manipulating the data in respect to different imaging modes. Outputs of the parallel preprocessors are coupled to separate area formers used to simultaneously reconstruct various desired echo information to form a multi-mode or multi-band image. The echo formation process is optionally performed in parallel.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

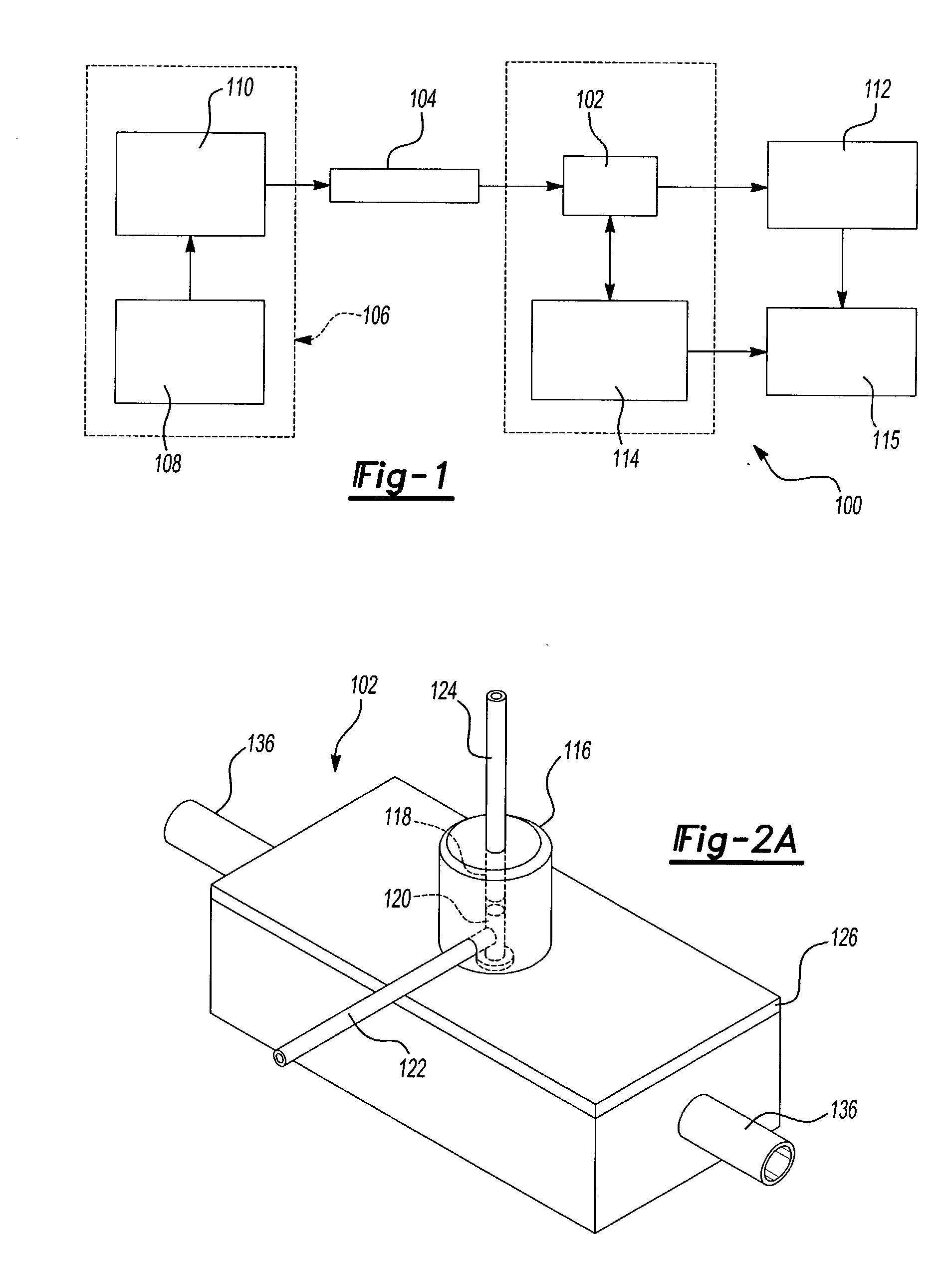

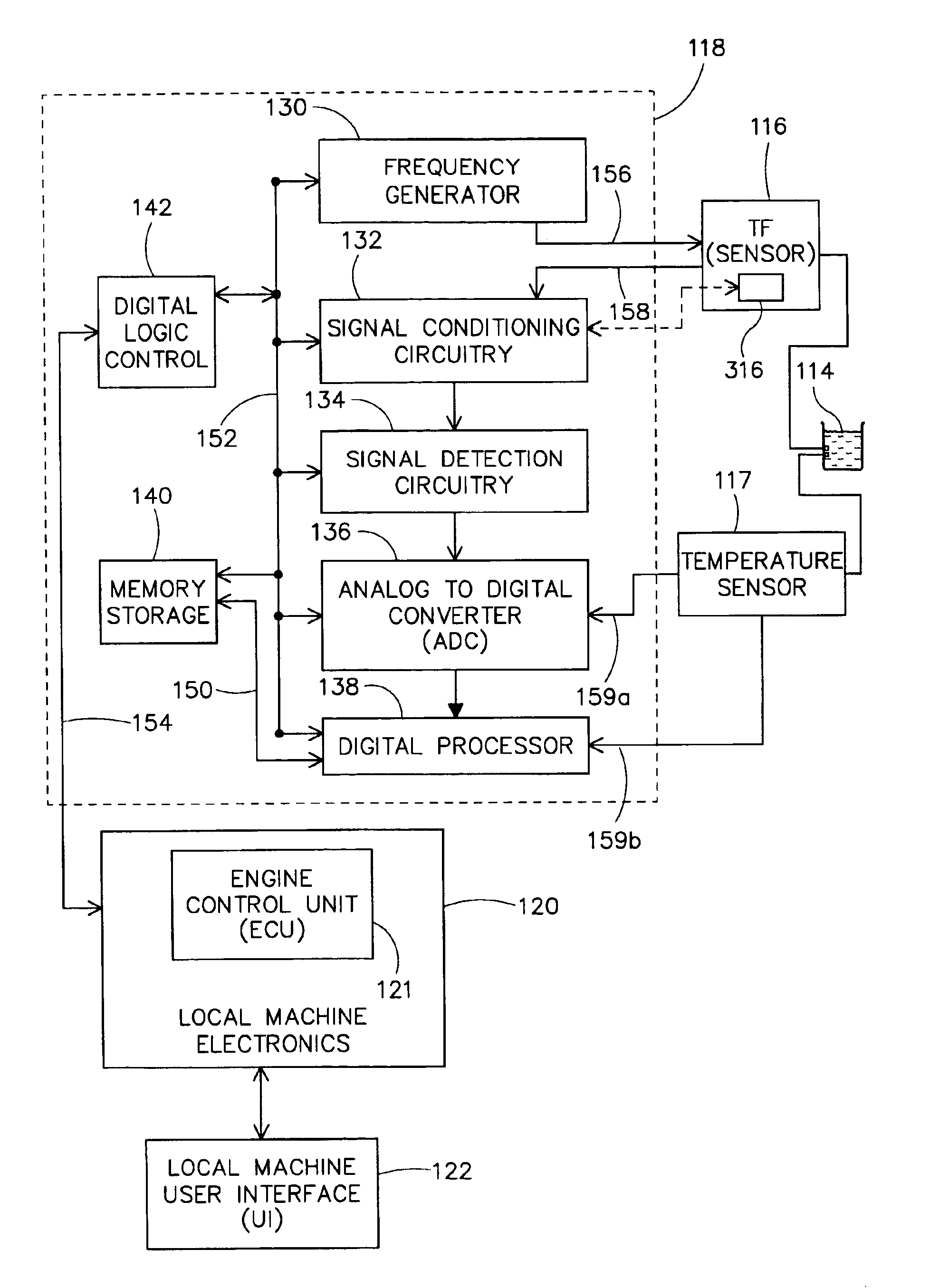

