Optical fiber gas sensing method and sensor

A gas sensor and gas sensing technology, applied in instruments, scientific instruments, material analysis by optical means, etc., can solve the problems of complex system device, difficult control of absorption optical path, large optical path coupling loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

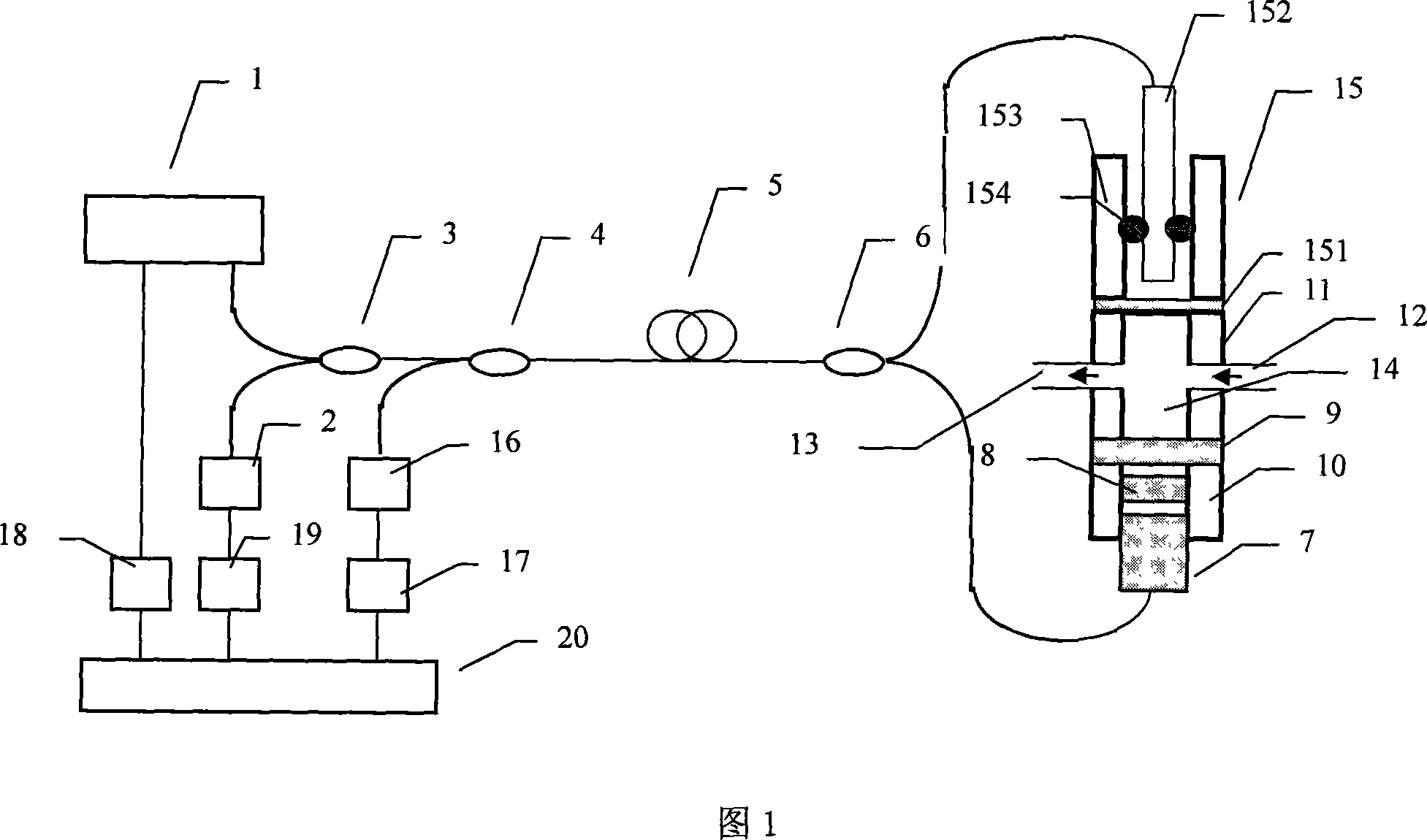

[0042] The structure shown in Figure 1. Wherein, the measurement light source 1 adopts a semiconductor laser with a wavelength of 1.55 microns. The excitation light source 2 adopts an LED with a wavelength of 1.65 microns, which corresponds to the gas absorption peak of methane. The optical fiber multiplexer 3 , the optical fiber light guide element 4 , and the optical fiber splitter 6 all use optical fiber couplers with a splitting ratio of 1:1. The transmission optical fiber 5 is a common commercial single-mode optical fiber. The gas chamber 11 is formed by a circular quartz tube. The air cavity window 9 is calcium fluoride glass. Both the vibrating diaphragm 151 and the casing 153 in the low-finesse Fabry-Perot interference module 15 are made of quartz material, so as to improve the structural stability of the low-finesse Fabry-Perot interference module 15 . The photodetection unit 16 uses an InGaAs photodetector. The signal processing and control system 20 is composed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com