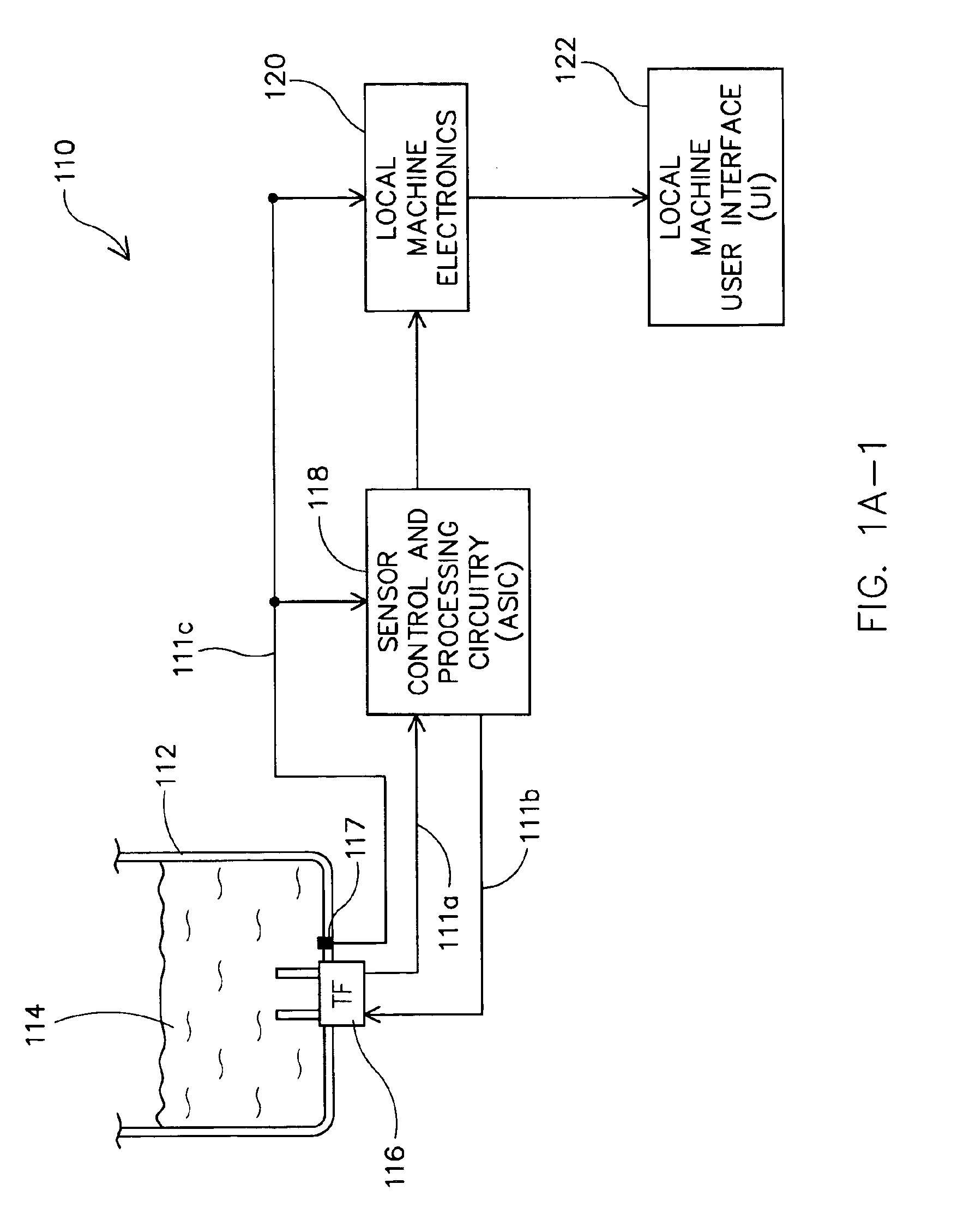

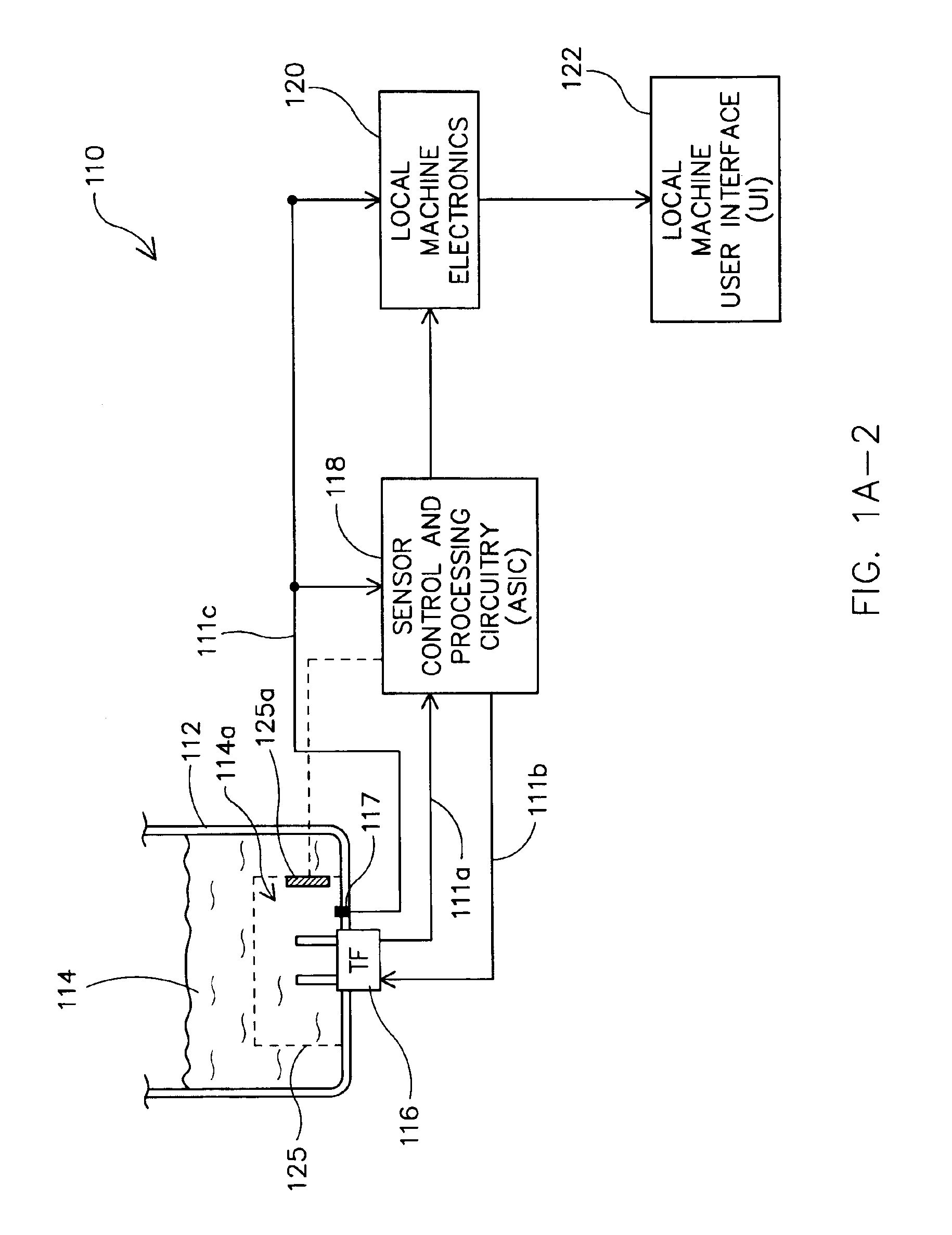

Application specific integrated circuitry for controlling analysis of a fluid

InactiveUS6873916B2Reducing analog signal offsetAnalysing fluids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationEngineeringAnalog signal

A circuit for determining characteristics of a fluid under-test is provided. The circuit includes analog-to-digital processing circuitry for interfacing with a sensor and host electronics. The analog-to-digital processing circuitry includes a frequency generator for providing stimulus to the sensor and receiving a response signal from the sensor. Conditioning circuitry for reducing analog signal offsets in the response signal and signal detection circuitry for identifying amplitude data of the response signal are provided. Further provided is analog-to-digital conversion circuitry for converting the detected amplitude data into digital form. Memory for holding calibration data and approximated fluid characteristics of the fluid under-test is included in the circuitry. The digital form of the response signal is processed in conjunction with the calibration data and approximated fluid characteristics to generate fluid characteristics of the actual fluid under-test.

Owner:MEAS FRANCE

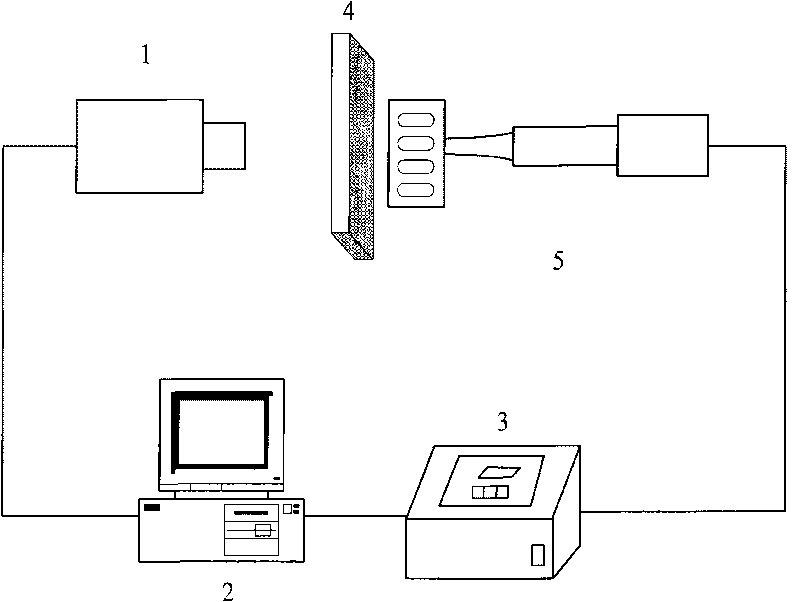

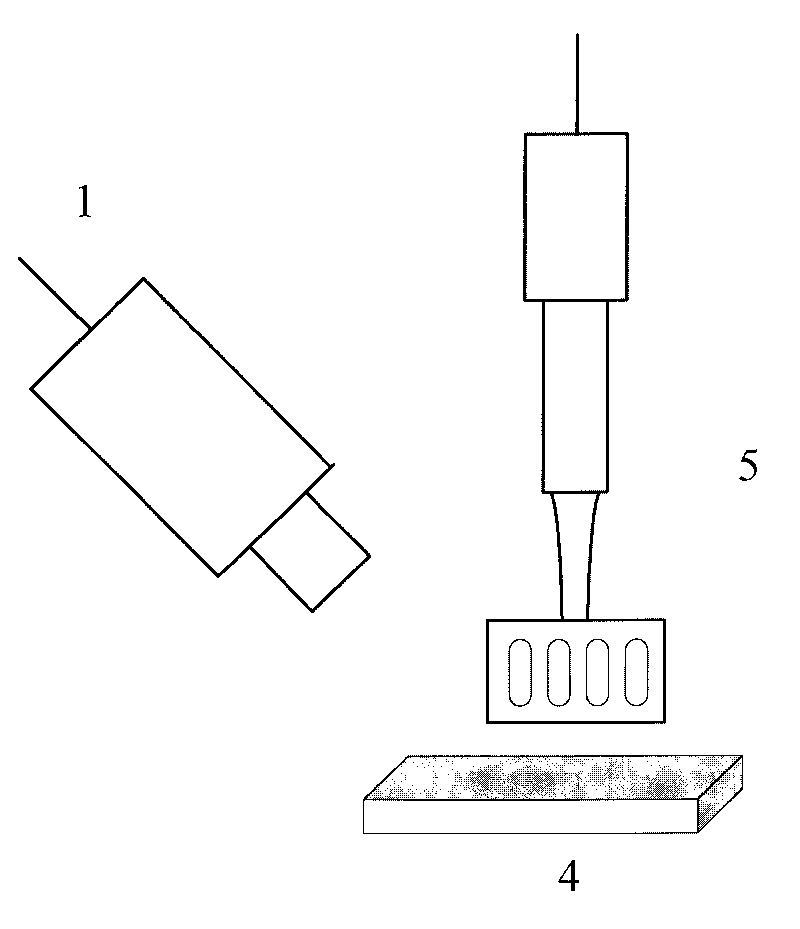

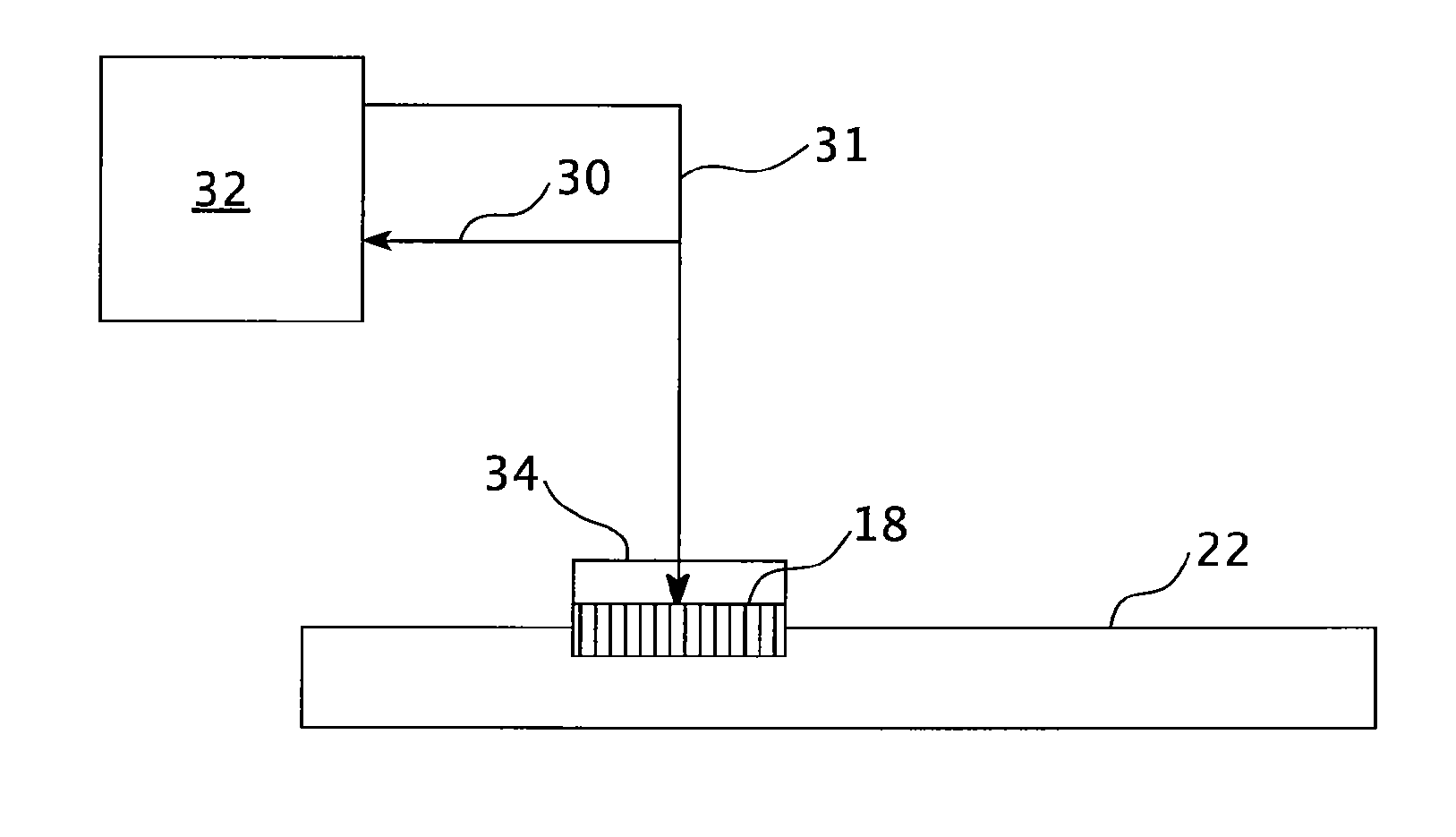

Non-contact ultrasonic thermal-excitation infrared imaging nondestructive detection method and system

ActiveCN101713756AFlexible placementHigh frequency of sound sourceUltrasonic/sonic/infrasonic wave generationMaterial flaws investigationSonificationControl signal

The invention relates to non-contact ultrasonic thermal-excitation infrared imaging nondestructive detection system used for detecting a test piece and comprising an ultrasonic launcher, an thermal infrared imager, a computer and an ultrasonic controller, wherein a test piece is arranged below or laterally below the ultrasonic launcher; the thermal infrared imager is arranged around the test piece and connected the computer; and the ultrasonic controller is connected with the ultrasonic launcher and the computer. The non-contact ultrasonic thermal-excitation infrared imaging nondestructive examination method comprises the following steps: (1) arranging a test piece to be detected below or laterally below an ultrasonic hammerhead of the ultrasonic launcher; setting needed parameters by the ultrasonic controller; (2) receiving a control signal of the ultrasonic controller and emitting sonic energy to the test piece by the ultrasonic launcher; (3) continuously observing and recording the temperature field variance of the test piece surface by the thermal infrared imager when enough ultrasonic energy is coupled in the test piece; and (4) utilizing the computer to collect data acquired by the thermal infrared imager to process and analyze the data and quantificationally diagnose the internal defects of the test piece.

Owner:杭州派肯科技有限公司

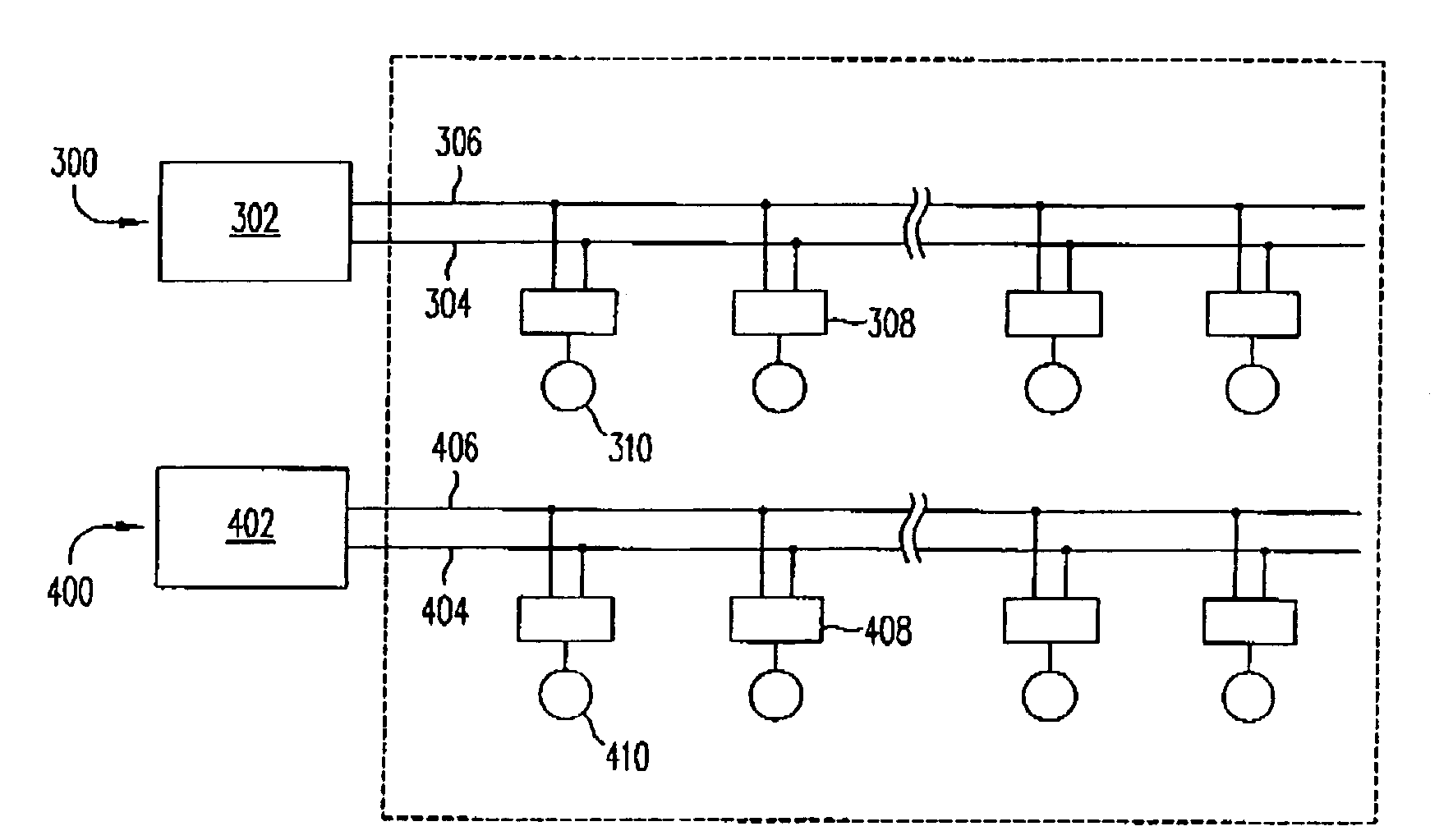

Method and apparatus for switching among elements of a structural health monitoring system

ActiveUS7395189B2Radiation pyrometryUltrasonic/sonic/infrasonic wave generationStructural health monitoringControl line

Use of a single line for switching multiple monitoring elements on / off, and a single line for sending signals to, or receiving signals from, those elements that are switched on. Monitoring elements each have an associated switching element, and each switching element is connected to a common switching line, or control line. A signal from the control line turns each switch on or off. Each monitoring element is also connected to a single signal line, and only those monitoring elements that are turned on can transmit / receive data signals along this signal line.

Owner:ACELLENT TECH

Optical fiber gas sensing method and sensor

InactiveCN101055243AReduce noiseNo polarization effectUltrasonic/sonic/infrasonic wave generationMaterial analysis by optical meansLight energyBand-pass filter

A optical fiber gas sensor employs a optical fiber Fabry-Perot interferometer constituting a low reflection cavity lens and a measurement optical fiber to detect sound pressure wave signal generated by gas after absorbing light energy, and a realization method for optical acoustic gas sense technique is provided. Pulse modulated excited light is emitted by an excitation light source, passes through a band-pass filter and enters a gas cavity from a gas cavity window; the excited light emitted into the gas cavity generates a sound pressure wave which strength corresponds to measured gas concentration in the gas cavity after absorbing by the measured gas; the sound pressure wave is transmitted to vibration of a vibrating film sheet by the vibrating film sheet which is equipped at other end of the gas cavity; a measuring light signal emitted by measuring light source driven by a first drive power supply passes through a optical fiber wave combination equipment, a transmission optical fiber and a optical fiber wave separation equipment and enters a measuring optical fiber of the Fabry-Perot interferometer; concentration value of the measured gas is obtained by optical path difference of the return light beam and the light beam directly reflected by an optical end face.

Owner:NANJING XUFEI PHOTOELECTRIC

Acoustic treatment performance testing

InactiveUS6155116AEliminate inconsistenciesMinimizing unwanted obstructionVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesSound sourcesLength wave

A method and system for acoustic treatment performance testing in a free-field acoustic environment is provided. A sound source directs a gated acoustic pulse at an acoustic treatment. Acoustic pressures of the gated acoustic pulse and reflected energy from the acoustic treatment are measured from a location approximately in-line with the source and the acoustic treatment. This measurement location is at least one-half the wavelength of the frequency of interest away from the source and is at least a distance equal to (t*c / 2) away from the acoustic treatment where t is equal to the duration of the gated acoustic pulse and c is equal to the speed of sound in the free-field acoustic environment. The acoustic pressures of the gated acoustic pulse and reflected energy are compared as an indication of performance of the acoustic treatment at a frequency of interest.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

Method and apparatus for characterization of clot formation

ActiveUS20110034805A1Analysing solids using sonic/ultrasonic/infrasonic wavesBlood flow measurement devicesTemporal changeHigh intensity

Owner:HEMOSONICS

Steam generator nondestructive examination method

ActiveUS7647829B2Analysing solids using sonic/ultrasonic/infrasonic wavesVibration measurement in fluidUltrasonic sensorReflected waves

A method of examining a steam generator heat exchange tube from the outside surface employing ultrasonic nondestructive inspection techniques. An ultrasonic transducer contacts the outside surface of the tube and transmits a pseudo helical Lamb wave into the wall of the tube chosen to have a mode that does not significantly interact with water in the tube. The reflected waves are then analyzed for changes in modes to identify defects in the wall of the tube.

Owner:WESTINGHOUSE ELECTRIC CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com